Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Electrochemical dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

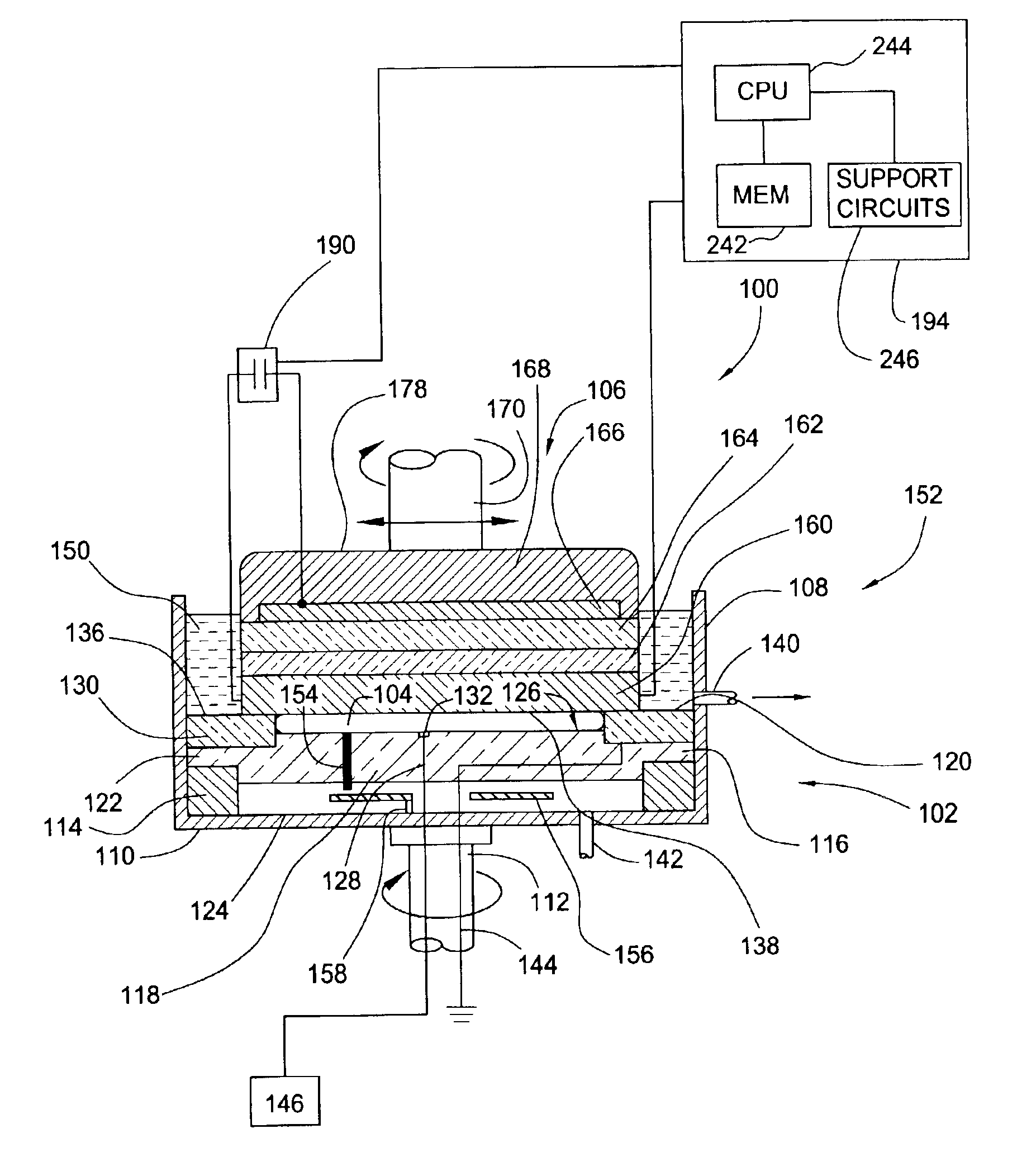

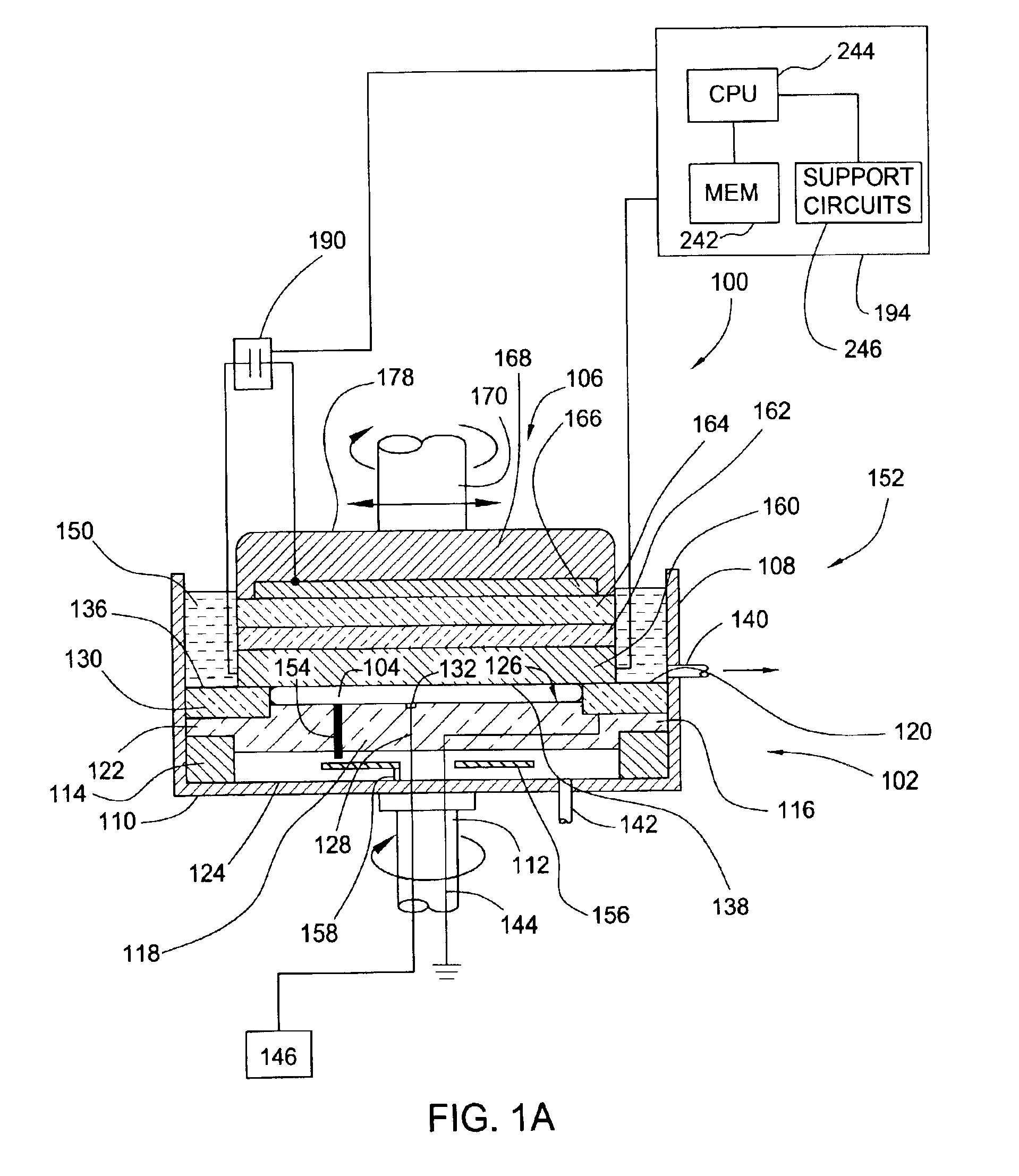

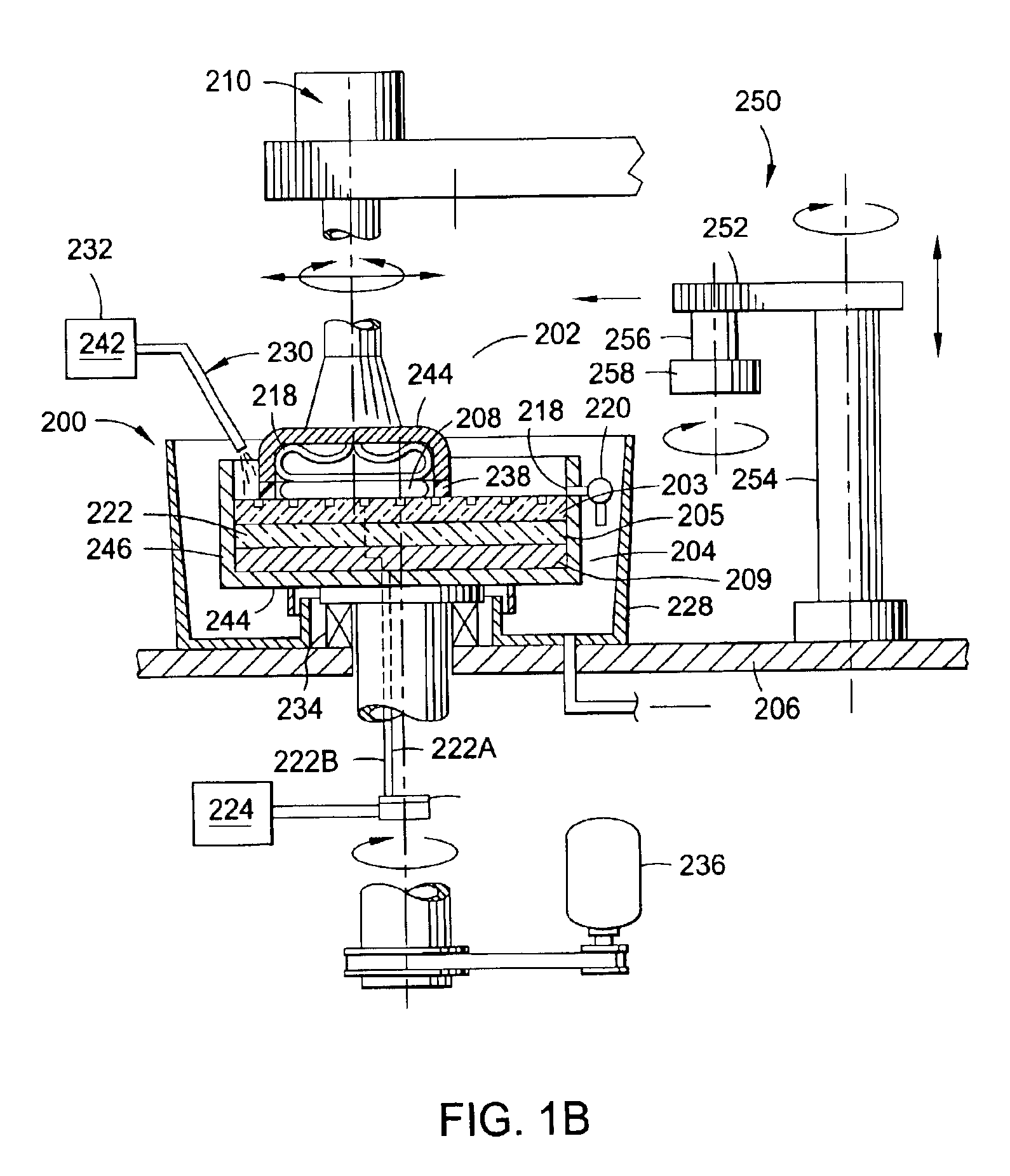

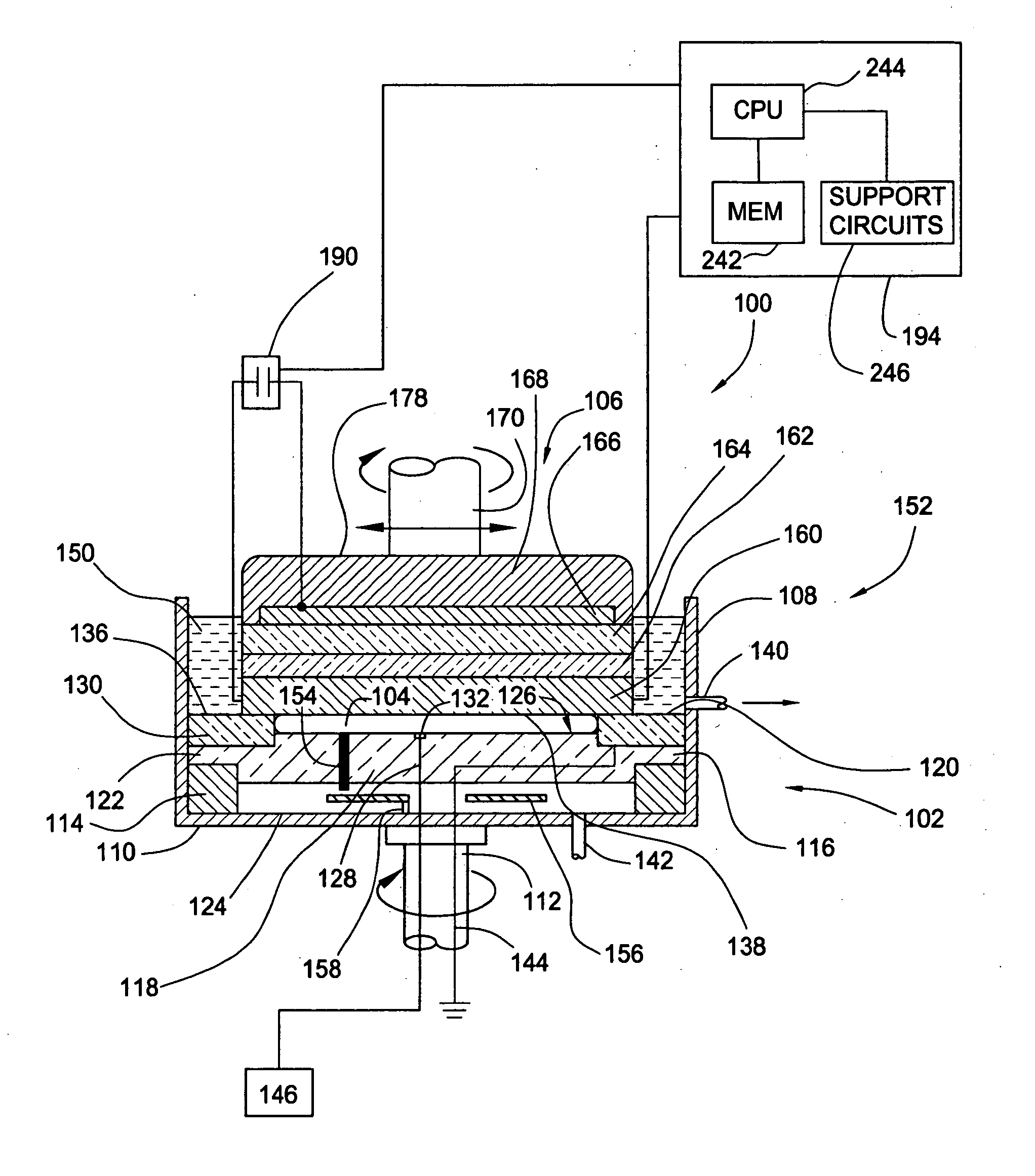

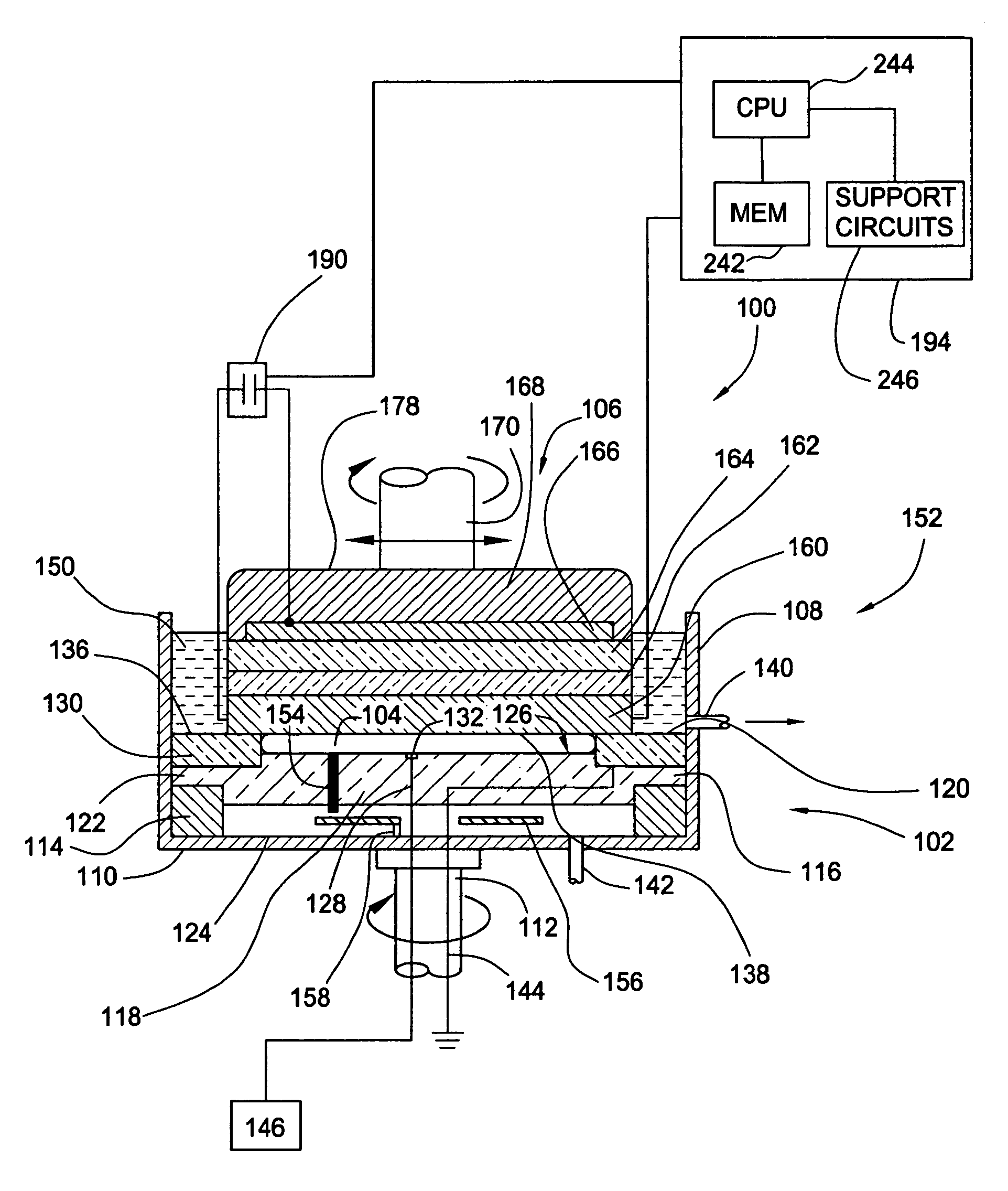

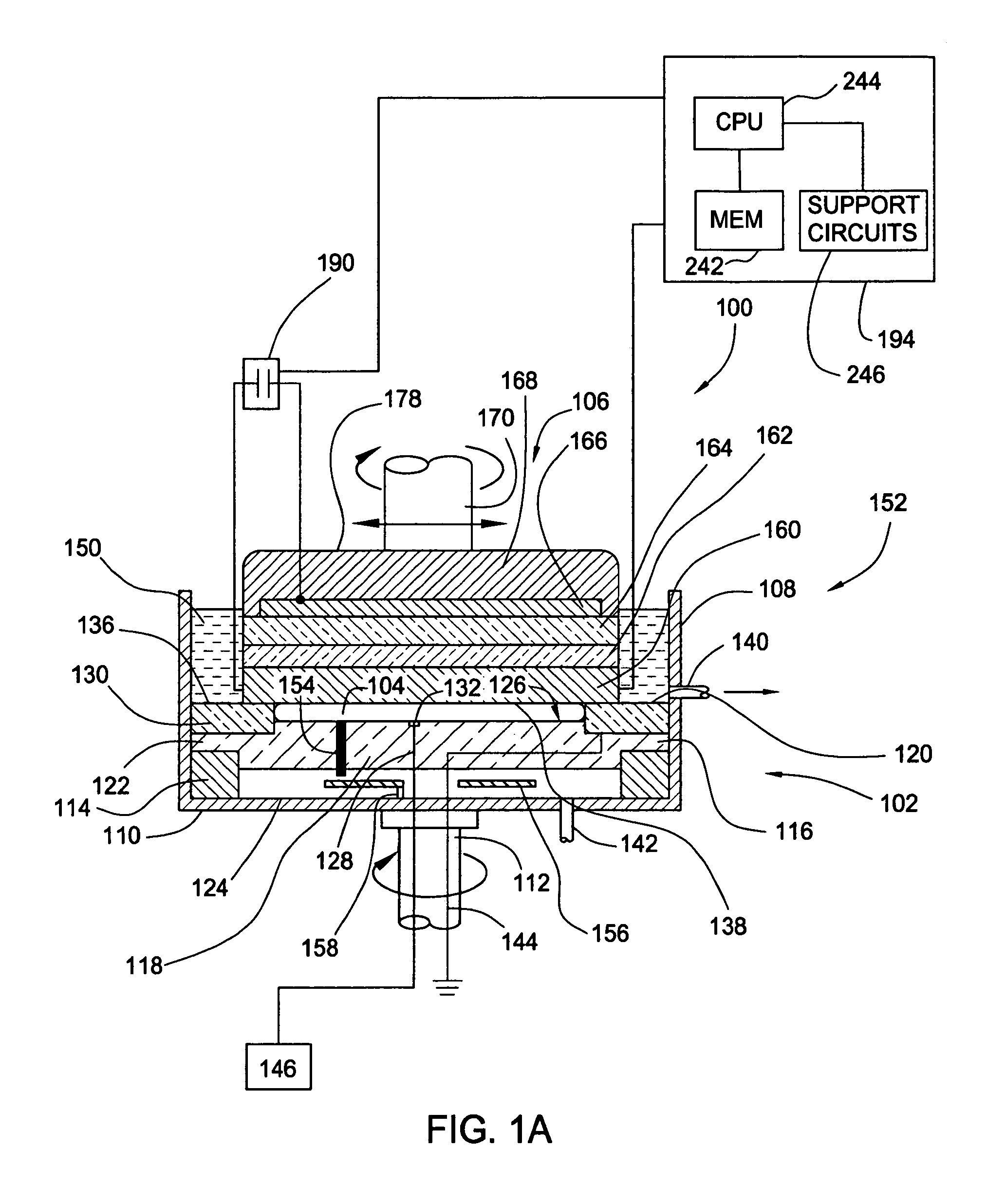

Process control in electrochemically assisted planarization

InactiveUS6848970B2Semiconductor/solid-state device manufacturingLapping machinesEngineeringElectrochemical dissolution

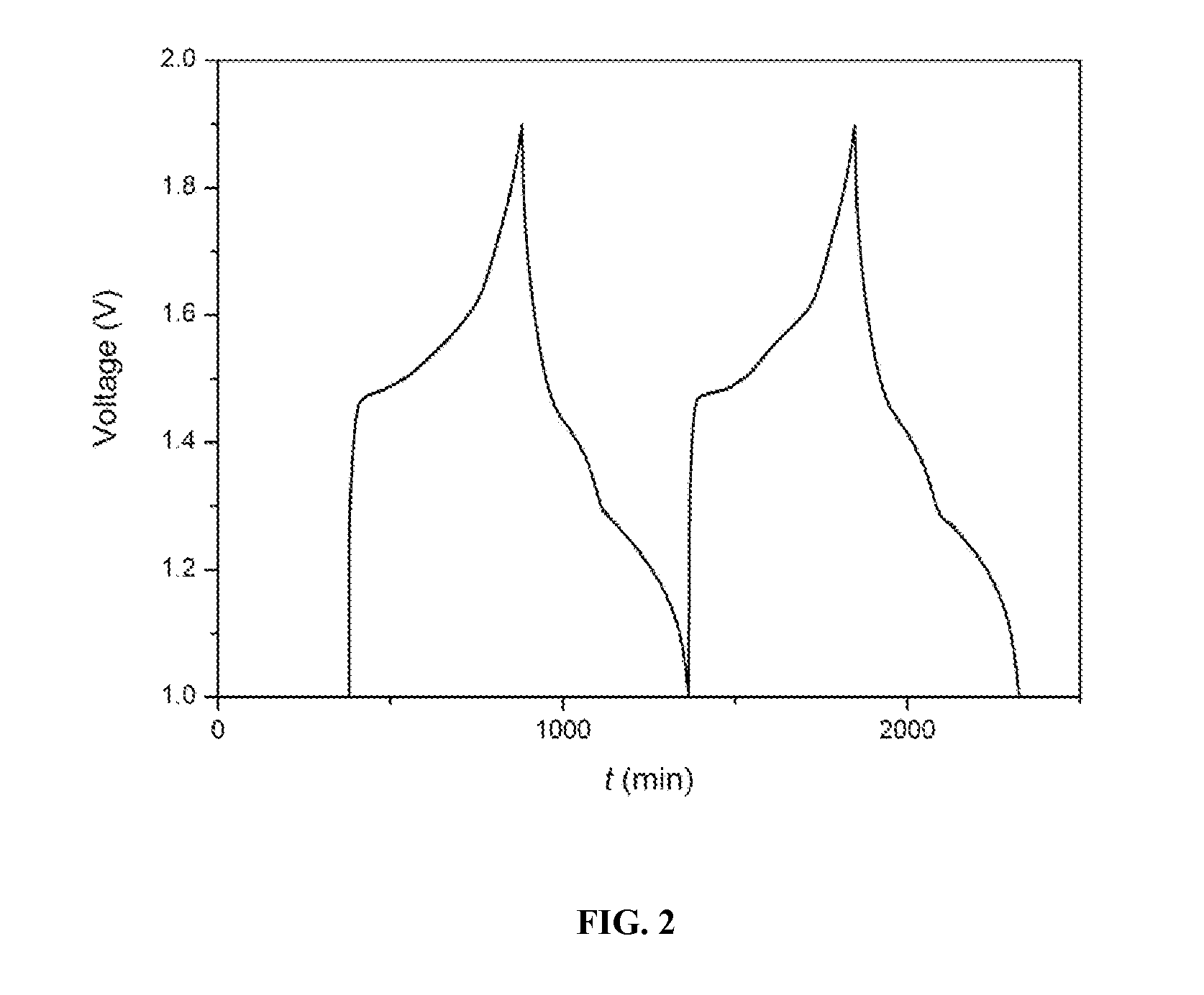

Aspects of the invention generally provide a method for polishing a material layer using electrochemical deposition techniques, electrochemical dissolution techniques, polishing techniques, and / or combinations thereof. In one aspect of the invention, the polishing method comprises applying a separate electrical bias, such as a voltage, to each of a plurality of zones of an electrode. Determining the separate biases comprises determining a time that at least one portion of the material layer is associated with each of the zones of the counter-electrode.

Owner:APPLIED MATERIALS INC

Process control in electrochemically assisted planarization

InactiveUS20050178743A1Polishing machinesRevolution surface grinding machinesEngineeringElectrochemical dissolution

Owner:APPLIED MATERIALS INC

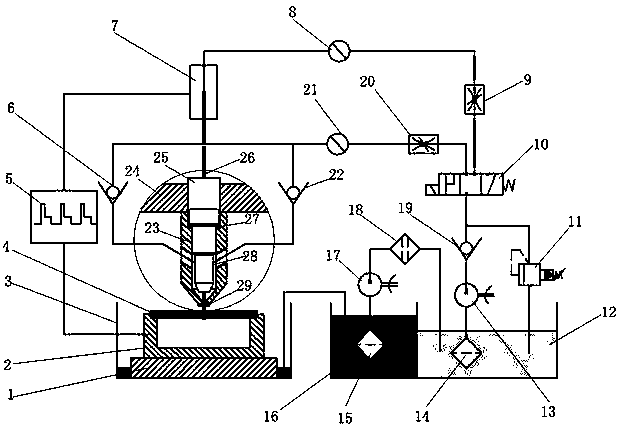

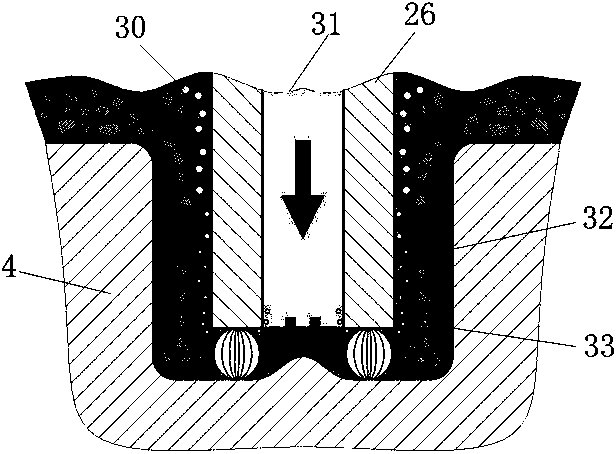

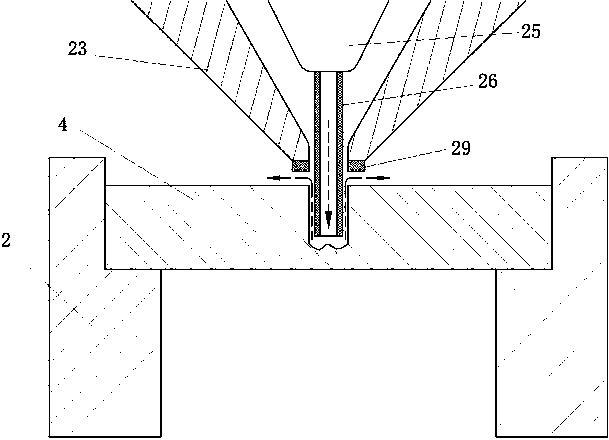

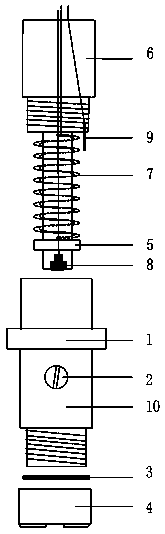

Synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and special tool of synchronous composite processing method

The invention provides a synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and a special tool of the synchronous composite processing method. The synchronous composite processing method includes that a tube electrode is switched to impulse voltage, and a neutral salt solution with ultra-low concentration flows into a processing area via the inner side of the tube electrode at a high speed, and then flows out of the processing area along a gap between the tube electrode and a workpiece; an end face of the tube electrode is subjected to high-speed punch processing with axial feeding of electric sparks under the ultra-low concentration of the neutral salt solution, and a hole wall processed by the electric sparks is subjected to radical electrochemical finishing and machining under the action of low-pressure voltage. By the synchronous composite processing method, processing precision is guaranteed, punching efficiency is improved, and processing requirements on various kinds of holes of an aircraft engine are met. Different from conventional electric spark processing and electrolytic processing, the synchronous composite processing method adopts the neutral salt solution with the ultra-low concentration, so that processing efficiency in electrochemical dissolution can be greatly improved and corrosion degree of equipment can be decreased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

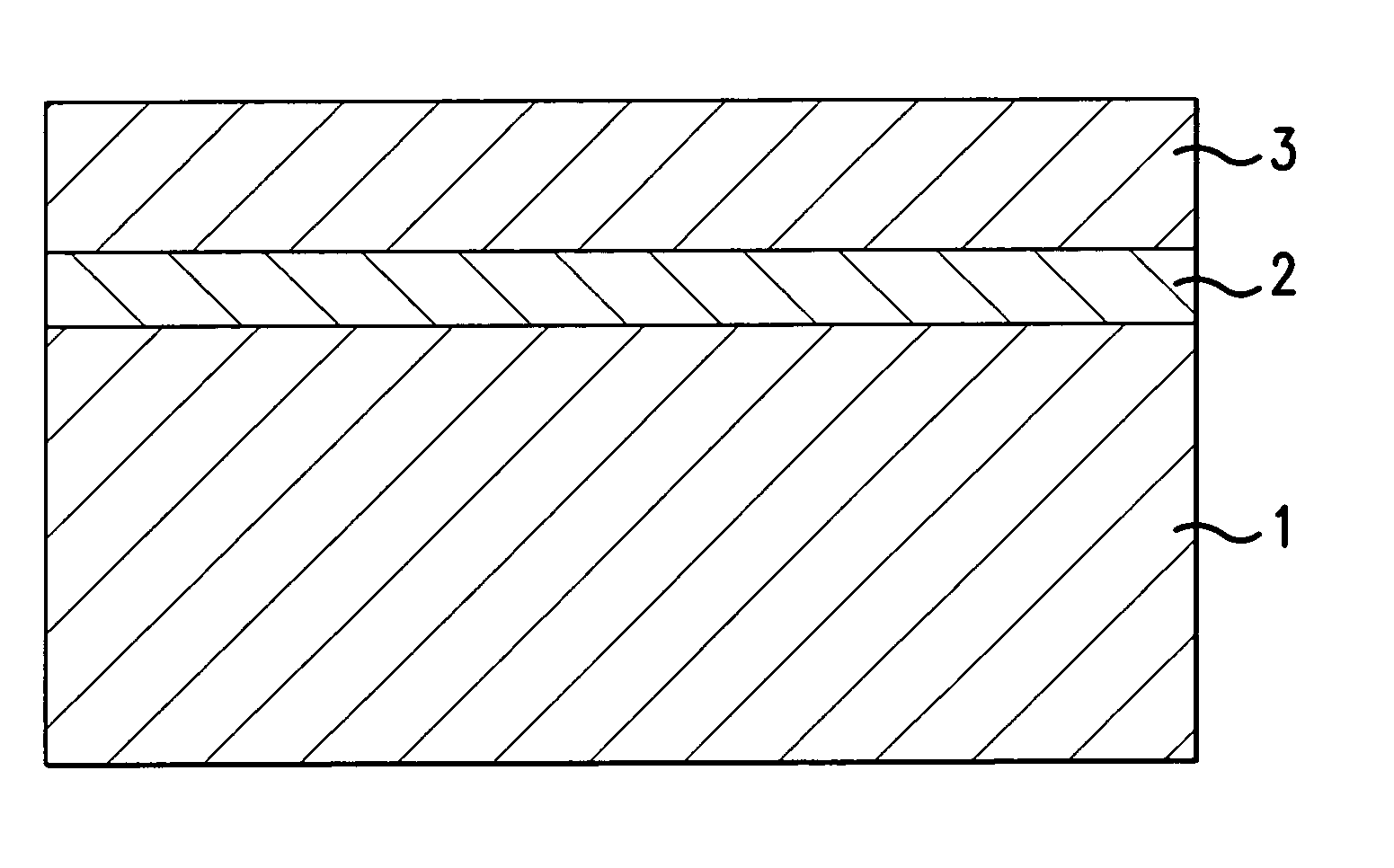

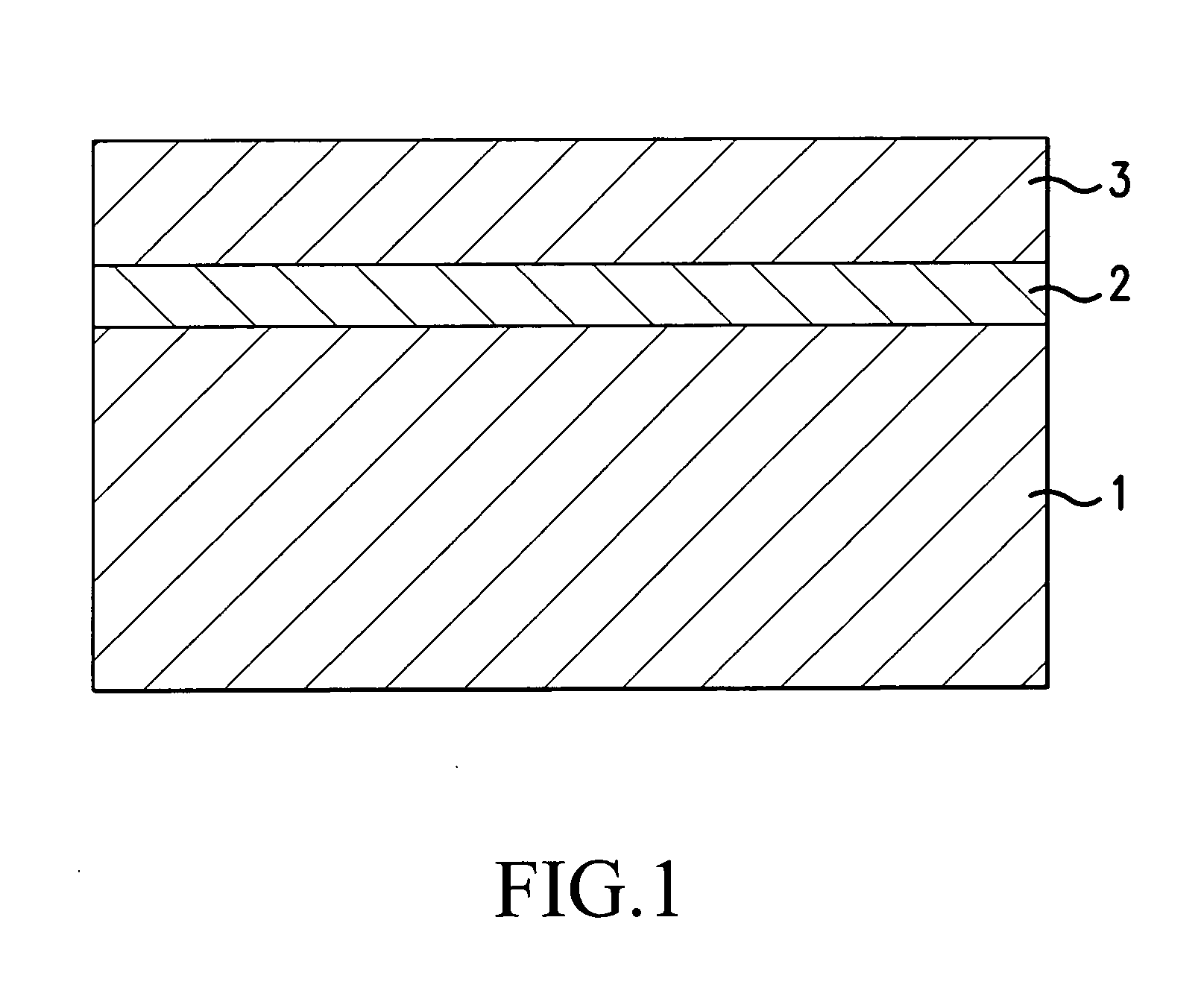

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS20050048306A1Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

An object of the present invention is to produce an ultra-thin copper foil with a carrier which has few pinholes and small surface roughness and which has an the thickness of less than 5 μm, and to produce the method of producing the foil, and further to produce a printed circuit board for fine pattern, a multilayer printed circuit board and a chip on film circuit board by using the ultra-thin copper foil with a carrier. The present invention provides an ultra-thin copper foil with a carrier produced by stacking a peeling layer and an ultra thin copper foil in order on the surface of a carrier copper foil which is made smooth so that the mean surface roughness of at least one side is Rz of 0.01 to 2.0 μm by the chemical polishing, the electrochemical dissolution, or the smoothing plating processing method independently, combining two or more, or further combining the mechanical polishing.

Owner:FURUKAWA ELECTRIC CO LTD

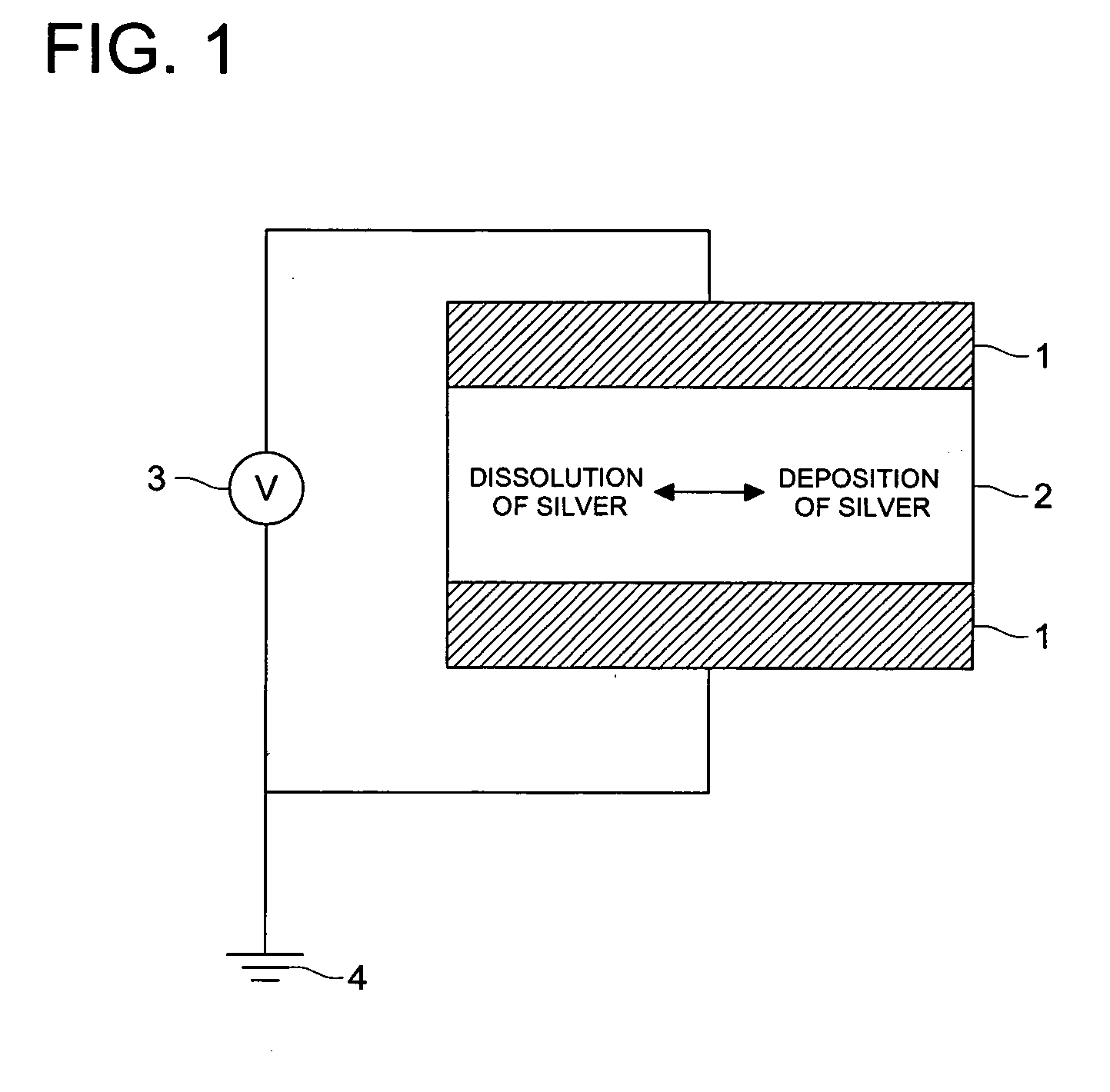

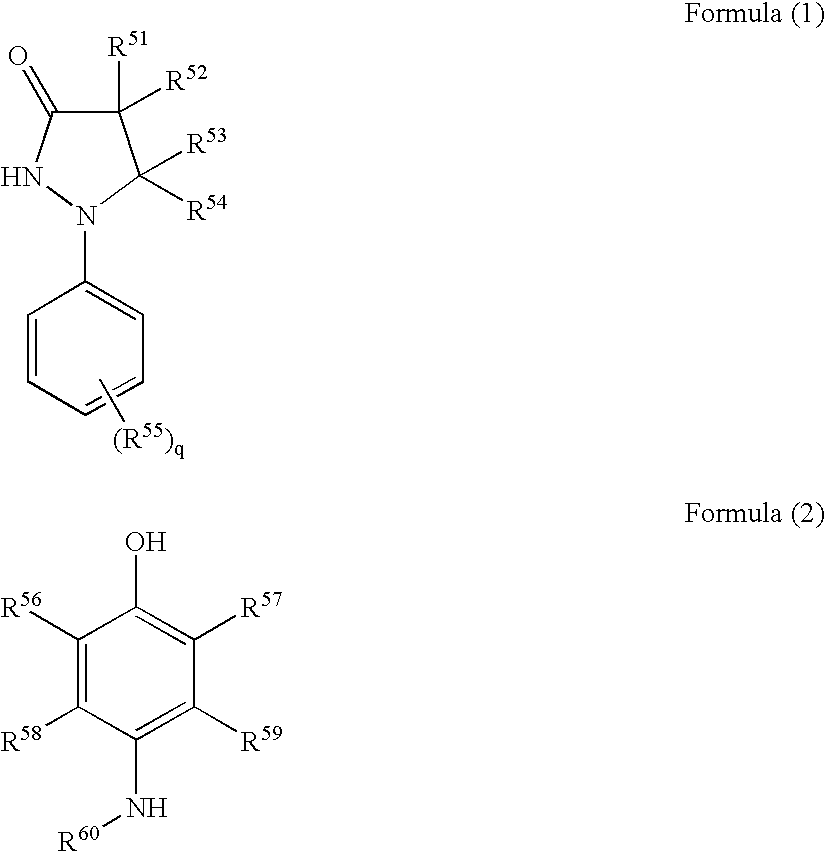

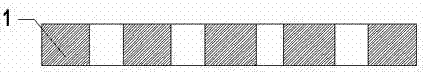

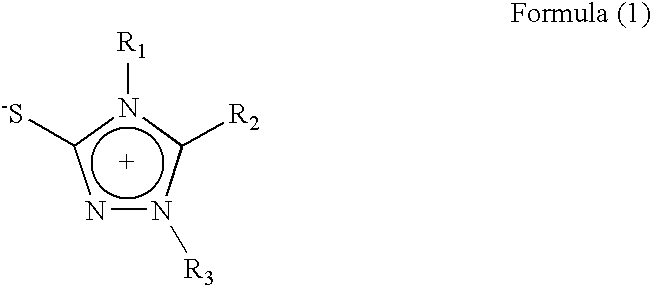

Display element

InactiveUS20050206994A1Easy constructionReduce the driving voltageNon-linear opticsIdentification meansCompound (substance)Electrochemical dissolution

A display element containing a pair of electrodes having therebetween an electrolyte layer containing silver or a silver-containing compound, the display element being driven by the pair of electodes so as to electrochemically dissolve silver or to electrochemically deposit silver, wherein the electrolyte layer contains a compound represented by on of Formulae (1) to (7) described in the specification or a derivative thereof.

Owner:KONICA MINOLTA INC

Ni-pt alloy and target comprising the alloy

InactiveUS20070098590A1Easily perform cool rollingGood effectPhotography auxillary processesVacuum evaporation coatingActivated carbon filtrationFiltration

The present invention provides a Ni—Pt alloy superior in workability containing Pt in a content of 0.1 to 20 wt % and having a Vickers hardness of 40 to 90, and a target comprising the Ni—Pt alloy. The present invention also provides a manufacturing method of Ni—Pt alloy superior in workability comprising a step of subjecting a raw material Ni having a purity of 3N level to electrochemical dissolution, a step of neutralizing the electrolytically leached solution with ammonia, a step of removing impurities through filtration with activated carbon, a step of blowing carbon dioxide into the resultant solution to form nickel carbonate and exposing the resultant product to a reducing atmosphere to prepare high purity Ni powder, a step of leaching a raw material Pt having a purity of 3N level with acid, a step of subjecting the leached solution to electrolysis to prepare high purity electrodeposited Pt, and a step of dissolving the resultant high purity Ni powder and high purity electrodeposited Pt. The foregoing method enables the rolling of the Ni—Pt alloy ingot upon reducing the hardness thereof, which results in the stable and efficient manufacture of a rolled target.

Owner:JX NIPPON MINING& METALS CORP

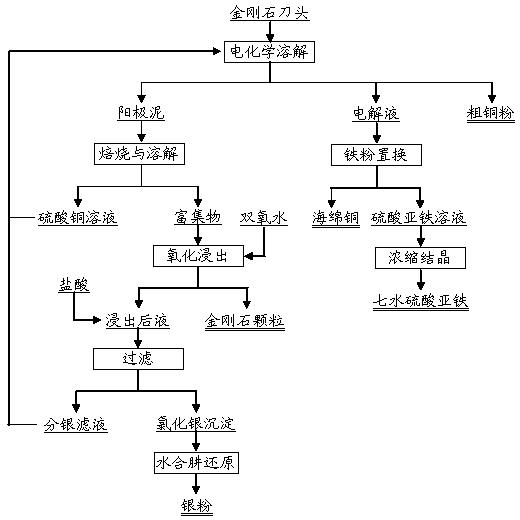

Method for processing waste copper/iron-based diamond tool bit

InactiveCN104046785AEfficient separationRealize closed loopProcess efficiency improvementIron sulfateClosed loop

The invention provides a method for processing waste copper / iron-based diamond tool bit. The method comprises the following steps: firstly, electrochemically dissolving the waste diamond tool bit in a sulfuric acid system so that most part of copper and iron are dissolved into the solution, while silver, diamond and the like are enriched into anode mud; secondly, roasting and oxidizing the anode mud and then adding the oxidized anode mud to the sulfuric acid so that the residual most part of copper is dissolved; next, adding the rest undissolved copper, silver and diamond particles to the sulfuric acid solution of hydrogen peroxide for further oxidizing leaching, recovering the diamond particles which are not dissolved, precipitating the silver in the solution by use of the hydrochloric acid and reducing the hydrazine hydrate to generate simple substance silver powder; finally, after displacing copper with iron powder, concentrating and crystalizing the electrolyte to directly prepare iron sulfate heptahydrate. The recovery rate of the copper is above 96%, while the recovery rate of the diamond particles and the silver is above 99%; the industrial-grade iron sulfate heptahydrate is directly produced, the recovery rate of iron is greater than 98%, closed-loop circulation can be realized, the production labor intensity is low and the method is environmental friendly.

Owner:CENT SOUTH UNIV

Electrochemical dissolving method for noble metal

InactiveCN1579605AReduce consumptionNo pollution in the processDissolvingElectricityAlternating current

The invention discloses an approach of electrochemically dissolving noble metal. Its characters are: 1. make noble metal as electrodes; 2. put the electrodes into electrolytic cell with concentrated acid; 3. load AC of 10-100Hz, 2-100V, 0.01-5 A / CM2 to solve the noble metal and get acid solution. Highly pure chloroplatinic acid solution without NO3 ion can be produced in terms of the invention. The approach has a simple operation, low muriatic acid consumption and no NOx pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS7223481B2Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

Owner:FURUKAWA ELECTRIC CO LTD

Method to recycle valuable metal components in lithium-ion battery waste

ActiveCN108075203AMaximize utilizationEffective controlWaste accumulators reclaimingBattery recyclingCobaltLithium-ion battery

The invention discloses a method to recycle valuable metal components in lithium-ion battery waste. The method comprises: mixing well lithium-ion cathode and anode wastes, and performing thermal treatment at 800-1000 DEG C; grinding the sintering product, performing soaking-floatation treatment, reclaiming graphite floated up, filtering the rest solid-liquid mixture, and drying; reclaiming lithiumcarbonate from the filtrate by means of precipitating or evaporative crystallization; subjecting the solid material to electrochemical dissolution, and extracting the metal resources, nickel and cobalt. The method has the advantages that waste lithium-ion battery anode graphite is made full use as a reducing agent, the lithium resource in the anode material is reclaimed, and waste is maximally utilized; the high-value metal resources, such as nickel, cobalt and lithium, are selectively extracted, and the separation process is simple; the method rarely produces massive acidic-alkaline wastewater and is highly worthy of industrial application.

Owner:CENT SOUTH UNIV

Rechargeable zinc ion battery based on carbon cathode

ActiveUS20150255792A1Improve battery performanceNonoxidizableCell electrodesFinal product manufactureZinc ionAqueous electrolyte

The present invention discloses a rechargeable zinc ion battery, in which anodic zinc will be electrochemically dissolved as Zn2+ ions, diffuses to the cathodic electrode / electrolyte interface through the electrolyte, and zinc ions subsequently inserted in carbon material during discharging. In charging, above-mentioned process will be reverse. The rechargeable zinc ion battery comprises a carbon cathode; a zinc anode separated from cathode; an aqueous electrolyte contains zinc ions.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

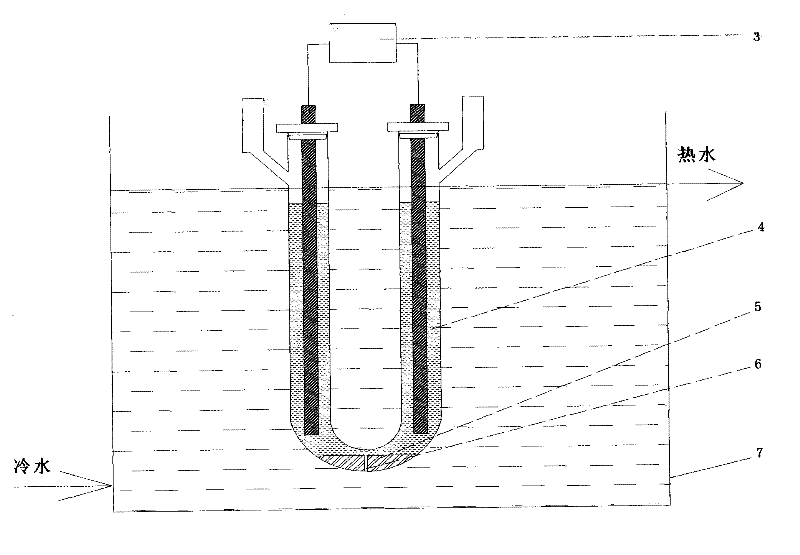

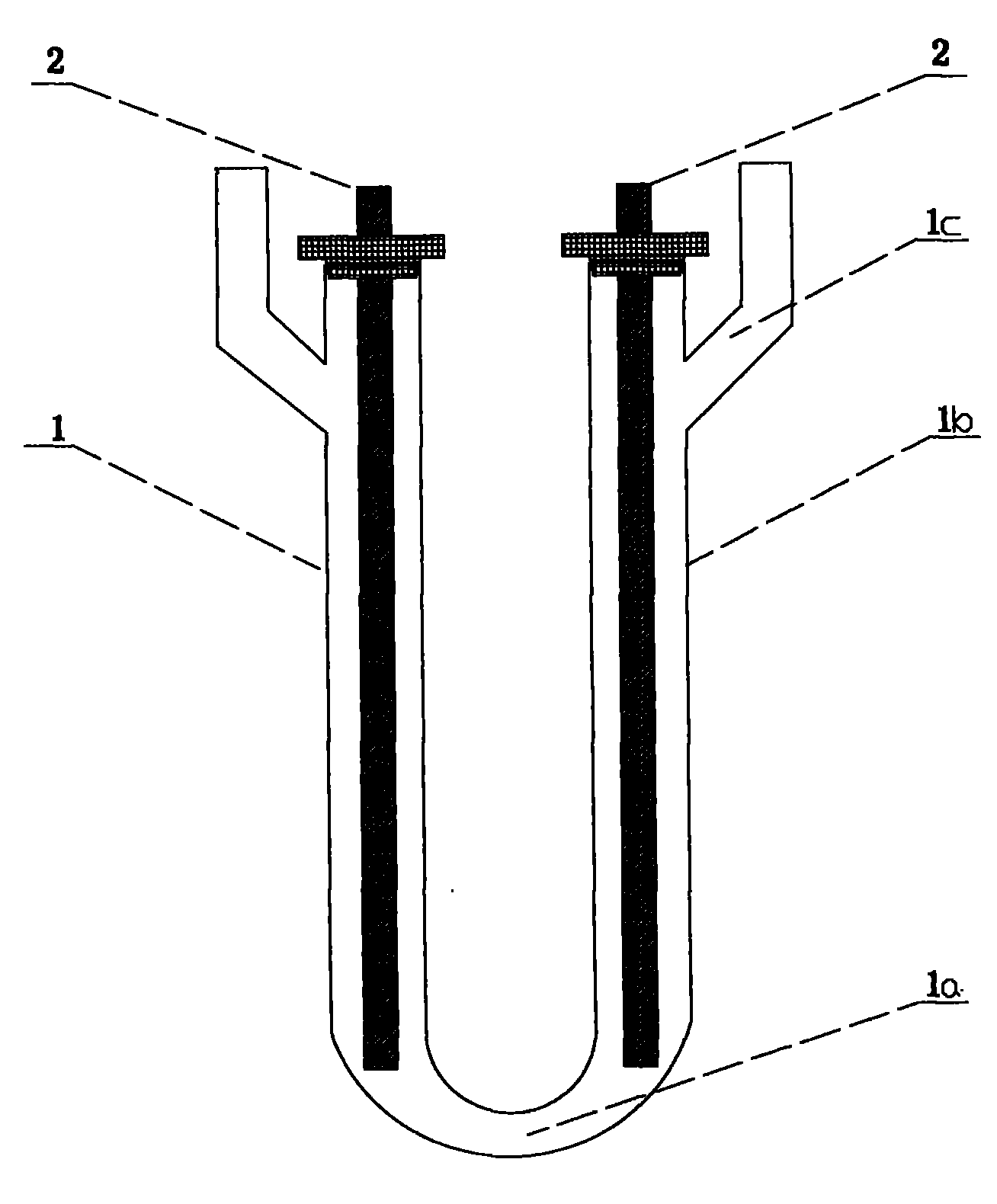

Electrochemical dissolving method for iridium powder

ActiveCN102408134AThe dissolution process is simpleHigh purityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsIridiumAqueous solution

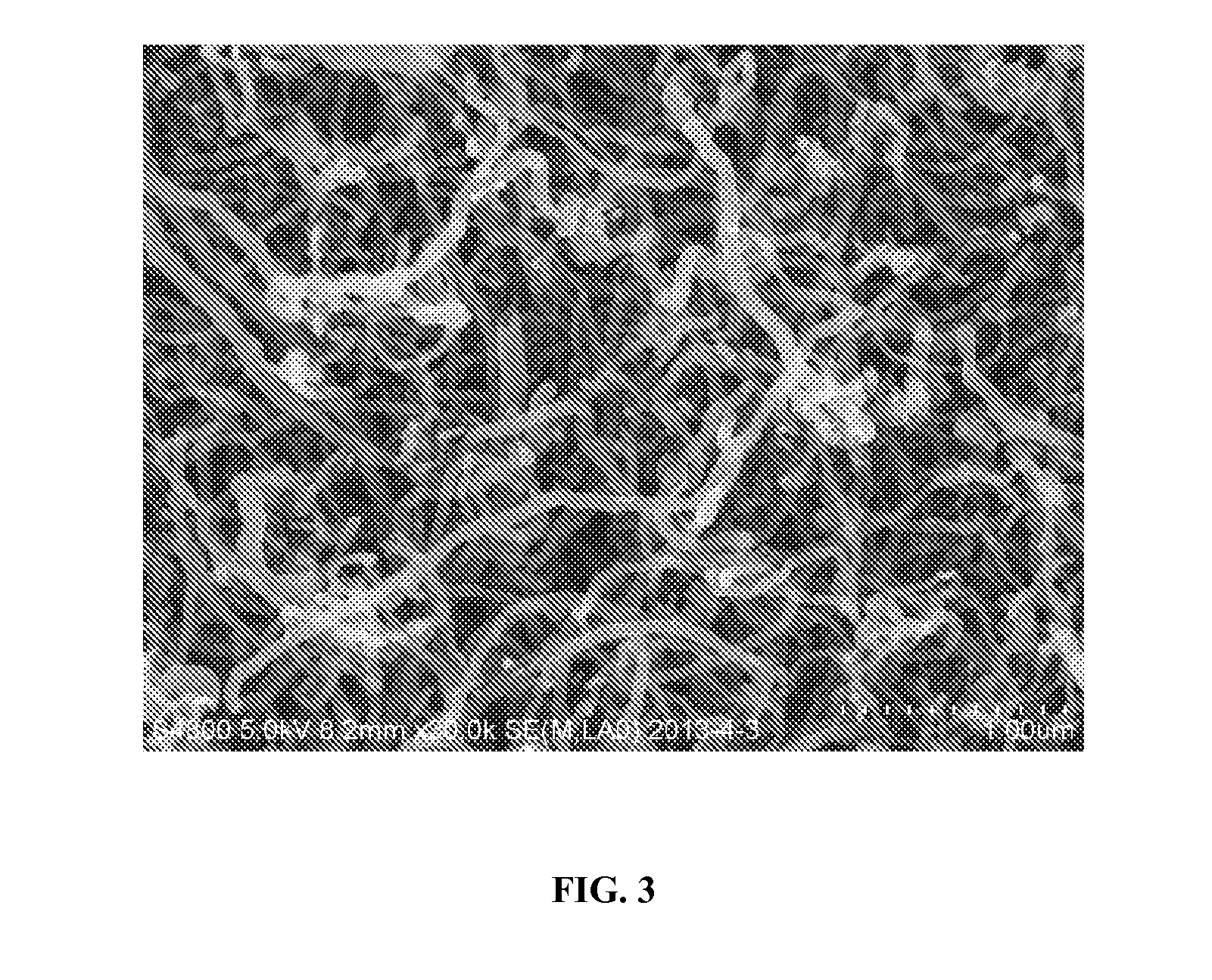

The invention relates to an electrochemical dissolving method for iridium powder, which is comprises the following steps: adding a hydrochloric acid solution and iridium powder in a U-shaped electrolytic bath, loading the alternating current at two ends of electrode of the U-shaped electrolytic bath, directly dissolving iridium powder in hydrochloric acid to obtain a chloro-iridic acid aqueous solution; filtering the chloro-iridic acid aqueous solution, then distilling to obtain a chloro-iridic acid concentrate. The electrochemical dissolving method for iridium powder is characterized in that the raw material iridium powder is directly dissolved in hydrochloric acid without adding any other reagents, the impurities interference can be avoided when the high purity iridium powder is taken as a raw material, so that the high purity chloro-iridic acid H3IrCl6 aqueous solution is prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Display element

InactiveUS7324259B2Easy constructionReduce the driving voltageStatic indicating devicesNon-linear opticsHydroquinone CompoundPhosphoric acid

A display element comprising a pair of electrodes having therebetween an electrolyte layer containing silver or a silver-containing compound, the display element being driven by the pair of electrodes so as to electrochemically dissolve silver or to electrochemically deposit silver, wherein the electrolyte layer contains an antioxidant selected from the group consisting of a phenolic antioxidant, a phosphoric acid antioxidant, a sulfur-containing antioxidant, an amine antioxidant and a hydroquinone derivative.

Owner:KONICA MINOLTA INC

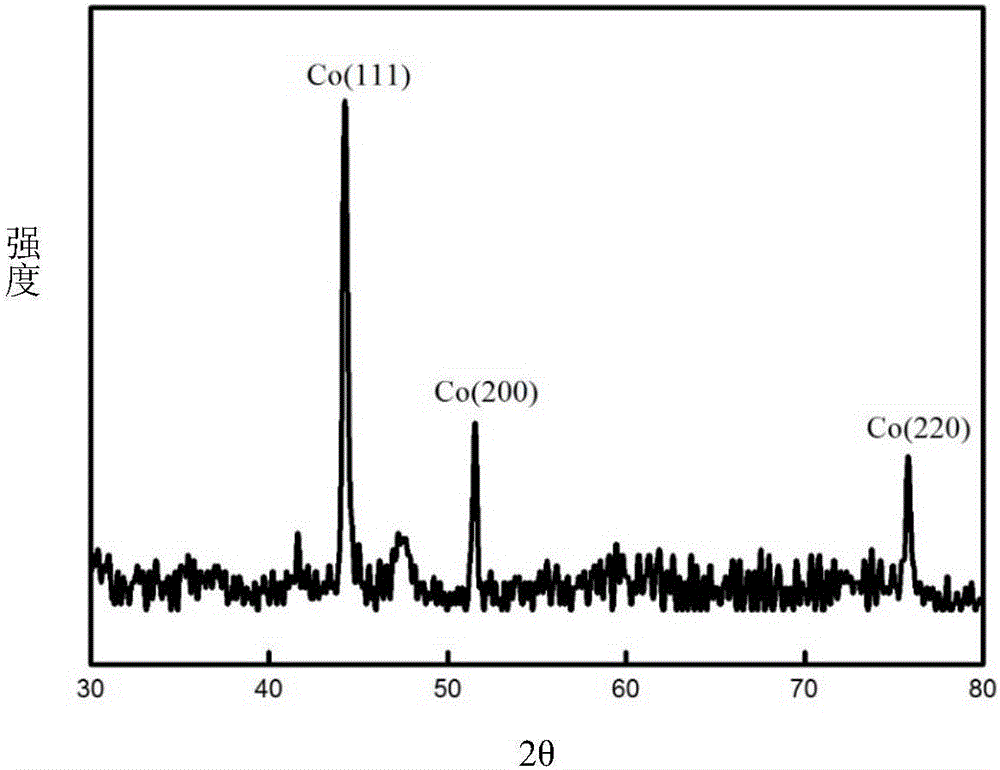

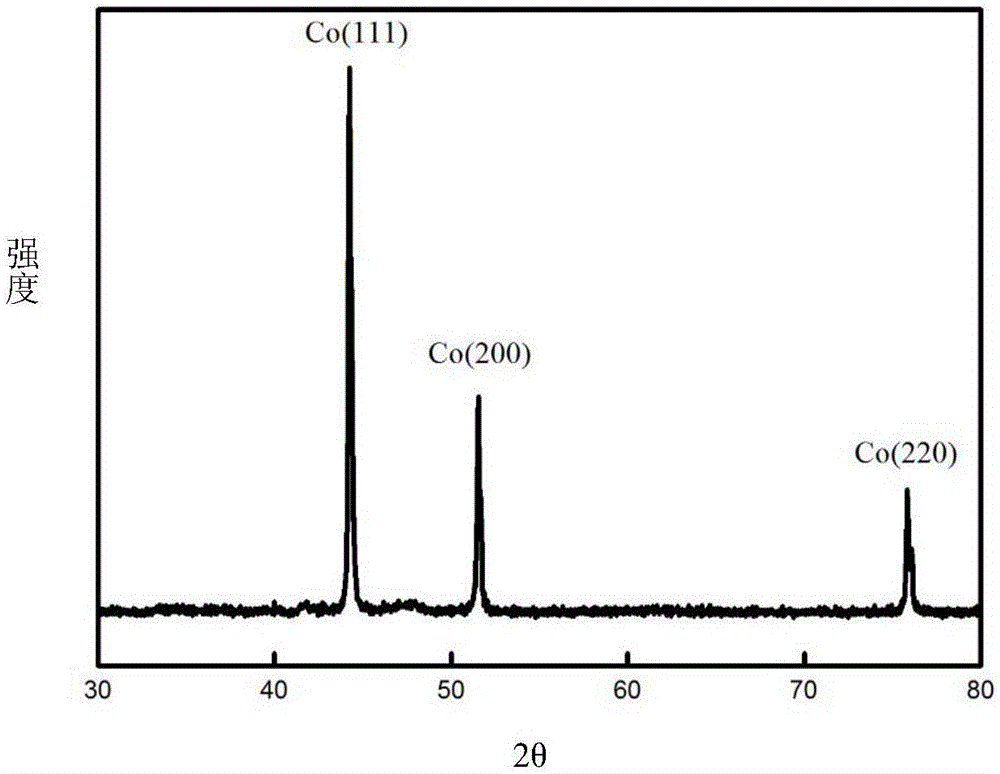

Method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy

ActiveCN108622943AMild responseReduce pollutionCobalt sulfatesNickel compounds preparationNew energyEvaporation

The invention discloses a method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy. The method comprises the following steps of performing pretreatment on nickel cobalt alloy waste materials; then, performing electrochemical dissolution; removing impurities such as iron, chromium and aluminum from the obtained solution step by step by a chemical method andan extraction method; firstly extracting cobalt from the solution subjected to impurity removal; then extracting nickel; thus respectively obtaining extraction liquid containing cobalt and nickel; after the reverse extraction, obtaining nickel sulfate and cobalt sulfate solution; then, respectively performing evaporation, cooling crystallization, and centrifugal dewatering on the solution to obtain a product of the battery grade nickel sulfate and cobalt sulfate. The problems of low nickel and cobalt leaching efficiency, low dissolution speed and the like in the waste nickel and cobalt alloy recovery process by a conventional wet process can be effectively solved; the battery grade nickel sulfate and cobalt sulfate conforming to the product quality standard requirement can be produced, andcan be used as a new energy source battery raw material to be applied to the field of new energy source battery manufacturing. The process is simple; the environment pollution is low; the metal recovery rate is high; good practical values and economic values are realized.

Owner:HOHAI UNIV

Method for recycling metal in tungsten carbide waste through fluoride electrolysis

ActiveCN106544701AImprove electrochemical activityAccelerate the speed of electrochemical dissolutionLoss rateElectrolysis

The invention provides a method for recycling metal in tungsten carbide waste through fluoride electrolysis. The method is characterized in that the tungsten carbide waste is taken as an anode; high-temperature fluoride is taken as electrolyte; the high-temperature fluoride is one or more of NaF, KF, MgF2, RbF and CaF2; and the tungsten carbide waste is WC alloy waste or WC alloy waste containing Co with mass fraction being 2-20%. According to the method provided by the invention, a fluoride molten salt system has the characteristics of a relatively high electrochemical window at a high temperature, relatively great ionic conductivity, a relatively low molten salt loss rate and relatively strong corrosion; the fluoride molten salt system is taken as a molten salt dielectric medium, so that electrochemical activities, at a high temperature, of WC waste and a waste hard alloy are improved, and therefore, electrochemical dissolution speed of WC waste and the waste hard alloy is quickened.

Owner:BEIJING UNIV OF TECH

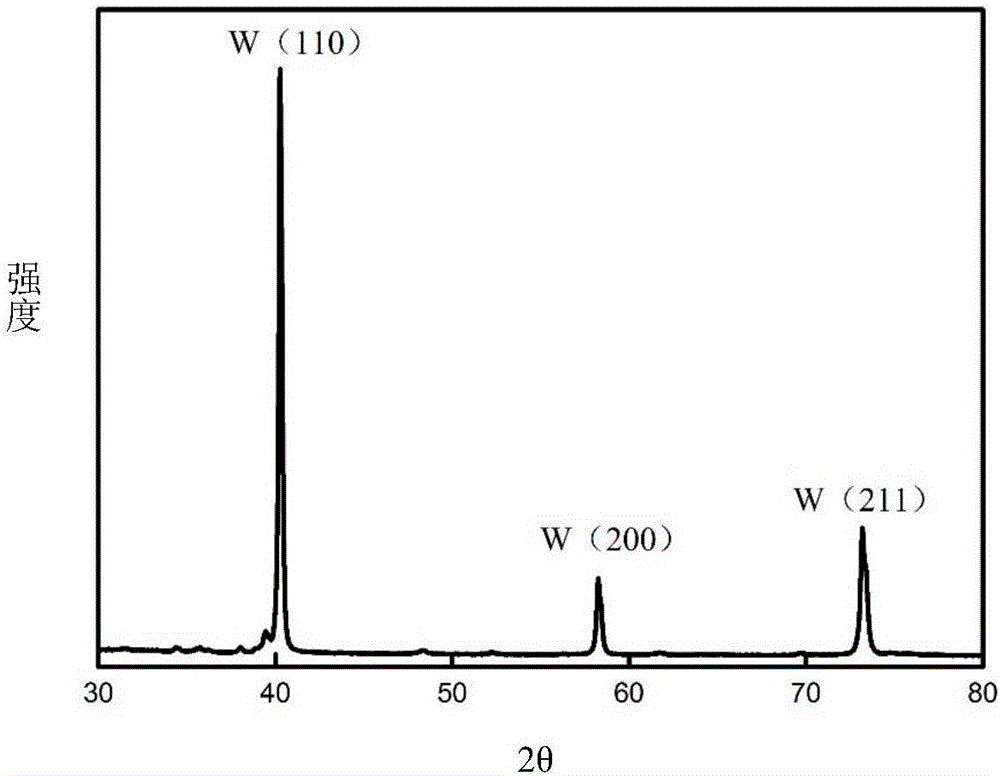

Method for recycling rhenium from tungsten-rhenium alloy waste

ActiveCN106430320AHigh energy consumptionReduced current efficiencyProcess efficiency improvementRhenium compoundsRheniumPotassium

The invention provides a method for recycling rhenium from tungsten-rhenium alloy waste. The method comprises the following steps that 1, the tungsten-rhenium alloy waste is subjected to electrochemical dissolution, and a rhenium-containing solution is obtained; 2, excessive potassium chloride is added into the rhenium-containing solution, rhenium in the rhenium-containing solution is made to perform a precipitation reaction with potassium chloride to generate KReO4 precipitations, then, the KReO4 precipitations are subjected to recrystallization, and high-purity KReO4 is obtained. The technology is simple, the problem of collecting rhenium in a comparison oxidation volatilization method does not exist, and the rhenium recovery rate is high. Due to the fact that both a traditional oxidation volatilization method and a niter fusion-ion exchange method are implemented under the high-temperature condition, comparatively, the technology is low in energy consumption.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method of crude gold purification

InactiveCN1442498AGrade range widenedImprove adaptabilityPhotography auxillary processesElectrolysisCrucible

A process for purifying raw gold whose purity is 85-99.5% includes such steps as electrolysis in which said raw gold is used to make anode plate, pure gold or titanium is used to make cathode, the ceramic crucible is used as the diaphragm of cathode and diluted hydrochloric acid is uses a electrolyte to conver the raw gold to gold solution, and reducing the gold solution to gold powder No.1. Its advantages are low requirement to raw gold and low cost.

Owner:SHANDONG GOLD MINING CO LTD

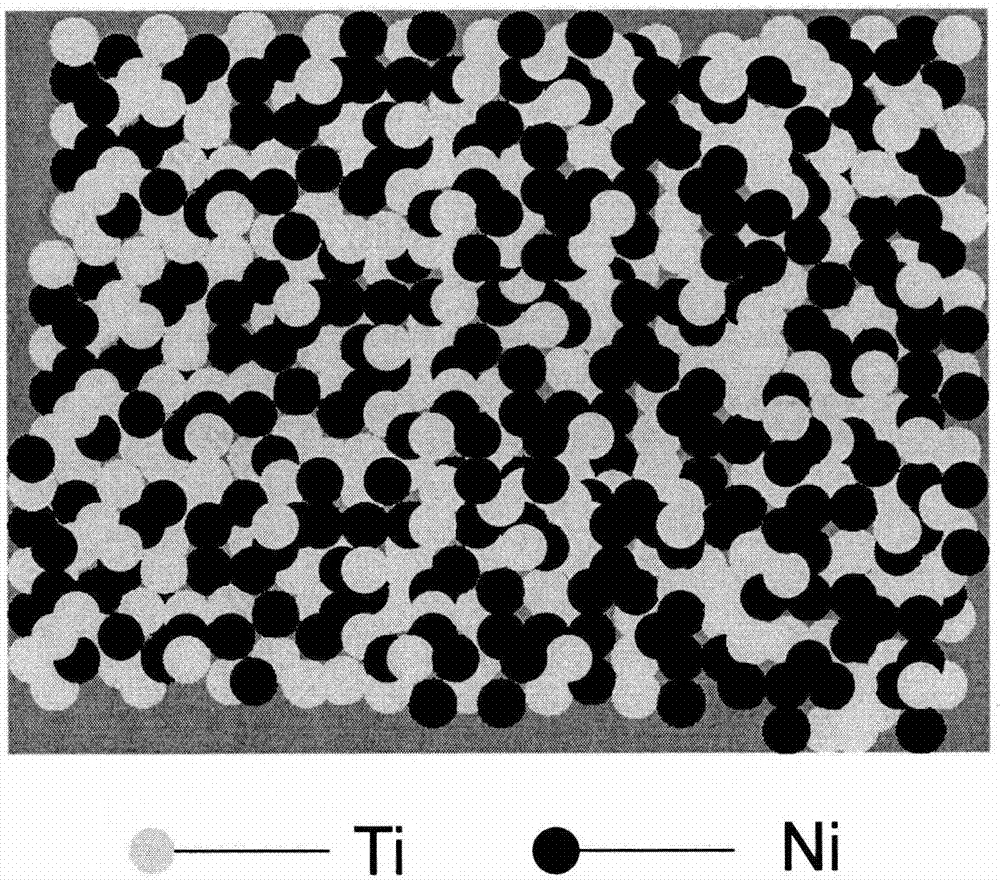

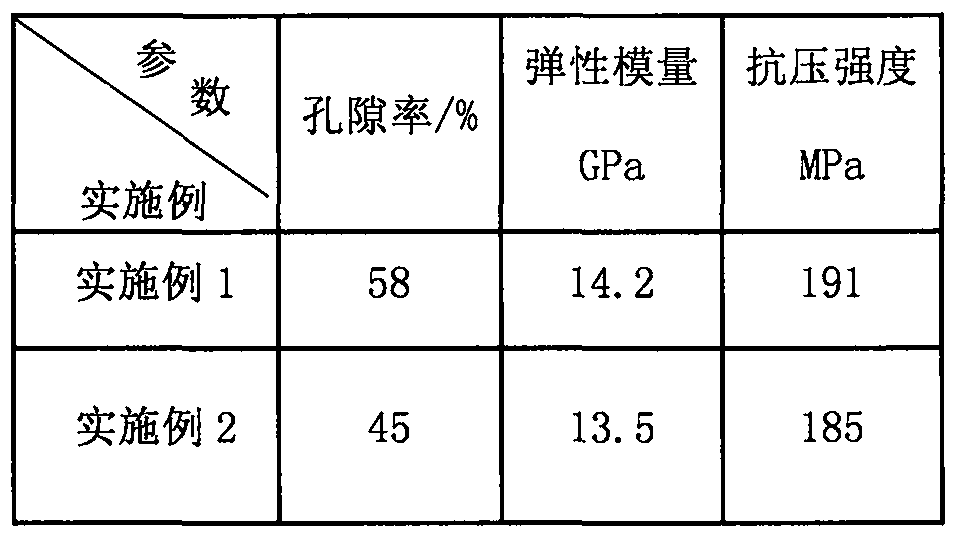

Preparation method of porous titanium and titanium alloy

InactiveCN107012352AUniform distribution of poresControllable size arrangementFiltration separationProsthesisRoom temperatureGraphite

The invention discloses a preparation method of porous titanium and titanium alloy, comprising the following steps: uniformly mixing Ti metal powder and alloy powder, the mass percentage of Ti metal powder in the obtained mixed powder is 45%-95%, and the mass percentage of alloy powder The percentage is 55%~5%; put the obtained mixed powder into a graphite or silicon carbide mold, place it in a vacuum sintering furnace for sintering, the vacuum degree is 0.1~10Pa, the one-way pressure is 200~1000MPa, and the heating rate is 20~100℃ / min, sintering temperature 800-1400°C, sintering 10-60min, then cooling to room temperature with the furnace and taking it out to obtain the alloy green body; use the obtained alloy green body as an anode to electrochemically dissolve the alloy metal powder, dissolve the metal wire mold, and be porous titanium. The pores of the porous titanium obtained in the invention have uniform distribution of pores and controllable size arrangement, and can be applied to medical porous titanium and titanium alloy materials and titanium and titanium alloy filter core materials.

Owner:BAOJI UNIV OF ARTS & SCI

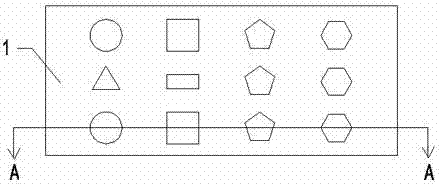

Processing method for double-side outward-expanded metal micro-hole array

InactiveCN102764920AHigh porosityEfficient mass productionElectrochemical machining apparatusElectroforming processesMetal moldElectrochemical dissolution

The invention discloses a processing method for a double-side outward-expanded metal micro-hole array. By adoption of the characteristics that inert metal is hard to be electrochemically dissolved, an inert metal mold plate with a miniature through hole array is taken as a basis and is prepared to obtain high-performance double-side outward-expanded metal micro-hole array through an electroforming and electrolyzing combined technology. The method has the advantages of greatly reducing cost, simplifying technology and efficiently producing double-side outward-expanded metal micro-hole array with small aperture, high percentage of opening, and large thickness in batch.

Owner:HENAN POLYTECHNIC UNIV

Display element

InactiveUS20050213186A1Easy constructionReduce the driving voltageNon-linear opticsChemical inhibitorsO-Phosphoric AcidHydroquinone Compound

A display element comprising a pair of electrodes having therebetween an electrolyte layer containing silver or a silver-containing compound, the display element being driven by the pair of electrodes so as to electrochemically dissolve silver or to electrochemically deposit silver, wherein the electrolyte layer contains an antioxidant selected from the group consisting of a phenolic antioxidant, a phosphoric acid antioxidant, a sulfur-containing antioxidant, an amine antioxidant and a hydroquinone derivative.

Owner:KONICA MINOLTA INC

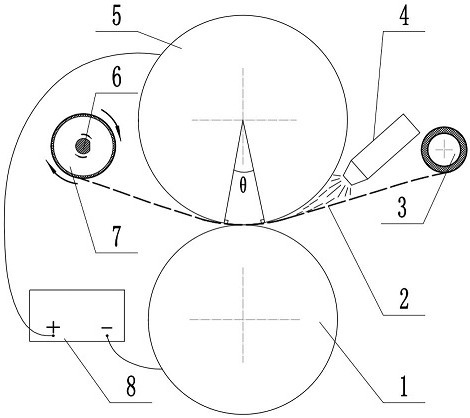

Device for continuous mask electrolytic machining of metal microstructure

ActiveCN112404618AImprove consistencyImprove applicabilityElectrolysis componentsConnection managementElectrolytic agentMachined surface

The invention discloses a device for continuous mask electrolytic machining of a metal microstructure. The device comprises a liquid spraying nozzle, an electrolytic power source, a workpiece positiveelectrode, a tool negative electrode, a gas spraying nozzle, a mask belt, a belt storage wheel, a belt recovery wheel, a driving source, a carrier roller and a tensioning wheel, wherein the mask beltwith a hollow pattern or seepage micropores is tightly pressed and attached to the surface of the tool negative electrode under the combined action of the belt recovery wheel, the tensioning wheel, the belt storage wheel and the like to form a wrap angle, and then is tightly pressed and attached to the to-be-machined surface of the rotatable or movable workpiece positive electrode; the belt recovery wheel continuously recovers the mask belt and drives the workpiece positive electrode and the tool negative electrode to do synchronous uniform motion; the liquid spraying nozzle sprays electrolyte at a high speed; and the workpiece positive electrode is subjected to uniform localized electrochemical dissolution alternately under the combined action of an electric field and a flow field untilthe workpiece is machined. The invention provides a new technology for continuous mask electrolytic machining of the metal microstructure, the process adaptability and stability of movable mask electrolytic machining can be improved, and a metal micro-nano structure with high precision and high surface quality is obtained.

Owner:HENAN POLYTECHNIC UNIV

Method for preparing precursor of nickel-cobalt-aluminum ternary positive-electrode material by utilizing high-temperature alloy waste material

ActiveCN107585793AEliminate the extraction and separation processIncrease added valueCell electrodesNickel compoundsFiltrationSuperalloy

The invention discloses a method for preparing a precursor of a nickel-cobalt-aluminum ternary positive-electrode material by utilizing a high-temperature alloy waste material. The method comprises the following steps: 1, carrying out electrochemical dissolution on high-temperature alloy waste to obtain an electrolyte; 2, carrying out filtration and adsorption treatment on the electrolyte to obtain a mixed solution A; 3, adjusting the nickel-cobalt-aluminum proportion and the pH value in the mixed solution A to obtain a mixed solution B; 4, adding the mixed solution B, ammonia water and a sodium hydroxide solution into a reactor containing a base solution for reaction, so as to obtain a nickel-cobalt-aluminum mixed precipitate; and 5, ageing the mixed precipitate, and performing washing, filtering and drying to obtain the precursor of the nickel-cobalt-aluminum ternary positive-electrode material. The invention aims at the difficult problems that the high-temperature alloy waste recovery is difficult, the cost is high and the added value of products is low, and provides the method for preparing the precursor of the nickel-cobalt-aluminum ternary positive-electrode material by utilizing the high-temperature alloy waste material. The preparation method has a short technological process and high added value of products, and has a good industrial prospect.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

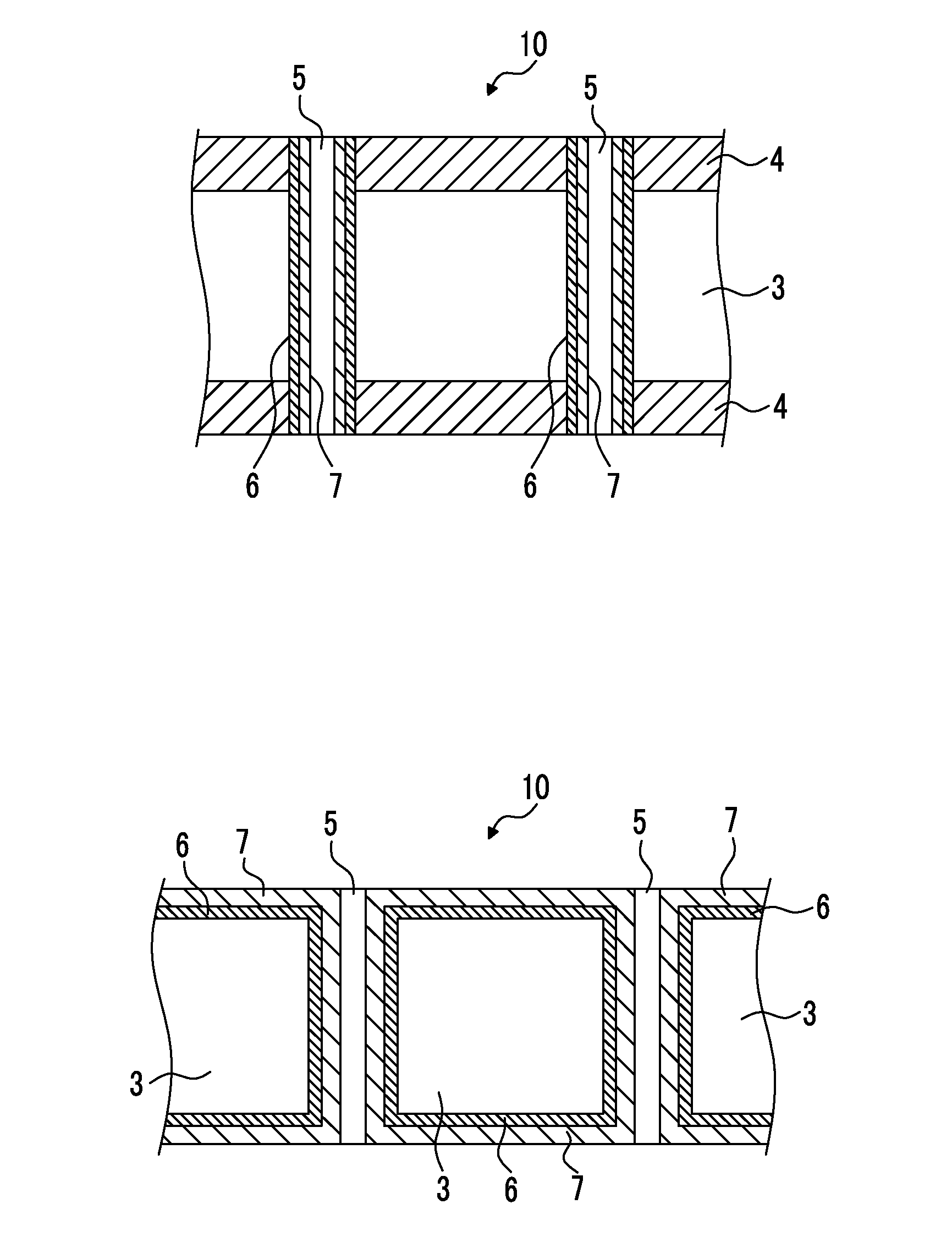

Method for manufacturing aluminum plate, aluminum plate, collector for storage device, and storage device

ActiveUS20160294002A1High in productivenessImprove adhesionElectrochemical processing of electrodesElectrode carriers/collectorsProduction rateAluminum substrate

An object of the present invention is to provide a method for manufacturing an aluminum plate which is simple, is high in productiveness, allows the use of arbitrary aluminum materials, and can be suitably used for collectors having excellent adhesiveness to active material layers, a collector for a storage device, and a storage device. The method for manufacturing an aluminum plate of the present invention is a method for manufacturing an aluminum plate having an aluminum substrate having a plurality of through holes in a thickness direction, including an oxidized film-forming step of forming an oxidized film by carrying out an oxidized film-forming treatment on a surface of the aluminum substrate having a thickness in a range of 5 μm to 1,000 μm and a through hole-forming step of forming through holes by carrying out an electrochemical dissolution treatment after the oxidized film-forming step.

Owner:FUJIFILM CORP

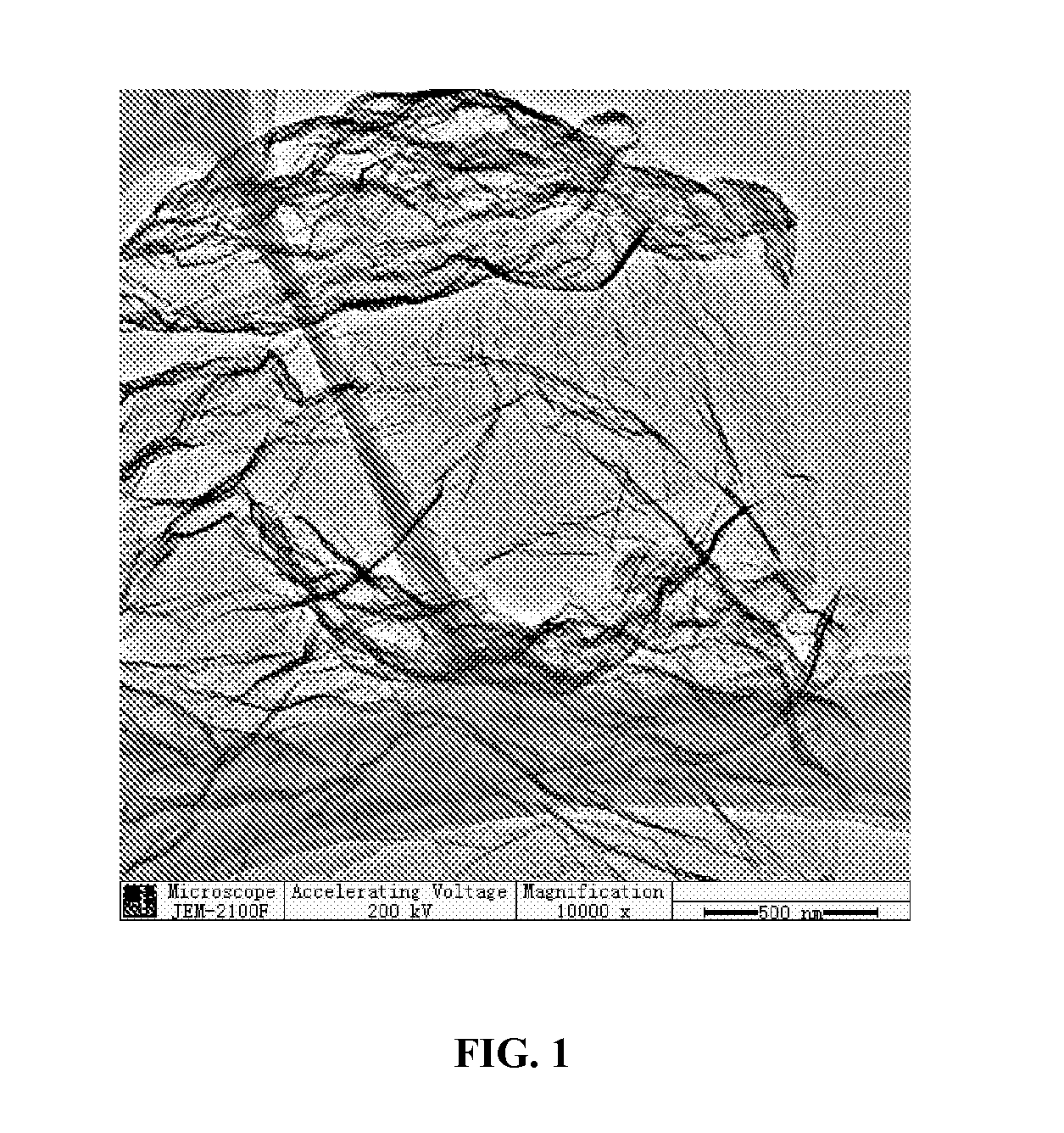

Speckle preparation method for prefabricated deformed pure titanium and pure titanium detwinning characterization method

ActiveCN109709120AReduce the impactConvenient researchMaterial analysis using wave/particle radiationSurface reaction electrolytic coatingCrystal twinningTitanium

The invention discloses a speckle preparation method for prefabricated deformed pure titanium and a pure titanium detwinning characterization method. The pure titanium detwinning characterization method comprises steps that (1), prefabricated deformed pure titanium having twin crystal is prepared; (2), characteristic speckles are prepared on the surface of the prefabricated deformed pure titanium,and then EBSD characterization is performed; (3), the detwinning deformed pure titanium is prepared; and (4), EBSD characterization of the detwinning pure titanium is performed; wherein, in the (2),an electrolytic cell is used, the prefabricated deformed pure titanium is used as an anode, the electrolyte includes perchloric acid and methanol, the voltage is 15-19V, the current is 0.85-1.15A, theelectrolysis time is 2-4 minutes, and the electrolyte temperature is -31-35 DEG C. The method is advantaged in that the characteristic speckles are prepared by an electrochemical dissolution phenomenon, other speckle materials different from the pure titanium are not used, the effect of the speckle material on EBSD characterization is reduced, secondly, the characteristic speckles can satisfy both EBSD characterization and DIC analysis before and after detwinning, and the method is conducive to the deeper study of the twinning mechanism and the detwinning mechanism.

Owner:SOUTHWEST JIAOTONG UNIV

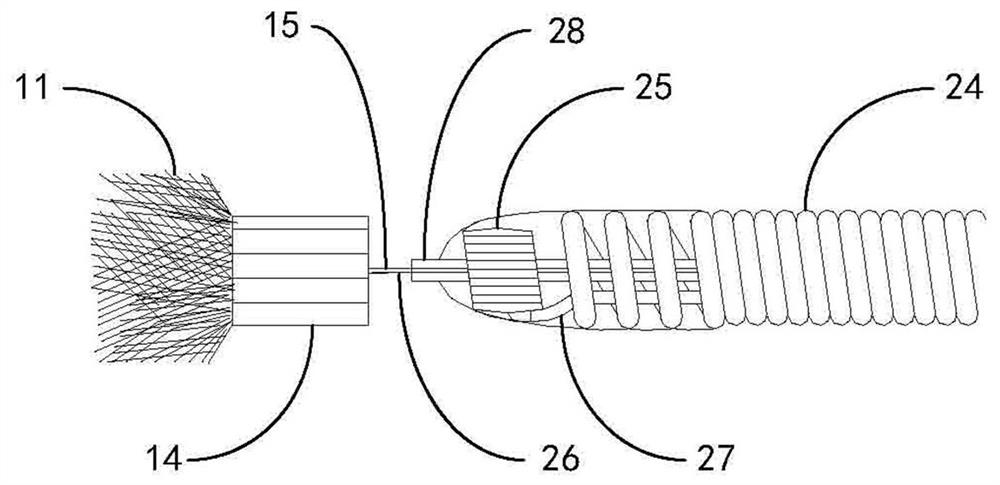

Net disk turbulence device and turbulence device conveying system

The invention relates to a net disk turbulence device which comprises a turbulence net disk, the turbulence net disk comprises a disk body part and a combination part, the outer side of the combination part is provided with a development mark, the inner side of the combination part is connected with an embolism object through a polymer wire, the outer side of the development mark is connected witha release part, and the disk body part of the turbulence net disk is attached to the inner wall of a tumor cavity. The invention further relates to a turbulence device conveying system which comprises the net disc turbulence device and a conveying steel pipe, the near end of the conveying steel pipe is sleeved with an insulating pipe, and the insulating pipe is sleeved with a conductive pipe. A supporting spring is arranged at the far end of the conveying steel pipe, a second negative electrode is arranged at the far end of the supporting spring, the second negative electrode is connected with the conveying steel pipe through a negative electrode conductive wire arranged in the conveying steel pipe in a penetrating mode, and a second positive electrode is arranged at the far end of the second negative electrode and connected with the conductive pipe through a positive electrode conductive wire arranged in the conveying steel pipe in a penetrating mode; the far end of the second positive electrode is connected with the release part; the second positive electrode and the second negative electrode can be communicated through electrolyte in blood to form a loop, the release part is broken through electrochemical dissolution, and the net disc turbulence device is left in the tumor cavity.

Owner:BEIJING TAIJIE WEIYE TECH

Electrochemical dissolving method for iridium powder

ActiveCN102408134BThe dissolution process is simpleHigh purityElectrolysis componentsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsIridiumAlternating current

The invention relates to an electrochemical dissolving method for iridium powder, which is comprises the following steps: adding a hydrochloric acid solution and iridium powder in a U-shaped electrolytic bath, loading the alternating current at two ends of electrode of the U-shaped electrolytic bath, directly dissolving iridium powder in hydrochloric acid to obtain a chloro-iridic acid aqueous solution; filtering the chloro-iridic acid aqueous solution, then distilling to obtain a chloro-iridic acid concentrate. The electrochemical dissolving method for iridium powder is characterized in that the raw material iridium powder is directly dissolved in hydrochloric acid without adding any other reagents, the impurities interference can be avoided when the high purity iridium powder is taken as a raw material, so that the high purity chloro-iridic acid H3IrCl6 aqueous solution is prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrochemical gold dissolving device and method

InactiveCN104294313AReduce pollutionSave the nitrate processPhotography auxillary processesDiaphragmsIridiumElectrochemical dissolution

The invention discloses an electrochemical gold dissolving device and method. An ion exchange membrane electrolytic process is taken as a core technology, the electrochemical gold dissolving method adopting double membranes and double cathode rooms is adopted, a ruthenium iridium titanium-coated basket is taken as an anode, a ruthenium iridium titanium-coated net is taken as a cathode, hydrochloric acid is taken as electrolyte and aqua regia is not used, so that a nitrate removing process is cancelled, process flow is greatly simplified, chemical corrosion on equipment is reduced and environmental pollution is lowered. Besides, an ion exchange membrane is adopted, so that gold dissolved out on the anode can be prevented from entering the cathode region and separating out again on the cathode, and thus, the production efficiency is improved, the energy conservation and emission reduction of production are realized, and great economic benefits and social benefits can be produced.

Owner:CHANGZHOU YIJIN ENVIRONMENTAL PROTECTION TECH

Display element

InactiveUS7184198B2Easy constructionReduce the driving voltageNon-linear opticsIdentification meansCompound (substance)Electrochemical dissolution

A display element containing a pair of electrodes having therebetween an electrolyte layer containing silver or a silver-containing compound, the display element being driven by the pair of electodes so as to electrochemically dissolve silver or to electrochemically deposit silver, wherein the electrolyte layer contains a compound represented by on of Formulae (1) to (7) described in the specification or a derivative thereof.

Owner:KONICA MINOLTA INC

Three-electrode electrochemistry dissolved oxygen sensor

ActiveCN109001275AImprove response speedImprove stabilityMaterial electrochemical variablesAdditive ingredientPotassium

The invention relates to the field of dissolved oxygen content detection, in particular to a three-electrode electrochemistry dissolved oxygen sensor. The sensor comprises a cylindrical shell of the sensor, a replaceable oxygen permeation membrane, a membrane cover, a gold electrode, a sliver electrode and a platinum electrode, wherein the gold electrode is arranged in the cavity of the cylindrical shell to serve as a working electrode, the sliver electrode serves as an auxiliary electrode, the platinum electrode serve as a sliver protection electrode, and the silver electrode, the gold electrode and the platinum electrode are independently connected with a polarization circuit through leads; the cavity of the cylindrical shell is full of a liquid reaction electrolyte, wherein the electrolyte reaction liquid comprises the following ingredients in parts by weight: 74.55 parts by weight of potassium chloride, 0.561 parts by weight of potassium hydroxide and 1000 parts by weight of water.By use of the electrochemistry dissolved oxygen sensor disclosed by the invention, in a measurement process, oxygen in a water sample is not consumed, detection accuracy is improved, an auxiliary electrode adopts a double-helix structure to increase a contact area with the electrolyte, the response speed of the sensor is improved, the sensor adopts a three-electrode system structure, the electrolyte in the electrolyte is not consumed, the silver of the auxiliary electrode is not consumed, and the service life is greatly prolonged.

Owner:BEIJING UNIV OF CHEM TECH

Process control in electrochemically assisted planarization

Aspects of the invention generally provide a method for polishing a material layer using electrochemical deposition techniques, electrochemical dissolution techniques, polishing techniques, and / or combinations thereof. In one aspect of the invention, the polishing method comprises applying a separate electrical bias, such as a voltage, to each of a plurality of zones of an electrode. Determining the separate biases comprises determining a time that at least one portion of the material layer is associated with each of the zones of the counter-electrode.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com