Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

924results about How to "Reliable removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

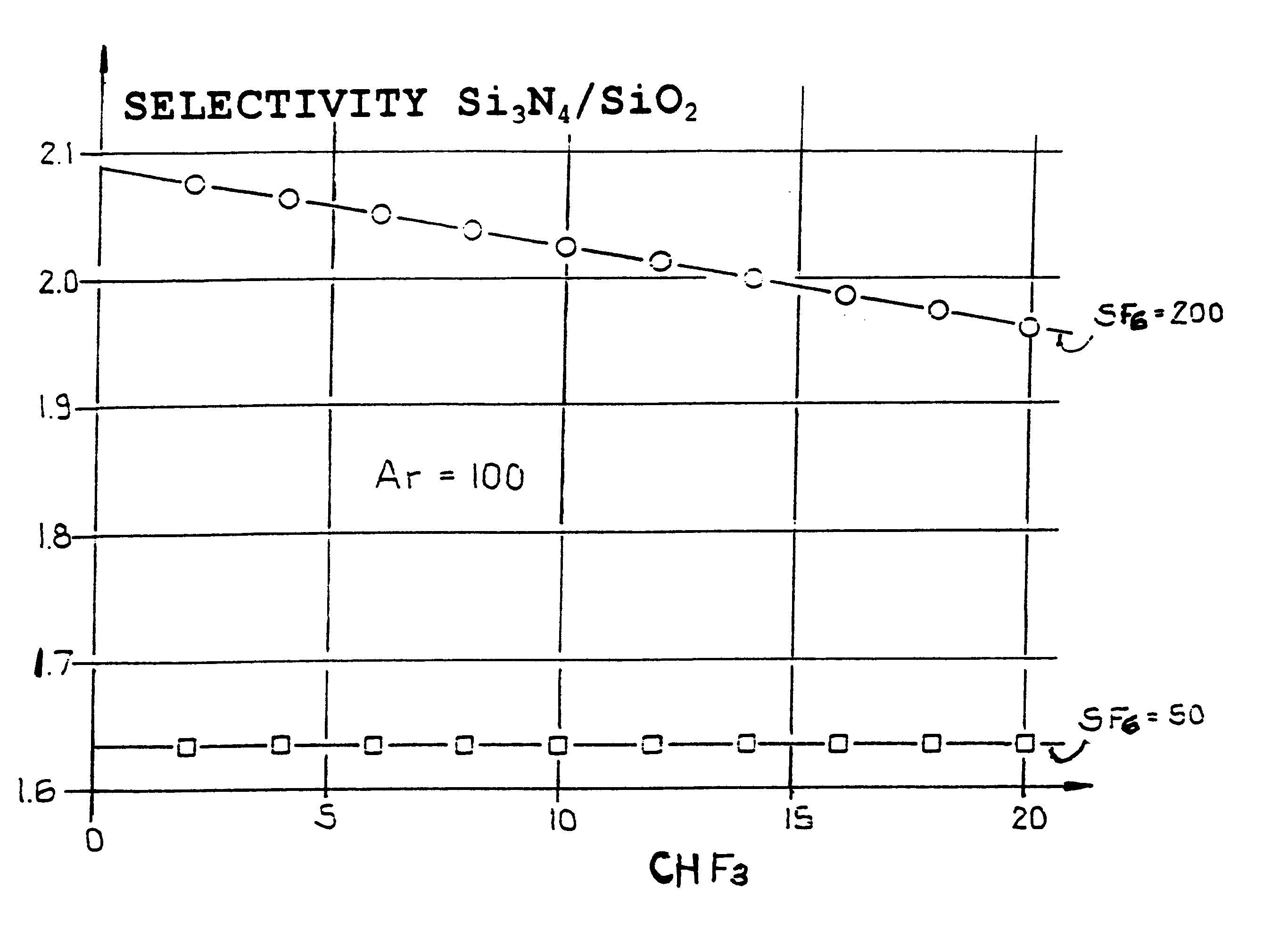

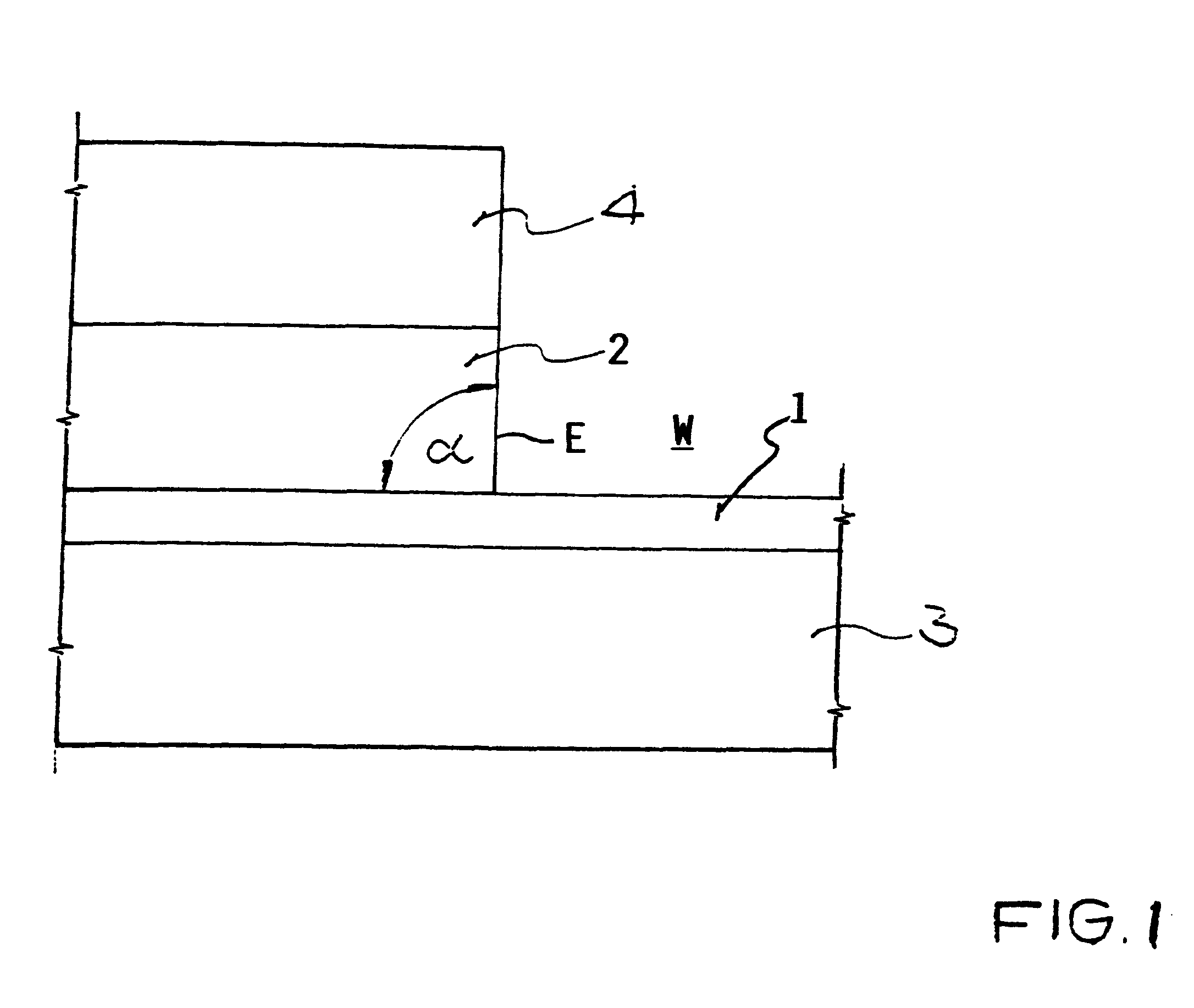

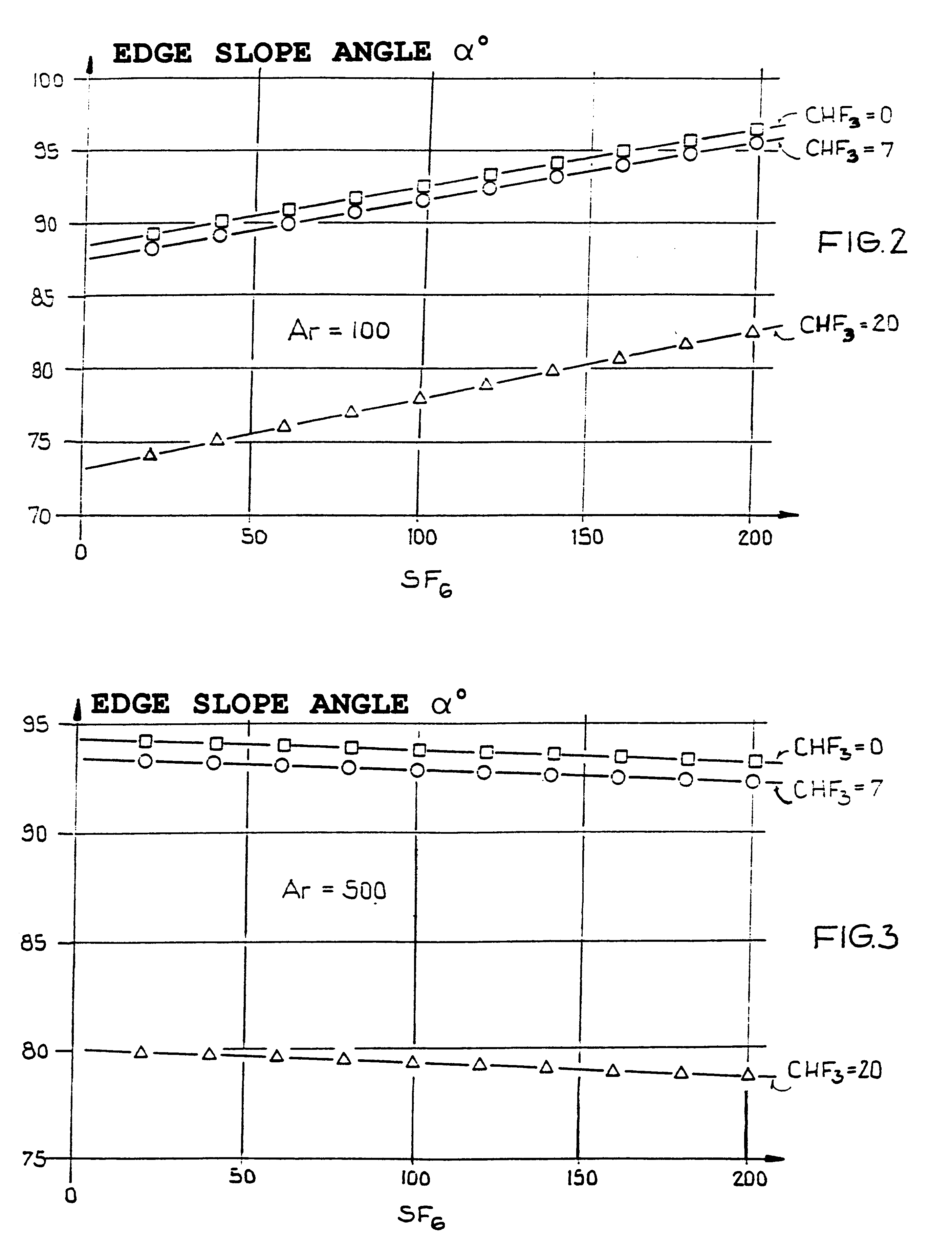

Method for anisotropic plasma-chemical dry etching of silicon nitride layers using a gas mixture containing fluorine

InactiveUS6569773B1Improve uniformityHigh atomic weightSemiconductor/solid-state device manufacturingSilicon oxideOxygen

An etching gas mixture containing CHF3, SF6 and a non-oxidizing gas such as Ar is used as an etching gas mixture for the anisotropic plasma-chemical dry-etching of a silicon nitride layer differentially or selectively relative to a silicon oxide layer. The gas mixture does not contain oxygen, chlorine, bromine, iodine or halides in addition to the above mentioned constituents, so that the process can be carried out in reactor systems equipped with oxidizable electrodes. By adjusting the gas flow rates or composition ratios of CHF3, SF6, and argon in the etching gas mixture, it is possible to adjust the resulting etching selectivity of silicon nitride relative to silicon oxide, and the particular edge slope angle of the etched edge of the remaining silicon nitride layer. A high etch rate for the silicon nitride is simultaneously achieved.

Owner:ATMEL CORP +1

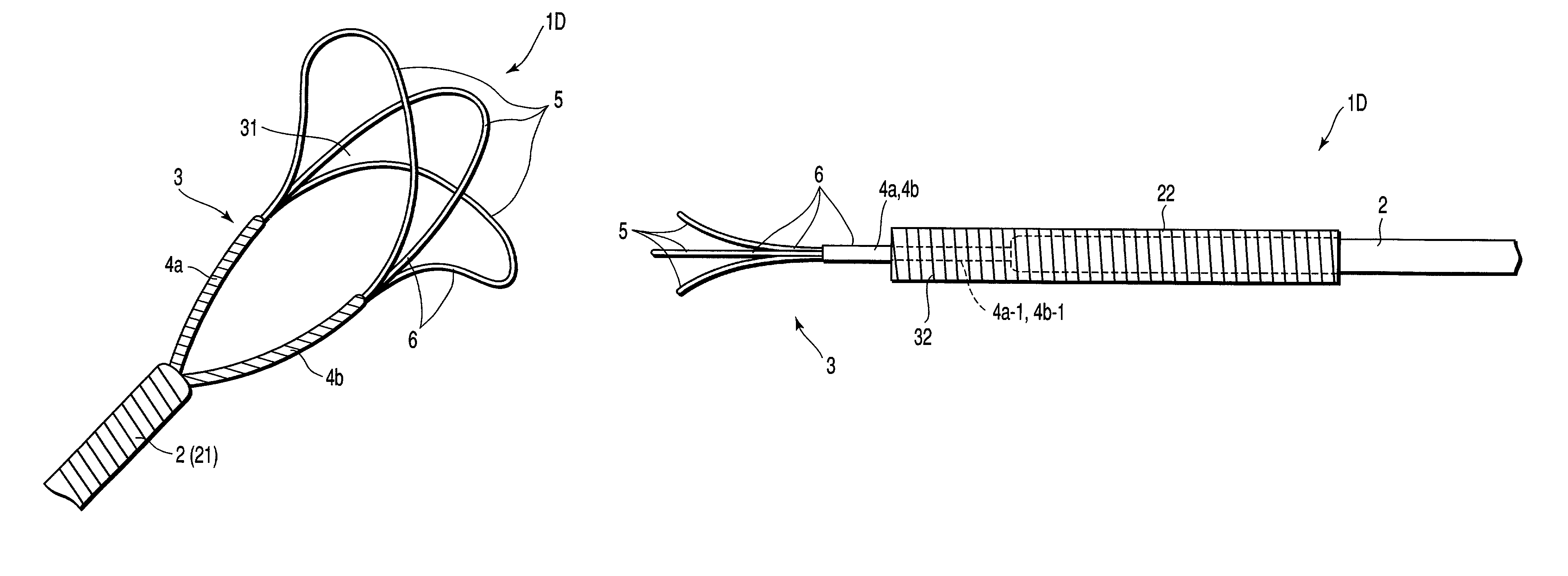

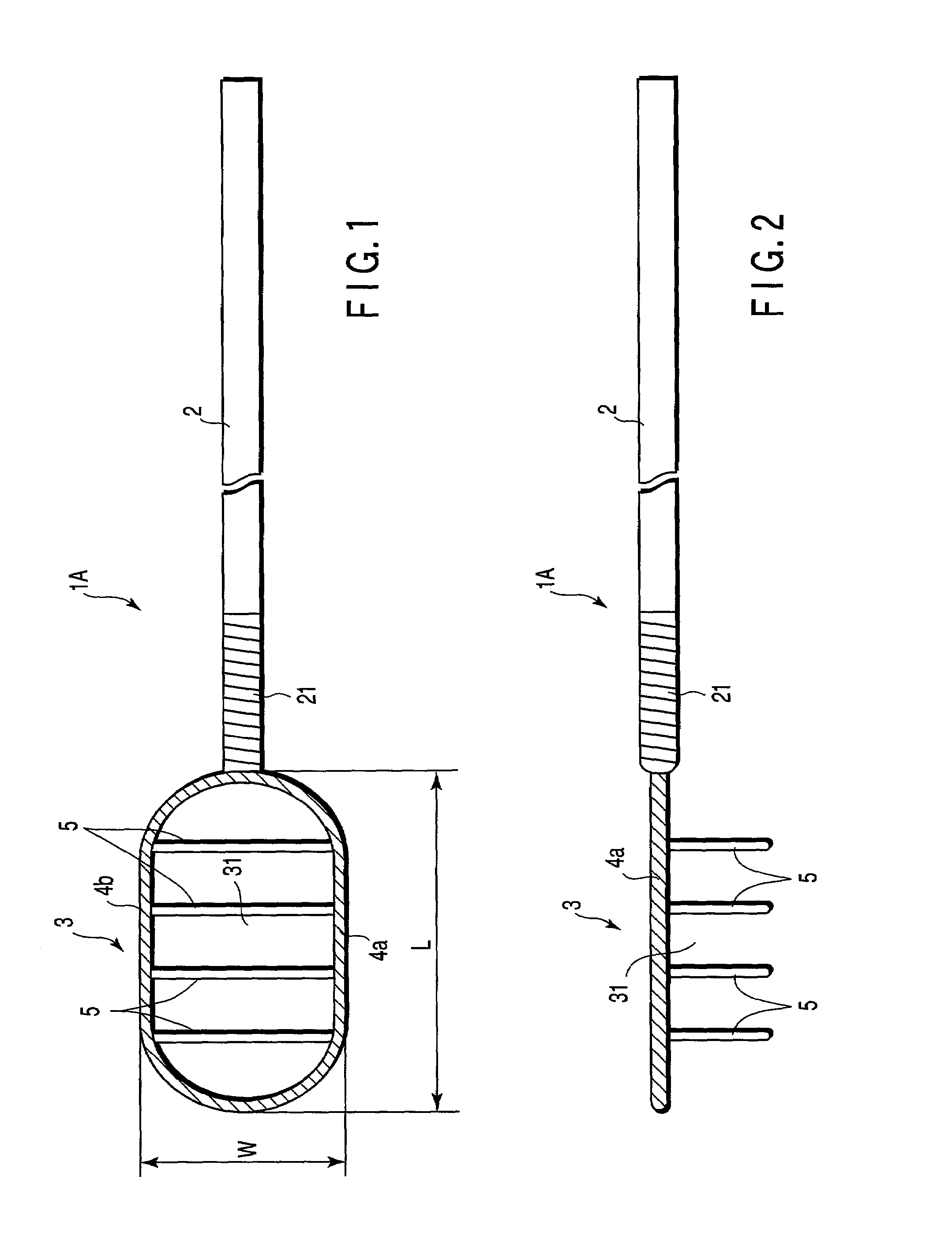

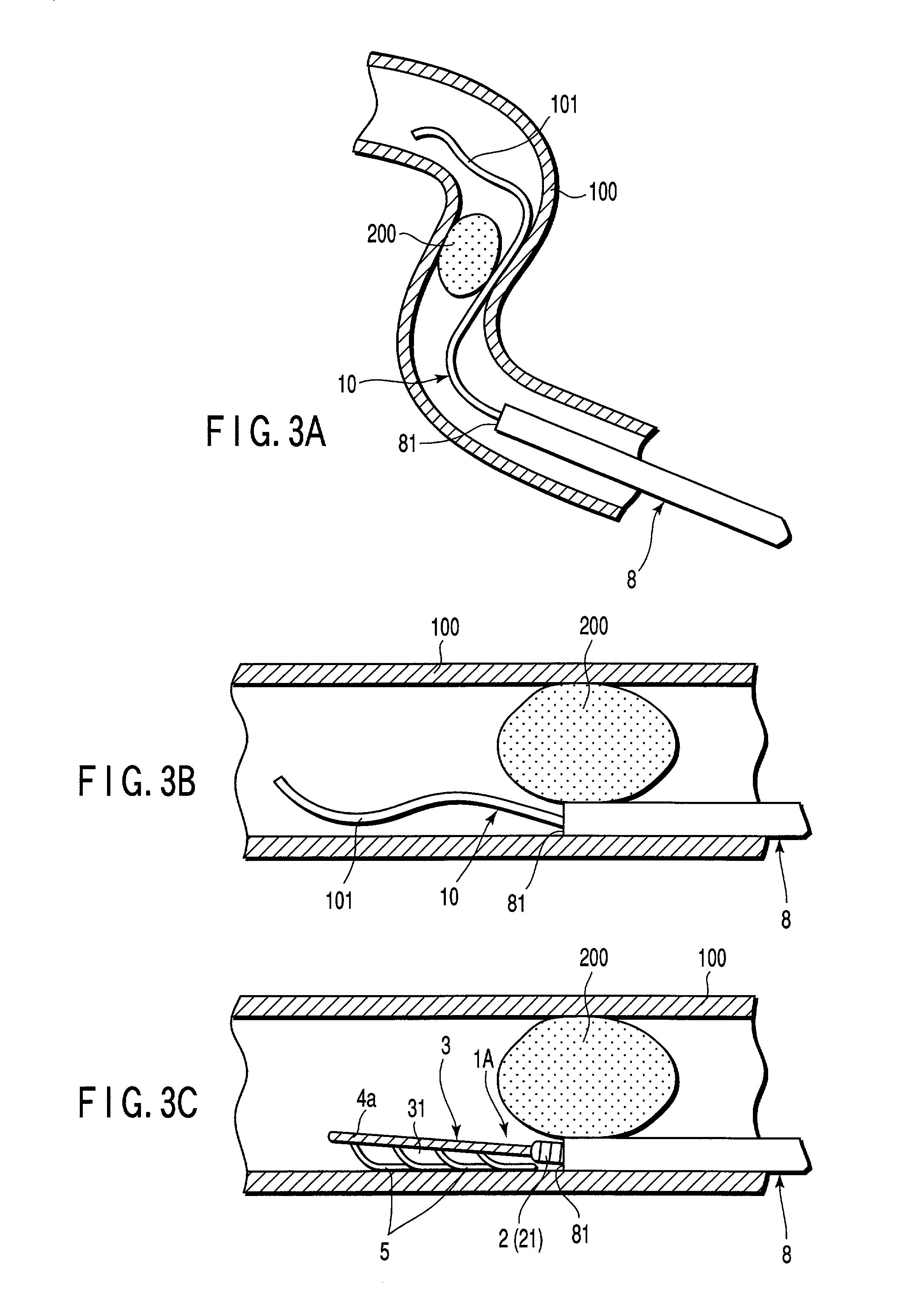

Intravascular obstruction removing wire and medical instrument

An intravascular obstruction removing wire includes an elongate wire body, at least two non-branched wire portions having distal ends and proximal ends which are connected to a distal end of the wire main body, and a plurality of filament portions extending across the wire portions. The non-branched wire portions and the filament portions form a trapping portion. The trapping portion is deformable from a large-diameter state in which the non-branched portions branch to the distal end of the wire body forward in different directions and the filament portions are separated from each other, so that a space surrounded by the non-branched wire portions and the filament portions is formed to trap therein an obstruction in a blood vessel, to a small-diameter state in which the non-branched wire portions are positioned so that a distance between the wire portions is smaller than that of the wire portions in the large-diameter state.

Owner:TERUMO KK +1

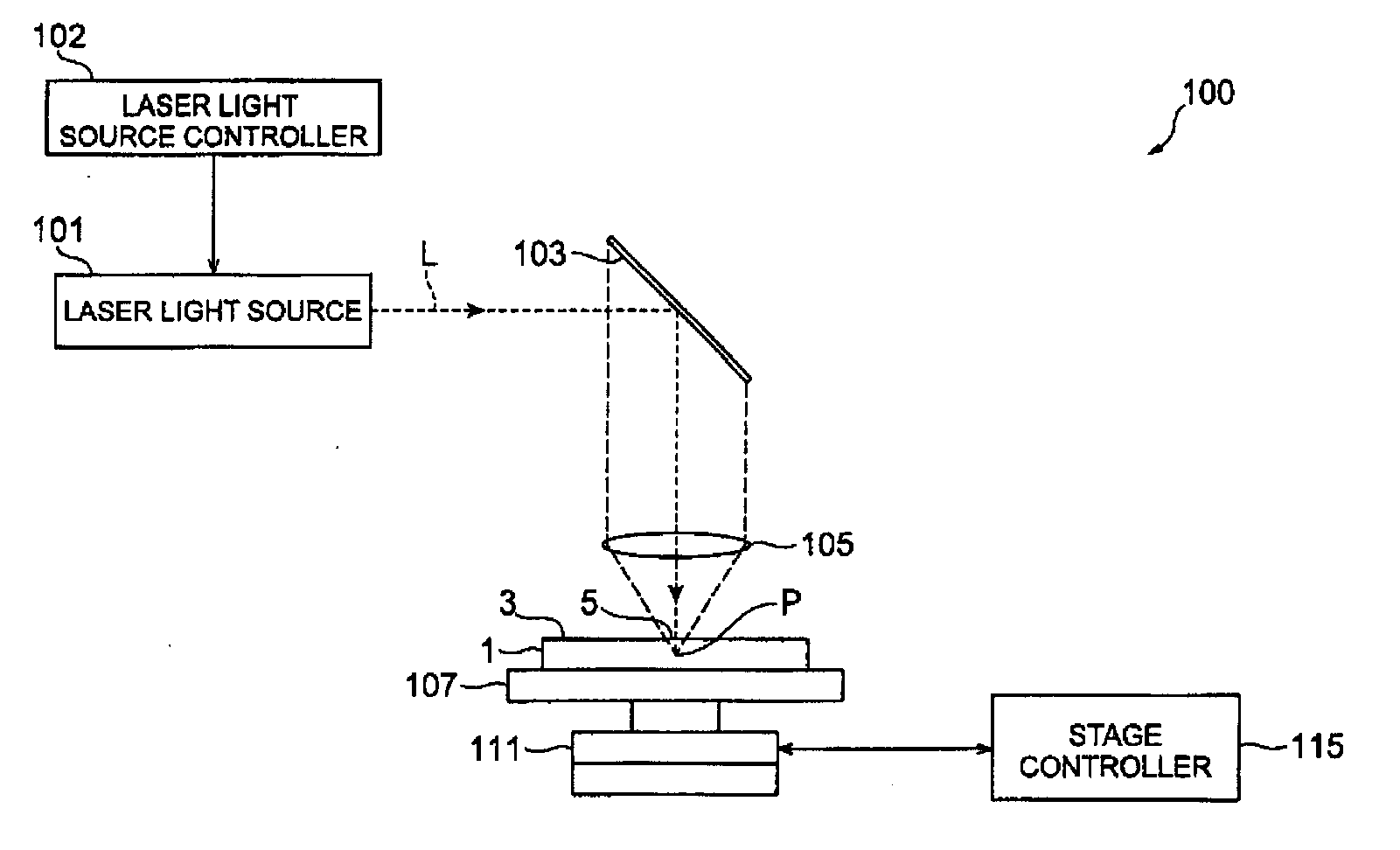

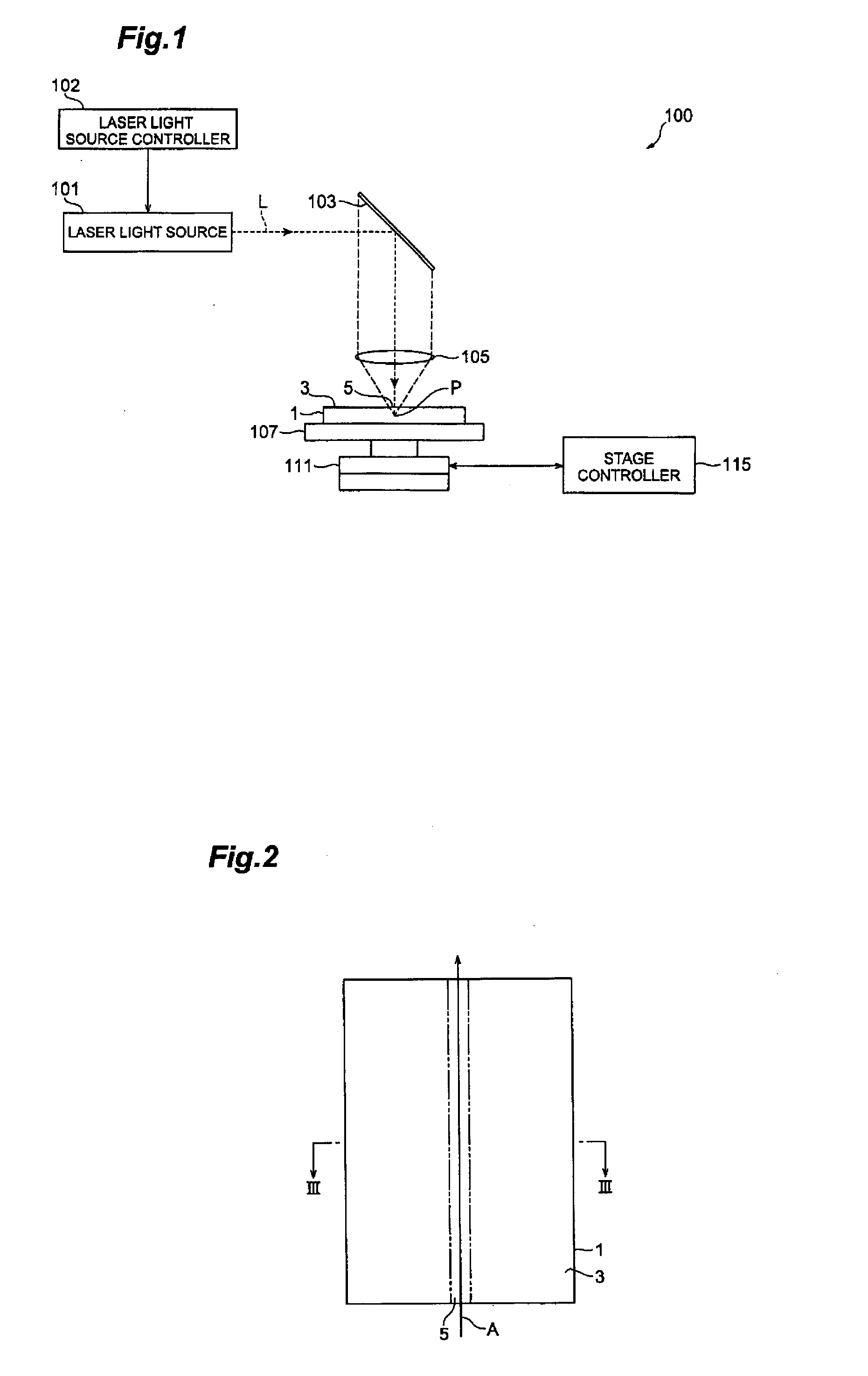

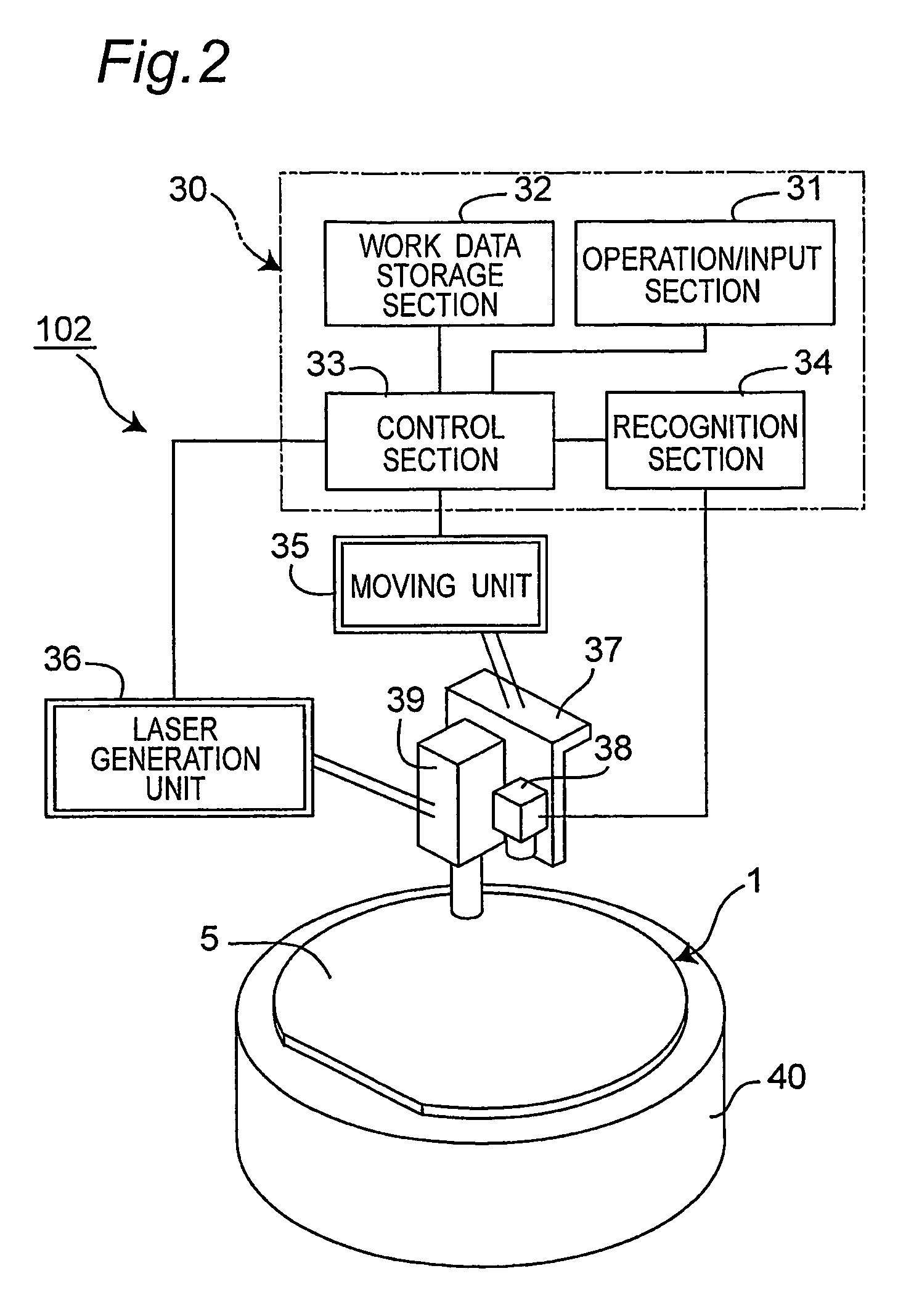

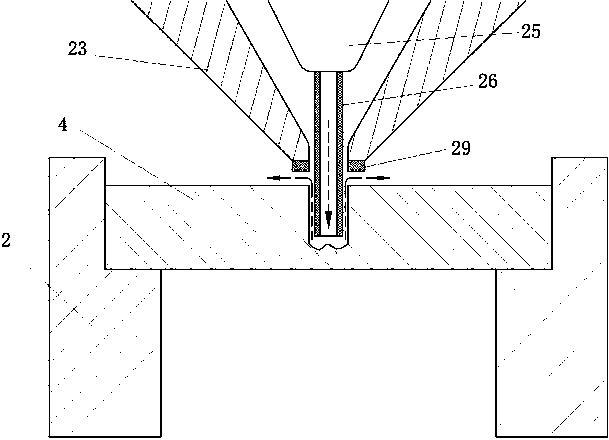

Object cutting method

ActiveUS20090098713A1Reliable preventionReliably preventedSemiconductor/solid-state device manufacturingWorking accessoriesProcess regionSemiconductor chip

An object cutting method which can reliably remove particles remaining on cut sections of chips is provided. An expandable tape 23 is electrically charged in a state where a plurality of semiconductor chips 25 obtained by cutting a planar object to be processed along a line to cut are separated from each other on the expandable tape 23. This electric action causes particles remaining on cut sections of the semiconductor chips 25 to eject therefrom even when a molten processed region is formed in the cut sections Therefore, particles remaining on the cut sections of the chips 25 can reliably be removed.

Owner:HAMAMATSU PHOTONICS KK

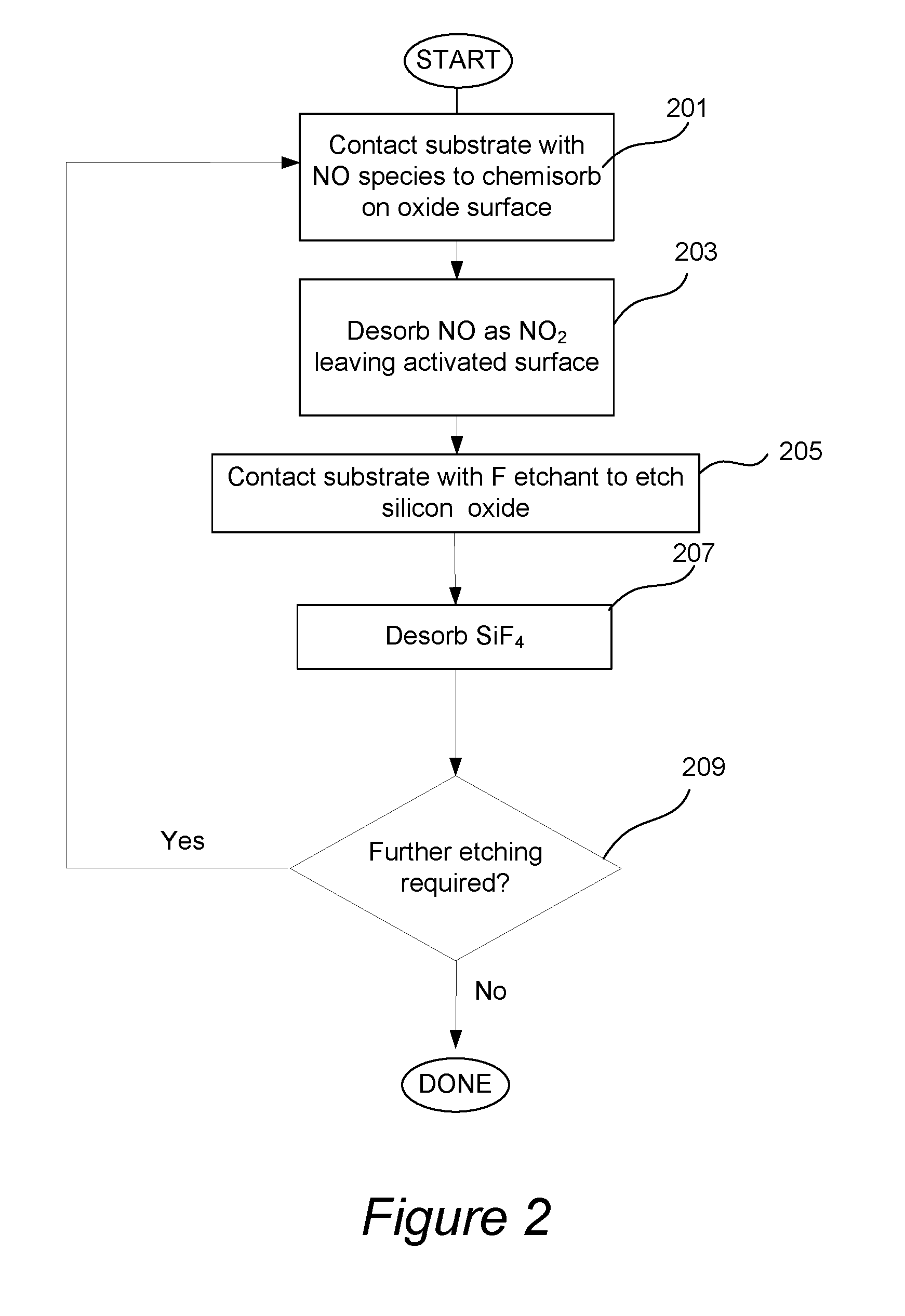

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS9425041B2High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

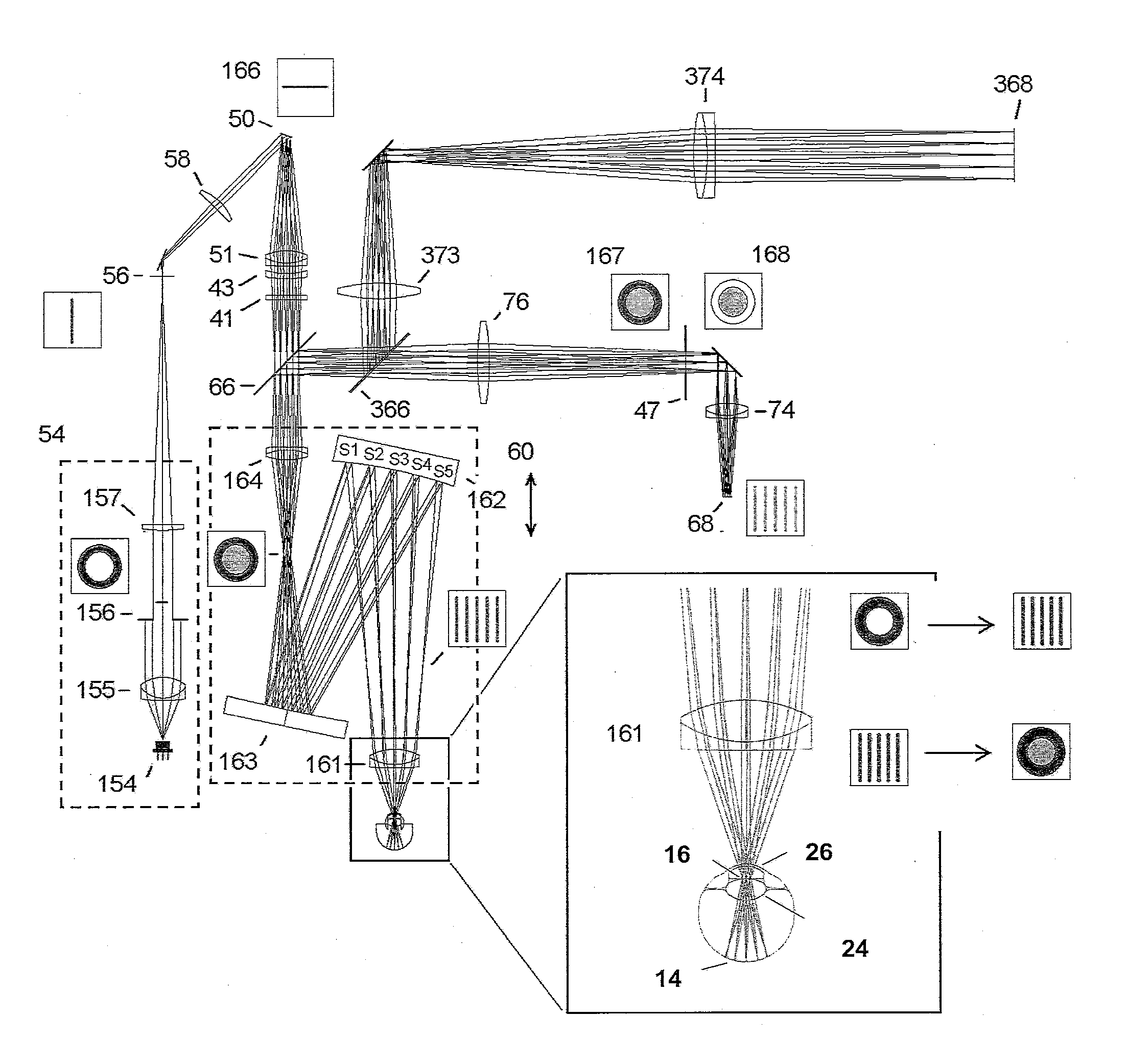

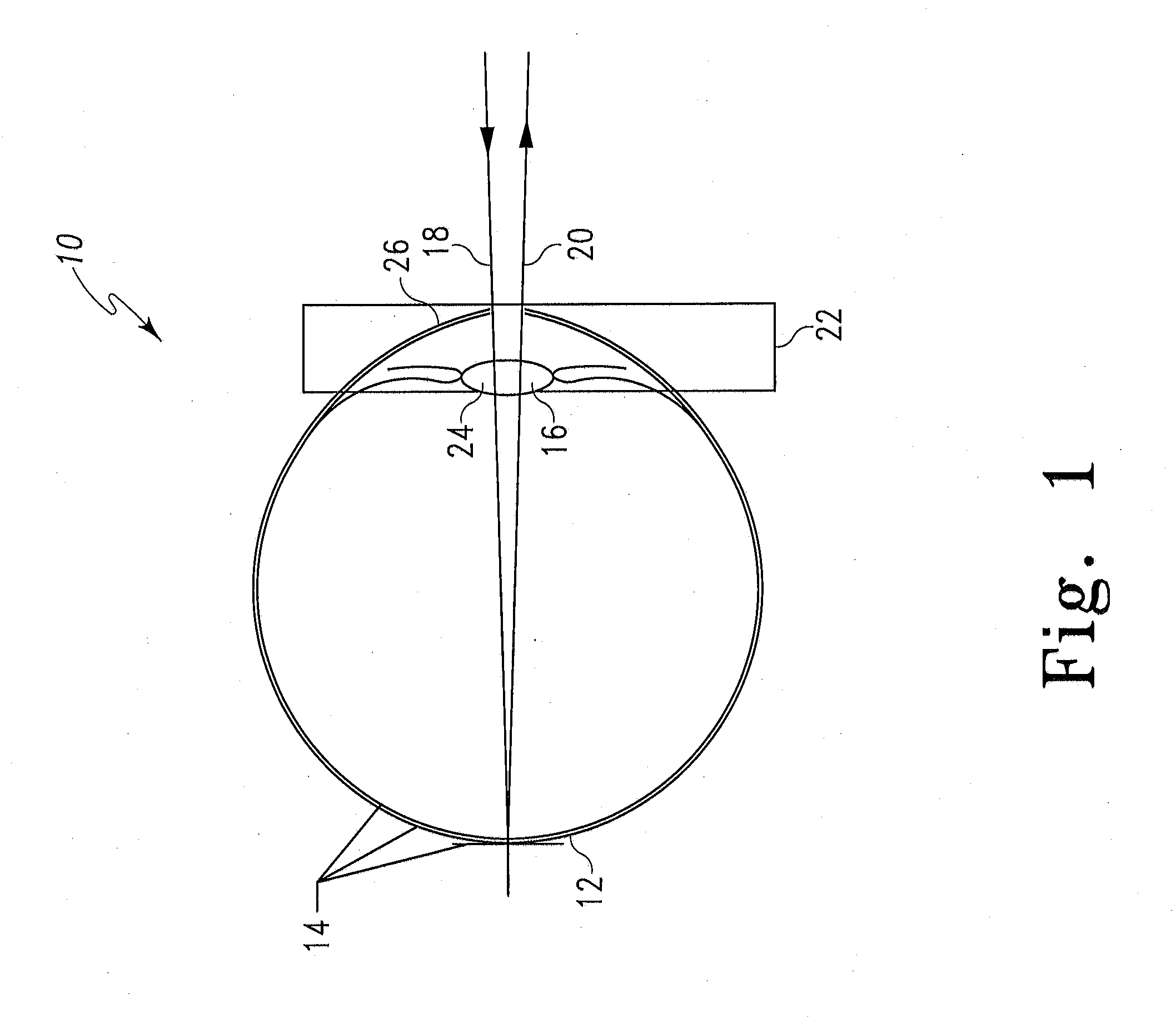

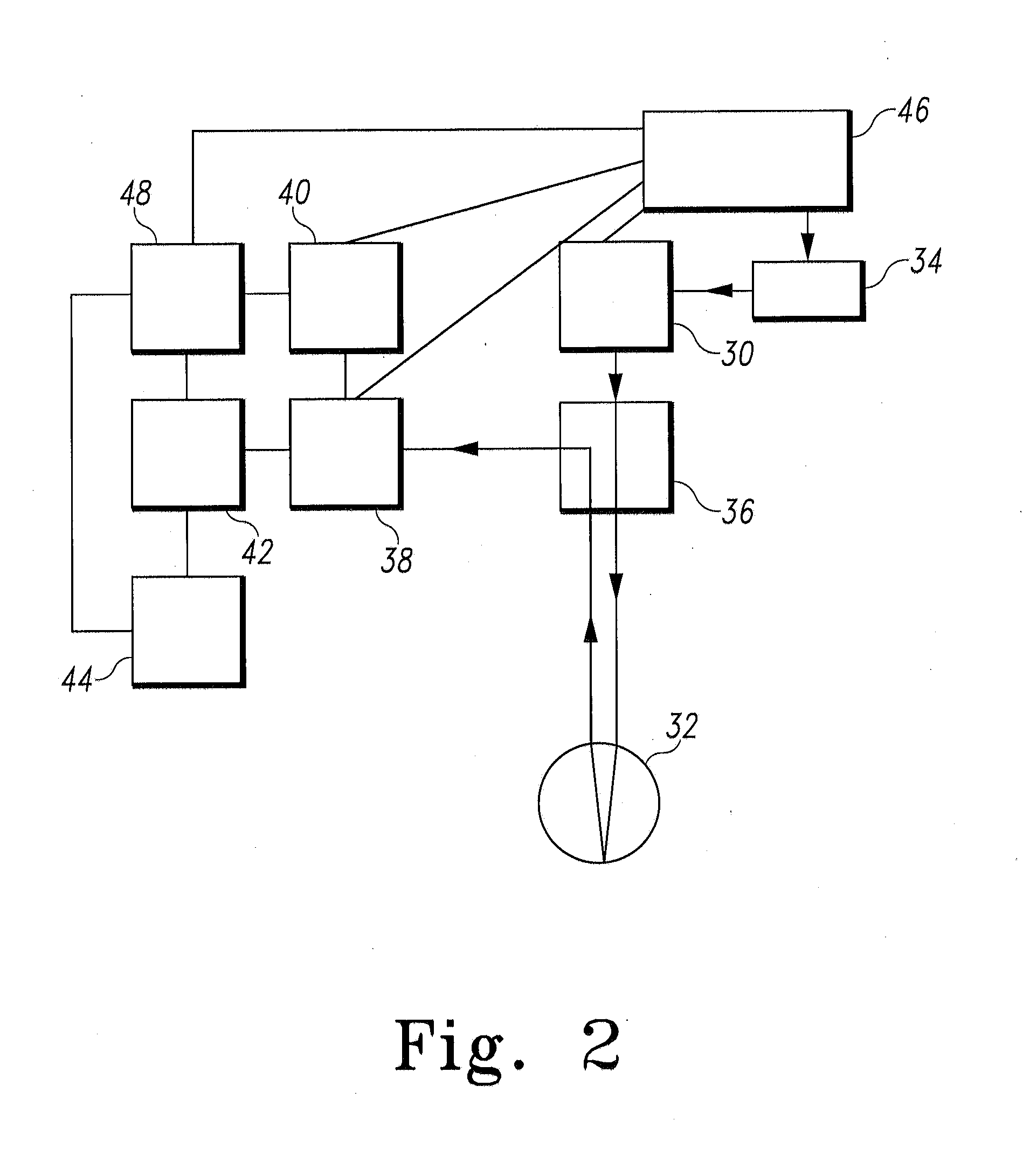

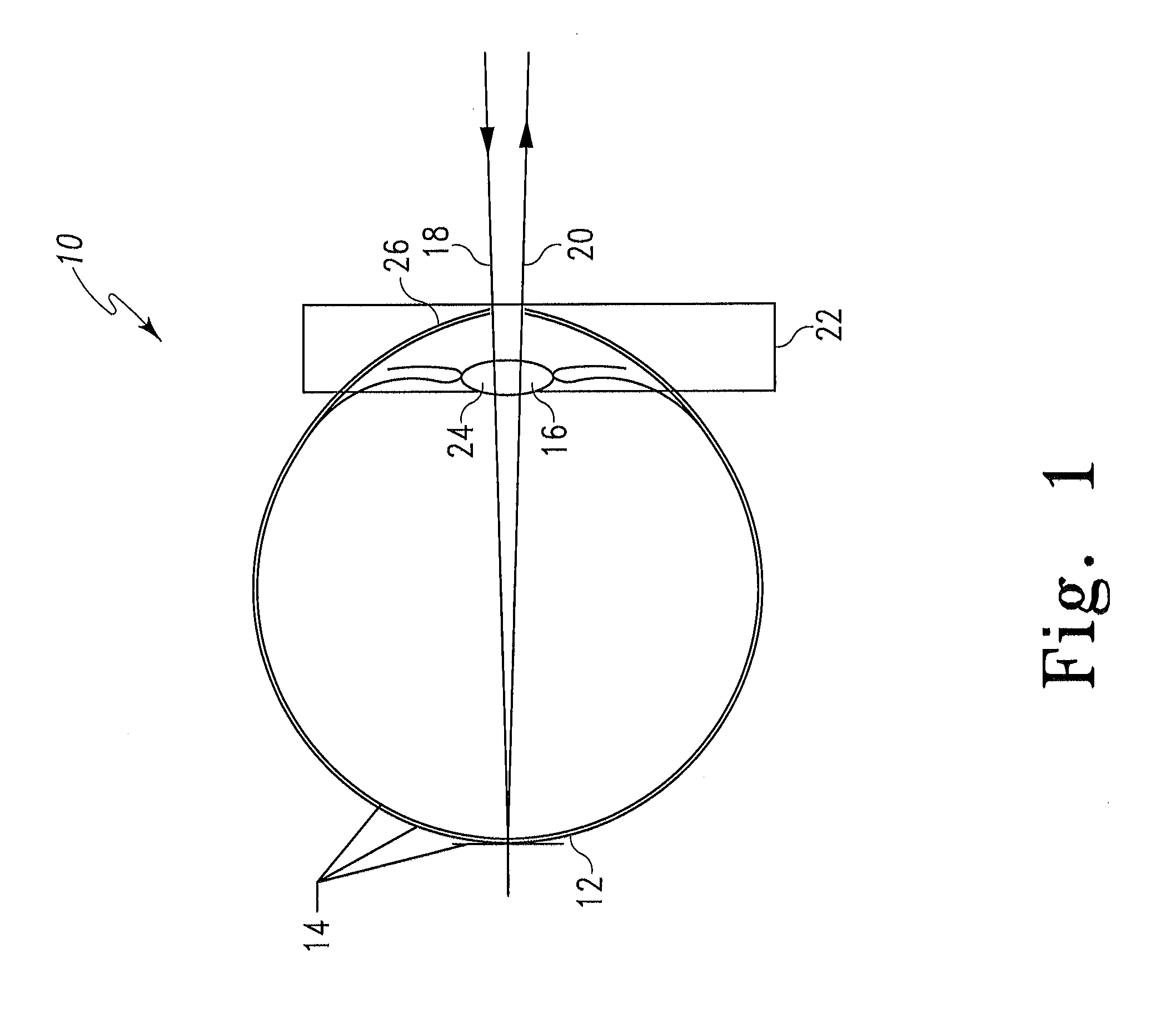

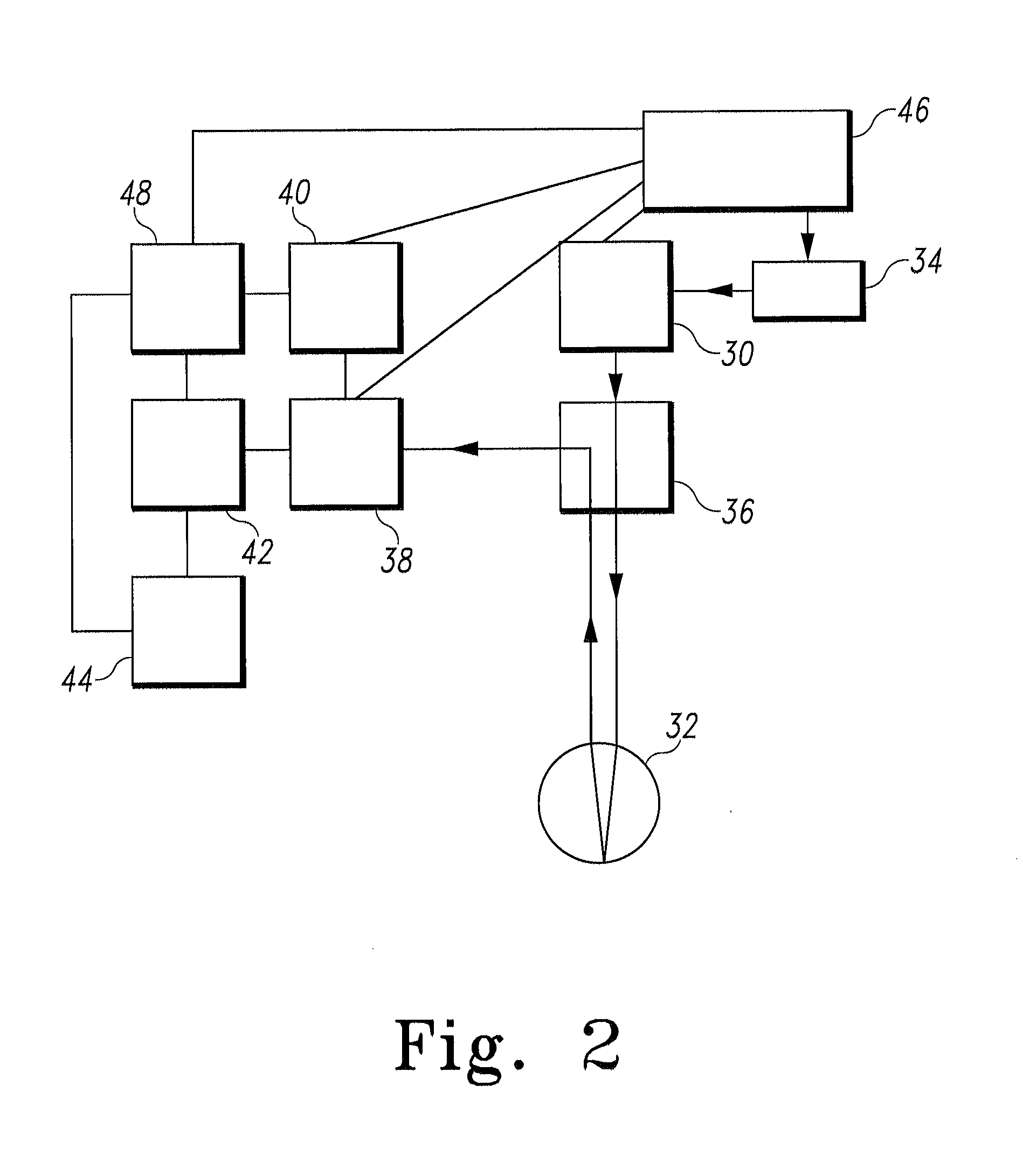

Laser scanning digital camera with pupil periphery illumination and potential for multiply scattered light imaging

ActiveUS20100128221A1Imaging is performedIncrease illuminationCharacter and pattern recognitionColor television detailsScattered lightLaser scanning

A portable, lightweight digital imaging device uses a slit scanning arrangement to obtain an image of the eye, in particular the retina. In at least one embodiment, a digital retinal imaging device includes an illumination source operable to produce a source beam, wherein the source beam defines an illumination pathway, a scanning mechanism operable to cause a scanning motion of the illumination pathway in one dimension with respect to a target, an optical element situated within the illumination pathway, the optical element operable to focus the illumination pathway into an illumination slit at a plane conjugate to the target, wherein the illumination slit is slit shaped, a first two dimensional detector array operable to detect illumination returning from the target and acquire one or more data sets from the detected illumination, wherein the returning illumination defines a detection pathway, and a shaping mechanism positioned within the illumination pathway, wherein the shaping mechanism shapes the source beam into at least one arc at a plane conjugate to the pupil. In at least one exemplary embodiment, the digital retinal imaging device is operable to minimize at least one aberration from the optical element or an unwanted reflection from the target or a reflection from a device.

Owner:INDIANA UNIV RES & TECH CORP

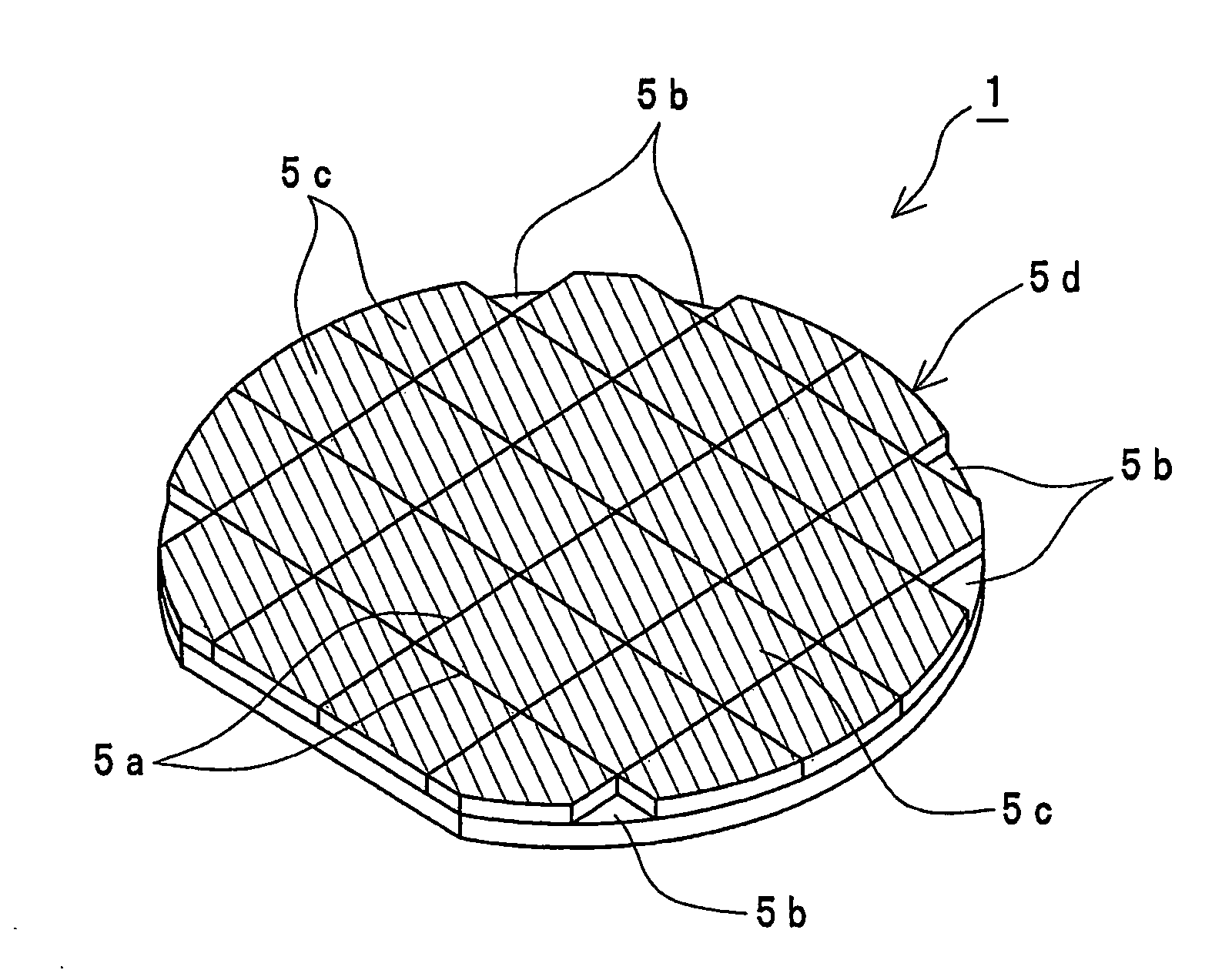

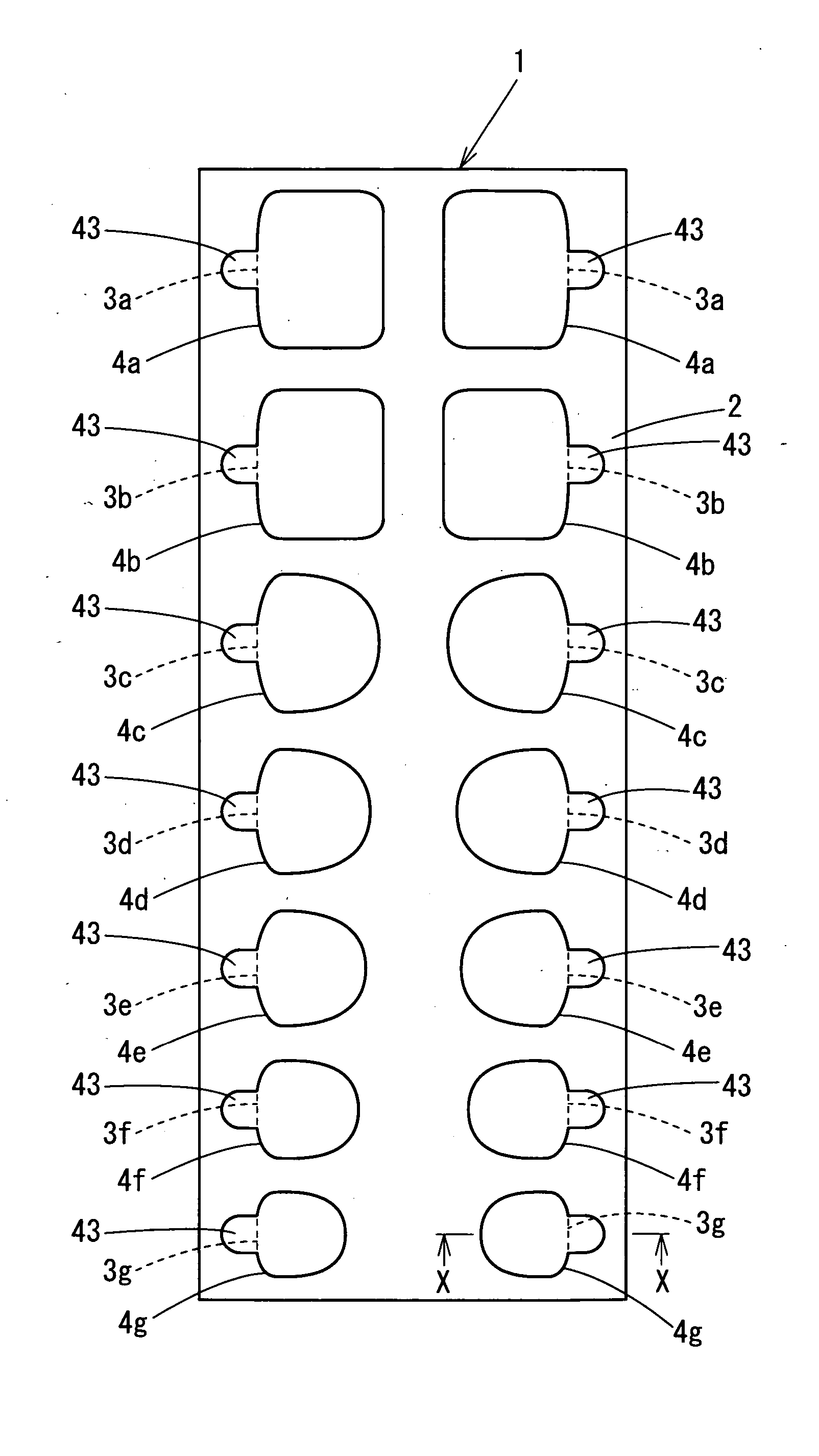

Method for dividing semiconductor wafer and manufacturing method for semiconductor devices

ActiveUS7927973B2Formation of comparatively small pieces in the semiconductor wafer can be preventedInhibition formationSemiconductor/solid-state device manufacturingSplit linesEngineering

In a semiconductor wafer including a plurality of imaginary-divided-regions which are partitioned by imaginary-dividing-lines that are respectively arranged in a grid-like arrangement on the semiconductor wafer and a circumferential line that is the outer periphery outline of the semiconductor wafer, a mask is placed so as to expose an entirety of surfaces of the wafer corresponding to respective removal-regions. The removal-regions are regions in approximately triangular form partitioned by the circumferential line of the wafer and the imaginary-dividing-lines. Then, plasma etching is performed on a mask placement-side surface of the wafer, by which the semiconductor wafer is divided into the individual semiconductor devices along dividing lines while portions corresponding to the removal-regions of the wafer are removed.

Owner:PANASONIC CORP

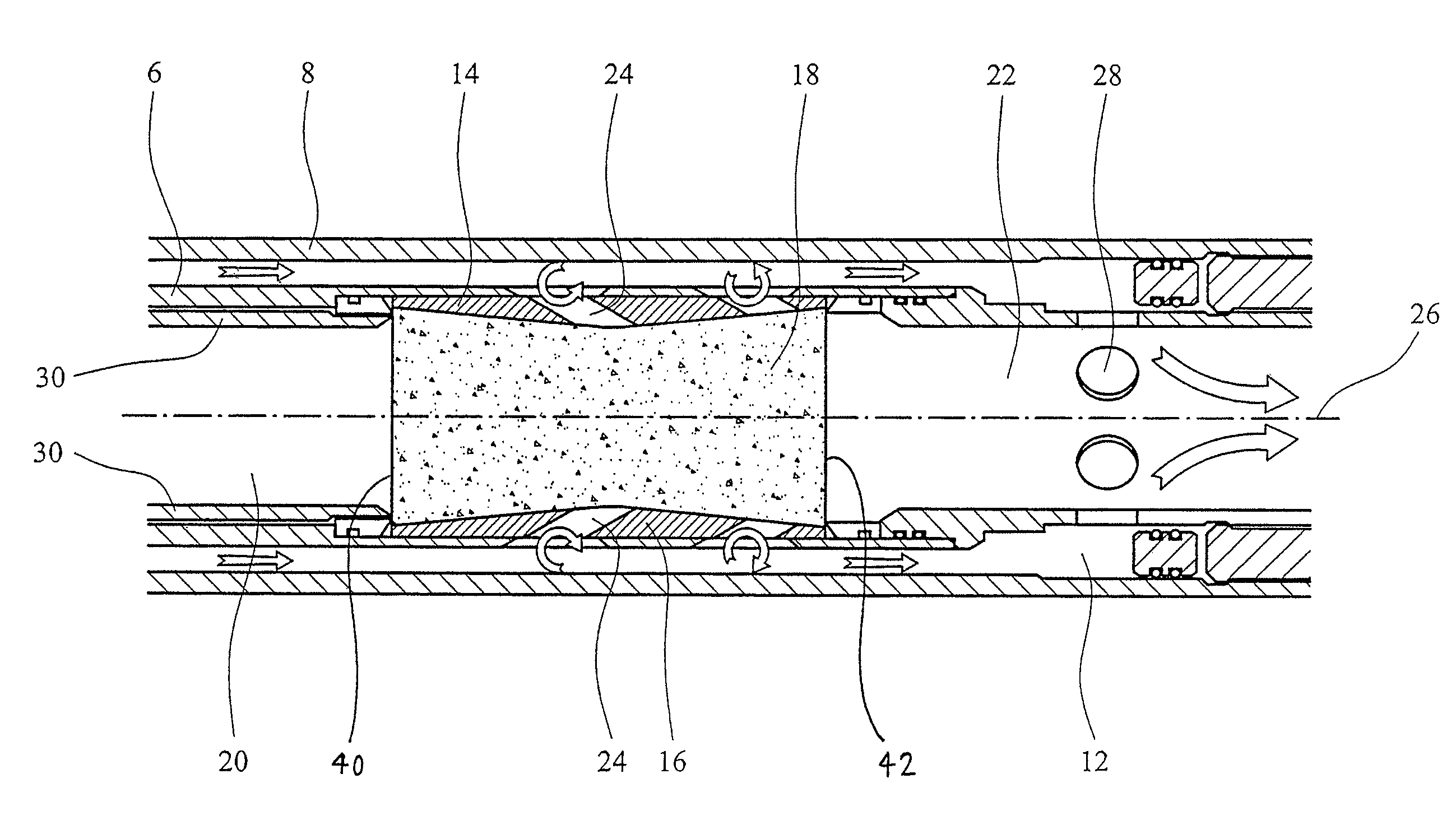

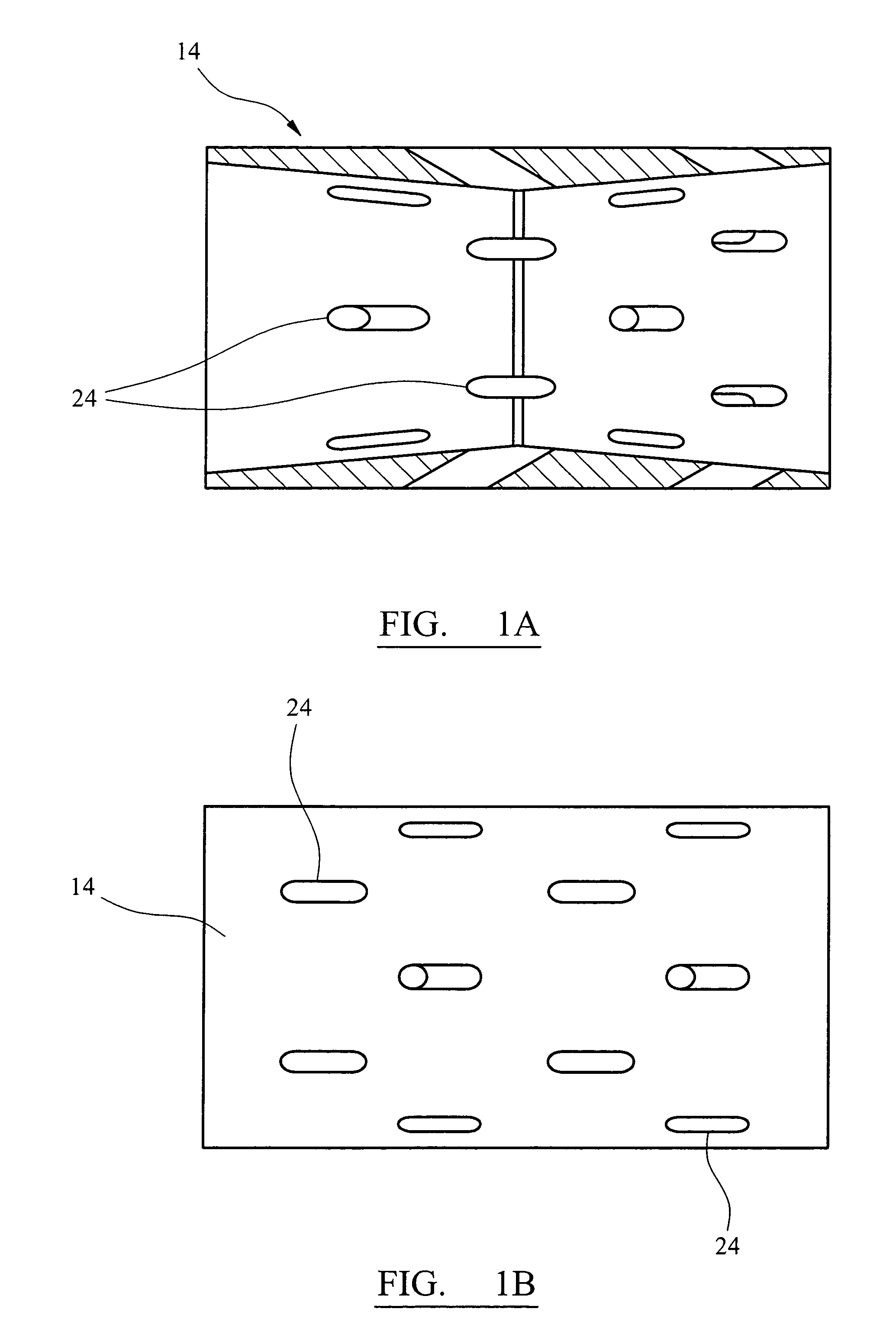

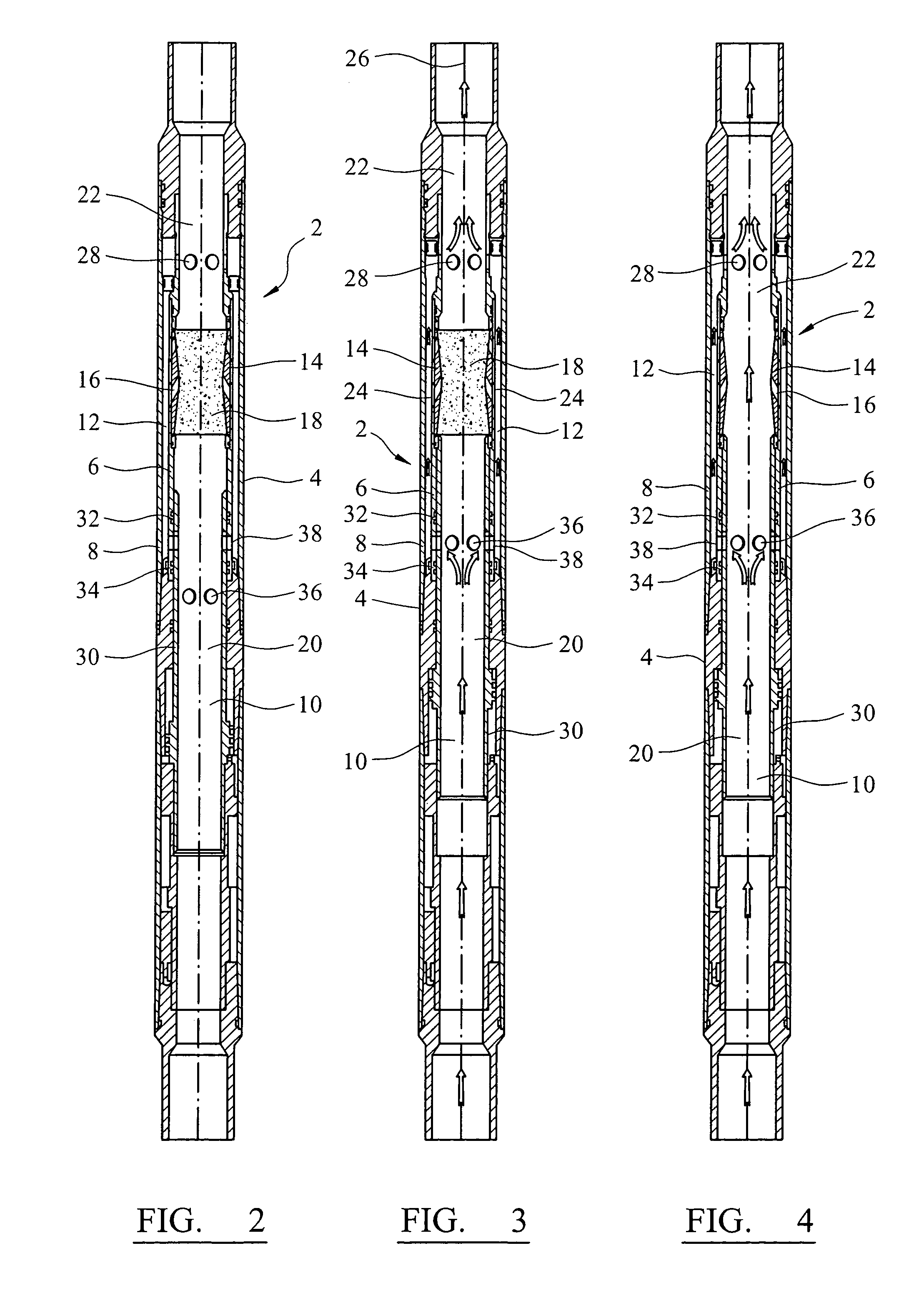

Pressure barrier apparatus

InactiveUS7703511B2Minimising risk of erosionReliable removalFluid removalWell/borehole valve arrangementsGuide tubeBiomedical engineering

A pressure barrier apparatus 2 for providing a removable pressure barrier in a borehole is described. The apparatus comprises a housing 6, 8 defining a central bore 10 having a first part 20 and a second part 22 separated by an erodeable pressure barrier member 18. The housing also defines a second fluid flow passage 12 for connecting the first part to the second part, and a plurality of conduits 24 for directing fluid onto the barrier member. A sleeve 30 has a first condition in which fluid communication between the first part 20 and the second fluid flow passage 12 is prevented, and a second condition in which fluid is permitted to flow from the first part to the second fluid flow passage to cause erosion of the barrier member.

Owner:OMEGA COMPLETION TECH

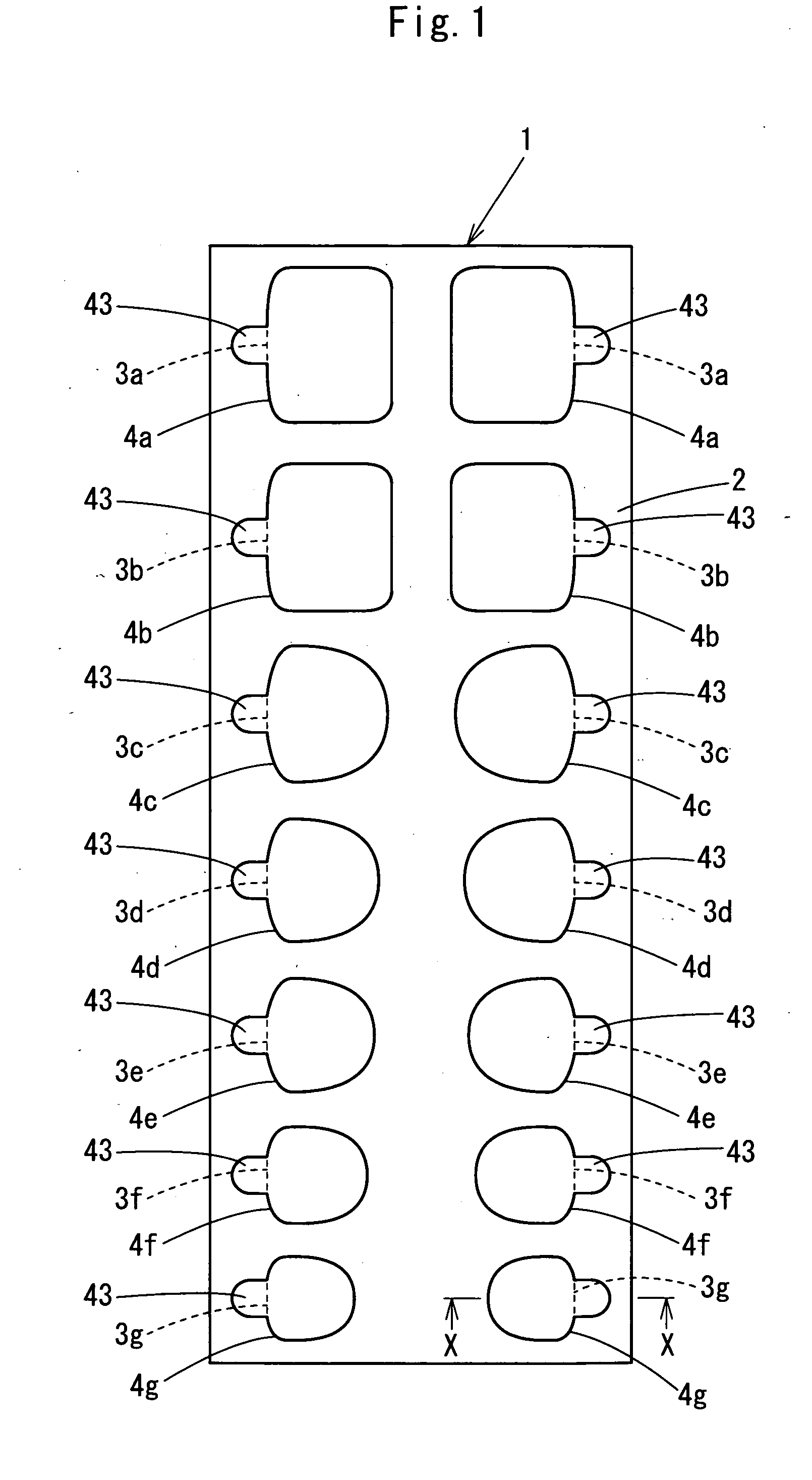

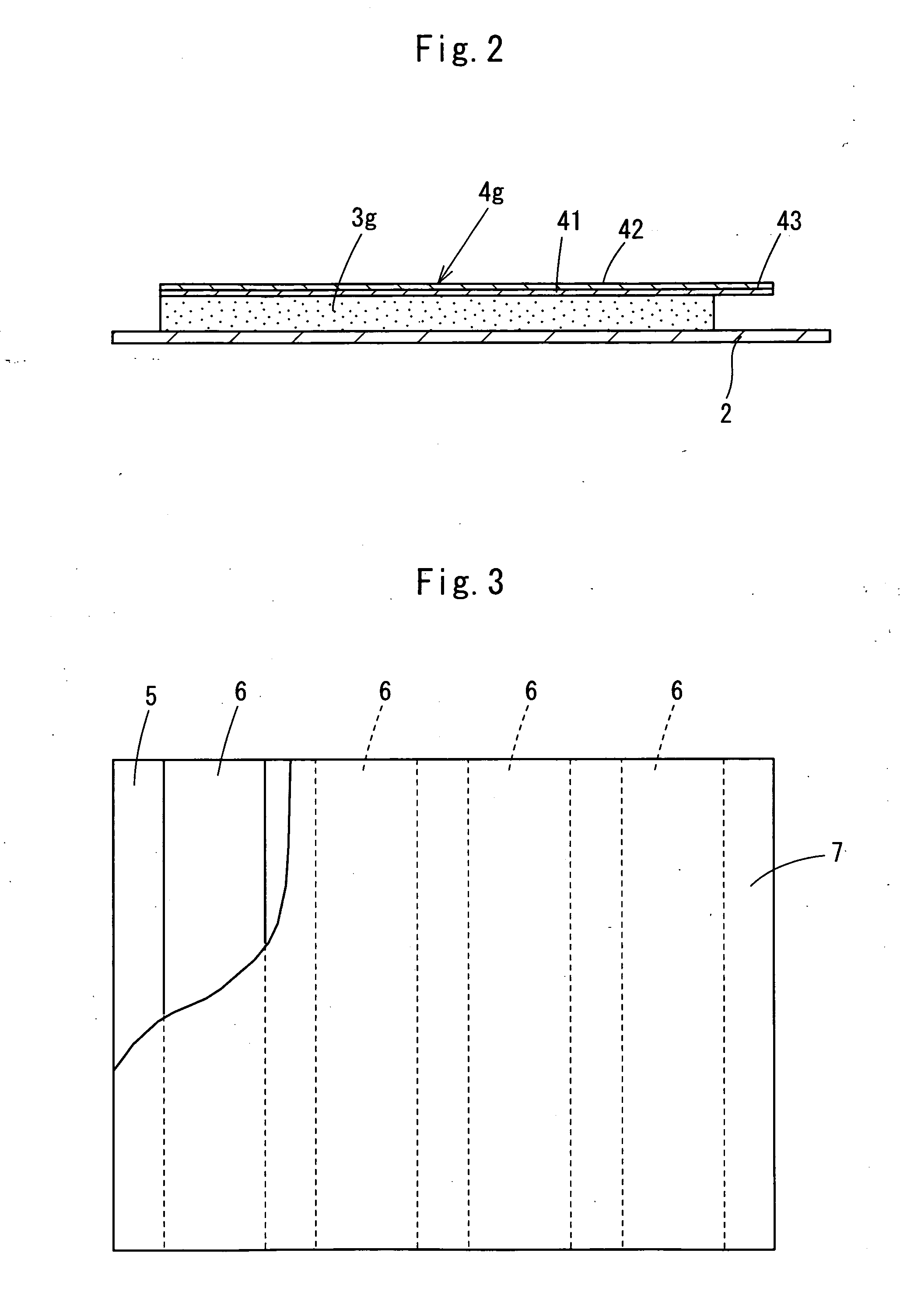

Adhesive sheet for artificial nail

An adhesive sheet for an artificial nail comprises a releasable protective film having, at a tip end side of a bare nail to which a double-sided adhesive sheet member is attached, a peeling tongue piece having a width smaller than the width of the double-sided adhesive sheet member and projecting outward from the double-sided adhesive sheet member, wherein the double-sided adhesive sheet member and the releasable protective film are chamfered in a convex R shape from a base end of the peeling tongue piece toward both sides in a width direction.

Owner:MURAKI

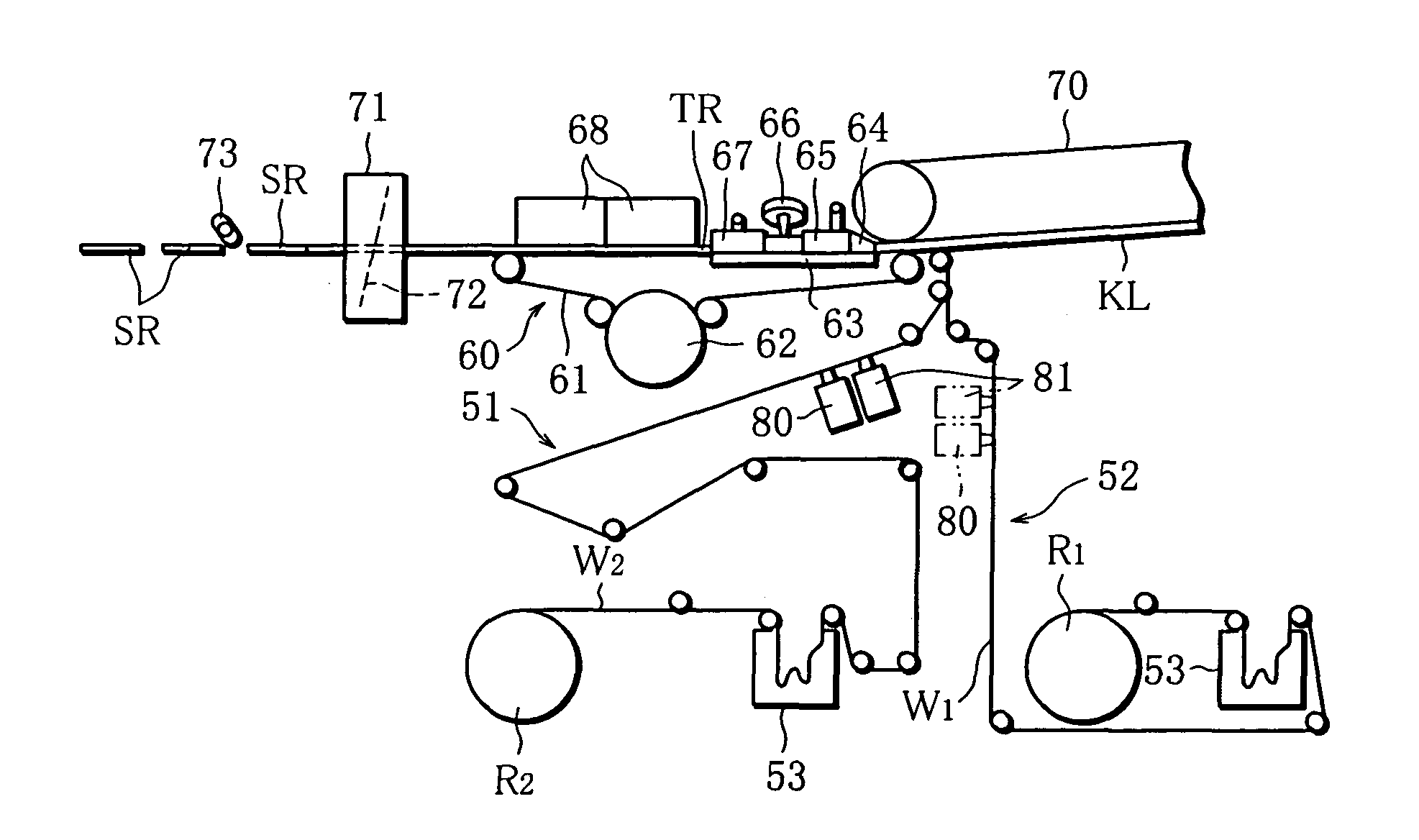

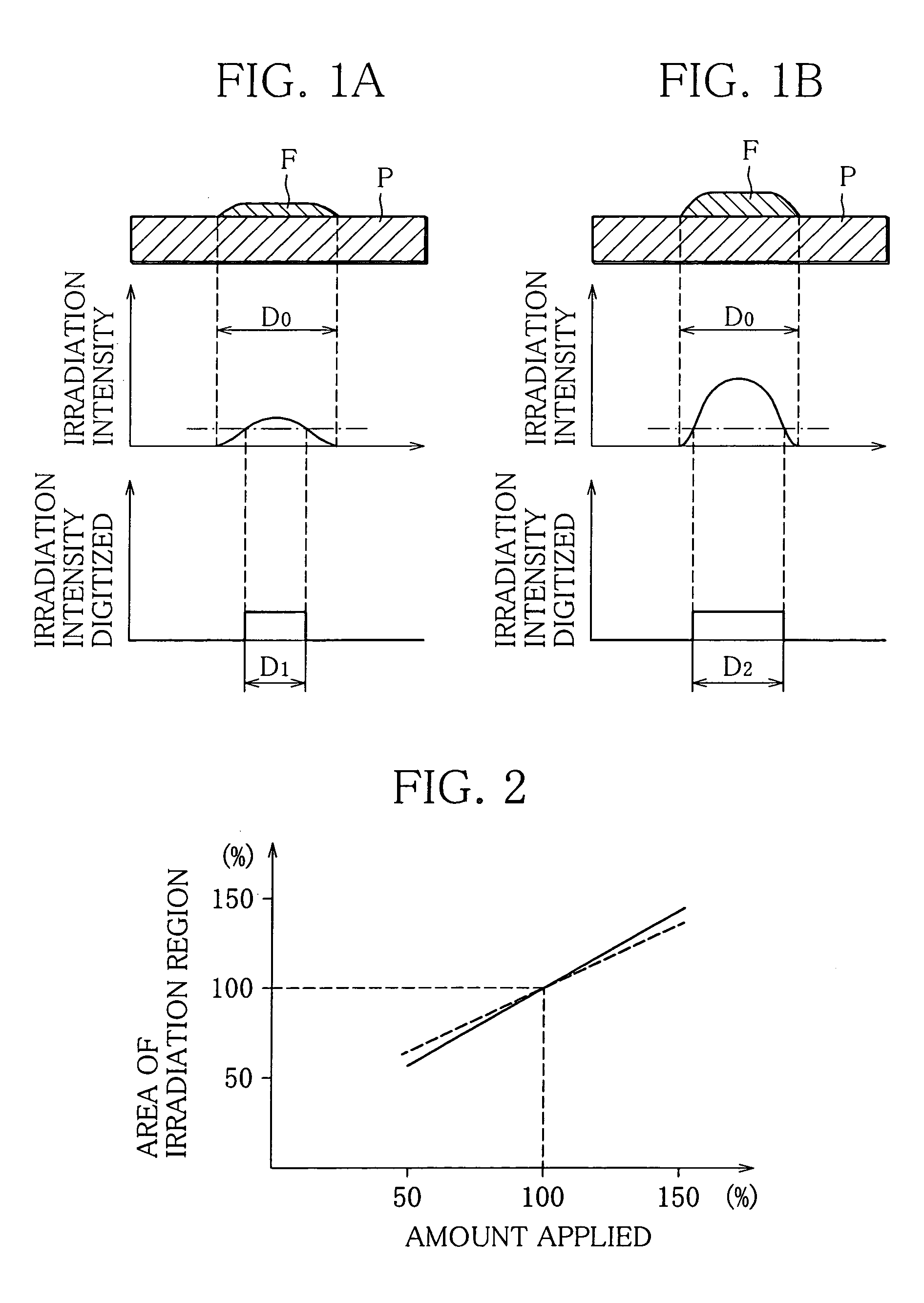

Applied flavoring-material inspection device and cigarette making machine provided with same

InactiveUS7938124B2Odor suppressionInspected reliably and easilyCigarette manufactureFluorescence/phosphorescenceImaging processingFluorescence

Owner:JAPAN TOBACCO INC

Led illumination device

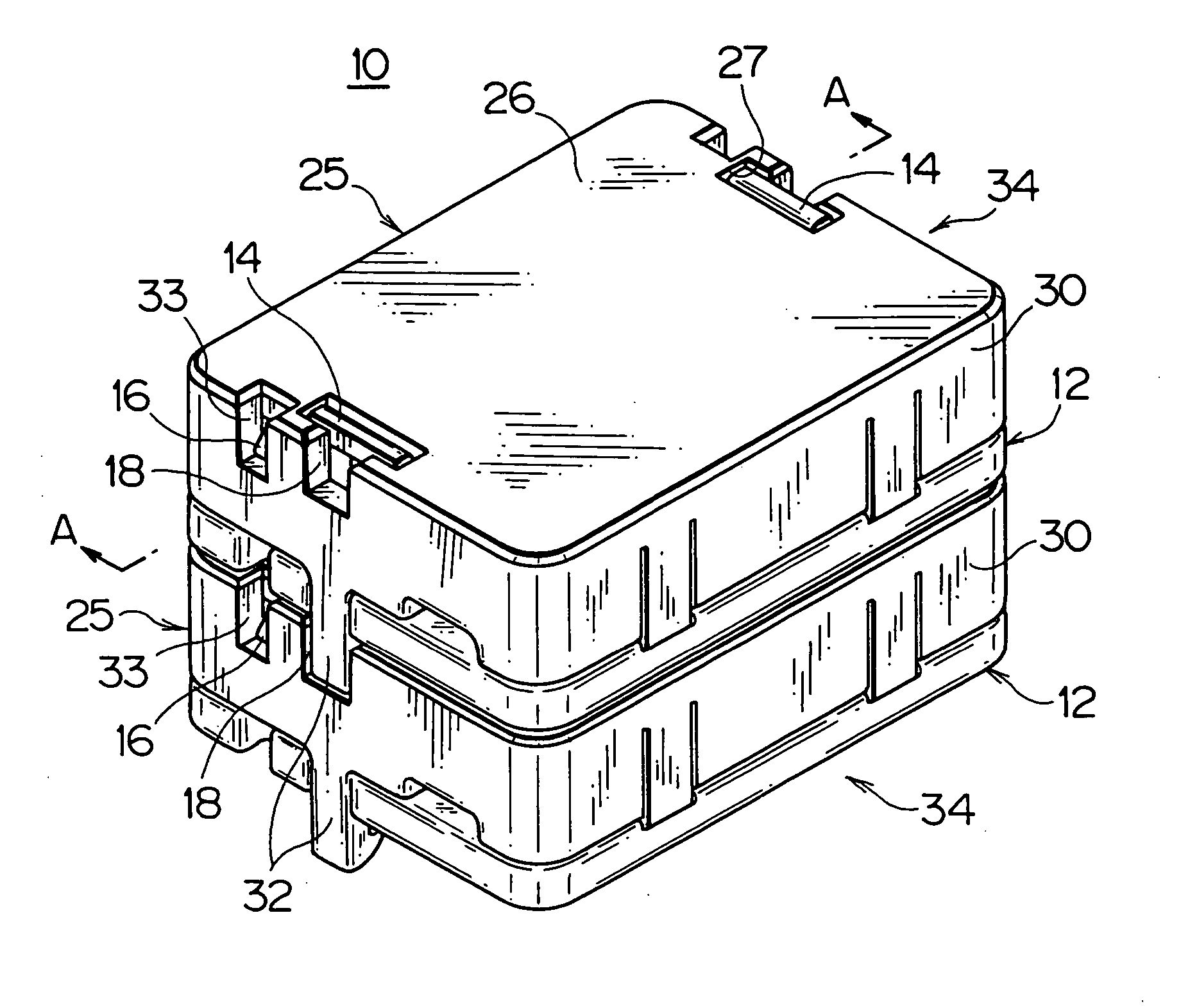

InactiveUS20070064450A1Improve design flexibilityPrevent reliably removingCoupling device connectionsPoint-like light sourceLed illumination

An LED illumination device includes LED lamp modules 34 coupled in a vertical direction. Each of said LED lamp modules 34 includes a base 12, a bus bar circuit 35 formed on the base 12, and a cover 25 connected to the base 12 to cover the bus bar circuit 35. A locking frame 14 (coupling portion) to be coupled with the upper LED lamp module 34 is formed on said base 12. A locking arm 32 (mating coupling portion) to be coupled with said locking frame 14 on the base 12 of the lower LED lamp module 34 is formed on said cover 25. Further, a guiding groove 18, into which said locking arm 34 is inserted, is formed on said base 12 near the locking frame 14, and a guiding hole 27, into which said locking frame 14 is inserted, is formed on the cover 25 near the locking arm 32.

Owner:YAZAKI CORP

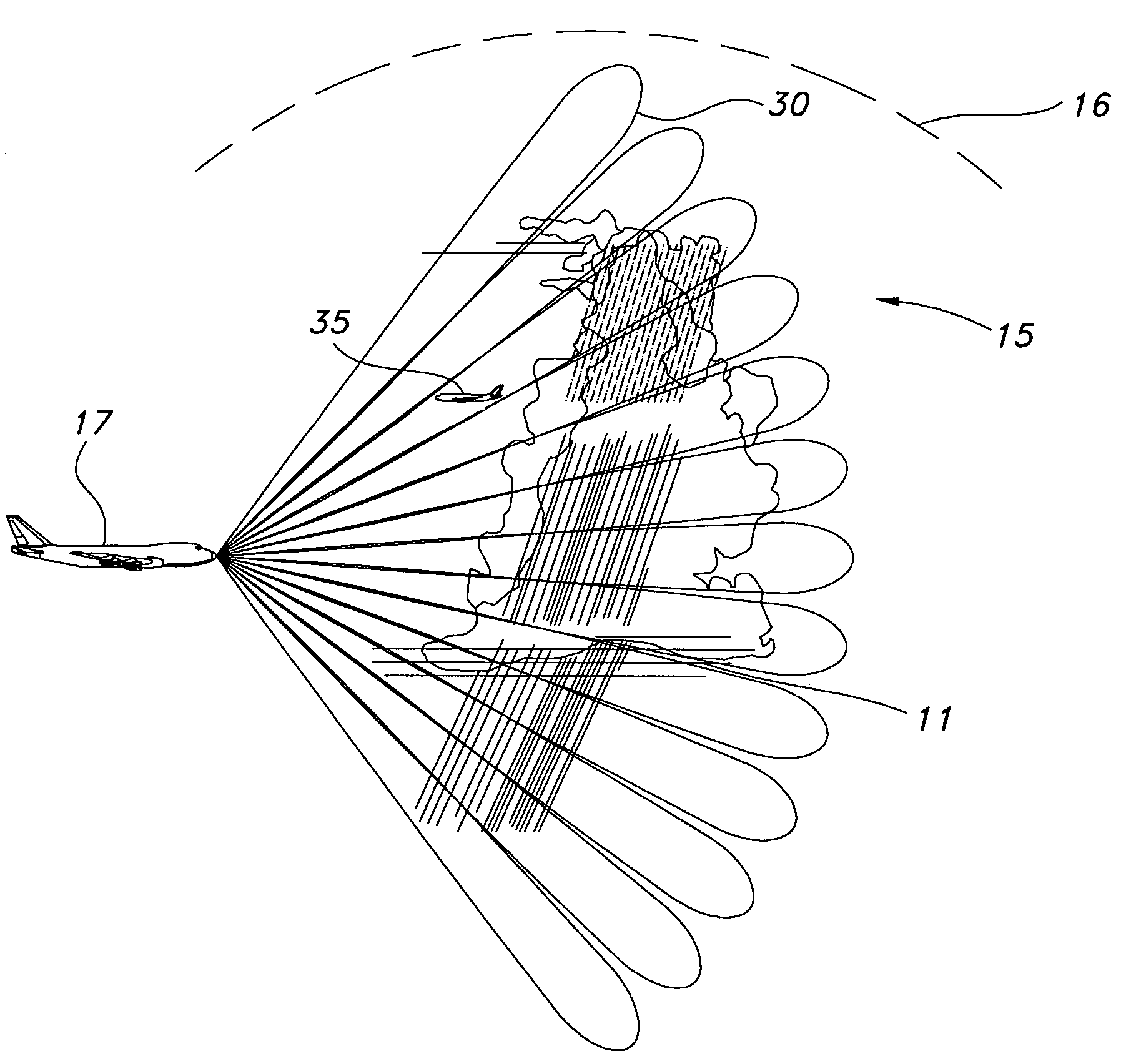

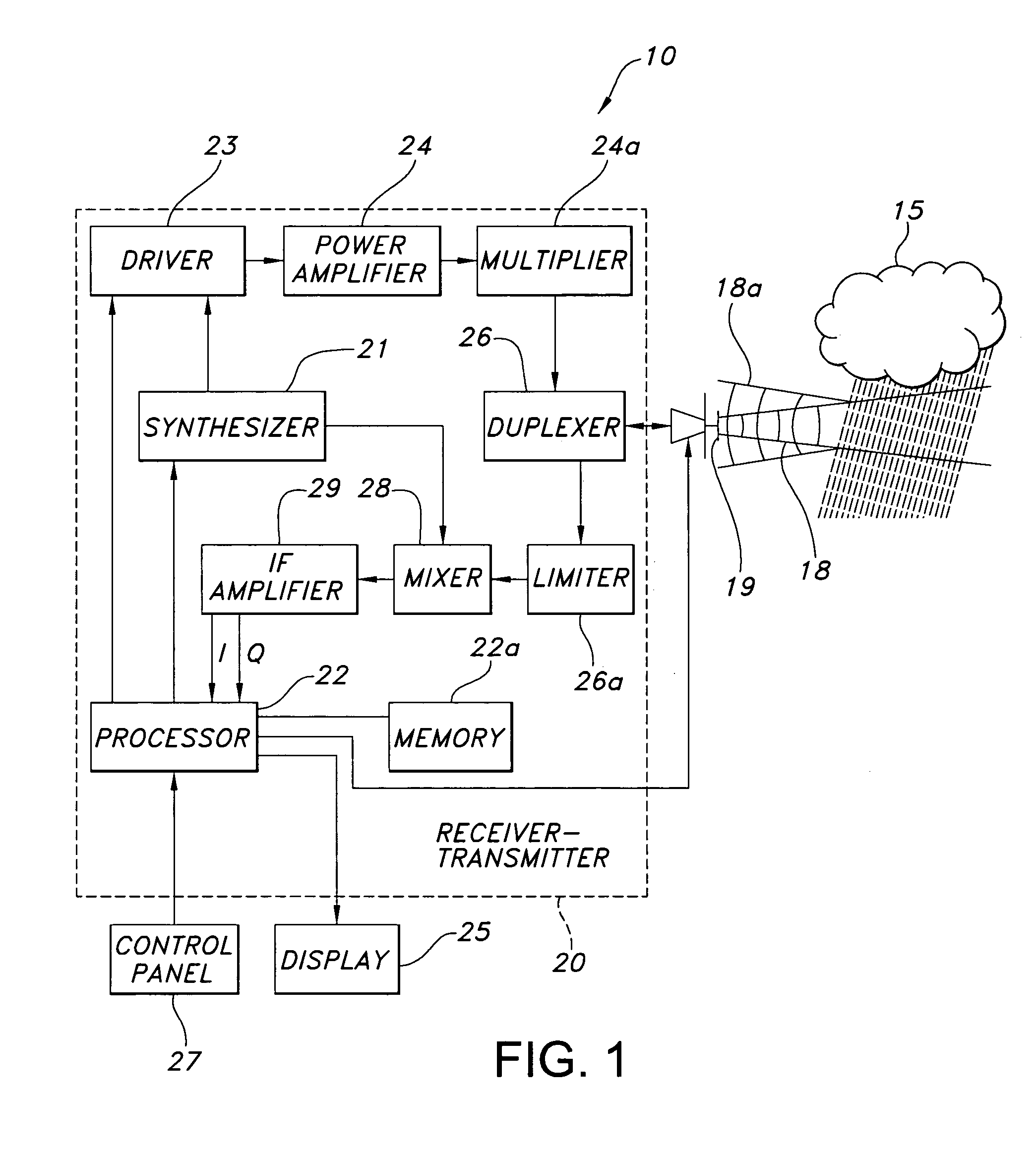

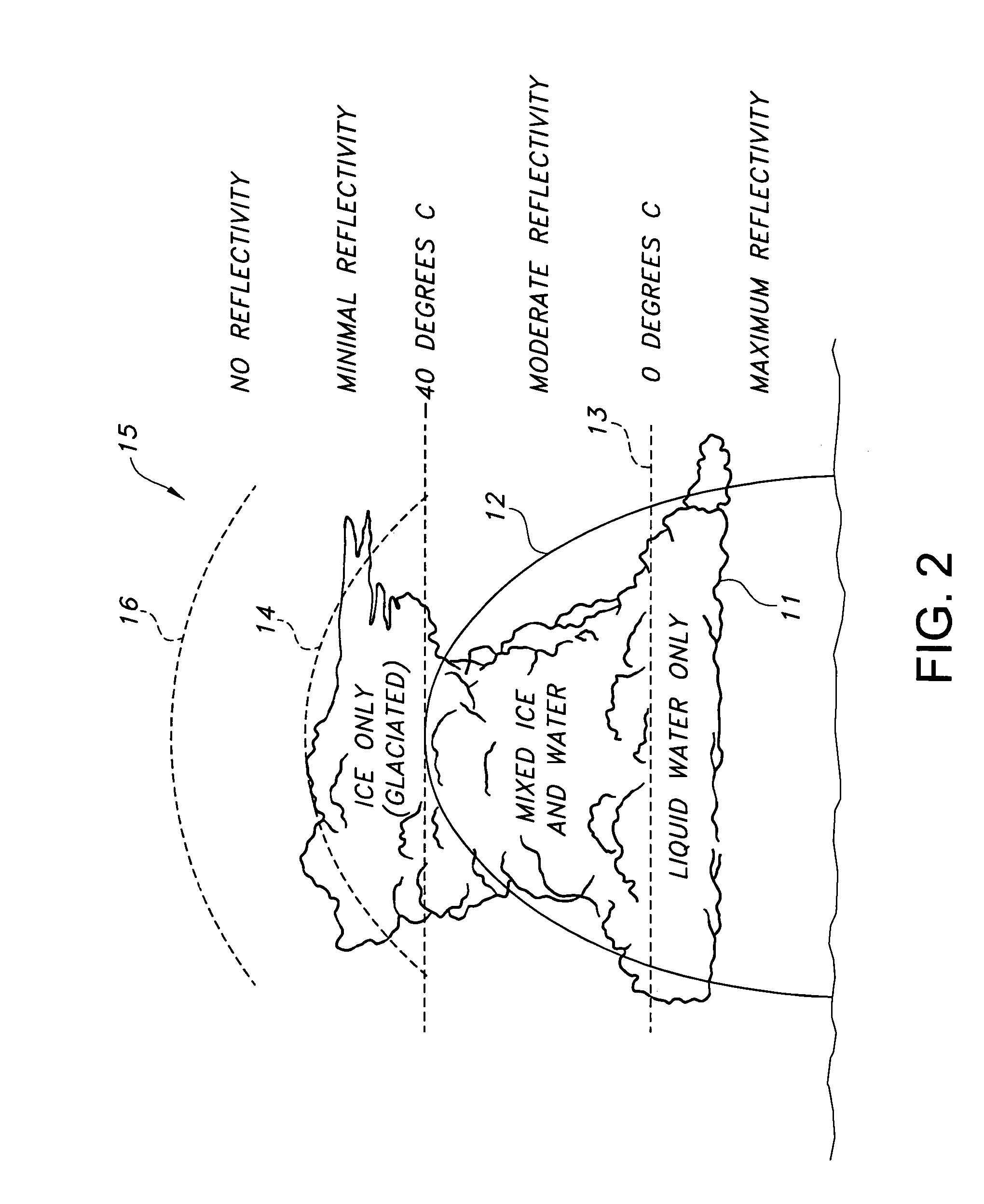

Removal of spurious aircraft detections on weather radar

ActiveUS7417578B1Improve performanceAvoid confusionRadio wave reradiation/reflectionICT adaptationDoppler velocitySpectral width

A weather radar detects and removes spurious aircraft from a weather radar display by using one of the methods of differentiating radar return length, estimating a vertical gradient of reflectivity, tracking radar returns into regions that are eliminated from the weather display to provide differentiation, tracking areas of radar returns that allow detection and removal of the spurious aircraft in relative geometries, differentiating Doppler velocity, and differentiating spectral width. The methods may be used individually or in combination to improve performance.

Owner:ROCKWELL COLLINS INC

Laser scanning digital camera with pupil periphery illumination and potential for multiply scattered light imaging

ActiveUS8488895B2Increase illuminationConvenient lightingCharacter and pattern recognitionColor television detailsTwo dimensional detectorDigital imaging

Owner:INDIANA UNIV RES & TECH CORP

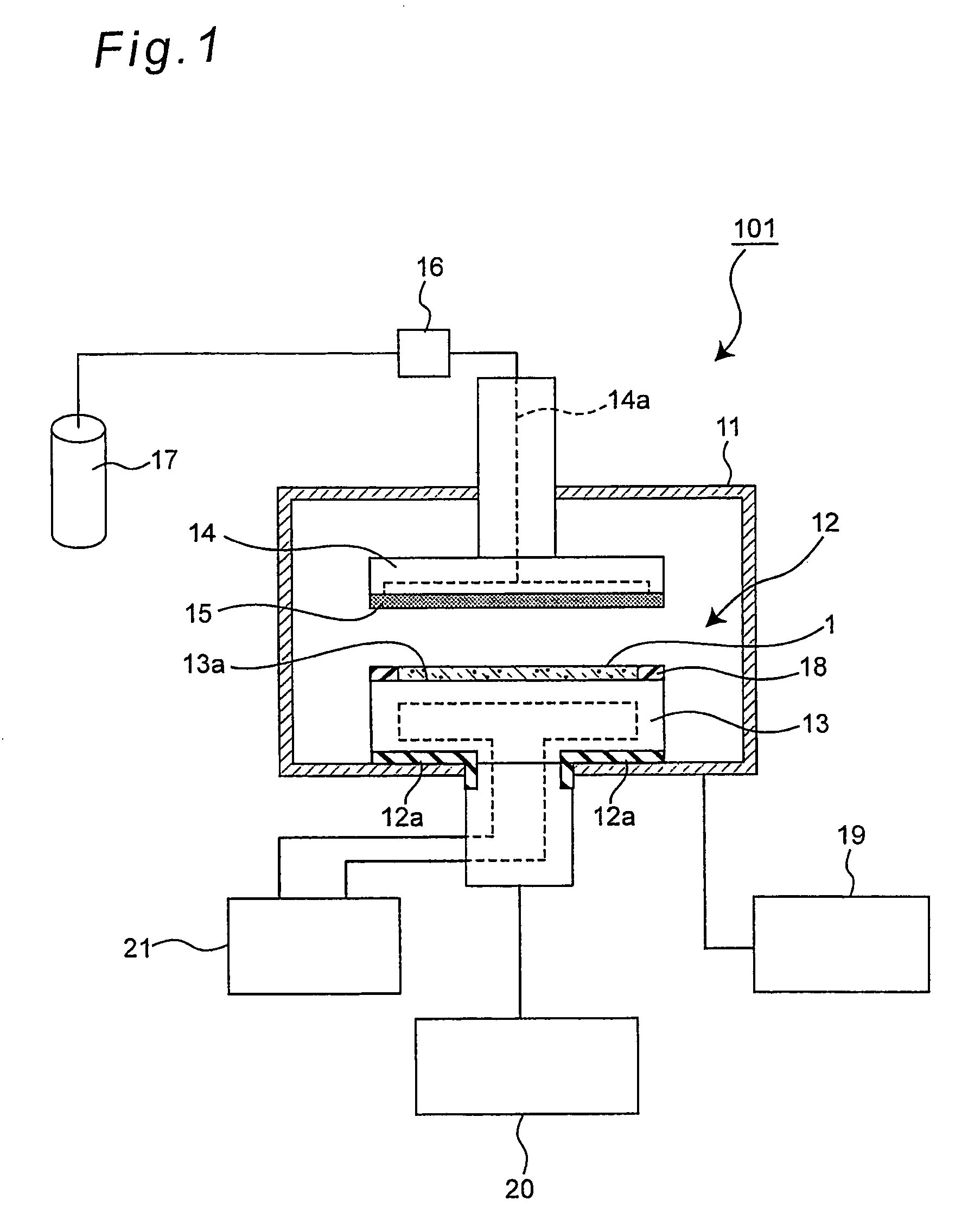

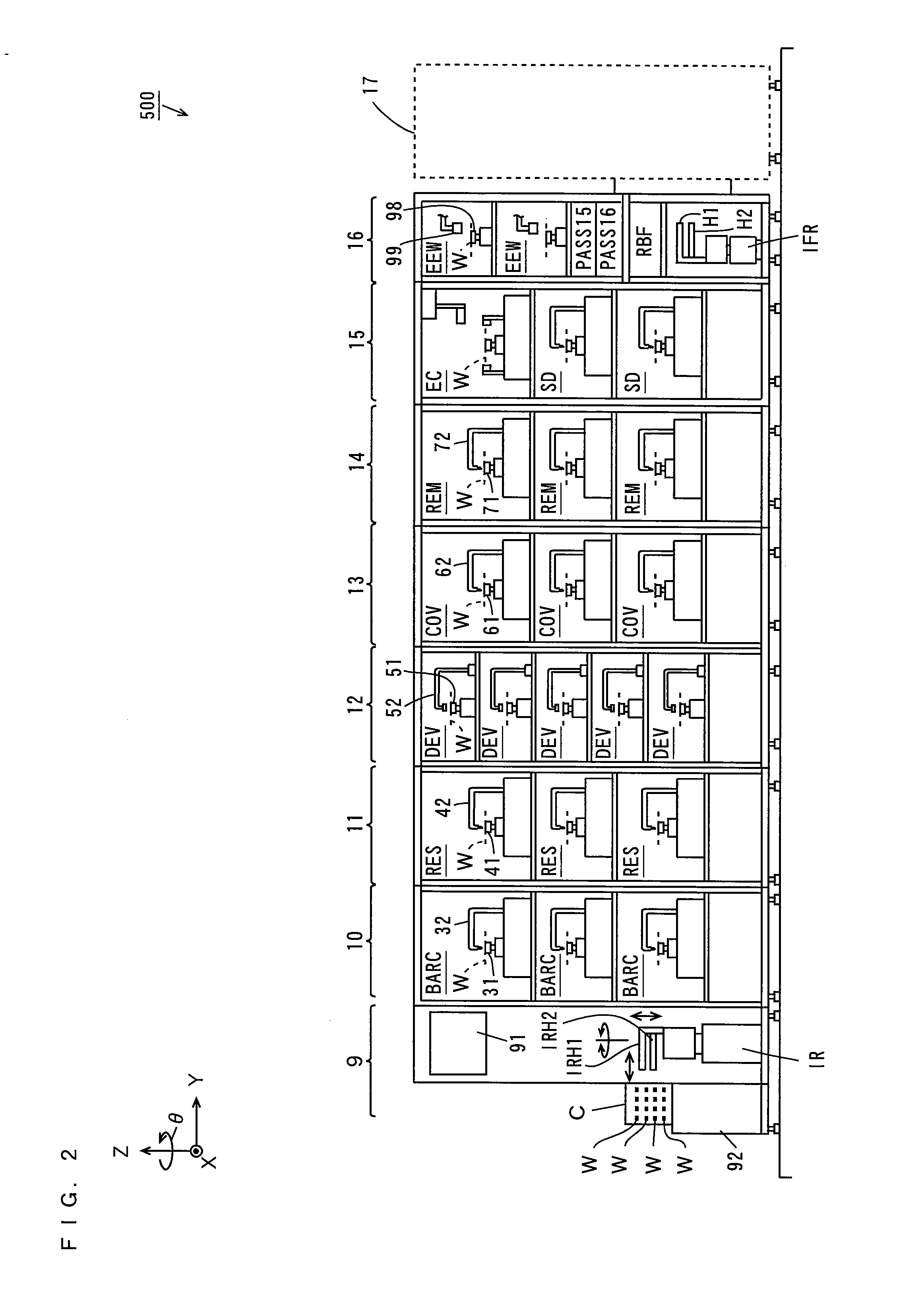

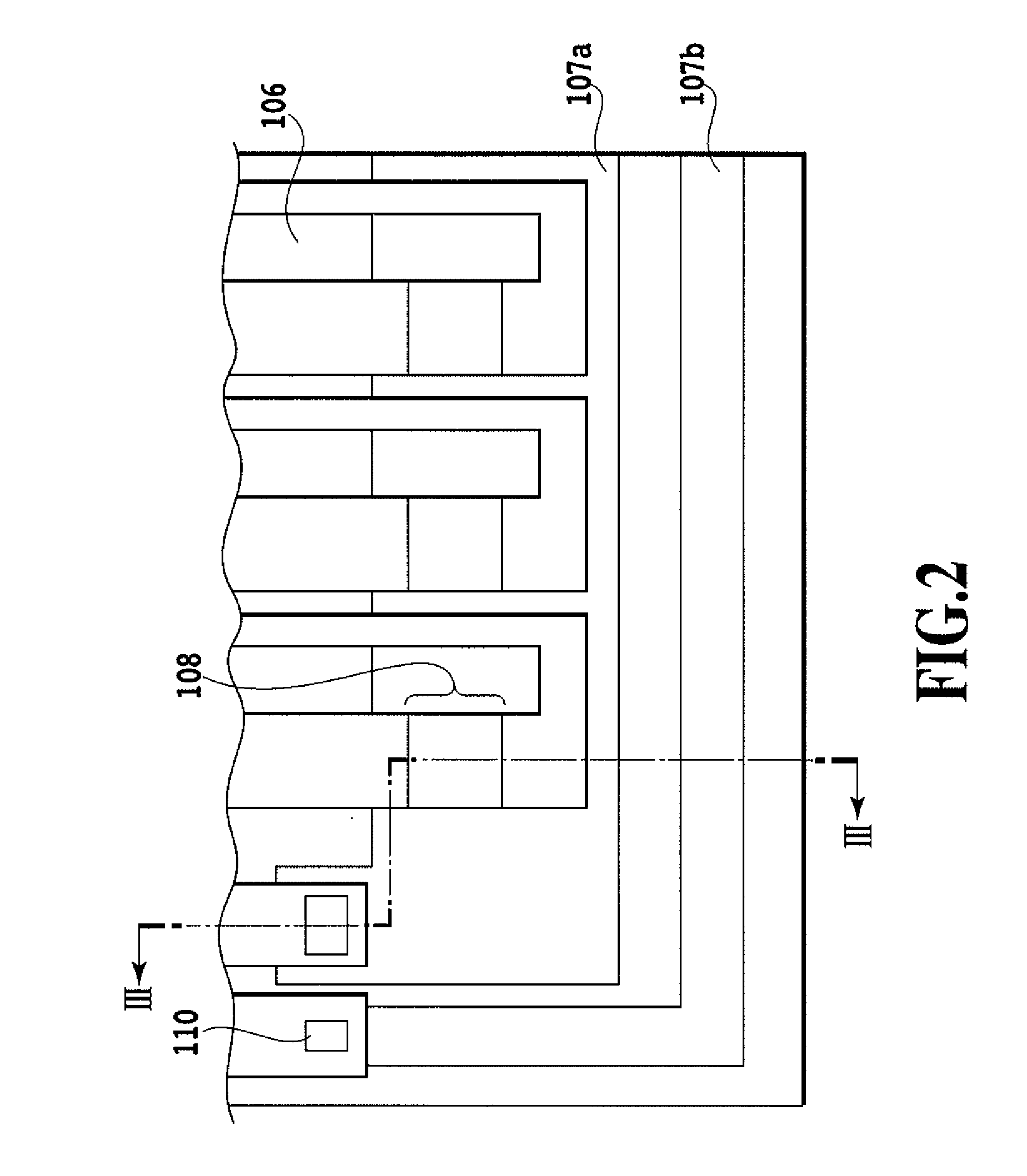

Substrate processing apparatus

InactiveUS20070190437A1Uniform cleaning effectReliable removalPhotomechanical apparatusSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an anti-reflection film processing block, a resist film processing block, a development processing block, a resist cover film processing block, a resist cover film removal block, a cleaning / drying processing block, and an interface block. An exposure device is arranged adjacent to the interface block in the substrate processing apparatus. The exposure device subjects a substrate to exposure processing by means of an immersion method. In the edge cleaning unit in the cleaning / drying processing block, a blush abuts against an end of the rotating substrate, so that the edge of the substrate before the exposure processing is cleaned. At this time, the position where the substrate is cleaned is corrected.

Owner:SOKUDO CO LTD

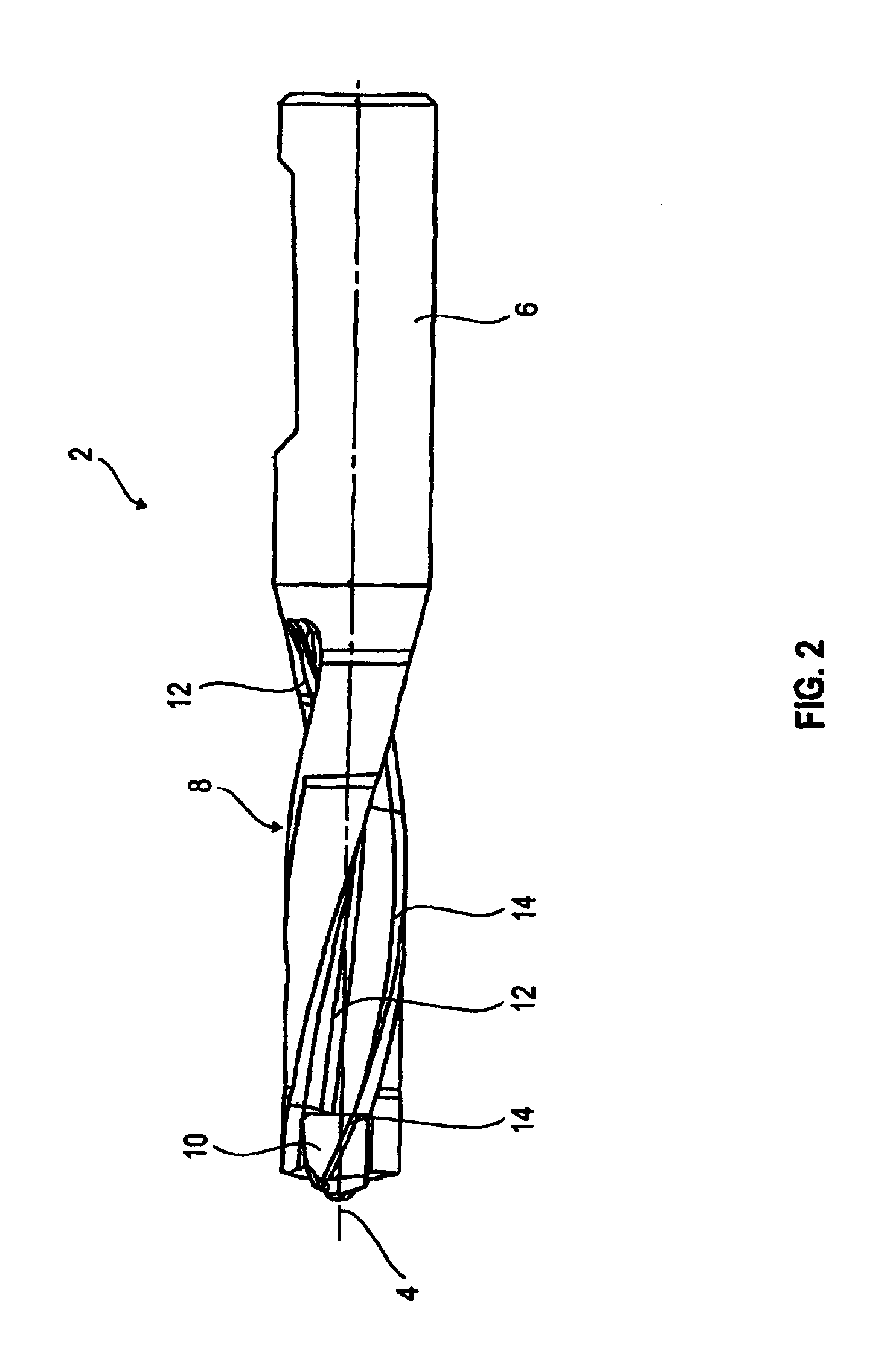

Drill bit for drilling having at least two cutting edges, each with two cutting portions and a non-cutting portion between the two cutting portions

ActiveUS20100092259A1Reliable removalGuaranteed uptimeWood turning toolsTransportation and packagingTrademarkEngineering

A drill bit for drilling having at least two cutting edges, each with two cutting portions and a non-cutting portion between the two cutting portions. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

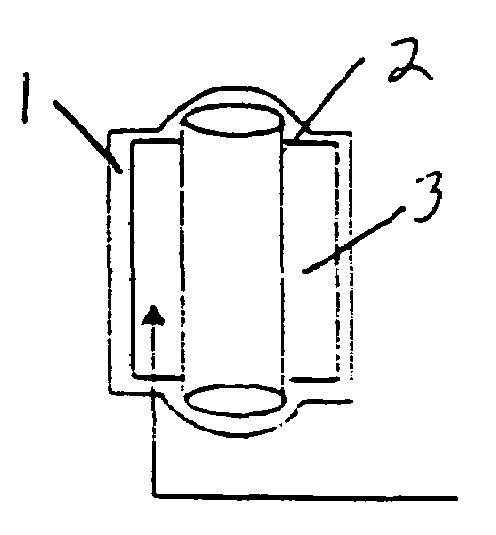

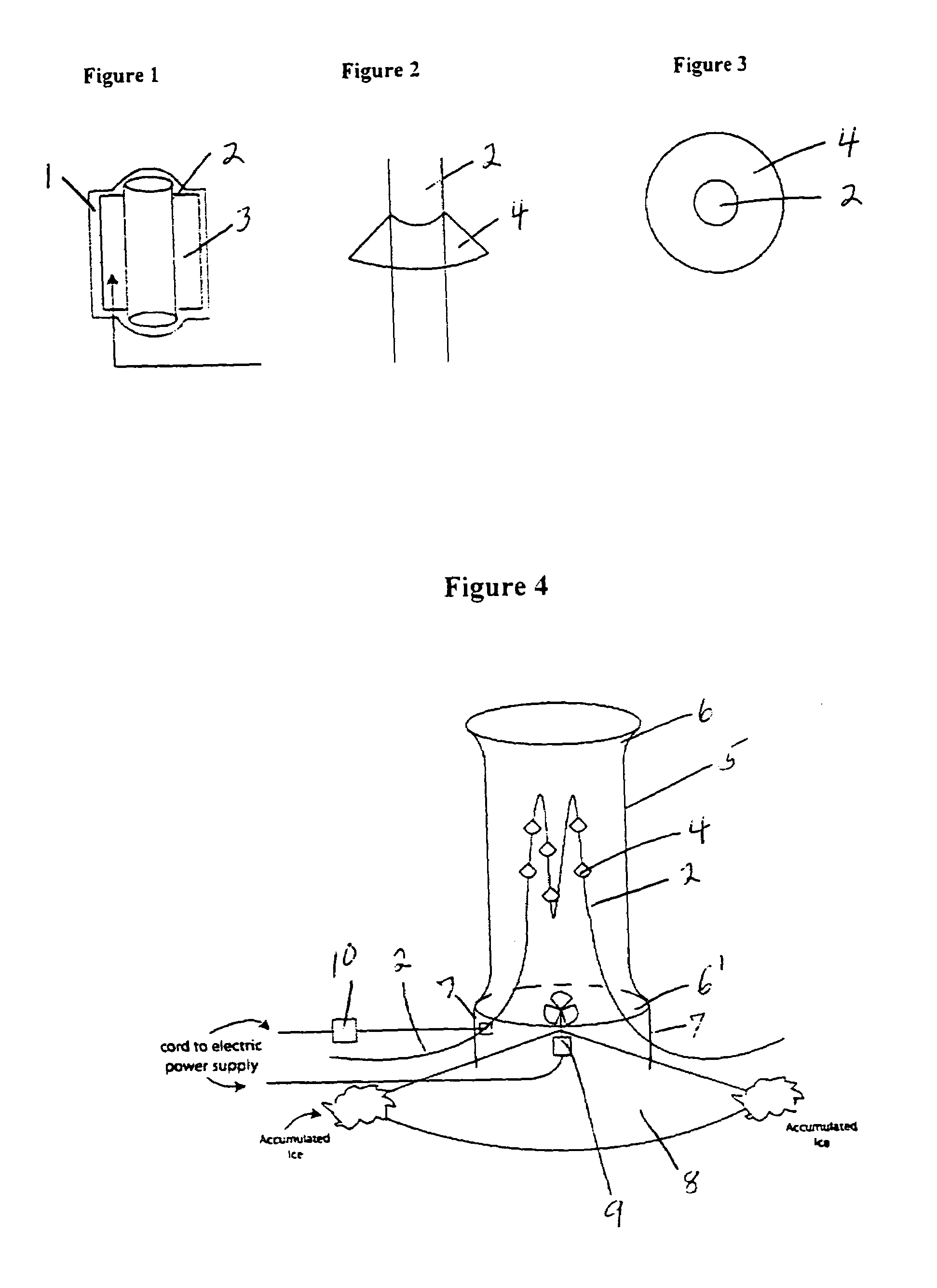

Method and apparatus for inhibiting ice accumulation in HVAC systems

InactiveUS6971248B1Degrades design efficiencyEasy to operateAir heatersCorrosion preventionHeat sinkHeating system

A non-stick coating, which inhibits frozen moisture accumulation, is applied to exterior exposed portions of heating and cooling systems where ice or other frozen moisture can accumulate and impair system design operational efficiencies; where heat exchange tubing and fins are downwardly sloped or angled; with an optional protective shell encasement which can be shaped to provide a vena contracta effect; with an optional electric fan to enhance airflow for heat exchange; with an optional electric vibrator to enhance inhibition of frozen moisture accumulation; with a downwardly sloped base to direct falling frozen moisture away from the heat exchange equipment; for use in conjunction with an air source heat pump system, an evaporative cooling system or a chiller, or as a supplement to a water-source heat pump system or to a direct expansion heat pump system; and for use with any other refrigerant-based heating system or cooling system.

Owner:WIGGS B RYLAND

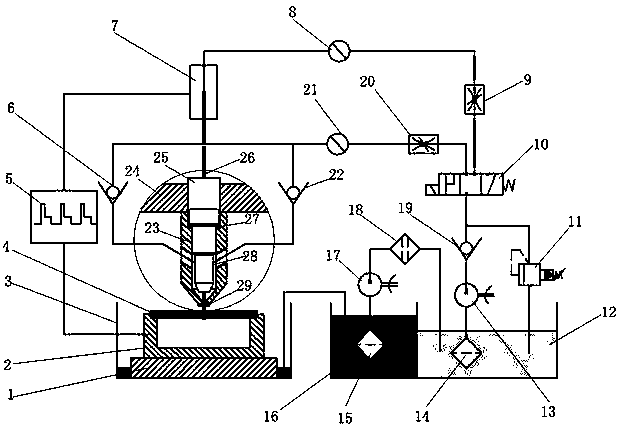

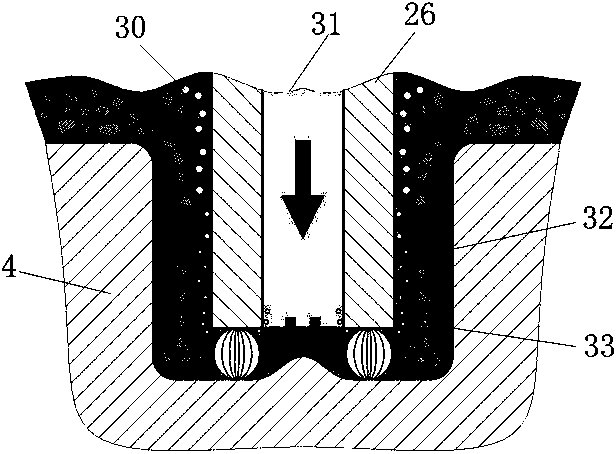

Synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and special tool of synchronous composite processing method

The invention provides a synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and a special tool of the synchronous composite processing method. The synchronous composite processing method includes that a tube electrode is switched to impulse voltage, and a neutral salt solution with ultra-low concentration flows into a processing area via the inner side of the tube electrode at a high speed, and then flows out of the processing area along a gap between the tube electrode and a workpiece; an end face of the tube electrode is subjected to high-speed punch processing with axial feeding of electric sparks under the ultra-low concentration of the neutral salt solution, and a hole wall processed by the electric sparks is subjected to radical electrochemical finishing and machining under the action of low-pressure voltage. By the synchronous composite processing method, processing precision is guaranteed, punching efficiency is improved, and processing requirements on various kinds of holes of an aircraft engine are met. Different from conventional electric spark processing and electrolytic processing, the synchronous composite processing method adopts the neutral salt solution with the ultra-low concentration, so that processing efficiency in electrochemical dissolution can be greatly improved and corrosion degree of equipment can be decreased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

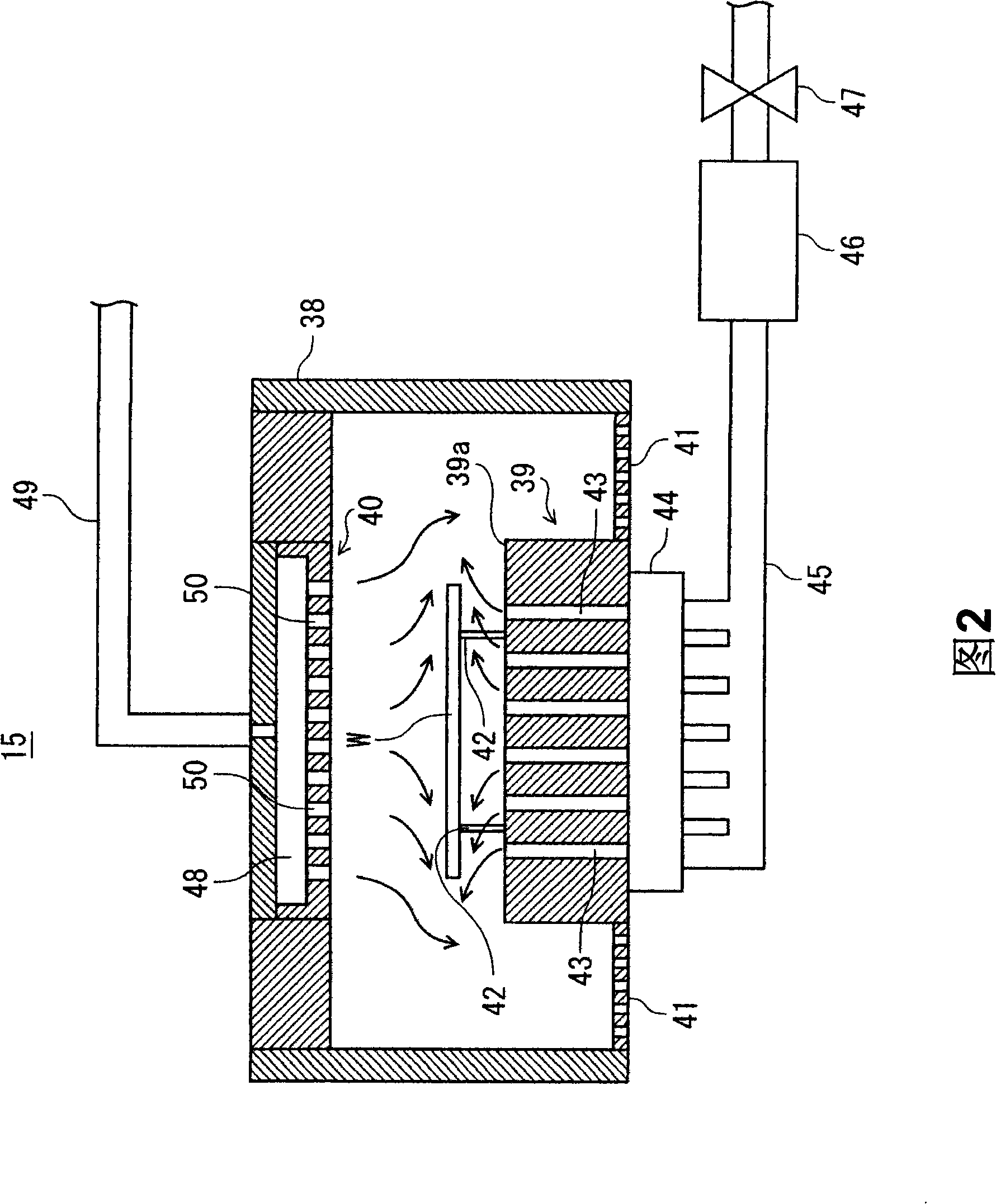

Substrate processing system and substrate cleaning apparatus

InactiveCN101276739AReduce gravityReliable removalSemiconductor/solid-state device manufacturingCleaning using liquidsForeign matterGas phase

This invention provides a substrate processing system that enables foreign matter adhered to a rear surface or a periphery of a substrate to be completely removed. A processing assembly (15) of a substrate cleaning apparatus of the substrate processing system (10) including: a chamber (38) for accepting a wafer (W); a holding table (39) configured at the bottom of the chamber (38) and for placing the wafer W; a spray head configured at the top in the chamber (38) and opposite to the holding table (39).The holding table (39) jets the mixed cleaning agent of cleaning substrate (such as pure water) and inactive gas (such as N2) in two phases of a gas phase and a liquid phase at the back side or edge part facing to the wafer (W). The spray head (40) generates the down-flow facing to the surface of the wafer (W).

Owner:TOKYO ELECTRON LTD

Method and device for removing a cover from a storage box

InactiveUS20050160704A1Reduced adhesion strengthNarrow sizeOpening closed containersBottle/container closureEngineering

The present invention relates to a method and a device for removing a cover from a storage box that is closed using a lid-like cover attached thereto at the edges. For removal, the adhesive strength of the cover is reduced in the region of a few of the sealed edges and the cover is then removed by peeling it off the storage box, whereby the cover is peeled off by rolling it onto a roller.

Owner:GRONINGER

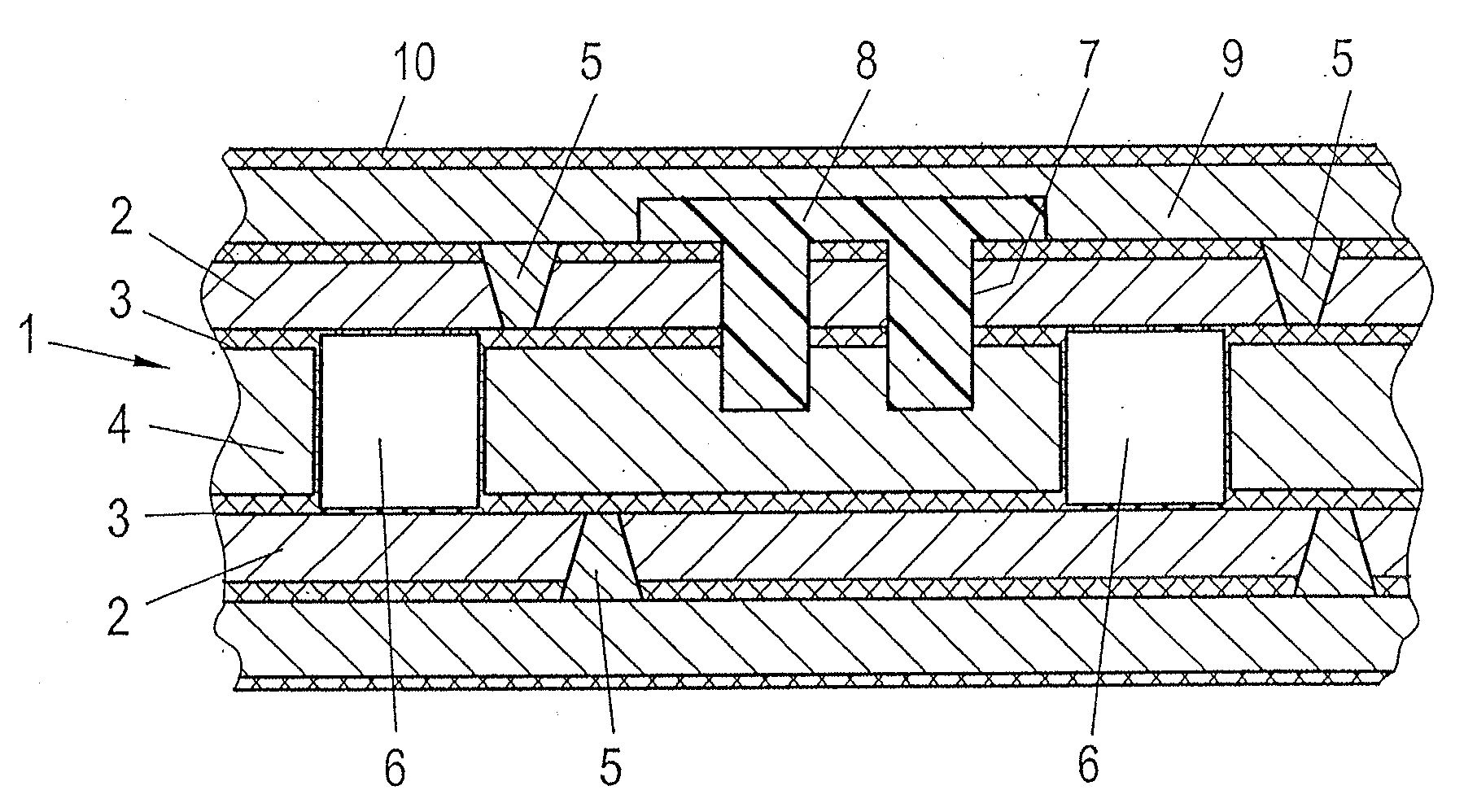

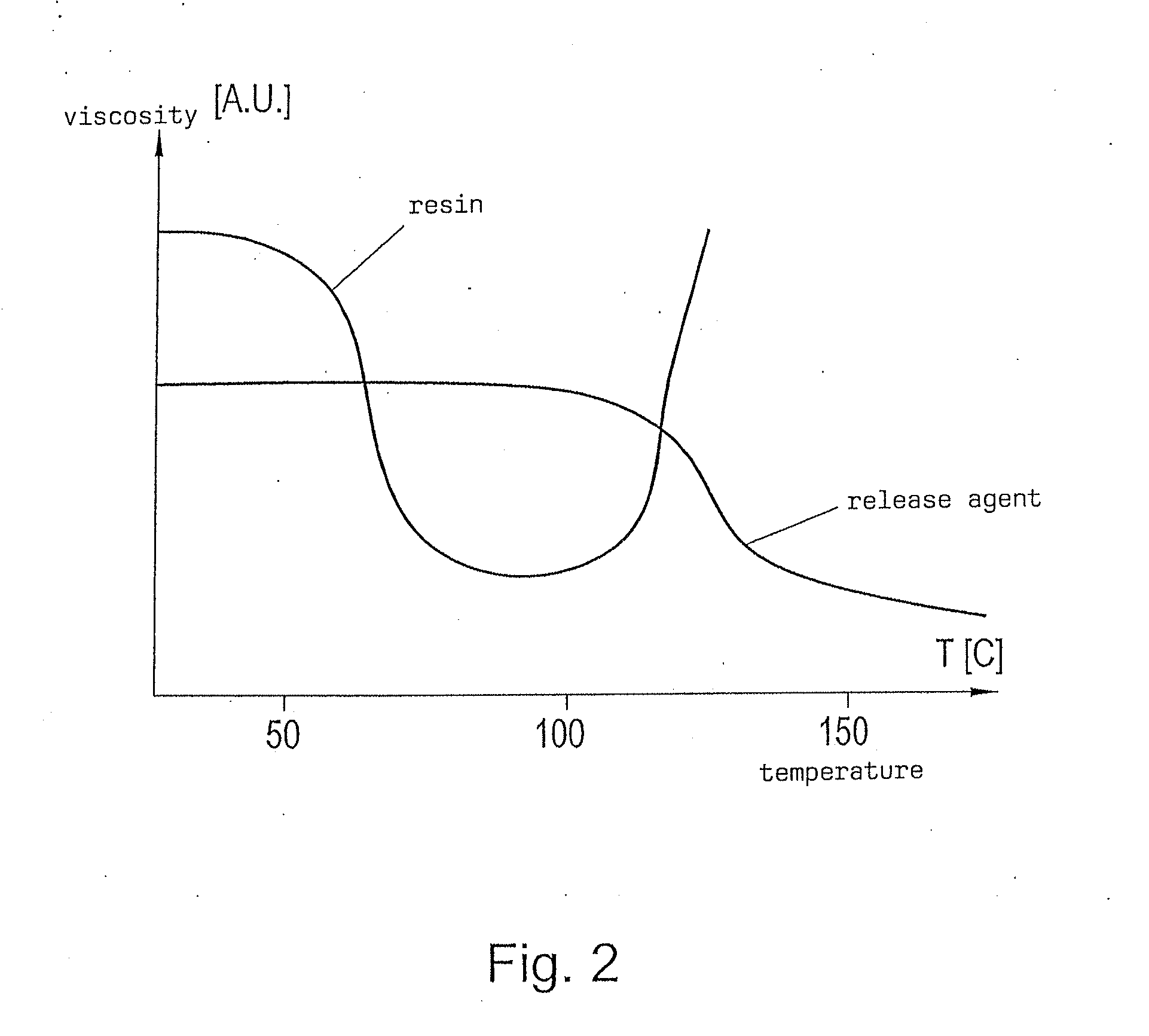

Method for producing a multilayer printed circuit board, adhesion prevention material and multilayer printed circuit board and use of such a method

ActiveUS20110272177A1Readily and reliably applicable material preventing adhesionReadily and reliablyPrinted circuit aspectsCoatingsSolventFatty acid

In a method for producing a multilayer printed circuit board from a plurality of conducting or conductive and non-conducting or insulating layers or plies to be connected to each other, in particular to be pressed together, wherein after connecting at least partially planar layers at least a partial region (11) thereof is removed, and wherein in order to prevent adherence of the partial region (11) to be removed a material (8) preventing adhesion is applied in accordance with the partial region to be removed onto a layer (9) which adjoins the partial region to be removed, it is provided that the material (8) preventing adhesion is formed by a mixture comprising a release agent on the basis of at least one metal soap, preferably the fatty acid salts of Al, Mg, Ca, Na and Zn, a binding agent, and a solvent, whereby a partial region to be removed can be removed easily and reliably after appropriate treatment and / or processing steps of the multilayer printed circuit board. In addition, an adhesion prevention material and a use of the method in connection with the production of a multilayer printed circuit board (1) are provided.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

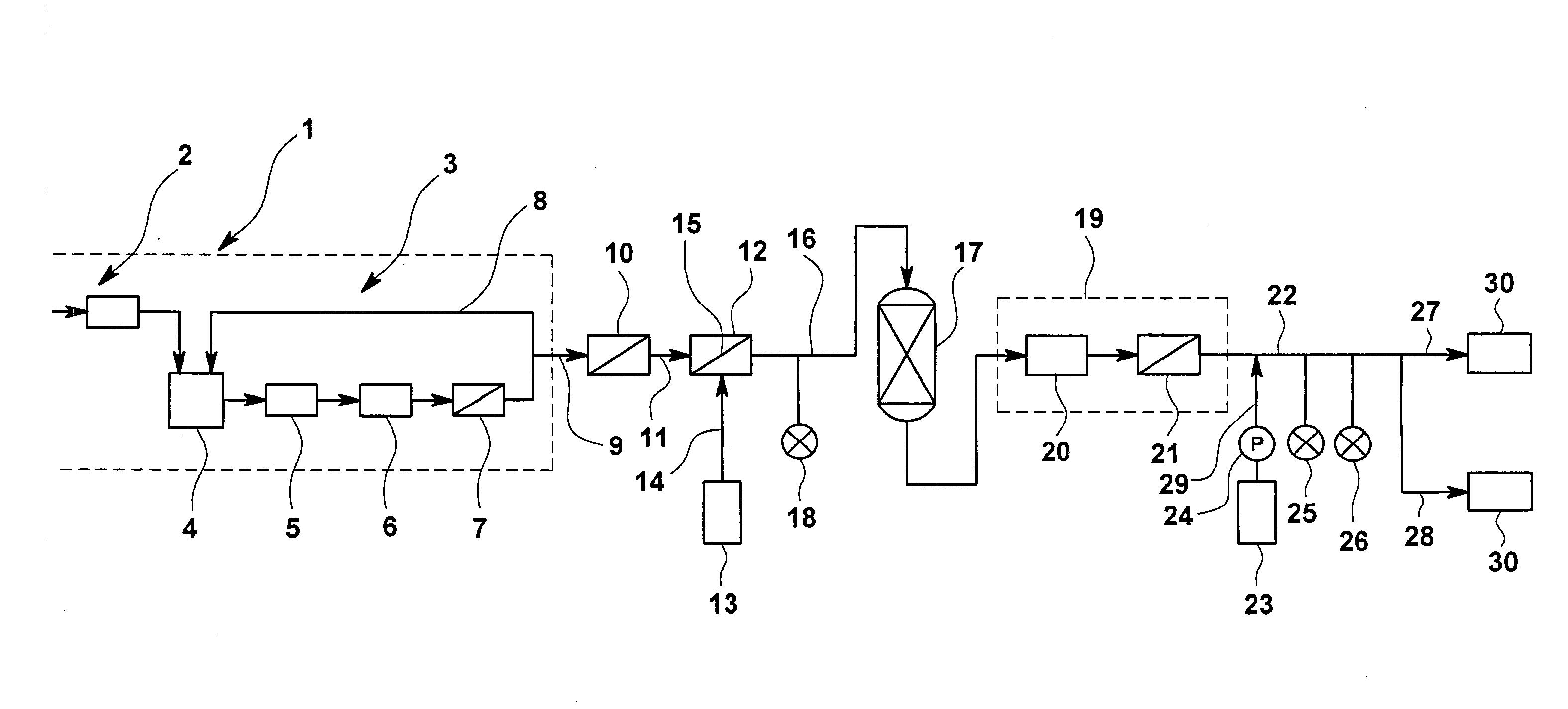

Method and facility for sorting and separating waste plastic

InactiveCN102574304AEfficient implementation of recyclingReliable removalElectrostatic separationPlastic recyclingElectrostatic separationCrusher

Disclosed is a facility for precisely sorting, by material, waste plastic that includes many types of material. Said facility is provided with: a crusher (11) that pulverizes a waste plastic feedstock into waste plastic fragments having a prescribed size; a steam-cleaning device (13) that is disposed downstream from the crusher and that cleans the waste plastic fragments; a primary wet specific-gravity sorter (14) and a secondary wet specific-gravity sorter (15) that are disposed downstream from the steam-cleaning device and that use separation liquids, which have specific gravities in the middle of the specific gravities of the materials included in the waste plastic fragments, to separate out at most three types of floating or sinking specific-gravity-sorted fragments; and first through third electrostatic separation devices (16A-16C), each of which is disposed downstream of the primary and secondary wet specific-gravity sorters and has a frictional charging device, which frictionally charges the specific-gravity-sorted fragments, and an electrostatic sorter that puts the frictionally-charged specific-gravity-sorted fragments in an electrostatic field between a rotating drum electrode to which a high voltage is applied and an opposing electrode, thereby changing the direction the fragments fall and separating said fragments by material.

Owner:HITACHI ZOSEN CORP +1

Circuit board for ink jet head, ink jet head having the same, method for cleaning the head and ink jet printing apparatus using the head

ActiveUS20070146428A1Reliable high-quality printingReliably to stabilize an ink ejection characteristicInking apparatusThermal energyElectrochemical response

In an ink jet head using a thermal energy for ejecting ink, this invention aims to reliably and uniformly remove kogations deposited on a heat application portion in contact with the ink. To realize this objective, the upper protective layer is arranged in an area including the heat application portion so that it can be electrically connected to serve as an electrode which causes an electrochemical reaction with the ink. The upper protective layer is formed of a material containing a metal which is dissolved by the electrochemical reaction and which does not form, on heating, an oxide film which hinders the dissolution. With this arrangement, a reliable electrochemical reaction can be produced to dissolve a surface layer of the upper protective layer, thereby removing kogations on the heat application portion reliably and uniformly.

Owner:CANON KK

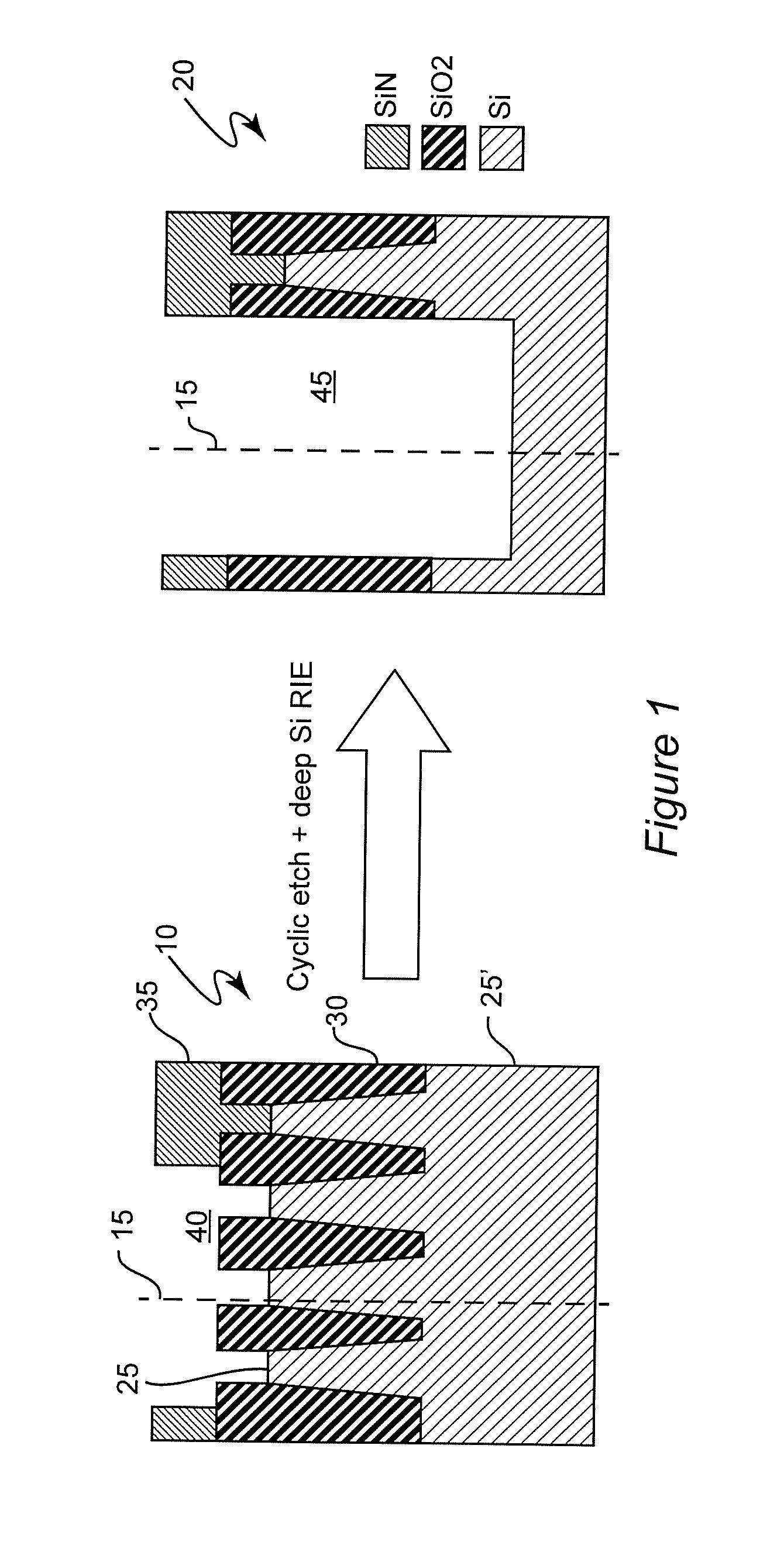

finFET isolation by selective cyclic etch

InactiveUS20150145065A1High selectivityEasy to controlTransistorSolid-state devicesSemiconductor materialsEngineering

Etching interleaved structures of semiconductor material forming fins of finFETs and local isolation material interposed between the fins is performed alternately and cyclically by alternating etchants cyclically such as by alternating gases during reactive ion etching. Etchants are preferably alternated when one of the semiconductor material and the local isolation material protrudes above the other by a predetermined distance. Since protruding surfaces are etched more rapidly than recessed surfaces, the overall etching process is accelerated and completed in less time such that erosion of other materials to which the etchants are less than optimally selective is reduced and allow improved etching of trenches for improved isolation structures to be formed.

Owner:GLOBALFOUNDRIES INC

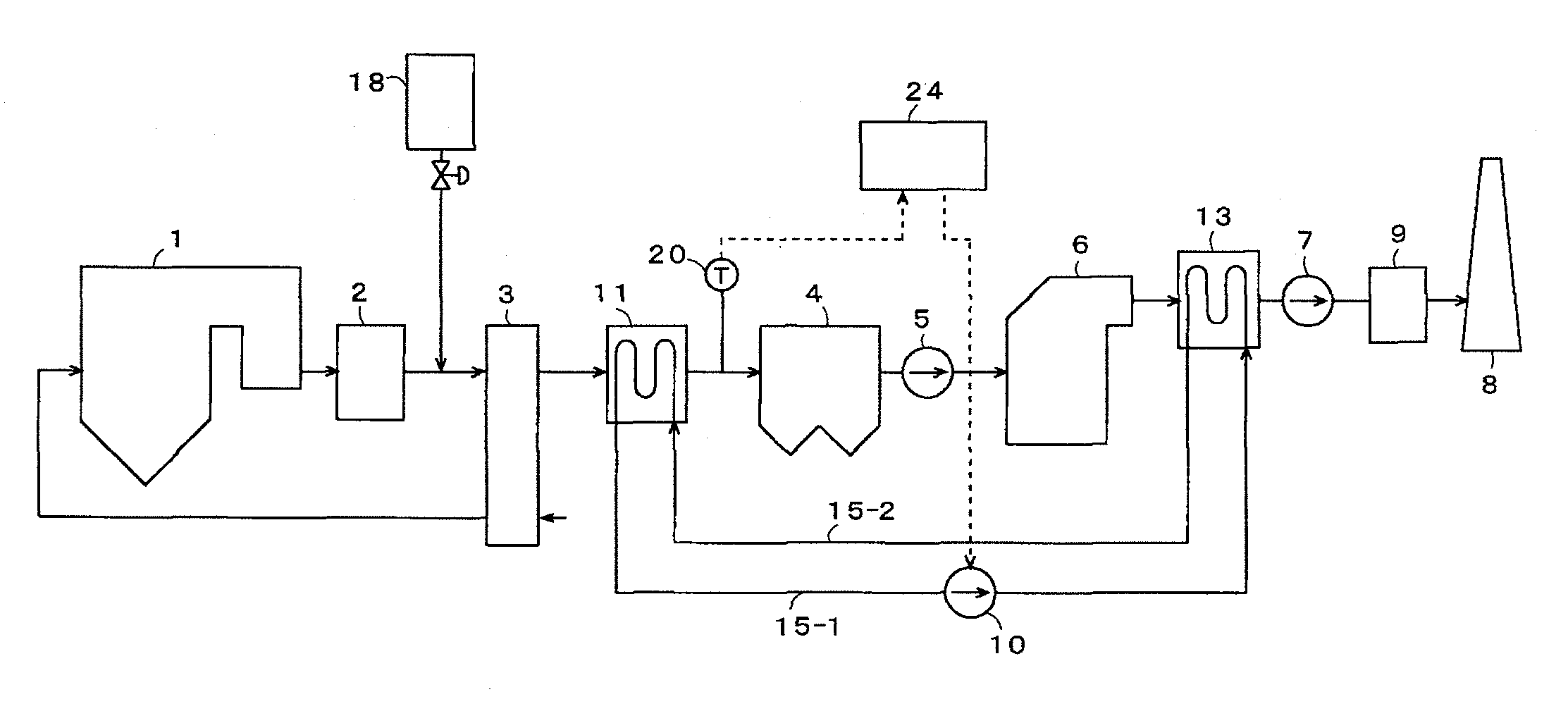

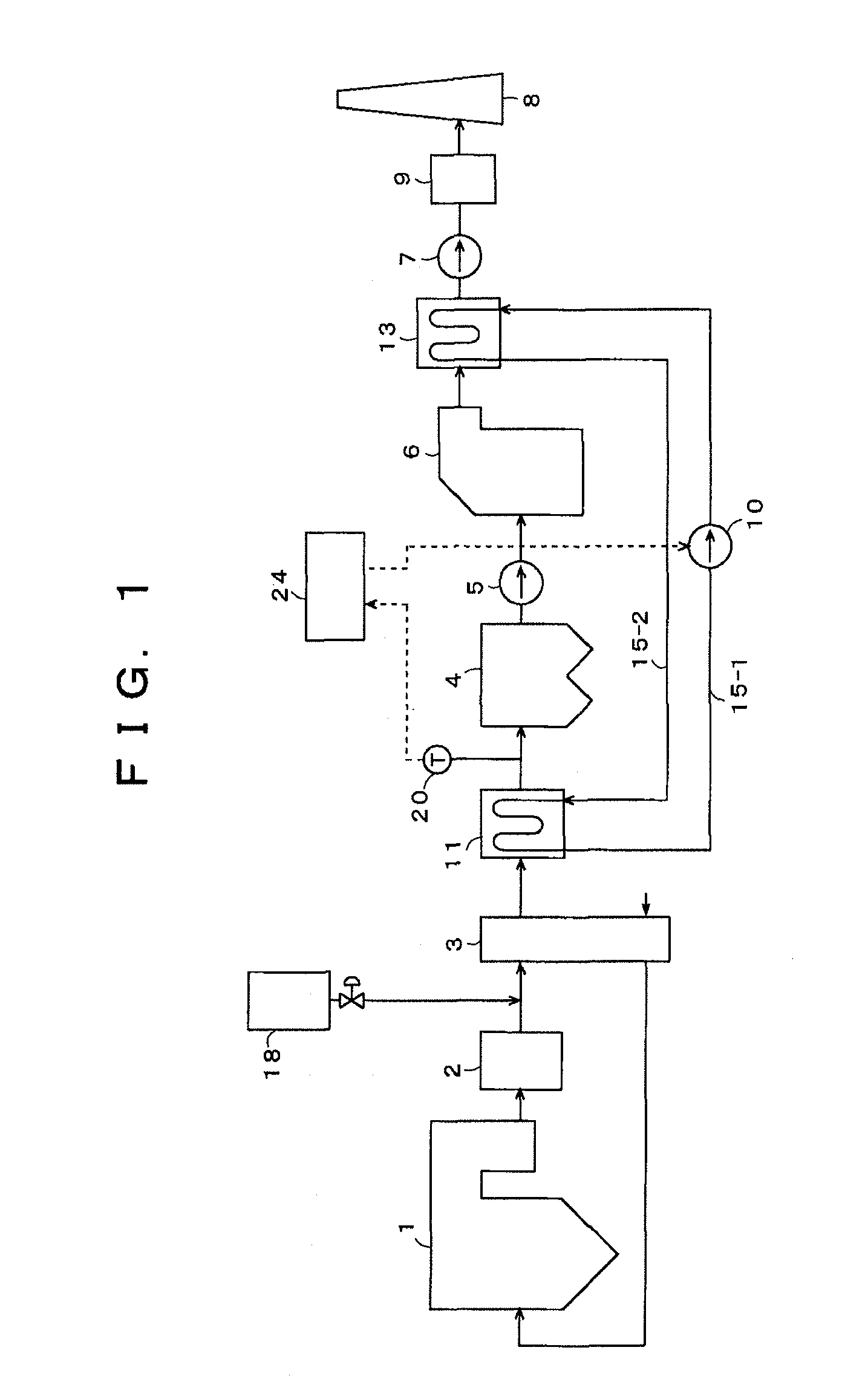

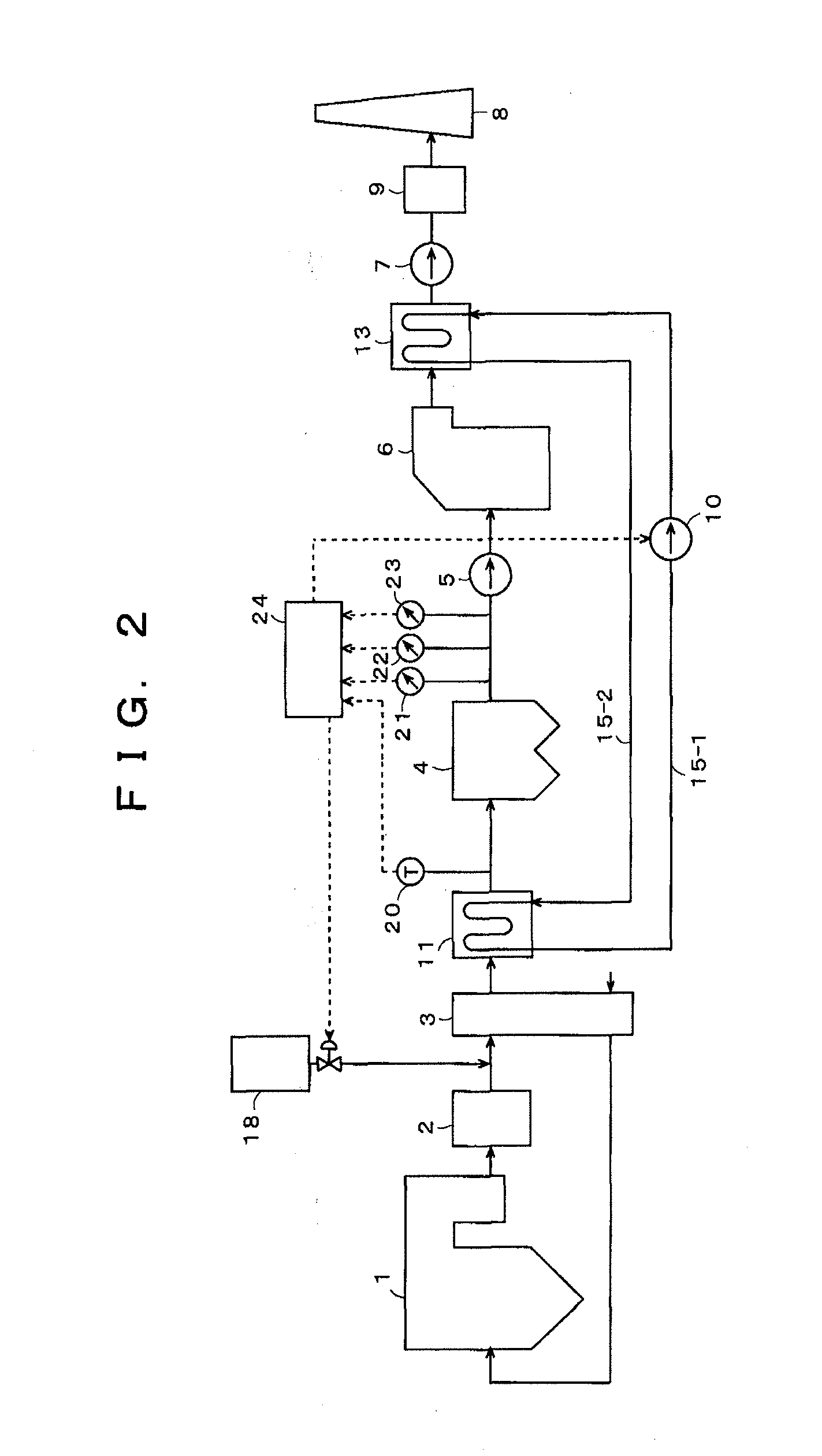

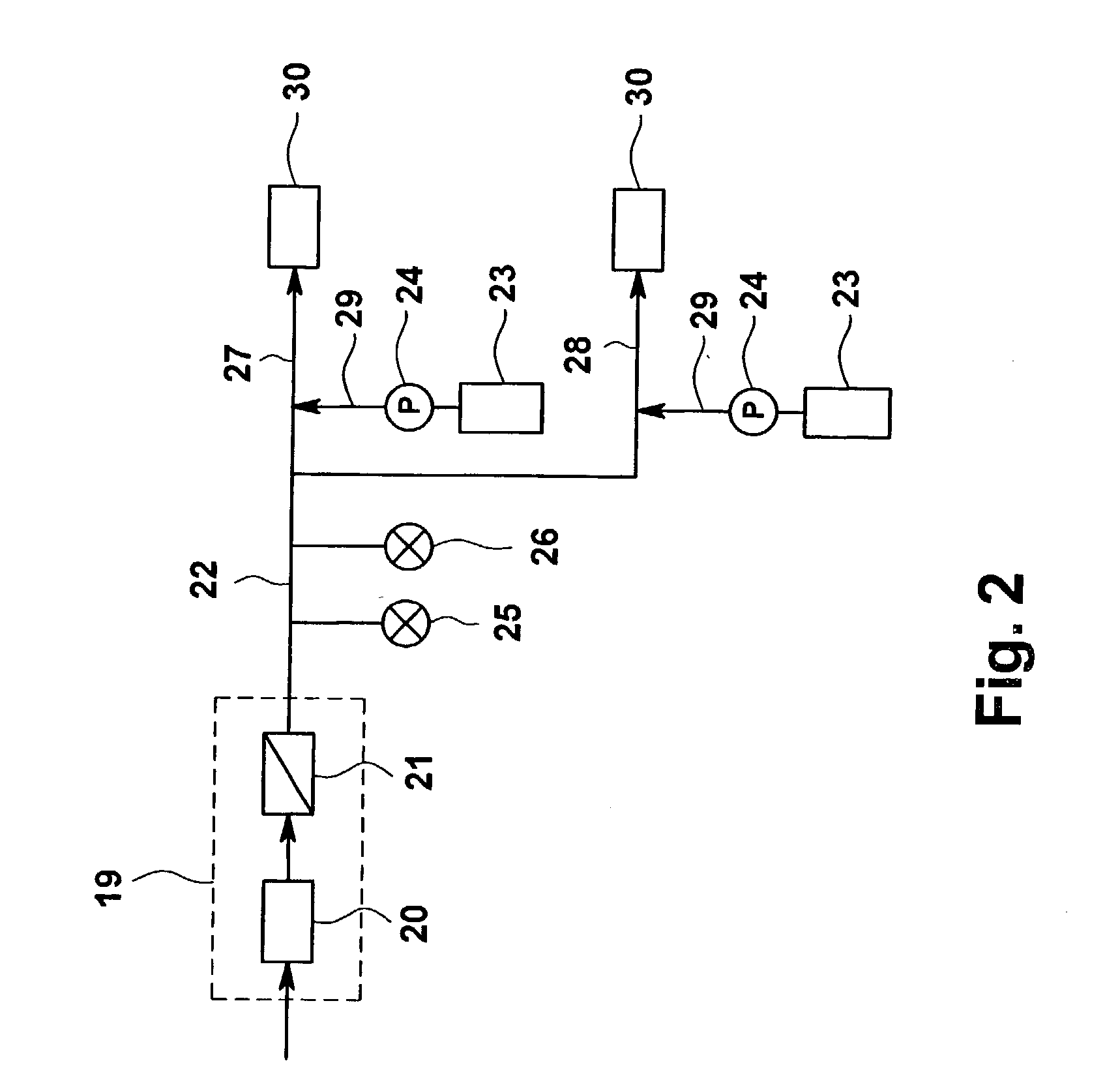

Method and apparatus for treating discharge gas

ActiveUS20100074817A1Reduce concentrationImprove adsorption capacityCombination devicesNitrogen compoundsAir preheaterSorbent

The following devices are successively disposed in the following order from an upstream side to a downstream side in an exhaust gas duct of a combustion apparatus: an air preheater, preheating combustion air for use in an exhaust gas treating apparatus; a heat recovery unit, recovering exhaust gas heat at an exit of the air preheater; a precipitator, collecting soot / dust contained in an exhaust gas at an exit of the heat recovery unit; a wet flue gas desulfurizer, removing sulfur oxides contained in the exhaust gas at the exit of the precipitator; and a reheater, heating the exhaust gas at the exit of the wet flue gas desulfurizer. Each of the heat recovery unit and the reheater has a heat exchanger tube, and a circulation line is disposed to connect the heat exchanger tubes. A sulfur trioxide (SO3) removing agent is supplied to the upstream side of the heat recovery unit, and the temperature of the exhaust gas at the exit of the heat recovery unit is adjusted to not more than a dew point of sulfur trioxide. As the sulfur trioxide removing agent, use is preferably made of at least one among a sulfur trioxide adsorbent, a sulfur trioxide reducing agent, and a sulfur trioxide neutralizing agent. Thus, even when coal with a high sulfur content is used as fuel, heavy metals contained in the exhaust gas can be removed effectively from the exhaust gas.

Owner:MITSUBISHI POWER LTD

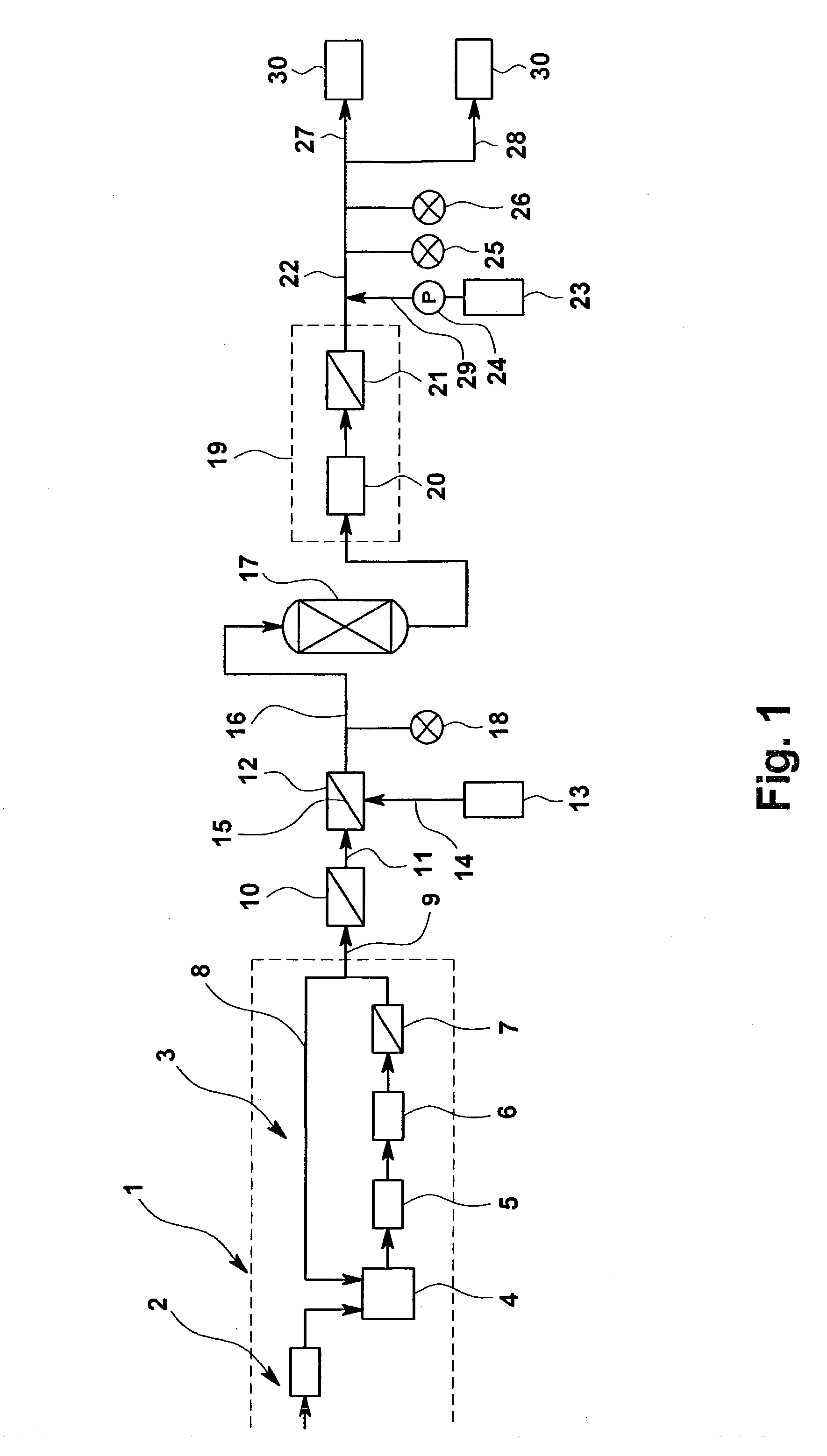

Hydrogen-dissolved water production apparatus

InactiveUS20030132104A1Avoid quality lossQuality improvementUltrafiltrationReverse osmosisParticulatesHydrogen

A degassing device (10), a hydrogen dissolving device (12), and a palladium catalyst column (17) are provided in that order downstream of a high-purity water production device (1), and an impurity removal device (19) is connected to the exit side of treated water of the palladium catalyst column (17). The impurity removal device (19) removes impurity ions which are eluted into the water to be treated or impurity particulates which mix in with the water to be treated during the treatment in the palladium catalyst column (17). The impurity removal device (19) comprises an ion exchange device (20) and a membrane treatment device (21) such as a ultrafiltration membrane device, a reverse osmosis membrane device or the like. By providing an impurity removal device (19) in this manner, it is possible to remove impurities generated during hydrogen peroxide removal treatment by the palladium catalyst and to prevent degradation in quality of hydrogen-dissolved water.

Owner:ORGANO CORP

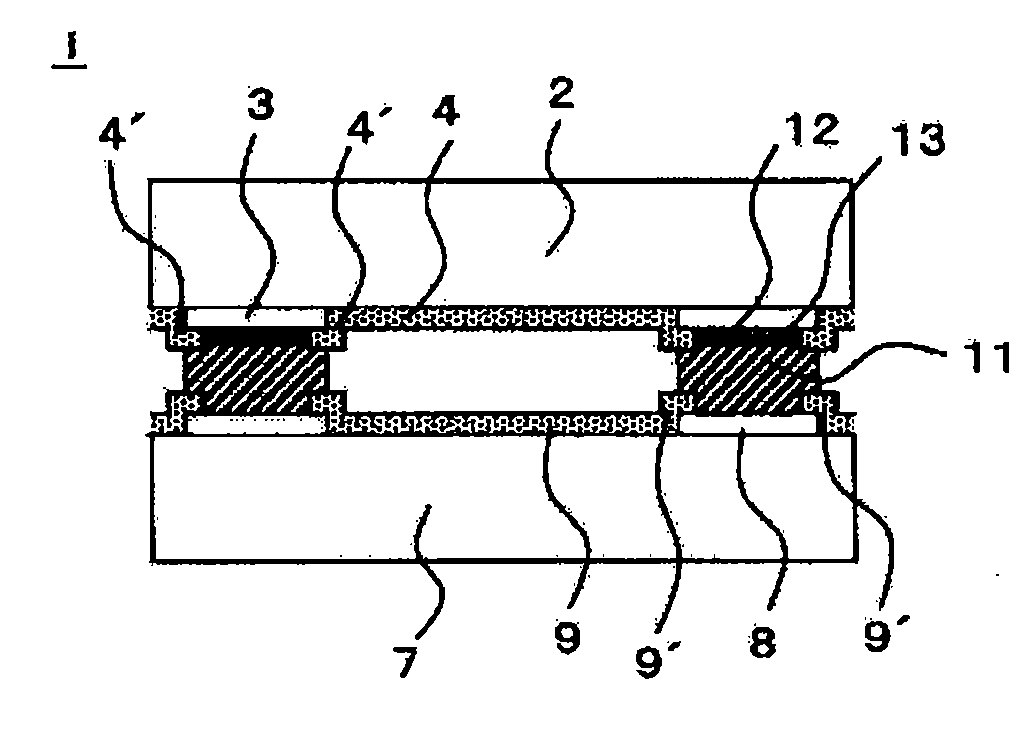

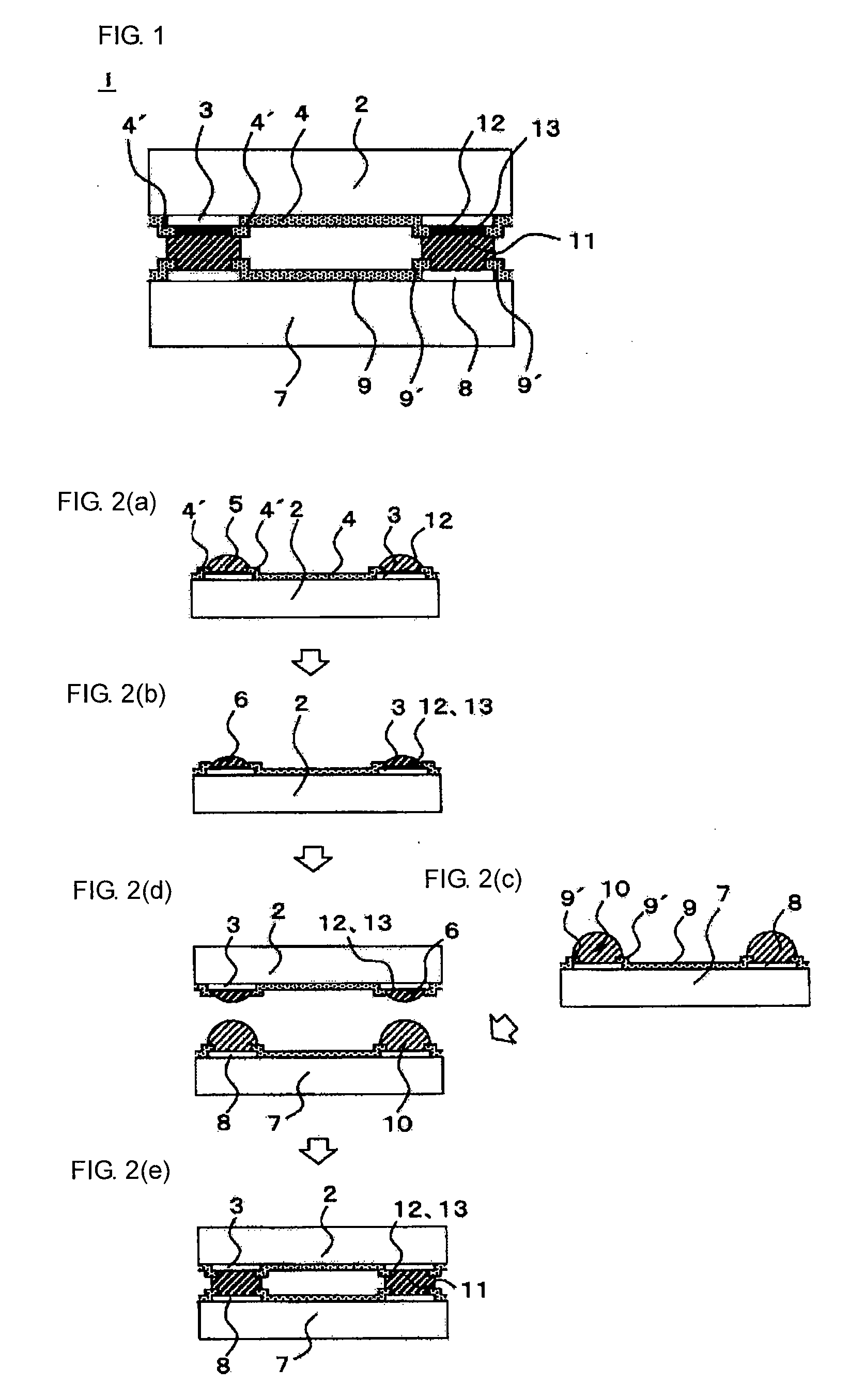

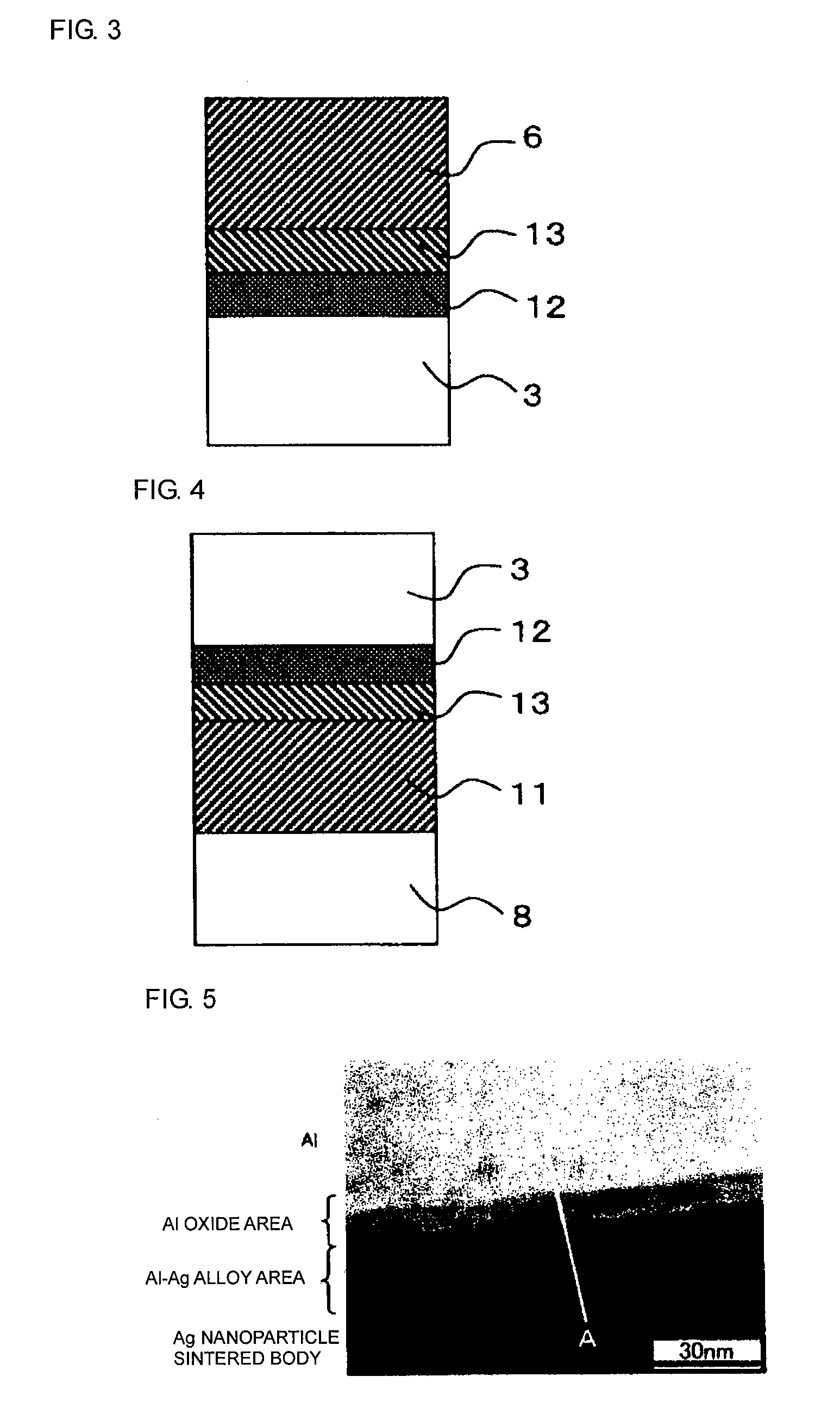

Electronic Element, Electronic Element Device Using the Same, and Manufacturing Method Thereof

ActiveUS20090039507A1Bonding reliability can be stablyAvoid insufficient thicknessNanotechSemiconductor/solid-state device detailsBond interfaceElement composition

An electronic element including an electronic element base and electrodes each of which has a first electrode having a surface composed of at least Al or an Al alloy and a second electrode composed of a metal nanoparticle sintered body and bonded to the first electrode. A bonding interface between the first electrode and the second electrode has a multilayer structure including, from the side of the first electrode to the side of the second electrode, (a) a first layer primarily composed of Al, (b) a second layer primarily composed of an Al oxide, (c) a third layer primarily composed of an alloy of Al and a constituent element of metal nanoparticles, and (d) a fourth layer primarily composed of the constituent element of the metal nanoparticles.

Owner:MURATA MFG CO LTD

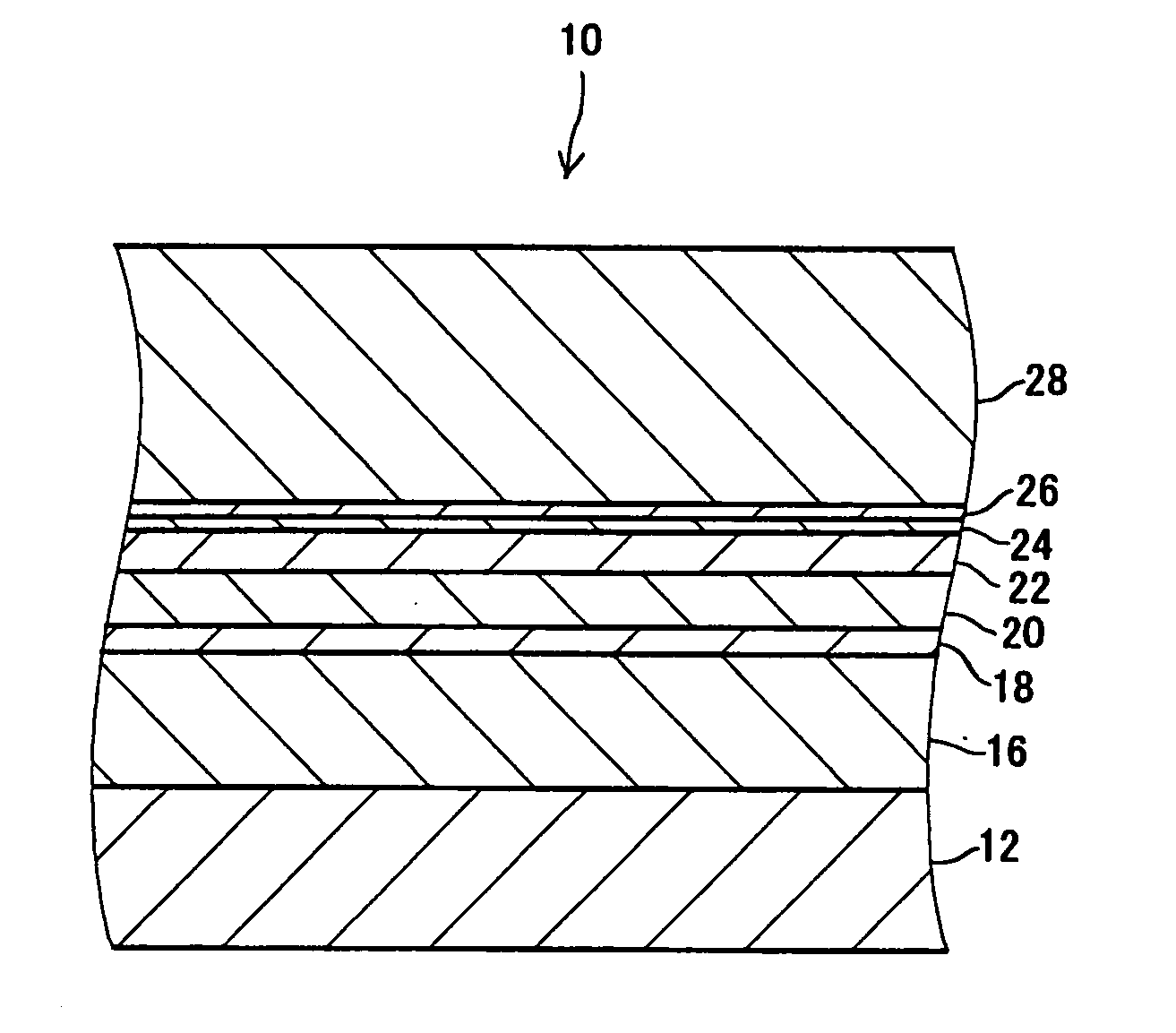

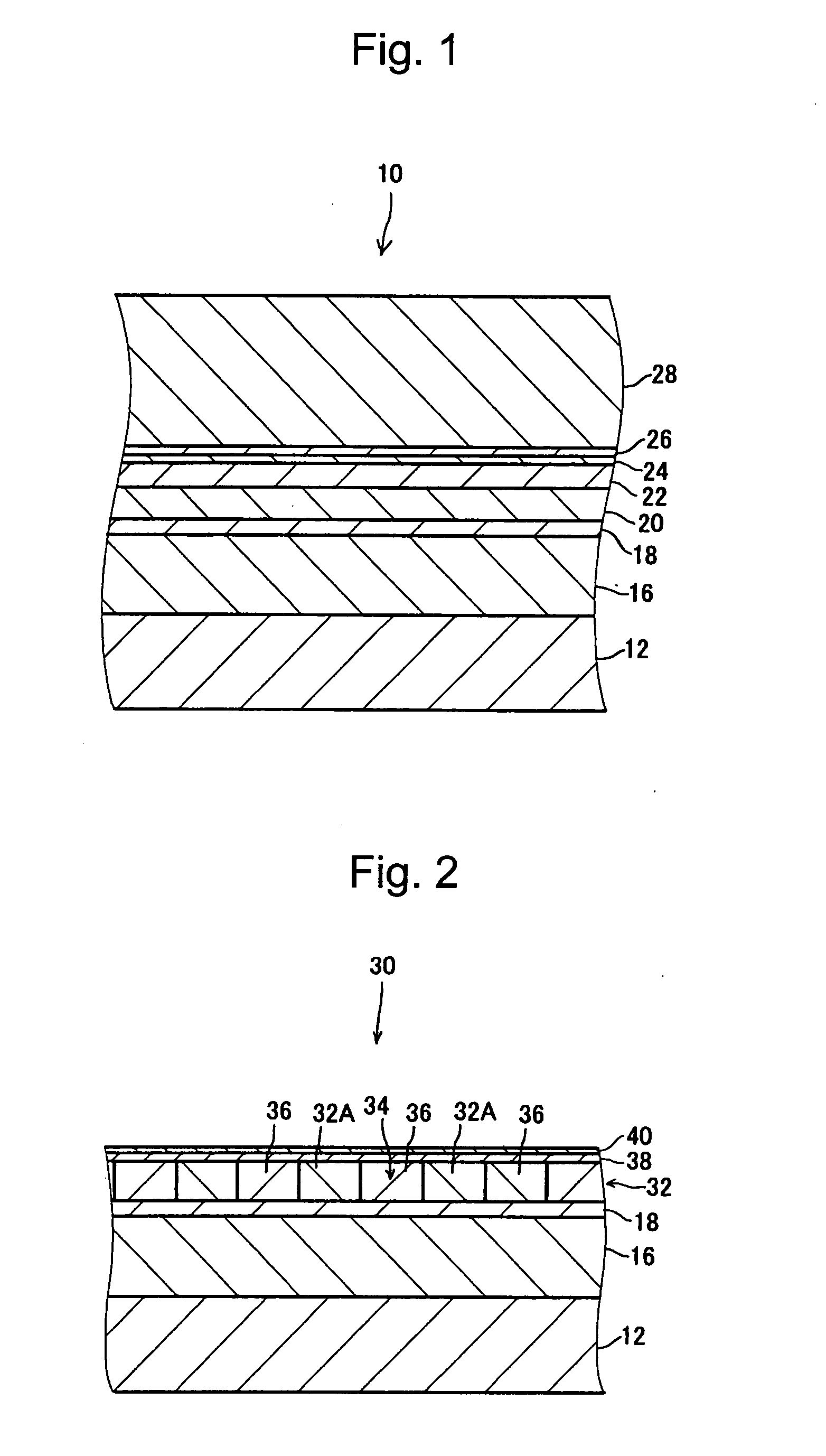

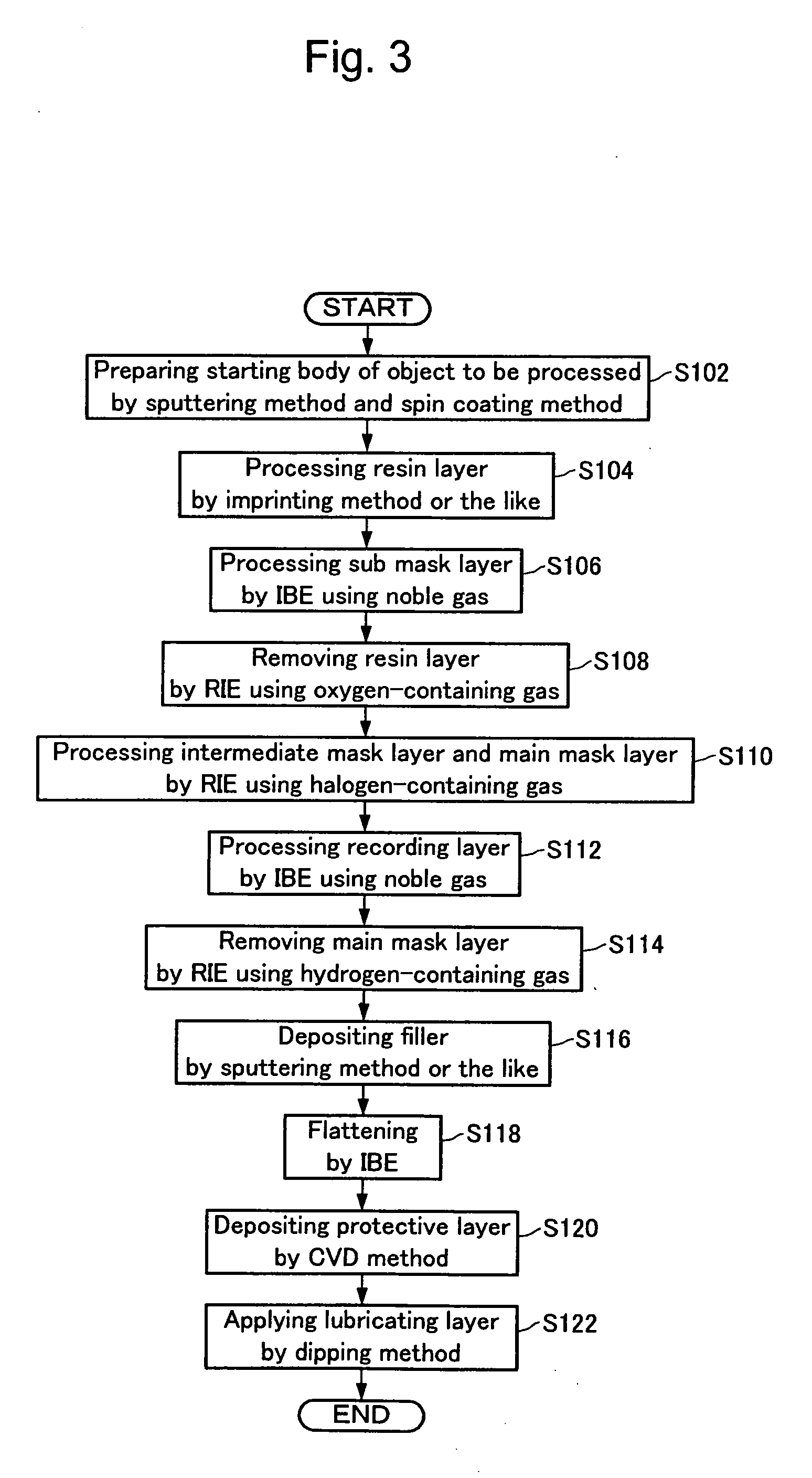

Method for manufacturing magnetic recording medium

InactiveUS20080078739A1Improve accuracyReliable removalDecorative surface effectsNanoinformaticsHalogenOptoelectronics

A method for manufacturing a magnetic recording medium with excellent production efficiency is provided in which the recording layer can be processed into a desired concavo-convex pattern with high precision and the resin layer can reliably and thoroughly be removed. A sub-mask layer having corrosion resistance against an oxygen-containing gas is provided over a main mask layer composed mainly of carbon. Furthermore, an intermediate mask layer is provided between the main mask layer and the sub-mask layer. The intermediate mask layer has corrosion resistance against the oxygen-containing gas, and its etching rate is higher for a halogen-containing gas than for the oxygen-containing gas. The resin layer removing step is conducted between the sub-mask layer processing step and the intermediate mask layer processing step (the main mask layer processing step). The resin layer removing step uses the oxygen-containing gas, and the intermediate mask layer processing step uses the halogen-containing gas.

Owner:TDK CORPARATION

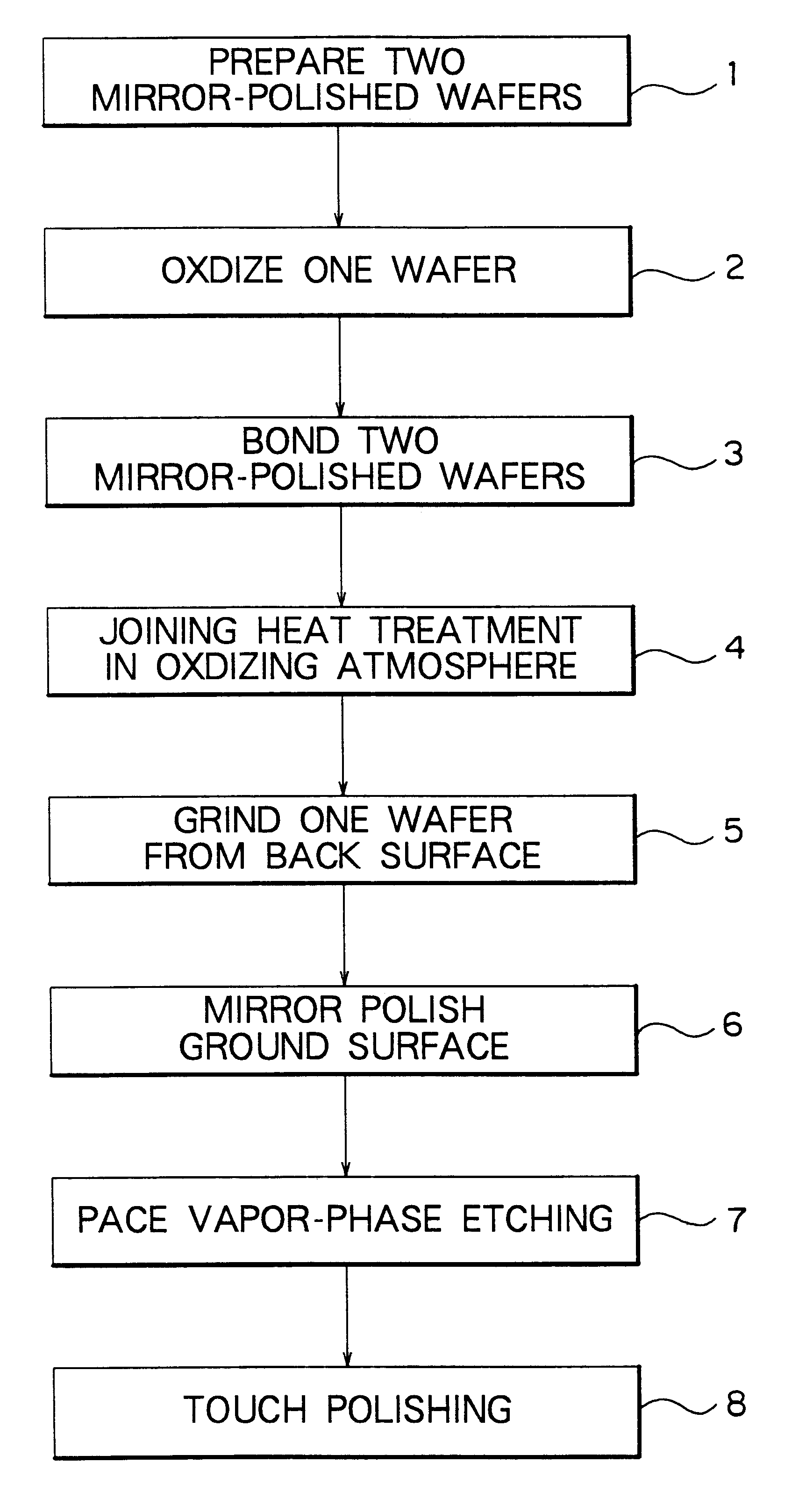

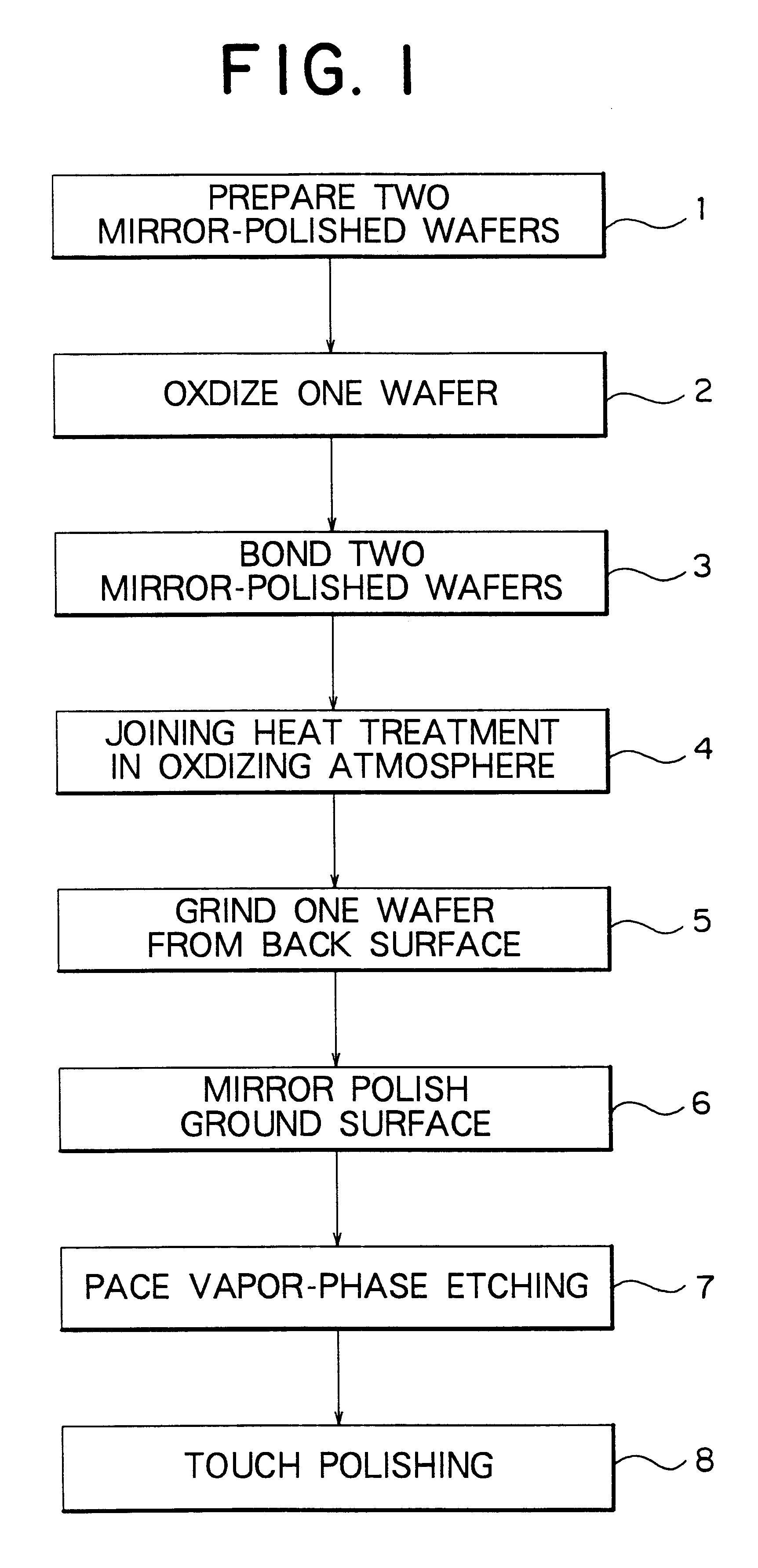

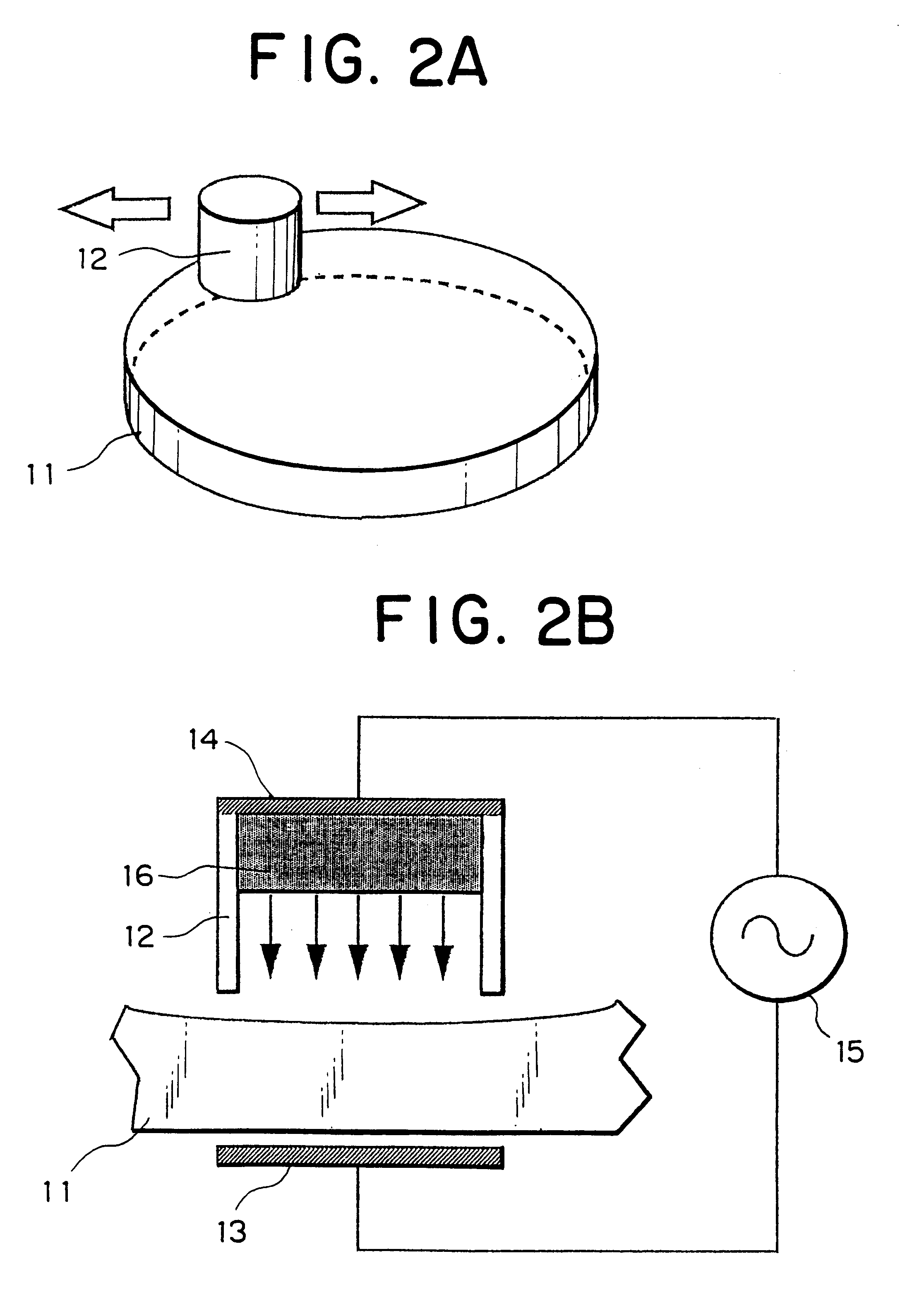

Method of forming oxide film on an SOI layer and method of fabricating a bonded wafer

InactiveUS6239004B1Avoid it happening againPromote generationSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface oxidation

In a method of fabricating a bonded wafer, an oxide film is first formed on the surface of at least one of two mirror-polished silicon wafers. The two silicon wafers are superposed such that the mirror-polished surfaces come into close contact with each other, and heat treatment is performed in order to join the wafers together firmly. Subsequently, the thickness of one of the wafers is reduced so as to yield a thin film, the surface of which is then polished and subjected to vapor-phase etching in order to make the thickness of the thin film uniform. Optionally, the vapor-phase-etched surface is then mirror-polished. The surface of the bonded wafer is oxidized, and the generated surface oxide film is then removed. In the method, the thickness of the oxide film formed on the surface of the bonded wafer is made not greater than 50 nm. The method reliably eliminates damage and crystal defects generated during etching in accordance with PACE method or subsequent mirror polishing, and thereby enables relatively simple and low cost manufacture of bonded wafers having a very thin SOI layer that has good thickness uniformity and excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

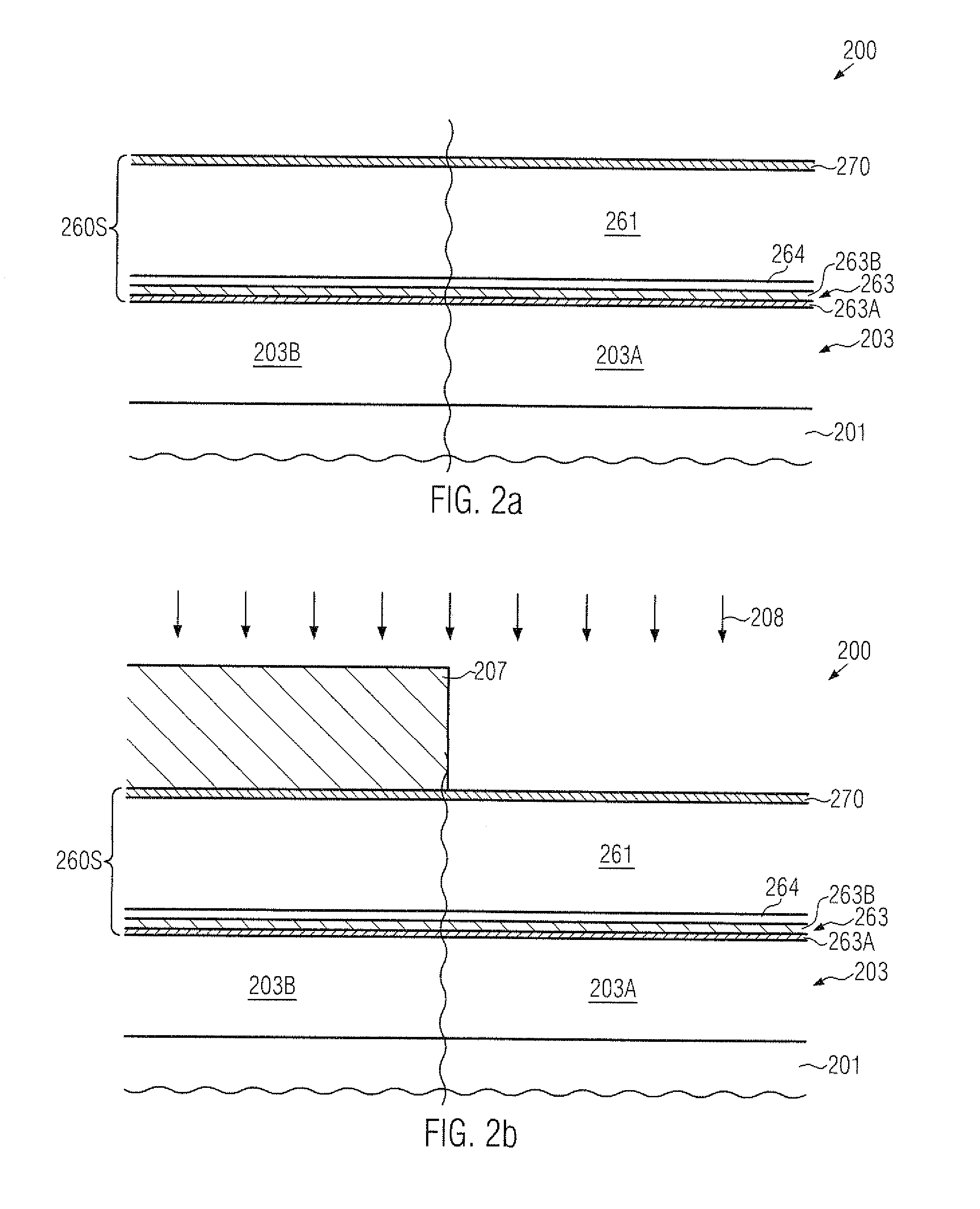

High-k metal gate electrode structures formed by separate removal of placeholder materials using a masking regime prior to gate patterning

ActiveUS20110127613A1Reduce or even completely avoid any additional lithography processesMaterial is limitedTransistorSemiconductor/solid-state device manufacturingWork functionEngineering

In a replacement gate approach in sophisticated semiconductor devices, the place-holder material of gate electrode structures of different type are separately removed. Furthermore, electrode metal may be selectively formed in the resulting gate opening, thereby providing superior process conditions in adjusting a respective work function of gate electrode structures of different type. In one illustrative embodiment, the separate forming of gate openings in gate electrode structures of different type may be based on a mask material that is provided in a gate layer stack.

Owner:GLOBALFOUNDRIES US INC

Low pressure drinking water purifier

InactiveUS20080197077A1Extended service lifeNo wasteWater treatment parameter controlMembranesUltrafiltrationEnvironmental engineering

An inexpensive device for removing microorganisms from drinking water includes an Ultrafiltration membrane filter equipped with a pressure regulating mechanism to supply purified water to a suitable low-pressure reservoir equipped with a bi-directional hydrophobic membrane vent filter having a 0.01-0.05-micron pore size. The purified water may be supplied to the storage reservoir at a static pressure in the range of 1 to 8 pounds per square inch.

Owner:SWARTLEY JOHN S +1

Method of manufacturing a field effect transistor device with recessed channel and corner gate device

InactiveUS20070155119A1Reliable removalEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricElectrical conductor

Fabrication of recessed channel array transistors (RCAT) with a corner gate device includes forming pockets between a semiconductor fin that includes a gate groove and neighboring shallow trench isolations that extend along longs sides of the semiconductor fin. A protection liner covers the semiconductor fin and the trench isolations in a bottom portion of the gate groove and the pockets. An insulator collar is formed in the exposed upper sections of the gate groove and the pockets, wherein a lower edge of the insulator collar corresponds to a lower edge of source / drain regions formed within the semiconductor fin. The protection liner is removed. The bottom portion of the gate groove and the pockets are covered with a gate dielectric and a buried gate conductor layer. The protection liner avoids residuals of polycrystalline silicon between the active area in the semiconductor fin and the insulator collar.

Owner:POLARIS INNOVATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com