Preparation method of fiber composite gelatin for plugging oil coat macropore

A technology of fiber composite and composite gel, which is applied in earthwork drilling, sealing/isolation, wellbore/well parts, etc., can solve the problems of low cost, short gelation time, weak strength, etc., and achieve flow resistance and durability Effects of improved scouring capacity, increased cost, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of fiber composite into glue

[0028] 1) Add 0.2 part of SF fiber to 100 parts of water, stir slightly to make it evenly suspended in tap water.

[0029] 2) Add 0.4 parts of water blocking agent to the above solution, including 0.2 parts of granular polyacrylamide, 0.1 part of phenol, and 0.1 part of hexamethylenetetramine, stir for 10 minutes to make it uniform, and form a composite fiber glue.

[0030] (2) Simulation of large pores and test procedures

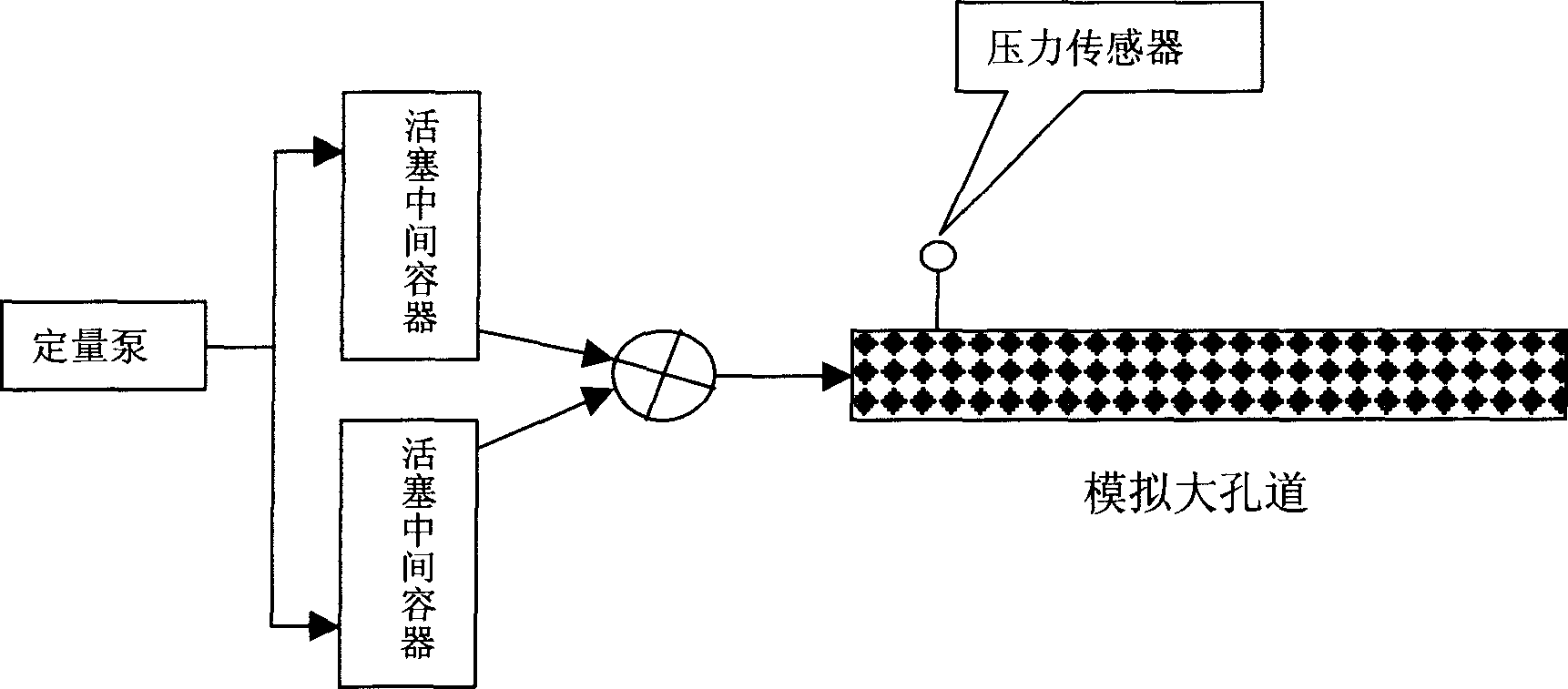

[0031] In order to simulate the large pores formed by long-term water injection in the oil layer, 5-10 mesh quartz sand was filled into a core tube with a diameter of 40 mm and a length of 300 mm. For the core flow test procedure, see figure 1 .

[0032] (3) Experimental steps

[0033] 1) The fiber gelling solution and the ordinary gelling solution are respectively injected into two simulated large pores filled with quartz sand of the same particle size.

[0034] 2) Seal both ends of the two core t...

Embodiment 2

[0039] (1) Preparation of fiber composite into glue

[0040] 1) Add 1 part of SF fiber to 100 parts of water, stir slightly to make it evenly suspended in tap water.

[0041] 2) Add 1 part of water blocking agent to the above solution, including 0.5 part of granular polyacrylamide, 0.25 part of phenol, and 0.25 part of hexamethylenetetramine, stir for 10 minutes to make it uniform, and form a composite fiber glue.

[0042] (2) Experimental results

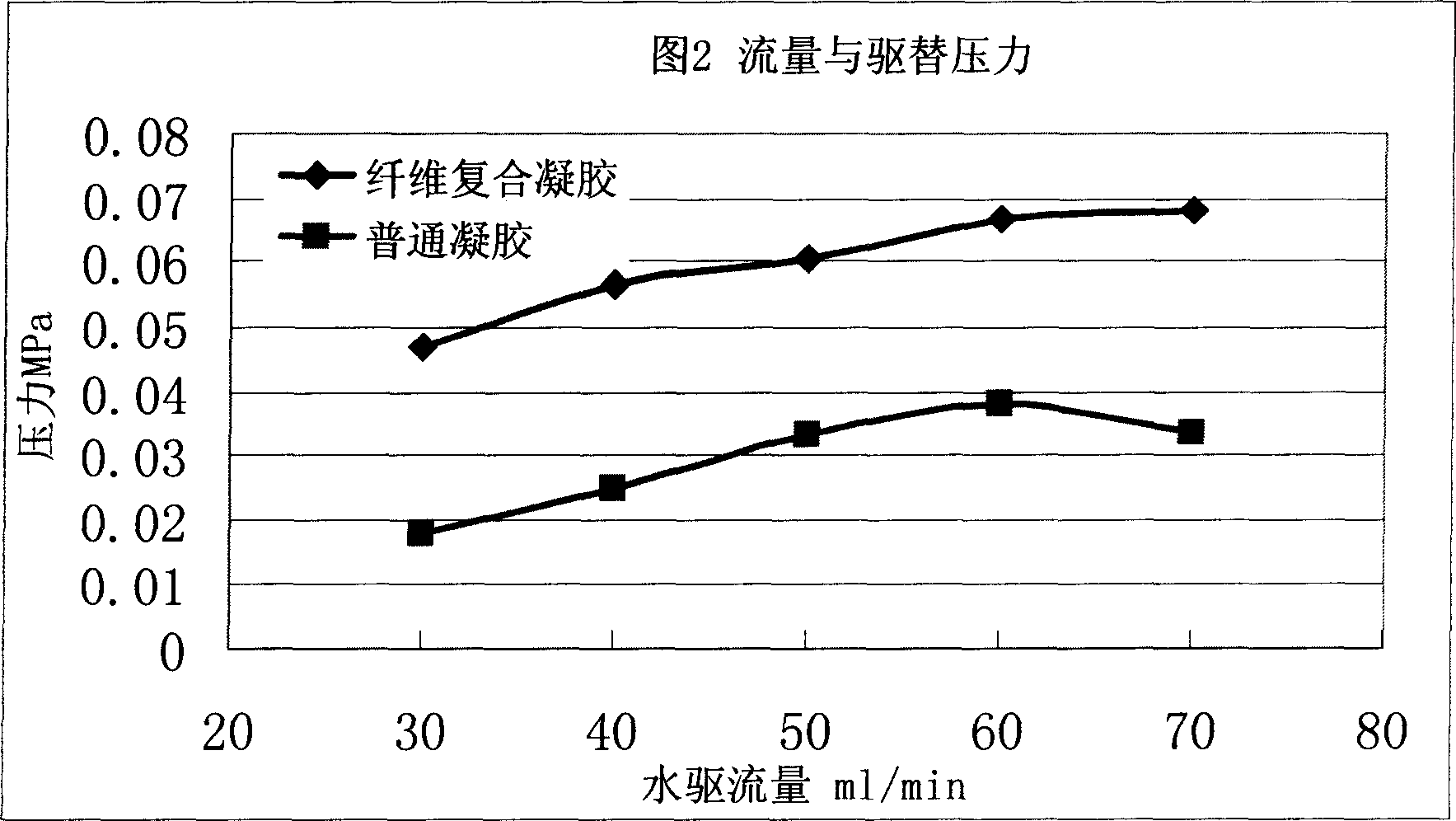

[0043] The results of simulated large pore test show that the flow resistance of the fiber composite gel to water flow and its erosion resistance ability are significantly improved.

Embodiment 3

[0045] (1) Preparation of fiber composite into glue

[0046] 1) Add 0.05 part of SF fiber to 100 parts of water, stir slightly to make it evenly suspended in tap water.

[0047] 2) Add 0.05 parts of water blocking agent to the above solution, including 0.25 parts of granular polyacrylamide, 0.125 parts of phenol, and 0.125 parts of hexamethylenetetramine, stir for 10 minutes to make it uniform, and form a composite fiber glue.

[0048] (2) Experimental results

[0049] The results of simulated large pore test show that the flow resistance of the fiber composite gel to water flow and its erosion resistance ability are significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com