Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14276results about "Trocar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

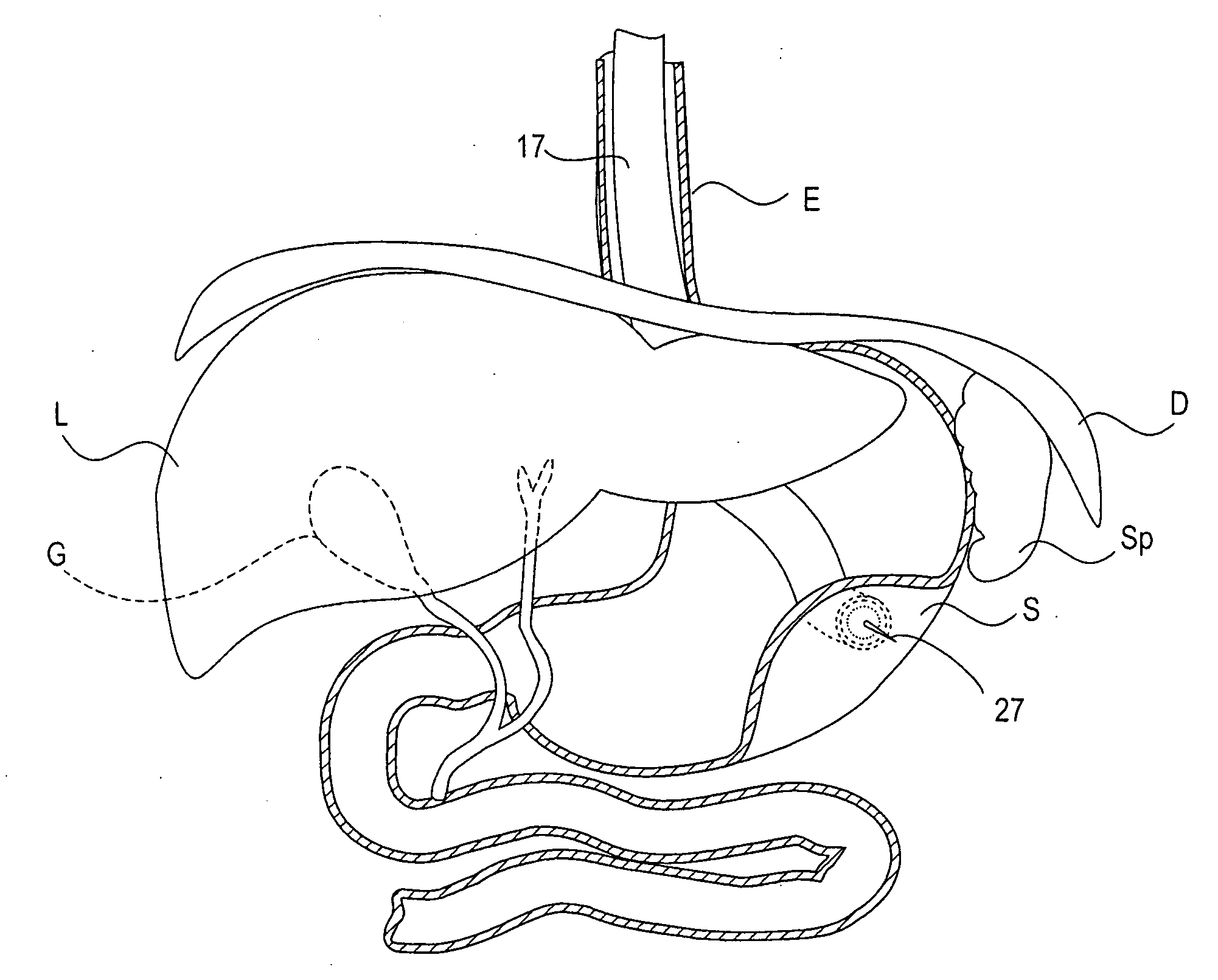

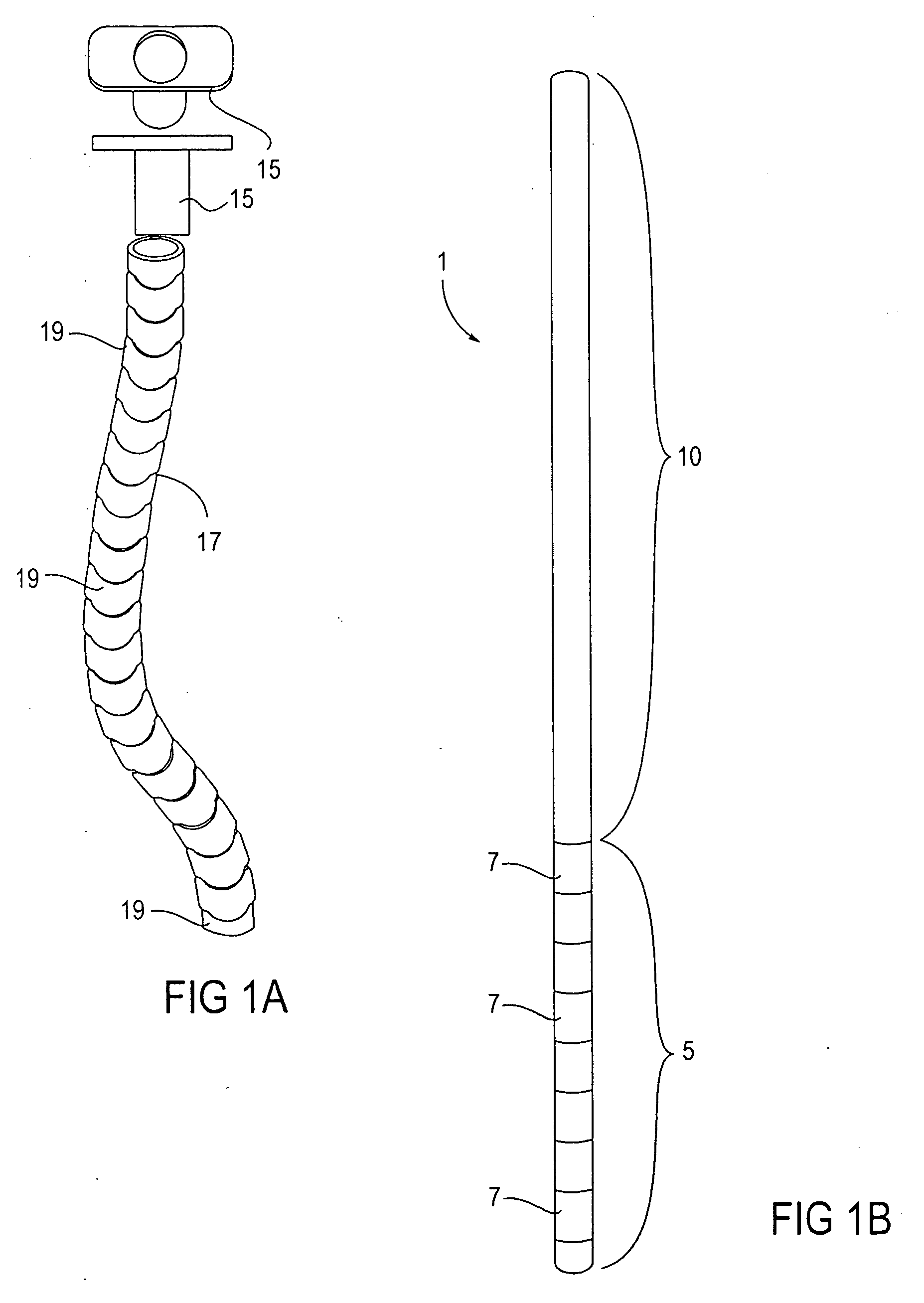

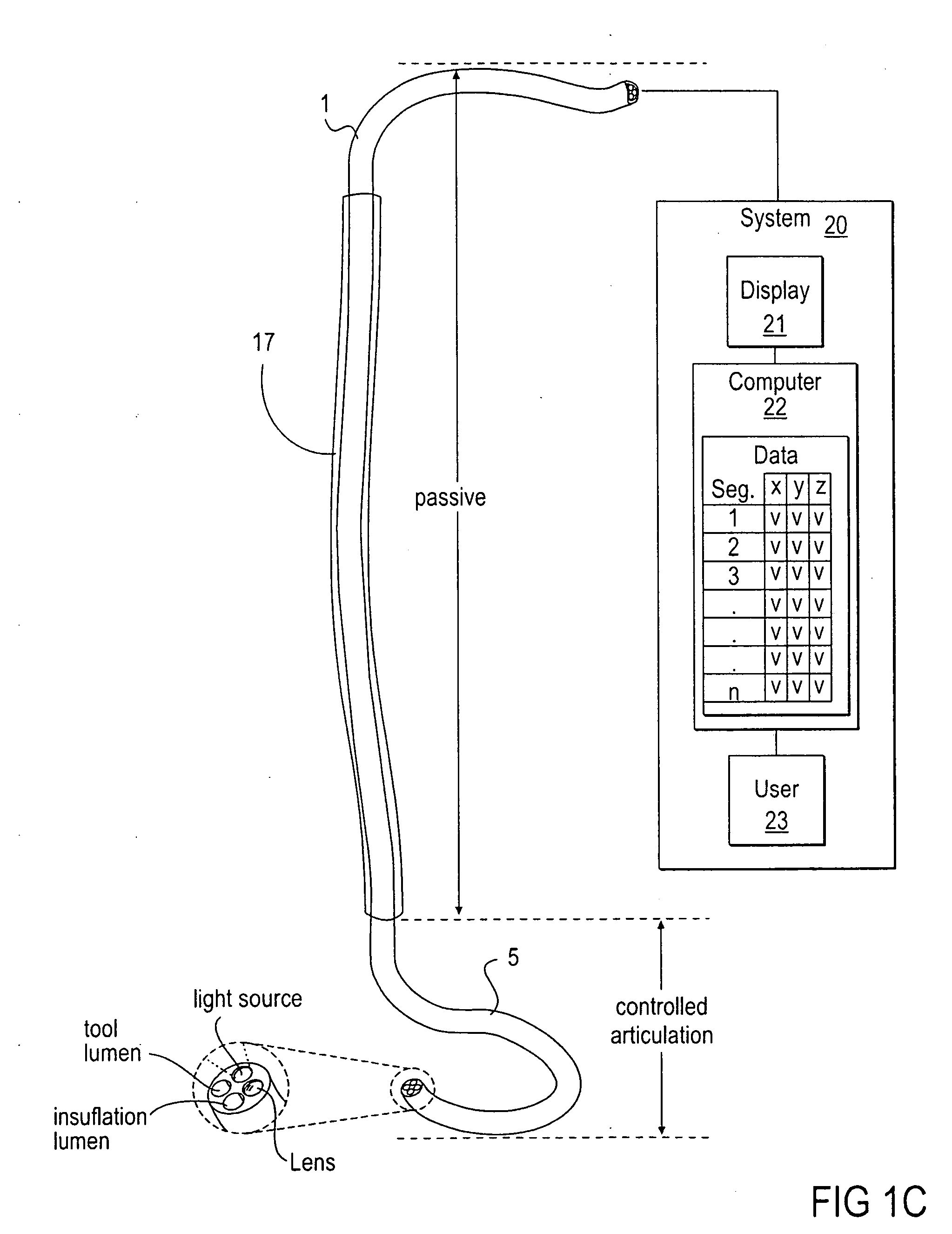

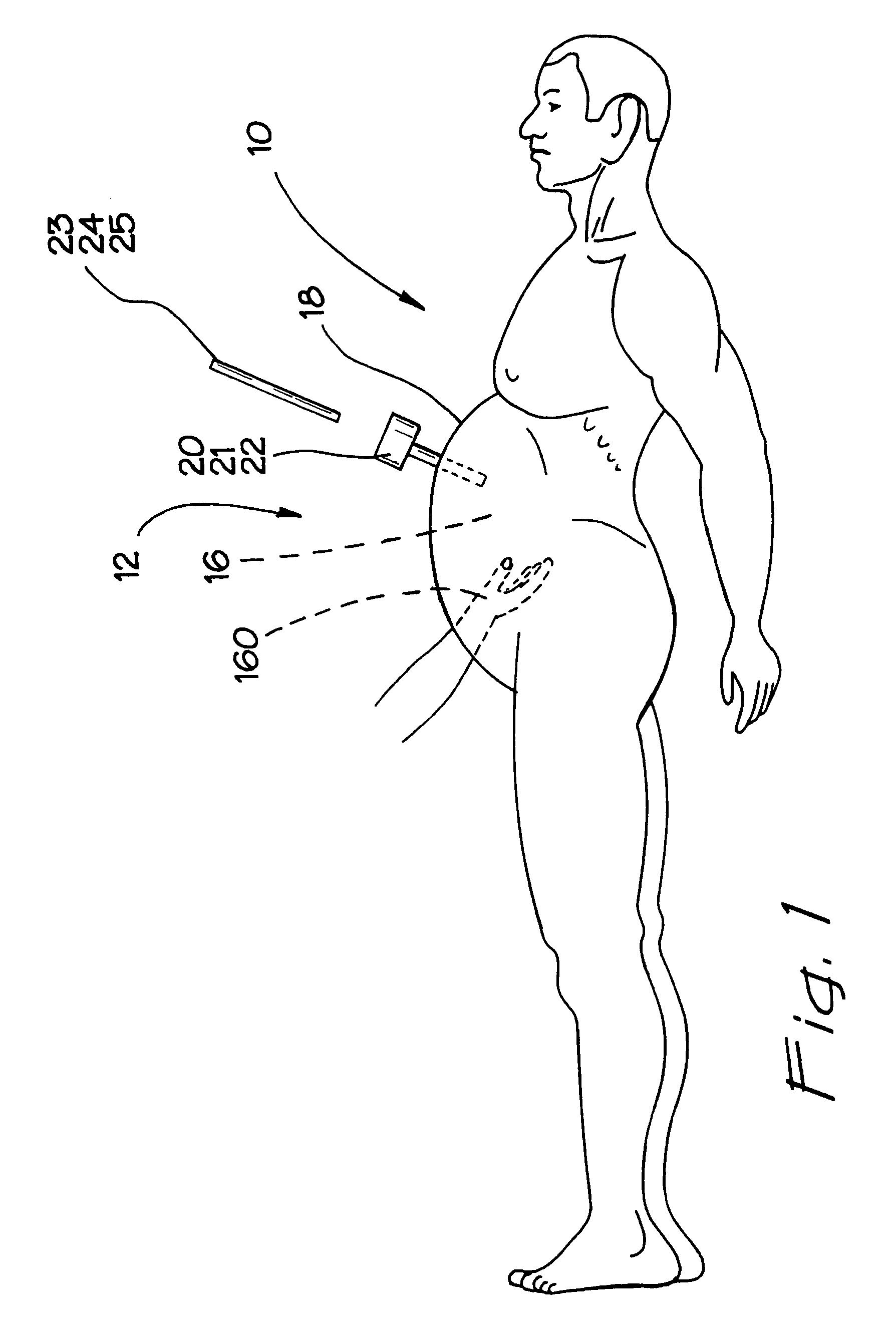

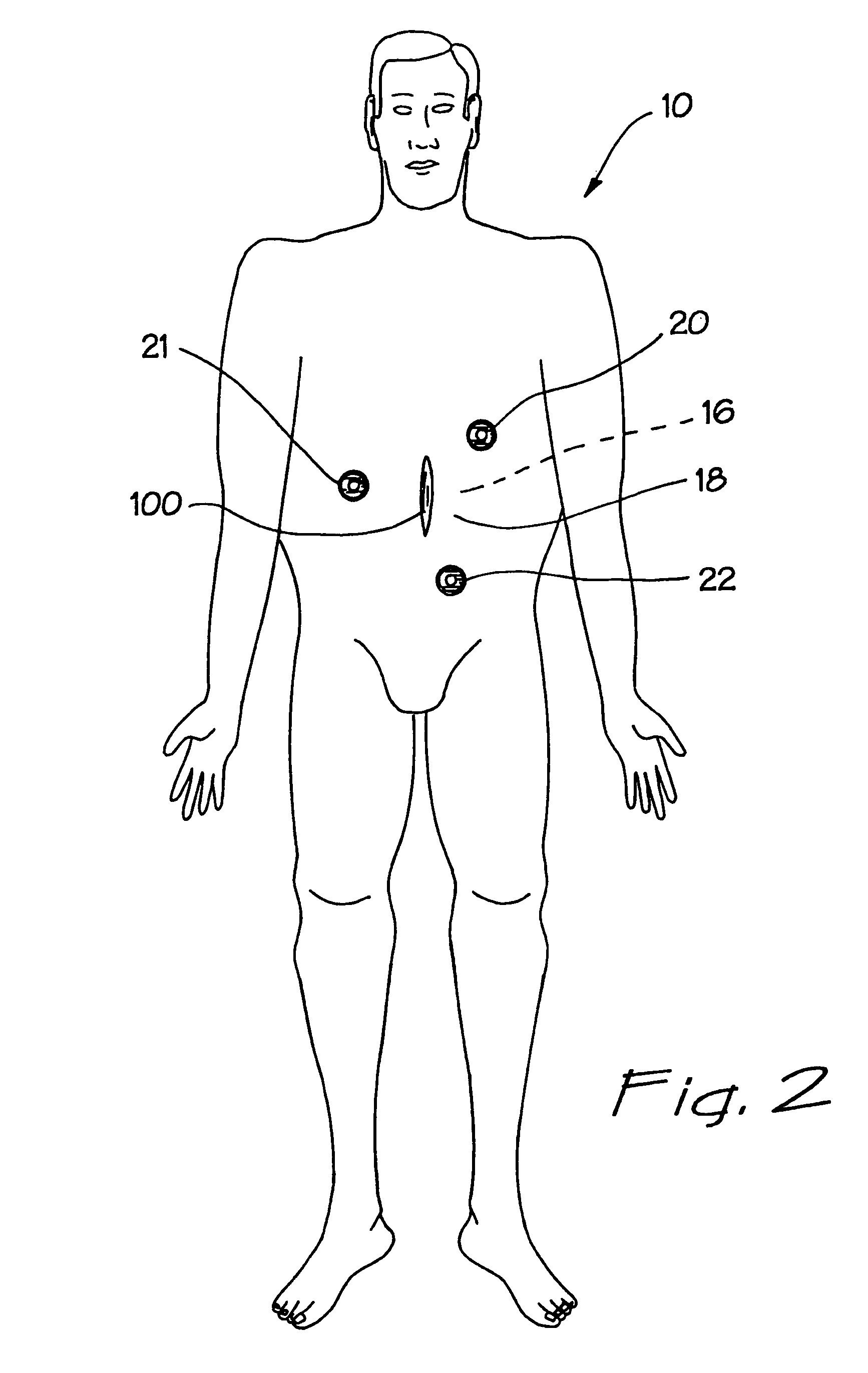

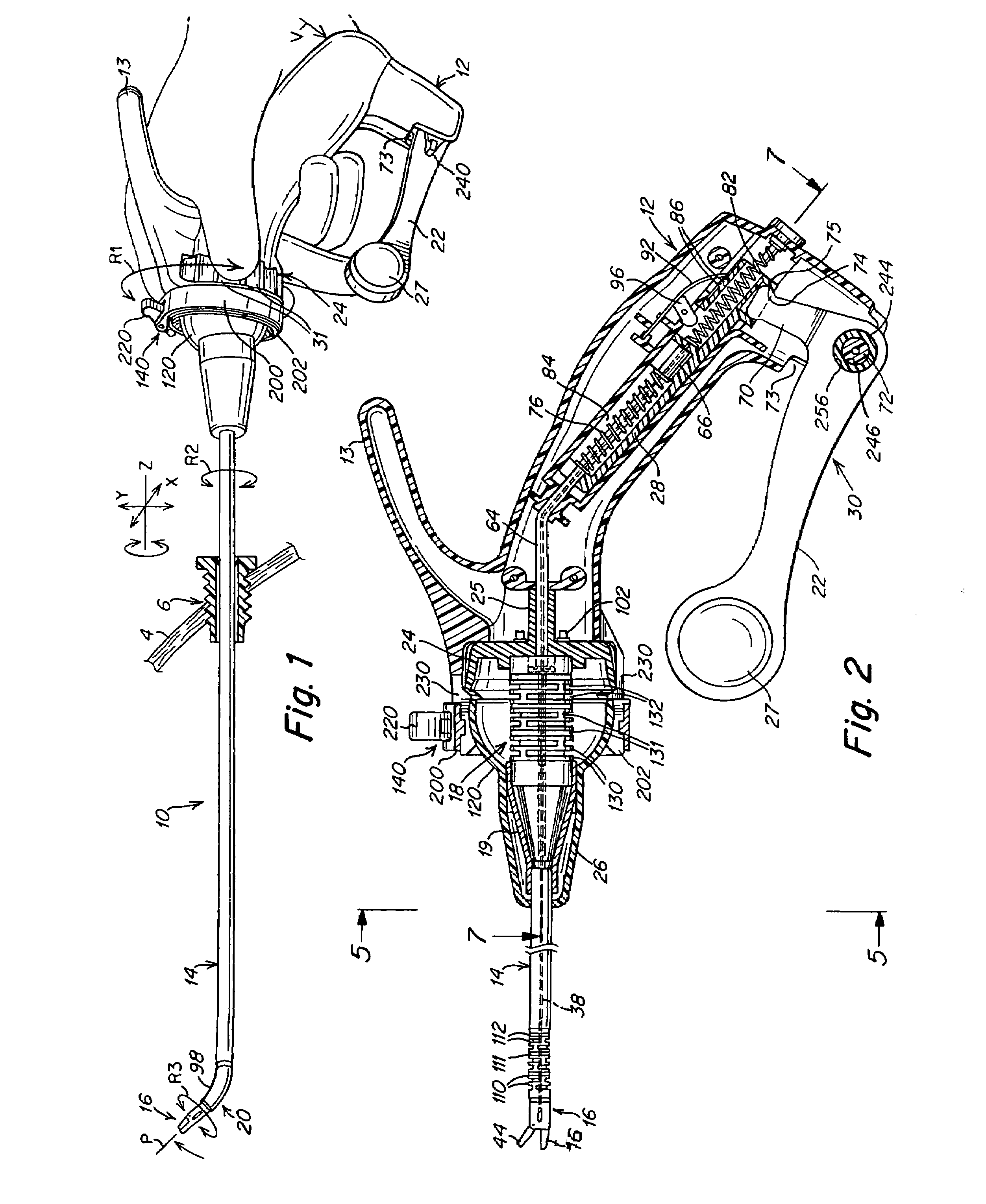

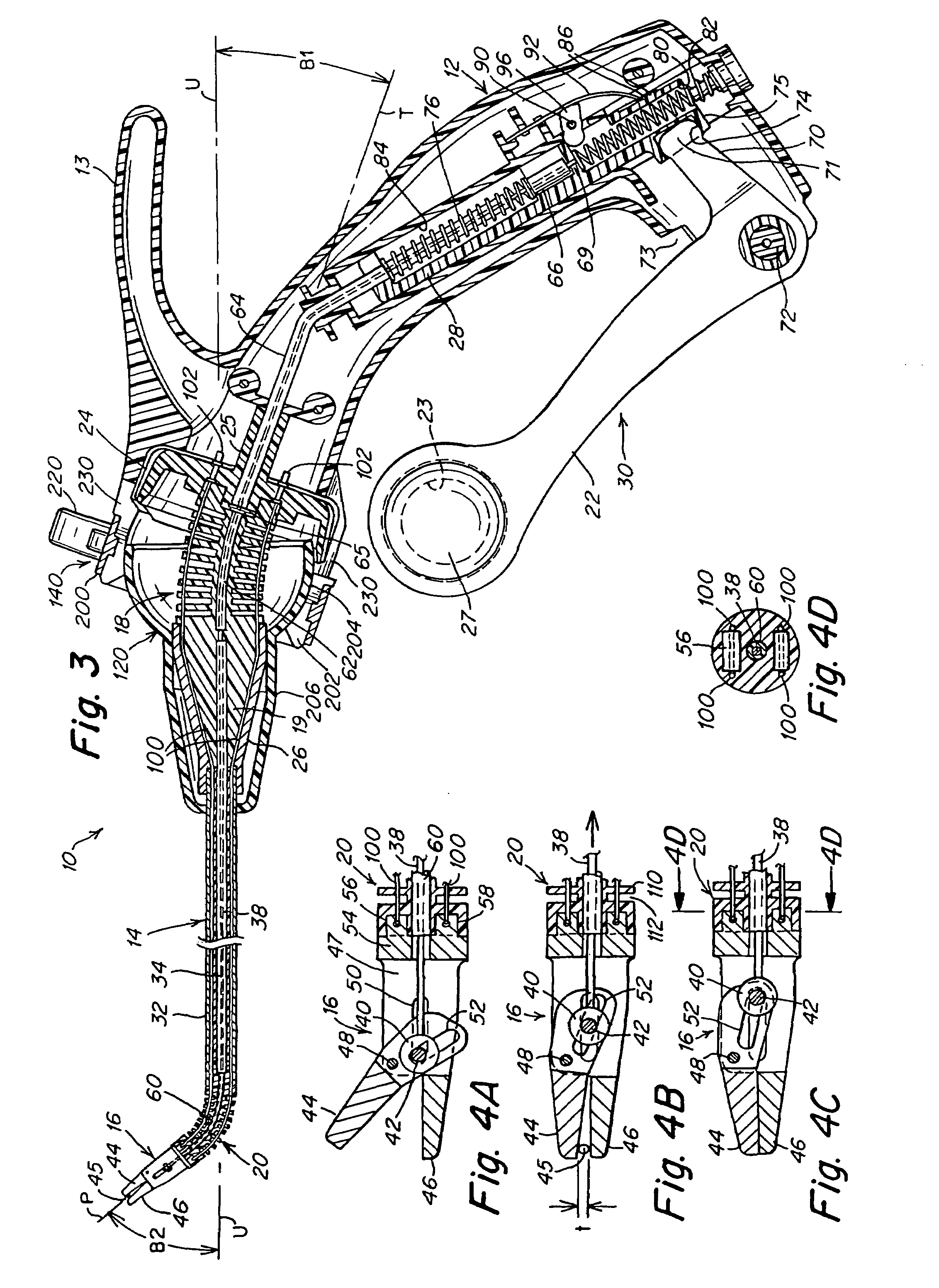

Methods and apparatus for performing transluminal and other procedures

InactiveUS20070135803A1Prevent overflowPrevent leakageSuture equipmentsEar treatmentSurgeryInstrumentation

Owner:INTUITIVE SURGICAL OPERATIONS INC

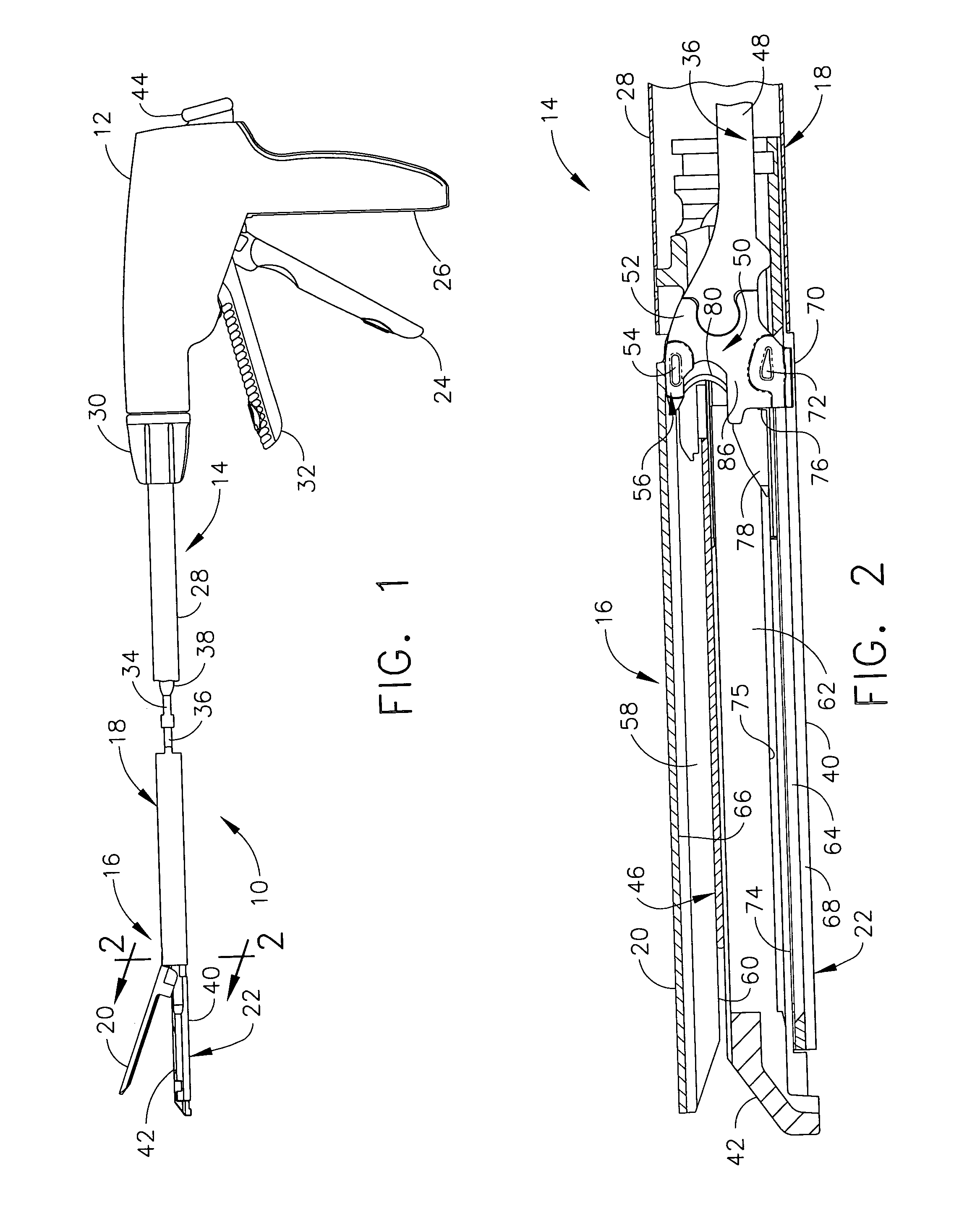

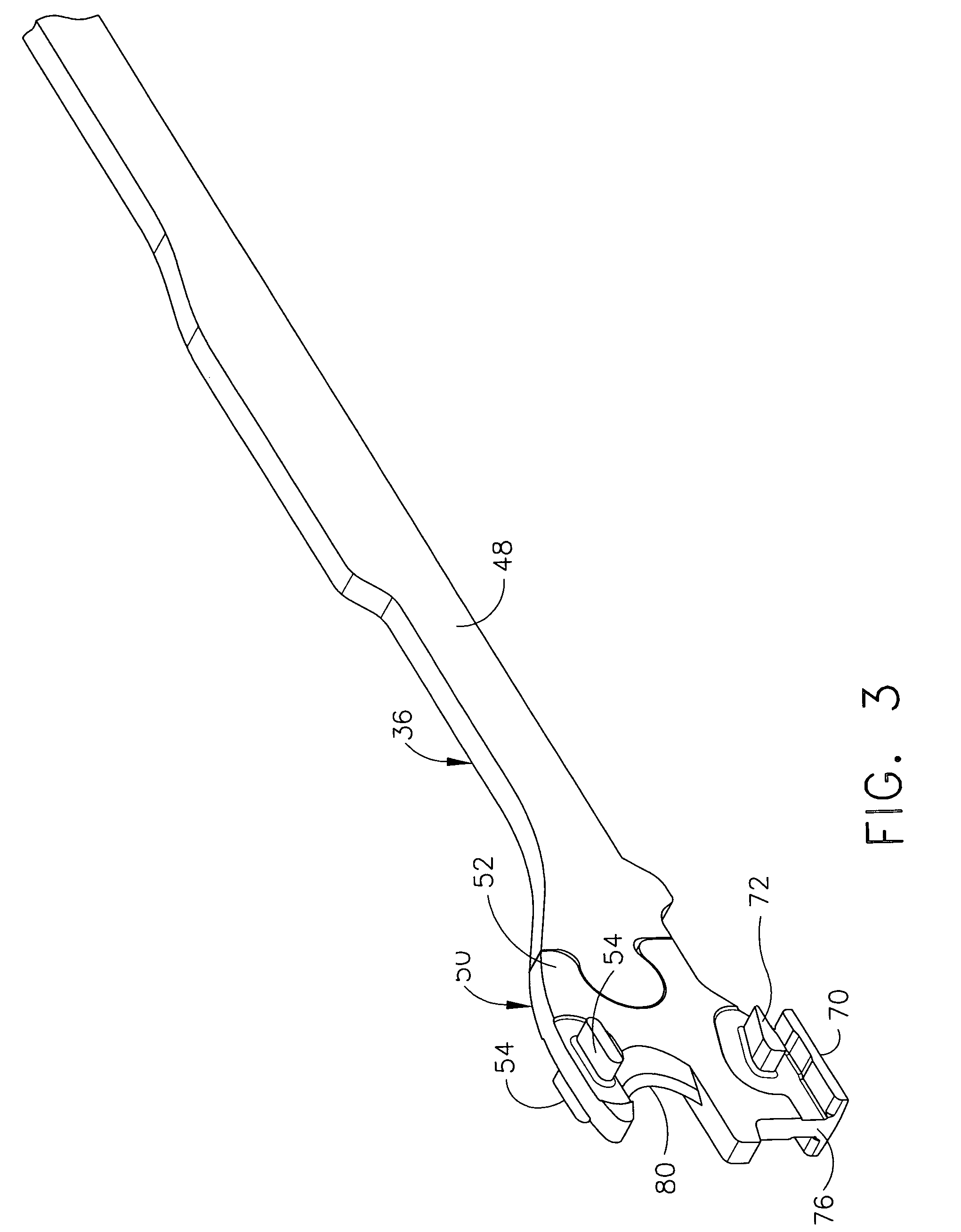

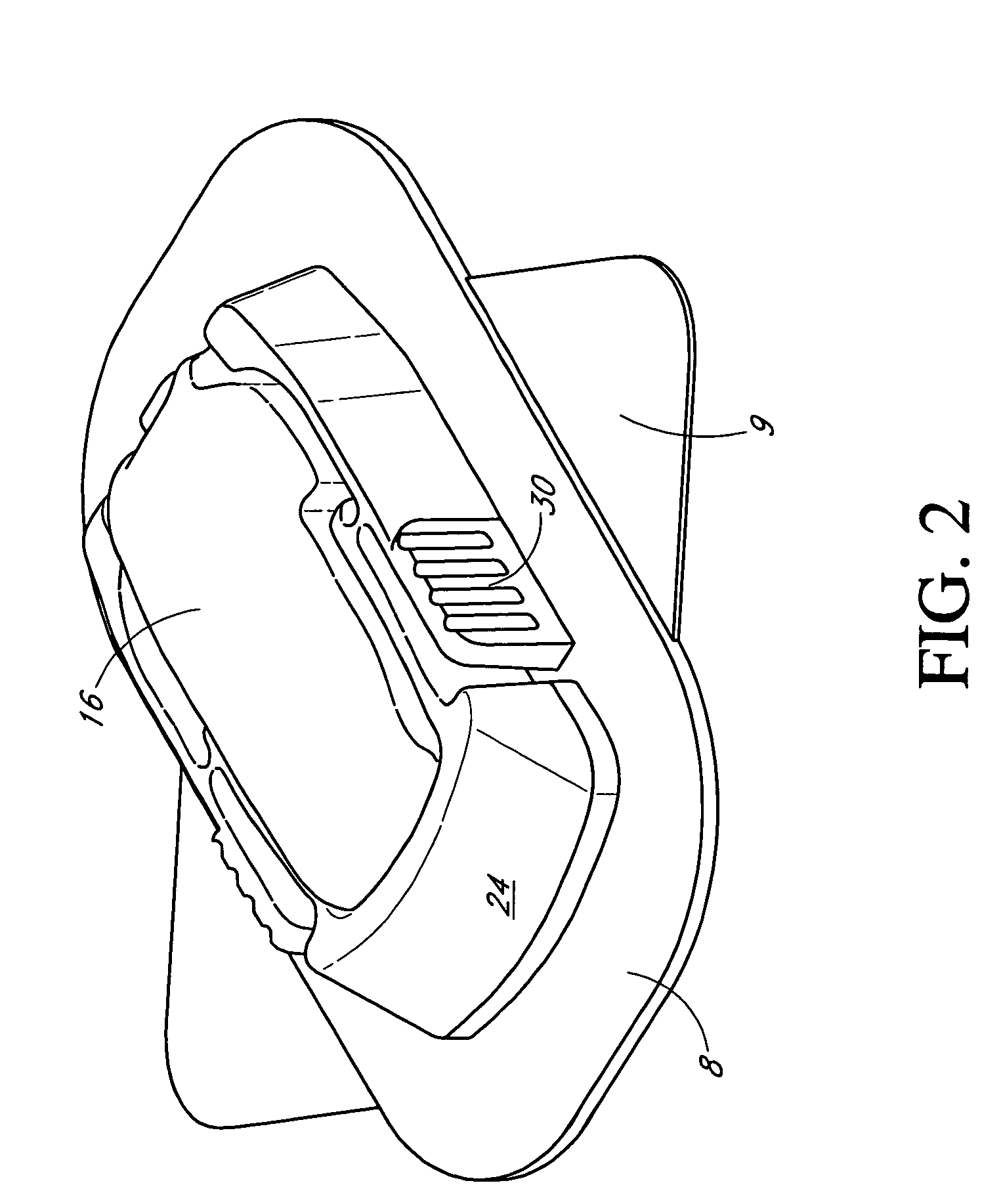

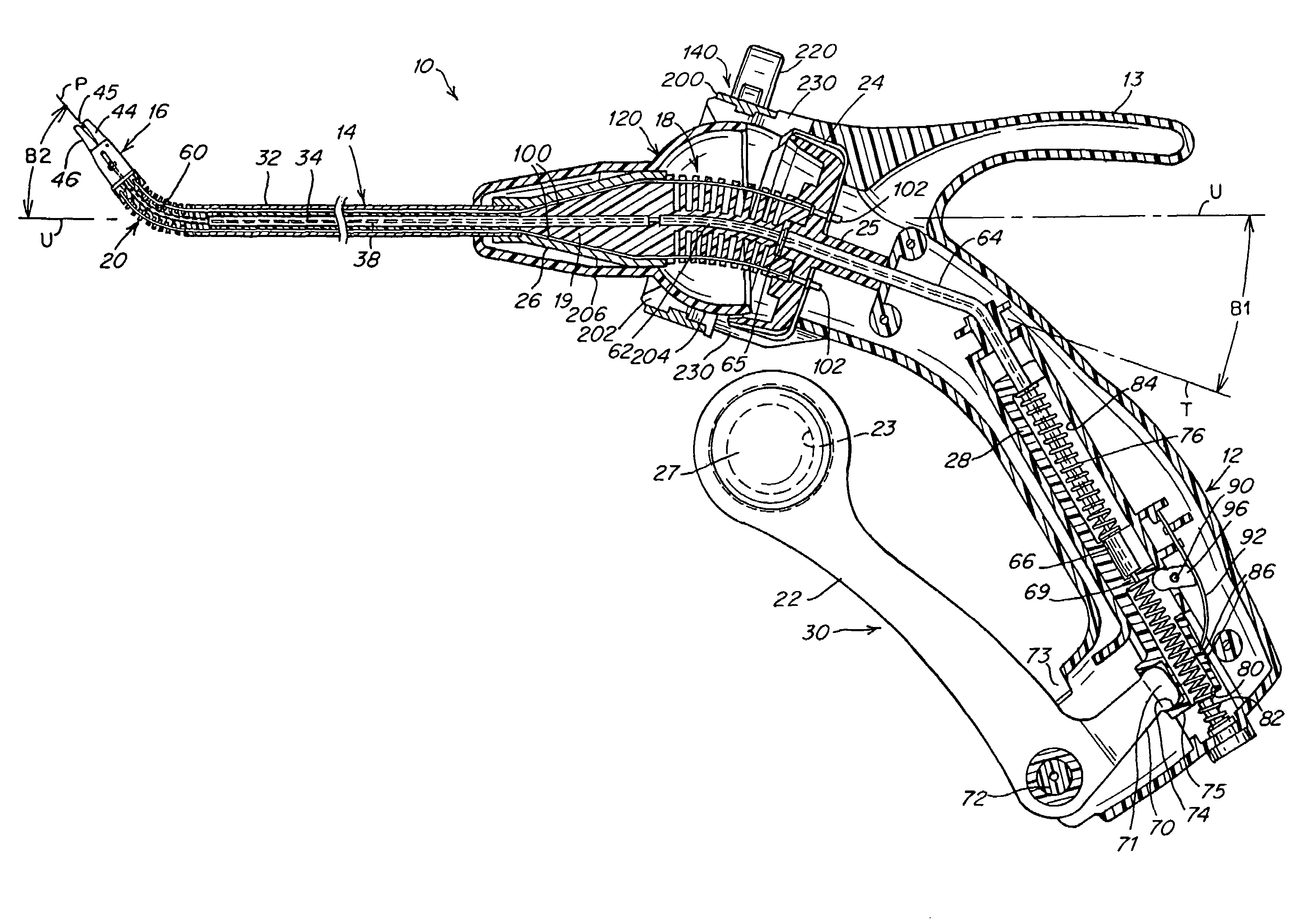

Surgical stapling instrument with mechanical mechanism for limiting maximum tissue compression

Various forms of surgical instruments are disclosed. In various embodiments, the instrument includes a cartridge supporting assembly for operably supporting a staple cartridge therein. The cartridge supporting assembly may be responsive to firing and retraction motions applied thereto from a firing assembly. An anvil may be operably coupled to an anvil closure assembly. The anvil closure assembly may be constructed to selectively move the anvil in a proximal direction toward the cartridge supporting assembly to enable a portion of tissue to be clamped between a cartridge supported by the cartridge supporting assembly and the anvil under a predetermined amount of compression. The device may further include a compression limiting assembly that interacts with the anvil closure assembly to prevent further travel of the anvil in the proximal direction toward the cartridge supporting assembly when the predetermined amount of compression has been attained.

Owner:ETHICON ENDO SURGERY INC

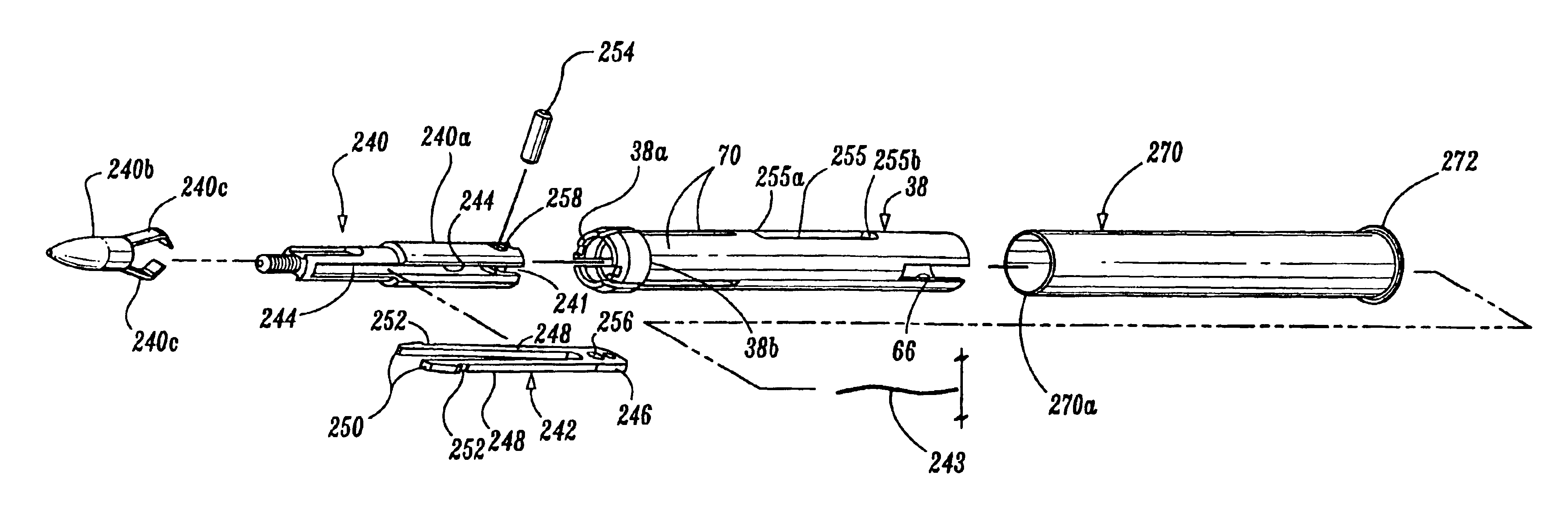

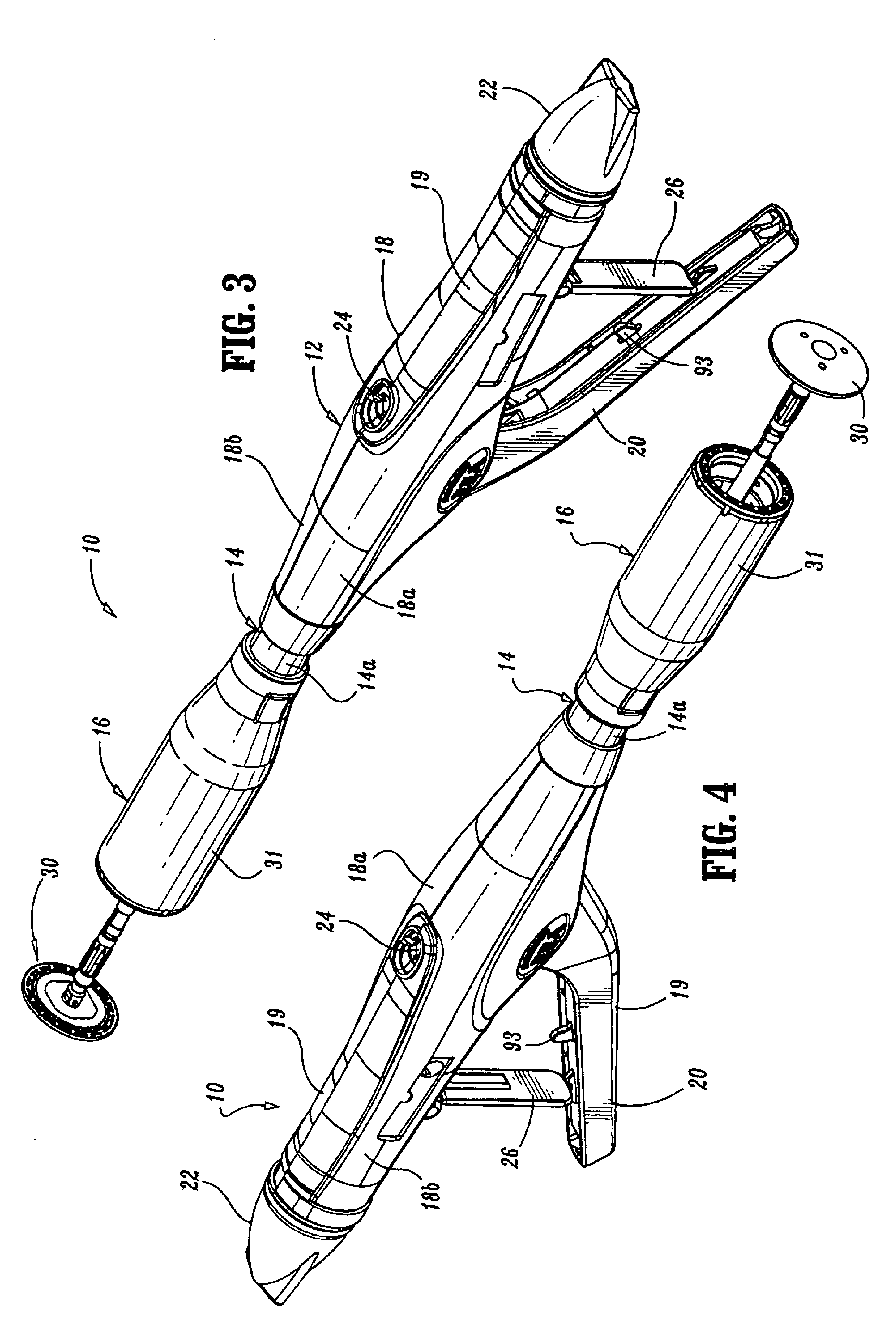

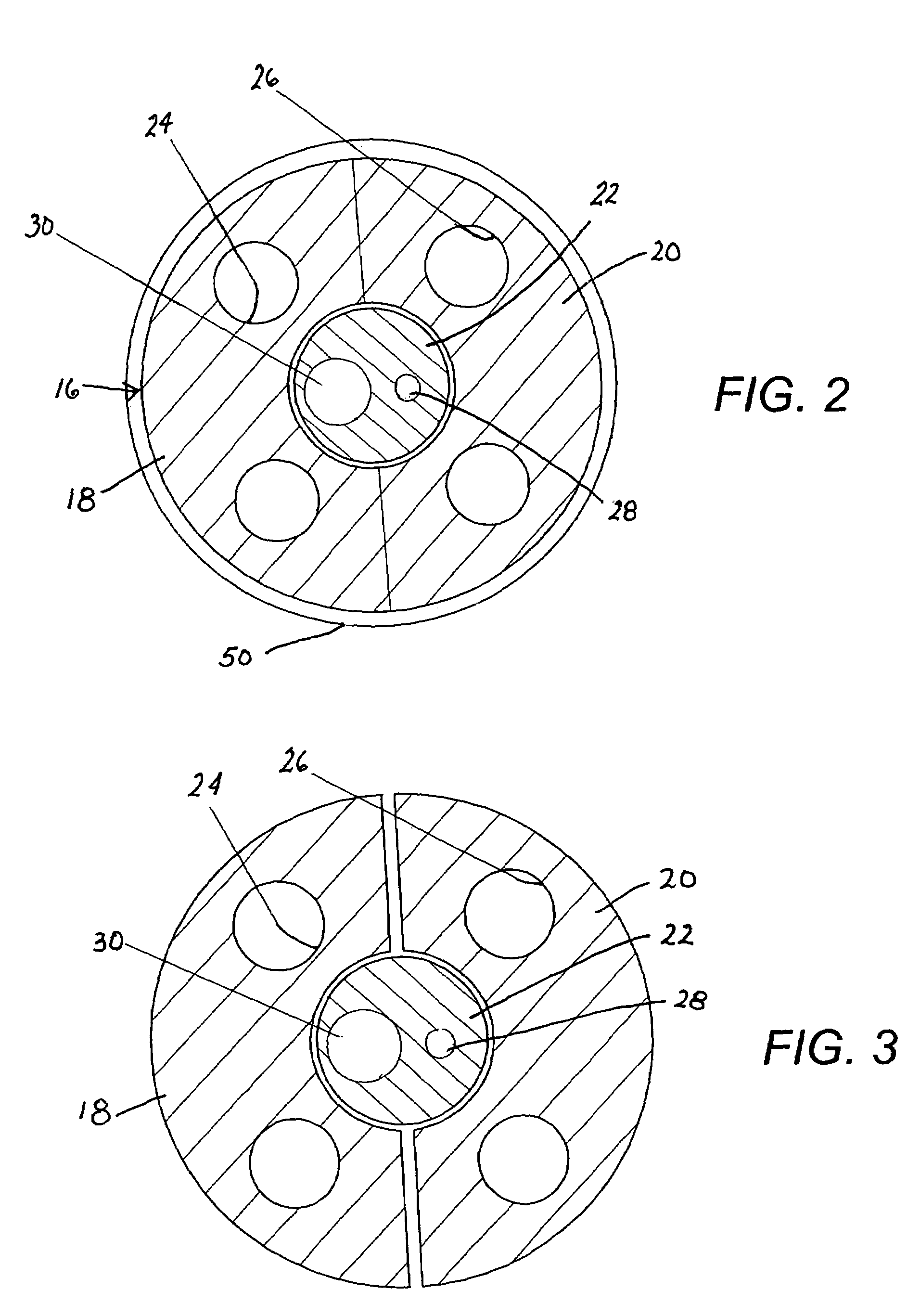

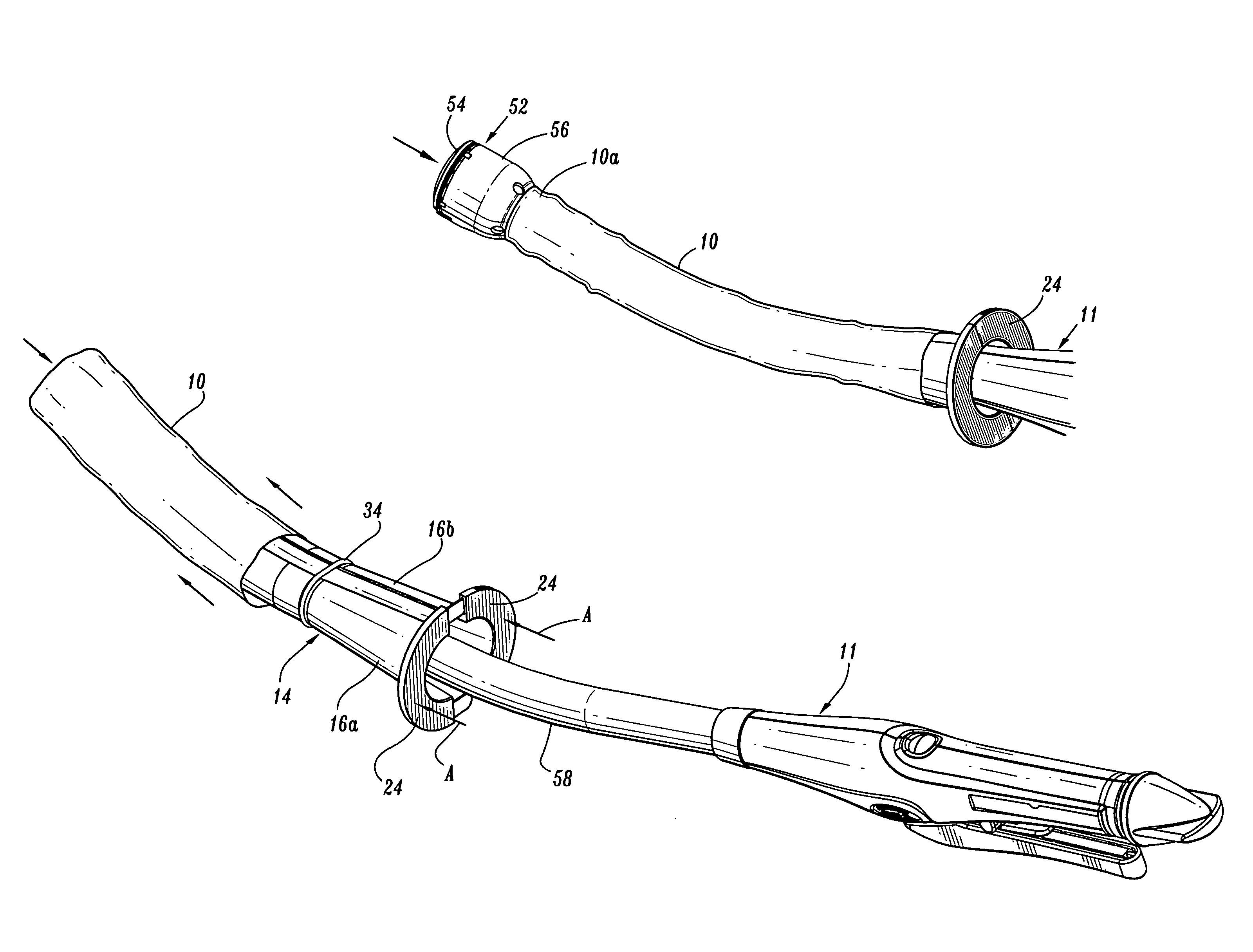

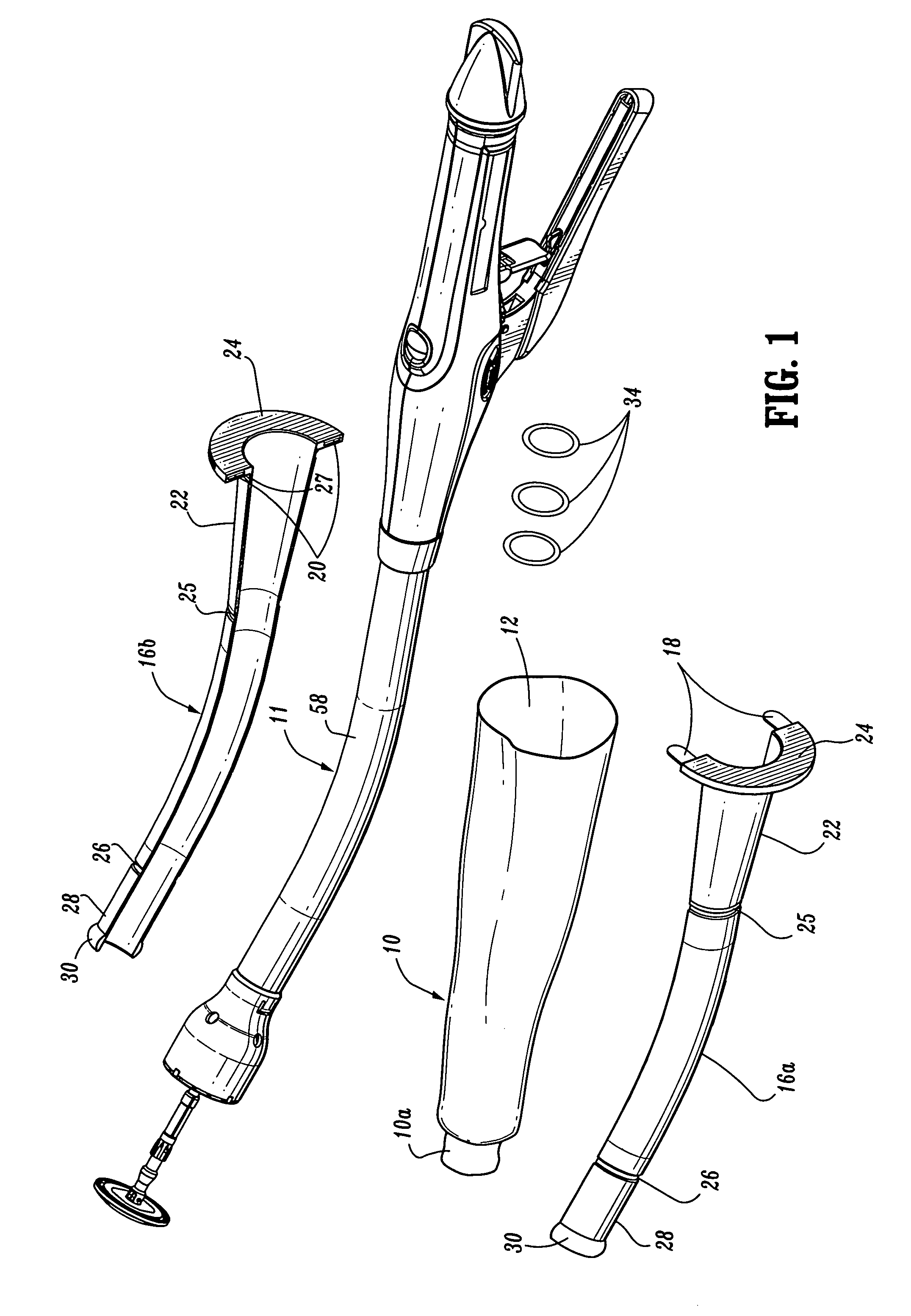

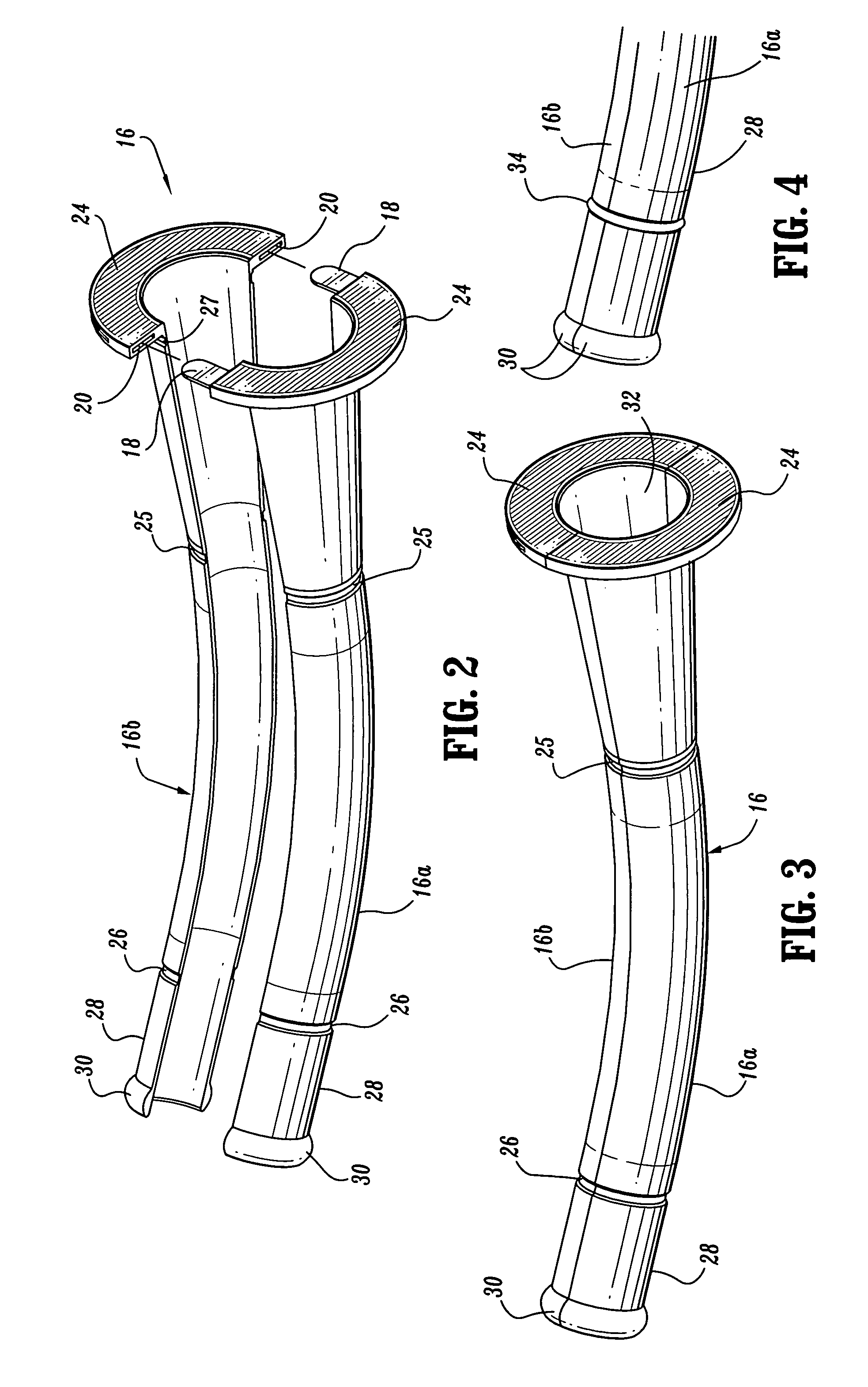

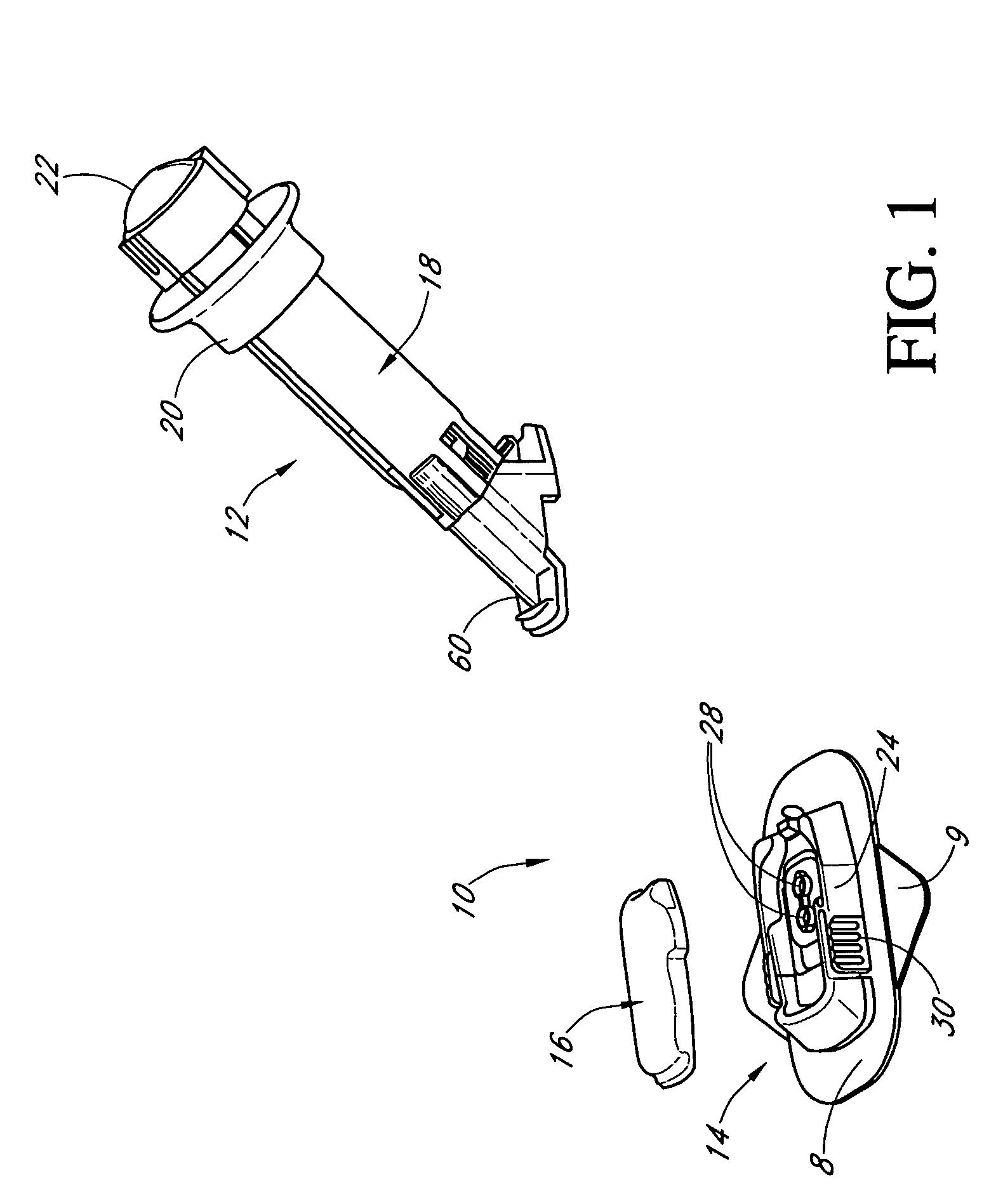

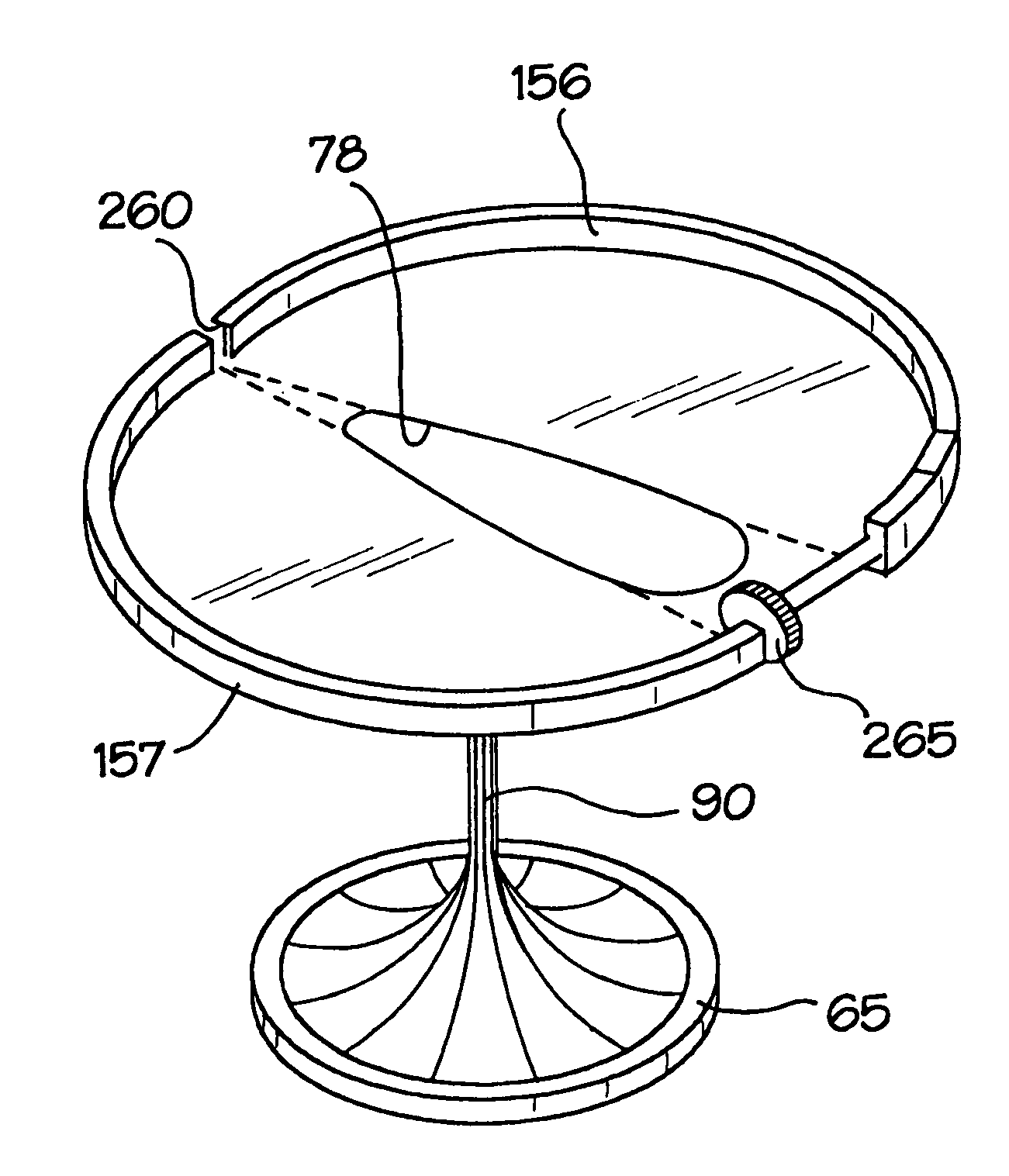

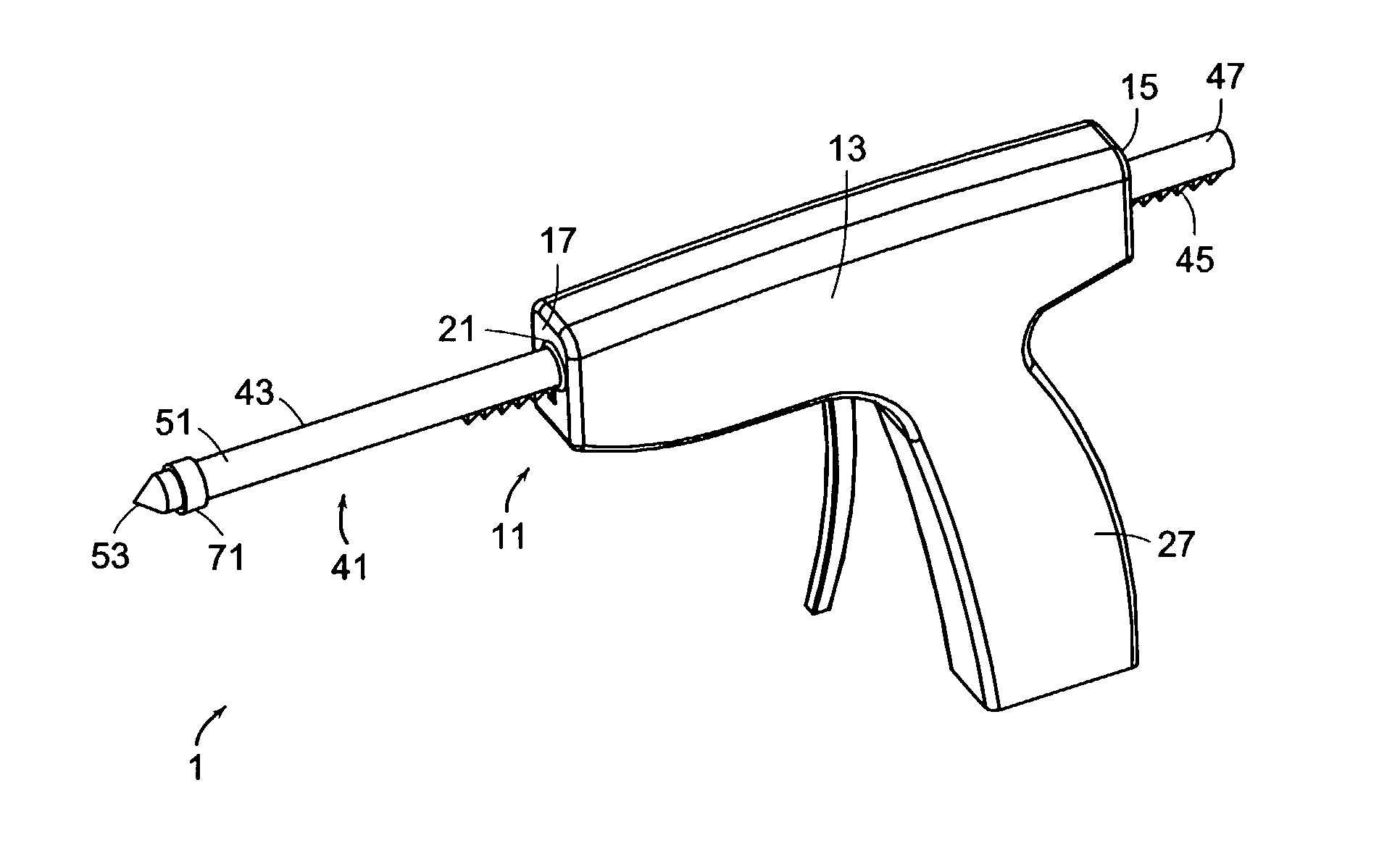

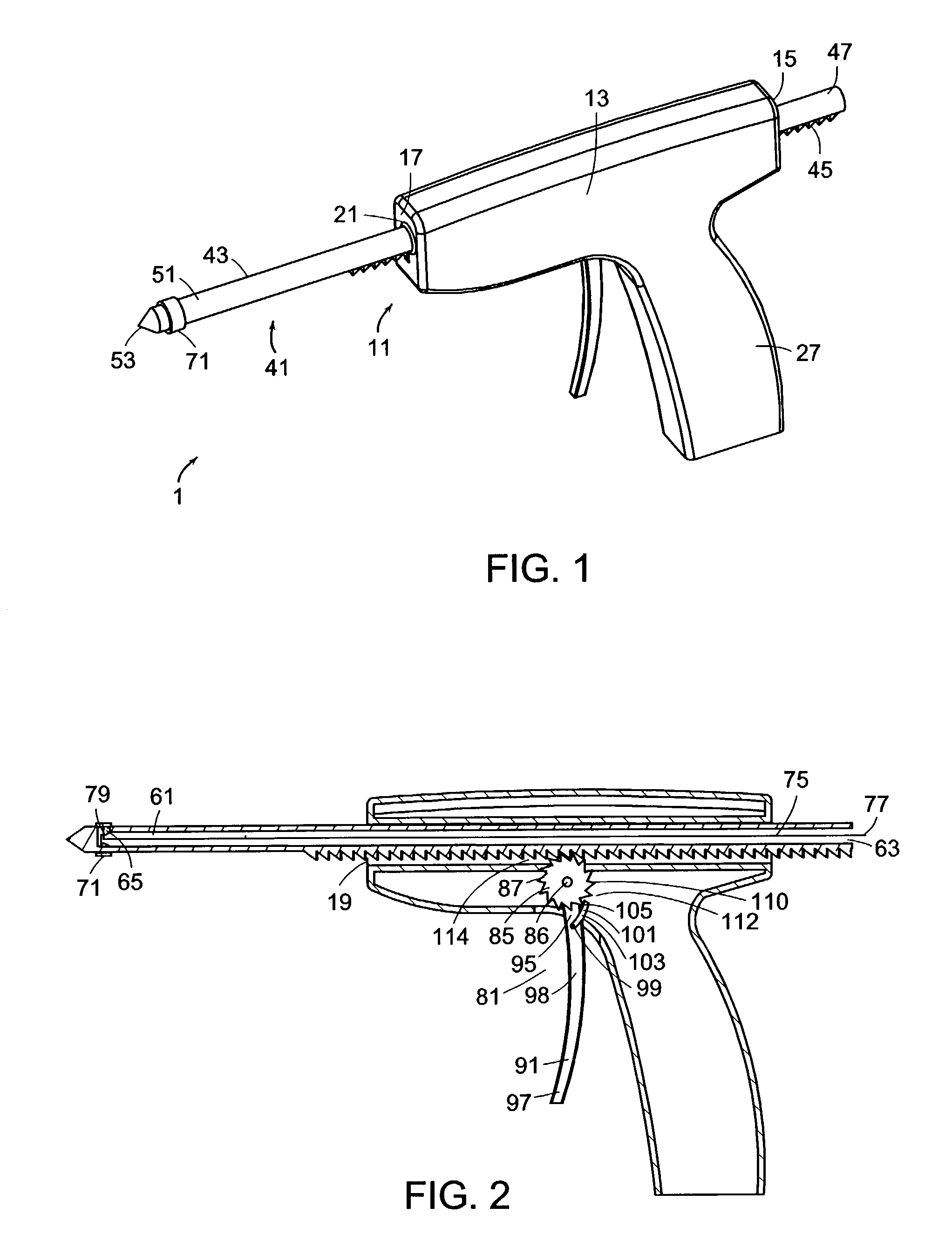

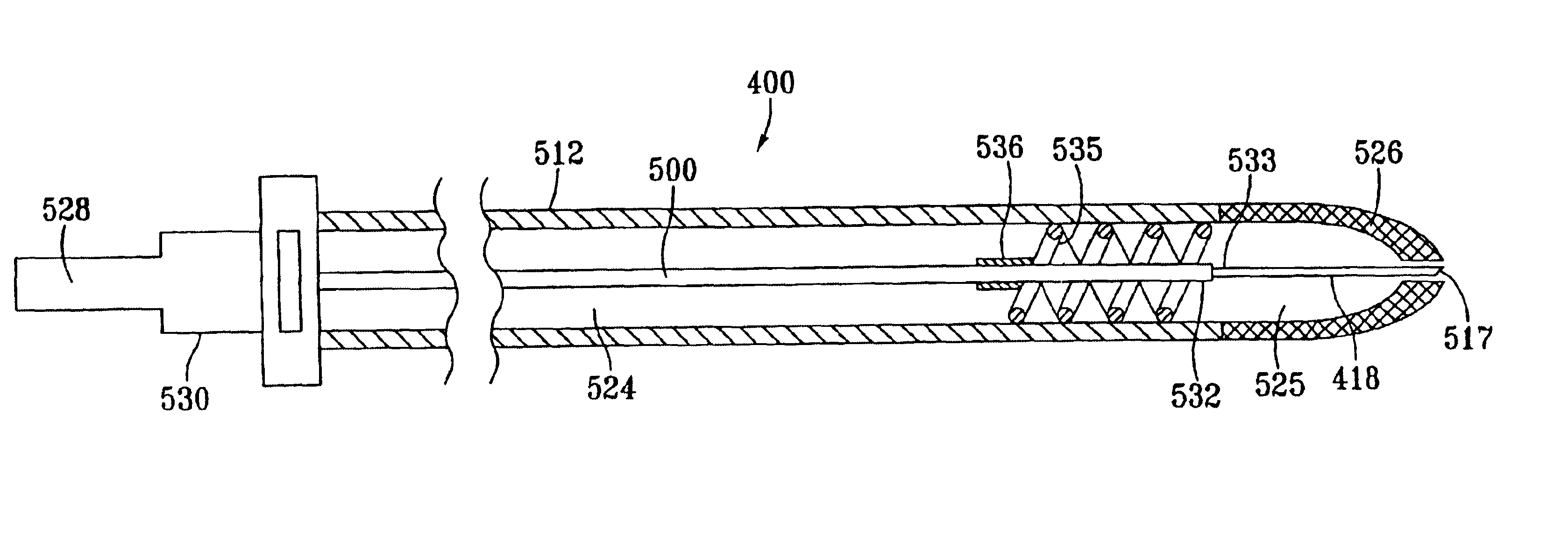

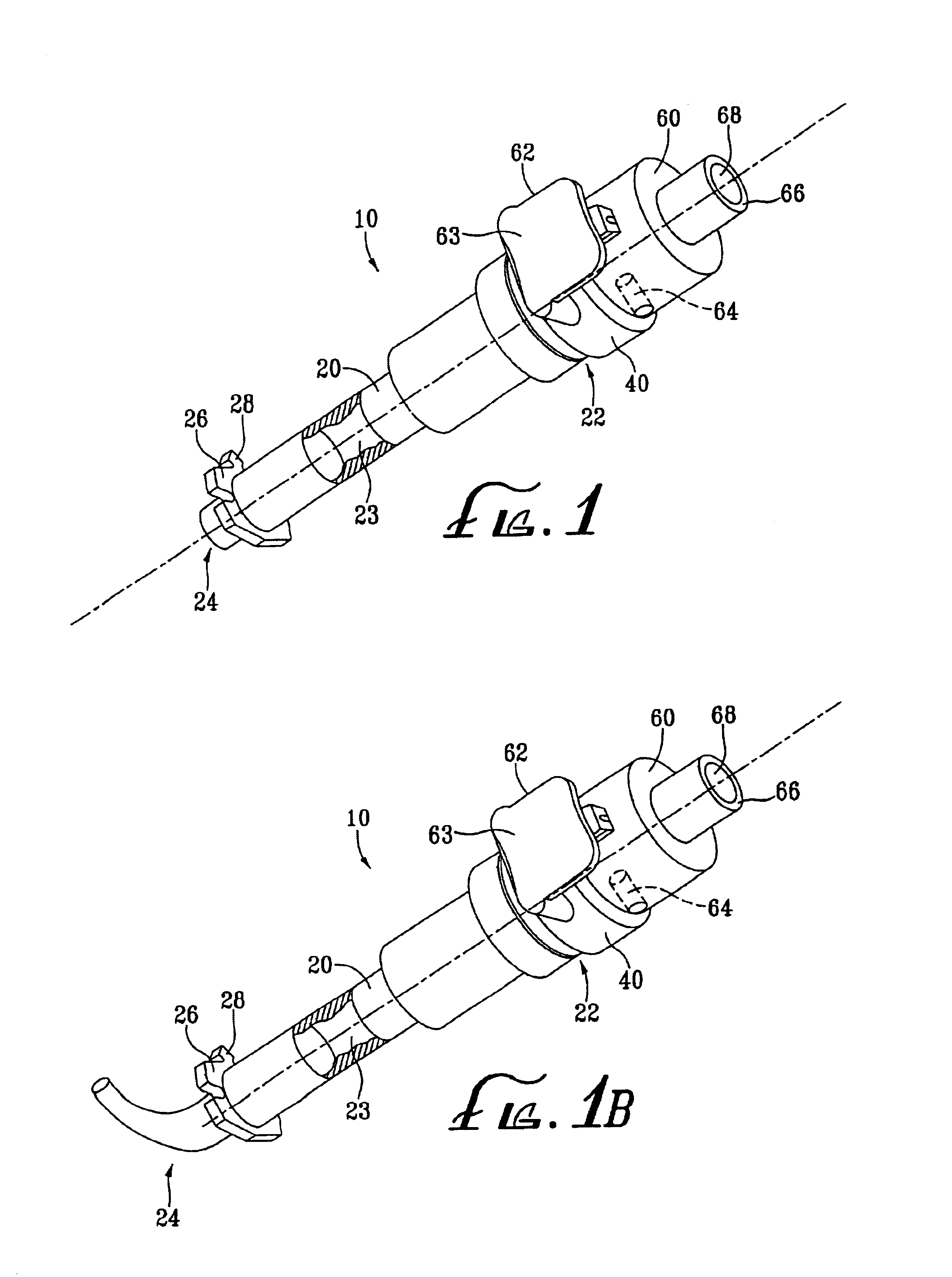

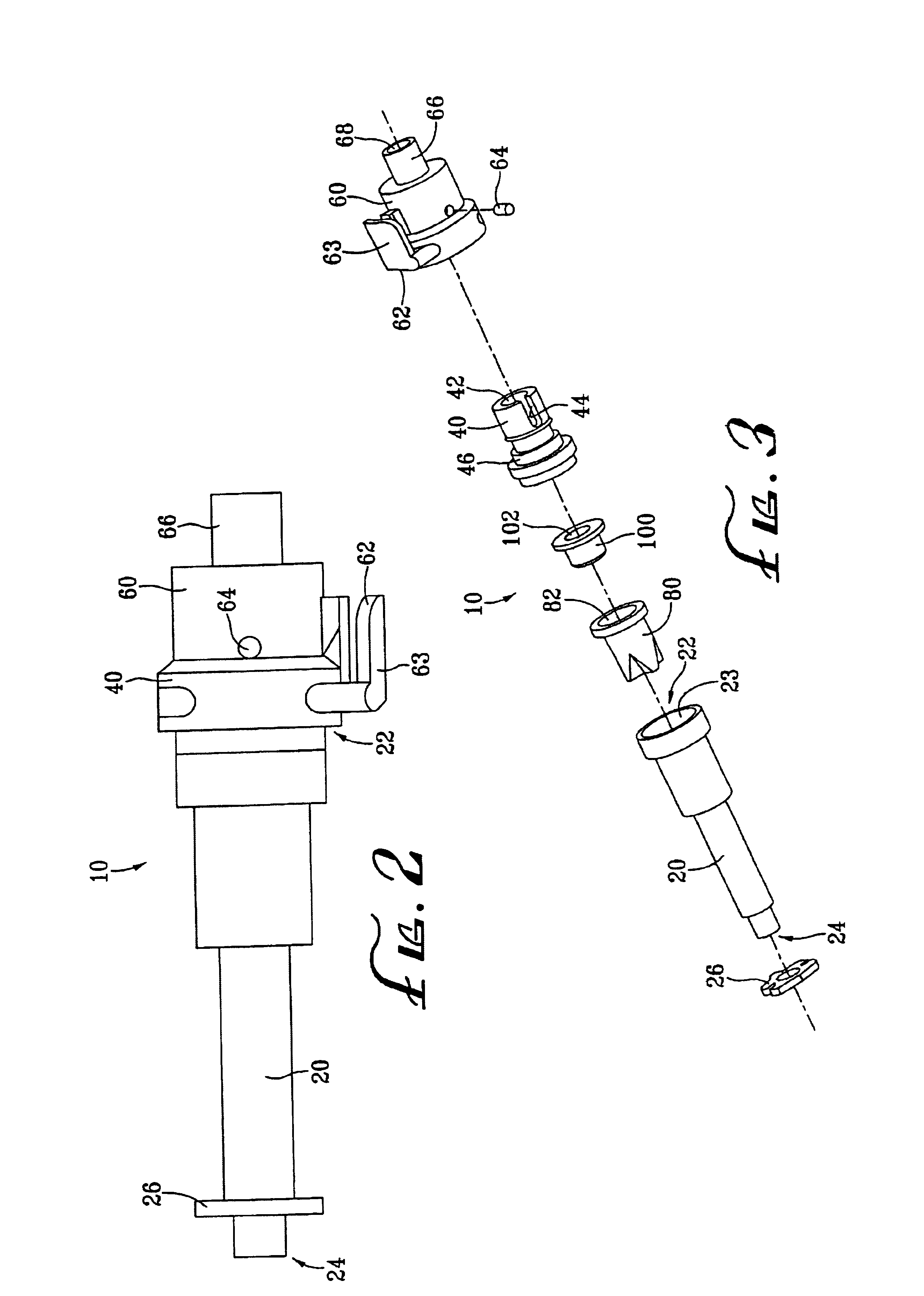

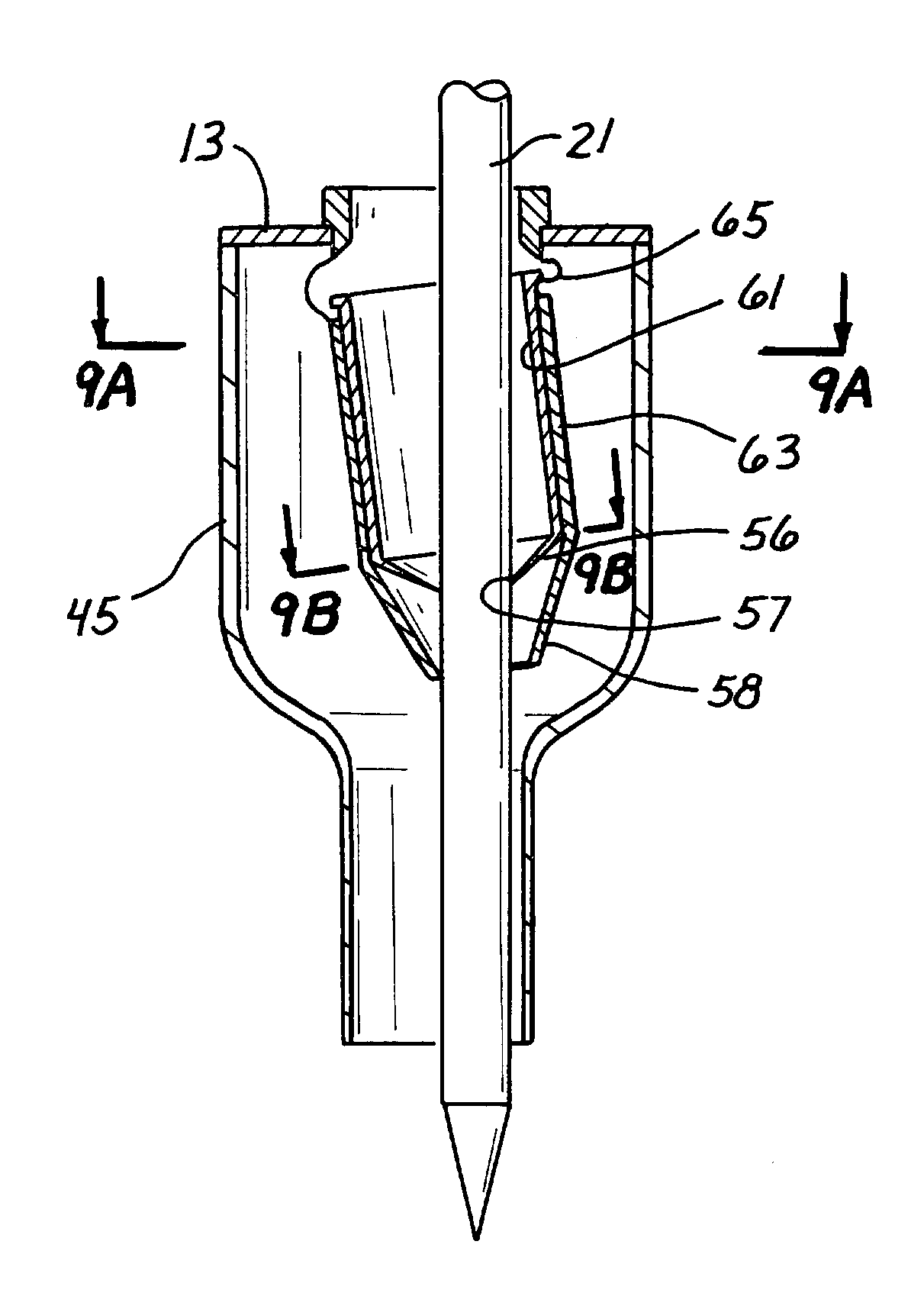

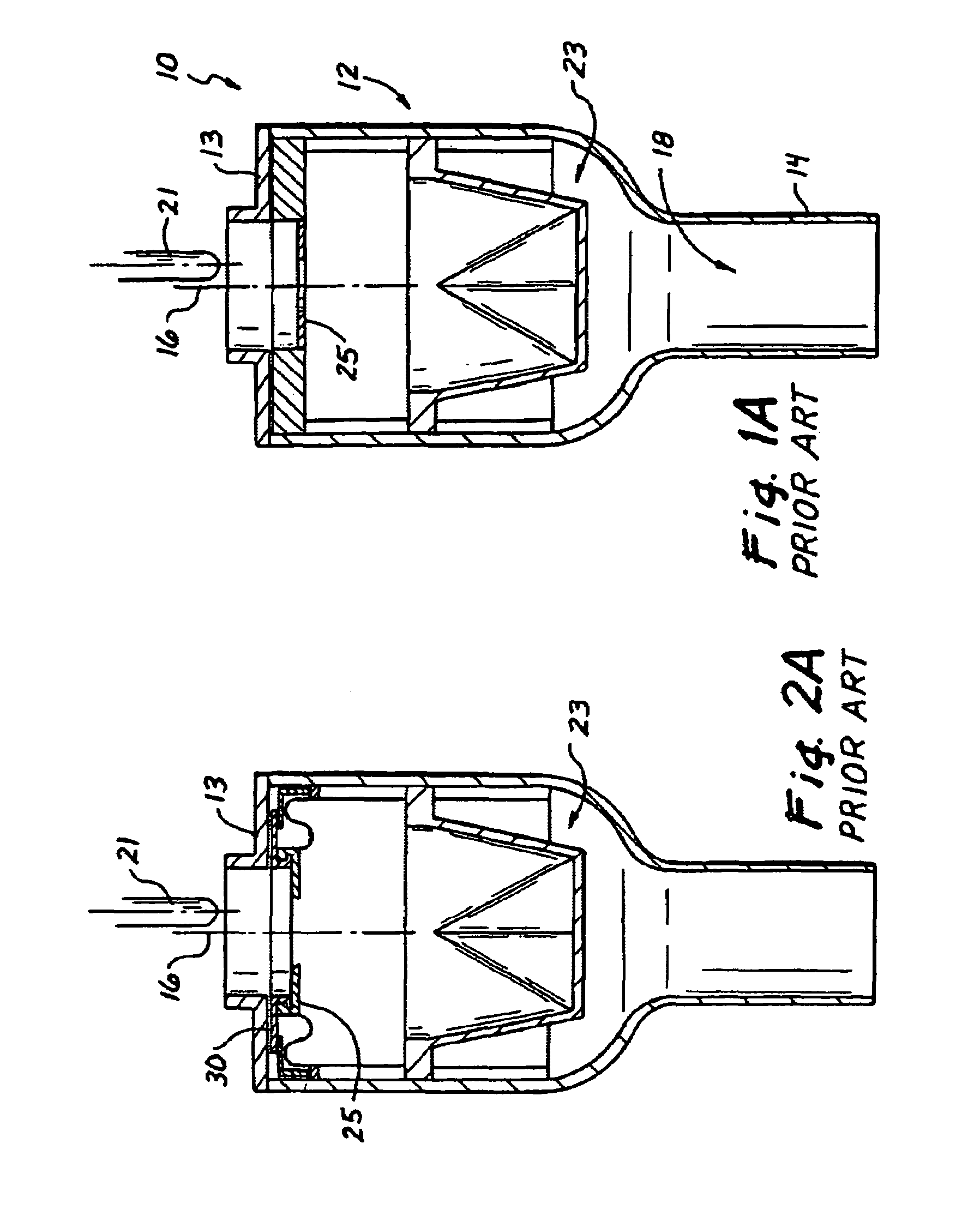

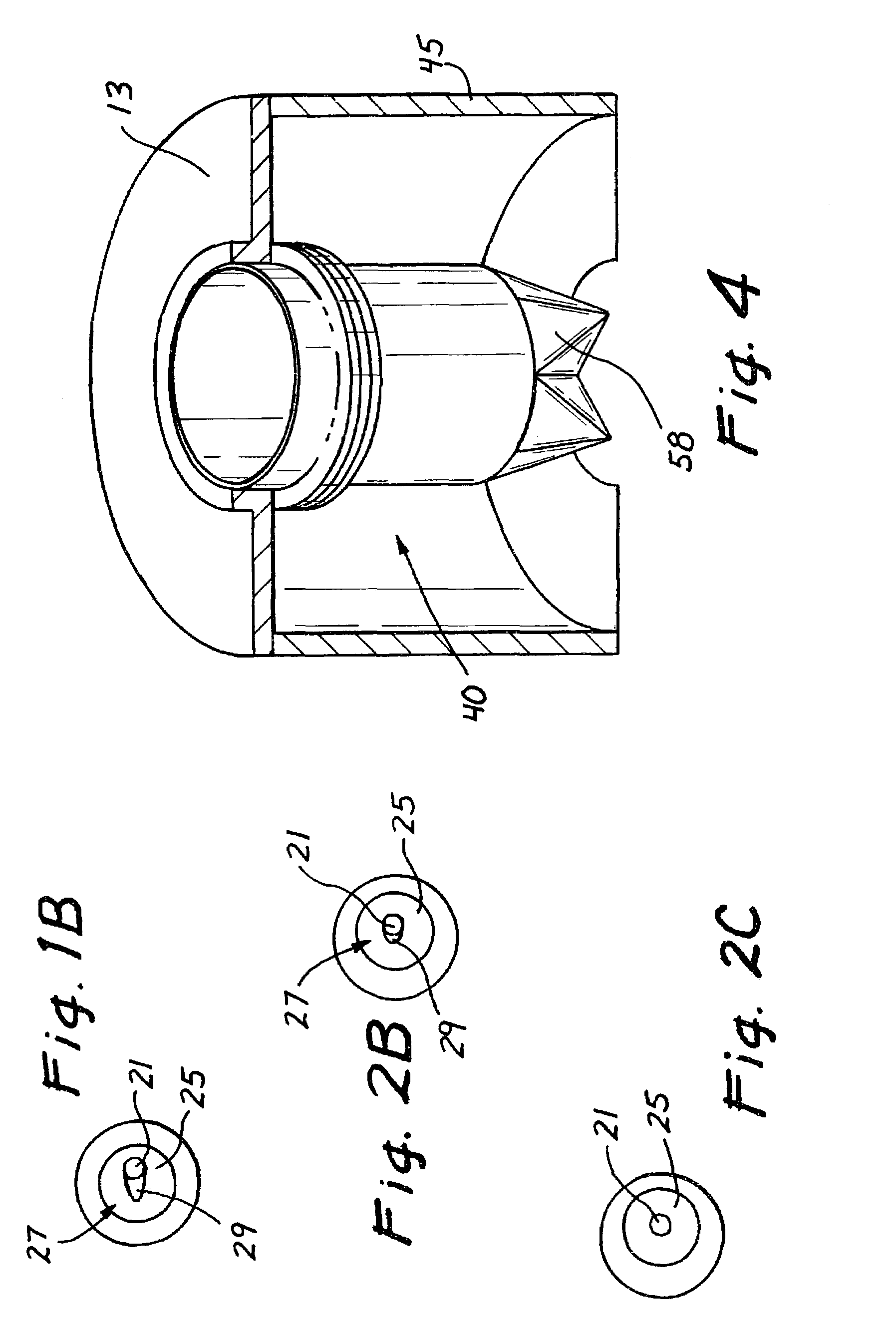

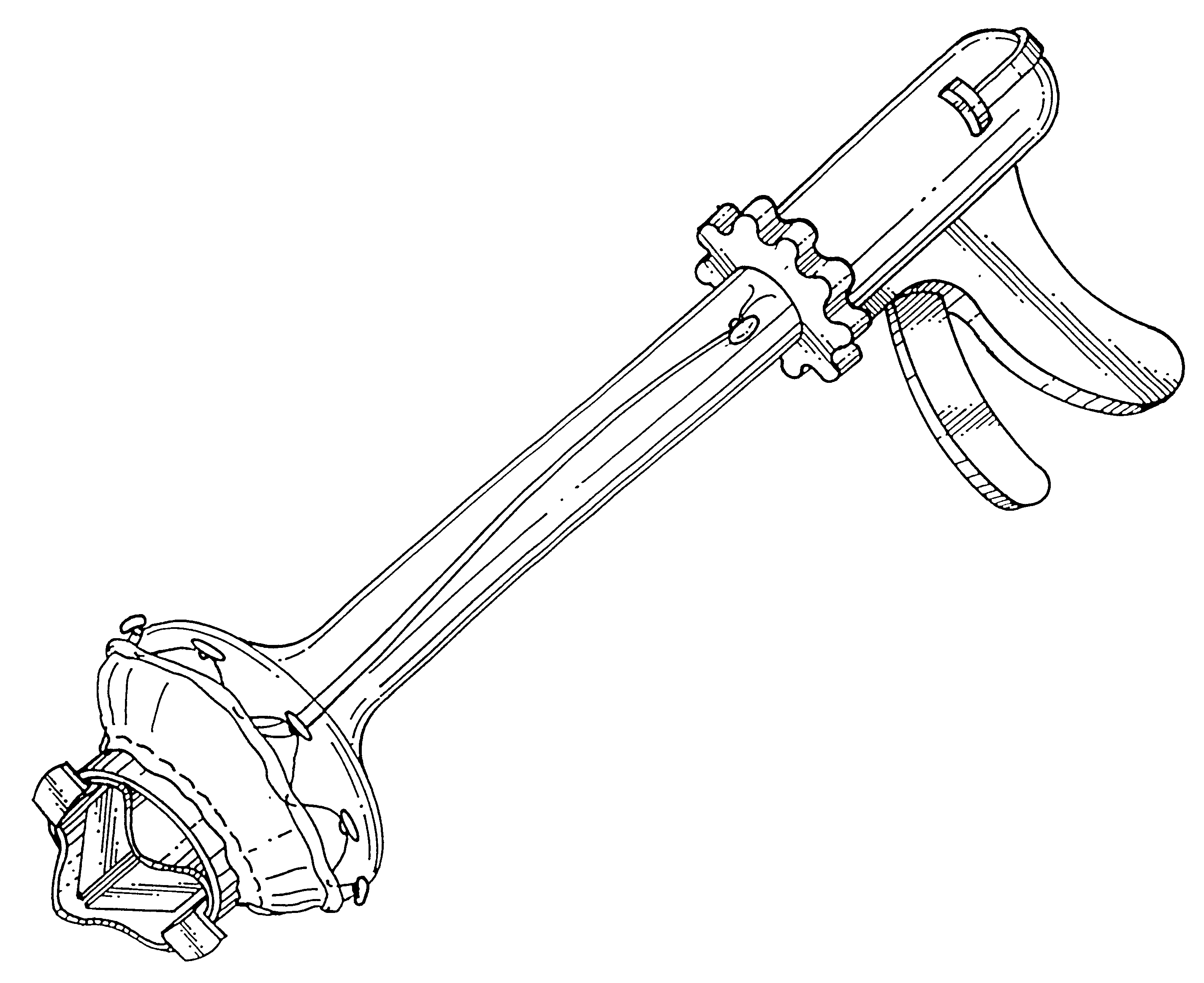

Surgical stapling device for performing circular anastomoses

InactiveUS6945444B2Enhanced advantageReduce firing forceSuture equipmentsStapling toolsEngineeringSurgical department

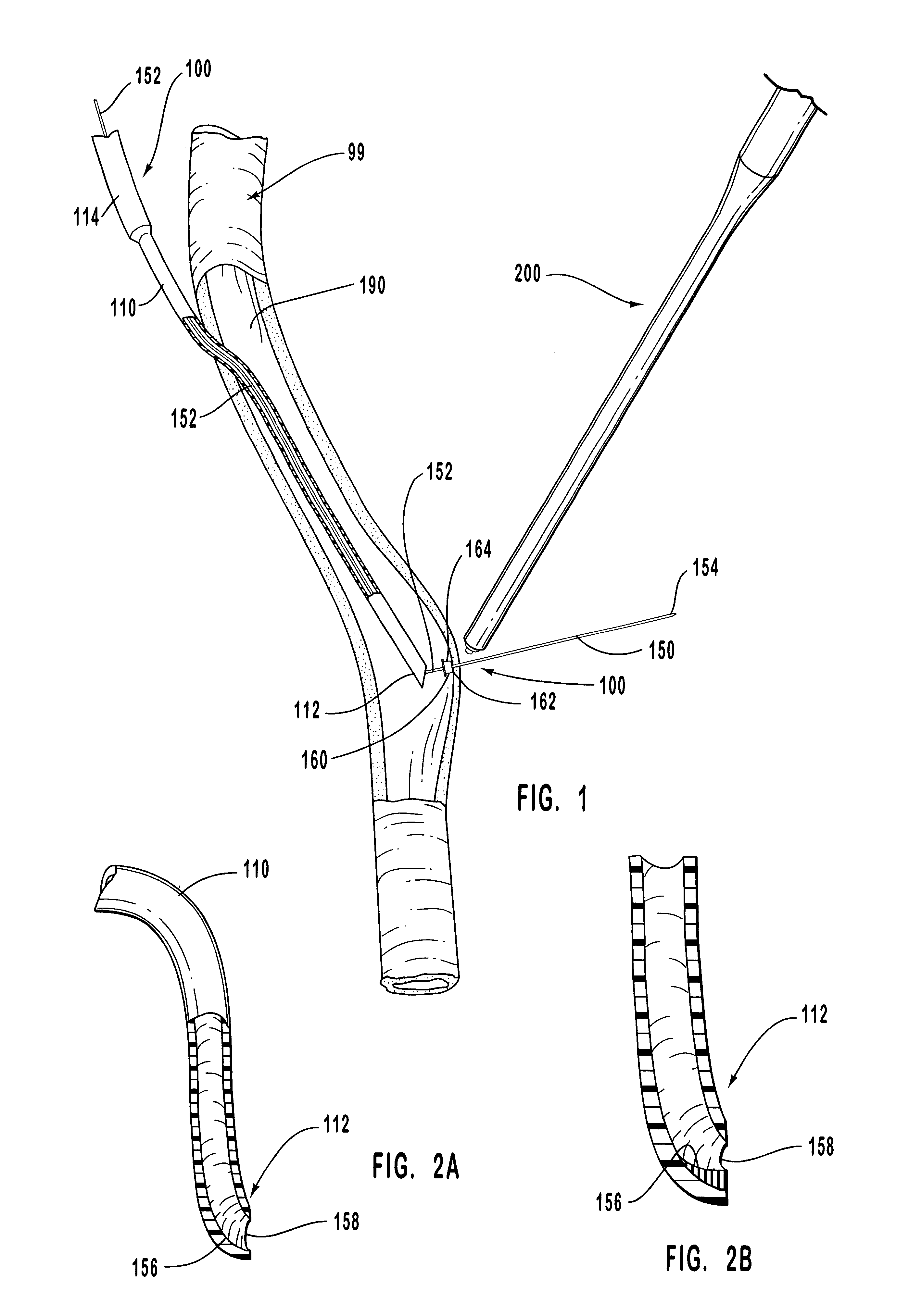

This application is directed to a surgical stapling device for performing circular anastomoses. The stapling device includes a retractable trocar which is slidably supported by an anvil retainer and movable from a retracted position located within the anvil retainer to an advanced position extending from the anvil retainer. The trocar defines a sensor and is operatively connected to an indicator assembly. The indicator assembly is operatively associated with an anvil assembly such that the indicator will not move from a fire-not ready position to a fire-ready position until an anvil assembly has been mounted to the anvil retainer.

Owner:TYCO HEALTHCARE GRP LP

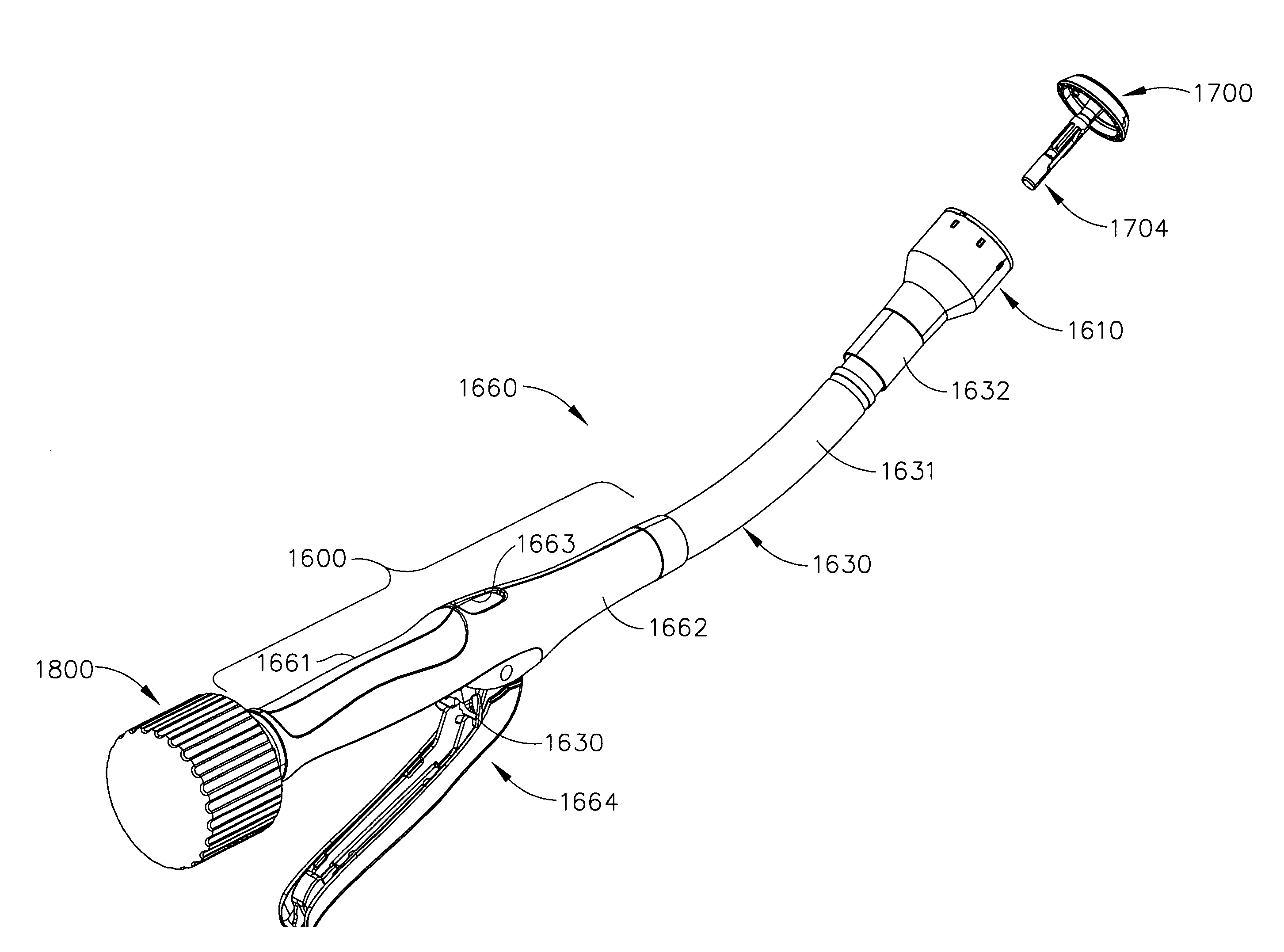

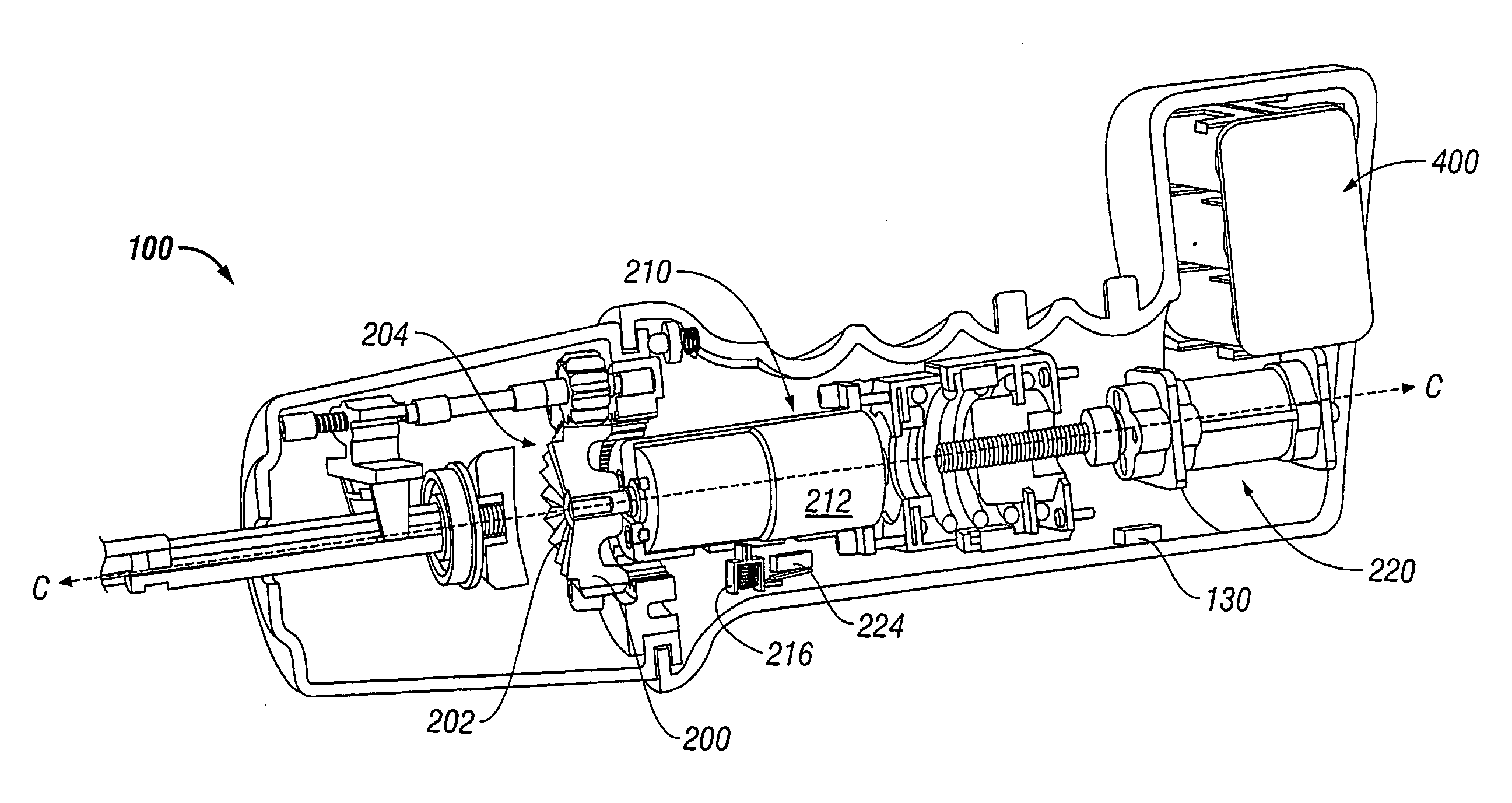

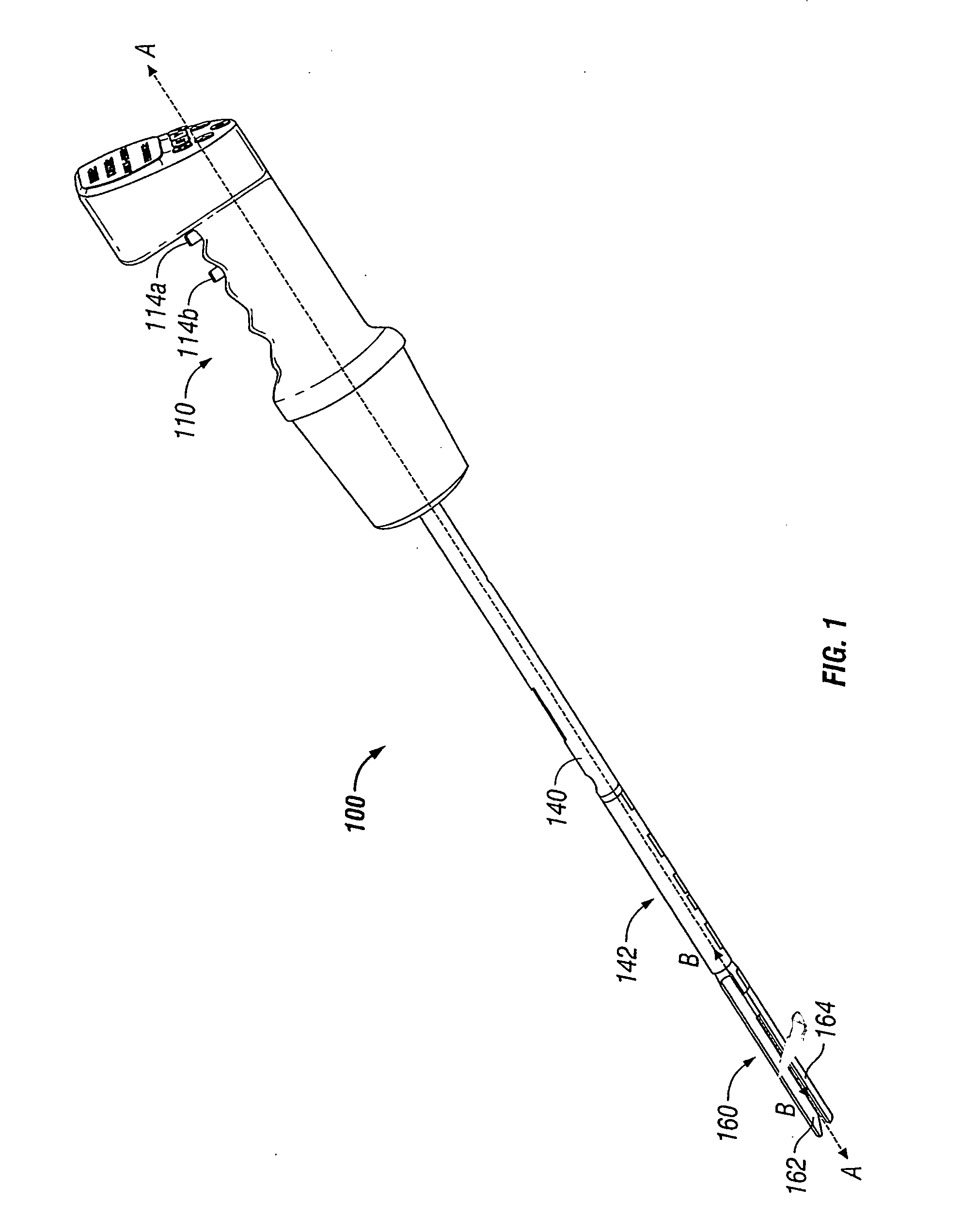

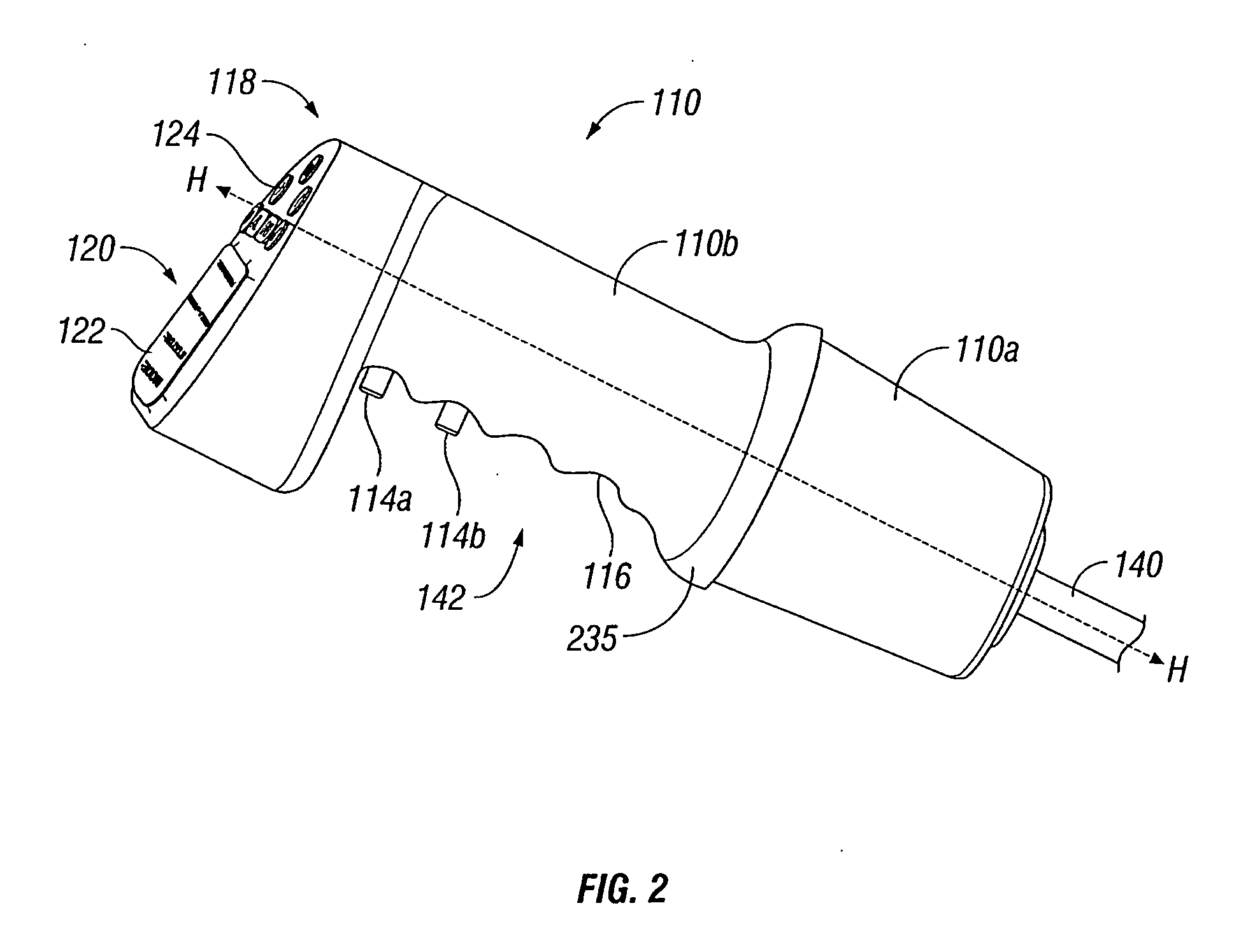

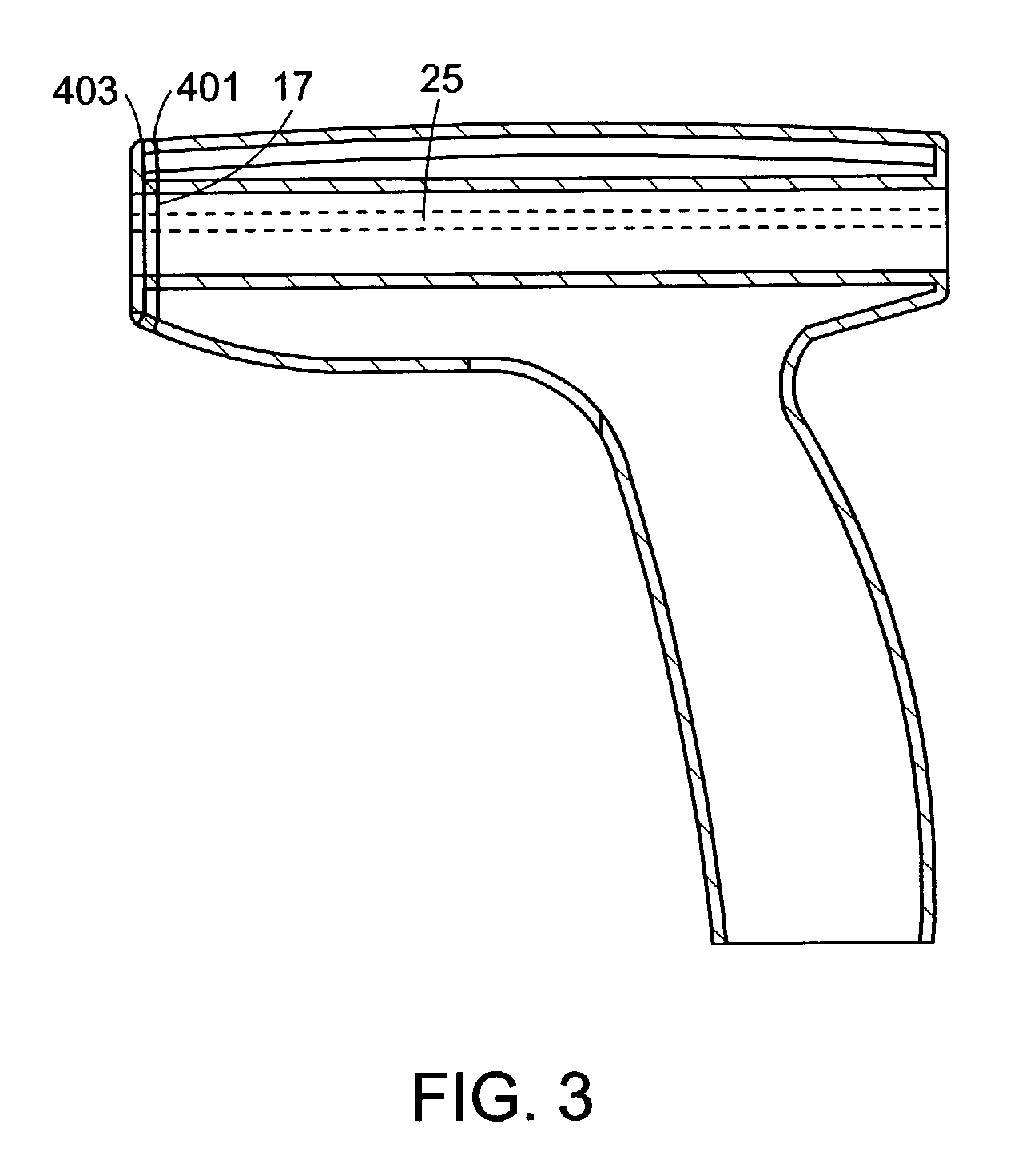

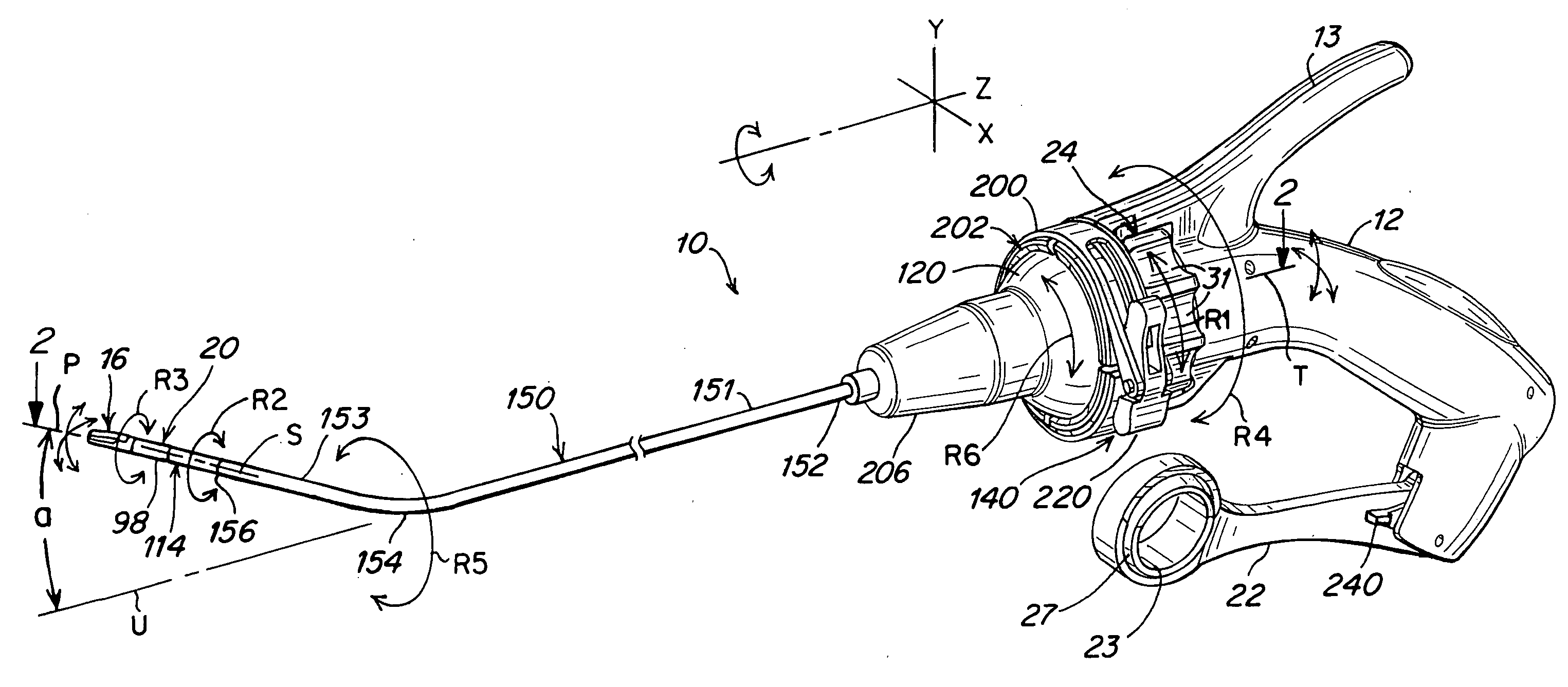

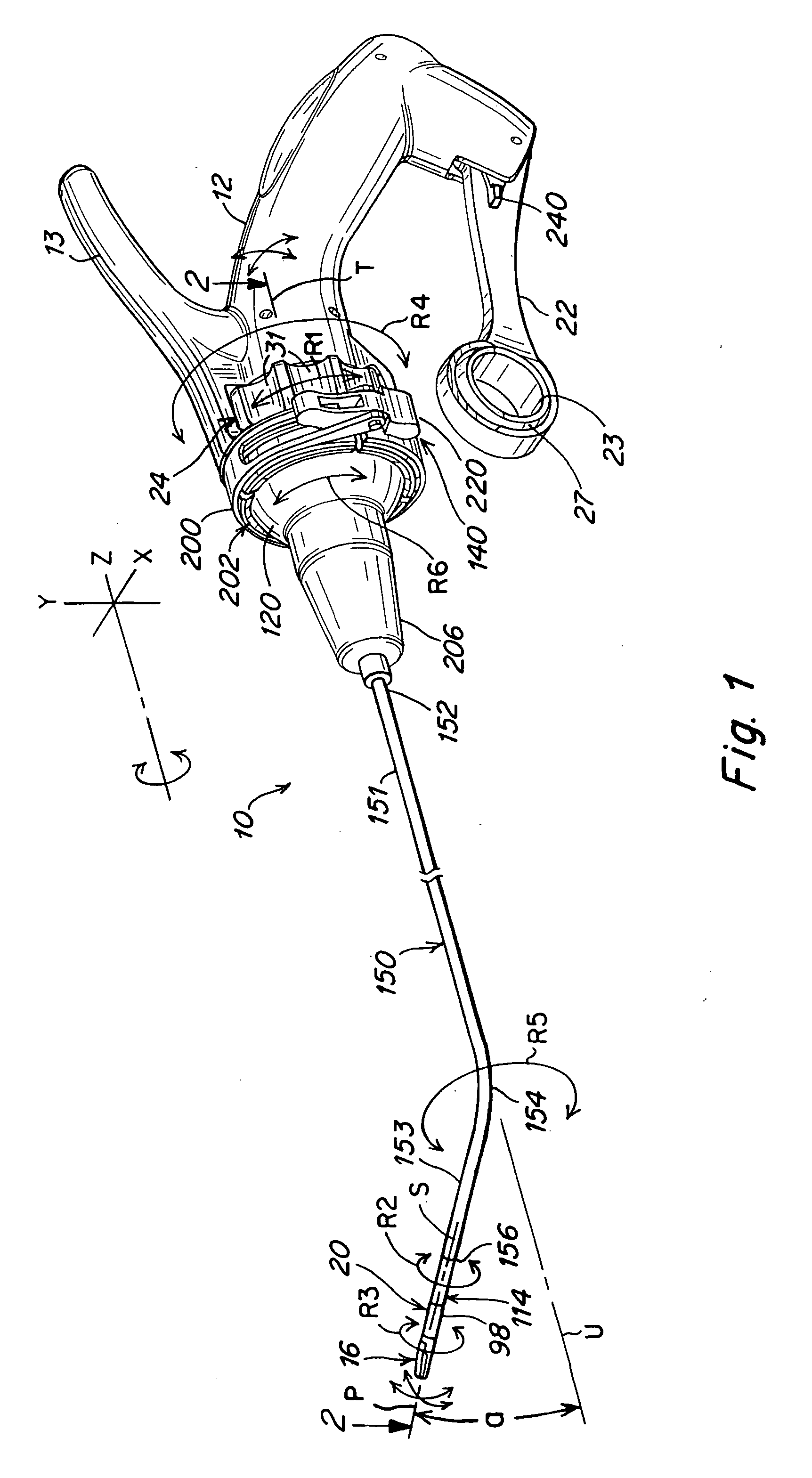

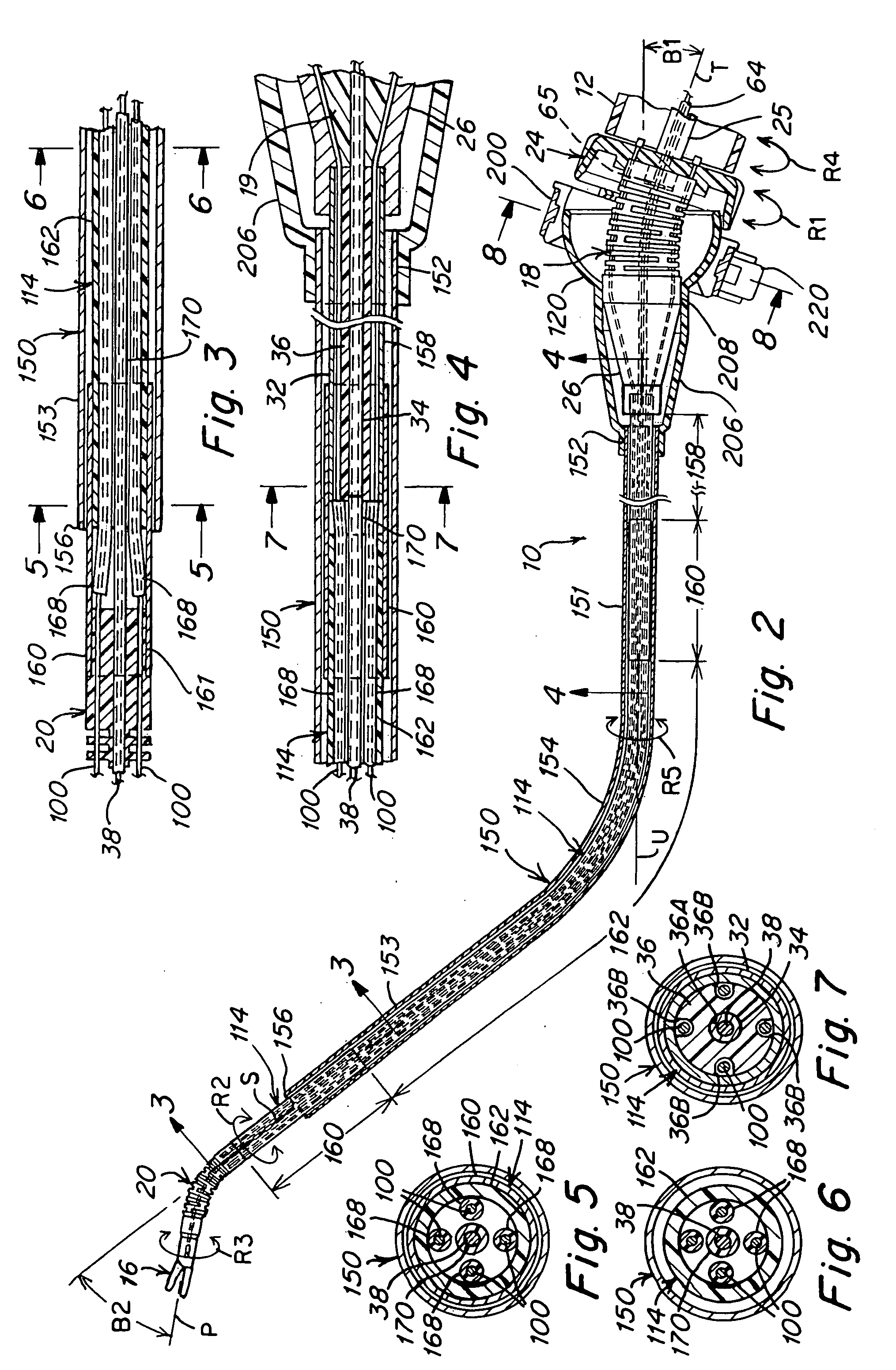

Powered surgical instrument

A surgical instrument including a housing, an endoscopic portion, a shaft portion and an end effector is disclosed. The endoscopic portion extends distally from the housing and defines a longitudinal axis. The shaft portion is selectively connectable to a distal end of the endoscopic portion. The end effector is selectively connectable to a distal end of the shaft portion.

Owner:TYCO HEALTHCARE GRP LP

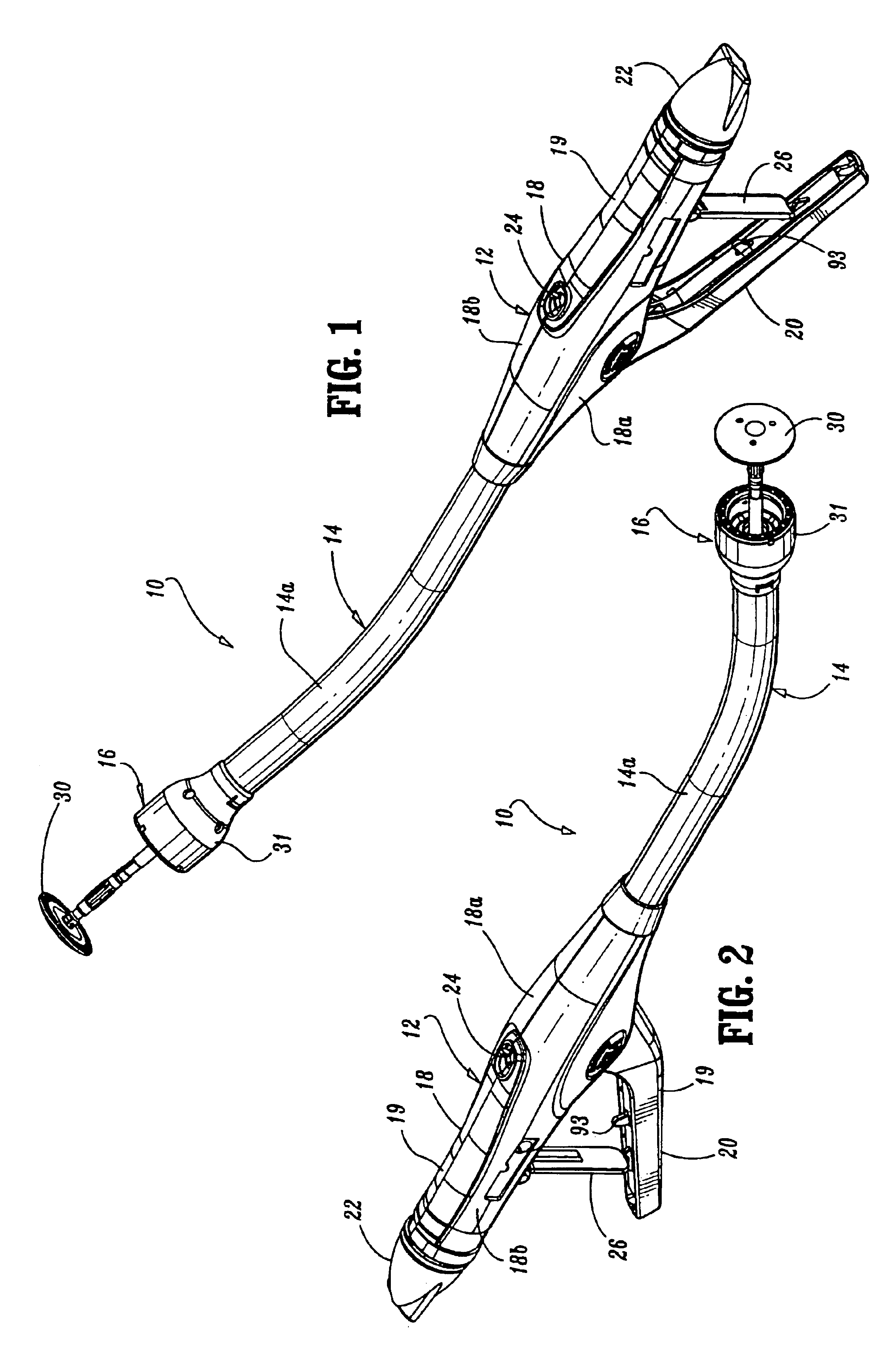

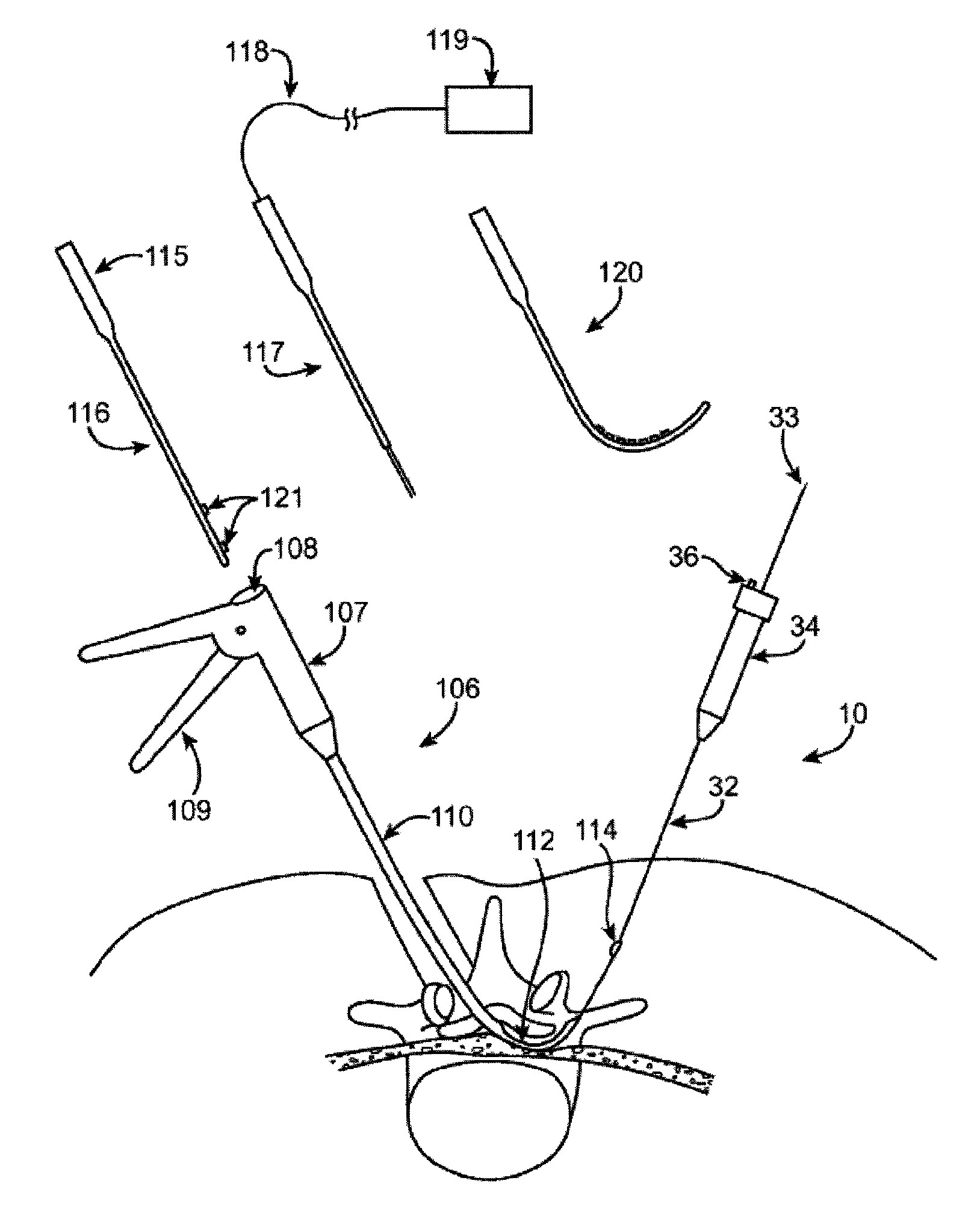

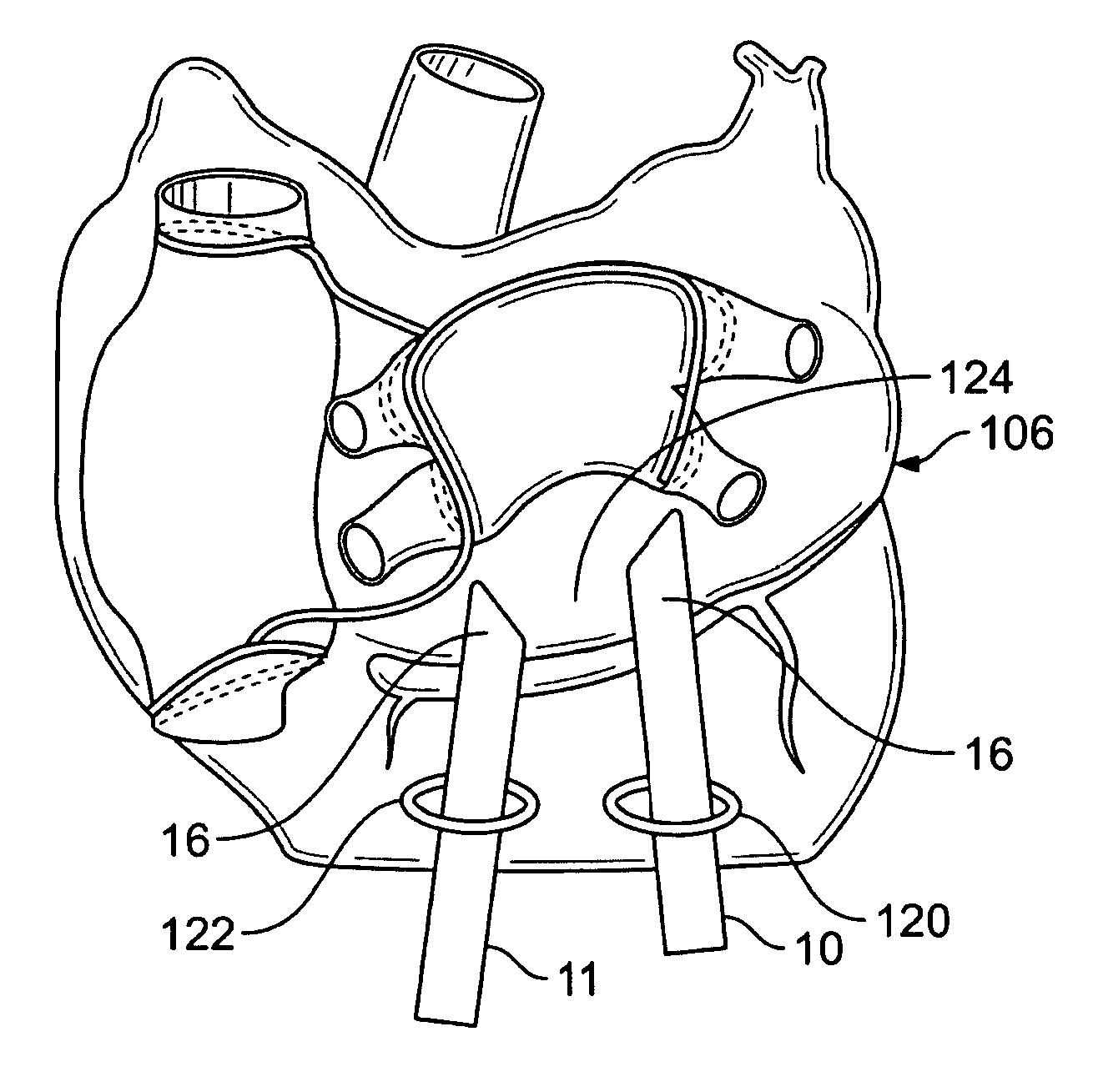

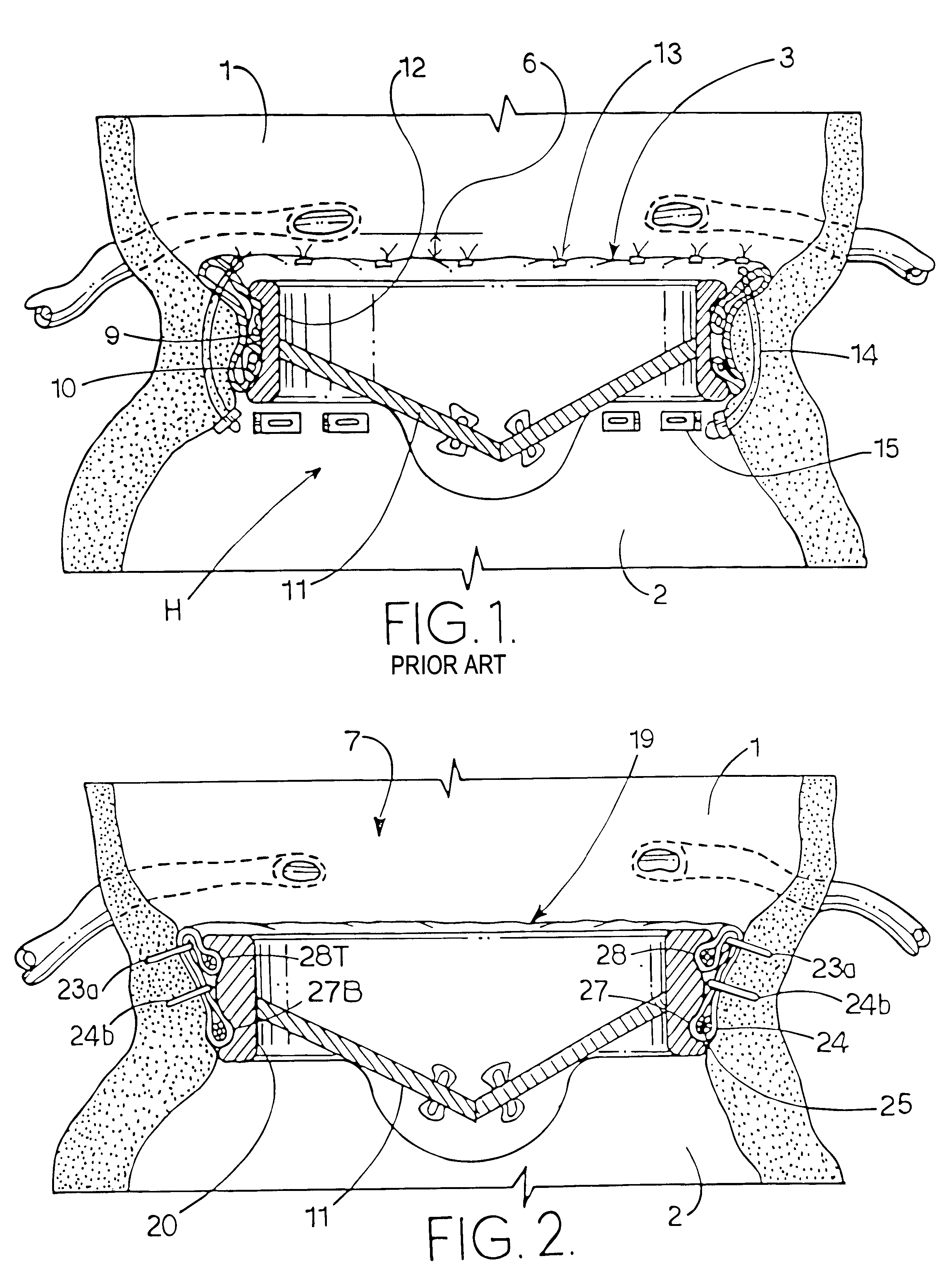

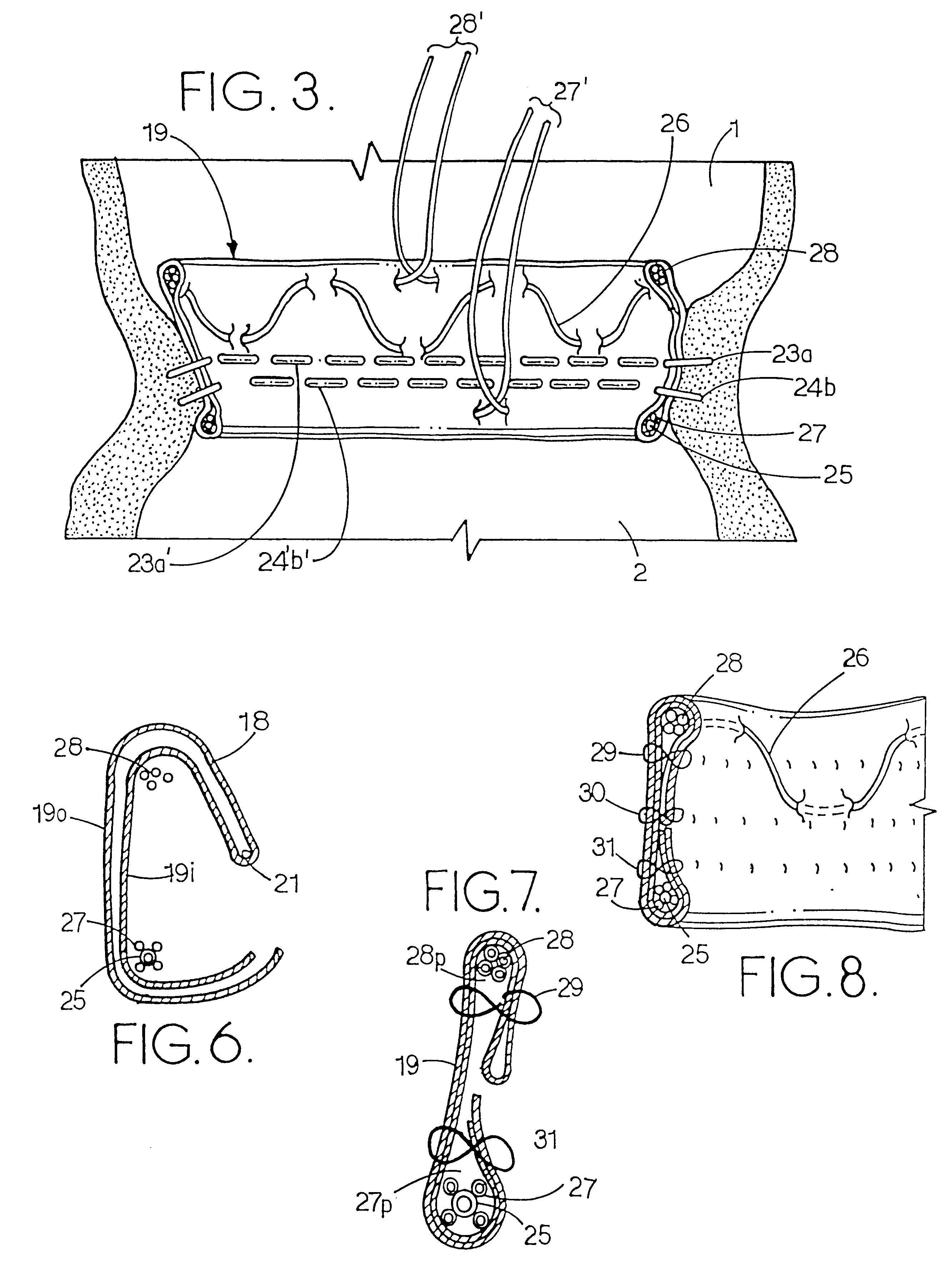

Means and method of replacing a heart valve in a minimally invasive manner

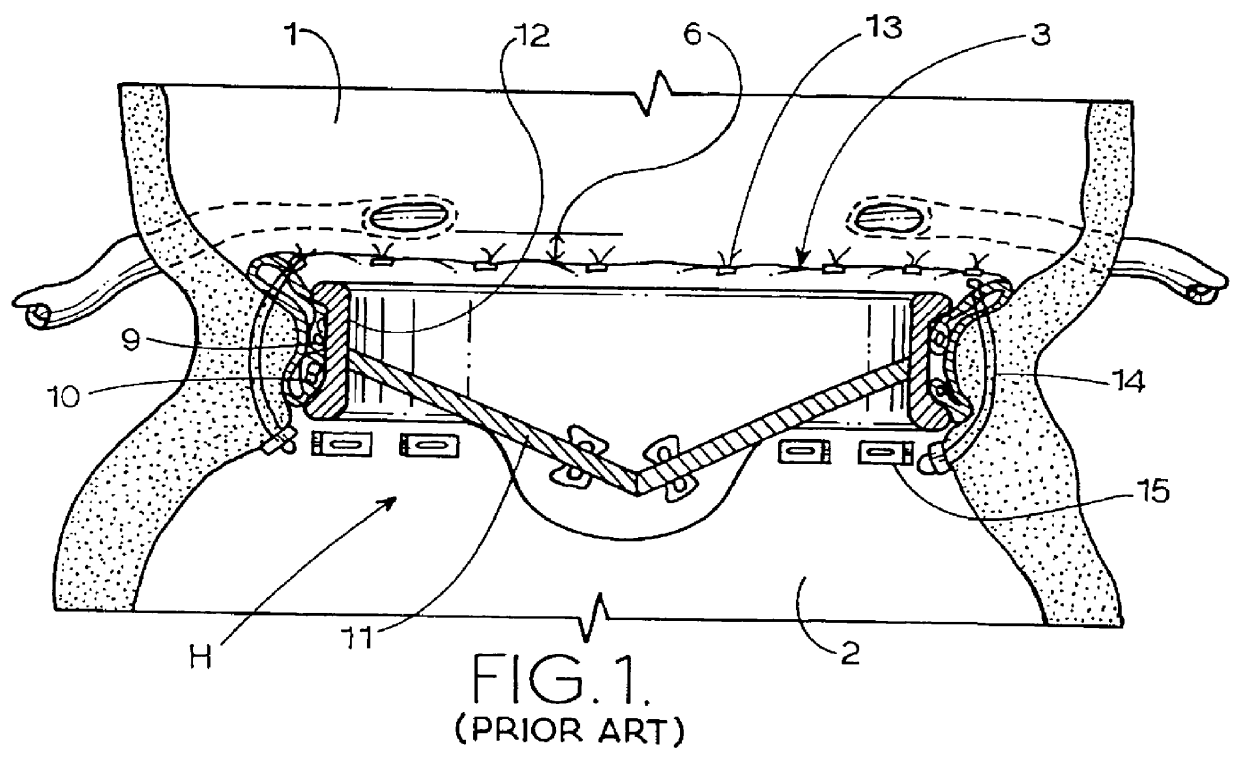

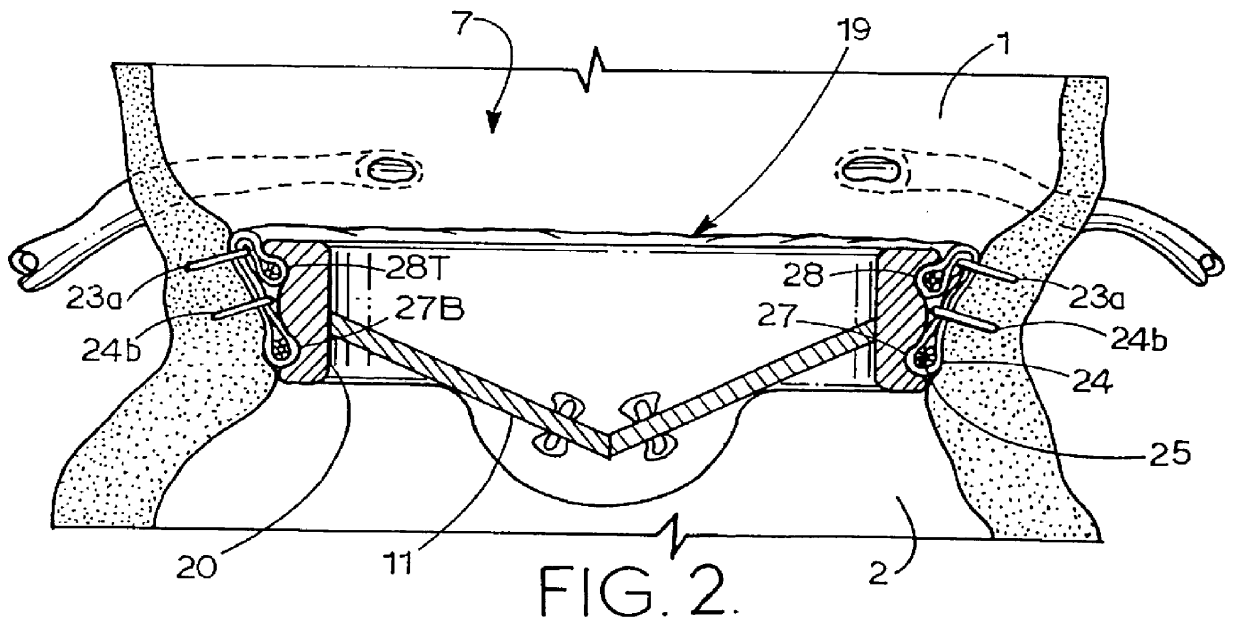

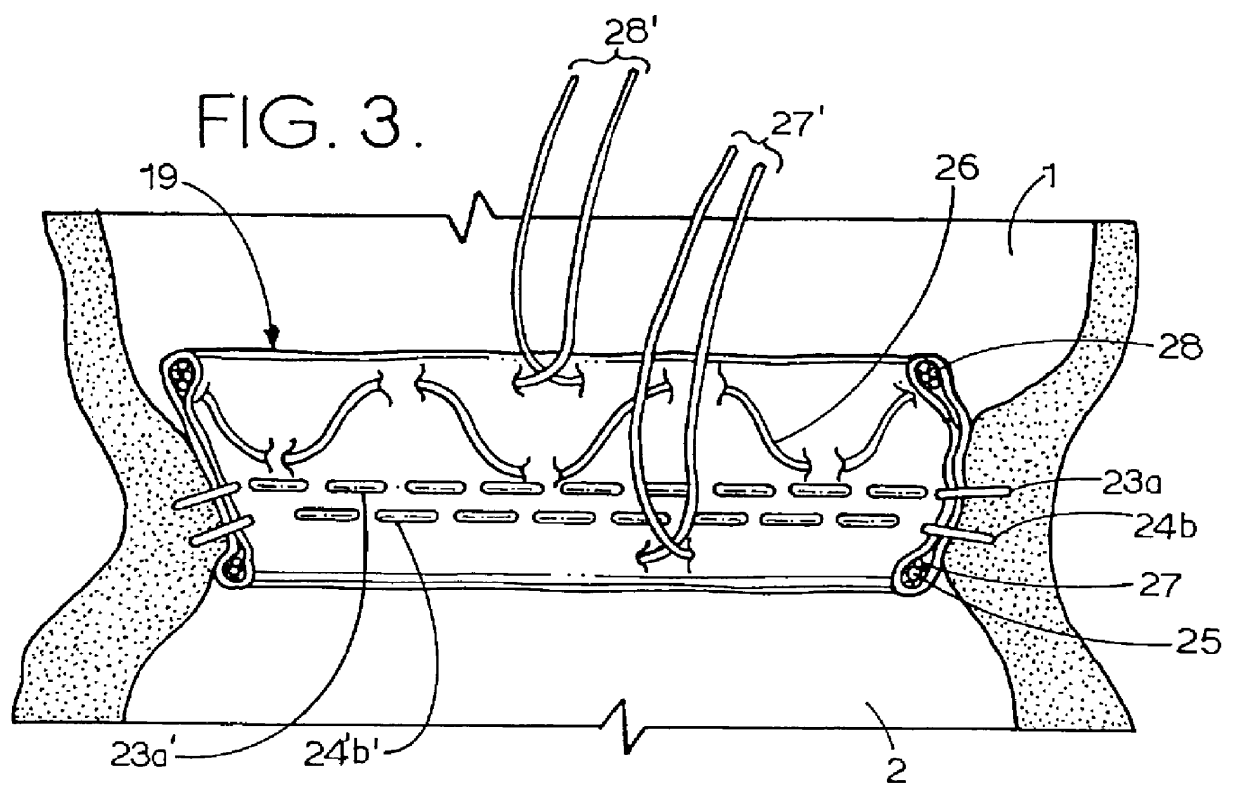

InactiveUS6042607AMinimally invasiveEfficient and effectiveSuture equipmentsHeart valvesLess invasive surgeryCuff

A heart valve can be replaced using minimally invasive methods which include a sutureless sewing cuff that and a fastener delivery tool that holds the cuff against the patient's tissue while delivering fasteners, two at a time to attach the cuff to the tissue from the inside out. The tool stores a plurality of fasteners. Drawstrings are operated from outside the patient's body and cinch the sewing cuff to the valve body. The cuff is releasably mounted on the tool and the tool holds the cuff against tissue and drives the fastener through the cuff and the tissue before folding over the legs of the fastener whereby secure securement between the cuff and the tissue is assured. At least two rows of staggered fasteners are formed whereby fasteners are located continuously throughout the entire circumference of the cuff. A minimally invasive surgical method is disclosed, and a method and tool are disclosed for repairing abdominal aortic aneurysms in a minimally invasive manner.

Owner:MEDTRONIC INC

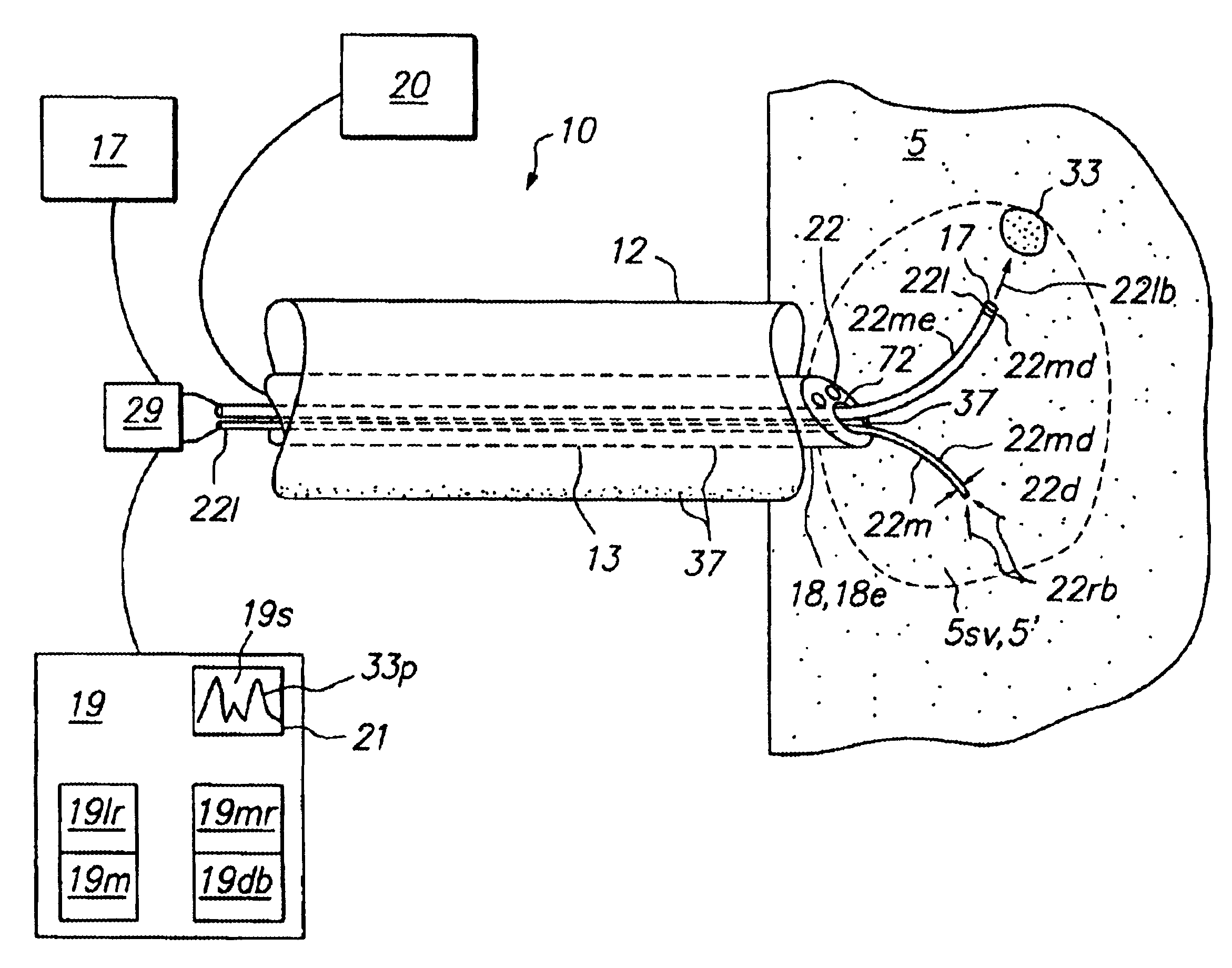

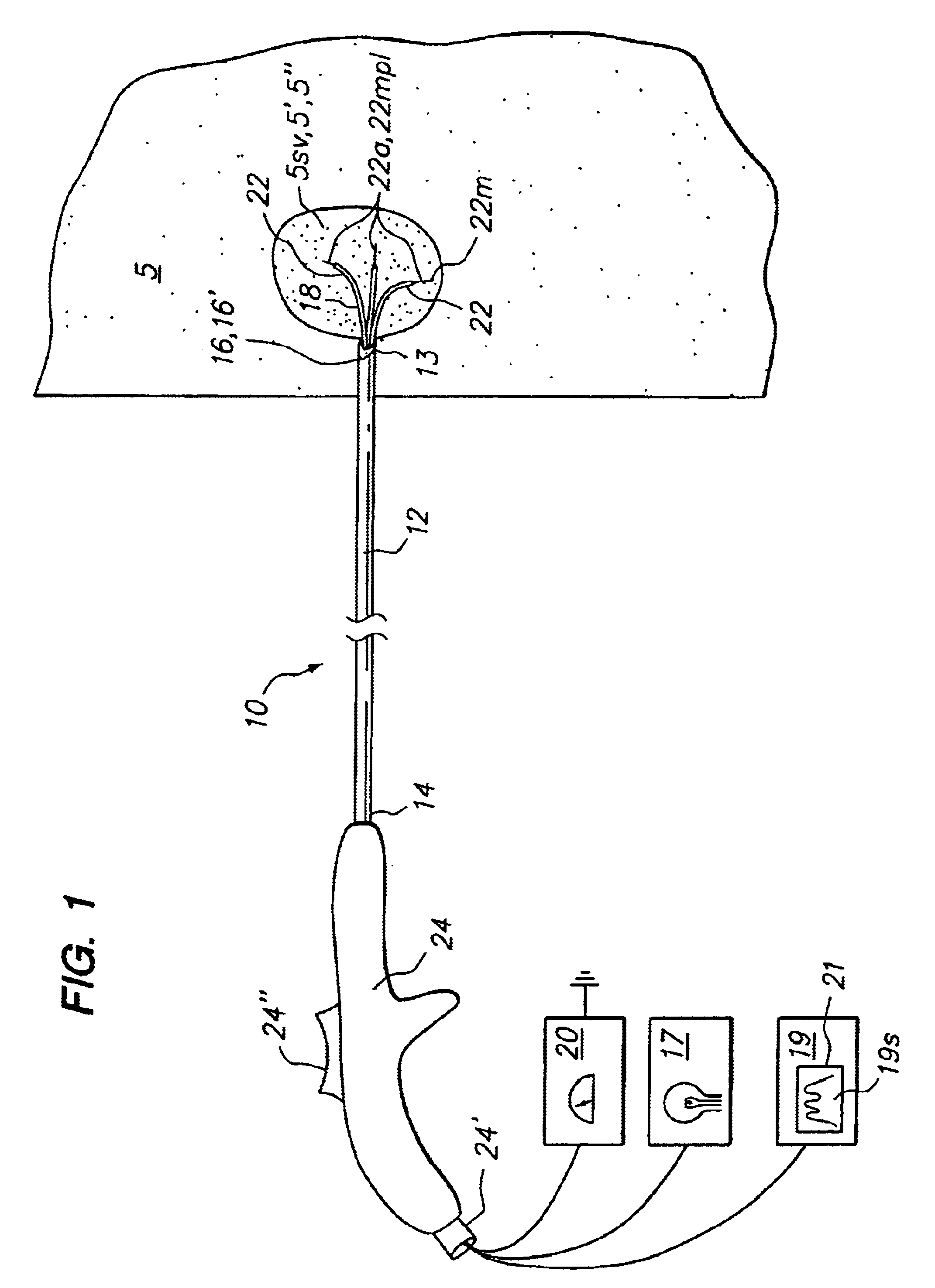

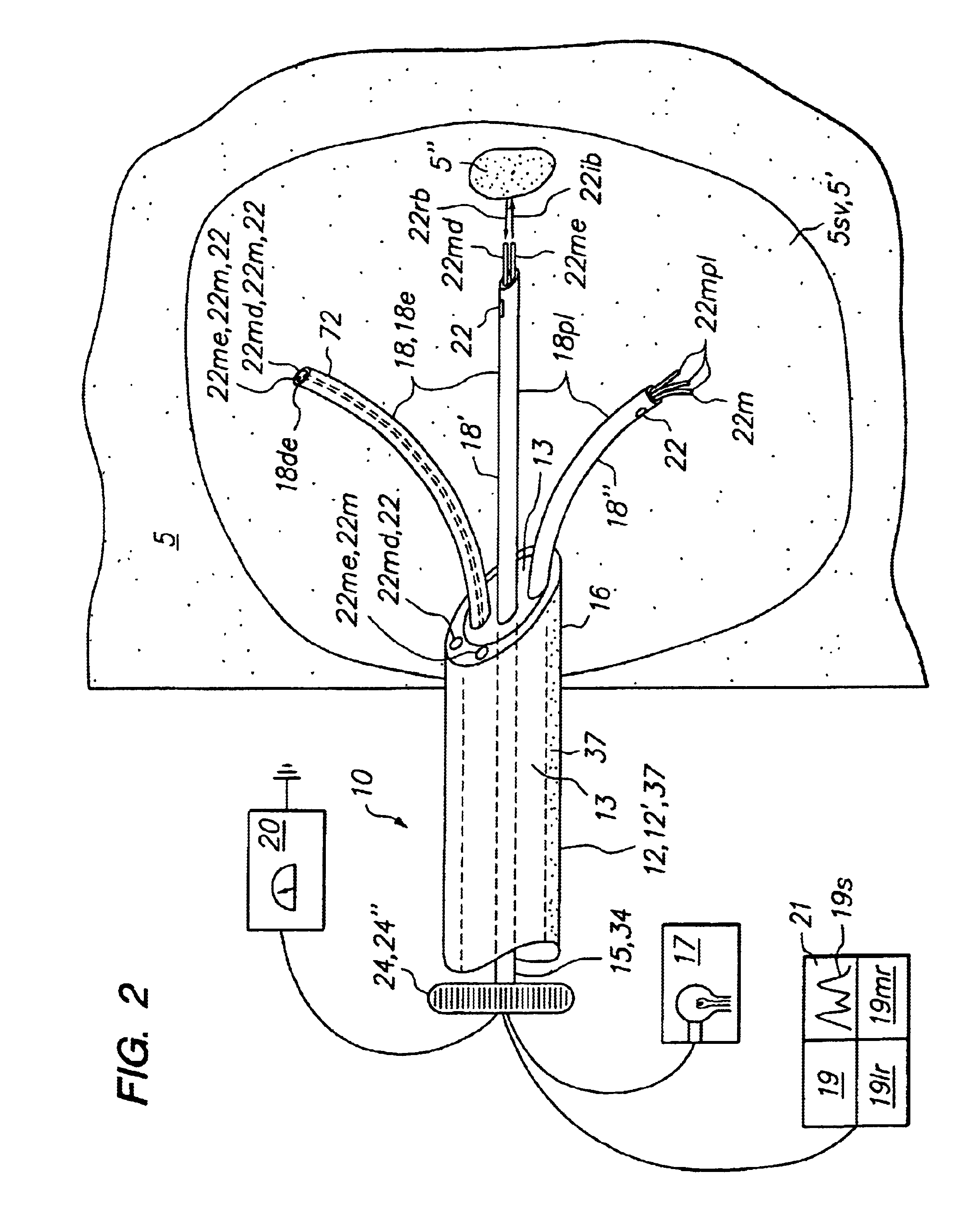

Anastomosis apparatus for use in intraluminally directed vascular anastomosis

InactiveUS6248117B1Surgical needlesSurgical staplesVascular anastomosisMinimally invasive procedures

The present invention relates to new and useful apparatus for use with an intraluminally directed anvil apparatus for intraluminally directed vascular anastomosis of an end of a graft vessel to the wall of a receiving blood vessel that is performed according to a minimally invasive procedure. The intraluminally directed vascular anastomosis does not require the interruption of blood flow in the receiving blood vessel and it is versatile enough to suitably combine a variety of cutting, welding, soldering, sealing, and joining techniques such as stapling. The intraluminally directed anvil apparatus comprises an anvil and a wire used for signaling the optimal anastomosis site; this signaling can be performed when the initial exploration is performed. The intraluminally directed anvil apparatus is typically used with a catheter.

Owner:VITAL ACCESS CORP

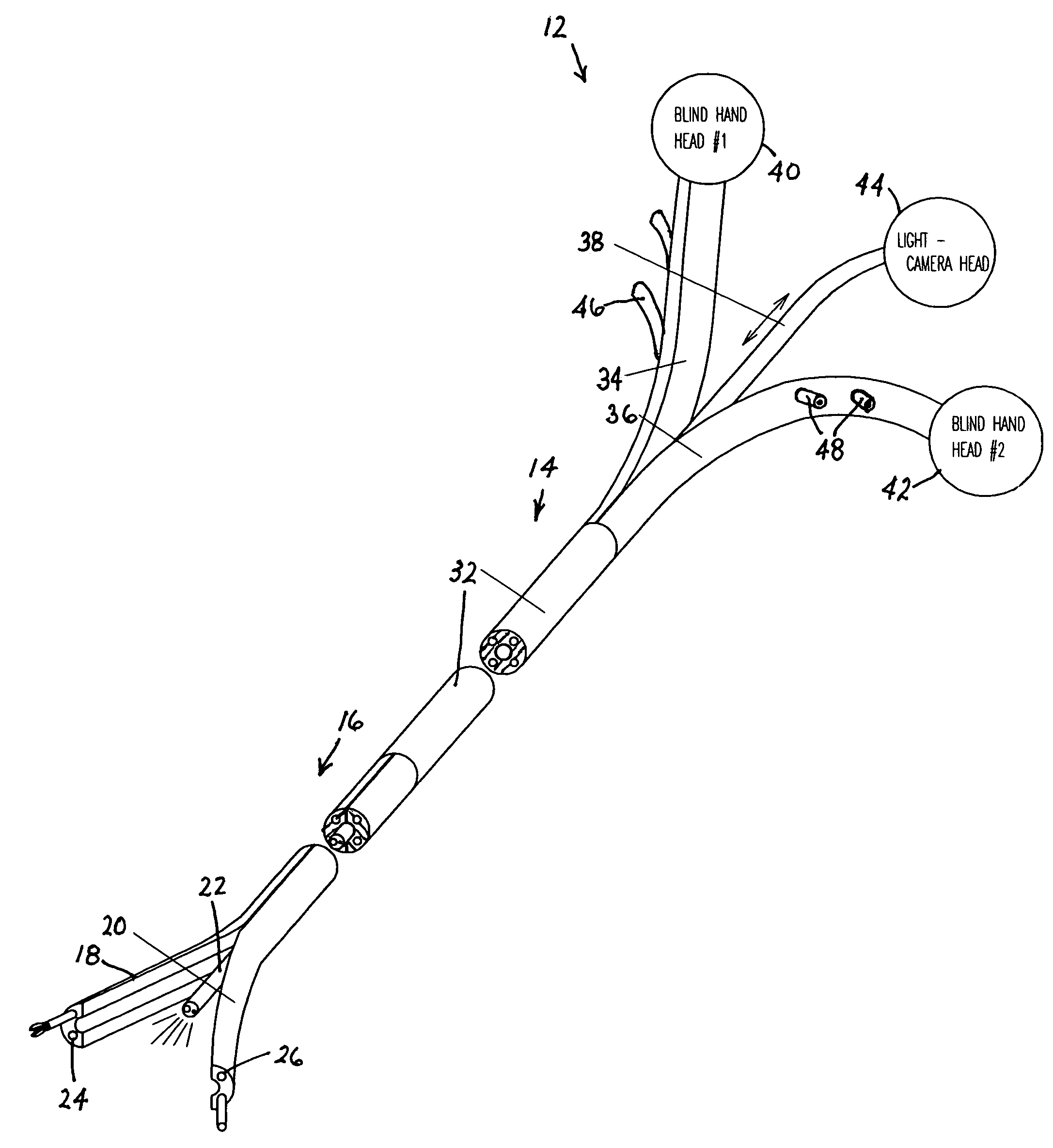

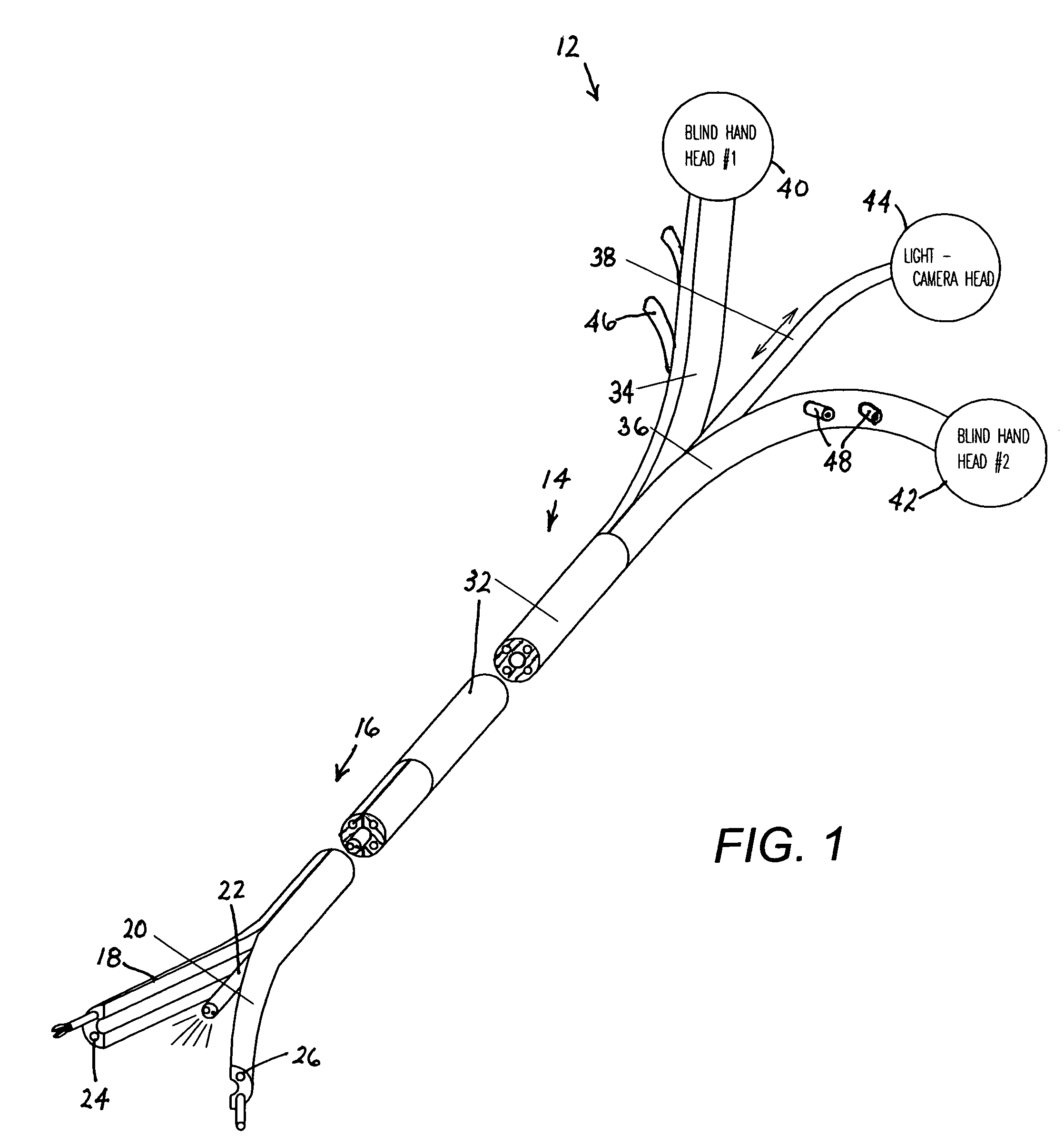

Endoscope having multiple working segments

InactiveUS7029435B2Improve performanceEasy to insertSuture equipmentsCannulasEngineeringIntroduction procedure

A flexible fiberoptic endoscope has an insertion member with a distal end portion split longitudinally into a plurality of independently operable working segments each provided with at least one longitudinally extending working channel. Visualization optics are provided in the working segments or a separate central segment surrounded by the working segments. A sheath temporarily joins the working segments to one another during an introduction procedure. The sheath is removed upon insertion of the endoscope, so that the working segments may be / separated from one another and independently maneuvered via proximal control heads to facilitate the performance of an endoscopic surgical procedure.

Owner:GRANIT MEDICAL INNOVATION

Tool member cover and cover deployment device

Owner:COVIDIEN LP

Instrument introducer

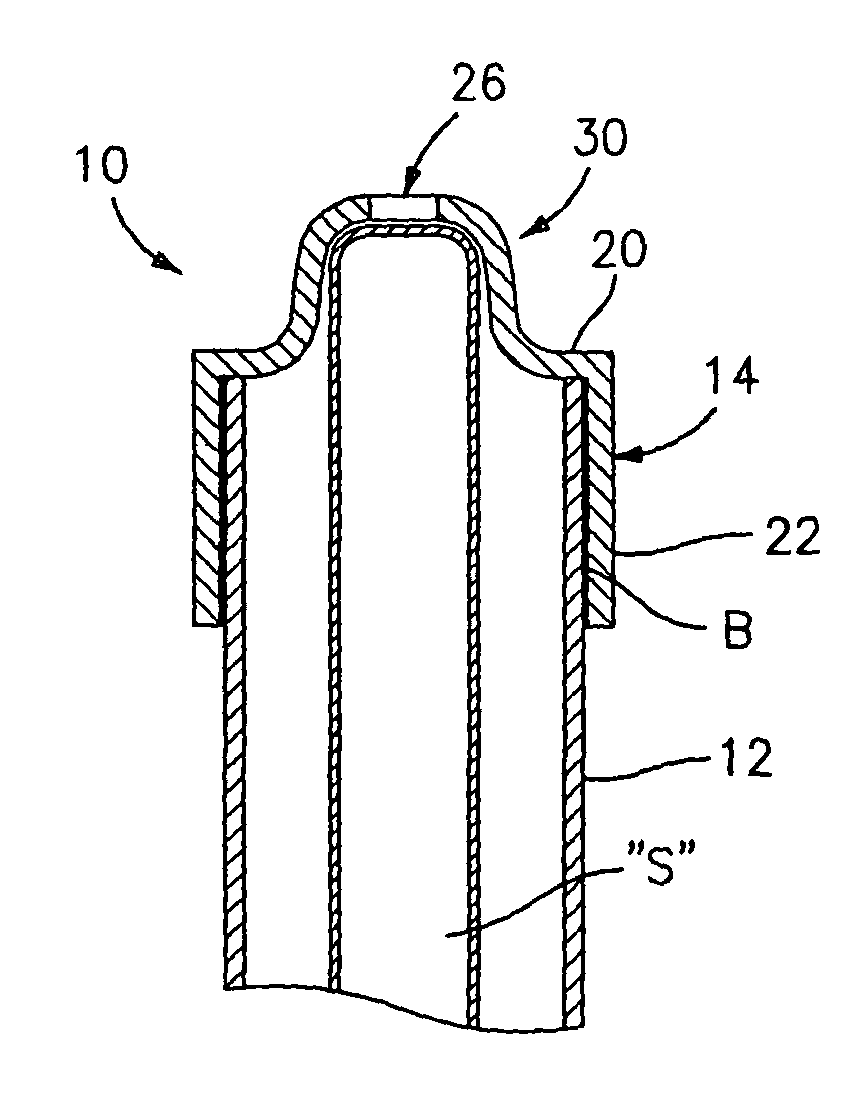

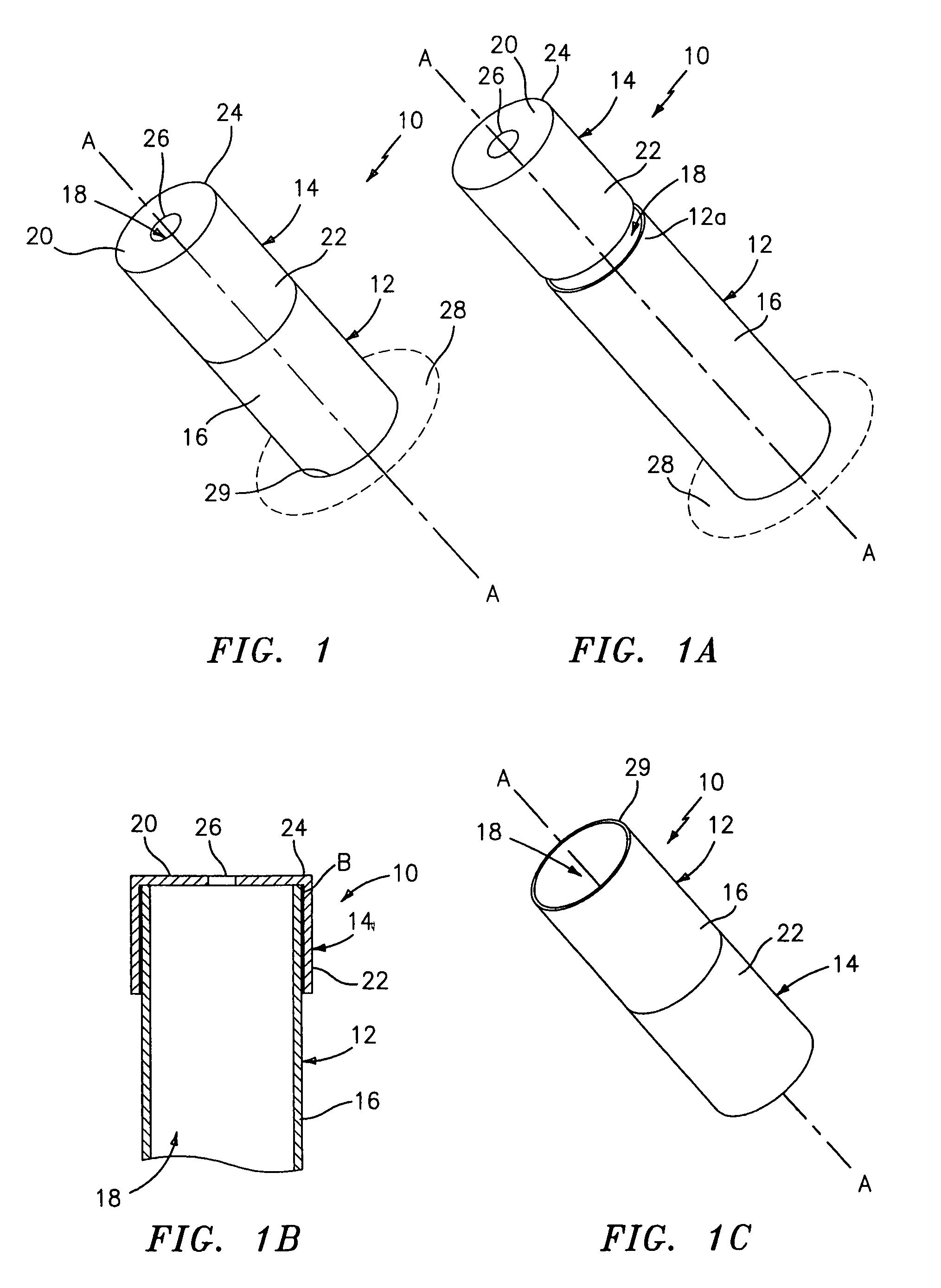

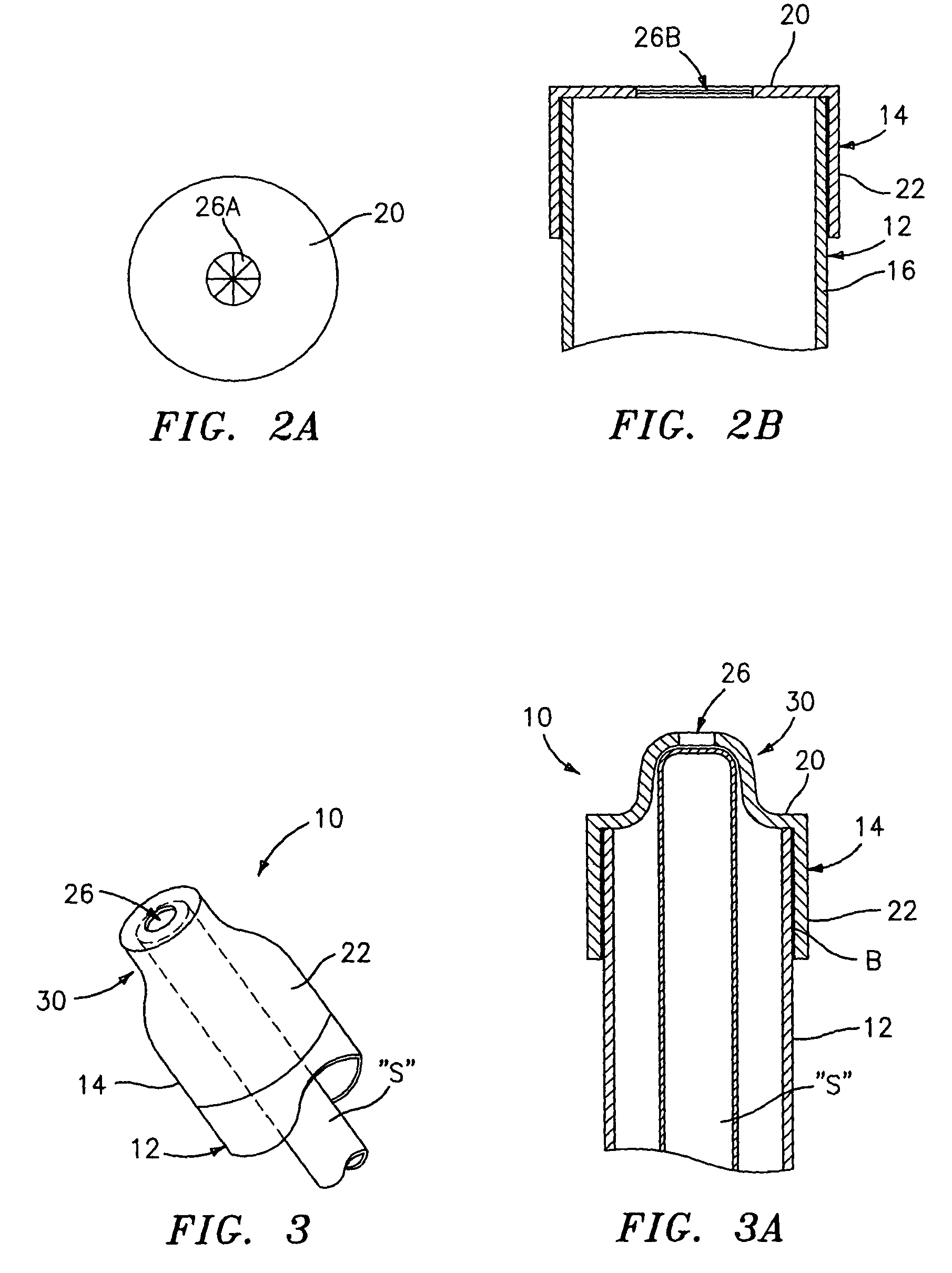

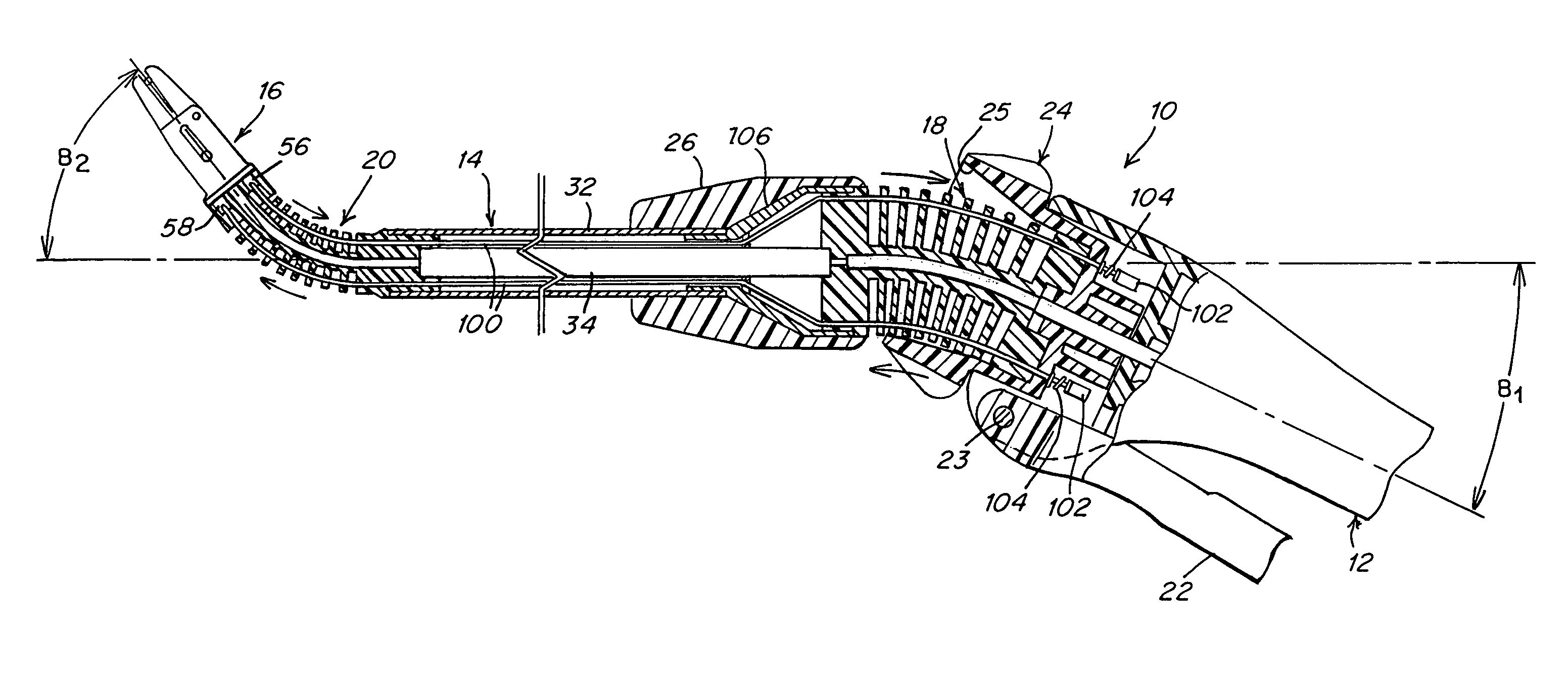

InactiveUS7846149B2Easy to insertLower potentialInternal osteosythesisCannulasDistal portionSurgical device

Instrument introducers are disclosed which facilitate the insertion of a surgical instrument into a cavity or a body of a patient. In one embodiment, the instrument introducer includes a hollow elongate cylindrical body including a distal end portion terminating in a distal edge and a proximal end portion, the cylindrical body defining a central longitudinal axis, and an elastomeric cap secured to the distal end portion of the cylindrical body, the cap including a distal end wall having an outer terminal edge and an annular side wall depending from the outer terminal edge thereof. The distal end wall includes an aperture formed therein, wherein a center of the aperture is coaxially aligned with the central longitudinal axis.

Owner:TYCO HEALTHCARE GRP LP

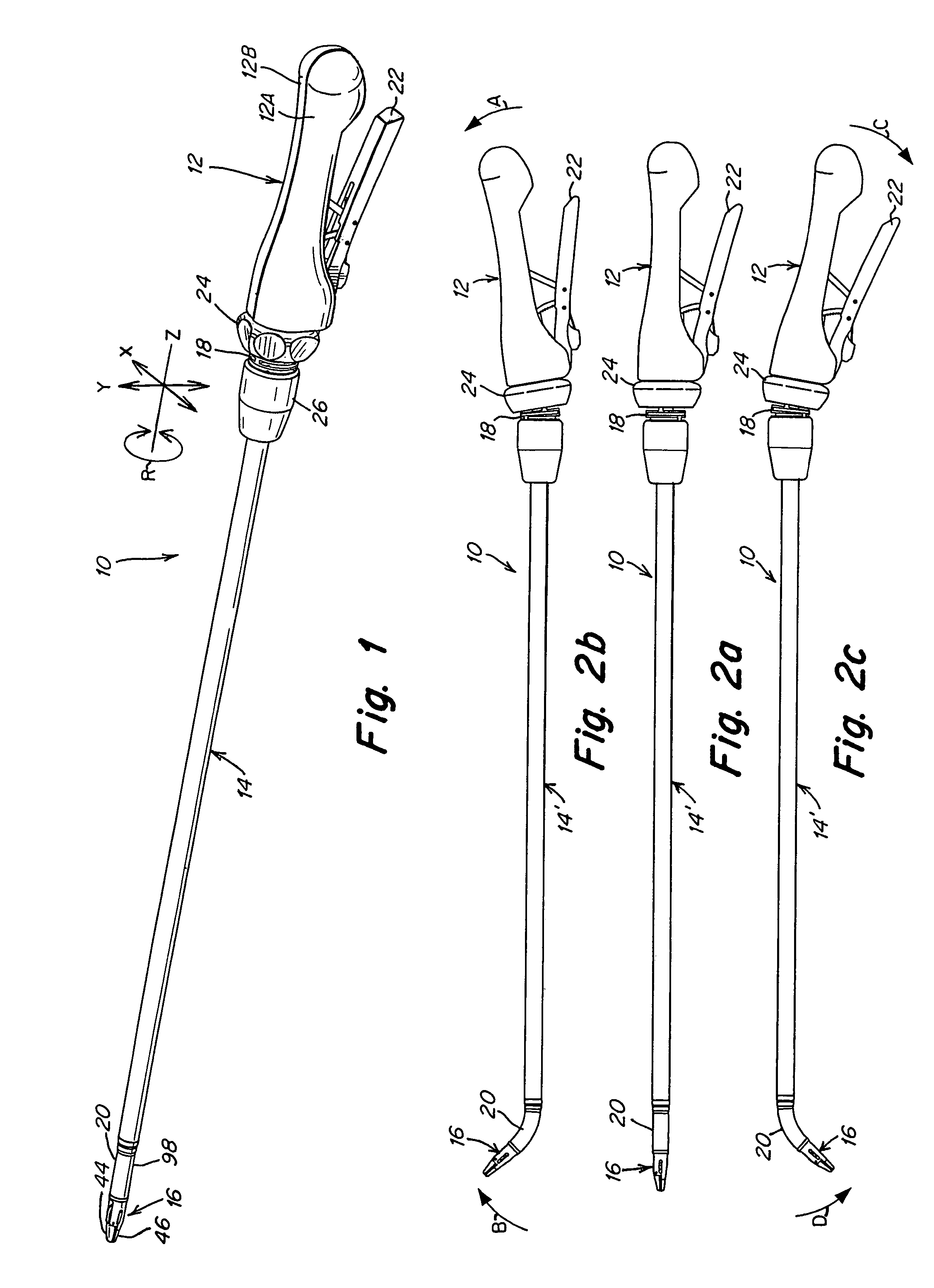

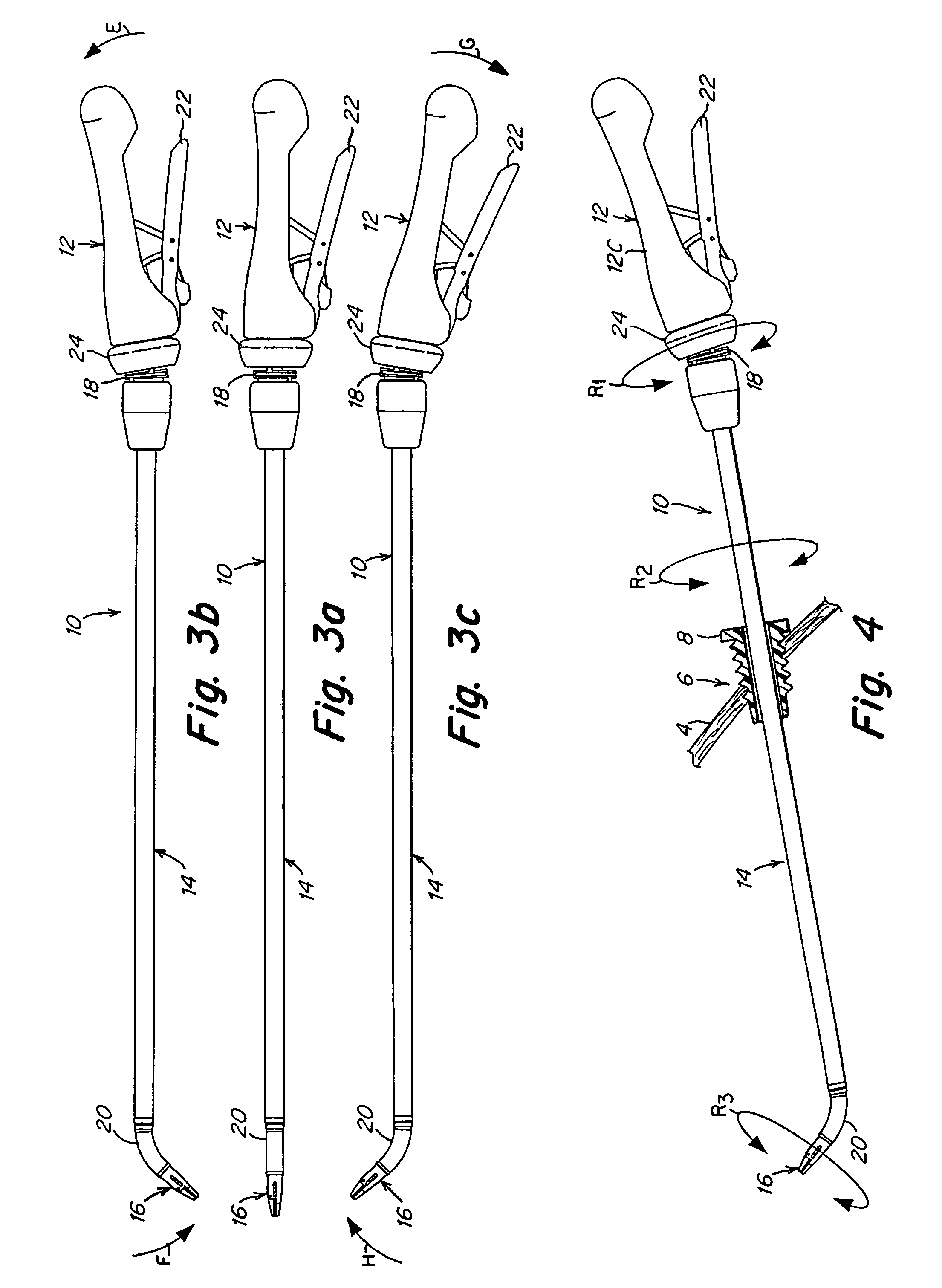

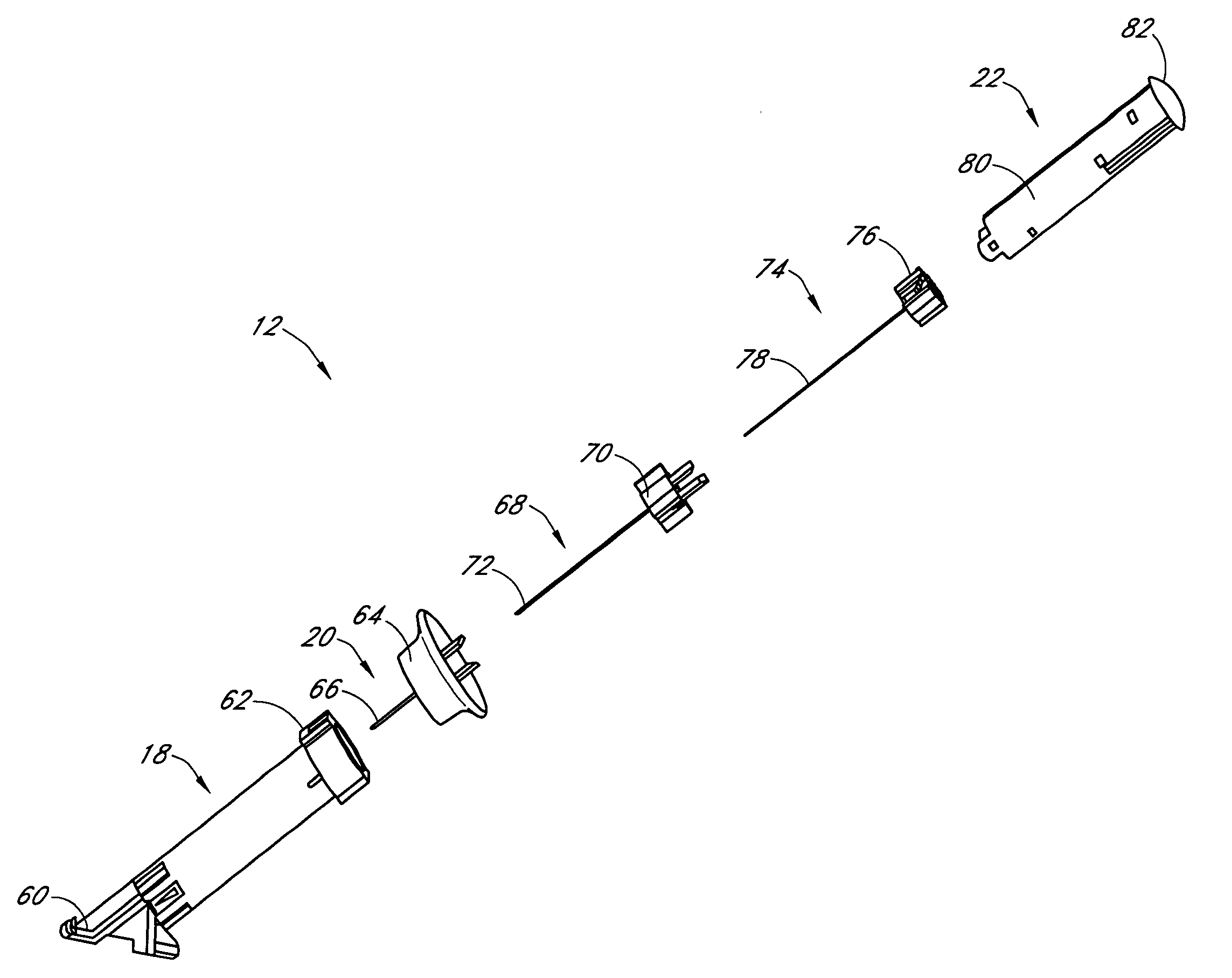

Surgical instrument

The surgical instrument includes a distal tool, a rigid or flexible elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. A manually rotatable member is arranged adjacent to the control handle for manually rotating the instrument shaft and working member relative to the control handle.

Owner:ENDOBOTICS LLC

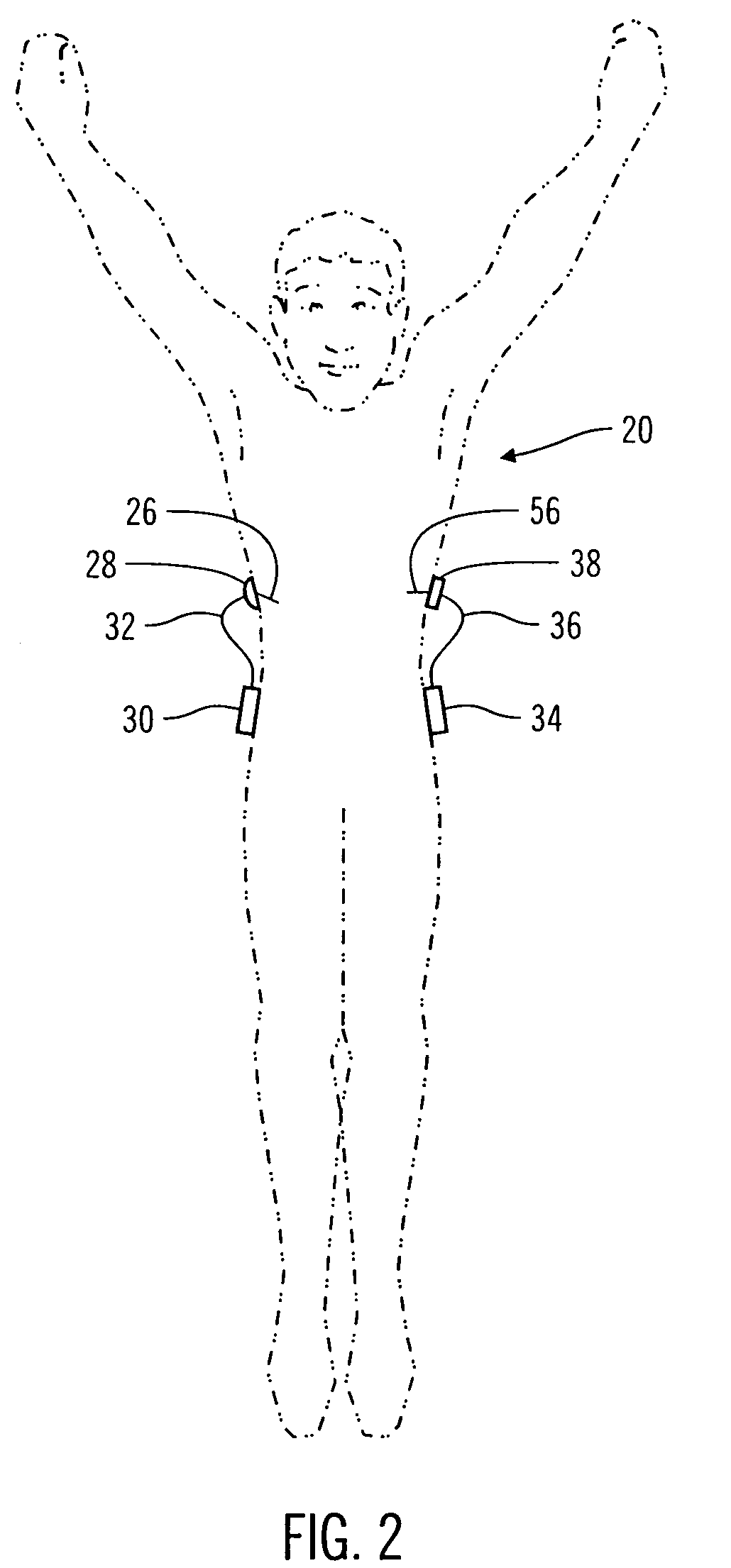

Methods and systems for inserting a transcutaneous analyte sensor

The present invention relates generally to systems and methods for measuring an analyte in a host. More particularly, the present invention relates to systems and methods for transcutaneous measurement of glucose in a host.

Owner:DEXCOM INC

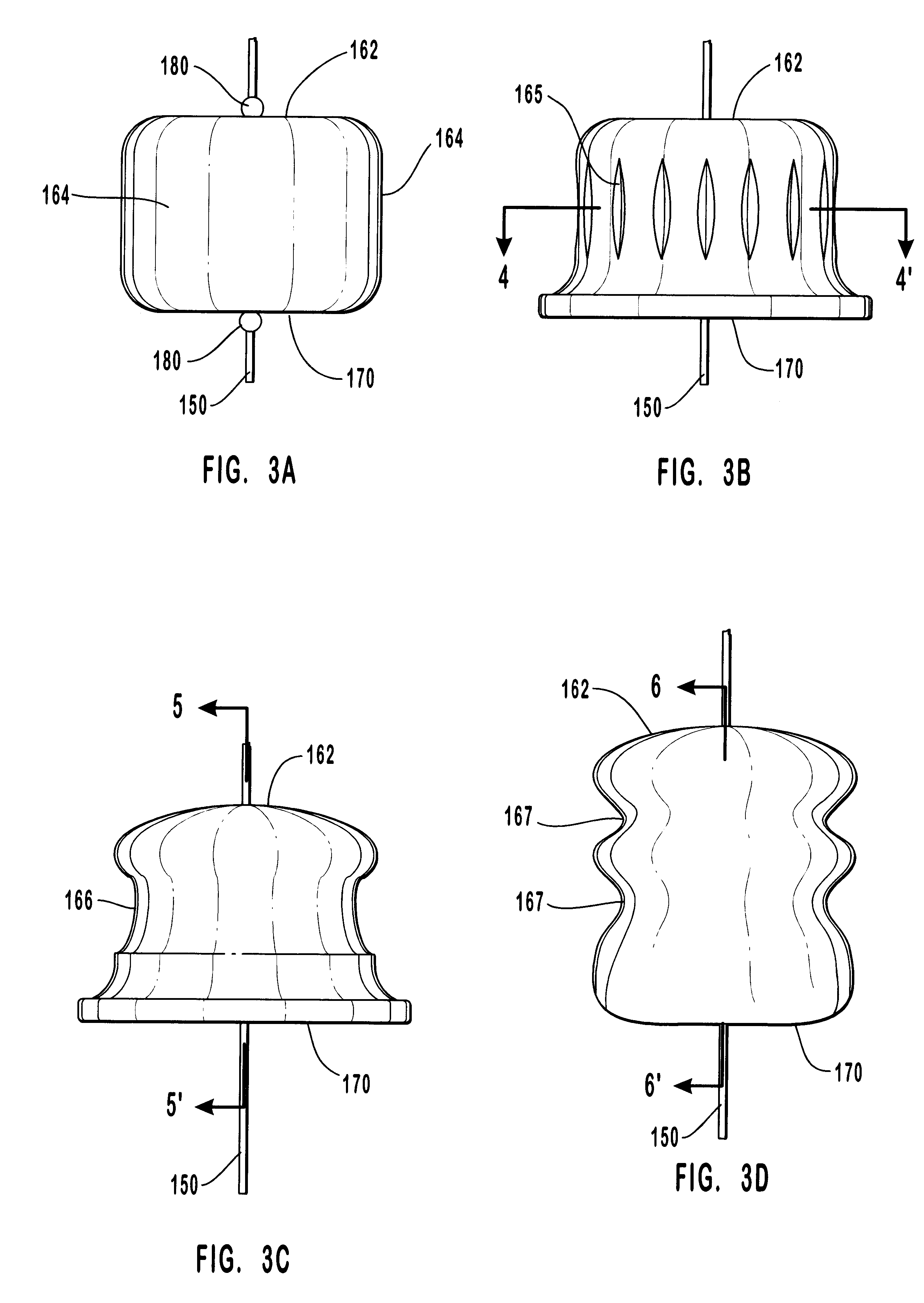

Sealed surgical access device

InactiveUS7052454B2” laparoscopy is greatly facilitatedFulfil requirementsEar treatmentCannulasCouplingEngineering

A surgical access device is adapted to facilitate access through an incision in a body wall having an inner surface and an outer surface, and into a body cavity of a patient. The device includes first and second retention members adapted to be disposed in proximity to the outer surface and the inner surface of the body wall, respectively. A membrane extending between the two retention members forms a throat which is adapted to extend through the incision and form a first funnel extending from the first retention member into the throat, and a second funnel extending from the second retention member into the throat. The throat of the membrane has characteristics for forming an instrument seal in the presence of an instrument and a zero seal in the absence of an instrument. The first retention member may include a ring with either a fixed or variable diameter. The ring can be formed in first and second sections, each having two ends. Couplings can be disposed between the ends to accommodate variations in the size of the first retention member. The first retention member can also be formed as an inflatable toroid, a self-expanding foam, or a circumferential spring. A plurality of inflatable chambers can also provide the surgical access device with a working channel adapted for disposition across the body wall. A first retention member with a plurality of retention stations functions with a plurality of tethers connected to the membrane to change the shape of the membrane and the working channel. A stabilizing platform can be used to support the access device generally independent of any movement of the body wall.

Owner:APPL MEDICAL RESOURCES CORP

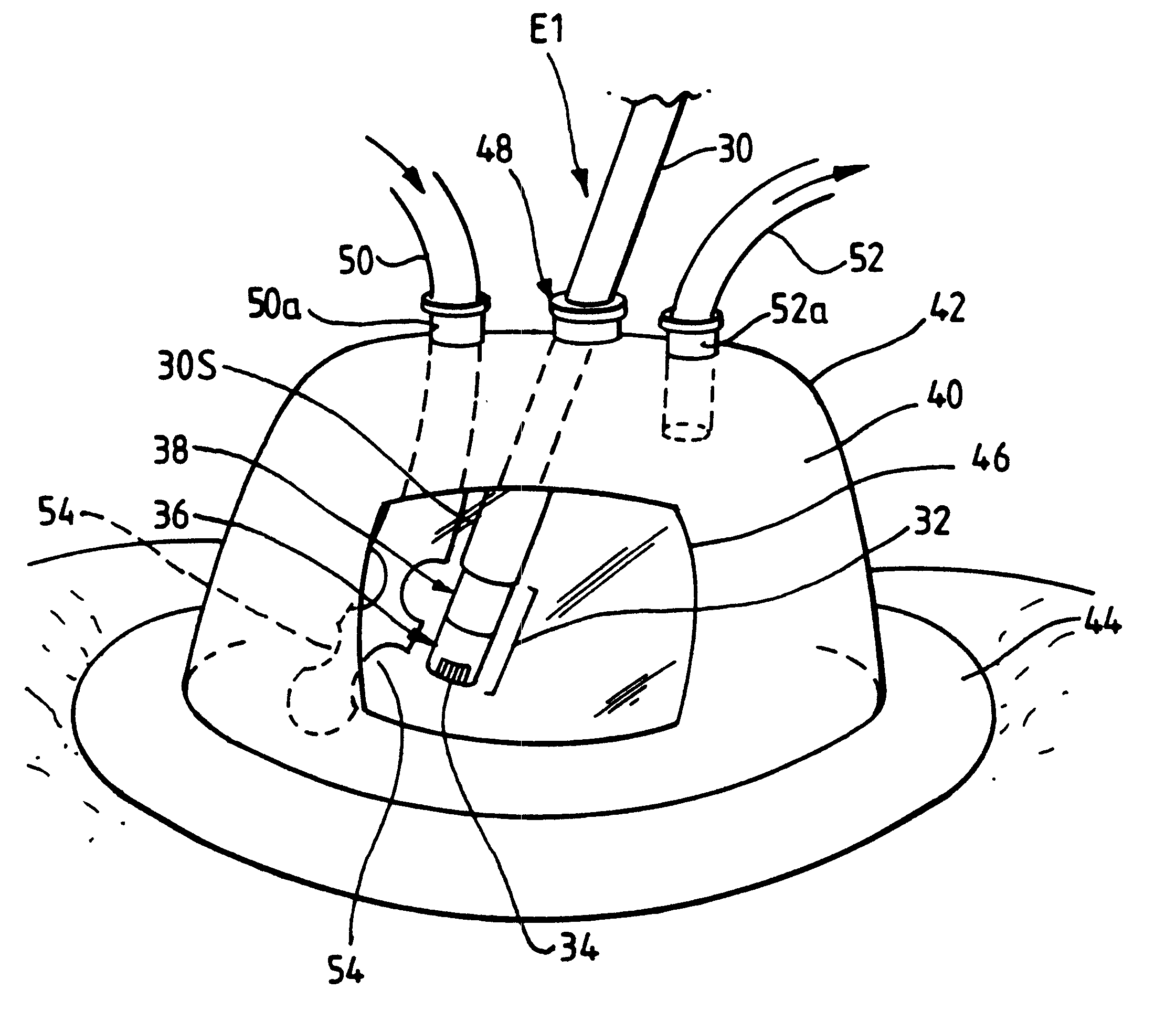

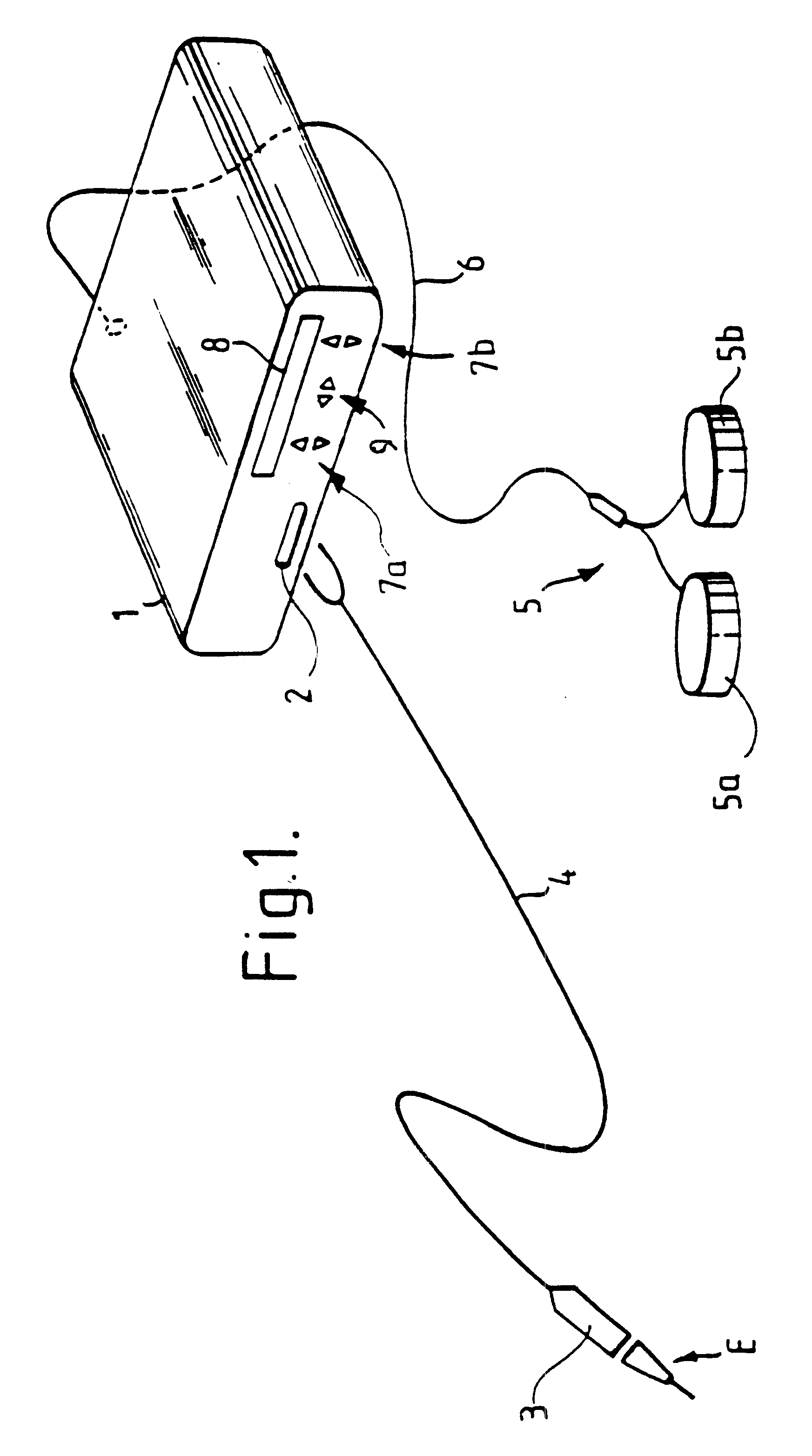

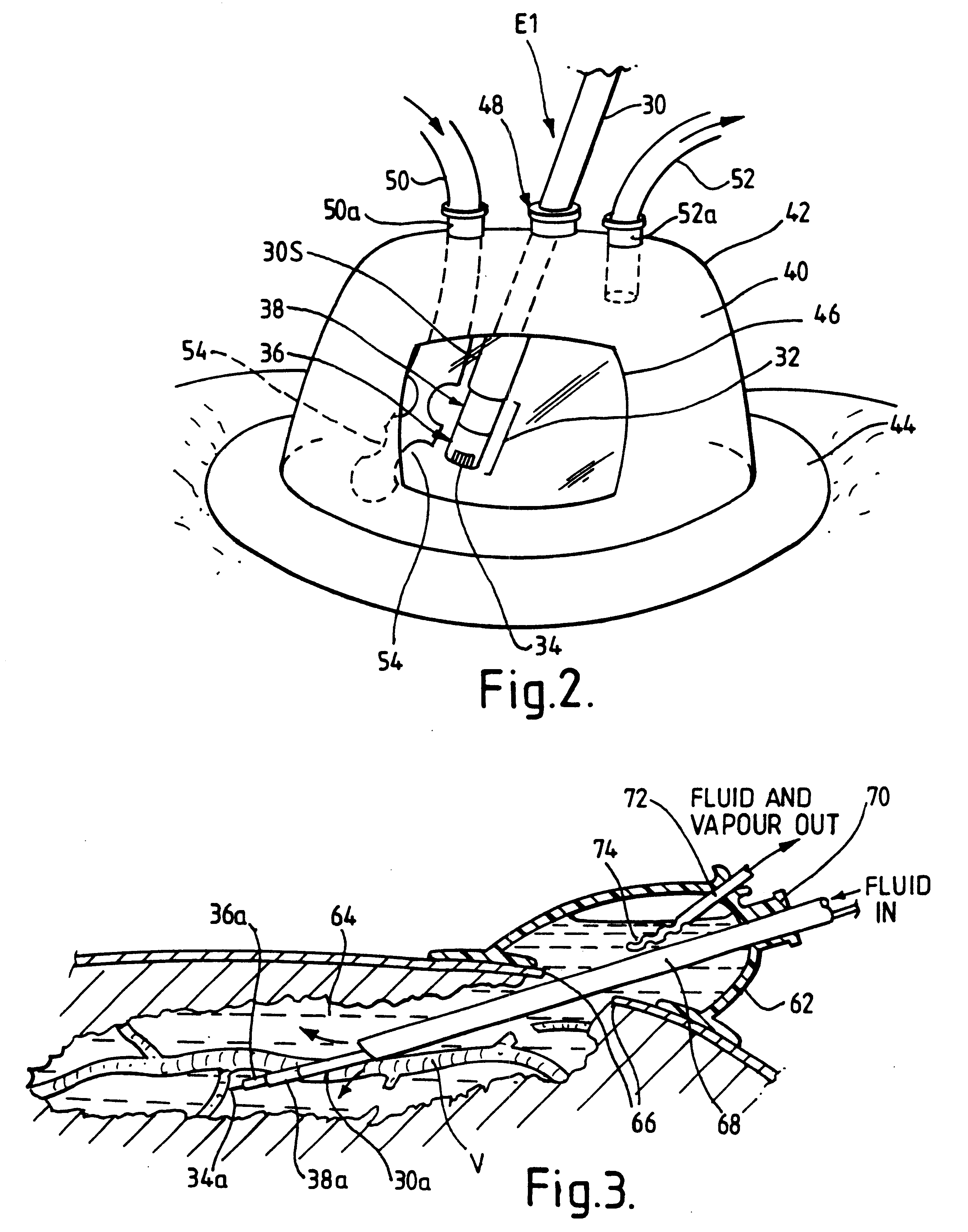

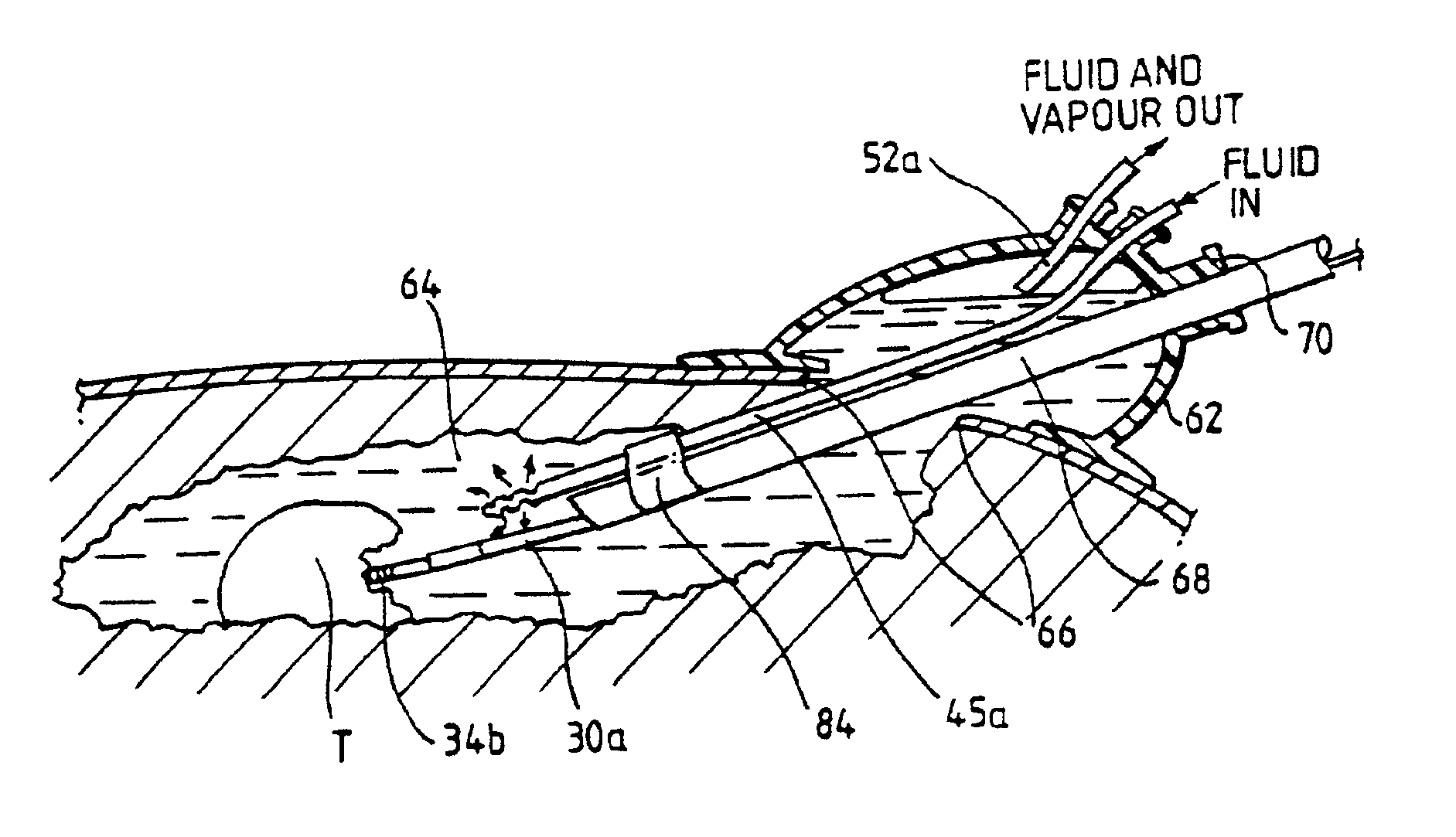

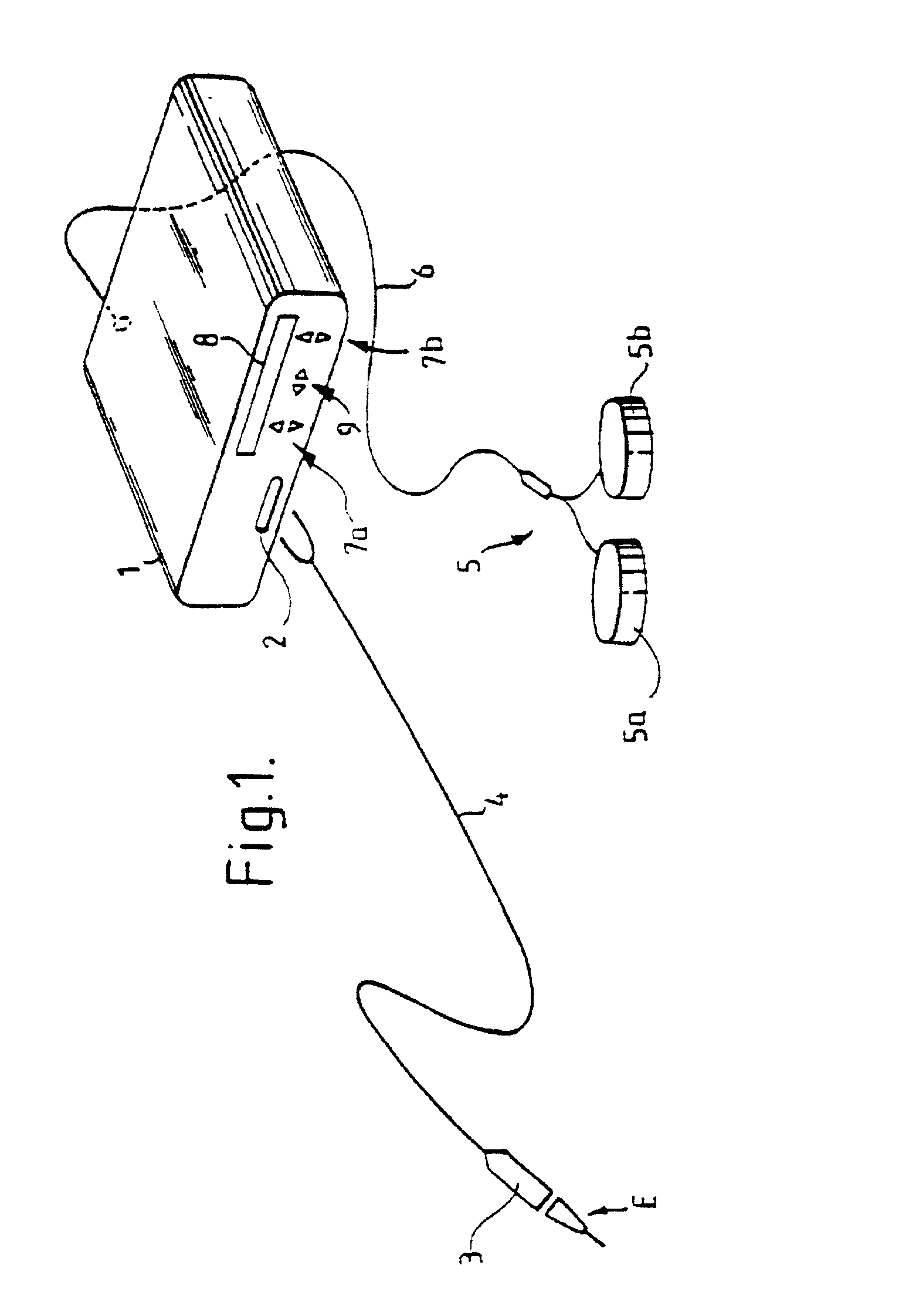

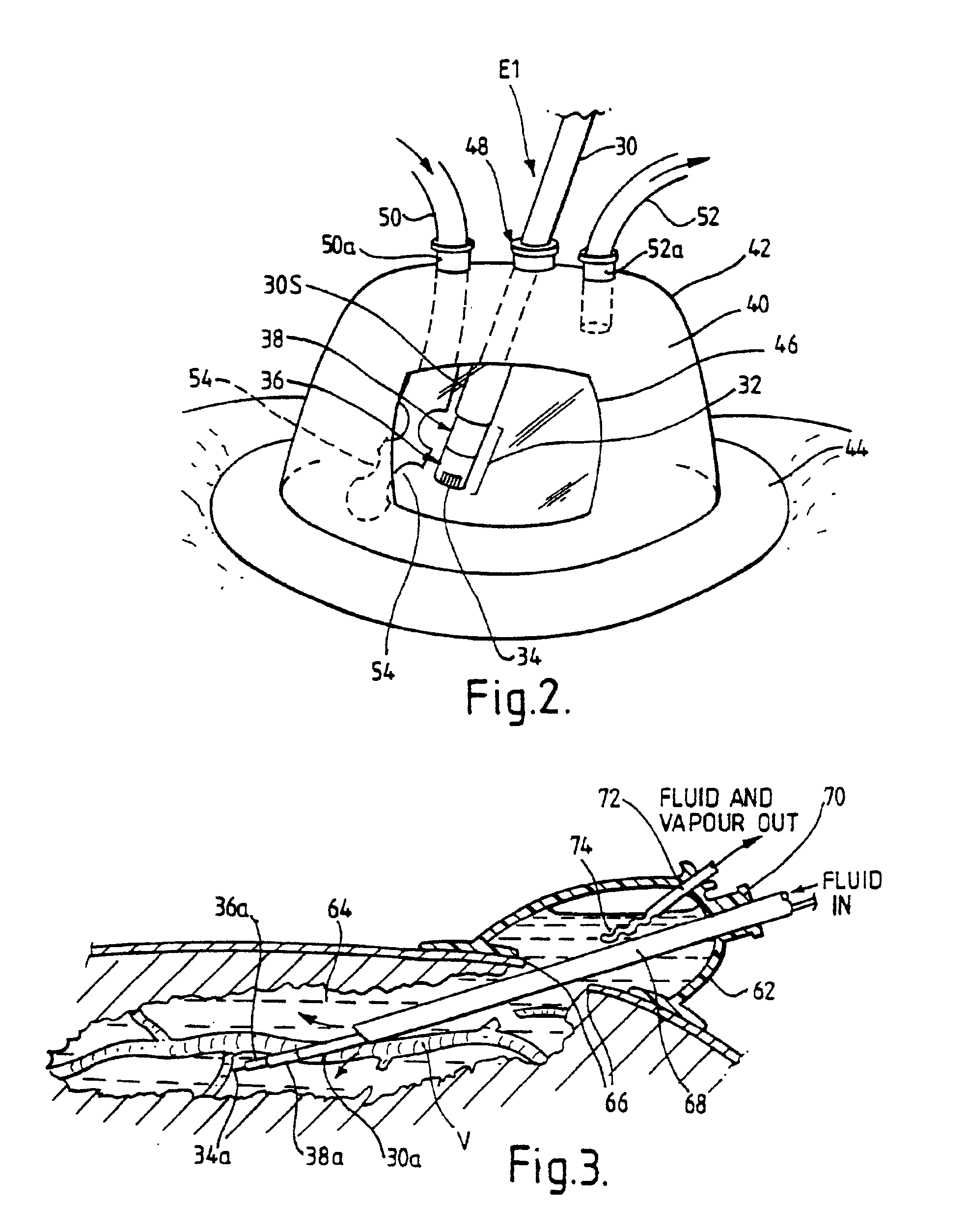

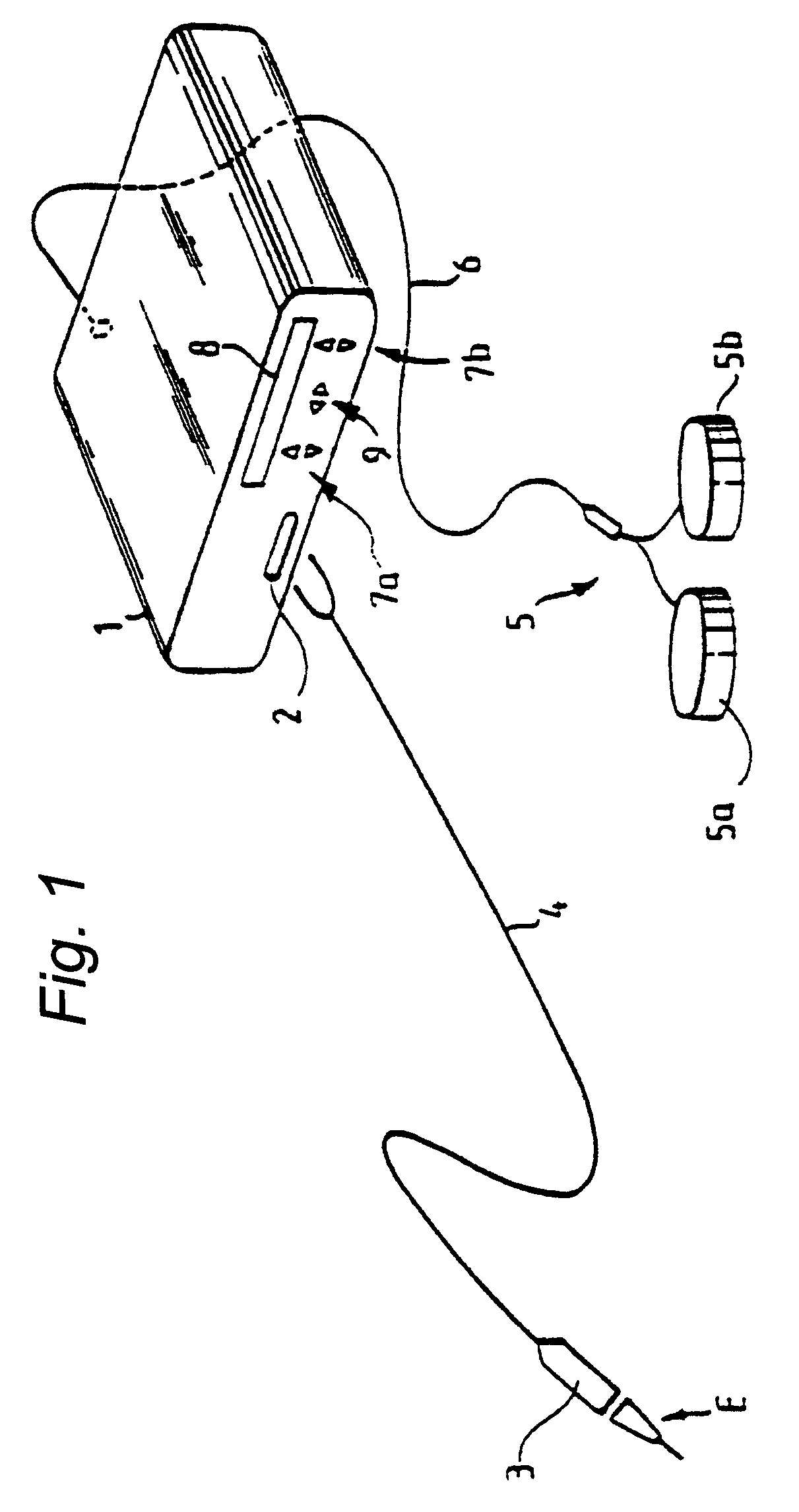

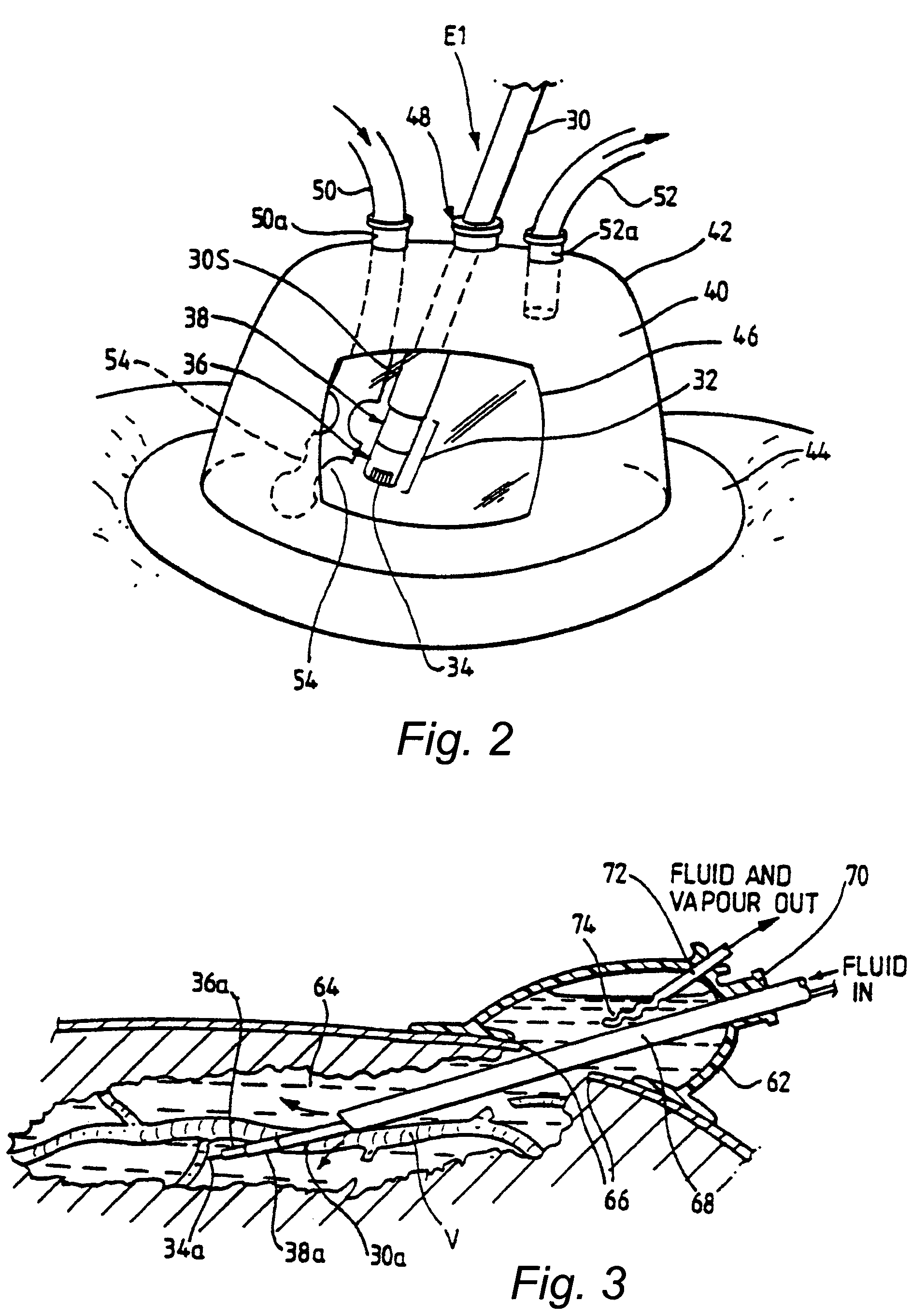

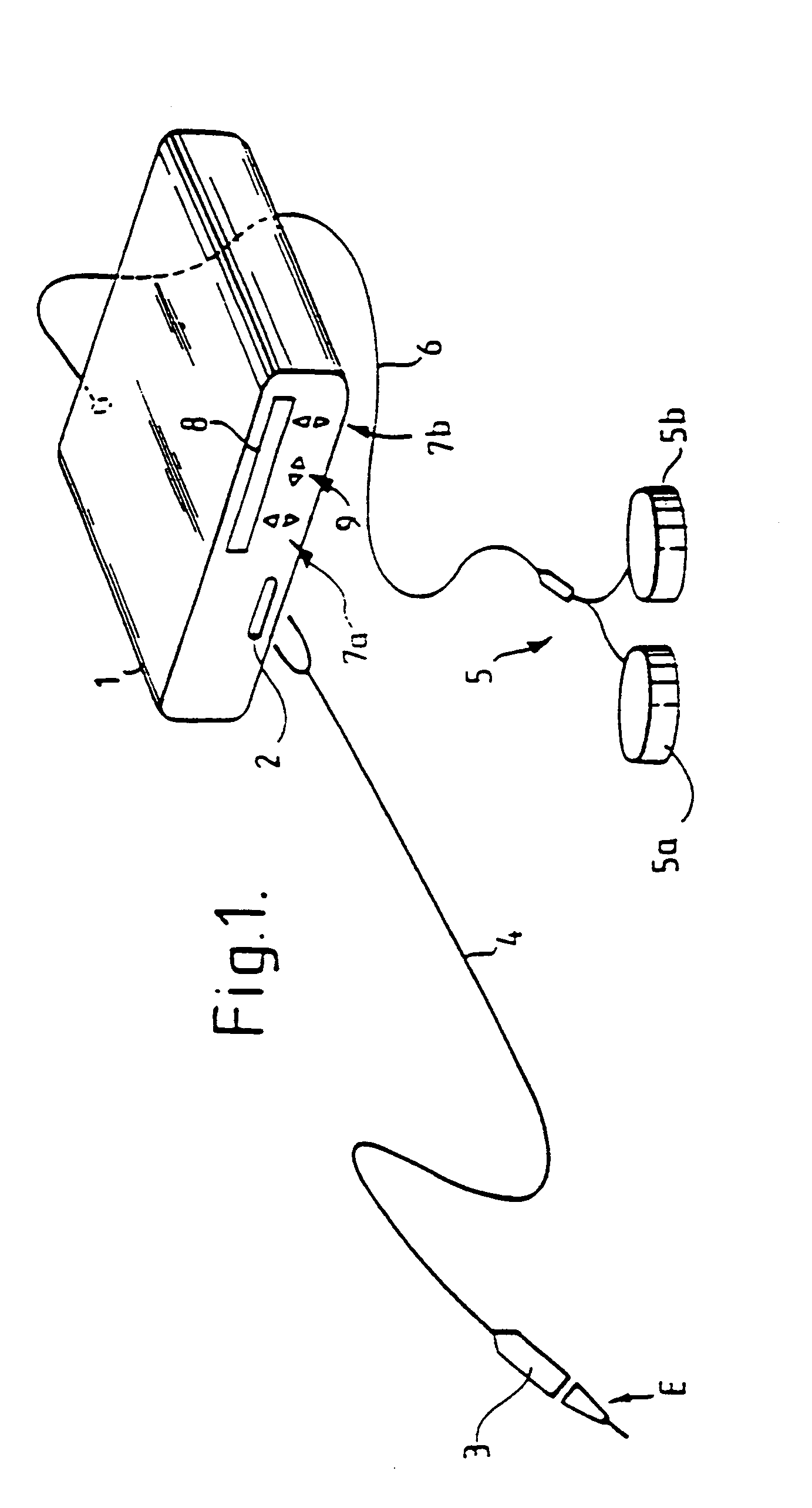

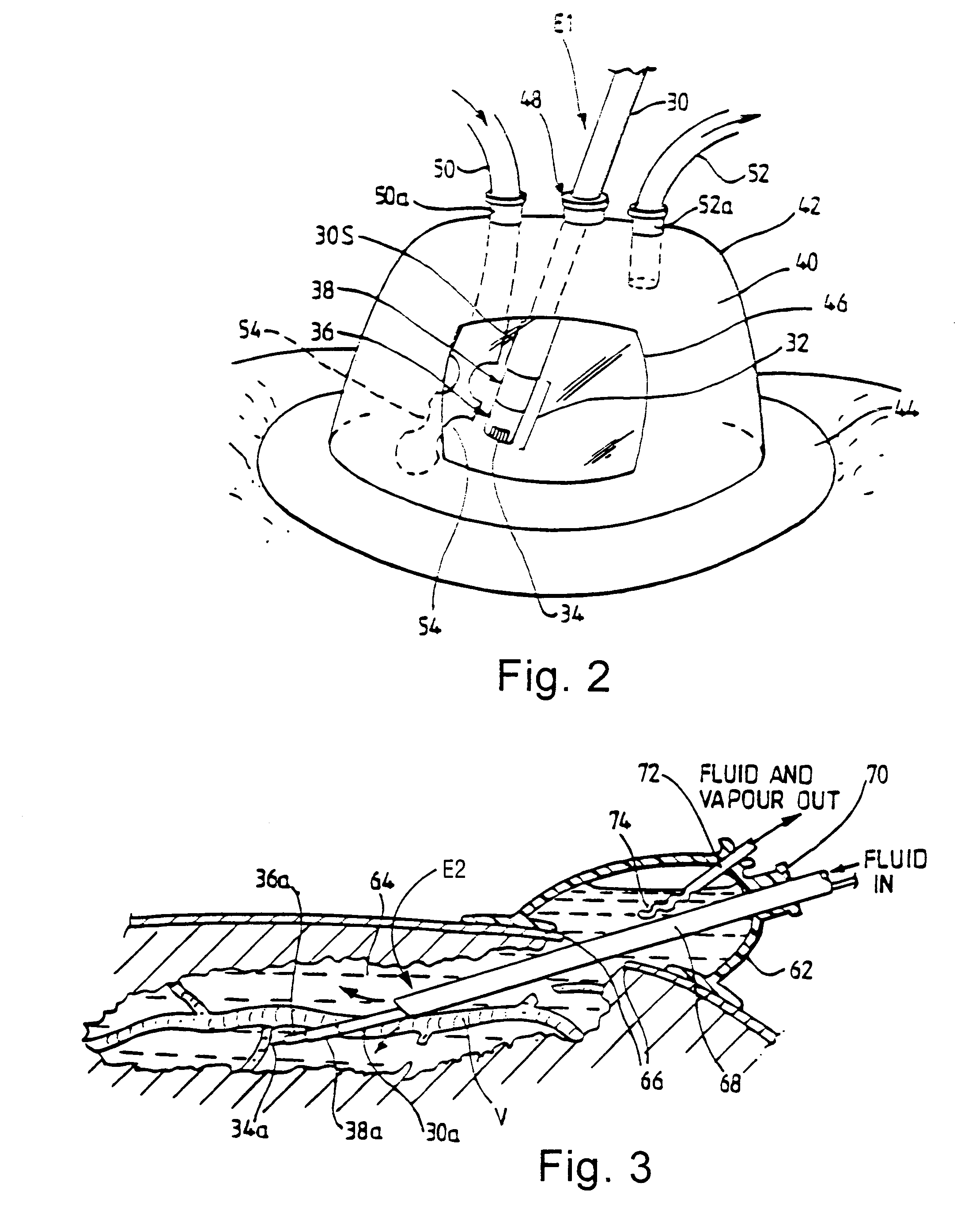

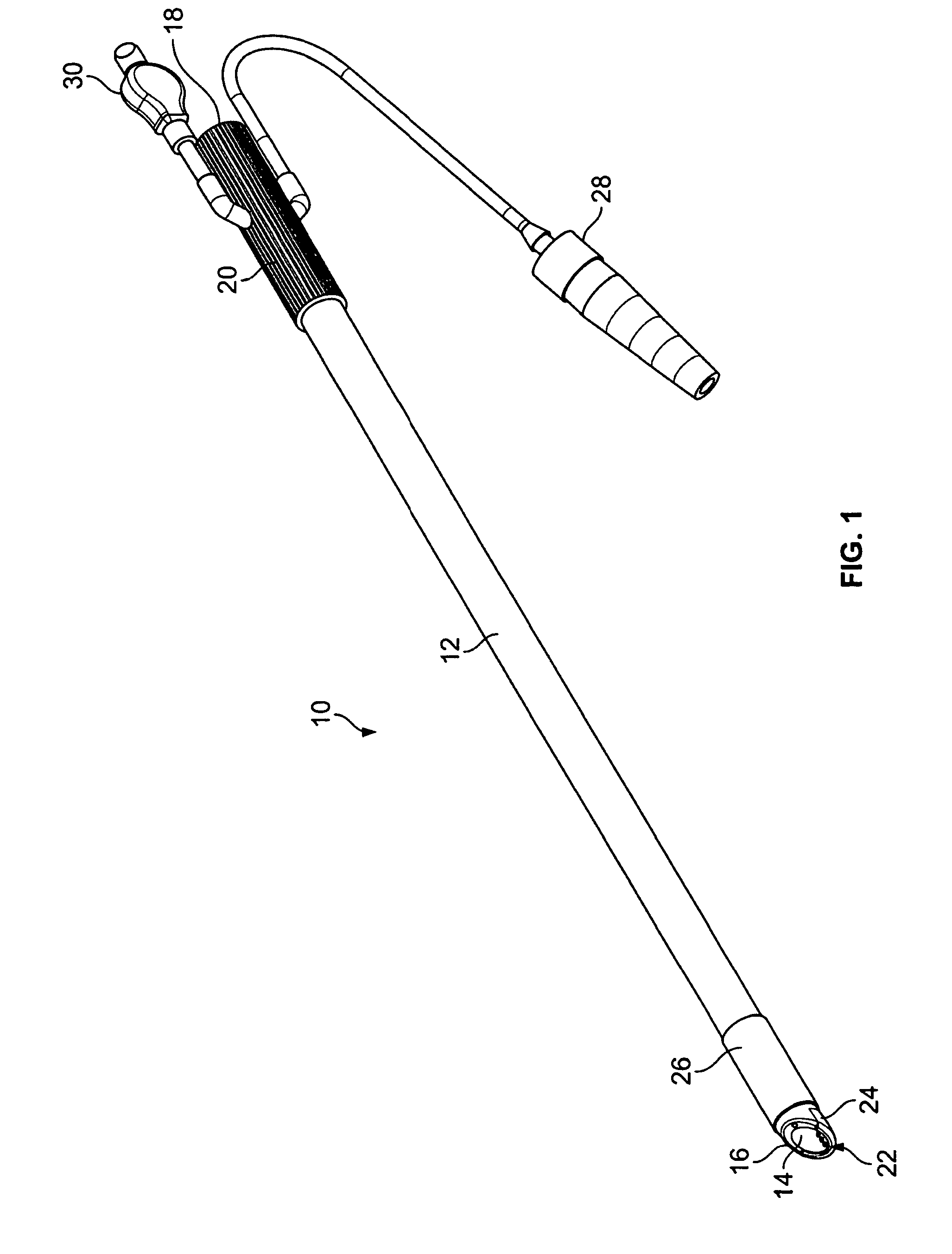

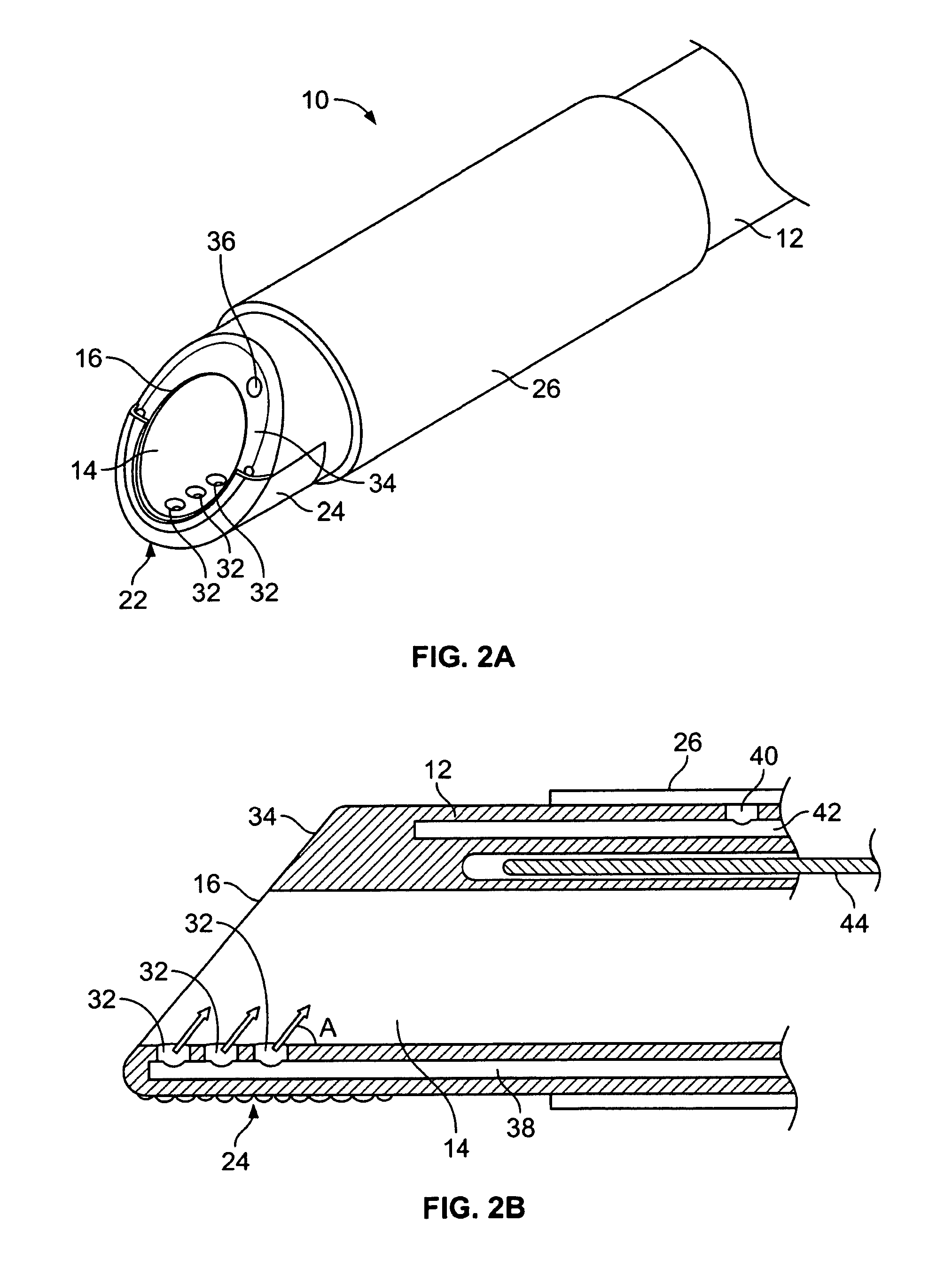

Electrosurgical system

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure.

Owner:GYRUS MEDICAL LTD

Surgical instrument

A surgical instrument that includes an instrument shaft having proximal and distal ends, a tool disposed from the distal end of the instrument shaft, a control handle disposed from the proximal end of the instrument shaft, a distal motion member for coupling the distal end of the instrument shaft to the tool, a proximal motion member for coupling the proximal end of the instrument shaft to the handle, actuation means extending between the distal and proximal motion members for coupling motion of the proximal motion member to the distal motion member for controlling the positioning of the tool and a locking mechanism for fixing the position of the tool at a selected position and having locked and unlocked states.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES INC

Device for advancing a functional element through tissue

This invention relates to an apparatus for incrementally advancing functional probes through tissue.

Owner:DEPUY ACROMED INC

Electrosurgical system and method

An electrosurgical system comprises a radio frequency generator (1), an electrosurgical instrument (E1), and a fluid enclosure (42). The generator (1) has a radio frequency output for delivery of power to the electrosurgical instrument (E1) when immersed in an electrically-conductive fluid. The electrosurgical instrument (E1) has an electrode assembly (32) at the distal end thereof, the electrode assembly comprising a tissue treatment electrode (34), and a return electrode (38) axially spaced therefrom in such a manner as to define, in use, a conductive fluid path that completes an electrical circuit between the tissue treatment electrode and the return electrode. The fluid enclosure (42) is adapted to surround an operation site on the skin of a patient or an incision leading to a cavity surgically created within the patient's body. The fluid enclosure (42) includes sealing means (44) for sealing against the patient's tissue, and the fluid enclosure includes at least one port (50a, 52a) through which the electrosurgical (E1) is insertable, and through which the electrically-conductive fluid can enter and / or leave the enclosure. The fluid enclosure device of the present invention can also be used to treat tumours within the colon. The enclosure, which includes a proximal and a distal bung, is inserted into the colon in a deflated condition and then inflated with a conductive fluid or gas. The colon can be supported against the pressure of the fluid or gas with a pressure sleeve that has been inserted to surround the region of the colon being treated. An electrosurgical instrument is then inserted into the colon and manipulated to vaporize the tumor.

Owner:GYRUS MEDICAL LTD

Electrosurgical instrument

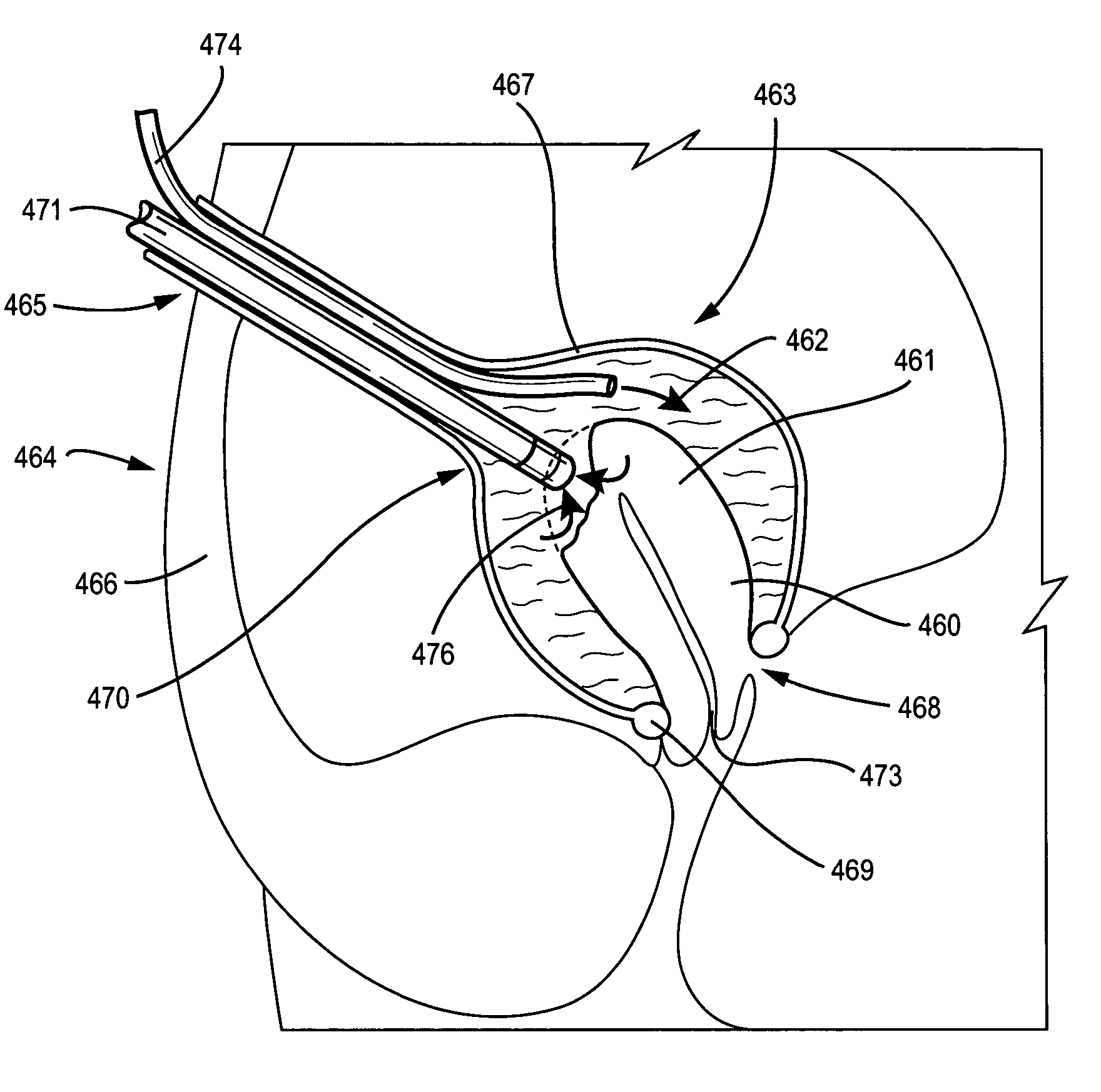

InactiveUS7278994B2Lower impedanceReduced effectivenessCannulasDiagnosticsGynecologyPeritoneal cavity

A system and method are disclosed for removing a uterus using a fluid enclosure inserted in the peritoneal cavity of a patient so as to enclose the uterus. The fluid enclosure includes a distal open end surrounded by an adjustable loop, that can be tightened, a first proximal opening for inserting an electrosurgical instrument into the fluid enclosure, and a second proximal opening for inserting an endoscope. The loop is either a resilient band extending around the edge of the distal open end or a drawstring type of arrangement that can be tightened and released. The fluid enclosure is partially inserted into the peritoneal cavity of a patient in a deflated condition and then manipulated within the peritoneal cavity over the body and fundus of the uterus to the level of the uterocervical junction. The loop is tightened around the uterocervical junction, after which the enclosure is inflated using a conductive fluid. The loop forms a pressure seal against the uterocervical junction to contain the conductive fluid used to fill the fluid enclosure. Endoscopically inserted into the fluid enclosure is an electrosurgical instrument that is manipulated to vaporize and morcellate the fundus and body of the uterus. The fundus and body tissue that is vaporized and morcellated is then removed from the fluid enclosure through the shaft of the instrument, which includes a hollow interior that is connected to a suction pump The fundus and body are removed after the uterus has been disconnected from the tissue surrounding uterus.

Owner:GYRUS MEDICAL LTD

Medical device introducer and obturator

An introducer having an elongate tubular member and a device connector releasably attached to a proximal end of the tubular member. The introducer allows exchange of medical instruments, such as a blood filter and cardioplegia catheter, through a single lumen. An obturator having a retractable blade for making incision on a tissue is insertable through the lumen of the introducer. Methods of using the obturator and the introducer for introducing medical device(s) into body cavity, such as a vessel or cardiac tissue, are also disclosed.

Owner:EDWARDS LIFESCIENCES CORP

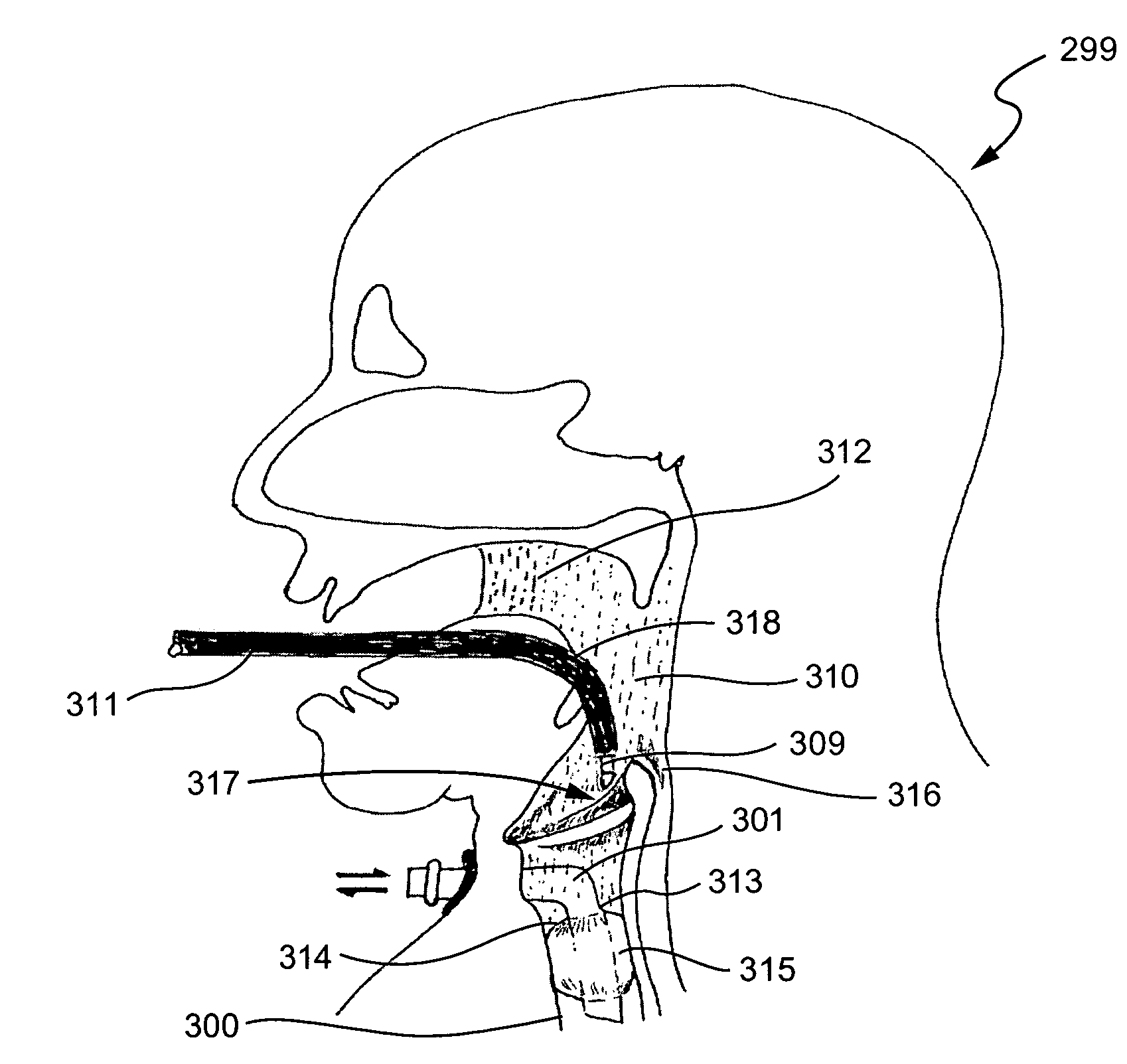

Electrosurgical system and method

InactiveUS7001380B2Lower impedanceMinimizing char formationCannulasDiagnosticsBenign conditionEnlarged tonsils

A method is disclosed for treating benign conditions, such as enlarged tonsils and / or adenoids located in a patient's throat or nasopharynx, or soft tissue lesions located in a patient's oropharynx or larynx. According to the method, a space containing the patient's nasopharynx, oropharynx or pharynx and larynx is isolated from the patient's trachea and lungs using an inflatable cuff tracheostomy tube or nasotracheal tube inserted in the patient's trachea. The cuff is inflated to occlude the trachea. The patient is placed in a supine position, whereupon at least a portion of the space containing the nasopharynx and / or oropharynx and larynx is filled with saline. An endoscope is then inserted into the space to view the operative site in which the tonsils or tissue lesion are to be treated. An electrosurgical instrument having an active tissue treatment electrode and a return electrode connected to an electrosurgical generator is then inserted into the space, either along side the endoscope or through the endoscope's working channel. The generator is then operated to apply a radio frequency voltage between the active and return electrodes of the electrosurgical instrument, whereby a conduction path is formed between the active and return electrodes, at least partially through the saline, whereupon the active electrode is manipulated to debulk or otherwise treat the soft tissue lesion or enlarged tonsils and / or adenoids.

Owner:GYRUS MEDICAL LTD

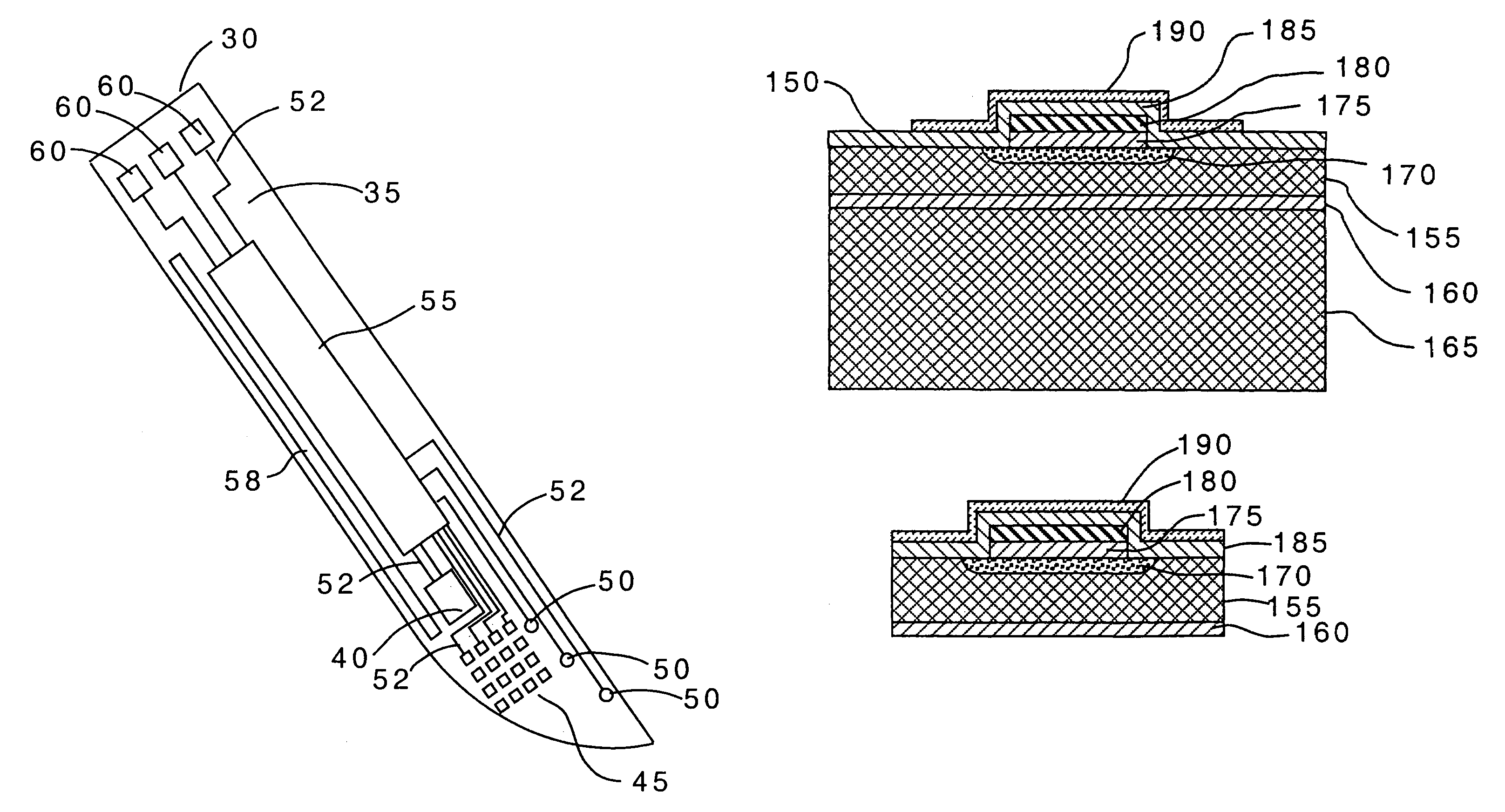

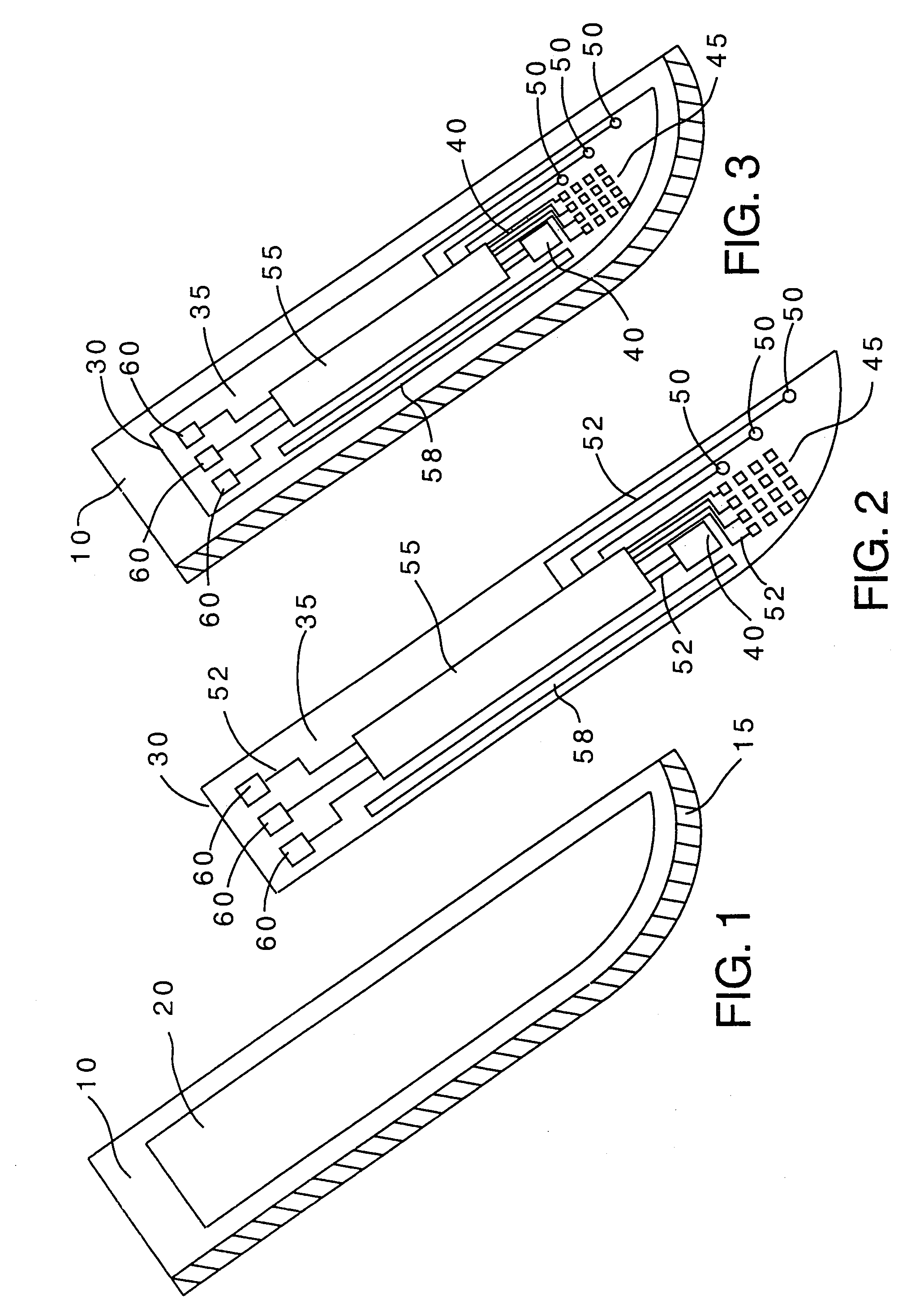

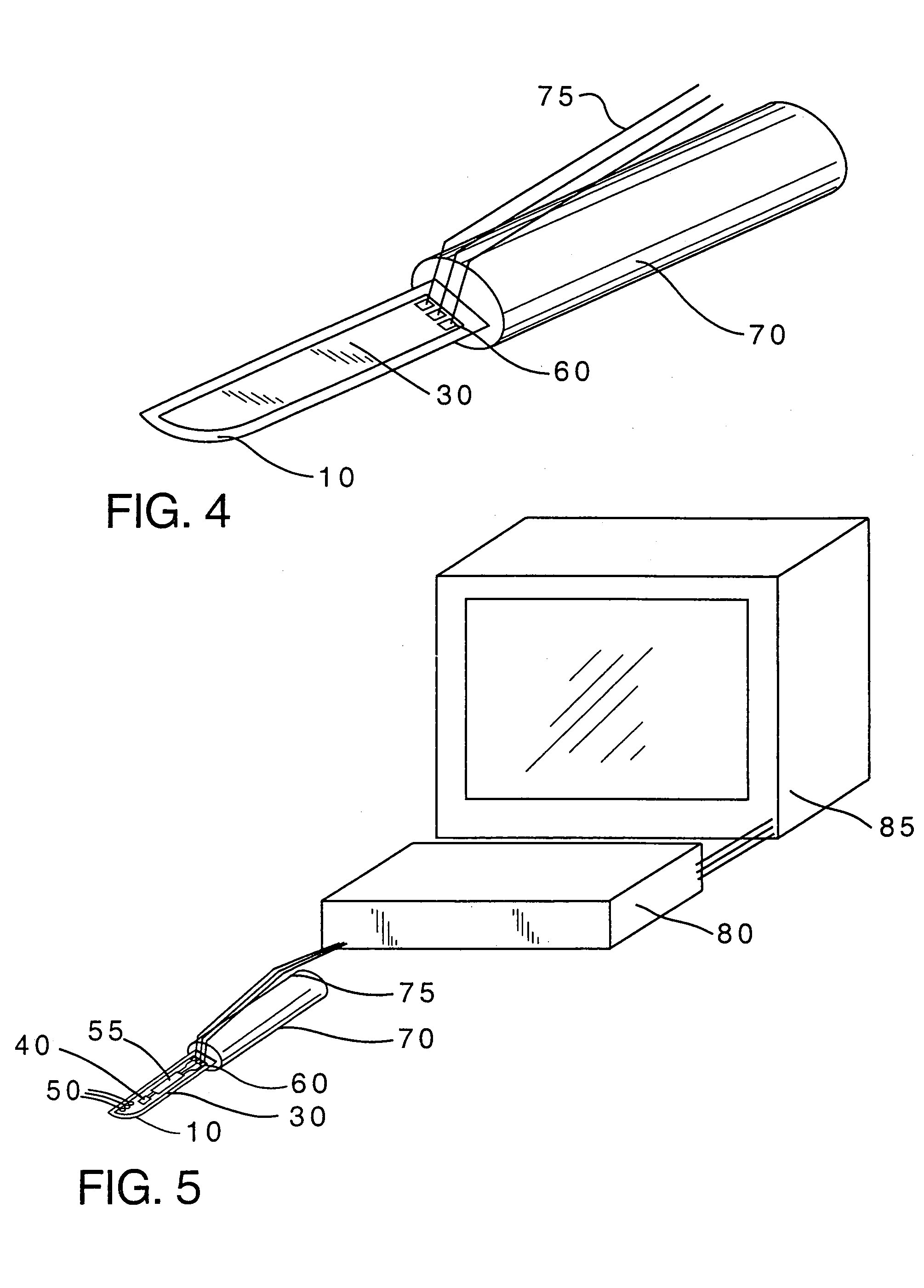

Method of making a cutting instrument having integrated sensors

A cutting instrument including a metal blade has a recess formed therein and a semiconductor substrate affixed to the blade in the recess. The semiconductor substrate includes at least one sensor formed thereon. The sensor formed on the semiconductor substrate may comprise at least one or an array of a strain sensors, pressure sensors, nerve sensors, temperature sensors, density sensors, accelerometers, and gyroscopes. The cutting instrument may also further include a handle wherein the blade is affixed to the handle and the semiconductor substrate is electrically coupled to the handle. The handle may then be coupled, either physically or by wireless transmission, to a computer that is adapted to display information to a person using the cutting instrument based on signals generated by one or more of the sensors formed on the semiconductor substrate. The computer or handle may also be adapted to store data based on the signals generated by one or more of the sensors. A method of making said cutting instrument includes the steps of at least one sensor being formed on a semiconductor wafer and a layer of photoresist being applied on a top side of the semiconductor wafer according to a pattern that matches the defined shape of the semiconductor substrate. The portion of the semiconductor wafer not covered by the photoresist is removed and thereafter the photoresist is removed from the semiconductor wafer, thereby leaving the semiconductor substrate having a defined shape and at least one sensor formed thereon. The semiconductor substrate having a defined shape and at least one sensor formed thereon is then affixed to a metal blade in a recess formed in said blade.

Owner:VERIMETRA

Tissue biopsy and treatment apparatus and method

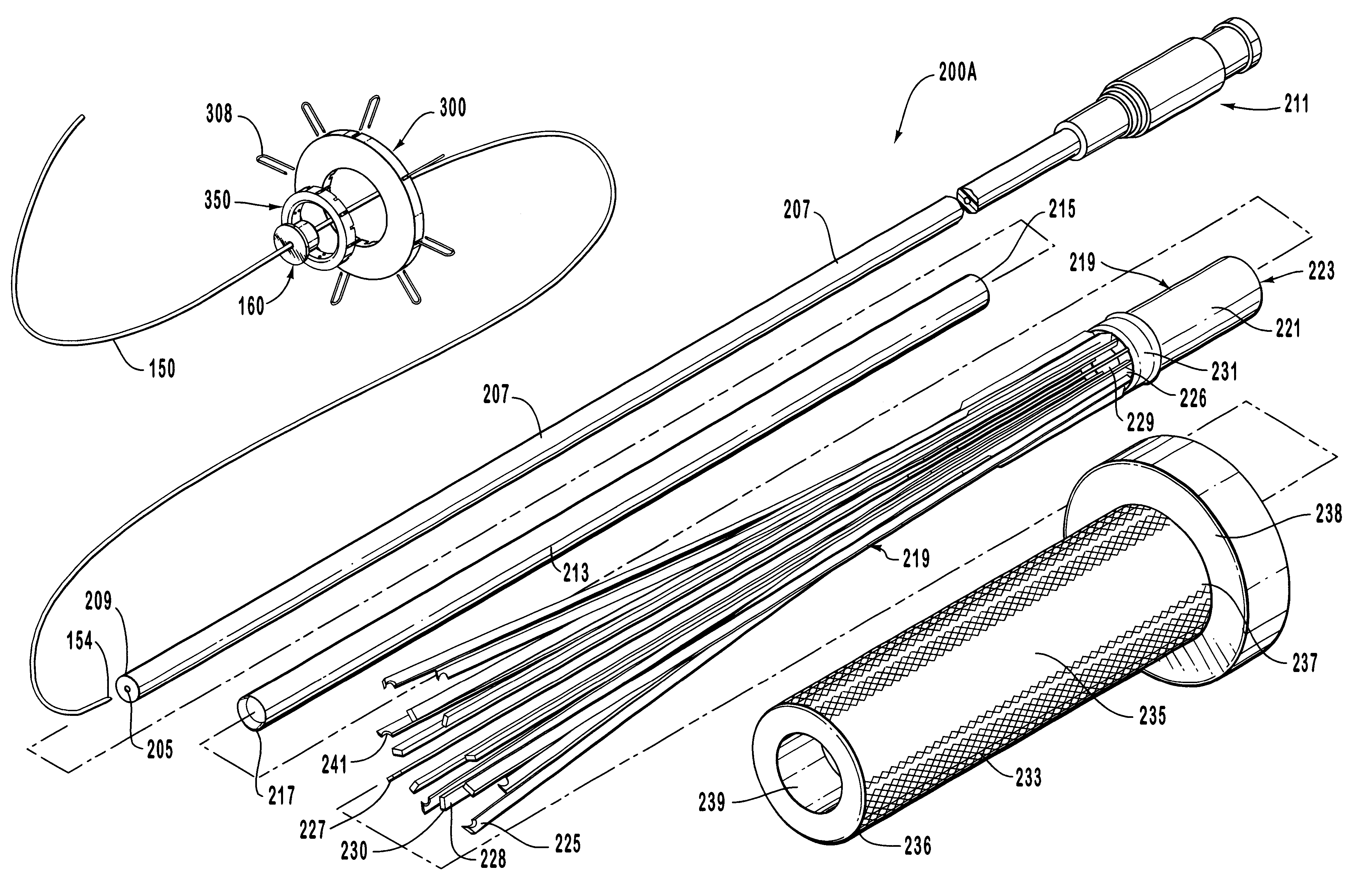

InactiveUS6869430B2Improve clinical outcomesPrecise positioningSurgical needlesControlling energy of instrumentSensor arrayTissue biopsy

An embodiment of the invention provides a tissue biopsy and treatment apparatus that comprises an elongated delivery device that is positionable in tissue and includes a lumen. A sensor array having a plurality of resilient members is deployable from the elongated delivery device. At least one of the plurality of resilient members is positionable in the elongated delivery device in a compacted state and deployable with curvature into tissue from the elongated delivery device in a deployed state. At least one of the plurality of resilient members includes at least one of a sensor, a tissue piercing distal end or a lumen. The sensor array has a geometric configuration adapted to volumetrically sample tissue at a tissue site to differentiate or identify tissue at the target tissue site. At least one energy delivery device is coupled to one of the sensor array, at least one of the plurality of resilient members or the elongated delivery device.

Owner:ANGIODYNAMICS INC

Guidewire exchange systems to treat spinal stenosis

Guidewire exchange systems, devices and methods, for positioning and actuating surgical devices in a desired position between two tissues in a patient's body are described. A guidewire may be coupled to a surgical device for positioning and actuating (e.g., urging against a target tissue). The guidewire may be exchanged between different surgical devices during the same procedure, and the guidewire and surgical devices may be releaseably or permanently coupled. The surgical device generally includes one or more guidewire coupling members. A system may include a guidewire and a surgical device having a guidewire coupling member. Methods, devices and systems may be used in open, less-invasive or percutaneous surgical procedures.

Owner:SPINAL ELEMENTS INC +1

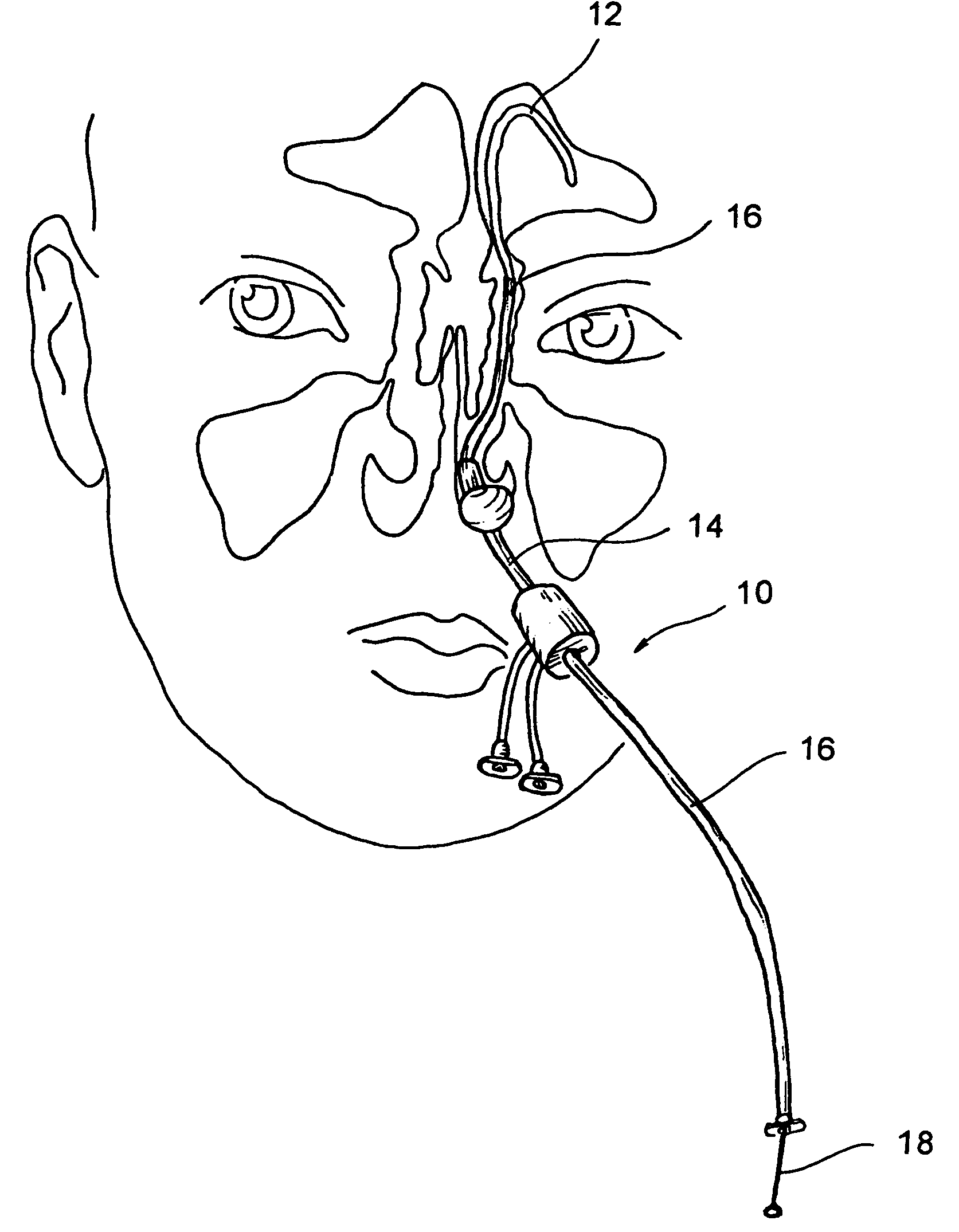

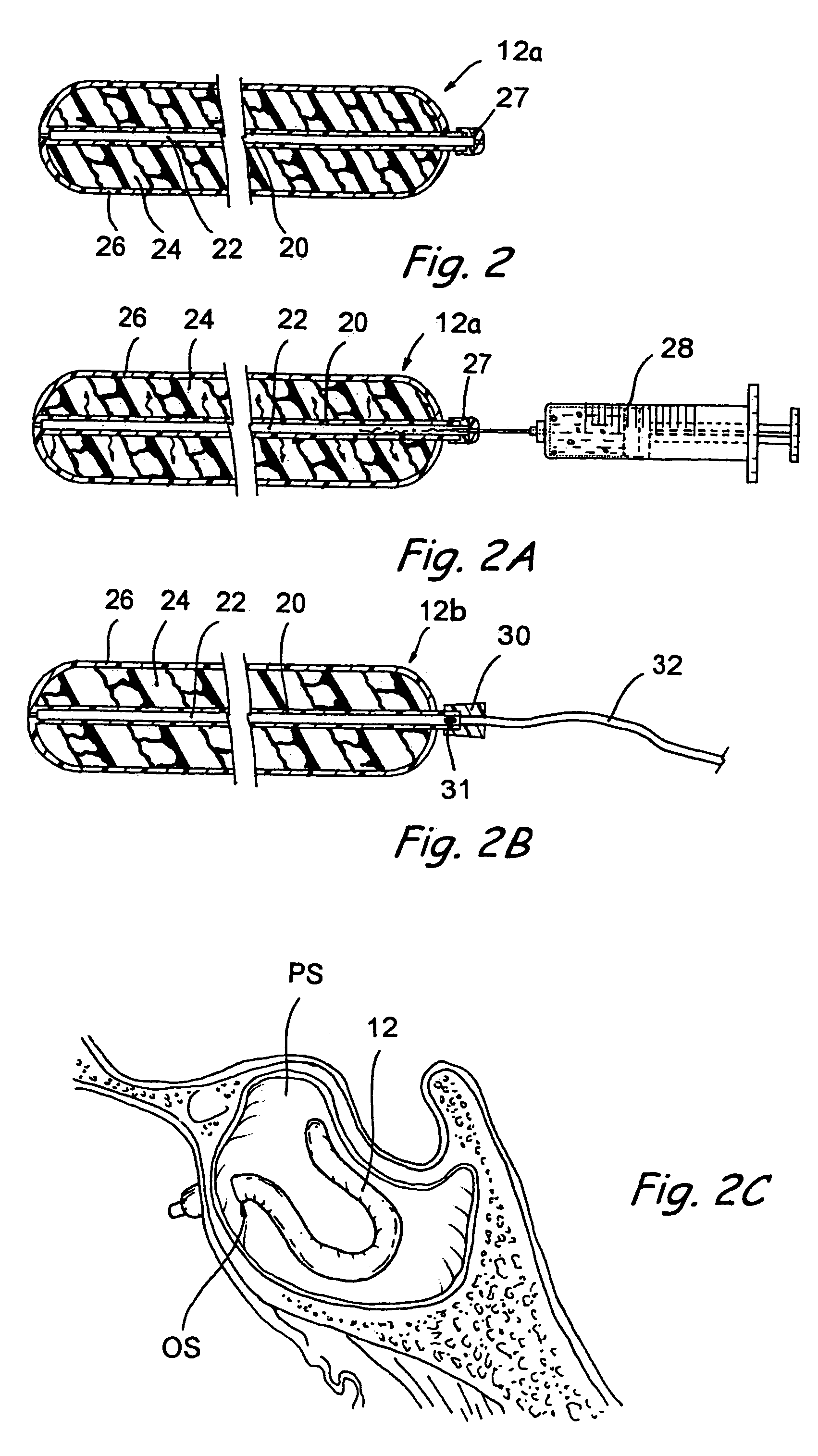

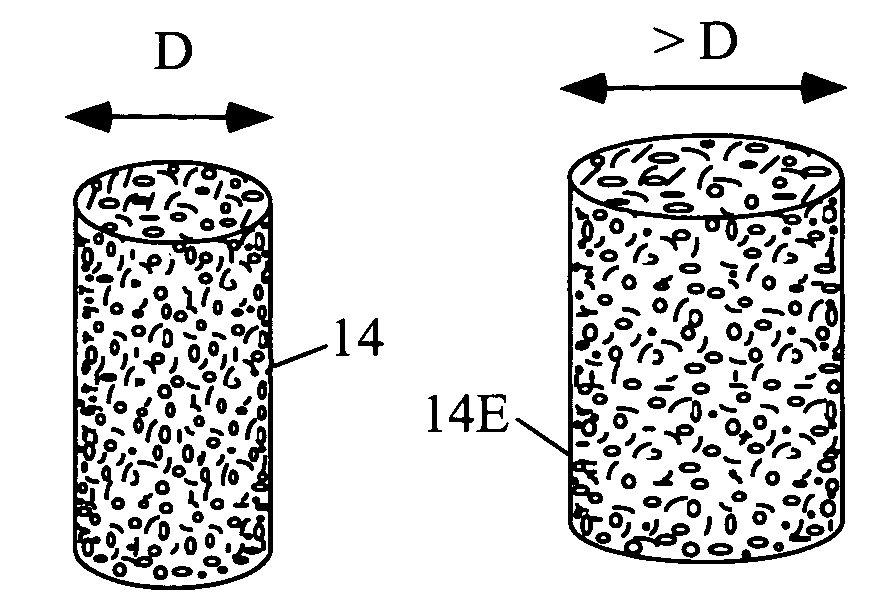

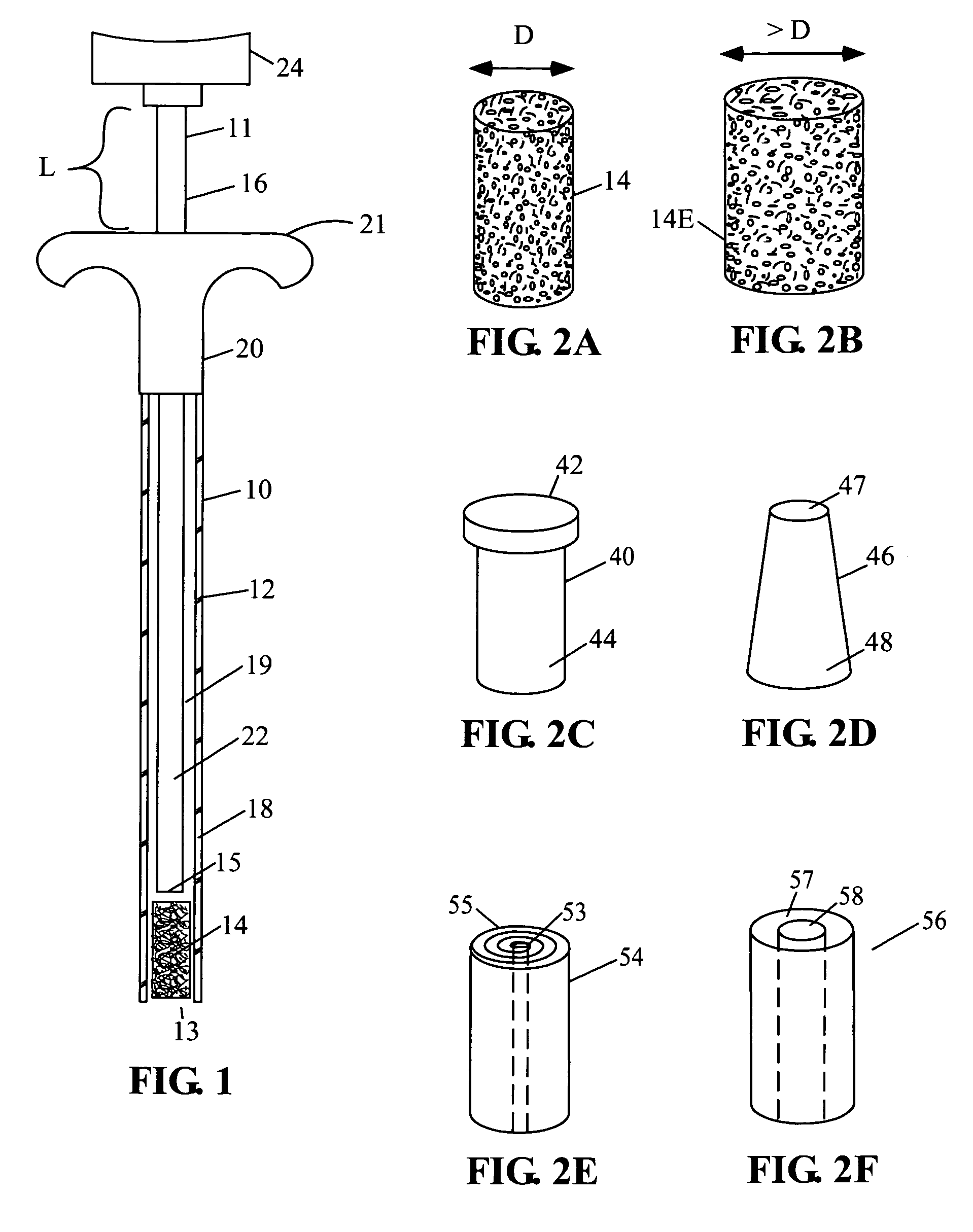

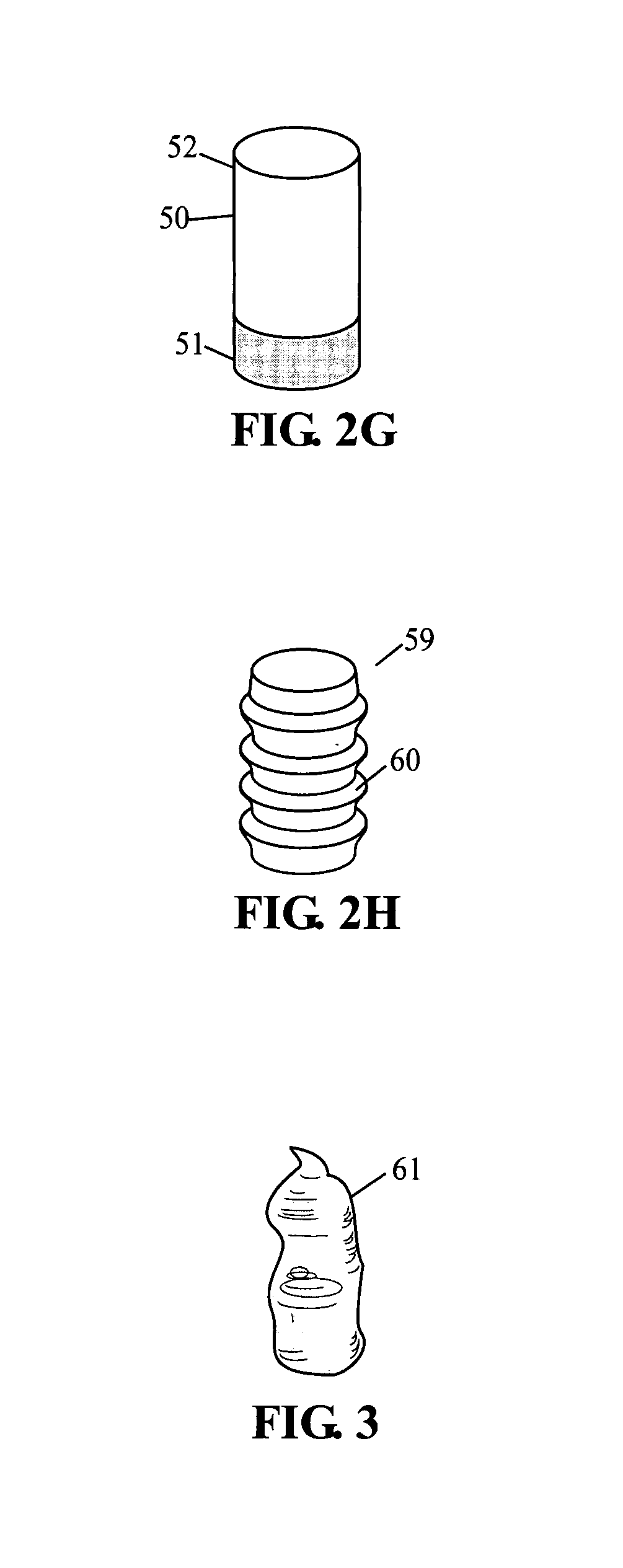

Implantable device and methods for delivering drugs and other substances to treat sinusitis and other disorders

Implantable devices and methods for delivering drugs and other substances to locations within the body of a human or animal subject to treat or diagnose sinusitis and a variety of other disorders. The invention includes implantable substance delivery devices that comprise reservoirs and barriers that control the rate at which substances pass out of the reservoirs. The delivery devices may be advanced into the body using guidewires, catheters, ports, introducers and other access apparatus. In some embodiments the delivery devices may be loaded with one or more desired substance before their introduction into the body. In other embodiments the delivery devices are loaded and / or reloaded with a desired substance after the delivery device has been introduced into the body.

Owner:ACCLARENT INC

Surgical instrument

A medical instrument that includes an instrument shaft having proximal and distal ends; a tool for performing a medical procedure; a control handle; a distal motion member for coupling the distal end of the instrument shaft to the tool; a proximal motion member for coupling the proximal end of the instrument shaft to the control handle; actuation means extending between the distal and proximal motion members for coupling motion of the proximal motion member to the distal motion member for controlling the positioning of the tool; a control tube through which the instrument shaft and tool extend; the control tube including, along the length thereof, a curved section; the curved section of the control tube, upon rotation thereof, providing an additional degree of freedom by displacing the tool out of a plane defined by the curved section of the control tube.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES

Devices and methods for treating defects in the tissue of a living being

InactiveUS7166133B2Restore mechanical and architectural and structural competenceSuture equipmentsPeptide/protein ingredientsHost tissueBiomedical engineering

Owner:DSM IP ASSETS BV

Dissecting cannula and methods of use thereof

Methods and devices described herein facilitate improved access of locations within the body by providing a variety of dissection modes on a single access device.

Owner:ATRICURE

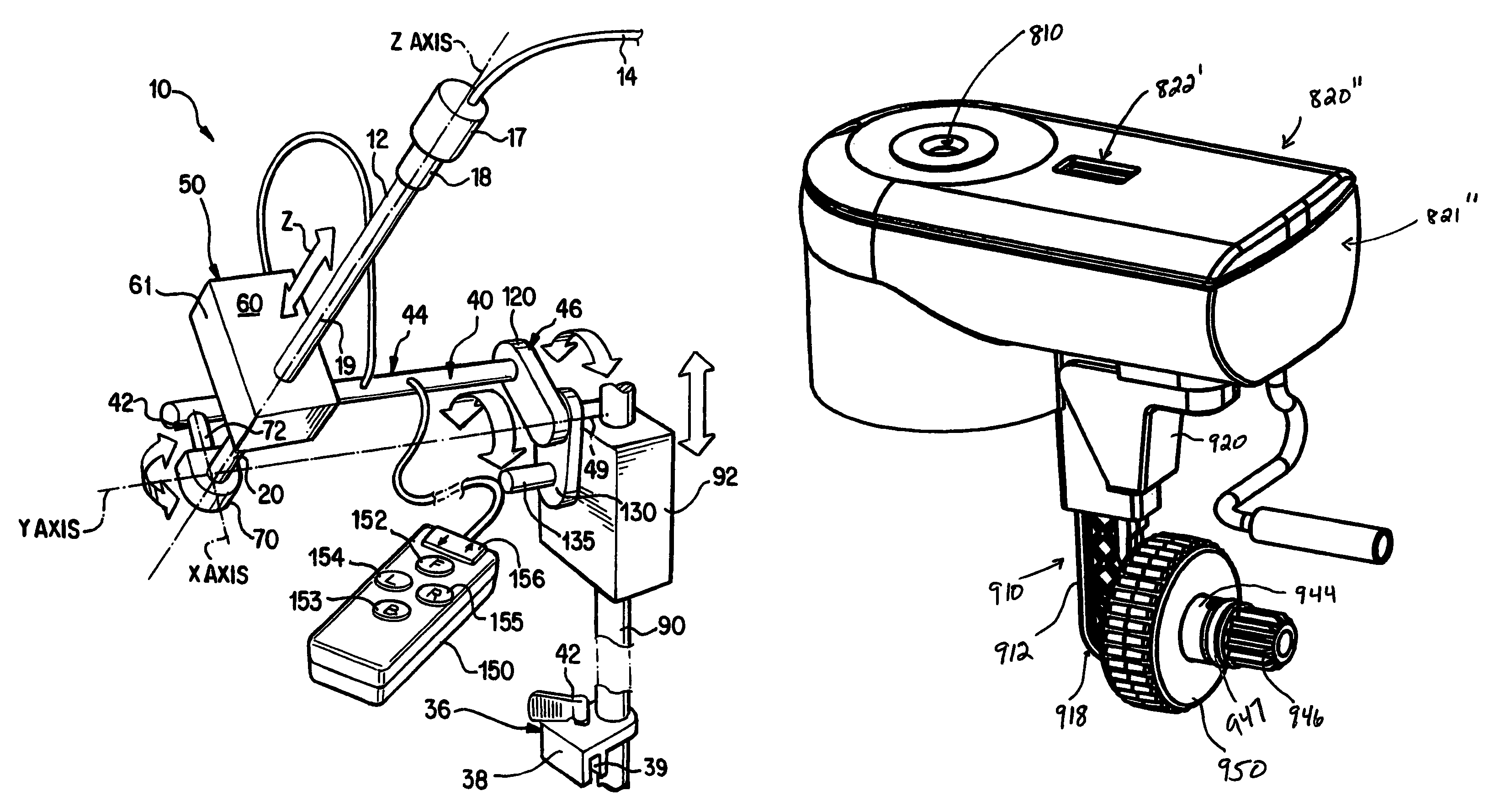

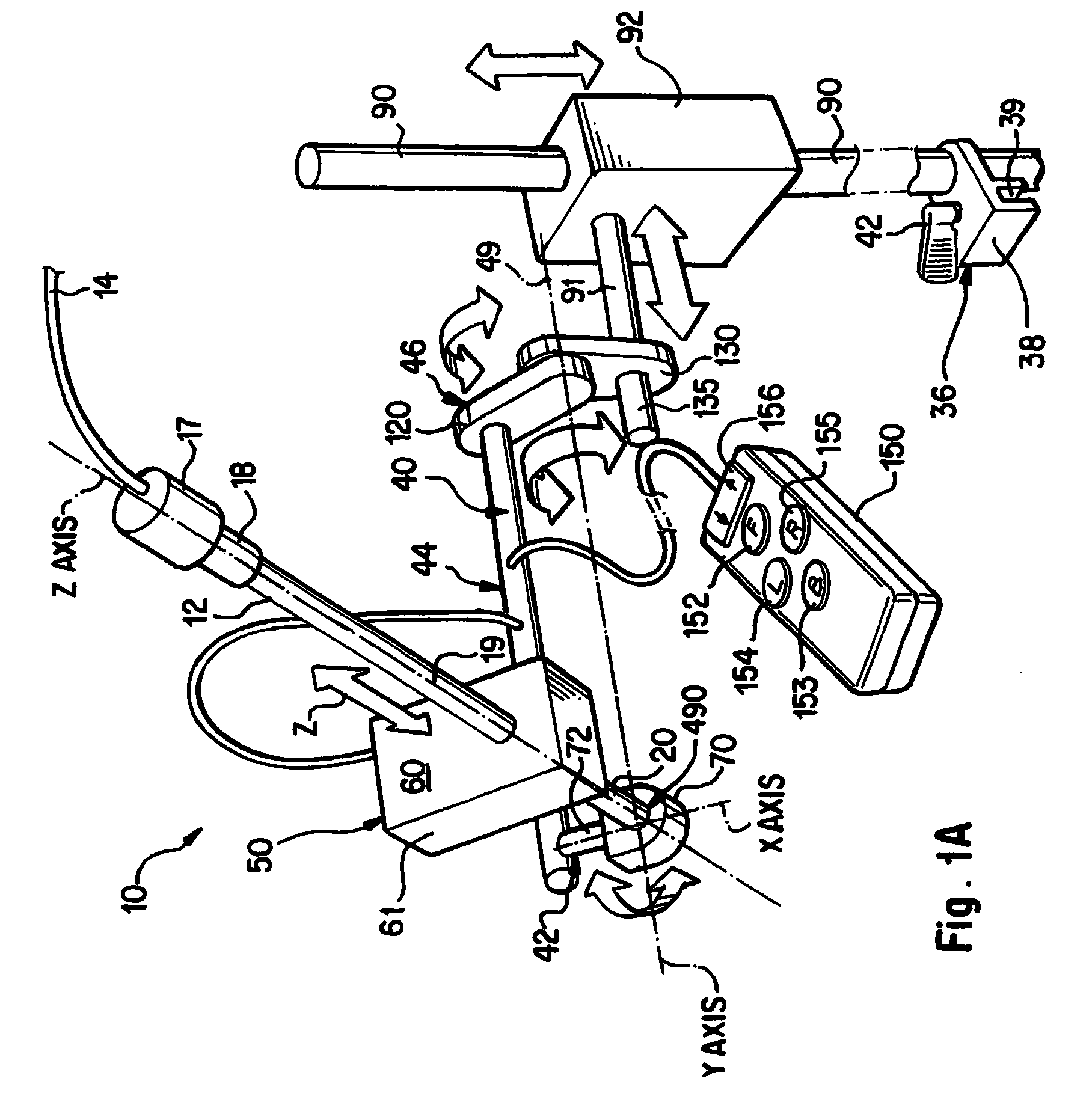

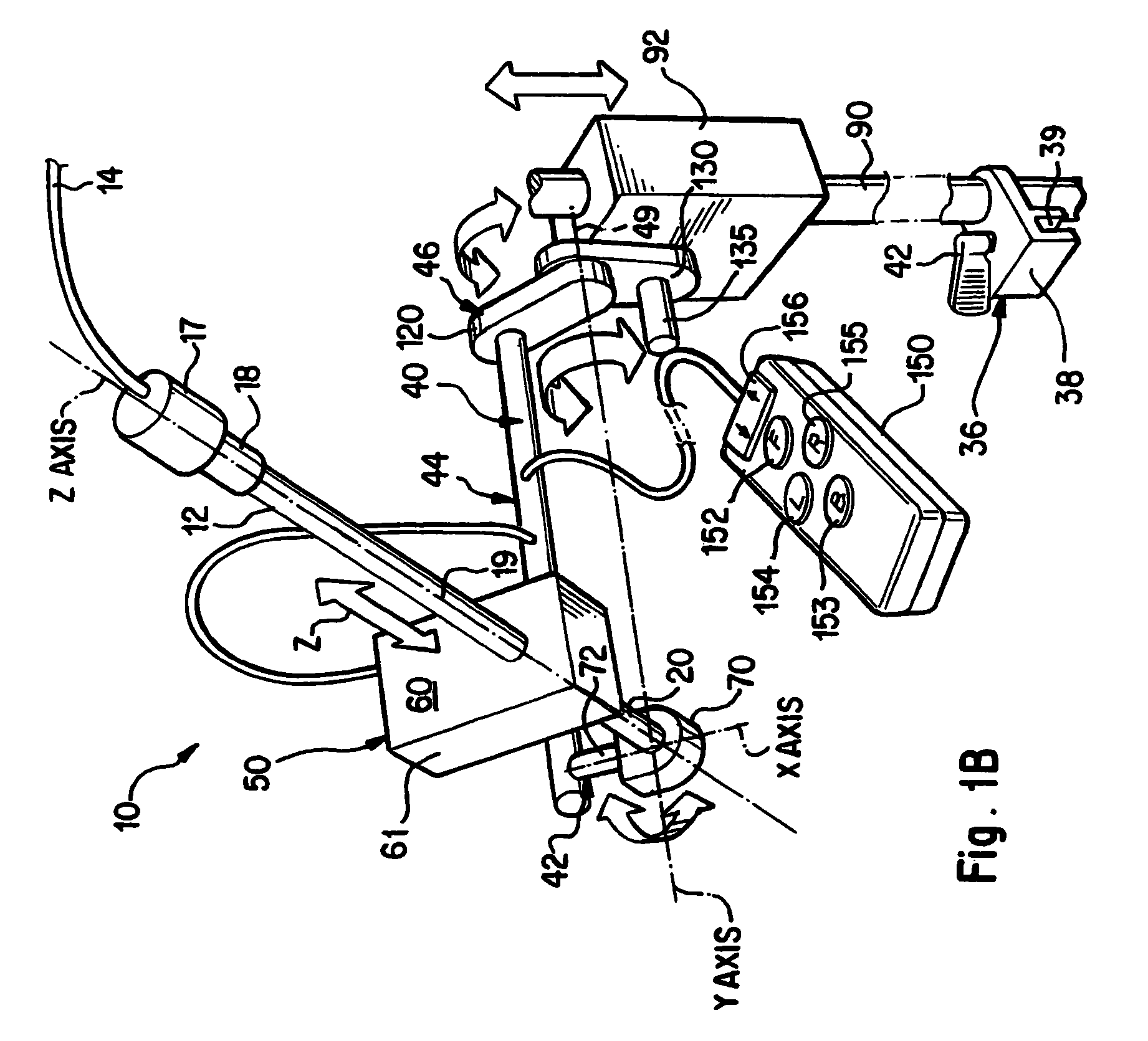

Apparatus for positioning a medical instrument

InactiveUS7674270B2Reduce in quantityLess cumbersomeCannulasSurgical needlesEngineeringPositioning system

The present device provides an apparatus for securely positioning a medical instrument relative to a patient. The apparatus comprises a drive assembly for moving the medical instrument along a first axis that is substantially parallel to the length of the instrument; an adapter comprising an elongated member and a pair of cooperating hubs for connecting the drive assembly to a positioning system. The cooperating hubs serving to allow separation of sterile from non sterile components. The positioning system comprises two motors each for moving the instrument about a different axis than the drive assembly. The apparatus moving the instrument about a point which is external to the patient. The device further comprises a sterile bag which encloses the positioning system, the bag having at least one opening for receiving an axel from a sterile adapter assembly, thereby rendering the entire apparatus sterile.

Owner:LAPAROCISION

Surgical access device with pendent valve

InactiveUS7083626B2Precise positioningMaximize ease and safetyEar treatmentCannulasSurgical departmentVALVE PORT

A surgical access device, such as a trocar, includes a pendent valve having an elongate structure extending from a proximal end to a septum valve disposed at a distal end. In operation, the elongate structure follows the angle of the instrument to pre-position the septum valve into the path of the instrument where it is not significantly challenged during instrument insertion or manipulation. The pendant valve can be made to float at both the proximal end and the distal end of the elongate structure, to further reduce the vulnerability of the septum valve. Since the valve is less vulnerable to instrument insertion, it can be formed to minimize friction and maximize the functional range of the access device.

Owner:APPL MEDICAL RESOURCES CORP

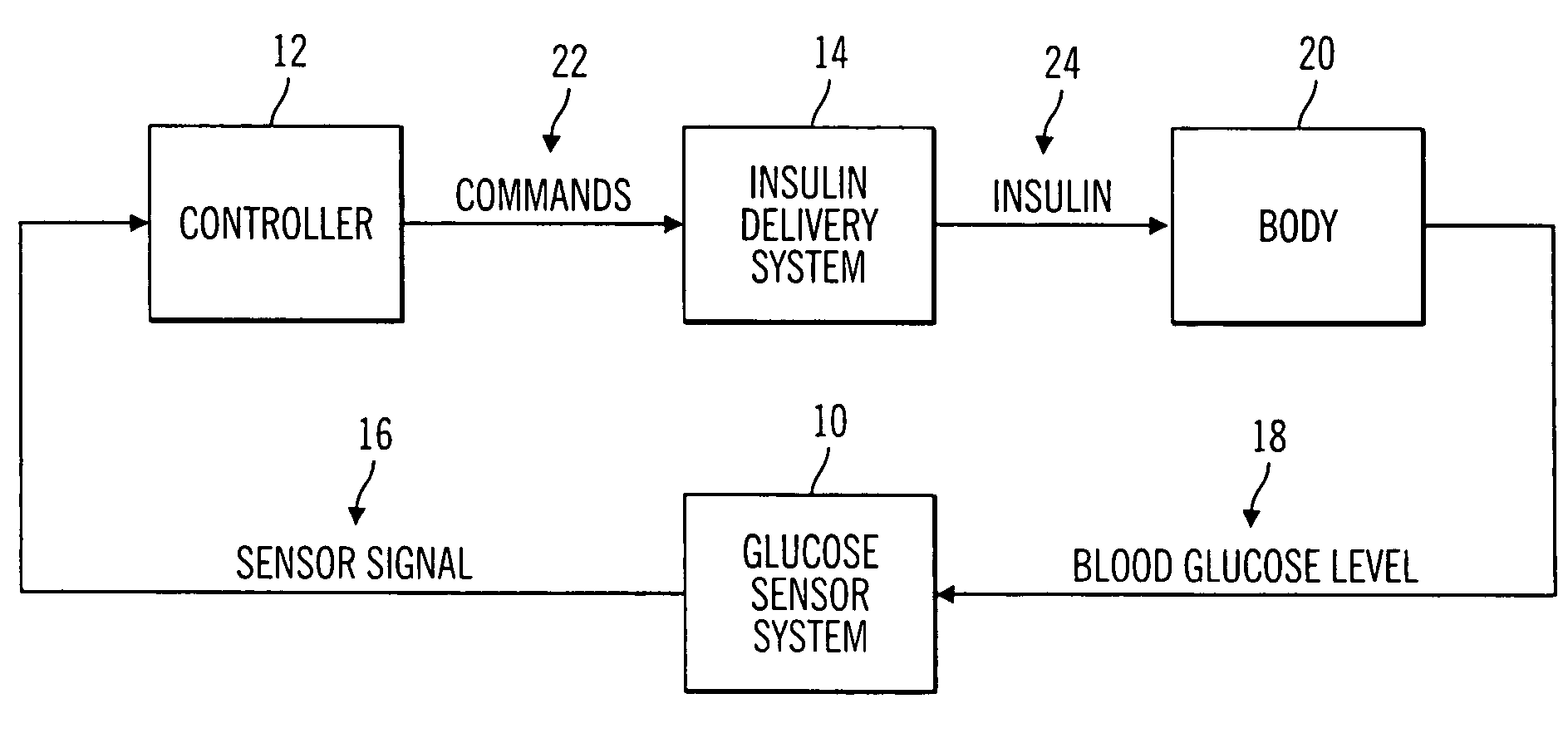

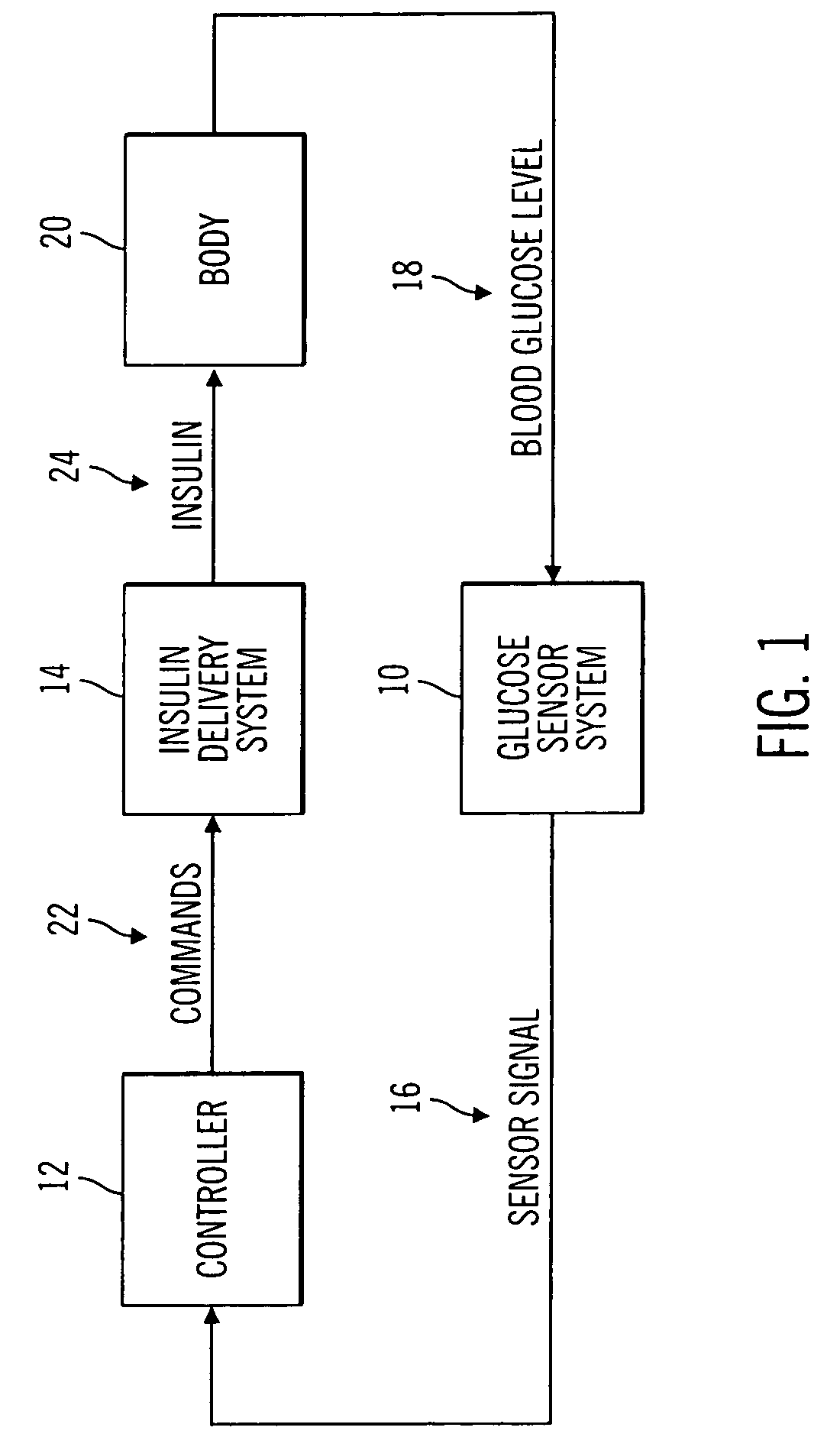

Closed-loop method for controlling insulin infusion

A closed loop infusion system controls the rate that fluid is infused into the body of a user. The closed loop infusion system includes a sensor system, a controller, and a delivery system. The sensor system includes a sensor for monitoring a condition of the user. The sensor produces a sensor signal, which is representative of the condition of the user. The sensor signal is used to generate a controller input. The controller uses the controller input to generate commands to operate the delivery system. The delivery system infuses a liquid into the user at a rate dictated by the commands from the controller. Preferably, the sensor system monitors the glucose concentration in the body of the user, and the liquid infused by the delivery system into the body of the user includes insulin.

Owner:MEDTRONIC MIMIMED INC

Means and method of replacing a heart valve in a minimally invasive manner

A heart valve can be replaced using minimally invasive methods which include a sutureless sewing cuff that and a fastener delivery tool that holds the cuff against the patient's tissue while delivering fasteners to attach the cuff to the tissue from the inside out. The tool stores a plurality of fasteners and is self-contained whereby a fastener is delivered and placed all from inside a vessel. The fasteners are self-forming whereby they do not need an anvil to be formed. Anchor elements are operated from outside the patient's body to cinch a prosthesis to an anchoring cuff of the valve body. The cuff is releasably mounted on the tool and the tool holds the cuff against tissue and drives the fastener through the cuff and the tissue before folding over the legs of the fastener whereby secure securement between the cuff and the tissue is assured. Fasteners are placed and formed whereby fasteners are located continuously throughout the entire circumference of the cuff. A minimally invasive surgical method is disclosed, and a method and tool are disclosed for repairing abdominal aortic aneurysms in a minimally invasive manner. Fasteners that are permanently deformed during the process of attaching the cuff are disclosed as are fasteners that are not permanently deformed during the attaching process.

Owner:MEDTRONIC INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com