Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5244 results about "Metal foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

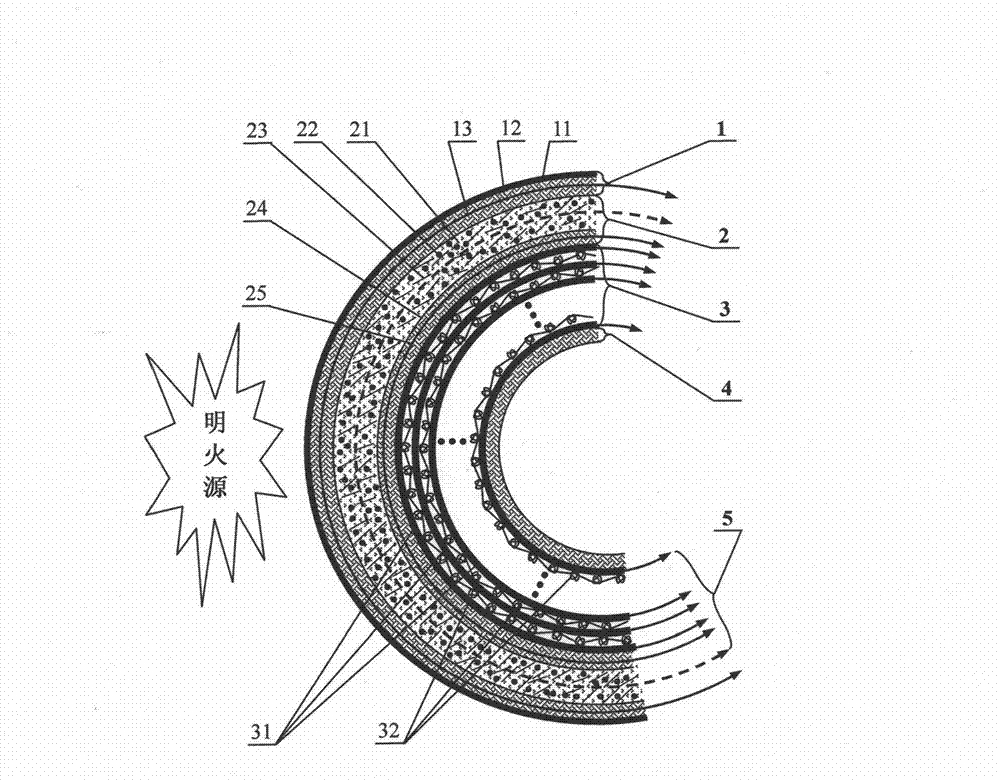

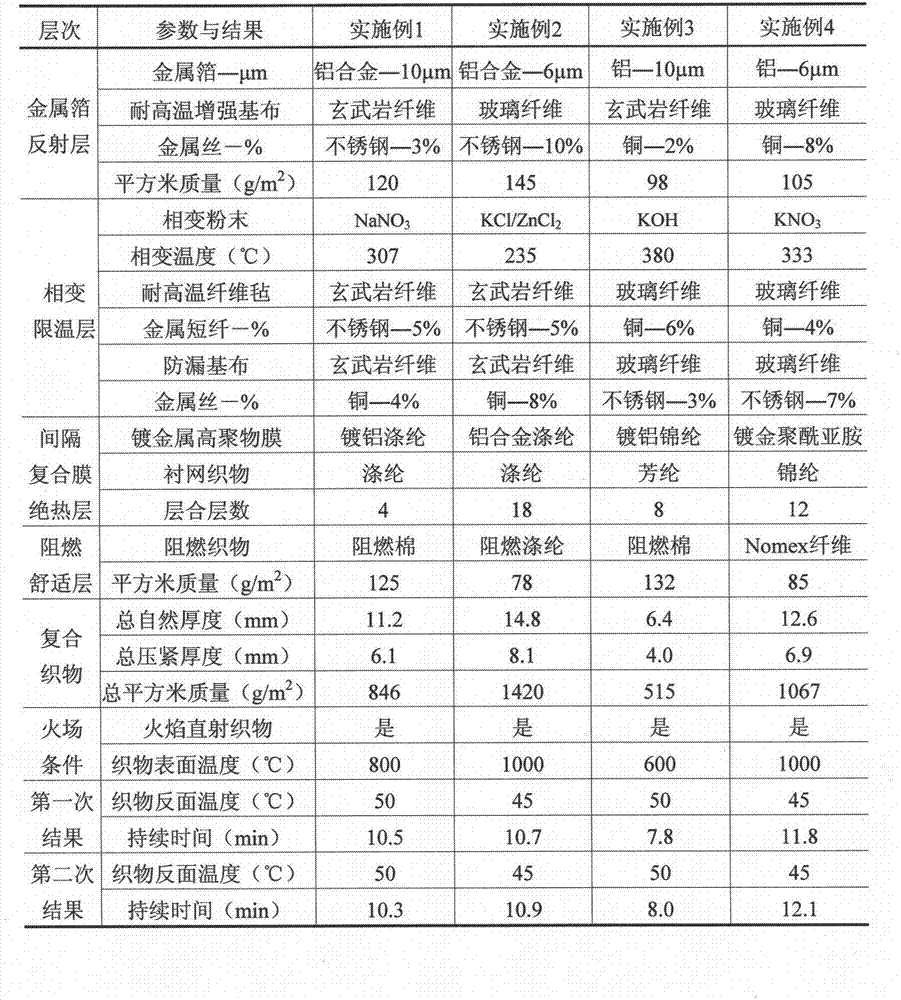

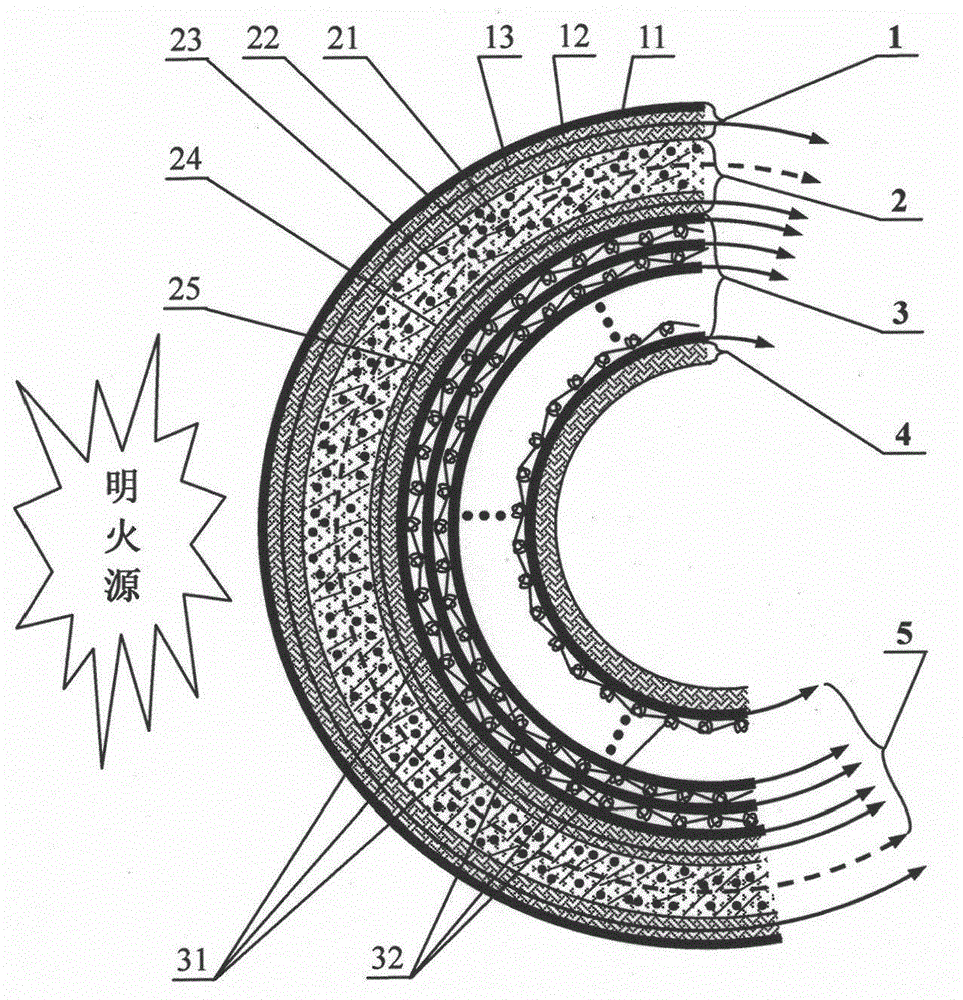

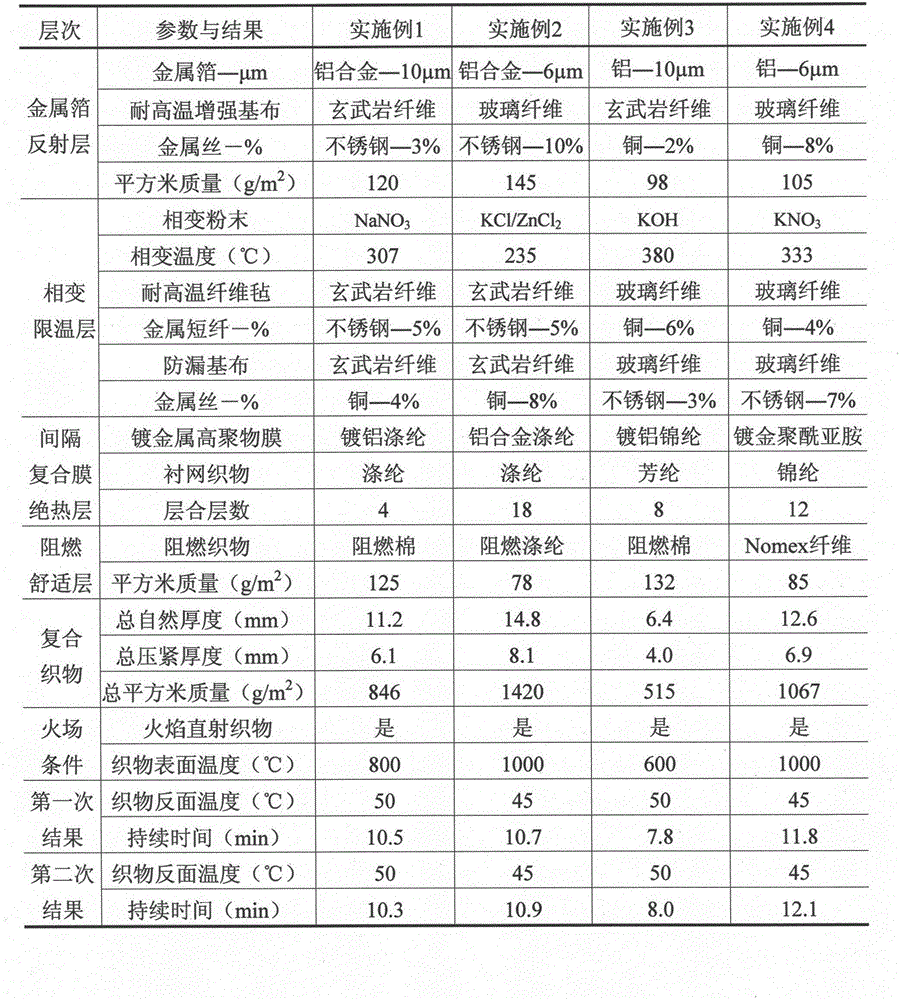

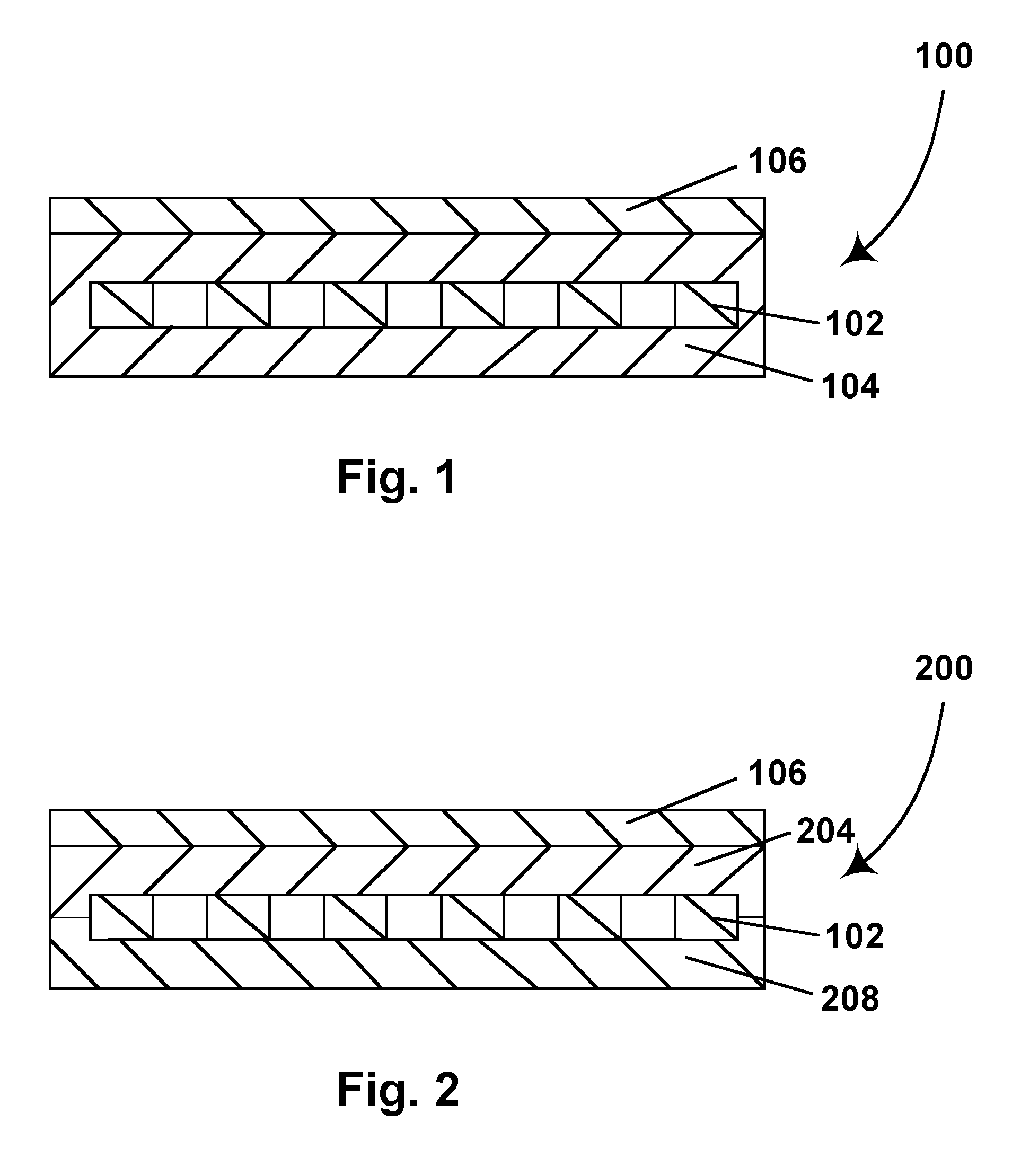

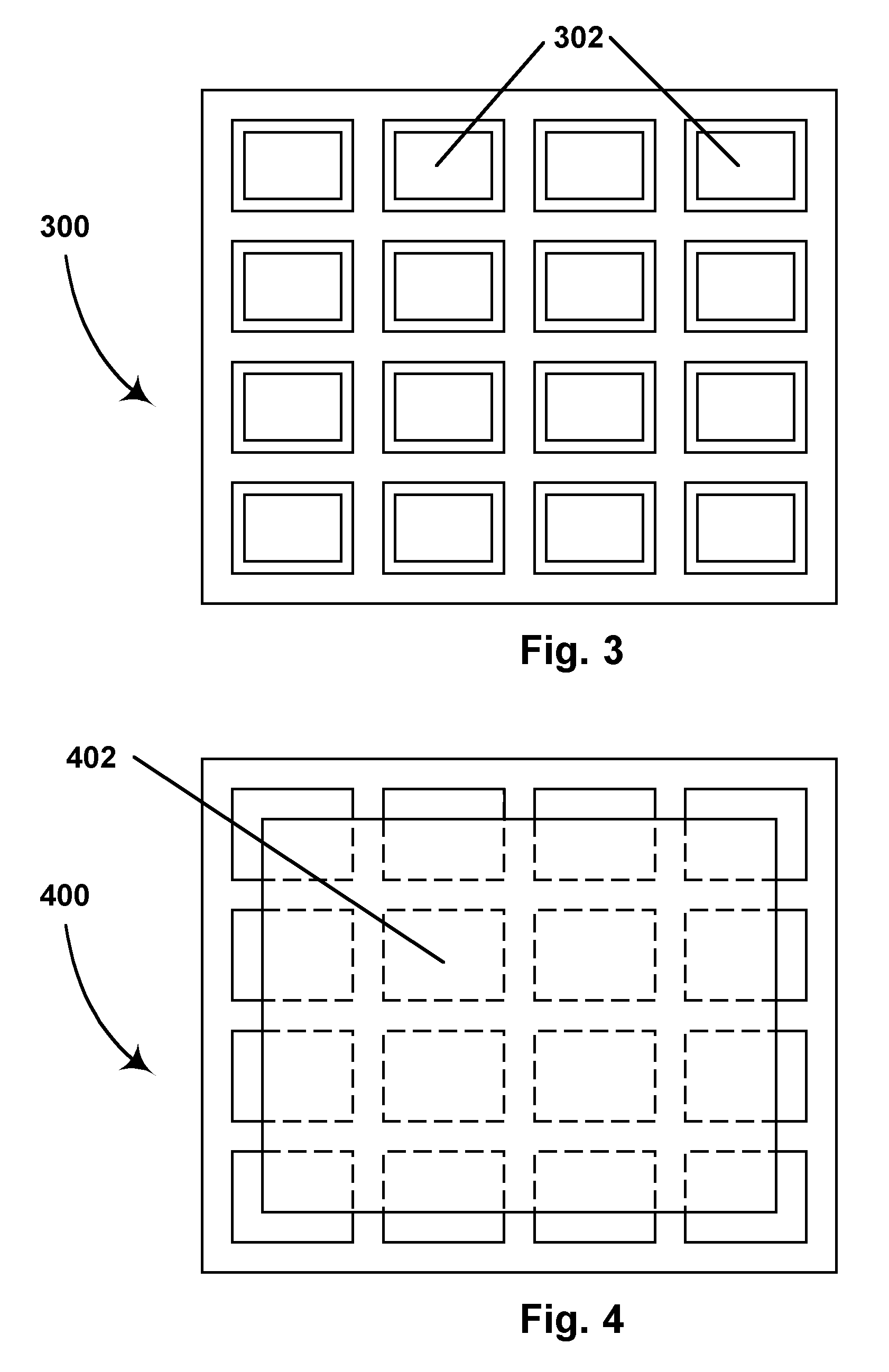

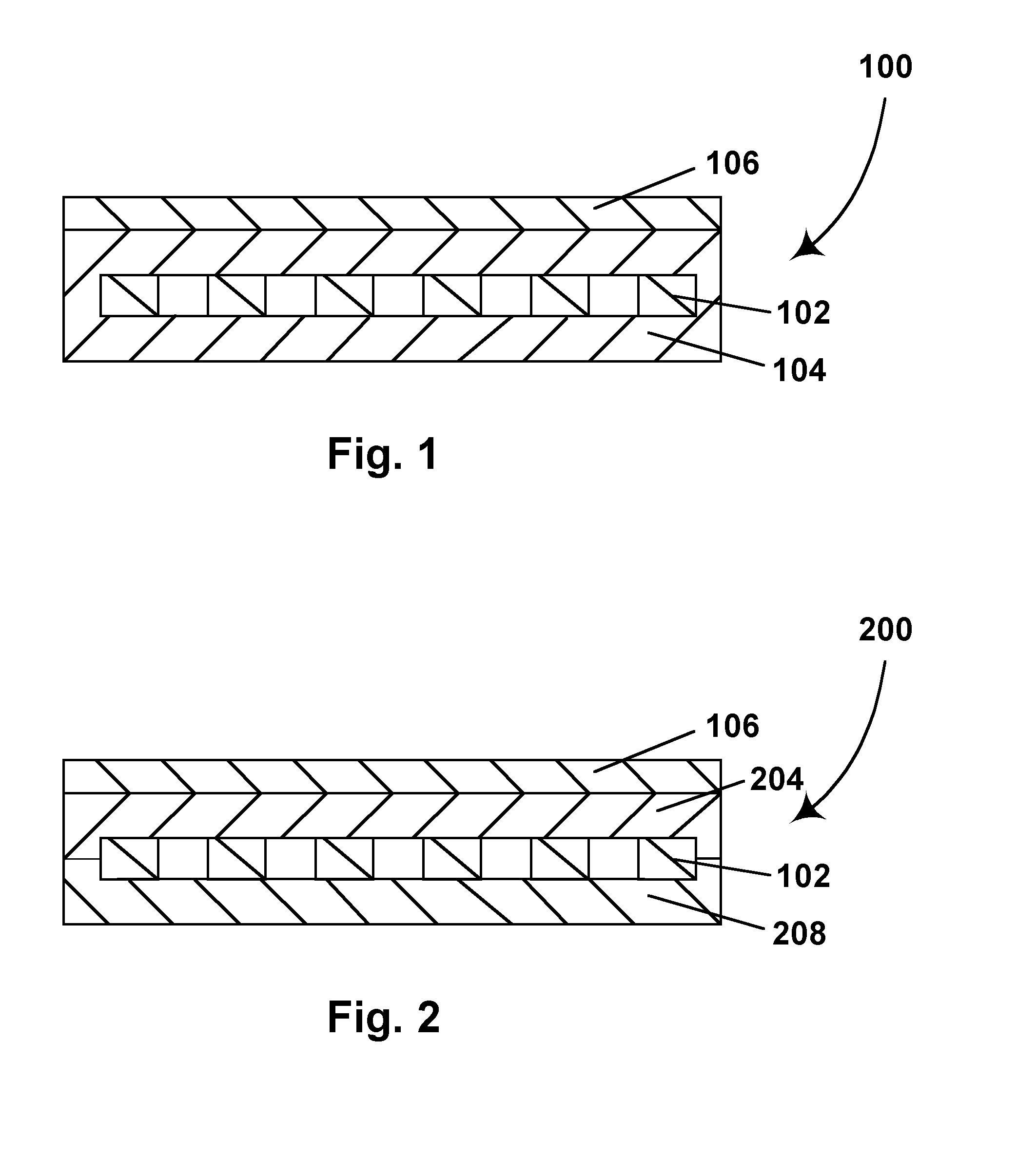

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

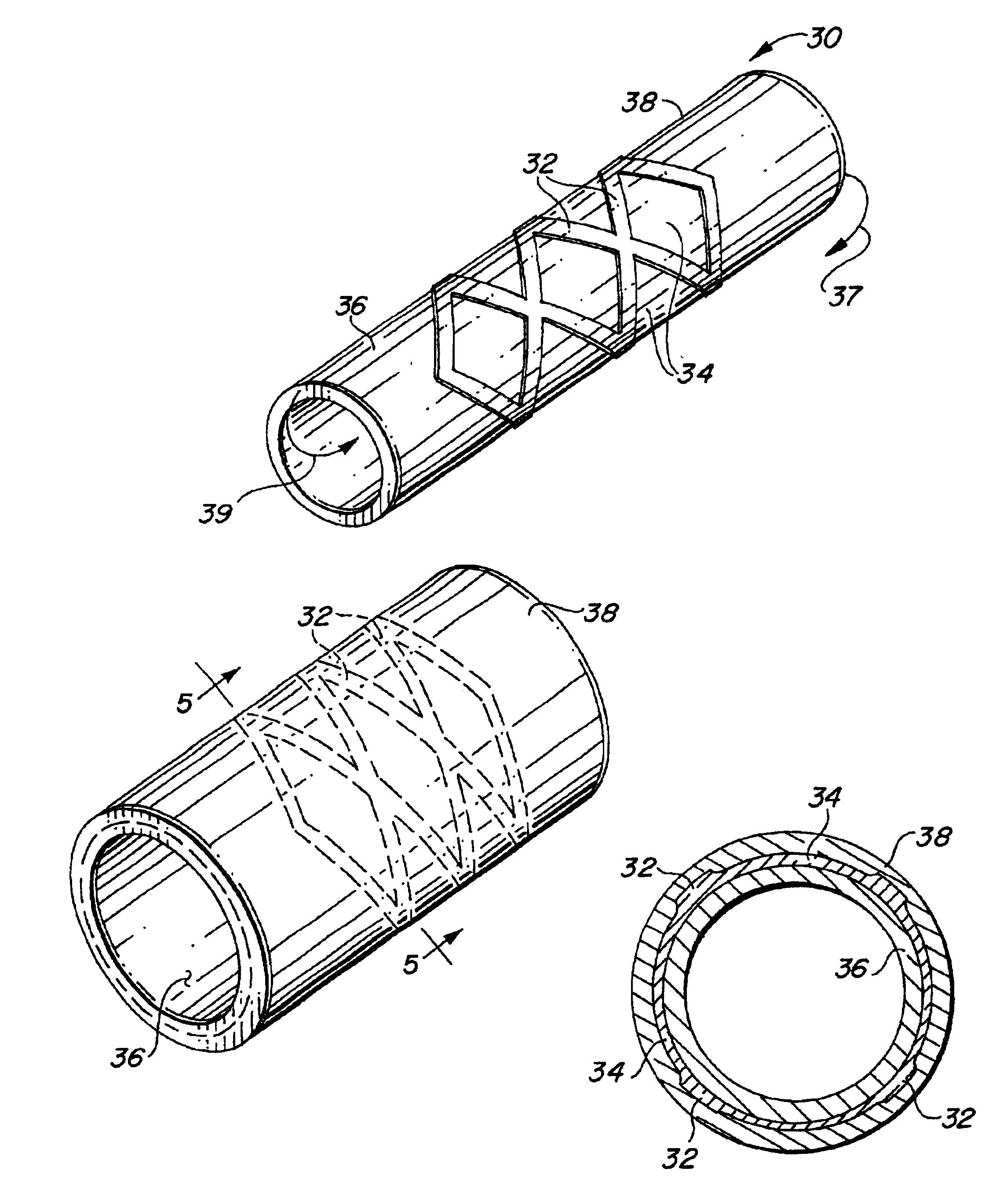

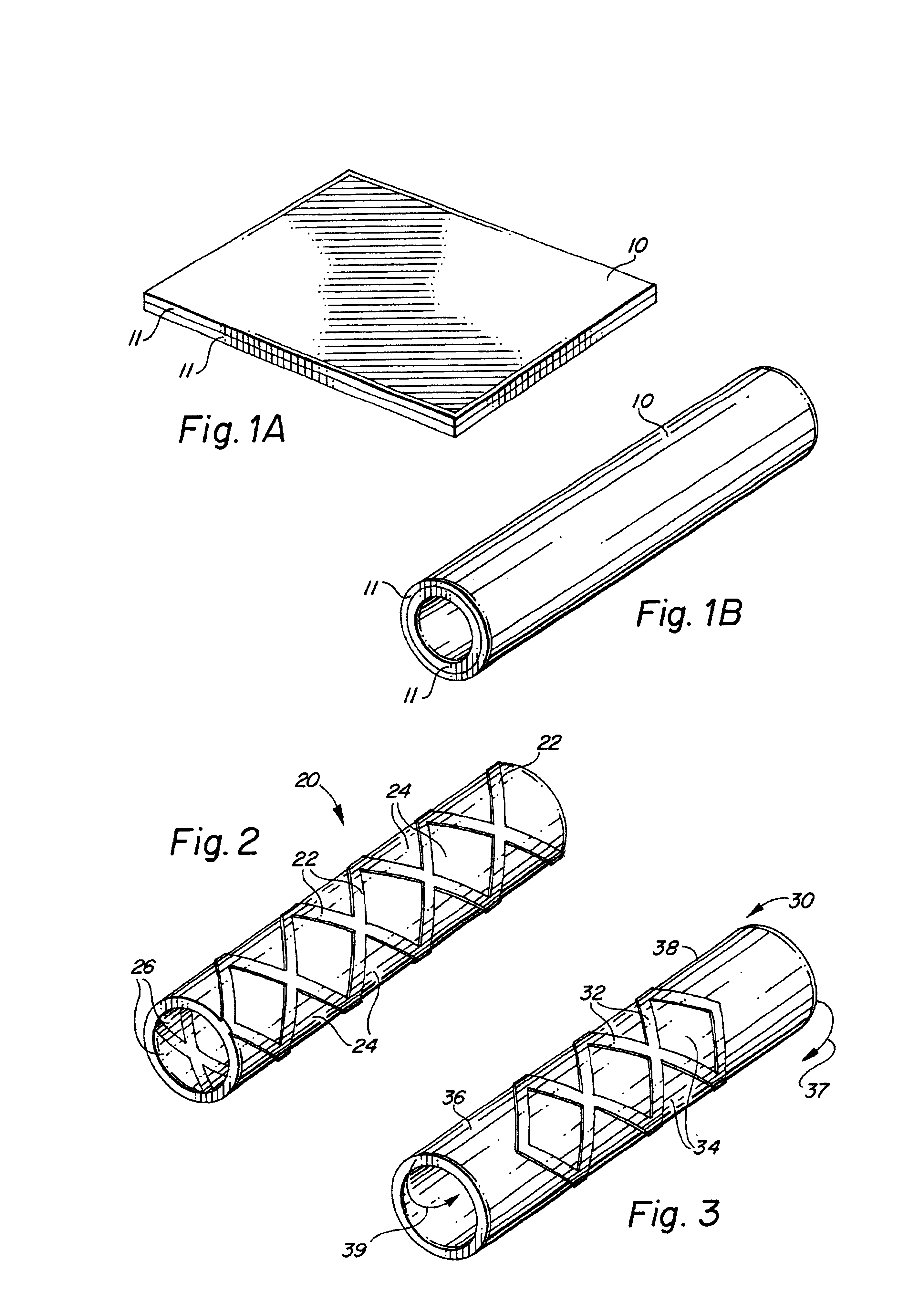

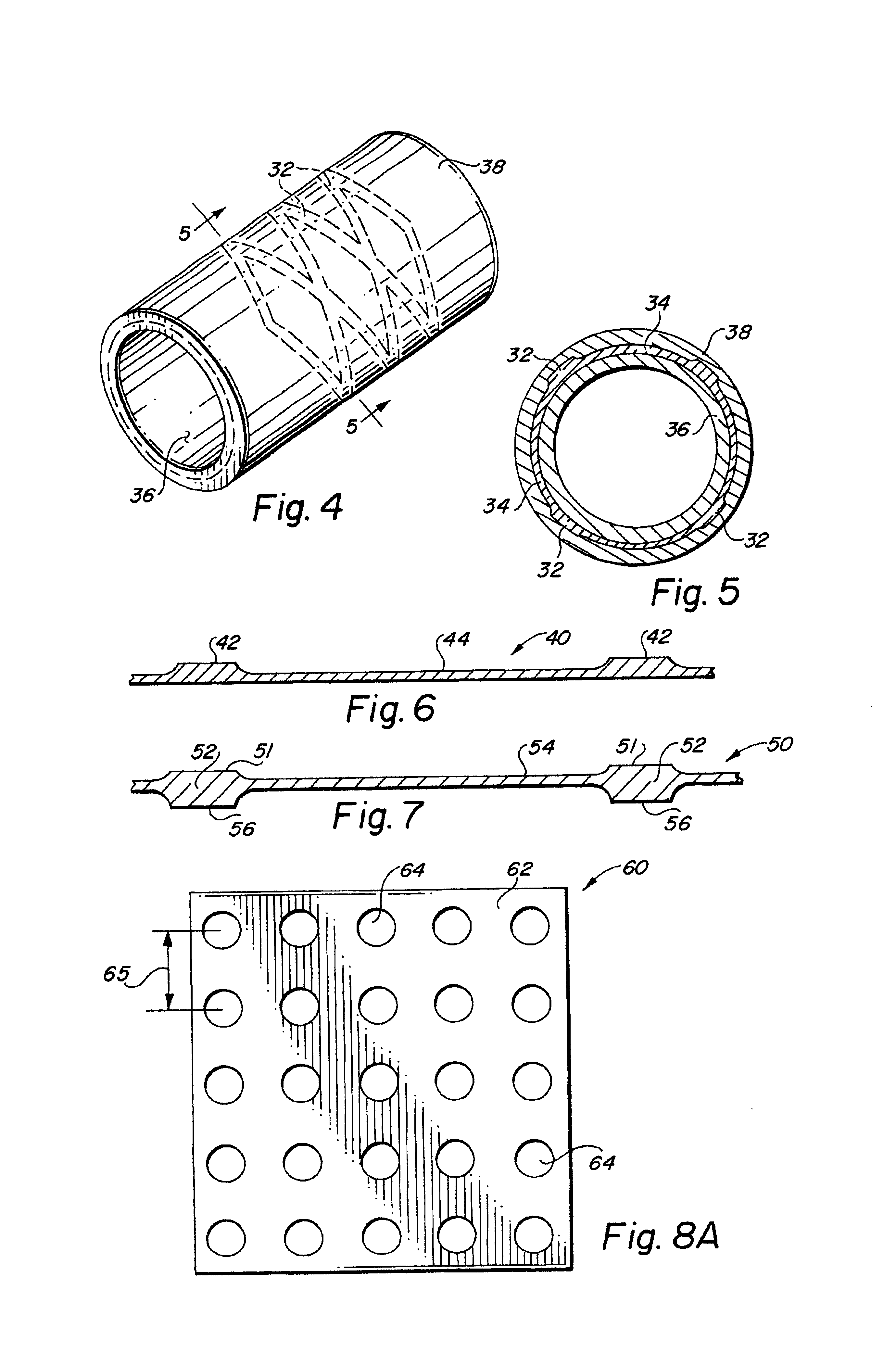

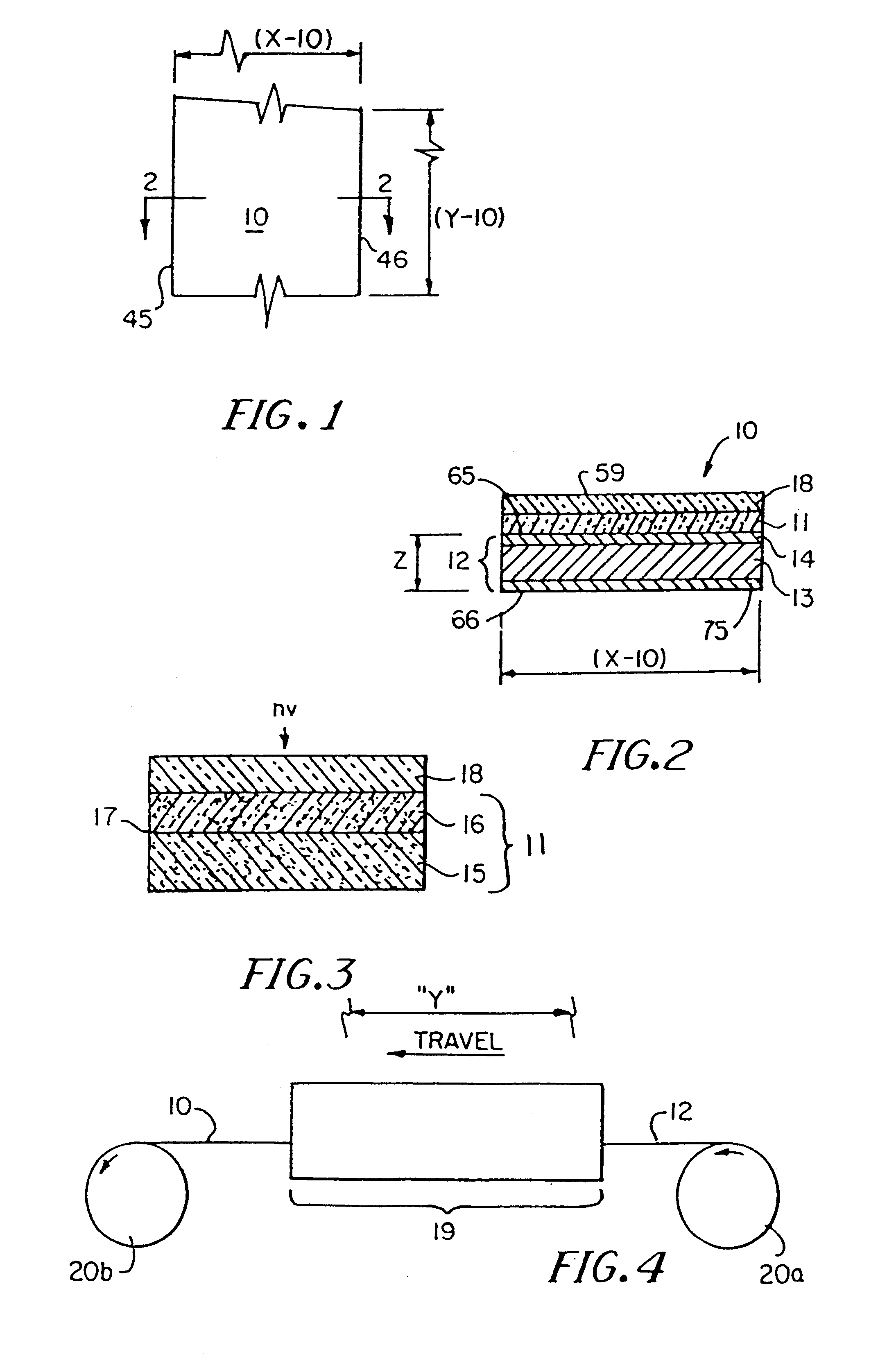

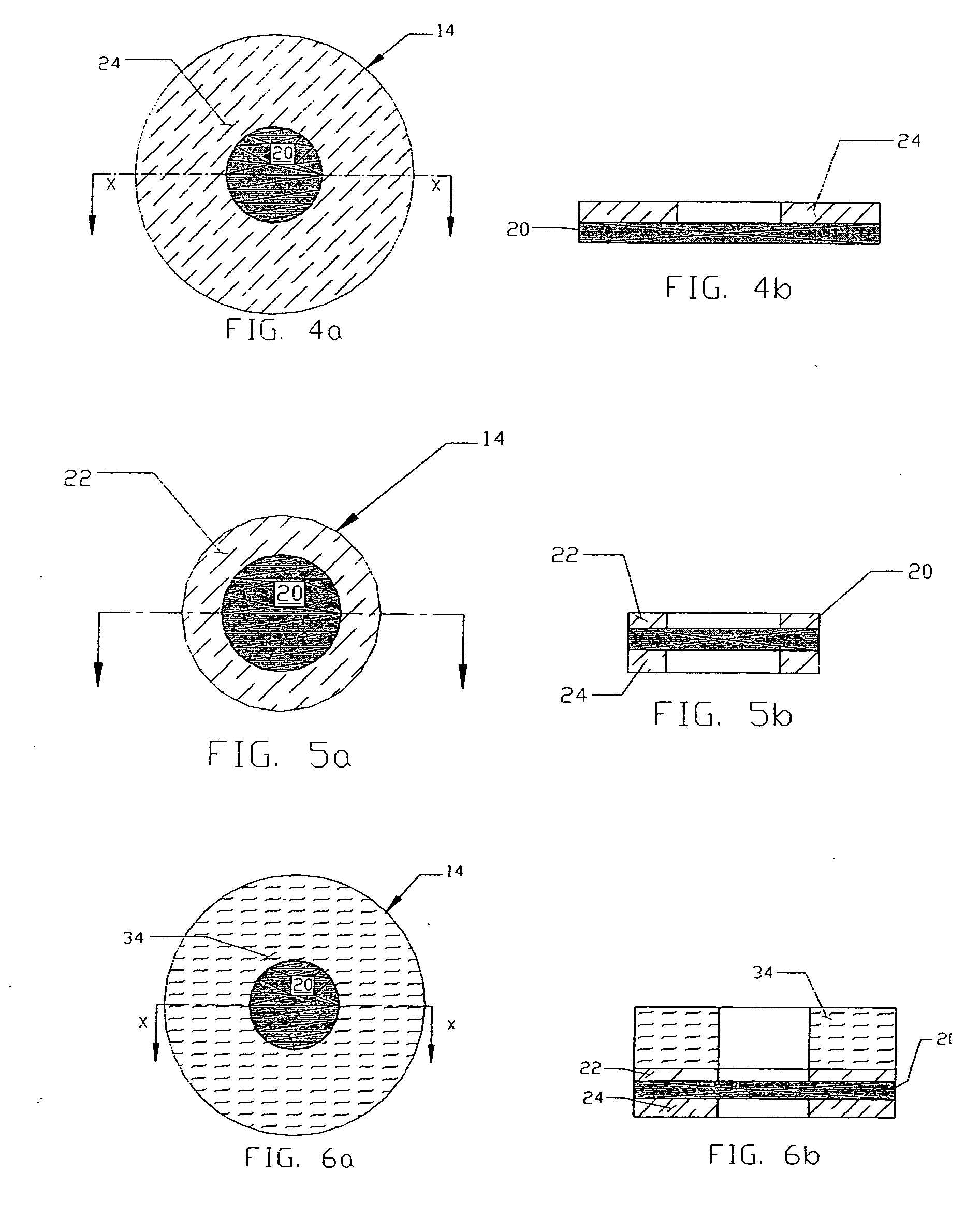

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

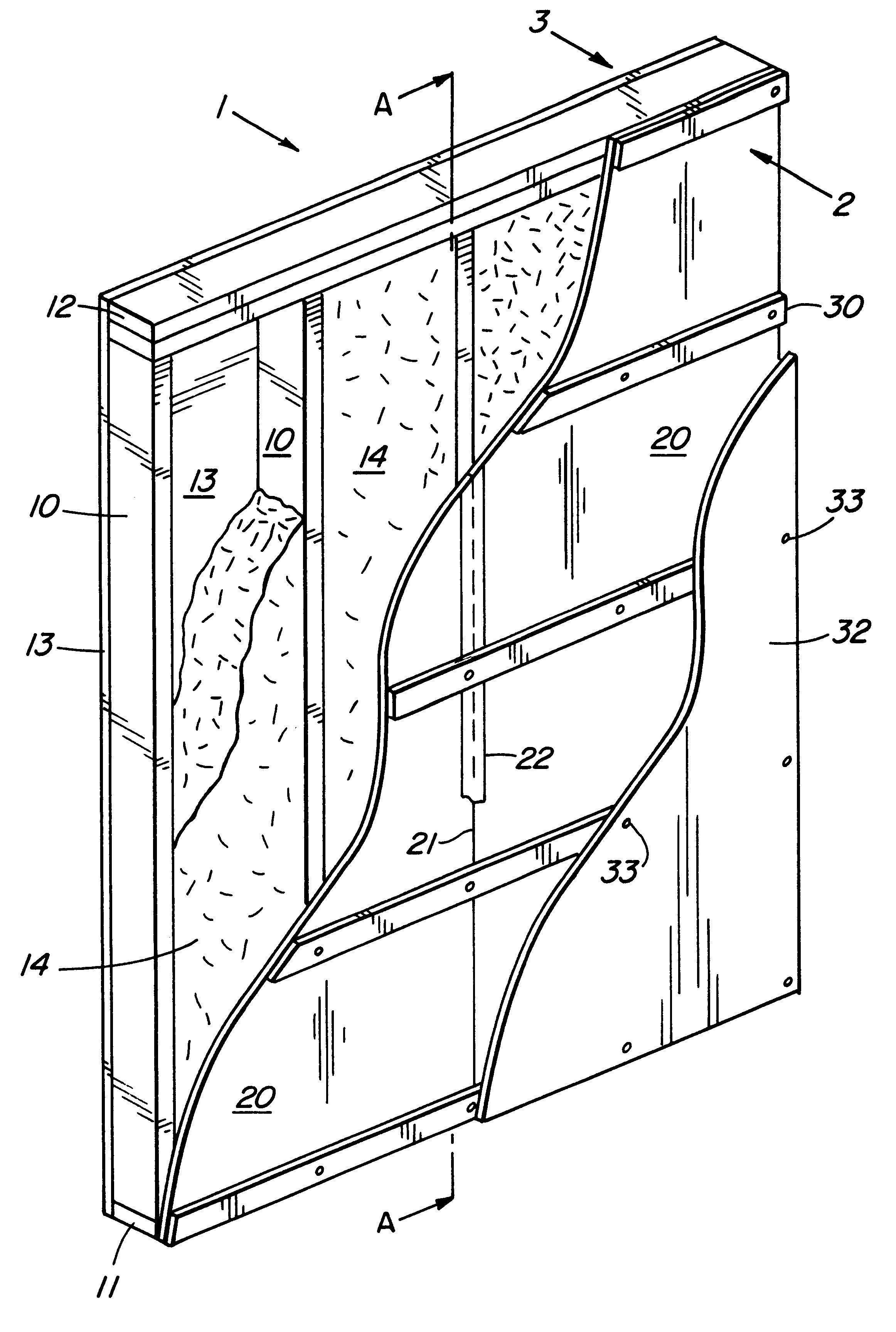

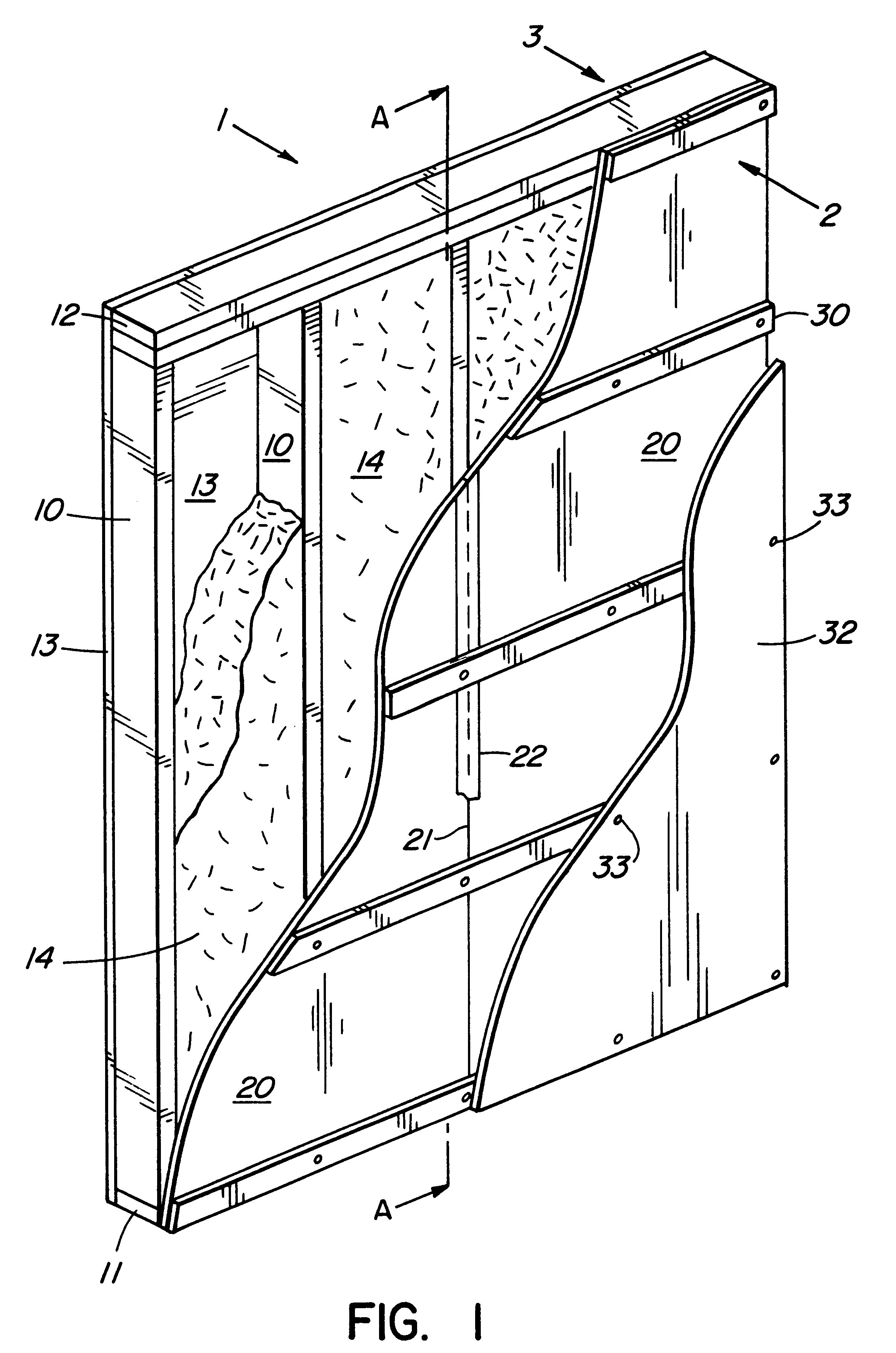

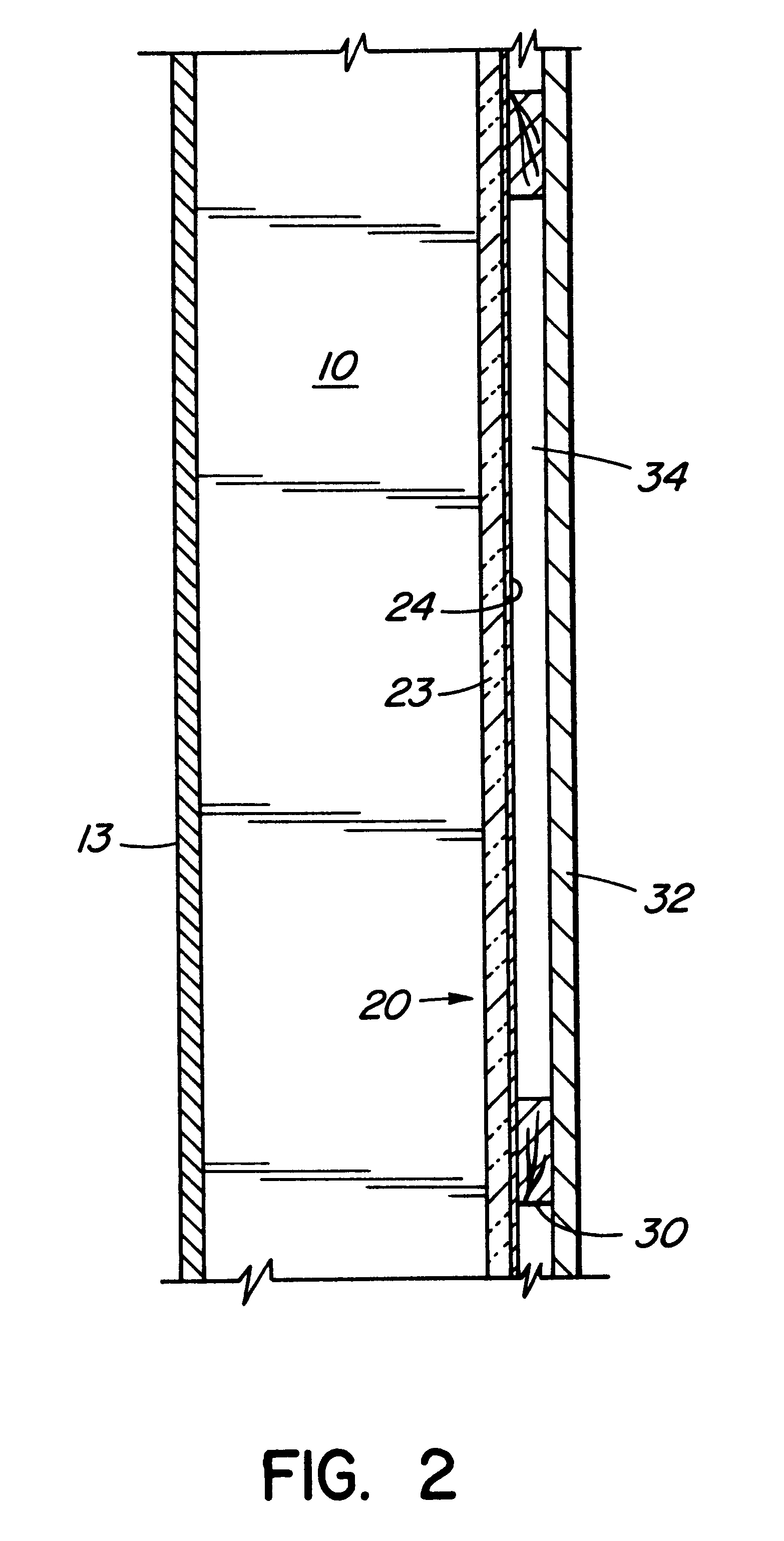

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

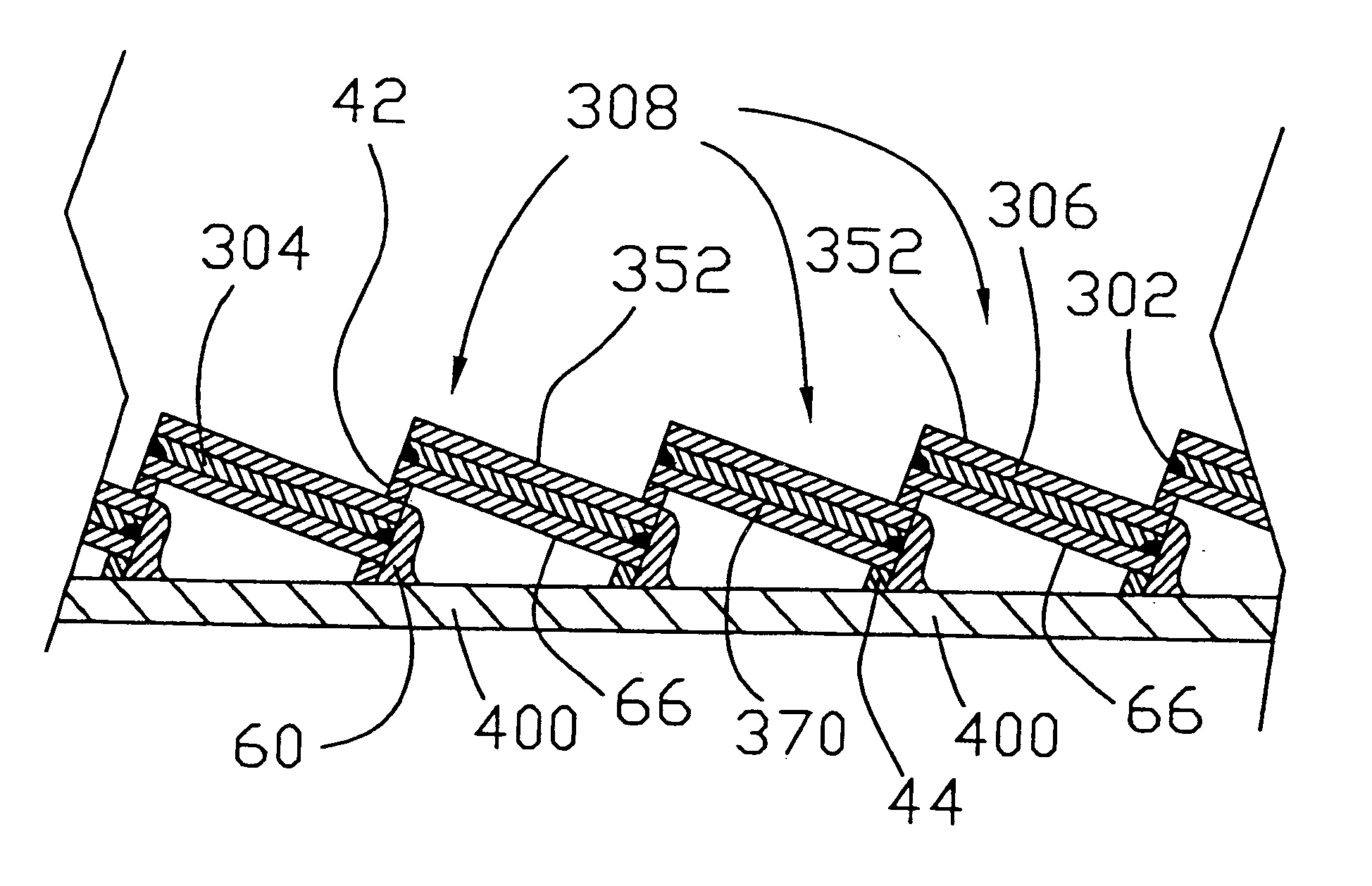

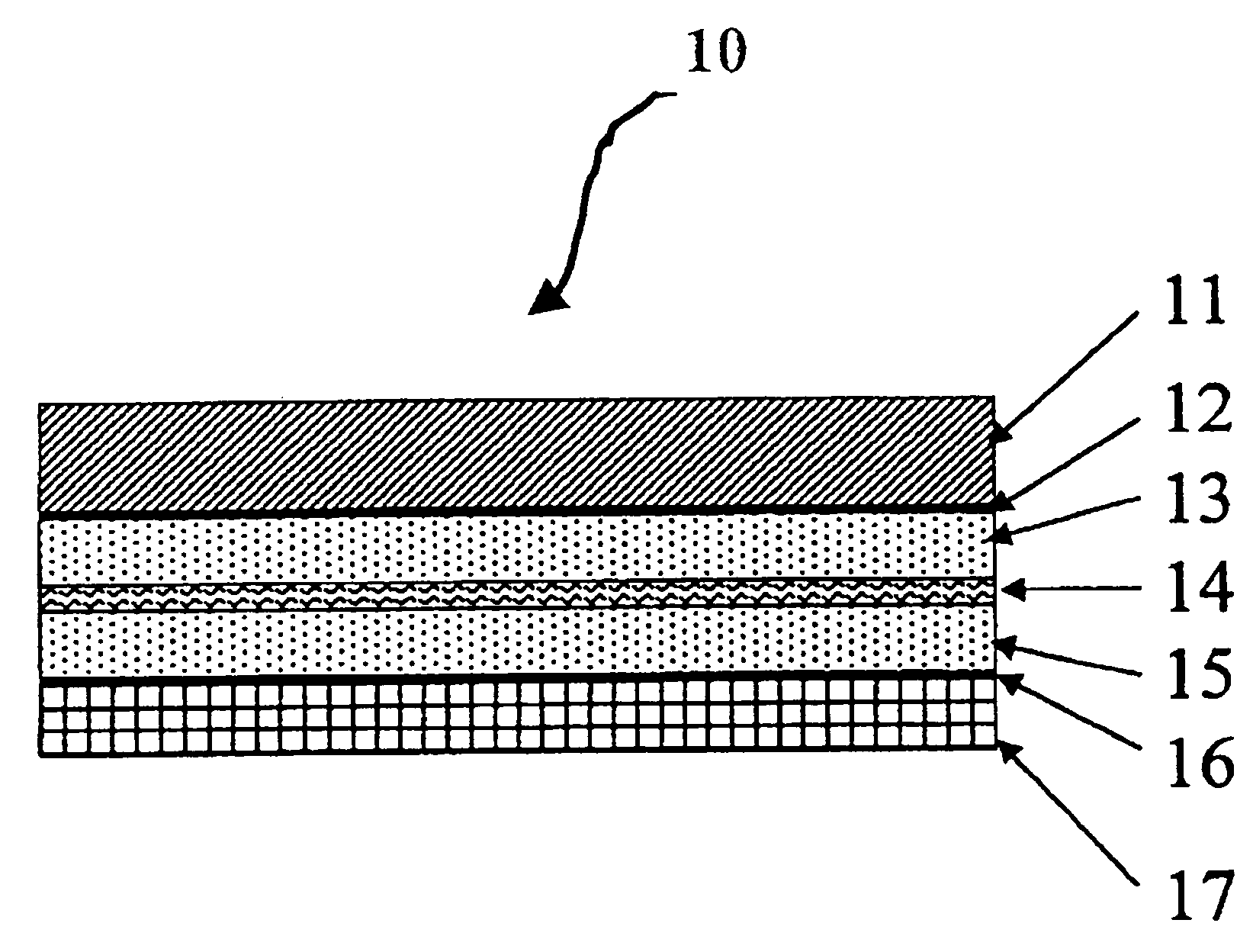

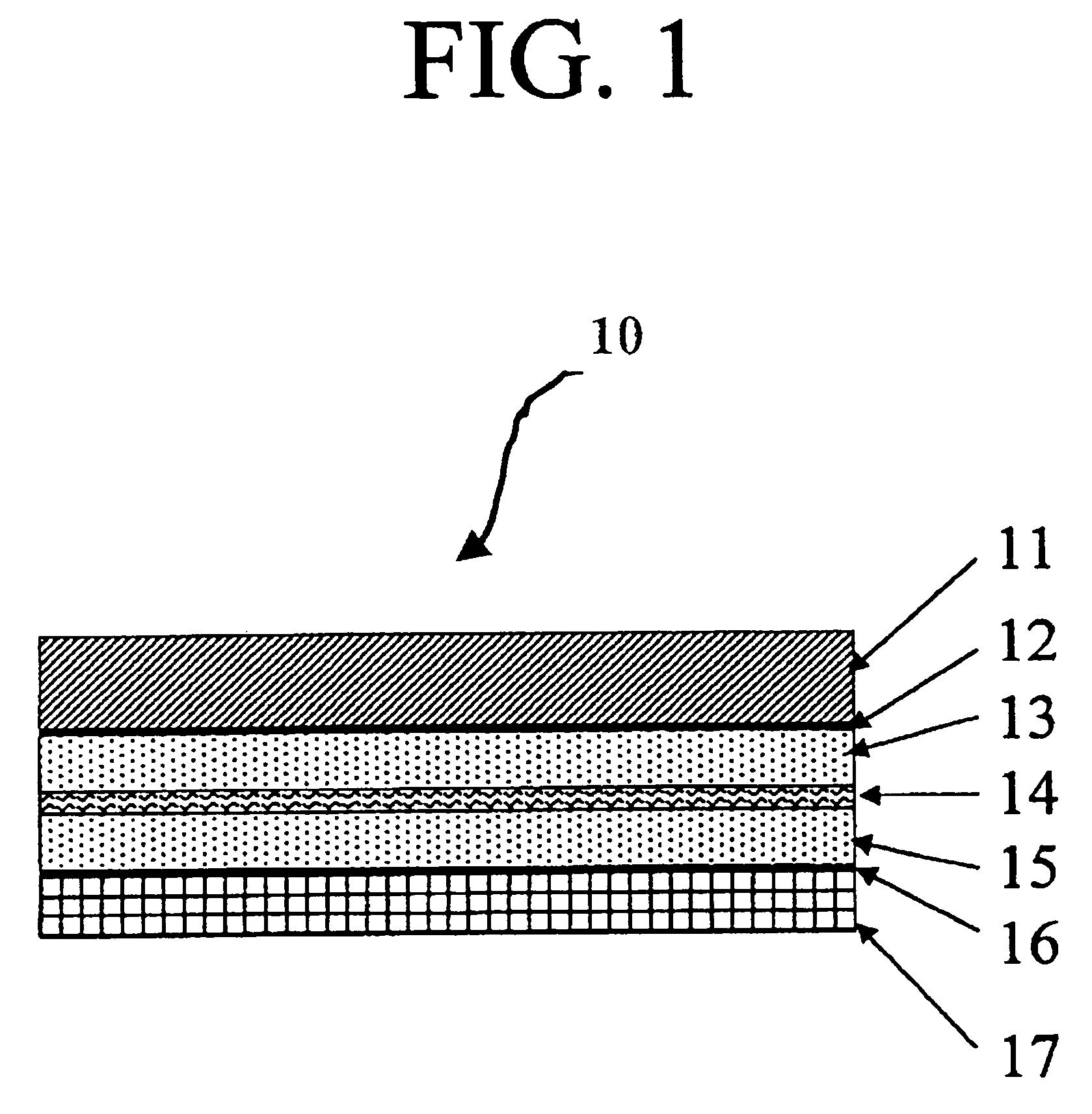

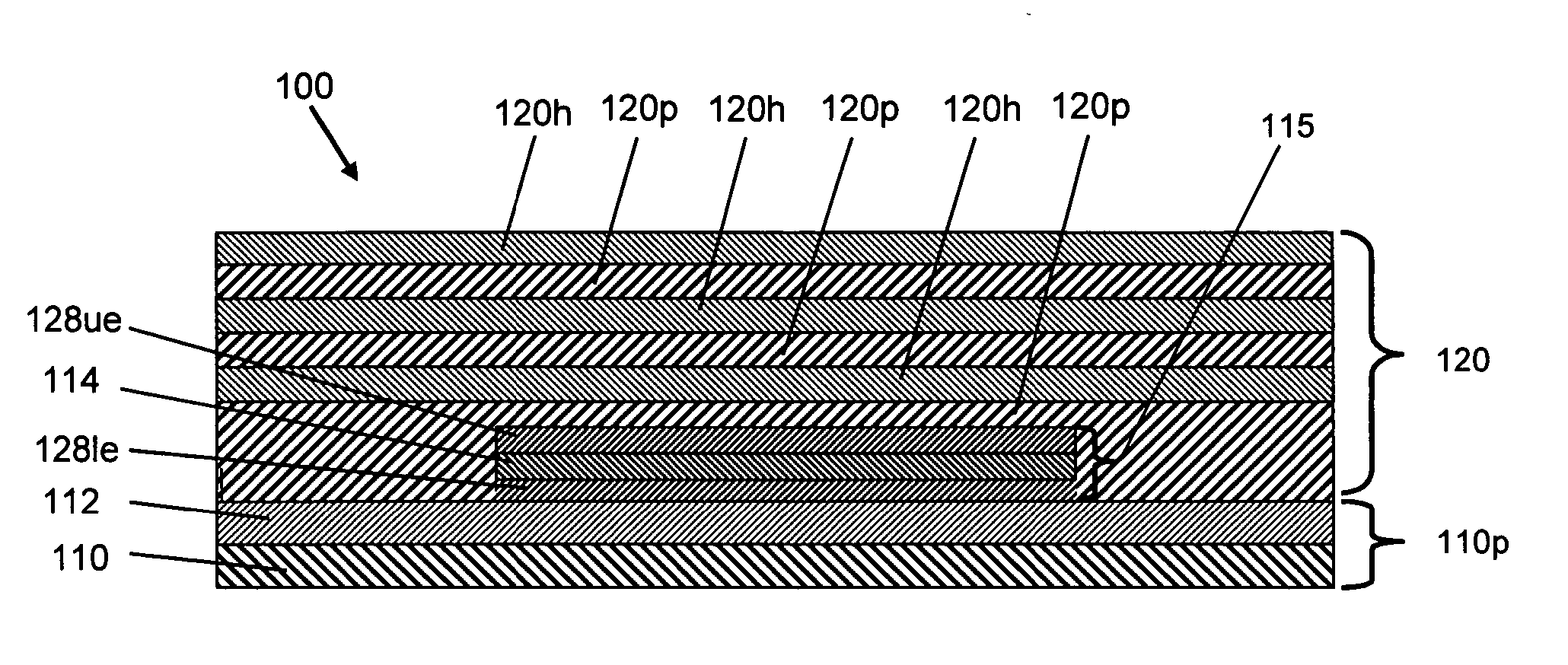

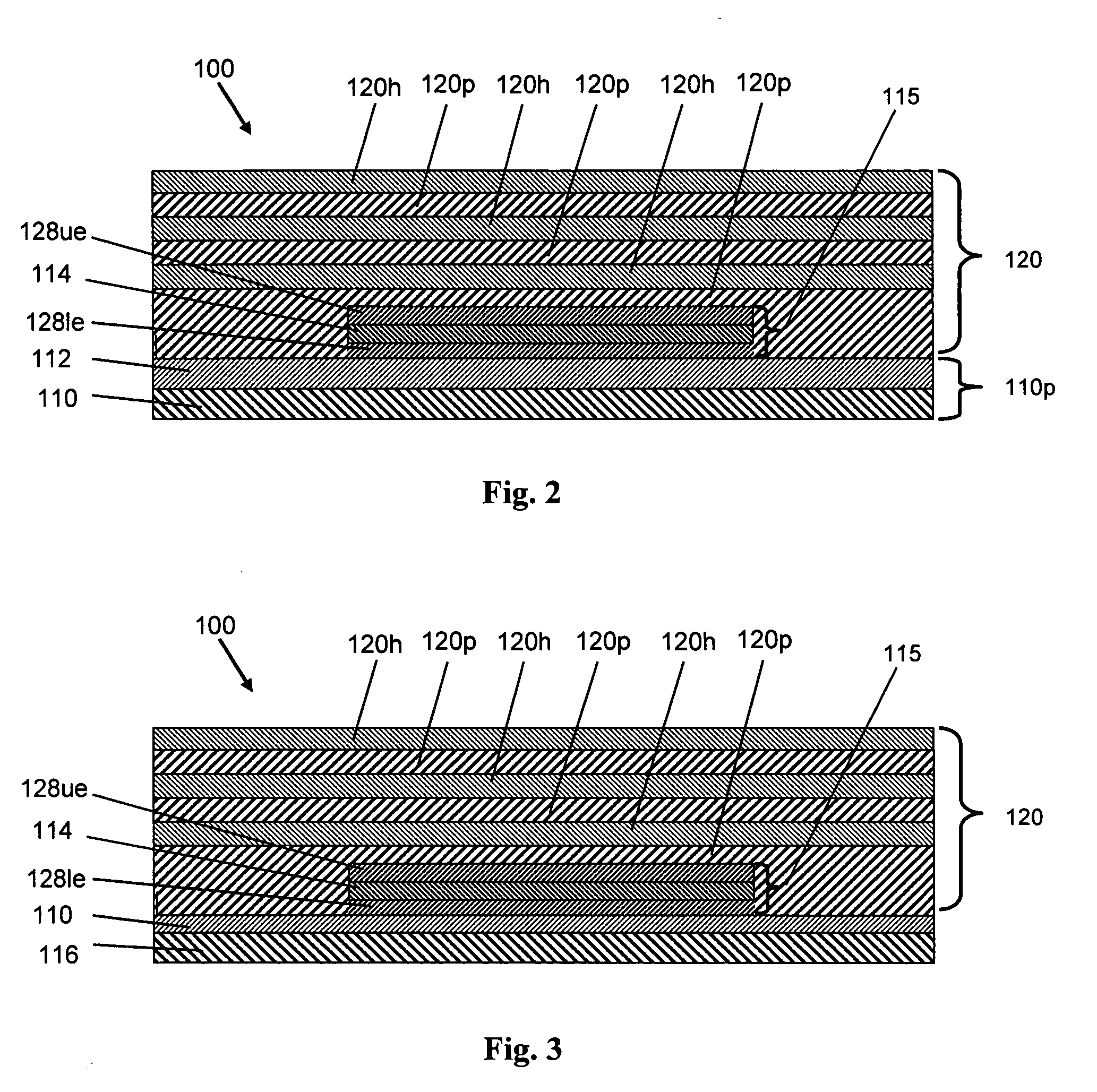

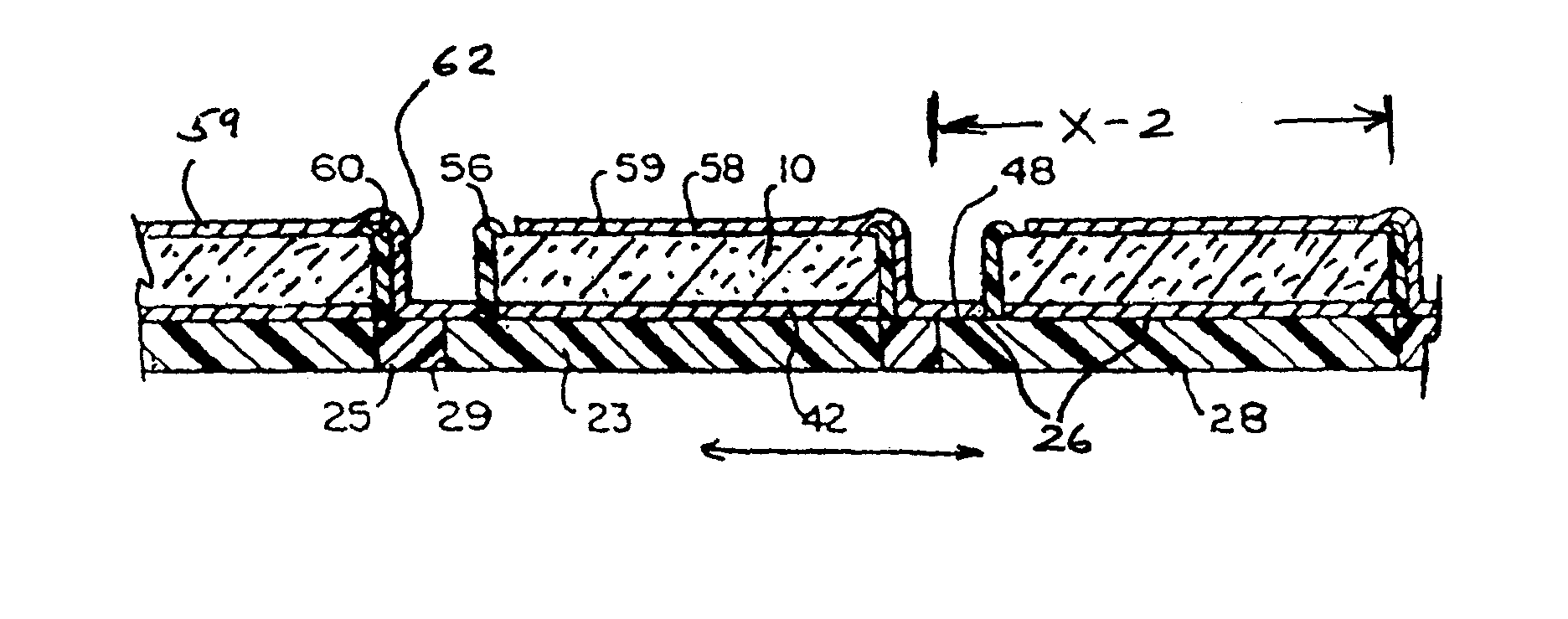

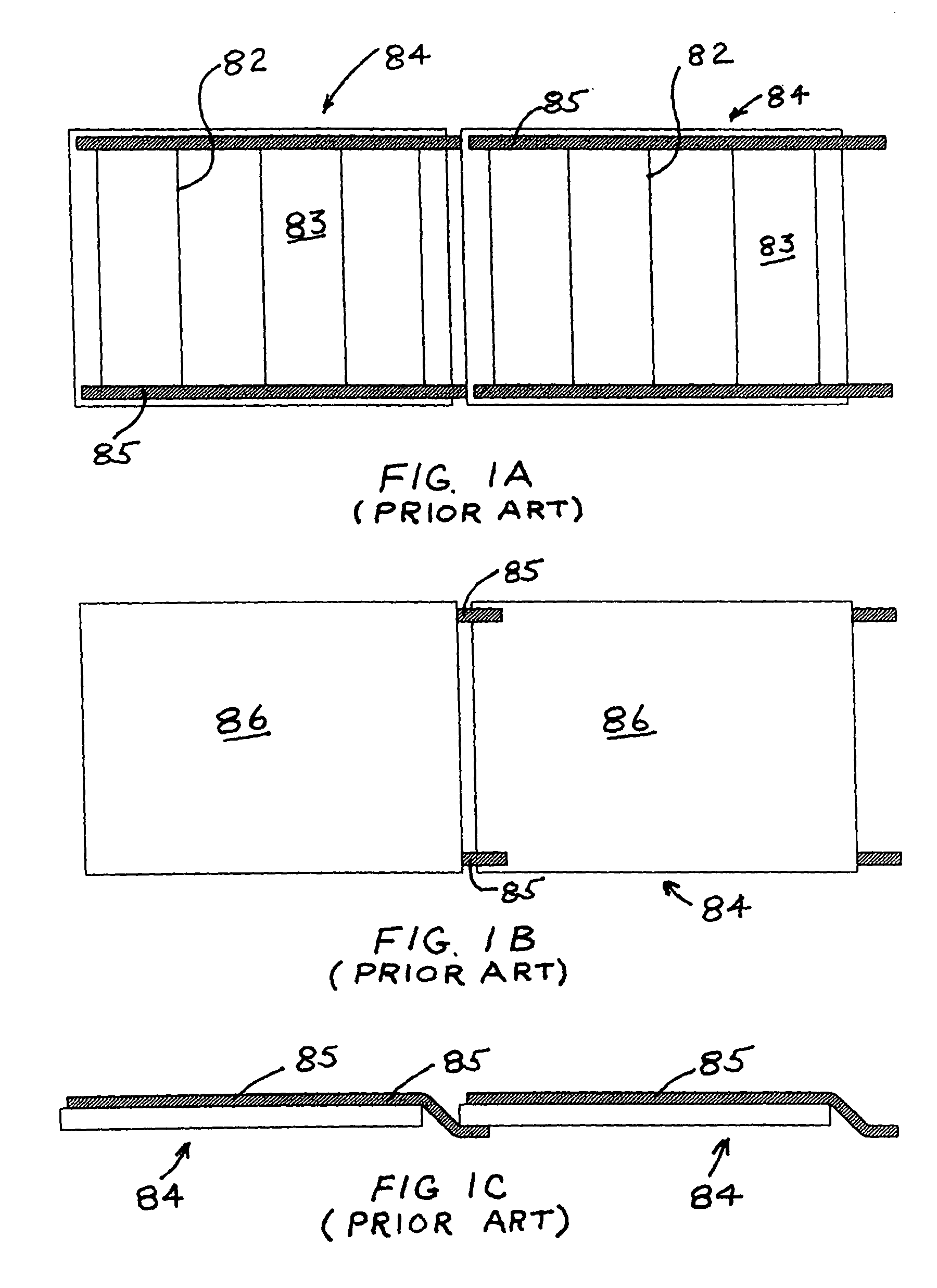

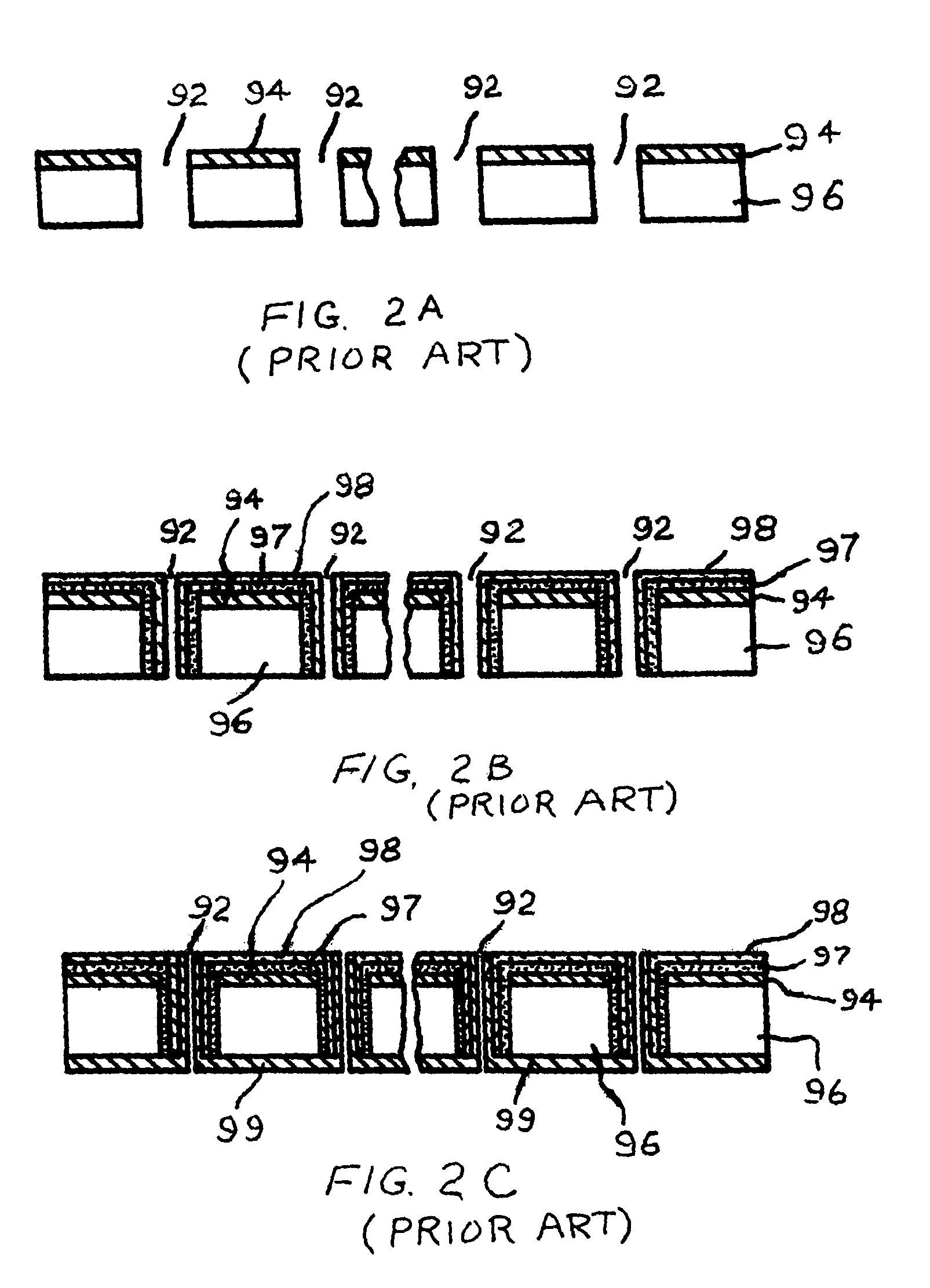

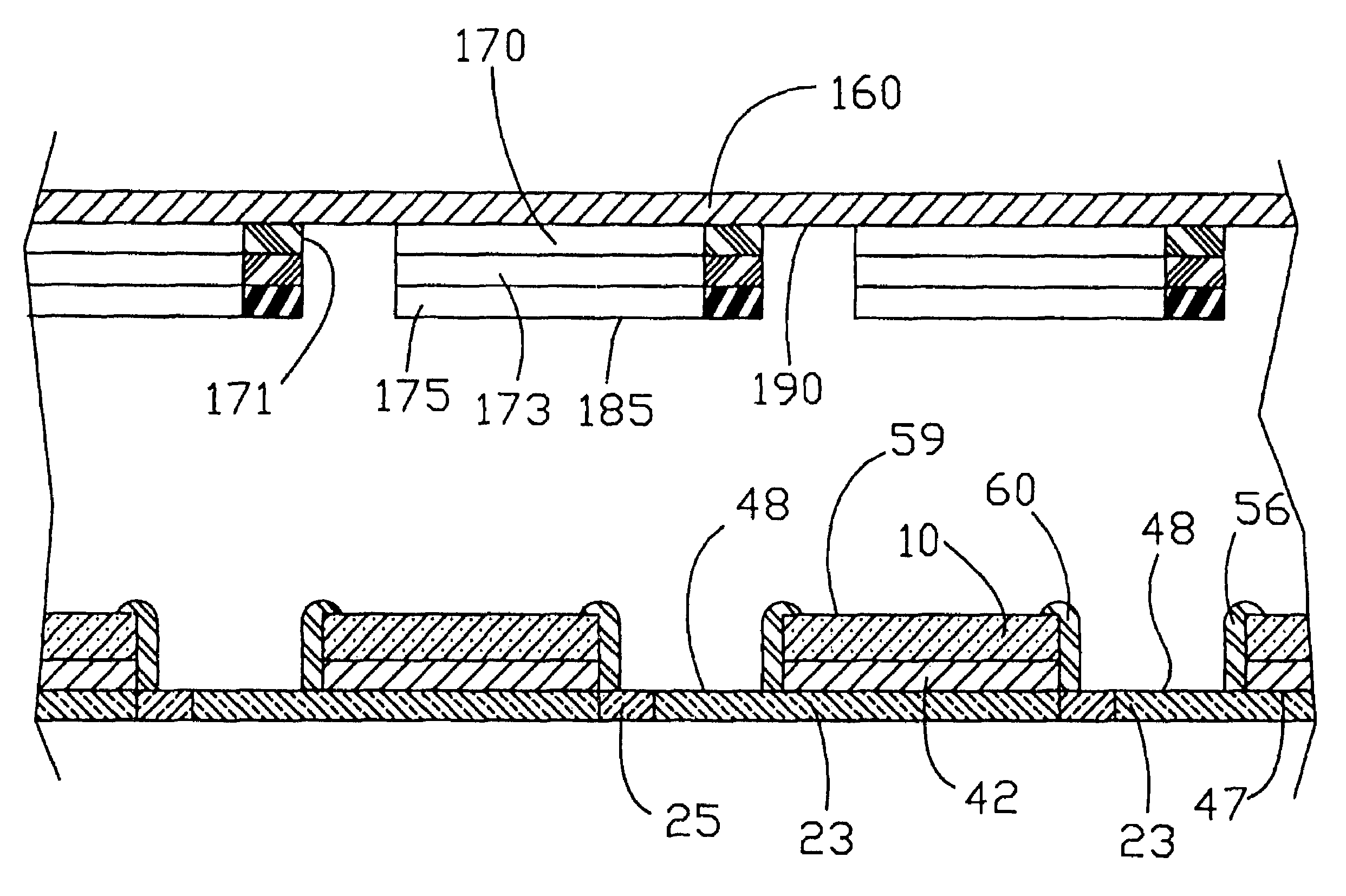

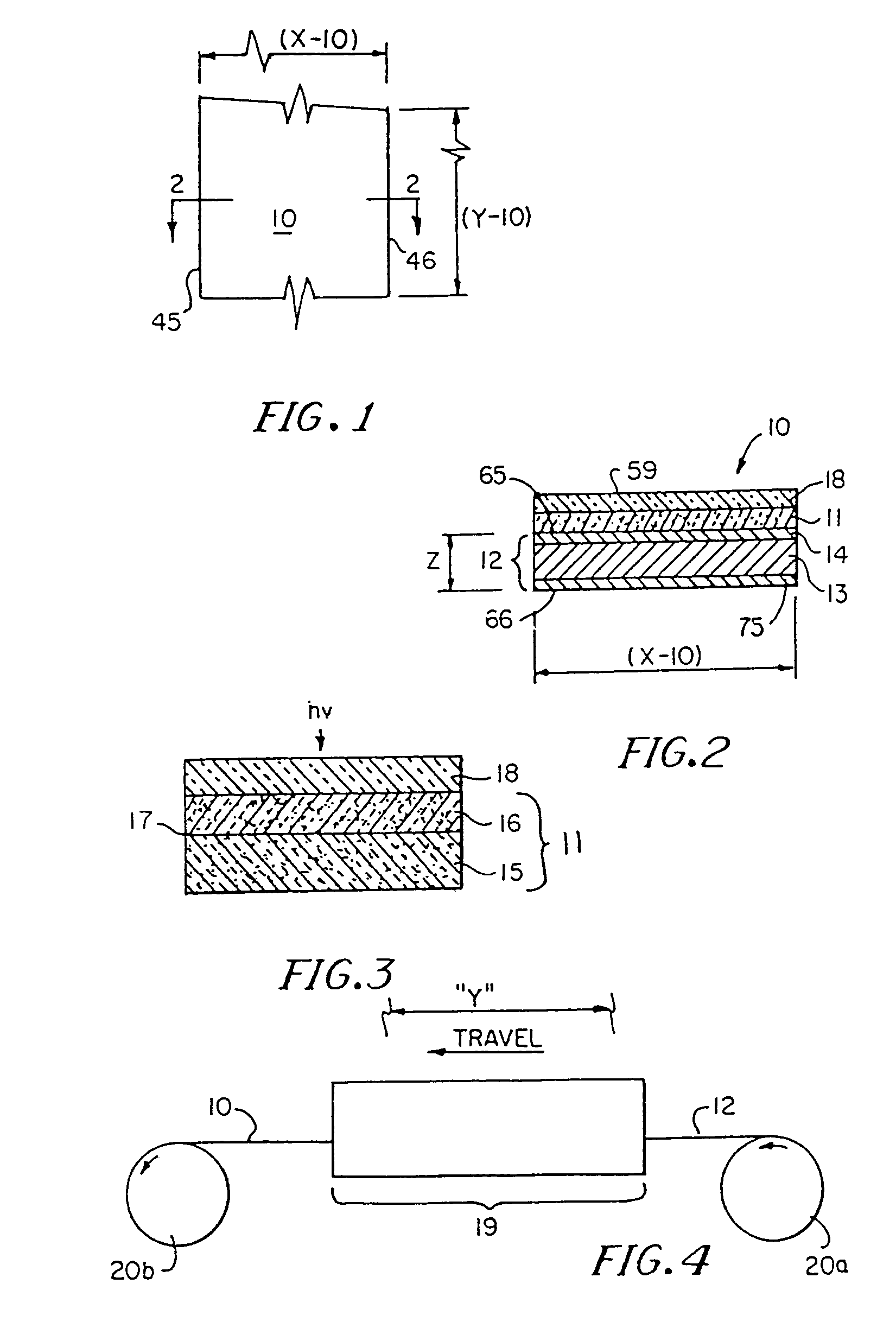

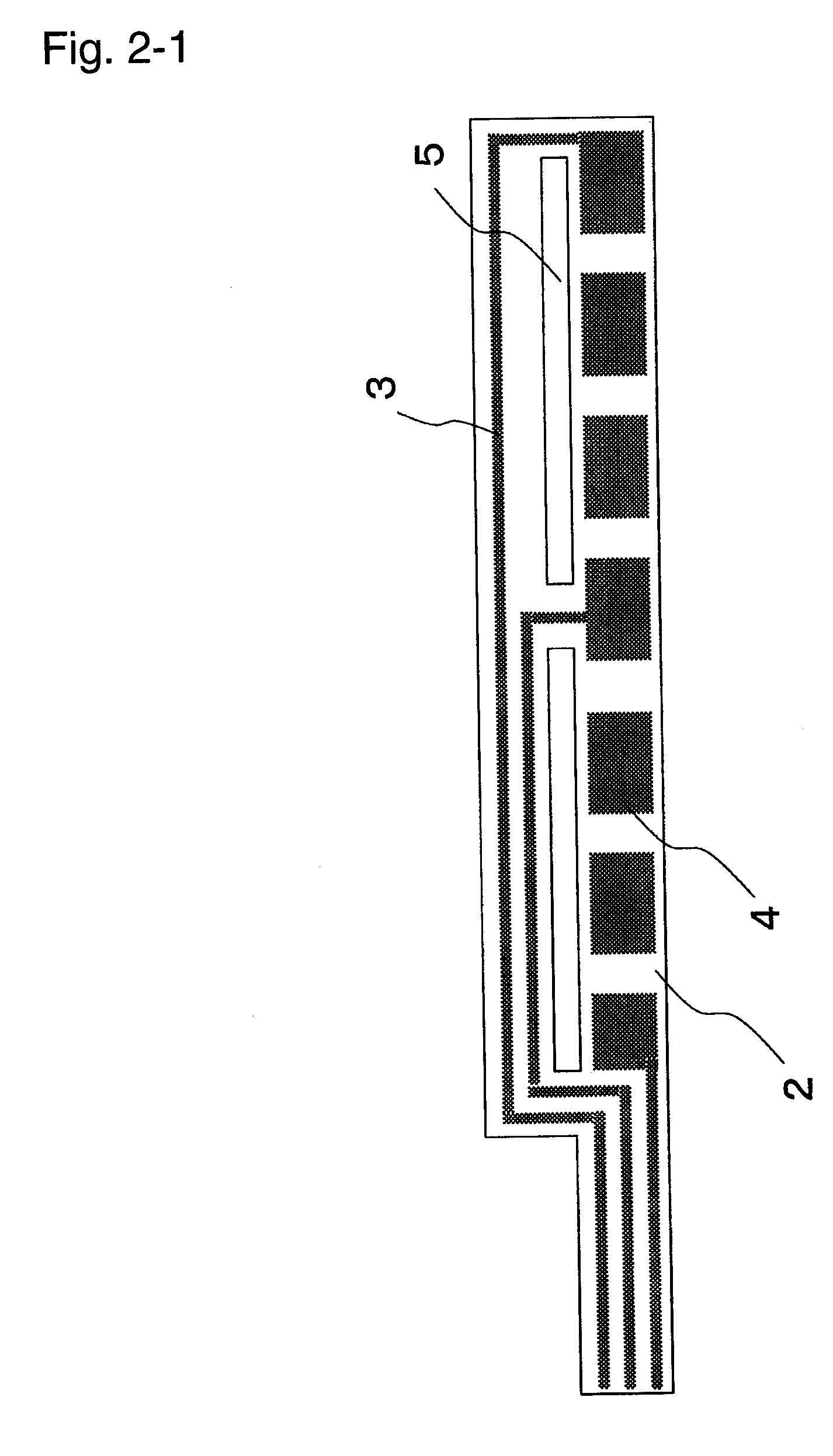

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS6414235B1Eliminate deficienciesCheap productionPV power plantsElectrode carriers/collectorsRoll-to-roll processingMetal foil

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

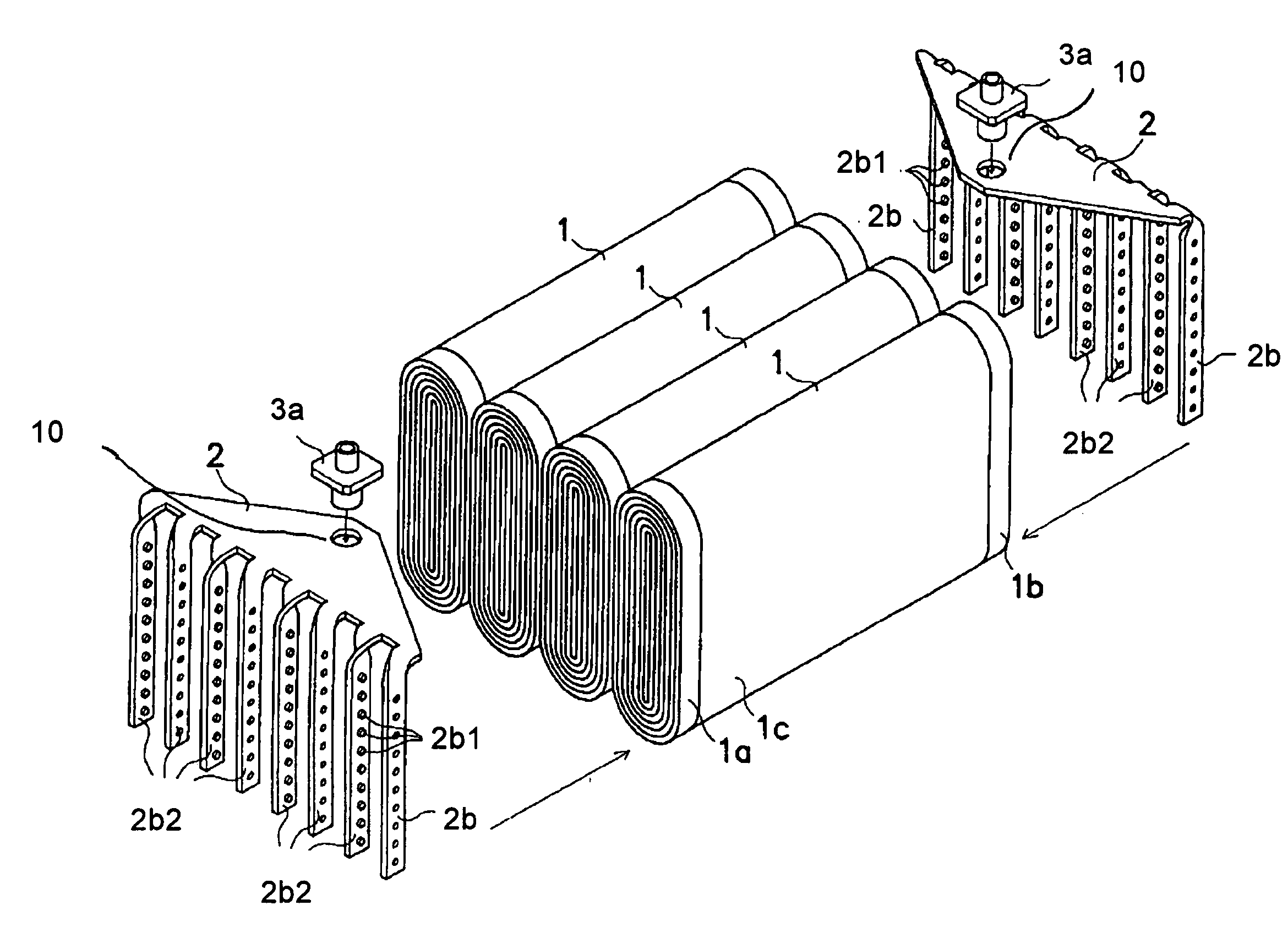

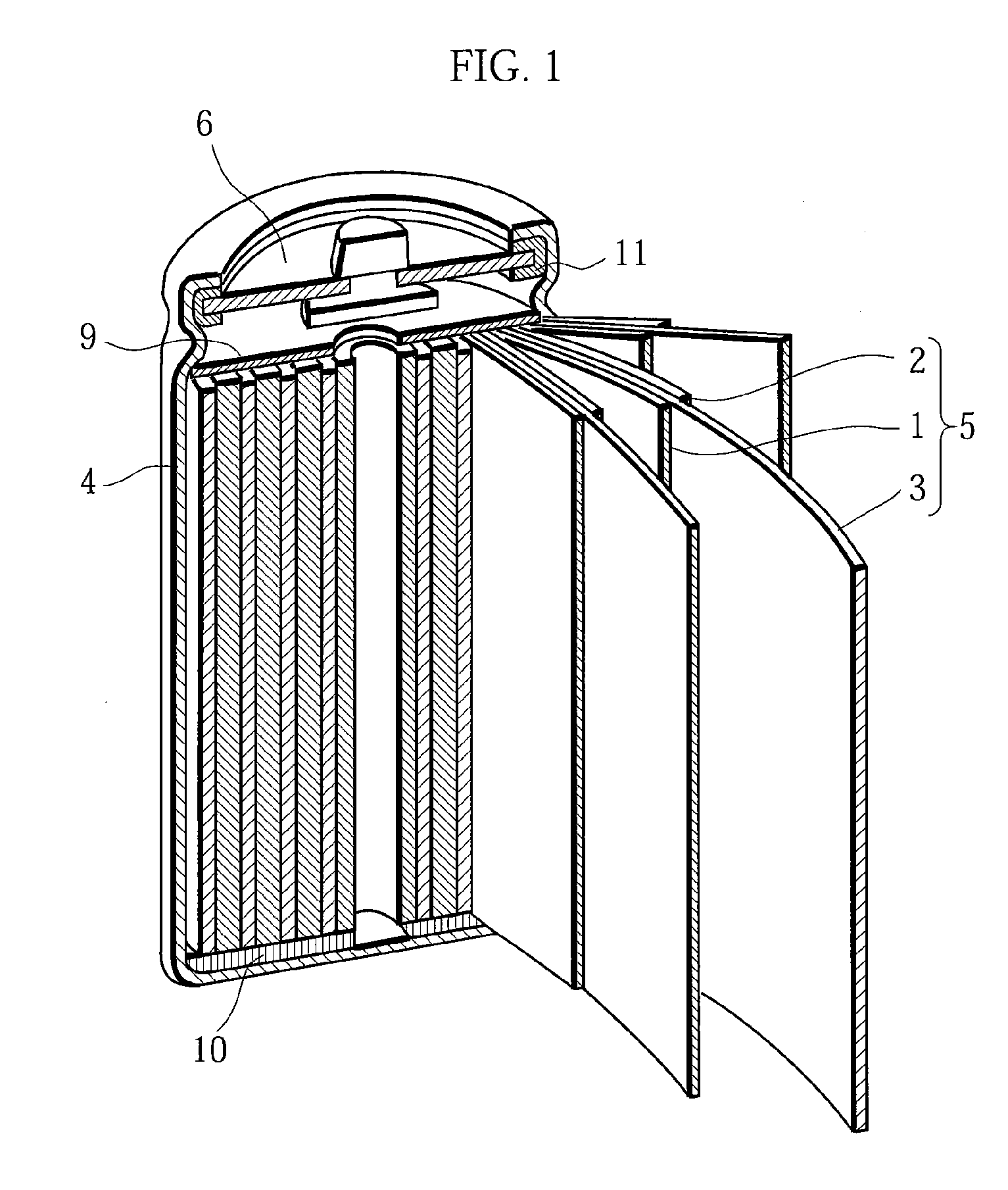

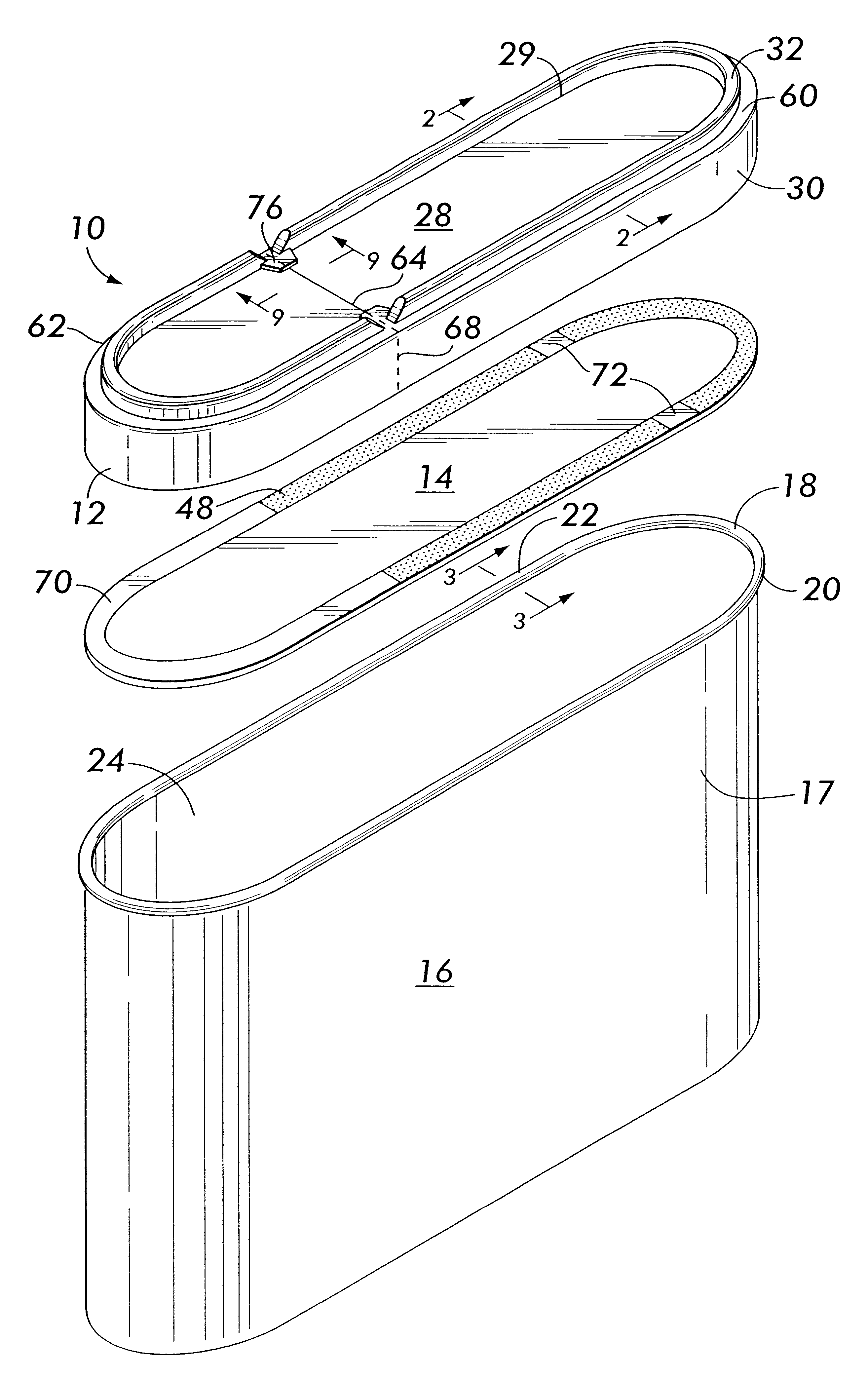

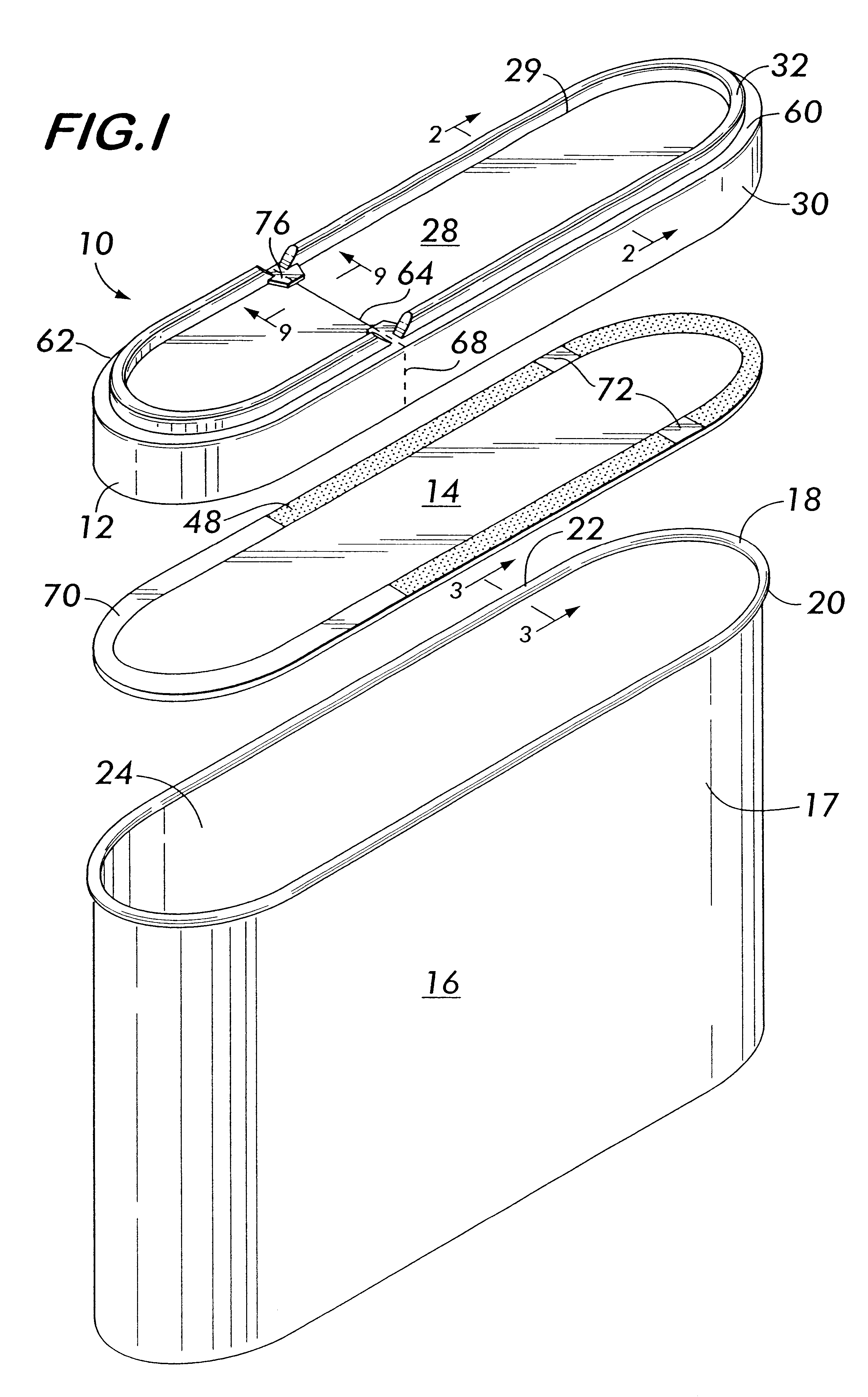

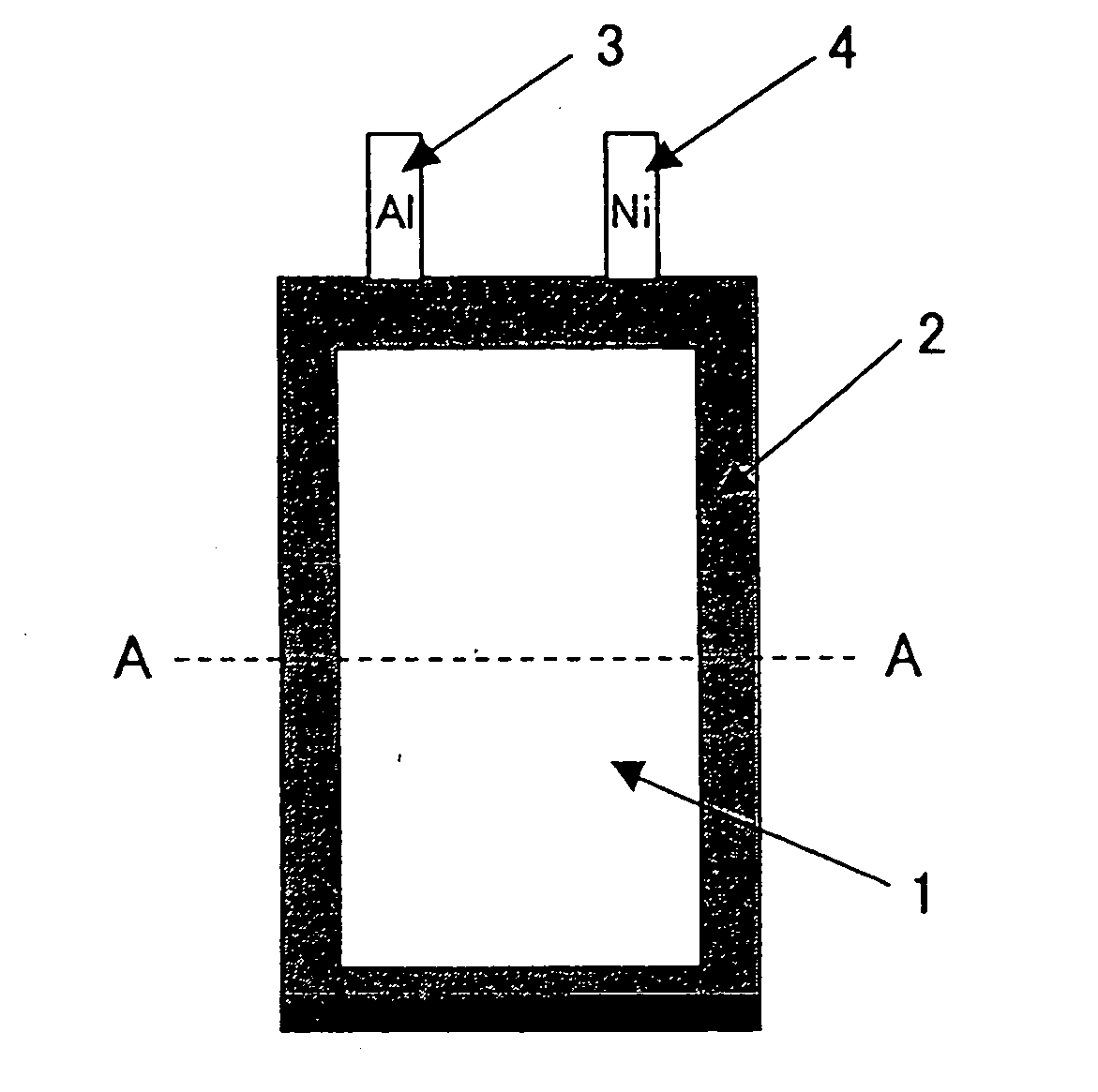

Battery

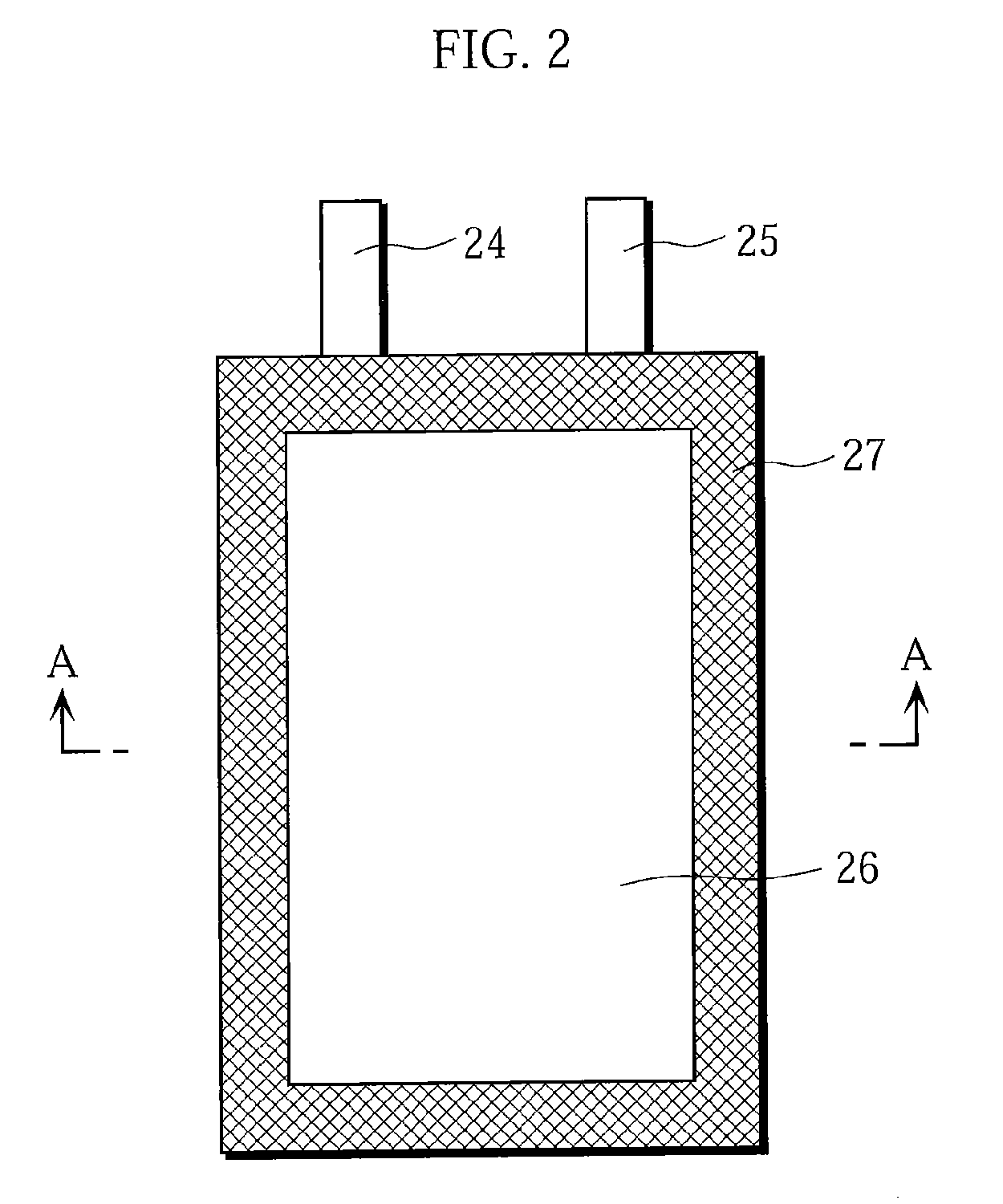

ActiveUS20060051664A1Simple working processImprove reliabilityFinal product manufactureActive material electrodesMetal foilEngineering

The metal foil of the positive electrode 1a or the negative electrode 1b in the power generating element 1 is connected along the connecting plate portion 2b which is folded, twisted, and provided in a protruding condition from the main portion 2a of the current-collector connector 2; hence the shape of the current-collector connector 2 becomes easy to form, and a battery capable of enhancing current collection efficiency, reliability and workability can be provided.

Owner:GS YUASA INT LTD

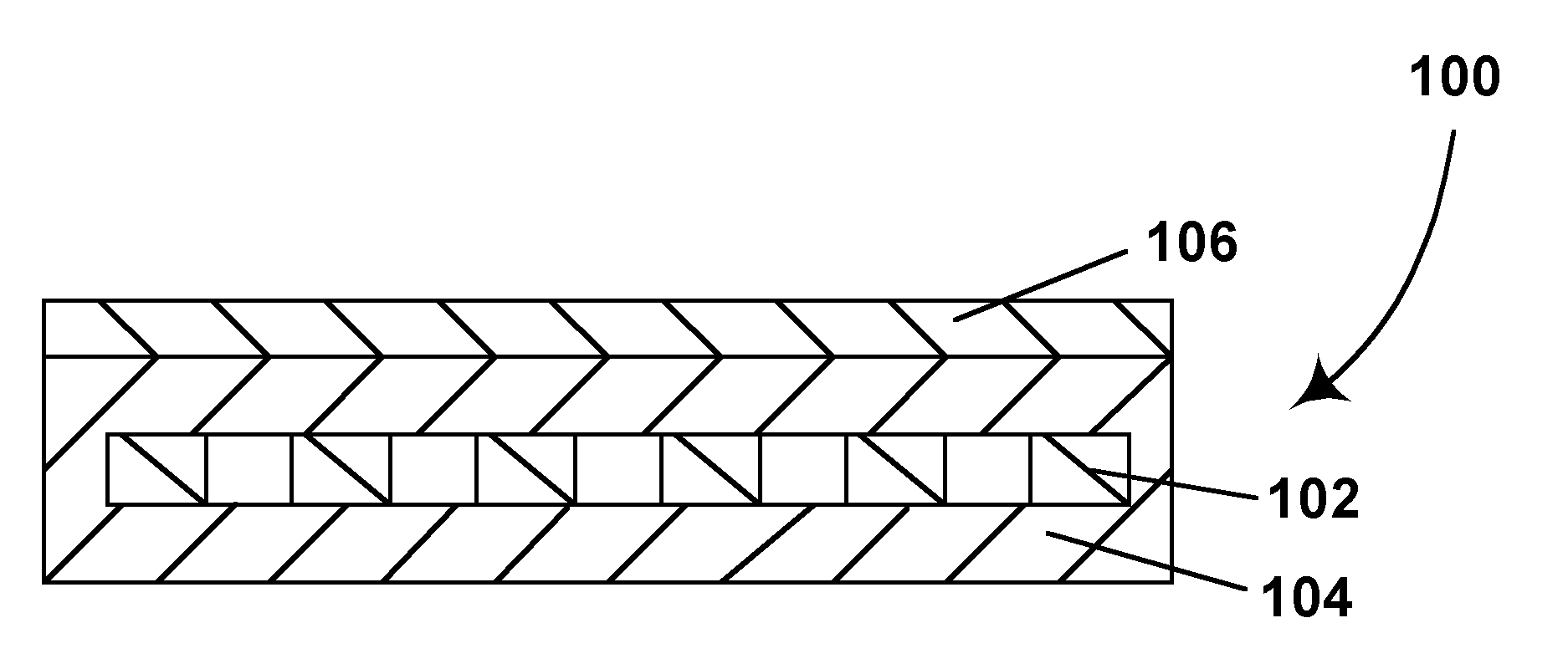

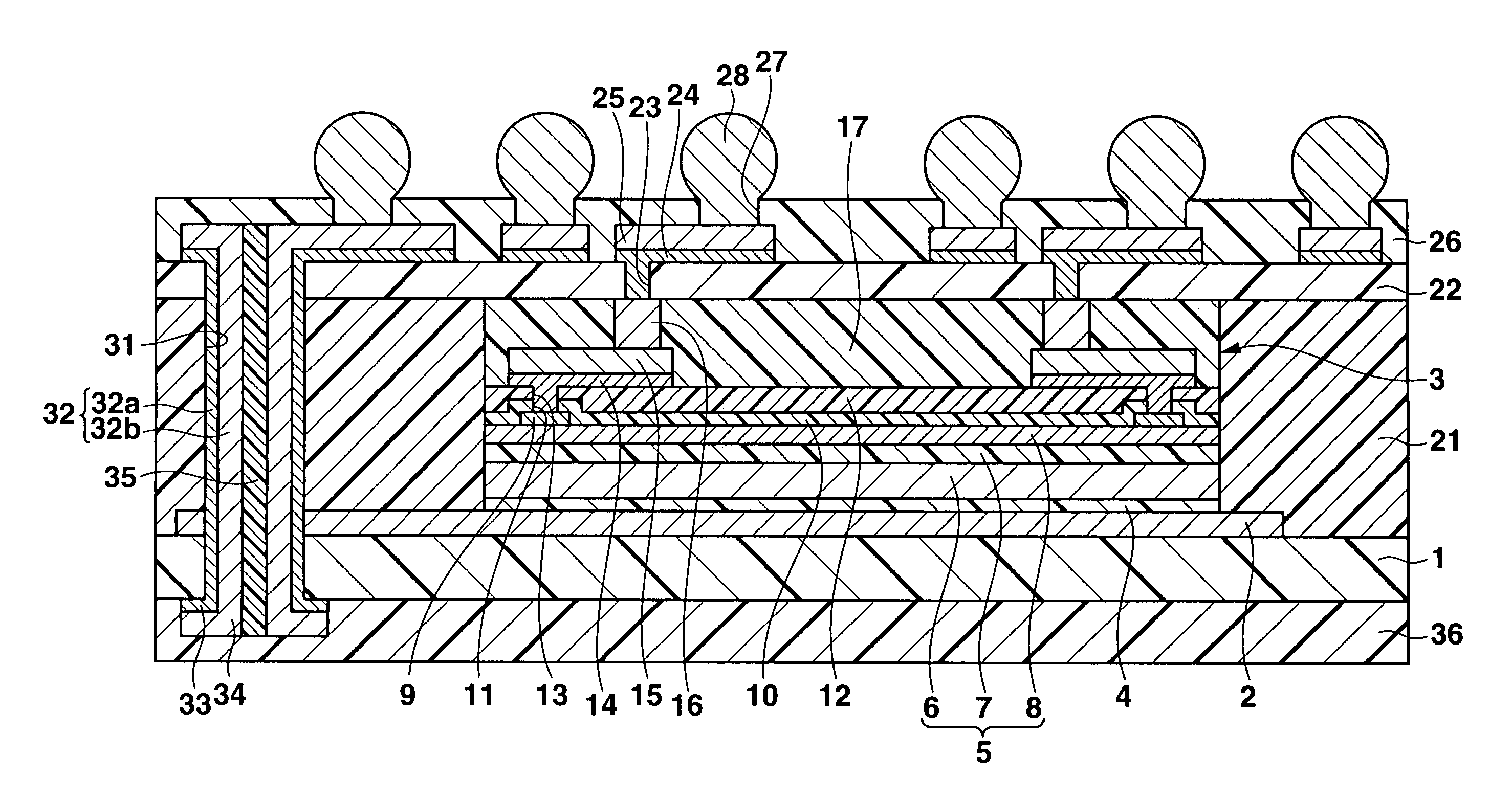

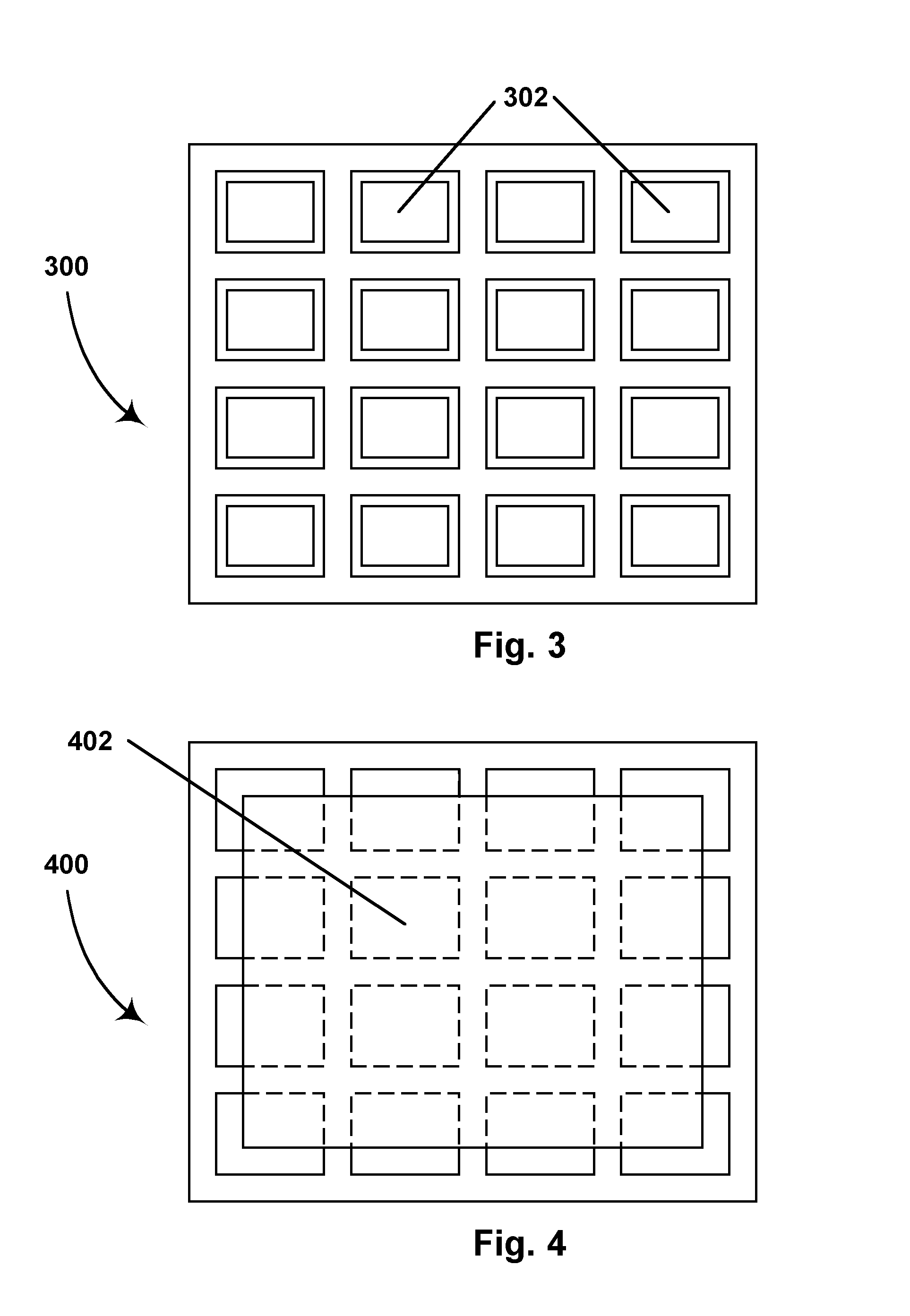

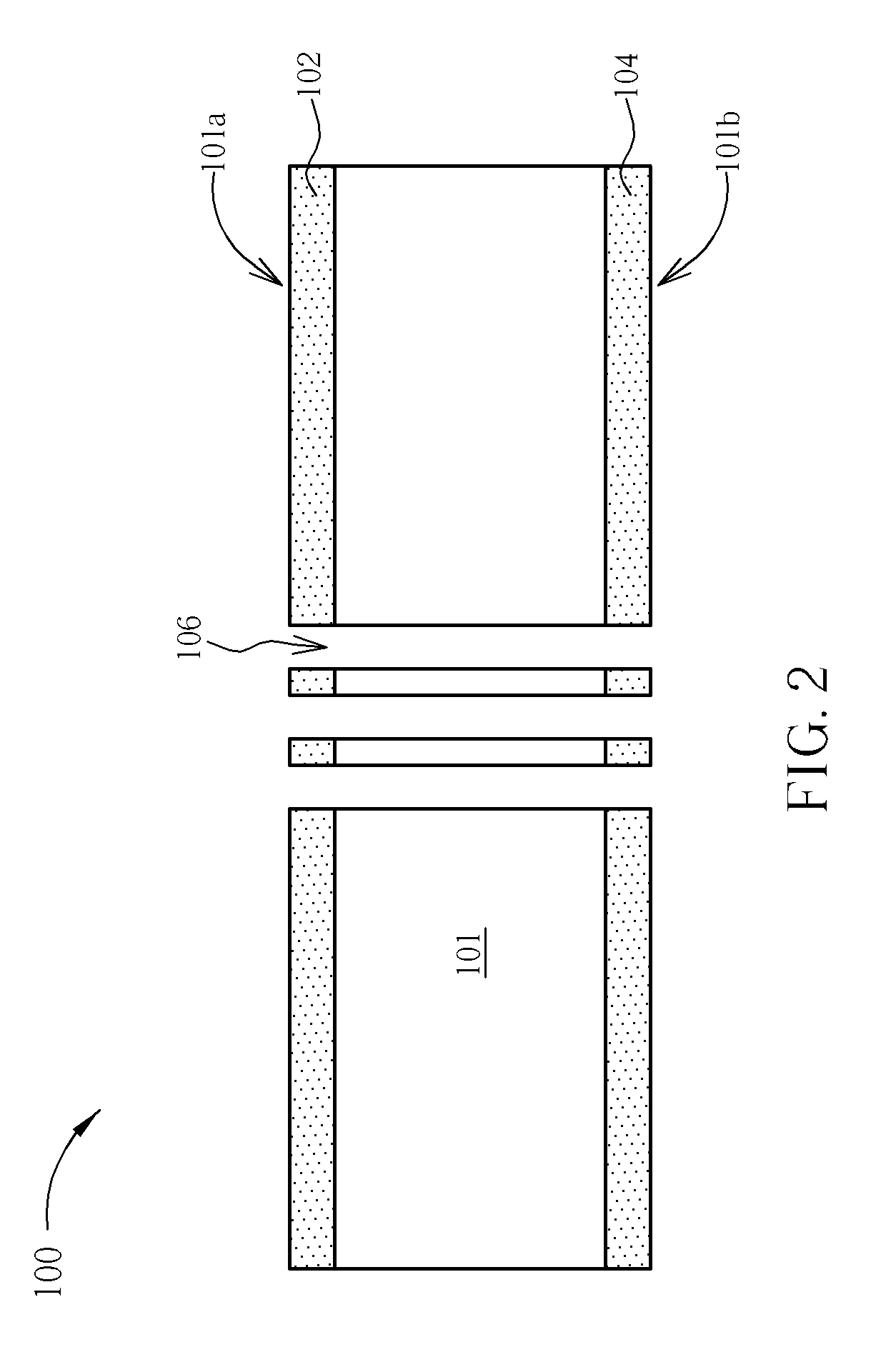

Flexible electronic circuits and displays including a backplane comprising a patterned metal foil having a plurality of apertures extending therethrough

A backplane for use in an electro-optic display comprises a patterned metal foil having a plurality of apertures extending therethrough, coated on at least side with an insulating polymeric material and having a plurality of thin film electronic devices provided on the insulating polymeric material.

Owner:E INK CORPORATION

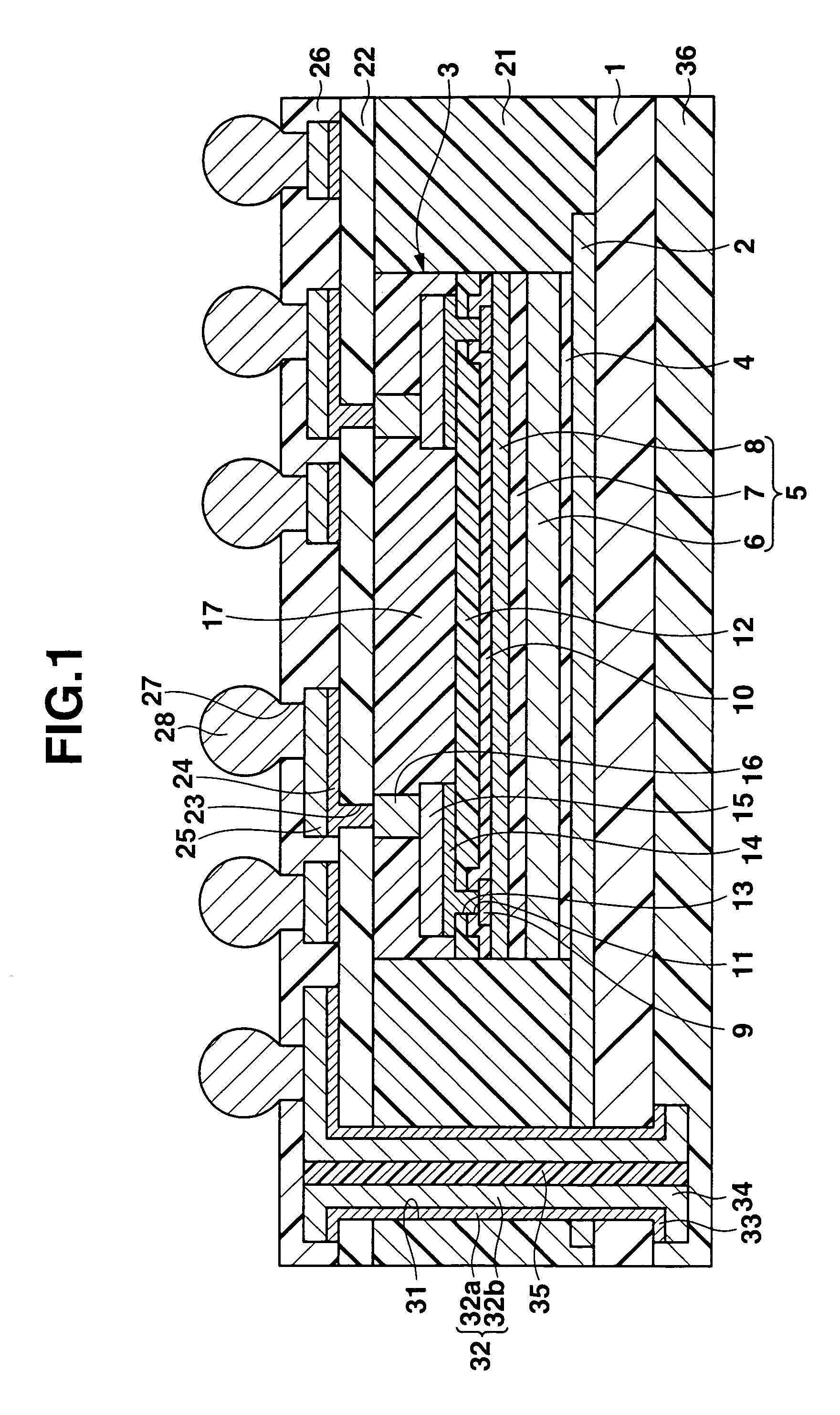

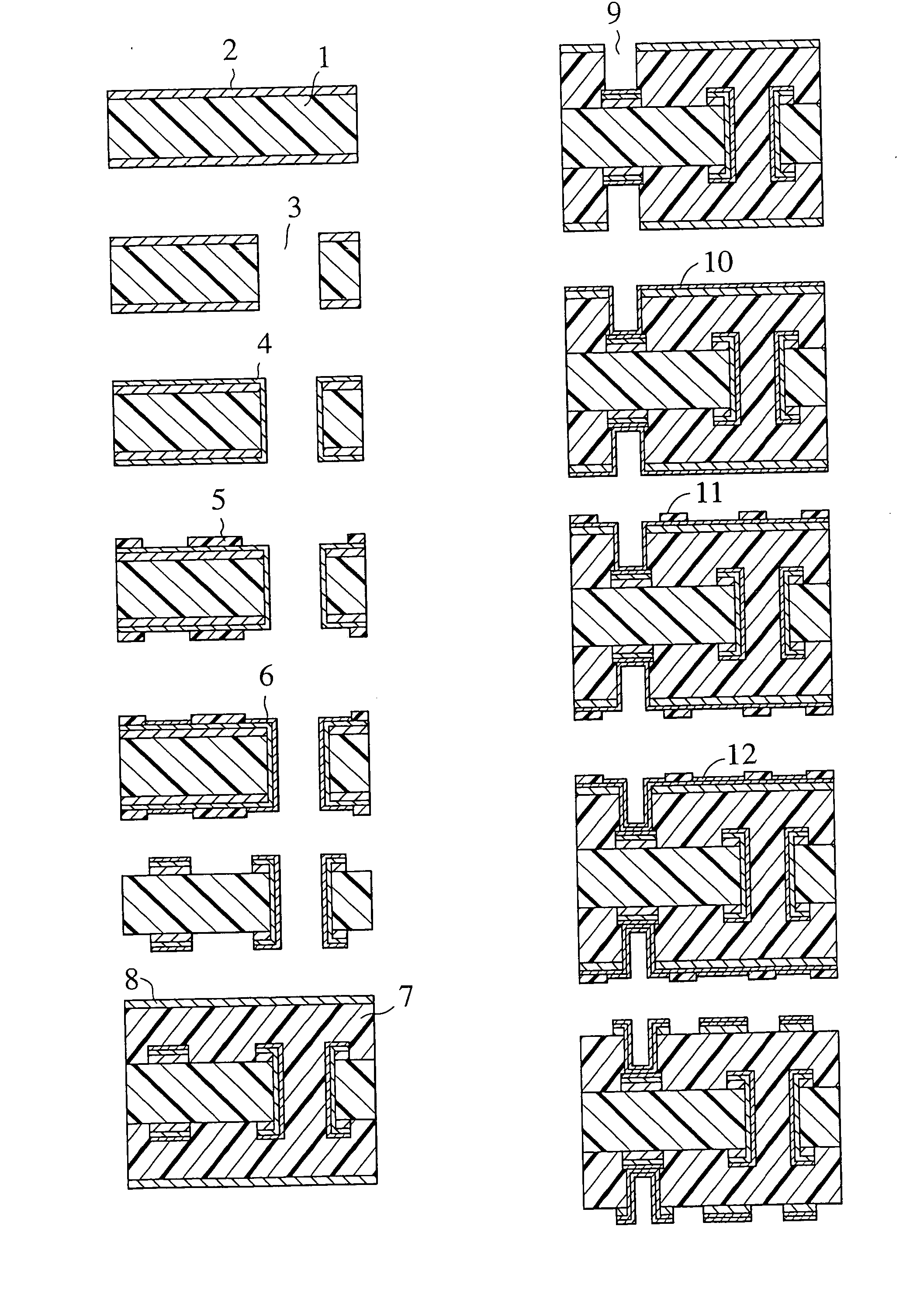

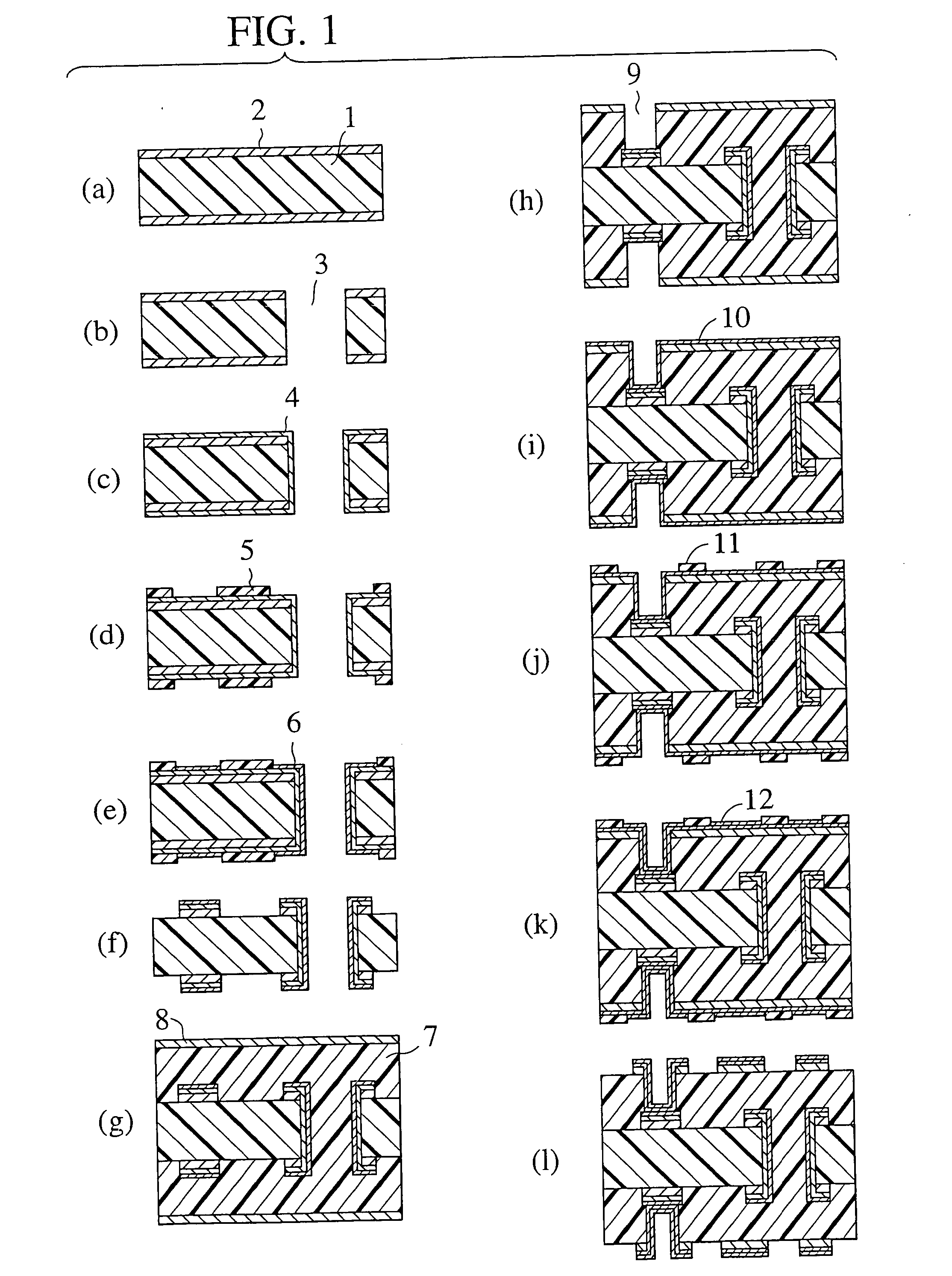

Semiconductor device incorporating a semiconductor constructing body and an interconnecting layer which is connected to a ground layer via a vertical conducting portion

InactiveUS7279750B2Deterioration of characteristic can be suppressedDownsize the electronic apparatusSemiconductor/solid-state device detailsNoise reduction constructionMetal foilSemiconductor

A semiconductor device includes metal foil to which a ground potential is applied, at a semiconductor constructing body provided on the metal foil and having a semiconductor substrate and a plurality of external connection electrodes provided on the semiconductor substrate. An insulating layer is provided around the semiconductor constructing body and has a thickness substantially equal to the semiconductor constructing body. An one upper interconnecting layer is provided on the semiconductor constructing body and insulating layer, and electrically connected to the external connection electrodes. A vertical conducting portion extends through the insulating layer and electrically connects the metal foil and upper interconnecting layer.

Owner:CMK

Packaging for primary and secondary batteries

InactiveUS20050112461A1Extended calendar lifeDeferred-action cellsSynthetic resin layered productsMetal foilEngineering

Owner:UCHICAGO ARGONNE LLC

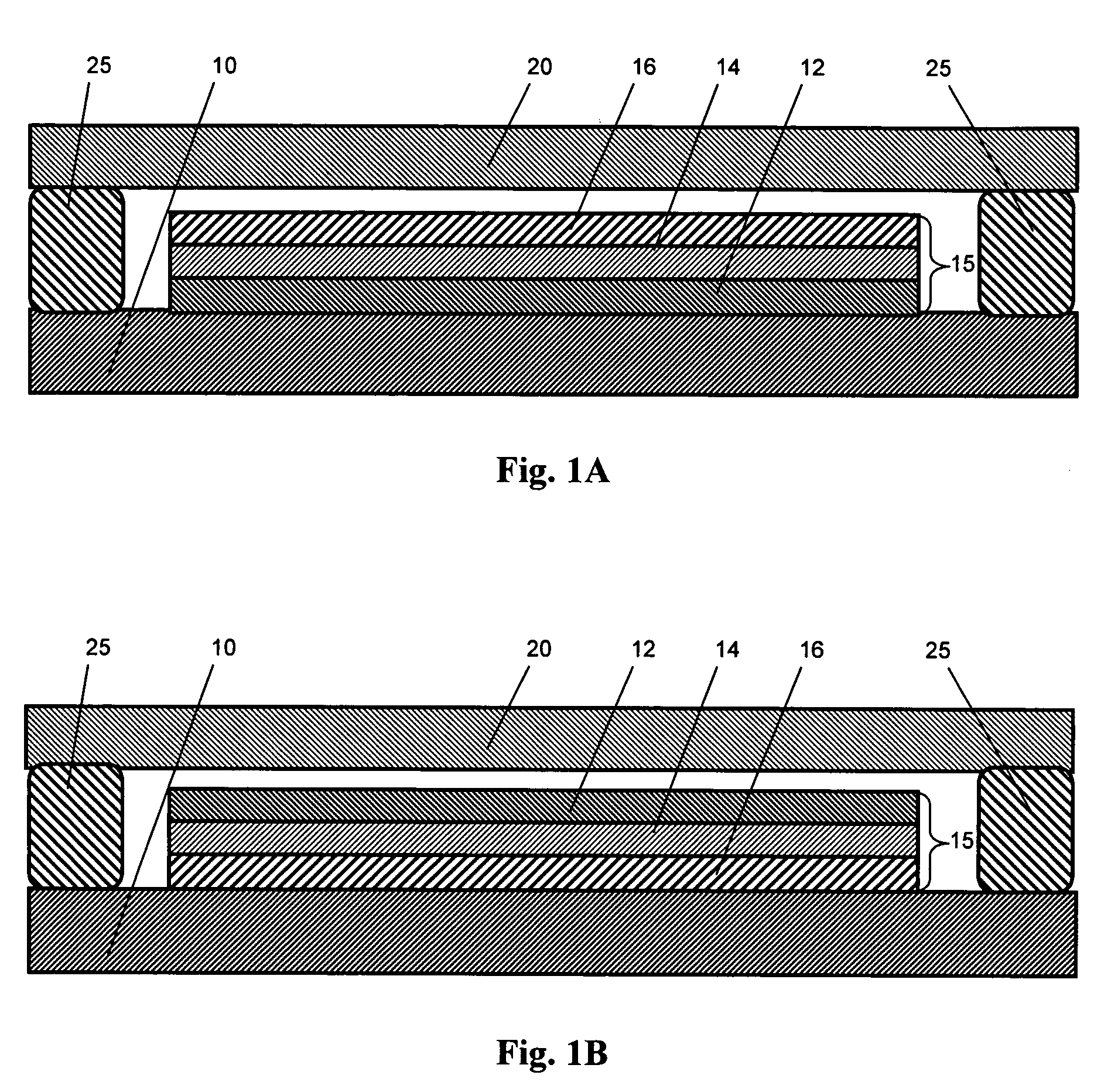

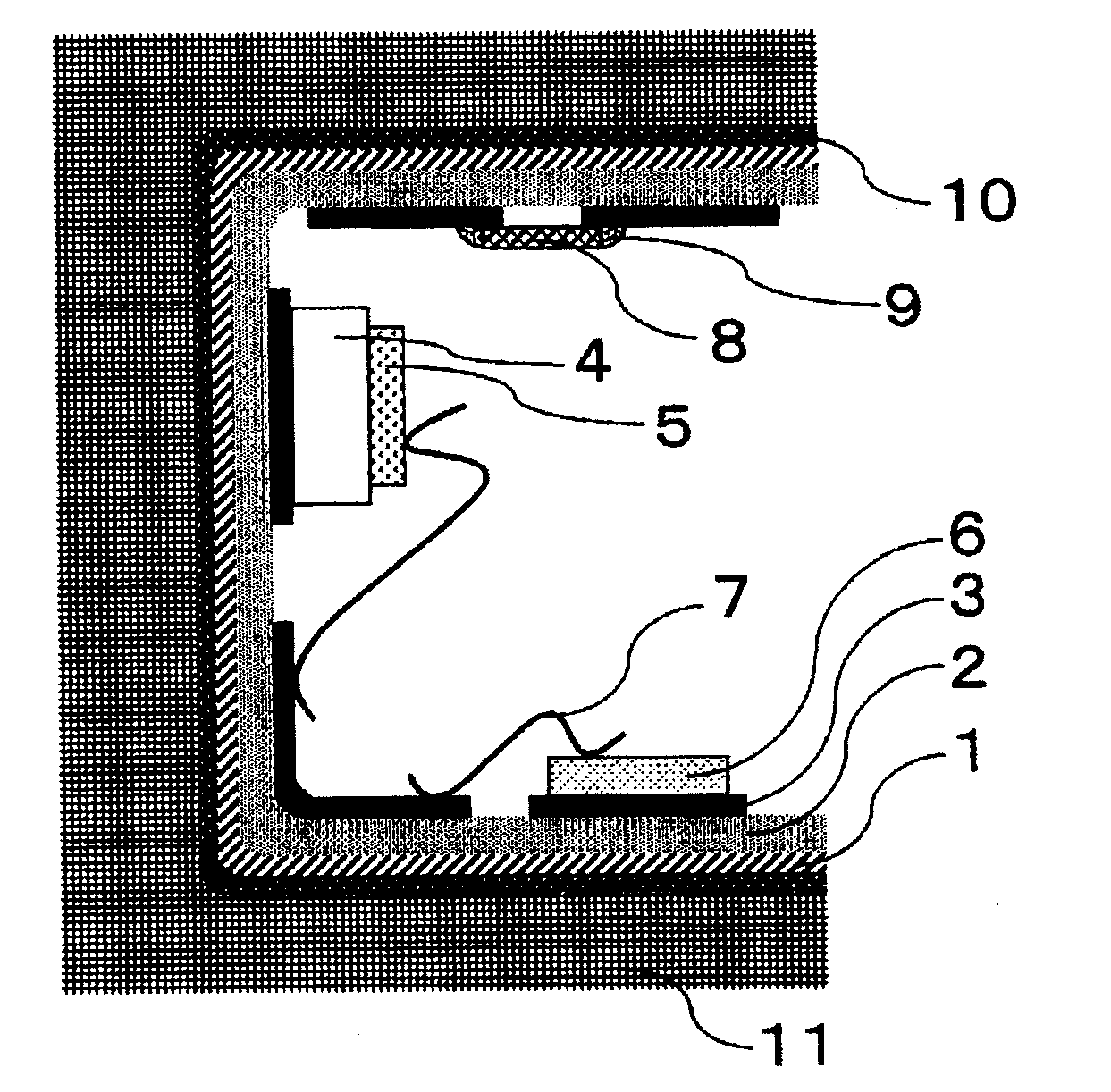

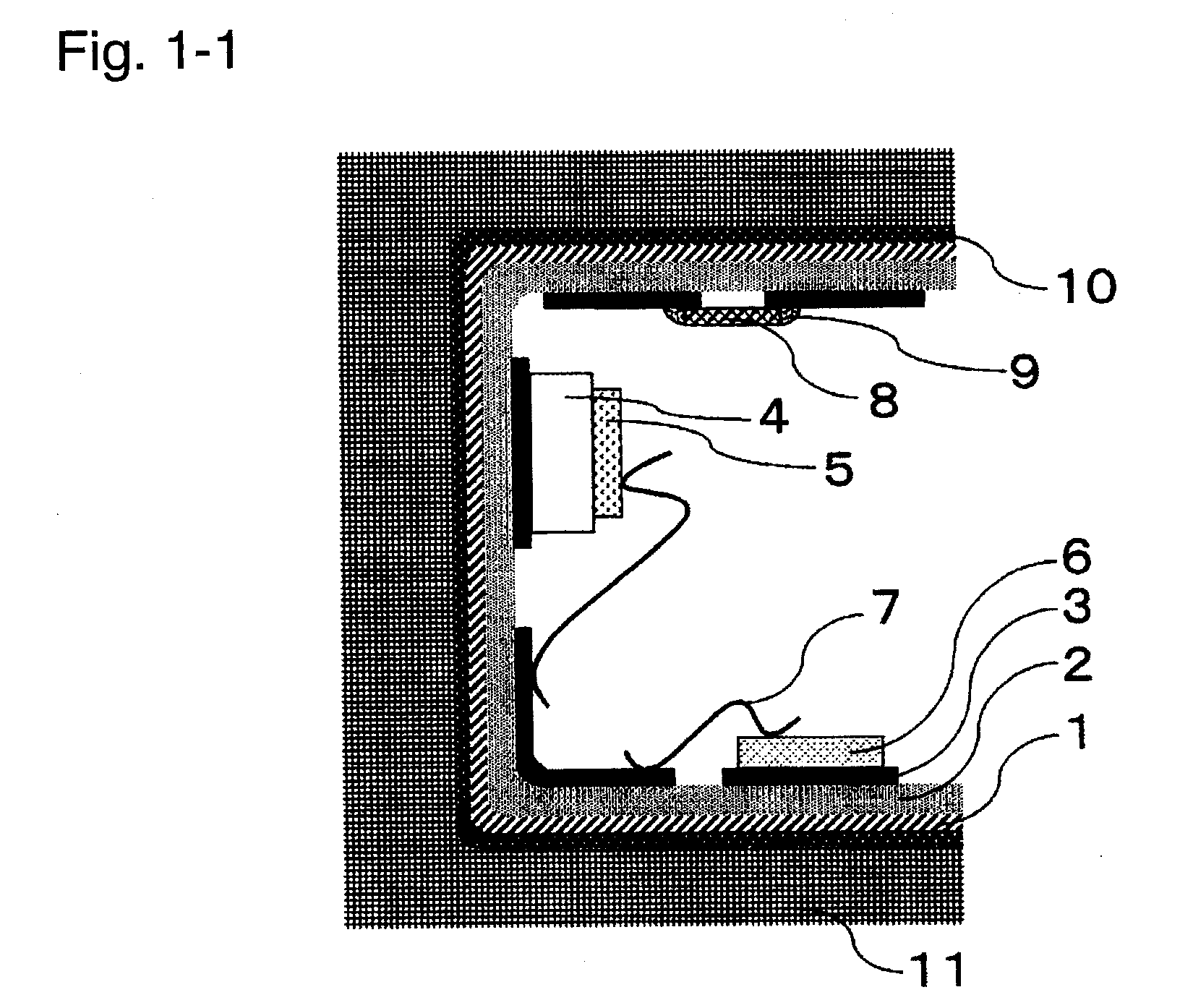

Anti-stiction technique for electromechanical systems and electromechanical device employing same

ActiveUS20060246631A1Operating environment limitedMaterial nanotechnologySolid-state devicesMetal foilEngineering

A mechanical structure is disposed in a chamber, at least a portion of which is defined by the encapsulation structure. A first method provides a channel cap having at least one preform portion disposed over or in at least a portion of an anti-stiction channel to seal the anti-stiction channel, at least in part. A second method provides a channel cap having at least one portion disposed over or in at least a portion of an anti-stiction channel to seal the anti-stiction channel, at least in part. The at least one portion is fabricated apart from the electromechanical device and thereafter affixed to the electromechanical device. A third method provides a channel cap having at least one portion disposed over or in at least a portion of the anti-stiction channel to seal an anti-stiction channel, at least in part. The at least one portion may comprise a wire ball, a stud, metal foil or a solder preform. A device includes a substrate, an encapsulation structure and a mechanical structure. An anti-stiction layer is disposed on at least a portion of the mechanical structure. An anti-stiction channel is formed in at least one of the substrate and the encapsulation structure. A cap has at least one preform portion disposed over or in at least a portion of the anti-stiction channel to seal the anti-stiction channel, at least in part.

Owner:ROBERT BOSCH GMBH

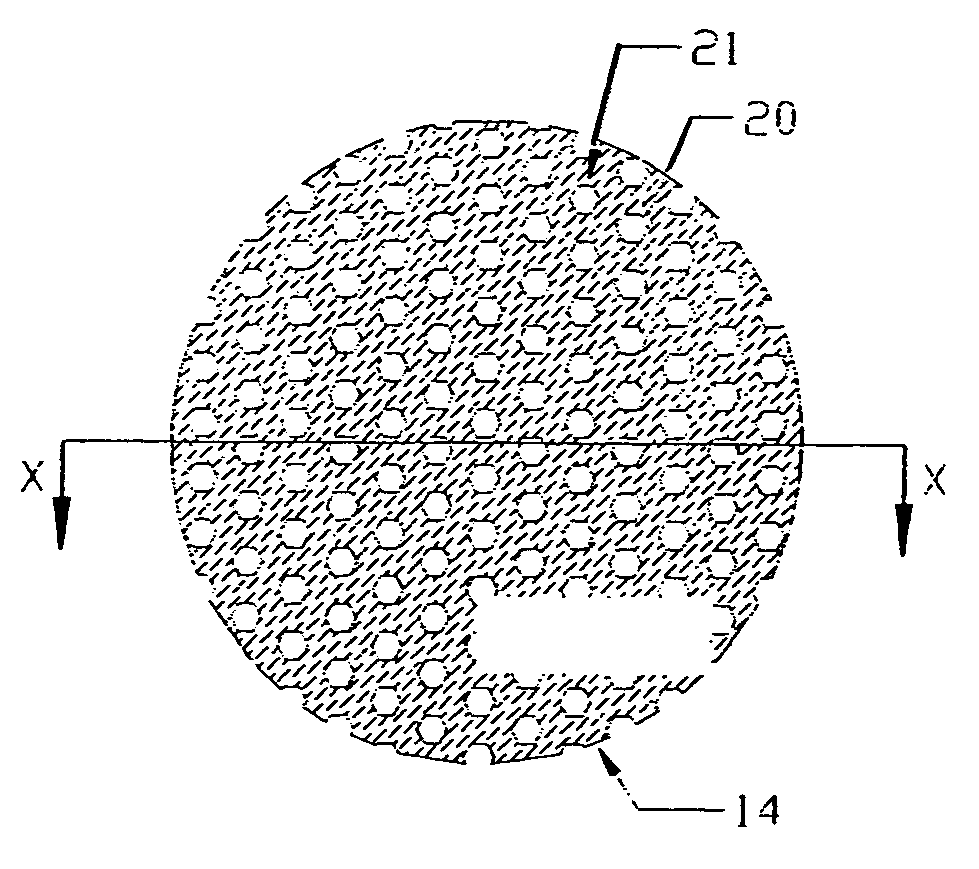

Protective acoustic cover assembly

A protective acoustic cover assembly including a metal foil with perforations, and a treatment on one or more surfaces of said metal foil. The treatment is a hydrophobic or oleophobic treatment, or both. The protective acoustic cover assembly has an average specific acoustic resistance of less than about 11 Rayls MKS from 250-300 Hz, an average specific acoustic reactance magnitude of less than about 1 Rayls MKS from 250-300 Hz, and an instantaneous water entry pressure value of greater than about 11 cm. The perforations of the metal foil preferably have an average maximum pore size of less than about 150 micrometers. The protective acoustic cover assembly further includes an adhesive mounting system, and the preferred metal foil is nickel.

Owner:WL GORE & ASSOC INC

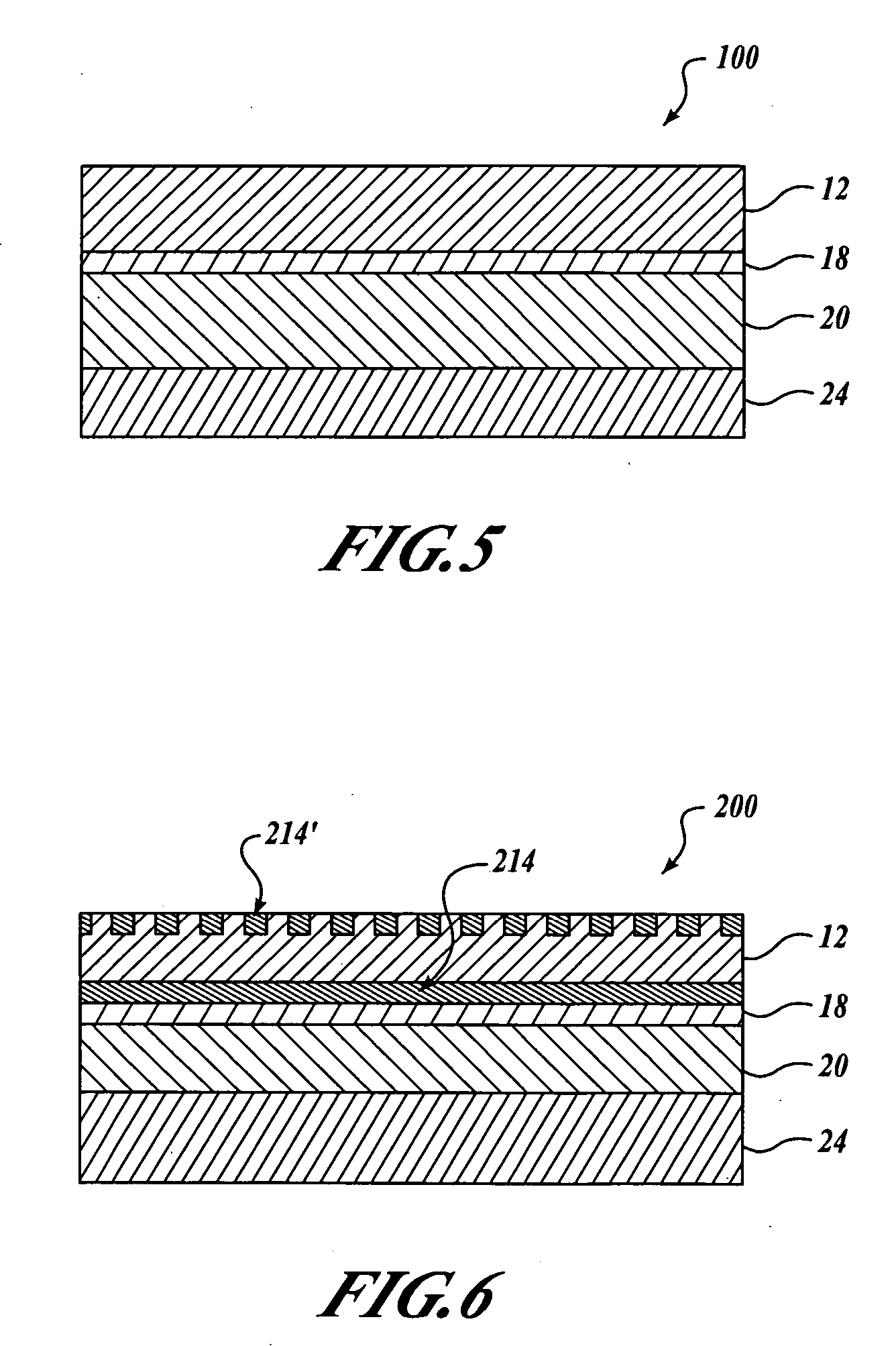

Protected organic electronic devices and methods for making the same

InactiveUS20050269943A1Increase resistanceHigh strengthDischarge tube luminescnet screensElectroluminescent light sourcesMetal foilYoung's modulus

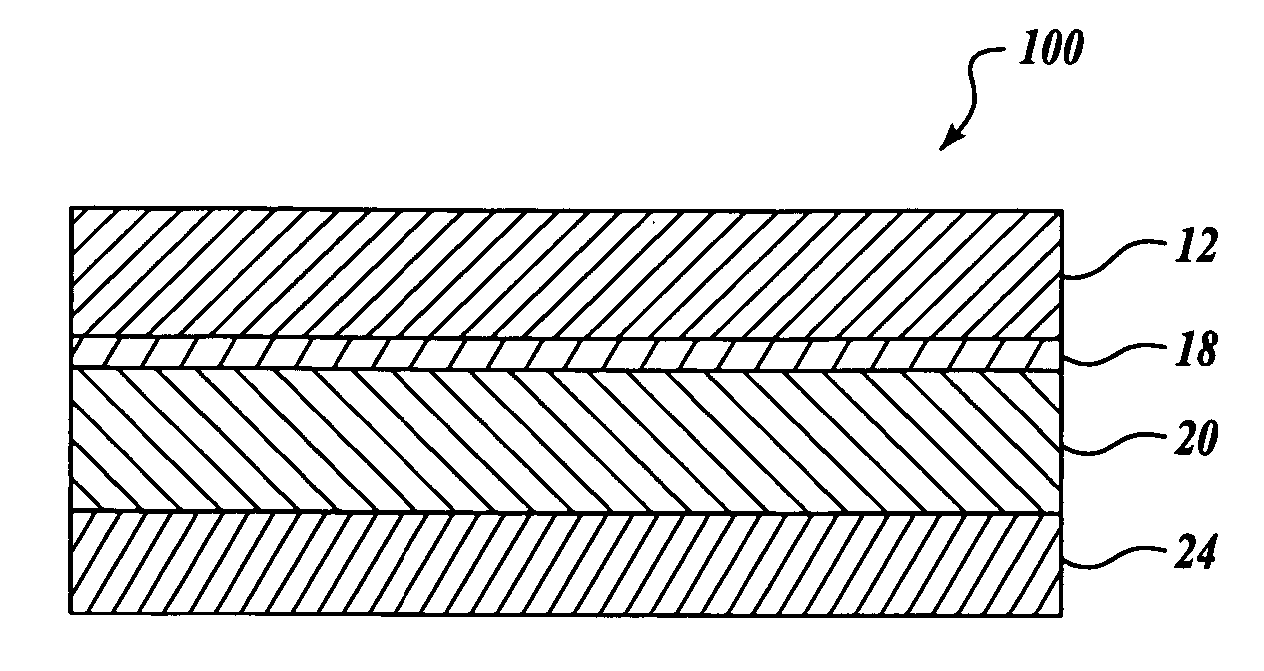

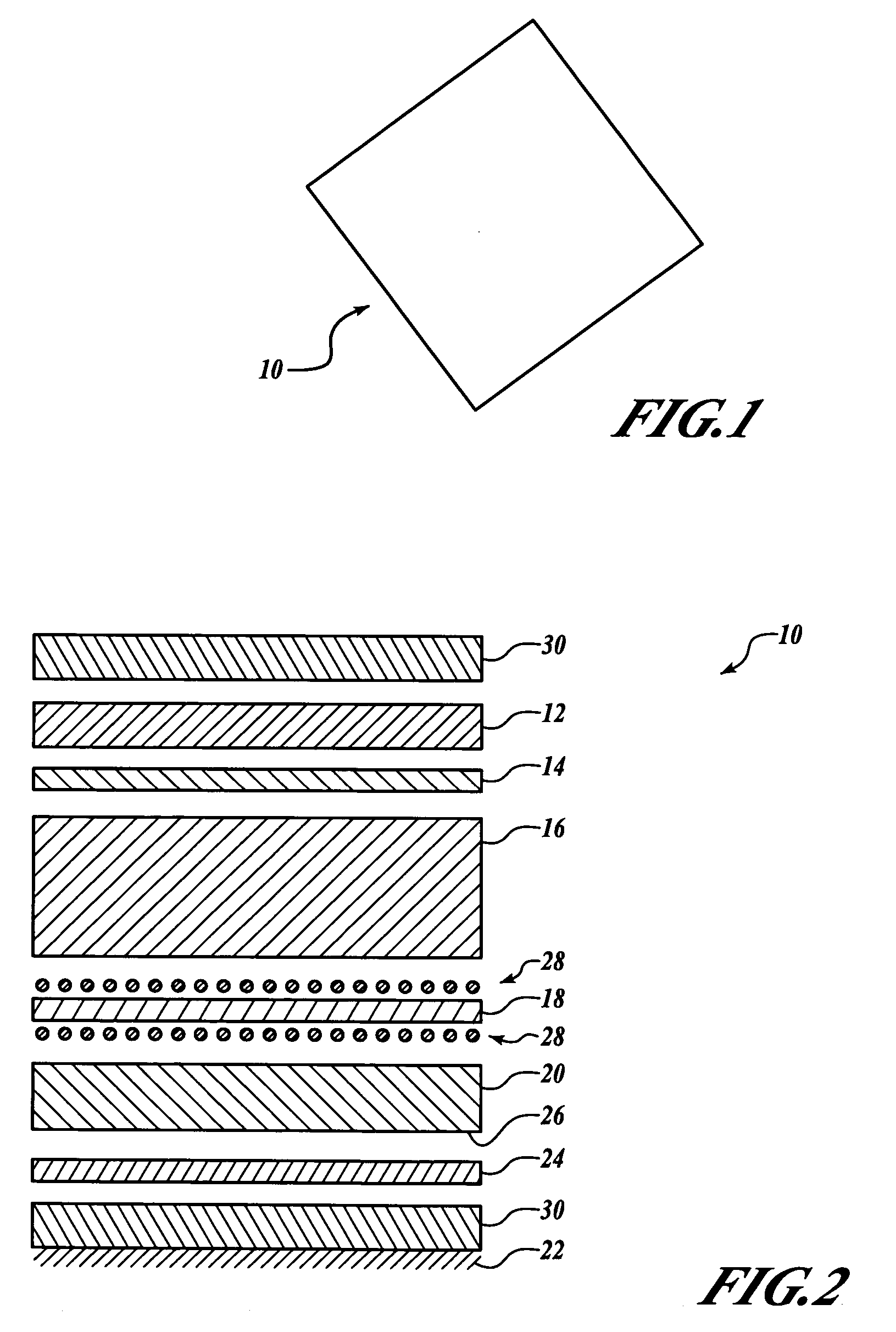

The present invention relates to structures and components for protecting organic light emitting diodes from environmental elements such as moisture and oxygen. According to a first aspect of the invention, top-emitting, high-resolution, OLED structures are provided which include a metal foil substrate; a planarization layer disposed over the metal foil substrate; an OLED stack (which includes lower and upper electrodes as well as an organic region disposed between the electrodes) disposed over the planarization layer; and a multilayer barrier region disposed over the OLED stack. A second aspect of the invention is directed to flexible, top emitting OLED structures which include the following: thin substrate region (i.e., a substrate having a thickness that is less than 200 microns); an OLED stack disposed over the flexible substrate region; a transparent upper barrier region that cooperates with the flexible substrate region to encapsulate the OLED stack, thereby protecting it from outside species such as water or oxygen; and a polymeric reinforcement layer which has a Young's Modulus ranging from about 0.3 to 7 GPa, which is disposed (i) below the substrate region, (ii) above the upper barrier region (in which case it is transparent), or (iii) both below the substrate region and above the upper barrier region.

Owner:UNIVERSAL DISPLAY

Reinforcement laminate

InactiveUSH2047H1High strength bondImprove the immunityFilm/foil adhesivesSynthetic resin layered productsEpoxyPolyol

A thermosettable adhesive is used to secure a laminate having a compliant layer (for example, a foamable composition containing a diene rubber), a layer comprised of a thermosettable resin capable of being cured to a rigid state, and an optional carrier layer (for example, a metal foil) to a substrate for the purpose of strengthening, stiffening, or otherwise reinforcing the substrate. The substrate may, for example, be a metal vehicle door. The thermosettable adhesive is comprised of at least one polyol such as a polyether polyol, at least one epoxy resin, and at least one polyisocyanate.

Owner:HENKEL CORP

Metal foil with resin and metal-clad laminate, and printed wiring board using the same and method for production thereof

InactiveUS20050121229A1Cost efficiency and handlingCircuit formability highInsulating substrate metal adhesion improvementSynthetic resin layered productsElectrical conductorMetal foil

The present invention provides a metal clad laminate or a resin coated metal foil having a metal foil whose both surfaces are not substantially roughening-treated and an insulating resin composition layer using generally used insulating resin, and a printed wiring board and a manufacturing method thereof, in which the metal clad laminate or the resin coated metal foil is used, the reliability and circuit formability are high, and the conductor loss is extremely low.

Owner:HITACHI CHEM CO LTD

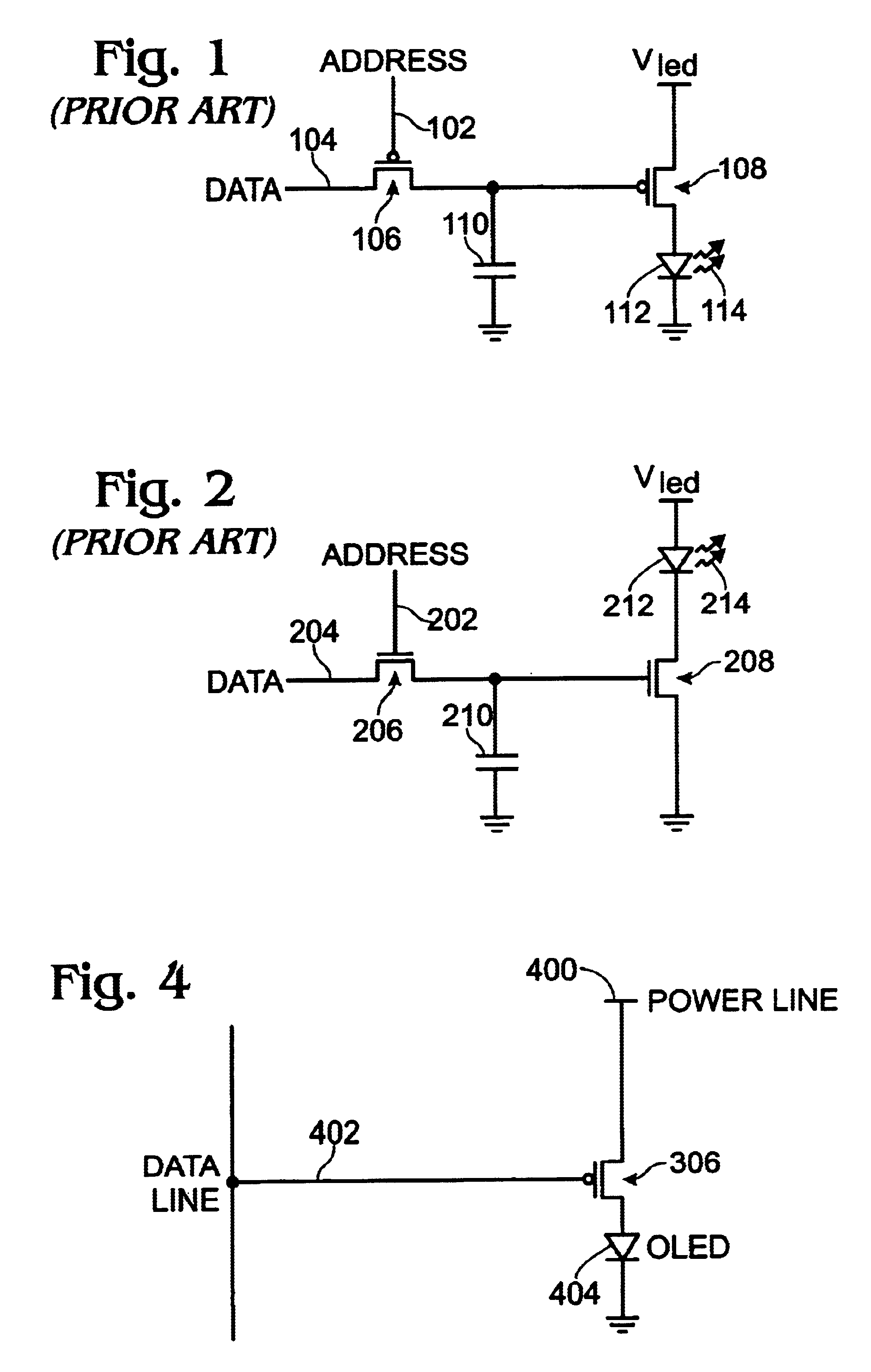

Flexible electronic circuits and displays

InactiveUS20110140744A1Adhesive processesSemiconductor/solid-state device manufacturingMetal foilDisplay device

A backplane for use in an electro-optic display comprises a patterned metal foil having a plurality of apertures extending therethrough, coated on at least side with an insulating polymeric material and having a plurality of thin film electronic devices provided on the insulating polymeric material.

Owner:E INK CORPORATION

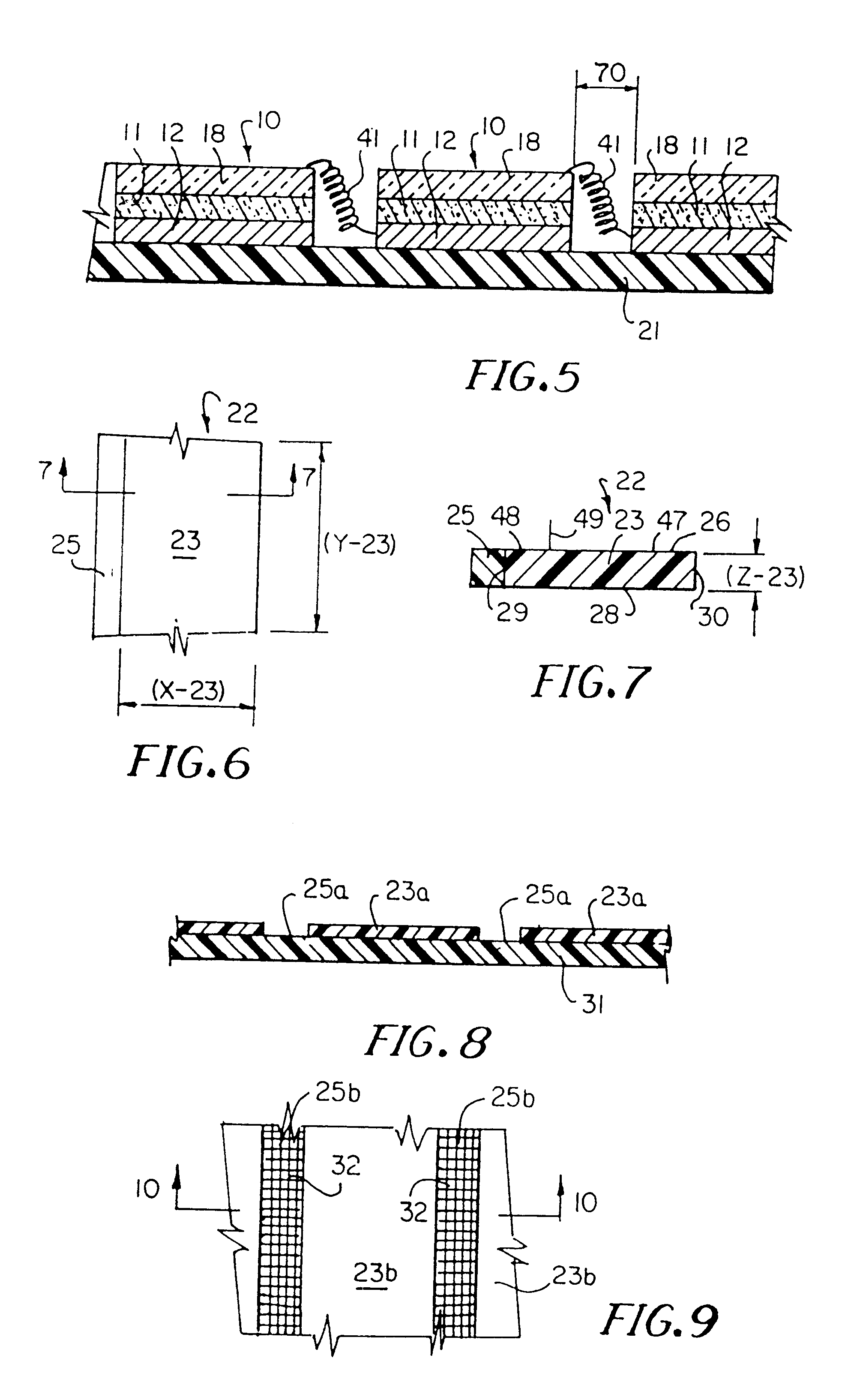

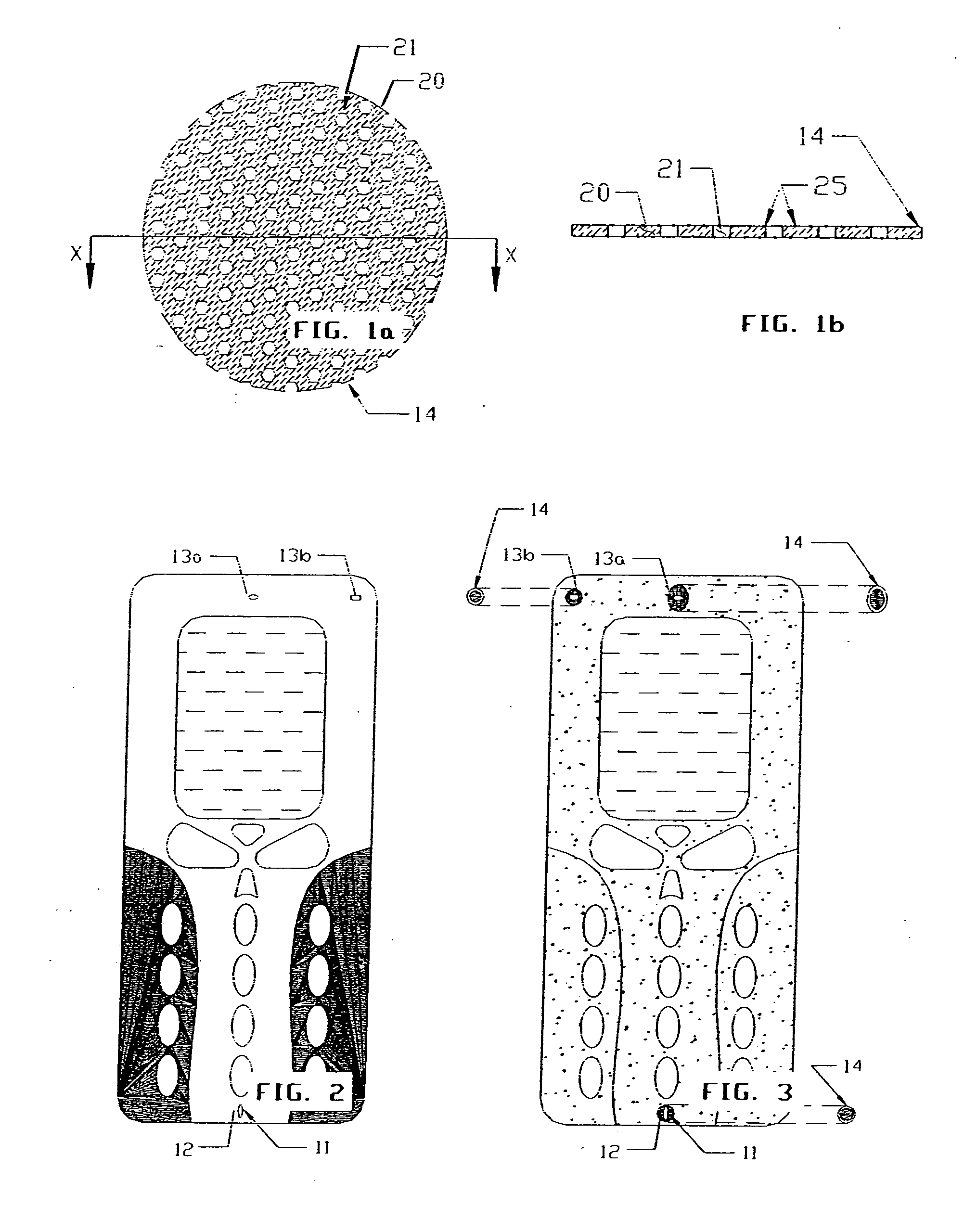

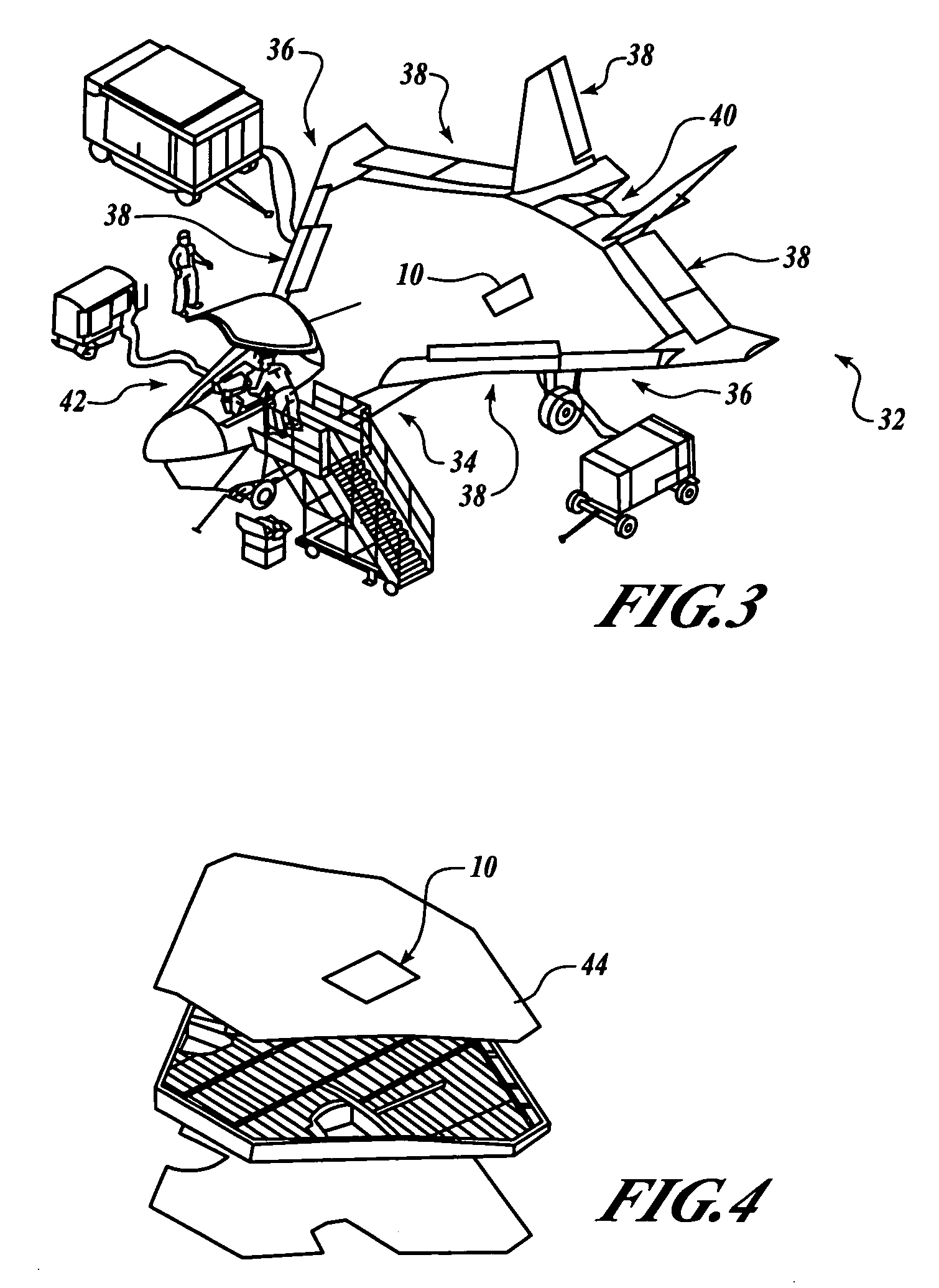

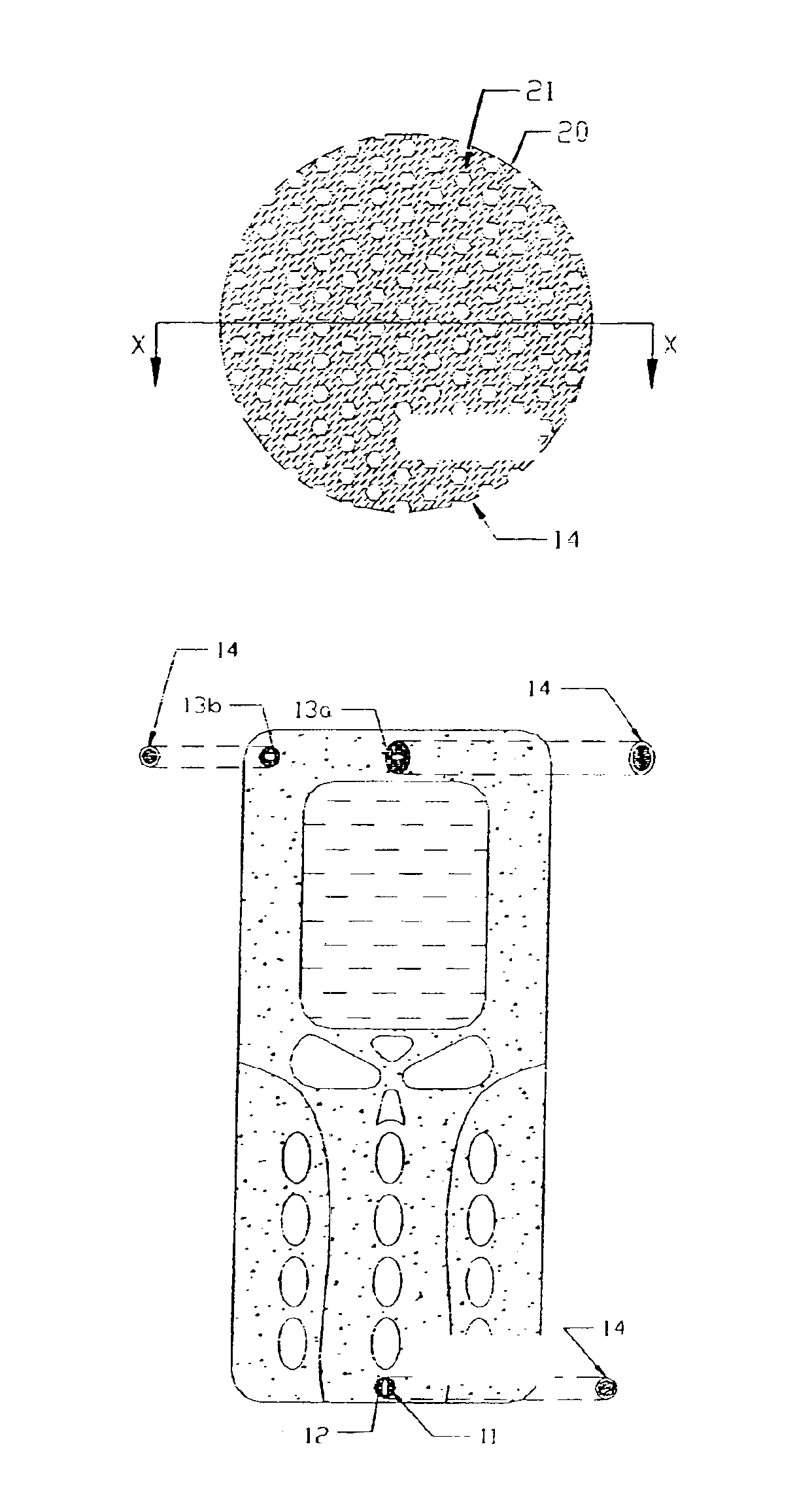

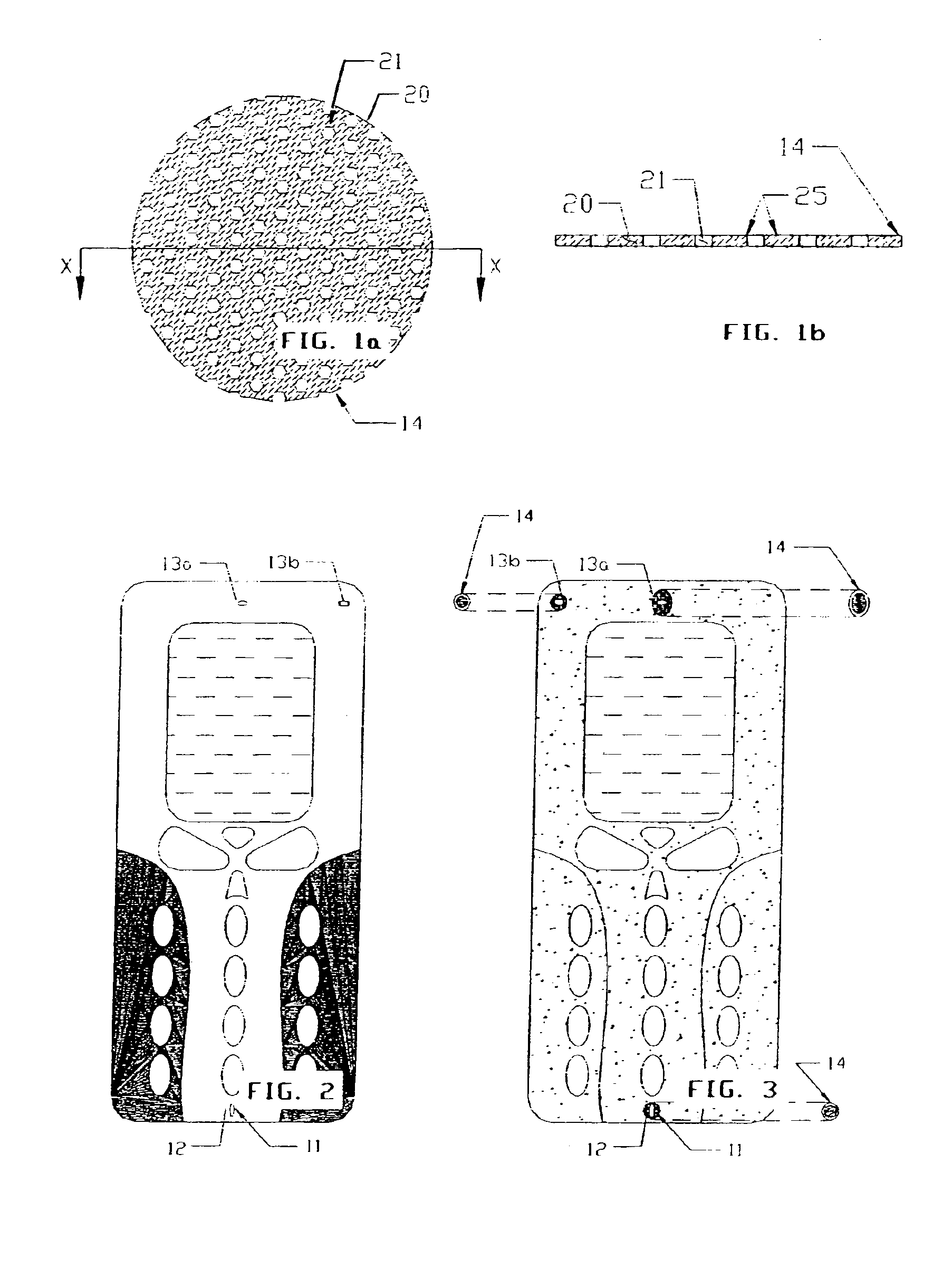

Applique

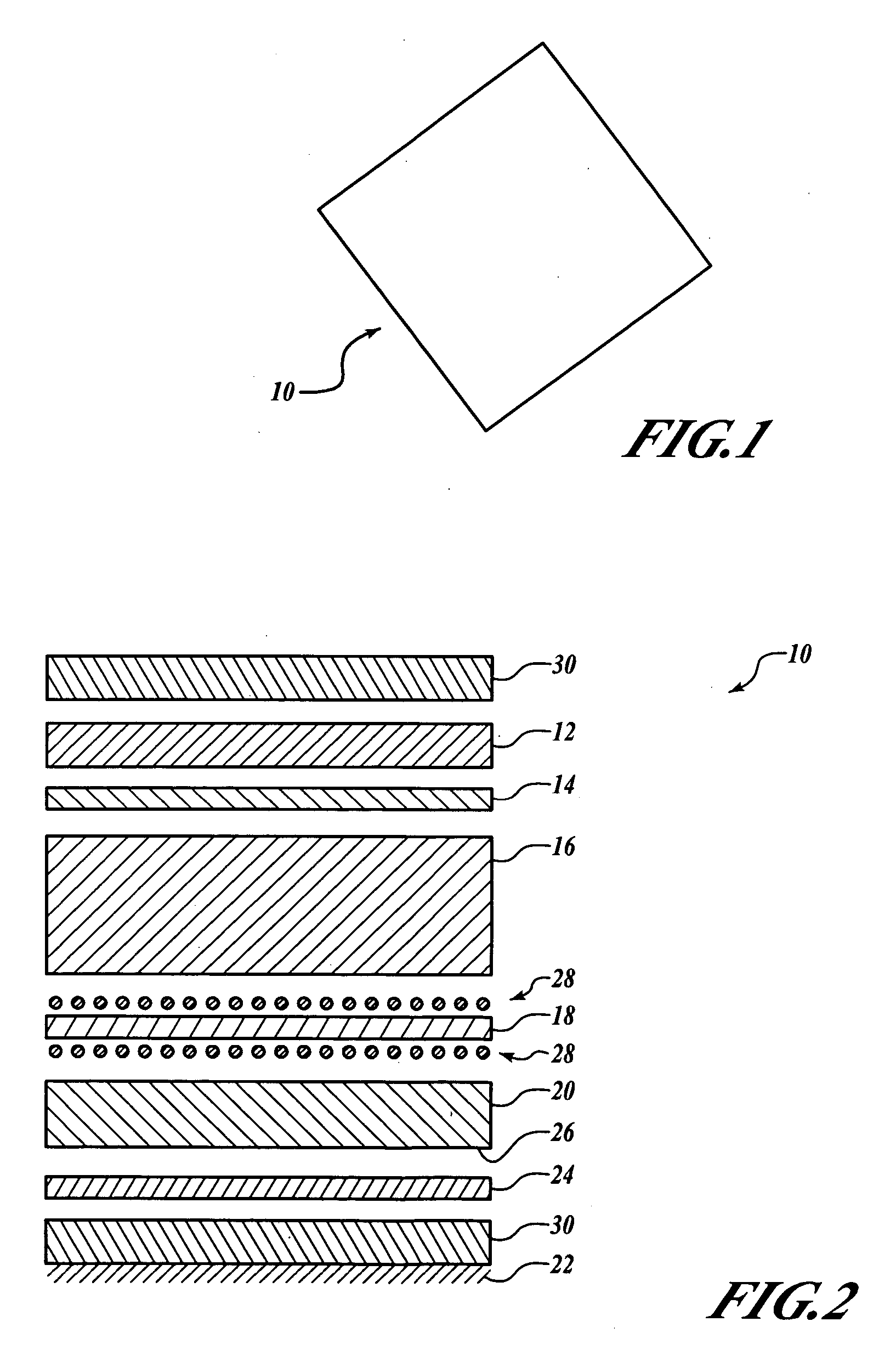

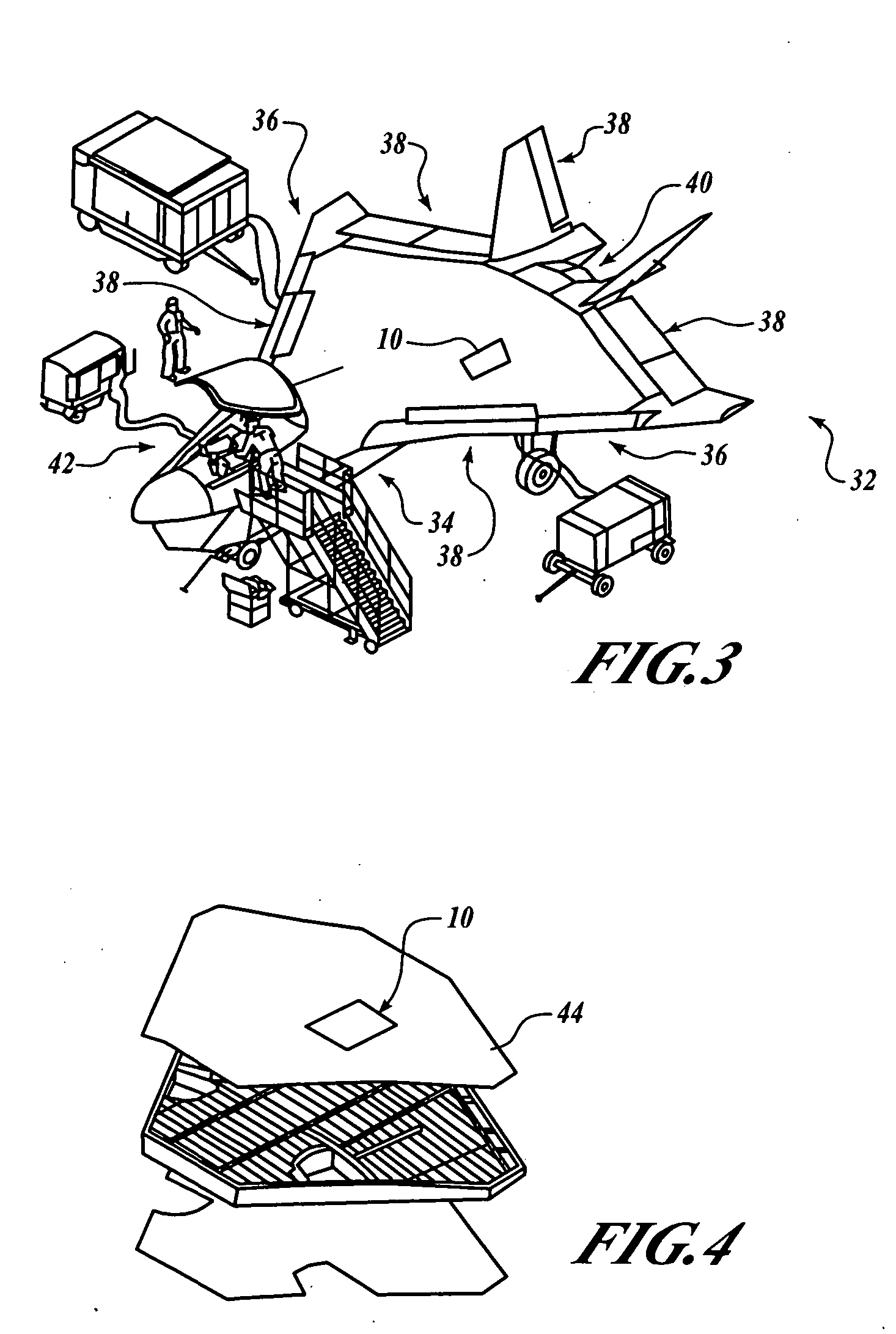

ActiveUS20050181203A1High porosityEnhancing static charge migrationDecorative surface effectsWingsFiberPolymer science

According to a non-limiting embodiment of the present invention, an appliqué coating is provided for a substrate. The appliqué coating includes a metal foil and a first polymer film underlying the metal foil. A topcoat overlying the metal foil may be provided as a layer of paint or as a second polymer film. An adhesive, such as a pressure sensitive adhesive, underlying the first polymer film may be provided to affix the appliqué coating to the substrate. If desired, fibers may be dispersed throughout the second polymer film to provide anti-static properties. Also, an ink layer may be provided between the metal foil and the second polymer film, if desired, for aesthetic and / or anti-static purposes.

Owner:THE BOEING CO

Packaging substrate with embedded chip and buried heatsink

InactiveUS20080315398A1Easy to useSimple structureSemiconductor/solid-state device detailsPrinted circuit aspectsResistMetal foil

An embedded chip package includes a substrate having a dielectric interposer, a first metal foil on a first surface and a second metal foil on a second surface of the substrate, wherein the substrate has a cavity recessed into the first surface; a metal heatsink embedded within the cavity; a semiconductor die mounted on a flat bottom of the metal heatsink; a dielectric layer covering the first surface of the substrate; at least one built-up circuit trace layer on the dielectric layer; a solder resist layer on the built-up circuit trace layer and on the dielectric layer; a heat-dissipating metal layer on the second metal foil; and heat-dissipating plugs connecting the flat bottom of the metal heatsink and the heat-dissipating metal layer.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

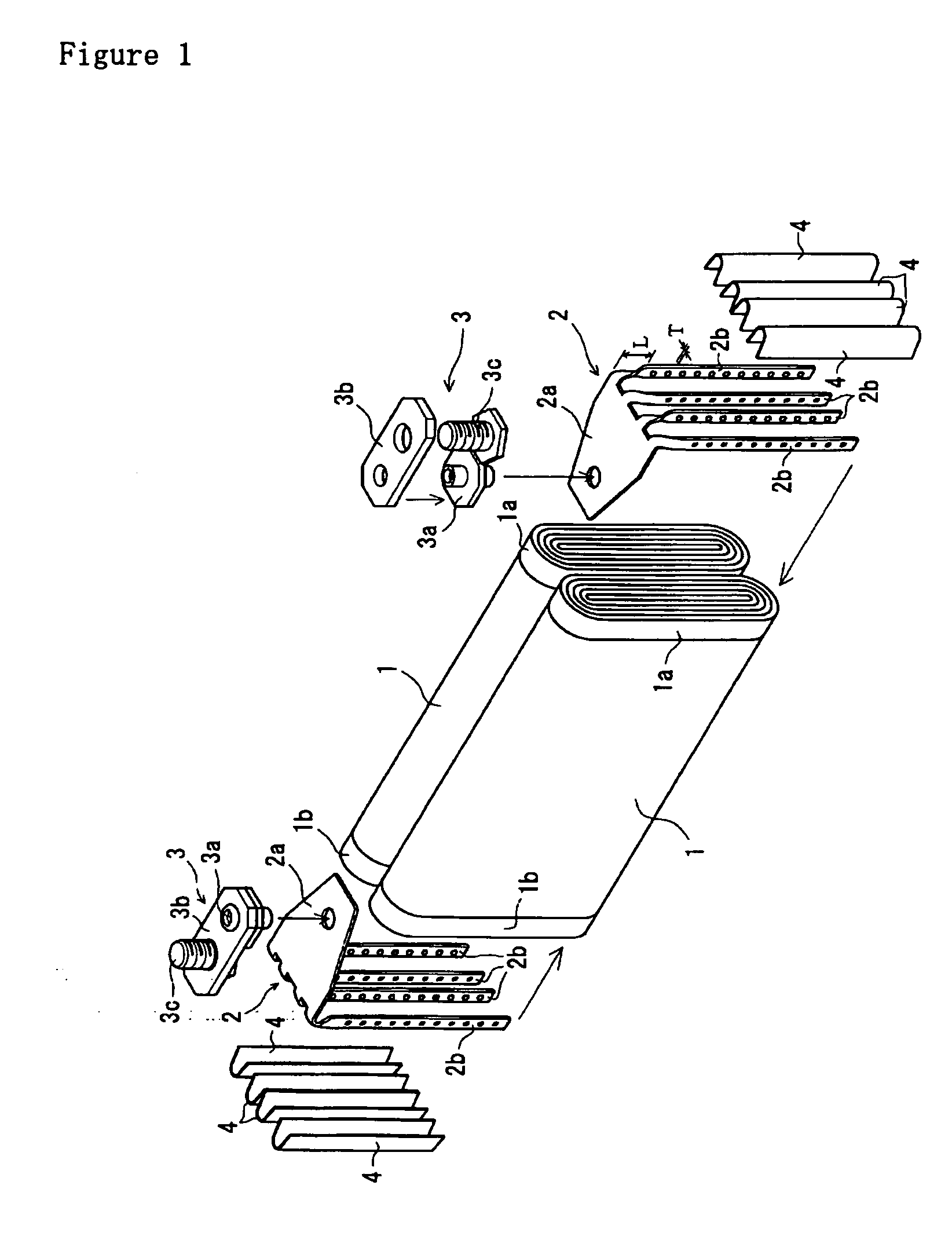

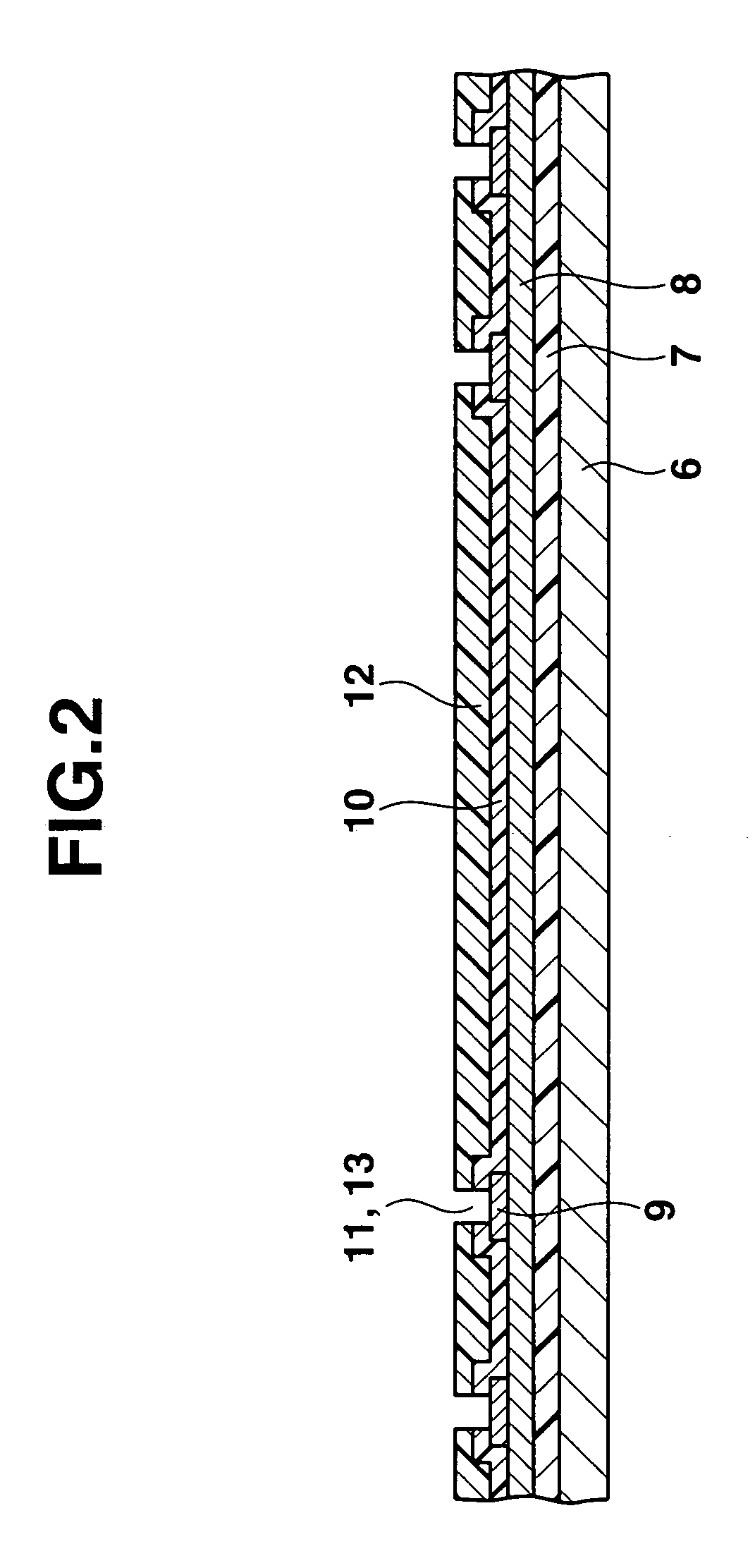

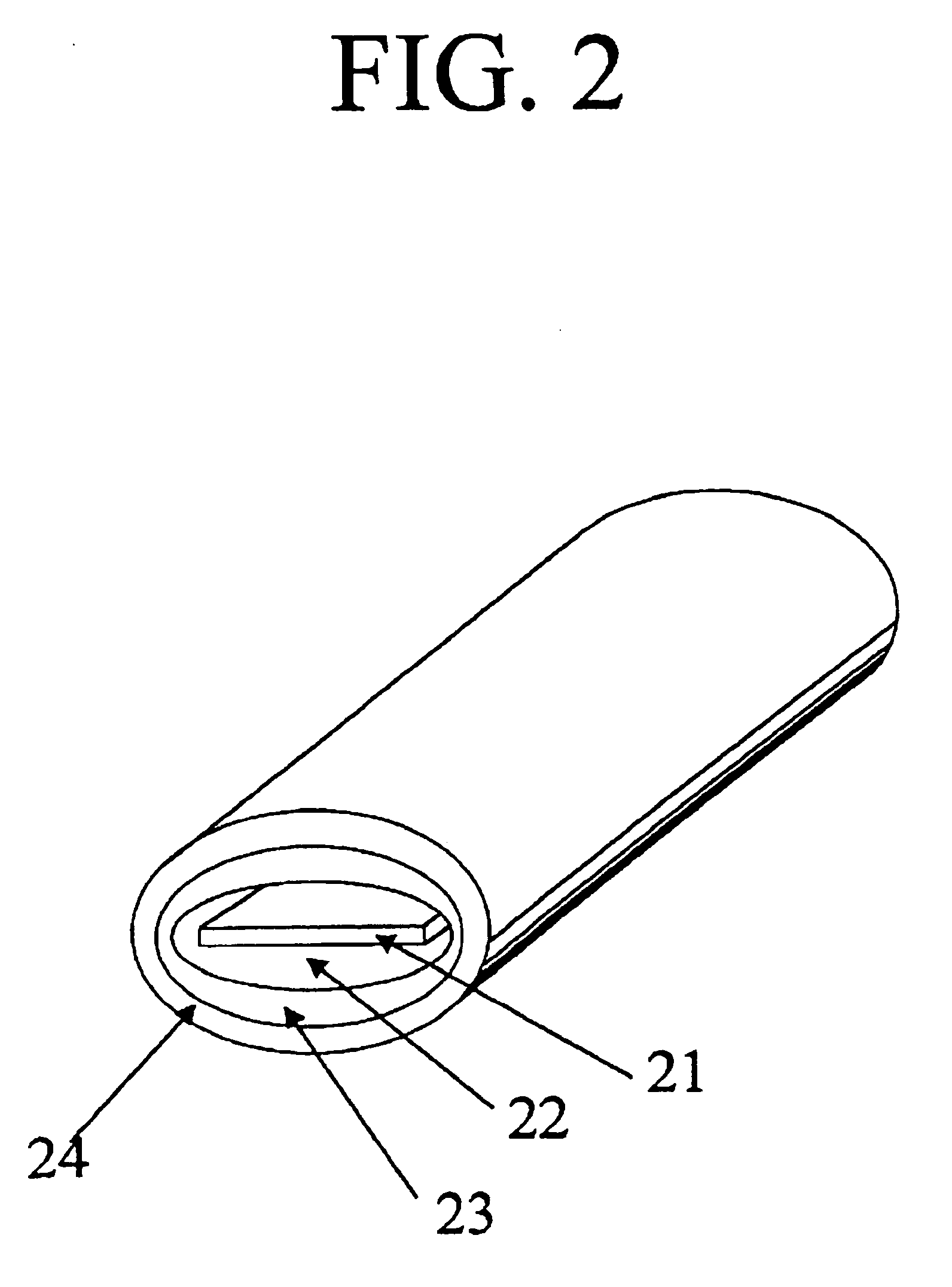

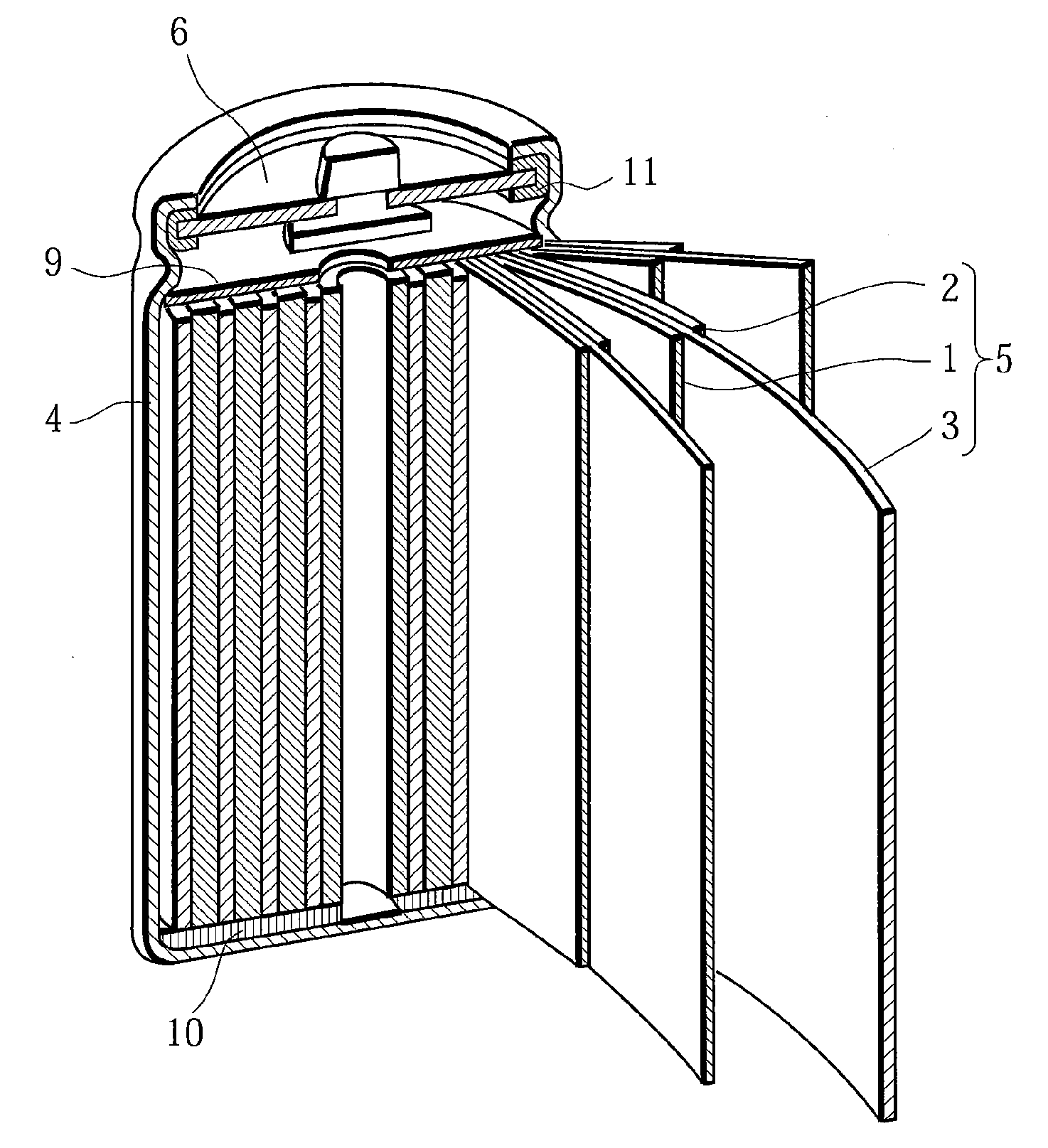

Cylindrical lithium secondary battery

InactiveUS20080241647A1Increase energy densityHigh mechanical strengthFinal product manufactureElectrode carriers/collectorsLithiumMetal foil

A cylindrical lithium secondary battery includes a positive electrode (1) having a positive electrode mixture layer disposed on a surface of a positive electrode current collector made of a conductive metal foil and containing a positive electrode active material, and a negative electrode (2) having a negative electrode mixture layer disposed on a surface of a negative electrode current collector made of a conductive metal foil and having a negative electrode active material containing silicon particles and / or silicon alloy particles. The amount of the positive electrode active material is 50 mg or less per 1 cm2 of the positive electrode, the average particle size of the silicon particles and / or silicon alloy particles is from 5 μm to 15 μm, and the theoretical electrical capacity ratio of the negative electrode to the positive electrode is 1.2 or greater.

Owner:SANYO ELECTRIC CO LTD

Wide area lightning diverter overlay

ActiveUS20060051592A1Reduce sparksReduction of Explosion HazardsDecorative surface effectsDuplicating/marking methodsWide areaParticulates

An overlay of patterned metal foil above a substrate to be protected supports development of localized coronas after a lightning strike. The localized coronas transport energy of a lightning strike above the substrate's surface with limited removal of metal foil from the lightning strike attachment point. A first polymer film underlies patterned metal foil. A topcoat overlies the patterned metal foil. An adhesive, underlying the first polymer film affixes the lightning diverter overlay to the substrate. If desired, semiconductor particulates may be dispersed throughout the second polymer film to contribute to instantaneous generation of localized coronas. Also, an ink layer may be provided between the patterned metal foil and the topcoat or on the exterior, if desired, for aesthetic and / or anti-static purposes.

Owner:THE BOEING CO

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7732243B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

Owner:SOLANNEX

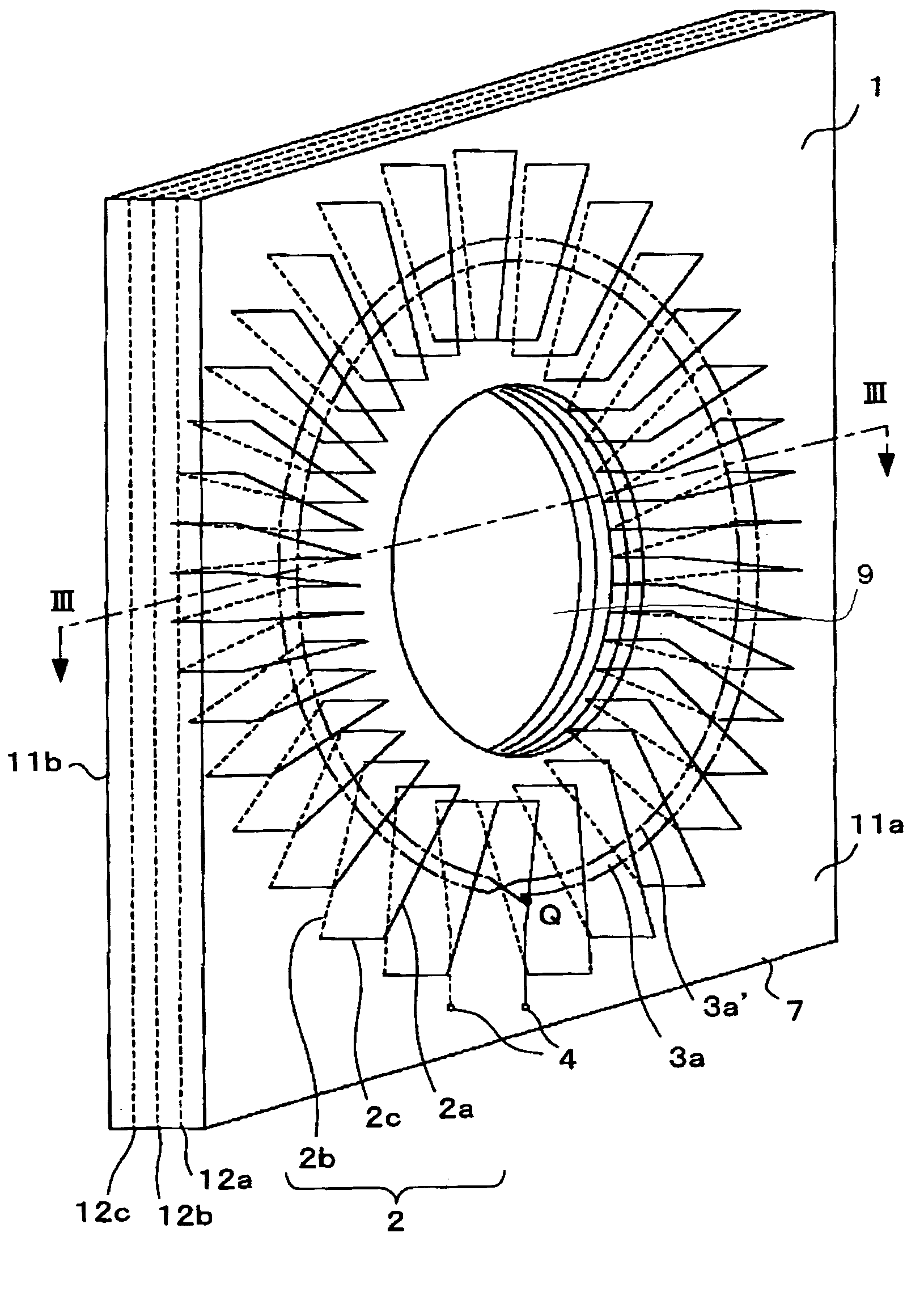

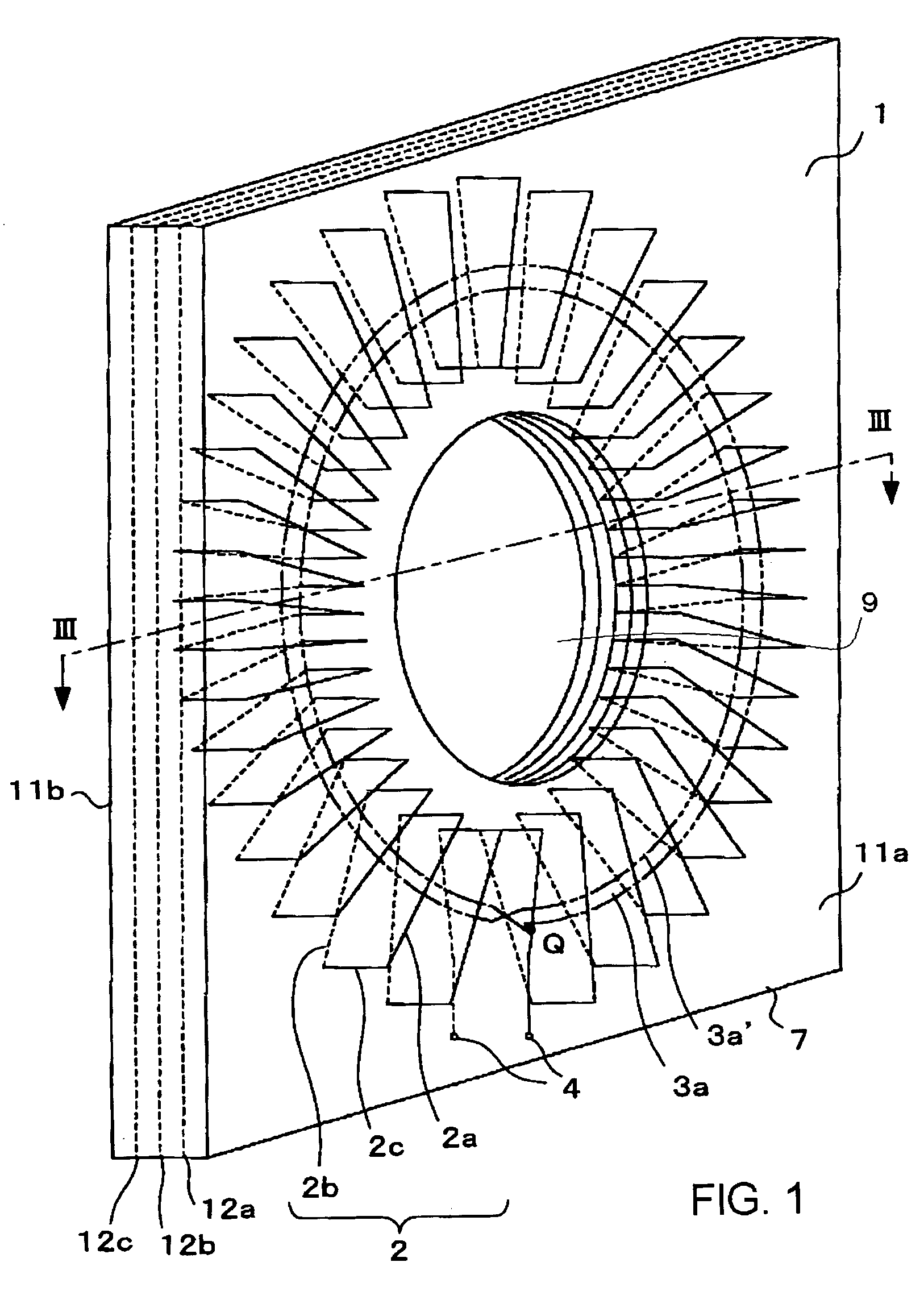

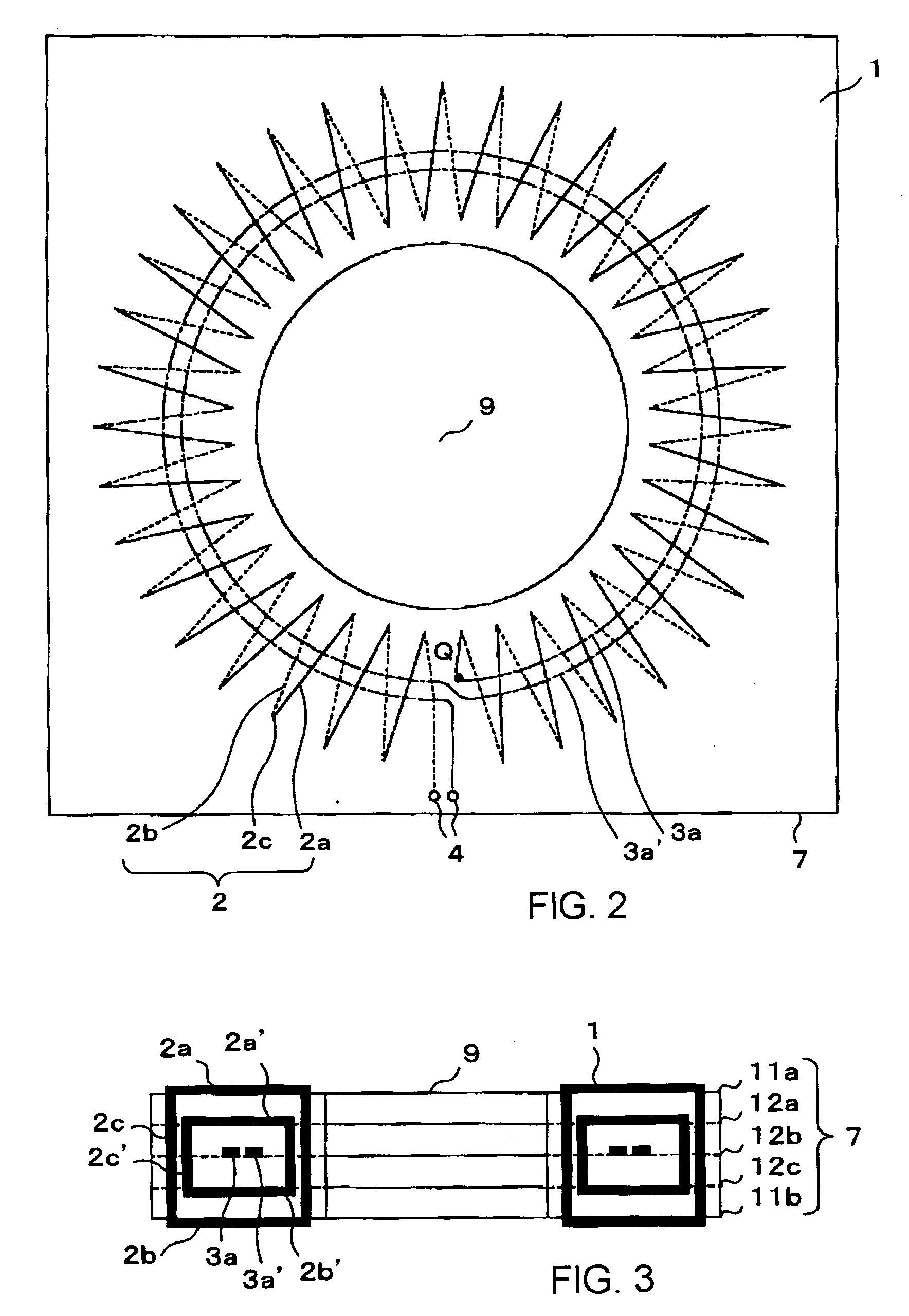

Current transformer

InactiveUS20040178875A1High measure of qualityImprove noiseTransformersCurrent/voltage measurementElectrical conductorMetal foil

A current transformer includes a Rogowski coil, having an opening at the center in which a conductor penetrates, comprising, a printed circuit board having a plurality of layers forming at least first to fourth circuit board surfaces including a circuit board top surface, a circuit board bottom surface and circuit board conducting internal surfaces between the circuit board top surface and the circuit board bottom surface, a plurality of radial metal foils, each metal foil radiating from a center that is approximately the center of the opening, mounted on the first to fourth circuit board surfaces, a first winding formed by electrically connecting metal foils on the first and second circuit board surfaces with first plated through holes penetrating the first and second circuit board surfaces in a thickness direction of the printed circuit board, a second winding formed by electrically connecting metal foils on the third and fourth circuit board surfaces with second plated through holes penetrating the third and fourth circuit board surfaces in a thickness direction of the printed circuit board, a first return circuit line electrically connected with the first winding in series, a second return circuit line electrically connected with the second winding in series, and a pair of the first winding and the first return circuit line and a pair of the second winding and the second return circuit line being electrically connected in series.

Owner:KK TOSHIBA

Stackable hinged container lid having detents

A lid and a container using the lid are disclosed, the lid having a central panel of paperboard with a resilient plastic skirt joined about its perimeter. A metal foil membrane having heat activated adhesive layers is attached to the lid and the rim of the container by inductive heating. Detents project from an inside surface of the skirt and cooperate with the rim on the container to hold the lid in an open position. A stacking lip extends from the skirt and interfits within an identical lid to allow the lids to be stacked for shipment. A hinge extends transversely across the central panel and divides the lid into movable and fixed portions. Weakened regions on the skirt separate when the lid is opened and provide evidence of potential tampering.

Owner:DOUBLE H PLASTICS

Spacing profile for double-glazing unit

A spacing profile for a spacing frame, which is to be fitted in the edge area of a double-glazing unit, forming an interspace, with a profile body of a material possessing low thermal conductivity and with a diffusion-impermeable metal foil which is bonded to the profile body so as to establish a material fit, is characterized in that the metal foil is, at least on the surface facing away from the profile body, provided with a corrosion preventing coating which comprises a colored lacquer coating and / or a layer of chromium or of a chromium alloy, wherein the corrosion preventing coating comprises a thickness which is lower by at least a factor of 2.5, preferably by at least a factor of 10 and further preferred by at least a factor of 20, as compared to the thickness of the metal foil.

Owner:PILKINGTON DEUTLAND

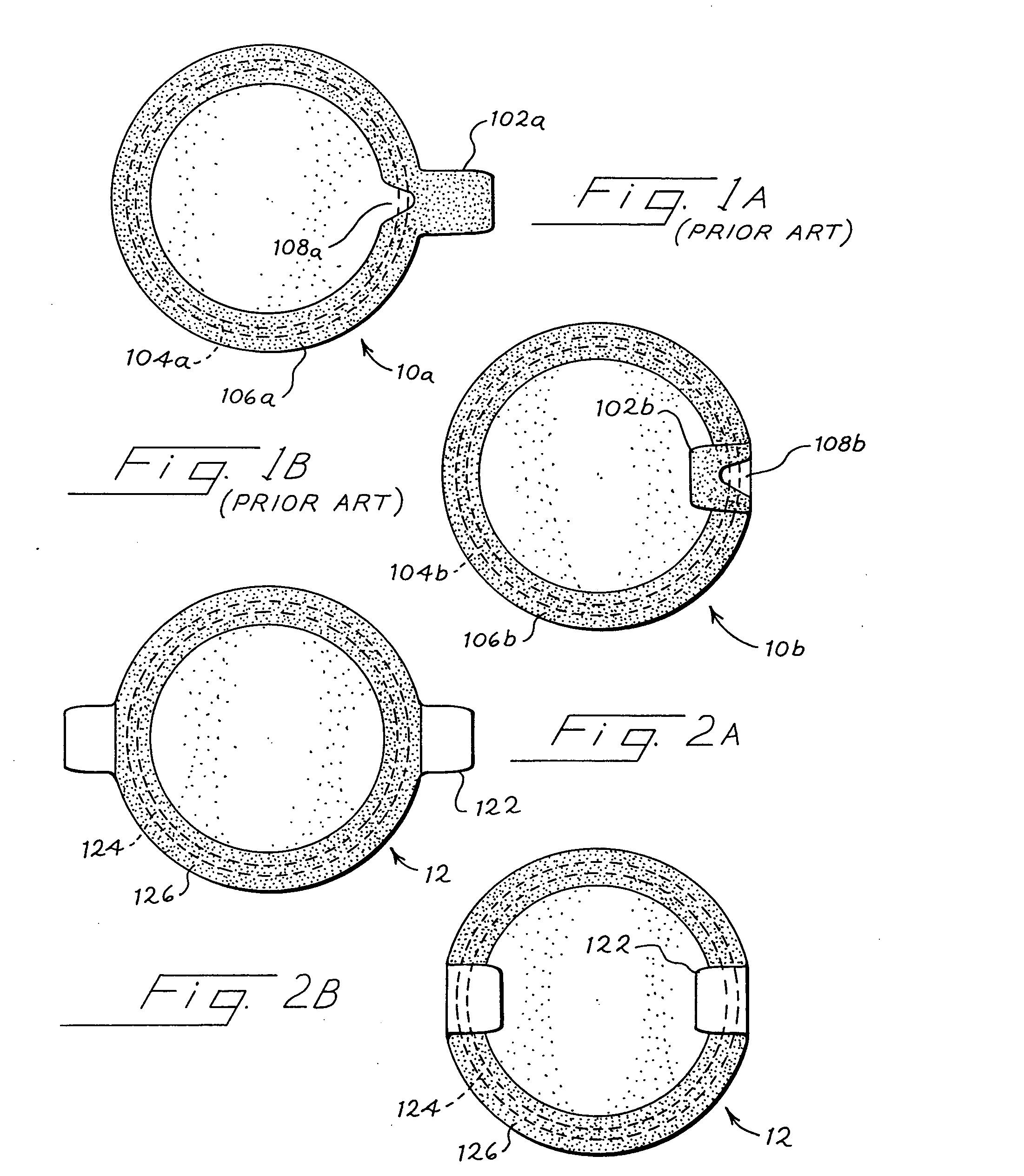

Tabbed container seal and method of manufacture

InactiveUS20080073308A1Easy to manufactureReliable and consistent sealCapsClosure using stoppersSurface layerMetal foil

An improved container seal including at least one metal-free tab member is provided. The container seal comprises a flexible, metal-free cover sheet and a flexible sealant sheet. The cover sheet comprises at least one layer of a flexible sheet material and includes a body portion that is sized and shaped to at least cover a container finish and has at least one metal-free tab portion extending from the periphery of the body portion. The flexible sealant sheet comprises a thermoplastic sealing surface layer, an inner surface layer and a layer of metal foil. The flexible sealant sheet is of the same size and shape as the body portion of the cover sheet. The inner surface of the sealant sheet and the inner surface of the body portion of the cover sheet are bonded together in opposed, congruent contact with each other. A method of manufacturing the container seal is also provided.

Owner:TEKNI PLEX

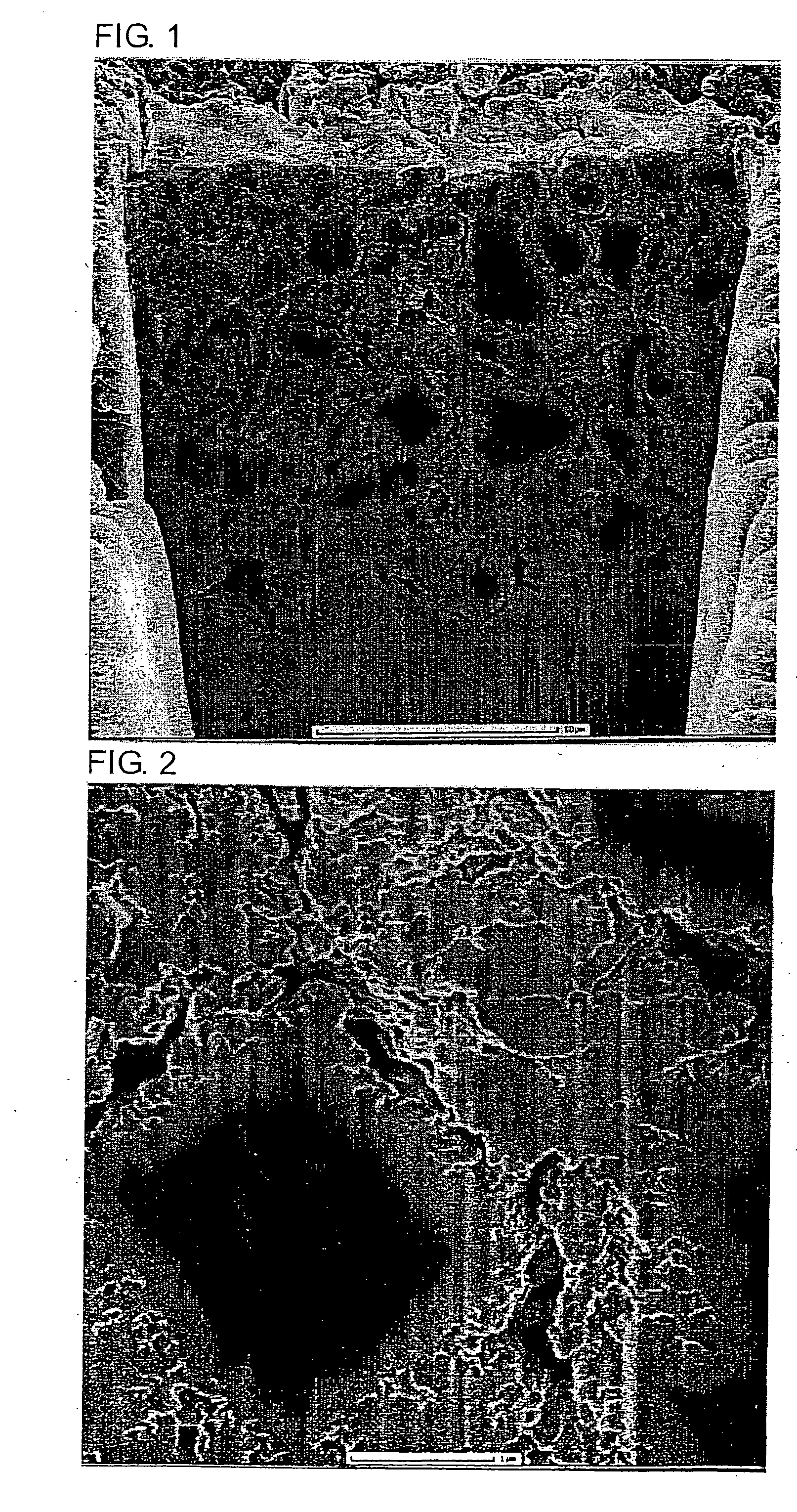

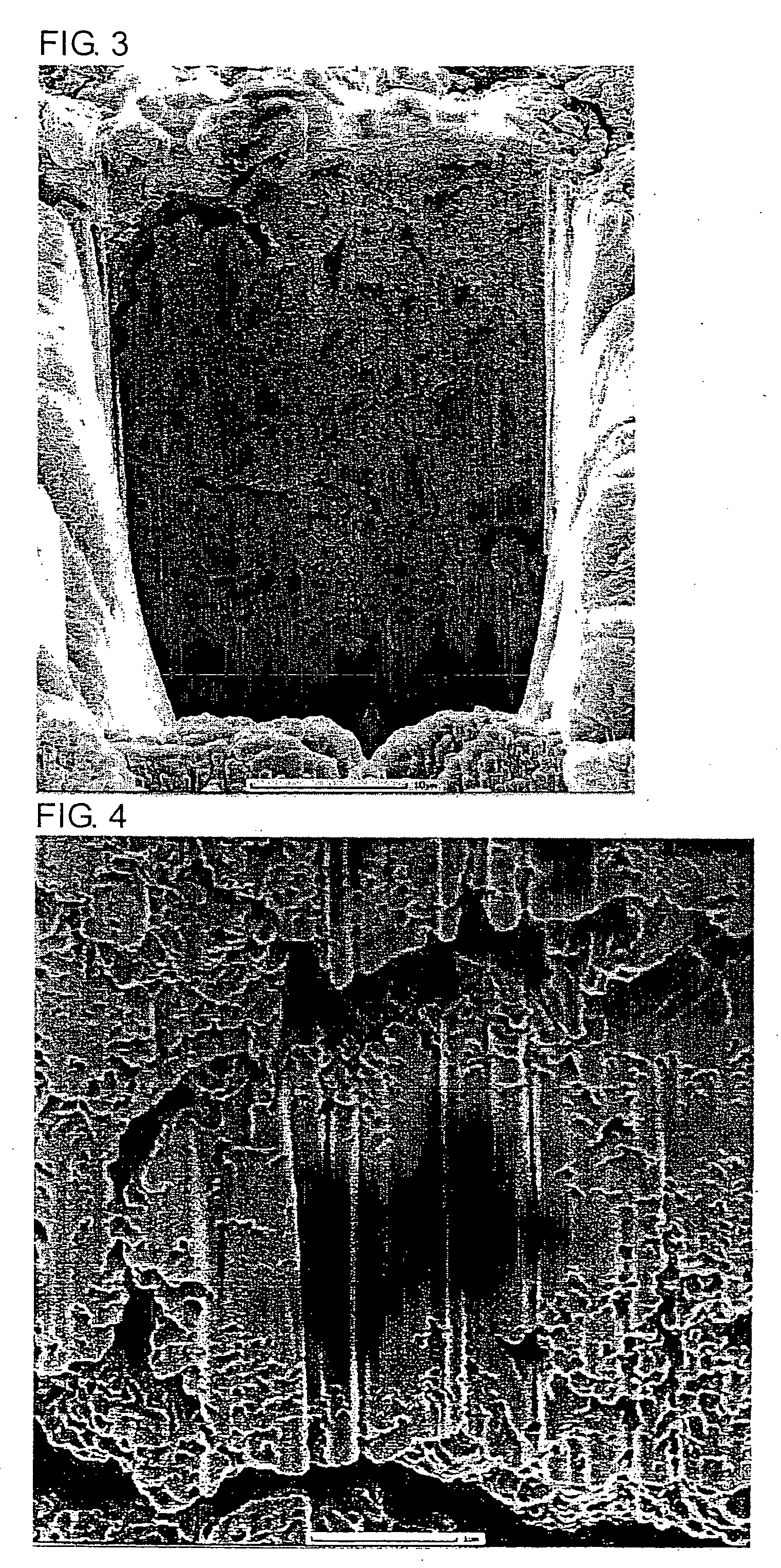

Lithium secondary battery and method for producing same

ActiveUS20060003226A1High charge and discharge capacityExcellent cycle characteristicsElectrode thermal treatmentFinal product manufactureSilicon alloyMetal foil

A rechargeable lithium battery including a negative electrode made by sintering, on a surface of a conductive metal foil as a current collector, a layer of a mixture of active material particles containing silicon and / or a silicon alloy and a binder, a positive electrode and a nonaqueous electrolyte, characterized in that the nonaqueous electrolyte contains carbon dioxide dissolved therein.

Owner:SANYO ELECTRIC CO LTD

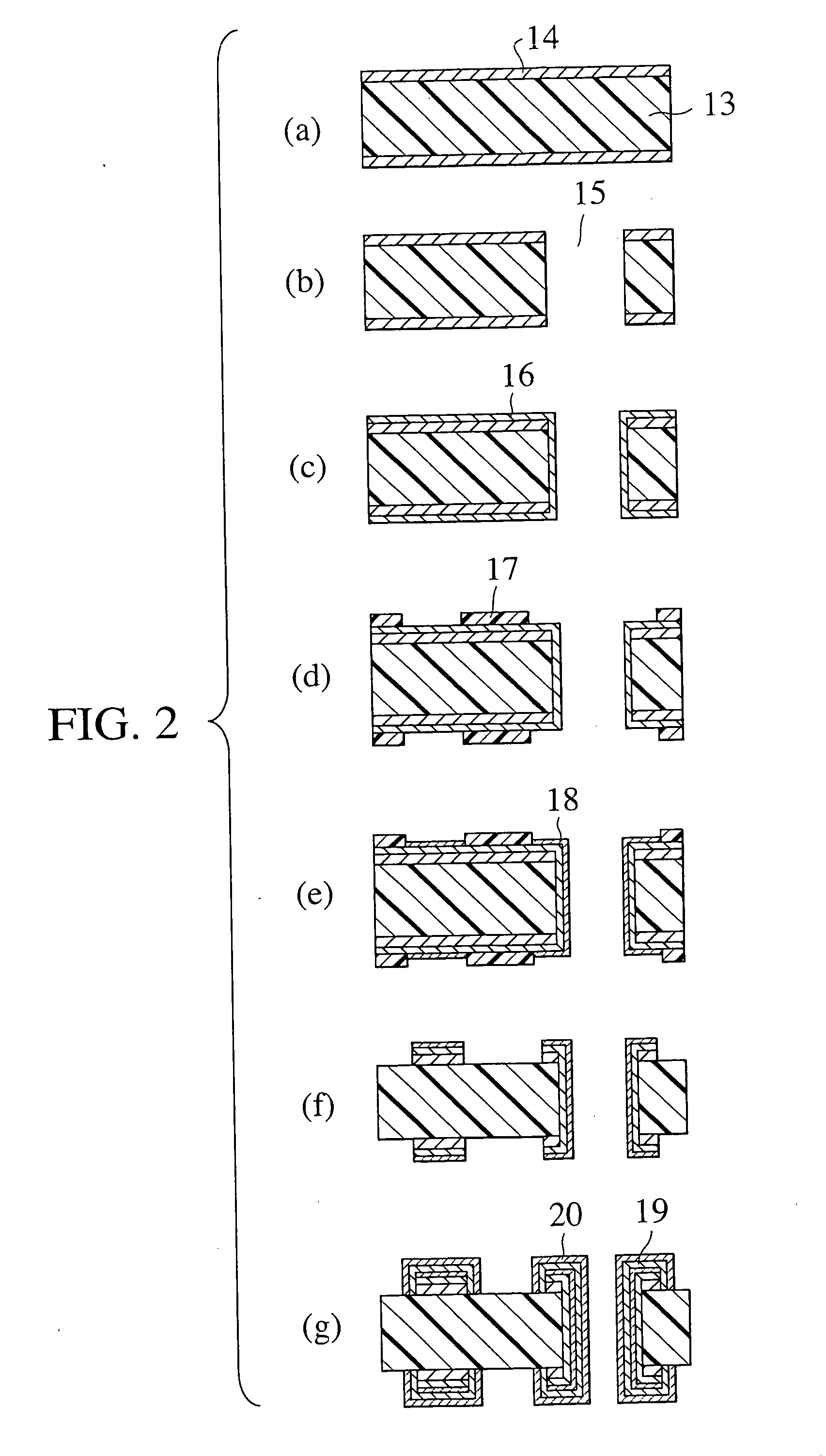

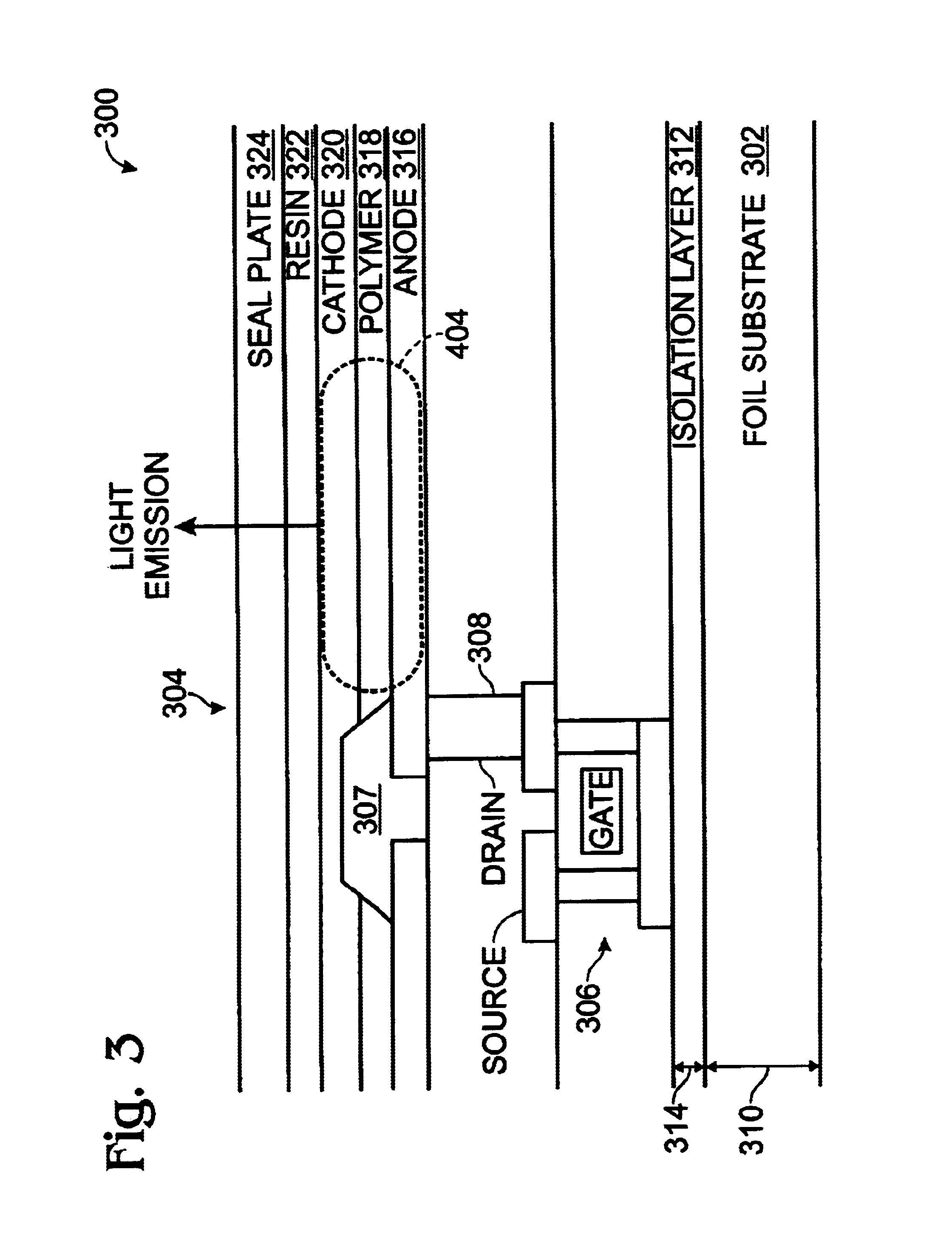

Flexible metal foil substrate display and method for forming same

A flexible metal foil substrate organic light emitting diode (OLED) display and a method for forming the same are provided. The method comprises: supplying a metal foil substrate such as titanium (Ti), Inconel alloy, or Kovar, having a thickness in the range of 10 to 500 microns; planarizing the metal foil substrate surface; depositing an electrical isolation layer having a thickness in the range of 0.5 to 2 microns overlying the planarized metal foil substrate surface; depositing amorphous silicon having a thickness in the range of 25 to 150 nanometers (nm) overlying the electrical insulation layer; from the amorphous silicon, forming polycrystalline silicon overlying the electrical insulation layer; forming thin-film transistors (TFTs) in the polycrystalline silicon; and, forming an electronic circuit using the TFTs, such as an OLED display.

Owner:GLOBAL OLED TECH

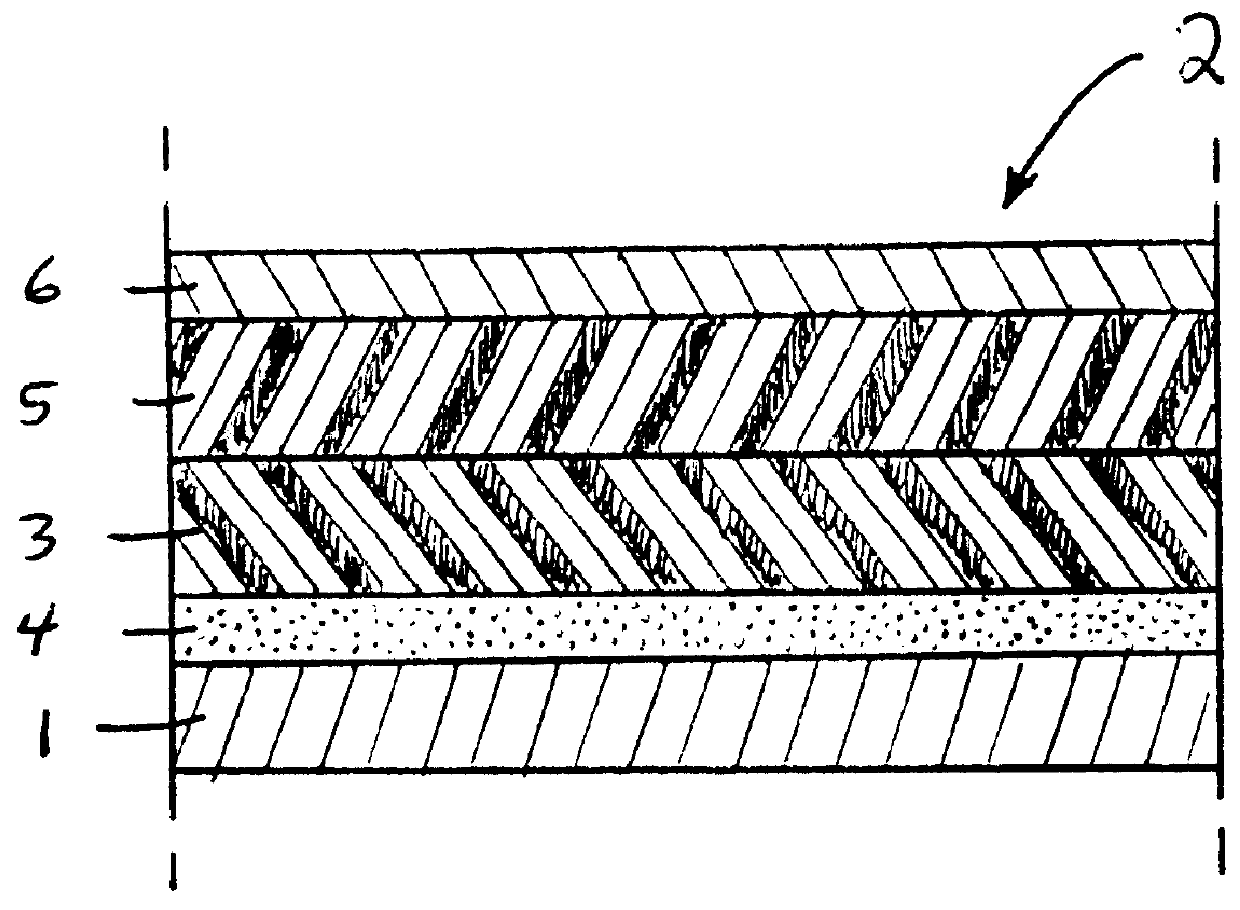

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

Protective acoustic cover assembly

A protective acoustic cover assembly including a metal foil with perforations, and a treatment on one or more surfaces of said metal foil. The treatment is a hydrophobic or oleophobic treatment, or both. The protective acoustic cover assembly has an average specific acoustic resistance of less than about 11 Rayls MKS from 250-300 Hz, an average specific acoustic reactance magnitude of less than about 1 Rayls MKS from 250-300 Hz, and an instantaneous water entry pressure value of greater than about 11 cm. The perforations of the metal foil preferably have an average maximum pore size of less than about 150 micrometers. The protective acoustic cover assembly further includes an adhesive mounting system, and the preferred metal foil is nickel.

Owner:WL GORE & ASSOC INC

Substrate and collector grid structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7507903B2Eliminate deficienciesInexpensive productionPV power plantsSolid-state devicesRoll-to-roll processingMetal foil

This invention comprises deposition of thin film photovoltaic junctions on metal substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation an interconnection substrate structure is produced in a continuous roll-to-roll fashion. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Cells comprising the metal foil supported photovoltaic junctions are then laminated to the interconnection substrate structure. Conductive interconnections are deposited to complete the array. The conductive interconnections can be accomplished with a separately prepared interconnection component. The interconnected array is produced using continuous roll-to-roll processing which avoids the need to use the expensive and intricate material removal operations currently taught in the art to achieve electrical interconnections among arrays of photovoltaic cells.

Owner:SOLANNEX

Metal base circuit board, LED, and LED light source unit

ActiveUS20090032295A1Easy to bendSmall sizePoint-like light sourcePrinted electric component incorporationThin metalMetal foil

To provide a thin metal base circuit board which can be not only installed on a flat portion but also closely attached to a side or bottom surface of a case or to a stepped or curved portion and which is excellent in heat dissipation performance, electrical insulating performance and flexibility; a process for its production; and a hybrid integrated circuit, an LED module and a bright, ultra-long-life LED light source employing it.A metal base circuit board having insulating layers and conductive circuits or metal foils alternately laminated, characterized in that the thickness of each conductive circuit or metal foil is from 5 μm to 450 μm, each insulating layer is made of a cured product of a resin composition comprising an inorganic filler and a thermosetting resin, and the thickness of each insulating layer is from 9 μm to 300 μm; and a hybrid circuit board employing it. The metal base circuit board wherein a coverlay is provided, and a layer having a magnetic loss or a layer having a dielectric loss is laminated on the surface of the coverlay. A LED light source unit having at least one light-emitting diode (LED) mounted on the conductive circuit.

Owner:DENKA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com