Self-healing epoxy powdery coating containing microcapsule and preparation method thereof

A technology of epoxy powder and powder coating, which is applied in the field of coatings, can solve the problems of increasing economic costs, etc., and achieve the effects of reducing cumbersome work, stable storage, and improving the effect of self-healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 5 g of urea in 200 ml of 2.5% ethylene maleic anhydride (EMA) solution under stirring environment. After all the urea is dissolved, add 0.5 g of ammonium chloride and resorcinol respectively. Use hydrochloric acid and sodium hydroxide to adjust the pH of the reaction system to 4-5, then add 60ml of dicyclopentadiene, and after the emulsion is formed stably, finally add 13g of 37% formaldehyde solution. The system was heated to 55°C at 1°C / min and reacted for 4h. Cool to room temperature, filter and wash, and air dry naturally.

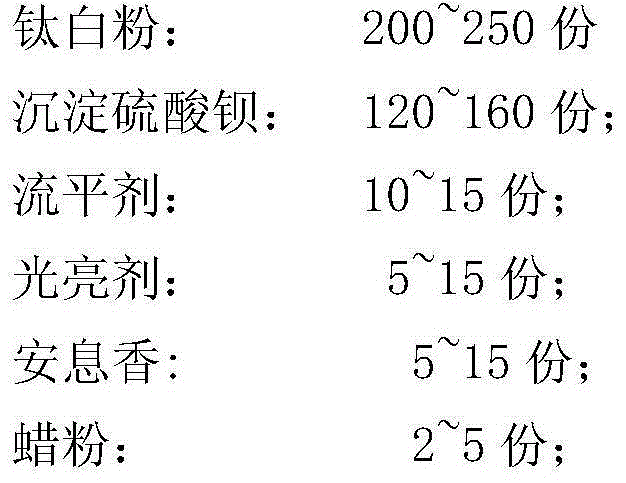

[0037] Epoxy resin: 300 parts; polyester resin: 300 parts, titanium dioxide: 200 parts; precipitated barium sulfate: 150 parts; leveling agent: 15 parts; brightener: 15 parts; benzoin: 15 parts; wax powder: 5 parts ; Mixing and extruding with a twin-screw extruder. After secondary pulverization, 15 parts of self-healing microcapsules and 3 parts of Grubbs catalyst were added and mixed evenly. Spray under electrostatic conditions, the...

Embodiment 2

[0039] Dissolve 5 g of urea in 200 ml of 2.5% ethylene maleic anhydride (EMA) solution under stirring environment. After all the urea is dissolved, add 0.5 g of ammonium chloride and resorcinol respectively. Use hydrochloric acid and sodium hydroxide to adjust the pH of the reaction system to 4-5, then add 60ml of dicyclopentadiene, and after the emulsion is formed stably, finally add 13g of 37% formaldehyde solution. The system was heated to 55°C at 1°C / min and reacted for 4h. Cool to room temperature, filter and wash, and air dry naturally.

[0040] Epoxy resin: 300 parts; polyester resin: 300 parts, titanium dioxide: 220 parts; precipitated barium sulfate: 140 parts; leveling agent: 15 parts; brightener: 15 parts; benzoin: 15 parts; wax powder: 5 parts ; Mixing and extruding with a twin-screw extruder. After secondary pulverization, add 10 parts of self-healing microcapsules and 3 parts of Grubbs catalyst and mix well. Spray under electrostatic conditions, then cure at 1...

Embodiment 3

[0042] Dissolve 5 g of urea in 200 ml of 2.5% ethylene maleic anhydride (EMA) solution under stirring environment. After all the urea is dissolved, add 0.5 g of ammonium chloride and resorcinol respectively. Use hydrochloric acid and sodium hydroxide to adjust the pH of the reaction system to 4-5, then add 60ml of dicyclopentadiene, and after the emulsion is formed stably, finally add 13g of 37% formaldehyde solution. The system was heated to 55°C at 1°C / min and reacted for 4h. Cool to room temperature, filter and wash, and air dry naturally.

[0043] Epoxy resin: 350 parts; polyester resin: 250 parts, titanium dioxide: 200 parts; precipitated barium sulfate: 150 parts; leveling agent: 15 parts; brightener: 15 parts; benzoin: 15 parts; wax powder: 5 parts ; Mixing and extruding with a twin-screw extruder. After secondary pulverization, 5 parts of self-healing microcapsules and 3 parts of Grubbs catalyst were added and mixed evenly. Spray under electrostatic conditions, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com