Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Yttrium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thortveitite is a mineral consisting of scandium yttrium silicate (Sc,Y)2Si2O7. It is the primary source of scandium. Occurrence is in granitic pegmatites. It was named after Olaus Thortveit, a Norwegian engineer. It is grayish-green, black or gray in color.

Implementing atomic layer deposition for gate dielectrics

PendingUS20170110313A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricLanthanum

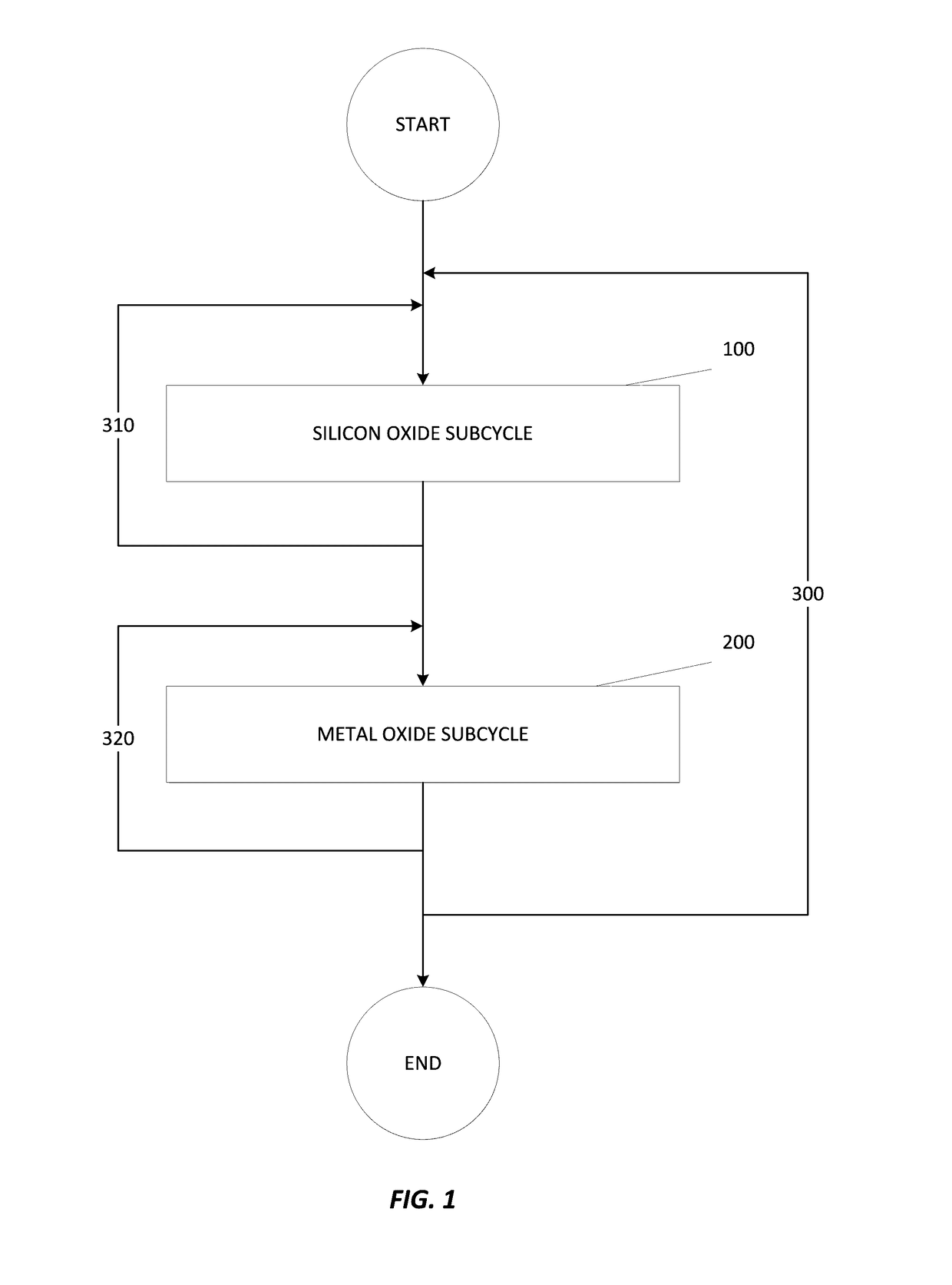

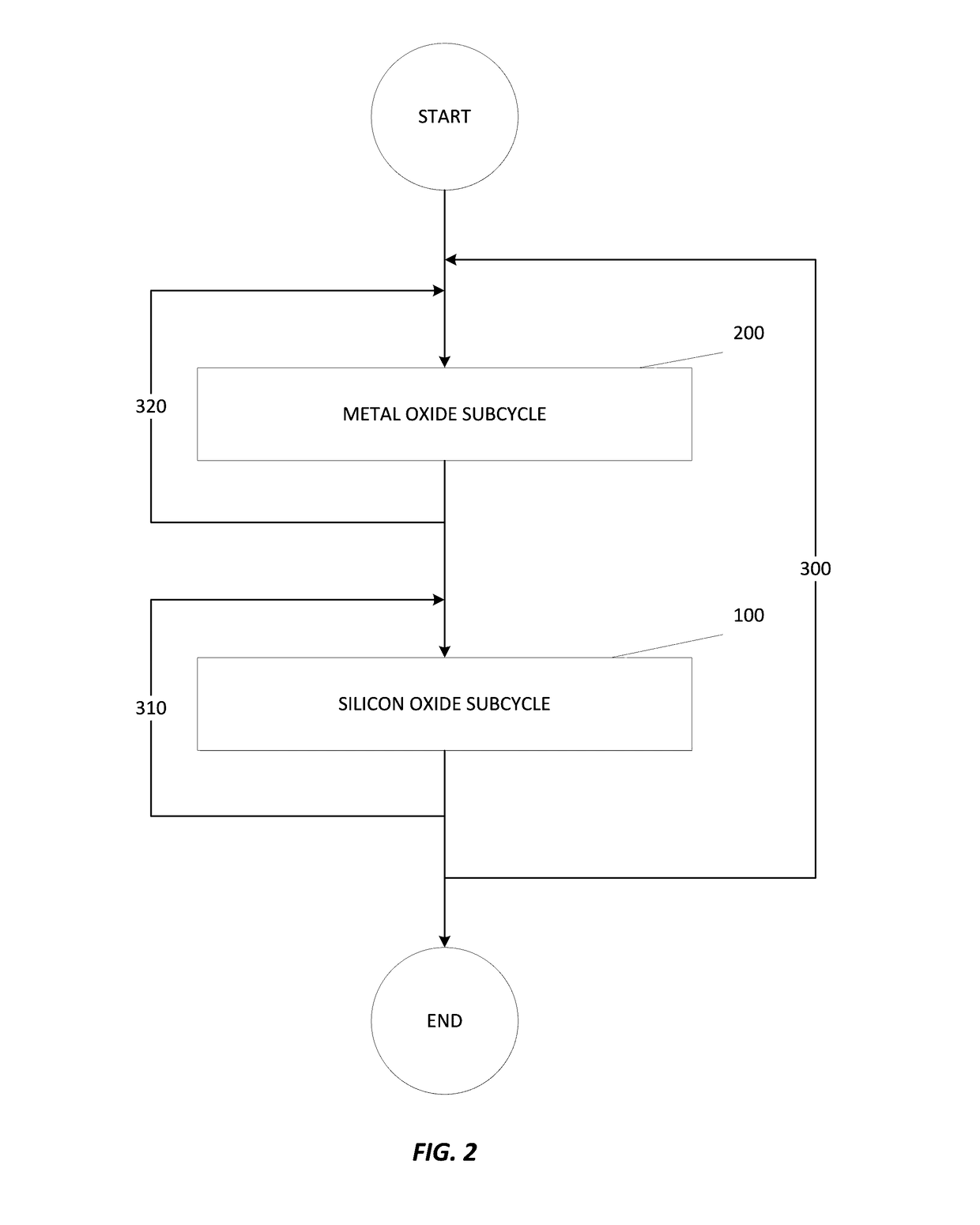

A method for depositing a thin film onto a substrate is disclosed. In particular, the method forms a transitional metal silicate onto the substrate. The transitional metal silicate may comprise a lanthanum silicate or yttrium silicate, for example. The transitional metal silicate indicates reliability as well as good electrical characteristics for use in a gate dielectric material.

Owner:ASM IP HLDG BV

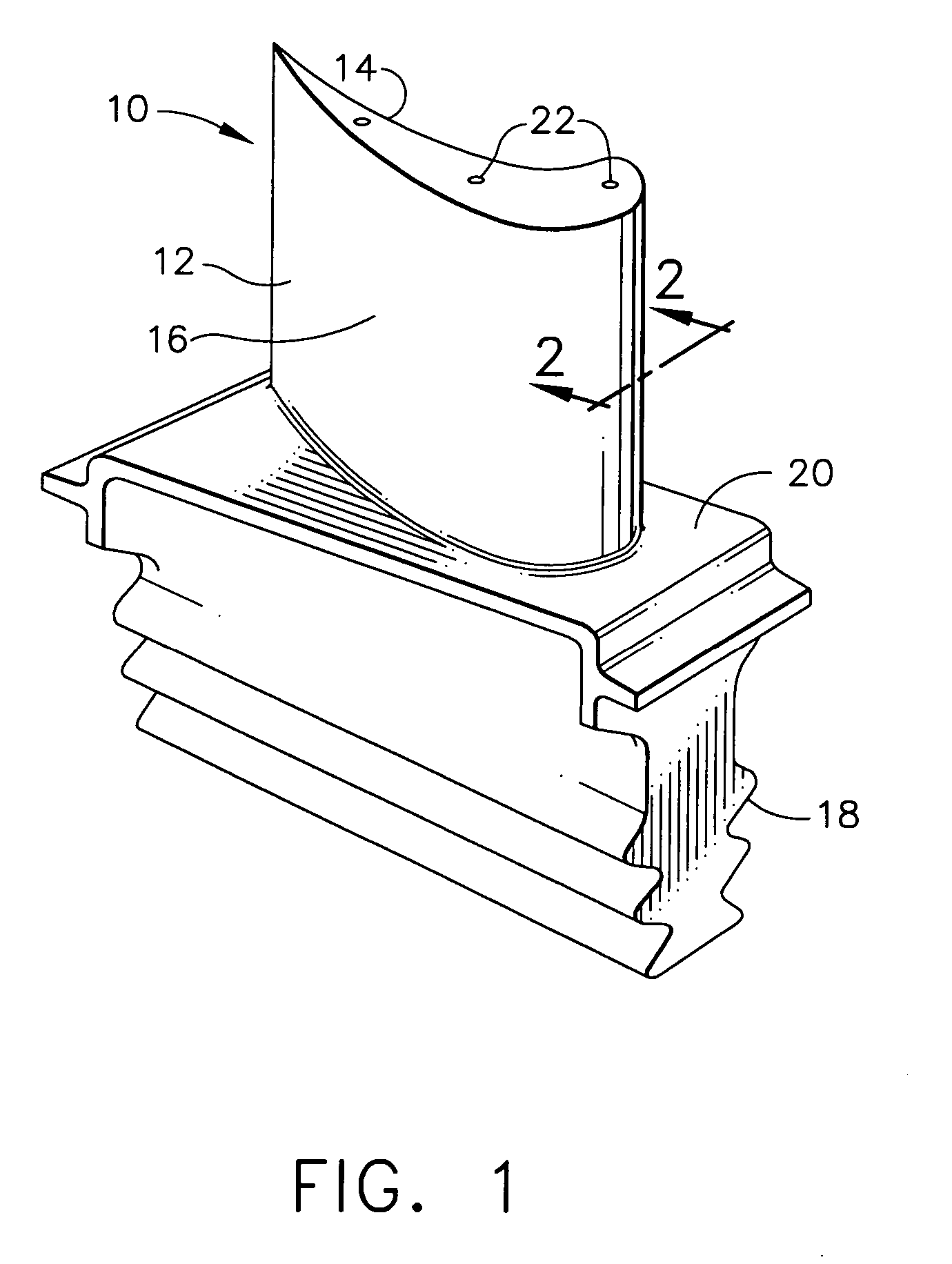

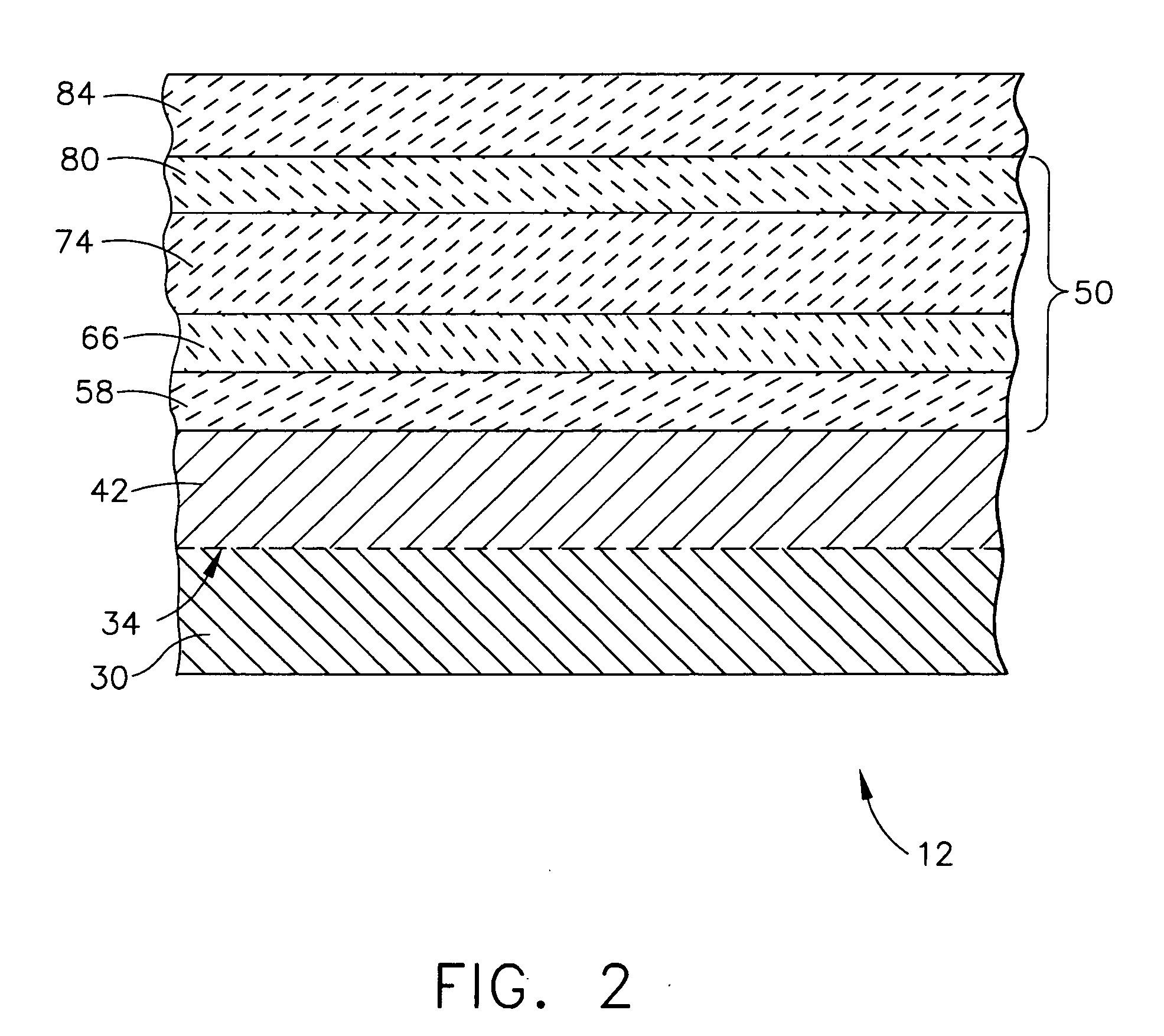

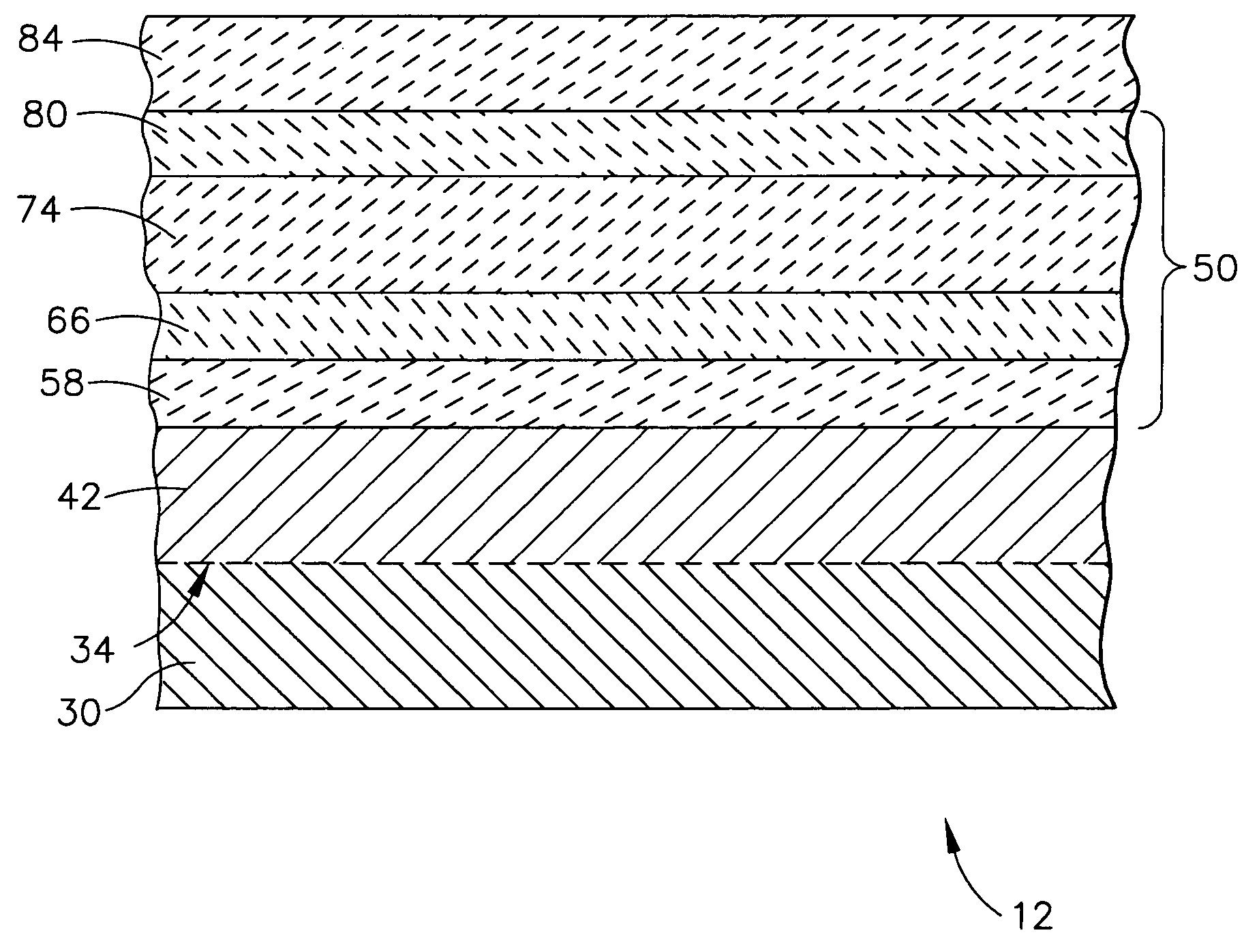

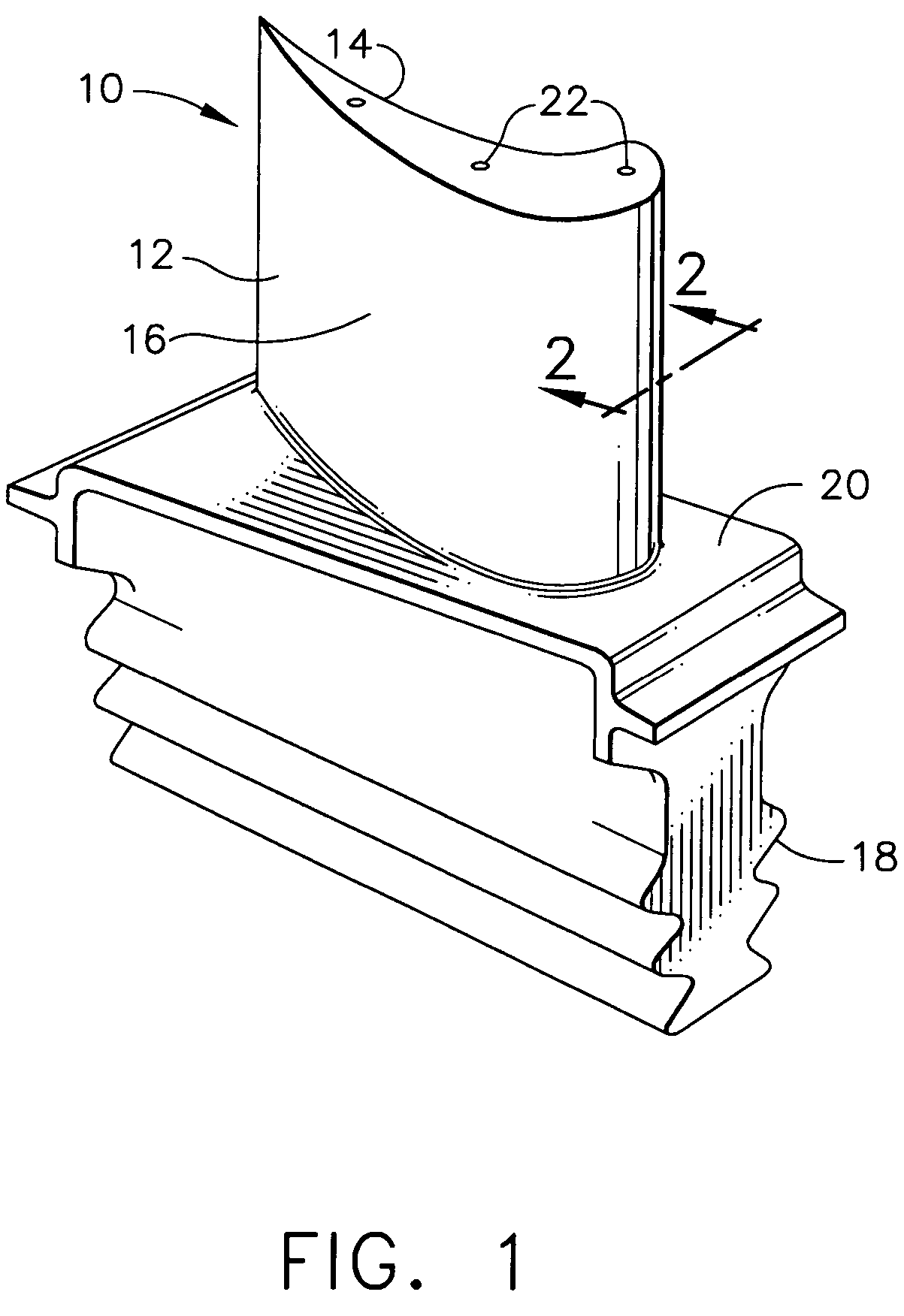

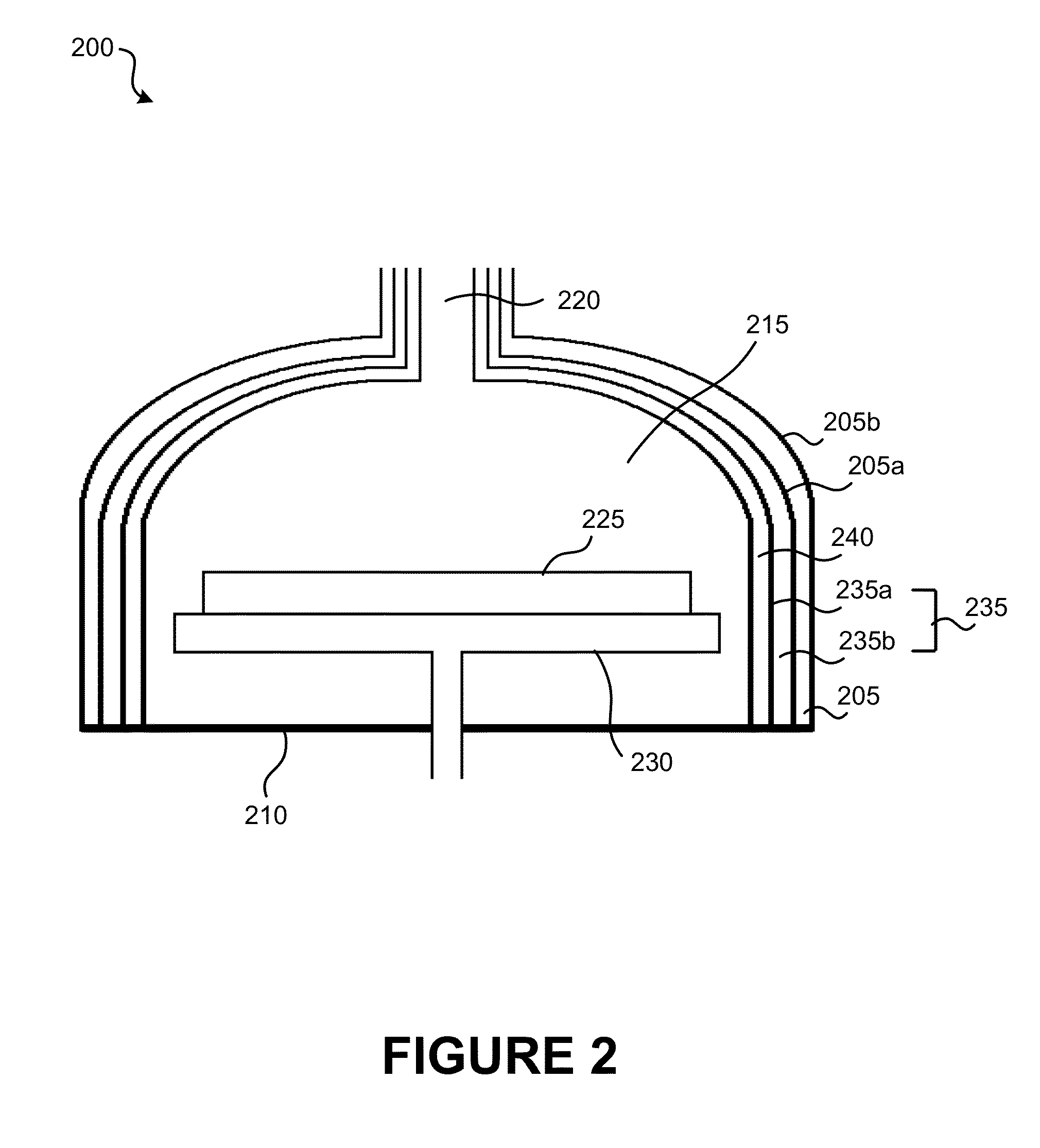

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS20060280953A1Improve adhesionHigh melting pointLiquid surface applicatorsMolten spray coatingCalcium silicateAlkaline earth metal

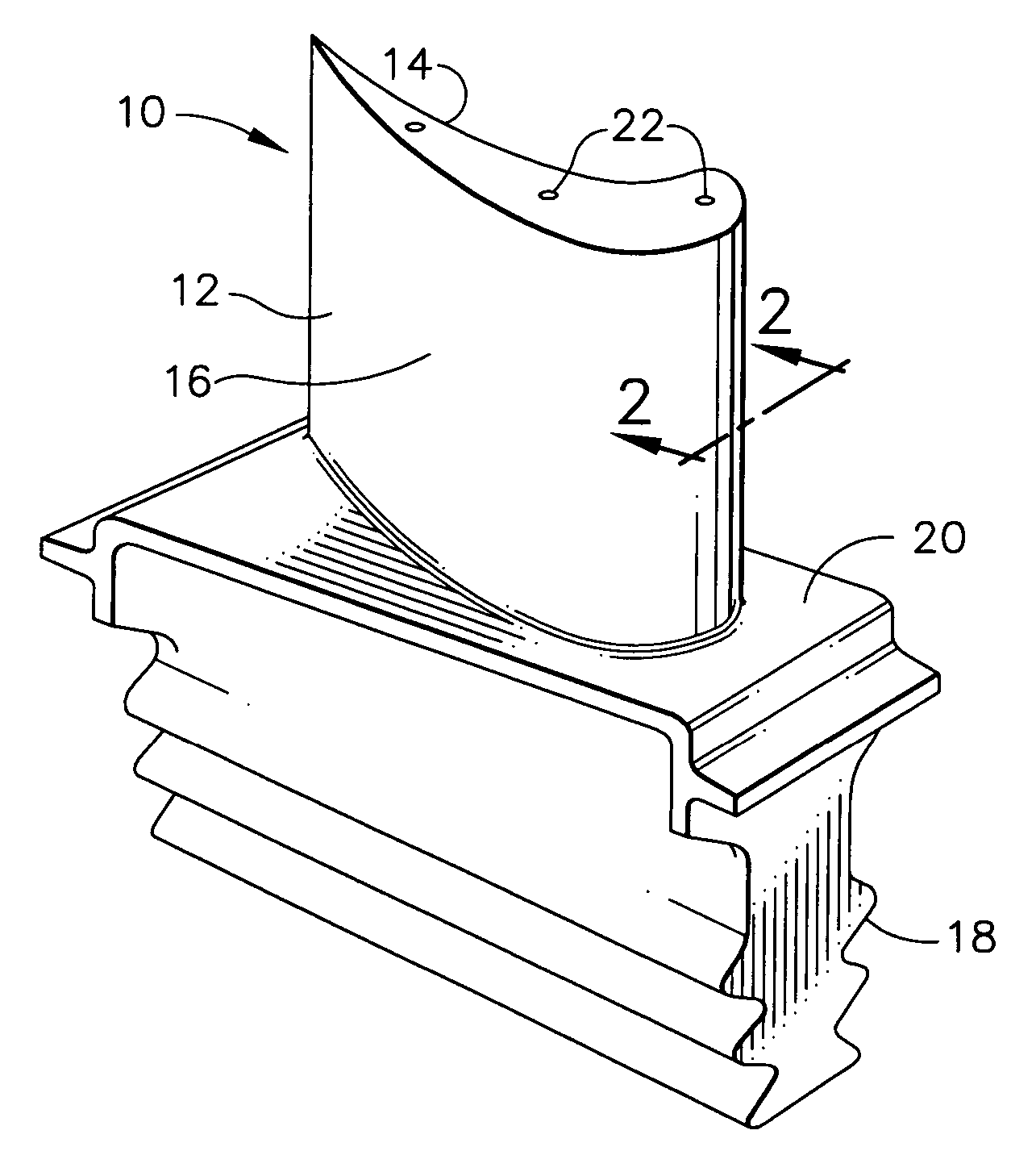

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS7442444B2Improve adhesionHigh melting pointMolten spray coatingVacuum evaporation coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

High temperature anti-oxidation coating and slurry for same of Cf/SiC composite material and preparation method thereof

InactiveCN101613209AThe coefficient of thermal expansion is close toSmall coefficient of thermal expansionCeramic layered productsMass ratioViscous flow

The invention discloses a slurry for high temperature anti-oxidation coating of Cf / SiC composite material and a preparation method thereof; the slurry is suspension liquid containing solid-phase components and organic carrier in a mass ratio of (1-4):1, the solid-phase components comprise BaO-Al2O3-SiO2 glass powder and oxide mixed powder in a mass ratio of (0-1):1 and the oxide mixed powder comprises Y2O3 powder and SiO2 powder in a molar ratio of 1:2. The invention also discloses a high temperature anti-oxidation coating of Cf / SiC composite material which is prepared from the slurry and a specific preparation method thereof. The coating is yttrium silicate composite coating or multilayer composite coating which is superimposed with various yttrium silicate composite coatings. The coating prepared by the method of the invention has low expansion coefficient and sufficient consistency, suitable high temperature viscous flow property and strong chemical bond with the protected composite material.

Owner:NAT UNIV OF DEFENSE TECH

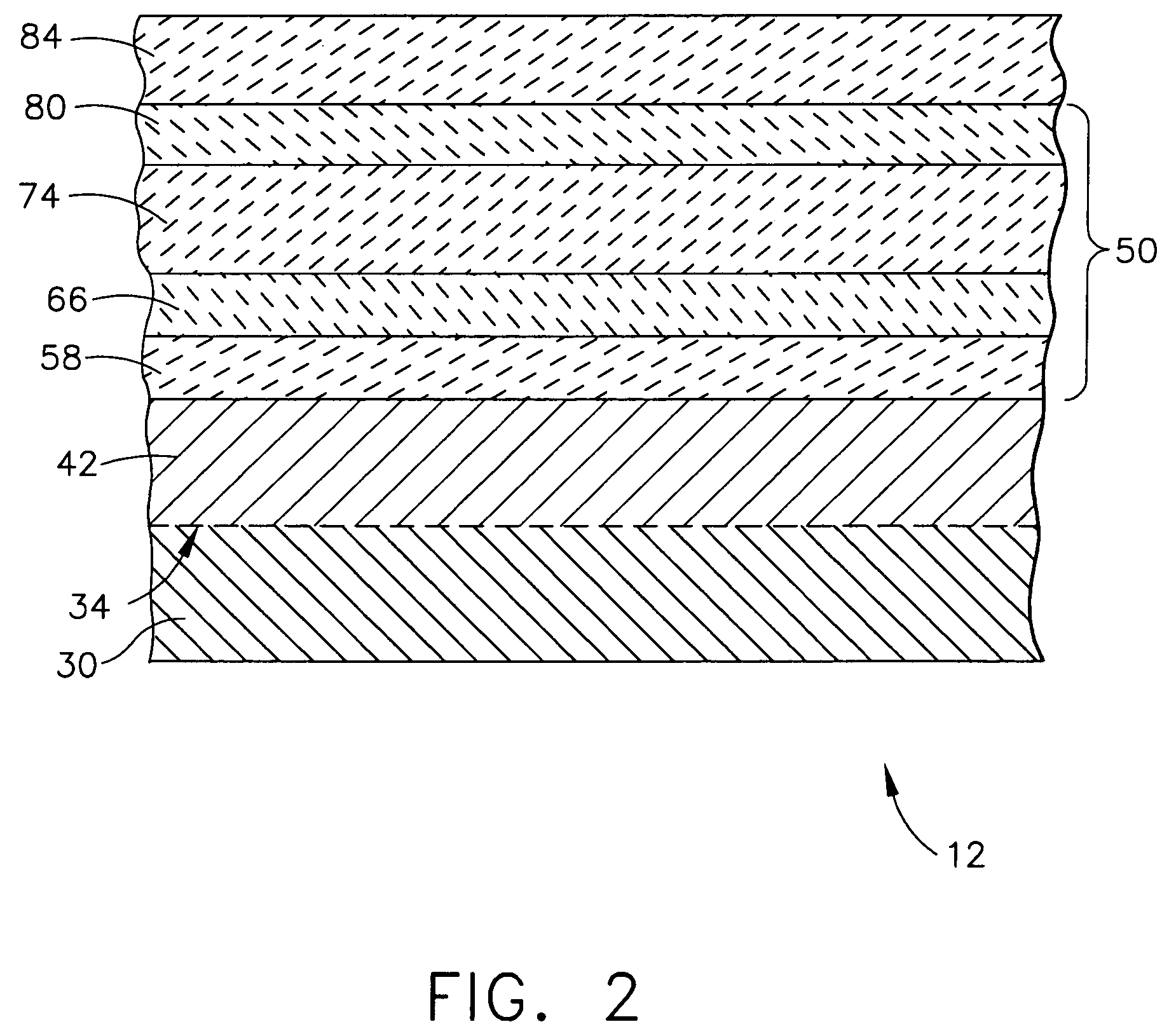

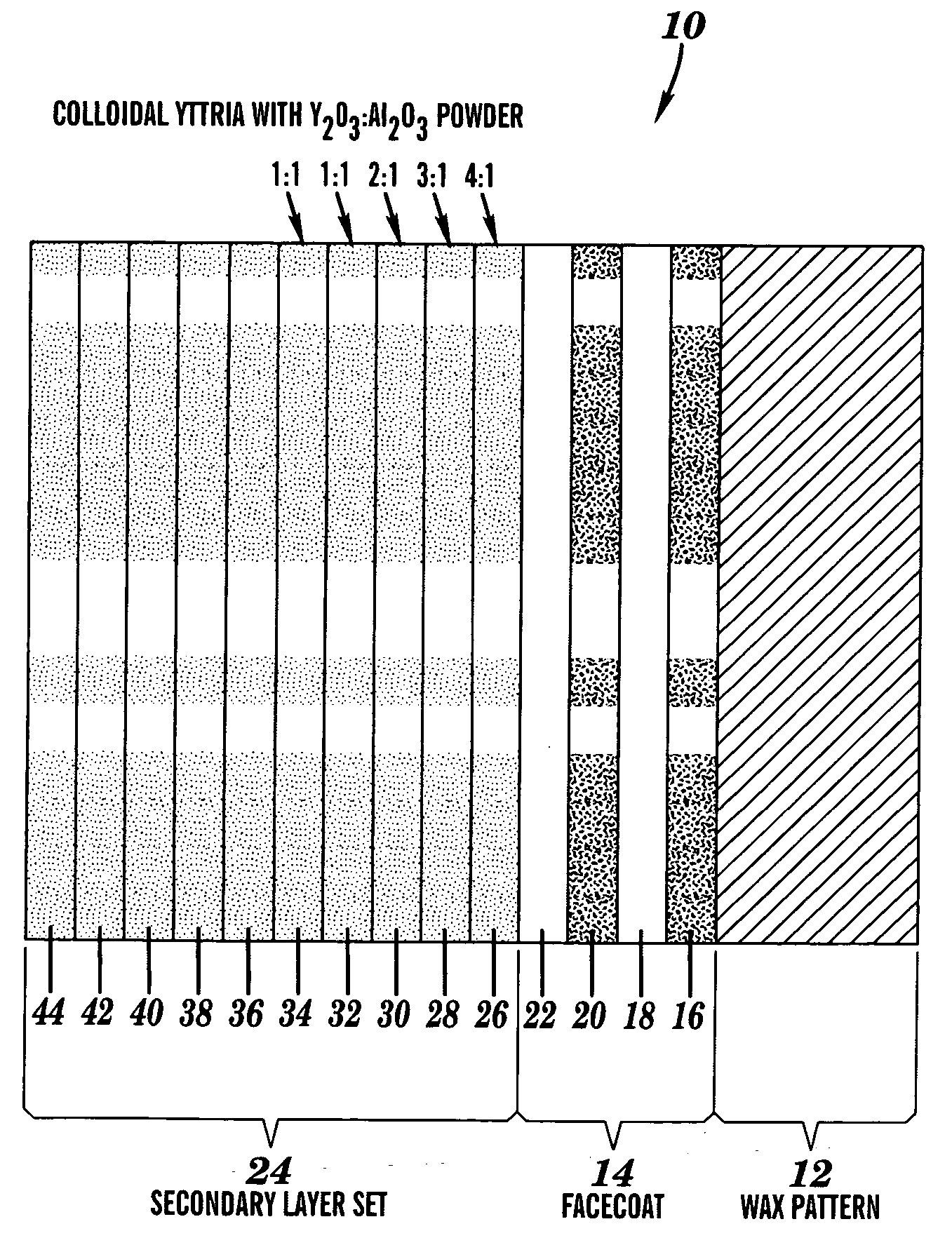

Shell mold for casting niobium-silicide alloys, and related compositions and processes

A shell mold for casting molten material to form an article is described. The mold includes a shell for containing the molten material, formed from at least one of yttrium silicates, zirconium silicates, hafnium silicates, and rare earth silicates. The mold also includes a facecoat disposed on an inner surface of the shell that contacts the molten material. The facecoat can be made from the materials described above. A method of casting a niobium-silicide article is also described, using the shell mold described herein. A method of making the ceramic shell mold is described as well, along with a slurry composition used in the manufacture of the shell mold.

Owner:GENERAL ELECTRIC CO

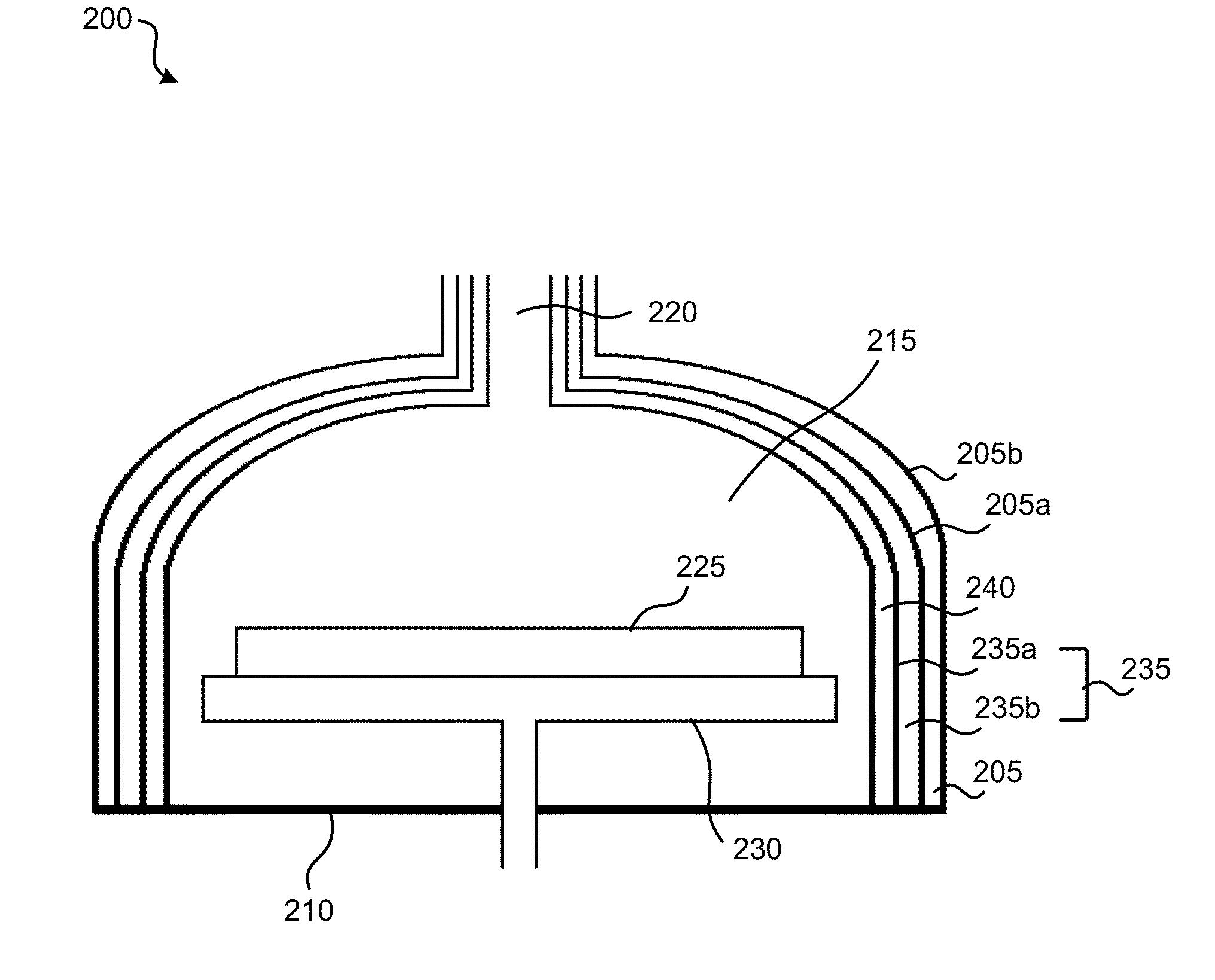

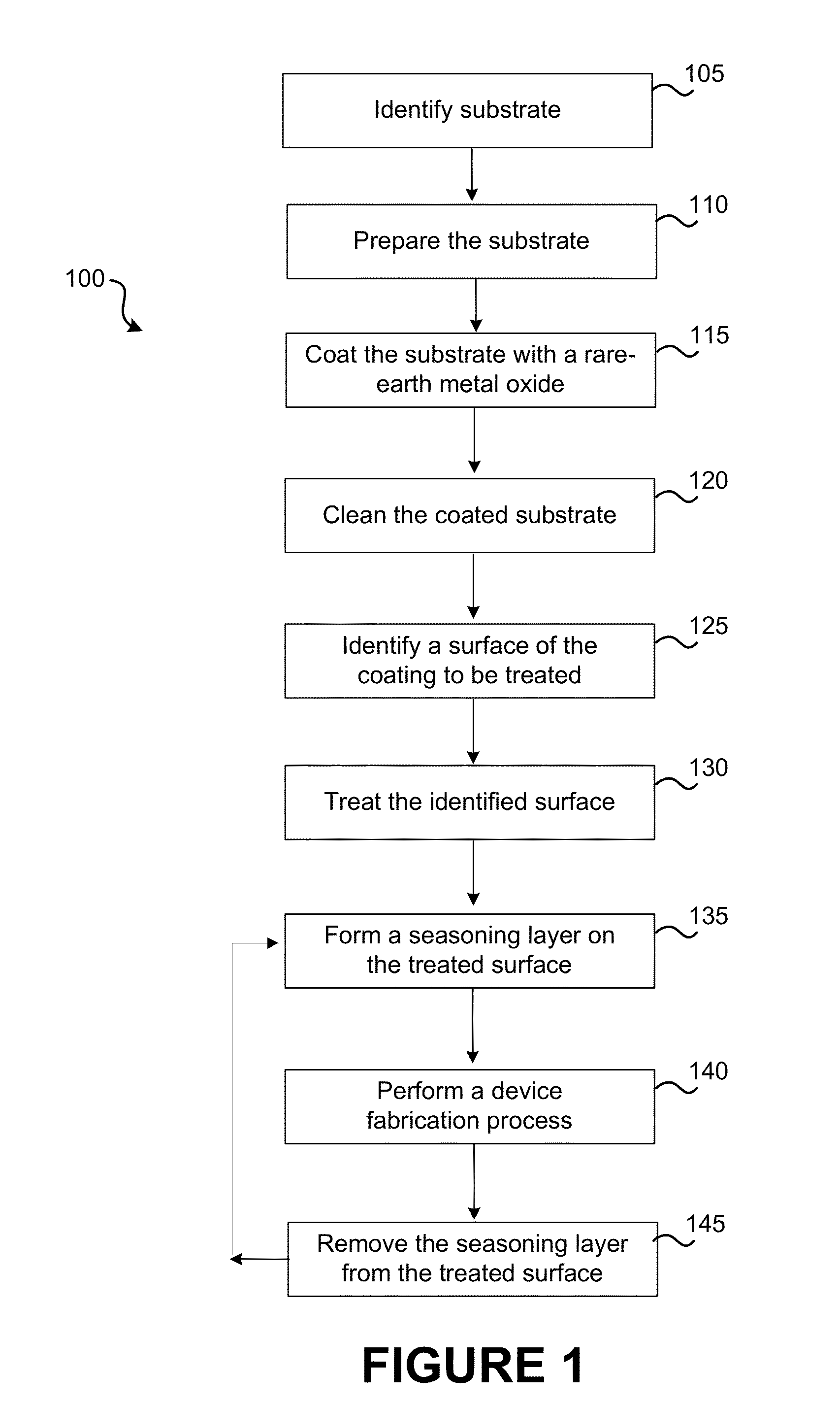

Multilayer rare-earth oxide coatings and methods of making

InactiveUS20130115418A1Control roughness/smoothnessPrecise maintenanceLiquid surface applicatorsMolten spray coatingRare earthOptoelectronics

Embodiments relate to a coated substrate and a method of making and using the same. A plasma-spray coated layer may be formed on a substrate, wherein the plasma-sprayed coated layer comprises a rare-earth oxide (e.g., yttrium oxide), a rare-earth fluoride (e.g. yttrium fluoride), or a rare-earth silicate (e.g. yttrium silicate). An exposed surface of the plasma-spray coated layer may be irradiated to form a treated portion of the layer, wherein the treated portion of the layer has a mean spacing of local peaks (S value) between about 100 and 200 microns. A second layer may be formed on the treated portion of the plasma-spray coated layer, wherein the second layer comprises a dielectric material.

Owner:COORSTEK INC

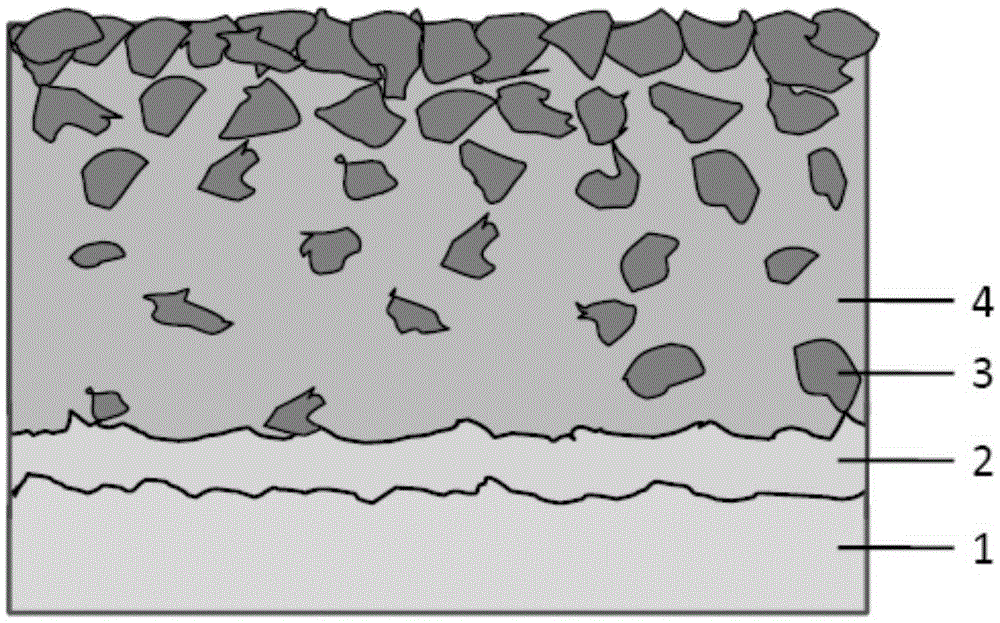

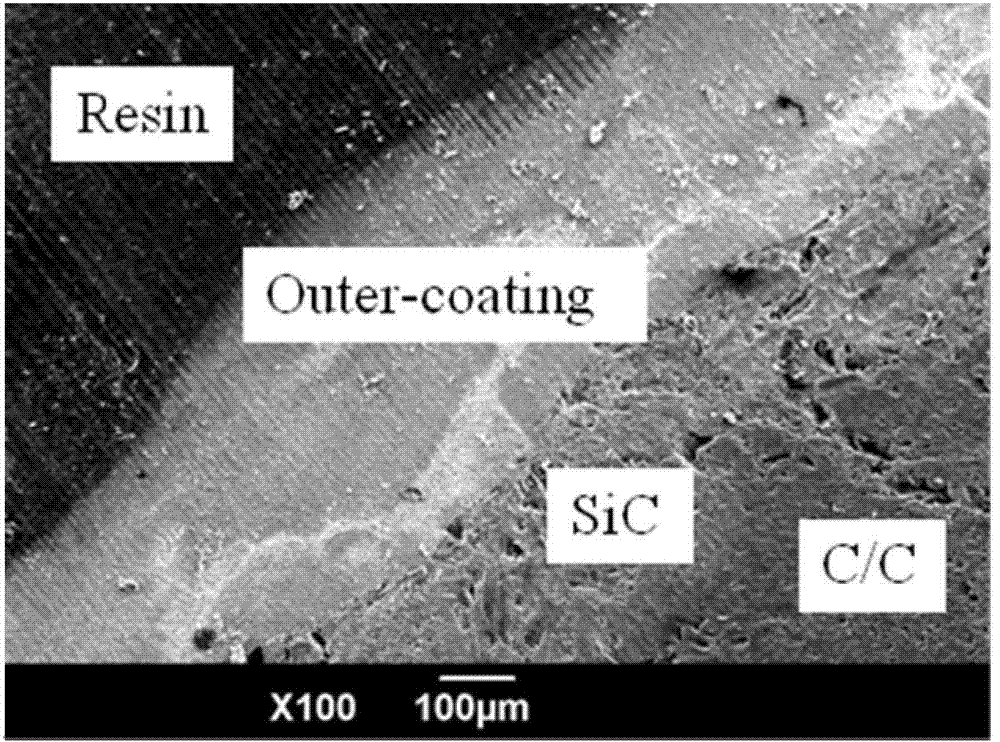

Environmental barrier coating used for ceramic base composite material matrix, and making method thereof

ActiveCN105384467AAlleviate or eliminate spalling and crackingReduce thermal matching differenceSurface layerThermal expansion

The invention provides an environmental barrier coating used for a ceramic base composite material matrix, and a making method thereof. The base layer of the environmental barrier coating selects a chemical vapor deposited SiC coating (transition layer), and the surface layer of the environmental barrier coating selects a plasma sprayed yttrium silicate and / or mullite coating. The SiC base layer and the ceramic base composite material matrix have extremely approaching thermal expansion coefficients, so cracking and spalling of the coating from the matrix are avoided; and the surface layer material selects a yttrium silicate doped mullite material, so the specific gravity of a mullite powder material is gradually increased from inside to outside; the yttrium silicate material has strong combination force with SiC, is matched with SiC in the thermal expansion coefficient, and also has the characteristics of low volatility and low oxygen permeability, so failure of the coating, caused by cracking of a base layer-surface layer interface, is avoided; and the mullite material has the advantages of good scouring resistance and high thermal stability, and can work in high temperature environment.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

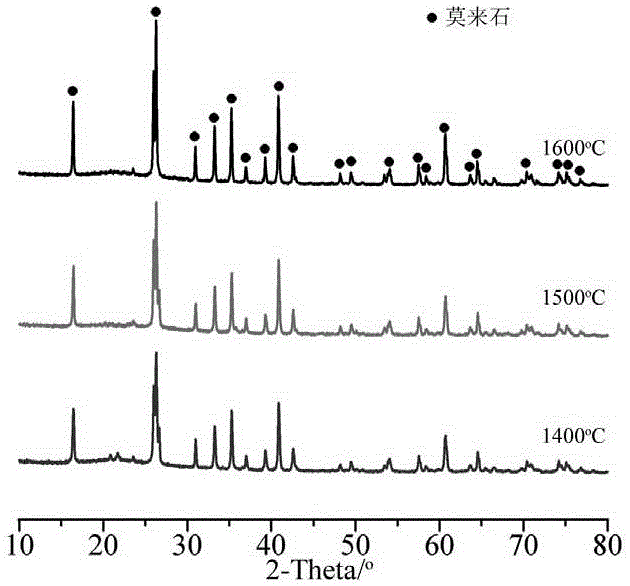

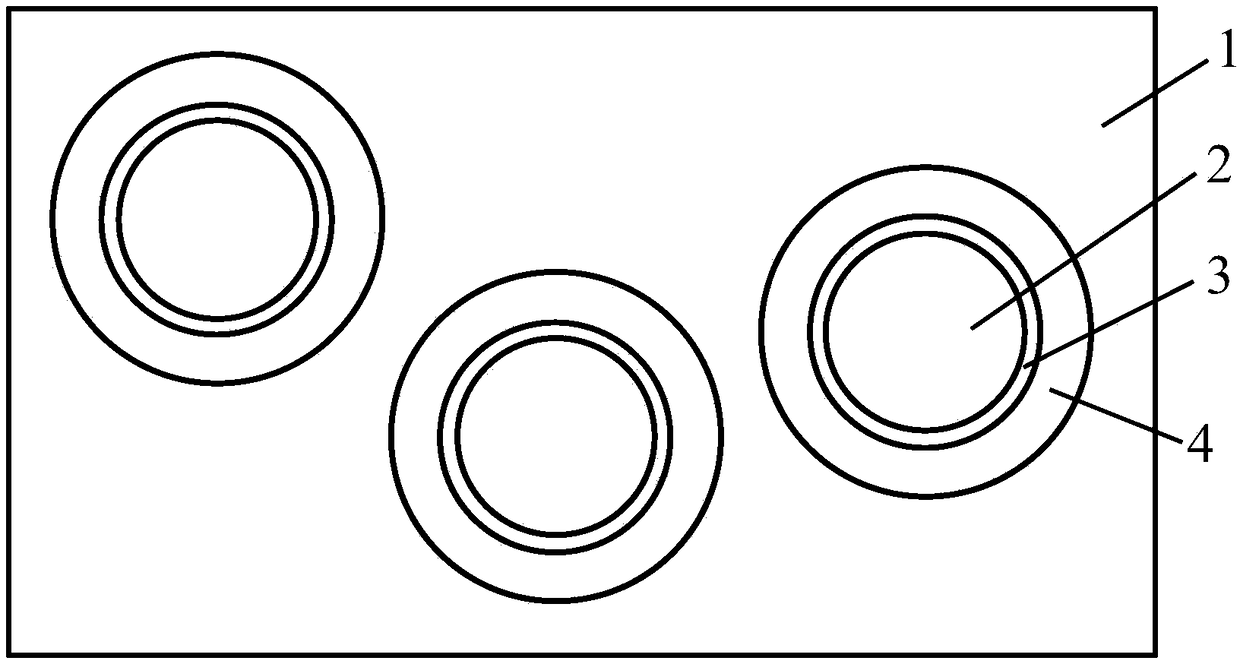

C/SiC composite surface coating system and preparation method thereof

The invention discloses a C / SiC composite surface coating system and a preparation method thereof. The surface coating system is arranged on the surface of a substrate of a C / SiC composite and comprises a mullite coating and an yttrium silicate coating which are sequentially distributed from bottom to top. The preparation method comprises steps as follows: (1), preparing Al2O3-SiO2 composite sol; (2), preparing raw mud materials of the yttrium silicate coating; (3), preparing the mullite coating; and (4), preparing the single-layer yttrium silicate coating or the multi-layered yttrium silicate coating. The C / SiC composite surface coating system has the characteristics of high densification and high temperature resistance, and the preparation method of the C / SiC composite surface coating system has engineering application universality.

Owner:NAT UNIV OF DEFENSE TECH

Shell mold for casting niobium-silicide alloys, and related compositions and processes

A shell mold for casting molten material to form an article is described. The mold includes a shell for containing the molten material, formed from at least one of yttrium silicates, zirconium silicates, hafnium silicates, and rare earth silicates. The mold also includes a facecoat disposed on an inner surface of the shell that contacts the molten material. The facecoat can be made from the materials described above. A method of casting a niobium-silicide article is also described, using the shell mold described herein. A method of making the ceramic shell mold is described as well, along with a slurry composition used in the manufacture of the shell mold.

Owner:GENERAL ELECTRIC CO

Surface coating system of fiber reinforced ceramic matrix composite material and preparation method therefor

The present invention provides a surface coating system of fiber reinforced ceramic matrix composite material, wherein the surface coating system is arranged on the substrate surface of the fiber reinforced ceramic matrix composite material and comprises a Sic coating layer, a mullite coating layer and a yttrium silicate coating layer laid in order from bottom to top. The preparation method comprises the following steps of preparing sludge raw materials of the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer respectively, and preparing the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer. The present invention is used for the surface coating system of the fiber reinforced ceramic matrix composite material, has the advantages of high density, high temperature resistance and anti-oxidation.

Owner:NAT UNIV OF DEFENSE TECH

Water heat electrophoresis deposition method of gradient iridium silicate coating layer

InactiveCN1904144AAddress heat damageGood antioxidant propertiesElectrophoretic coatingsYttriumChemistry

This invention relates to a kind of water-thermo electrophoresis deposition process which use gradient silicic acid yttrium smear layer. This process applies wet chemistry method to synthesize gradient component and three kinds of expected crystal phase structure silicic acid yttrium micropower, then dispersing them in liquid medium, applying water-thermo electrophoresis deposition process in low temperature to gain satisfactory gradient silicic acid yttrium smear layer, solving the problem of heat injury of basis body in the process. The feature is: cohering strength of smear layer and basis body exceed 28MPa; excellent antioxygen performance; valid protection to carbon material at 1600 DEG C can last 260hours; oxidizing weight loss is below 2%.

Owner:SHAANXI UNIV OF SCI & TECH

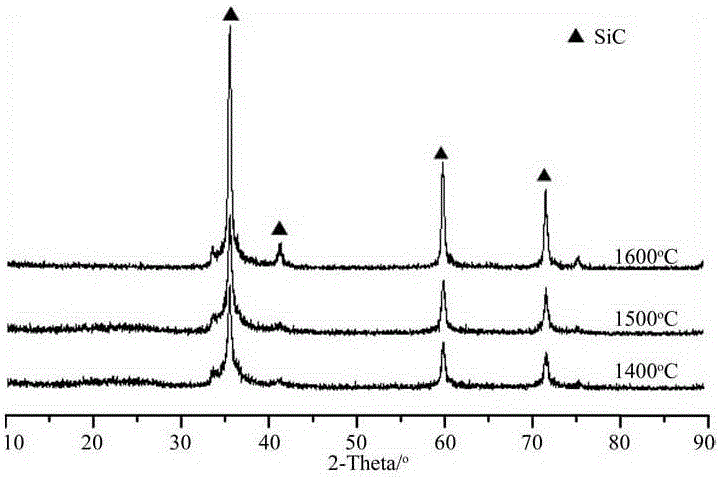

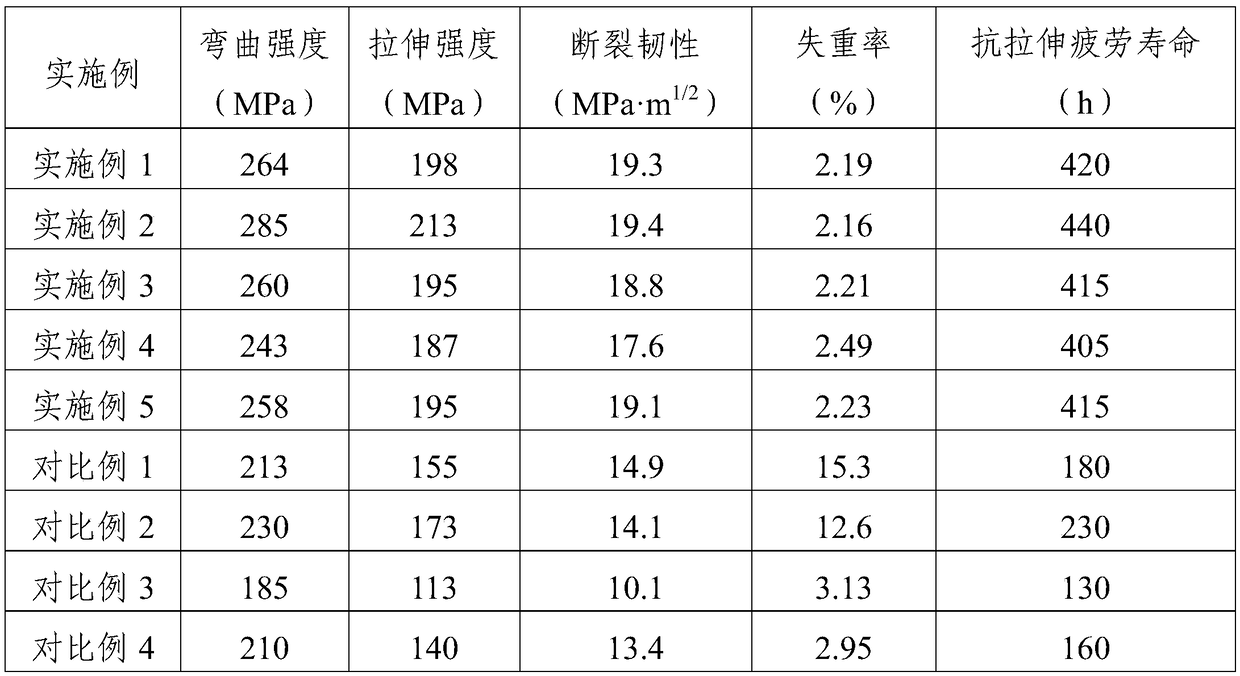

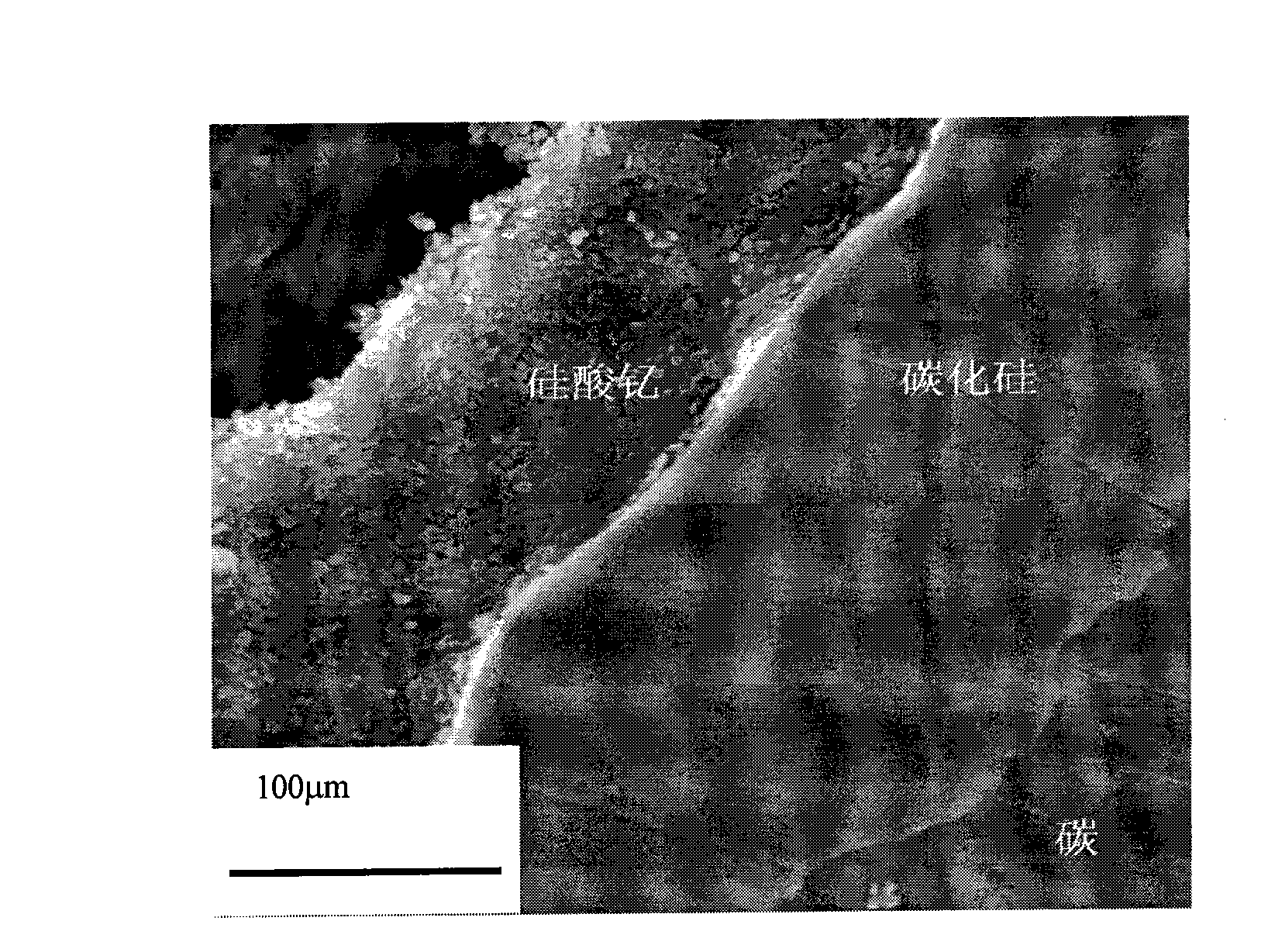

Yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109053207AGood chemical stabilityImprove high temperature resistanceWater vaporInterface layer

The invention relates to a yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially preparing a yttrium silicate interface layer and a silicon carbide interface layer on the surface of a silicon carbide fiber prefabricated body so as to obtain a yttrium silicate modified silicon carbide fiber prefabricated body; (2) soaking the yttrium silicate modified silicon carbide fiber prefabricated body prepared in the step (1) into a carbon precursor solution, and sequentially carrying out a curing step and a cracking step on the soaked yttrium silicate modified silicon carbide fiber prefabricated body; (3) at least repeating the step (2) once so as to obtaina porous silicon carbide fiber prefabricated body; (4) carrying out a liquid silicon infiltration reaction on the porous silicon carbide fiber prefabricated body prepared in the step (3), thereby obtaining a yttrium silicate modified SiC / SiC composite material. The yttrium silicate modified SiC / SiC composite material provided by the invention has excellent oxidation resistance, temperature resistance, vapor corrosion resistance, and the like, and is excellent in comprehensive property.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for preparing yttrium silicate coat by cathode rotation hydrothermal electrophoretic deposition

InactiveCN101514473ASimple process controlAvoid duplicationElectrophoretic coatingsMetallurgyVoltage

The invention relates to a method for preparing an yttrium silicate coat by cathode rotation hydrothermal electrophoretic deposition. A cathode rotation hydrothermal electrophoretic deposition method is used for preparing an yttrium silicate antioxidant coat on the surface of carbon / carbon-carborundum composite. Yttrium silicate powder is used as raw material to be respectively made into the yttrium silicate coats with compact structure, microcrack and different thickness in certain powder material proportion, under certain temperature and voltage and at different cathode rotation speeds. The method has the advantages of simple technical control and uniform coat, avoids repeated operation to certain extent and can be used for product with complex surface, and the method can obtain the yttrium silicate coat with controllable structure and good performance under low temperature.

Owner:SHAANXI UNIV OF SCI & TECH

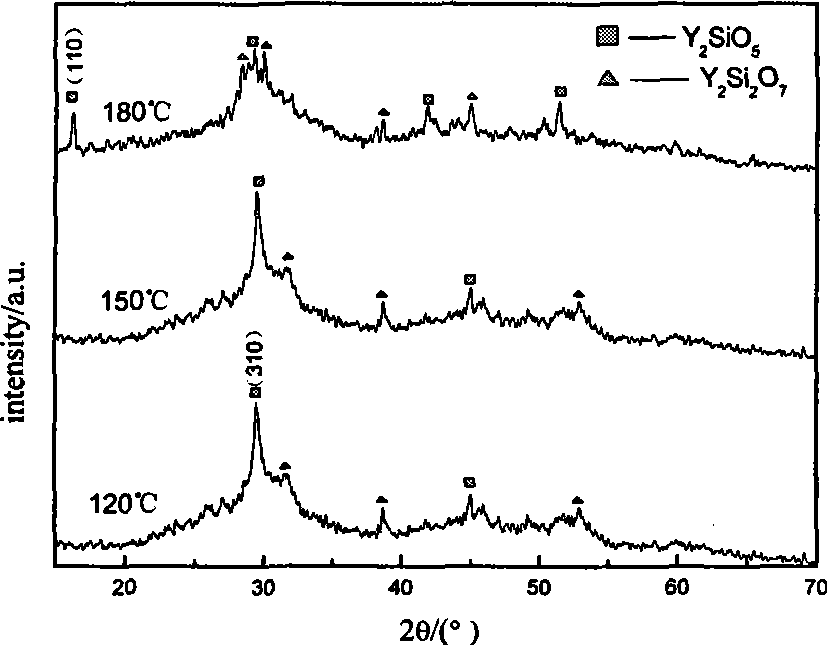

Method for preparing yttrium silicate nano powder

InactiveCN101391796AShort reaction cycleGood repeatabilityRare earth metal compoundsFiltrationRoom temperature

The invention relates to a preparation method of for an yttrium silicate nanopowder is disclosed, comprising the following steps: analytically pure Y(NO3)3 question mark 6H2O, Na2SiO3 question mark 9H2O and NaOH are added into distilled water and then stirred for obtaining solution A; the solution A is poured into a hydrothermal reaction kettle; the hydrothermal temperature is controlled at 120 to 180 DEG C; the reaction time is controlled at 10min to 60min; after the reaction is finished, the solution A is naturally cooled to the room temperature so as to obtain solution B; the products of the solution B are collected by pumping filtration of filter paper, which are then washed and dried for 0.5 to 1h, finally product C which contains yttrium silicate nanopowder is obtained. By using a microwave hydrothermal method, the invnetion can rapidly prepare yttrium silicate nanopowder with controllable crystal form and size. The controllable yttrium silicate nanopowder prepared by the process has the advantages of short reaction cycle, good reproducibility, simple process, convenient operation, easy obtaining of raw materials, and lower preparation cost.

Owner:SHAANXI UNIV OF SCI & TECH

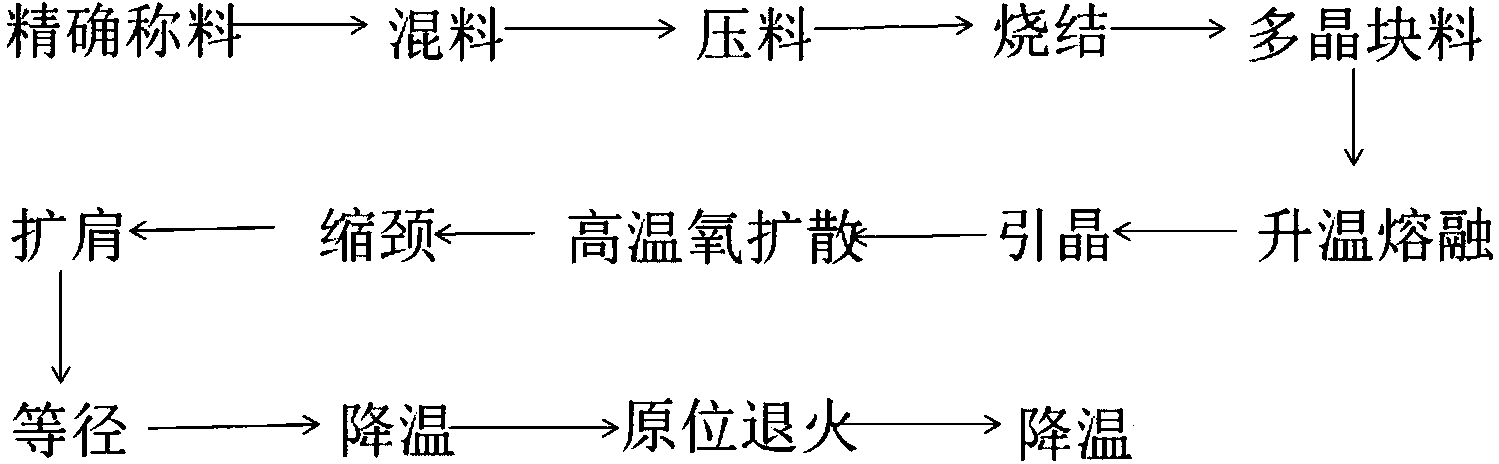

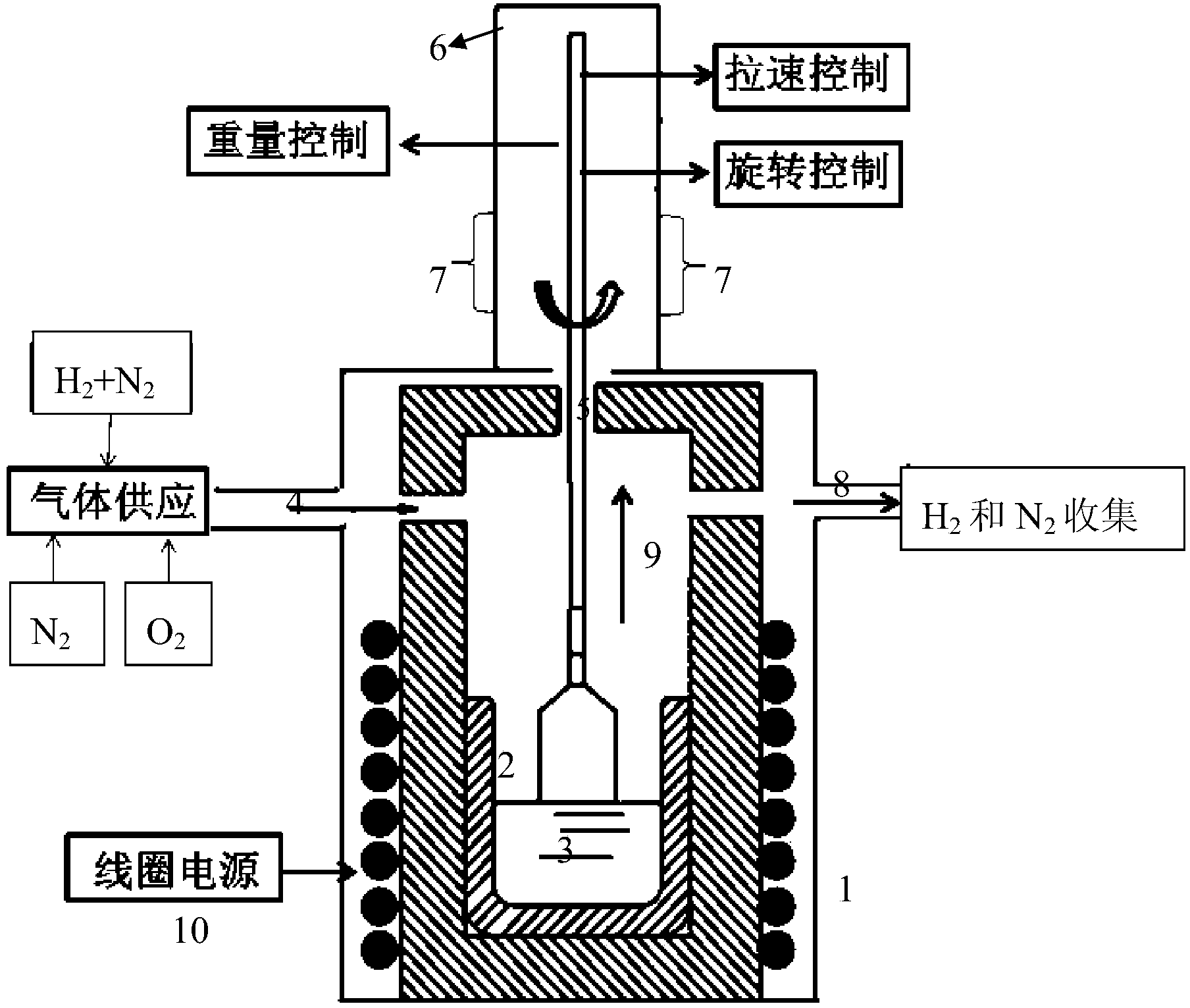

Method for growing Ce<3+> doped lutetium yttrium silicate scintillation crystal

ActiveCN103849933AAchieve oxygen balanceImprove crystal qualityPolycrystalline material growthAfter-treatment detailsLutetiumScintillation crystals

The invention relates to a method for growing a Ce<3+> doped lutetium yttrium silicate scintillation crystal. The method is characterized by comprising the concrete steps of (1) weighing and mixing; (2) pressing and sintering; (3) heating for fusing; (4) seeding; (5) high temperature oxygen diffusion; (6) necking, shoulder extending and keeping constant-diameter; (7) cooling; (8) in-situ annealing. According to the invention, a crystal growth furnace is properly modified, so that high-temperature oxygen diffusion and in-situ annealing at a reducing atmosphere can be simultaneously realized, oxygen balance can also be realized, and furthermore, the crystal is not easy to crack and become yellow and the good crystal quality is kept. The success rate for growing the crystal is increased from 40-45% to 75-85%.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

Preparation method of controllable yttrium silicate nano-rod

InactiveCN101555619ANarrow particle size distributionControllable grain morphologyPolycrystalline material growthFrom normal temperature solutionsNanostructureThermal methods

The invention relates to a preparation method of a controllable yttrium silicate nano-rod. The preparation method comprises the following steps: respectively adding NaOH and analytically pure (NO3)3.6H2O and Na2SiO3.9H2O into distilled water, adjusting the pH to 4-13 and obtaining a solution A; adding the solution A into a hydro-thermal reaction kettle, sealing the hydro-thermal reaction kettle, placing the hydro-thermal reaction kettle into a temperature and pressure double-control microwave hydro-thermal reaction instrument, naturally cooling to room temperature after reaction, and obtaining a solution B; opening the hydro-thermal reaction kettle, collecting the product through filtering, washing the product by respectively adopting de-ionized water and absolute ethyl alcohol or isopropanol, drying the product in an electrothermal blowing dry box and obtaining a final product, i.e. yttrium silicate nano-powder. The invention adopts microwave hydro-thermal method to synthesize yttrium silicate nano-crystal, and then controls the yttrium silicate nano-structure through processes of anneal, and the like. The invention has the advantages of simple process preparation, convenient operation, easily obtained materials, low preparation cost, short reaction period, low temperature and good repetitiveness. The yttrium silicate nano-powder prepared by the method has narrow distribution of grain diameter, controllable crystal grain shape and higher purity.

Owner:SHAANXI UNIV OF SCI & TECH

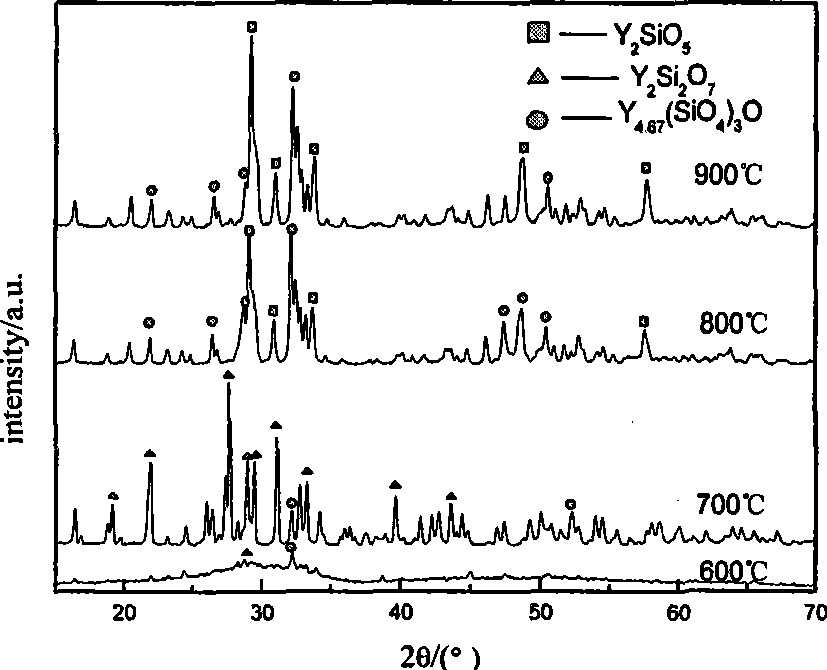

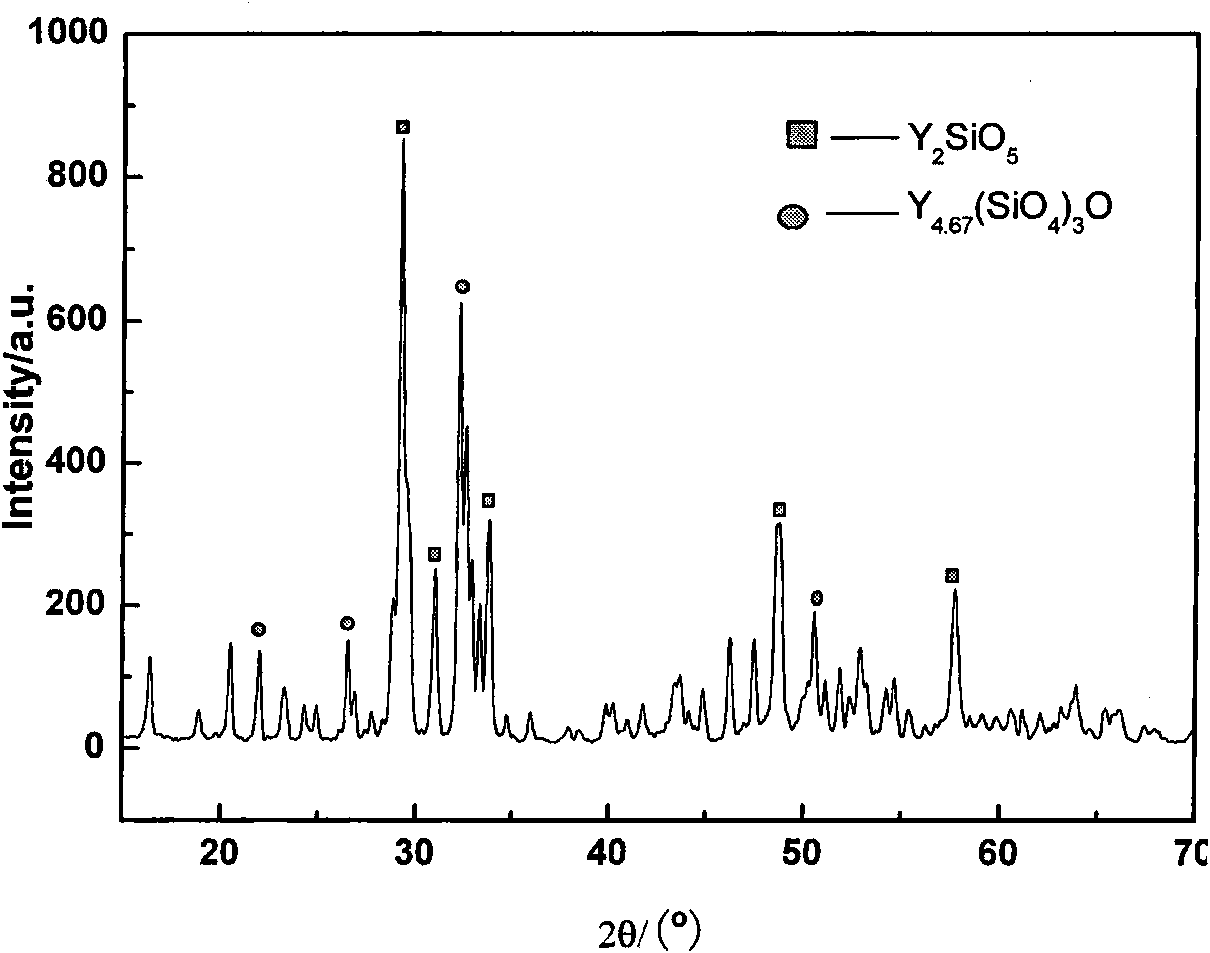

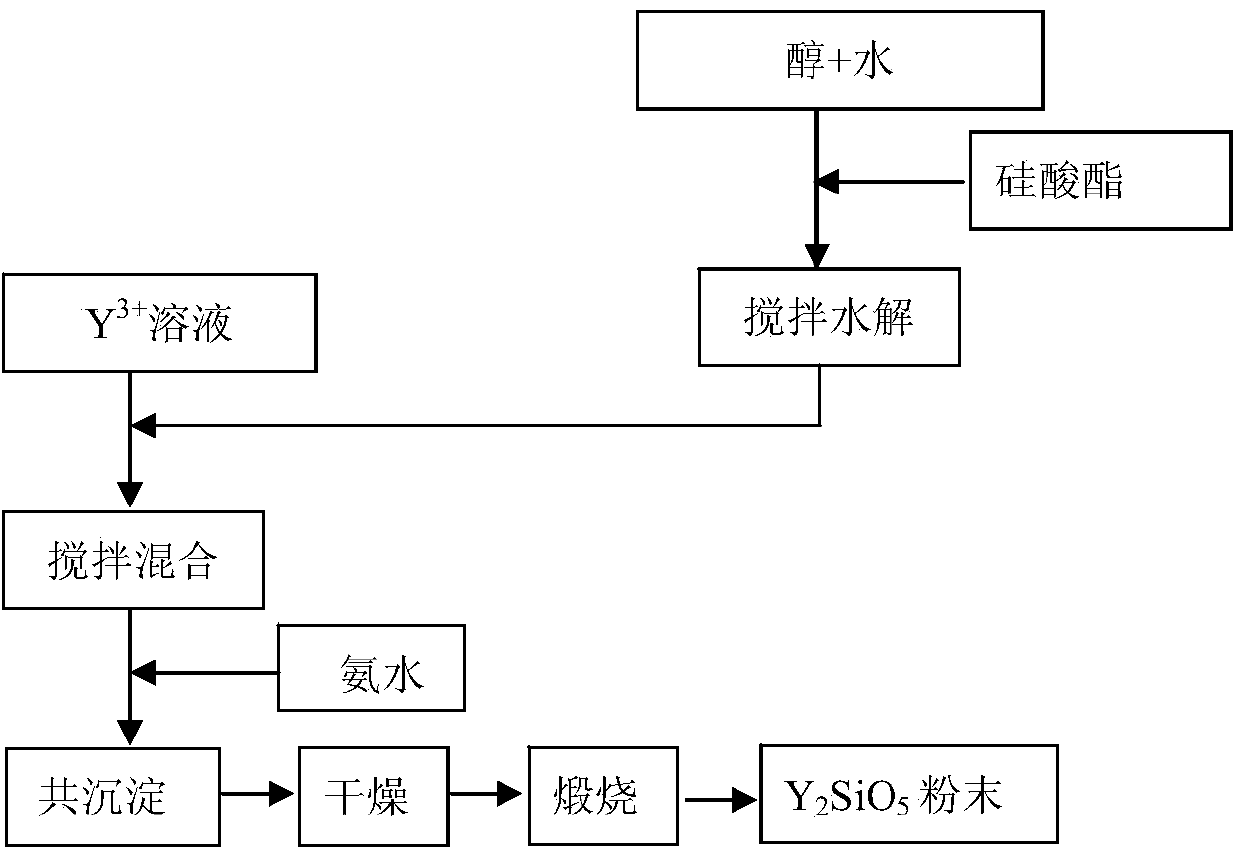

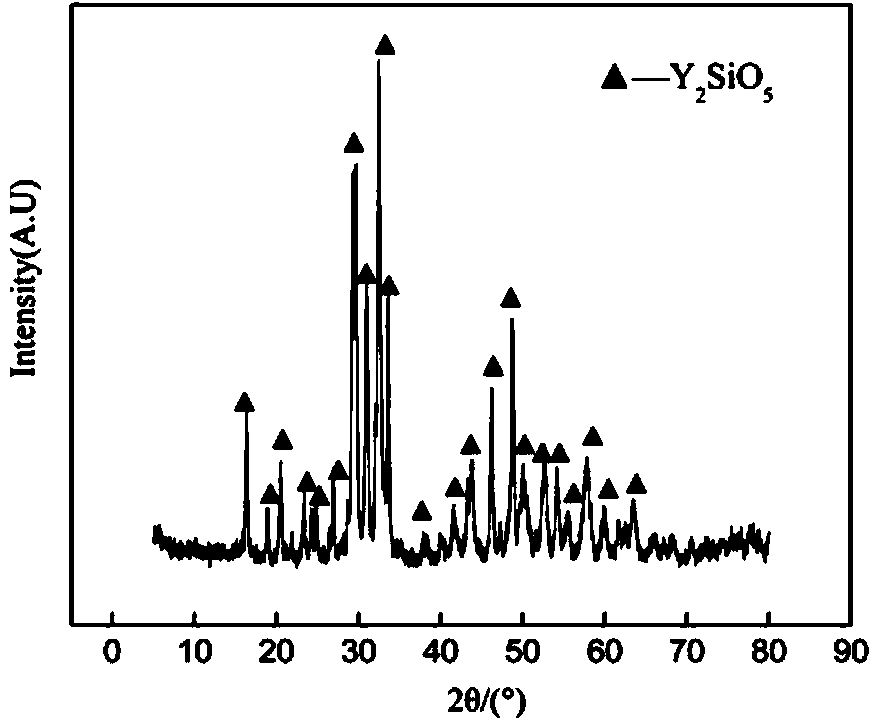

Preparation method of yttrium silicate ceramic powder

The invention relates to a preparation method of yttrium silicate ceramic powder, in particular relates to a preparation method of yttrium silicate ceramic powder for environment barrier coating, and belongs to the technical field of oxide ceramic material preparation. The method comprises the following steps: using a yttrium solution with Y<3+> ion concentration of 0.6-1.5 mol / L as solution A; weighing silicate ester according to a molar ratio of Y to Si being 2: 1; adding alcohol and water in the weighed silicate ester according to a volume ratio of the silicate ester to alcohol to water being 1: 1-2: 2-6 to obtain solution B; uniformly mixing the solutions A and B solution to obtain the mixed solution containing aluminum and silicon; adding the mixed solution containing aluminum and silicon into ammonium hydroxide with pH value of 9-10 at a speed of dropwise adding 0.2-0.5 L of the mixed solution containing aluminum and silicon in 1L of precipitator every minute, and stirring to obtain the co-precipitate; after the reaction is finished, standing, filtering, washing and drying the residue, calcining for at least 4 hours at 800-1000 DEG.C to obtain the Y2SiO5 ceramic composite powder. The method provided by the invention is short in reaction period and good in repeatability; and the obtained product is high in purity and is of a single crystal form.

Owner:CENT SOUTH UNIV

Method for growing gadolinium orthosilicate scintillation crystal

InactiveCN1544709ASolve crackingImprove yieldPolycrystalline material growthBy pulling from meltCalcium silicateGadolinium

The invention is a gadolinium silicate scintillator growing method, mainly using the crystals with structures similar to gadolinium silicate's, like lutecium silicate, yttrium silicate and lutecium yttrium silicate, their chemical general formula: (Lu1-xYx)2SiO5(0<=x<=1), as seed crystals, and by selecting a proper seeding temperature, generally at 2200-1980 deg.C, able to grow uncracked gadolinium silicate crystal. It solves the cracking problem of seed crystals when processing, primely solves the problem of cracking or breaking at the seed crystals when crystal growing, and extremely enhancing the yield.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

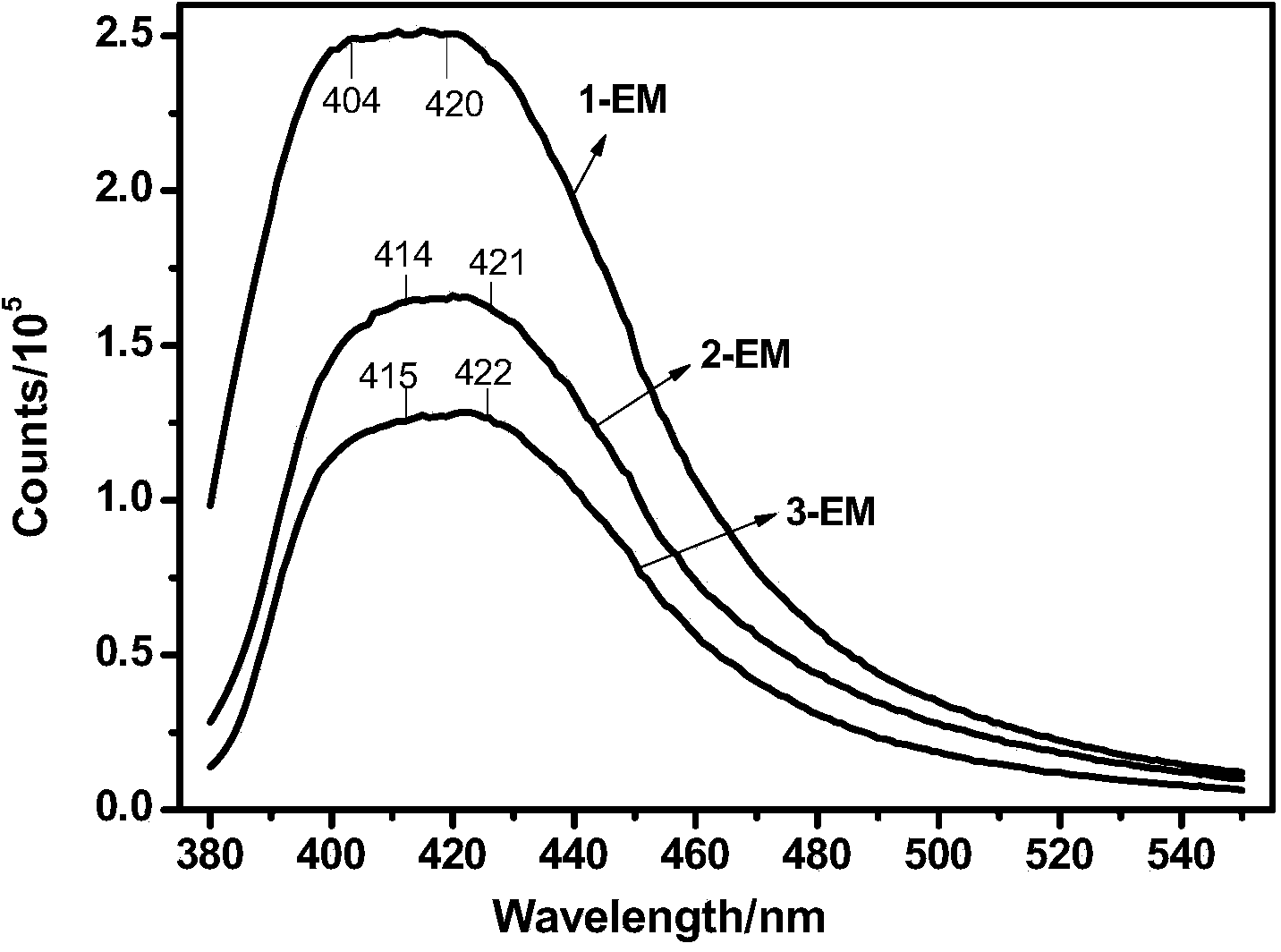

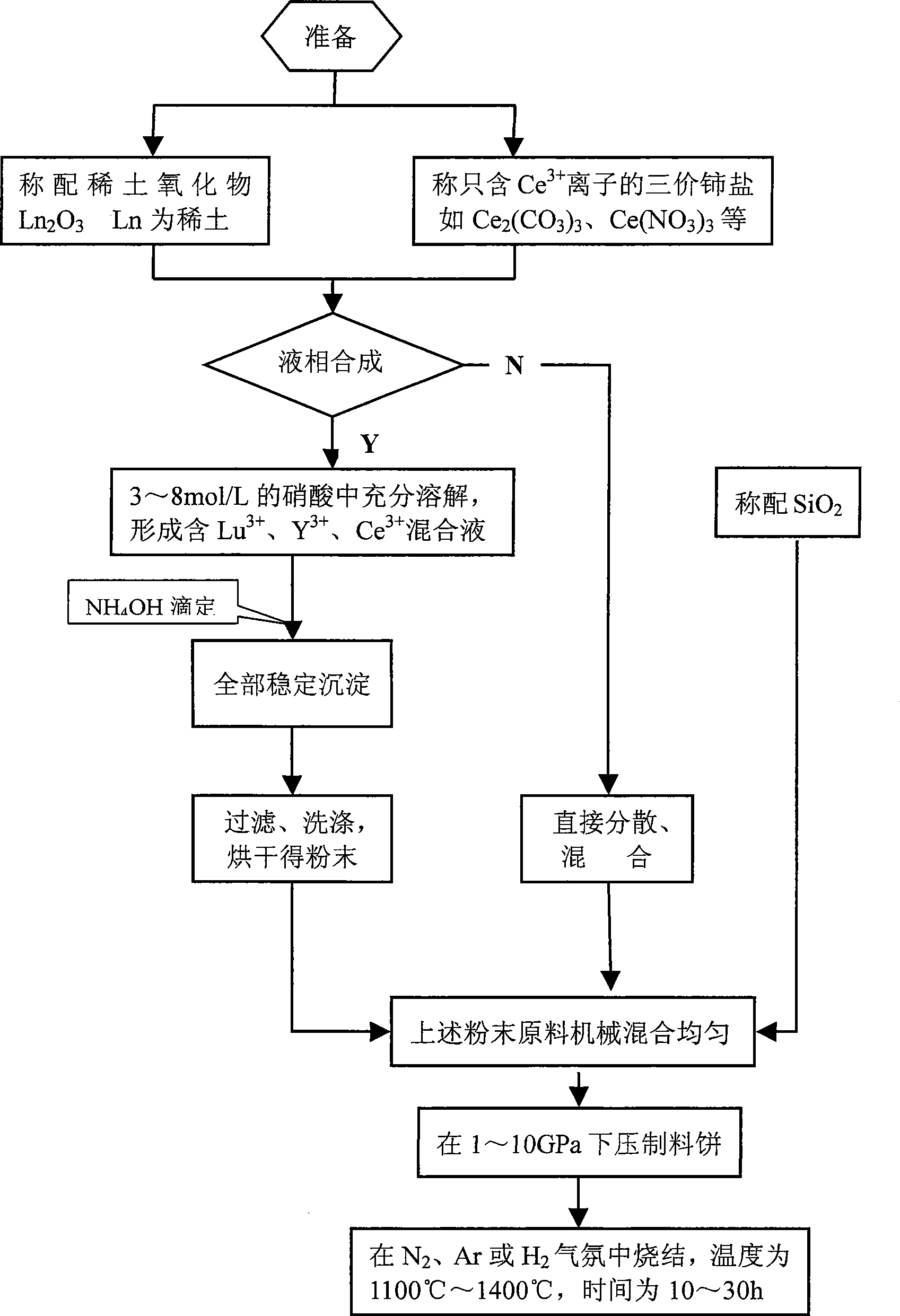

Rare earth silicates polycrystal material doped with Ce<3+> and preparing method thereof

InactiveCN101377020ALower sintering temperatureHigh purityPolycrystalline material growthSingle crystal growth detailsRare earthQuenching

The invention relates to a cerous ion-doped rare earth silicate polycrystal material and a preparation method thereof, which is characterized in that the rare earth silicate is lutecium silicate, yttrium silicate or lutecium and yttrium silicate; the mol percentage of the doped cerous compound is 0.2 percent to 2 percent; the general formula of the doped rare earth silicate is Ln<2(1-x)>Ce2xSiO3, wherein, x is equal to0.002 to 0.02, and Lu is one or two types of Y and Lu. The doped cerous compound is Ce2(CO3)3, Ce(NO3)3, Ce2(C2O4)3, Ce(CH3COO)3 or Ce(OH)3. The polycrystal material is directly synthesized or prepared by doping the cerous compound and liquid-phase mixing. The invention most reduces the introduction of Ce<+4> raw material, eliminates the quenching impact of the Ce<+4> on the luminescence of Ce<+3>, reduces the sintering temperature of the polycrystal material, and improves the scintillation properties of the material, such as light output, energy resolution and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

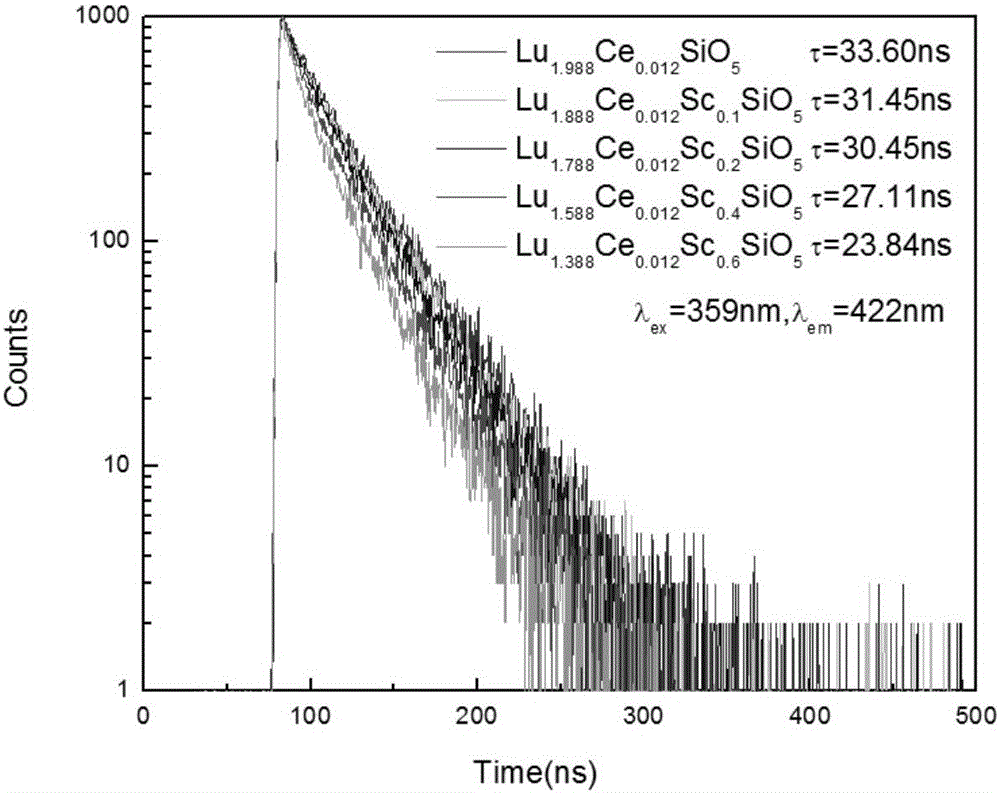

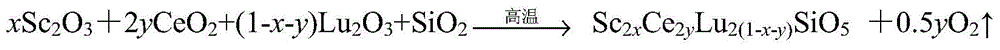

Sc/Ce-codoped lutetium silicate and lutetium yttrium silicate crystals and melt-process growth method thereof

InactiveCN105986320ALong luminous lifeImprove performancePolycrystalline material growthSingle crystal growth detailsLutetiumDip-coating

The invention discloses Sc / Ce-codoped lutetium silicate and lutetium yttrium silicate crystals and a melt-process growth method thereof. The molecular formulae are Sc[2x]Ce[2y]Lu2[(1-x-y)]SiO[5] and Sc[2x]Ce[2y]Y[2z]Lu[2(1-x-y-z)]SiO[5]. The melt-process growth method comprises the following steps: as for the Sc[2x]Ce[2y]Lu2[(1-x-y)]SiO[5], proportionally preparing Sc2O3, CeO2, Lu2O3 and SiO2, sufficiently mixing, carrying out press forming, and carrying out high-temperature sintering to obtain a crystal growth initial raw material; or as for the Sc[2x]Ce[2y]Y[2z]Lu[2(1-x-y-z)]SiO[5], proportionally preparing Sc2O3, CeO2, Y2O3, Lu2O3 and SiO2, sufficiently mixing, carrying out press forming, and carrying out high-temperature sintering to obtain a crystal growth initial raw material; and heating to melt the growth initial raw material, and growing by a dip coating process or crucible descent process to obtain the scintillator monocrystals.

Owner:ANHUI FIRESKY CRYSTAL SCI & TECH +1

Rare earth silicate coating and method for preparing coating on surface of C/SiC composite material

The invention relates to a rare earth silicate coating and a method for preparing a coating on the surface of a C / SiC composite material. In the method, a yttrium silicate coating and a ytterbium silicate coating with a relatively wide application prospect are synthesized by virtue of a chemical vapor reaction mechanism, combination of the coatings and a substrate is relatively tight, and the coatings are relatively dense. The method is simple in principle; the preparation temperature is relatively low; the coatings are not affected by the external shape of the substrate, so that large-scale industrial production can be achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing carbon/carbon composite yttrium silicate whisker reinforced C-AlPO4-SiCn complex external coating

ActiveCN103044086AImprove bindingImproved coefficient of thermal expansionCarbon compositesSuspended particles

The invention relates to a method for preparing a carbon / carbon composite yttrium silicate whisker reinforced C-AlPO4-SiCn complex external coating. An induction heating auxiliary impulse arc discharge deposition method is adopted for preparing the carbon / carbon composite yttrium silicate whisker reinforced C-AlPO4-SiCn complex external coating which has a uniform surface free from microcracks, is uniform in thickness, has no penetrable holes or cracks, and is higher in binding force and good in oxidation resistance. As suspended charge particles have high energy and are high in diffusion migration rate under the condition of induction heating, the reaction is accomplished in a water heat kettle at one time, and pulsed arc discharge sintering is accompanied; the coating is dense and uniform, has a higher interface binding force, and is not required to be subjected to post heat treatment; the preparation cost is low; and the method is simple to operate and short in preparation cycle. In addition, the electromagnetic induction heating can allow local high temperature and high pressure to be generated in a reaction system rapidly, so that the reaction activation energy of yttrium silicate whiskers, and C-AlPO4 and SiCn suspended particles is reduced effectively, the yttrium silicate whiskers, and C-AlPO4 and SiCn suspended particles can react more completely and sufficiently during the pulsed arc discharge deposition process; and the coating with a dense structure is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

SiC/SiC composite material wide temperature range thermal protective coating and preparation method thereof

ActiveCN109320301AImprove high temperature oxidation resistanceGood compatibilityGas phaseOxidation resistant

The invention relates to a SiC / SiC composite material wide temperature range thermal protective coating. The coating is composed of a transition layer, a hole-sealing layer and an anti-washout layer.The transition layer is made of SiC and SiBCN ceramic prepared through a polymer precursor infiltration and pyrolysis (PIP) technology. The hole-sealing layer is made of SiBCN ceramic prepared througha slurry method and CVD-SiC prepared through a chemical vapor deposition technology. The anti-washout layer is made of a yttrium silicate coating prepared through a molten-salt growth method. The invention further relates to a preparation method of the SiC / SiC composite material wide temperature range thermal protective coating. The coating has excellent thermal shock resistance and antioxidant property in the wide temperature range of 800-1300 DEG C, and has wide application prospects in hot end parts such as aero-engine exhaust nozzles, heat shields and turbine outer rings and thermal protective structures of aircrafts with high Mach number such as leading edges and rudders.

Owner:AVIC BASIC TECH RES INST

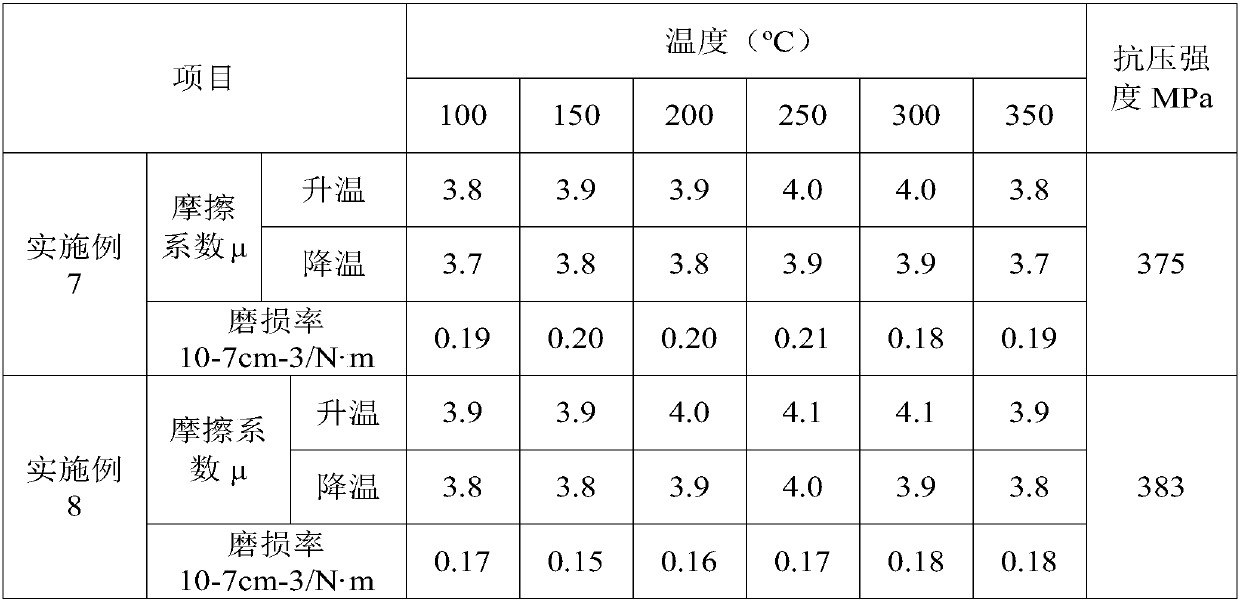

Brake pad friction material composition and preparation method thereof, and brake pad

ActiveCN107676413AGood toughening effectIncrease coefficient of frictionOther chemical processesFriction liningHeat stabilityMullite

Owner:麻莲莲

Preparation method for yttrium silicate coating with antioxygenic property

InactiveCN101343192AImprove antioxidant capacityImprove compactnessOxidation resistantMaterials science

The invention provides a preparation method of an yttrium silicates coating having the oxidation resistance, the method adopts a novel hydrothermal electrophoretic deposition technique to prepare the yttrium silicates coating with oxidation resistance, and the method has the advantages of high efficiency, low manufacturing cost, good coating compactness and excellent oxidation resistance of the coating.

Owner:孙金枝

Antioxidative ZrB2-SiC-Y2O3 coating on surface of C-C composite material and preparation method thereof

The invention discloses an antioxidative ZrB2-SiC-Y2O3 coating on the surface of a C-C composite material and a preparation method thereof. The preparation method comprises the following steps: preparing thermally-spraying spherical agglomerated powder by virtue of a spray granulation technology; and then preparing the ZrB2-SiC-Y2O3 multi-element composite coating by virtue of an atmospheric plasma spraying technology. According to the invention, the rare earth oxide Y2O3 is introduced into ZrB2-SiC ceramic powder, so the effects of enhancing ZrO2-phase stability and inhibiting phase change are achieved, and the oxidation ablation resistance of the coating can be improved. The ZrB2-SiC-Y2O3 composite coating is prepared by adopting the atmospheric plasma spraying technology, so thermal damage to a C / C composite material matrix is small, and the thickness of the coating is controllable. The coating system forms yttrium silicate with low oxygen diffusivity under the condition of oxidation at 1450 DEG C, can effectively inhibit the volatilization of a SiO2 glass phase, and has a certain self-healing effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing carbon/carbon composite yttrium silicate whisker reinforced mullite-C-AlPO4 complex external coating

ActiveCN103044076ALow oxygen permeabilitySmall coefficient of thermal expansionCarbon compositesMullite

The invention relates to a method for preparing a carbon / carbon composite yttrium silicate whisker reinforced mullite-C-AlPO4 complex external coating. A pulsed arc discharge deposition method is adopted to prepare the yttrium silicate whisker reinforced mullite-C-AlPO4 complex antioxidant external coating; the reaction is accomplished in a water heat kettle at one time; pulsed arc discharge sintering is accompanied; the obtained coating is dense and uniform, has a higher interface binding force and is not required to be subjected to post heat treatment; the advantages of yttrium silicate whiskers, mullite and C-AlPO4 are integrated well; and the prepared yttrium silicate whisker reinforced mullite-C-AlPO4 complex antioxidant external coating has a uniform surface without microcracks, is uniform in thickness, has no penetrable holes or cracks, and is higher in binding force and good in oxidation resistance.

Owner:SHAANXI UNIV OF SCI & TECH

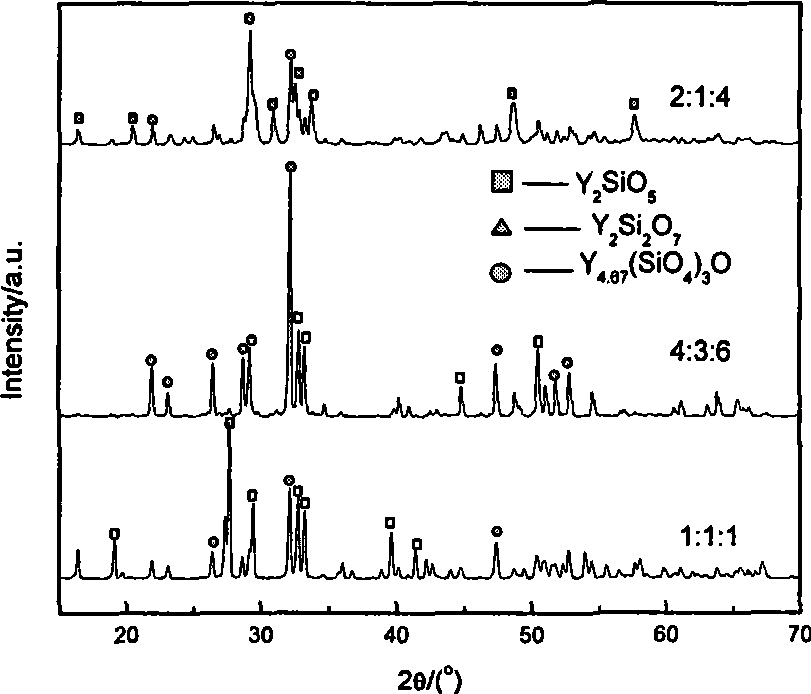

Yttrium silicate hot-spray composite powder and preparation method thereof

InactiveCN102560321AImproved coefficient of thermal expansionNot easy to peel offMolten spray coatingThermal sprayingMechanical crushing

The invention relates to the field of hot-spray coating materials, particularly an yttrium silicate hot-spray composite powder and a preparation method thereof. The hot-spray composite powder is prepared from the following raw materials in percentage by weight: 23-27% of SiO2 and 73-77% of Y2O3. The particle size of SiO2 is smaller than 25 mu m, and the particle size of the Y2O3 is smaller than 15 mu m. The preparation method comprises the following steps: evenly mixing SiO2 and Y2O3 powder in a mixer for 20-24 hours, prepressing the mixed powder under the pressure of 600-800kPa, sintering at 1500-1700 DEG C in air for 4-6 hours, and finally, carrying out mechanical crushing and screening. The components of the hot-spray composite powder are Y2SiO5 and Y2Si2O7, the particle size is 45-125 mu m, the flowability is smaller than or equal to 55s / 50g, and the loose density is 1.5-3.0g / cm<3>. The coating prepared by the powder can effectively enhance the high-temperature oxidation resistance of the C / C-SiC composite material surface, has important application value, and can solve the problem of high-temperature oxidation of the material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material and preparation method thereof

ActiveCN107640976AImprove antioxidant capacityImprove high temperature resistanceCeramicwarePorosityFiber

The invention discloses a three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material. The composite material comprises a three-dimensional silicon carbide fiber preform and yttrium silicate, the yttrium silicate is a mixed crystalline phase of Y2Si2O7 and Y2SiO5, a crystalline phase of the Y2Si2O7 or a crystalline phase of the Y2SiO5, the pores of the three-dimensional silicon carbide fiber preform are uniformly filled with the yttrium silicate, and the porosity of the three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material is 10%-16%. A preparation method comprises the following steps: (1) preparing a Y2O3-SiO2 composite sol; (2) performing impregnating; (3) performing drying; (4) performing heat treatment; and (5)repeating processes including impregnating-drying-heat treatment in the steps (2)-(4). The three-dimensional silicon carbide fiber preform reinforced yttrium silicate composite material has the advantages of low porosity, a high compact degree, high-temperature resistance, oxidation resistance, excellent mechanical properties and the like; and the preparation efficiency of the preparation methodis high, and the compact degree and mechanical properties of the prepared composite material are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

Yttrium silicate upconversion luminous fluorescent powder, preparation method and application thereof

ActiveCN103059858AEasy to prepareLow costSolid-state devicesSemiconductor/solid-state device manufacturingUpconversion luminescenceLong wave radiation

The invention belongs to the field of fluorescent powder, and discloses an yttrium silicate upconversion luminous fluorescent powder, and a preparation method and application thereof. The fluorescent powder has a structure of Y2-xSiO5:xHo<3+>; Ho<3+> is a doping ion; and x is in the range from 0.02 to 0.1. The yttrium silicate upconversion luminous fluorescent powder prepared by the invention can realize blue short-wavelength light emitting through excitation by long-wave radiation from infrared to green ray. Therefore, the fluorescent powder can make up for the lack of blue material in current display and luminous material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com