Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2686results about How to "Improve the blocking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

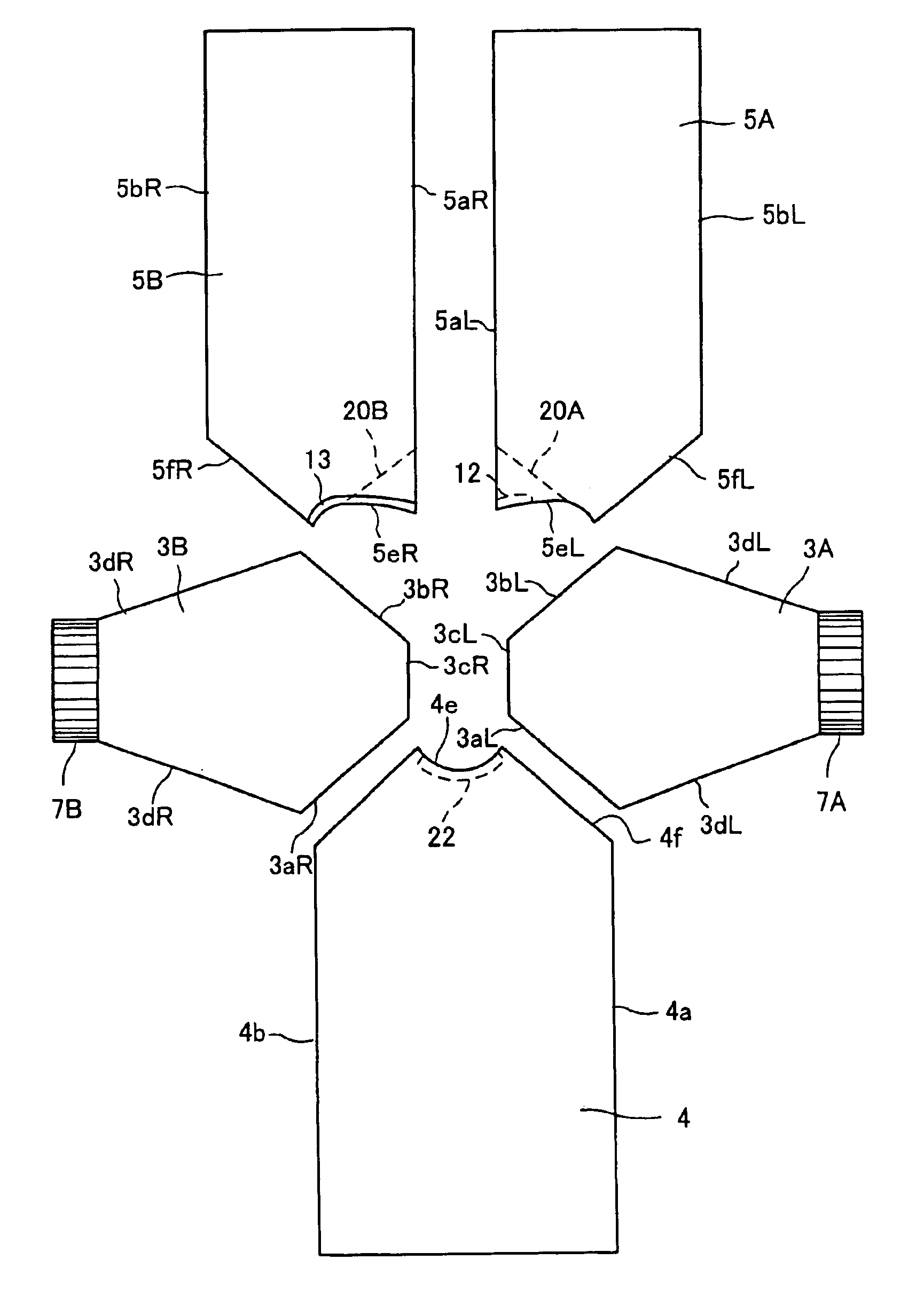

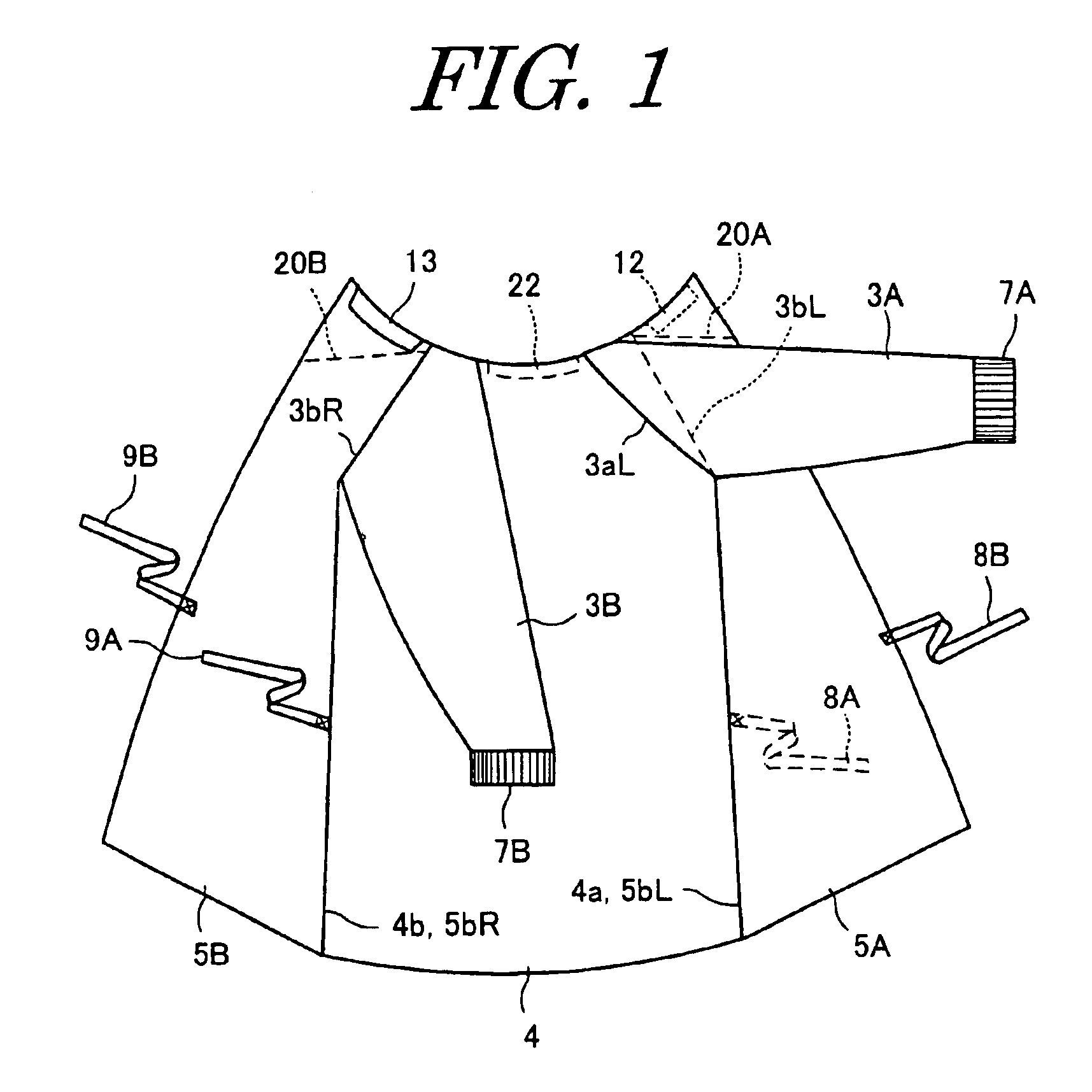

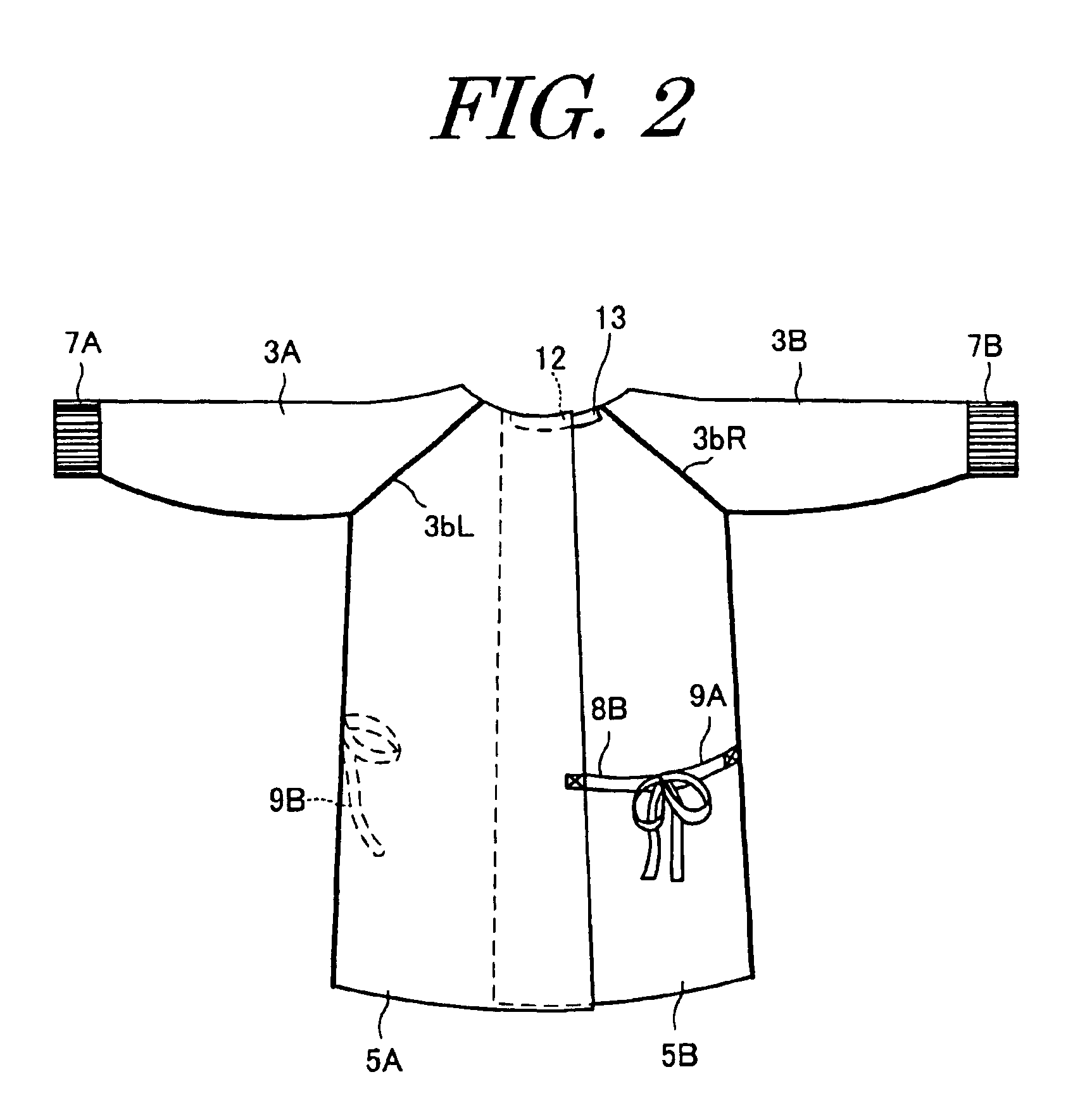

Disposable surgical gown

InactiveUS6851125B2Improve the blocking effectInhibition of exudationGarment special featuresBaby linensSurgical GownsEngineering

A disposable surgical gown includes a main body including a front body and a back body; and sleeves extending from both sides of upper ends of the main body. The main body comprises a plurality of assembly sheets having air permeability and liquid non-permeability. The assembly sheets are bonded to each other along a continuous bonding line extending along edges of the sheets.

Owner:UNI CHARM CORP

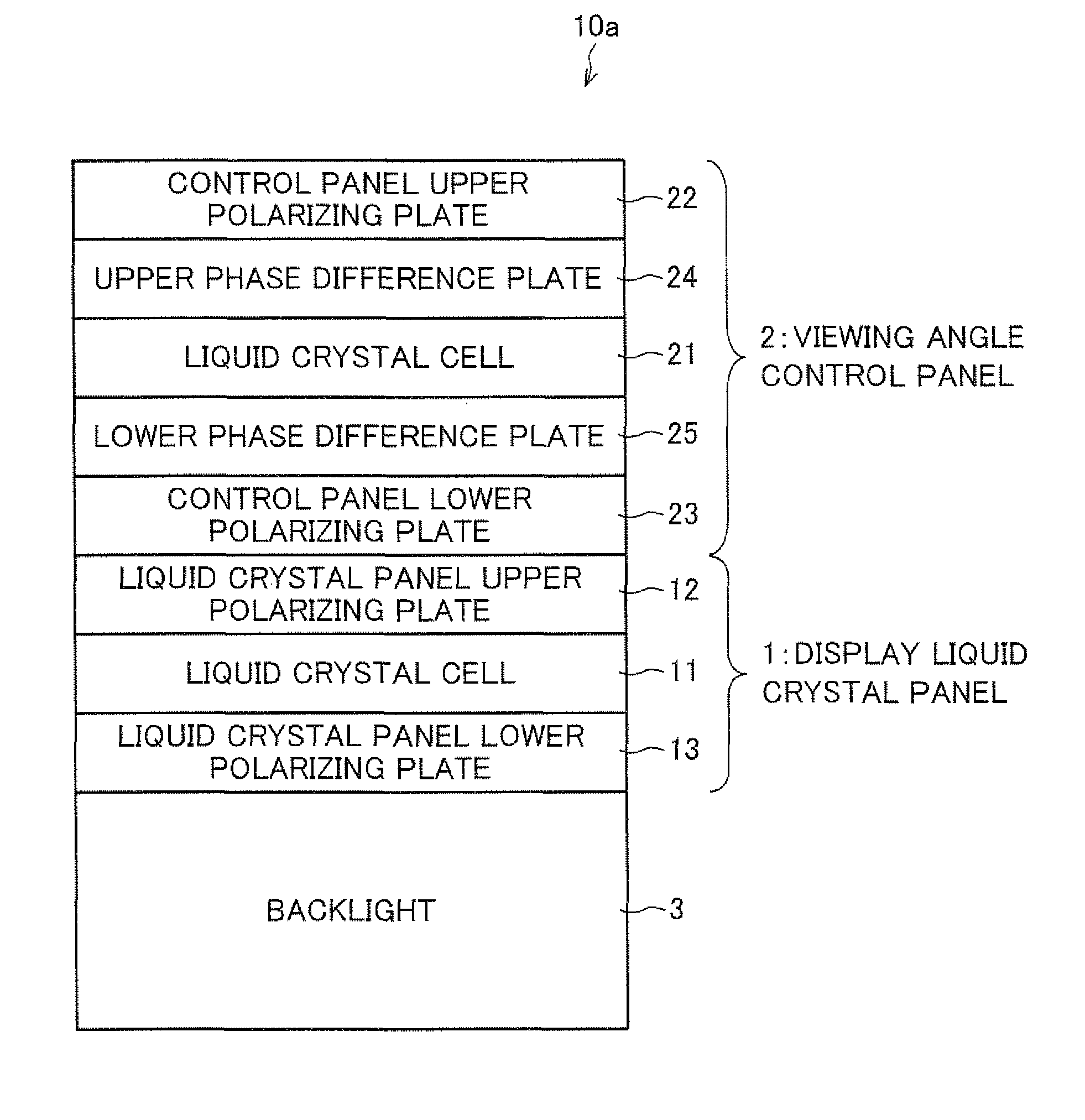

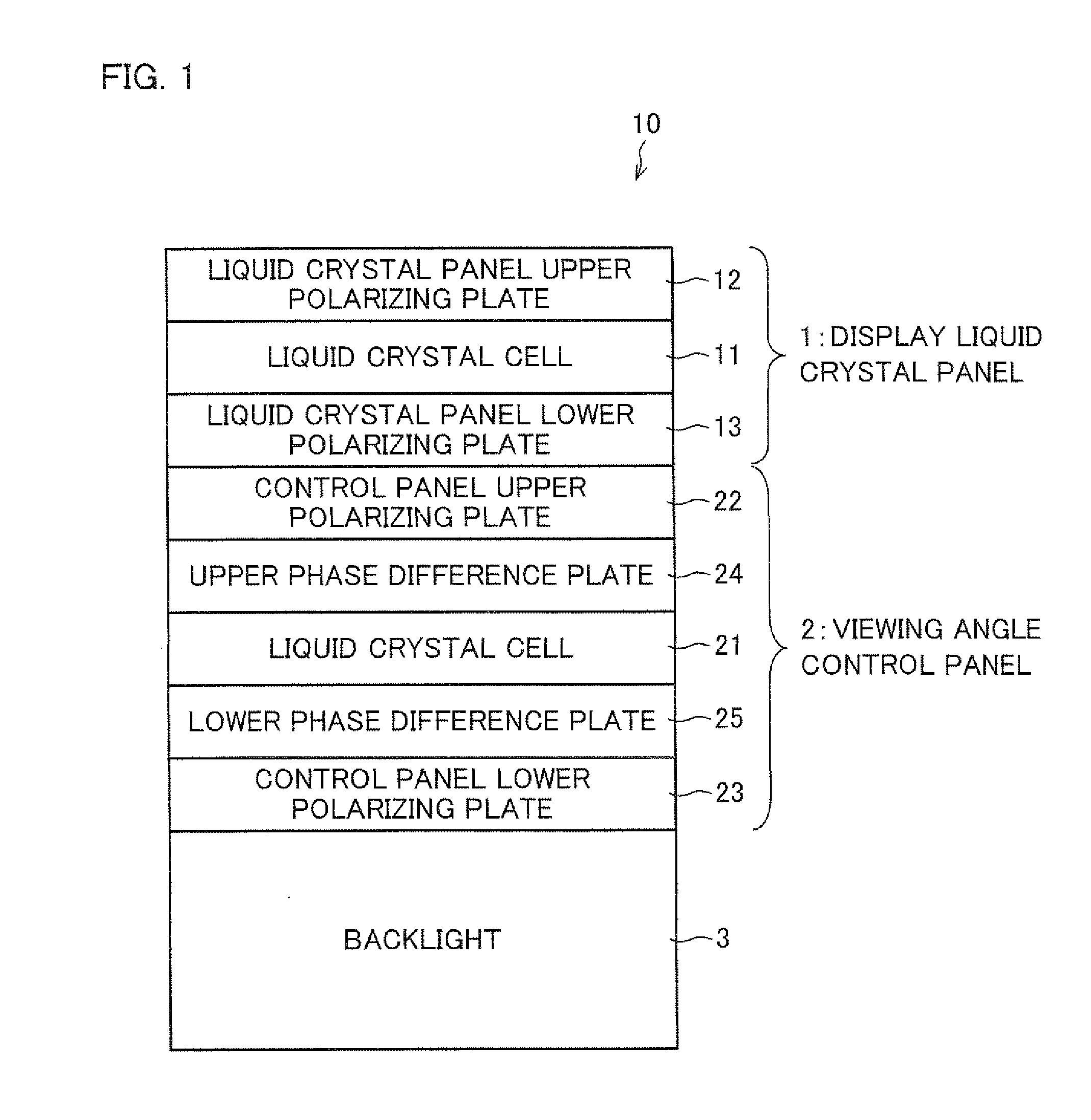

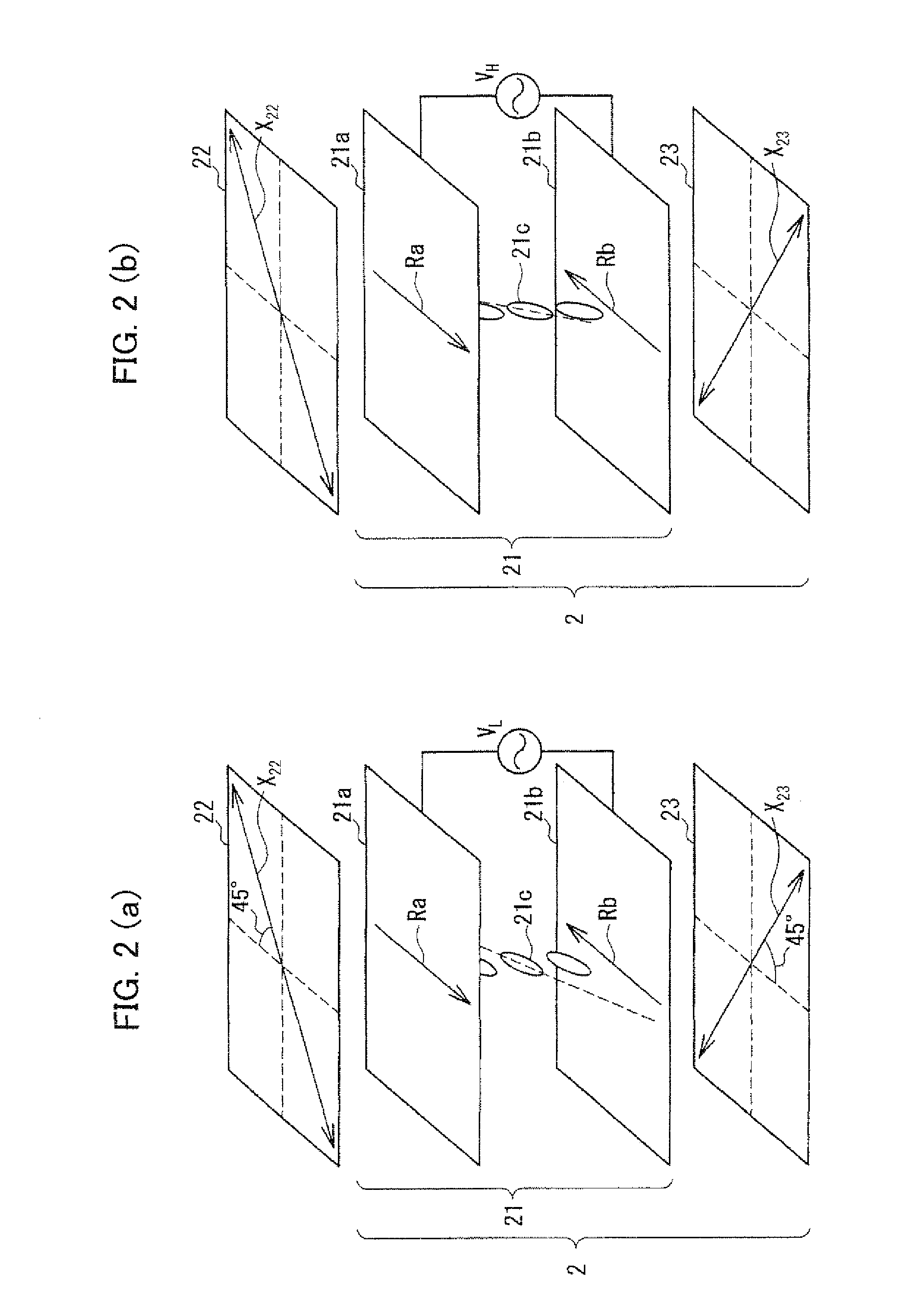

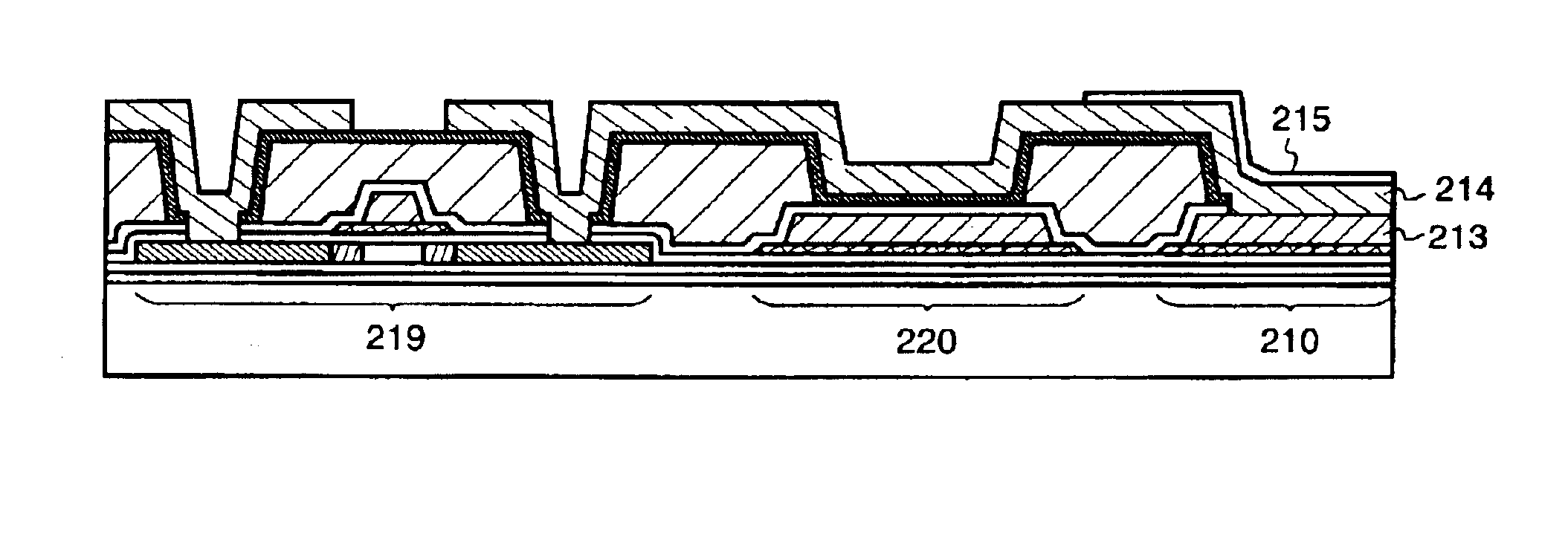

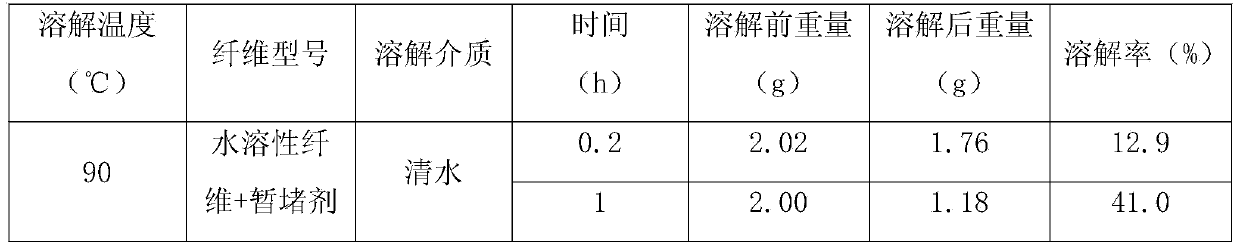

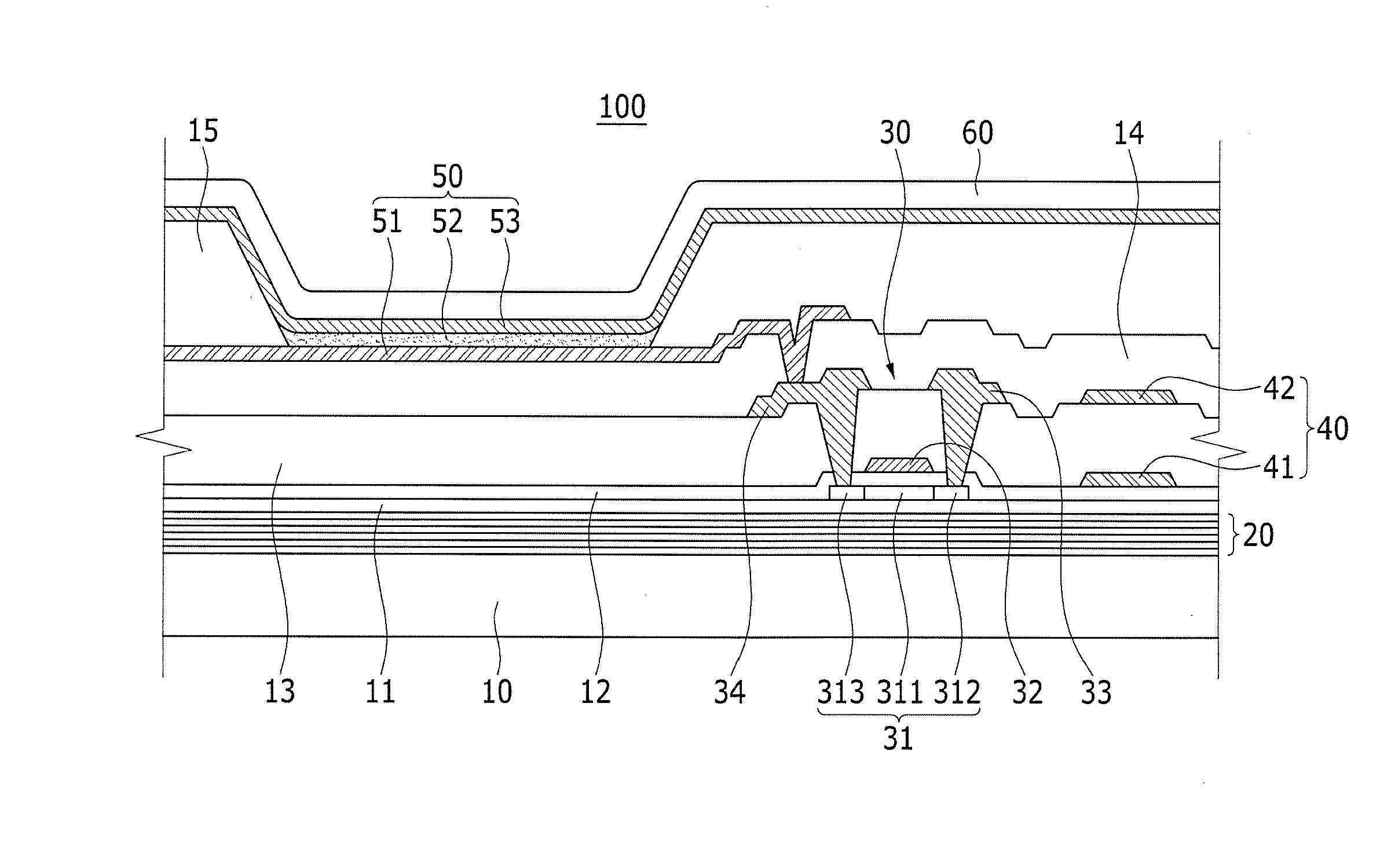

Liquid crystal display device and viewing angle control panel

ActiveUS20100128200A1Improve the blocking effectNon-linear opticsMechanical engineeringLiquid crystal cell

A liquid crystal display device (10) of the present invention includes a backlight (3), a display liquid crystal panel (1) and a viewing angle control panel (2) for switching a viewing angle of the display liquid crystal panel (1) between a wide viewing angle mode and a narrow viewing angle mode. The viewing angle control panel (2) includes a control panel upper polarizing plate (22), a liquid crystal cell (21) and a control panel lower polarizing plate (23) stacked in this order, and phase difference plates (24, 25) are provided between the polarizing plates (22, 23) and the liquid crystal cell (21), respectively. The viewing angle control panel (2) is arranged such that Re1 in a white display portion in the wide viewing angle mode is nλ / 2 (n is an integer of 1 or more), Re2 in a white display portion in the narrow viewing angle mode is nλ / 2 (n is an integer of 1 or more), and Re3 in a black display portion in the narrow viewing angle mode is nλ (n is an integer of 1 or more).

Owner:SHARP KK

Polyacrylamide reversed-phase microemulsion and preparation method thereof

The invention relates to polyacrylamide reversed-phase microemulsion and a preparation method thereof. The polyacrylamide reversed-phase microemulsion is mainly used for solving the problem that product solid content is low and emulsion is unstable in the prior art. A semicontinuous polymerization method is adopted to add an aqueous phase containing monomers such as acrylamide into an oil phase containing an emulsifier, so that polymerization process control of the microemulsion is relatively stable, the microemulsion stability is good, and the content of solids capable of being separated out is high. By adopting a technical scheme that the polyacrylamide reversed-phase microemulsion comprises the following components in parts by weight: 20-70 parts of an oil-soluble solvent, 5-20 parts of an emulsifier and a co-emulsifier and 20-70 parts of an aqueous phase containing acrylamide polymer, the problem is solved well; the prepared polyacrylamide reversed-phase microemulsion is directly used or compounded with other oil-field chemicals so as to use for field application such as deep profile control, water shutoff and displacement of reservoir oil, which can be used for increasing recovery efficiency, for oil-field tertiary oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

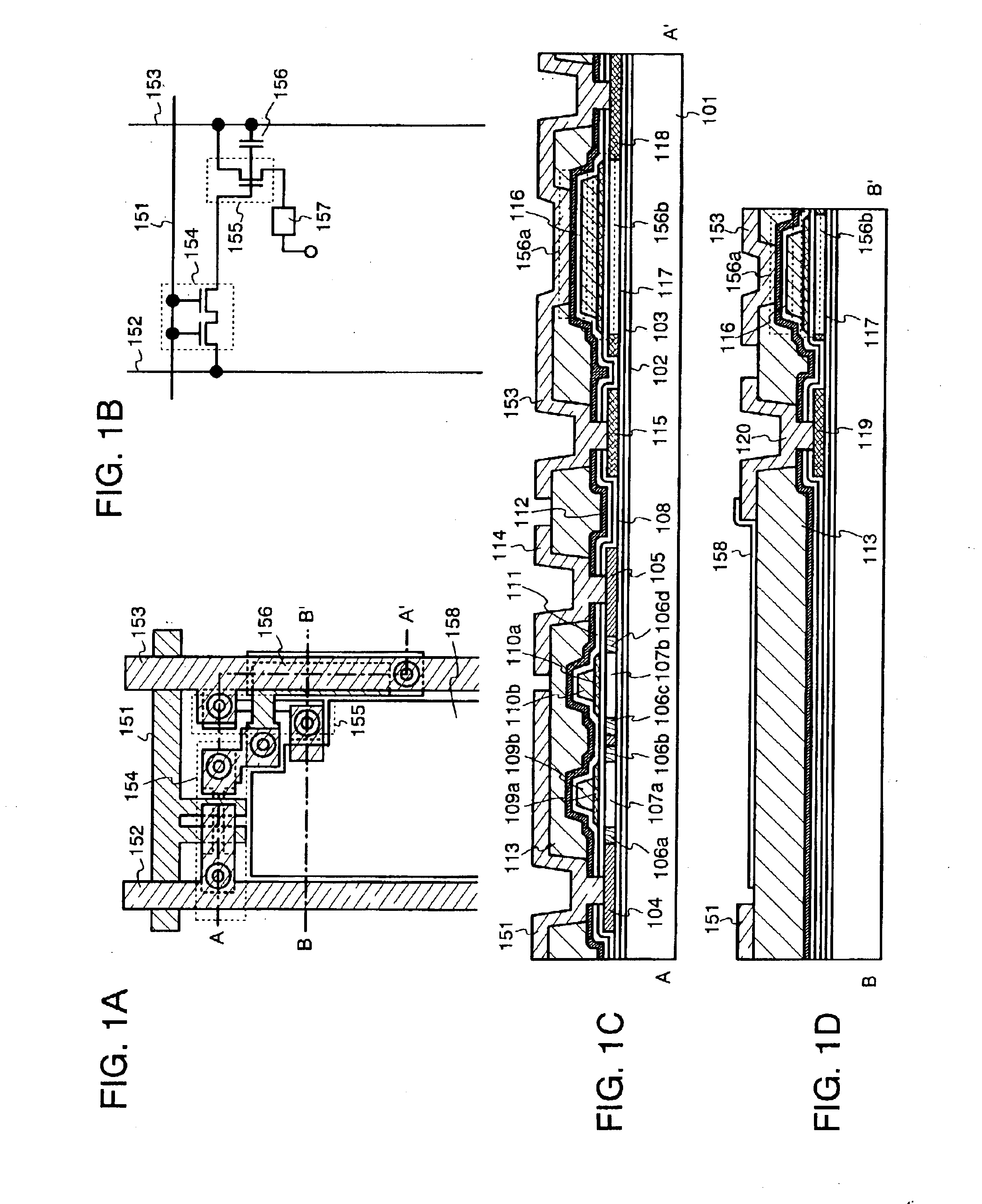

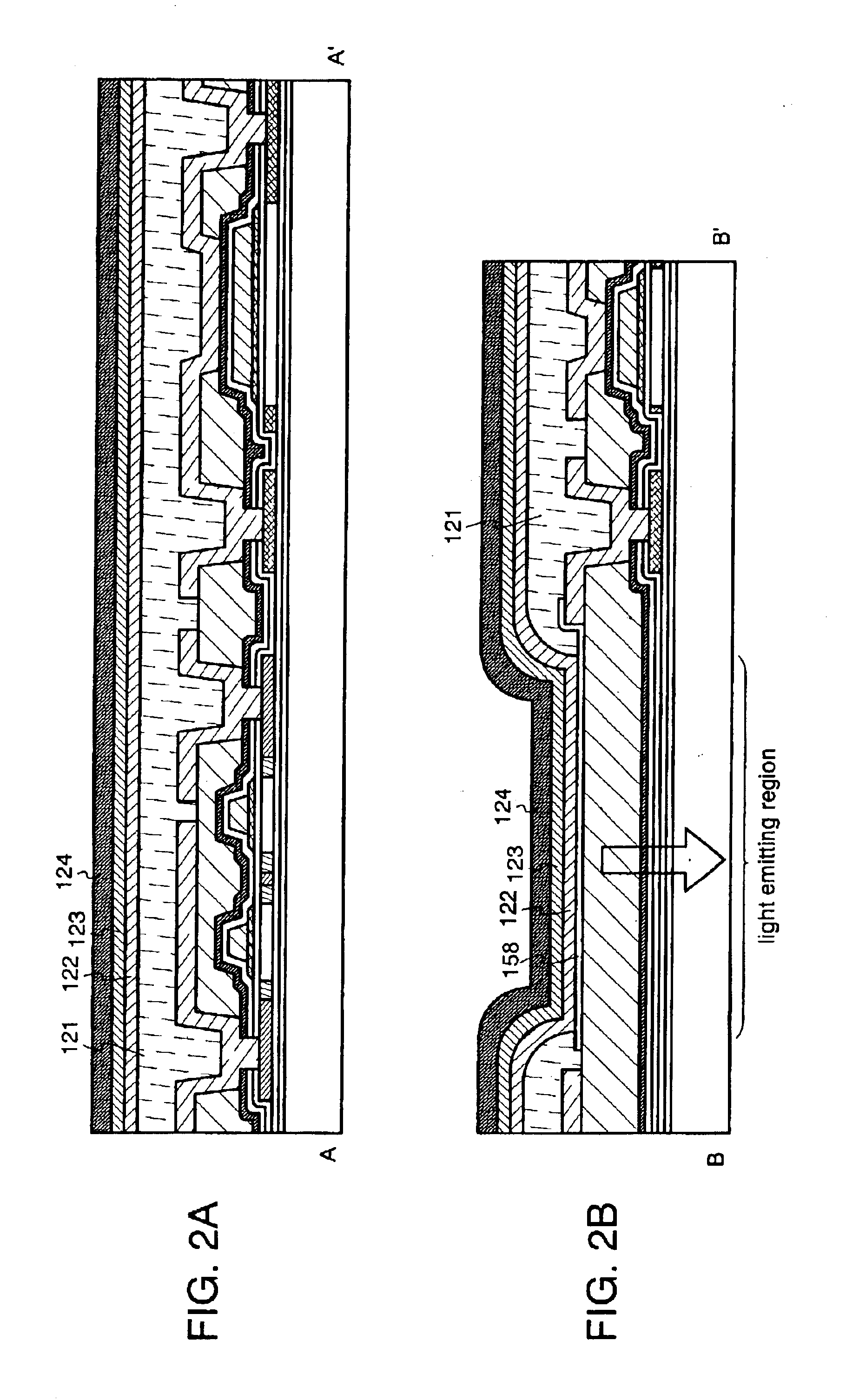

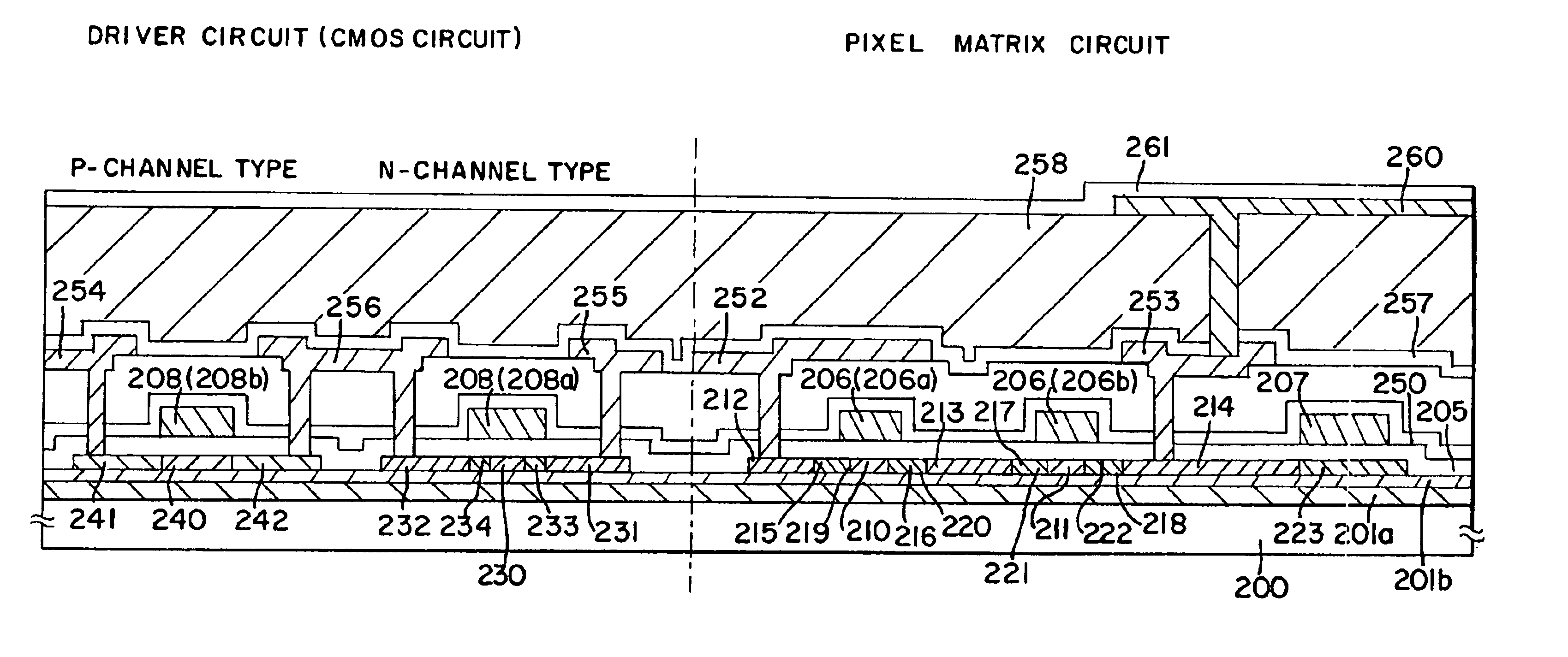

Display device

InactiveUS6960786B2Reduce impactSuppress mutationTransistorElectroluminescent light sourcesDisplay deviceOptoelectronics

Owner:SEMICON ENERGY LAB CO LTD

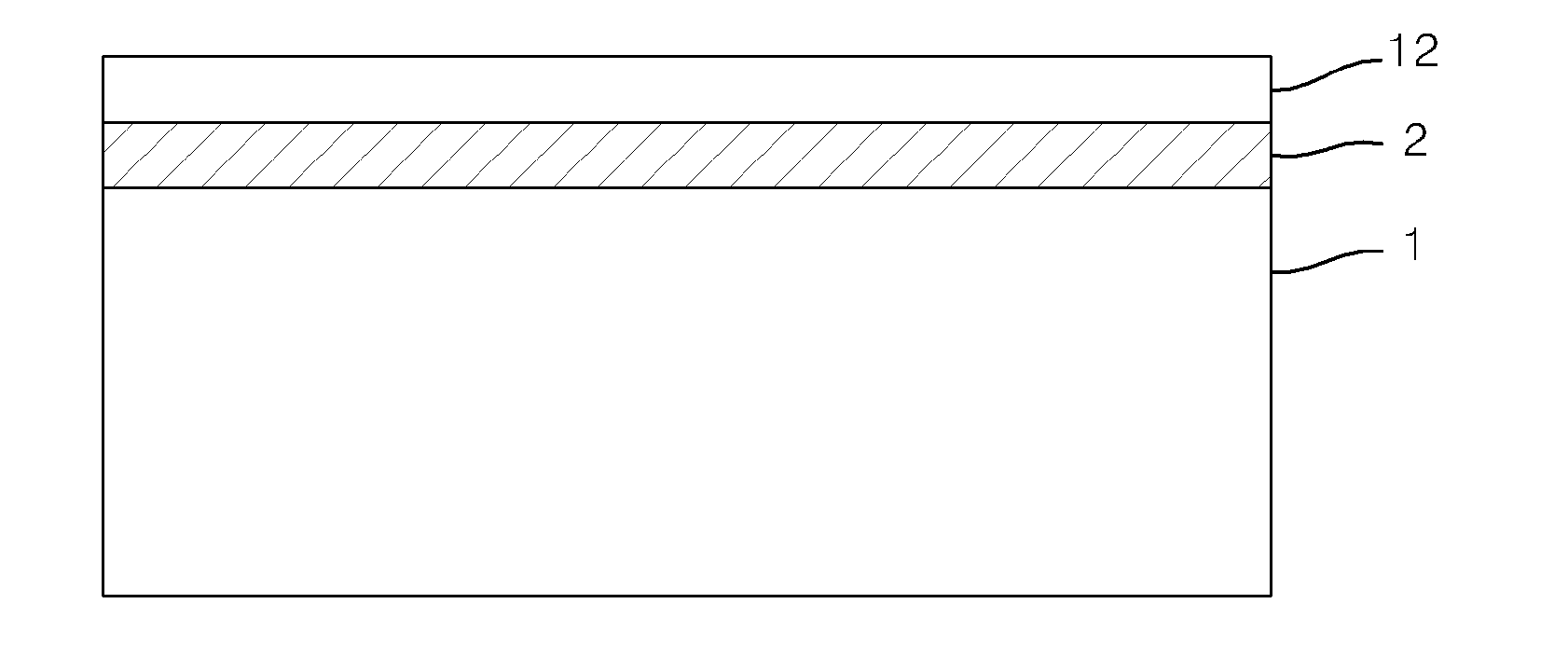

Gas barrier film including graphene layer, flexible substrate including the same, and manufacturing method thereof

InactiveUS20140272350A1Improve blockageHigh light transmittanceSynthetic resin layered productsSolid-state devicesCvd graphenePolymer

The present invention relates to a gas barrier film, a flexible substrate including the same, and a manufacturing method thereof. More specifically, a barrier film of the present invention relates to a first polymer layer, a gas barrier film including a graphene layer formed on the first polymer layer, a flexible substrate including the same, and a manufacturing method thereof.

Owner:CHEIL IND INC

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

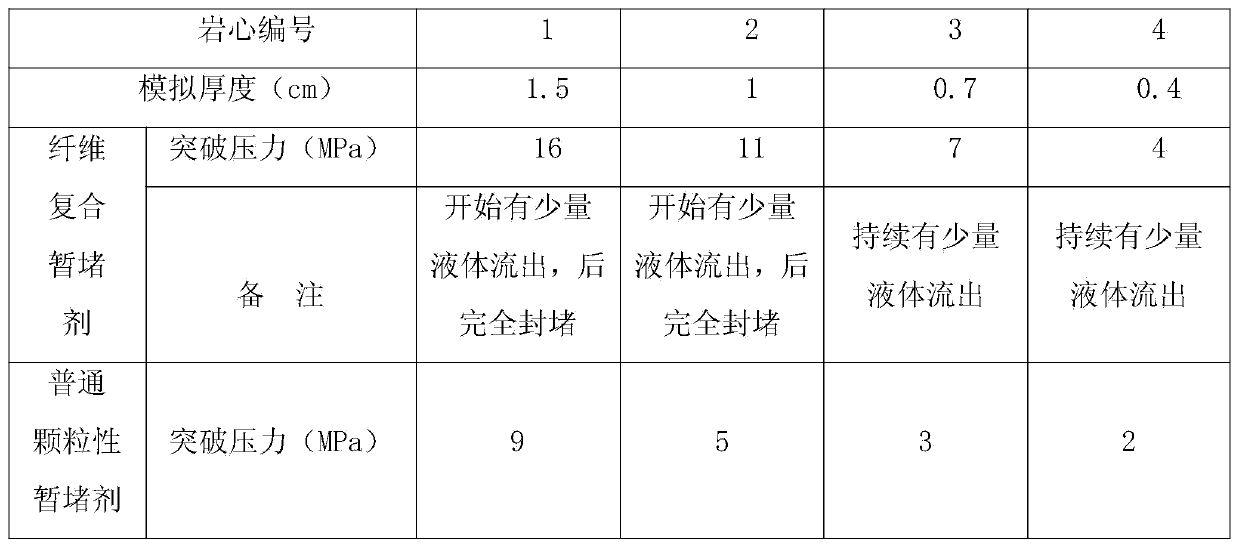

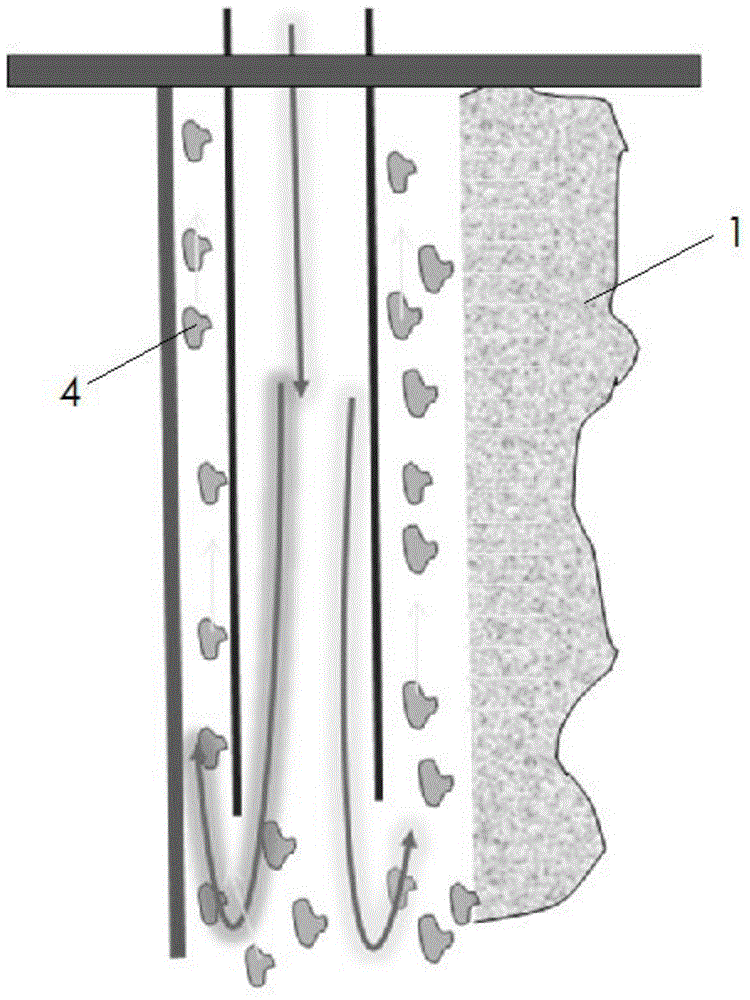

Fibre compound temporary plugging agent

ActiveCN103725277AHigh strengthGood blocking effectDrilling compositionSpace NetworkSodium carbonate

The invention discloses a fibre compound temporary plugging agent which comprises the following raw materials in parts by weight: 55-75 parts of transport fluid, 20-30 parts of temporary plugging agent grains and 0.5-2 parts of temporary plugging fibre. The transport fluid comprises the following raw materials in parts by weight: 0.2-0.6 part of guar gum, 0.1-0.5 part of sterilizing agent, 0.3-0.7 part of adhesive agent, 0.3-0.8 part of discharging agent and 0.1-0.5 part of sodium carbonate. The fibre capable of dissolving under certain conditions is added to the soluble temporary plugging agent grains. The fibre and the temporary plugging agent grains are used according to a certain proportion. The soluble fibre can form a space network structure which firmly bounds the temporary plugging grains to form an organic integrity, thereby greatly improving the intensity of the temporary plugging layer. The fibre compound temporary plugging agent has the advantages that the plugging effect is good and the plugging is easily and automatically unfastened after fracture and acidification with little hurt for the plugging layer. The success efficiency for working is obviously enhanced.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

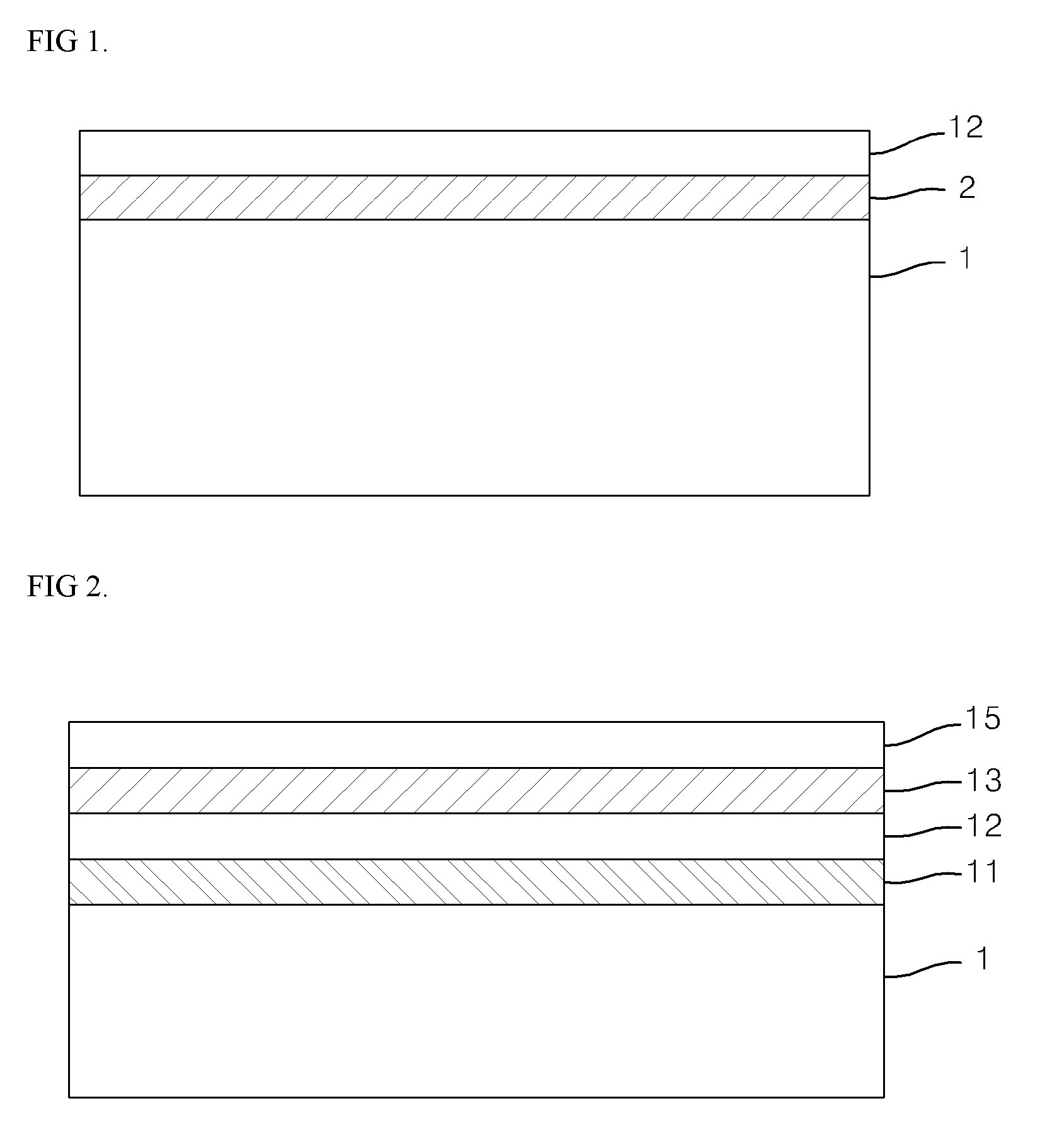

Organic light emitting diode display

ActiveUS20150102324A1Increase flexibilityHigh transparencyElectroluminescent light sourcesSolid-state devicesInsulation layerDisplay device

An organic light emitting diode (OLED) display includes a flexible substrate, a barrier layer disposed on the flexible substrate, and an organic light emitting diode disposed on the barrier layer. The barrier layer includes a plurality of metal layers and a plurality of insulation layers in which the metal layers and the insulation layers are alternatively stacked with each other on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

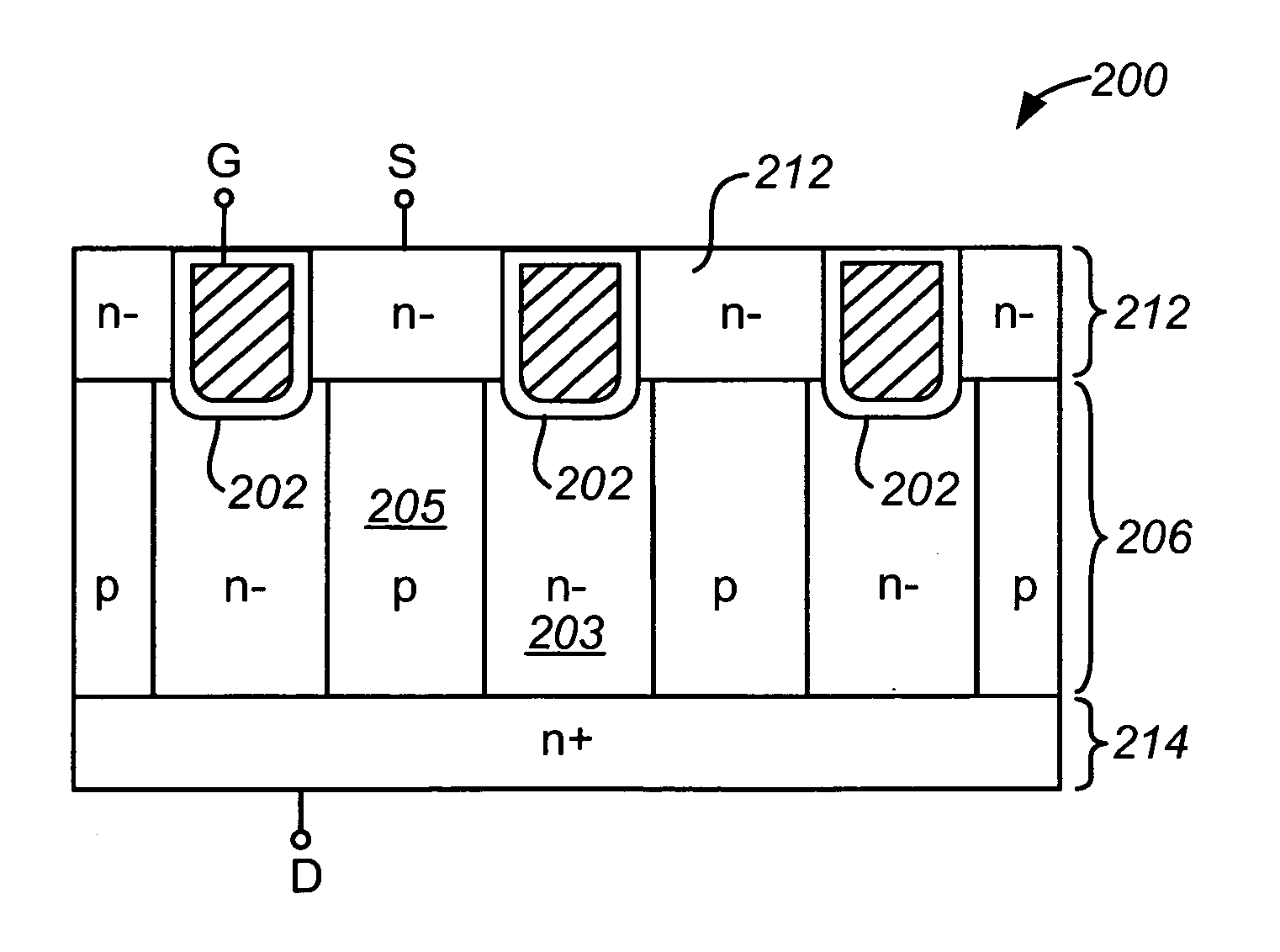

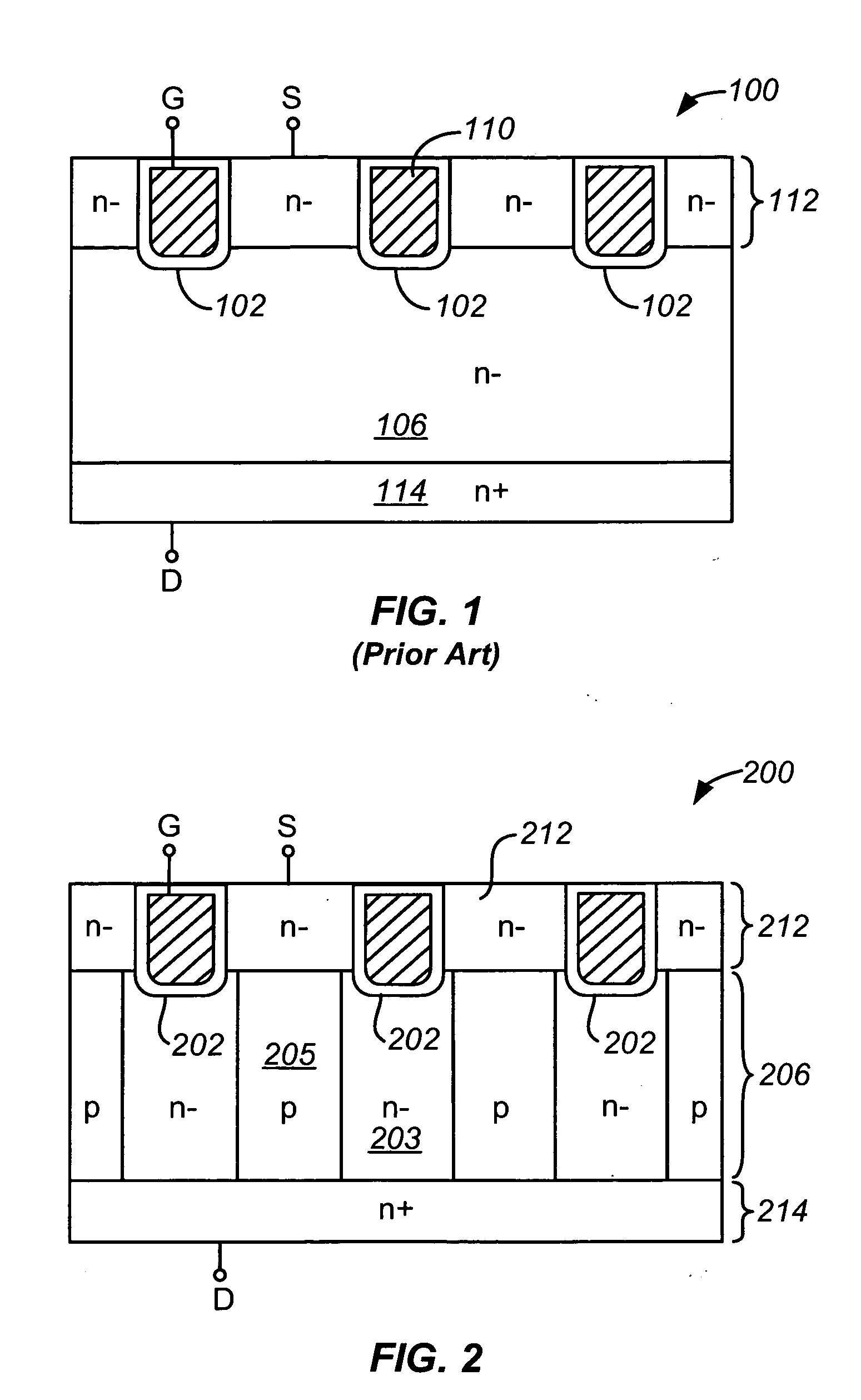

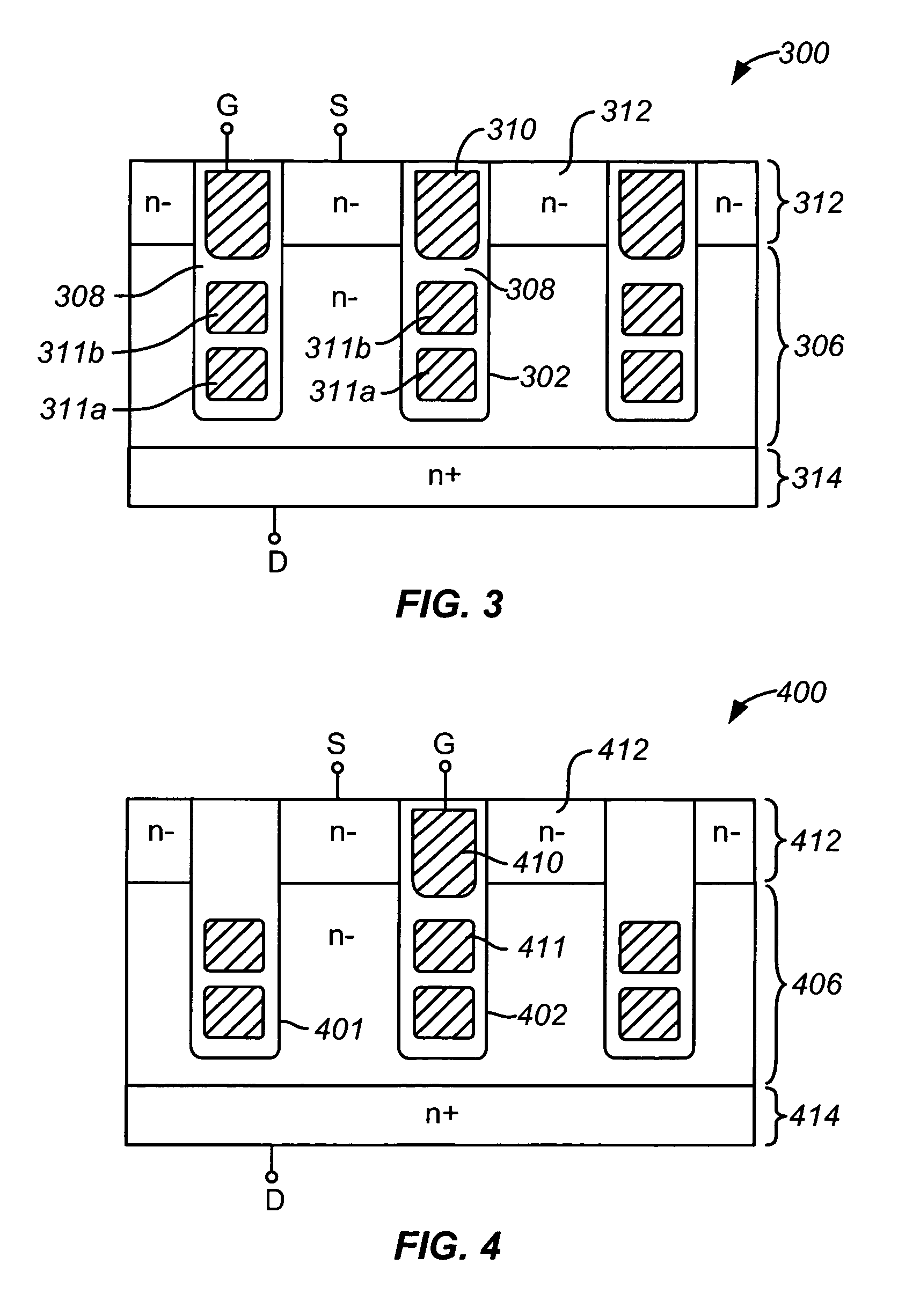

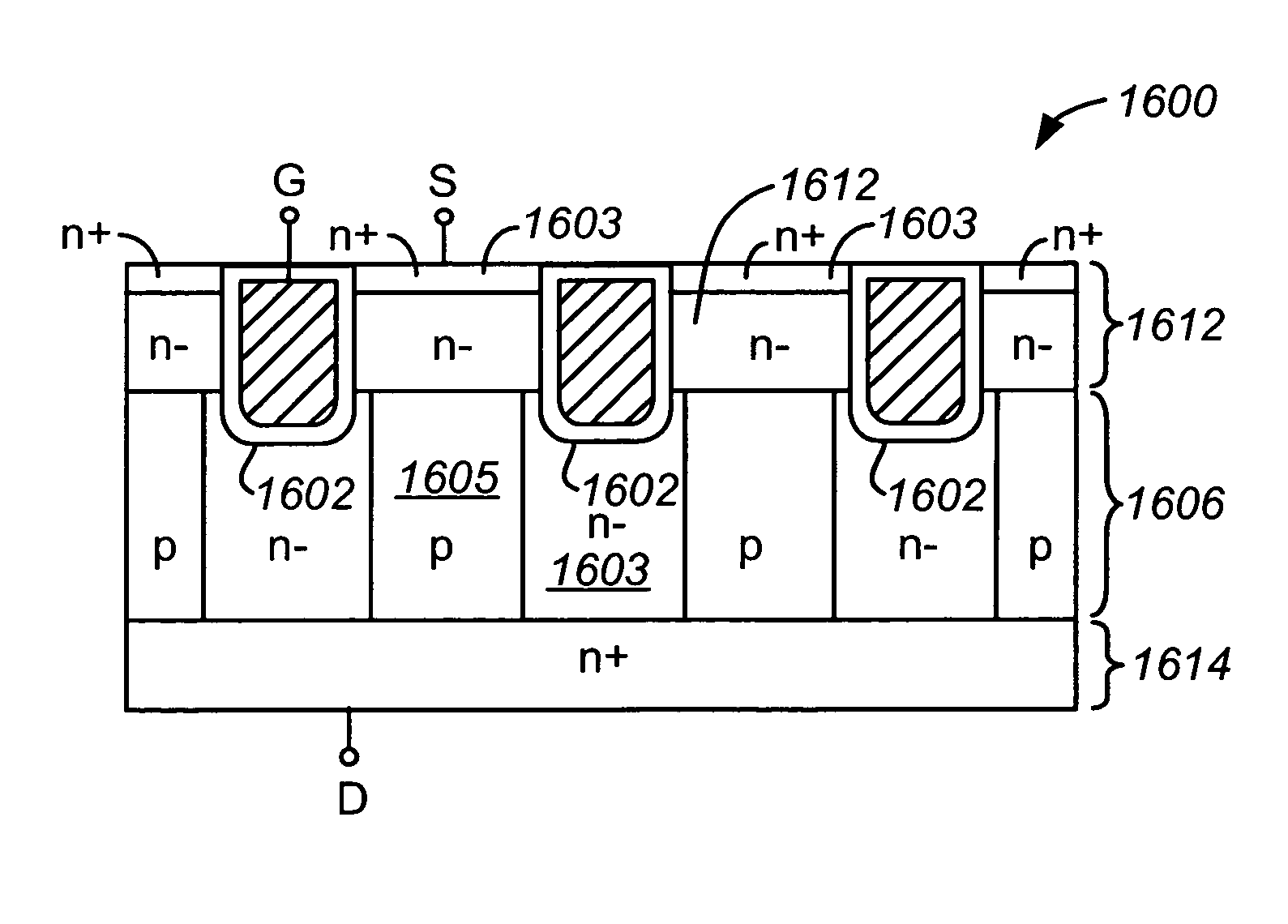

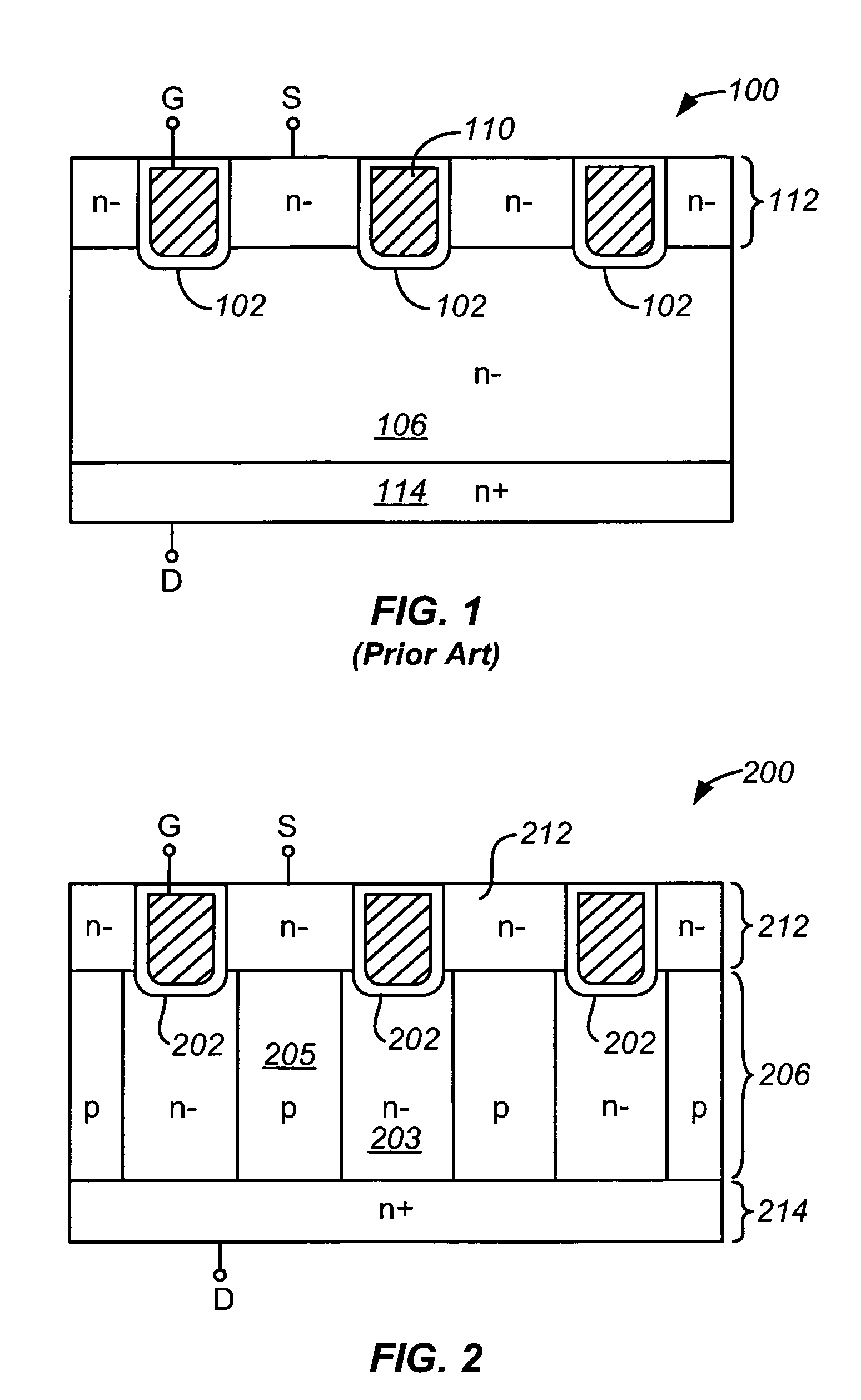

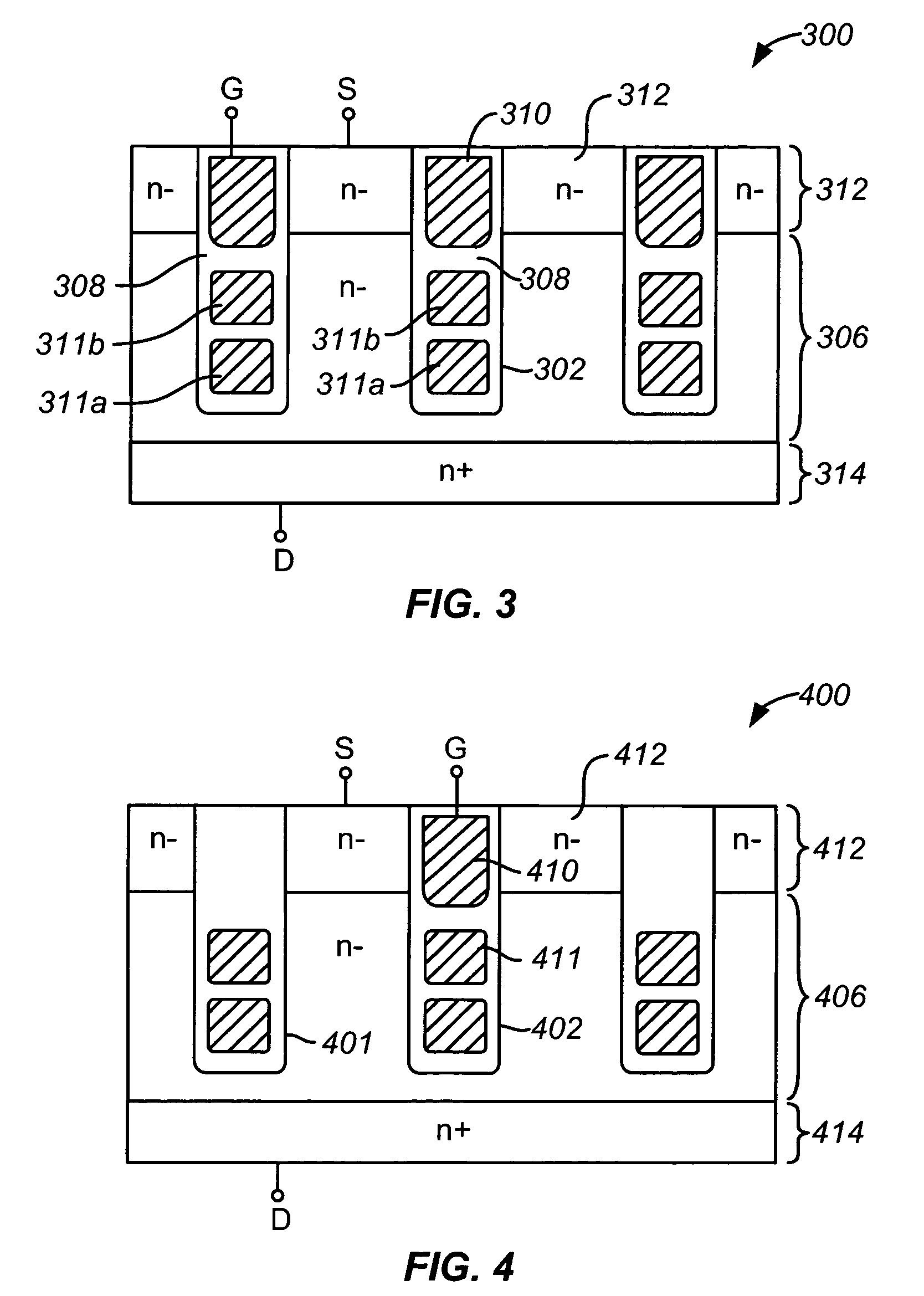

Accumulation device with charge balance structure and method of forming the same

ActiveUS20060011962A1Improve the blocking effectTransistorEfficient power electronics conversionEngineeringField-effect transistor

An accumulation-mode field effect transistor includes a plurality of gates and a semiconductor region having a channel region adjacent to but insulated from each of the plurality of gates. The semiconductor region further includes a conduction region wherein the channel regions and the conduction region are of a first conductivity type. The transistor further includes a drain terminal and a source terminal configured so that when the accumulation-mode field effect transistor is in the on state a current flows from the drain terminal to the source terminal through the conduction region and the channel regions. A number of charge balancing structures are integrated with the semiconductor region so as to extend parallel to the current flow. In a blocking state, the charge balancing structures influence an electric field in the conduction region so as to increase the blocking capability of the accumulation-mode field effect transistor.

Owner:SEMICON COMPONENTS IND LLC

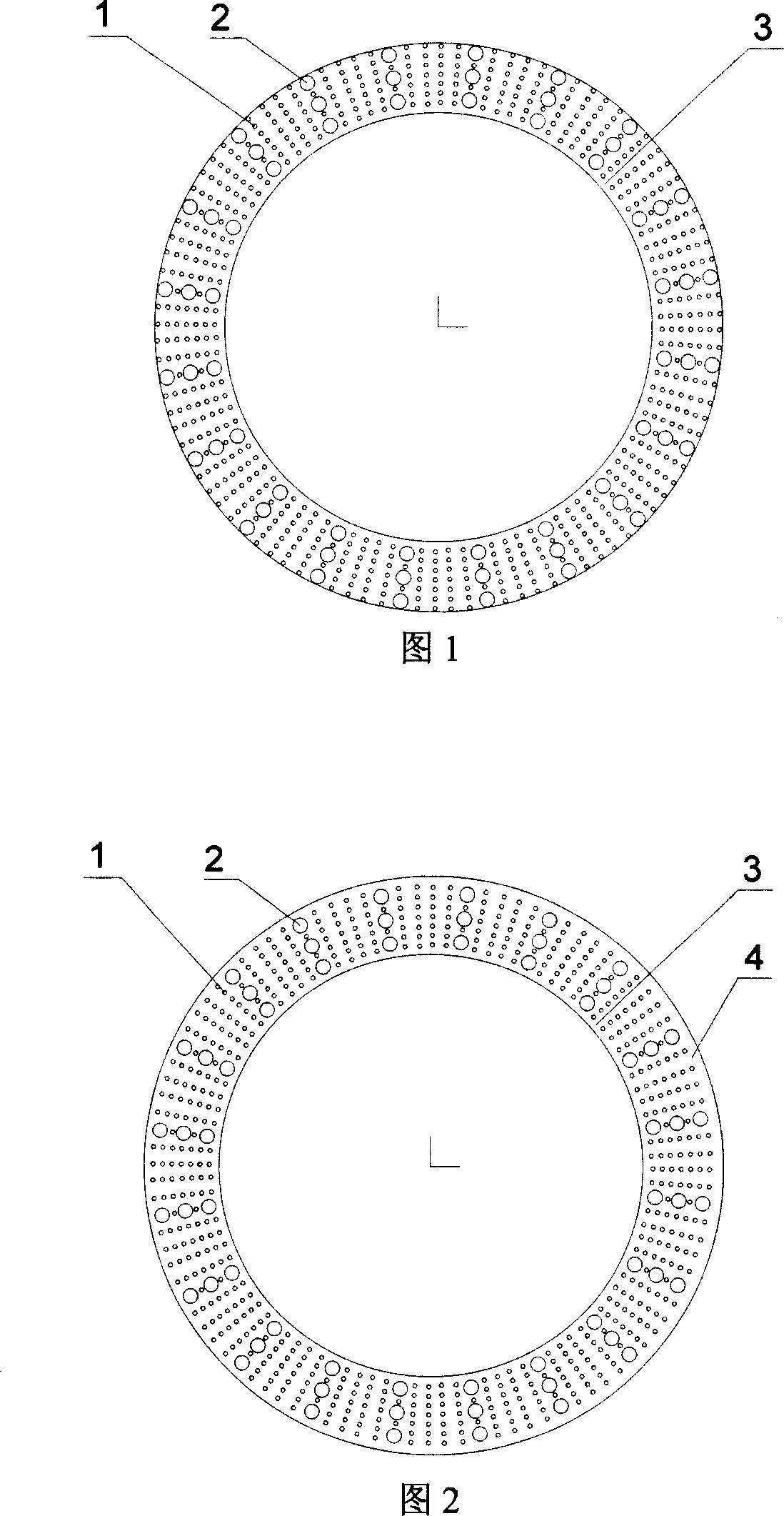

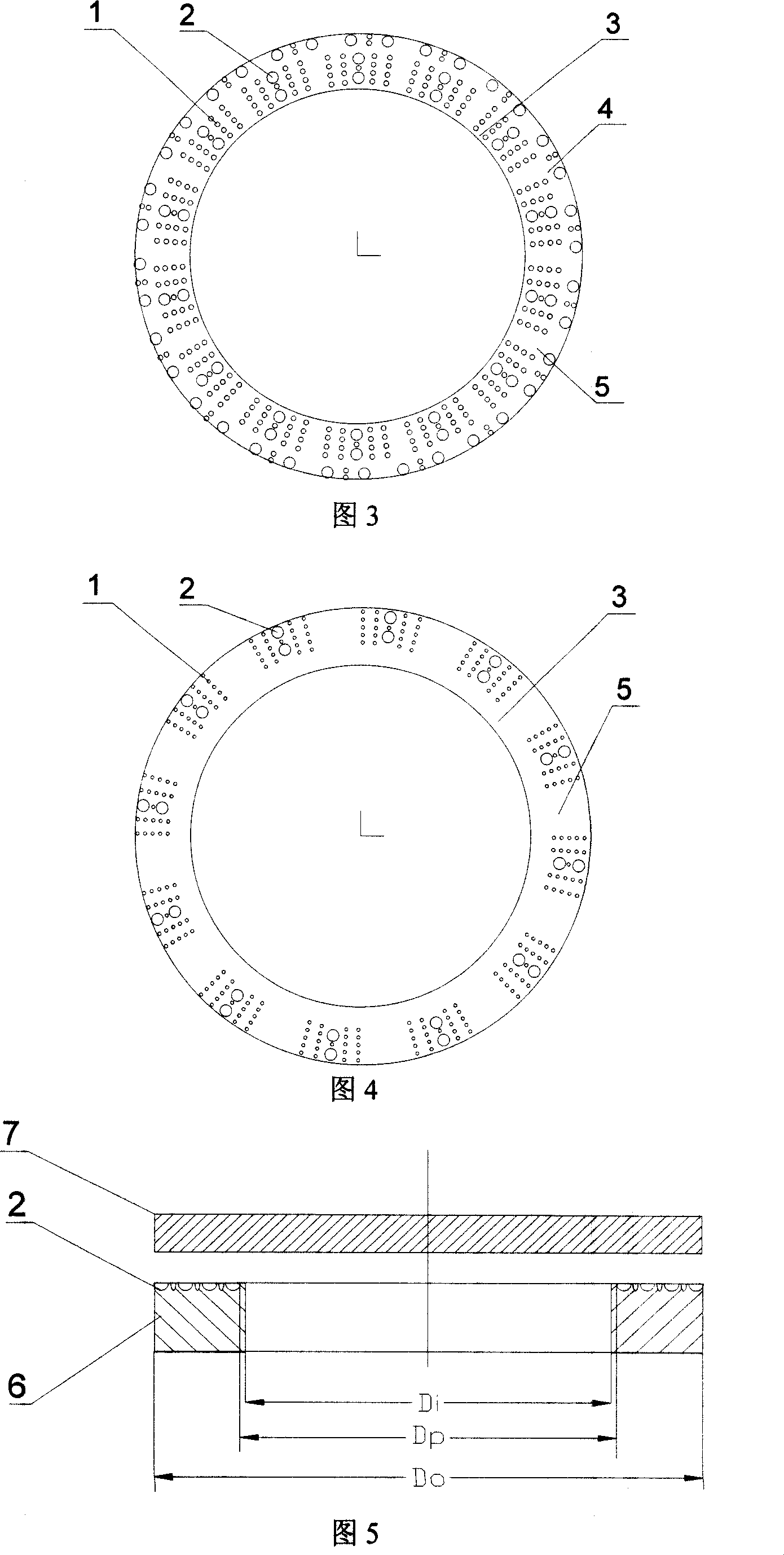

Variable distribution porous end face mechanical sealing structure

ActiveCN101016949AImprove wear resistanceImproved opening/stopping performanceEngine sealsHigh pressureWear resistance

The invention relates ton a variable-distribution porous end mechanical sealing structure, comprising a movable ring and a stable ring which are mechanically sealed, to form an annular sealing end. One side of the sealing end is high pressure side as ascending, while another end is low pressure side as descending, at least one sealing end is disposed with porous structure in different sizes symmetry distributed on the sealed end. Compared with present screw or groove mechanical sealing structure, the invention has better pressure resistance, abrasion resistance and better dynamic pressure effect on fluid membrane, to improve the carrier ability of fluid membrane.

Owner:ZHEJIANG UNIV OF TECH

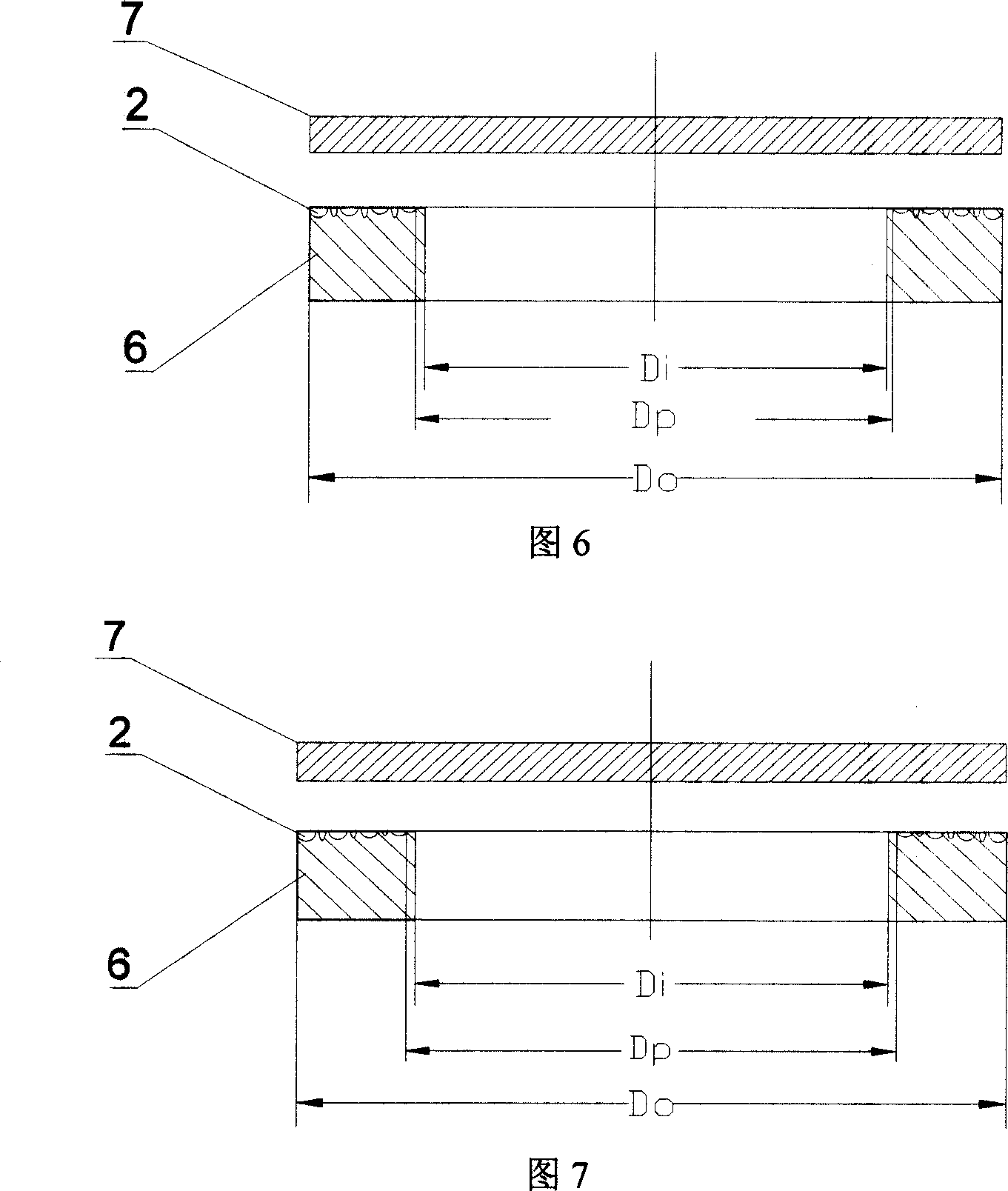

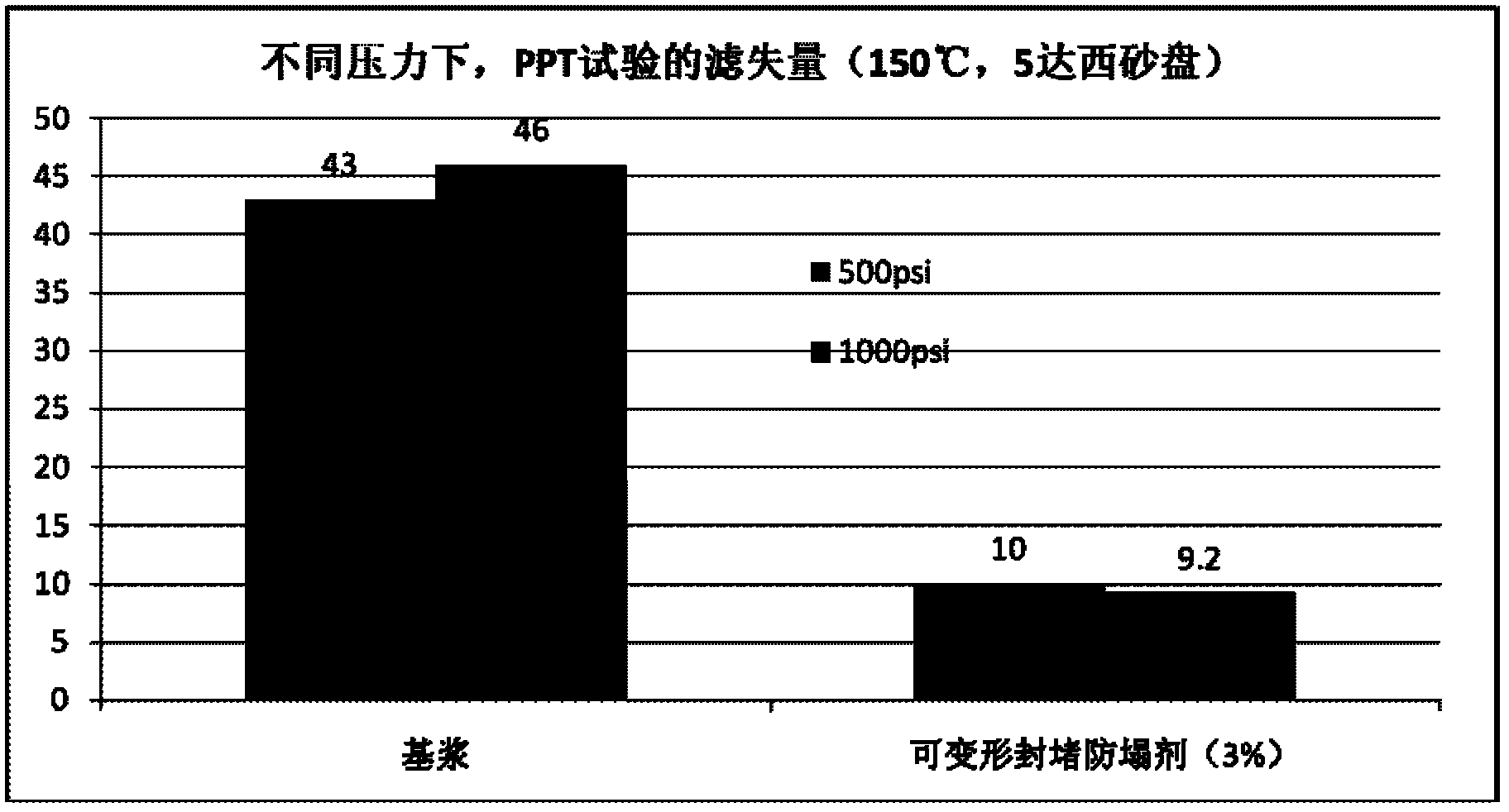

Deformable plugging and anti-sloughing agent for drilling fluid

ActiveCN102676141AImprove the blocking effectImprove compactnessDrilling compositionEngineeringNatural polymers

The invention relates to a deformable plugging and anti-sloughing agent for drilling fluid, and the deformable plugging and anti-sloughing agent comprises 10-90 parts by weight of non-deformable material, 20-80 parts by weight of nano-scale deformable redispersible polymer and 10-60 parts by weight of natural polymer modified material. The invention further relates to a preparation method of the deformable plugging and anti-sloughing agent for the drilling fluid. The preparation method comprises the following steps: mixing all the components according to the corresponding mixture ratio, mixing by virtue of a mixing and stirring machine for 80-120 minutes and screening by virtue of a 100-300 mesh screen, thus obtaining the deformable plugging and anti-sloughing agent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

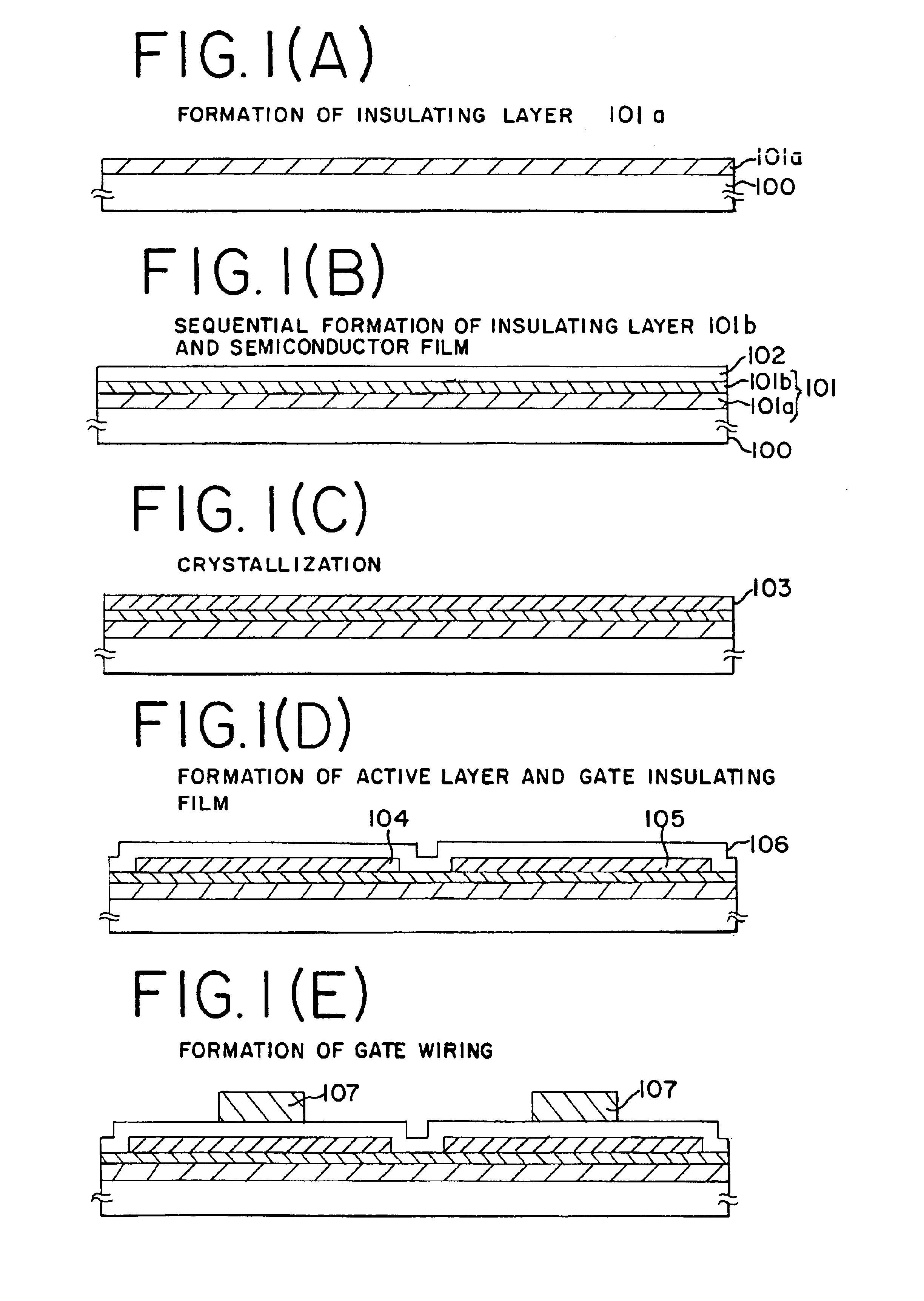

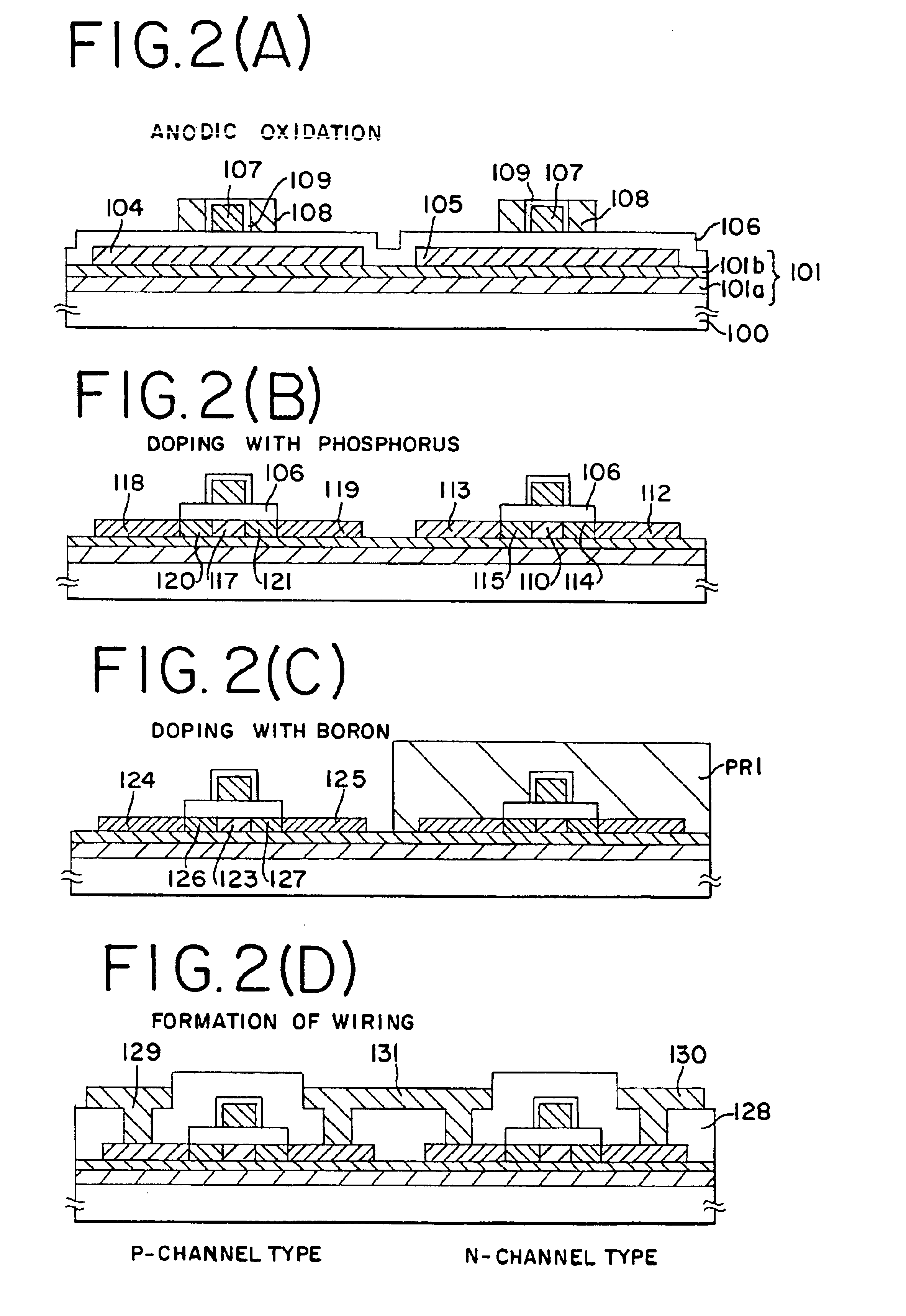

Semiconductor device and method for manufacturing the same

InactiveUS6858898B1Improve reliabilityEliminate the problemTransistorSemiconductor/solid-state device detailsDevice materialSilicon oxide

An object of the present invention is to prevent the deterioration of a TFT (thin film transistor). The deterioration of the TFT by a BT test is prevented by forming a silicon oxide nitride film between the semiconductor layer of the TFT and a substrate, wherein the silicon oxide nitride film ranges from 0.3 to 1.6 in a ratio of the concentration of N to the concentration of Si.

Owner:SEMICON ENERGY LAB CO LTD

Accumulation device with charge balance structure and method of forming the same

ActiveUS7368777B2Improve the blocking effectTransistorEfficient power electronics conversionField-effect transistorSemiconductor

An accumulation-mode field effect transistor includes a plurality of gates and a semiconductor region having a channel region adjacent to but insulated from each of the plurality of gates. The semiconductor region further includes a conduction region wherein the channel regions and the conduction region are of a first conductivity type. The transistor further includes a drain terminal and a source terminal configured so that when the accumulation-mode field effect transistor is in the on state a current flows from the drain terminal to the source terminal through the conduction region and the channel regions. A number of charge balancing structures are integrated with the semiconductor region so as to extend parallel to the current flow. In a blocking state, the charge balancing structures influence an electric field in the conduction region so as to increase the blocking capability of the accumulation-mode field effect transistor.

Owner:SEMICON COMPONENTS IND LLC

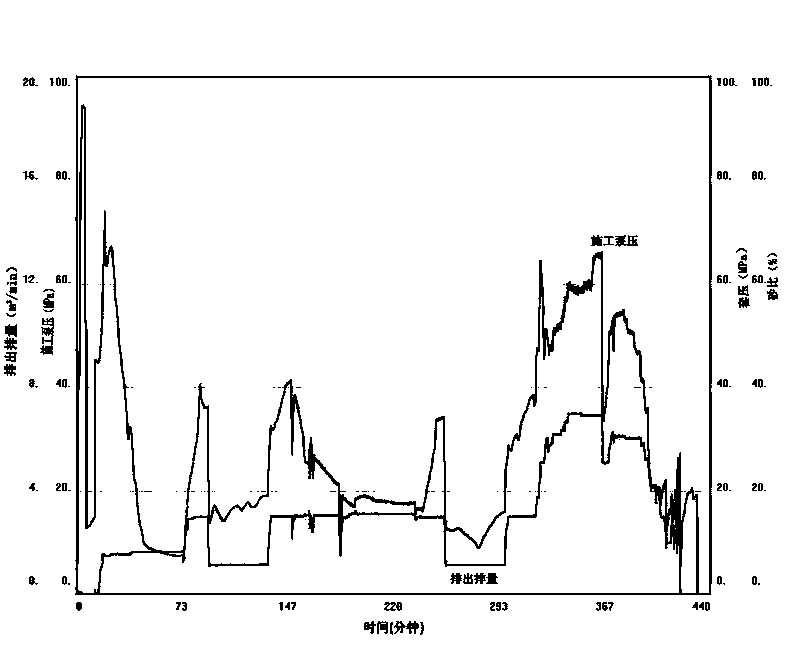

Offshore oilfield water injection well online one-step-process acidification technology

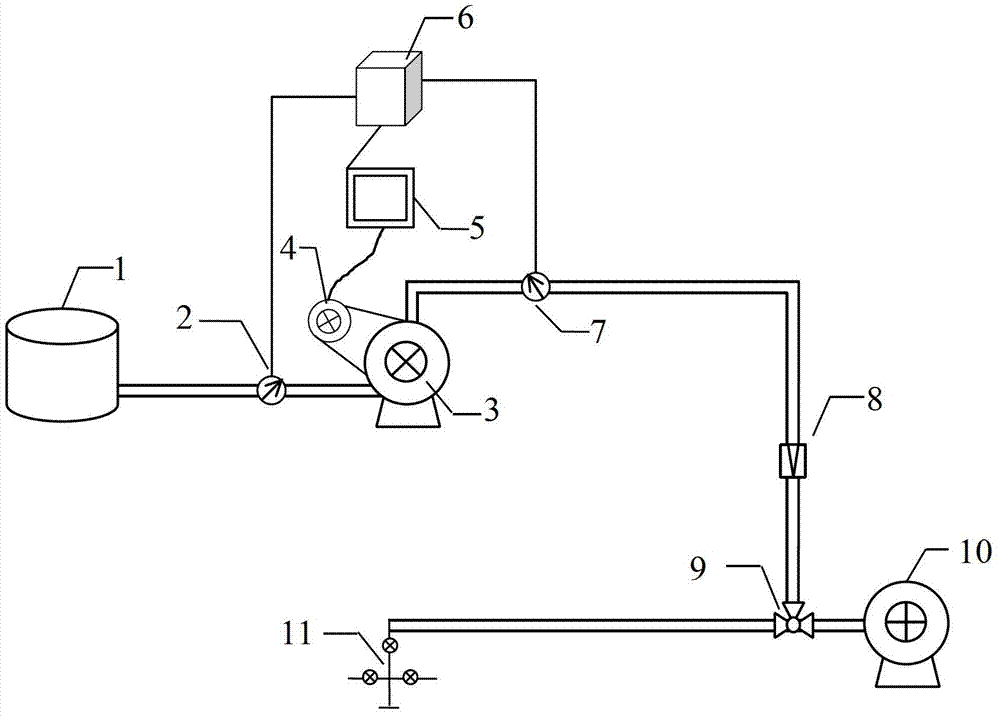

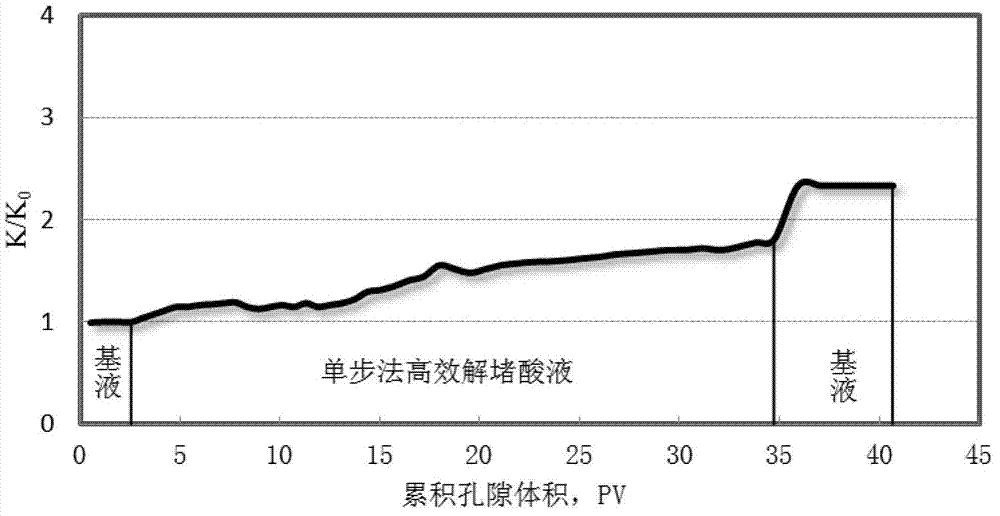

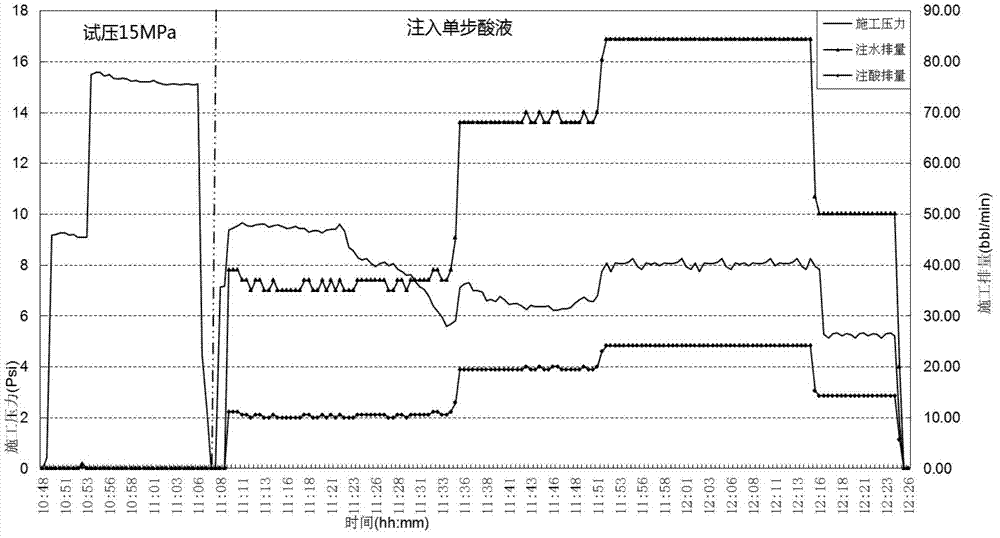

ActiveCN102828734ASimplified recipeSimplify the construction processFluid removalDrilling compositionHydrogen fluorideAcetic acid

The invention relates to an offshore oilfield water injection well online one-step-process acidification technology, which comprises following steps of (1) preparing one-step acid liquor, wherein the one-step acid liquor consists of following components by weight percent: 20 to 40 percent of industrial acetic acid, 15 to 40 percent of industrial hydrochloric acid, 3 to 15 percent of deposition inhibitor, 5 to 15 percent of discharging aiding agent, 3 to 15 percent of corrosion inhibitor, 5 to 15 percent of antiswelling agent, 5 to 15 percent of iron ion stabilizer and 2 to 10 percent of hydrogen fluoride; (2) storing the acid liquor into an acid storage tank of an injection system, wherein the injection system consists of the acid storage tank, an acid resistant pump, a motor, a frequency converter, a flow sensor, a pressure sensor, a computer, a check valve, a three-way pipe and an acid injection pipe; (3) utilizing the acid resistant pump to pump the acid liquor into the water injection flow; (4) monitoring the variation of the pressure and the flow of the injected acid, and calculating skin coefficients in real time; and (5) keeping the water injection after stopping the acid injection. Due to the adoption of the offshore oilfield water injection well online one-step-process acidification technology, high efficiency, rapidness and large scale in plug removal of an offshore oilfield water injection well can be realized, the water injection pressure can be reduced, and the water injection quantity can be improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

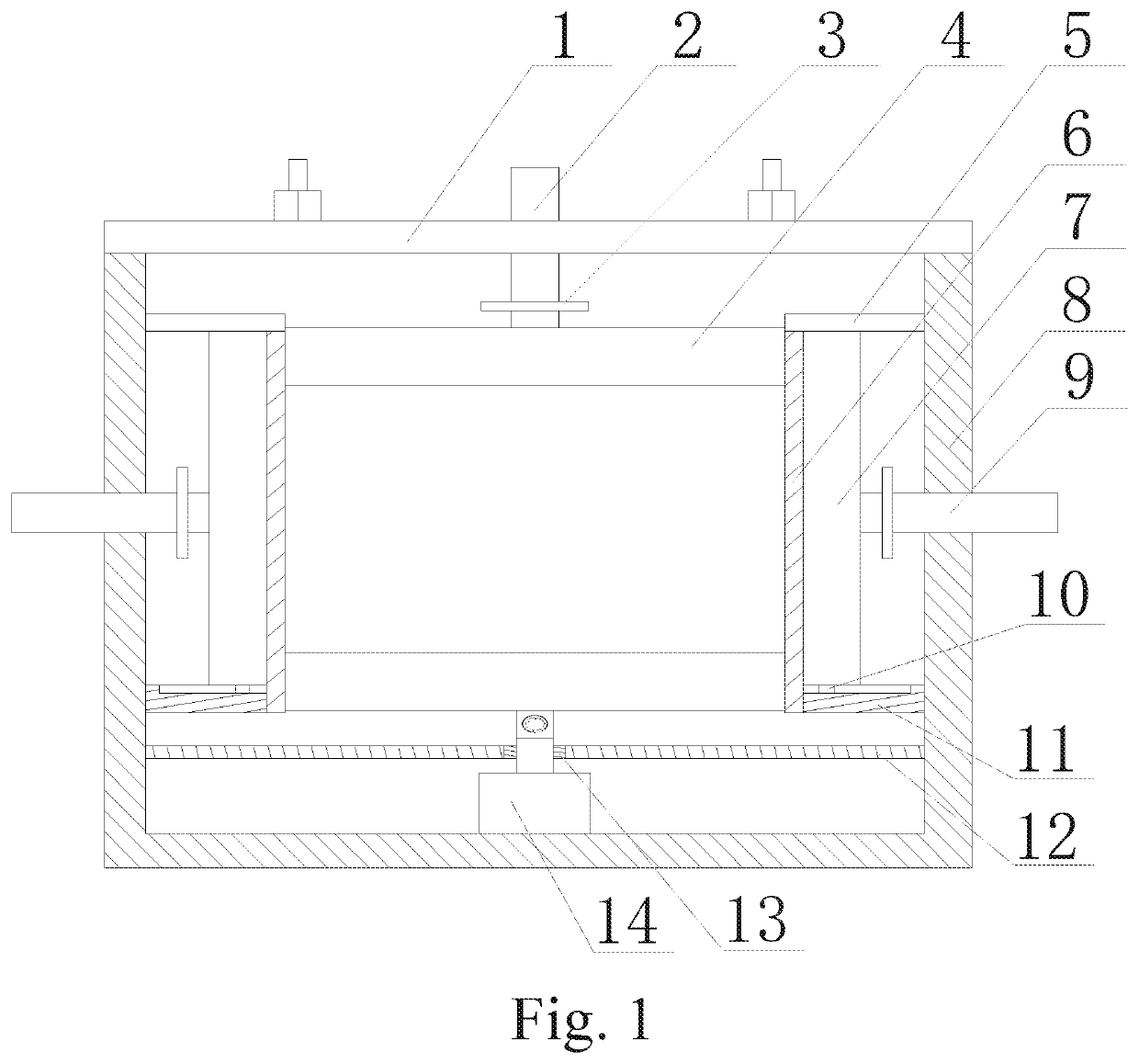

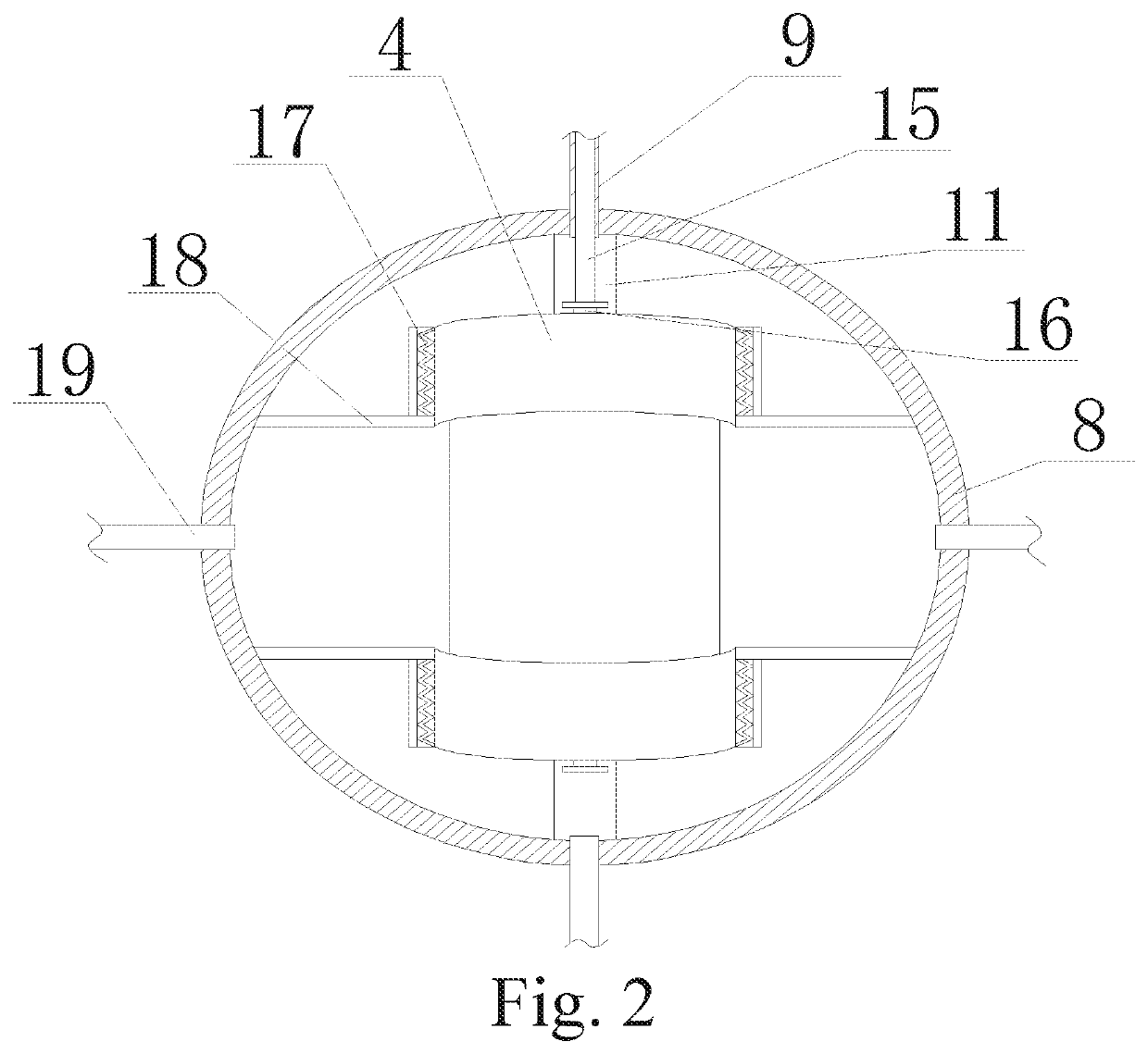

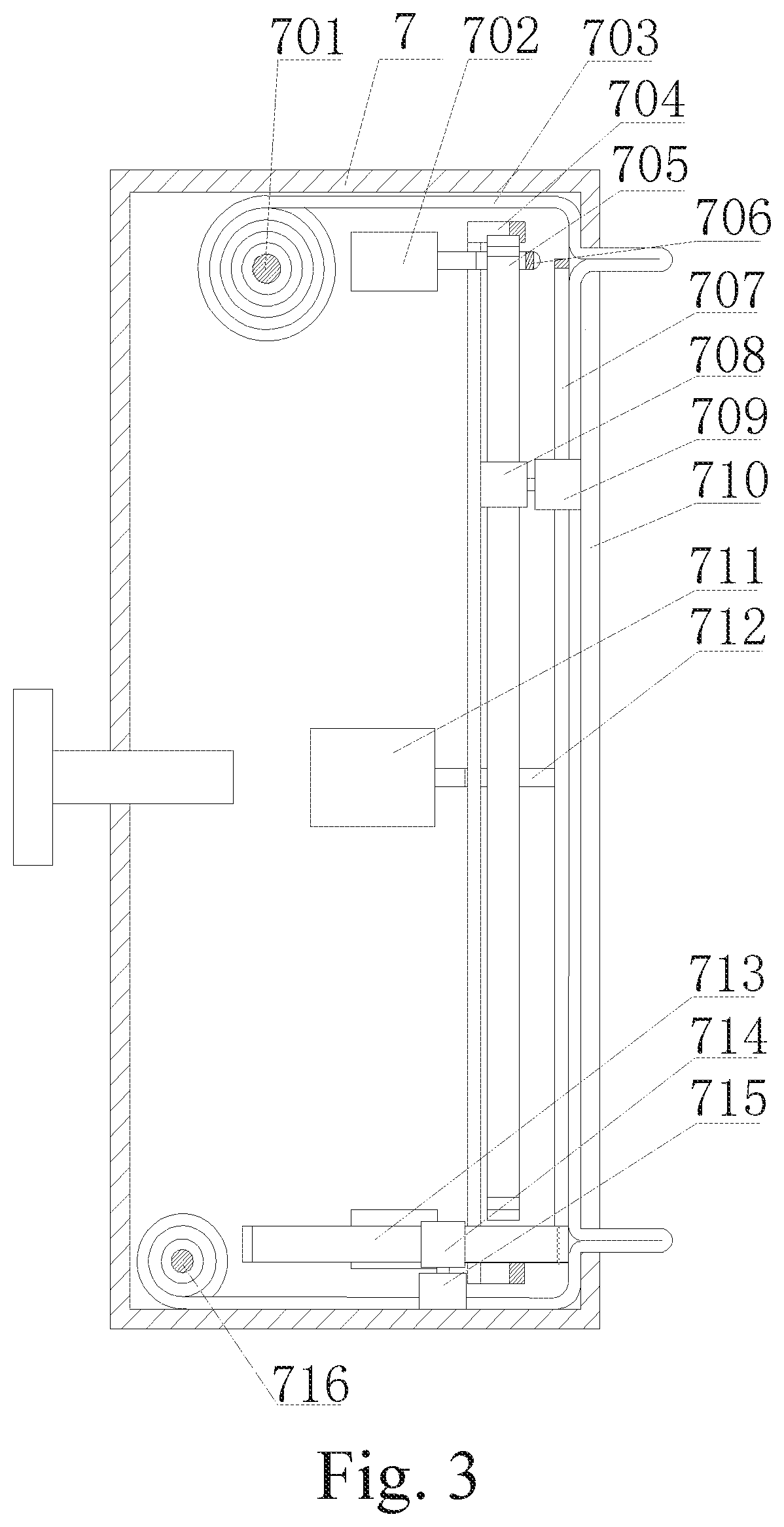

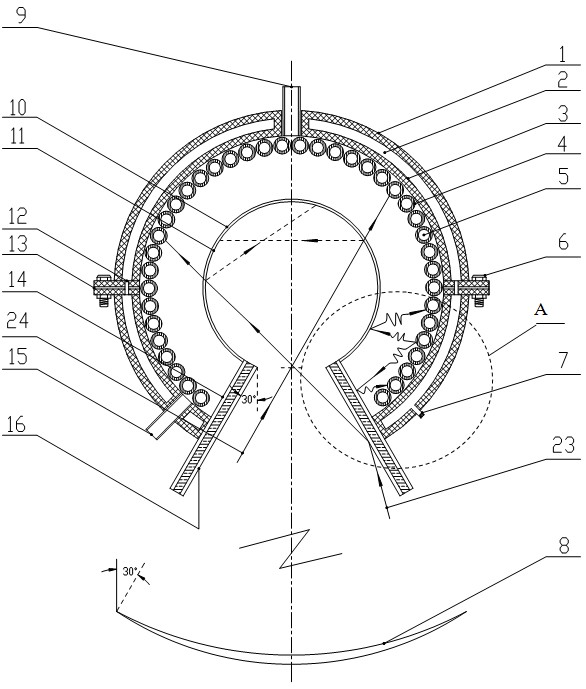

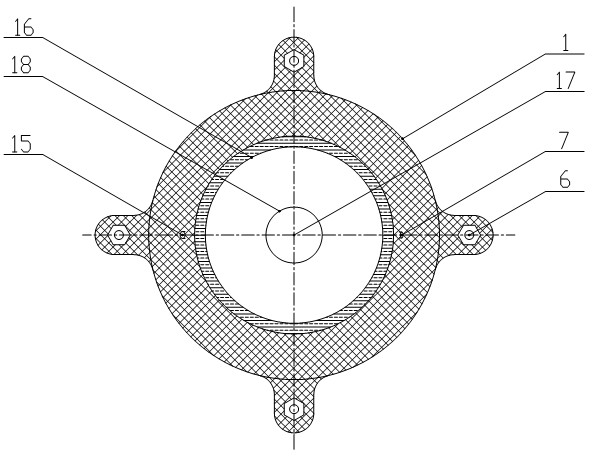

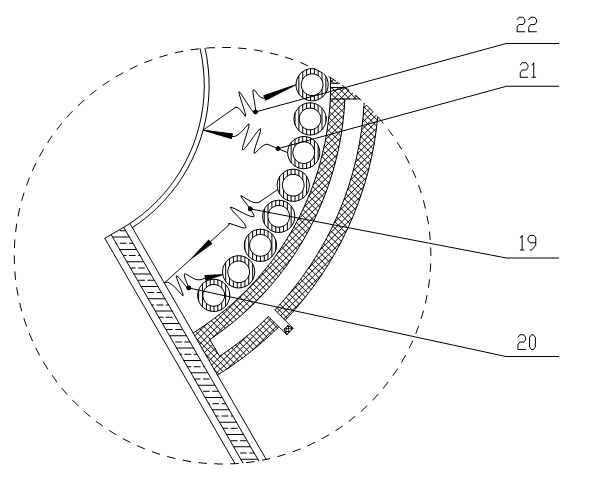

Irregular rock sample high-pressure permeation device with adjustable flow direction and test method thereof

ActiveUS20200018681A1Eliminate vibrationReduce time consumptionEarth material testingTesting waterThin membraneWater block

An irregular rock sample high-pressure permeation device with an adjustable flow direction and a test method thereof are provided, wherein two blocking mechanisms I and two blocking mechanisms II are arranged inside a cylinder body; partitioning plates are respectively arranged on both sides of each of the blocking mechanisms I; water blocking plates are respectively arranged at both sides of each of the blocking mechanisms I; one end of each of the water blocking plates is connected to the sidewall of each of the partitioning plates, and the other end of each of the water blocking plates is connected to an internal portion of the cylinder body; a water injection pipe is disposed between the water blocking plates on a same side. The present invention combines flexible film amorphous close fit properties and easy charging and discharging of free gas.

Owner:SOUTHWEST PETROLEUM UNIV

Potassium carbonate polyamine drilling fluid

InactiveCN101747876AStrong inhibitory abilityReduced tendency to absorb moistureDrilling compositionParaffin waxChemistry

The invention relates to a potassium carbonate polyamine drilling fluid used for the petroleum drilling process. The potassium carbonate polyamine drilling fluid mainly comprises 1-60 percent of potassium carbonate, 0.5-25 percent of calcium oxide, 0.5-5 percent of polyamine shale inhibiting agent, 0-5 percent of bentonite, 0.5-3 percent of filter reducer, 0.1-0.5 percent of coating agent, 0.1-0.8 percent of tackifier, 0.5-5 percent of plugging agent, 0.1-2 percent of lubricating agent and a proper amount of weighing agent (added according to the requirement). The potassium carbonate polyamine drilling fluid can provide K+ with high concentration and has strong inhibiting capability on shale; the potassium carbonate and the calcium oxide react in equal mole ratio to generate micrometer and nanometer calcium carbonate superfine powder, thus CO32-anions generated by dissolving the potassium carbonate can be removed, the mineralization can be reduced and the influence of high mineralization on the action efficiency of other processing agents can be eliminated; and by matching, the calcium carbonate superfine powder can be deformed into asphalt and paraffin particles which can be usedfor plugging a microcrack shale stratum.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

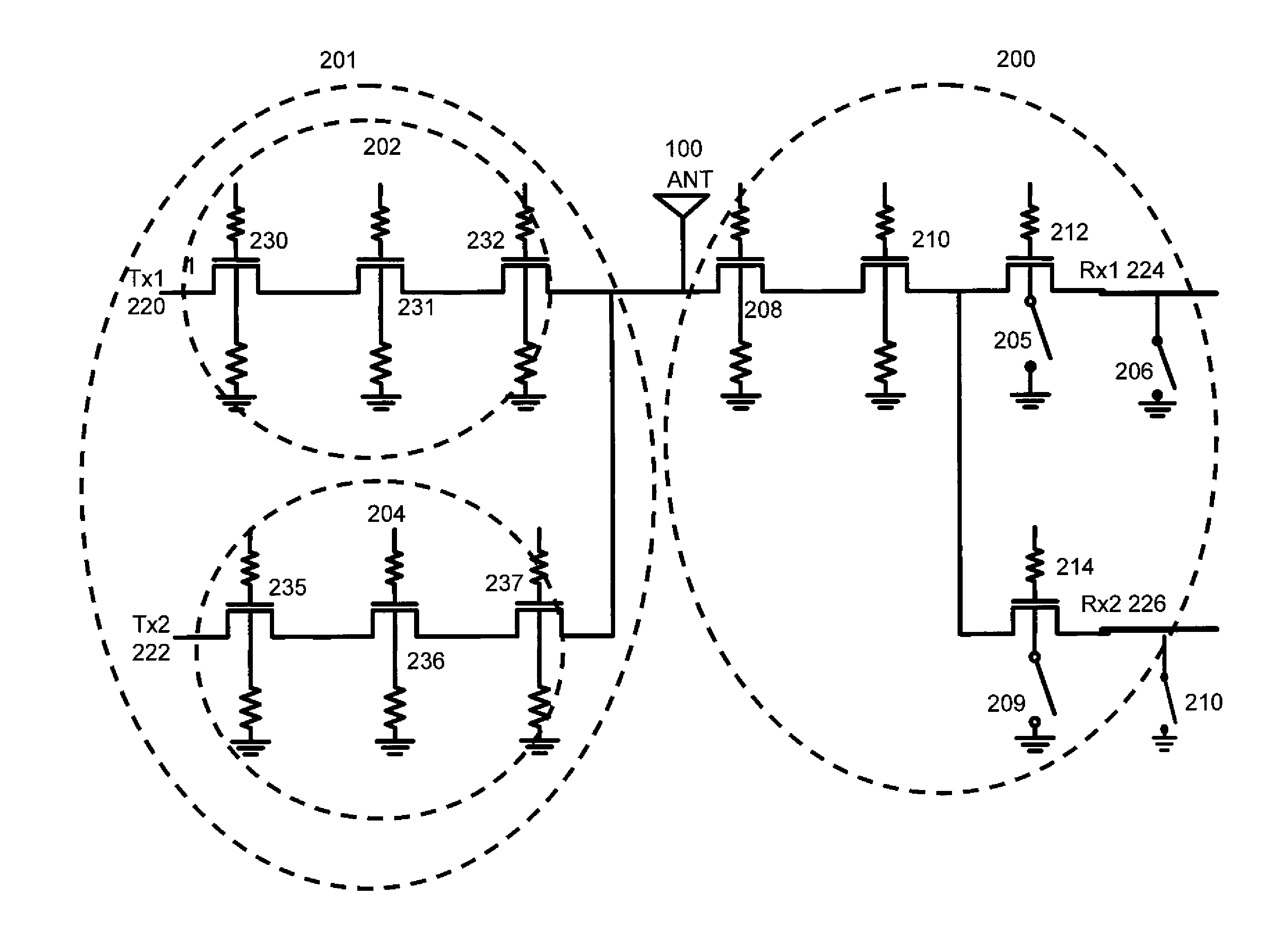

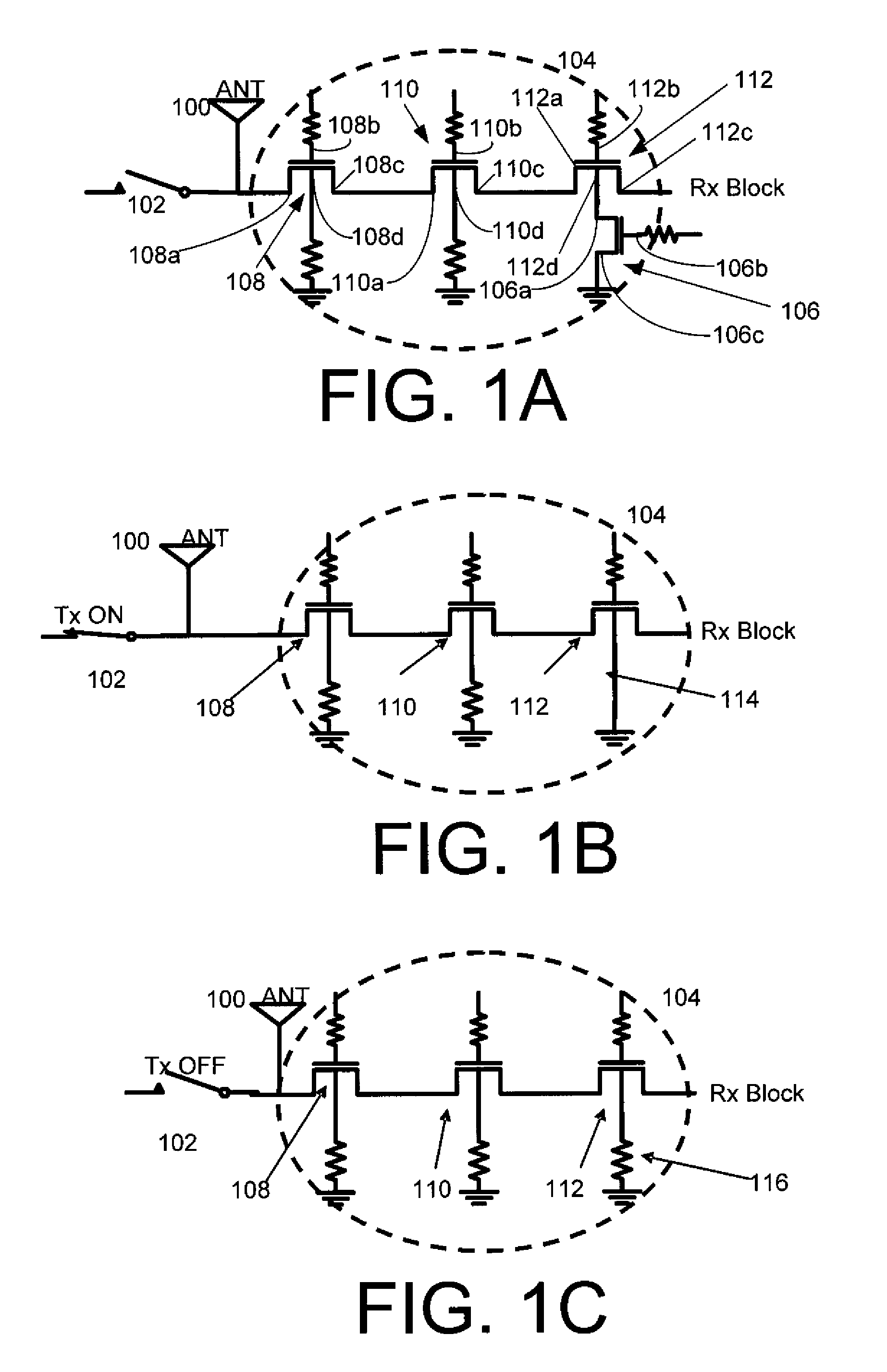

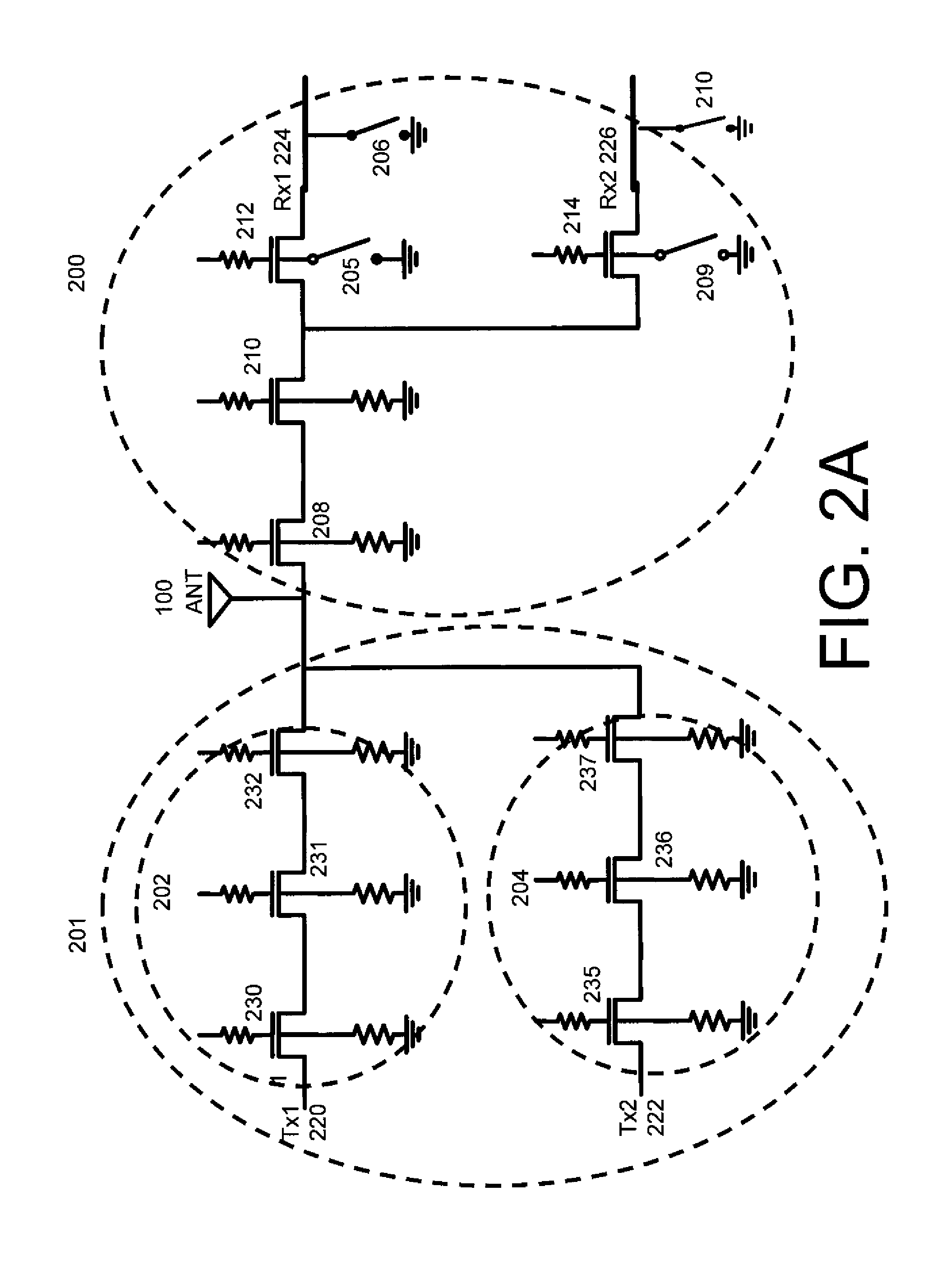

Systems, methods, and apparatuses for complementary metal oxide semiconductor (CMOS) antenna switches using body switching in multistacking structure

InactiveUS7890063B2High Power Handling CapabilityImprove the blocking effectTransistorElectronic switchingCMOSSemiconductor

Embodiments of the invention may provide for a CMOS antenna switch, which may be referred to as a CMOS SP4T switch. The CMOS antenna switch may operate at a plurality of frequencies, perhaps around 900 MHz and 1.9 GHz according to an embodiment of the invention. The CMOS antenna switch may include both a receiver switch and a transmit switch. The receiver switch may utilize a multi-stack transistor with body substrate tuning to block high power signals from the transmit path as well as to maintain low insertion loss at the receiver path. On the other hand, in the transmit switch, a body substrate tuning technique may be applied to maintain high power delivery to the antenna. Example embodiments of the CMOS antenna switch may provide for 31 dBm P 1 dB at both bands (e.g., 900 MHz and 1.8 GHz). In addition, a 0.9 dB and −1.1 dB insertion loss at 900 MHz and 1.9 GHz, respectively, may be obtained according to example embodiments of the invention.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Spherical cavity type solar heat absorber with inwardly concave glass cover

InactiveCN102322694AImprove capture abilityNot easy to spillSolar heating energySolar heat devicesGlass coverEngineering

The invention discloses a spherical cavity type solar heat absorber with an inwardly concave glass cover. The heat absorber is mainly used for collecting sunlight and converting the sunlight into heat energy in a butterfly type solar high-temperature heat utilization system. The heat absorber mainly comprises a heat exchange coil pipe, the inwardly concave glass cover, an outer shell, an inner shell, a vacuum layer, a reflective wind shield and a heat conductive fluid. Different from the traditional opening type heat absorber and the cavity type heat absorber with the glass window at the cavity opening, the cavity type heat absorber disclosed by the invention is the opening type spherical heat absorber with the inwardly concave glass cover, therefore, the cavity type heat absorber not only has the light capturing capacity of the opening cavity type heat absorber but also has low heat loss of the cavity type heat absorber with the glass window at the cavity opening; meanwhile, the cavity type heat absorber is provided with the reflective wind shield, therefore, the capturing on deviated light can be strengthened, and the heat radiation on the inner wall and the convection heat transfer loss resulted from external natural wind can be reduced; and the cavity type heat absorber comprises the vacuum layer between the inner shell and the outer shell, therefore, the lost heat throughthe shells can be effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH

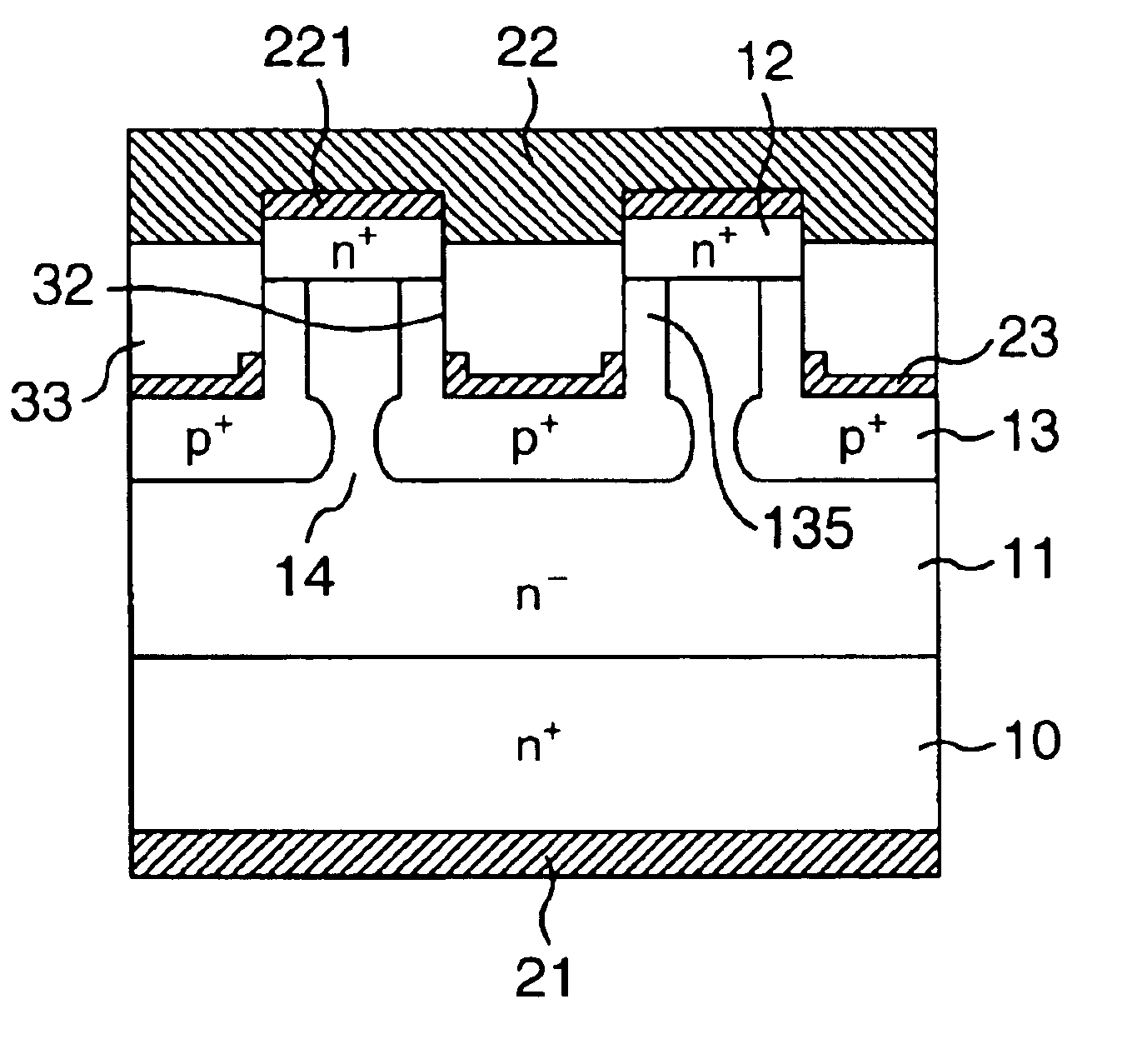

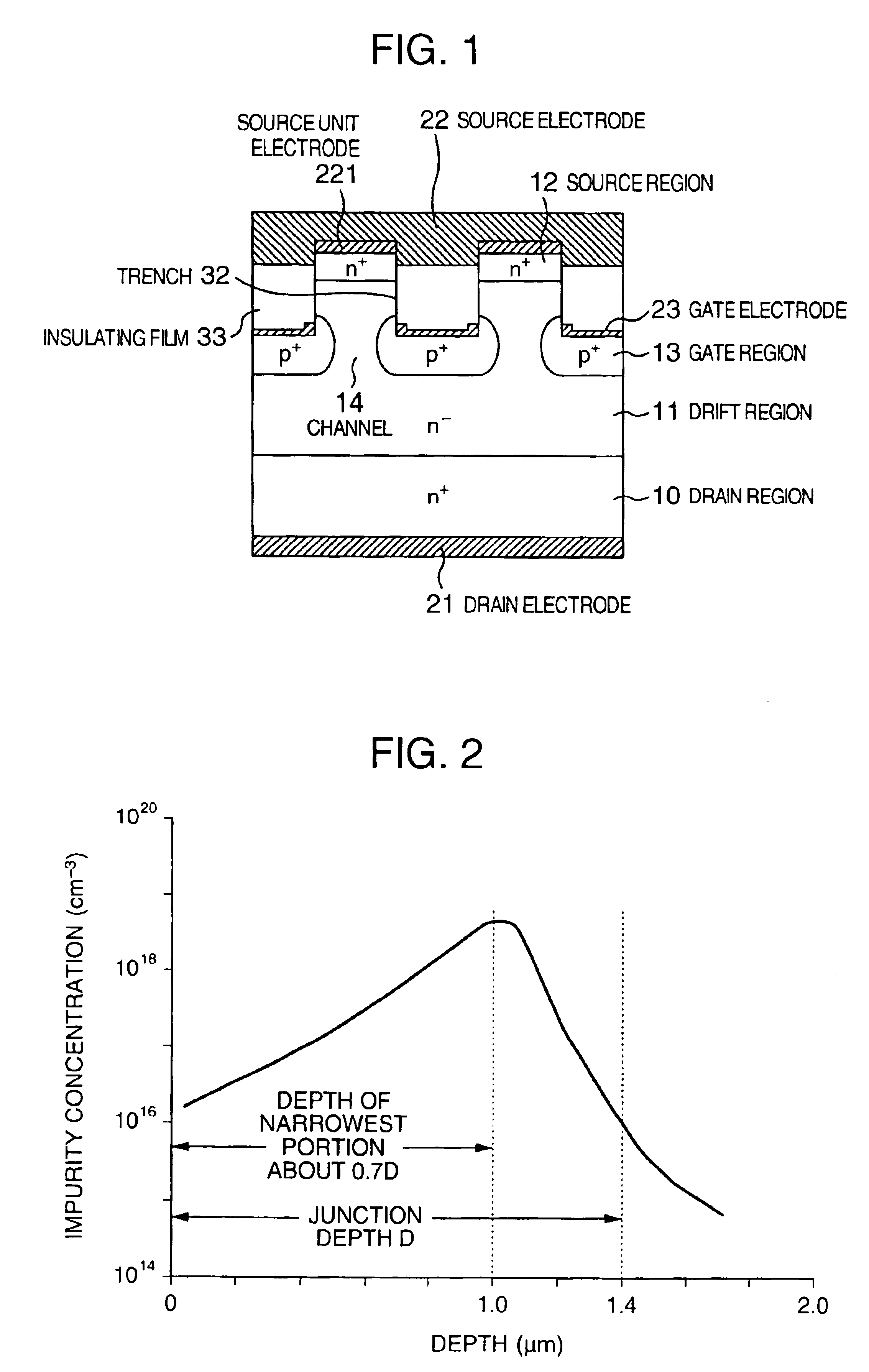

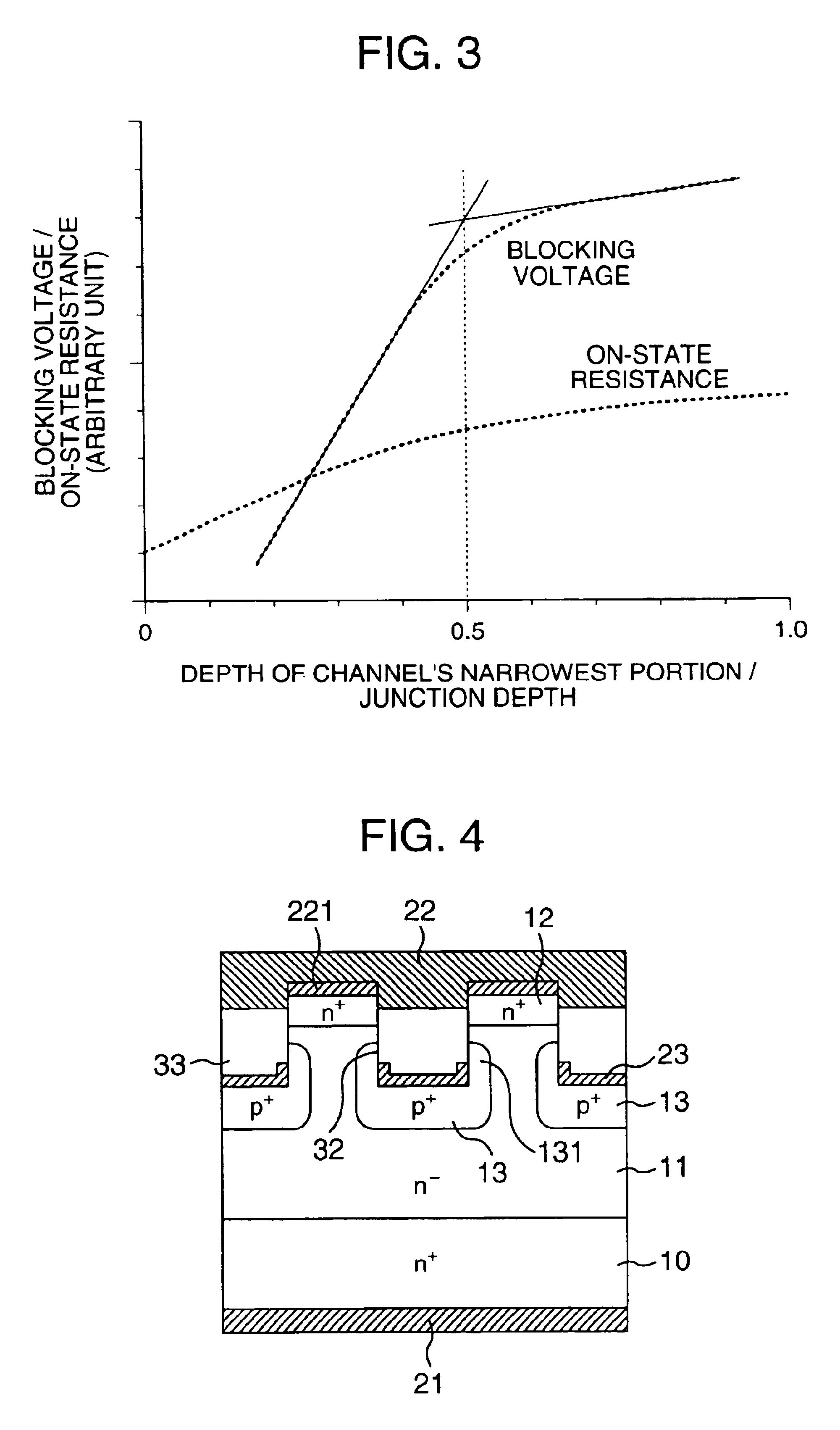

Semiconductor device

ActiveUS6917054B2Improve the blocking effectNarrow channel widthTransistorSemiconductor/solid-state device manufacturingSemiconductorJunction depth

A semiconductor device includes a trench formed on a source side of a drift region, a p-type gate region and a gate formed at the bottom of the trench, and the source formed over the entire surface of the unit device through an insulating film. The narrowest portion of a channel of the device is deeper than one-half the junction depth of the p-type gate region. This allows the width of the channel on the drain side to be reduced even when a lower energy ion implantation manufacturing process is used.

Owner:HITACHI LTD

Elastic plugging agent

ActiveCN104559973AGood deformabilityImprove the blocking effectDrilling compositionSolid particleMonomer

The invention relates to an elastic plugging agent which comprises the following components in parts by weight: 1 part of elastic temporary plugging particles and 0.1-10 parts of a bridging agent, wherein the elastic temporary plugging particles are prepared in such a way that a monomer, an initiating agent, a dispersing agent, rigid solid particles and elastic gel are added into water, stirred uniformly, heated to 60-150 DEG C, and dried after reaction is finished. The elastic plugging agent provided by the invention plays a unidirectional plugging effect, and has favorable adaptability to holes with inlets in different shapes owing to the characteristic of variable elasticity.

Owner:东营市大用石油助剂有限责任公司

Water-based drilling fluid suitable for shale gas development

InactiveCN105255460AIncreased shale stabilityStable rheologyDrilling compositionShale gasDrilling fluid

The invention provides a water-based drilling fluid suitable for shale gas development. The water-based drilling fluid is prepared from the following raw materials in volume on the basis of water: 100 percent of water, 2 to 6 percent of lubricating agents, 1 to 5 percent of inhibitors, 1 to 5 percent of blocking anti-collapse agents, 1 to 5 percent of shale blocking agents, 1 to 5 percent of nanometer blocking agents, 1 to 3 percent of fluid loss additives, 1 to 3 percent of additives, 0 to 0.4 percent of shearing potentiator, 0.1 to 0.6 percent of pH regulator and 0 to 300 percent of weighting agents. The water-based drilling fluid has low filter loss, shale cracks can be effectively blocked, and the stability of a well wall is increased; the lubricating performance is good, and the problems of friction and torque caused by a shale gas horizontal well are preferably solved; the rheological property is excellent.

Owner:SINOPEC JIANGHAN OILFIELD SERVICE CORP +1

Composite multifunctional chemical unblocking agent

The composite multifunctional chemical unblocking agent consists of organic multifunctional unblocking agent in 50-100%, inorganic multifunctional unblocking agent in 5-35% and composite synergist 25-35%. Its main components include C7-C10 aromatic hydrocarbon organic solvent, polyethenoxy ether as surfactant, oil soluble water dispersed polyether demulsifier, T penetrator, polyether wetting agent, mutual solvent, insoluble scale converting agent, composite organic / inorganic acid, cationic polymer as clay stabilizer, water soluble polyether demulsifier, iron ion stabilizer, polyether wetting improver, corrosion assistant, corrosion retardant, cationic polymer as sand stabilizer, etc. The composite multifunctional chemical unblocking agent is injected into treated oil well to produce lasting unblocking effect 10 times that of earth acid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

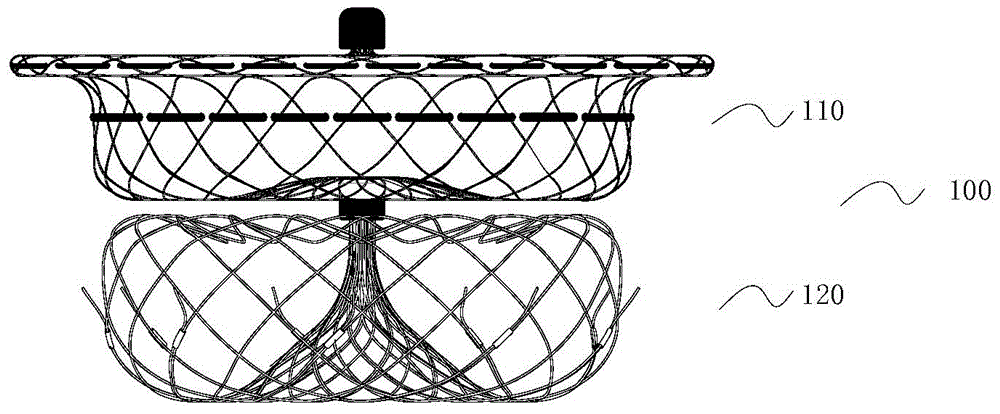

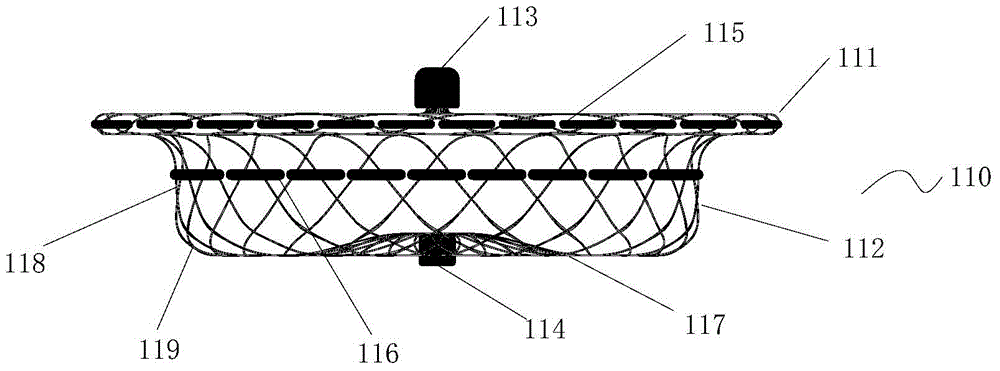

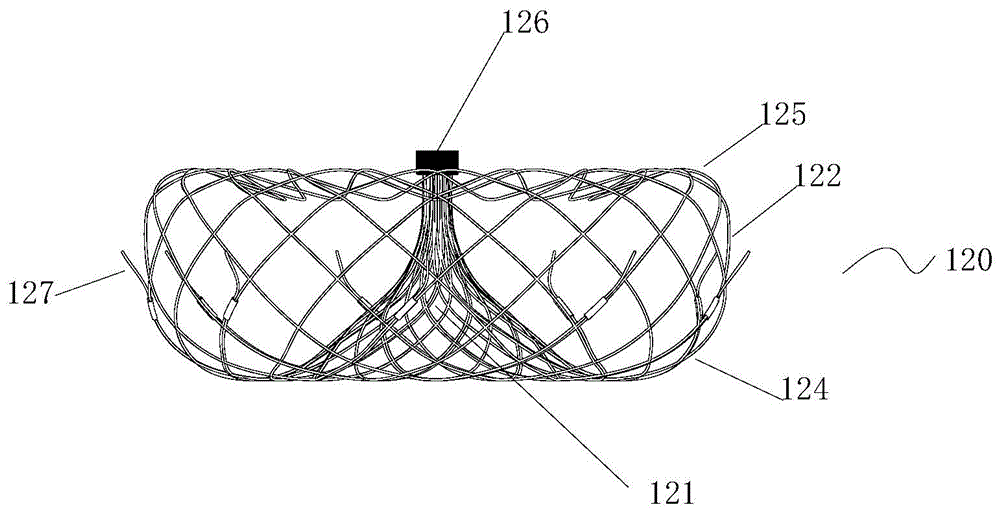

A left auricle occluding device

ActiveCN104958087AReduced risk of punctureEliminate local stress concentrationOcculdersHyper elasticBiomedical engineering

The invention discloses a left auricle occluding device. The left auricle occluding device comprises a sealing disc and an anchoring device, both of which are connected. The position where the anchoring device is matched with a left auricle is an anchoring net of a boneless structure. The overall anchoring device is of a boneless structure and formed by weaving of hyper-elastic metal wires or memory alloy metal wires. The far end of the anchoring device is in the shape of an opening. The near end of the anchoring device is collected and connected with the sealing disc to form a conical net. The far end of the anchoring device is opened and turned up towards the near end to form the anchoring net surrounding the conical net. The anchoring net is joined with the conical net by means of a circular transition area. The left auricle occluding device has following beneficial effects: force can be uniformly distributed to be anchored in the interior of the left auricle in order to eliminate concentration of local stress and can also be repeatedly released; and an opening part of the left auricle is effectively and reliably blocked.

Owner:HANGZHOU NUOMAO MEDTECH CO LTD

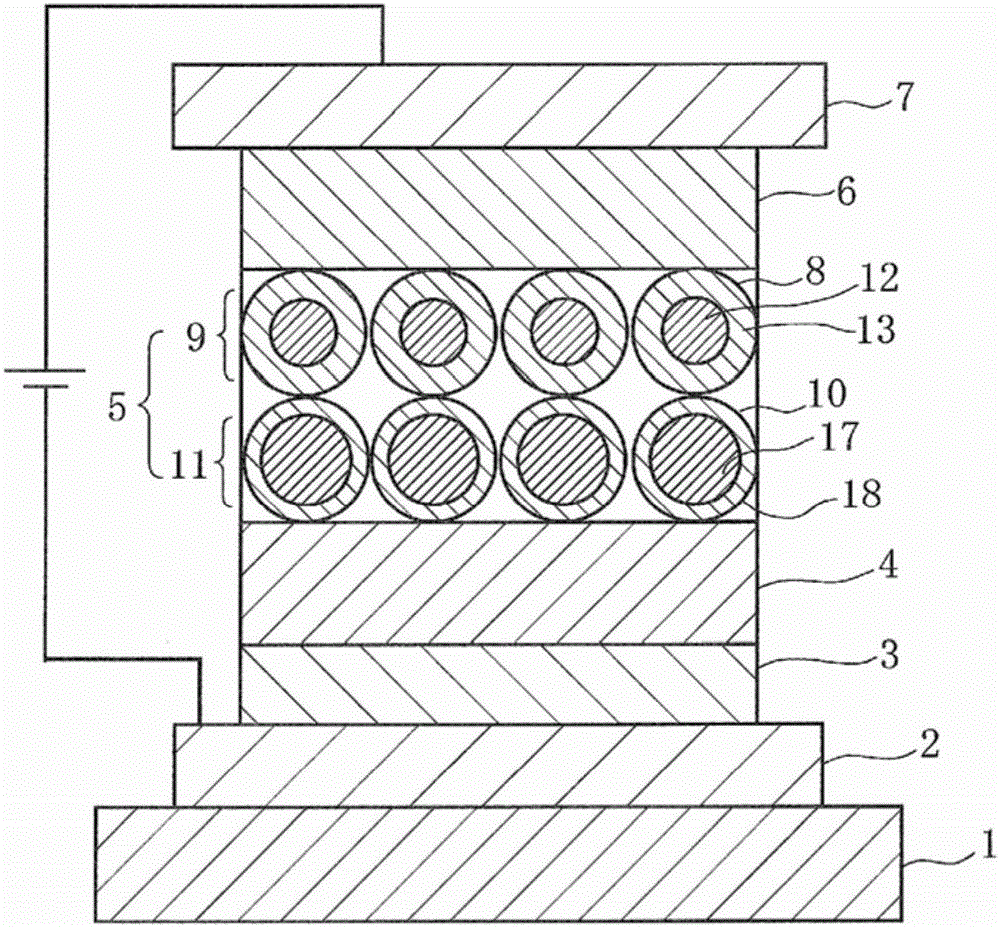

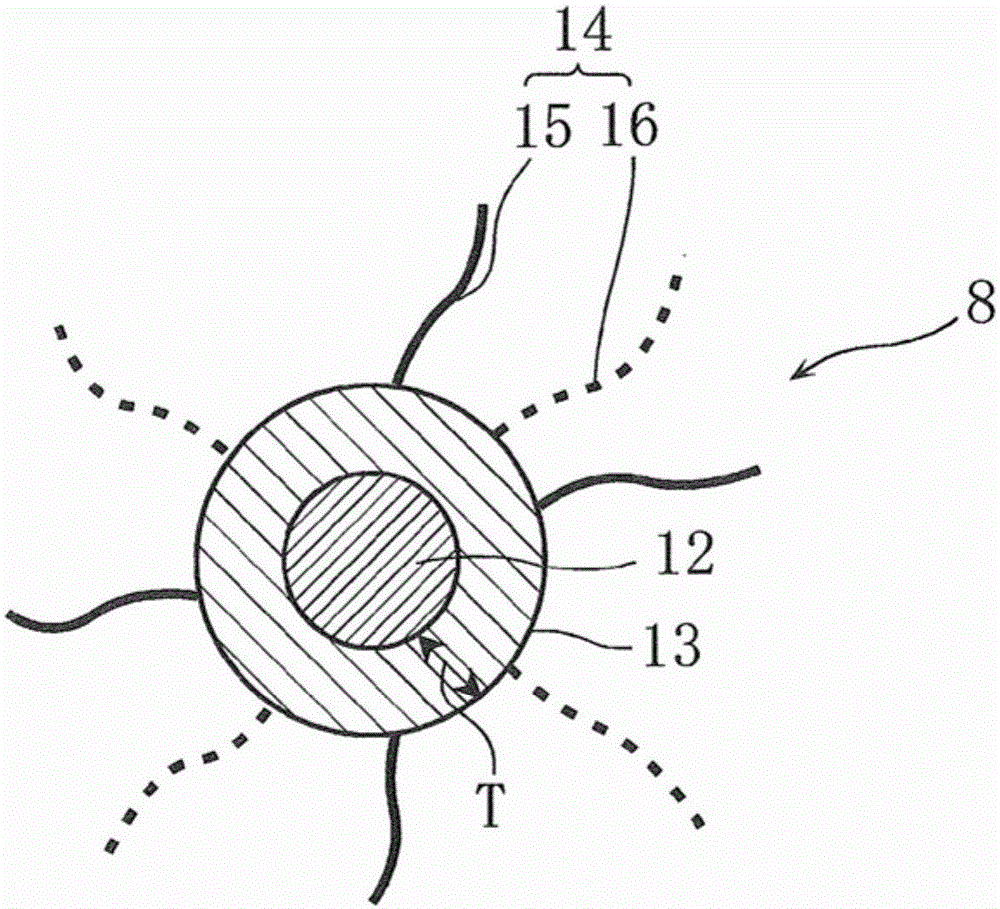

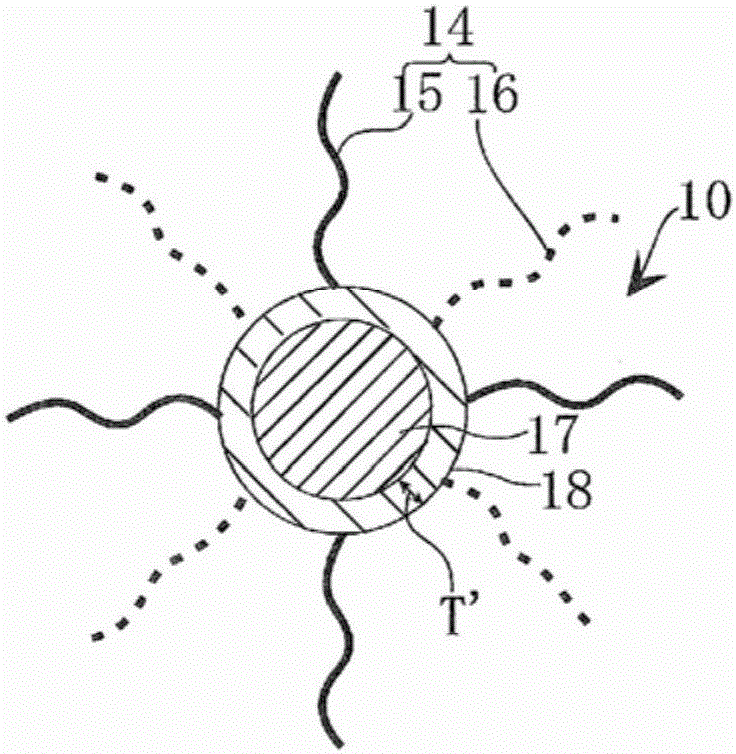

Nano-particle material, and light-emitting device

ActiveCN105684555AReduced transportabilityImprove the blocking effectElectroluminescent light sourcesSolid-state devicesCharge carrierDevice material

A first quantum dot (8) has a core (12) and a shell (13), the surface of the shell (13) is coated with a surfactant, and the thickness of the shell (13) is 3-5 ML expressed in terms of the molecules constituting the shell (13). A second quantum dot (10) has a core (17) and a shell (18); the surface of the shell (18) is coated with two types of surfactants, one having a hole-transport property and one having an electron-transport property; and the thickness of the shell (18) is less than 3 ML expressed in terms of the molecules constituting the shell (18). A first light-emitting layer (9) is formed by the first quantum dots (8) and a second light-emitting layer (11) is formed by the second quantum dots (10). This minimizes external leaking of holes and increases the probability of recombination while maintaining the efficiency with which a carrier is injected into the nano-particle material, so as to yield a nano-particle material suitable as a light-emitting device material able to emit light at high efficiency, and a light-emitting device in which this nano-particle material is used in the light-emitting layer.

Owner:MURATA MFG CO LTD

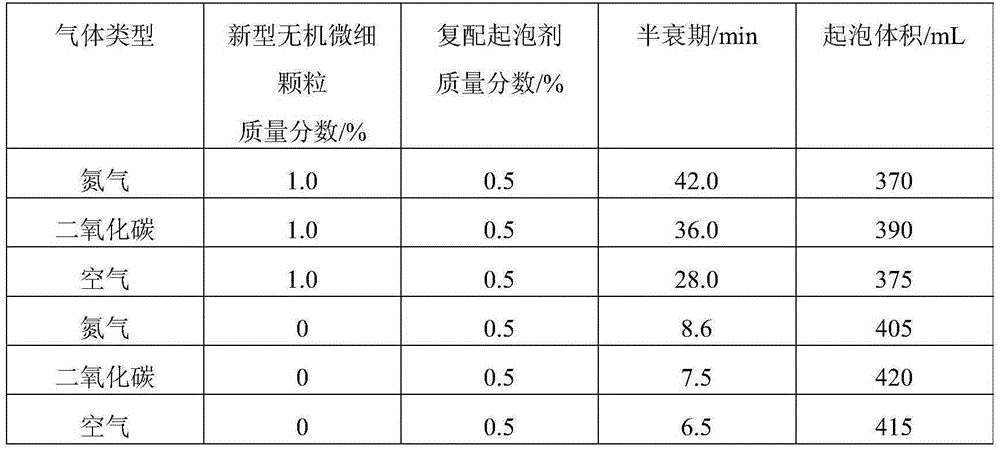

Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

ActiveCN105238380AFormation damage is smallImprove performanceDrilling compositionFoaming agentGas phase

The invention relates to a novel inorganic fine particle enhanced foam system for oil and gas fields, and a preparation method thereof. The enhanced foam system comprises a gas phase and a liquid phase; the gas phase is nitrogen, carbon dioxide or air; the liquid phase comprises 0.2-0.8wt% of a foaming agent, 0.5-2.0wt% of novel inorganic fine particles, and the balance of water; and the novel inorganic fine particles are fine particles with the particle size being not greater than 2.5[mu]m, trapped and screened from air. The invention also provides the preparation method of the foam system. The enhanced foam system can be used to benefit efficient exploitation of oil and gas resources, can change the novel inorganic fine particles into valuables, reduces pollution of the novel inorganic fine particles to air environment, and has the advantages of low cost of the raw materials, simple preparation process, low operation cost, good oil and gas yield increasing effect, and high economic benefit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

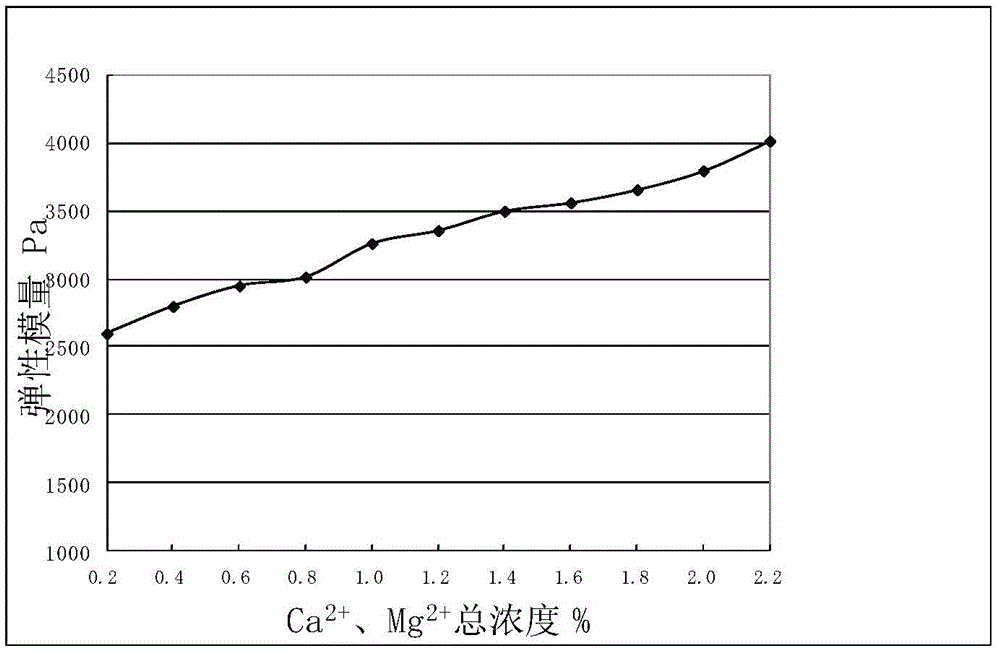

High-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and preparation method and application thereof

ActiveCN102533233ABreak usabilityBreak the limitationsFluid removalDrilling compositionBenzaldehydeCyclodextrin

The invention relates to a high-temperature-resistant and high-salinity-resistant water-plugging profile control agent, and a preparation method and application thereof. The water-plugging profile control agent comprises polyacrylamide, a composite crosslinking agent, cyclodextrin, metaphenylene diamine and deoxidant, wherein the composite crosslinking agent consists of aldehyde, phenol and aluminum citrate; the aldehyde is one or the combination of benzaldehyde and paraformaldehyde; and the phenol is one or more of phenol, resorcinol and hydroquinone. The water-plugging profile control agent can resist the temperature of 120 DEG C, can be directly prepared by using water with mineralization degree of 150,000 mg / L, and has high crosslinking performance and long-term stability. The preparation method for the water-plugging profile control agent is simple, convenient to operate, and easy to control, and water-plugging profile control agent has a good plugging effect, and construction can be performed after the water-plugging profile control agent is directly prepared on site.

Owner:PETROCHINA CO LTD

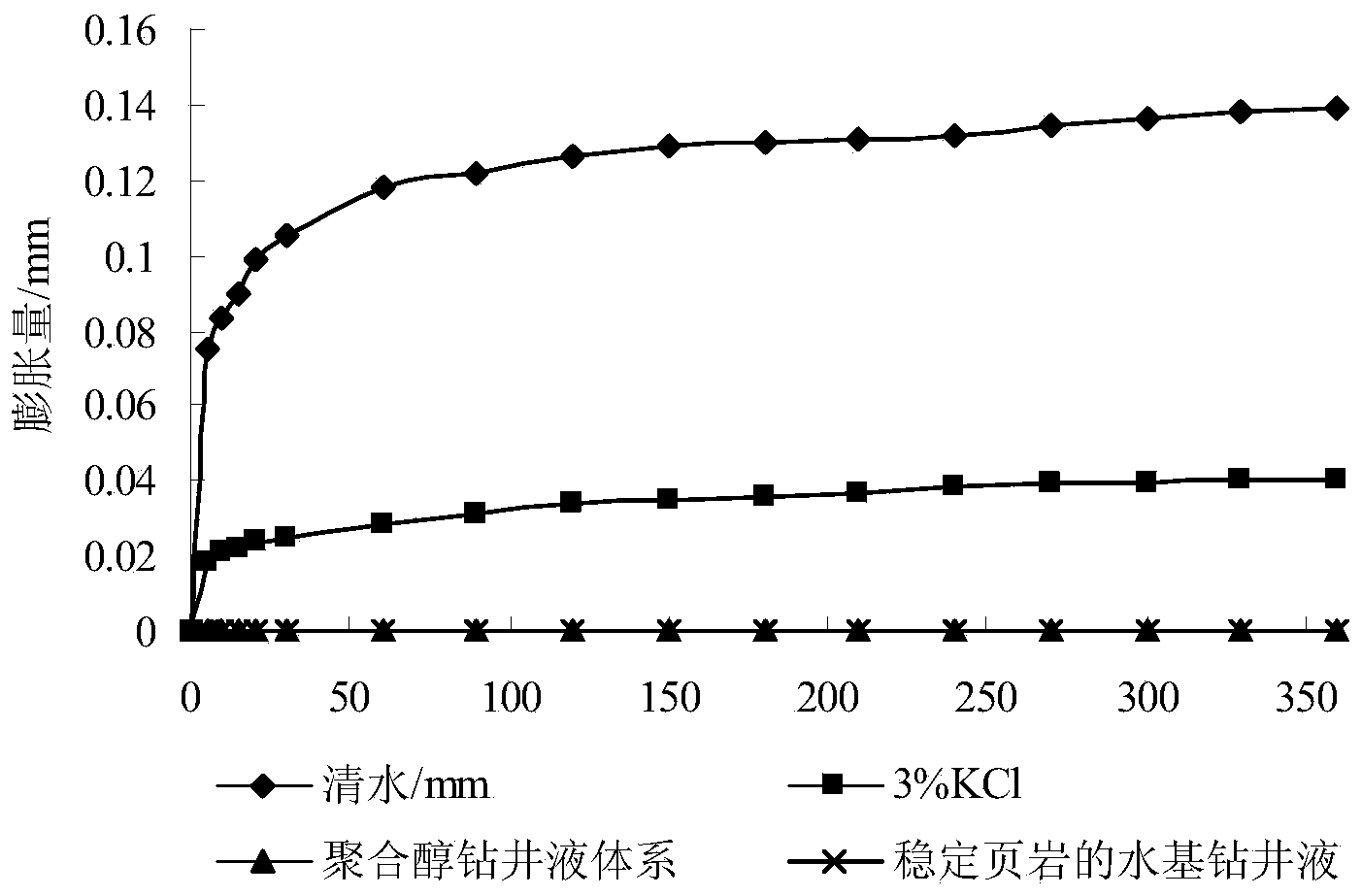

Water-based drilling fluid for stabilizing shale

ActiveCN103725272AImprove rheologyGood filter loss reduction effectDrilling compositionWater basedWell drilling

The invention provides water-based drilling fluid for stabilizing shale. The drilling fluid is formed by mixing sodium-based bentonite, a shale inhibitor, a tackifier, a flow-pattern adjusting agent, a filtrate reducer, a high-temperature-resisting processing agent, a bridging agent, bridging particle and an anti-collapse agent. Calculated by the addition quantity in every 100 parts of water, the water-based drilling fluid comprises the following components in parts by mass: 5 parts of sodium-based bentonite, 1.5 to 1.8 parts of shale inhibitor, 0.5 to 0.7 part of tackifier, 0.1 to 0.2 part of flow-pattern adjusting agent, 0.7 to 0.9 part of filtrate reducer, 2.3 to 2.5 parts of high-temperature-resisting processing agent, 9.33 to 10.67 parts of bridging agent, 1.8 to 2.2 parts of bridging particle and 1.1 to 1.3 parts of anti-collapse agent. The drilling fluid is good in rheological property, filtrate reduction property and lubricating property and strong in inhabitation property, so that the requirement of the shale gas horizontal well drilling cuttings carrying and wall stability requirement can be met, and the probability of drilling seizure can be reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

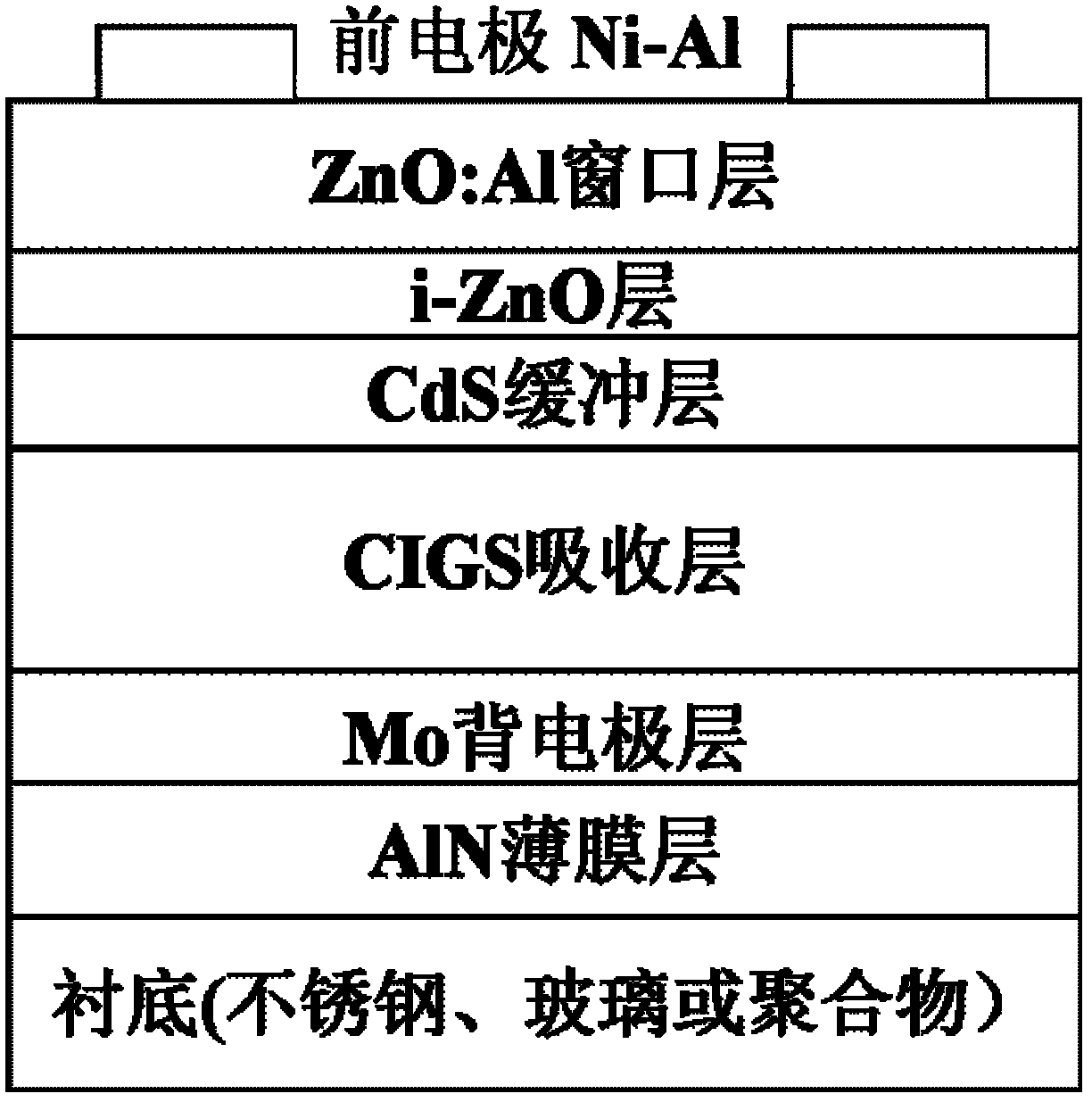

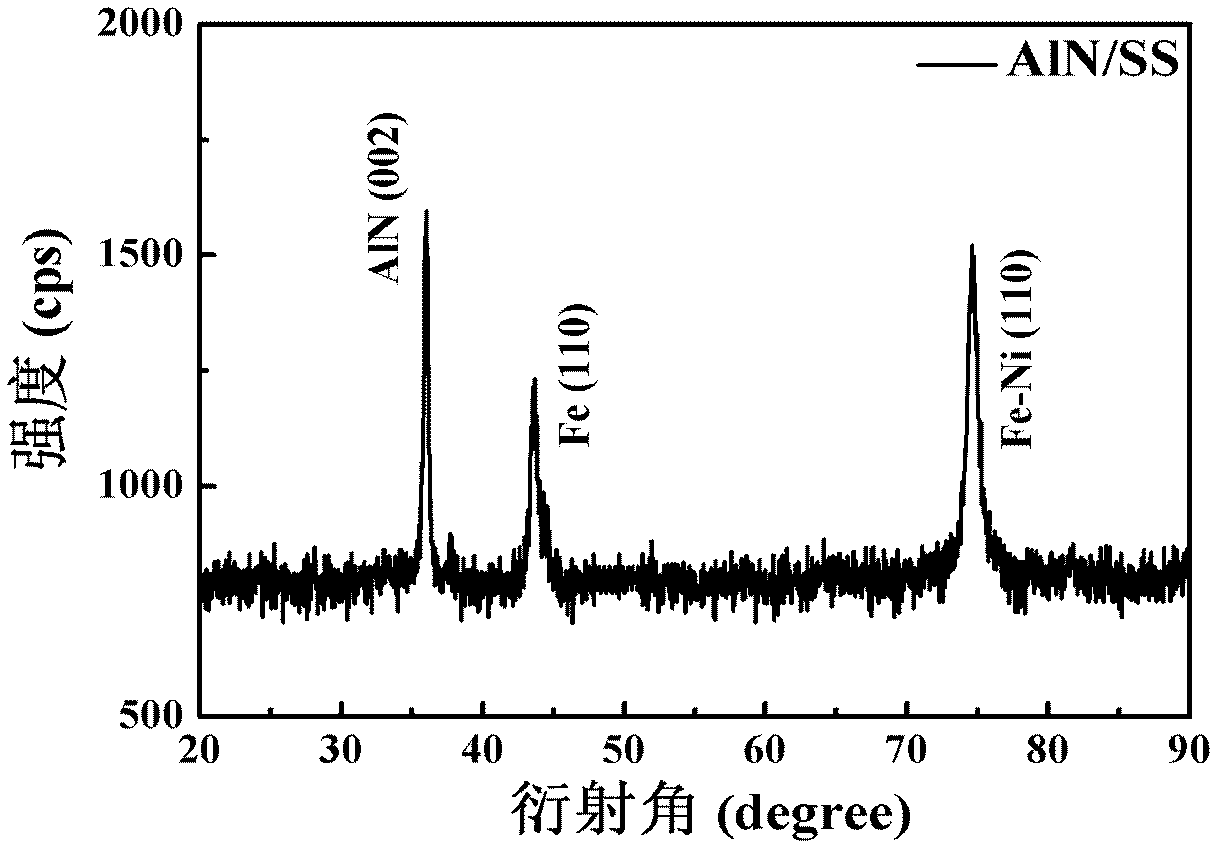

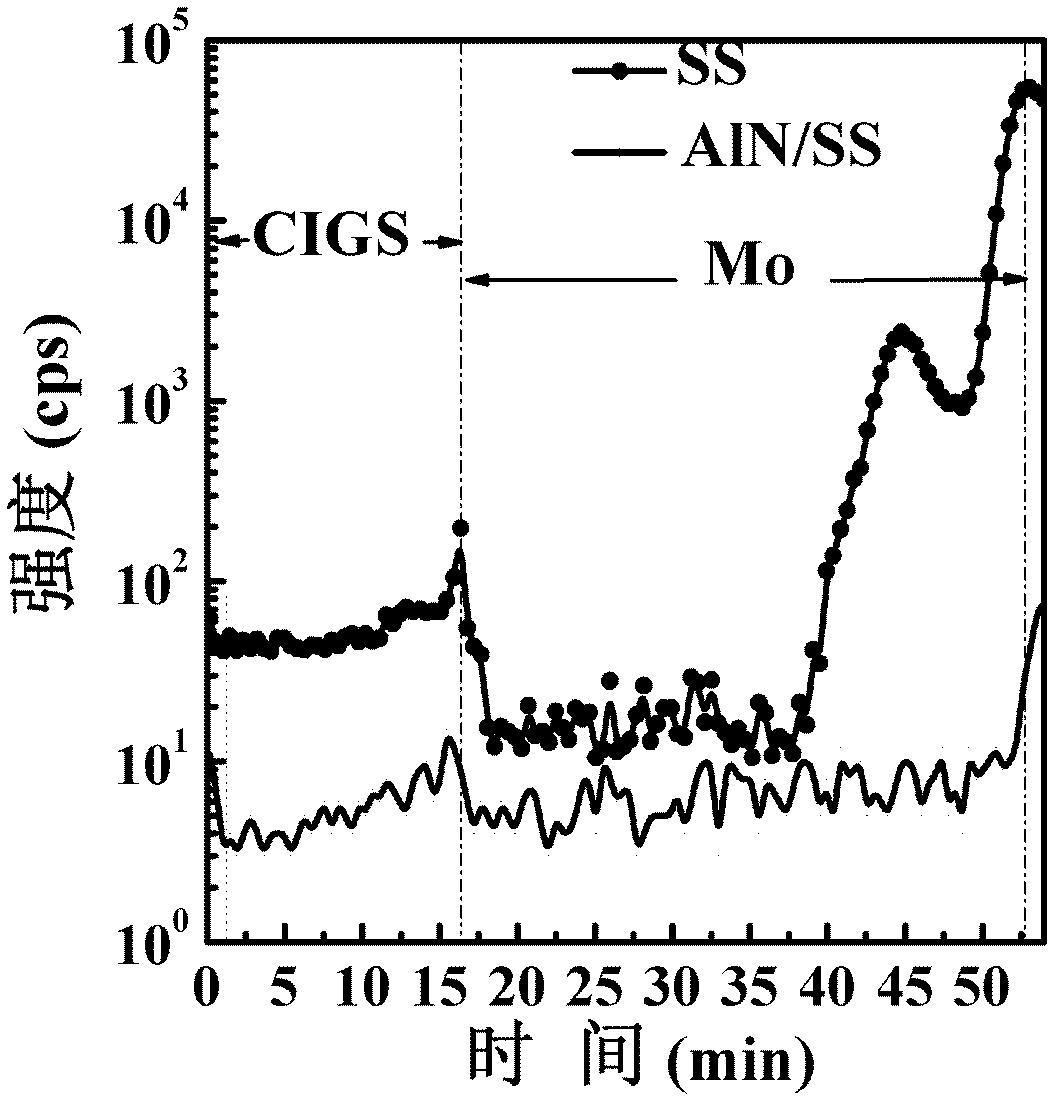

Copper indium gallium selenium thin film solar cell provided with aluminum nitride (AIN) thin film layer

InactiveCN102544138AInhibited DiffusionBarrier diffusion dopingPhotovoltaic energy generationSemiconductor devicesIndiumImpurity

A copper indium gallium selenium (CIGS) thin film solar cell provided with an aluminum nitride (AIN) thin film layer comprises a substrate, a molybdenum (Mo) back electrode layer, a CIGS absorbed layer, a cadmium dating sulphide (CdS) buffer layer, an intrinsic zinc oxide (i-ZnO) layer, a mixing zinc oxide (ZnO:AI) window layer and front electrode nickel aluminum. The AIN thin film layer is arranged between the substrate and the Mo back electrode layer and serves as an electric insulation impurity barrier layer when the substrate is made of metal, the AIN thin film layer serves as an impurity barrier and stress intermediate layer when the substrate is made of glass, and the AIN thin film layer serves as a heat buffer layer when the substrate is made of polymer. The thin film solar cell has the advantages of adopting simple and cheap magnetic control sputtering technology to prepare an AIN thin film to serve as the impurity barrier layer or the electrical insulating layer of the substrate, being capable of having good resisting effects and keeping insulation characteristics of metal atoms even through the solar cell is prepared at high substrate temperature, and providing prerequisite conditions for manufacturing inline type tinsel substrate thin film solar cells.

Owner:NANKAI UNIV

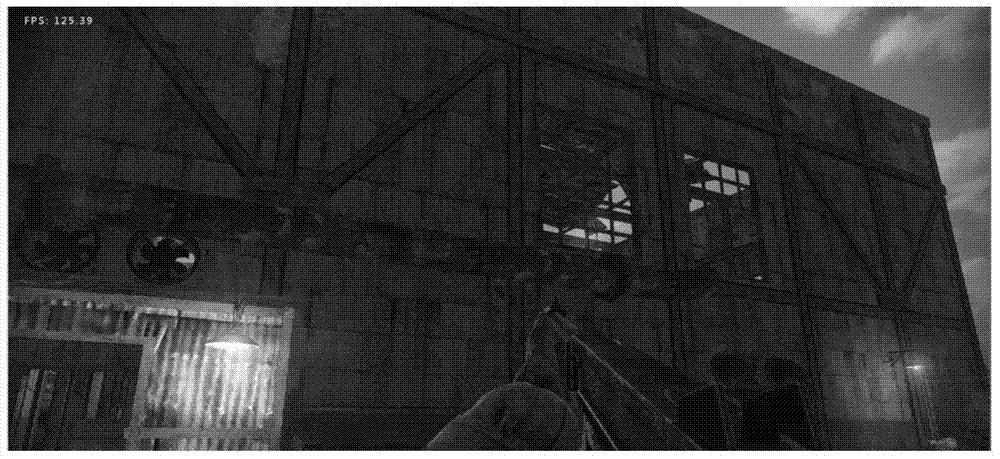

Occlusion culling and acceleration method for drawing outdoor ground surface in real time based on depth map

ActiveCN104331918AImprove the blocking effectDraw in real timeImage analysis3D-image renderingOcclusion effectDepth map

The invention discloses an occlusion culling and acceleration method for drawing an outdoor ground surface in real time based on a depth map. The method comprises the following steps: drawing a current scene and storing the depth value of the scene to a piece of depth map through an acceleration algorithm; and carrying out rasterization on a bounding box of a model to be detected and judging the value of pixels in the bounding box of the model to be detected and the magnitude of the depth value in the previous step, and thus the result of occlusion culling is obtained. A portion sight line occlusion body is arranged in a scene editor in an engine, then, all objects in the scene are drawn; the least depth value of the sight line occlusion body in the current scene is recorded; and the depth value of the bounding box of the object to be detected is compared with the least depth value obtained by scene drawing, and visibility of the object is obtained. The purposes of good occlusion effect and real-time drawing can be realized.

Owner:WUXI FANTIAN INFORMATION TECH

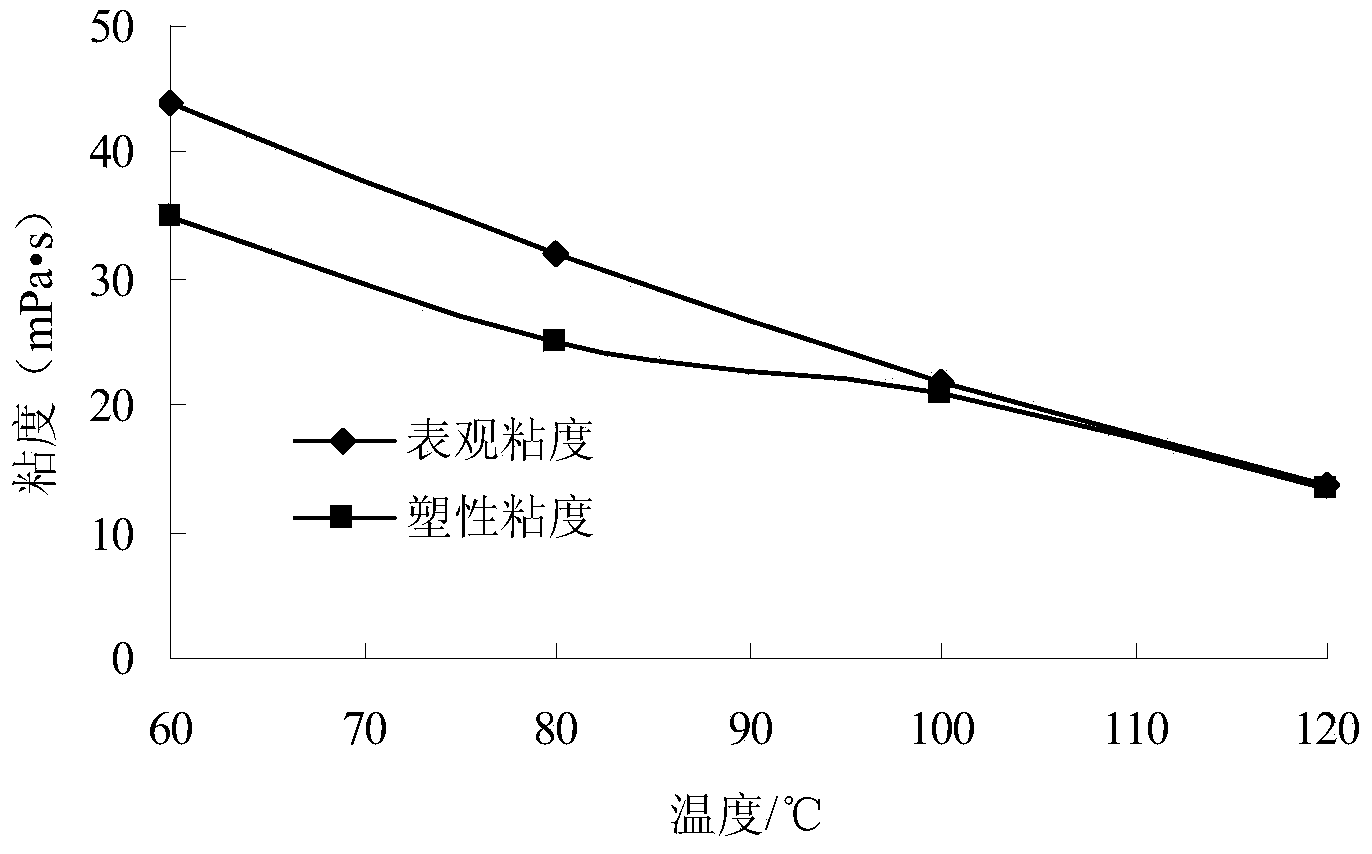

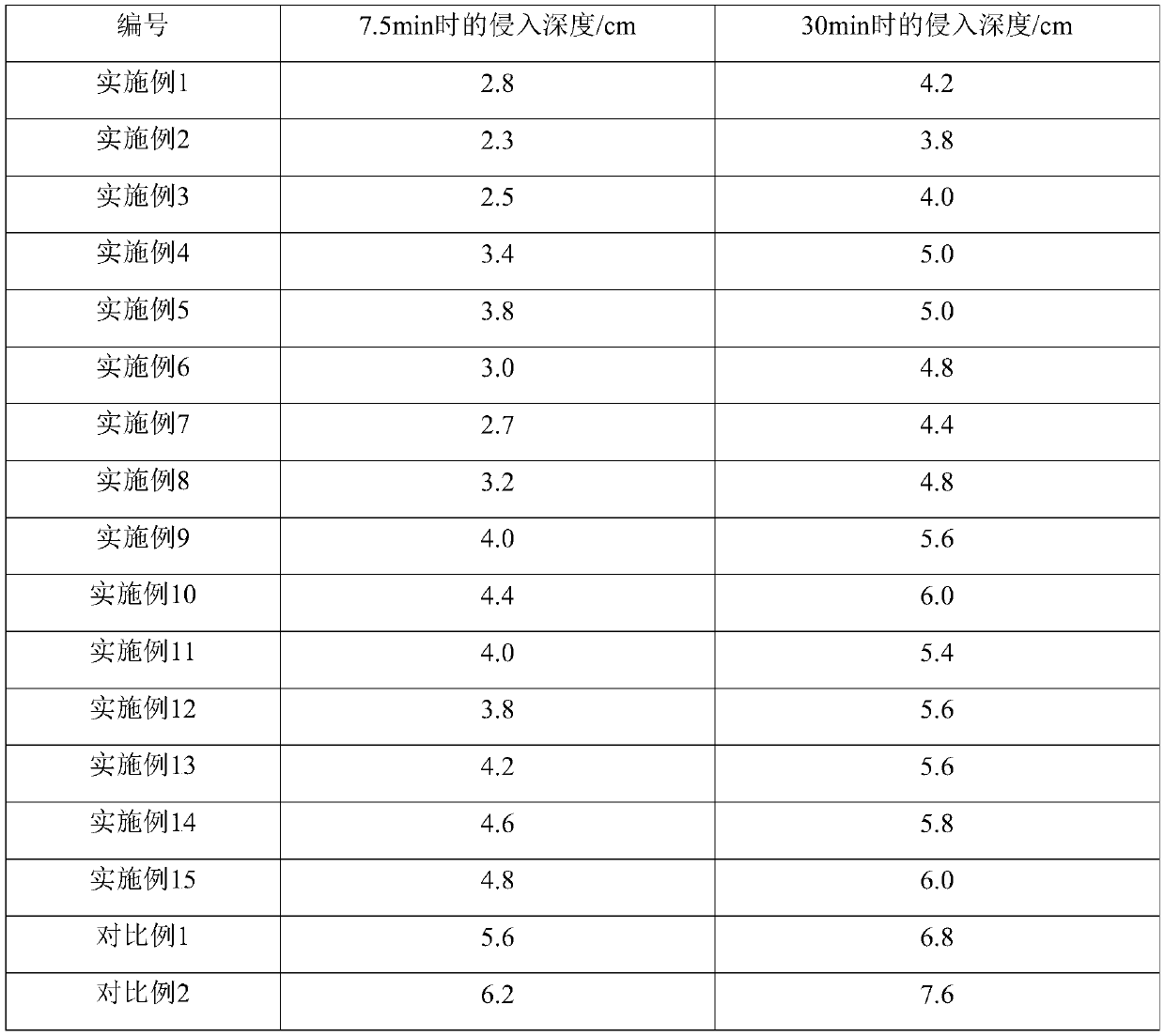

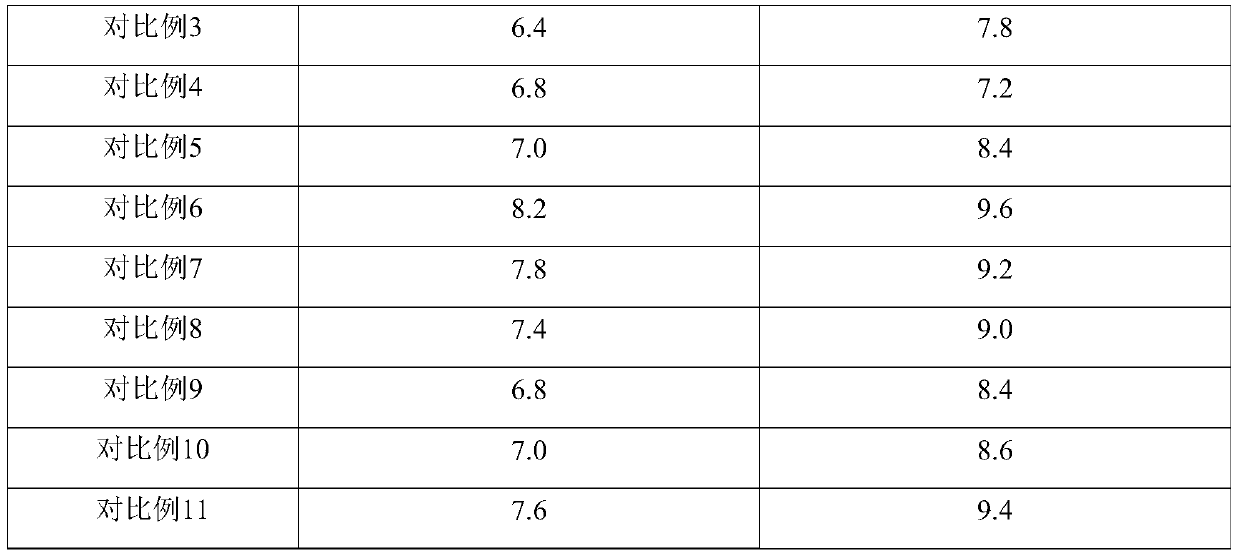

High-plugging-performance drilling fluid composition and preparation method and application thereof

ActiveCN110205104AImprove the blocking effectLess intrusiveCarbon compoundsDrilling compositionMicro nanoPressure transmission

The invention relates to the field of drilling fluid, and discloses a high-plugging-performance drilling fluid composition and a preparation method and application thereof. The high-plugging-performance drilling fluid composition contains water, bentonite, Na2CO3, a shale inhibitor, a filtrate loss reducer, a viscosity reducer, an anti-collapse agent, a nanometer plugging agent, a lubricant and aweighting agent, wherein the shale inhibitor is modified asphalt GLA, the anti-collapse agent is calcium carbonate superfine powder C80, and the nanometer plugging agent is nanometer graphene subjected to surface modification by polyethylene glycol. According to the high-plugging-performance drilling fluid composition, the modified asphalt GLA as the shale inhibitor, the calcium carbonate superfine powder C80 as the anti-collapse agent and the nanometer plugging agent are adopted for effectively plugging micro-nano cracks of the shale stratum of the large-displacement horizontal segment of a deep well, a drilling fluid phase is prevented from entering the cracks, the lasting and compact plugging barrier is formed near the well wall, and therefore pore pressure transmission is further prevented, the wedge effect of waterpower is further reduced, the block shedding phenomenon is avoided, collapsing of the stratum is effectively prevented, and the stratum is kept stable.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com