Copper indium gallium selenium thin film solar cell provided with aluminum nitride (AIN) thin film layer

A technology of thin-film solar cells and copper indium gallium selenide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high equipment investment intensity, expensive raw materials, unfavorable solar cells, etc., to reduce production equipment investment and improve horizontal Uniformity, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

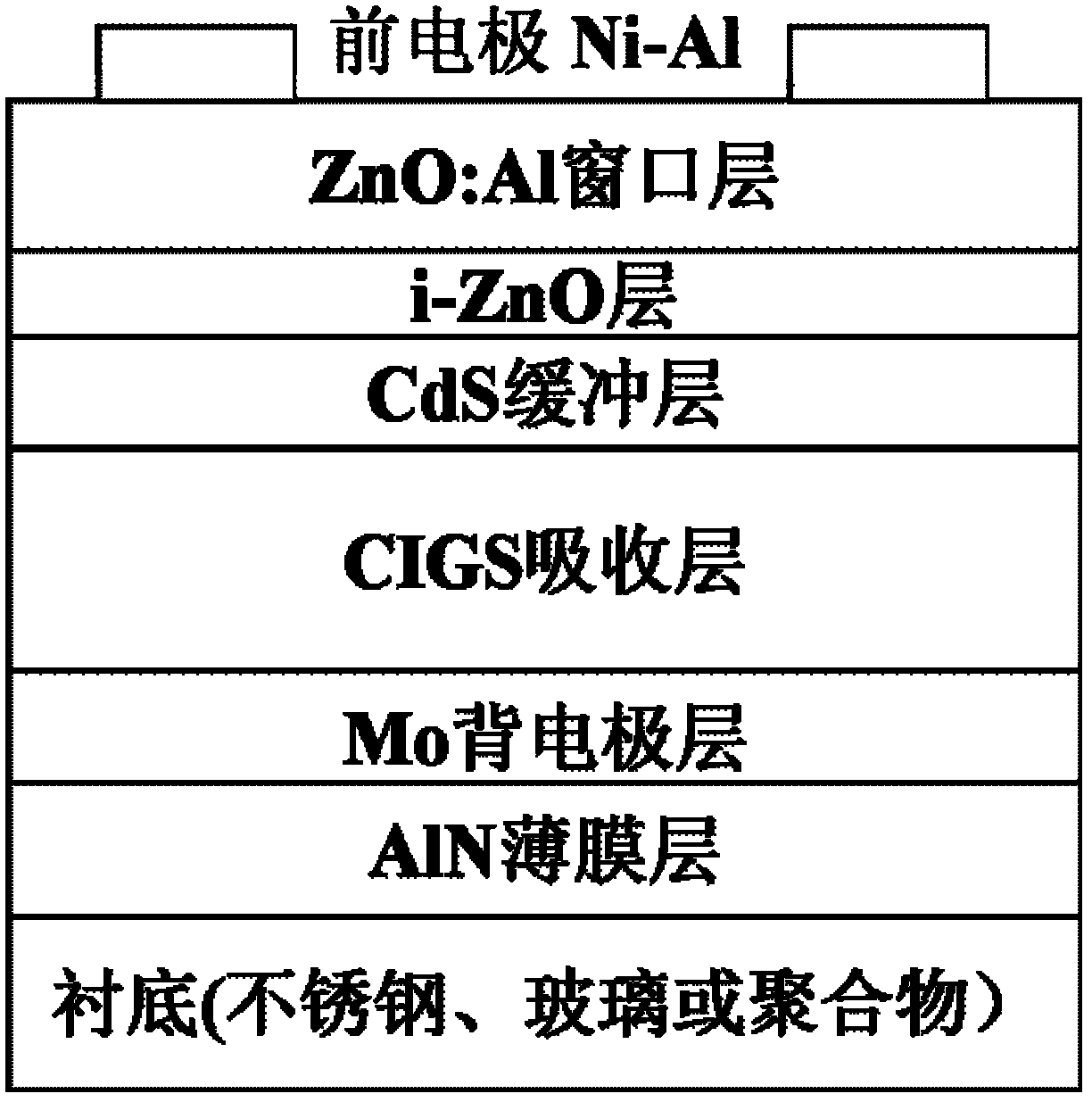

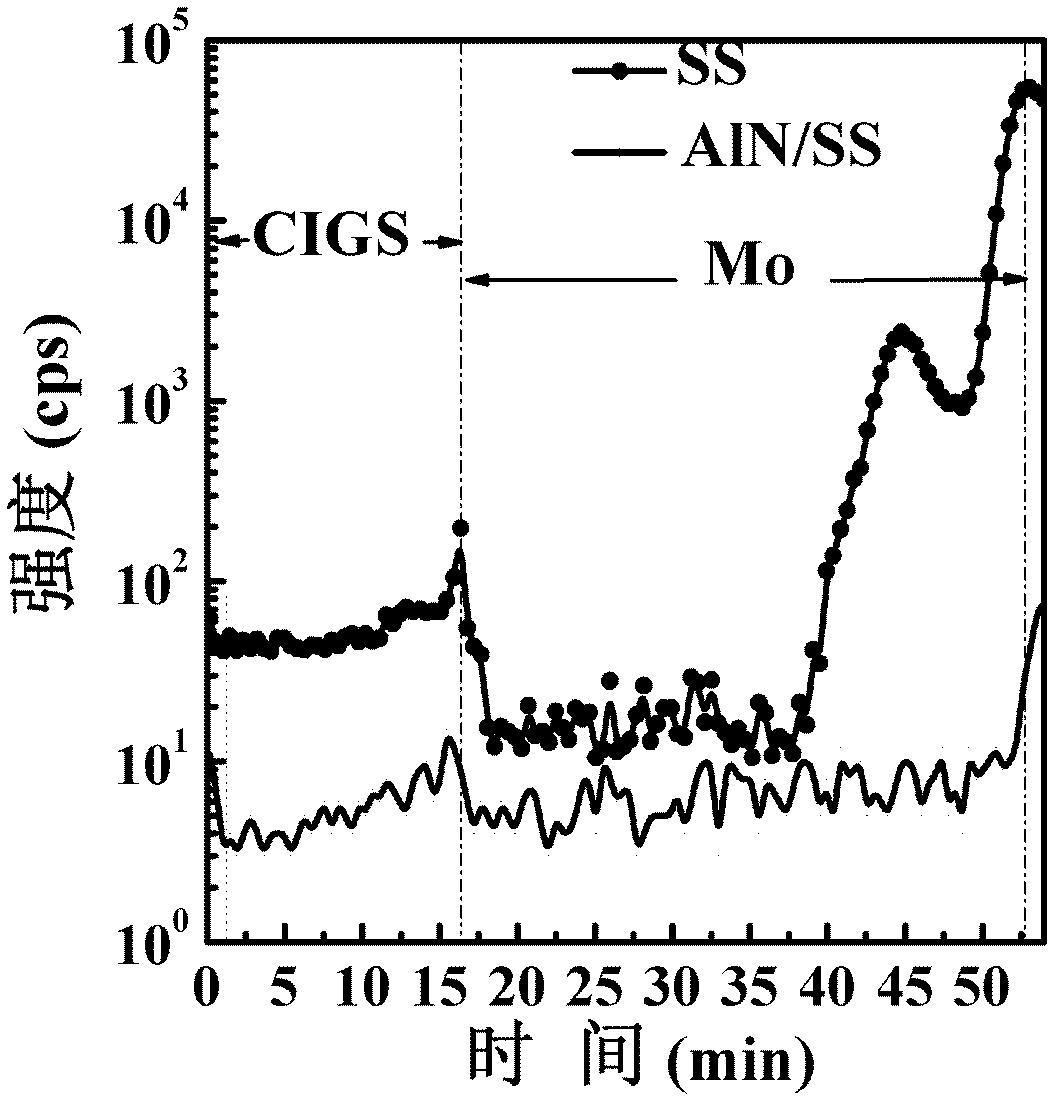

[0031]A kind of copper indium gallium selenium thin film solar cell with AlN thin film layer, see figure 1 , using stainless steel as the substrate and using magnetron sputtering to prepare an AlN film as an electrically insulating impurity barrier layer, the preparation steps are as follows:

[0032] 1) The 0.05 μm stainless steel foil (SS) is ultrasonically cleaned, dehydrated and dried, then placed in the vacuum chamber of the magnetron sputtering deposition system, dehydrated and degassed;

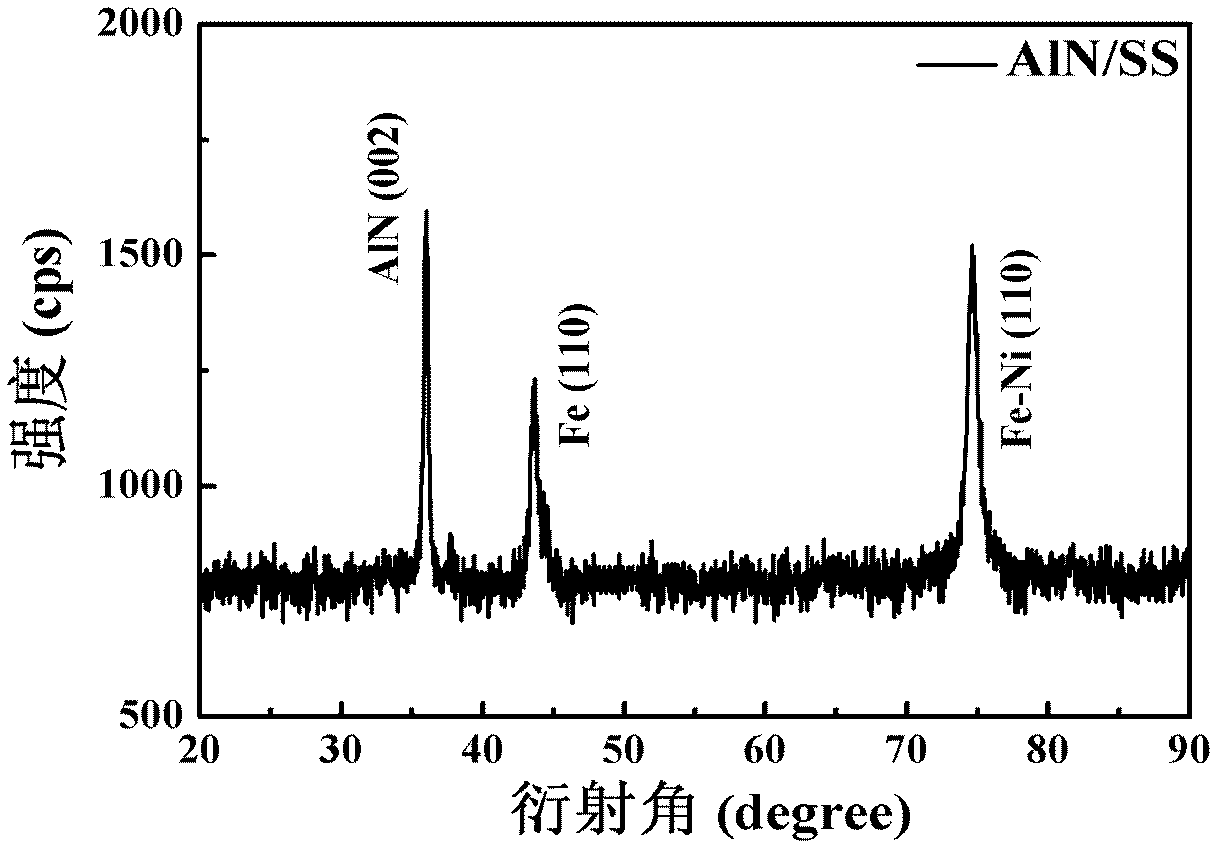

[0033] 2) The AlN film was prepared on the stainless steel substrate by magnetron sputtering, and the process parameters: the background vacuum was 3×10 -3 Pa, the substrate temperature is 150°C, the target distance of the metal Al target is 60mm, and the Ar and N 2 The flow rate of the mixed gas is 25sccm, Ar and N 2 The volume ratio is 1.5:1, the working gas pressure in the vacuum chamber is 0.5Pa, and the sputtering power density is 1.2W / cm 2 , the thickness of the prepared AlN f...

Embodiment 2

[0043] A kind of copper indium gallium selenium thin film solar cell with AlN thin film layer, see Figure 4 , using stainless steel as a substrate to prepare AlN / Cr composite film as an electrical insulation and impurity barrier layer, the preparation steps are as follows:

[0044] 1) The 0.05 μm stainless steel foil (SS) is ultrasonically cleaned, dehydrated and dried, then placed in the vacuum chamber of the magnetron sputtering deposition system, dehydrated and degassed;

[0045] 2) The Cr film was prepared on the stainless steel substrate by magnetron sputtering, and the process parameters: the background vacuum was 3×10 -3 Pa, the flow rate of Ar is 15sccm, the target-base distance is 60mm, the working gas pressure of the vacuum chamber is 0.8Pa, and the sputtering power density is 0.8W / cm 2 , the thickness of the prepared Cr film is 500nm, and the same method as in Example 1 is used to prepare an AlN film with a thickness of 200nm on the Cr film, and then AlN / Cr / SS is ...

Embodiment 3

[0049] A copper indium gallium selenium thin film solar cell with an AlN thin film layer is prepared with glass as a substrate to prepare an AlN thin film as an impurity barrier and stress transition layer, see figure 1 , the preparation steps are as follows:

[0050] 1) Ultrasonic cleaning is performed on a 2mm glass substrate, dehydrated and dried, and then placed in a vacuum chamber of a magnetron sputtering deposition system for dehydration and degassing;

[0051] 2) Prepare AlN thin film on glass substrate by magnetron sputtering, process parameters: background vacuum is 3×10 -3 Pa, the substrate temperature is 300°C, the target distance of the metal Al target is 60mm, and the Ar and N 2 The flow of mixed gas is 30sccm, Ar and N 2 The volume ratio is 1:1, the working gas pressure in the vacuum chamber is 1Pa, and the sputtering power density is 1.2W / cm 2 , the thickness of the prepared AlN film is 0.5 μm;

[0052] 3) A low-pressure single-layer Mo back electrode was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com