Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

938results about How to "Improve erosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

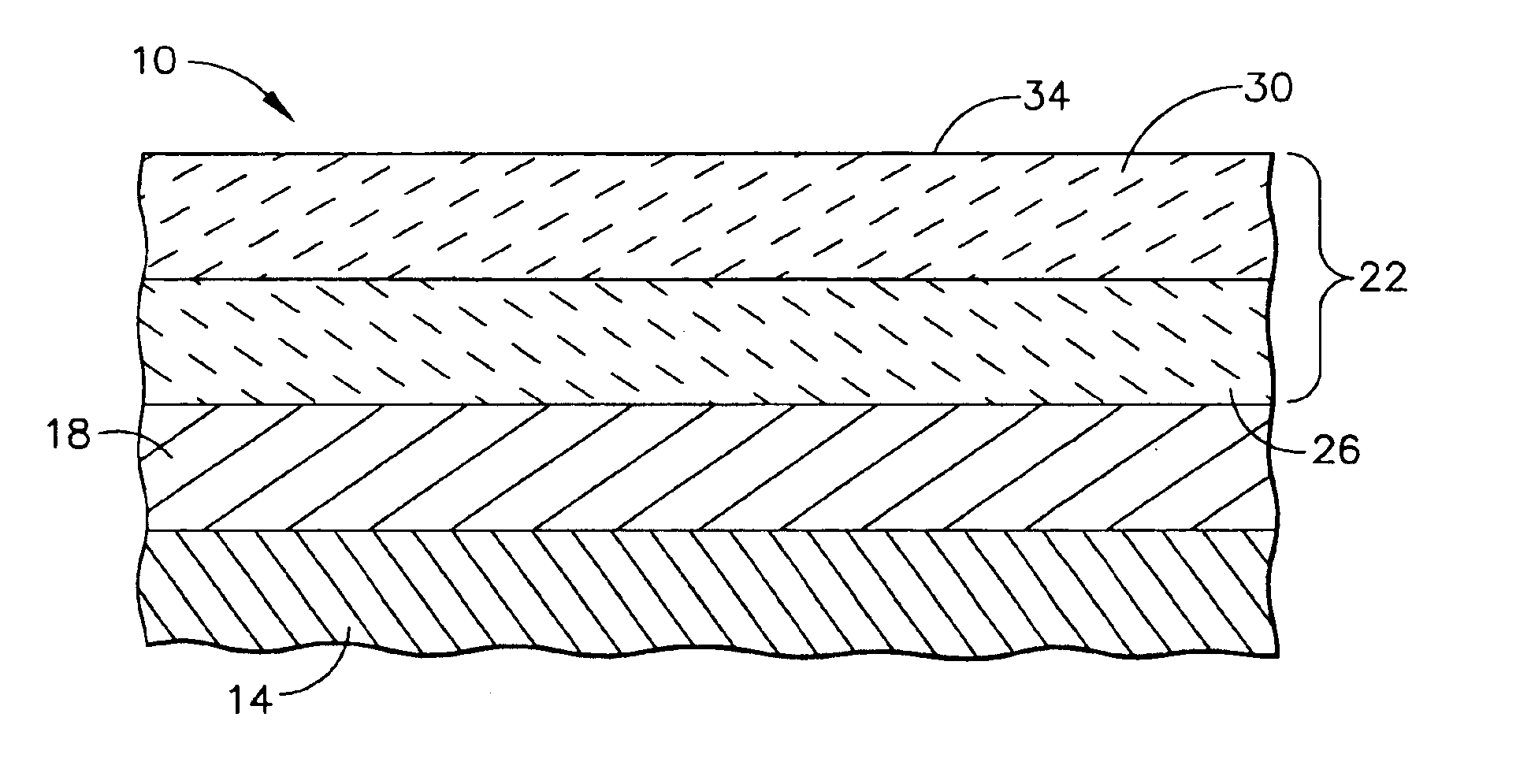

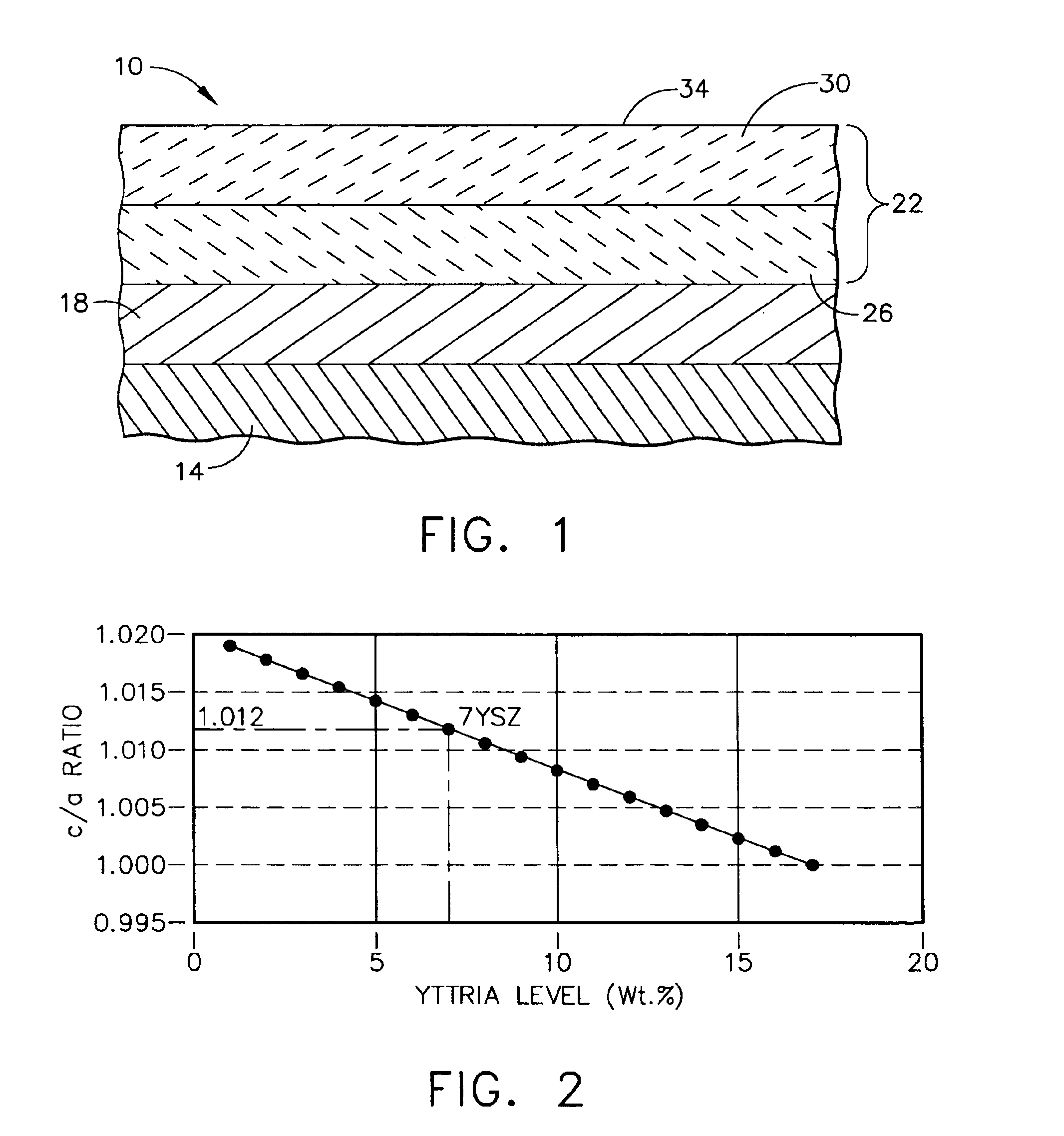

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

Clad metal sheet and heat exchanger tubing etc. made therefrom

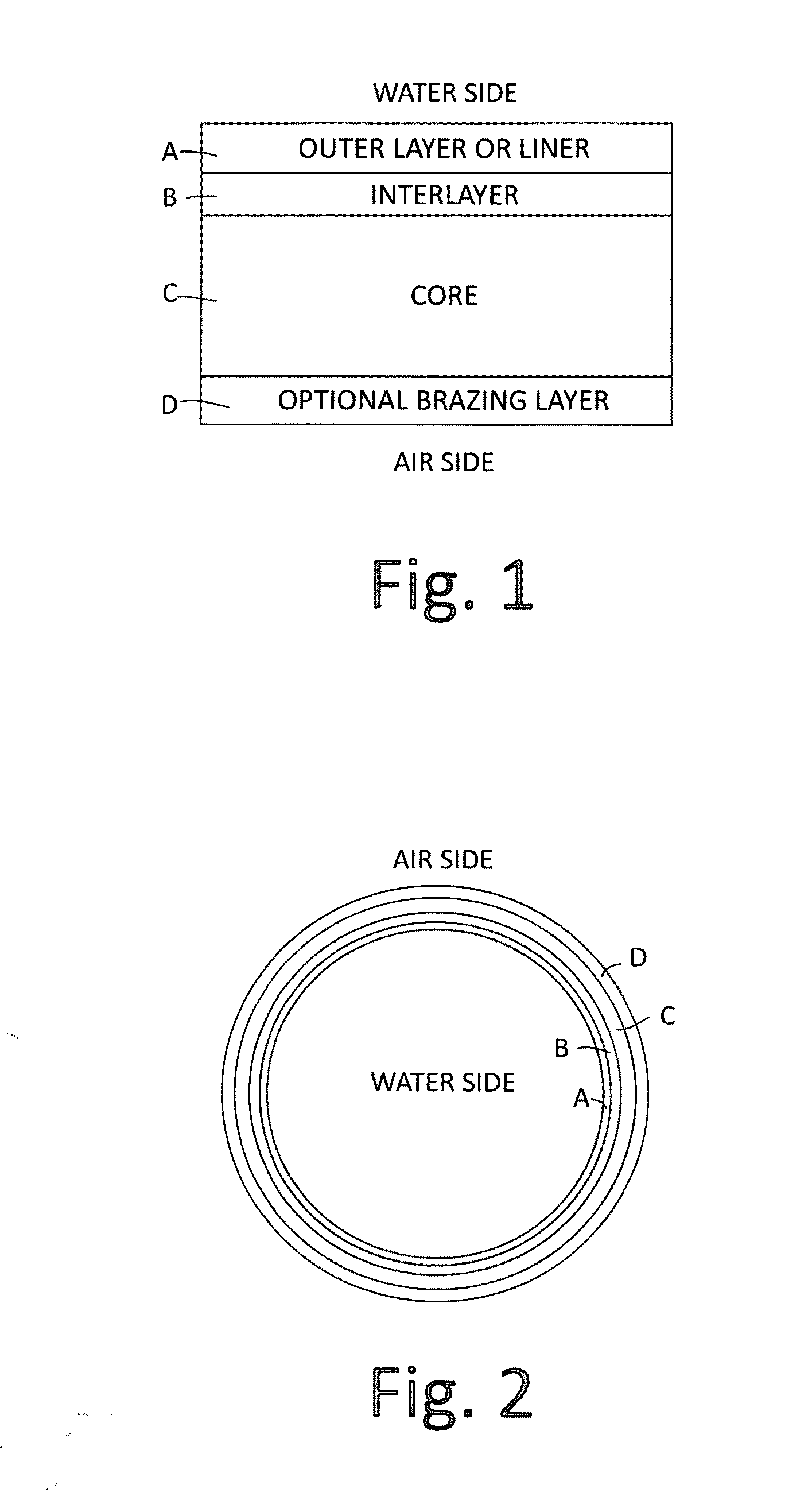

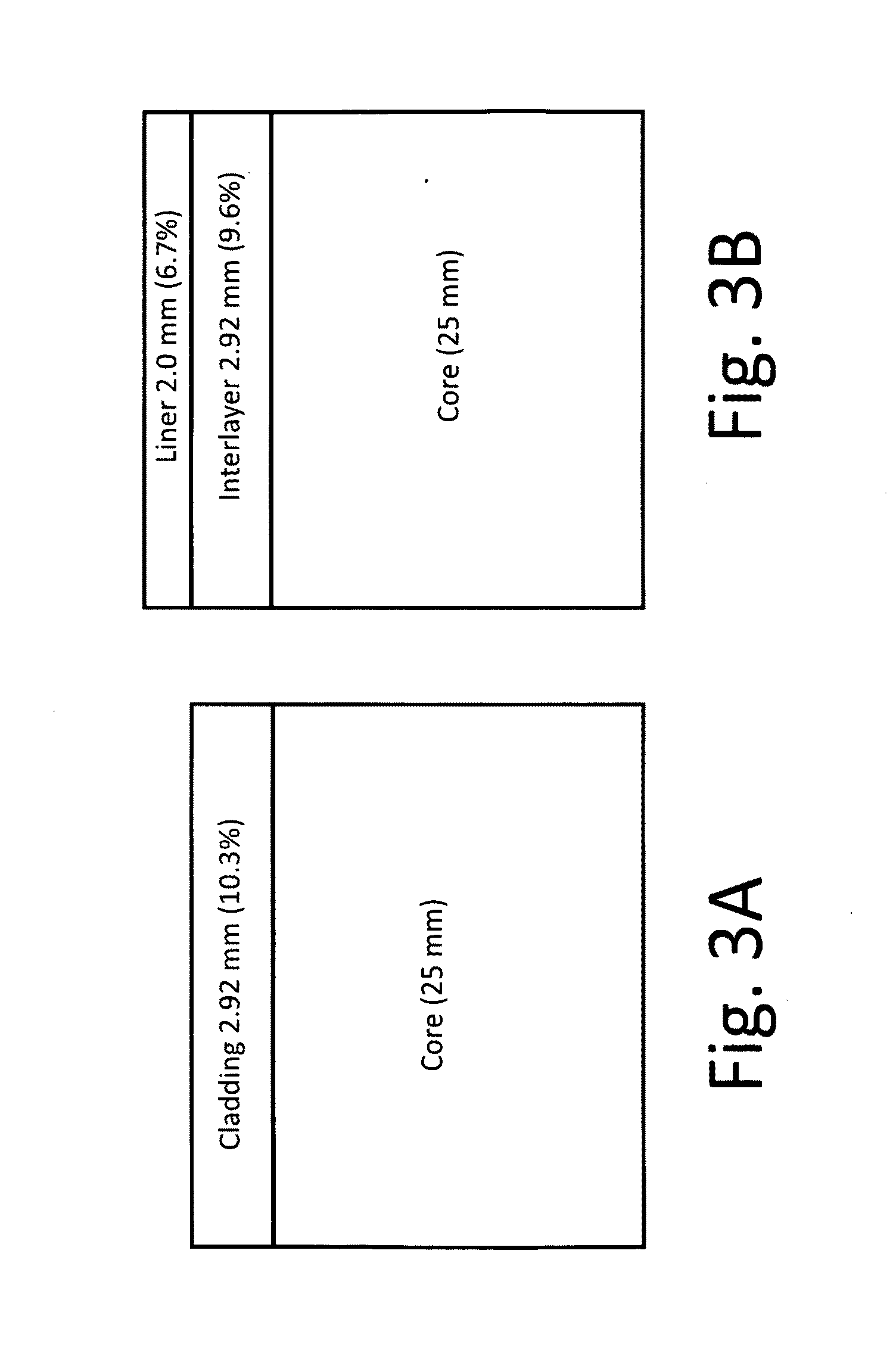

ActiveUS20100159272A1Reducing internal corrosionImprove corrosion resistanceWelding/cutting media/materialsCoatingsInter layerMetal sheet

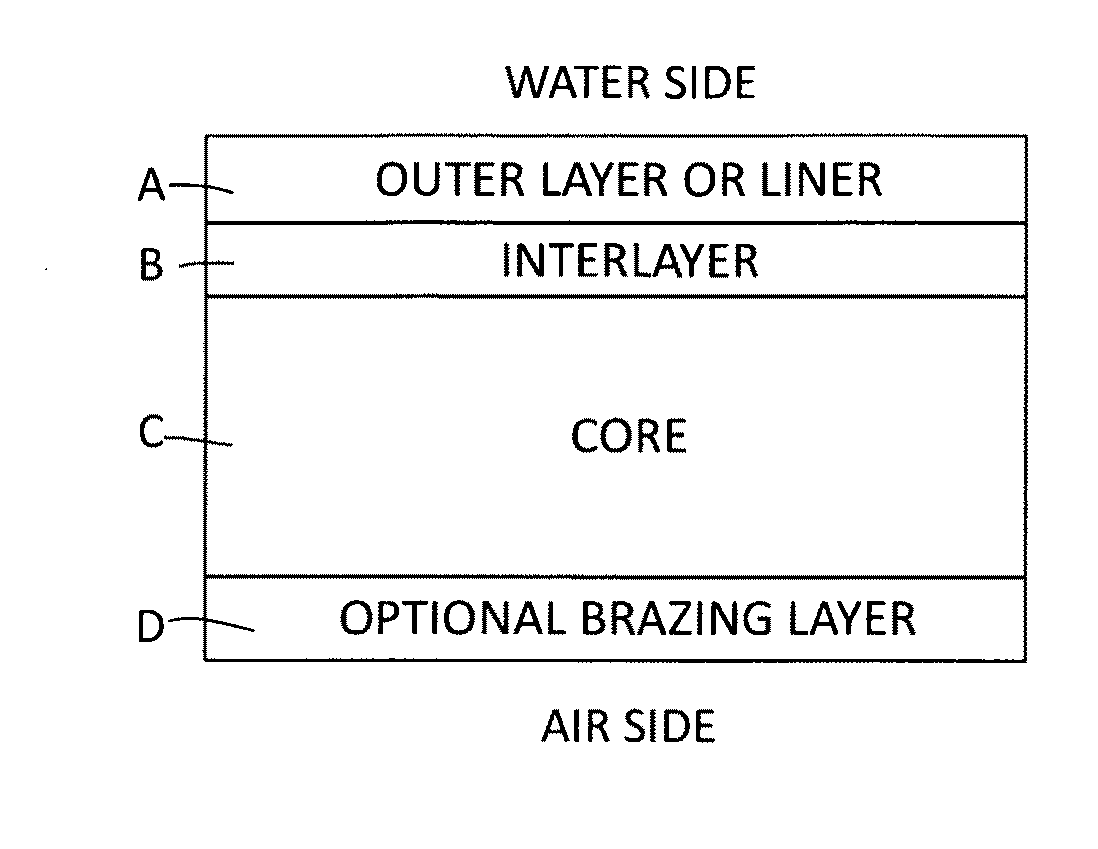

The exemplary embodiments relate to a multilayer aluminum alloy sheet material suitable for fabrication into coolant-conveying tubes, headers and the like used for heat exchangers, and to the tubes and headers, etc., fabricated from the sheet. The multi-layer metal sheet has a core layer of aluminum alloy having first and second sides. The first side has an interlayer made of a Zn-containing aluminum alloy positioned between a Zn-containing outer layer and the core layer. The alloy of the outer layer is more electronegative than the alloy of the interlayer. The alloy of the interlayer is preferably more electronegative than the alloy of the core layer. The first side clad in this way is the side intended for exposure to the coolant, and provides good resistance to corrosion and erosion.

Owner:NOVELIS INC

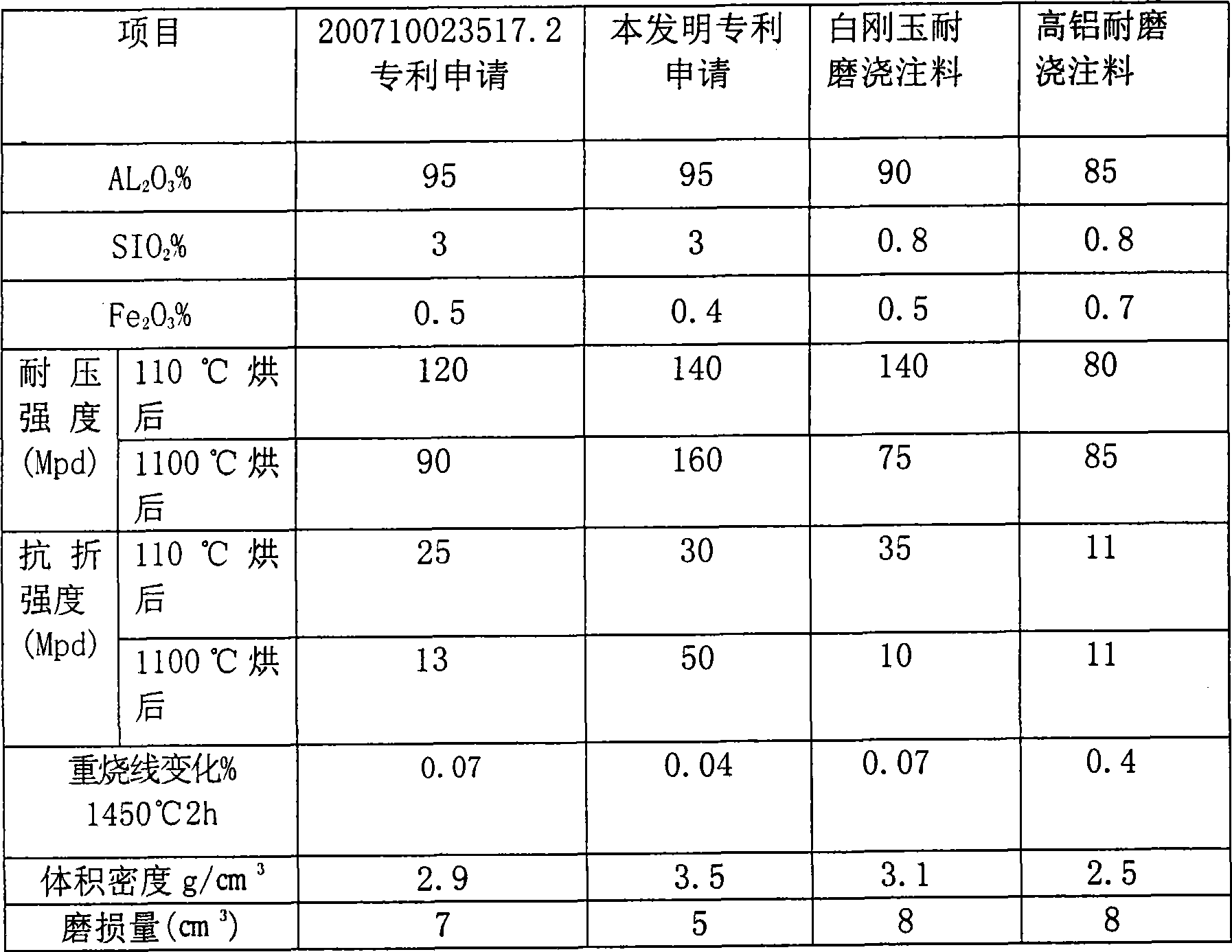

High temperature resistant ceramic matrix composite material and preparation method thereof

The invention relates to an ultra-high temperature resistant ceramic-based composite and a preparation method, which adopts carbon or boron nitride fabric cloth as reinforcing phases, ceramic powders of high melting point or high-temperature resistant metal powders as the stuffing, and carbon / silicon carbide as the base. Through the blending and ball milling of the adhesives and the powder stuffing, the sizing agent thus acquired is coated on the reinforcing phase fabric cloth, and then overlapping, molding, cross-bonding, high-temperature pyrolysis, and repeated densification are carried out in preparing the composite. The ultra-high temperature resistant ceramic composite has the advantages of excellent thermal shock resistance, low density, and low ablating rate under ultra-high temperature.

Owner:NAT UNIV OF DEFENSE TECH

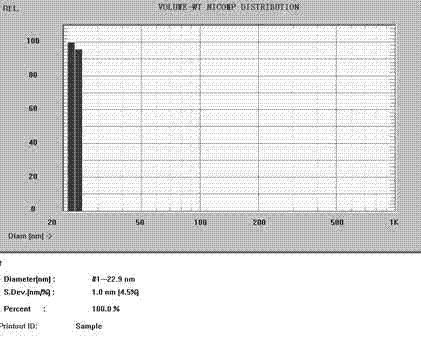

A kind of nano-silica sol modified exterior wall latex paint and preparation method thereof

The invention relates to a nanometer silica sol modified exterior wall emulsion paint. The emulsion paint comprises, by mass, 10-30% of water, 15-30% of an emulsion, 5-10% of a nanometer silica sol, 5-15% of heavy calcium, 1-3% of talc, 0.5-1.5% of propylene glycol, 5-25% of titanium dioxide, 0.05-2% of a wetting agent, 0.5-1% of an antifoaming agent, 0.1-0.5% of a dispersant, 1-2% of a thickening agent, and 0.5-2% of a film forming assistant. The preparation method comprises the following steps: dispersion grinding: adding water, powders and early assistants to a dispenser, grinding, and filtering; and post-treating: adding the emulsion, the nanometer silica sol, later water and later assistants to a dispersed slurry, and adjusting the PH value and the viscosity to prepare the emulsion paint. According to the invention, the exterior wall emulsion paint, which is prepared by completing simple technologies of dispersing, sand milling, filtering and the like, has the advantages of no pollution, low VOC (volatile organic compound) discharge, environmental protection, strong adhesion, and good storage stability, washing resistance, contamination resistance and weather resistance.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

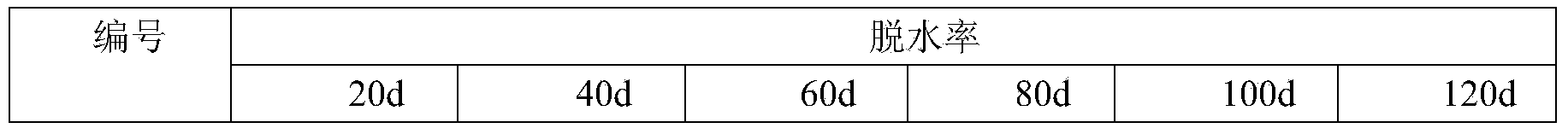

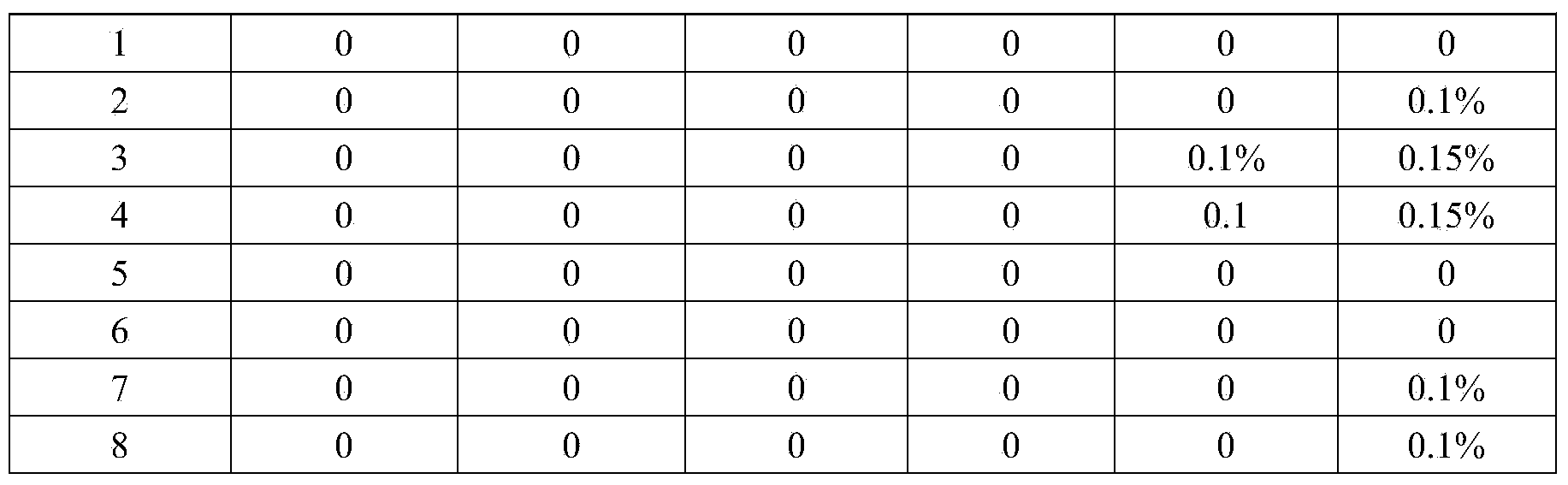

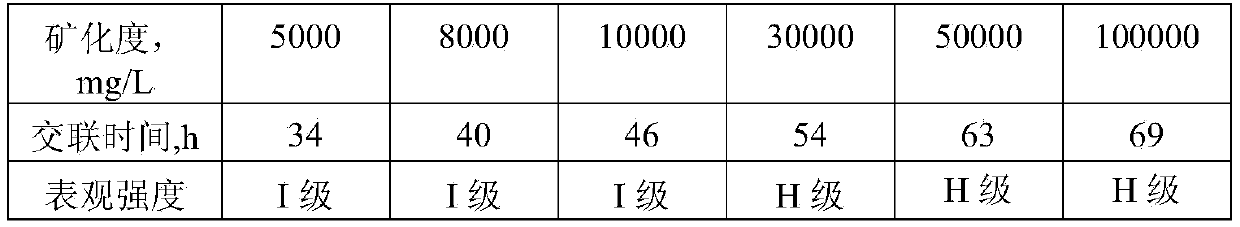

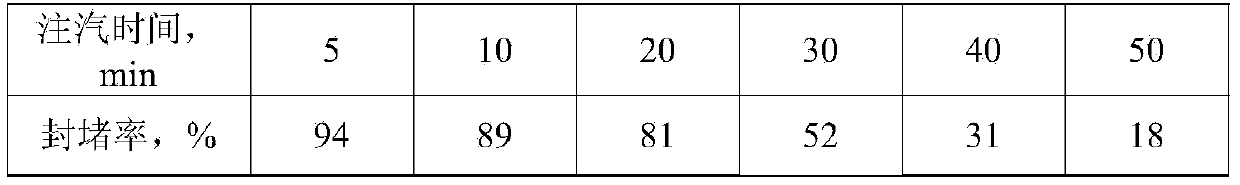

Polyethyleneimine jelly profile-control water-blocking agent

The invention provides a polyethyleneimine jelly profile-control water-blocking agent. The profile-control water-blocking agent is prepared by reacting partially-hydrolyzed polyacrylamide and a cross-linking agent polyethyleneimine. The profile-control water-blocking agent comprises following components by weight: 0.3-0.8% of the partially-hydrolyzed polyacrylamide, 0.2-0.5% of the cross-linking agent polyethyleneimine and 0.3-0.8% of an additive, with the balance being water, wherein the partially-hydrolyzed polyacrylamide adopts anionic polyacrylamide, and the additive is one compound selected from a group of sodium sulfite, sodium bisulfate, and sodium hyposulfite or thiourea, or is a mixture of several compounds selected from the group. The jelly forming time of the profile-control water-blocking agent is adjustable and the jelly has high strength. The profile-control water-blocking agent can block underground water having a temperature lower than 110 DEG C and a NaCl mineralization degree of 50000 mg / L. The profile-control water-blocking agent has good temperature toleration and cannot be dehydrated for 120 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Waterproof antiseptic wearproof nano paint, preparation method, use method and application thereof

ActiveCN101643612APrevent penetrationStrong rust resistanceLiquid surface applicatorsAnti-corrosive paintsEpoxyPolyamide

The invention discloses a waterproof antiseptic wearproof nano paint, a preparation method, a use method and application thereof. The paint has a middle layer, a surface layer or a bottom layer, a middle layer and a surface layer outwards orderly from the contact surface of a metal substrate surface; each layer comprises components by weight percent: the bottom layer comprises 10% to 25% of epoxysolution, 10% to 25% of polyamide solution, 50% to 78% of zinc powder and 2% to 10% of ferrous phosphorus powder; the middle layer comprises 15% to 30% of epoxy solution, 10% to 28% of polyamide solution, 42% to 70% of micaceous iron oxide, 2% to 10% of ferrous phosphorus powder and 2% to 8% of talcum powder; the surface layer comprises 25% to 50% of modified epoxy resin solution, 20% to 44% of polyamide solution, 5% to 20% of carborundum, 0.5% to 3% of nano carborundum and 10% to 25% of alumina and proper defoaming agents are added respectively to each layer of paint. The paint largely enhances the waterproof, antiseptic and wearproof performance of substrate, largely prolongs the service life and has good market prospect and practical popularization value.

Owner:广州汤普新材料有限公司

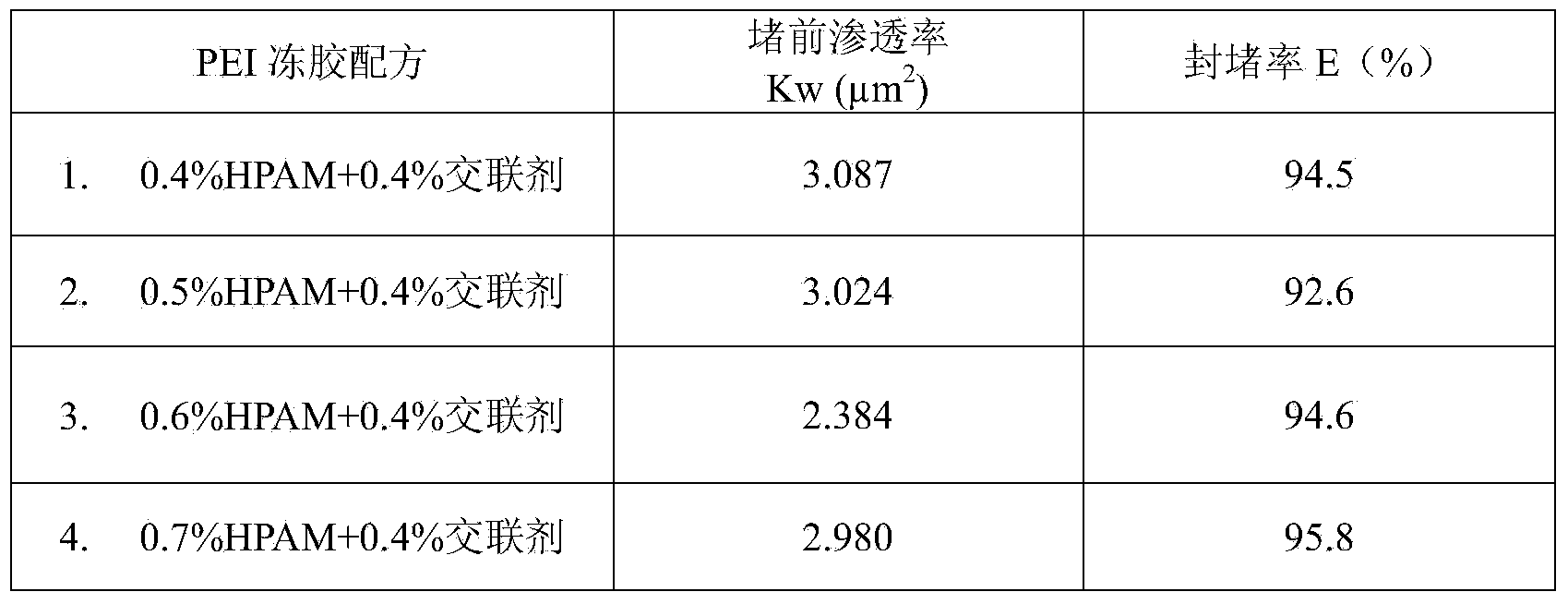

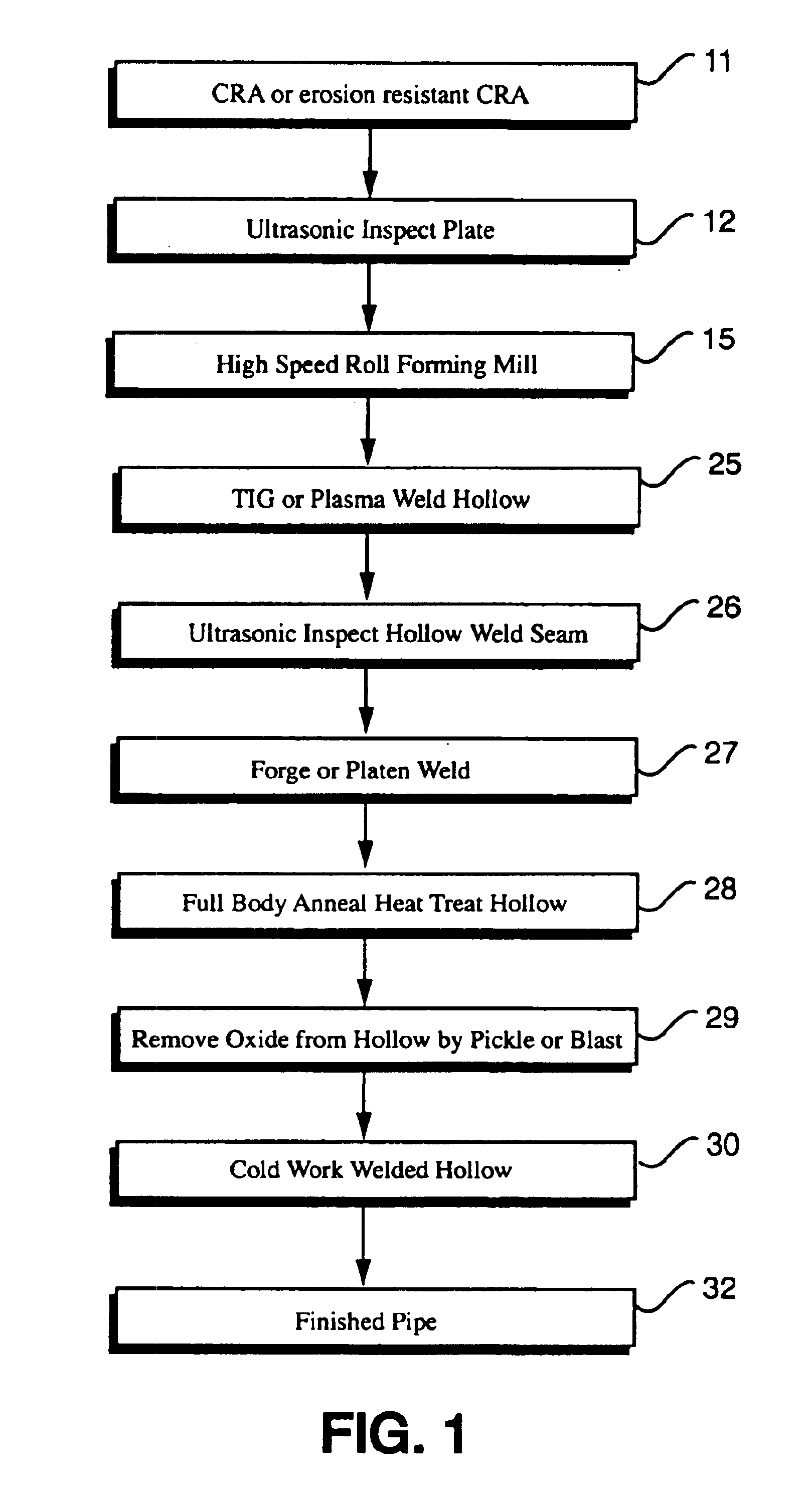

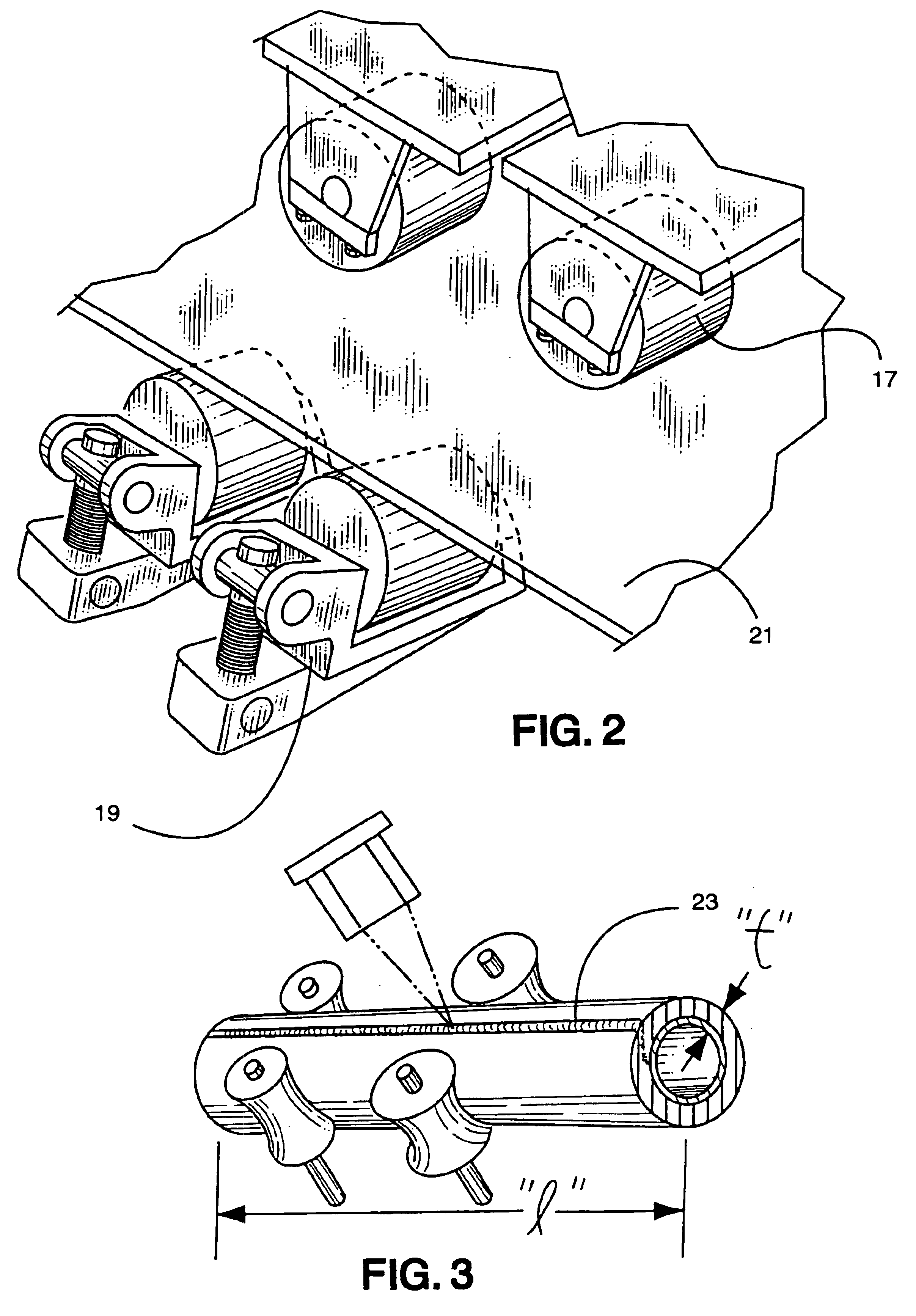

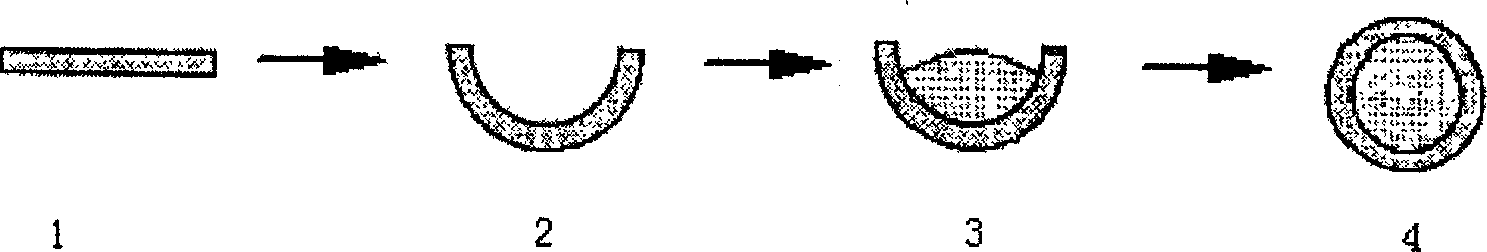

Method of manufacturing cold worked, high strength seamless CRA PIPE

InactiveUS6880220B2High tensile strengthHigh yield strengthSoldering apparatusArc welding apparatusRoll formingCorrosion

A process produces a welded seamless PIPE having good yield strength and excellent corrosion and / or erosion resistance. Up to a maximum outside diameter corrosion and / or erosion resistant CRA PIPE is cold worked from a welded hollow, rather than using the traditional seamless pierced hollow method. A high-speed roll-forming mill is also utilized, rather than using the slow traditional break press to form the welded hollow. Welded hollow dimensions can be achieved which comply with the method of cold working's capability to produce the yield strengths and dimensional tolerances required to meet the service criteria of the PIPE's intended application.

Owner:CORROSION RESISTANT ALLOYS

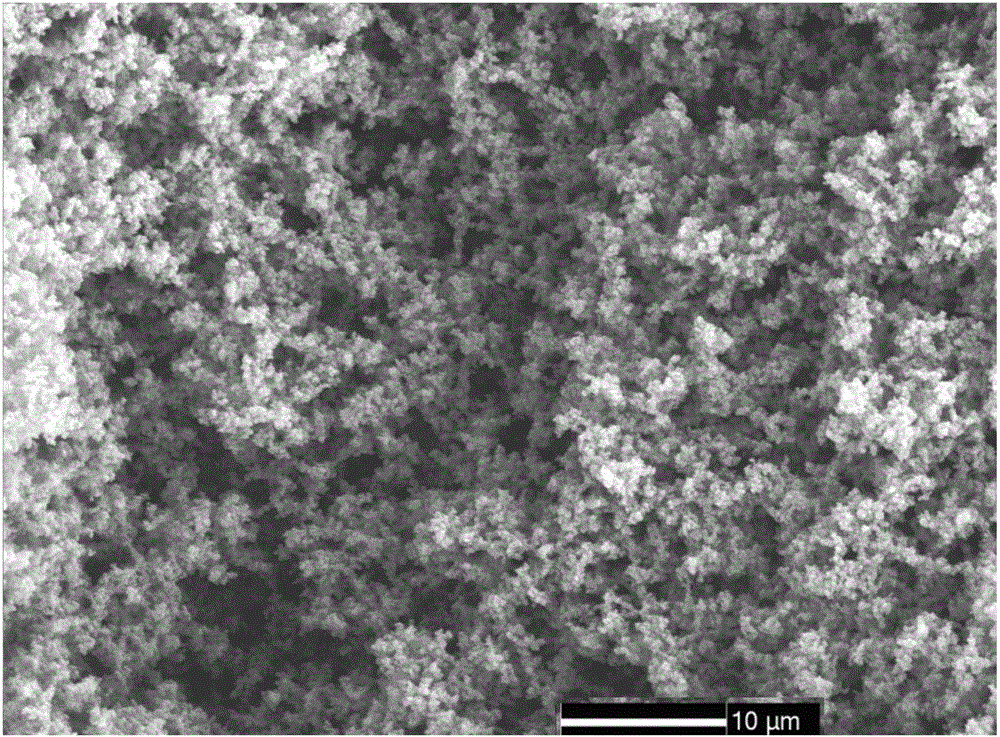

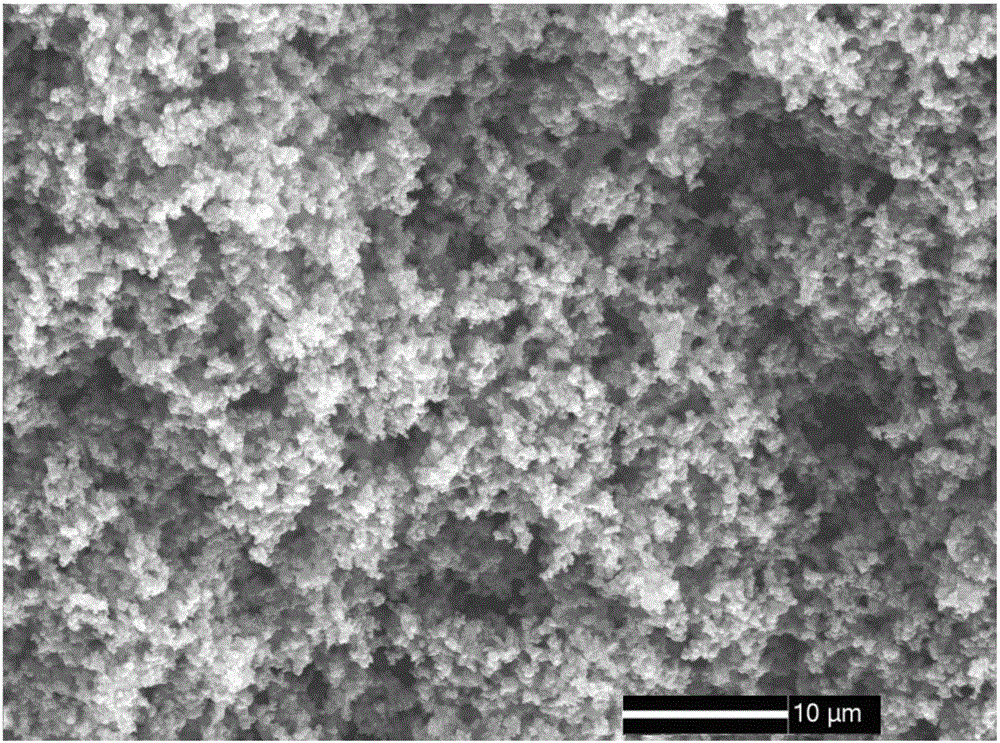

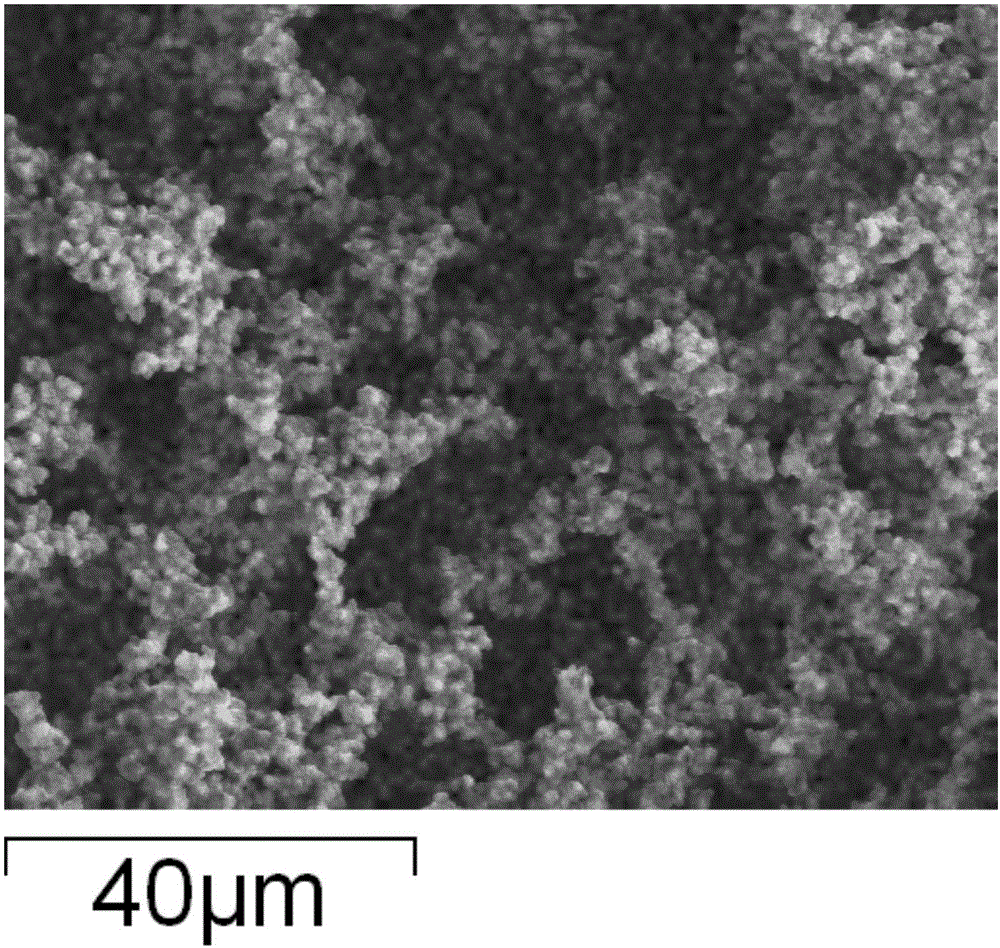

Nano micrometer modefied wear resistant erosion resistant thermal coated tubular wire

The present invention relates to surface processing material technology, and especially a kind of nanometer modified wear resistant and erosion resistant arc sprayed wire material. The wire material has coating of Fe or Ni, and powdered core comprising high carbon ferrochrome 45-60 wt%, Ni 10-20 wt%, ferrosilicon 4-10 wt%, ferroboron 5-10 wt%, Cr3C2, TiB2 or TiC 10-15 wt%, micron level TiB2 5-15 wt%, nanometer level Al2O3 5-15 wt%, and optional wollastonite 1-3 wt%, ZrO2 2-5 wt% and TiO2 5-15 wt%. The material is used mainly for coating the surface of blower blade, pipe wall in power station boiler, etc. and the coated layer can increase the surface life of the said parts.

Owner:BEIJING UNIV OF TECH

Organic/inorganic phenolic resin hybrid aerogel and preparation method thereof

ActiveCN105838022AImprove high temperature resistanceImprove antioxidant capacityAmbient pressureOxidation resistant

The invention relates to organic / inorganic phenolic resin hybrid aerogel and a preparation method thereof, in particular to porous hybrid phenolic resin aerogel and a preparation method thereof, and is mainly applied to the technical field of light heat shielding / insulation heat protection systems. The hybrid aerogel takes cheap and available commercial phenolic resin and tetraethl orthosilicate as raw materials, and the organic / inorganic phenolic resin hybrid aerogel can be obtained through a mild reaction route and an ambient pressure drying method; the hybrid aerogel is good in high temperature resistance and oxidation resistance and high in carbonated structural strength; the hybrid aerogel is good in heat insulation efficiency, low in heat conductivity and good in high-temperature scour resistance; the hybrid aerogel has a great application value in the field of advanced heat protection materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

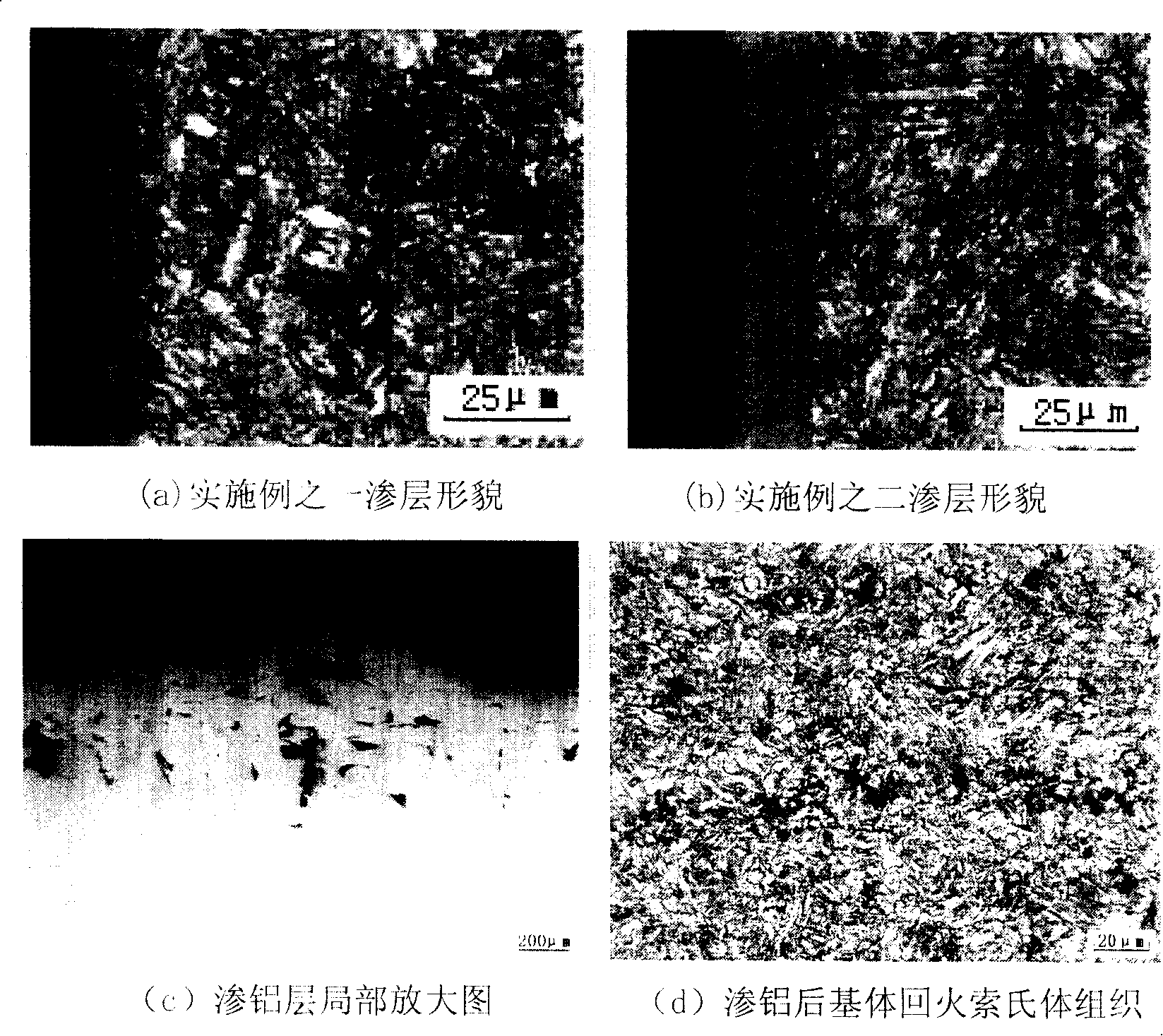

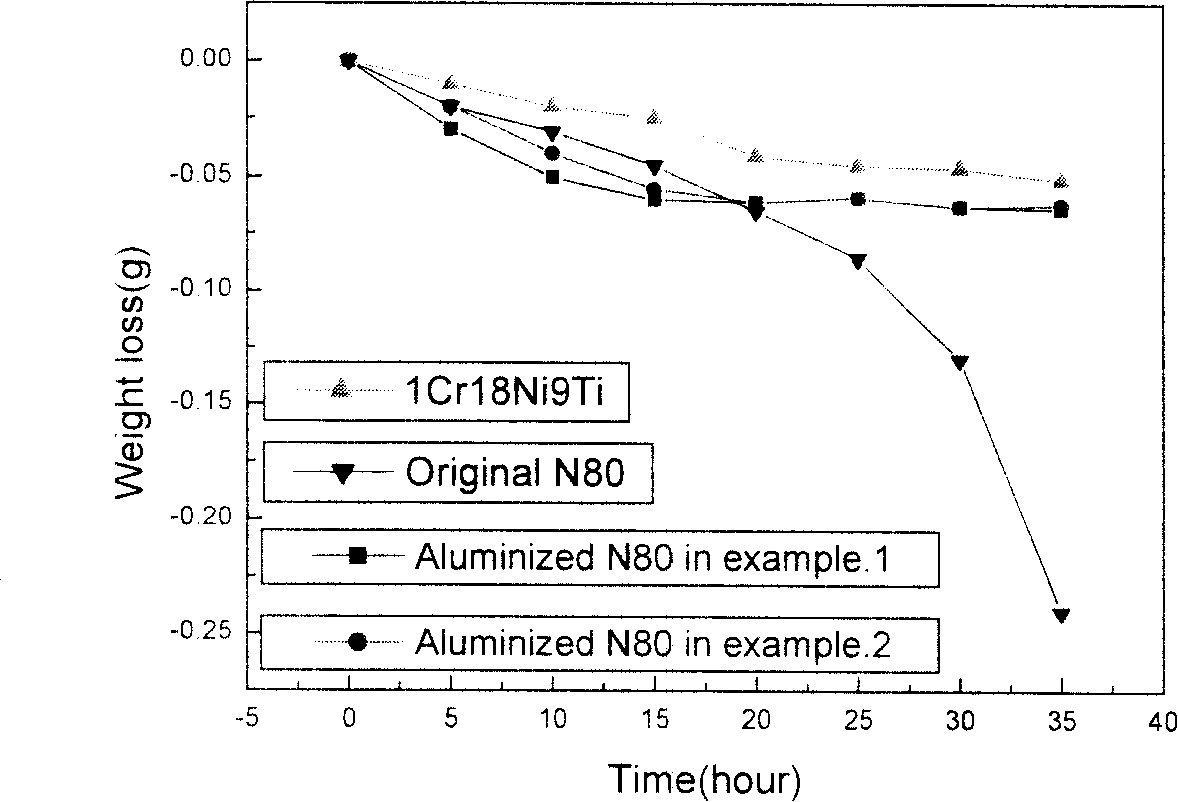

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

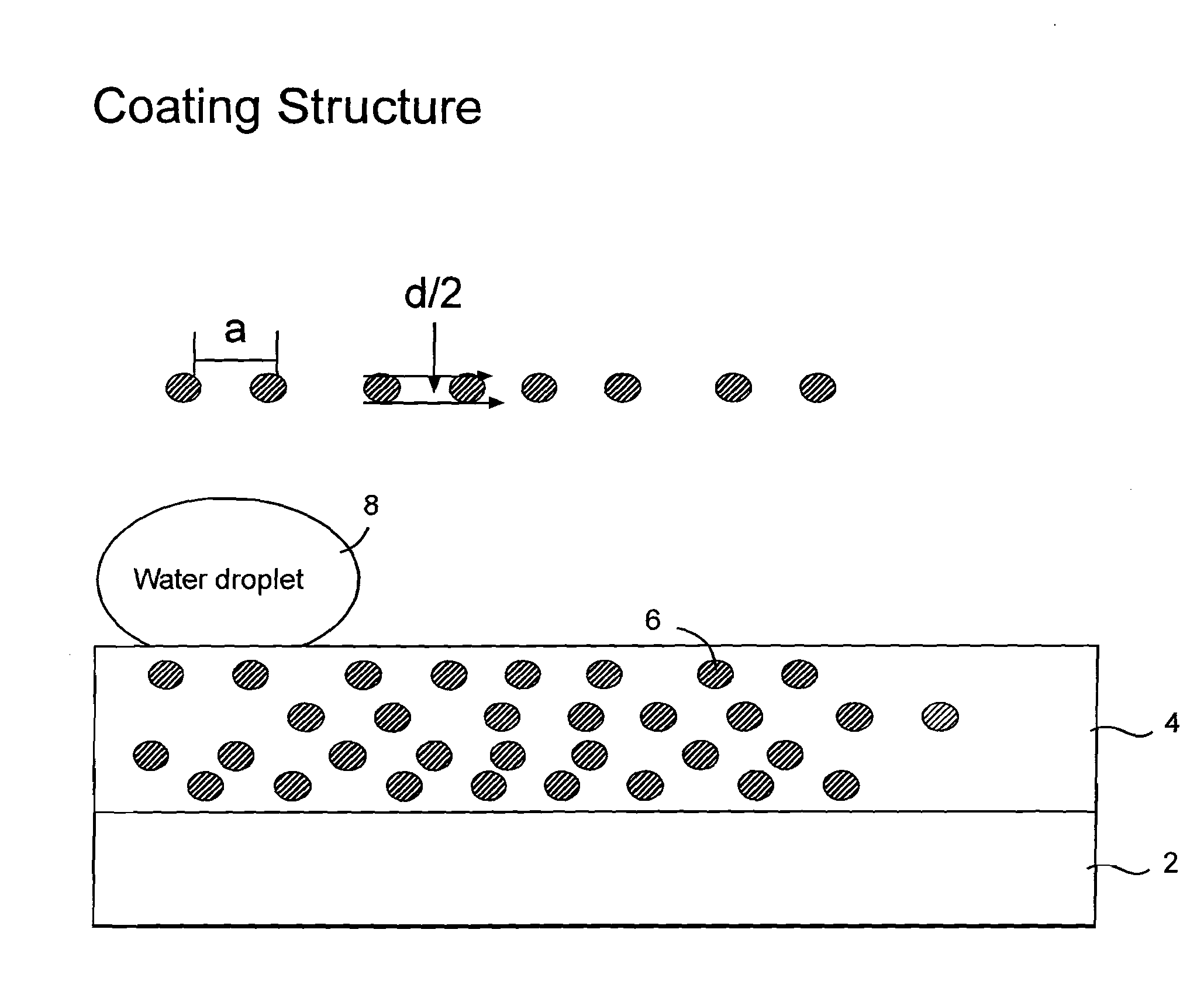

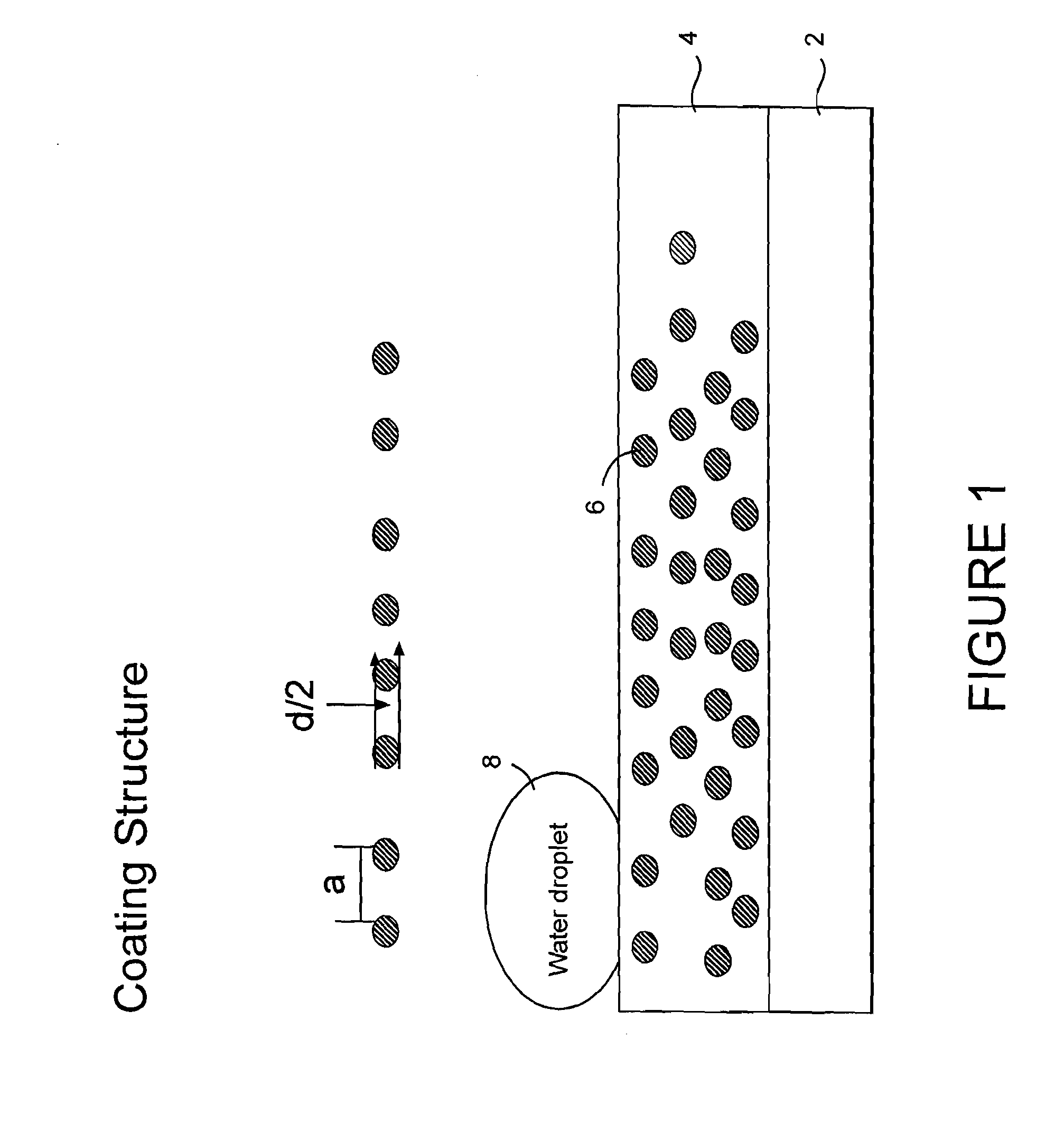

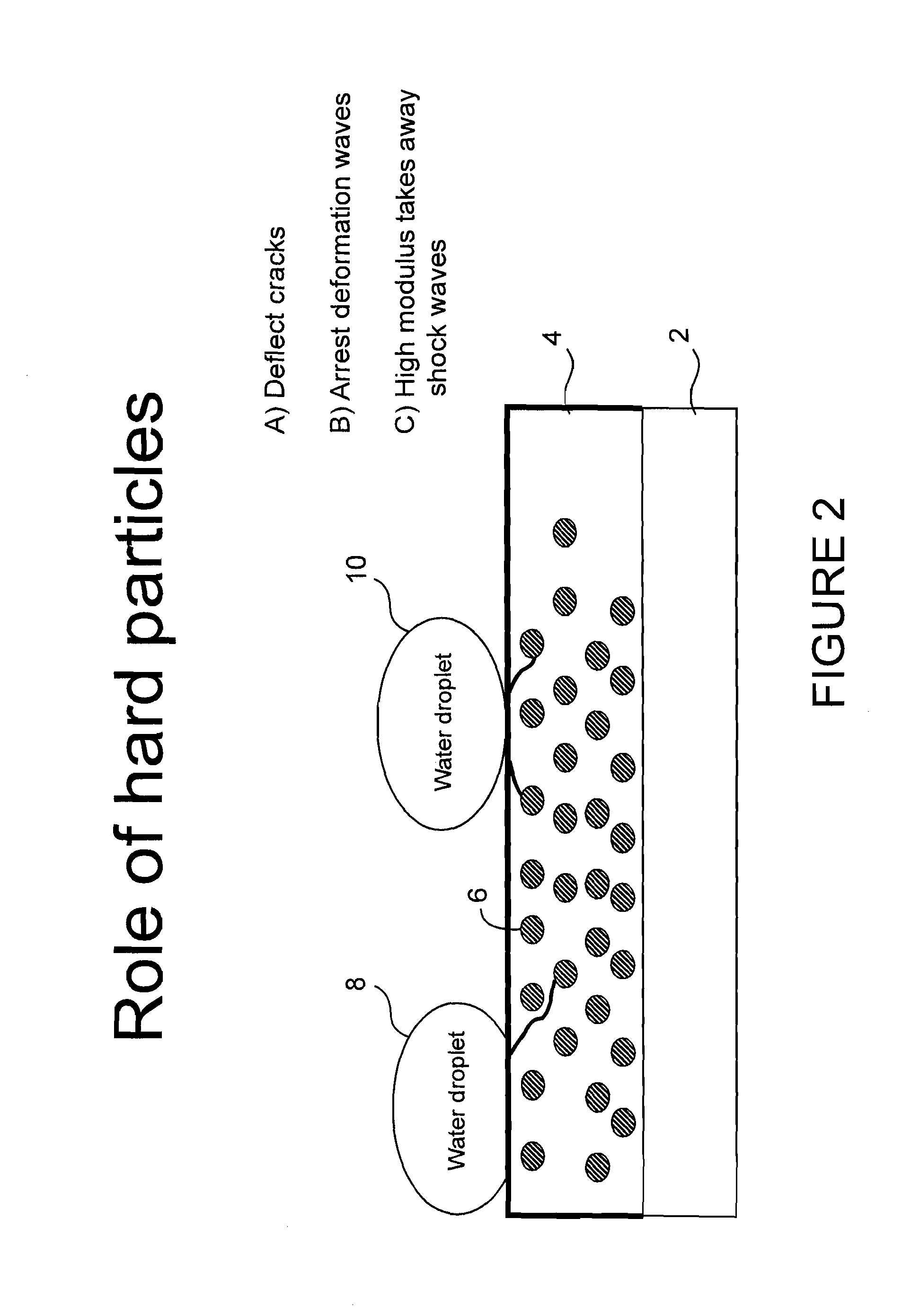

Erosion and corrosion resistant coating system for compressor

InactiveUS20110165433A1Improve corrosion resistanceImprove erosion resistanceLiquid surface applicatorsBlade accessoriesCoating systemVanadium nitride

Process for providing a protective coating to a metal surface by applying a nickel or tantalum plate layer to the surface and dispersing particles of a hard material such as diamond, alumina, vanadium nitride, tantalum carbide and / or tungsten carbide within the nickel or tantalum plate layer as the plating is occurring.

Owner:GENERAL ELECTRIC CO

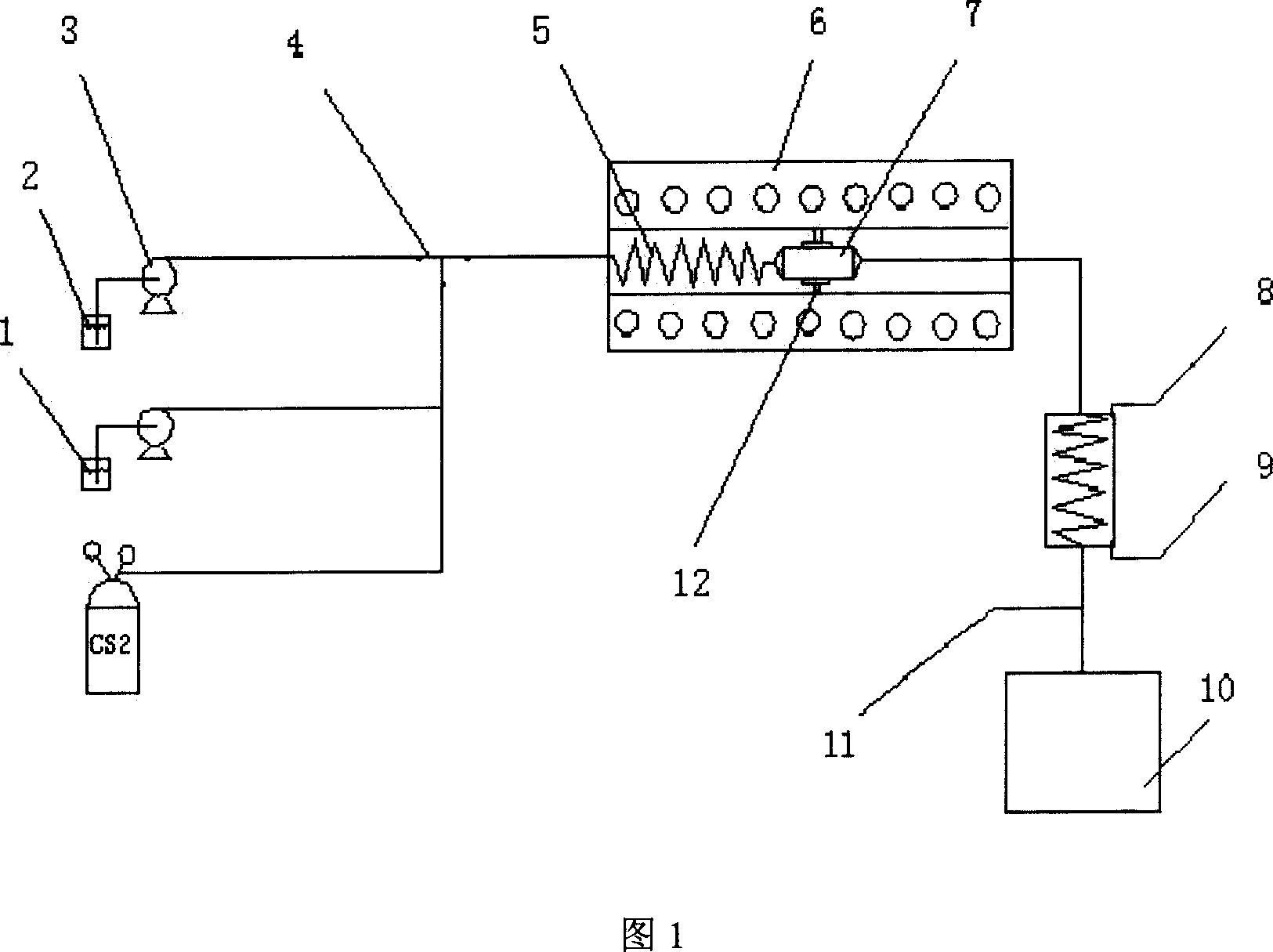

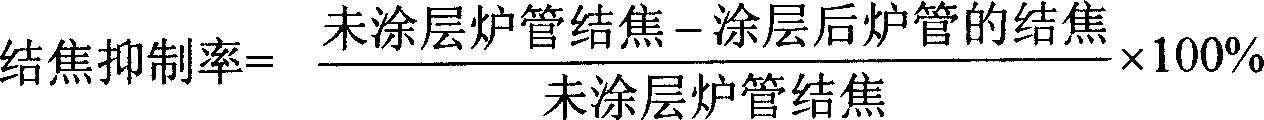

Method of on-line pretreatment inhibiting coking by hydrocarbon pyrolysis apparatus

InactiveCN1928020AImprove erosion resistanceInhibition lossThermal non-catalytic crackingPre treatmentBurning out

The present invention relates to method of online inhibiting coking in hydrocarbon cracking apparatus. The method is that after the coke is burnt out, the hydrocarbon cracking apparatus is pre-treated with chemical(s) containing S, Si and Mg and inert gas at 400-1000 deg.c for 1-8 hr. The technological process first poisons the catalyst n the furnace tube surface and then deposit one layer of compact ceramic coating combined tightly to the furnace tube, and can reduce coking greatly and increase the production period. The method is simple and may be completed repeatedly.

Owner:EAST CHINA UNIV OF SCI & TECH

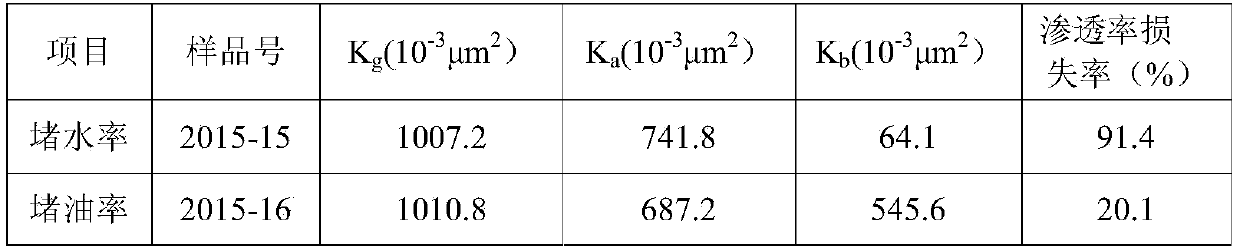

Oil well profile control agent and preparation therefor and application thereof

ActiveCN105368425AImprove development efficiencyRealize deep profile controlDrilling compositionTanninWater block

The present invention provides an oil well profile control agent and preparation therefor and application thereof. The profile control agent is prepared by the components in percentage by weight: 4-10% of a sulfonated tannin extract, 2-5% of a crosslinking agent, 0.2-0.8% of a curing agent, 0.5-2% of a flexibilizer, 0.2-1% of a dispersing agent, 0.02-0.1% of a retarder, 0.2-0.6% of a pH value modifier and the balance of water; the percentage by weight is based on the total weight of the profile control agent which is 100%. The water blocking rate of the fireflooding gas injecting well profile control agent reaches 91.4%; the oil blocking rate reaches 20.1%; the temperature resistance reaches 350 DEG C; the mineralization resistance reaches up to 100000 mg / L, and the validity period under a 300 DEG C steam condition can reach longer than 6 months.

Owner:PETROCHINA CO LTD

Cermet composition and method for preparing cermet coat on metal surface

A metal-ceramic composition and coating it on metal surface are both disclosed herewith. It consists both parts of mixed powders containing Cr, B, Si, Fe, Al, La rare-earth oxides and Ni, and carbide materials, TiC or WC. It is coated as following: mixing metal-ceramic composition with polyvinyl alcohol or ethyl estate as binding agent to be slurry, coating it onto metal surface, drying, and firing in gas protecting furnace or vacuum furnace to obtain metal-ceramic coated metal parts. It is available to various shaped parts with different materials, and reduces energy consumption.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

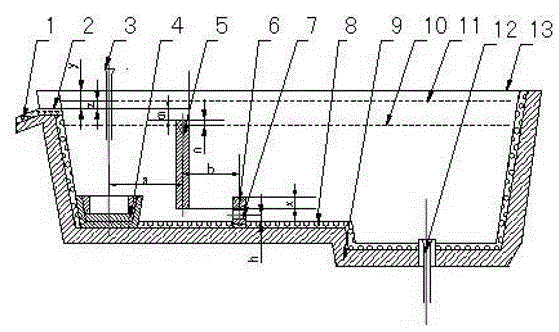

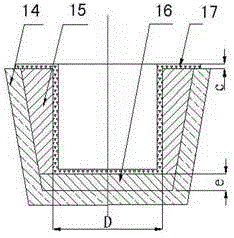

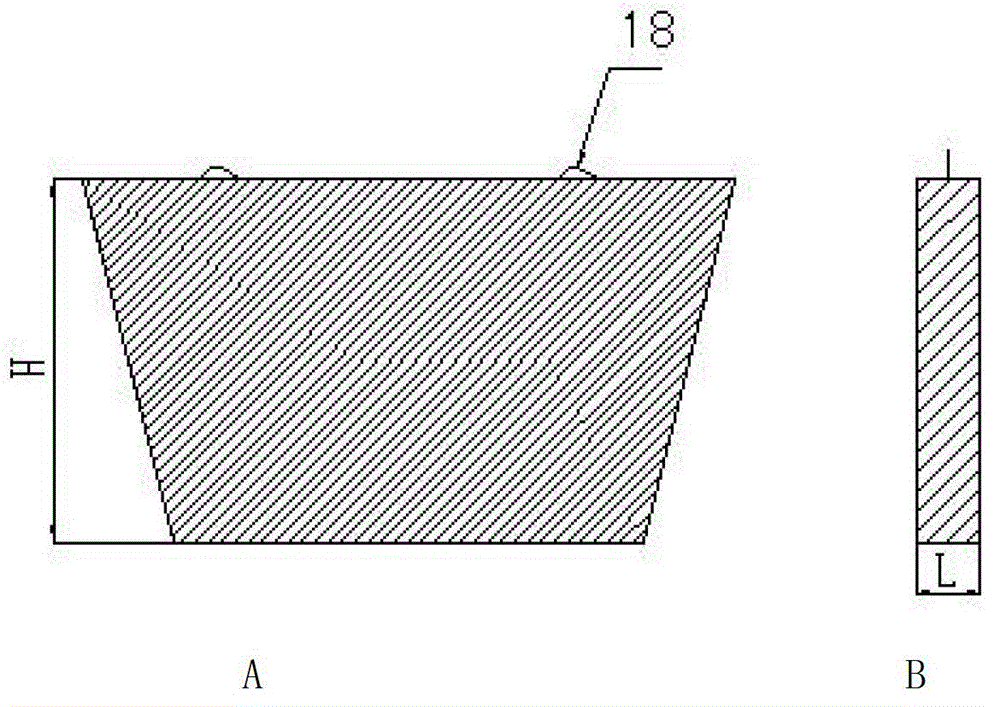

Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

ActiveCN102744393AReduce the balanceImprove erosion resistanceMelt-holding vesselsCasting cleaning apparatusSlab casterSlag

The invention relates to a tundish flow control device for a slab casting machine, a preparation method of the tundish flow control device and a slagging method using the tundish flow control device, and belongs to the technical field of the ferrous metallurgy slab casting tundish technology. The tundish flow control device for the slab casting machine comprises a turbulence controller, a slag blockage weir and a slag blockage dam, and is characterized in that the upper edge of the slag blockage weir (5) is higher than the highest liquid level (10) of molten steel normally poured by the tundish, but is lower than the working face of tundish overflow port coating (1); the slag blockage weir (5) and the slag blockage dam (6) are vertically staggered; two ends of the slag blockage dam (6) are respectively provided with a through hole; a center distance a between the slag blockage weir (5) and the turbulence controller (4) is 400-600mm; and a center distance b between the slag blockage weir (5) and the slag blockage dam (6) is 300-400mm. After the tundish flow control device for the slab casting machine is adopted, slab tundish injection residue can be reduced by more than 25%, the service life of the flow control device is improved by one time and is above 14 hours, and the production cost of continuous casting refractory material is lowered by more than 30%.

Owner:LAIWU IRON & STEEL GRP

OOCr13Ni5Mo ultralow-carbon martensitic stainless steel and producing method thereof

ActiveCN101104909AImprove stabilityImprove securityRoll mill control devicesMetal rolling arrangementsChemical compositionIngot casting

The invention discloses a 00Cr13Ni5Mo ultralow-carbon martensitic stainless steel and the manufacturing method thereof. The chemical components, by weight percentage, are as follows: C less than or equal to 0.03, Mn 0.50-1, Si less than or equal to 0.5, P less than or equal to 0.025, S less than or equal to 0.015, Cr 12-14, Ni 4.5-6, Mo 0.5-1, and Fe and inevitable impurity in balance. The manufacturing method mainly comprises, in order, primary smelting in an electric furnace, refining in a refining furnace, steel ingot casting, steel ingot annealing, forging rolling of blank, and heat treatment of blank. This type of steel has high strength, toughness and weldability; and has excellent resistance against erosion, wear and corrosion. The steel is mainly used, in large hydropower station, as key parts such as rotating wheel with thick section and good weldability and lower ring for hydropower station, and used as material for valve and gate valve systems.

Owner:ZHEJIANG DALONG ALLOY STEEL

Waterless stemming for blast furnace

InactiveCN1523120AImprove workabilityEasy to squeeze outBlast furnace componentsBlast furnace detailsAnthraceneContraction rate

The present invention provides an anhydrous stemming for blast furnace. Its composition includes (wt%) coarse brown corundun 1-4%, fine brown corundum 2-5%, coarse mullite 7-15%, fine mullite 9-20%, coke powder 15-20%, clay 10-19%, silicon carbide 7-11%, sericite 5-8%, bitumen 2-4% and anthracene oil 15-25%. It has good working property, stable high temperature resistance, excellent caking property, quick agglutinating property, low ton-iron stemming consumption, low contraction rate and high strength, it can raise tap up-to-standard rate to 100% from original 61.5%, can raise production safety of blast furnace, and can raise smelting strength.

Owner:WUKUN STEEL

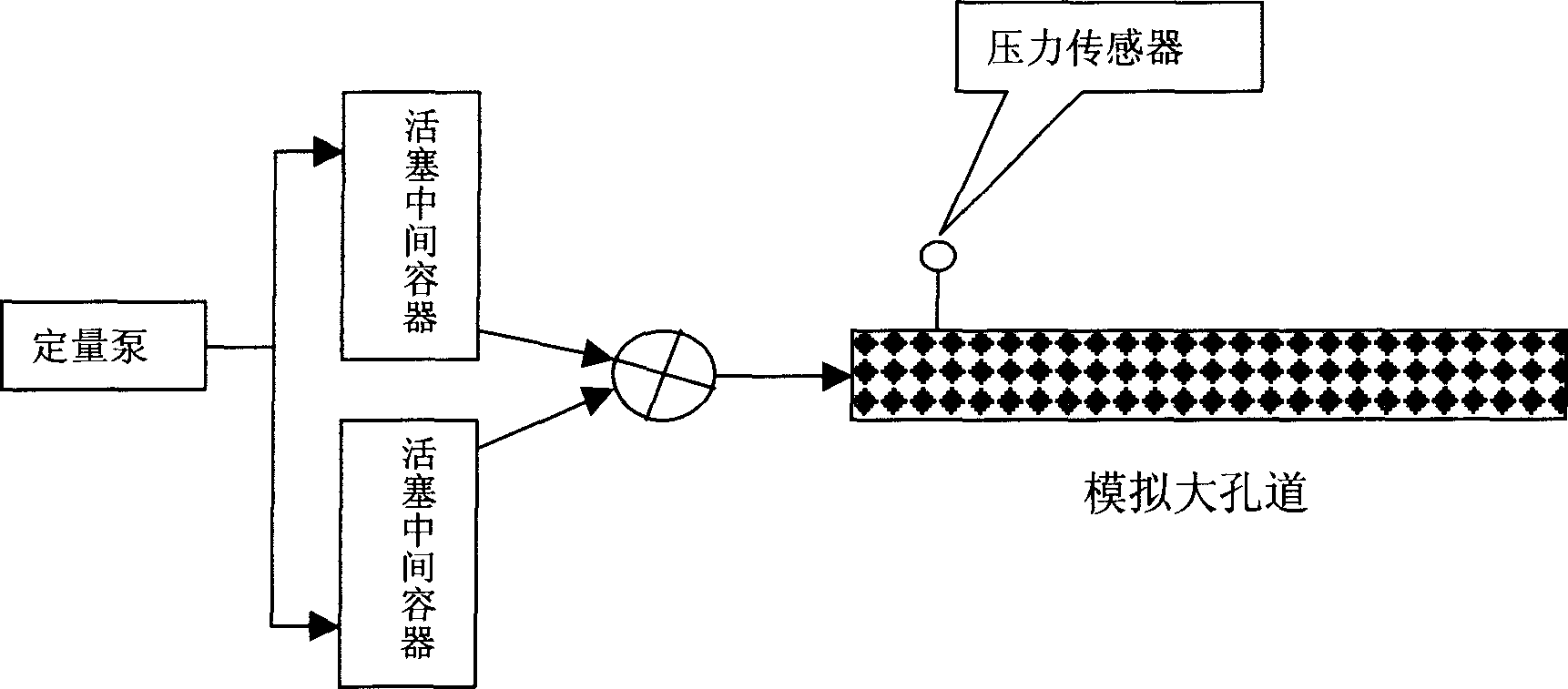

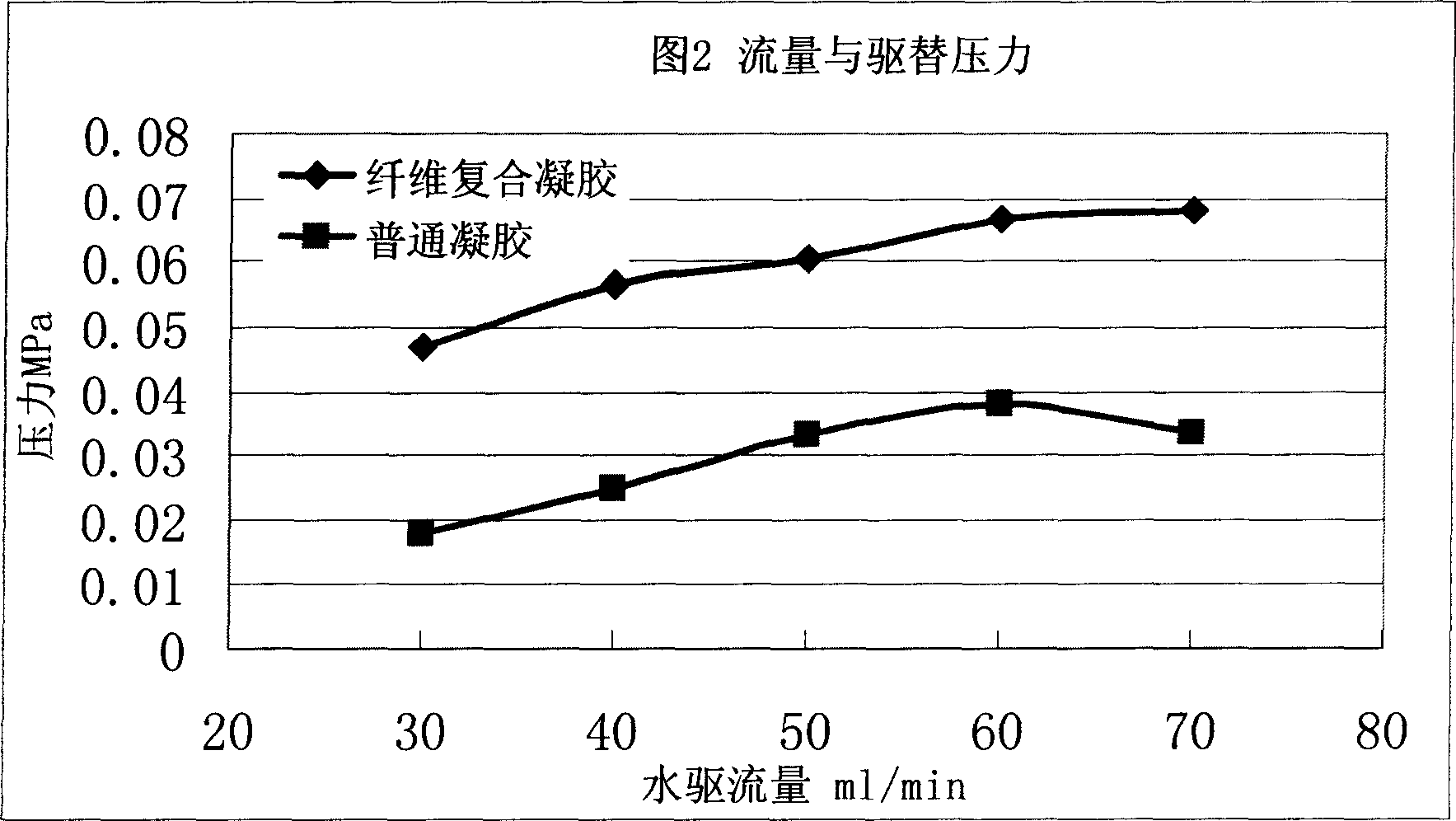

Preparation method of fiber composite gelatin for plugging oil coat macropore

The invention discloses a method for preparing fiber complex gel used for plugging oil layer large opening, which is formed because of long time water injection and for controlling ineffective cycle of injected water and improving water-drive development effect; the preparation method for fiber complex gel comprises following steps: (1) adding 0.05-1 unit fiber into water of 100 units, stirring evenly to make fiber float on water; (2) adding 0.05-1 unit of water block off agent, stirring for 10 minutes to prepare fiber jellied liquid; (3) heating said liquid until it becomes gelatineous, and preparing fiber complex gel. The addition of fiber into formulation to prepare fiber complex gel after injection into large opening, which greatly increases plugging strength and flushing-endurance of block off agent in large opening and makes subsequent injected water flow to position with low penetration factor of oil layer, enlarges contact volume and drives out more oil.

Owner:PETROCHINA CO LTD

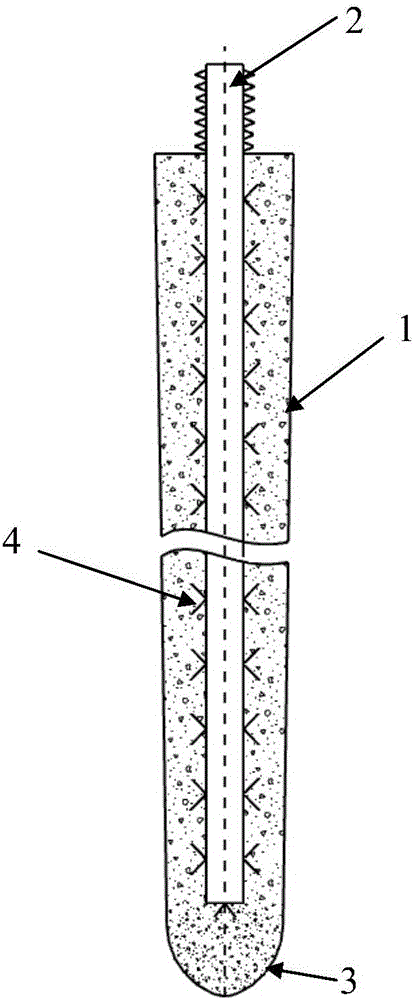

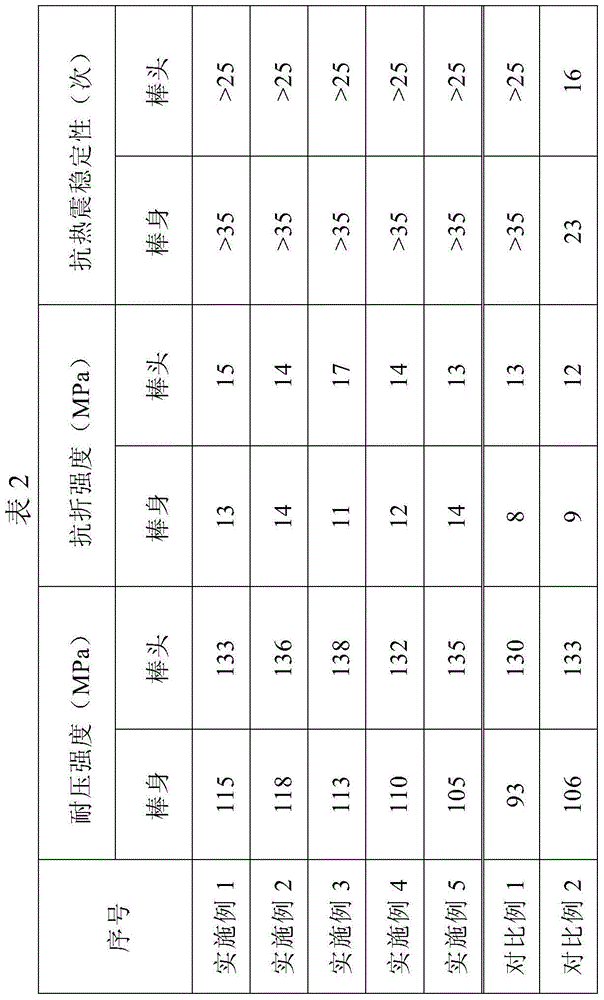

Low carbon magnesium integral composite stopper rod

InactiveCN101134238AGood erosion resistanceExcellent anti-corrosion performance of calcium treated molten steelMelt-holding vesselsAluminiumMagnesium

The present invention relates to one kind of integral composite stopper for continuous casting. The integral composite stopper includes one stopper head and one stopper body of Al-C material, and features the stopper head of low carbon magnesium material comprising fused magnesia with magnesium oxide content over 96 wt% in 50-80 wt%, magnesia alumina spinel in 0-30 wt%, graphite with carbon content over 95 wt% in 5-12 wt%, one or several of Si, Al, silicon carbide and boron carbide in 2-10 wt%, and phenolic resin as binder in 4-8 wt%. The integral composite stopper has high scour resistance, high molten steel erosion resistance, high thermal shock resistance, and long service life.

Owner:BAOSHAN IRON & STEEL CO LTD

Ceramic membrane for treating dusty, poisonous and high-temperature gases and preparation method thereof

ActiveCN103495346AHigh filtration precisionImprove permeabilitySemi-permeable membranesDispersed particle separationSilicon-controlled rectifierMetallic materials

The invention belongs to the field of inorganic nonmetal materials and particularly relates to a ceramic membrane for treating dusty, poisonous and high-temperature gases and a preparation method thereof. 90-99% by mass of ceramic membrane supporting body and 1-10% by mass of catalyst are prepared into a complex, and then, a ceramic membrane coating is spray coated on the outer surface of the complex to prepare the ceramic membrane. The catalyst is an SCR (Silicon Controlled Rectifier) denitration catalyst, and the ceramic membrane supporting body is prepared from aggregate, a high temperature binder, a pore forming agent, a forming assistant and a release agent. The preparation method is as follows: firstly, preparing the ceramic membrane supporting body, and then, compounding the catalyst in the pore of the supporting body, spray coating a layer of ceramic membrane coating material on the outer surface of the supporting body, and carrying out heat treatment to prepare a ceramic membrane material. The prepared ceramic membrane material has the advantages of high filtering precision, high permeability and erosion resistance and has dust removal and catalysis functions, thereby integrating denitration with dust removal and changing the traditional mode of gradual operation of independent operation units.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Continuous casting monolithic stopper and method of manufacture thereof

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

High-temperature wear-resistant repairing coating and preparation method thereof

ActiveCN102134164AHigh compressive strengthHigh densityFireproof paintsSpecial surfacesWear resistantZircon

The invention relates to a high-temperature wear-resistant repairing coating and a preparation method thereof, and the coating comprises a material A and a material B with a weight ratio of 70-85:30-15, wherein the material A is prepared by zirconia corundum fine powder, kyanite, aluminium titanates, silicon micropowder, magnesium zircon sand, alumina micropowder, pure calcium aluminate cement, sodium tripolyphosphate, fused calcium chromate, and zinc aluminate gahnite; and the B material is prepared by phosphoric acid, ink-grade aluminium hydroxide, aluminium chloride, yttrium-stabilized zirconium, borax, and a medium-temperature agglutinant. The product has excellent wear resistance, corrosion resistance, erosion resistance, thermal shock stability, and a high caking property; using the product, the running period of a circulating fluidized bed boiler is increased from about 3500 hours to over 18000 hours for accumulating running time; the problem that the boiler liner needs to be repaired and replaced frequently is overcome; human and material resources are saved; and the production efficiency is greatly improved.

Owner:YIXING GUOQIANG FURNACE IND

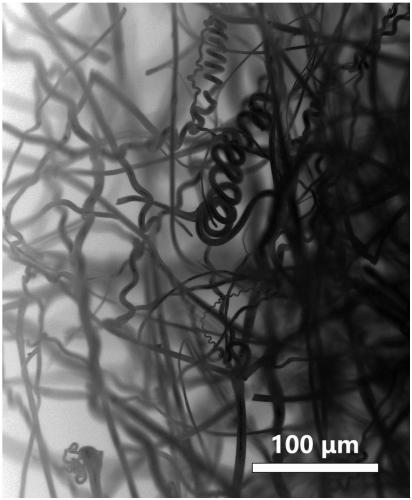

Ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application thereof

ActiveCN109161331AImprove the interface binding forceImprove erosion resistanceFireproof paintsPolymer scienceThermal insulation

The invention relates to a ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application of the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating, the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating is a double-layer composite coating systemand is compounded from a TI thermal insulation coating on the inner layer and a TA ablation resistance coating on the outer layer, the thickness ratio of the TI thermal insulation coating to the TA ablation resistance coating is (4-7):(2-5), a component B is added in a component A of the TI coating prepared according to the formula in the application, the mixture is blended by using a solvent inthe component A to the specified spraying viscosity and is blade-coated, roller-coated or sprayed to the thickness of 4-7 mm on the surface of a device; a component D is added in a component C of theTA coating prepared according to the formula, the mixture is blended by using a solvent in the component C to the specified spraying viscosity, is sprayed on the surface of a dried TI coating film, and is blade-coated or roller-coated to the thickness of 2-5 mm. Compared with the prior art, the bonding strength of a formed coating is high, and the coating can resist the instantaneous high temperature of more than 1500 DEG C, has an excellent heatproof effect, effectively protects a launcher against ablation damages, and is higher in strength.

Owner:SHANGHAI JIAO TONG UNIV +1

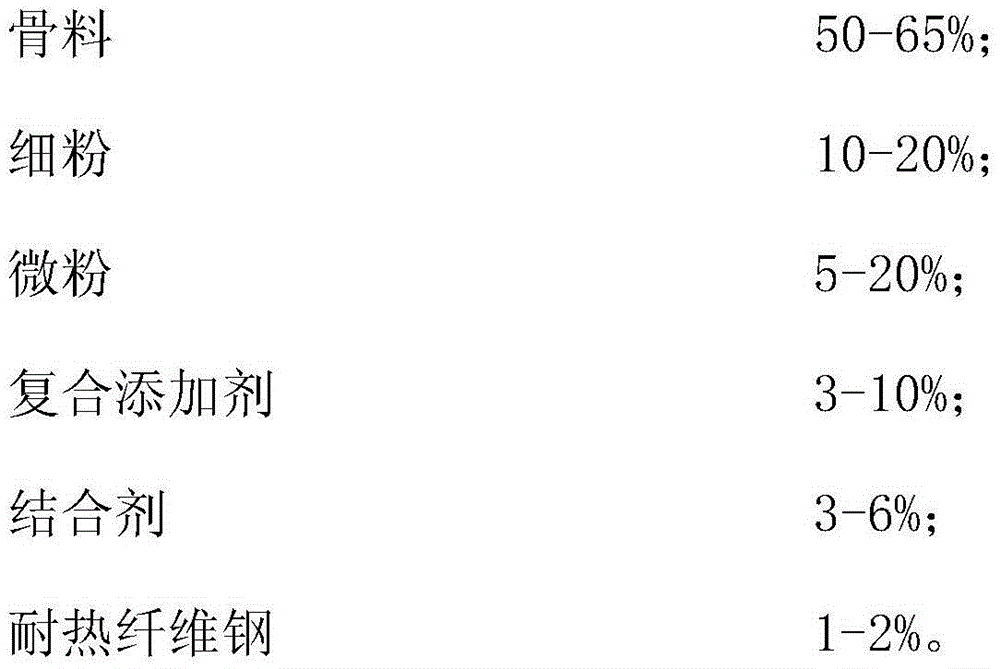

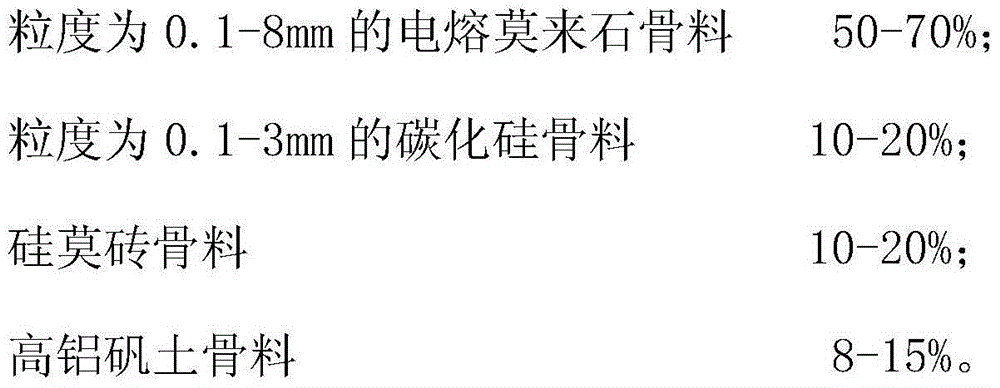

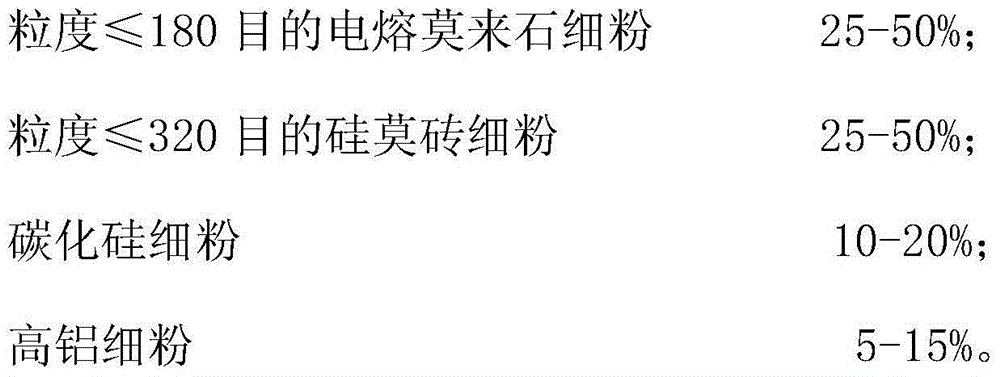

Silicon carbide mullite wear-resisting casting material

The invention discloses a silicon carbide mullite wear-resisting casting material which comprises the following components in percentage by mass: 50-65% of aggregate, 10-20% of refined powder, 5-20% of micro powder, 3-10% of a composite additive, 3-6% of a binding agent and 1-2% of thermal resisting fiber steel. As mullite aggregate and silicon carbide aggregate are adopted as the aggregate, the casting material has properties of good temperature resistance, scouring resistance, erosion resistance and thermal shock resistance; as the silicon dioxide micro powder and the activated aluminum oxide micro powder are introduced and the ratio of the silicon dioxide micro powder to the activated aluminum oxide micro powder is adjusted, the high-temperature strength, the wear-resistance and the corrosion resistance of the material are greatly improved; a waste material, namely, silicon-mullite bricks, is utilized, so that the energy is saved, the emission is reduced, the high-temperature application property of the casting material is improved, and through addition of organic and inorganic composite additives, the high-temperature application property of the casting material is improved.

Owner:长兴兴鹰新型耐火建材有限公司

Stemming for taphole of ore hearth and preparation method thereof

The invention relates to stemming for a taphole of an ore hearth and a preparation method thereof. The technical scheme adopted by the stemming disclosed by the invention lies in that the preparation method comprises the following steps of: firstly using 40-60wt% of bauxite, 5-15wt% of kyanite, 10-20wt% of brown fused alumina fine powder, 5-15wt% of chromium oxide fine powder, 5-15wt% of silicon carbide fine powder, 5-10wt% of silicon micro powder, 1-5wt% of titanium oxide fine powder, 1-3wt% of cerium oxide fine powder, 1-3wt% of bentonite fine powder and 1-5wt% of Al2O3 / Si2N2O / SiC / C composite powder as raw materials, additionally adding an oxide additive accounting for 1-5wt% of the raw materials, and pre-mixing the raw materials and the oxide additive for 5-10 minutes in a mixing and grinding machine so as to obtain premix powder; and then adding a retarder accounting for 0.05-0.25wt% of the raw materials and an aluminum dihydrogen phosphate aqueous solution accounting for 7-15wt% of the raw materials to the premix powder, grinding the premix powder, the retarder and the aluminum dihydrogen phosphate aqueous solution for 20-30 minutes in a wet manner, and then performing stemming extrusion and shaping through a stemming extruder so as to obtain the stemming for the taphole of the ore hearth. The stemming for the taphole of the ore hearth prepared by the preparation method disclosed by the invention has the characteristics of being low in cost, high in intensity, excellent in washing resistance and excellent in corrosion resistance.

Owner:湖南立达高新材料有限公司 +1

Preparation method of jelly-type oily sludge profile control agent

A preparation method of a jelly-type oily sludge profile control agent comprises the following steps: adding oily sludge and water into a stirrer to be stirred and pre-treated to enable the viscosity of pre-treated oily sludge to be 0.3-0.5 Pa.s; adding an emulsifier into the pre-treated oily sludge to enable oily sludge to be fully dispersed; sequentially adding a zwitterionic polymer, a cross-linking agent and a jelly promoter; uniformly stirring to obtain the jelly-type oily sludge profile control agent. The preparation method is simple in manufacture process, economical and effective and suitable for on-site construction conditions, and can effectively prevent oily sludge from environmental pollution; oily sludge in the profile control agent comes from an oil reservoir, has good compatibility with the oil reservoir, and causes less damage to the oil reservoir; the jelly-type oily sludge profile control agent is good in jelly forming performance, adjustable in jelly forming strength, excellent in stability after felly forming and high in plugging strength and erosion resistance.

Owner:XI'AN PETROLEUM UNIVERSITY

Skimming tool

InactiveCN1944343AImprove erosion resistanceImprove antioxidant capacityBlast furnace componentsBlast furnace detailsSlagSilicon

The skimming tool is made with dense corundum or brown corundum 43-48 wt%, silicon carbide 29-33 wt%, pelleted pitch 2-3 wt%, calcium aluminate cement 2.5-3 wt%, fine alpha-Al2O3 powder 8-10 wt%, fine uf-SiO2 powder 2-2.5 wt%, metal aluminum powder 0.5-1.5 wt%, metal silicon powder 1-3 wt%, composite additive 0.3-0.5 wt%, and water 3.5-5.5 wt%. The skimming tool of the present invention has excellent washing, oxidizing and slag erosion resisting performance and long service life.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Oxide and non-oxide composite integral stopper rod

InactiveCN102489695ASmall coefficient of thermal expansionImprove erosion resistanceMelt-holding vesselsOxide compositeRefractory

The invention belongs to the field of novel refractory materials with a continuous casting function, and provides an oxide and non-oxide composite integral stopper rod for continuous casting. The rod body of the integral stopper rod is made of an aluminum-carbon material; the head of the stopper rod is made of an oxide and non-oxide composite material; the space between the rod head and the rod body is formed by a mixed transition material between the rod head and the rod body; and the rod head comprises 65 to 80 percent of electric melting magnesia serving as a main raw material and is added with 5 to 20 percent of non-oxide, 7 to 12 percent of graphite and 8 to 12 percent of phenolic resin. According to the stopper rod, the molten steel scouring and corrosion resistance of the rod head material during use is improved by adding the non-oxide, appropriately reducing the content of the graphite and fully utilizing the advantages of high melting point, low thermal expansion rate, high thermal shock stability and difficulty in molten steel infiltration of the non-oxide.

Owner:北京利尔高温材料股份有限公司 +2

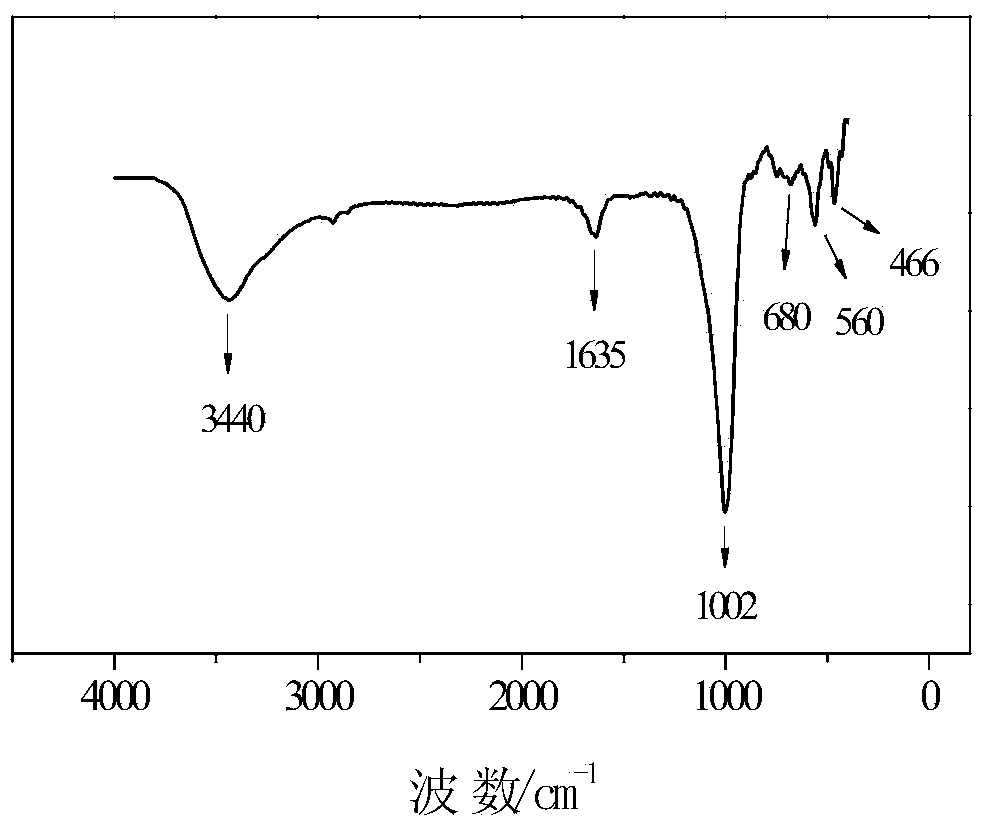

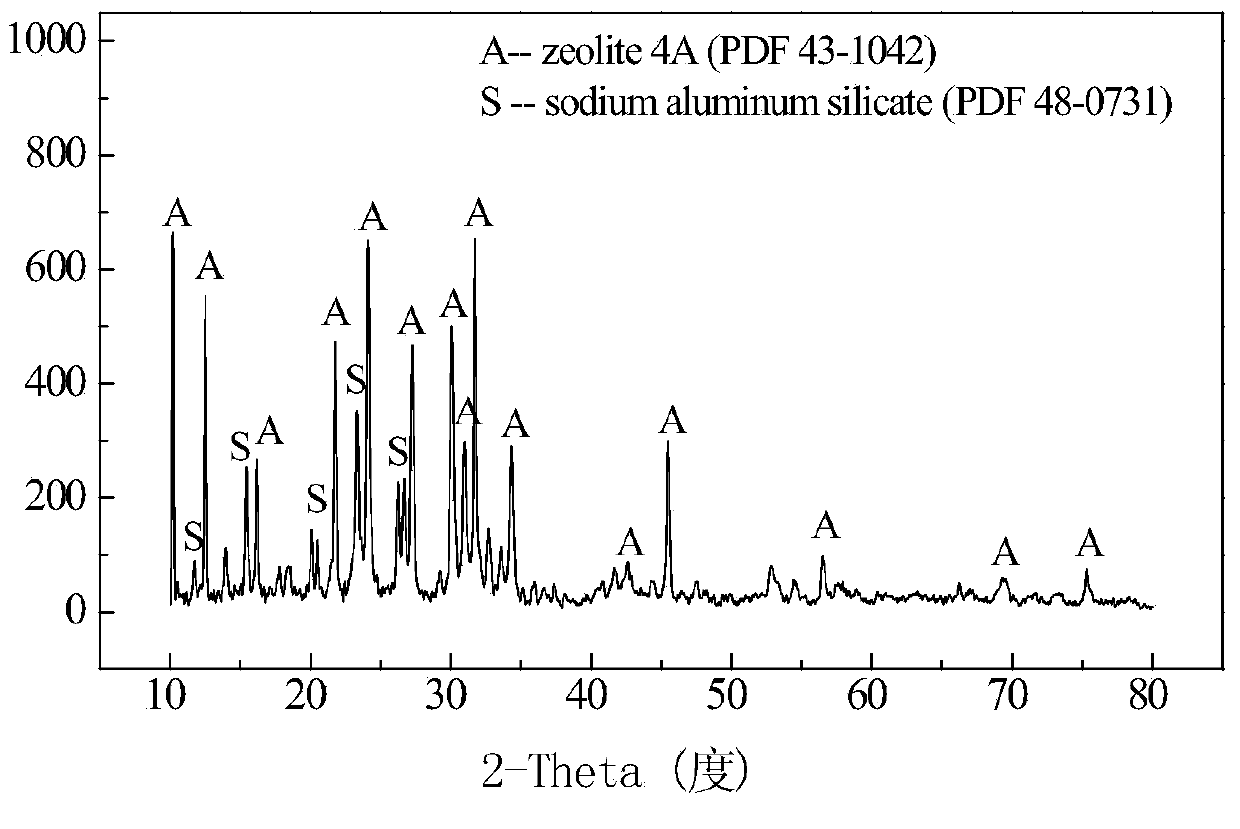

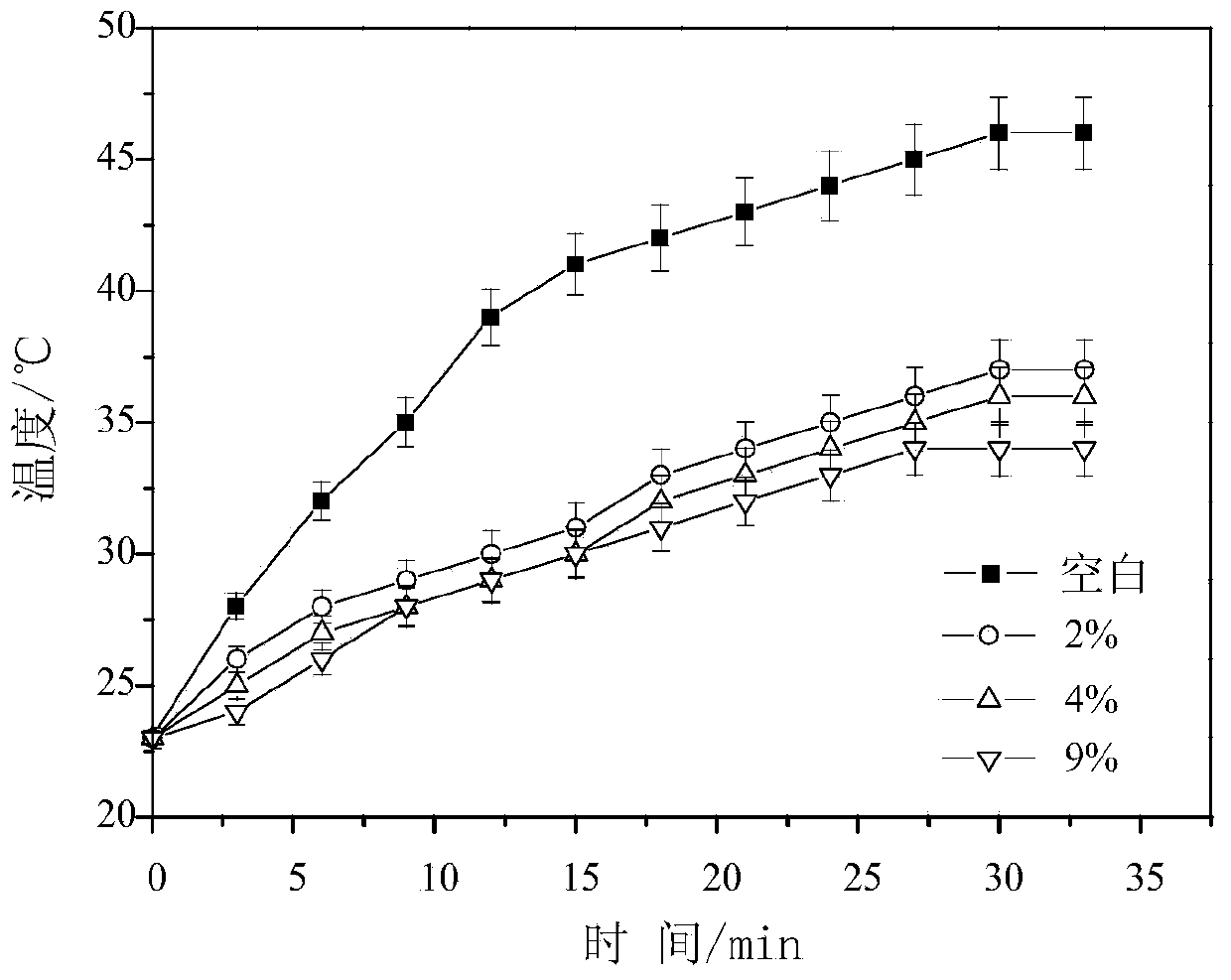

Heat insulating and preserving coating for exterior wall of building

ActiveCN103740188AHigh compressive strengthImprove stabilityCoatingsDefoaming AgentsPolymer chemistry

The invention provides a heat insulating and preserving coating for an exterior wall of a building. The heat insulating and preserving coating comprises the components: polymer emulsion, functional filler, titanium dioxide, a thickening agent, a wetting agent, a dispersing agent, a defoaming agent and water, wherein the functional filler is a self-prepared fly ash zeolite molecular sieve; the polymer emulsion is soft styrene-acrylic emulsion. The coating has the advantages that a coating layer formed on a building wall body is outstanding in performance, the heat insulating and preserving effect is superior to that of other similar heat preserving coatings, and the temperature difference can reach more than 10 DEG C compared with a blank phase; in addition, the heat insulating and preserving coating has the advantages of being environmentally-friendly, nontoxic, high in adhesive force, difficult to crack, easy to construct, etc., is applicable to the coating layer for heat preserving of the exterior wall of the building, and shows a remarkable environmental protection and energy saving effect.

Owner:SHANXI UNIV

High temperature abrasion-proof paint and method for producing the same

The invention relates to a 318 high-temperature wear-resistant coating and a preparation method thereof, in particular to a rapid repair material for repairing various abrasive bricks and wear-resistant casting damage positions in circulating fluidized bed boilers of fuel electric plants. At the same time, the invention provides a method for producing the high-temperature wear-resistant coating, and belongs to the technical field of refractory material. The rapid repair material consists of a material A and a material B according to the weight portion proportion of 70-85 to 30-15, wherein the material A is prepared by zircon corundum, fine corundum powder, cyanite, yttrium-stabilized zirconium, silicon micropowder, alumina micropowder, pure calcium aluminate cement, trimeric sodium phosphate, and fused calcium chromate; and the material B is prepared by phosphorous acid, ink grade aluminum hydroxide, zirconia ultrafine powder, yttrium-stabilized zirconium, and fused calcium chromate.

Owner:YIXING GUOQIANG FURNACE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com