Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2139 results about "FORMALDEHYDE SOLUTION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of formalin : a clear aqueous solution of formaldehyde and methanol used especially as a preservative : a clear aqueous solution of formaldehyde containing a small amount of methanol

Micro-crack self-repairing microcapsule and preparation method thereof

ActiveCN102702838ARealize automatic curingFill crack voidsAnti-corrosive paintsMicroballoon preparationCyclohexanoneSolvent

The invention discloses a micro-crack self-repairing microcapsule, which comprises a capsule core and a capsule wall, wherein the capsule core comprises the following ingredients in part by weight: 10 to 60 parts of isocyanate derivative, 0.1 to 10 parts of capsule core diluent and 2 to 40 parts of cosolvent; and the capsule wall comprises ingredients with the following mol ratio: urea: formaldehyde solution, prepolymer=1: (1.0-4.0): (2.0-6.0), wherein the prepolymer is formed from the ingredients with the mol ratio: isocyanate derivative: cyclohexanone: chain extender=1: (2.0-5.0): (0.3-3.0). The invention also discloses a micro-crack self-repairing anti-corrosion coating utilizing the capsule. The micro-crack self-repairing microcapsule is free from additionally adding a repairing catalyst or an initiator, can realize completely automatic repairing function, can be widely applied to the protection field of a metal surface coating in a wet environment, and solves the problems that the contact probability between functional filling material flowing into cracks in the intelligent anticorrosion coating and the catalyst or the initiator is small.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

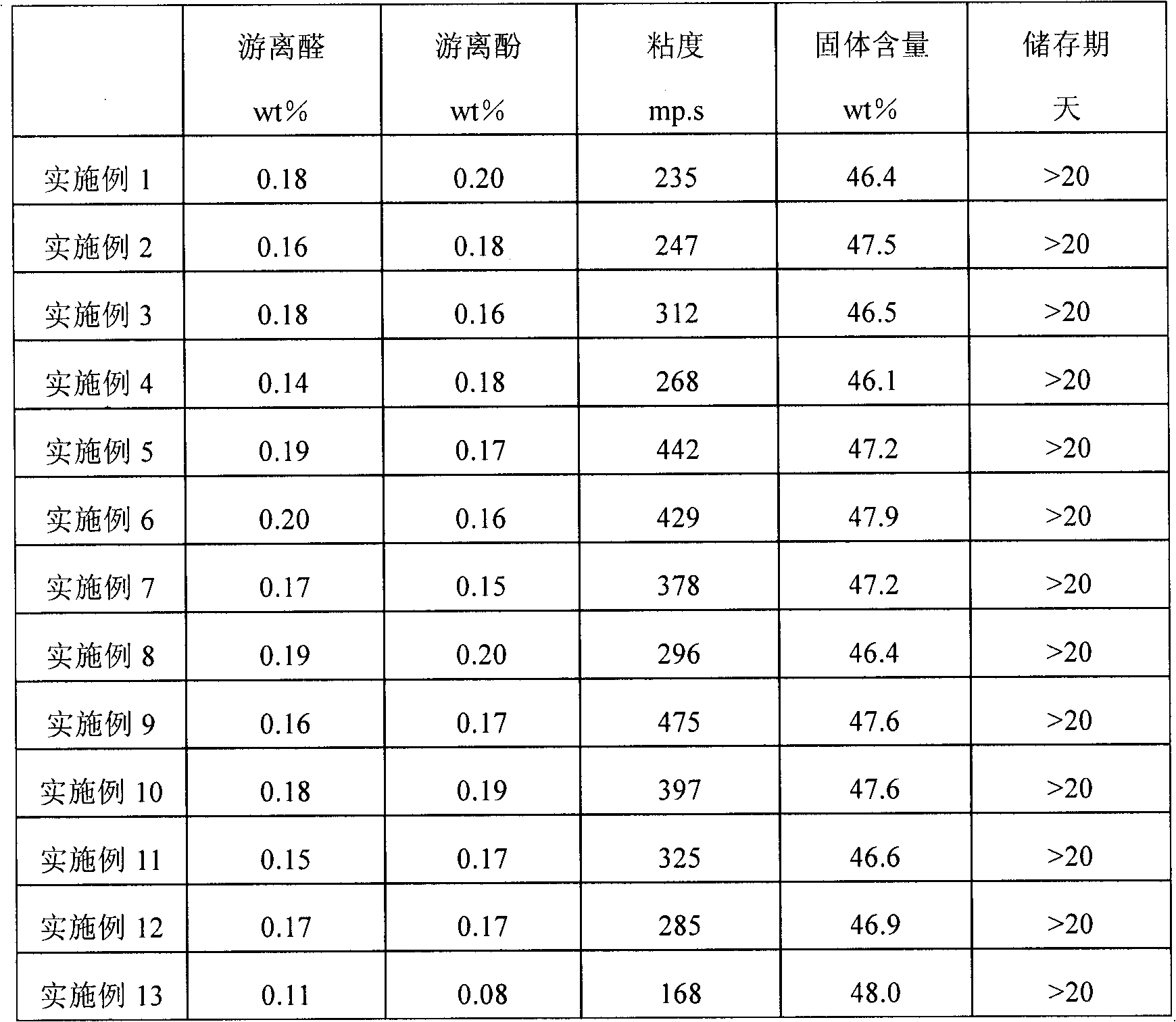

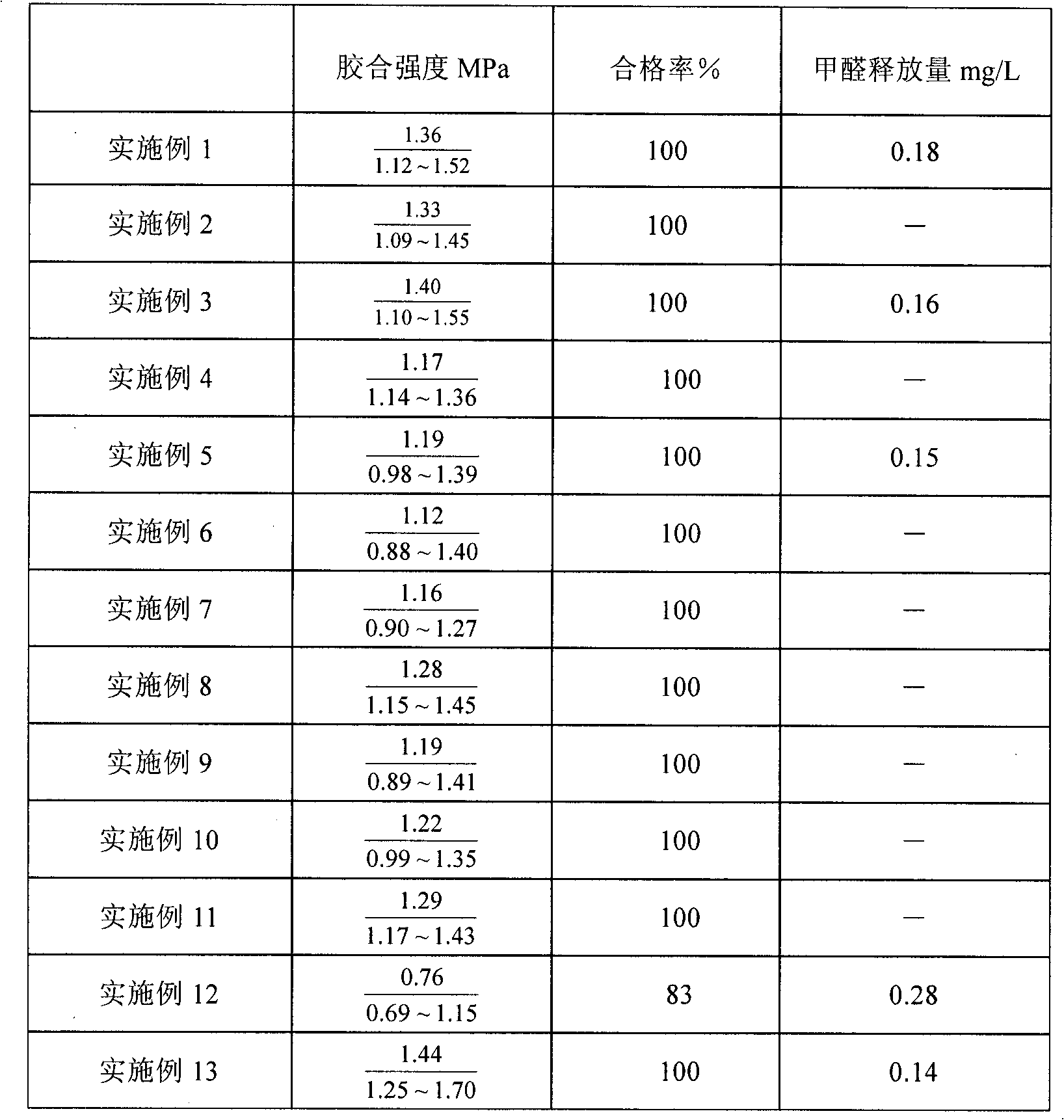

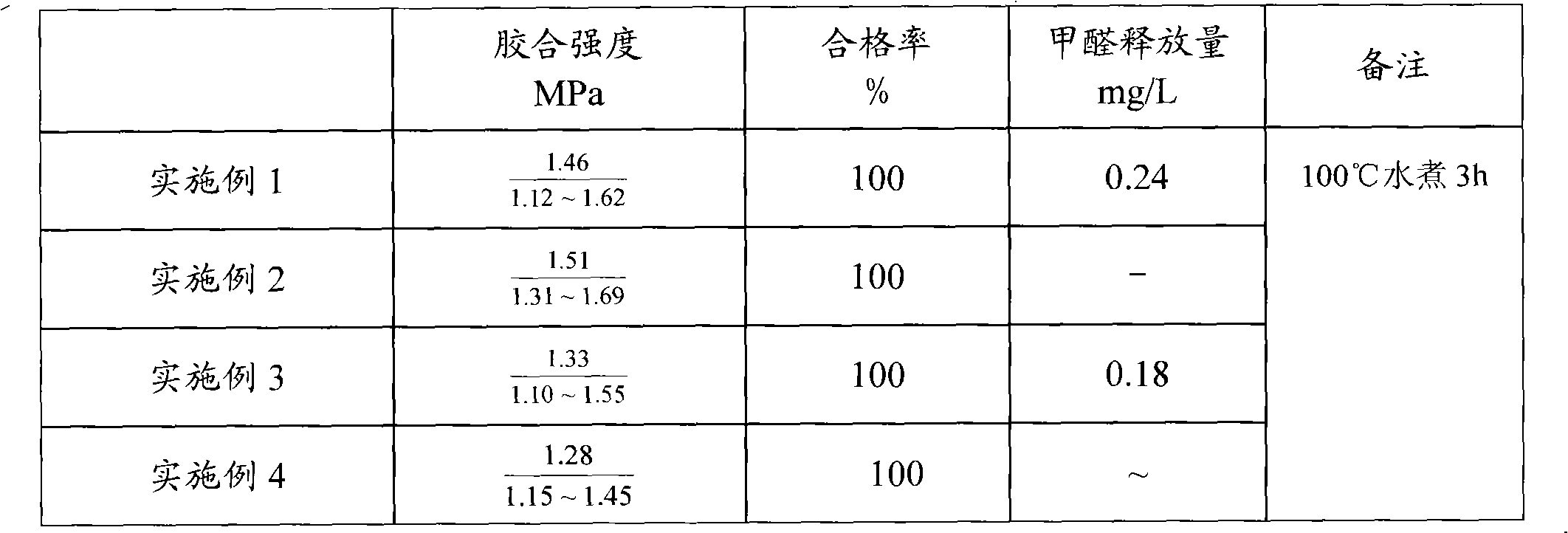

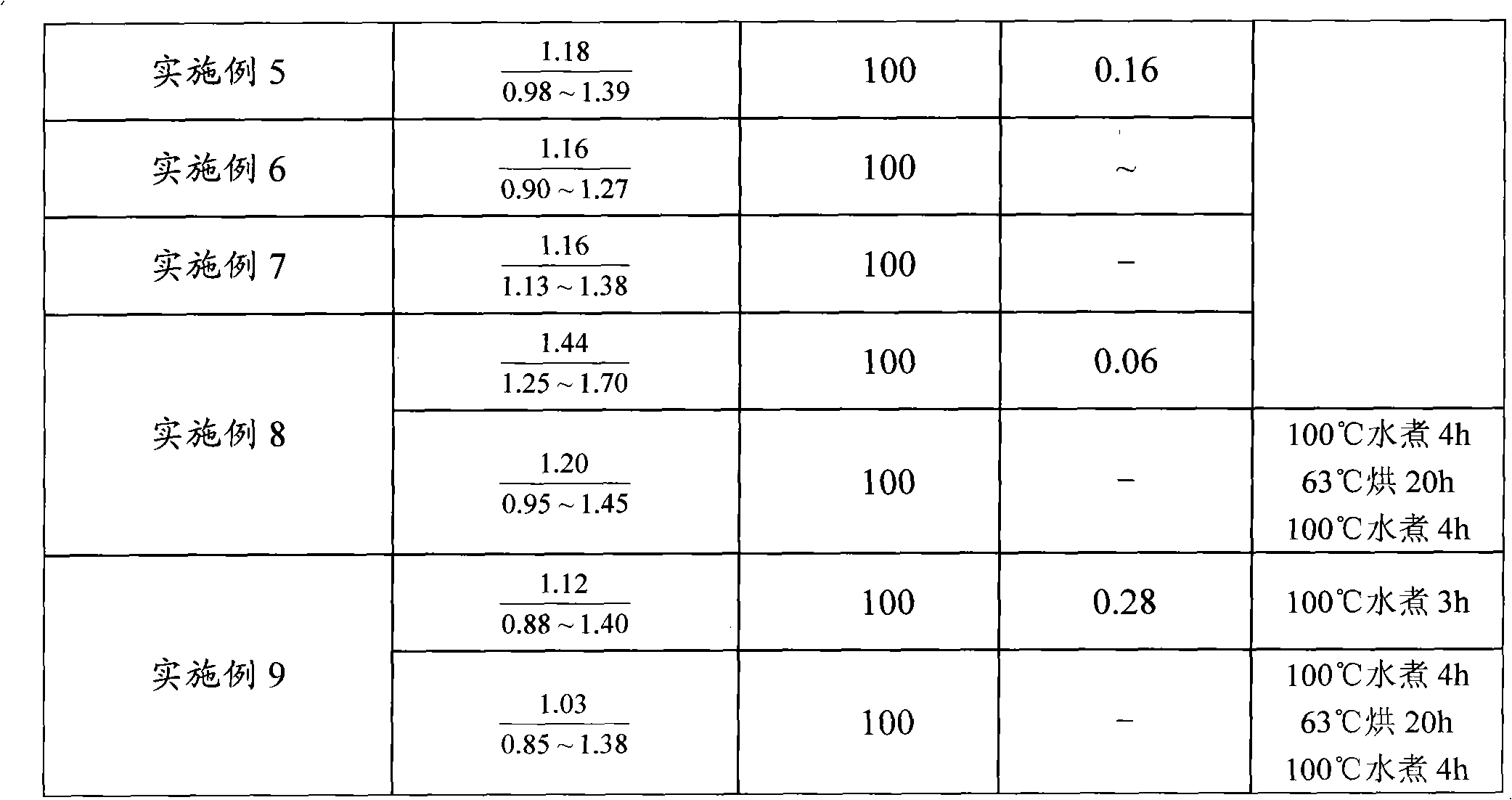

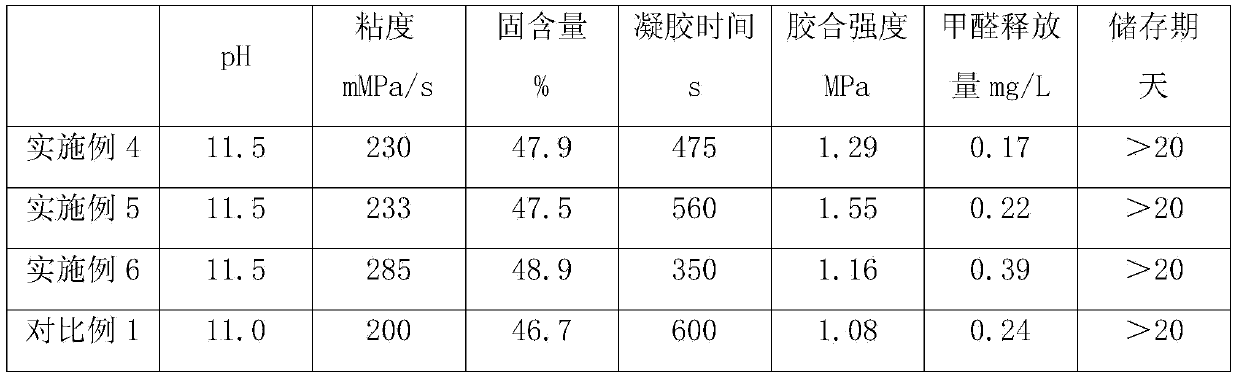

Method for preparing environmentally-friendly adhesive for lignin-based timber

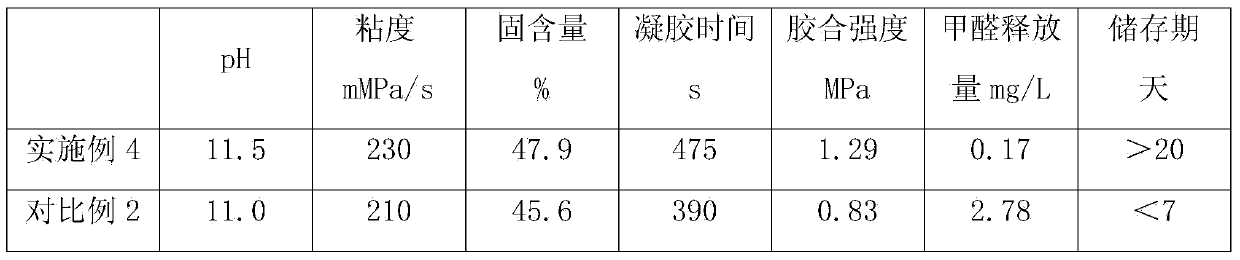

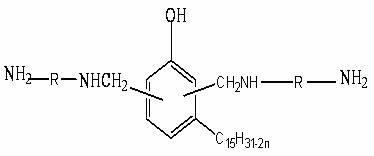

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522AOrderly and fast responseAdequate responseAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

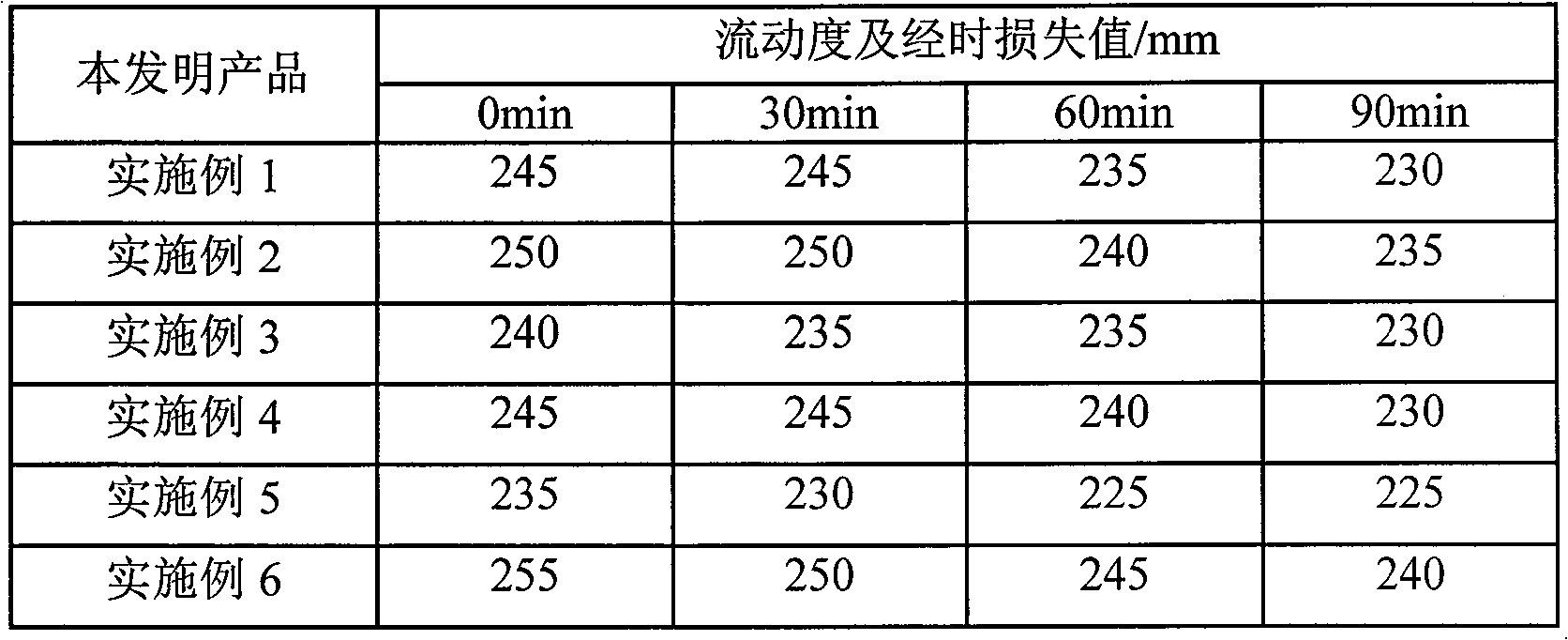

Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

The invention relates to a method for preparing a modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate, belonging to the field of concrete water-reducing agents. The invention adopts acetone and formaldehyde as condensation monomers and lignosulfonate as a modifying agent and carries out sulfonating and condensation reactions under an alkaline condition to produce anovel high-efficiency concrete water-reducing agent. The preparation method of the novel high-efficiency concrete water-reducing agent comprises the following steps: (1) adding a sulfonating agent, acetone and water to a reactor, increasing the temperature to 25-65 DEG C and reacting for 0.1-1.5 hours; (2) dipping part of formaldehyde solution for 0.25-2.5 hours, increasing the temperature to 70-95 DEG C and reacting for 1-6 hours; and (3) decreasing the temperature to below 60 DEG C, adding the lignosulfonate and the rest of the formaldehyde solution to the reactor, using an alkaline regulator to regulate a pH value of the system to be 8.0-14.0, increasing the temperature to 70-98 DEG C, reacting for 1-5 hours and decreasing the temperature before discharging. The modified aliphatic high-efficiency water-reducing agent is suitable for producing commercial concrete which has similar color as normal concrete and has smaller collapsed slump loss. By adjusting the process, such as proportioning raw materials, and the like and effectively utilizing the lignosulfonate, the invention not only decreases the product cost, but also lessens environmental pollutants and has favorable industrialized prospects.

Owner:NANJING FORESTRY UNIV

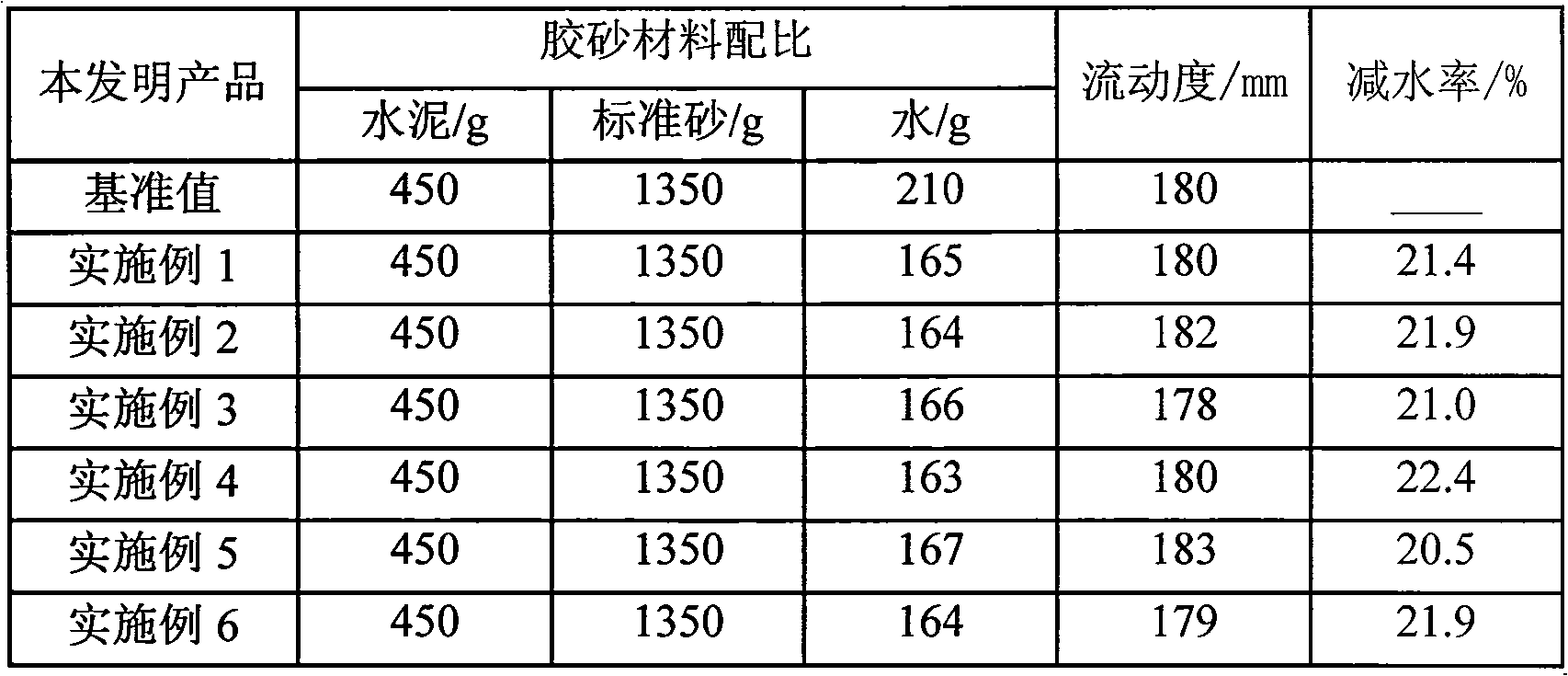

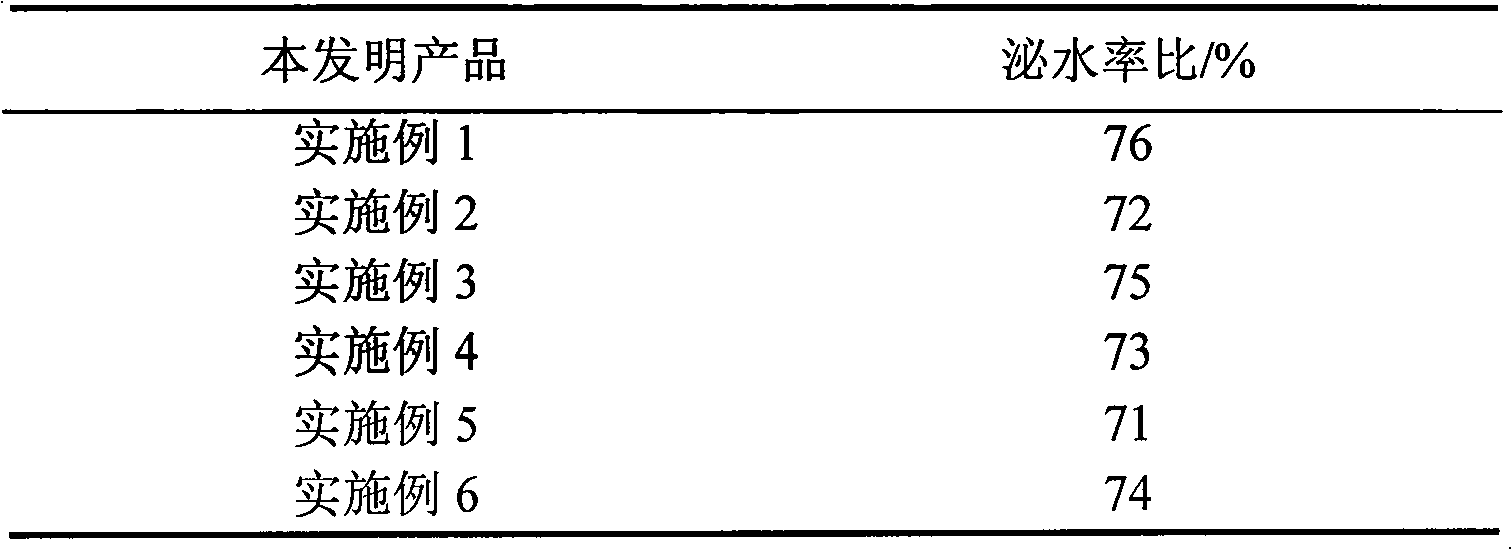

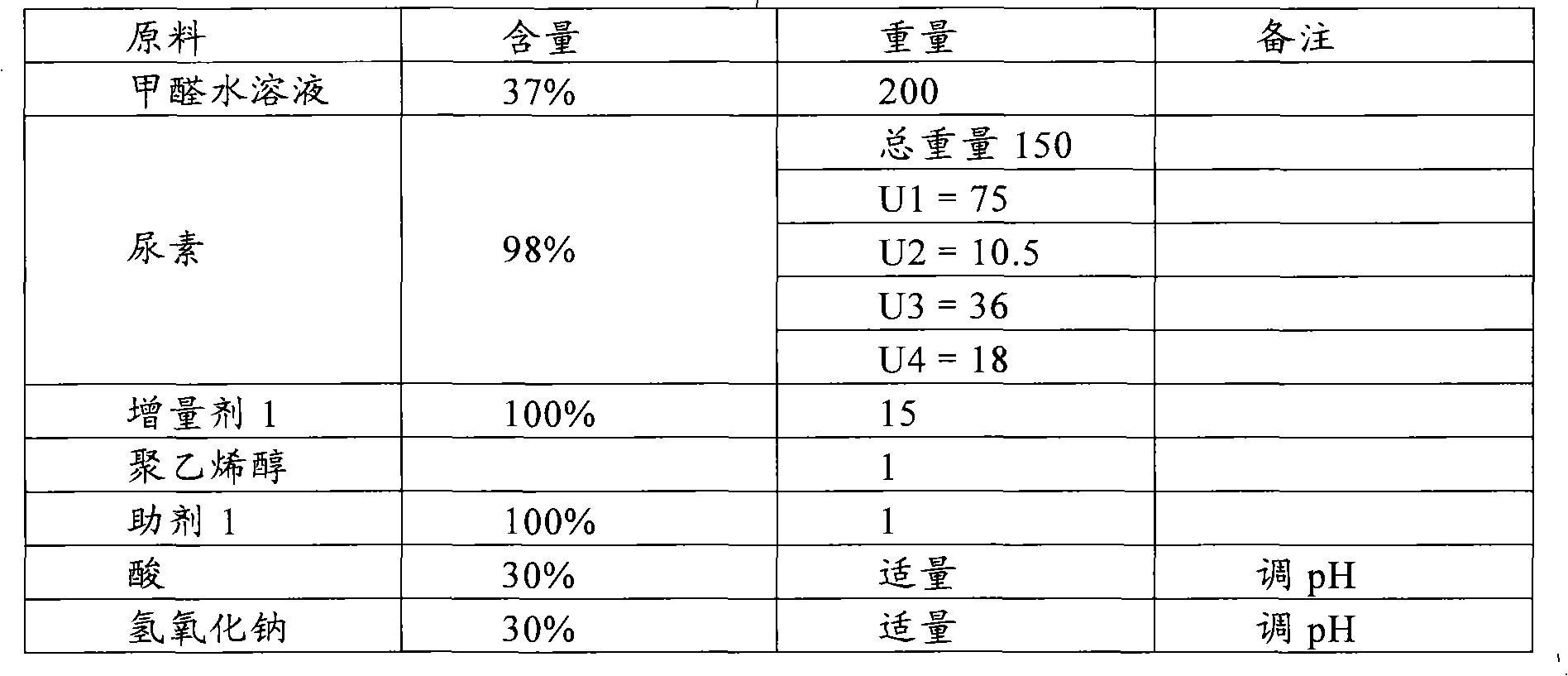

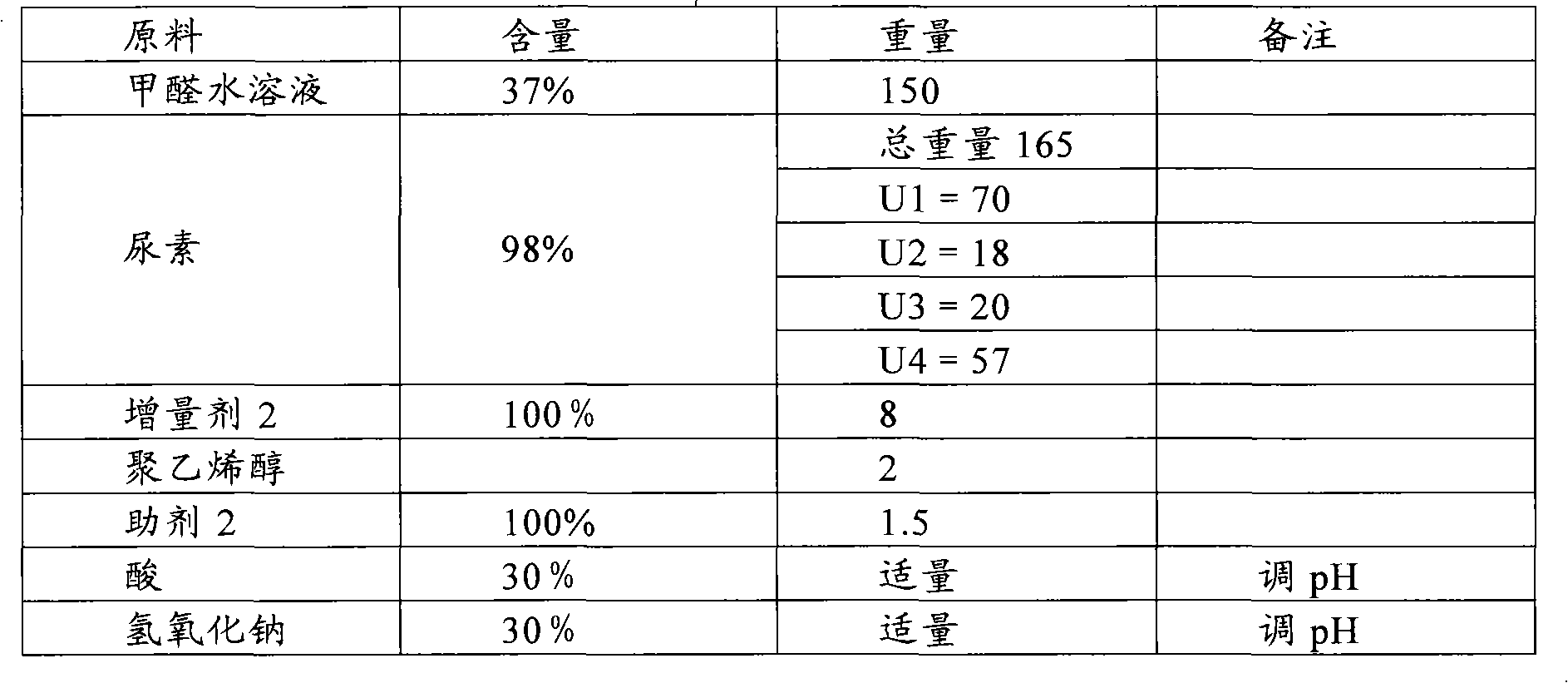

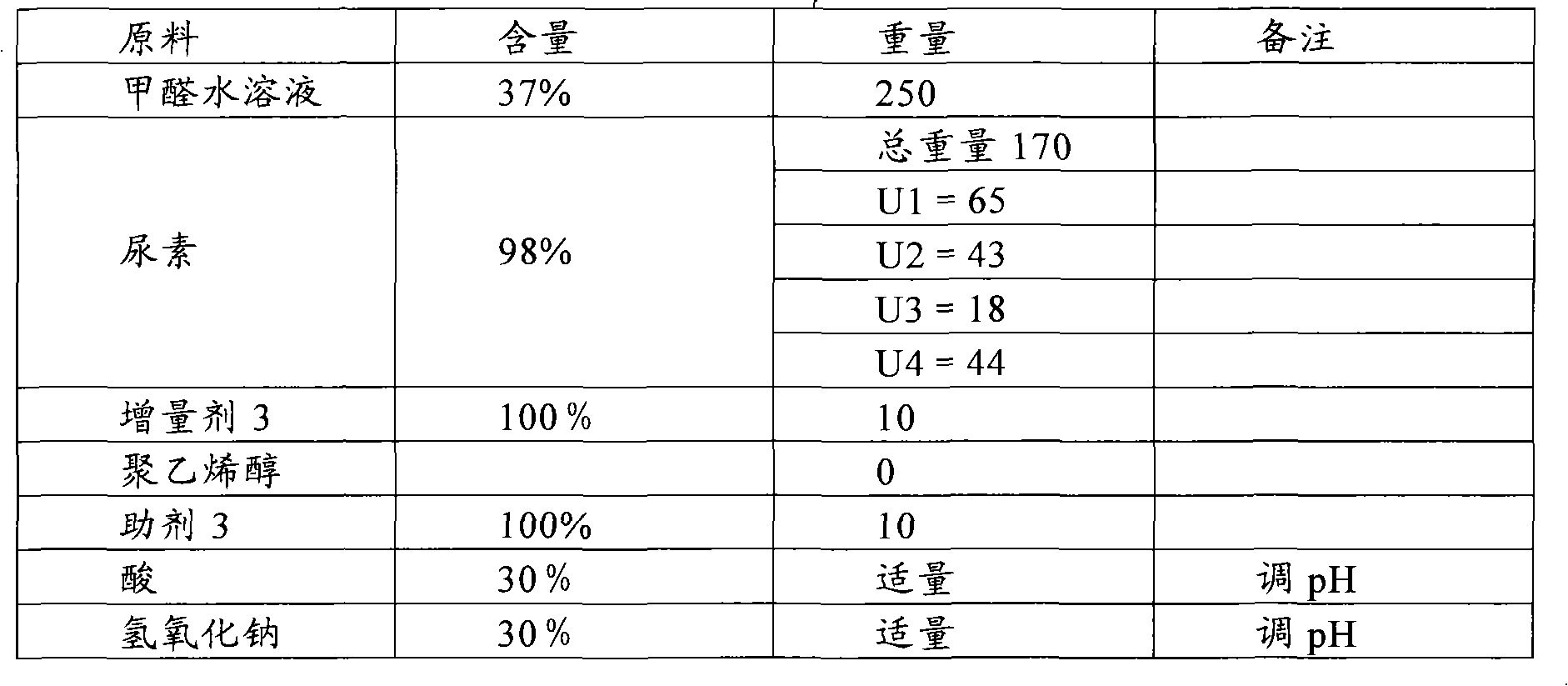

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

Fluorenyl bi-benzoxazine monomer and method of preparing the same

InactiveCN101367774AHigh glass transition temperatureSmall water absorptionOrganic chemistryOrganic solventGlass transition

The present invention provides a fluorylbis-benzoxazoly monomer and a preparation method thereof. In a container with a mixer, a cooling pipe and a thermometer, formaldehyde solution of 37 percent and an organic solvent are added according to a weight ratio of (1 to 4) to 1, primary amine is added into the formaldehyde solution at the temperature between 5 DEG C and 10 DEG C, the reaction solution is continuously mixed for reaction for 1 to 4 hours and heated to be between 70 DEG C and 120 DEG C, an organic solvent with dissolved bisphenol fluorine is added, weight percentage of the bisphenol fluorine in the organic solvent is 20 percent to 50 percent, the molar ratio of the bisphenol fluorine and the primary amine is (1 to 2) to 3; the reaction continues to last for 4 to 10 hours at the temperature between 70 DEG C and 120 DEG C, and ultimately the fluorylbis-benzoxazoly monomer can be acquired through post processing. Because of the fluorine structure, the rigidity of molecular chains of the product can be enhanced, and the glass-transition temperature of resin can be improved; because of the enhanced nonpolarity of molecules, the hygroscopicity of the resin is lowered, thereby improving the wet-hot aging performance of the resin is greatly improved.

Owner:HARBIN ENG UNIV

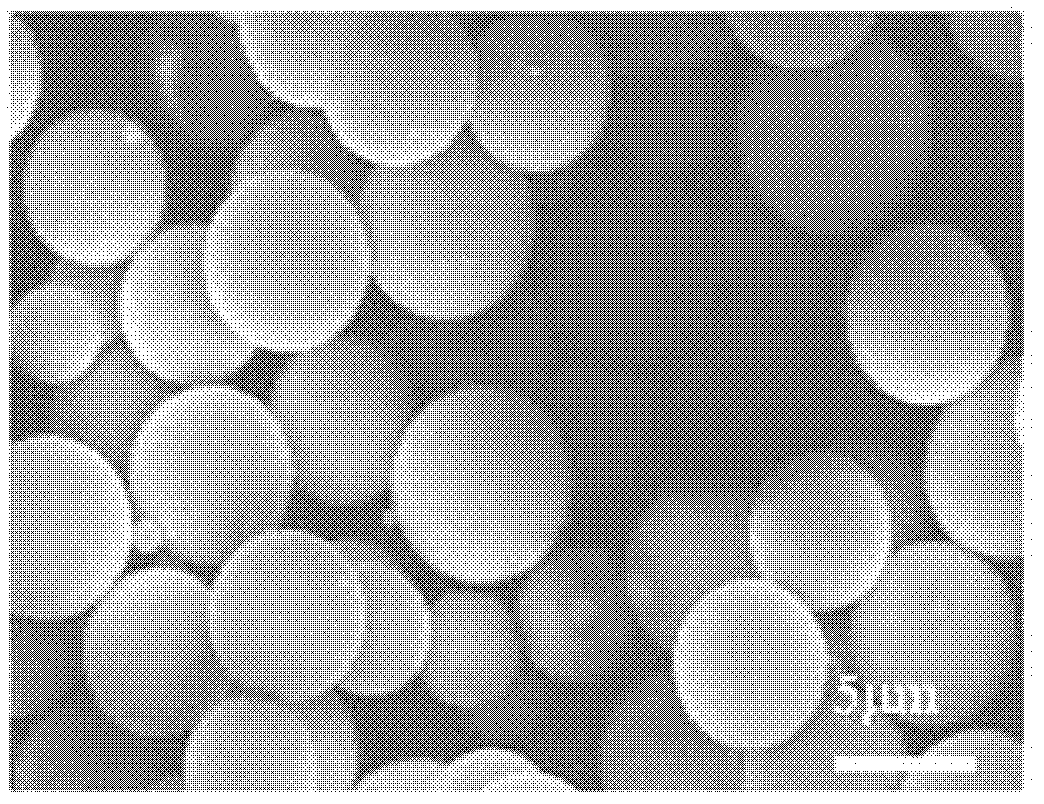

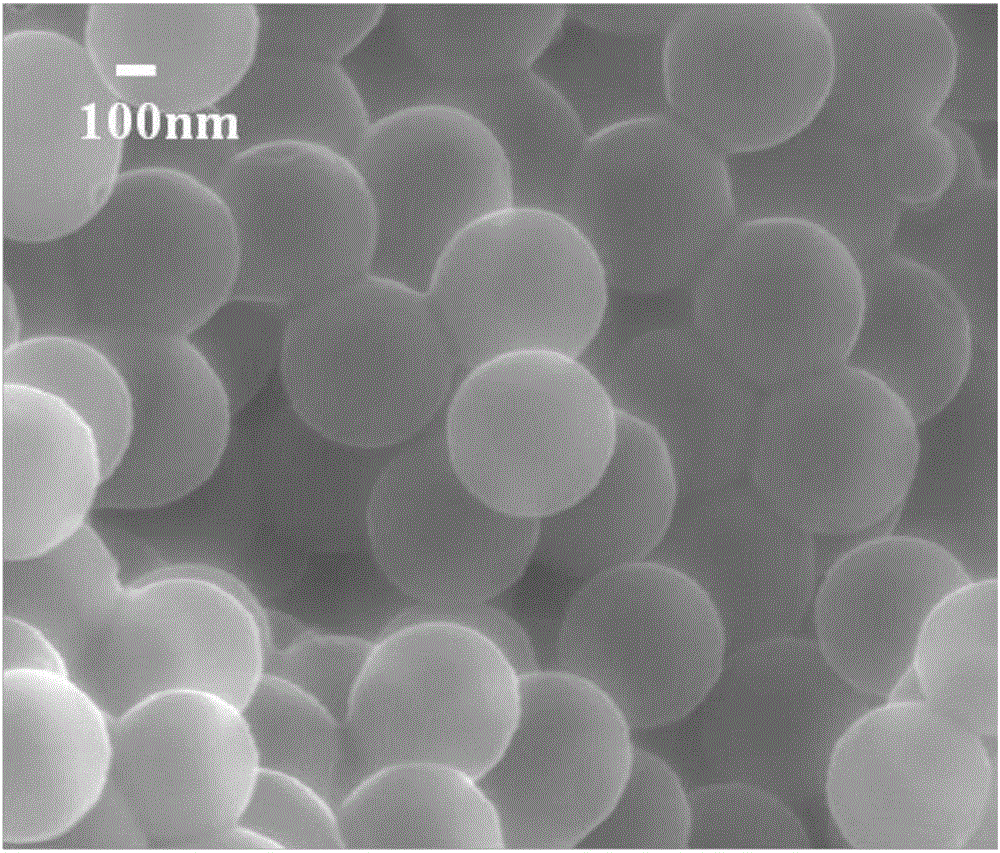

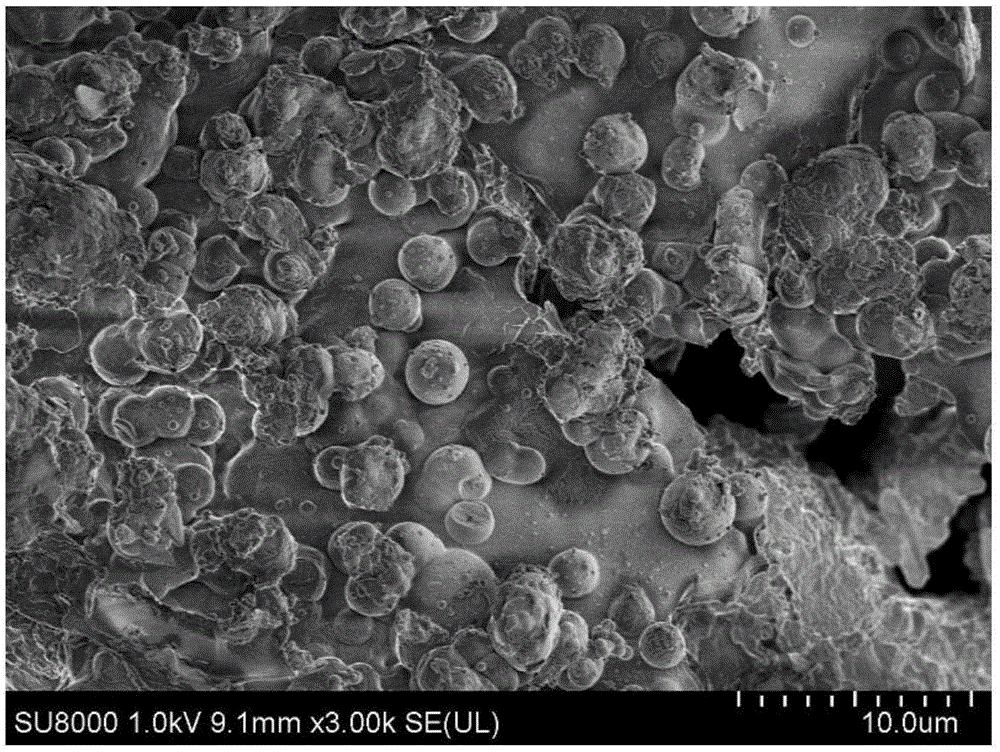

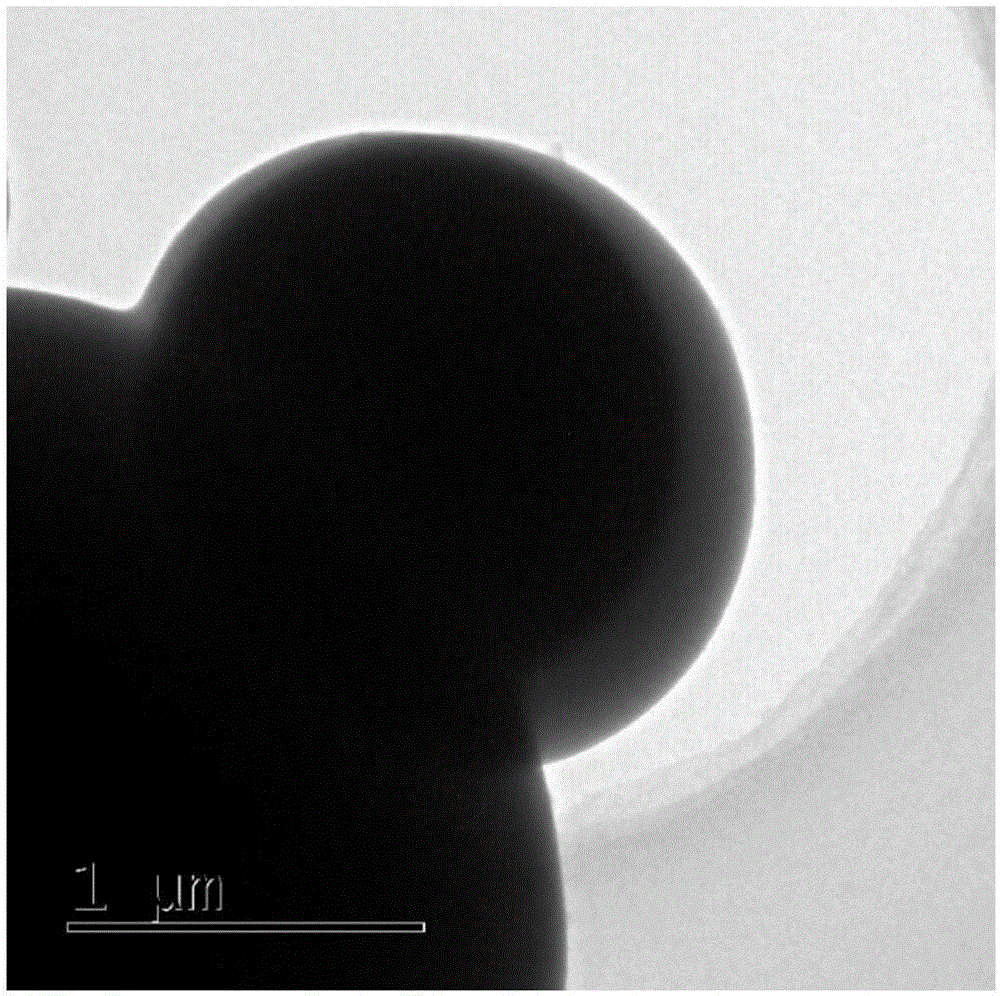

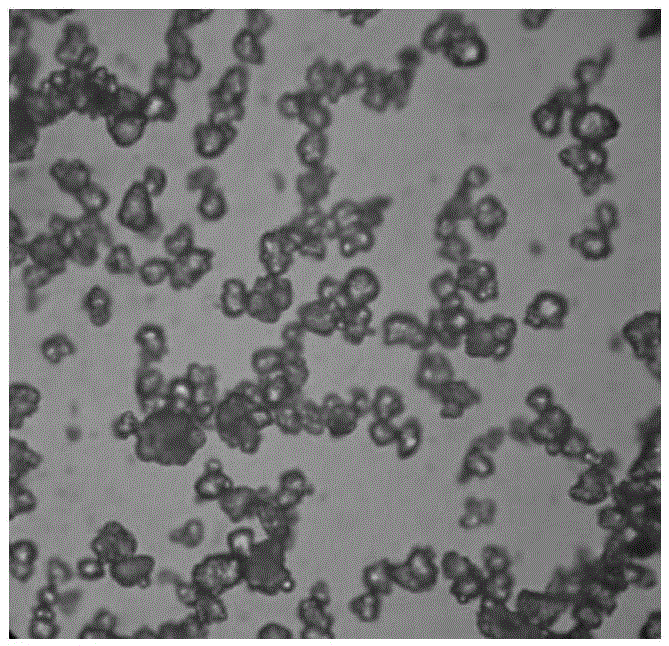

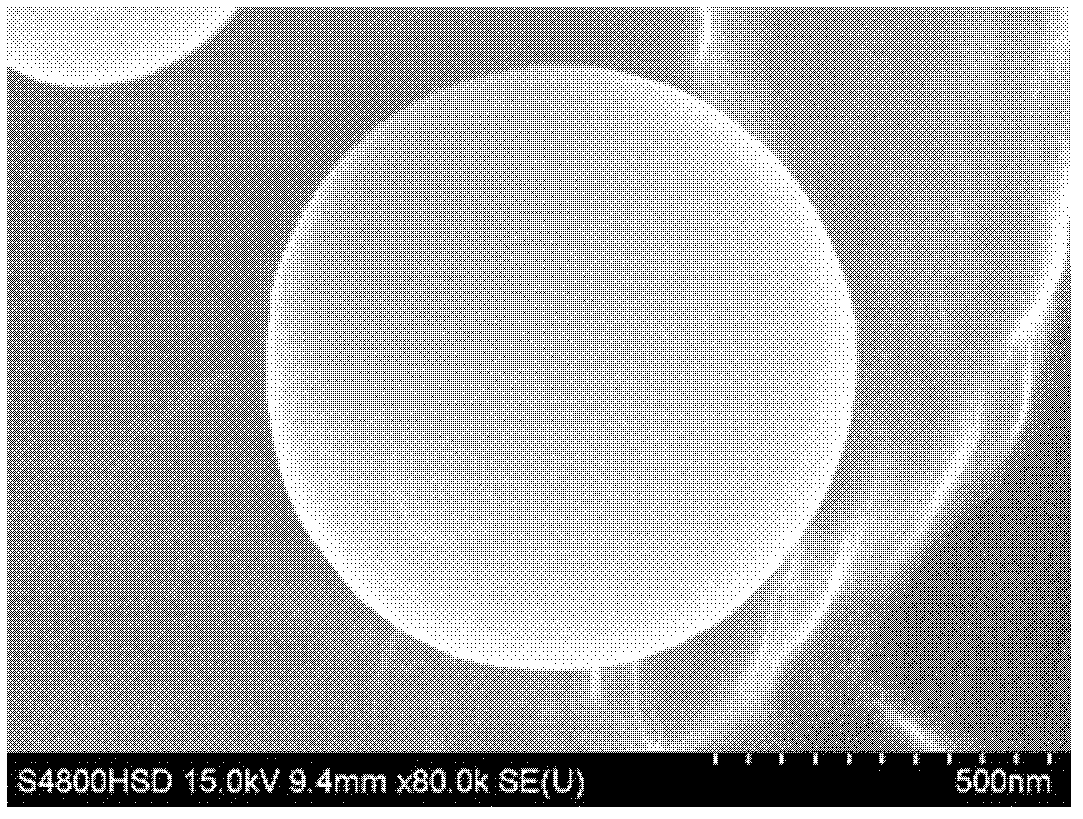

Method for preparing nitrogenous graphitized hollow carbon microspheres

InactiveCN102637533AEasy to makeLow costCarbon compoundsElectrolytic capacitorsSynthesis methodsMicrosphere

The invention relates to a method for preparing nitrogenous graphitized hollow carbon microspheres, which relates to a method for preparing hollow carbon microspheres. The method disclosed by the invention aims to solve the technical problem that in the existing method for preparing nitrogenous graphitized hollow carbon microspheres, because a template agent is utilized, the preparation process is complicated, and the cost is increased. The method comprises the following steps: adding melamine powder and a formaldehyde solution into deionized water, and after heating for reaction, obtaining reaction liquid; then, transferring the reaction liquid into a reaction kettle, and after carrying out hydrothermal reaction on the reaction liquid, obtaining melamine resin microspheres; and putting the melamine resin microspheres into a quartz tube type furnace, and heating the melamine resin microspheres so as to split the melamine resin microspheres, thereby obtaining nitrogenous graphitized hollow carbon microspheres. The average diameter of the nitrogenous graphitized hollow carbon microspheres is 1-5 microns; and by using the method, no template agent and no catalyst are required to be added in the preparation process, the preparation process in a synthesis method is simple, the cost is low, and microspheres are easy to be performed mass production and can be used as electrode materials or carrier materials of active substances of electrodes in the fields of electrochemical super capacitors, lithium ion batteries, fuel cells and the like.

Owner:HEILONGJIANG UNIV

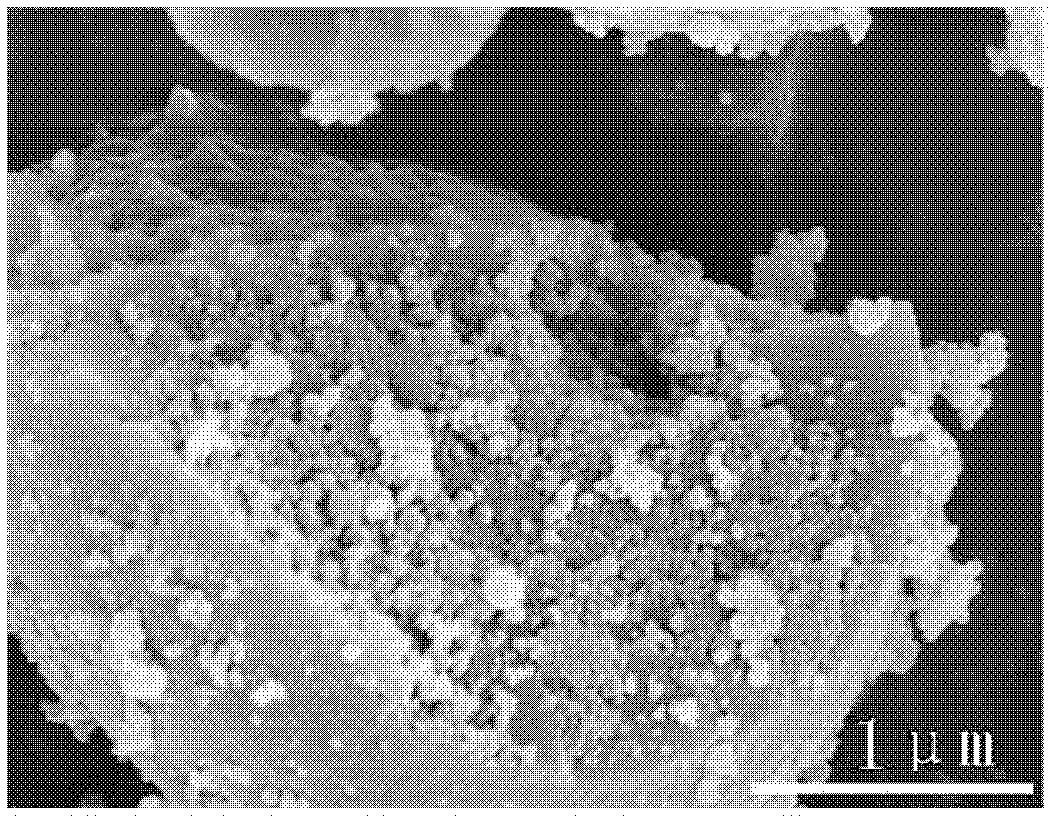

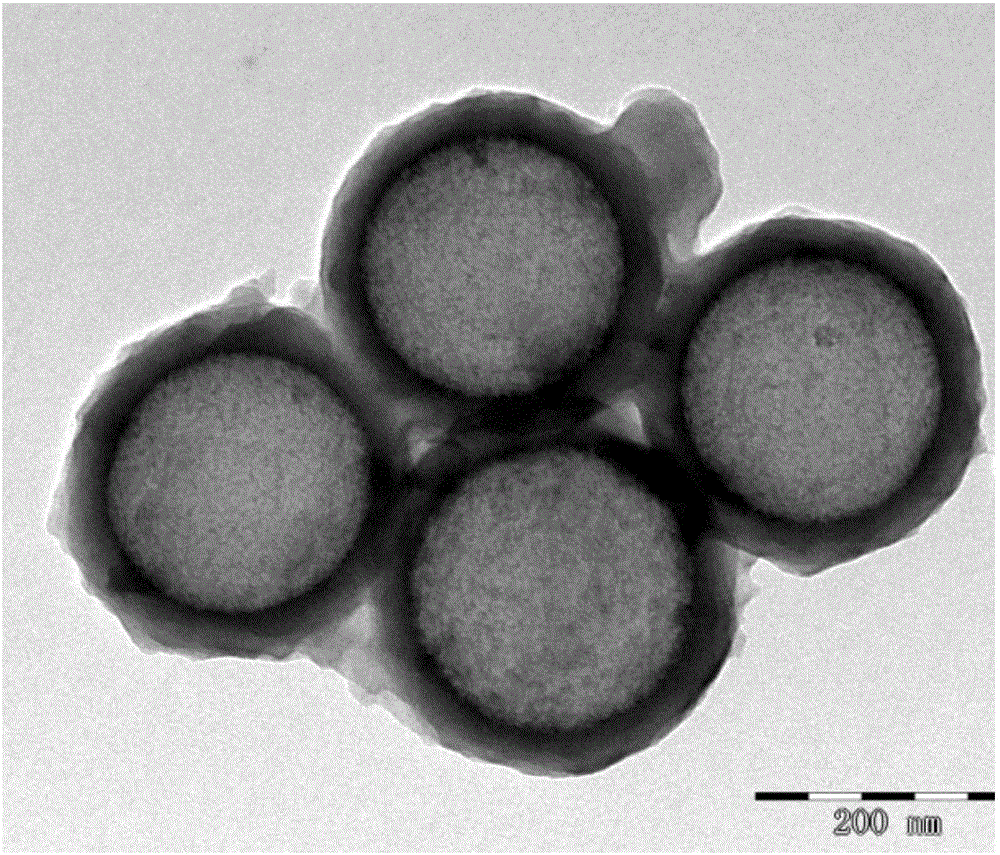

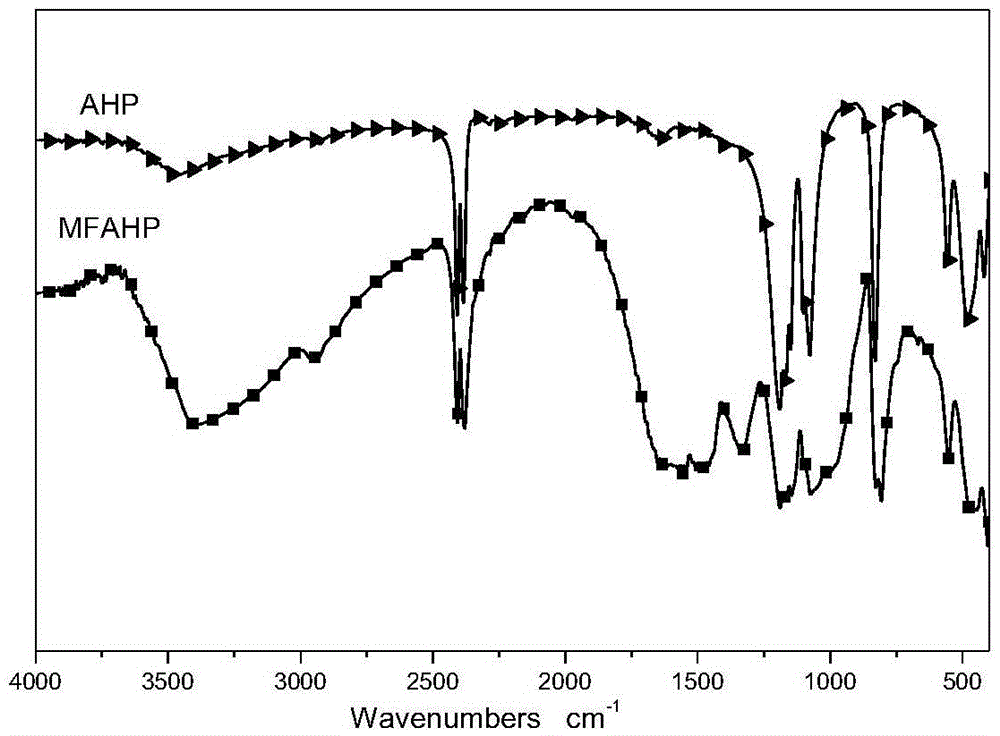

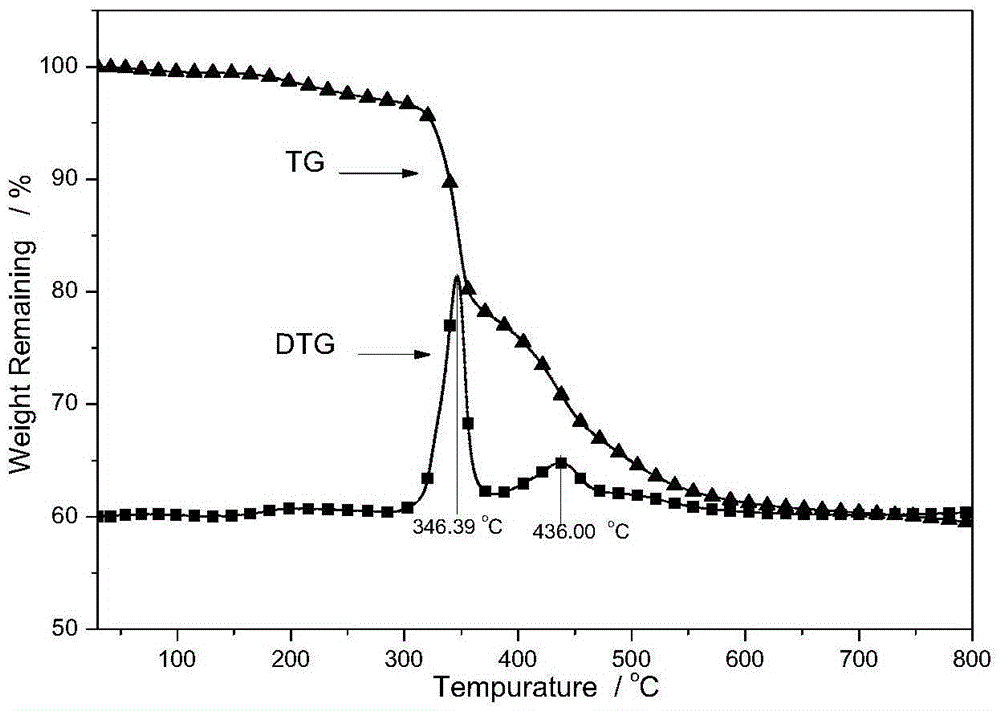

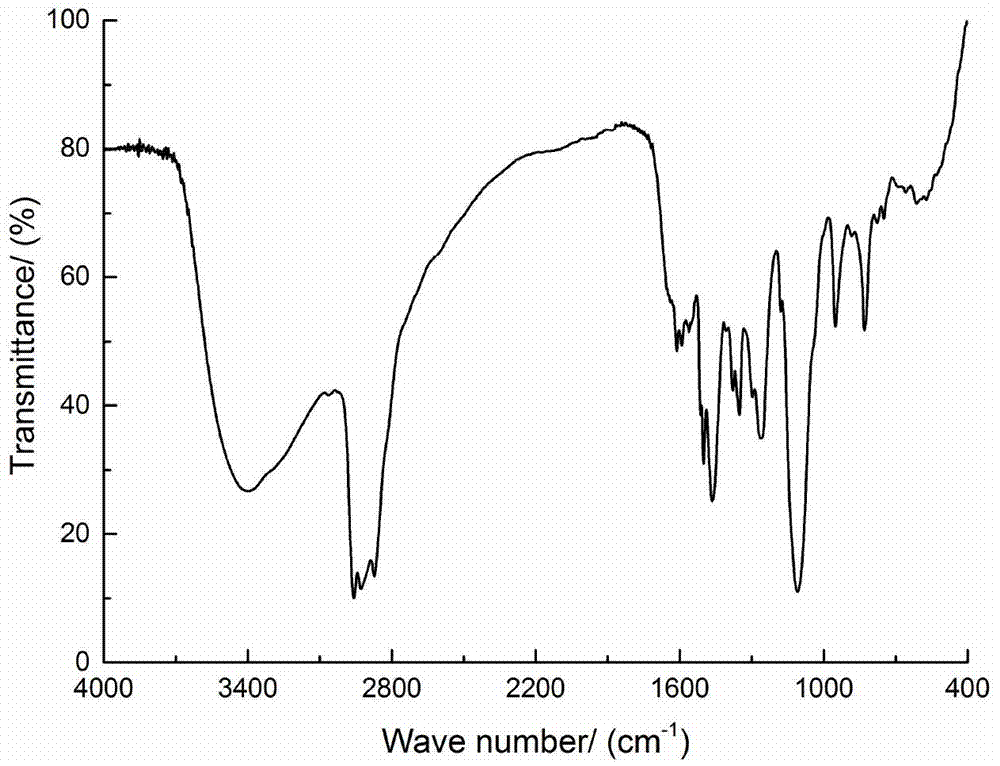

Ureaformaldehyde resin coating epoxy microcapsule for material self-repair and preparing method thereof

InactiveCN1927443ALow viscosityImprove mechanical propertiesMicroballoon preparationMicrocapsule preparationEpoxyReaction temperature

The invention relates to an ureaformaldehyde resin packed epoxy microcapsule used to recover the material. Wherein, the invention is characterized in that: it comprises aquacare, formaldehyde solution, epoxy resin, epoxy active diluent, water, emulsifier and defoaming agent. And the production comprises mixing formaldehyde and aquacare in boiling flask; when the aquacare is dissolved, adjusting pH and increasing temperature, controlling the reaction temperature and time, to obtain the pre-polymerized element of formaldehyde; when it is cooled, adding the water solutin with emulsifier and defoaming agent; adding epoxy resin and active diluent, to be mixed to obtain acid adjusting solution, increasing temperature and ending reaction; washing the product with water and acetone solution, filtering and drying to obtain white microcapsule. The invention has low cost and wide application, to prolong the service life of compound.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

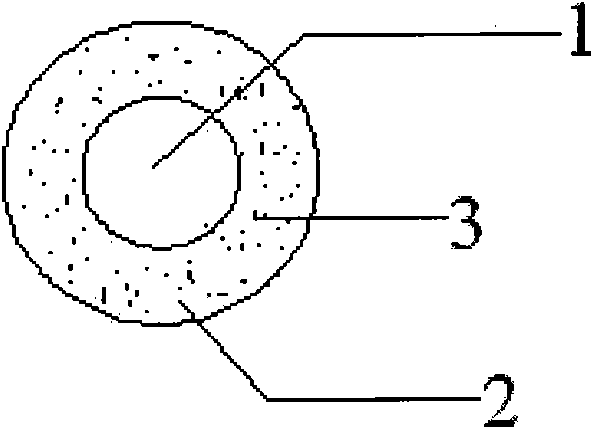

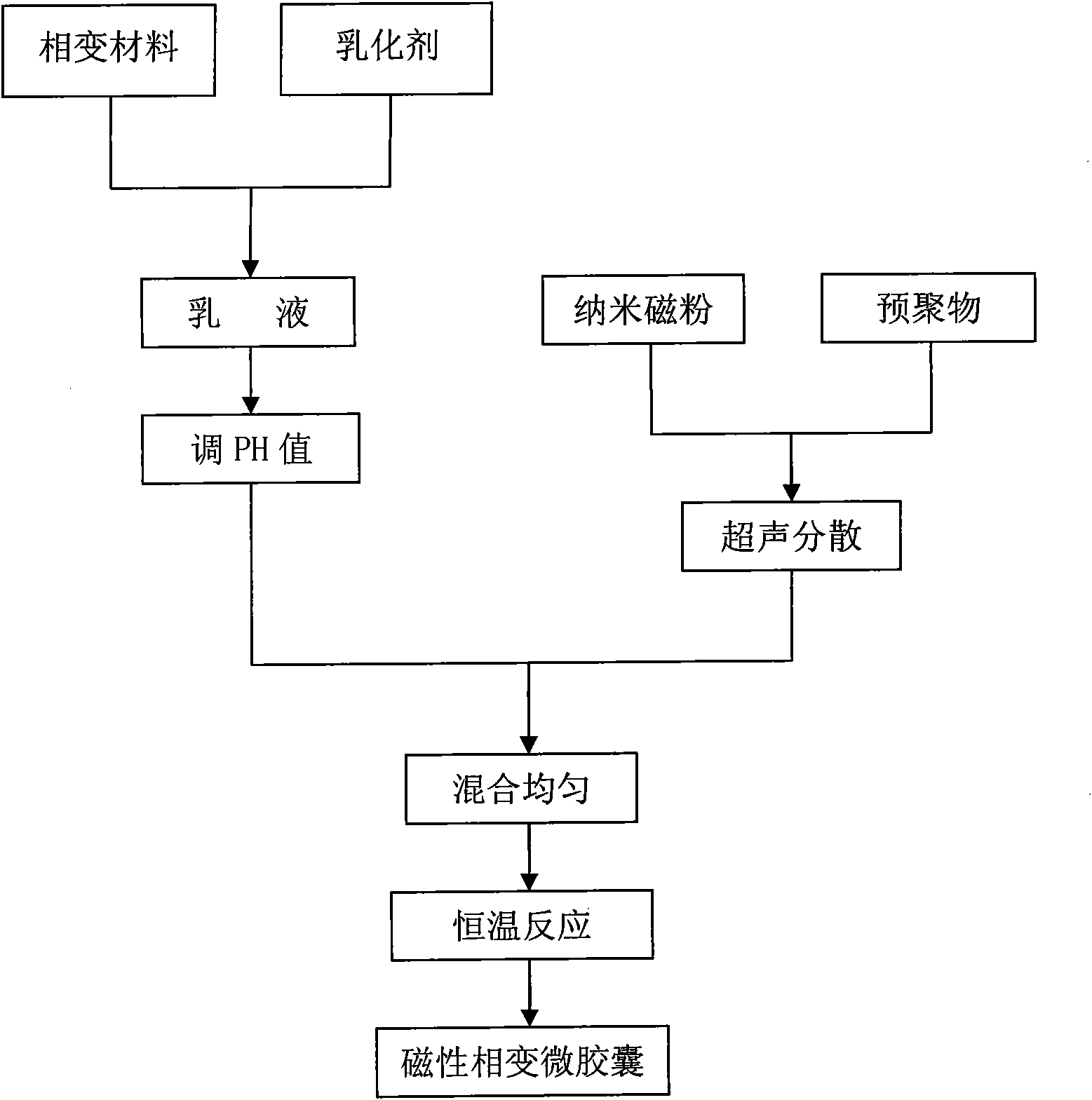

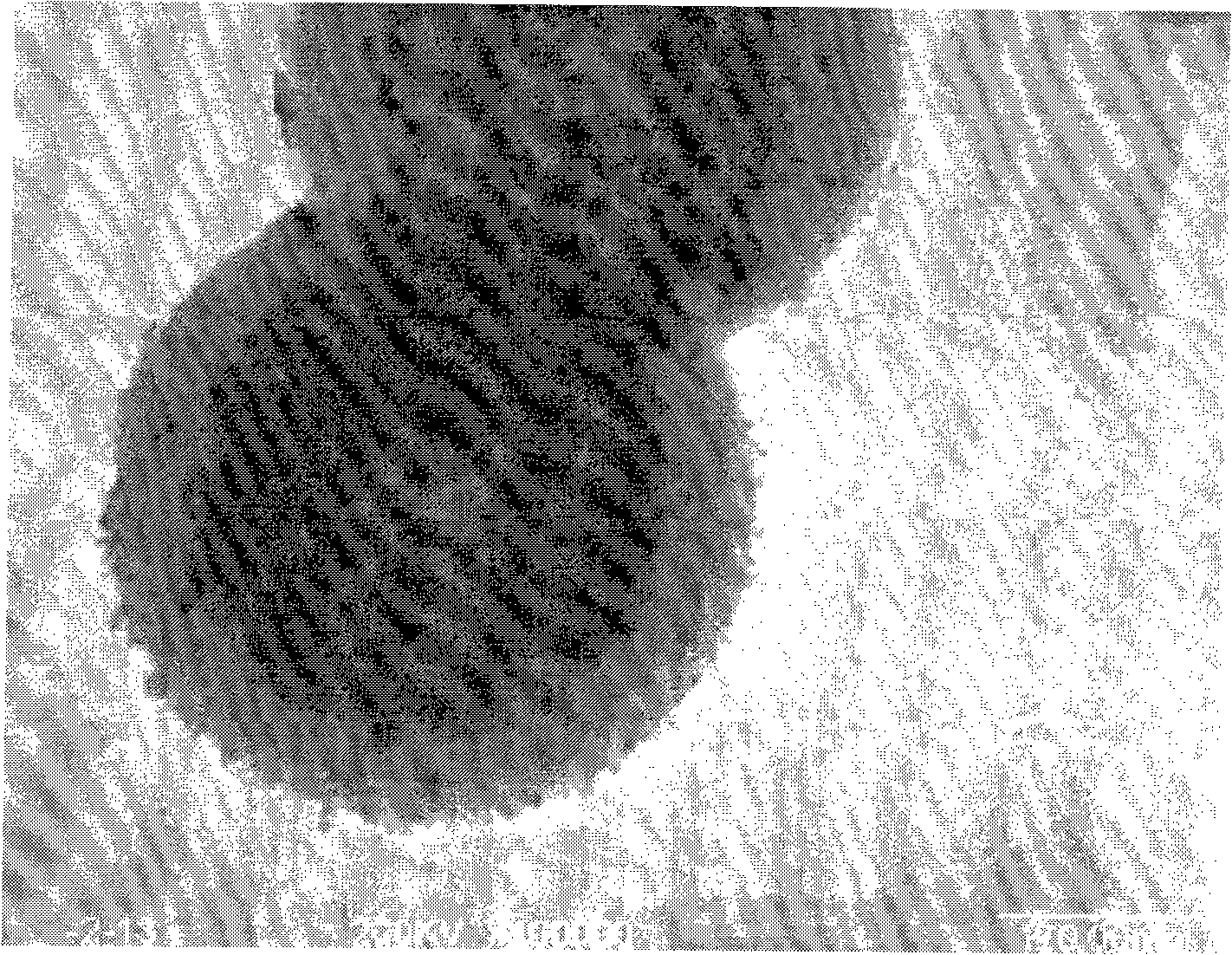

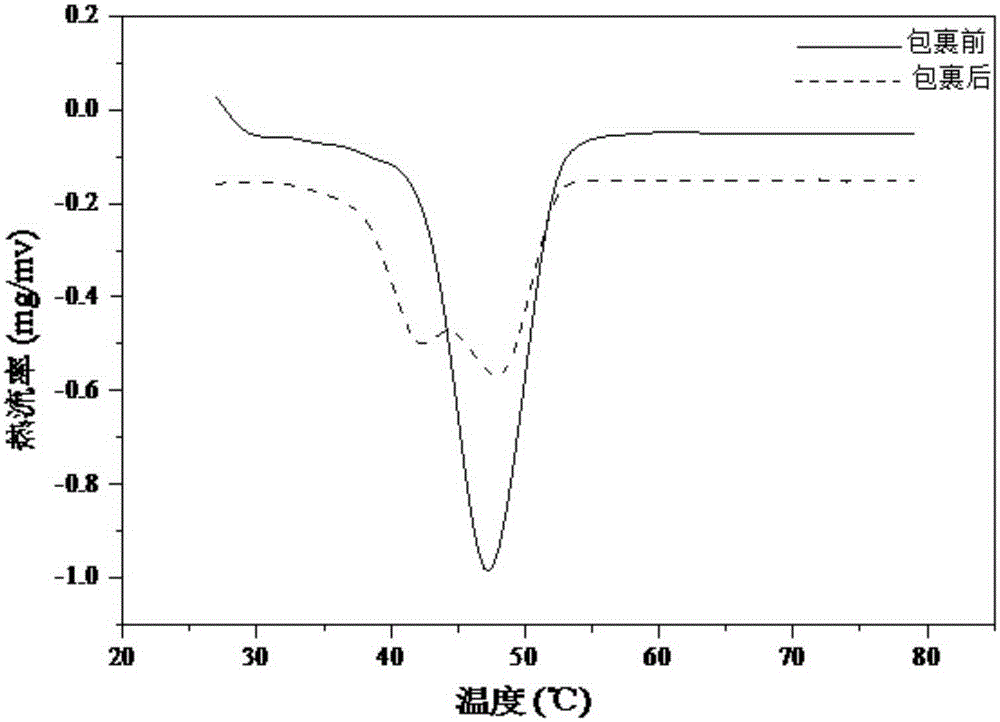

Magnetic phase transition microcapsule and preparation method thereof

InactiveCN101574637AReduce consumptionEasy to controlHeat-exchange elementsMicroballoon preparationUltrasonic dispersionFORMALDEHYDE SOLUTION

The invention discloses a magnetic phase transition microcapsule and a preparation method thereof. Nanometer magnetic powder is filled in a microcapsule material to form a shell, and a core material is wrapped in the shell. The magnetic phase transition microcapsule is prepared by the following steps: firstly, adding urea to a formaldehyde solution to dissolve or adding melamine to the formaldehyde solution, or adding the urea to the formaldehyde solution and adding melamine after fully dissolving the urea; then, reacting under stirring at a constant temperature to obtain a prepolymer solution; adding the nanometer magnetic powder to the prepolymer solution and dispersing the solution under ultrasound; dissolving an emulsifying agent in the water, adding an organic phase transition material and cutting and emulsifying the organic phase transition material at a high speed to prepare an emulsion; and uniformly mixing the emulsion and the prepolymer solution after ultrasonic dispersion and reacting under stirring at the constant temperature to obtain the magnetic phase transition microcapsule. The magnetic phase transition microcapsule has magnetism and can reach specific parts under the guide of an external magnetic field while the magnetic phase transition microcapsule is applied to a latent heat type functional fluid so as to control the flow of the fluid.

Owner:NANJING UNIV OF SCI & TECH

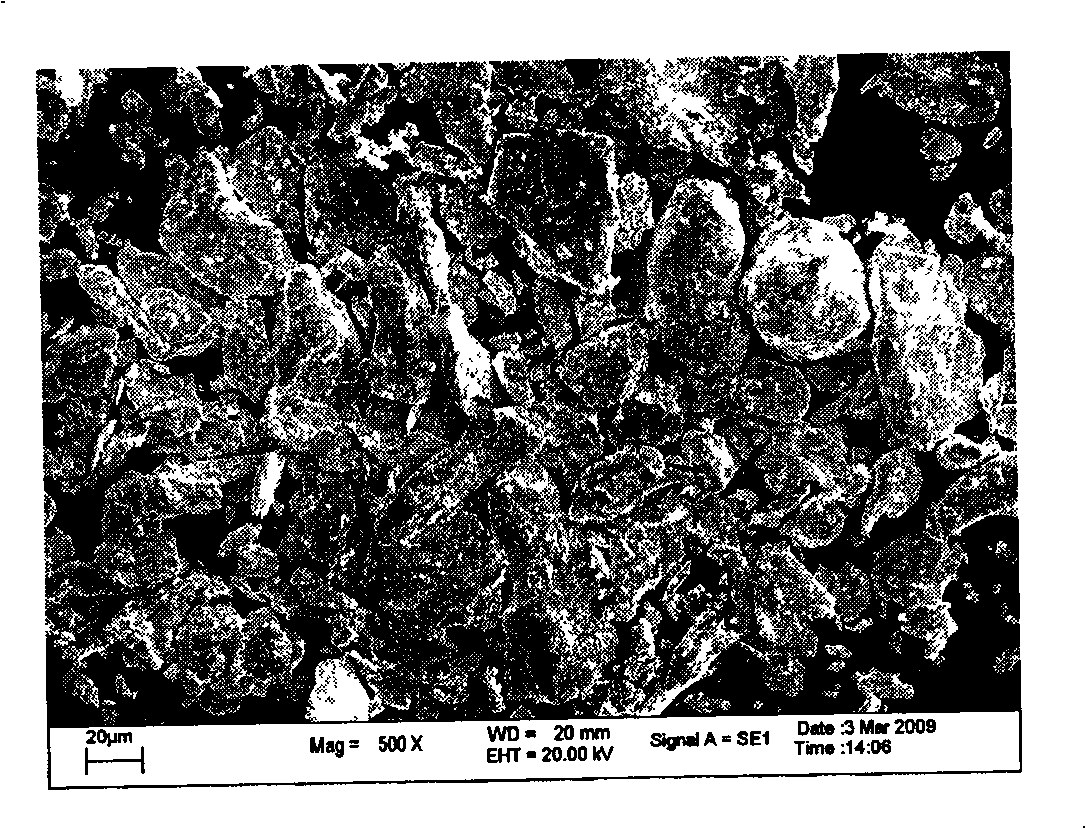

Loaded nano-copper magnetic catalyst used for catalysis of solution of formaldehyde for preparing hydrogen and preparation method thereof

InactiveCN101862656AHigh activityImprove reuse efficiencyCatalyst carriersHydrogenHydrazine compoundFORMALDEHYDE SOLUTION

The invention relates to a loaded nano-copper magnetic catalyst used for catalytic conversion of aqueous solution of formaldehyde for preparing hydrogen and a preparation method thereof. The method comprises the following steps of: preparing magnetic Fe3O4 from low-cost FeCl2.4H2O and FeCl3.6H2O; coating a layer of SiO2 on the surface of the Fe3O4 to prepare a magnetic Fe3O4@SiO2 catalyst carrier; dispersing the magnetic Fe3O4@SiO2 in a copper ammonia complex; and reducing the dispersed substance by using a hydrazine hydrate to obtain a Cu / Fe3O4@SiO2 magnetic catalyst having a nano-scale Cu active ingredient. High-purity hydrogen can be obtained under a room temperature condition by applying the Cu / Fe3O4@SiO2 magnetic catalyst to the catalytic reaction of the solution of formaldehyde for preparing hydrogen and the separation of the catalyst from reactants can be realized easily by adding a magnetic field outside. Simultaneously, the catalyst can be reused repeatedly.

Owner:BEIJING UNIV OF CHEM TECH

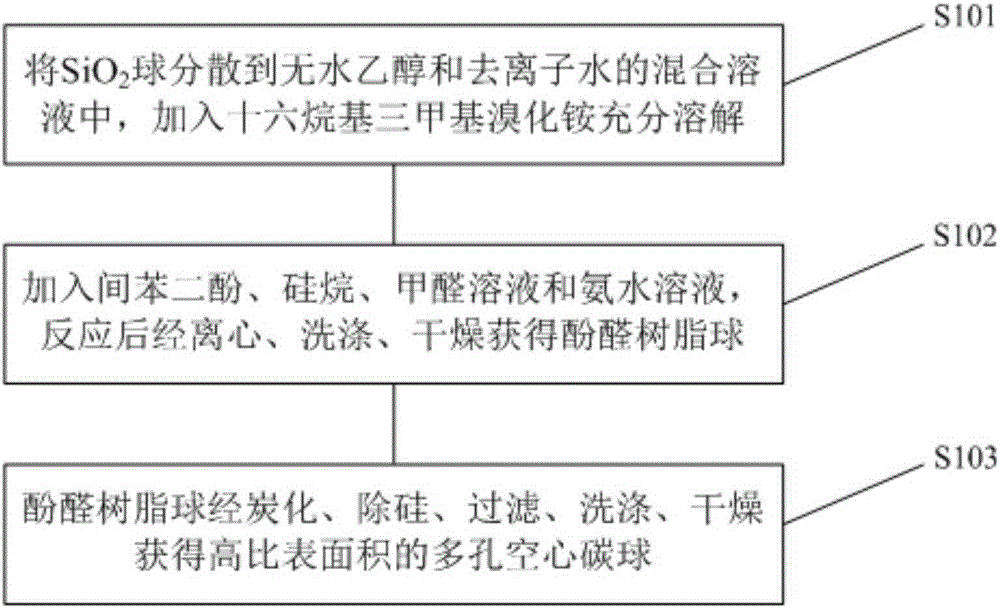

Preparation method of hollow porous carbon spheres with high specific surface area

The invention discloses a preparation method of hollow porous carbon spheres with high specific surface area. The preparation method comprises the steps of dispersing SiO2 spheres into a mixed solution of absolute ethanol and deionized water, adding cetyltrimethylammonium bromide, and sufficiently dissolving; adding resorcinol, silane, a formaldehyde solution and an ammonia solution, and centrifuging, washing and drying after reacting to obtain phenolic resin spheres; and carbonizing the phenolic resin spheres, removing silicon, filtering, washing and drying to obtain hollow porous carbon spheres with high specific surface area. The hollow carbon spheres are obtained by taking SiO2 spheres as templates, silane as a pore-forming agent as well as formaldehyde and resorcinol as carbon sources through the operation process of carbonizing, removing silicon and the like by using a coating technology. The preparation method is simple in process, easily available in raw materials as well as simple and convenient in operation; and the prepared hollow porous carbon spheres have the characteristics of high specific surface area, high specific volume, controllable particle size and wall thickness and the like.

Owner:BEIJING UNIV OF TECH

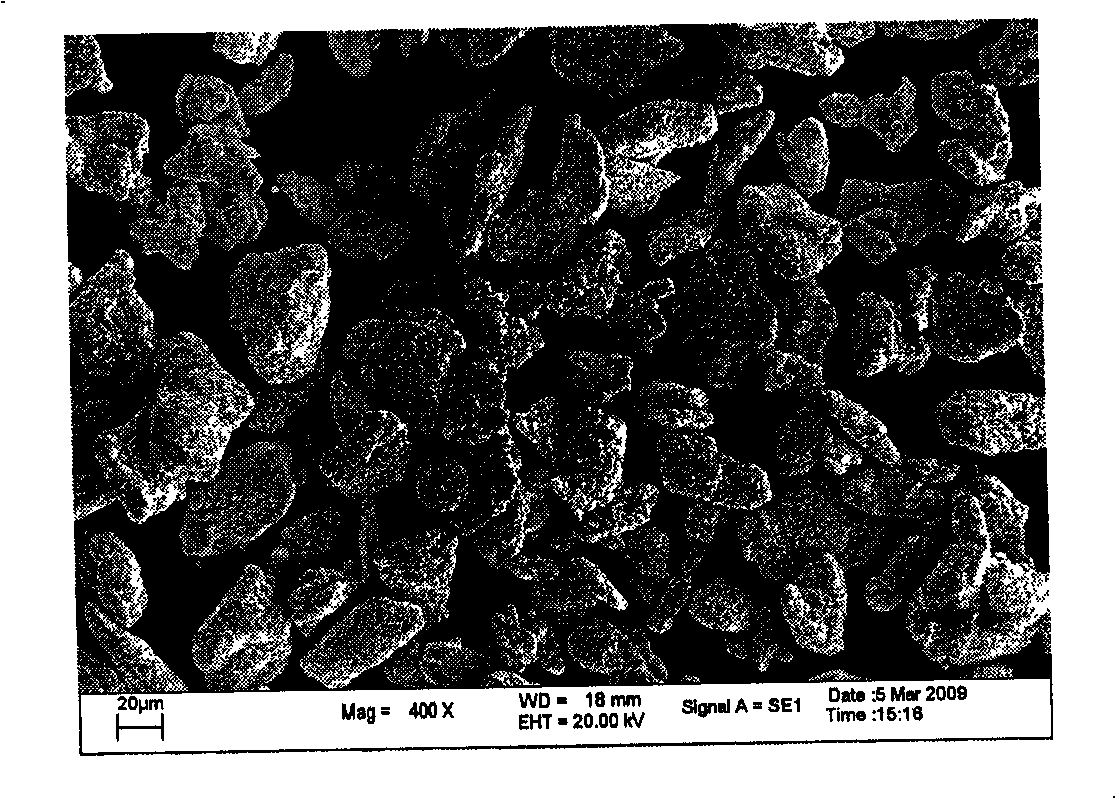

Preparation method of copper-coated tungsten composite powder

InactiveCN101537491AHigh sintering activityUniform thicknessLiquid/solution decomposition chemical coatingWater bathsBipyridine

The invention discloses a preparation method of copper-coated tungsten composite powder, belonging to the technical field of powder metallurgy. Corresponding tungsten powder and blue vitriod are employed according to the weight ratio of composite powder to be prepared and the tungsten powder is pre-treated; copper sulphate and seignette sol are dissolved into solution; bipyridine is added and NaOH is used to adjust pH value to 12-14; an appropriate amount of formaldehyde solution and the tungsten powder are added; the mixture is heated and then stirred continuously in constant-temperature bathing at 30-60 DEG C until the tungsten powder is red; the tungsten powder is washed, dried, reduced and annealed, thereby obtaining copper-coated tungsten composite powder. The preparation method of copper-coated tungsten composite powder has wide application range and is applicable to tungsten-powder coating coppers with different finenesses and shapes. The preparation method of copper-coated tungsten composite powder prepares copper-coated tungsten composite powder in different content ratios according to different requirements. The copper-coated tungsten composite powder obtained by the method of the invention has excellent sintering activity, thereby improving the combination property of tungsten copper alloy.

Owner:UNIV OF SCI & TECH BEIJING

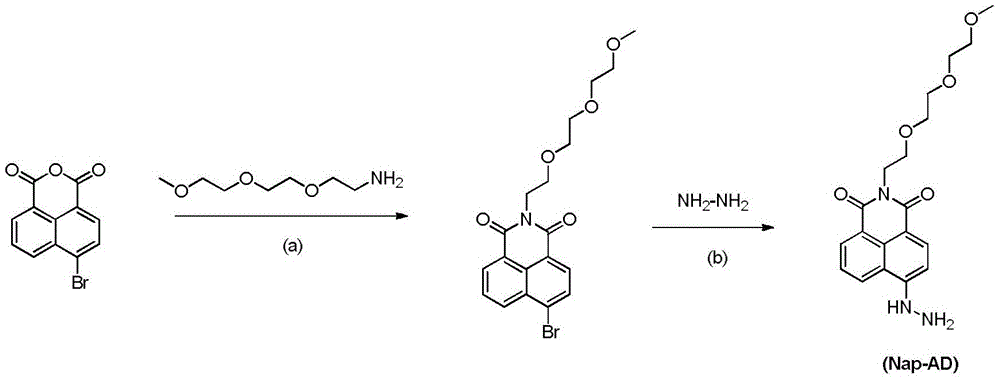

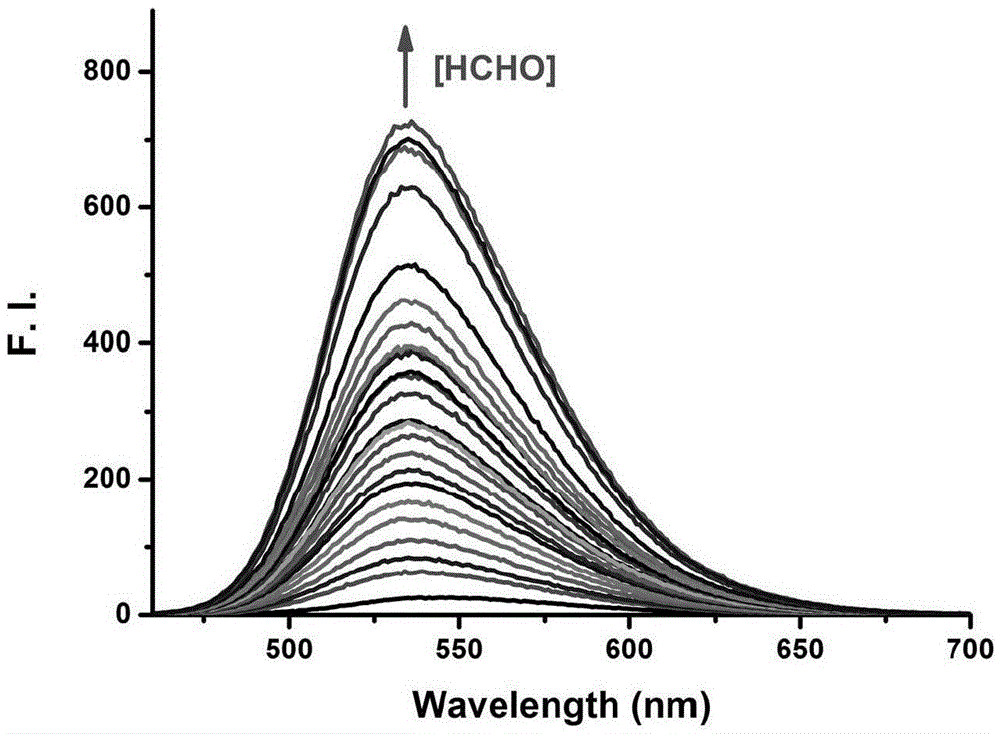

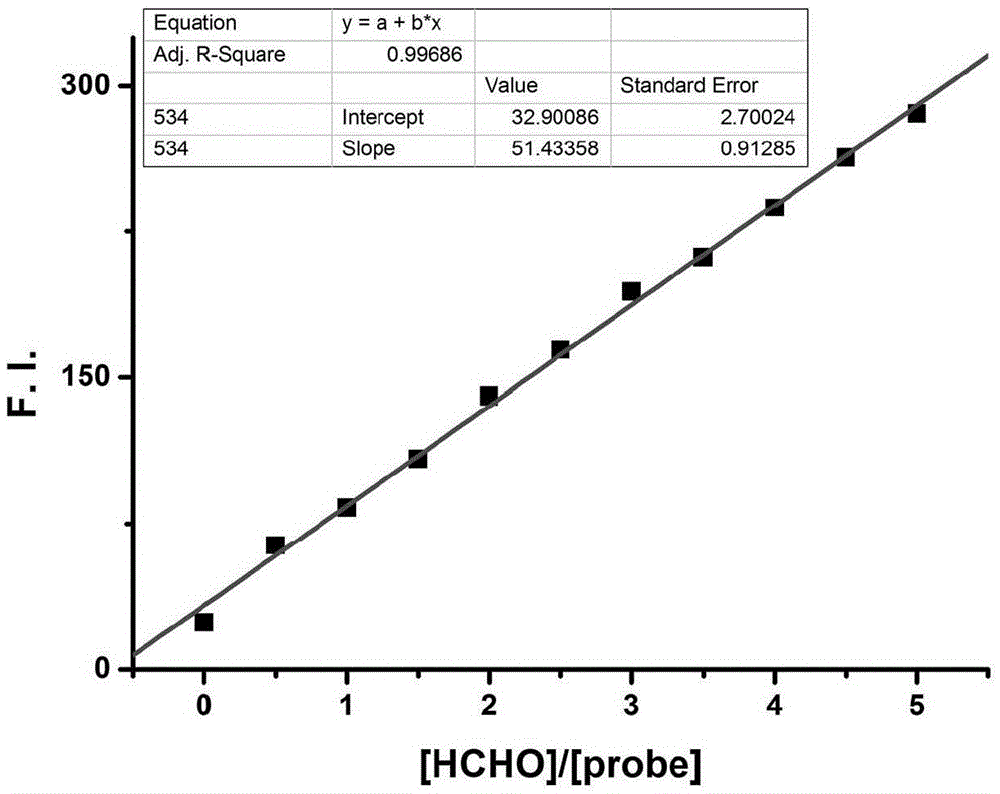

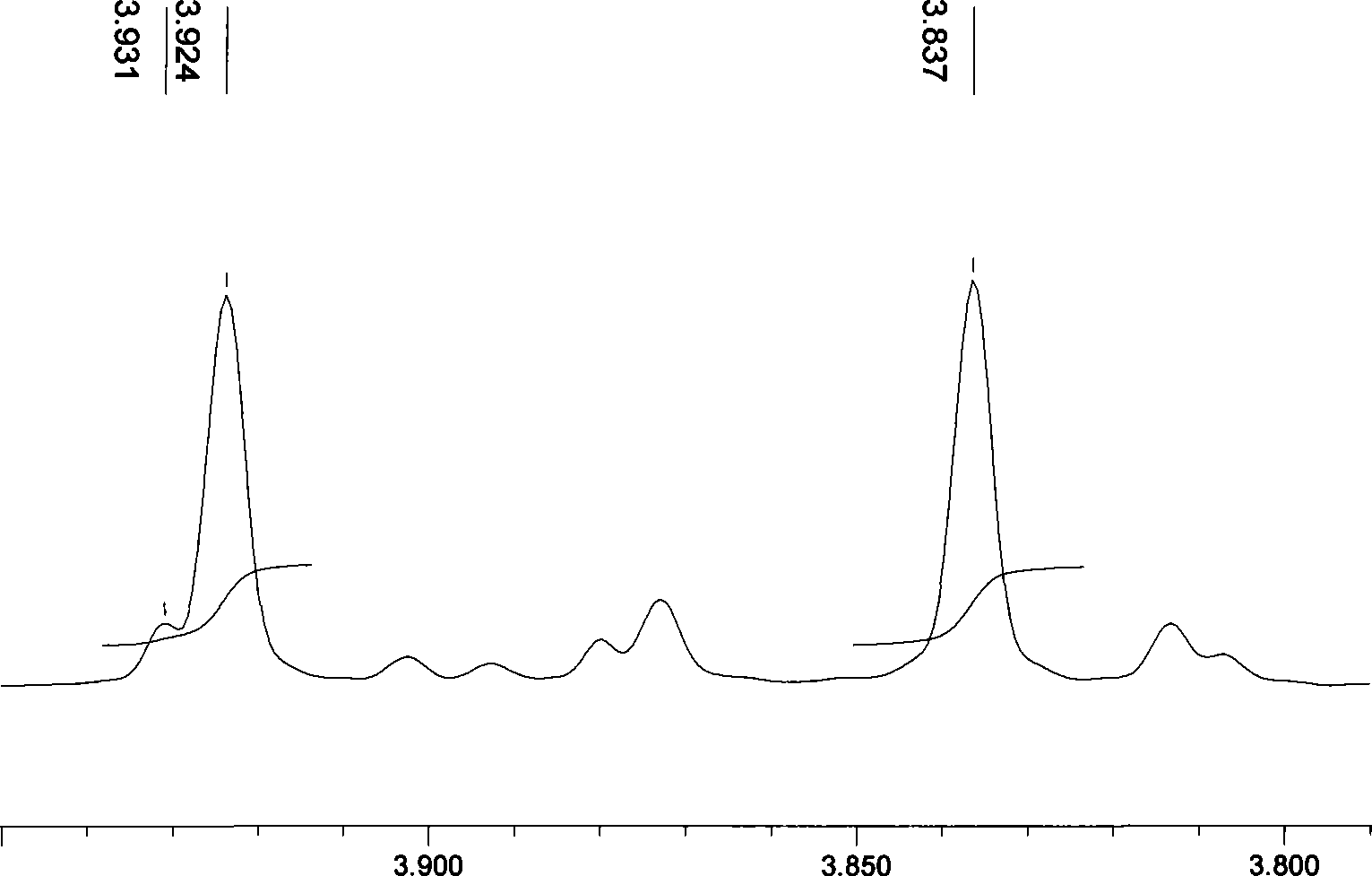

Fluorescent probe for detecting formaldehyde as well as preparation method and application of fluorescent probe

ActiveCN105542756AGuaranteed water solubilityGuaranteed stabilityOrganic chemistryFluorescence/phosphorescenceSpecific detectionFluorescence

The invention discloses a fluorescent probe for detecting formaldehyde as well as a preparation method and an application of the fluorescent probe. The structure of the fluorescent probe is presented by a formula I (shown in the specification). A kit for detecting formaldehyde comprises a compound represented by the formula I and a solvent. The ''off-on'' type formaldehyde probe for naphthalimide dyes and the specific detection kit have good responses to a formaldehyde solution, can be used for detecting formaldehyde in cells and have the characteristics of being simple and convenient to operate, low in cost, sensitive in response and easy to popularize and apply.

Owner:ZHEJIANG SCI-TECH UNIV

Method for synthesizing high content of 4,4'-dihydroxydiphenylmethane by one-step method

InactiveCN101440022AReduce the feed ratioReduce stepsOrganic chemistryOrganic compound preparationSodium bicarbonateWater baths

The invention discloses a method for synthesizing dihydroxy diphenyl methane with high 4, 4' site content by one stage process, relates to a method for synthesizing bisphenol F with high 4, 4' site content and provides a method for synthesizing dihydroxy diphenyl methane with high 4, 4' site content by one stage process, which reduces dosage of phenol and production cost and has yield of more than 60 percent. The method comprises the following steps: adding the phenol into a container provided with an electric stirrer, a thermometer and a reflux condensation tube, heating the phenol in water bath, adding phosphoric acid after the phenol is fully melted, stirring the mixture, and fully mixing the phenol and the phosphoric acid to obtain mixed solution; adding formaldehyde solution into the mixed solution, separating acid after reaction, neutralizing an oil phase by sodium bicarbonate, separating water and an organic phase, decompressing and distilling the mixed solution, removing the phenol and the water, and cooling, crystallizing and filtering the mixed solution to obtain products.

Owner:XIAMEN UNIV

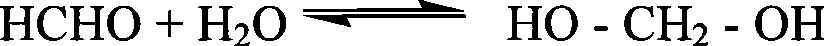

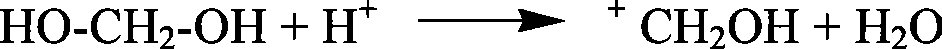

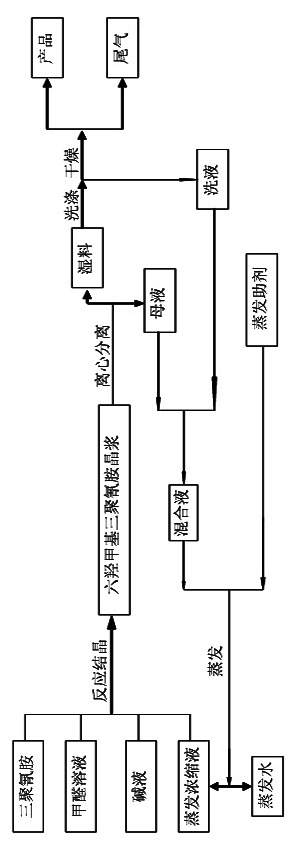

Process for producing hexamethylol melamine

ActiveCN102010380AReduce processingReduce processing difficultyOrganic chemistryWater/sewage treatment by heatingFormateEvaporation

The invention discloses a process for producing hexamethylol melamine, belonging to the field of production and preparation of hexamethylol melamine. The process comprises the steps such as mixing, reaction and crystallization, centrifugalization, evaporation and the like, wherein evaporation auxiliary formate is added when in evaporation so as to change the relative volatility of formaldehyde and water. Furthermore, the process for producing the hexamethylol melamine together with a formaldehyde device can also be used for co-production, so that the concentration of the produced formaldehyde solution is improved to 45wt%-55wt%. The produced hexamethylol melamine provided by the invention has the advantages of small amount of waste water and low formaldehyde content, namely, if 1 ton of hexamethylol melamine is produced, 1 ton of waste water containing 0.84wt% of formaldehyde is discharged. After the process provided by the invention and the formaldehyde device are used for co-production, the formaldehyde production cost and transportation cost are reduced, and the comprehensive cost is 10% less than that of other processes.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

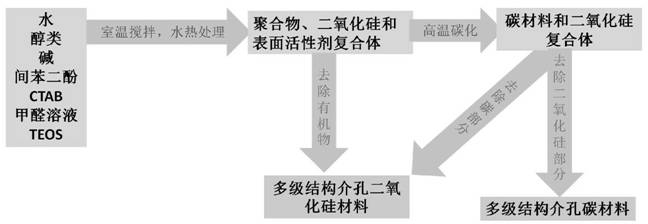

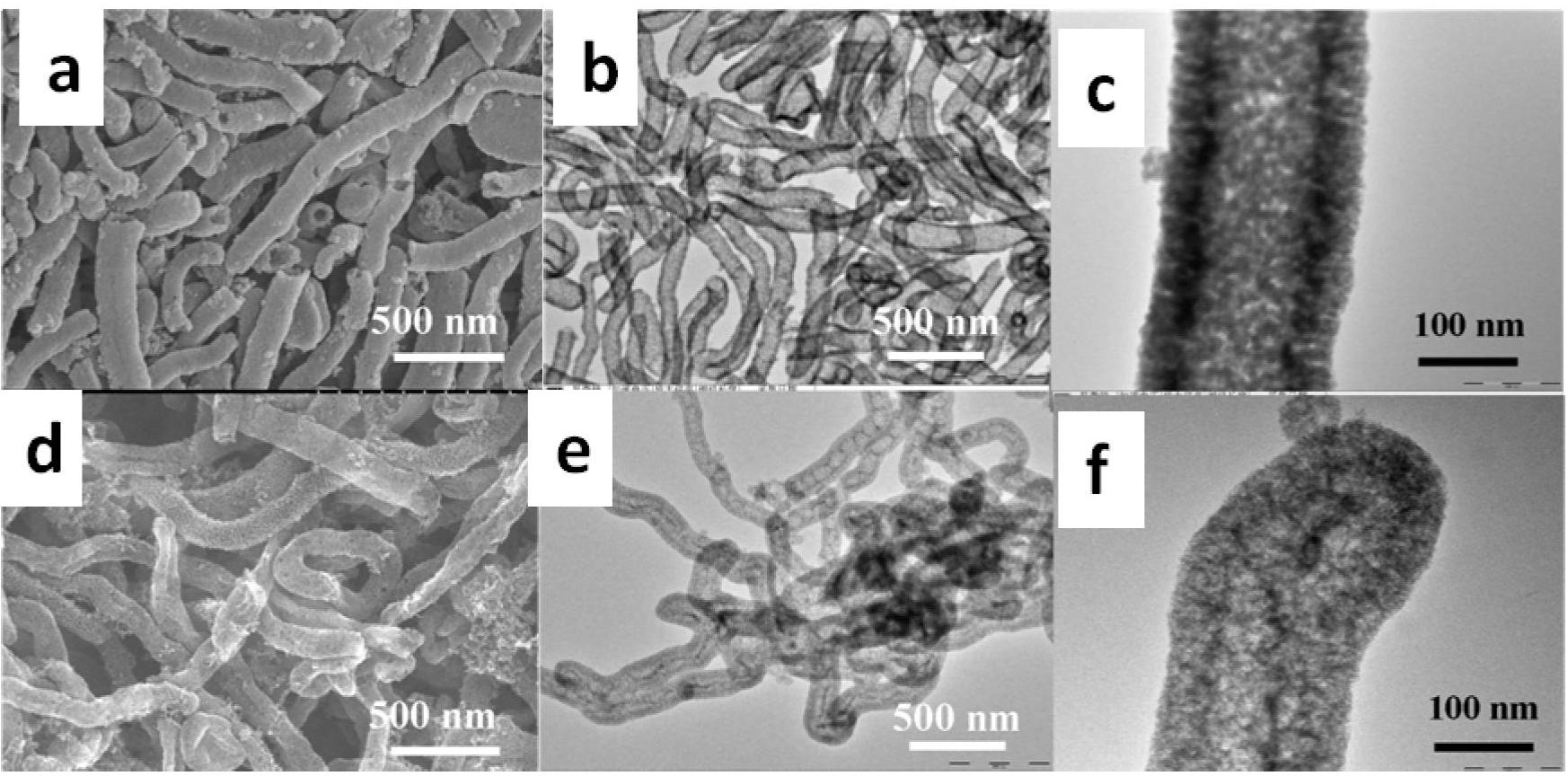

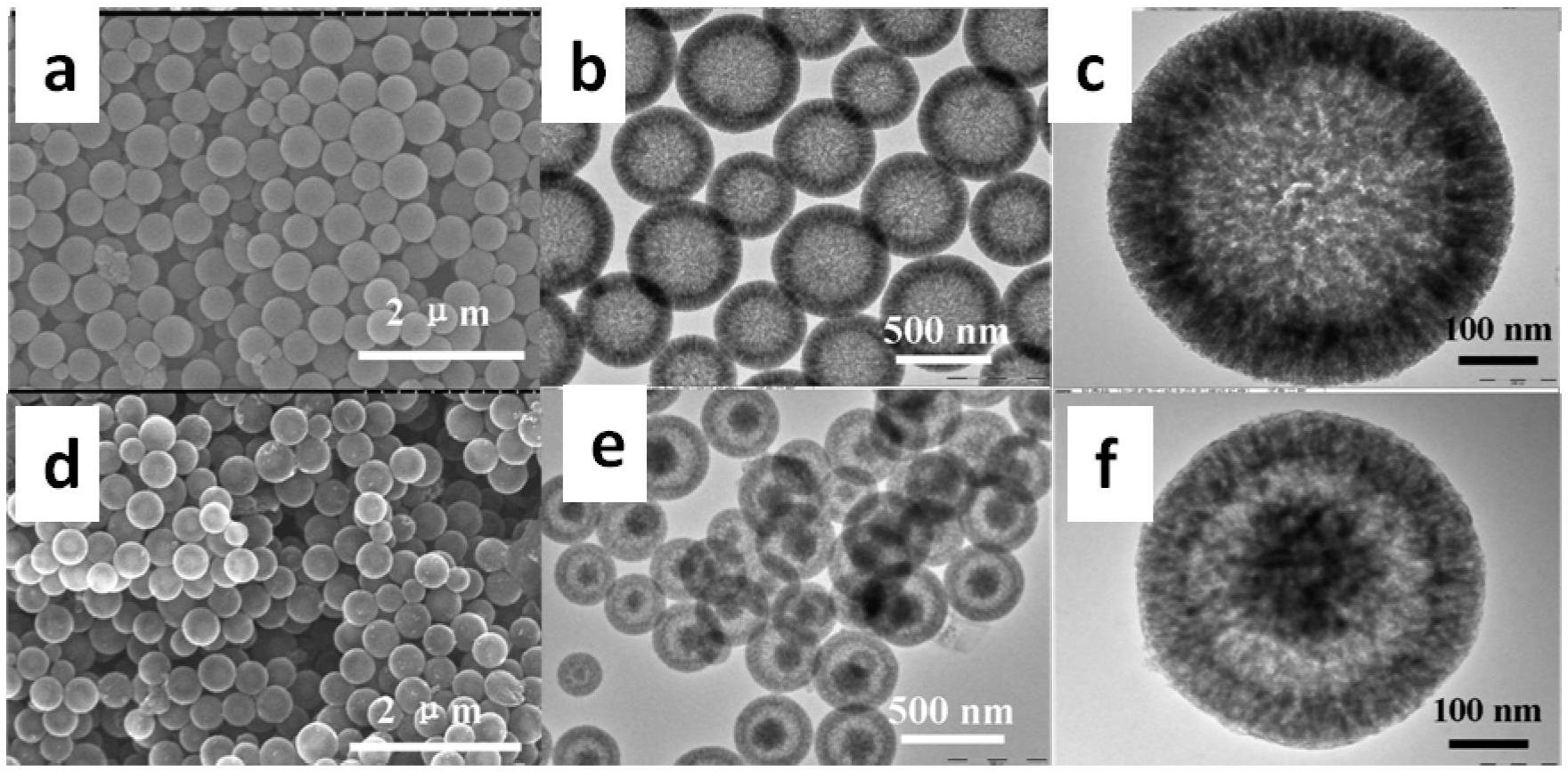

Method for simultaneously preparing multilevel-structure mesoporous silicon dioxide and carbon nano material

The invention relates to a method for simultaneously preparing multilevel-structure mesoporous silicon dioxide and a carbon nano material, belonging to the field of mesoporous nano material preparation. The method comprises the following steps: mixing water and alcohols to prepare a reaction solvent; adding a catalyst alkali, a reaction reagent resorcin and a surfactant CTAB (cetyltrimethylammonium bromide) into the reaction solvent; after stirring, adding a reaction reagent formaldehyde solution and TEOS (tetraethyl orthosilicate) to obtain a mixed solution; continuing stirring the mixed solution at room temperature, removing the supernatant to obtain a precipitate, and drying to obtain solid powder; calcining the solid powder at high temperature under inert gas shielding to carbonize the solid powder, thereby obtaining black solid powder; soaking the black solid powder in a hydrogen fluoride water solution or strongly alkaline solution to remove silicon dioxide, thereby obtaining a multilevel-structure mesoporous carbon material; and calcining the solid powder or black solid powder at high temperature in the air to obtain the multilevel-structure mesoporous silicon dioxide material. The method provided by the invention is simple to operate, has the advantage of low cost, and can implement large-scale production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of lignin-modified phenolic resin wood adhesive

InactiveCN104087219AReduce manufacturing costRealize the purpose of resource managementAldehyde/ketone condensation polymer adhesivesAdhesiveFORMALDEHYDE SOLUTION

A preparation method of lignin-modified phenolic resin wood adhesive. The preparation method includes following steps: adding 5-14 parts by mass of industrial alkali lignin, 6-12 parts by mass of a formaldehyde solution with a mass concentration being 35-40%, and 10-19 parts by mass of phenol to a reactor having a stirrer and a condenser pipe, starting a stirring operation, stating a heating operation for increasing a temperature to 80-90 DEG C within 35-45 min, maintaining the temperature and carrying out a reaction for 15-20 min to obtain the lignin-modified phenolic resin wood adhesive.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

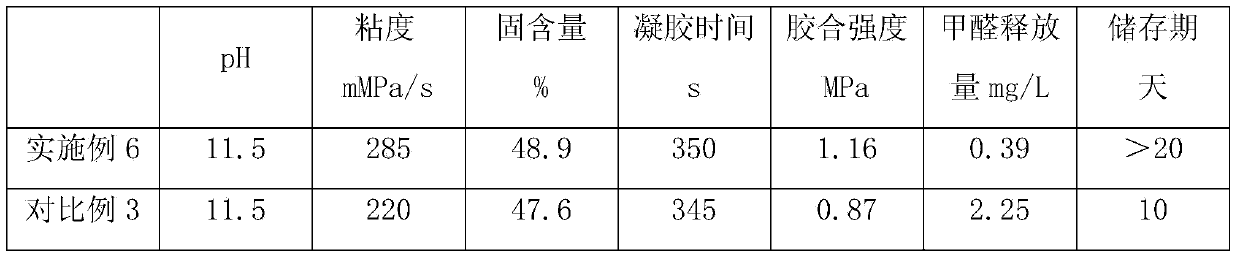

Polymerizable macromolecule photoinitiator and preparation method thereof

The present invention relates to a polymerizable macromolecule photoinitiator and a preparation method thereof. The preparation method comprises: adding 4-hydroxybenzophenone and a formaldehyde solution to a three-necked flask filled with an alkali adopted as a catalyst, carrying out heating stirring to a temperature of 95 DEG C, and carrying out a reaction for 2 hours; heating to a temperature of 150 DEG C, carrying out a reaction, and carrying out a reduced pressure suction filtration reaction for 20 minutes; cooling to a temperature of 105 DEG C after completing the reaction, and collecting the product; pouring the product into water to carry out precipitation, and carrying out suction filtration to obtain a benzophenone-containing macromolecule photoinitiator; dissolving the benzophenone-containing macromolecule photoinitiator in an organic solvent, and simultaneously adding the benzophenone-containing macromolecule photoinitiator and a tertiary amine to the three-necked flask to carry out stirring; dissolving acryloyl chloride in an organic solvent, and slowly adding the organic solvent containing the acryloyl chloride to the mixing solution in a dropwise manner, wherein thereaction temperature is 0-5 DEG C; after completing the addition, stirring for 3 hours at a room temperature, and standing overnight; carrying out suction filtration, washing and drying on the resulting solution; and carrying out rotary evaporation to remove the solvent to obtain the polymerizable macromolecule photoinitiator. The photoinitiator prepared by the preparation method of the present invention has characteristics of large molecular weight, relatively small mobility, self-polymerization, and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Synthesis of urea-formaldehyde controlled releasing fertilizer

InactiveCN1506335AAvoid excessive cross-linking reactionsImprove effectivenessUrea compound fertilisersFertilizer mixturesVegetable oilFORMALDEHYDE SOLUTION

The synthesis process of urea-formaldehyde controlled releasing fertilizer includes mixing gelatinized starch and urea, adding the mixture of polymer water absorbing resin and formaldehyde solution, adding vegetable oil, organic matter including turf and stalk and adsorbent including zeolite, adding sulfuric acid for acidifying to obtain solid product, and final drying, crushing and sieving to obtain the product. The said process avoids excessive crosslinking of polymer to raise the utility of nitrogen, avoids volatizing of formaldehyde during reaction to raise environment quality and production efficiency, and adds zeolite and other inorganic stuffing to raise product quality and provide water maintaining and fertilizer maintaining function and trace elements. In addition, phosphate fertilizer and potash fertilizer may be also added to produce re-compounded fertilizer.

Owner:北京市农林科学院植物营养与资源研究所

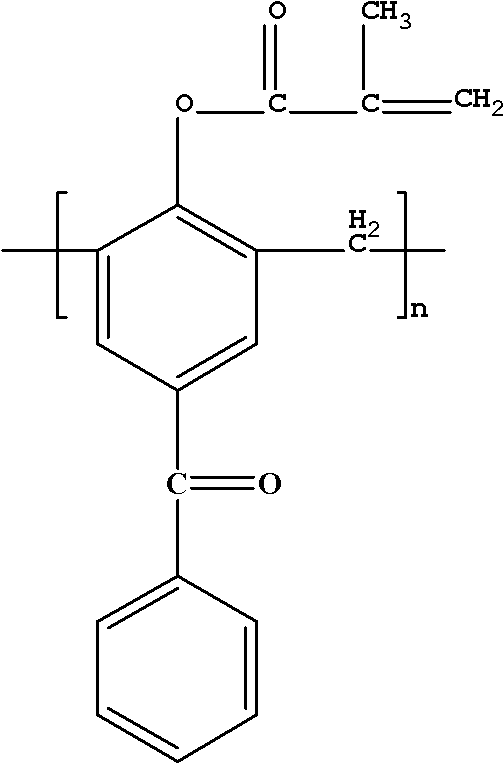

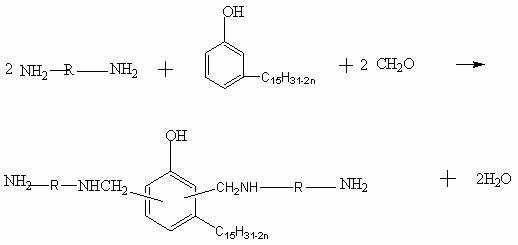

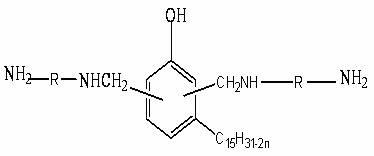

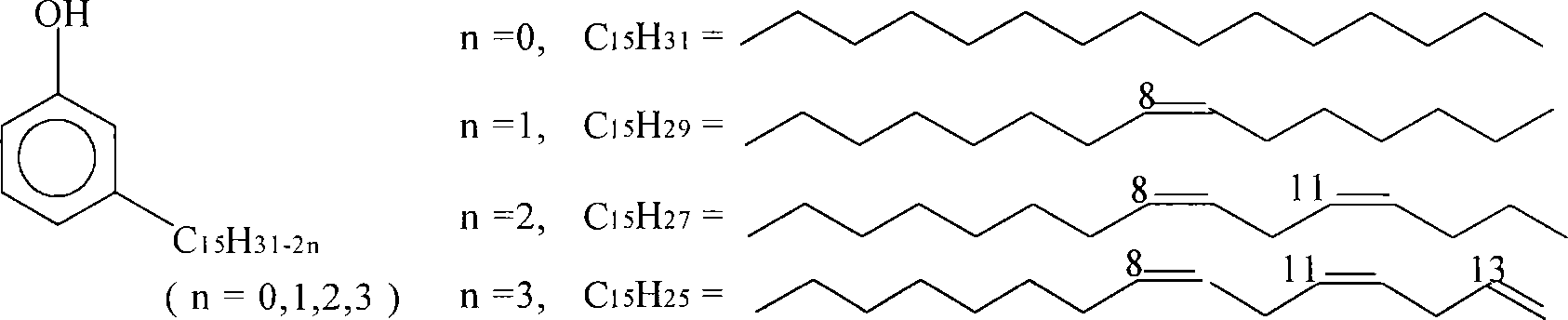

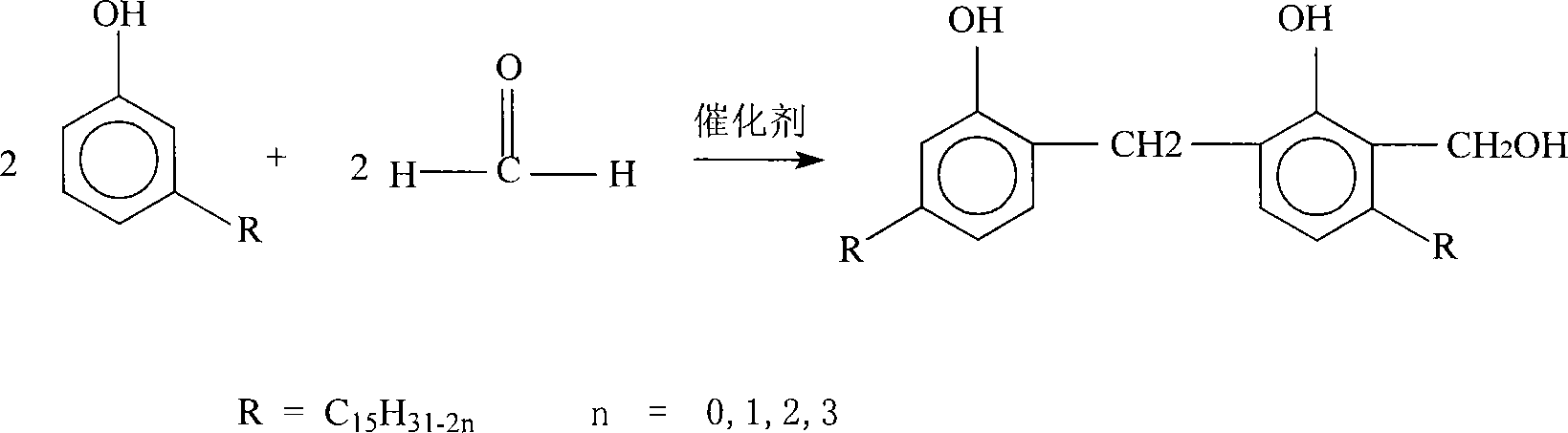

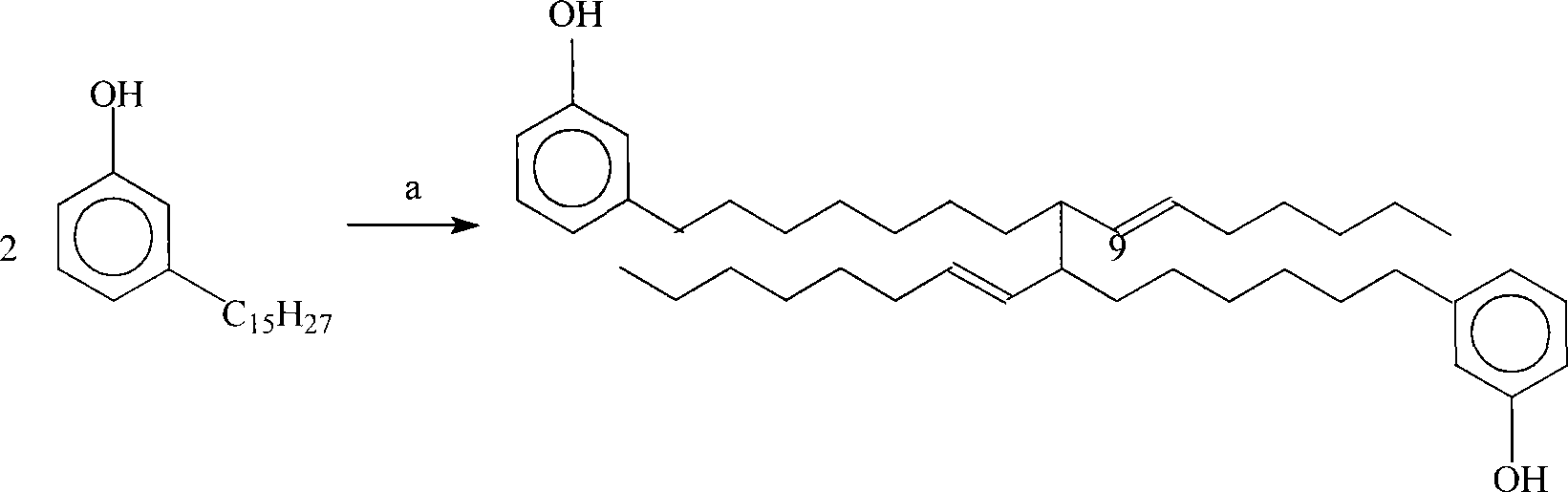

Cardanol epoxy floor curing agent and preparation method thereof

InactiveCN102134306AImprove smoothnessAvoid disadvantagesOrganic compound preparationEpoxy resin coatingsNatural productMechanical property

The invention discloses a cardanol epoxy floor curing agent and a preparation method thereof. Cardanol extracted from cashew shell oil which is a natural product serves as a raw material, and the cardanol with 15 long-chain hydrocarbyl substituents of carbon is reacted with alicyclic amine and a formaldehyde solution to prepare the cardanol epoxy floor curing agent, wherein the molar ratio of the cardanol to the alicyclic amine to the formaldehyde solution is 1:(1-1.5):(1-1.5); in the reaction, the cardanol is firstly added into a reactor, the formaldehyde solution is then added into the reactor for reaction, the alicyclic amine is dropwise added in the reactor, and the cardanol epoxy floor curing agent can be obtained after the material is discharged. In the invention, the synthesis is performed at low temperature; synthetic products have a longer application period; and alicyclics with higher rigidity and better stability are introduced in molecular structures of the products, therefore, an epoxy resin curing product has excellent mechanical properties.

Owner:GUANGDONG UNIV OF TECH +1

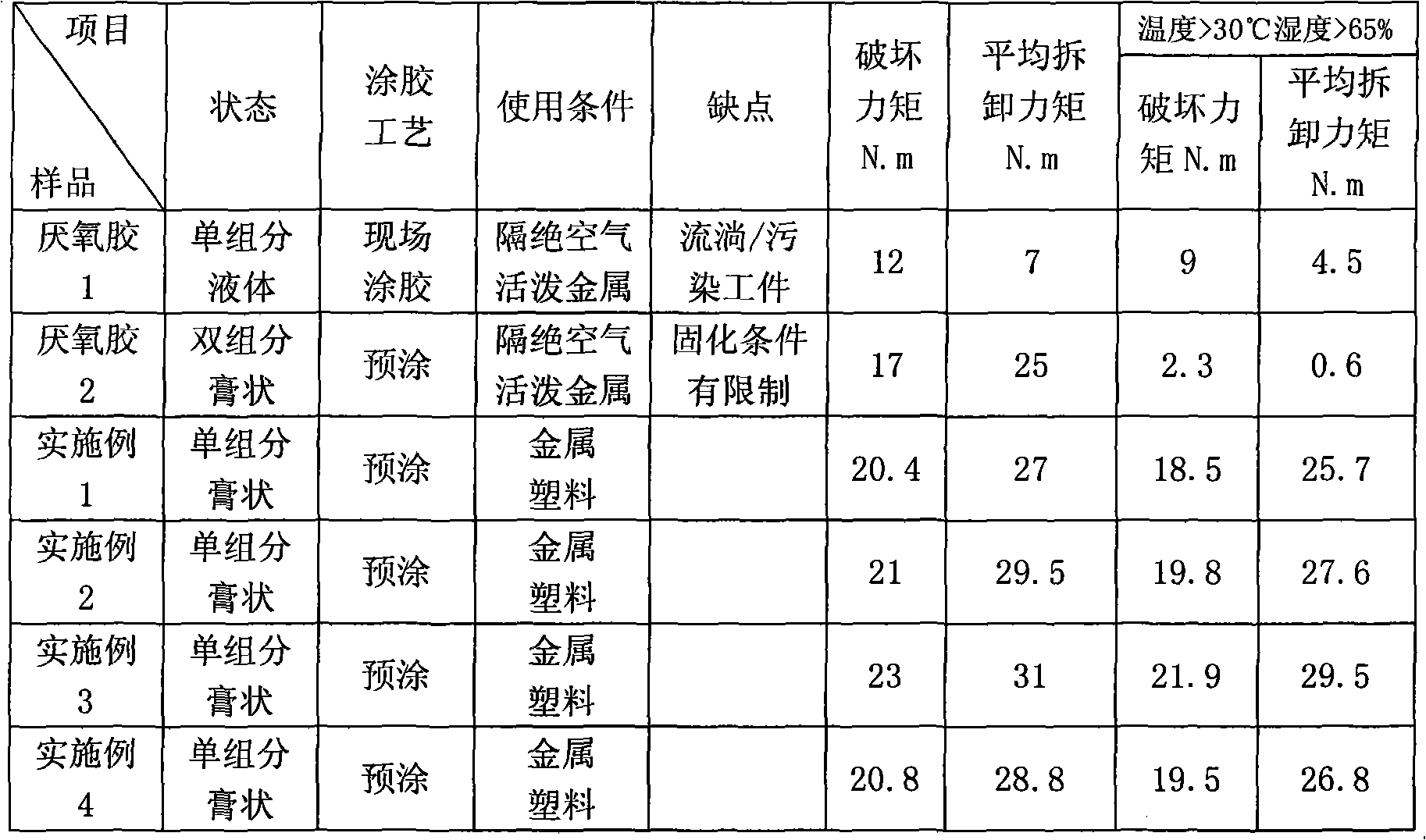

Single-component thread locking epoxy precoated adhesive and preparation method thereof

InactiveCN101665674AStable storageNo chemical reactionNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention discloses a single-component thread locking epoxy precoated adhesive which is characterized by being prepared from the following components in proportion by weight: 40-70 parts of epoxyresin, 10-80 parts of activated thinner, 20-60 parts of epoxy hardener, 8-20 parts of urea, 30-60 parts of formaldehyde solution, 10-30 parts of hydroxyphenol, 0.5-5 parts of stuffing, 5-15 parts of surfactant, 80-200 parts of distilled water, 0.5-2 parts of membrane material, 0.1-1 part of hydrolysis inhibitor and 5-10 parts of solvent; and a preparation method comprises the steps: firstly, respectively microencapsulating the epoxy resin and the epoxy hardener are and then uniformly mixing with other components in proportion. The single-component thread locking epoxy precoated adhesive has the characteristics of convenient construction, applicable workpiece material diversification, less curing condition restriction, good moisture resistance and high destabilizing moment and average disassembly moment, ensures the locking performance and better guarantees the safe reliability of products.

Owner:YANTAI DARBOND TECH

Reversible thermochromic microcapsule pigment preparation method

InactiveCN105170041AIncrease coverageImprove stabilityOrganic dyesTenebresent compositionsColor changesFORMALDEHYDE SOLUTION

The present invention discloses a reversible thermochromic microcapsule pigment preparation method, which comprises: weighing 0.08-0.1% by mass of crystal violet lactone, 0.4-0.5% by mass of bisphenol A, 3-6% by mass of hexadecanol, 2-4% by mass of melamine, 4.03-5% by mass of a formaldehyde solution, 0.4-0.6% by mass of sodium dodecyl benzene sulfonate, 0.09-0.11% by mass of sodium dodecyl sulfate ammonium, and 87-90% by mass of distilled water, preparing a complex A, preparing an O / W type emulsion and a melamine-formaldehyde pre-polymerization liquid, and carrying out a condensation polymerization reaction to prepare the pigment. According to the present invention, advantages of high color change sensitivity, low color change temperature and good color change stability are provided when the prepared monomer thermochromic material is adopted as the pigment, and the prepared reversible thermochromic microcapsule pigment can be widely used in the fields of anti-counterfeiting inks, temperature showing materials, and the like.

Owner:XIAN UNIV OF TECH

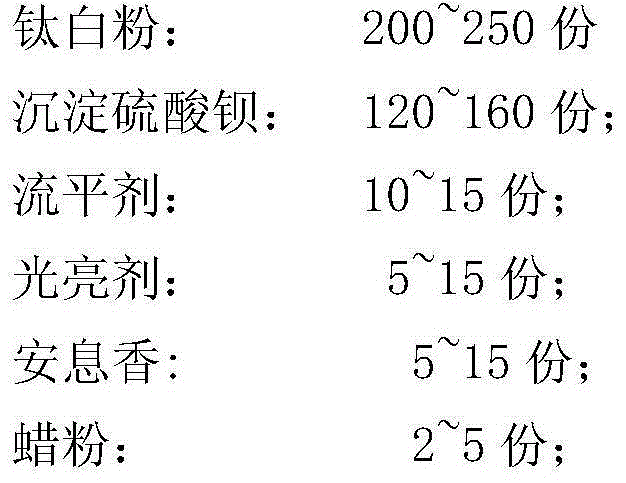

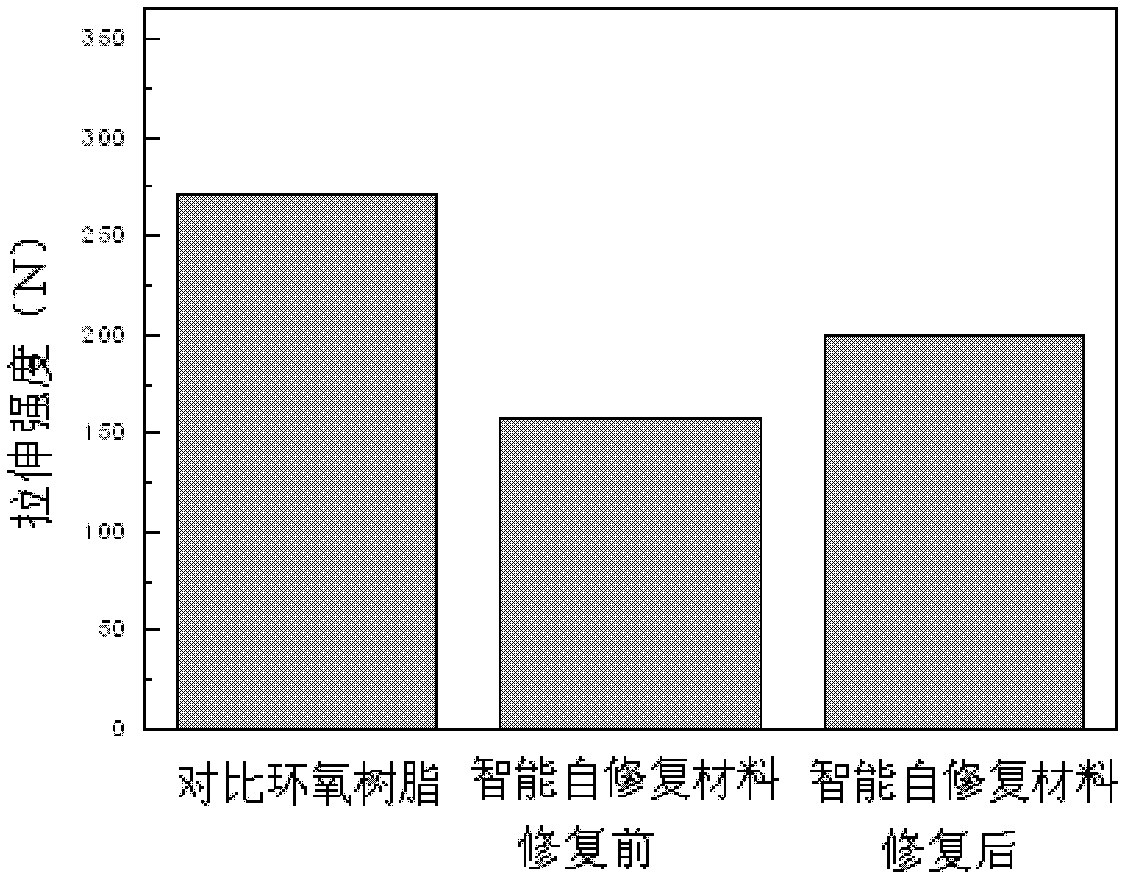

Self-healing epoxy powdery coating containing microcapsule and preparation method thereof

InactiveCN105038502AAvoid breakingPrevent peelingPowdery paintsEpoxy resin coatingsSelf-healingEpoxy

The present invention discloses a self-healing epoxy powdery coating containing microcapsule. The self-healing epoxy powdery coating containing microcapsule consists of the following components by weight: 5-15 parts of microcrack self-healing capsule, 2-4 parts of a Grubbs catalyst and 89-93 parts of epoxy powder resin matrix. The capsule wall of the self-healing microcapsule is theurea-formaldehyde resin prepared from urea and 37% formaldehyde solution in molar ratio of 0.5-0.6:1, and the capsule core is dicyclopentadiene by blending and high pressure electrostatic spraying. The housing capsule wall of the microcapsule is urea-formaldehyde resin; and the mass ratio of the inner capsule core to capsule wall is 5:1. When the coating cracks, the microcapsule ruptures, and dicyclopentadiene rapidly penetrates into the crazing and the met Grubbs catalyst to produce cross-linking, in order to achieve the purpose of repair. The invention prolongs the service life of the powdery coating and is applicable to novel industrial production.

Owner:南通南京大学材料工程技术研究院

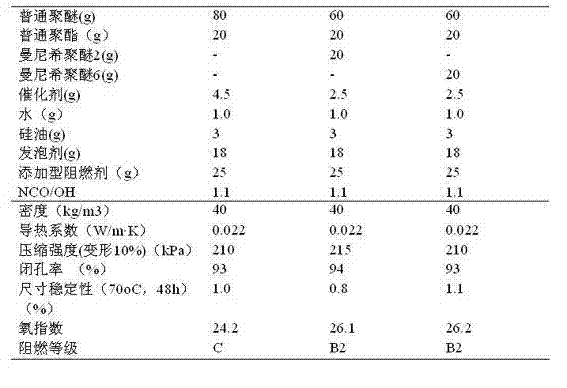

Preparation method and applications of reaction type Mannich polyether polyol with permanent flame retardant effect

The invention provides a preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect. The preparation method of reaction type Mannich polyether polyol with permanent flame retardant effect comprises the following steps: reacting paraformaldehyde or formaldehyde solution with diethanol amine to obtain 3-ethoxyl-1,3-oxazolidine reaction liquid, and then carrying out reduced pressure distillation to obtain the product 3-ethoxyl-1,3-oxazolidine; reacting aromatic phenol compounds or / and melamine compounds with 3-ethoxyl-1,3-oxazolidine to obtain Mannich base as intermediate; and carrying out polymerization reaction between the intermediate Mannich base and epoxy compound to obtain crude product of reaction type Mannich polyether polyol with permanent flame retardant effect, then carrying out reduced pressure distillation to remove impurities with low boiling points, and thus obtaining finished product. The reaction type Mannich polyether polyol simultaneously has the high stability and thermal stability of rigid polyurethane foam and the flame resistance of phenolic foam, is applied to foaming rigid polyurethane foam, and has wide application prospect.

Owner:JIANGSU YOKE TECH

Preparation method of cashew nut oil modified alkyd resin

InactiveCN101081890AGood flexibilityPlay the role of internal plasticizationMetal layered productsPolymer scienceSolvent

The present invention is process of preparing cashew nut oil modified phenolic resin. The process includes the following steps: preparing the resin A; mixing the resin A 100 weight portions, formaldehyde solution 80-280 weight portions and alkaline catalyst 0.1-5 weight portions; reaction at 70-100 deg.c for 1-5 hr; vacuum distilling in a vacuum distilling kettle at temperature of 40-80 deg.c and vacuum degree of -0.03 MPa to -0.1 MPa to dewater to water content of 0.5-20 %, cooling to room temperature, and adding solvent while stirring to regulate the solid resin content to 30-70 % and viscosity at 25 deg.c to 40-400 cp to obtain the cashew nut oil modified phenolic resin. The cashew nut oil modified phenolic resin has high heat resistance, flame resistance and high toughness, and may be applied as the base material for copper clad panel.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Adhesive for artificial board, and preparation method and application thereof

ActiveCN103173170AHigh strengthImprove the defect of low strengthNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCross-linkPolyvinyl alcohol

The invention relates to an adhesive for producing an artificial board having a strong strength and a low formaldehyde release amount, and a preparation method and an application of the adhesive in the artificial board production field. The adhesive comprises the following components, by weight, 200 parts of formaldehyde, 150-170 parts of urea, 1-3 parts of polyvinyl alcohol, 12-15 parts of melamine, 5-8 parts of a formaldehyde catching agent, and 0.5-2 parts of a cross-linking agent, wherein the formaldehyde is an aqueous formaldehyde solution having a mass concentration of 35-40%. The preparation method of the adhesive comprises the following steps: adding urea three times, adding the formaldehyde catching agent and the cross-linking agent in the resin synthesis, and sequentially carrying out reactions in a weak alkaline medium, an acidic medium and a neutral medium. The artificial adhesive-bonded board produced through using the adhesive has a low formaldehyde release amount and a bonding strength reaching requirements of Chinese standard adhesive-bonded boards II.

Owner:北京海天科林技术有限公司

Preparation method of microcapsule aluminum hypophosphite flame retardant

ActiveCN105457574AOvercome water solubleOvercome the disadvantage of being flammableMicroballoon preparationMicrocapsule preparationPhosphoric acidALUMINUM PHOSPHATE

The present invention relates to a preparation method of a microcapsule aluminum hypophosphite flame retardant. The method comprises the steps of: first reacting melamine, a formaldehyde solution and a resin modifier under reaction conditions of pH of 8-10 and a temperature of 50-80 DEG C for 0.5-2 h to prepare a melamine resin prepolymer; then slowly adding the prepolymer to water with aluminum phosphate dispersed therein, reacting at 65-95 DEG C for 1-5 h, and treating to obtain the microcapsule coated inorganic aluminum phosphate flame retardant. The obtained microcapsule inorganic aluminum hypophosphite flame retardant has greatly improved water resistance, boiling residual rate of 92% to 97% and average particle diameter of 10-35 mum, solves the disadvantage of flammability of inorganic aluminum hypophosphite, and greatly improves the safety of the production and application process.

Owner:JINAN TAIXING FINE CHEM

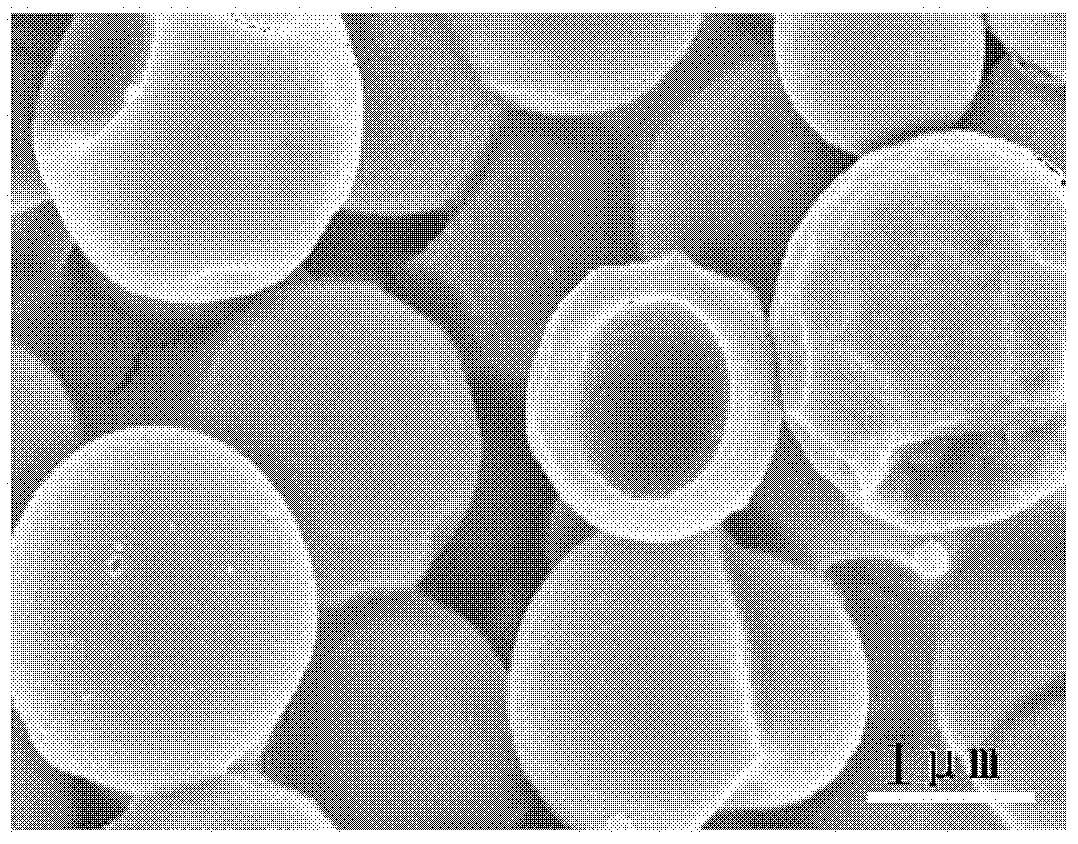

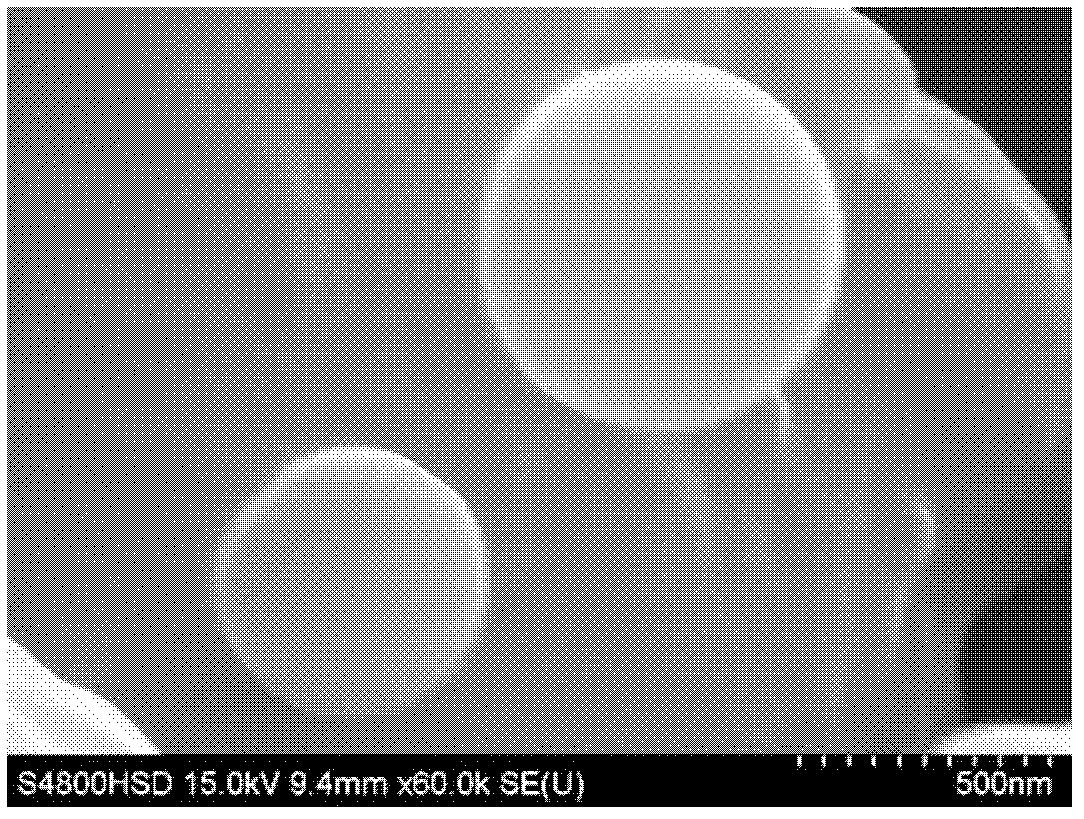

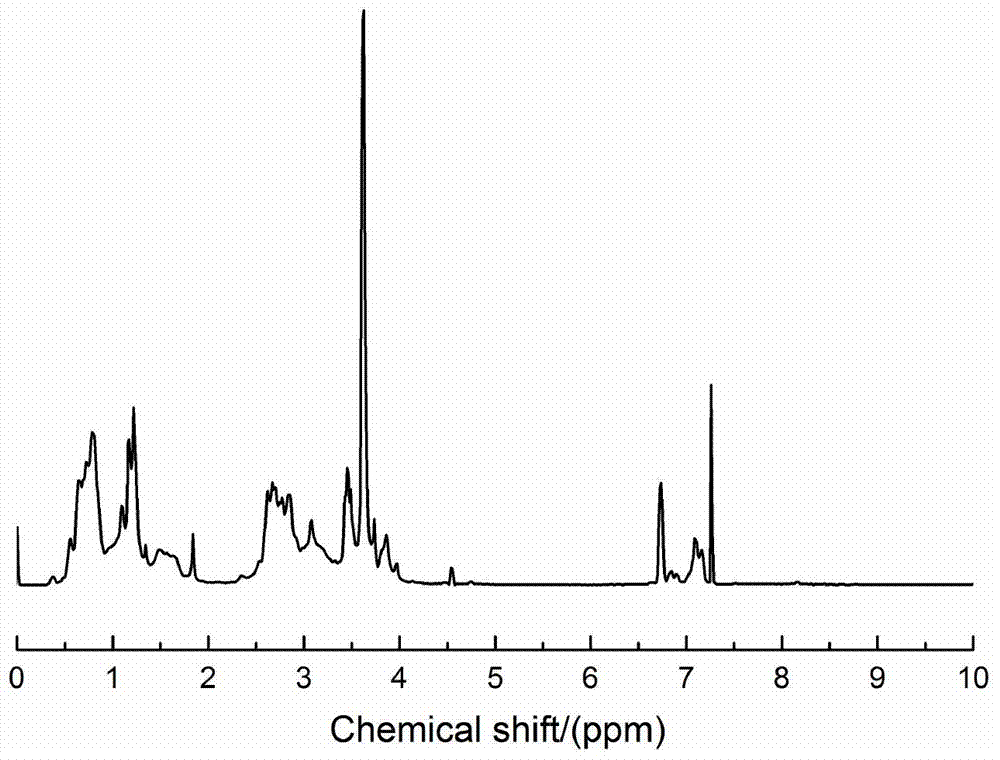

Urea resin wrapped dicyclopentadiene nanometer microcapsule, and synthetic method and application thereof

InactiveCN102492174AEasy to prepareEasy to operateMicroballoon preparationMicrocapsule preparationRepair materialPrepolymer

The invention discloses a urea resin wrapped dicyclopentadiene nanometer microcapsule, and a synthetic method and application thereof, and relates to a self-repair material, and a synthetic method and application thereof. The urea resin wrapped dicyclopentadiene nanometer microcapsule is a nanometer spherical granule prepared from urea resin used as a wall shell, and dicyclopentadiene used as a core material. The method comprises the following steps of: adding urea and a formaldehyde solution into a reactor, stirring uniformly, adding resorcinol and NH4Cl, regulating a pH value, and heating and reacting to obtain a prepolymer; and adding a sodium dodecyl benzene sulfonate solution into the dicyclopentadiene and the prepolymer, mixing the dicyclopentadiene and the prepolymer, regulating the pH value until the solution is acidic, heating, cooling the obtained suspension, washing, filtering and drying to obtain the urea resin wrapped dicyclopentadiene nanometer microcapsule. The self-repair efficiency of the nanometer microcapsule is over 60 percent, the preparation method is simple and easy to operate, and the yield is between 80 and 85 percent. The urea resin wrapped dicyclopentadiene nanometer microcapsule can be used for composite materials of aerospace.

Owner:HARBIN INST OF TECH

Method for preparing adhesive for grade-E0 medium density fiberboards

InactiveCN102134468ALow free formaldehyde contentModerate curing timeAldehyde/ketone condensation polymer adhesivesAdhesivePolyvinyl alcohol

The invention provides an adhesive for grade-E0 medium density fiberboards. The raw materials of the adhesive include formaldehyde, polyvinyl alcohol, urea and tripolycyanamide. The production process of the adhesive comprises: firstly, adding all formaldehyde into a reaction kettle, regulating the pH value of formaldehyde solution to 7.5 to 8.5 by using sodium hydroxide solution, adding the 40 to 50 percent of polyvinyl alcohol and urea and adding 80 to 90 percent of tripolycyanamide and adding the 10 to 20 percent of urea; secondly, adjusting the pH value to 5 to 6 by using formic acid, reacting for 20 to 30 minutes till a cloud point, regulating the pH value to 705 to 8.5 with caustic soda solution, and adding the 10 to 20 percent of tripolycyanamide and 20 to 30 percent of urea; and finally, adding 10 to 20 percent of urea, regulating the pH value of the adhesive to 6.6 to 7.5, and discharging. The adhesive has the advantages that: the free formaldehyde content is very low, and the manufactured medium density board is of grade E0; the curing time is proper, the storage stability is high, and the normal-temperature storage period is about 1 month; and the manufactured medium density board has high internal combining strength and high waterproof and dampproof performance.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure and preparation method thereof

InactiveCN104262589AThe synthesis process is simpleThe synthesis process is simple and controllableOrganic compound preparationAmino-hyroxy compound preparationWater basedEpoxy

The invention discloses a nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure, of which the molecular general formula is disclosed in the specification. The preparation method comprises the following steps: 1) adding alkyl phenol, polyamine and formalin in a solvent to carry out Mannich reaction, and removing the solvent and byproduct after the reaction finishes, thereby obtaining Mannich amine containing primary amine group; and 2) sufficiently reacting the Mannich amine containing primary amine group with diglycidyl ether, cooling after the reaction finishes, adding water, and sufficiently dispersing to obtain an emulsion, thereby obtaining the product. The synthesis technique is simple and pollution-free; the synthesized curing agent does not need to perform salification reaction to implement self-emulsifying action by using organic acid; the epoxy curing agent has the advantages in the Gemini surfactant and has the characteristics of excellent wettability, excellent emulsibility, excellent stability and the like; and the epoxy curing agent can directly emulsify and cure the liquid epoxy resin, and can also cure an epoxy resin dispersion solution.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com