Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Reduce device thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

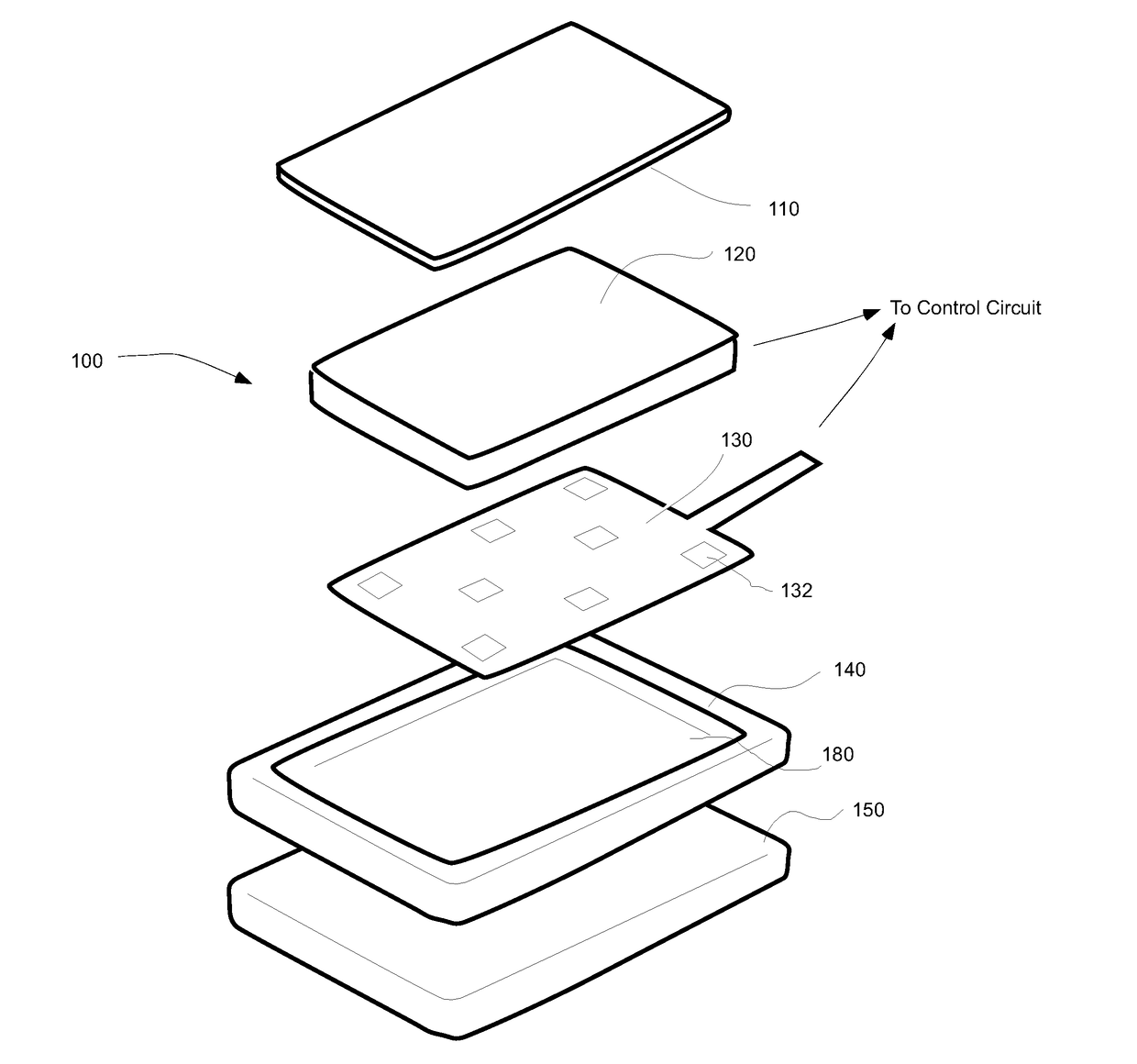

Liquid crystal display with mirror mode having top reflective polarizer

InactiveUS7057681B2Improve seismic performanceQuality improvementPolarising elementsIlluminated signsLiquid-crystal displayDisplay device

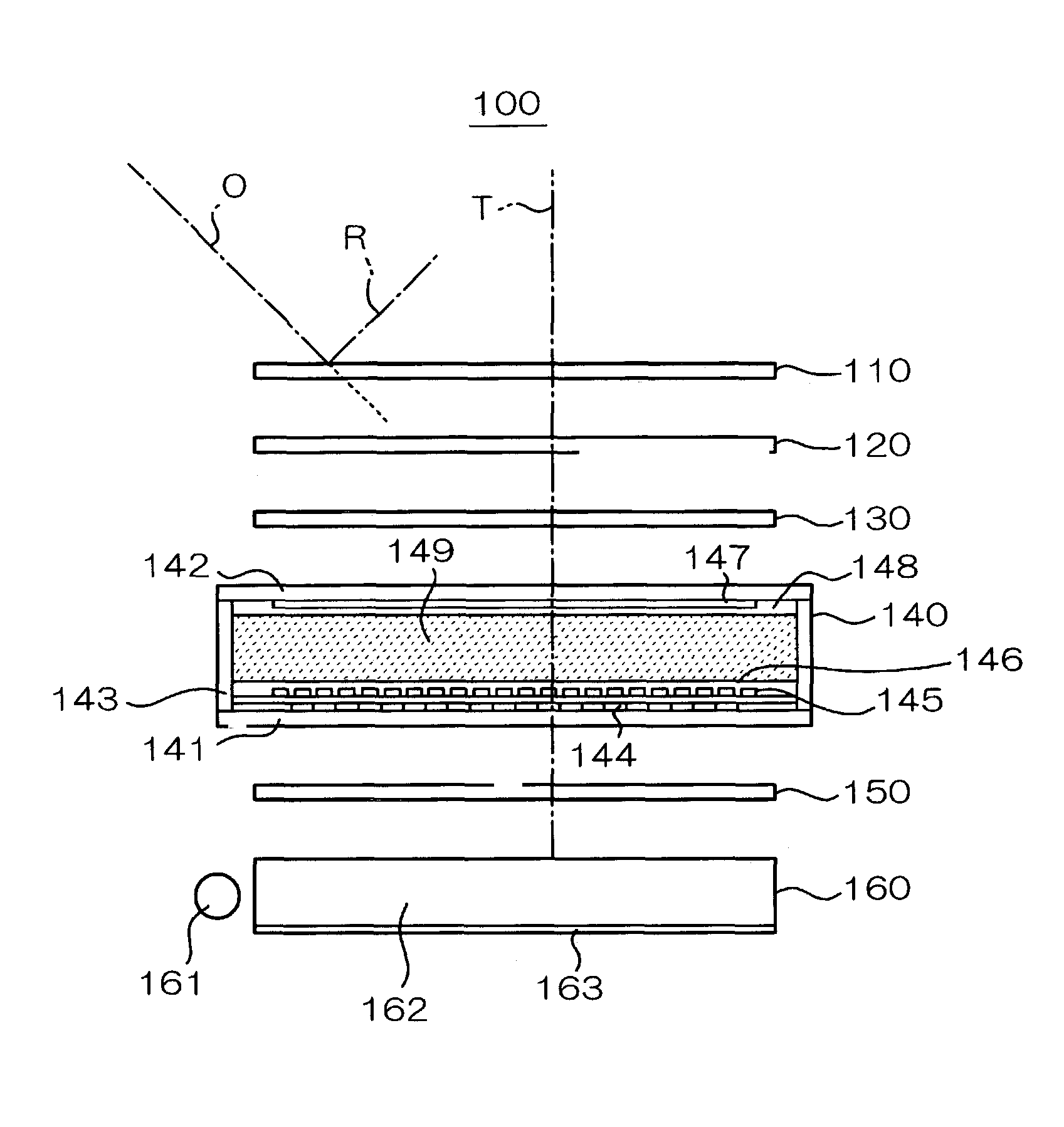

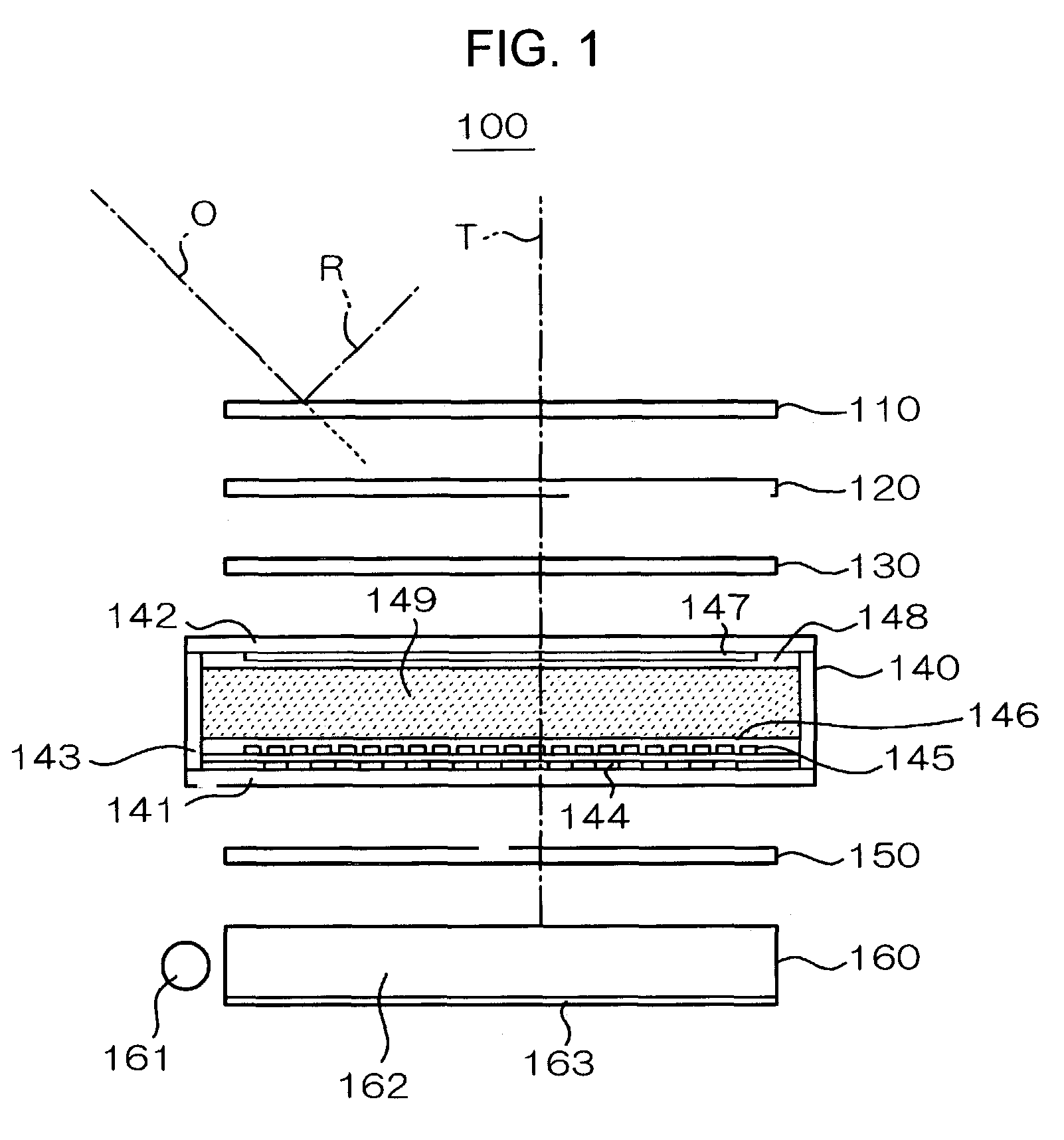

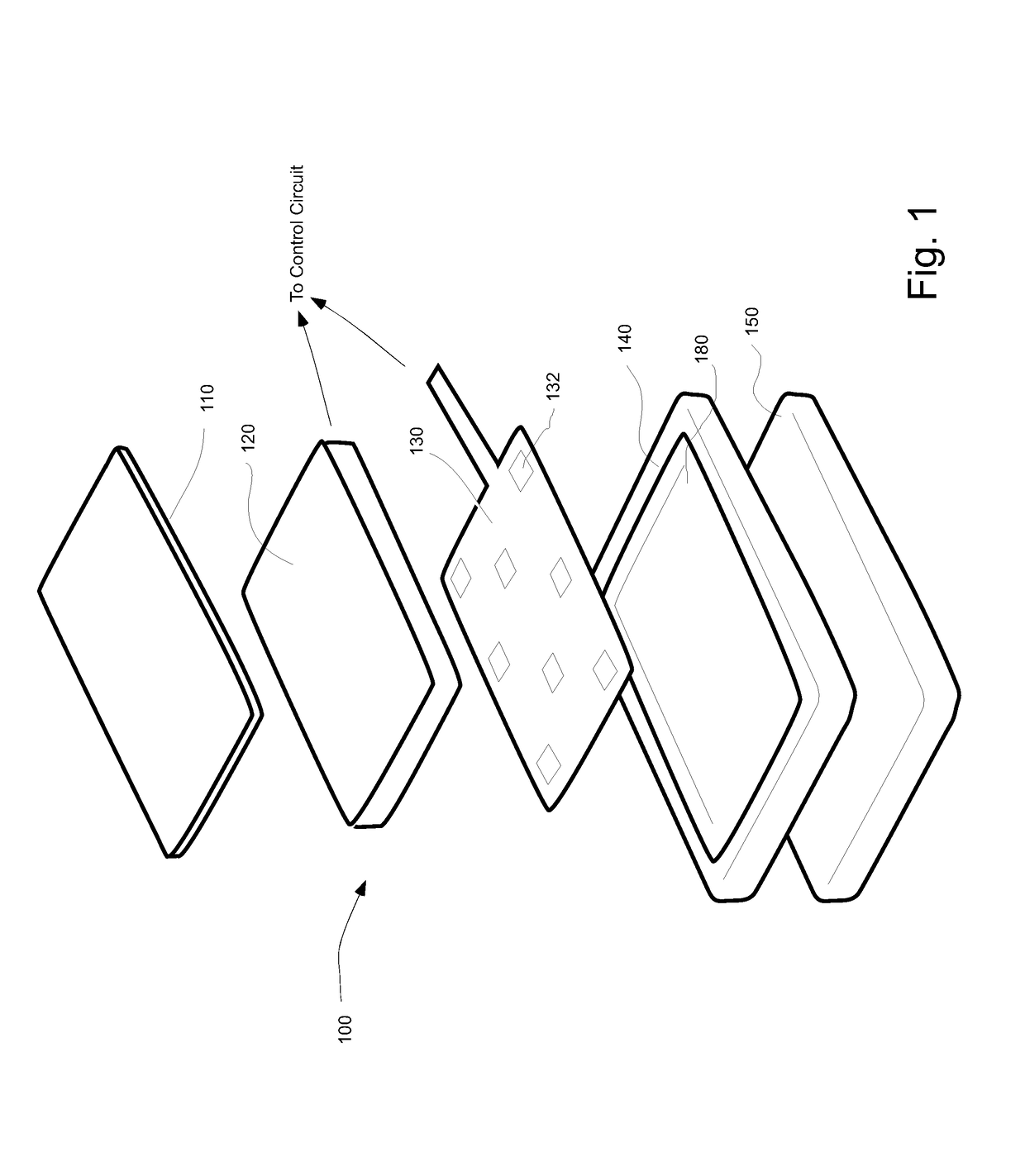

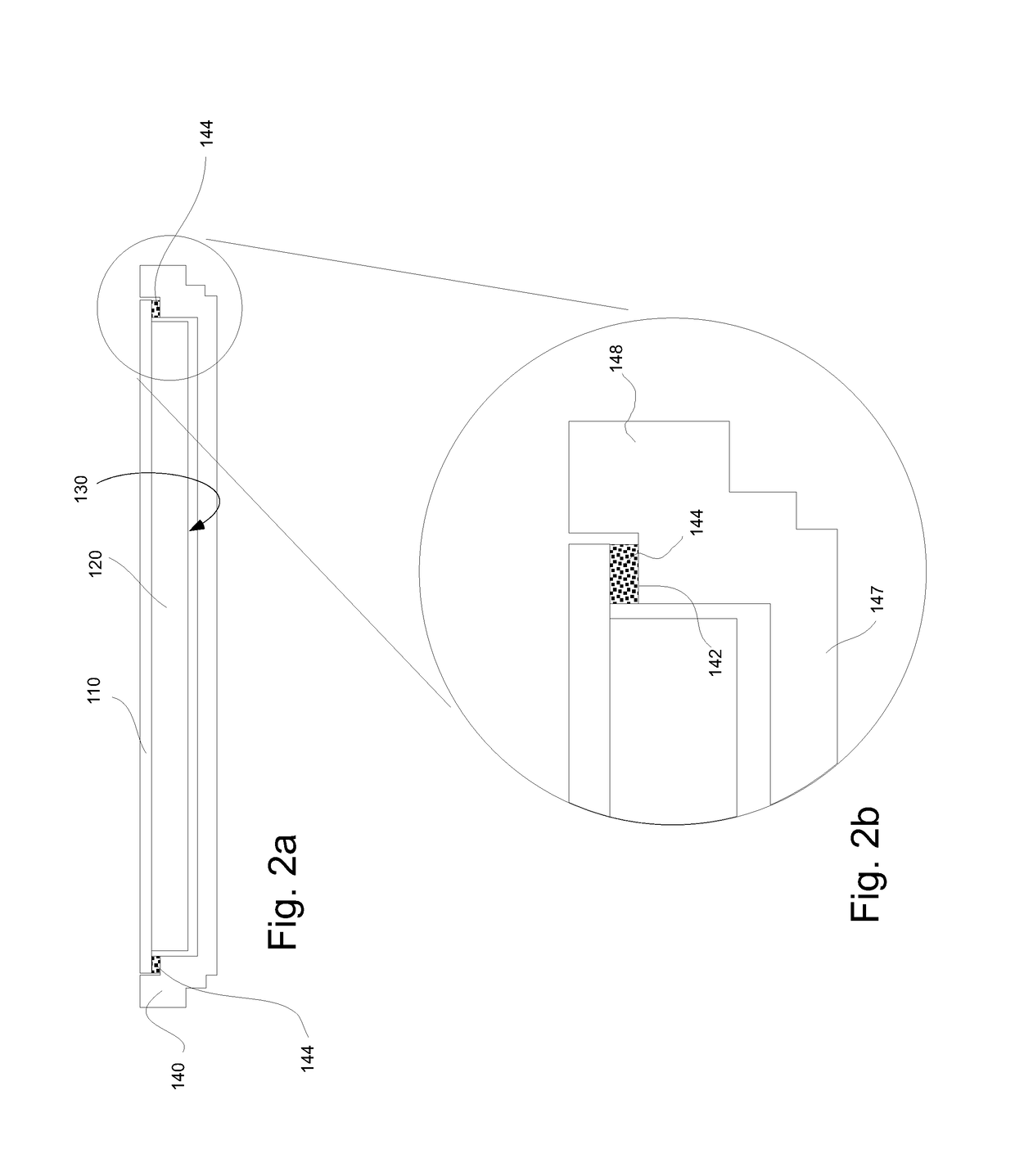

In a display device 100, a reflective polarizer 110, a polarizer 120, a retarder 130, a liquid crystal panel 140, a polarizer 150, and a backlight 160 are disposed sequentially from the viewing side. When the liquid crystal panel 140 is set in a light blocking state or the backlight 160 is set in an unlit state, the reflection of an outside light “O” turns the display screen into a mirror state. When the backlight 160 is set in a lit state to drive the liquid crystal panel 140, a transmitted light “T” allows a particular display screen to be visually recognized.

Owner:BOE TECH GRP CO LTD

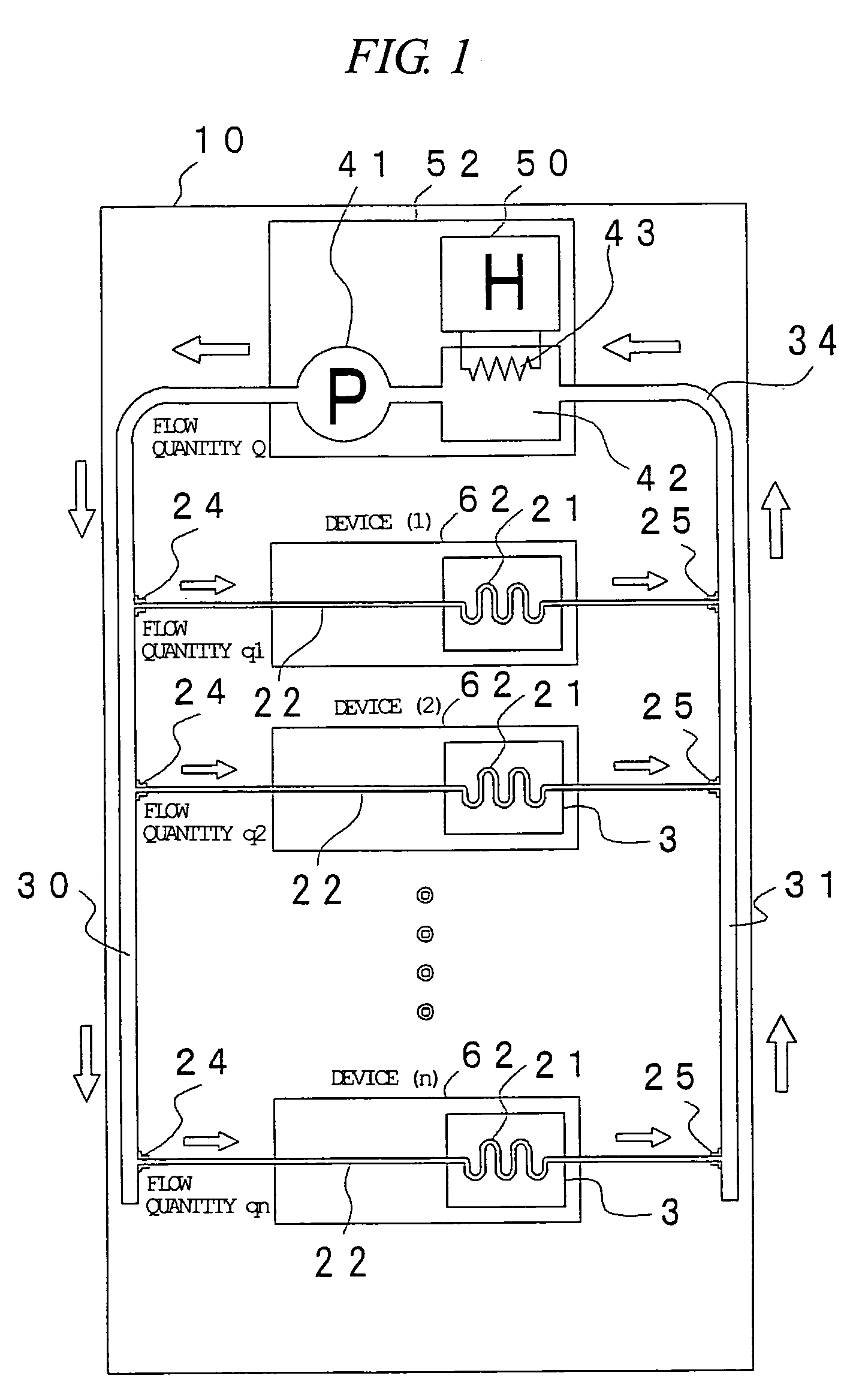

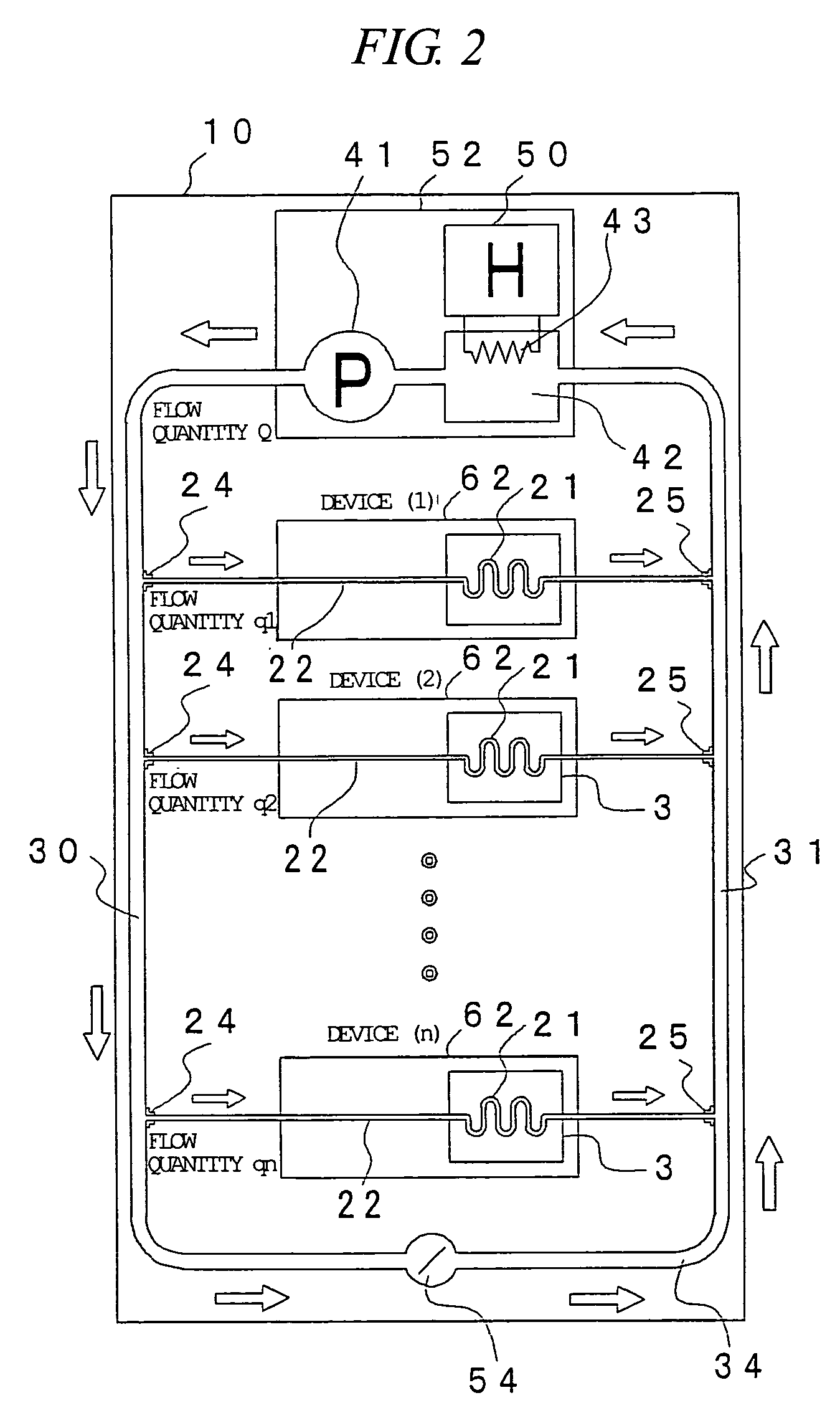

Liquid cooling system for a rack-mount server system

ActiveUS7318322B2Suppress mutationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringComputer module

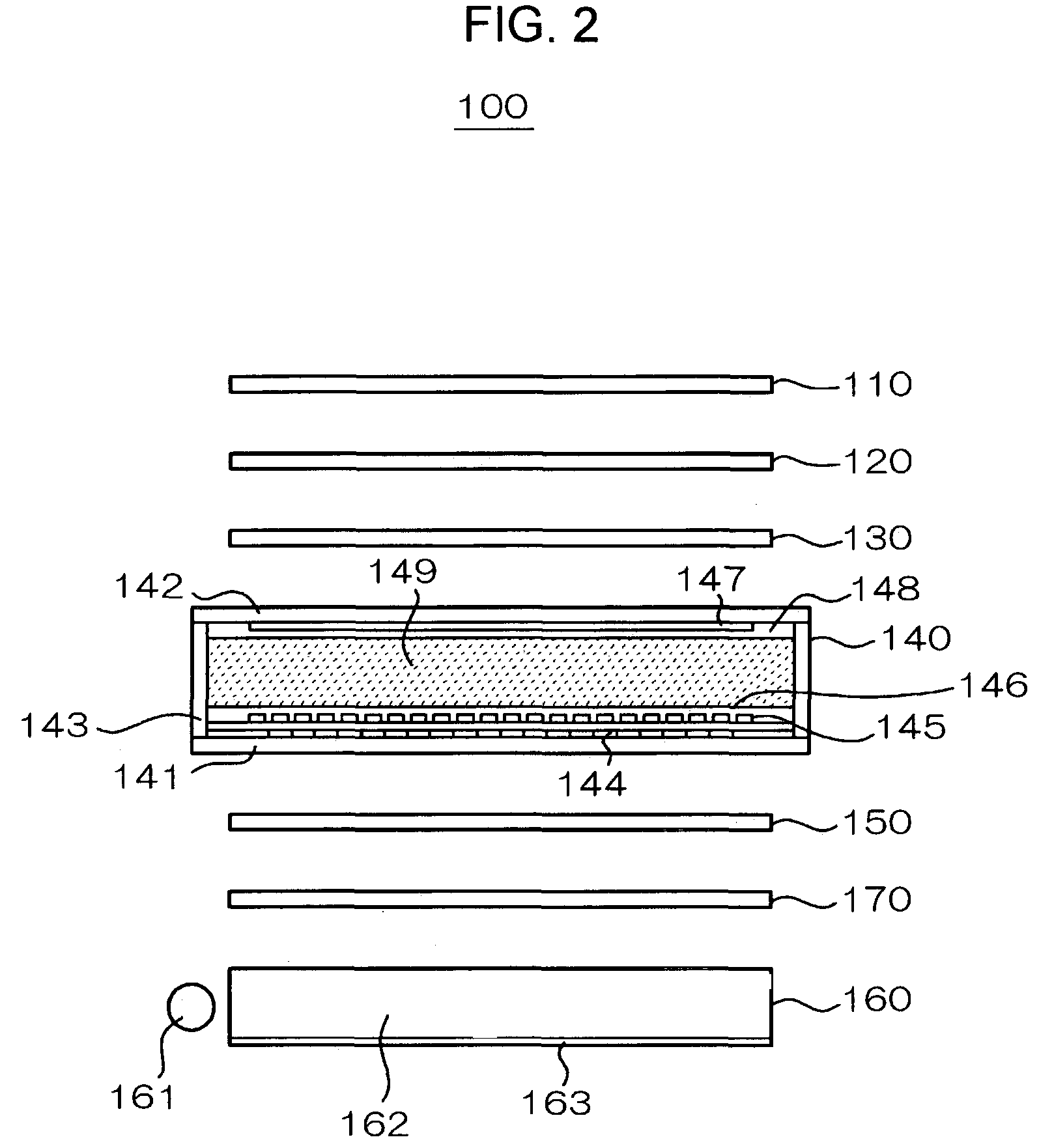

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as a CPU is cooled by a coolant has a plurality of server modules with heat-generating components which are cooled by the circulating coolant. The server modules are connected in parallel to a circulation coolant path through which the coolant to cool the server modules is circulated. In the middle of the coolant circulation path is a cooling unit that cools the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules.

Owner:MAXELL HLDG LTD

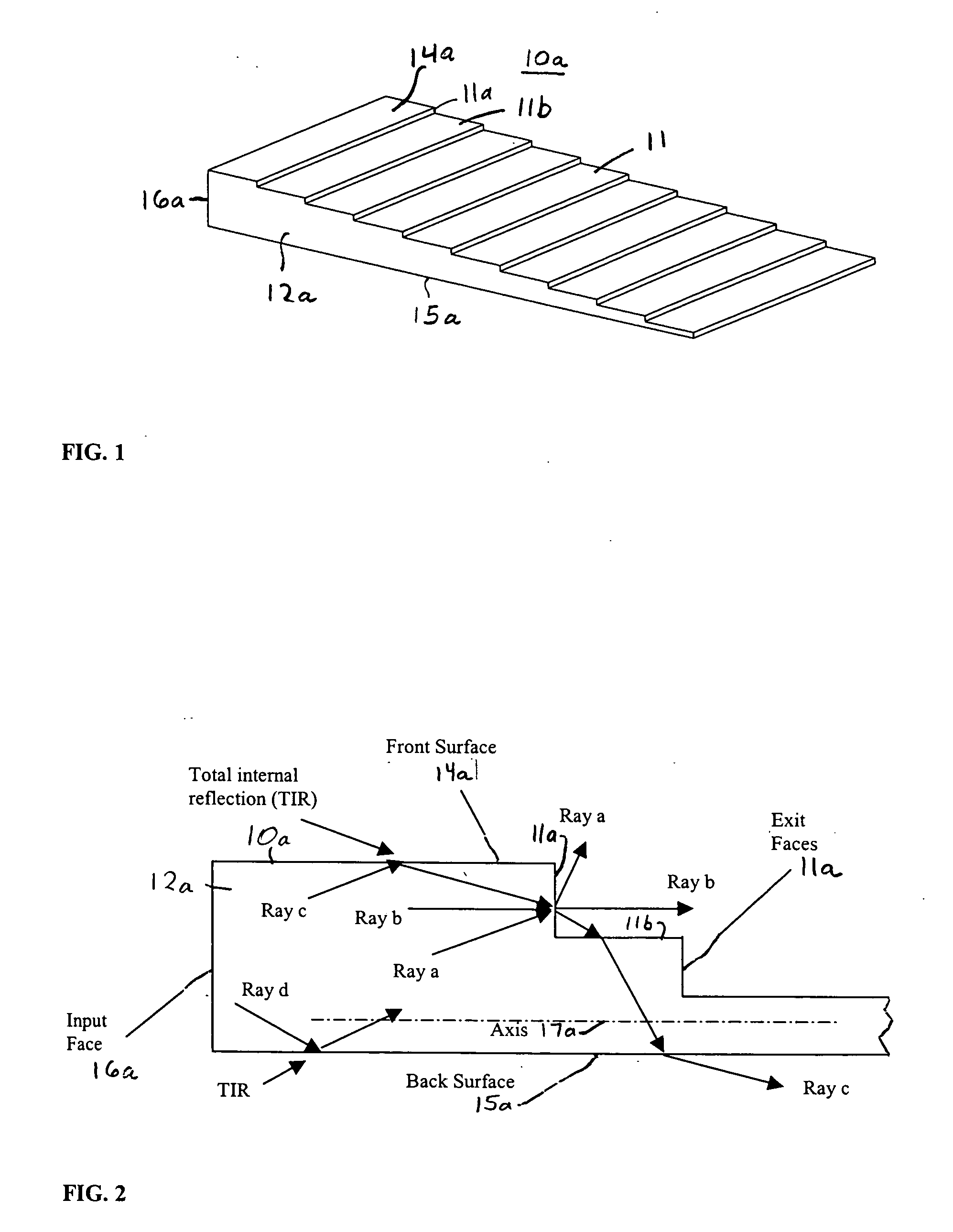

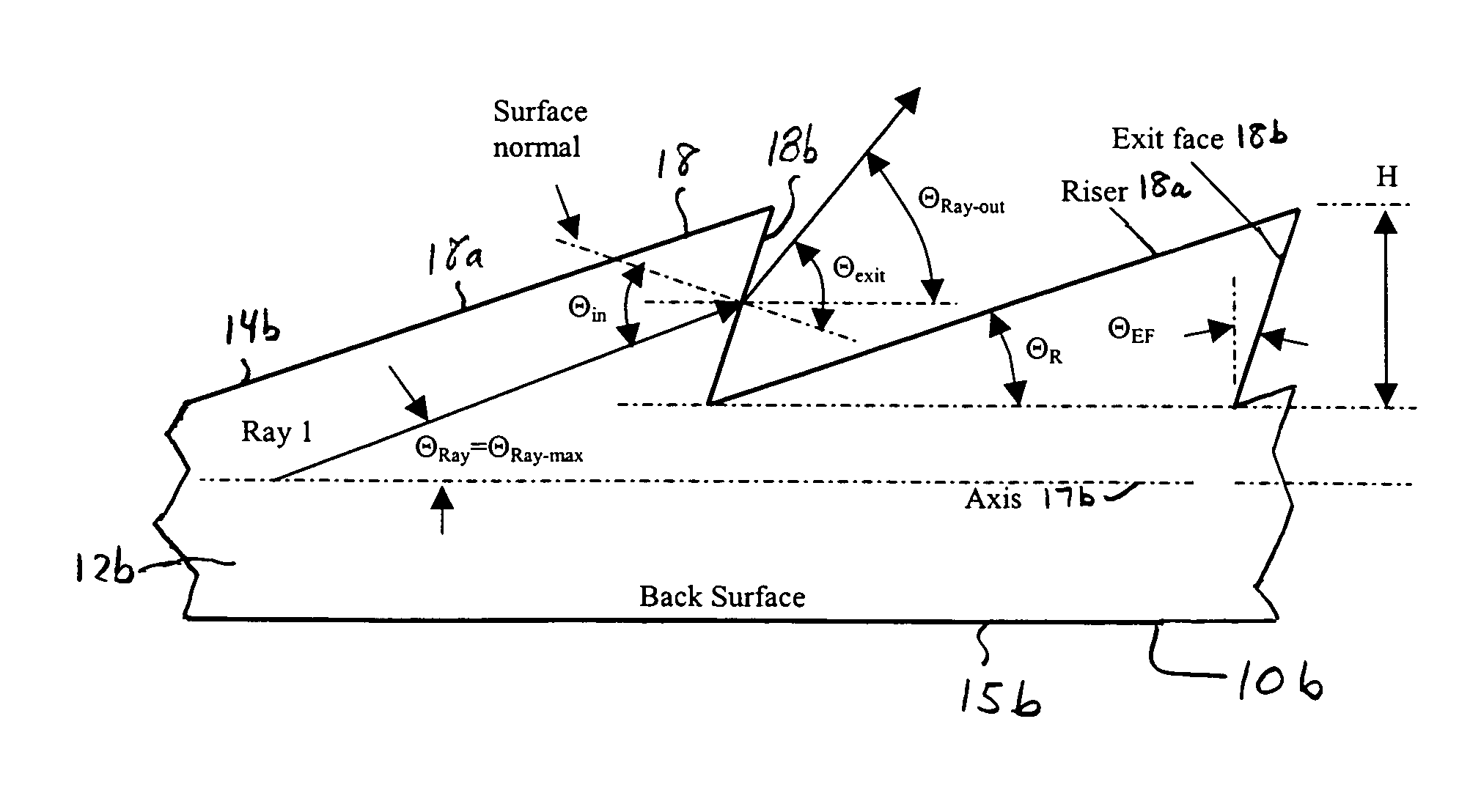

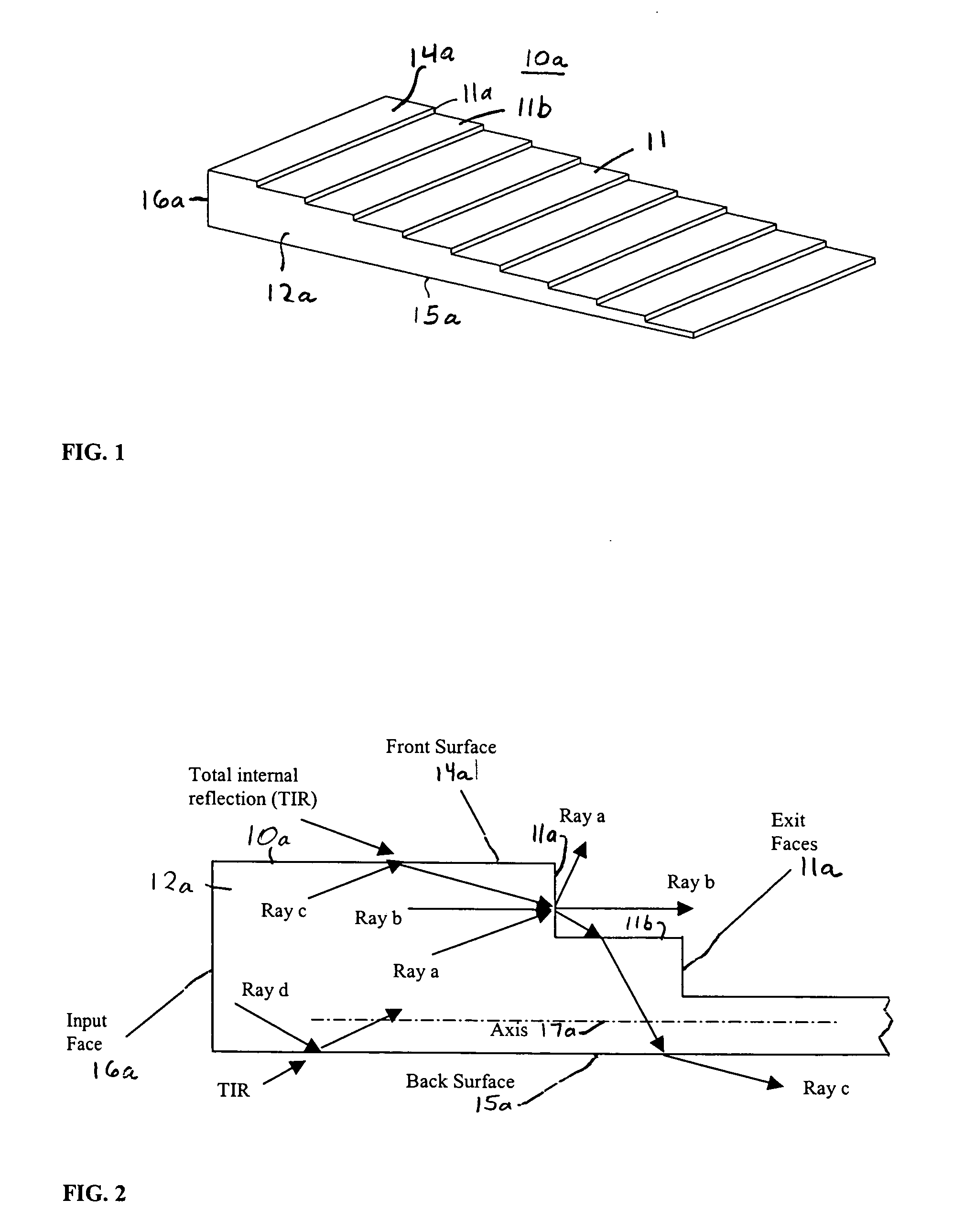

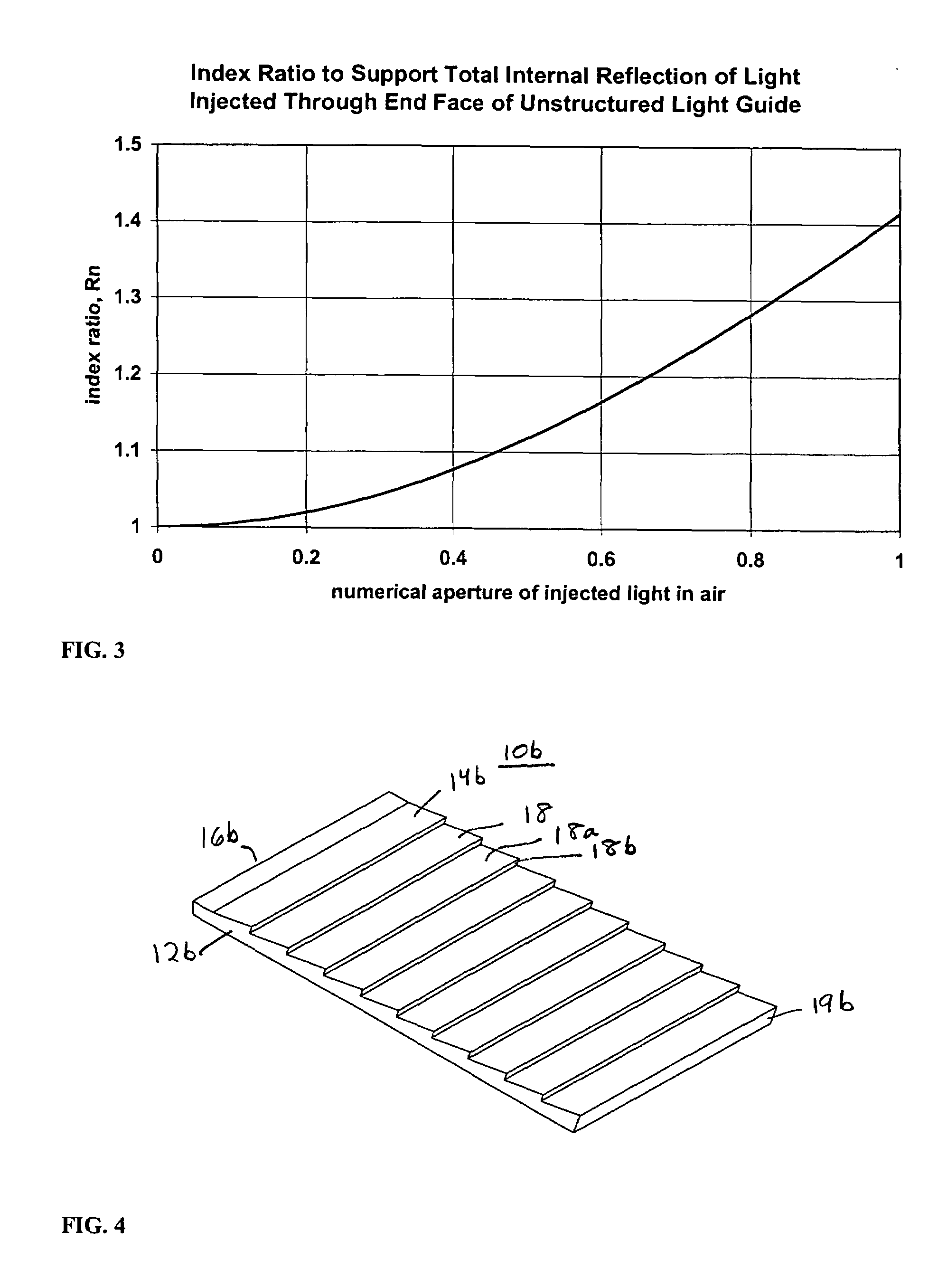

Optical devices for guiding illumination

ActiveUS20070189701A1Reduce numerical apertureReduce device thicknessPrismsMirrorsOptical materialsAngular direction

Owner:VIAVI SOLUTIONS INC

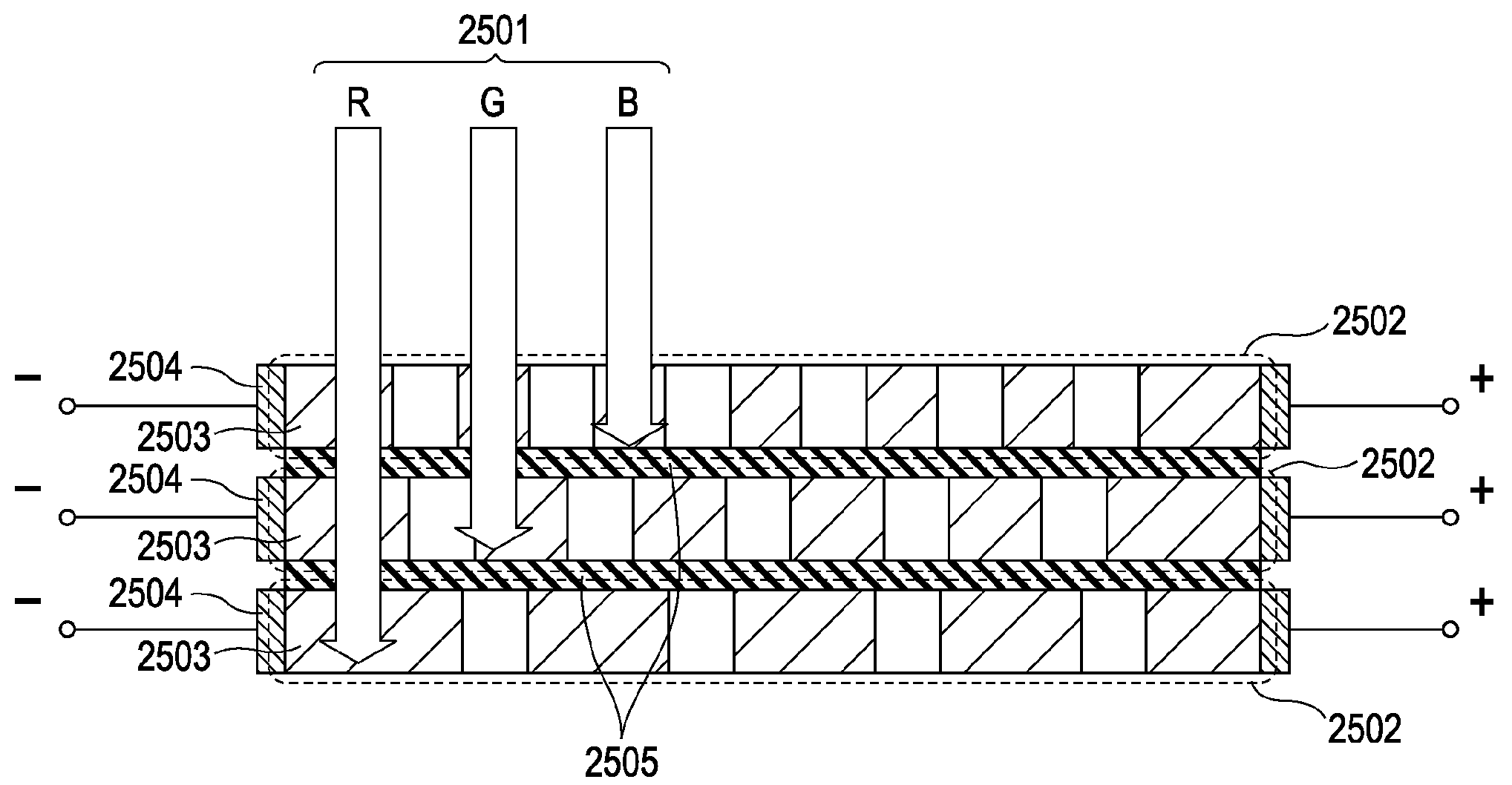

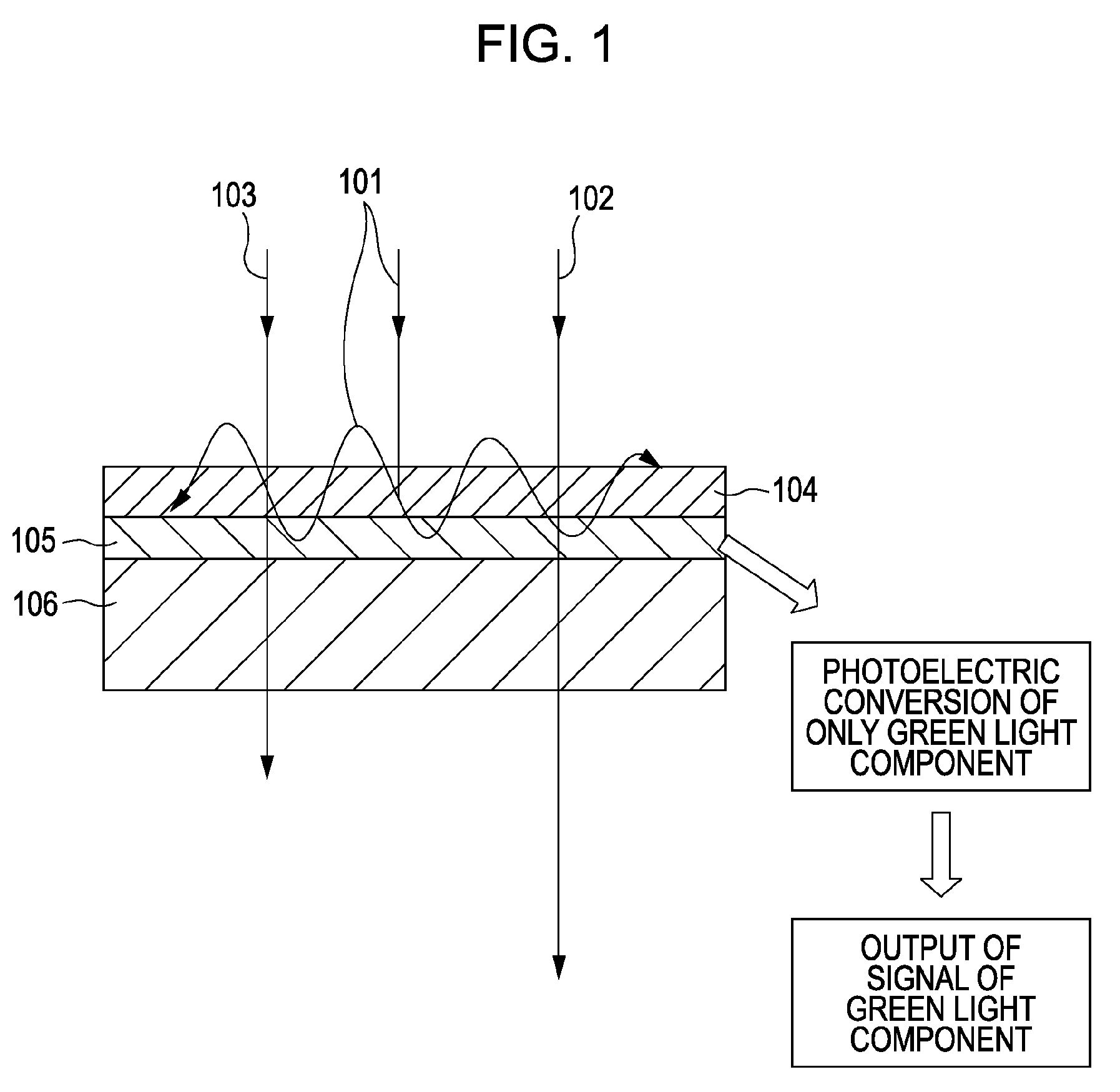

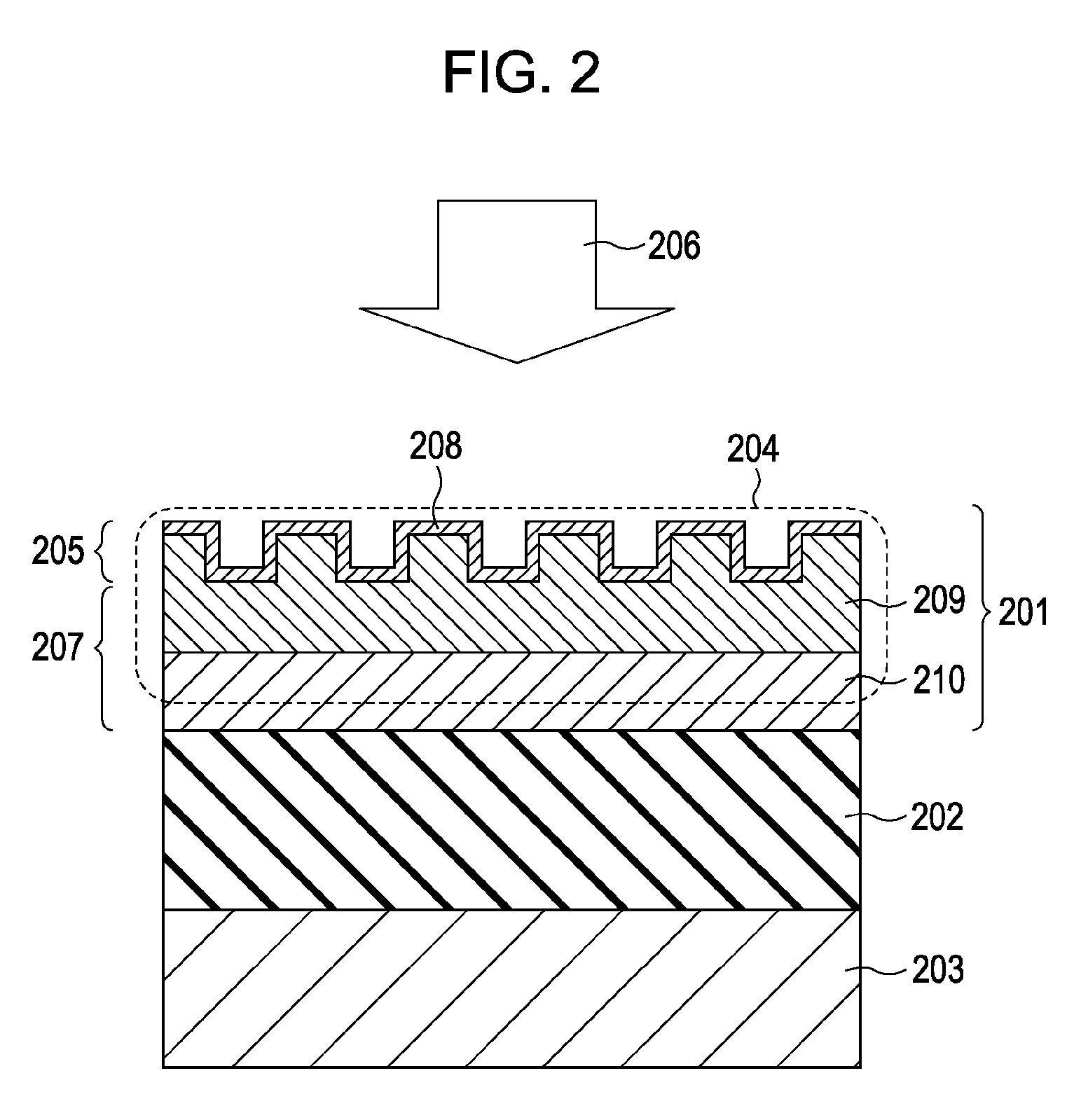

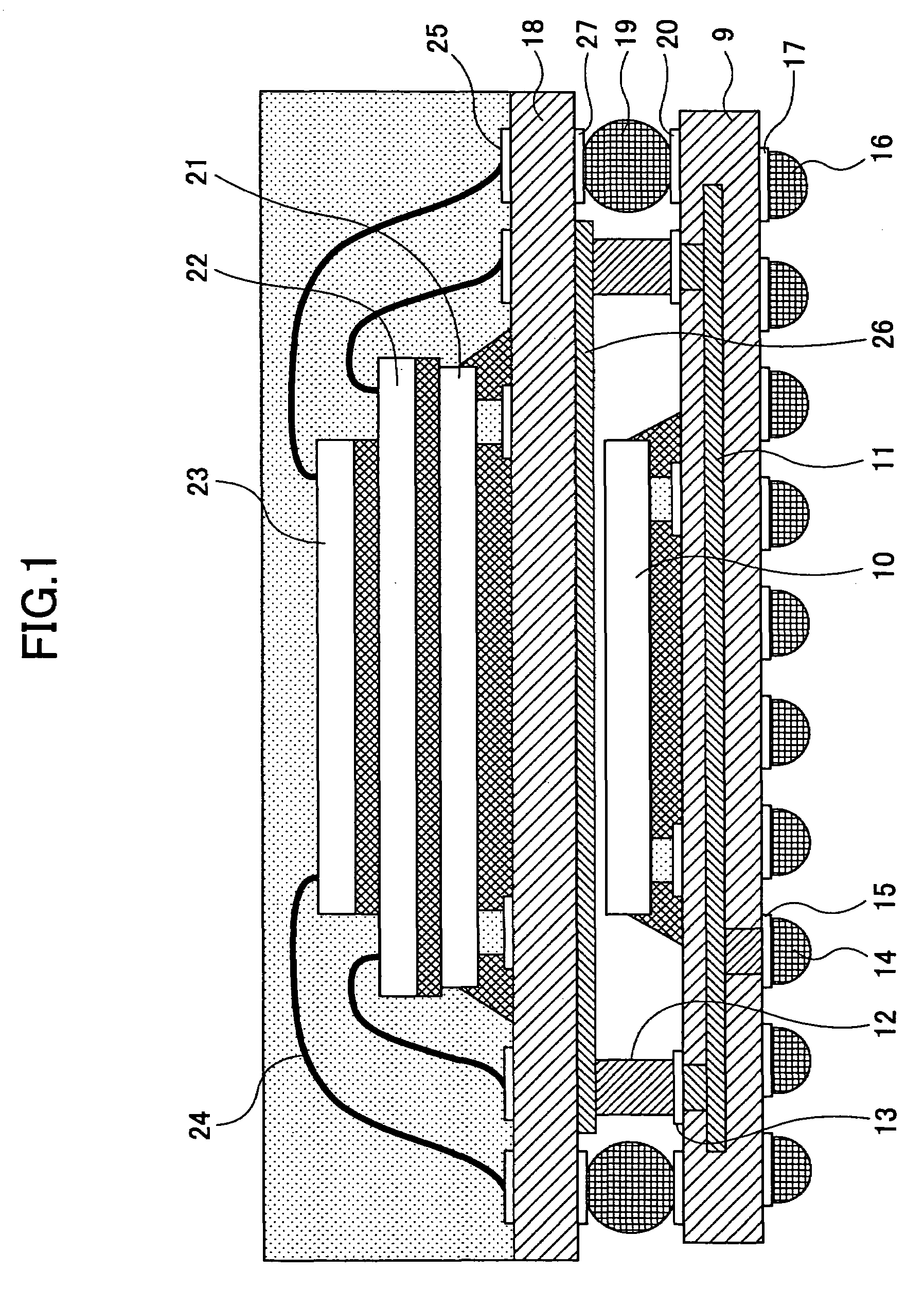

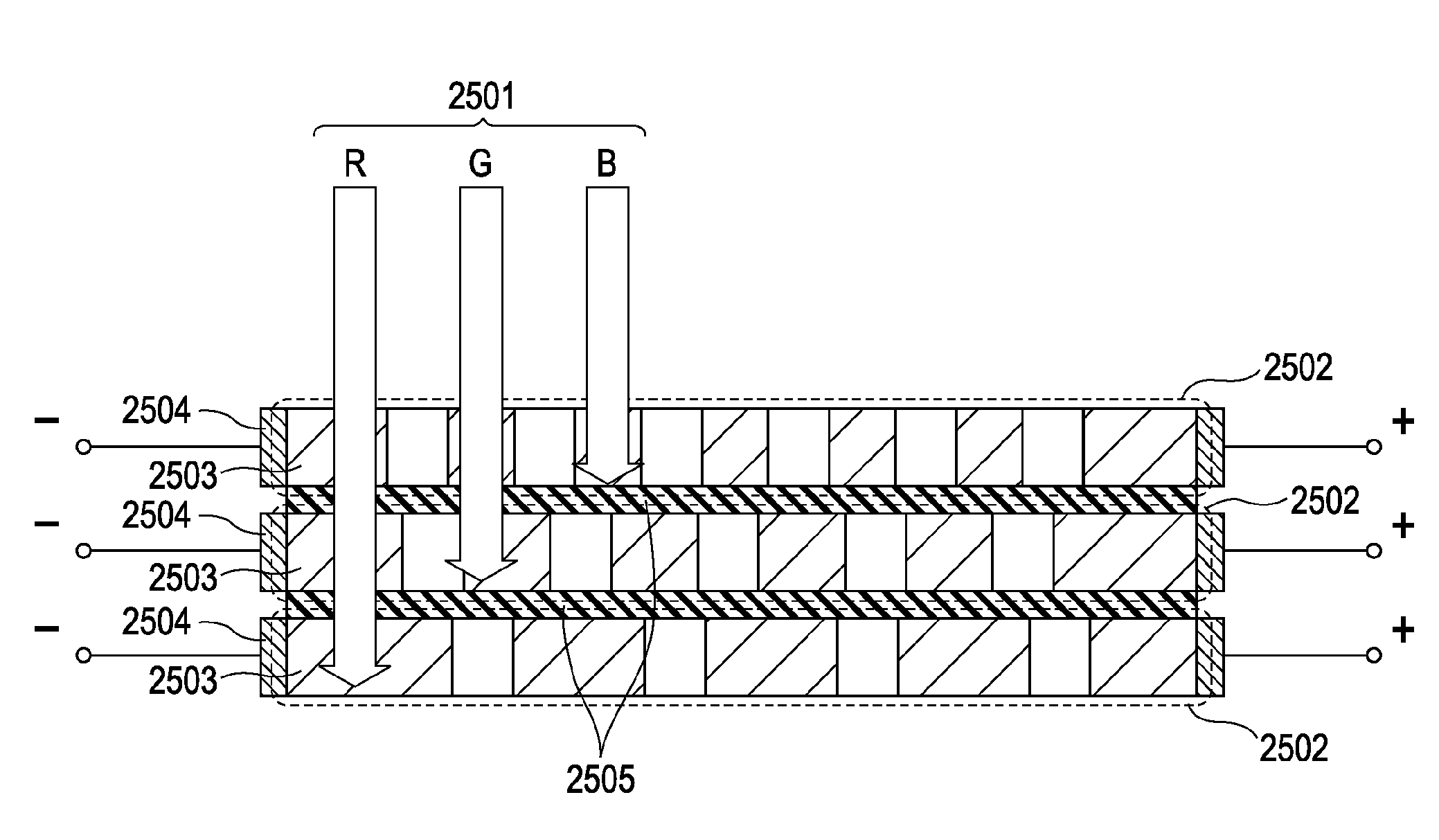

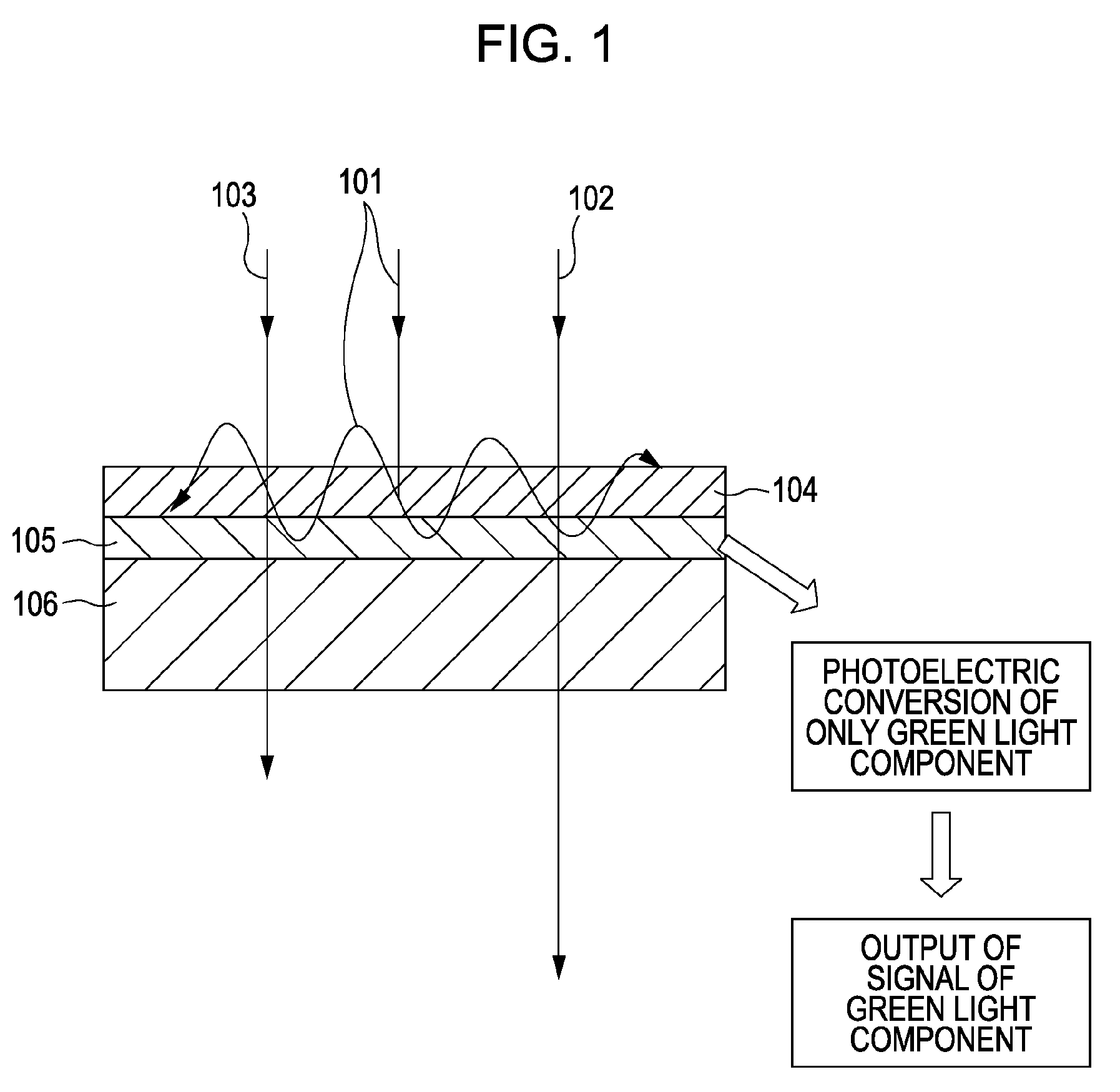

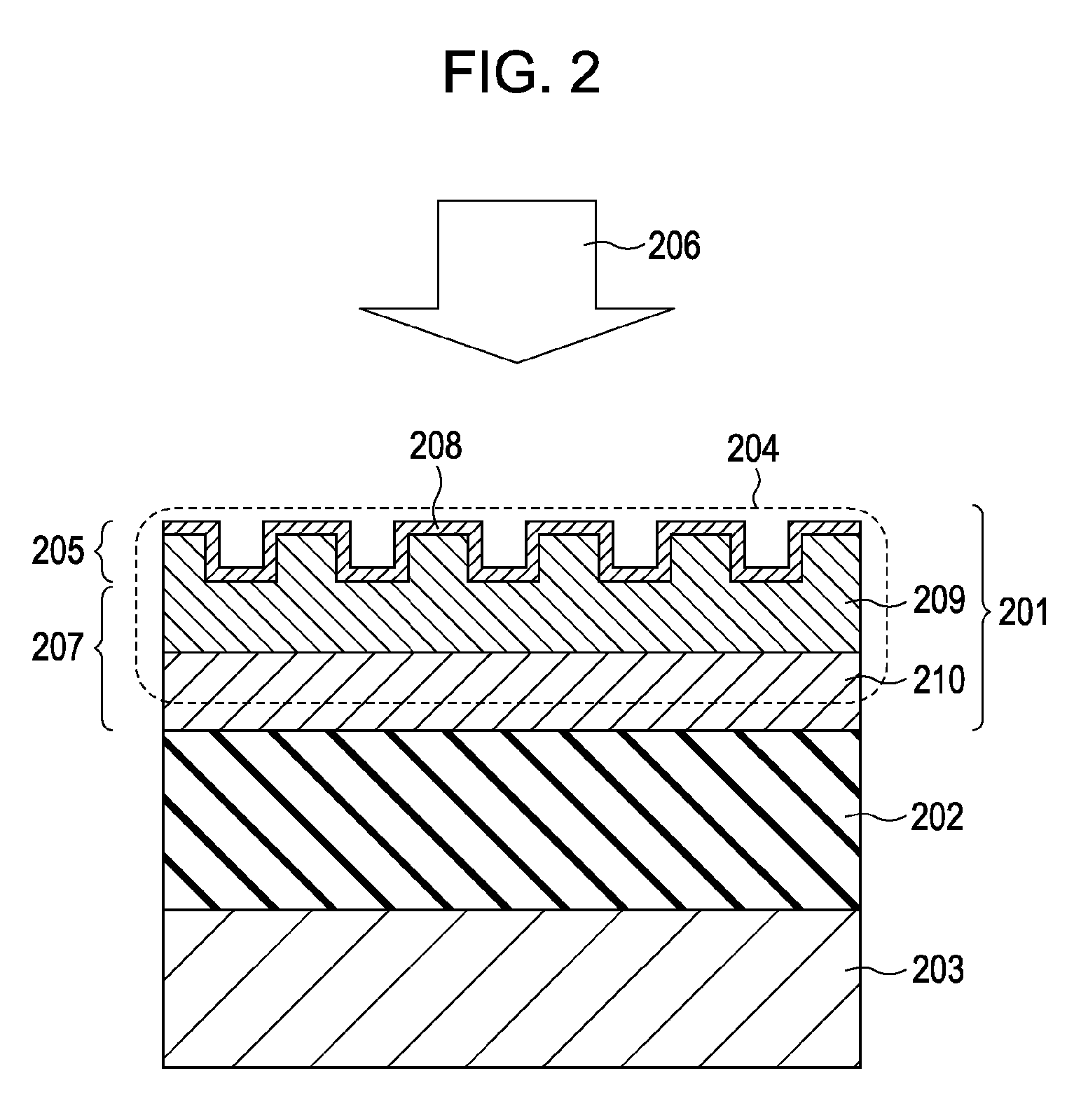

Photo detector, image sensor, photo-detection method, and imaging method

InactiveUS20090008735A1Reduce device thicknessSuppress color mixingTelevision system detailsSolid-state devicesSemiconductor materialsResonance

A photo detector includes a photoelectric conversion layer having a periodic structure made of a semiconductor material on a surface of the photoelectric conversion layer. In the photo detector, at least a part of a resonance region formed by the periodic structure is included in the photoelectric conversion layer of the photo detector.

Owner:CANON KK

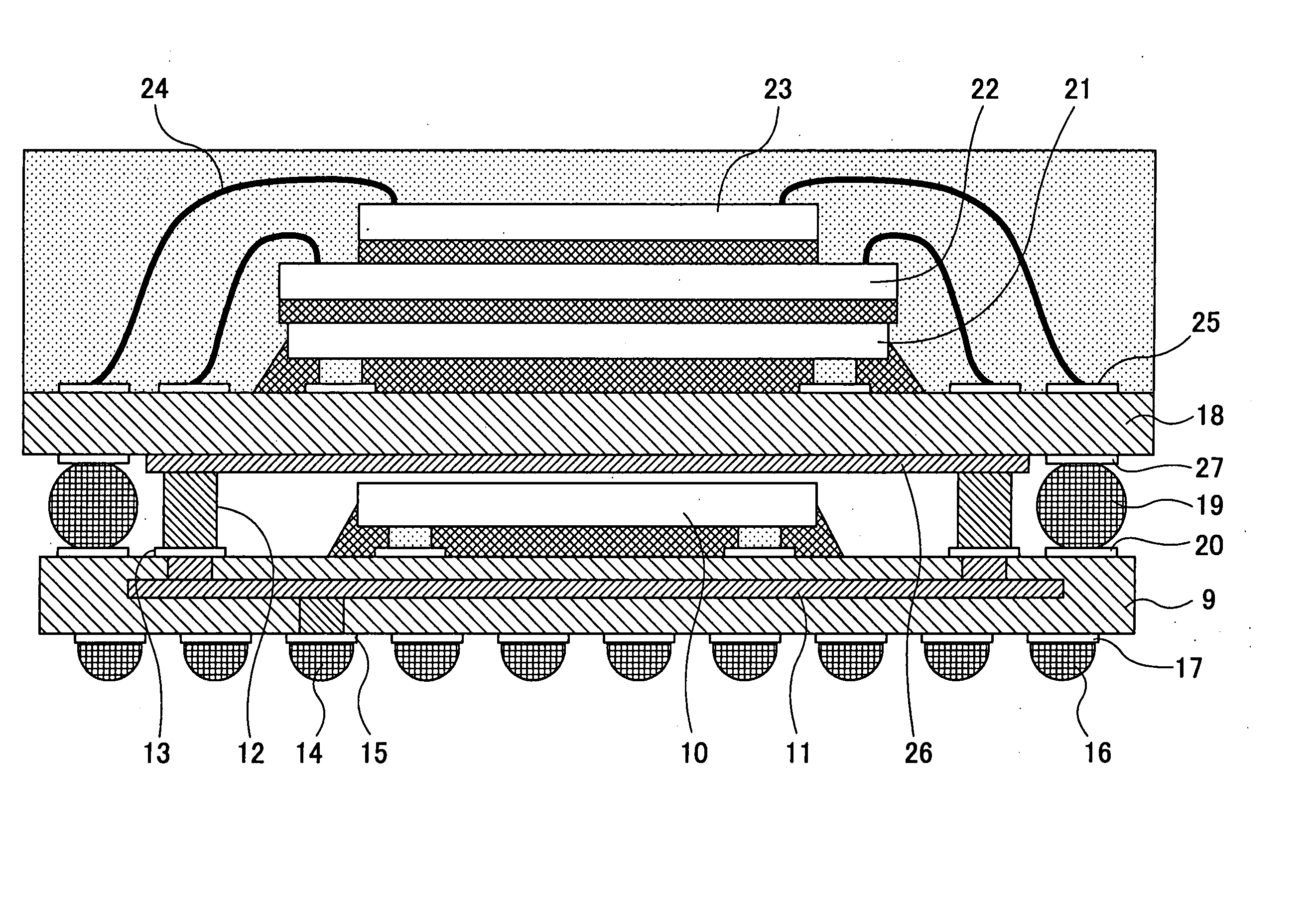

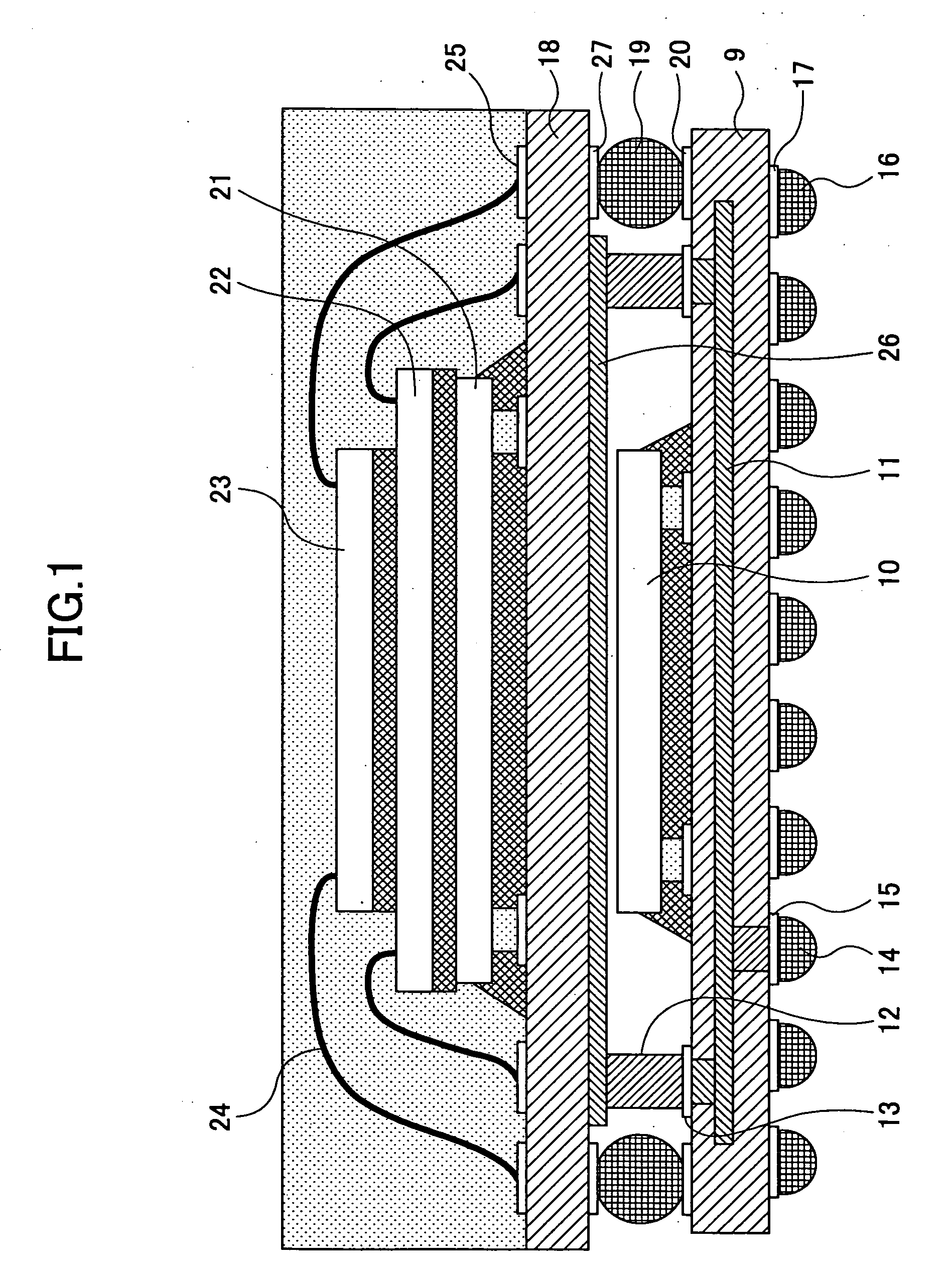

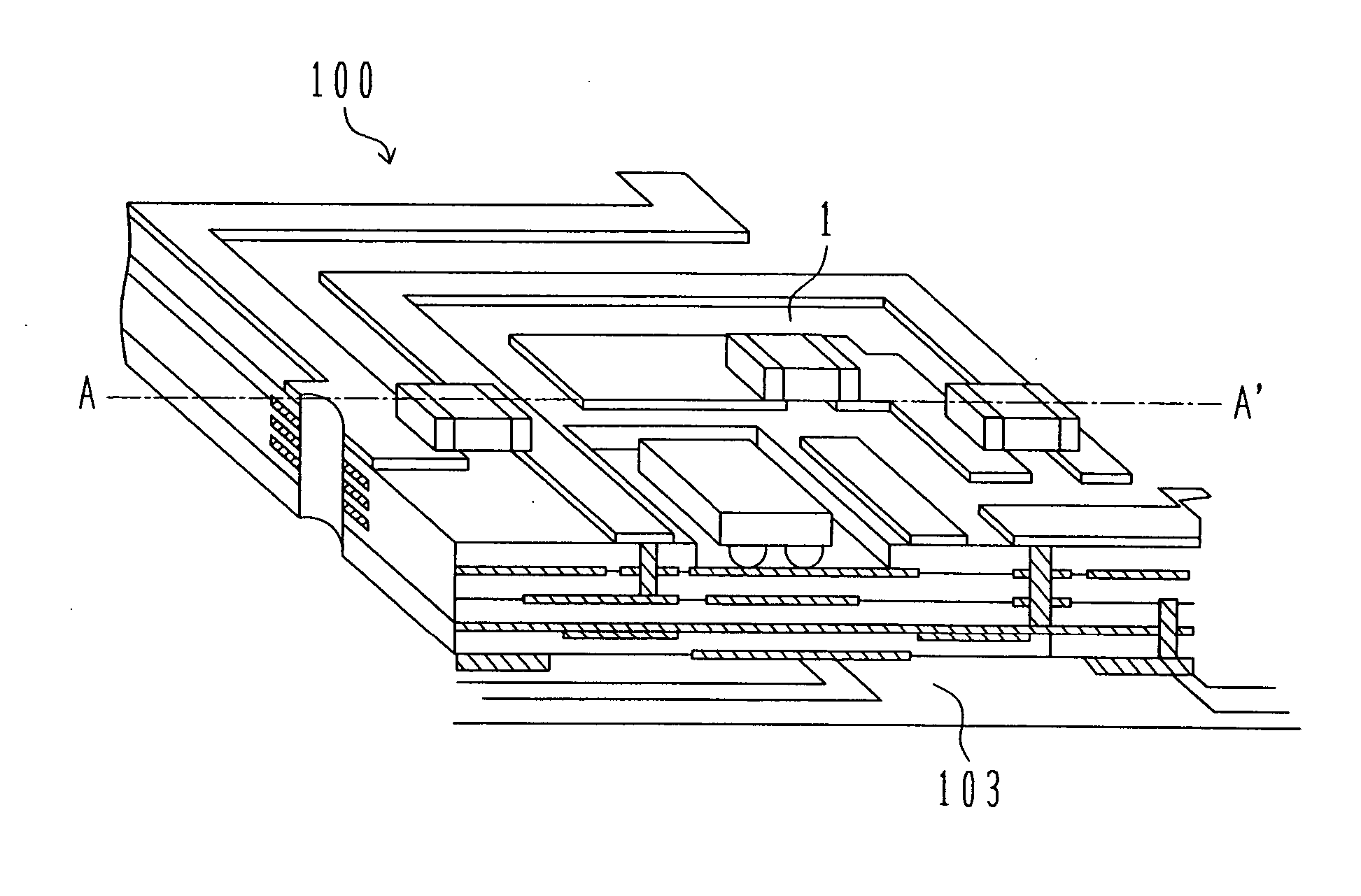

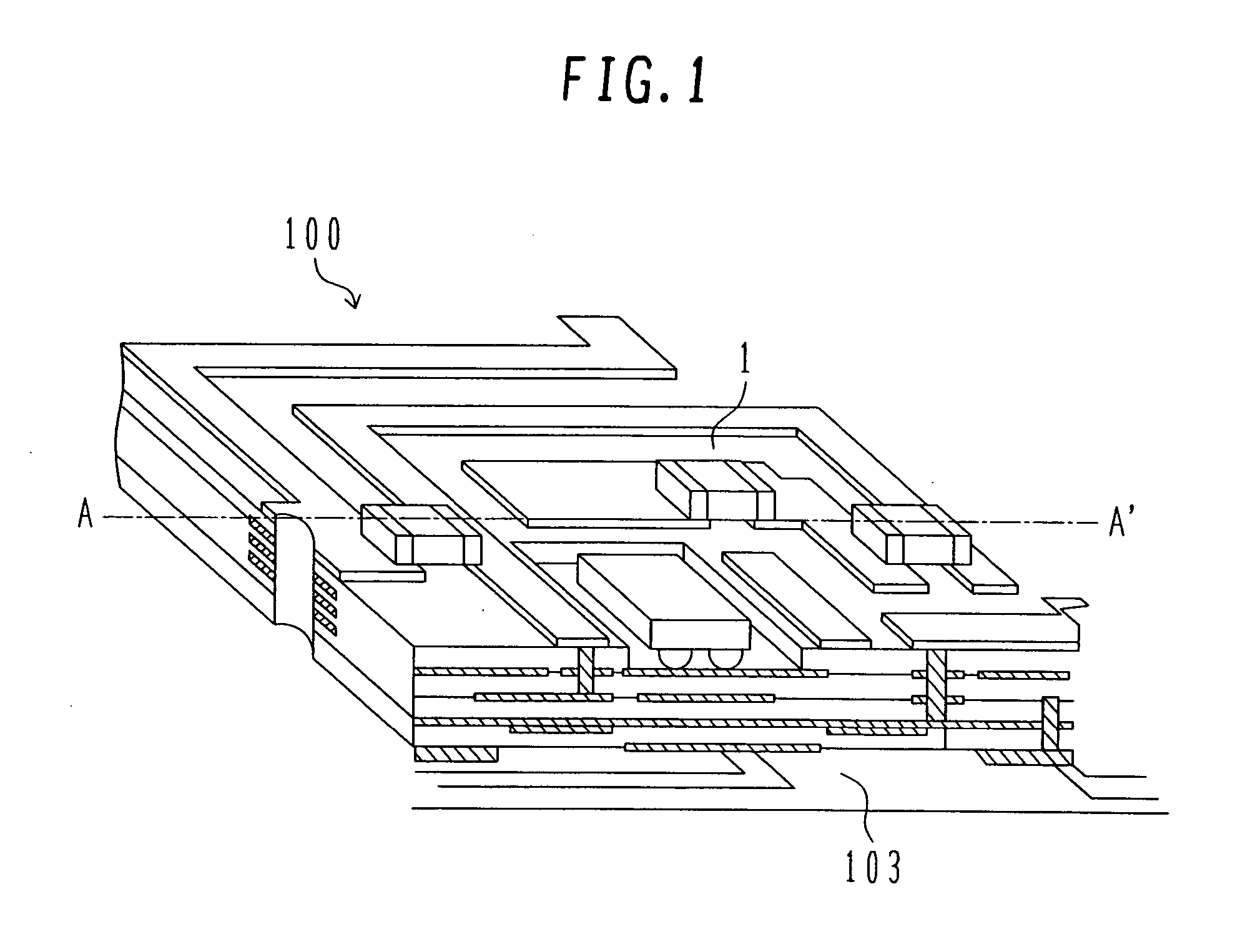

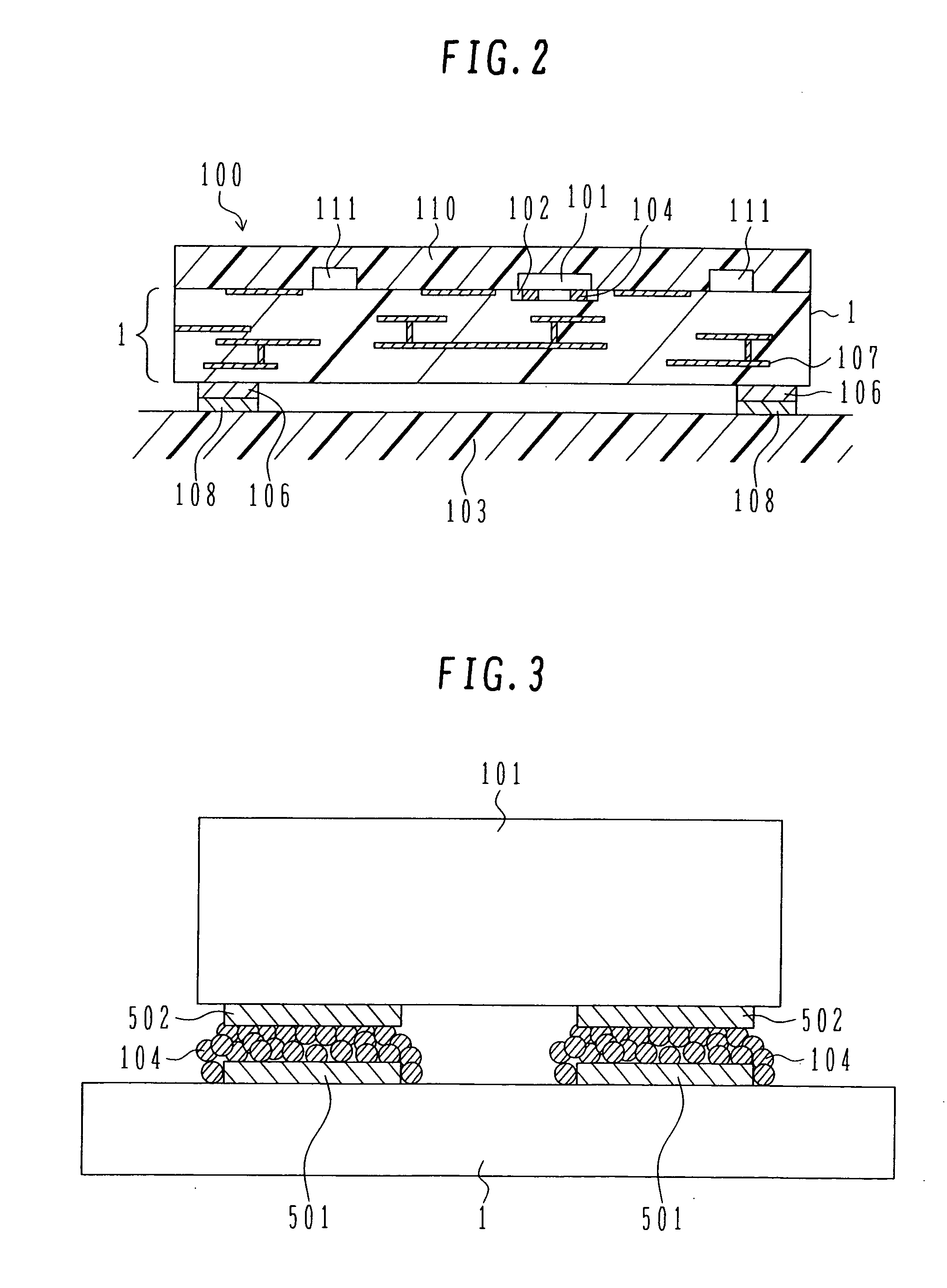

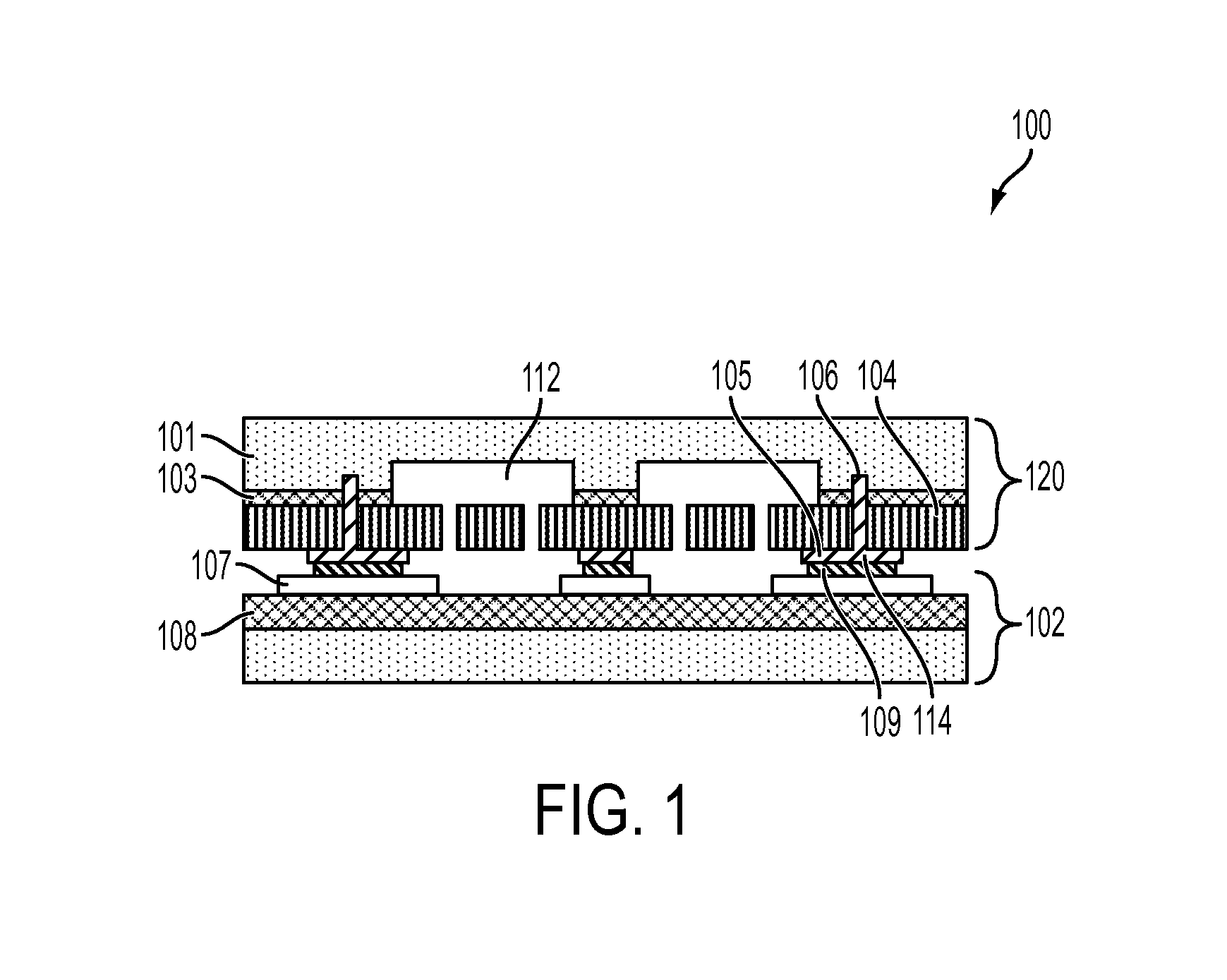

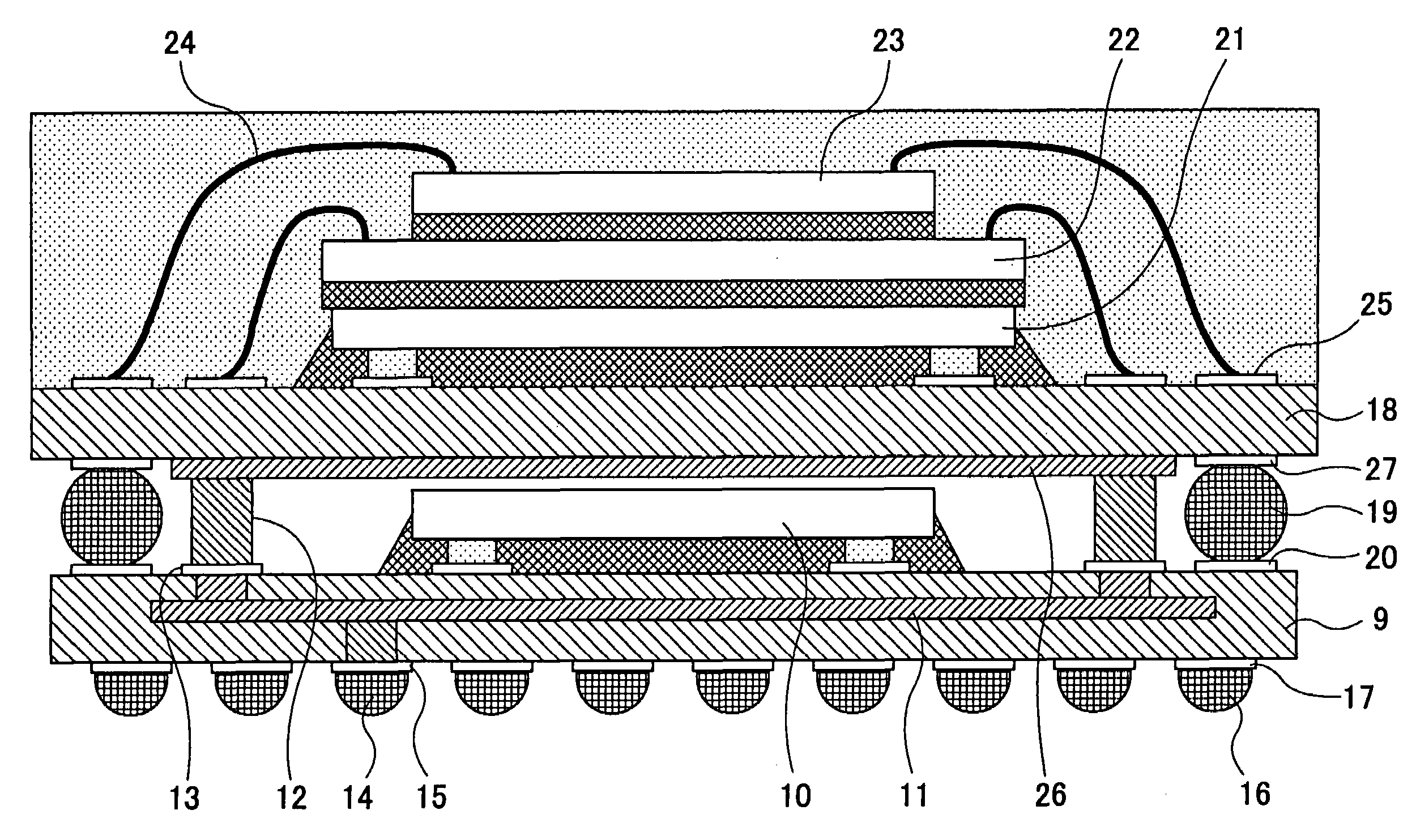

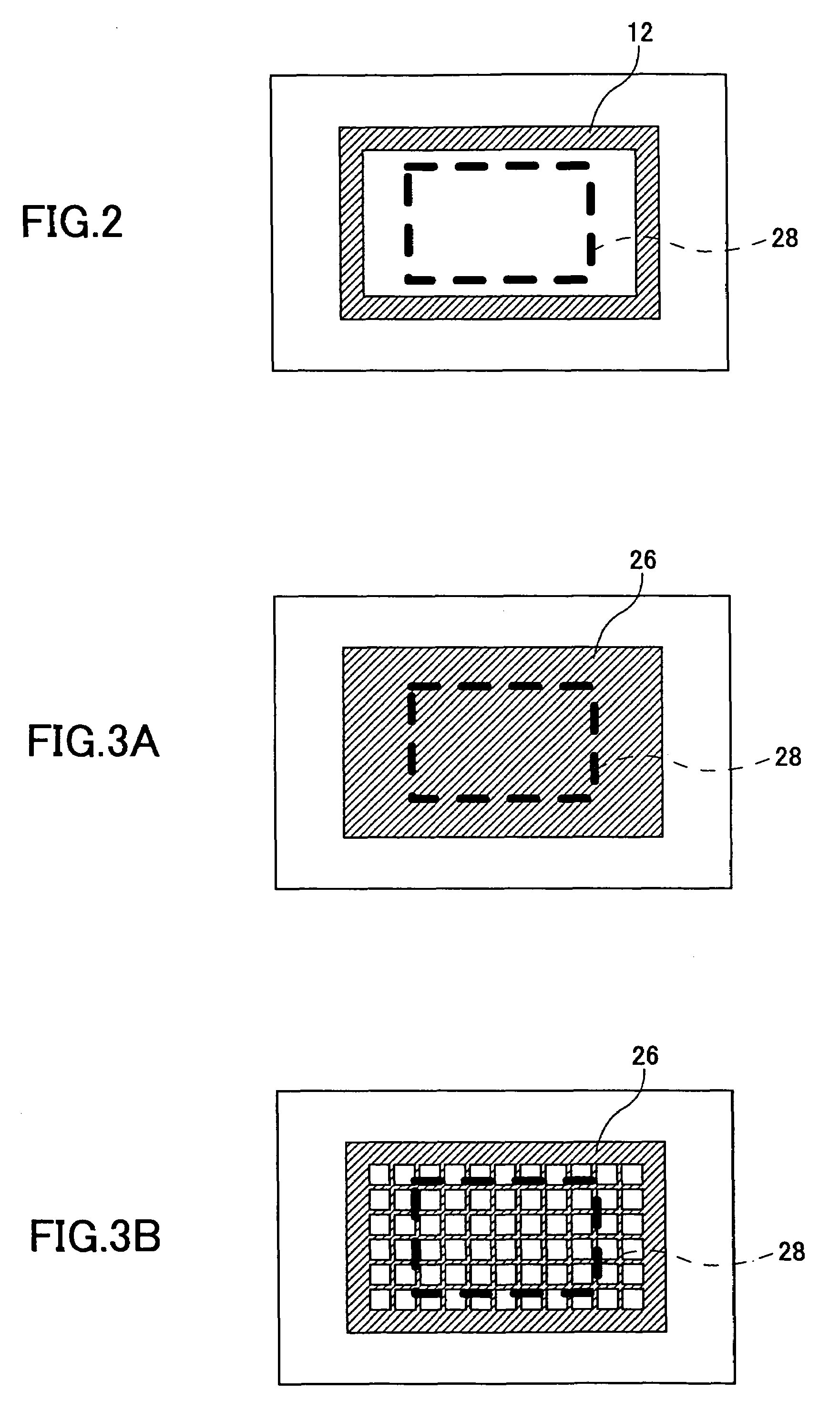

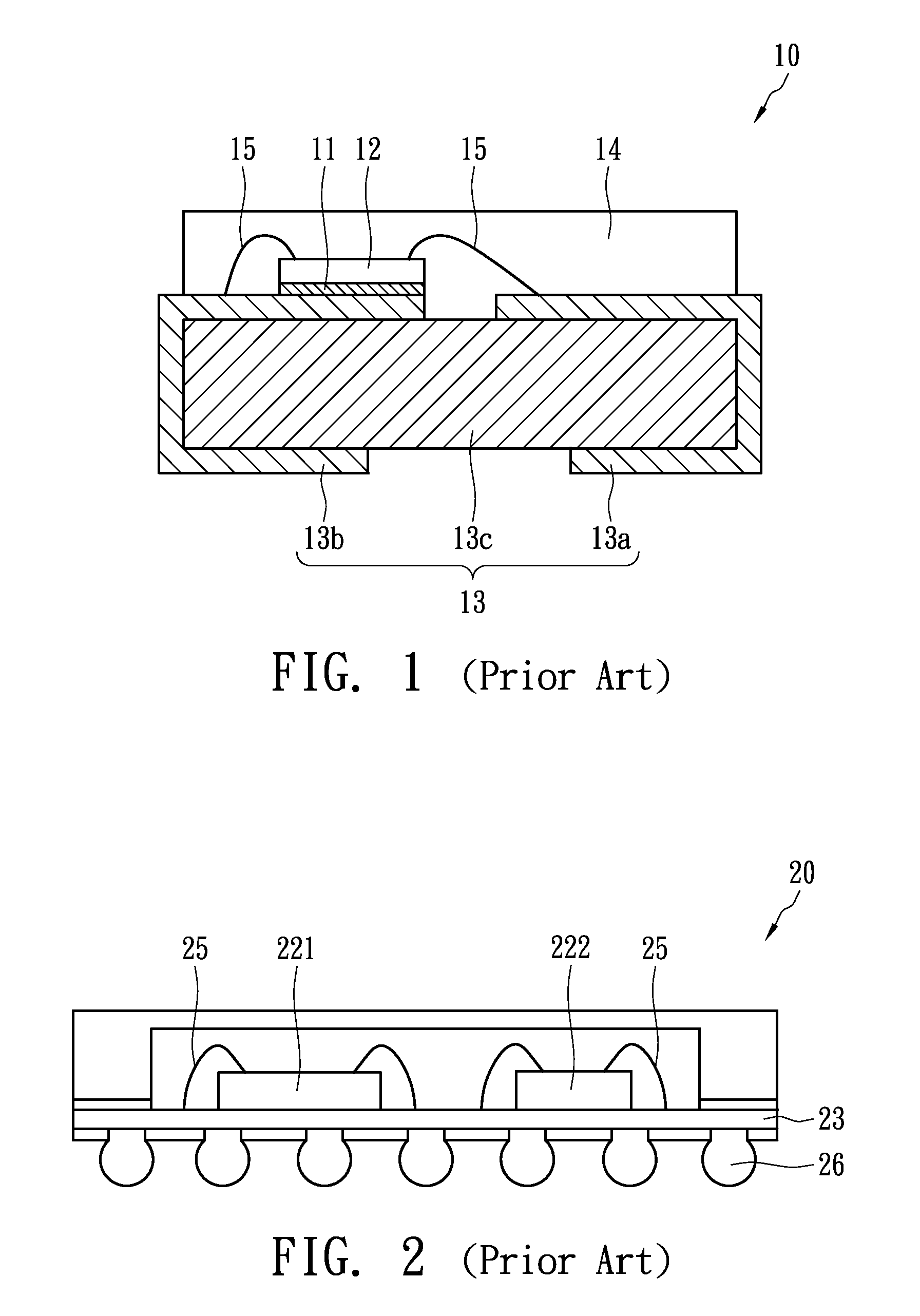

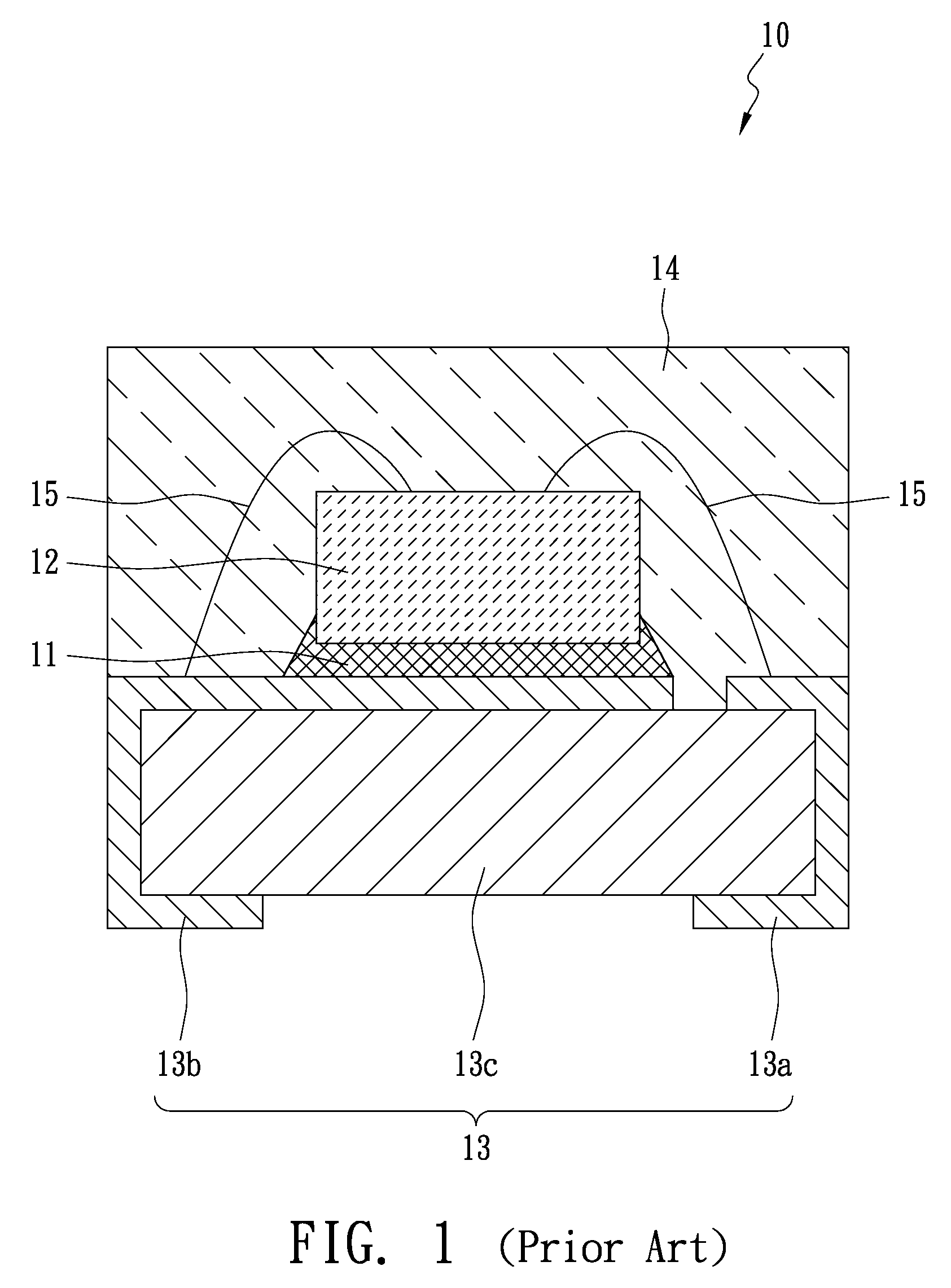

Stacked-type semiconductor device

ActiveUS20050006745A1Reduce thicknessImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A stacked-type semiconductor device includes a first wiring substrate on which a semiconductor device element is mounted, a second wiring substrate stacked on the first wiring substrate through a plurality of electrode terminals which are electrically connected with the first wiring substrate, and a conductor supporting member disposed around the semiconductor device element, and connected with grounding wiring layers provided in the first and second wiring substrate.

Owner:SOCIONEXT INC

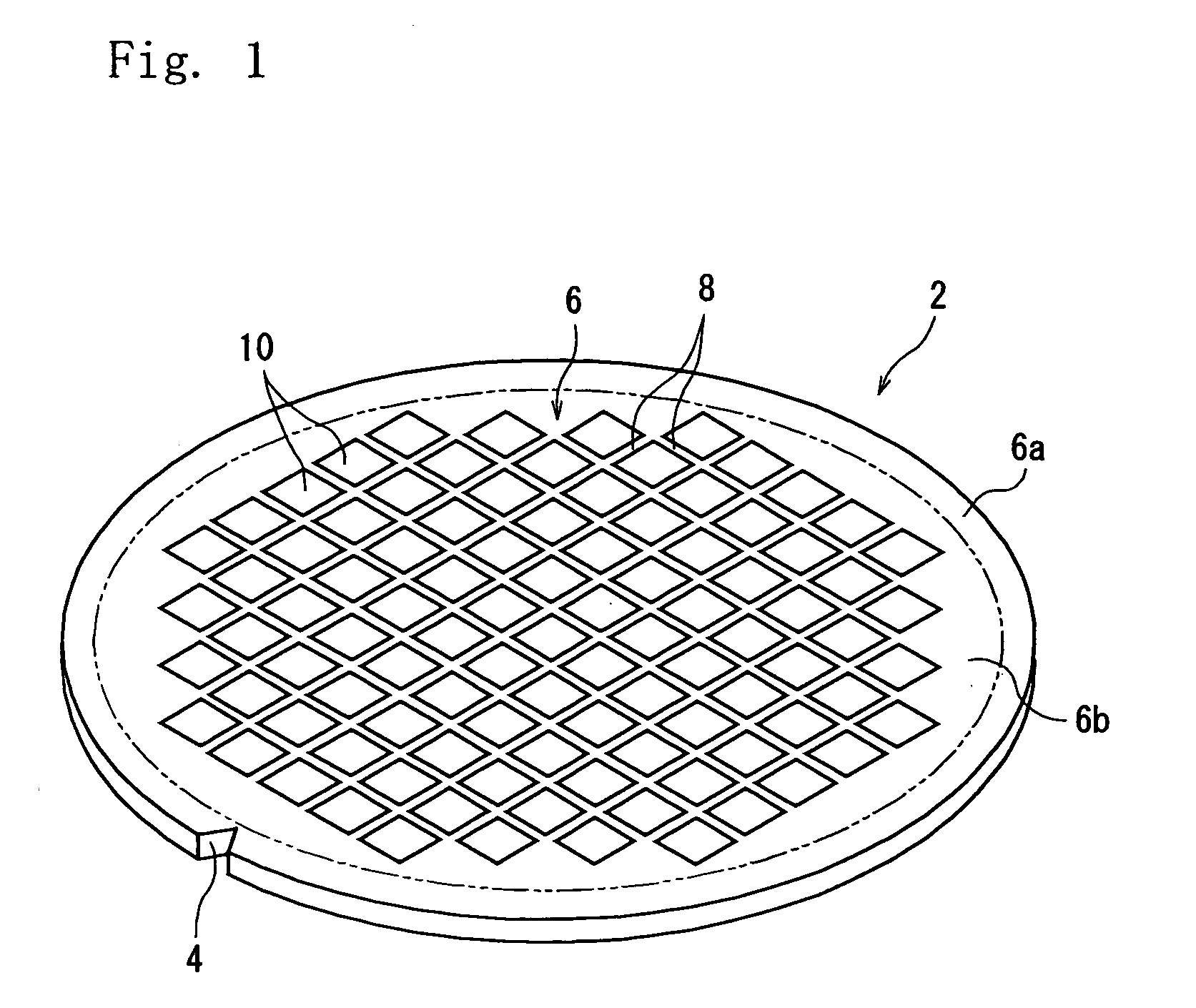

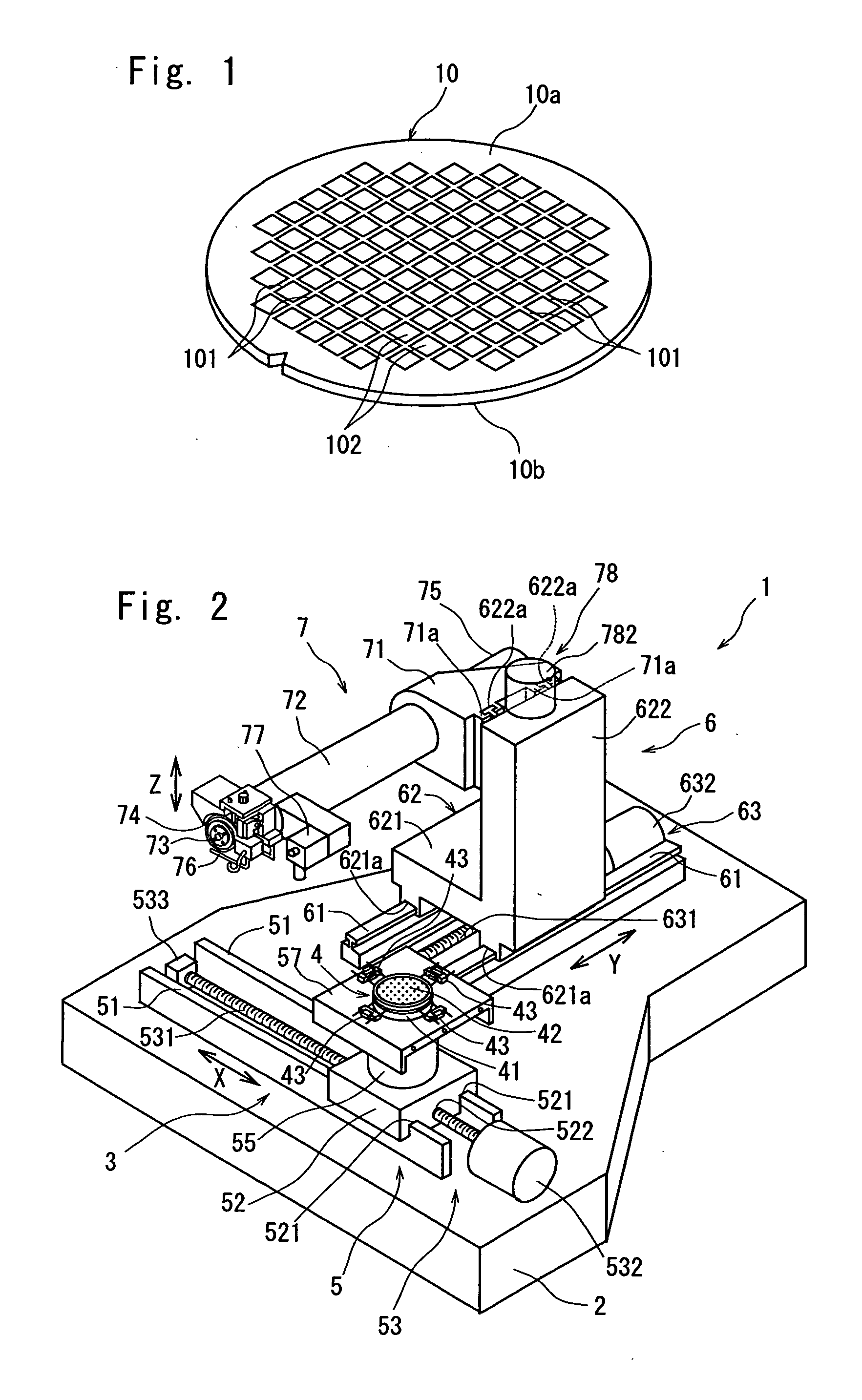

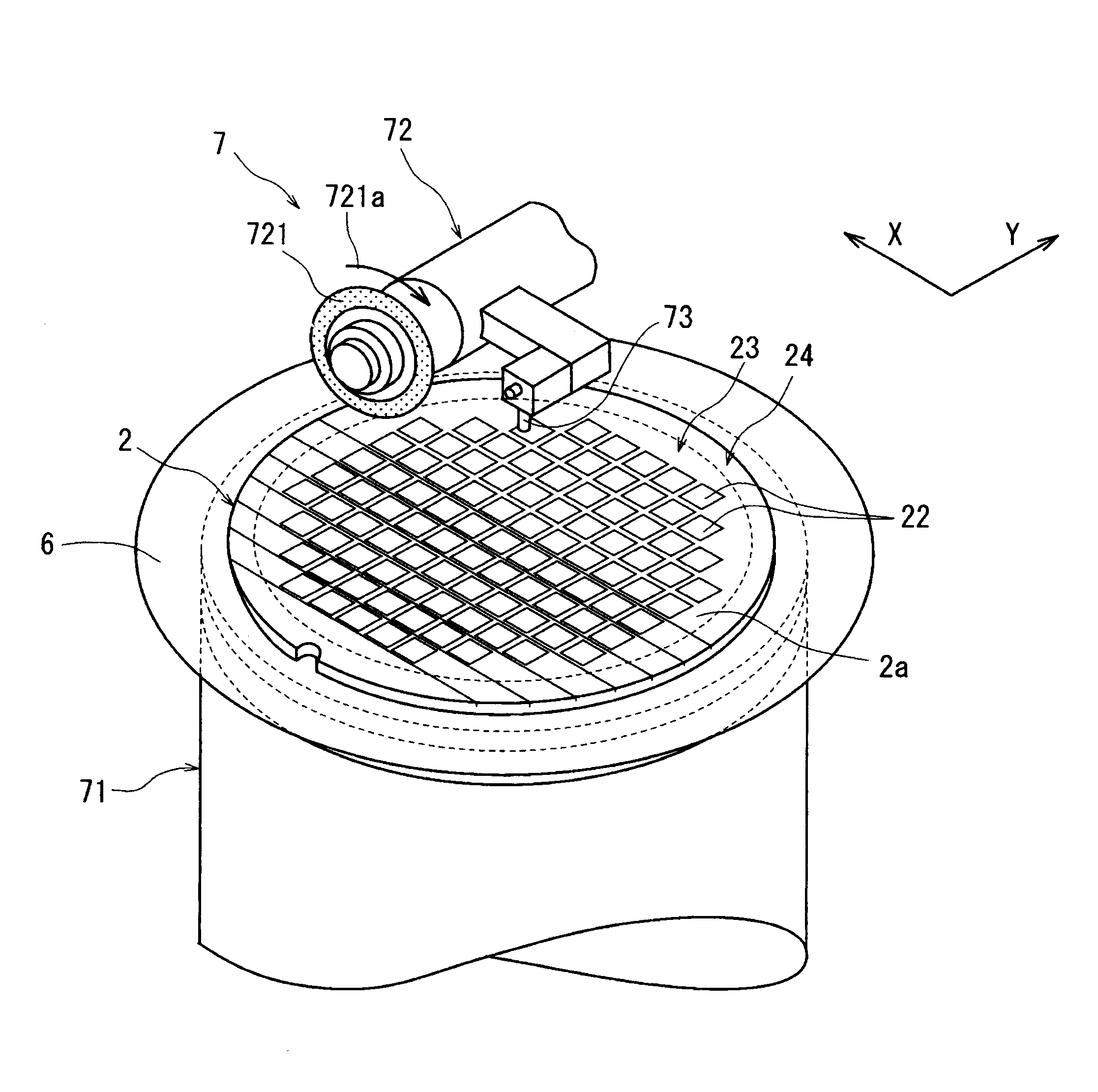

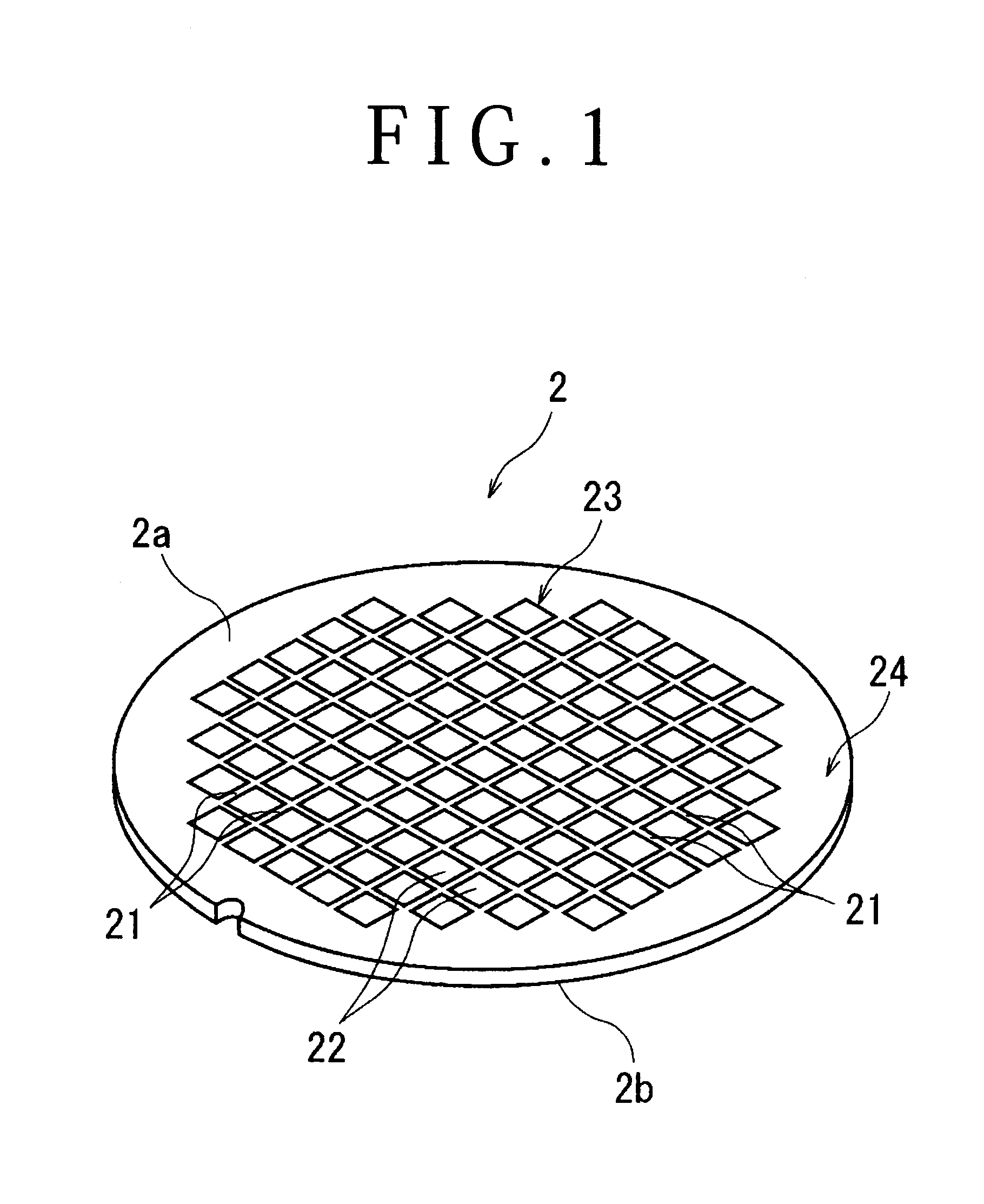

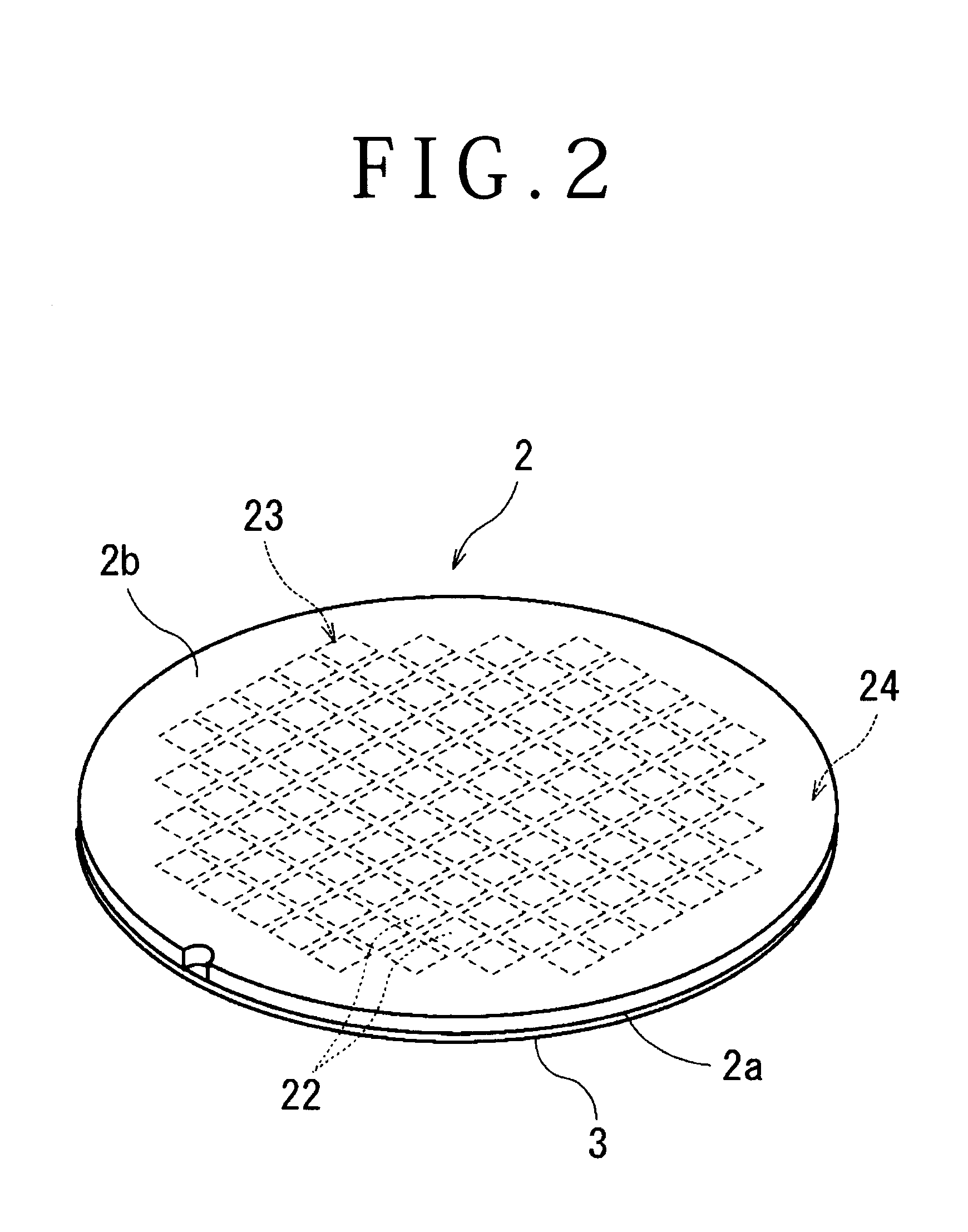

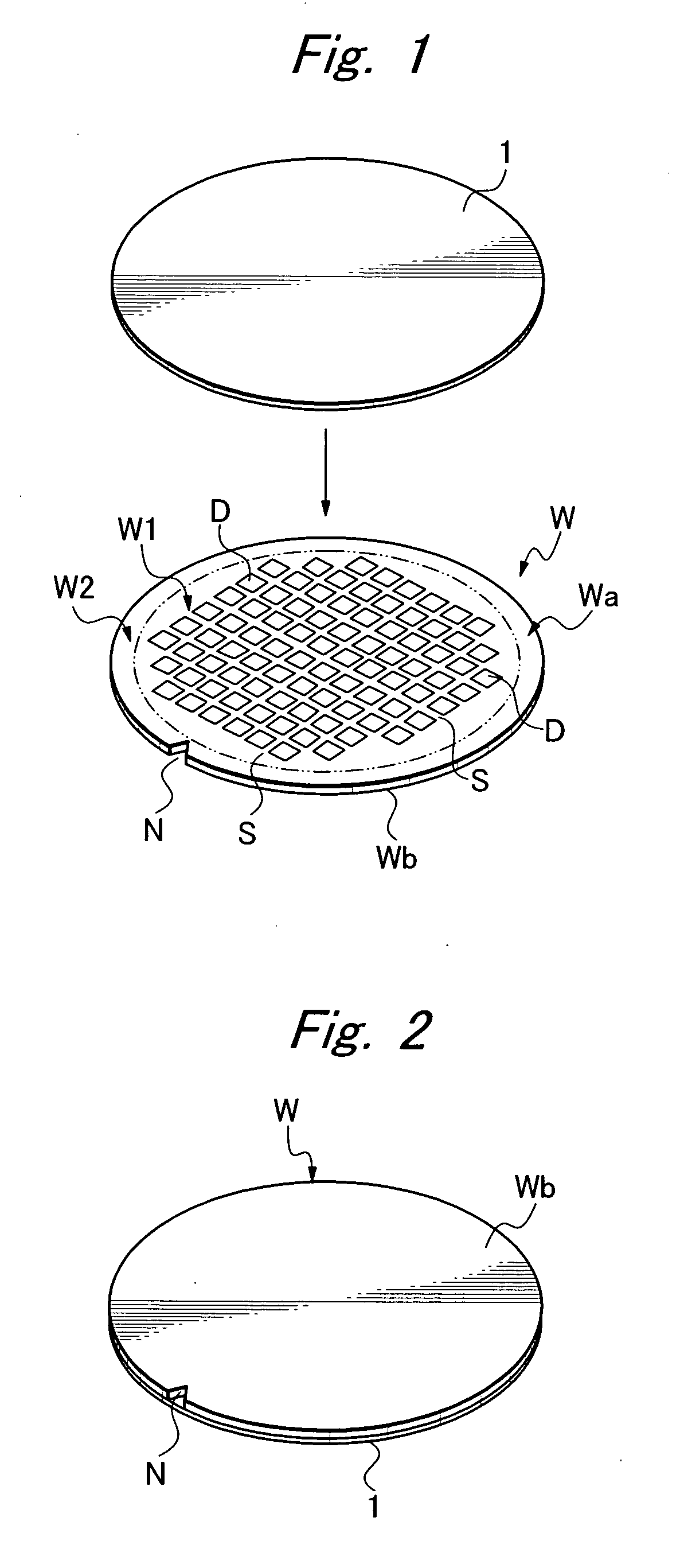

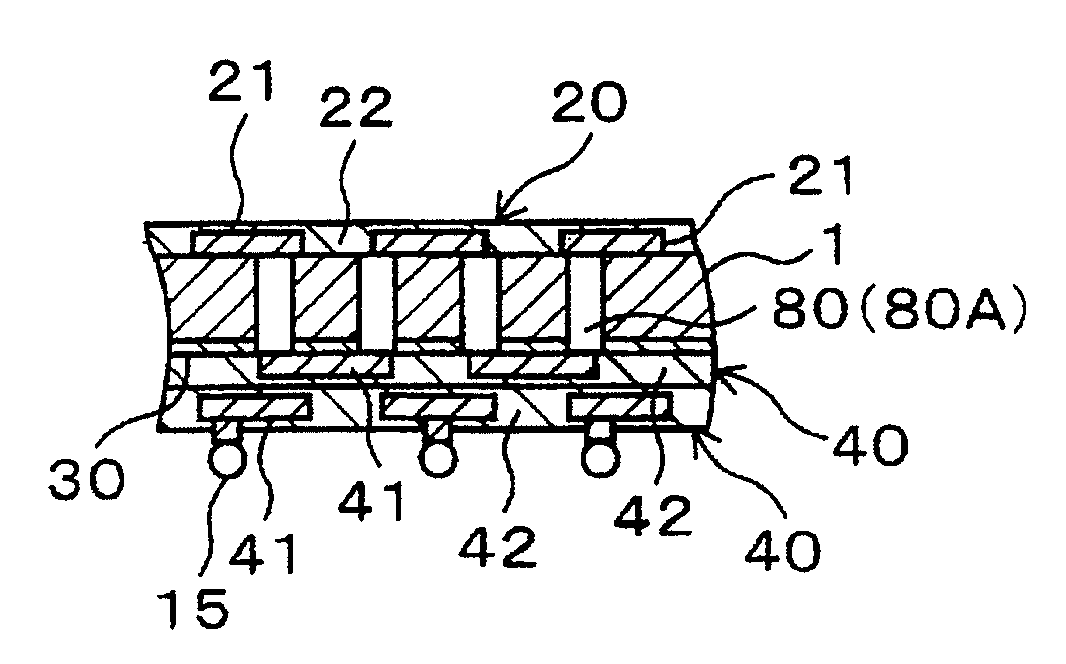

Semiconductor wafer and processing method for same

ActiveUS20060244096A1Avoid difficultyRisk minimizationSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDevice materialSemiconductor

A semiconductor wafer which is generally circular, and which has on its face an annular surplus region present in an outer peripheral edge portion of the face, and a circular device region surrounded by the surplus region, the device region having many semiconductor devices disposed therein. A circular concavity is formed in the back of the semiconductor wafer in correspondence with the device region, and the device region is relatively thin, while the surplus region is relatively thick.

Owner:DISCO CORP

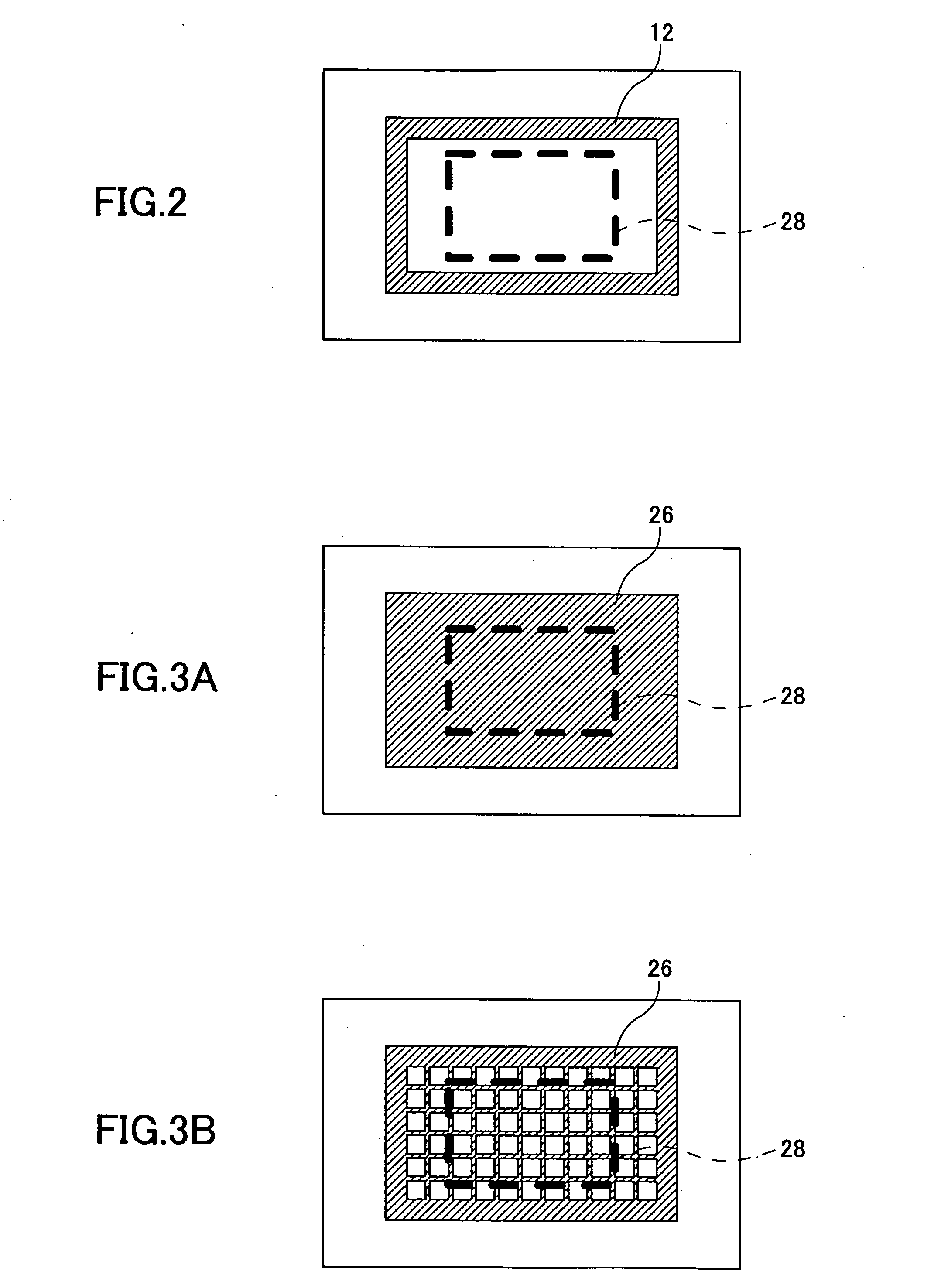

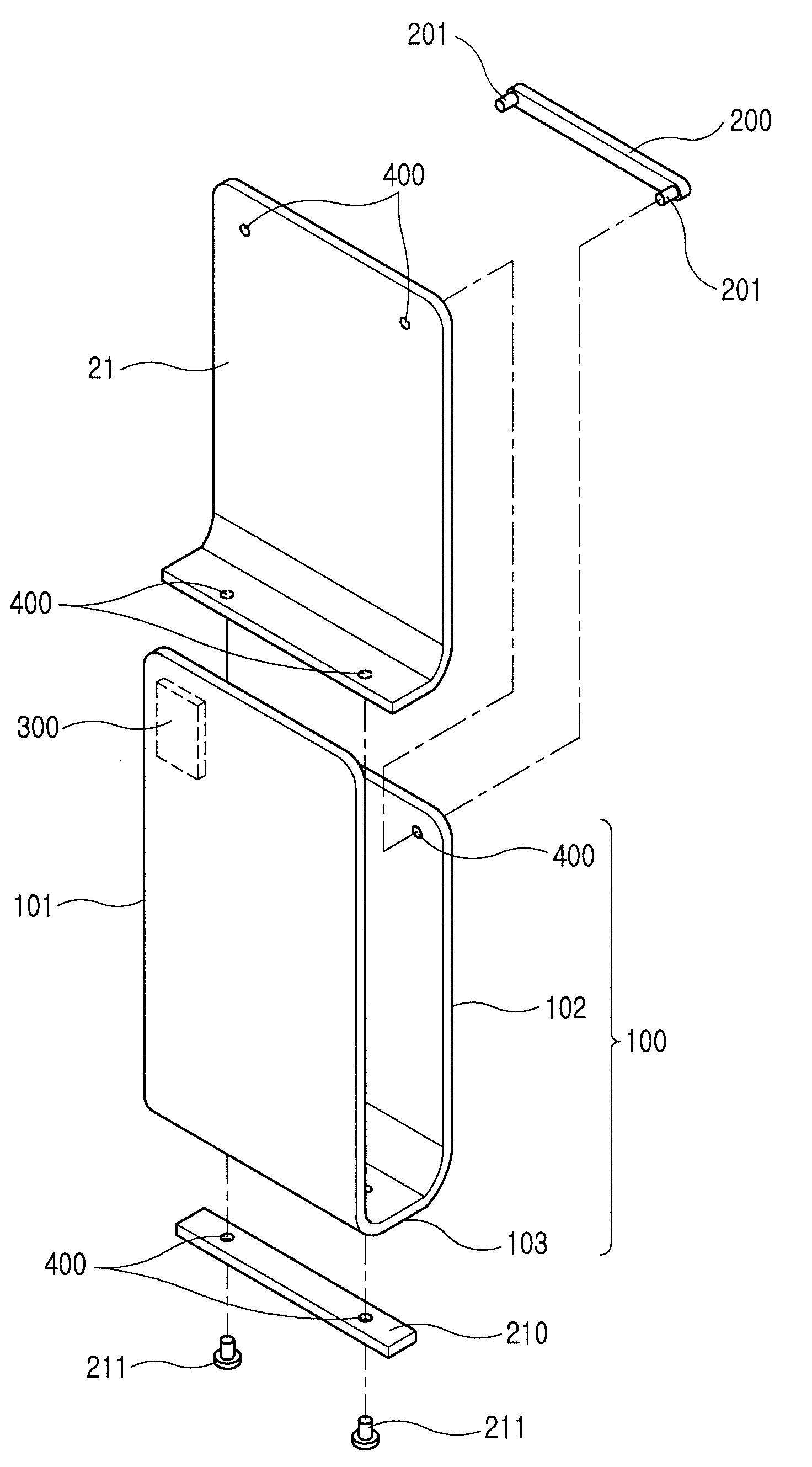

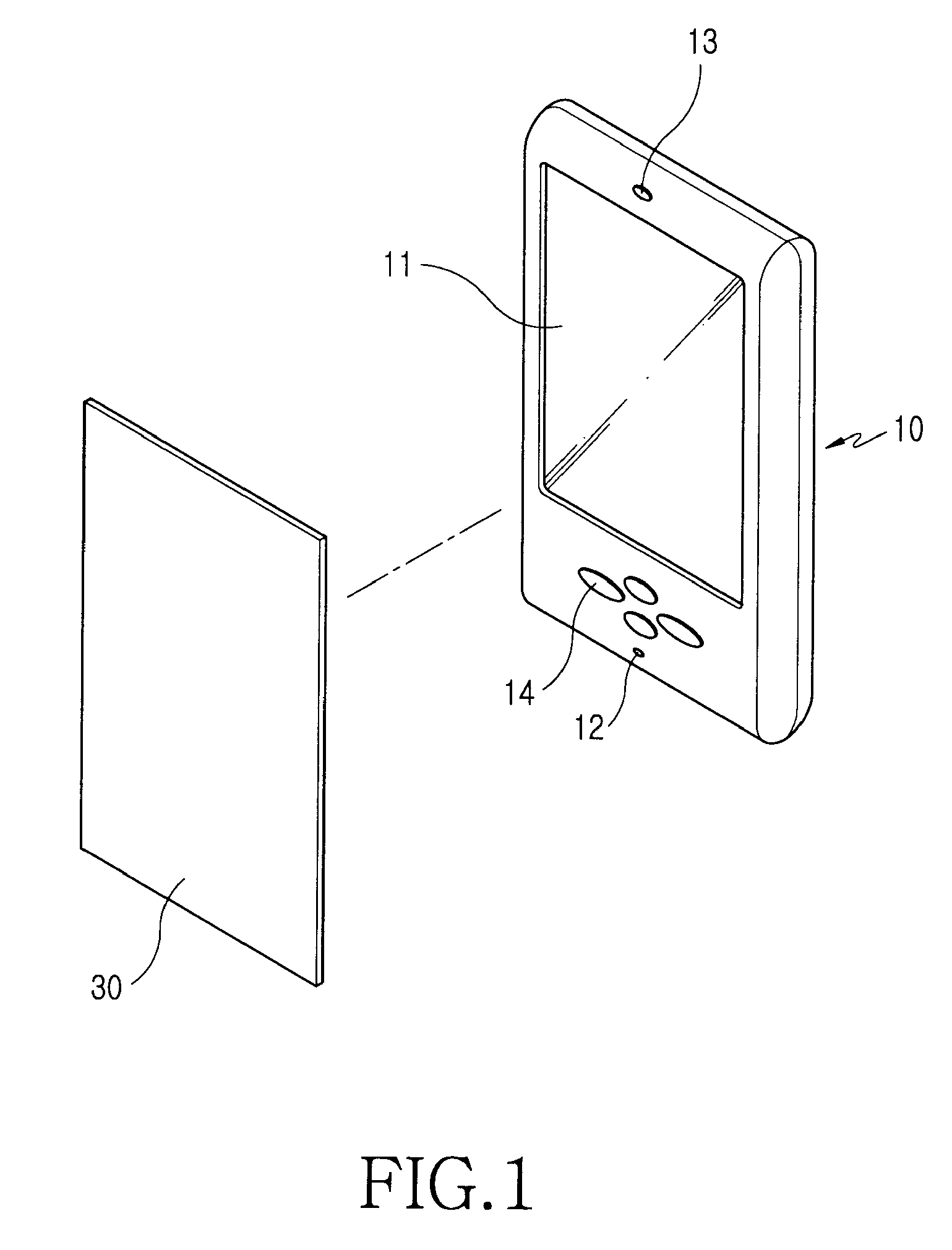

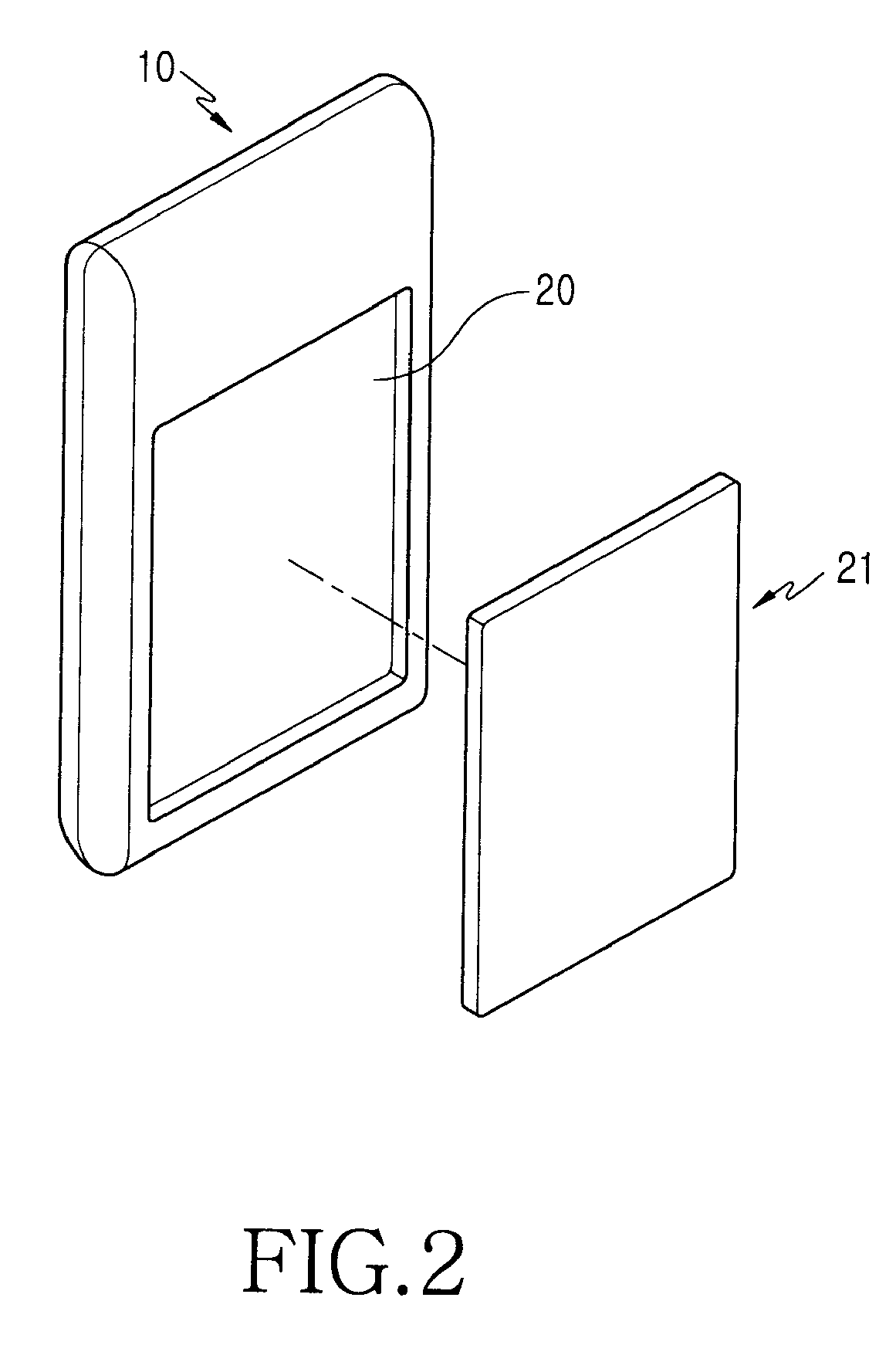

Protective cover for portable communication device

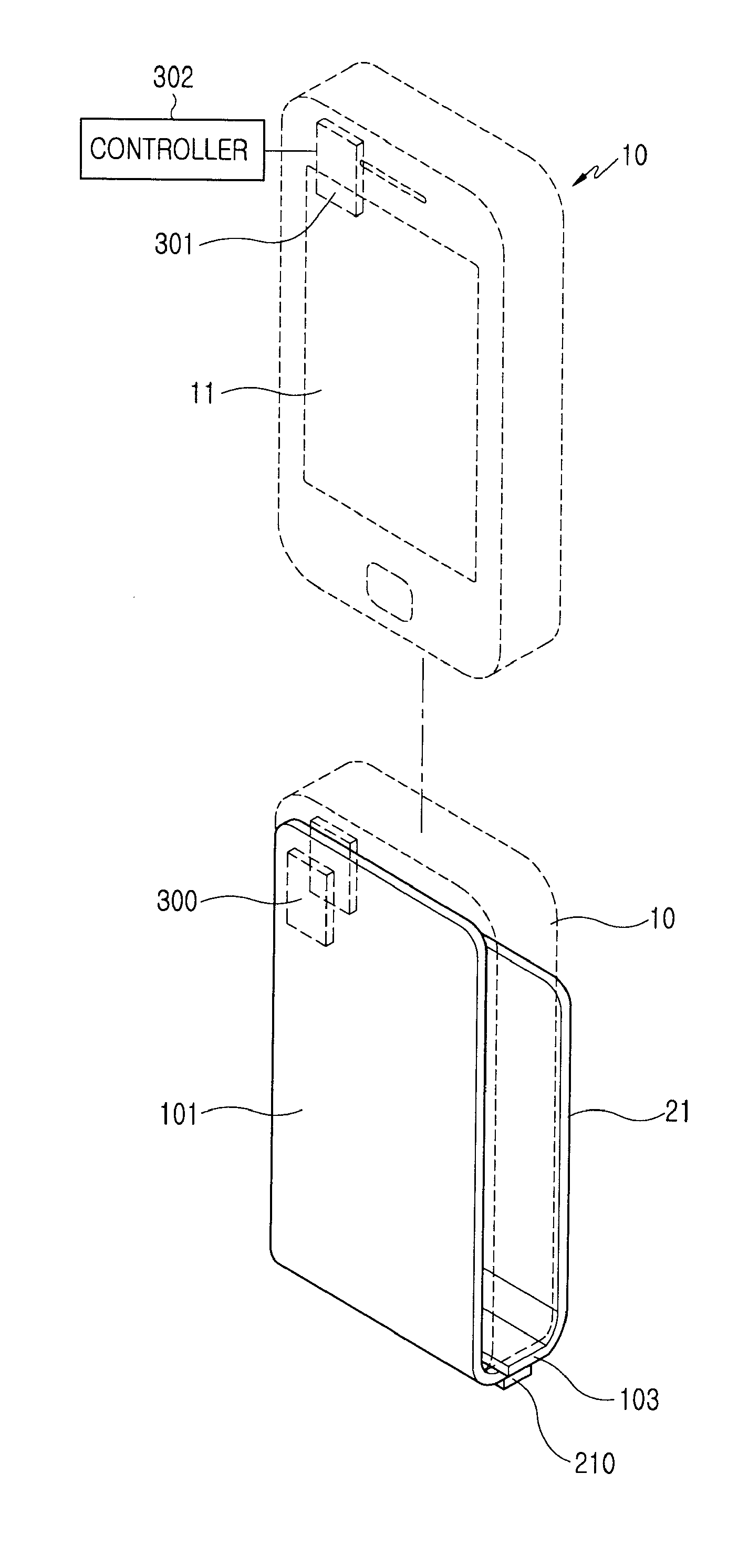

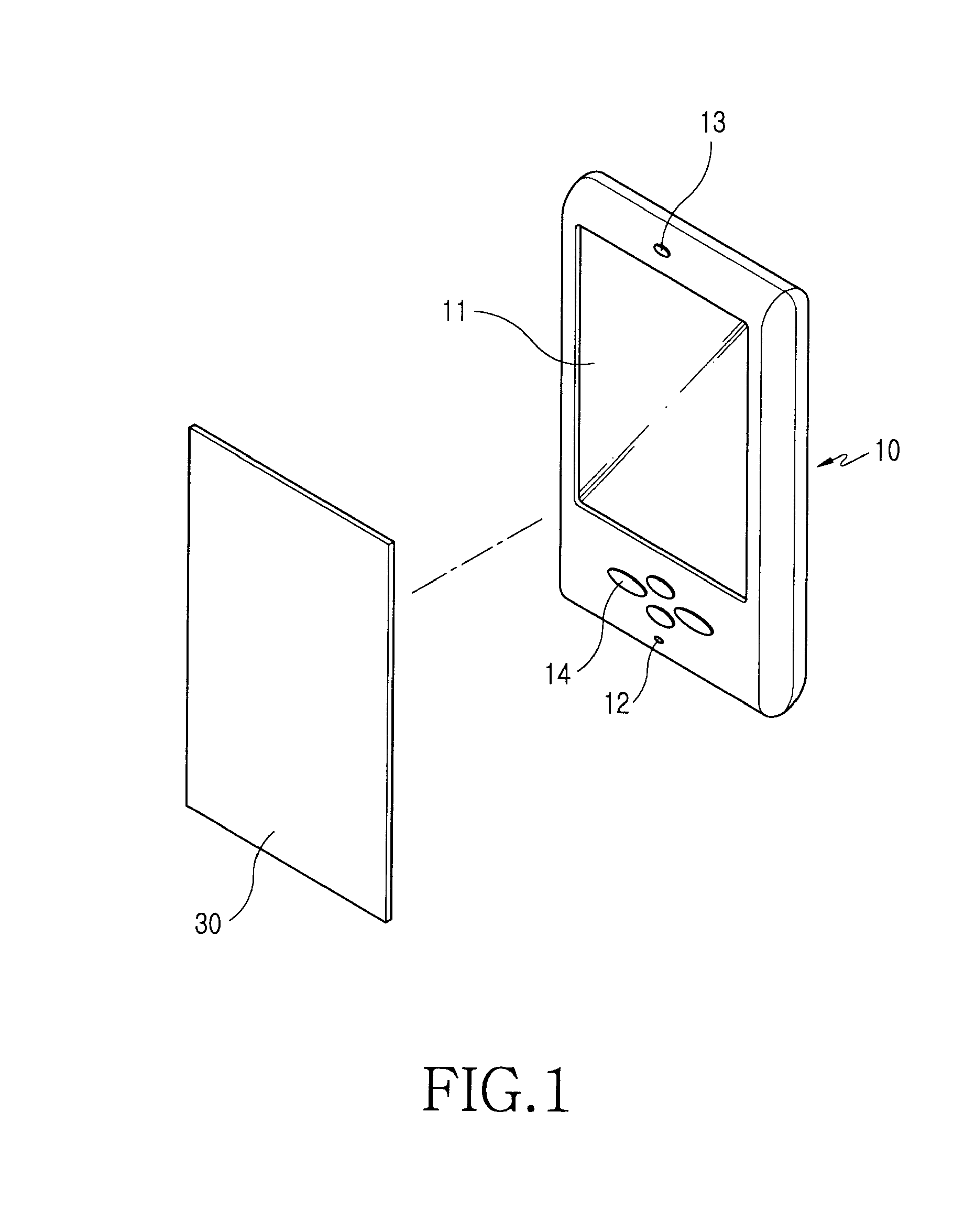

ActiveUS7747007B2Improve portabilityLoss of the covers may be preventedInterconnection arrangementsDigital data processing detailsEngineeringPortable communications device

A protective cover for a portable communication device includes a battery cover and a protective cover part coupled with the battery cover. The protective cover is detachably coupled with the portable communication device, and the protective cover part is disposed at a front surface of a display unit part of the portable communication device when the protective cover is coupled with the portable communication device. The portable communication device being turned off / on when the portable communication device is attached to / detached from the protective cover.

Owner:SAMSUNG ELECTRONICS CO LTD

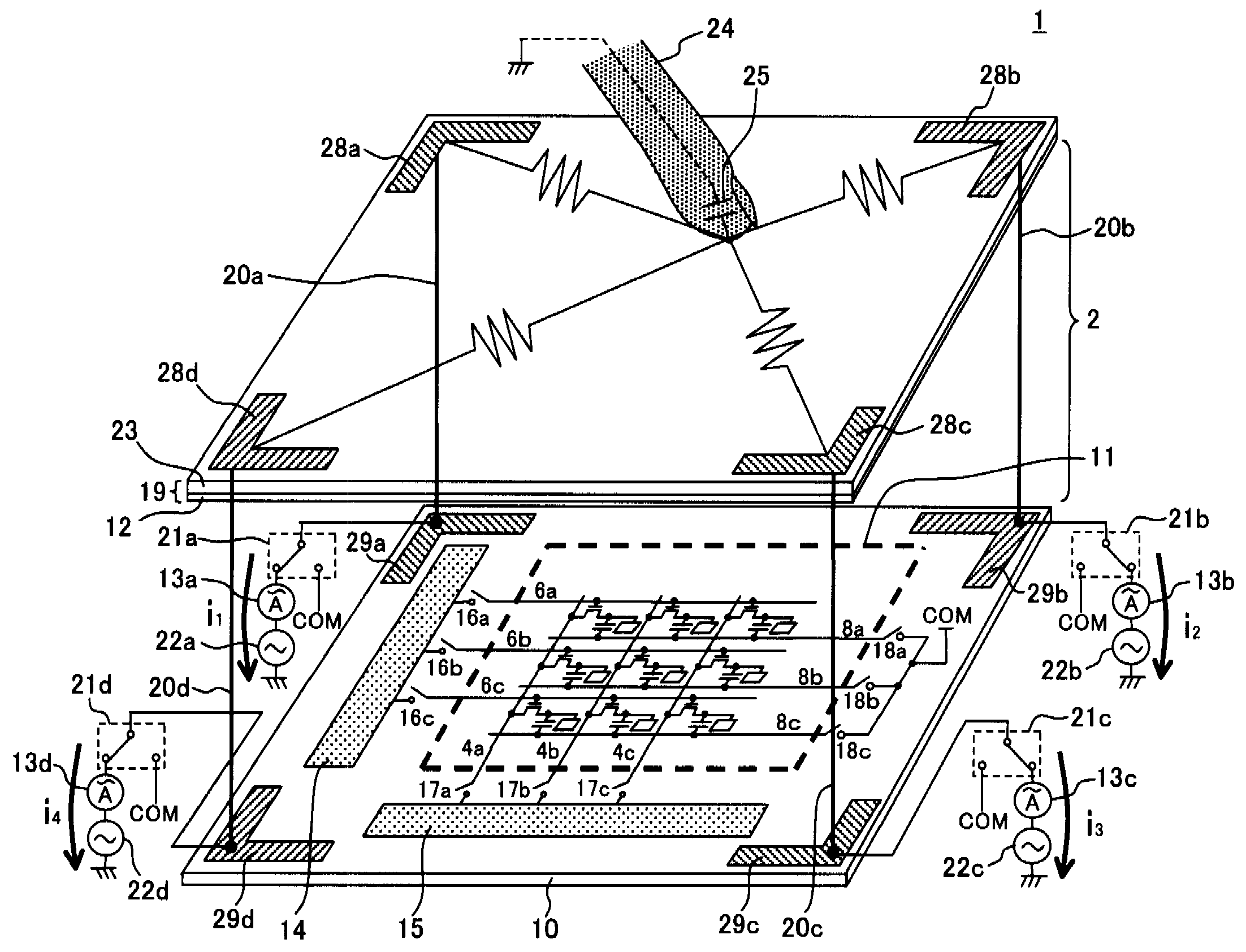

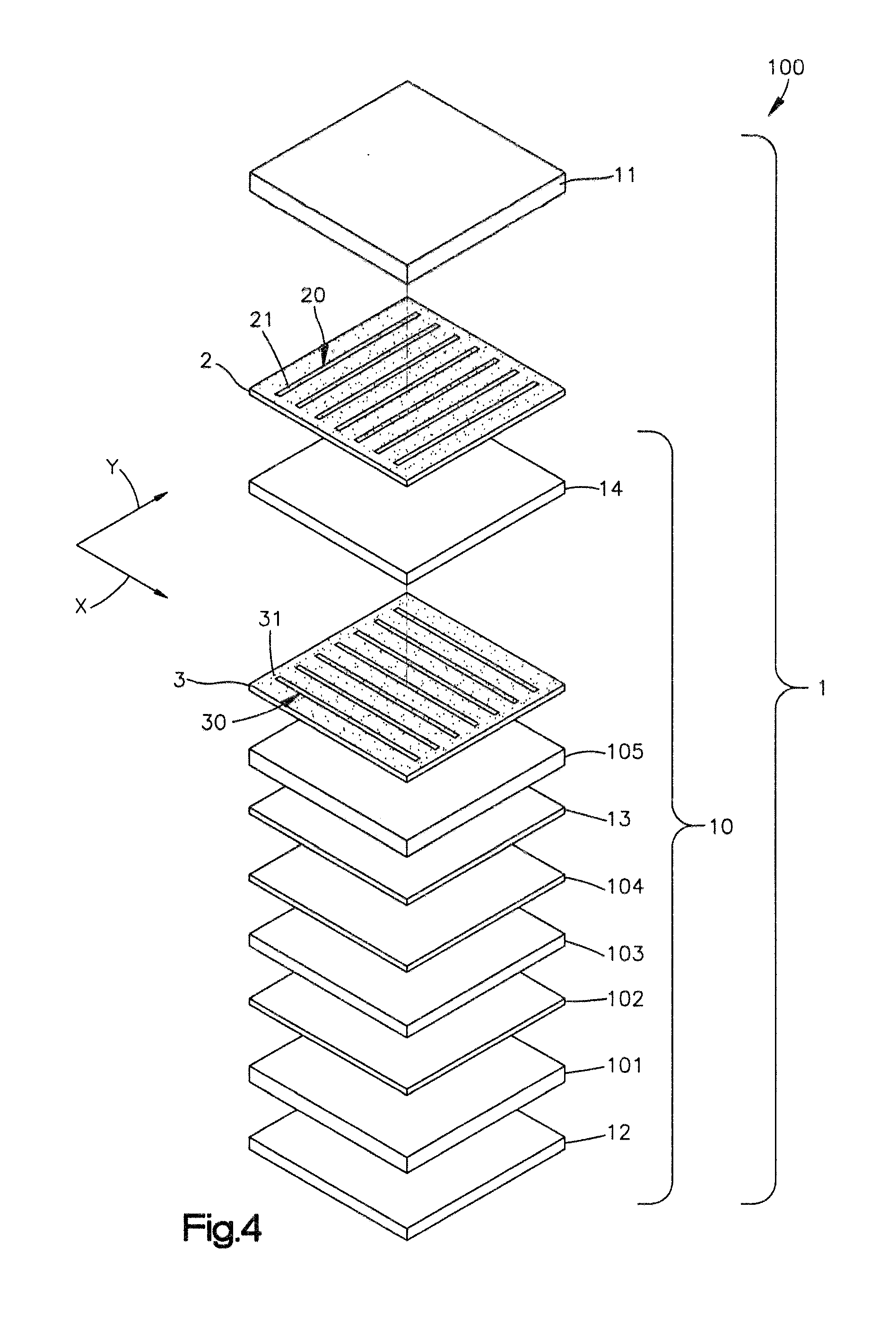

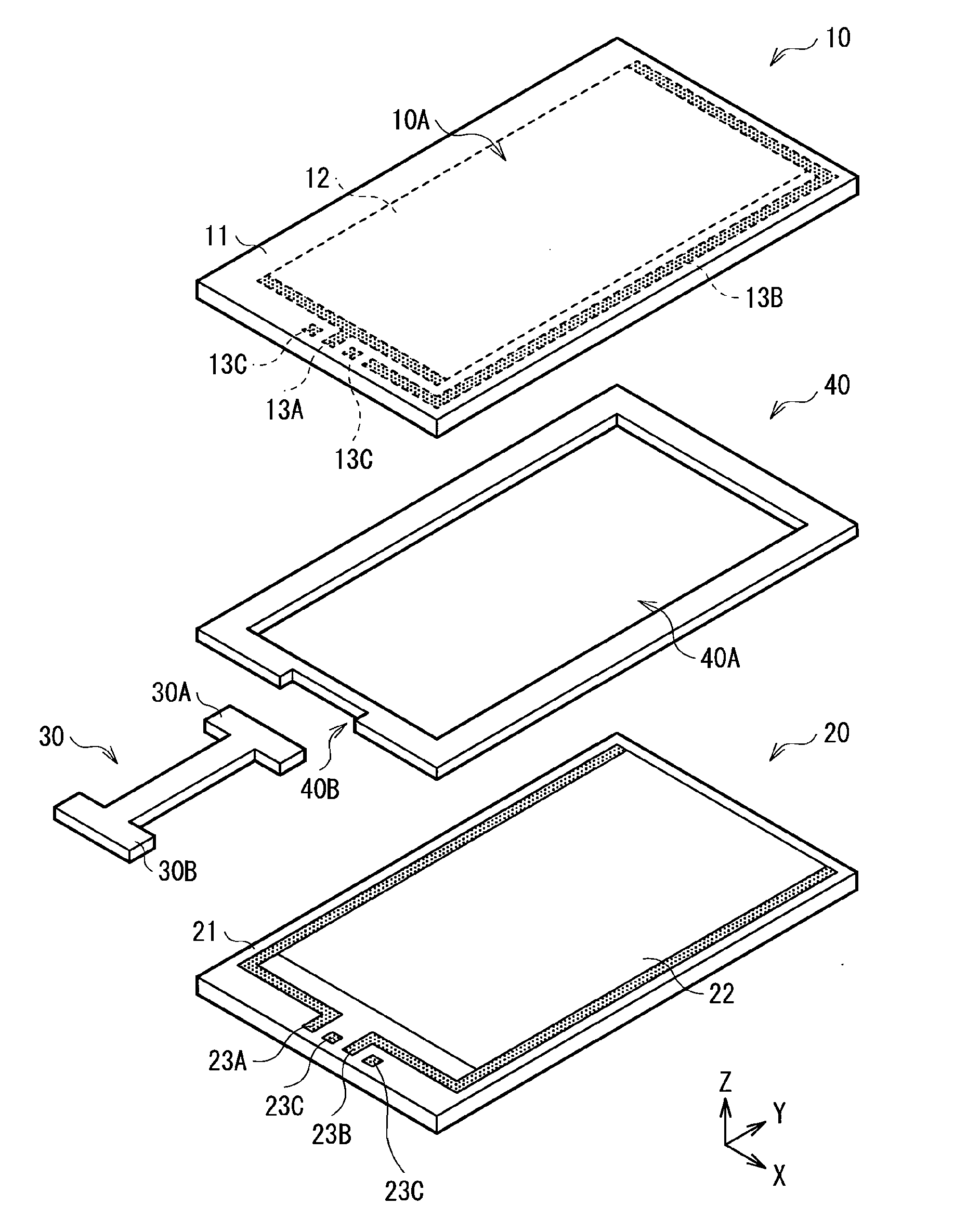

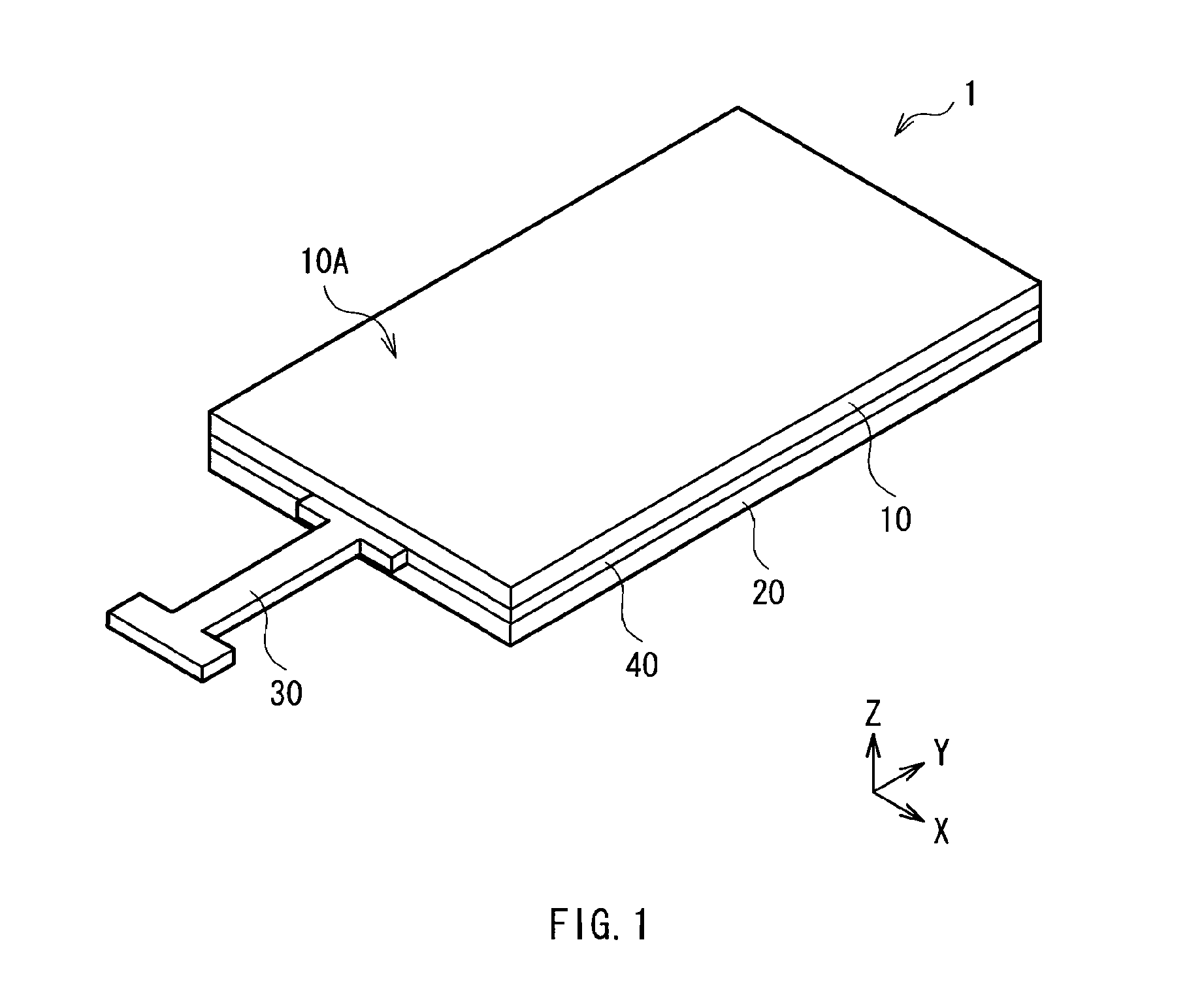

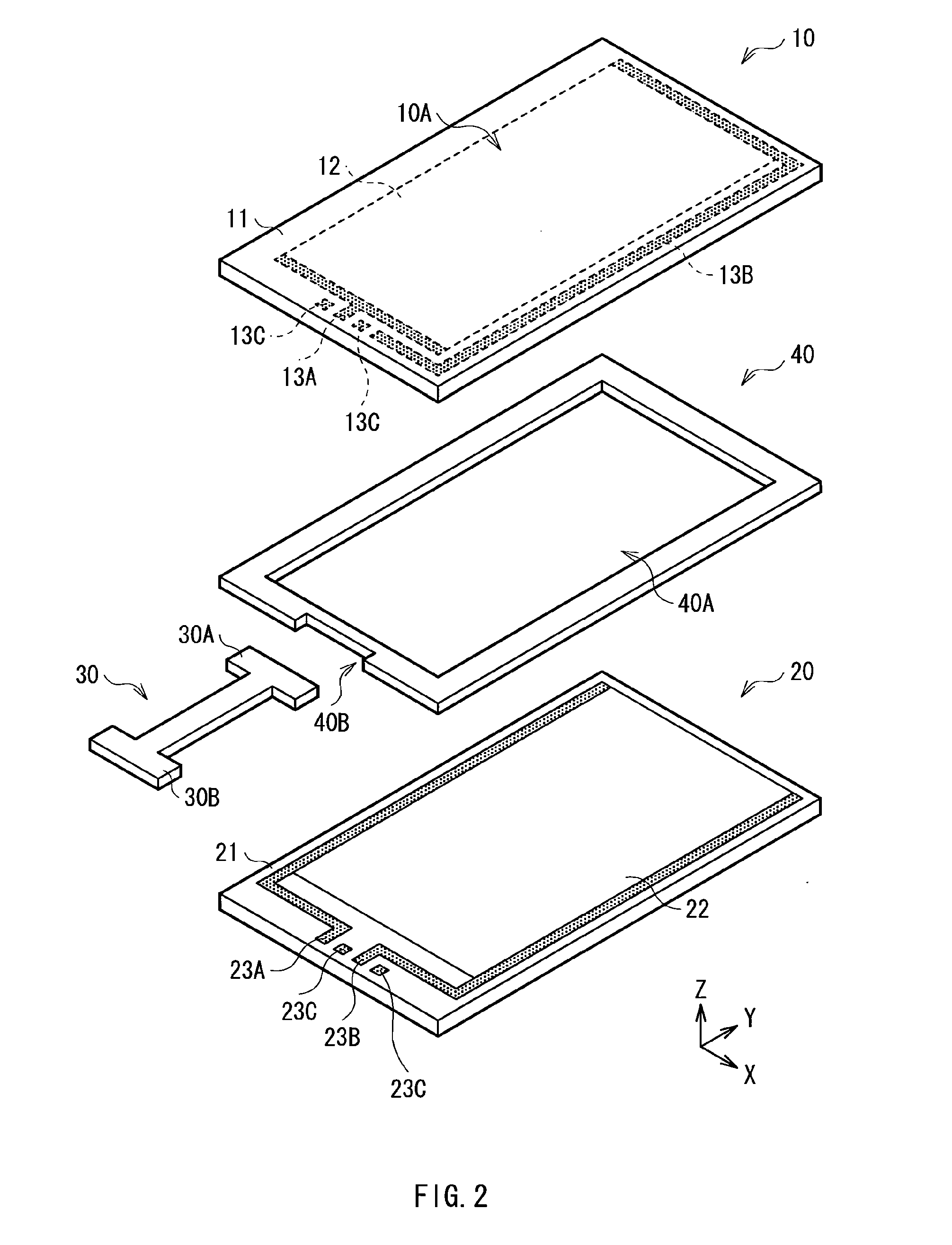

Flat- panel display device and electronic apparatus

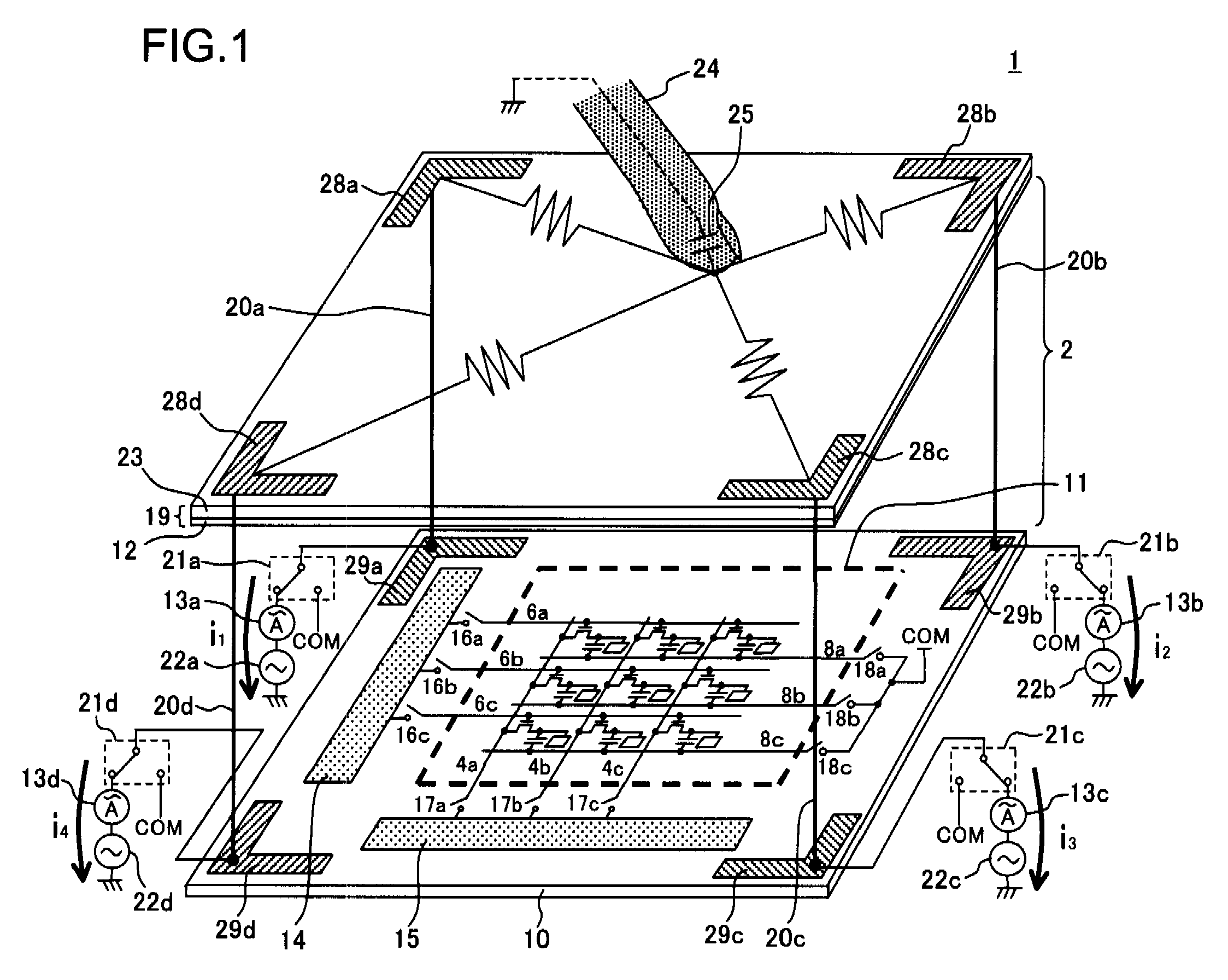

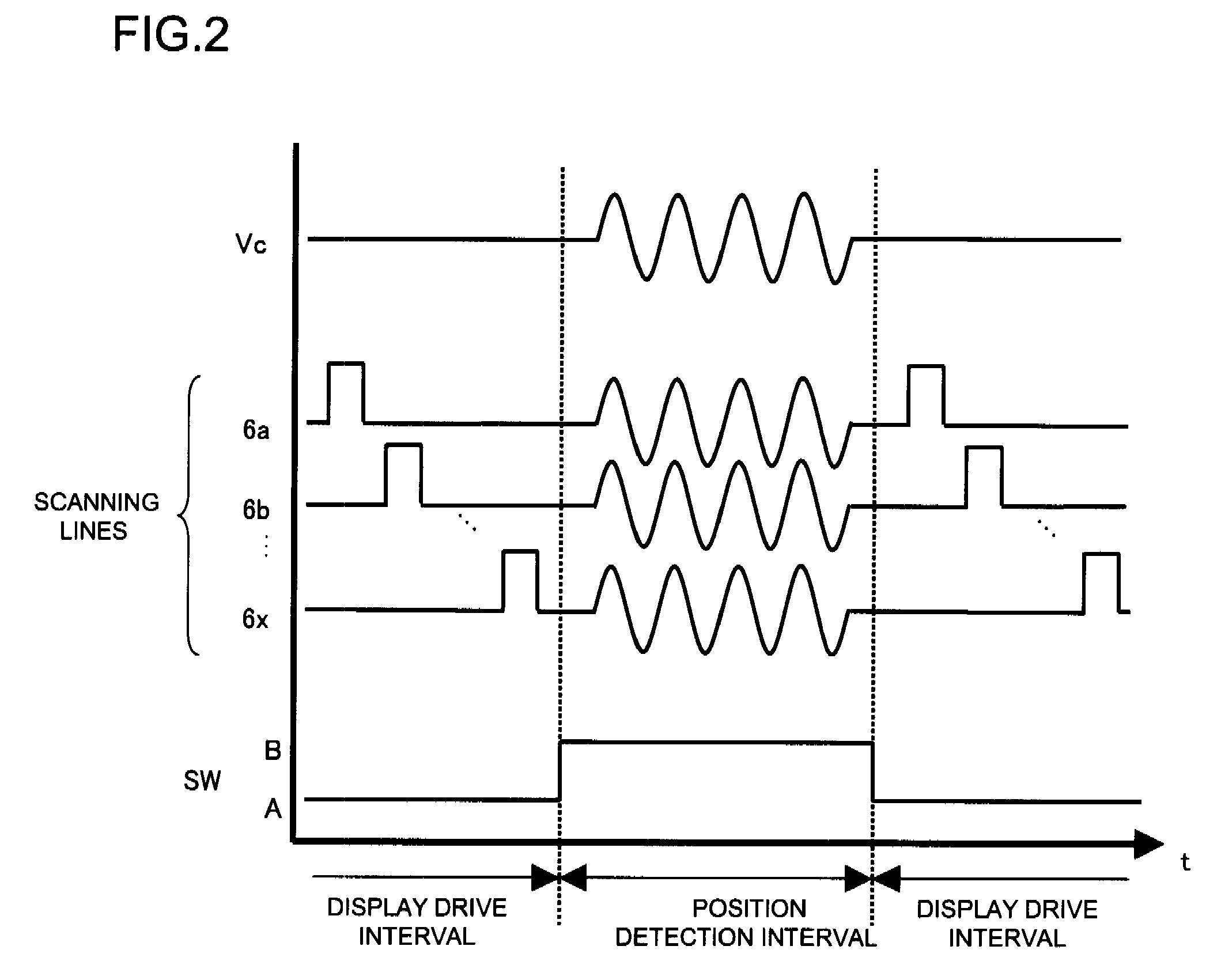

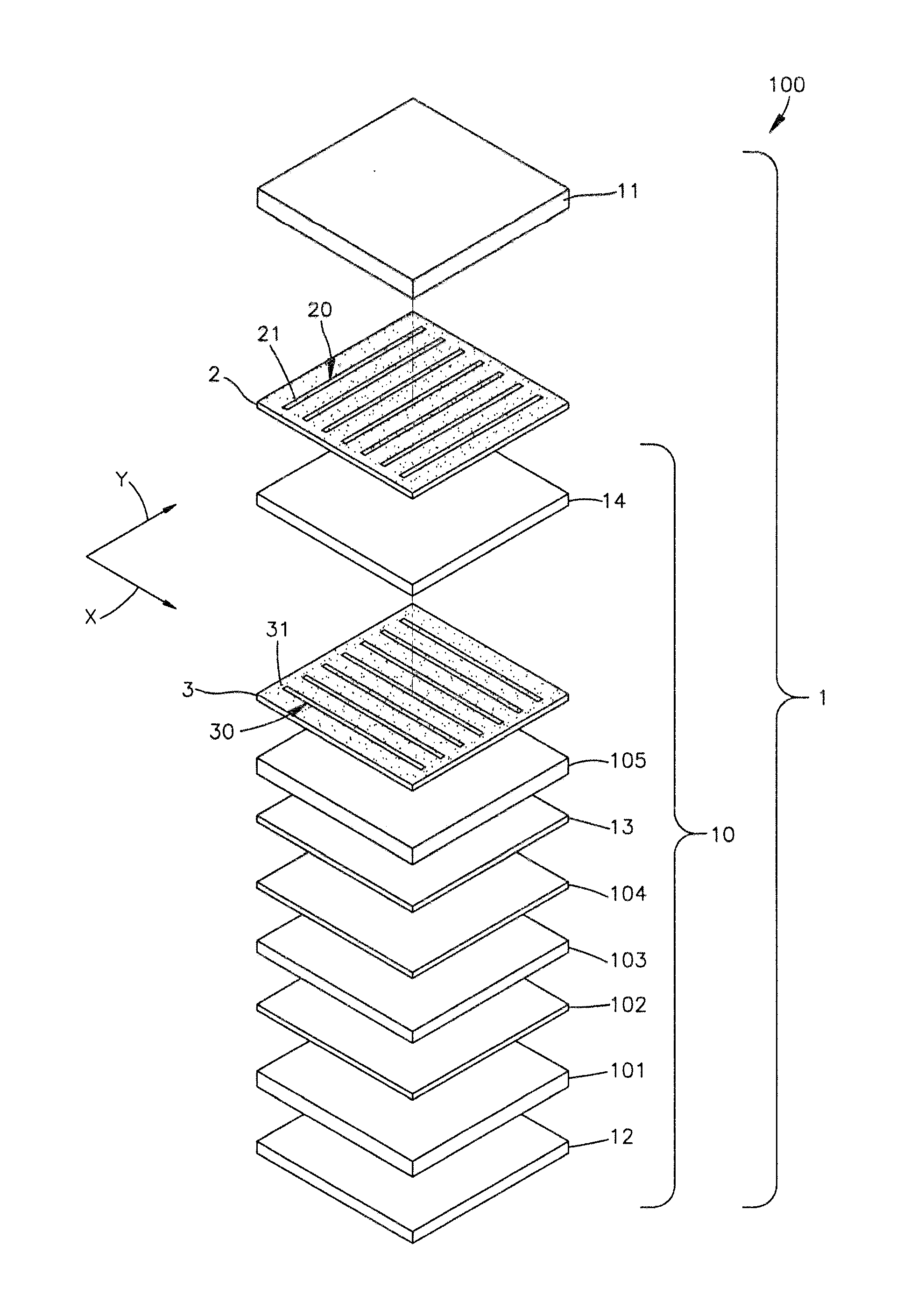

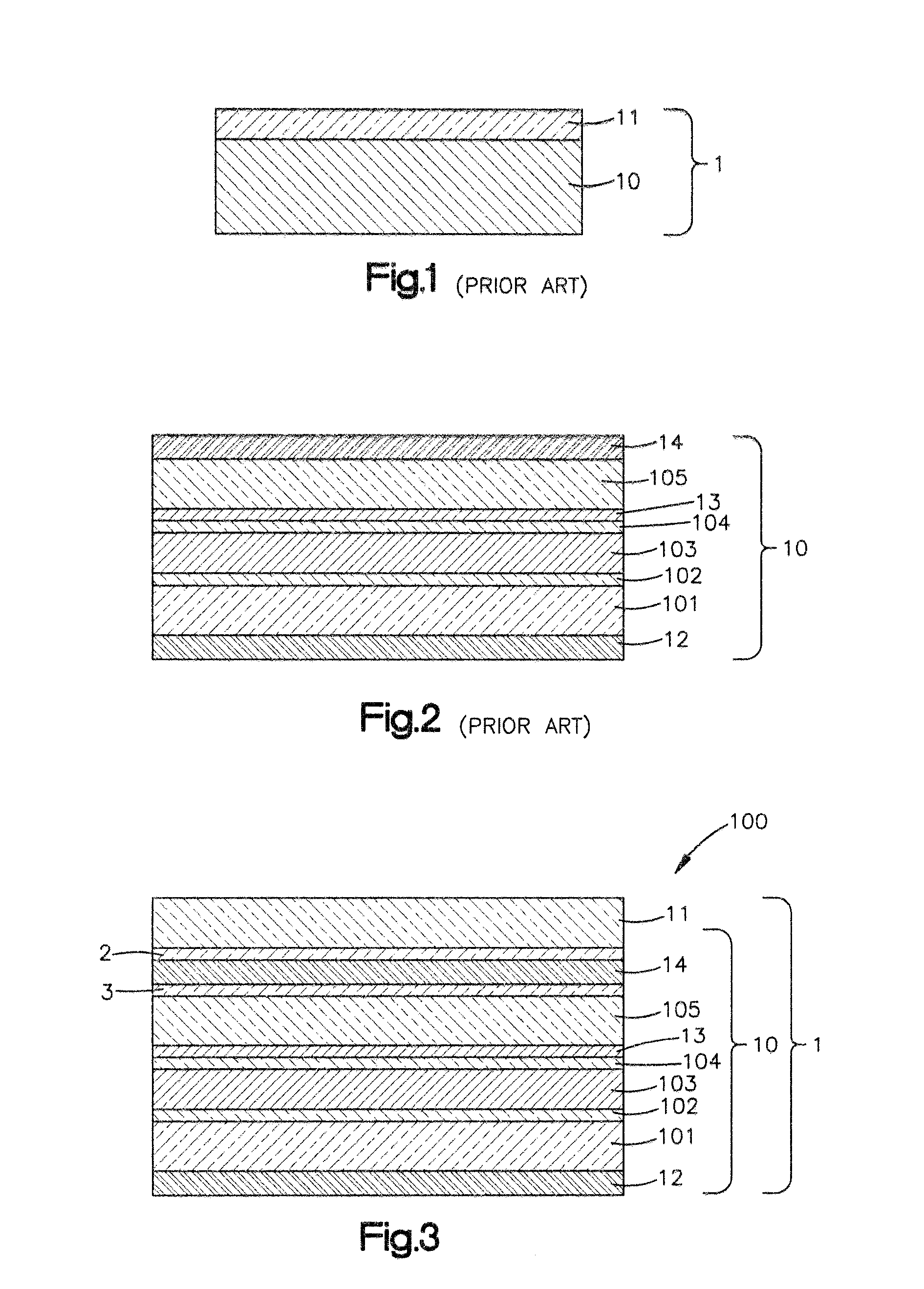

ActiveUS20090040192A1No decline in display characteristicImprove signal-to-noise ratioInput/output processes for data processingCapacitanceElectricity

A combination flat-panel touch sensor / display device includes a display device substrate on which signal lines, scanning lines and storage capacitance lines for applying electrical signals to liquid crystal are formed. A surface of the flat-panel display device corresponding to a display area has a transparent conductive film serving as an impedance surface. The device further includes current detecting circuits for detecting currents that flow through the impedance surface. In an interval over which the current detecting circuits detect current, at least one of the signal lines, scanning lines and storage capacitance lines is placed at a high impedance. The device reduces thickness without decline in display characteristics.

Owner:NEC LCD TECH CORP

Liquid crystal display integrated with capacitive touch devices

InactiveUS20100231549A1Simple manufacturing processHigh yield rateNon-linear opticsInput/output processes for data processingLiquid-crystal displayEngineering

A liquid crystal display integrated with a capacitive touch device is provided. A first electrode layer is formed immediately on an upper surface of a polarizing plate of a liquid crystal display panel, and a second electrode layer is formed on the bottom surface of the polarizing plate of the liquid crystal display panel. When an object touches the capacitive touch device, it becomes capacitively coupled to the first electrode layer and the second electrode layer to generate a signal corresponding to the touched position.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

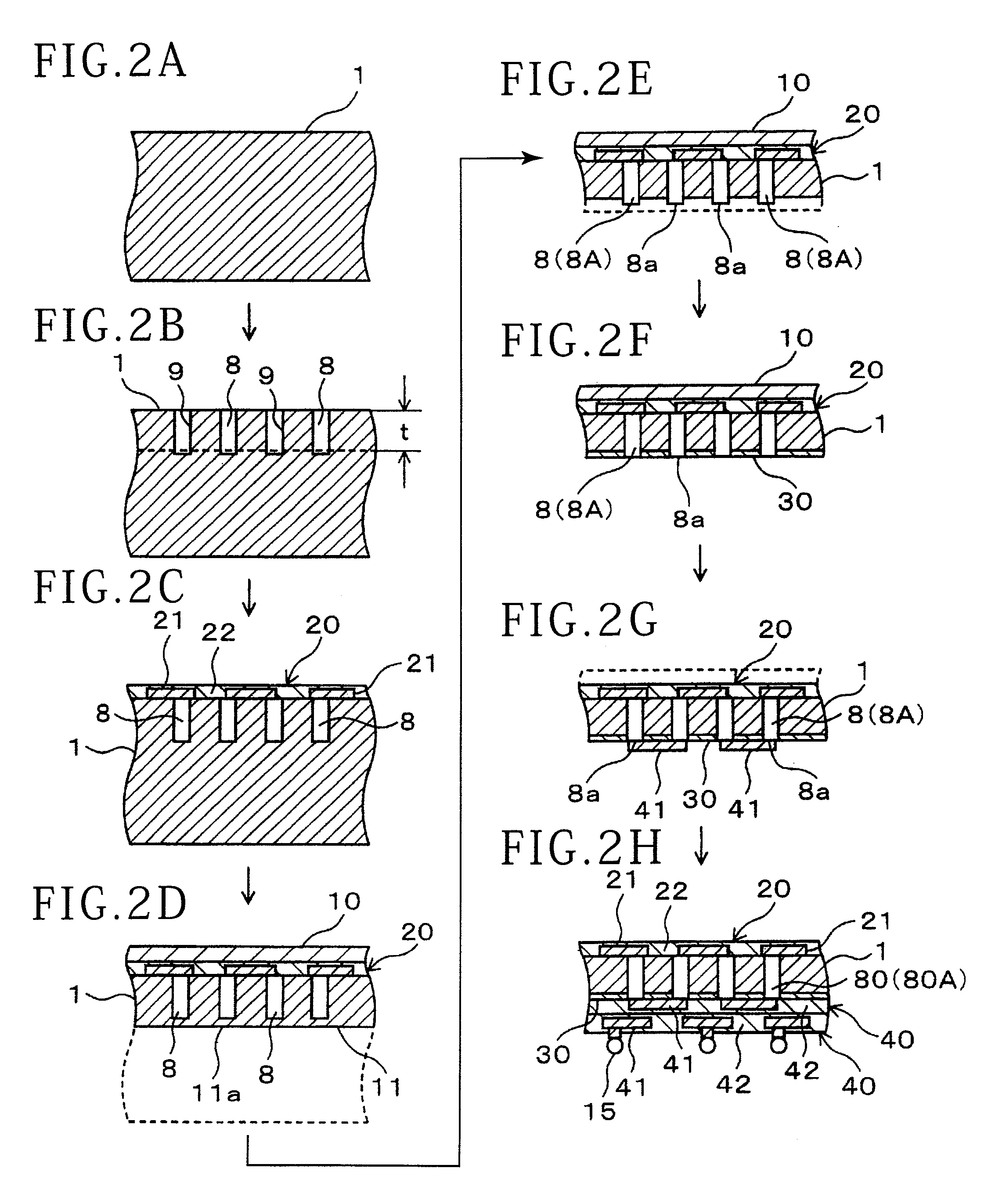

Electronic part mounting method, semiconductor module, and semiconductor device

InactiveUS20060267218A1Suppression of increase in mounting areaReduce device thicknessFinal product manufactureSemiconductor/solid-state device detailsMetal particleSemiconductor

An electronic part mounting method, a semiconductor module, and a semiconductor device, which can reduce a mounting area and a device thickness. In an electronic part mounting method for bonding an electrode formed on a substrate and an electrode formed on an electronic part to each other, the method comprises the step of bonding both the electrodes through a metal layer made up of aggregated particles of at least one kind of metal. Then, the metal particles have an average particle size of 1 to 50 nm. Preferably, the metal particles form a metal layer having a thickness of 5 to 100 μm.

Owner:HITACHI LTD

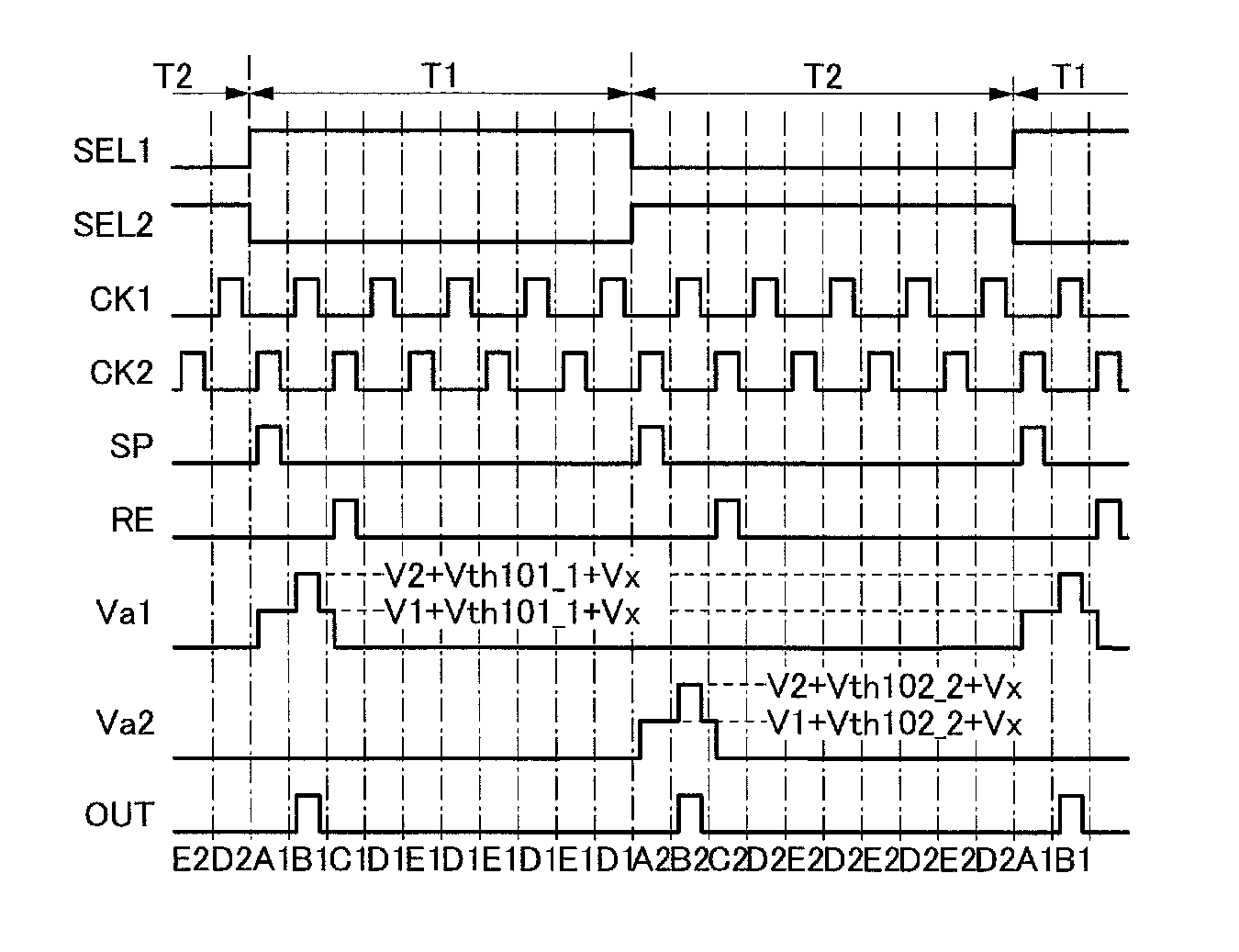

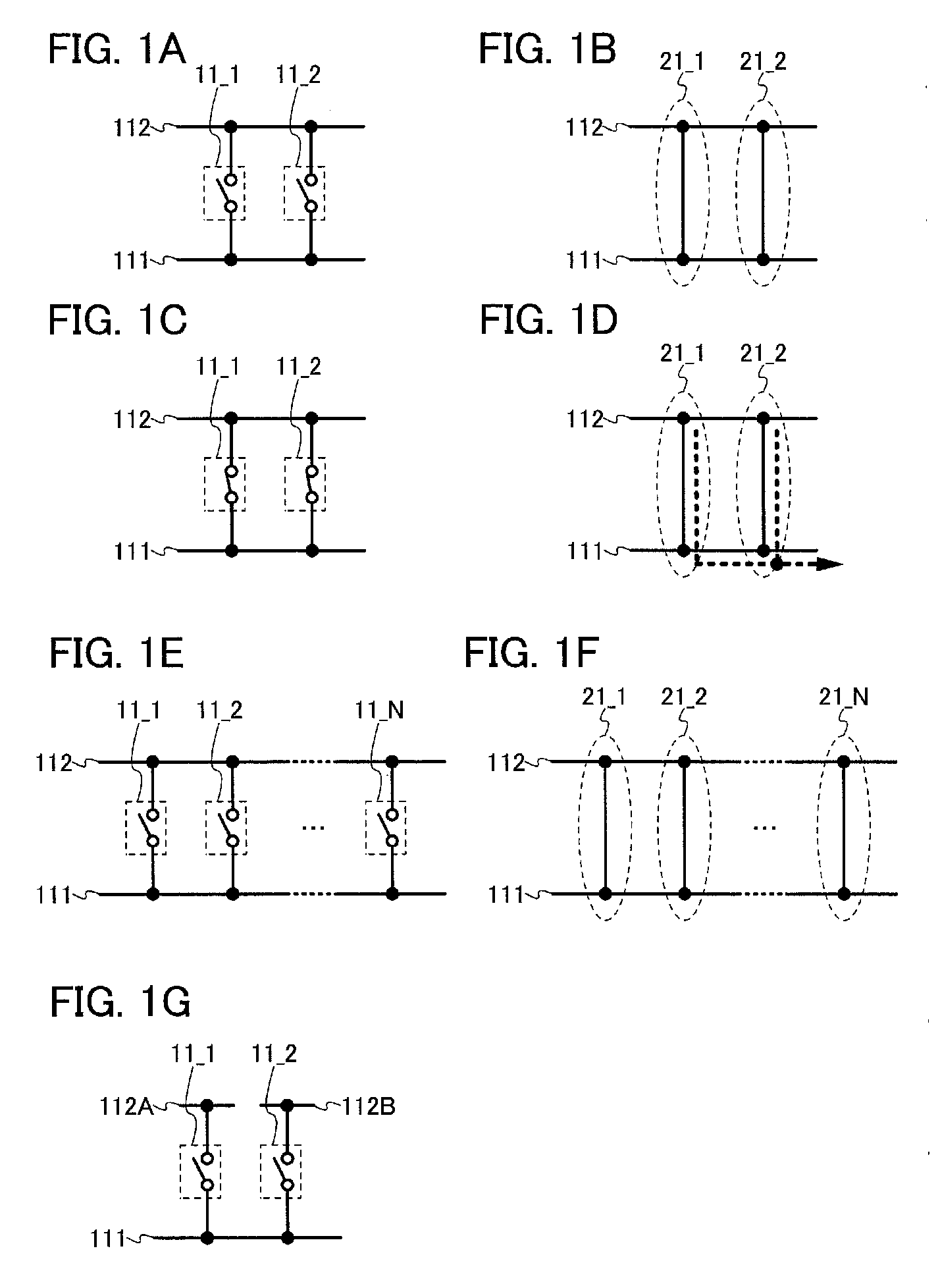

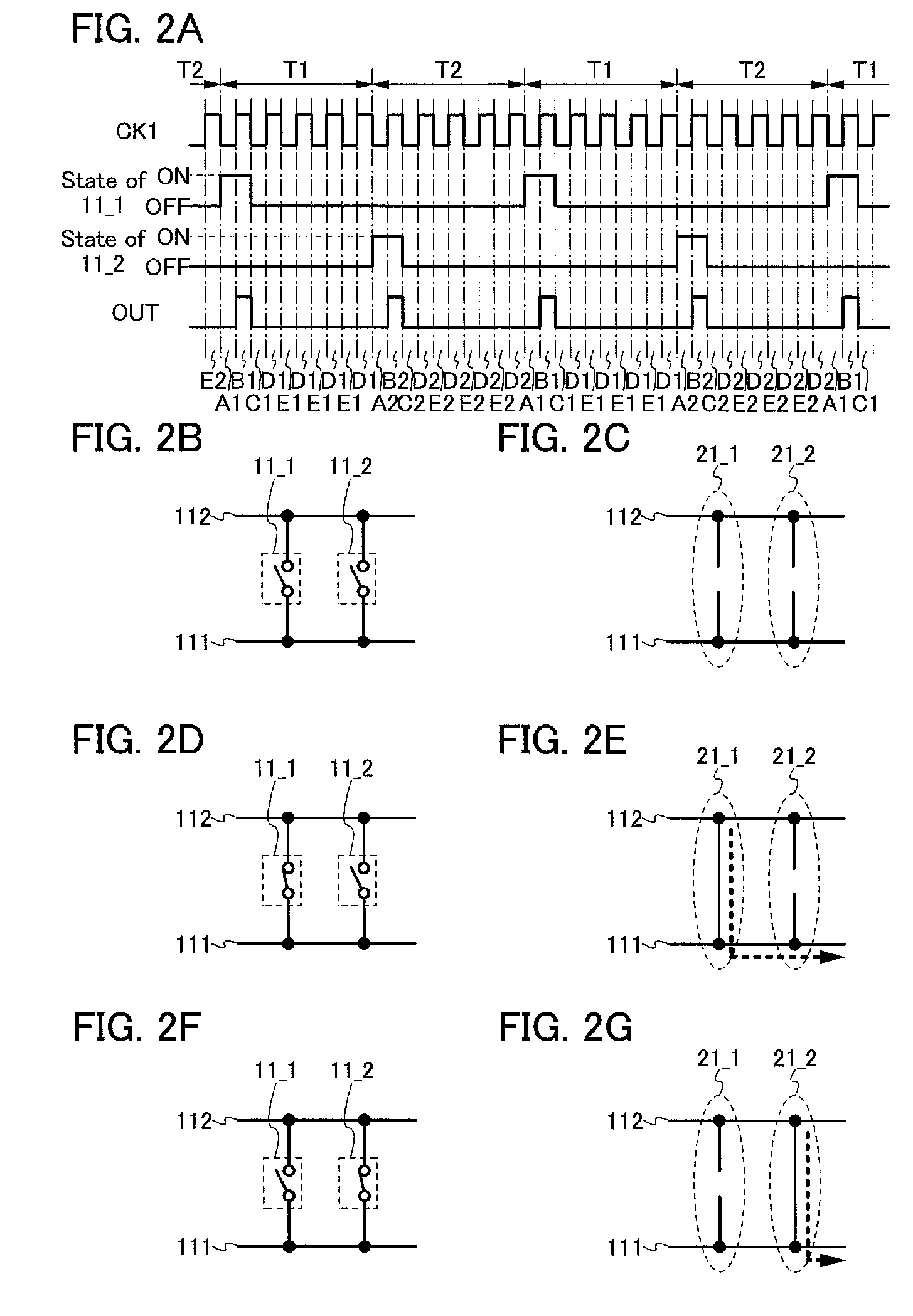

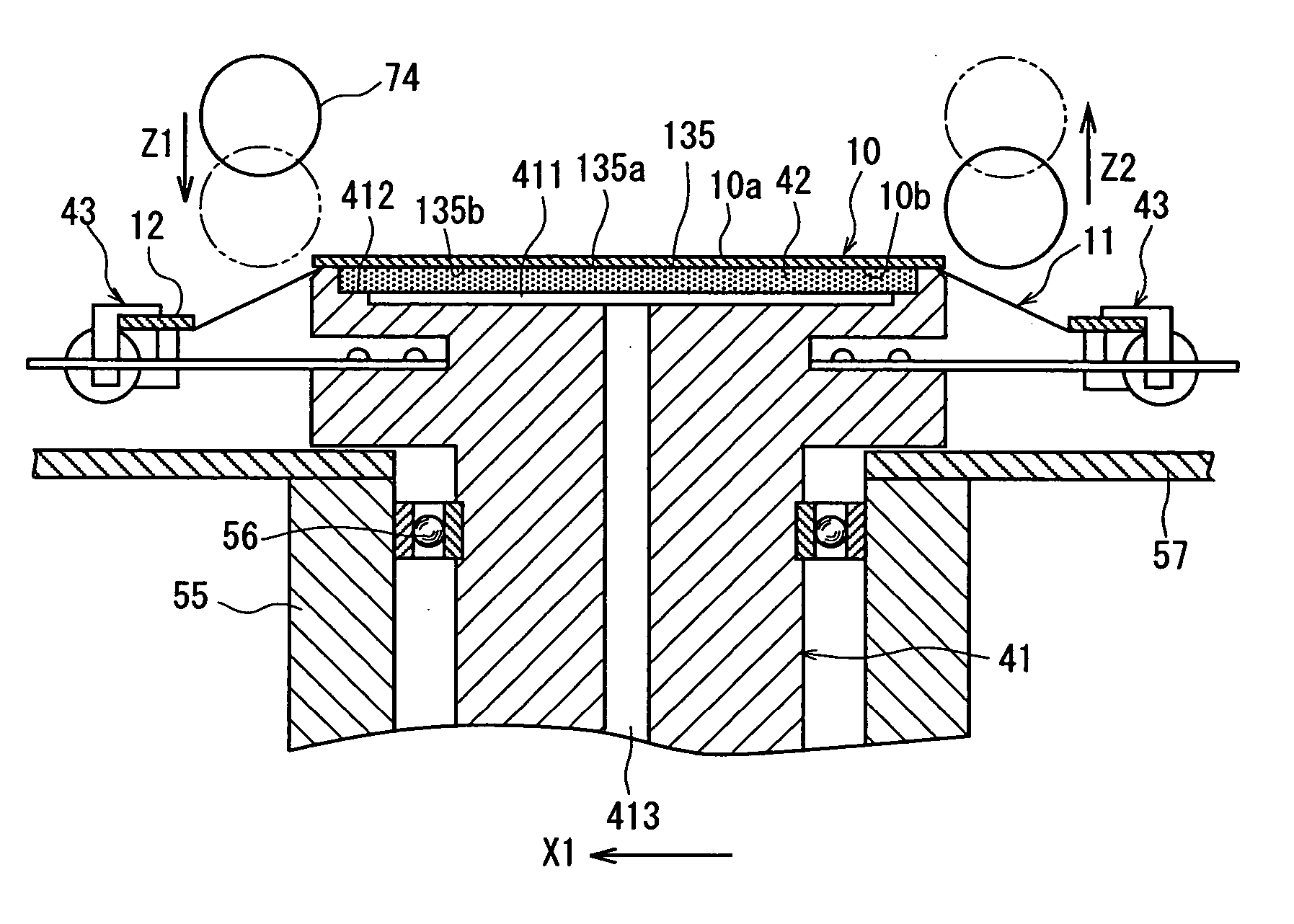

Liquid crystal display device, driving method of the same, and electronic device including the same

InactiveUS20100245335A1Inhibit deteriorationChannel width reductionCathode-ray tube indicatorsDigital storageDriver circuitElectricity

It is an object to suppress deterioration of characteristics of a transistor in a driver circuit. A first switch for controlling whether to set a potential state of an output signal by being turned on and off in accordance with the first input signal, and a second switch for controlling whether to set a potential state of an output signal by being turned on and off in accordance with the second input signal are included. A first wiring and a second wiring are brought into electrical continuity by turning on and off of the first switch or the second switch.

Owner:SEMICON ENERGY LAB CO LTD

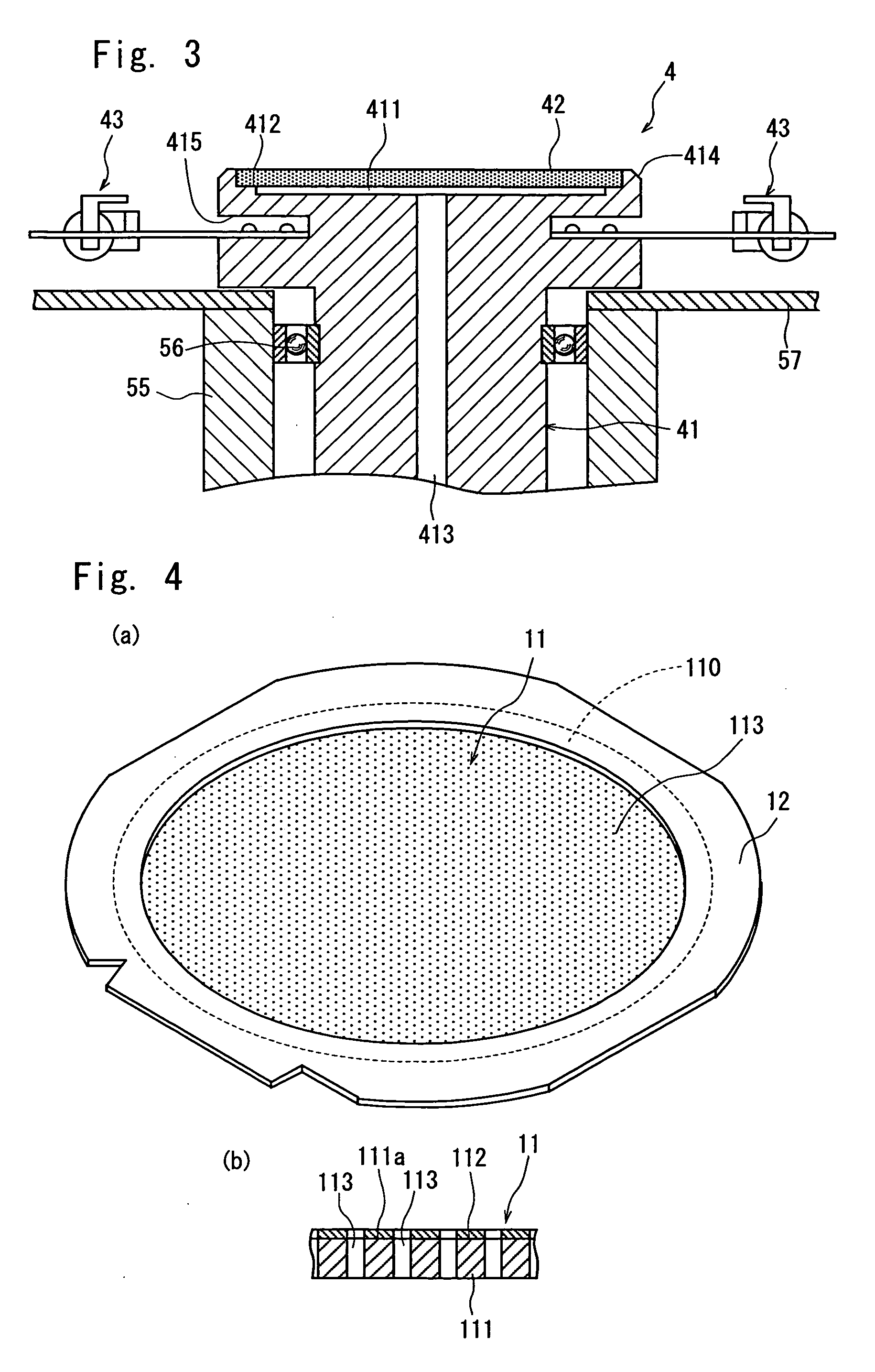

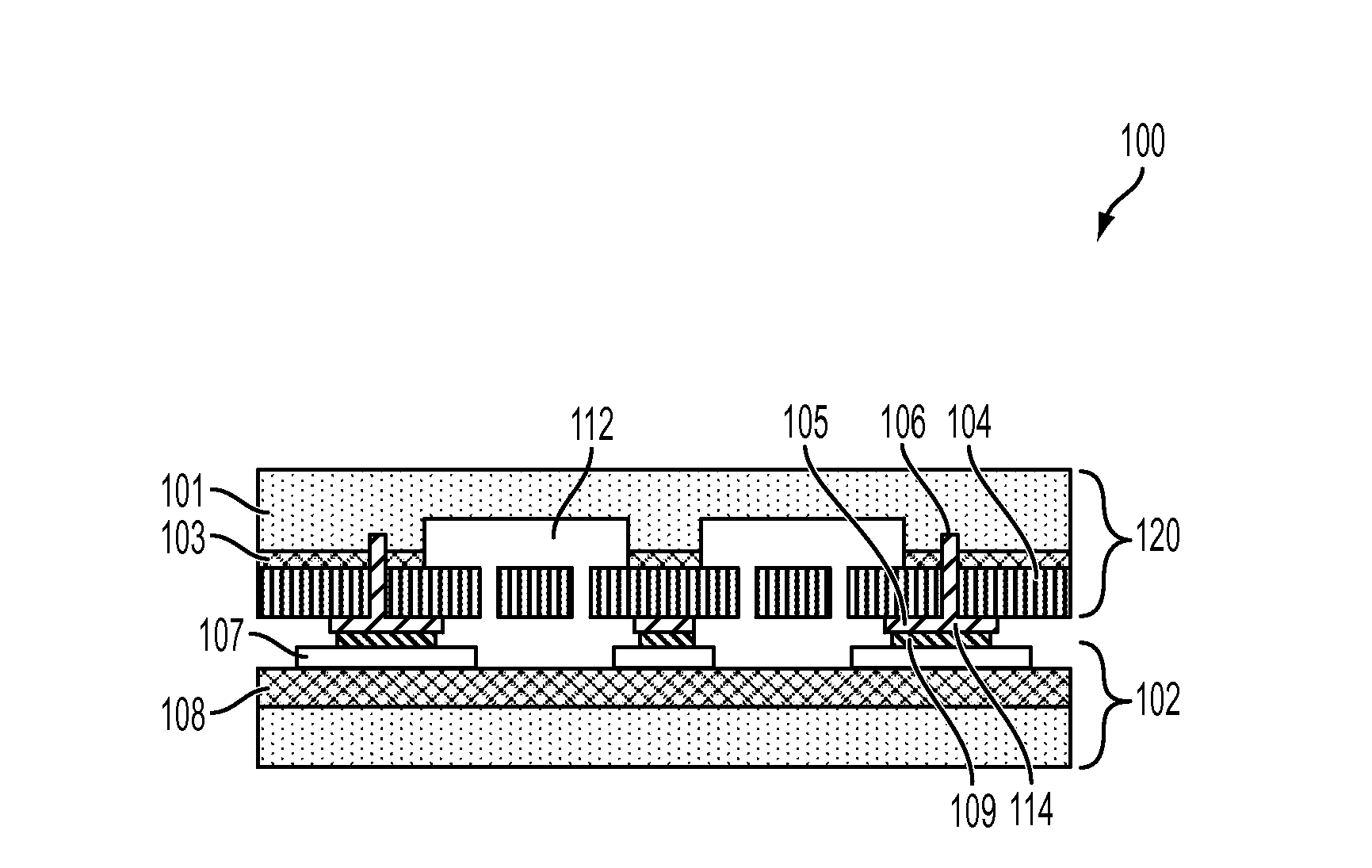

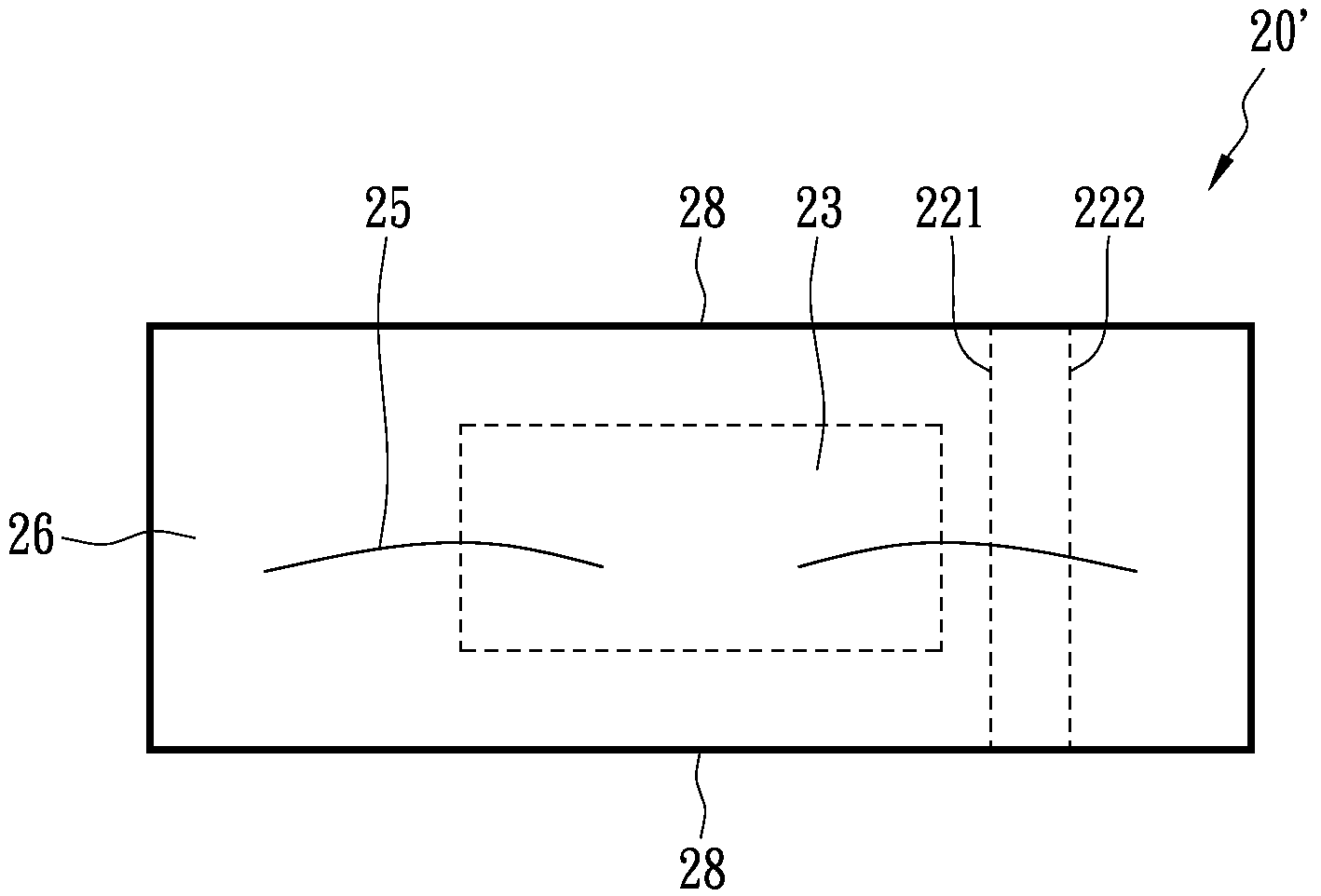

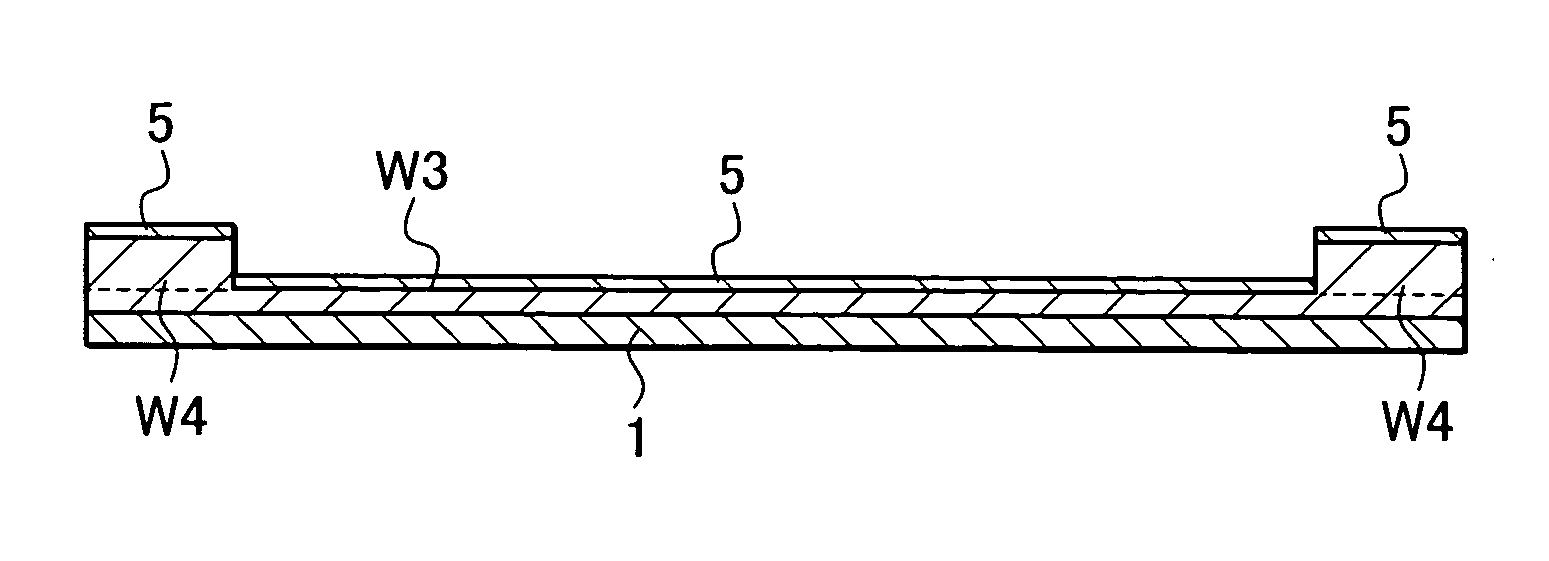

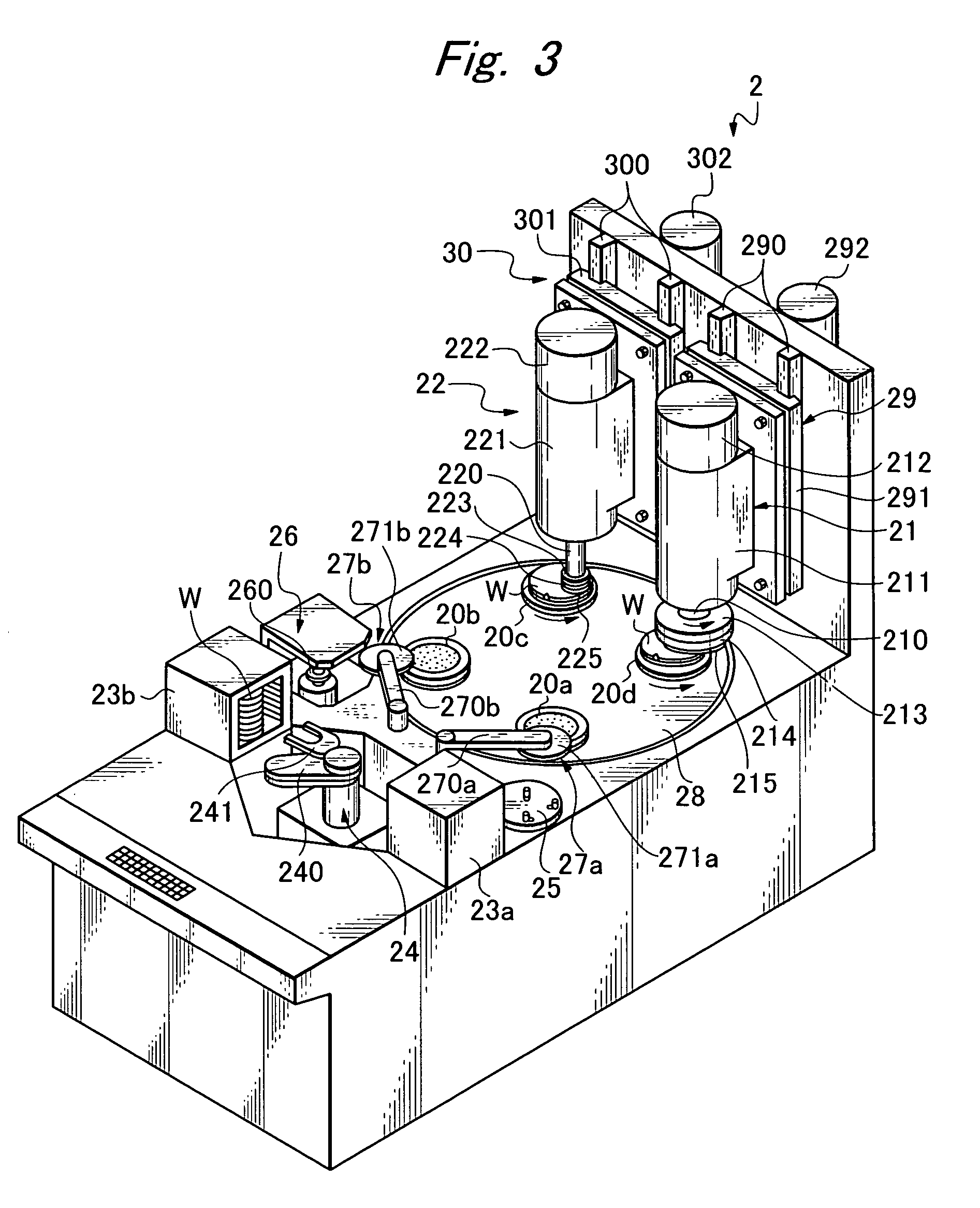

Wafer processing method and adhesive tape used in the wafer processing method

ActiveUS20070045799A1Maintain stiffnessReduce device thicknessSemiconductor/solid-state device detailsSolid-state devicesSuction forceDevice form

A method of processing a wafer having a plurality of streets formed on the front surface in a lattice pattern and a plurality of devices formed in a plurality of areas sectioned by the plurality of streets, comprising an adhesive tape amounting step for mounting the front surface of the outer peripheral portion of an adhesive tape having an adhesive layer on the front surface and a plurality of via holes onto an opening of an annular frame to cover it; a frame fixing step for placing the rear surface of the adhesive tape mounted on the annular frame on the chuck table for suction-holding a workpiece of a processing machine and fixing the annular frame; a wafer affixing step for placing the wafer on the front surface of the wafer affixing area of the adhesive tape, suction-holding the adhesive tape on the suction-holding area of the chuck table by exerting suction-force to the suction-holding area, and sucking the wafer to affix it to the front surface of the adhesive tape; and a processing step for processing the wafer along the streets.

Owner:DISCO CORP

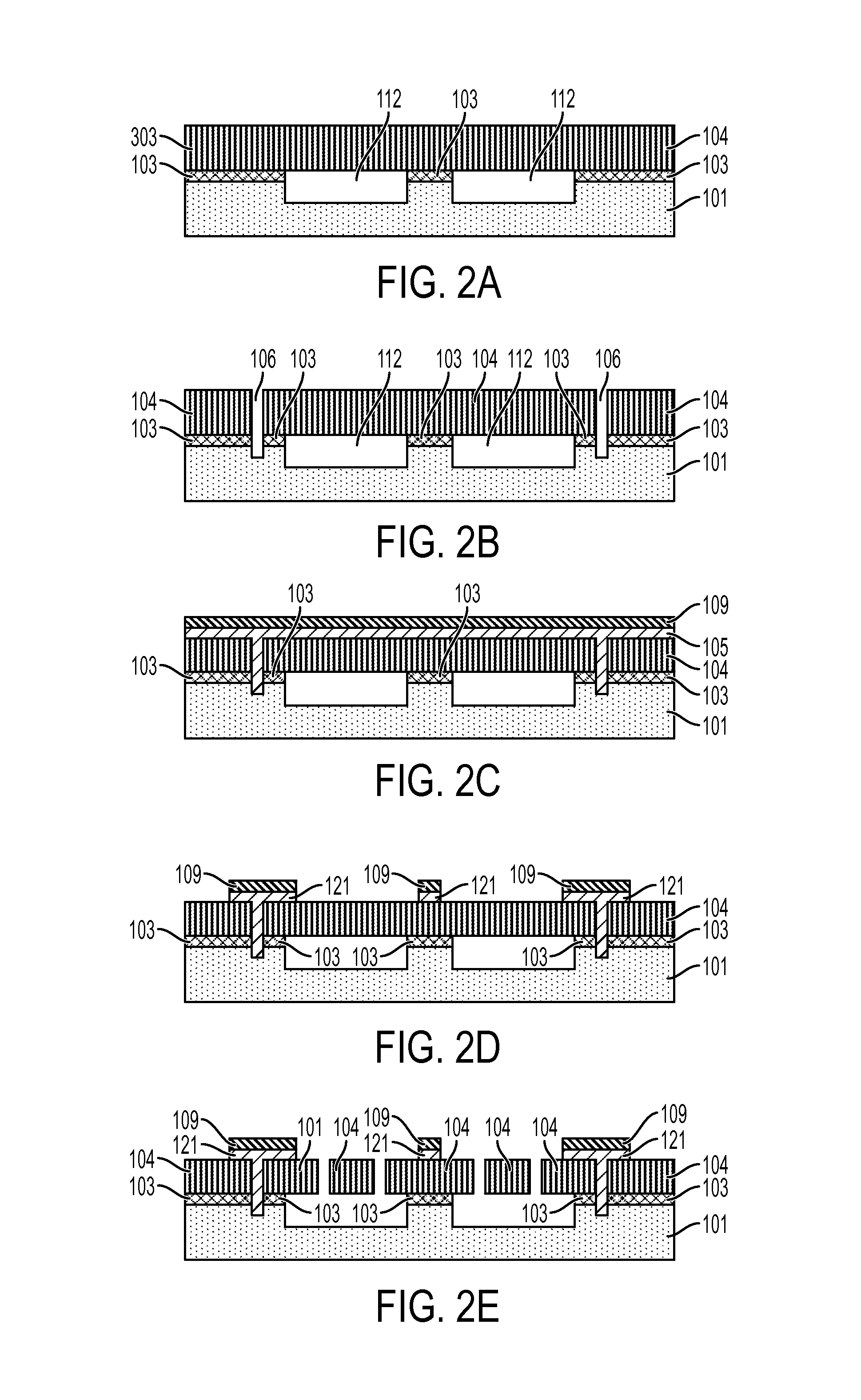

Internal electrical contact for enclosed MEMS devices

ActiveUS8564076B1Reduce device thicknessEliminate needSolid-state devicesForming microstructural systemsElectrical conductorCoupling

A MEMS device is disclosed. The MEMS device comprises a MEMS substrate. The MEMS substrate includes a first semiconductor layer connected to a second semiconductor layer with a dielectric layer in between. MEMS structures are formed from the second semiconductor layer and include a plurality of first conductive pads. The MEMS device further includes a base substrate which includes a plurality of second conductive pads thereon. The second conductive pads are connected to the first conductive pads. Finally, the MEMS device includes a conductive connector formed through the dielectric layer of the MEMS substrate to provide electrical coupling between the first semiconductor layer and the second semiconductor layer. The base substrate is electrically connected to the second semiconductor layer and the first semiconductor layer.

Owner:INVENSENSE

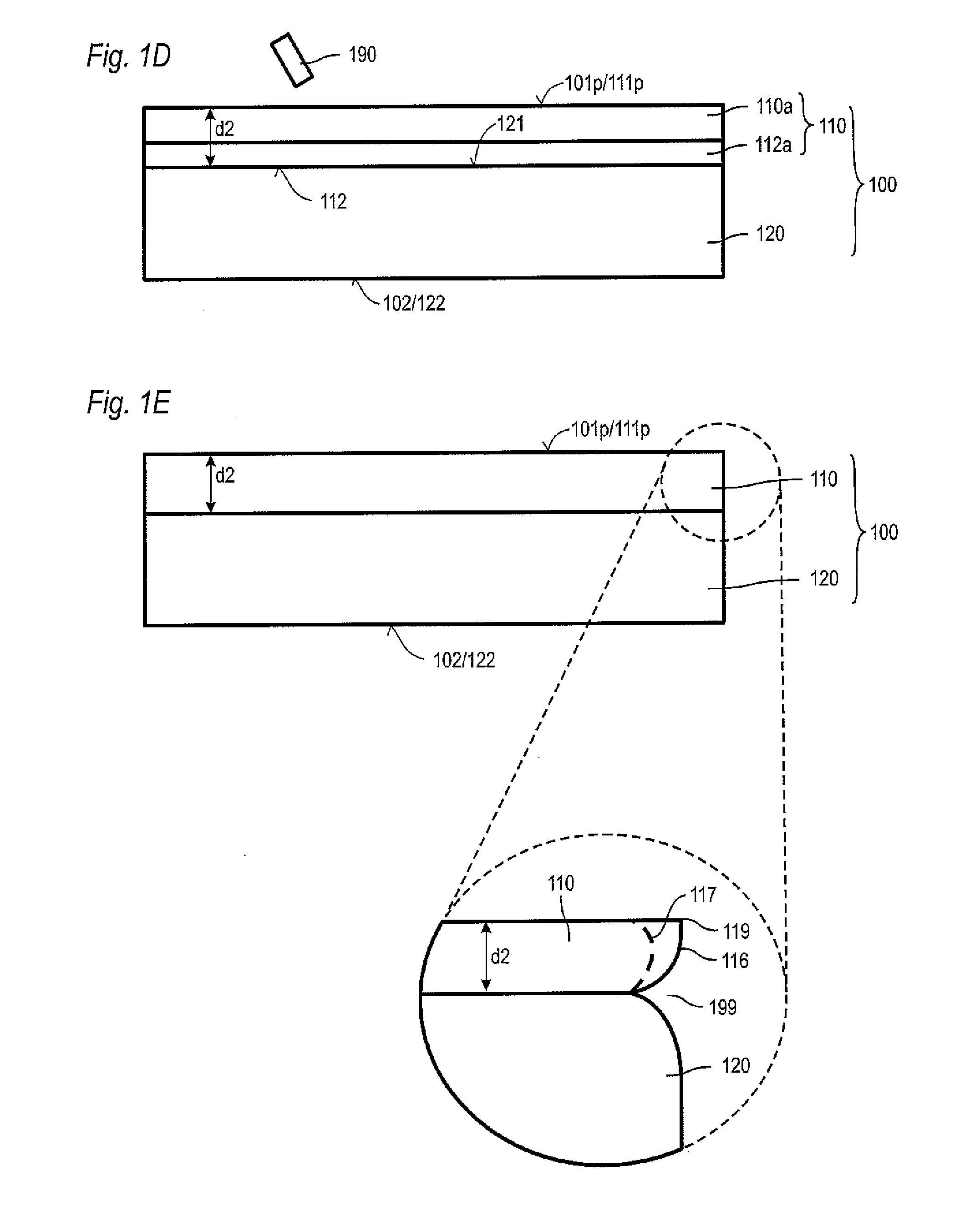

Stacked-type semiconductor device

ActiveUS7217993B2Saving production costReduce device thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

A stacked-type semiconductor device includes a first wiring substrate on which a semiconductor device element is mounted, a second wiring substrate stacked on the first wiring substrate through a plurality of electrode terminals which are electrically connected with the first wiring substrate, and a conductor supporting member disposed around the semiconductor device element, and connected with grounding wiring layers provided in the first and second wiring substrate.

Owner:SOCIONEXT INC

Photo detector, image sensor, photo-detection method, and imaging method

InactiveUS7847362B2Reduce device thicknessSuppress color mixingTelevision system detailsSolid-state devicesSemiconductor materialsResonance

A photo detector includes a photoelectric conversion layer having a periodic structure made of a semiconductor material on a surface of the photoelectric conversion layer. In the photo detector, at least a part of a resonance region formed by the periodic structure is included in the photoelectric conversion layer of the photo detector.

Owner:CANON KK

Force-sensing touch screen input device

InactiveUS20170102809A1Reduce thicknessImprove reliabilityInput/output processes for data processingPolymeric surfaceDisplay device

A force sensing touch screen input device is a solid assembly of multiple layers including a display with a touch-sensitive external surface, a first and second electrode layers separated by a compressible dielectric structure—forming a capacitive force-sensing array, and a rigid planar substrate. One or both electrode layers may be formed by metallizing a polymer surface of the rigid substrate or by creating a conductive electrode onto an internal surface of the display. To increase reliability, each layer is permanently adhered to or formed onto an adjacent layer over its entire surface, whereby preventing internal shifts therebetween. To increase response time, the cover glass flexibility, compressible dielectric structure and the gasket structure between the cover glass and the rigid planar substrates are selected to provide elastic compression and recovery during normal operating conditions.

Owner:PRESSURE PROFILE SYST +1

Protective cover for portable communication device

ActiveUS20090052654A1Improve portabilityReduce device thicknessInterconnection arrangementsDigital data processing detailsEngineeringPortable communications device

A protective cover for a portable communication device includes a battery cover and a protective cover part coupled with the battery cover. The protective cover is detachably coupled with the portable communication device, and the protective cover part is disposed at a front surface of a display unit part of the portable communication device when the protective cover is coupled with the portable communication device. The portable communication device being turned off / on when the portable communication device is attached to / detached from the protective cover.

Owner:SAMSUNG ELECTRONICS CO LTD

Optical devices for guiding illumination

ActiveUS7593615B2Reduce device thicknessReduce thicknessPrismsMirrorsTotal internal reflectionAngular orientation

Owner:VIAVI SOLUTIONS INC

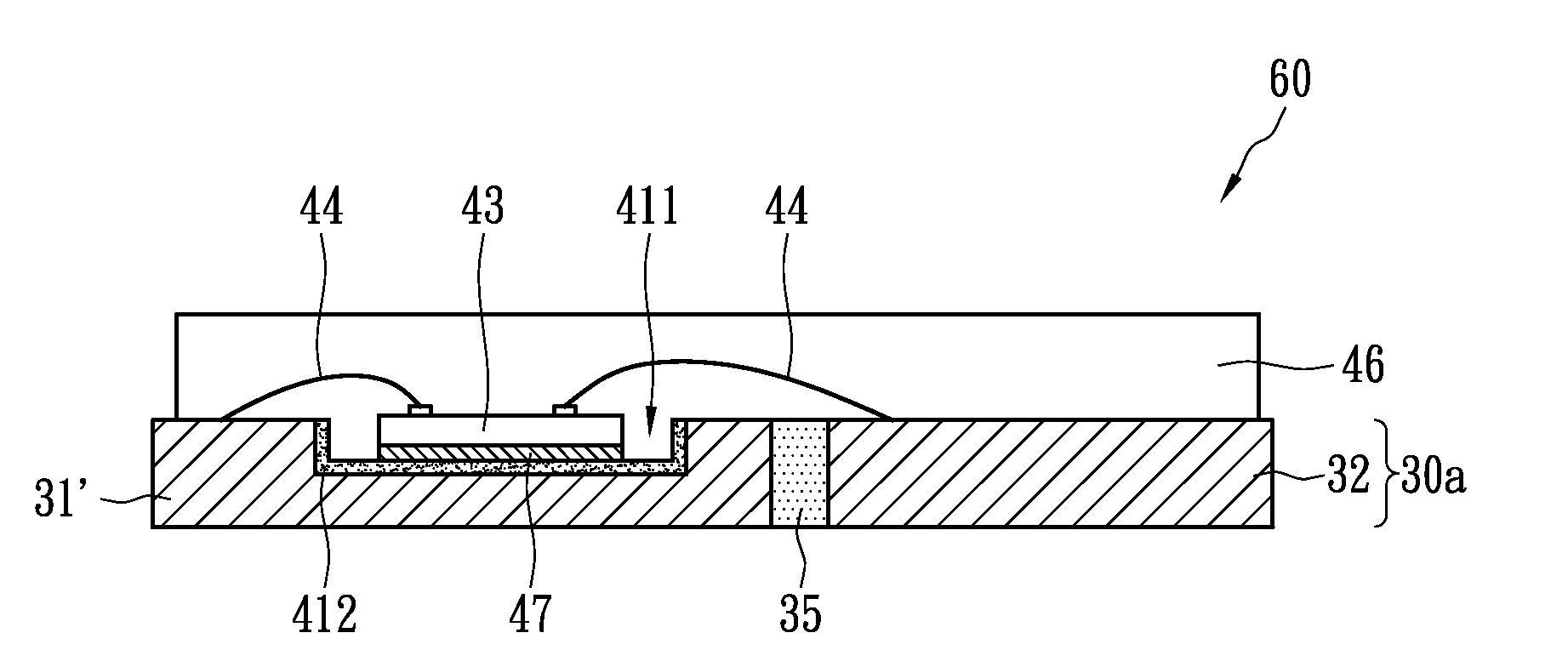

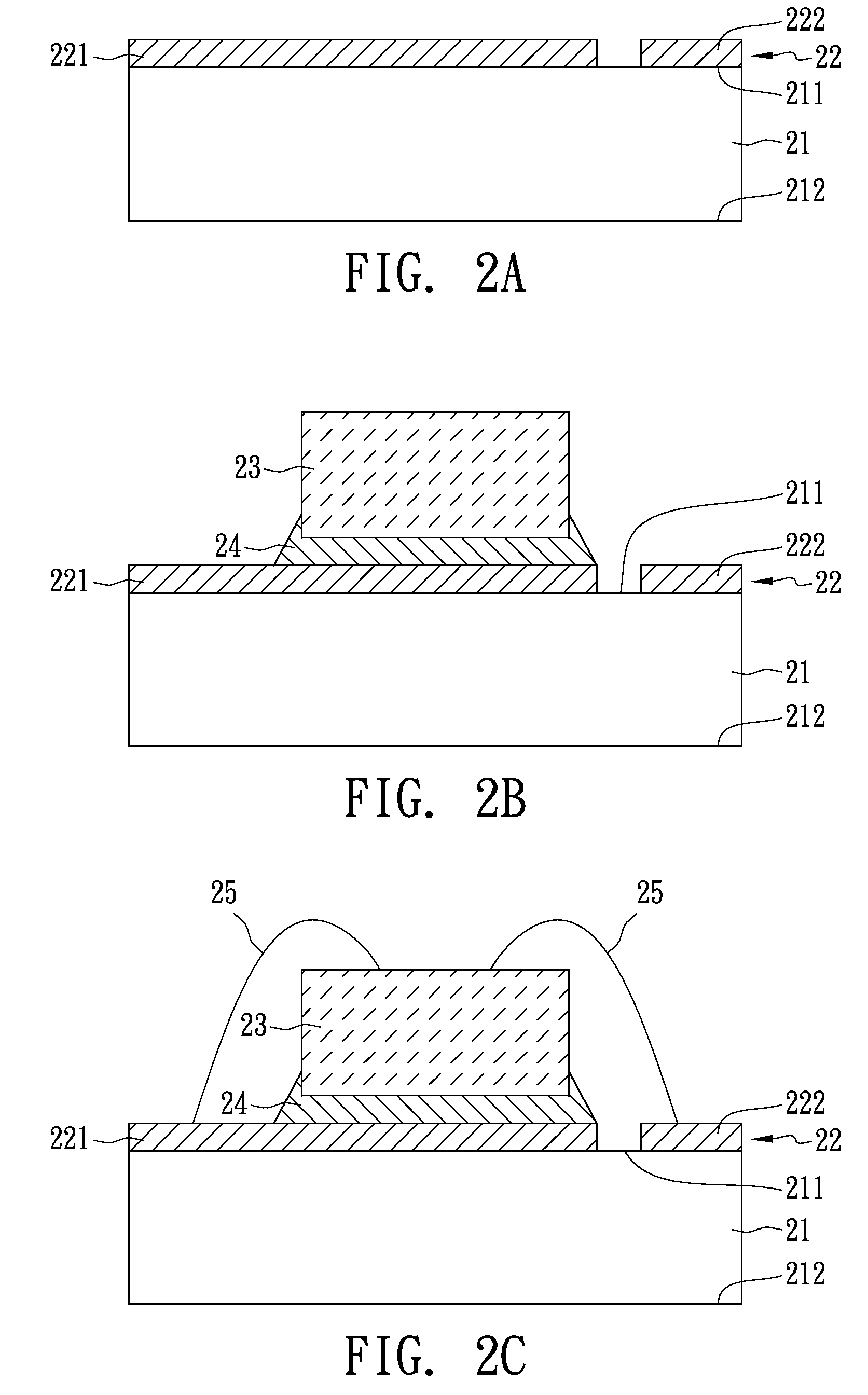

Package structure of compound semiconductor device and fabricating method thereof

InactiveUS20090206358A1Improve heat dissipationImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveMetal

A package structure of a compound semiconductor device comprises a thin film substrate, a die, at least one metal wire and a transparent encapsulation material. The thin film substrate comprises a first conductive film, a second conductive film, and an insulating dielectric material. The die is mounted on the surface of the first conductive film, and is electrically connected to the first conductive film and the second conductive film through the metal wire. The transparent encapsulation material overlays the first conductive film, second conductive film, and die. The surfaces of the first conductive film and second conductive film which is opposite the transparent encapsulation material act as electrodes. The insulating dielectric material is between the first conductive film and second conductive film.

Owner:ADVANCED OPTOELECTRONICS TECH

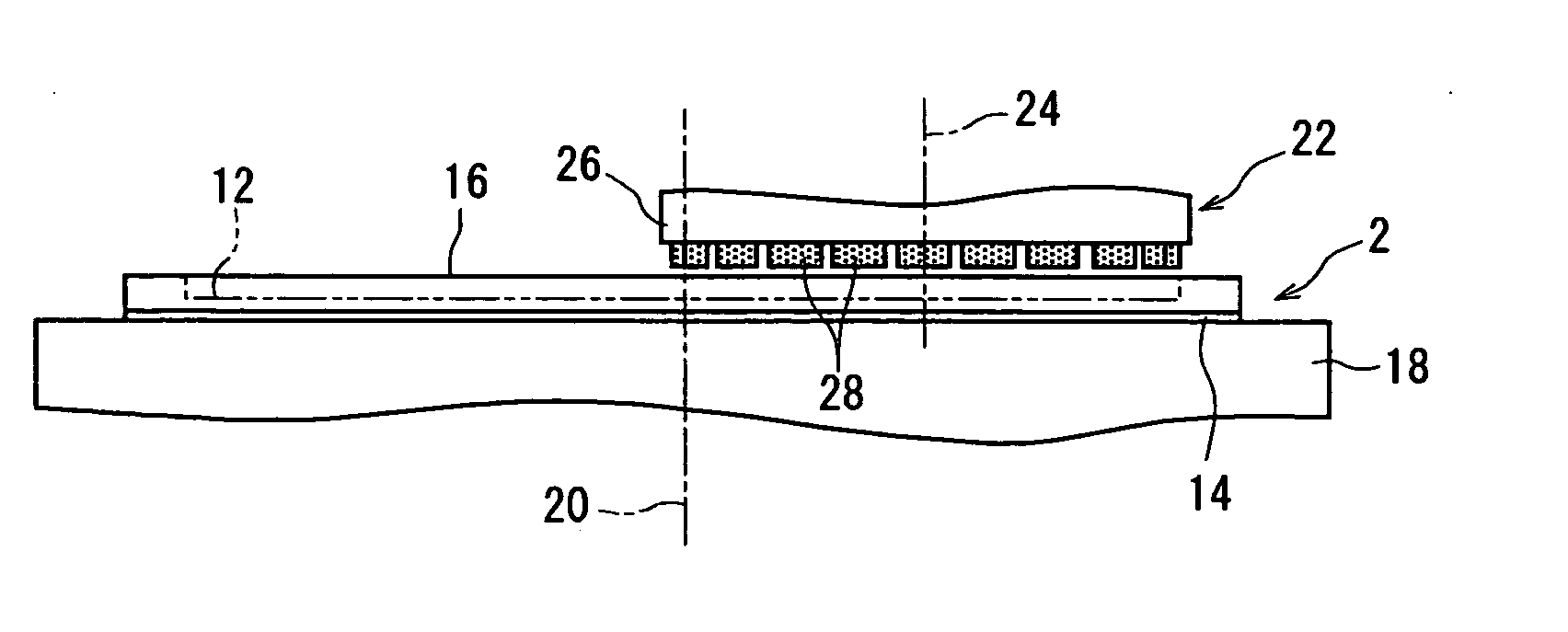

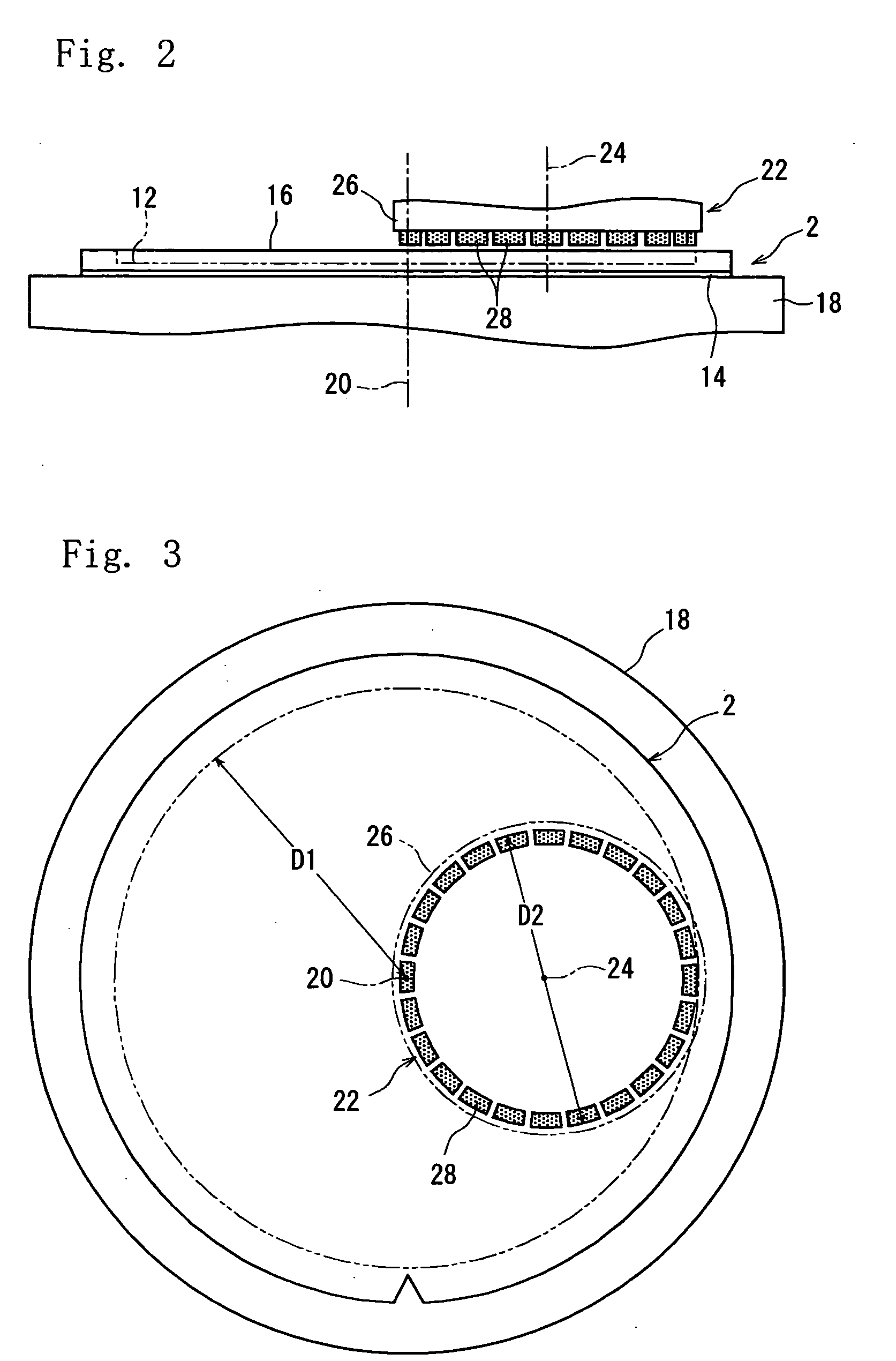

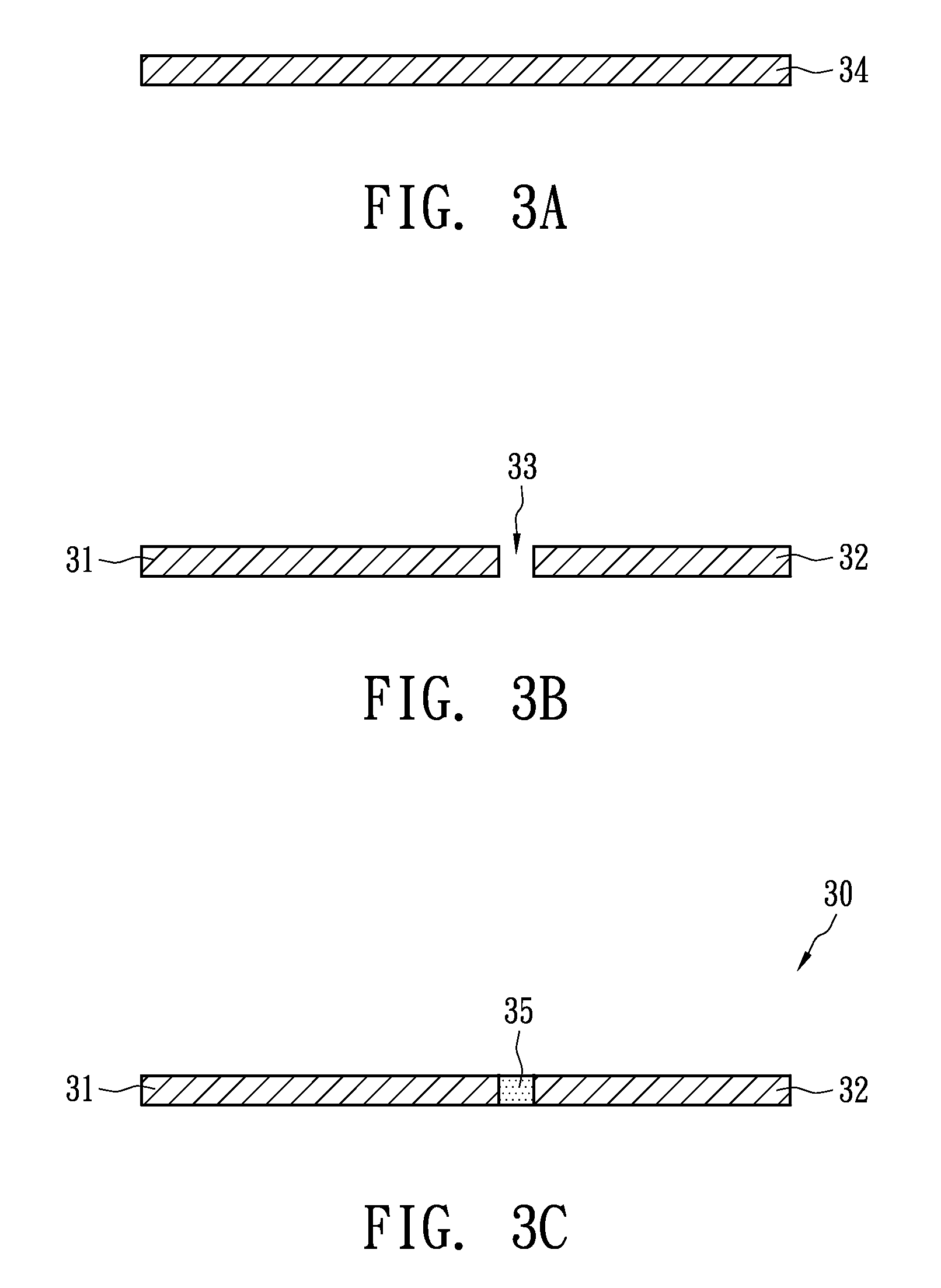

Wafer processing method

ActiveUS20100055877A1Reliable removalReliably removedSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

Disclosed herein is a wafer processing method for dividing a wafer along a plurality of streets. The wafer processing method includes a back grinding step of grinding the back side of the wafer in an area corresponding to a device area to thereby reduce the thickness of the device area to a predetermined finished thickness and to simultaneously form an annular reinforcing portion on the back side of the wafer in an area corresponding to a peripheral marginal area, a wafer supporting step of attaching the back side of the wafer to a dicing tape, a kerf forming step of cutting the front side of the wafer along each street to thereby form a kerf having a depth corresponding to the thickness of the device area along each street, thereby dividing the device area into individual devices, and a peripheral marginal area removing step of peeling off the peripheral marginal area from the dicing tape.

Owner:DISCO CORP

Package structure of compound semiconductor device and fabricating method thereof

InactiveUS20090022198A1Improve cooling effectReduce device thicknessLaser detailsSolid-state devicesMetalSemiconductor device

A package structure of a compound semiconductor device comprises a thin conductive film with a pattern, a die, at least one metal wire or metal bump and a transparent encapsulation material. The die is mounted on the first surface of the thin conductive film, and is electrically connected to the thin conductive film through the metal wire or the metal bump. The transparent encapsulation material is overlaid on the first surface of the conductive film and the die. A second surface of the conductive film is not covered by the transparent encapsulation material, and is opposite the first surface.

Owner:ADVANCED OPTOELECTRONICS TECH

Processing method and grinding apparatus of wafer

ActiveUS20070020887A1Easy to disassembleDecrease productivitySemiconductor/solid-state device manufacturingPlane surface grinding machinesDevice formEngineering

To facilitate handling of a wafer in processing or carrying after the wafer being reduced in thickness by grinding, the whole back of a wafer having a surface on which a device region having a plurality of devices formed therein and a peripheral surplus region enclosing the device region are formed, is ground to be formed into a wafer having a predetermined thickness, and then a region corresponding to the device region in the back of the wafer is ground to form a concave portion having a predetermined thickness, so that a ring-like reinforcement portion is formed in a peripheral side of the concave portion, thereby the wafer is easily handled in a subsequent step or in wafer carrying between respective steps.

Owner:DISCO CORP

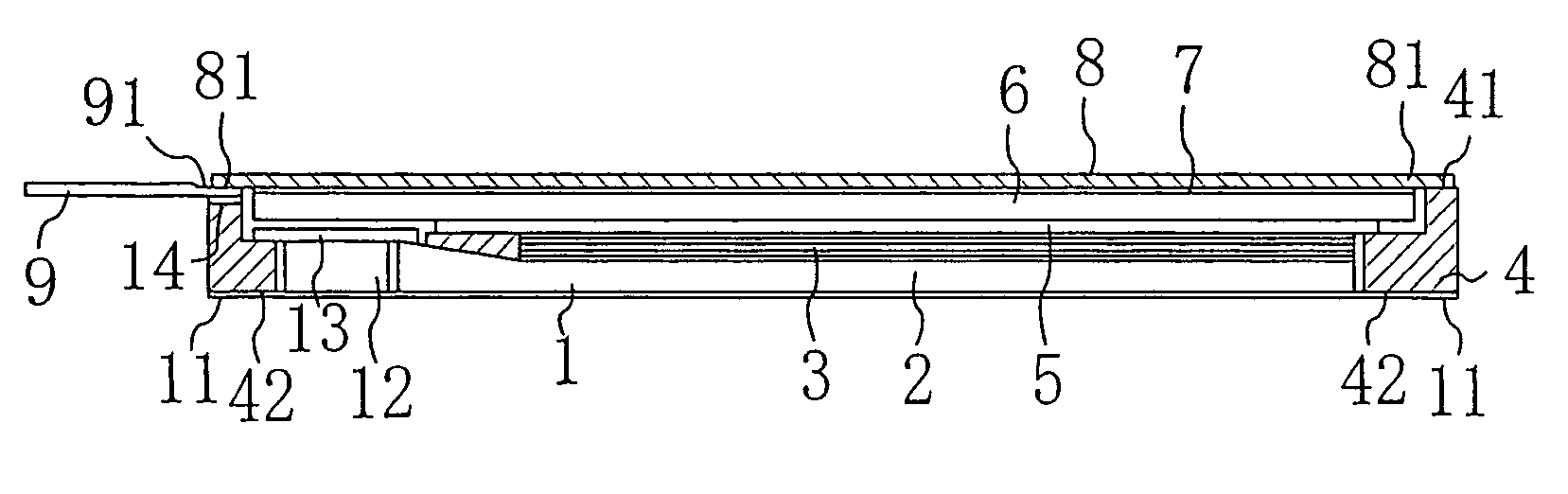

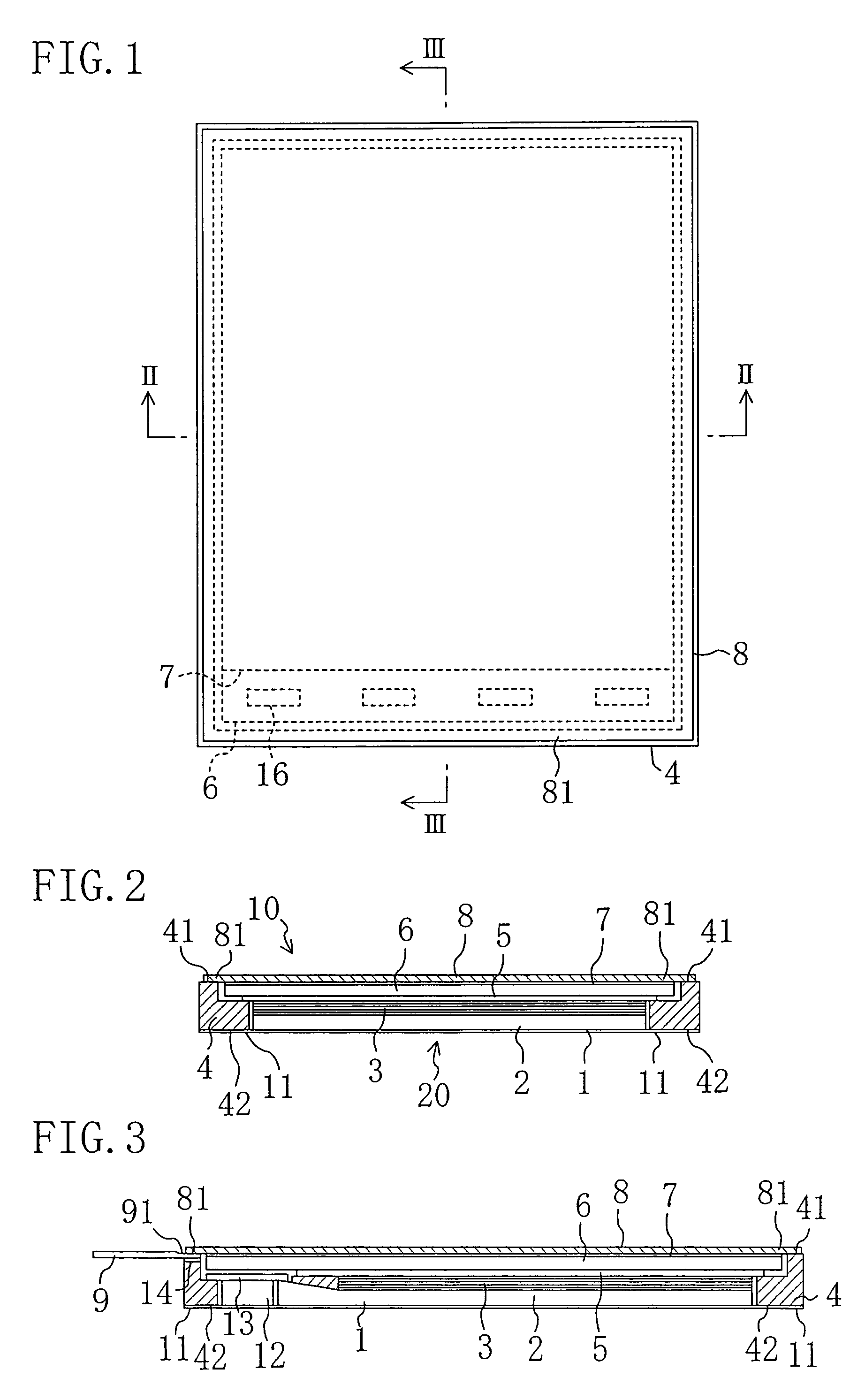

Liquid crystal display device

InactiveUS8134675B2Cost reductionReduce thicknessNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display device includes at least: a liquid crystal display panel; a light source provided on a back side of the liquid crystal display panel; and a frame accommodating the liquid crystal display panel and the light source and having an upper opening and a lower opening in an upper portion and a lower portion of the frame, respectively. The liquid crystal display panel includes a TFT substrate provided on a side of the light source, a CF substrate, a liquid crystal layer interposed between the TFT substrate and the CF substrate, a thin film driving circuit formed on the TFT substrate for driving the liquid crystal layer, and a front polarizing plate provided on a front surface of the CF substrate and having an overhanging portion overhanging from a periphery of the CF substrate. The front polarizing plate covers the upper opening of the frame and the overhanging portion is fixed to an upper end surface of the frame.

Owner:SHARP KK

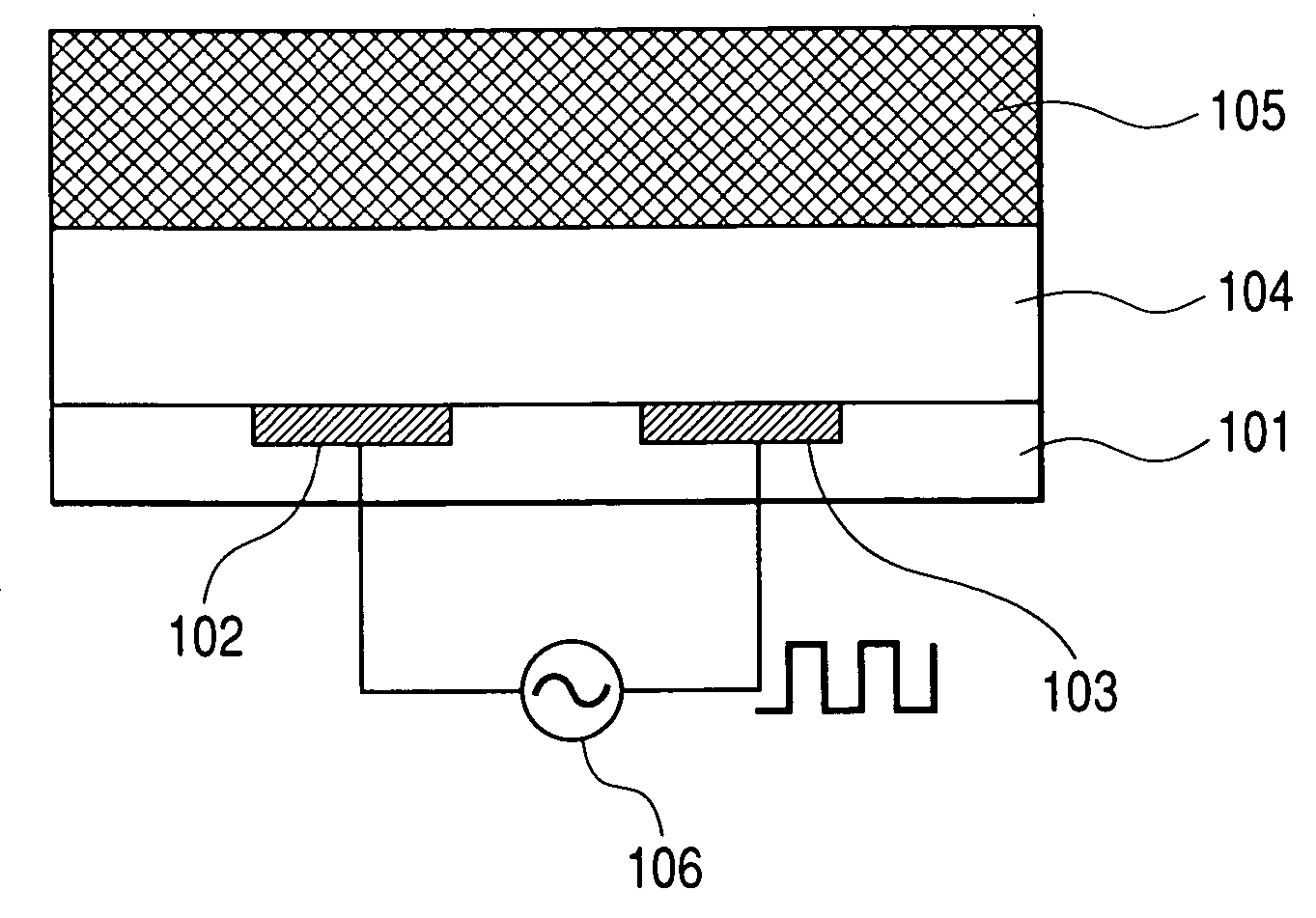

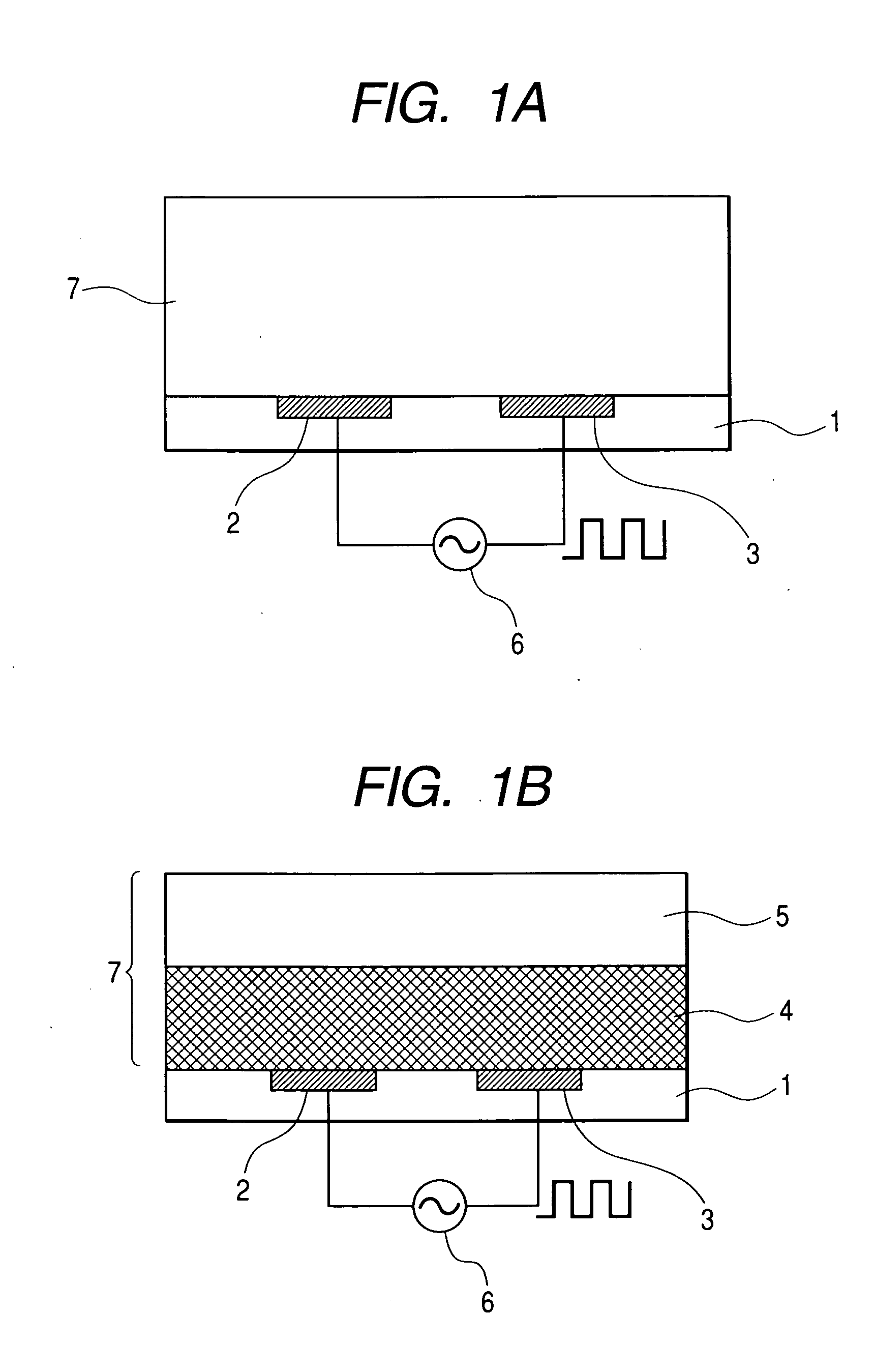

Display and displaying method

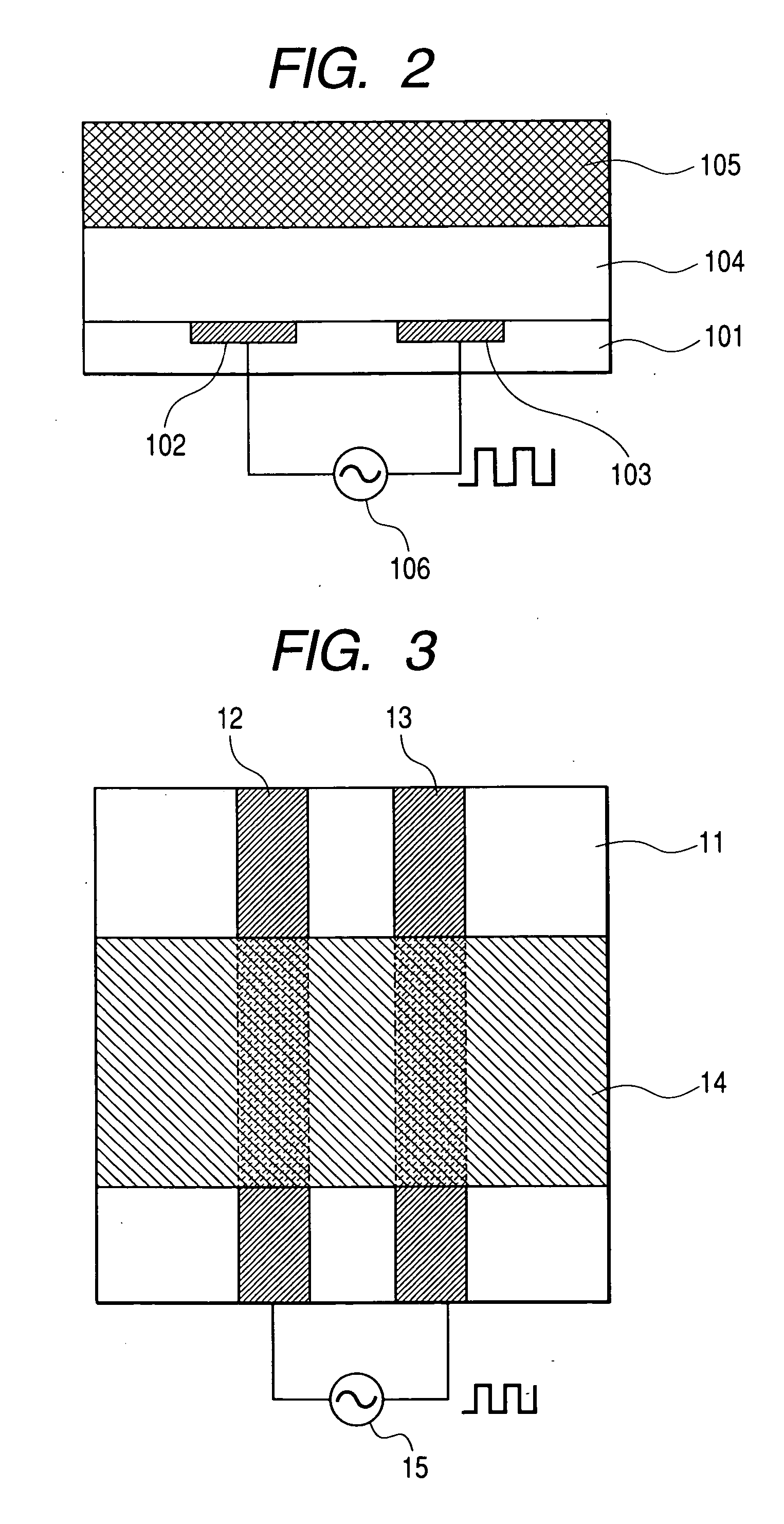

InactiveUS20060018001A1Bright can be producedImprove light utilization efficiencyNon-linear opticsDisplay deviceEngineering

An electrochromic device with high transmittance is for use as a display device. The electrochromic device includes at least a first and a second electrode formed on an insulative substrate and a conductive layer formed in contact with the insulative substrate, the first electrode, and the second electrode. Since an electrode layer functions in one layer, the transmittance through the device is enhanced, and the device can be fabricated in a simple process, allowing a reduction in the device fabrication costs.

Owner:HITACHI LTD

Flexible printed circuit, touch panel, display panel and display

ActiveUS20090315855A1Small thicknessReduce device thicknessPrinted circuit detailsPrinted circuit aspectsTouch panelElectrical and Electronics engineering

Owner:SONY CORP

Integrated touch-control transparent AMOLED display device and preparation method thereof

ActiveCN104851905AReduce device thicknessLow cost of preparationSolid-state devicesSemiconductor/solid-state device manufacturingLow-temperature polycrystalline siliconDisplay device

The invention discloses a preparation method of an integrated touch-control transparent active matrix organic light emitting diode (AMOLED) display device. The preparation method comprises: manufacturing a buffer layer on a carrier; manufacturing a first transparent thin-film hardening layer on the buffer layer; manufacturing a first barrier layer on the first transparent thin-film hardening layer; manufacturing a touch screen sensor on the first barrier layer; manufacturing a transparent flexible substrate on the touch screen sensor; manufacturing a shielding layer and a second barrier layer on the transparent flexible substrate; preparing a low-temperature polycrystalline thin-film transistor layer on the second barrier layer; manufacturing a transparent OLED element layer on the low-temperature polycrystalline thin-film transistor layer; manufacturing a protection layer on the transparent OLED element layer; manufacturing a transparent packaging cover plate on the protection layer; manufacturing a second transparent thin-film hardening layer on the transparent packaging cover plate; and removing the carrier and the buffer layer. On the basis of the technical scheme, the thickness and cost of the integrated touch-control transparent AMOLED display device can be reduced and the parallax can be eliminated.

Owner:TRULY HUIZHOU SMART DISPLAY

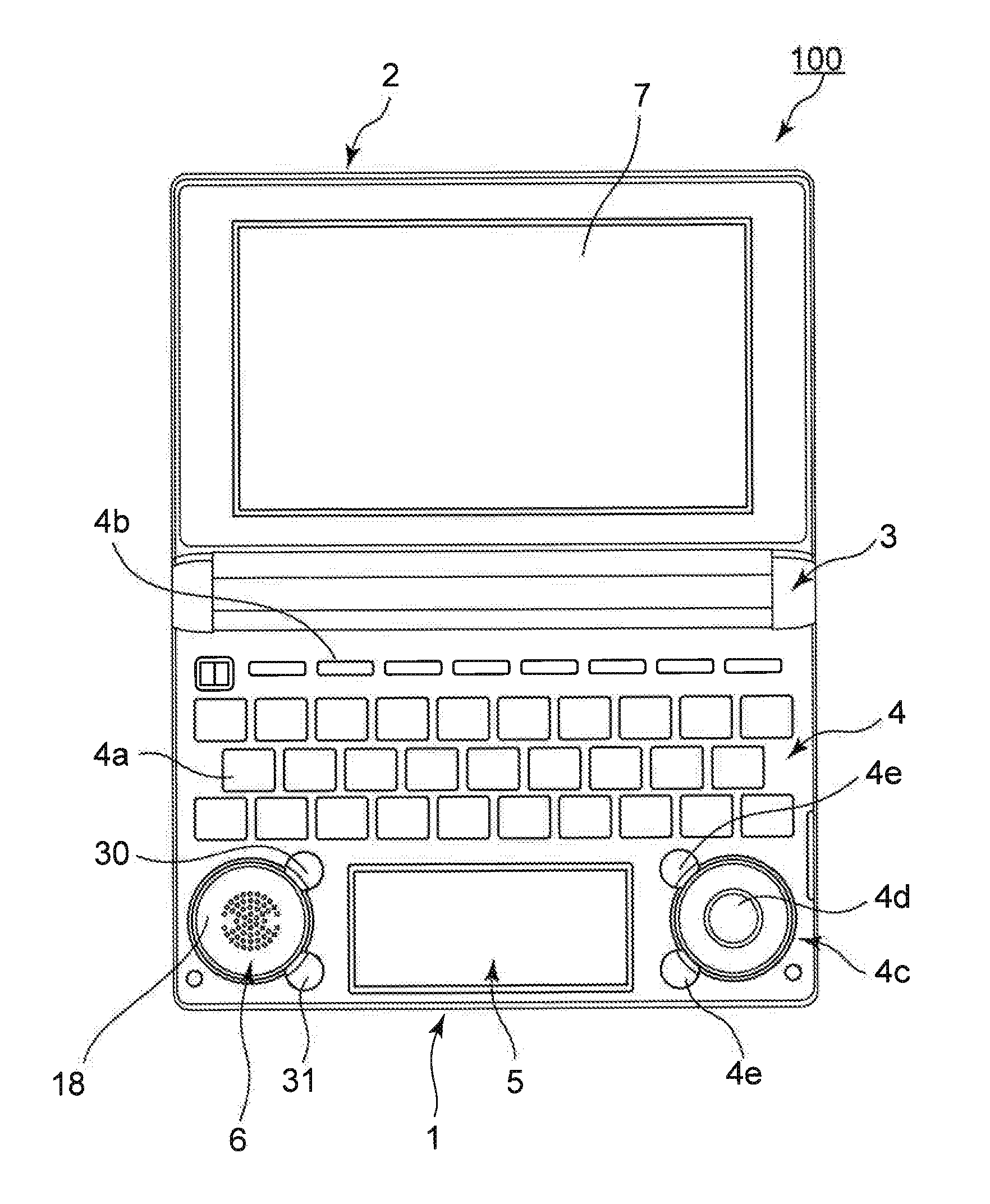

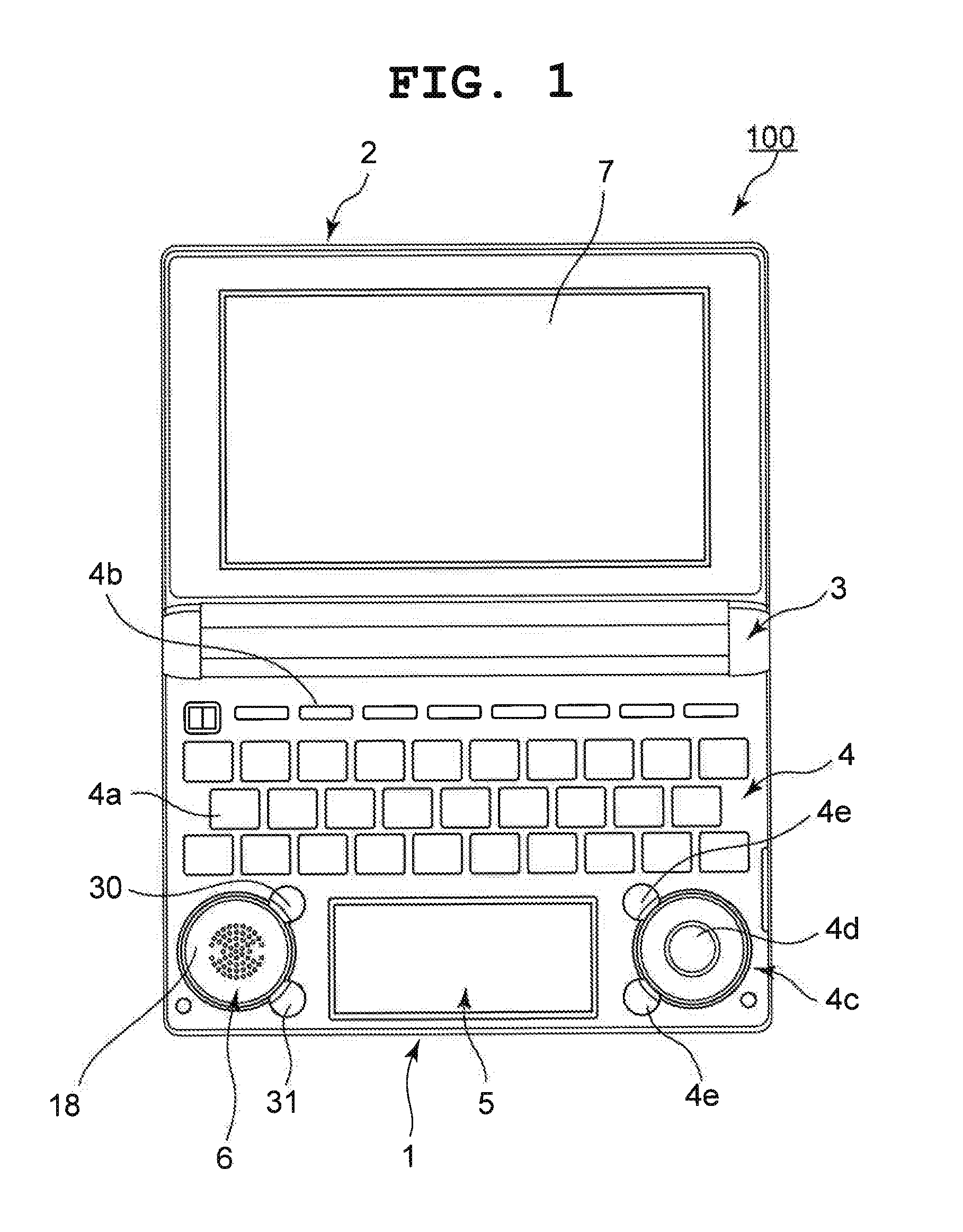

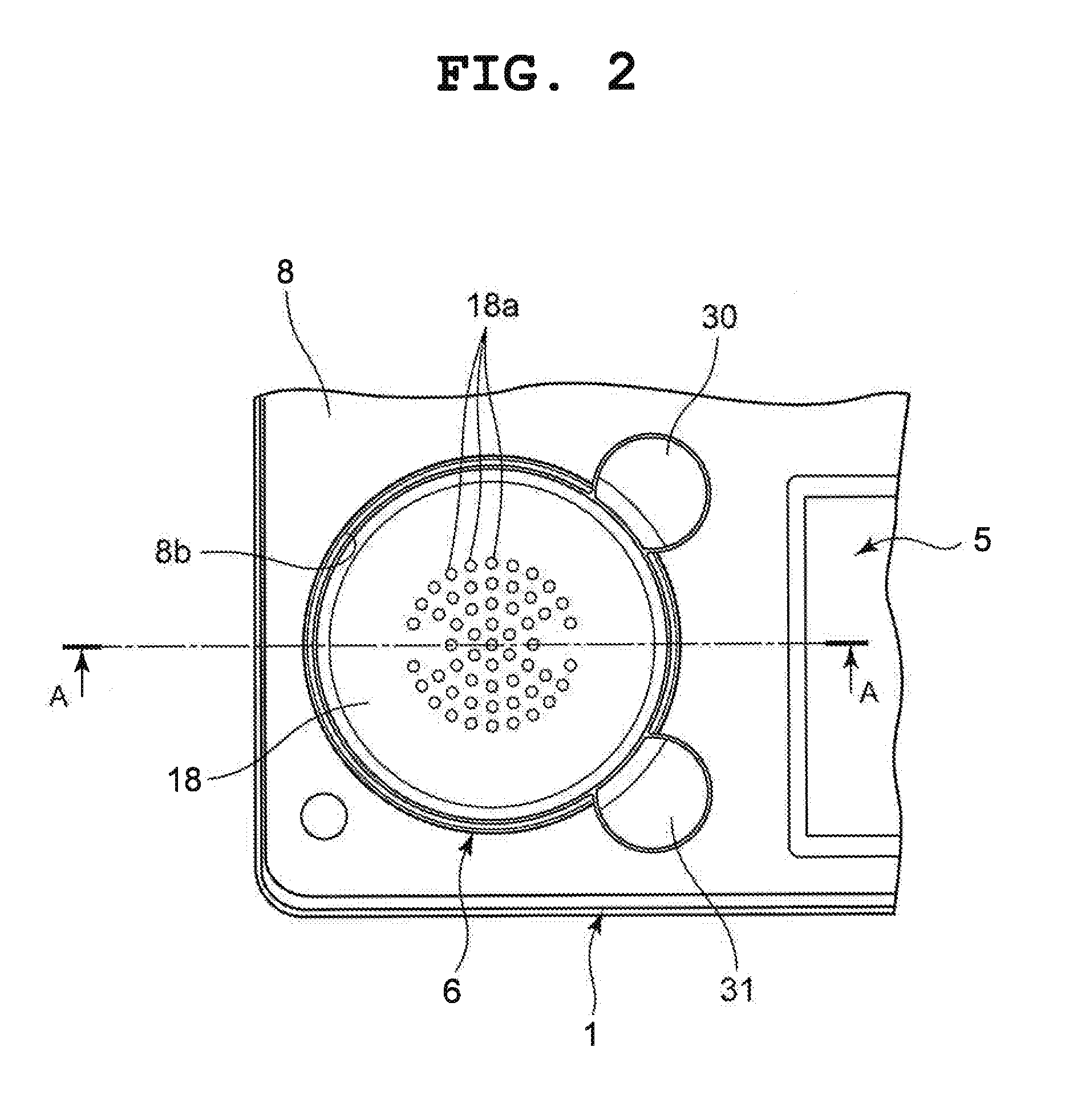

Electronic device

ActiveUS20120128196A1Simple installation structureGood adhesionPiezoelectric/electrostrictive microphonesContact surface shape/structureEngineeringLoudspeaker

In an electronic device, a speaker attaching section 17 which is vertically open with respect to a circuit board 10 and into which a speaker 16 is press-fitted is integrally formed on a contact sheet 13 arranged on the circuit board 10 provided inside an upper case 8. Therefore, the speaker 16 can be easily attached in a manner that sound therefrom does not leak, simply by the speaker 16 being press-fitted into the speaker attaching section 17 of the contact sheet 13. Accordingly, in the present invention, the structure of the speaker section 6 is simple and the number of its components is small, whereby the thickness of the speaker section 6 can be reduced. In addition, sound generated by the speaker can be favorably and reliably emitted from the speaker attaching section 17 to the outside of the upper case 8, without chattering noise being generated.

Owner:CASIO COMPUTER CO LTD

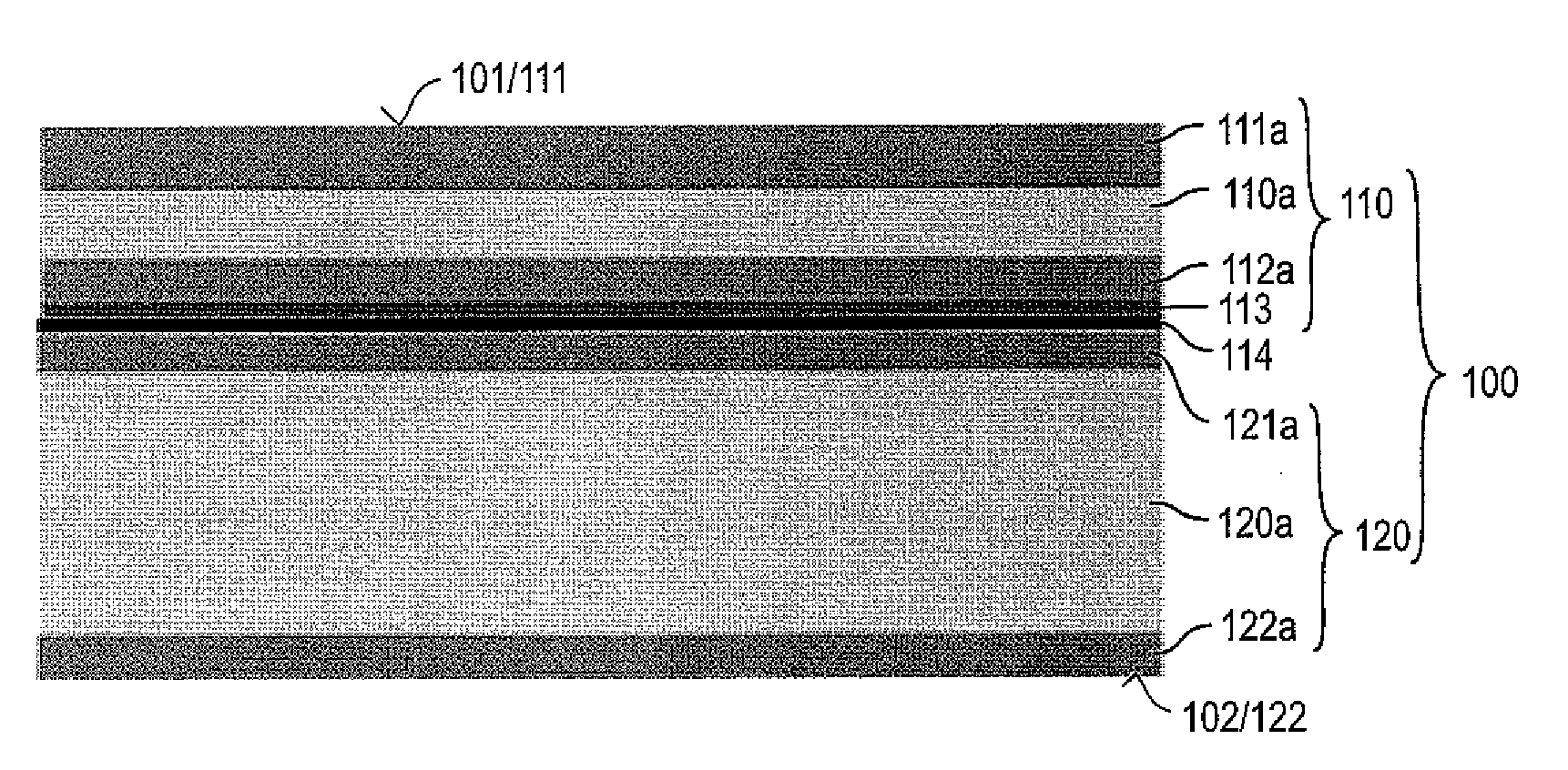

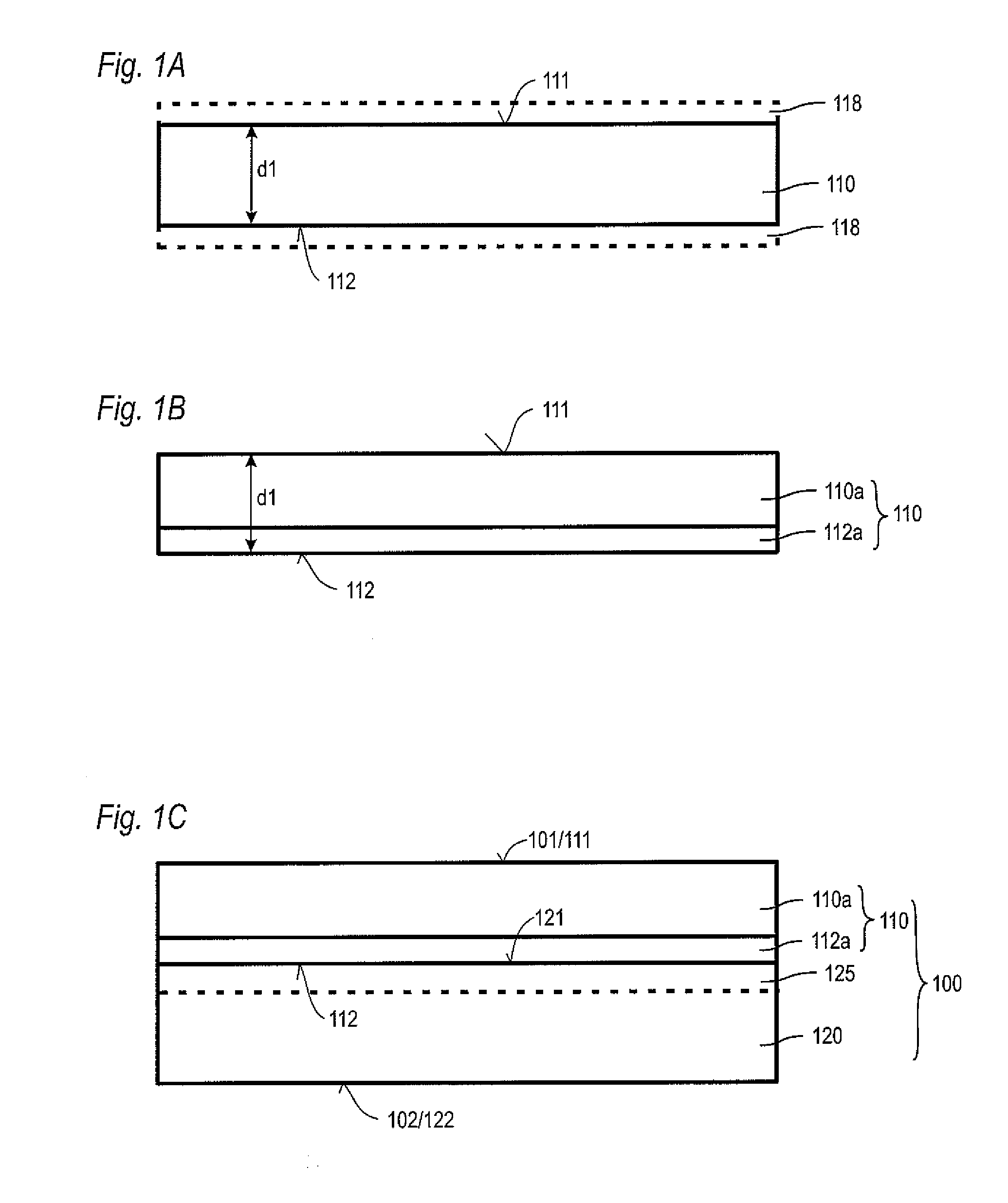

Method for Manufacturing a Semiconductor Wafer, and Semiconductor Device Having a Low Concentration of Interstitial Oxygen

ActiveUS20160104622A1Low oxygenReduce device thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringOxygen content

A method for manufacturing a substrate wafer 100 includes providing a device wafer (110) having a first side (111) and a second side (112); subjecting the device wafer (110) to a first high temperature process for reducing the oxygen content of the device wafer (110) at least in a region (112a) at the second side (112); bonding the second side (112) of the device wafer (110) to a first side (121) of a carrier wafer (120) to form a substrate wafer (100); processing the first side (101) of the substrate wafer (100) to reduce the thickness of the device wafer (110); subjecting the substrate wafer (100) to a second high temperature process for reducing the oxygen content at least of the device wafer (110); and at least partially integrating at least one semiconductor component (140) into the device wafer (110) after the second high temperature process.

Owner:INFINEON TECH AG

Wafer processing method

ActiveUS20090017623A1Easy to carrySmooth shiftingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A wafer processing method having a step of reducing the thickness of a wafer in only a device forming area where semiconductor chips are formed by grinding and etching the back side of the wafer to thereby form a recess on the back side of the wafer. At the same time, an annular projection is formed around the recess to thereby ensure the rigidity of the wafer. Accordingly, handling in shifting the wafer from the back side recess forming step to a subsequent step of forming a back side rewiring layer can be performed safely and easily.

Owner:DISCO CORP

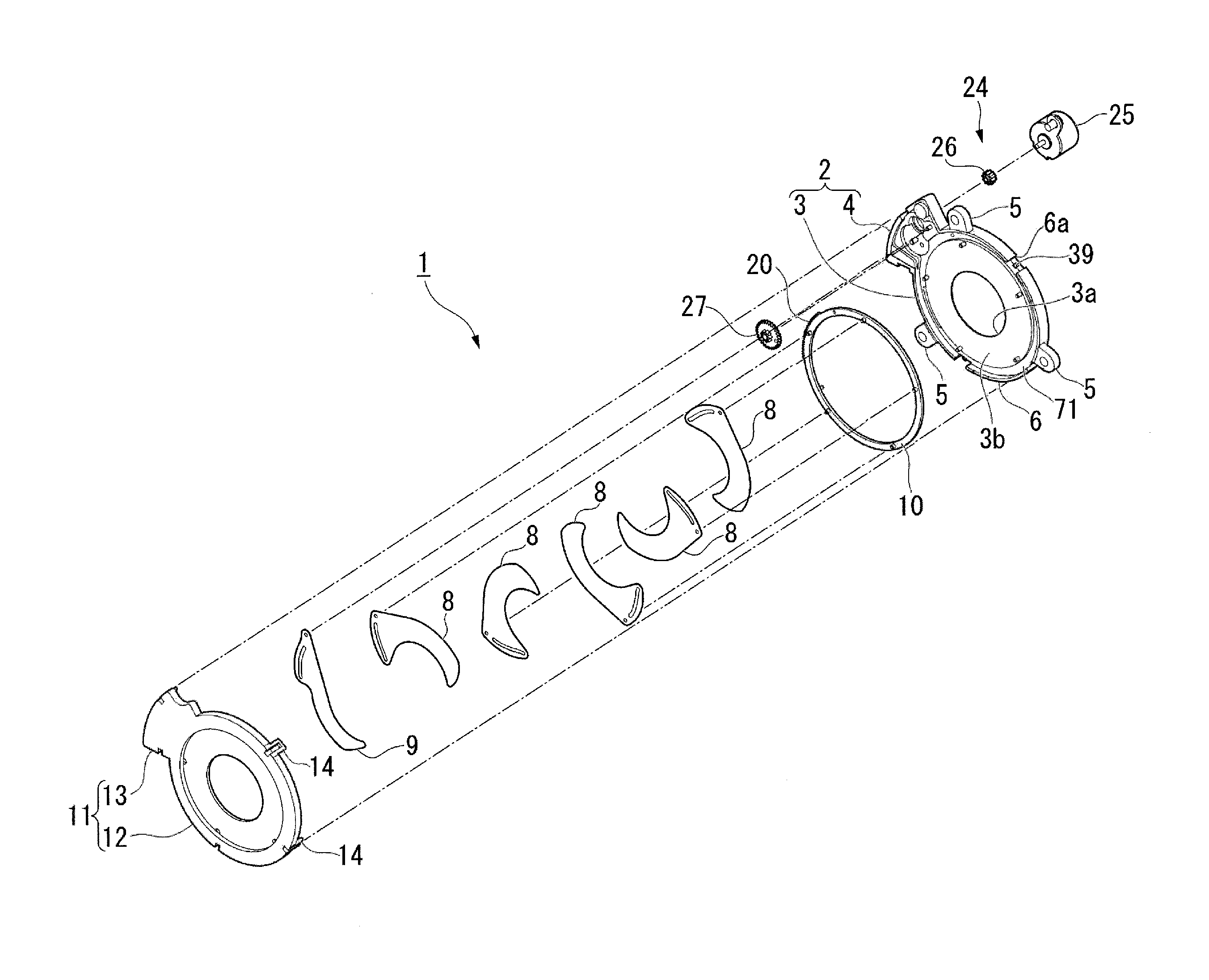

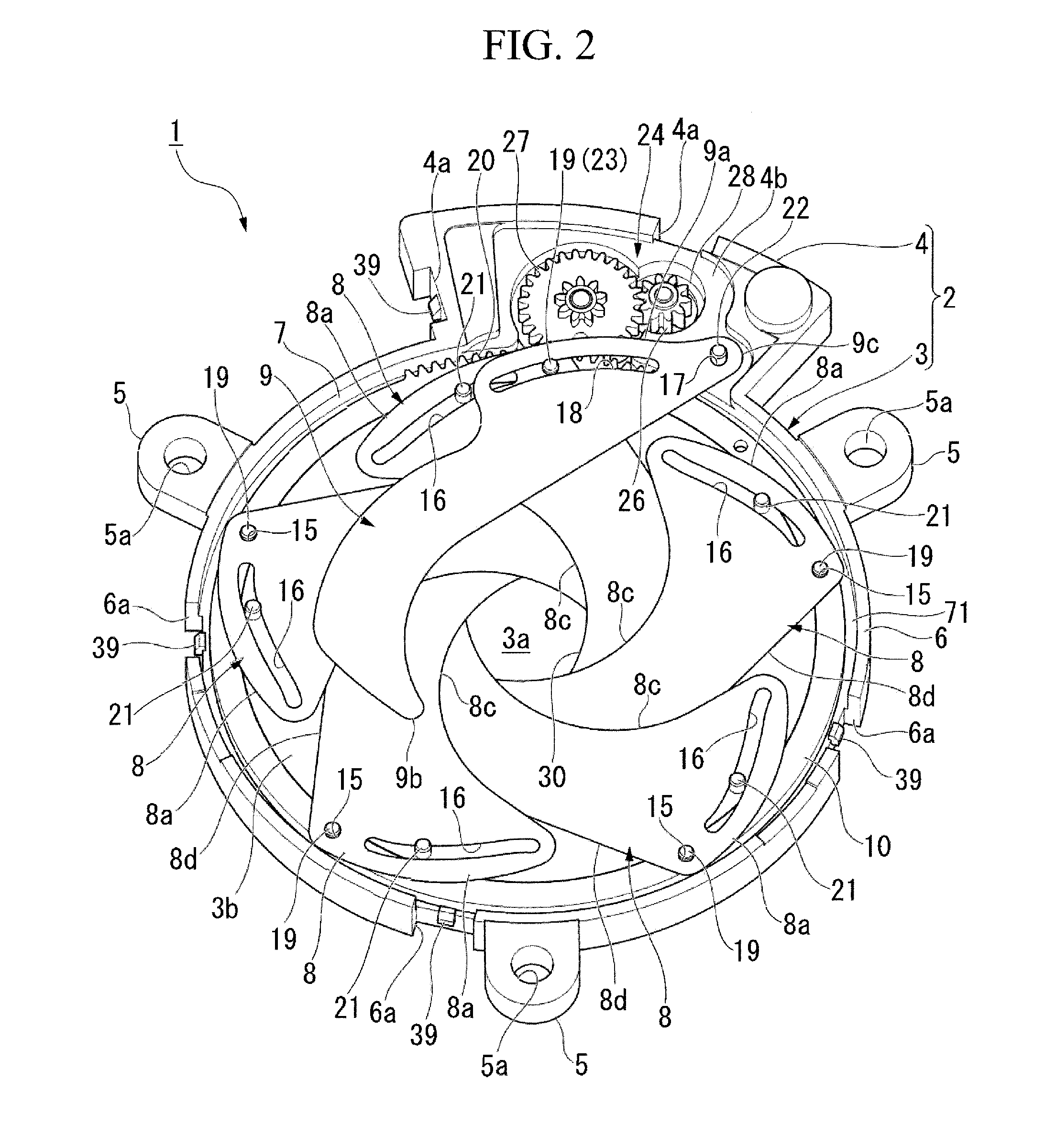

Diaphragm device and optical instrument

ActiveUS20160139491A1Reduce thicknessReduce device thicknessCamera diaphragmsEngineeringOptical instrument

Owner:SEIKO HLDG KK TRADING AS SEIKO HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com