Tabbed container seal and method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

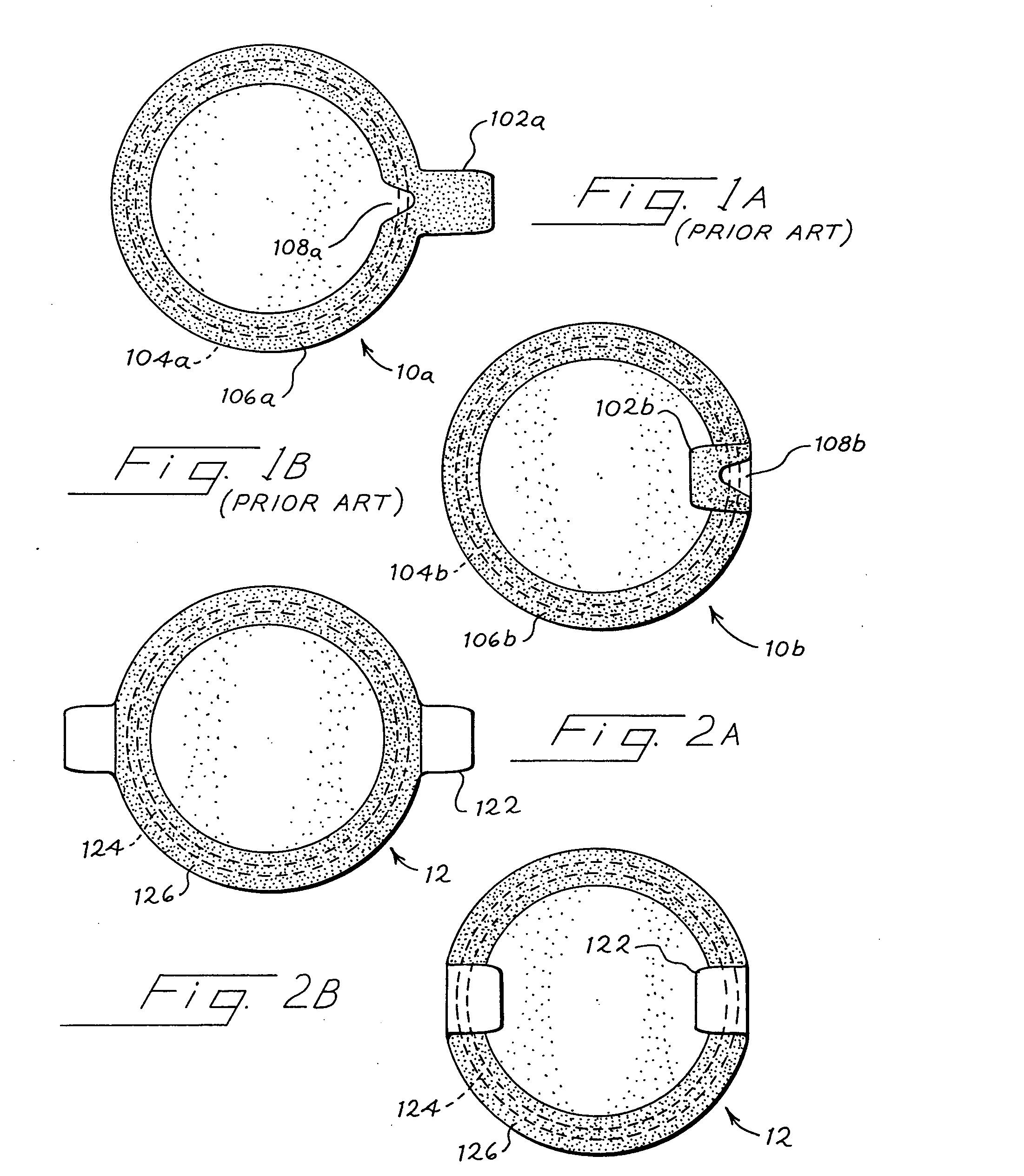

Image

Examples

Embodiment Construction

[0037]As used herein and in the appended claims, the term “closure” and grammatical variations thereof, refers to a lid or cap, such as a threaded cap, a lug-type cap, a snap-cap, and the like, that is designed to be repeatedly secured to and removed from a container finish, such that when the cap or lid is secured to the container finish, a seal is formed that protects the contents of the container from contamination and leakage.

[0038]The terms “lining material” and “liner” refer to a sheet material that is compressible and preferably semirigid, and is suitable for use within a closure to provide a resealable seal between the closure and a container finish. The term “liner” also refers to a section of lining material that has been cut to fit snugly within a closure against the upper inside surface thereof.

[0039]The term “seal”, when used as a noun, refers to a film or multilayer laminate material that is adhesively secured or heat-sealed over the finish of a container to provide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com