Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

467results about How to "Solve cleaning problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

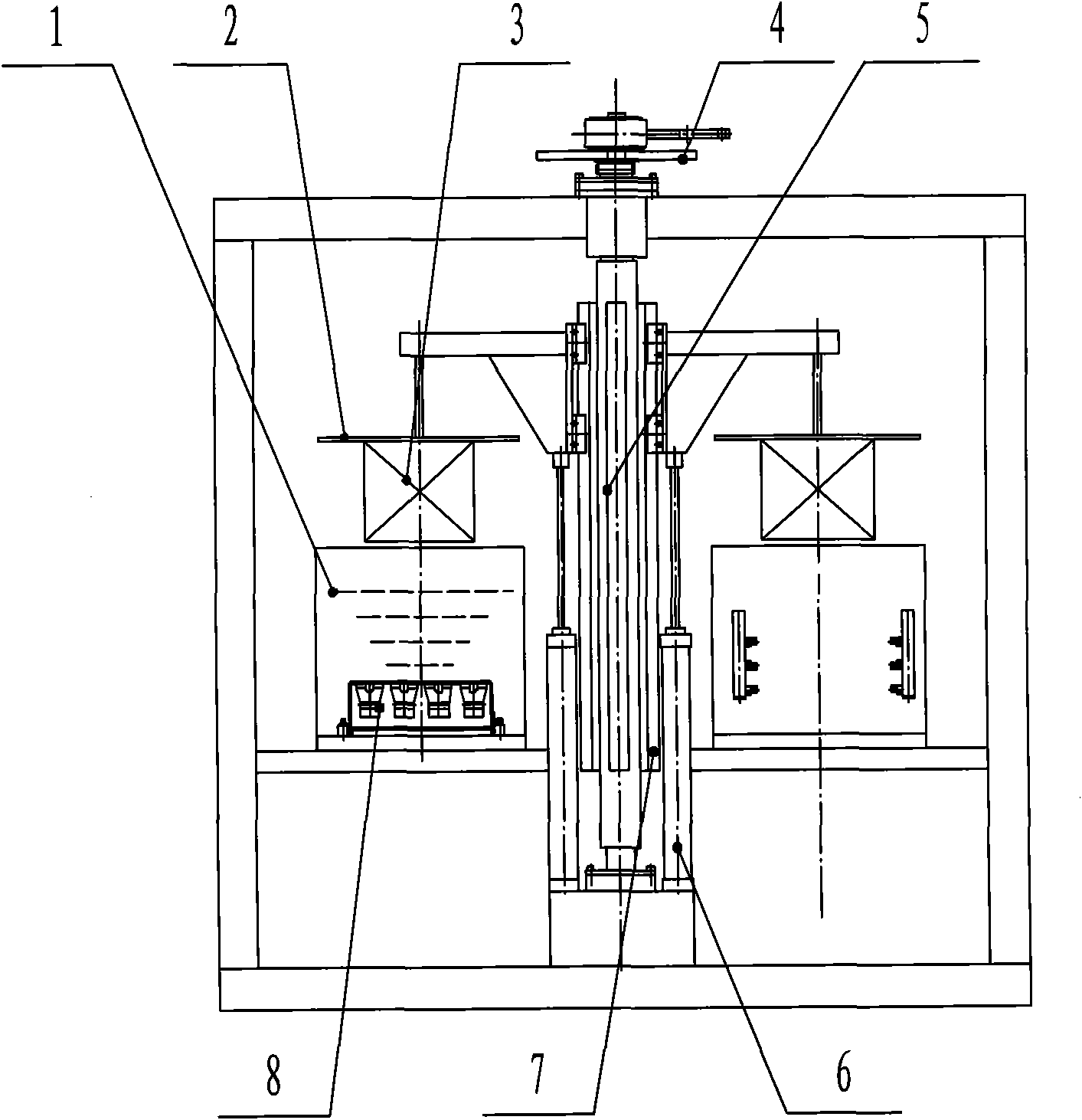

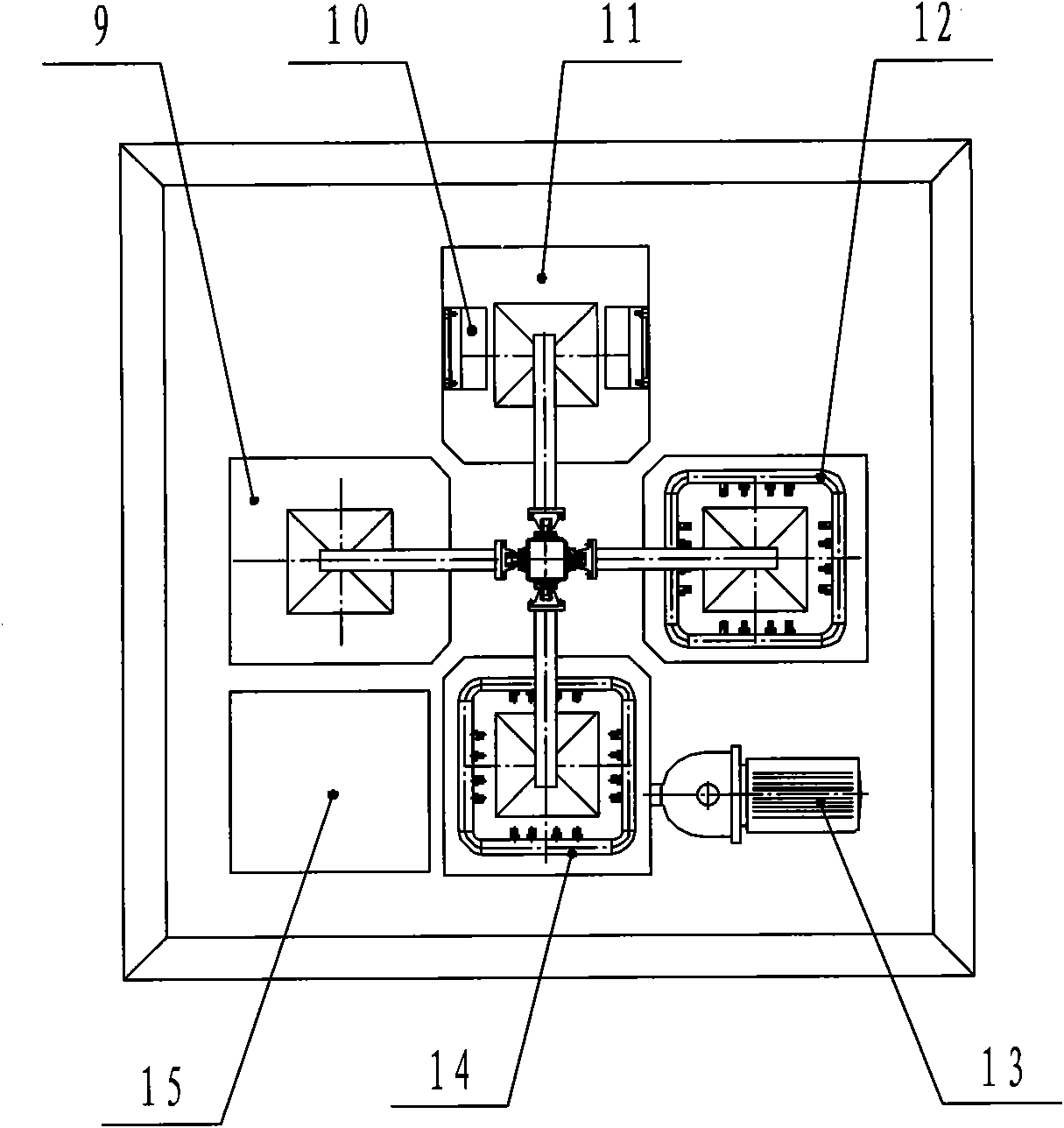

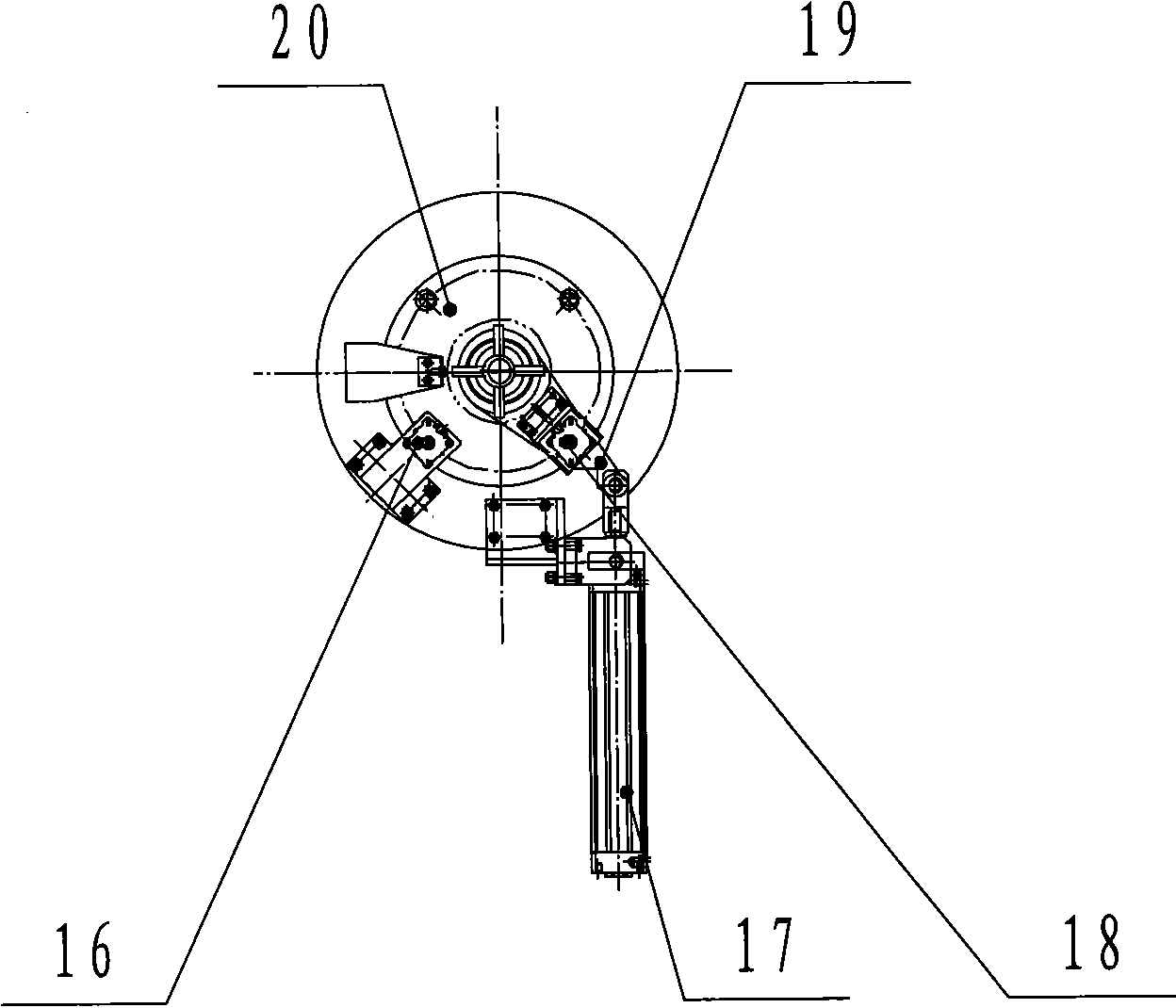

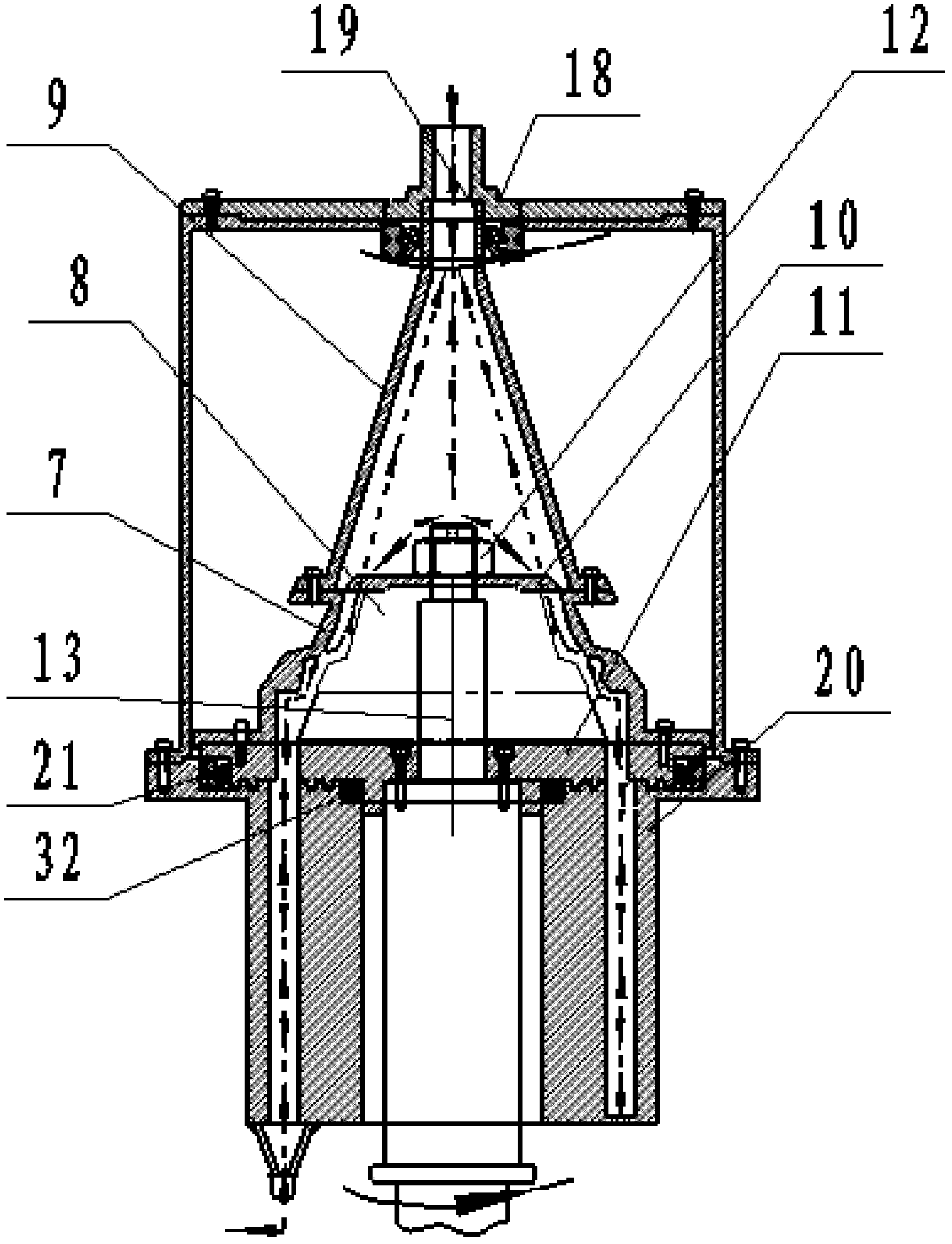

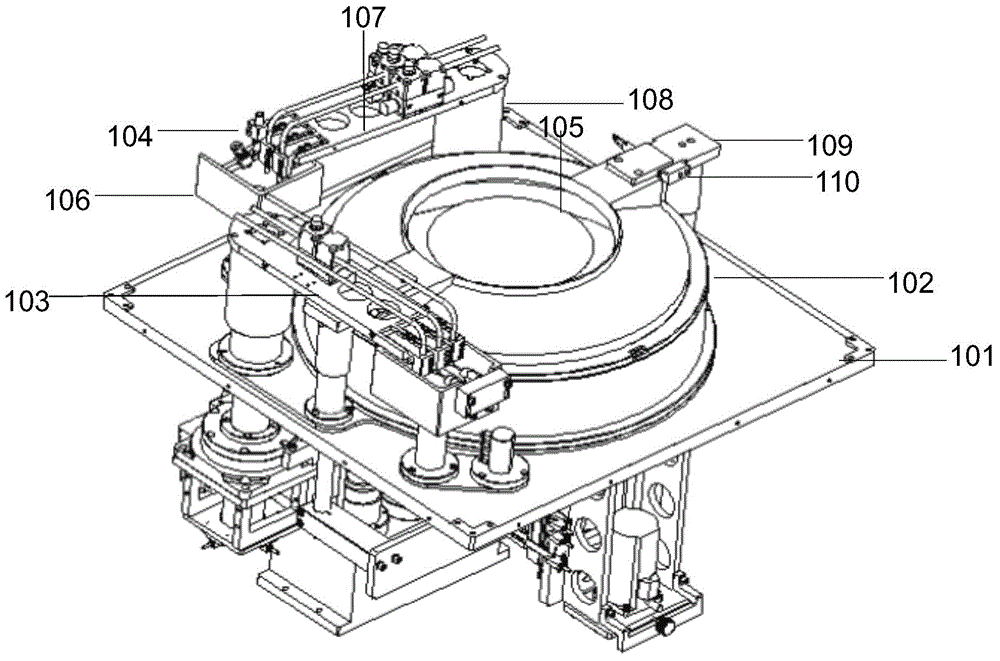

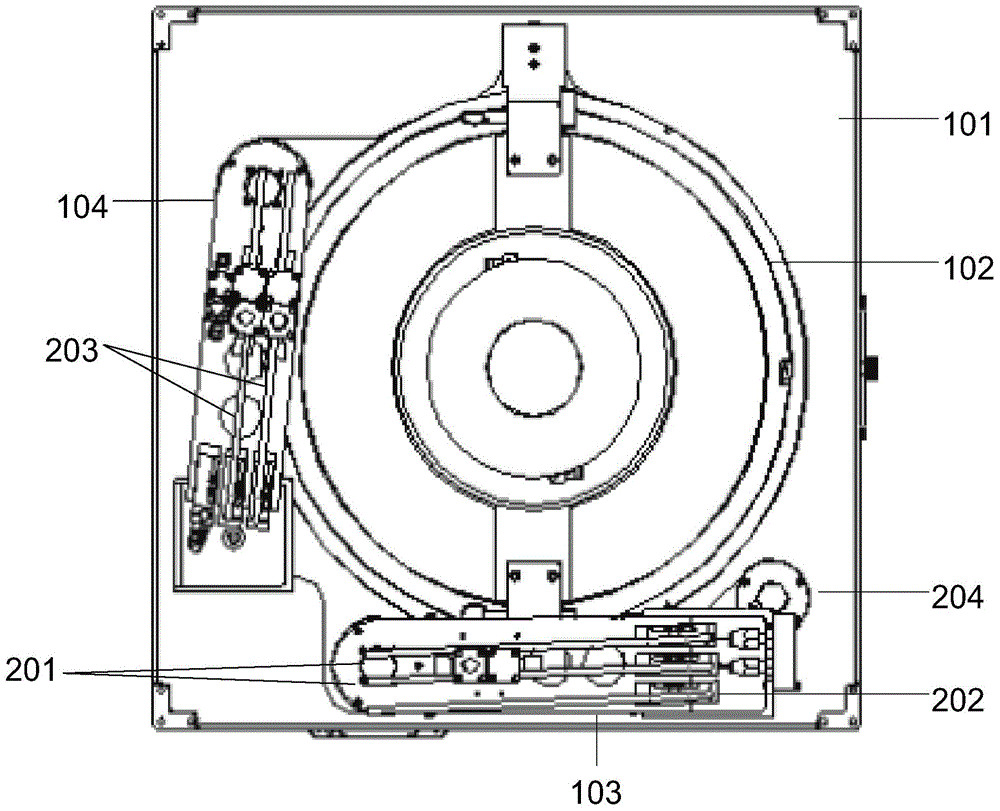

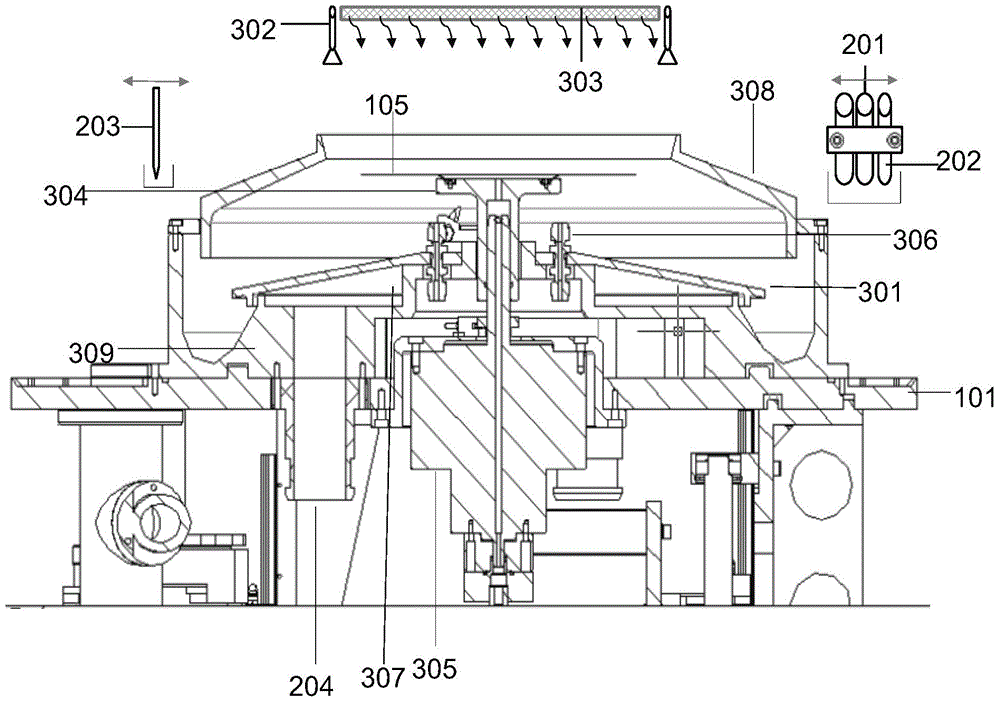

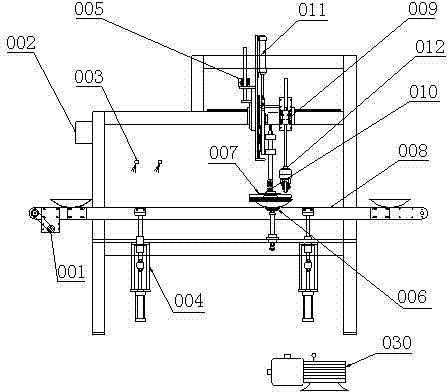

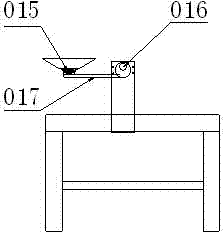

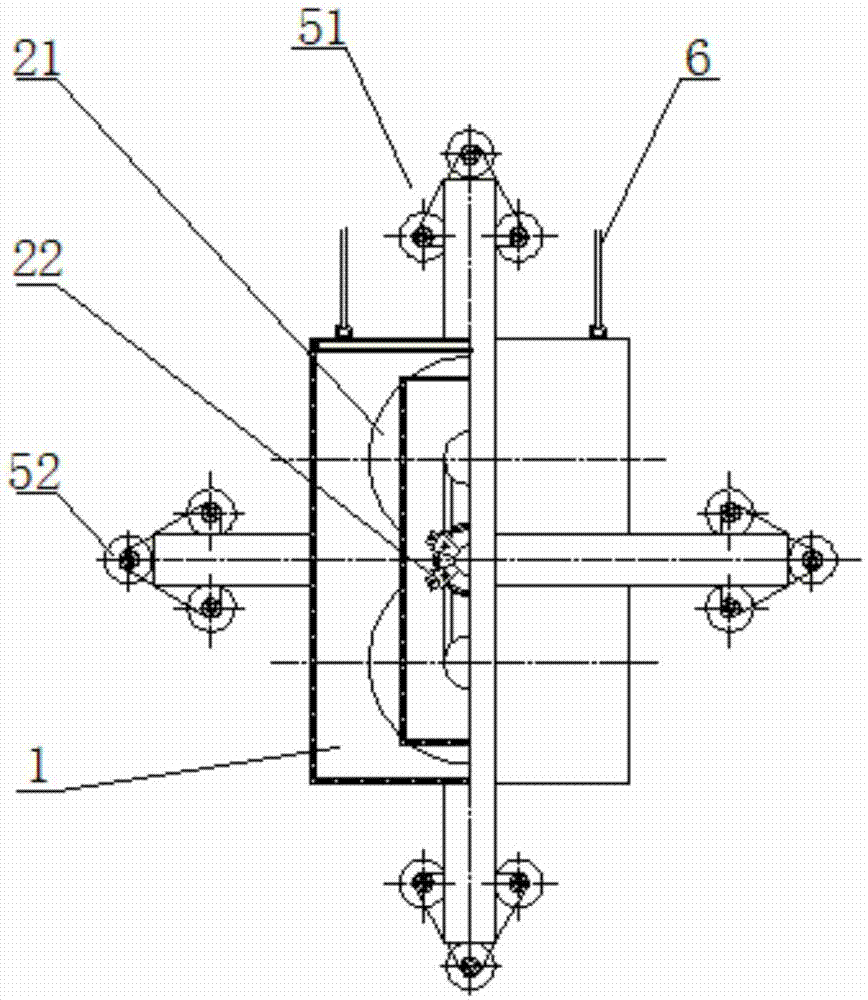

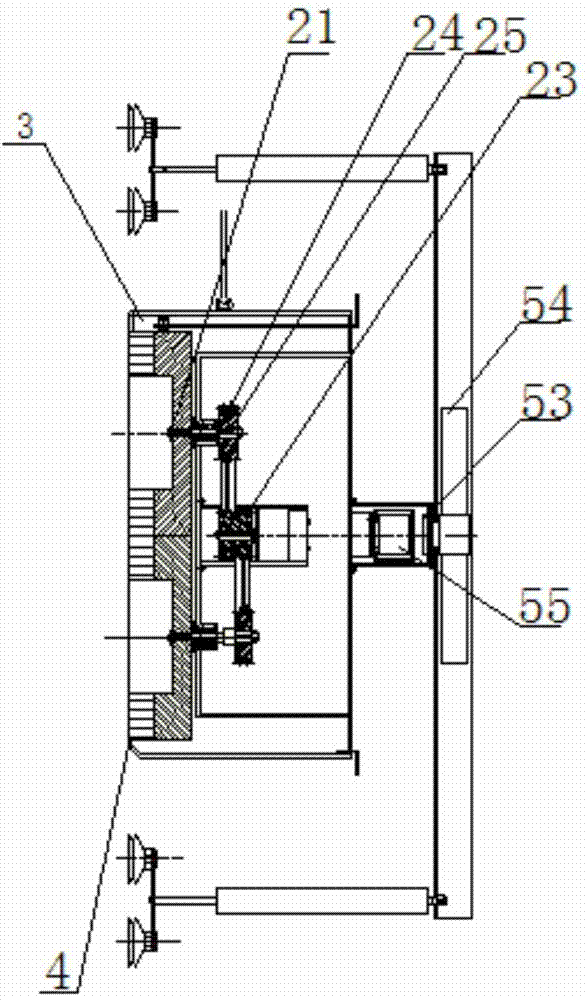

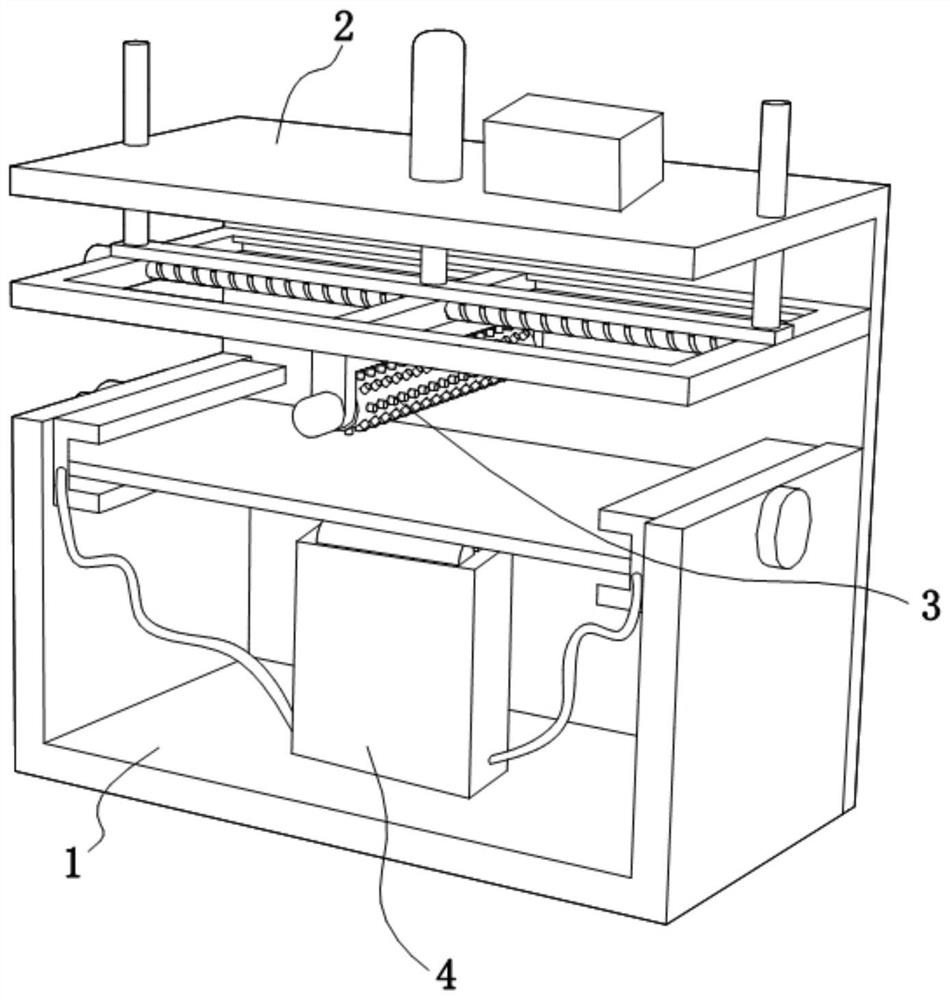

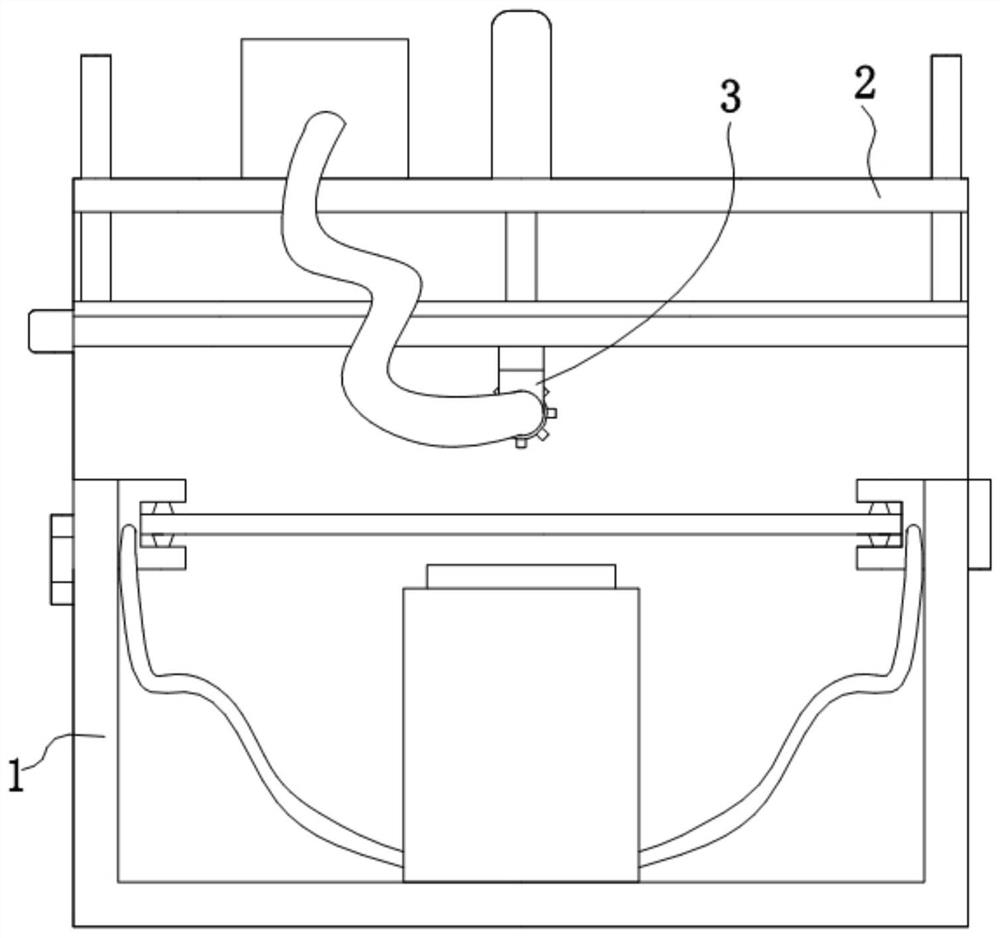

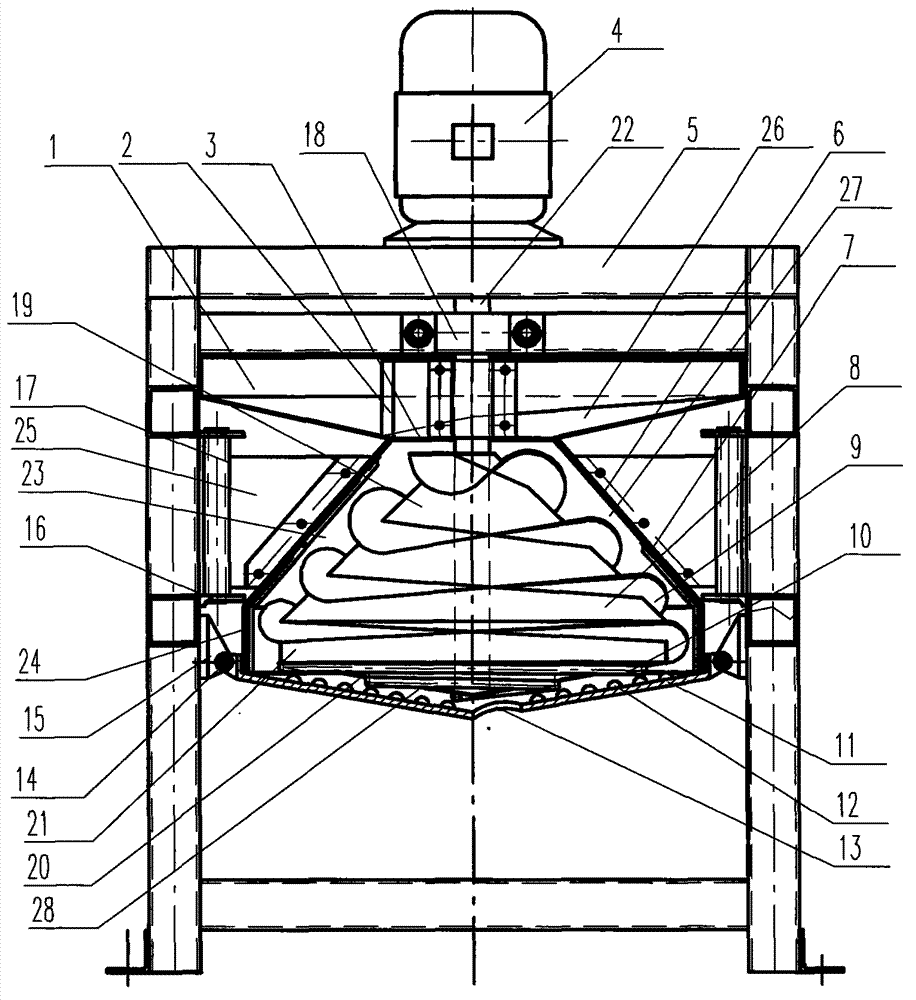

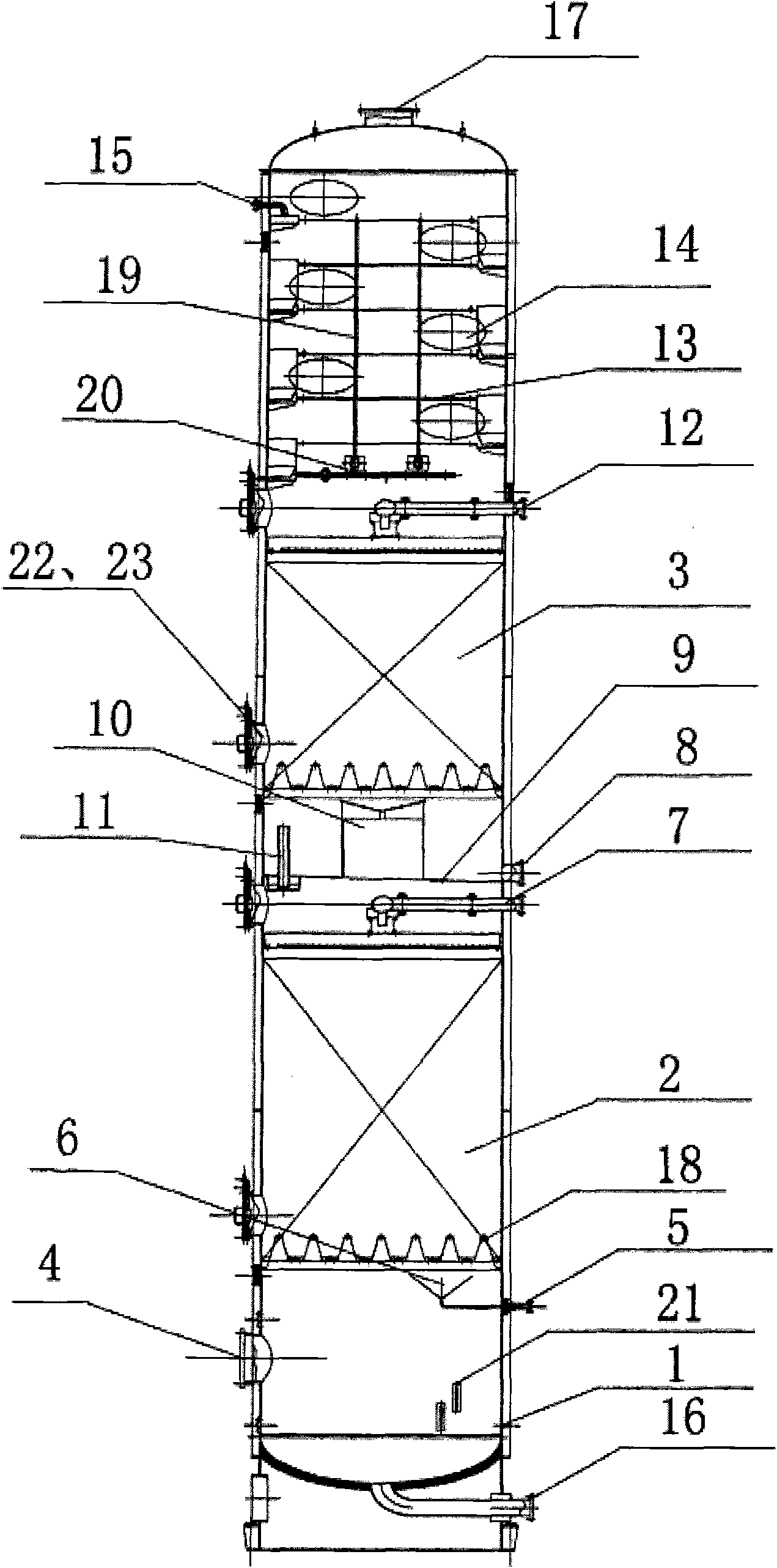

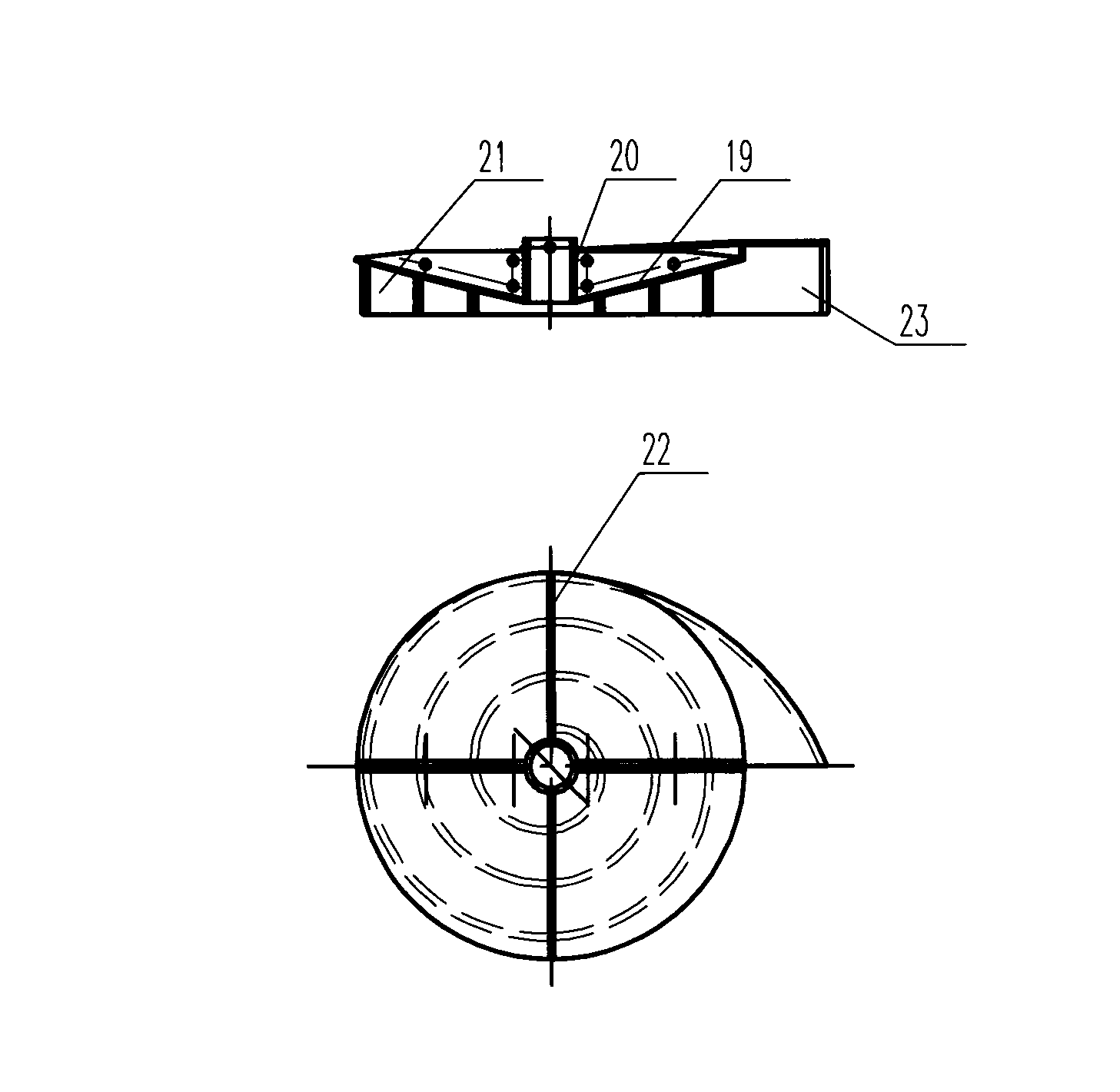

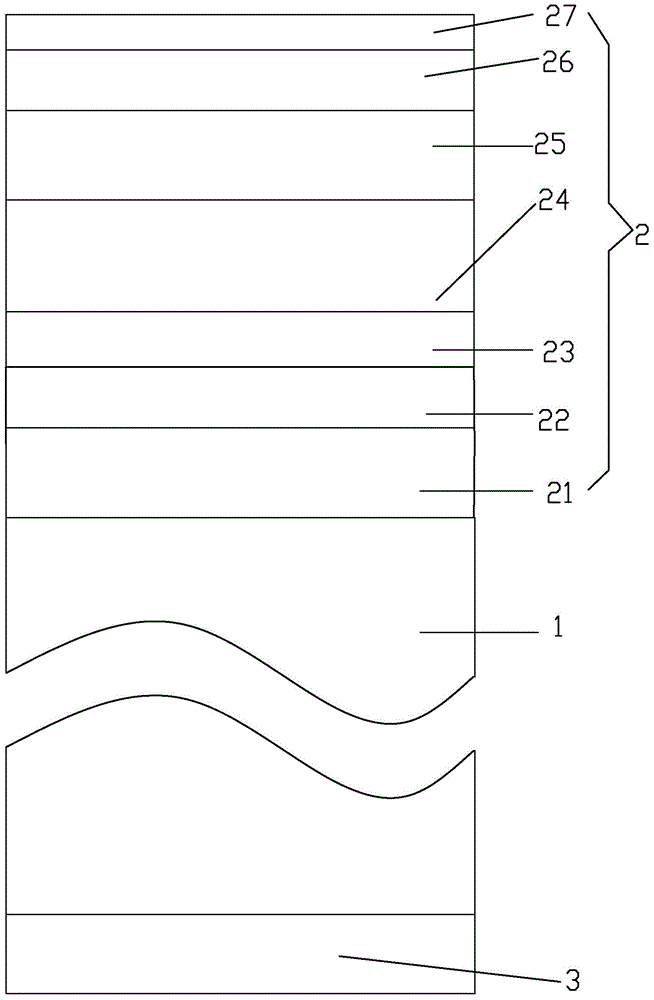

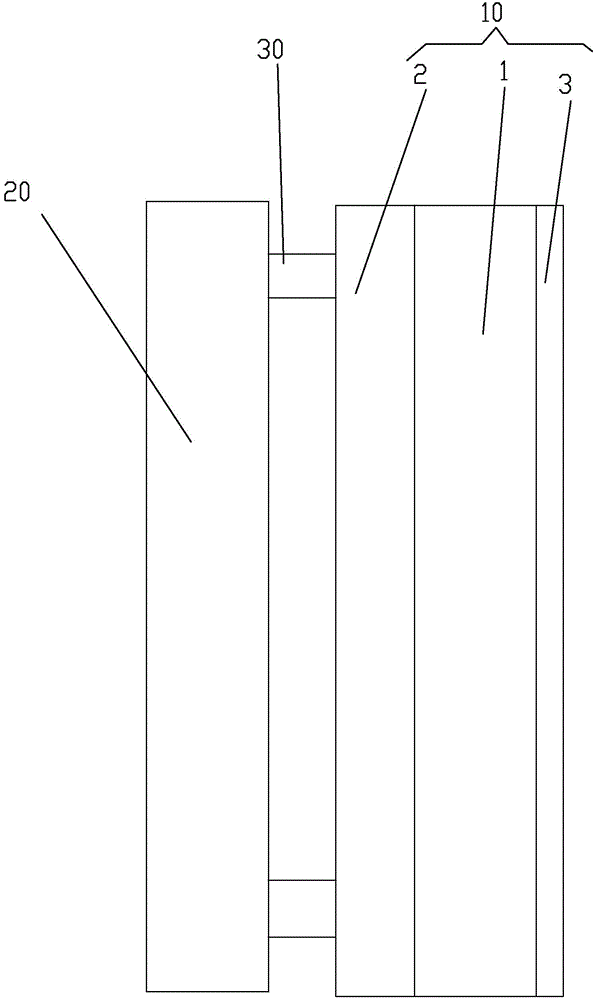

Rotary type multi-station lifting ultrasonic washer

InactiveCN101648191AImprove cleaning qualitySmall footprintCleaning using liquidsSmall footprintEngineering

The invention relates to a rotary type multi-station lifting ultrasonic washer which comprises a water pump and a liquid storage groove body. The washer is internally provided with a plurality of working groove bodies, the central position of each working groove body is provided with a workpiece cradle lifting and rotating mechanism, wherein a workpiece cradle is connected with the workpiece cradle lifting and rotating mechanism. The invention provides a structural form which adopts a plurality of working grooves, and the working groove bodies are set into a plurality of stations for ultrasonic washing, spray washing, blow-drying, drying, and the like so as to ensure that workpieces can be loaded and clamped in one step and automatically finish all working procedures from washing to drying, and obtain higher washing quality. A lifting rotary type workpiece conveying device is arranged among the working groove bodies and used for conveying the workpieces. The invention has small occupation area and low manufacturing cost and effectively solves the problem of realization of multi-station part washing under the condition of small occupation area.

Owner:YICHANG ENHANCE ULTRASONIC ELECTRIC

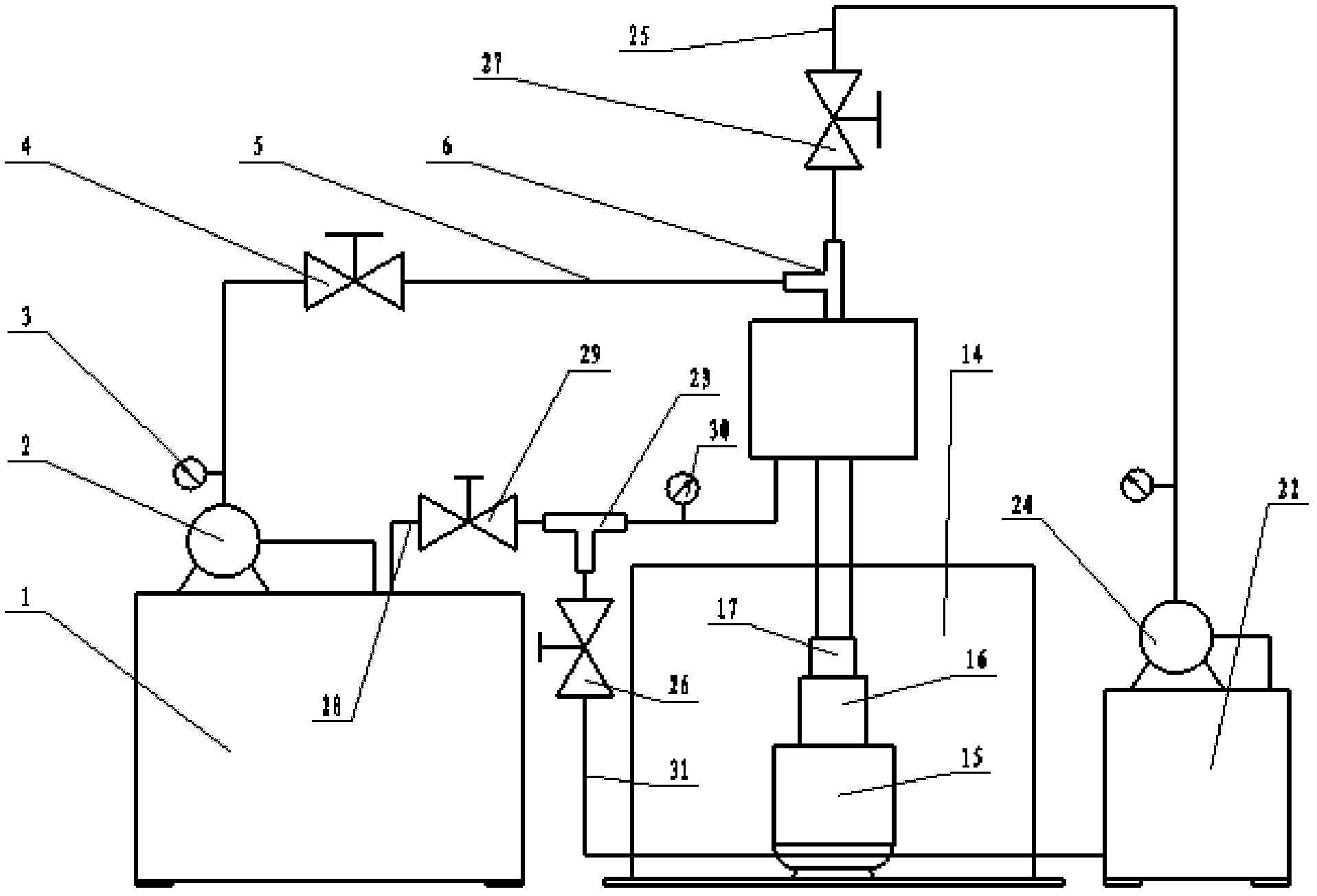

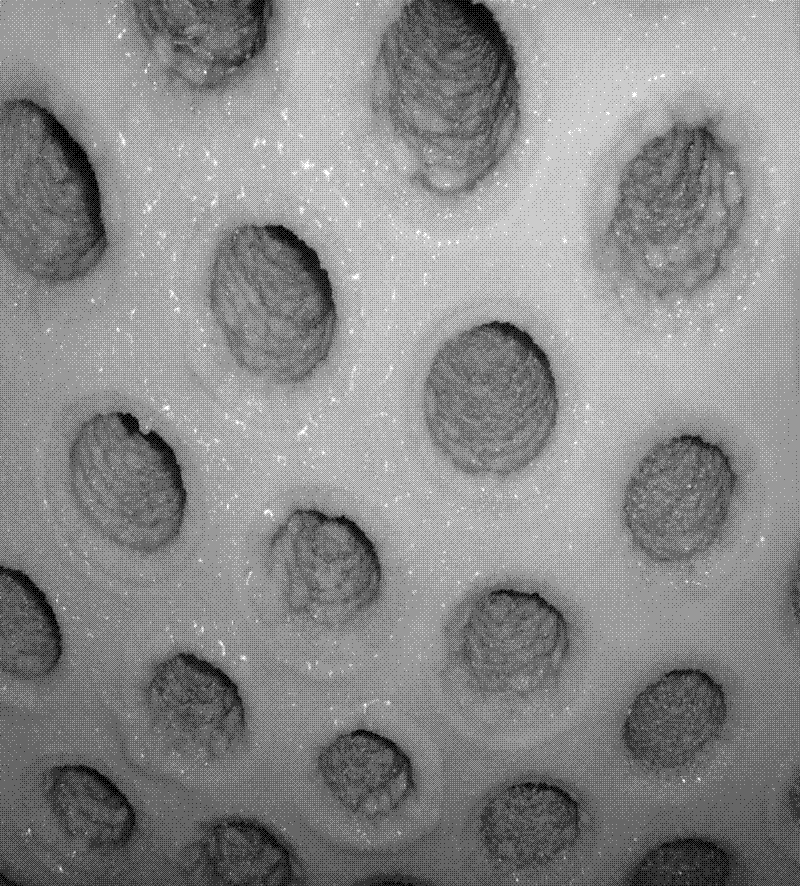

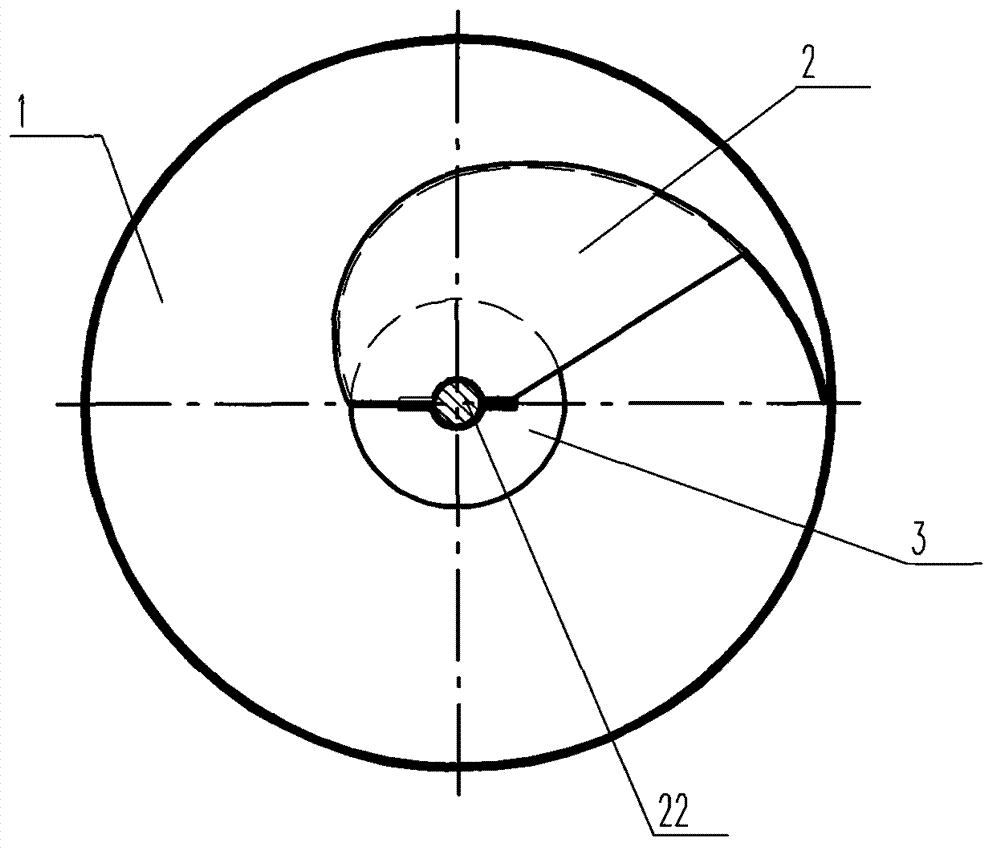

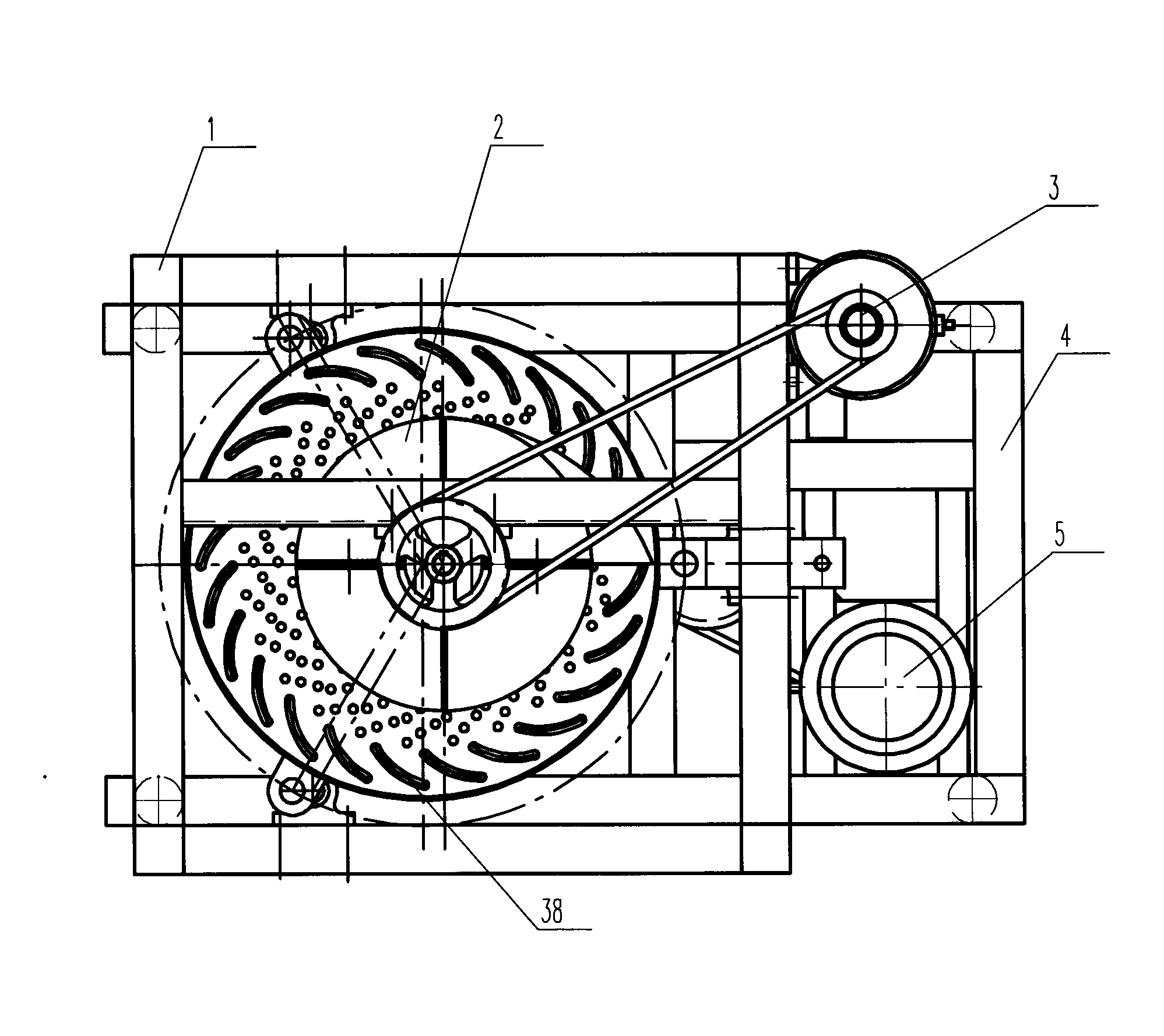

Polishing method for rotating abrasive stream of entire impeller part

ActiveCN102615597AEvenly distributedUniform distribution of pressure fieldAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The invention discloses a polishing method for rotating an abrasive stream of an entire impeller part. The polishing method is characterized by comprising the following steps of: firstly, protecting non-polished faces, such as upper and lower end faces of an impeller and outer edges of blades, by virtue of a special shape clamp cover, and integrally fixing with a workpiece; secondly, properly buffering and adjusting before the workpiece is polished by abrasive through an abrasive stream drainage device, so that a pressure field in a sealing cavity is uniformly distributed; thirdly, driving an equipment spindle and the workpiece to rotate by using a power system consisting of a motor and a speed reducer; and finally, converting to a high-pressure water cleaning system to wash the workpiece and an equipment pipeline after polishing. According to the polishing method provided by the invention, the problems in a polishing process of the entire impeller part of easiness of interference, excessive polished blades, chamfering, dead angle and uniform polishing can be solved; the abrasive circularly flows in double directions so as to be easy to recycle; the machining efficiency is improved; and clean-in and clean-out in a machining process can be realized through the water washing system after the polishing process.

Owner:DALIAN UNIV OF TECH

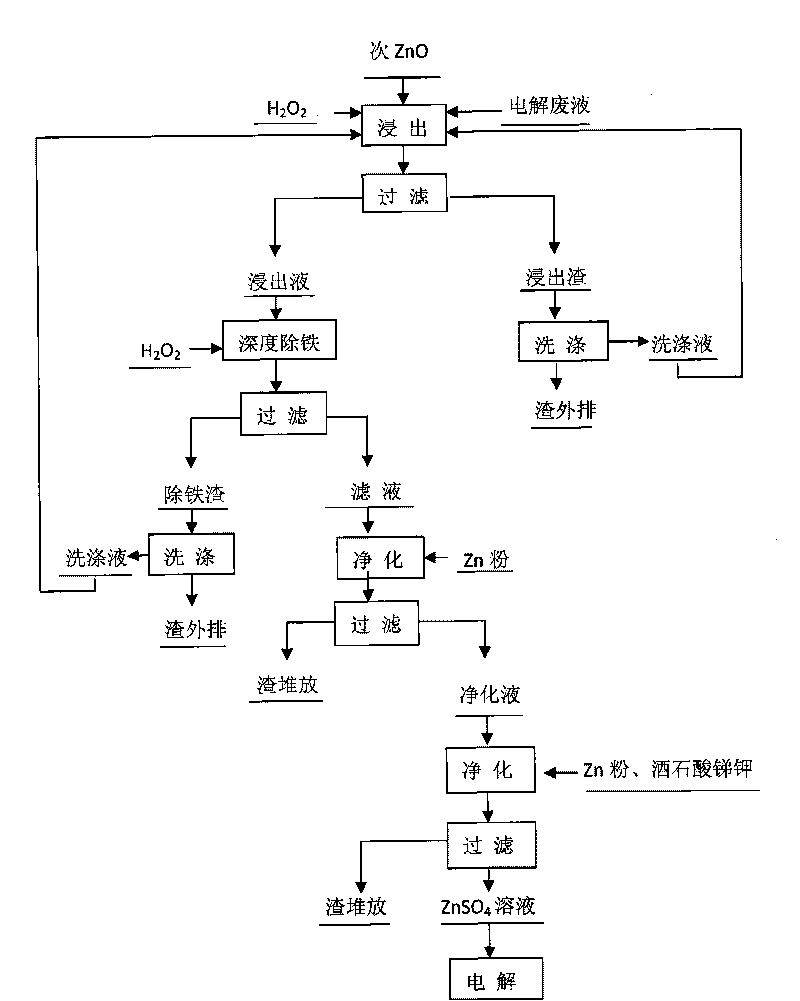

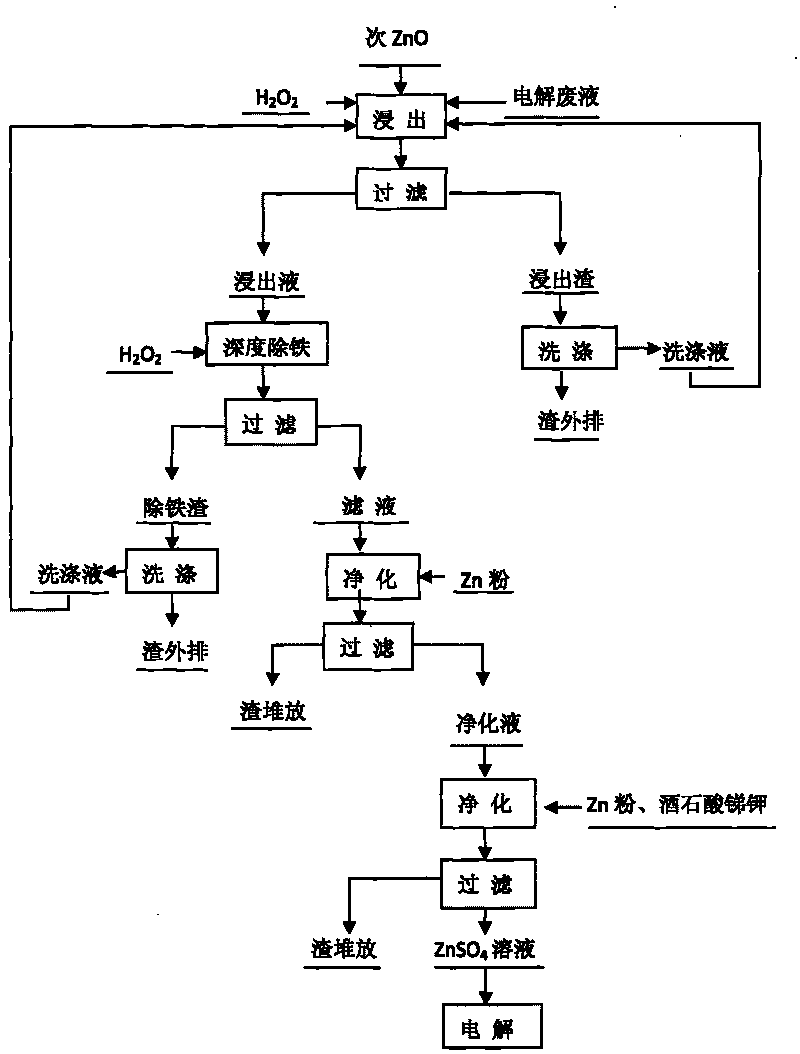

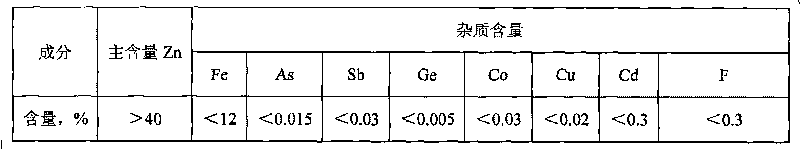

Method for removing impurities by oxidation in process of zinc hydrometallurgy

A method for removing impurities by oxidation in the process of zinc hydrometallurgy with sub-zinc oxide high in iron content as the raw material specifically comprises the following five procedures: A. primary impurity removal during leaching of sub-zinc oxide; B. deep impurity removal of ZnSO4 solution; C. first-stage purification of ZnSO4 solution; D. second-stage purification of ZnSO4 solution; and E. filtration to finally obtain the ZnSO4 solution in accordance with the requirement for producing zinc by electrolysis. The method better solves the problem of impurity removal in the process of producing electrolytic zinc with sub-zinc oxide as the raw material, especially the removal of As, Sb, Ge, F and Fe, and ensures the electrolytic zinc to be produced smoothly and ensures high product quality. In the method, the industrial grade H2O2 is used as the oxidant to remove the impurities from the leachate of zinc oxide and can not bring in the impurities harmful to the electrolytic zinc, thus ensuring smooth production, improving the product quality and the production yield and lowering the cost, in addition, the industrial grade H2O2 is relatively cheap and easy to purchase, thus the method is suitable for popularization and application in large scale.

Owner:孙位成

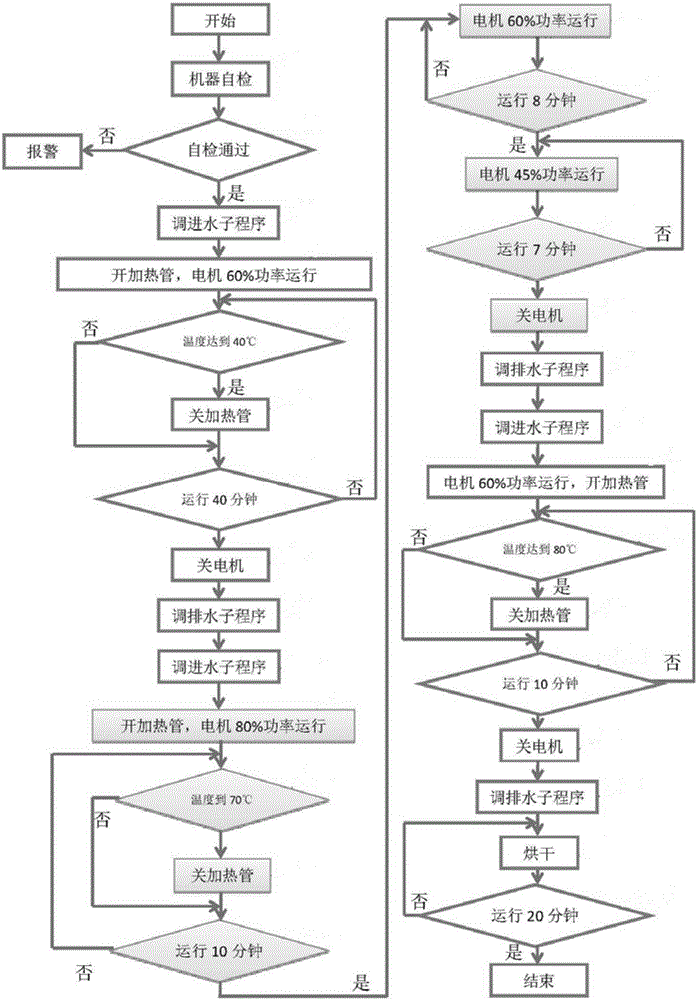

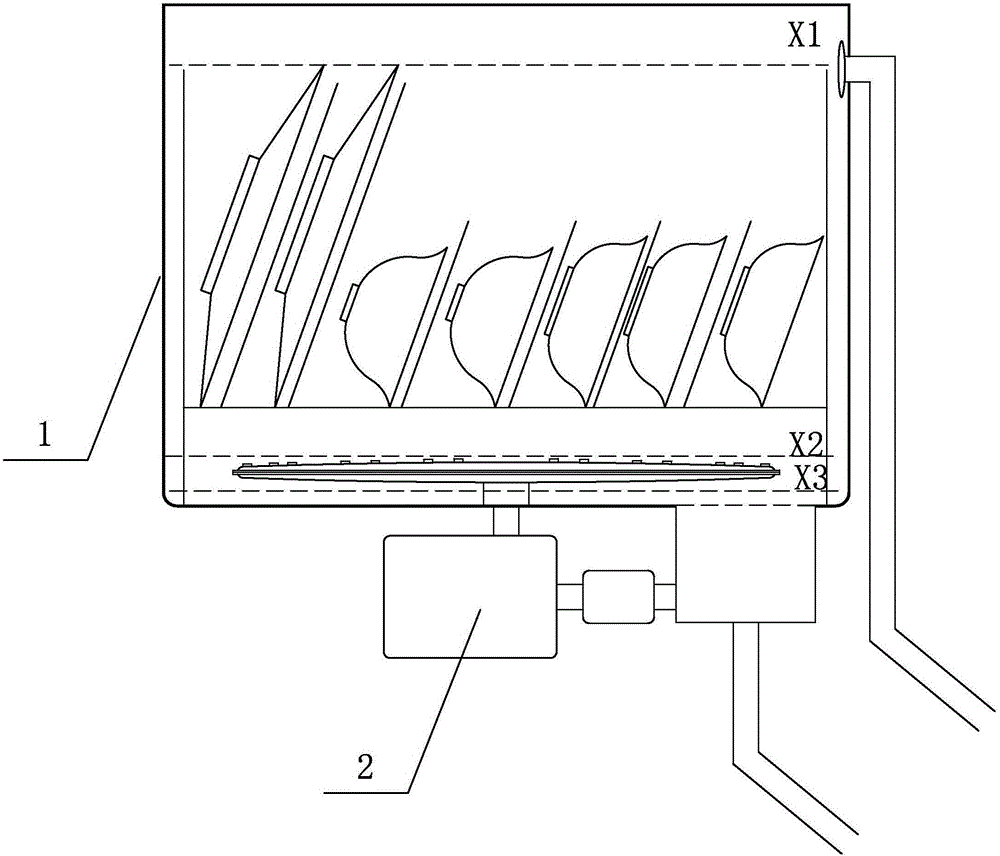

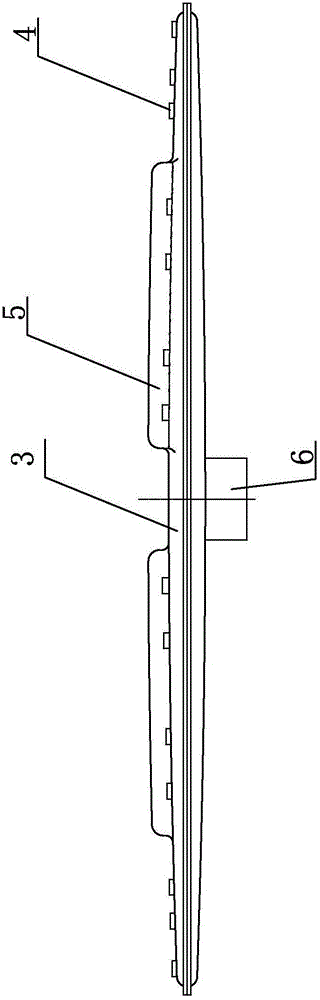

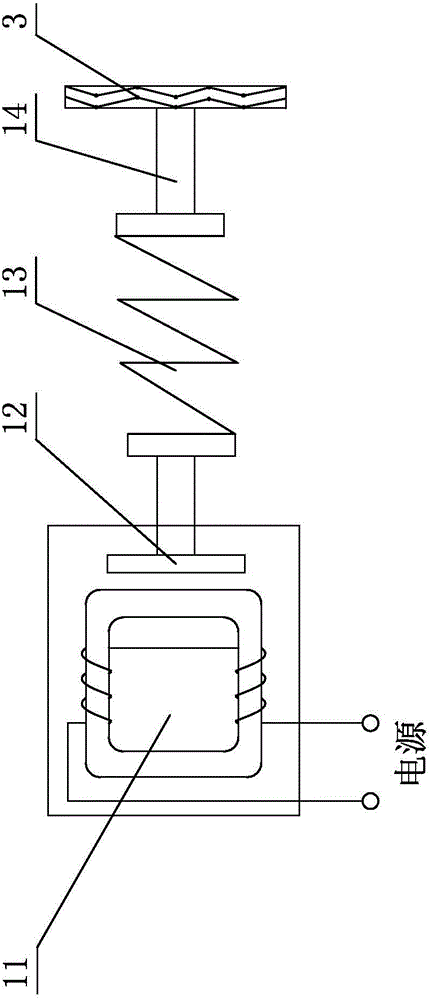

Washing method for water tank type dish washer

ActiveCN104983379AAvoid collisionIncrease flushing powerTableware washing/rinsing machinesHome appliance efficiency improvementElectricityPulp and paper industry

The invention discloses a washing method for a water tank type dish washer. The method includes the following steps that firstly, at the prewashing stage, water is injected, heating is started when the amount of injected water reaches a preset water amount, a circulating water pump starts running at the power accounting for 50% to 60% of the rated power, and eddy stirring is conducted through fins arranged on the upper surfaces of rotating spraying arms; secondly, at the main washing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct spraying of different spraying strengths and different spraying angles in a segmented mode by setting the rated power of the circulating water pump in a segmented mode and setting the execution time in a segmented time; thirdly, at the rinsing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct rinsing spraying. The washing method for the water tank type dish washer can solve various problems of Chinese style dishes, the washing efficiency can be effectively improved, more water and electricity are saved, and a mixing program is obtained.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

Particulate matter filtering device with automatic cleaning function and control method thereof

ActiveCN104374057ASolve cleaning problemsDecreased cooling and heating efficiencyMechanical apparatusCondensate preventionParticulatesAir volume

Provided are a particulate matter filtering device with an automatic cleaning function and a control method thereof. The particulate matter filtering device with the automatic cleaning function comprises a spraying device, an electromagnetic vibrator, a filtering screen assembly, an air quality sensor, a control center, a water receiving tray, a water drainage hole and a water drainage pipe. The control center is in electric control connection with the spraying device, the electromagnetic vibrator and the air quality sensor. By means of the improvement on the structure, the cleaning problem of an air conditioner unit or the filtering screen assembly of the air purification device is solved, users or after-sales maintenance personnel do not need to manually clean away dust on the air conditioner unit or the filtering screen assembly of the air purification device, the particulate matter filtering device can automatically remove the dust on the filtering screen assembly and discharge the dust out of the room, therefore, the maintenance burden of the users is reduced, and indoor air is kept clean. In addition, the dust on the filtering screen assembly can be removed automatically so that decrease of the air volume and the refrigerating and heating efficiency of the air conditioner can be prevented. The particulate matter filtering device with the automatic cleaning function can be widely applied to all kinds of air conditioner units and air purification devices and has a wide application range.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

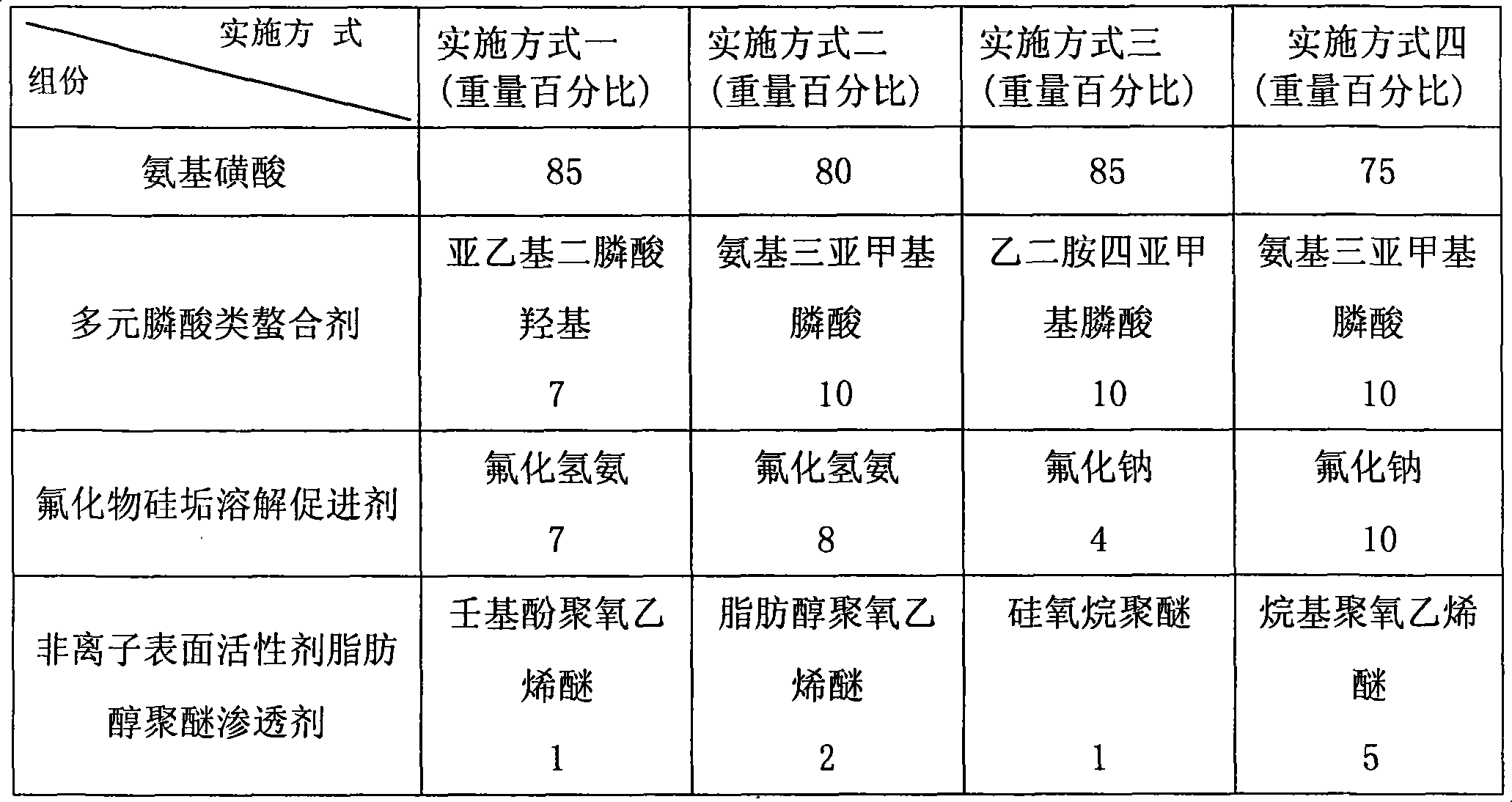

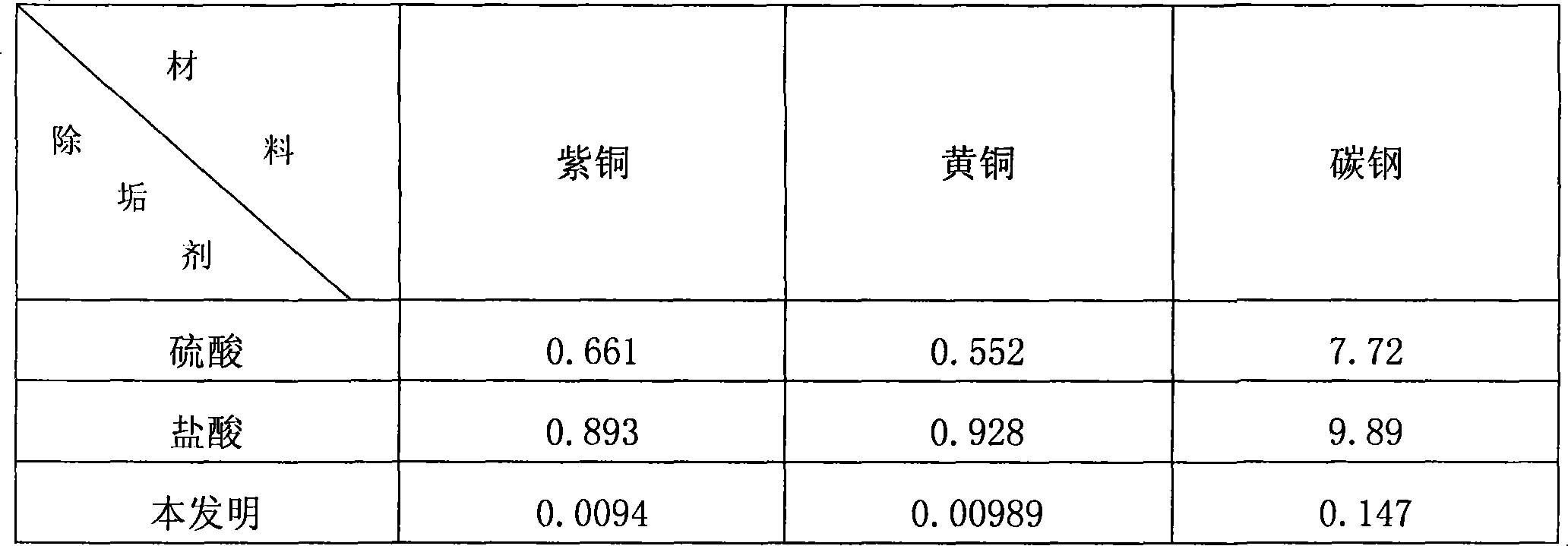

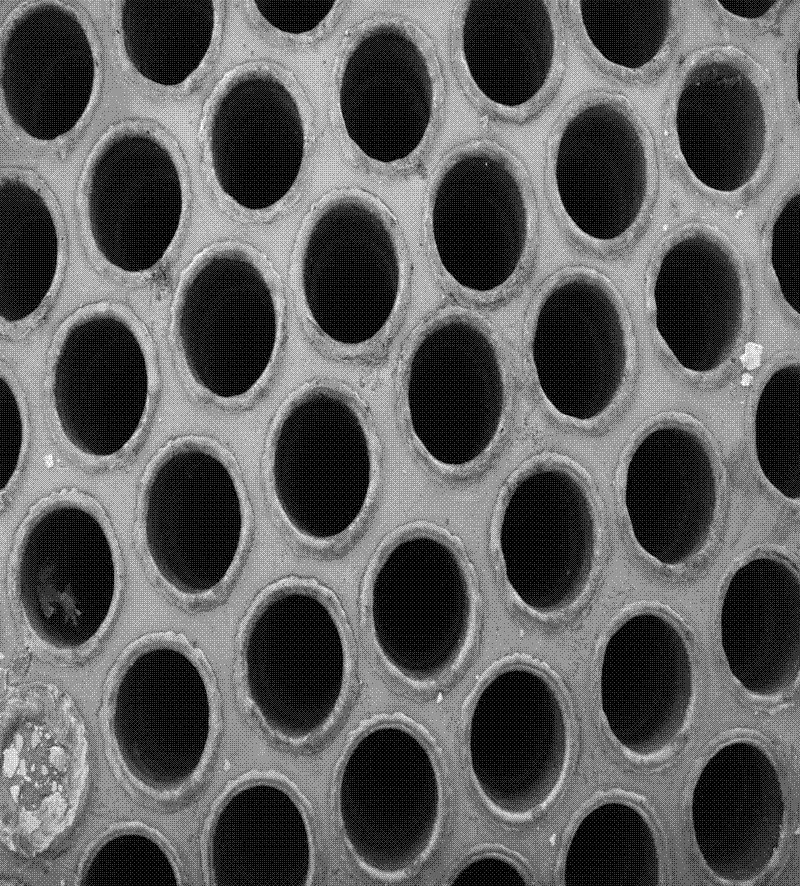

Descaling agent for cleaning central air conditioner main machine

InactiveCN101086065ASolve cleaning problemsStrong acidity of solid organic acidPolyesterHexamethylenetetramine

The invention relates to a scale and rust remover used for cleaning main frame of central air-conditioner. It is characterized in that it comprises solid mixture and liquid inhibitor; said solid mixture comprises amidosulfonic acid, polyphosphinic acid chelating agent, silicofluoride scale and rust dissolution promotor, non-ionic surface activator aliphatic alcohol polyester penetrant, their weight proportions in order are as follows: 75%-85%, 5%-10%, 5%-10%, 1%-5%; said inhibitor is liquid and comprises hexamethylene tetramin, aniline and methyl azimido-benzene according to weight proportion of 2: 2: 1. Said inhibitor is added into acidic washing solution with its weight amount being 0.3% of that of water amount. The product can dissolve carbonate, silicate, sulfate and iron oxide, the descaling speed at room temperature is fast, and is increased within 60 Deg. C, the corrosive rate to metal is pretty low, and there is no acid mist and harmful gas generation during desaling process.

Owner:长沙科惠洁水质处理服务有限公司

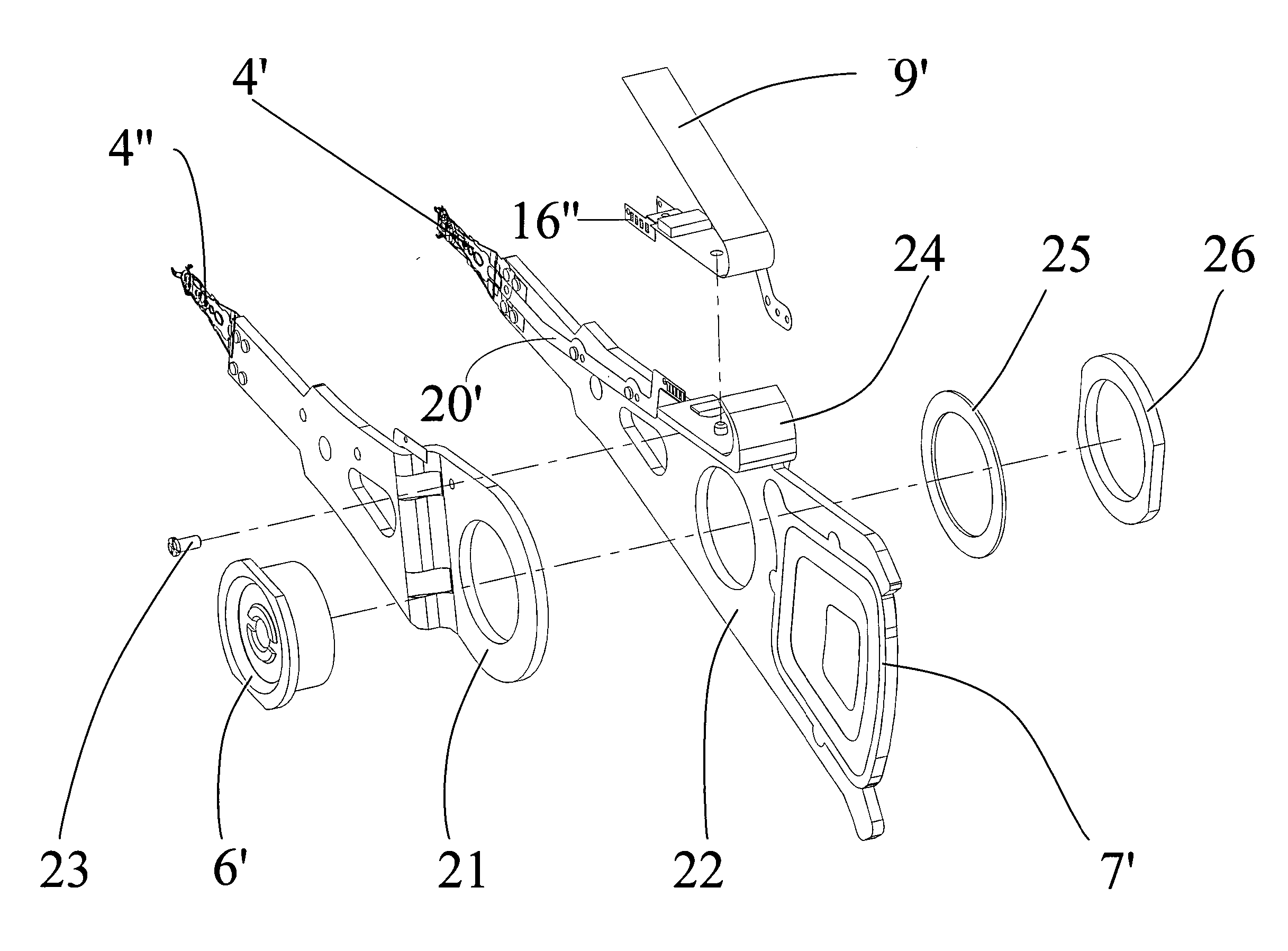

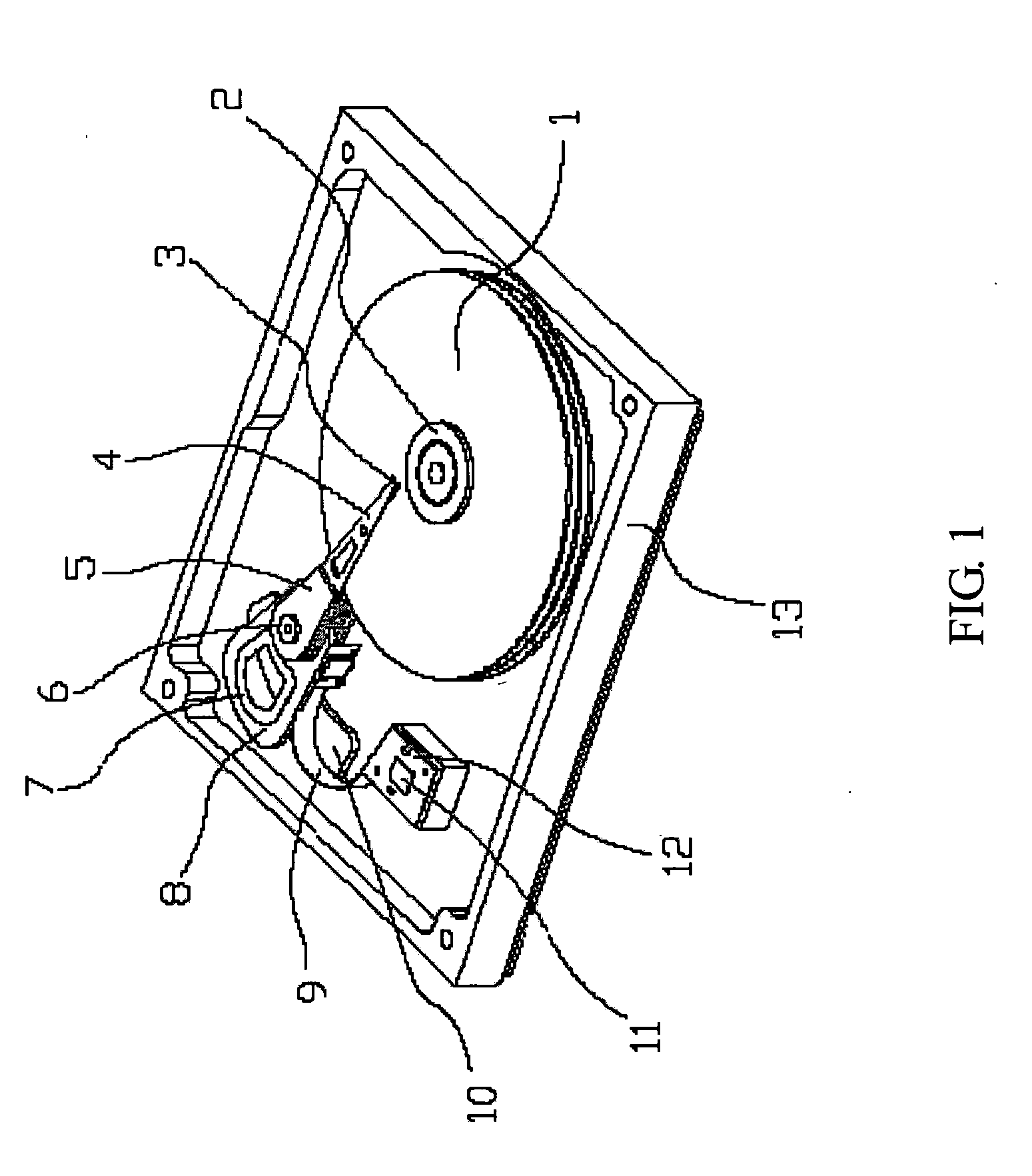

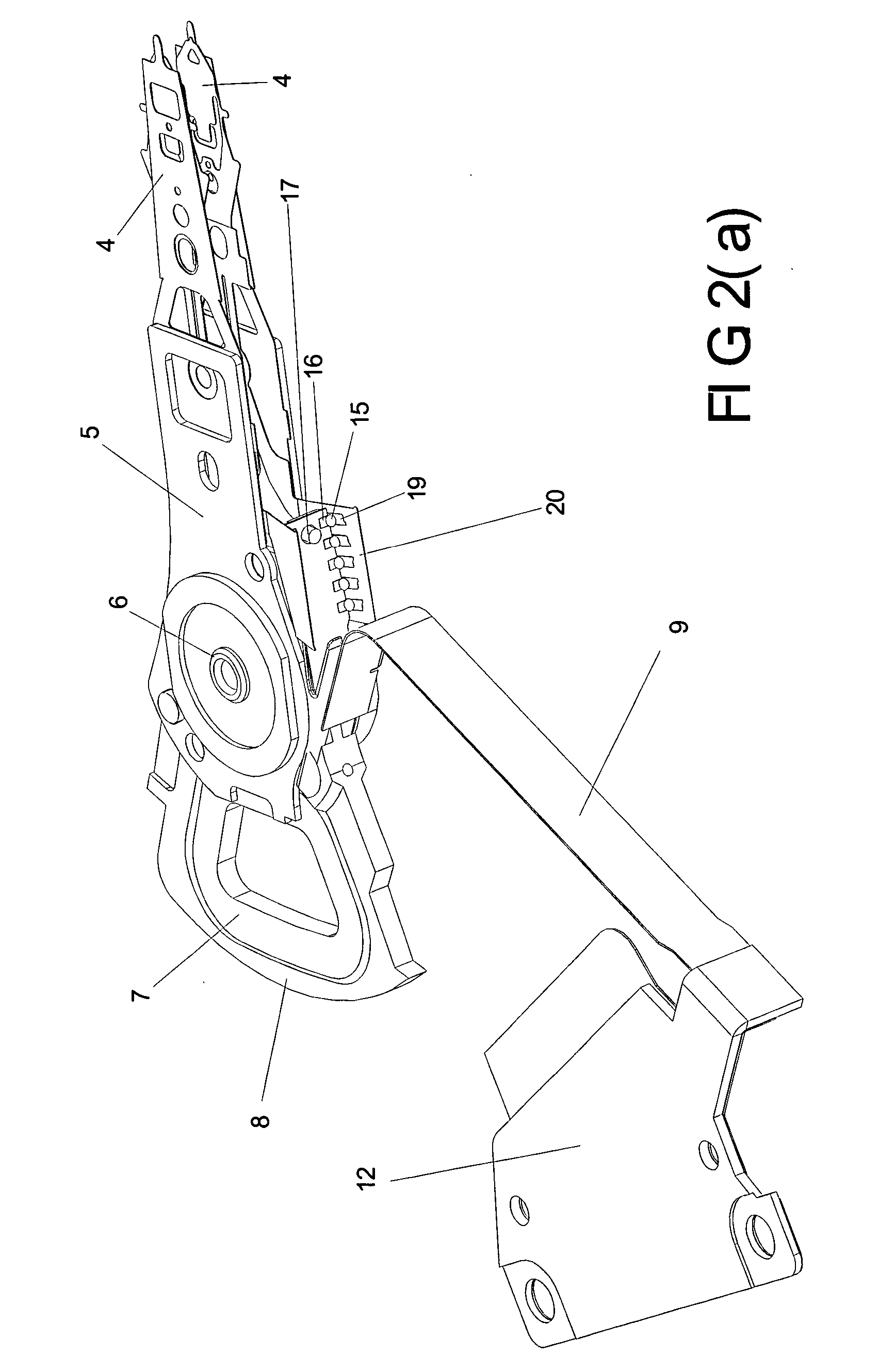

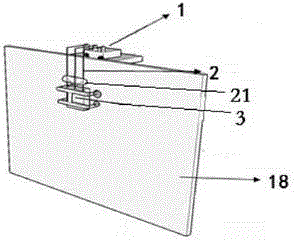

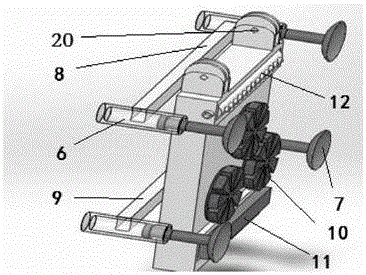

Head stack assembly and manufacturing thereof

InactiveUS20050243472A1Convenient and safe manufacturingConvenient and safe manufacturing methodPrinted circuit assemblingPrinted circuit aspectsEpoxyAnisotropic conductive film

A method for manufacturing a head stack assembly (HSA) of a disk drive unit includes including the steps of: forming a head arm assembly (HAA) having an overmolded suspension flexure cable thereon and a flexible printed circuit assembly; and bonding the suspension flexure cable with the flexible printed circuit assembly by conductive epoxy to attain an electrical connection therebetween. In the invention, the conductive epoxy is preferably anisotropic conductive film. Forming the head arm assembly further comprises forming a drive arm, and overmolding a suspension, a bracket, and a voice coil thereonto. Also, the method may further include a step of forming another HAA as a part of the HSA. In addition, a structure of the HSA is also disclosed in the present invention.

Owner:SAE MAGNETICS (HK) LTD

Building outer facade washing robot system and using method thereof

ActiveCN104983369ASolve cleaning problemsSafe and automated cleaning workCarpet cleanersFloor cleanersRobotic systemsEngineering

The invention discloses a building outer facade washing robot system and a using method thereof. The building outer facade washing robot system comprises a safety servo trolley, and a cleaning machine body is connected to the lower portion of the safety servo trolley through a safety cable; a movement track is arranged on the cleaning machine body, robot feet are connected to the movement track through sliding blocks, transverse rods are connected to the lower portions of the sliding blocks, telescopic devices are connected to the transverse rods, and sucking cups are connected to the bottoms of the telescopic devices; and the robot feet comprise the front foot and the back foot. By means of the building outer facade washing robot system and the using method, safe and efficient automation cleaning work on the outer surface of a building can be done, and therefore the aim of cleaning the outer surface of the high-rise building is achieved. By means of the system, on the premise that the cleaning requirement is met, the working efficiency is improved, the work danger coefficient is reduced, and the using rate of the labor force is improved while the development tendency of the contemporary science and technology is met.

Owner:FUJIAN UNIV OF TECH

Wafer gumming machine and gumming method

InactiveCN105289923ASolve cleaning problemsLiquid surface applicatorsSemiconductor/solid-state device manufacturingTime costNozzle

The invention relates to a wafer gumming machine and a gumming method. The wafer gumming machine can carry out gumming on wafers of different sizes. The wafer gumming machine is provided with at least one technological cavity. A cavity cleaning nozzle is arranged at the top of the technological cavity so that the wafer gumming machine can be automatically cleaned without starting the machine, and the time cost and manpower cost consumed by machine table cleaning are greatly saved. The gumming method suitable for the wafer gumming machine is further provided. A good gumming effect is achieved.

Owner:ACM RES SHANGHAI

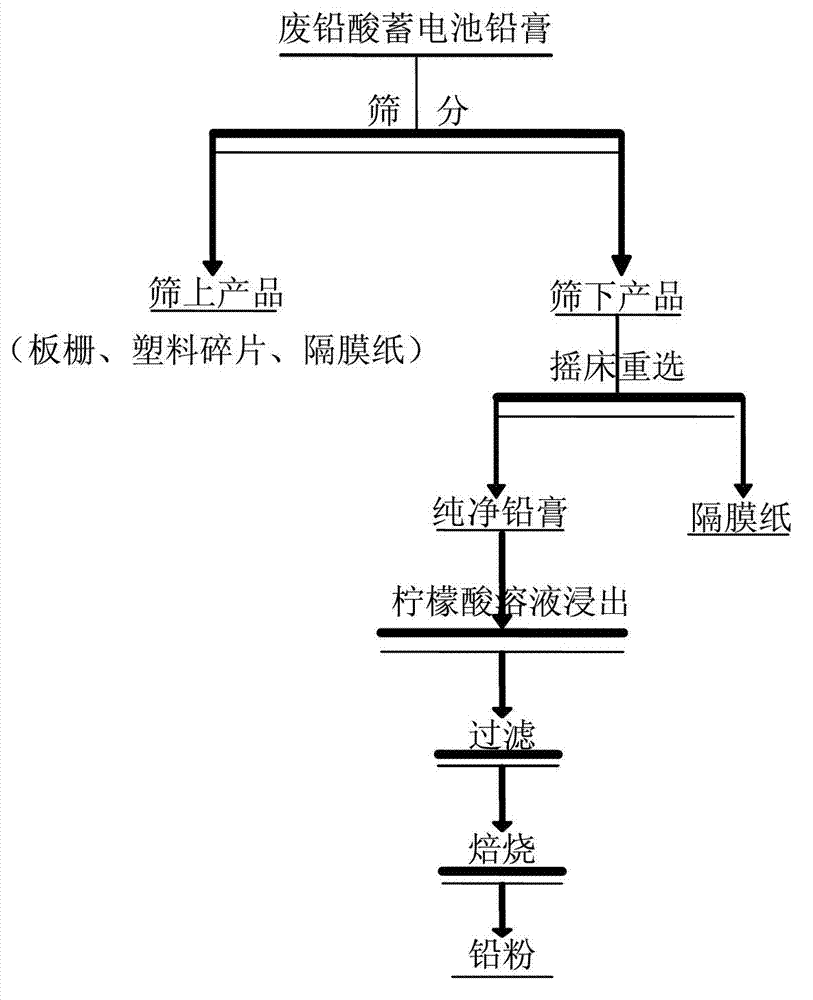

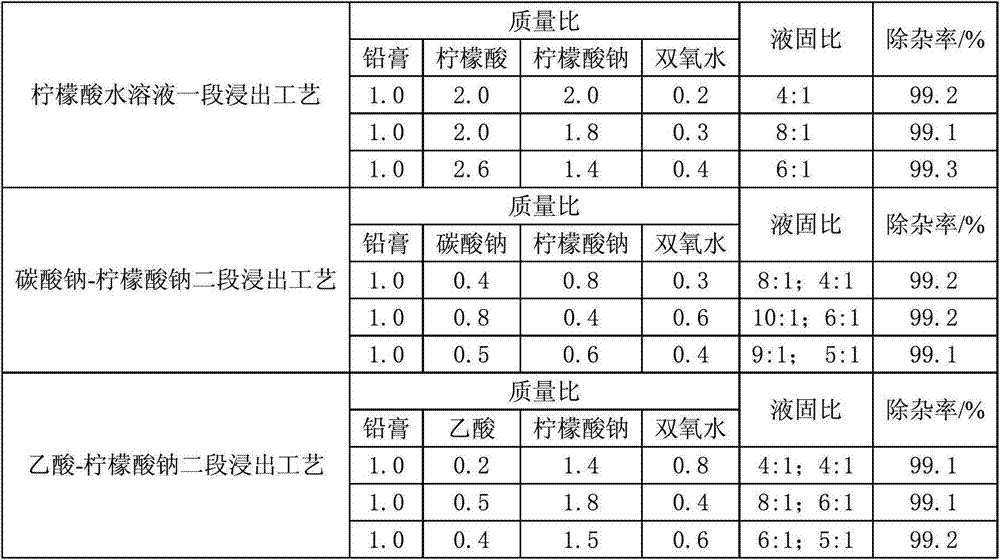

Pretreatment method for lead plaster of waste lead-acid accumulators

ActiveCN103050745AAchieve separationLess investmentWaste accumulators reclaimingBattery recyclingAcetic acidPretreatment method

The invention belongs to the field of utilizing waste lead-acid accumulators to produce secondary lead, and relates to a novel pretreatment method for lead plaster of the waste lead-acid accumulators. The pretreatment method comprises the steps that after the waste lead-acid accumulators are crushed and subjected to preliminary separation, waste lead plaster is obtained; wet sieving or dry sieving is conducted on the waste lead plaster by a 0.85mm-0.106mm sieve; plate grid and plastic fragment products are obtained; table reconcentration is conducted on undersize products; diaphragm paper products and pure lead plaster are obtained; the plate grid and plastic fragment products and the diaphragm paper products can enter a fire smelting system; the pure lead plaster is treated by a citric acid aqueous solution or sodium carbonate or a new acetic acid leaching technology; and lead powder is obtained, and can be used for preparing the lead-acid accumulators directly. The pretreatment method for the lead plaster of the waste lead-acid accumulators is simple in technological equipment, low in investment, low in cost, high in impurity removal rate, clean, highly-efficient and energy-saving.

Owner:HUAZHONG UNIV OF SCI & TECH +1

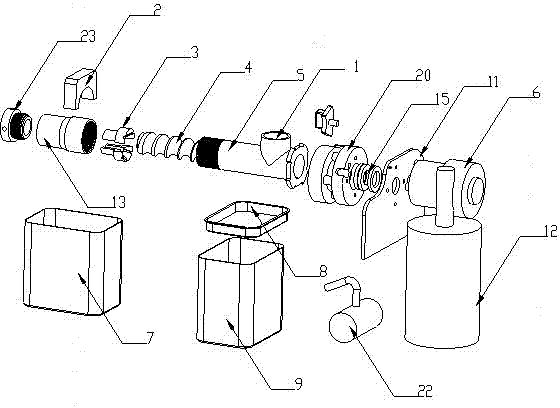

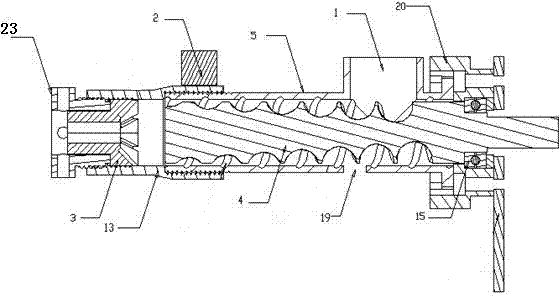

Household two-level pressing low temperature oil press

InactiveCN102774029AAchieving secondary pressingImprove oil yieldPressesReduction driveElectric machine

The invention relates to a household two-level pressing low temperature oil press. The oil press comprises an oil press base, a pressing mechanism and a driving mechanism, the pressing mechanism is installed on the oil press base, the driving mechanism is used for providing motive power for the pressing mechanism, the pressing mechanism includes a barrel, a pressing head, a pressing shaft and a pressing head casing, the barrel is provided with a feed port and an oil outlet, one end of the barrel is connected with the oil press base, the pressing head casing is connected with the other end of the barrel, one end of the pressing shaft is provided with screw threads and sleeved in a chamber formed by the barrel and the pressing head casing, the other end of the pressing shaft extends out of the barrel to serve as a rotating bar to be connected with the driving mechanism, the pressing head is installed in the pressing head casing, pressing space is formed by one side of the pressing head and one corresponding end of the pressing shaft, one or a plurality of material passing holes is / are arranged on the pressing head, one side surface of the pressing head where the pressing head is in a cut grafting with the pressing shaft is provided with a groove, one or a plurality of oil guide grooves which is / are communicated with the material passing holes is / are mounted on the wall surface of the groove, a heater is arranged on the pressing head casing or the barrel, and the driving mechanism and the heater are connected with a power supply. The driving mechanism includes a motor and a speed reducer which are disposed on the oil press base, and the speed reducer is in a transmission connection with a rotating shaft of the motor and the rotating bar of the pressing shaft. By means of the household two-level pressing low temperature oil press, the low temperature cold pressing can be achieved, the oil yield is high, the produced oil quality is good, and the oil press is easy to clean.

Owner:唐华

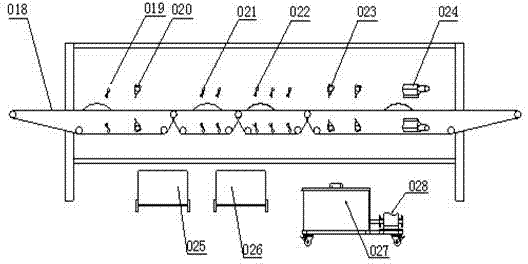

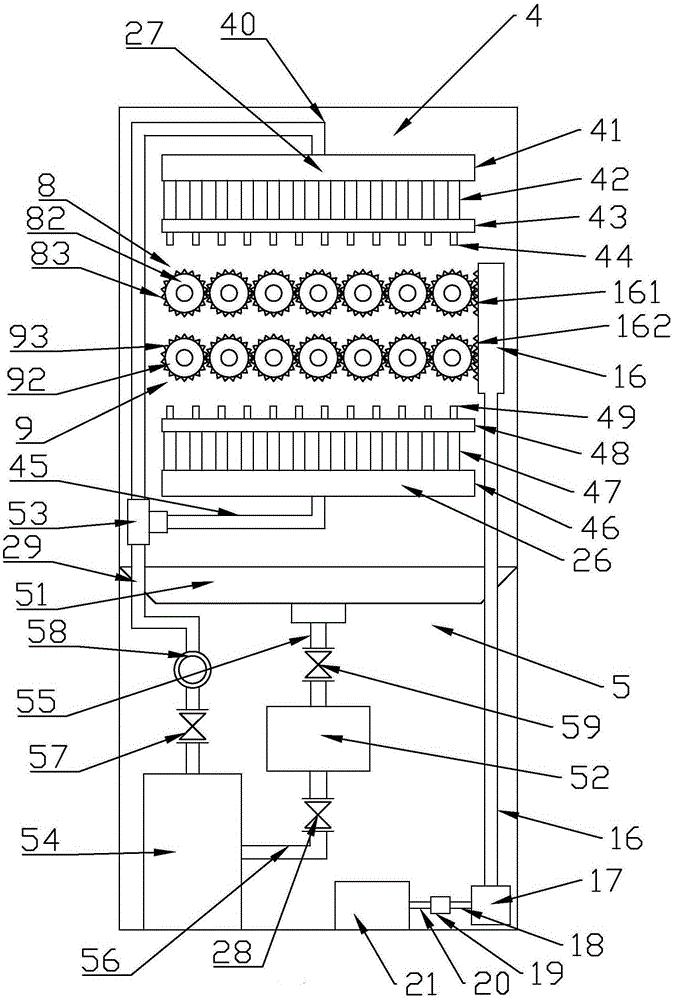

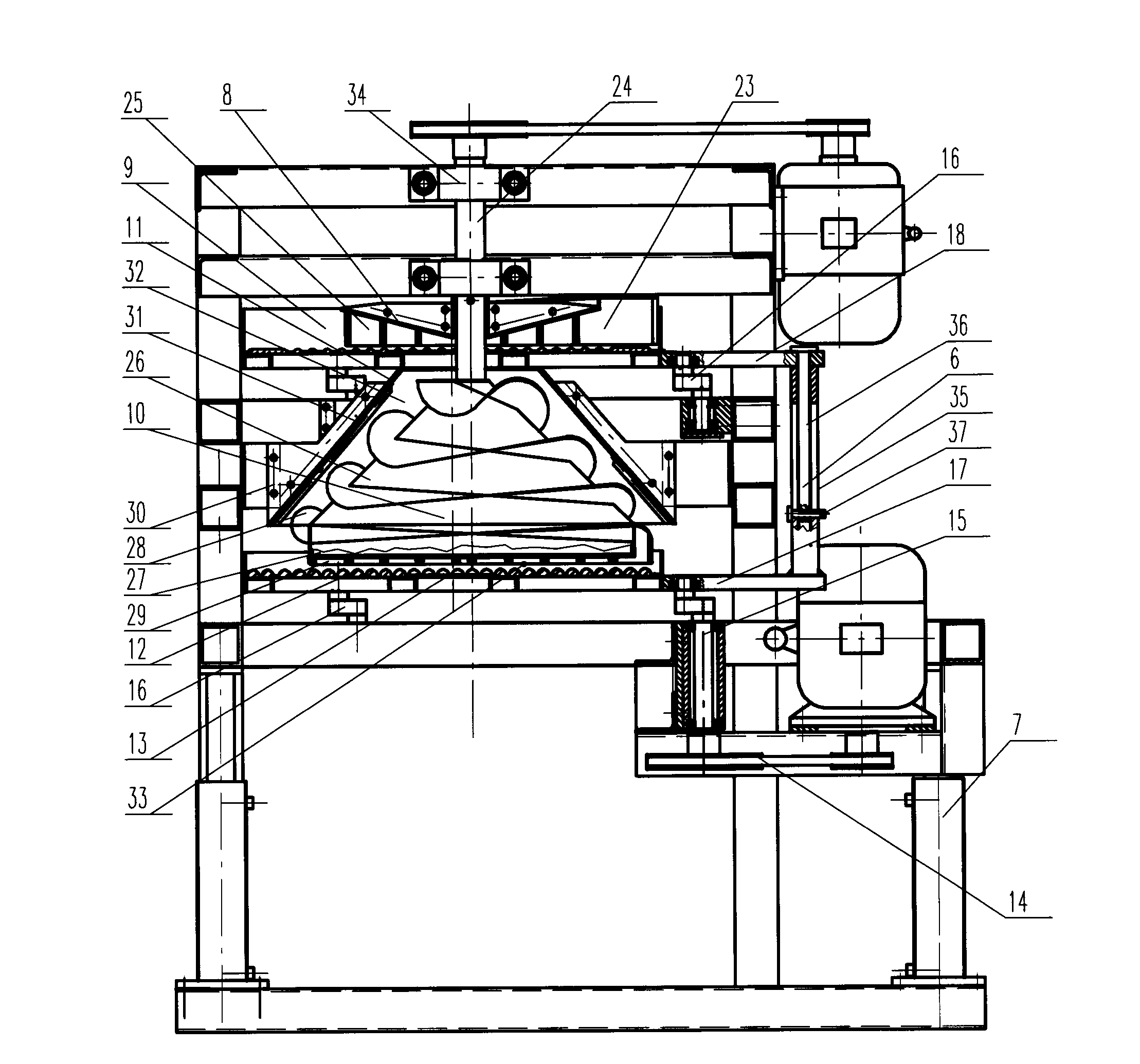

Deep-curvature glass cleaning machine

InactiveCN102343344ASolve cleaning problemsEasy to cleanCleaning processes and apparatusEngineeringWorkbench

The invention discloses a deep-curvature glass cleaning machine, belonging to the technical field of automatic equipment and relating to equipment for secondary cleaning and drying before electroplating of solar glass and deep-curvature automobile mirror glass. The cleaning machine mainly comprises a front washing part and a back flushing and drying part, wherein the front washing part comprises a conveying mechanism, a high-pressure cleaning table and a suspension cleaning brush rotating workbench; the back flushing and drying part comprises an overturning mechanism, a stain removal flushingunit, a repeated flushing unit, a tail flushing unit and a drying unit; and each unit is provided with a glass detection sensor. The cleaning machine can be used for cleaning concave-surface, convex-surface and flat-plate glass of which the thickness is 2-6 millimeters, the size is not more than 400*400 millimeters and the spherical radius is more than or equal to 250 millimeters. In the washing structure of the cleaning machine, a disk brush and a glass surface are well jointed, so that the spherical glass with deep-curvature concave and convex surfaces can be effectively cleaned; and the deep-curvature glass cleaning machine has the advantages of full cleaning, high cleanliness, saving in energy and water and high production efficiency, and is ideal equipment for solving the problem of difficulty in cleaning deep-curvature glass.

Owner:南京烨拓自动化设备有限公司

Acidic optical glass cleaner and use method thereof

InactiveCN106811328AHigh decontamination efficiencySolve cleaning problemsNon-ionic surface-active compoundsOrganic detergent compounding agentsOrganic solventPhosphoric acid

The invention provides an acidic optical glass cleaner. The acidic optical glass cleaner comprises acid, a chelating agent, an organic solvent, a suffactant and water; the acid is one or more of phosphoric acid, oxalic acid and citric acid; the quality of the acid is 0.5%-2.5% of that of the acidic optical glass cleaner; the quality of the chelating agent is 1.0%-2.0% of that of the acidic optical glass cleaner; the quality of the organic solvent is 0.5%-2.5% of that of the acidic optical glass cleaner; the quality of the suffactant is 1.5%-5% of that of the acidic optical glass cleaner. Compared with the prior art, the acidic optical glass cleaner is simple in preparation method, low in cost, moderate in condition and environment friendly and safe, decontamination efficiency of optical glass is high through mutual cooperation of the various components, and the problem about cleaning of abrasive powder and a polishing solution is solved.

Owner:LENS TECH CHANGSHA

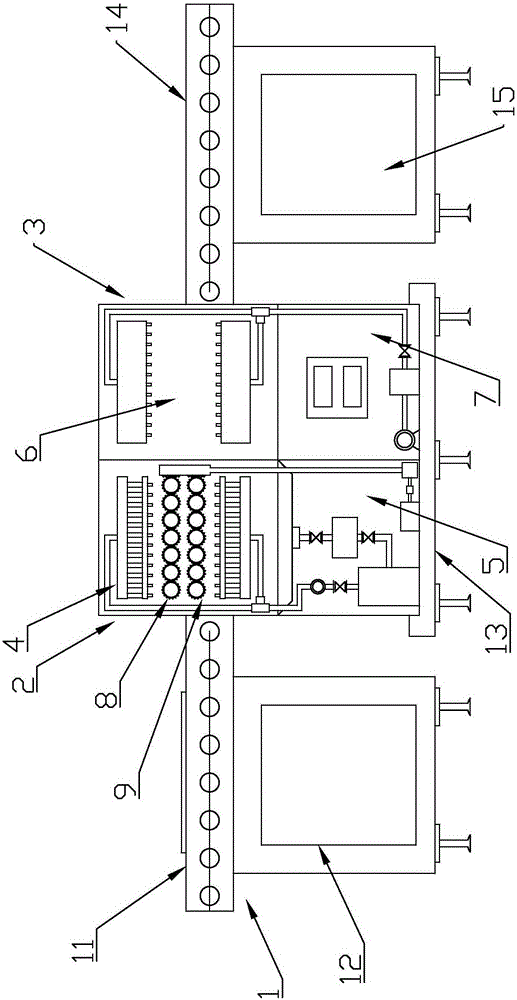

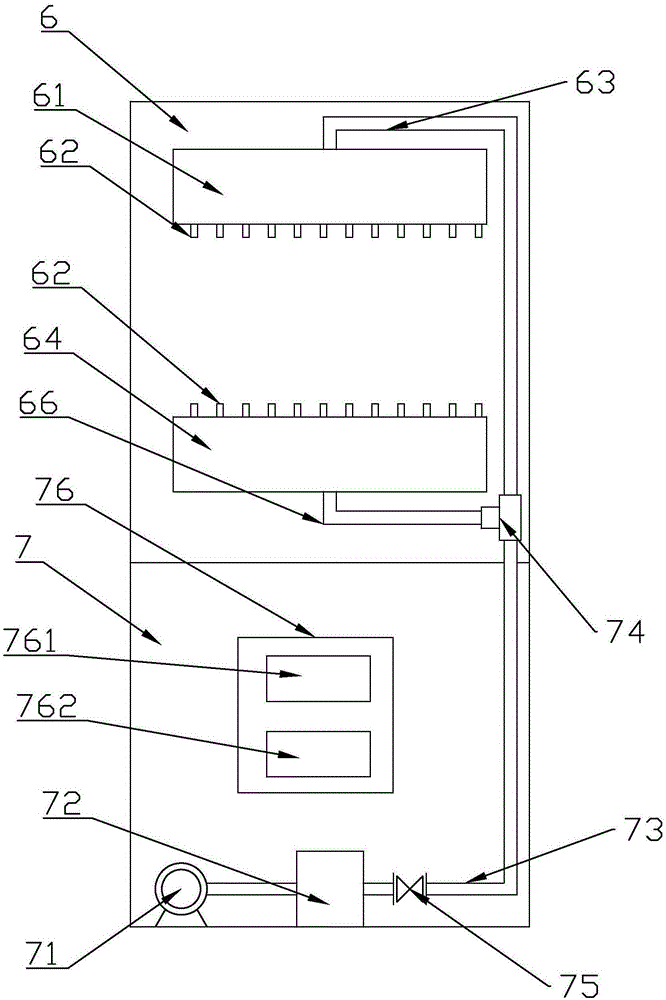

Cleaning machine applied to glass production and processing

InactiveCN105170498ASolve cleaning problemsSimple structureDrying gas arrangementsFlexible article cleaningMechanical engineeringGlass production

The invention discloses a cleaning machine applied to glass production and processing. The cleaning machine comprises a machine frame, a cleaning device and a drying device. The machine frame comprises an input platform, an input support, a main support, an output platform and an output support. The input support supports the input platform, and the output support supports the output platform. Both the cleaning device and the drying device are fixedly installed on the main support. The left side of the cleaning device is connected with an input platform, and the right side of the drying device is connected with the output platform. The cleaning device comprises a cleaning chamber and a cleaning control chamber. A scrubbing mechanism and a flushing mechanism are arranged in the cleaning chamber. The scrubbing mechanism comprises an upper scrubbing mechanism body and a lower scrubbing mechanism body. The flushing mechanism comprises an upper flushing mechanism body and a lower flushing mechanism body. The upper scrubbing mechanism body and the lower scrubbing mechanism body are connected with a scrubbing driving mechanism. The drying device comprises a drying chamber and a drying control chamber located at the lower end of the drying chamber. According to the cleaning machine, the whole cleaning and drying working process is automatic, working efficiency is high, and the cleaning and drying effects are good.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

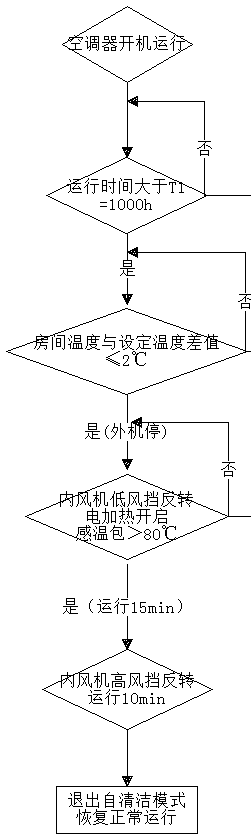

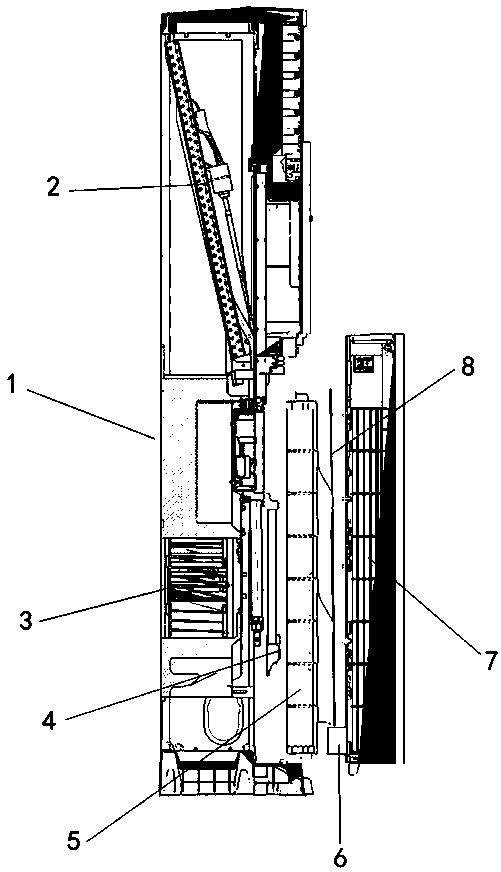

Control method for cleaning filter screen of air conditioner, computer readable storage medium and air conditioner

InactiveCN110887179AEnsure safe and healthy useGuaranteed automatic cleanupMechanical apparatusDrying gas arrangementsPhysical healthProcess engineering

The invention provides a control method for cleaning a filter screen of an air conditioner, a computer readable storage medium and the air conditioner. The accumulated running time of the air conditioner is detected, and if the accumulated running time of the air conditioner exceeds a preset threshold value, a system automatically cleans the filter screen, specifically, the filter screen is driedat high temperature, and an inner fan runs reversely. Through the newly added logic relationship, the air conditioning system realizes the timed cleaning of the filter screen, the high temperature isutilized to sterilize the filter screen, meanwhile, the high temperature reduces the adhesive force of dust, the inner fan reversely runs to blow off the dust, the automatic cleaning of the filter screen is realized accordingly, the use experience of a user is improved, and the physical health of the user is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

High-rise glass curtain cleaning machine

InactiveCN103584805AReduce weightRealize the cleaning functionCarpet cleanersFloor cleanersPulleyElectric motor

The invention relates to the field of automatic cleaning devices, in particular to a high-rise glass curtain cleaning machine. The high-rise glass curtain cleaning machine comprises a supporting frame, wherein a cleaning mechanism, a sucker fixing mechanism and a moving mechanism for driving the supporting frame to move are arranged on the supporting frame, the cleaning mechanism comprises a round cleaning brush and a motor for driving the cleaning brush, a driving belt pulley is arranged on a rotating shaft of the motor and is connected with a transmission belt pulley through a belt, the transmission belt pulley is arranged on a rotary shaft, and the rotary shaft is connected with the cleaning brush. The high-rise glass curtain cleaning machine is compact in structure, light in mass, low in cost and high in cleaning capacity of the cleaning mechanism, and a glass curtain can be cleaned more cleanly.

Owner:SHANGHAI INST OF TECH

Metal surface modification method through emulsion jet

The invention provides a metal surface modification method through emulsion jet, belonging to the processing technology of metal material surface. The metal surface modification method mainly comprises the following steps: preparing an emulsion which can produce effective cavitation bubbles and jet effect; immersing a component to be processed in the emulsion; adjusting a jet nozzle, a jet pressure and a distance between the jet nozzle and the processed metal; carrying out jet processing on the metal surface in the emulsion medium; taking the emulsion as a medium for producing cavitation jet; and forming the metal surface modification method through emulsion jet, thus improving fatigue strength of a test piece by 56% and 11% respectively. The metal surface modification method through emulsion jet of the invention has the advantages of generating the effective cavitation bubbles and improving processing efficiency of the metal surface, generating no corrosion for the metal surface, polluting no environment, having low cost, being not easy to damage the metal surface, having low investment cost and use cost, good use effects and being easy to be promoted and applied; in addition, residual emulsion does not corrode the metal surface.

Owner:CHINA UNIV OF MINING & TECH

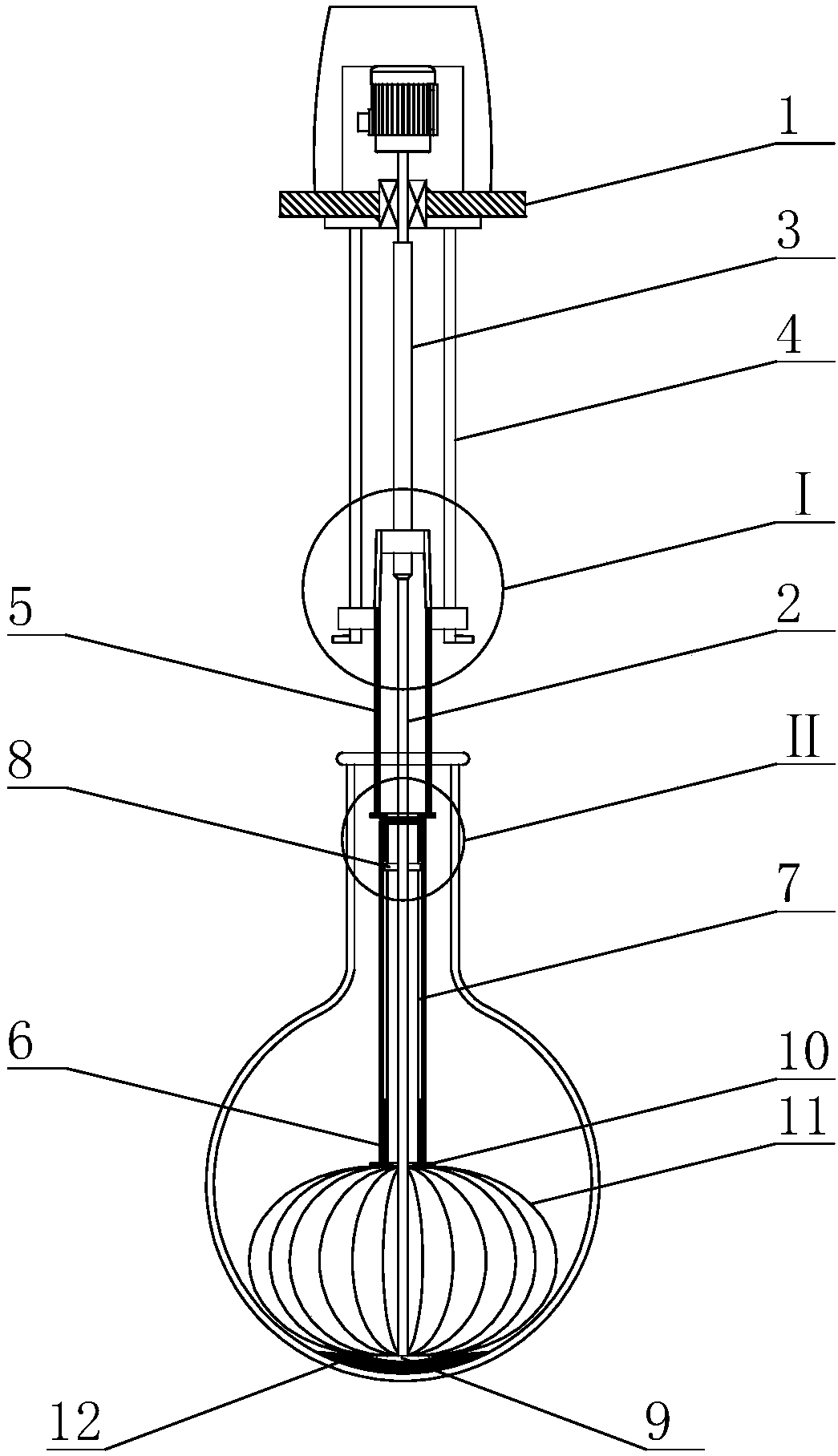

Self-adaptive flask brush head mechanism, flask brush and flask cleaning device

InactiveCN108514210AEasy accessSolve cleaning problemsBrush bodiesHollow article cleaningBristleEngineering

The invention discloses an self-adaptive flask brush head mechanism, a flask brush and a flask cleaning device, and mainly relates to the field of laboratory instrument cleaning. The device comprisesa mounting base. A rotating central shaft is mounted on the mounting base, a first lead screw is arranged on the upper part of the middle shaft, and a rail frame is fixed on the mounting base. The rail frame is provided with a lifting frame which is slidably connected to the lifting rail, and the first thread of the first screw is fixed on the lifting frame. The bottom end of the lifting frame isconnected with a control tube through the inference bearing, and the control tube and the central axis are circumferentially limited. The bottom end of the control tube is provided with an upper brushdisc, and the bottom end of the middle shaft is provided with a lower brush disc. An elastic rod is disposed between the upper brush plate and the lower brush plate, and the elastic rod surrounds thecentral axis annular array and is provided with bristles. The device has the beneficial effects of effectively solving the cleaning problem of the round bottom flask, greatly improving the efficiencyof the brushing with and significantly improved cleaning effect. The cleanliness of the experimental vessels is guaranteed.

Owner:焦梓轩

Chemical cleaning method for scales on tube of evaporator for producing ammonium sulfate

ActiveCN102400167ASolve cleaning problemsSimple processMetallic material coating processesSulfateSURFACTANT BLEND

The invention belongs to the field of the cleaning of scales on a tube of an evaporator, and discloses a chemical cleaning method for the scales on the tube of the evaporator for producing ammonium sulfate, which comprises the following steps: dredging and water washing; alkali washing: namely, adding water to carry out circulation, adding 10-40% of alkali, 0.5-1.0% of anionic surfactant and 0.5-3.3% of trisodium orthophosphate according to the amount of the water, and then, heating up to 65-95 DEG C, maintaining the temperature, monitoring the concentration of the alkali once per two hours, replenishing the alkali in time when the concentration of the alkali is less than 5%, so that the final concentration of the alkali is not less than 5%, discharging a cleaning solution outside, and adding the water again for cleaning, thereby completing the alkali washing; pickling: namely, adding the water for carrying out the circulation, adding 0.2-1.0% of pickling corrosion inhibitor and 5-10%of acid according to the amount of the water, reacting at a normal temperature, monitoring the concentration of the acid once per 0.5 hour, replenishing the acid in time when the concentration of theacid is less than 2%, and maintaining the final concentration of the acid to be 0.5-2.0%, thereby completing the pickling; and the water washing and passivating: namely, adding the water to carry outthe circulation, cleaning to be neutral, adding 2-5% of the alkali and 0.5-1.0% of the trisodium orthophosphate, circulating at the normal temperature, and carrying out passivation. By using the chemical cleaning method for the scales on the tube of the evaporator for producing the ammonium sulfate, the scales of sulfates and silicates on the tube of the evaporator can be thoroughly cleaned cleanly, thereby reaching a mirror face state.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

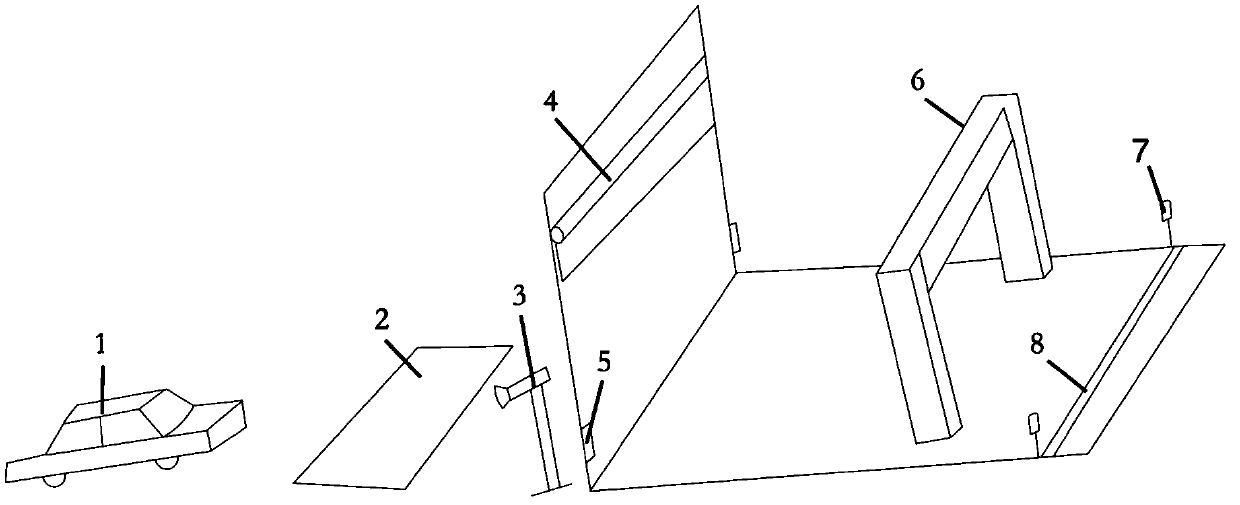

Intelligent unmanned vehicle washing room, method and system

PendingCN108674386ALow costImprove car wash efficiencyDoor/window protective devicesCleaning apparatus for vehicle exteriorsAutomotive engineering

The invention discloses an intelligent unmanned vehicle washing room, method and system. The intelligent unmanned vehicle washing room comprises a room body which is provided with an electric rollingdoor, a plate number recognizing camera which is arranged outside the electric rolling door to recognize the plate number of a vehicle getting close to the electric rolling door, a vehicle cleaning device which is arranged in the room body to clean the vehicle entering the room body and a controlling device which is connected with the plate number recognizing camera to control the plate number recognizing camera to recognize the plate number information of the vehicle; the controlling device is connected with the electric rolling door to control the electric rolling door to open or close; andthe controlling device is connected with the vehicle cleaning device to control the vehicle cleaning device to start or stop. In this way, unmanned vehicle cleaning is achieved, cost is lowered and vehicle cleaning efficiency is high.

Owner:春笋新科技(深圳)有限公司

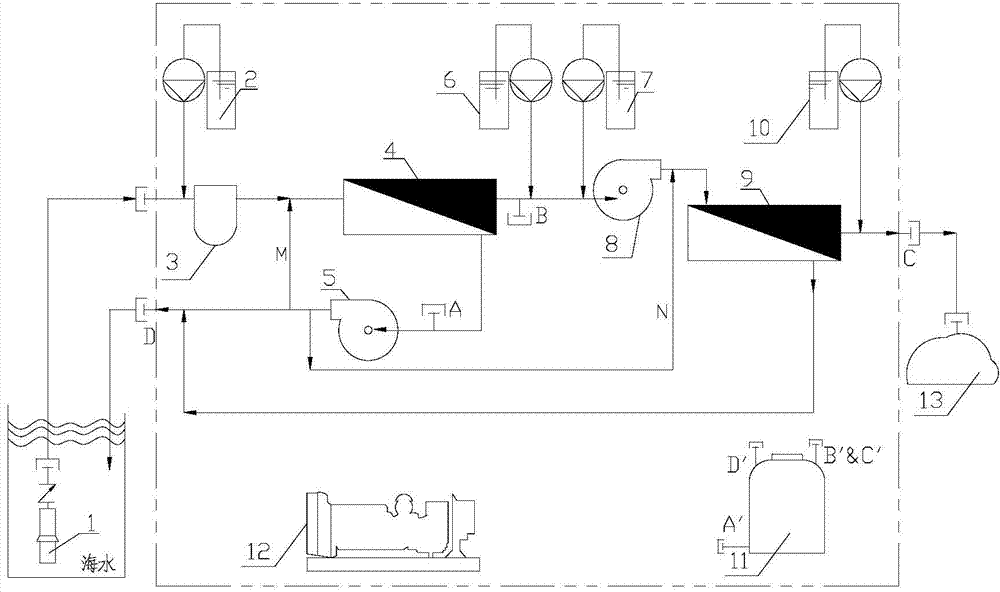

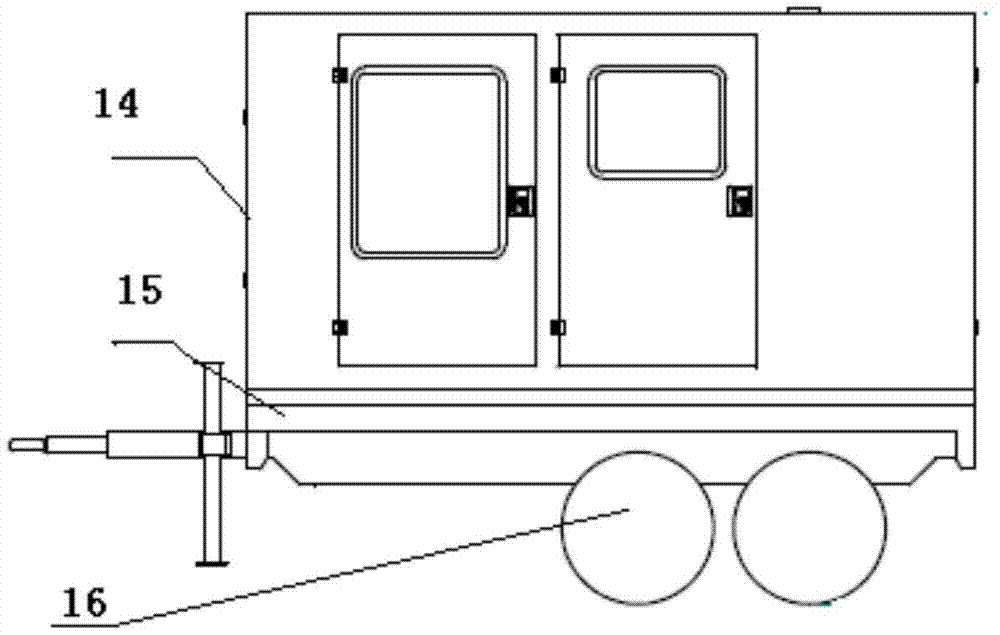

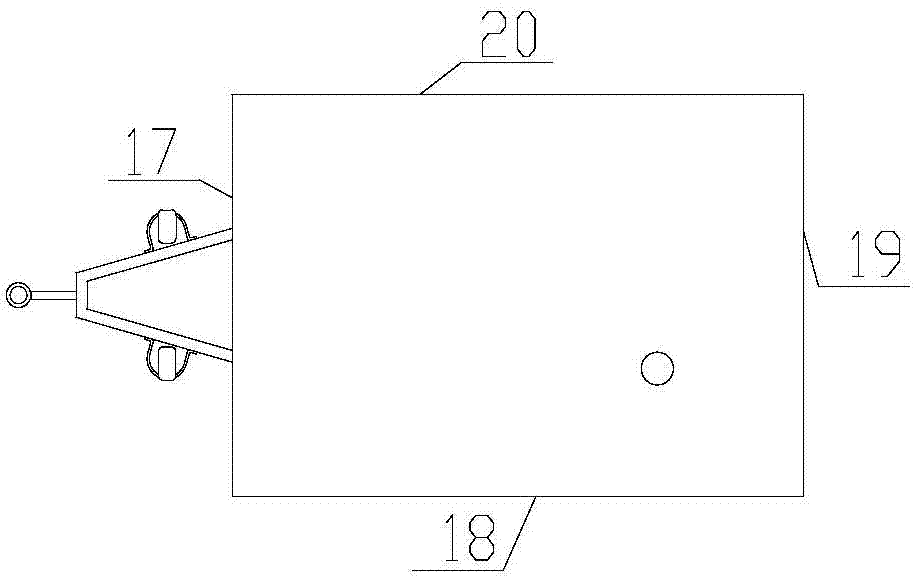

Modular portable reverse osmosis seawater desalination integration apparatus and use method thereof

InactiveCN104326591AReduce volumeReduce weightWater treatment parameter controlGeneral water supply conservationAviationWhole body

The invention relates to the field of seawater desalination, and concretely relates to a modular portable reverse osmosis seawater desalination integration apparatus and a use method thereof. The apparatus is characterized in that a water intake pump, a bactericide dosing device, a filter, an ultrafiltration membrane assembly, a circulating pump, a reducing agent dosing device, a scale inhibitor dosing device, a high pressure pump, a reverse osmosis membrane assembly, a post-treatment dosing system, a cleaning water tank and a foldable water storage bag form a reverse osmosis seawater desalination system, the above devices except the water intake pump, the cleaning water tank and the foldable water storage bag all are fixedly installed in a trailer box body, and the whole body is a reverse osmosis desalination module. A pretreatment unit, a reverse osmosis desalination unit, a chemical dosing unit, a chemical cleaning unit and an electric and control unit are compactly, stably and reasonably integrated in the trailer with a closed box body trough a filter + ultrafiltration + reverse osmosis double membrane process, so the apparatus has the advantages of small size, light weight, flexible movement, and realization of transportation through aviation, highway, railways and ships.

Owner:沈阳远大固废处理有限公司

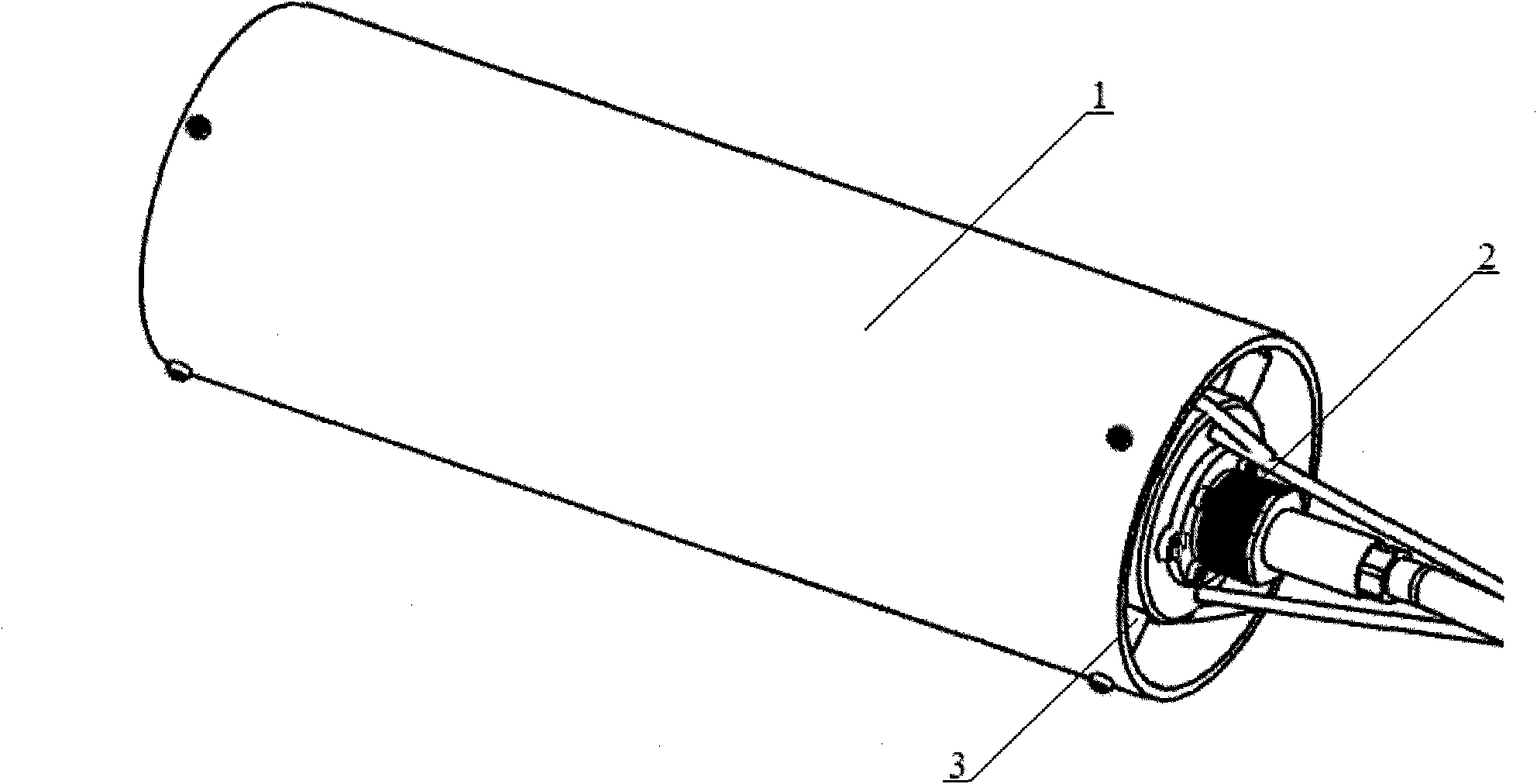

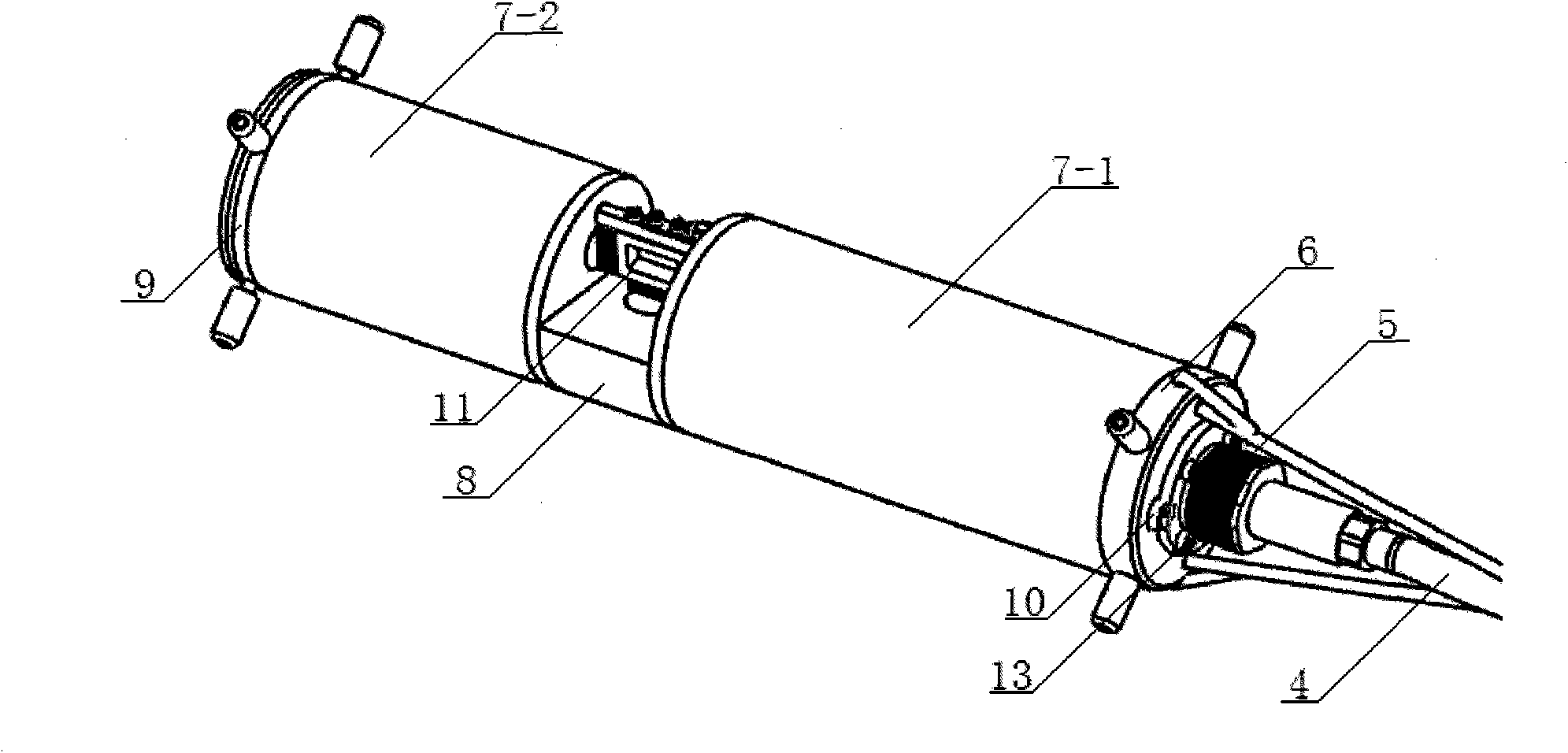

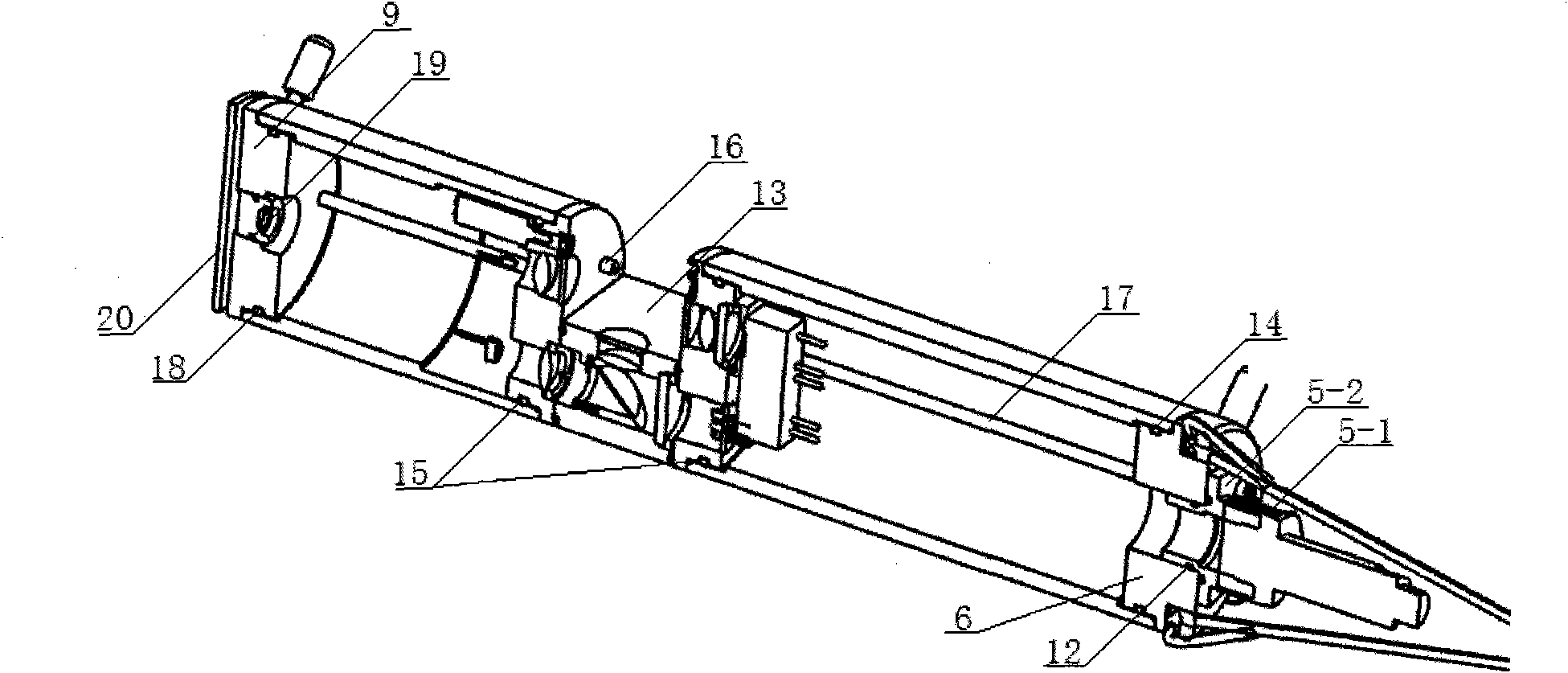

Portable optical mechanical system of underwater in-situ luminoscope

InactiveCN101957320ARealize measurementUse light weightFluorescence/phosphorescenceFluorescenceUnderwater

The invention discloses a portable optical mechanical system of an underwater in-situ luminoscope, which comprises black nylon cylinders. A hollow semicircular base is arranged among the black nylon cylinders to form a monitoring cylinder, and end covers are arranged in cylinder openings at two ends of the monitoring cylinder which is sleeved with a black nylon shell. The invention realizes fluorometric management of water samples and real-time monitoring of the influence of measurement light in the fluorometric management. The portable optical mechanical system is integrated with temperature and pressure sensors which can be used for monitoring water temperature and pressure. A window cleaning brush is used in the portable optical machine system for cleaning windows of the sensors which are used underwater for a long term. The portable optical mechanical system can be used for quickly detecting water samples in wild fields by environment monitoring departments, has the advantages of light weight, easy carrying and the like, and also can be installed on a buoy or an automatic monitoring station for long-term continuous monitoring of water bodies of a fixed monitoring point.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Cleaning device for tempered glass deep processing

ActiveCN112958571ASolve cleaning problemsClean and comprehensiveDrying gas arrangementsFlexible article cleaningEngineeringToughened glass

The invention belongs to the technical field of glass processing, and discloses a cleaning device for tempered glass deep processing. The cleaning device comprises a bottom mechanism, a transmission mechanism is arranged at the bottom of the inner side of the bottom mechanism, a sliding mechanism is arranged at the top of the bottom mechanism, a cleaning mechanism is slidably connected to the bottom end of the sliding mechanism, and the bottom mechanism comprises a supporting frame; and shaft holes are formed in the opposite inner walls of the supporting frame, a rotating shaft is rotationally connected into the shaft holes, a fixed plate is arranged at one end of the rotating shaft, first air bags are communicated with the two sides of the fixed plate, clamping plates are arranged at the other sides of the first air bags, and communicating air channels are formed in the clamping plates. By means of the cleaning device, transmission, clamping, cleaning and overturning of to-be-tempered glass can be simply and conveniently completed, cleaning is comprehensive and free of dead corners, meanwhile, soft contact clamping of the to-be-tempered glass can be achieved by means of the air bags, the clamping effect is good, and wind power drying and impurity removal, impurity liquid flow guiding and recycling and the like can be conducted on the to-be-tempered glass.

Owner:广西荆楚新型建材有限责任公司

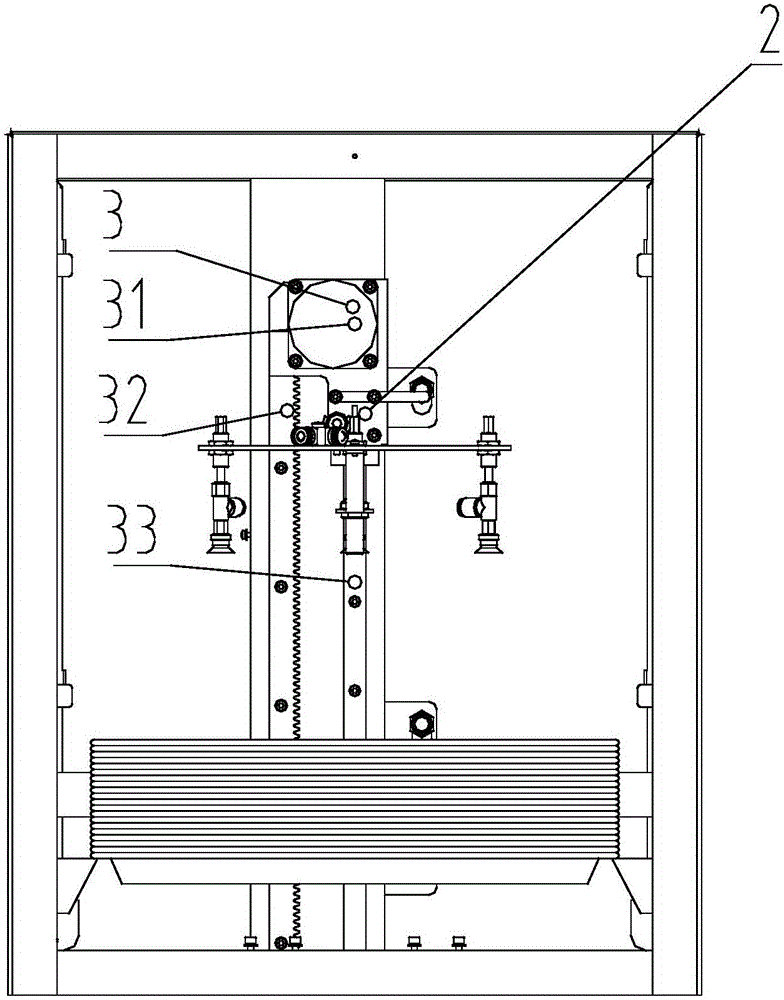

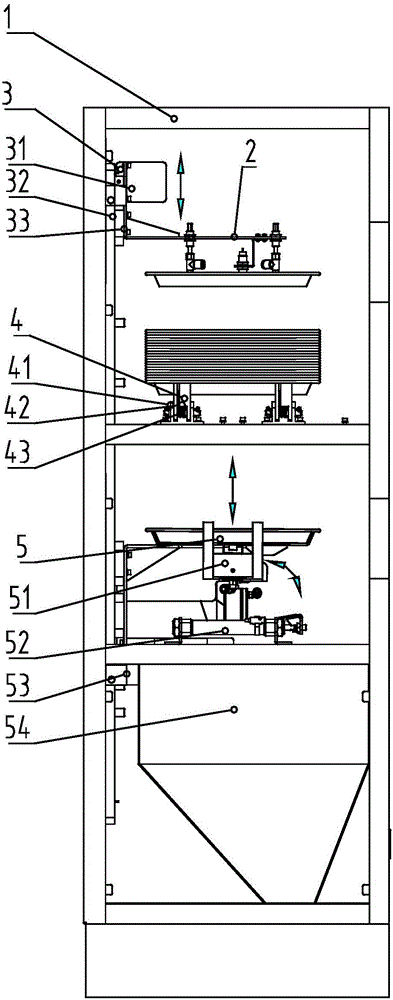

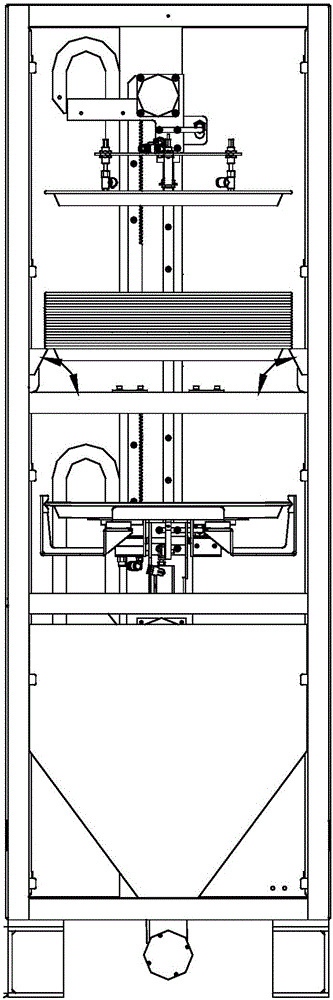

Storing and picking device and method for sample plates

The invention provides a storing and picking device for sample plates. The storing and picking device comprises a box body, a sample plate grabbing assembly, a sample plate stacking mechanism and a lifting mechanism, wherein the sample plate grabbing assembly and the sample plate stacking mechanism are located inside the box body and are sequentially arranged from top to bottom, the sample plates are stacked on the sample plate stacking mechanism, and the lifting mechanism drives the sample plate grabbing assembly to be vertically lifted for grabbing and lifting the sample plates. According to the storing and picking device for the sample plates, the lifting mechanism drives the sample plate grabbing assembly to be vertically lifted, one sample plate is lifted each time, and therefore the load in the lifting process of a motor is lowered, and the failure rate of the motor is lowered. Furthermore, a sample plate rejecting mechanism capable of picking the sample plates and rejecting the sample plates simultaneously is arranged additionally, and therefore the sample plates can be swept. According to the storing and picking device for the sample plates, the storing and picking function and the sweeping function are integrated, the occupied space of equipment is reduced, and the size of the equipment is reduced. In addition, the invention provides a storing and picking method for the sample plates.

Owner:长沙开元仪器有限公司

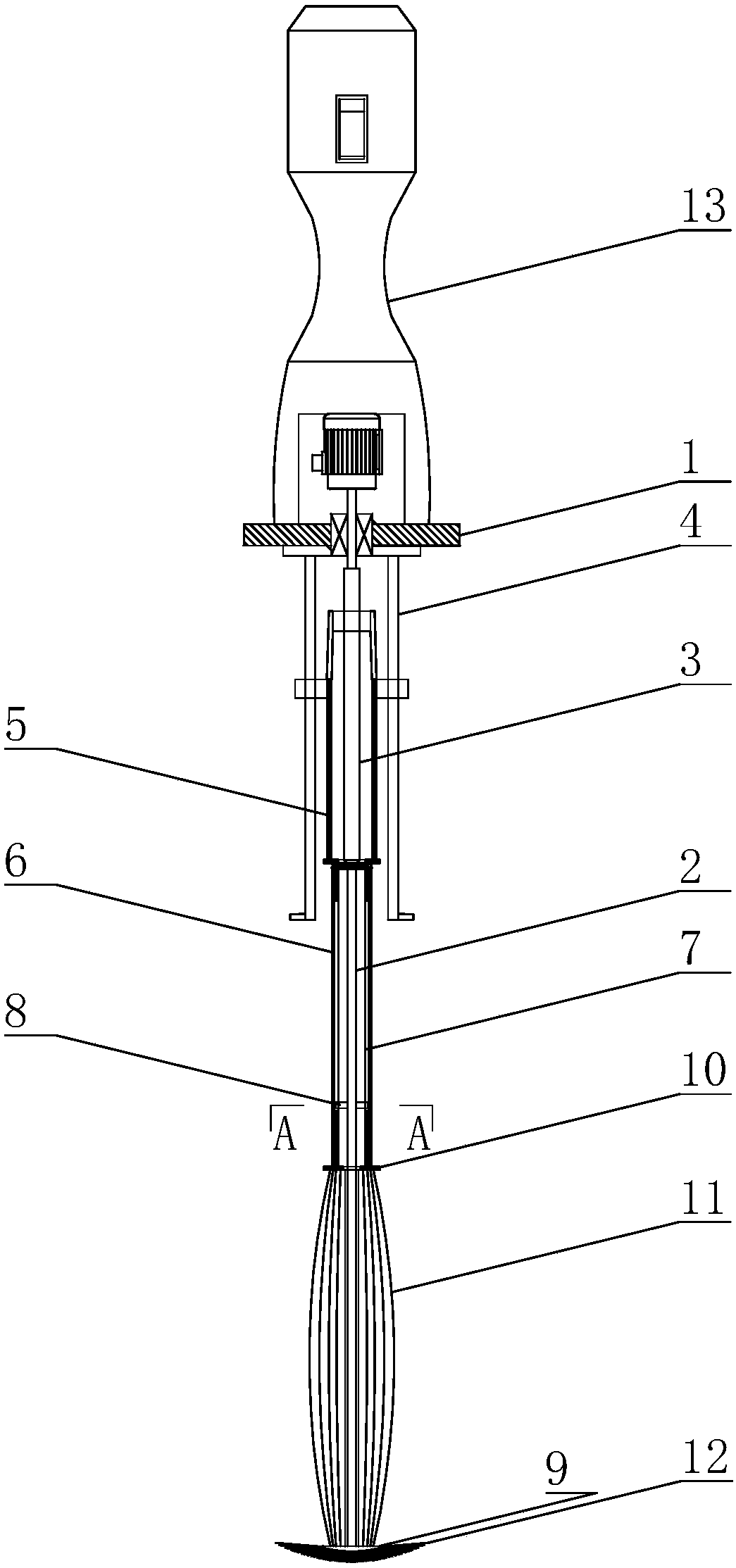

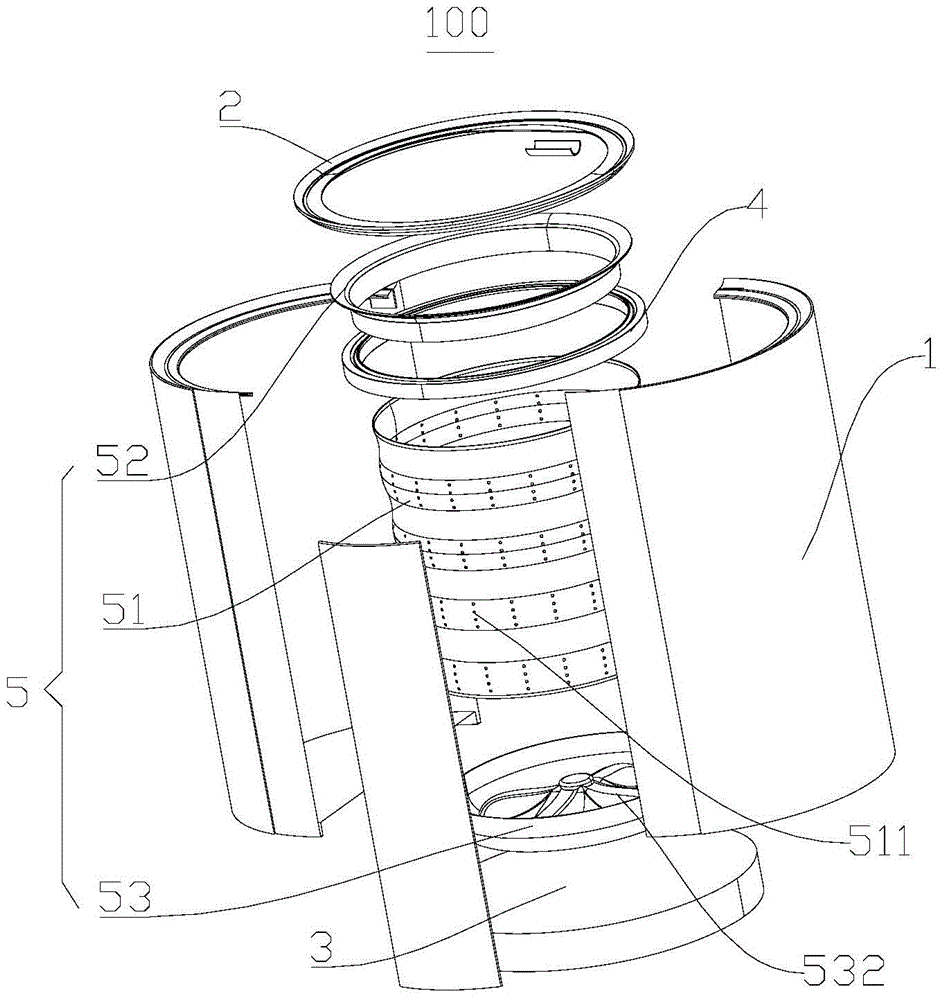

Continuous tea twisting machine

ActiveCN102771583ASolve cleaning problemsEasy to cleanPre-extraction tea treatmentCircular discDrive shaft

The invention relates to a continuous tea twisting machine, which comprises a frame, a twisting device and a transmission mechanism, wherein the twisting device comprises a feeding hopper, a material sweeper, a twisting core, a shell and a kneading plate; the feeding hopper and the material sweeper are arranged above the twisting core; the material feeder is arranged inside the feeding hopper; the twisting core is arranged in a space formed by the shell and the kneading plate; the kneading plate is arranged below the twisting core; a discharge hole is arranged at the bottom part of the twisting plate; the center of the discharge hole deviates from the center of the kneading plate; the kneading core is composed of a cone and a disk of which the middle part sinks; spiral guide-leaf plates are arranged at the upper part and middle part of the twisting core; a spiral guide-leaf rib is arranged at the bottom part of the twisting core; the feeding hopper and the material sweeper form a primary conglobation area; the upper part of the twisting core and the shell form a kneading transition area; the bottom part of the twisting core and the kneading plate form a twisting forming area; the shell is vertically halved; the left and right halves can be opened; the kneading plate can be opened downwards; an axial transmission shaft is arranged at the upper end part of the twisting core; and a bearing block of the transmission shaft is arranged on the frame, and the transmission shaft and the transmission mechanism are in transmission connection.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

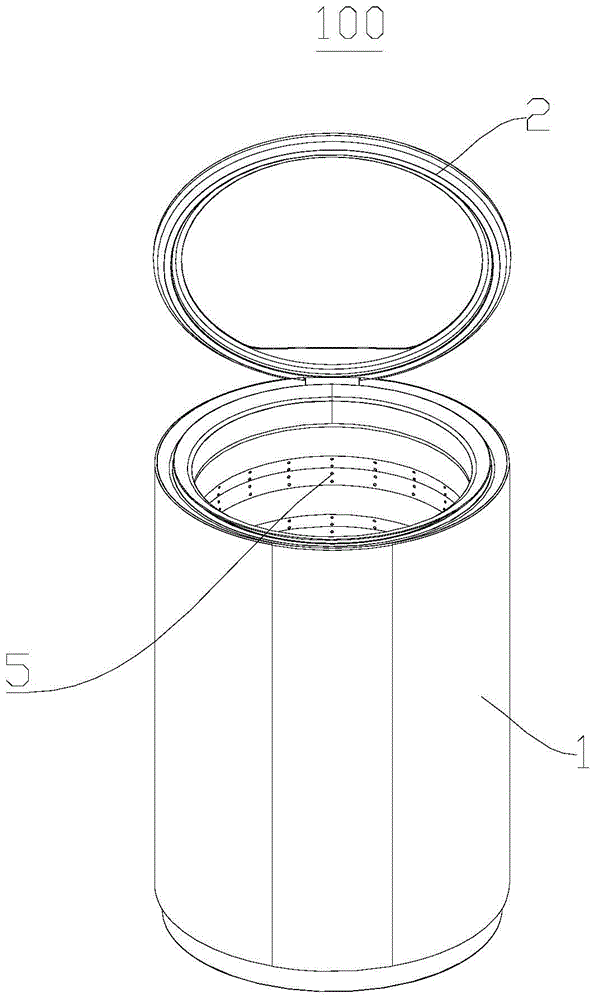

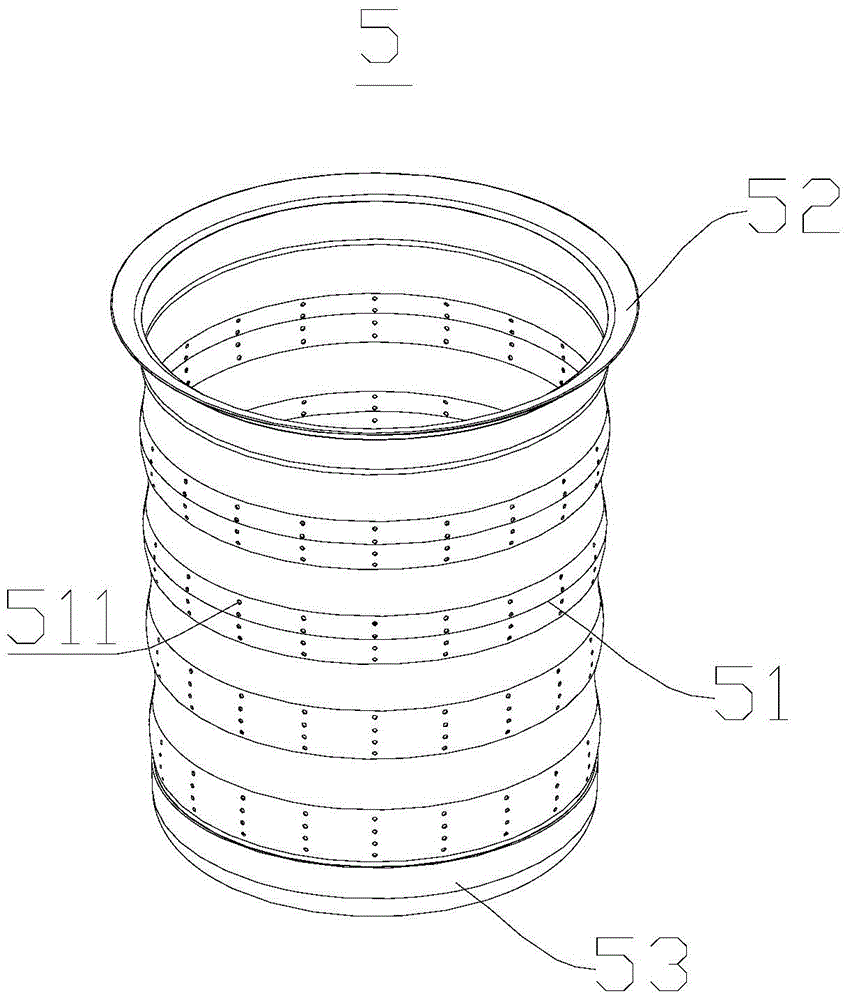

Washing machine

InactiveCN105040348ASolve cleaning problemsOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a washing machine which comprises the components of a housing, a machine cover, a driving assembly, a supporting member and a drum assembly. A mounting space is limited in the housing. The machine cover is arranged at the top of the housing in an openable manner for opening and closing the mounting space. The driving assembly is arranged at the bottom in the mounting space. The supporting member is arranged at the upper part in the mounting space. The drum assembly is detachably arranged in the mounting space. The upper end of the drum assembly is rotatably hanged on the supporting member, and the lower end matches the driving assembly in a separatable manner. The drum assembly is constructed in a manner that the driving assembly drives the drum assembly to rotate in matching with the driving assembly. According to the washing machine, through arranging the drum assembly which can be easily detached and lifted out, not only is a problem for cleaning the drum assembly settled, but also multiple functions of one drum are realized, thereby satisfying a comprehensive requirement of specific and classified washing and individual customization.

Owner:WUXI LITTLE SWAN CO LTD

Formaldehyde absorption tower

InactiveCN101670230AAddressing Absorption EfficiencyRedistributionOrganic chemistryDispersed particle separationHigh concentrationHigh absorption

The invention discloses a formaldehyde absorption tower. The absorption tower comprises a tower kettle, wherein the lower part of the tower kettle is provided with a mixed gas inlet and a finished product formaldehyde outlet, the upper part of the tower kettle is provided with a water inlet and a exhaust gas outlet, two layers of packing are arranged in the tower kettle, and formaldehyde solutioncirculating pipes are arranged between packing layers. During the displacement process that mixed gas moves from bottom to top and water flows from top to bottom, formaldehyde in the mixed gas is dissolved in water to form formaldehyde solution, wherein the formaldehyde solution is circulated between two layers of packing so as to gradually increase the concentration of formaldehyde. A sprinkler used for wetting the inner wall of the tower kettle is arranged below the packing layers so as to prevent the wall-cling phenomenon of the formaldehyde absorption solution. The formaldehyde absorptiontower can be used to prepare high concentration formaldehyde and has higher absorption efficiency; in addition, the absorption tower can solve the problem of formaldehyde polymerization in the production process of high concentration formaldehyde.

Owner:江阴市华燕石化机械装备有限公司

Polishing liquid for grinding and polishing micro crystal glass

InactiveCN1858132AIncrease reaction rateReduce surface roughnessAqueous dispersionsPolishing compositions with abrasivesIonChemistry

Owner:HEBEI UNIV OF TECH

Continuous double-layer tea rolling machine

ActiveCN103843918AMeet the requirements of the processing lineUniform kneading qualityPre-extraction tea treatmentEngineeringParallelogram

The invention relates to a continuous double-layer tea rolling machine comprising a stand, a rolling device, a transmission mechanism (1), a lifting platform, a parallelogram mechanism, a linkage rod and a lifting mechanism, wherein the rolling device comprises a spiral dish, an upper rolling dish, a rolling core, an outer casing of the rolling core, and a main rolling dish; the spiral dish and the upper rolling dish are positioned above the rolling core; the spiral dish is loaded in the upper rolling dish; the rolling core is loaded in a space formed by the outer casing of the rolling core and the main rolling dish; the main rolling dish is positioned below the rolling core; a circular hole is formed in the center of the main rolling dish for serving as a discharge hole; the outer casing of the rolling core is fixed and immovable, the upper rolling dish and the main rolling dish do uniform plane circular motion, and the spiral dish and the rolling core do rotation motion. Rolling areas comprise a primary rolling shrinking area, a kneading transition area and a rolling area. The continuous double-layer tea rolling machine is a tea manufacturing machine which is uniform in tea rolling quality, easy to operate and convenient to rinse. By utilizing the continuous double-layer tea rolling machine, requirements of a tea process line can be met, and requirements on cultural qualities of operators are not high.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com