Method for preparing antioxidant soldering powder

An anti-oxidation and solder powder technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as unstable solder paste viscosity, affecting solder paste quality and welding reliability, and prone to tin beads, etc., to reduce agglomeration Phenomenon, enhanced antioxidant performance, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

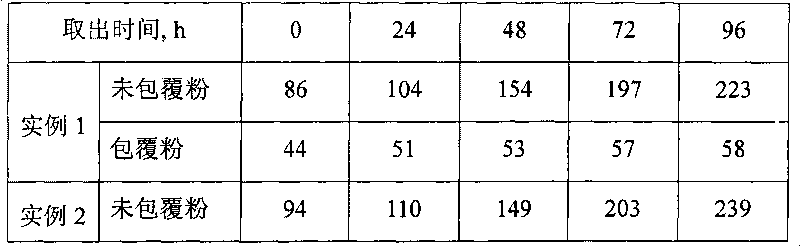

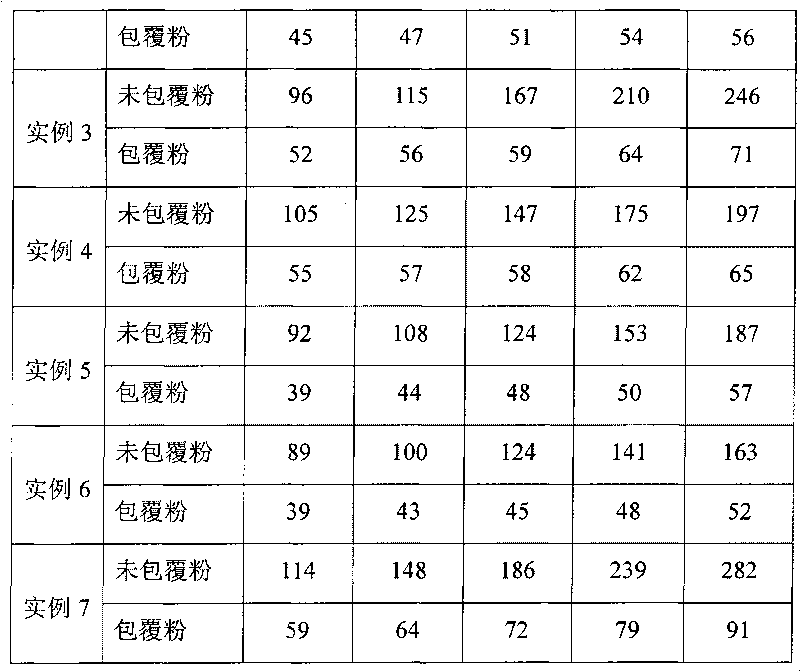

Examples

Embodiment 1

[0028] Coating solution ratio (wt%):

[0029] Malonic acid 2

[0030] Oleic acid 5

[0031] Sebacic acid 2

[0032] Nonylphenol polyoxyethylene ether OP-10 8

[0033] Diethylene glycol 20

[0034] N-Methylpyrrolidone Balance

[0035] The solder powder used is SnAgCu305 4# powder.

[0036] Heat 500g of the coating solution to 145-150°C, add 200g of solder powder, stir to suspend the solder powder in the coating solution, keep it for 20min, filter, and rinse with a 1:1 mixed solution of absolute ethanol and acetone to remove Excess coating solution on the surface of solder powder. Spread the solder powder over a large area, and dry it in vacuum at 40° C. for 1 hour to obtain coated solder powder.

Embodiment 2

[0038] Coating solution ratio (wt%):

[0039] Succinic acid 15

[0040] Glutaric acid 10

[0041] Benzotriazole 2

[0042] Diethylene glycol octyl ether balance

[0043]The solder powder used is SnAgCu305 5# powder.

[0044] Heat 500g of the coating solution to 145-150°C, add 200g of solder powder, stir to suspend the solder powder in the coating solution, keep it for 15min, filter, and rinse with a 1:1 mixed solution of absolute ethanol and acetone for several times to remove Excess coating solution on the surface of solder powder. Spread the solder powder over a large area, and dry it in vacuum at 40° C. for 1 hour to obtain coated solder powder.

Embodiment 3

[0046] Coating solution ratio (wt%):

[0047] Lactic acid 5.5

[0048] Glutaric acid 3

[0049] p-tert-Butylbenzoic acid 1

[0050] Fatty alcohol polyoxyethylene ether AEO-8 20

[0051] Diethylene glycol butyl ether balance

[0052] The solder powder used is SnBi58 3# powder.

[0053] Heat 500g of the coating solution to 103-108°C, add 500g of solder powder, stir to suspend the solder powder in the coating solution, keep it for 30min, filter, rinse with acetone several times to remove excess coating solution on the surface of the solder powder. Spread the solder powder over a large area, and dry it in vacuum at 40° C. for 1 hour to obtain coated solder powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com