Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2727 results about "Hexamethylenetetramine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexamethylenetetramine or methenamine, also known as hexamine or urotropin, is a heterocyclic organic compound with the formula (CH₂)₆N₄. This white crystalline compound is highly soluble in water and polar organic solvents. It has a cage-like structure similar to adamantane. It is useful in the synthesis of other chemical compounds, e.g., plastics, pharmaceuticals, rubber additives. It sublimes in vacuum at 280 °C.

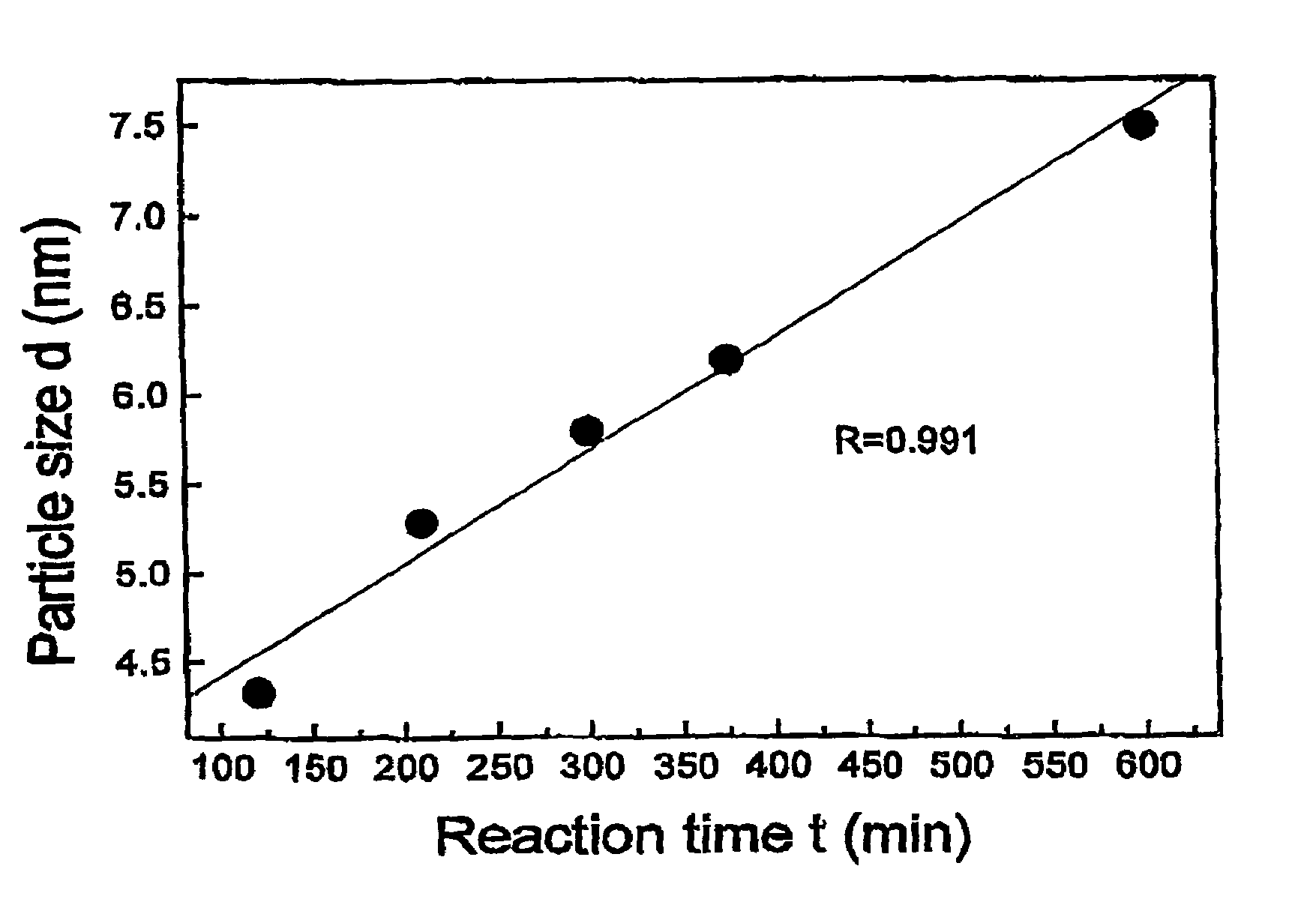

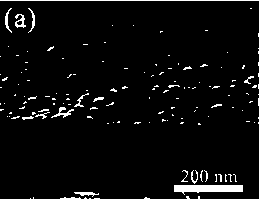

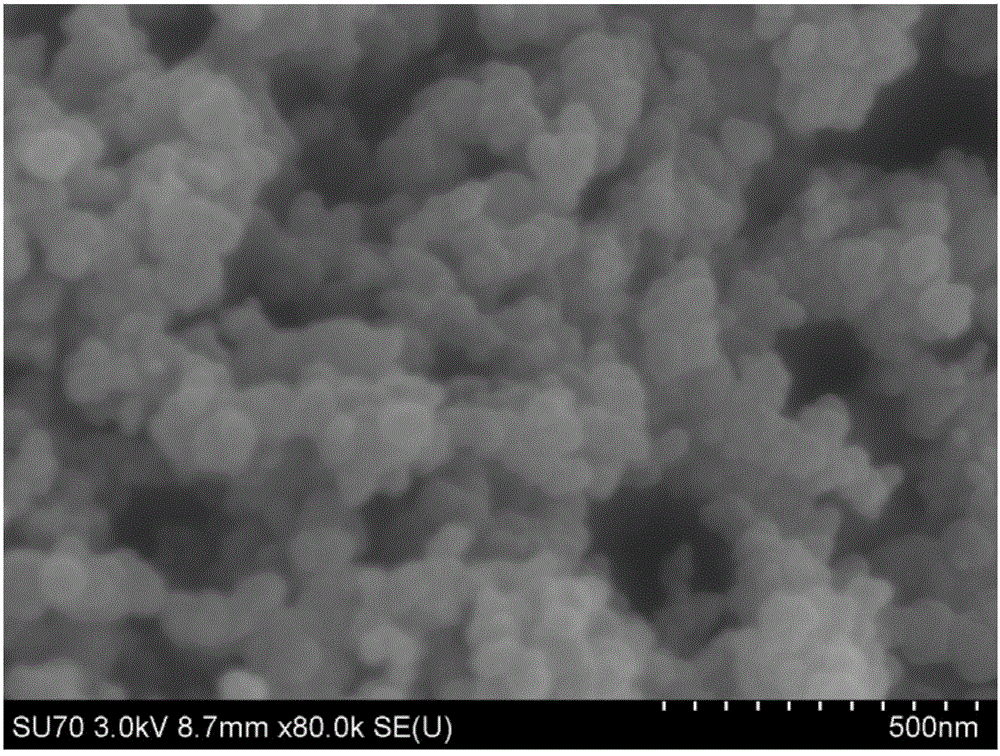

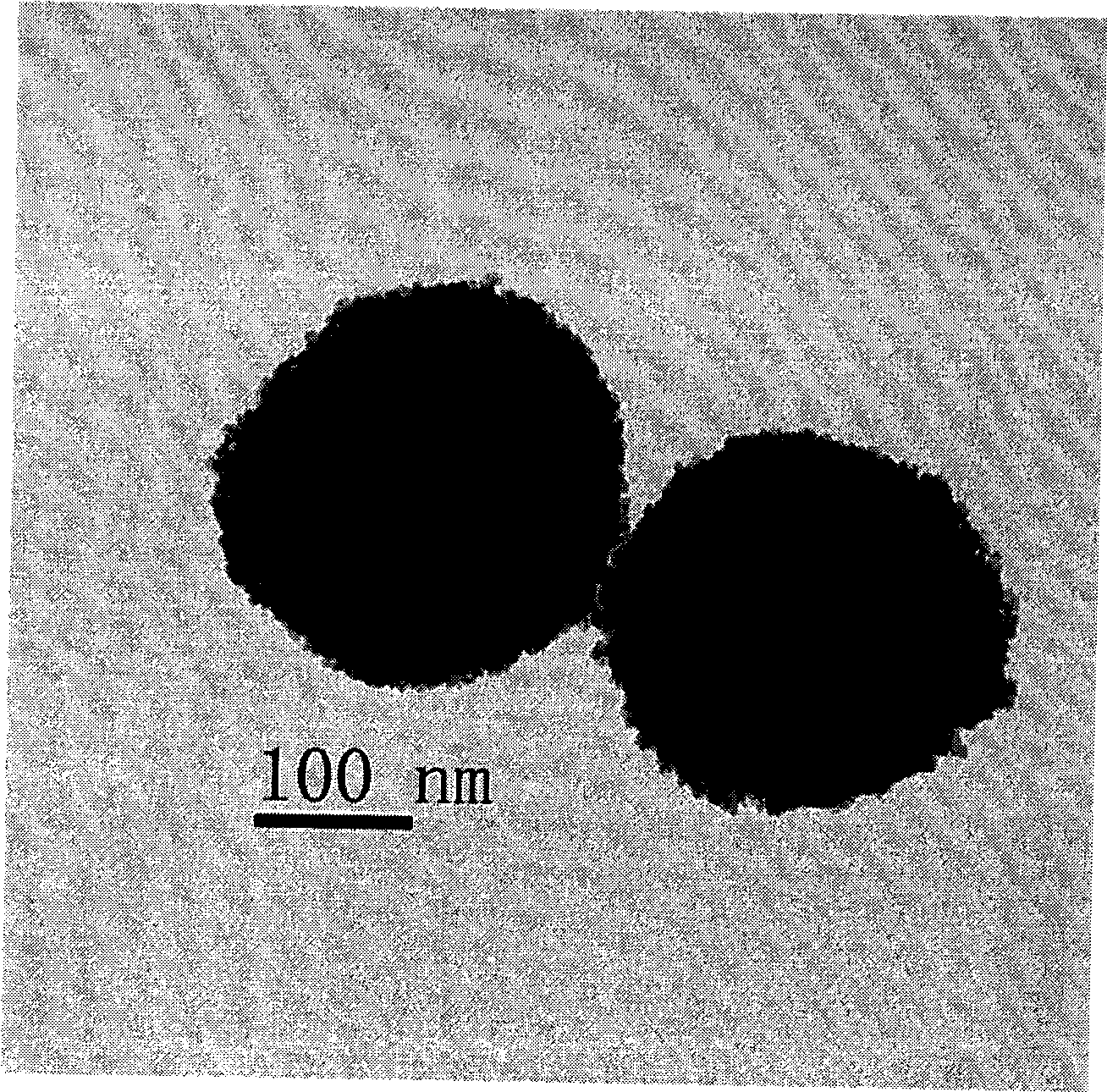

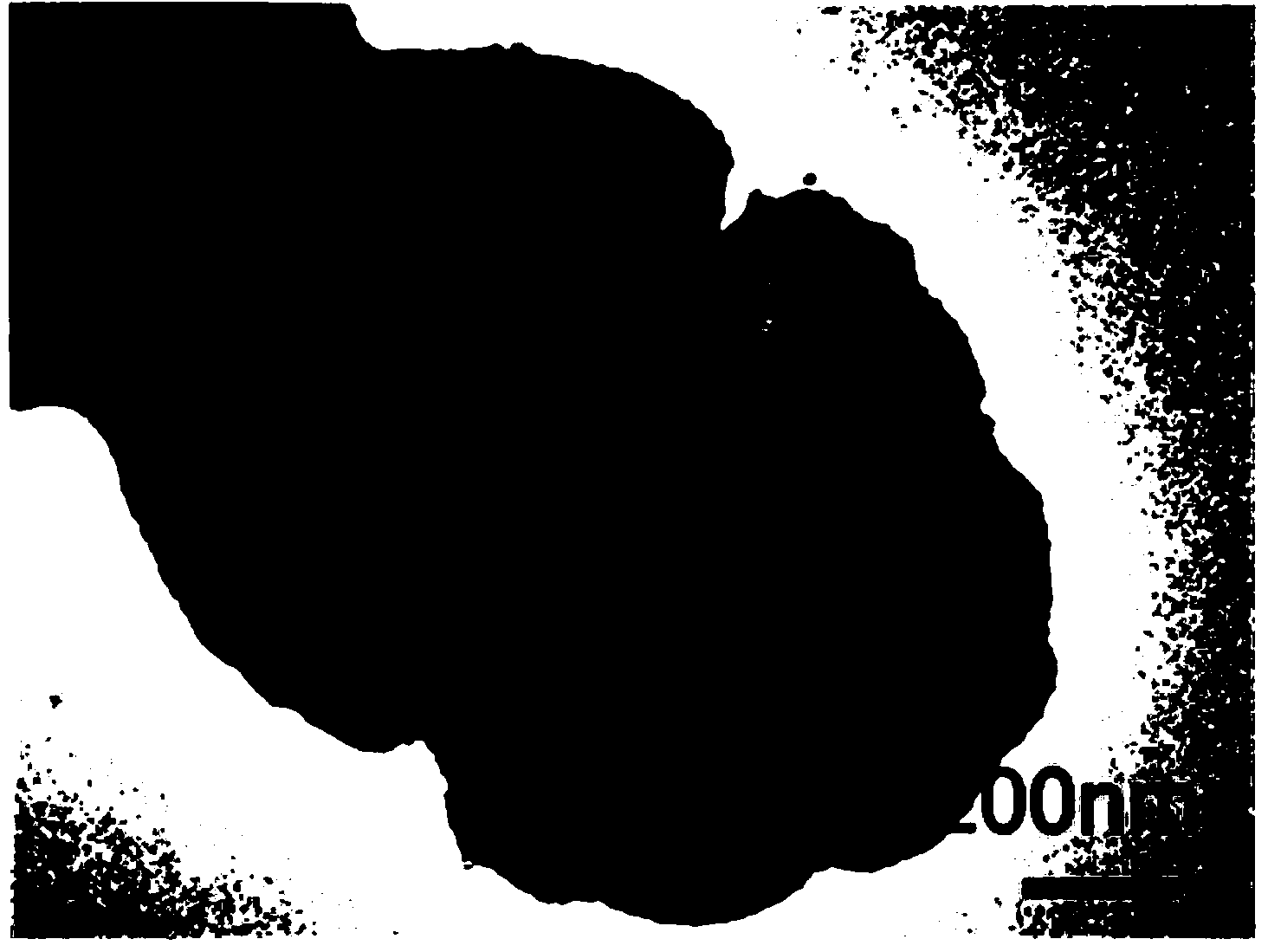

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS20050031517A1Quick responseReaction time is thus limitedMaterial nanotechnologyMixing methodsCerium nitrateNanoparticle

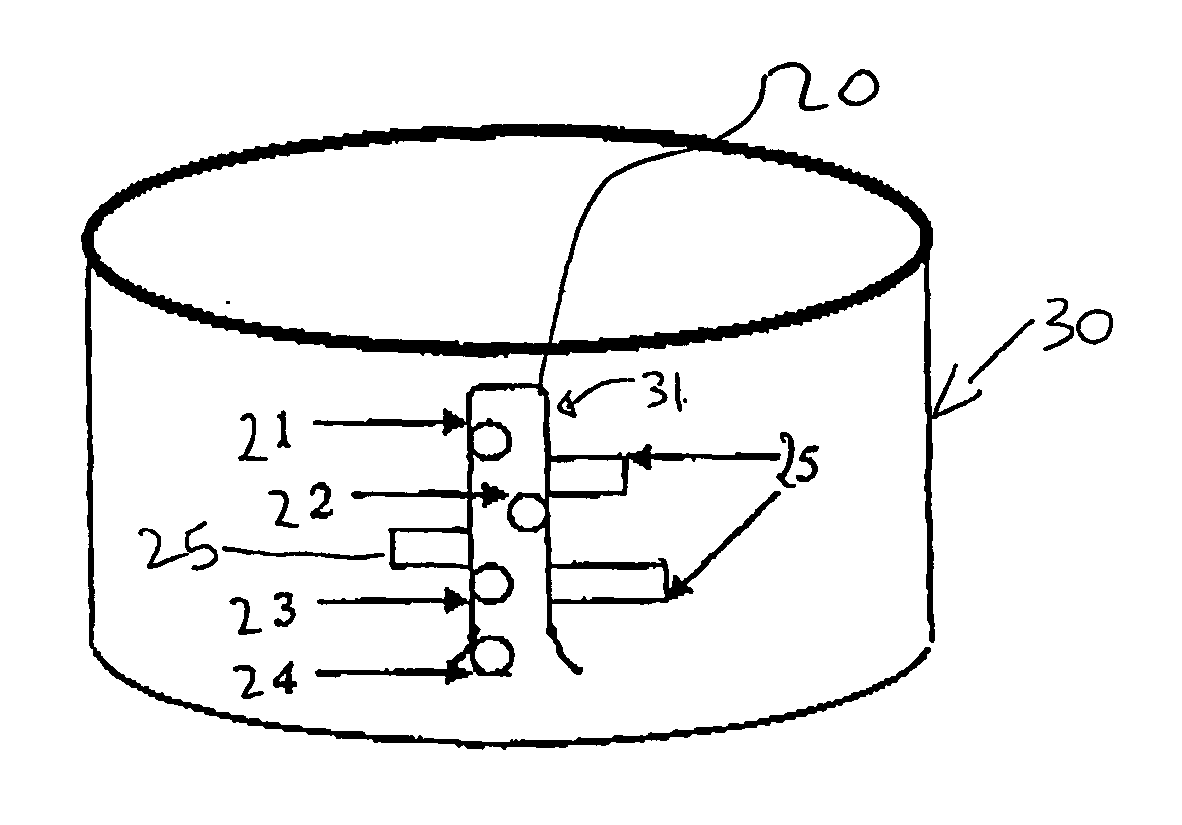

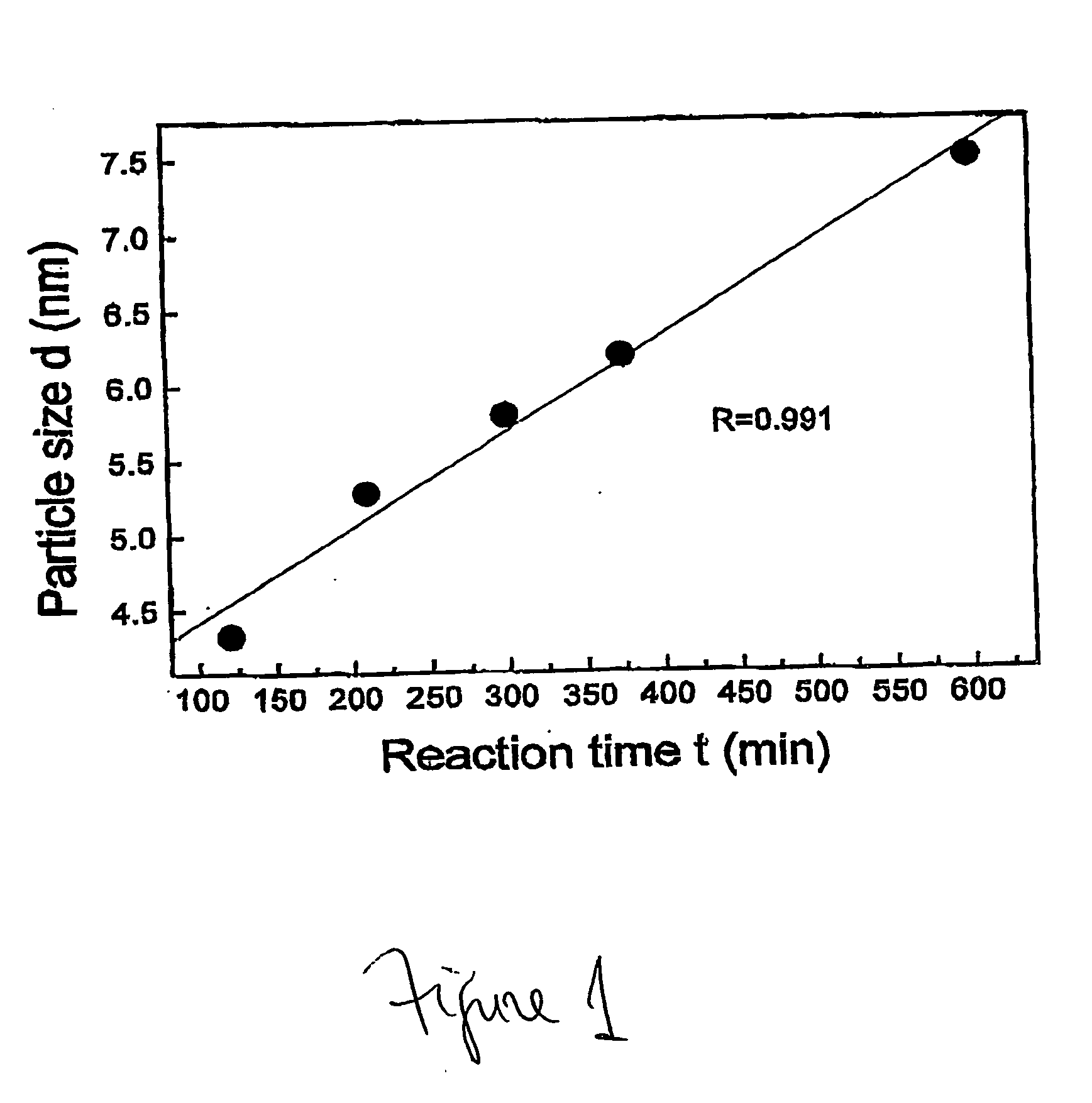

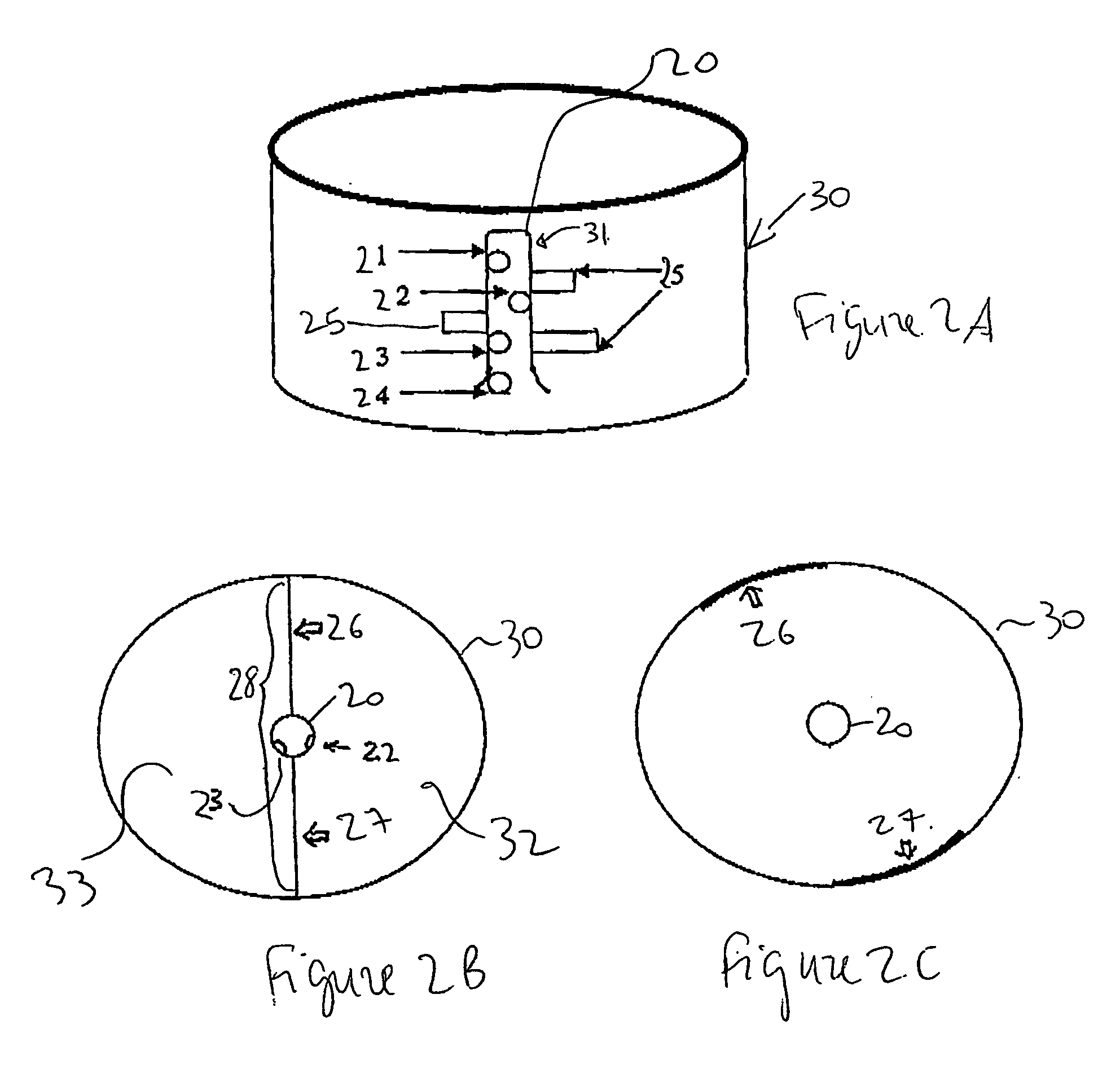

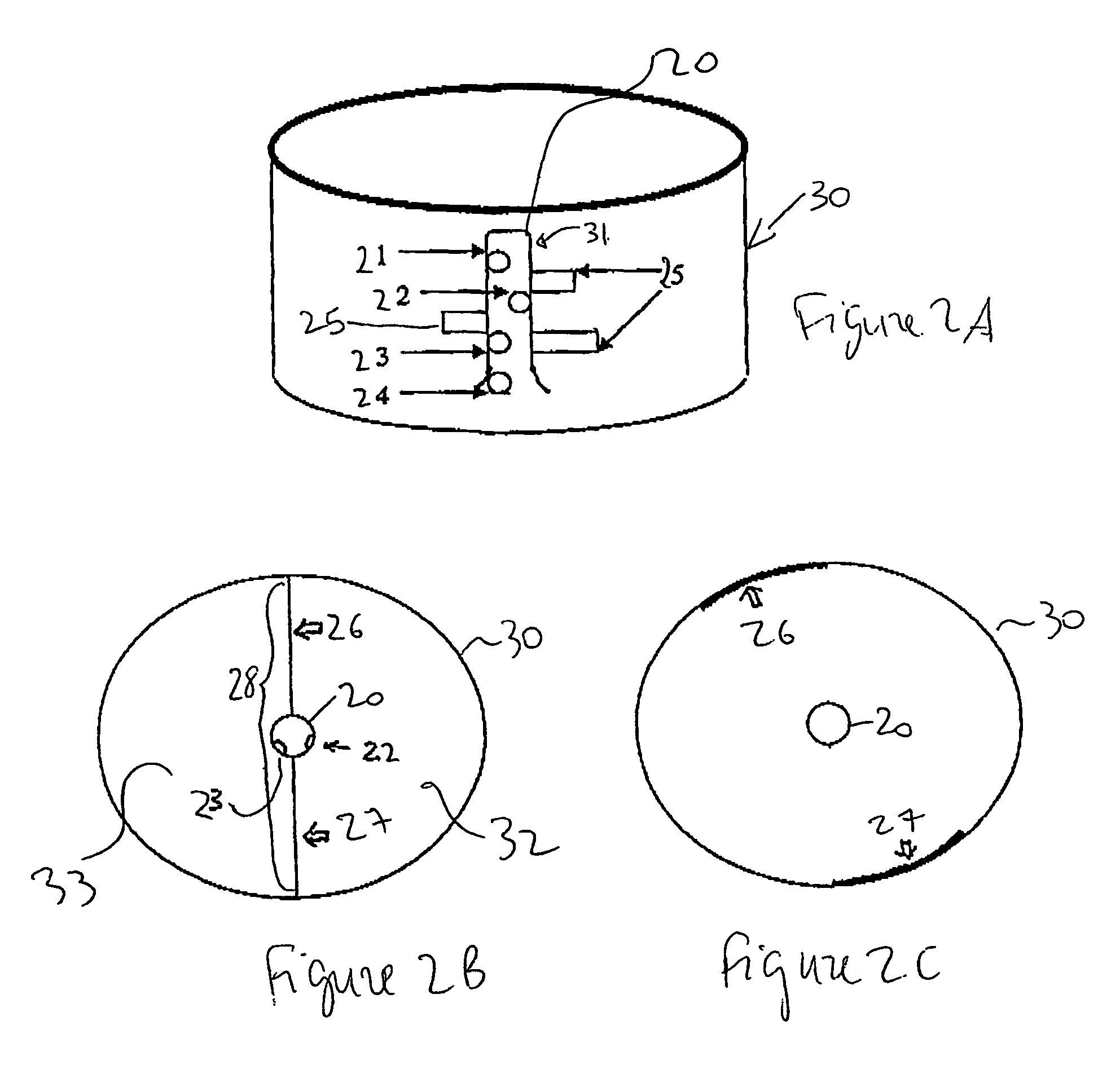

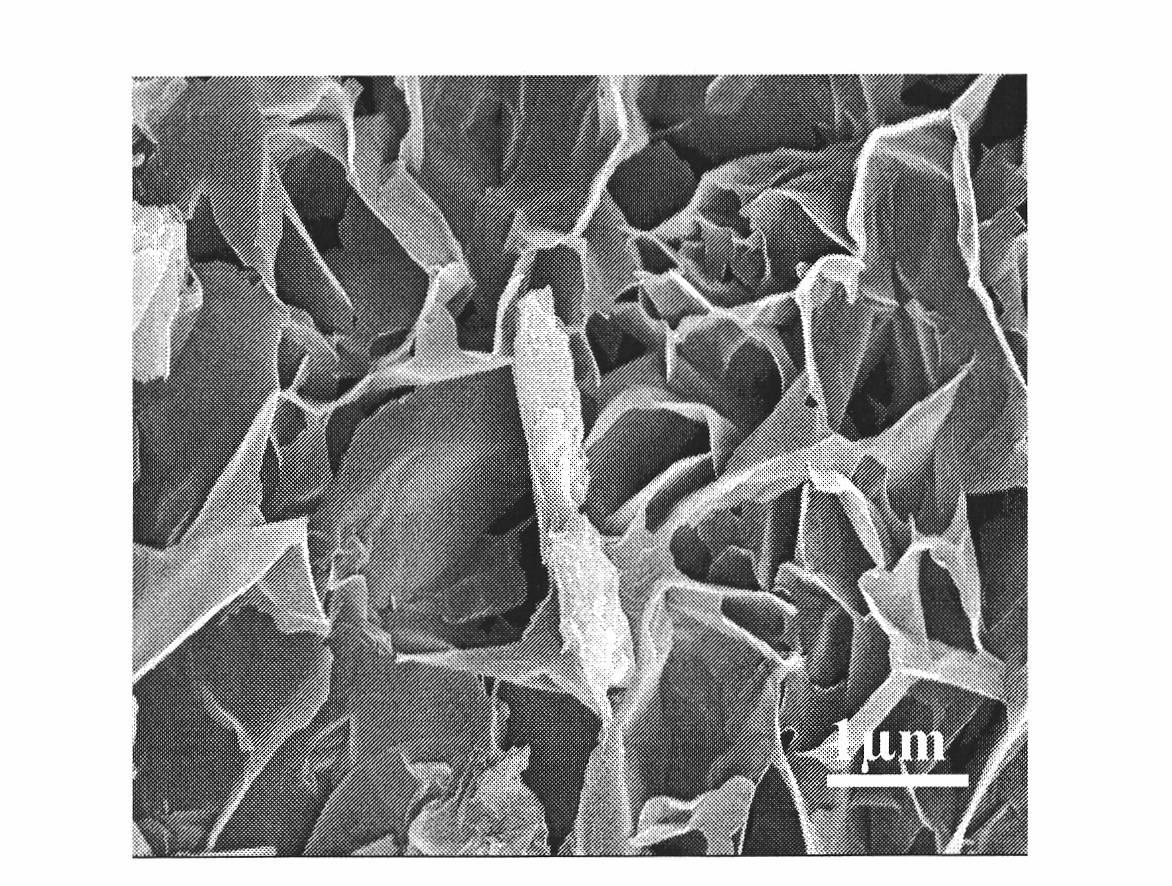

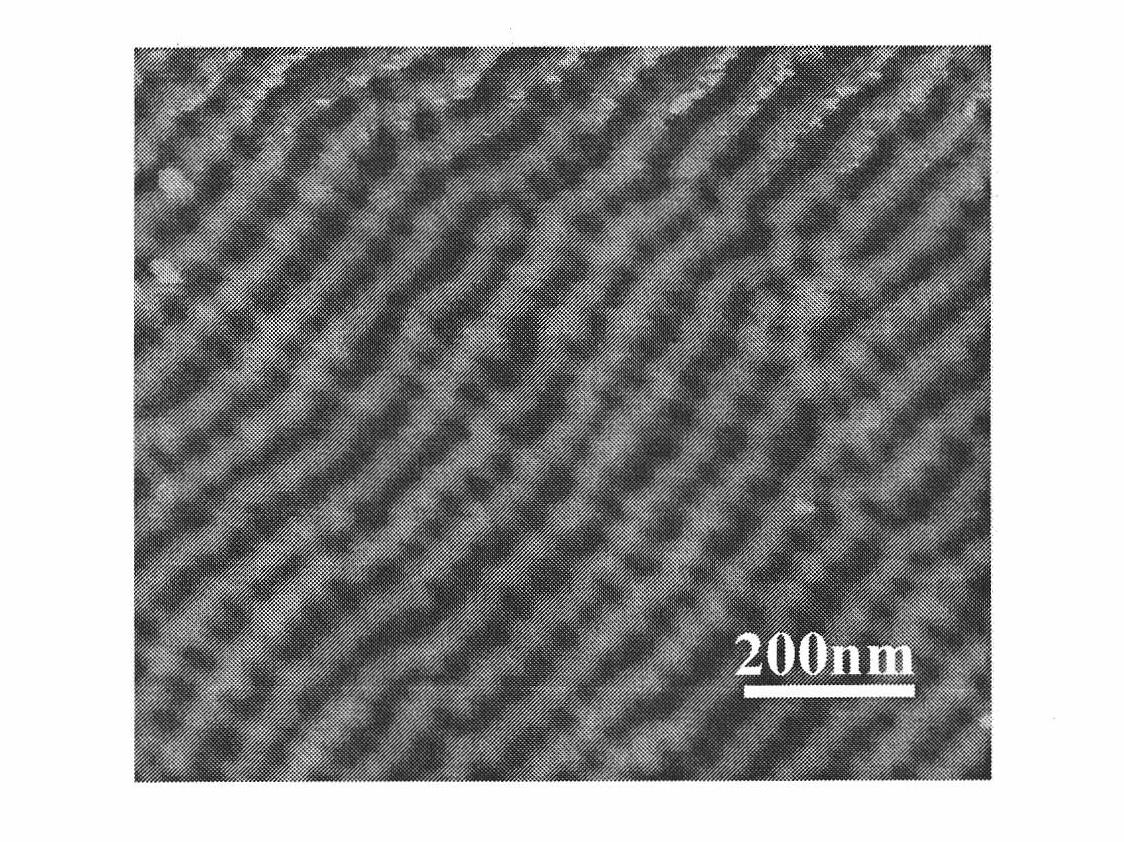

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments. When the retractable partition is retracted, rapid mixing of the first aqueous solution with the second aqueous solution takes place to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles therein.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

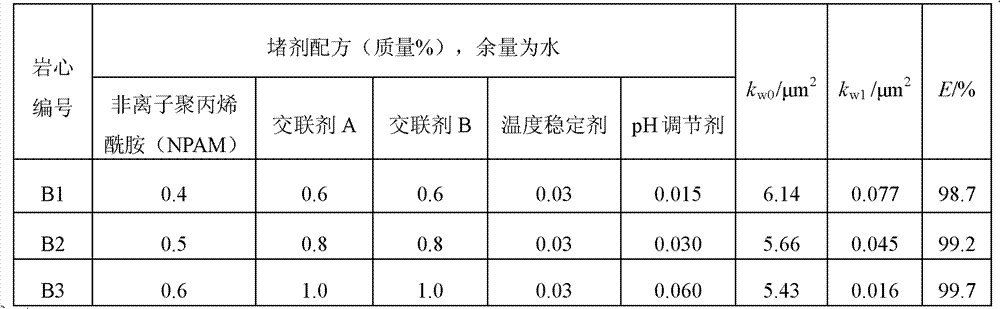

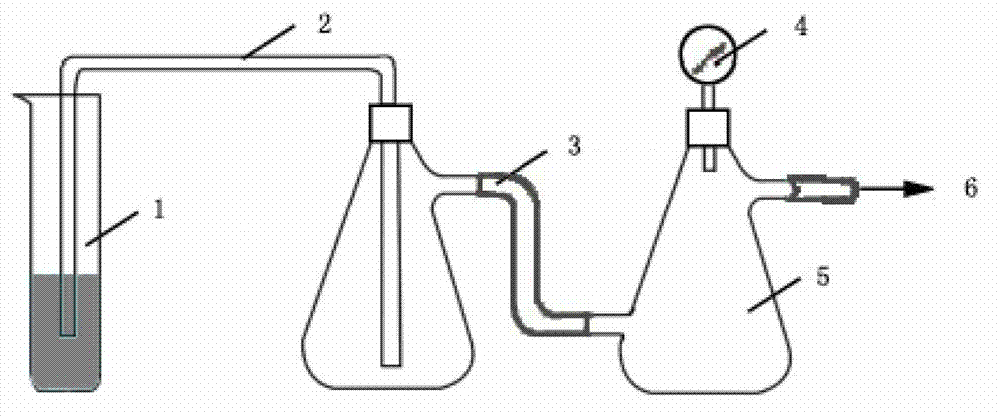

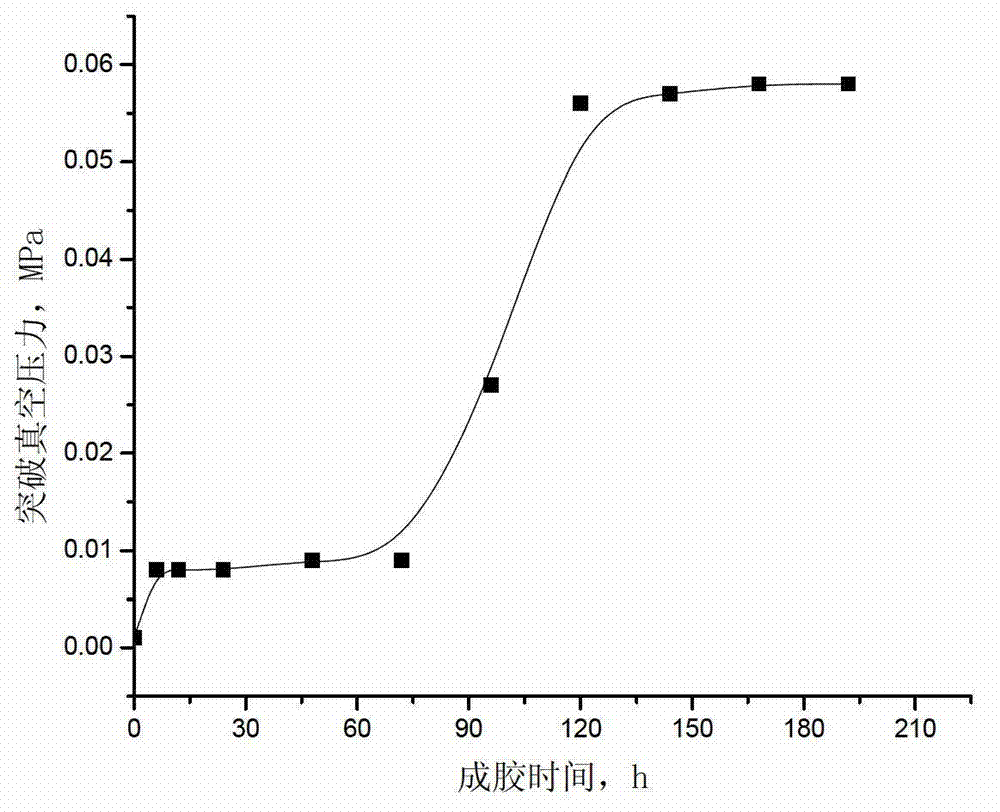

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing high-density spherical lithium iron phosphate

InactiveCN1632969AHigh bulk densitySimple processElectrode manufacturing processesPhosphatesKeroseneHexamethylenetetramine

This invention discloses a high density ball ferric phosphate lithium process method in energy material process technique, which comprises the following steps: to use ferric nitrate, phosphate chrome and acetic acid lithium as materials and to add deionized water to process solution A; to mix impurity metal compound or carbon source into the solution A; to make solution of hexamethylenetetramine and carbamide to process solution B; to make solution C by adding solution B into solution A; to drop solution C with kerosene and to heat it into gel for deposition; to get the ball dry gel front driver after centrifugal separation; to get the high volume proportion capacity high density ferric phosphate lithium through high temperature process.

Owner:TSINGHUA UNIV

Descaling method of phospheric acid concentration heat exchanger

ActiveCN1724965AEfficient removalRemove completelyOrganic detergent compounding agentsSurface-active detergent compositionsHexamethylenetetraminePhosphoric acid

The invention discloses a method for decaling phosphoric acid concentration heat exchanger, namely a technique of adopting a washing-liquor composed of thin fluosilicic acid solution, organic phosphonic acid sustained-releasing agent and film forming matter and firstly washing the heat exchanger with water and then washing out the foul with the washing liquor. In the washing liquor, the fluosilicic acid is a 5%-20% thin acid, the organic phosphonic acid sustained-releasing agent includes amino tri- sub-methylene phosphoric acid, hydroxyl sub-ethyl di-phosphoric acid and hydroxyl-l, 1-subethyl di-phosphoric acid; the film forming matter includes nitrous phenylhydroxylamine ammonium salt and wuluotuopin as well as sodium molybdate. As using, adding in surface active agent alkyl sulphonate. The invention can make high efficiency and thorough decaling the graphite heat exchanger and simultaneously effectively control the corrosion of the washing liquor to the equipment and as compared with traditional washing methods, the invention improves the productivity of the equipment.

Owner:WENGFU (GRP) CO LTD +1

High-strength core-preparing precoated sand and preparation process thereof

ActiveCN102688977AHigh strengthHigh melting pointFoundry mouldsFoundry coresHexamethylenetetraminePhysical chemistry

The invention discloses high-strength core-preparing precoated sand comprising the following components by weight percent: 4.8%-14.7% of iron sand, 1.65%-1.76% of mixed resin, 0.18%-0.24% of methenamine, 0.07%-0.11% of calcium stearate, 0.34%-0.54% of water and the balance of silica sand. The preparation process comprises the following steps of: adding basic roughing sand to a sand mixing machine after the basic roughing sand is heated to be 125-135 DEG C; adding the mixed resin accounting for 1.7%-1.8% of the weight of the basic roughing sand to the sand mixing machine for mixing and grinding; when the sand temperature in the sand mixing machine is reduced to be 102-108 DEG C, adding a methenamine solution for continuously mixing and grinding; and when the sand temperature in the sand mixing machine is reduced to be 70-75 DEG C, adding the calcium stearate, and screening and cooling after mixing and grinding so as to obtain finished sand. With the adoption of the preparation process, formation of N2 is effectively controlled, restraint to defects of subcutaneous blowholes is up to more than 96%, the barrier in the prior art is broken through, and the formation of nitrogen holes is truly prevented.

Owner:西峡县众德汽车部件有限公司

Apparatus and method for preparing cerium oxide nanoparticles

InactiveUS7141227B2Quick responseMaterial nanotechnologyTransportation and packagingCerium nitrateHexamethylenetetramine

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Gel foam selective water blockoff agent and use thereof

InactiveCN101481604AImprove stabilityLong water blocking periodDrilling compositionFoaming agentHexamethylenetetramine

The invention relates to gel-foam selective plugging agent and the application thereof, belonging to the technical field of oilfield chemistry. The plugging agent comprises the components: 30-50% of acrylamide, 20-40% of hexamethylenetetramine, 5-15% of phenol, 5-15% of tetraethylene pentamine and 5-15% of foaming agent. The aqueous solution with the mass ratio of 0.5-2% can be prepared in site and is injected into a well after being evenly dissolved, so that the plugging agent is used for plugging water in the oil well at the temperature of 90-150 DEG C. The plugging agent uses organic cross linker for cross bonding polymer to form gel foam under the condition of high temperature, so as to be resistant to the high temperature of 90-150 DEG C and have long period of validity in plugging water.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

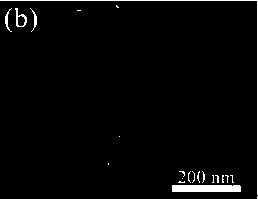

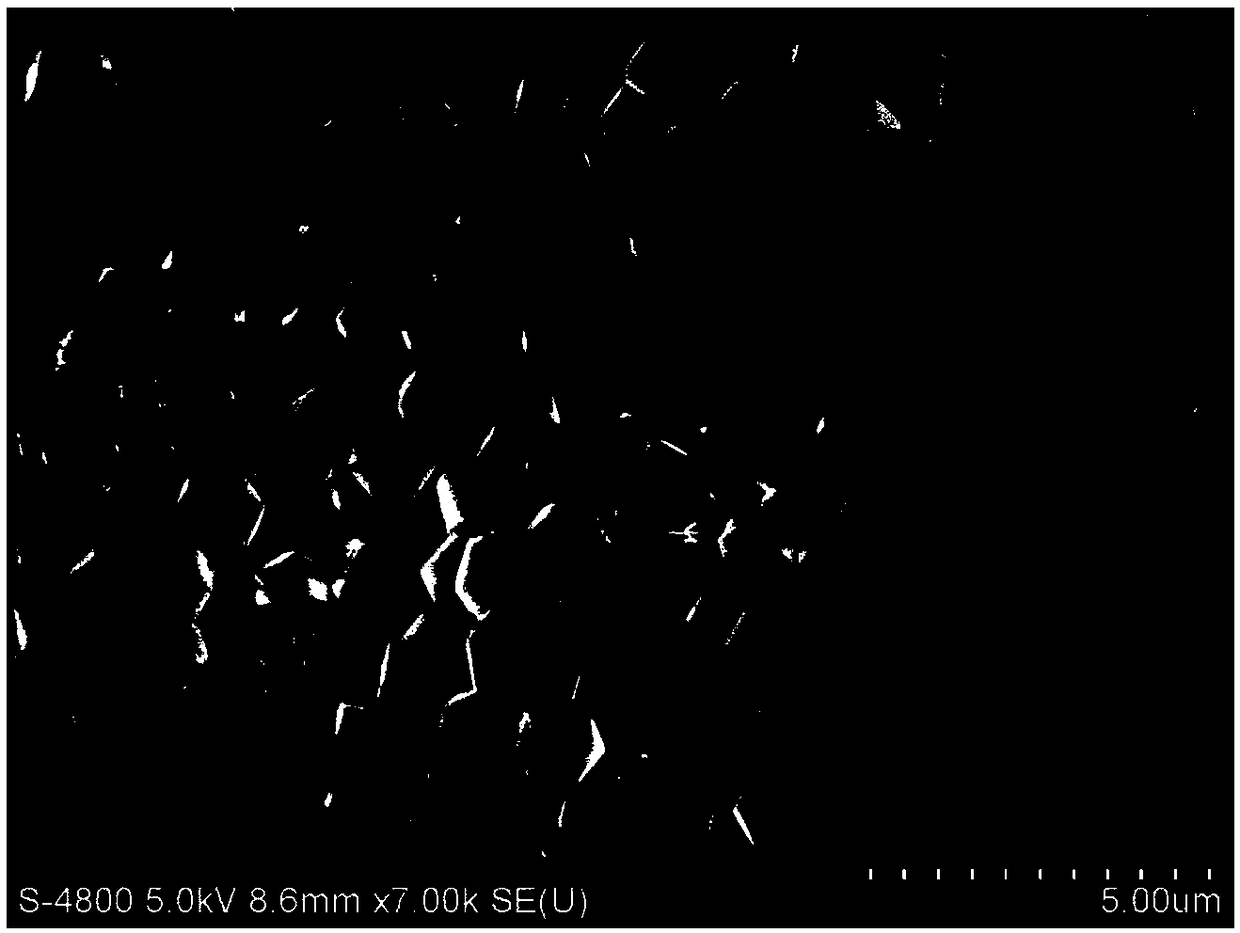

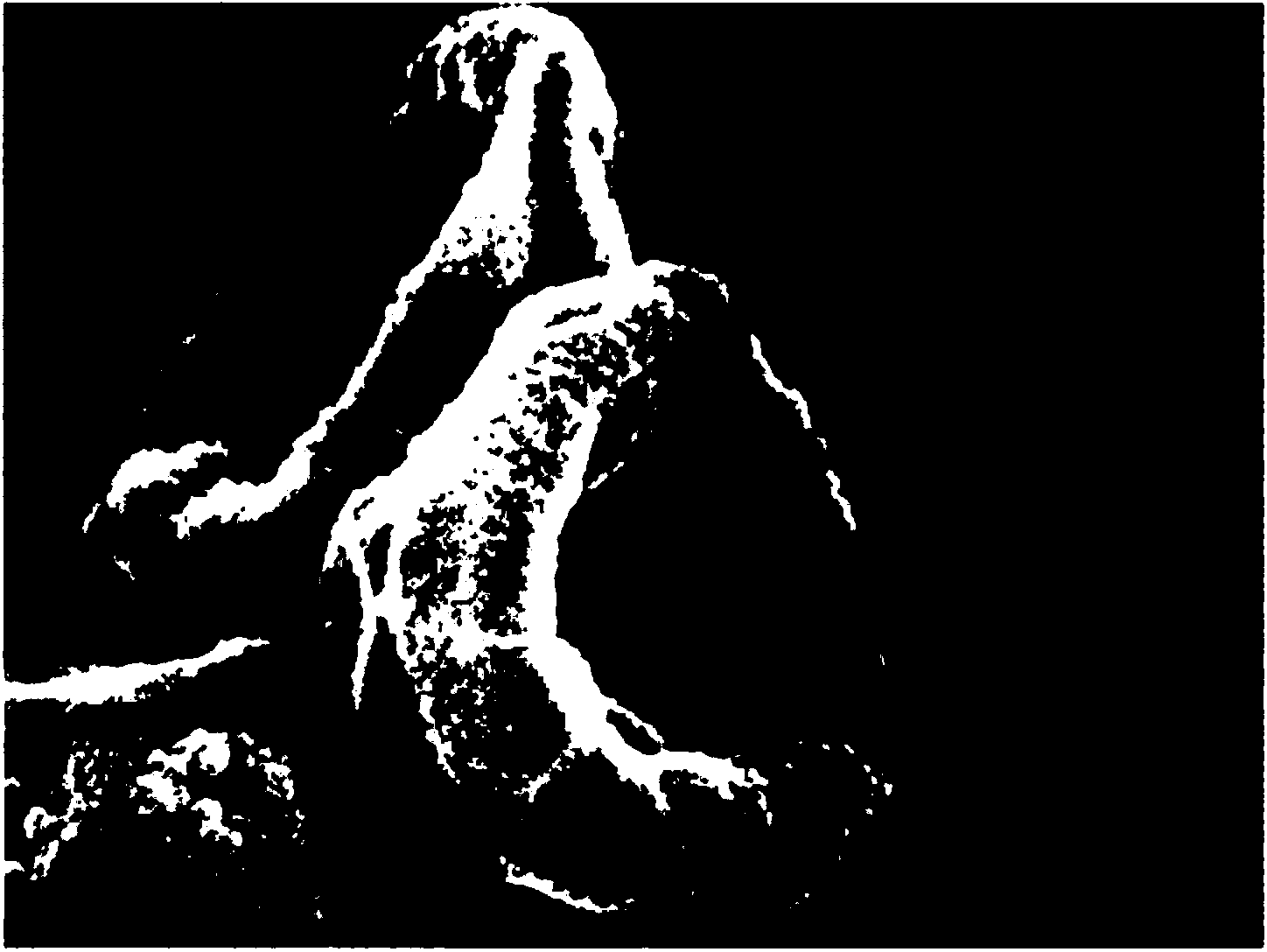

Continuous large-area zinc oxide nano-sheet and preparation method thereof

The invention relates to continuous large-area zinc oxide nano sheets and a preparation method thereof, belonging to the technical field of nano material. The preparation method comprises the following steps: building a micro-nano structure on a metal and metal oxide substrate as required; dispersing zinc nitrate and hexamethylenetetramine in deionized water by use of the hydrothermal synthesis method, and softly stirring for dissolution; subsequently, reacting at a constant temperature of 70 to 110 DEG C for 10 minutes to 10 hours, taking out the sample, cleaning and drying to obtain a continuous porous membrane consisting of zinc oxide nano sheets on the substrate. The thickness of the obtained zinc oxide nano sheets is between 1 to 100 nanometers, and the nano sheets are connected with each other on the substrate to form a porous structure, wherein the aperture of the porous structure is between 0.5 to 3 mu m and the total thickness of the porous zinc oxide layer is between 100 nm to 50 mu m. Such continuous zinc oxide porous membrane can form a free independent structure after the substrate is removed, and the application field thereof includes gas sensor, solar battery material, surface coating, nano photoelectric device and so on.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

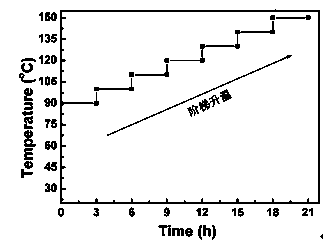

Preparation method of zinc-oxide nanorod array film

InactiveCN103397382AImprove UV Luminescence PerformanceHigh UV Luminescence PerformancePolycrystalline material growthAfter-treatment detailsNanogeneratorHexamethylenetetramine

The invention belongs to the technical field of semiconductor film preparation, and particularly relates to a preparation method of a zinc-oxide nanorod array film. The technical scheme adopted by the invention is as follows: the preparation method comprises the following steps of: (1) on the basis of adopting height (001)-oriented ZnO as a seed layer, putting the ZnO seed layer into an aqueous solution of zinc nitrate (Zn(NO3)2), polyethyleneimine (PEI) and hexamethylenetetramine (HMT) for epitaxial growth to obtain a (001) preferred-orientation ultralong ZnO nanorod array film; (2) carrying out fast annealing treatment on the film, and improving the photoluminescence performance of the ZnO array film. The technology has the advantages that the continuous growth of the ZnO nanorod at the temperature higher than 100 DEG C can be realized; due to the high-temperature growth condition, the crystallization quality of the nanorod is improved, the internal defects are obviously reduced; the zinc-oxide nanorod array film has excellent photoelectric performance, and is more conductive to being applied in photoelectric devices such as dye-sensitized solar batteries, ultraviolet detectors, field-effect transistors, light-emitting diodes and nanogenerators.

Owner:UNIV OF JINAN

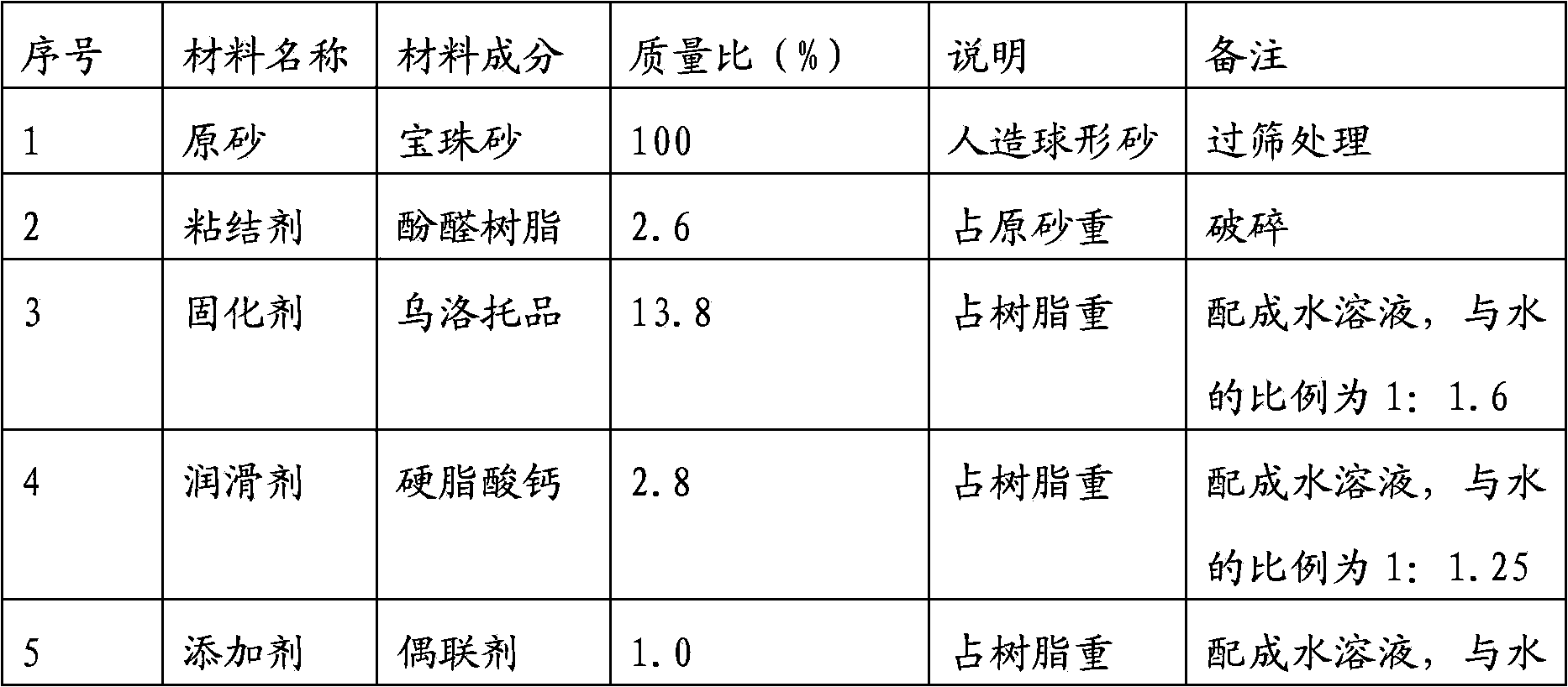

Production technology of precoated sand for selective laser sintering and quick molding technology

InactiveCN103567352AReduce intensityHigh strengthFoundry mouldsFoundry coresThermoplasticSelective laser sintering

The invention discloses a production technology of a precoated sand for a selective laser sintering and quick molding technology. The formula of the precoated sand comprises the following components: crude sands, a binding agent, a curing agent, a lubricant, and an addictive; wherein the crude sands are selected from a foundry sand with a particle size of 100 to 200 meshes, the binding agent is selected from a PF-1904 thermoplastic solid phenolic resin whose melting point is from 80 to 90 DEG C, the curing agent is selected from white or colorless crystal urotropine powder, the lubricant is selected from white calcium stearate powder, and the addictive is selected from silane colorless transparent liquid coupling agent KH-550. The production technology of the precoated sand for the selective laser sintering and quick molding technology adopts a fine and round foundry sand, selects a resin with a low melting point, reduces the addition amount of the resin, strictly controls the temperature when the binding agent and the curing agent are added, and adds a proper amount of addictive so as to manufacture a high strength and low gas evolution precoated sand, which is suitable for the selective laser sintering and quick molding technology.

Owner:GUANGXI YUCHAI MASCH CO LTD

High-efficiency solid pickling inhibitor for many metals

The invention belongs to the technical field of fine chemistry industry, and in particular relates to a high-efficiency solid pickling inhibitor for many kinds of metal of the field of industrial cleaning. The inhibitor is prepared from the following components by weight percent through crushing and mixing: 50 to 80% of rodine, 10 to 20% of hexamethylenetetramine, 10 to 20% of thiocarbamide, 5 to 10% of benzene azimide and 1 to 5% of surfactant. The invention has the advantages of synergistic effect, low use level and portability, and is suitable for many metals or alloys, including carbon steel, stainless steel, copper, zinc, aluminum, titanium and the like, thereby having high practical value.

Owner:KESHENG ENVIRONMENTAL PROTECTION TECH CO LTD

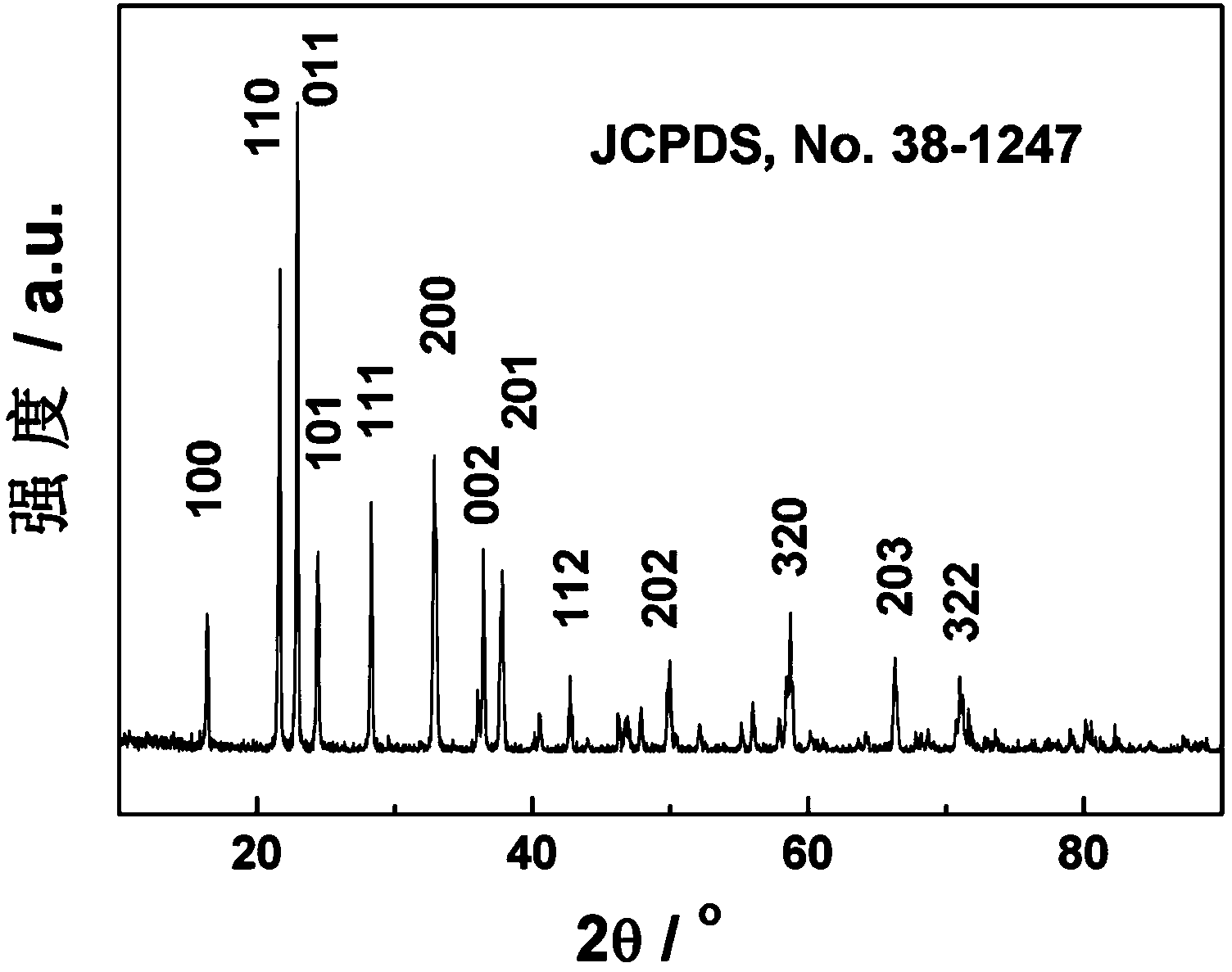

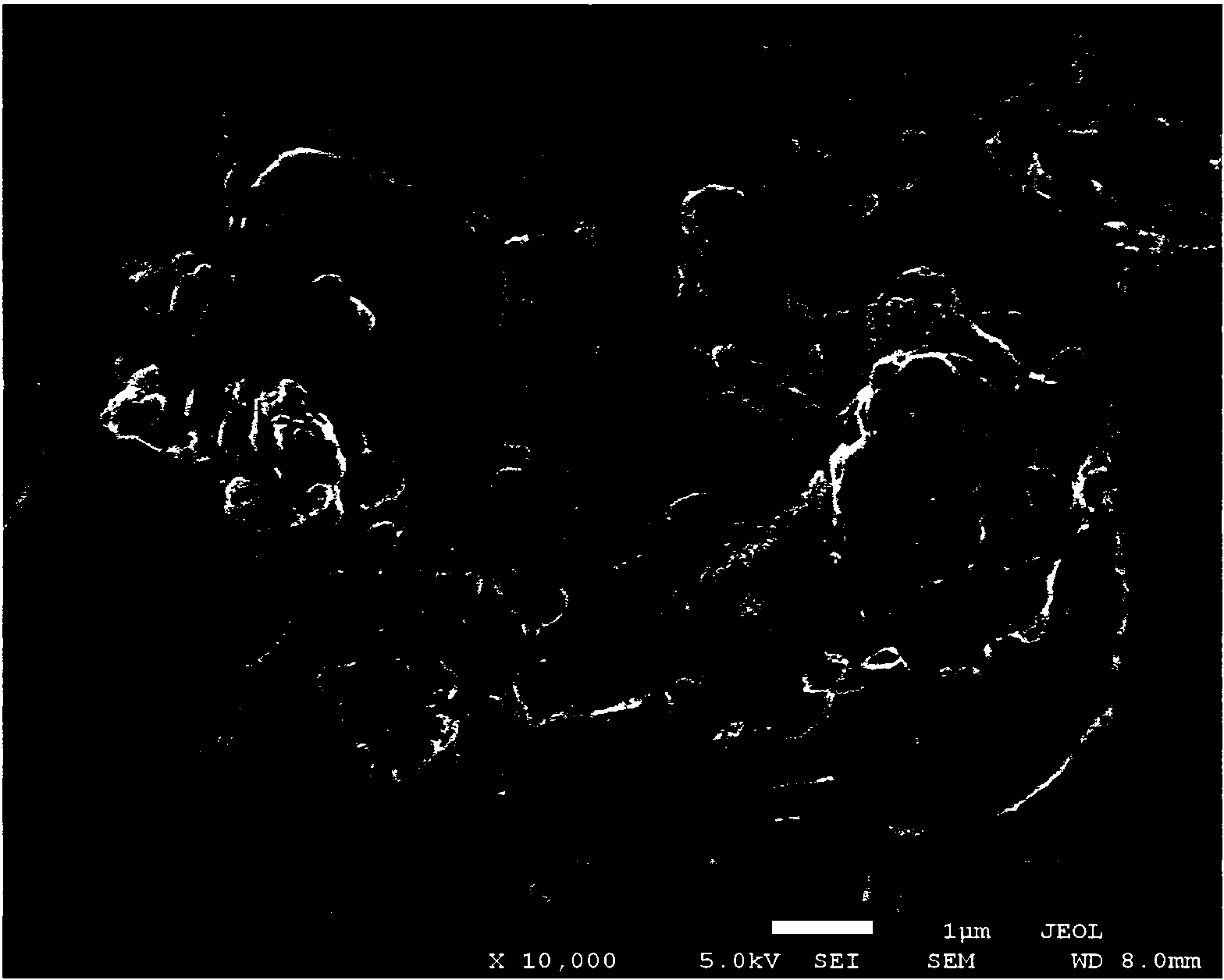

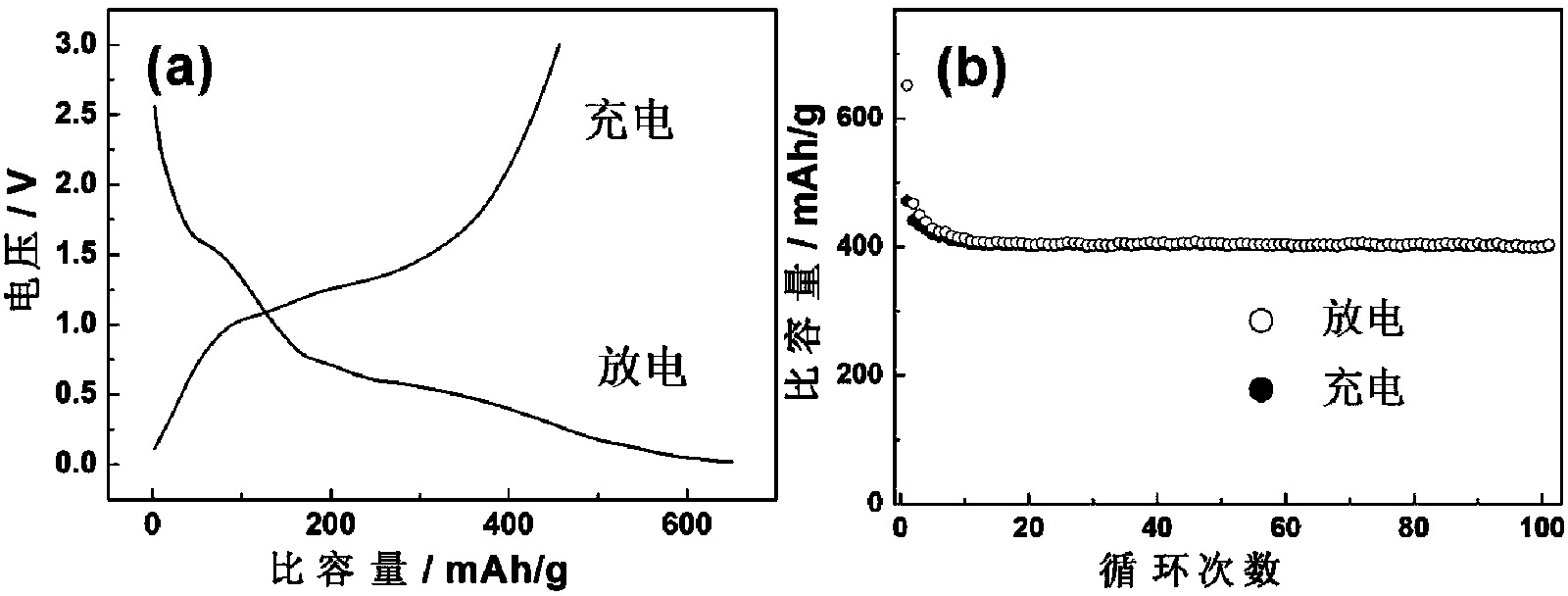

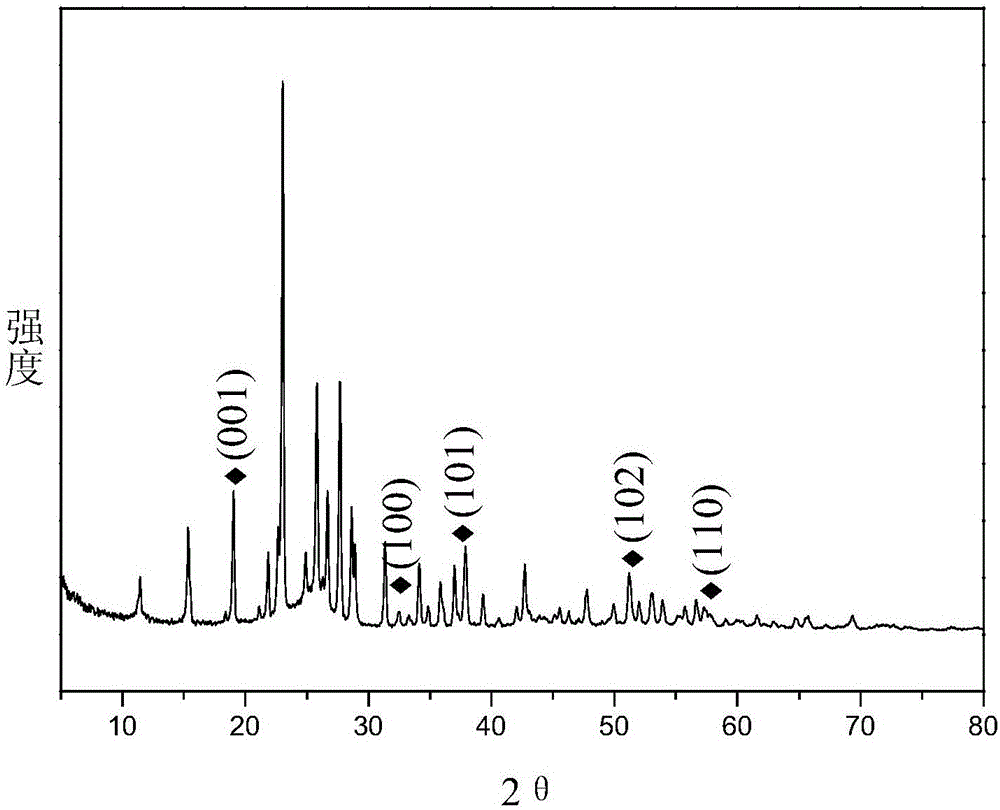

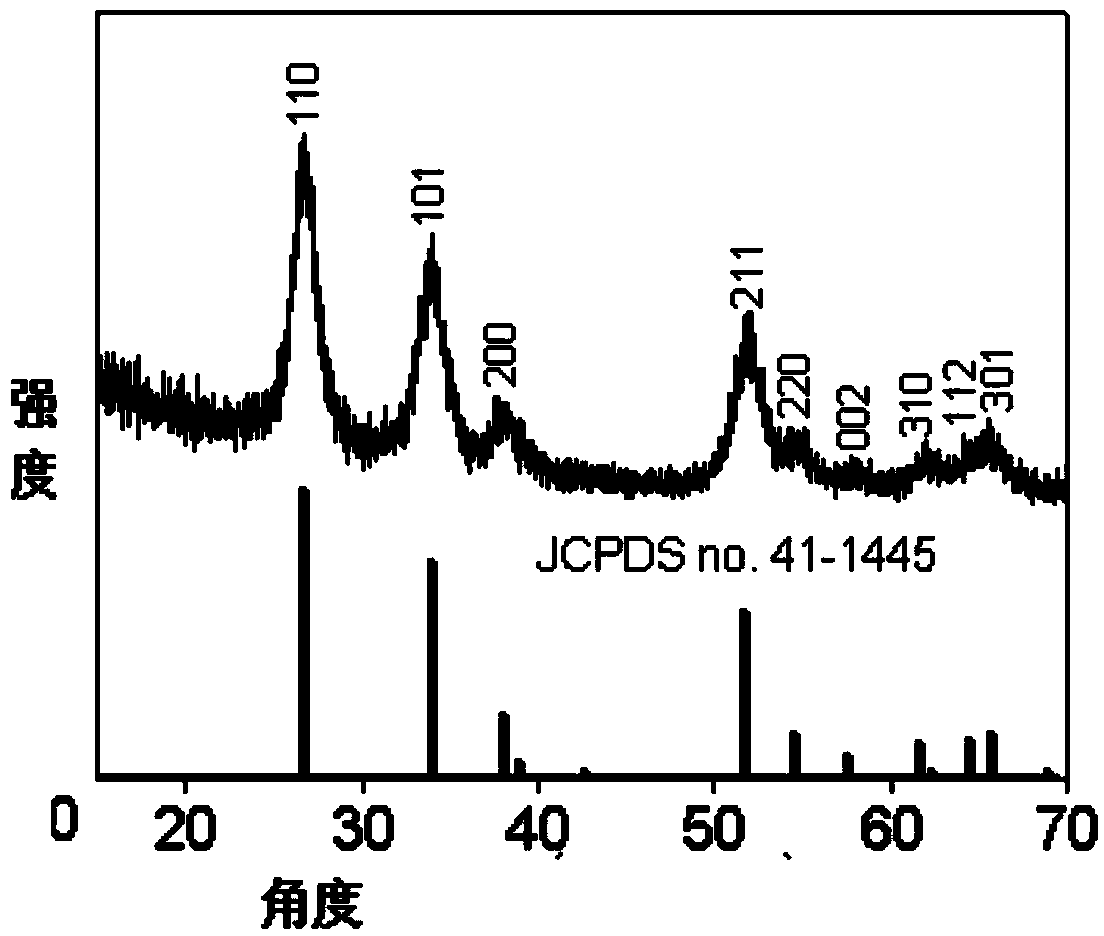

Lithium ion battery anode material Li3VO4 and preparation method thereof

The invention provides a Li3VO4 cathode anode material and a preparation method thereof, particularly a novel lithium ion battery anode material Li3VO4 prapared by carrying out hydrothermal reaction on vanadium pentoxide, lithium carbonate and hexamethylenetetramine used as precursors. The hydrothermal reaction is utilized to prepare an intermediate phase product, and the intermediate phase product is gradually subjected to solid-phase reaction while reaction energy is supplied by high temperature heating, thereby finally obtaining the Li3VO4 with favorable crystallinity. The first charge and discharge capacities of the Li3VO4 are respectively 523 and 423 mAh / g, and the charge and discharge capacities after 100 loops are still 398 mAh / g; and the grain size is uniform, and is less than 200nm.

Owner:CHINA THREE GORGES UNIV

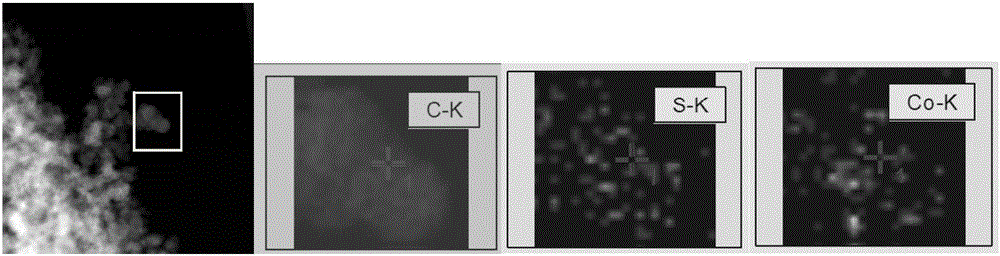

Metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material, and preparation method and application thereof

ActiveCN105118972AImprove cycle lifeHigh electrochemical redox activityMaterial nanotechnologyCell electrodesHexamethylenetetramineLithium sulfur

The invention discloses a metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material, and a preparation method and an application thereof. The preparation method comprises the following steps: uniformly grinding sublimed sulfur and conductive carbon black, and carrying out heat treatment fusion for uniform mixing to obtain sulfur and carbon black composite powder; and dissolving metal salt and hexamethylenetetramine in water, adding polyvinylpyrrolidone and the sulfur and carbon black composite powder, stirring, carrying out ultrasonic treatment to obtain a black mixed liquor, carrying out hydrothermal treatment on the black mixed liquor at 80-100DEG C for 2-5h, cooling, centrifuging, and drying to obtain the material. The metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material prepared in the invention inhibits the shuttle effect of polysulfide, improves the conductive performance of sulfur, and improves the cycle performances of batteries. The metal hydroxide coated carbon and sulfur lithium-sulfur battery positive electrode material is used to make a lithium-sulfur positive electrode, the lithium-sulfur positive electrode is applied in a lithium-sulfur battery, and the lithium-sulfur battery has high capacity and protruding cycle performances.

Owner:杭州亿昇达新能源科技有限公司

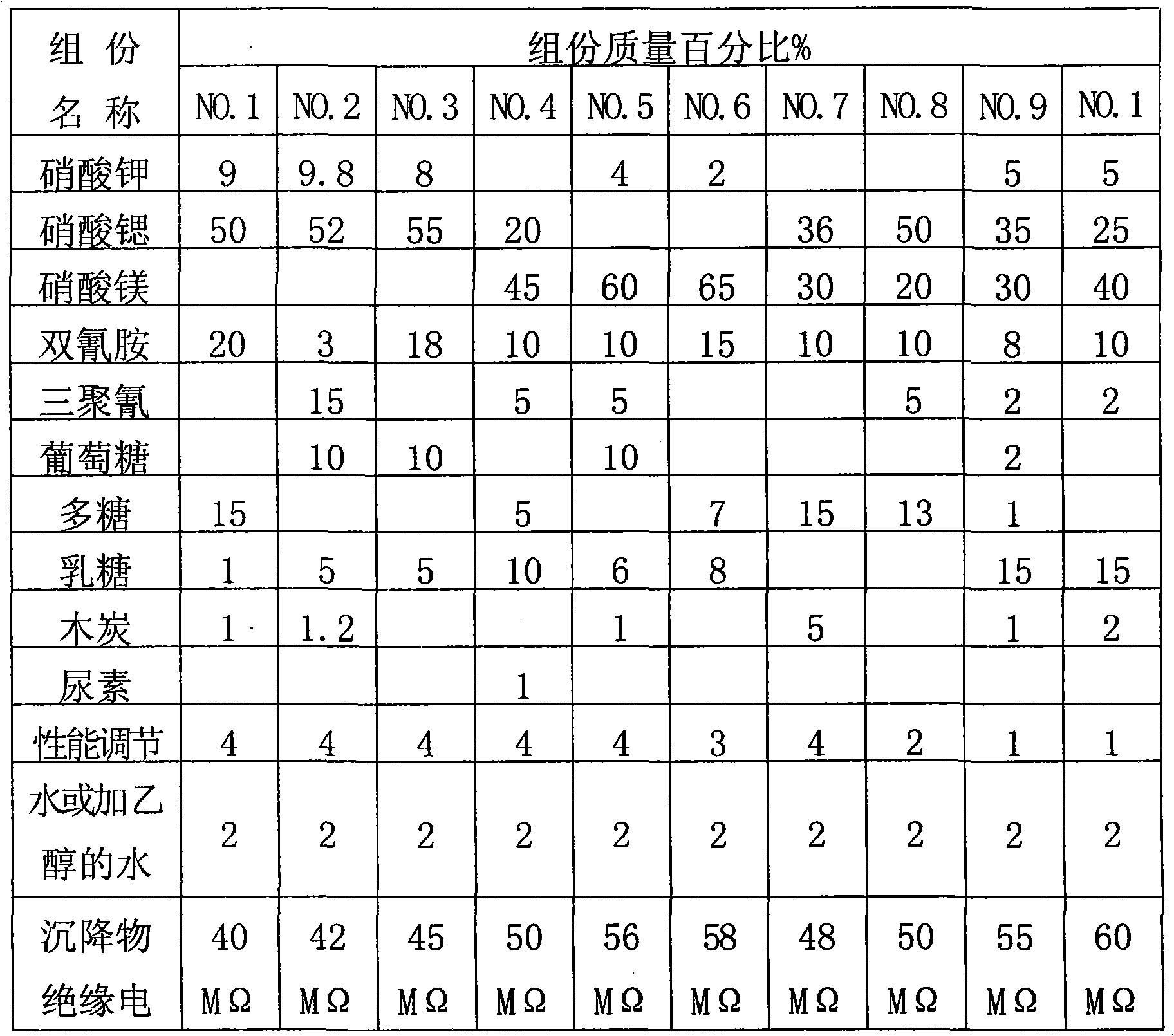

Compound type aerosol extinguishing agent

InactiveCN101862517ALow fire extinguishing concentrationImprove corrosion resistanceFire extinguisherSucroseNuclear chemistry

The invention discloses a compound type aerosol extinguishing agent comprising the following components in percentage by weight: 30-75 percent of oxidizing agent, 20-50 percent of reducing agent, 2-15 percent of performance regulating agent and no more than 2 percent of binding agent. The oxidizing agent is prepared by matching any two or three matched components selected from potassium nitrate, strontium nitrate and magnesium nitrate; the reducing agent is prepared by matching two or more components selected from polyhexose, glucose, starch, sorbitol, xylitol, lactose, dicyandiamide, melamine, carbamide and sucrose; the performance regulating agent is prepared by matching one or more component selected from carbon powder, light magnesium carbonate, magnesium stearate, aluminium nitrate, hexamethylenetetramine, aluminium oxide, magnesium oxide and light metal oxide; and the binding agent is prepared by matching water or 20-30 percent of ethanol added into the water. In the invention, production raw materials have a wide source and low cost, can be constantly obtained and are safe and reliable, and burnt residues have no toxicity and good environmental protection performance.

Owner:湖南省金鼎消防器材有限公司

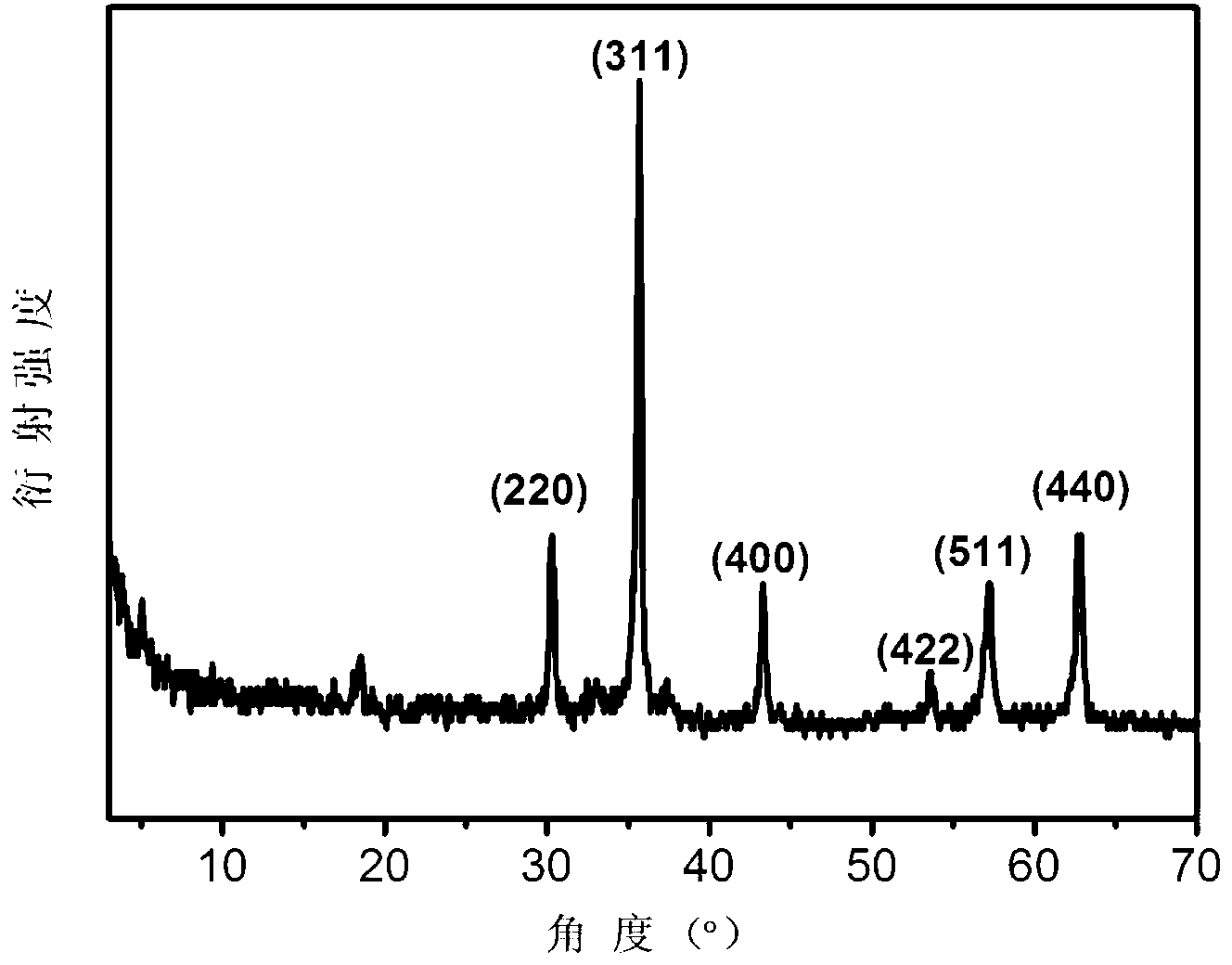

Preparation method of spinel-type porous high entropy oxide material

ActiveCN108821351AAchieving a stoichiometric ratioReduce energy consumptionMaterial nanotechnologyNickel compoundsHexamethylenetetramineSynthesis methods

Belonging to the field of inorganic oxide powder materials, the invention discloses a preparation method of a spinel-type porous high entropy oxide material. The method is low temperature combustion synthesis method. Specifically, a metal nitrate is adopted as the metal source, one of or a mixture of several of citric acid, ethylenediamine tetraacetic acid, hexamethylenetetramine and glucose is adopted as the fuel, by controlling the concentration of the metal salt raw materials, the fuel type and adding amount, the combustion improver type and adding amount, and the ignition way, the granularity, morphology and other characteristics of the spinel-type transition metal high entropy oxide (CoCrFeMnNi)3O4 nanopowder can be regulated. The preparation method adopts liquid phase compounding toensure molecular level uniform mixing of the raw materials, and the product achieves stoichiometric ratio. At the same time, the method has the advantages of energy saving, high production efficiency,green and environmental protection, no need for complicated post-treatment and the like. The high entropy oxide powder prepared by the method provided by the invention has high purity and uniform particle size distribution.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

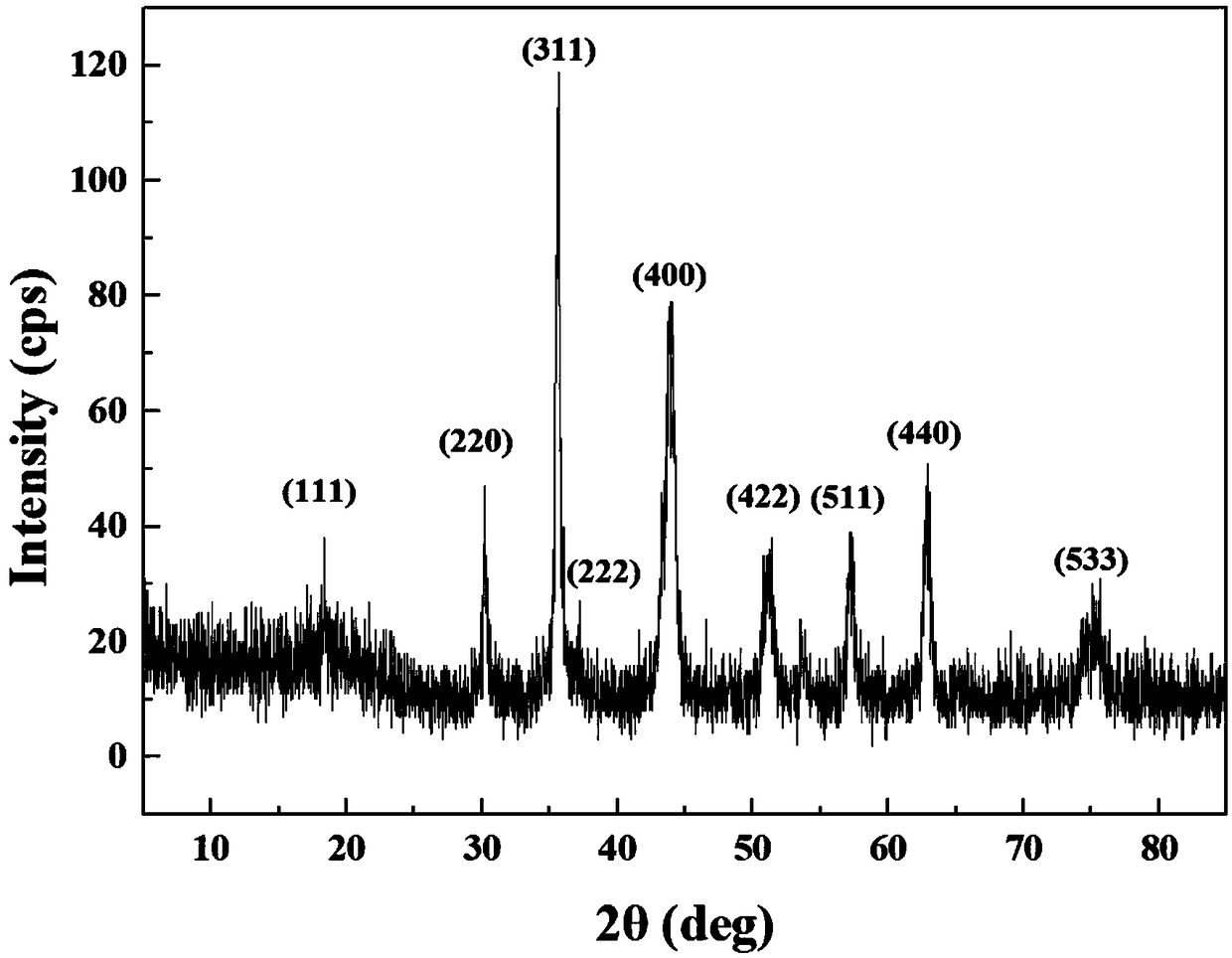

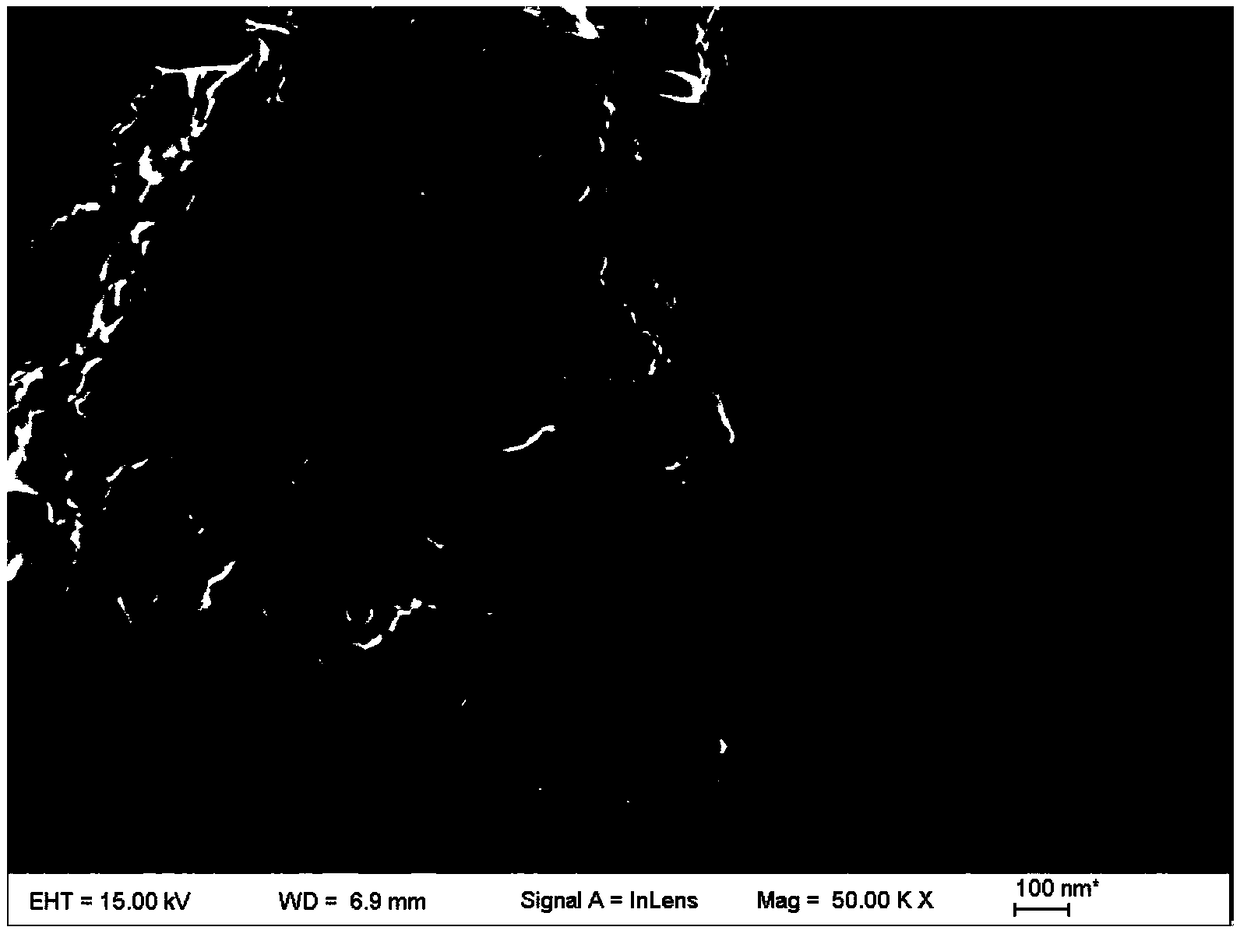

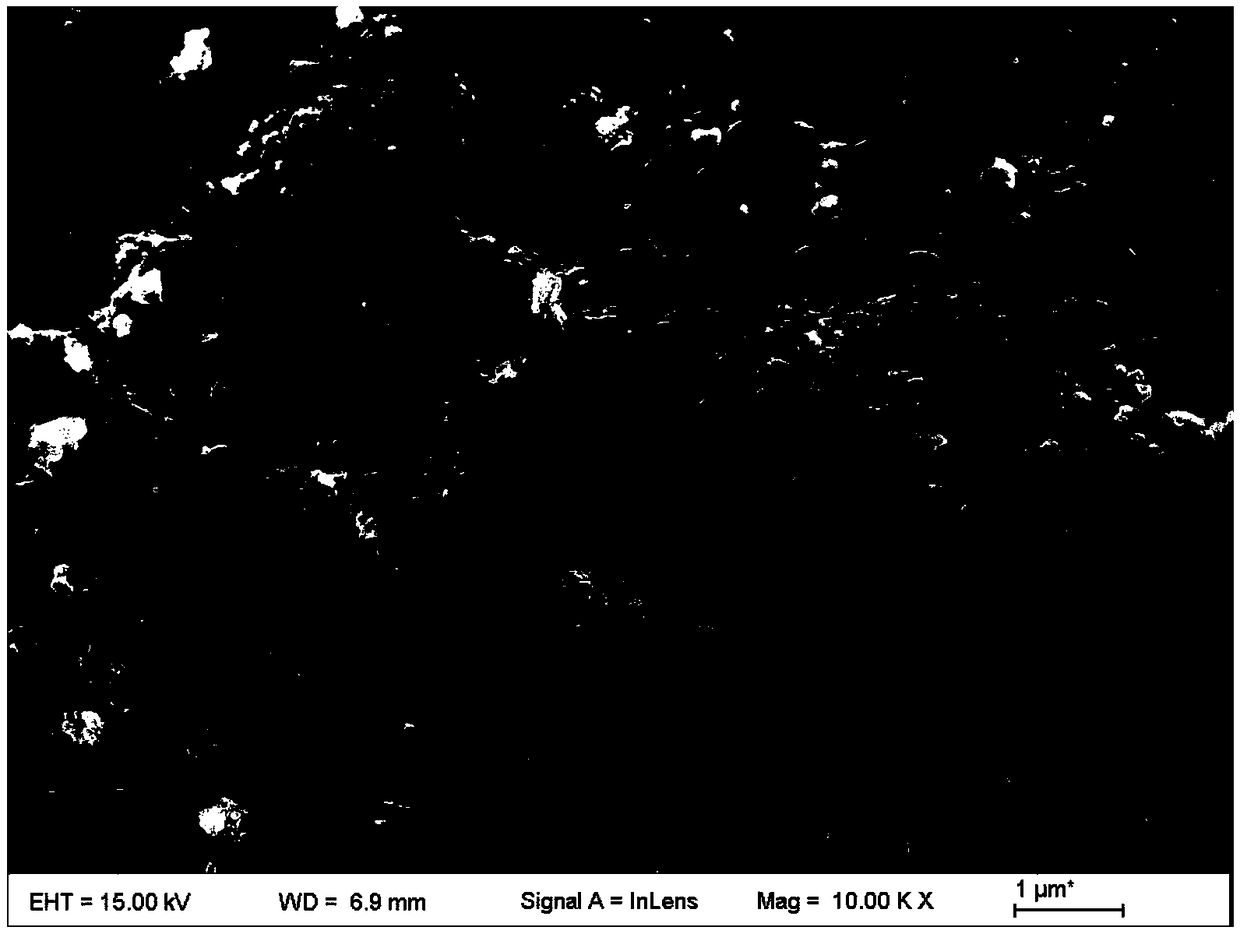

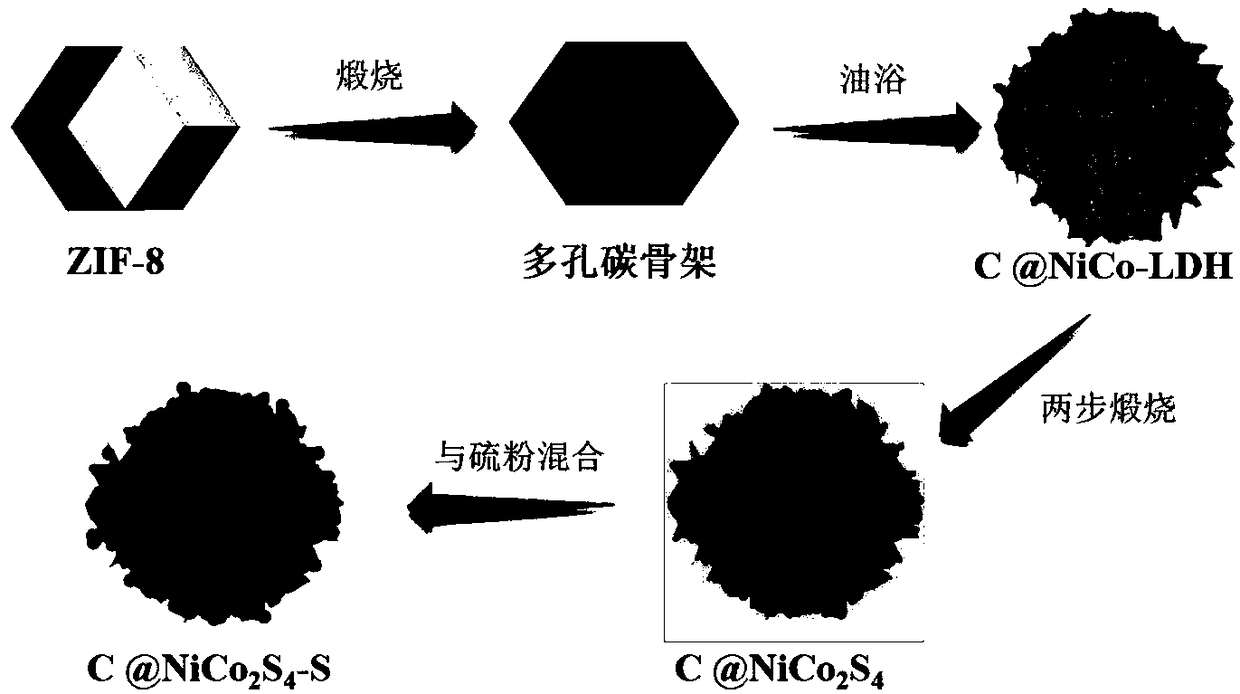

Preparation method of NiCo2S4-coated porous carbon skeleton for positive electrode material of lithium-sulphur battery

ActiveCN109378449AFacilitated DiffusionImprove conductivityCell electrodesLi-accumulatorsPorous carbonHexamethylenetetramine

The invention relates to a preparation method of a NiCo2S4-coated porous carbon skeleton for a positive electrode material of a lithium-sulphur battery. The preparation method comprises the followingsteps: preparing a nitrogen-doped porous carbon skeleton; preparing a C@NiCo-LDH composite material: adding the nitrogen-doped porous carbon skeleton prepared in the last step, cobalt nitrate hexahydrate, nickel nitrate hexahydrate, urotropin and sodium citrate according to the molar ratio of (10-15): (60-120): (30-60):30:10 into deionized water, after stirring uniformly, carrying out oil bathingat a temperature of 70-90 DEG C, carrying out condensation and returning for 3-6 hours, centrifuging reaction products using the deionized water and alcohol, drying to obtain the NiCo-LDH-coated porous composite material which is marked as C@NiCo-LDH; preparing the C@NiCo2S4 composite material; and loading sulfur on the C@NiCo2S4 composite material.

Owner:TIANJIN UNIV

Gas self-production system used for plug removal and energy increase of oil-water well and application method thereof

ActiveCN103333670ALess equipment required for preparationSimple processDrilling compositionHexamethylenetetraminePotassium nitrite

The invention relates to a gas self-production system used for plug removal and energy increase of an oil-water well and an application method thereof. The gas self-production system comprises, by weight, 3-10% of urea, 5-25% of a nitrite, 5-25% of an activator and 40-85% of water. The nitrite is one of sodium nitrite, ammonium nitrite and potassium nitrite. The activator is one of methyl formate, ammonium amidosulfonate, ammonium-monochloracetat, hexamethylenetetramine and formaldehyde. When the gas self-production system is used, the above materials are mixed at ambient temperature under ambient pressure, and injected into oil-bearing strata having a temperature higher than 50 DEG C, so as to remove plug, increase energy and increase enhance rate. The gas self-production system can be applied for plug removal and energy increasing of low-pressure low-energy wells in an oil field scattered reserve unit.

Owner:CHINA PETROCHEM & CHEM JIANGSU OILFIELD BRANCH +2

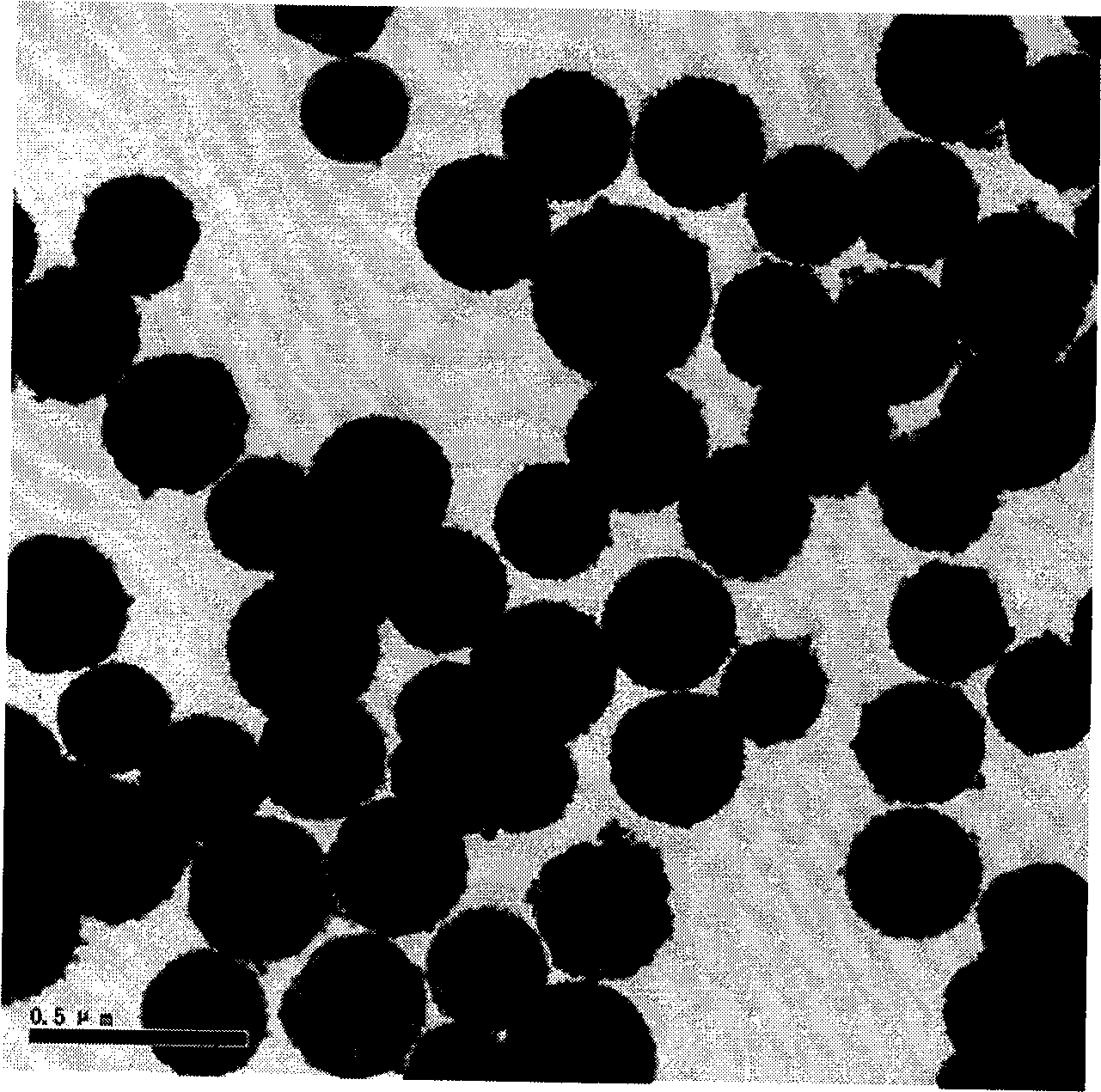

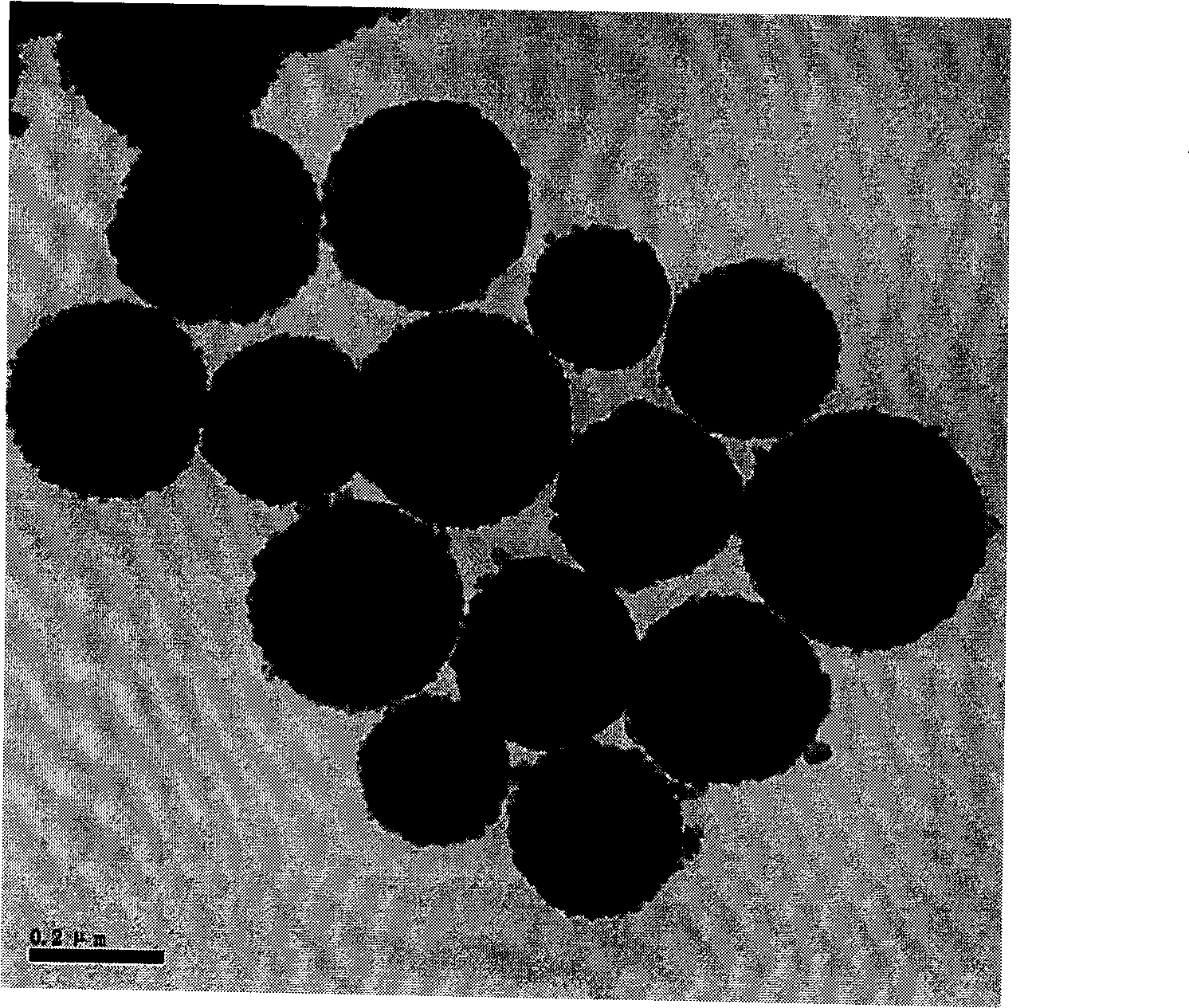

Preparation and use of cerium oxide / silicon oxide compound abrasive

ActiveCN101475791ACoated evenlyGood monodispersityOther chemical processesHexamethylenetetramineCerium

The invention relates to a method for preparing a ceria / monox compounded abrasive, and application of the compounded abrasive. The method uses monodisperse spherical monox as a kernel of a coating type compounded abrasive, hexamethylenetetramine (HMT) as a precipitator and cerium salt as a raw material, and adopts an even precipitation method process to synthesize the ceria / monox compounded abrasive. Through the optimization of process parameters, such as the use amount ratio of monox master particles to the cerium salt, the molar ratio of the HMT to the cerium salt, and reaction and calcination temperature, the method controls the covering amount, the shape and the distribution state of ceria particles on the surface of the monox, thereby preparing the ceria / monox compounded abrasive of which the nanometer-level ceria particles evenly cover on the surface of the monox and which has good monodispersity; the method does not need complex equipment; and the needed chemical materials have less varieties, cheap prices and good experiment repeatability. The ceria / monox compounded abrasive is prepared into polishing slurry for chemical mechanical polishing of a gallium arsenide chip so as to obtain the polishing surface with the roughness in sub-nanometer magnitude and further improve polishing speed, reduce polishing pass and improve efficiency.

Owner:溧阳常大技术转移中心有限公司

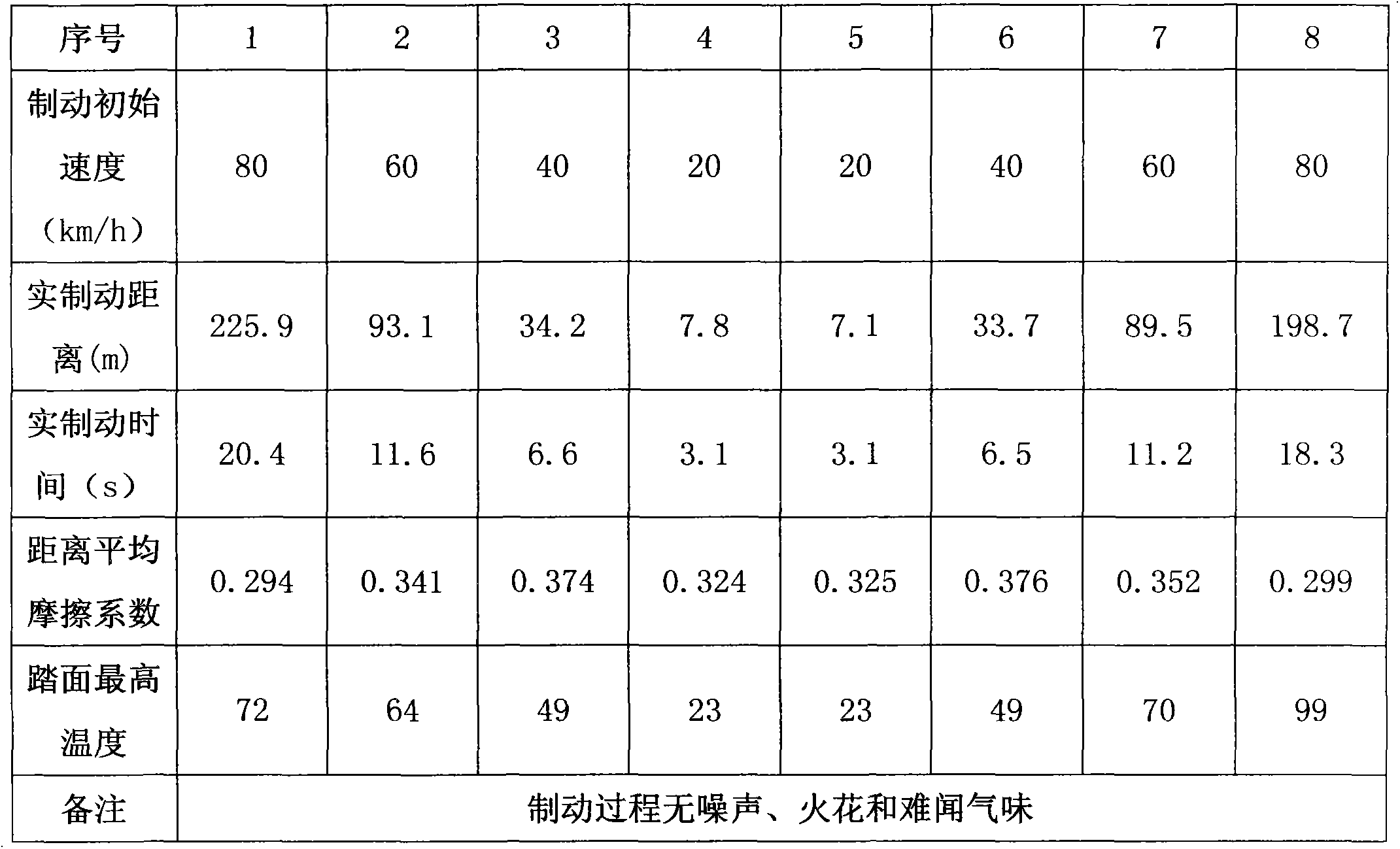

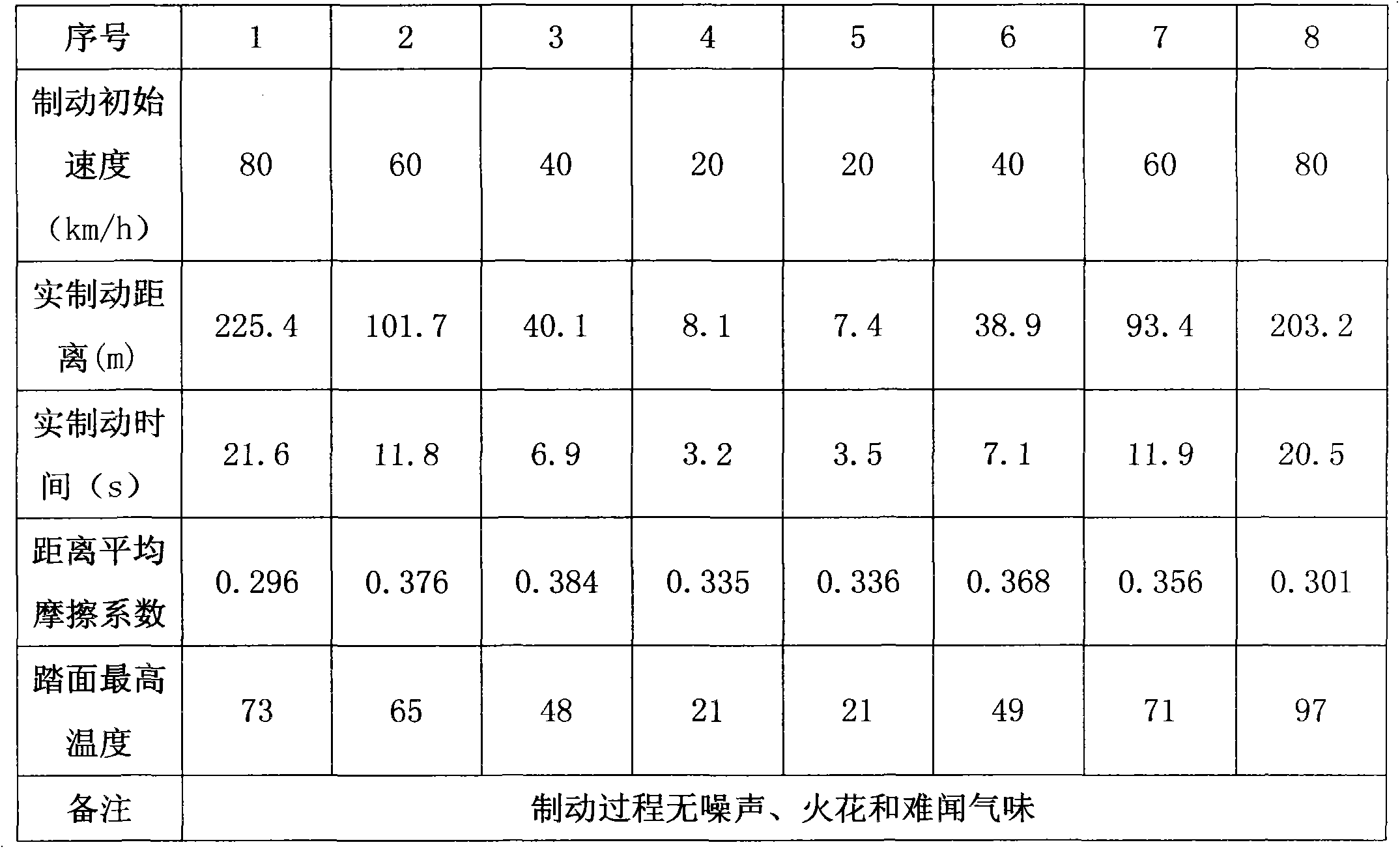

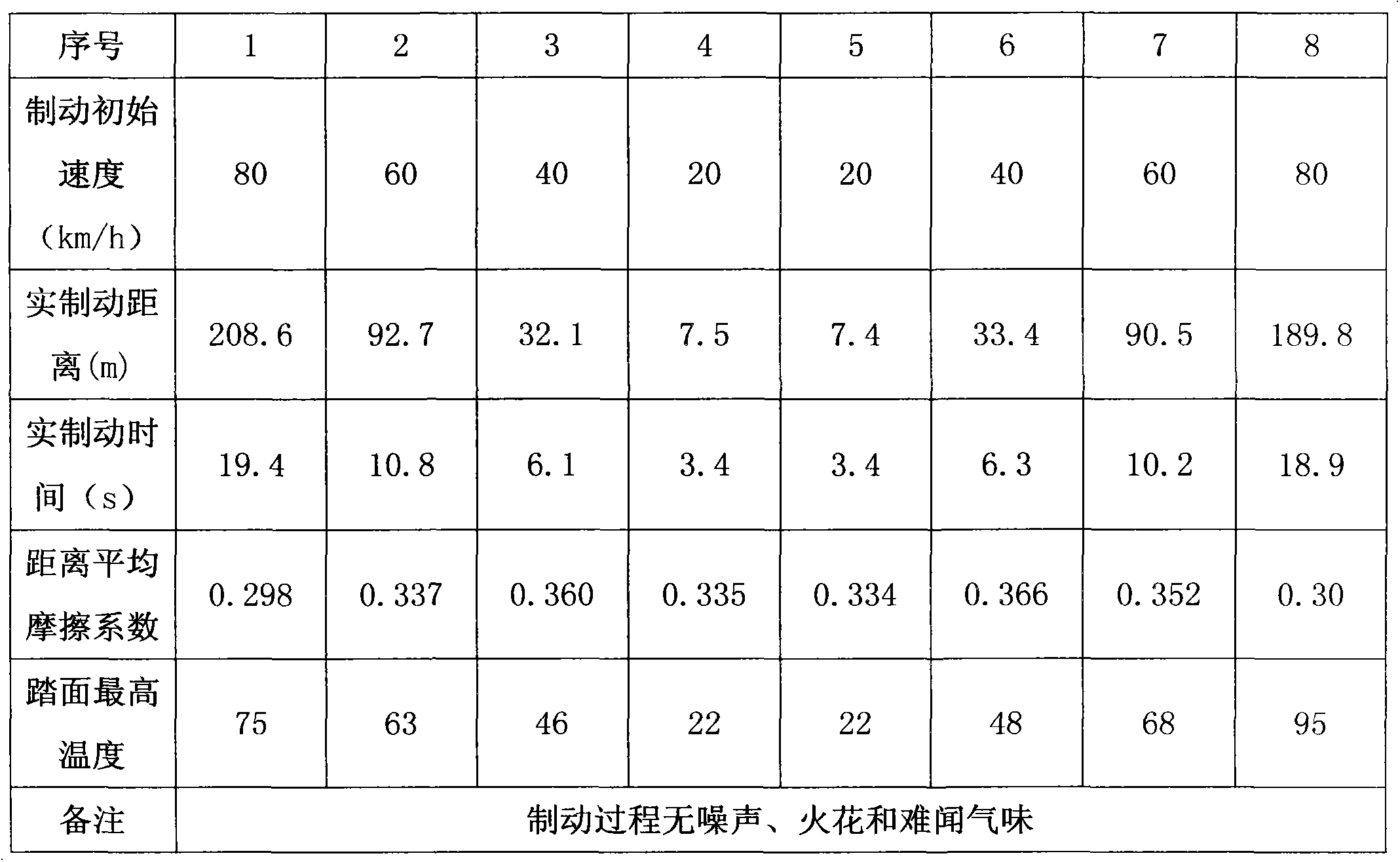

Composition brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893AImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

The invention relates to a composition brake shoe for an urban rail vehicle and a manufacturing method of the composition brake shoe for the urban rail vehicle. The composition brake shoe comprises the following components of, by weight, 10-15 parts of butadiene-acrylonitrile rubber, 10-20 parts of cashew nut shell oil modified phenolic resin, 6-10 parts of basalt fibers, 4-8 parts of carbon fibers, 8-15 parts of steel fibers, 5-8 parts of sepiolite fibers, 2-6 parts of hexamethylenetetramine, 5-8 parts of iron oxide powder, 5-7 parts of crystalline flake graphite, 5-7 parts of chromite, 6-9 parts of barium sulfate, 3-6 parts of potassium feldspar and 5-8 parts of frictional powder. The manufacturing method of the composition brake shoe is a dry method production technology, and comprises the steps of steel back production, abrasive blasting processing, shaping, burdening, mixing, hot compacting, heat processing, subsequent processing, finished product forming and inspection. The manufactured composition brake shoe is inspected through the 1:1 rack test, is excellent in friction and abrasion resisting performance, stable in brake performance, safe and environmentally friendly, and solves the problem that the friction coefficient drops too fast under the conditions of damascene of the composition brake shoe for the urban rail vehicle, hot cracks, hot spots and rain and snow weather.

Owner:GUANGXI UNIV FOR NATITIES

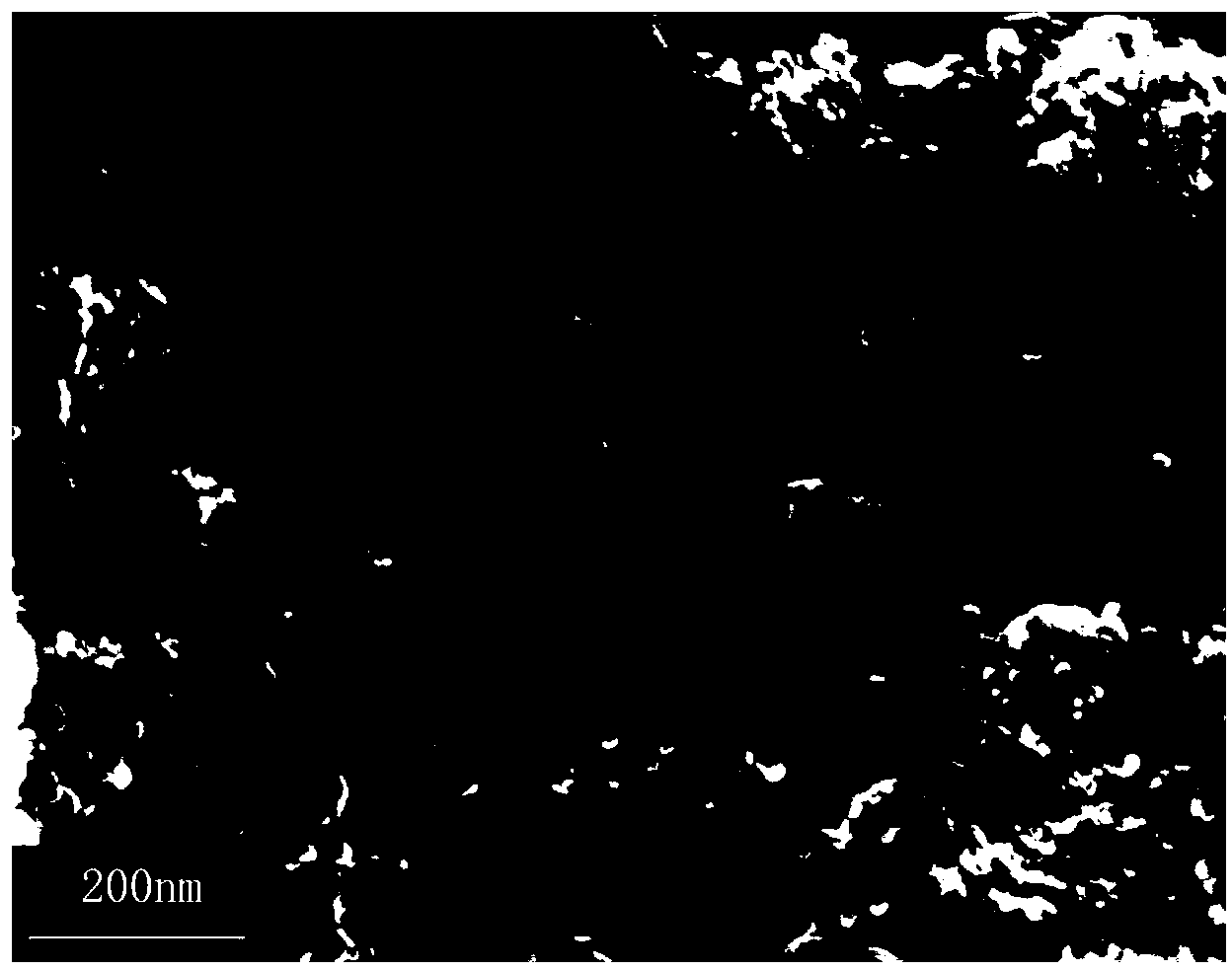

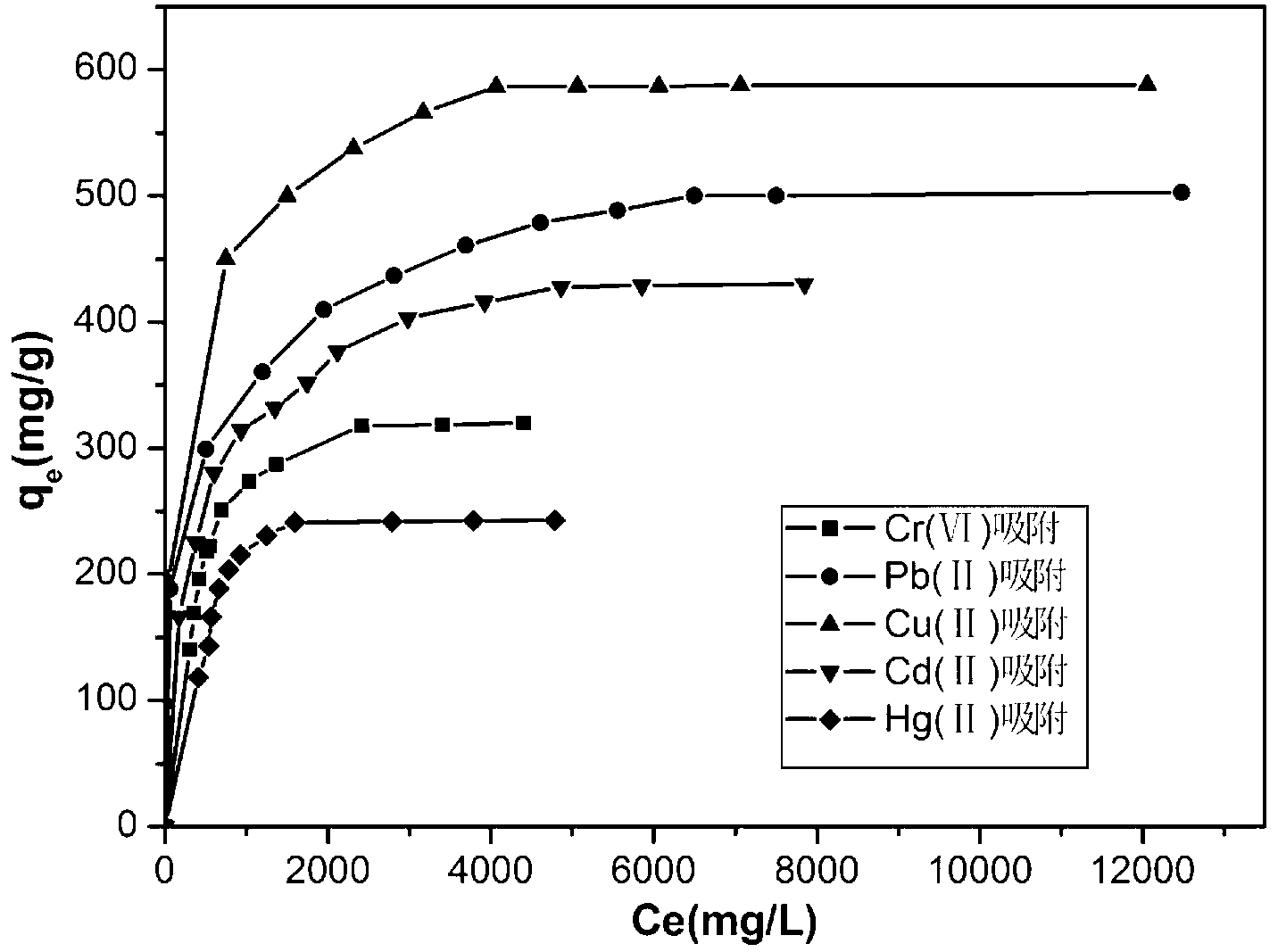

Ferrite/graphene composite adsorbent and preparation and using methods thereof

InactiveCN103191699AMagneticHighly uniform dispersionOther chemical processesWater/sewage treatment by sorptionSorbentHexamethylenetetramine

The invention discloses a ferrite / graphene composite adsorbent and preparation and using methods thereof, and belongs to the technical field of adsorbents. The ferrite MFe2O4 / graphene composite adsorbent is prepared by taking hexamethylenetetramine as a precipitator and a reducing agent and decomposing the hexamethylenetetramine under a hydrothermal condition to generate alkaline and reducing substances by one step. M is Mn, Ni, Co and Zn; the mass percentage of the ferrite is 40-70 percent; ferrite nano particles are dispersed on the sheet type graphene surface; the particle sizes of the ferrite nano particles are 5-30 nanometers; and the specific surface area of the ferrite / graphene composite adsorbent is 60-300 m<2> / g. The ferrite / graphene composite adsorbent has the advantages that the shortcomings of high reaction temperature, non-uniform reactants and low product structure and composition uniformity of the conventional ferrite composite metal oxide prepared by solid phase reaction are overcome; an effect of adsorbing heavy metal ions Cr<6+>, Pb<2+>, Cu<2+>, Cd<2+> and Hg<2+> in water is achieved; and a wide application prospect is realized.

Owner:BEIJING UNIV OF CHEM TECH

Plugging agent for deep profile control and water plugging and preparation method thereof

ActiveCN102816558AImprove stabilityGel forming time is controllableDrilling compositionHexamethylenetetramineSulfite salt

The invention relates to a plugging agent for deep profile control and water plugging and a preparation method thereof. The plugging agent comprises the following raw materials in percentage by weight: 0.10-0.30% of partially hydrolyzed polyacrylamide, 0.09-0.20% of potassium dichromate, 0.15-0.30% of sodium sulfite, 0.08-0.3% of hexamethylenetetramine, 0.06-0.24% of phenol, 0.04-0.14% of ammonium chloride and the balance of water. The invention also provides the preparation method of the plugging agent. The variation of the gelatinization strength of the plugging agent system along with time is in an obvious double-step trend. Thus, the plugging agent can be effectively prevented from leaking into a low-permeability layer in the injection process, and can effectively plug a high-permeability stratum when the plugging agent reaches the deep stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Adhesive removing agent as well as preparation and using methods thereof

InactiveCN105199877AEasy to useEfficient removalOrganic non-surface-active detergent compositionsCleaning using liquidsKeroseneHexamethylenetetramine

The invention discloses an adhesive removing agent as well as preparation and using methods thereof. The adhesive removing agent comprises turpentine oil, rosin water, 120# gasoline, kerosene, benzene, methylbenzene, dimethylbenzene, acetone, urotropine, oxalic acid, ethyl acetate, butyl acetate and ethyl alcohol. The turpentine oil, the rosin water, the 120# gasoline and the kerosene are evenly mixed firstly, the benzene, the methylbenzene and the dimethylbenzene are sequentially added, the mixture is evenly mixed, the urotropine is added after complete dissolution, then the oxalic acid, the ethyl acetate and the butyl acetate are added sequentially, the acetone and the ethyl alcohol are added finally, and the mixture is evenly mixed. A plastic layer on the surface of an object is removed by hand, the adhesive removing agent is sprayed on the surface of the adhesive object and soaks the object, the adhesive is wiped with rag, and the object is washed with clear water. The adhesive removing agent can effectively remove the adhesive object and thoroughly remove adhesive objects such as signboards, adhesive tapes and the like, the using method is simple, heating is not required, and the adhesive removing agent can be used through brushing or spraying at the normal temperature and is short in washing time, good in removal effect, environment-friendly and efficient.

Owner:朱建权

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

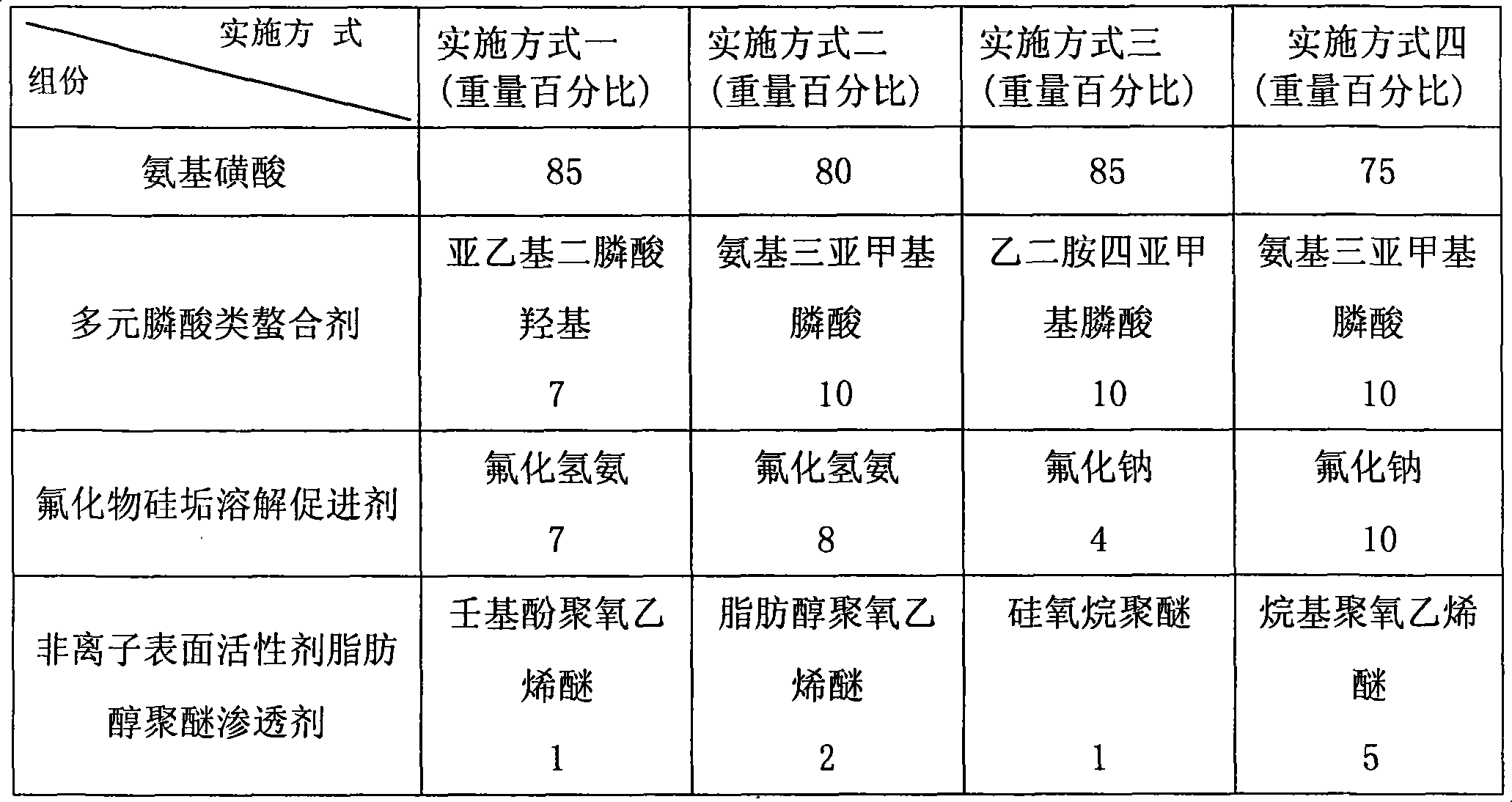

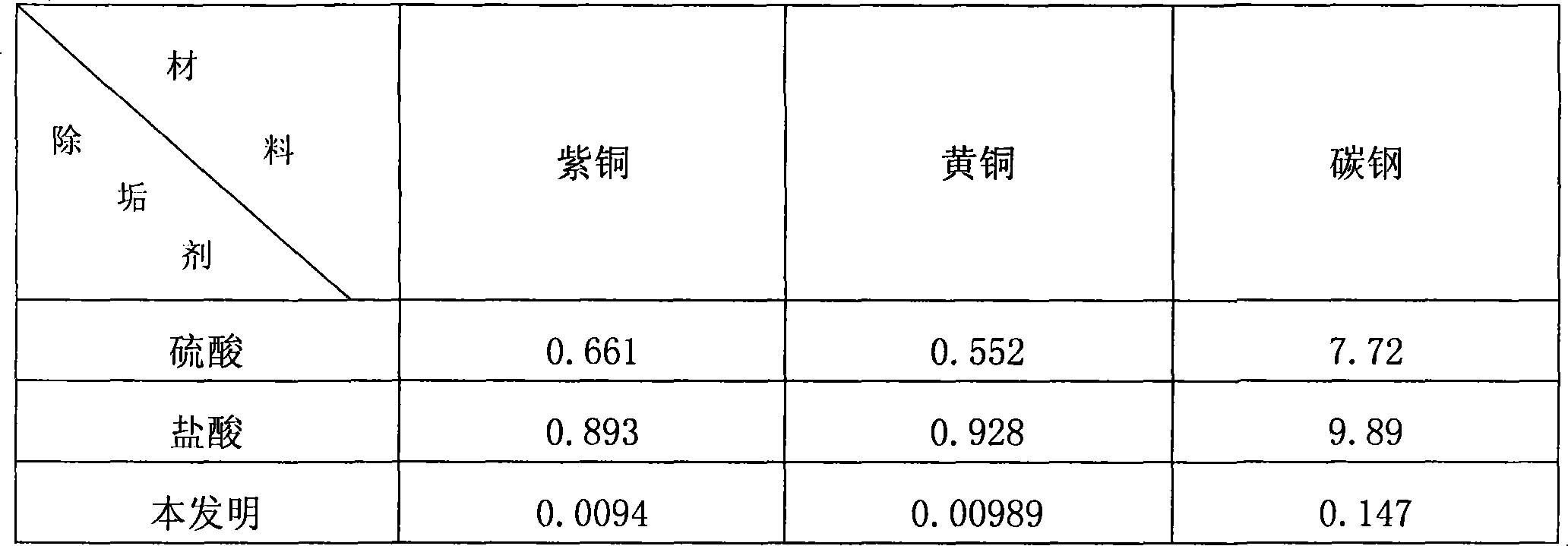

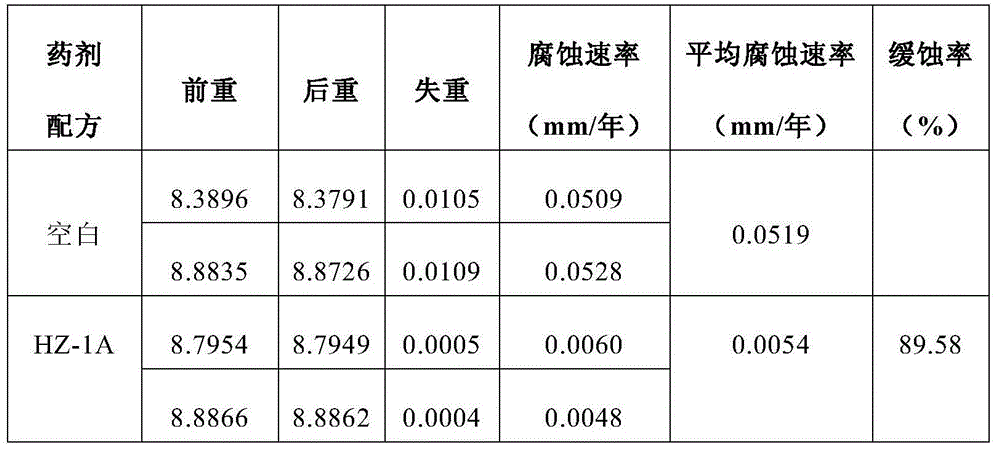

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

Salt tolerant corrosion and scale inhibitor for underground oil-gas wells and preparation method thereof

ActiveCN104650838APrevent penetrationEnhanced inhibitory effectDrilling compositionBorehole/well accessoriesPyridiniumThiourea

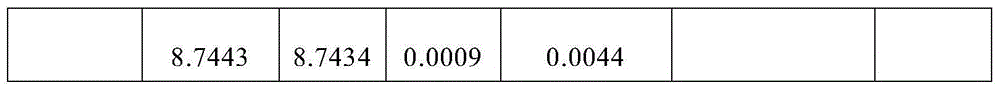

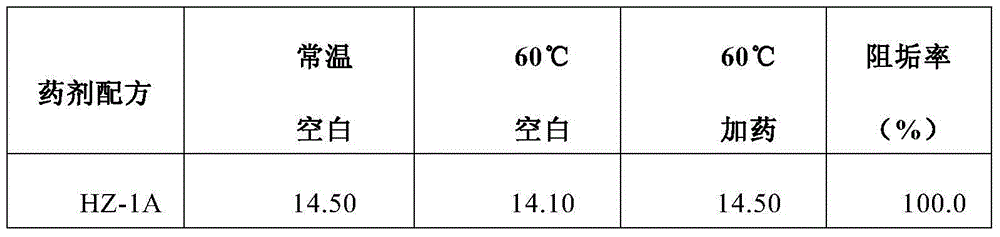

The invention relates to a salt tolerant corrosion and scale inhibitor for underground oil-gas wells and a preparation method thereof. The salt tolerant corrosion and scale inhibitor is composed of an oxazoline derivative, thiourea, cetyl pyridinium chloride, dodecyl dimethyl benzyl ammonium chloride, amino trimethylene phosphonic acid, hydroxyethylidene diphosphonic acid, hexamethylenetetramine, and methanol. The corrosion and scale inhibitor has very strong salt resistance, and under high salinity conditions (100000-200000mg / L), has a significant inhibiting effect on metal corrosion, and the corrosion inhibition rate can reach more than 80%. The organic phosphonic acid molecular structure of the reagent contain a double bond structure, the structure and the calcium ions and magnesium ions in water can chelate to form a stable complex to be adsorbed on seed crystal surface active sites, thereby inhibiting crystal normal growth. With significant scale inhibiting effect and a scale inhibiting rate up to 94%, the product is suitable for inhibiting corrosion and scaling phenomena of oil-gas well rods and pipes containing carbon dioxide, hydrogen sulfide and other complex media conditions under high salinity.

Owner:PETROCHINA CO LTD

Preparation method of hollow bowl-shaped carbon-based metal oxide composite material

ActiveCN104241602AIncrease packing densityHigh packing density, greatly improving the volumetric energy density of the batteryCell electrodesSecondary cellsHexamethylenetetramineOxide composite

The invention discloses a preparation method of a hollow bowl-shaped carbon-based metal oxide composite material. The preparation method comprises the following steps: preparing a precursor of the hollow bowl-shaped carbon-based metal oxide composite material through a precipitation method; carrying out calcination carbonation to obtain a hollow bowl-shaped carbon-based metal oxide composite lithium storage active material; preparing component and structure controllable composite by adjusting the ratio among a template, metal salt, hexamethylenetetramine and citrate, so as to realize the purpose of controllable electrochemical performance. The preparation method has the characteristic that a hollow bowl-shaped polystyrene micro ball template is adopted and hollow bowl-shaped carbon-based metal oxide composite materials of various components are prepared through a common method; not only does the material of the shape reserve all the advantages of a hollow structure material, more importantly, the problem that the space utilization rate of the hollow material is low, is solved; the filling density of the active material is improved; the volume energy density is extremely improved; thus the energy density, capacity, cycle performance and magnification performance of a single cell are improved.

Owner:XI AN JIAOTONG UNIV

Preparation method of lightweight heat-proof phenolic resin radical foam charcoal

ActiveCN101041432AControl and decision structureControl and determine pore size distributionIndirect heating destructive distillationFoaming agentOrganic solvent

The invention discloses a preparing method of lightweight heat-proof phenol resin group foam carbon, which comprises the following steps: making thermoplastic phenol resin as base-material; fetching hexamethylenetetramine as hardener; adding foaming agent and hardener; dissolving evenly with organic solvent at normal temperature; decanting into open container carefully; putting the container on the example shelf; putting into high temperature autoclave; leading into high-purity N2; pressurizing and keeping at 0.5-2.0MPa; heating to 200-300 deg.c through temperature-program and foaming; hardening; getting phenol resin group foam carbon solidifying forerunner body; using graphous graphite powder and pulverized coke compound as charring heat conducting medium; heating to 800-1200 deg.c in the high temperature retort; getting phenol resin group foam carbon.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing collagen sugar

InactiveCN101270061AReduce lossHigh reaction yieldOrganic compound preparationAmino-carboxyl compound preparationGlycineAcetic acid

The present invention discloses a preparation method of glycine. In the preparation method, chloroacetic acid and ammonia are used as raw materials; urotropine is used as the catalyst of the reaction; low-carbon alcohol solvent is used as a reaction medium; organic amine is added into the reaction system to be used as an acid binding agent; after the reaction is completed, the glycine with high content can be prepared through filtration. The preparation method solves the problems of the solvent that can not be recycled, serious solvent consumption, high cost, low yield, serious three-waste pollution and so on in the prior art. And the preparation method is suitable for the industrial production of the glycine.

Owner:CHINA AGRI UNIV

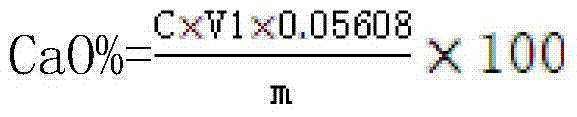

Method for determining calcium oxide and magnesium oxide in iron slag grains

ActiveCN103760158AReduce adsorptionEasy to separateMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationSlagHexamethylenetetramine

The invention provides a method for determining calcium oxide and magnesium oxide in iron slag grains. The determination method comprises the following steps: weighing a sample; heating and dissolving by using acid; adding perchloric acid until the perchloric acid is fumed at a wet salt state; cooling, adding a 20% hexamethylenetetramine solution to adjust the pH (Potential of Hydrogen) value to 7-8, and preserving the temperature; adding a 1% copper reagent, diluting by water and filtering, wherein a filtering solution is a solution to be detected; separately taking the filtering solution, and mixing with the water; adding 1:1 triethanolamine and adjusting the pH to be more than 12 by using 20% potassium hydroxide; adding a calcium carboxylic acid indication agent; titrating by using an EDTA (Ethylene Diamine Tetraacetic Acid) standard solution and calculating the mass percent of the calcium oxide according to a formula shown in the specification; separately taking the filtering solution and mixing with the water in a ratio of 1:1, wherein the amount of the filtering solution is the same as that in the step 4; adding the 1:1 triethanolamine and adding an ammonia buffering solution with the pH of 10; adding a 1% chromium black T indication agent and titrating by using the EDTA standard solution; and calculating the mass percent of the magnesium oxide according to a formula shown in the specification. The method is short in flow and high in speed, and the aims of simplicity, rapidness and accuracy are realized.

Owner:SHENWU TECH GRP CO LTD

Neutral blockage removing agent composition used for oilfield mechanical recovery well and preparation method thereof

ActiveCN104194757AGood compatibilityGood miscibilityDrilling compositionSodium acetateActivated attapulgite

The invention relates to a neutral blockage removing agent composition used for a mechanical recovery well in an oilfield. The neutral blockage removing agent composition is prepared from the following components in parts by weight: 16-20 parts of polyepoxysuccinic acid amine, 7-12 parts of hydroxyethylidene dipllosphate sodium, 21-25 parts of divinyl pentaacetic acid amine, 20-25 parts of hydroxyl ammonium acetate, 12-16 parts of activated attapulgite, 21-25 parts of ammonium persulfate, 9-12 parts ofdicyclohexyl sulfobutanedioate sodium, 7-9 parts of butyl lactate, 0.2-0.3 part of vanadium pentoxide, 5-8 parts of straight chain sodium dodecylbenzenesulfonate, 10-14 parts of nitrilotriacetic acid sodium salt, 4-7 parts of urotropin and 0.1-0.3 part of glycerin fatty acid ester. The neutral blockage removing agent composition is suitable for scale removal and blockage removal of an oil pumping unit well and a screw pump well, can effectively control the reaction speed of the blockage removing agent and the scale of the oil pumping unit well and the scaled screw pump well, and prevent the falling-off of big scale residues to result in the secondary blockage of the mechanical recovery well and an oil recovery pump thereof, has high blockage removal speed, is neutral and is free of corrosion; the waste liquid for blockage removal does not need to be discharged onto the ground to be subjected to sewage treatment, the blockage removal time does not exceed 24 hours, and the effect of safe and corrosion-free blockage removal is achieved.

Owner:GANSU HEIMA PETROCHEM ENG

Polypropylene hollow fiber ultrafiltration membrane coated with polymer composite coating

ActiveCN105080361AImprove antibacterial propertiesHigh strengthAntifouling/underwater paintsUltrafiltrationEpoxyFiber

The invention relates to a polypropylene hollow fiber ultrafiltration membrane coated with a polymer composite coating. The polypropylene hollow fiber ultrafiltration membrane comprises a water inlet surface and a water outlet surface which are respectively coated with a coating; the coating on the water inlet surface comprises the following raw materials: tricresyl phosphate, dioctyl phthalate, a modified polysiloxane polymer, polyether-ether-ketone (PEEK), methenamine and the like; and the coating on the water outlet surface comprises the following raw materials: allyl polyoxy alkyl epoxy ether, pentaerythritol, polyethylene glycol lauric acid diester, polyoxyethylene alkylamine, nano silver and the like. The polypropylene hollow fiber ultrafiltration membrane is capable of increasing the retention rate for macromolecular organic matter and emulsified oil, so that the COD removal rate of sewage is greatly increased, the electrostatic effect on the surface of the membrane is changed, the adsorption for contaminants of the surface of the membrane is prevented, the membrane can be continuously used for a long time under the condition of high membrane flux, and the service life of the membrane is prolonged. The addition of the nano silver effectively improves the antibacterial mildew properties of the membrane.

Owner:广州市纳清环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com