Bag-in-container with prepressurized space between inner bag and outer container

a bag-in-container and prepressurized technology, applied in rigid containers, pliable tubular containers, transportation and packaging, etc., can solve the problems of uncontrollable bag collapse, inability to connect to a source of pressurized gas, and inability to control the collapse of the bag, so as to prolong the shelf life of the fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The Bag-In-Container

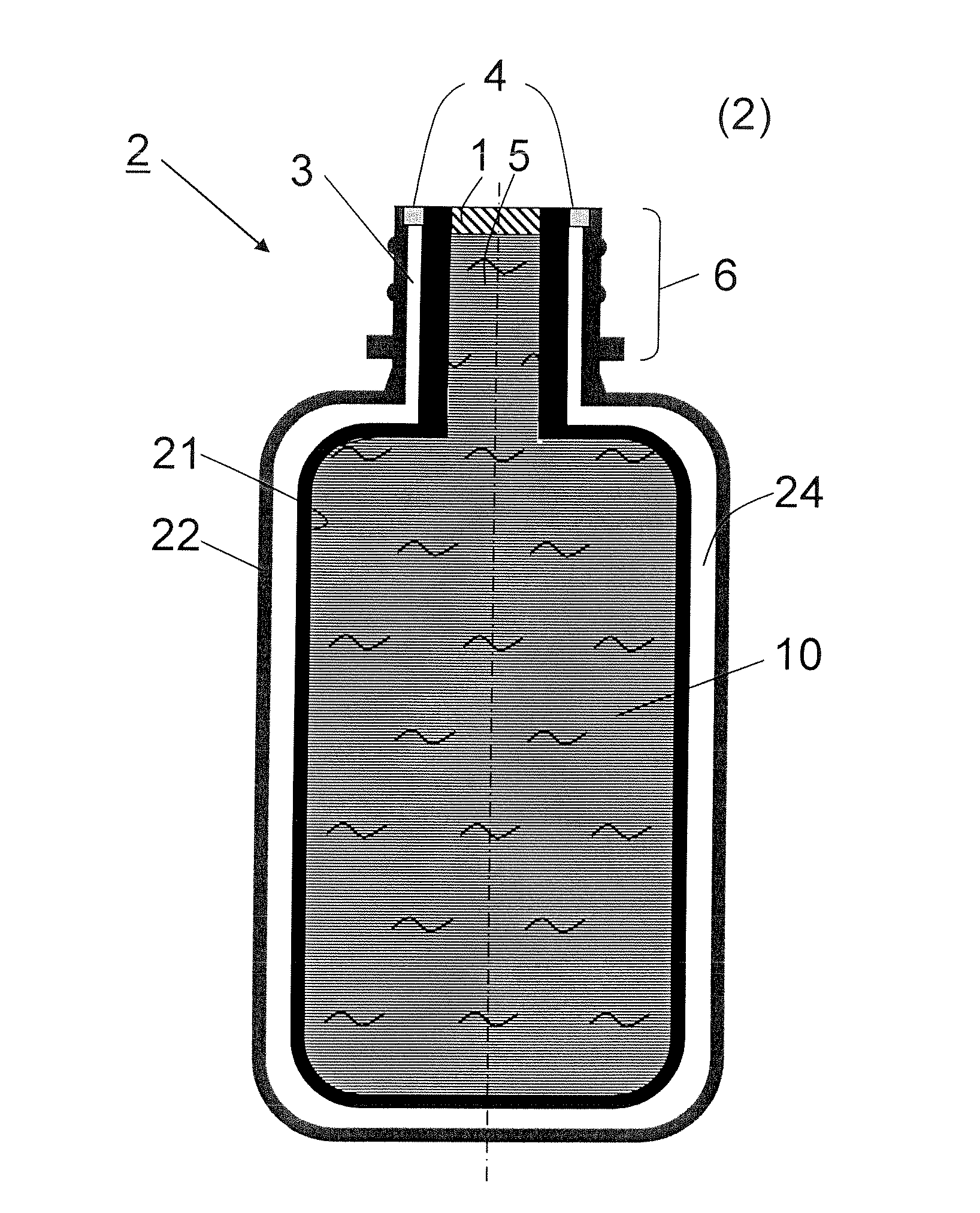

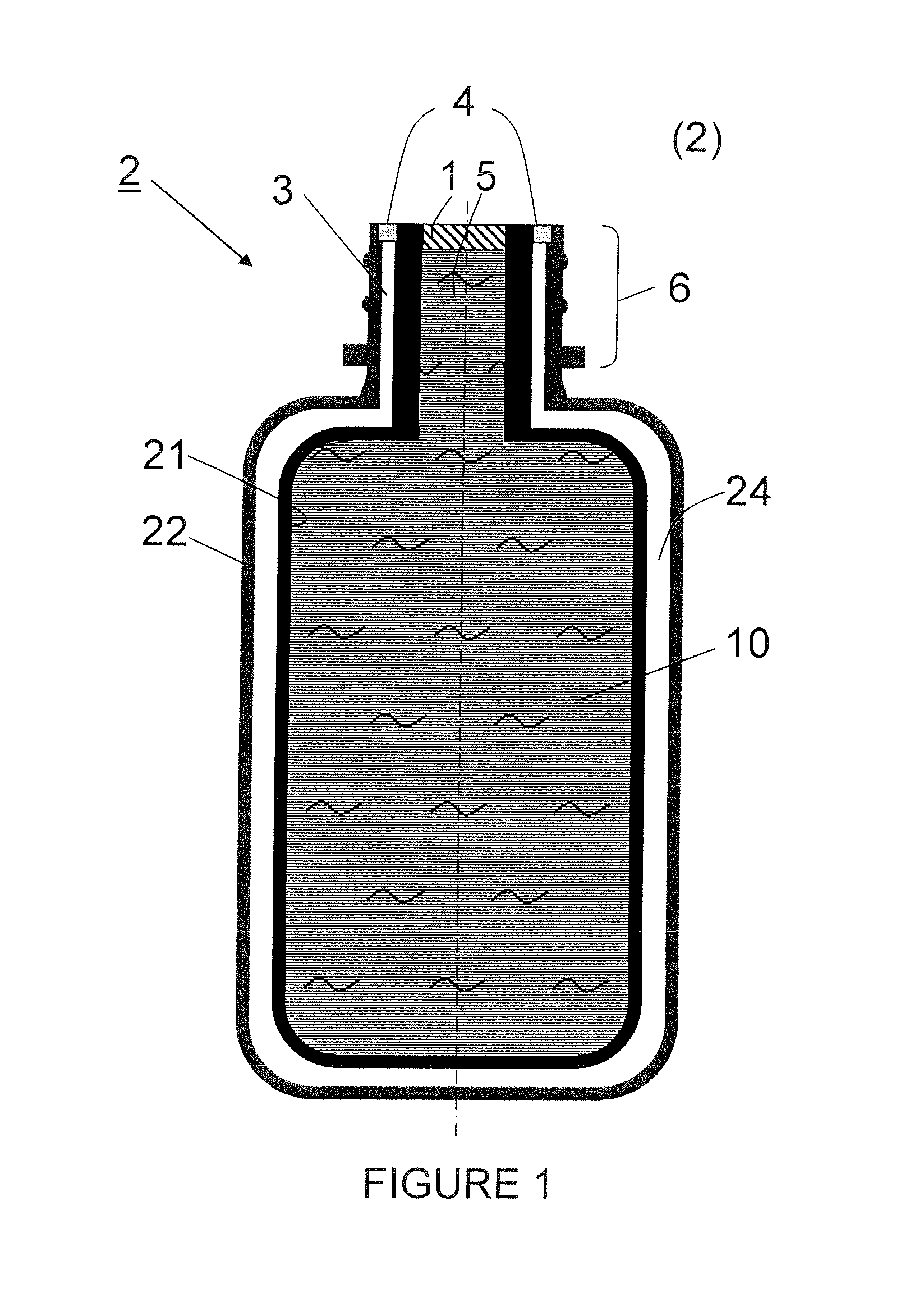

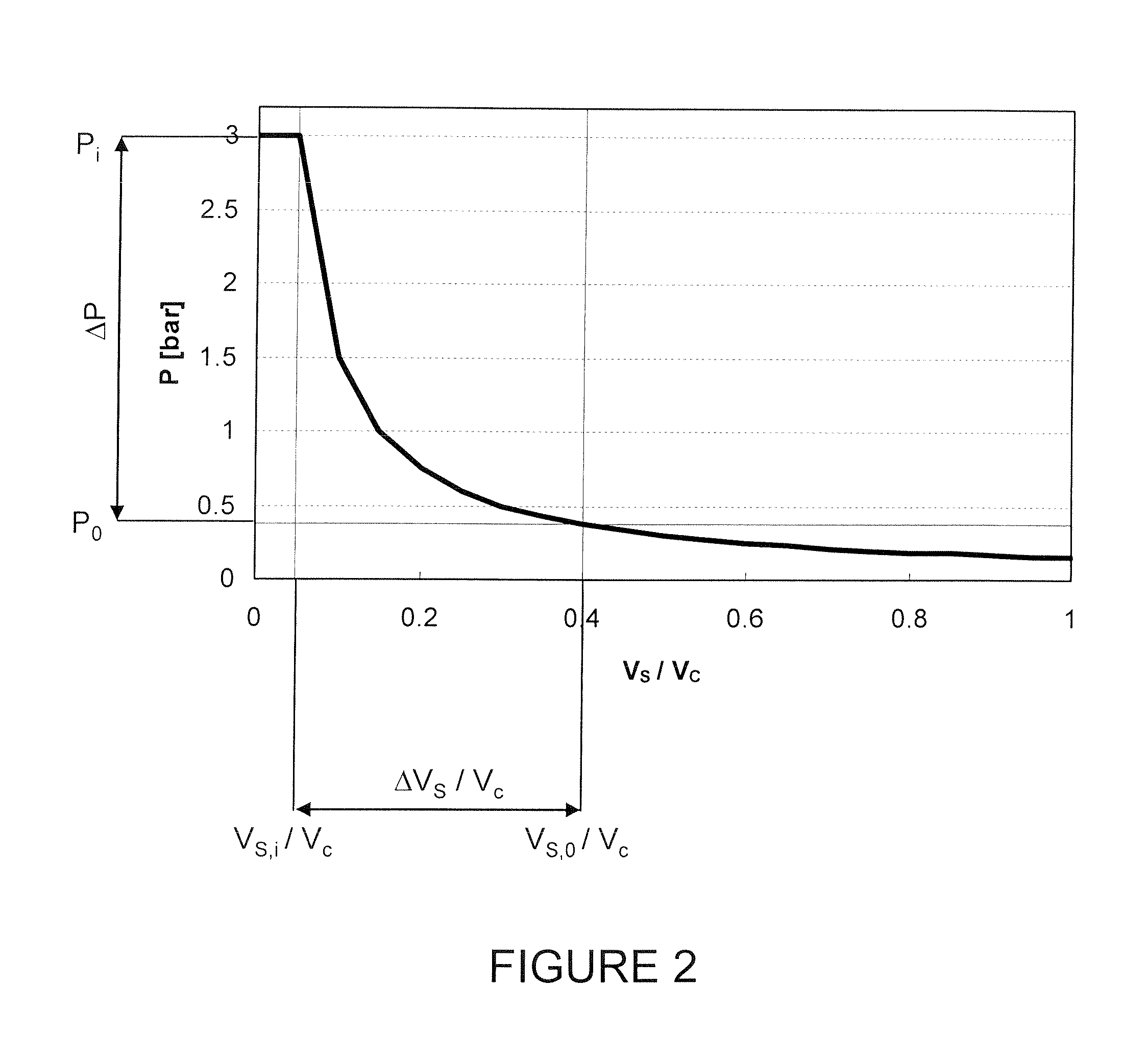

[0030]Referring now to appended FIG. 1, there is illustrated a bag-in-container (2) comprising an inner bag (21) filled with a fluid (10) and an outer container (22) joined at least at the level of the neck region (6) by an interface (not shown in the Figure). The space (24) of volume (VS,i) between the inner bag and outer container (21) and (22) is in fluid communication with at least one vent (3) and is filled with a certain amount of pre-pressurizing gas at a pressure (Pi) stored in the initial space volume (VS,i) which will be defined below. Said vent is separated from the atmosphere by closing means (4) suitable for controlling the gas flow across the vent (3). A closing means is herein considered as controlling the flow across vent (3) if it can alternate at least once from a closed position preventing any gas flow, to an open position allowing gas flow across vent (3). A simple stopper or cap usually found in pressurized bag-in-containers is not considered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com