Washing method for water tank type dish washer

A washing method and dishwasher technology, which are applied in the direction of tableware washing machine/rinsing machine, sustainable building, cleaning equipment, etc., can solve the problem that the dishwasher does not clean the tableware, it is difficult to solve the dead angle of dish spraying, and no It has the problems of eddy washing tableware, etc., to avoid excessive eddy scouring force, low noise, good loosening and softening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

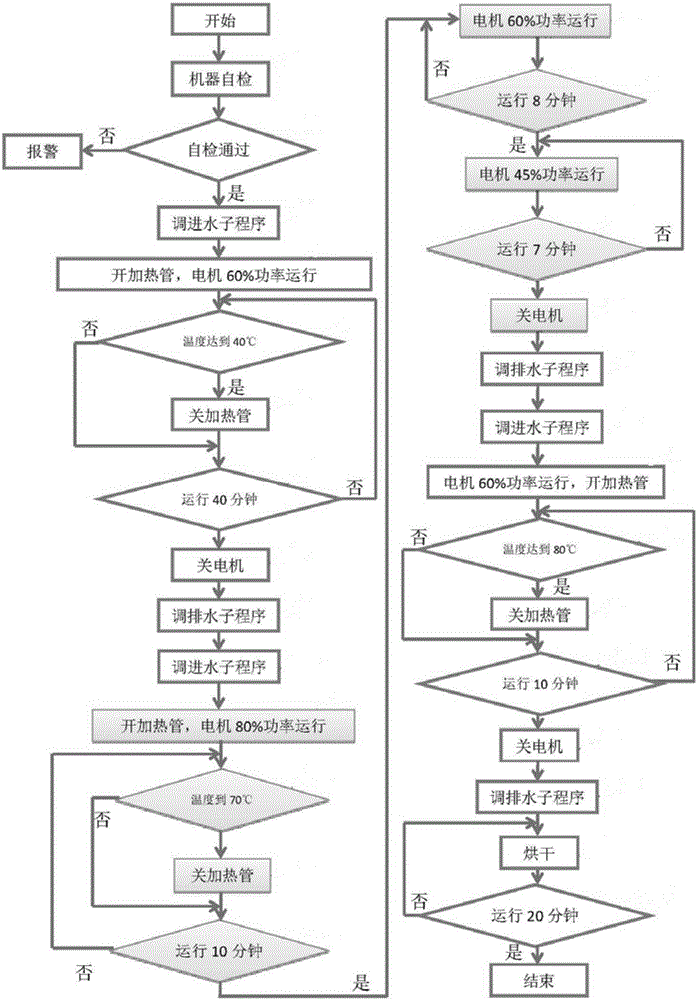

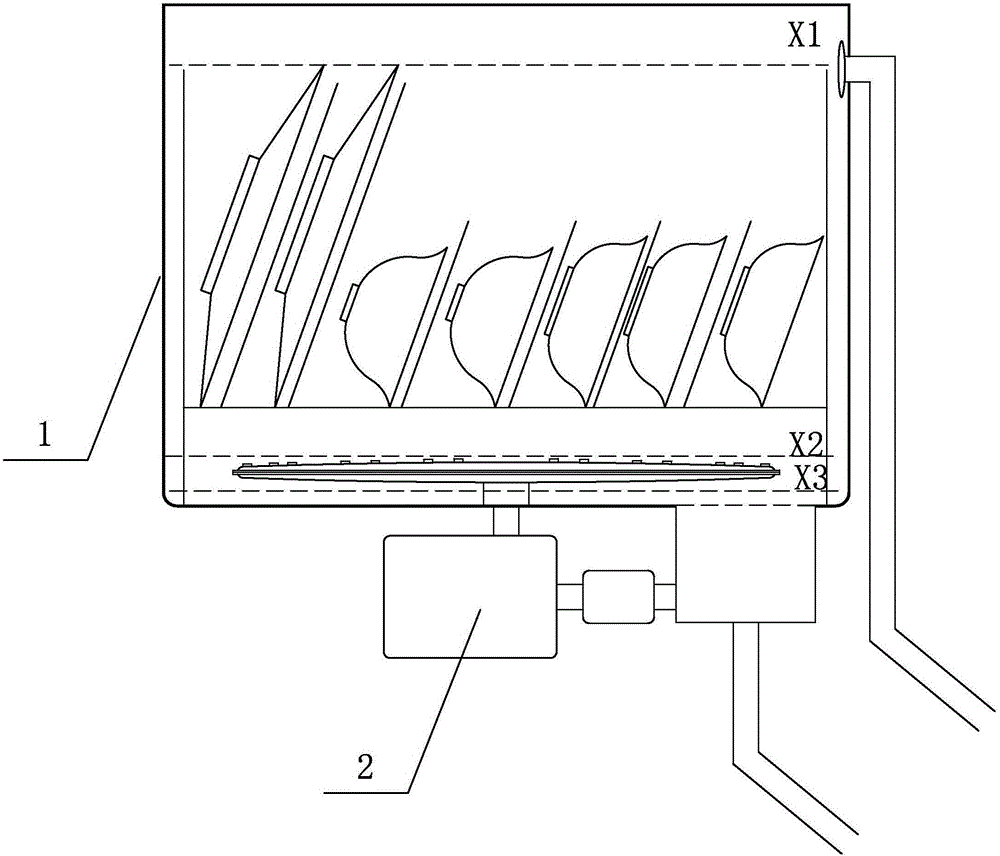

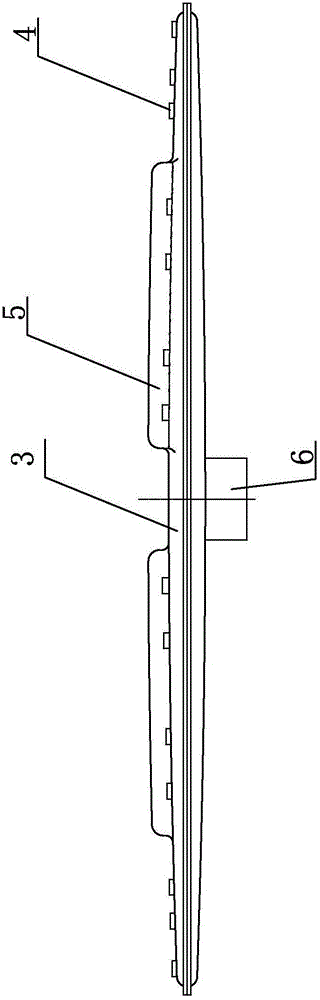

[0022] like Figure 1-5 As shown, a washing method for a sink type dishwasher includes a sink 1, an inlet pipe for water supply to the sink 1, a drain pipe for draining the water tank 1, a circulating water pump and a heating device, and the bottom of the sink 1 rotates A rotating spray arm is connected, and the washing method includes a prewashing stage, a main washing stage and a rinsing stage;

[0023] In the preparation stage, the machine self-inspection, if there is no alarm, the self-inspection passes;

[0024] Pre-washing stage: adjust the water subroutine, open the water inlet pipe, when the water inlet reaches any position from the water level line X2 on the upper surface of the rotating spray arm to 1 / 3 of the predetermined water volume full of the dishes, turn on the heating The tube starts to heat up; (such as figure 2 As shown, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com