Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Improves Antioxidant Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-chromium high-resistance electrothermal alloy

ActiveCN101899593AImproves antioxidant propertiesUniform heatingOperating temperatureOxidation resistant

The invention discloses a nickel-chromium high-resistance electrothermal alloy. The alloy is characterized by comprising the following components in percentage by mass: 0.02 to 0.06 percent of C, 0.010 to 0.020 percent of P, 0.010 to 0.015 percent of S, 0.02 to 0.60 percent of Mn, 1.00 to 1.50 percent of Si, 20.0 to 23.0 percent of Cr, 0.1 to 0.20 percent of Al, 0.4 to 0.8 percent of Fe, 0.1 to 0.20 percent of Ti, 0.20 to 0.50 percent of Zr, 0.01 to 0.05 percent of RE and the balance of Ni. Metal zirconium and a rare-earth material are added into a metal alloy, the zirconium is contacted with the air to form a zirconia protective layer, so that the surface oxidation resistance of the alloy is greatly improved; and moreover, far infrared rays can be generated, and heating is uniform, so that the highest operating temperature of the alloy steel can be up to 1,300 DEG C, and the surface load of the alloy steel can be up to 5 W / cm<2>.

Owner:JIANGSU LIXIN ALLOY IND GENERAL

Preparation method of coated copper-silver metal powder

InactiveCN101664803AIncrease contact areaImproves antioxidant propertiesLiquid/solution decomposition chemical coatingNitrogen gasCopper

The invention discloses a preparation method of coated copper-silver metal powder which contains the pretreatment of copper powder, the preparation of silver solution and the preparation of copper-silver metal powder, wherein the preparation method of copper-silver metal powder comprises the following steps: dropwise adding dilute nitric acid in the sol of copper powder to adjusting the pH value to 3.0-5.0, adding ionic masking agent with the dosage of 1-30g / L, fully stirring, injecting inert protective gas such as nitrogen, argon or the like to remove the air in a reactor for protection, thenslowly dropping silver nitrate solution in the sol of copper powder while stirring to fully react for 30min, then dropping dilute ammonia water to adjusting the pH value to 7.0-11.0, continuously reacting for 30min, washing the reaction solution with deionized water, 5% of dilute sulphuric acid and ethanol solution for several times after the reaction and drying the obtained copper-silver metal powder at 60-80 DEG C to obtain the finished product. The product obtained by the method of the invention has excellent high temperature oxidation resistance and conductivity and narrow particle size distribution.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

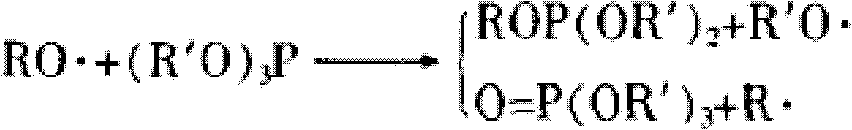

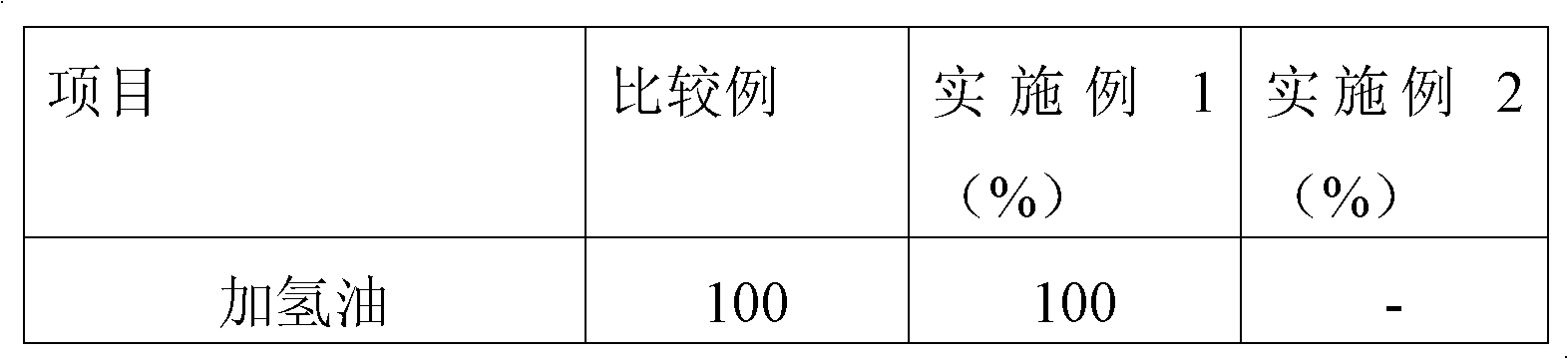

Screw air compressor oil composition

InactiveCN103184090AImproves antioxidant propertiesSludge formation trend is goodAdditivesCorrosionSemi synthetic

The invention relates to a screw type air compressor oil composition, by calculating the weight of base oil as 100%, the screw type air compressor oil composition comprises the following components: 1-5% of high temperature anti-oxidant, 0.01-5% of extreme-pressure anti-grinding agent, 0.01-0.5% of corrosion resistance agent and 0.01-0.5% of antirust agent, wherein the high temperature anti-oxidant is composed of an amine type anti-oxidant, a phenol type anti-oxidant and a phosphite type anti-oxidant, and the weight ratio of amine type anti-oxidant to phenol type anti-oxidant to phosphite type anti-oxidant is 20: 30: 50-50: 30: 20; the phosphite type anti-oxidant is introduced in the screw compressor oil, and is synergized with the phenol or amine type anti-oxidant, compared with a common amine and phenol type anti-oxidant system, the antioxidation performance of the oil product can be greatly increased, the oil sludge generation trend can be better controlled, and the composition is suitable for the screw compressor oil which takes hydrogenation oil, PAO synthetic oil and semi-synthetic oil as base oil.

Owner:PETROCHINA CO LTD

Preparation method of water-resistant soy protein adhesive

ActiveCN108624285AHigh reactivityImproves antioxidant propertiesNon-macromolecular adhesive additivesProtein adhesivesEndopeptidaseSolvent

Owner:广东合顺涂层材料有限公司

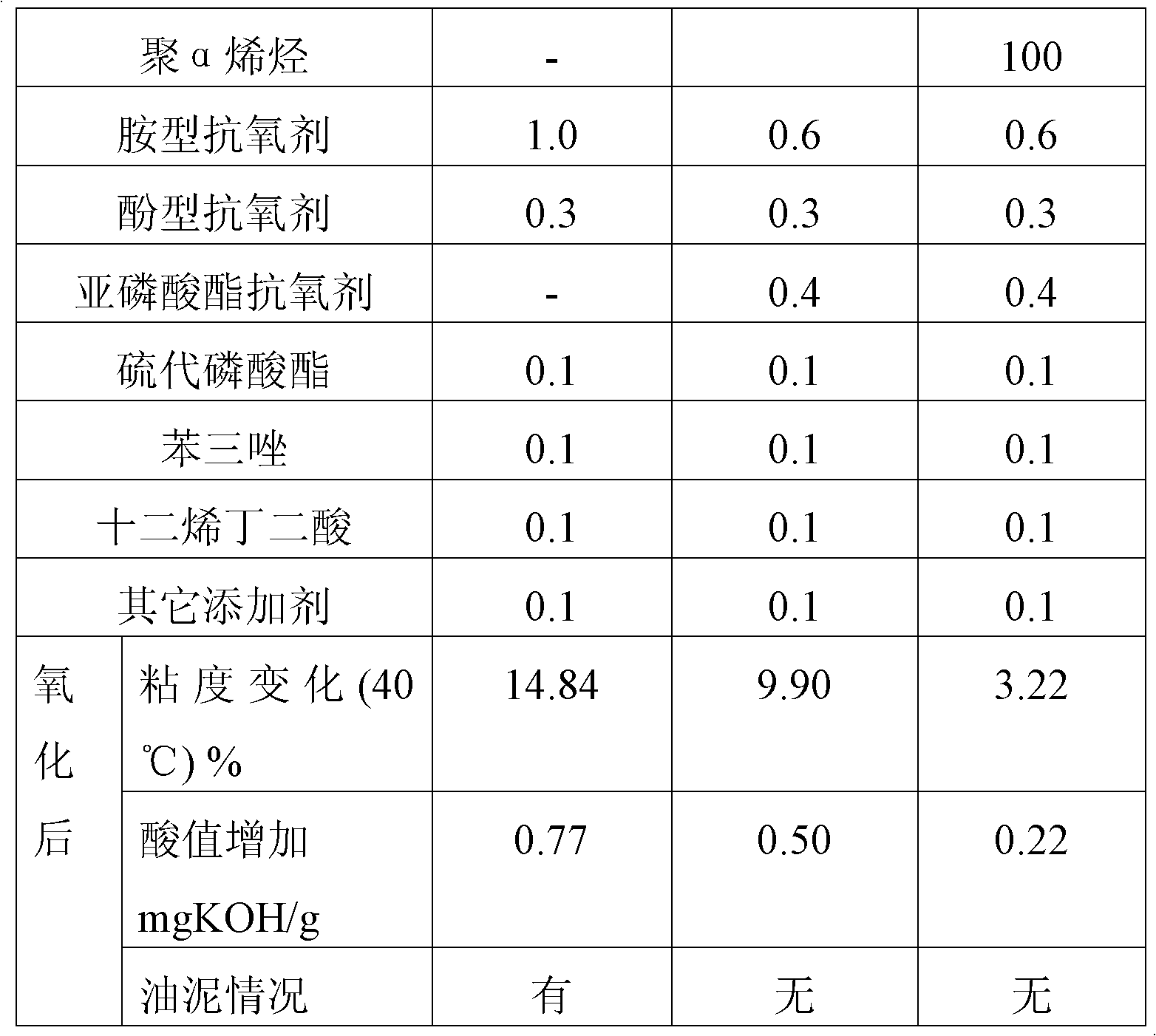

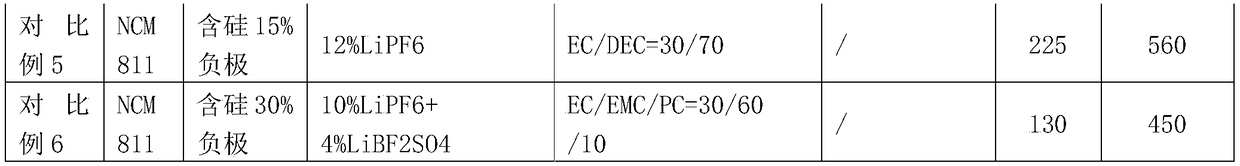

High-energy-density lithium-ion battery electrolyte

InactiveCN109301324AImproves Antioxidant PropertiesImprove compatibilityFinal product manufactureSecondary cells servicing/maintenanceOrganic solventHigh energy

The invention provides a high-energy-density lithium-ion battery electrolyte prepared from, by weight, 20-60% of lithium salt, 20-60% of a non-aqueous organic solvent and 0.5-10% of an additive, all the components adding to 100%. The lithium salt includes lithium hexafluorophosphate, lithium bifluorosulfonimide and lithium sulfate difluoroborate. The electrolyte is very short in self-extinguishingtime and is even incombustible, wherein the additive has excellent film-forming effect, so that an SEI film, having ultralow resistance and high thermo-stability, can be formed between cathode-anodeinterfaces.

Owner:TIANJIN ENERGIES

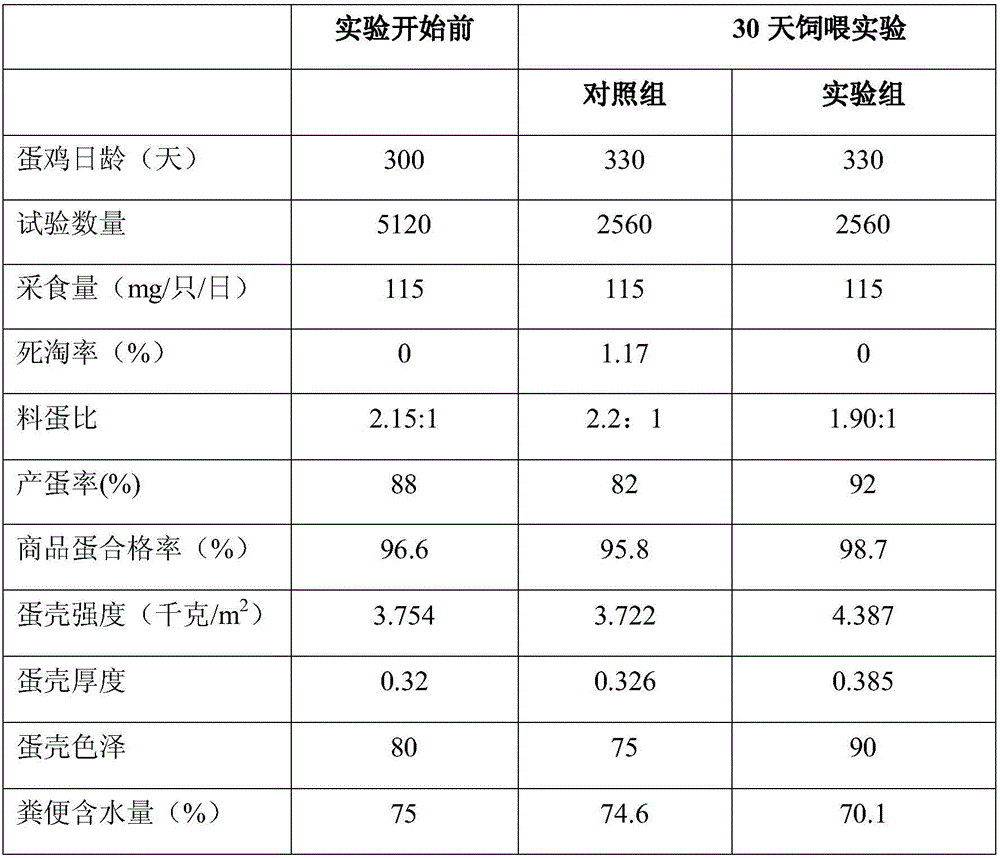

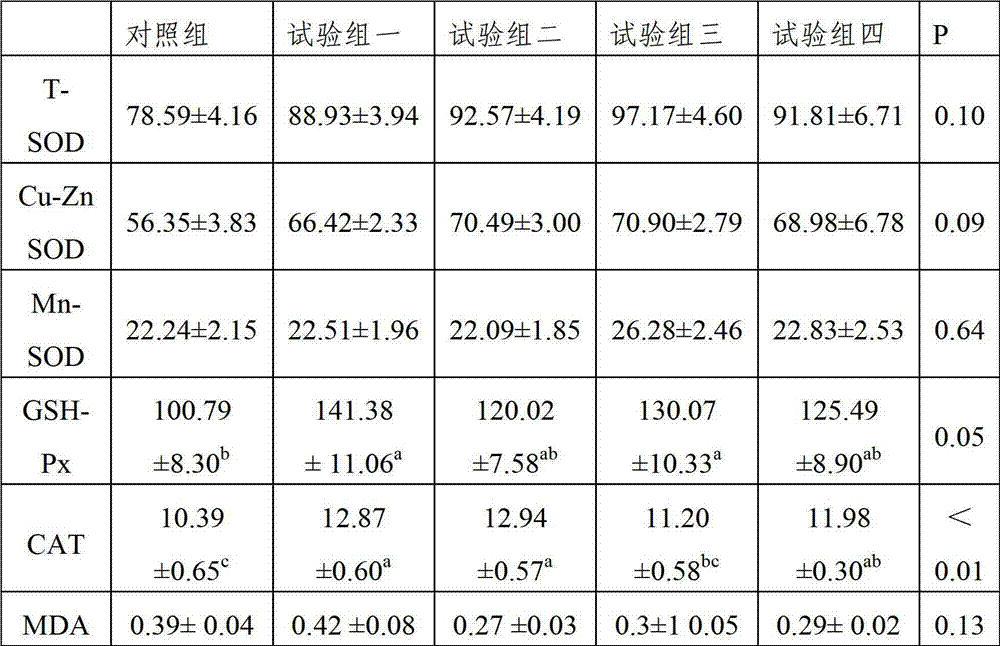

Premix mate for laying hens in egg producing period and preparation and application of premix mate

InactiveCN106615933AIncrease egg productionEasy to remove hairFood processingAnimal feeding stuffSodium bicarbonateMycoprotein

The invention provides a premix mate for laying hens in an egg producing period and a preparation and application of the premix mate and belongs to the field of animal feeds. The premix mate for the laying hens in the egg producing period is prepared from the following raw materials in parts by weight: peanut meal, hot chili residues, fermented cake meal and amino acid, sodium bicarbonate, betaine, hemoprotein, limestone powder, mycoprotein, a shell treasure, calcium hydrophosphate, quercetin, a mildew inhibitor, perennial sowthistle powder, compound probiotics and the like. According to the premix mate for the laying hens in the egg producing period, one part of bean pulp in a complete formula feed can be replaced, the antioxidant activity of the laying hen bodies can be effectively improved, the digestion and absorption rate and the conversion rate of the laying hens in the egg producing period are effectively improved, the immunity is significantly improved, healthy intestinal tracts of the laying hens are ensured, too thin faeces are prevented, unhairing of the egg producing period is improved and slow growth condition of feather is improved. For the conditions of poor quality of egg shells, multiple broken eggs and a short peak laying period, the colors and the quality of the egg shells are effectively improved, the health of bodies is promoted, the production performance is improved and the egg production period is prolonged.

Owner:ZHENGZHOU HEFENG ANIMAL HUSBANDRY +1

Preparation method of hard composite carbon fiber heat insulation material

InactiveCN102531658AIncreased interlaminar shear strengthImproves antioxidant propertiesAntioxidantGraphite

The invention relates to a preparation method of a hard composite carbon fiber heat insulation material, belonging to the technical field of the surface treatment process of heat insulation materials. The preparation method comprises the following steps: (1) soaking a blank made of soft carbon felt into a binding agent mixed with a surfactant, and fully and uniformly stirring; (2) curing the material obtained in the step (1), then coating a layer of antioxidant on the surface of the cured blank and drying; and (3) placing the blank dried in the step (2) into a high-temperature graphitizing furnace, and performing high-temperature graphitizing at the temperature higher than 2200 DEG C to finally obtain the high-performance hard composite carbon fiber heat insulation material. According to the preparation method disclosed by the invention, the binding agent and the carbon felt are mixed fully, the interlayer viscosity of the carbon felt can be enhanced, inter-layer shearing strength and anti-oxidation performance are improved, and the degree of graphitizing is higher and fuller; moreover, volatile substances can be effectively prevented from invading the inner layer of a graphite felt and the service life is further prolonged.

Owner:HUNAN HAIXIN NEW MATERIALS

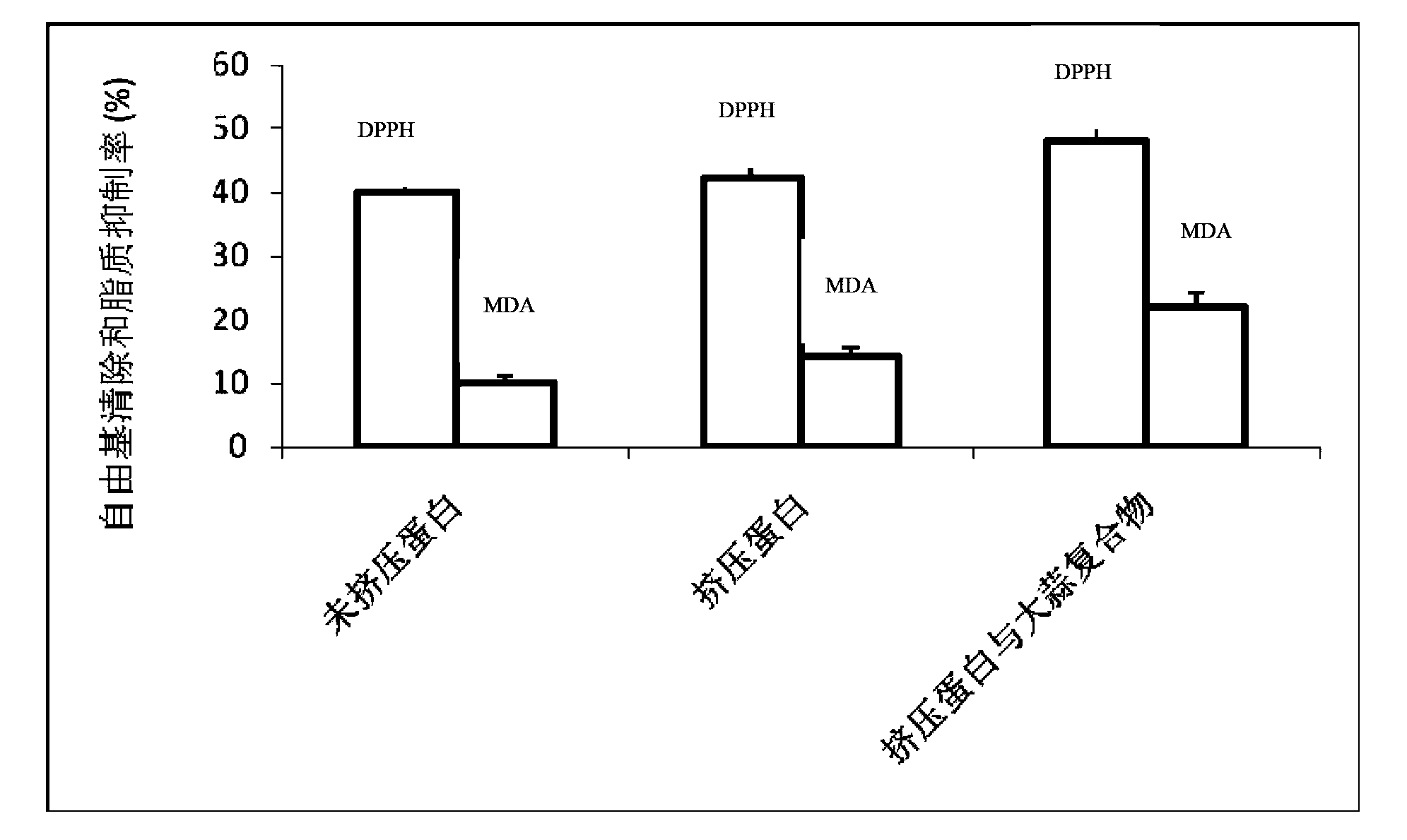

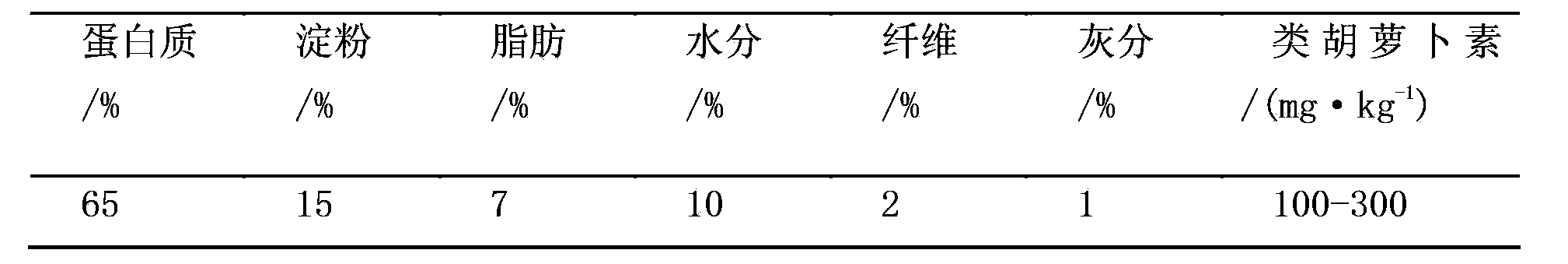

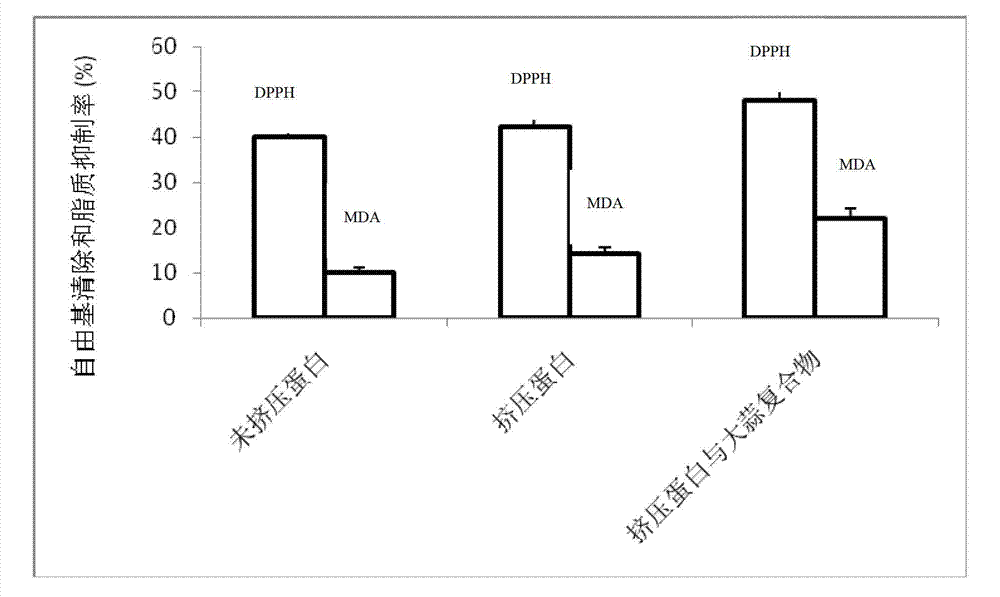

Preparation method for corn protein film with high antioxidation characteristic

The invention discloses a preparation method for a corn protein film with a high antioxidation characteristic. The preparation method comprises the following steps: adding water in corn protein powder, carrying out extruding by using a twin screw extruder and carrying out preprocessing; subjecting garlic to peeling and crushing, adding deionized water and carrying out extraction, filtration, concentration and drying so as to obtain an aqueous garlic extract; adding extruded corn protein powder into an aqueous solution of ethanol and carrying out extraction, concentration and drying so as to obtain zein; and adding the aqueous garlic extract and the aqueous solution of ethanol into the zein, carrying out stirring, adding glycerol, continuing stirring and carrying out coating so as to obtain the corn protein film with the high antioxidation characteristic. According to results of experiments in the invention, the corn protein film with the high antioxidation characteristic has high capability in removing DPPH free radicals and a high inhibitory effect on lipid peroxidation.

Owner:万洲胶粘制品(江苏)有限公司

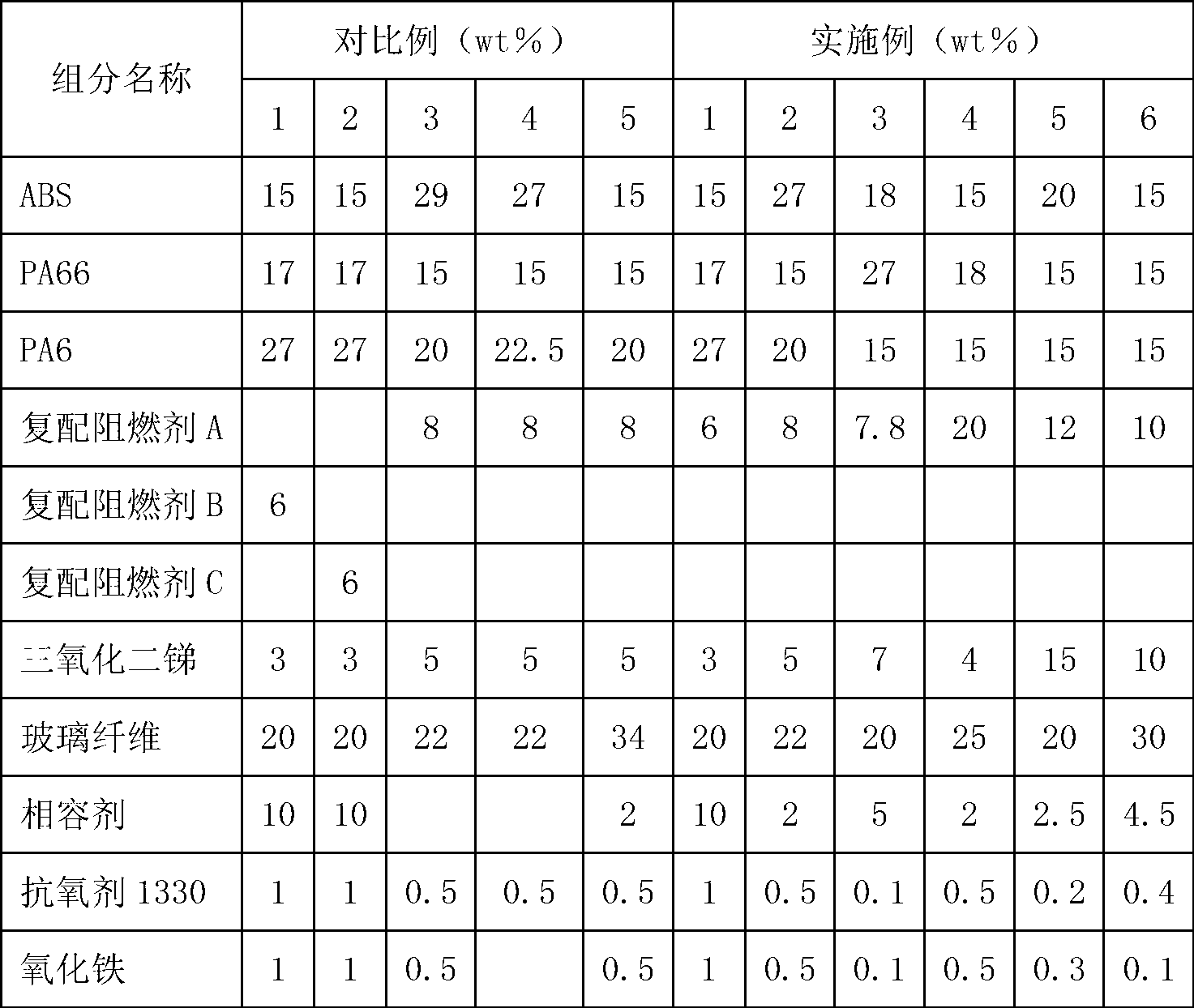

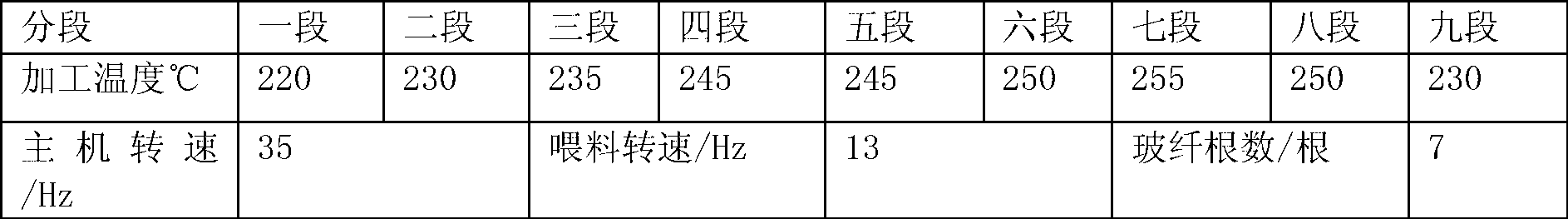

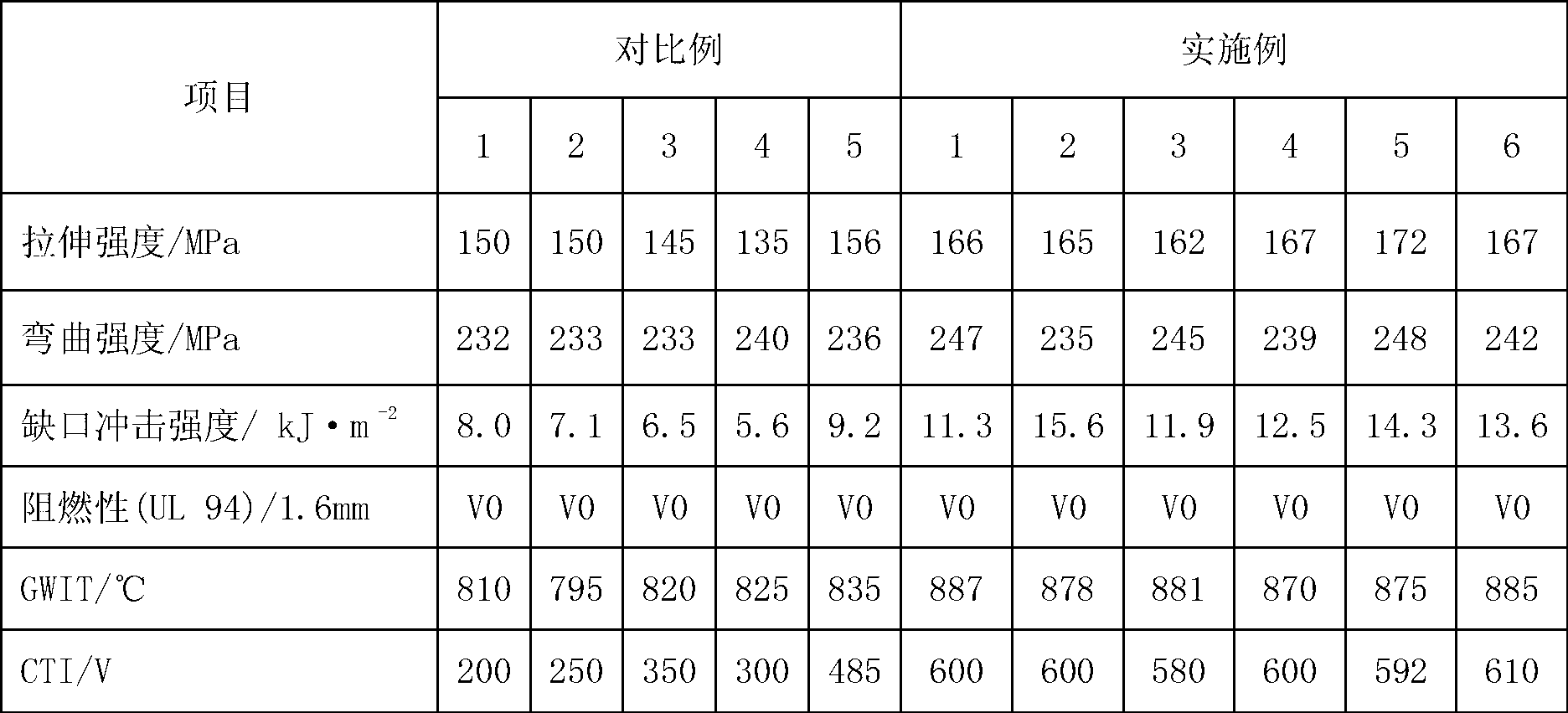

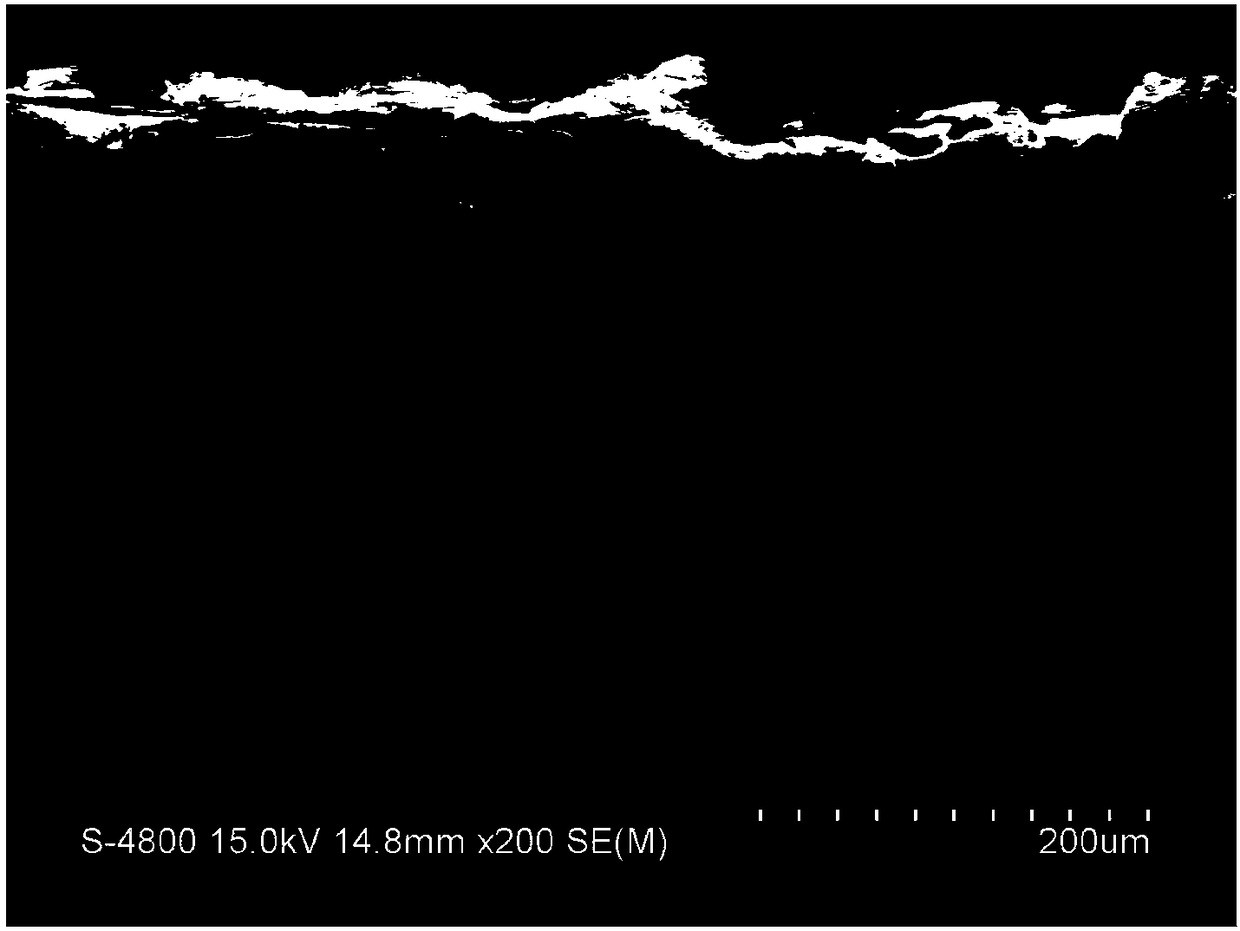

Flame-retardant glass fiber-reinforced ABS/PA6/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced ABS / PA6 / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 15 to 27% of ABS, 15 to 27% of PA66, 15 to 27% of PA6, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. In preparation of the alloy material, all the components are added into a high-speed mixer for mixing for 2 to 5 min, and then discharging and extrusion granulation are carried out, wherein extrusion temperature is 220 to 255 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness, balanced comprehensive properties and the like and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

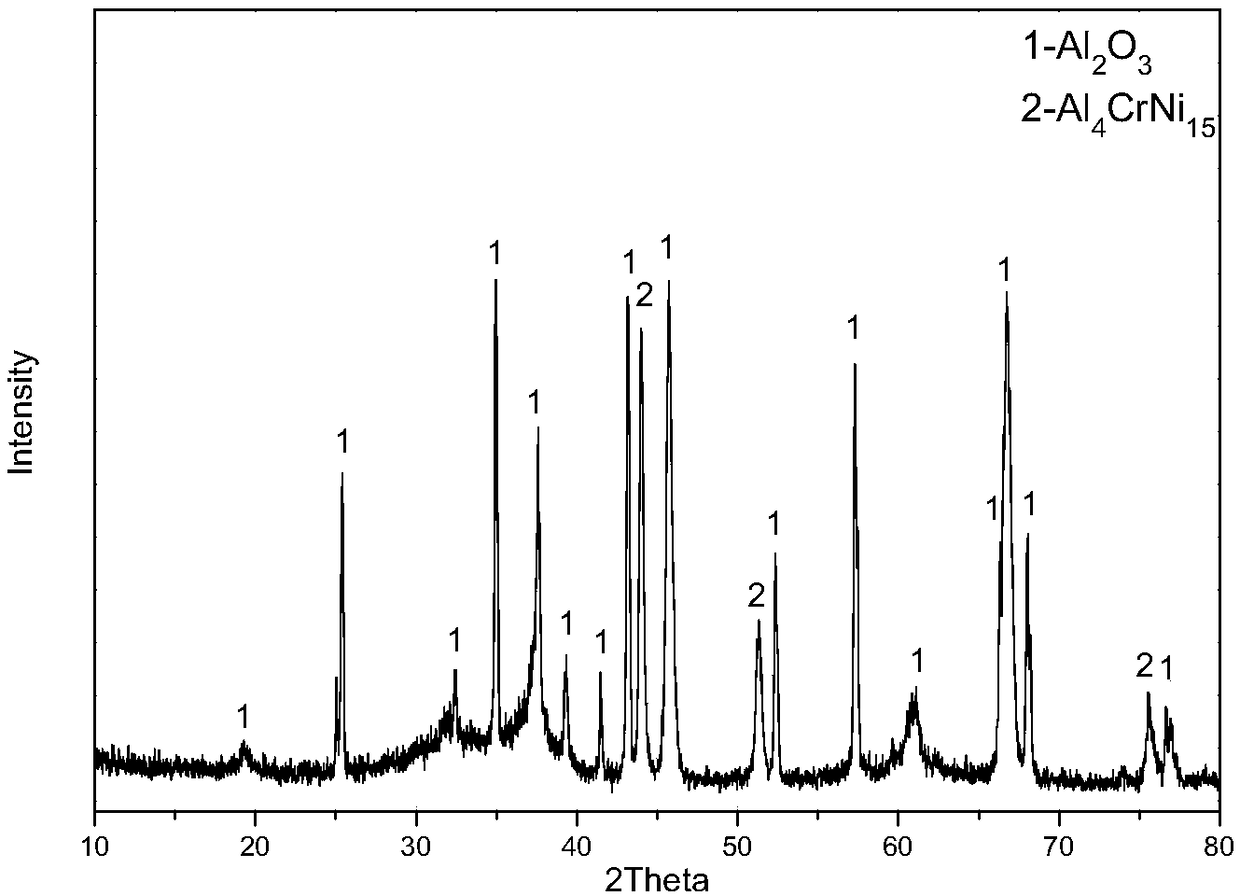

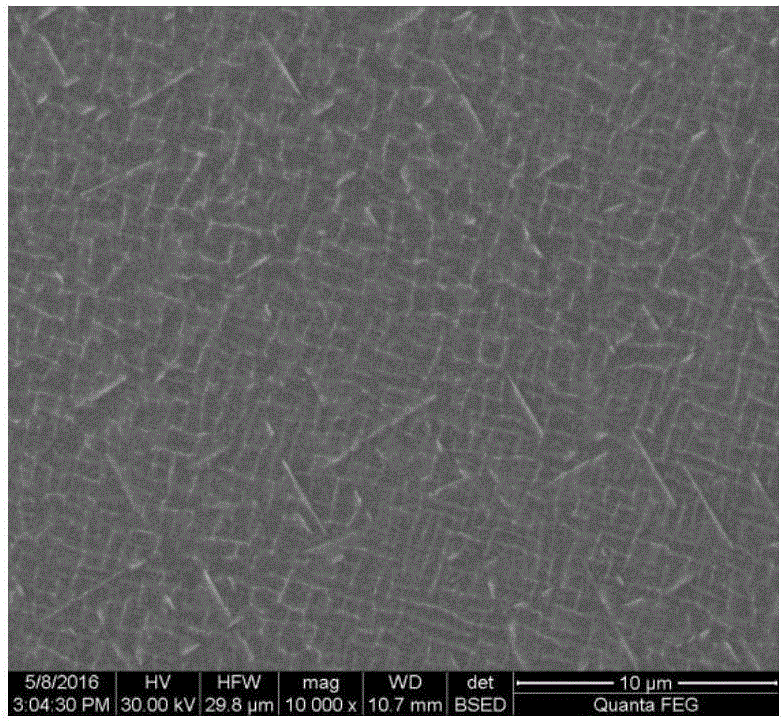

Preparation method of NiCr/Al2O3 composite coating

The invention discloses a preparation method of a NiCr / Al2O3 composite coating. The preparation method comprises the steps of firstly, mechanically mixing Ni-Cr alloy powder with Al2O3 powder, and conducting ultrasonic oscillation, so that NiCr / Al2O3 composite powder is obtained; and then, conducting plasma spraying, so that the NiCr / Al2O3 composite coating with the NiCr content ranging from 10% to 30% is synthesized. By means of the preparation method, bonding strength of an Al2O3 coating is improved, and the defect that corrosion resistance of an aluminum oxide coating is lost in a strong acid environment is overcome.

Owner:HEBEI UNIV OF TECH

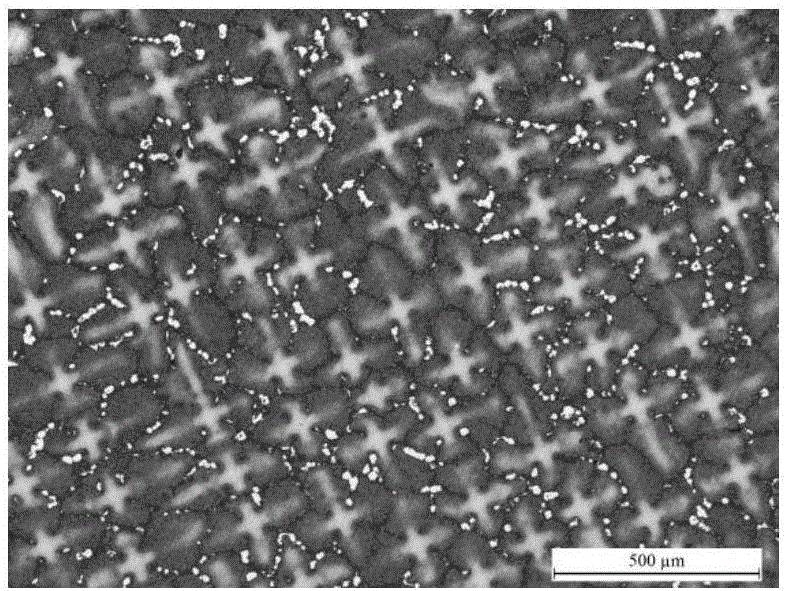

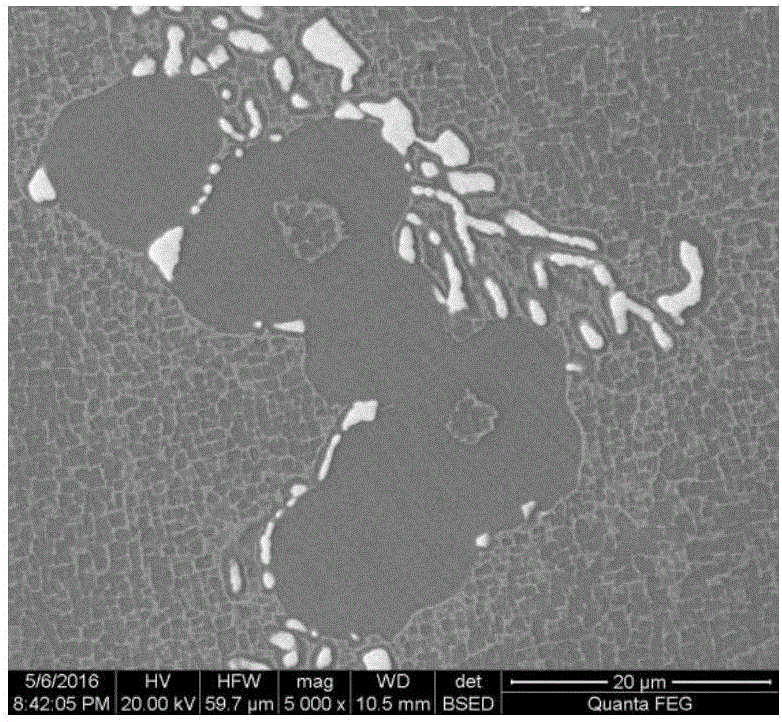

High-Mo Ni3Al-based monocrystal high-temperature alloy modified by rare earth and preparation method of high-Mo Ni3Al-based monocrystal high-temperature alloy

InactiveCN106521244AImproves antioxidant propertiesLow densityPolycrystalline material growthFrom frozen solutionsRare-earth elementOxidation resistant

The invention discloses high-Mo Ni3Al-based monocrystal high-temperature alloy modified by rare earth and a preparation method of the high-Mo Ni3Al-based monocrystal high-temperature alloy and belongs to the technical field of high-temperature alloy. The alloy comprises Ni, Al, Mo, Re, Ta, Cr, C, Y and Dy or Ce, an alloy casting-state structure comprises three phase structures including the gamma' phase, the gamma phase and the white precipitated phase rich in Mo and Re, the density is 7.9-8.1 g / cm<3>, and the alloy can reach the complete oxidization resistance level or the oxidization resistance level or the secondary oxidization resistance level at the temperature of 1100 DEG C. The method comprises the steps of preparing a liquid metal cooling medium, preparing a mother alloy bar, preparing Ni3Al-based monocrystal alloy seed crystals not containing rare earth elements, preparing high-Mo Ni3Al-based high-temperature alloy containing the rare earth elements through a direction monocrystal furnace, and conducting post heat treatment. The Ni3Al-based monocrystal high-temperature alloy provided by the invention is low in density and can meet the low-density requirement of aircraft engines, and the oxidization resistance of the alloy can reach the complete oxidization resistance level or the oxidization resistance level or the secondary oxidization resistance level at the temperature of 1100 DEG C.

Owner:BEIHANG UNIV

Method for preparing anti-oxidation coating of carbon/carbon composite material

ActiveCN103030427AImprove surface densityImproves antioxidant propertiesOxidation resistantCarbon composites

The invention belongs to the field of inorganic functional coating materials and is mainly applied to preparation for a high-temperature anti-oxidation coating of a carbon / carbon composite material. The preparation method comprises the following steps: introducing a silicon-enriched layer into the surface of the carbon / carbon composite material in advance; depositing carbon on the surface of and in the holes of the silicon-enriched layer through chemical vapor deposition to form a continuous carbon layer; and forming a continuous silicon carbide coating through reactive sintering. Compared with a gradient transition silicon carbide coating obtained by the traditional sintering method, the silicon carbide coating obtained by the method provided by the invention greatly improves the surface density and improves the anti-oxidation performance by more than one time; and after the coating is sealed and glazed, the long-time service performance is greatly improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Corrosion-resistant Sn-Zn-based lead-free solder with high oxidation resistance

InactiveCN102152022AImproves antioxidant propertiesImprove oxidation resistanceWelding/cutting media/materialsSoldering mediaSurface oxidationCorrosion resistant

A corrosion-resistant Sn-Zn-based lead-free solder with high oxidation resistance contains Bi 1wt% to 4wt%, Zn 4wt% to 10wt%, Al 0.001 wt% to 1.0 wt%, Ge 0.001 wt% to 0.1 wt%, Ga 0.001 wt% to 0.1 wt% and the balance of Sn. The solder alloy has a melting point of 195 to 215 DEG C, and has high mechanical strength, excellent creep resistance, good wettability and high corrosion resistance. In addition, the solder alloy can effectively suppress the surface oxidation of Zn, and has good manufacturability and solder joint reliability.

Owner:宁波喜汉锡焊料有限公司

Composite particle material and radiant panel for shielding neutron gamma radiation by high strength

PendingCN107722425AImprove adhesionTotal reflectionSynthetic resin layered productsShieldingFiberColemanite

The invention discloses a composite particle material and a radiant panel for shielding neutron gamma radiation by high strength, and relates to the technical field of radiation-shielding plates. Thecomposite particle material comprises, by mass, 26-33% of high-density polyethylene, 2.2-2.7% of polyvinyl alcohol, 10-12% of lead sand, 2.9-4.0% of boron carbide powder, 1.2-1.5% of polyethylene wax,1.7-2.3% of coupling agents, 0.6-1.2% of colemanite, 1.1-1.4% of aluminum hydroxide, 1.0-1.2% of carbon fibers, 2.1-2.3% of 2, 6-butylated hydroxytoluene, 0.6-1.1% of oleamide, 0.6-0.9% of powdered aluminum and the balance samarium powder and tungsten powder.

Owner:镇江奥特氟科技有限公司

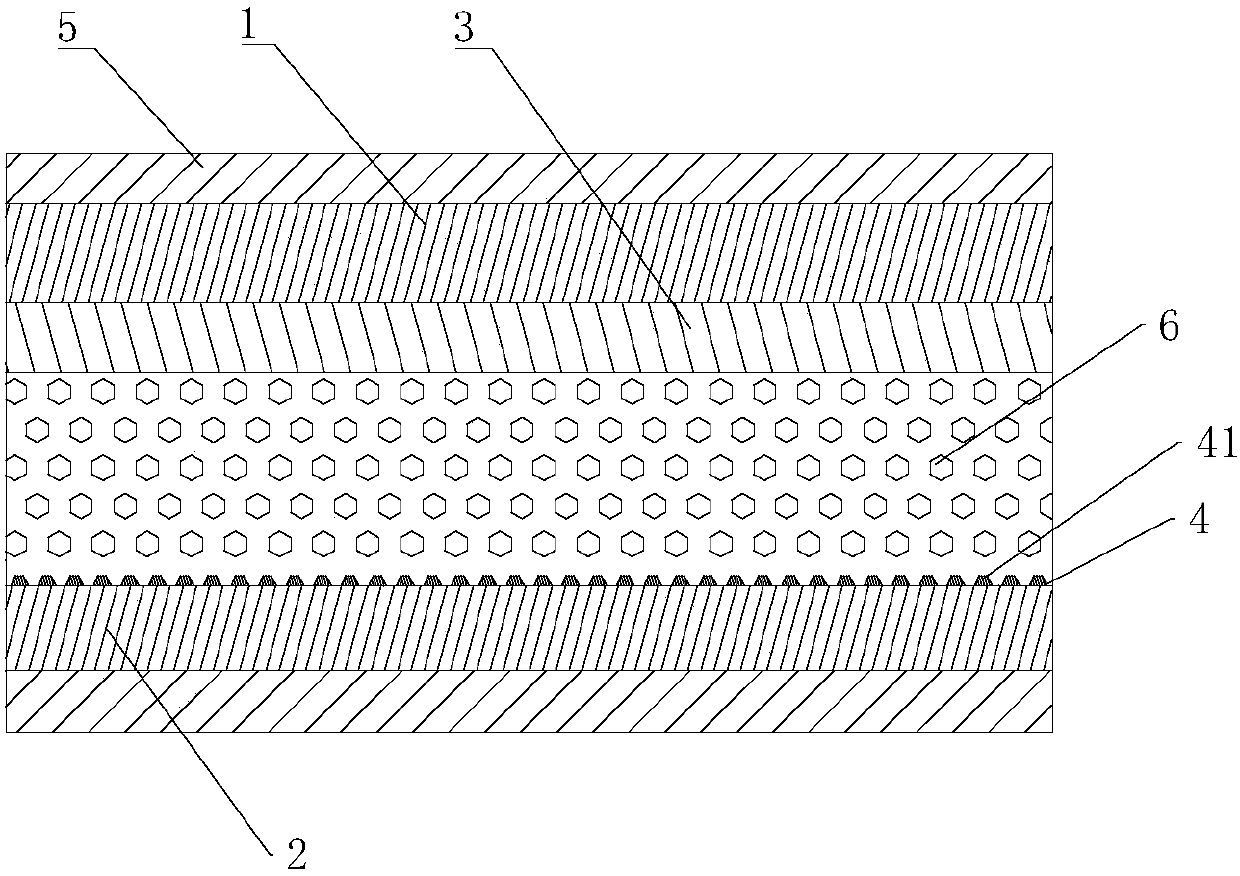

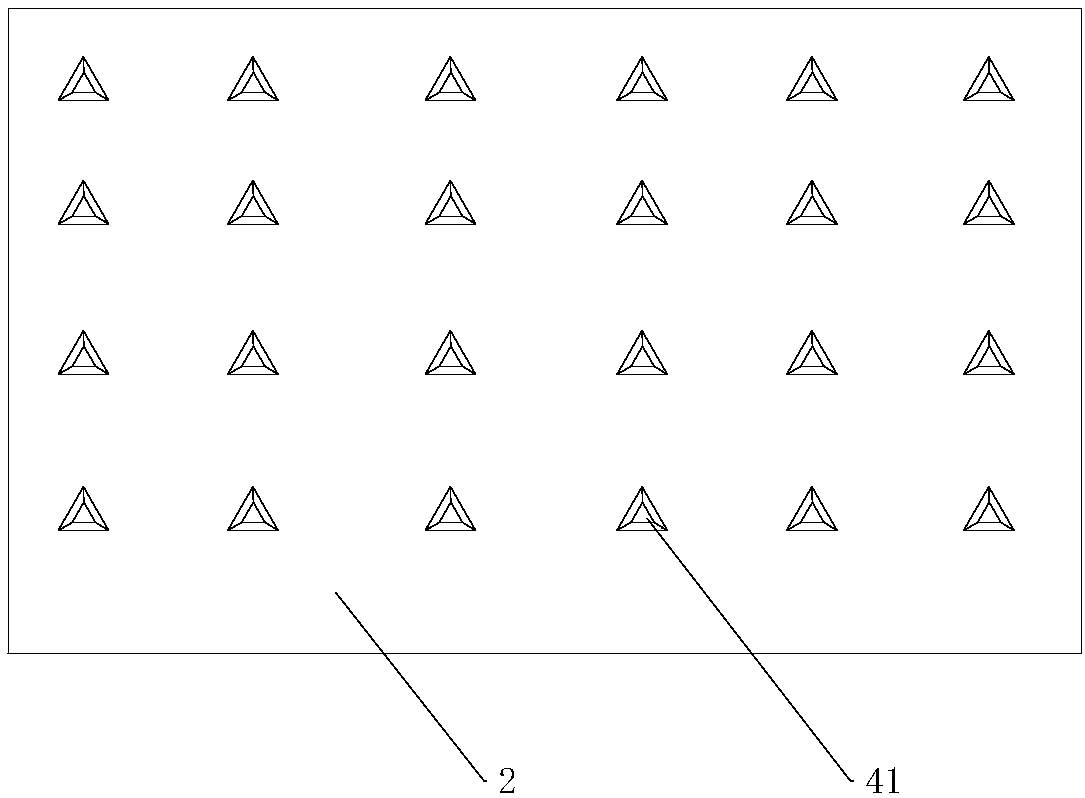

Multilayer antioxidant high-temperature-resistant SiC/Ta/C/Ta/SiC coating and preparation method thereof

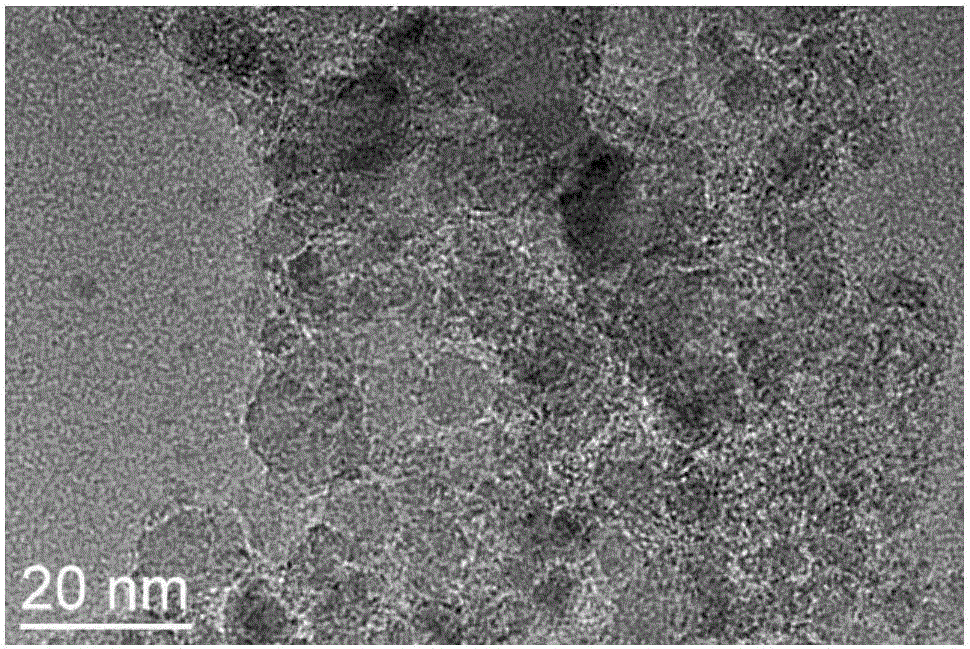

ActiveCN103722849AImproves antioxidant propertiesMitigates differences in coefficient of thermal expansionLayered productsOxidation resistantMicrostructure

The invention discloses a multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating and a preparation method thereof. The multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating is formed by laminating SiC layers, Ta layers and C layers, and is characterized in that the laminating sequence is the SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, and the SiC layer, or SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer, the SiC layer, SiC layer, the Ta layer, the C layer, the Ta layer and the SiC layer; both sides of the C layer are Ta layers; the innermost layer and the outermost layer are SiC layers; and the Ta layer, the C layer, the Ta layer and the SiC layer are sequentially deposited on the prepared SiC layer with a chemical vapor deposition method so as to obtain the multilayer antioxidant high-temperature-resistant SiC / Ta / C / Ta / SiC coating. According to the coating and the preparation method thereof, the outer SiC layer forms a layer of SiO2 film in a high-temperature aerobic environment, so that diffusion of oxygen atoms can be prevented effectively, and meanwhile, a TaC layer can be formed on a contact surface of the Ta layer and the C layer to further improve the antioxidation performance. Alternate deposition of coatings can effectively relieve differences of coefficients of thermal expansion of the coatings and improve the thermal shock performance of the coatings remarkably, the thickness and lay number of a matrix can be controlled by controlling deposition time and deposition times, and the microstructure of the composite coating can be controlled.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Preparation method for mullite in-situ reinforced silicon carbide porous ceramic sintered at low temperature

ActiveCN105541333AImprove high temperature mechanical propertiesImproves antioxidant propertiesCeramicwareMegasonic cleaningSintering

The invention discloses a preparation method for mullite in-situ reinforced silicon carbide porous ceramic sintered at low temperature. The preparation method comprises the following steps: subjecting Al2(SO4)3, Na2SO4 and B2O3 to mixing and ball milling so as to obtain a mixture A; then subjecting the mixture A, SiC powder and a pore forming agent to mixing and ball milling so as to obtain a mixture B; subjecting the mixture B to compression molding and then carrying out drying and calcining; and successively carrying out ultrasonic cleaning and drying on the calcined sample. The method promotes low-temperature sintering of silicon carbide porous ceramic; the method overcomes defects in usage of the silicon carbide porous ceramic at high temperature in the presence of a high-temperature binder or sintering agent and is favorable for further improving the porosity of the silicon carbide porous ceramic; and more importantly, SiO2 produced on the surface of silicon carbide due to oxidation is converted into a mullite crystal phase through a high temperature reaction, so the high-temperature mechanical properties and antioxidation performance of the silicon carbide porous ceramic are further improved.

Owner:JIANGXI UNIV OF SCI & TECH

Microconductive powder suitable for preparing anisotropic conductive rubber composition

InactiveCN1470588ALower surface energyHigh densityNon-macromolecular adhesive additivesElectrically-conducting adhesivesMicrometerOptoelectronics

The invented microconductive powder applicable to preparation of heterodirectionality conductive adhesive composite is mainly formed from metal conductive particles and insulating organic covering film formed on the surface of said particles, said metal conducting particles have diameter with 1-20 micrometers, and said insulating organic covering film has the thickness with 50-400 nm, and has thehot-pressing fluidity. Said insulating organic covering film is prepared by using silane containing active functional group, silane containing fluorine and a functional group compound which can be reacted with said active functional group or resin.

Owner:IND TECH RES INST

Daily ration regulation and control method for reducing mutton drip loss

ActiveCN103039741AImproves antioxidant propertiesImprove water retentionAnimal feeding stuffAnimal scienceOxidation resistance

The invention relates to application of a licorice extract as an additive agent of mutton daily ration for reducing mutton drip loss. According to the invention, the licorice extract which is highly matched with main mutton producing area of China is added in the mutton daily ration, so that the oxidation resistance of the mutton can be improved from the daily ration nutrition regulation perspective, the water retention performance of the mutton is improved, the mutton drip loss is reduced, therefore, the mutton quality is improved, and the product competitiveness is increased.

Owner:CHINA AGRI UNIV

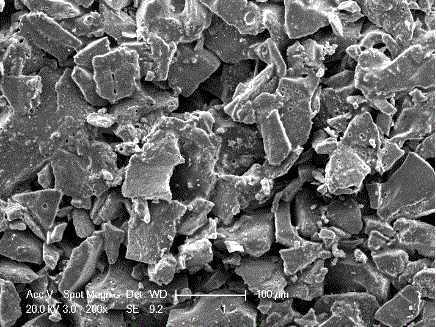

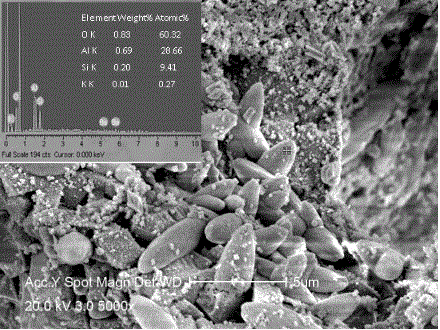

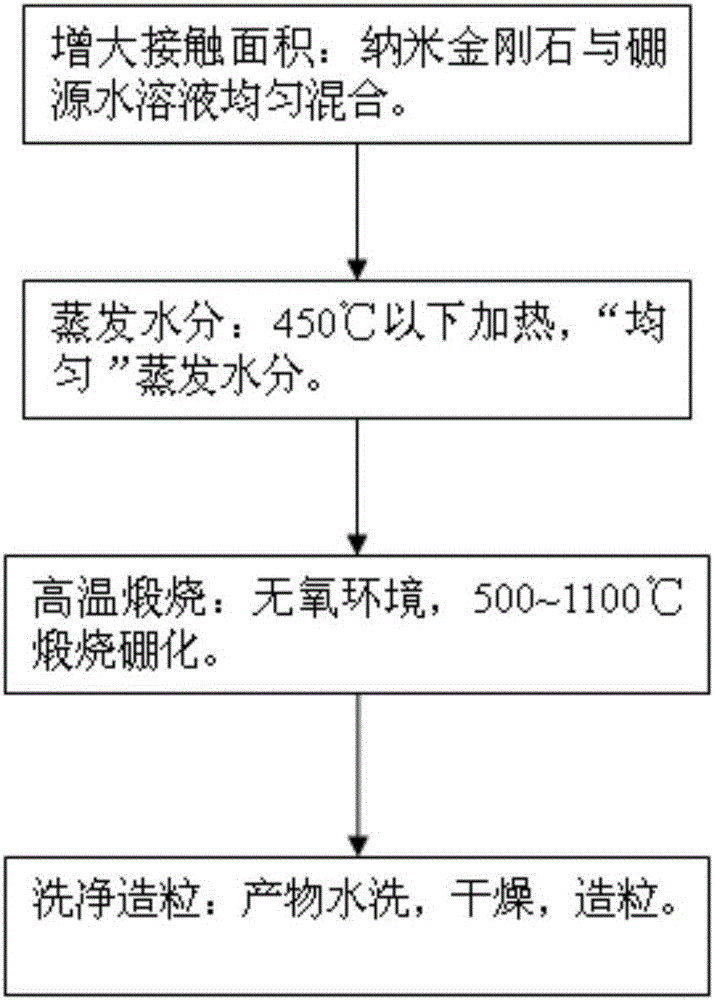

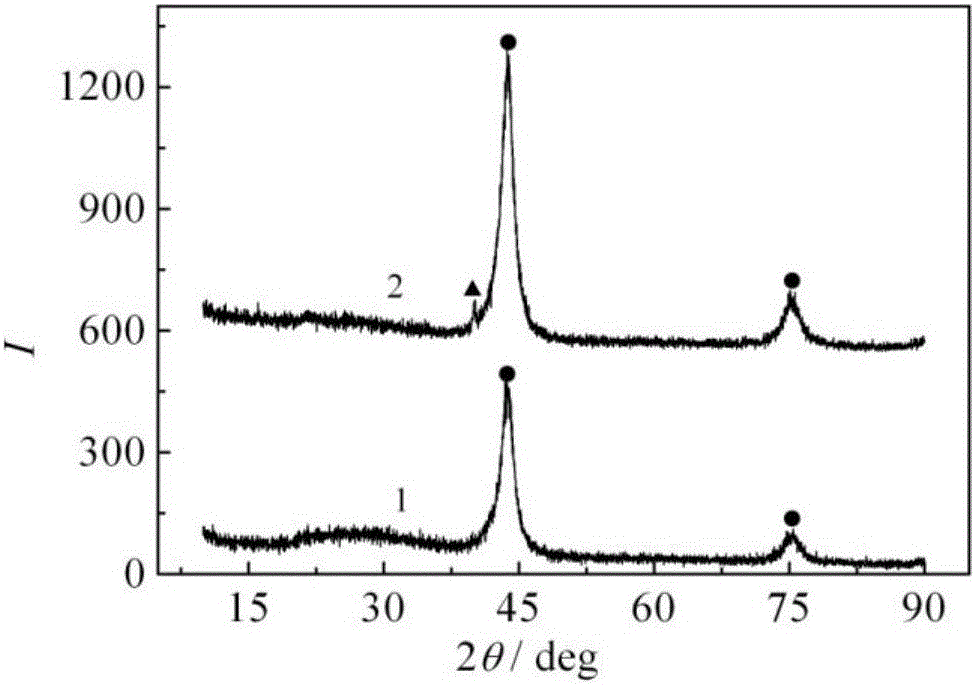

Nano-diamond surface boronation method

InactiveCN106115685AImproves antioxidant propertiesThe synthesis process is simpleMaterial nanotechnologyOxidation resistantWater soluble

The invention discloses a nano-diamond surface boronation method and belongs to the field of material processing. Nano-diamond particles and water-soluble boron sources are uniformly mixed and calcined in an oxygen-free environment at the temperature of 500-1,100 DEG C, finally, the water-soluble boron sources are washed away, and boronized nano-diamond particles coated with boron elements on the surfaces are prepared. The initial oxidation temperature of the prepared boronized nano-diamond particles in air is increased to 625 DEG C, 68% of diamond is not oxidized after the prepared boronized nano-diamond particles are heated to 1,150 DEG C, and the oxidation resistance of the nano-diamond is greatly improved; the boronized nano-diamond particles contain a large quantity of boron-oxygen hydrophilic groups on the surfaces, and dispersion in the solution is facilitated. A synthesis technology of the prepared nano-diamond boronized particles adopts a simple technique process and is efficient, environment-friendly and safe.

Owner:DALIAN UNIV OF TECH

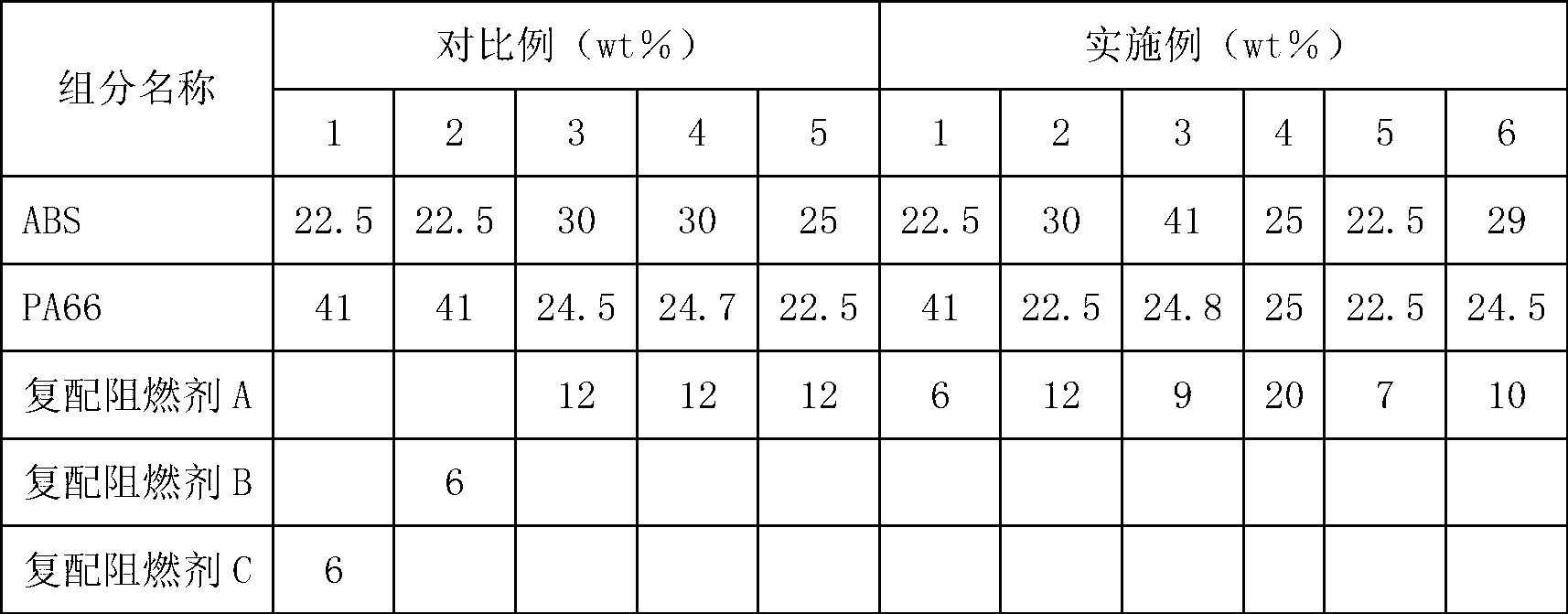

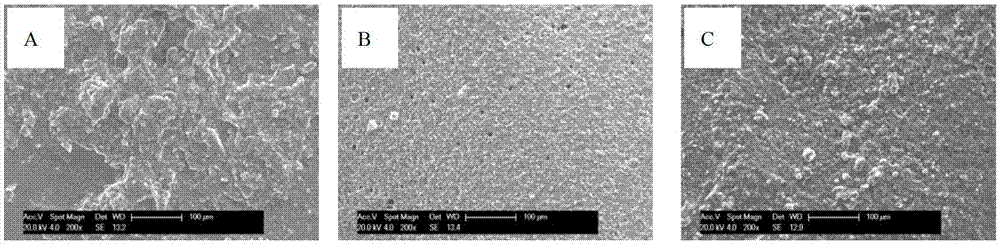

Flame-retardant glass fiber-reinforced ABS/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced ABS / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 22.5 to 41% of ABS, 22.5 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of a metallic oxide. In preparation of the alloy material, all the components are added into a high-speed mixer for mixing for 2 to 5 min, and then discharging and extrusion granulation are carried out, wherein extrusion temperature is 220 to 255 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high glow wire temperature, a high tracking index, environment-friendliness, balanced comprehensive properties and the like and can be extensively used for low-voltage electronic capacitor shells, load break switches, carbon brush supports and molded case circuit breakers.

Owner:SHANGHAI SUNNY

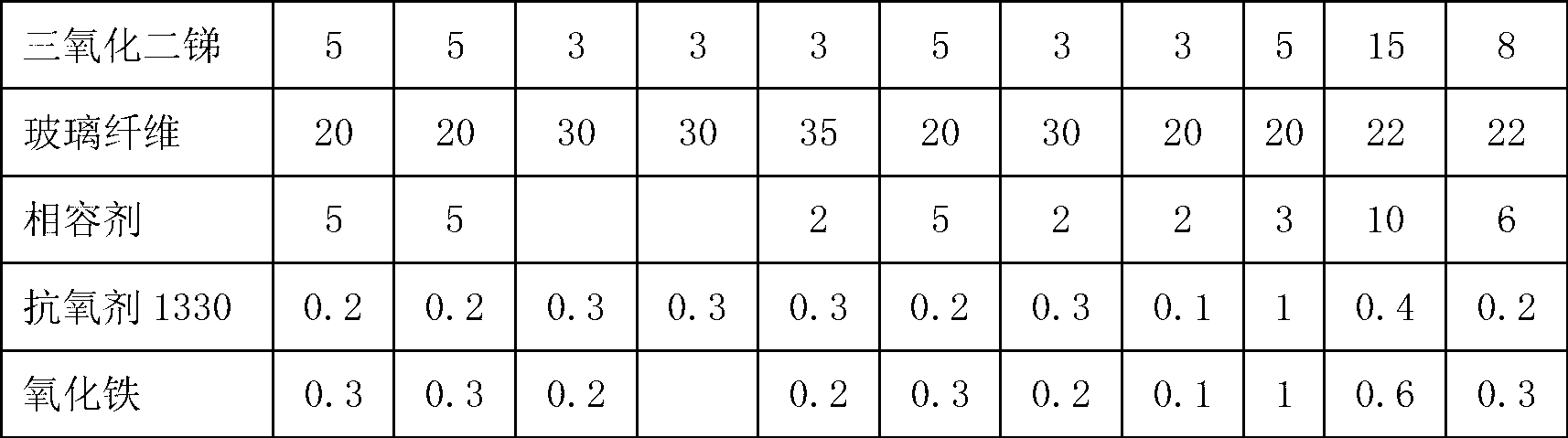

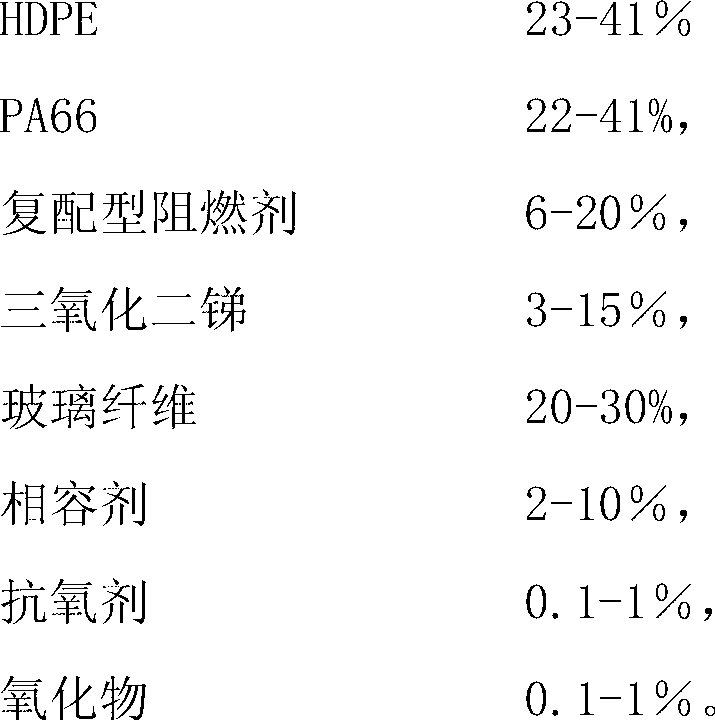

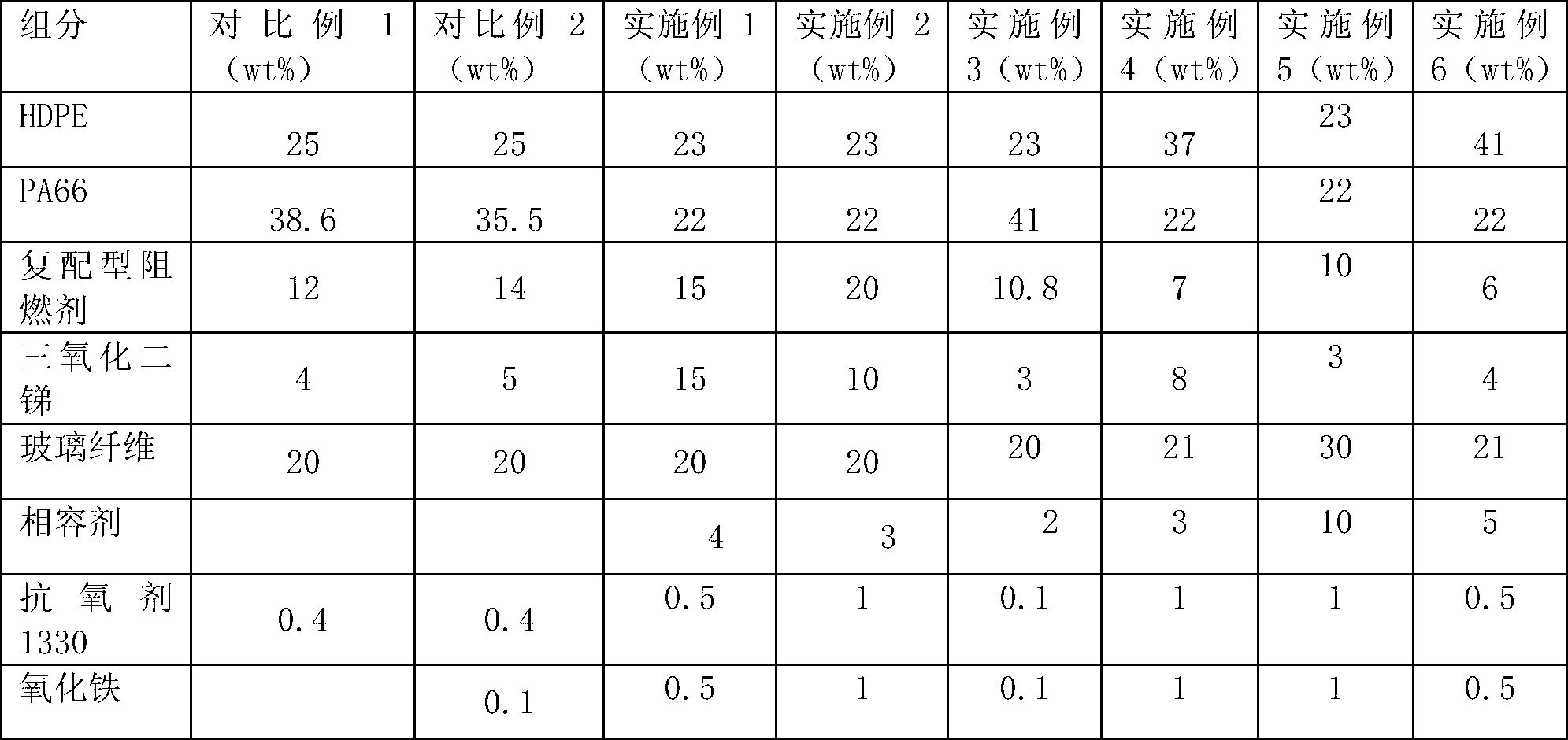

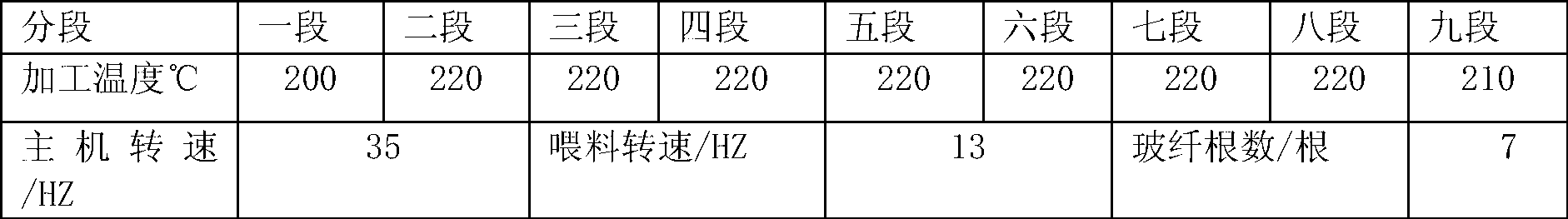

Flame-retardant glass fiber-reinforced HDPE/PA66 alloy material with high CTI value and high GWIT value

The invention discloses a flame-retardant glass fiber-reinforced HDPE / PA66 alloy material with a high CTI value and a high GWIT value. The alloy material comprises the following components: by weight, 23 to 41% of HDPE, 22 to 41% of PA66, 6 to 20% of a compound fire retardant, 3 to 15% of antimonony oxide, 20 to 30% of a glass fiber, 2 to 10% of a compatilizer, 0.1 to 1% of an anti-oxidant and 0.1 to 1% of an oxide. The invention also relates to a preparation method for the alloy material, and the method comprises the following steps: weighing the components in proportion, adding the weighed components into a high-speed mixer for mixing for 2 to 5 min, then carrying out discharging and finally carrying out extrusion granulation in a twin-screw extruder, wherein processing temperature is 220 to 240 DEG C and screw revolution is 30 to 40 Hz. Compared with the prior art, the alloy material provided by the invention has the advantages of a high CTI value, low precipitation performance, etc.

Owner:SHANGHAI SUNNY

A kind of preparation method of zein film with high anti-oxidation property

Owner:万洲胶粘制品(江苏)有限公司

Filter aid for rolling oil

InactiveCN1994553AClear colorImproves antioxidant propertiesOther chemical processesOxidation resistantCharoite

The invention relates to a filter aid used to rolling oil, wherein said filter aid comprises activate clay and bergmeal at 1:1-3. Compared with present technique, the rolling oil can be filtered completely, with improved oxidation resistance and 50-80% improved application period.

Owner:ANHUI XINKE NEW MATERIALS

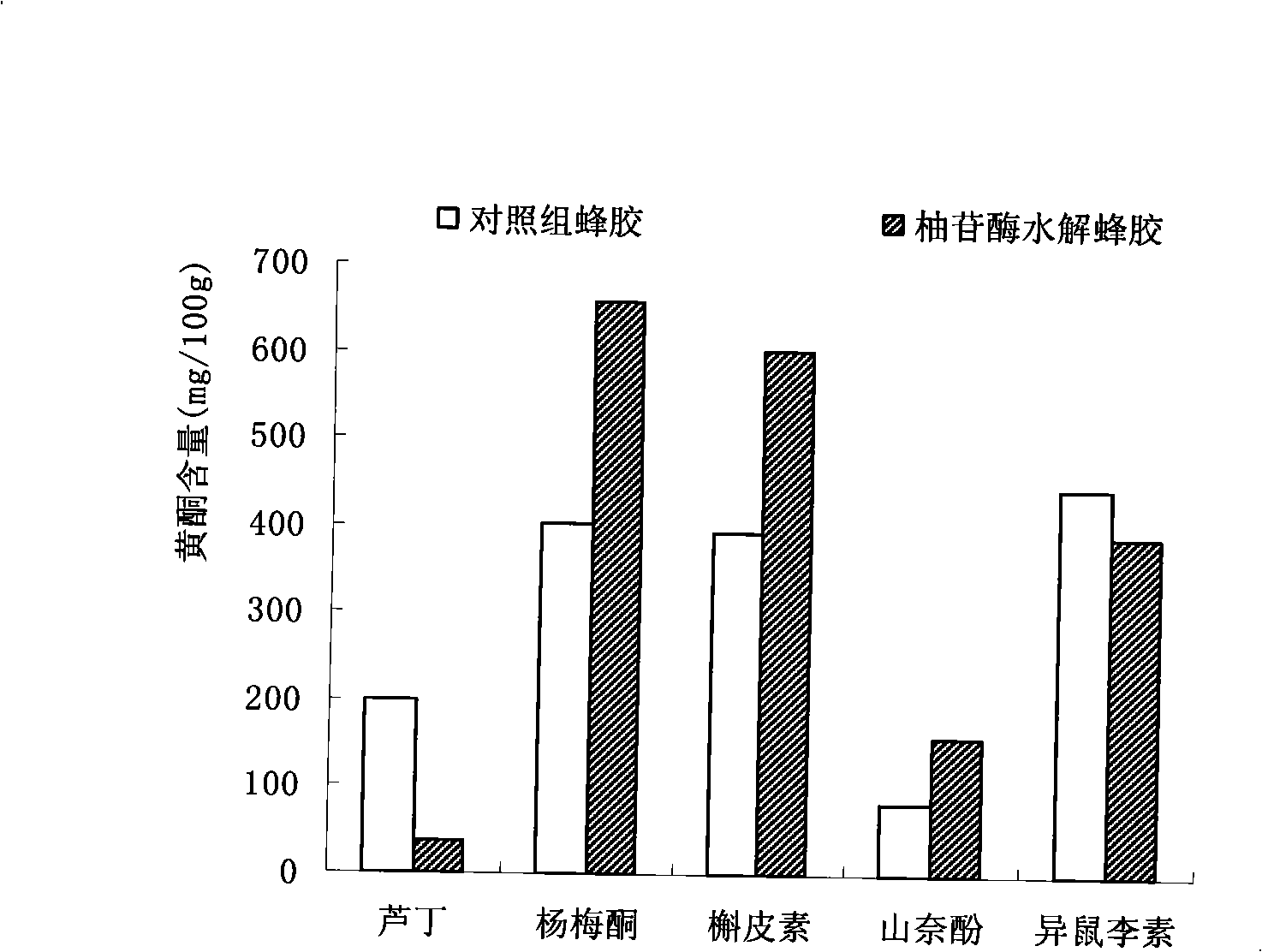

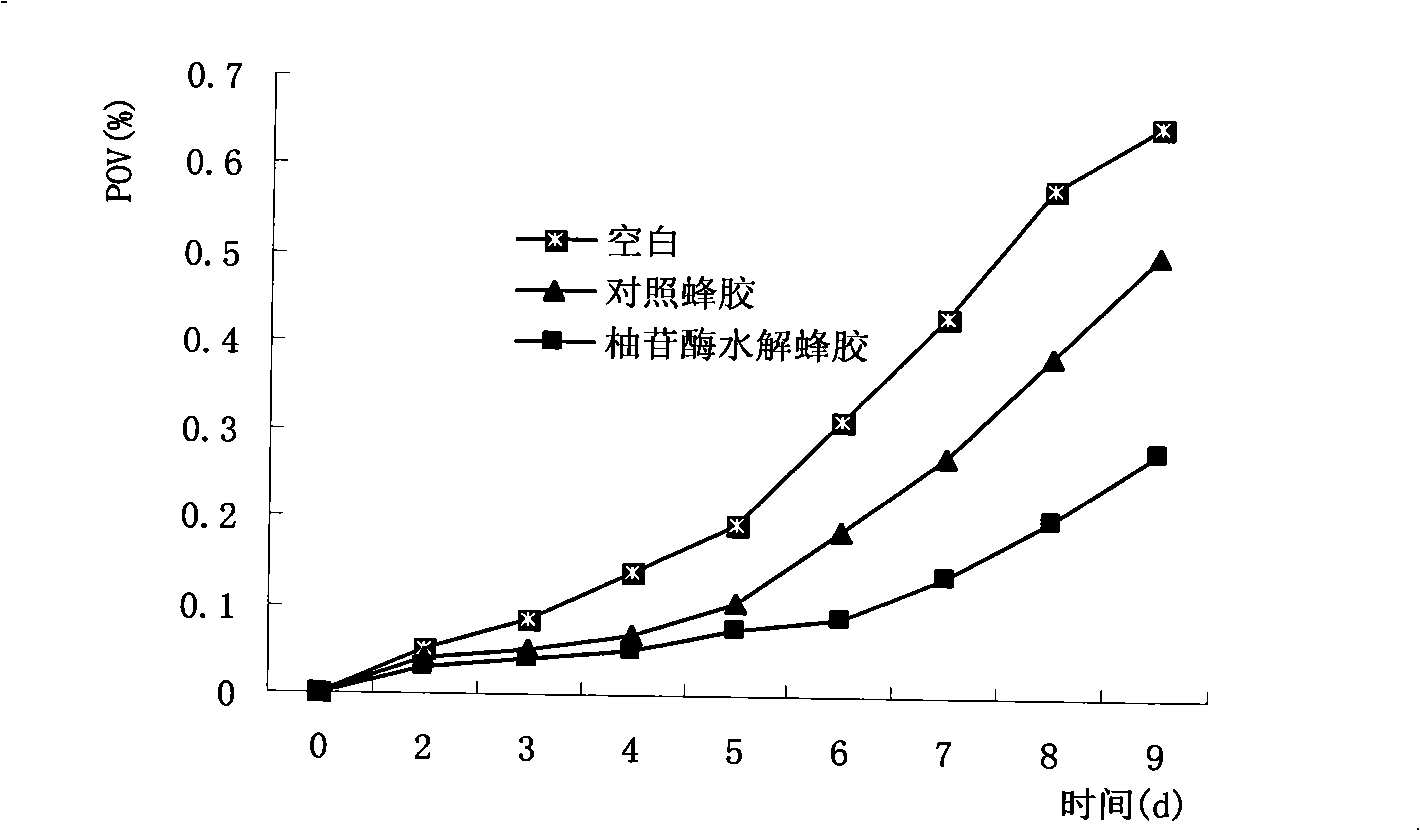

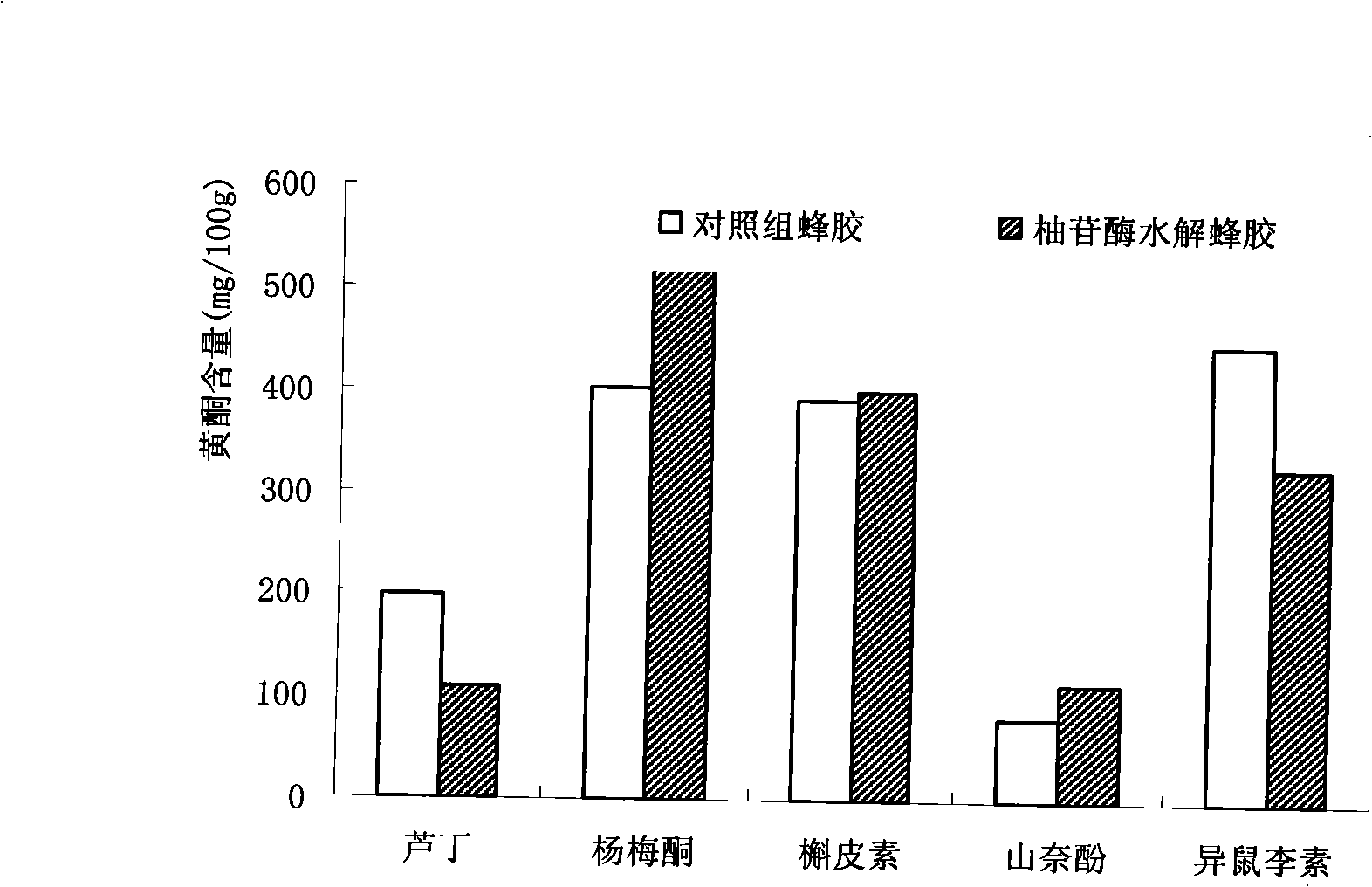

Method for hydrolyzing propolis flavonoid glycosideby by naringinase

InactiveCN101307344AImproves antioxidant propertiesIncrease added valueFermentationChemistryNaringinase

The invention provides a method for hydrolyzing propolis flavonoid glycoside by naringinase. The method is as follows: naringinase is adopted to carry out constant-temperature enzymolysis of propolis flavonoid glycoside; propolis flavonoid glycoside substance is hydrolyzed into flavonoid aglycone through enzymolysis; moreover, compared with raw materials, the antioxidation property of the product is reinforced. The content of flavonoid substances in the obtained enzymolysis products can be measured through high-efficiency liquid phase chromatogram, and the result shows that the content of flavonoid glycoside substances is reduced, while the content of flavonoid aglycone substances is obviously increased. The method realizes deep development and utilization of propolis products, and is propitious to increase the added value of bee products and expand the application range of bee products. Moreover, the made propolis enzymolysis products has remarkably increased antioxidation property, and can be better used in the fields of medicine, foodstuff and cosmetics, etc. as compared with raw material propolis.

Owner:ZHEJIANG UNIV

Surface nanocrystallization manufacture method for improving oxidation resistance performance of heat resistant steel

The invention provides a surface nanocrystallization manufacture method for improving the oxidation resistance performance of heat resistant steel. According to the surface nanocrystallization manufacture method, a spinning mechanical device is used for conducting circular rolling and grinding on the surface of a material, a rolling press head is made of hard alloy, grinding pressure is smaller than or equal to 20 MPa, effective grinding-rotating size ranges from 100 mm to fai 220 mm, the grinding time ranges from 30 minutes to 60 minutes, and the grinding-rotating speed is smaller than or equal to 65 rpm. The problem that by the adoption of an existing method, oxidation resistance performance is not ideal, a nanolayer easily drops from a base body, material oxidation is accelerated, environment is polluted and large-sized workpieces cannot be treated due to workpiece size influence is solved. The surface nanocrystallization manufacture method belongs to the field of performance improvement of the heat resistant steel.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Low-cost nontoxic thermal barrier coating and manufacturing method thereof

InactiveCN105088125AImproves antioxidant propertiesImprove insulationMolten spray coatingLap jointOxidation resistant

The invention discloses a low-cost nontoxic thermal barrier coating. The oxidation resistance of the ceramic phase and the permeability of matrix metal can be improved after modification through adding of aluminum powder and high-temperature calcination; part of particles are not fully melted in plasma jetting in the spraying process, the deformation degree is slightly weak in the matrix striking process, a porous structure in lap joint is prone to forming, and the heat insulation property of the coating is improved; through a modification method, Y3+ and Ce4+ in zirconium dioxide lattices replace Zr4+, and oxygen vacancy and a partial stress field are generated, so that phonon scattering in the lattices is increased, and the heat conductivity is obviously lowered; moreover, the atomic weight of the solid solution atom Ce is far larger than that of Y, the phonon scattering intensity in the coating can be remarkably improved, so that the heat conductivity is lowered. The low-cost nontoxic thermal barrier coating is good in process stability, low in cost and high in product particle uniformity and purity, has good sintering resistance and high temperature thermal stability, and is environmentally friendly and suitable for large-scale industrial production.

Owner:MAANSHAN LANKE REMFG TECH

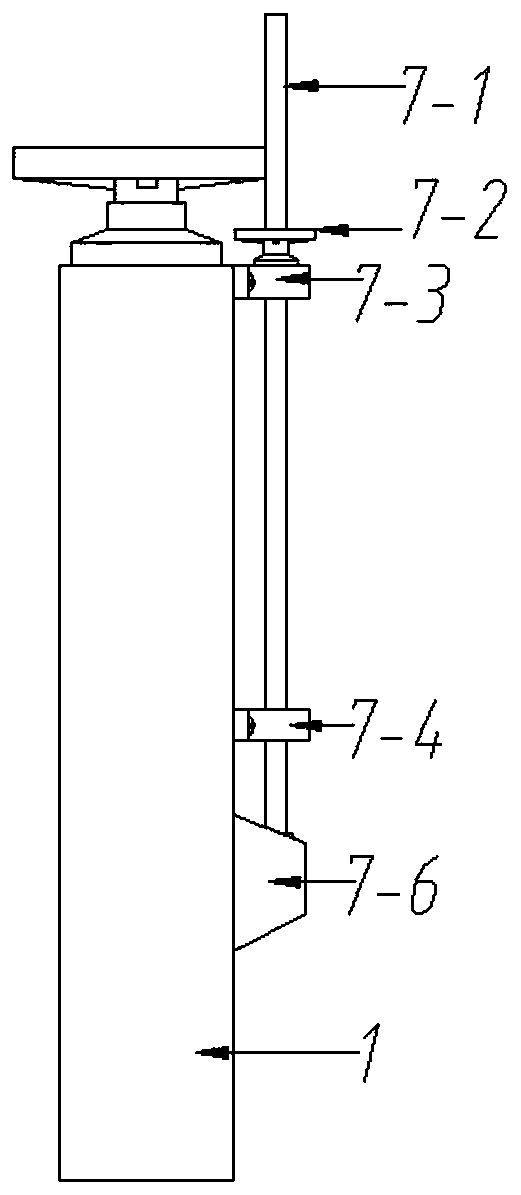

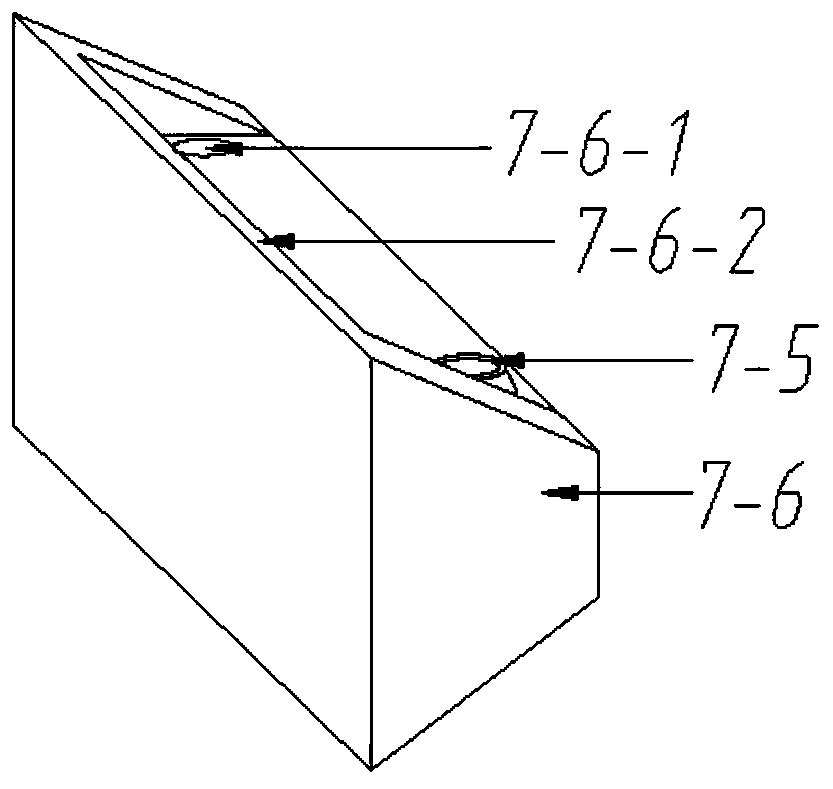

Gate device for small water conservancy project

PendingCN110847127AImproves antioxidant propertiesExtended service lifeBarrages/weirsOxidation resistantBall (bearing)

The invention relates to a gate device for a small water conservancy project, and relates to the technical field of water conservancy projects. The lower end of a guiding rod is fixed to a protectingplate, and the surface of the protecting plate is coated with an anti-oxidation coating, the protecting plate is arranged on the side face of a gate plate and is in fit arrangement with the side faceof the gate plate, the protecting plate is movably arranged in a gate frame below a cross bar in an up and down mode, a second bearing base is fixed to the top surface of the protecting plate, the lower end of a screw rod is inserted into a bearing fixed in the second bearing base, the screw rod is rotationally fixed on the cross bar through a screw rod base, the upper part of the screw rod is rotationally connected with an inner threaded sleeve through a ball bearing, the ball bearing is embedded in the first bearing base, the first bearing base is fixed on the side surface of the top edge ofthe gate frame, and an protecting plate lifting hand wheel sleeves the outer part of the inner threaded sleeve. The gate device can increase the oxidation resistance of the gate plate according to the using condition, the service life of the gate is effectively prolonged, meanwhile, impurities deposited at the bottom of the gate frame can be effectively eliminated, and the sealing performance ofthe gate plate is improved.

Owner:河南省河川工程监理有限公司

Repairing method of SiC/SiC ceramic-based composite material

A repairing method of a SiC / SiC ceramic-based composite material comprises the following steps: polishing the surface of a test sample, cleaning and drying, corroding the test sample by HF, cleaning and drying, ultrasonically cleaning, drying and soaking into a catalyst solution prepared from iron, cobalt or nickel, performing vacuum drying, wrapping the test sample with graphite paper and only exposing a fracture; and putting the test sample into a vacuum furnace, introducing methyltrichlorosilane, H2 and Ar, preserving heat for 5 to 20 hours, closing methyltrichlorosilane and H2, preservingheat for 10 to 100 minutes, closing Ar, introducing NH3, BCl3, H2 and N2, preserving heat for 5 to 20 hours, closing NH3 and BCl3, introducing methyltrichlorosilane and H2, preserving heat for 50 to 300 hours, taking out the test sample, removing the graphite paper, polishing and repairing the surface, putting the treated sample into the vacuum furnace, introducing methyltrichlorosilane, H2 and Ar, preserving heat for 5 to 30 hours, and spray-coating a composite coating consisting of yttrium silicate and mullite by a plasma spray-coating method. Main injury that the SiC / SiC composite materialis liable to generate can be repaired, the material composition is not changed after repairing, and the anti-oxidation property of the material under the high-temperature environment is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-temperature oxidation resistant grate piece and casting mould and technique thereof

ActiveCN107254641AImproves antioxidant propertiesImprove temperature resistanceFoundry mouldsFoundry coresOxidation resistantIron oxide

The invention discloses a high-temperature oxidation resistant grate piece made of a high-temperature oxidation resistant iron alloy. The high-temperature oxidation resistant iron alloy comprises the following substances, by weight, of 0.2%-0.5% of C, 1.5% or the less of Si, 1.5% or the less of Mn, 24%-28% of Cr, 4%-6% of Ni, 0.5% or the less of Mo, 0.01%-0.02% of Sc, 0.04% or the less of P, 0.04% or the less of S and the balance Fe and has the advantages of high-temperature oxidation resistance and long service life under the high-temperature condition. The invention further discloses a casting mould and technique of the grate piece. The grate piece made through the casting mould and technique is stable and balanced in performance and long in service life.

Owner:国润环保工程(常州)有限公司

Preparation method of oxidation-resistant blueberry bread

InactiveCN107173417AAntioxidant hasEnhance immune functionDough treatmentBakery productsFreeze-dryingChange color

The invention discloses a preparation method of oxidation-resistant blueberry bread. The method comprises the following steps of performing grinding on blueberry fruits to obtain blueberry fruit pulp and performing leaching; preparing dry powder; and performing mixing, adding water, and performing fermentation to obtain bread. According to the preparation method disclosed by the invention, blueberry freeze-dried fruit powder is added; blueberry fruit powder is prepared through the following steps of firstly extracting anthocyanidin with edible ethanol under ultrasonic wave condition, then adding malt essence and performing drying to obtain the powder; and finished products of the fruit powder have better drying resistance, fine and smooth qualities and oxidation resistance, when the fruit powder is used for making the bread, the bread is fine, smooth and delicious, and after the bread is exposed to air for a long term, good effects that the bread is not liable to change color, go bad and deteriorate can be achieved.

Owner:ANHUI JINYING AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com