Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Increase component density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

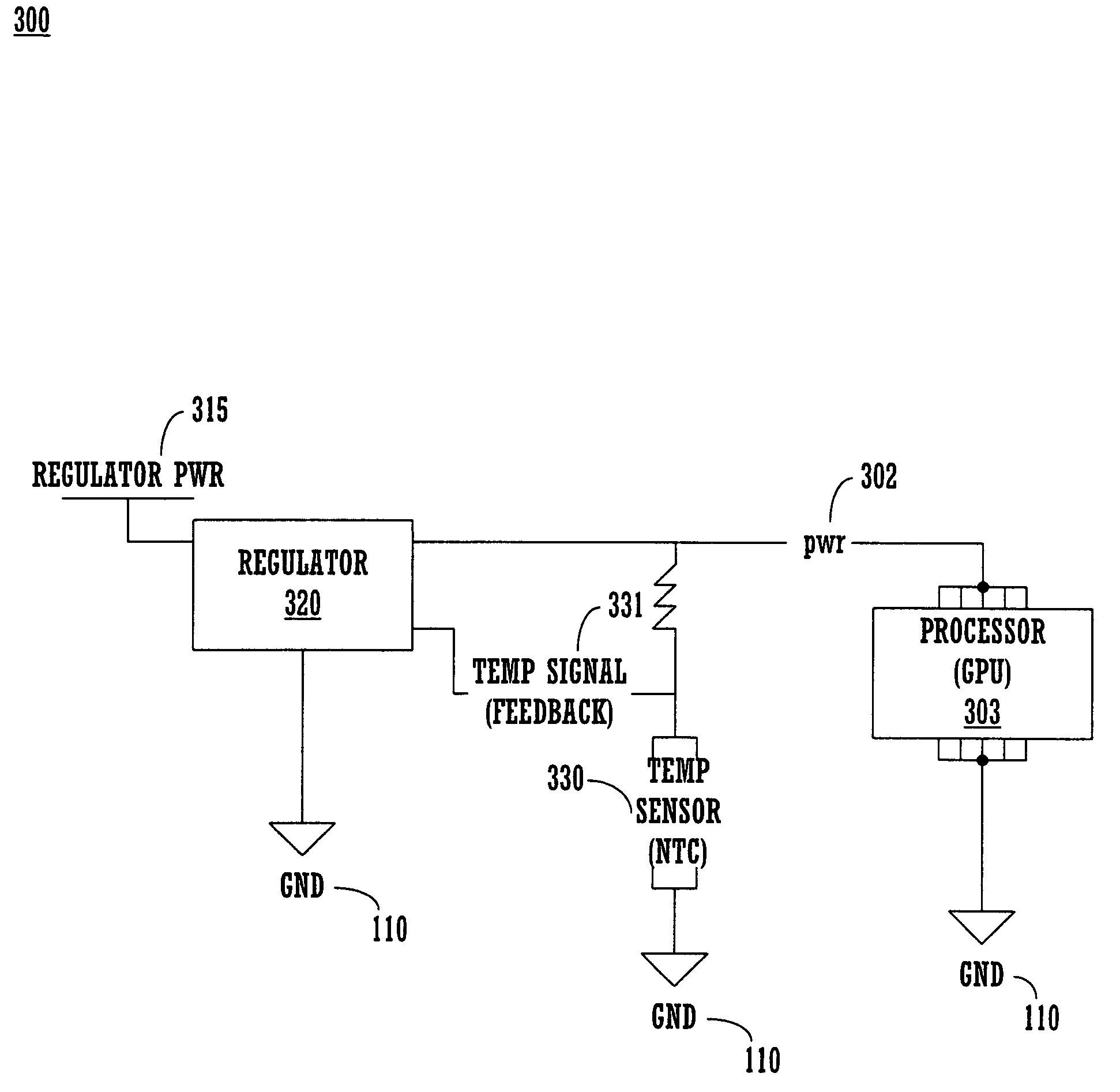

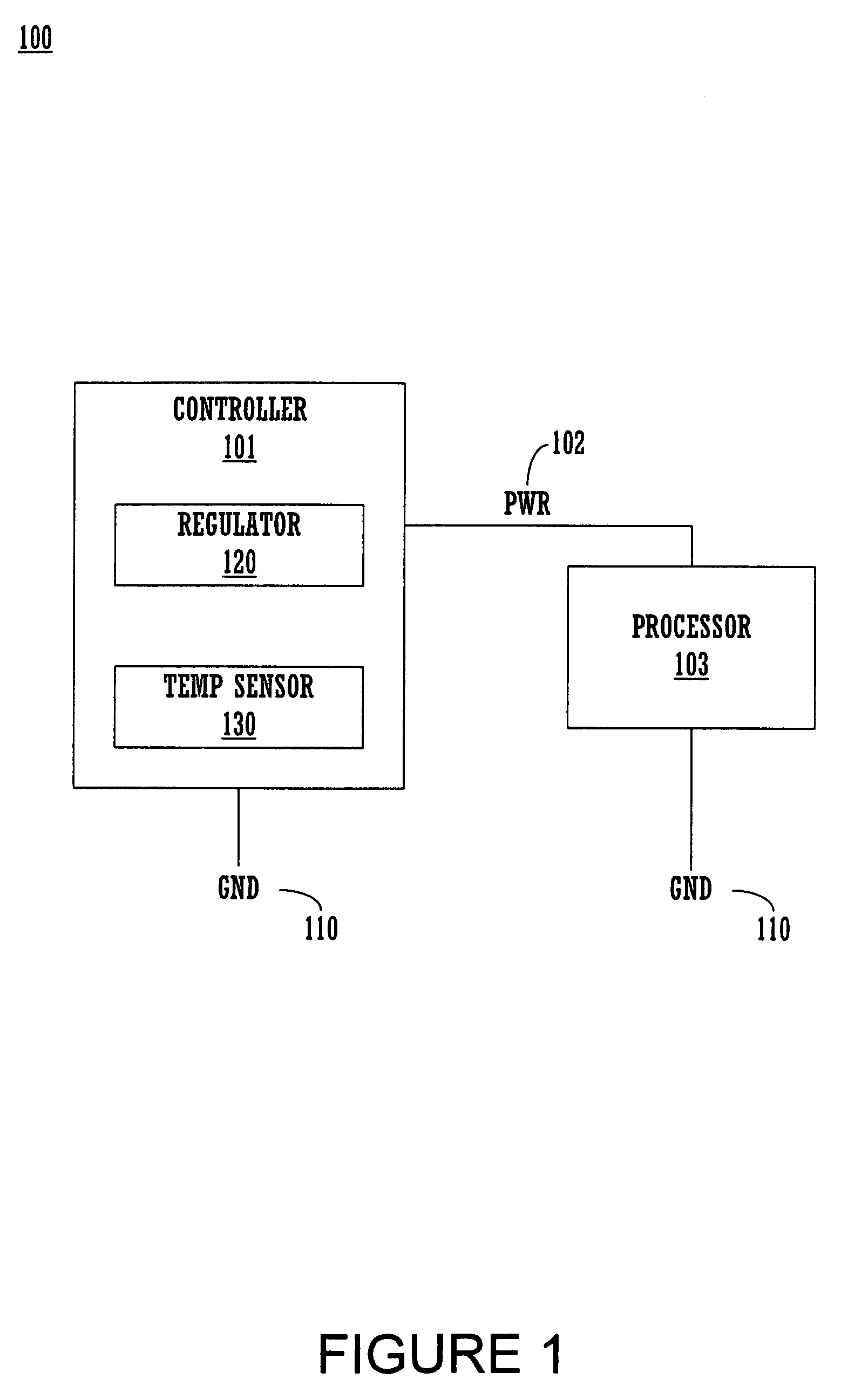

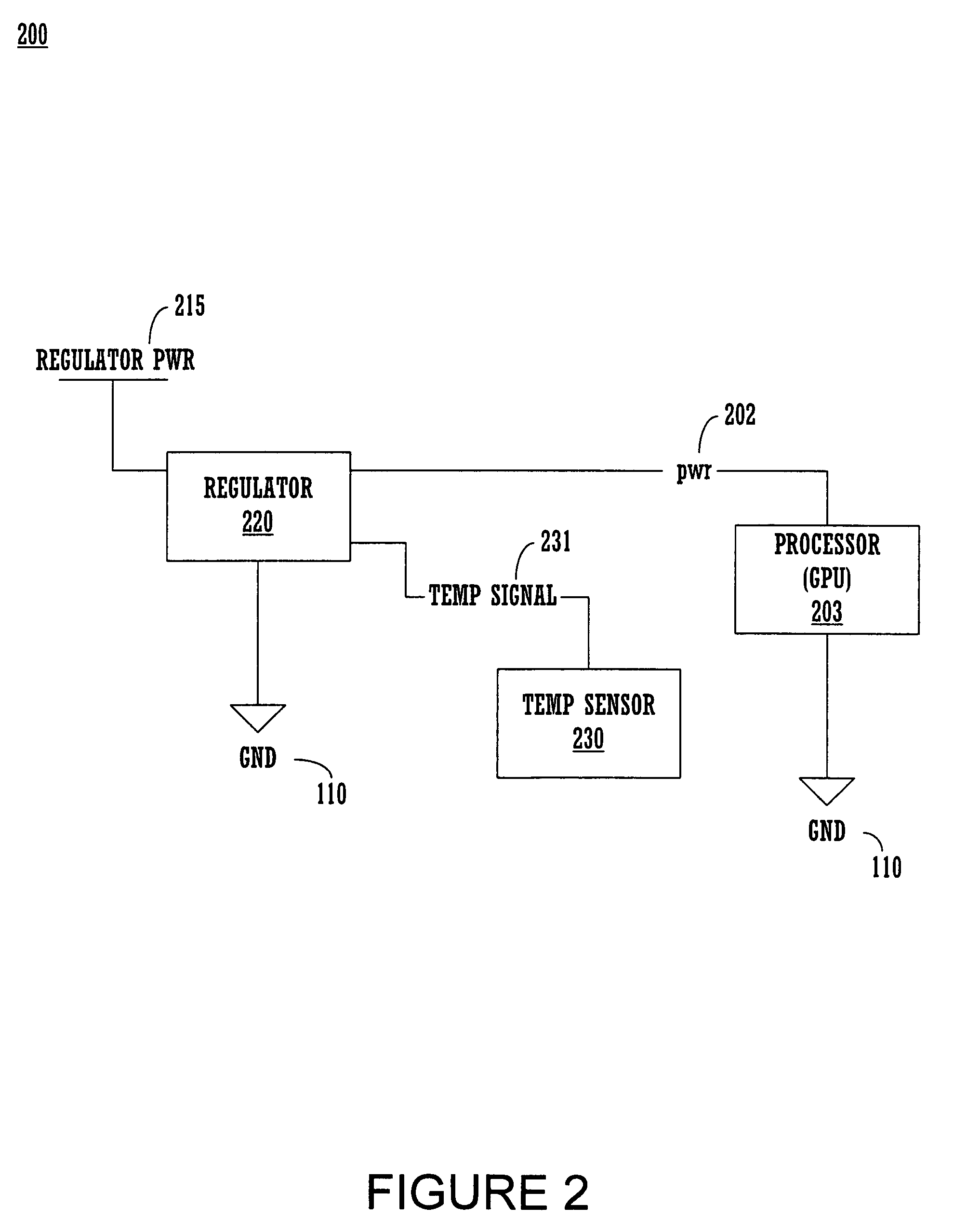

Method and system for dynamic power supply voltage adjustment for a semiconductor integrated circuit device

InactiveUS6947865B1Reduce performance limiting effect of crosstalk and jitter and noiseImprove the level ofThermometer detailsCurrent/voltage measurementSemiconductorCrosstalk

A processor power supply voltage controller. The controller includes a temperature sensor configured to sense a temperature of a processor and generate a temperature signal in accordance therewith. A regulator is coupled to provide a power supply voltage to the processor. The regulator is coupled to receive the temperature signal and control the power supply voltage to maintain a substantially stable crosstalk level within the processor.

Owner:NVIDIA CORP

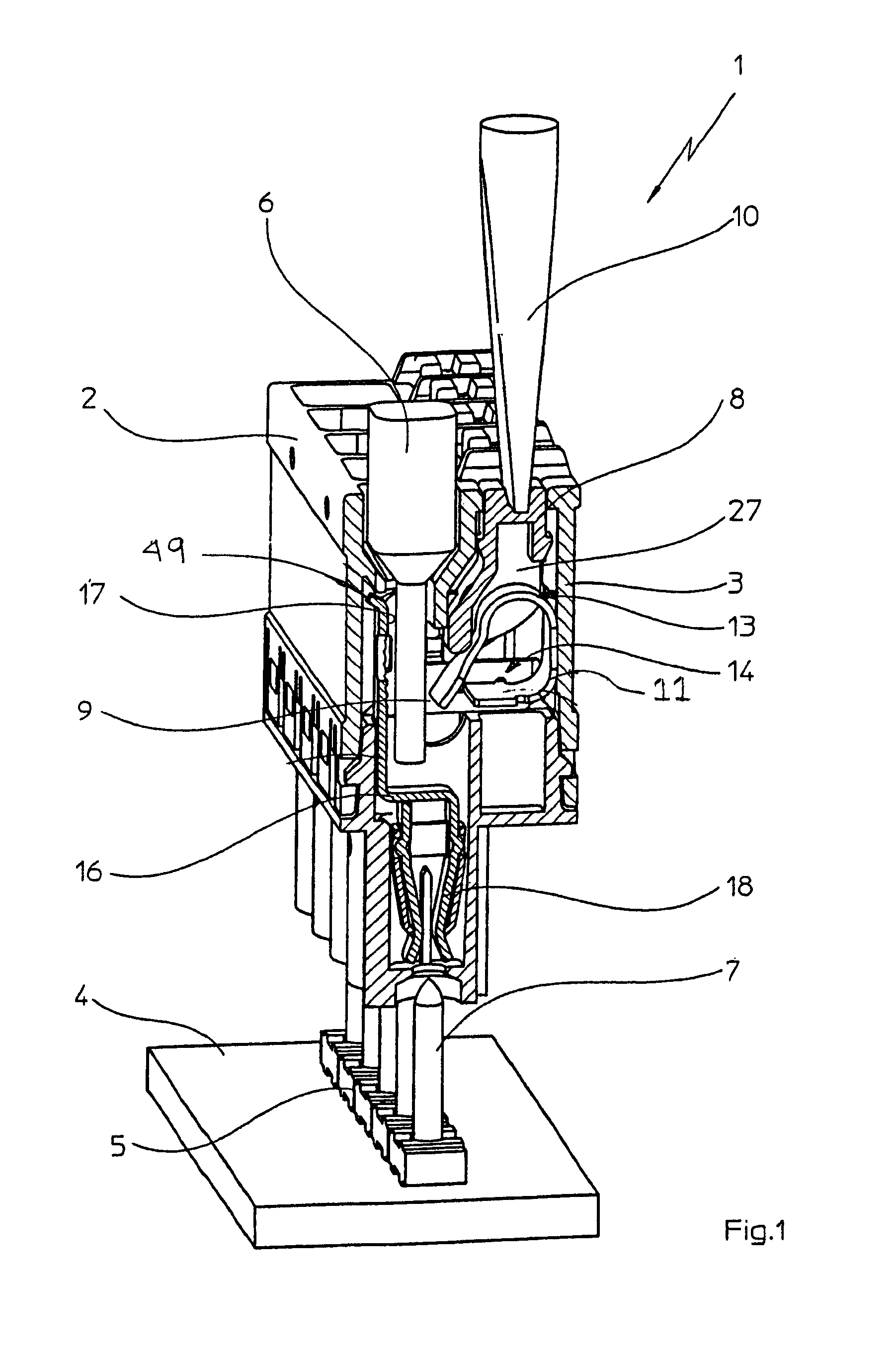

Use of polyester powder in a shaping process, and moldings produced from this polyester powder

ActiveUS20070126159A1Low polymer viscosityHigh dimensional accuracyAdditive manufacturing apparatusAdditive manufacturing with solidsPolyesterSusceptor

The present invention relates to the use of a powder which comprises specific polyesters for shaping processes, and to moldings produced powder. The shaping processes are layer-by-layer processes which use powder, which comprises selectively melting regions of a powder layer by applying electromagnetic energy. Selectivity can although there is no intention to restrict the invention thereto be achieved via a mask, or application of an inhibitor, of an absorber or of a susceptor, or via focusing of the energy input. After cooling, the regions then solidified can be removed as moldings from the powder bed. The process occurs by using a polyester powder obtained from an alcohol and from a diacid with no use of any aromatic monomer unit. These polyester powders combine high crystallinity and low melting point, and makes the construction process more reliable while good component quality, mechanical properties, density, dimensional accuracy, and low shrinkage are realized.

Owner:EVONIK OPERATIONS GMBH

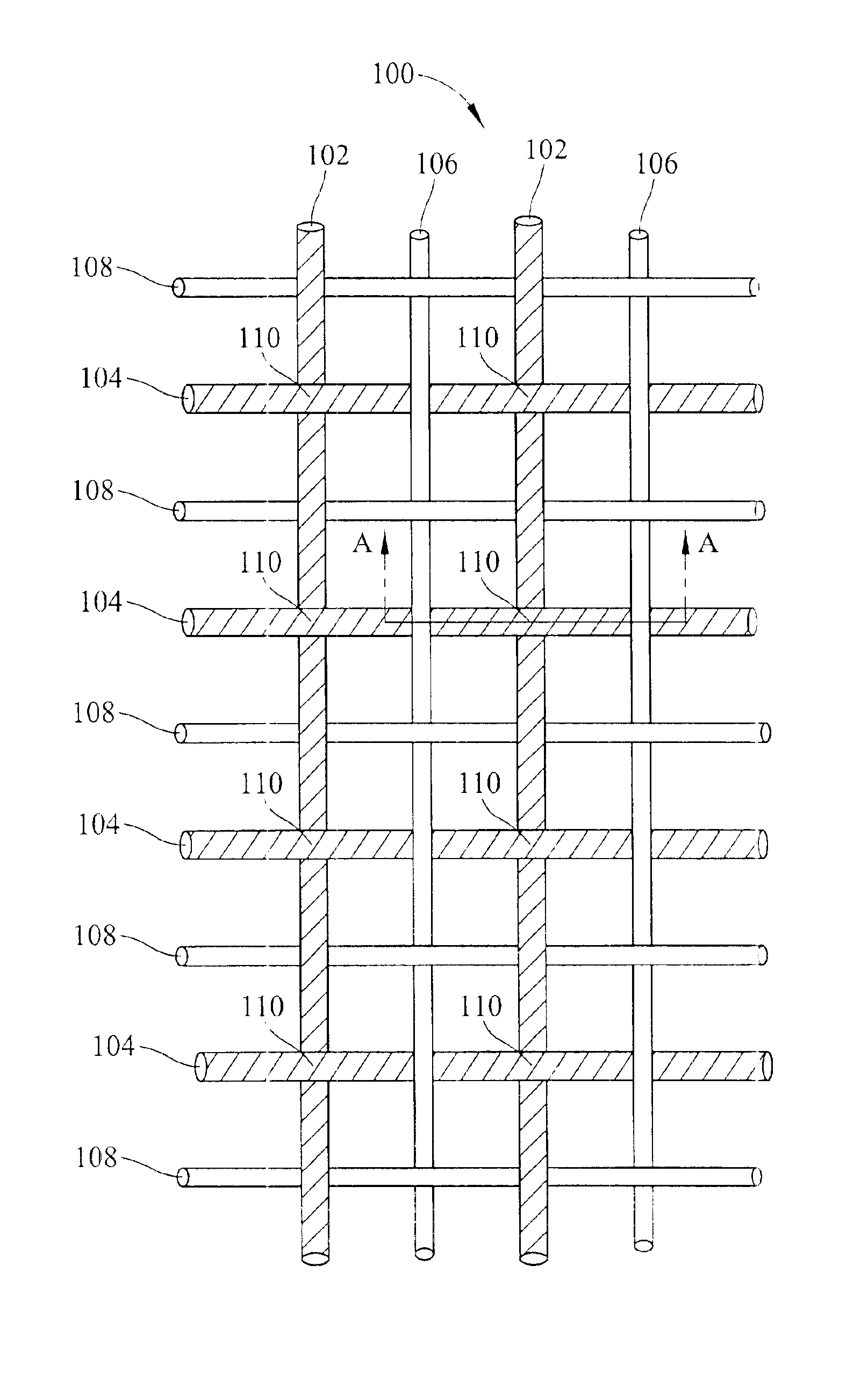

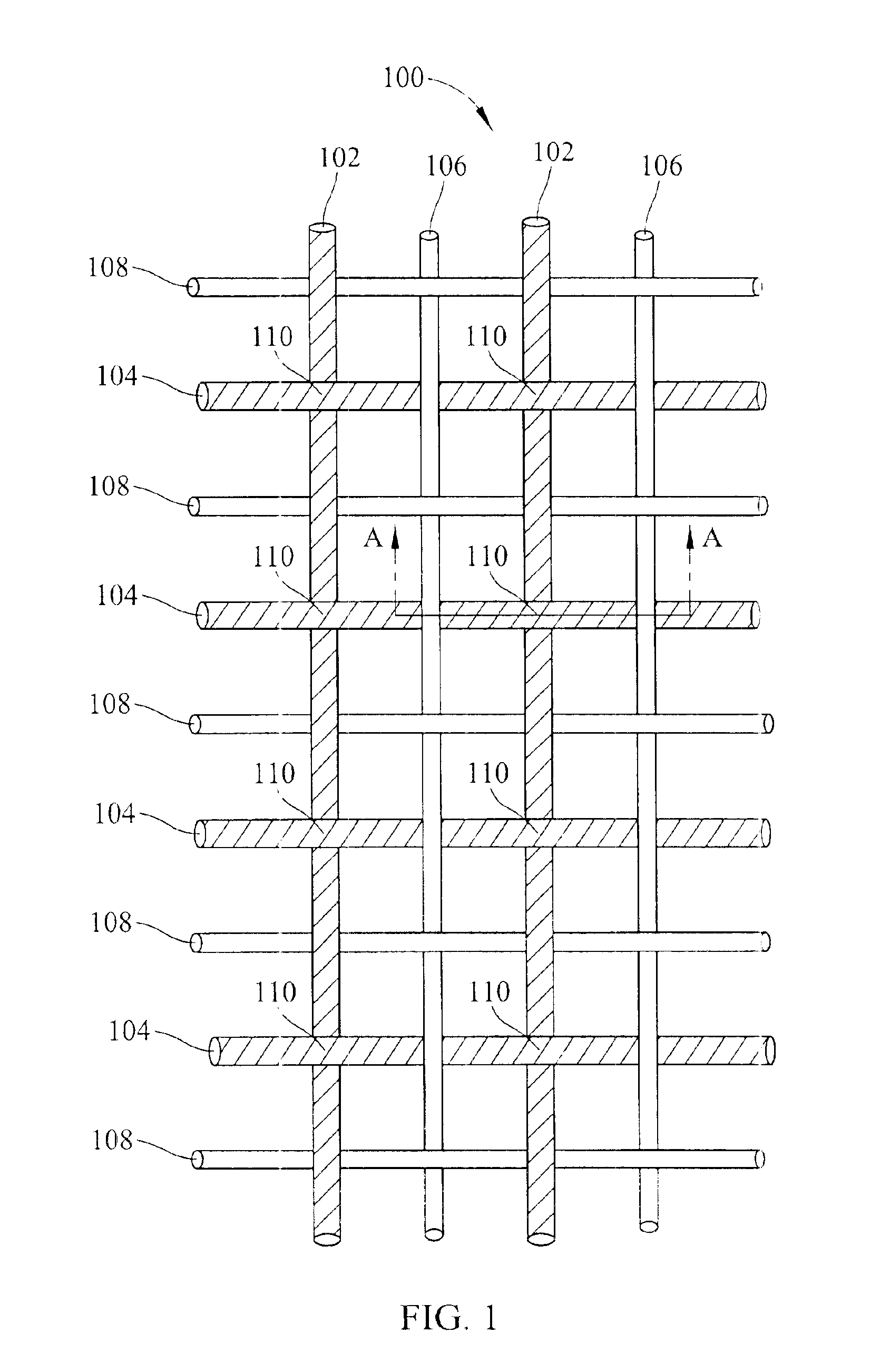

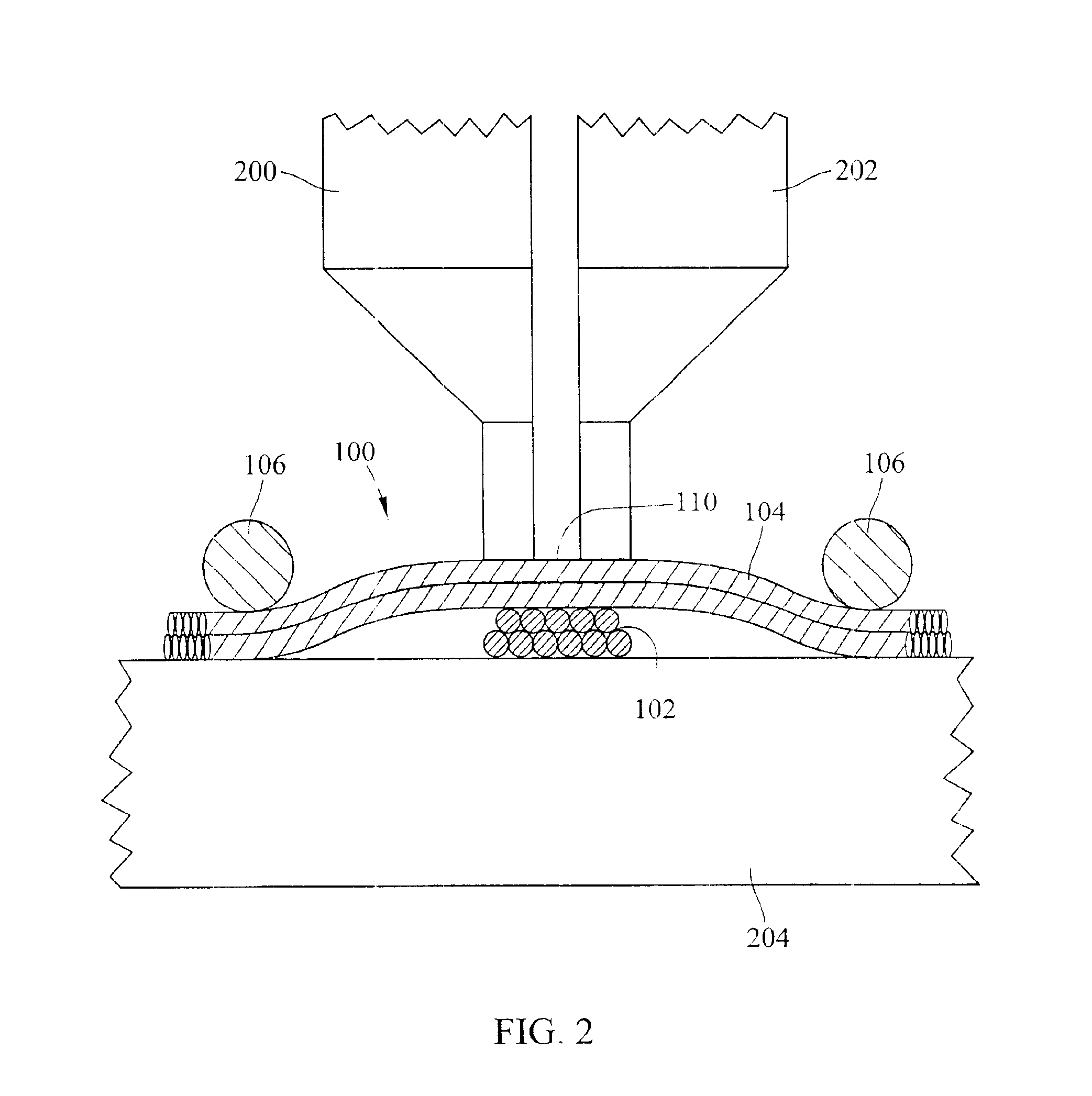

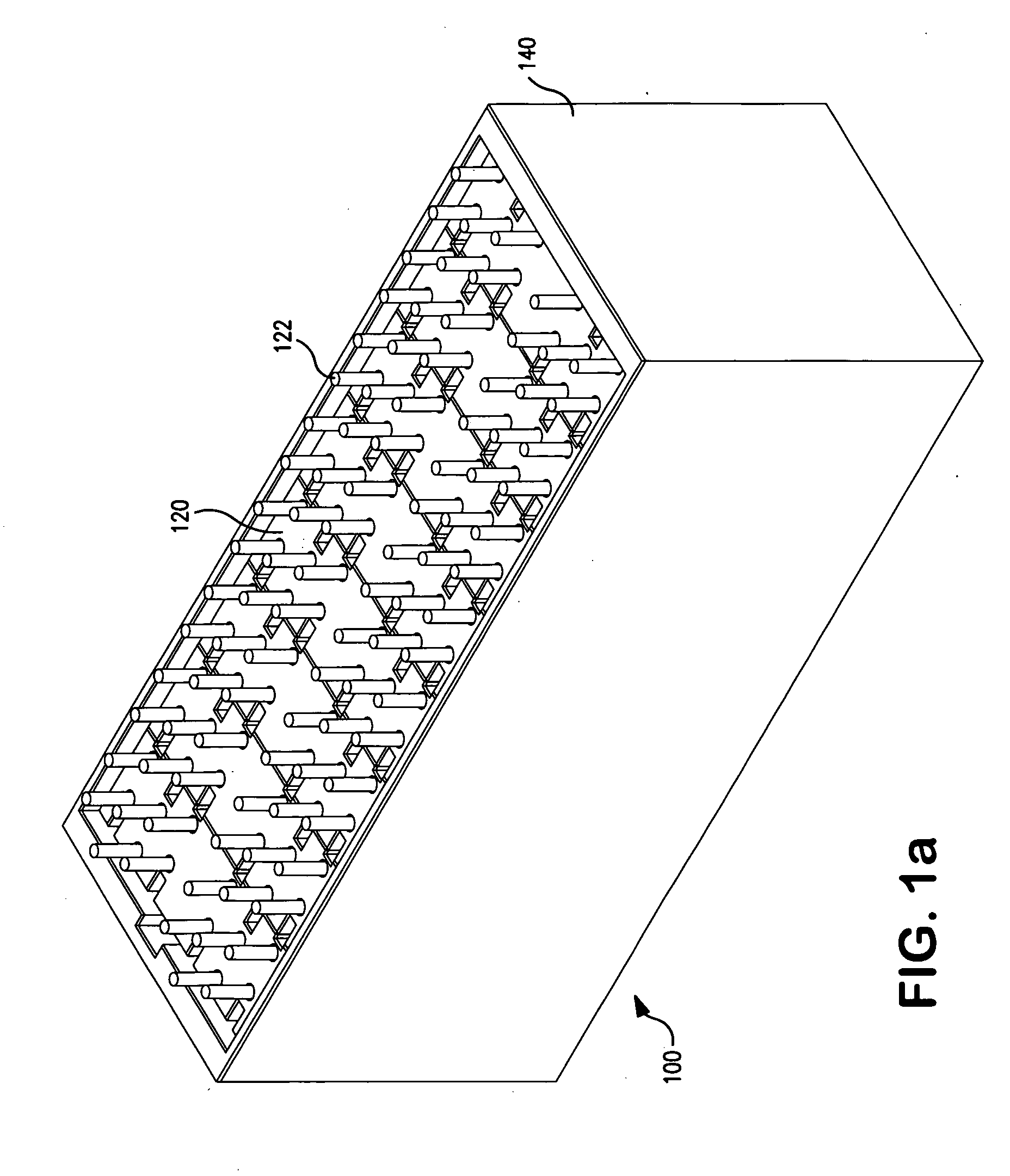

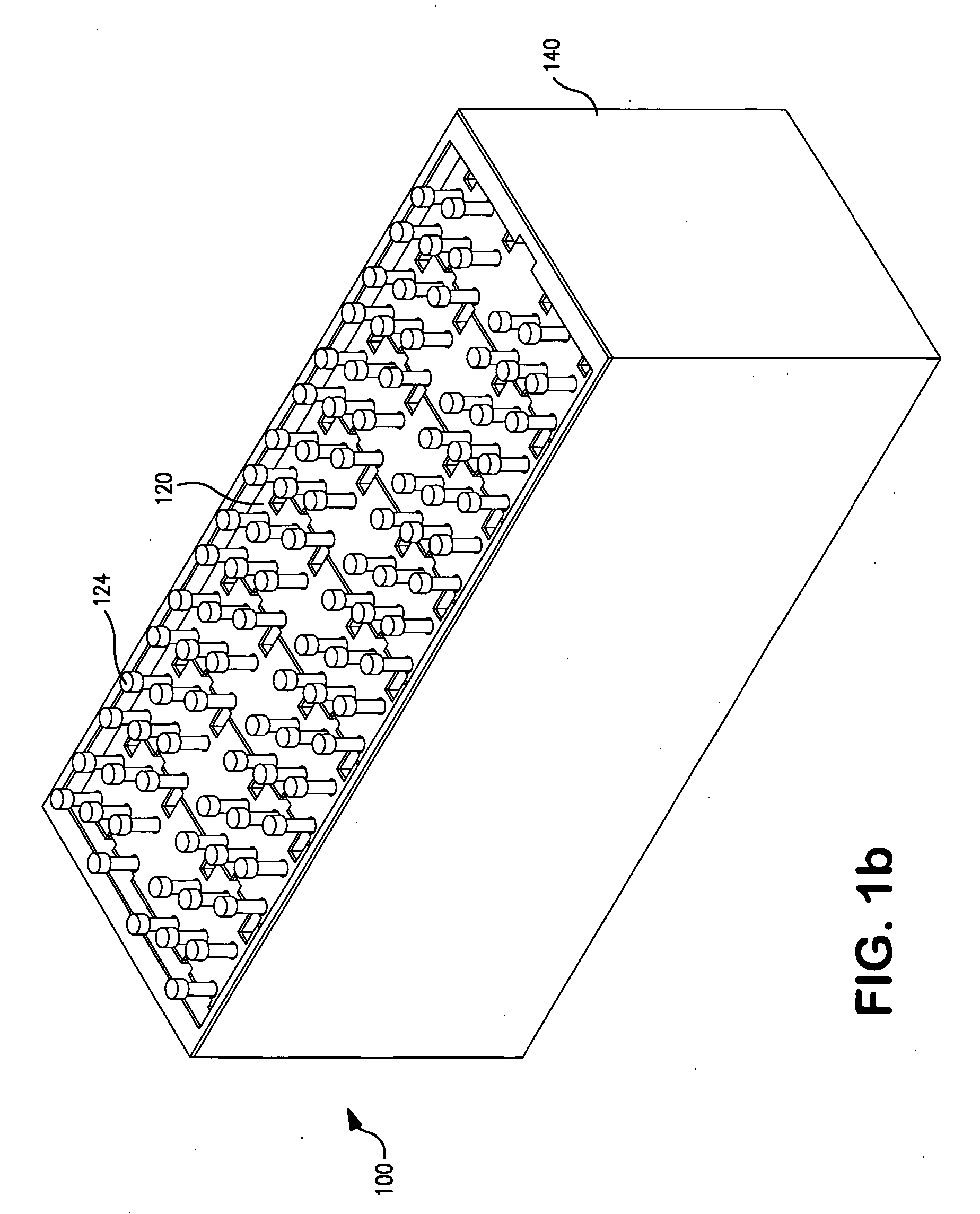

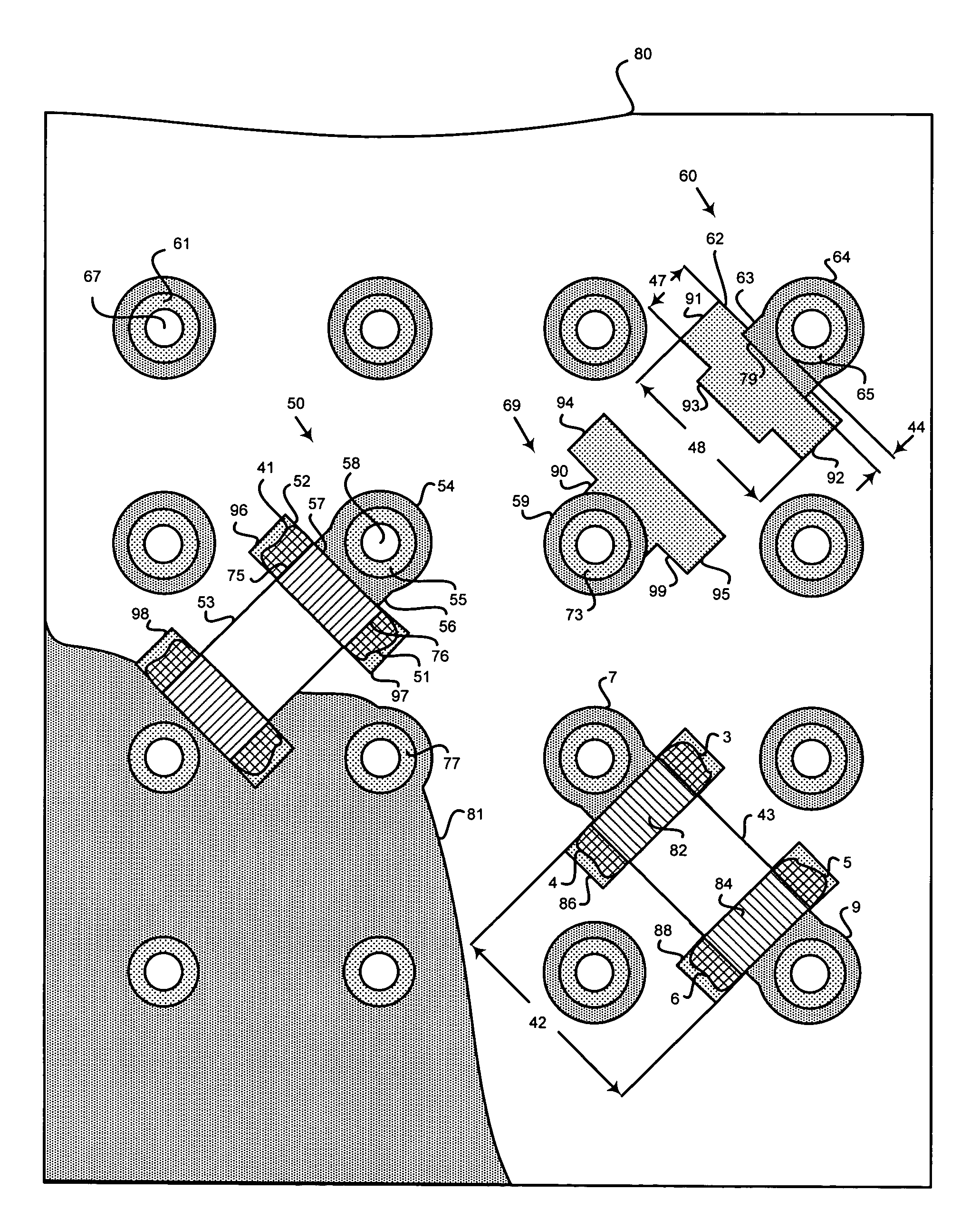

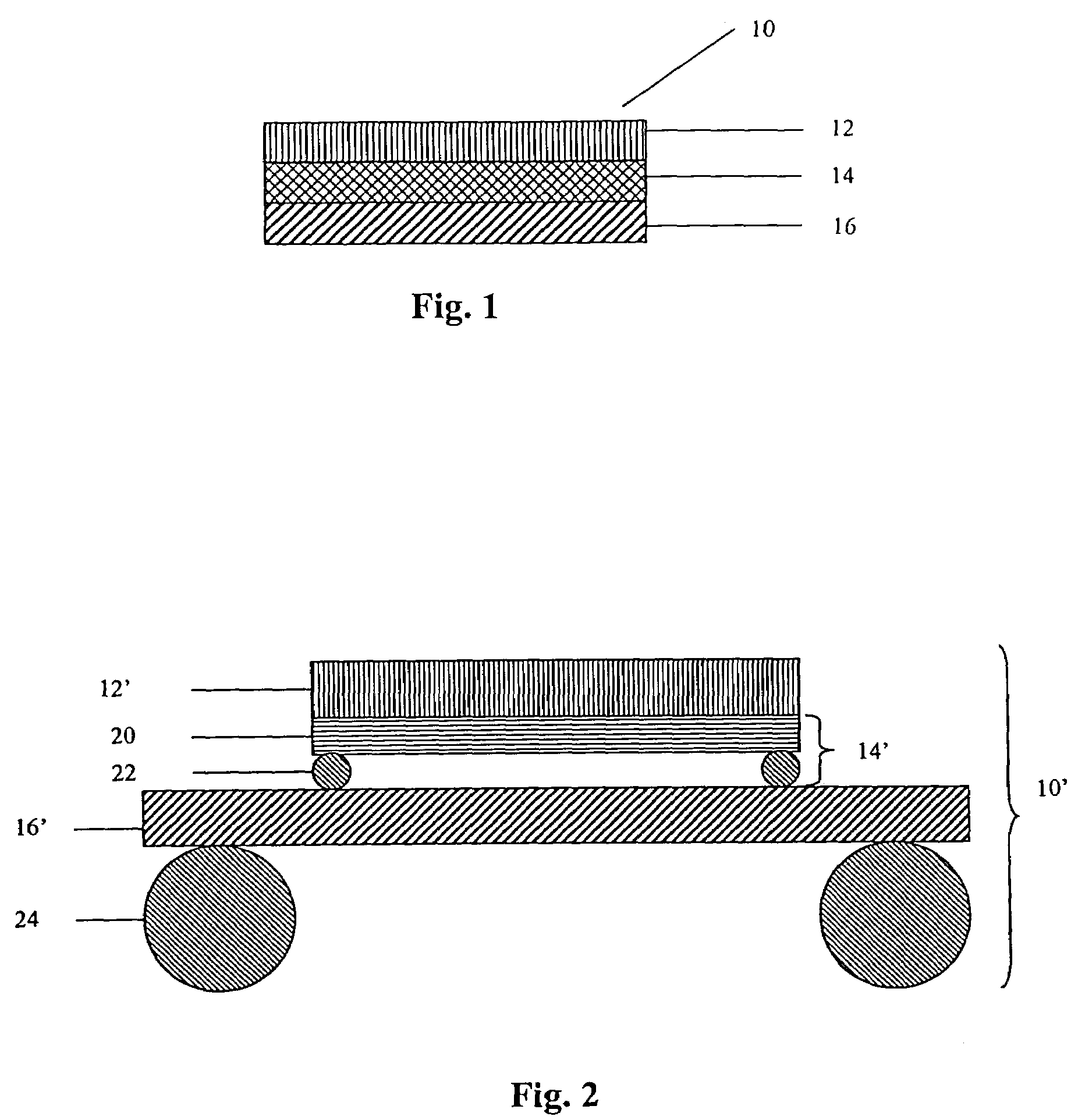

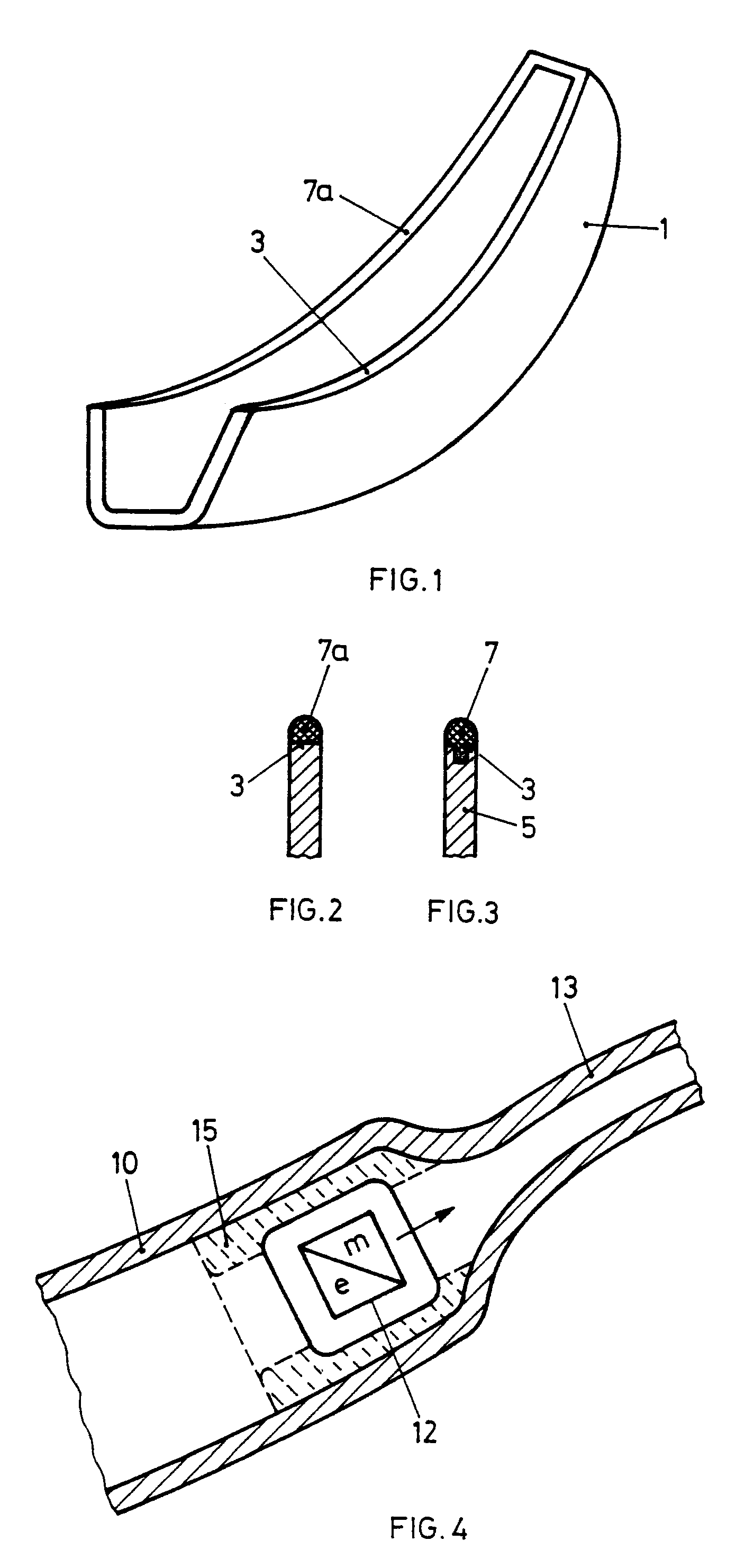

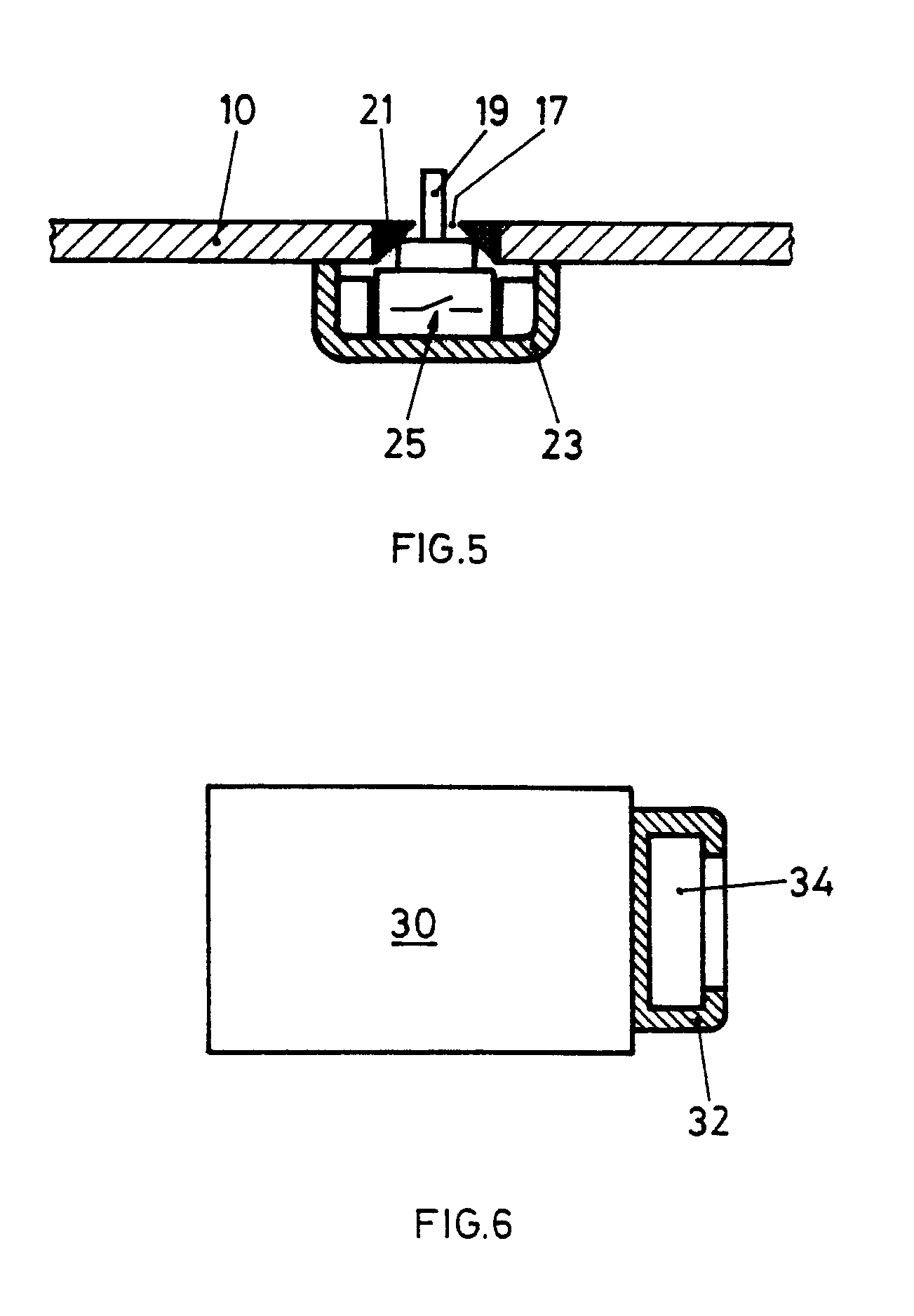

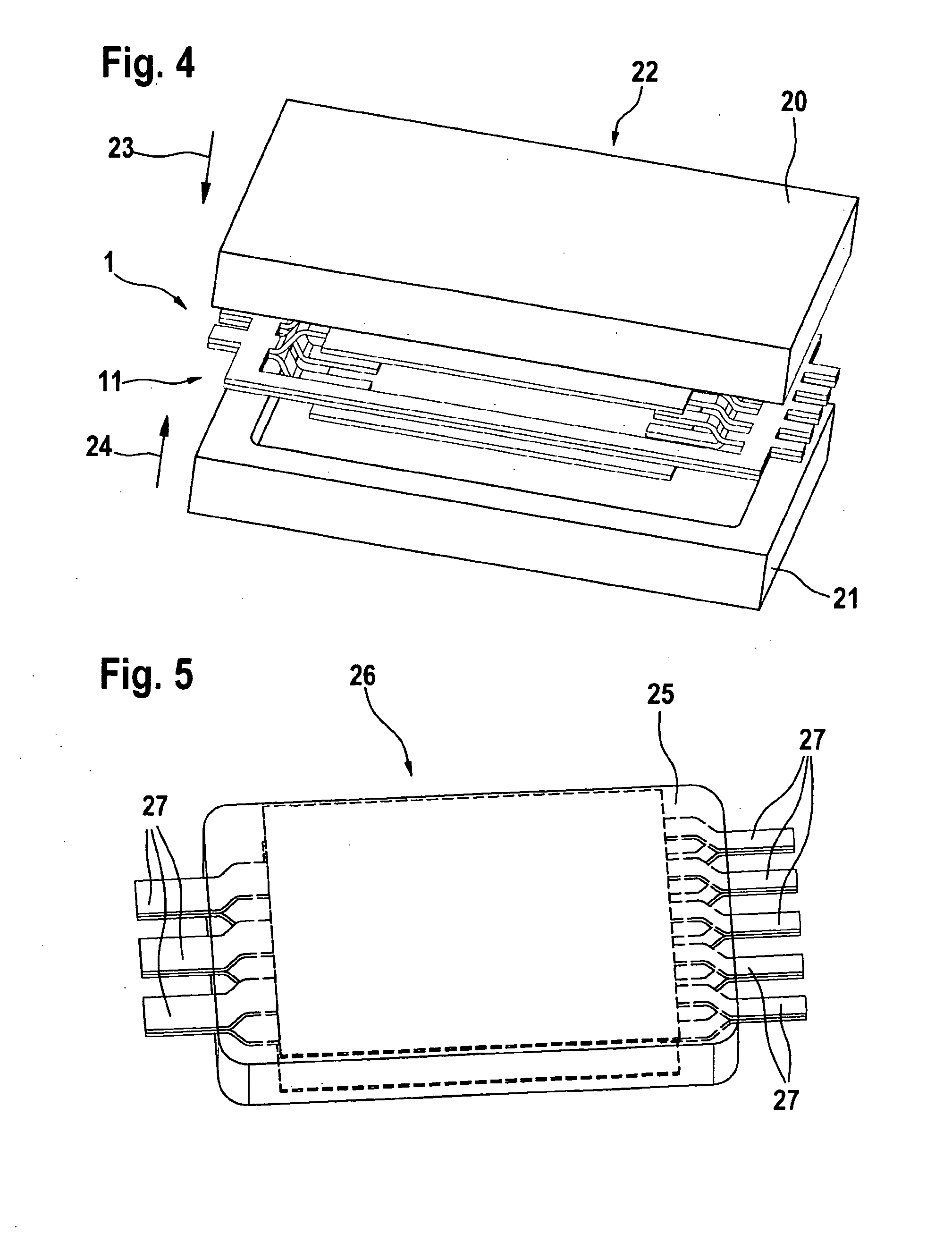

Methods and systems for selectively connecting and disconnecting conductors in a fabric

InactiveUS6852395B2Improve featuresReduced footprintThin material handlingMetal layered productsElectrical conductorEngineering

Methods and systems for selectively connecting and disconnecting conductors in a fabric are disclosed. First and second conductors are integrated into a fabric such that the conductors intersect at a crossover point. The conductors are bonded to each other at the crossover point to improve AC and DC characteristics. Disconnect areas may be provided near the crossover point to allow selective disconnection of the conductors from the crossover point.

Owner:NORTH CAROLINA STATE UNIV

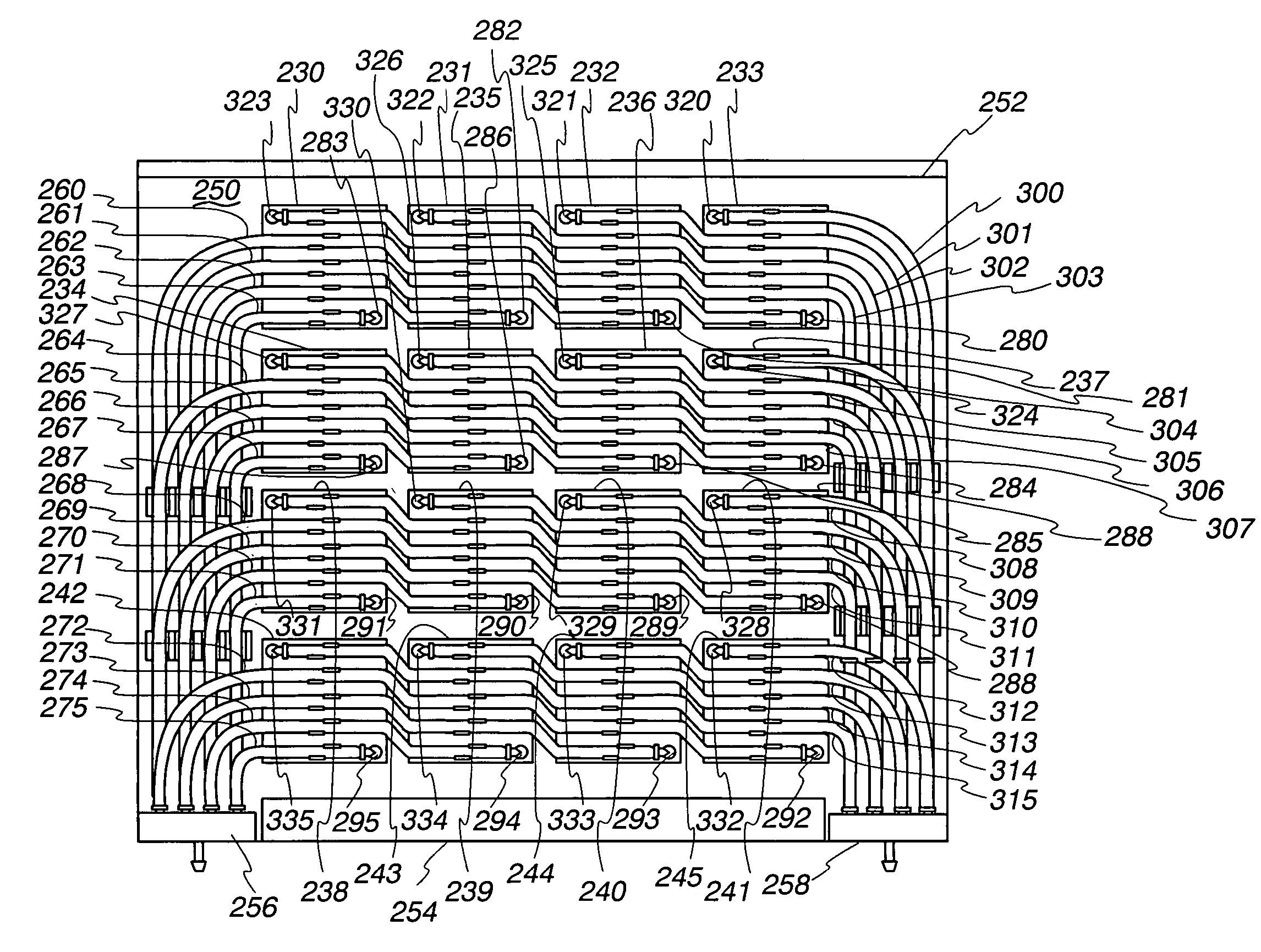

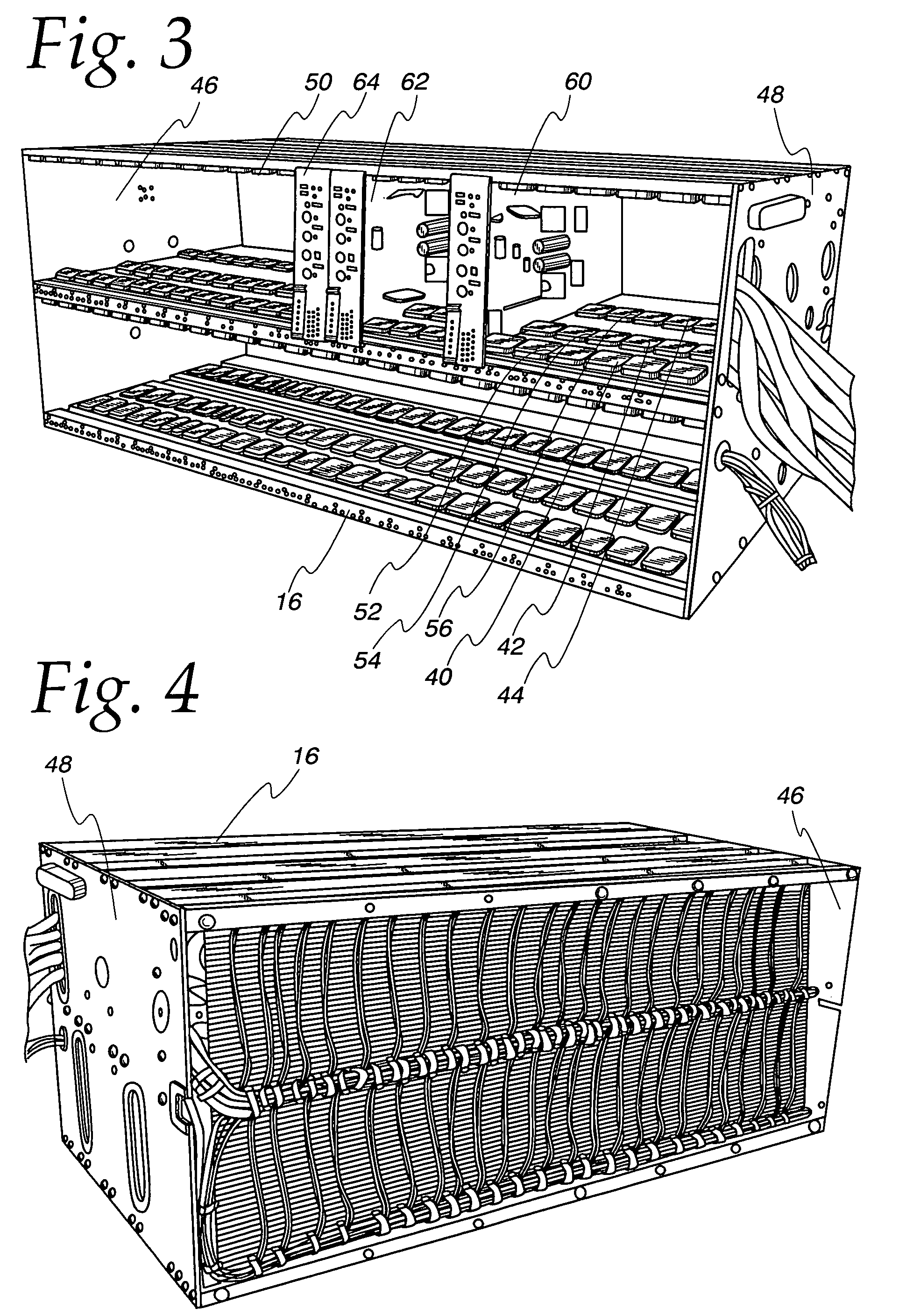

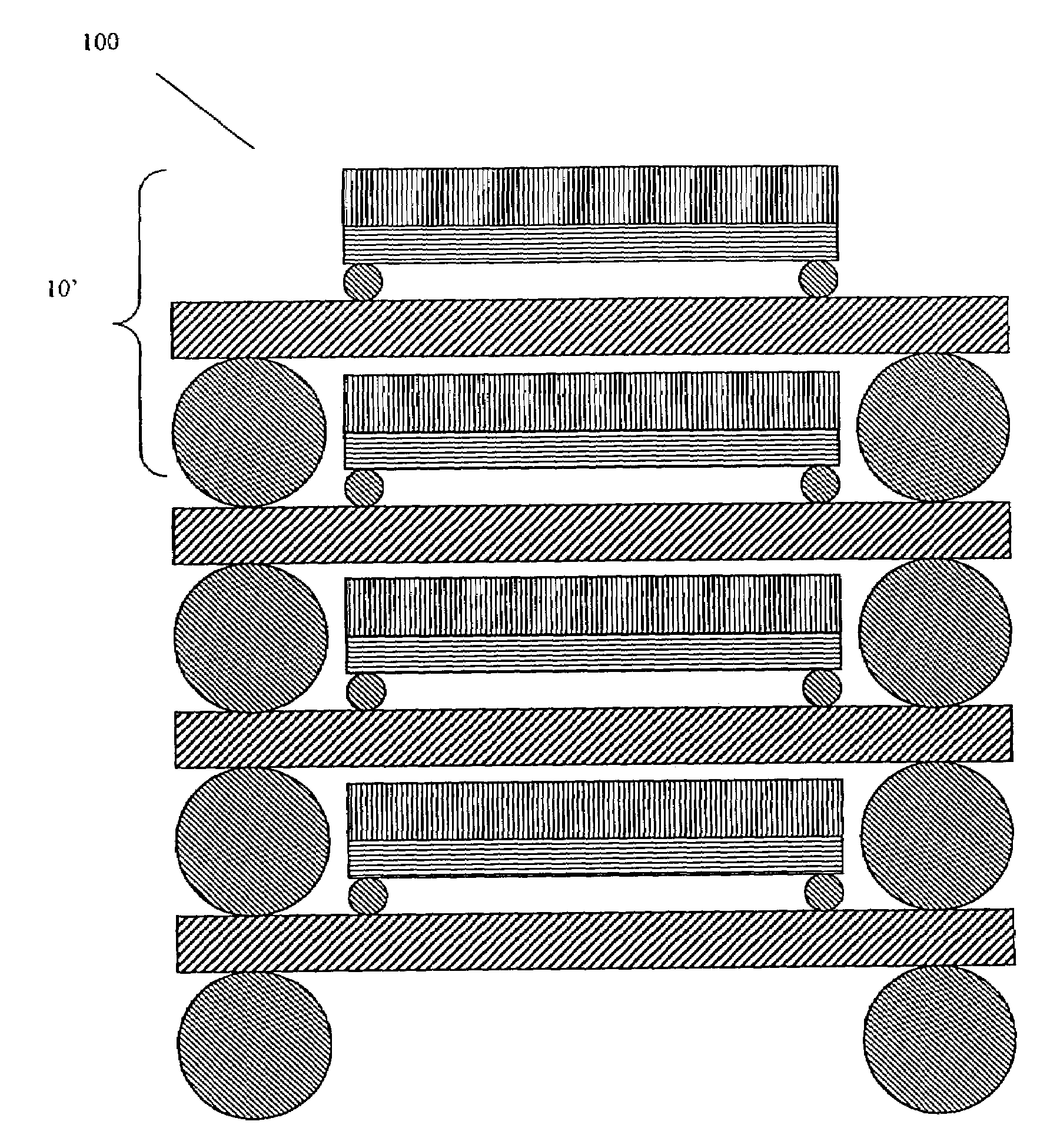

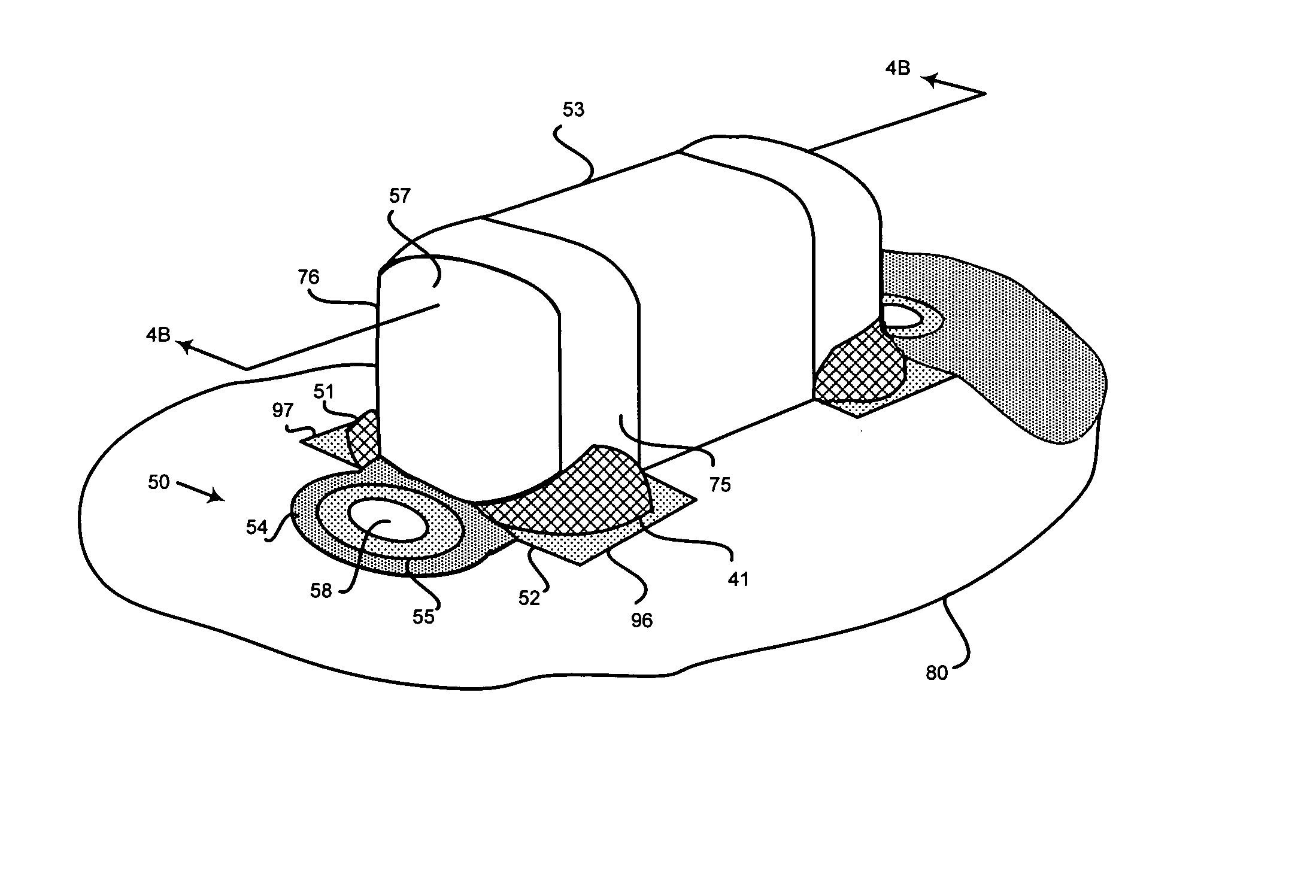

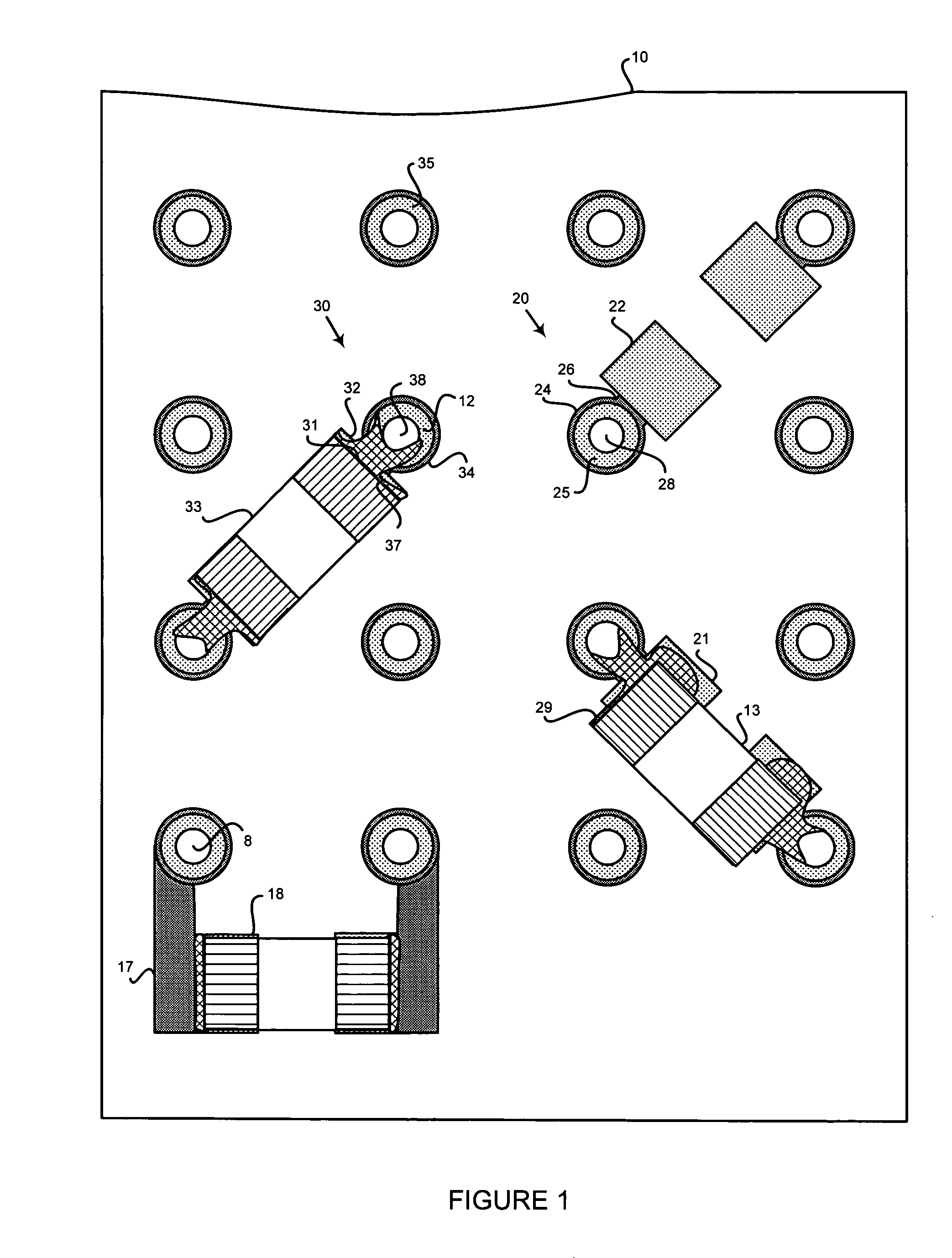

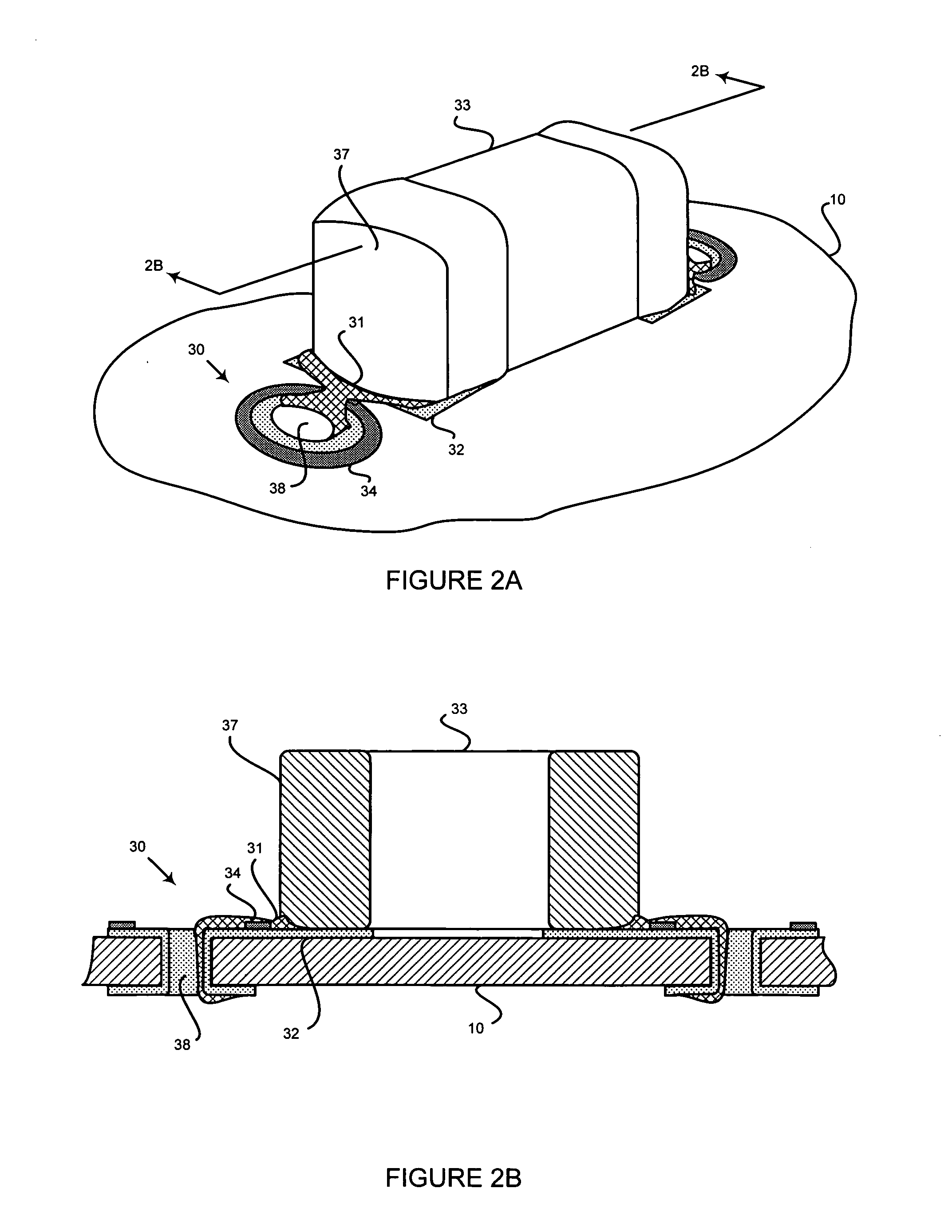

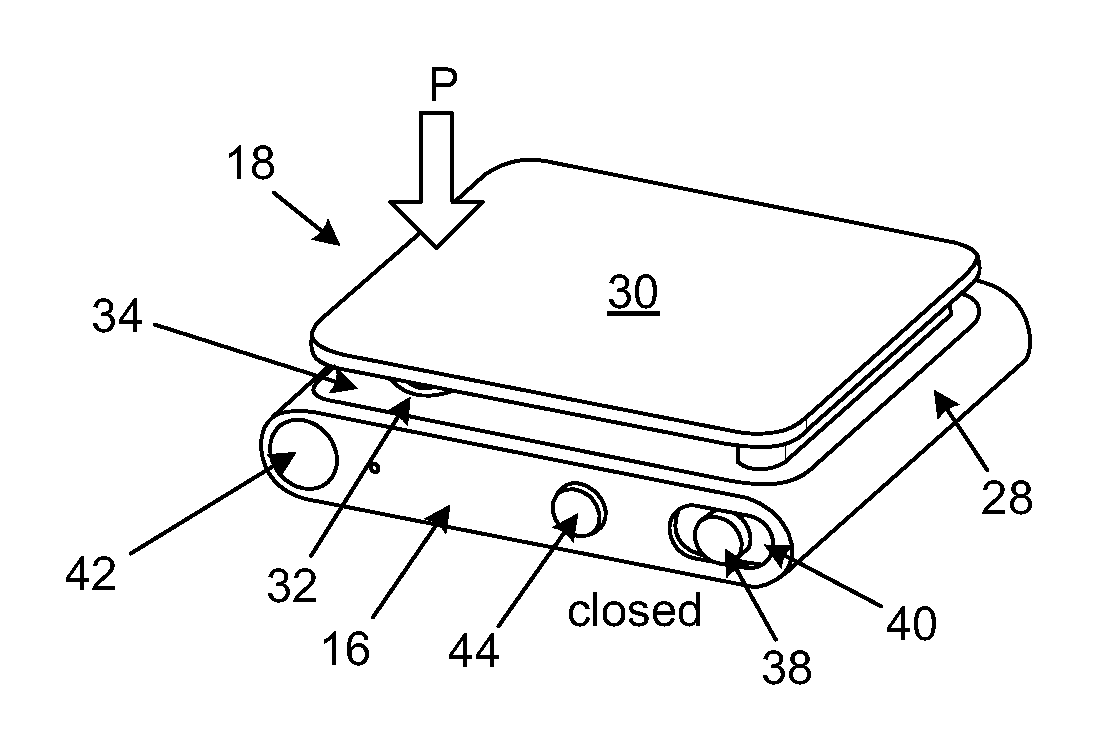

Cooling system for densely packed electronic components

InactiveUS7258161B2Increase component densityImprove cooling efficiencyMechanical apparatusSemiconductor/solid-state device detailsComputer moduleVolumetric Mass Density

A more efficient cooling system for densely packed electronic components for use in an out-of-doors equipment enclosure. An array of cooling assemblies are placed on heat generating components mounted to printed circuit boards mounted in enclosure racks. Each board has a manifold for intake and exhaust of refrigerant, and larger rack manifolds are substituted for rails and are attached to a backplane. A hybrid package including a ceramic hybrid power module and an attached array of cooling assemblies provide even more density of components and improved cooling.

Owner:EMERSON NETWORK POWER ENERGY SYST NORTH AMERICA

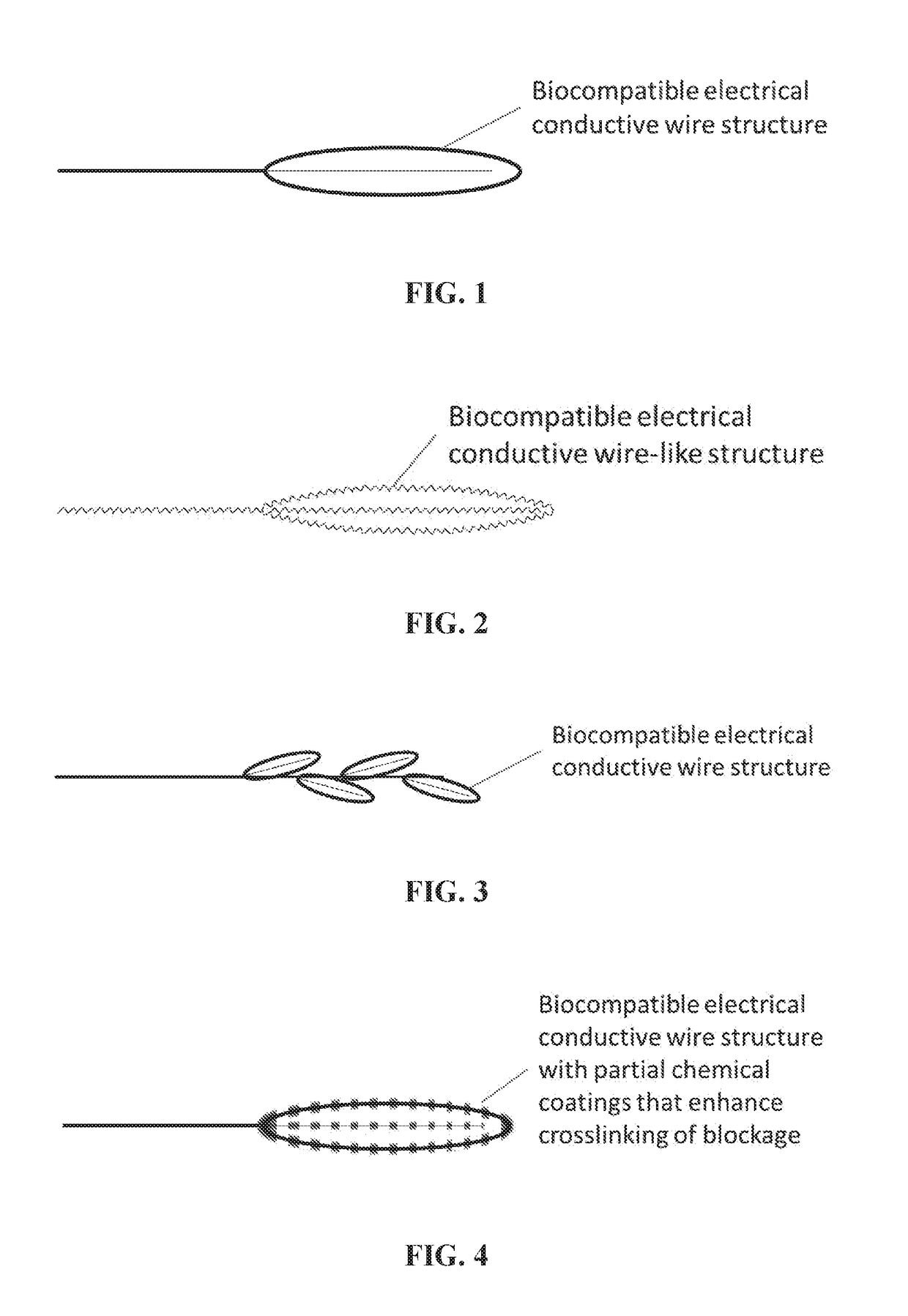

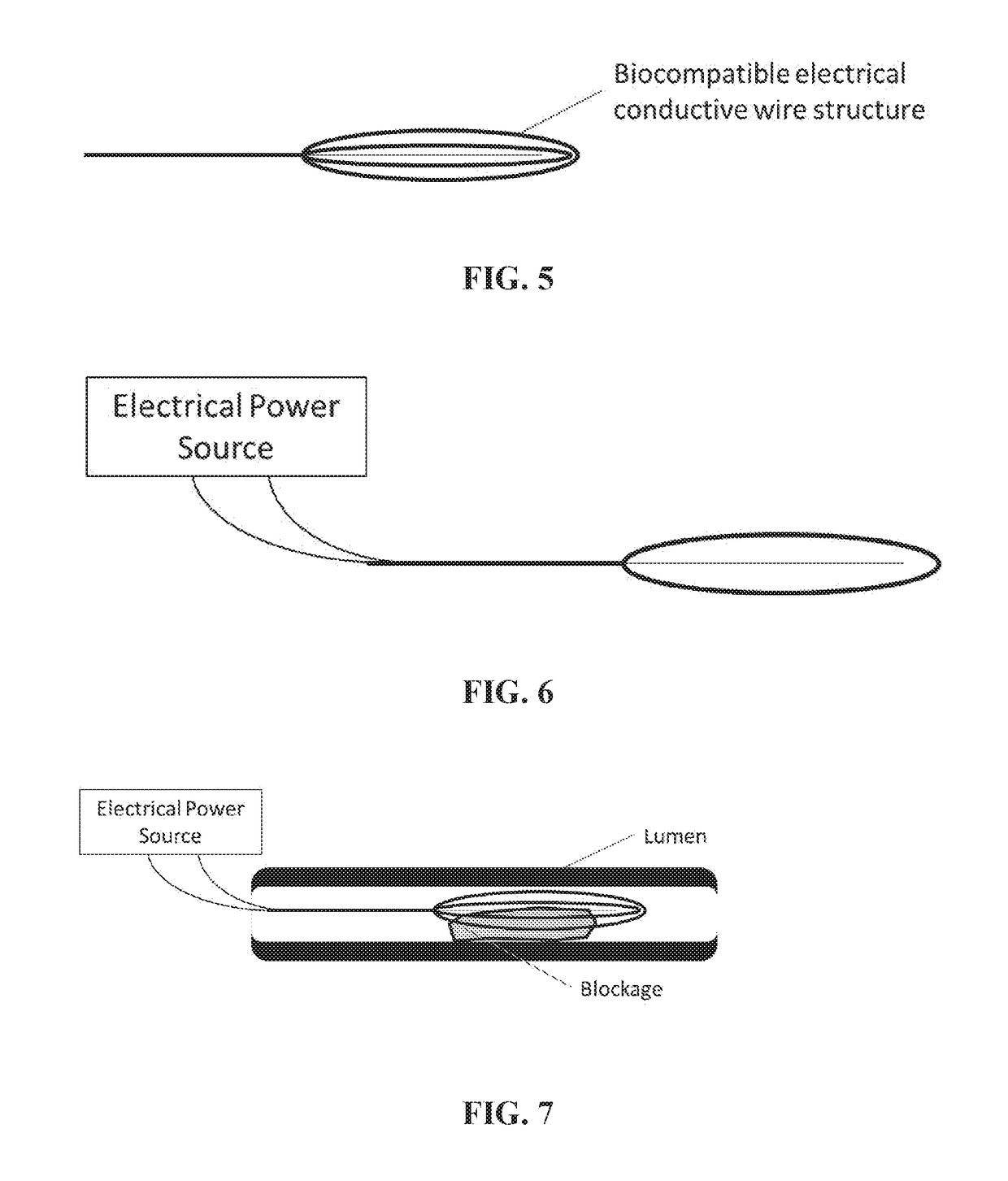

Radio frequency electro-thrombectomy device

ActiveUS20180140354A1Reduce riskImprove adhesionSurgical instruments for heatingCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumen blockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking density and interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage during the removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely captured during the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

Copolyamide powder and its preparation, use of copolyamide powder in a shaping process and mouldings produced from this copolyamide powder

ActiveUS20090236775A1Low viscosityHigh dimensional accuracyAdditive manufacturing apparatusElectric discharge heatingLaurolactamPolyamide

A task often encountered in very recent times is the rapid provision of prototypes. Particularly suitable processes are those based on pulverulent materials and in which the desired structures are produced layer-by-layer through selective melting and solidification. The invention provides the constitution, production and use of a copolyamide powder which was produced using the following monomer units: a) laurolactam or ω-aminoundecanoic acid, and also b) dodecanedioic acid, and either c) decanediamine or dodecanediamine, in shaping processes, and also to mouldings produced through a layer-by-layer process which selectively melts regions of a powder layer, using this specific powder. Once the regions previously melted layer-by-layer have been cooled and solidified, the moulding can be removed from the powder bed. The mouldless layer-by-layer processes for the production of components using the copolyamide powder result in simplified and more reliable conduct of the process and better recyclability.

Owner:EVONIK OPERATIONS GMBH

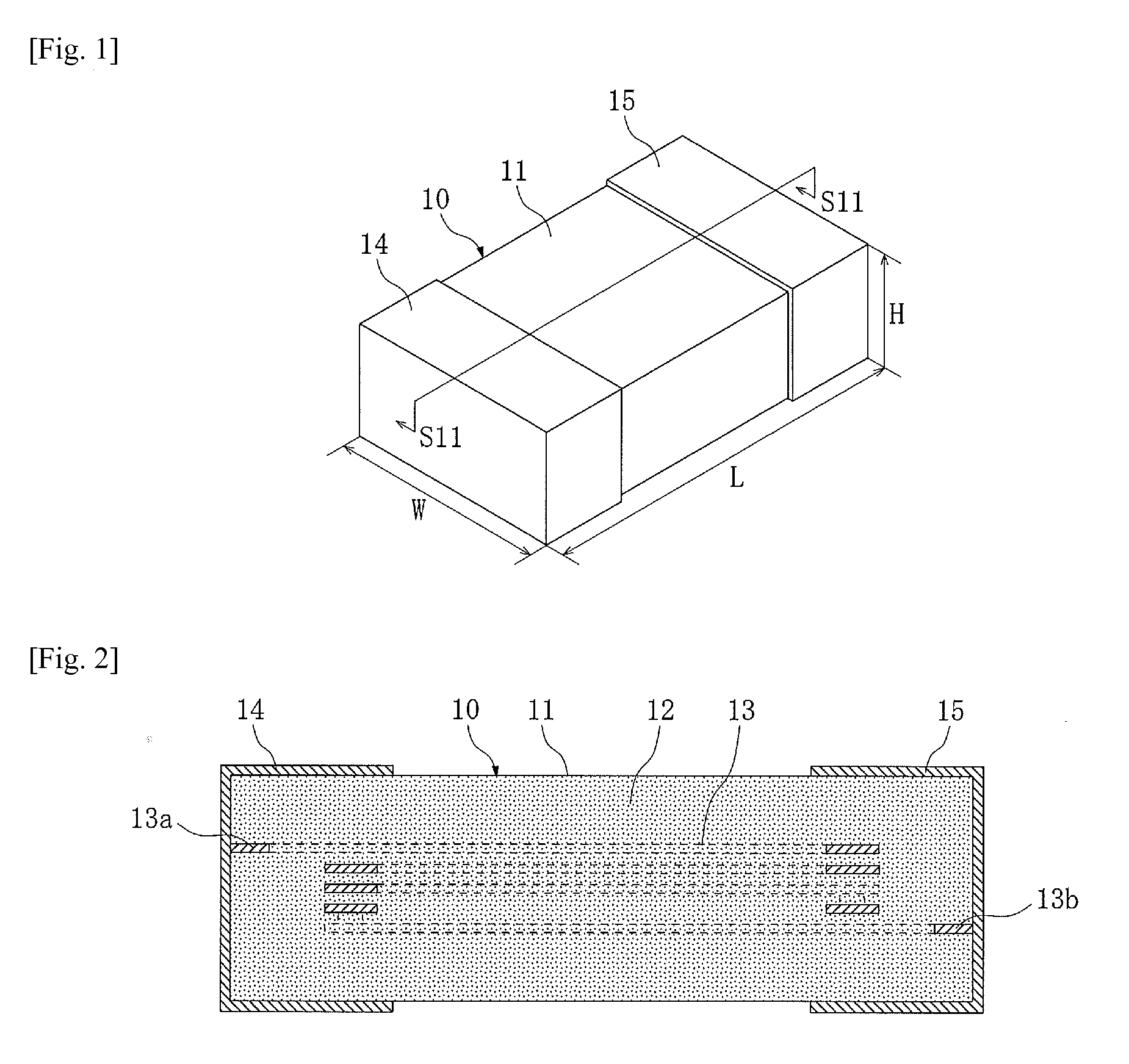

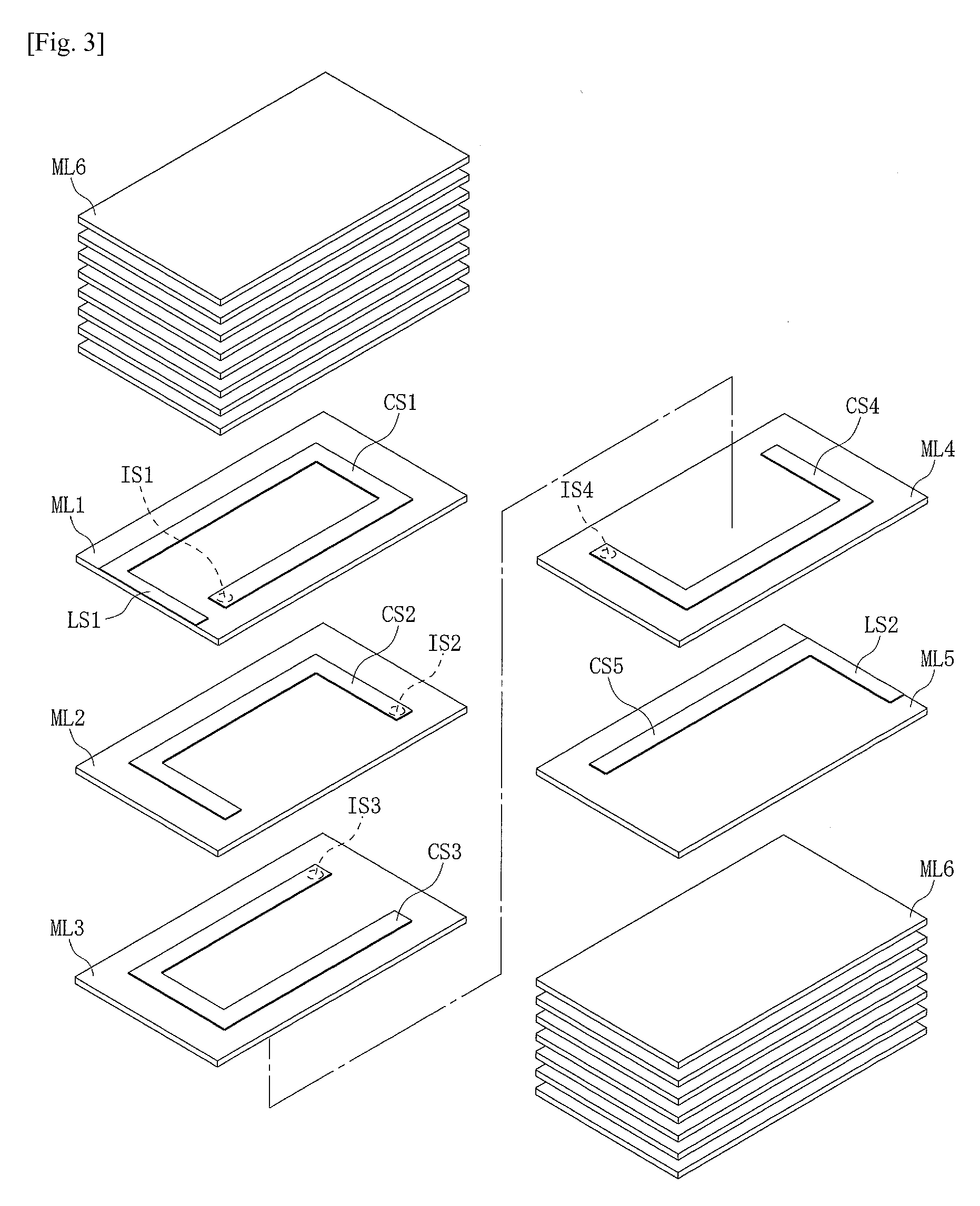

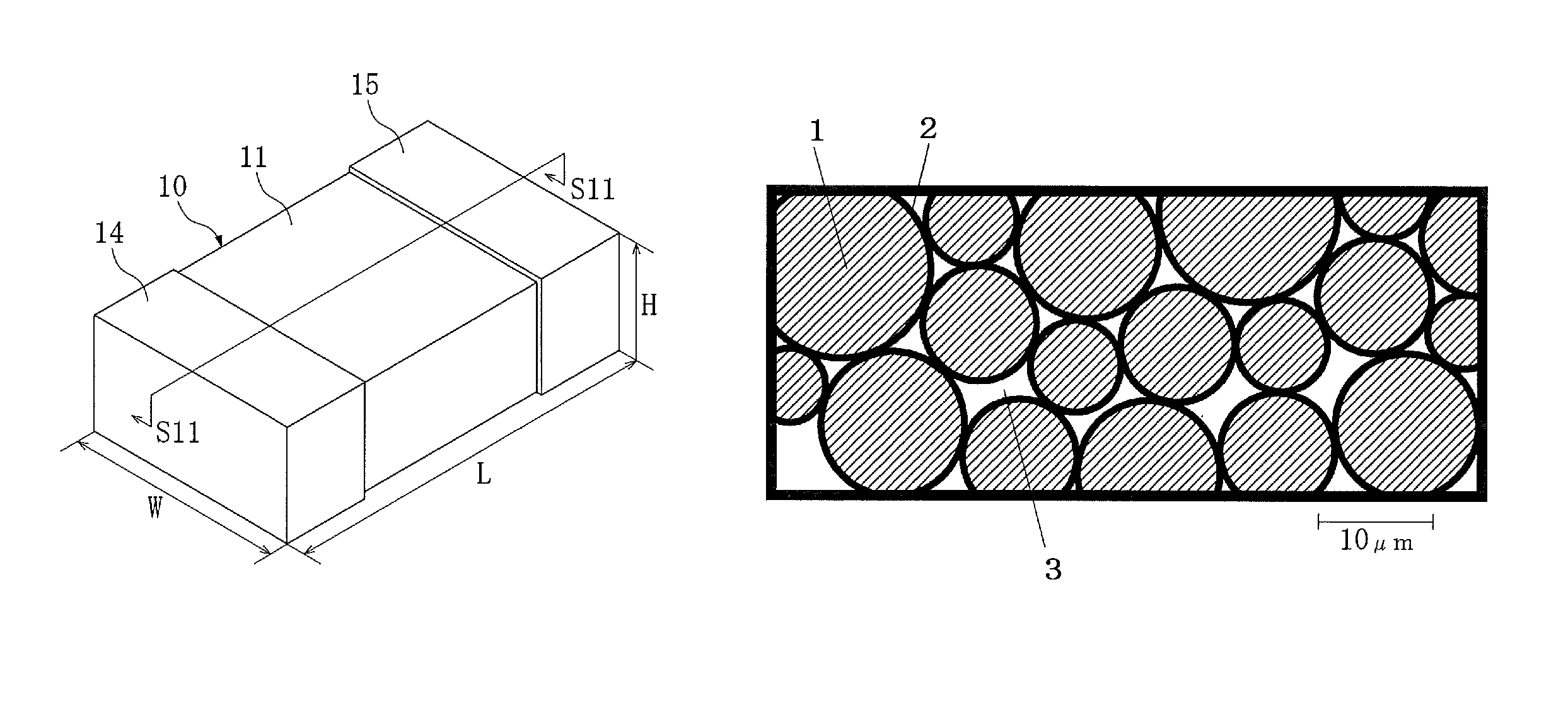

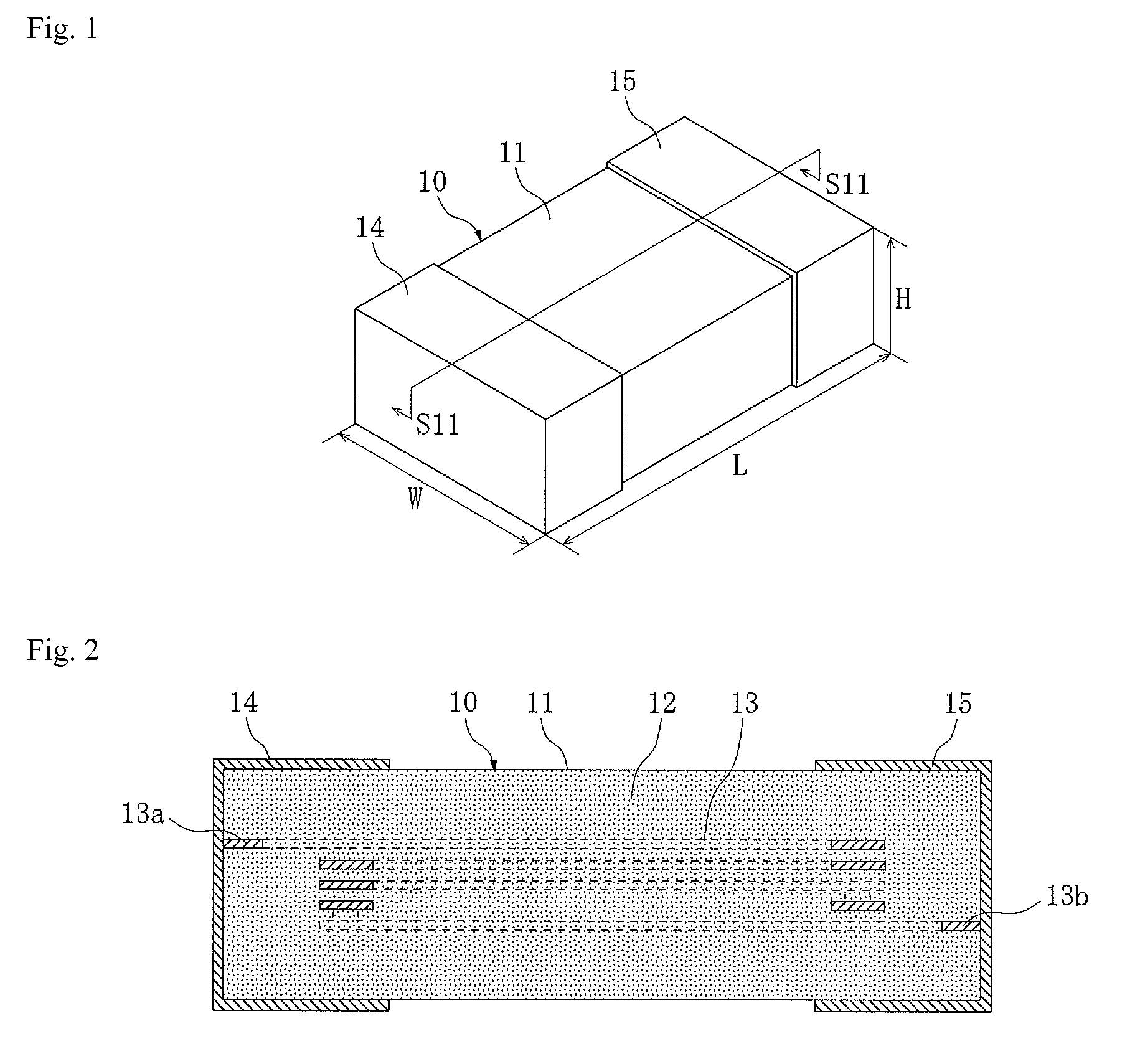

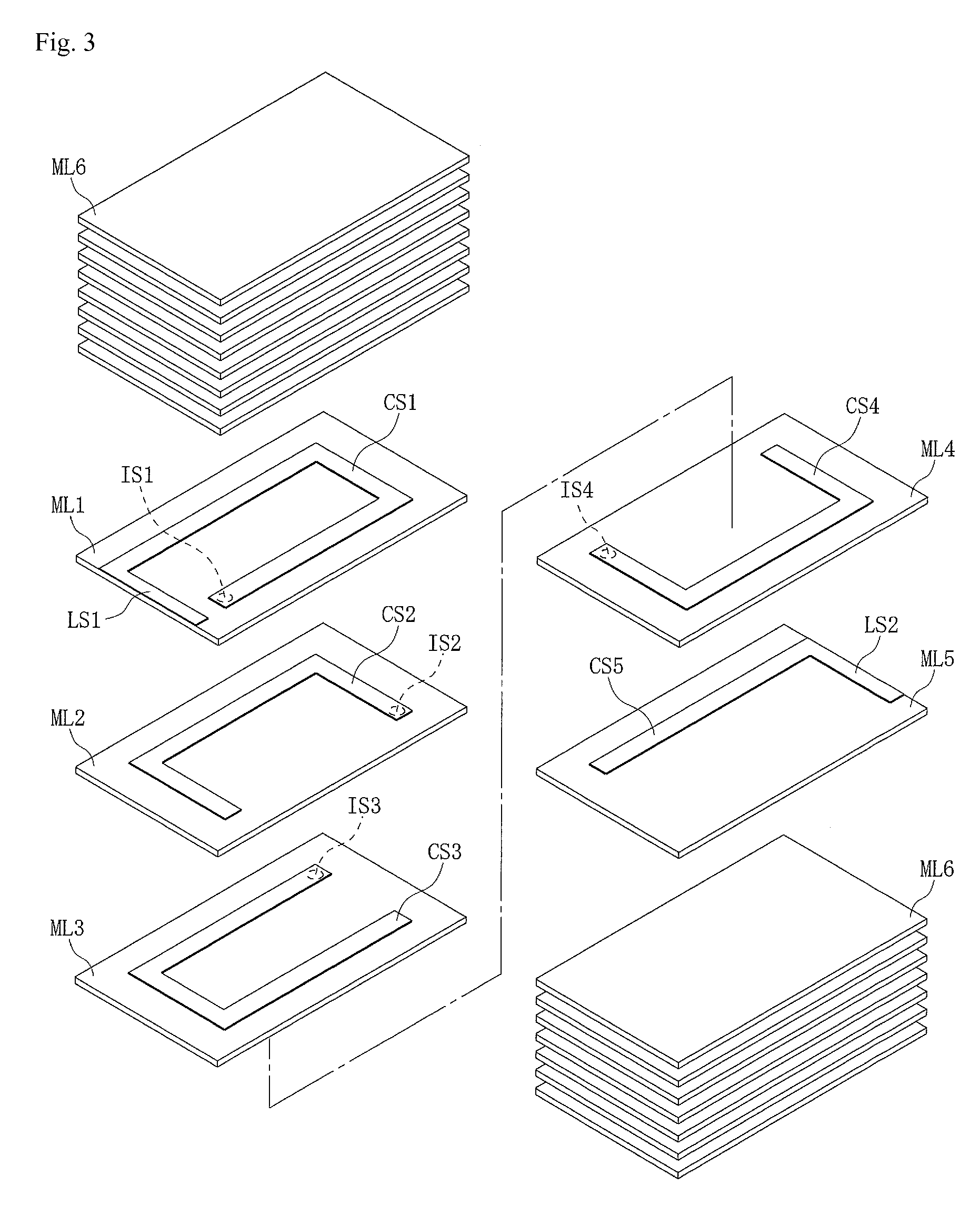

Coil component

ActiveUS20120188049A1High volume resistivityIncrease component densityTransportation and packagingMetal-working apparatusElectrical currentMaterials science

A coil component is of the type where a helical coil is directly contacting a magnetic body, which is still capable of meeting the demand for electrical current amplification. A coil component, comprising a magnetic body mainly constituted by magnetic alloy grains, and a coil formed on the magnetic body; wherein an oxide film of the magnetic alloy grains is present on the surface of each of the magnetic alloy grains, and based on grain size by volume standard, the magnetic alloy grains have a d50 in a range of 3.0 to 20.0 μm, d10 / d50 in a range of 0.1 to 0.7, and d90 / d50 in a range of 1.4 to 5.0.

Owner:TAIYO YUDEN KK

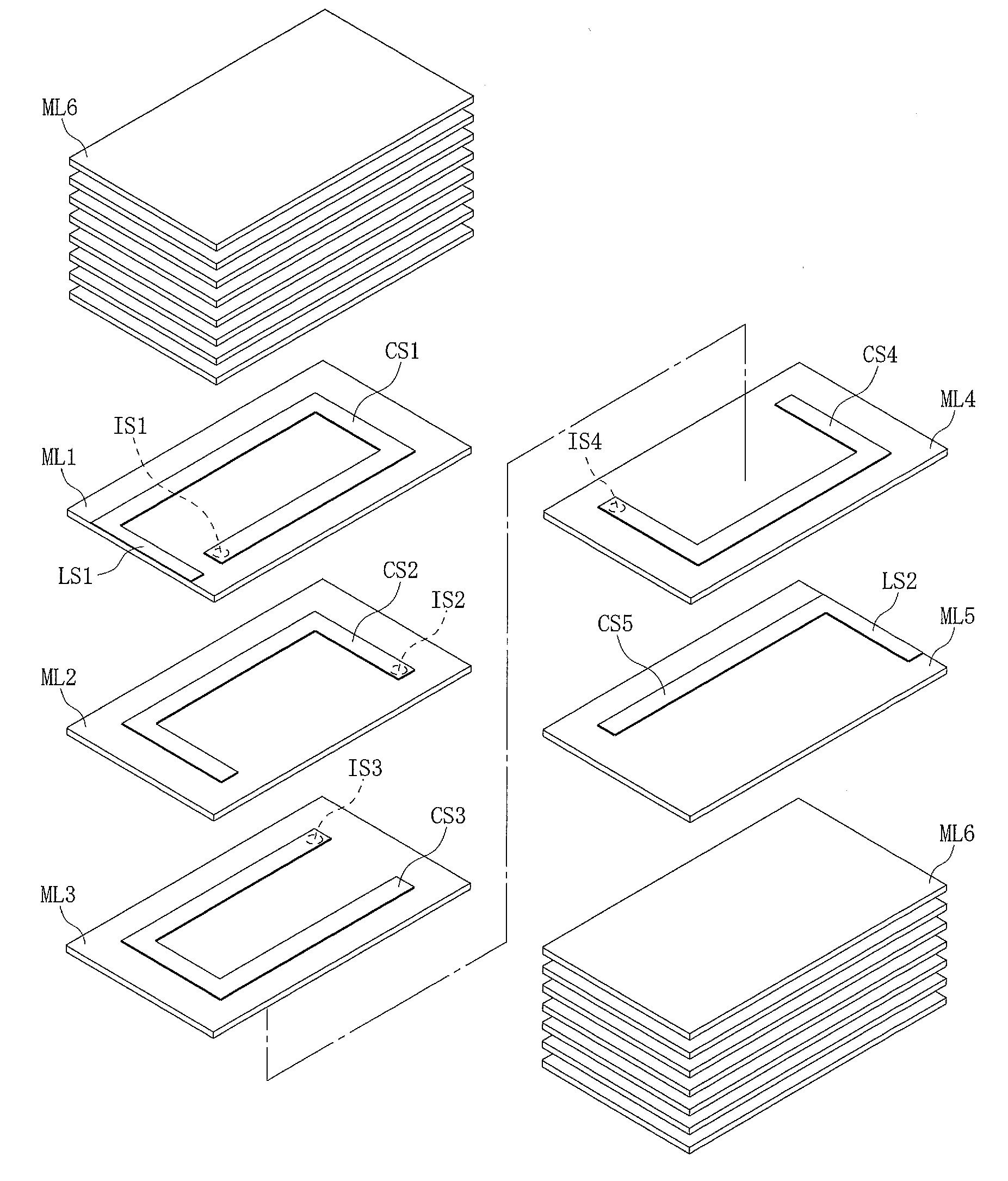

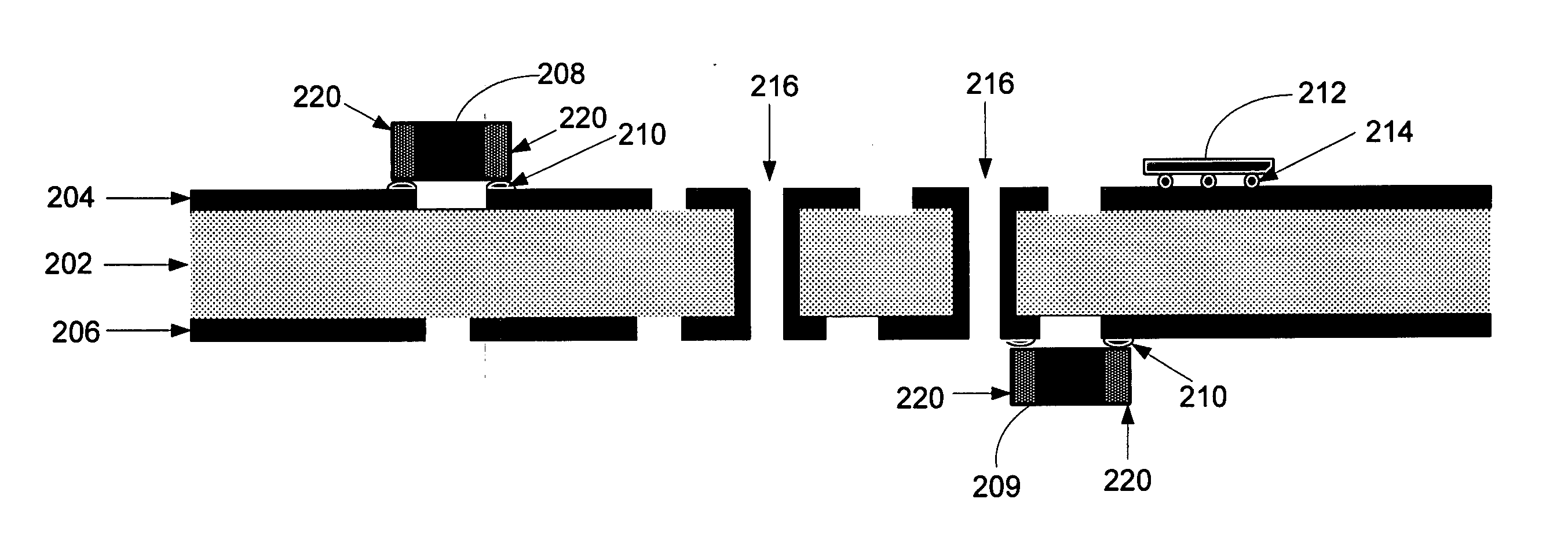

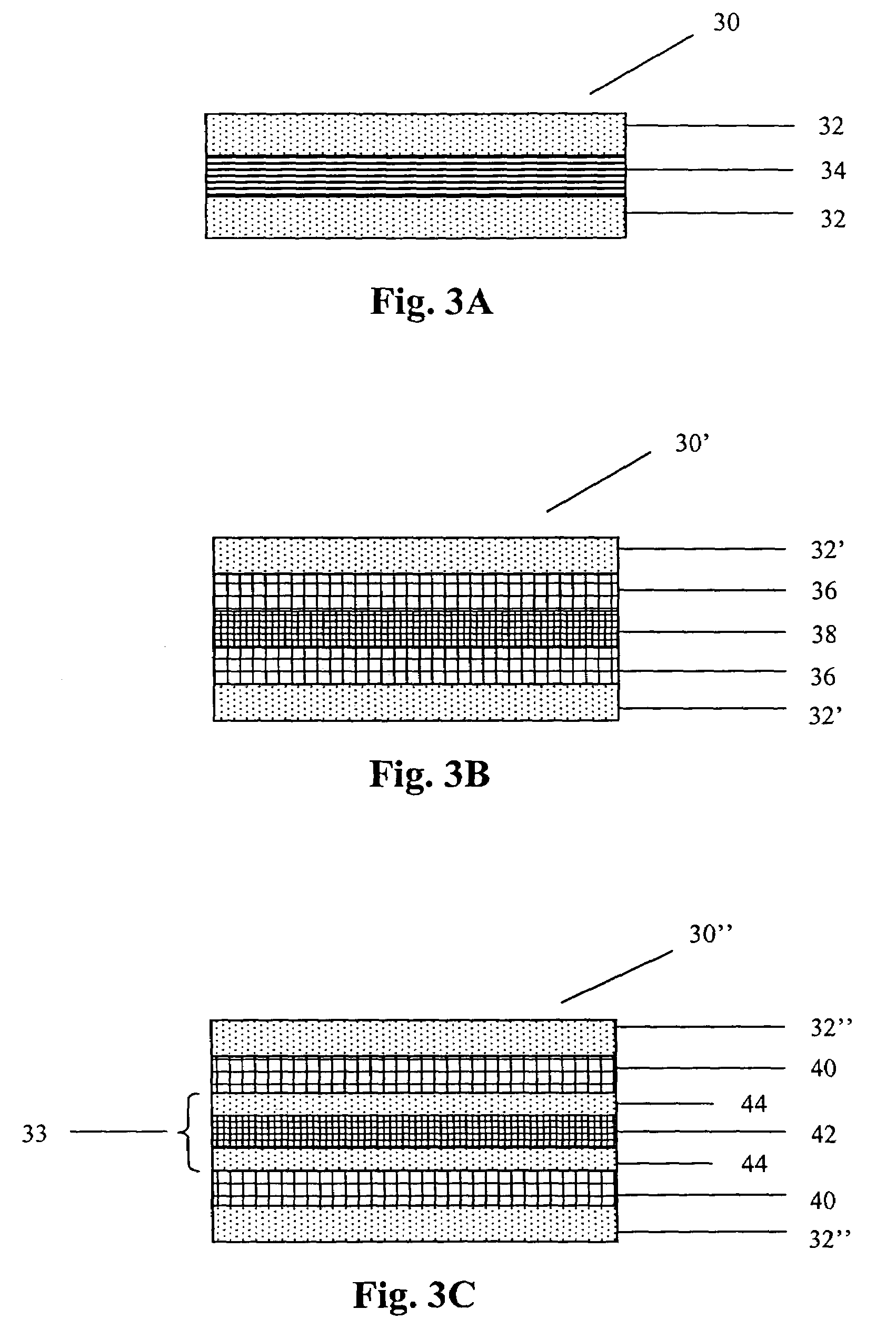

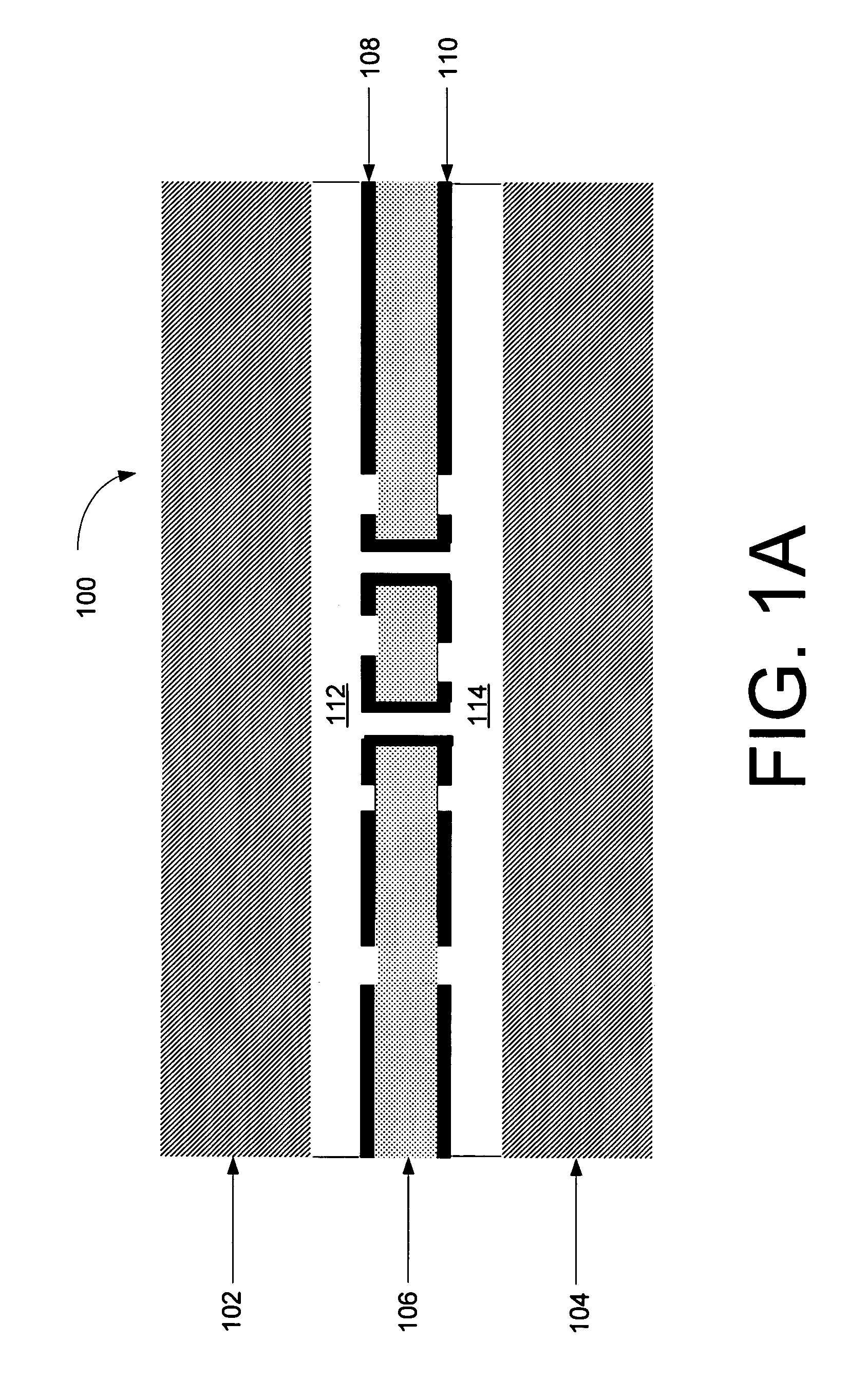

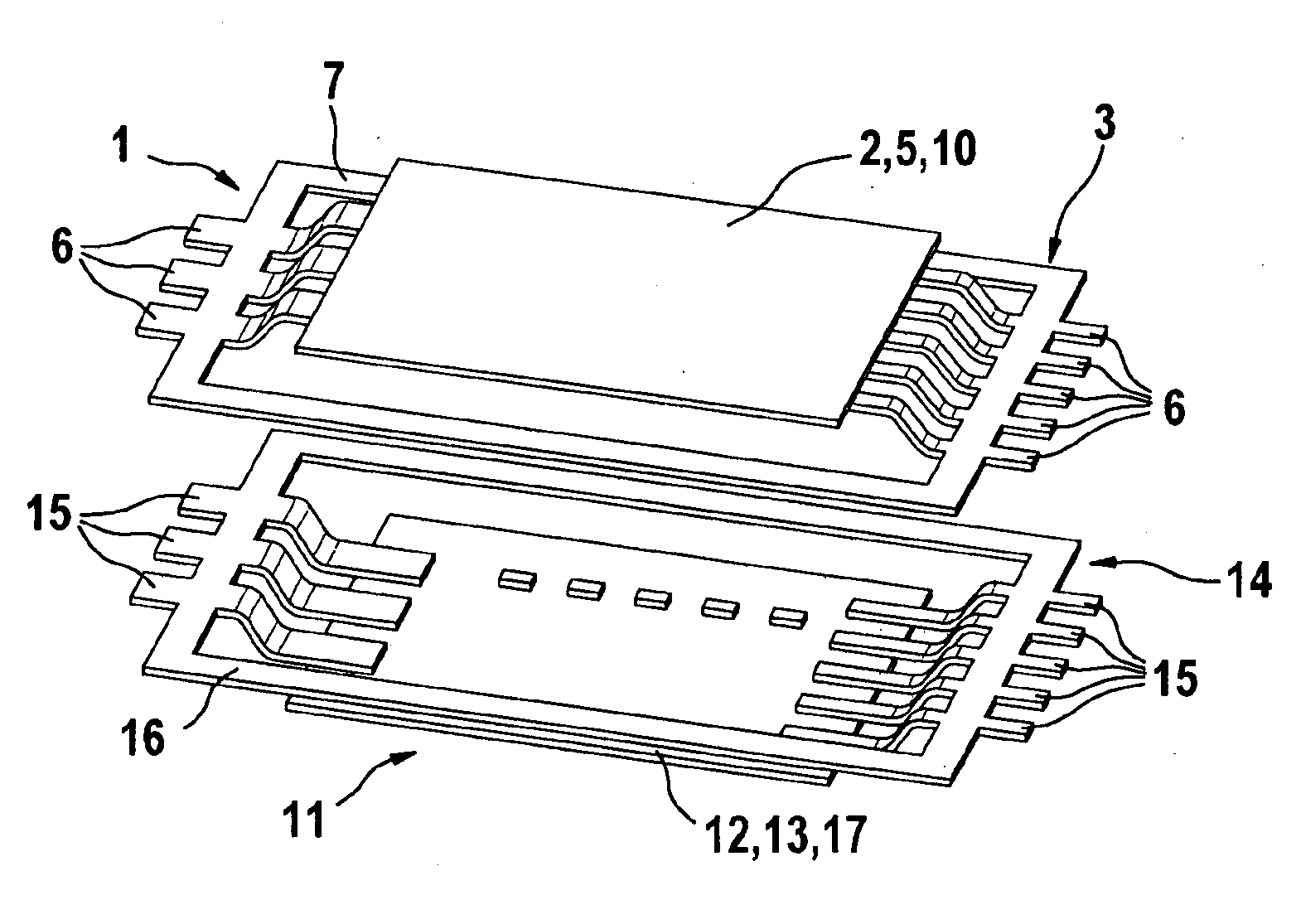

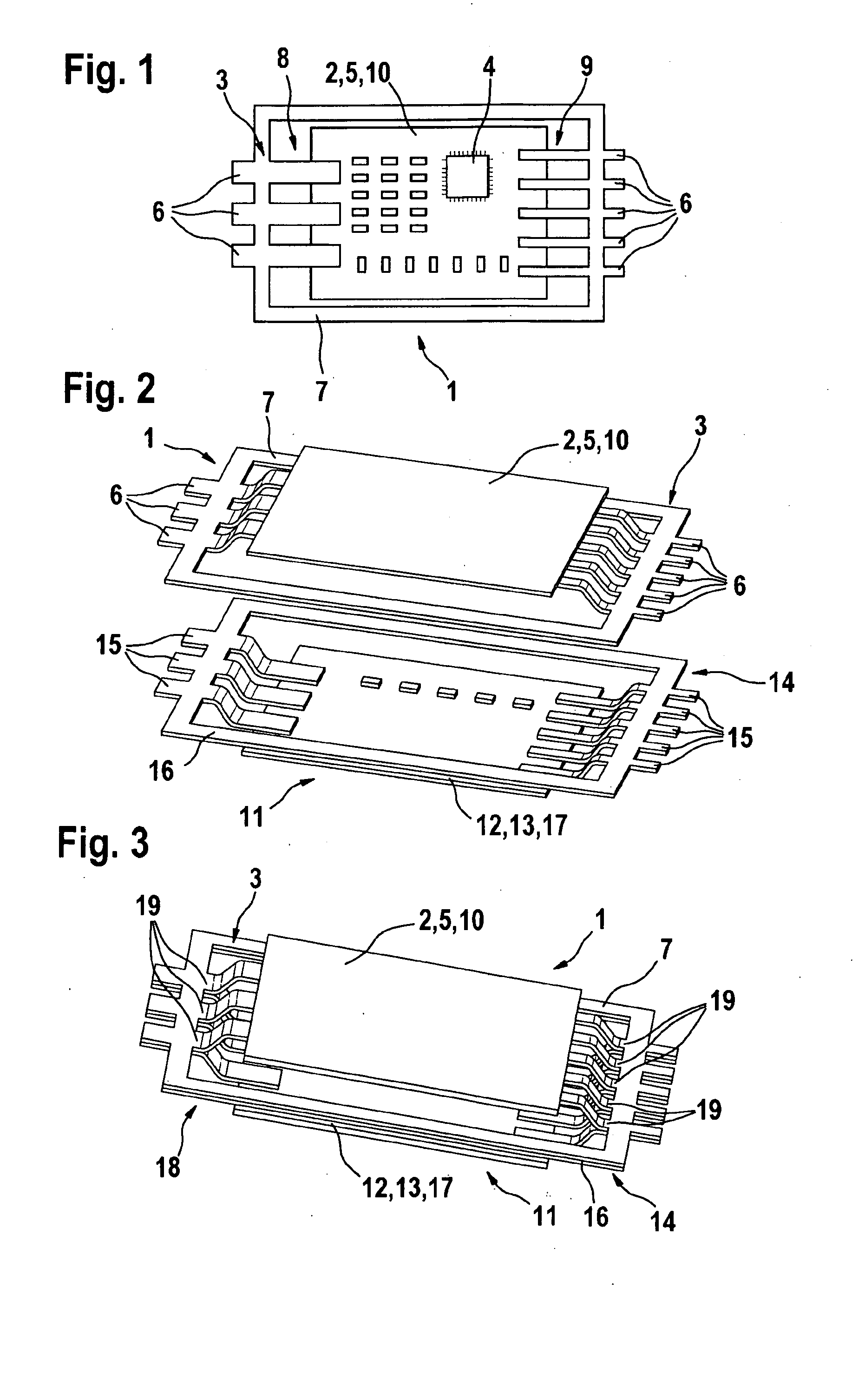

Heterogeneous organic laminate stack ups for high frequency applications

ActiveUS20060017152A1Shorten the counting processIncrease component densitySemiconductor/solid-state device detailsPrinted circuit aspectsSurface mountingLead bonding

Organic laminate stack ups are disclosed for a variety of applications, including high frequency RF applications. One or more inner core layers may be disposed between outer layers along with bondply or prepreg layers as needed. Discrete devices, including surface mount components and flip chips, may be embedded within the organic laminate stack up structures. The embedding of the discrete devices, which may be active or passive devices, may be in the form of a layer of bondply or prepreg encapsulating the discrete devices. In addition or in the alternative, cavities may be formed in at least the outer layers for housing discrete devices, which include surface mount components, flip chips, and wire bonded integrated circuits. A variety of caps may be utilized to seal the cavities. Further, shielding may be provided for the organic laminate stack up structure, including through a wall of vias or a plated trench cut along at least one side of the stack up structure. Each stack up structure may be packaged in a variety of ways, including as a surface mount component, ball grid array, or land grid array.

Owner:KYOCERA AVX COMPONENTS CORP

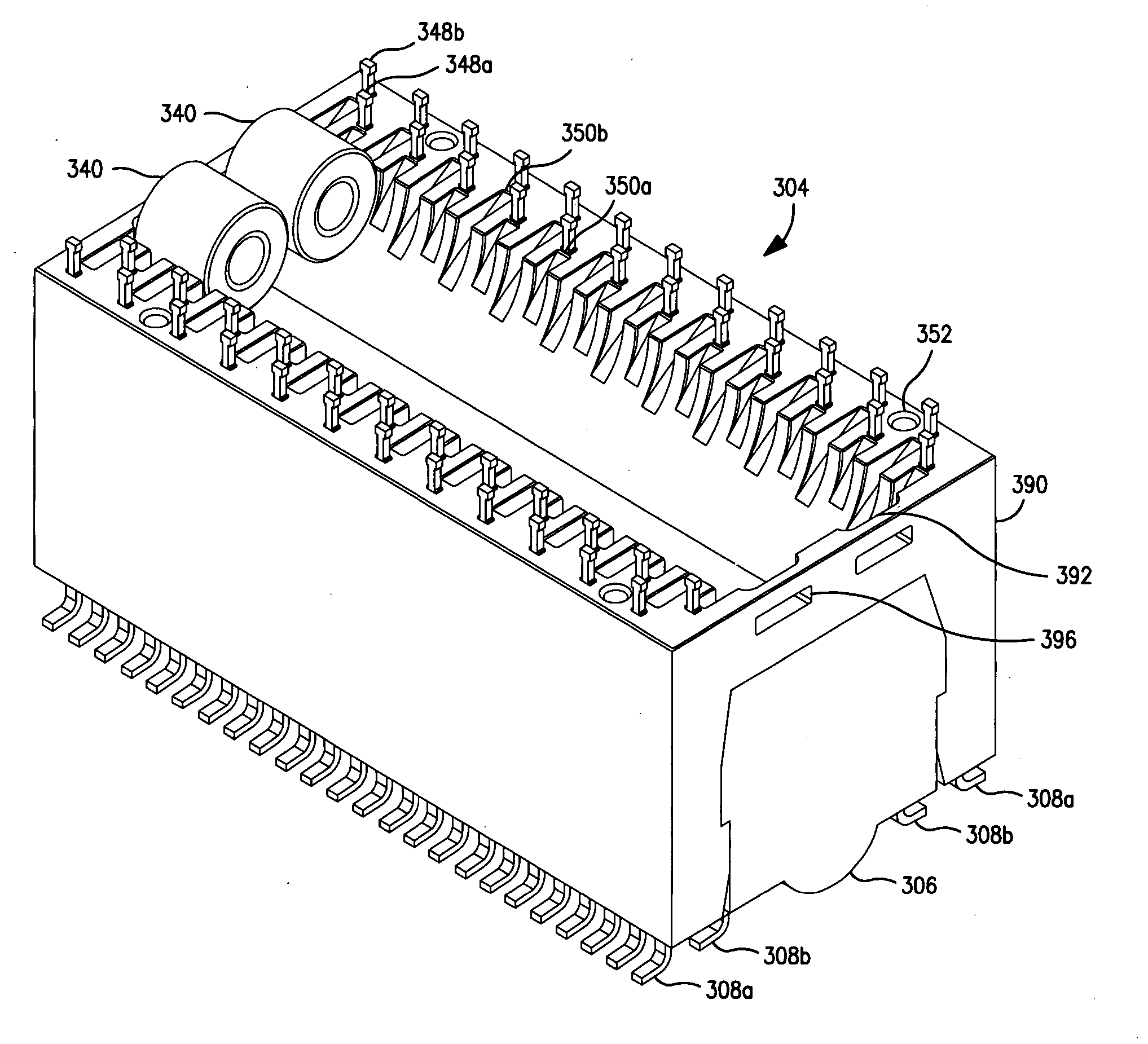

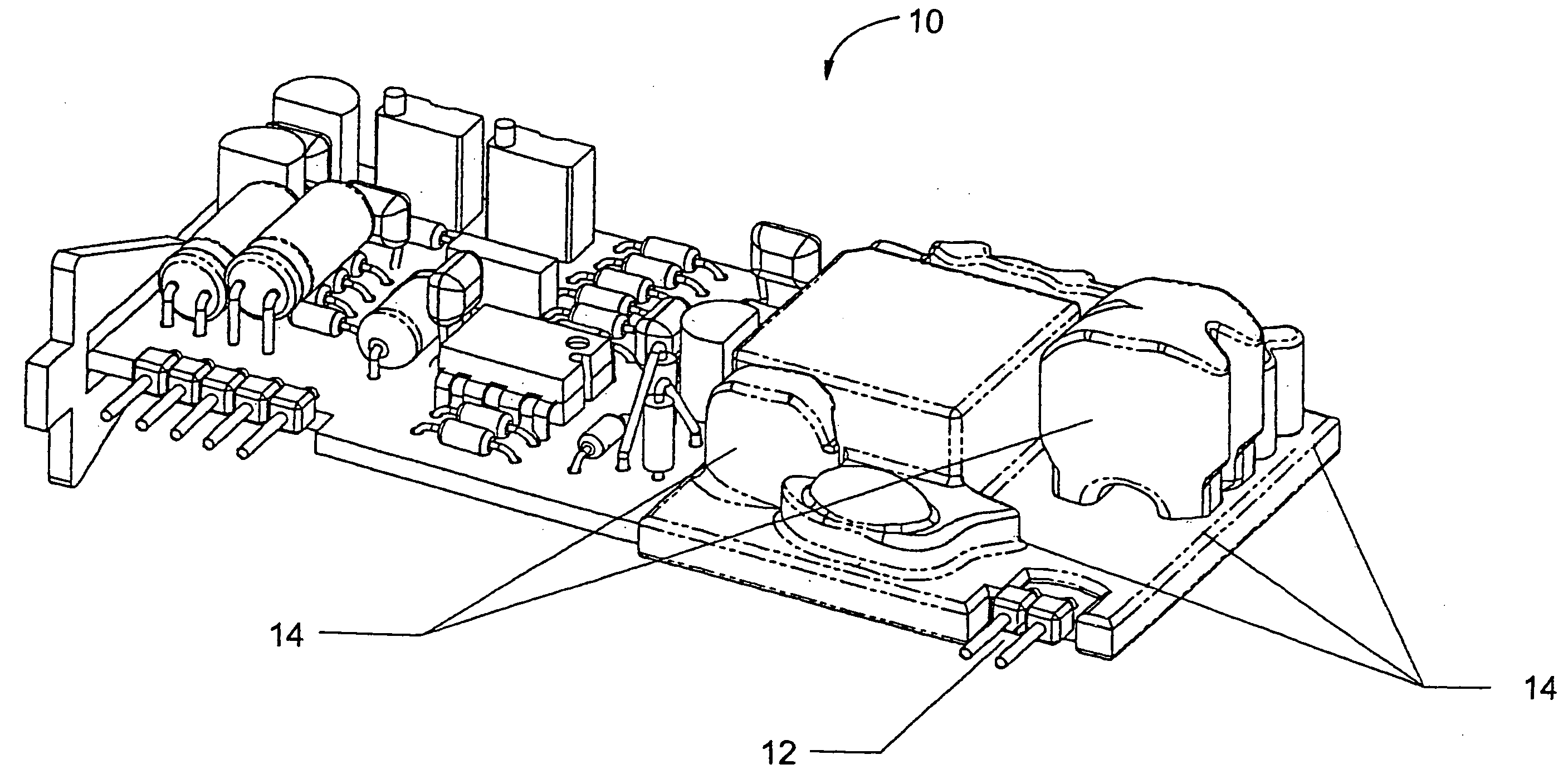

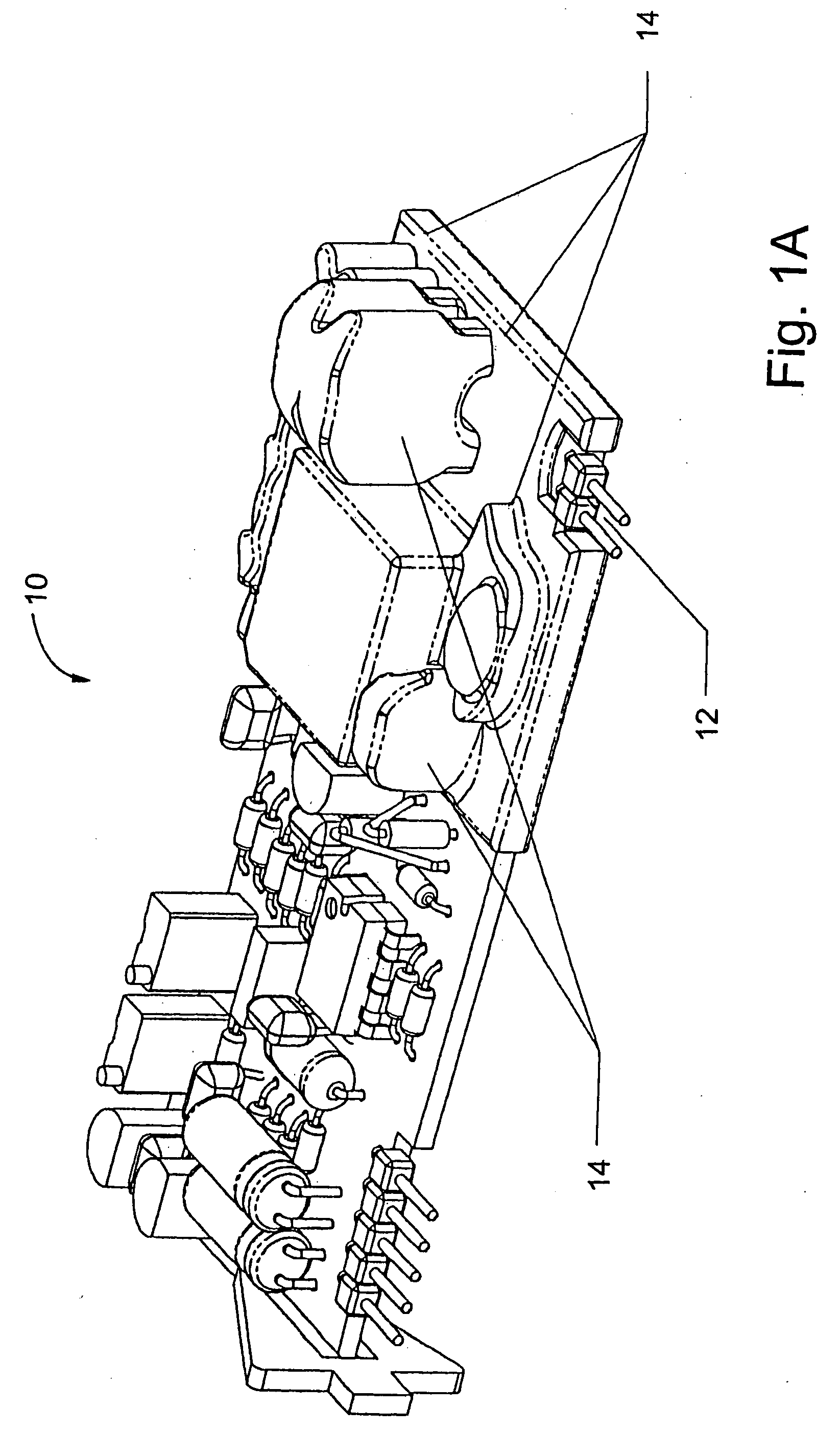

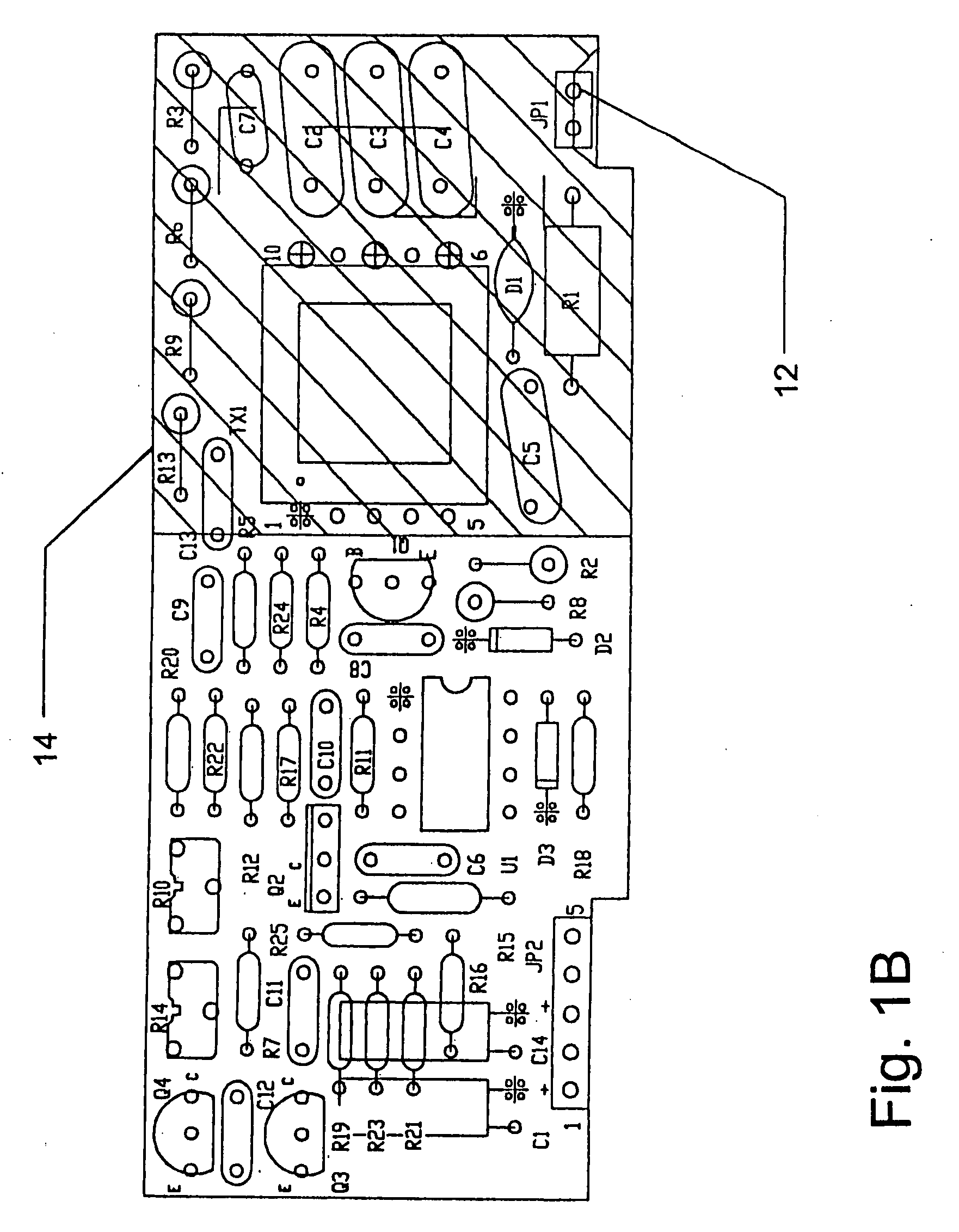

Modular electronic header assembly and methods of manufacture

ActiveUS20070238359A1Improve reliabilityEasy to weldTransformersTransformers/inductances casingsModularityEngineering

A device for electrically interconnecting and packaging electronic components. In one embodiment, a modular non-conducting base member having one or more component recesses and a plurality of lead channels formed therein is provided. At least one electronic component is disposed within the recess, and the wire leads of the component routed through the lead channels to a conductive lead terminal. A plurality of lead terminals, adapted to cooperate with the non-conducting base member, are received therein, and adapted to place the device in signal communication with an external printed circuit board. The modular non-conducting base members are assembled or stacked to form a unitary modular assembly. Methods for fabricating the device are also disclosed.

Owner:PULSE ELECTRONICS

Substrate with via and pad structures

ActiveUS7645940B2Increase solder formationReduce formationPrinted circuit assemblingFinal product manufactureSolder maskEngineering

This invention relates to a substrate with via and pad structure(s) to reduce solder wicking. Each via and pad structure connects a component to conductive layers associated with the substrate. The substrate includes one or more plated vias, solder mask(s) surrounding the plated vias, and a conductive pad with a conductive trace connected to each plated via. The conductive pad extends beyond the terminal sides to increase solder formation and the solder mask reduces solder formation at the terminal end of the component. The via and pad structure is suitable for a variety of components and high component density. The invention also provides a computer implemented method for calculating the maximum distance of a conductive pad extending beyond the terminal side of a component.

Owner:BRIGHT MASCH INC +1

Expansion constrained die stack

InactiveUS7173325B2High densityShorten the lengthSemiconductor/solid-state device detailsPrinted circuit aspectsInterconnectionEngineering

Structures and techniques for mounting semiconductor dies are disclosed. In one embodiment, the invention includes a stack of printed wiring board assemblies that are connected via interconnection components. At least one of the printed wiring board assemblies includes an interposer substrate having a constraining layer that includes carbon.

Owner:STABLCOR TECH

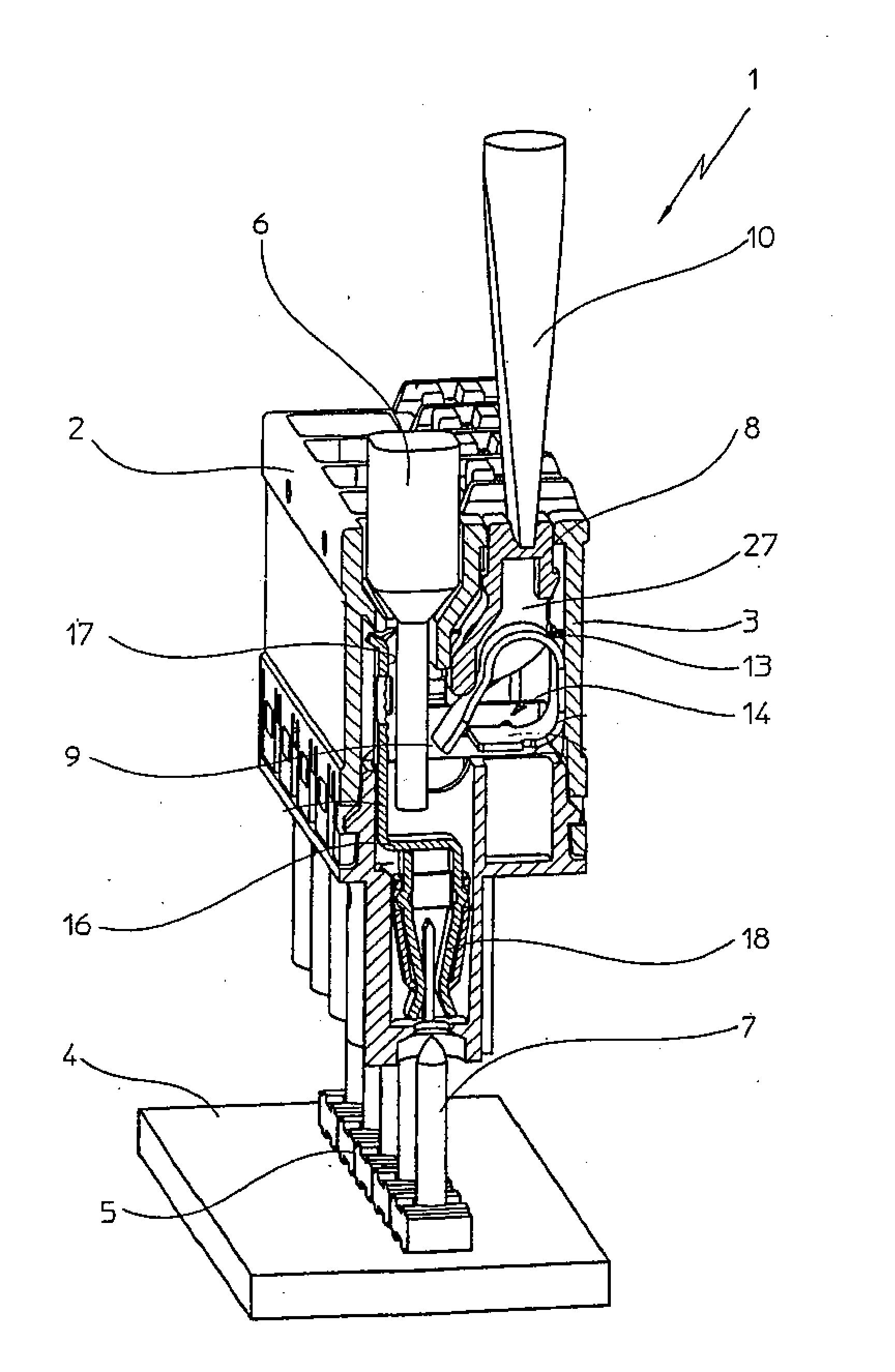

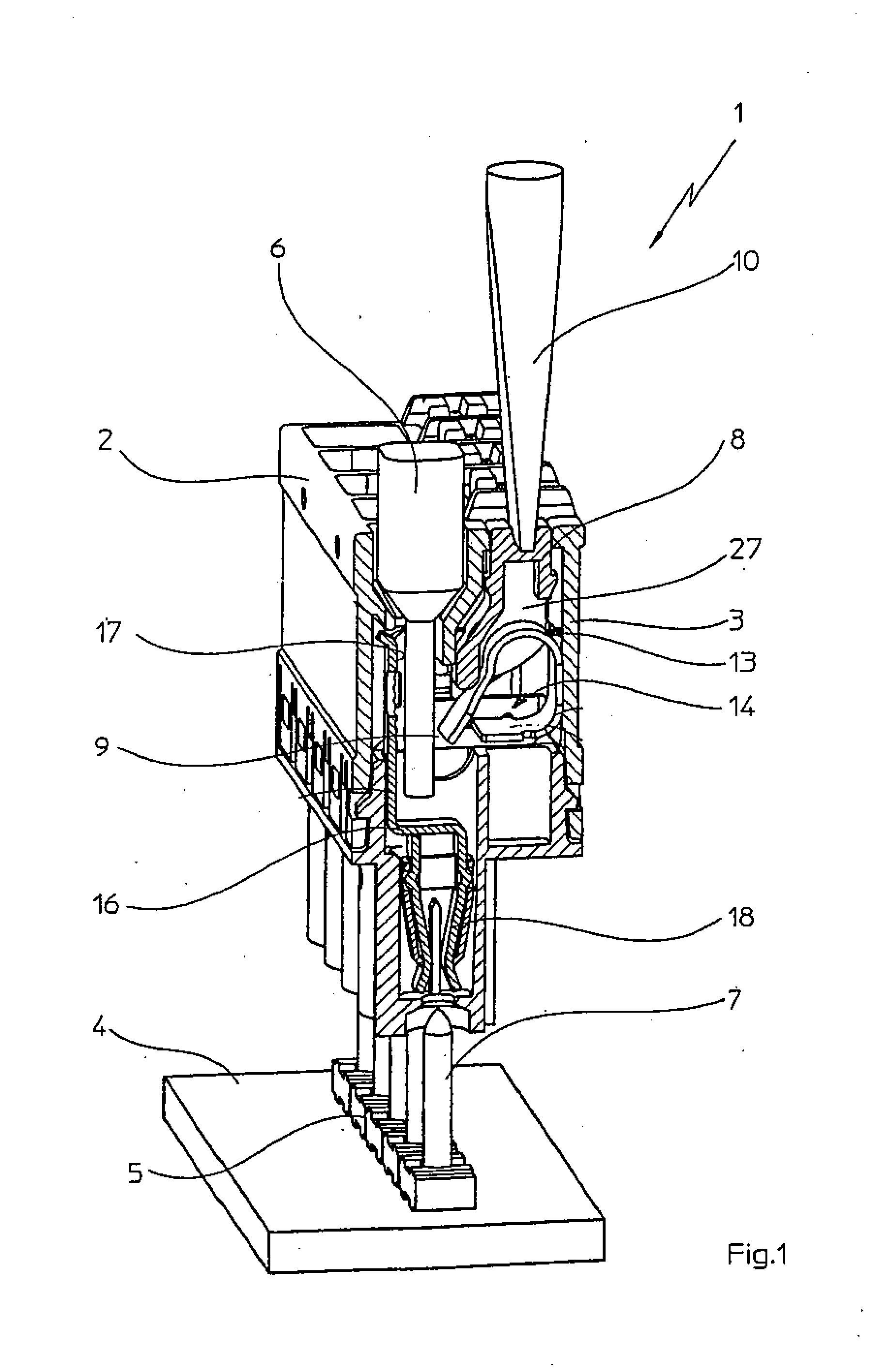

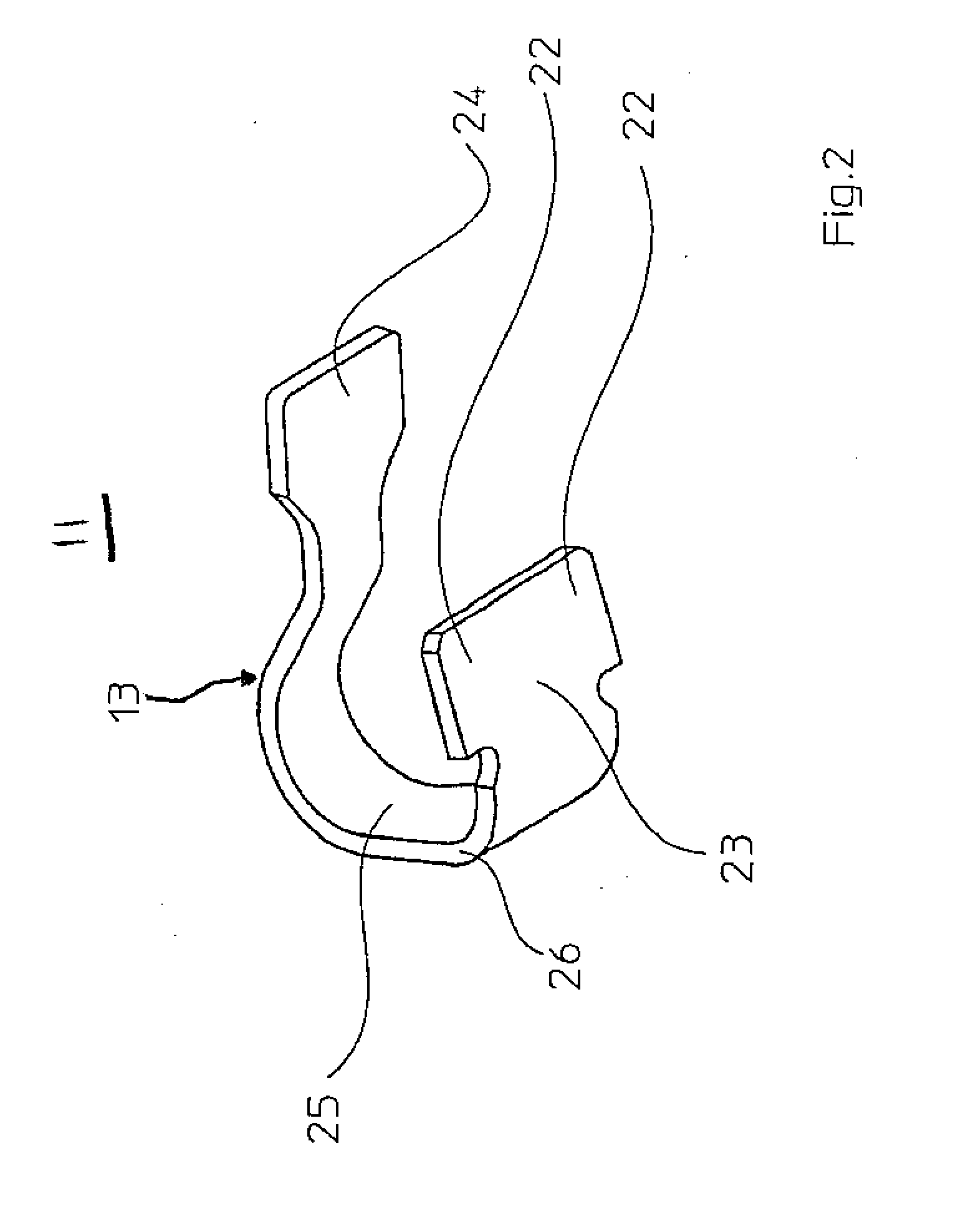

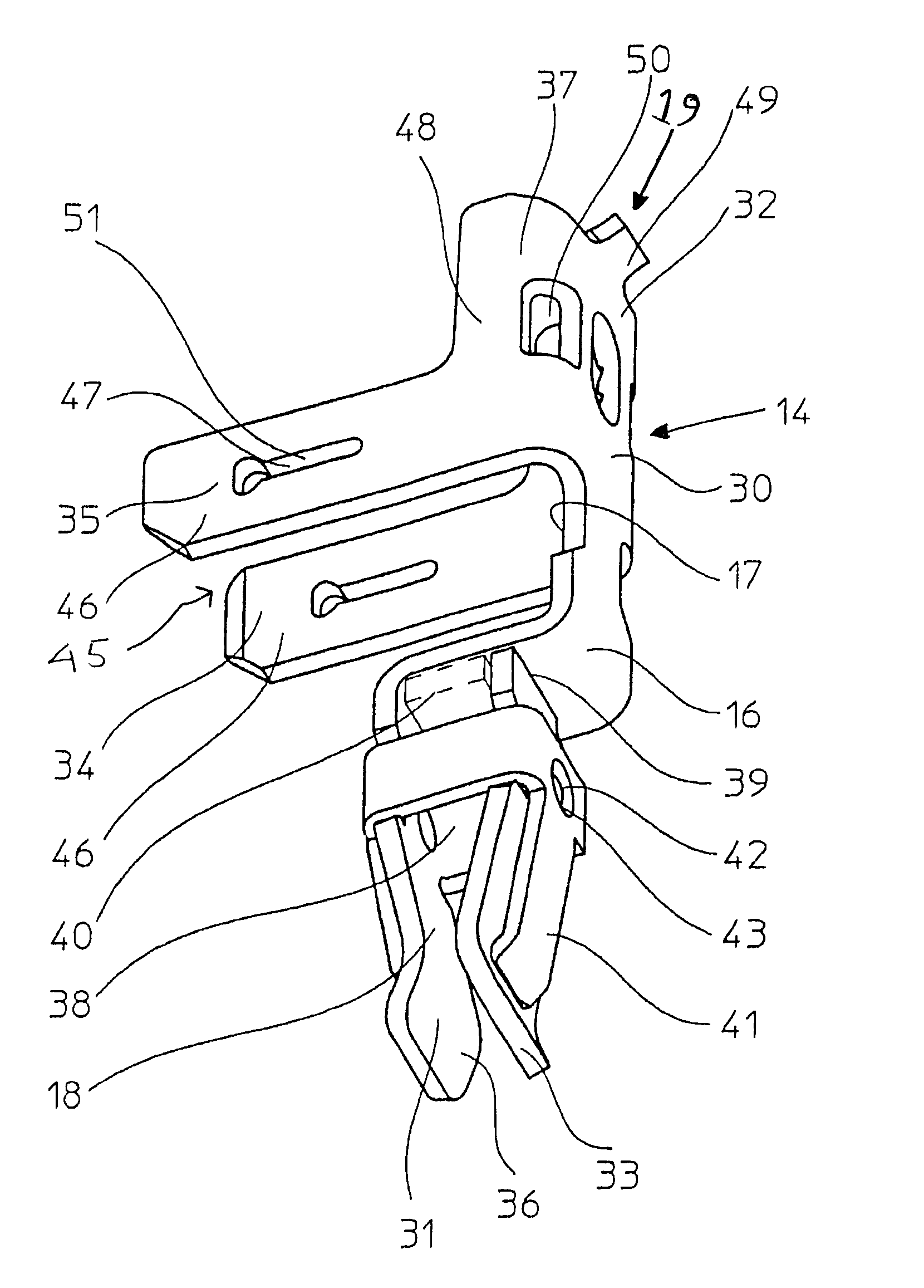

Connecting terminal for printed circuit boards

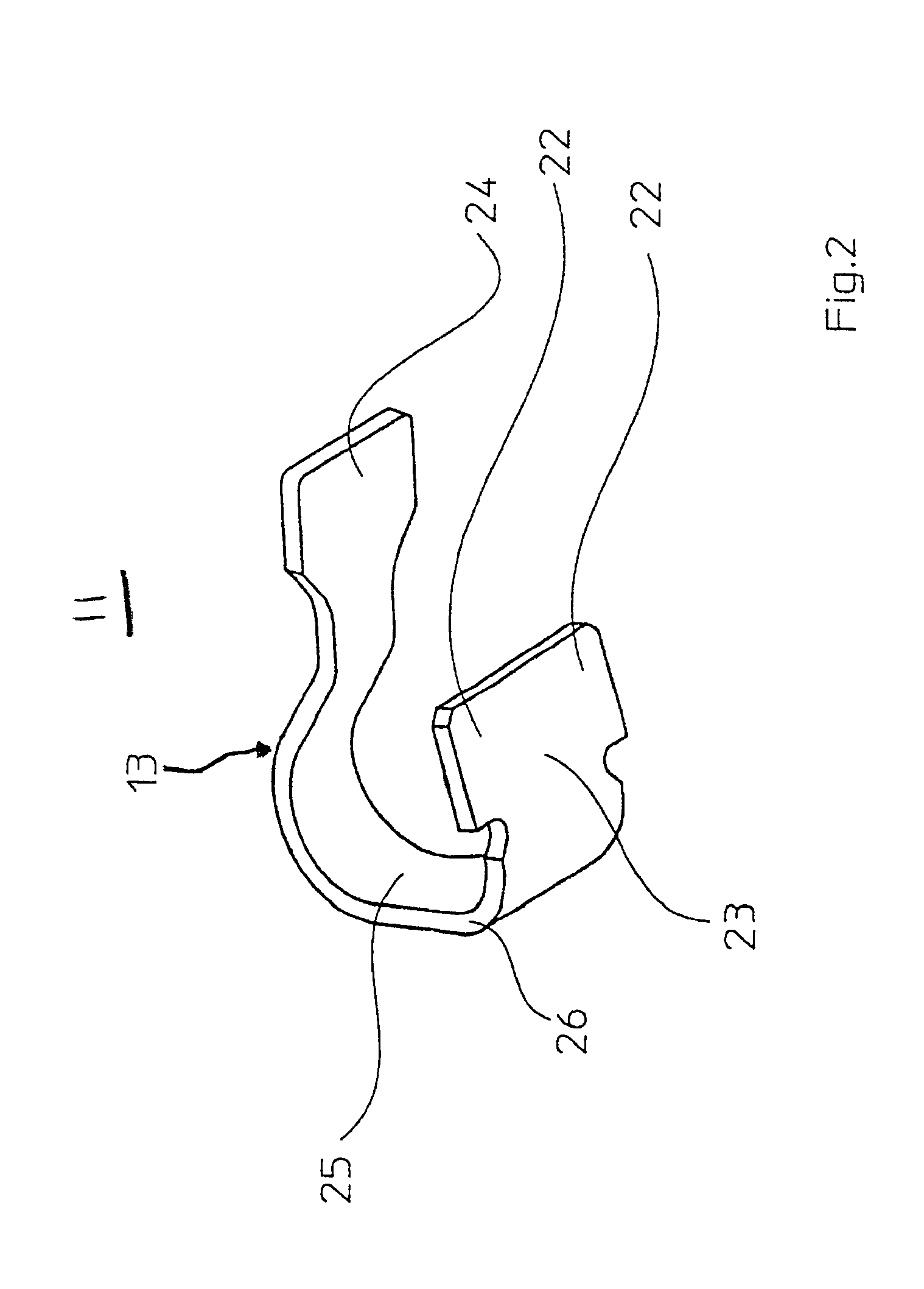

InactiveUS20100173531A1Simple functional designSmall installation sizeElectrically conductive connectionsCoupling contact membersSpring forcePrinted circuit board

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

Heterogeneous organic laminate stack ups for high frequency applications

ActiveUS8345433B2Shorten the counting processIncrease component densitySemiconductor/solid-state device detailsPrinted circuit aspectsSurface mountingEngineering

Organic laminate stack ups are disclosed for a variety of applications, including high frequency RF applications. One or more inner core layers may be disposed between outer layers along with bondply or prepreg layers as needed. Discrete devices, including surface mount components and flip chips, may be embedded within the organic laminate stack up structures. The embedding of the discrete devices, which may be active or passive devices, may be in the form of a layer of bondply or prepreg encapsulating the discrete devices. In addition or in the alternative, cavities may be formed in at least the outer layers for housing discrete devices, which include surface mount components, flip chips, and wire bonded integrated circuits. A variety of caps may be utilized to seal the cavities. Further, shielding may be provided for the organic laminate stack up structure, including through a wall of vias or a plated trench cut along at least one side of the stack up structure. Each stack up structure may be packaged in a variety of ways, including as a surface mount component, ball grid array, or land grid array.

Owner:KYOCERA AVX COMPONENTS CORP

Selective Encapsulation of Electronic Components

InactiveUS20070289129A1Reduce processing timeReduced material requirementsPrinted circuit assemblingLine/current collector detailsRoom temperatureEngineering

A method for the selective encapsulation of electronic components on a printed circuit board comprising, in one embodiment, the steps of delivering the printed circuit board to an encapsulating nest at room temperature; damming the target areas with a dam resin having a latent curing agent and deposited in the shape of walls of predetermined heights, according to the desired fill heights; dispensing a fill resin to fill the dammed areas; and curing the dam and fill resins for a suitable amount of time. In a different embodiment, the invention comprises the additional steps of laying resin beads, each in a position corresponding to the footprint of each target component; and of positioning the target components over the beads and soldering the components.

Owner:LHV POWER

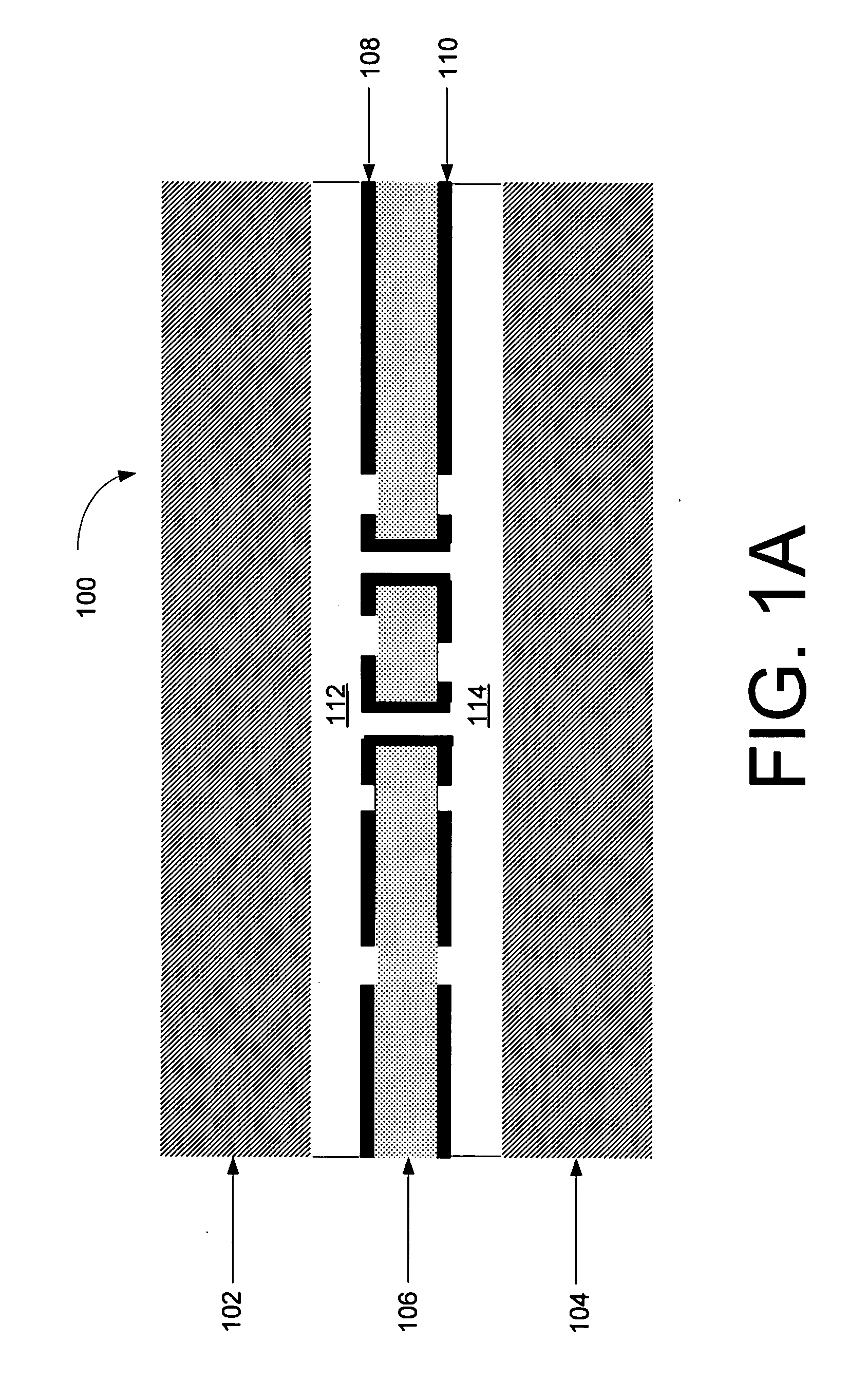

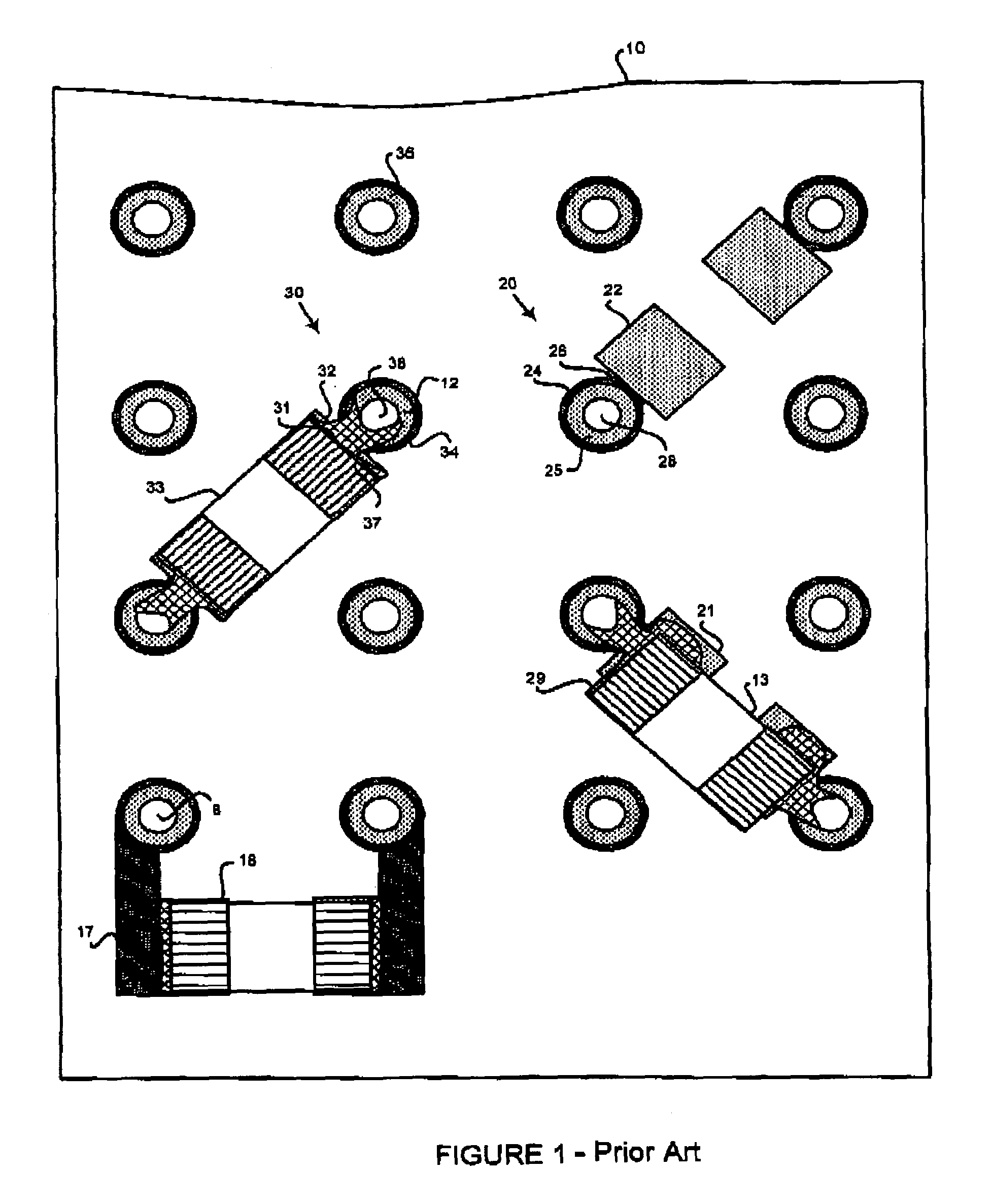

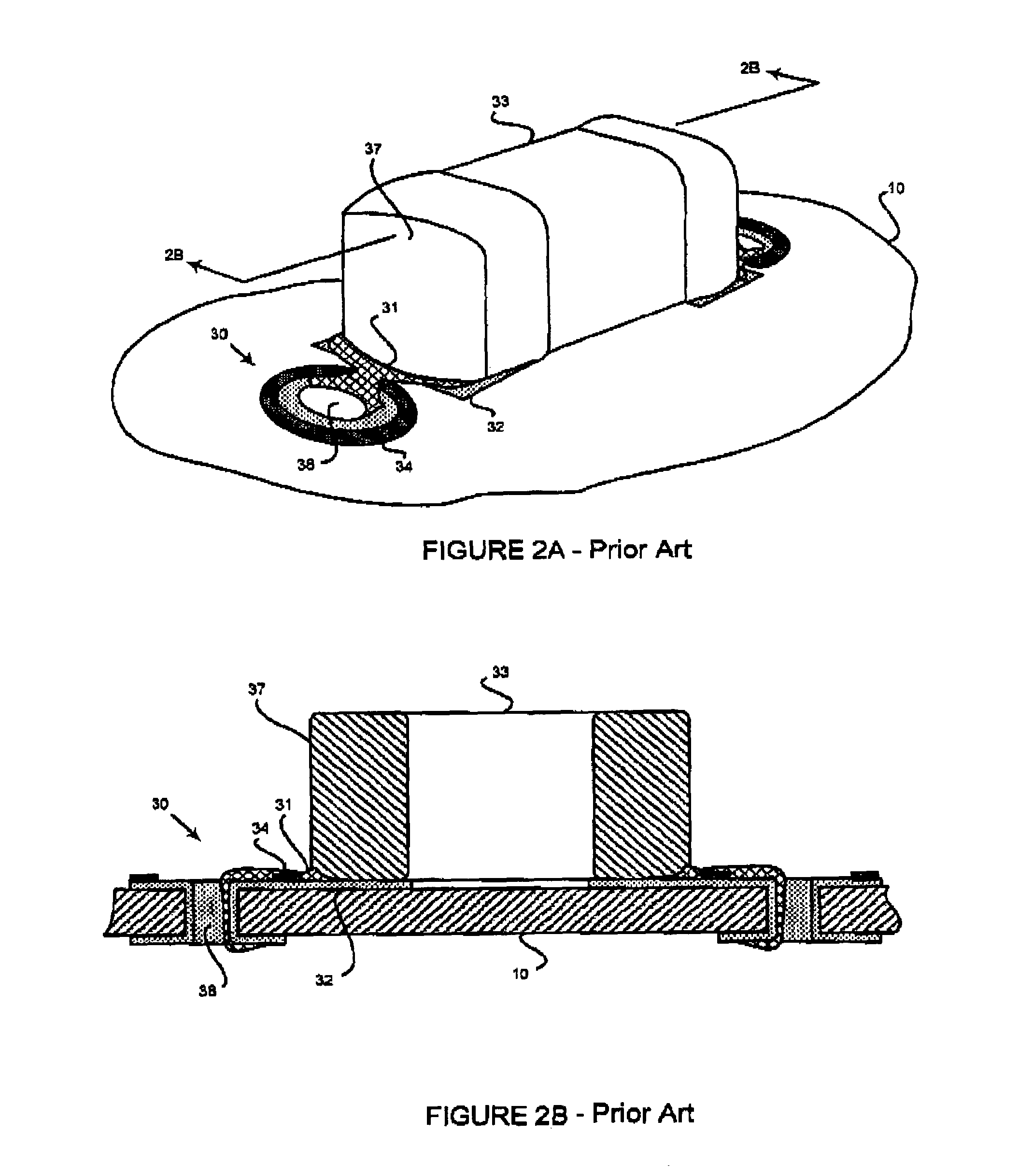

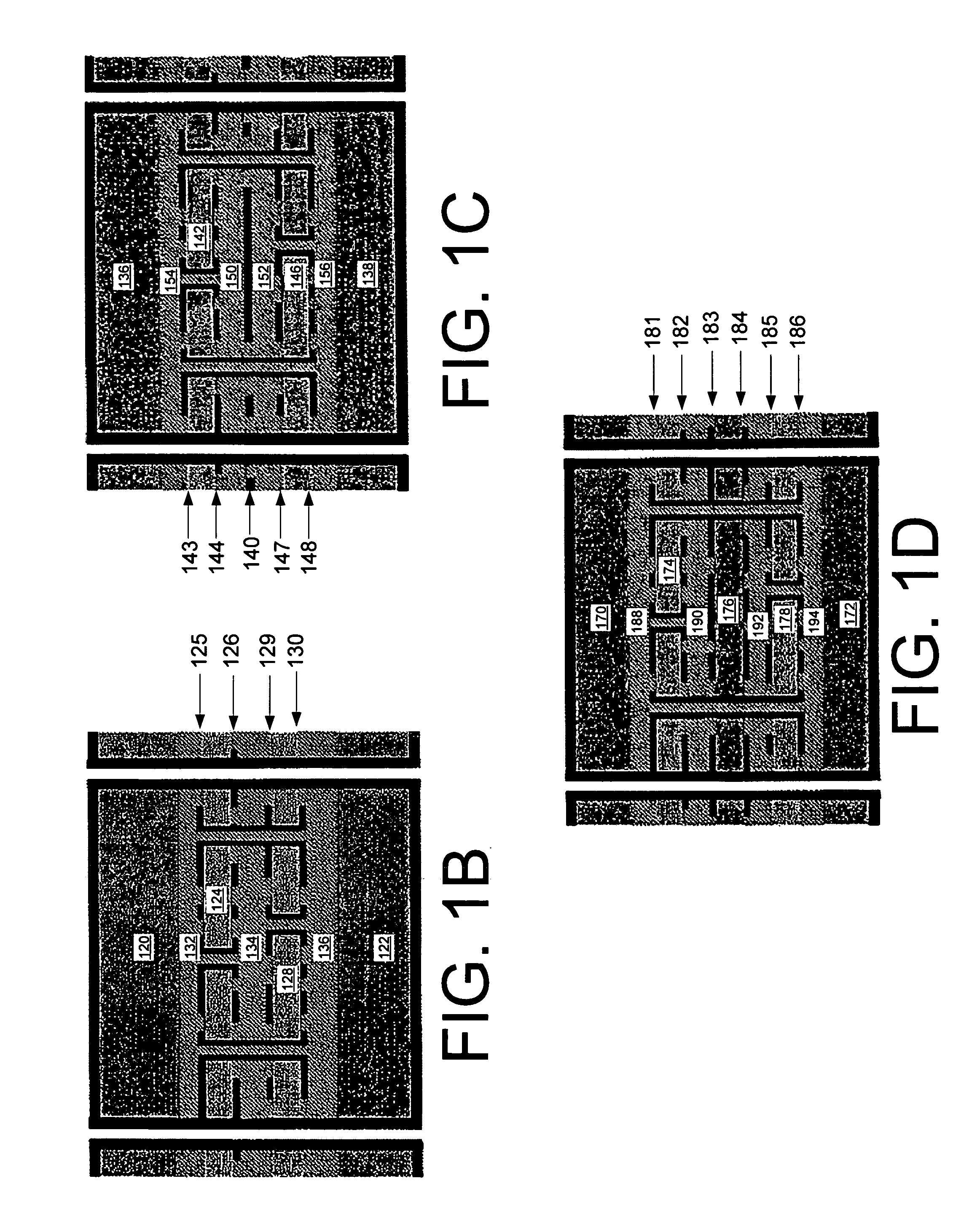

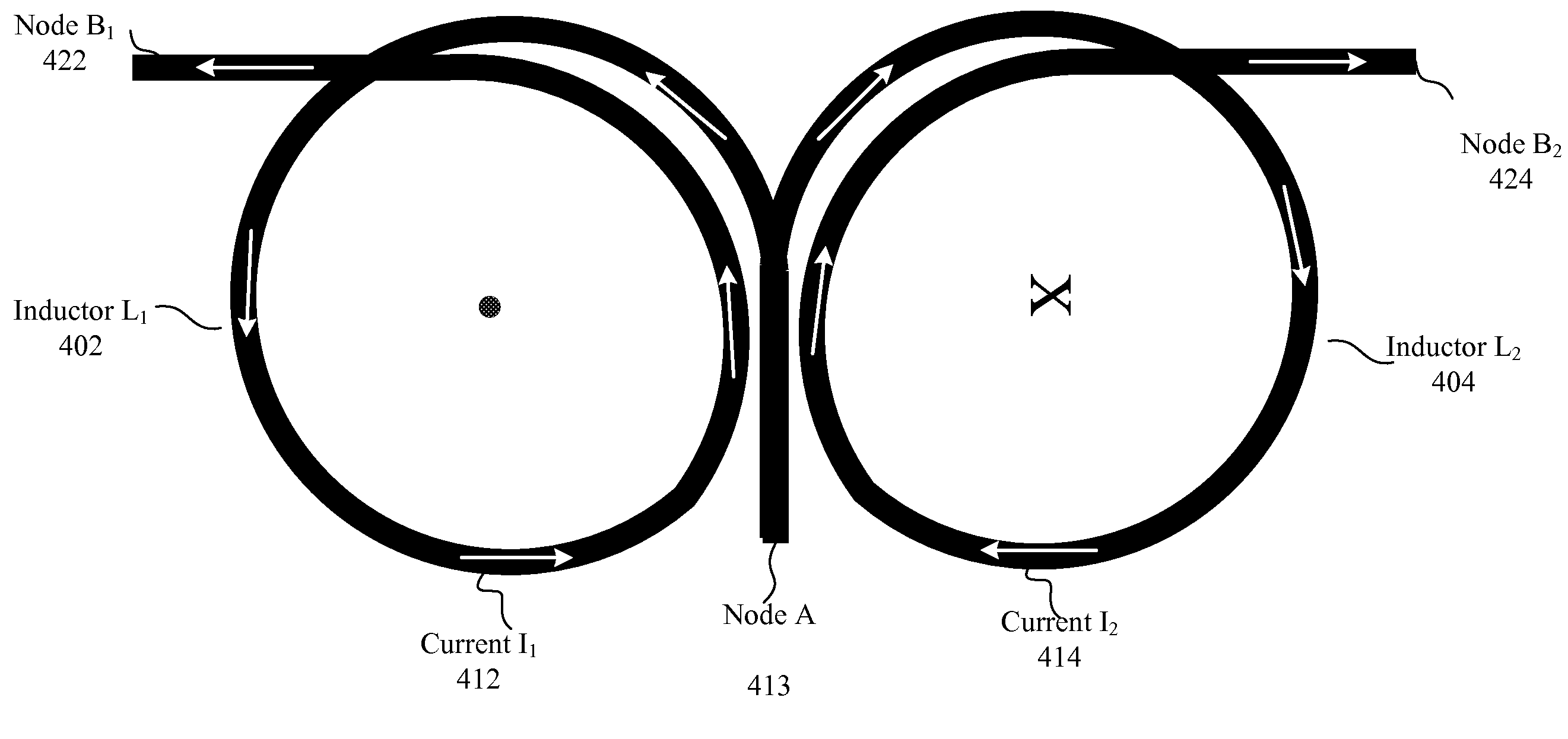

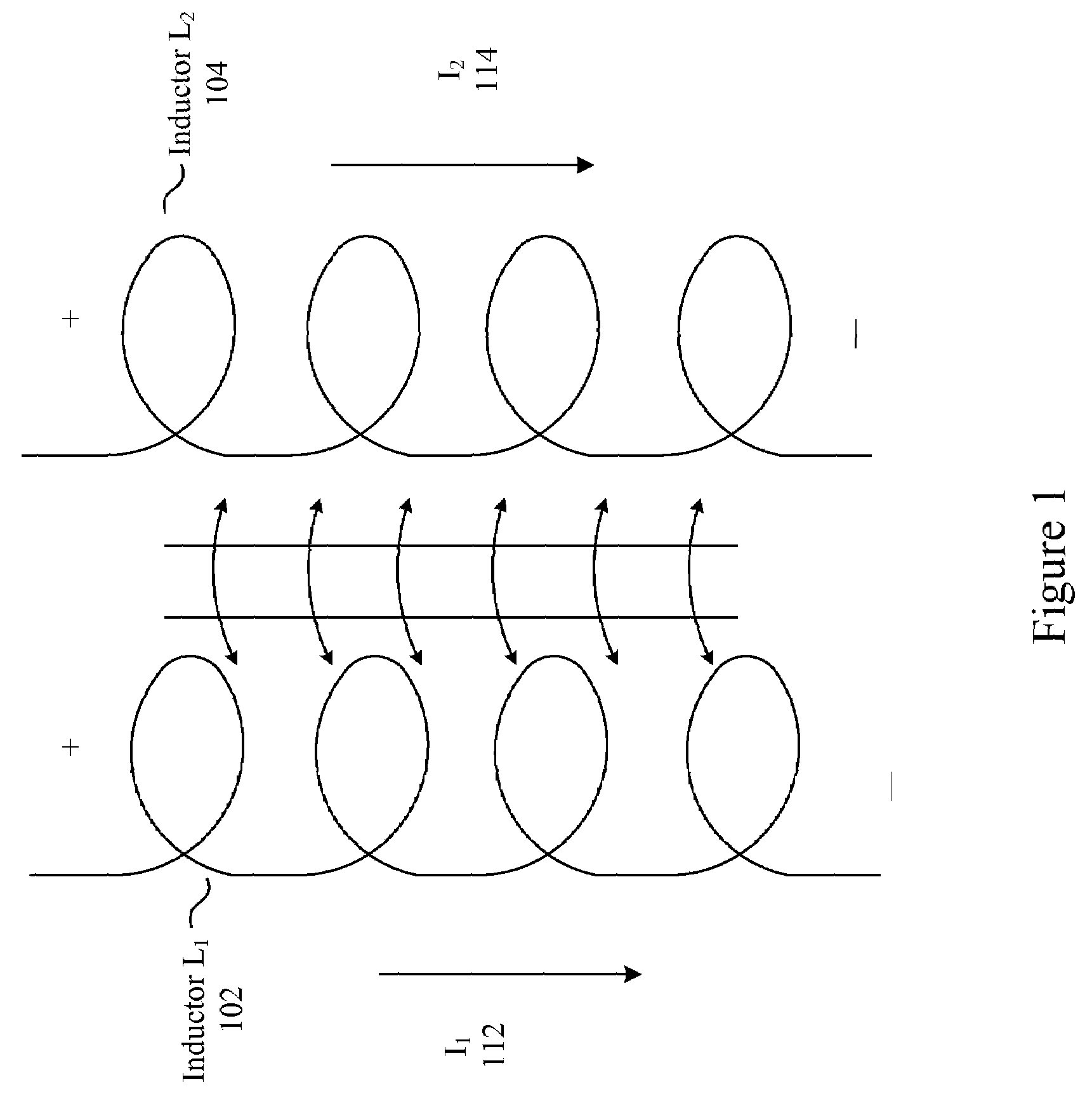

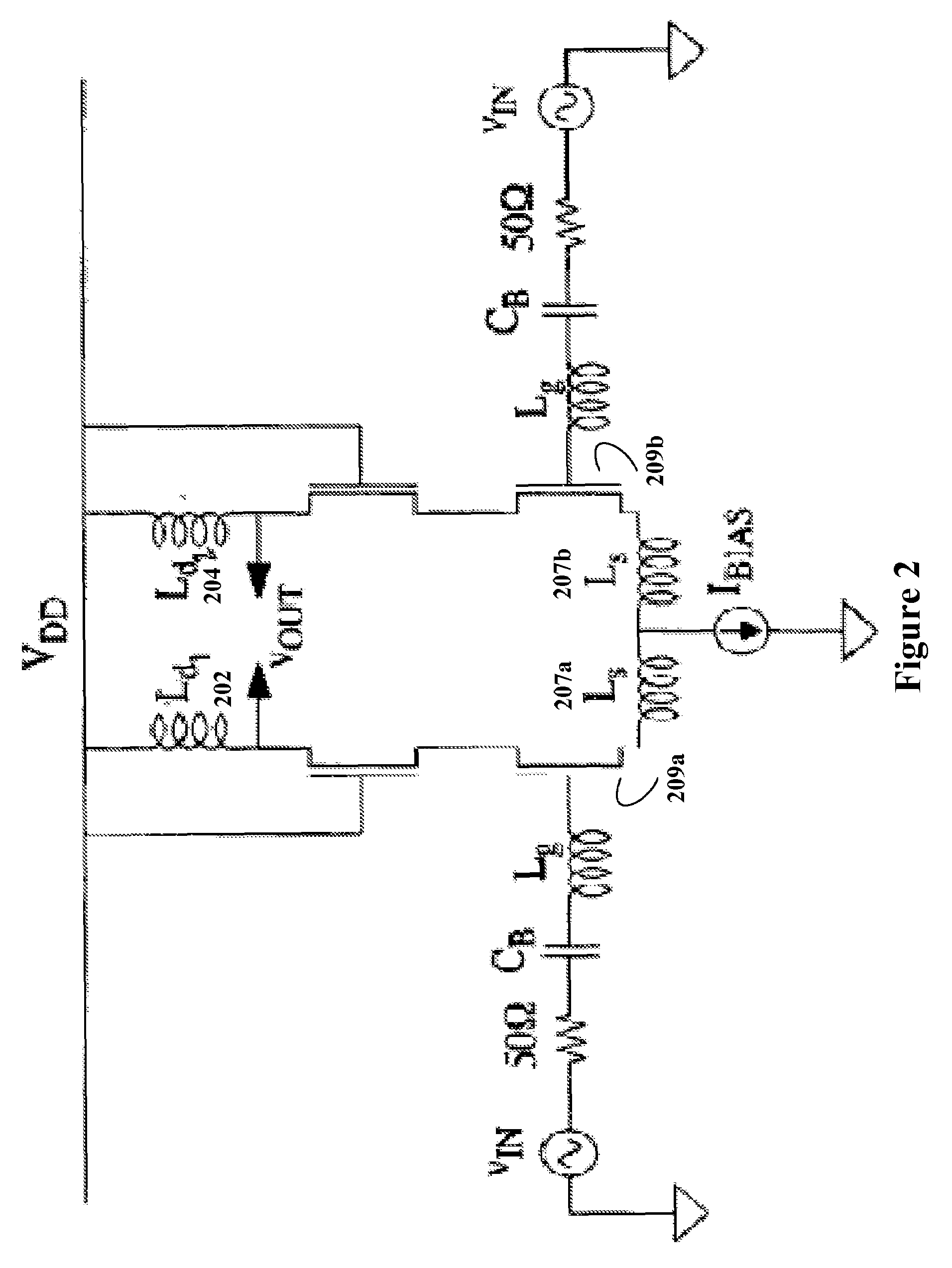

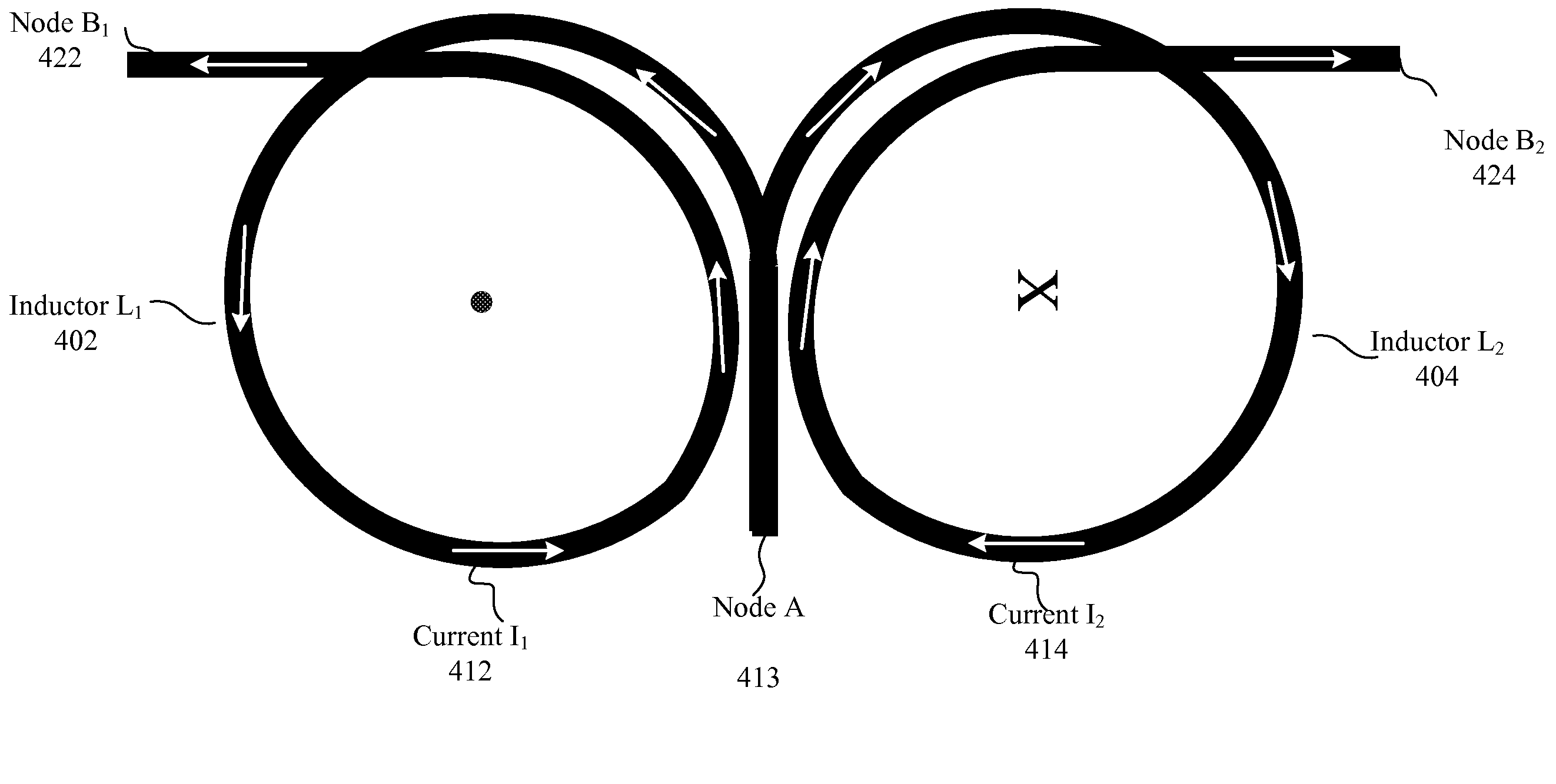

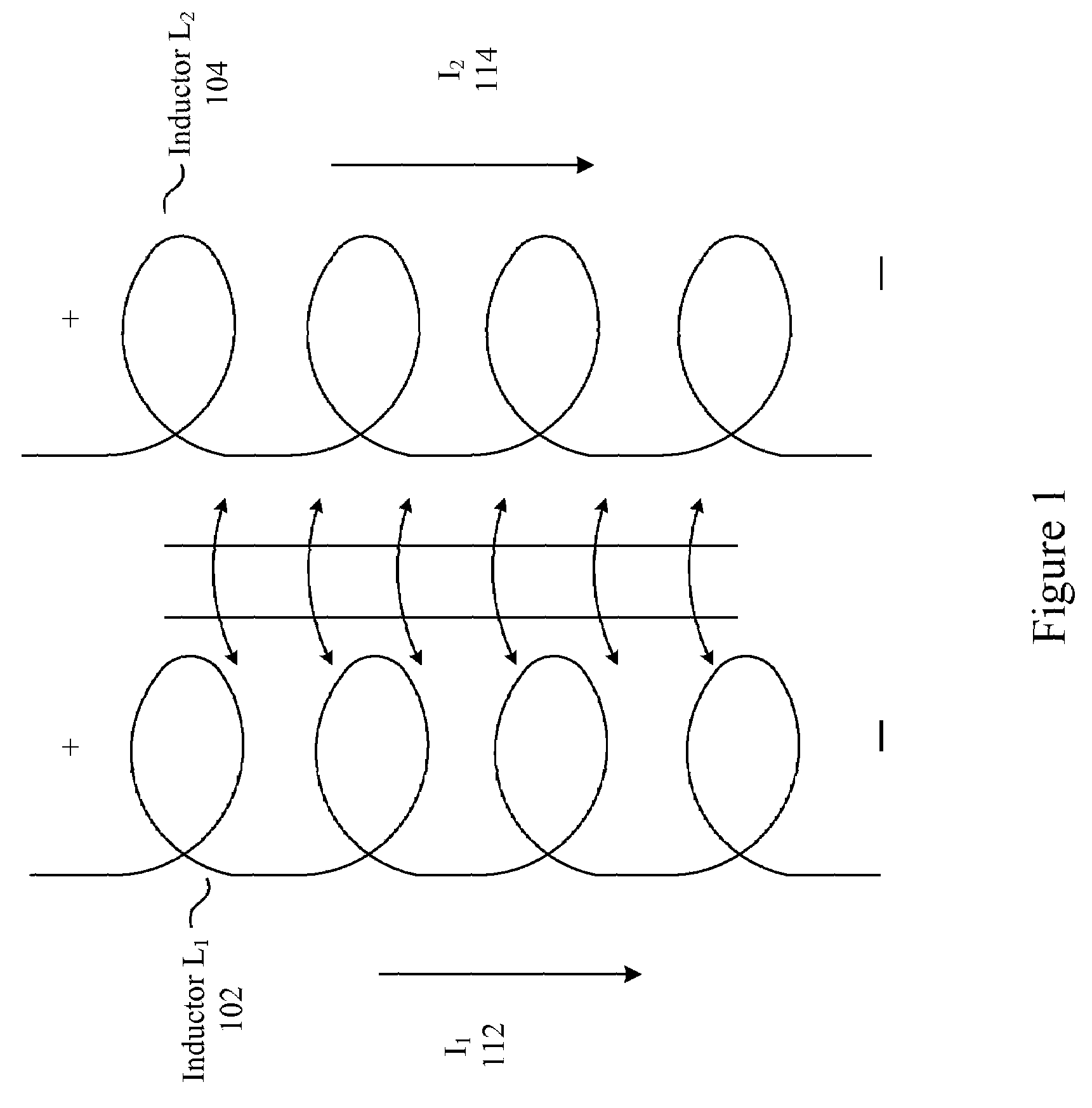

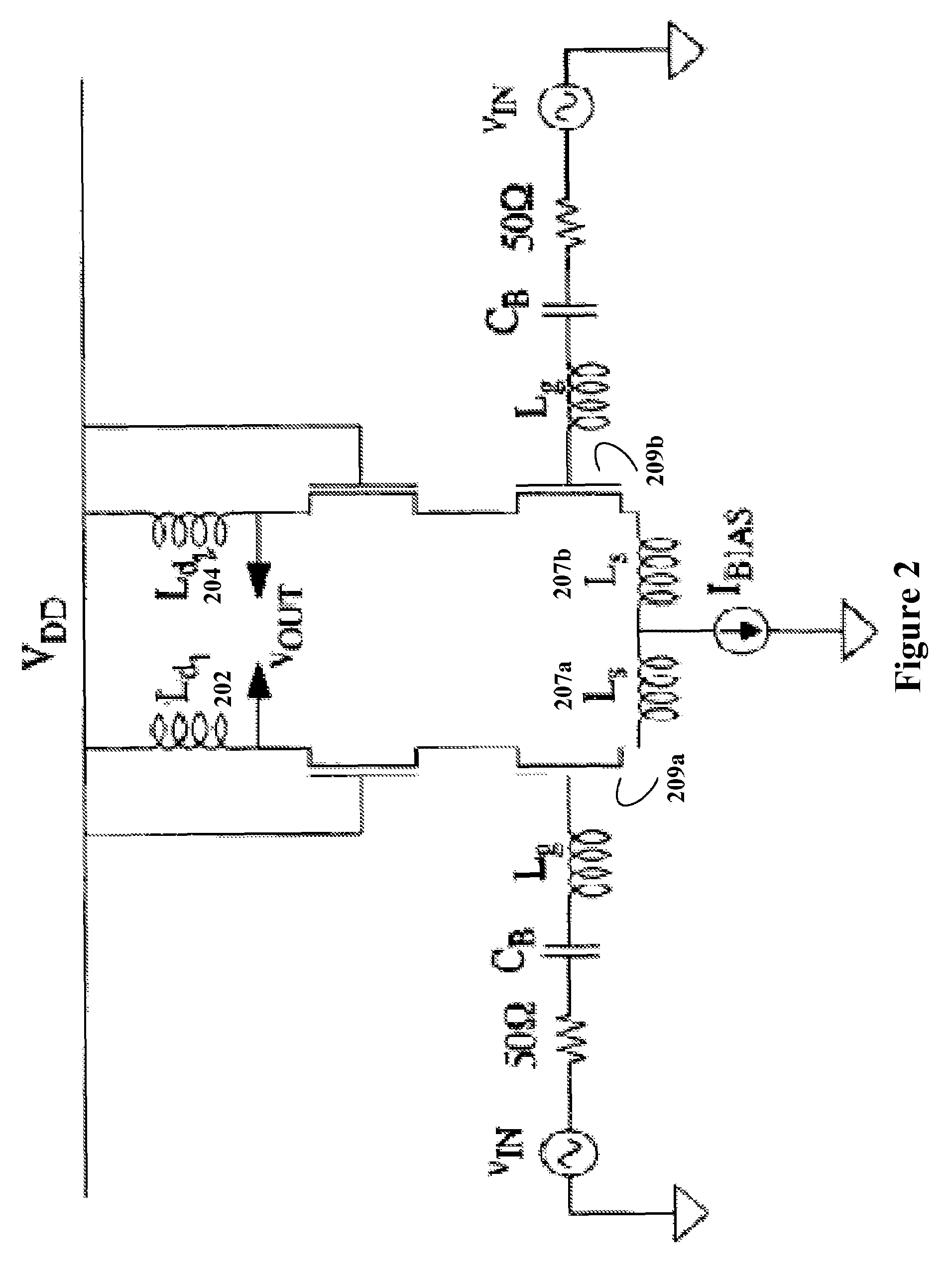

Low Mutual Inductance Matched Inductors

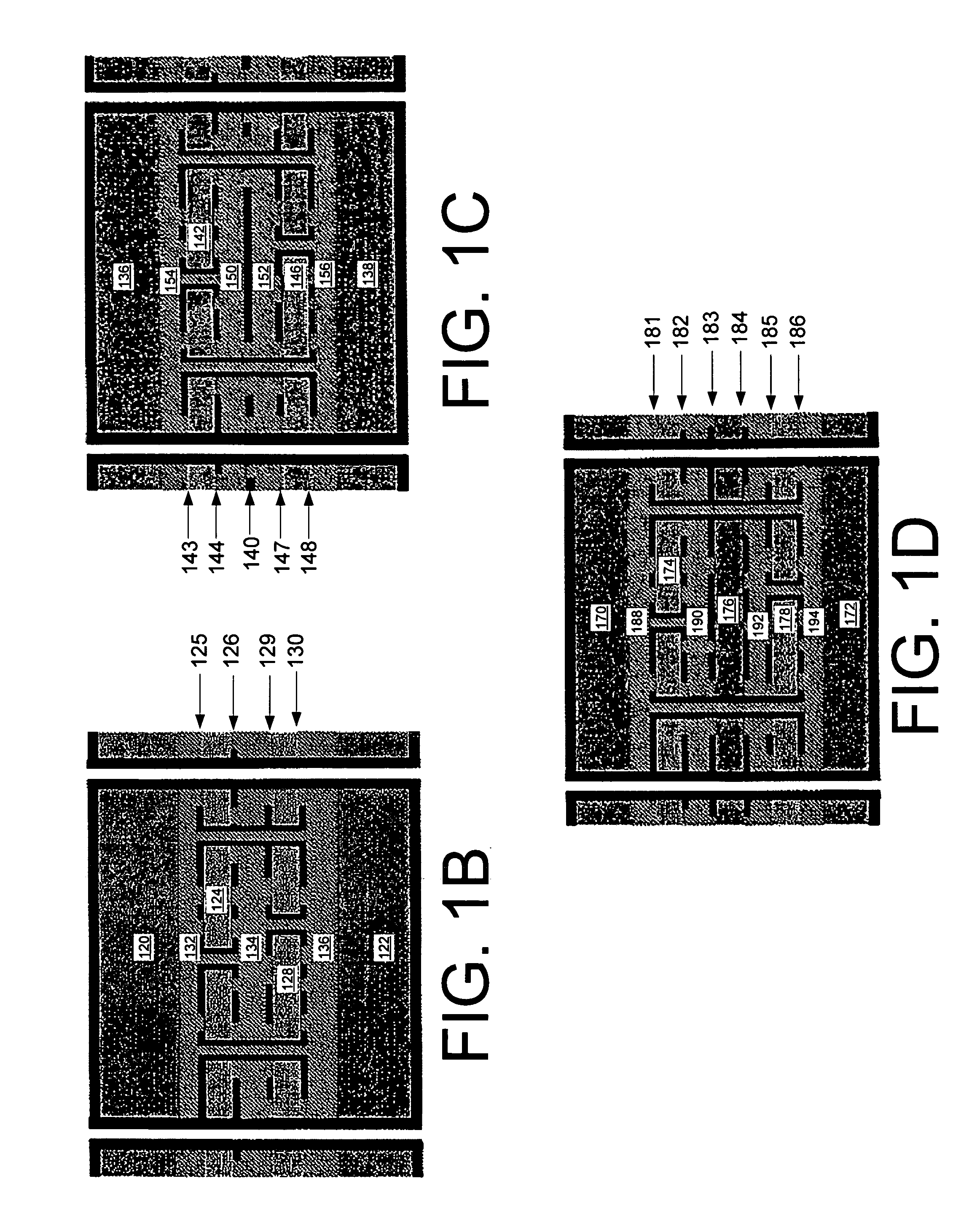

ActiveUS20080074228A1Minimize crosstalkOverall chip geometry may be reducedTransformers/inductances detailsAmplifiers controlled by lightElectrical polarityEngineering

Multiple inductor structures and methods for providing low mutual inductance between the inductors are described. In various embodiments of the invention, the polarities of the inductors are positioned such that parasitic mutual inductance is reduced by causing electro-magnetic fields to at least partially cancel resulting in a reduction in interference between the inductors. The polarities of the magnetic fields produced by each inductor are opposite to each other so that at least a partial cancellation results when the fields interfere with each other.

Owner:BELL SEMICON LLC

Connecting terminal for printed circuit boards

InactiveUS7993156B2Simple functional designSmall installation sizeCoupling contact membersContact members penetrating/cutting insulation/cable strandsSpring forceEngineering

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

Substrate with via and pad structures

ActiveUS20050173151A1Increase solder formationReduce formationPrinted circuit assemblingFinal product manufactureSolder maskElectrical and Electronics engineering

This invention relates to a substrate with via and pad structure(s) to reduce solder wicking. Each via and pad structure connects a component to conductive layers associated with the substrate. The substrate includes one or more plated vias, solder mask(s) surrounding the plated vias, and a conductive pad with a conductive trace connected to each plated via. The conductive pad extends beyond the terminal sides to increase solder formation and the solder mask reduces solder formation at the terminal end of the component. The via and pad structure is suitable for a variety of components and high component density. The invention also provides a computer implemented method for calculating the maximum distance of a conductive pad extending beyond the terminal side of a component.

Owner:BRIGHT MASCH INC +1

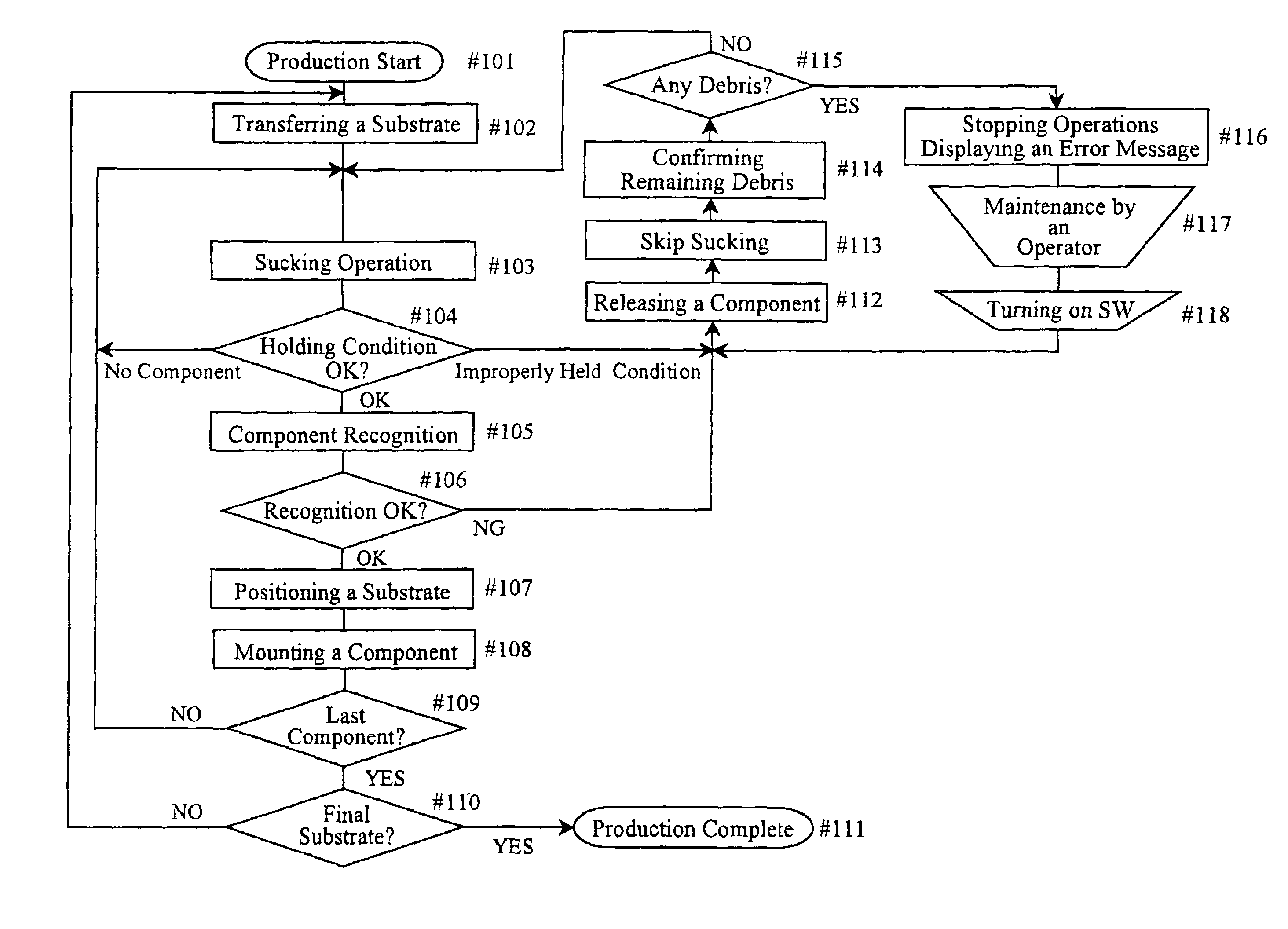

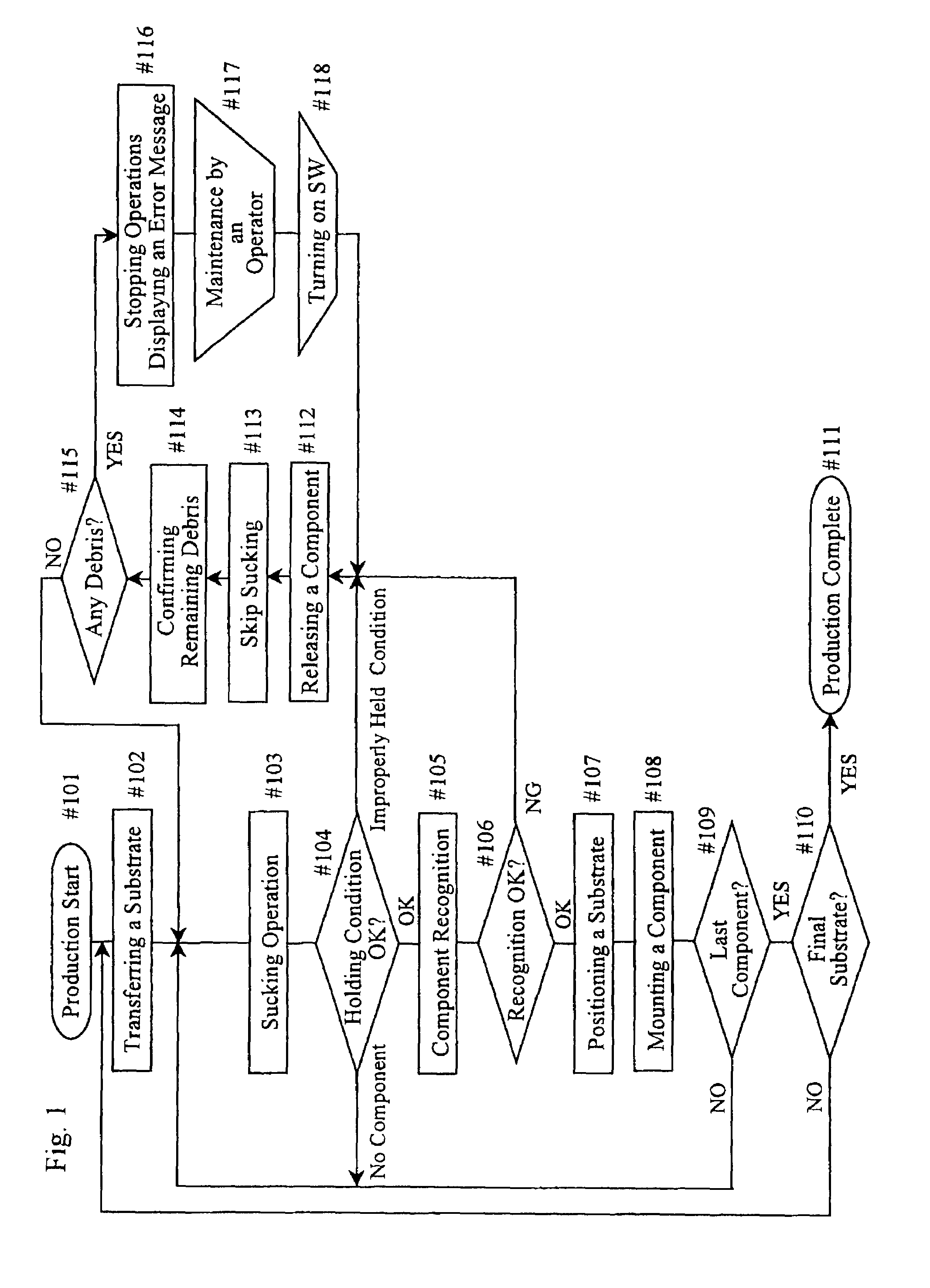

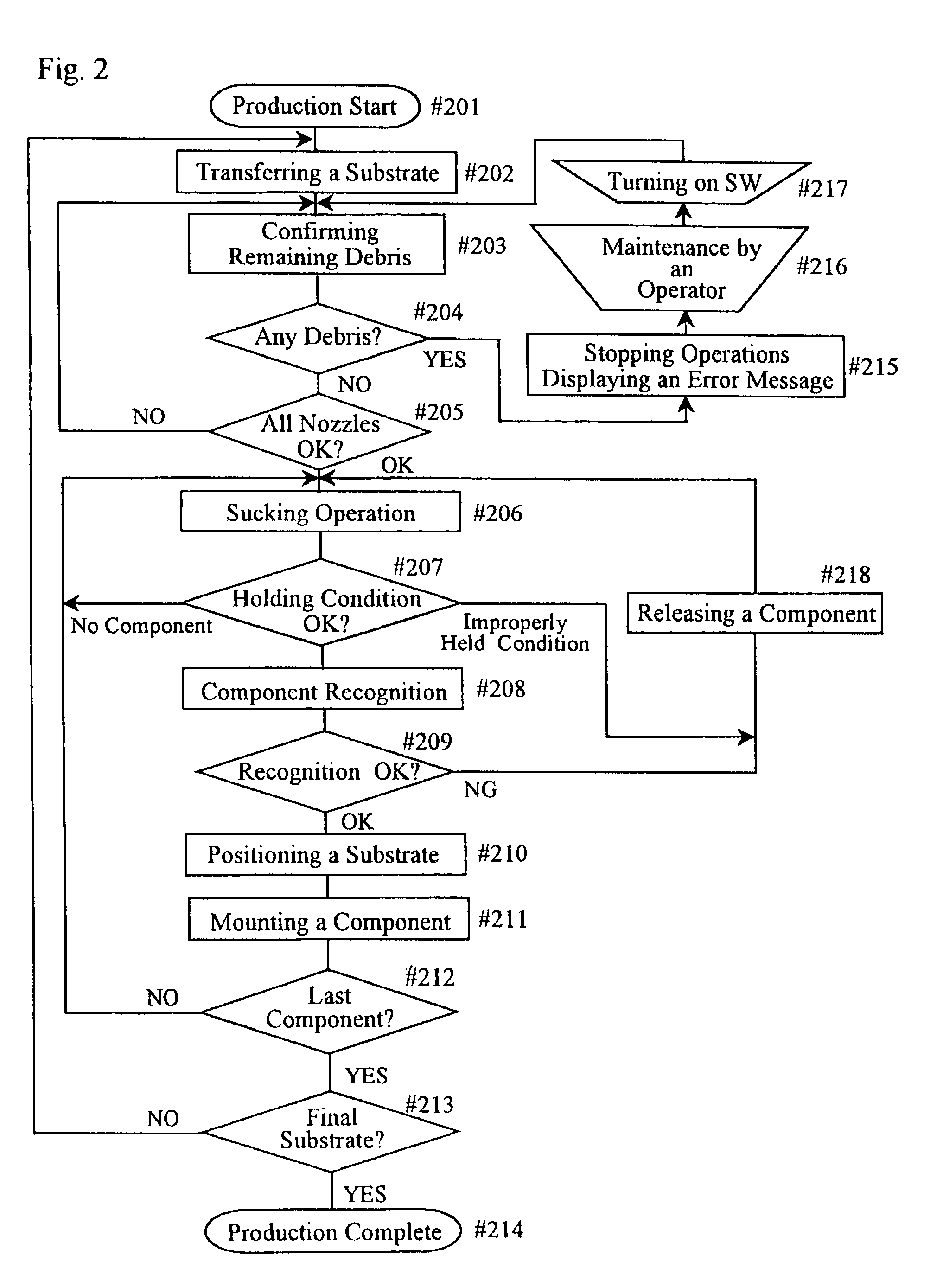

Method for component mounting

InactiveUS7065864B2Avoid negative effectsIncrease component densityPrinted circuit assemblingAutomatic control devicesReliability engineering

There are provided a method and apparatus of component mounting capable of avoiding damage caused by production operations with a component holder having debris thereon. If it is determined during a detecting step of a component holding condition that a component is held by a component holder in an improper condition for mounting, the component holder releases such a component into a collecting box, and skips a pick up operation at a next round of a pick up station. The component holder is then subjected to confirming whether any debris exists by using, preferably, a condition sensor, and the component holder picks up a new component if it is confirmed that no debris exists. If debris is found during the confirming step, production operations are stopped, or a warning is generated. After maintenance of the component holder is completed, production operations are restarted.

Owner:PANASONIC CORP

Method for manufacturing hearing aids, and a hearing aid

InactiveUS7174028B1Improve compactnessIncrease component densityElectrical transducersHearing aids housingInjection mouldingHearing perception

Owner:SONOVA AG

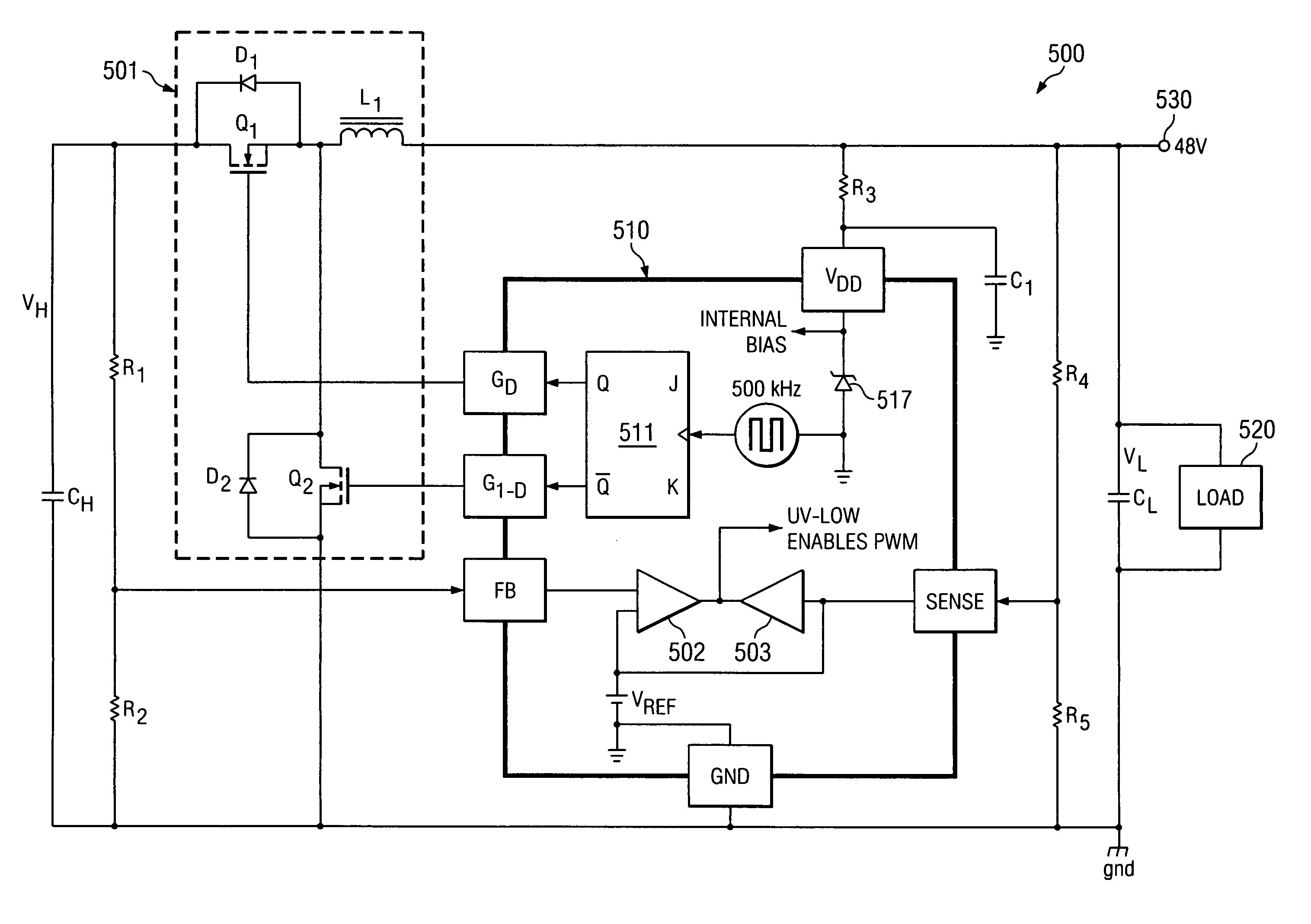

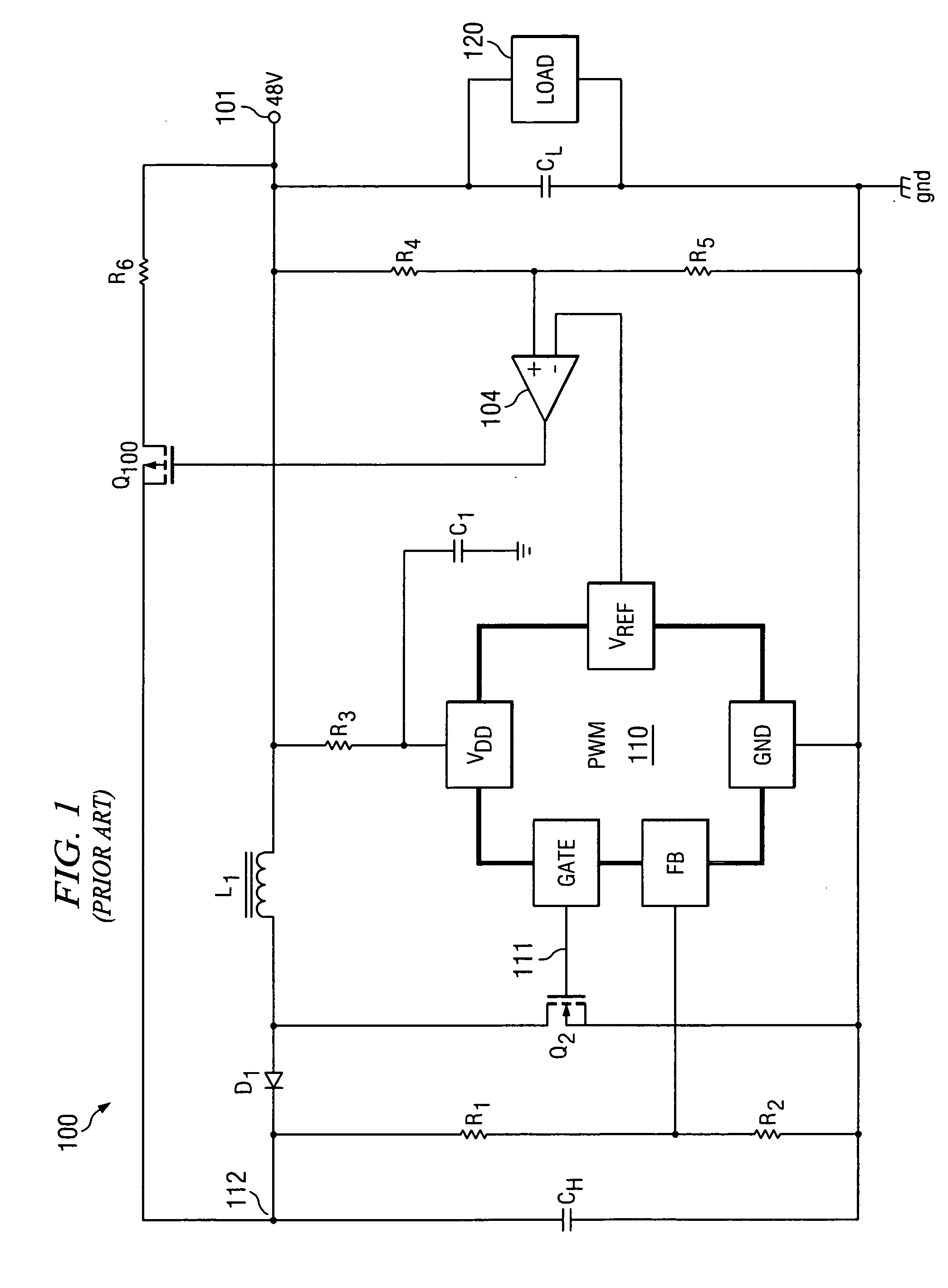

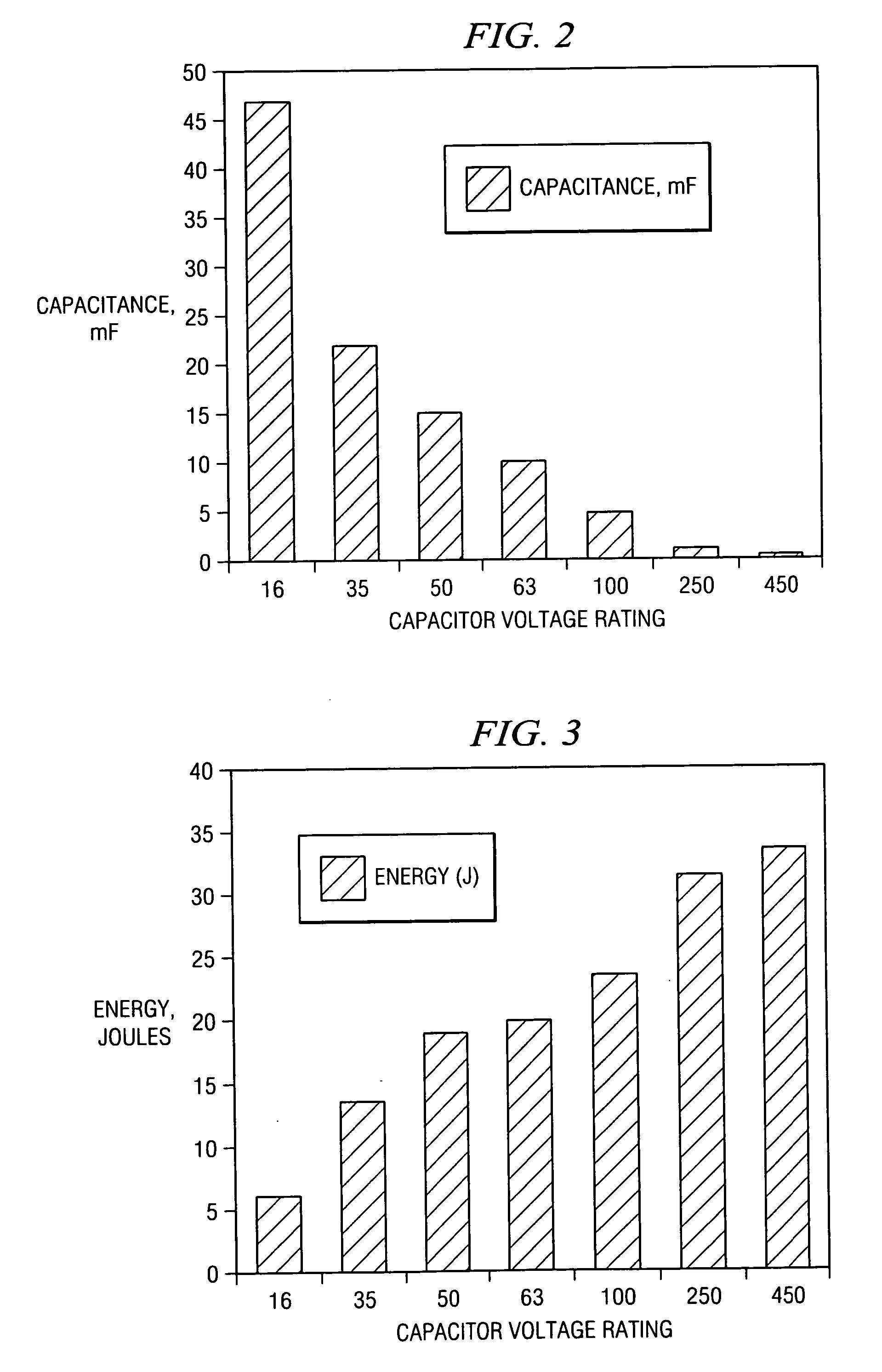

Holdover circuit for a power converter using a bi-directional switching regulator

ActiveUS20050281057A1Increase component densityReduce manufacturing costDc network circuit arrangementsBatteries circuit arrangementsVoltage regulationCharge and discharge

A holdover circuit is configured with a holdover capacitor, preferably an aluminum electrolytic capacitor, to provide uninterruptible operation for an electrical load operable over a limited range of input voltage during brief power interruptions. The holdover circuit includes a switching regulator configured with two active switches that are controlled with complementary duty cycles to charge and discharge the holdover capacitor at a voltage higher than the voltage of the load. The controller for the switching regulator may be configured to regulate the voltage of the holdover capacitor at a voltage proportional to the load voltage or at a constant voltage. The controller for the switching regulator is configured to operate in different modes during normal powered operation and during holdover.

Owner:TEXAS INSTR INC

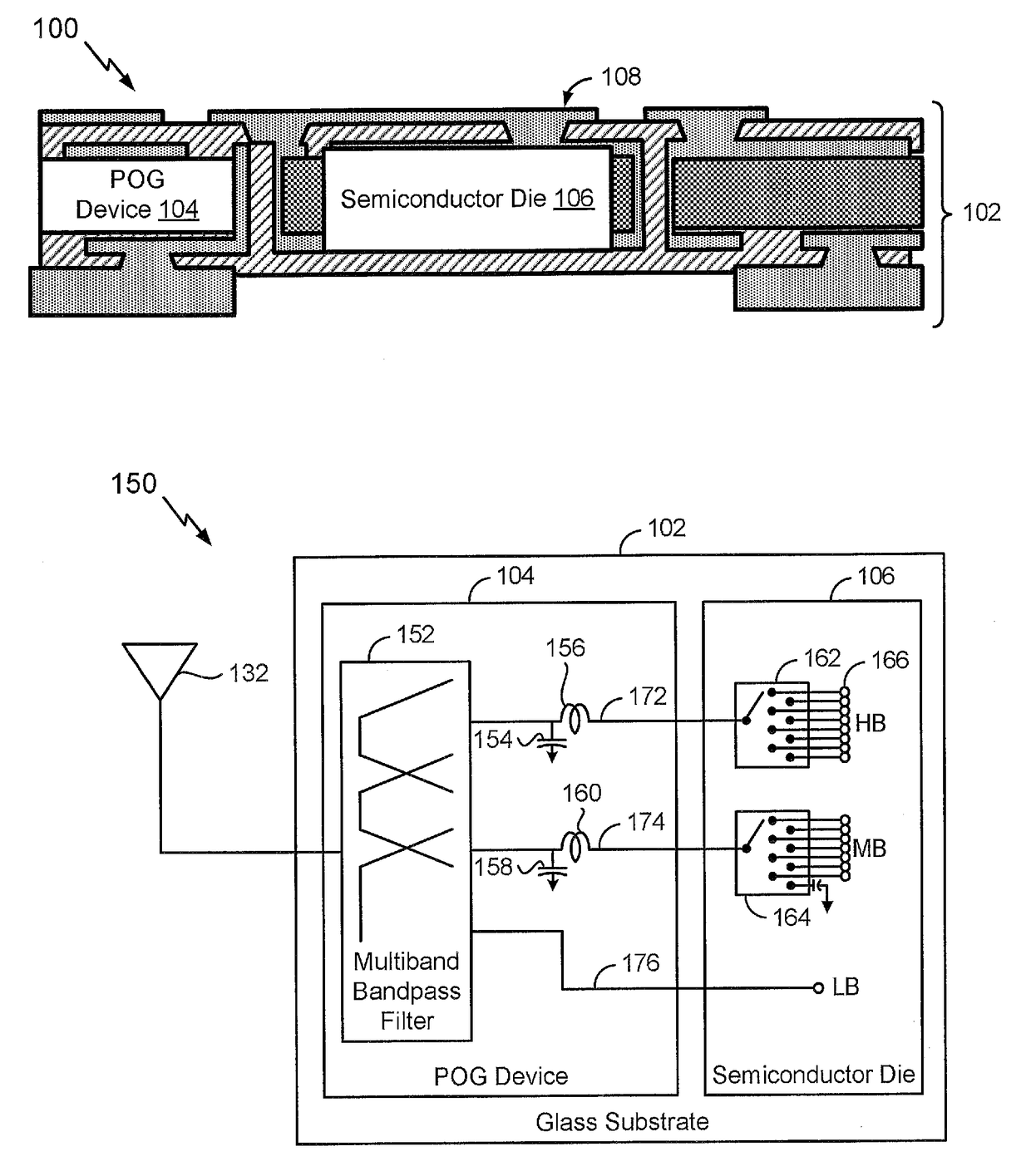

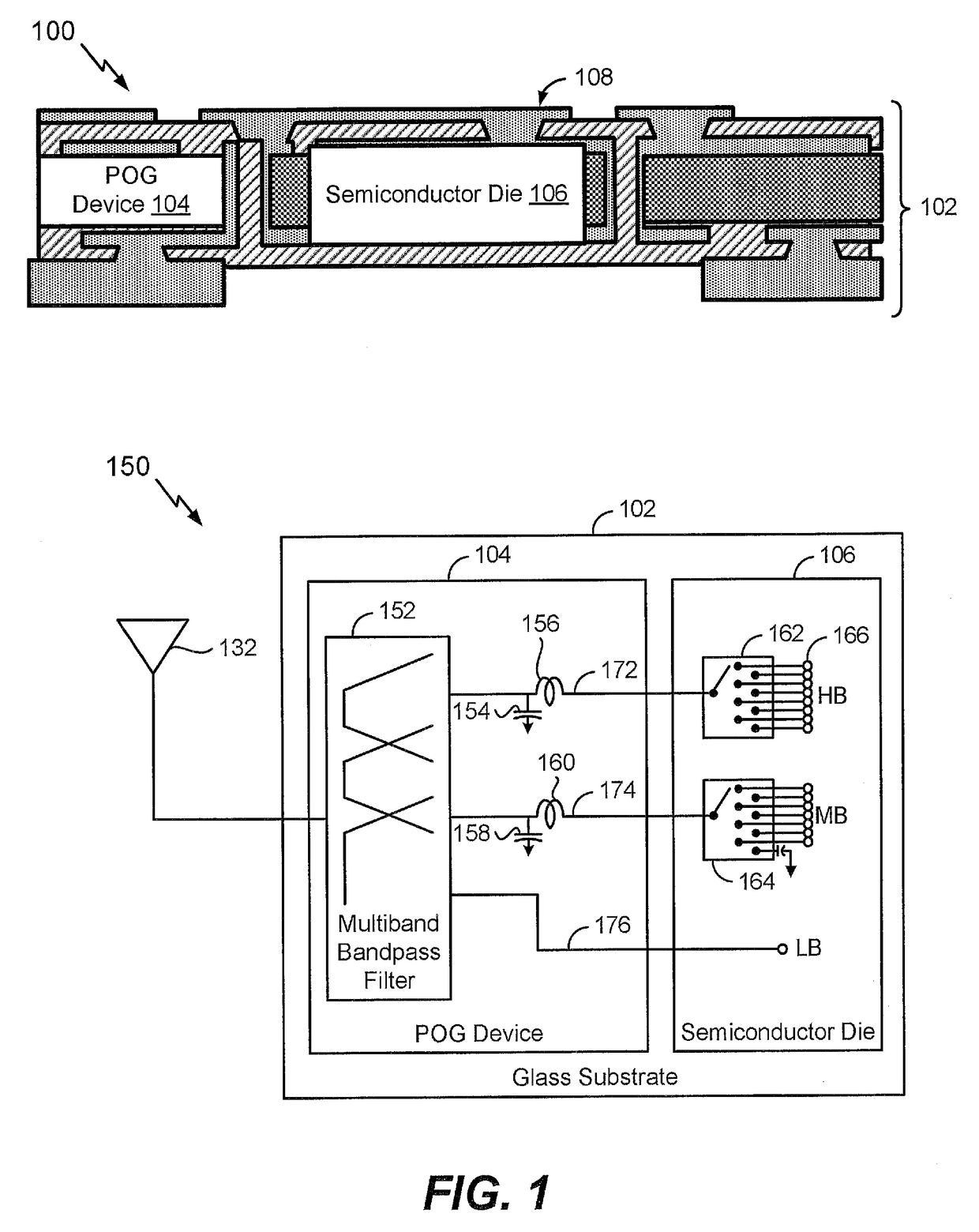

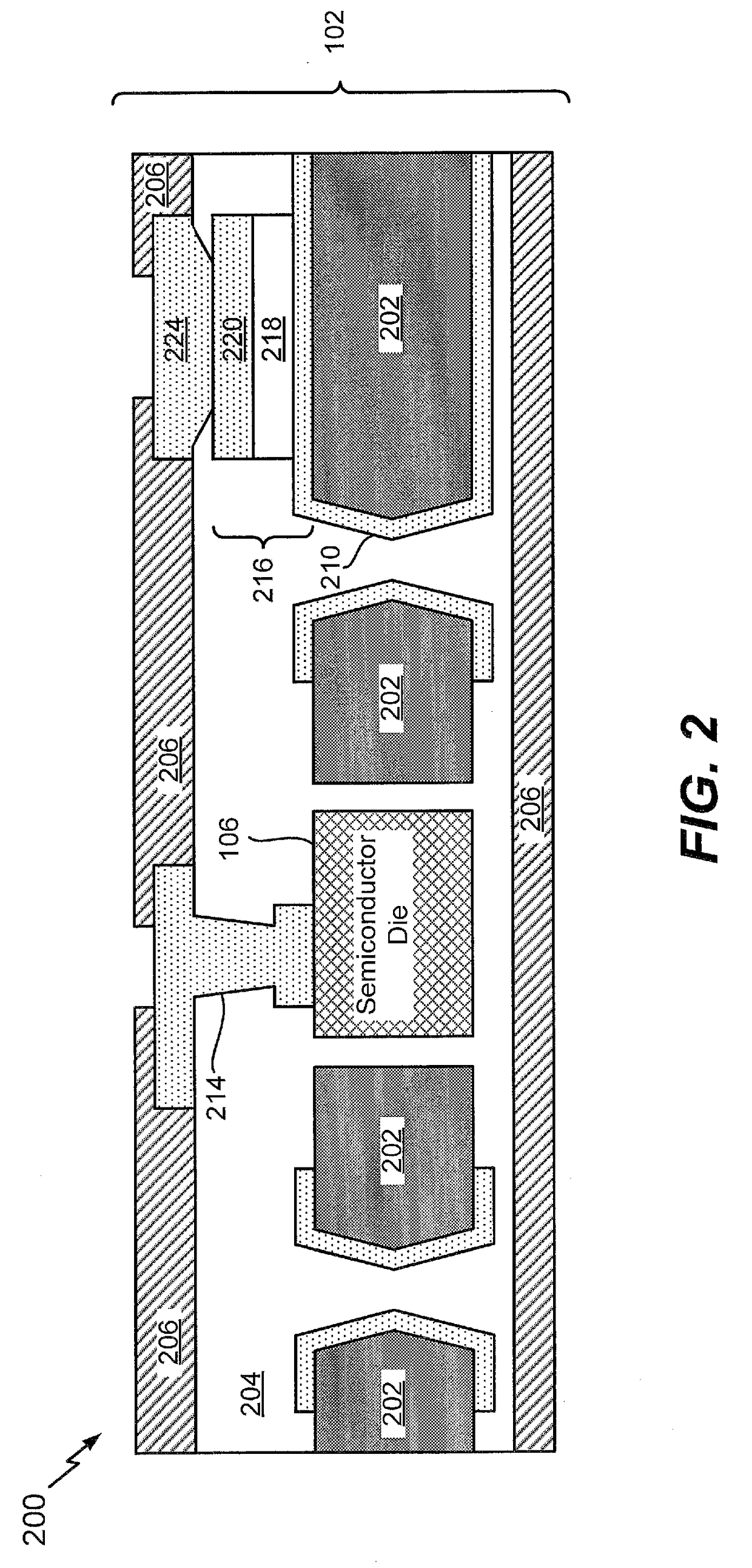

Glass substrate including passive-on-glass device and semiconductor die

ActiveUS20180026666A1Reduce device thicknessCircuitry attached to the surface of the glass substrate may be reduced or eliminatedMultiple-port networksSemiconductor/solid-state device detailsEngineeringSemiconductor

In an illustrative example, an apparatus includes a passive-on-glass (POG) device integrated within a glass substrate. The apparatus further includes a semiconductor die integrated within the glass substrate.

Owner:QUALCOMM INC

Low mutual inductance matched inductors

ActiveUS7535330B2Minimize crosstalkOverall chip geometry may be reducedTransformers/inductances detailsAmplifiers controlled by lightElectrical polarityEngineering

Multiple inductor structures and methods for providing low mutual inductance between the inductors are described. In various embodiments of the invention, the polarities of the inductors are positioned such that parasitic mutual inductance is reduced by causing electro-magnetic fields to at least partially cancel resulting in a reduction in interference between the inductors. The polarities of the magnetic fields produced by each inductor are opposite to each other so that at least a partial cancellation results when the fields interfere with each other.

Owner:BELL SEMICON LLC

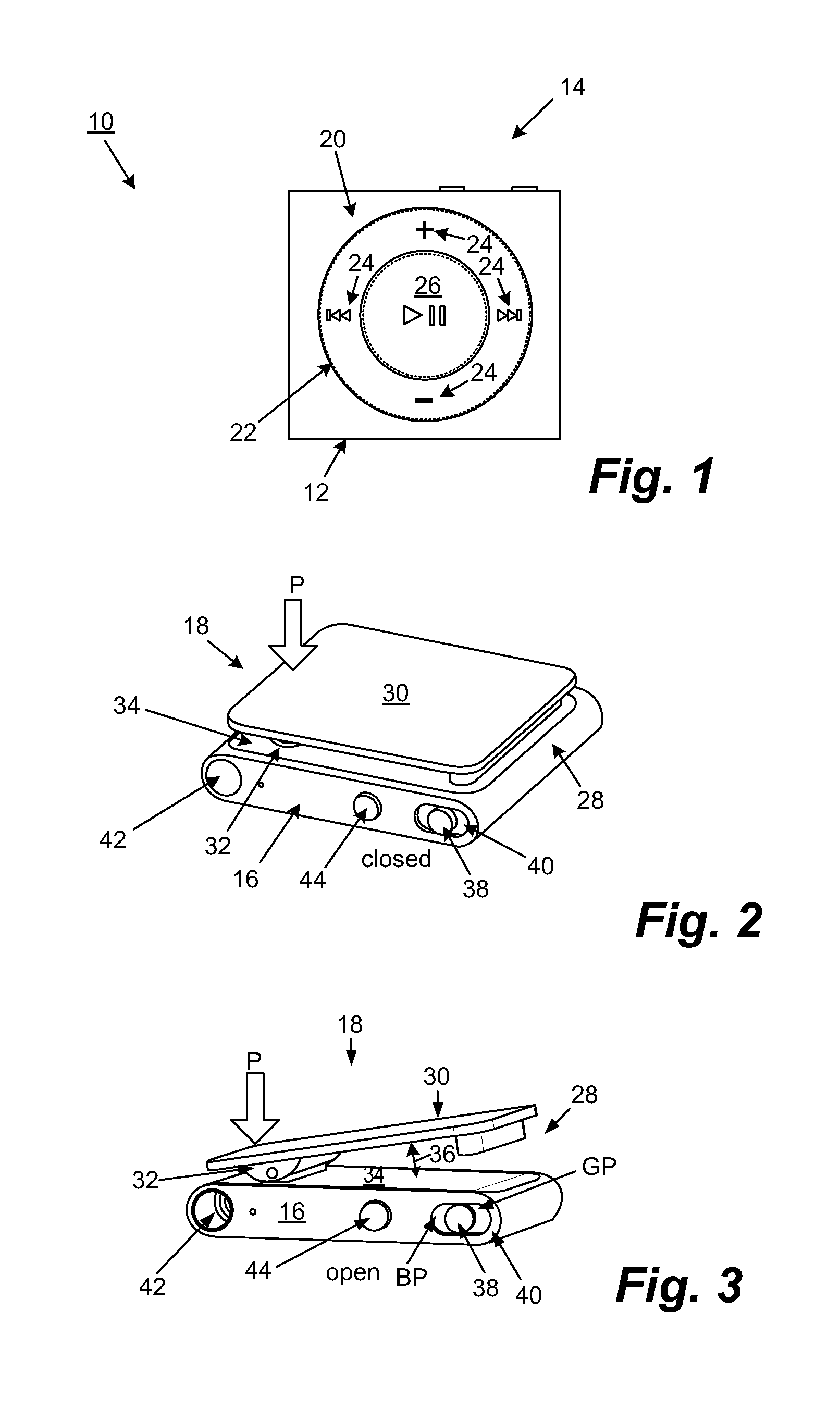

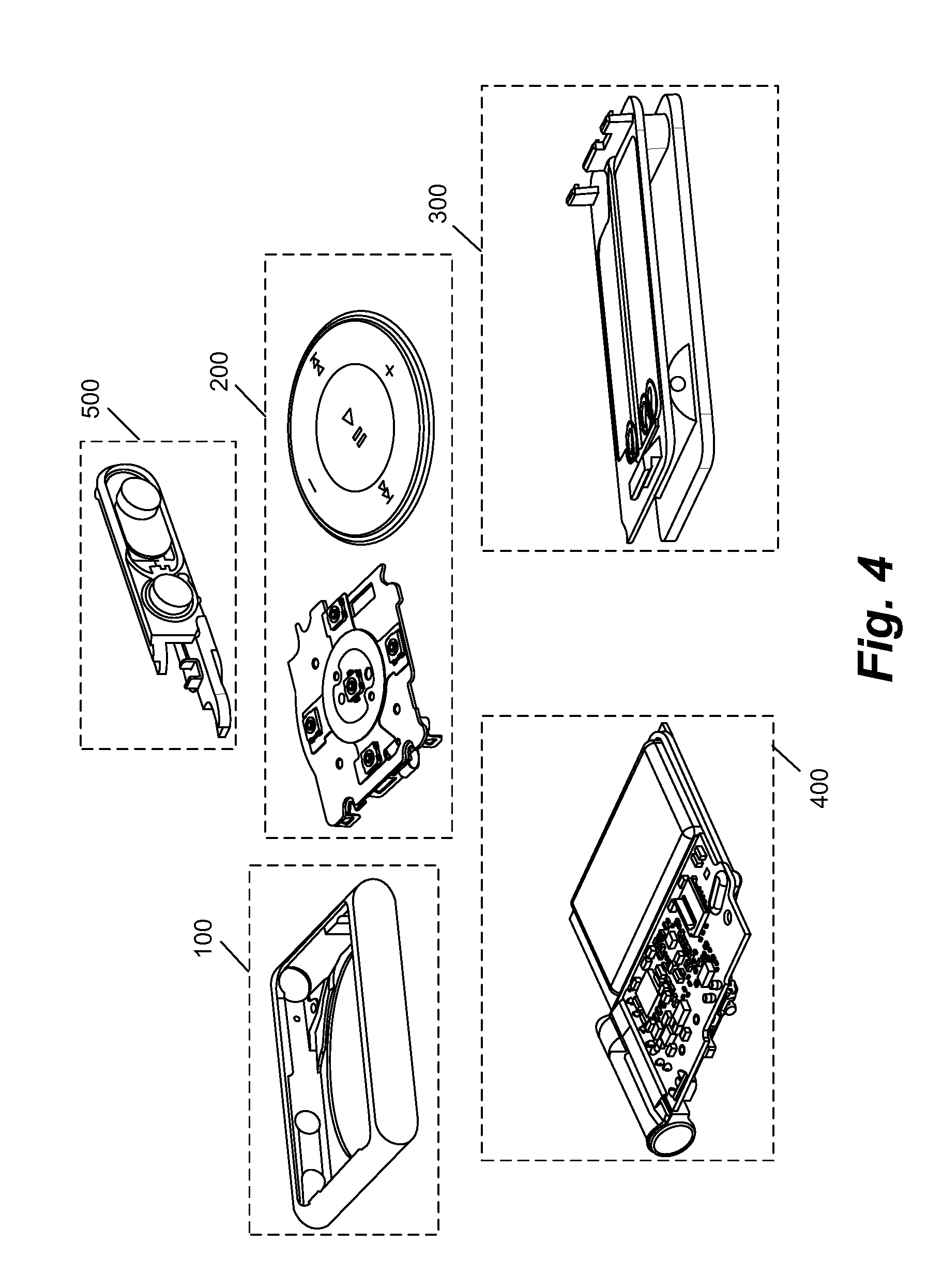

ESD protection in a very small form factor consumer electronic product

InactiveUS20120050938A1Increase component densitySmall sizePrinted circuit assemblingWave amplification devicesUser inputSmall form factor

A very small form factor consumer electronic product includes at least a single piece housing having an integral front and side walls that cooperate to form a cavity in cooperation with a front opening where an edge of the side walls define a rear opening and at least some of the edges have flanges. The consumer electronic product also includes an user input assembly having a size and shape in accordance with the front opening and a clip assembly having a size and shape in accordance with the rear opening and having an external user actionable clip, a plurality of internal hooking features, and a plurality of internal latching features. The clip assembly is secured by engaging at least some of the hooking features and the flanges on the edges of the housing and engaging the latching features and corresponding attachment features on the internal support plate.

Owner:APPLE INC

Electronic module and method for manufacturing an electronic module

InactiveUS20100170706A1High densityAdd supportPrinted circuit assemblingLine/current collector detailsElectronic componentElectronic modules

An electronic module includes a first substrate having at least one electronic component, and a housing embedded in the substrate and designed as an injection molded housing or a transfer molded housing, and which includes electrical leads protruding from the housing, connected to the first substrate and designed as a pressed screen. At least one further second substrate provided with second electrical is embedded in the housing, the second leads being designed as a second pressed screen, and the two pressed screens being directly connected to each other in at least one location.

Owner:ROBERT BOSCH GMBH

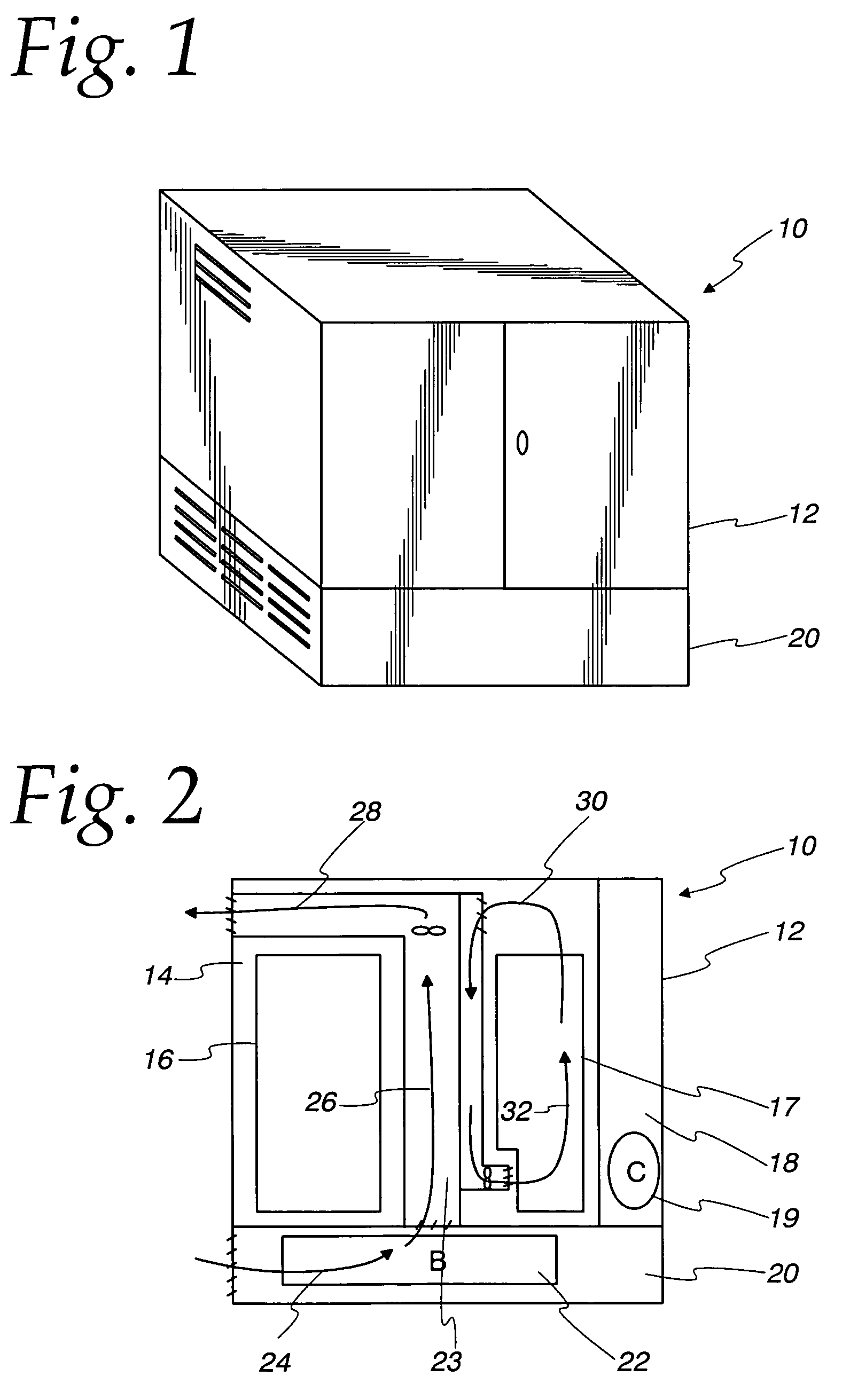

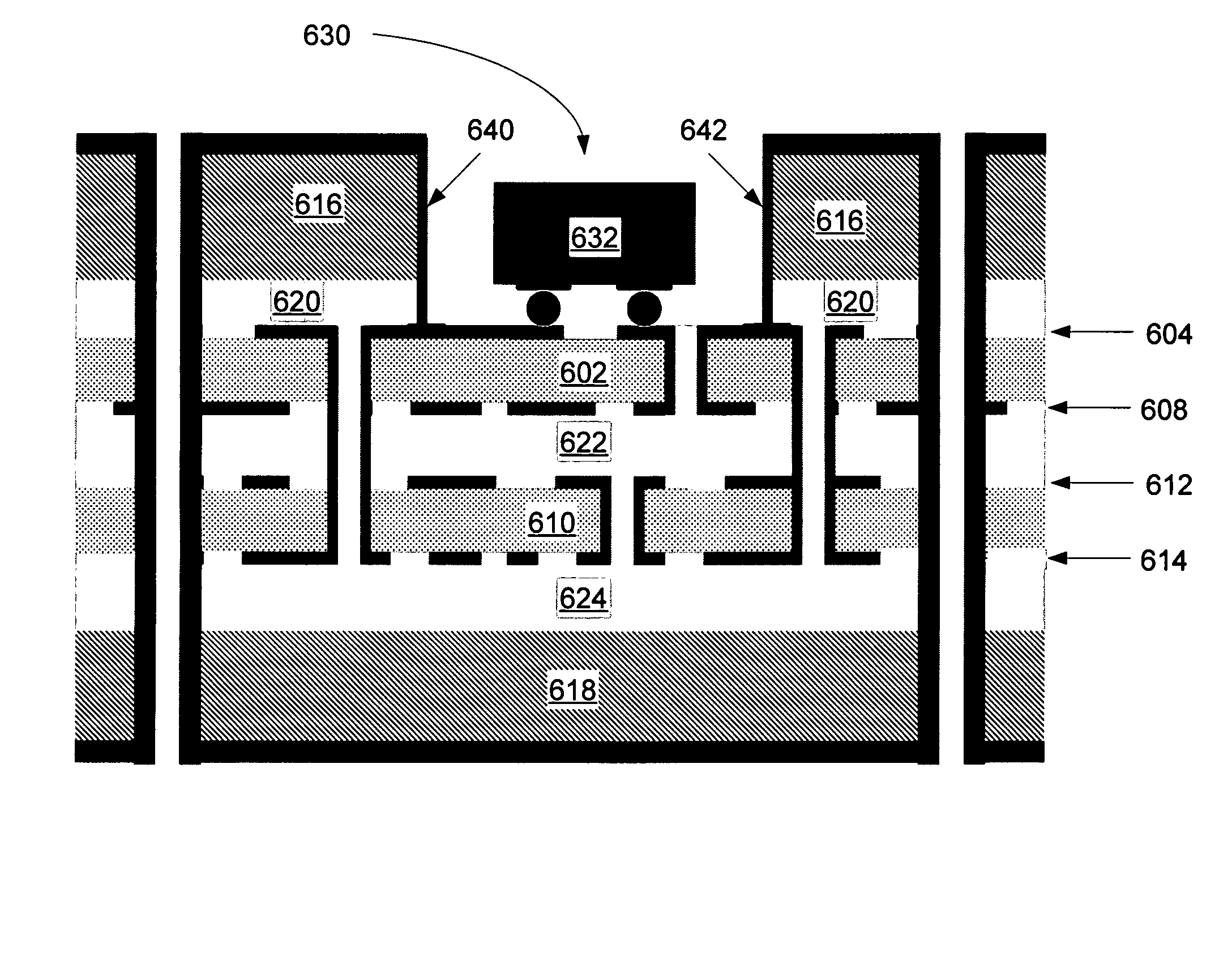

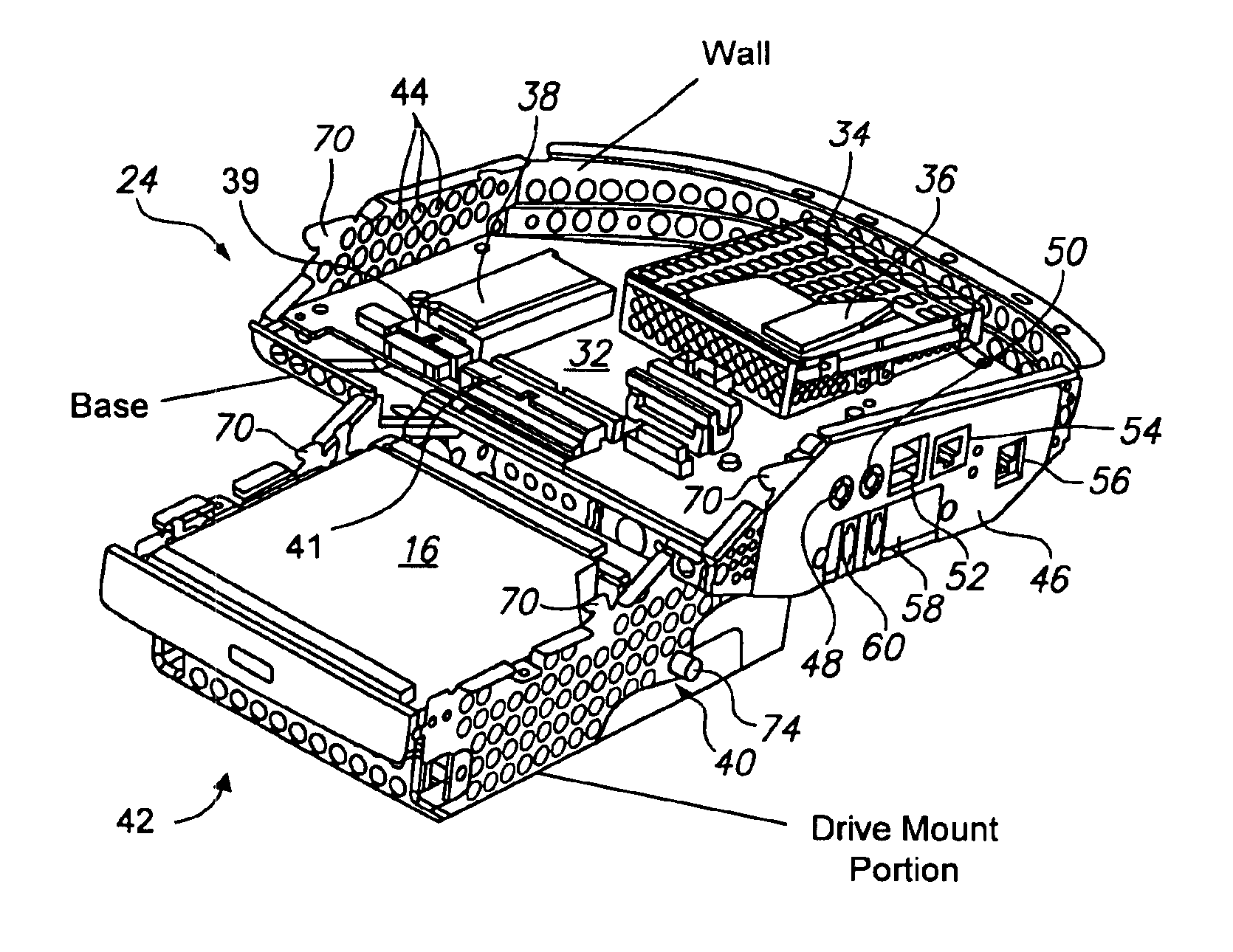

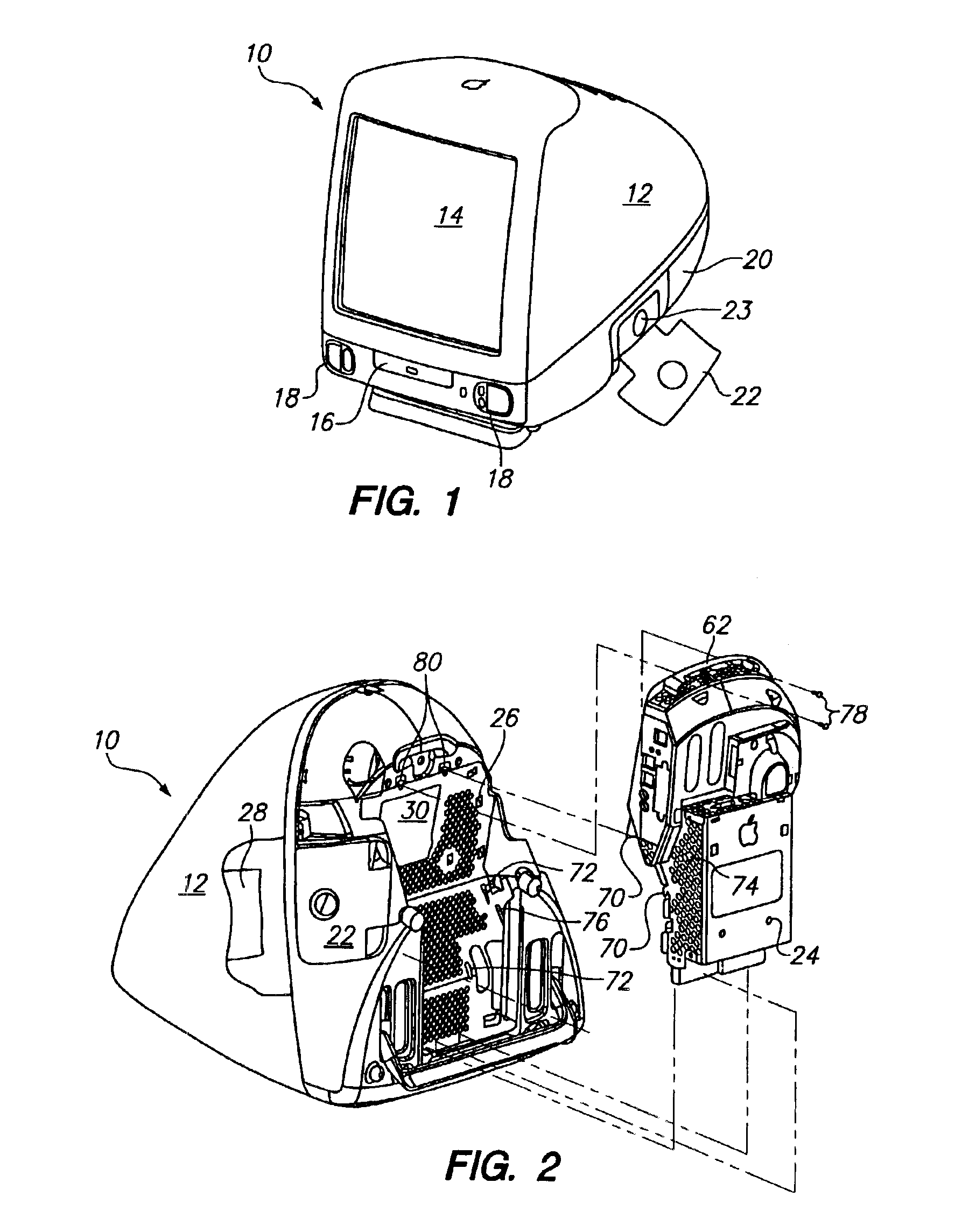

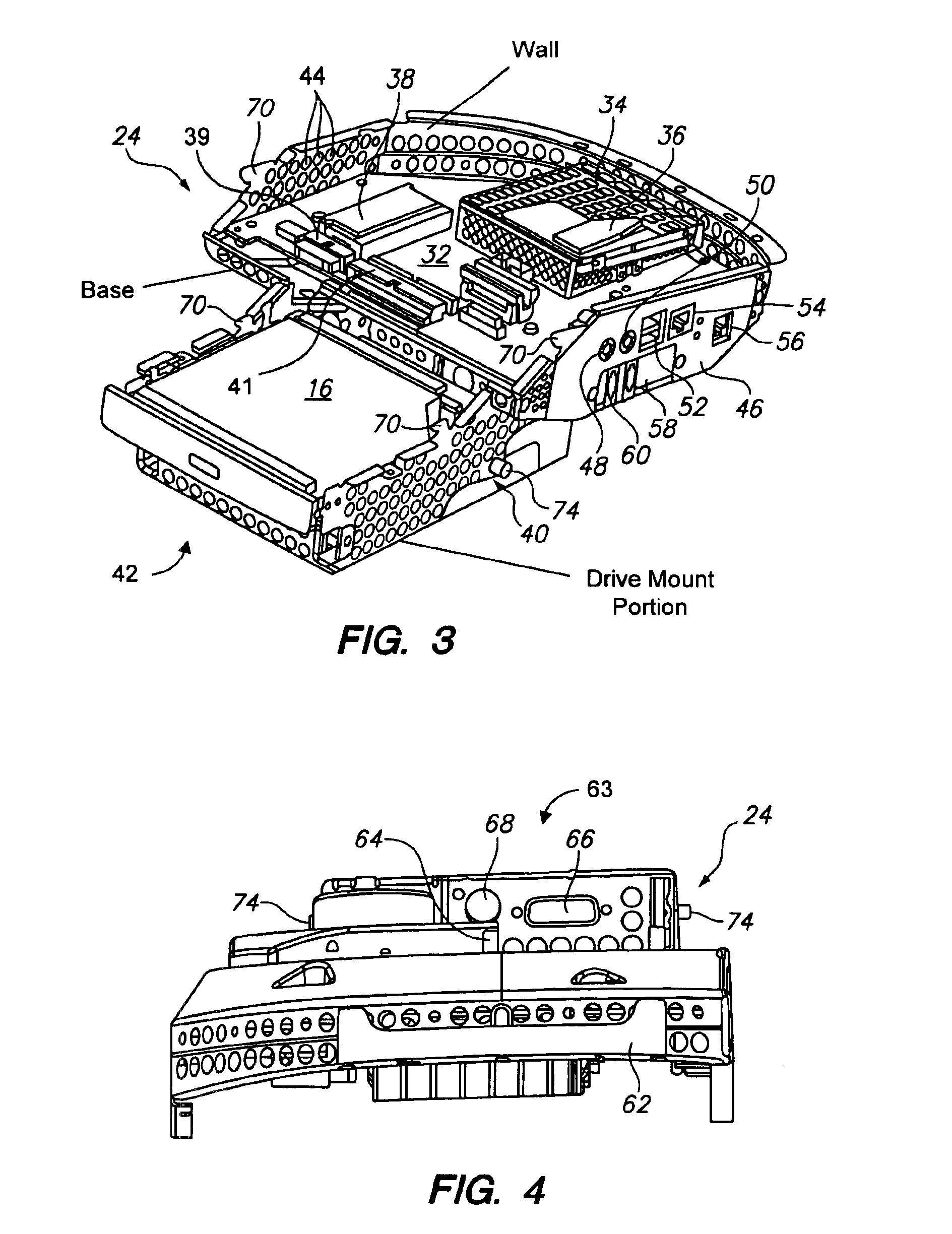

Modular logic board chassis for a desktop computer

InactiveUS6954353B2Increase component densityCompactTelevision system detailsColor television detailsData connectionComputer module

A computer (10) having a monitor housing (12) within which is affixed a logic module (24) having thereon a processor (36), a memory module (38), an internal power connector (39), a fixed disk drive (40), an internal data connector (41), and an external connector panel (46) all generally housed within a sheet metal housing (42) having therein a plurality of perforations (44) for allowing air from a fan assembly (30) to pass therethrough. A power supply (28) and monitor screen (14) are provided in the monitor housing (12) such that when the logic module (24) is mounted and electrically connected within the monitor housing (12) a generally complete computer (10) unit is provided. An auxiliary drive (16) is optionally provided and affixed to the logic module (24) such that the auxiliary drive (16) is externally accessible when the logic module (24) is affixed within the monitor housing (12).

Owner:APPLE INC

Coil component

ActiveUS8362866B2High volume resistivityIncrease component densityTransportation and packagingMetal-working apparatusHelical coilMaterials science

A coil component is of the type where a helical coil is directly contacting a magnetic body, which is still capable of meeting the demand for electrical current amplification. A coil component, comprising a magnetic body mainly constituted by magnetic alloy grains, and a coil formed on the magnetic body; wherein an oxide film of the magnetic alloy grains is present on the surface of each of the magnetic alloy grains, and based on grain size by volume standard, the magnetic alloy grains have a d50 in a range of 3.0 to 20.0 μm, d10 / d50 in a range of 0.1 to 0.7, and d90 / d50 in a range of 1.4 to 5.0.

Owner:TAIYO YUDEN KK

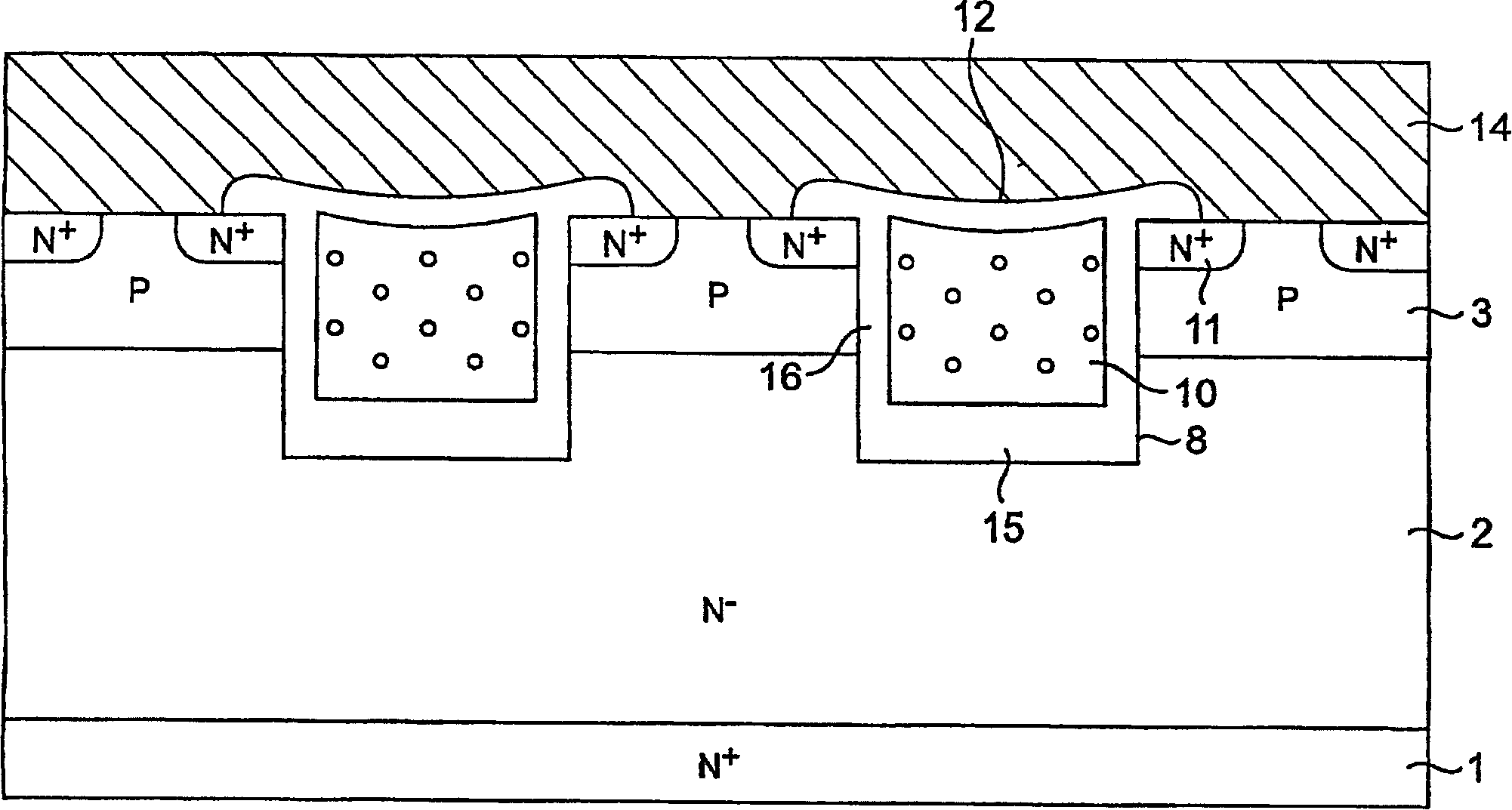

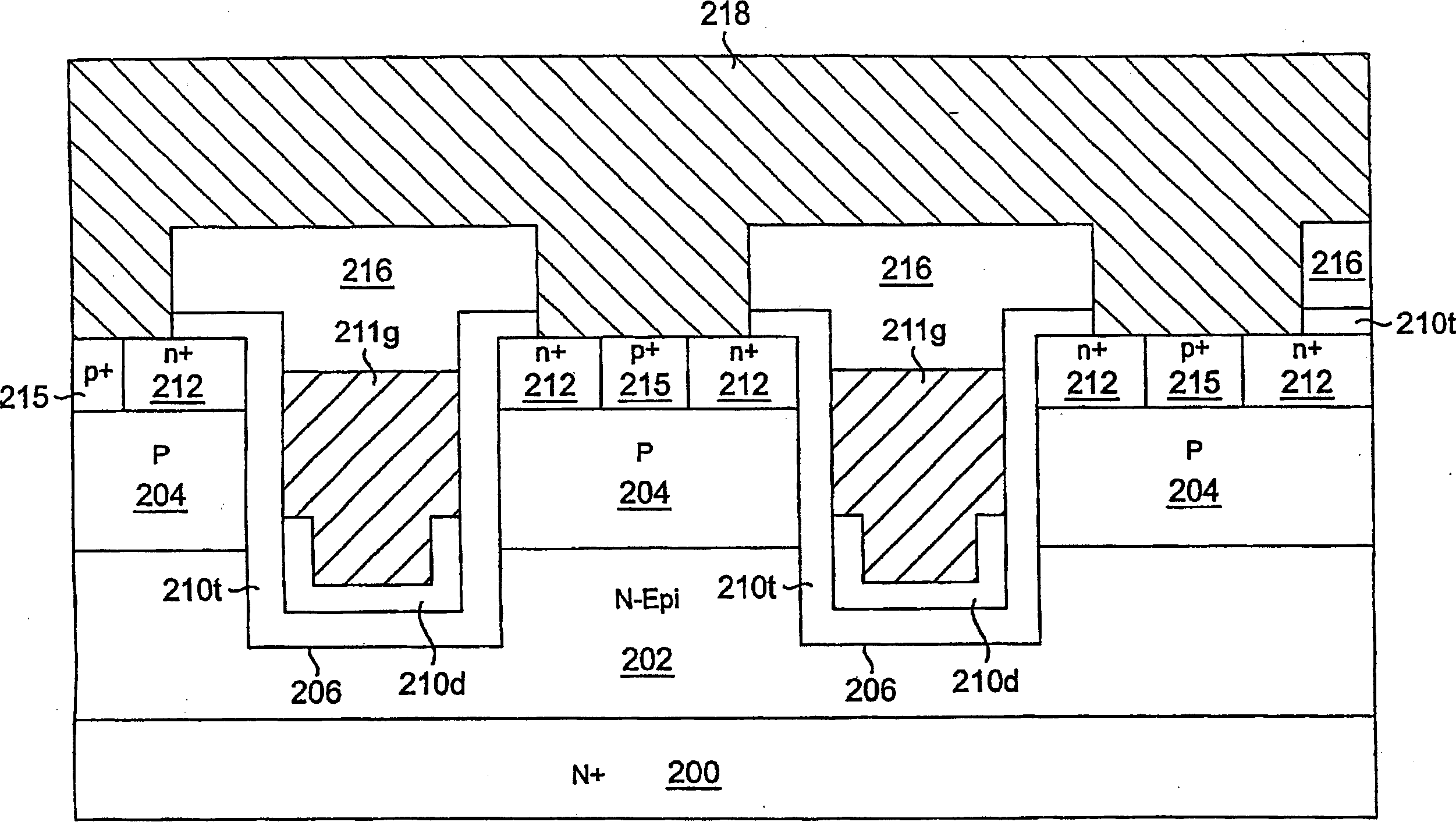

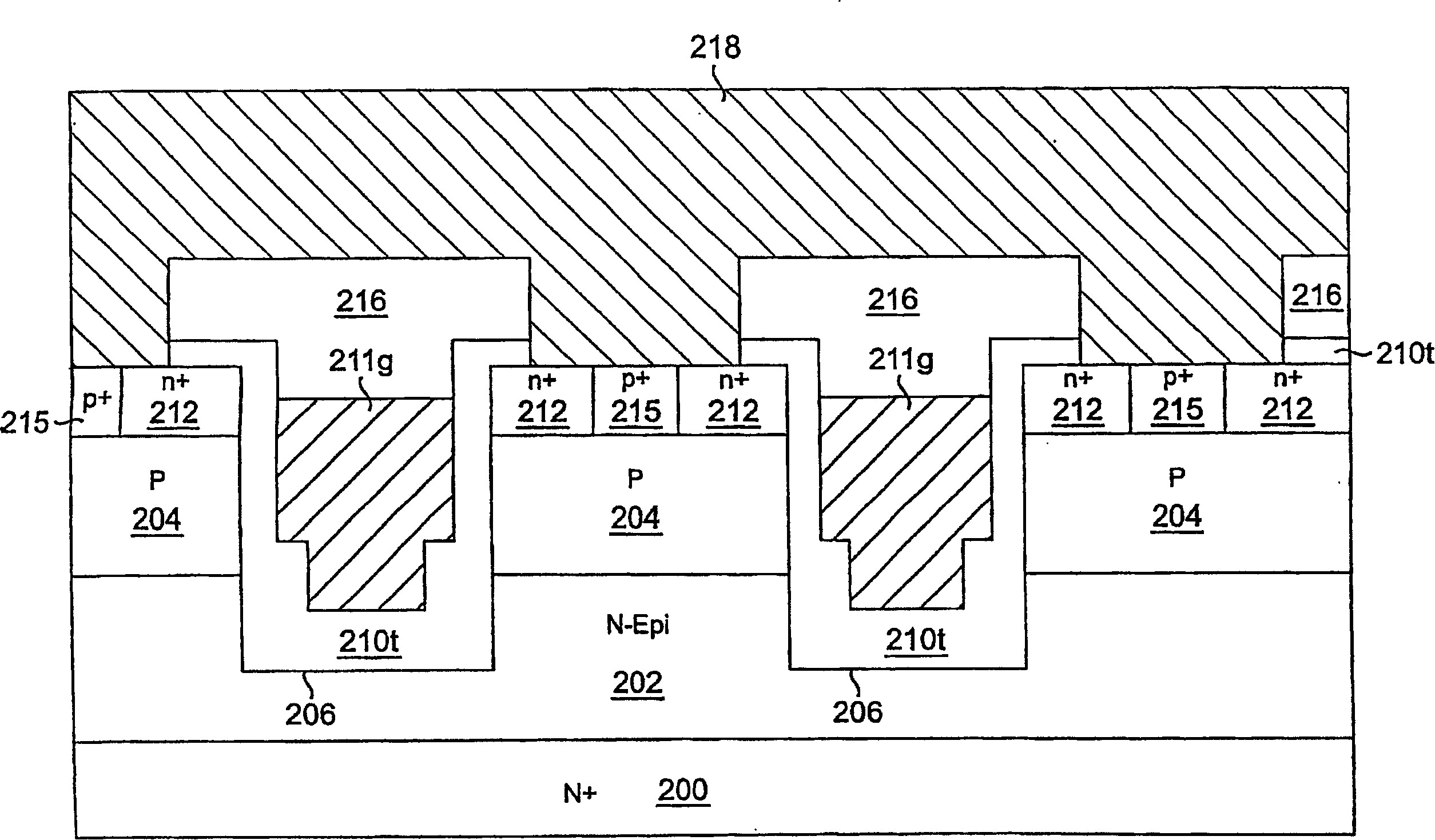

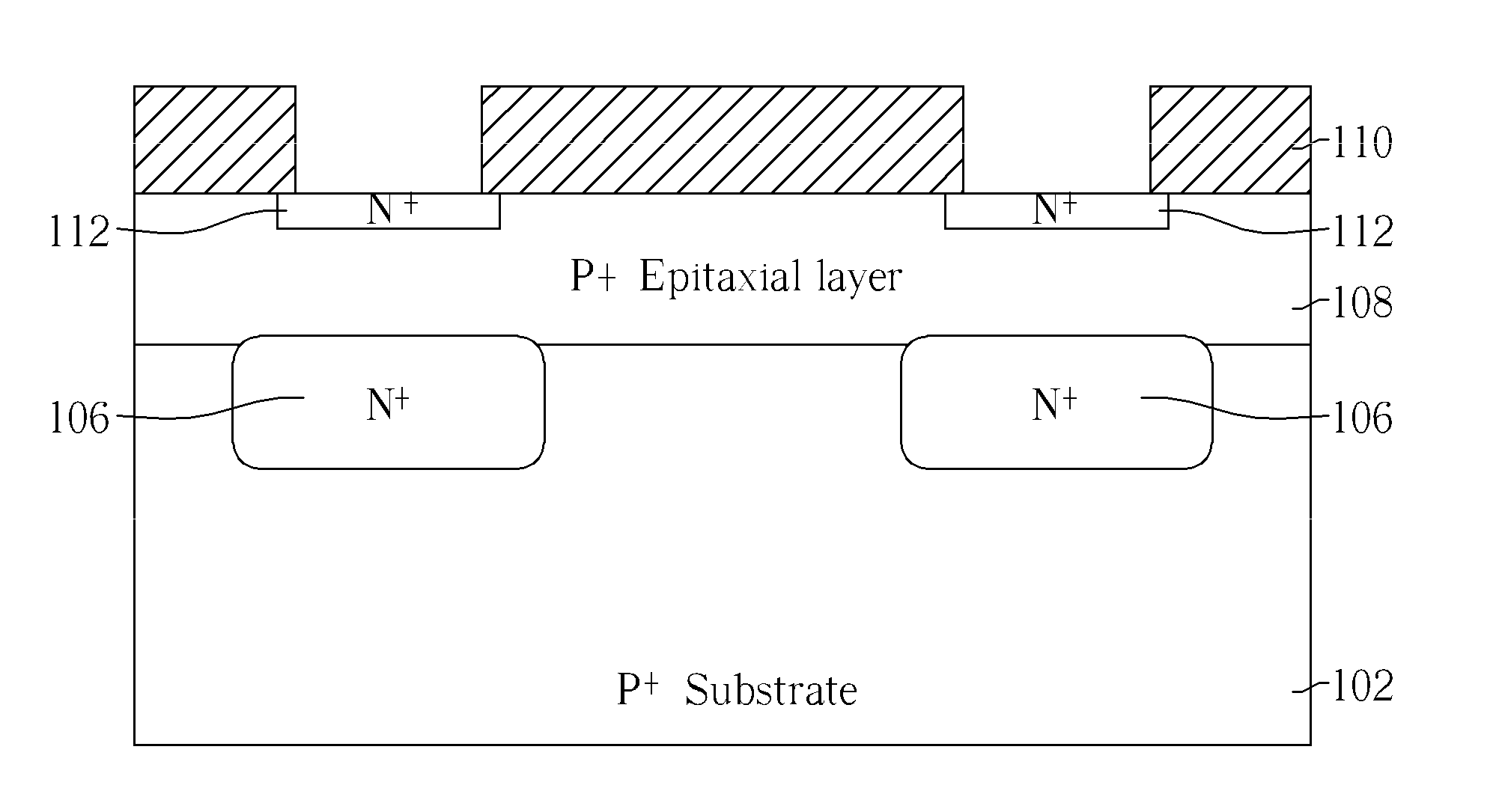

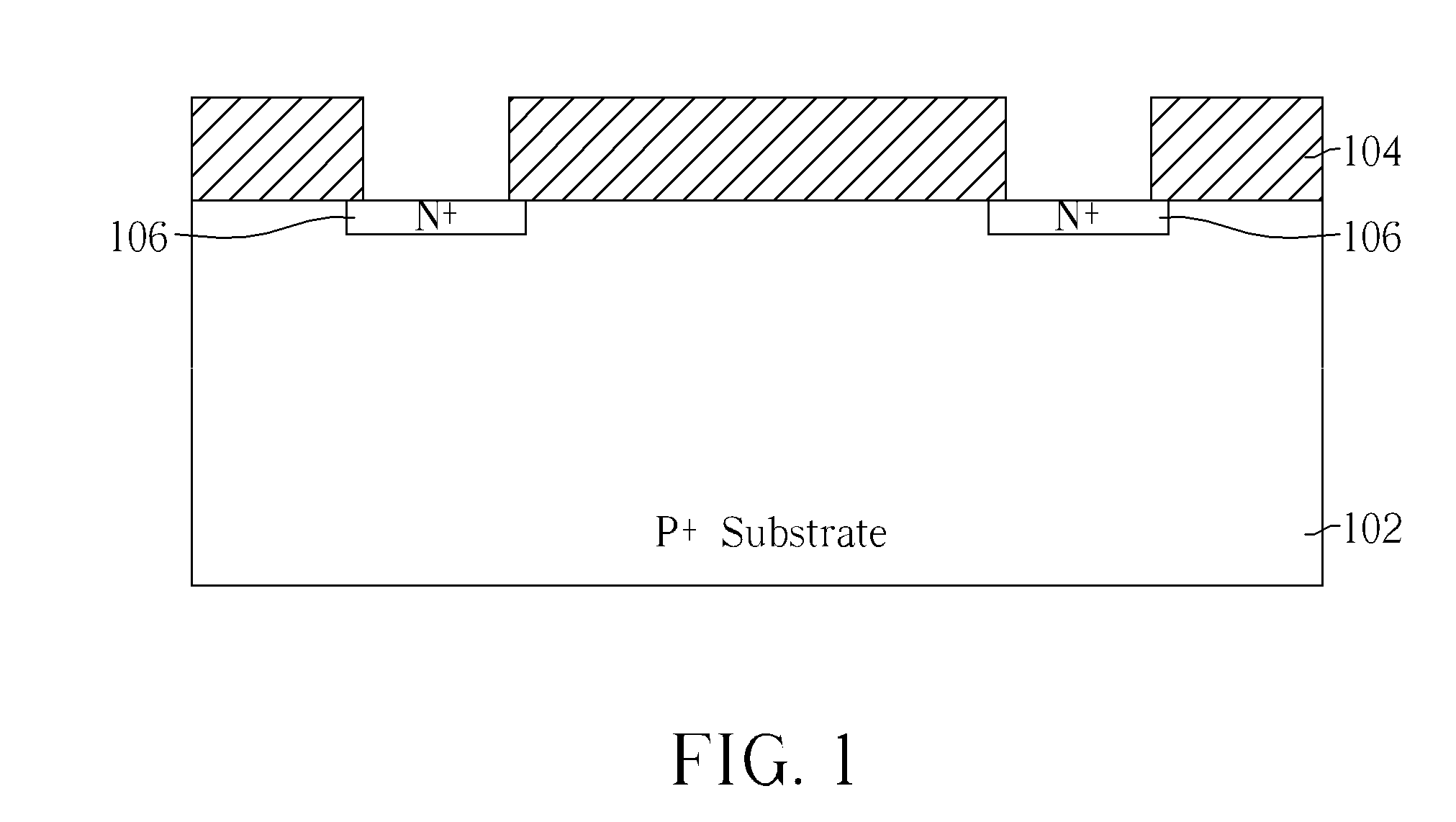

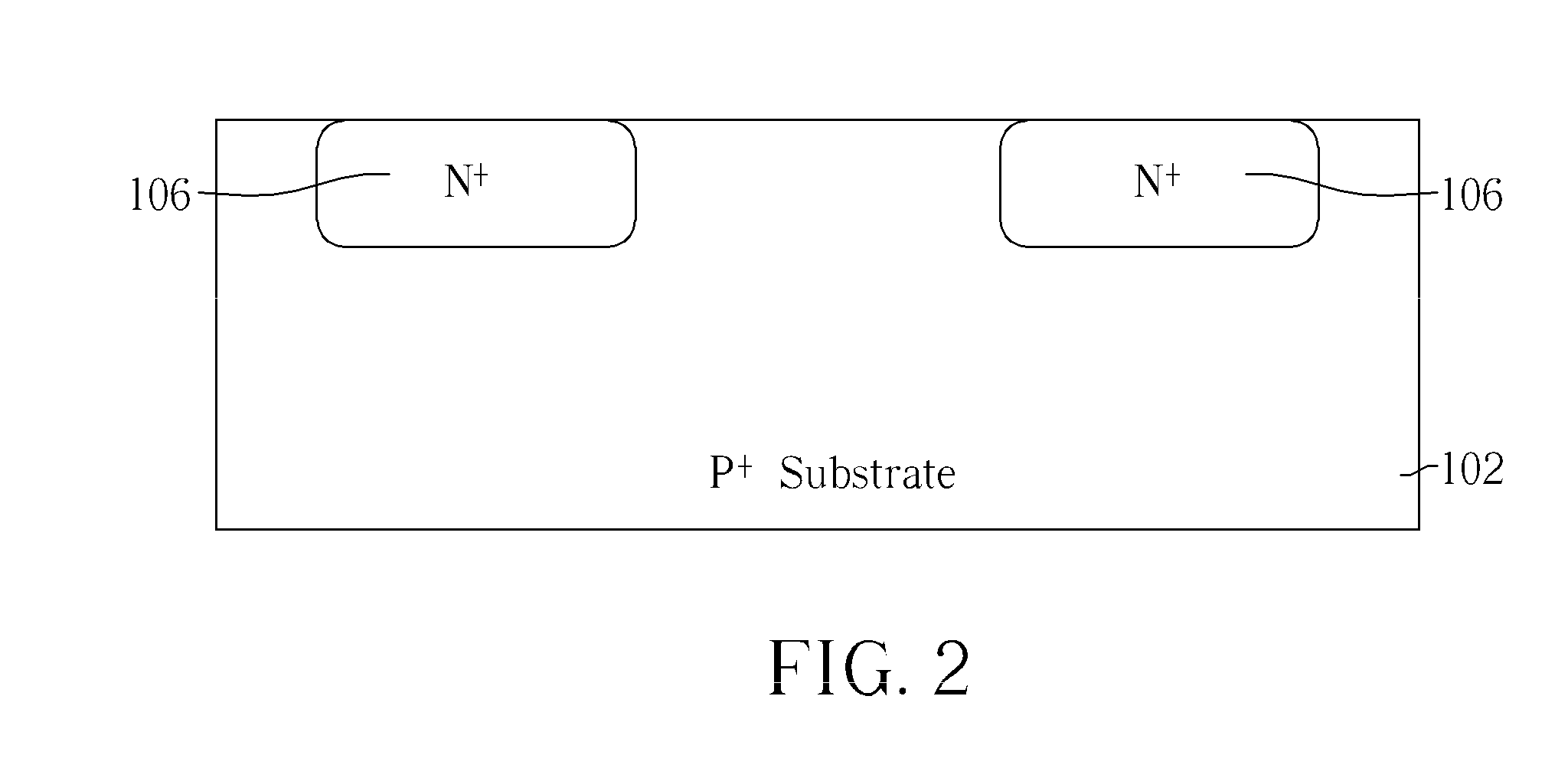

Trench mosfet having low gate charge

InactiveCN1586012AIncrease component densityLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetBody region

Owner:GEN SEMICON

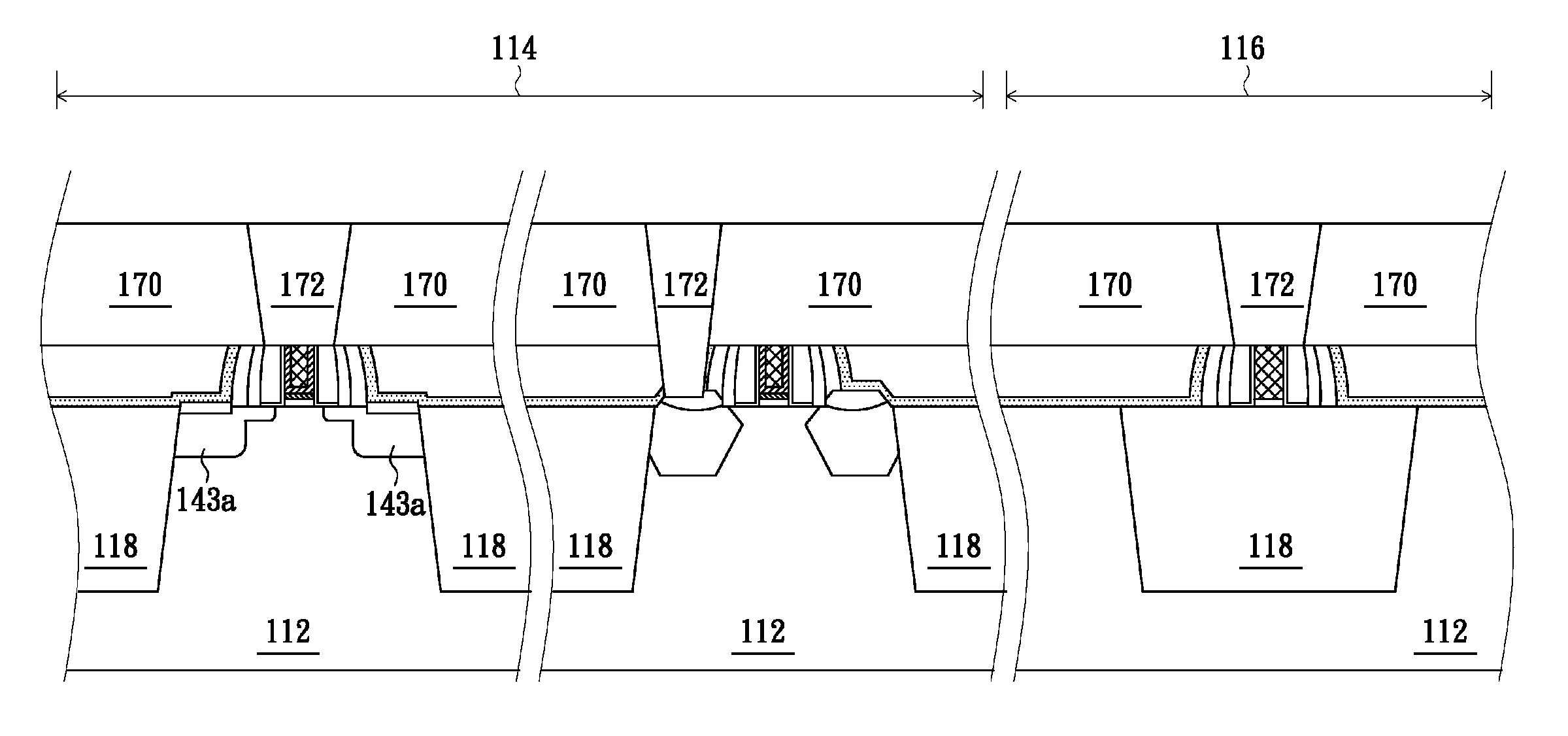

Method of forming an electrical fuse and a metal gate transistor and the related electrical fuse

ActiveUS8227890B2Increase component densityMinimize component sizeTransistorSemiconductor/solid-state device detailsWork functionGate stack

The present invention provides a method of integrating an electrical fuse process into a high-k / metal gate process. The method simultaneously forms a dummy gate stack of a transistor and a dummy gate stack of an e-fuse; and simultaneously removes the polysilicon of the dummy gate stack in the transistor region and the polysilicon of the dummy gate stack in the e-fuse region. Thereafter, the work function metal layer disposed in the opening of the e-fuse region is removed; and the opening in the transistor region and the opening in the e-fuse region with metal conductive structures are filled to form an e-fuse and a metal gate of a transistor.

Owner:UNITED MICROELECTRONICS CORP

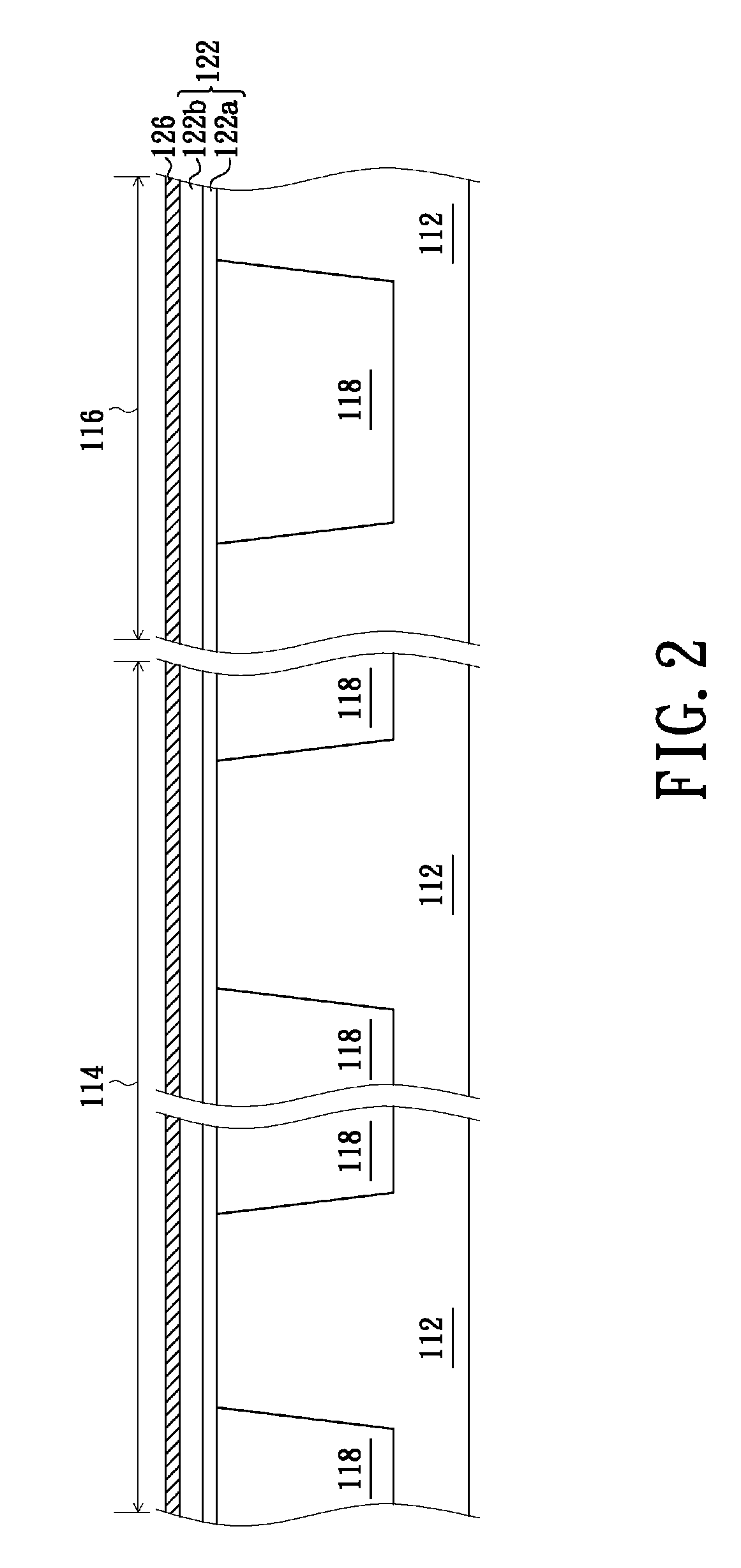

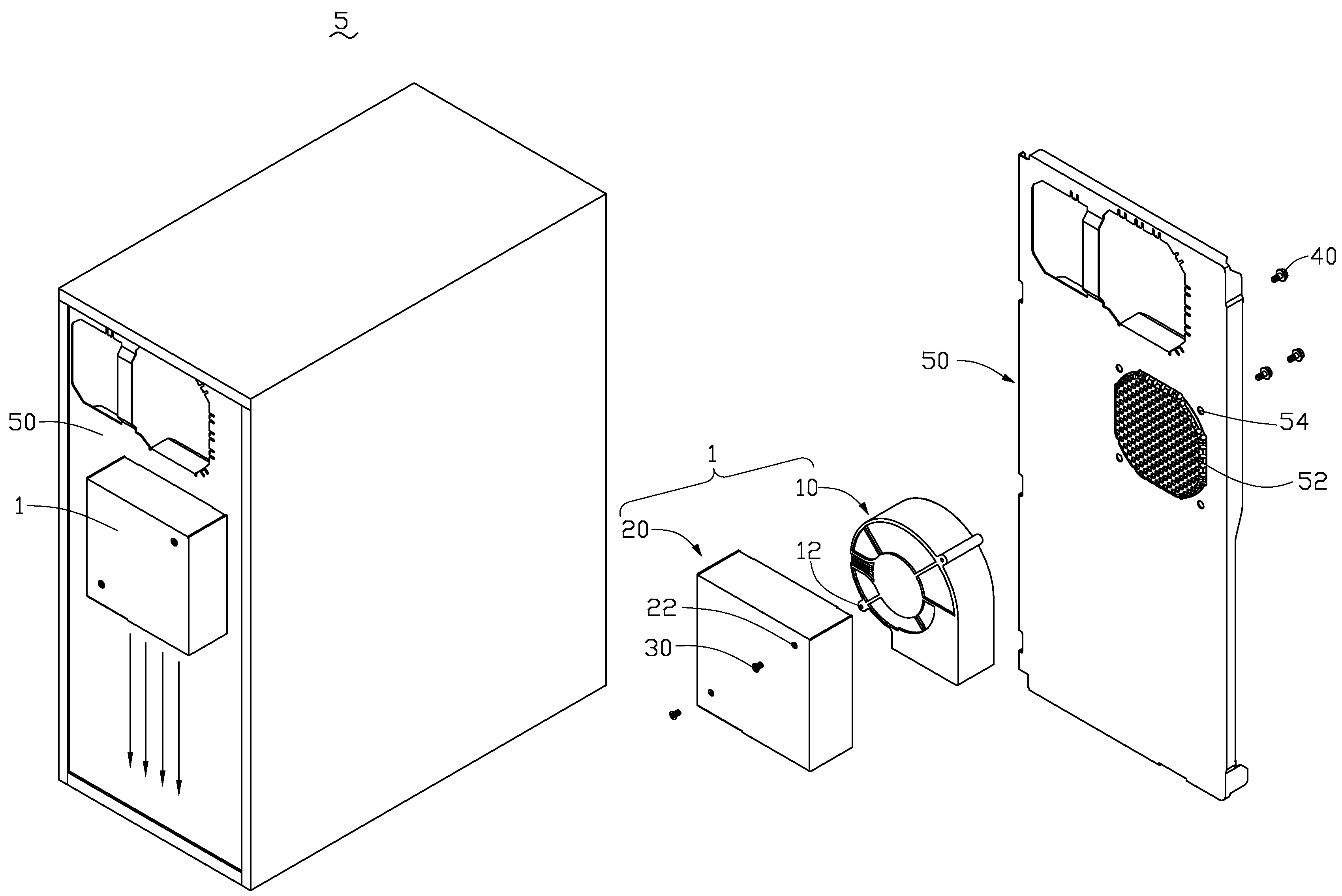

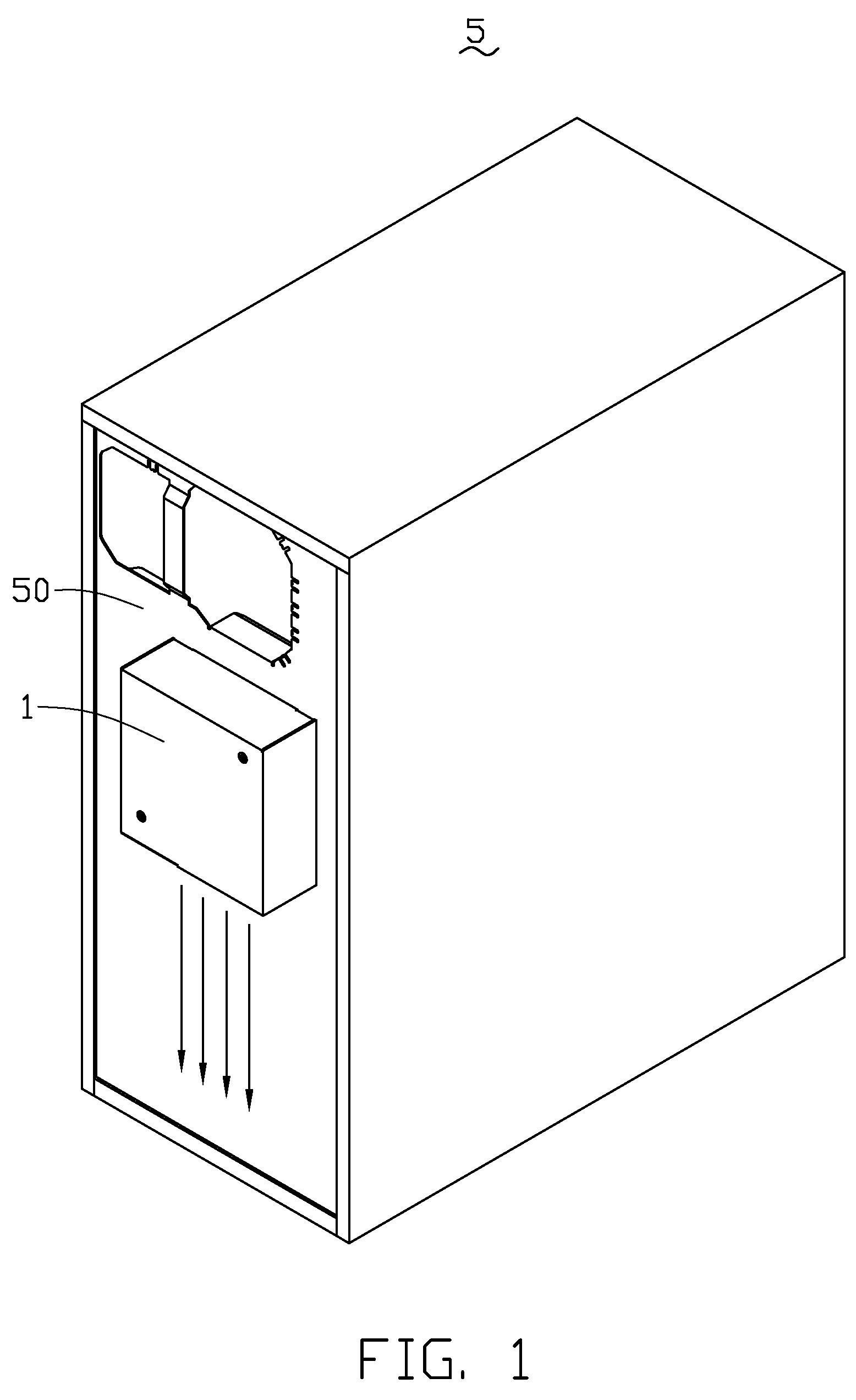

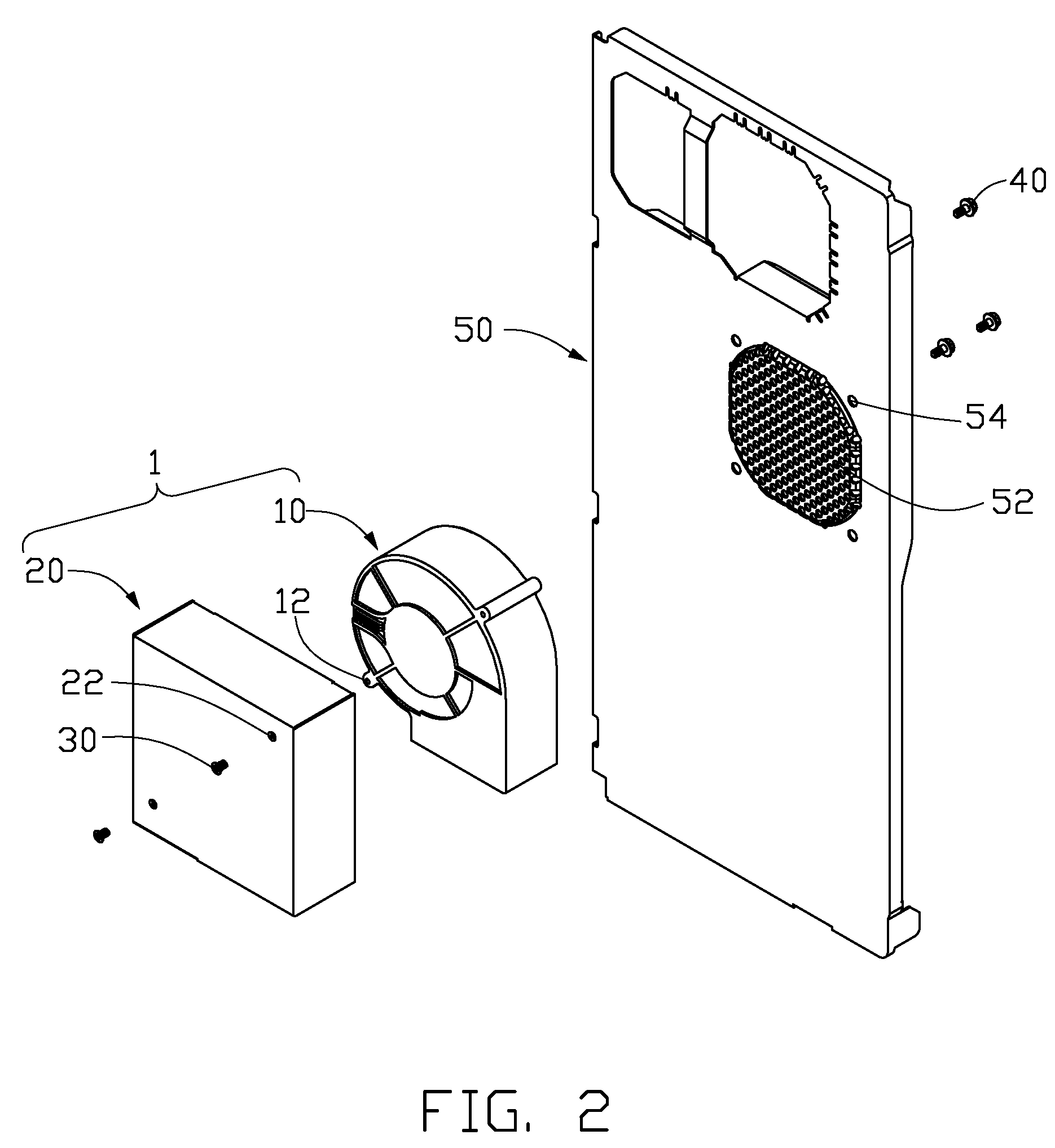

Computer case

InactiveUS7542275B2Function increaseIncrease component densityDigital data processing detailsFurniture partsComputer engineeringComputer case

A computer case includes a blower, a bracket, and an air outlet defined in the computer case. The blower is received in the bracket, which is fixed outside the computer case. The blower includes an intake and an outlet, which are used to take away the heated air in the computer case. The intake of the blower communicates with the air outlet of the computer case. The computer case with an outside set blower for heat dissipating suits a requirement of heat dissipation of high-power computer systems.

Owner:HON HAI PRECISION IND CO LTD

Integrated structure of IGBT and diode and method of forming the same

InactiveUS20100301386A1Low costIncrease component densityTransistorSolid-state devicesSemiconductorDiode

An integrated structure of an IGBT and a diode includes a plurality of doped cathode regions, and a method of forming the same is provided. The doped cathode regions are stacked in a semiconductor substrate, overlapping and contacting with each other. As compared with other doped cathode regions, the higher a doped cathode region is disposed, the larger implantation area the doped cathode region has. The doped cathode regions and the semiconductor substrate have different conductive types, and are applied as a cathode of the diode and a collector of the IGBT. The stacked doped cathode regions can increase the thinness of the cathode, and prevent the wafer from being overly thinned and broken.

Owner:ANPEC ELECTRONICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com