Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1219results about How to "Reduce clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

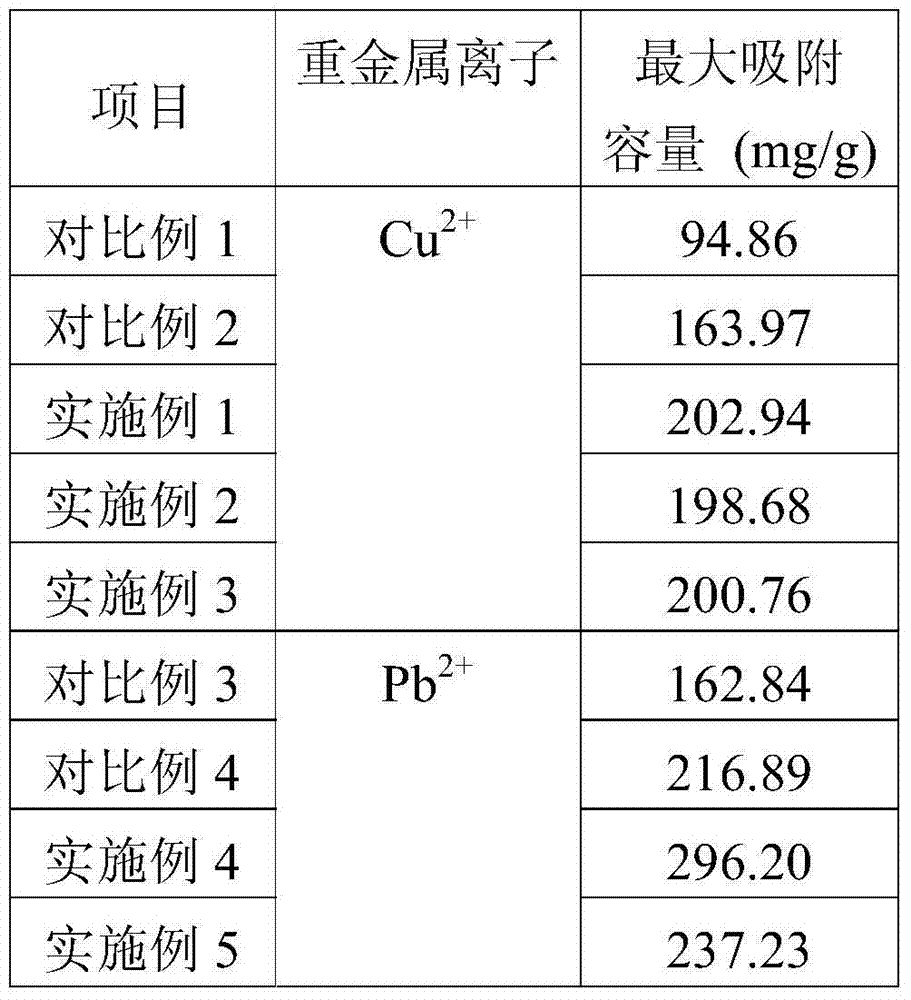

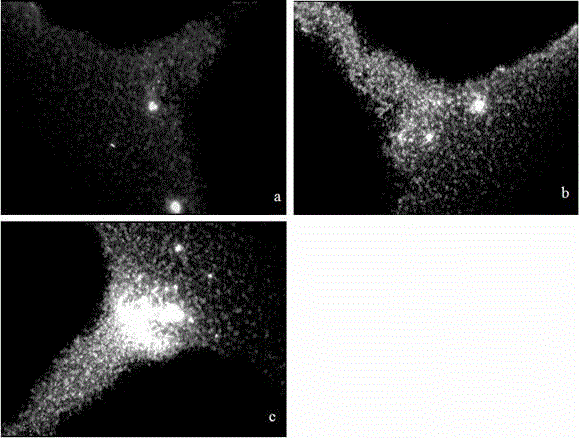

Composite hydrogel for adsorption of heavy metal ions and preparation method thereof

ActiveCN104226281ASimple preparation processGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesIonHeavy metals

The invention discloses composite hydrogel for adsorption of metal ions and a preparation method thereof. The hydrogel comprises, by weight, 5-95 parts of polyvinyl alcohol, 5-95 parts of chitosan, 0.1-20 parts of modified graphene oxide and 2-6 parts of sodium alginate, the weight ratio between the polyvinyl alcohol and the chitosan is (5: 95)-(95: 5), modified graphite oxide includes modified graphene oxide modified by dopamine and / or modified graphene oxide modified by ferroferric oxide, all components are uniformly mixed in a certain sequence, and the composite hydrogel is obtained under special conditions. The composite hydrogel for adsorption of the heavy metal ions and the preparation method thereof have the advantages that high speed, high efficiency, high adsorption capacity and high selectivity are achieved, the adsorption effect on the heavy metal ions is remarkable, meanwhile, the preparation process is simple, and the operability is high.

Owner:JIANGNAN UNIV

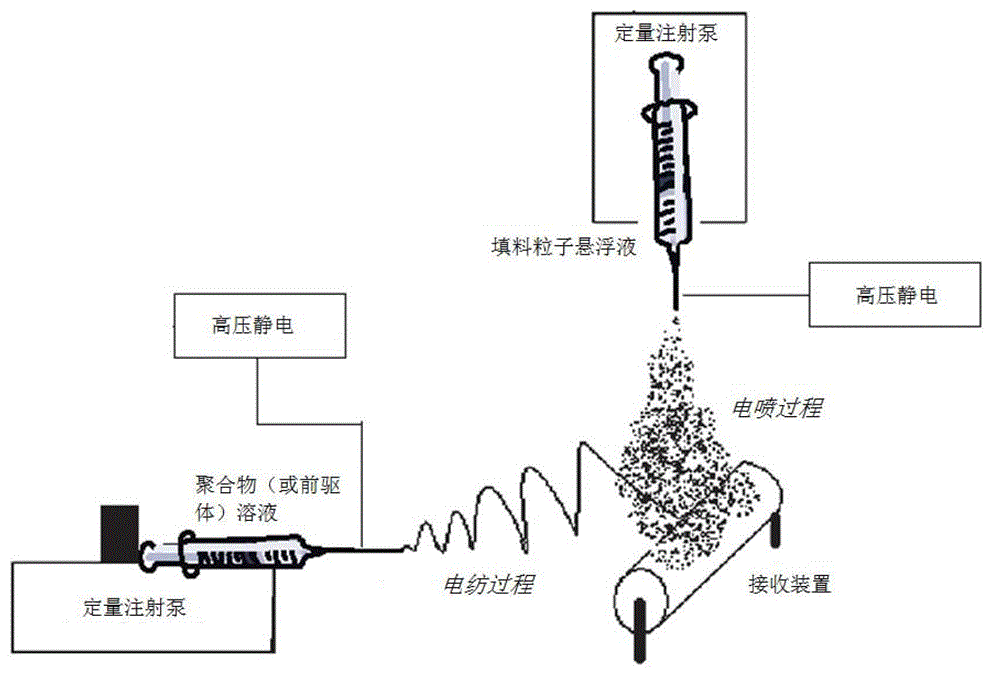

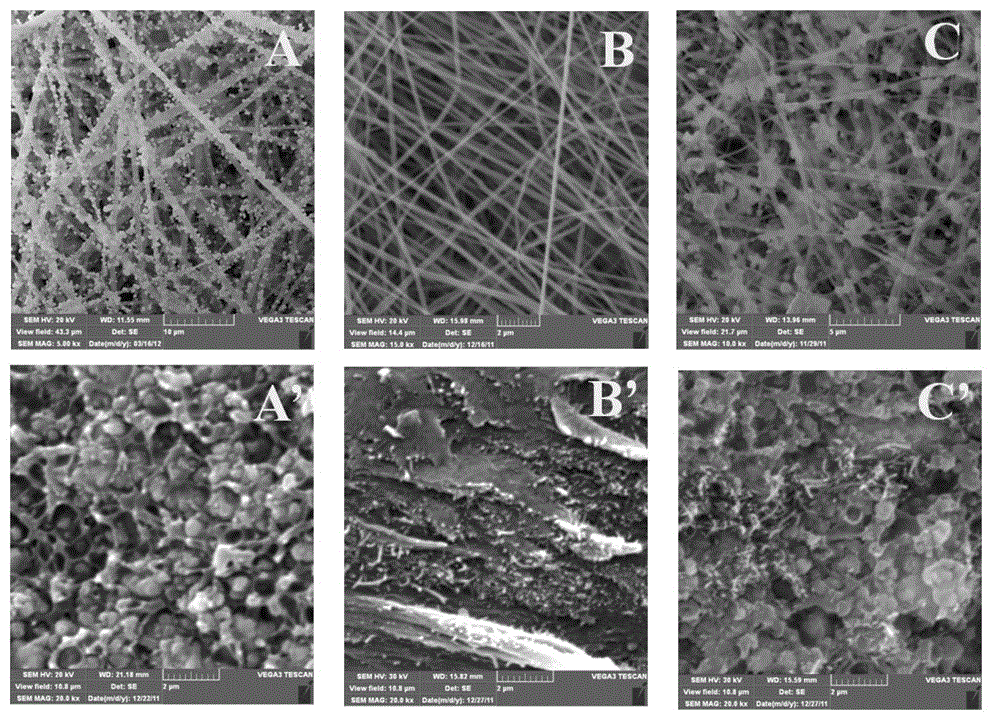

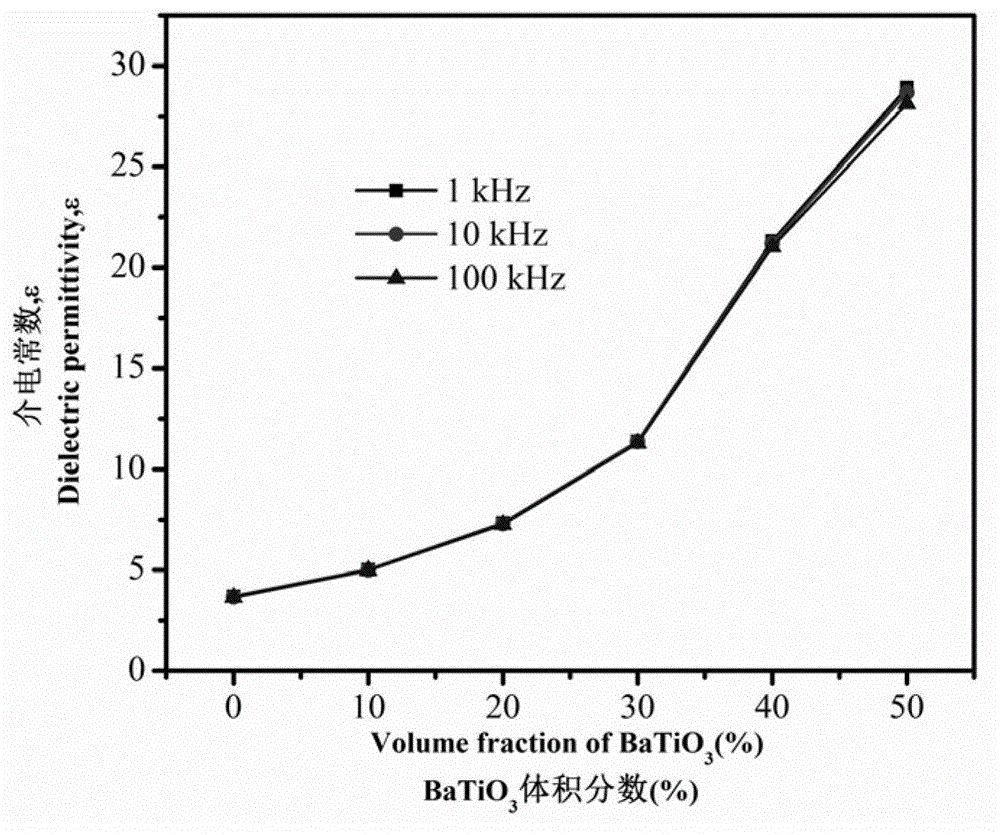

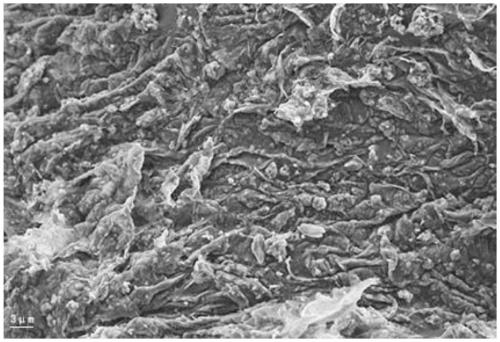

Method for preparing high dielectric constant polymer-based nano composite material

InactiveCN103147226AHigh dielectric constantControllable dielectric constantNon-woven fabricsFiberMatrix solution

The invention provides a method for preparing high dielectric constant polymer-based nano composite material. The method comprises the following steps: performing electrostatic spinning on a polymer matrix solution and simultaneously performing electrostatic spraying on a filler particle suspension; simultaneously receiving the products of the electrostatic spinning and the electrostatic spraying through a common receiving device to obtain a composite fiber membrane; and finally obtaining the high dielectric constant polymer-based nano composite material with filler particles uniformly dispersed after the composite fiber membrane is processed through a hot-pressing processing technique. The composite material prepared by the invention has the characteristics of high dielectric constant, low dielectric loss and the like; and at the same time the dielectric constant of the composite material can be adjusted through adjusting the content of the filler particles in the polymer matrix. The invention has the advantages of simple process, convenient operation and little environment pollution, can well solve the problem that the filler particles is uniformly dispersed in the polymer matrix, and is expected to the microelectronic industry as dielectric material and the like for preparing embedded capacitors.

Owner:JIANGXI NORMAL UNIV

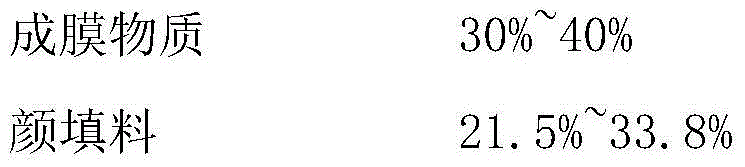

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

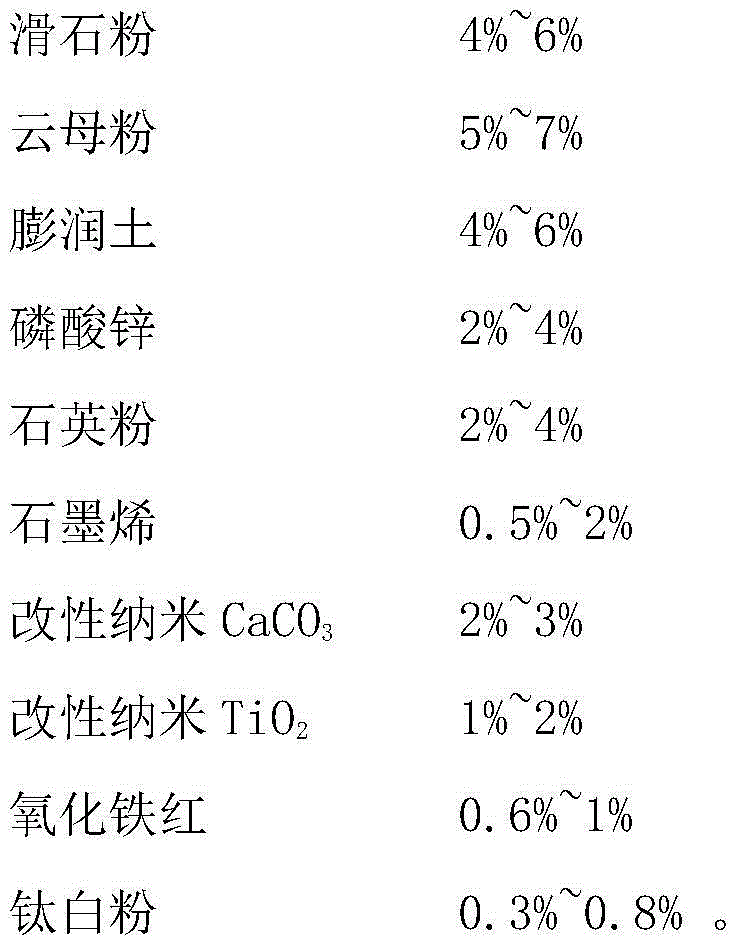

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

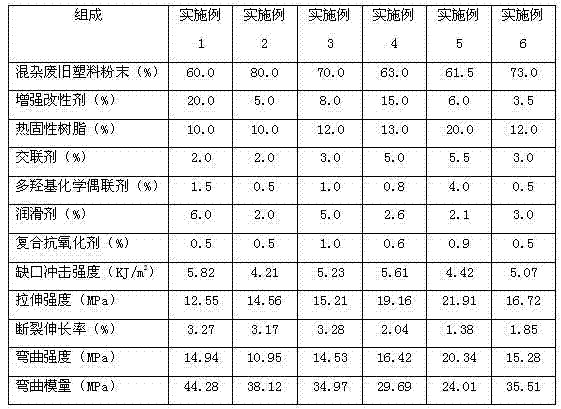

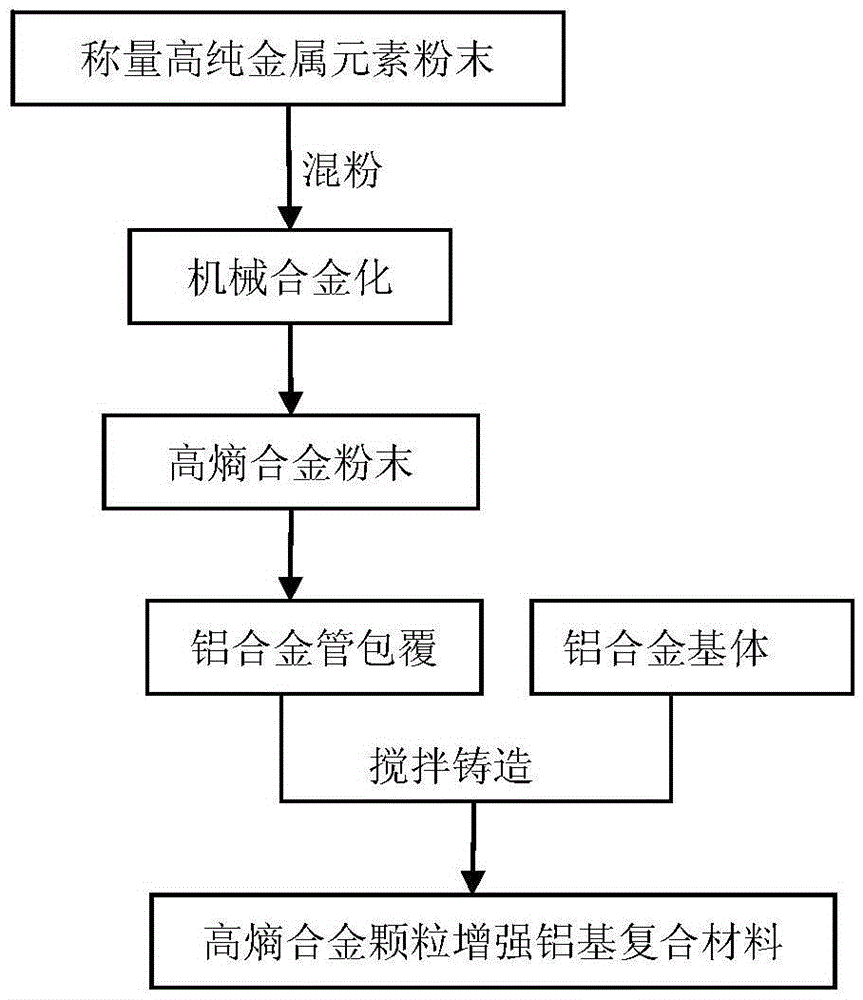

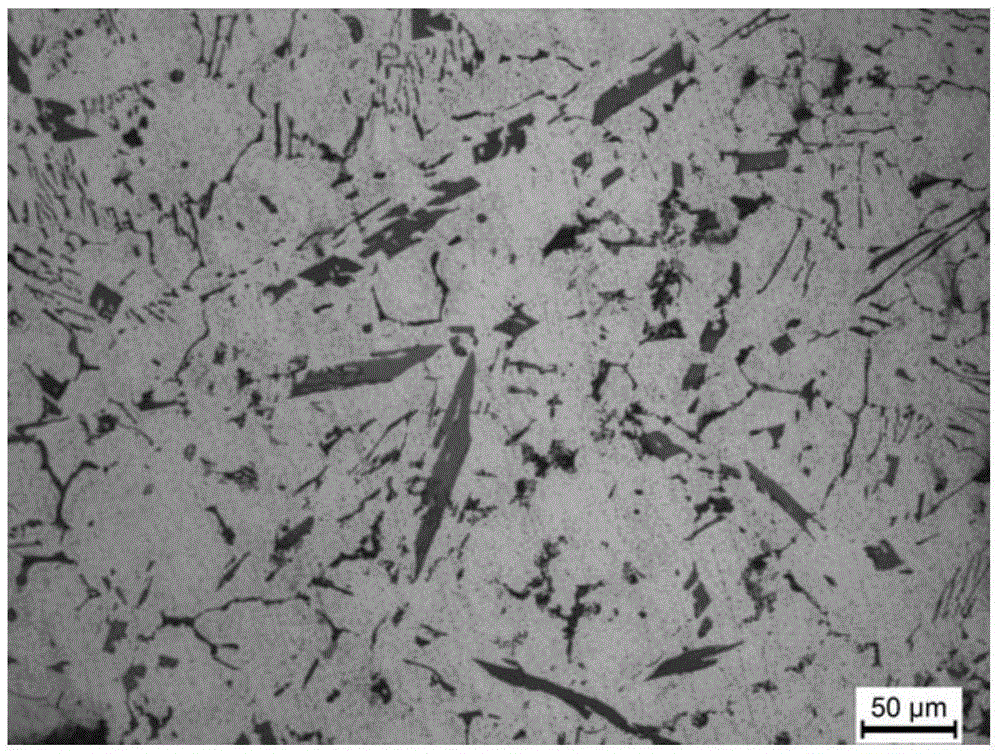

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

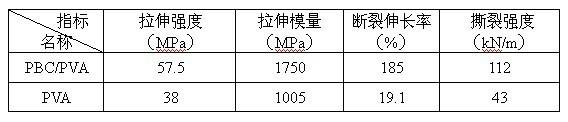

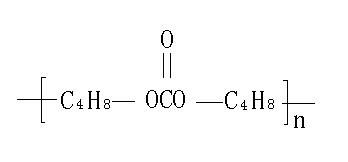

Biodegradable polycarbonate butylene terephthalate composite material and preparation method of biodegradable polycarbonate butylene terephthalate composite material

The invention relates to a biodegradable polycarbonate butylene terephthalate composite material and a preparation method of the biodegradable polycarbonate butylene terephthalate composite material. The biodegradable polycarbonate butylene terephthalate composite material is characterized in that the material comprises the following components in part by weight: 30 to 70 parts of aliphatic polycarbonate butylene terephthalate, 10 to 40 parts of other biodegradable materials, 1.0 to 10 parts of filler, 0.5 to 1.5 parts of rare earth composite nucleating agent, 0.5 to 1.5 parts of dispersant, 4.0 to 15 parts of plasticizer, 1.5 to 4 parts of heat resistance stabilizer, 0.05 to 1.5 parts of antioxidant, 0.5 to 1.0 part of lubricant, 0.1 to 1.0 part of anti-block agent and 0.05 to 0.5 part of biodegradation accelerator. The composite material has high melt strength, good film forming ability, high tensile strength, high tearing strength and good light-conversion effect.

Owner:JIANGSU XINGYE PLASTIC +1

Preparation method for high-performance epoxy resin composite material

InactiveCN101104725AReduce clumpingGood dispersionPigment treatment with non-polymer organic compoundsEpoxyCross-link

The invention relates to a preparation method of a high performance epoxy resin composite. First, carbon nano tubes are modified on the surface by acidification, acyl chlorination and amination to prepare carbon nano tubes with amino. The dispersion of the carbon nano tubes in the epoxy resin is improved; the high performance epoxy resin composite is obtained through proper ultrasonic oscillation and strong stirring dispersion and through the amino on the carbon nano tubes having chemical cross-linking with epoxy groups in the epoxy resin.

Owner:TONGJI UNIV

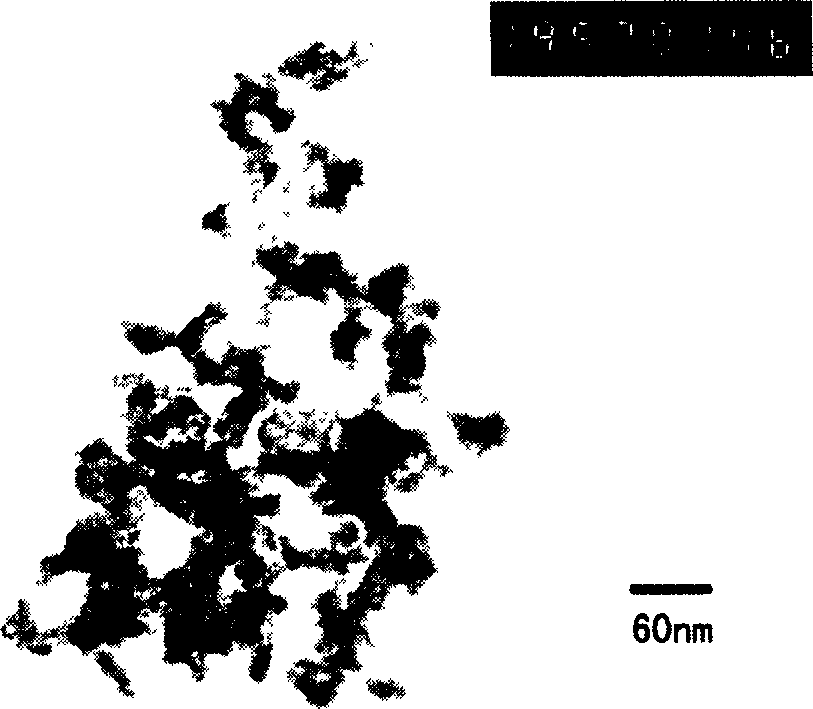

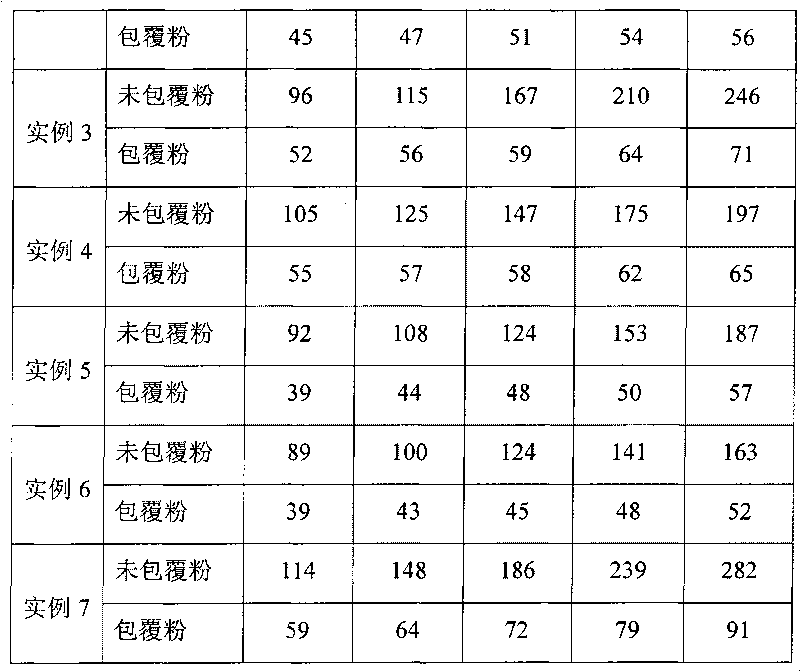

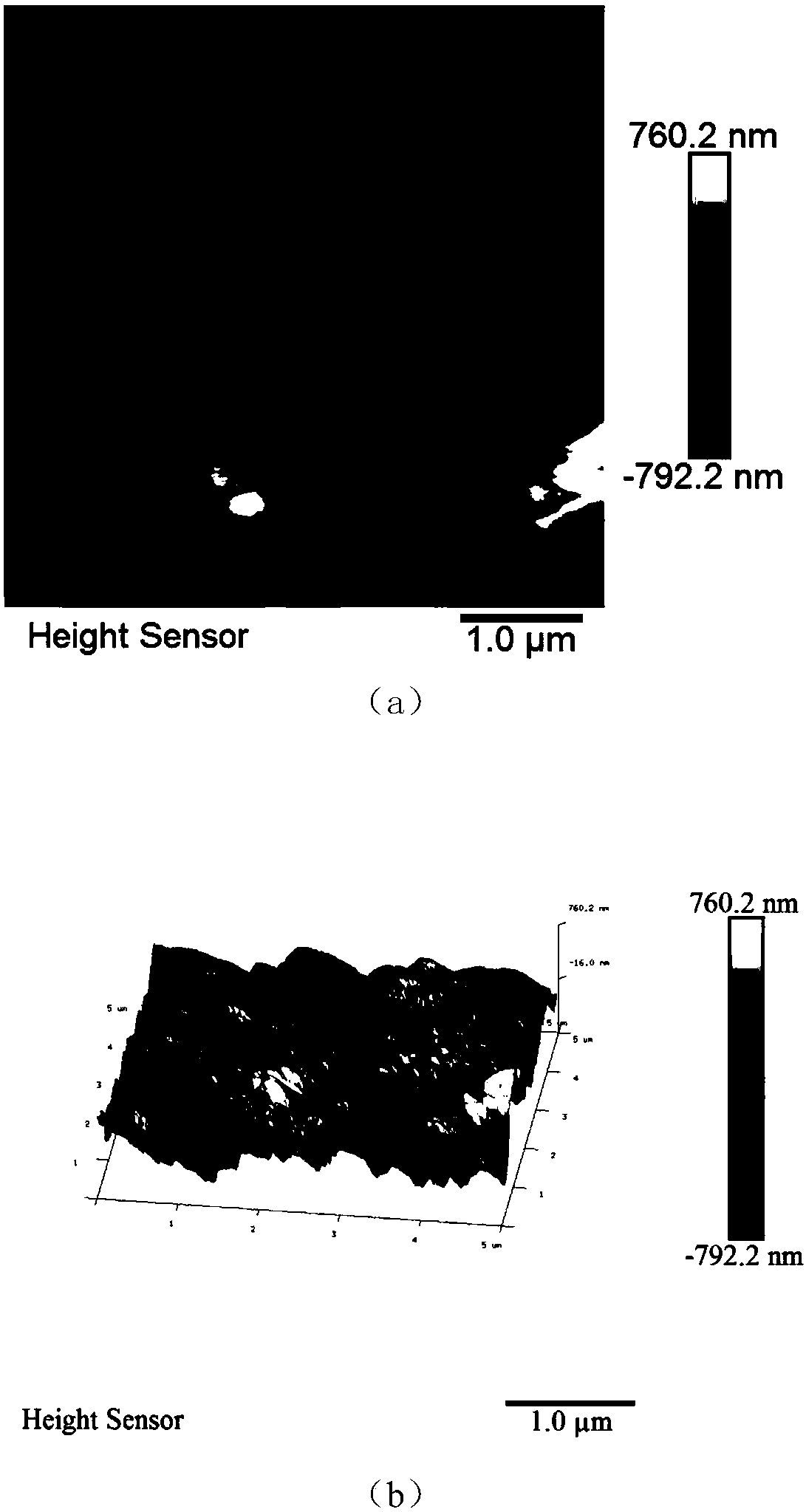

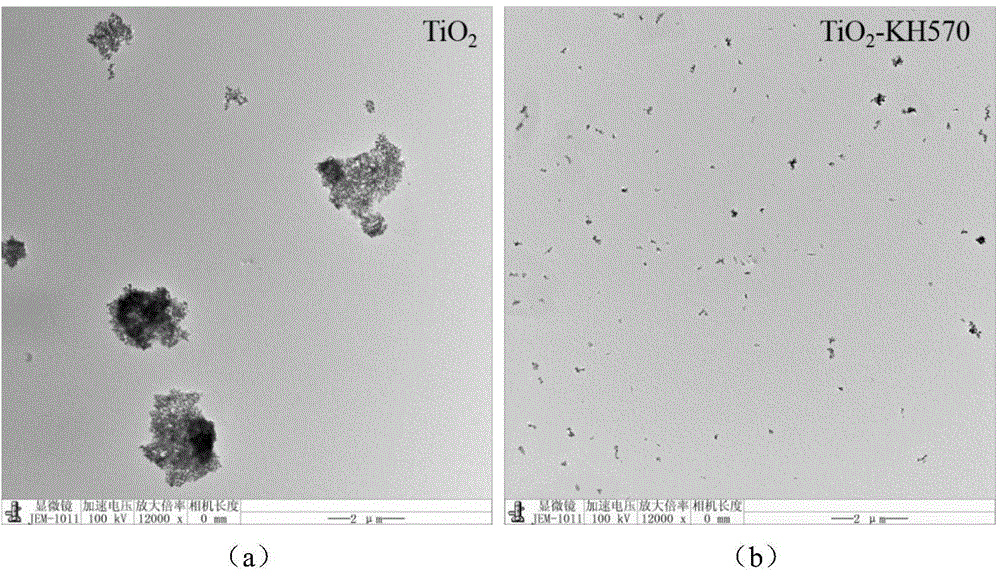

Nano titanium oxide inorganic surface treatment method

ActiveCN101255288AAvoid flocculationReduce clumpingInorganic pigment treatmentNanometreTitanium dioxide

The invention discloses a nm titanium dioxide inorganic surface treating method. The inorganic surface treating is performed when the nm titanium dioxide is in good dispersed state and the inorganic surface treatment effect is increased using the said method. The invention solves the flocculation and dispersion problem of nm titanium dioxide using ultrasonic field, mechanical agitation and film separation and phase integrating. During the process of treating the inorganic surface, on the one hand the nm titanium dioxide dispersion liquid is always under the action of mechanical agitation and ultrasonic, on the other hand, the impurity ions are continuously removed using membrane separation device, so as to make sure the inorganic surface coating reaction under the full dispersed state of the nm titanium dioxide.

Owner:江苏河海纳米科技股份有限公司 +1

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

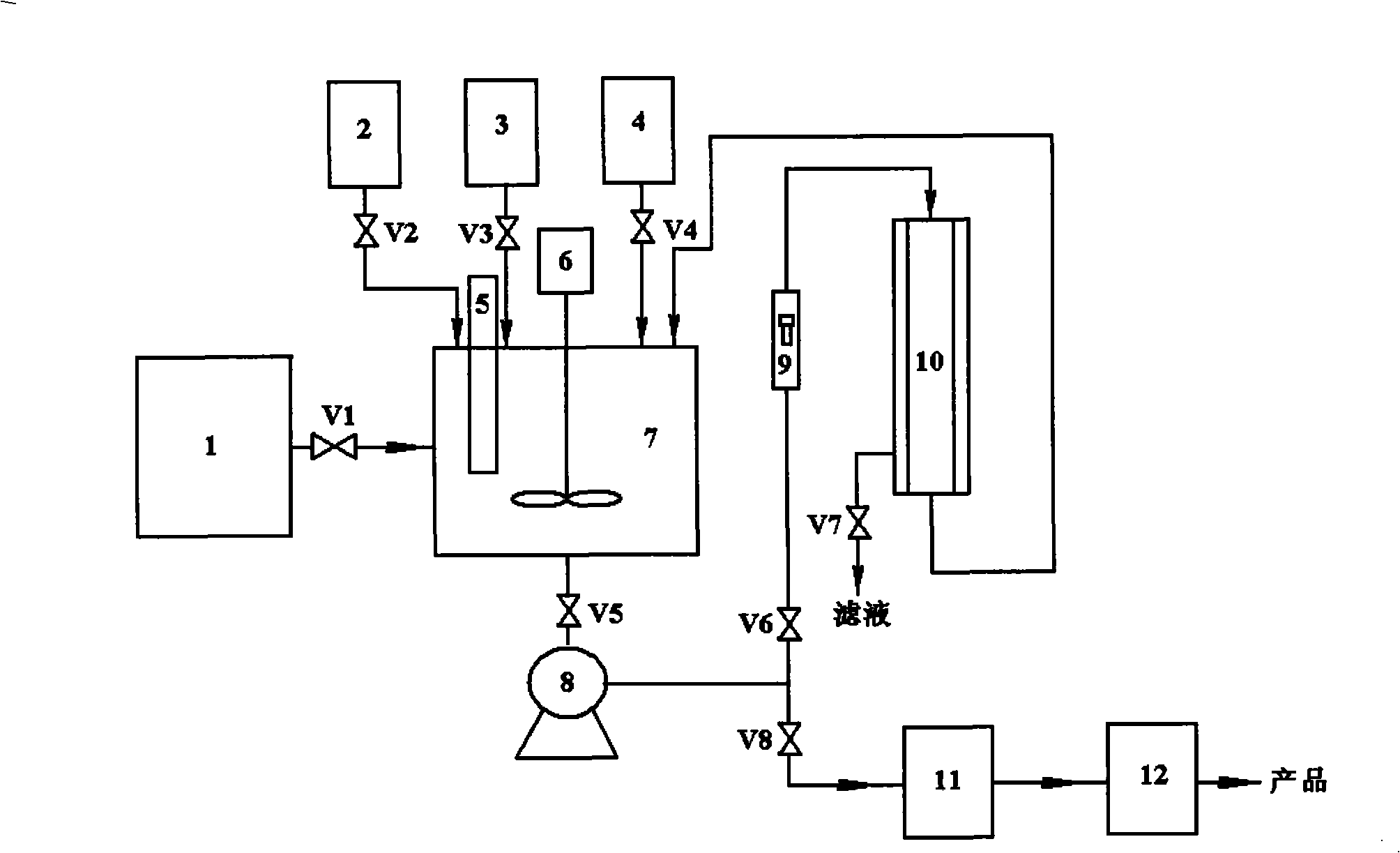

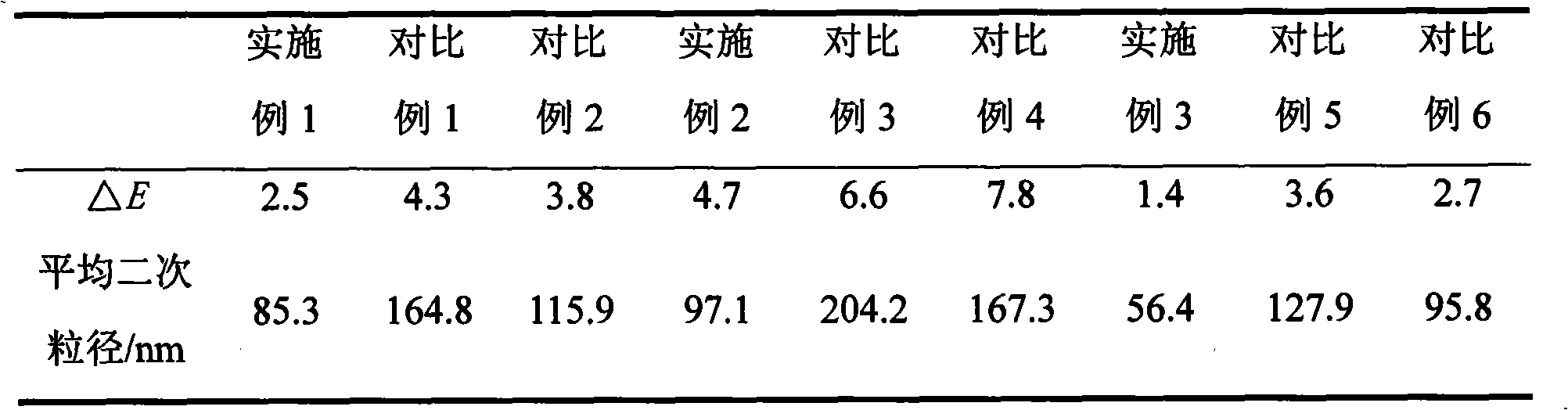

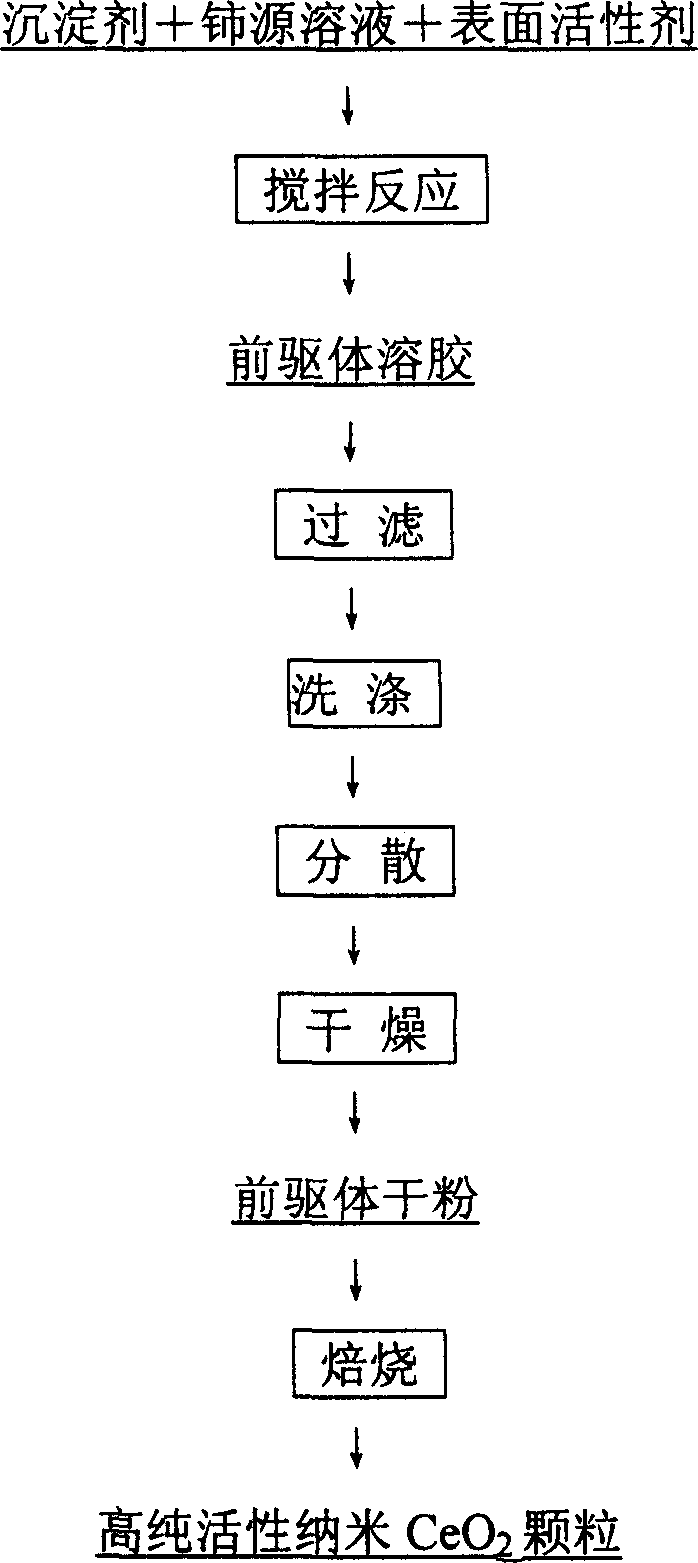

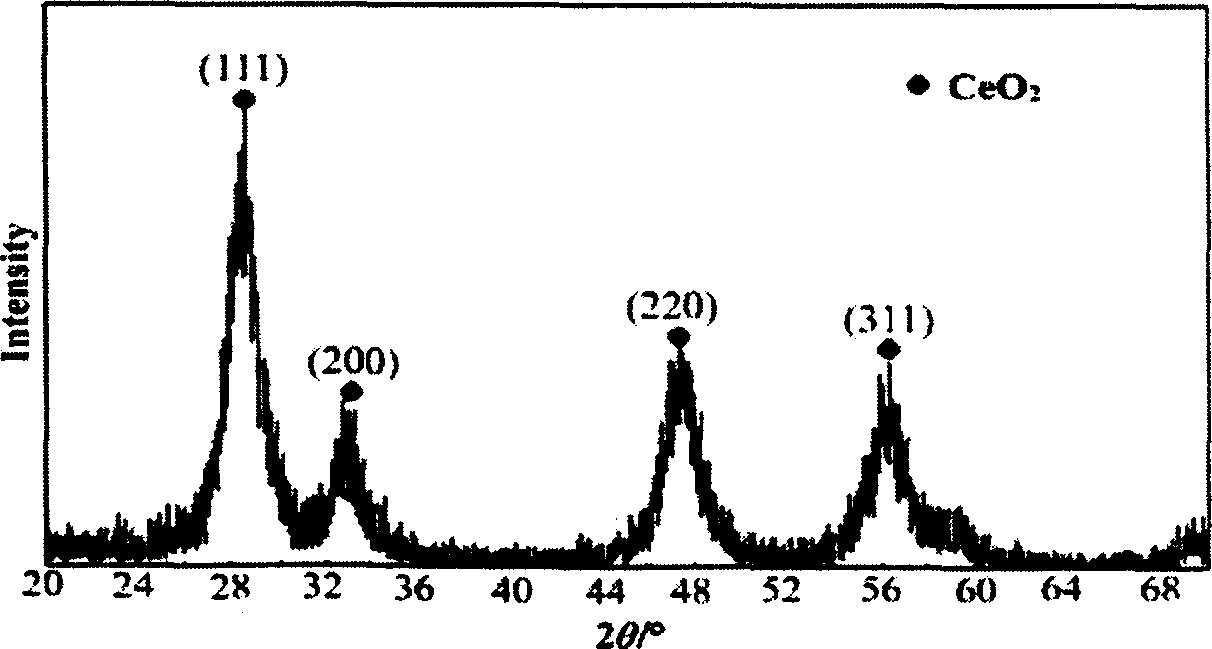

Process for preparing high purity active nano ceria

The invention discloses a process for preparing high purity nano cerium dioxide, which comprises using cerium salts as cerium source, using carbonates, oxalates or oxalic acid as precipitating reagent, charging surface active agent, carrying out chemical precipitation reaction under the mechanical stirring action, obtaining precursors, finally subjecting the precursors to filtration, scouring, dispersing, drying and sintering in Muffle type furnaces.

Owner:CENT SOUTH UNIV

Method for grinding superfine heavy calcium carbonate in dry method

ActiveCN101768378AReduce reunionIncrease the degree of ultra-refinementPigment physical treatmentMetallurgySURFACTANT BLEND

The invention provides a method for grinding superfine heavy calcium carbonate by a dry method. The method comprises the following steps of: adding coarse heavy calcium carbonate powder into a grinding device, adding a grinding assistant and a surfactant, grinding by adopting the dry method in a grinding medium, and simultaneously adding a wetting agent in the grinding process to obtain the superfine heavy calcium carbonate, wherein the weight of the superfine heavy calcium carbonate with the grain diameter being less than 2mum accounts for 35 to 55 percent relative to the total weight thereof.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

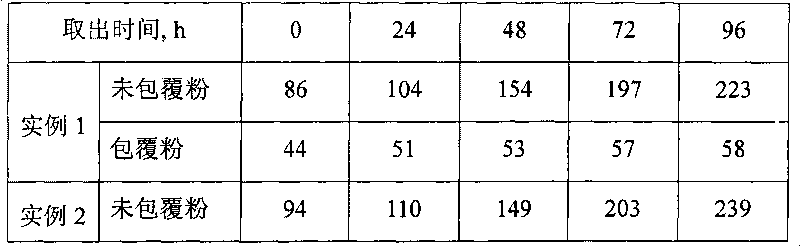

Method for preparing antioxidant soldering powder

ActiveCN101745636AExtended shelf lifeLow costWelding/cutting media/materialsSoldering mediaSolventActive agent

The invention relates to a method for preparing antioxidant soldering powder, comprising the following steps: adding soldering powder to solution containing 5-25 percent by weight of active agent and 2-20 percent by weight of coating agent; stirring the active agent, the coating agent and the soldering powder at the temperature of 30-80 DEG lower than the soldering powder melting point so that the soldering powder suspending in the solution for 10-90 min; and filtering the solution, eluting the solution with solvent and drying the solution in vacuum to obtain the antioxidant soldering powder. The invention is suitable for coating the alloy soldering powder such as SnPb soldering powder, SnPbAg soldering powder, SnPbBi soldering powder, SnBi soldering powder, SnCu soldering powder, SnBiCu soldering powder, SnAg soldering powder, SnAgCu soldering powder and SnZn soldering powder of any particle size and is particularly suitable for coating the alloy soldering power of small particle size or the alloy soldering power which is easily oxidized. The soldering powder is coated by removing an oxidation layer on the surface of the soldering powder, thus the effect of coating the soldering power with the coating agent is improved, the shelf life of the soldering powder is prolonged, the requirements for the package, the storage and the transportation of the soldering powder are lowered, the cost is saved and the waste of the resources is reduced.

Owner:BEIJING COMPO ADVANCED TECH

Method for improving conductive heat stability of polyaniline/inorganic nano conductive composite material

ActiveCN101376712AImprove electrical conductivity and thermal stabilityReduce clumpingOrganic conductorsThermal stabilityAzeotropic distillation

The invention discloses a method for improving the conductive thermal stability of a polyaniline / inorganic nano-conductive composite material, which comprises the following steps: a proton acid doped polyaniline / inorganic nano-conductive composite material filter cake is firstly prepared, then the obtained filter cake is carried out the azeotropic distillation treatment, water in the filter cake is removed, and the proton acid doped polyaniline / inorganic nano-conductive composite material is simultaneously transferred into an organic phase. The method easily prepares the proton acid doped polyaniline / inorganic nano-conductive composite material organic dispersion liquid with the excellent dispersion through the azeotropic distillation dehydration and the phase transfer process, thereby reducing the clustering phenomenon of the composite material, improving the dispersion of the composite material in the organic phase and improving the conductive thermal stability of the nano-conductive composite material.

Owner:溧阳常大技术转移中心有限公司

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

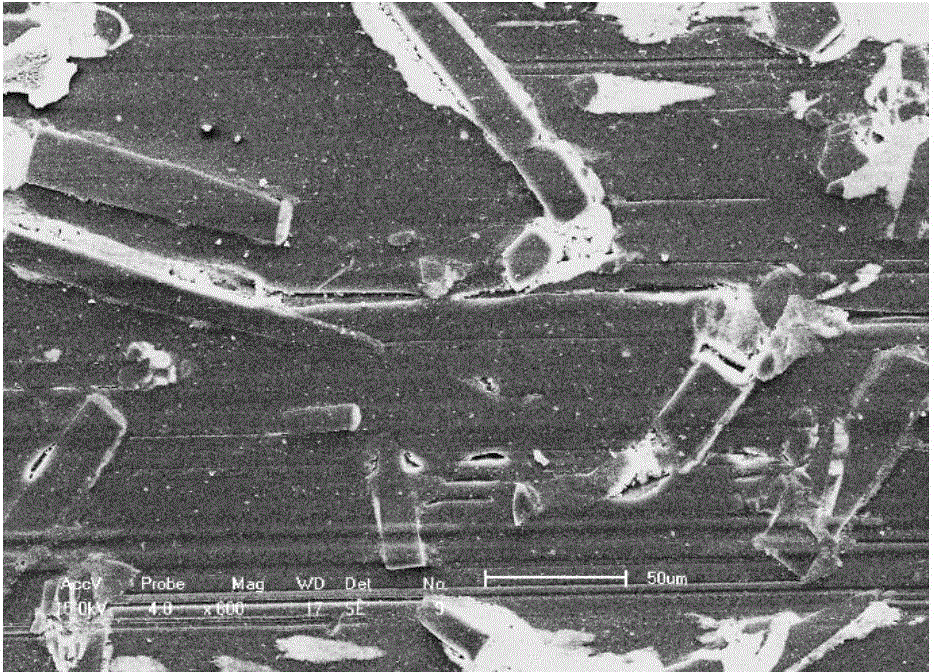

Polyetheretherketone-base composite, preparing method thereof and application thereof in friction reduction and wear resistance

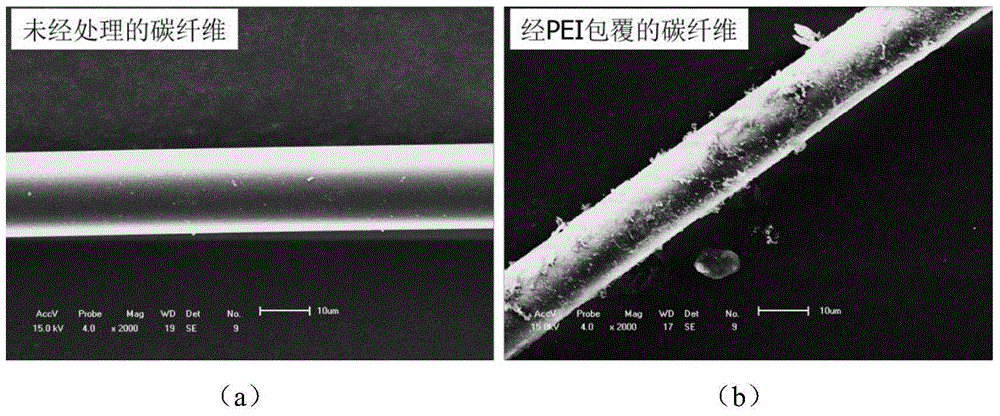

InactiveCN104927298AReduce coefficient of frictionReduce wear rateOther chemical processesDispersityFiber

The invention relates to a polyetheretherketone-base composite, a preparing method thereof and application thereof in friction reduction and wear resistance and belongs to the technical field of polymer composites. The polyetheretherketone-base composite, by 100% weight, 65% to 87% of polyetheretherketone, 10% to 30% of polyetherimide-coated carbon fiber, and 3% to 5% of coupler-modified titanium dioxide. In order to optimize the dispersity of micrometer chopped carbon fiber, polyetherimide which is well compatible with the polyetheretherketone and resistant to high temperature is used to coat the carbon fiber; the nano titanium dioxide is subjected to coupler inarching to reduce its agglomeration degree. Compared with fillers subjected to no treatment, the carbon fiber has the advantages such as uniform dispersity in composites and high interfacial action with matrixes. By adding the coated carbon fiber and the coupler-modified titanium dioxide, the friction and wear performance of the polyetheretherketone-base composite can be effectively improved, and the application in the friction-reducing wear-resistant environments is satisfied.

Owner:JILIN UNIV

Preparation method for organically-modified nano-silica/nylon 66 composite material

InactiveCN101570590AGood dispersionReduce clumpingPigment treatment with non-polymer organic compoundsIn situ polymerizationHigh pressure

The invention discloses an organically-modified nano-silica / nylon 66 composite material and a preparation method thereof. The method has the following advantages that: 1) the surface of nano-silica subjected to chemical modification has an epoxy group, an amino-group and other groups, the nano-silica can react with binary acid to form a chemical bond which is subjected to ultrasonic dispersion so as to reduce the agglomeration phenomenon of nano-silica particles, improve the dispersibility of the nano-silica and further obtain the composite material with good dispersibility; and 2) in the preparation process, a GSH-2 type high-pressure autoclave is adopted to prepare the composite material by in-situ polymerization, and the method has certain directive significance on industrialized production of the composite material.

Owner:XIANGTAN UNIV

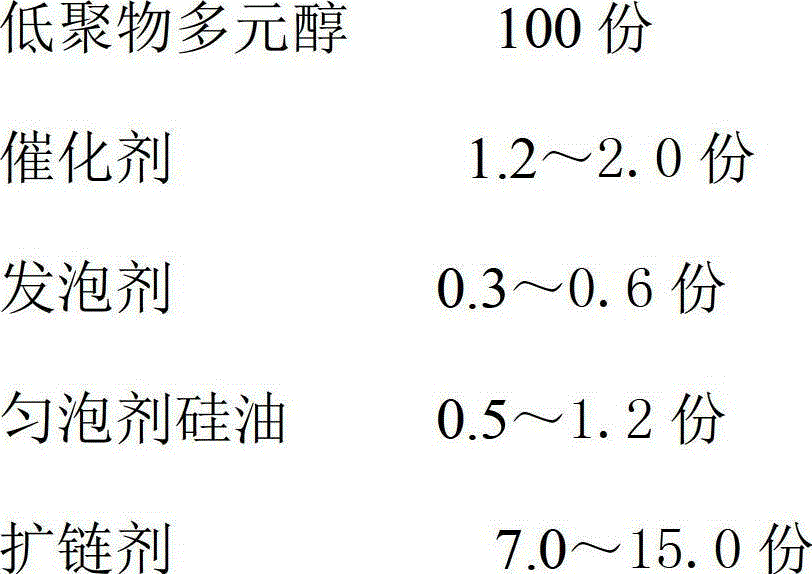

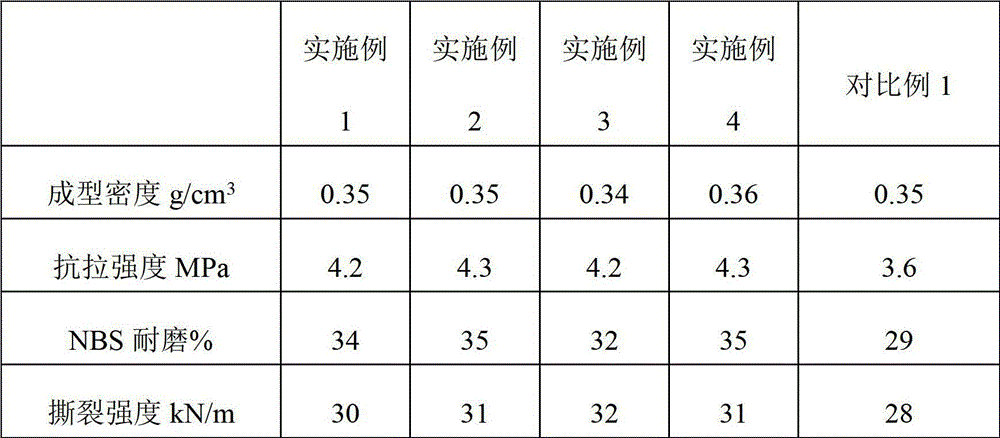

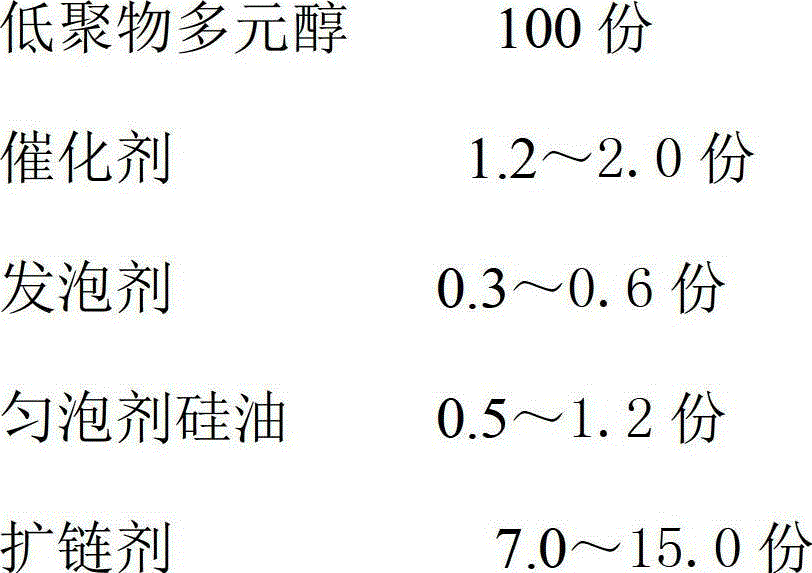

Method for filling polyurethane sole with waste rubber

The invention provides a method for filling a polyurethane sole with waste rubber. The method comprises the following steps that A components, B components and rubber particles are mixed to be poured into a sole mold to be in reaction forming, demolding is carried out, and curing is maintained in a 60-70 DEG C drying oven for 22-24 hours to obtain the polyurethane sole filled with the waste rubber particles; the A components comprise, by weight, 100 parts of low polymer polyhydric alcohols, 1.2-2.0 parts of catalytic agents, 0.3-0.6 part of foaming agents, 0.5-1.2 parts of foam stabilizer silicone oil, and 7.0-15.0 parts of chain extender; and the B components comprise, by weight, 30-90 parts of the low polymer polyhydric alcohols, and 100 parts of diisocyanate. According to the method, the obtained polyurethane sole is uniform in foam holes, smooth in surface, and higher than a common polyurethane sole in tensile strength, abrasion resistance and tearing strength, the problem of reuse of rubber waste is resolved, and the technological process is simple and efficient.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

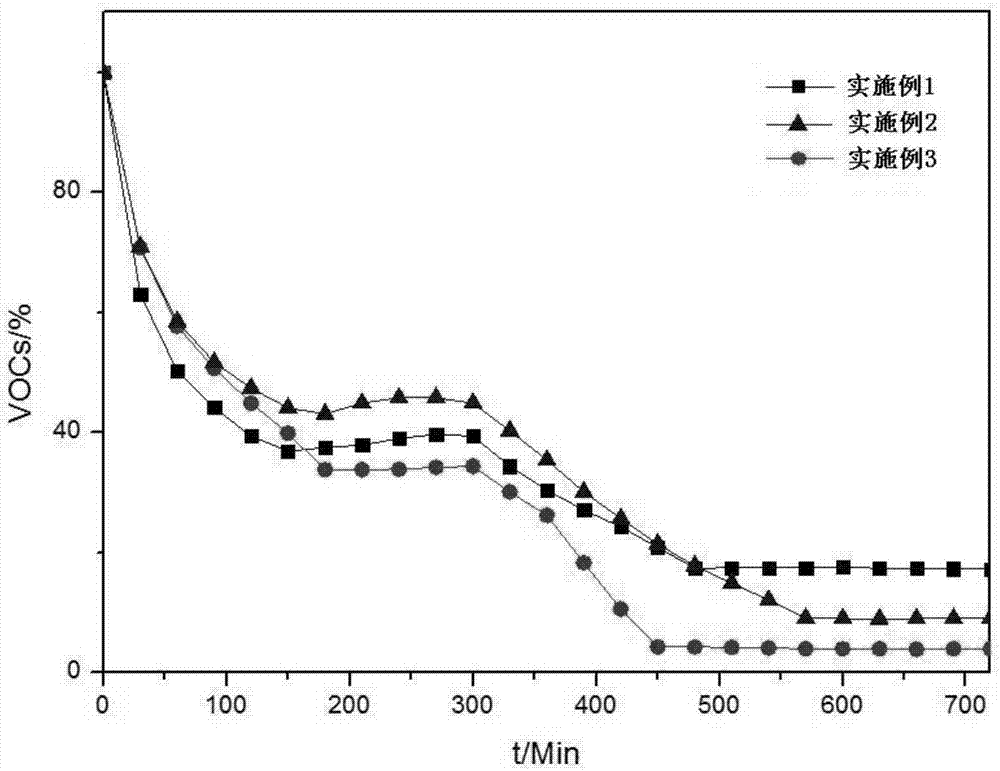

Graphene oxide/titanium dioxide-active carbon three-dimensional composite material and preparation method thereof

ActiveCN107362788AEfficient removalReduce the risk of secondary pollutionMaterial nanotechnologyGas treatmentFiberFiltration

The present invention belongs to the technical field of air purification, and particularly relates to a graphene oxide / titanium dioxide-active carbon three-dimensional composite material and a preparation method thereof, wherein a graphene oxide / titanium dioxide composite material is directly and densely adhered onto the surface of an active carbon filtration screen or a carbon fiber net so as to obtain the three-dimensional composite material. According to the present invention, the graphene oxide / titanium dioxide-active carbon three-dimensional composite material can provide excellent adsorption performance and excellent photocatalytic degradation performance on formaldehyde, wherein photocatalytic degradation is performed after formaldehyde is adsorbed, such that the actual removal of the formaldehyde can be achieved, and the secondary pollution caused by the desorption of the formaldehyde can be prevented; and after the adsorption degradation treatment is performed with the composite material of the present invention, the removal rate of the low concentration formaldehyde (concentration of 1.0 mg / m<3>) in the home within 10 h is up to 82.5-95.6%.

Owner:SICHUAN UNIV +1

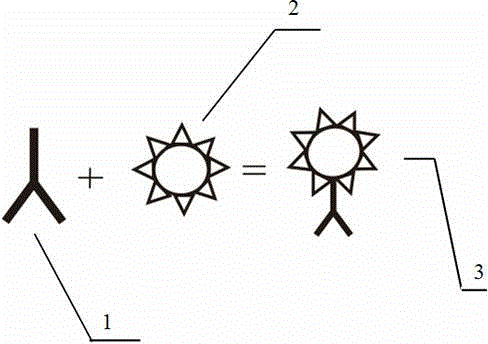

Preparation method of polystyrene fluorescent microsphere coupled with antibody

InactiveCN104530459AHigh coupling rateGood dispersionFluorescence/phosphorescenceAntiendomysial antibodiesPolystyrene

The invention discloses a preparation method of a polystyrene fluorescent microsphere coupled with an antibody, which comprises the following steps: 1. activating a carboxyl group on the surface of a fluorescent microsphere; 2. coupling an amino group of a monoclonal antibody with the carboxyl group on the surface of the fluorescent microsphere; 3. blocking activated groups not subjected to complete reaction on the surface of the fluorescent microsphere; and 4. preserving the polystyrene fluorescent microsphere coupled with the antibody. The preparation method disclosed by the invention is simple, easy to implement, low in cost and suitable for industrialization.

Owner:NANJING UNIV OF POSTS & TELECOMM

Nitrogen-doped carbon-coated Co-based MOF derivative material, preparation method thereof and application thereof

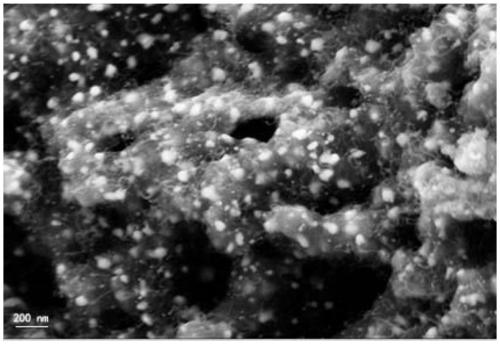

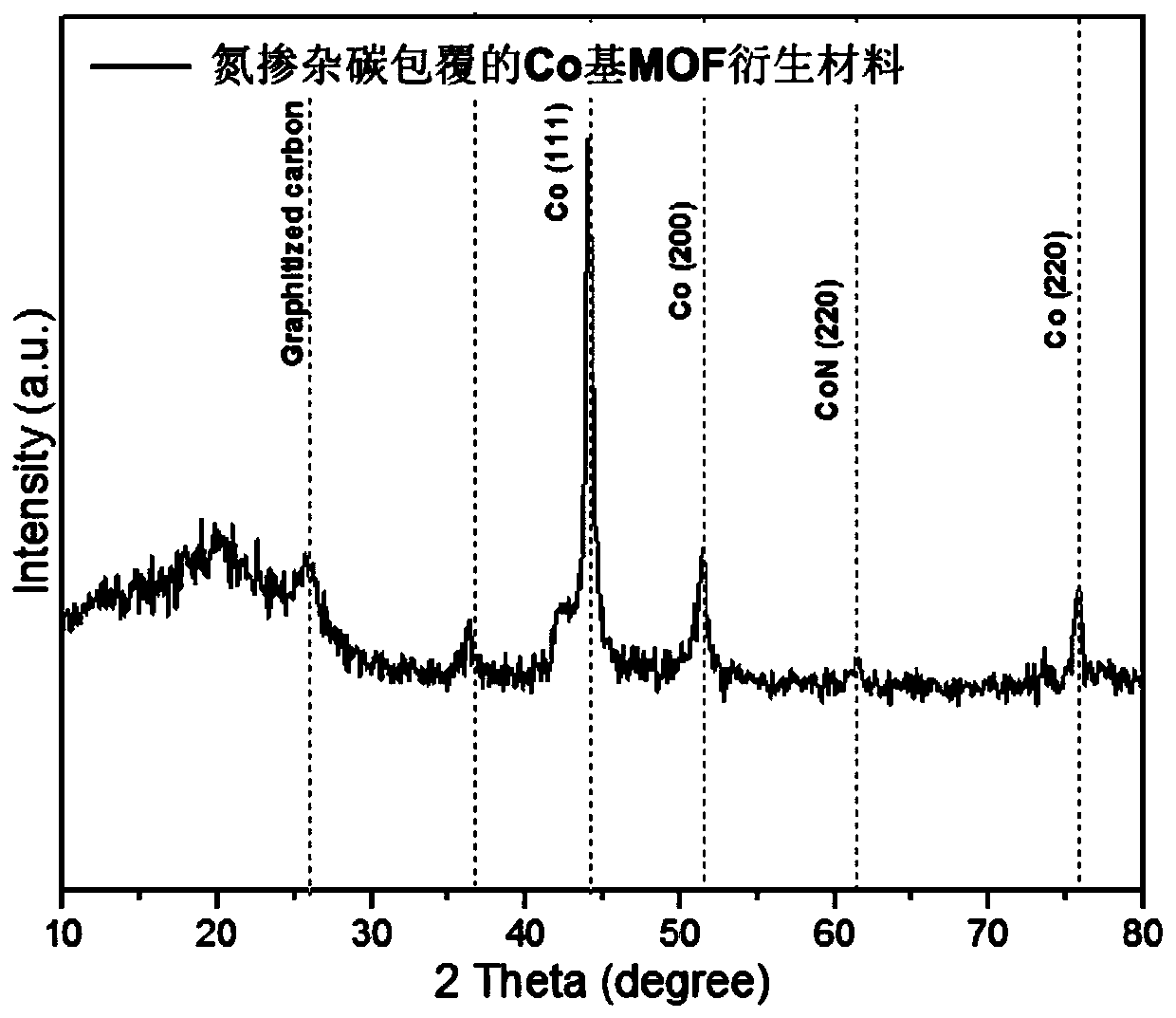

PendingCN110215930ARaw materials are readily availableThe synthetic route is simplePhysical/chemical process catalystsElectrodesElectrolysisCathodic reaction

The invention discloses a preparation method of a nitrogen-doped carbon-coated Co-based MOF derivative material, which comprises the following steps: preparing a metal organic framework compound ZIF-67, dissolving cobalt nitrate and methylimidazole in water in a reaction kettle, reacting at 150-200 DEG C for 2h, and cooling to obtain a metal organic framework compound ZIF-67; preparing a solid mixture: dissolving the metal organic framework compound ZIF-67, polyvinylpyrrolidone and melamine in water to obtain a mixed solution, freeze-drying that mixed solution to obtain the solid mixture; preparing the nitrogen-doped carbon-coated Co-based MOF derivative material: placing the solid mixture in a furnace, purging with argon, calcining at 800-1000 DEG C for 2 h, and cooling to obtain the nitrogen-doped carbon-coated Co-based MOF derivative material. In the process of preparation, the raw materials are easy to obtain and the synthetic route is simple, and the derived materials have good catalytic effect in both anodic and cathodic reactions during the process of electrolyzing water.

Owner:SOUTHWEST PETROLEUM UNIV

Low-dosage steel fiber modified powder concrete

The invention discloses low-dosage steel fiber modified powder concrete which comprises the following raw materials in parts by weight: 600-1000 parts of cement, 150-300 parts of active mineral admixture, 60-100 parts of inert admixture, 900-1300 parts of sand, 26-35 parts of a water reducing agent, 135-160 parts of water, 30-100 parts of extra-fine steel fibers and 7-12 parts of a corrosion inhibitor. According to the low-dosage steel fiber modified powder concrete, provided by the technical scheme of the invention, the extra-fine steel fibers with the diameters being smaller than 0.13 mm and the lengths being 6-12 mm are adopted for replacing common steel fibers, therefore on the one hand, the mechanical property of the concrete is improved, on the other hand, the additive amount of steel fibers in the concrete is further reduced, and the production cost of the low-dosage steel fiber modified powder concrete is reduced; besides, the low-dosage steel fiber modified powder concrete is relatively low in the wholesale cost, good in the fiber distribution uniformity, high in fracture resistance and shock resistance and is suitable for popularization and application in the constructional engineering industry.

Owner:黄贺明

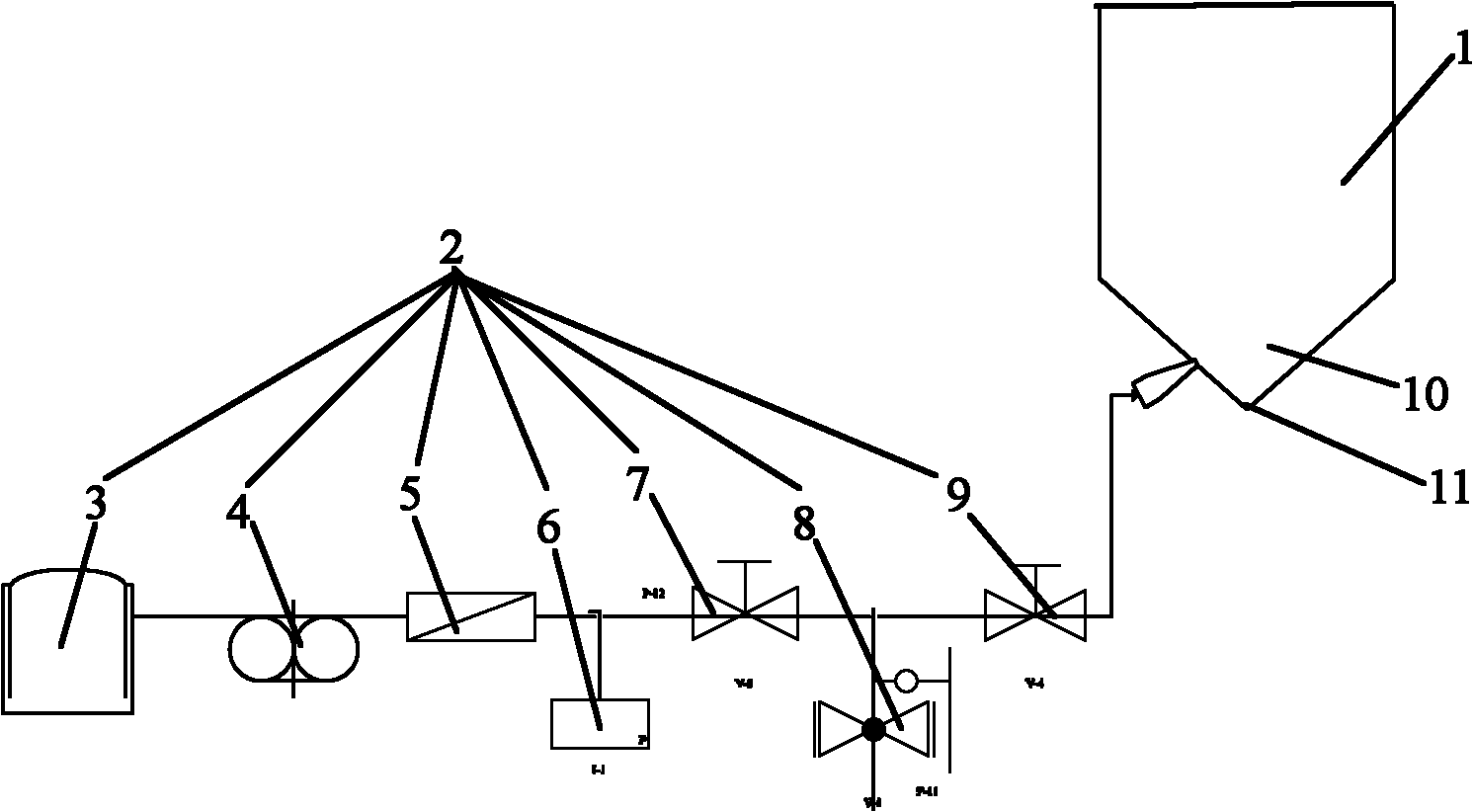

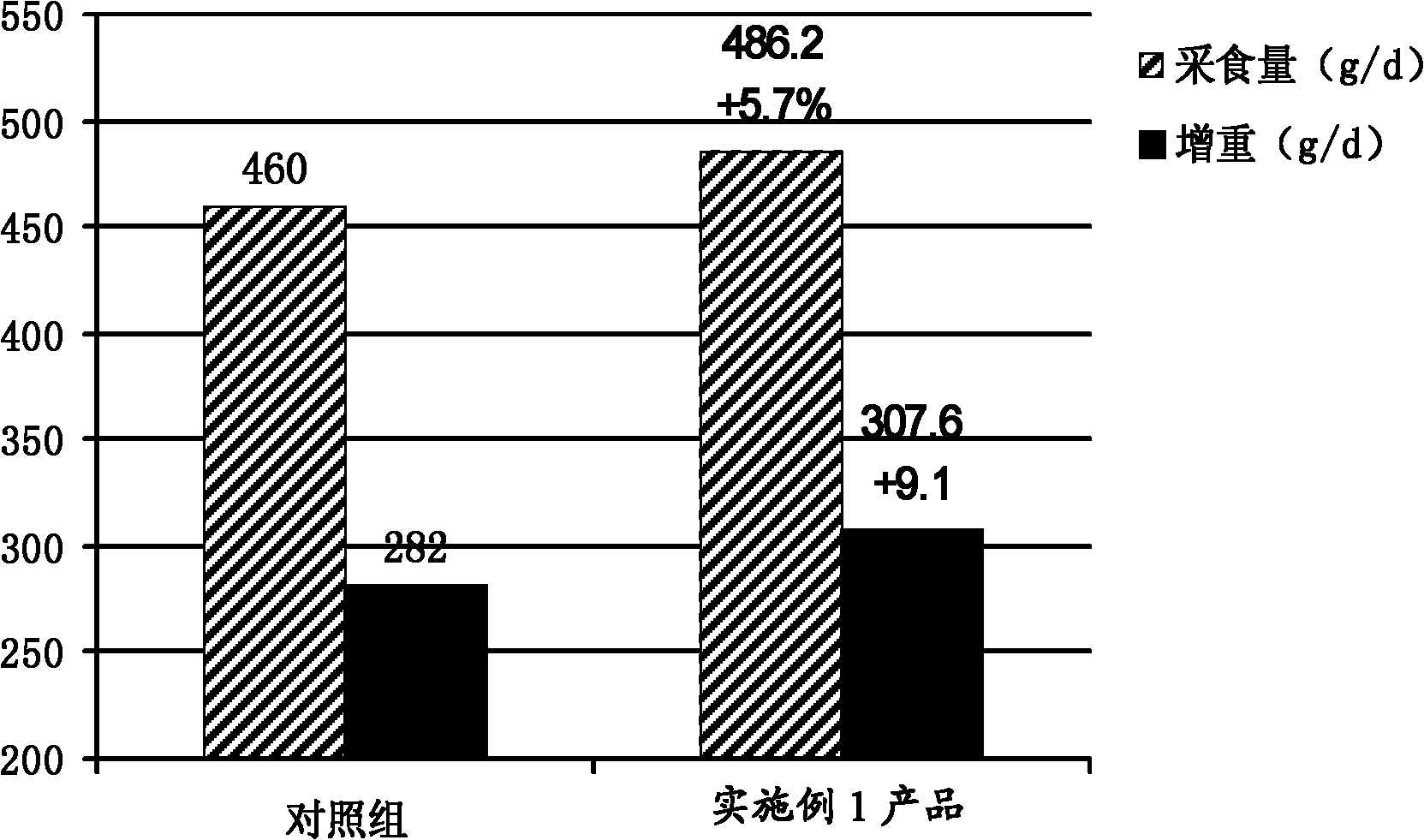

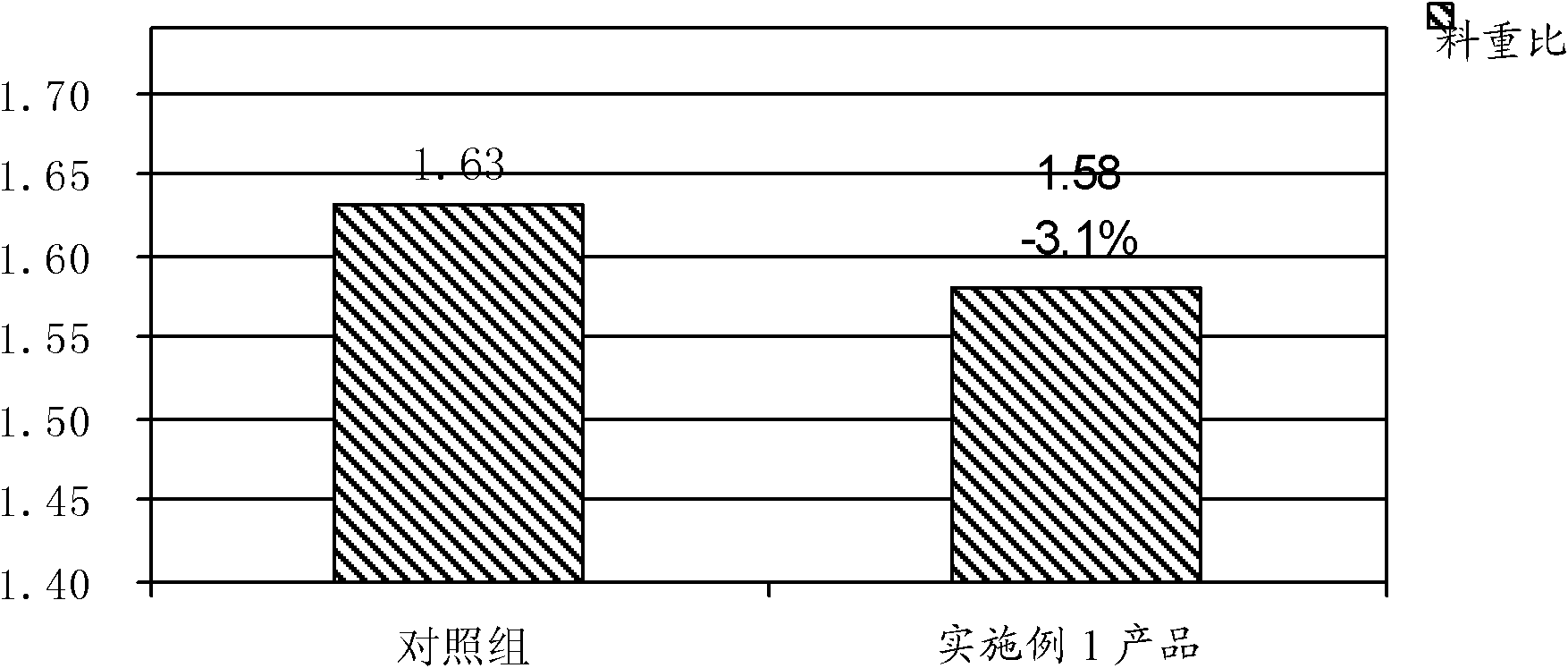

Feed compound sweetener and production method thereof

ActiveCN101965911AAvoiding the Problem of Poor Enhancer EffectsWell groomedAnimal feeding stuffAccessory food factorsFoaming agentSucrose

The invention relates to feed compound sweetener, which comprises 10 to 99 parts of saccharin or salt thereof by weight, 1 to 20 parts of synergist by weight and 0.1 to 10 parts of reinforcing agent by weight. The saccharin or salt thereof, the synergist and the reinforcing agent are heated and dissolved in water and then subjected to spray drying; preferably, the feed compound sweetener also comprises 0.1 to 5 parts of anti-caking agent by weight, which is mixed after the spray drying; and the spray drying is performed by an anti-caking device. The invention also provides a production methodof the feed compound sweetener. With skillful and unique design, the feed compound sweetener can eliminate the metal bitterness of sodium saccharin, improve the comprehensive mouthfeel of the sweetener and offer comfortable feel like the mouthfeel of cane sugar; moreover, the active ingredients are uniform so as to obtain comfortable mouthfeel of the finished products. According to the invention,the dispersion performance in feed is improved, the product stability is increased and the use convenience and effect expression is enhanced, thus the invention is suitable for large-scale popularization and application.

Owner:上海美农生物科技股份有限公司

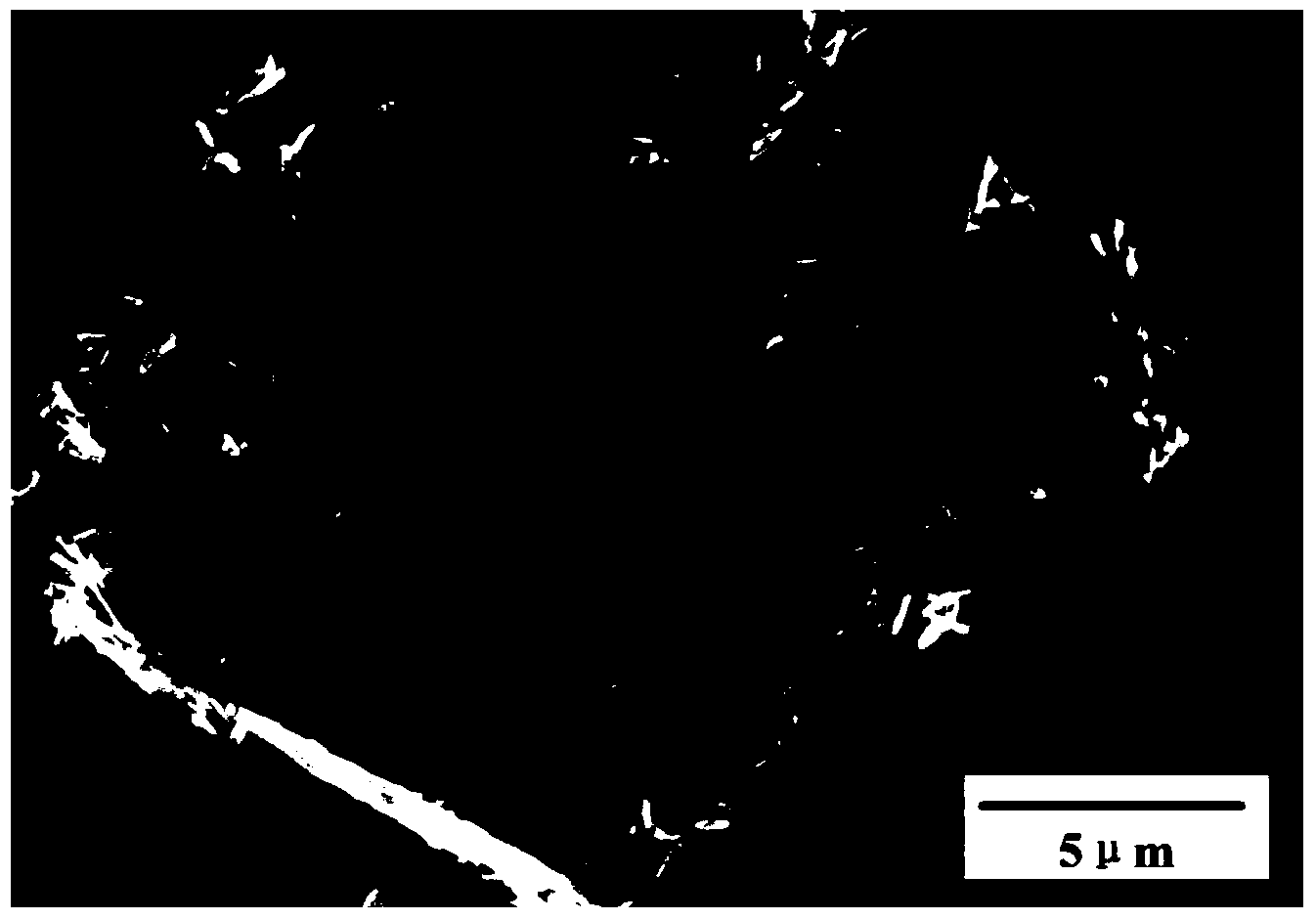

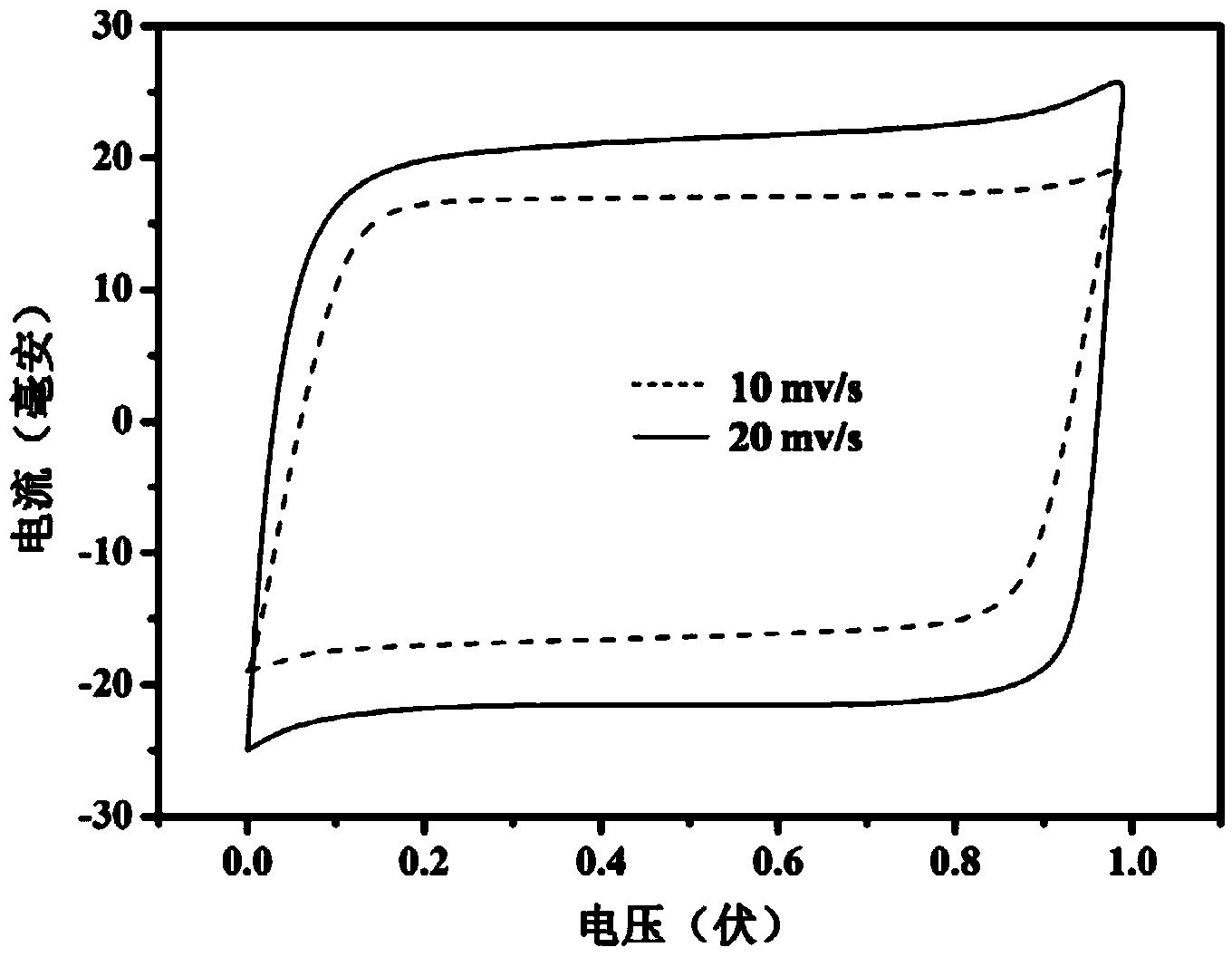

Manganese dioxide nanorod/graphene composite electrode material and preparation method thereof

InactiveCN103489660ALow costNo pollution in the processHybrid capacitor electrodesHybrid/EDL manufactureMaterials sciencePotassium permanganate

The invention belongs to the technical field of supercapacitor materials and provides a manganese dioxide nanorod / graphene composite electrode material and a preparation method thereof. The method comprises the following steps that graphite oxide is obtained through an improved Hummers method, the graphite oxide is reduced to be graphene by utilizing glucose and ammonium hydroxide, the graphene is dispersed into deionized water for ultrasonic processing and is mixed with equimolar manganese dioxide solution and potassium permanganate solution, and a precursor is obtained; hydrothermal reaction is conducted on the precursor for 8-24 hours at 120-180 DEG C; a reaction product is centrifuged, filtered, washed and dried for 24 hours at 180 DEG C, and the pure manganese dioxide nanorod / graphene composite electrode material is obtained. The preparation method of the manganese dioxide nanorod / graphene composite electrode material is simple in process and high in repeatability. The material has the good electrochemical property and is suitable for being used as an electrode material for a supercapacitor.

Owner:BEIJING UNIV OF TECH

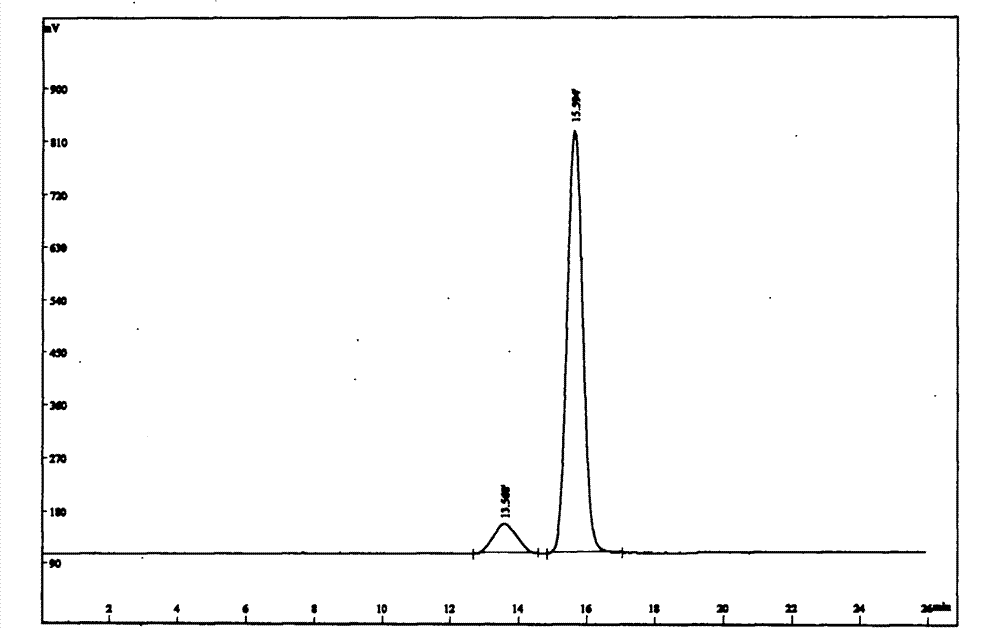

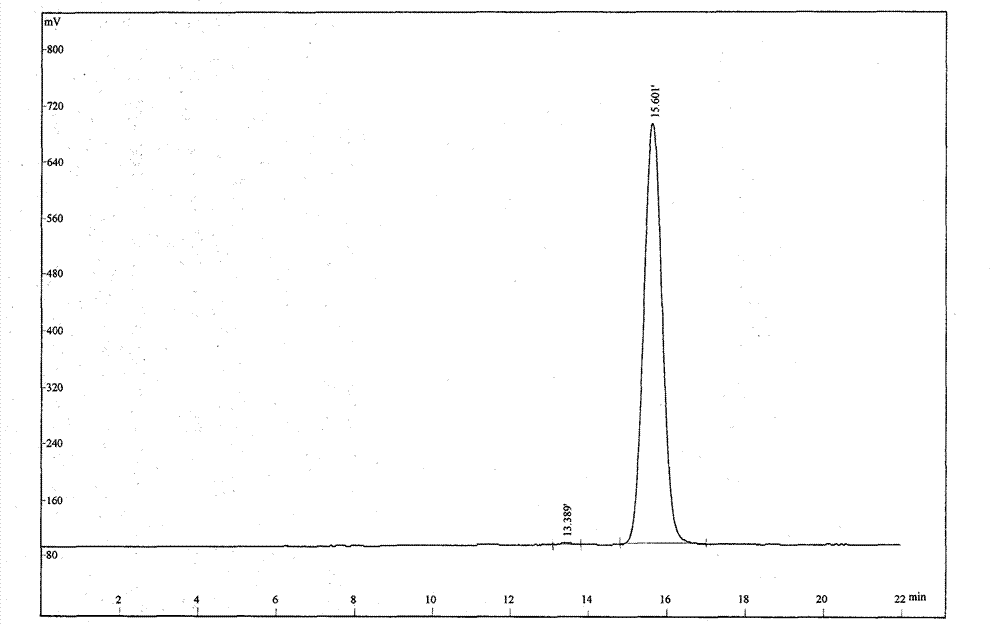

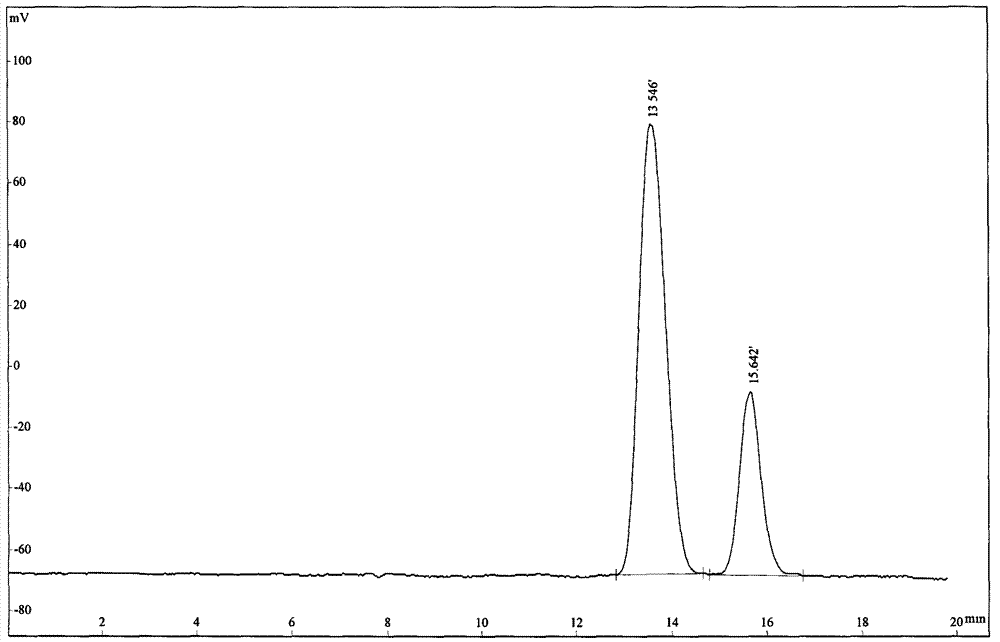

Preparation method of mannose

InactiveCN102807593AReduce viscosityOvercome the disadvantage of easy moisture absorptionSugar derivativesSugar derivatives preparationSimulated moving bedD-Glucose

The invention discloses a preparation method of D-mannose, which comprises the following steps that glucose is epimerized under a normal pressure or pressurized condition by using ammonium molybdate as catalyst to obtain mixed solution of glucose and mannose; the mixed solution is discolored, desalted and refined and then enters a simulated moving bed 1 for separation and purification to obtain a component A rich in mannose and a component B rich in glucose; the component A enters a simulated moving bed 2 for separation to obtain a component C rich in mannose and a component D rich in glucose; the component B is filtered through a membrane and then enters the step of epimerization; the component D is filtered through a membrane and then enters the simulated moving bed 1 for cyclic separation; and the component C is centrifugally spray-dried to obtain D-mannose finished products. The preparation method of the D-mannose has the advantages of simple steps and easiness in operation. The purity of the D-mannose finished products prepared by adopting the method reaches more than 99 percent and the total yield reaches 53-60.4 percent.

Owner:白心亮

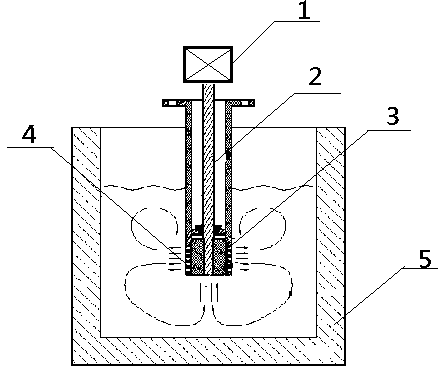

Preparation method of nano-particle reinforcement magnesium-based biocomposite material

InactiveCN103866168AImprove uniformityRefinement of Magnesium Alloy Matrix GrainCrystalliteCeramic particle

The invention relates to a preparation method of a nano-particle reinforcement magnesium-based biocomposite material. The preparation method comprises the following steps: (1) melting a matrix alloy raw material to form a melt; (2) mixing and grinding Ca-P ceramic particle powder after pre-heating treatment and pure magnesium particle powder; (3) adding the grinded mixed powder to the melt to mechanically stir, and then carrying out secondary stirring on the composite melt added with particles by adopting a melt shearing stirring device to obtain magnesium-based composite material melt sizing agent; (4) pouring the melt sizing agent into a preheating casting mould, and cooling to room temperature to obtain an as-cast magnesium-based composite material; and (5) carrying out equal channel angular pressing on the as-cast magnesium-based composite material after heating to improve distributive uniformity of the ceramic particles to prepare the target object, namely the nano-particle reinforcement magnesium-based biocomposite material. By utilizing the preparation method, distributive uniformity of ceramic phase particles in a magnesium metallic matrix can be improved, grain size of the magnesium metallic matrix can be thinned, and combination property of the magnesium-based composite material can be improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

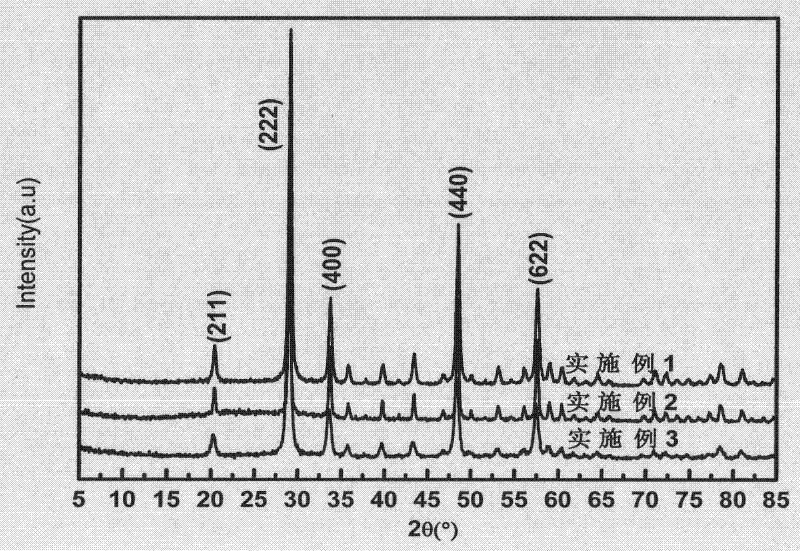

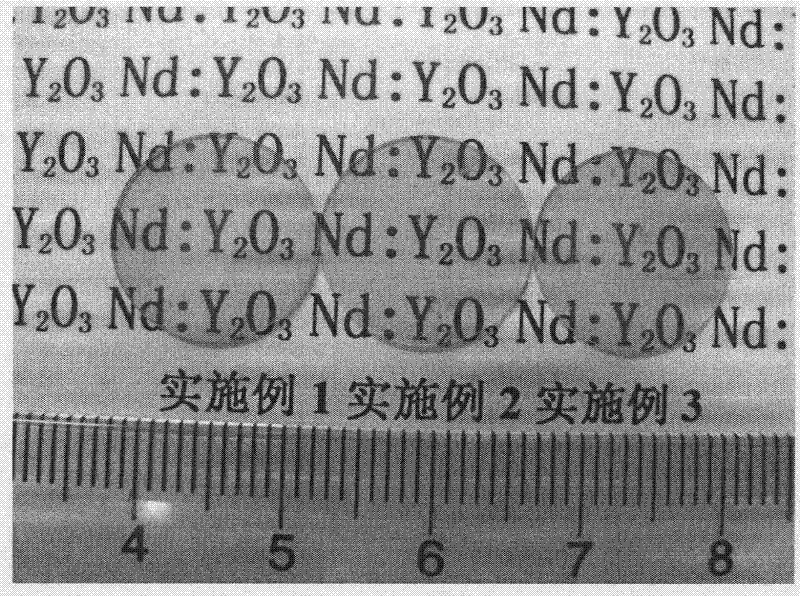

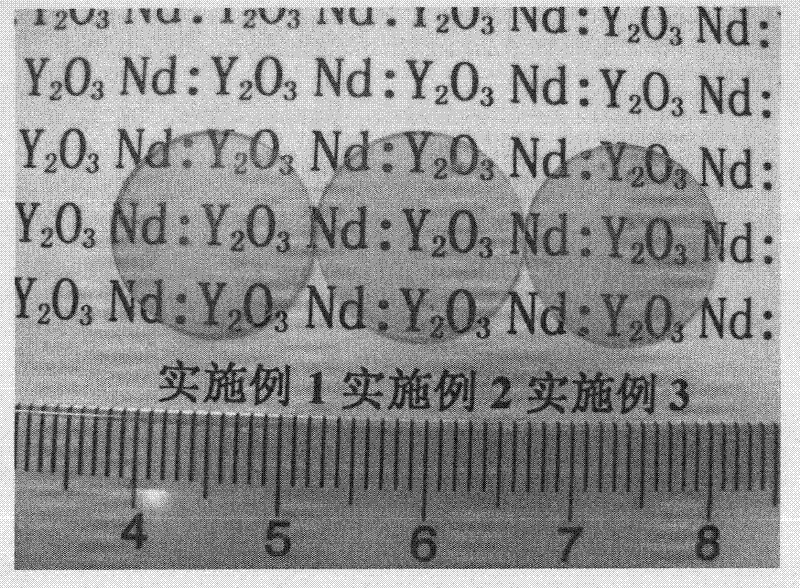

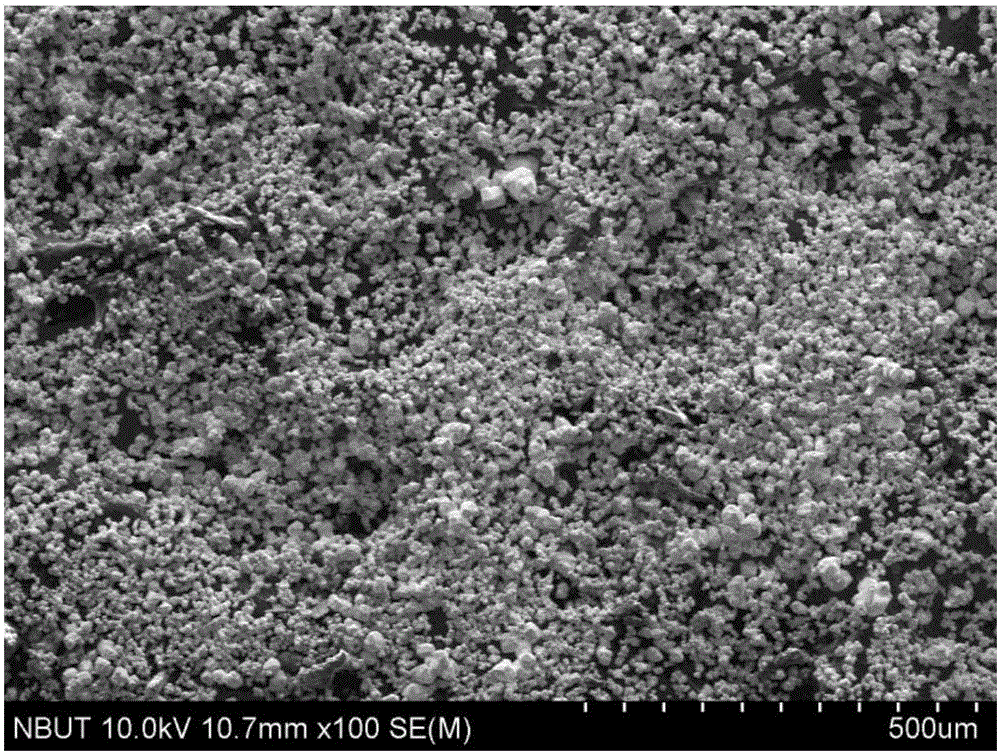

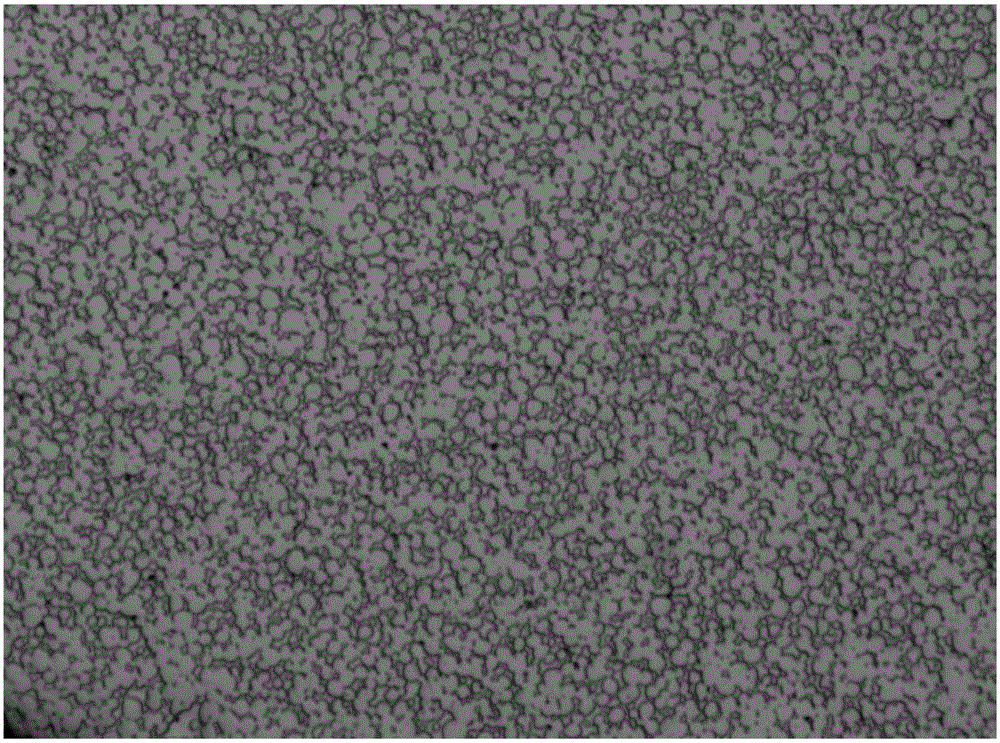

Preparation method of transparent yttria ceramic

The invention discloses a preparation method of transparent yttria ceramic, in particular relates to an ammonium bicarbonate co-precipitation method of Nd:Y2O3 nano powder. The method comprises the following steps: slowly dropwise adding a precipitator ammonium bicarbonate solution in a mixed solution prepared from yttrium, doped rare earth ion, (NH4)2SO4, polyacrylic acid (PAA) and MgSO4.7H2O at room temperature by using a positive-titration method so as to prepare a precursor, washing and drying; then calcining; carrying out preliminary press molding, cold isostatic pressing, vacuum sintering, annealing and polishing to obtain the transparent yttria ceramic. In the method, self-made high-activity nano powder is used for preparing the transparent yttria ceramic at low temperature; and the process is simple and practicable, and the prepared transparent yttria ceramic has a good optical property.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Modification method for super-hydrophobic packing particle for anti-contamination flashover coating and application

InactiveCN107760065AElimination of hydroxylReduce clumpingCoatingsPigment treatment with organosilicon compoundsPolymer scienceContamination

The invention discloses a modification method for super-hydrophobic packing particles for an anti-contamination flashover coating and application. The modification method comprises the following steps: 1) preparing a packing particle dispersion; 2) preparing an ethanol dispersion of a fluorinated silane coupling agent, and adjusting the pH value of the ethanol dispersion of the fluorinated silanecoupling agent to 3-5; 3) adding the fluorinated silane coupling agent into the dispersion obtained in the step 2), performing ultrasonic treatment to sufficiently hydrate the fluorinated silane coupling agent so as to obtain a fluorinated silane coupling agent solution for later use; 4) adding the fluorinated silane coupling agent solution prepared in the step 3) into the dispersion with the packing particles prepared in the step 1), and performing a heating stirring reaction to modify the surfaces of the packing particles; 5) drying the modified material, and grinding, thereby obtaining themodified packing particles. According to the modification method, the surfaces of the packing particles for the anti-contamination flashover coating are modified by using the fluorinated silane coupling agent, then the surfaces of the packing particles are hydrophobic but oleophilic, furthermore the hydrophobicity of the coating is improved, and the hydrophobic angle can be up to 150 degrees or larger.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Tungsten-copper alloy and production method thereof

ActiveCN106435319AGood dispersionReduce clumpingTransportation and packagingMetal-working apparatusDispersityCompression molding

The invention belongs to the field of alloy material production, and particularly relates to tungsten-copper alloy and a production method thereof. The tungsten-copper alloy and the production method thereof aim to solve the problem that alloy structures are not uniform because of two-phase segregation of tungsten and copper in tungsten-copper alloy produced through existing methods. According to the production method, after tungsten powder undergoes plasma spheroidization, copper powder serves as an inducer for chemical copper plating, then compression molding, pre-sintering and tungsten-copper infiltration are carried out, and finally the tungsten-copper alloy with uniform structures can be obtained. According to the method, the shape of the tungsten powder is changed into a spherical shape from a polygonal shape, the dispersity is improved, and uniform distribution of the tungsten and the copper in the chemical copper plating process is guaranteed. According to the produced alloy material, two-phase composition segregation of the tungsten and the copper can be effectively prevented, the thermal conductivity, the electrical conductivity, the arc ablation resistance, the high temperature performance, the plasticity and the machinability of the alloy material are greatly improved, and the alloy material can be widely applied to heat sink materials, encapsulating materials and high explosive anti-tank cartridge liner materials.

Owner:四川恒珲新材料科技有限公司

Preparation method for carbon nano-tube/epoxy resin high-performance composite material

The invention relates to a preparation method of an amino carbon nano tubes / epoxy resin high performance composite. The carbon nano tubes with amino are prepared through surface chemical modification to the carbon nano tubes by polyamine compound. The dispersion of the carbon nano tubes in the epoxy resin is improved; the connect force between the carbon nano tubes and the epoxy resin is enhanced, so that the high performance epoxy resin composite is obtained through proper ultrasonic oscillation and strong stirring dispersion and through the amino on the amino carbon nano tubes having cross-linking reaction with epoxy groups in the epoxy resin.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com