Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28890 results about "Sheet material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheet Materials are engineered woods that are made by binding the timber material together with adhesives. The timber is typically formed into tiny strips and bound to create layers with wooden veneers sometimes used if appearances are important.

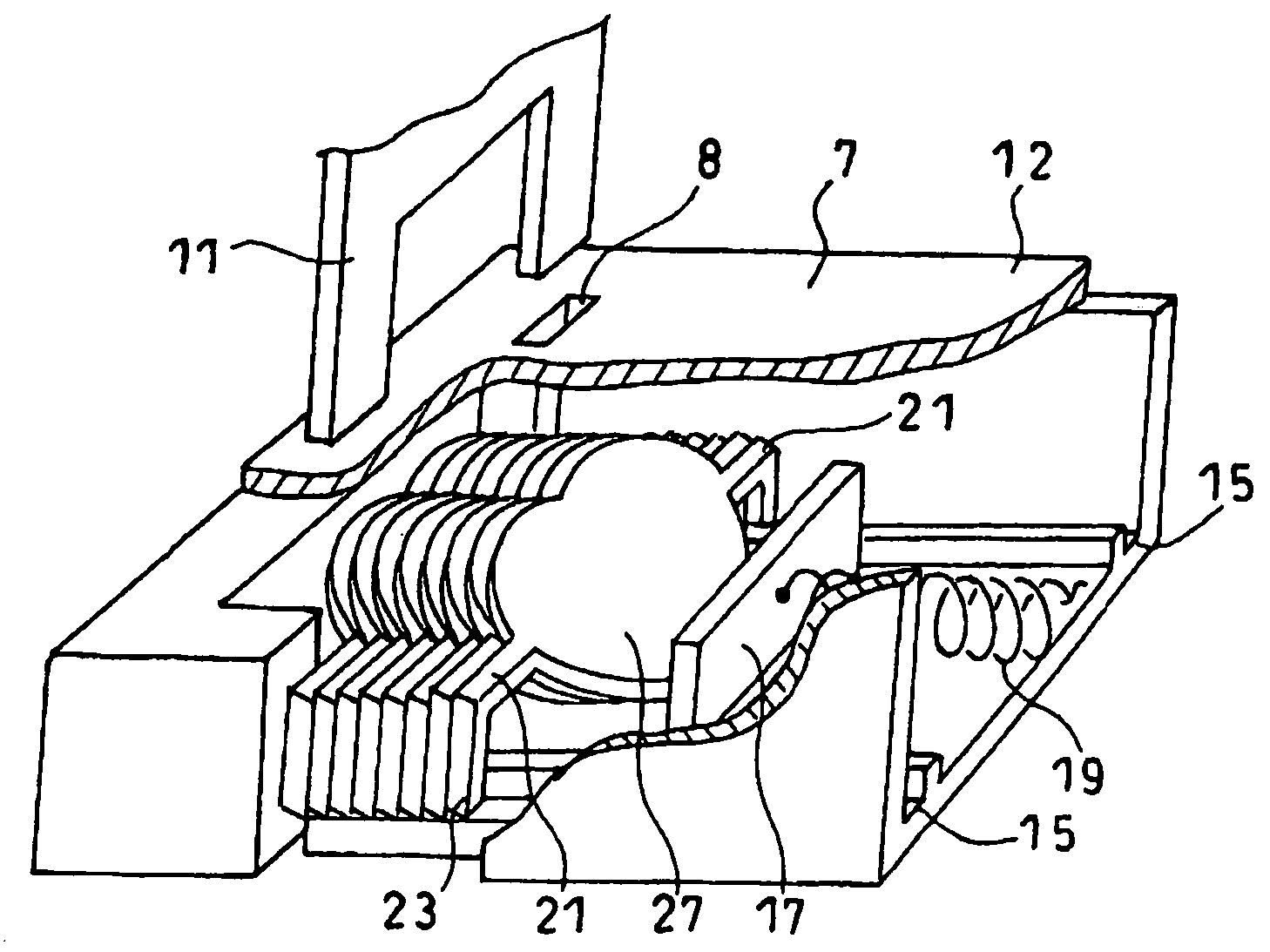

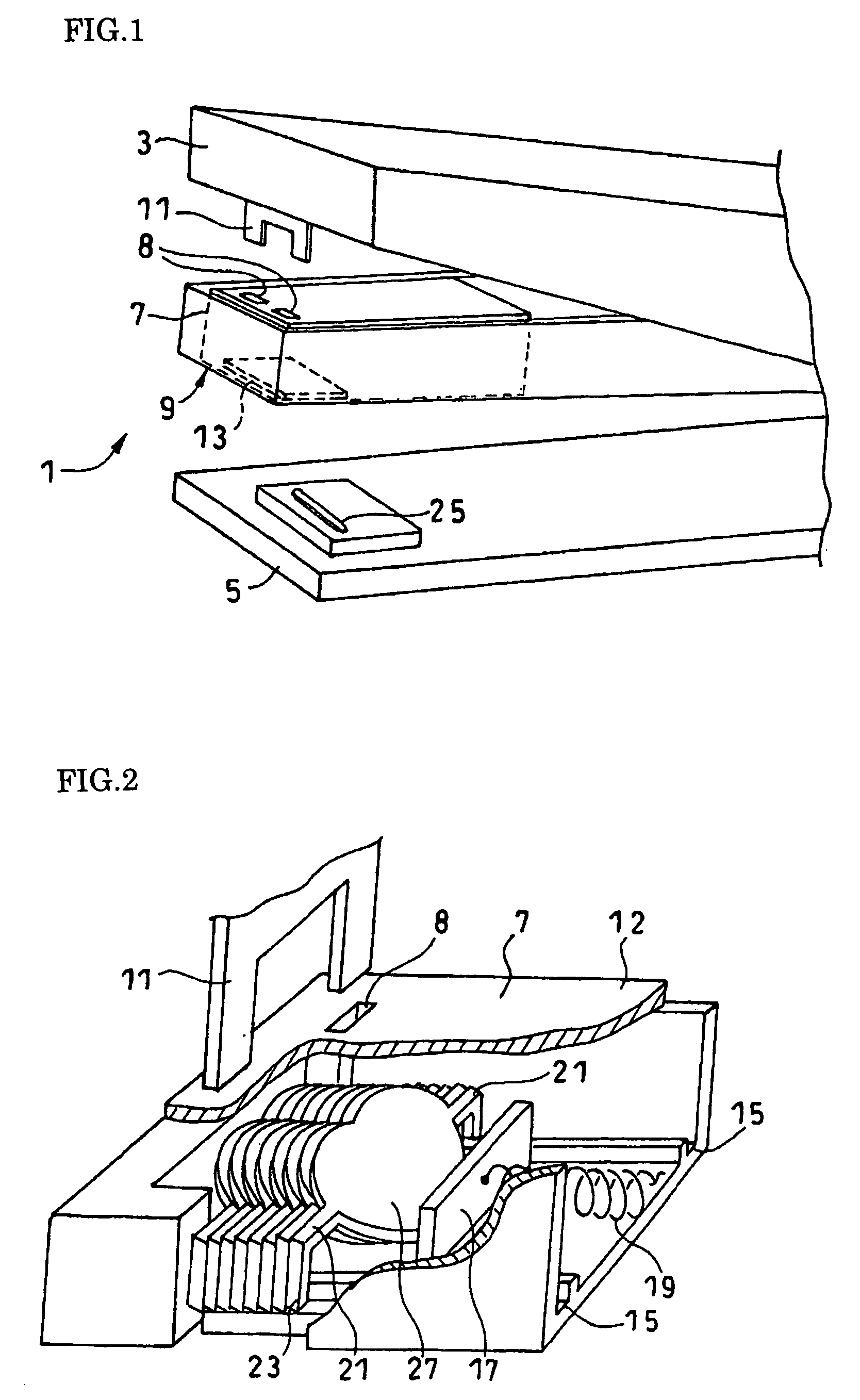

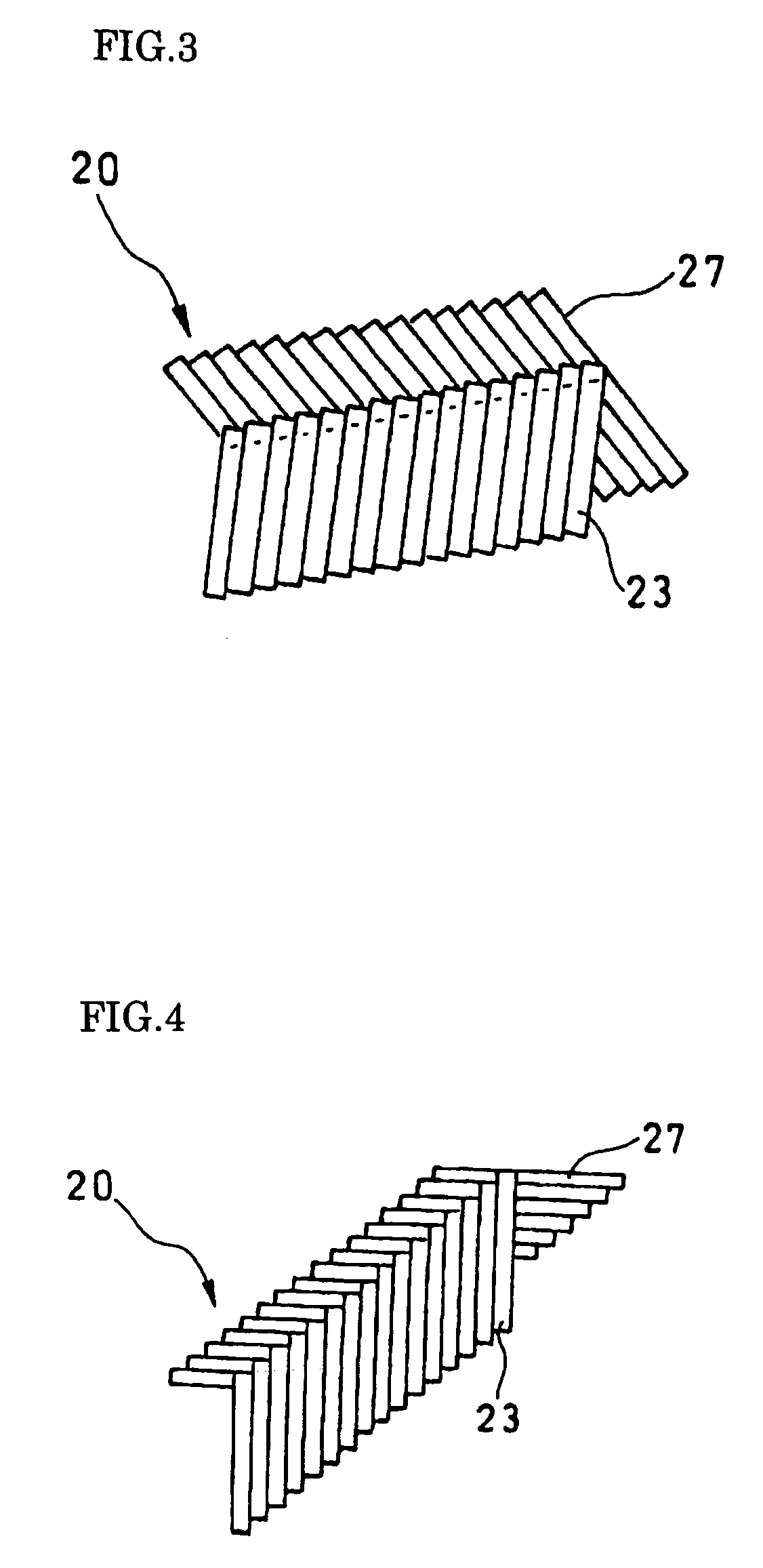

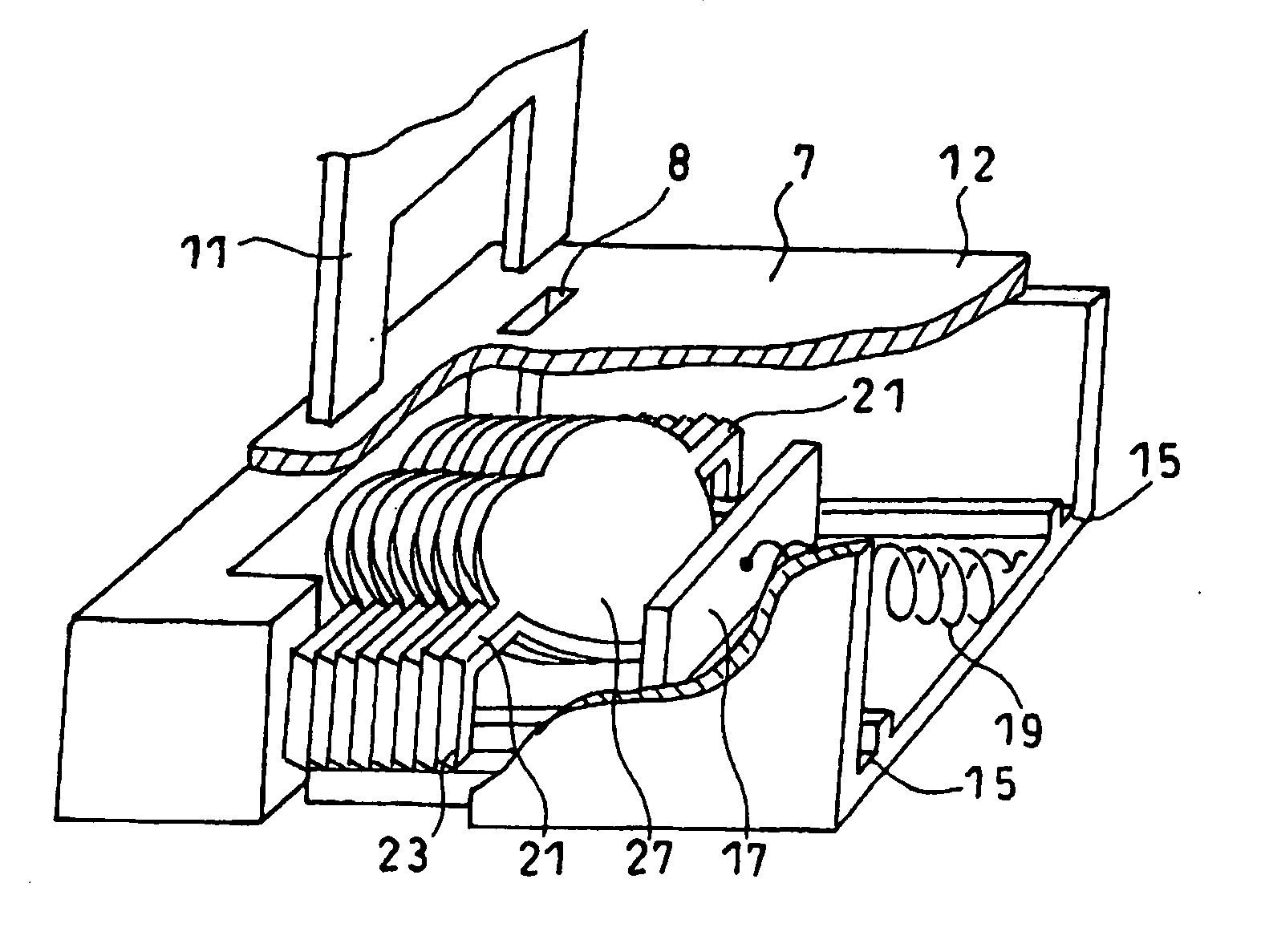

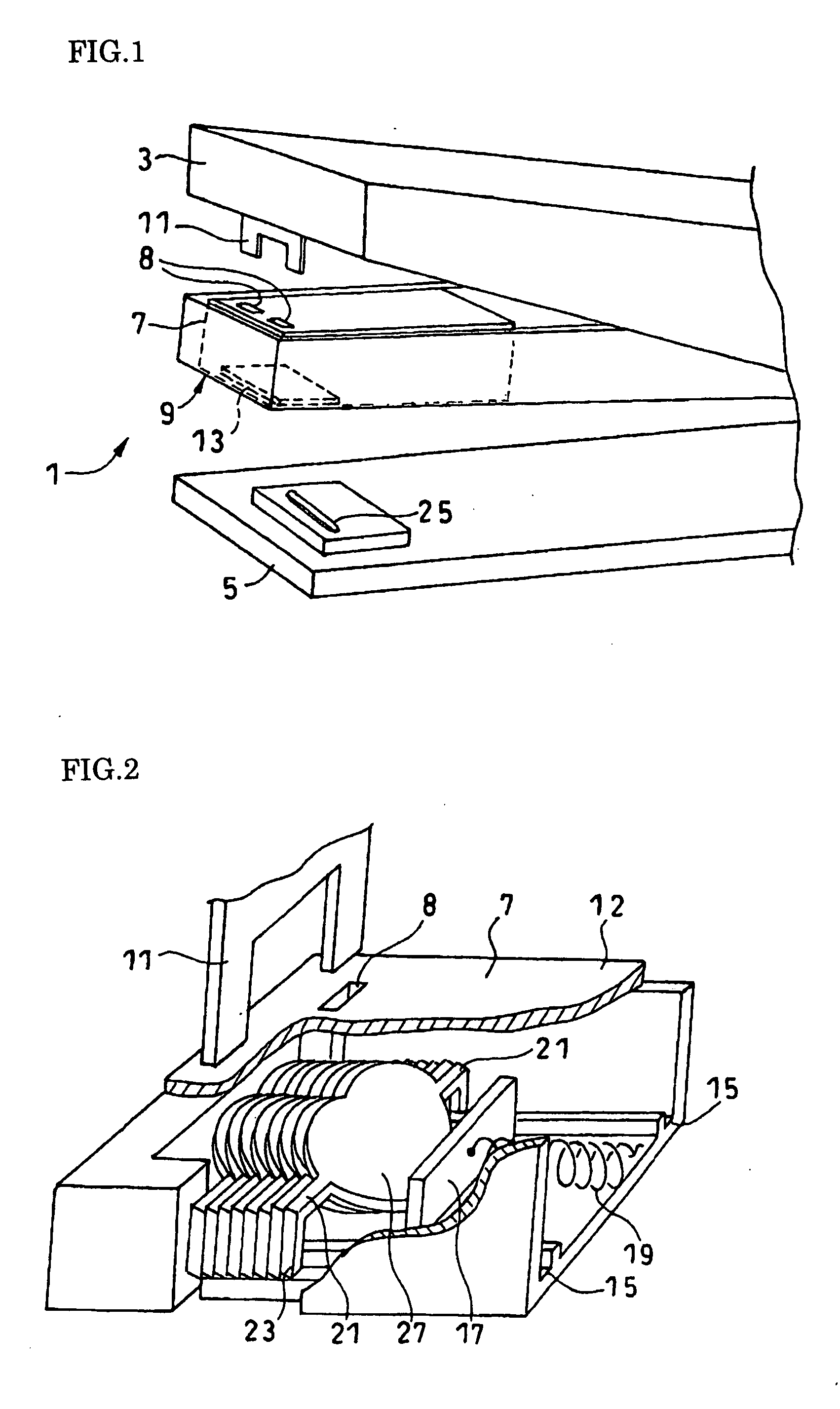

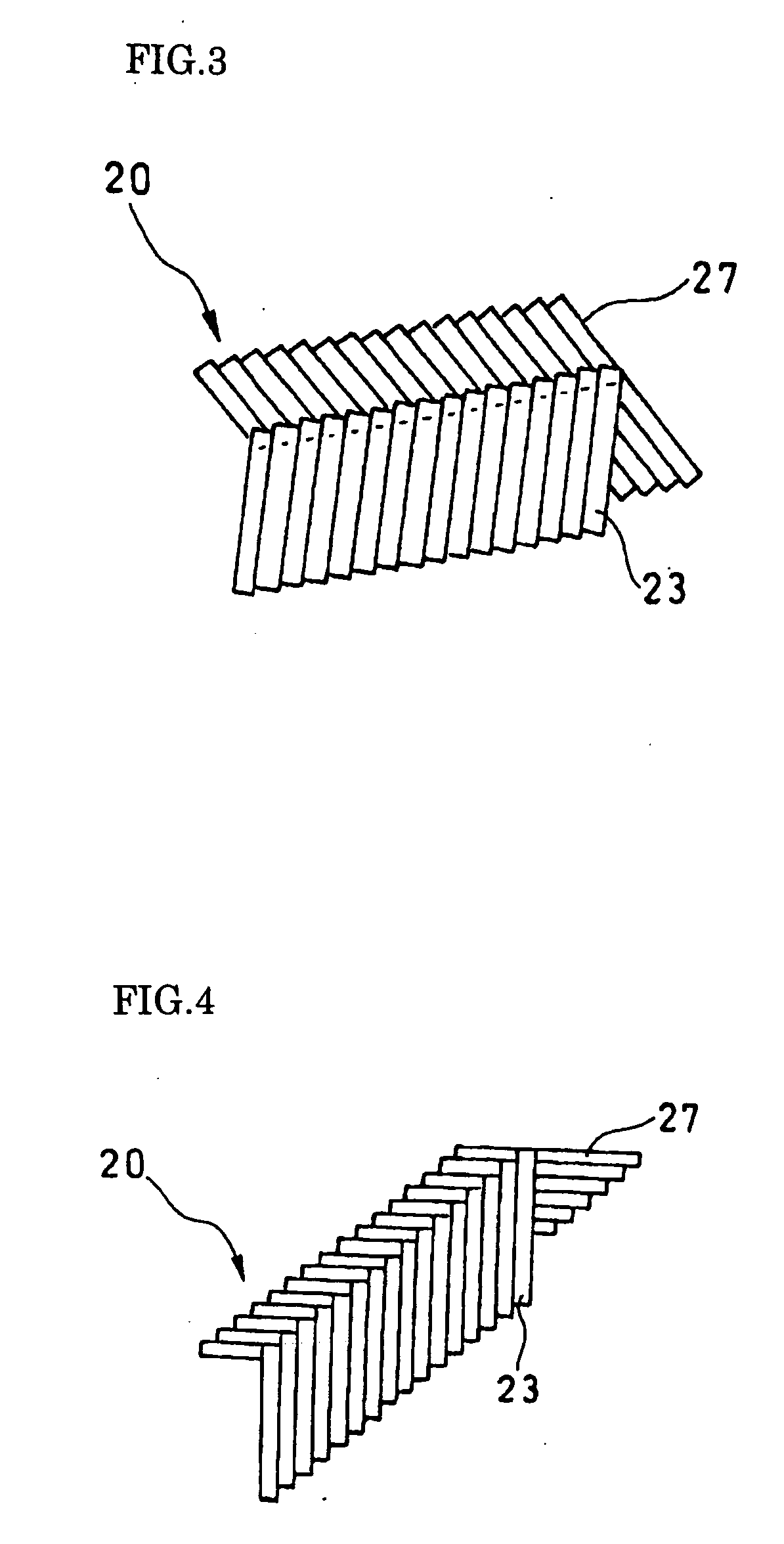

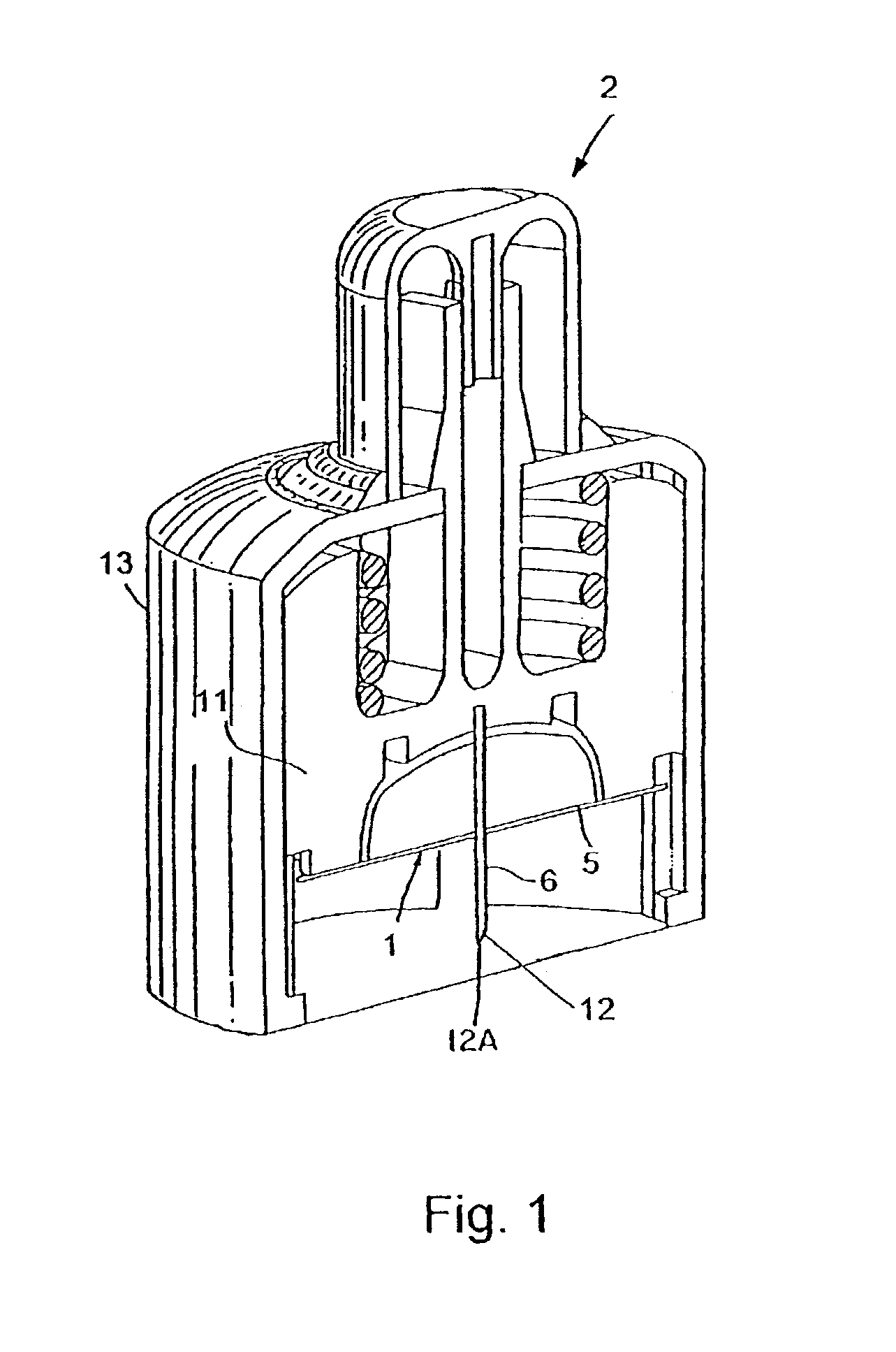

Cartridge for stapler and stapler

A stapler of the present invention includes a retaining part having a staple pusher, a storing section that stores a staple, and a receiving base that bends leg parts after piercing the staple pushed out by the staple pusher through a sheet material to bind the sheet material with the staple. The staple includes left and right shoulder parts against which the staple pusher abuts, leg parts extending substantially perpendicularly from the shoulder parts and a pattern part having an arbitrary shape and provided between the left and right shoulder parts. The pattern part is inclined against the leg parts and the storing section is provided, on one side thereof, with a take-out opening of the staple that is large enough to allow the pattern part to pass.

Owner:KAMEYAMA TOSHIYUKI

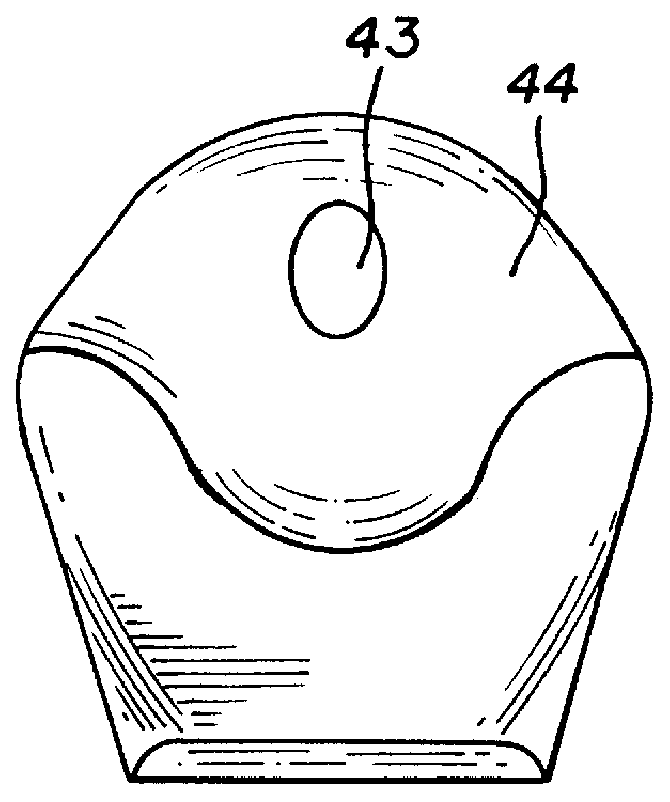

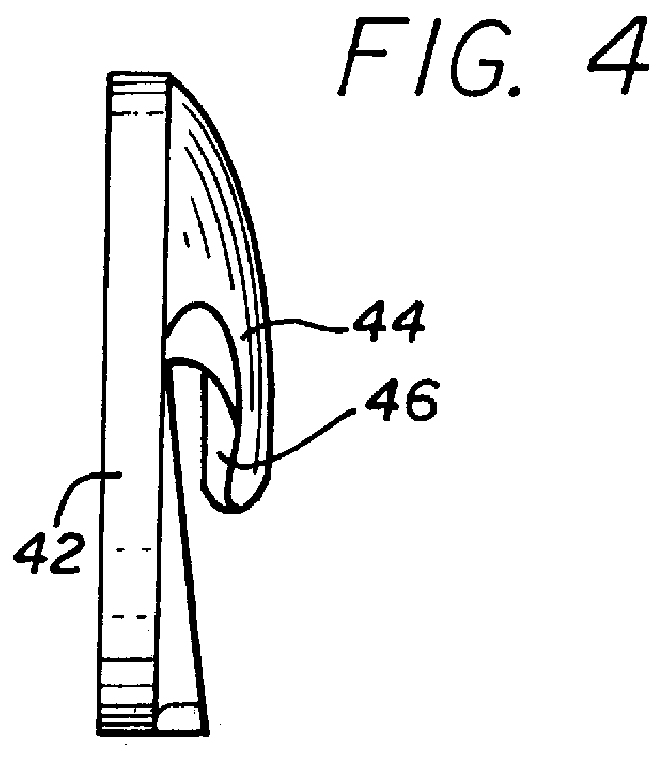

Cartridge for stapler and stapler

A stapler (1) of the present invention includes a retaining part (3) having a staple pusher (11), a storing section (9) that stores a staple (20), and a receiving base (5) that hat bents leg parts (23) after piercing the staple (2) pushed out by the staple pusher (11) through a sheet material to bind the sheet material (60) with the staple (20). The staple (20) includes left and right shoulder parts (21) against which the staple pusher (11) abuts, leg parts (23) extending substantially perpendicularly from the shoulder parts (21) and a pattern part (27) having an arbitrary shape and provided between the left and right shoulder parts (21). The pattern part (27) is inclined against the leg parts (23) and the storing section (9) is provided, on one side thereof, with a take-out opening (13) of the staple (20) that is large enough to allow the pattern part (27) to pass.

Owner:KAMEYAMA TOSHIYUKI

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

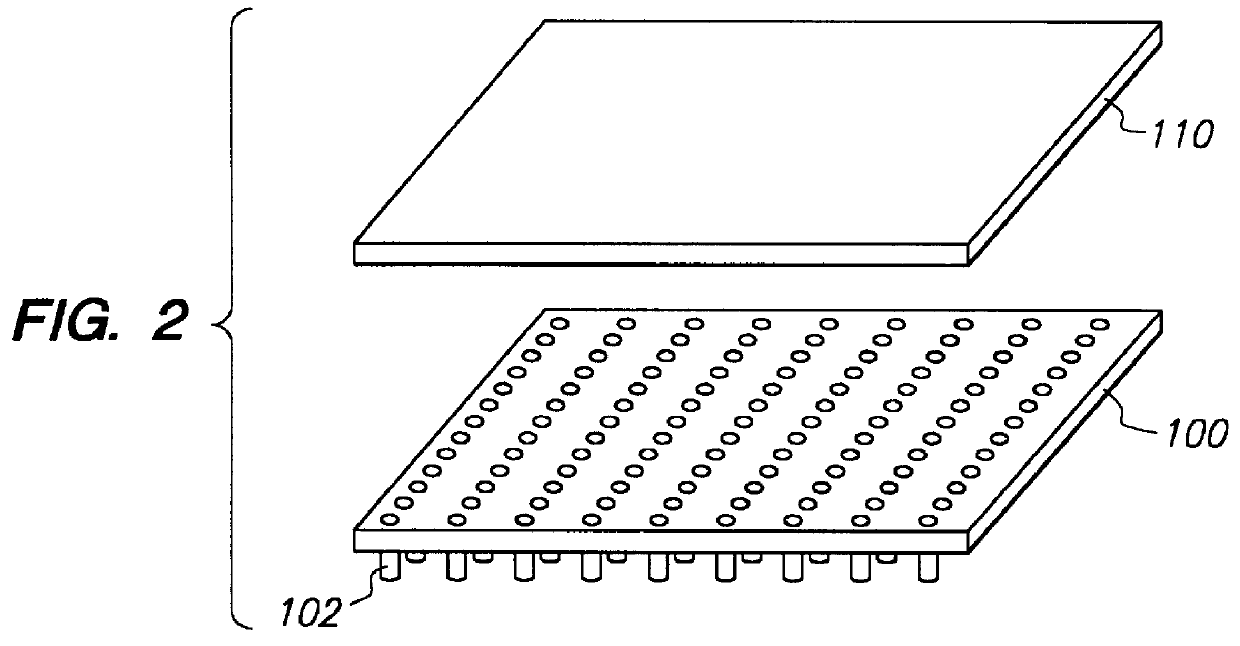

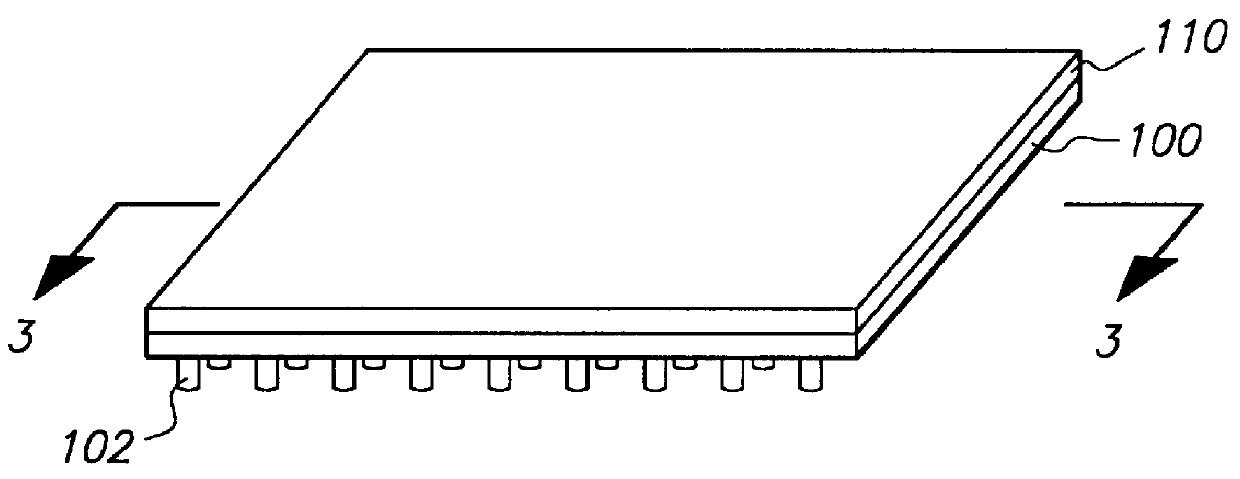

Capillary electroflow apparatus and method

The present invention concerns an apparatus for conducting a microfluidic process. The apparatus comprises integral first and second plates. The first plate comprises an array of sample receiving elements for receiving a plurality of samples from an array of sample containers and dispensing the samples. The second plate comprises a planar array of microfluidic networks of cavity structures and channels for conducting a microfluidic process. Also disclosed is a method for processing an array of samples. At least a portion of each sample in an array of sample wells is simultaneously transferred to a corresponding array of microfluidic networks of cavity structures and channels by means of a corresponding array of sample receiving elements that is in integral fluid communication with the array of microfluidic networks. The samples are then processed. Also disclosed is a device for conducting a microfluidic process wherein the device comprising a planar substrate having a planar array of microfluidic networks of cavity structures and channels for conducting a microfluidic process. A plurality of such devices may be present on a continuous sheet. The invention further includes kits for carrying out microfluidic processes comprising an apparatus as described above.

Owner:ACLARA BIOSCIENCES INC

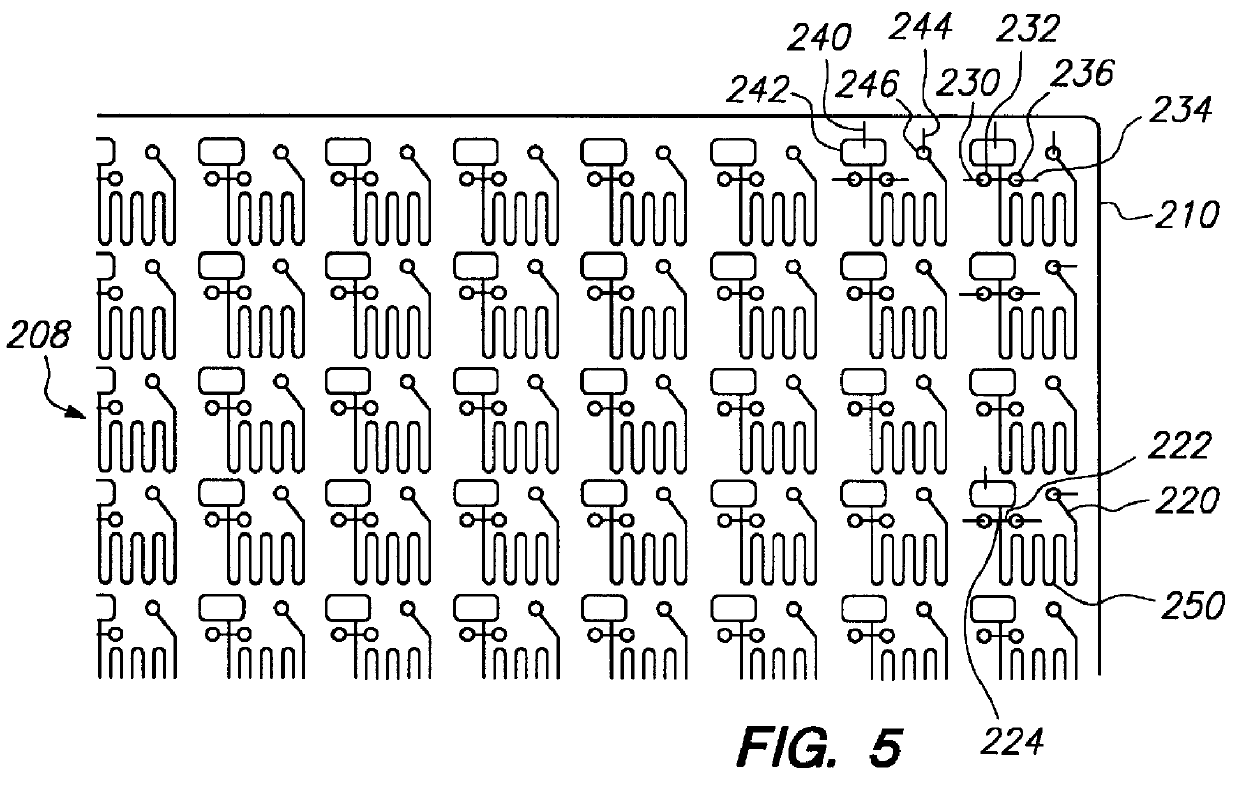

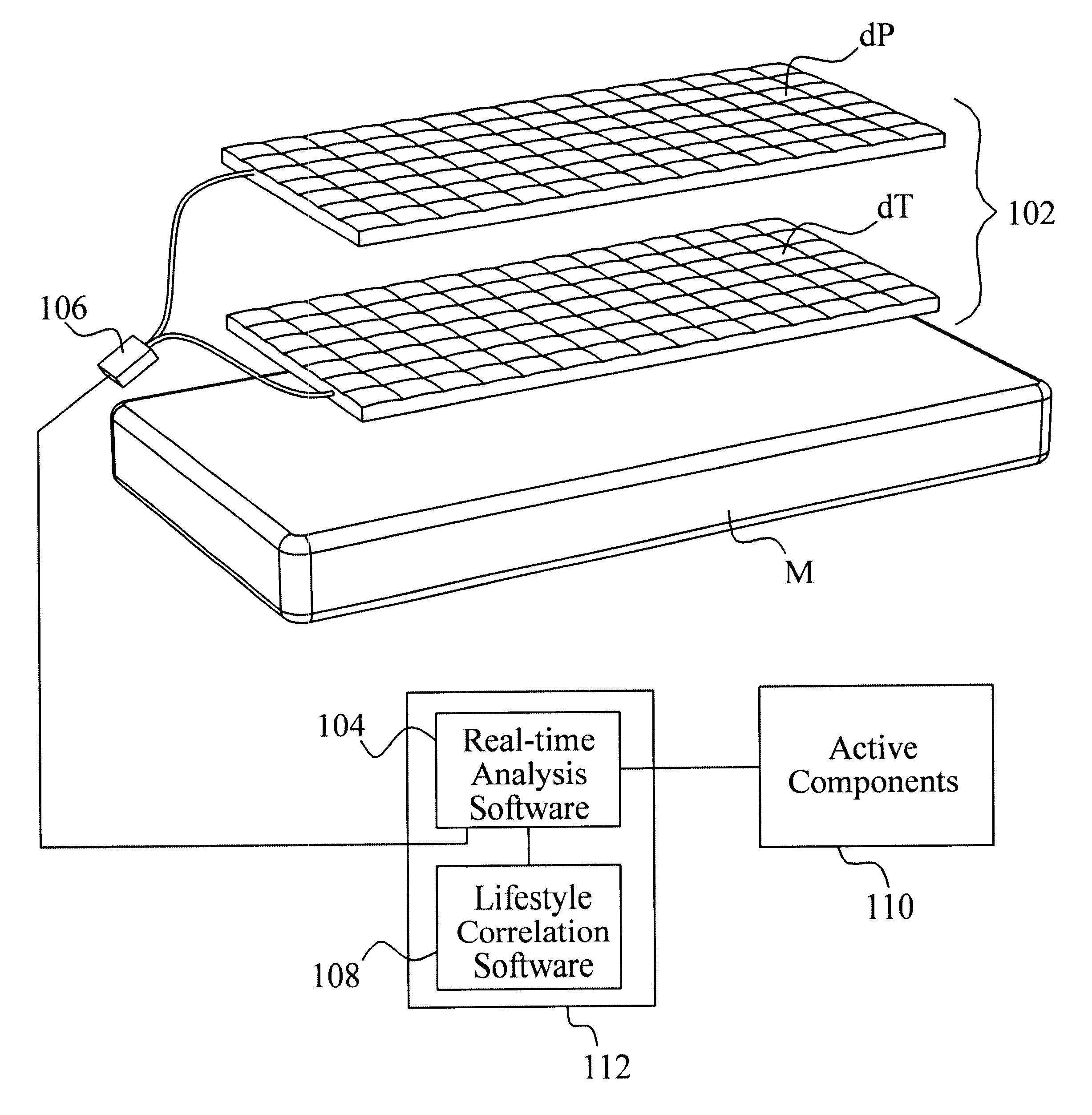

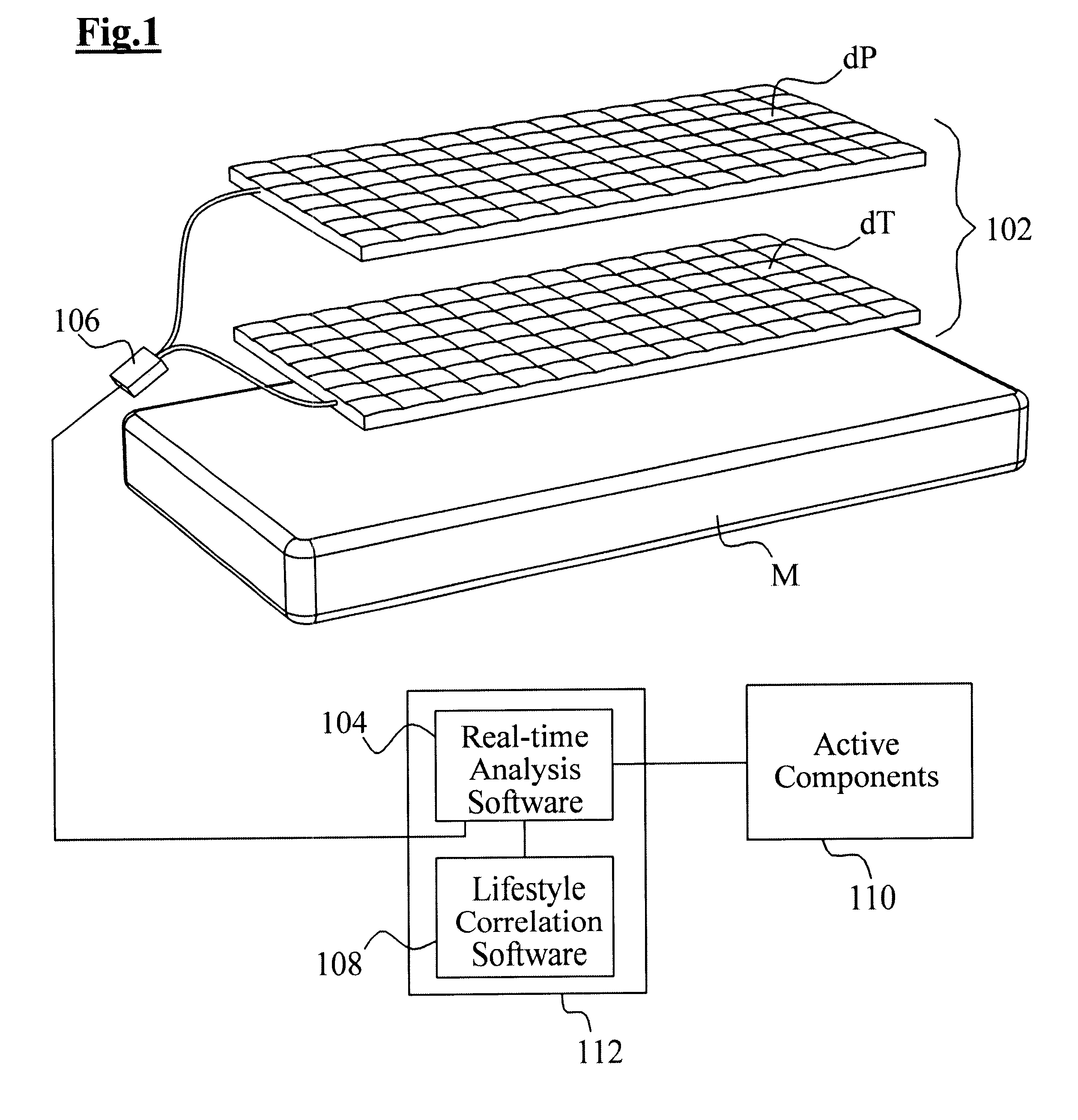

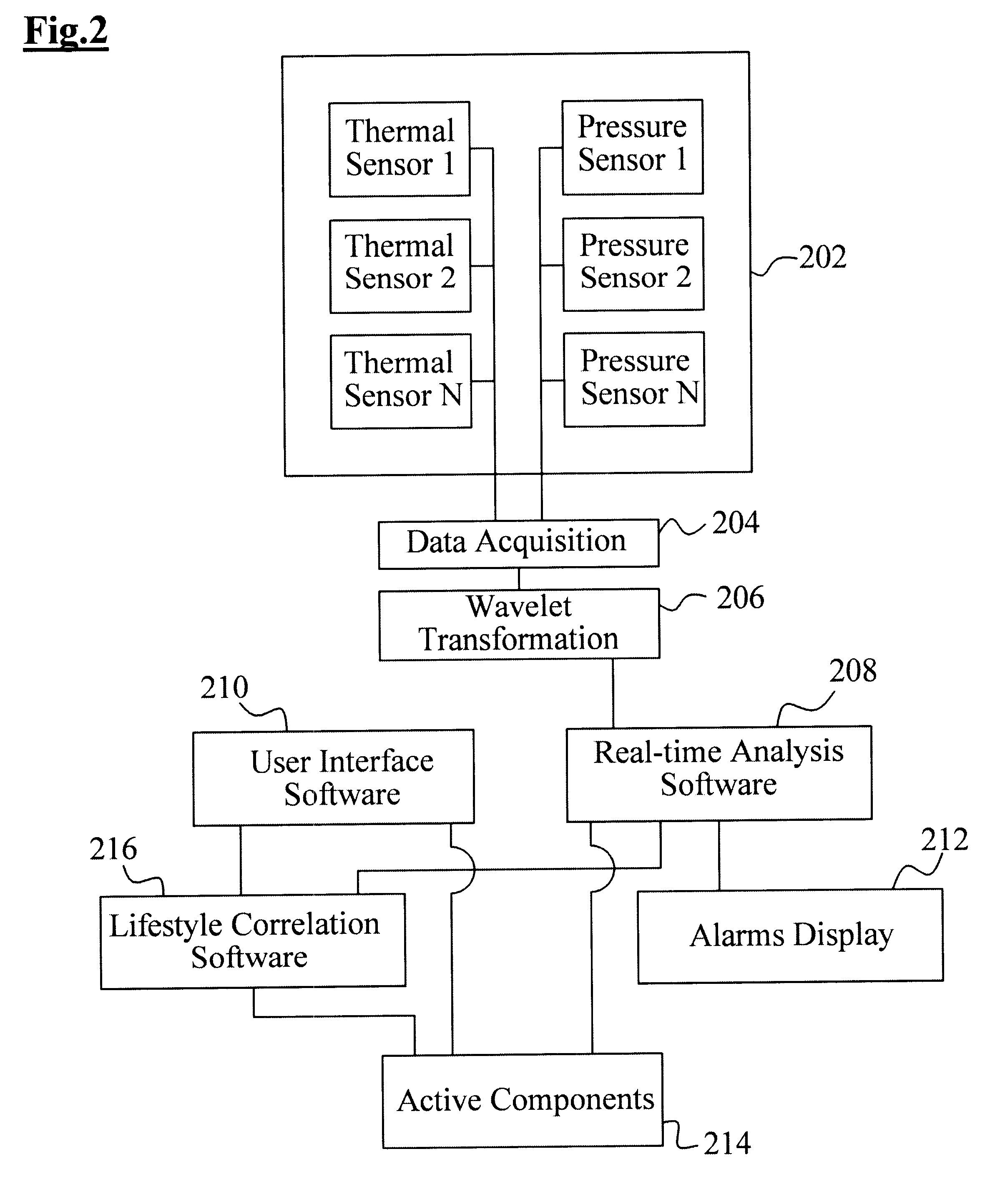

SleepSmart

A method and apparatus for measuring sleep quality that utilizes sensors incorporated in a sheet which is laid on top of a conventional mattress on which the subject sleeps. The sensors can collect information such as the subject's position, temperature, sound / vibration / movement, and optionally other physical properties. The apparatus for monitoring an individual's sleep quality is comprised of one or more layers of arrays of integrated sensors, which can be incorporated in layer pads, which is then placed on a conventional mattress; one or more controllers coupled with the arrays of integrated sensors in each layer pad for the purpose of acquiring data from the sensors; a real-time analysis software for analyzing data acquired by the controller from the array of integrated sensors; an interface software for collecting user lifestyle data; a lifestyle correlation software for correlating the lifestyle data with the data acquired by said array of sensors; one or more active components to improve sleep quality based on the data acquired through the sensors and the lifestyle data. The array of sensors provide one or more of the following data: position, temperature, sound, vibration, and movement data. Each layer pad can be individually removed or added as necessary depending on the data being collected.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

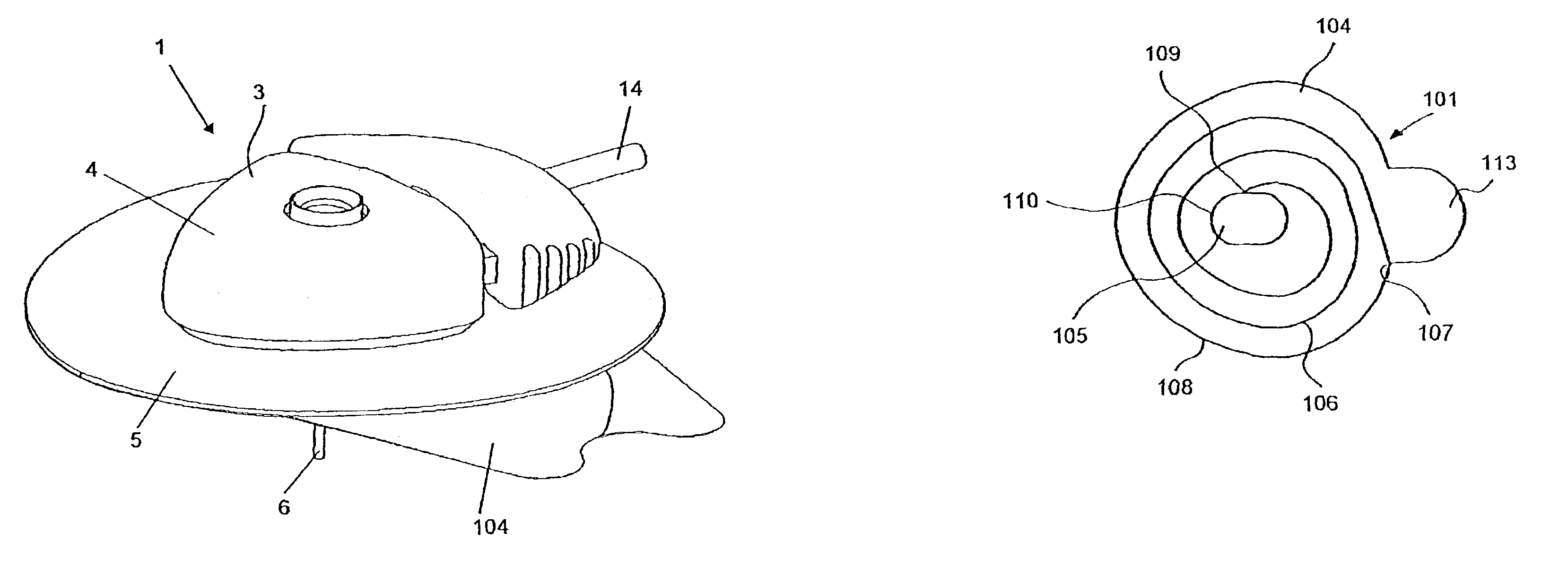

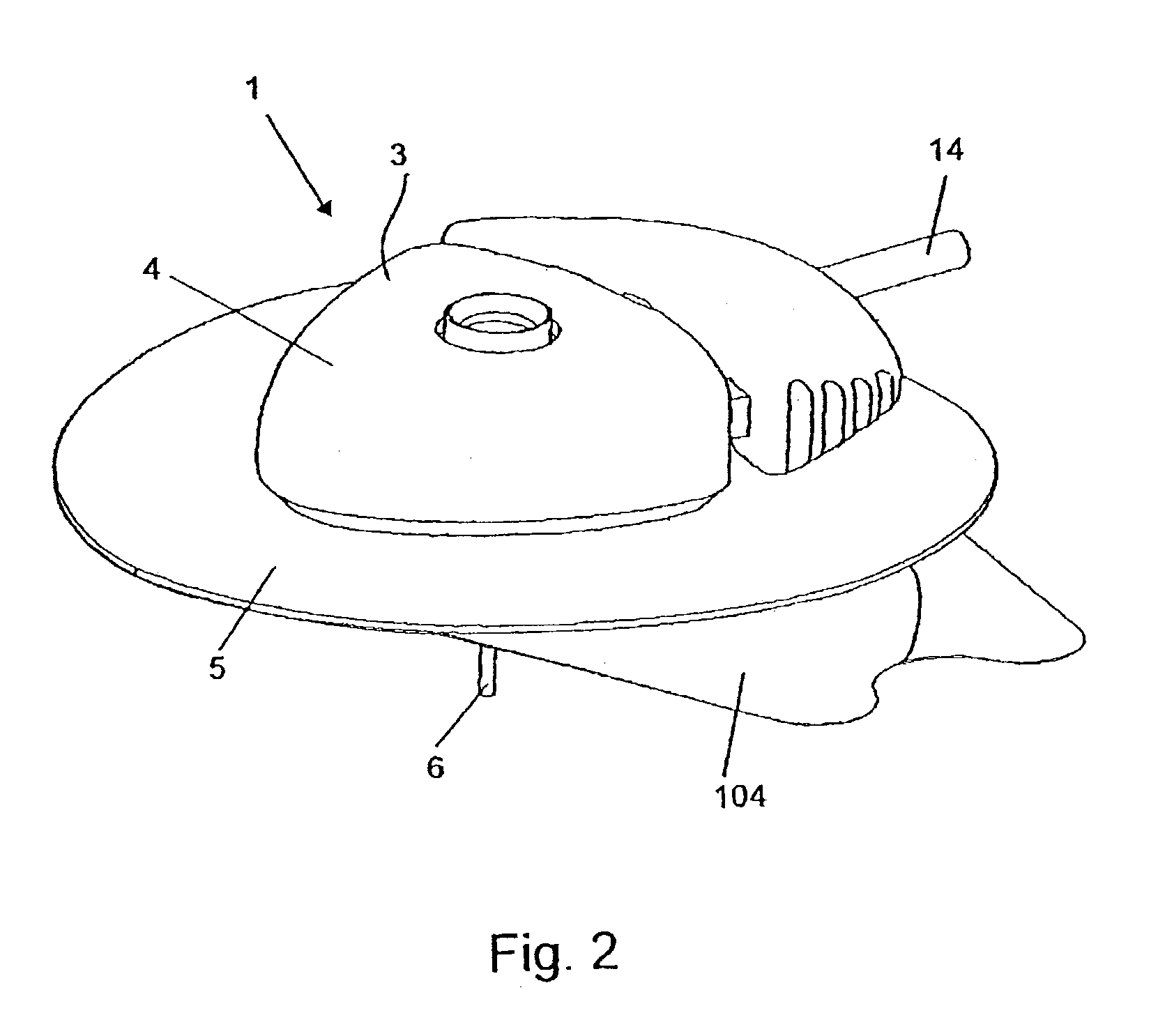

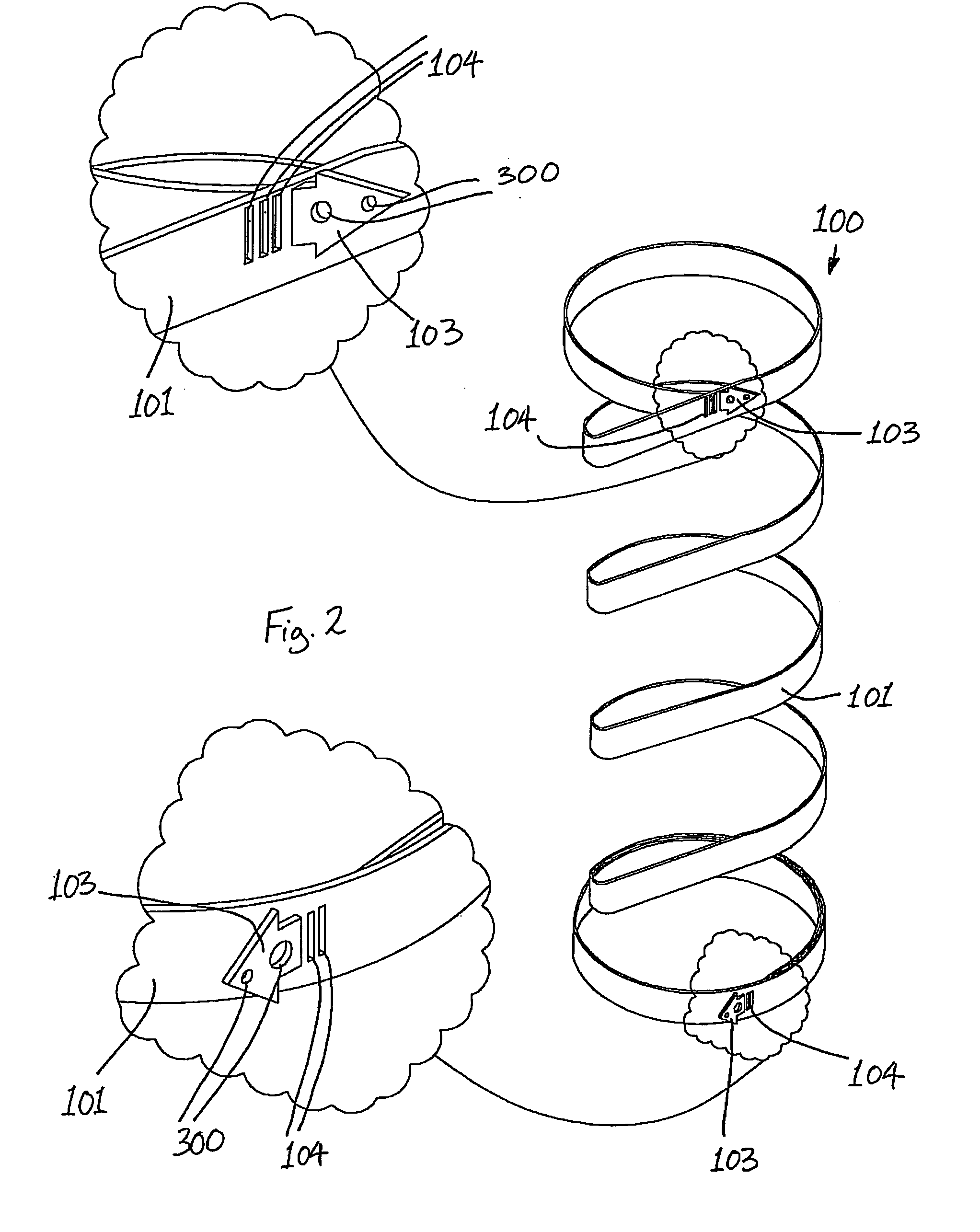

Infusion device and an adhesive sheet material and a release liner

ActiveUS7070580B2Easy to handleForce is smallPressure infusionInfusion needlesLower faceBiomedical engineering

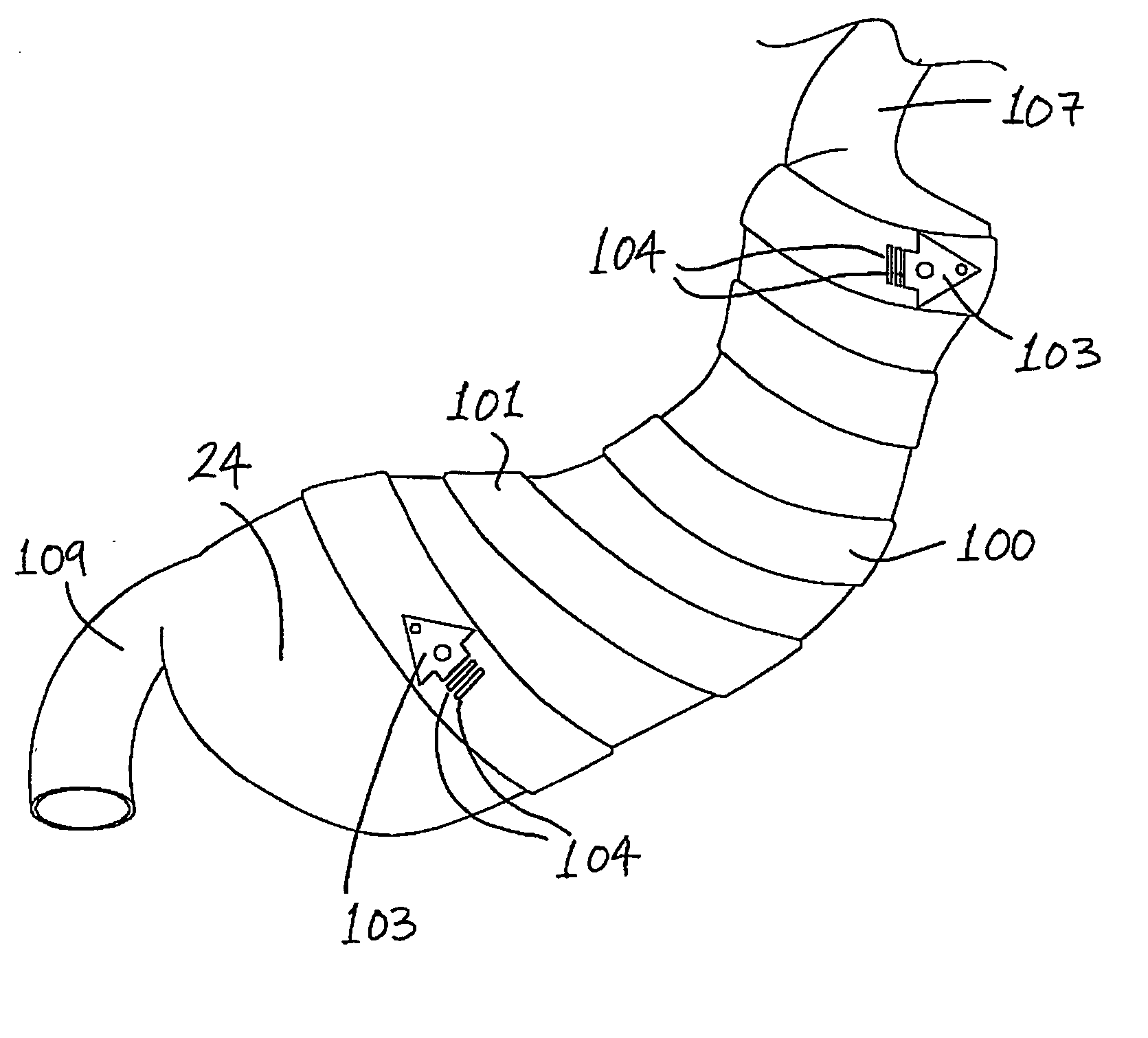

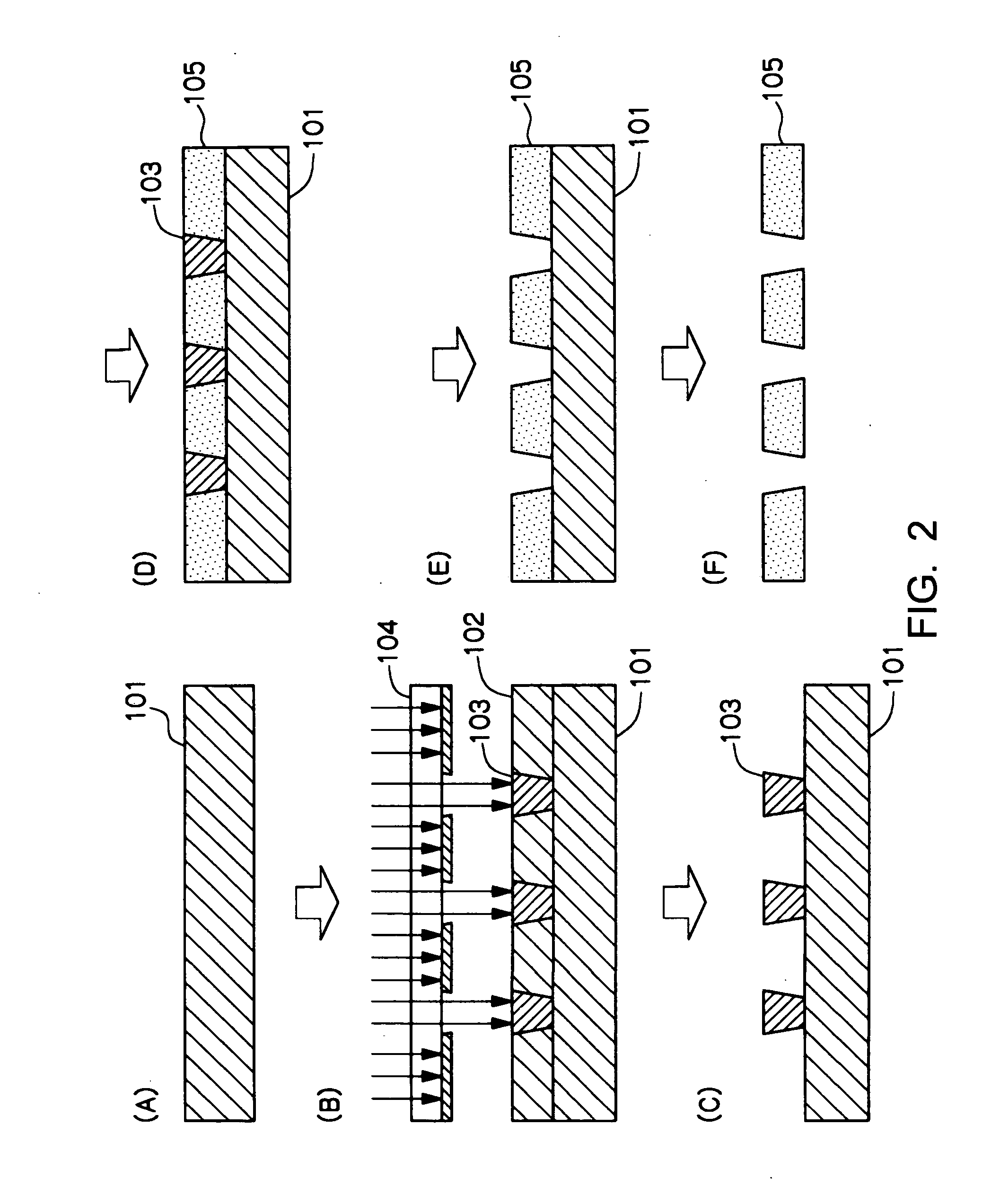

An infusion device (1) comprising a housing (3) with an upper face plate (4) and a lower face plate (5) and an adhesive sheet material (101) placed on the lower face plate (5) for securing the infusion device (1) to the skin, the adhesive sheet material (101) comprising a backing layer (102) which has an adhesive layer (103) on one surface, the adhesive layer (103) being covered by a removable release liner (104), and wherein the release liner (104) comprising at least one score line (106) comprising a spiral or helix, wherein the starting point (107) for the score line (106) is placed in the periphery (108) of the release liner (104) and wherein the score line (106) continues to an end point placed on the border of the periphery (110) of a central aperture (105) of the release liner.

Owner:UNOMEDICAL AS

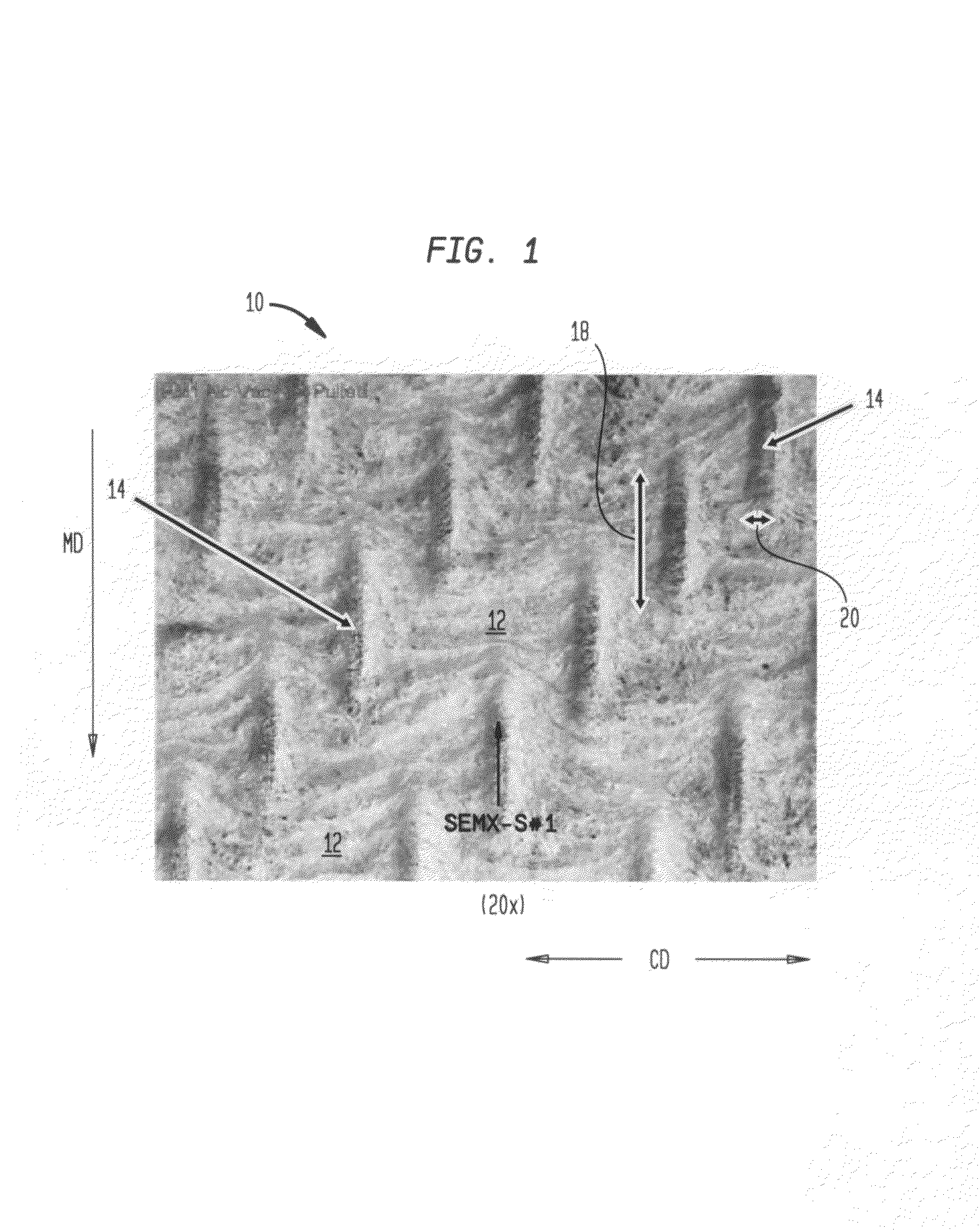

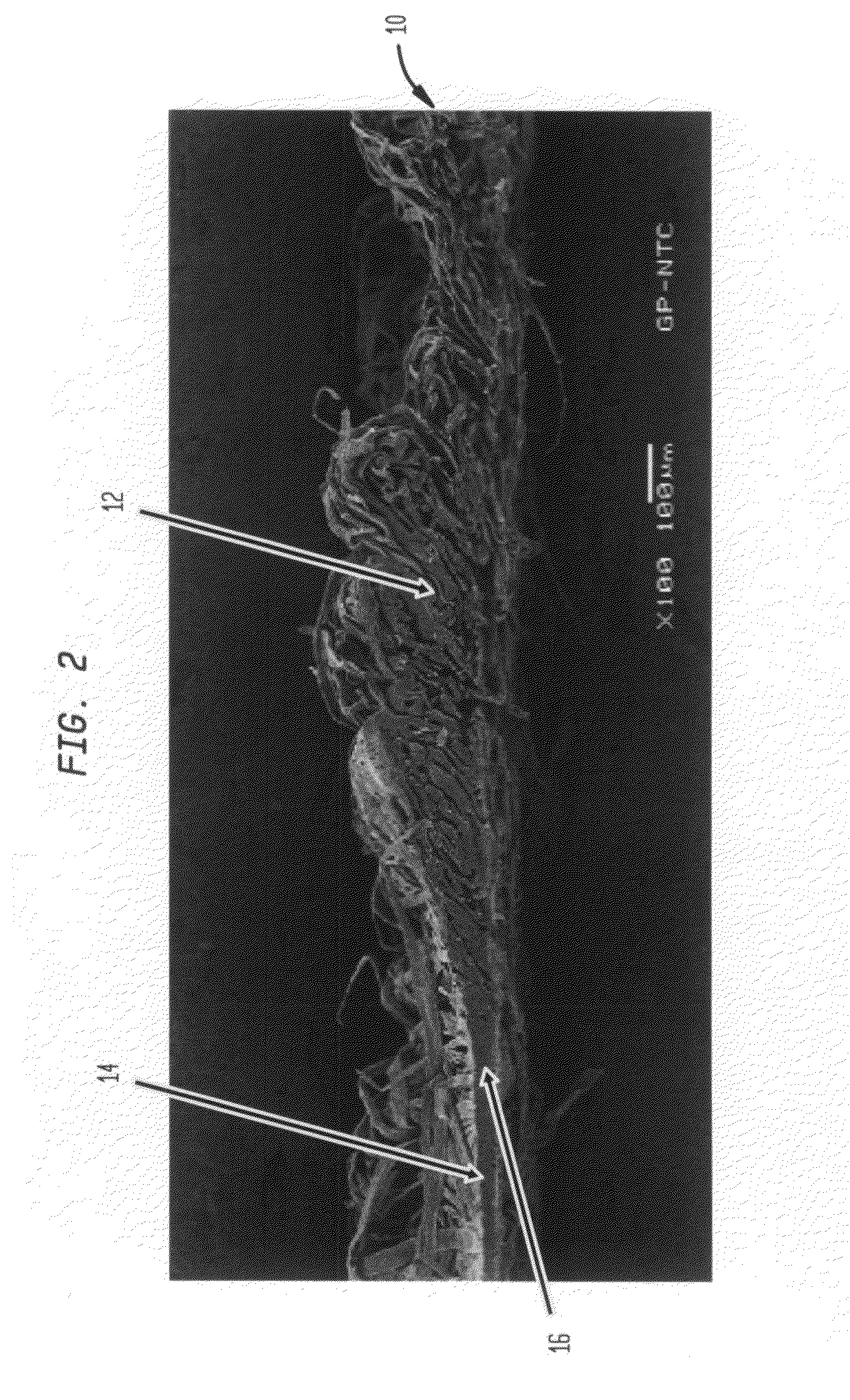

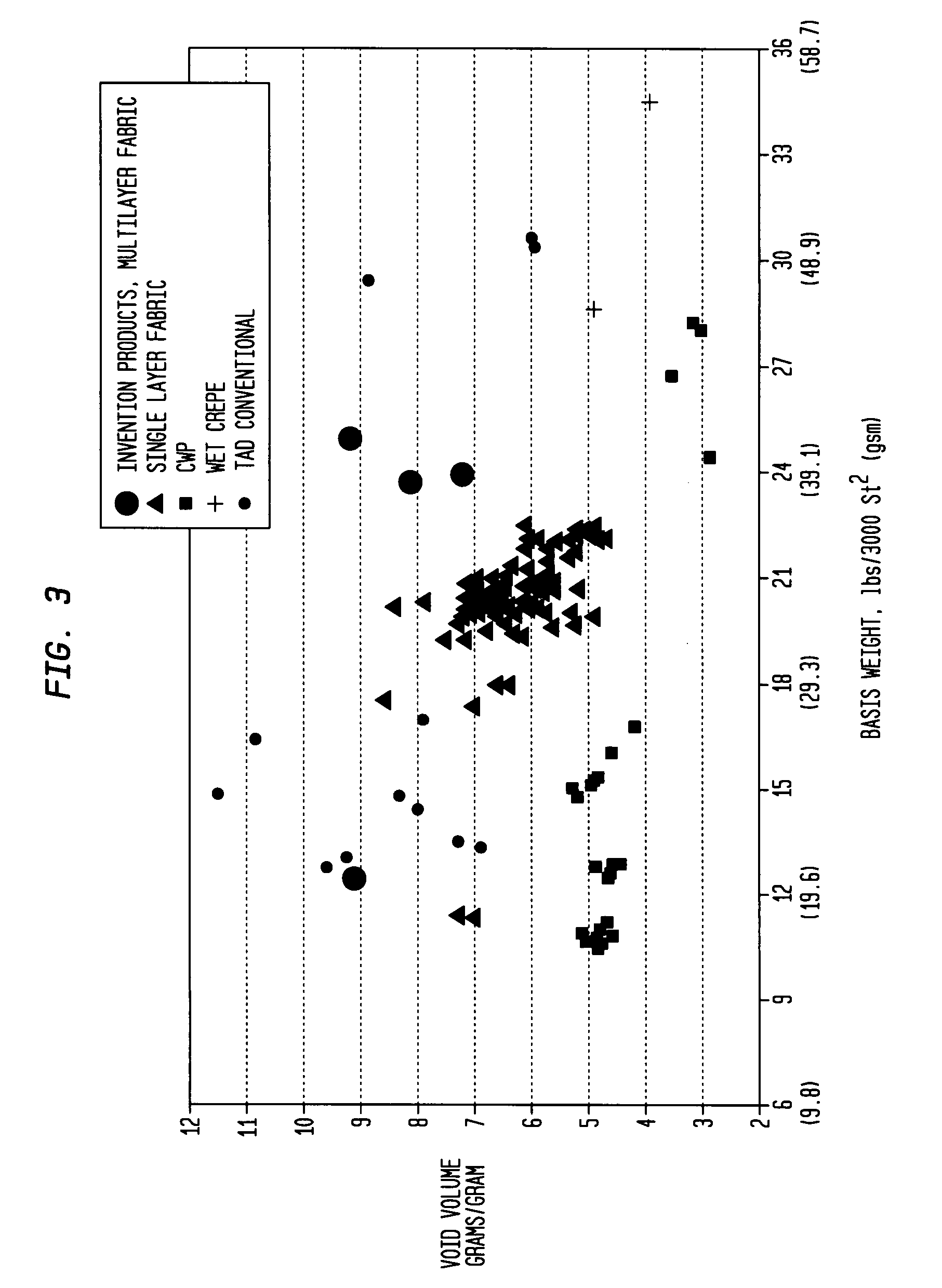

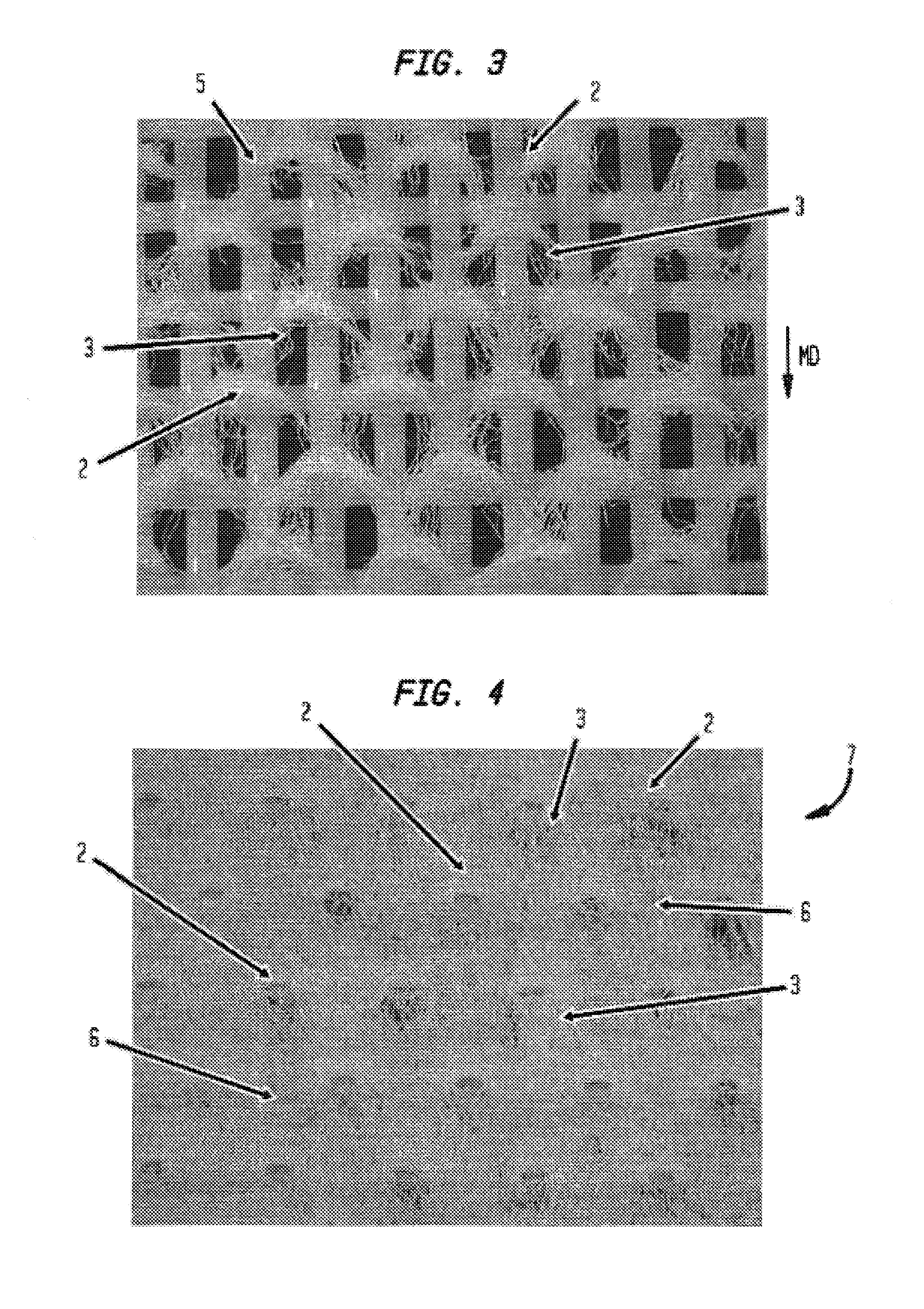

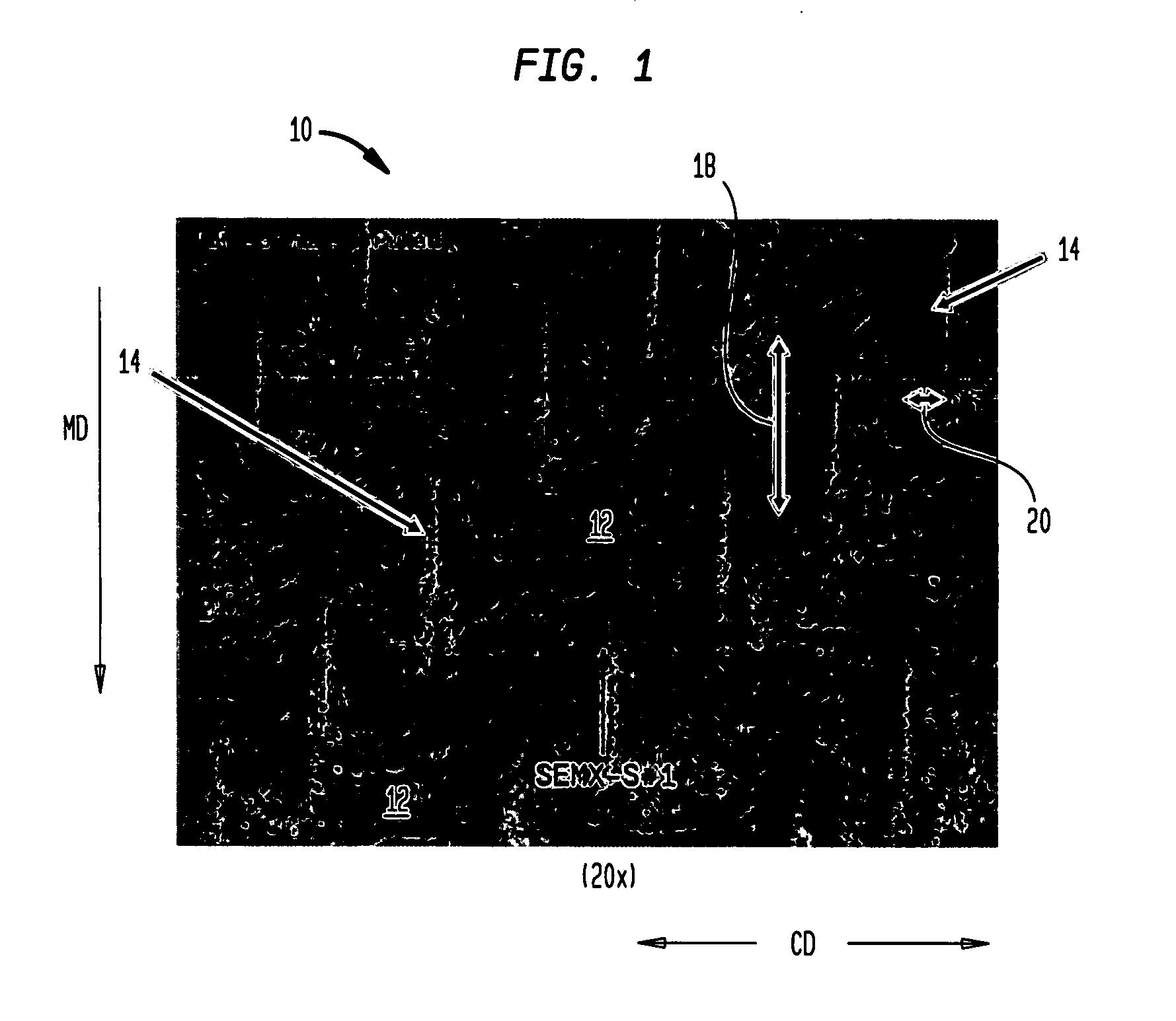

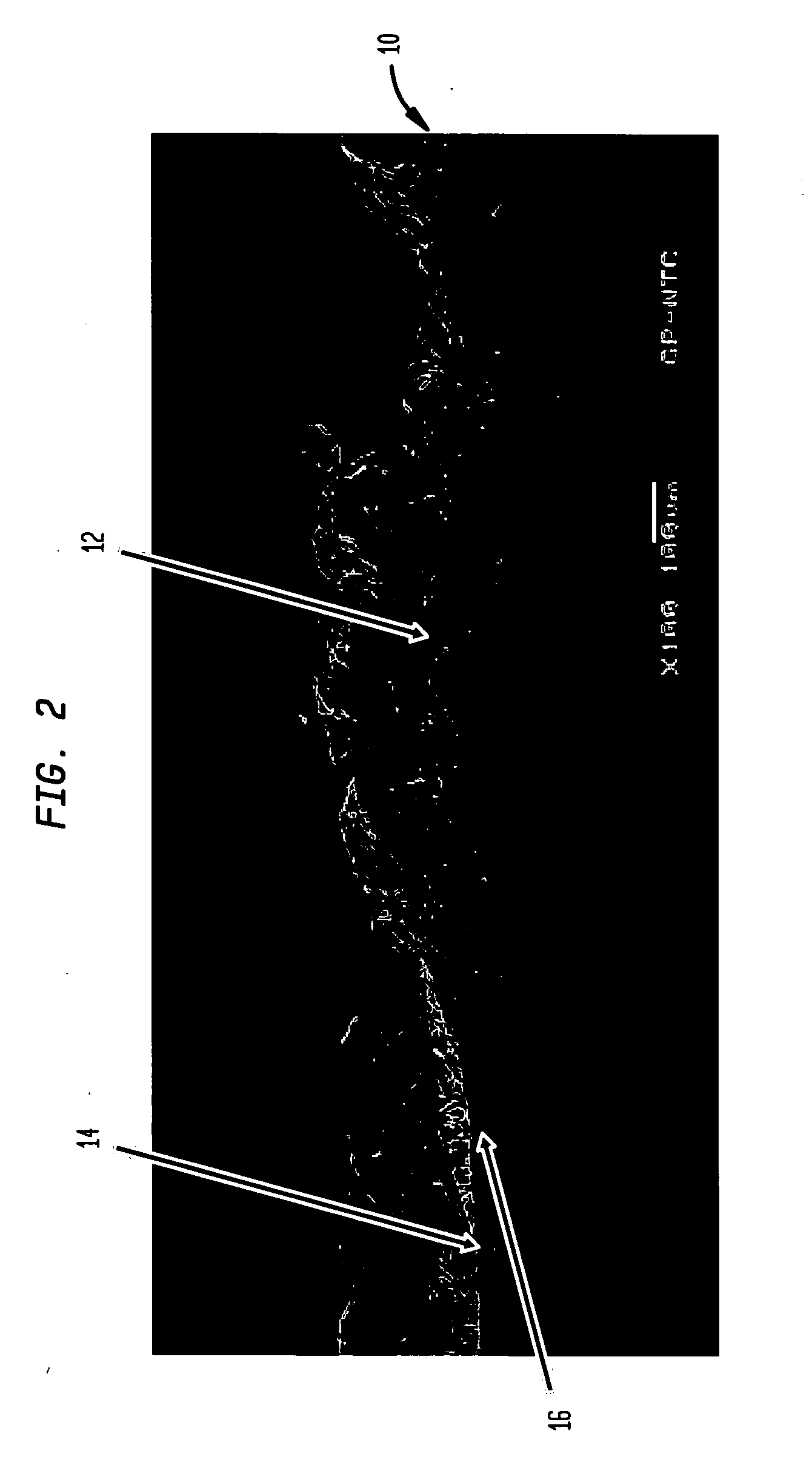

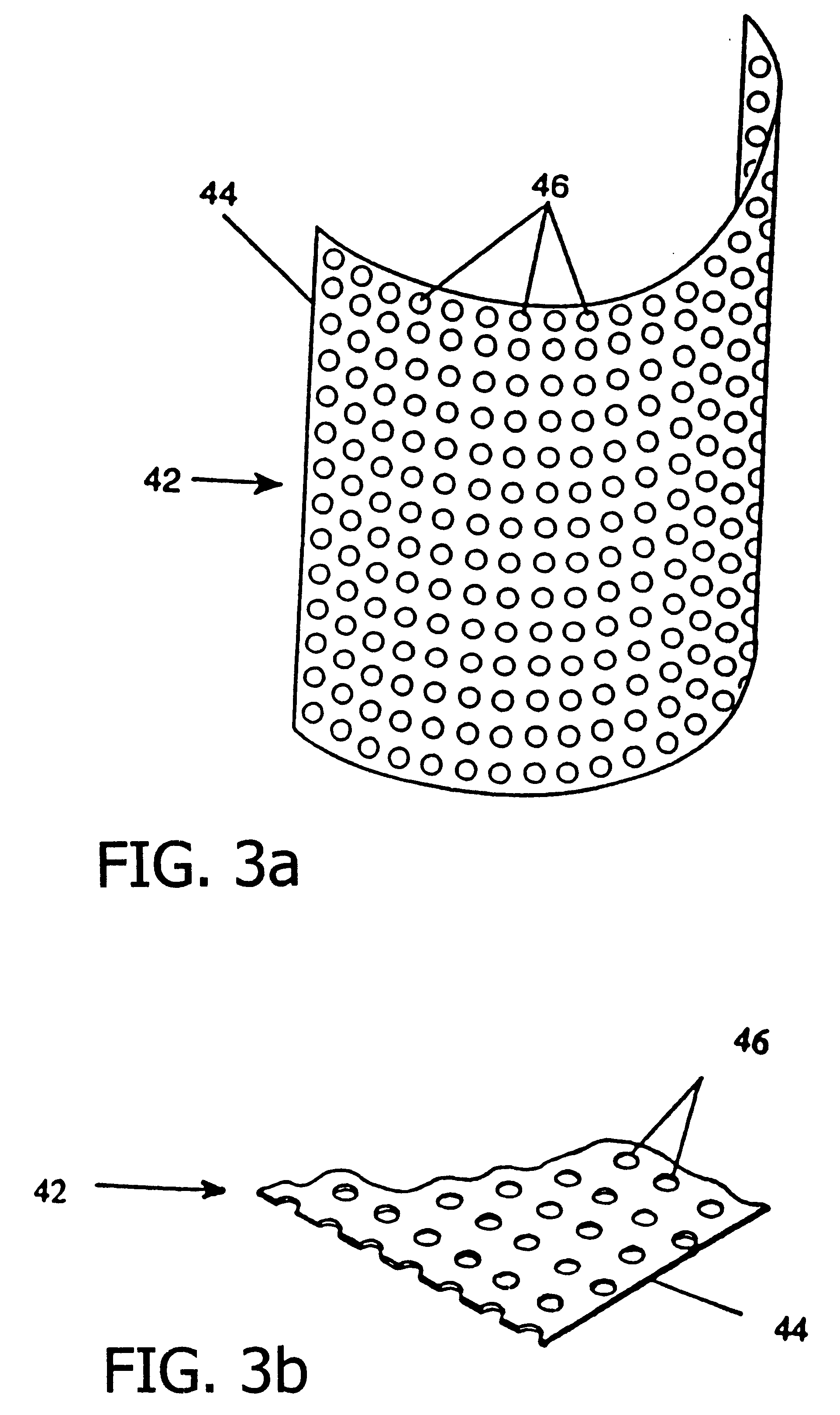

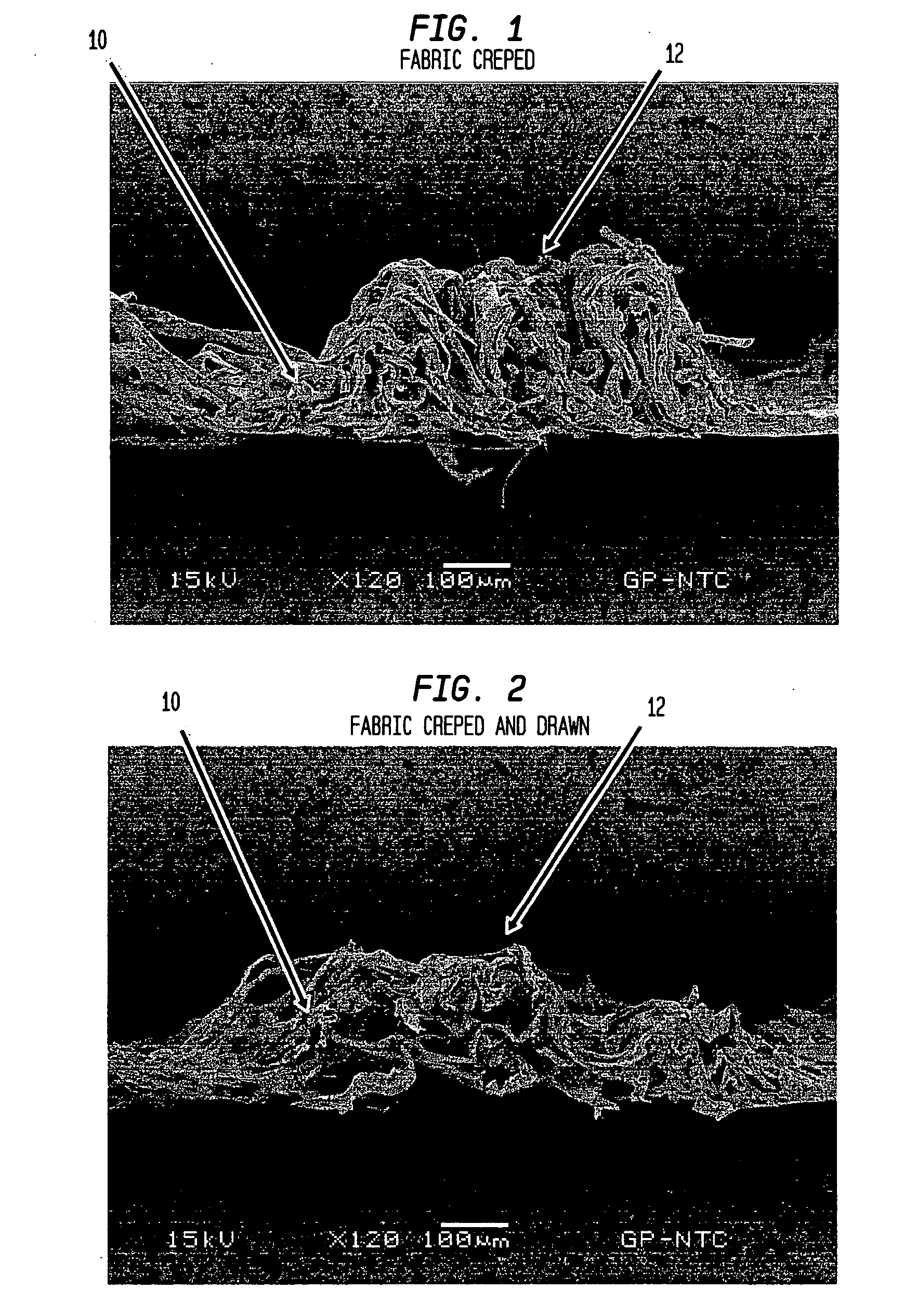

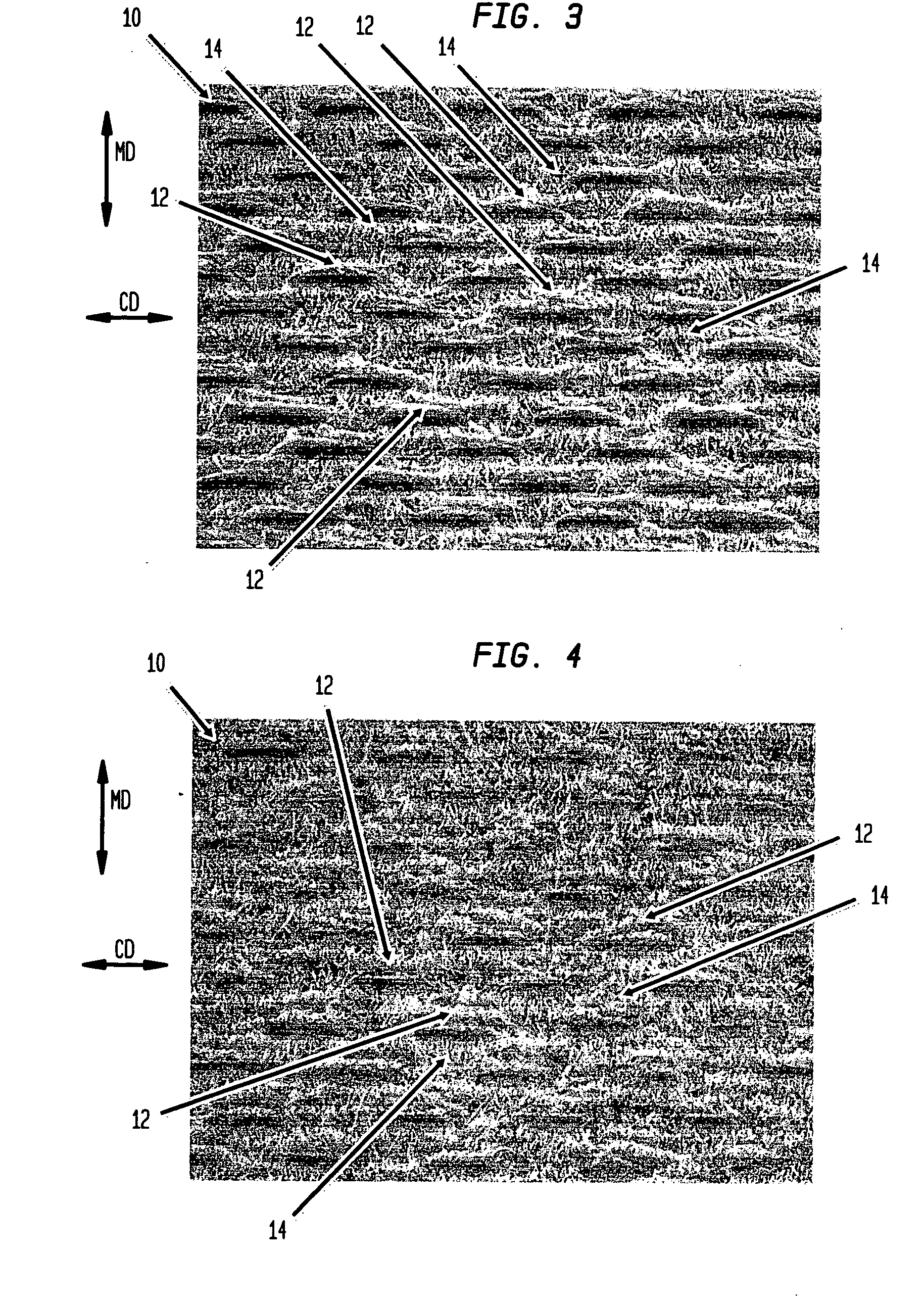

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

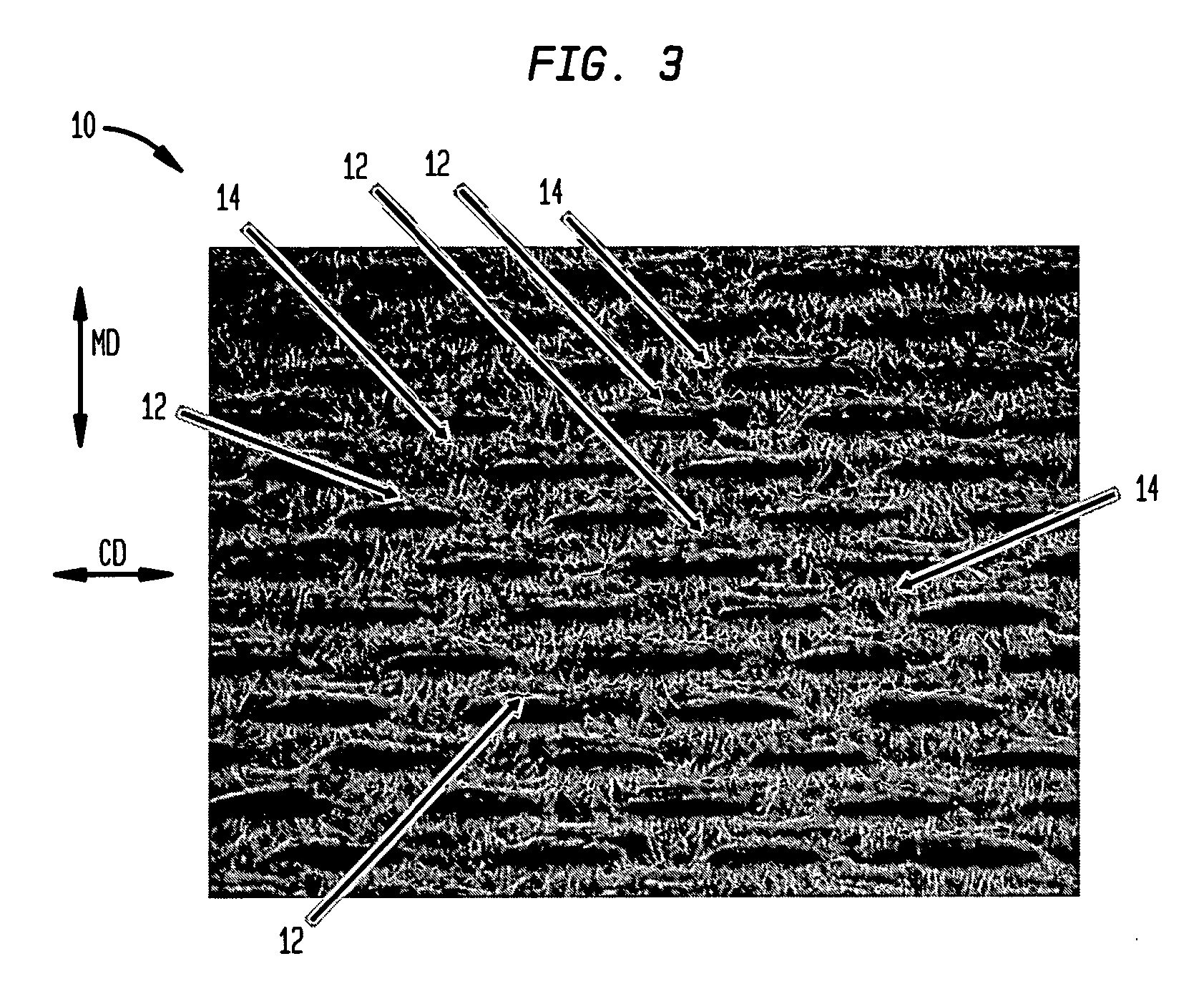

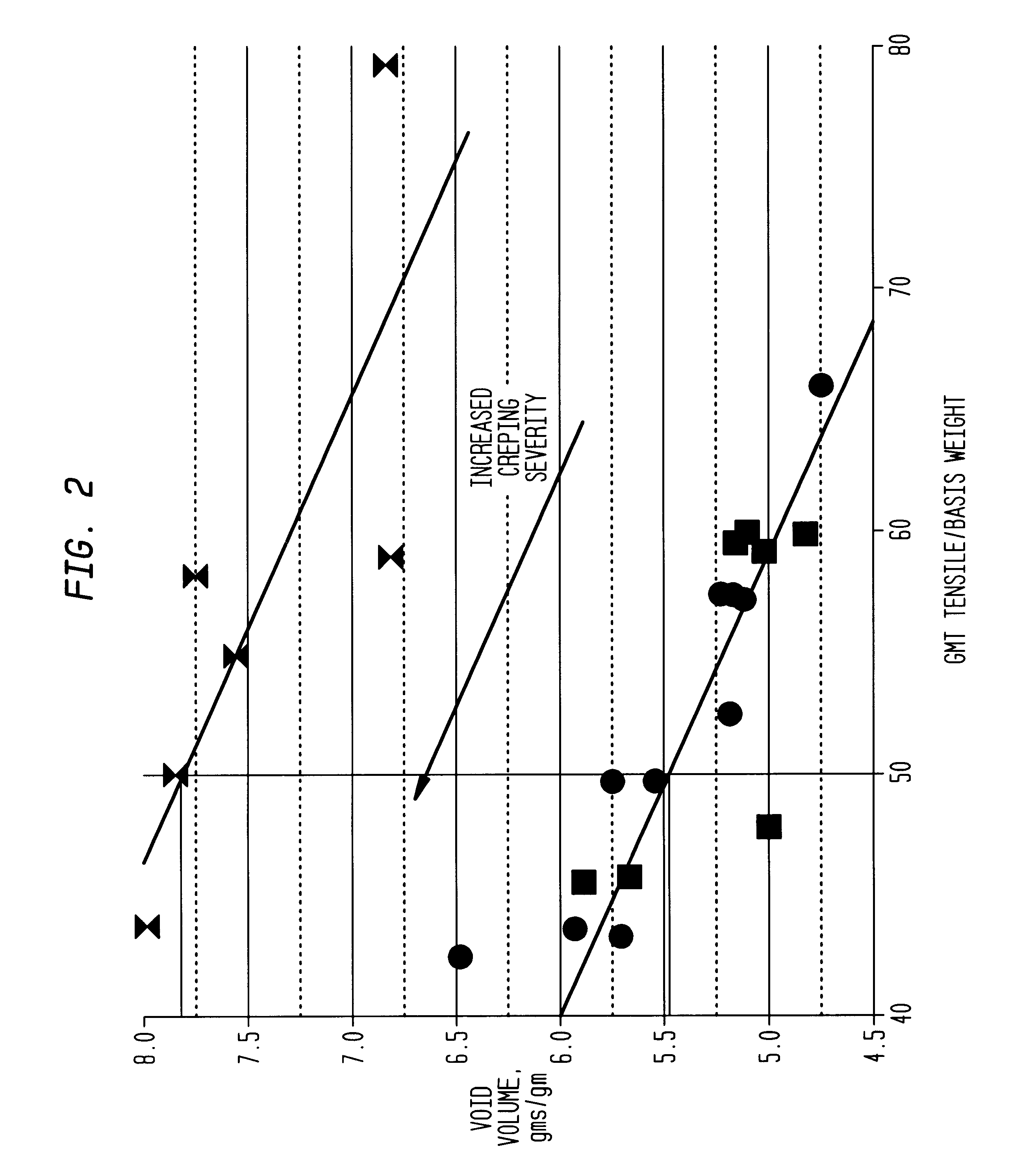

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

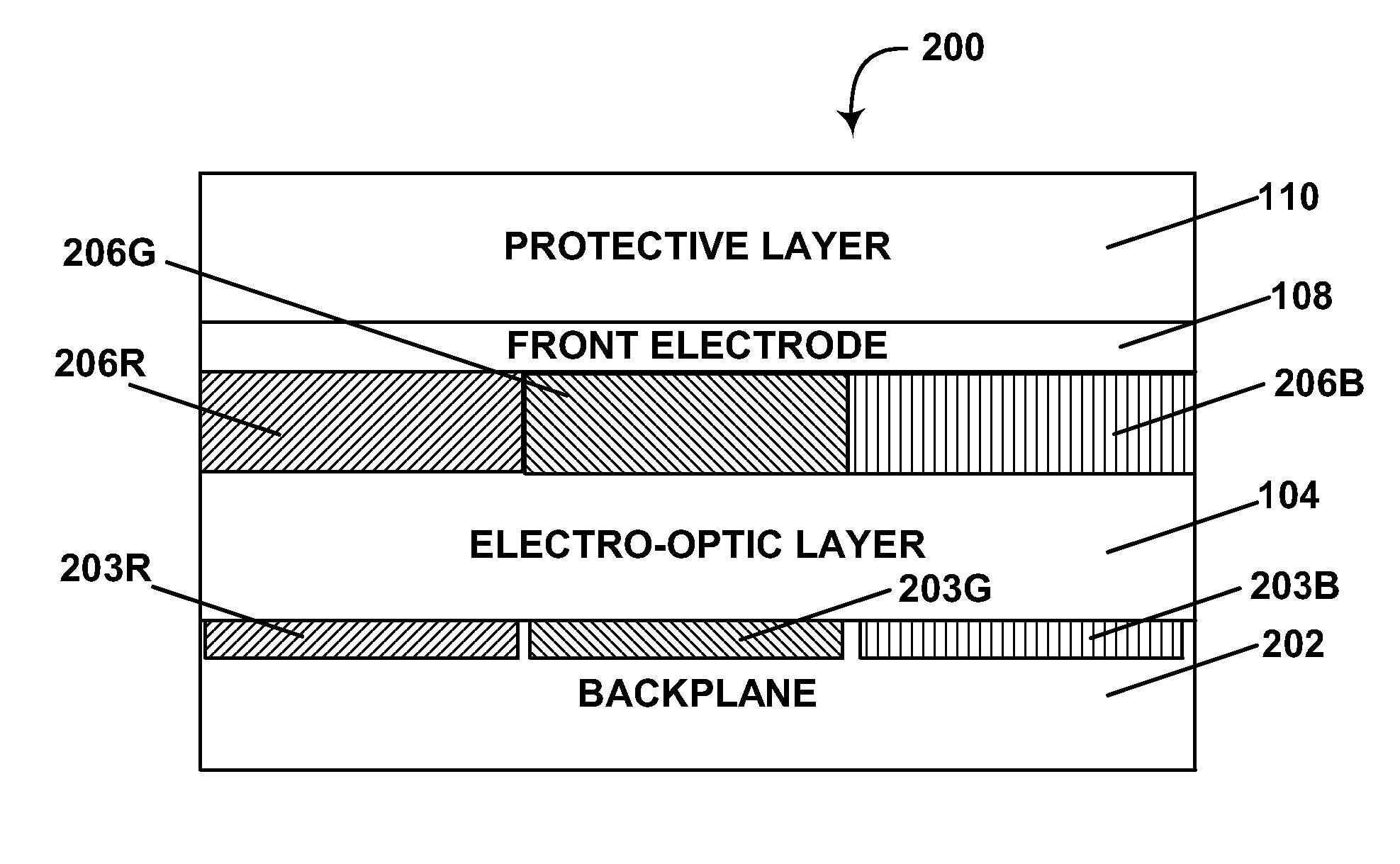

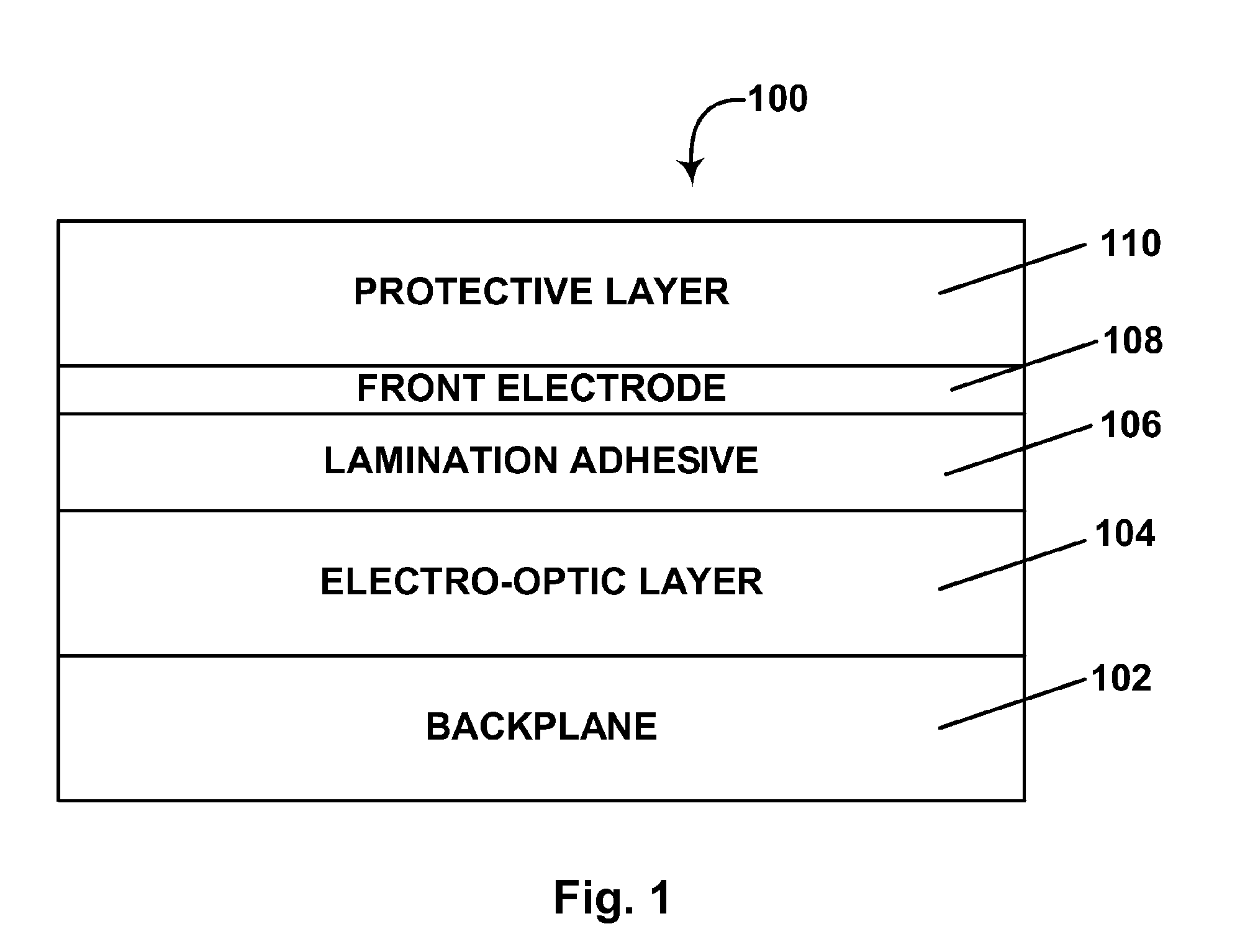

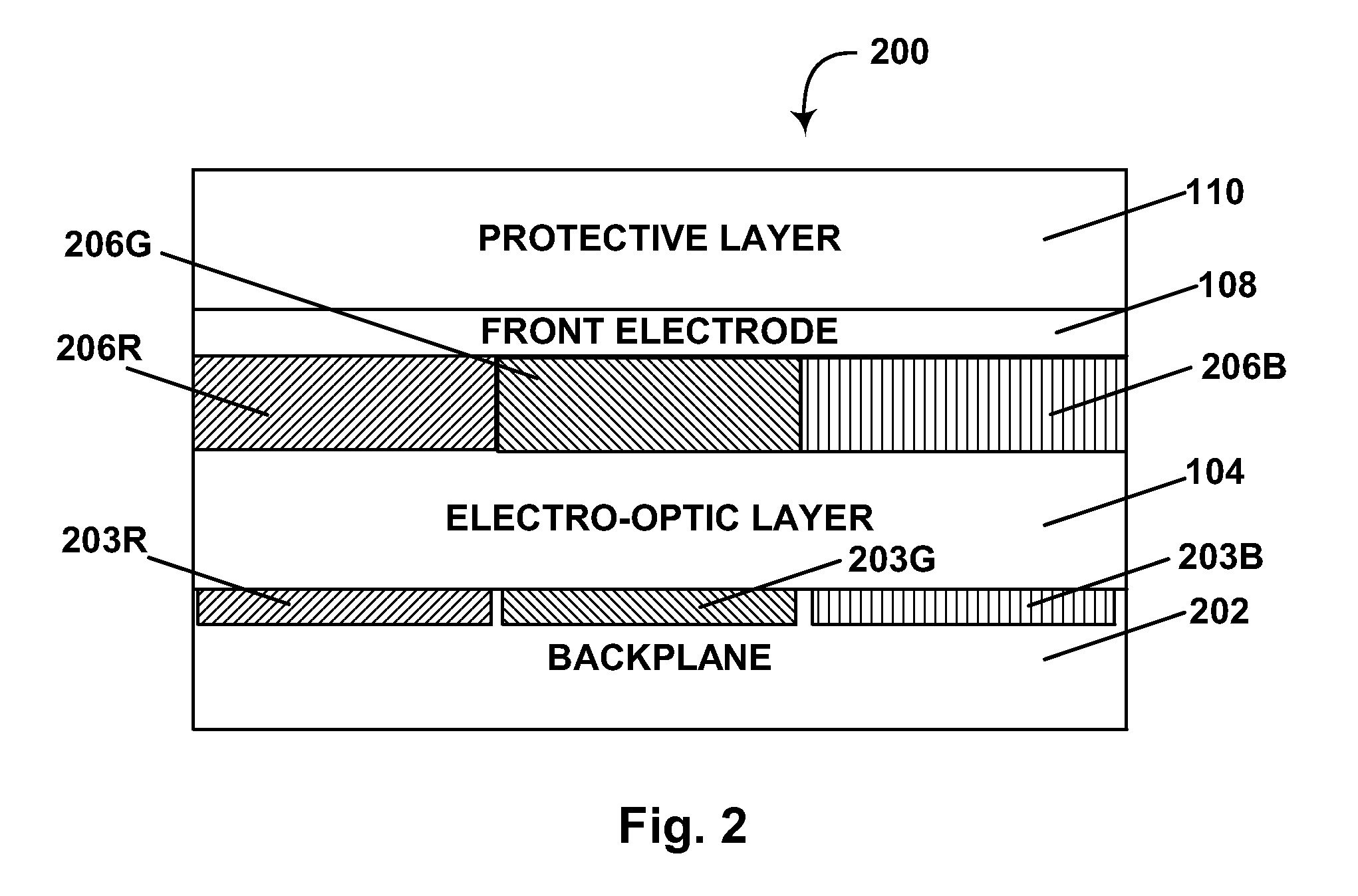

Components and methods for use in electro-optic displays

ActiveUS20070109219A1Flexible and convenientStatic indicating devicesNon-linear opticsAdhesiveImage resolution

An electro-optic display comprises, in order, a backplane comprising a plurality of pixel electrodes; a layer of a solid electro-optic medium; a main adhesive layer; and at least one of a light-transmissive protective layer and a light-transmissive electrically-conductive layer. The electro-optic layer may be in direct contact with the backplane or separated therefrom by a thin auxiliary layer of adhesive. The main adhesive layer may be colored to provide a color filter array. An inverted front plane laminate useful in forming such a display comprises the same layers except that the backplane is replaced by a release sheet. The display combines good low temperature performance and good resolution at higher temperatures.

Owner:E INK CORPORATION

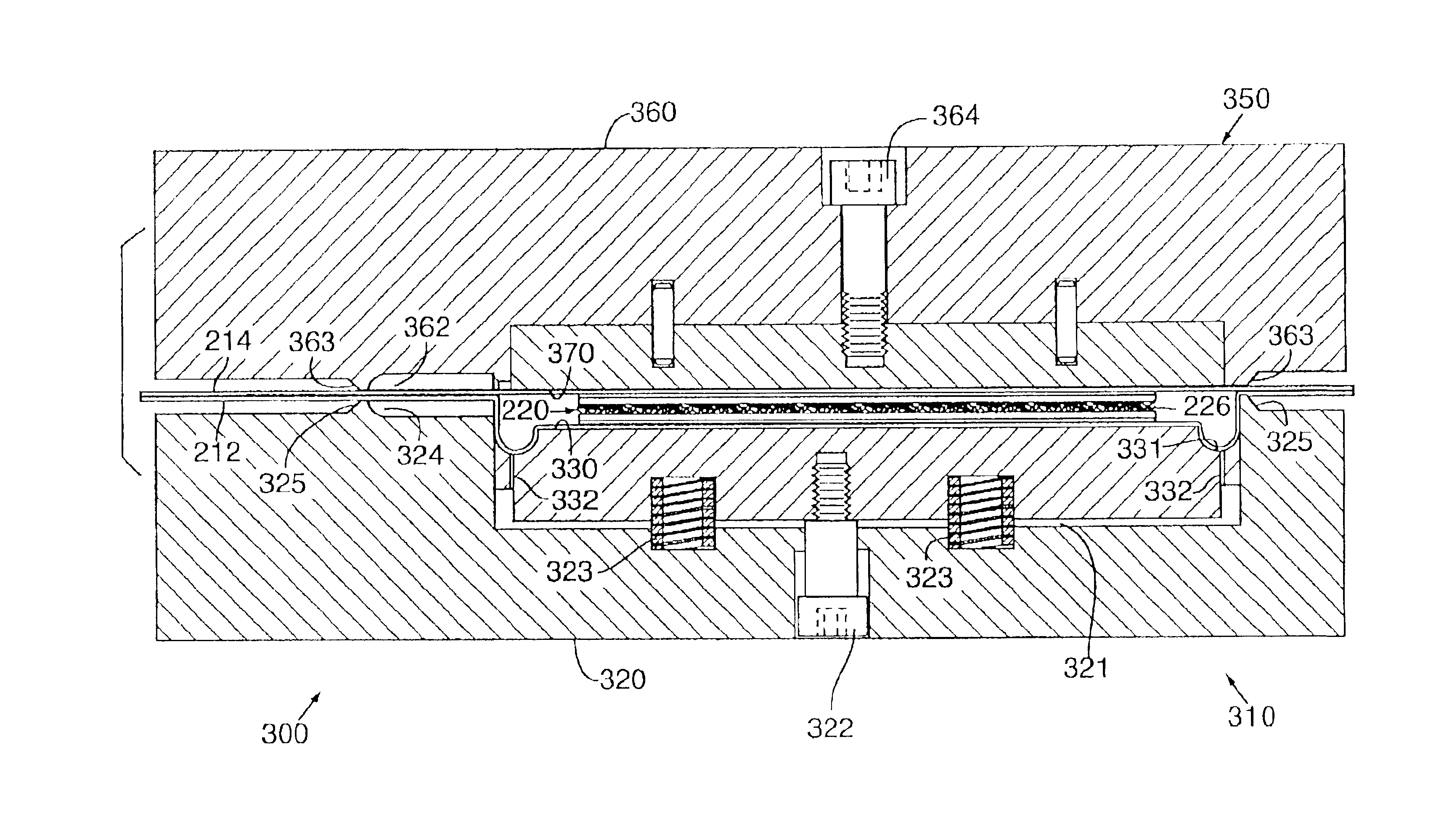

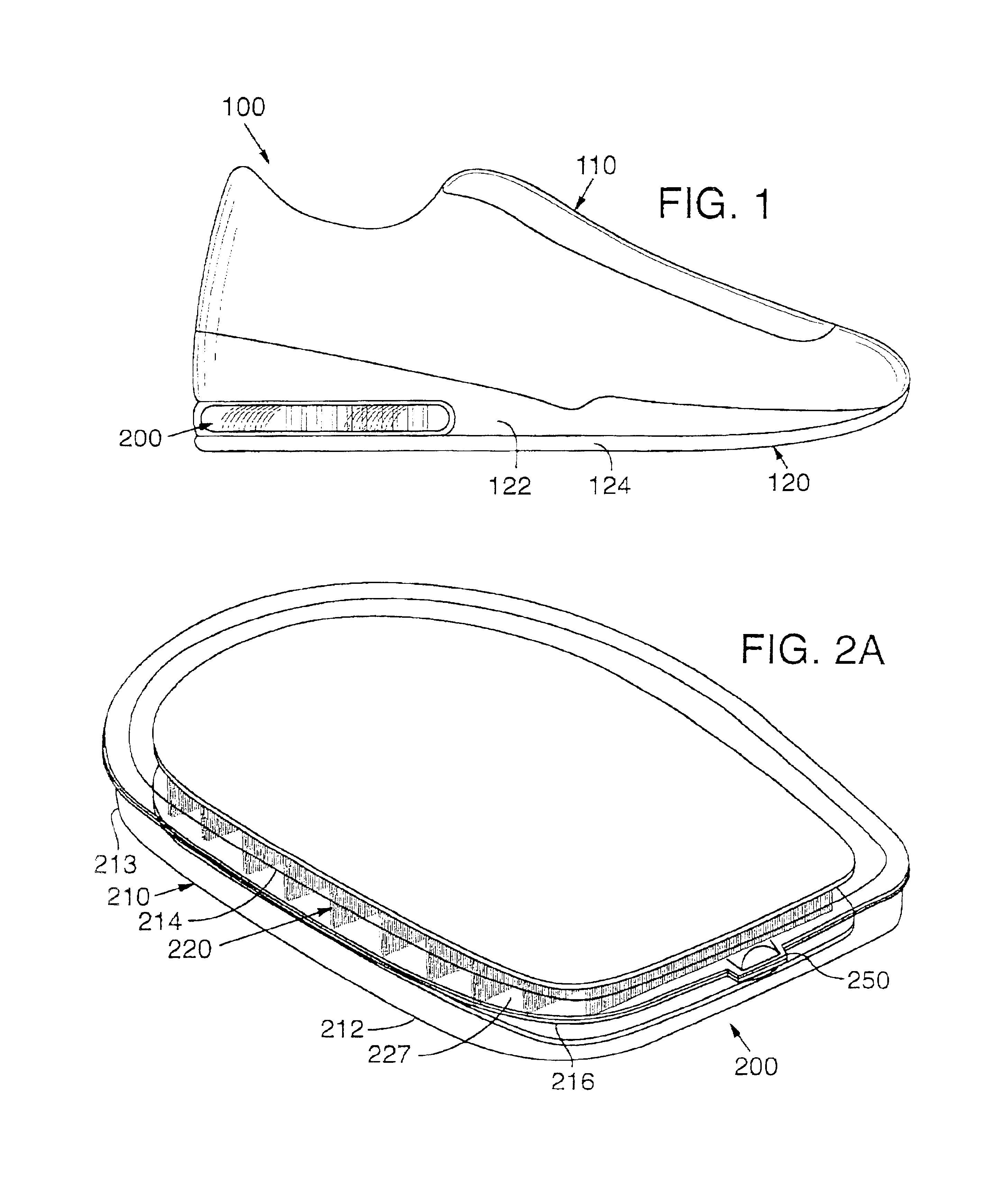

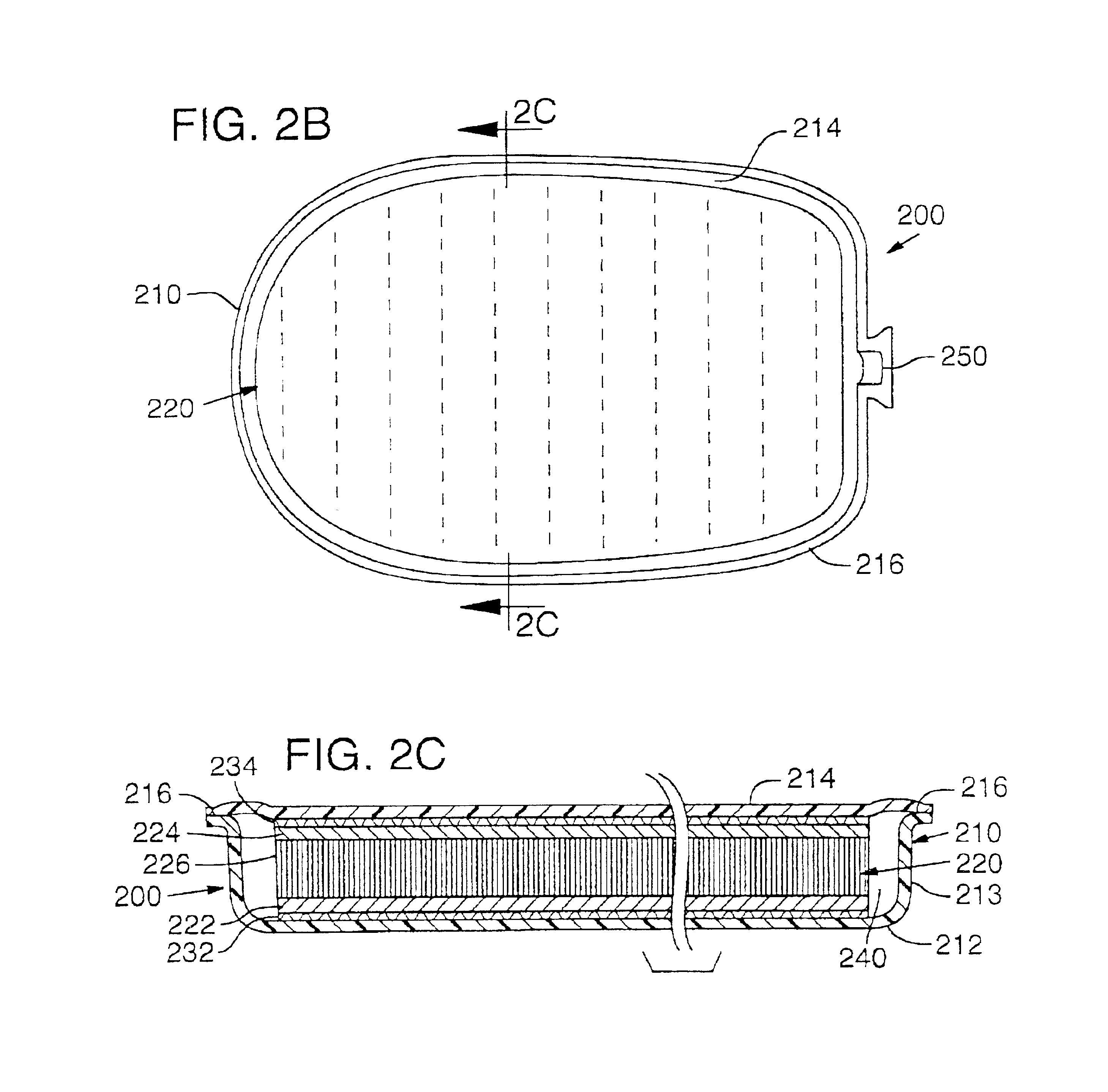

Method of thermoforming a bladder structure

InactiveUS6837951B2Increase awarenessImprove efficiencySolesOrnamental textile articlesBladder structureThermal contact

A method for thermoforming a resilient, fluid-filled bladder structure with thermal contact molding is disclosed. The bladder includes two sheets of thermoplastic material that are separated by at least one core formed of two spaced outer layers connected together by a plurality of connecting members. The bladder is formed by bonding the sheets to the core, bonding the sheets to each other around the periphery of the core and forming a sidewall between the sheets in a single mold. A fluid is then inserted into the space bounded by the peripheral bond and the two sheets such that the connecting members are extended.

Owner:NIKE INC

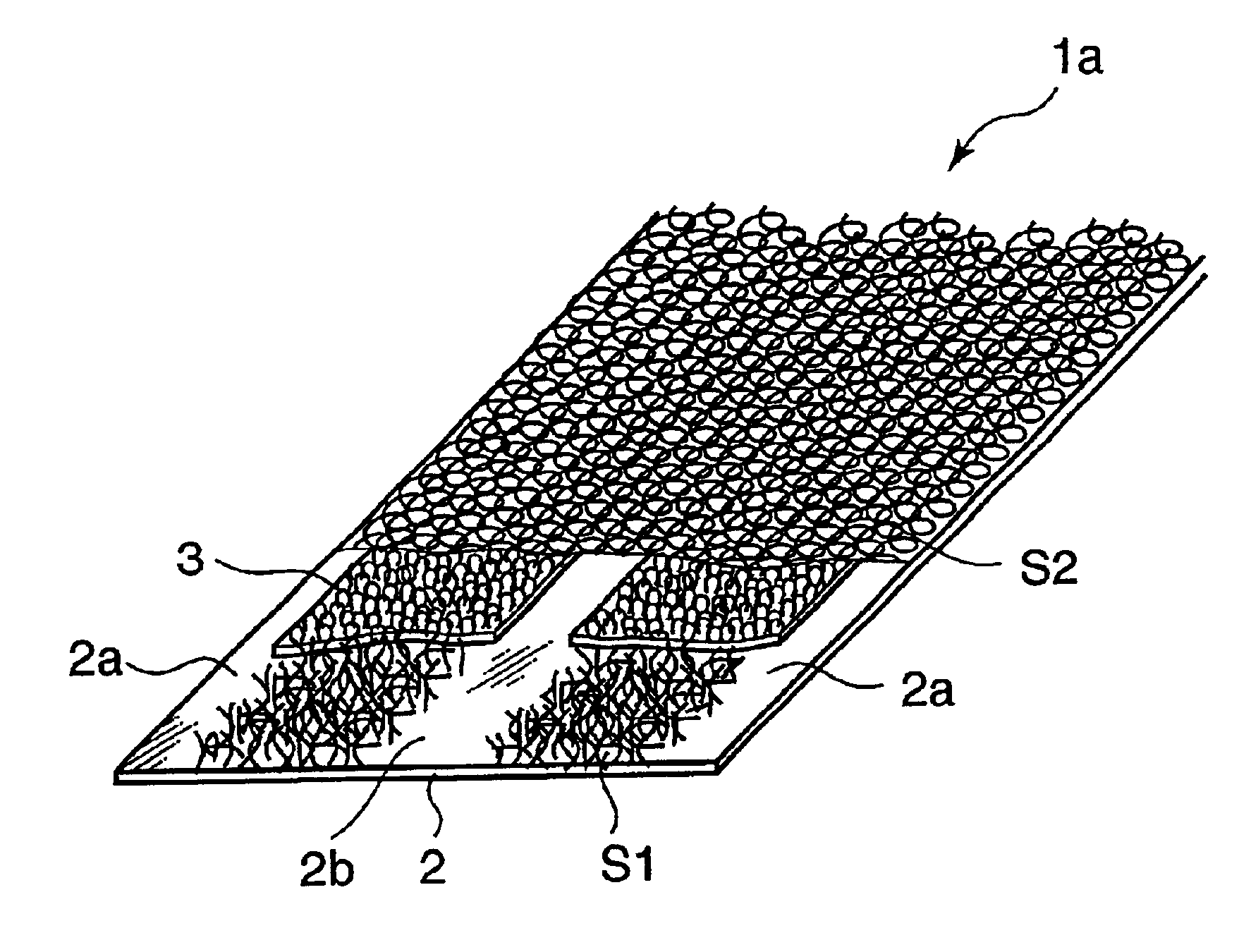

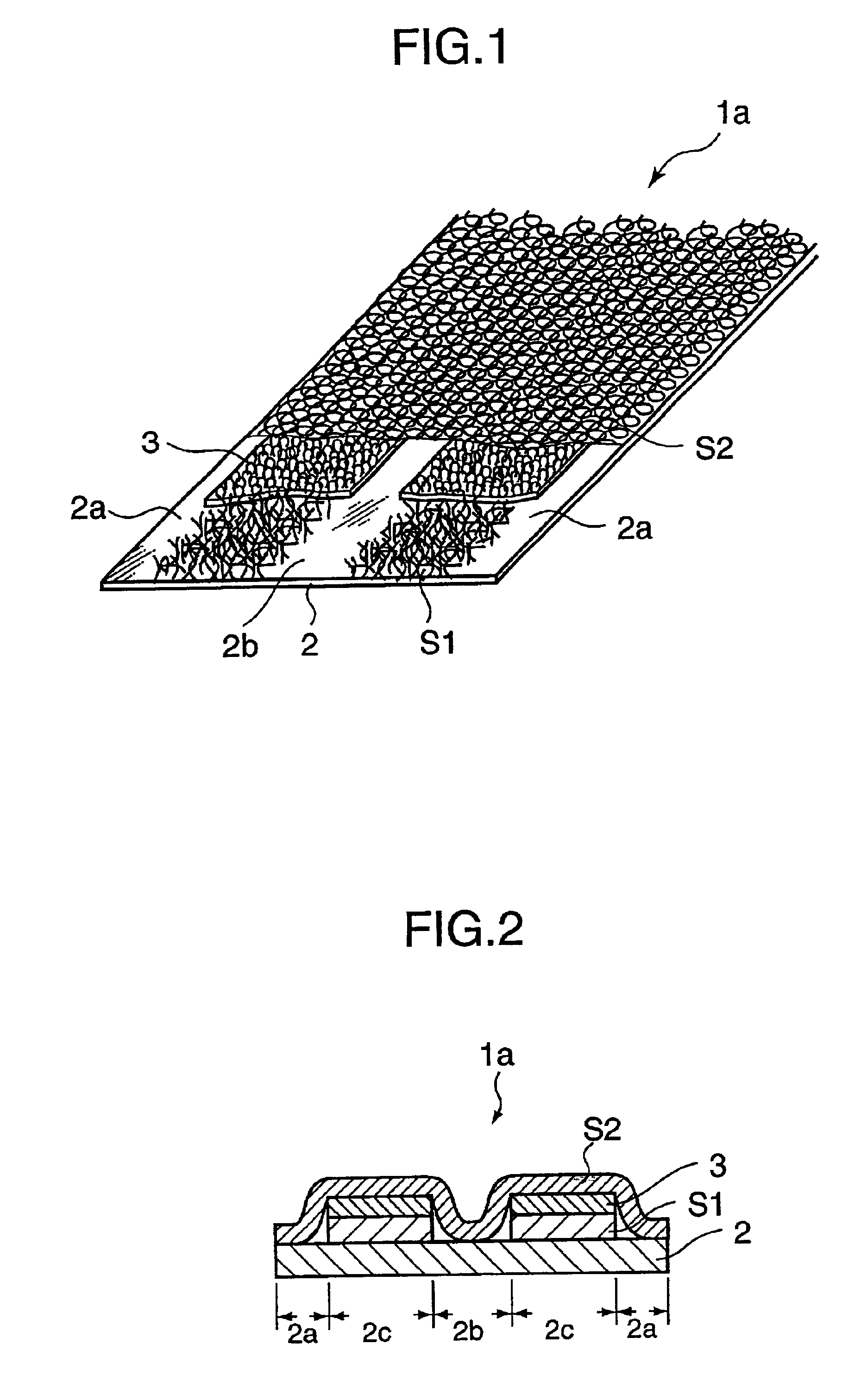

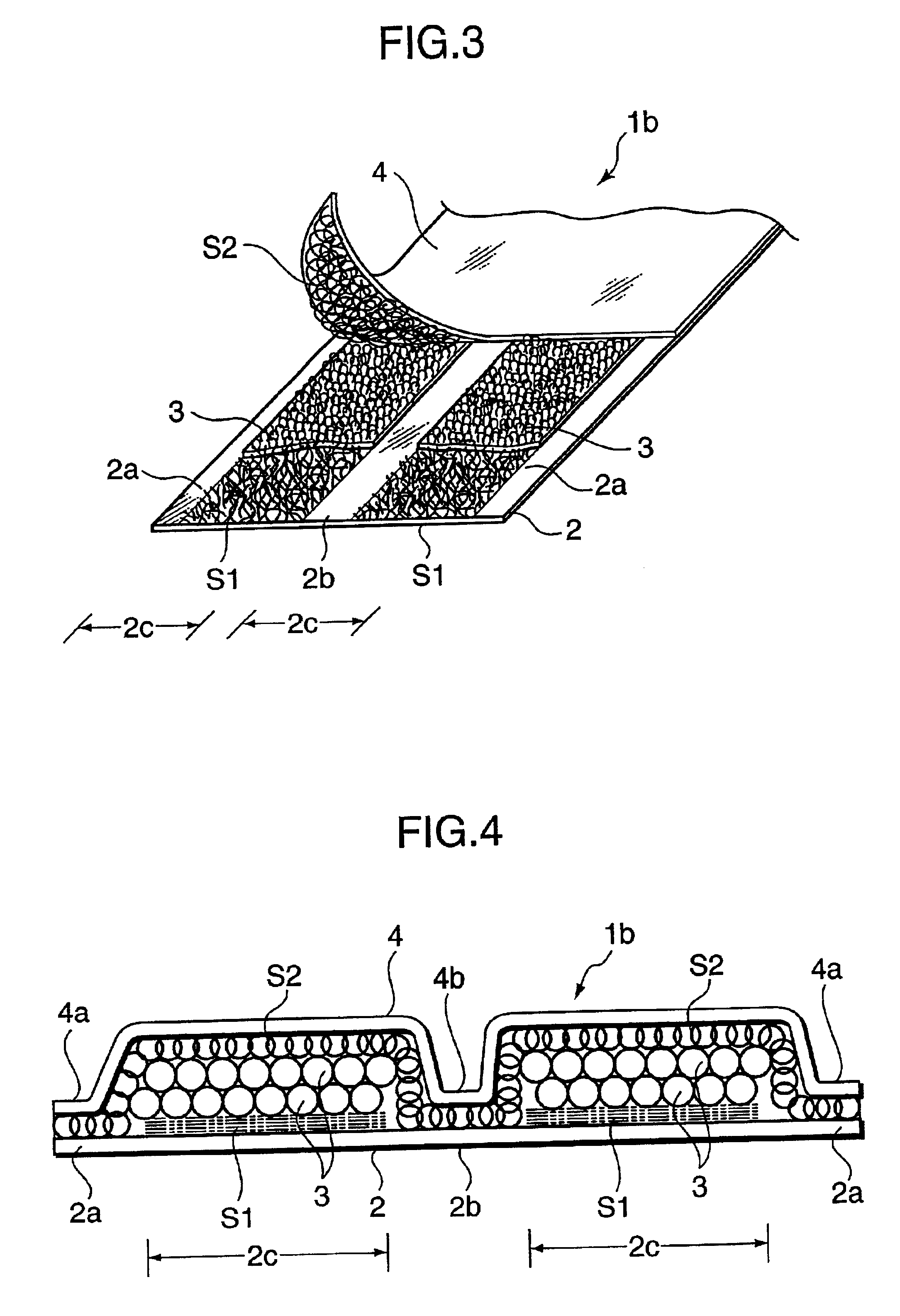

Ultra-thin absorbing sheet body, disposable absorbent article provided with ultra-thin absorbing sheet body and production device for ultra-thin absorbing sheet body

In an ultra-thin absorbent sheet member 1a in which an absorbent polymer powder 3 is adhered to one surface of a first nonwoven fabric 2 by a hotmelt adhesive such that absorbent polymer powder present areas 2c and absorbent polymer powder absent areas 2a, 2b exist; the absorbent polymer powder absent areas are present at opposite widthwise ends (2a) of the ultra-thin absorbent sheet member and at least one position (2b) between the opposite ends; the absorbent polymer powder 3 is bonded to the first nonwoven fabric 2 by first hotmelt adhesive layers S1 formed on an upper side of the first nonwoven fabric 2 and on a lower side of the absorbent polymer powder 3 and a second hotmelt adhesive layer S2 formed to cover upper sides of the absorbent polymer powder present areas 2c and the absorbent polymer powder absent areas 2a, 2b; and the first hotmelt adhesive layer S1 and the second hotmelt adhesive layer S2 are both made of an aggregate of linear hotmelt adhesive pieces.

Owner:TOOYOO EIZAI

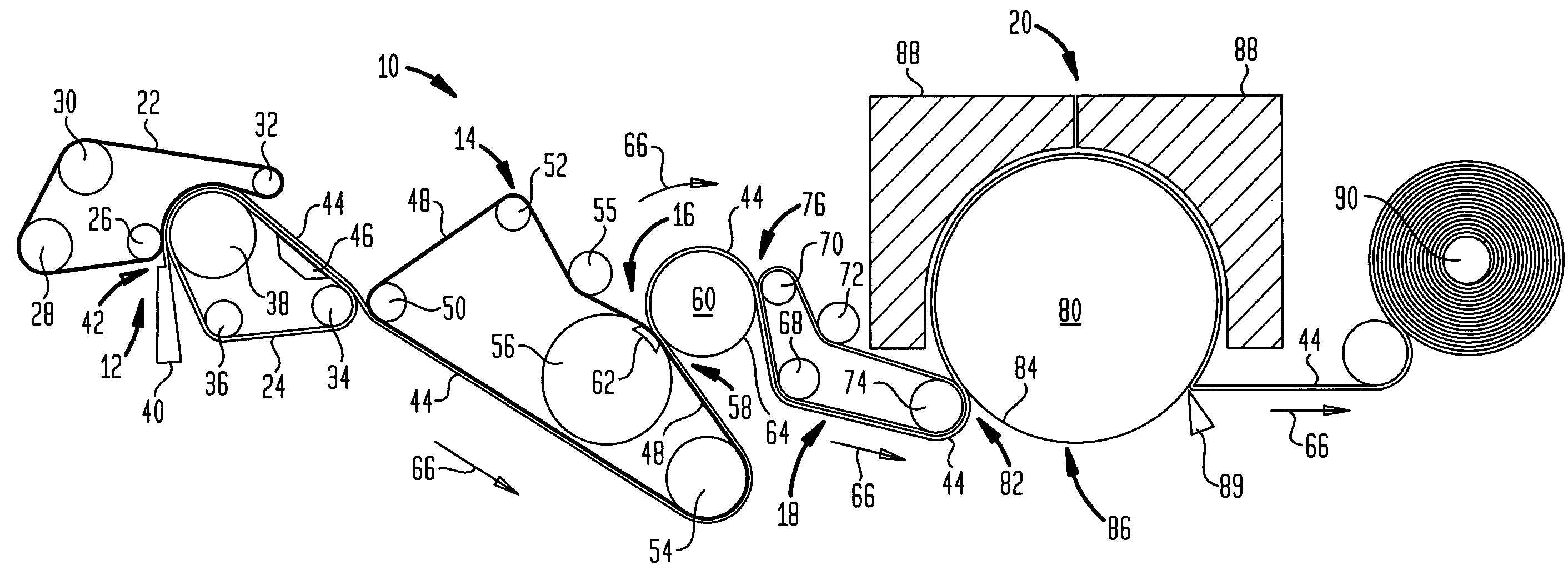

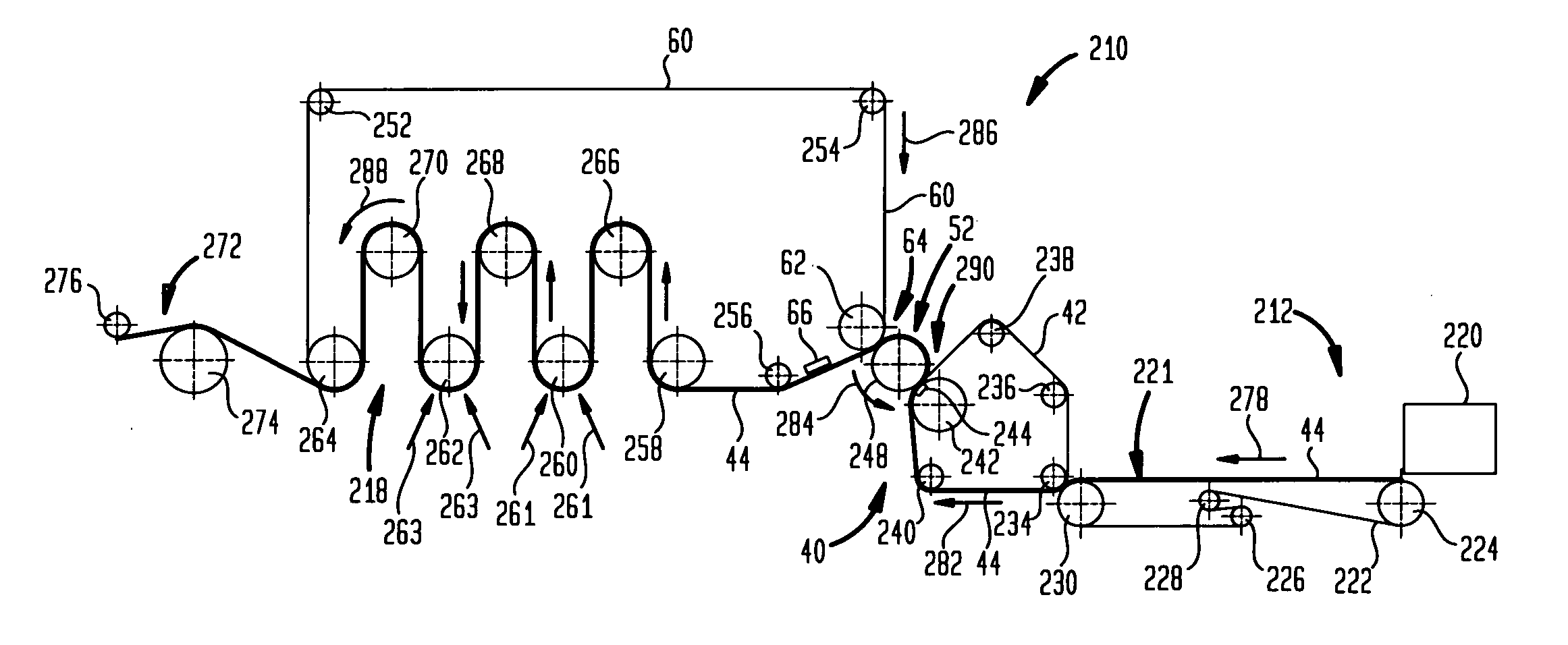

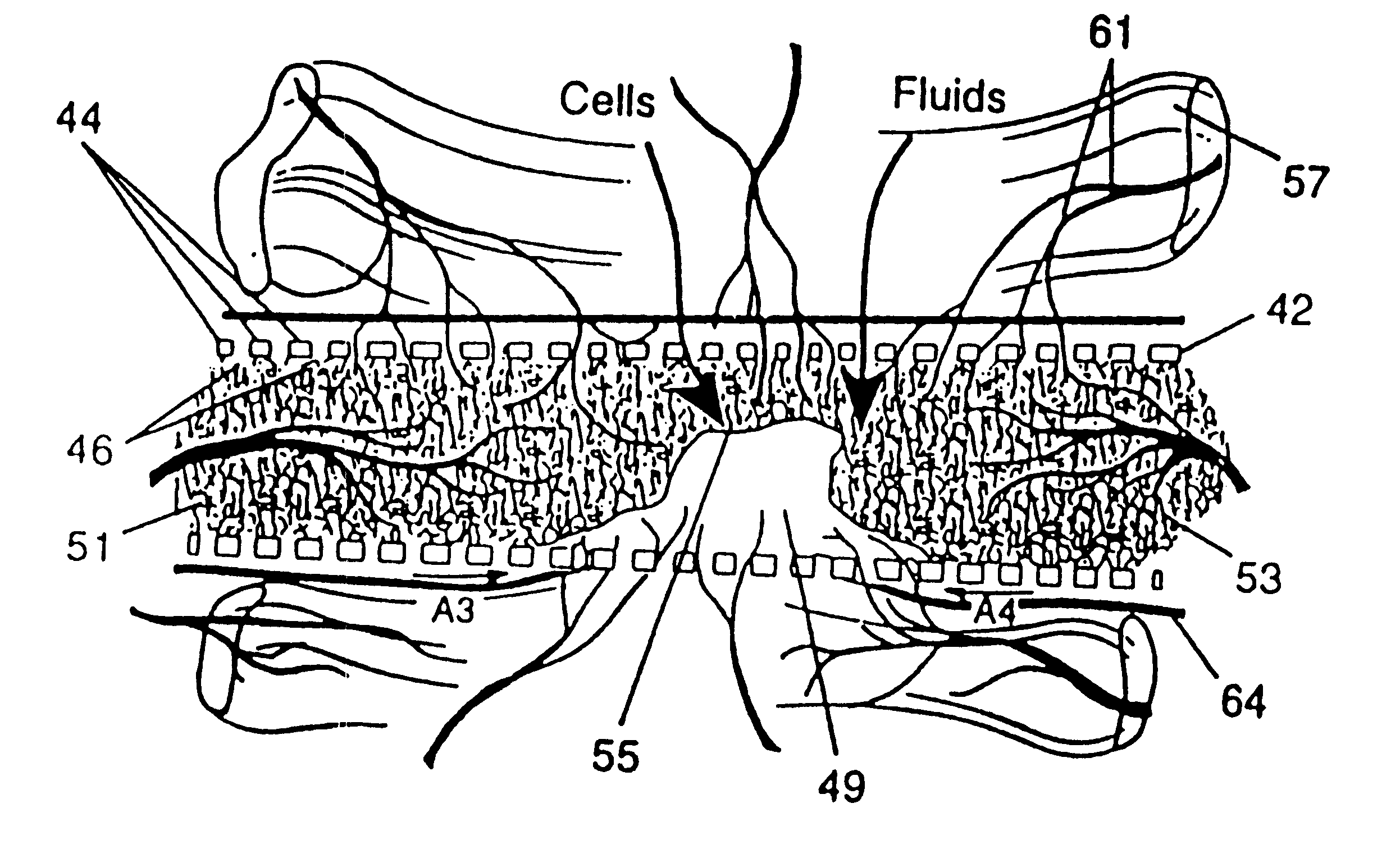

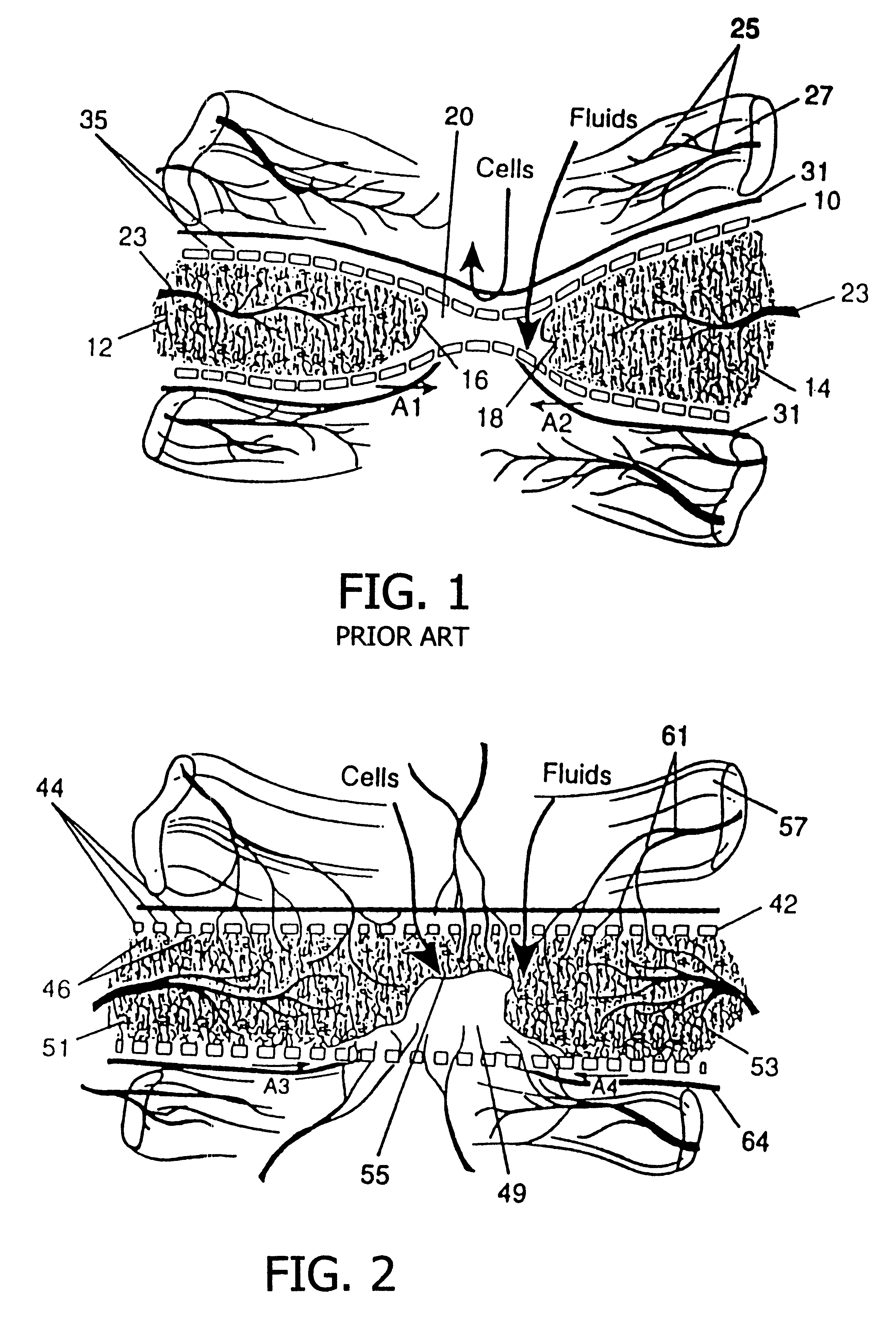

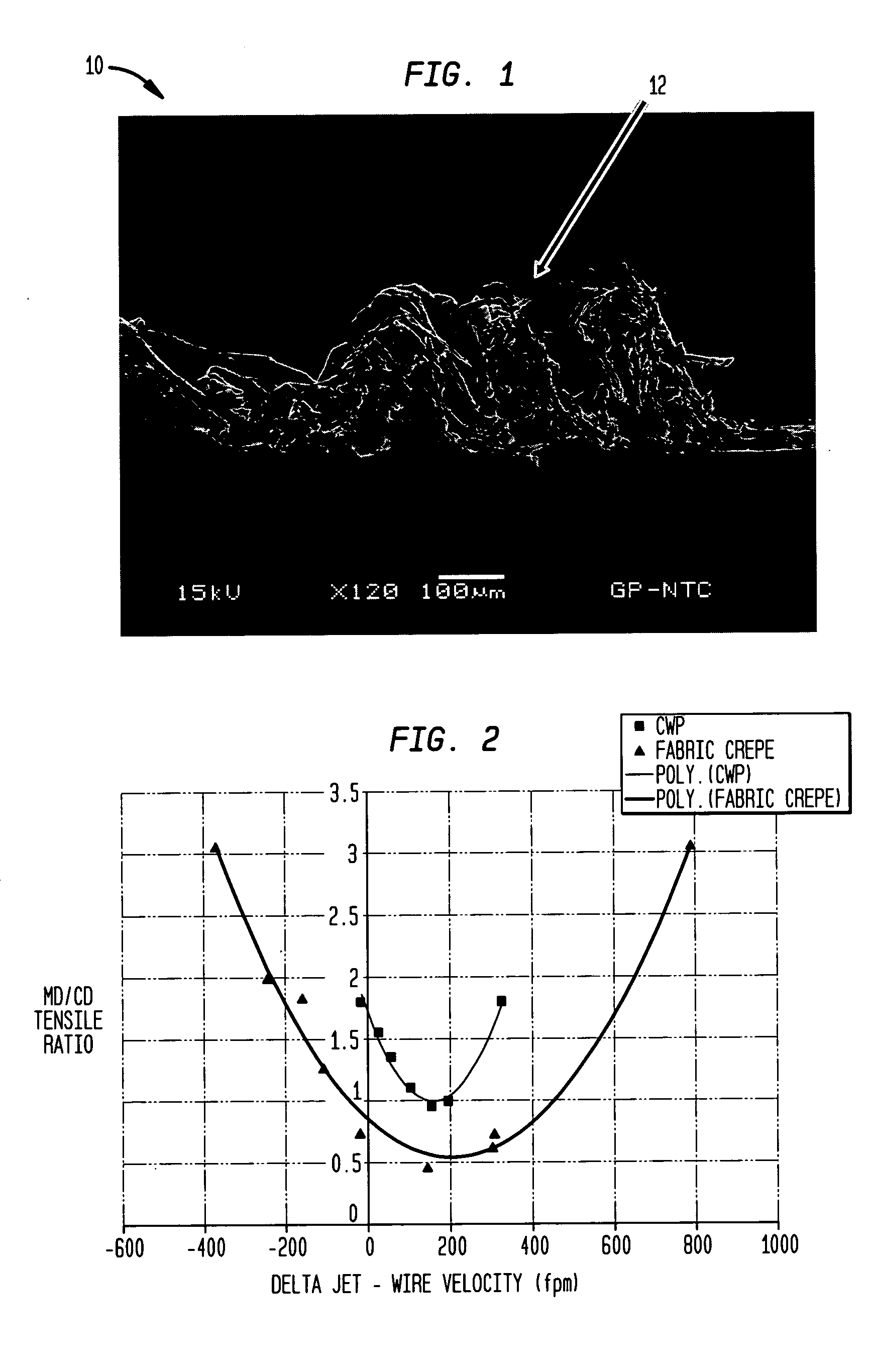

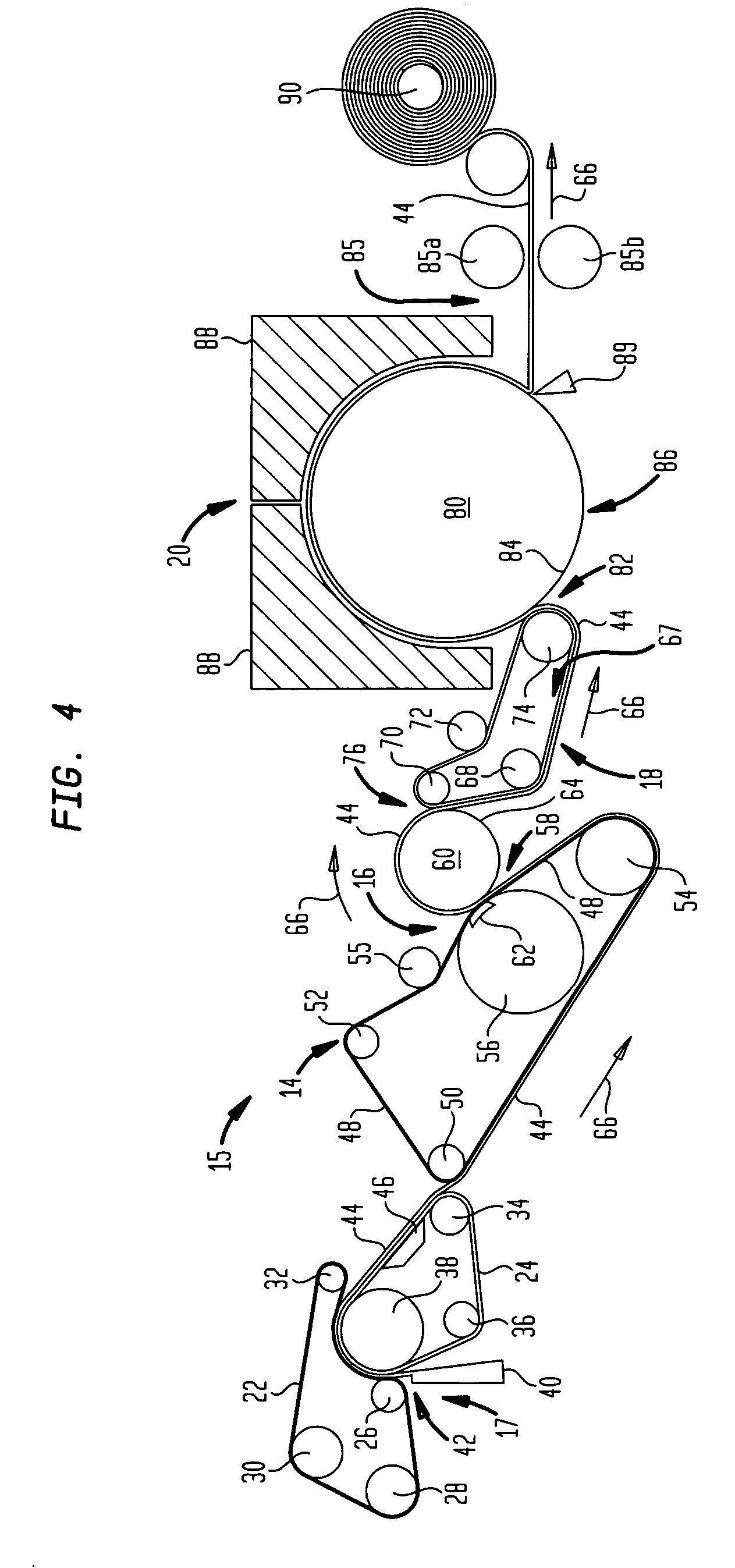

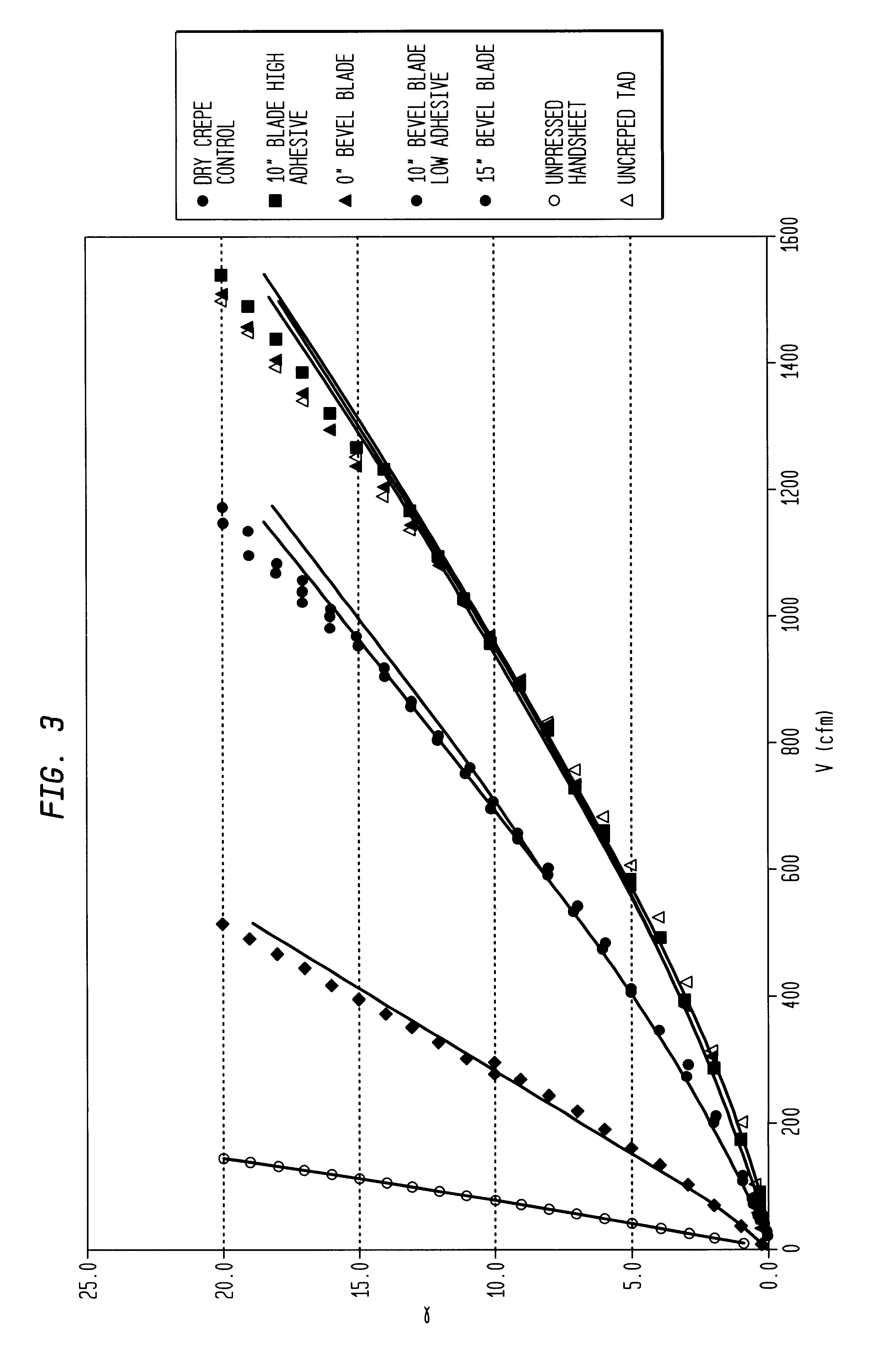

Fabric crepe process for making absorbent sheet

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

Fabric creped absorbent sheet with variable local basis weight

InactiveUS20080029235A1Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

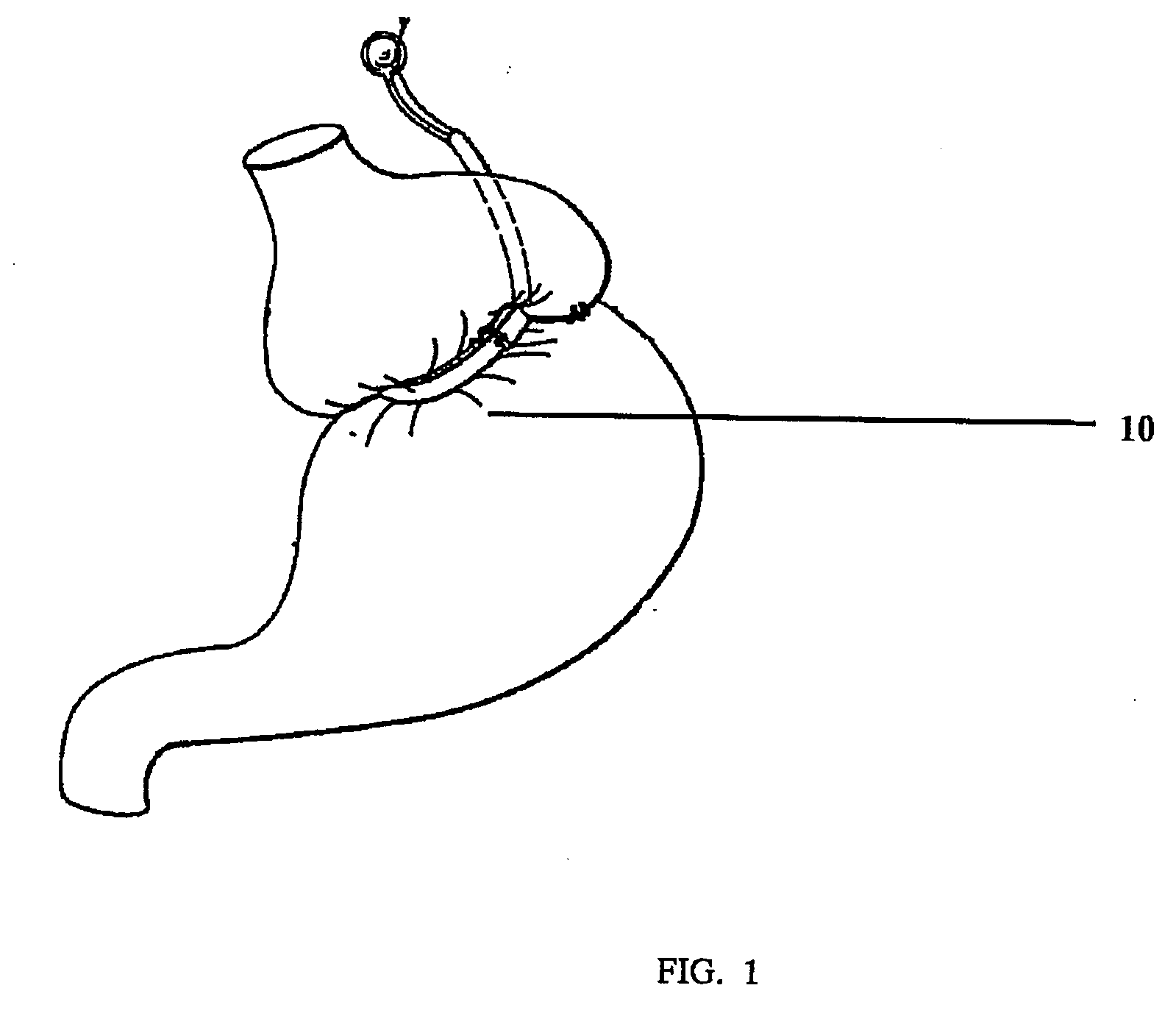

Gastric constriction device

ActiveUS20050119674A1Reduce volume potentialPrevent slippingNon-surgical orthopedic devicesObesity treatmentStomach wallsGeneral surgery

A gastric constriction device (160) comprises a sheet (131) extending over part of the wall of the stomach (24). Five bands (151) extend around the stomach (24) to fix the sheet (131) in position relative to the stomach (24). The lower two bands (151) extend from the first side (152) of the sheet (131) around the stomach (24) only partially towards the second side (153). These lower two bands (151) are not fixed to the second side (153). This arrangement results in an unconstricted portion of the stomach (161). In this manner, the device (160) restricts expansion of the majority of the stomach wall while facilitating expansion of this unconstricted portion (161). The unconstricted portion (161) is therefore free to expand or bulge outwardly upon ingestion. This expansion may trigger the feeling of satiation due to the presence of the vagal nerves in this portion (161) of the stomach (24).

Owner:PROXY BIOMEDICAL

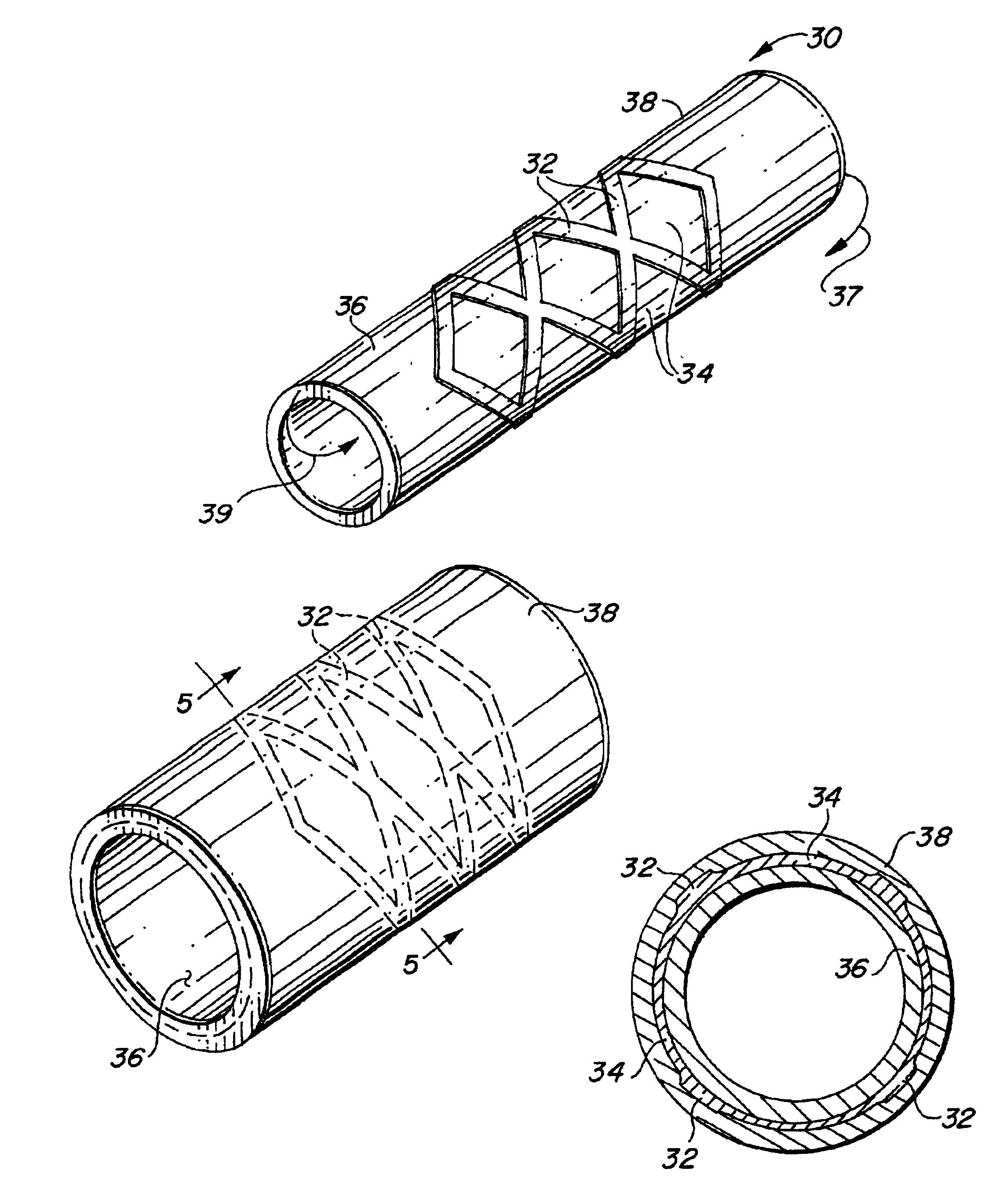

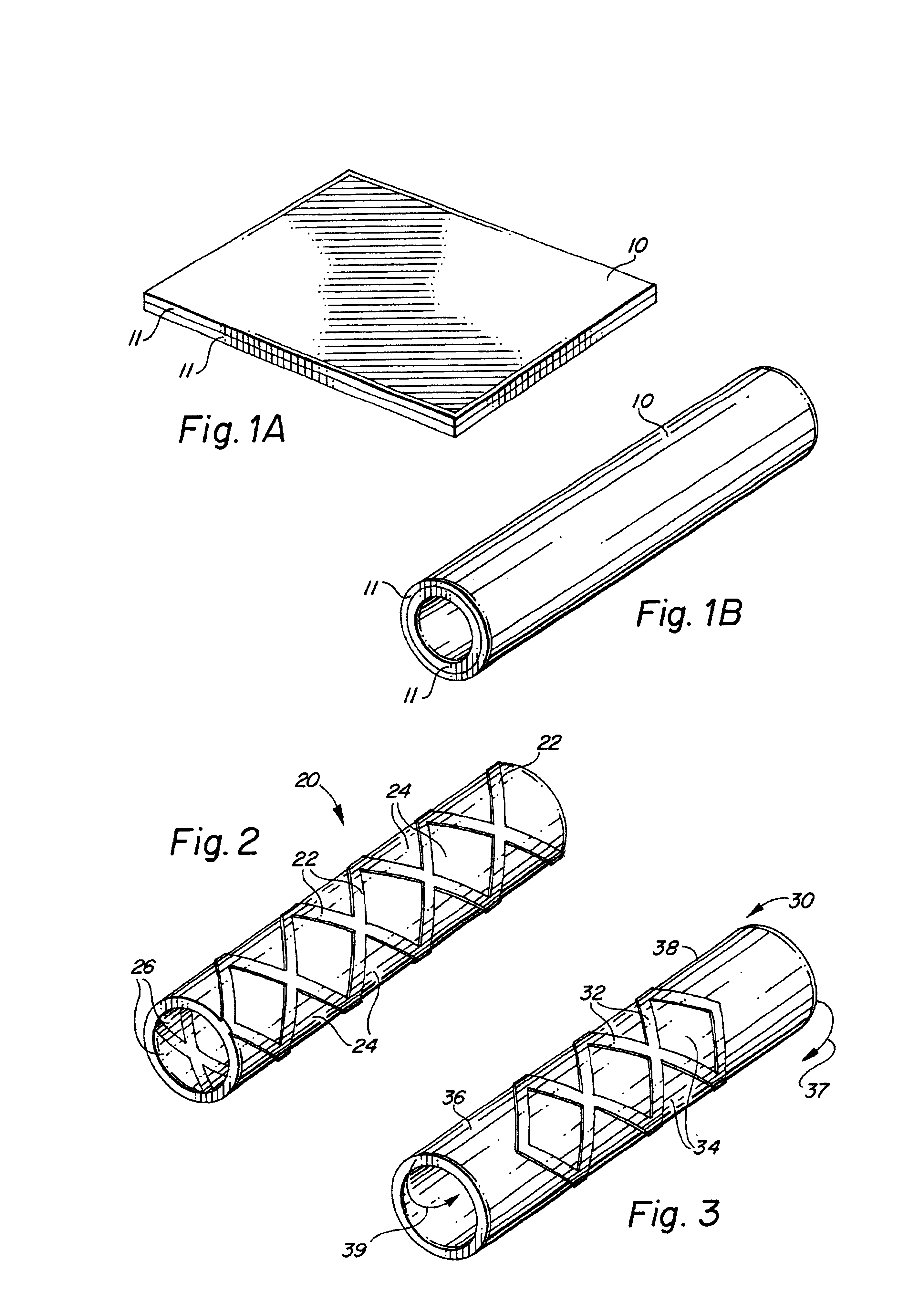

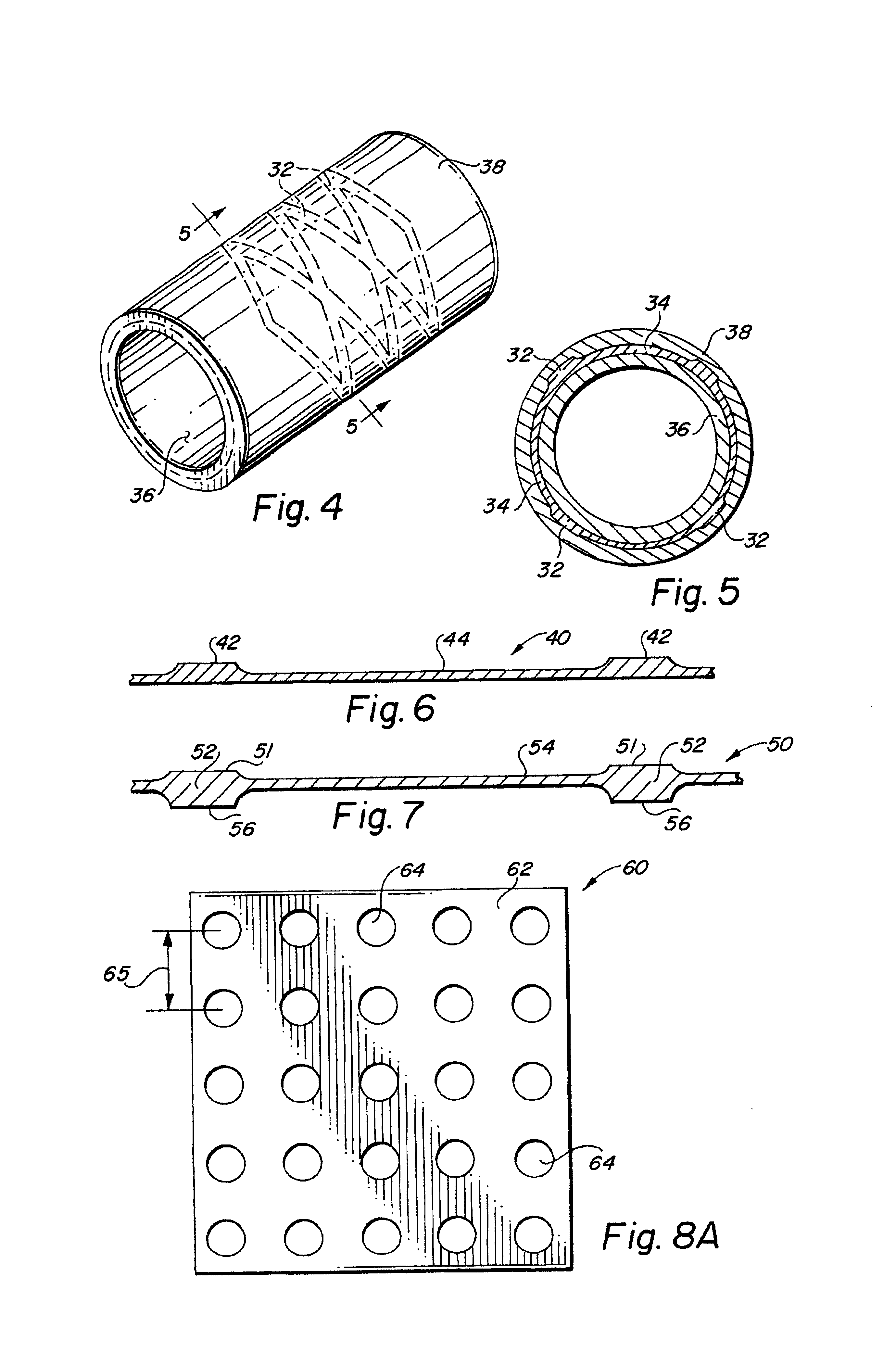

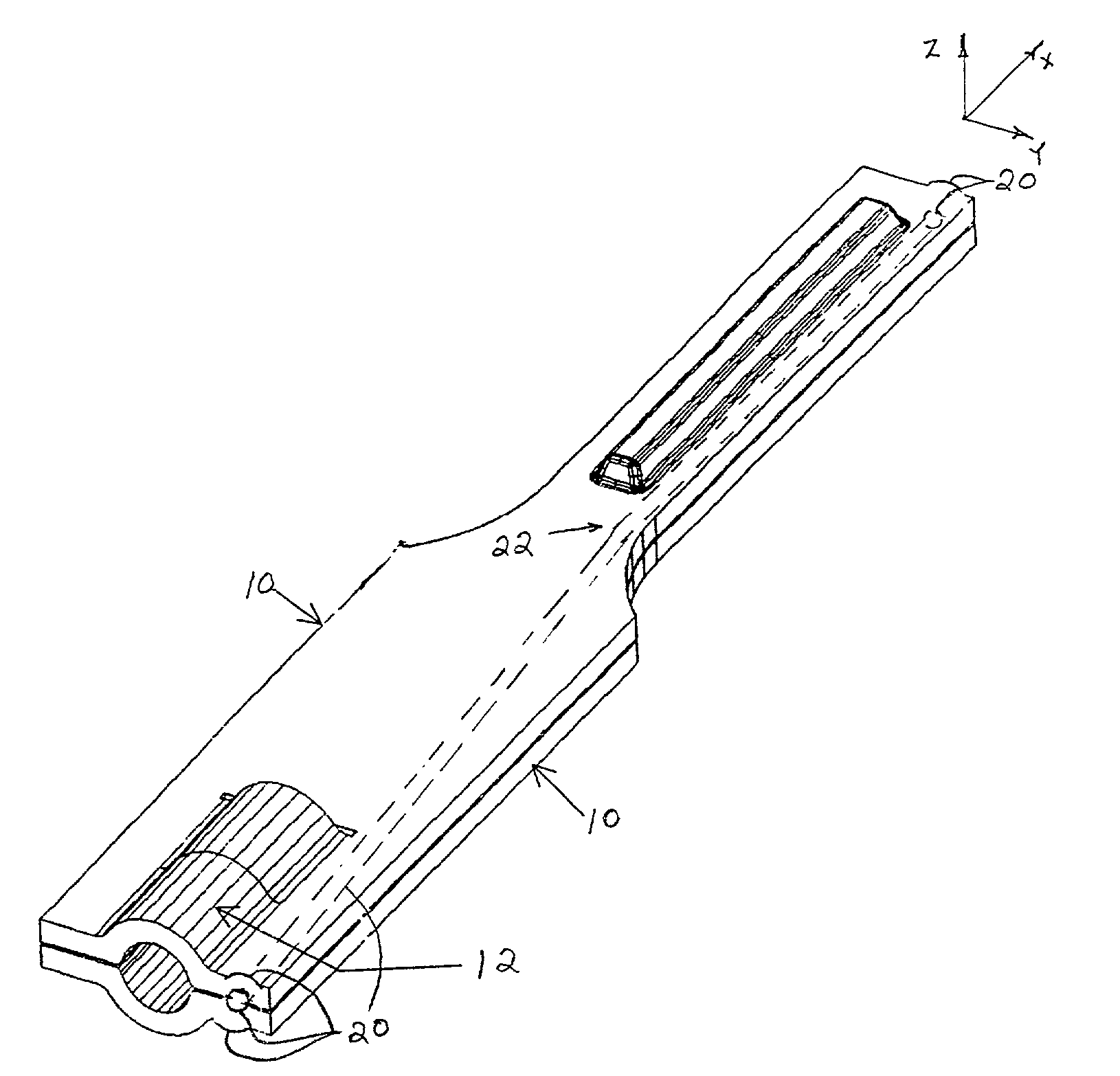

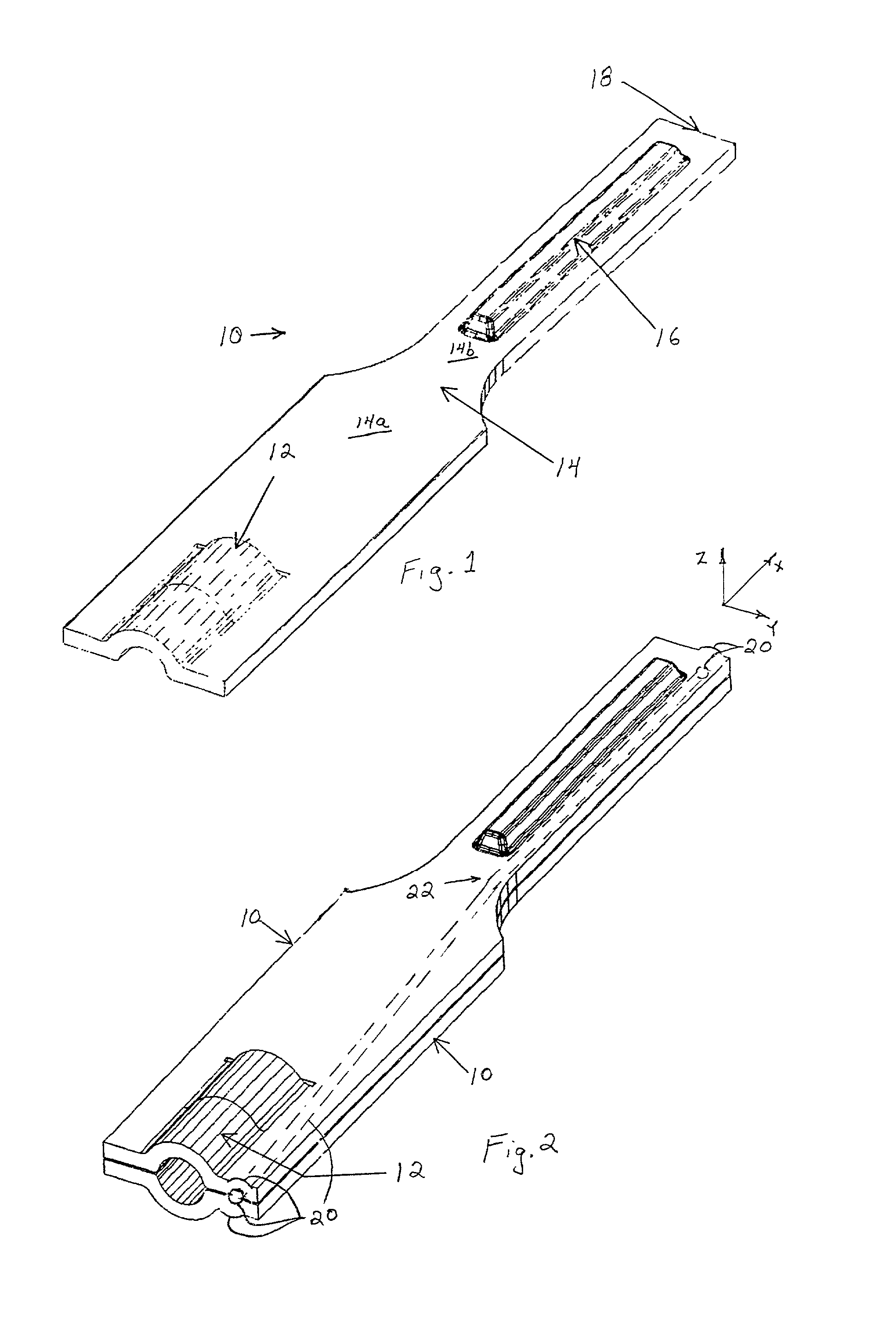

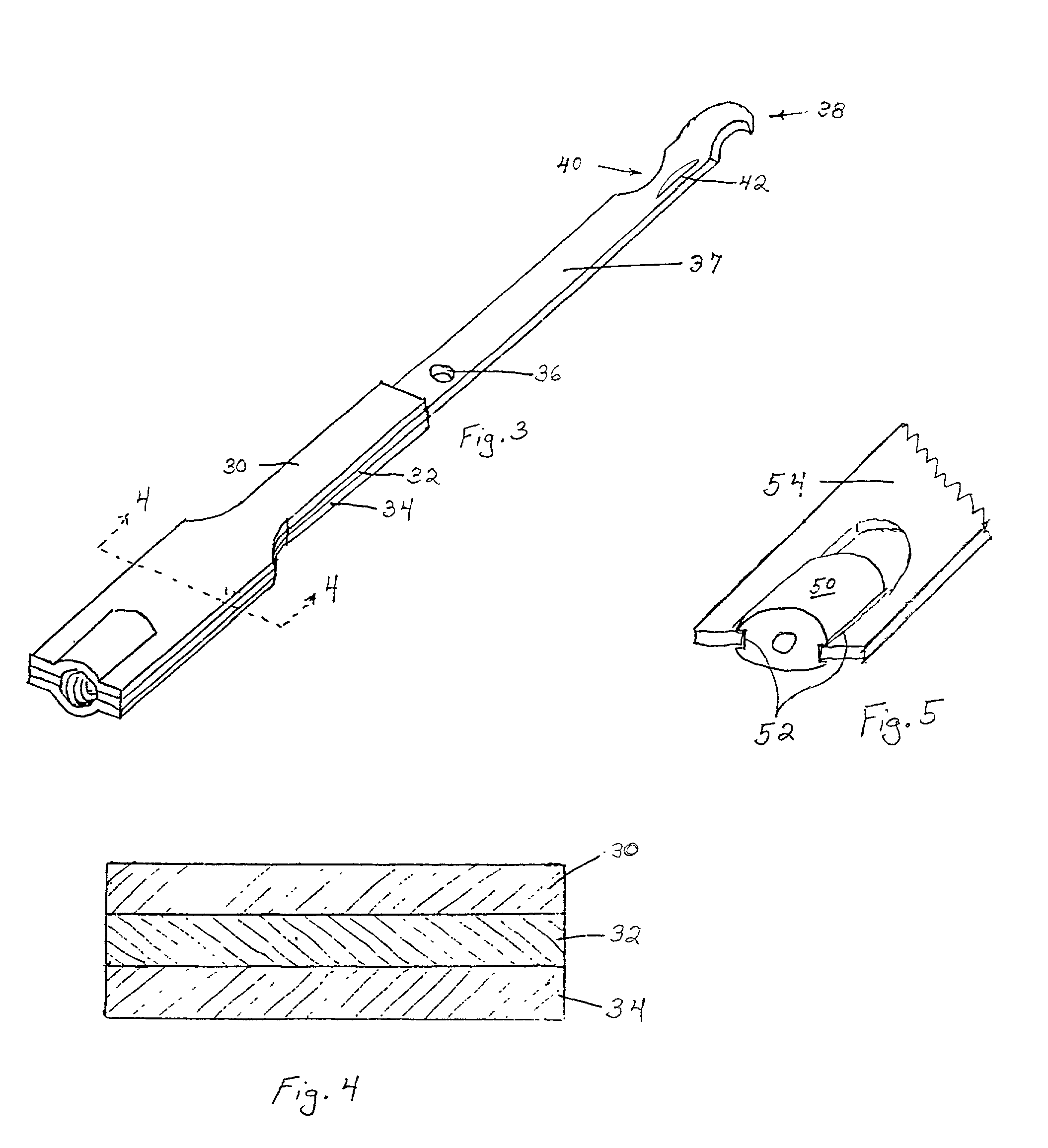

Laminated ultrasonic end effector

InactiveUS7530986B2Reduce manufacturing costReduce material wasteSurgical needlesTrocarEnergy transferAcoustic energy

A laminated ultrasonic waveguide and a method of fabrication thereof including stamping at least two pieces of sheet stock to form stamped parts of the laminated ultrasonic waveguide. The stamped parts are then laminated together to form a laminated ultrasonic waveguide for transferring ultrasonic acoustic energy along a longitudinal axis of the laminated ultrasonic waveguide. The laminated ultrasonic waveguide may be part of an ultrasonic surgical instrument having an active tip end-effector, which is placed in contact with tissue of a patient to couple ultrasonic energy transferred along the laminated ultrasonic waveguide to the tissue. The stamped pieces of sheet stock can also be stamped to form one or more channels extending along the length of the laminated ultrasonic waveguide. The laminated ultrasonic waveguide can also define a connector at a proximal end thereof to transfer ultrasonic energy into the laminated ultrasonic waveguide. In different embodiments, the laminated ultrasonic waveguide comprises first and second (and third or more) stamped pieces of sheet stock that are laminated together.

Owner:ETHICON ENDO SURGERY INC

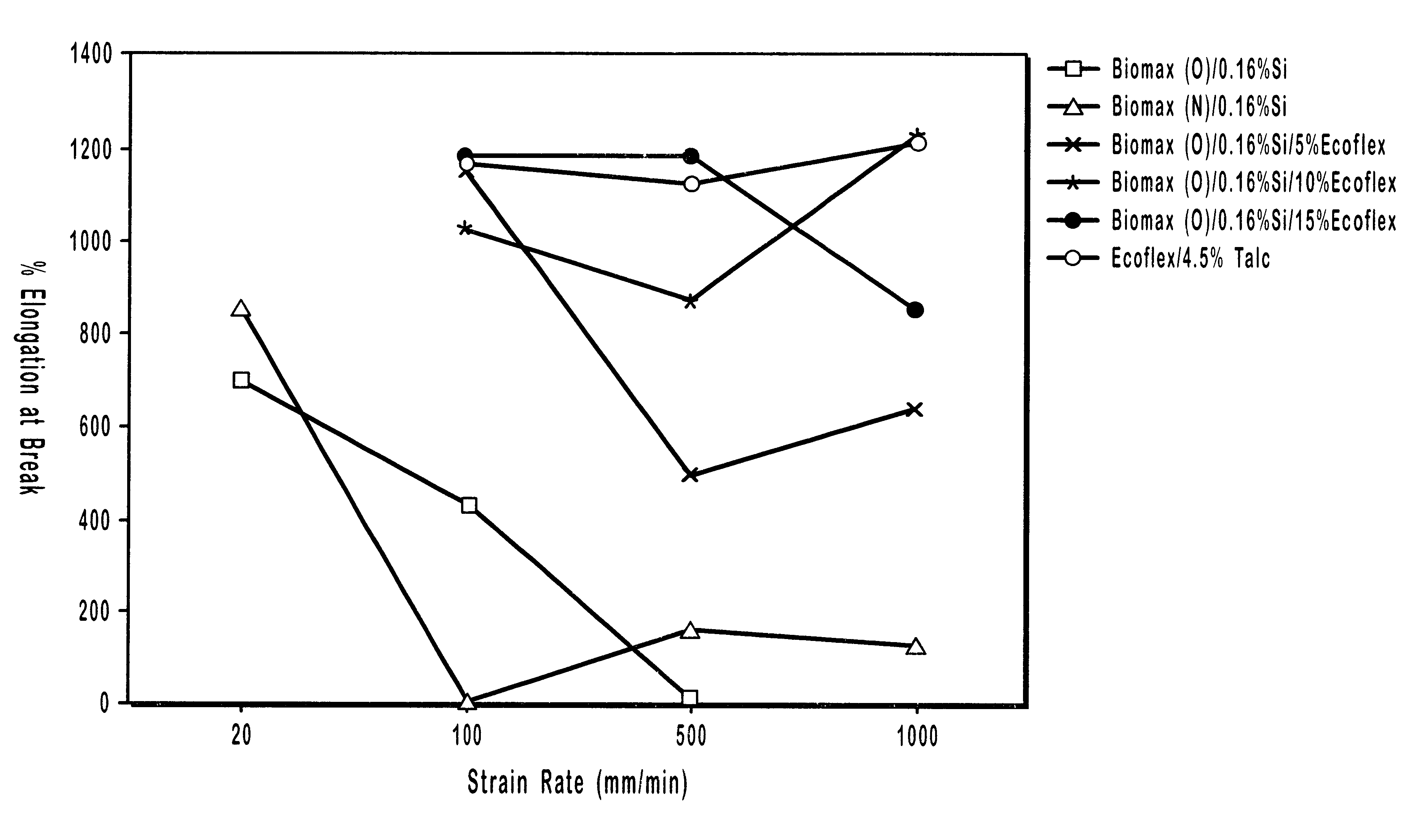

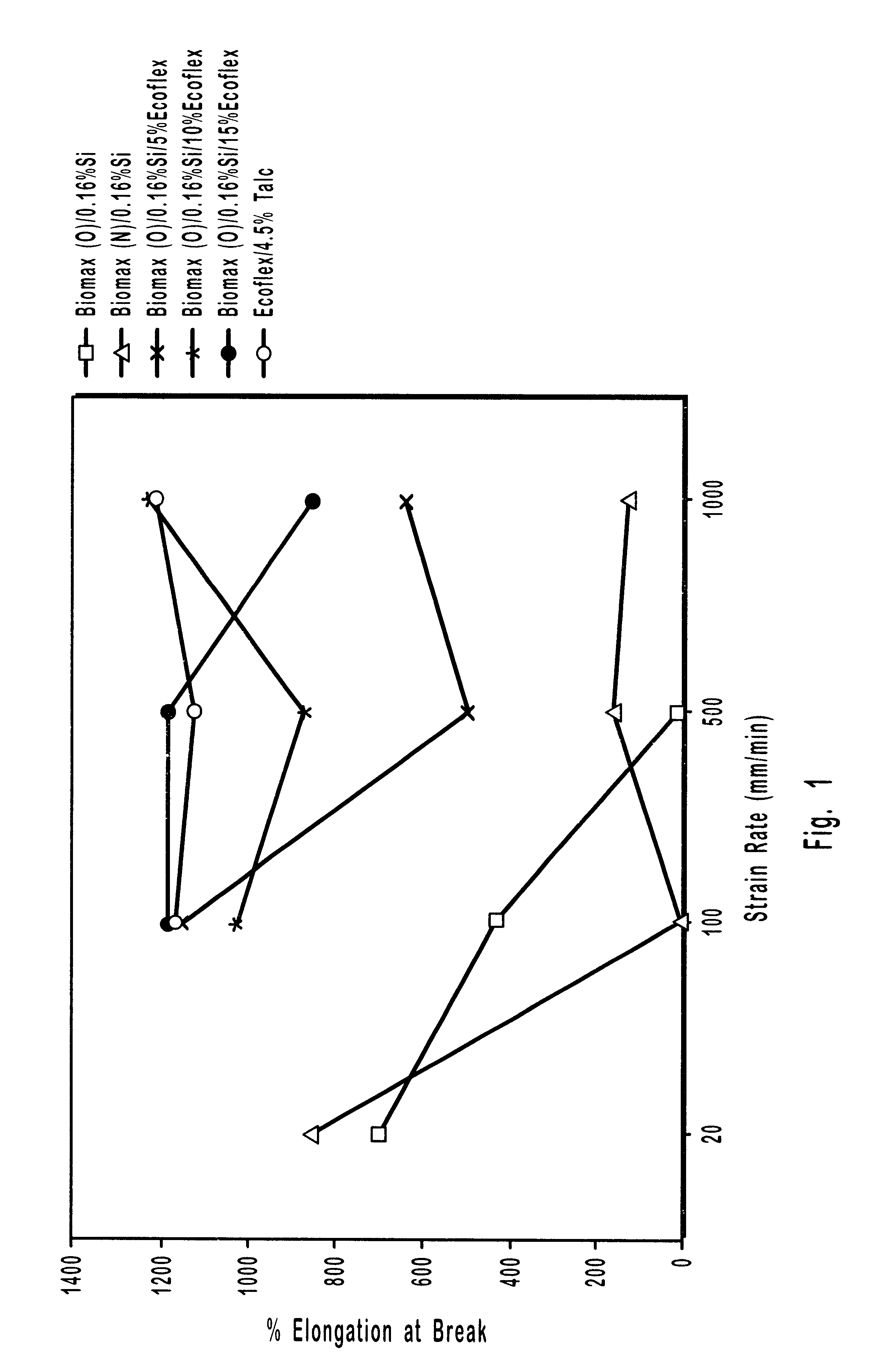

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

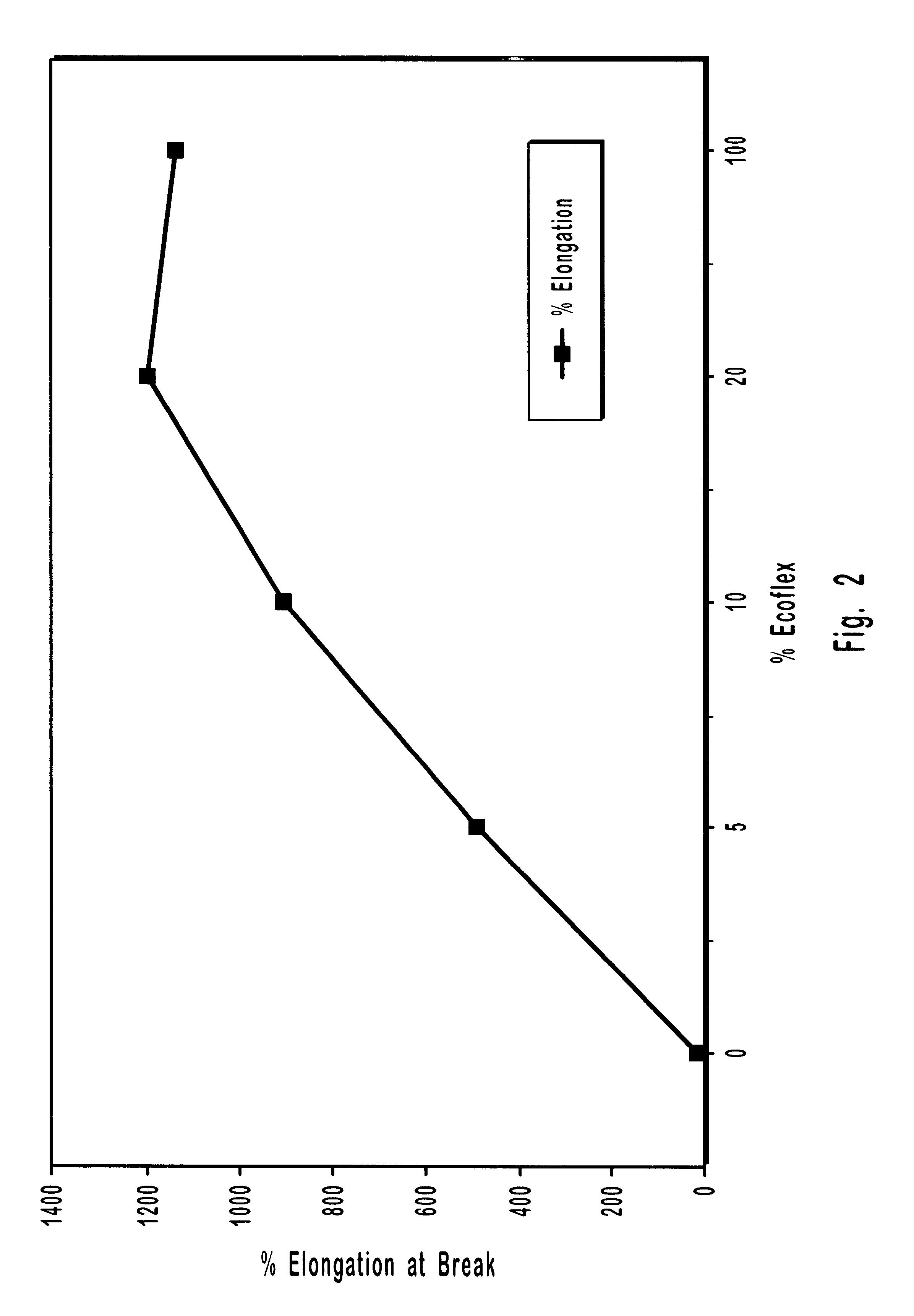

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

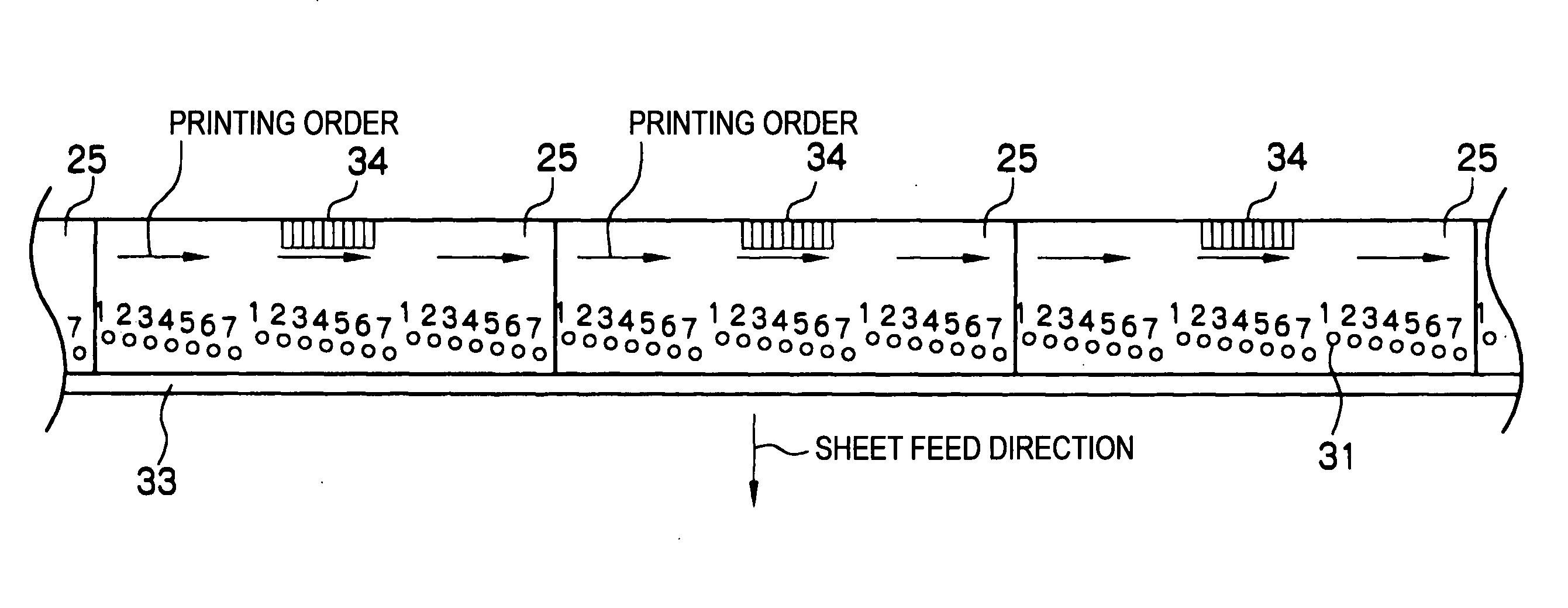

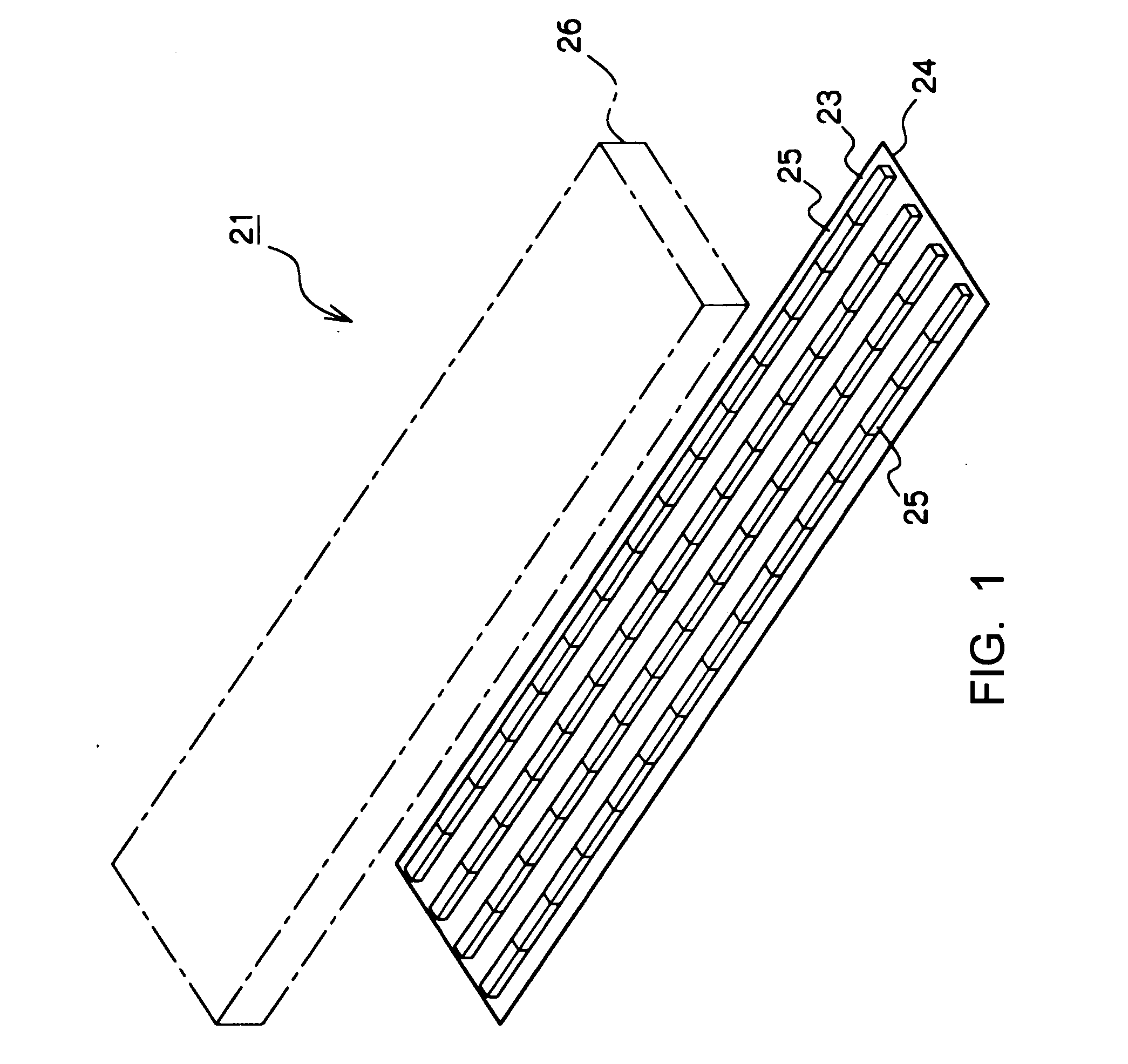

Ink jet print head, inkjet printer including the inkjet print head, and method of manufacturing inkjet print head

An inkjet print head includes one nozzle sheet (23) and a plurality of head chips (25) including a plurality of heaters. The nozzle sheet (23) is formed of an electroformed metal layer made of nickel or a material comprising nickel, and has discharge nozzle rows for respective colors disposed so that the discharge nozzles are in staggered arrangements and so that each set of discharge nozzles partly overlaps another set of discharge nozzles in a sheet-feed direction. The head chips are positioned at and affixed to a growth surface side of the nozzle sheet (23) in staggered arrangements so that the positions of the discharge nozzles and the positions of the heaters correspond to each other. Accordingly, reduction in printing quality caused by displacement of any of the discharge nozzles is prevented from occurring, and landing positions of discharged ink on a recording sheet are stabilized.

Owner:SONY CORP

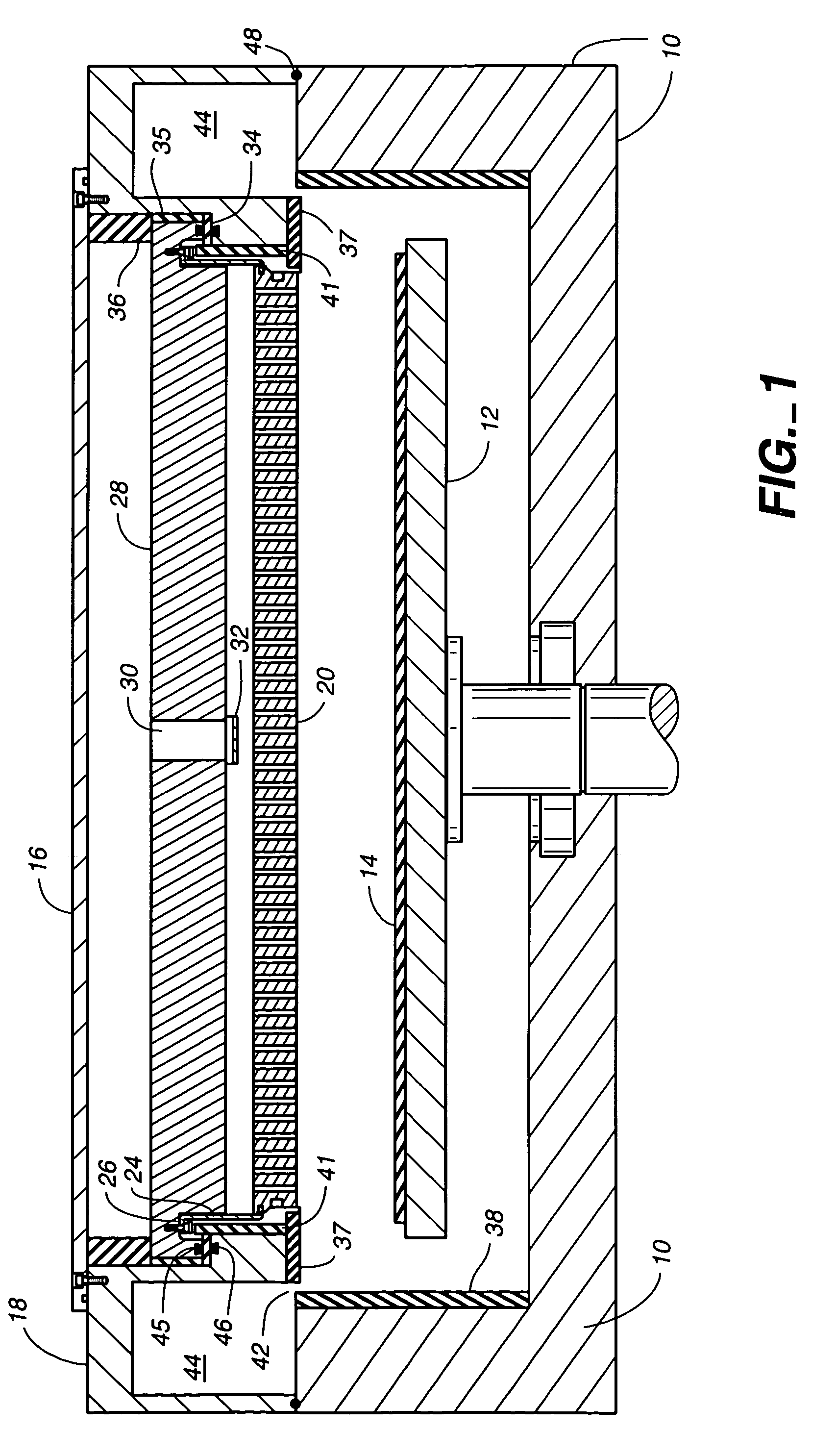

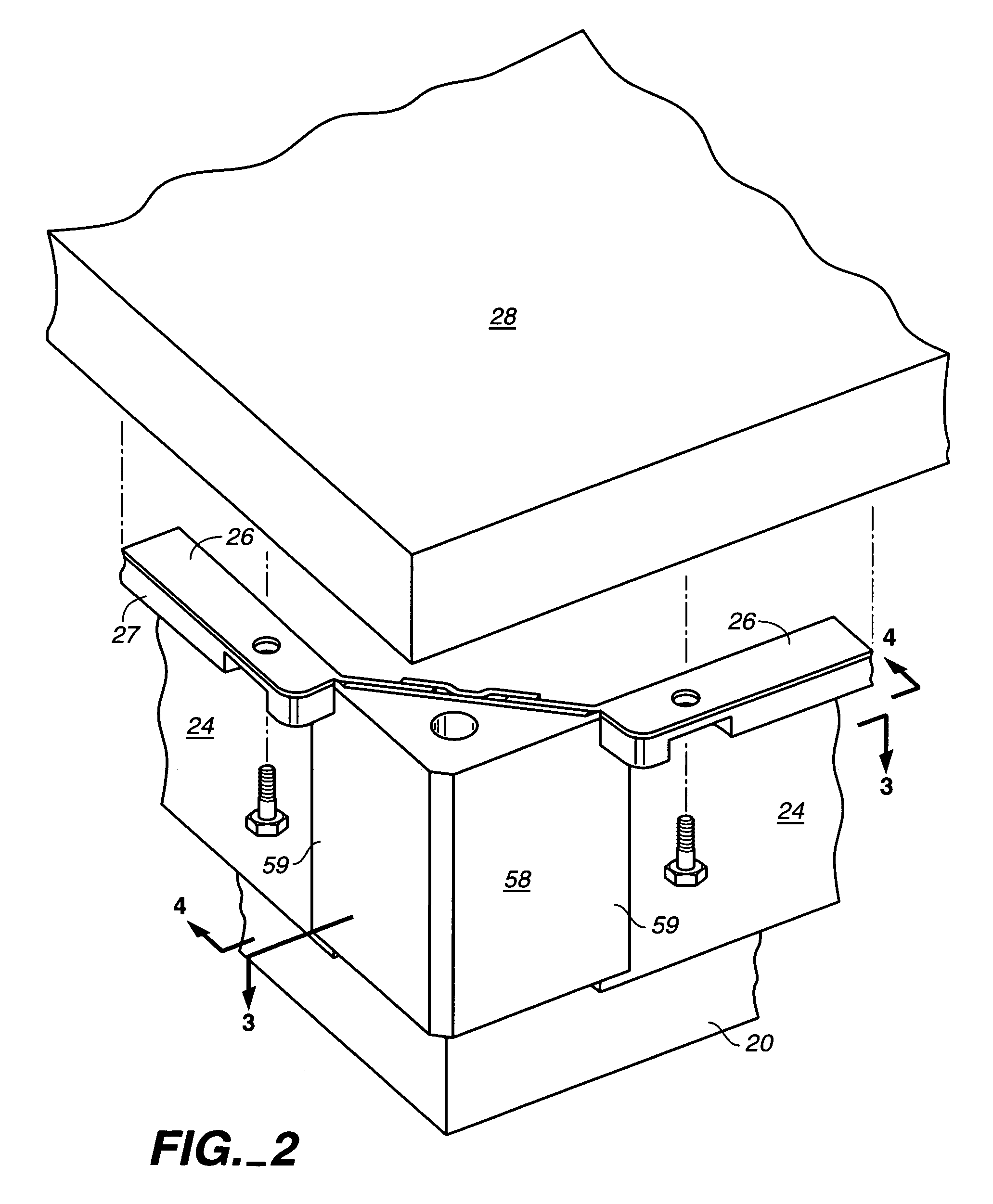

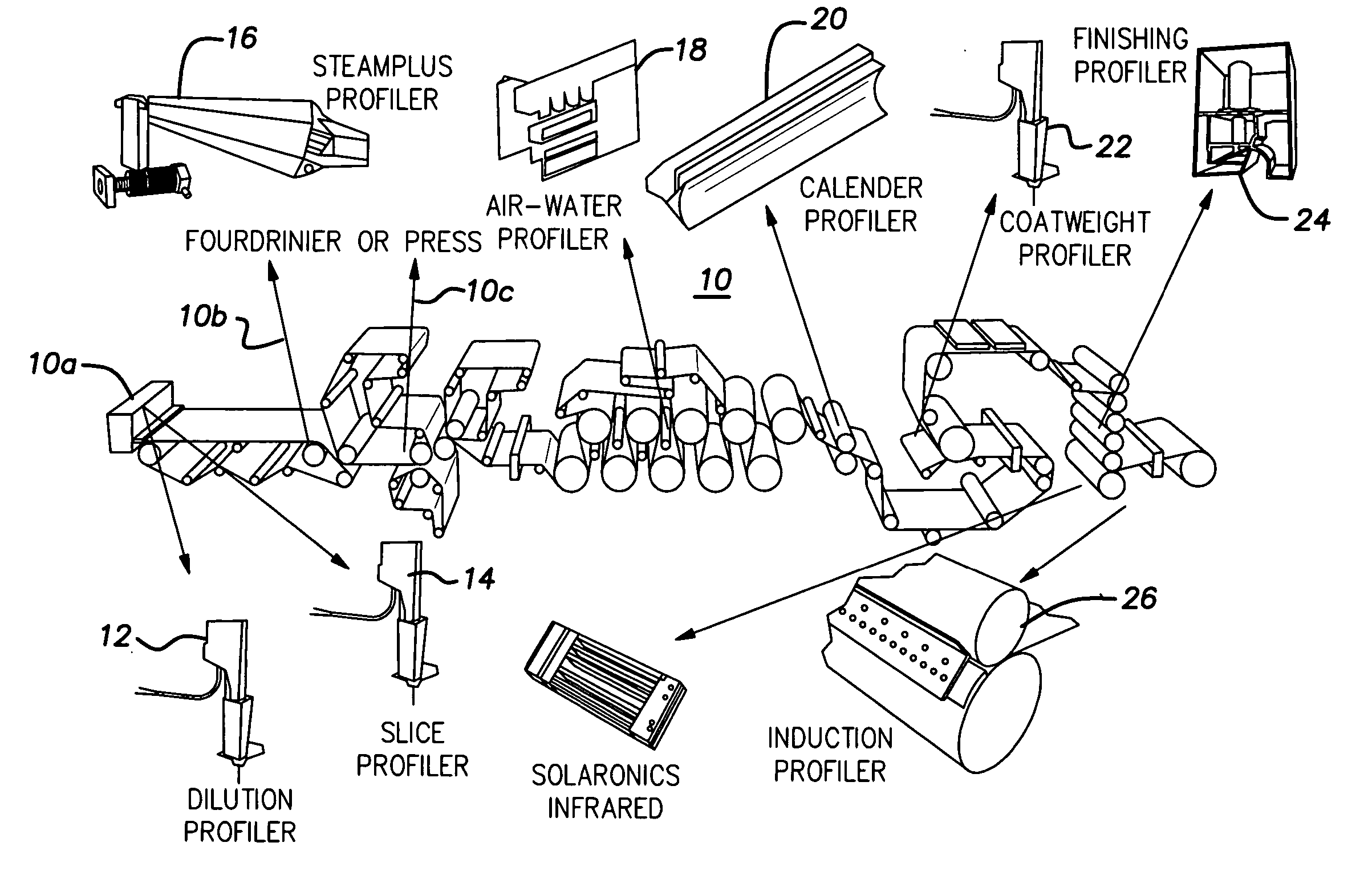

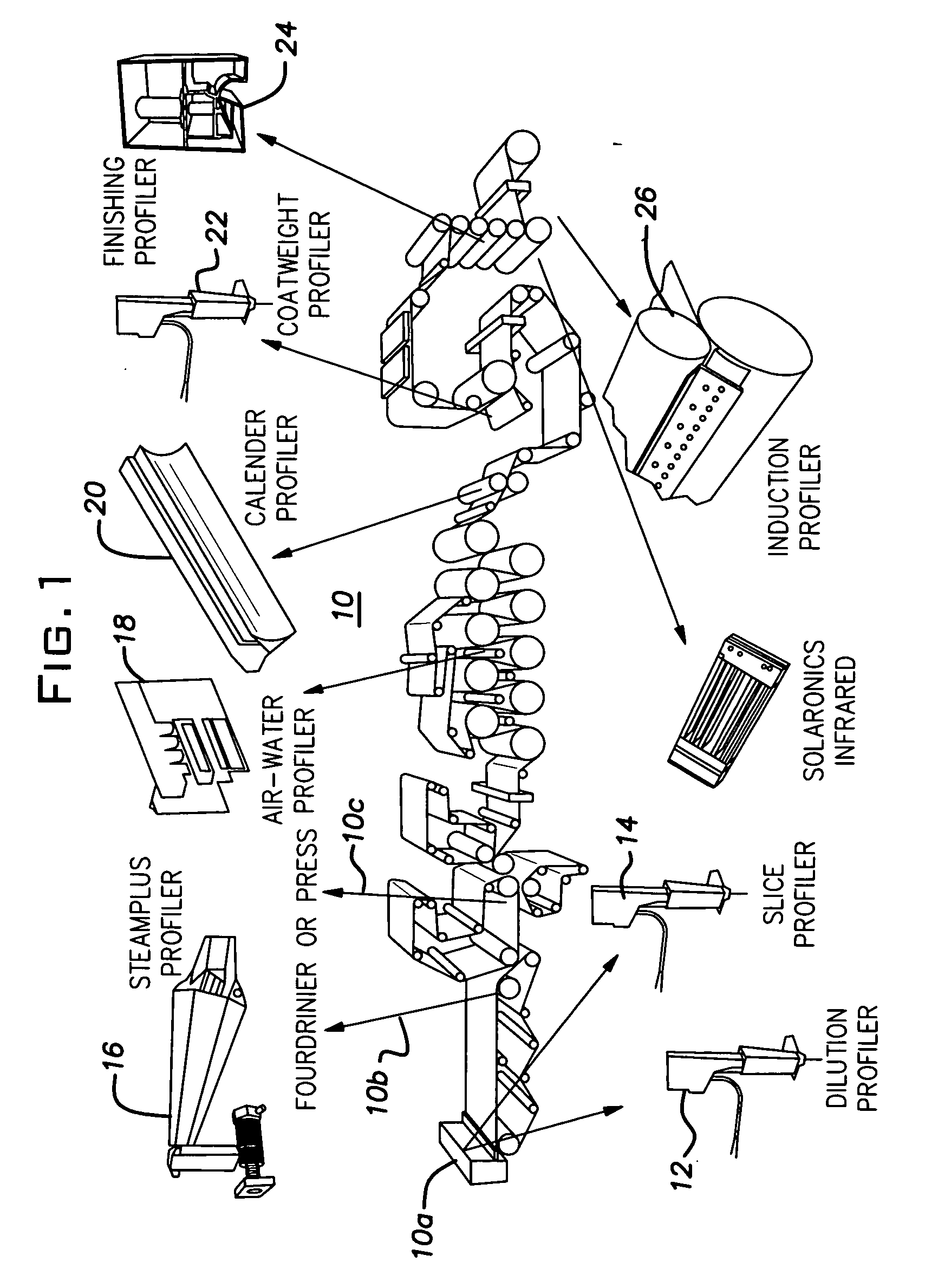

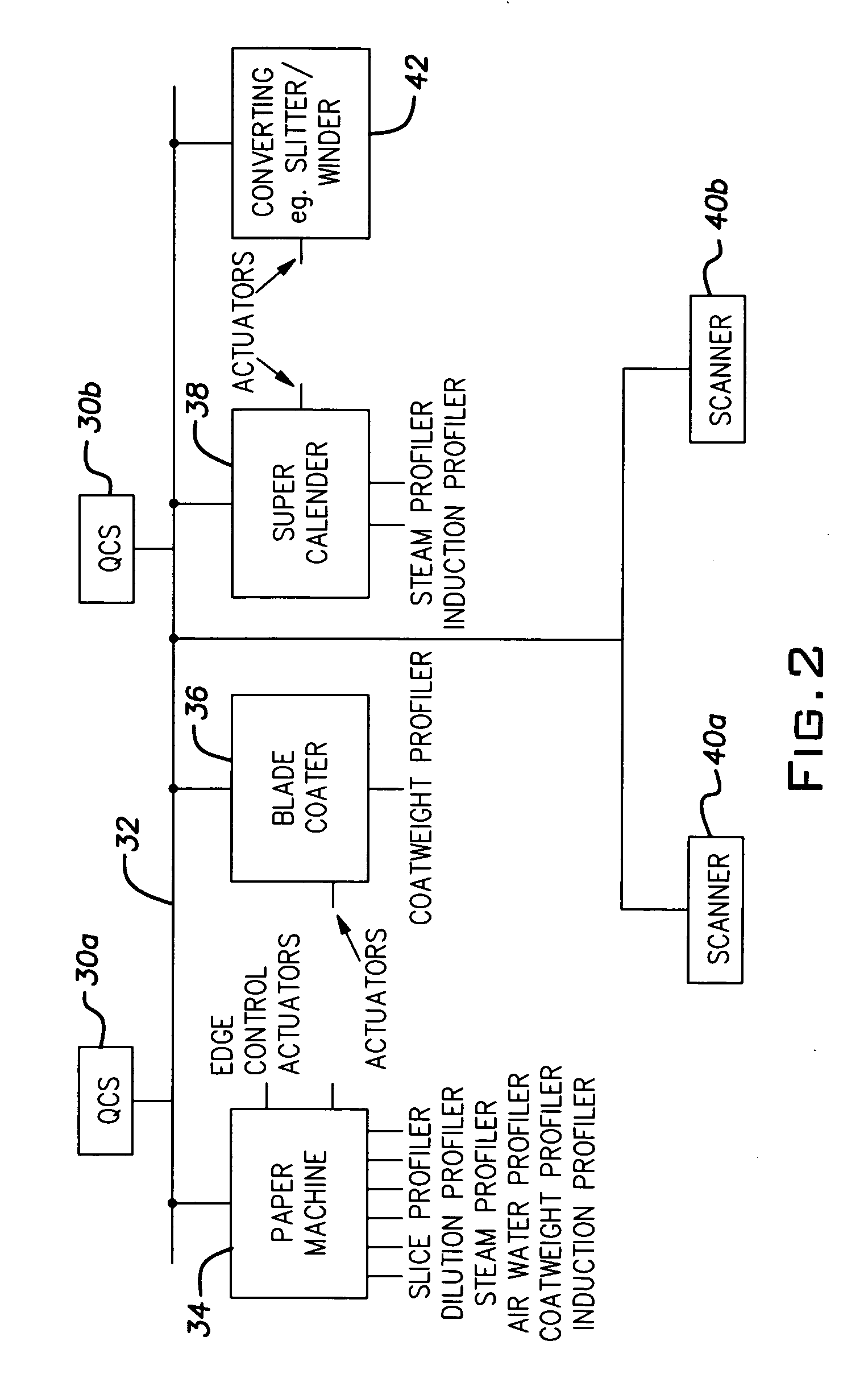

Actuator system for use in control of a sheet or web forming process

InactiveUS20060185809A1Digital differential analysersPaper-making machinesElectric power transmissionPower cable

One or more actuator driven devices on a sheet forming machine receive power and engage in bi-didrectional communications with one or more quality control systems either by having no physically connected cables to transmit the power to the actuators and no physically connected cables used for the bi-directional communications; or contactless power and communication on a power cable; or a cable connected from the power source to the actuators to provide both power and bi-directional communications; or power is provided to the actuators by a cable and the bi-directional communications are wireless.

Owner:ABB RES LTD +1

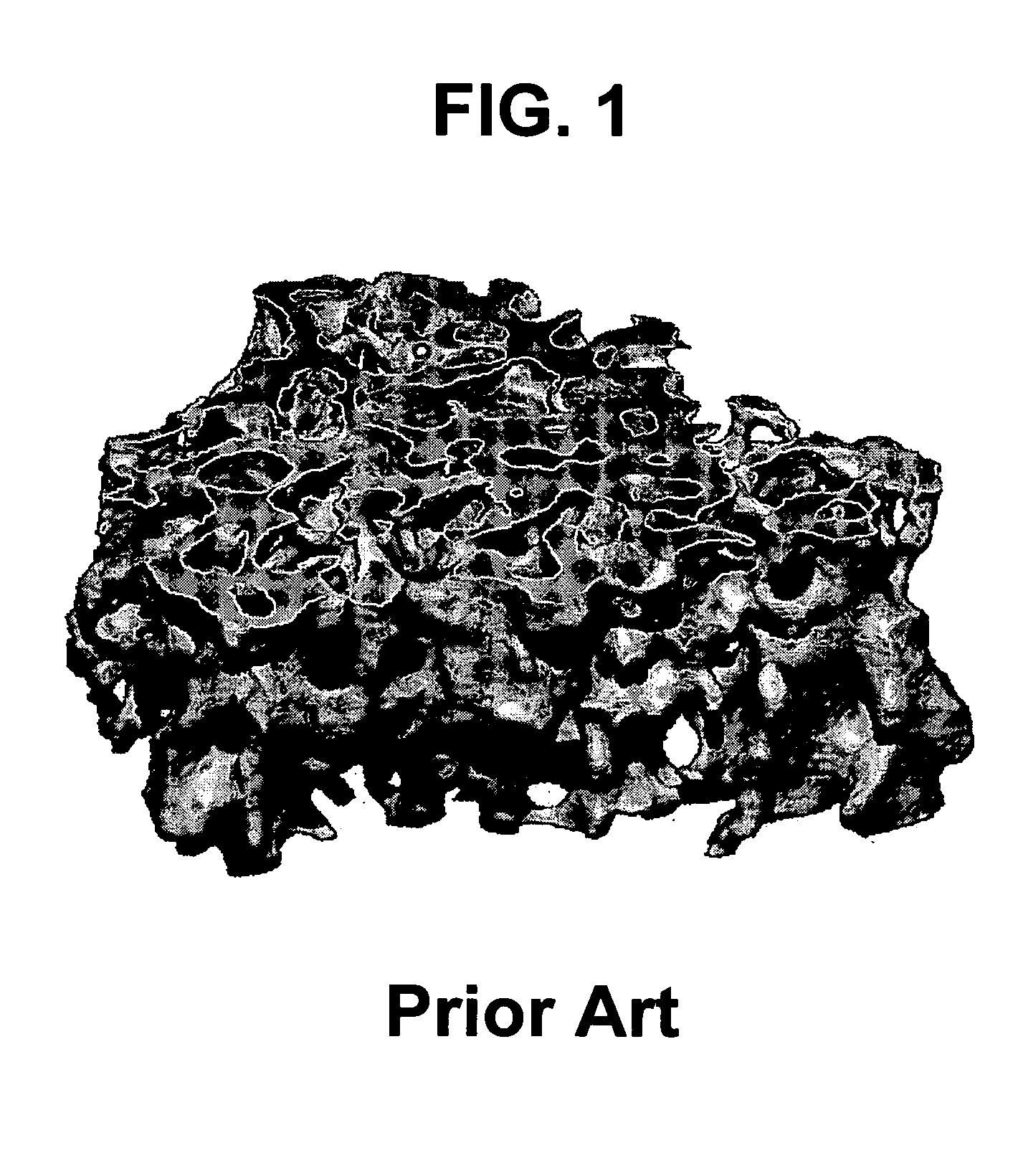

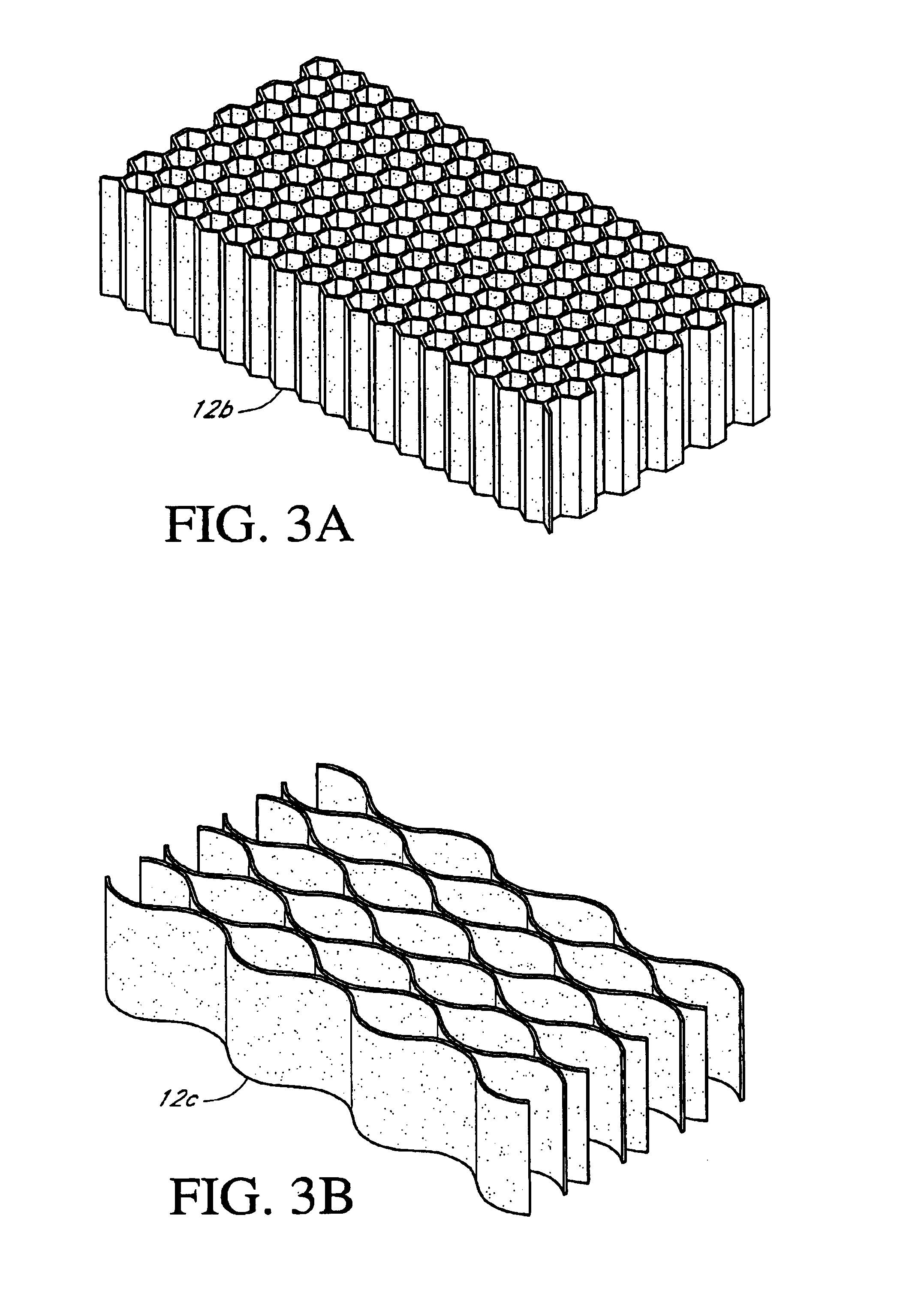

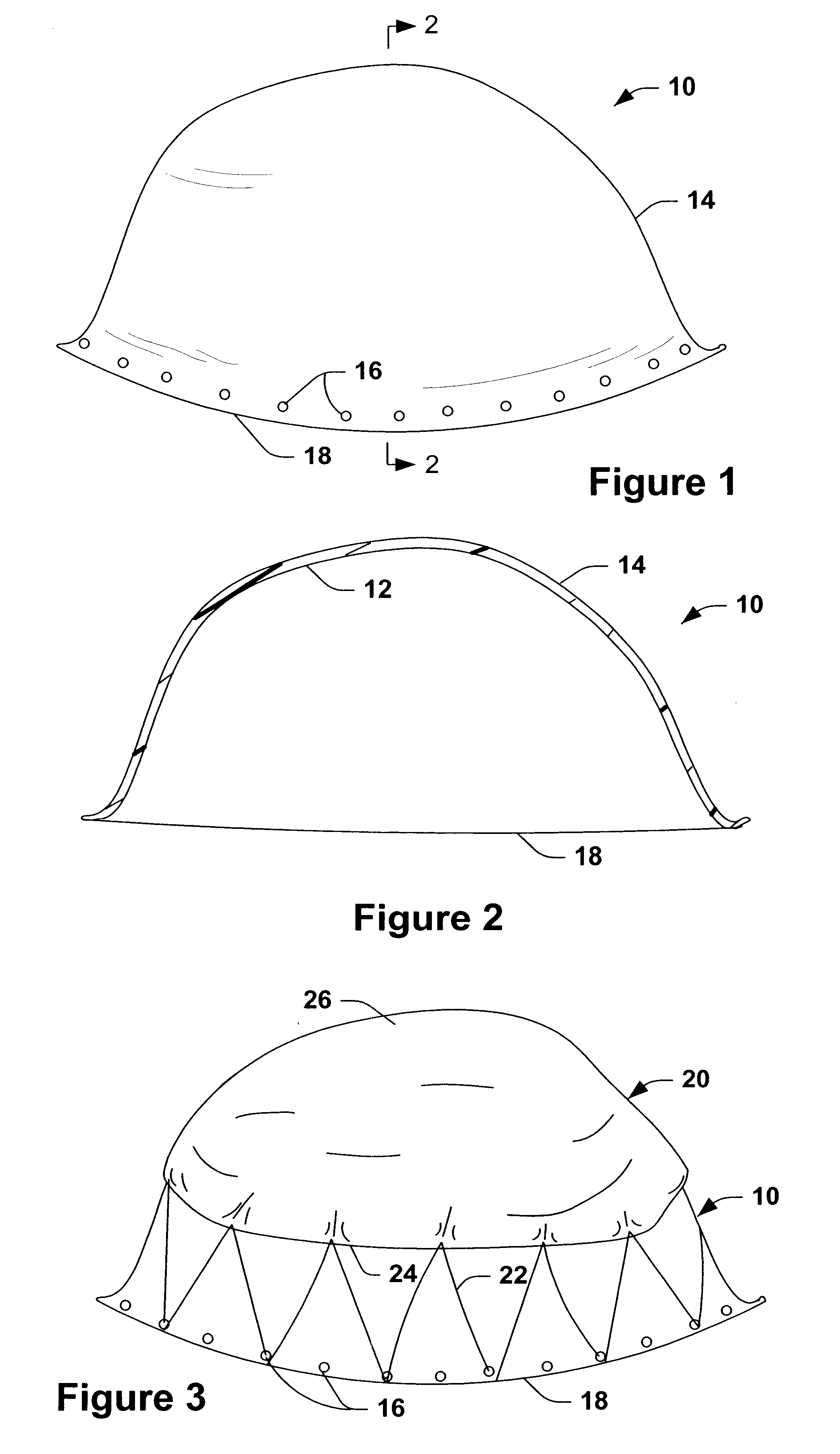

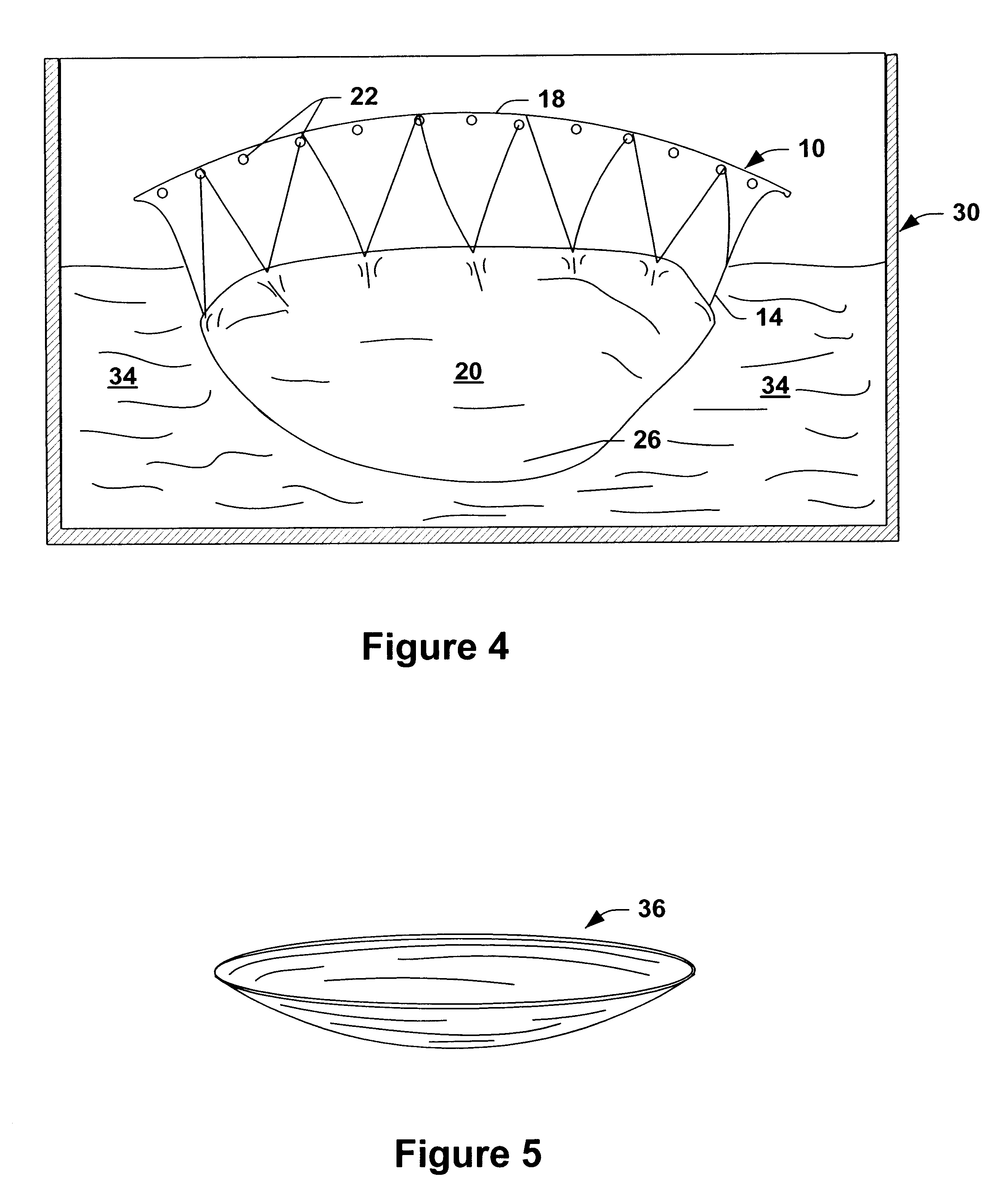

Bone and tissue scaffolding and method for producing same

InactiveUS20050100578A1Improves orthopedic implant performanceLow costBiocideBone implantPorous sheetMaterials science

Owner:UNIV OF NOTRE DAME DU LAC

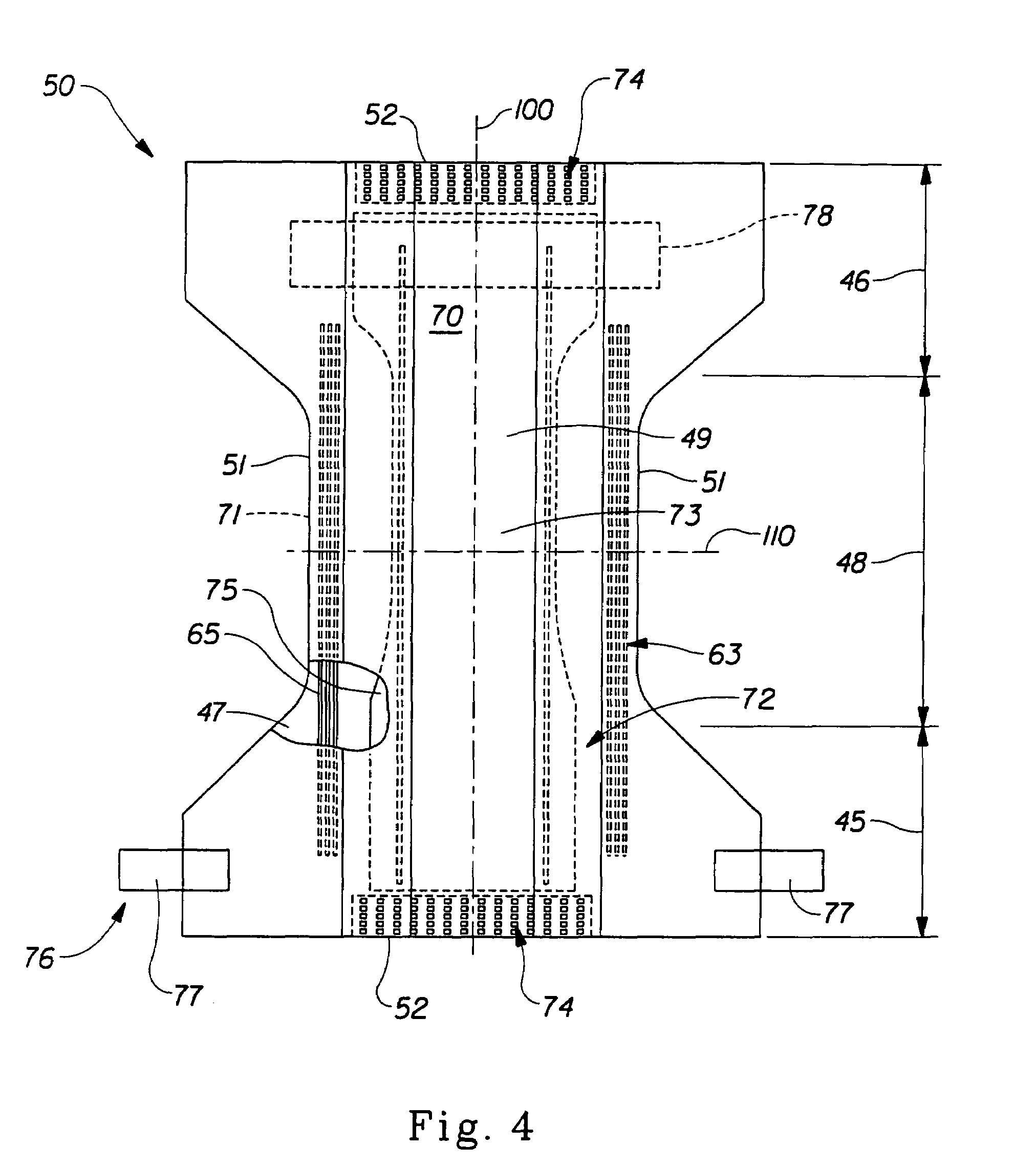

Breathable composite sheet structure and absorbent articles utilizing same

A breathable composite sheet material, a method for making such a sheet material, and an absorbent article utilizing the sheet material are provided. The composite sheet material is comprised of a thermoplastic film adhered directly to a fibrous substrate. The thermoplastic film comprises at least 50% by weight of a polymer material from the group of block copolyether esters, block copolyether amides and polyurethanes. The substrate comprises a fibrous web of at least 50% by weight of polyolefin polymer synthetic fibers. The composite sheet exhibits a peel strength of at least 0.1 N / cm, a dynamic fluid transmission of less than about 0.75 g / m2 when subjected to an impact energy of about 2400 joules / m2, and a moisture vapor transmission rate, according to the desiccant method, of at least 1500 g / m2 / 24 hr. The absorbent article comprises (a) a topsheet; (b) a backsheet; and (c) an absorbent core located between the topsheet and the backsheet; wherein the backsheet comprises the non-porous, substantially fluid impermeable, moisture vapor permeable composite sheet material described above. The composite sheet material is oriented such that the film layer of the composite sheet material faces toward the absorbent core. The absorbent article may comprise a disposable diaper.

Owner:THE PROCTER & GAMBLE COMPANY

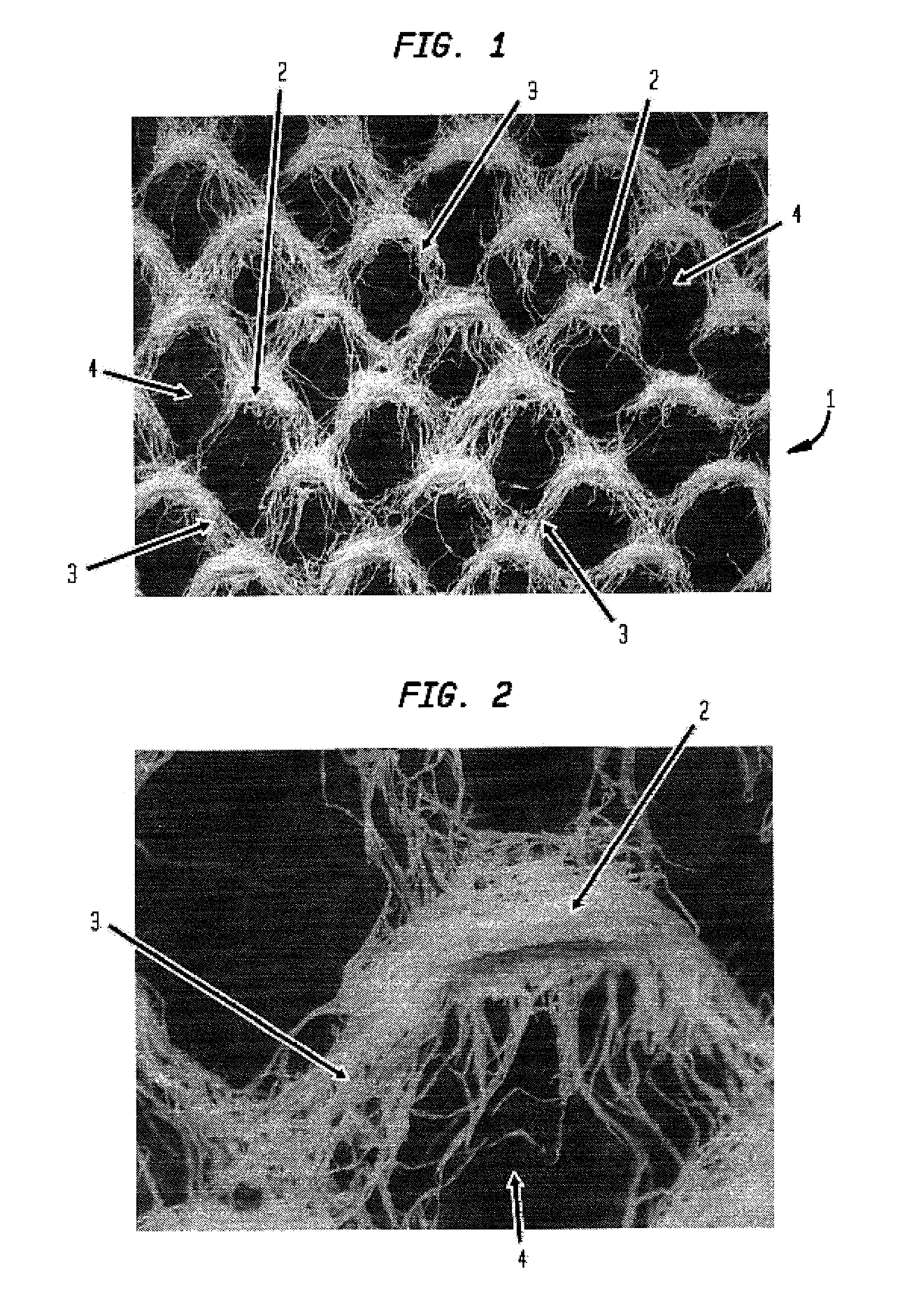

Resorbable, macro-porous, non-collapsing and flexible membrane barrier for skeletal repair and regeneration

A resorbable, flexible implant in the form of a continuous macro-porous sheet is disclosed. The implant is adapted to protect biological tissue defects, especially bone defects in the mammalian skeletal system, from the interposition of adjacent soft tissues during in vivo repair. The membrane has pores with diameters from 20 microns to 3000 microns. This porosity is such that vasculature and connective tissue cells derived from the adjacent soft tissues including the periosteum can proliferate through the membrane into the bone defect. The thickness of the sheet is such that the sheet has both sufficient flexibility to allow the sheet to be shaped to conform to the configuration of a skeletal region to be repaired, and sufficient tensile strength to allow the sheet to be so shaped without damage to the sheet. The sheet provides enough inherent mechanical strength to withstand pressure from adjacent musculature and does not collapse.

Owner:MACROPORE

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

ActiveUS20050241786A1The implementation process is simpleNatural cellulose pulp/paperMechanical working/deformationMedicineCellulose fiber

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

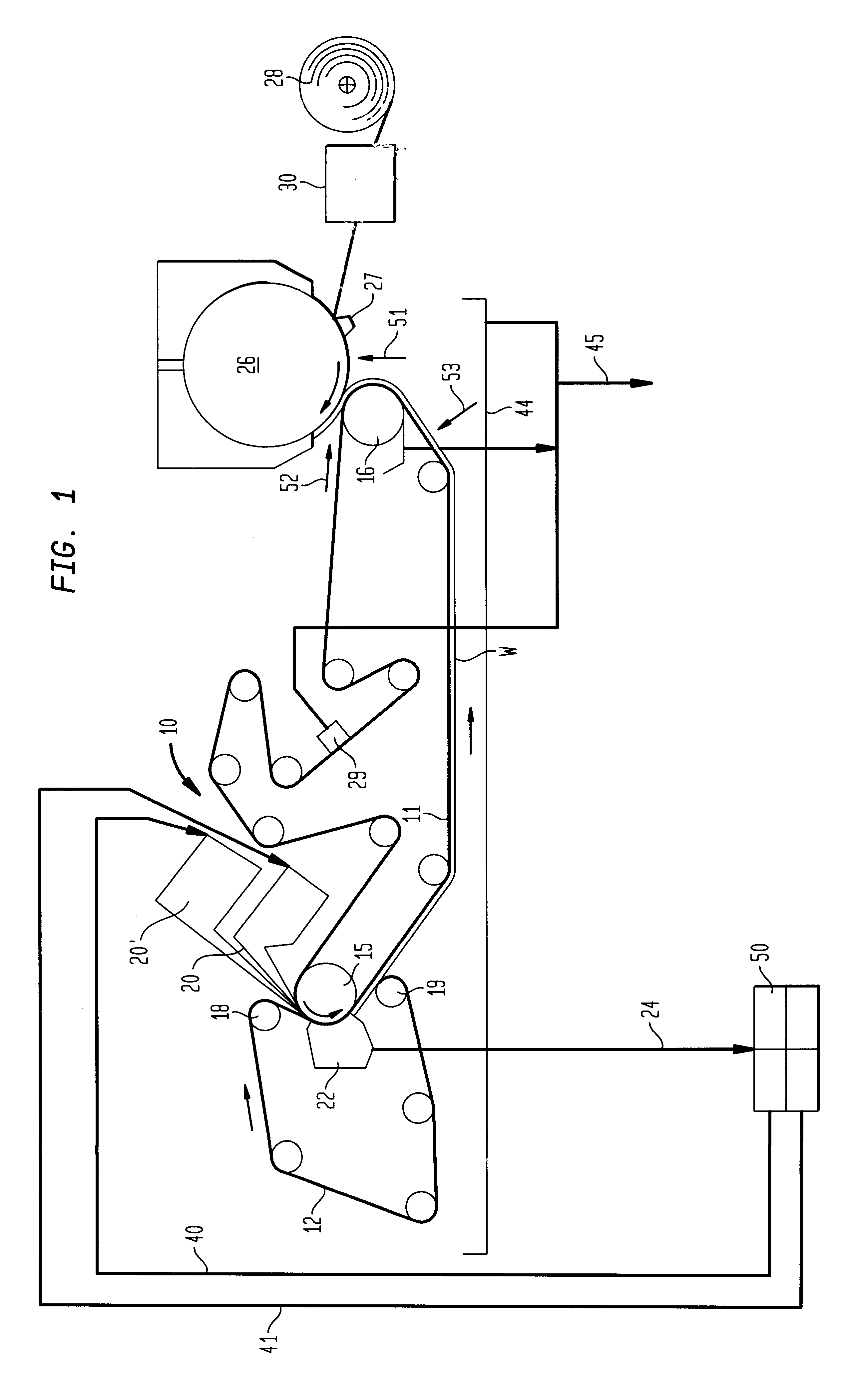

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

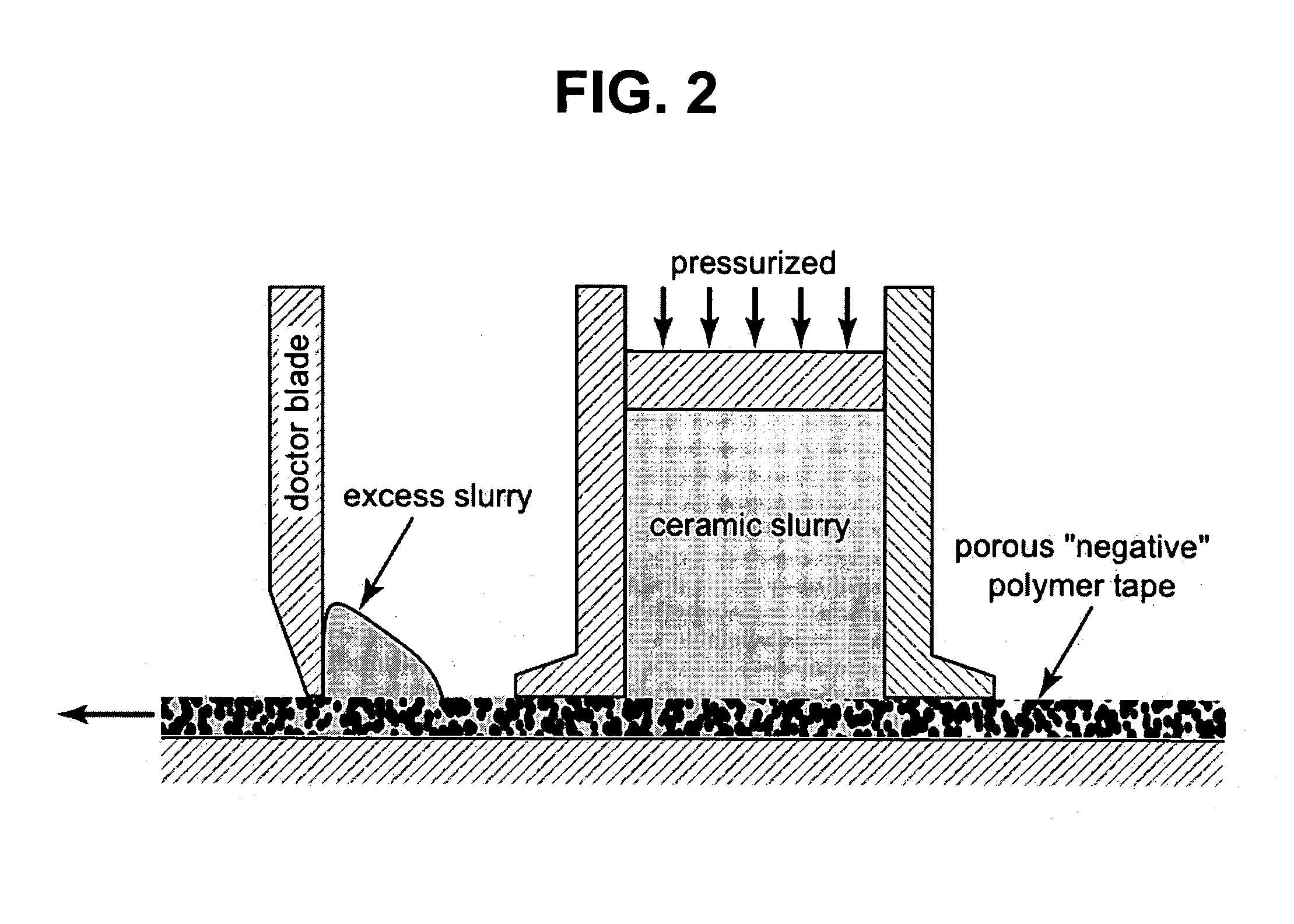

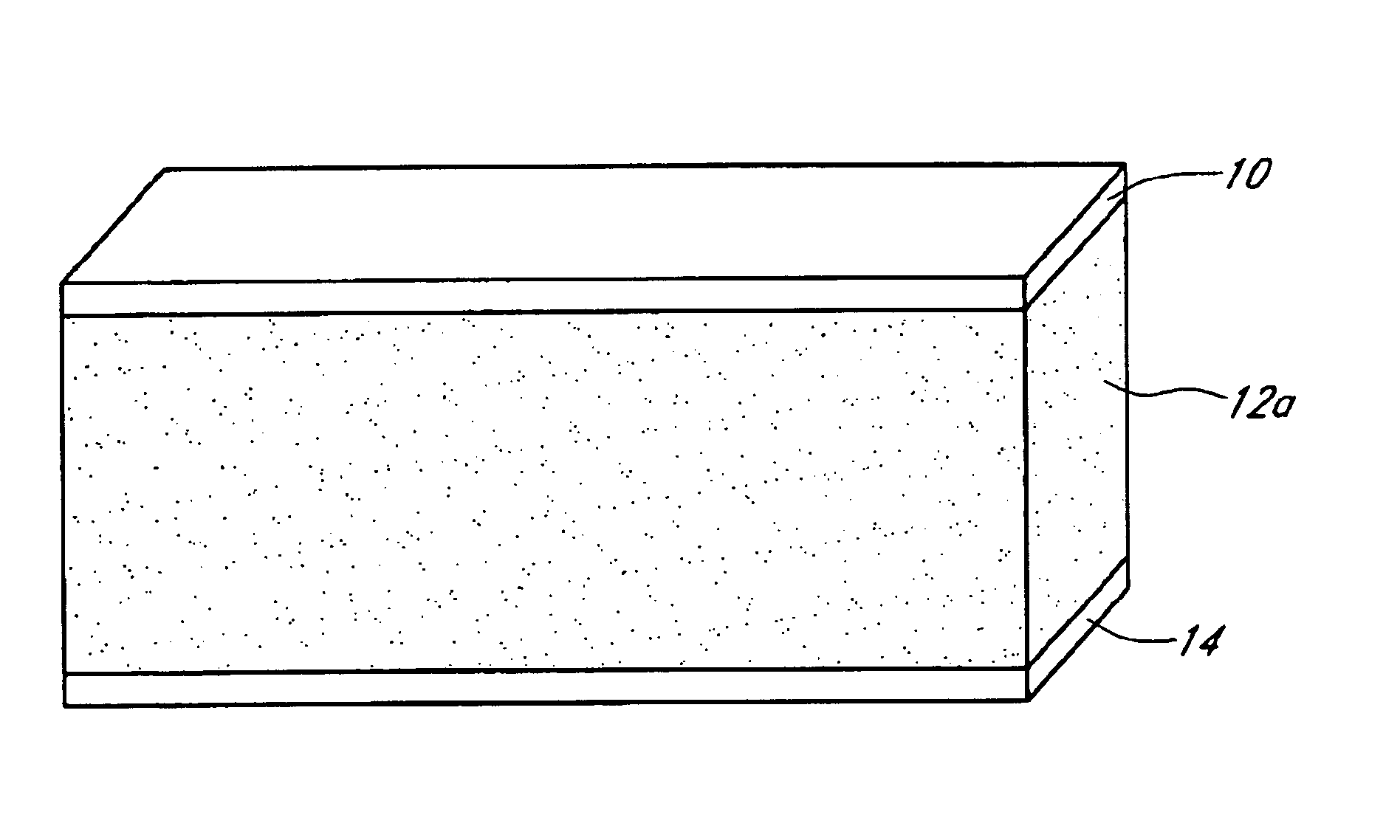

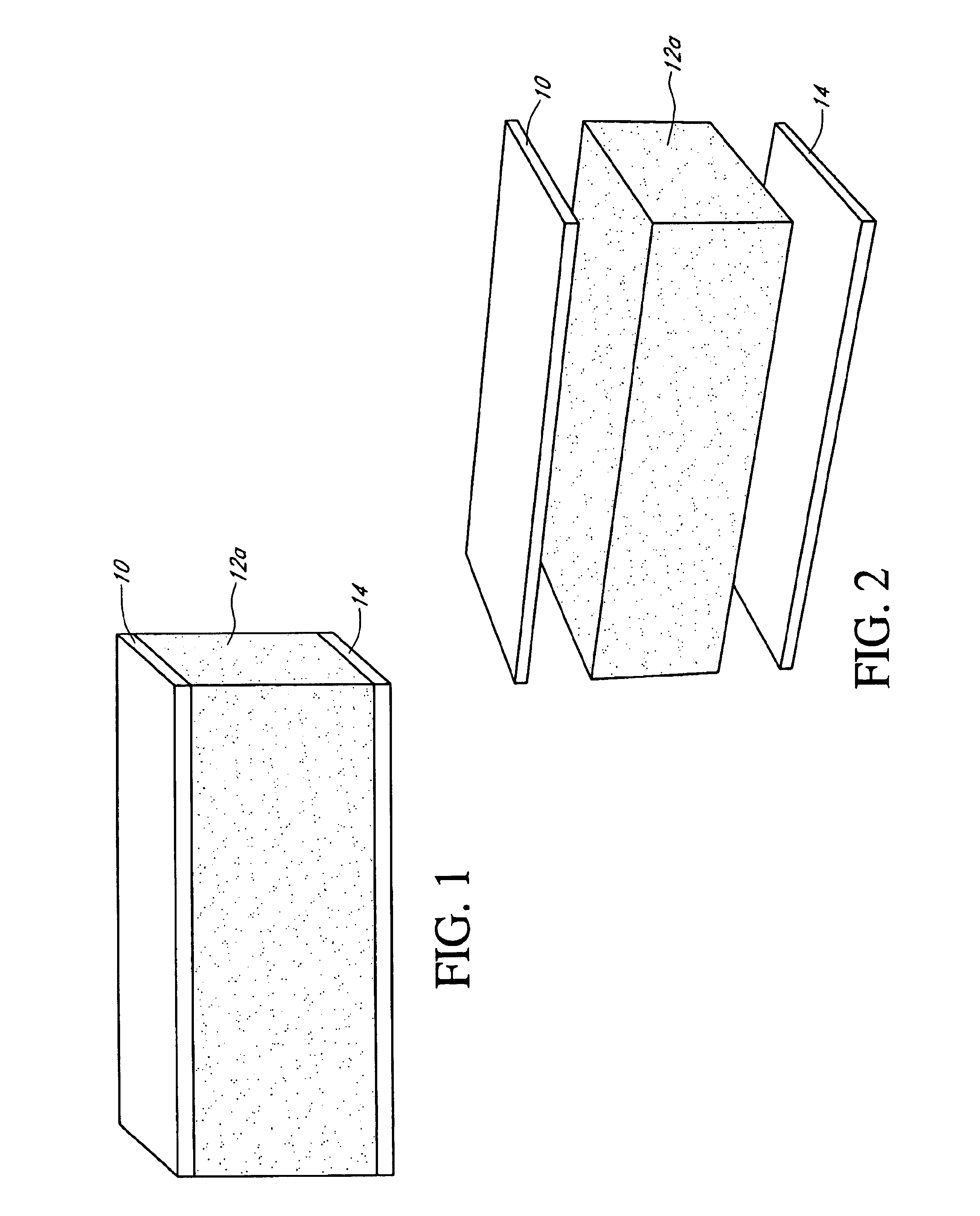

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

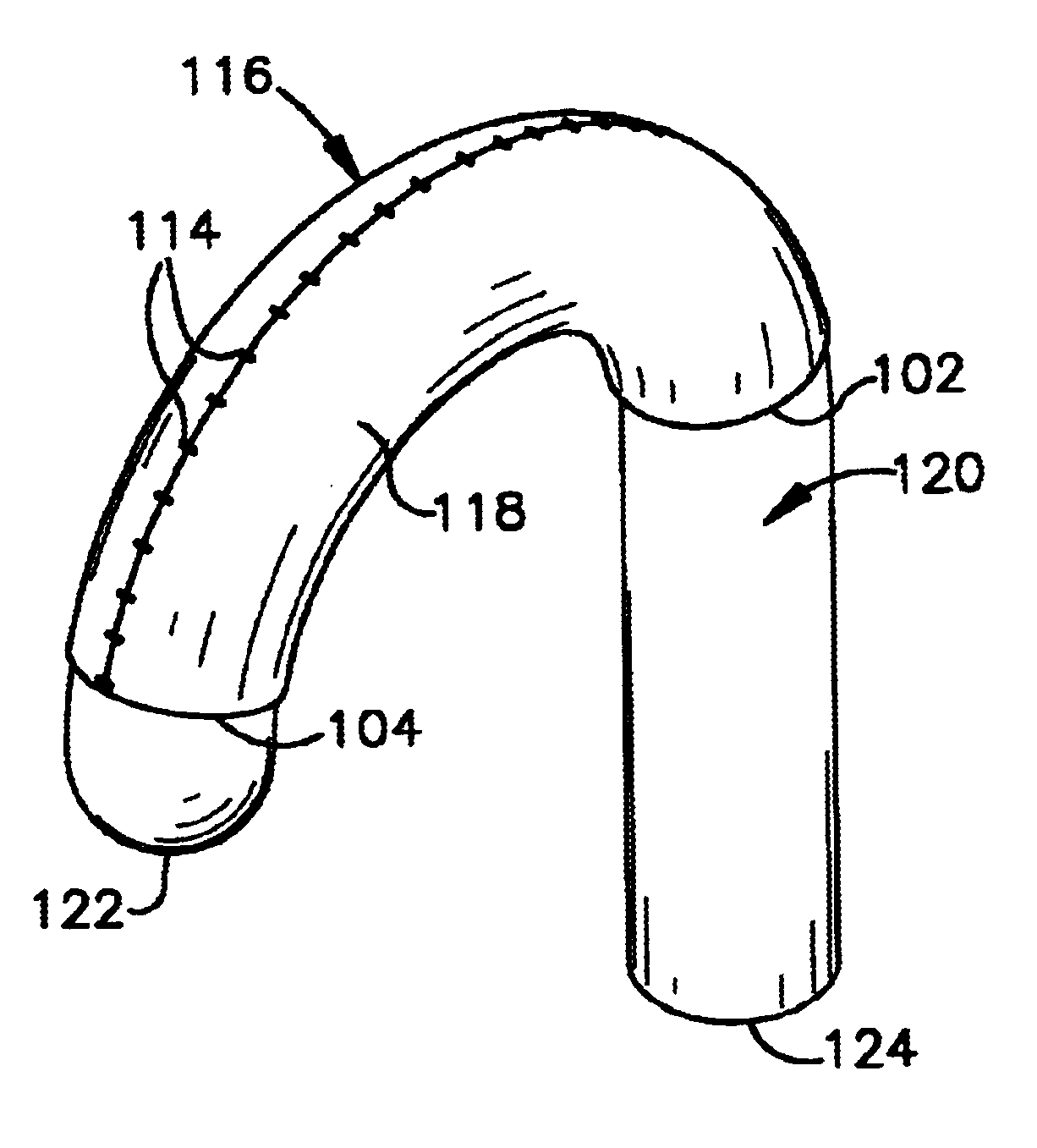

Curved implantable sheath and method of making same

Owner:GABBAY SHLOMO

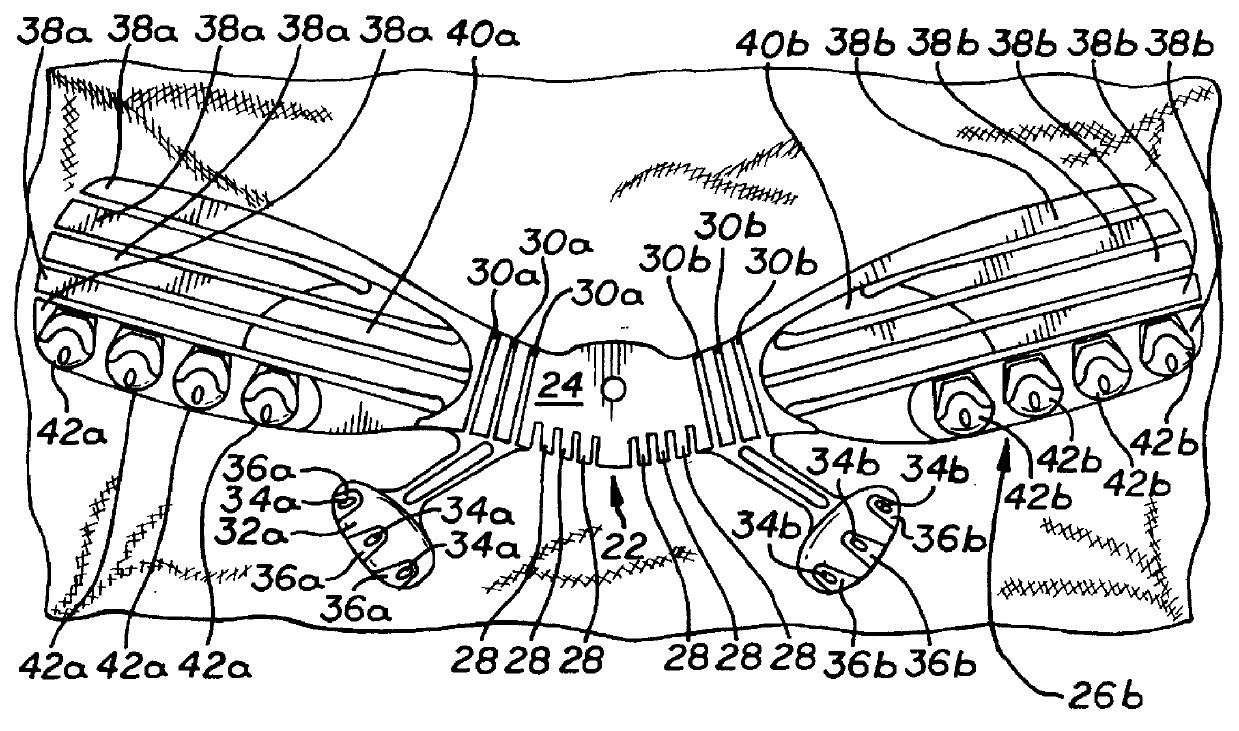

Orthopaedic devices with plastic injection molded onto fabric

InactiveUS6024712AReliable rapid lacingEfficient methodNon-surgical orthopedic devicesBandagesOrthopaedic deviceCombined use

The present invention pertains to an orthopedic support having a flexible inner member and an exo-skeleton that is molded directly onto the flexible inner member. In one particular embodiment, a versatile, multi-medium orthopedic ankle support assembly has an inner fabric support for extending at least partially around an injured part of the anatomy and for providing basic support for the injury. A plastic exo-support is injection molded into said fabric support and supplies supplemental support for resisting motion of the injured part in undesired directions. The fabric support has a main body portion for extending at least part way around the injured part of the anatomy and has edges to be secured together after the fabric support is fitted to the injured part. The invention is not limited to ankle braces, of course, as the general principle of molding an exo-skeleton onto a flexible inner member may be used in conjunction with numerous different supports. An efficient method for constructing an orthopedic support includes the steps of first placing a sheet of flexible material across a mold, cutting the sheet, injection molding the exo-structure onto the sheet material in the mold, and securing the sheet into an orthopedic support.

Owner:ROYCE MEDICAL PRODS +1

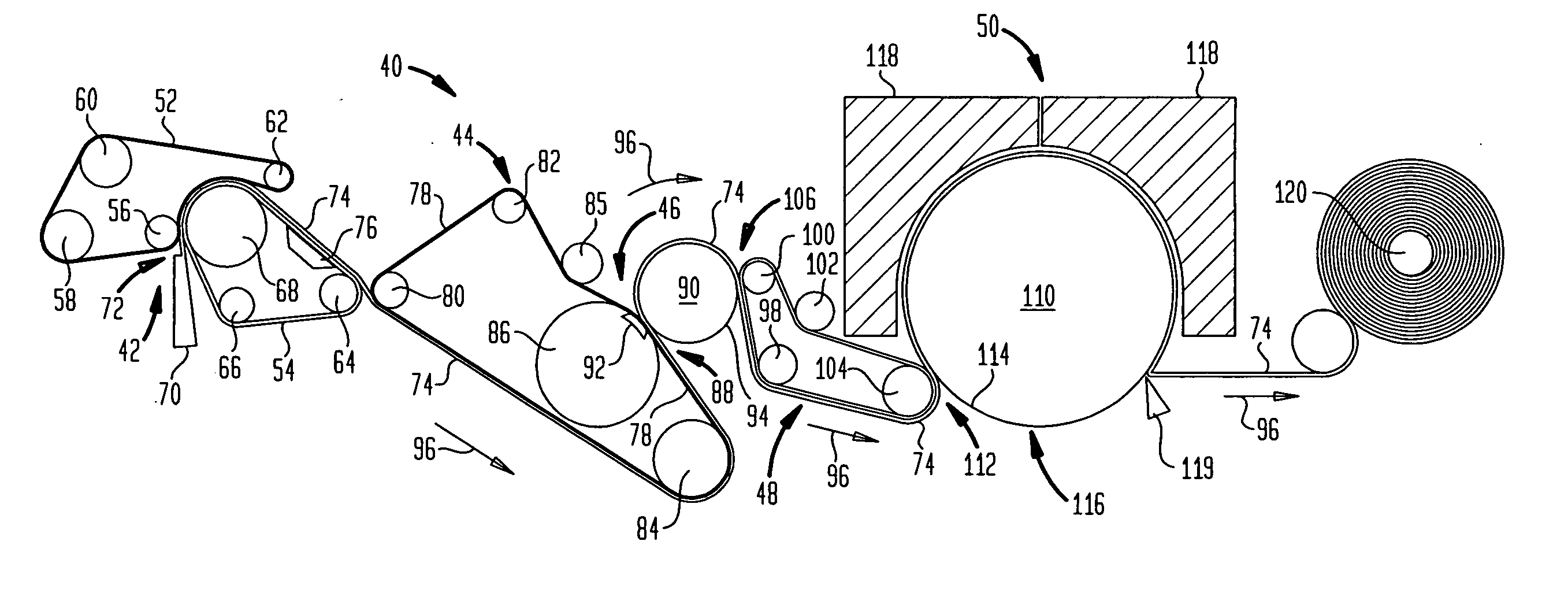

Fabric crepe/draw process for producing absorbent sheet

ActiveUS20050217814A1Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingFiberPapermaking

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

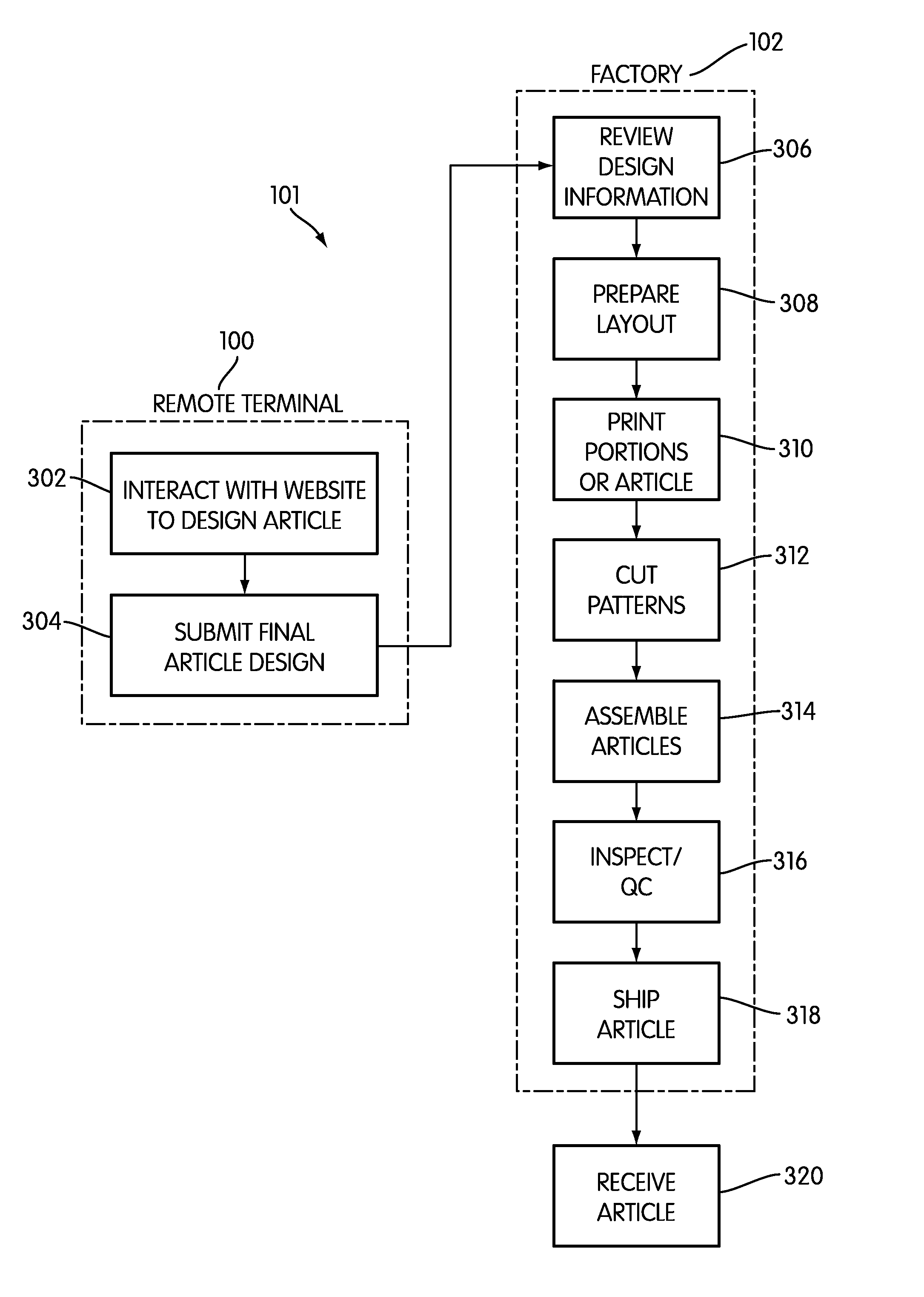

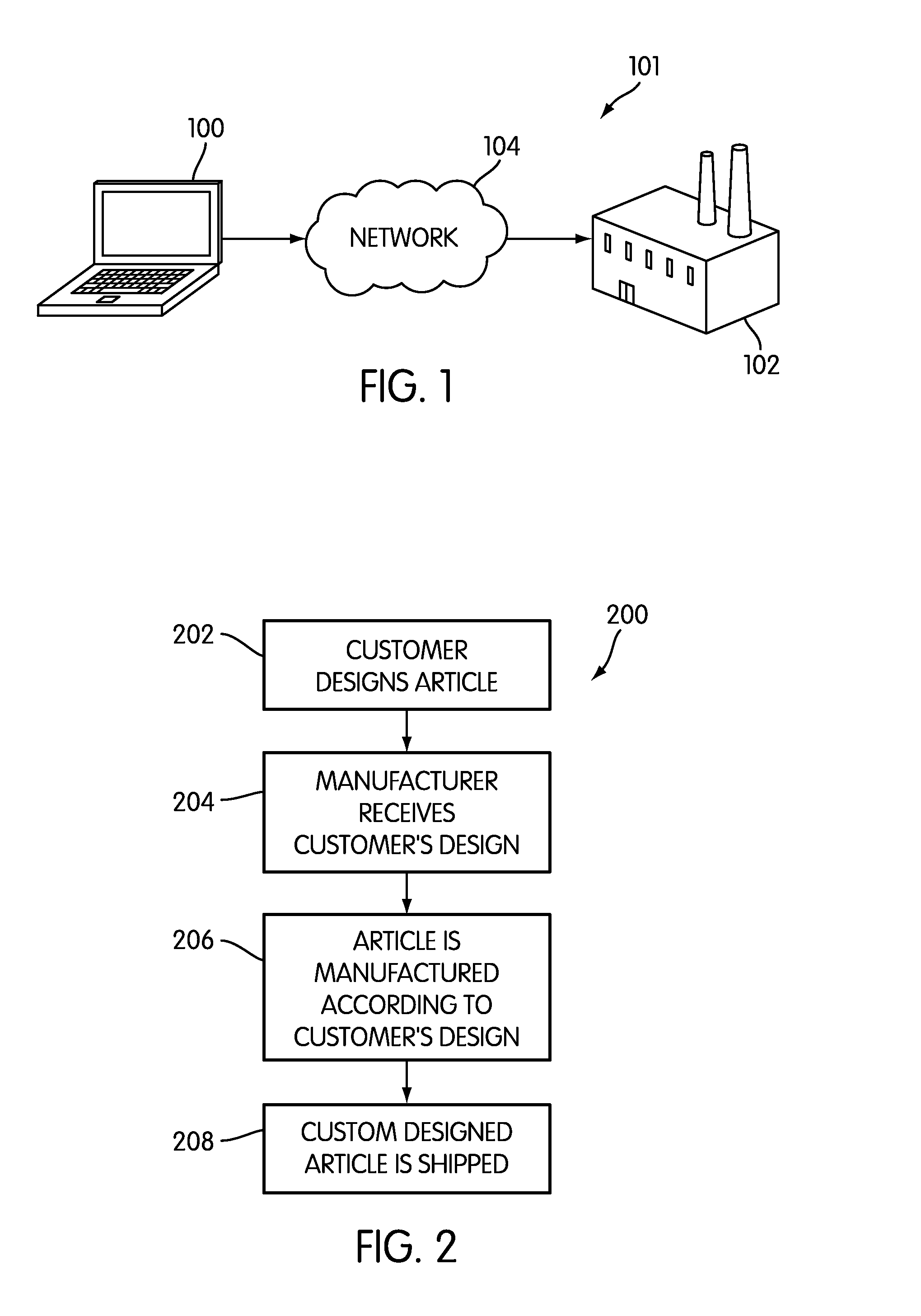

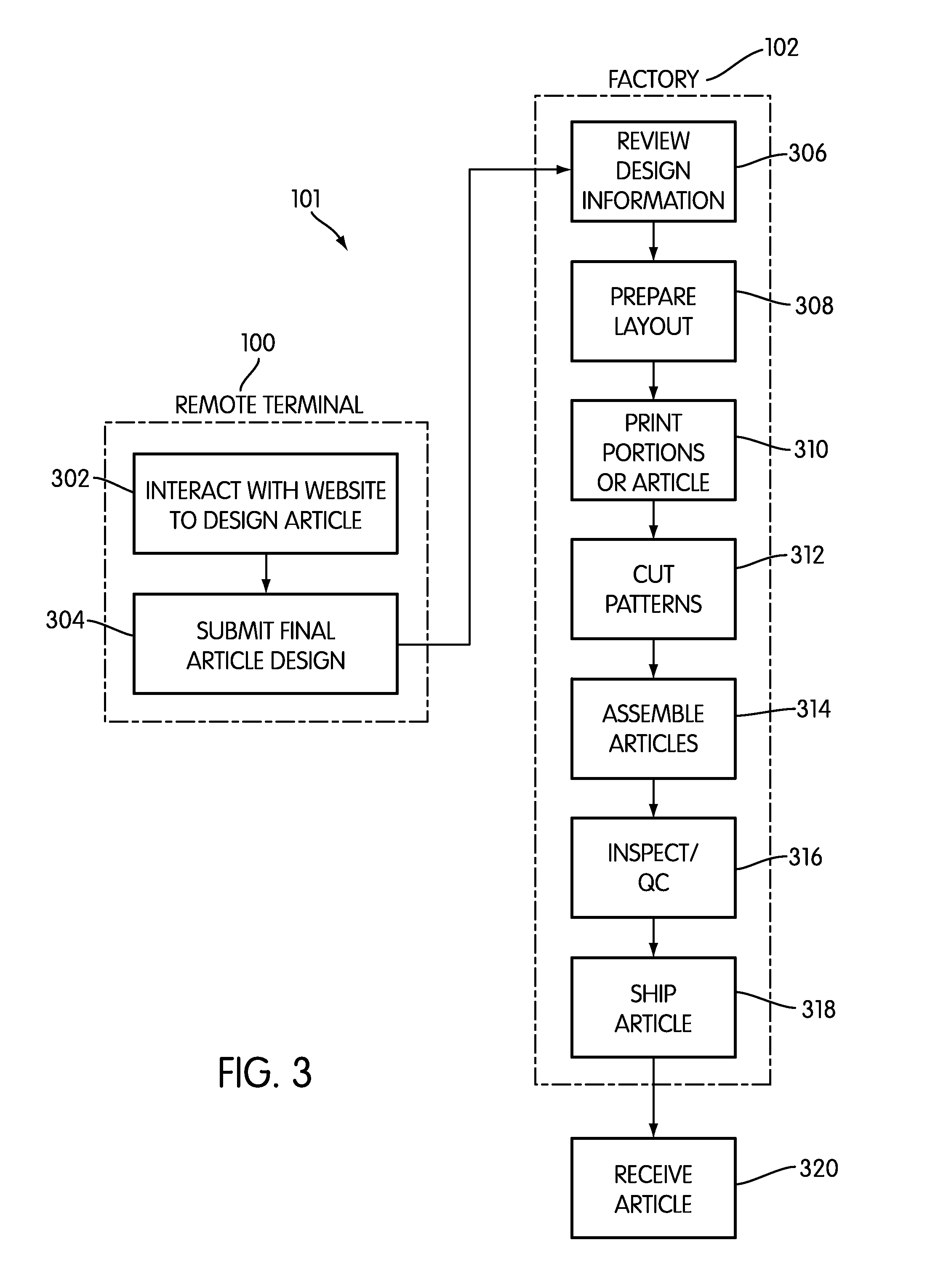

Method of Making an Article of Footwear

ActiveUS20080147219A1Area minimizationShoemaking devicesForecastingElectrical and Electronics engineeringSheet material

A method of making an article of footwear is disclosed. The method includes the steps of designing an article of footwear via a website, converting a footwear representation into a set of two-dimensional portions, printing the two dimensional portions onto a sheet material, cutting and assembling the two dimensional portions into a finalized article of footwear. The method further includes a step of shipping the article of footwear to a pre-designated shipping address.

Owner:NIKE INC

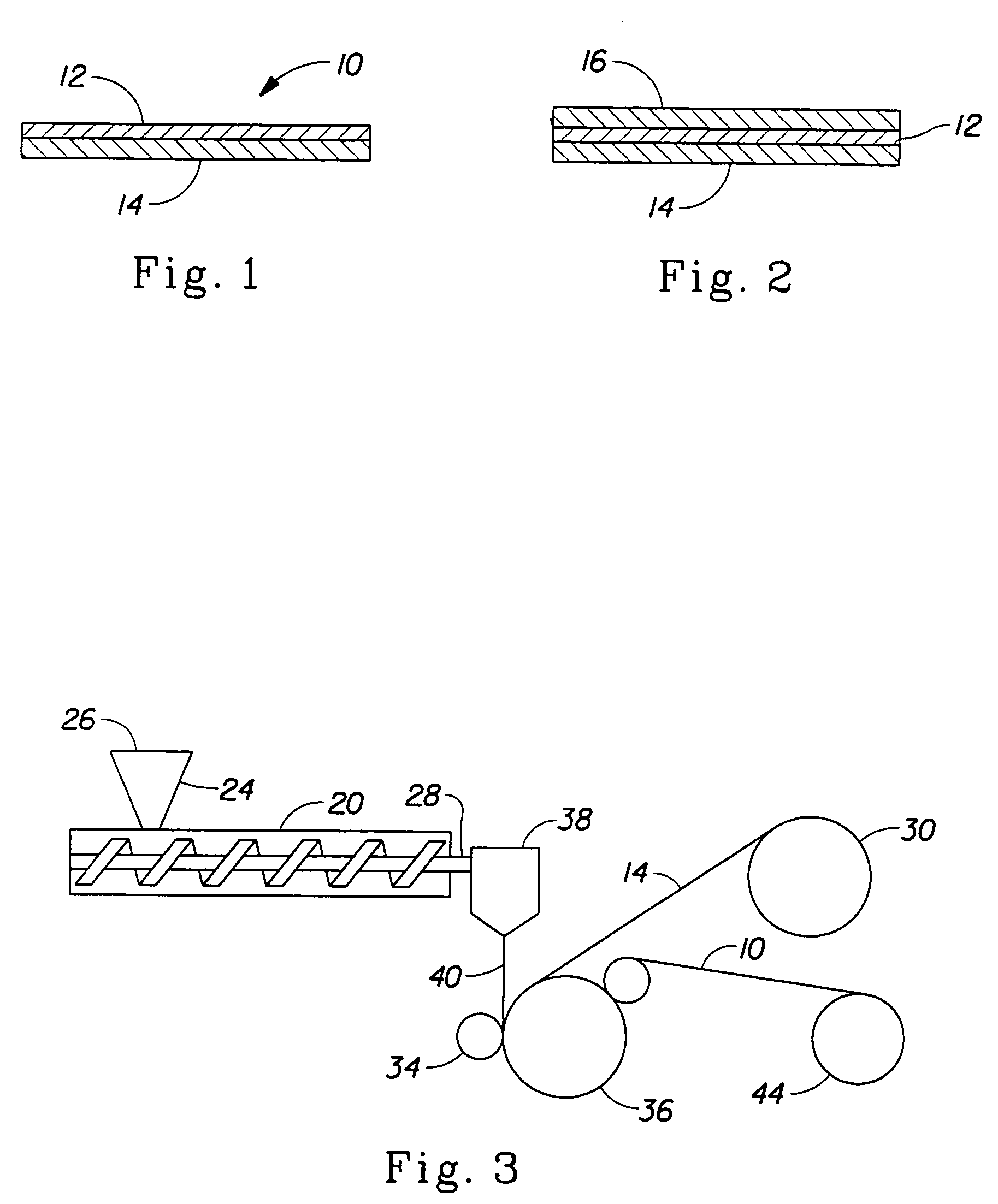

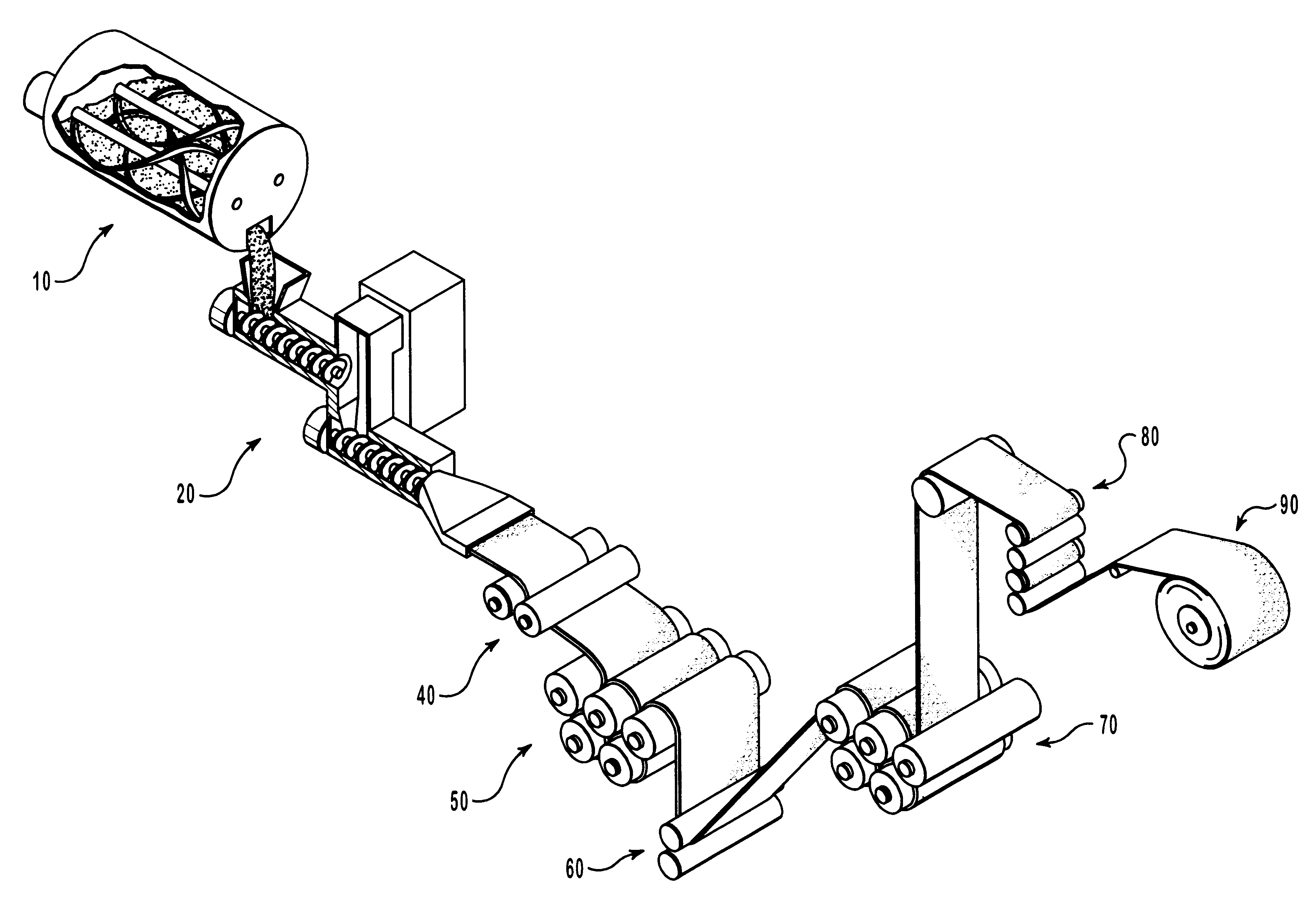

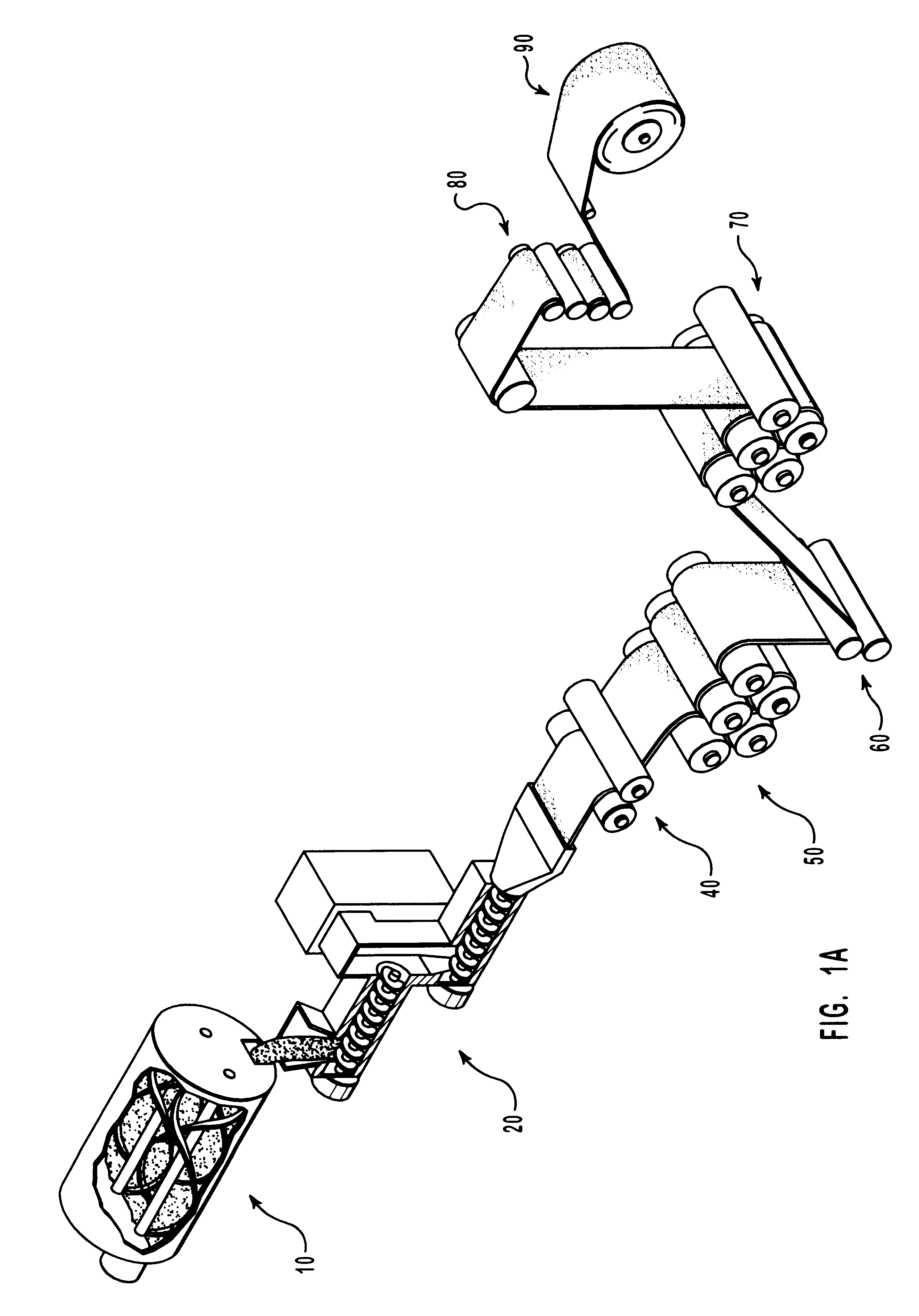

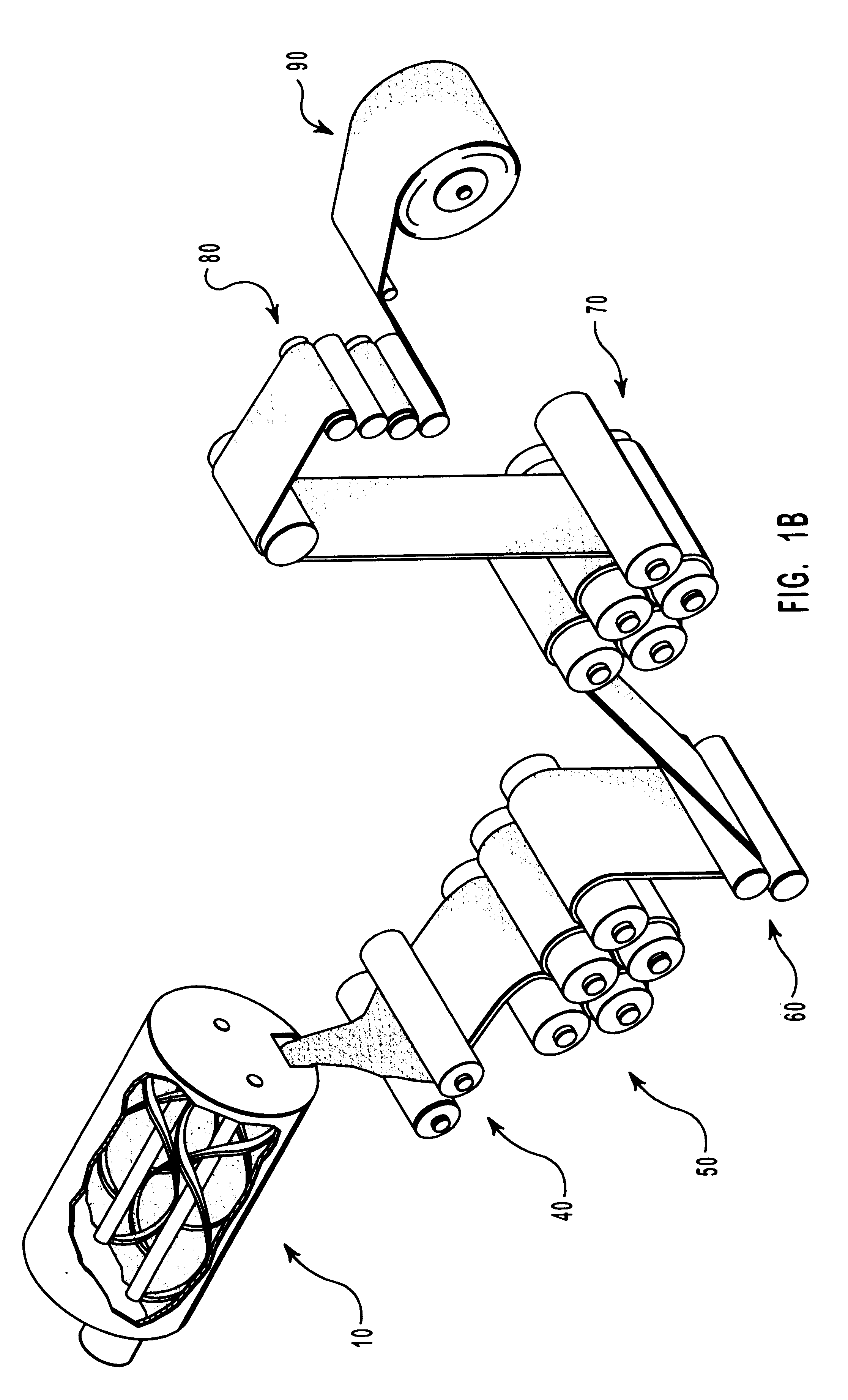

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com