Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9607 results about "Soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soldering (AmE: /ˈsɒdərɪŋ/, BrE: /ˈsoʊldərɪŋ/) is a process in which two or more items are joined together by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the work pieces. In brazing, the work piece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes.

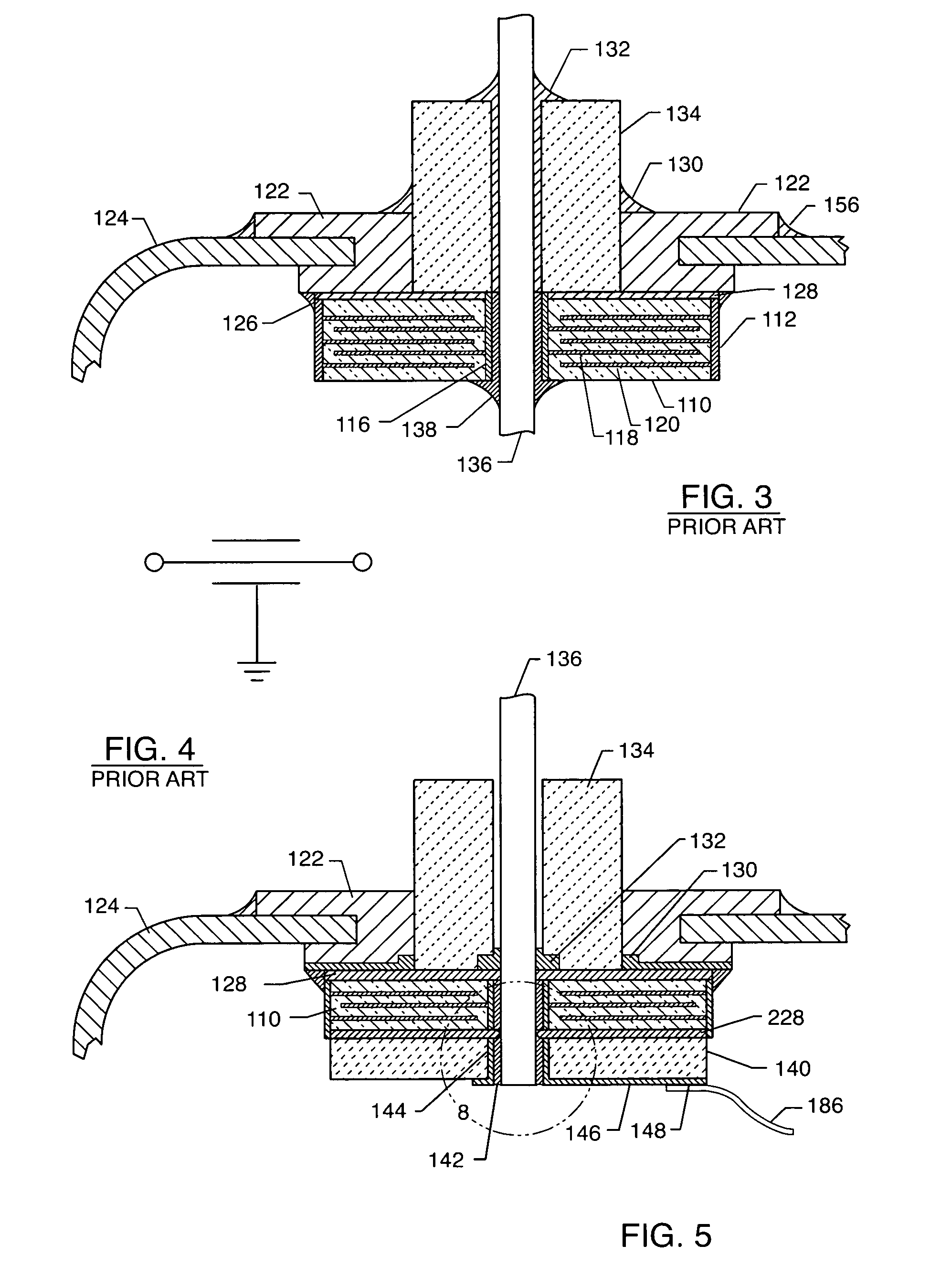

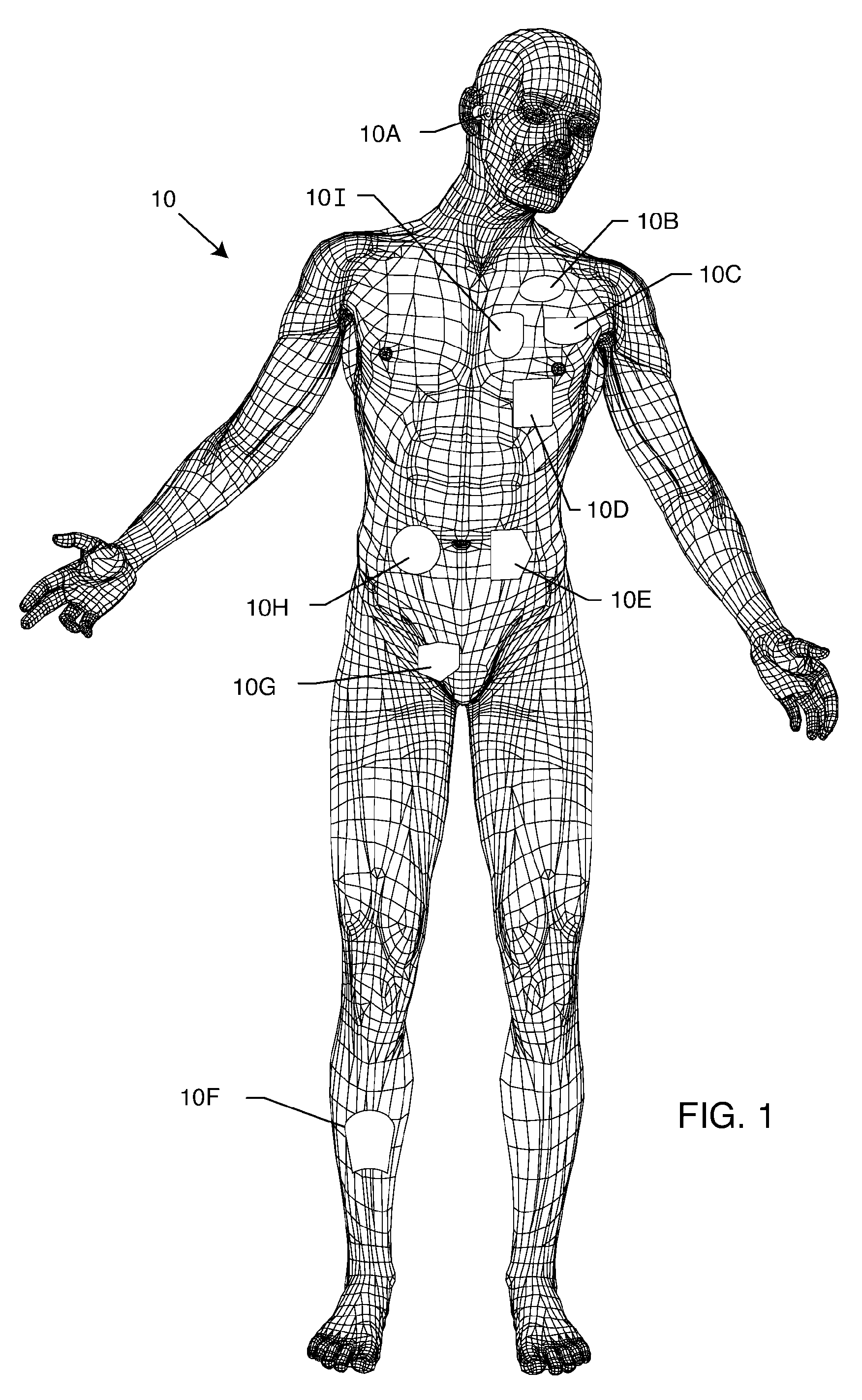

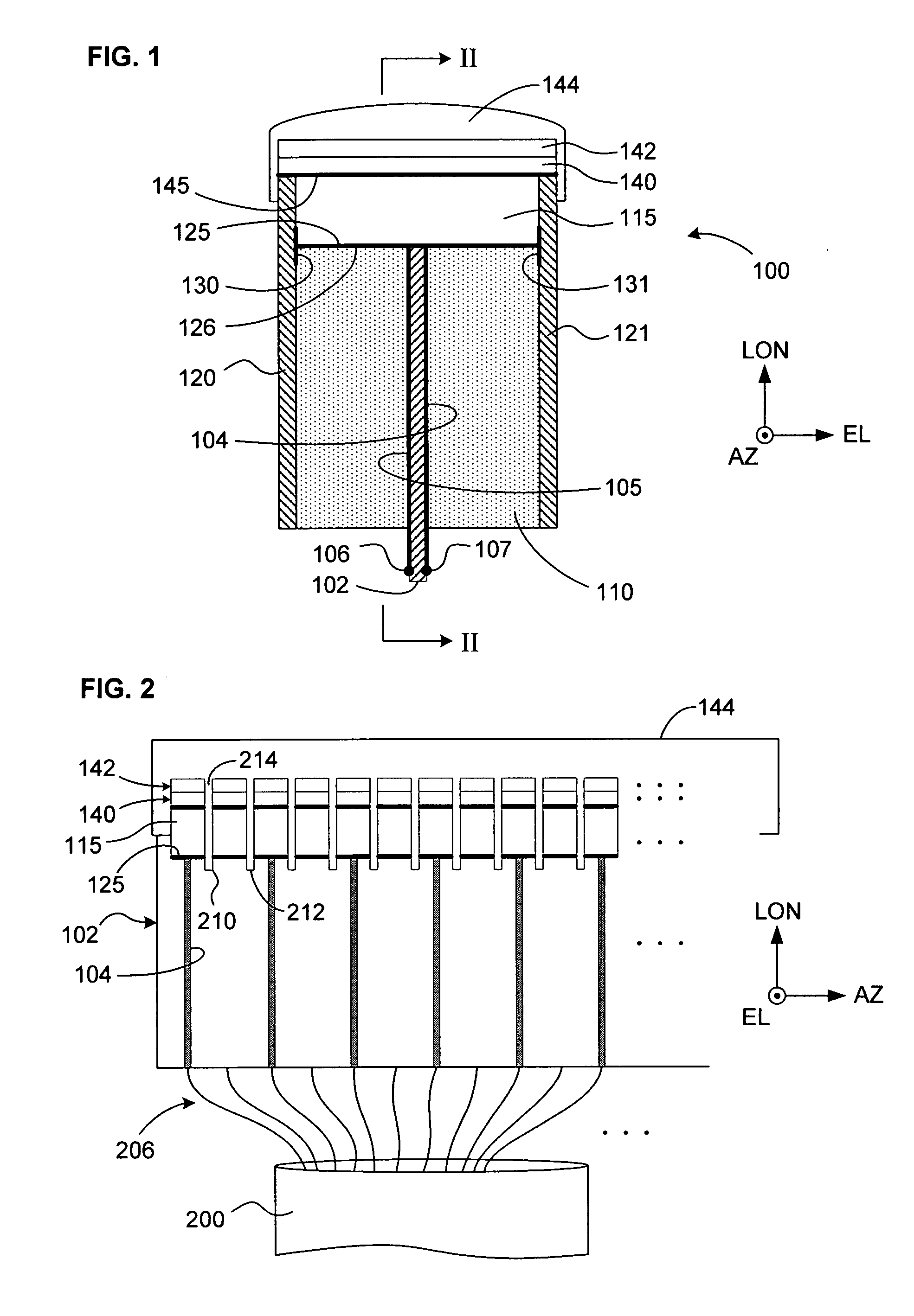

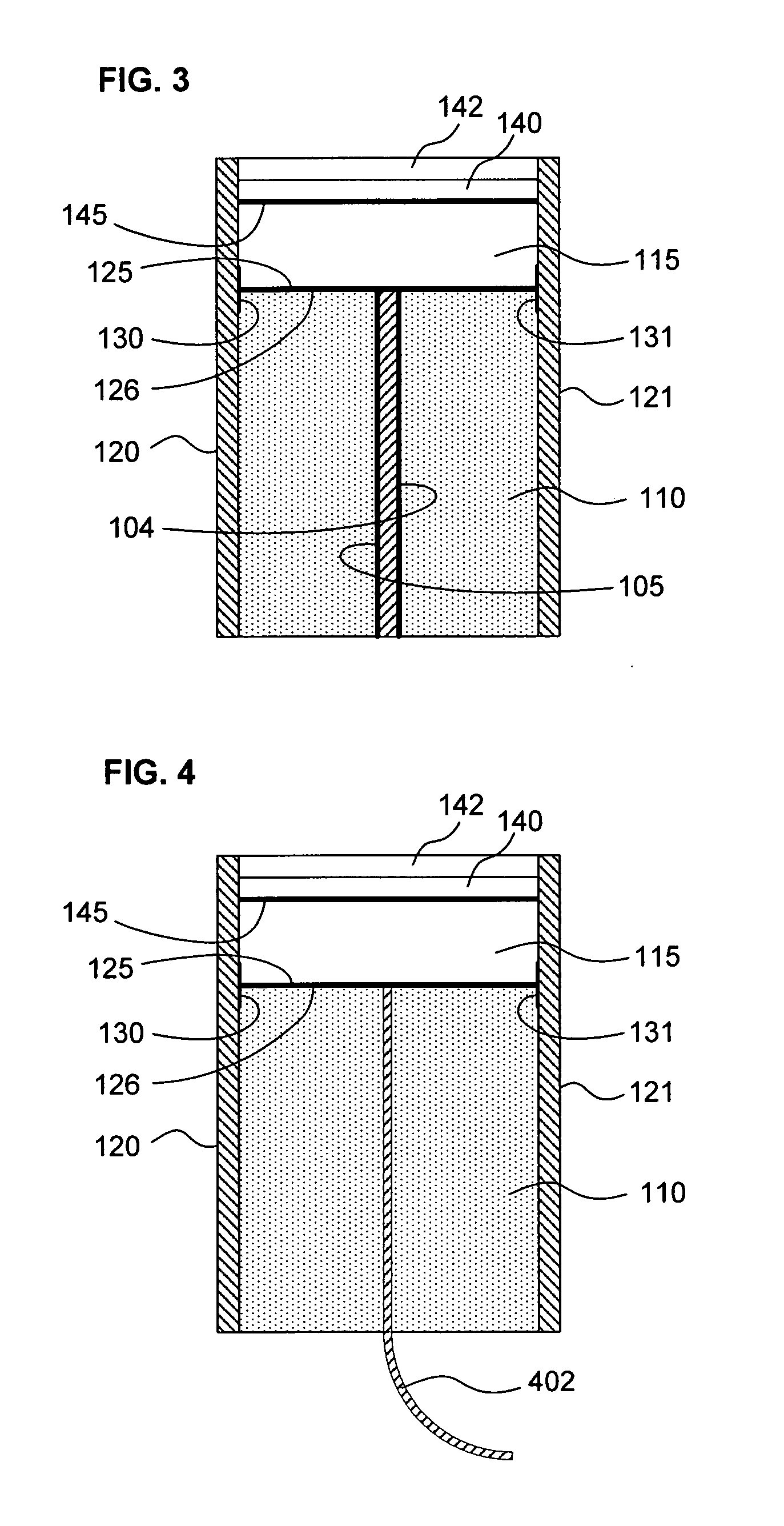

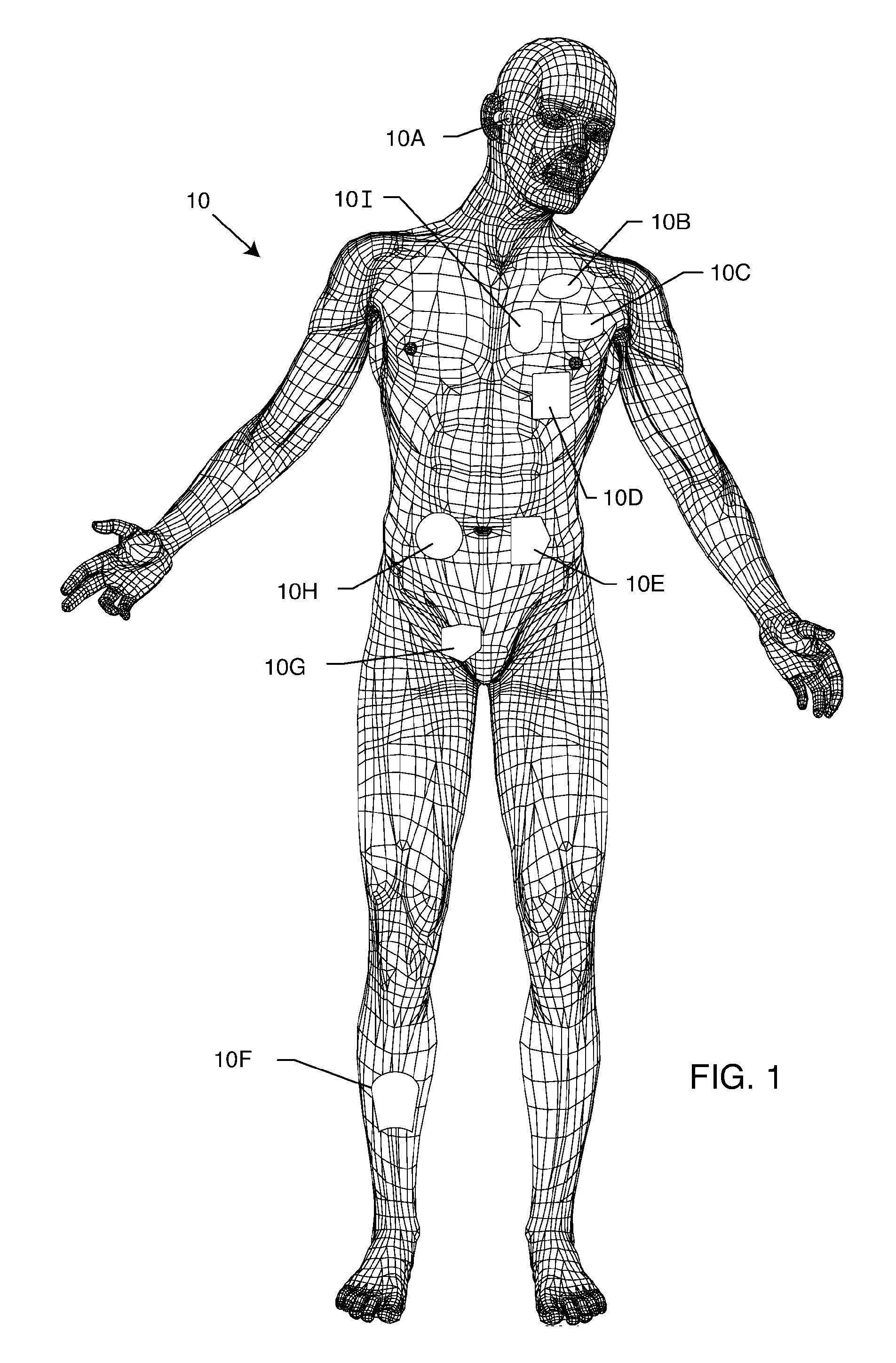

High-strength microwave antenna assemblies

InactiveUS6878147B2Avoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

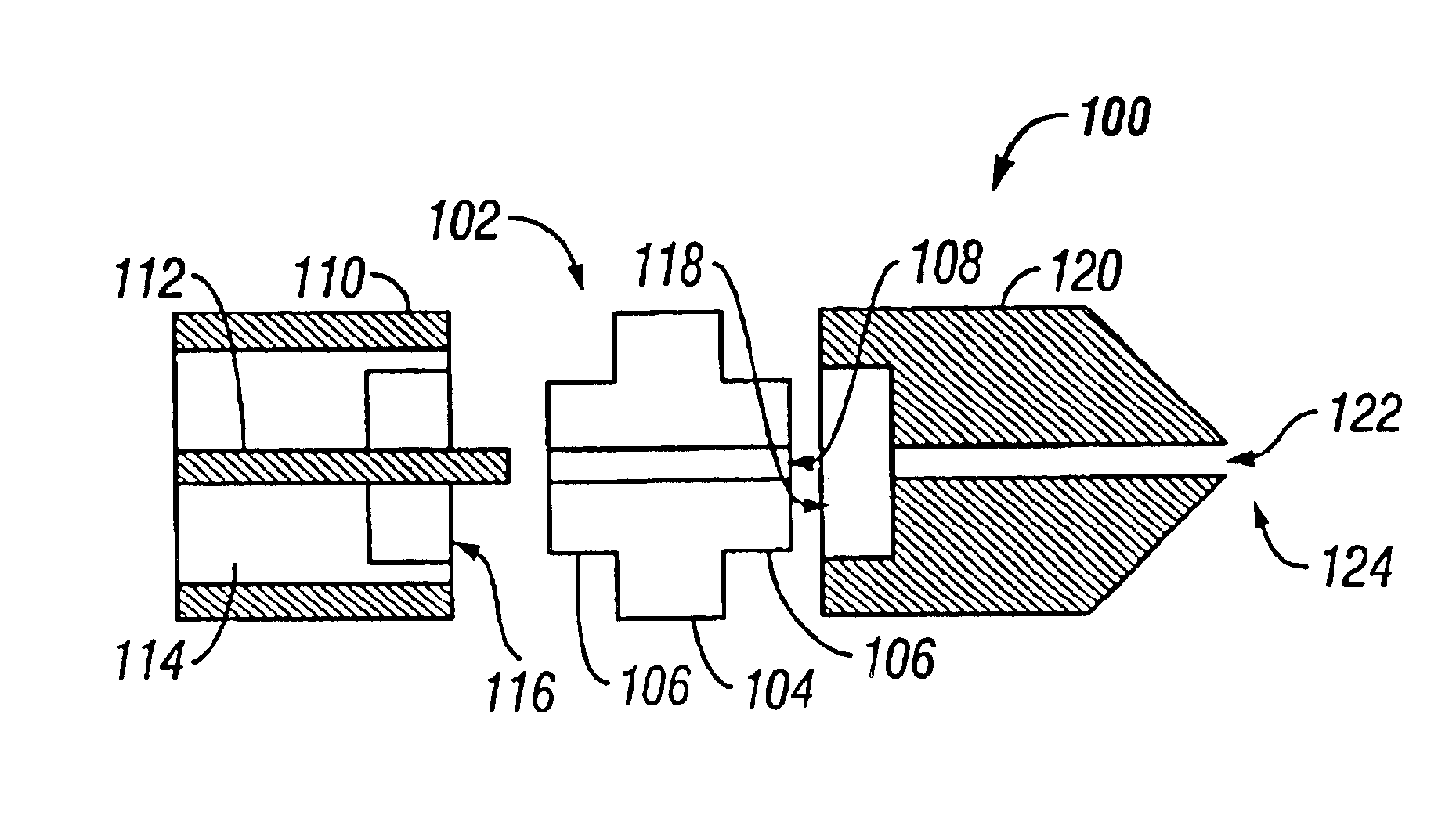

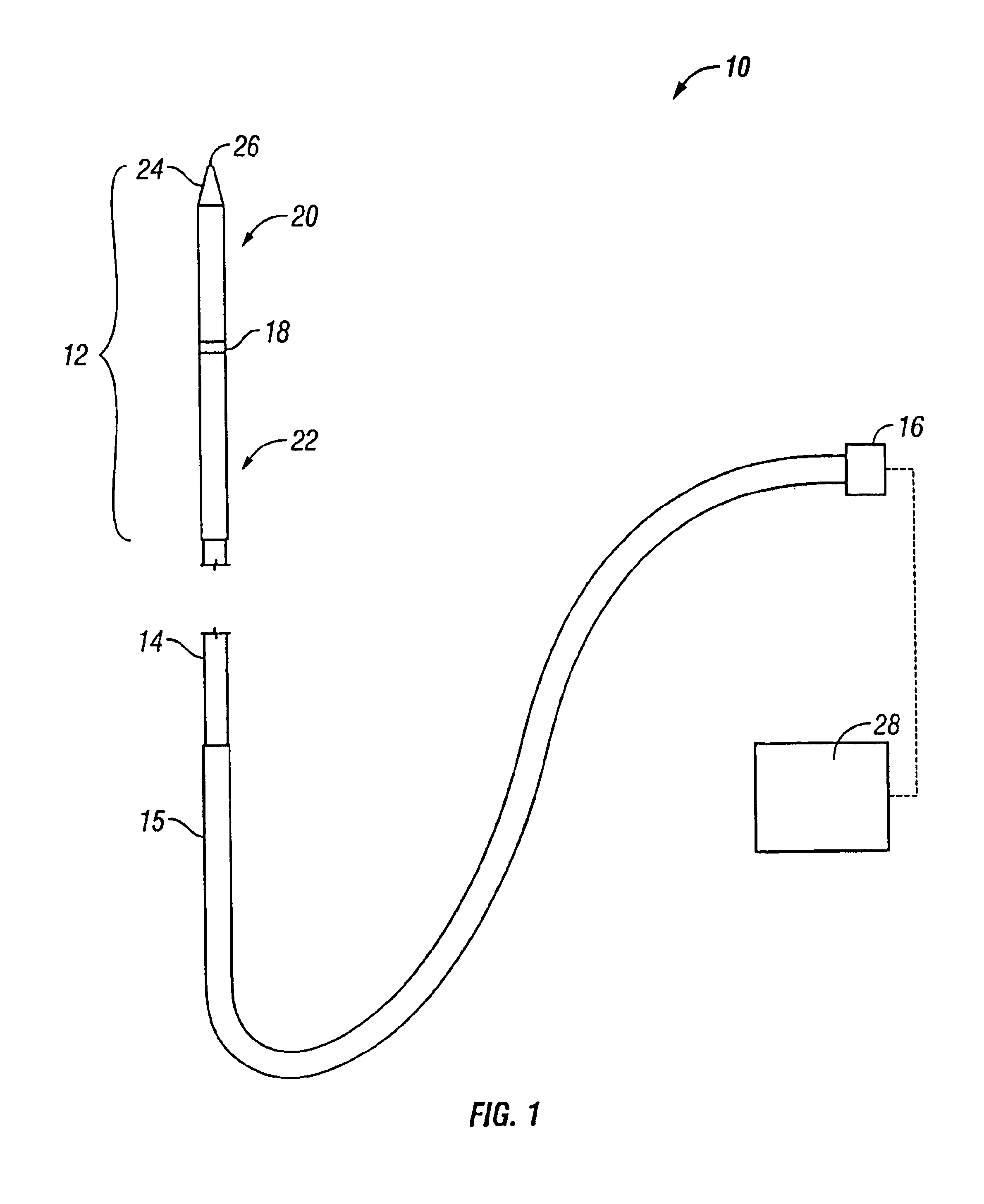

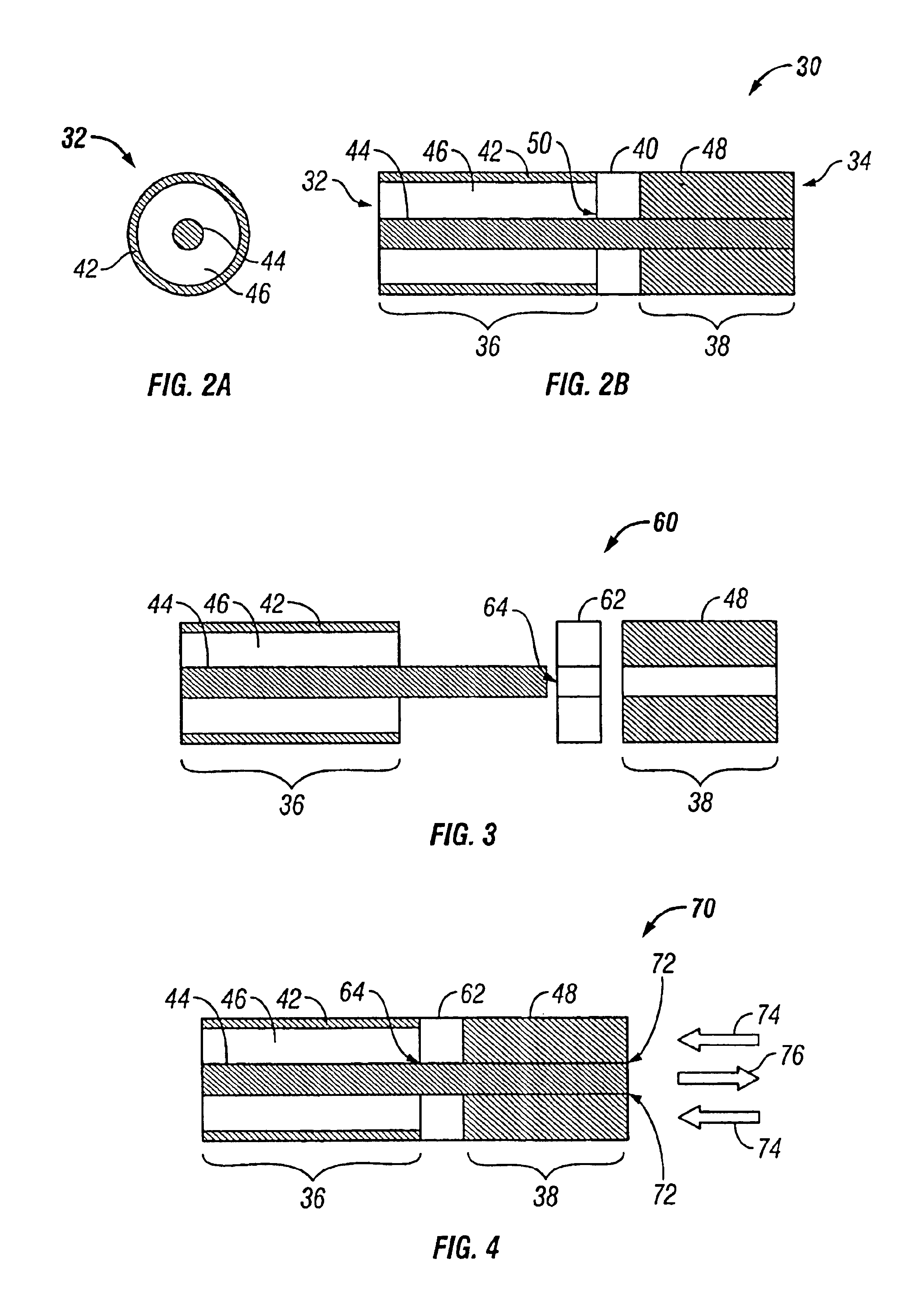

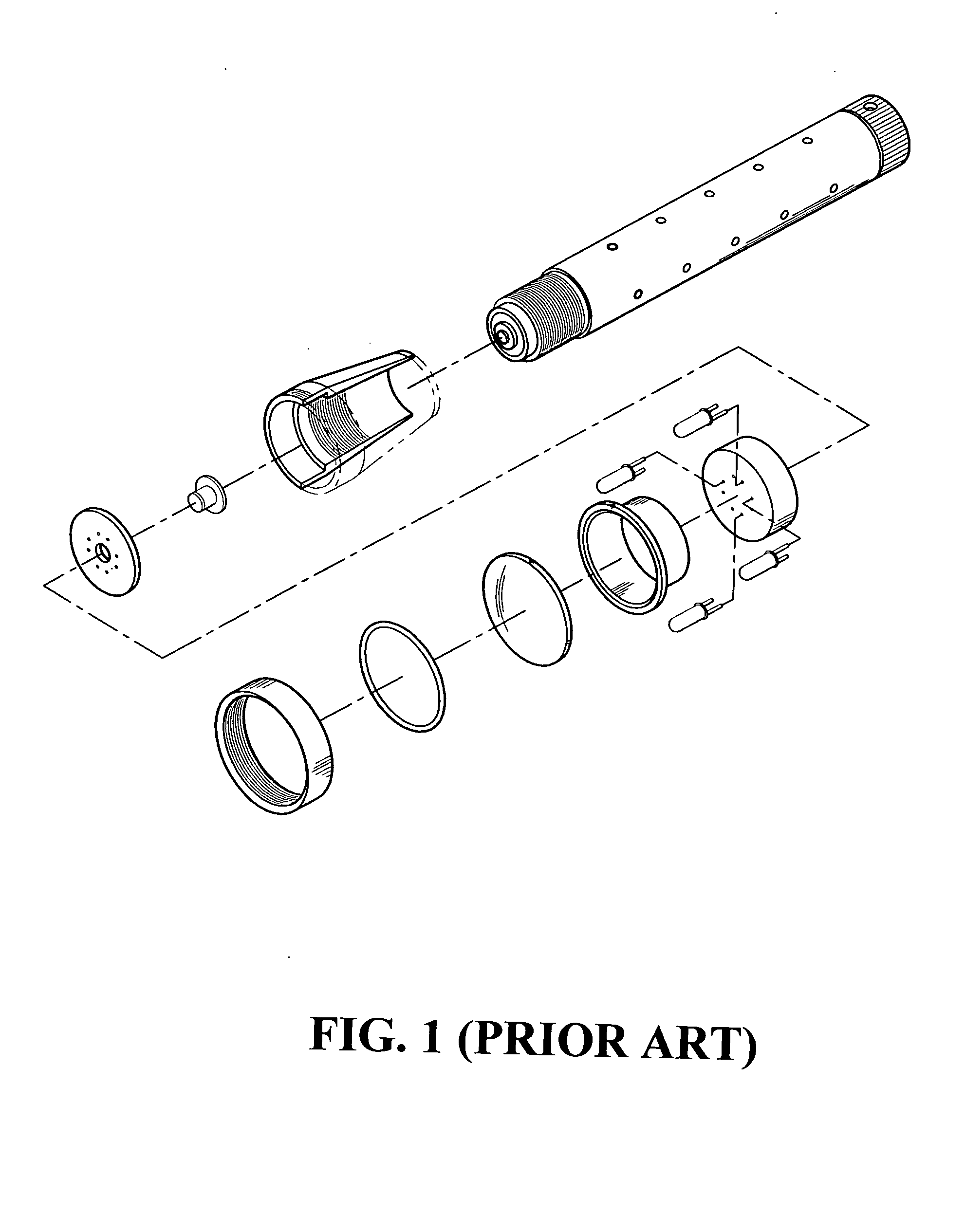

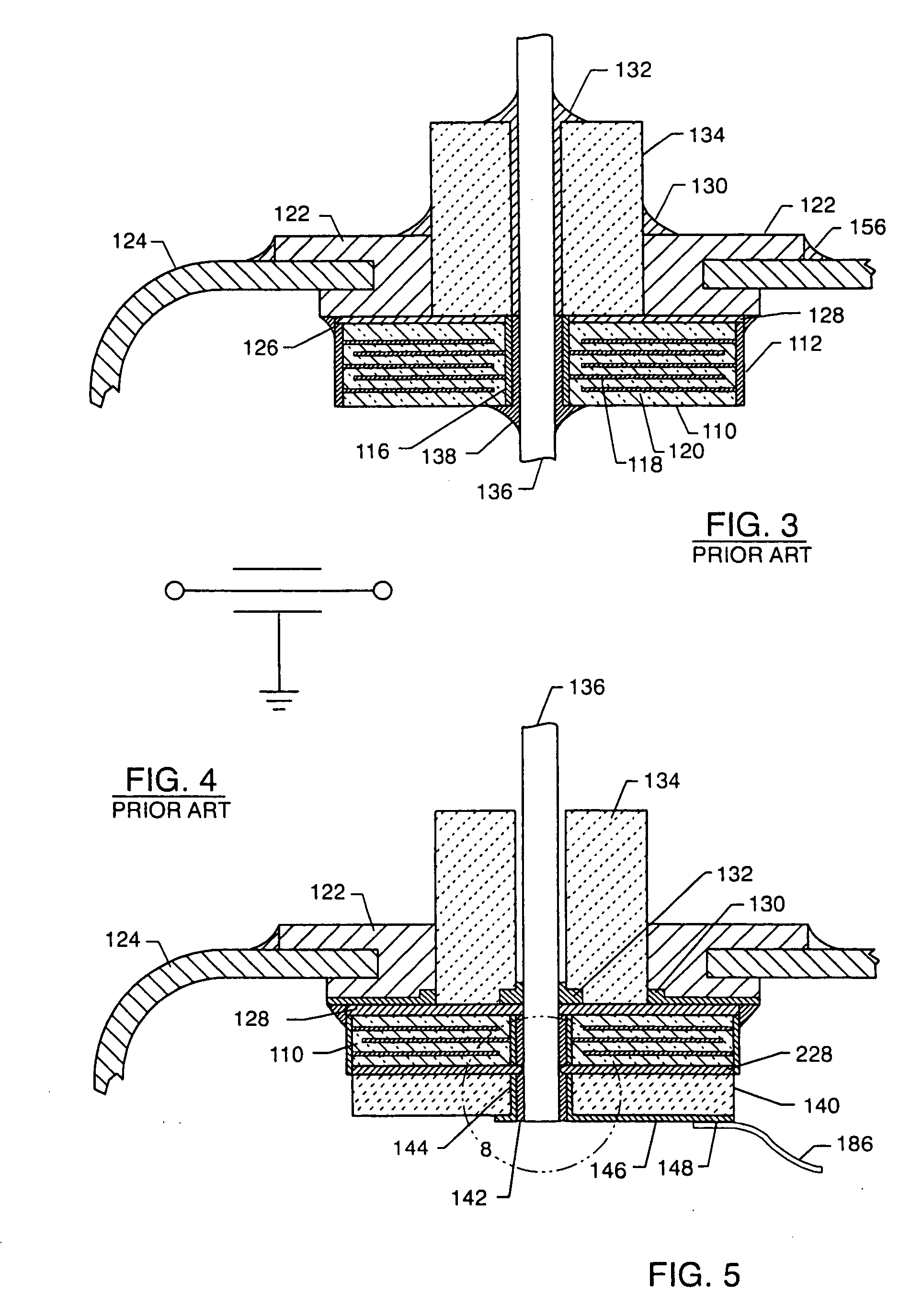

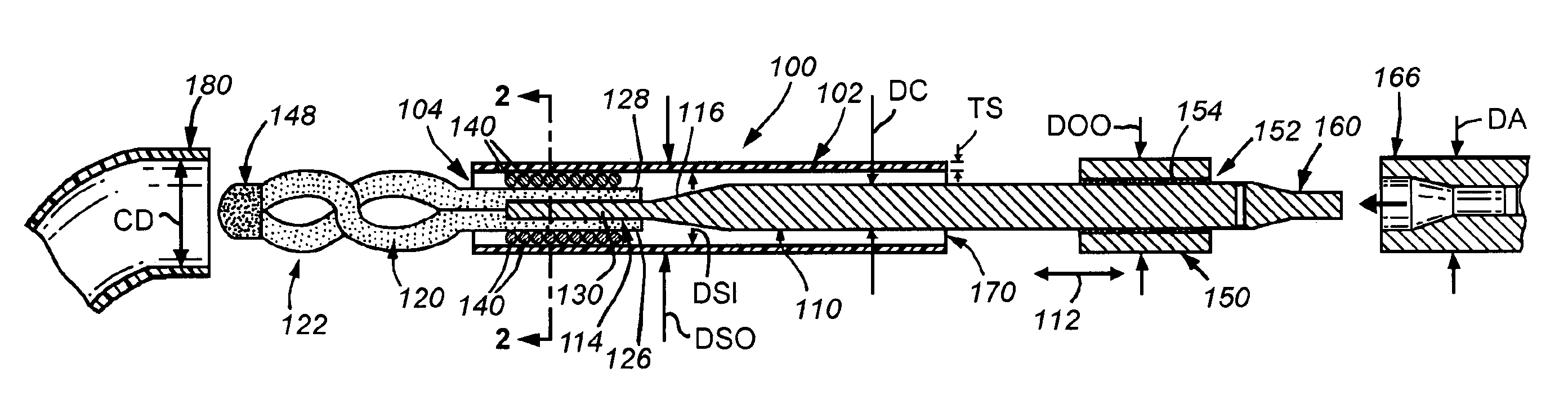

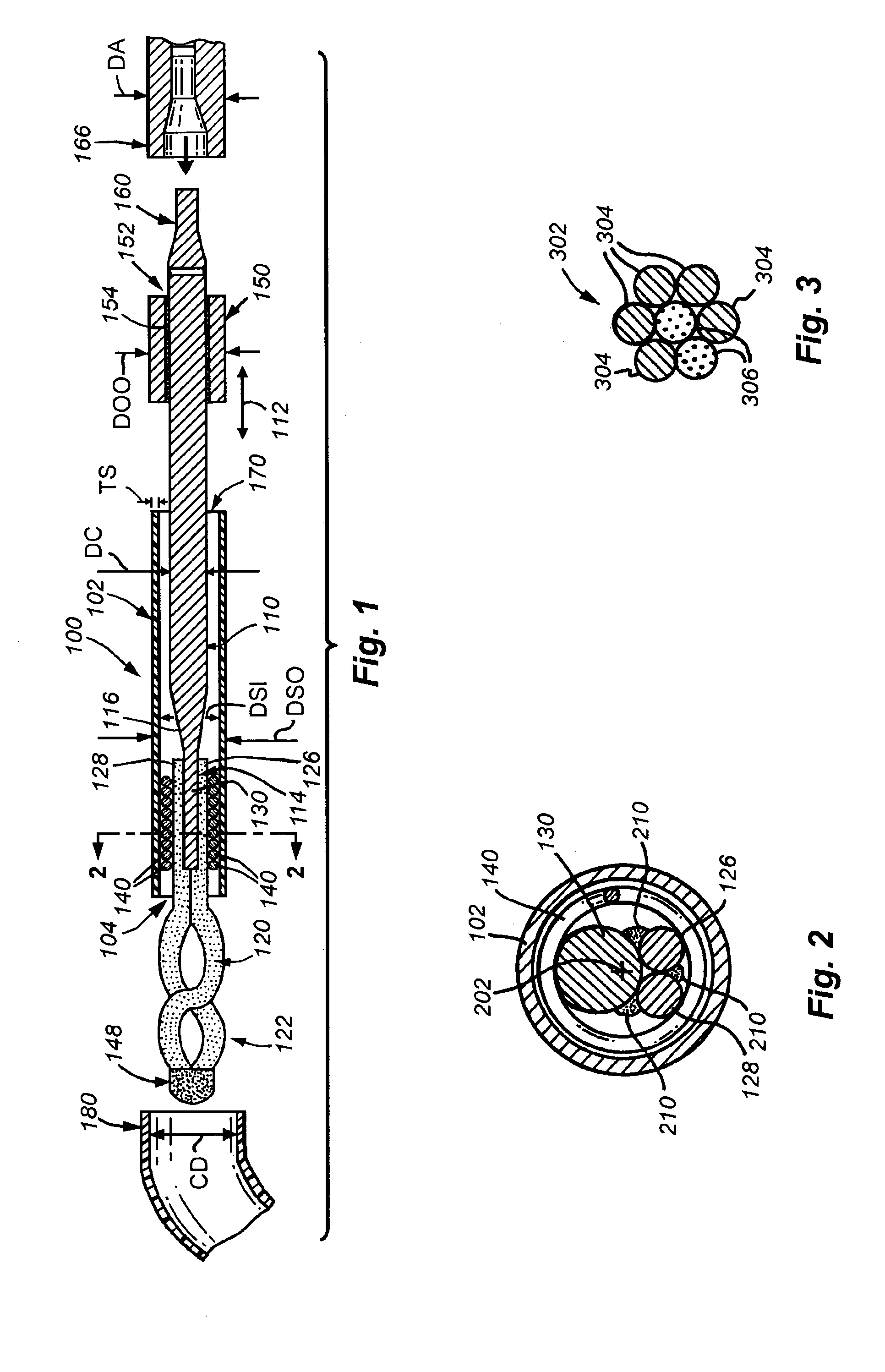

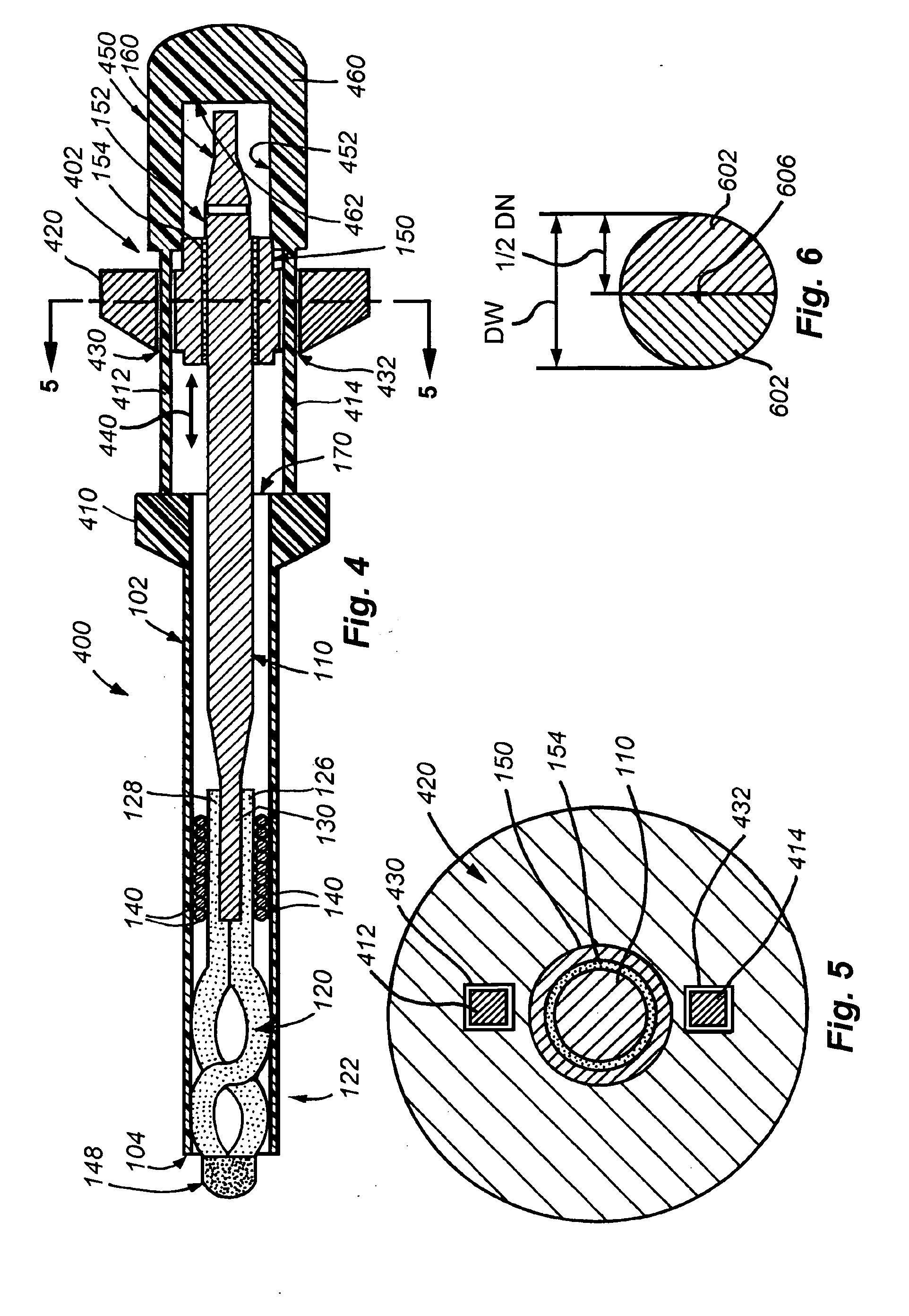

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:COVIDIEN LP

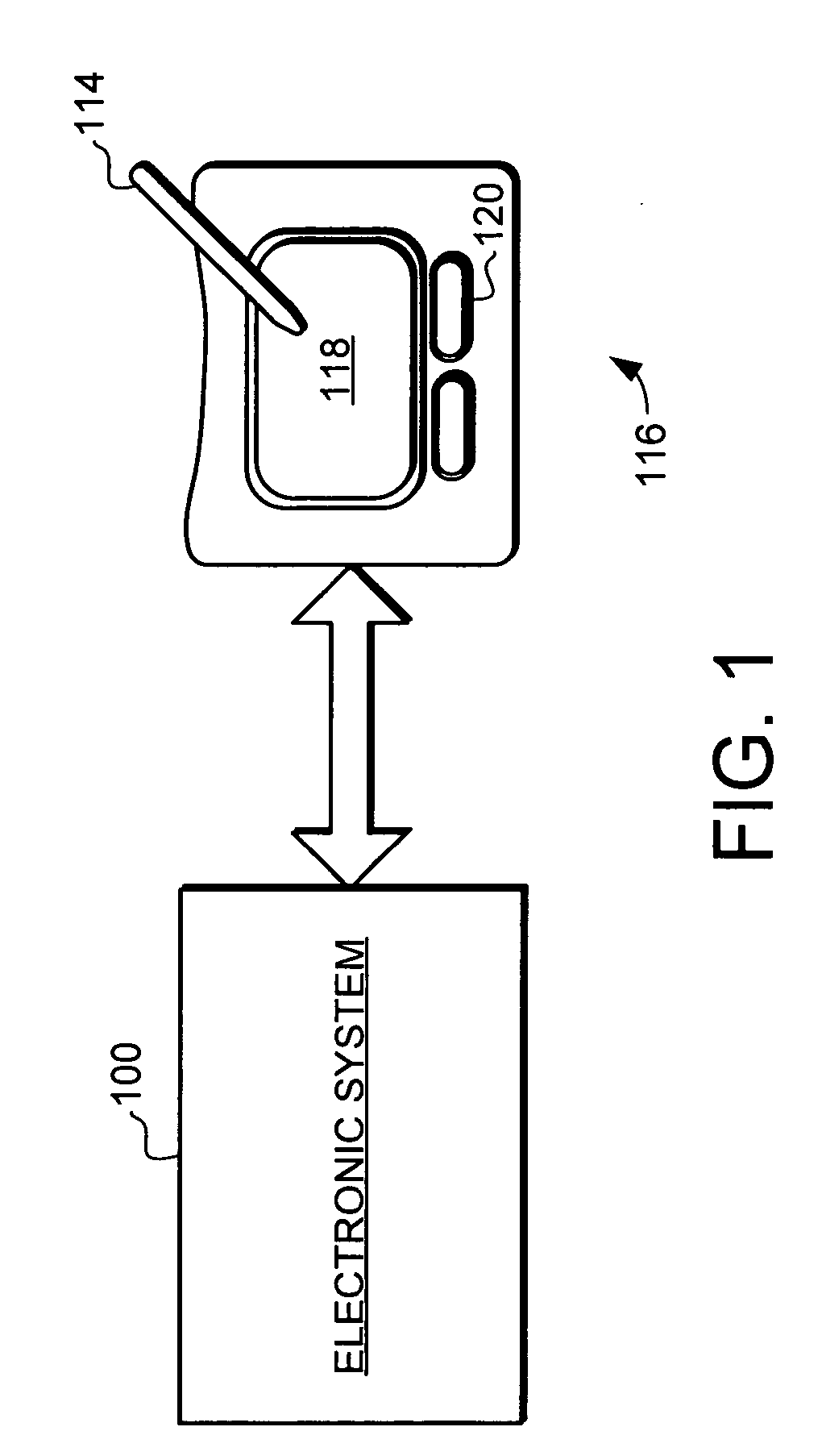

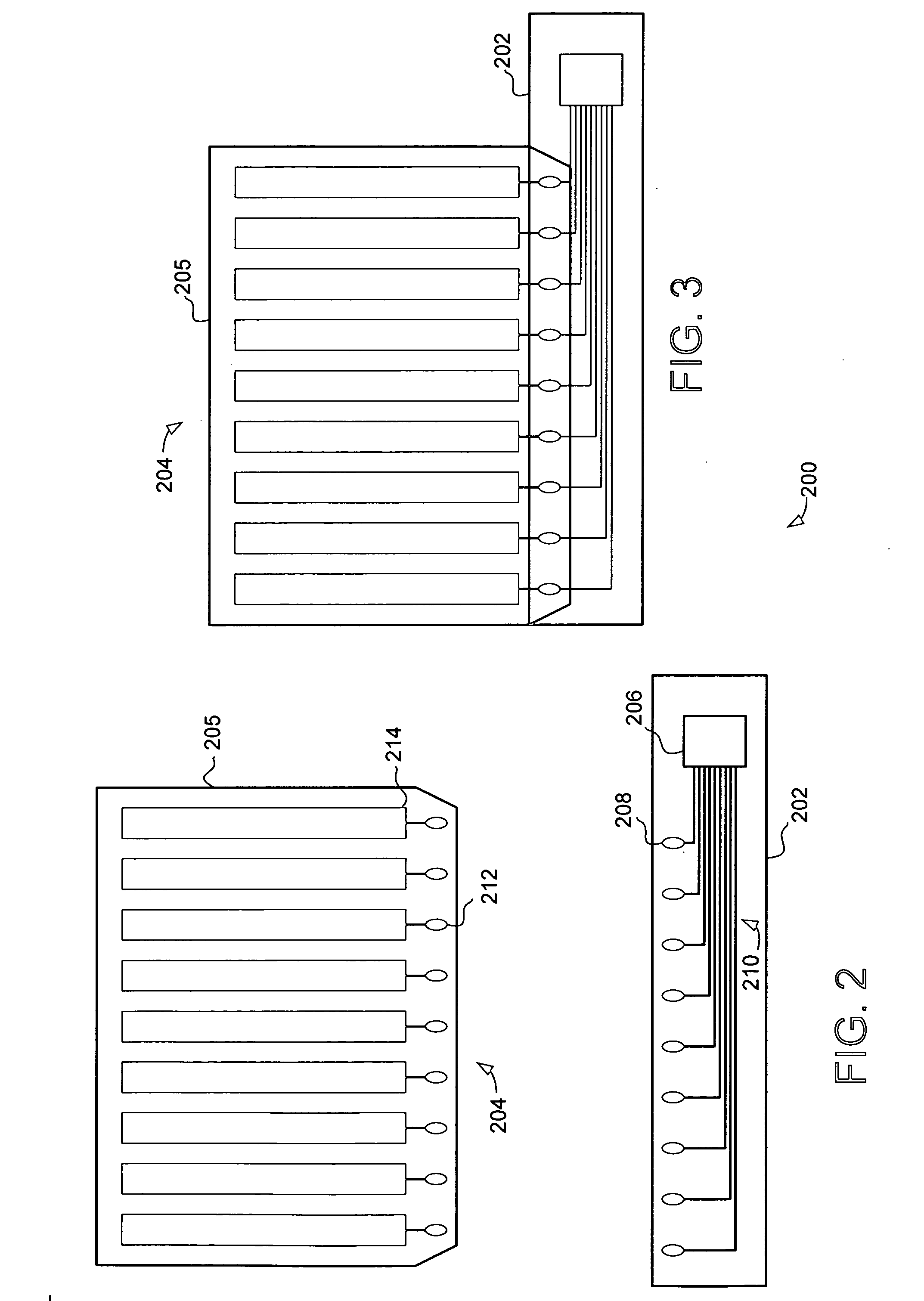

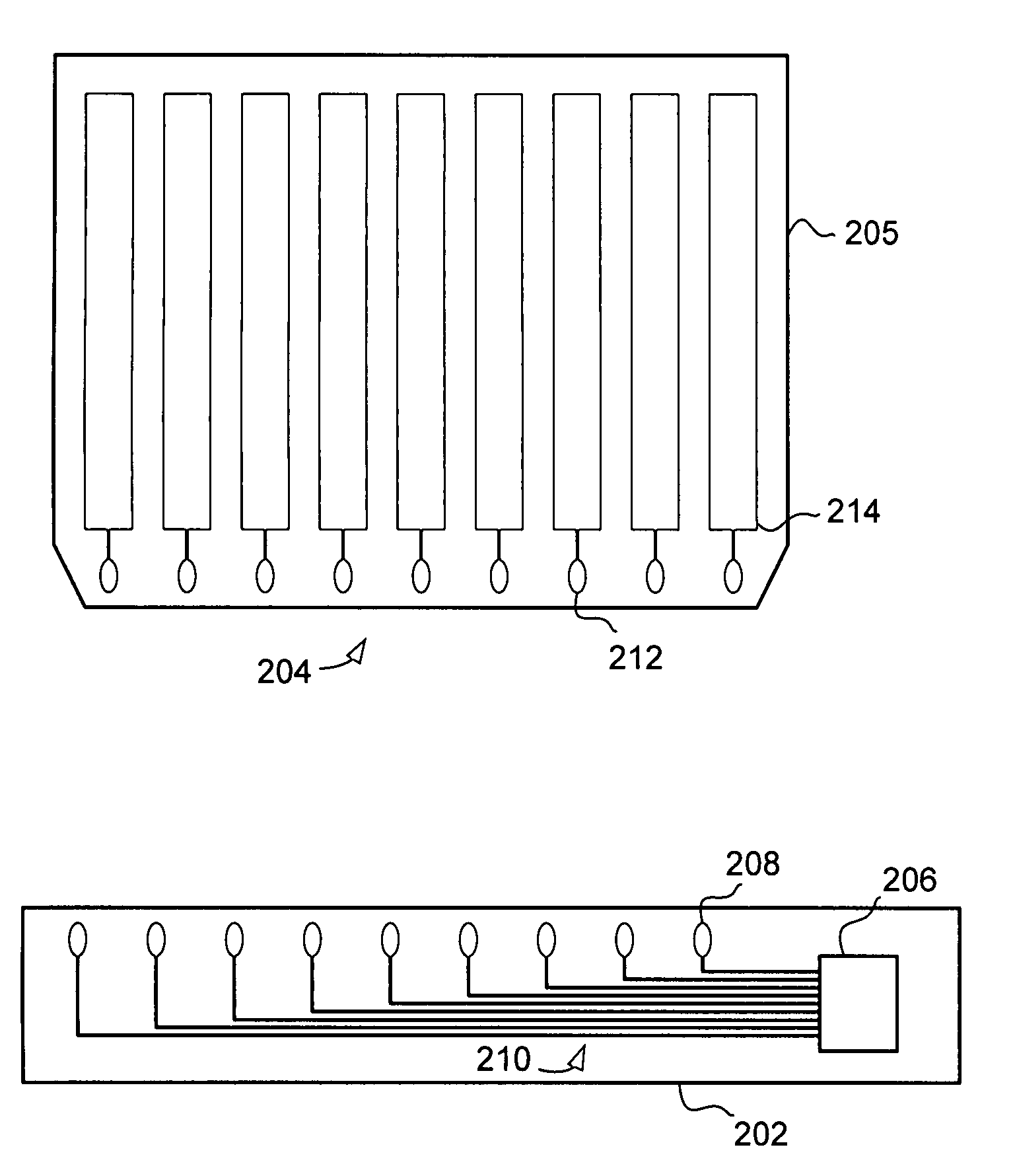

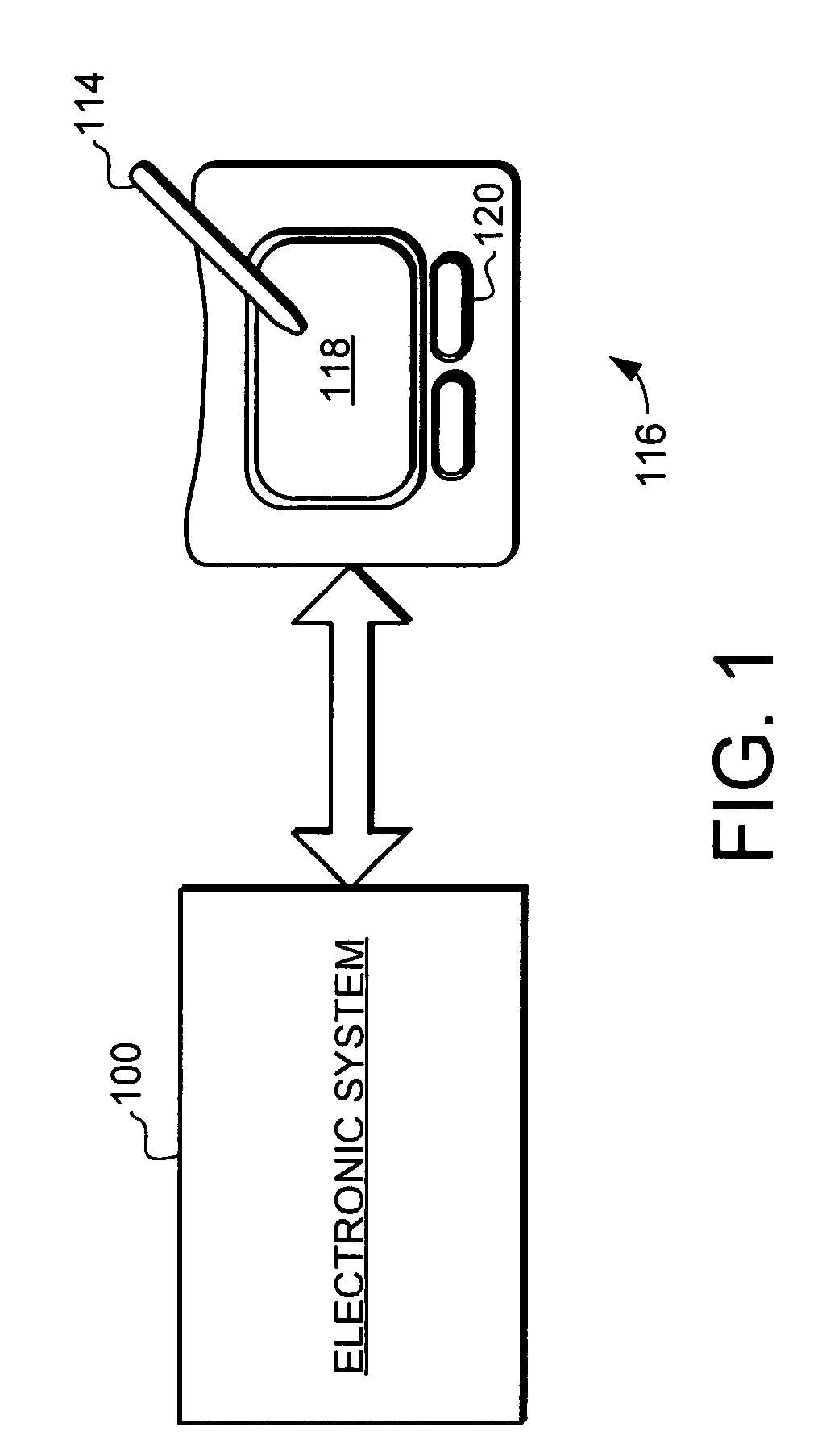

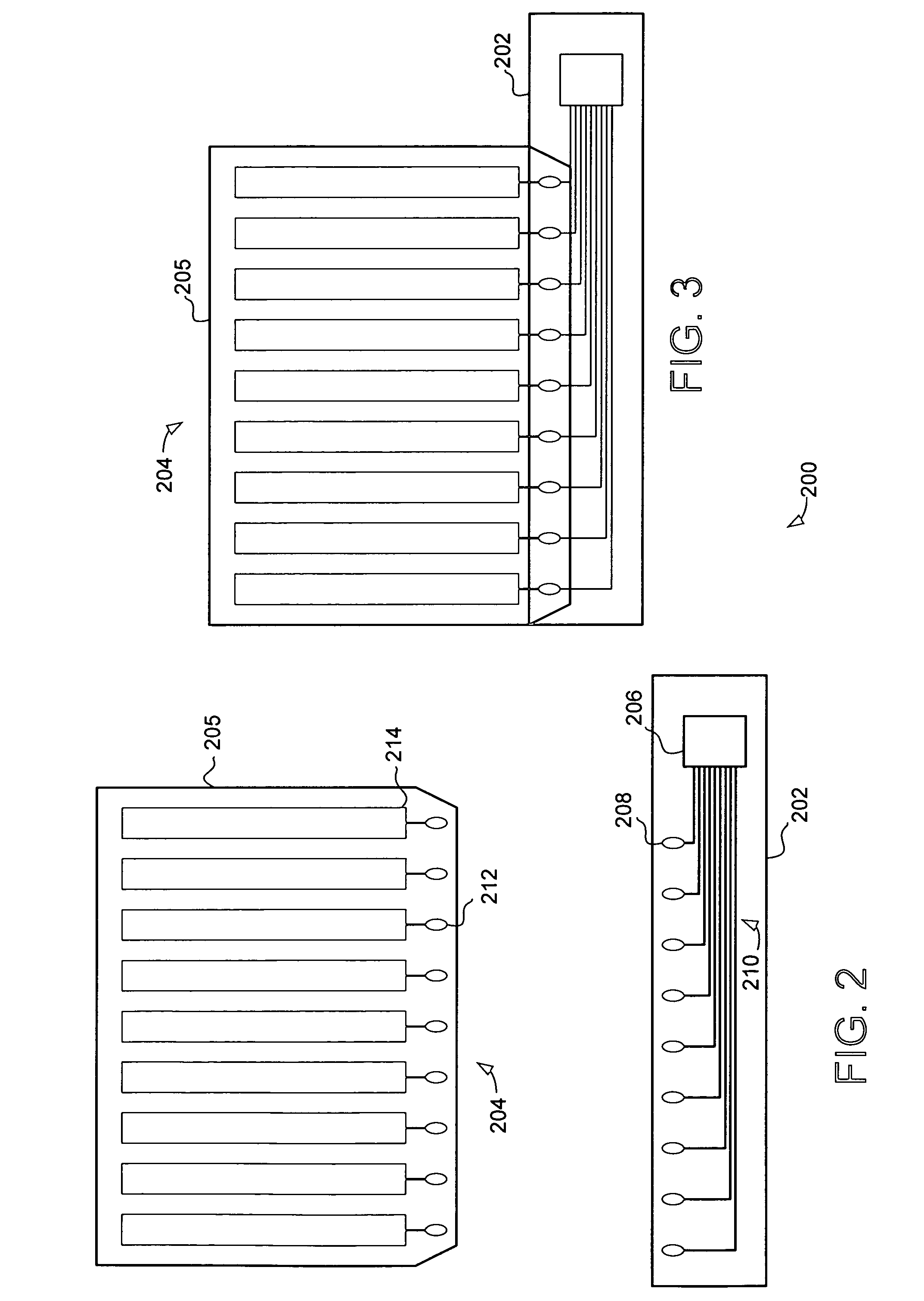

Touch pad with flexible substrate

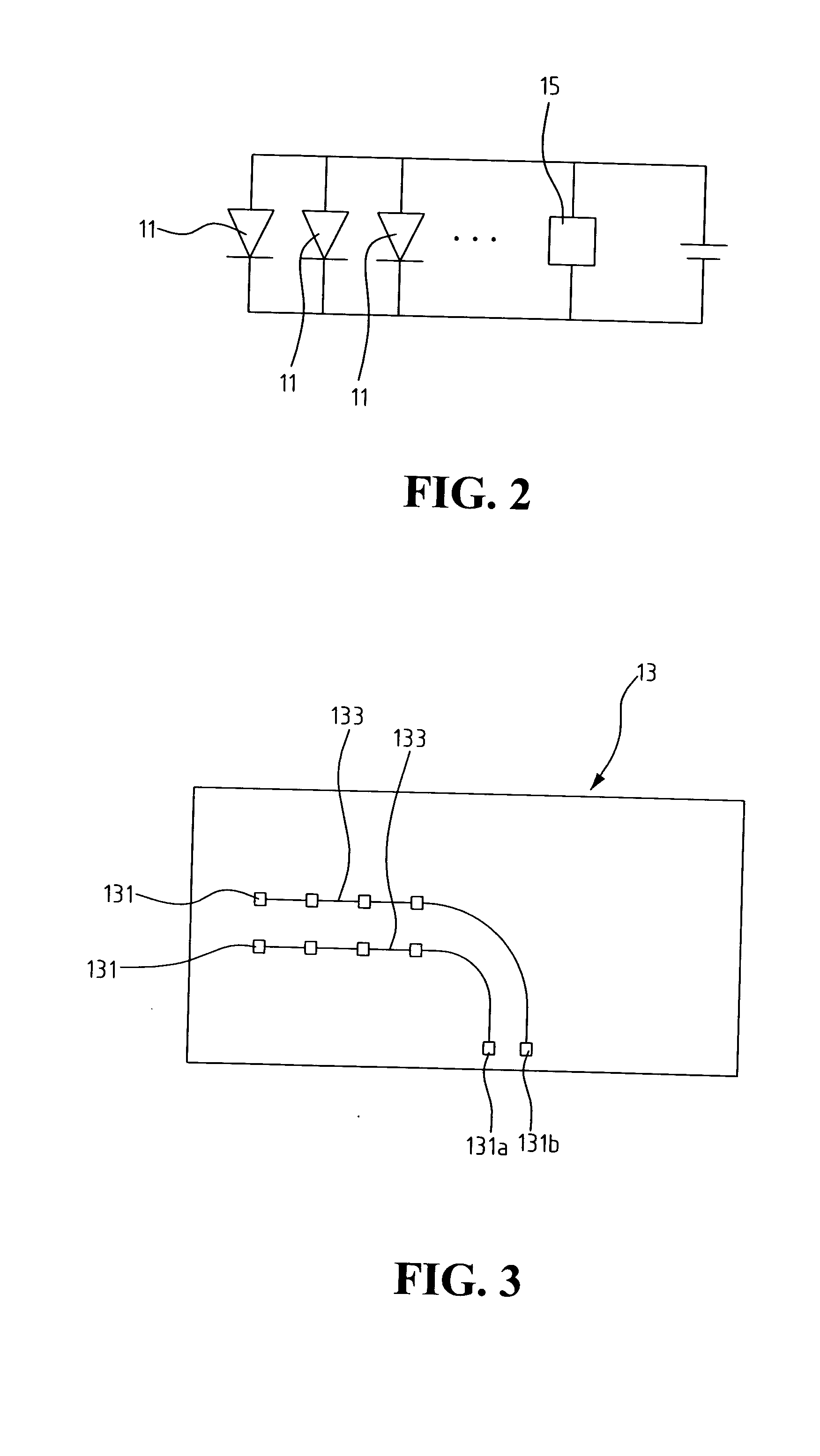

ActiveUS20060274055A1High temperature resistanceIncrease flexibilityCircuit optical detailsCross-talk/noise/interference reductionEffective solutionFlexible circuits

A touch sensor device is provided that uses a flexible circuit substrate to provide an improved input device. Specifically, the present invention uses a touch sensor controller affixed to the flexible circuit substrate, which is coupled to a sensor component to provide a flexible, reliable and cost effective touch sensor suitable for a wide variety of applications. In one embodiment the touch sensor uses a flexible circuit substrate that provides relatively high temperature resistance. This allows the touch sensor controller to be affixed using reliable techniques, such as various types of soldering. The sensor component can comprise a relatively low-temperature-resistant substrate that can provide a cost effective solution. Taken together, this embodiment of the touch sensor provides reliability and flexibility at relatively low cost.

Owner:SYNAPTICS INC

Touch pad with flexible substrate

ActiveUS7439962B2Low costHigh temperature resistanceCircuit optical detailsTransmission systemsEffective solutionFlexible circuits

Owner:SYNAPTICS INC

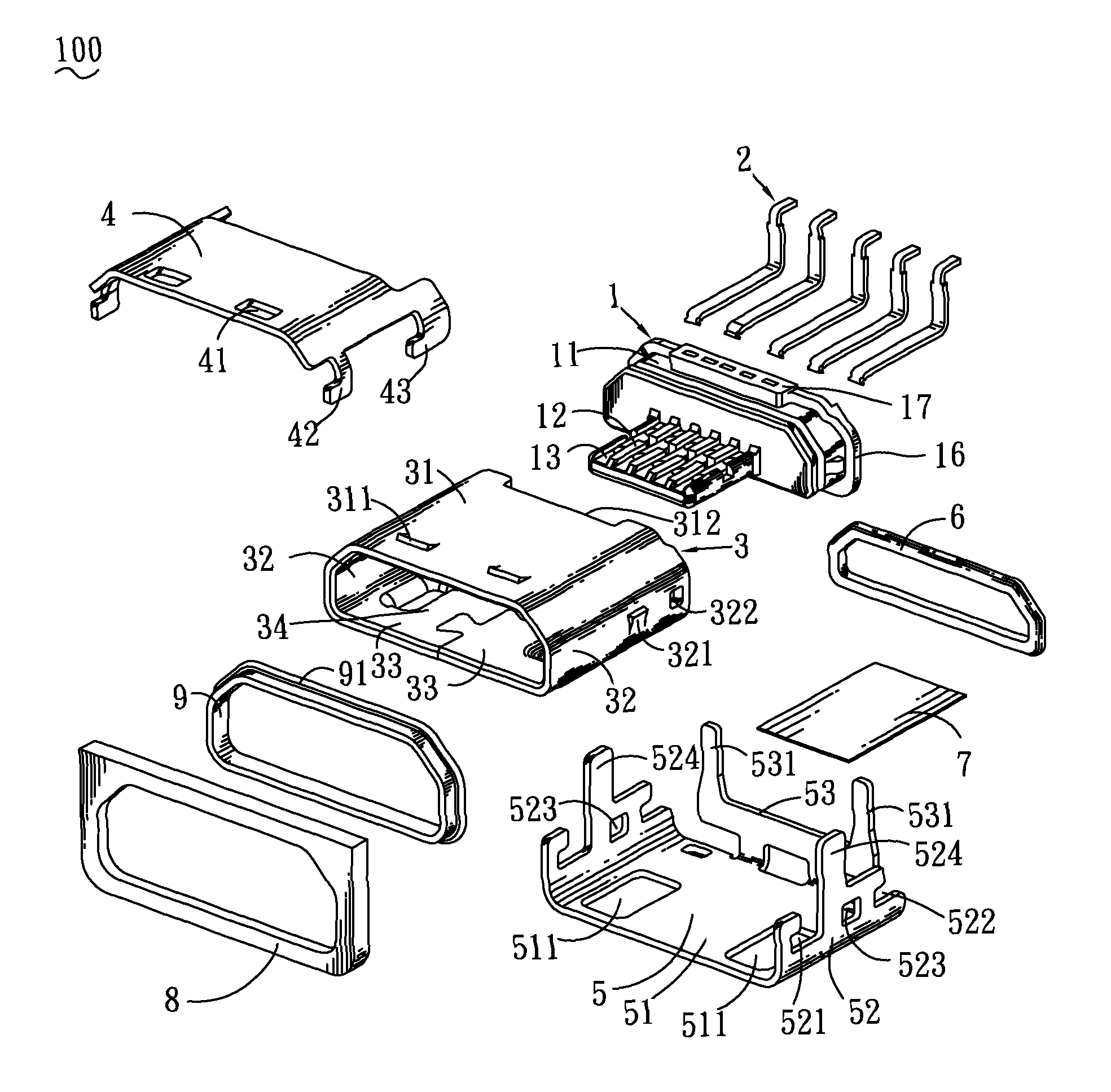

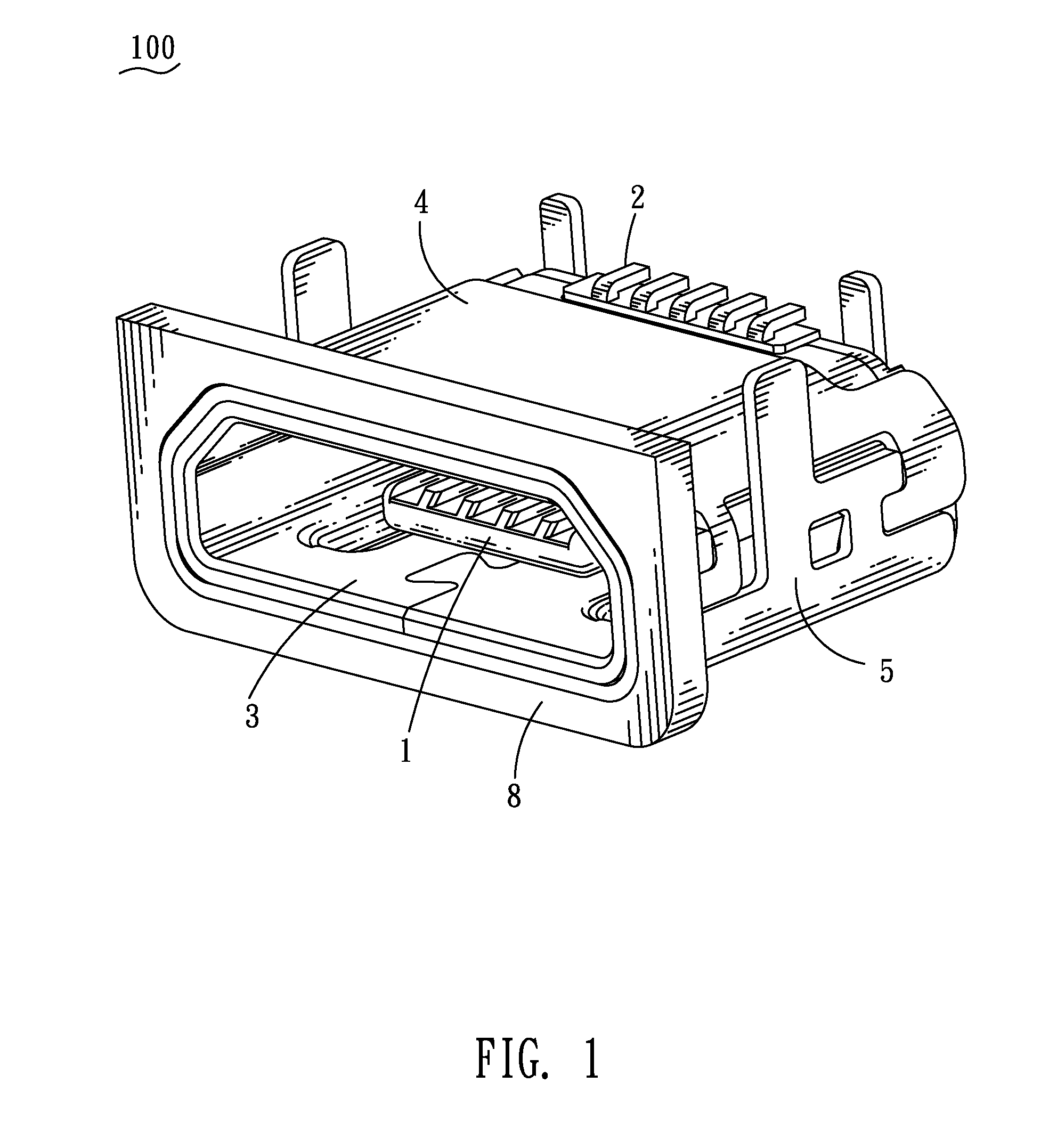

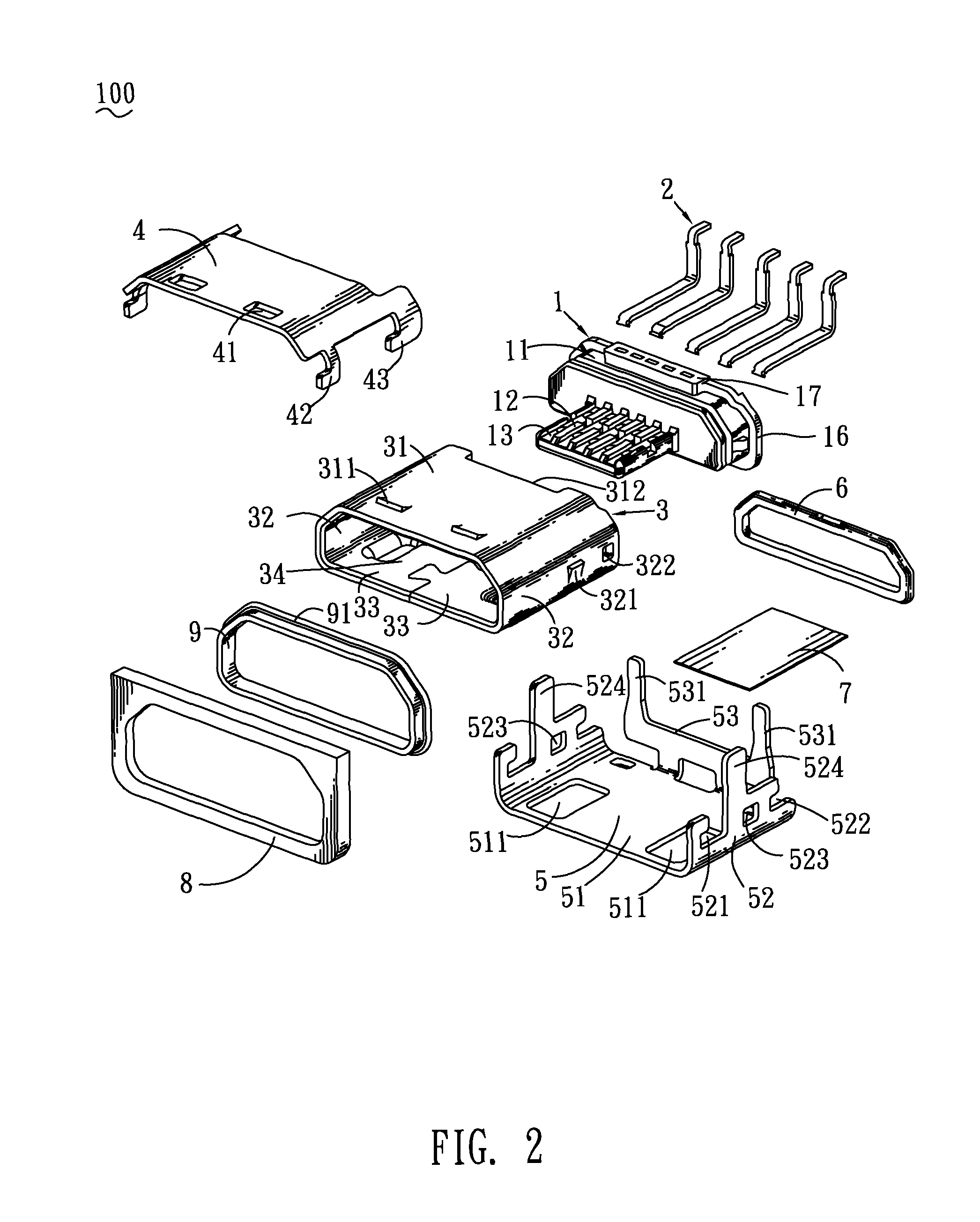

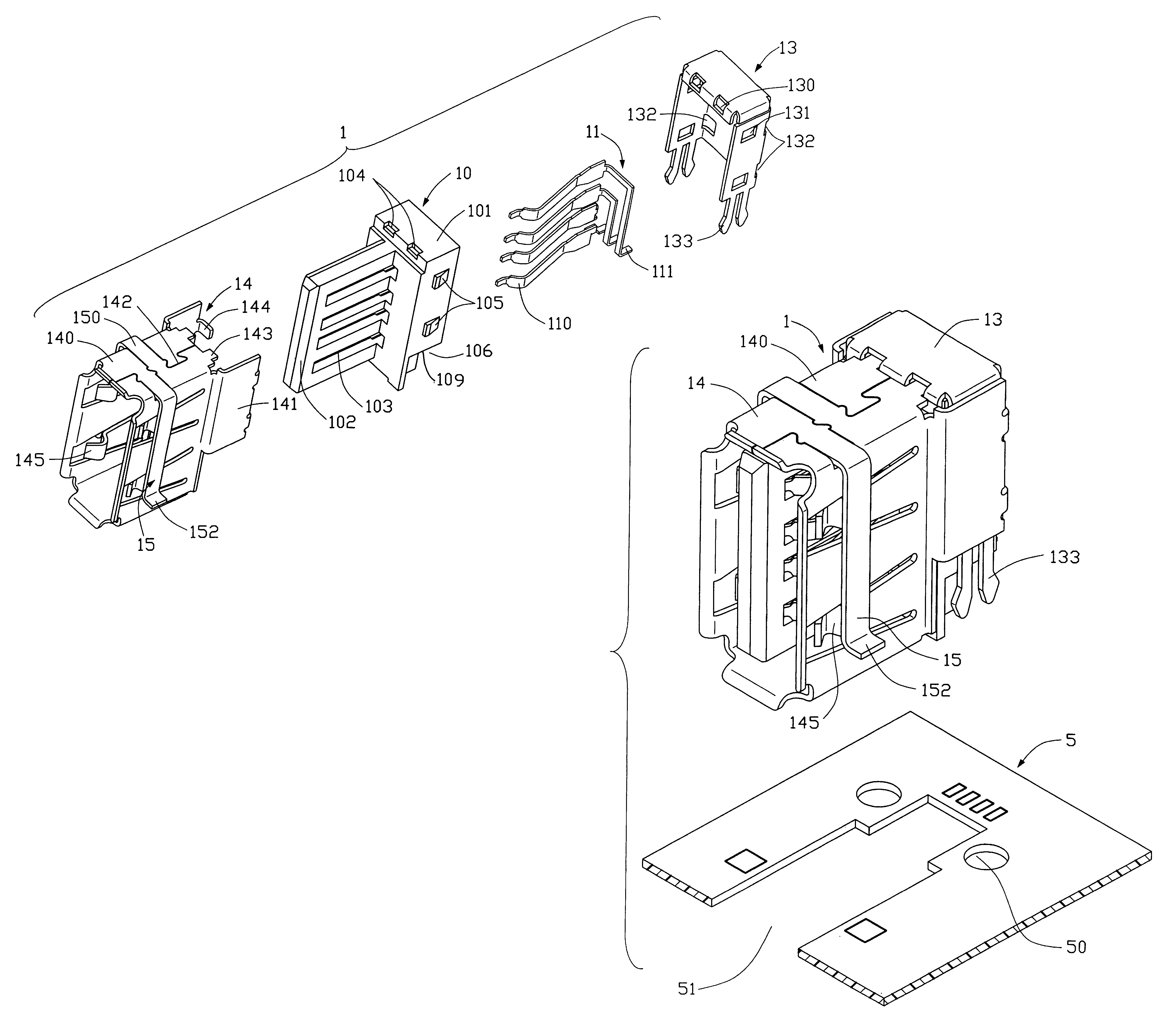

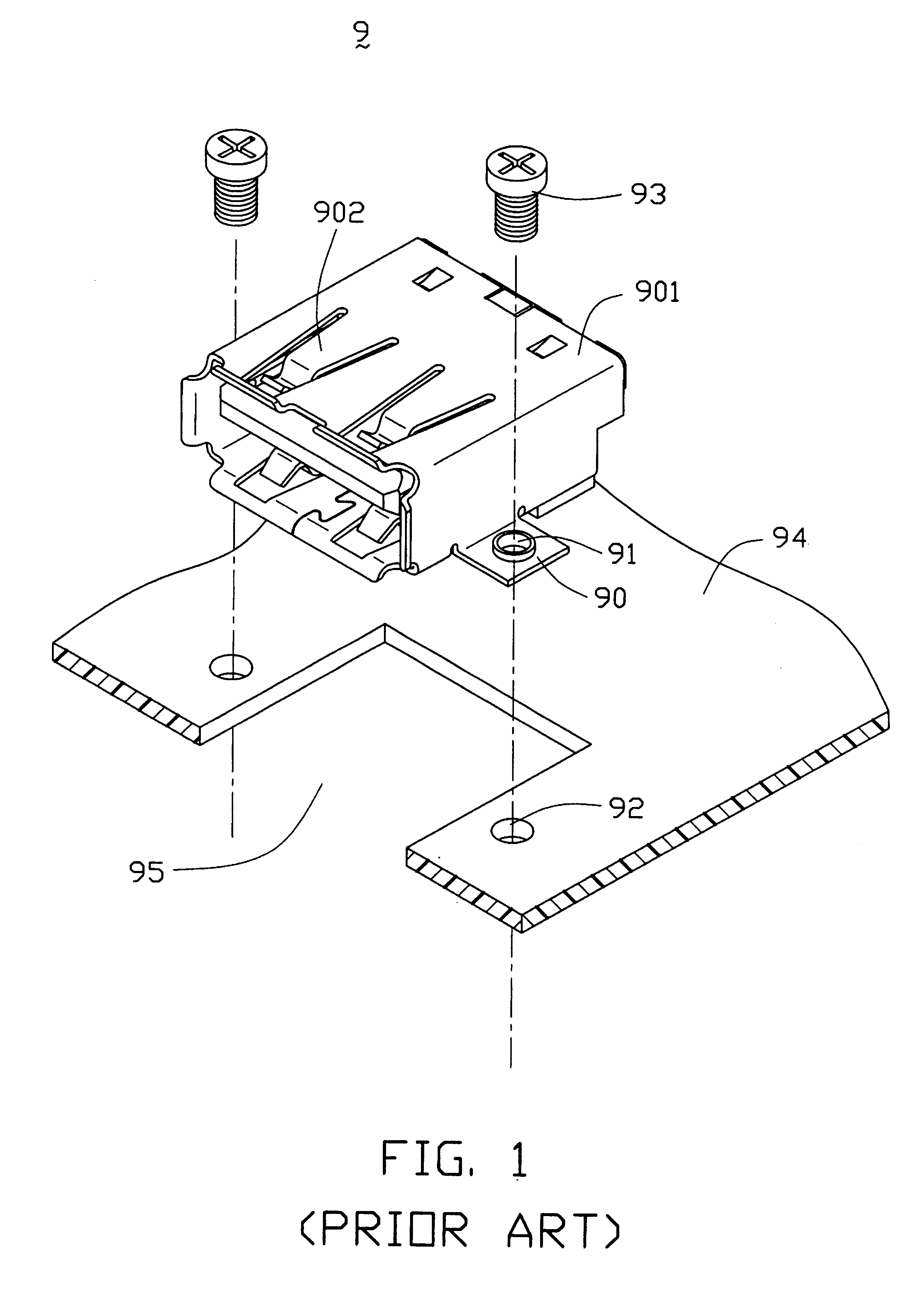

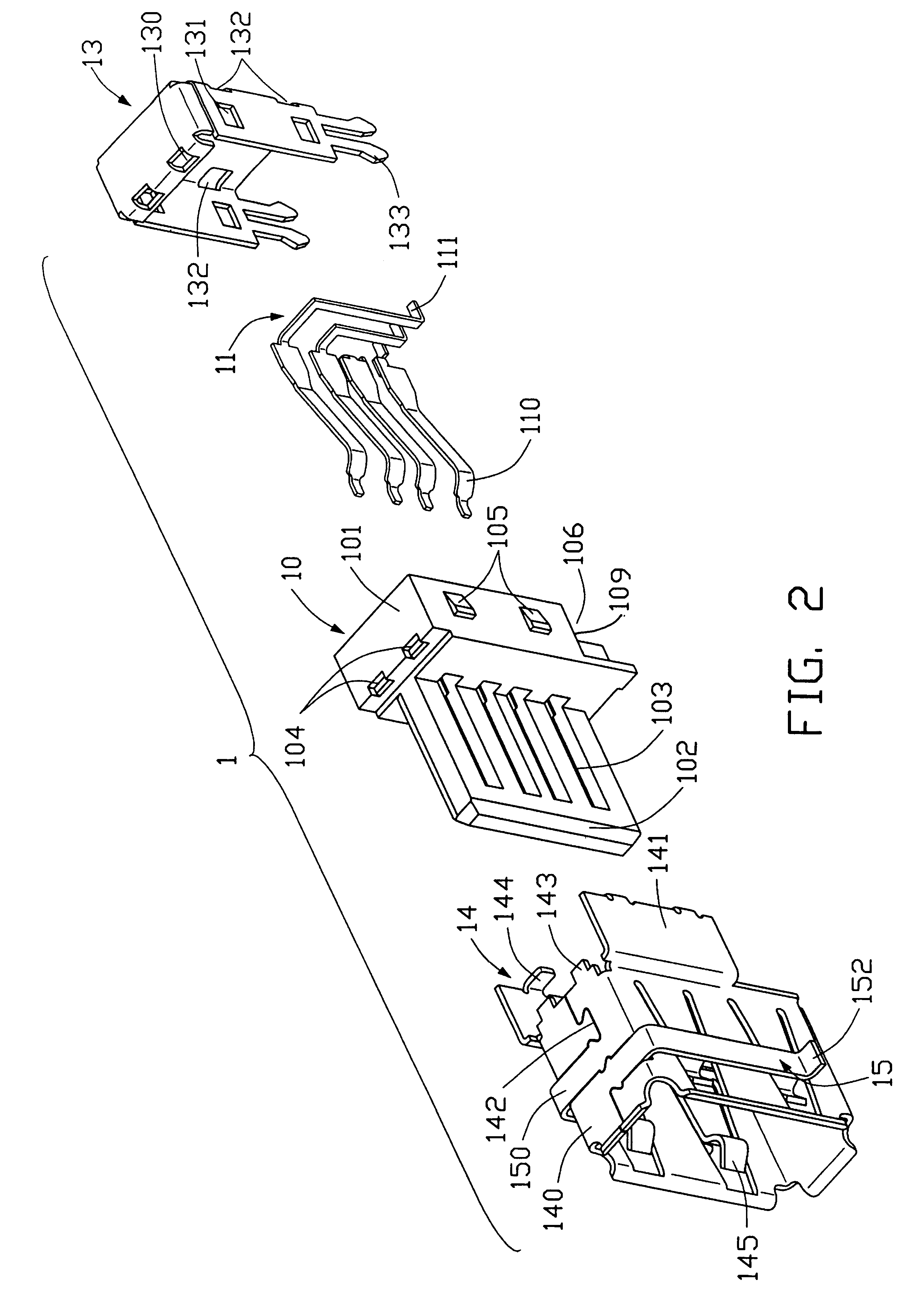

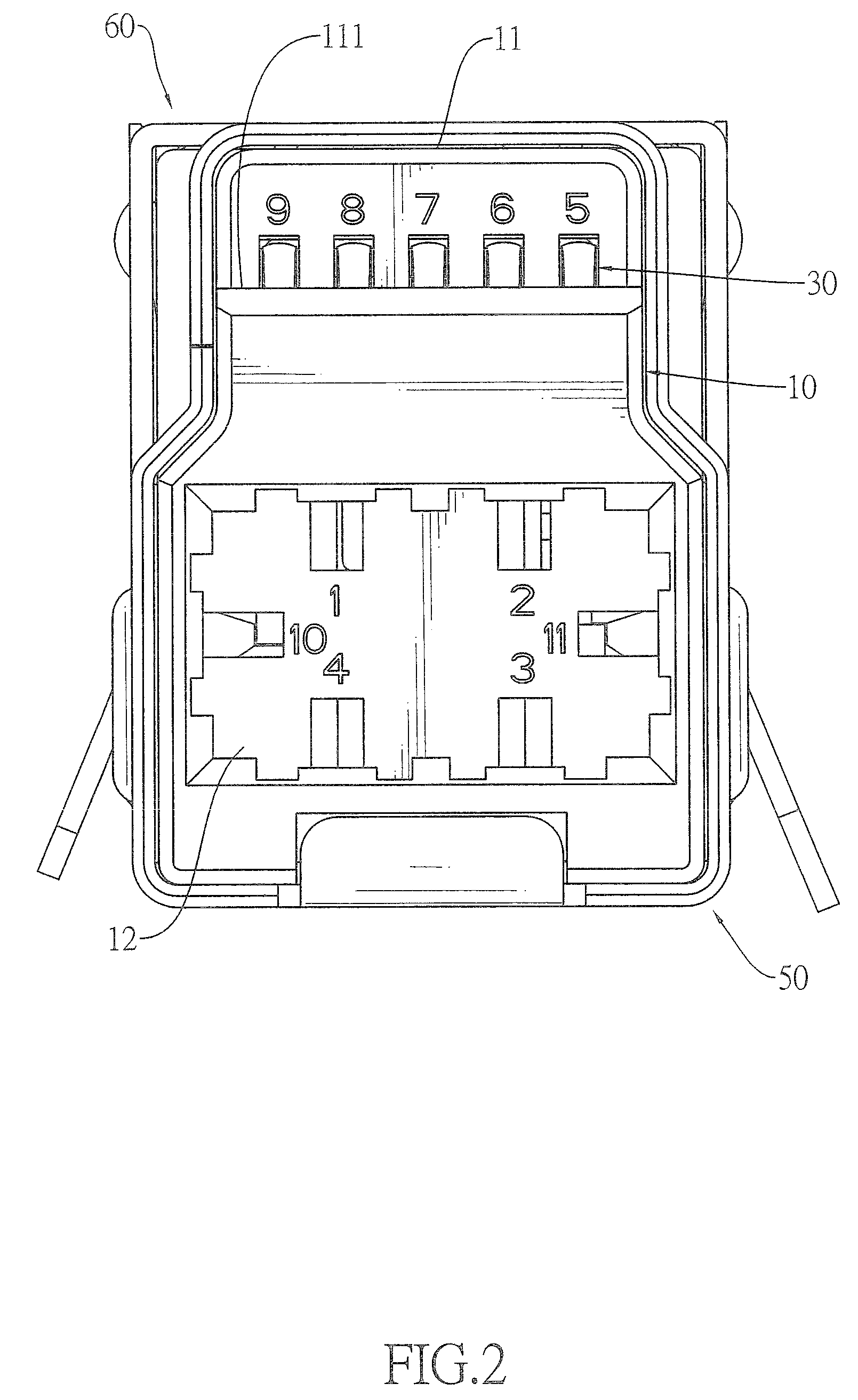

Electrical connector

InactiveUS7922535B1Avoid moisture accumulationAvoid enteringCouplings bases/casesTwo-part coupling devicesEngineeringElectrical connector

An electrical connector includes an inner shielding shell, an insulating housing, a plurality of terminals and an outer shielding shell. The inner shielding shell defines an accommodating chamber therein. The insulating housing has a base body engaged with a rear of the accommodating chamber and a tongue portion extended forward from the base portion to stretch into a front of the accommodating chamber. A ring-shaped cavity is opened in a periphery of the base body for receiving a waterproof washer therein. An outer periphery of the waterproof washer abuts against insides of the inner shielding shell. The terminals are disposed in the insulating housing. The outer shielding shell surrounds the inner shielding shell. The outer shielding shell has at least one soldering arm soldered to a printed circuit board for achieving a ground function of the inner shielding shell through the outer shielding shell.

Owner:CHENG UEI PRECISION IND CO LTD

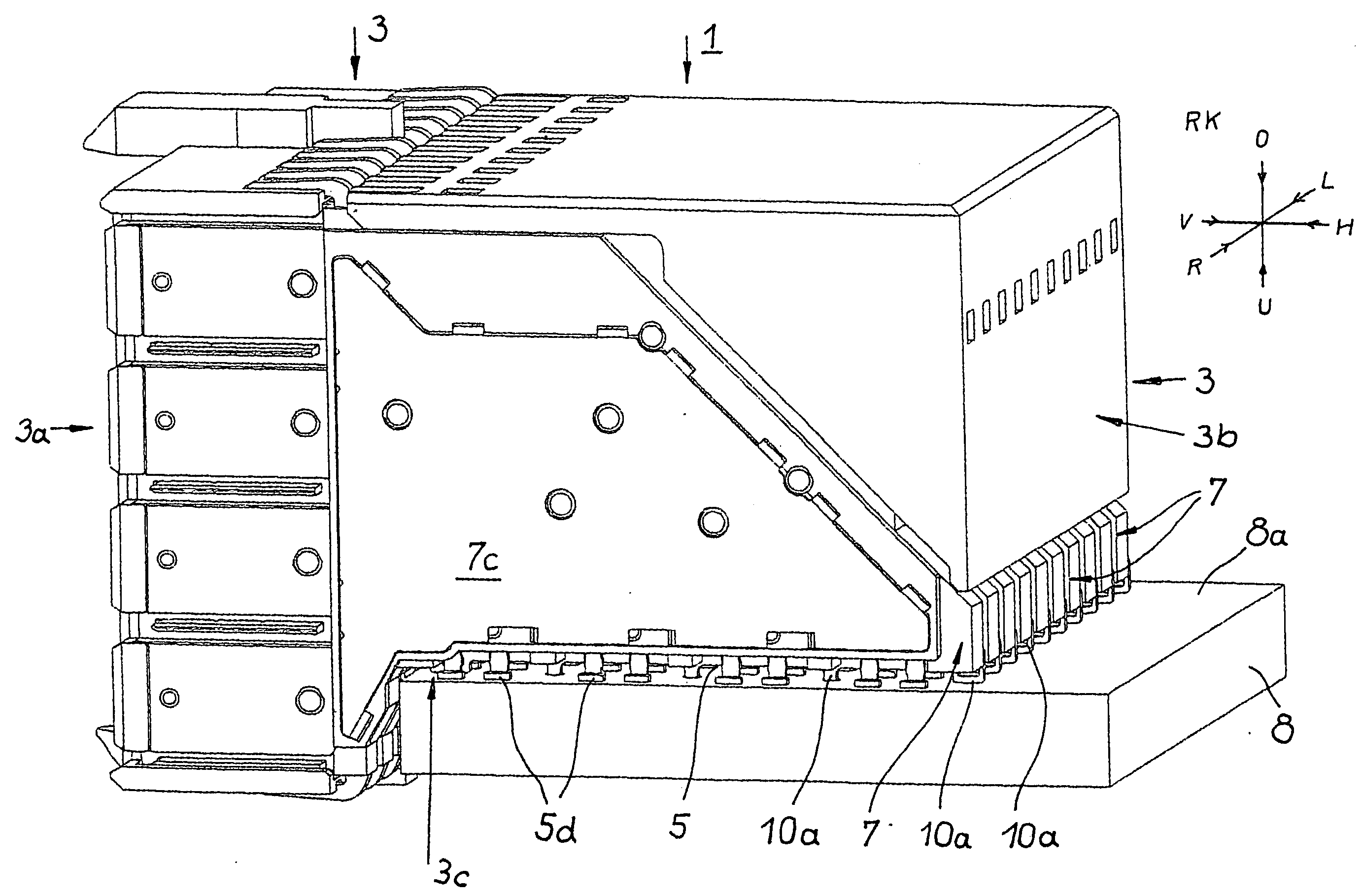

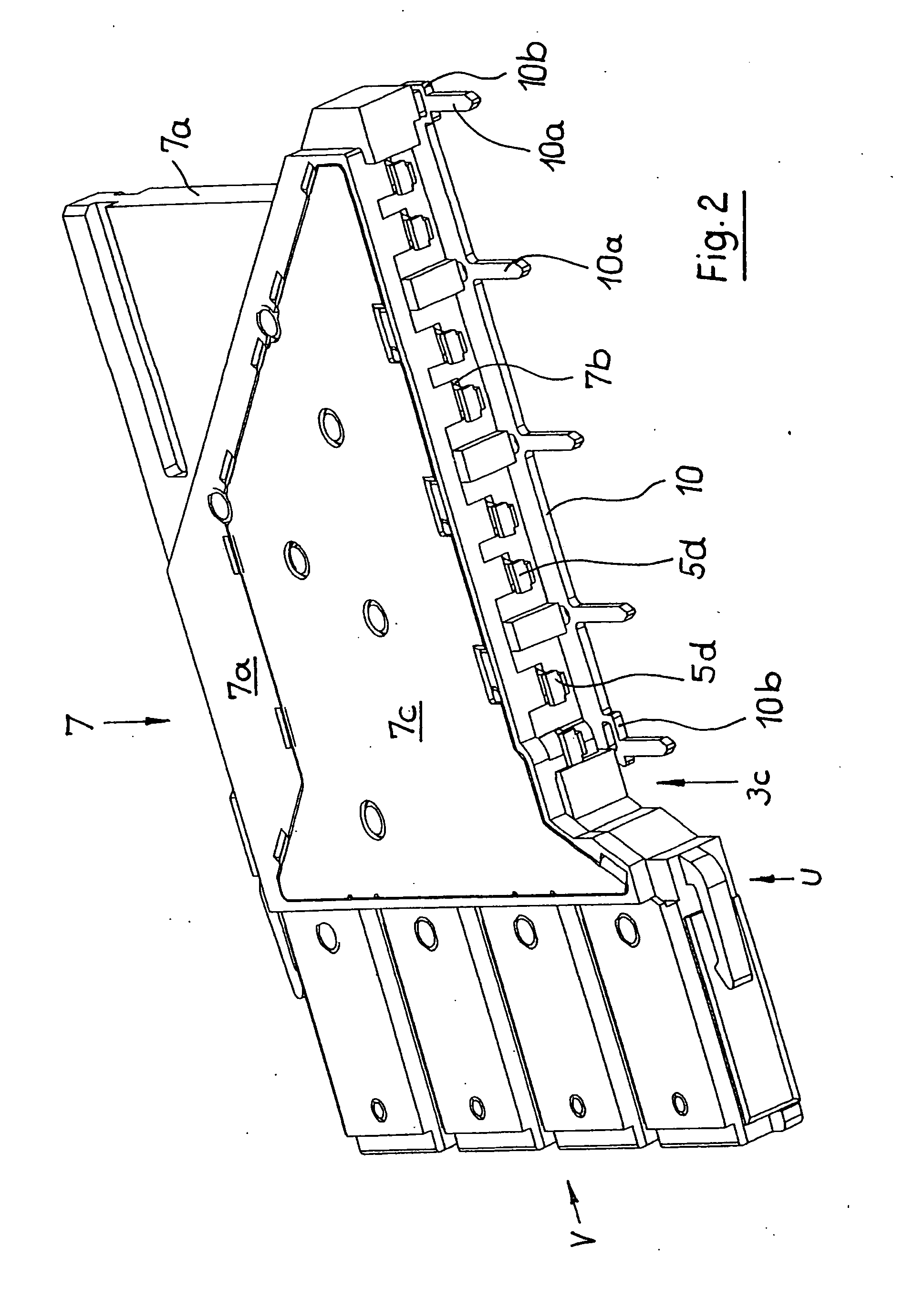

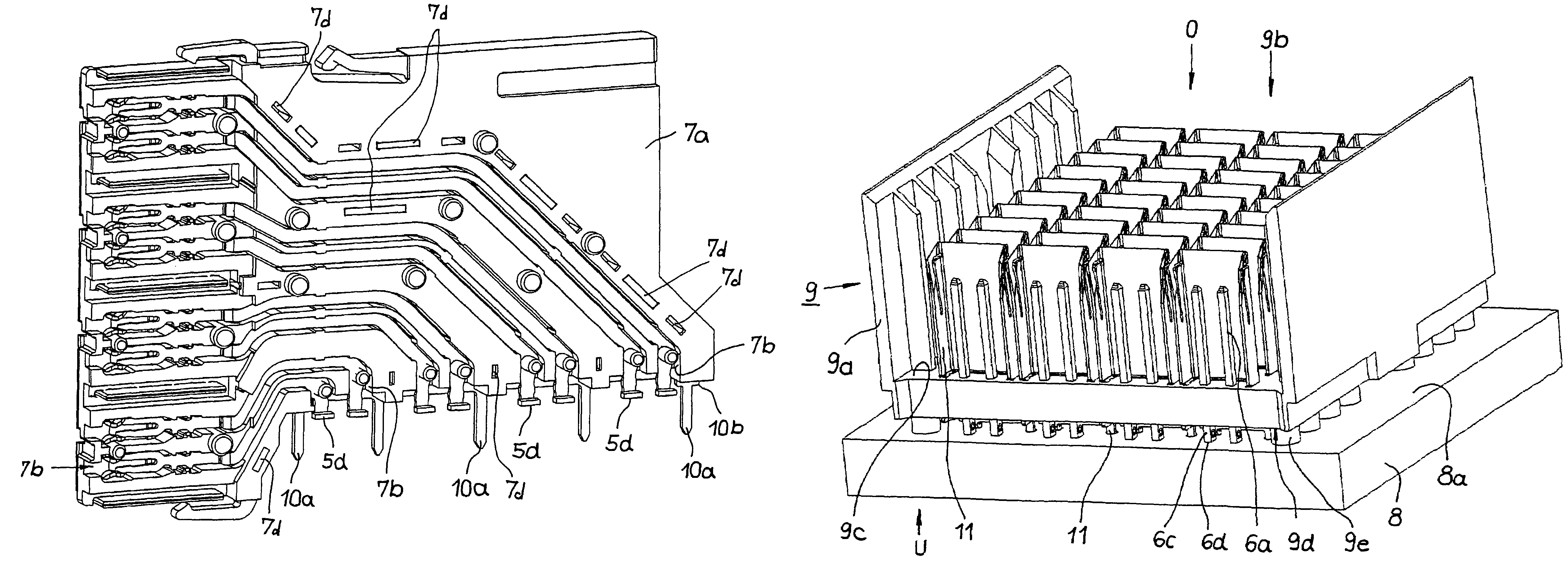

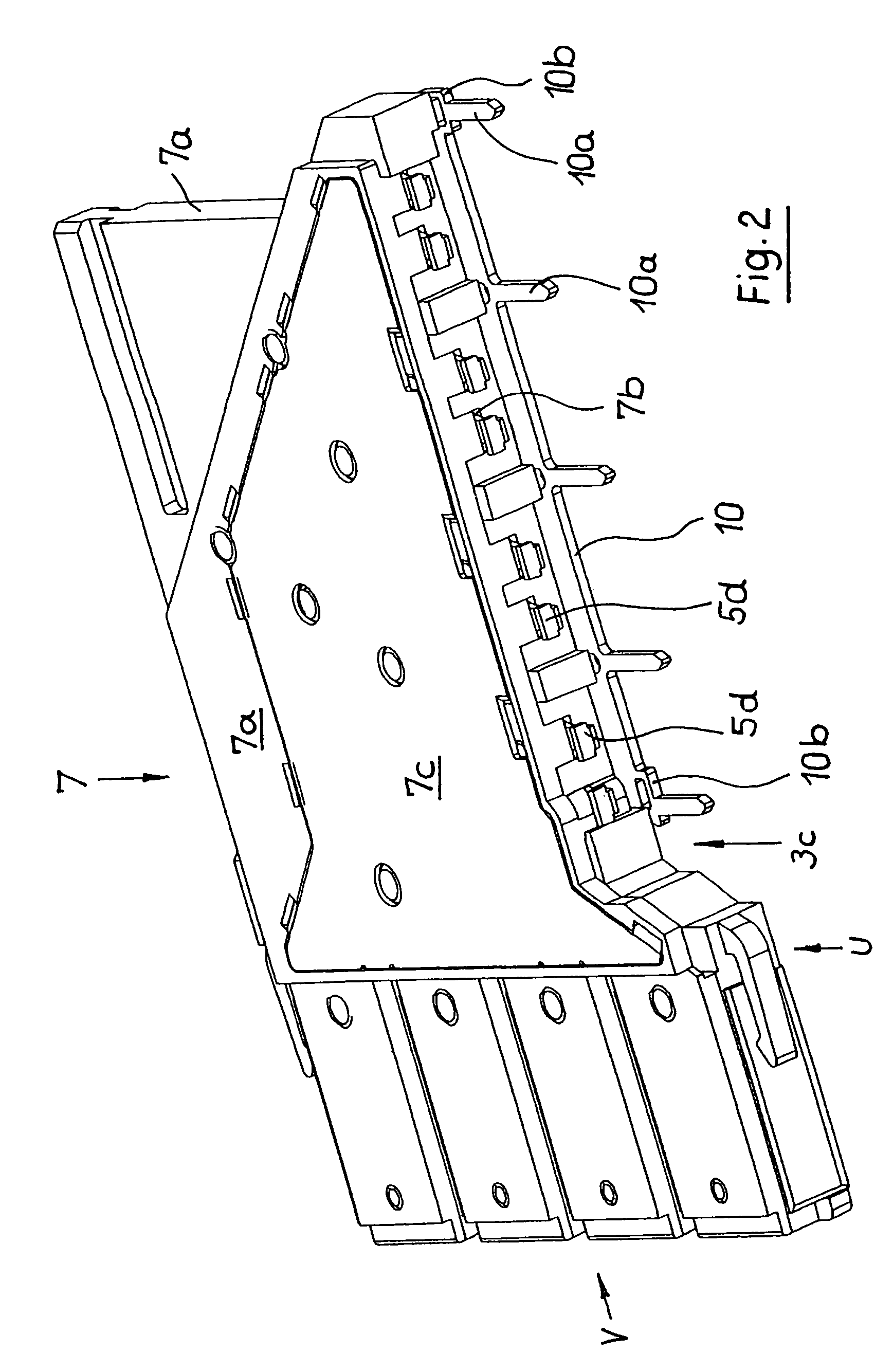

Plug-and-socket connector

ActiveUS20070155241A1High mechanical strengthGood electrical parametersCoupling protective earth/shielding arrangementsElectronic systemsEngineering

A multi-pole, multi-row plug-and-socket connector with shielding, for placement on printed circuit boards, circuit cards, and similar electrical components, which can be used in an electrical or electronic system includes electrical contact parts for the transmission of signals, which possess a connection section on one end and an electrically conductive attachment section on the other end, as well as an electrical shielding, which possesses at least one electrically conductive contact section. The free ends of the electrically conductive attachment sections of the electrical contact parts are SMD contacts. The at least one electrically conductive contact section of the shielding is, at the same time, an attachment pin which projects into a passage hole of the printed circuit board when the plug-and-socket connector is disposed on the same, for the purpose of connective soldering using THR technology.

Owner:ERNI PRODION GMBH

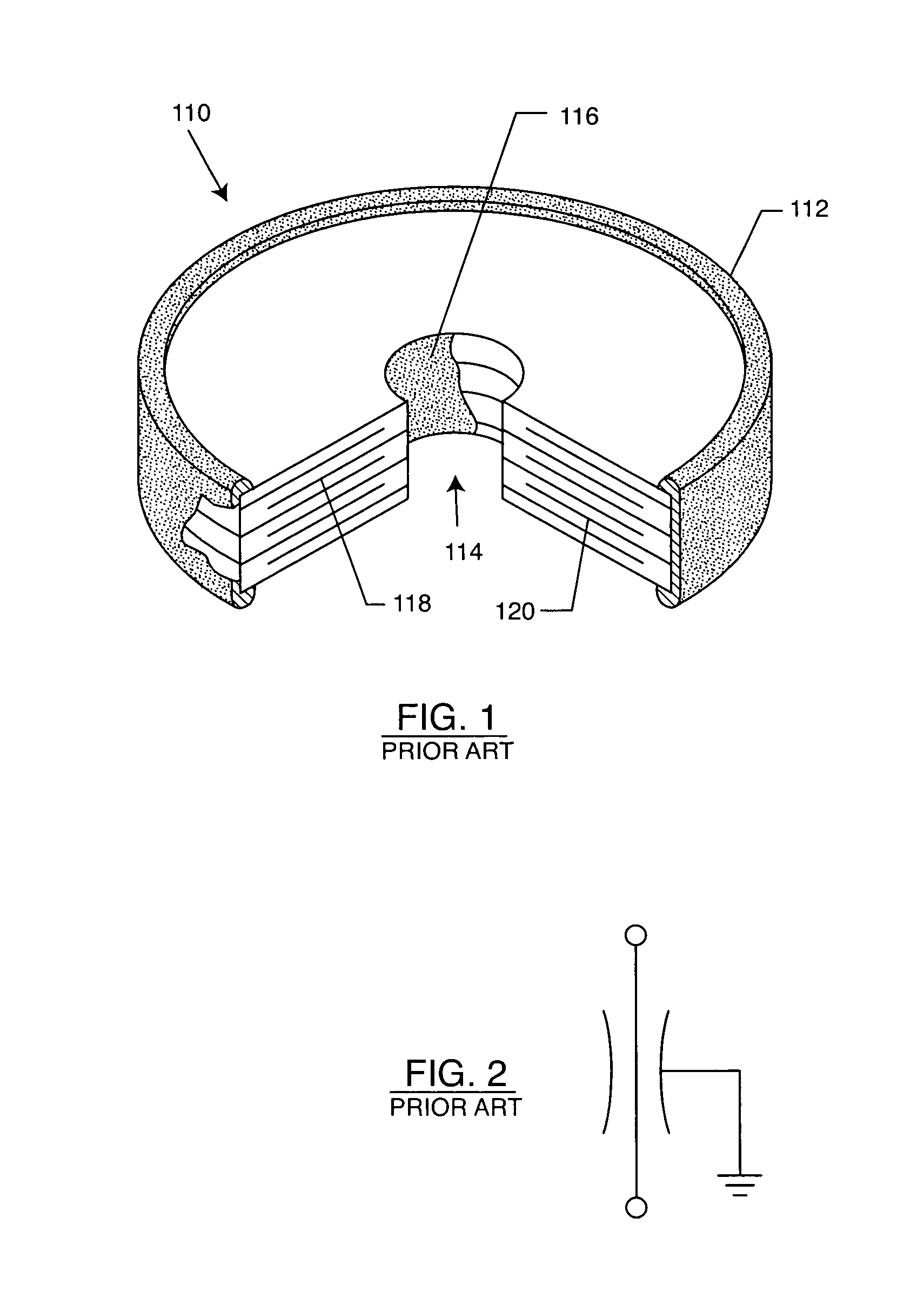

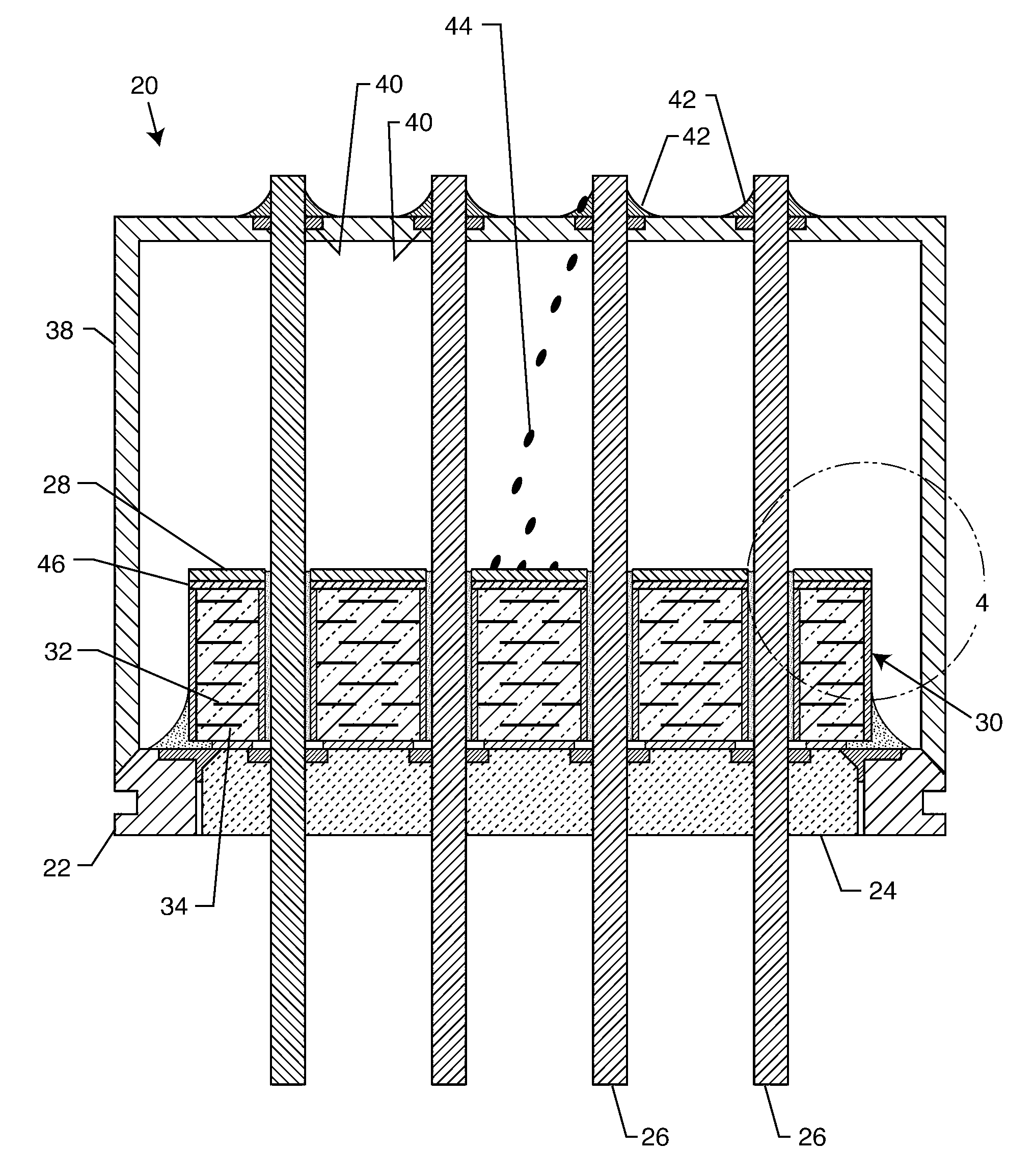

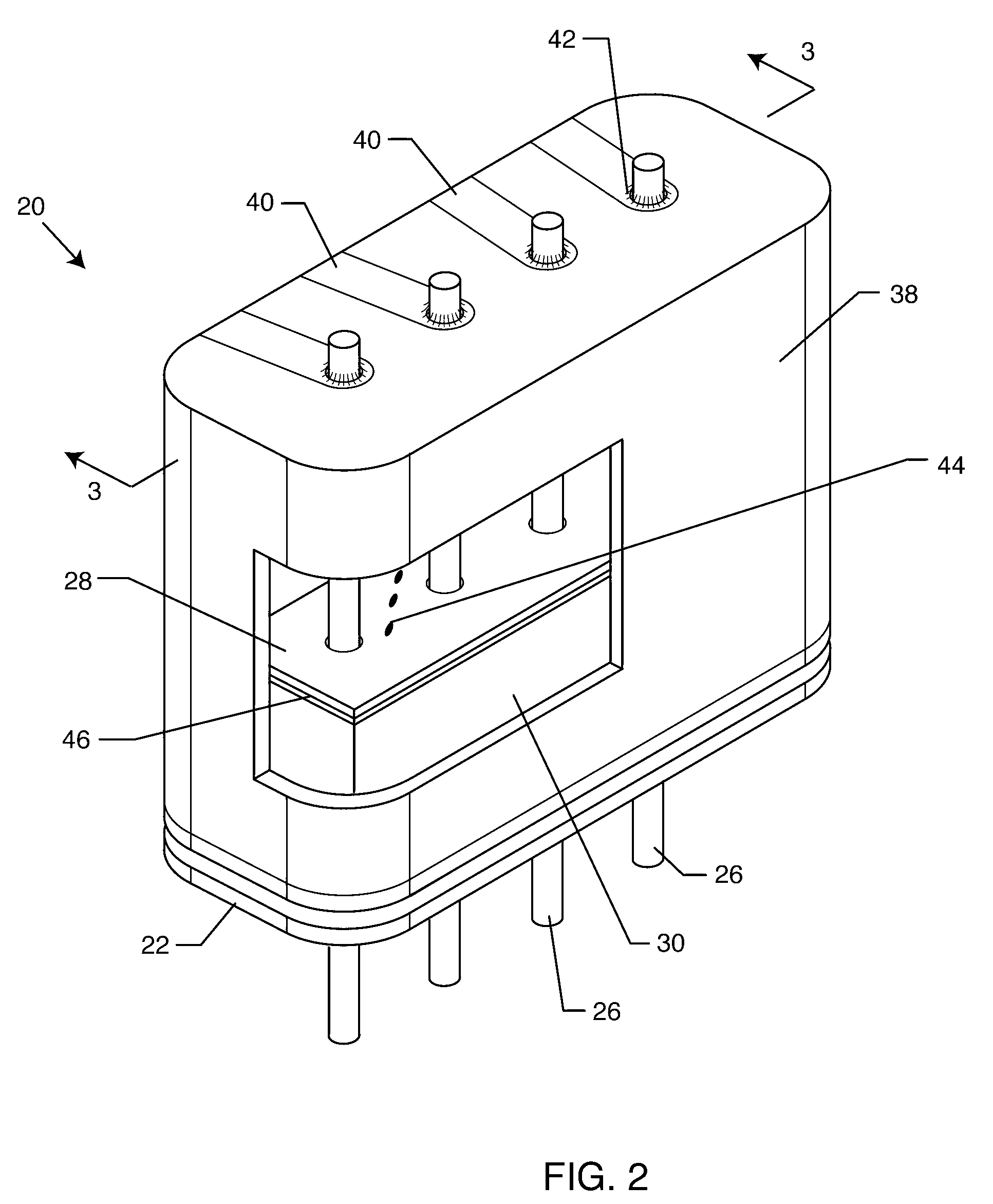

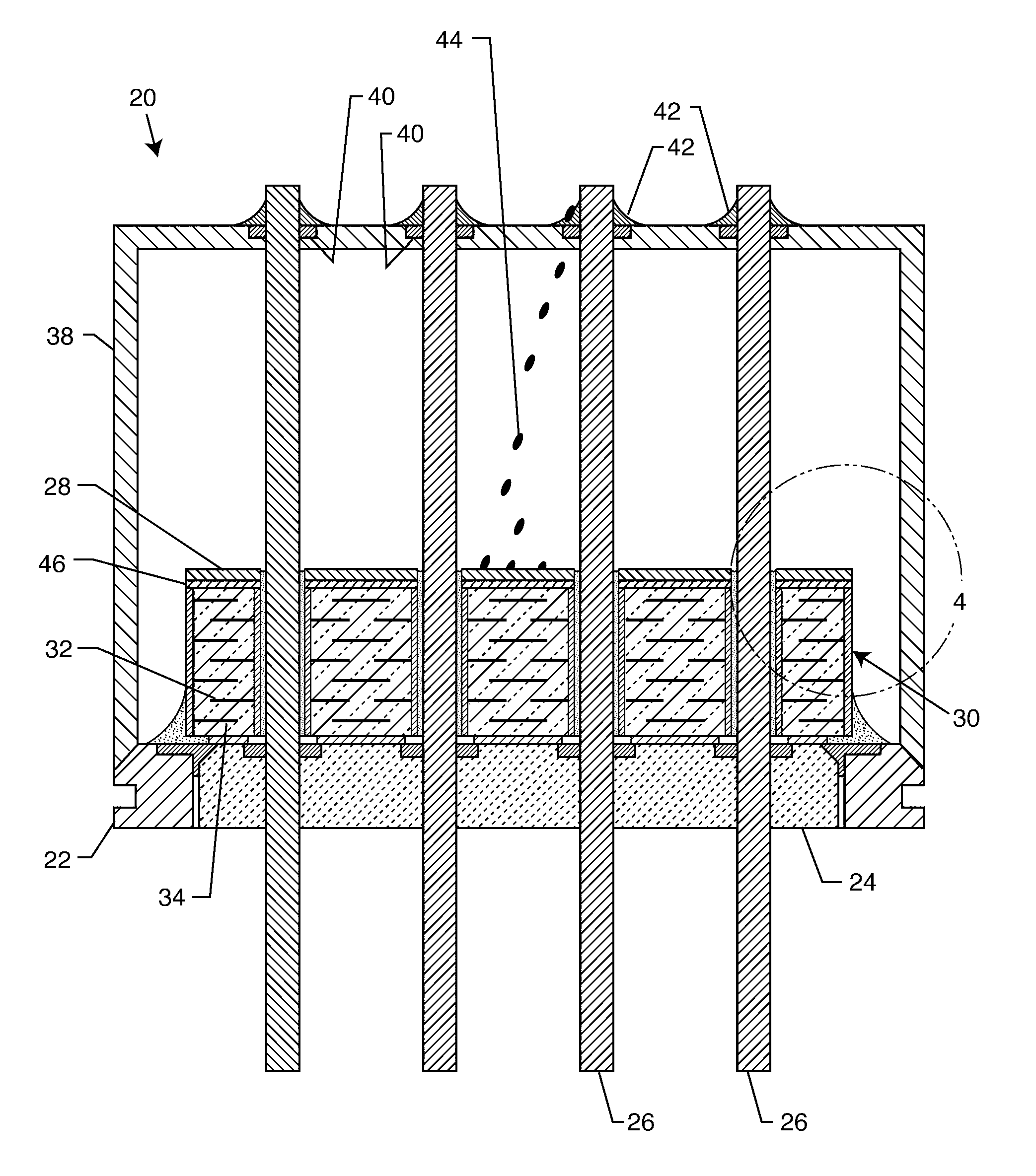

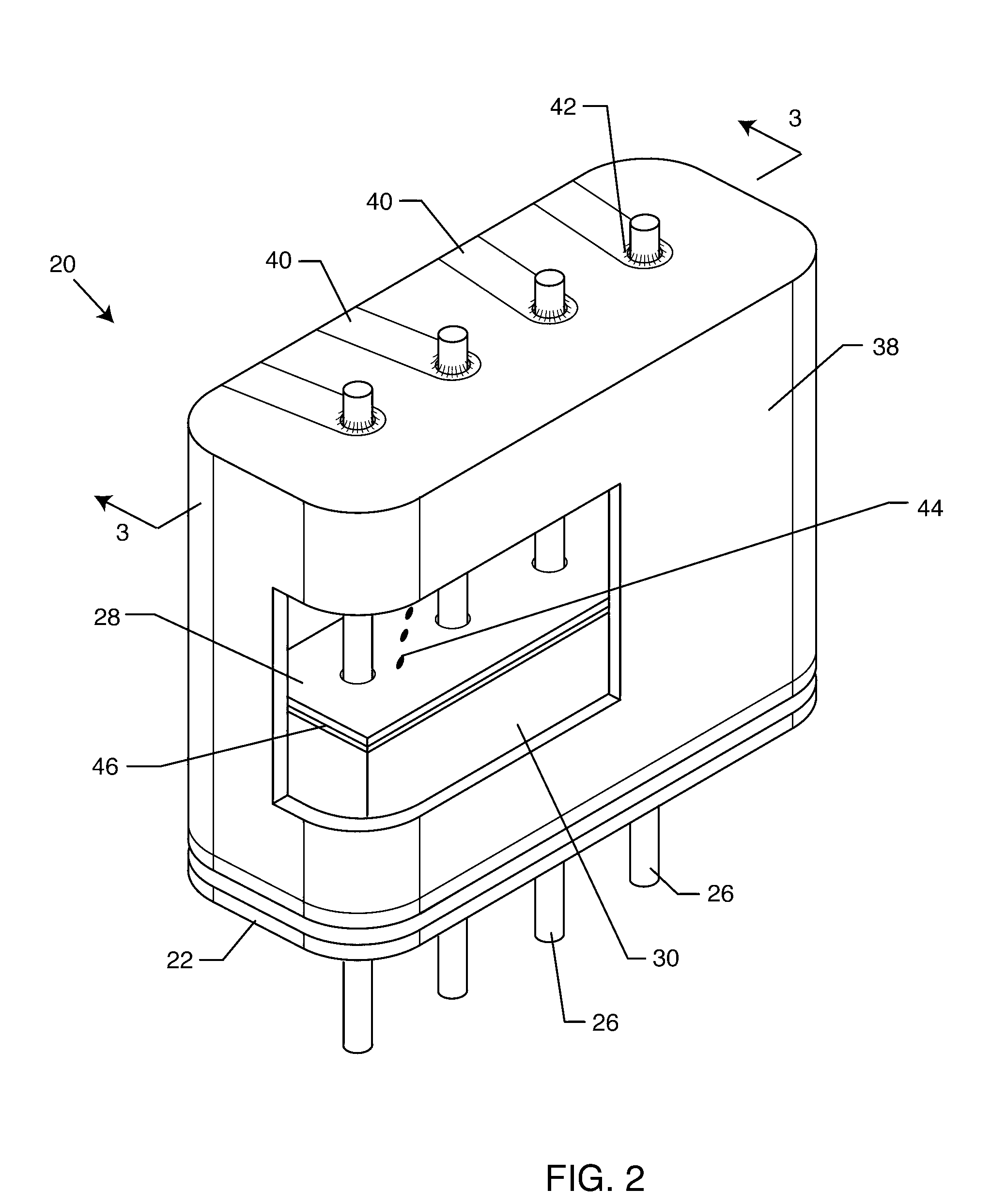

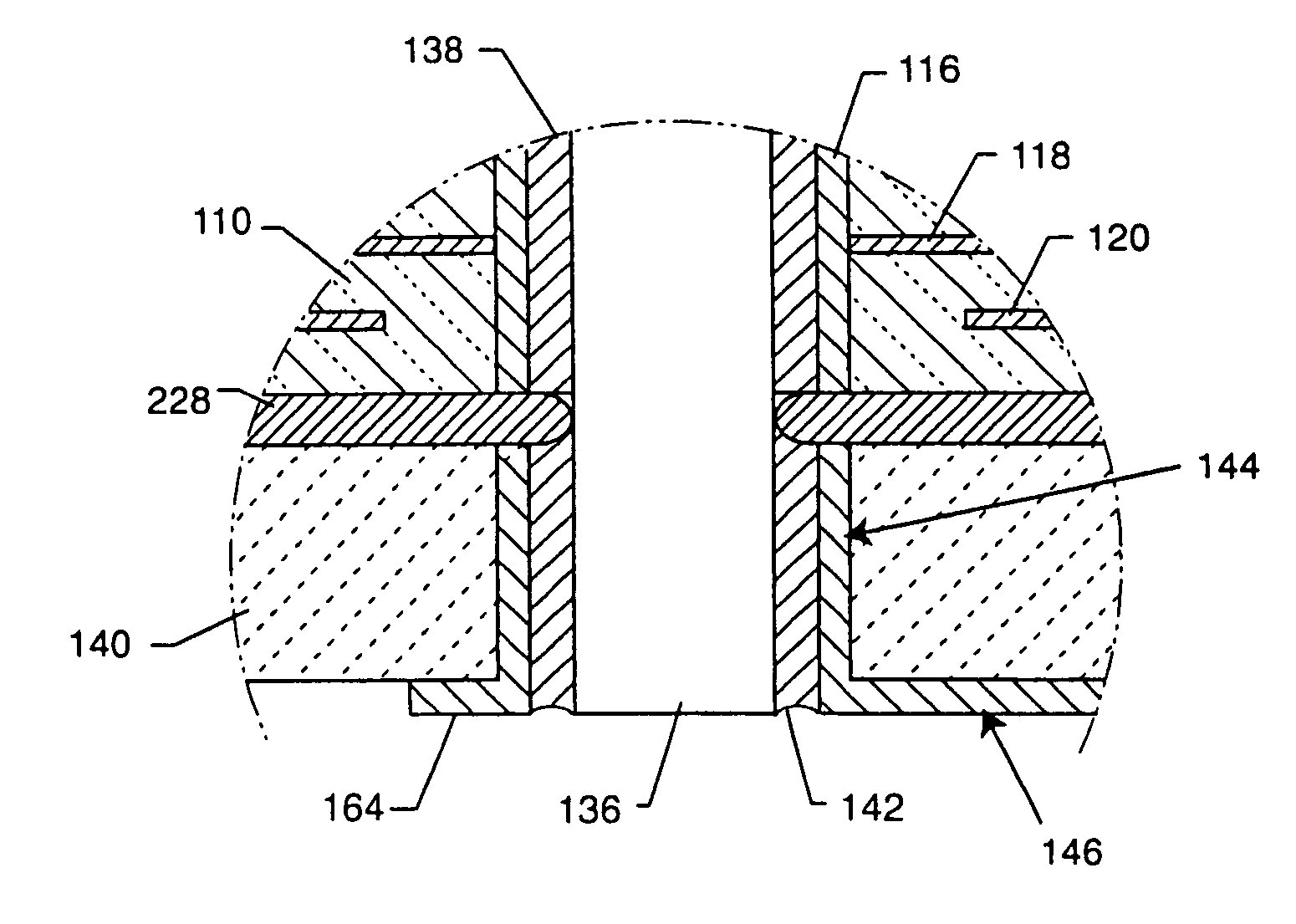

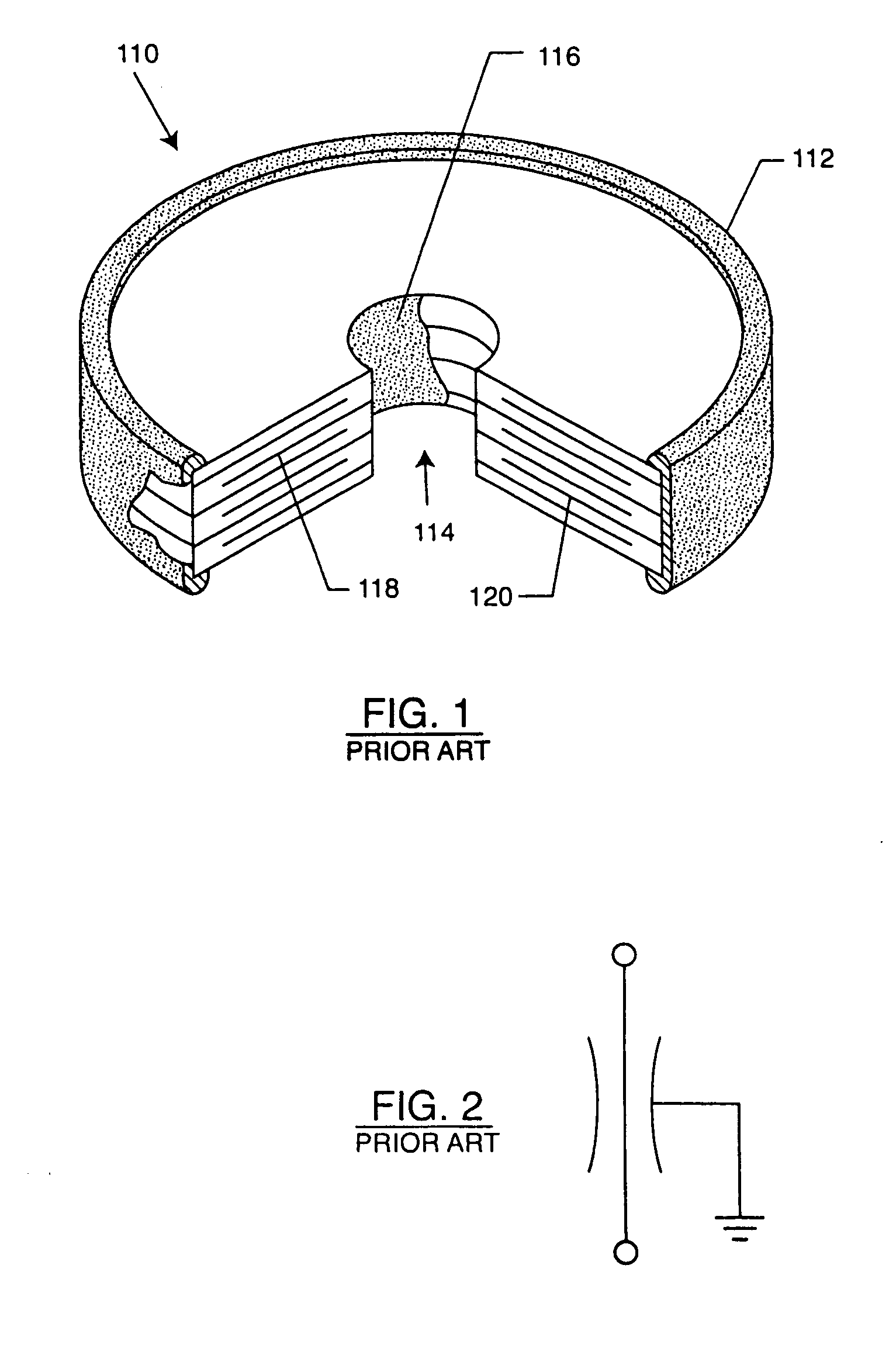

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050007718A1Avoid crackingAbsorbs stressMultiple-port networksElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

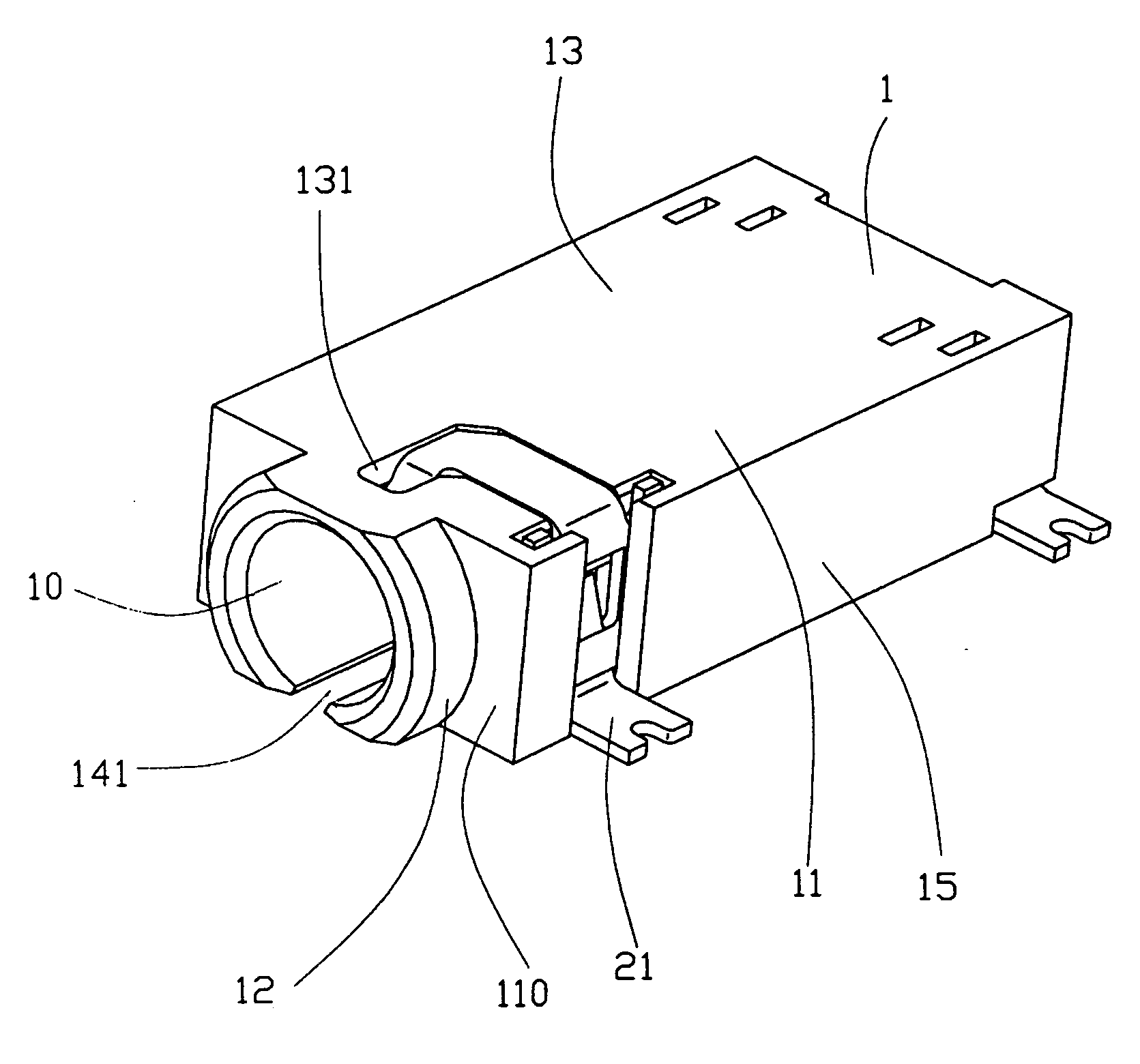

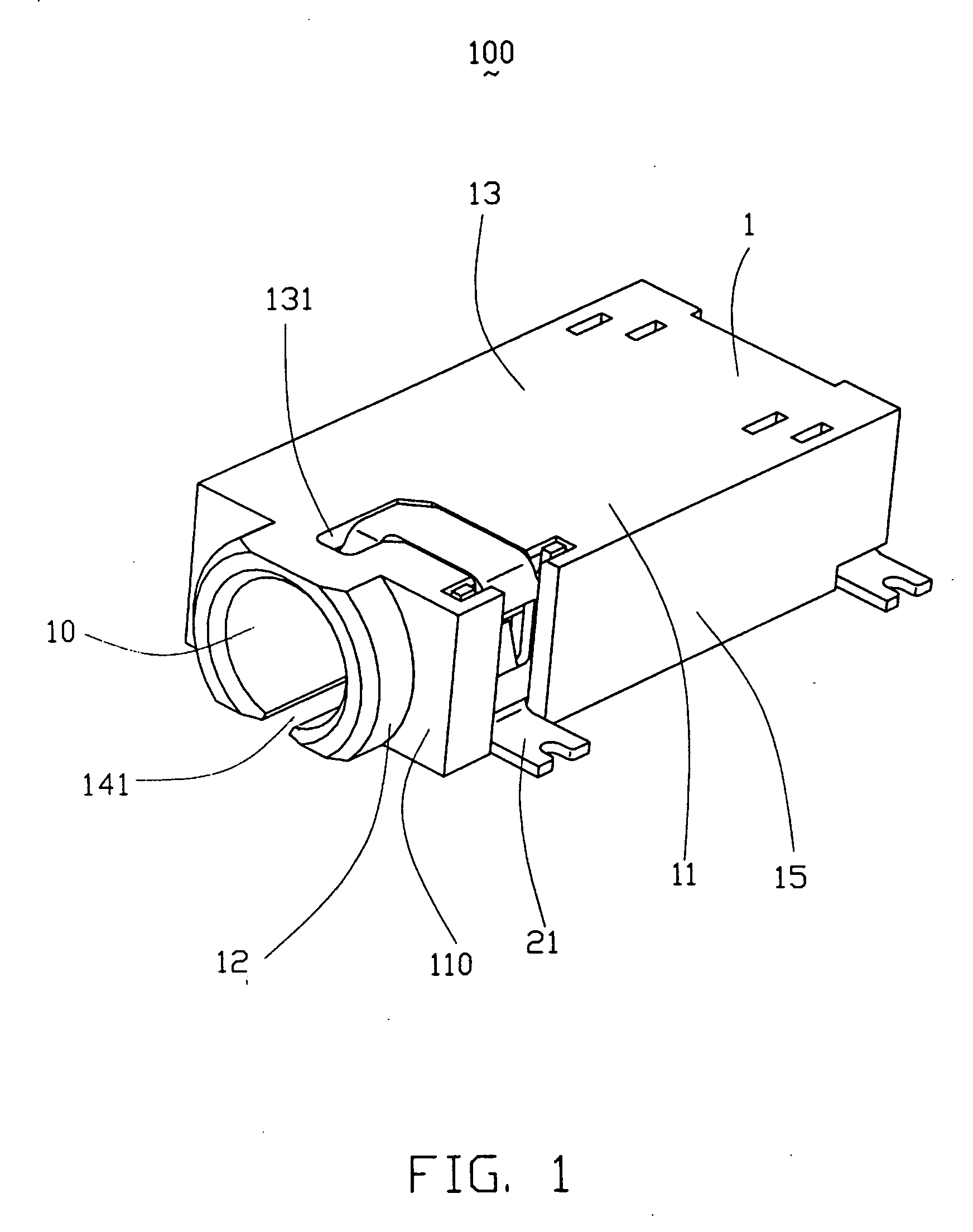

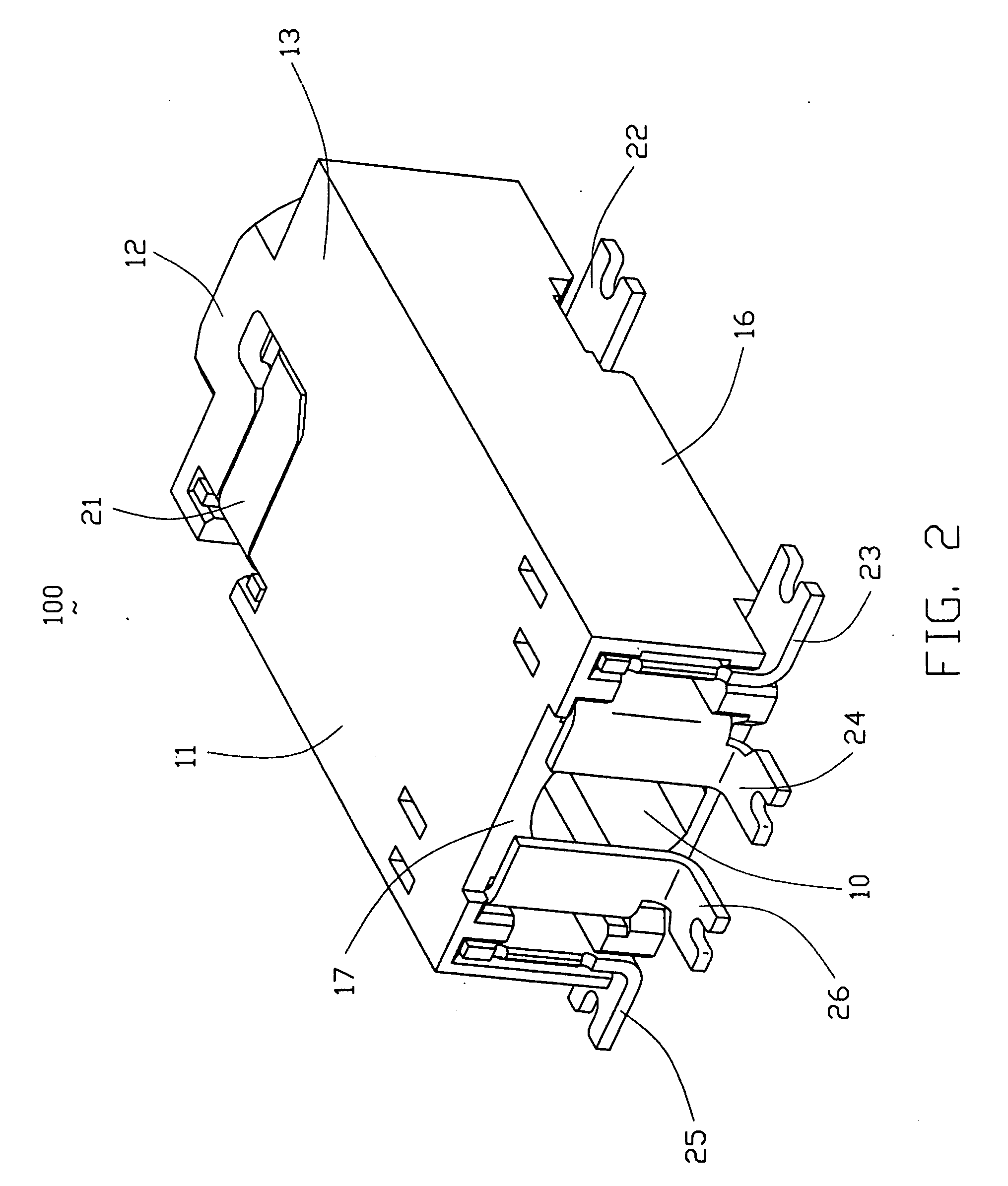

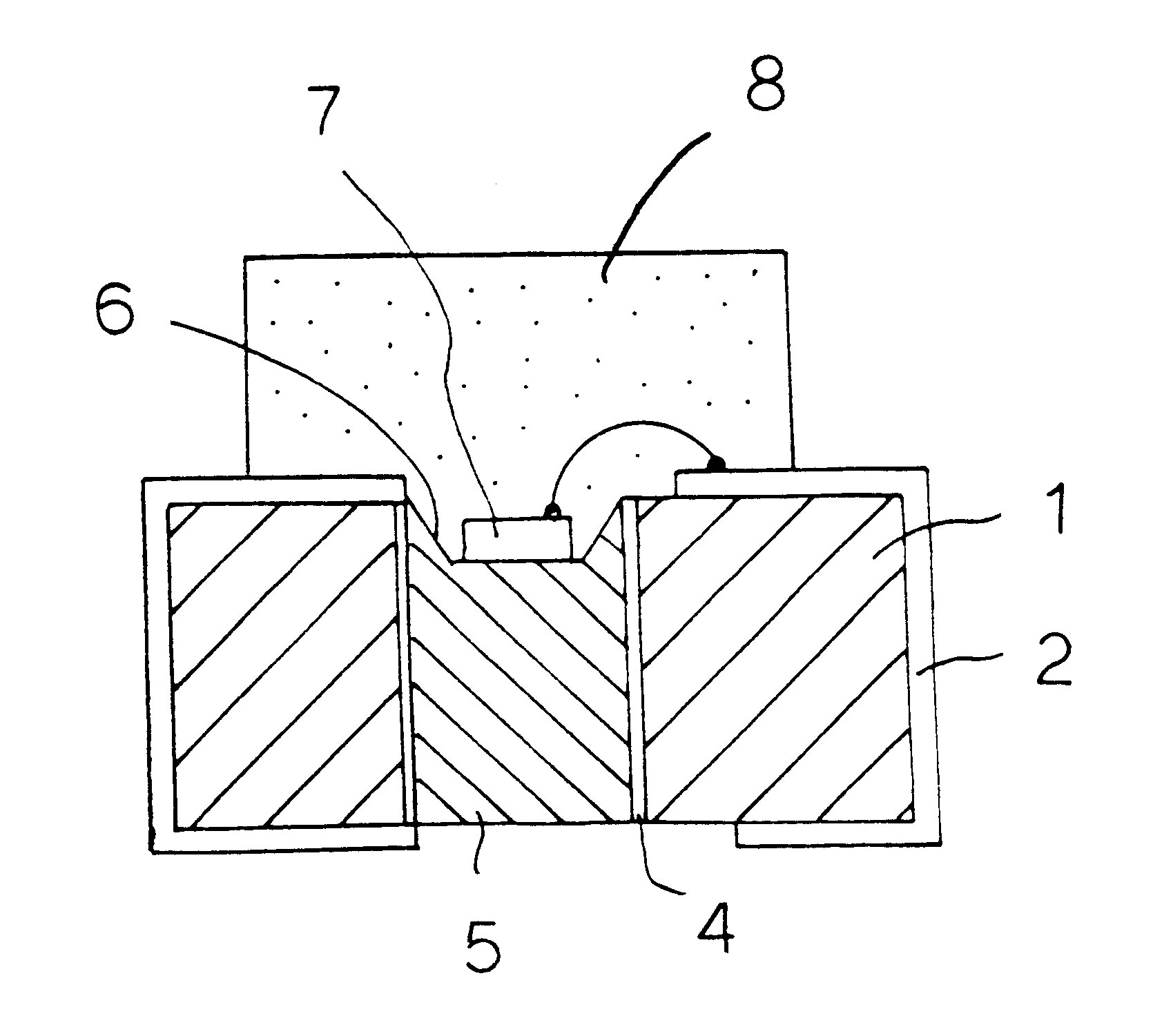

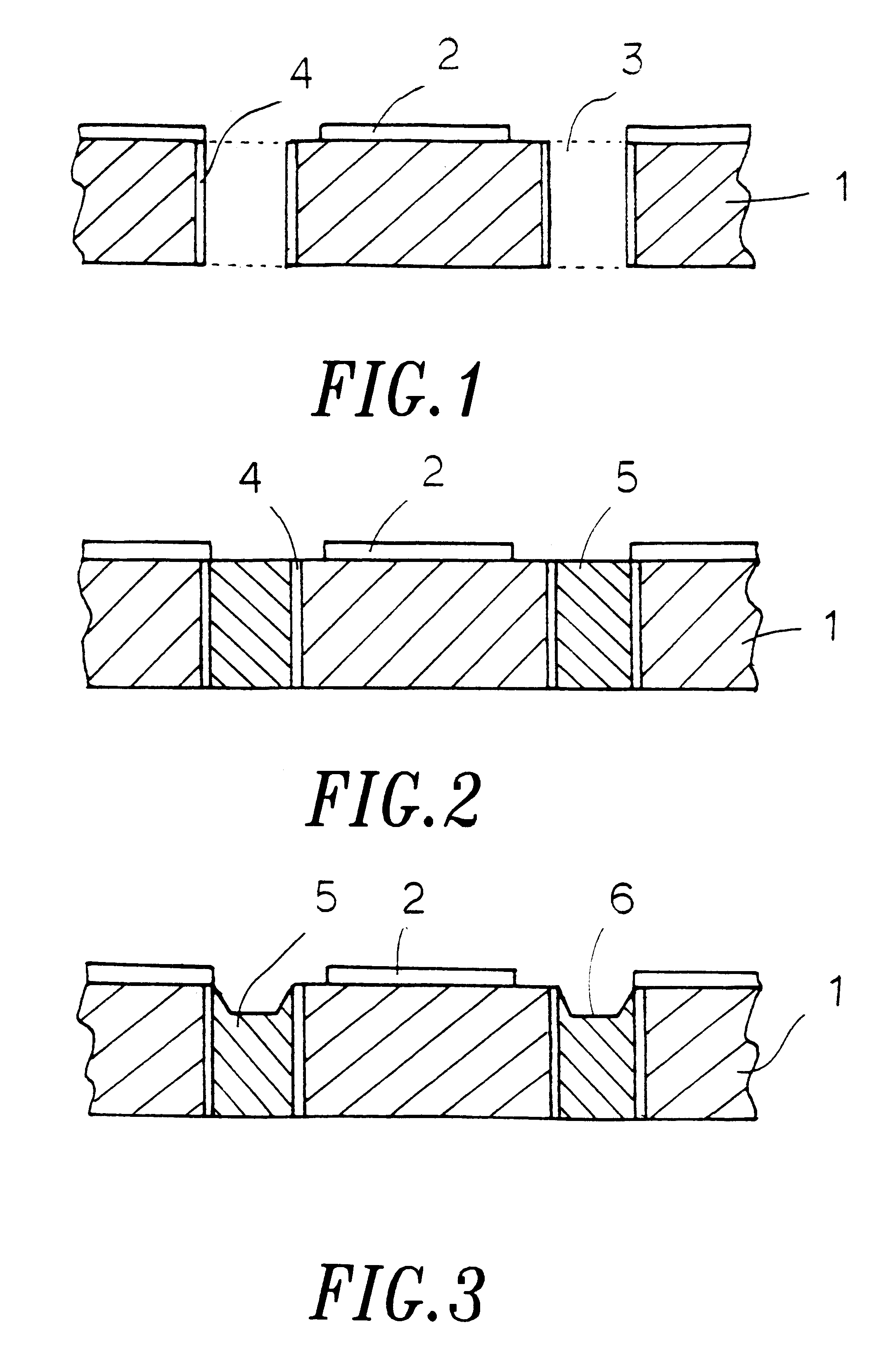

Electrical connector with improved soldering characteristic to be mounted on a printed circuit board

InactiveUS20070149062A1Two-part coupling devicesFour or more pole connectionsSurface mountingEngineering

An electrical connector (100) includes an insulative housing (1) for receiving a number of contacts (2). The insulative housing has a base (11) extending in a longitudinal direction and a mating portion (12) protruding forwardly from the base. The base (11) defines a slot (141) from an intermediate position thereof and extending forwardly through the mating portion (12). The mating portion (12) defines a receiving hole (10) extending into the base (11). The receiving hole (10) is in communication with the slot (141). The slot (141) can counteract a deformation of the insulative housing to ensure the soldering tails (213, 223, 233, 243, 253, 262) of the contacts coplanar with one another, thereby ensuring the contacts to be wonderfully surface mounted on a PCB.

Owner:HON HAI PRECISION IND CO LTD

Plug-and-socket connector

ActiveUS7267515B2High mechanical strengthGood electrical parametersCoupling protective earth/shielding arrangementsElectronic systemsEngineering

A multi-pole, multi-row plug-and-socket connector with shielding, for placement on printed circuit boards, circuit cards, and similar electrical components, which can be used in an electrical or electronic system includes electrical contact parts for the transmission of signals, which possess a connection section on one end and an electrically conductive attachment section on the other end, as well as an electrical shielding, which possesses at least one electrically conductive contact section. The free ends of the electrically conductive attachment sections of the electrical contact parts are SMD contacts. The at least one electrically conductive contact section of the shielding is, at the same time, an attachment pin which projects into a passage hole of the printed circuit board when the plug-and-socket connector is disposed on the same, for the purpose of connective soldering using THR technology.

Owner:ERNI PRODION GMBH

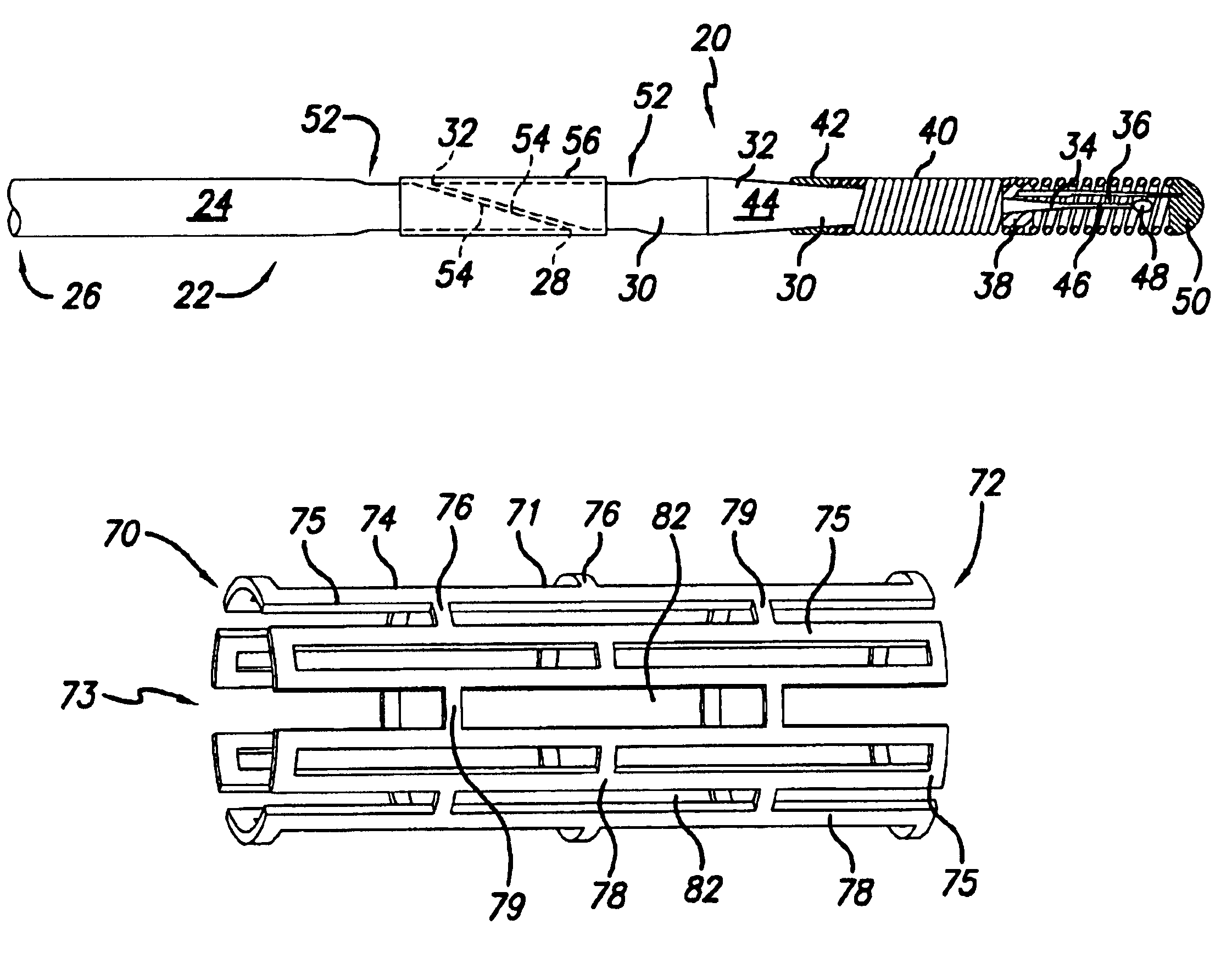

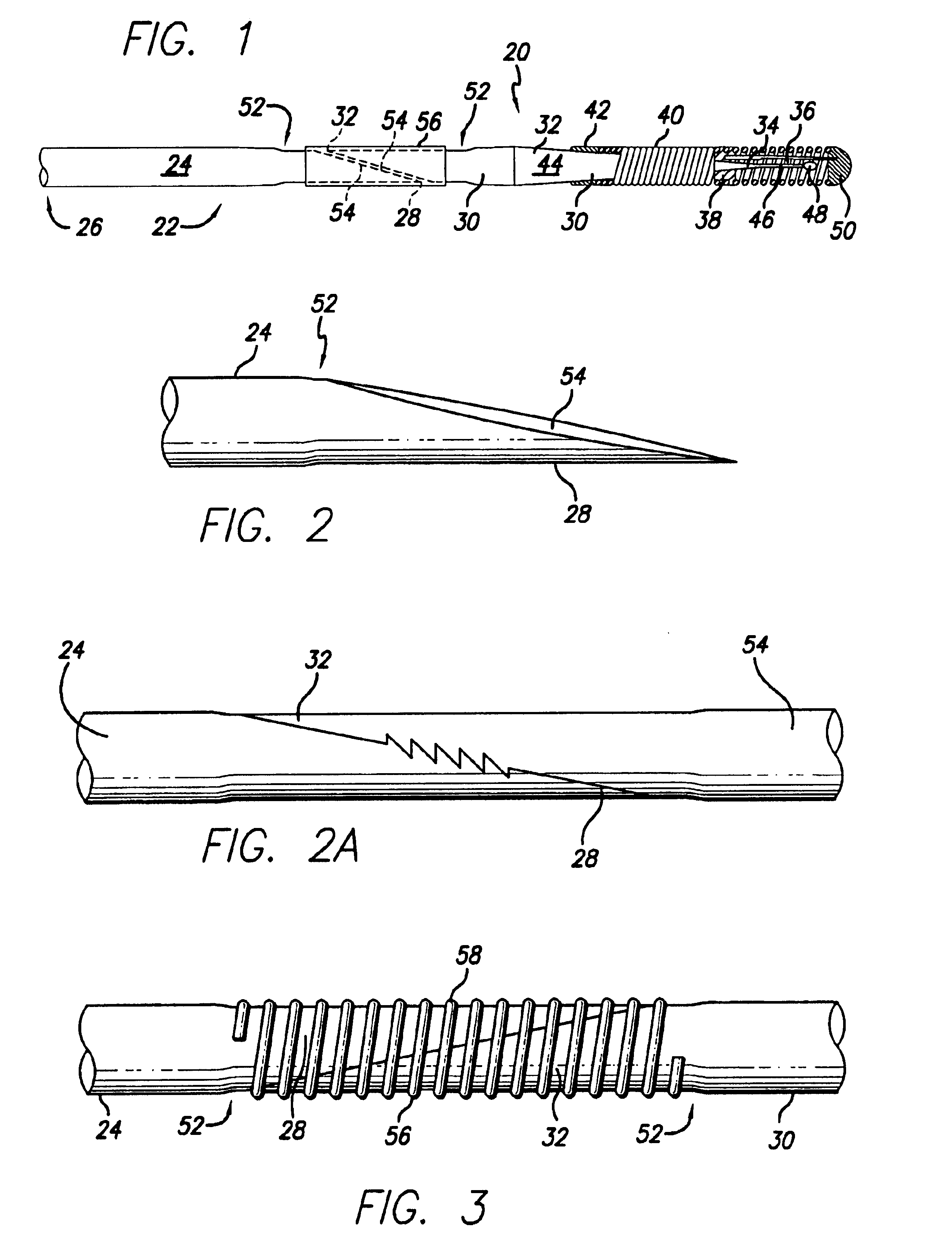

Enhanced method for joining two core wires

An intravascular guide wire having at least two core materials joined together. There is a wire core having a proximal core section with a proximal end and a distal end and a distal core section with a proximal end and a distal end. The distal end of the proximal core section and the proximal end of the distal core section are formed into complementary shapes, and then placed into a flexible sleeve in opposing directions. Inside the flexible sleeve, the complementary shaped ends are joined together through bonding, welding, brazing, cementing, or soldering. The flexible sleeve can be either a stretched coil or a polyimide sleeve, each with an outer diameter similar to the outer diameter of the core wire, therefore the guide wire does not require additional grinding to reduce the outer diameter of the joined section.

Owner:ABBOTT CARDIOVASCULAR

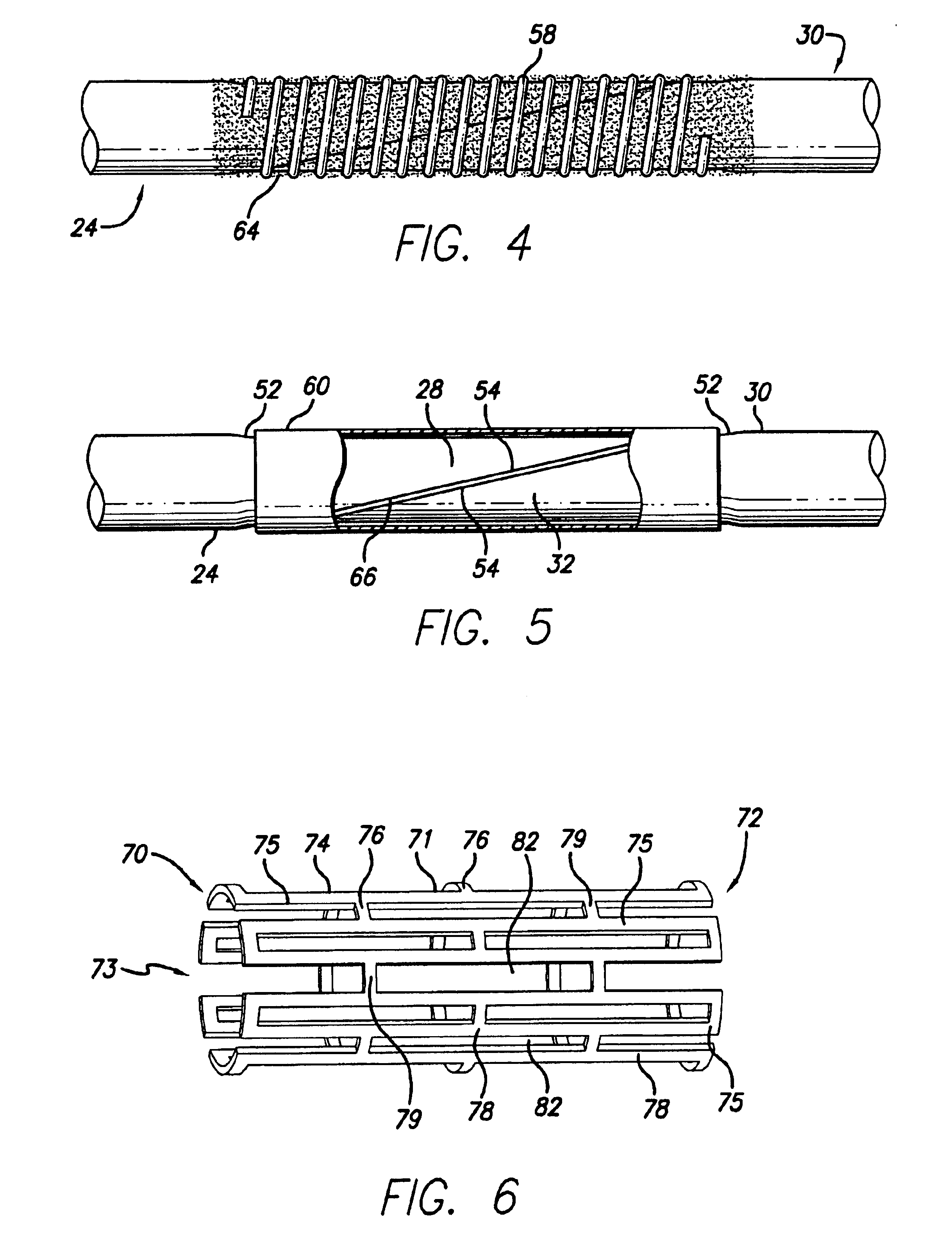

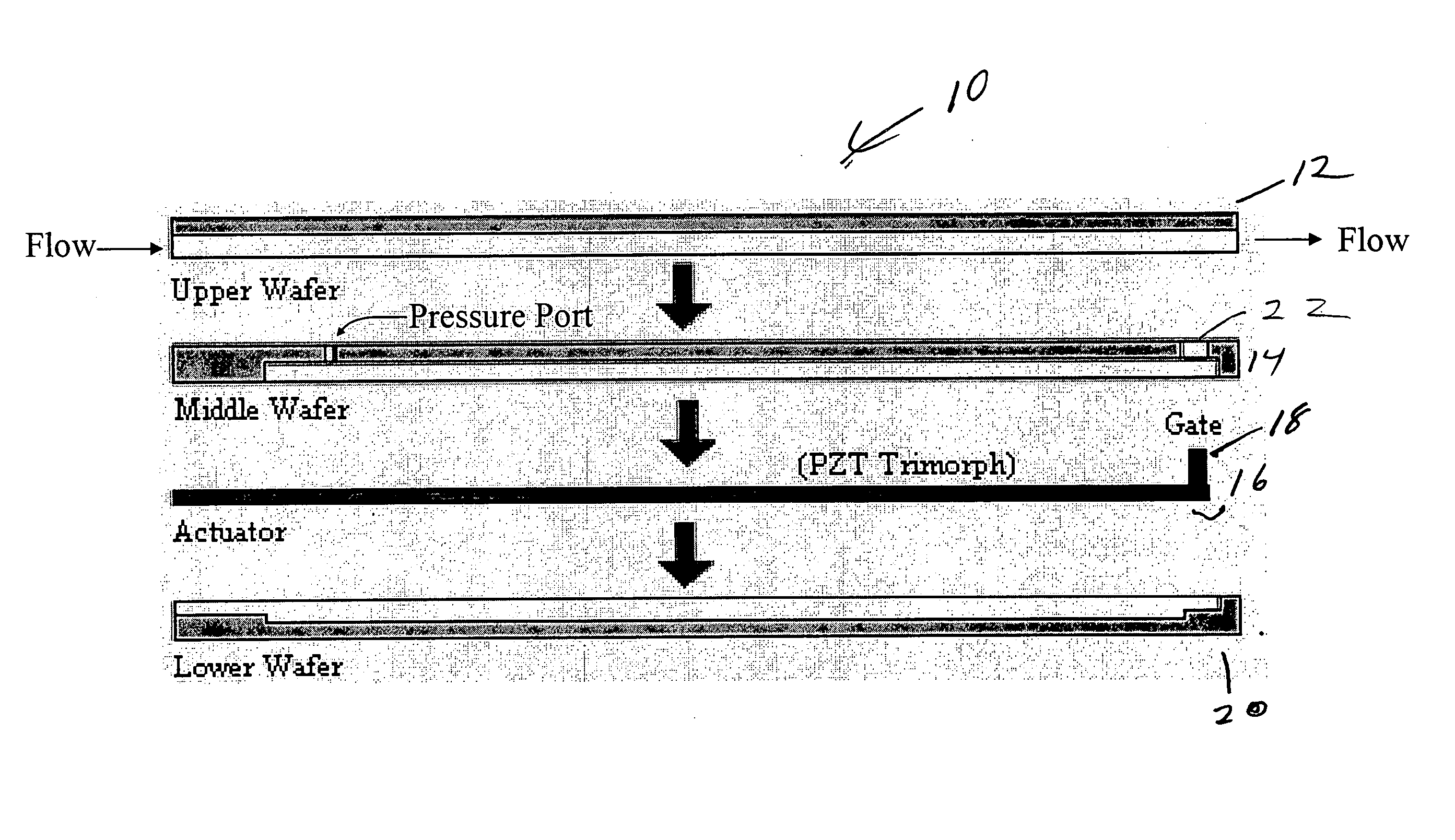

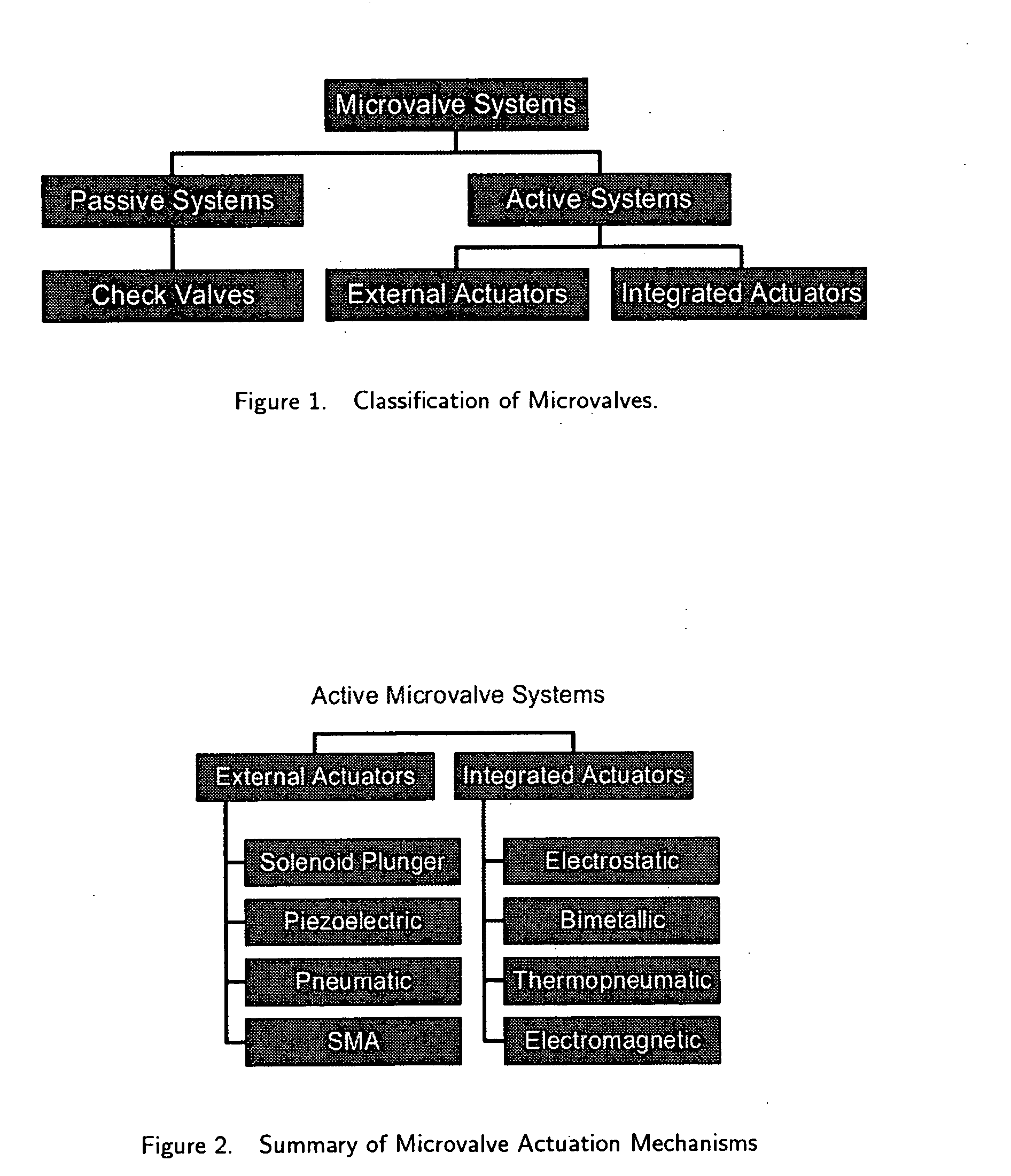

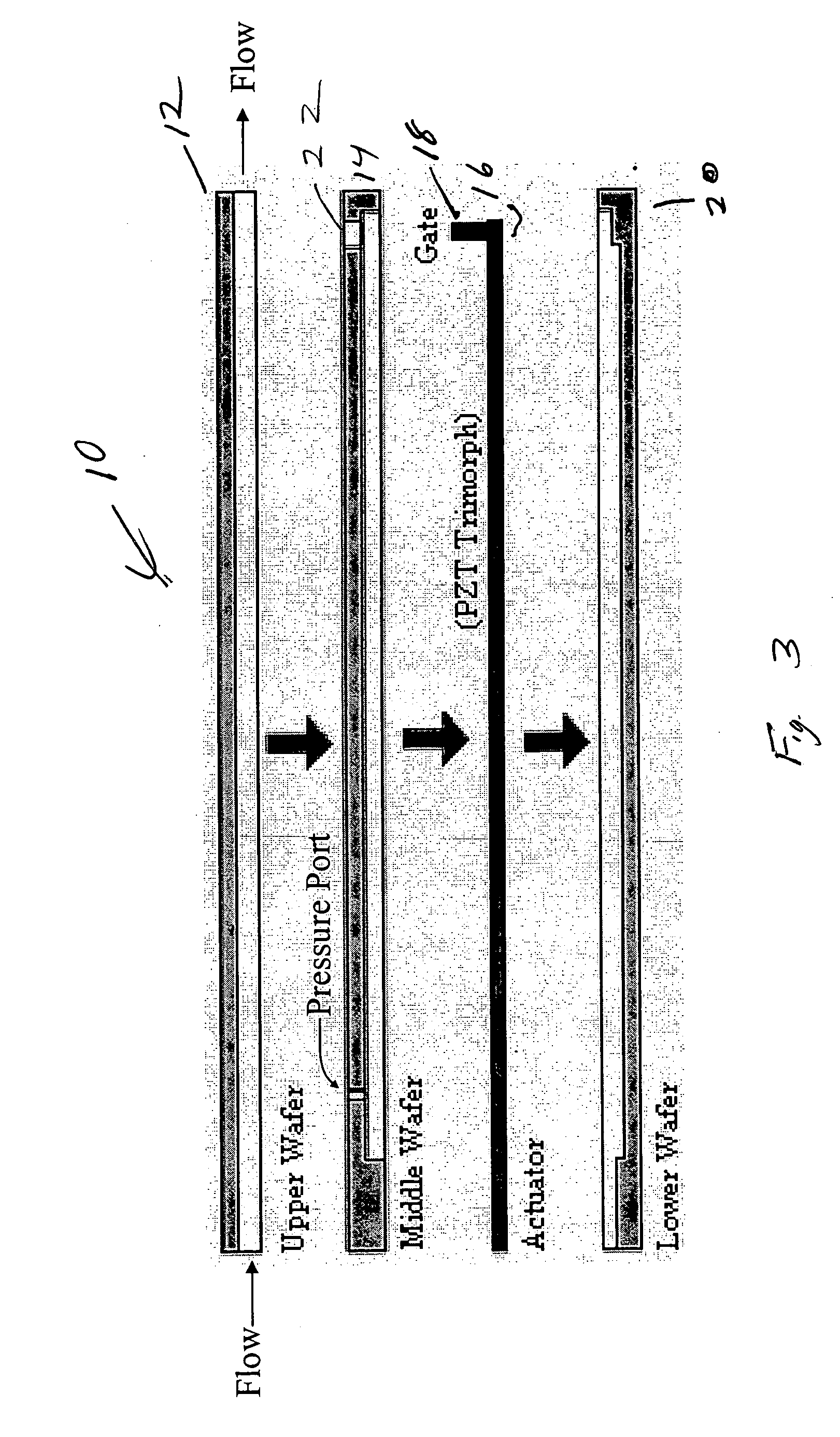

Piezoelectric axial flow microvalve

InactiveUS20040137300A1Operating means/releasing devices for valvesFinal product manufactureEpoxyPhotonics

This paper presents the fabrication and preliminary testing of a novel piezoelectric microvalve. Fabrication has three steps, which are the actuator fabrication, valve body fabrication and assembly of the microvalve. Fabricating an actuator involves cutting piezoelectric and brass beams, gluing the brass and piezoceramic beams into a trimorph sandwich structure, and curing them under pressure at elevated temperatures. Actuators are then wired either by using conductive epoxy or soldering. Valve body parts are constructed from single crystal silicon substrates using deep reactive ion etching (DRIE). DRIE is a subtractive process, whereby a mask is created on the surface of the stock, which will shield the parts that are not to be machined. Refinements in the actuator manufacturing process are made to increase the quality and decrease the fabrication time. Using a photonic probe, tip deflections of the actuators have been tested at various temperature and voltage levels. Currently, the valves are being assembled. Once assembled, multiple microvalves will undergo cold flow testing with air followed by extensive flow extensive flow testing at elevated temperatures with humidified hydrogen.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Solar cell stringing machine

Owner:GTAT CORPORATION

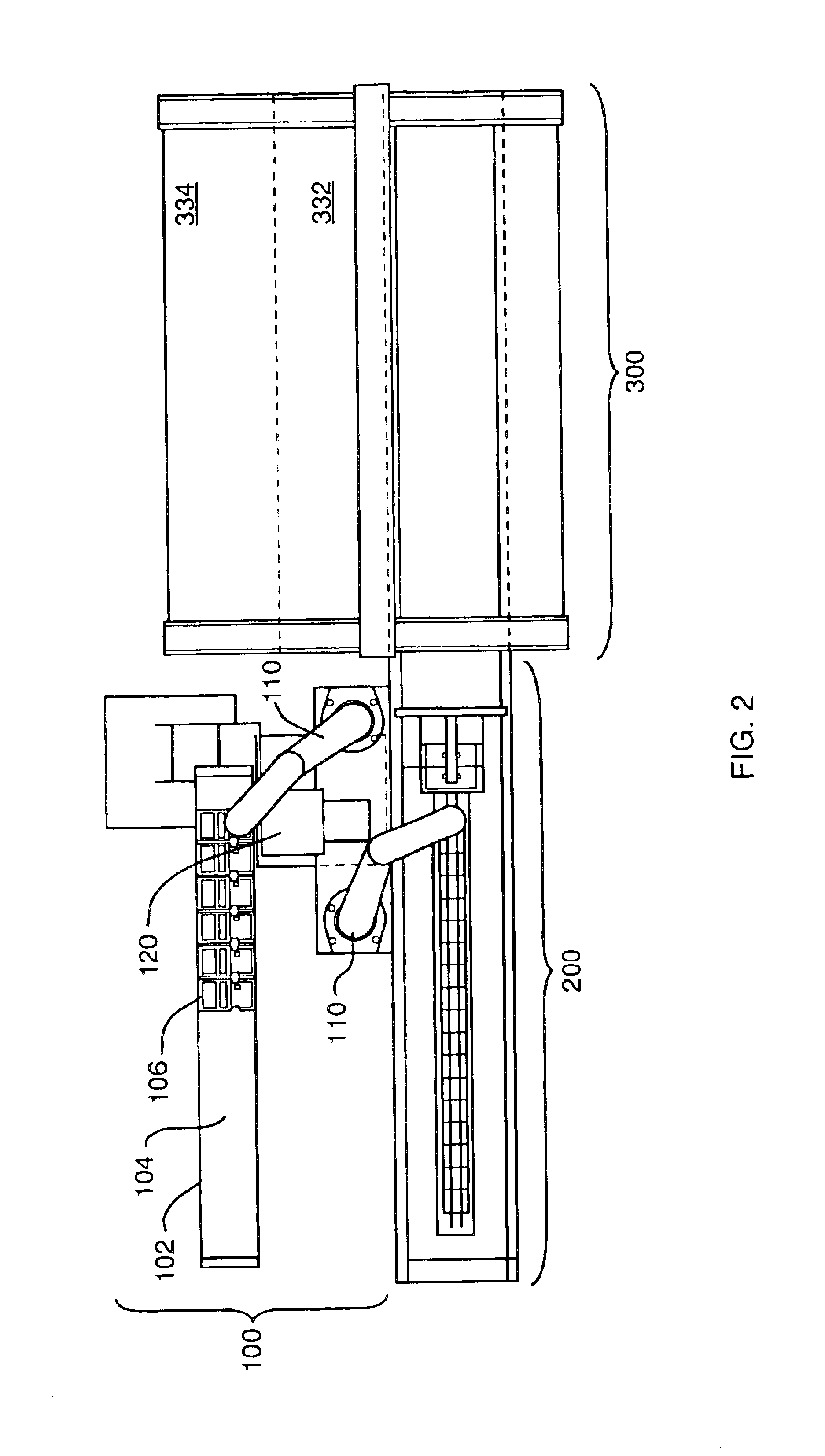

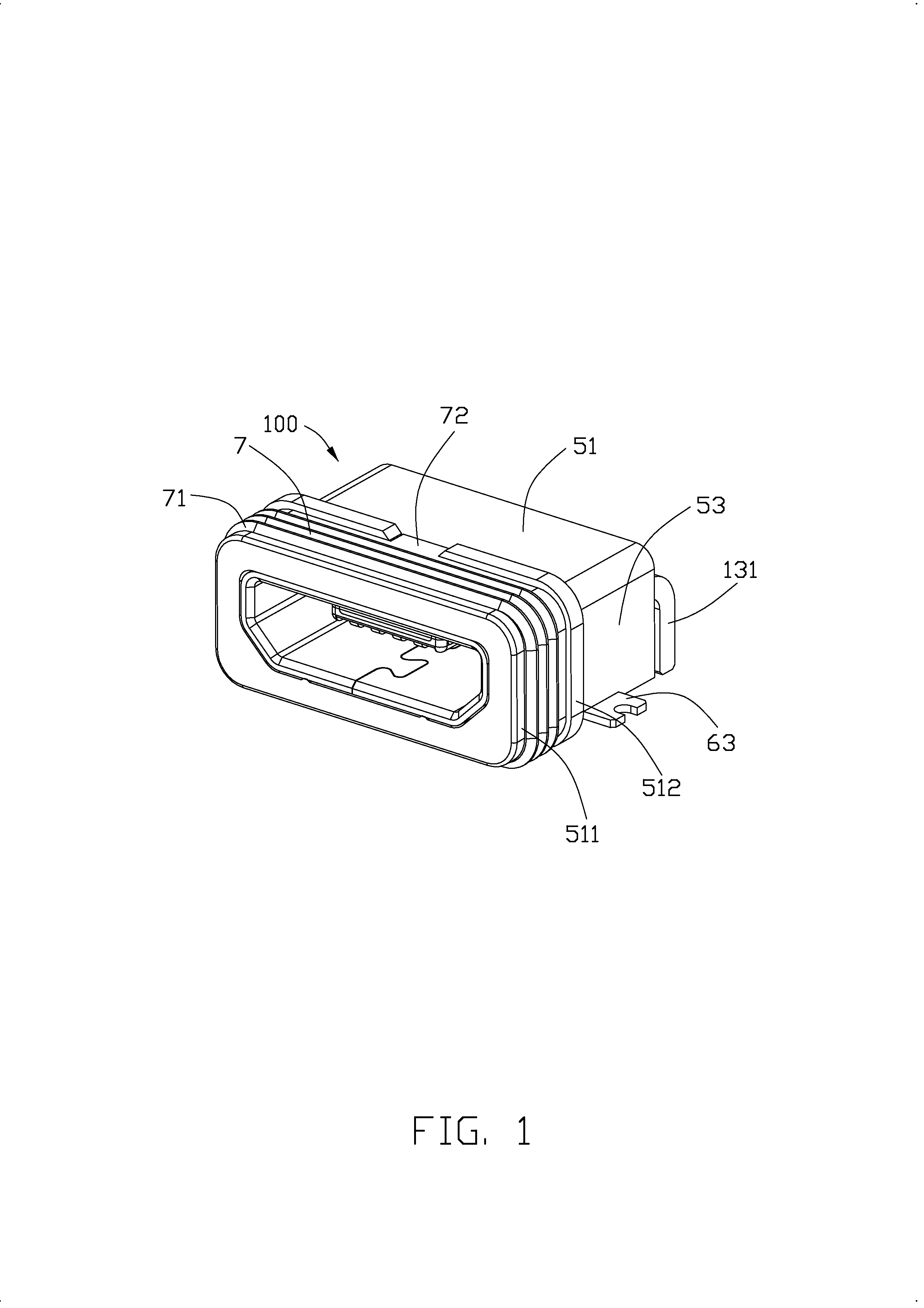

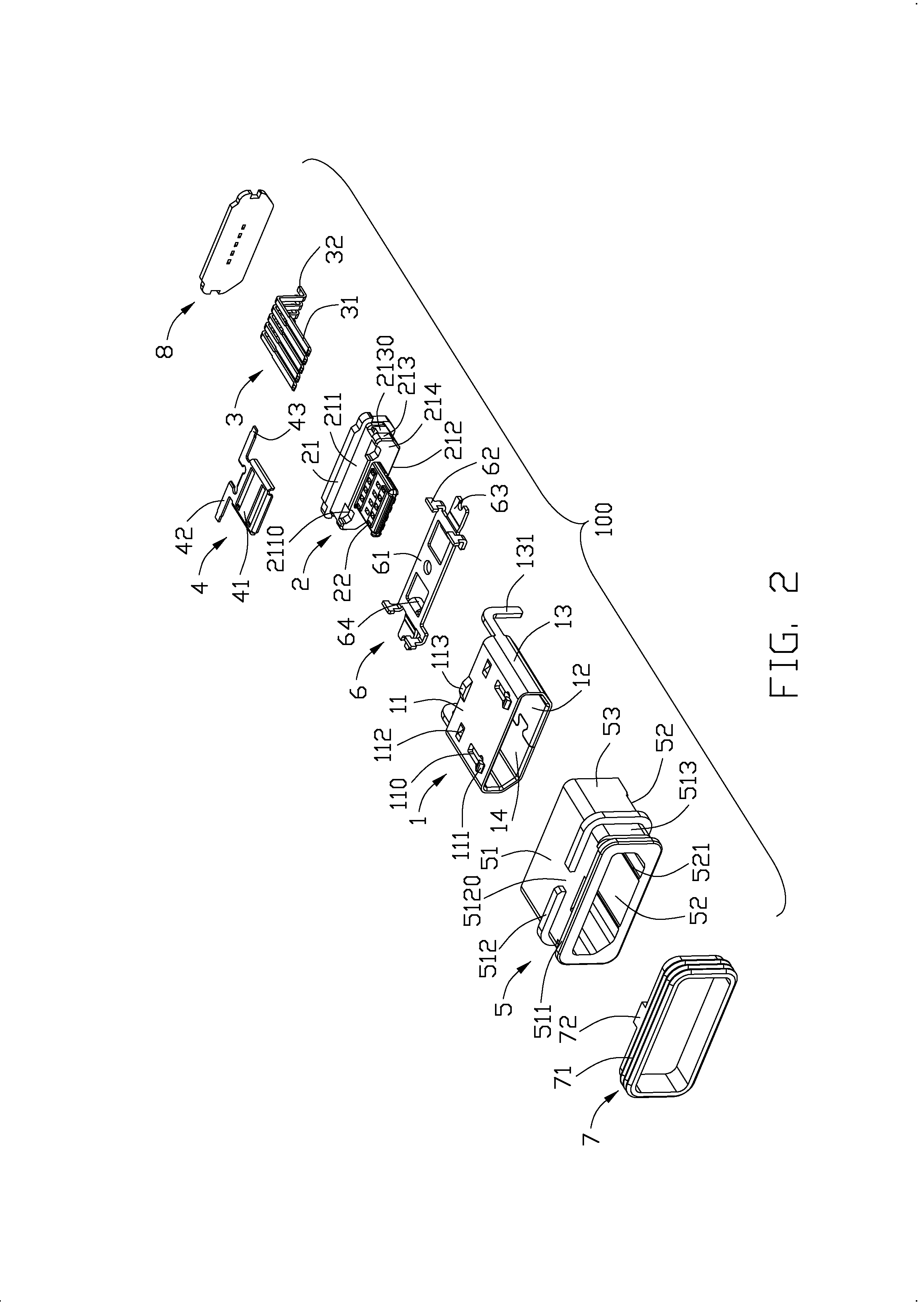

Waterproof electrical connector

ActiveUS20130183844A1Effectively preventing water from enteringResilient force resistorsElectric discharge tubesElectricitySoldering

An electrical connector (100) includes a metallic shell (1), an insulative housing (2) combined to the metallic shell, a plurality of terminals (3) retained in the insulative housing, an insulative cover (5) covering the metallic shell, a waterproof ring (7) and a waterproof plate (8) respectively attached to a front end and a rear face of the insulative cover, and a fixing member (6) attached to the insulative cover. The fixing member includes a rectangular portion (61), at least one corner portion (62) bending from the rectangular portion along a first vertical direction and penetrating into the insulative cover, at least one soldering pad (63) extending laterally from the rectangular portion, and at least one teared portion (64) bending from the rectangular portion towards a second vertical direction opposite to the first vertical direction.

Owner:HON HAI PRECISION IND CO LTD

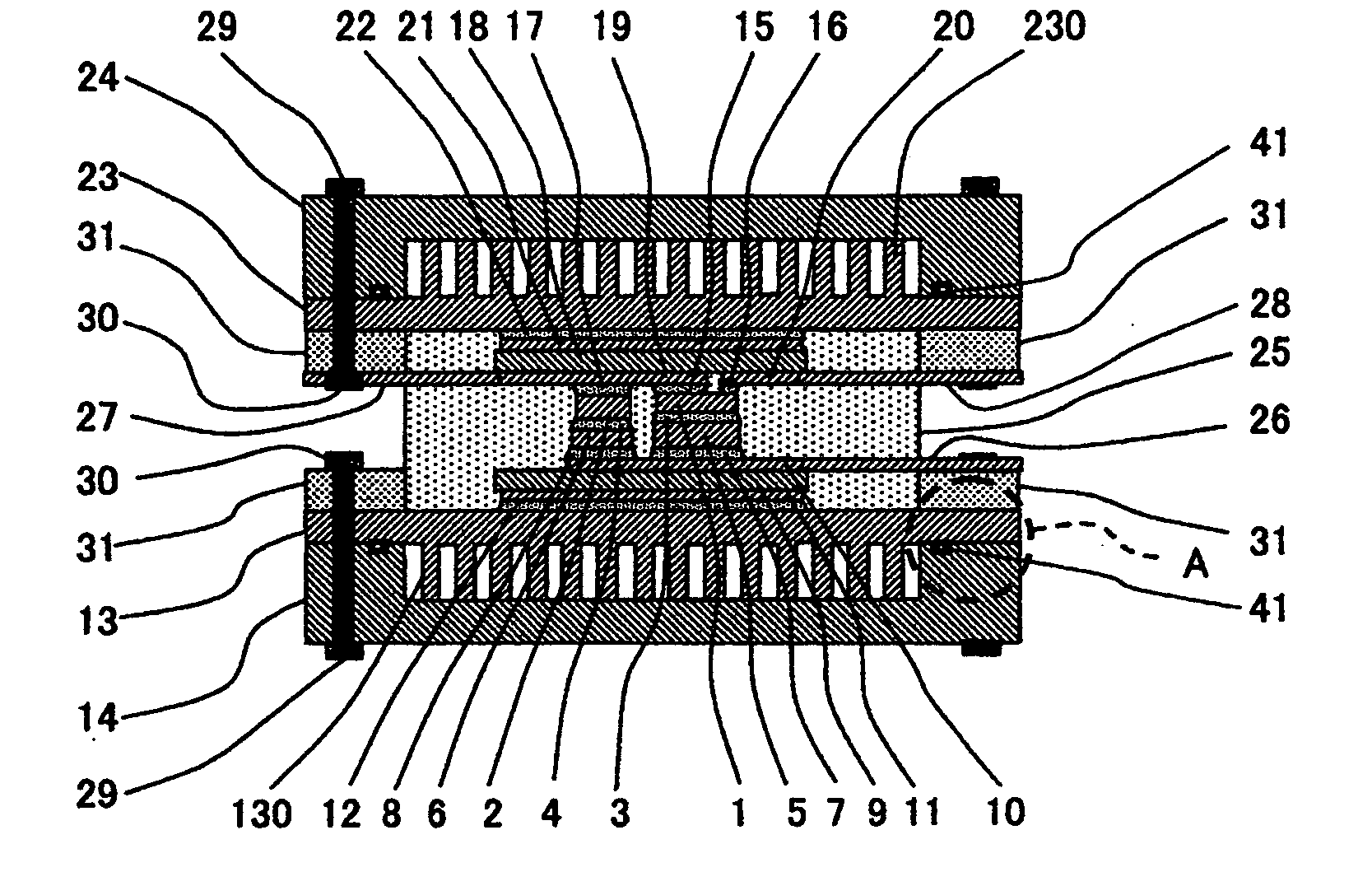

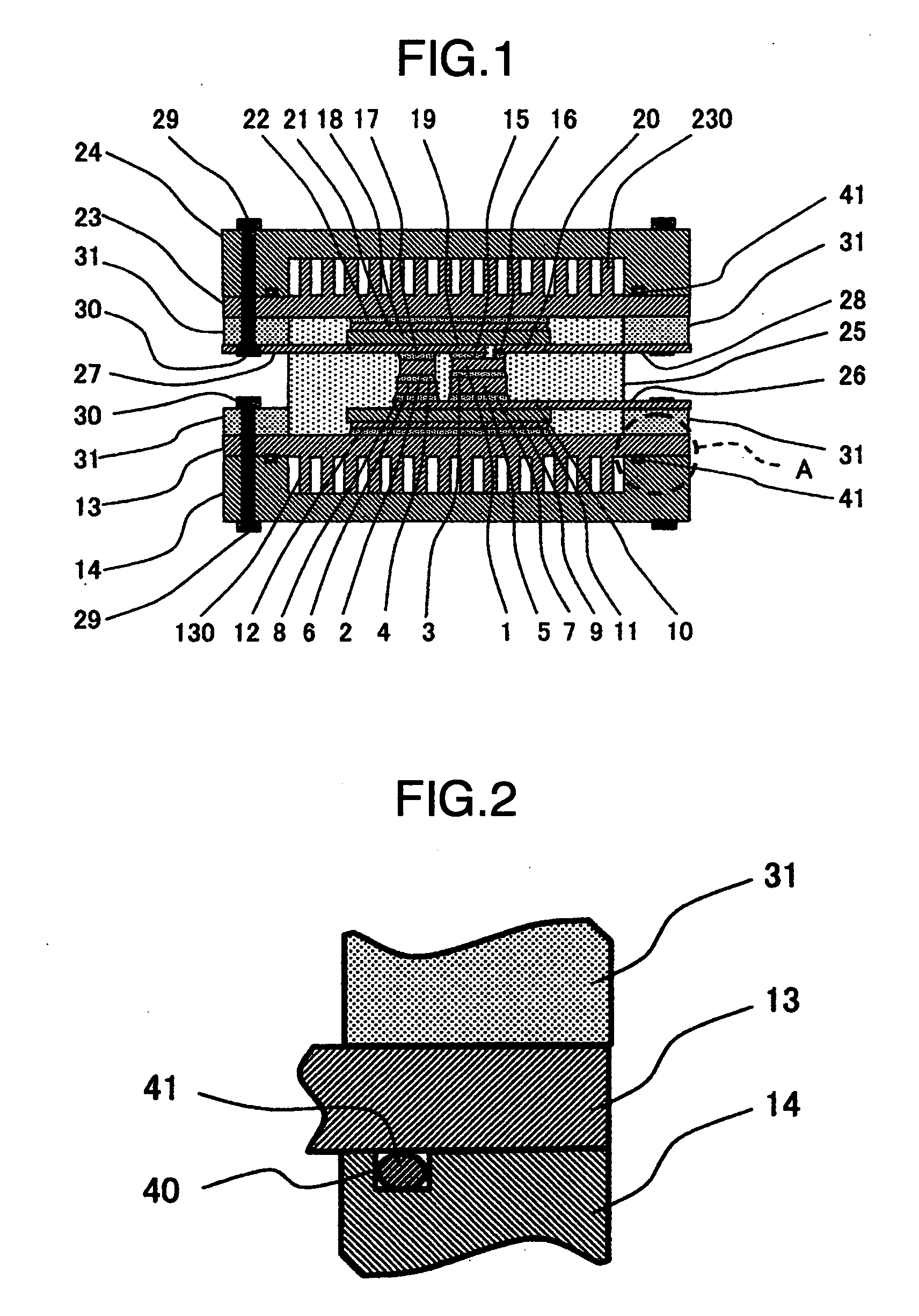

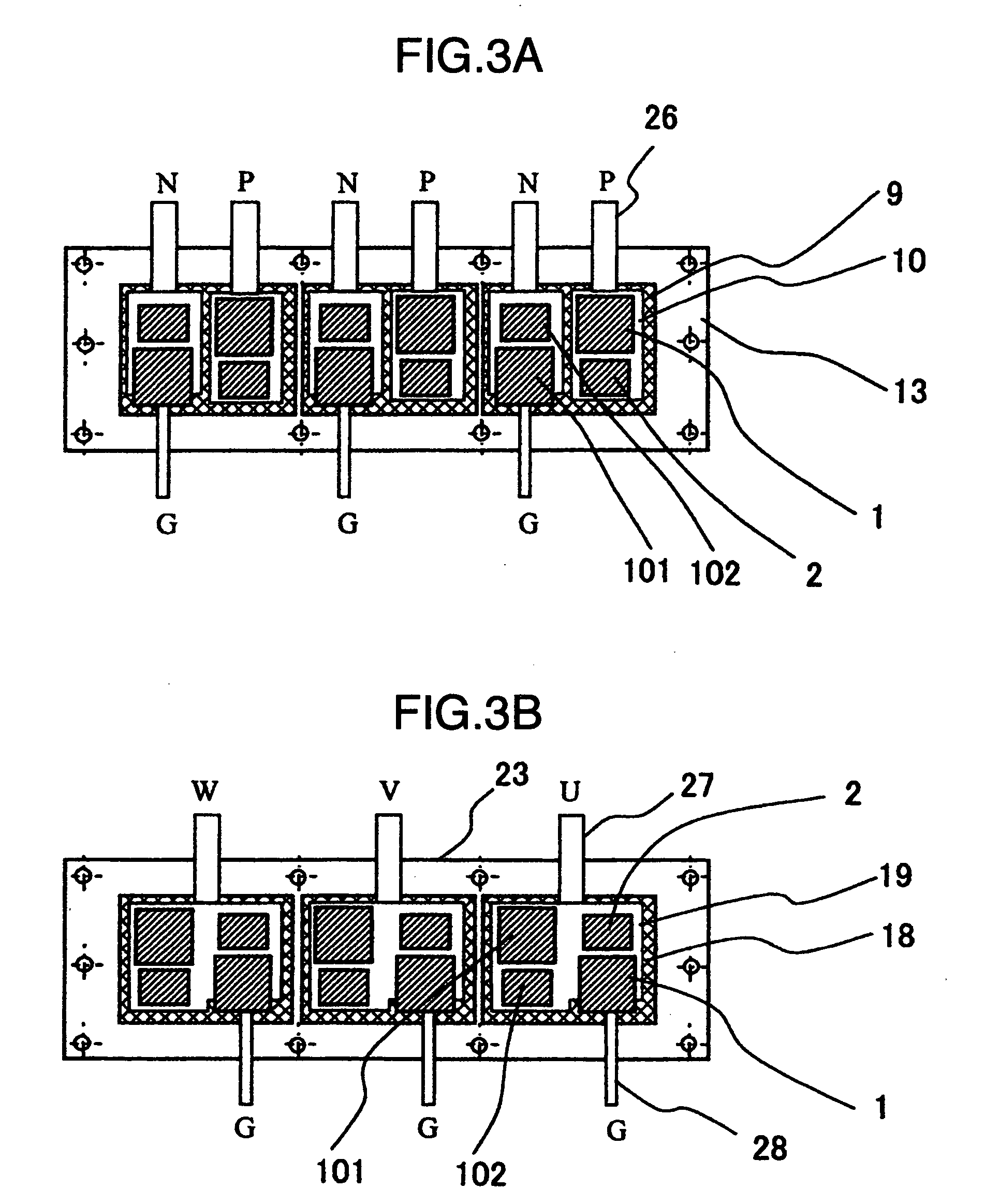

Power Semiconductor Module

InactiveUS20080224303A1Improve cooling effectThermal resistanceSemiconductor/solid-state device detailsConversion constructional detailsSemiconductor chipEngineering

A power semiconductor module with its thermal resistance and overall size reduced. Insulating substrates with electrode metal layers disposed thereon are joined to both the surfaces of a power semiconductor chip by using, for example, soldering. Metal layers are disposed also on the reverse surfaces of the insulating substrates and the metal layers are joined to the heat spreaders by using brazing. Heat radiating fins are provided on the heat radiating surface of at least one of the heat spreaders. The heat radiating side of each of the heat spreaders is covered by a casing to form a refrigerant chamber through which refrigerant flows to remove heat transmitted from the semiconductor chip to the heat spreader.

Owner:HITACHI LTD

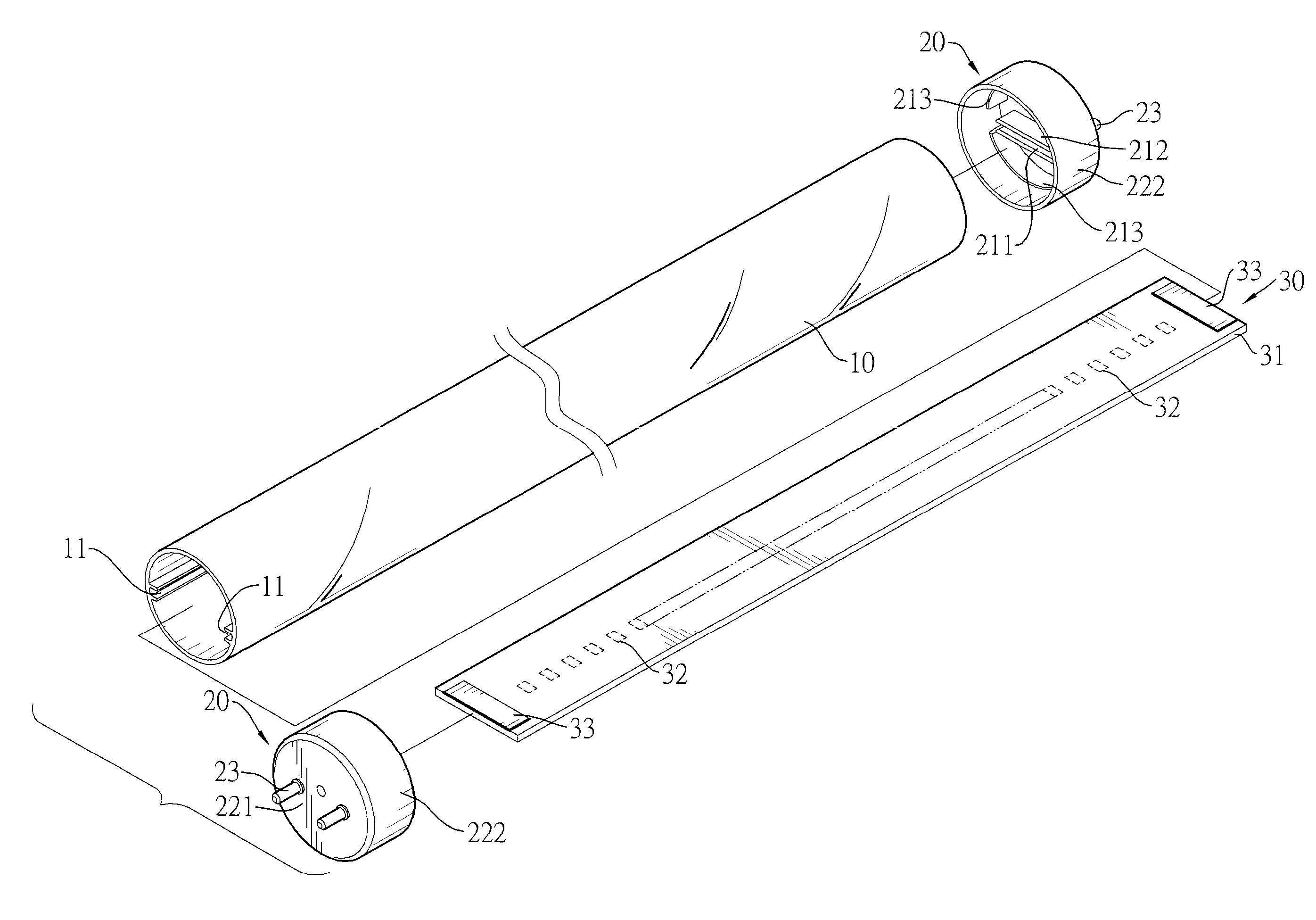

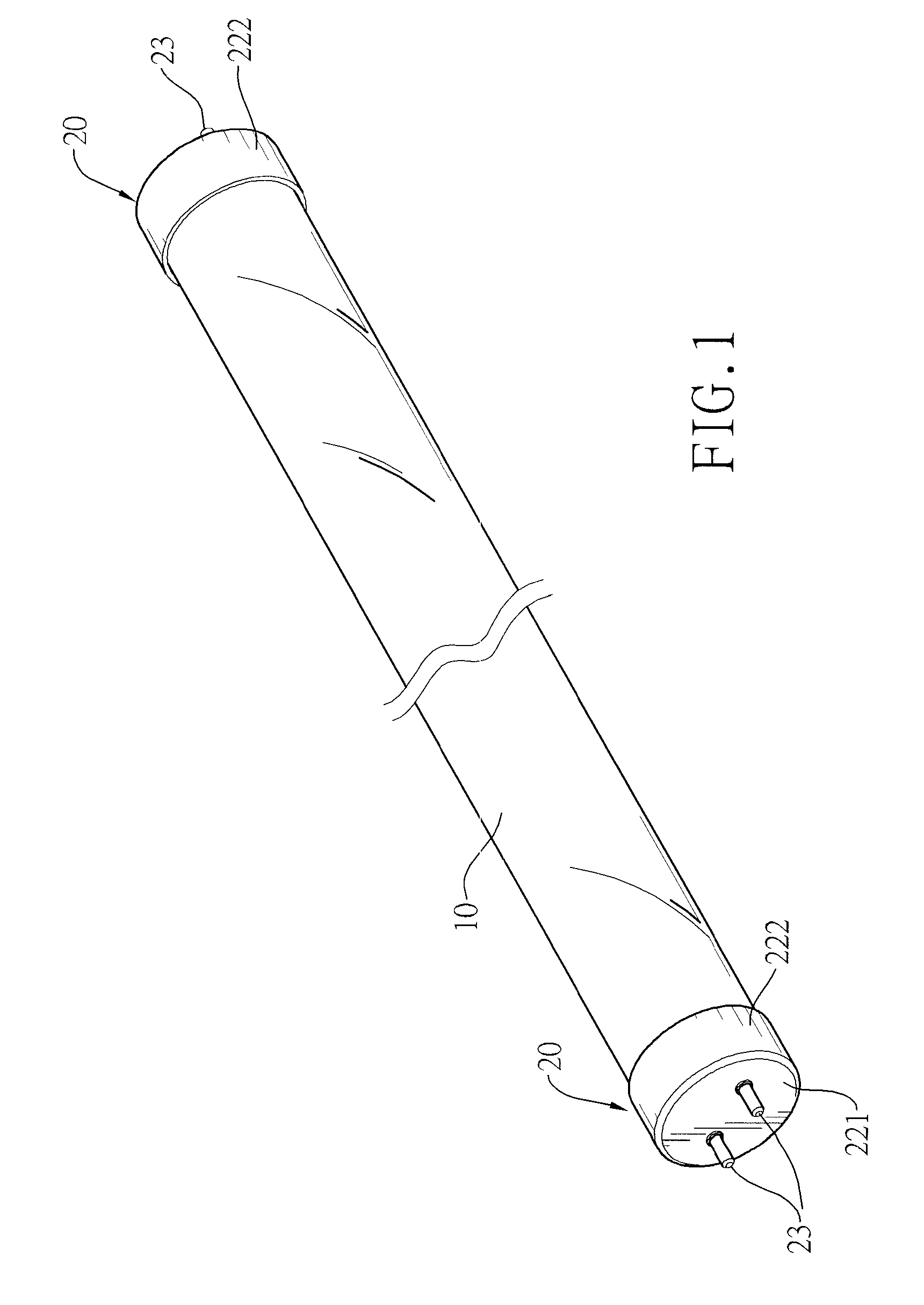

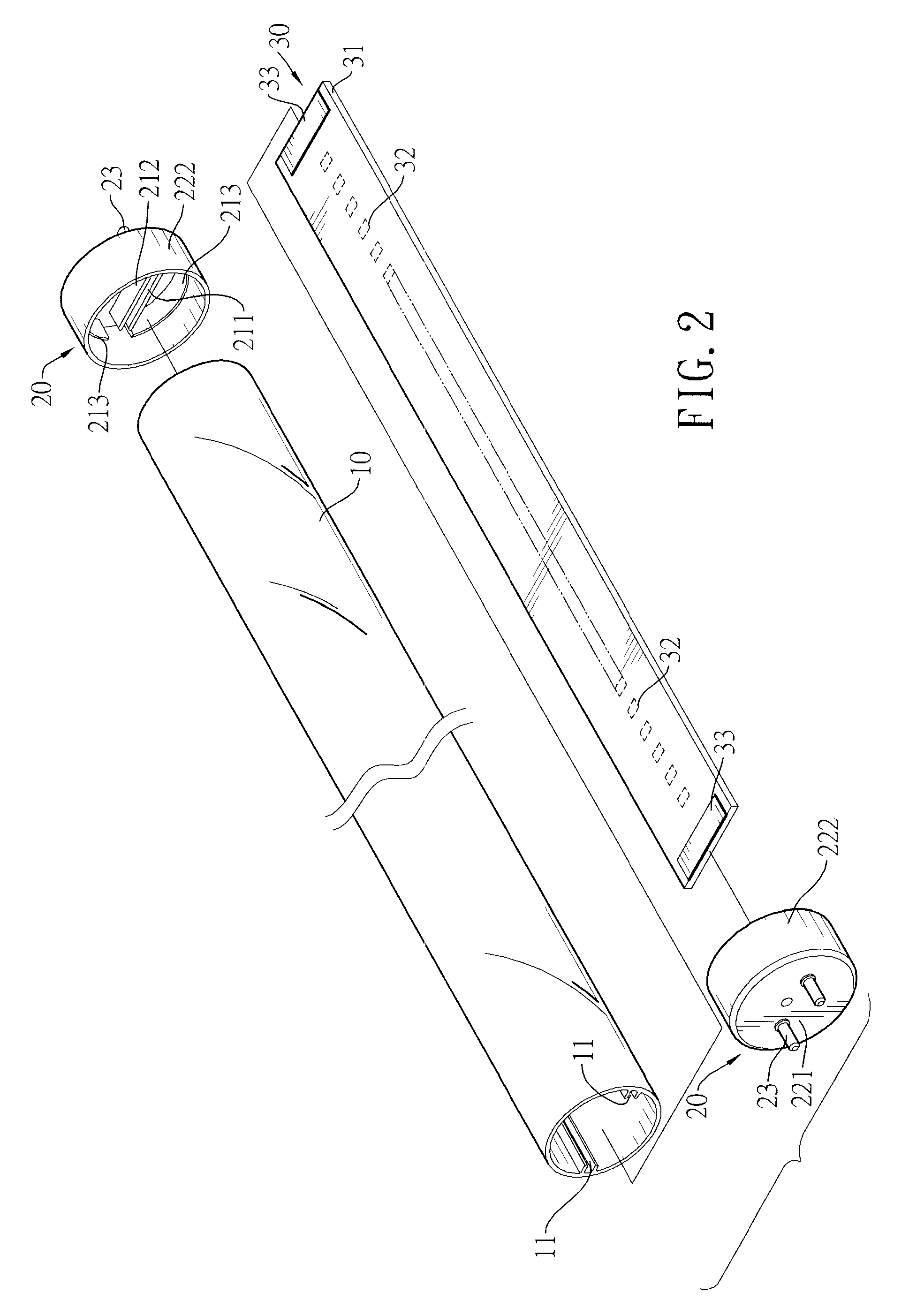

LED lamp and LED holder cap thereof

InactiveUS20120293991A1Insufficient soldering strengthReduced durabilityLighting support devicesPoint-like light sourceEngineeringSoldering

An LED lamp has an LED lamp board mounted in a lamp tube and two LED holder caps respectively mounted around two ends of the lamp tube. Each LED holder cap has a cap body, two pins and two parallel holding walls. One end of each pin is mounted in the circular board. One of the holding walls is conductive and connected with the pins. When the LED holder caps are respectively mounted around two ends of the lamp tube, the holding walls of each LED holder cap holds one end of the LED lamp board, and the conducting holding wall is electrically connected with a corresponding power contact of the LED lamp board so that the pins are respectively electrically connected with the power contacts. Accordingly, the problem of soldering wires with the LED lamp board and the pins of the LED holder caps can be eliminated.

Owner:LIN CHIU MIN

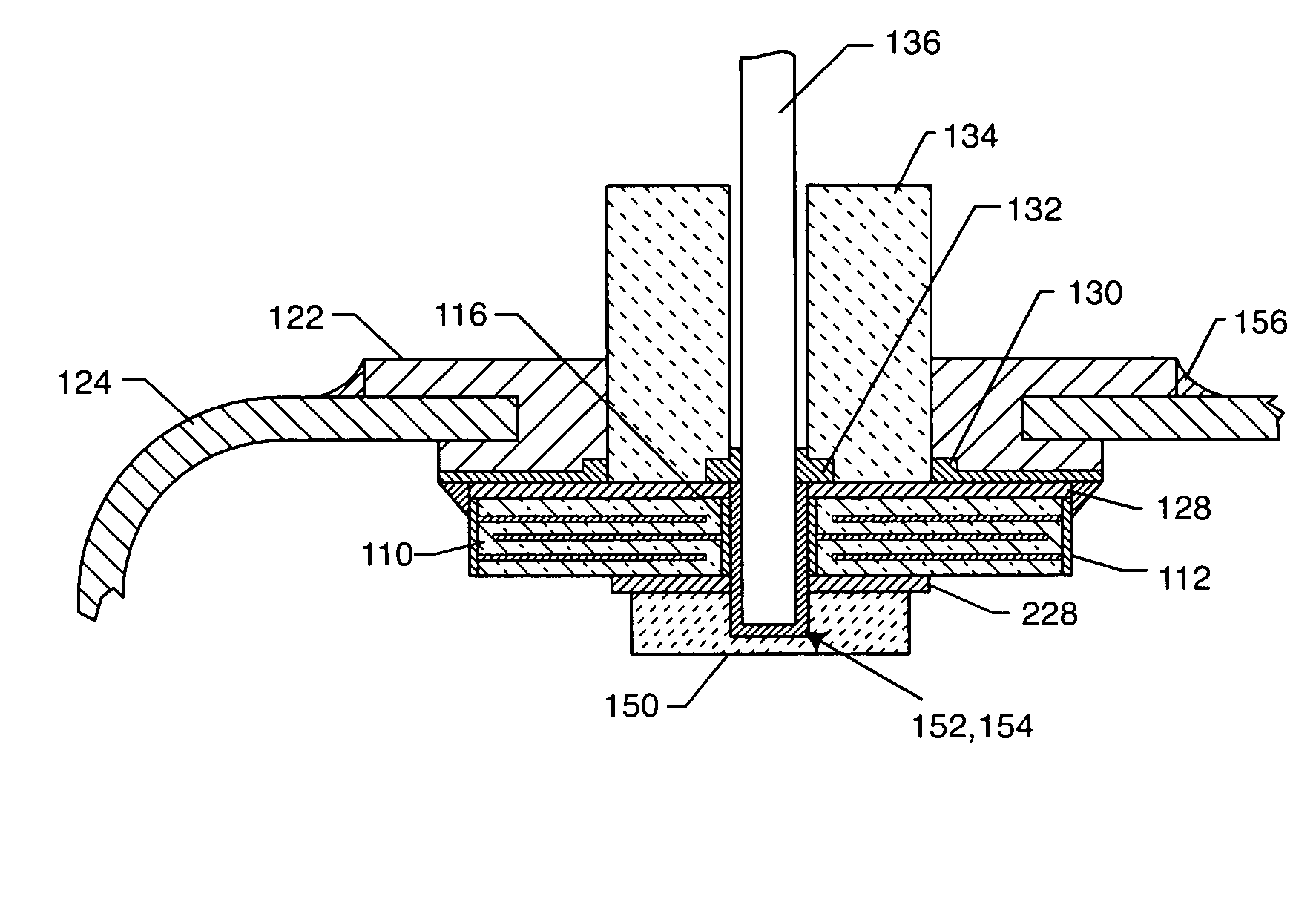

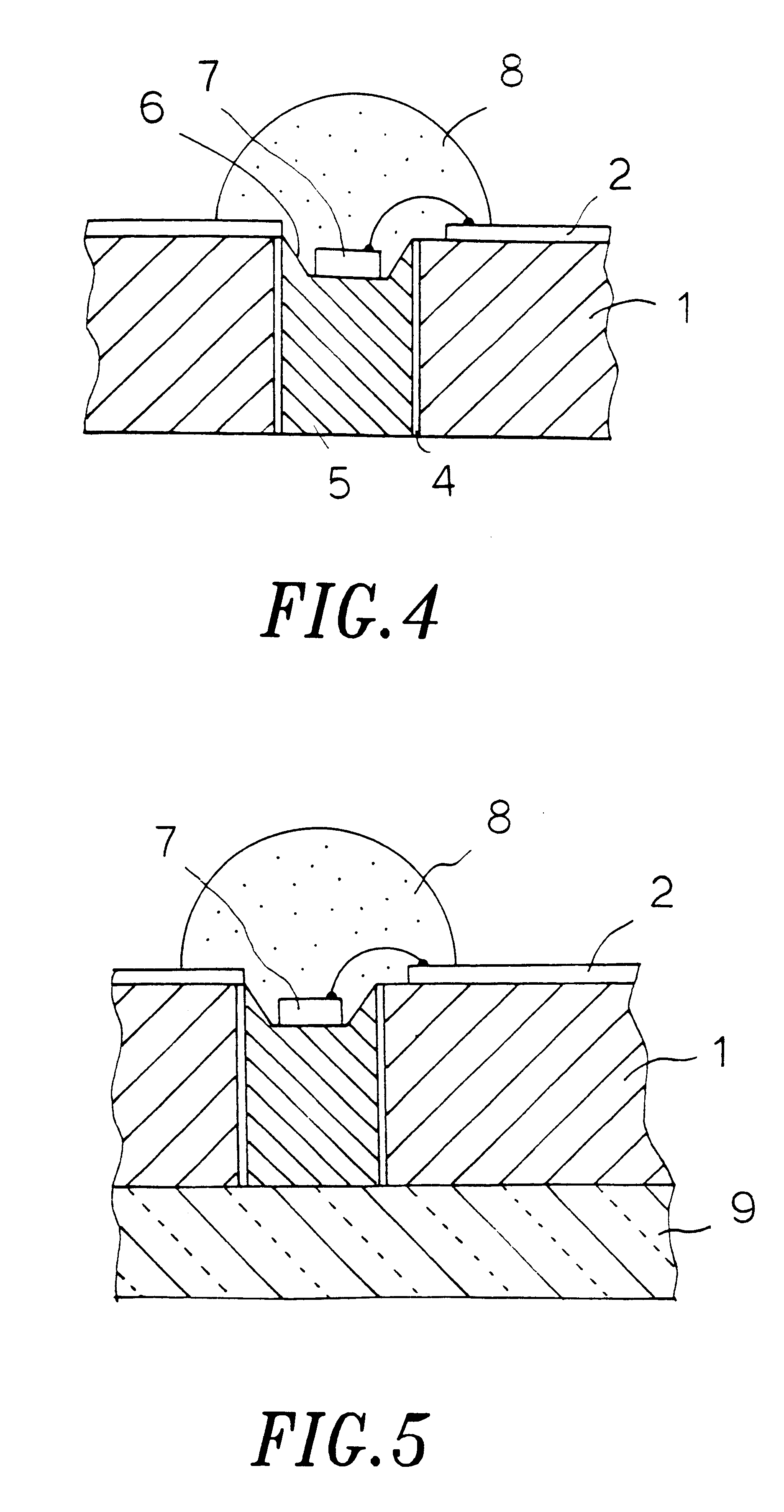

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

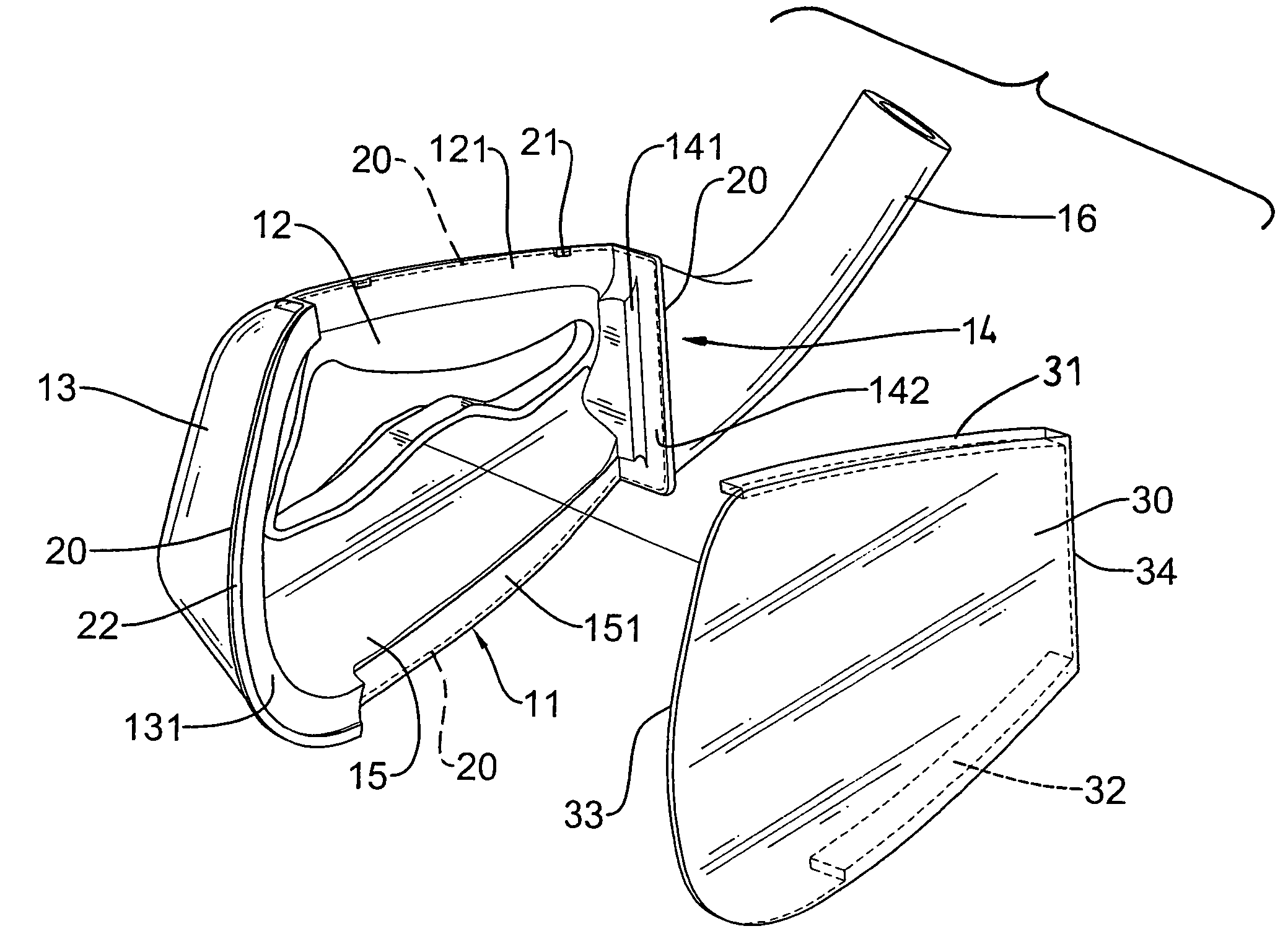

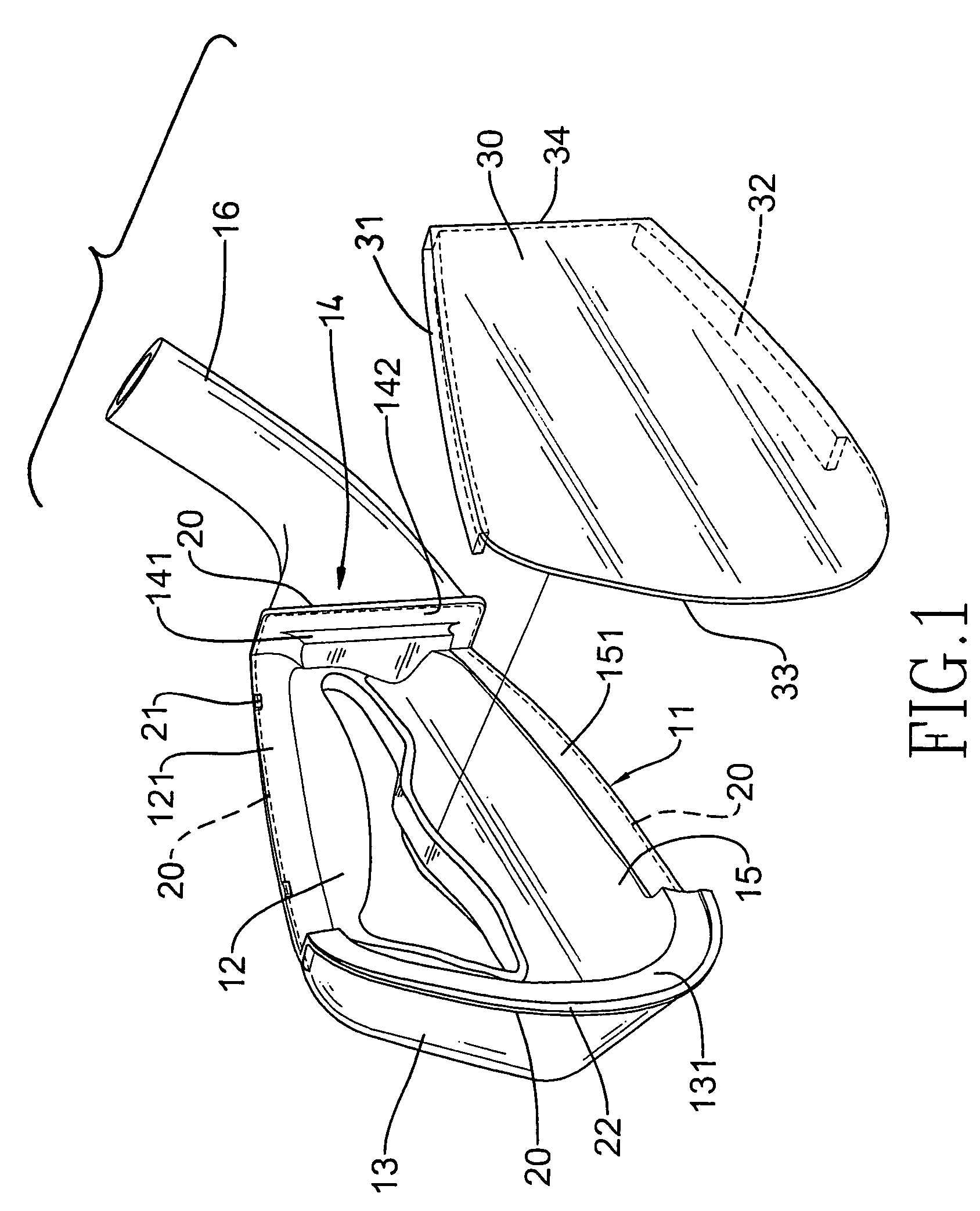

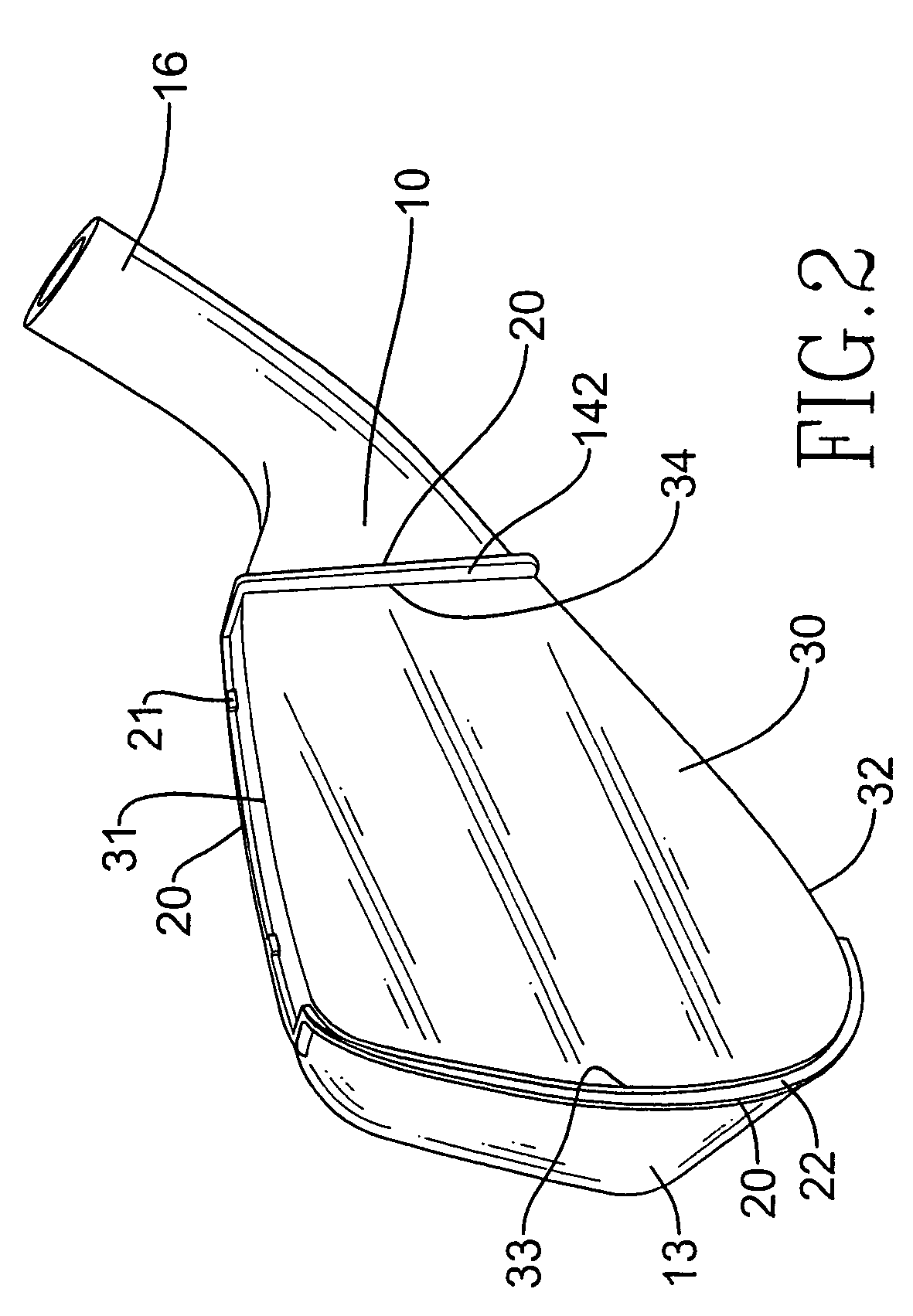

Positioning structure in a golf club head

InactiveUS7121958B2Optimize positioning structurePrecise dockingGolf clubsRacket sportsEngineeringFace flushing

A golf club head includes a head body having a recessed area defined in a central area of the head body and abutting faces formed along a periphery defining the recessed area. A soldering seam is formed on an outer periphery defining the recessed area and at least one positioning block is formed on one of the abutting faces and has a bottom face flush with a top face of the recessed area. A striking face is abutted to the abutting faces and the bottom face of the positioning block to allow the soldering seam to securely combine the head body and the striking face.

Owner:ADVANCED INT MILITIECH

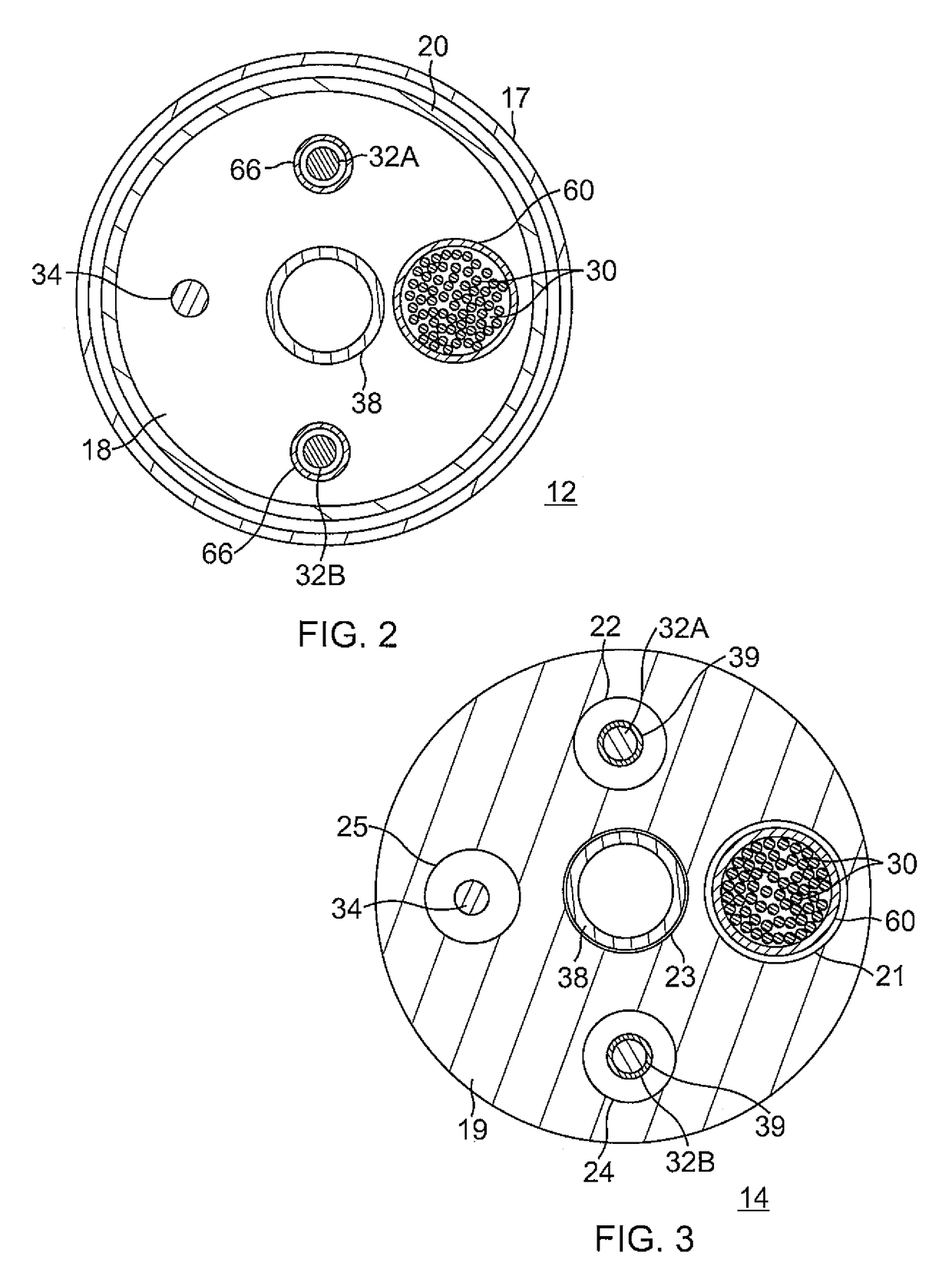

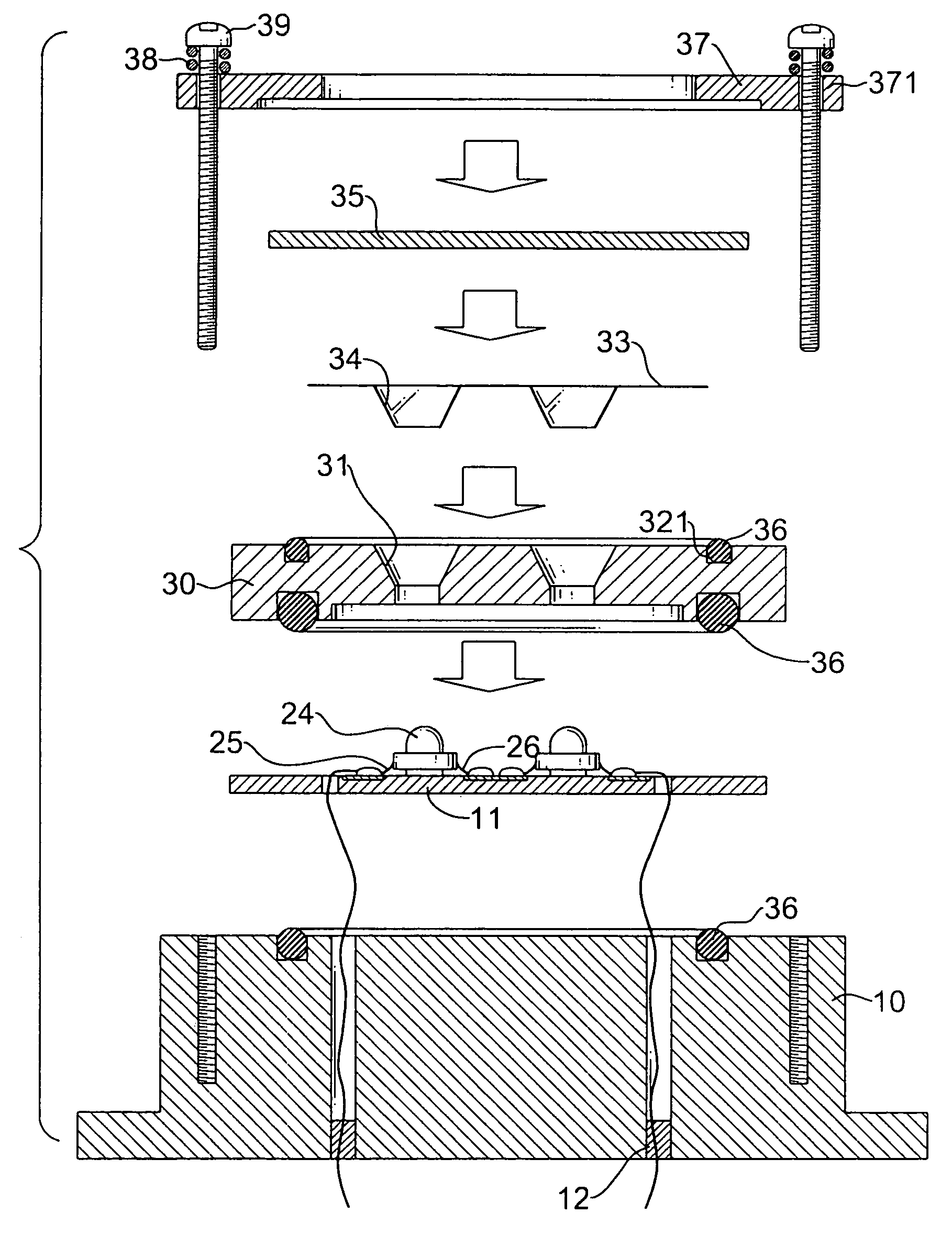

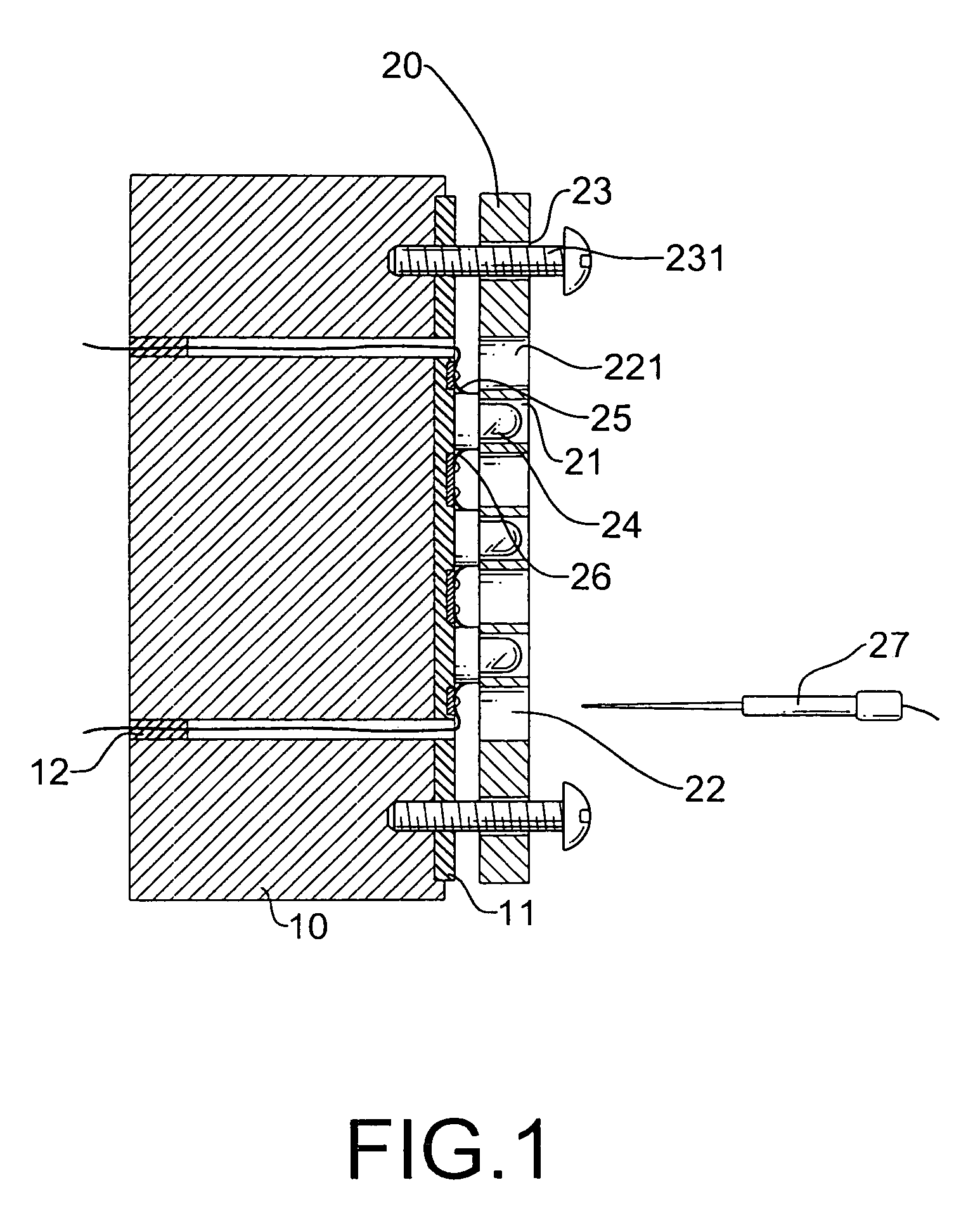

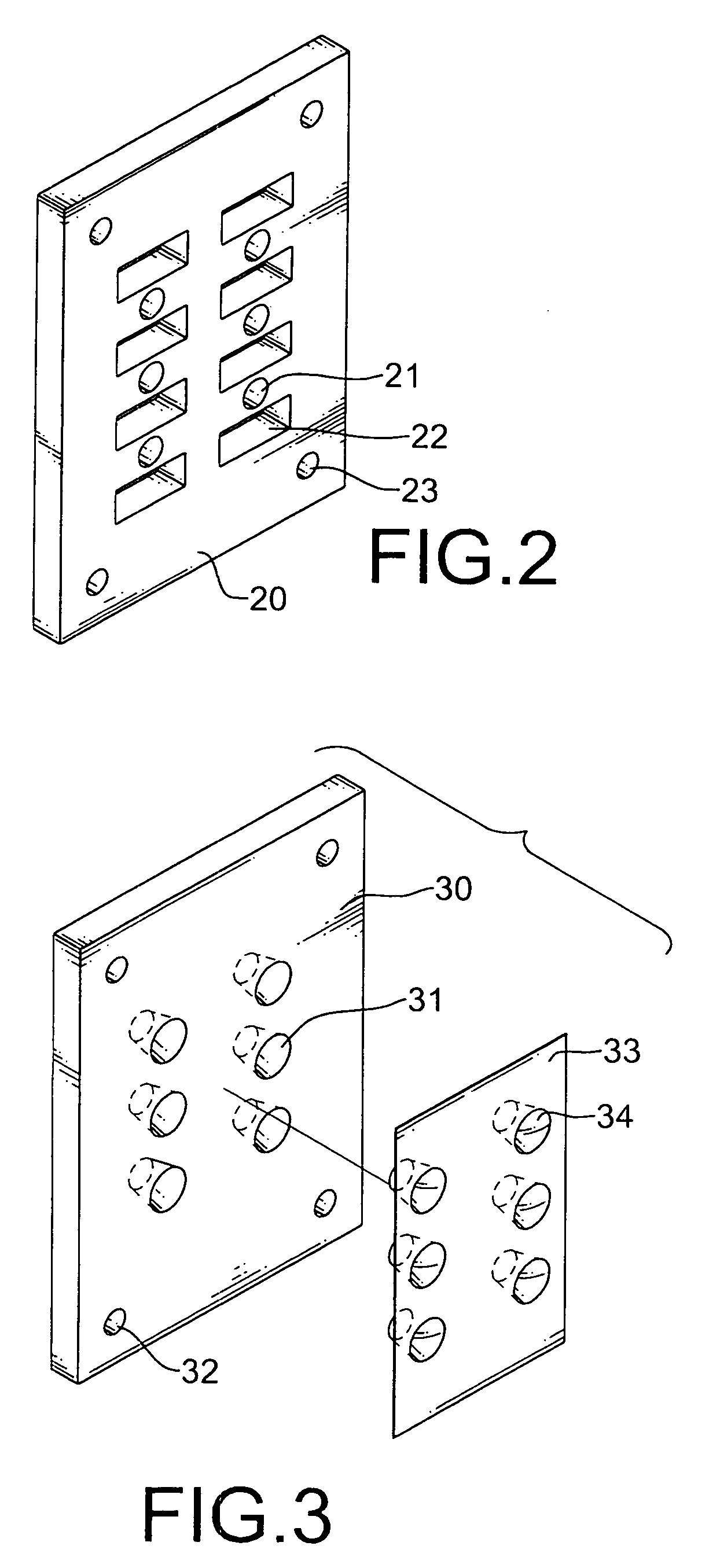

Packaging types of light-emitting diode

InactiveUS6562643B2Affect performanceIncrease temperaturePrinted electric component incorporationSolid-state devicesElectrical conductorEngineering

A LED packaging process is to place LED chips at predetermined positions on the printed circuit board substrate, followed by drilling holes to penetrate the substrate, followed by passing the printed circuit board through the solder furnace to completely fill the through-hole position with solder points, followed by using molds to make the soldering points into a groove reflector, followed by placing LED chips in the groove reflector, followed by wire bonding and using encapsulation resin for packaging to form SMD LED with reflectors. In the present invention, the filling with metal conductor in electrode through holes on the printed circuit board to form the groove reflector can enhance the heat dissipation of LED and the brightness of LED, which has the advantageous effects that traditional SMD LED can not have.

Owner:SOLIDLITE CORP

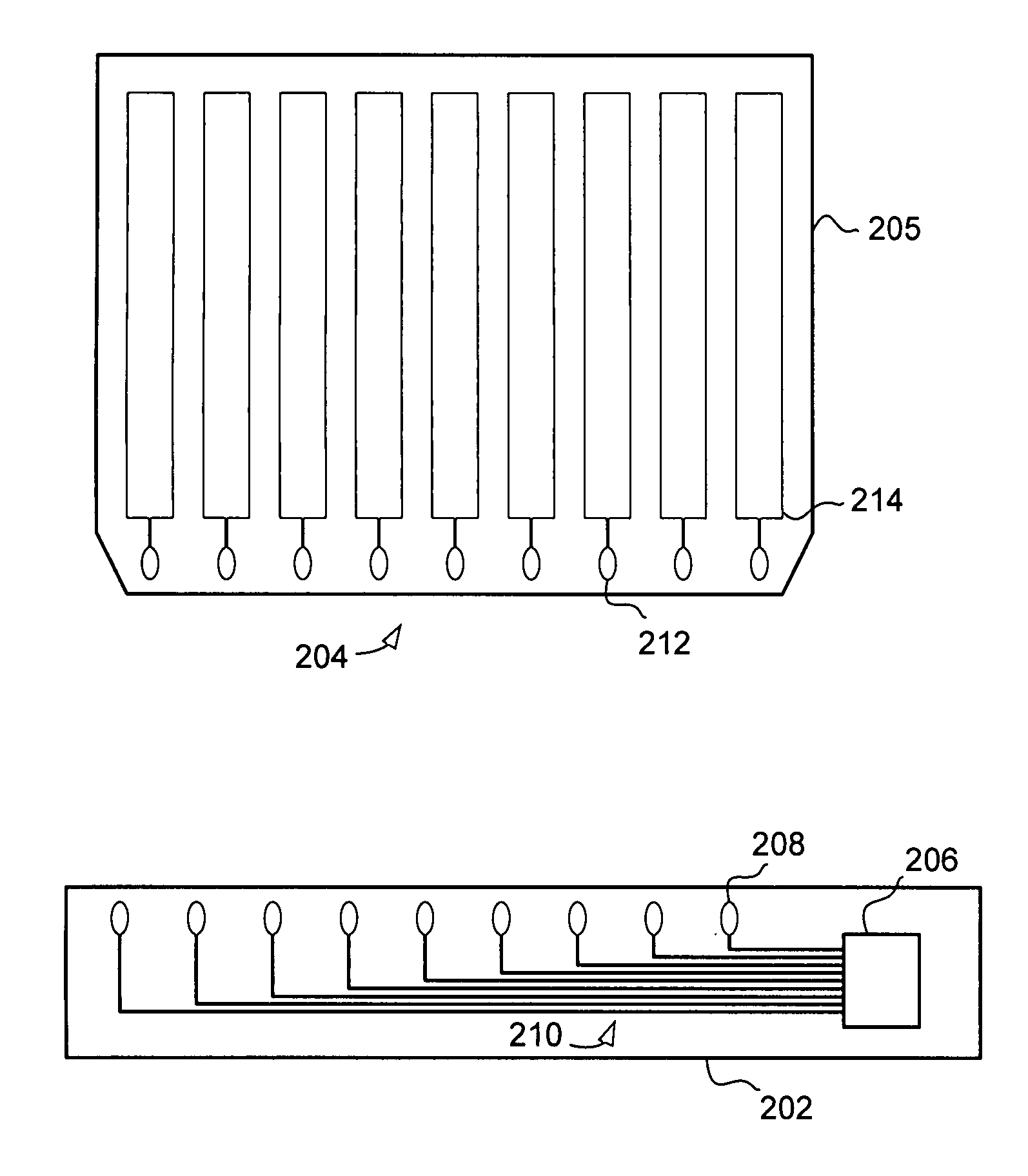

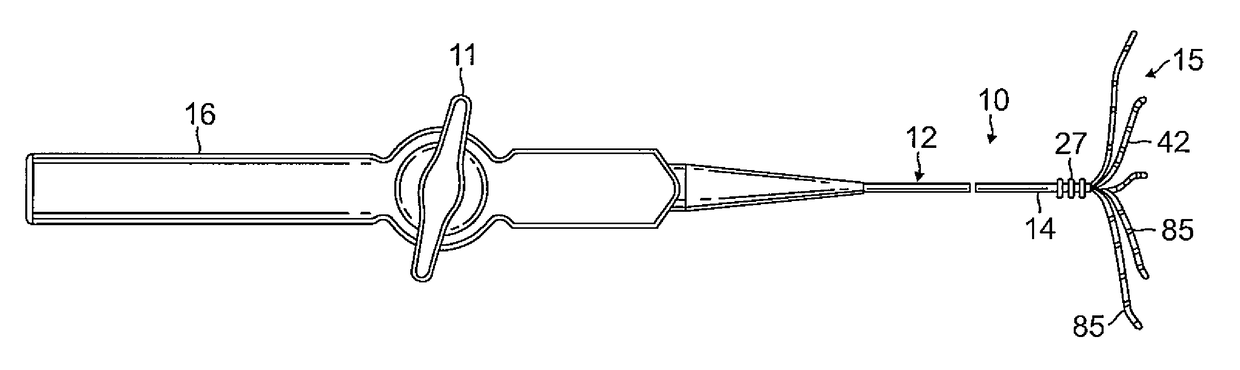

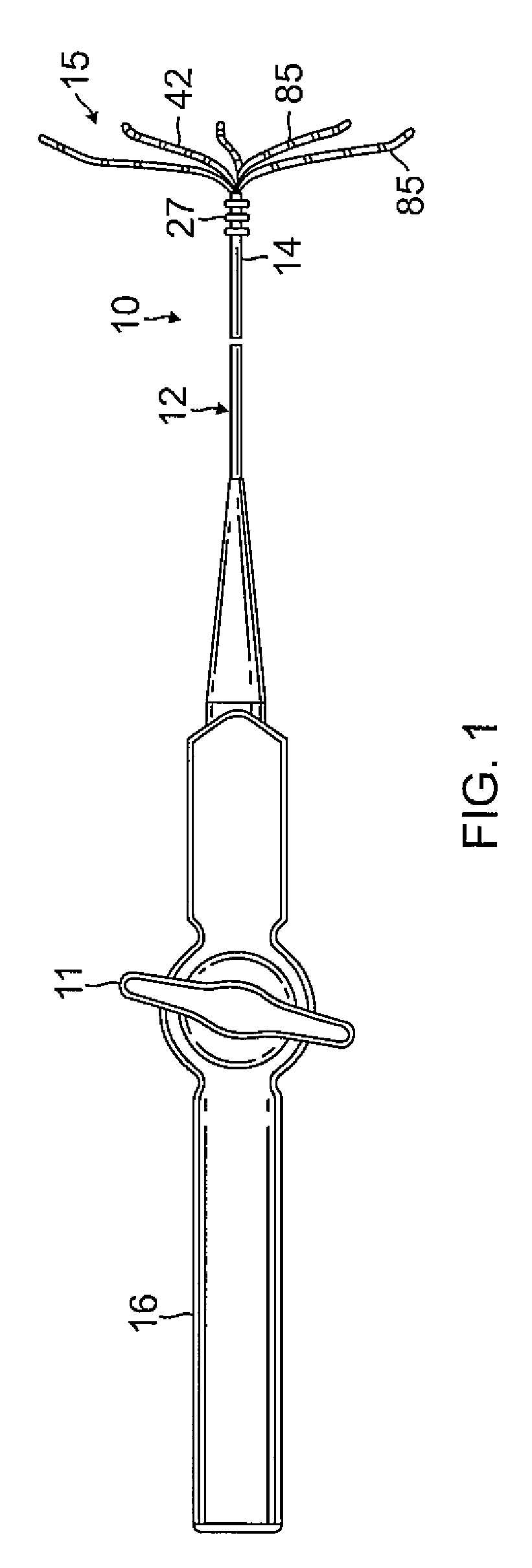

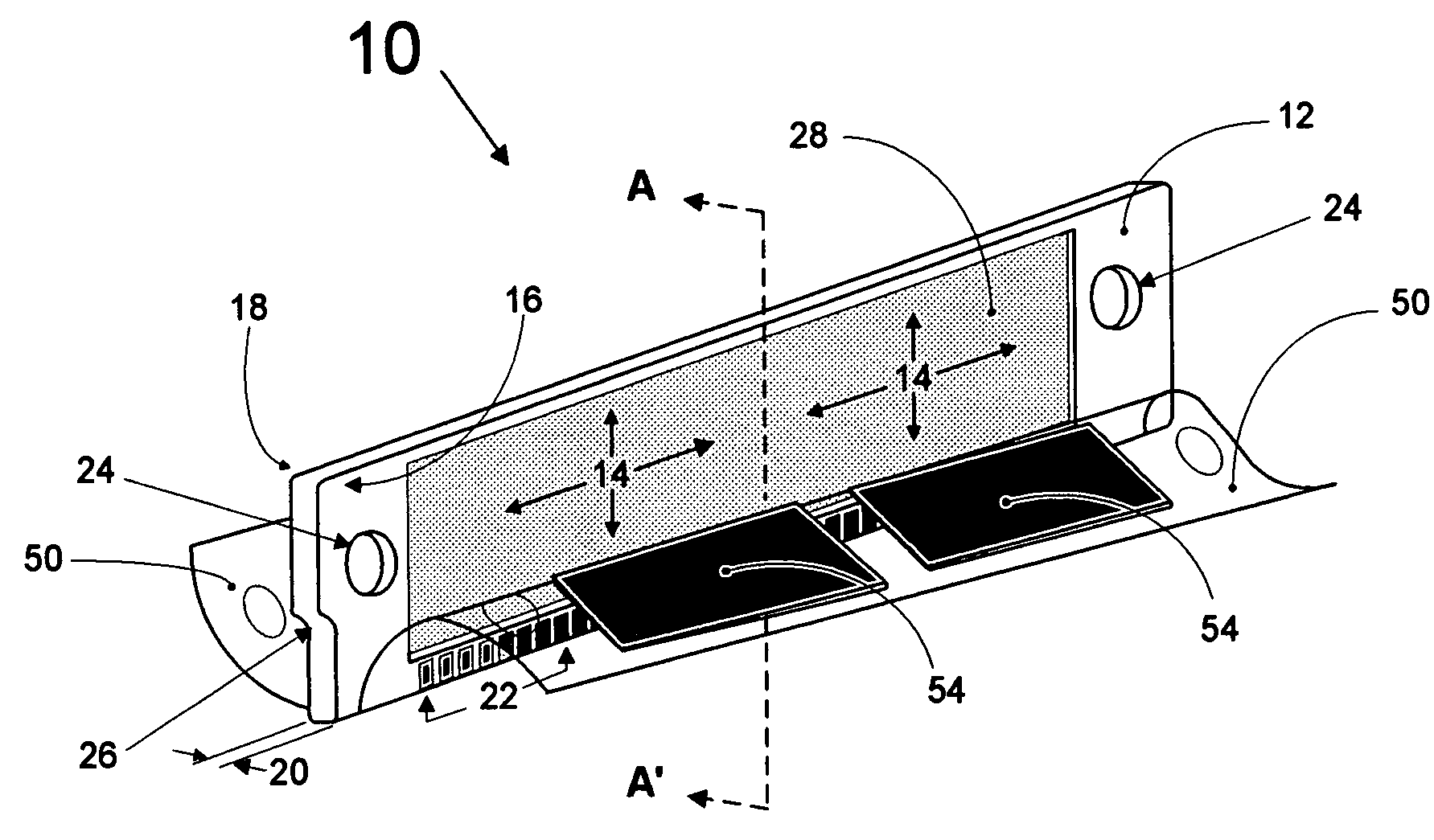

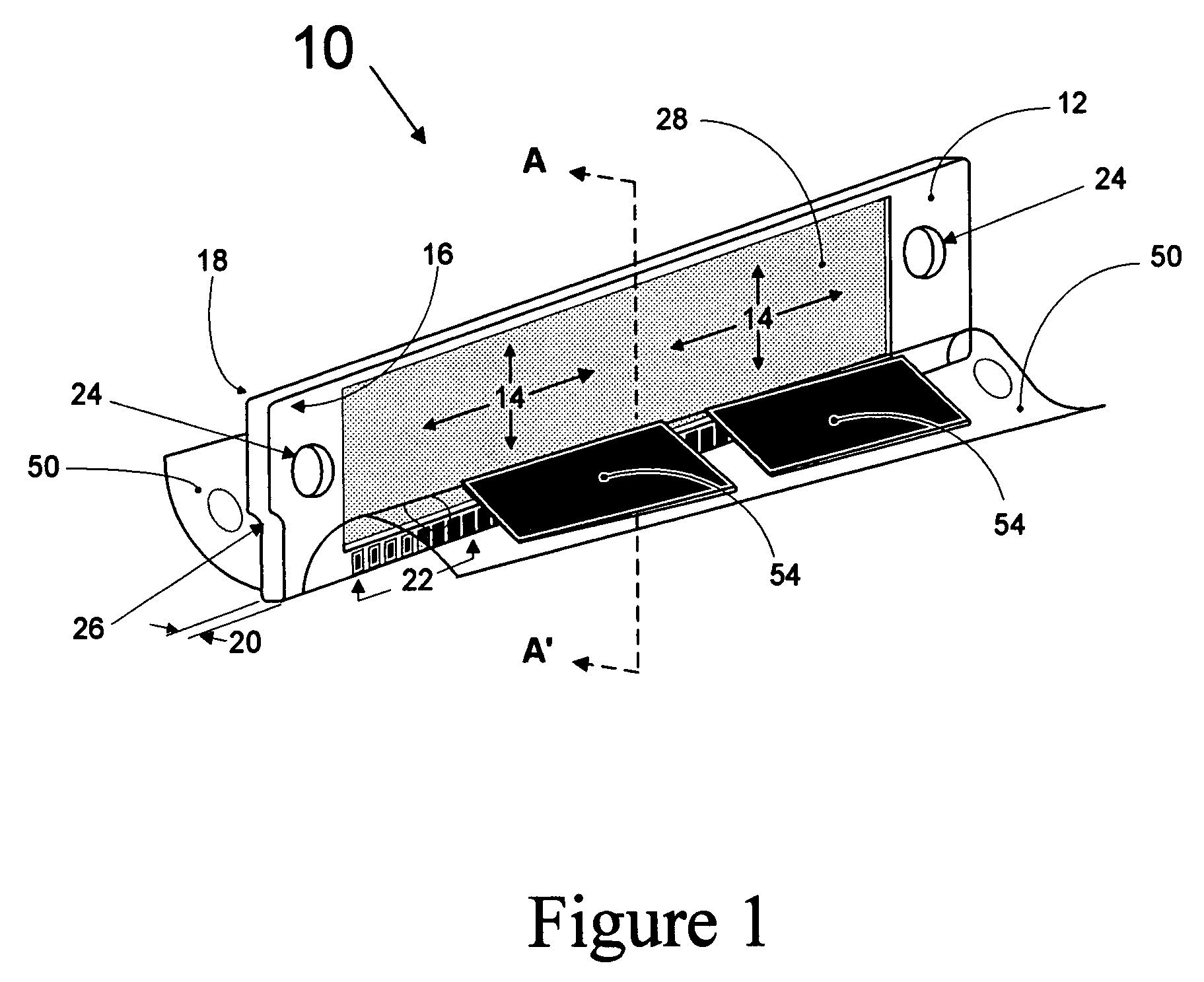

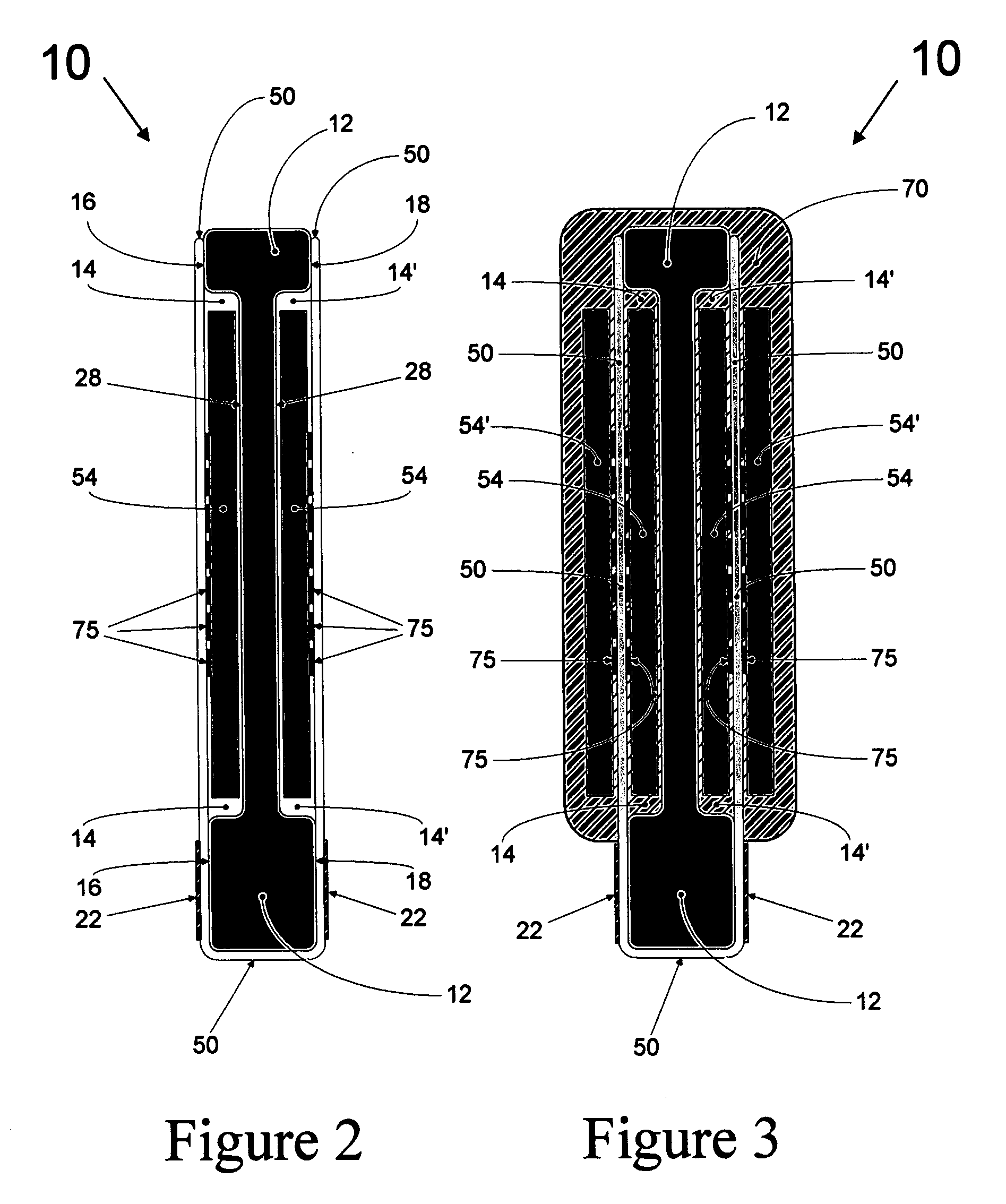

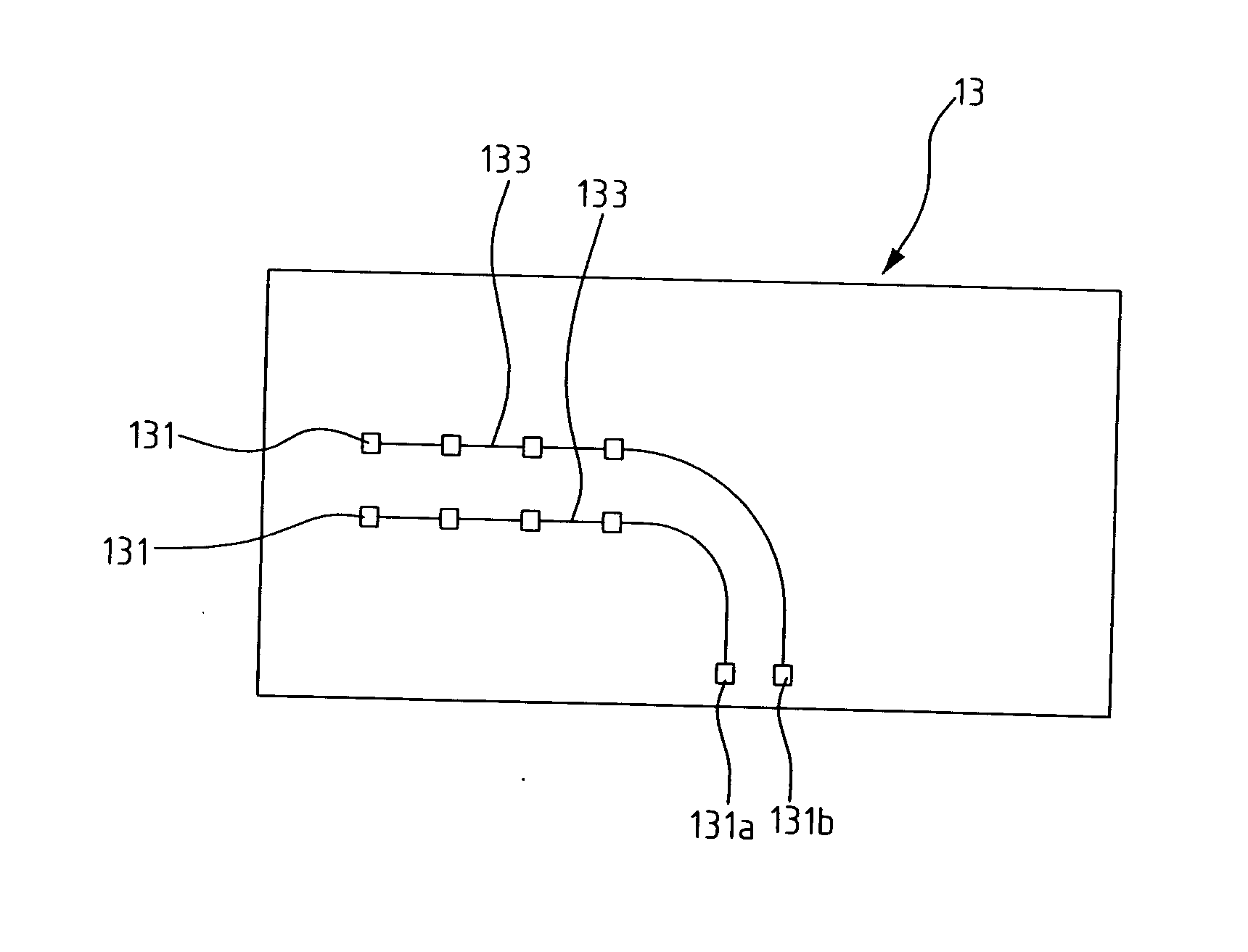

Catheter spine assembly with closely-spaced bipole microelectrodes

An electrophysiologic catheter with a distal electrode assembly carrying very closely-spaced bipole microelectrodes on a plurality of divergent spines that can flexibly spread over tissue surface area minimized detection of undesirable noise, including far-field signals. Each spine has a flexible microelectrode panel having a substrate, at least one pair of microelectrodes, a trace for each microelectrode, and a soldering pad. Adjacent microelectrodes of a bipole pair are separated by a space gap distance ranging between about 50-300 microns. Each microelectrode may have a width of about 200 or 300 microns.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Universal serial bus connector

InactiveUS6398587B1Substation/switching arrangement detailsTwo-part coupling devicesOn boardEngineering

An electrical connector comprises an insulative housing, a plurality of conductive contacts, and first and a metal shell. The housing includes a main body, and a tongue board extending forwardly from a front of the main body. The shell comprises first and second conductive shields. The first shield includes a pair of two-pronged fixing portions depending from opposite sides of the first shield respectively, for engaging in a circuit board. The second shield includes two arms depending from a top thereof over outer faces of opposite sidewalls thereof. Each arm forms a bent portion at a lower end thereof, for soldering to the circuit board. Each bent portion is located higher than a bottom of the shell. The fixing portions are disposed higher than the bottom of the shell. The connector is thus attached to the circuit board at four points evenly distributed around a periphery of the connector.

Owner:HON HAI PRECISION IND CO LTD

Diagnostic ultrasound transducer

ActiveUS20090034370A1Easy to guaranteeGood electrical contactUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorEngineering

An ultrasound transducer includes an array of PZT elements mounted on a non-recessed distal surface of a backing block. Between each element and the backing block is a conductive region formed as a portion of a metallic layer sputtered onto the distal surface. Traces on a longitudinally extending circuit board—preferably, a substantially rigid printed circuit board, which may be embedded within the block—connect the conductive region, and thus the PZT element, with any conventional external ultrasound imaging system. A substantially “T” or “inverted-L” shaped electrode is thereby formed for each element, with no need for soldering. At least one longitudinally extending metallic member mounted on a respective lateral surface of the backing block forms a heat sink and a common electrical ground. A thermally and electrically conductive layer, such as of foil, transfers heat from at least one matching layer mounted on the elements to the metallic member.

Owner:SHENZHEN MINDRAY SCIENTIFIC CO LTD

Plug connector

ActiveUS7695318B1Facilitates soldering terminalElectric discharge tubesTwo-part coupling devicesEngineeringSoldering

A plug connector has an insulative housing, a plurality of first terminals, a plurality of second terminals and a positioning bracket. The terminals are mounted in the insulative housing and each terminal has a soldering portion. The positioning bracket is mounted on the insulative housing and has a positioning protrusion having a top surface and a bottom surface respectively holding the soldering portions on two levels. The soldering portions are arranged in two levels to facilitate soldering wires to the soldering portions.

Owner:ADVANCED CONNECTEK INC

Thin multichip flex-module

ActiveUS20070212920A1Reduce manufacturing costIncrease component densityEngagement/disengagement of coupling partsContact member cases/bases manufactureComputer moduleEngineering

A socket assembly for multichip in-line modules comprises: at least three parallel in-line sockets, one of which is an edge-card socket adapted to matably engage electrodes on the edge of a printed circuit board, and the others of which are module sockets adapted to accept multichip in-line modules; and, internal connections between respective pins in each of the parallel sockets, whereby signals from the printed circuit board may be simultaneously carried to each of the multichip in-line modules. Alternatively, a socket assembly for multichip in-line modules comprises: a substantially rigid housing structure; at least two parallel in-line sockets adapted to accept multichip in-line modules; a set of electrodes adapted for soldering to a printed circuit board; and, internal connections between respective pins in each of the parallel sockets and the set of electrodes, whereby signals from the printed circuit board may be simultaneously carried to each of the multichip in-line modules.

Owner:MICROELECTRONICS ASSEMBLY TECH

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

InactiveUS20060028784A1Protect the surfaceAnti-noise capacitorsElectrotherapyManufacturing technologyCeramic capacitor

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

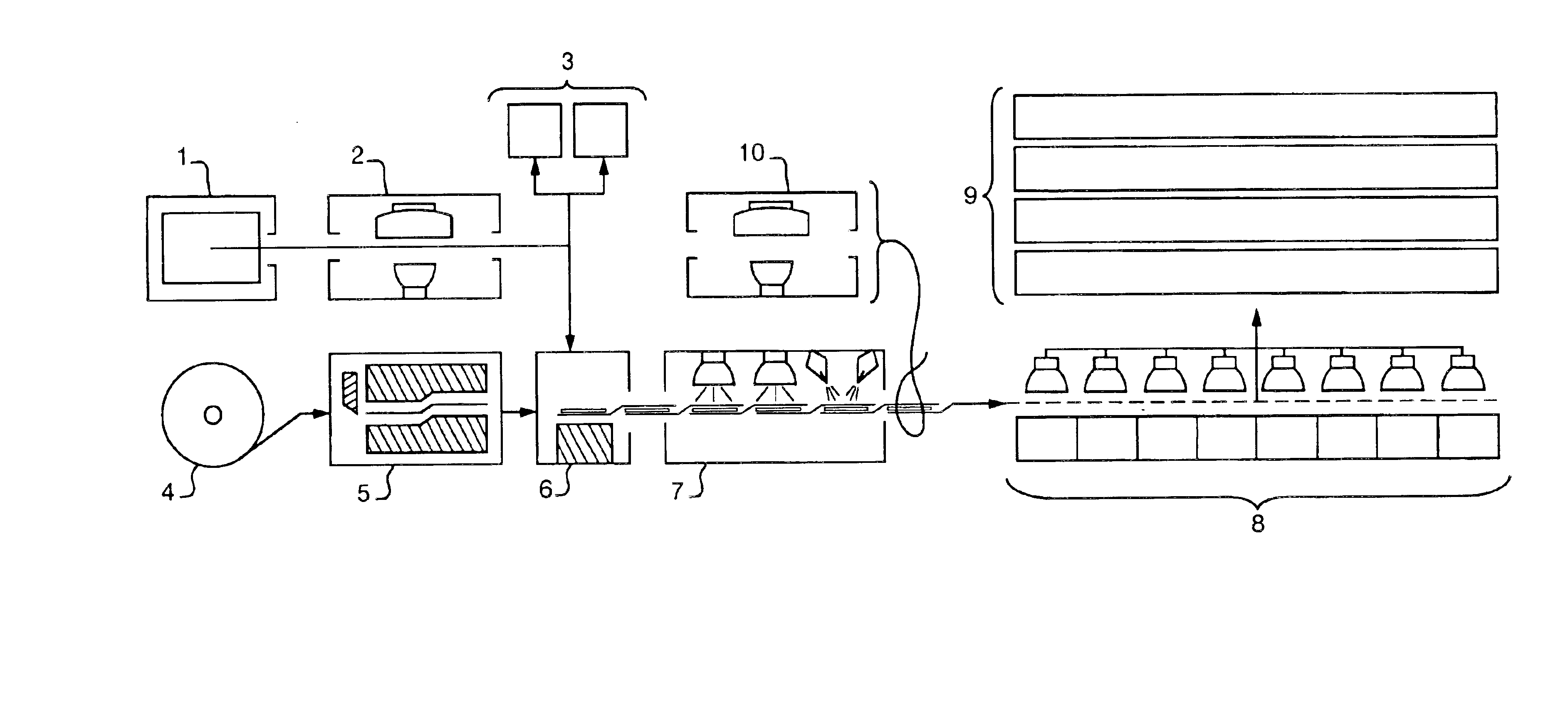

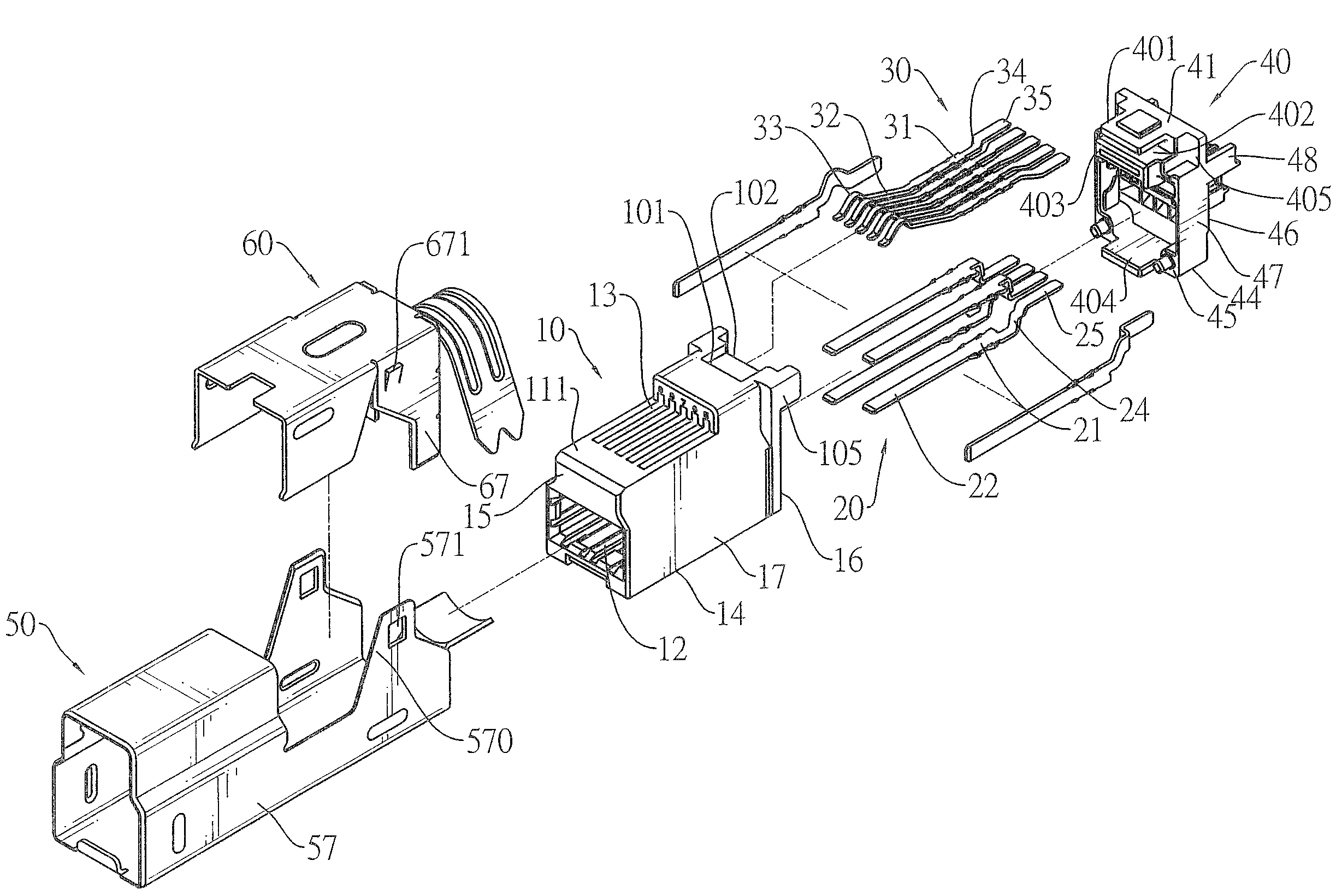

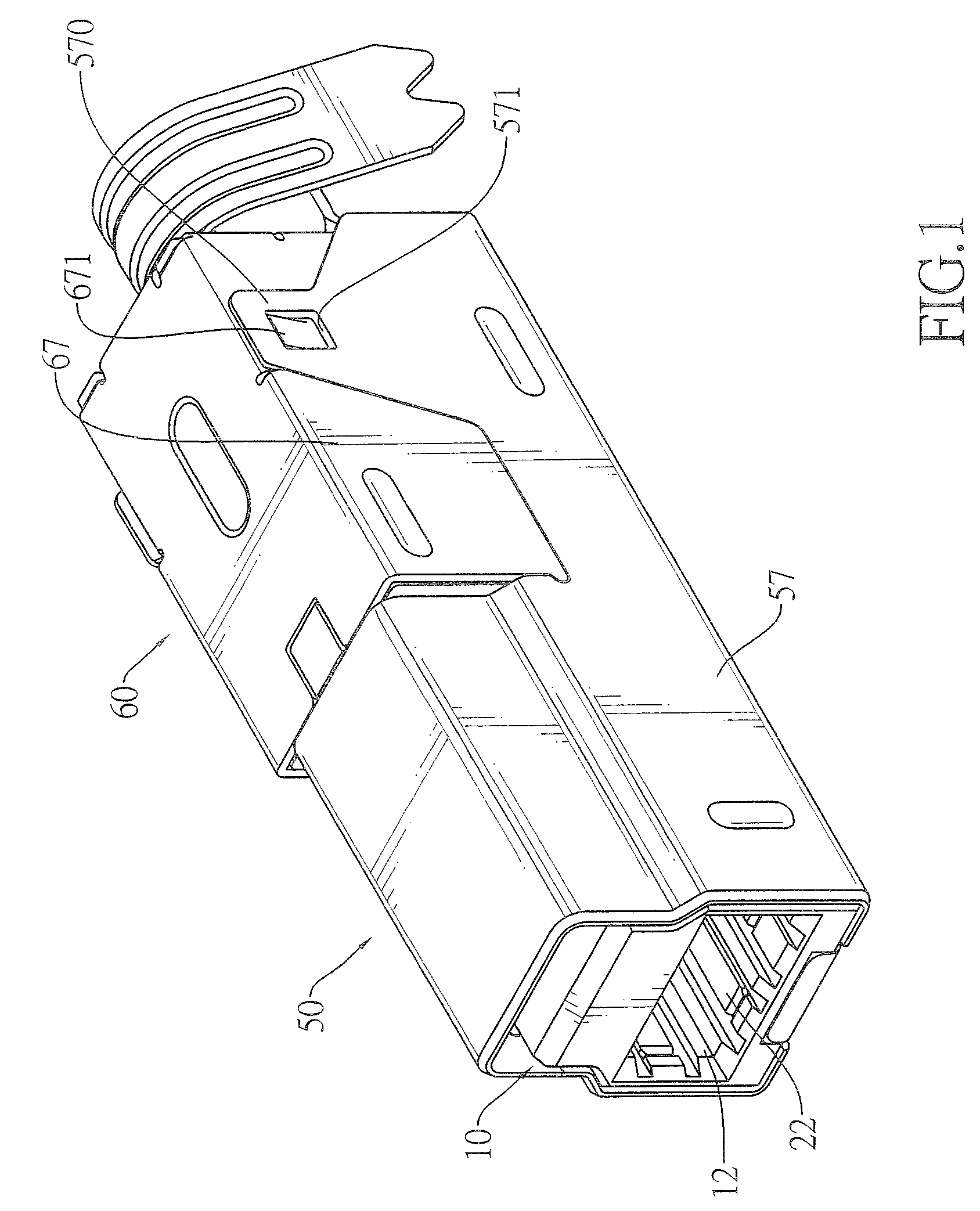

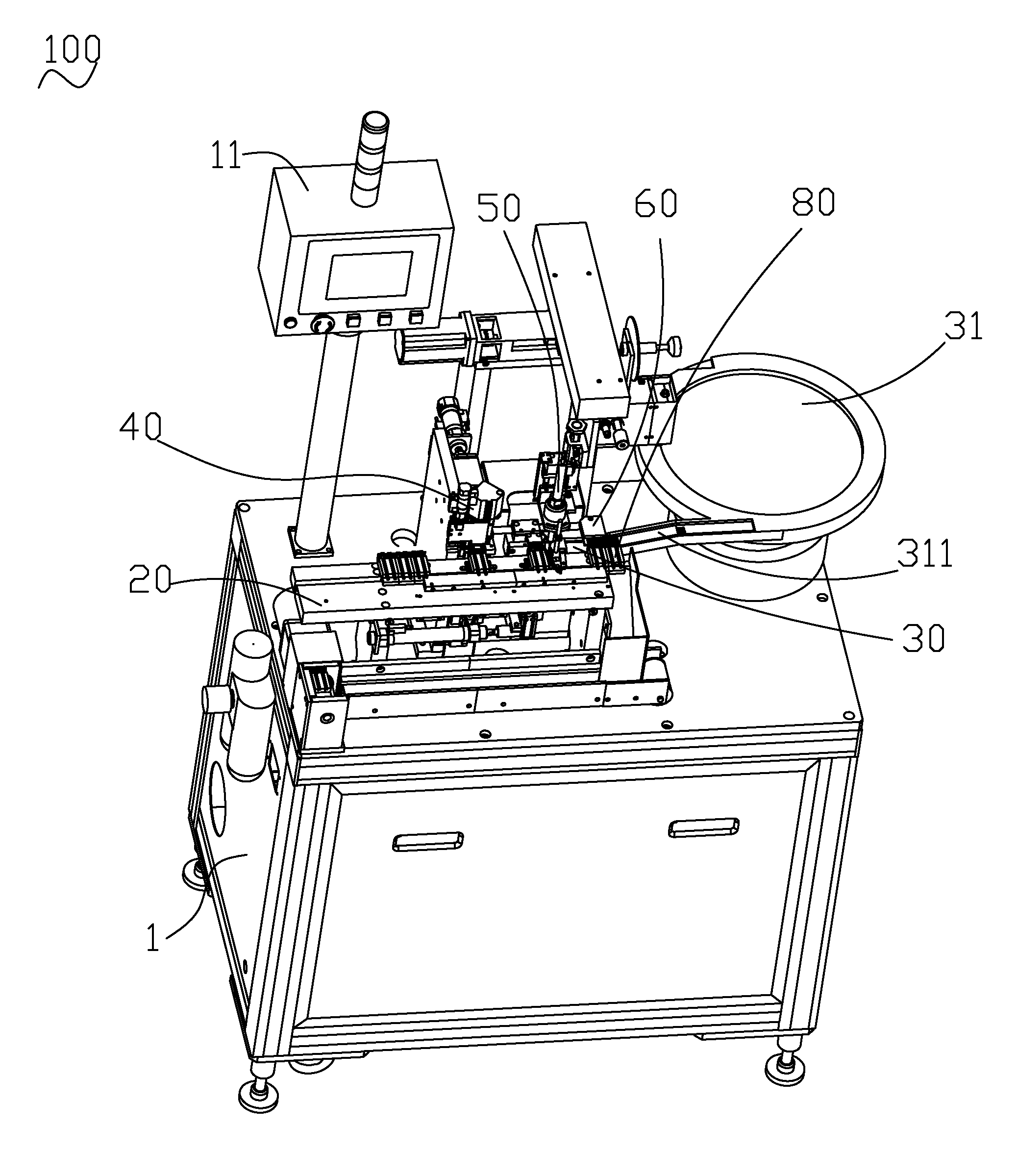

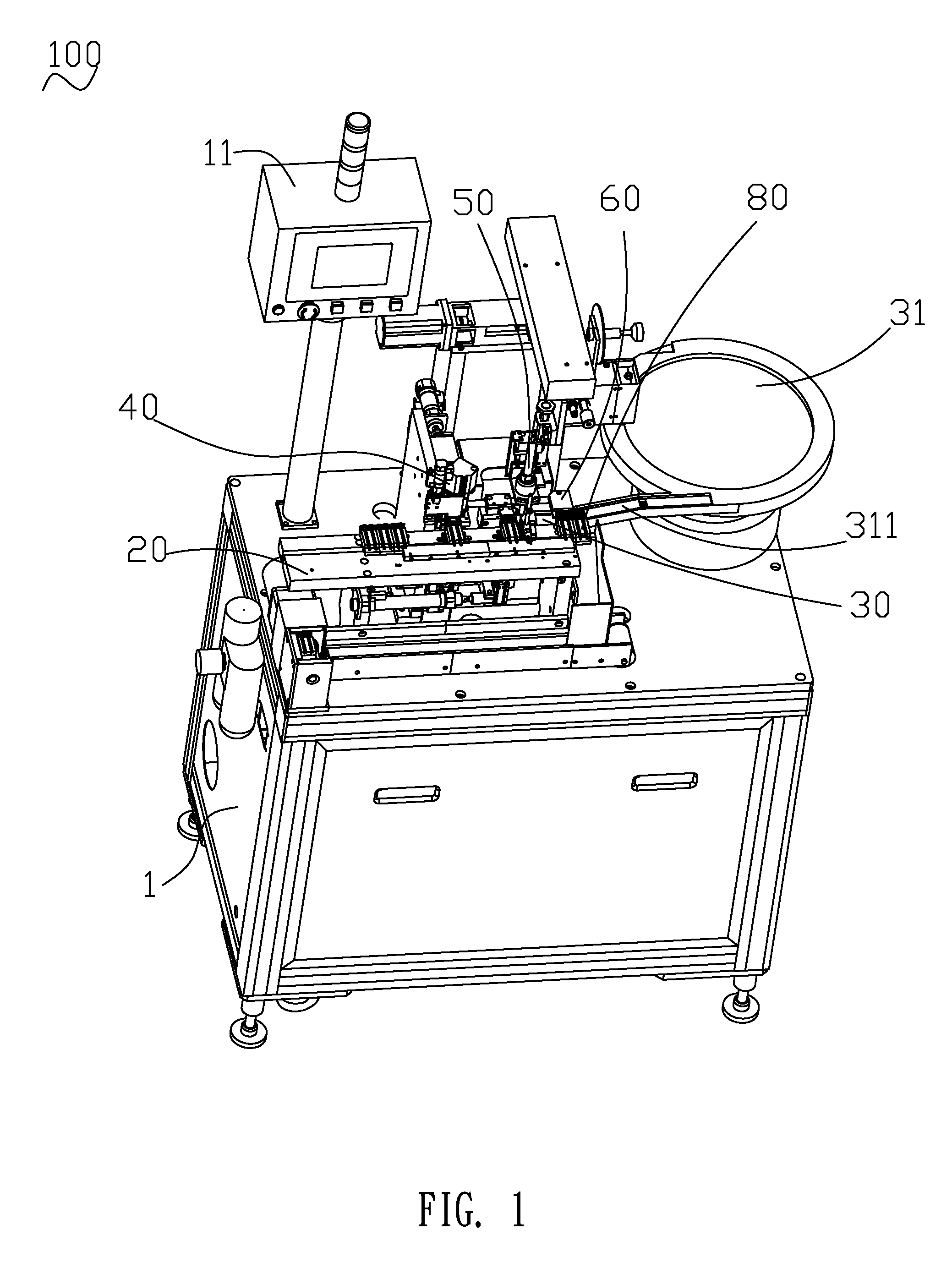

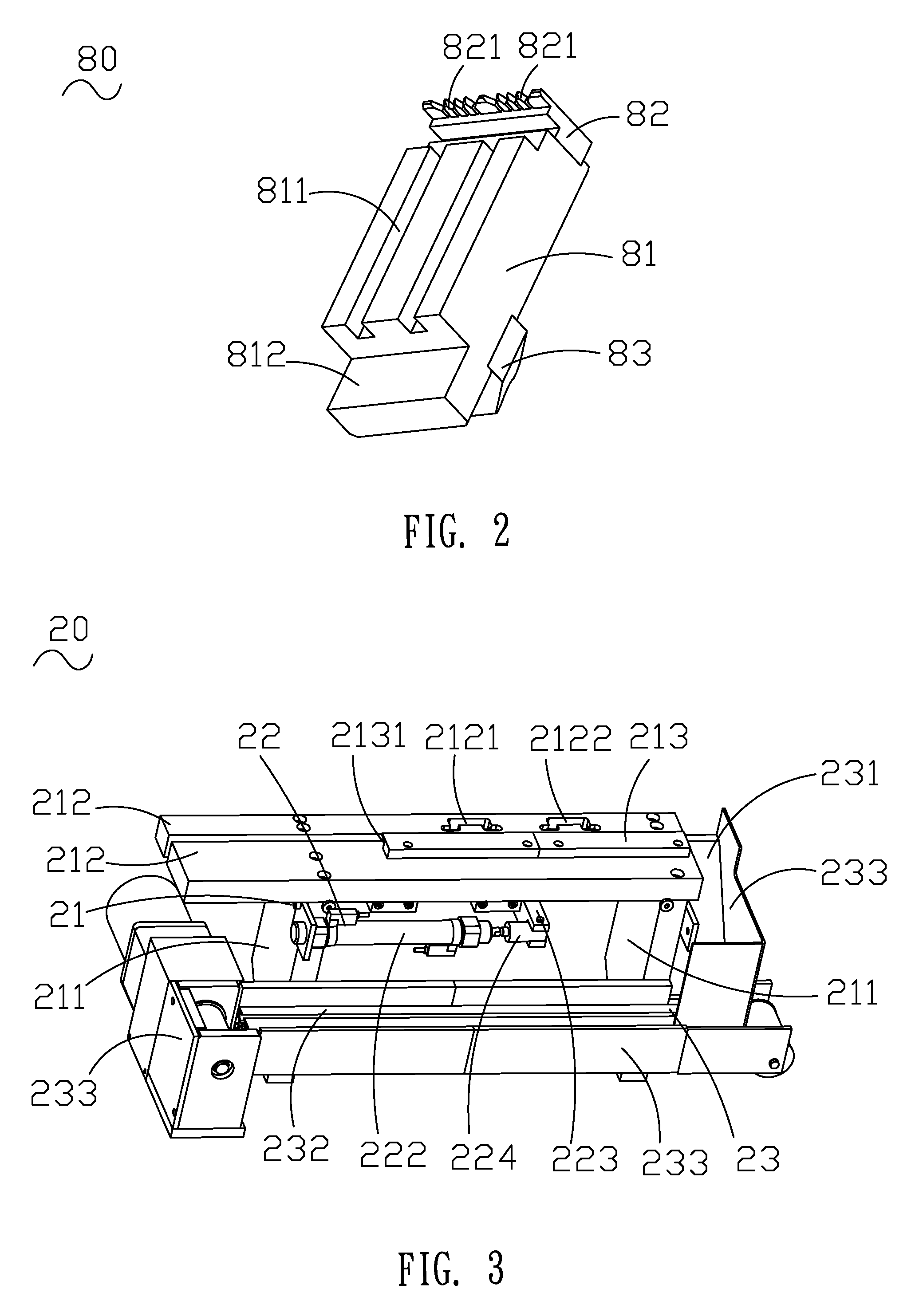

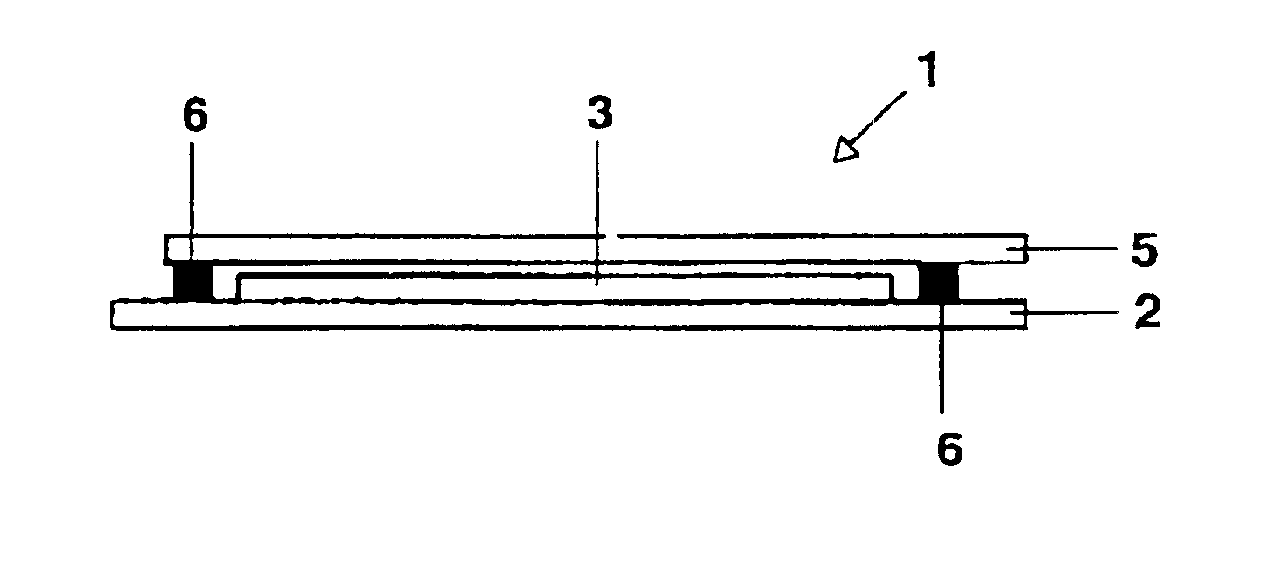

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

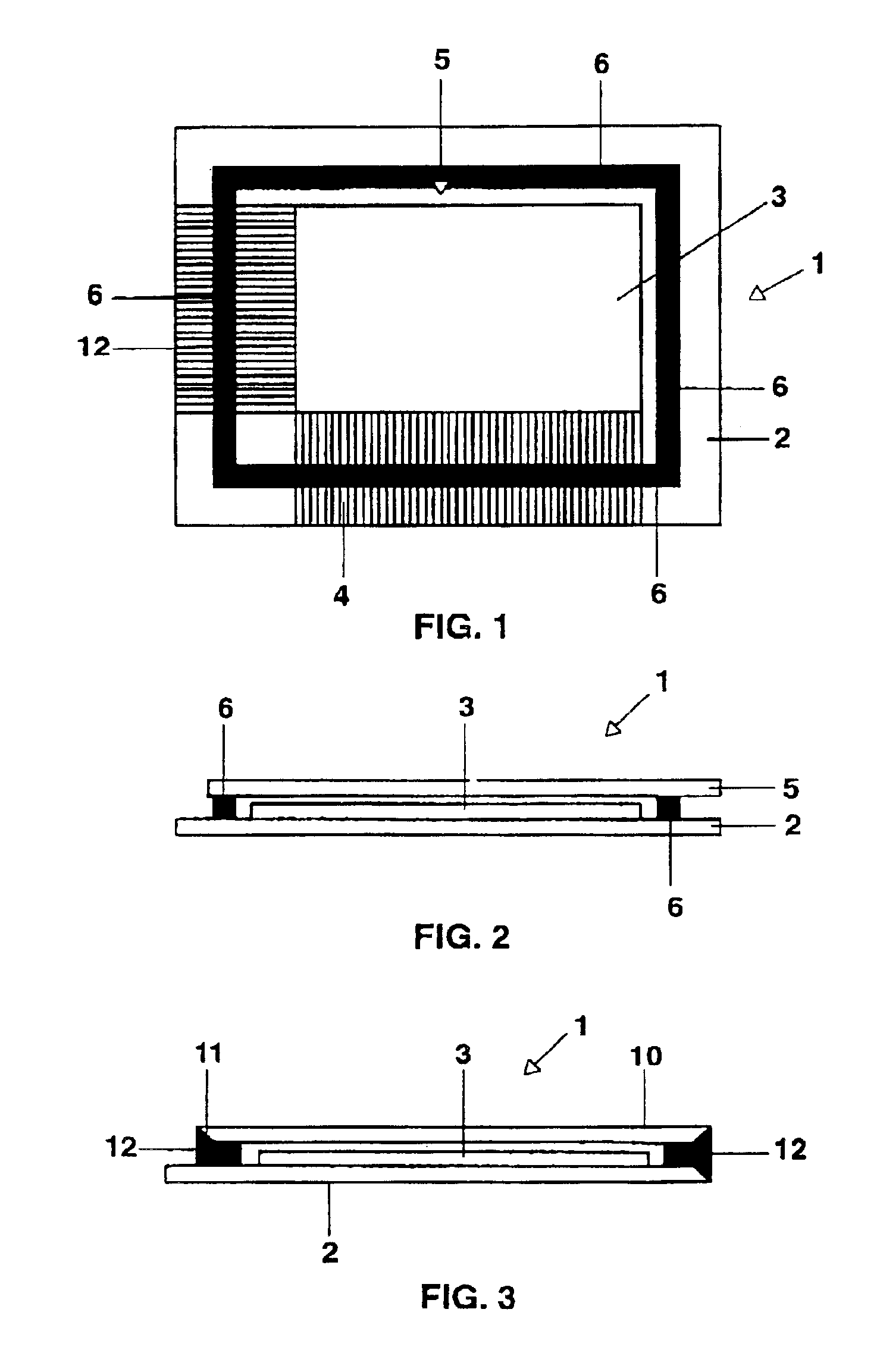

Process for encapsulating a component made of organic semiconductors

InactiveUS6936963B2Improve sealingLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesElectrical connectionThermal expansion

A process for encapsulating a component made of organic semiconductors is provided which includes steps of: a) providing a housing including a substrate with electrical connections and a cover; b) mixing a soldering glass with at least one of a binder and a solvent; c) applying the soldering glass at least to the cover, in the form of an encircling bank; d) expelling the binder or solvent; e) sintering-on of the solder; f) covering the substrate with layers which represent the semiconductor component together with electrodes; g) placing the cover onto the substrate; and h) locally heating the soldering glass by means of a light source with a predetermined peak wavelength, wherein the housing parts and soldering glass are matched to one another such that their coefficients of thermal expansion differ from one another by less than 1.0×10−6K−1.

Owner:PATENT TREUHAND GES GMBH

High illumosity lighting assembly

InactiveUS7182627B1Reinforcement and waterproofingPoint-like light sourceElectric circuit arrangementsEffect lightSoldering

A lighting assembly includes a circuit board having light emitting diodes, a heat conductive plate, a soldering plate removably connected to the circuit board and having multiple LED holes to correspond to the LEDs on the circuit board and a fixing plate securely connected to the circuit board after the soldering plate is removed from engagement with the circuit board. A cover has multiple positioning holes to allow extension of threaded bolts through the positioning holes, the fixing holes, the circuit board and into the heat conductive plate to secure engagement among the heat conductive plate, the circuit board, the fixing plate, the transparent plate and the cover.

Owner:ADVANCED THERMAL DEVICES

Light emitting diode lamp

InactiveUS20050078477A1Point-like light sourceWith electric batteriesElectricityElectrical connection

The present invention is to replace the original light sources with LED lamps in conventional lamp settings designed for fluorescent lamps, incandescent bulbs, and the bulb-based flash lights. It provides an LED lamp, comprising a plurality of LEDs, a circuit board for soldering said LEDs, a connecting base. The circuit board includes a plurality of solder points, each for soldering an LED, and a conductive line to electrically connect the soldered LEDs. The connecting base is electrically connected to the conductive line of said circuit board. The connecting base is also used to mount in the conventional lamp socket and make electrical connection. The connecting base is a column for encompassing the circuit board, wherein said circuit board is shaped according to the shape of the column, and the position of connecting to the column is designed according to the use in the preferred embodiments, such as fluorescent lights, incandescent bulbs, and bulb-based flash lights.

Owner:CHEN YUEH FU

EMI filter terminal assembly with wire bond pads for human implant applications

ActiveUS20050248907A1More stressImprove featuresAnti-noise capacitorsElectrotherapyElectromagnetic interferenceSoldering

An electromagnetic interference filter terminal assembly for active implantable medical devices includes a structural pad in the form of a substrate or attached wire bond pad, for convenient attachment of wires from the circuitry inside the implantable medical device to the capacitor structure via thermal or ultrasonic bonding, soldering or the like while shielding the capacitor from forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

Small-diameter snare

InactiveUS20050234474A1Maximize supportReduced cross sectionDiagnostic markersExcision instrumentsDistal portionEngineering

This invention provides a small diameter snare device consisting of a hollow, elongate, thin-walled polymer outer sheath. A single central core wire extends through the entire length of the sheath. The outer diameter of the core wire is sized close to the inner diameter of the sheath while allowing for axial sliding, in order to maximize the support to the body portion of the snare device. The distal end of the core wire has a tapered section of reduced diameter or cross section to provide a “guidewire-like” flexibility to the distal portion of the device. A second wire of about fifty percent of the inner diameter of the sheath is shaped to form a snare loop and the two ends are attached to the distal most portion of the central core wire via welding, soldering, or brazing. After assembly of the core and sheath, a second short, hollow tube is fitted over the proximal end of the central core and attached thereto to provide an actuating handle to slideably move the central core within the sheath, thus exposing and retracting the snare loop from the open distal end of the sheath. The loop is typically circular or oval shaped and can also be multiplanar (for example, a twisted, figure eight shape) so as to increase the ability to ensnare and capture objects. The loop attachment to the core wire is facilitated and strengthened by a wrapped coupling coil formed typically of 0.001-inch platinum wire applied to secure the loop prior to soldering (brazing or other metal-flowing joining techniques), and through which solder flows to permanently secure the loop to the core wire.

Owner:VASCULAR SOLUTIONS

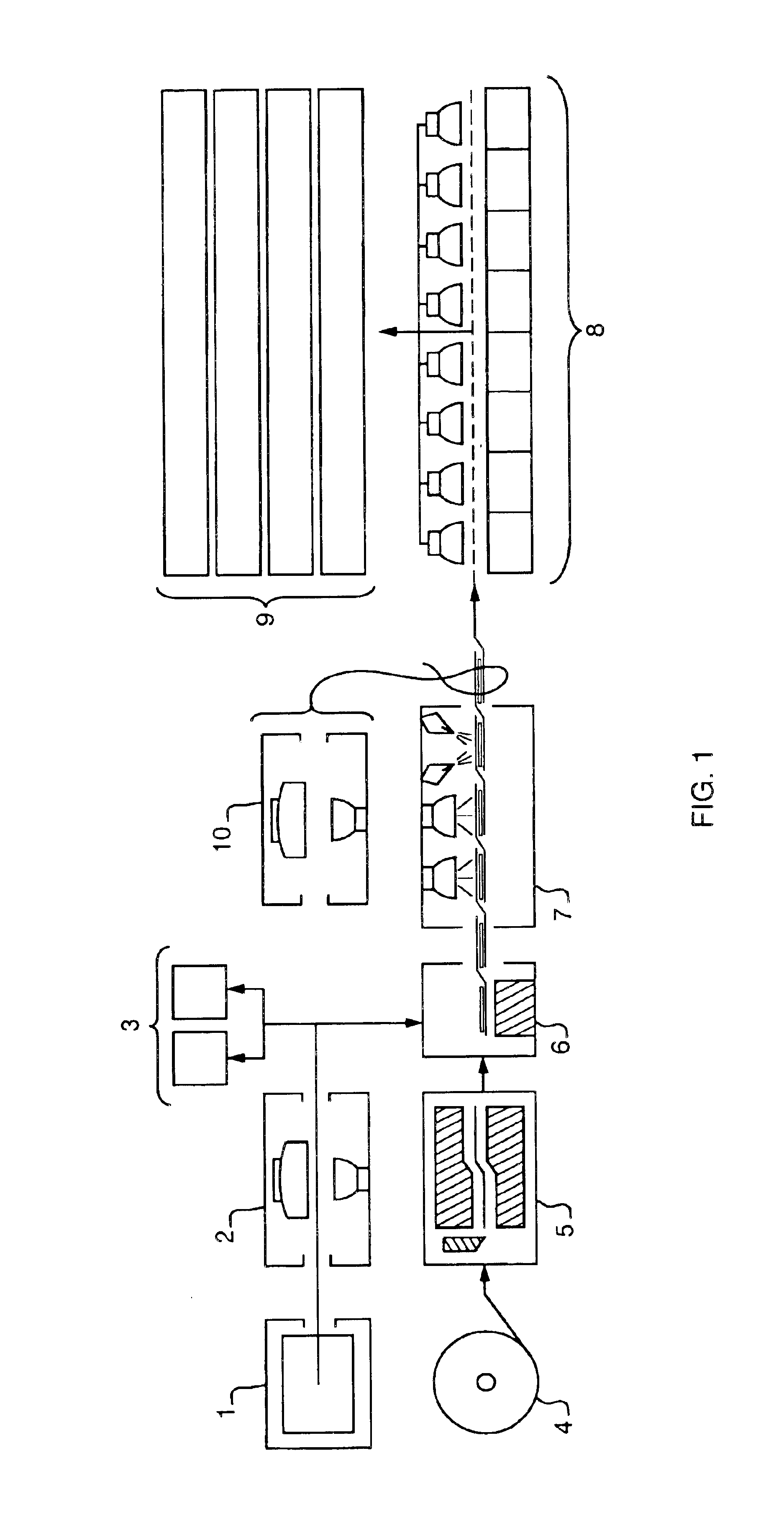

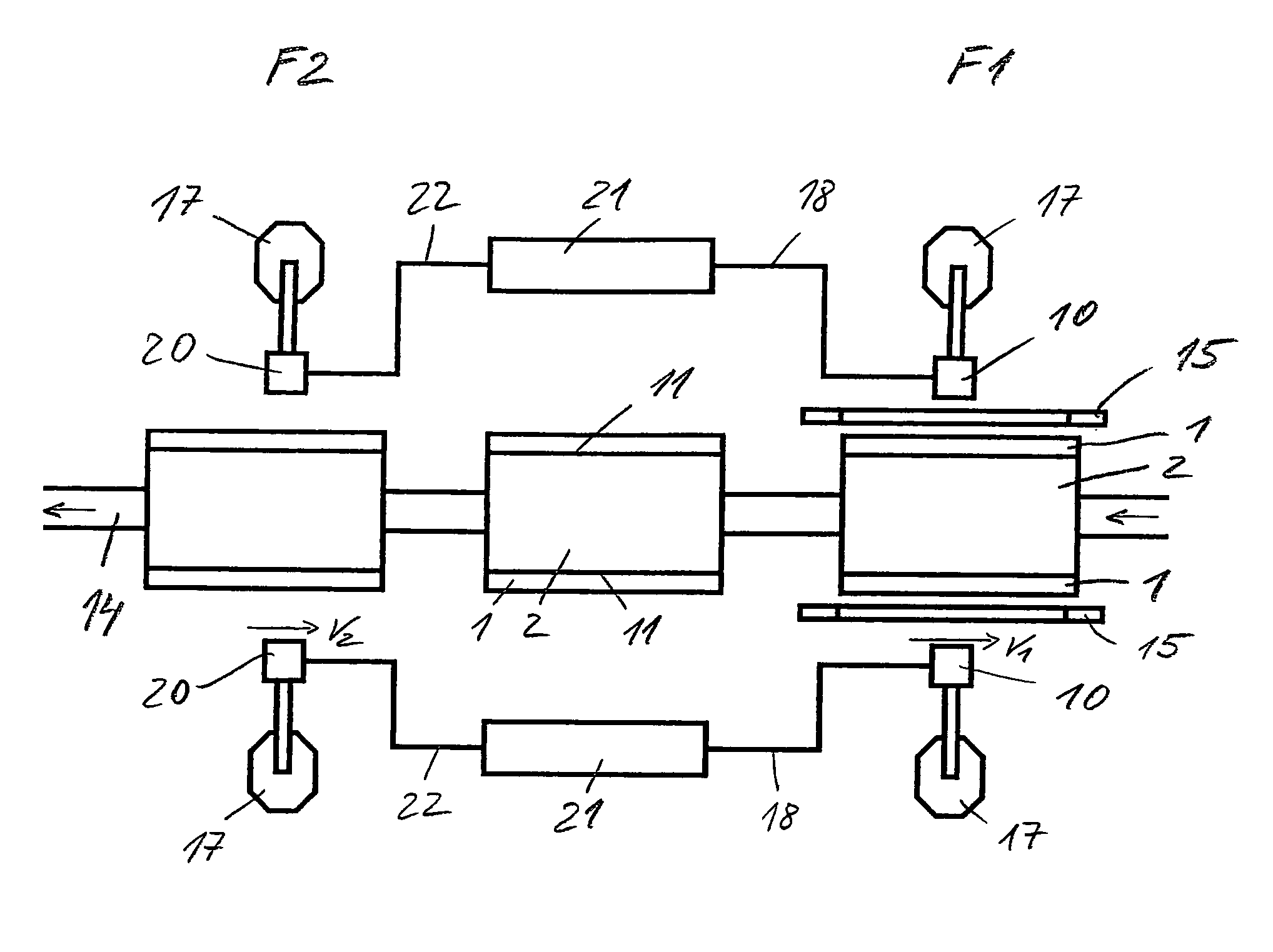

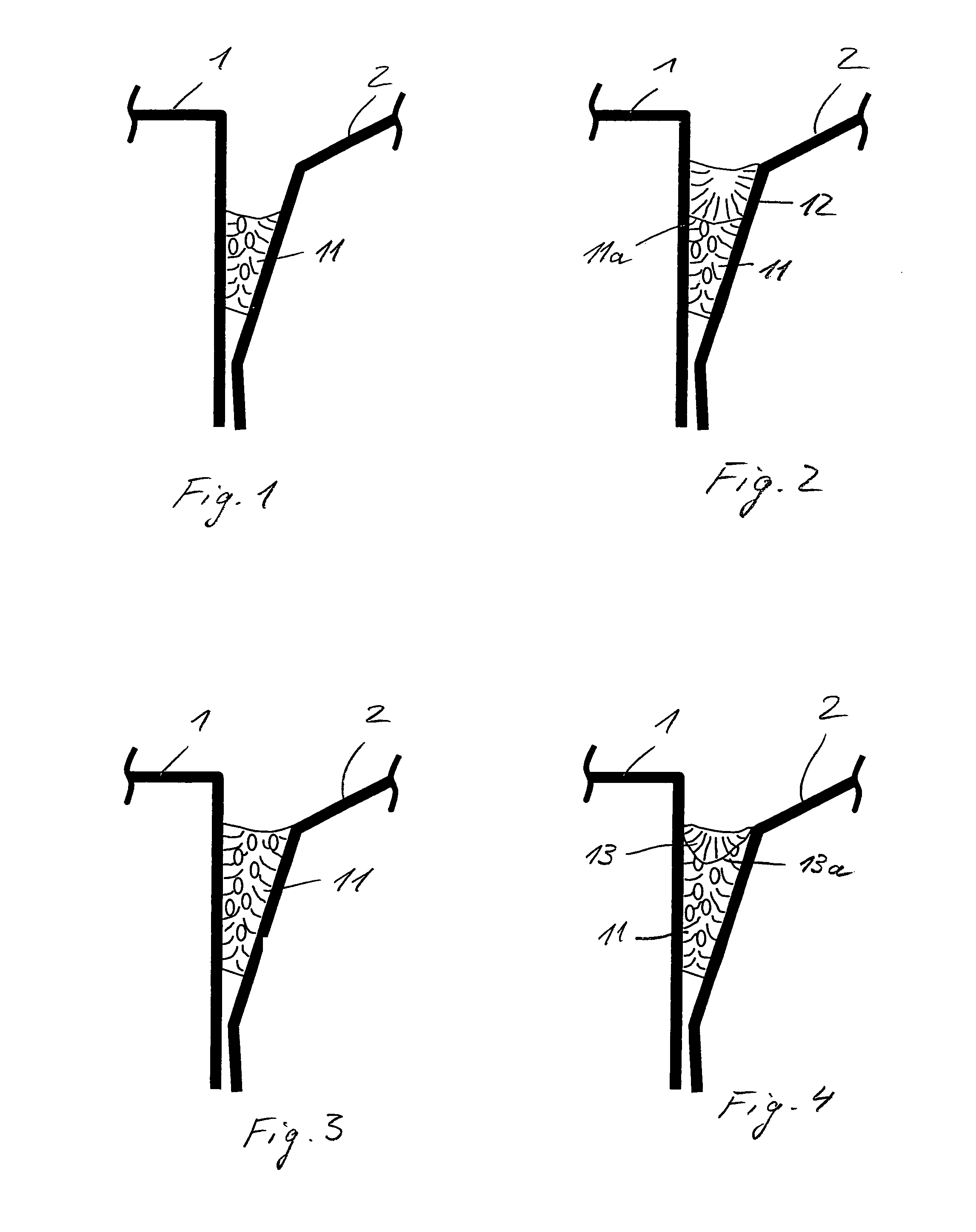

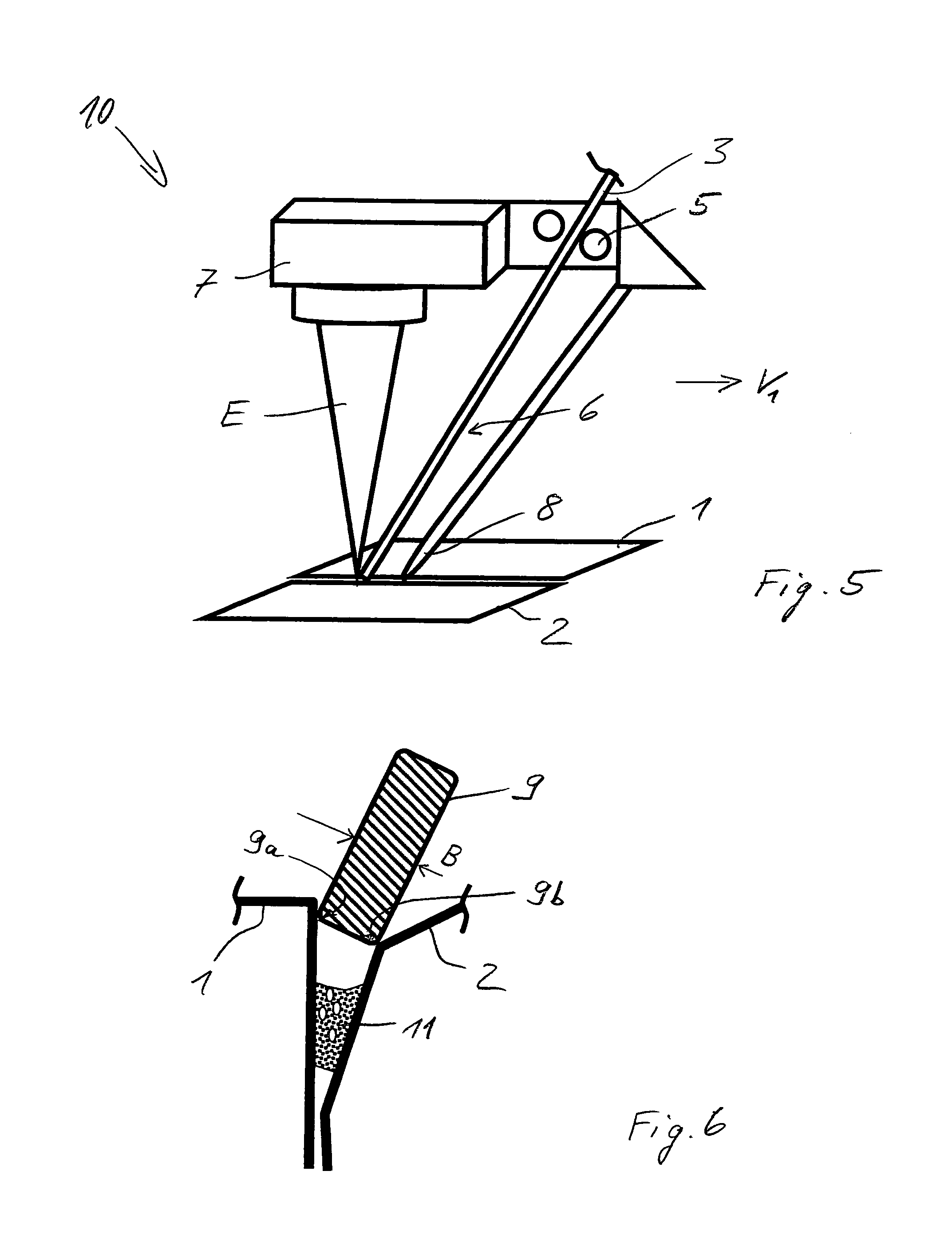

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com