Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

597 results about "Chip on film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

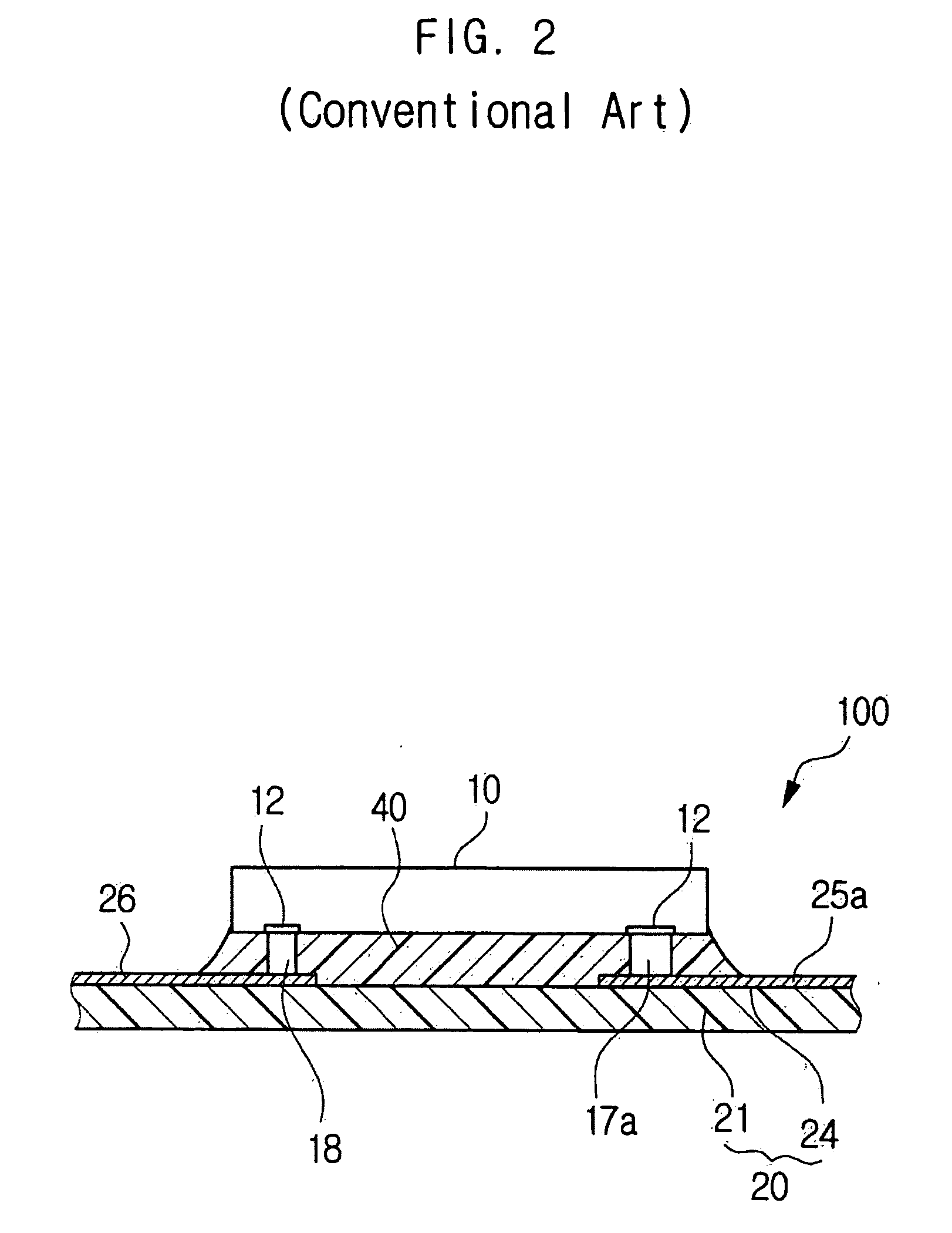

Abstract: COF (chip-on-film) is a new technology after TAB (tape-automated-bonding) and (COG) chip-on-glass in the interconnection of LCD drive ICs. The thickness of the film is more flexible than TAB, and can be as thin as 50 /spl mu/m.

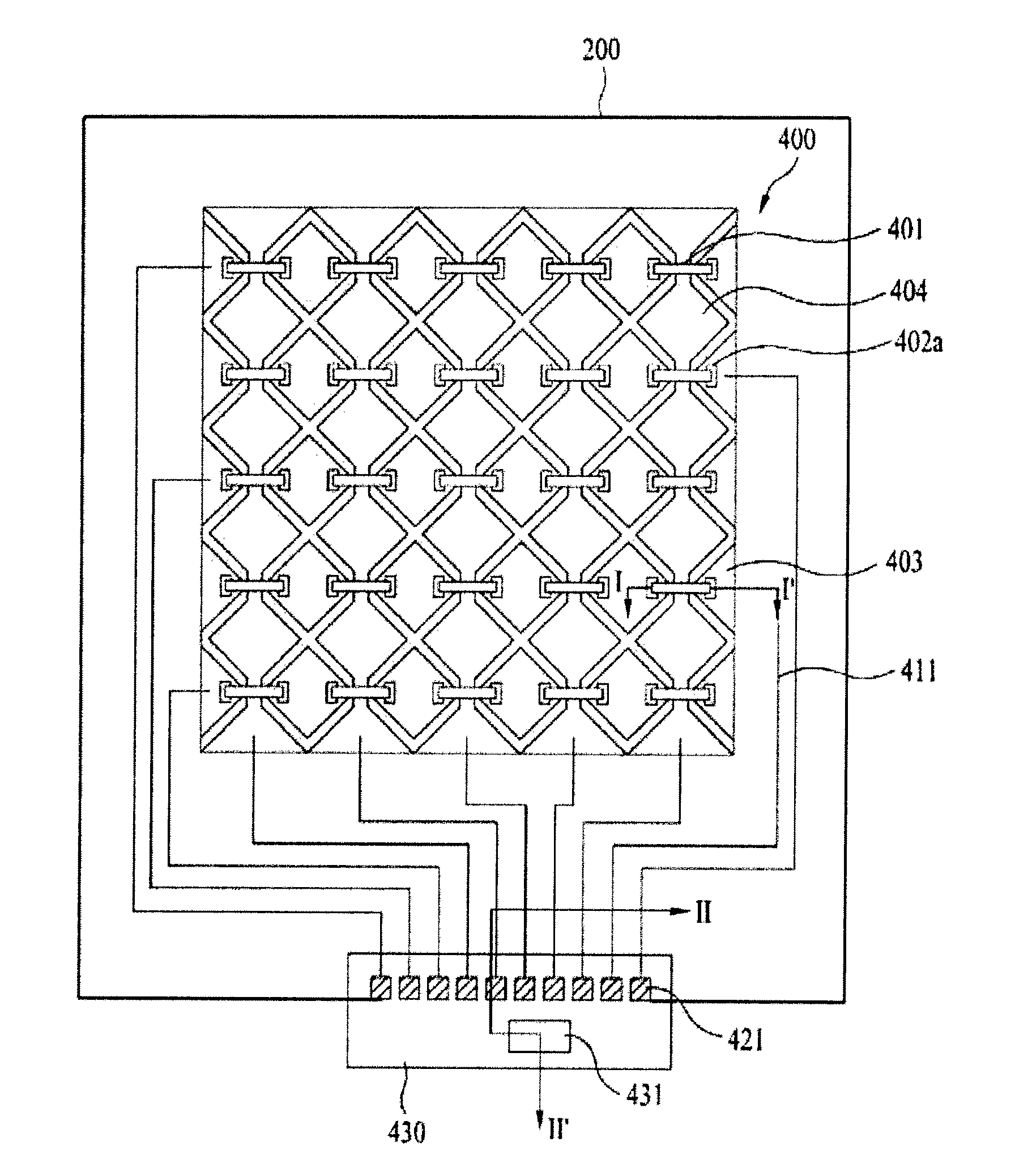

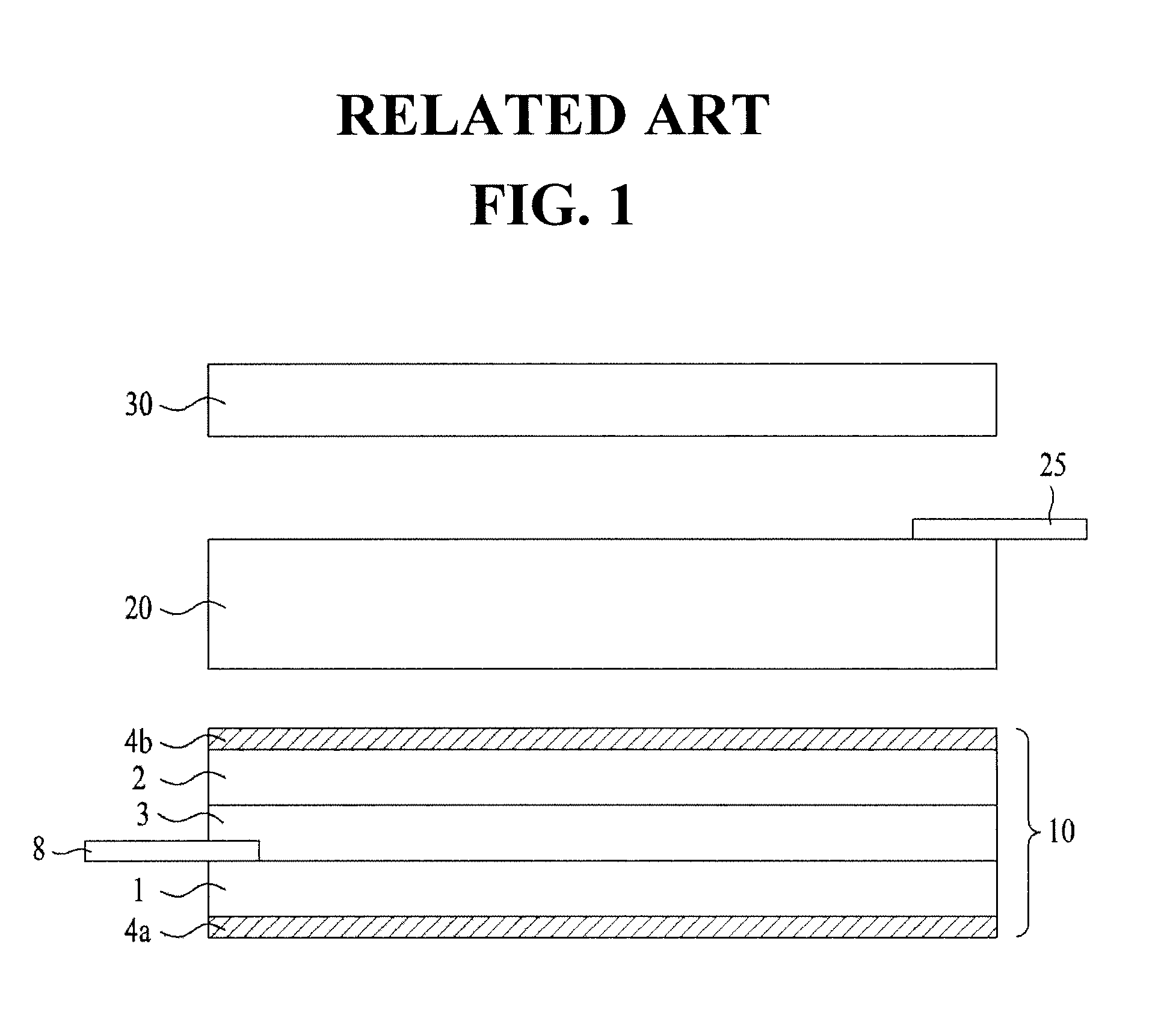

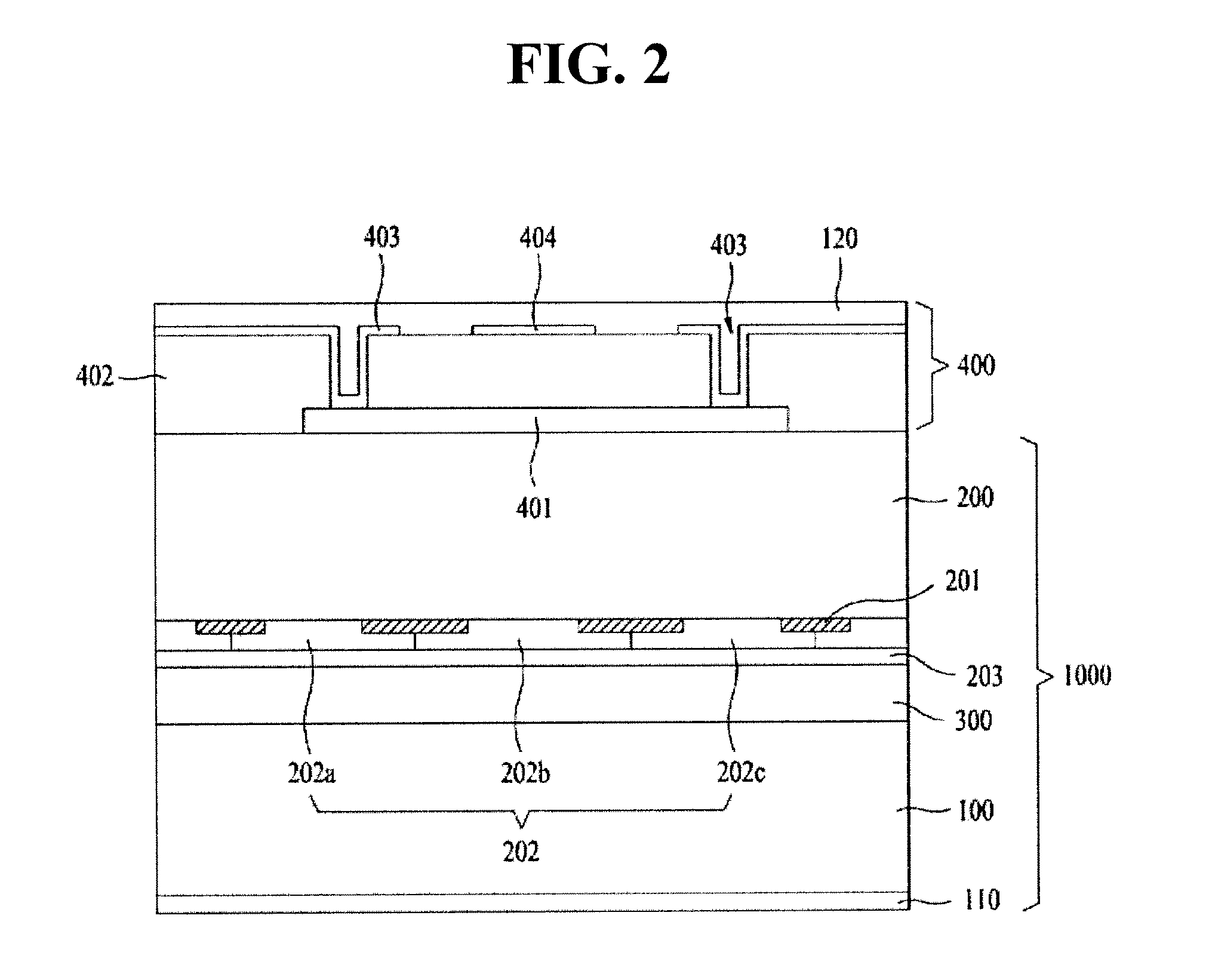

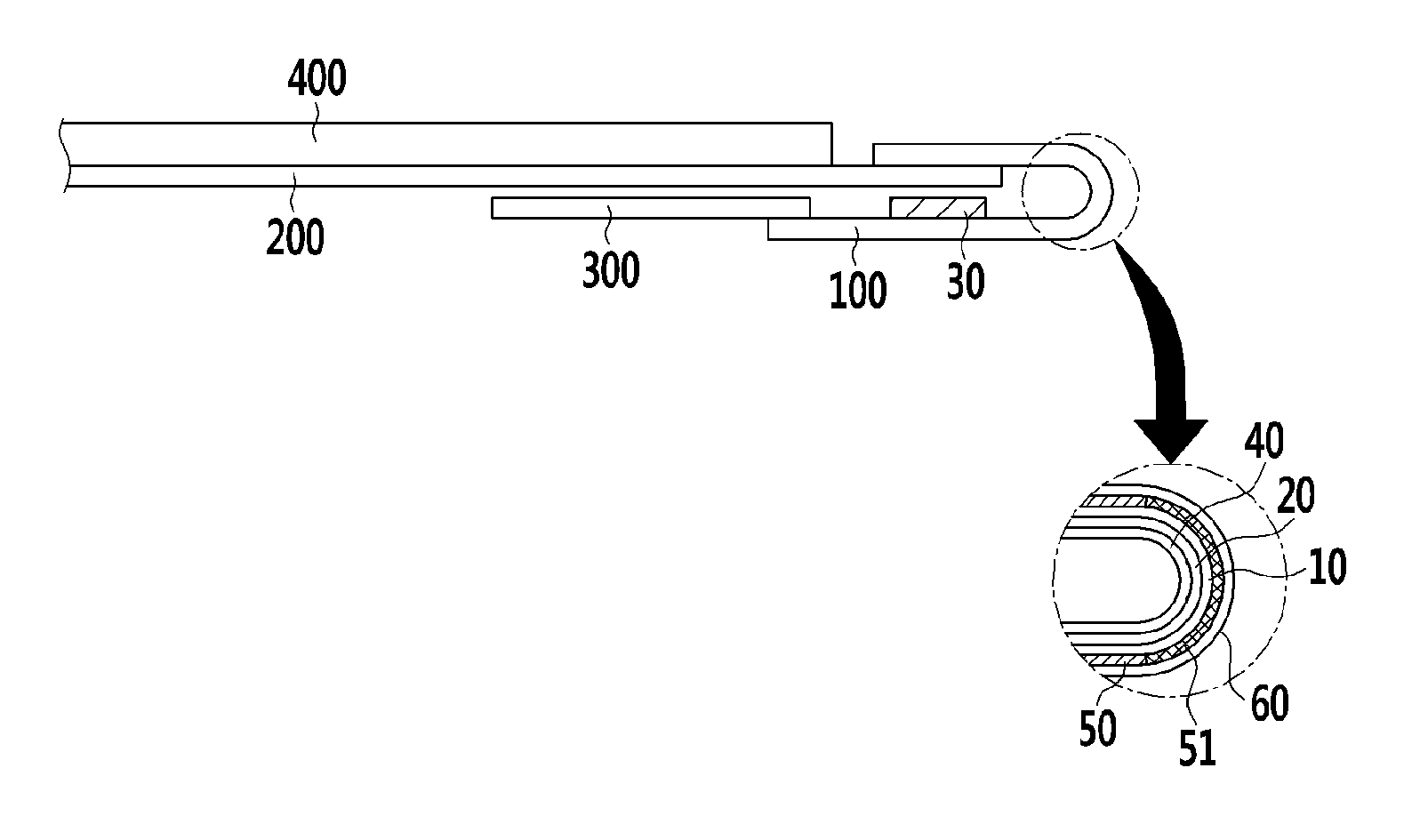

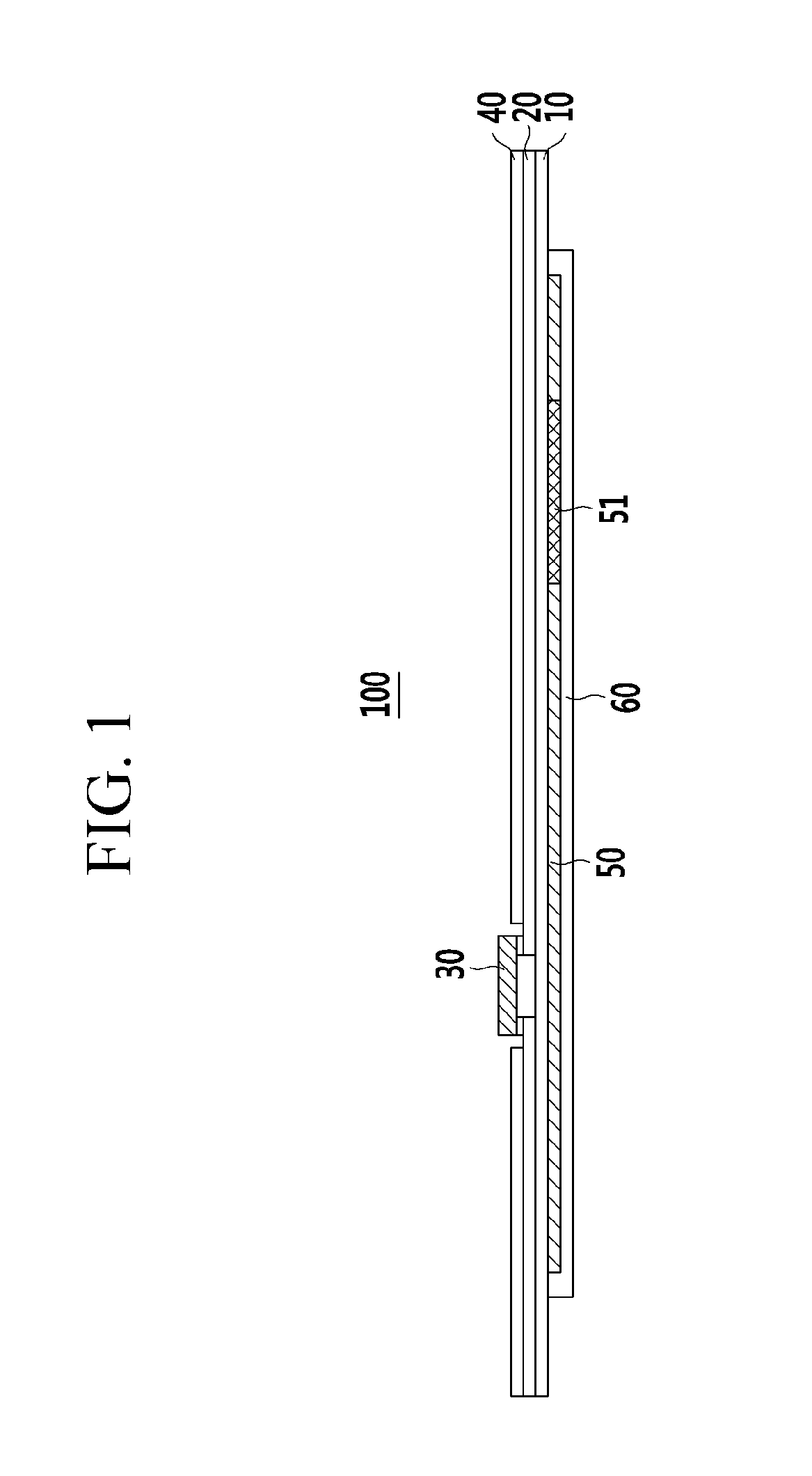

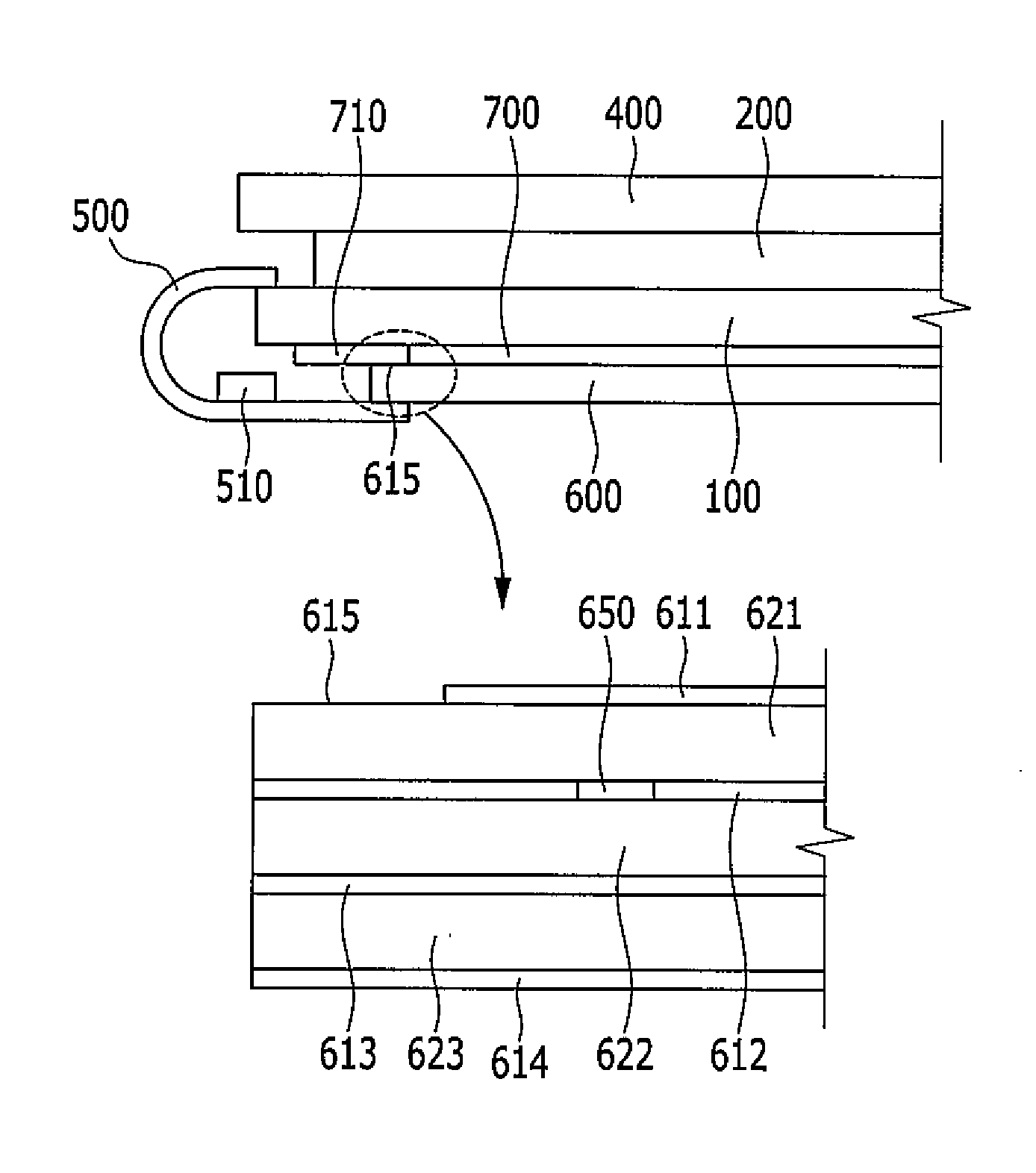

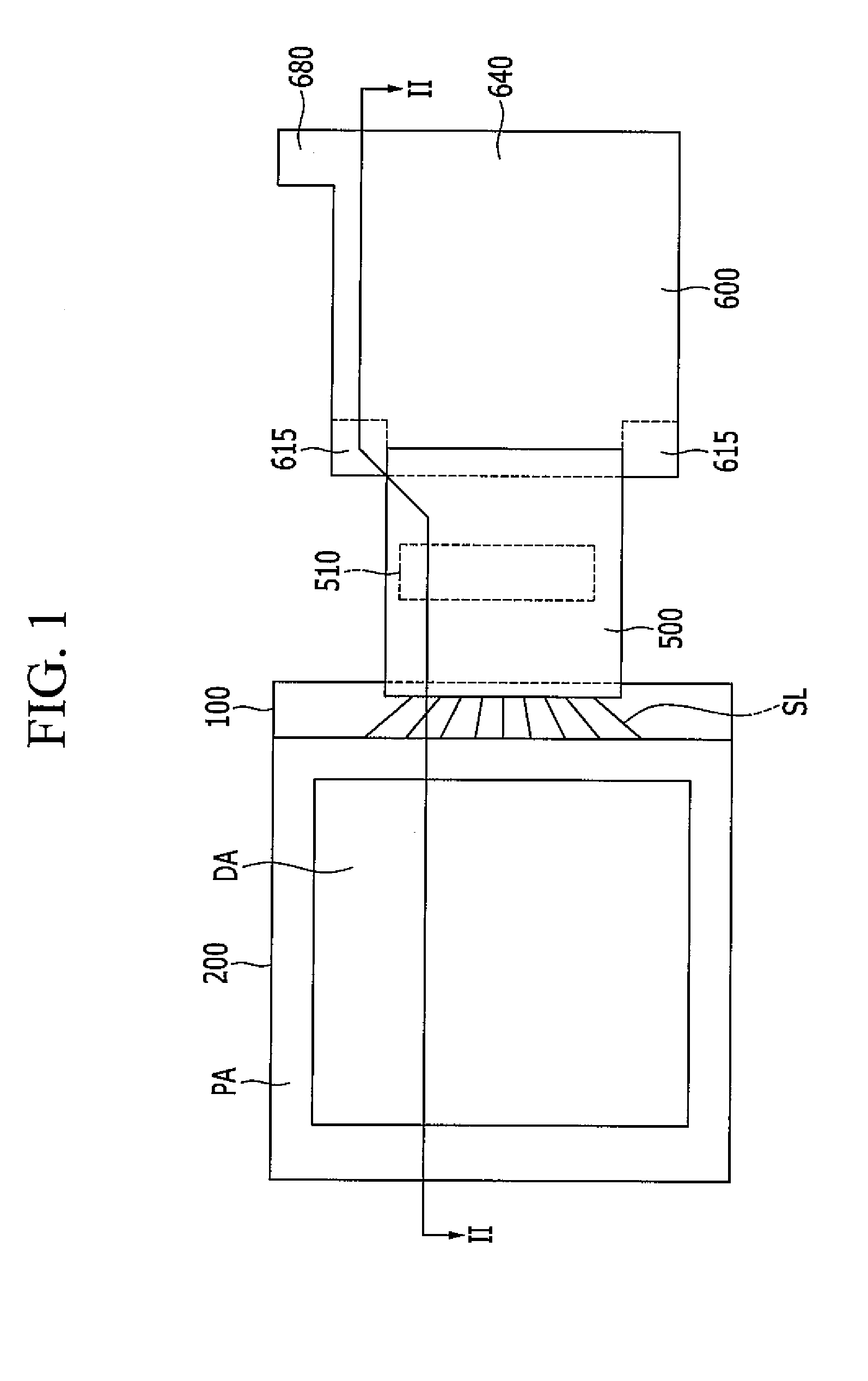

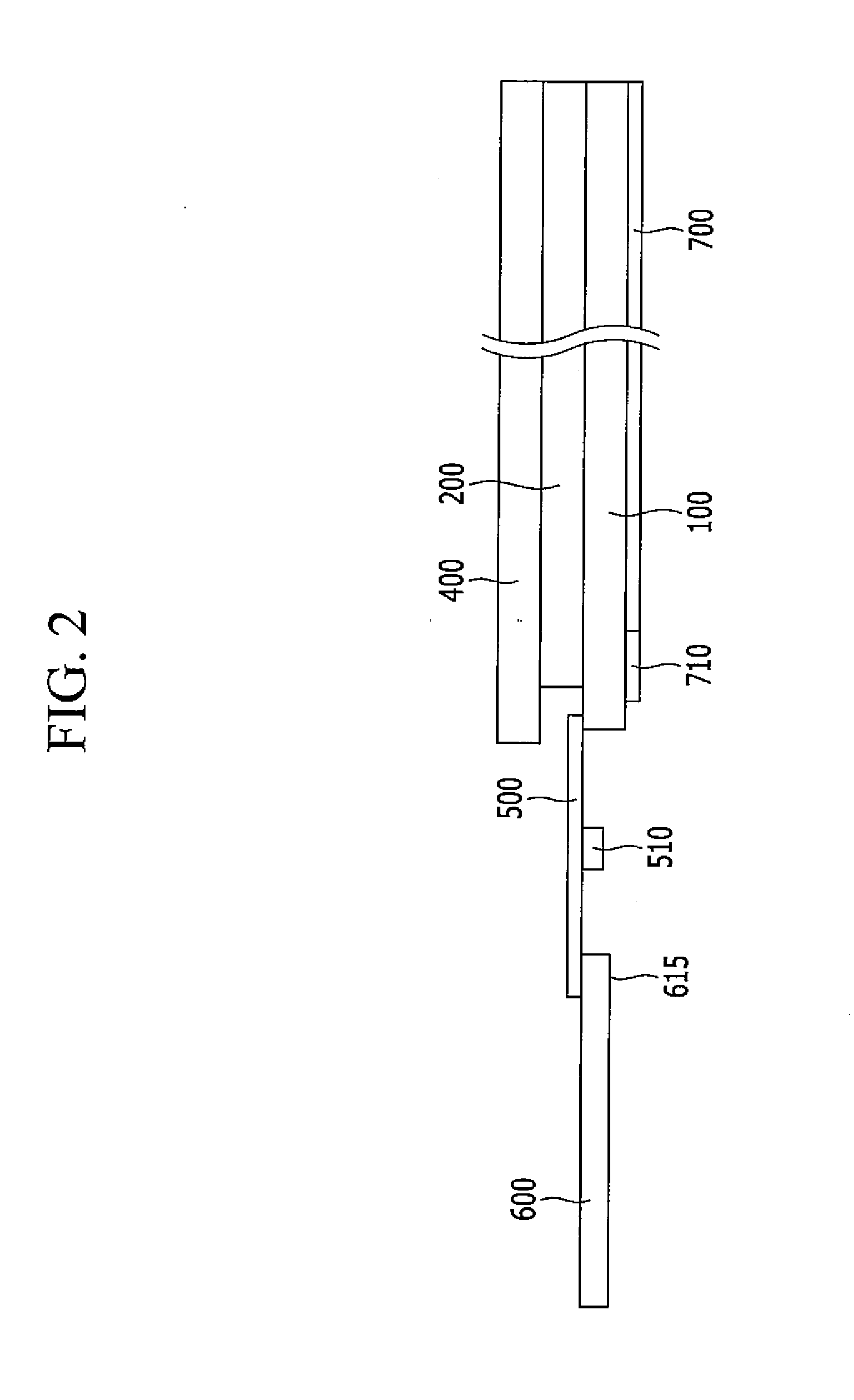

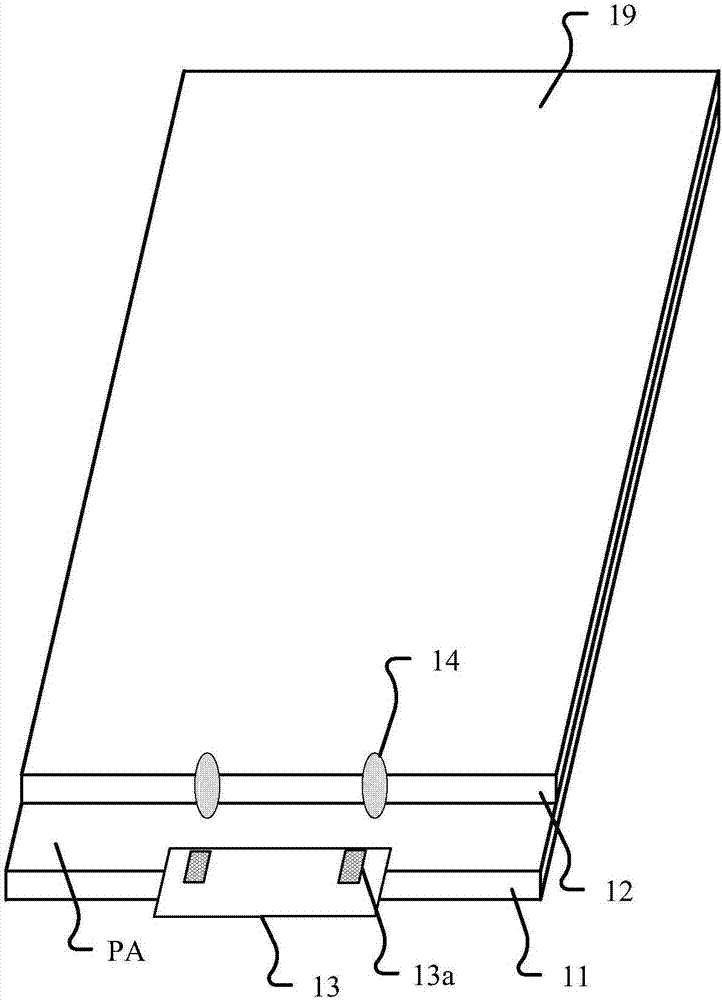

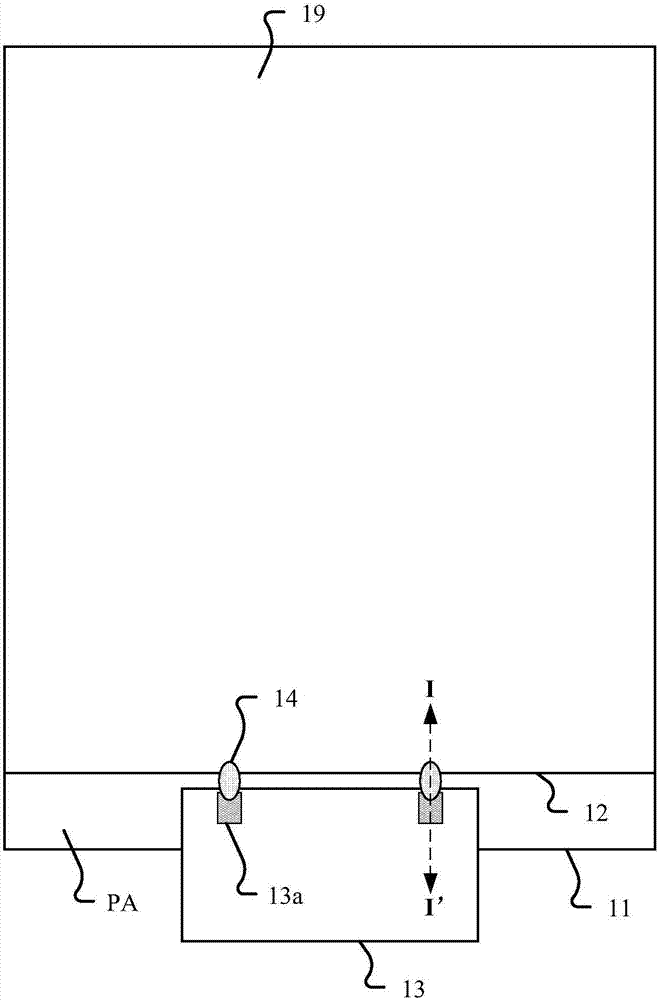

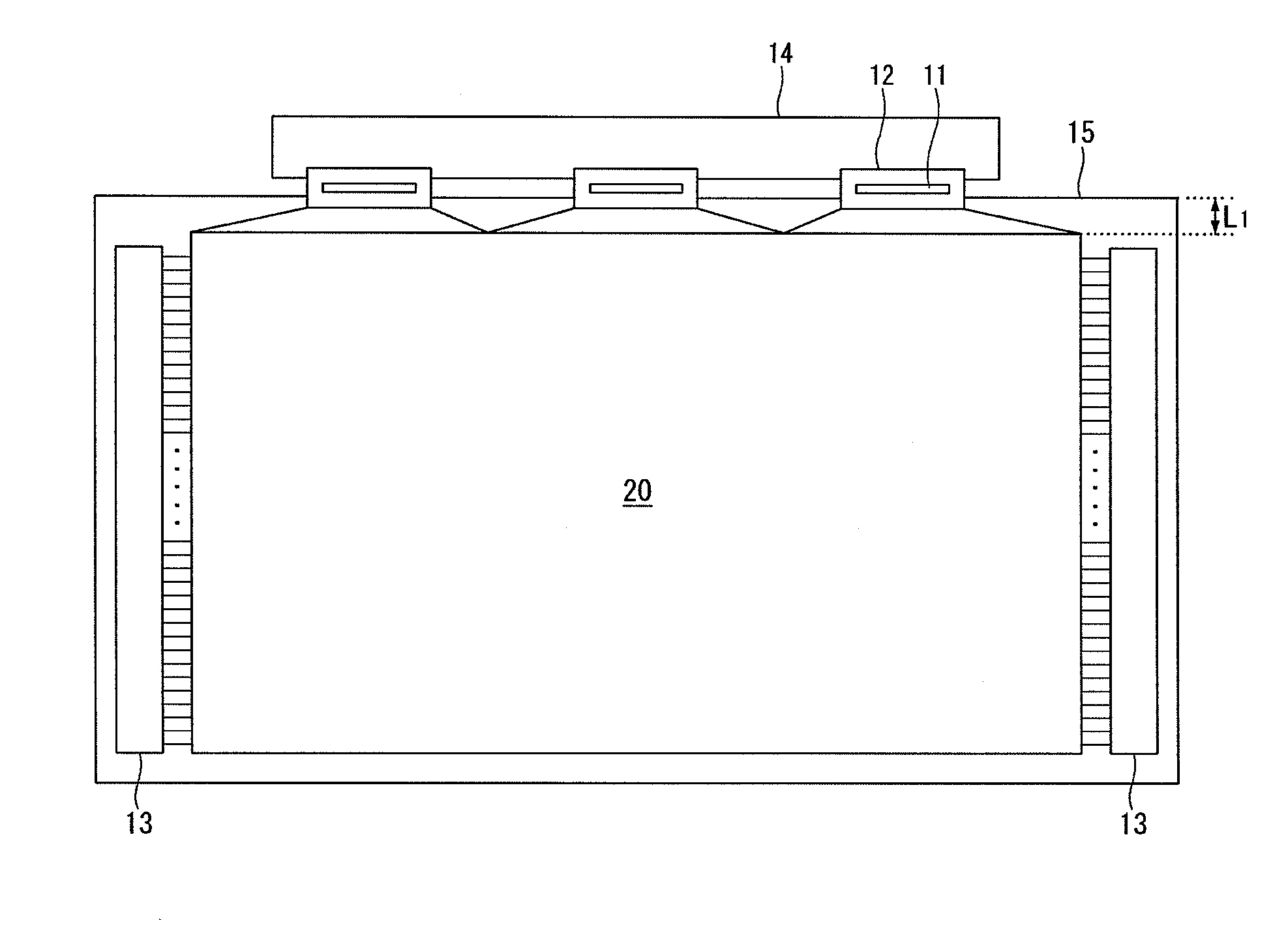

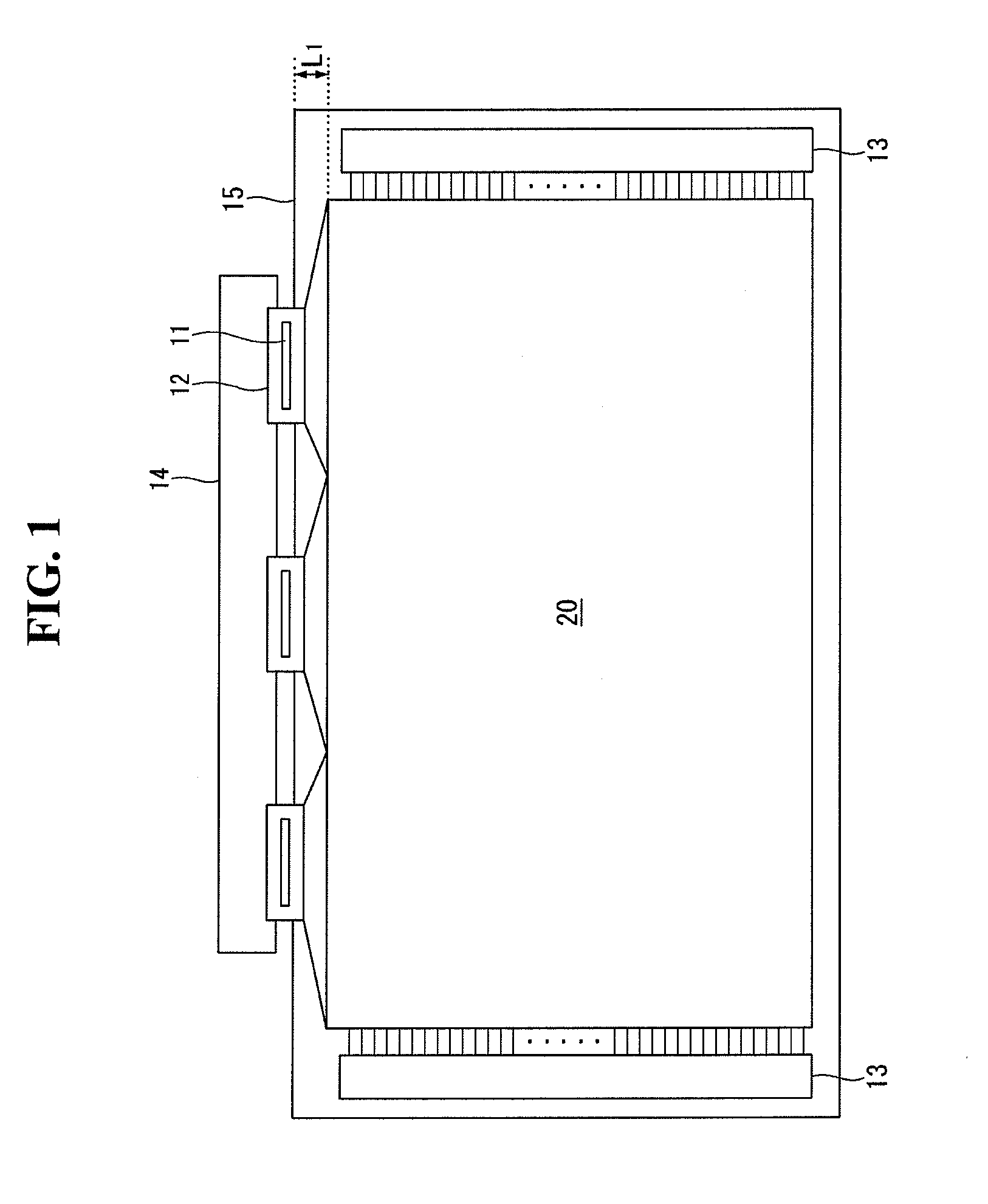

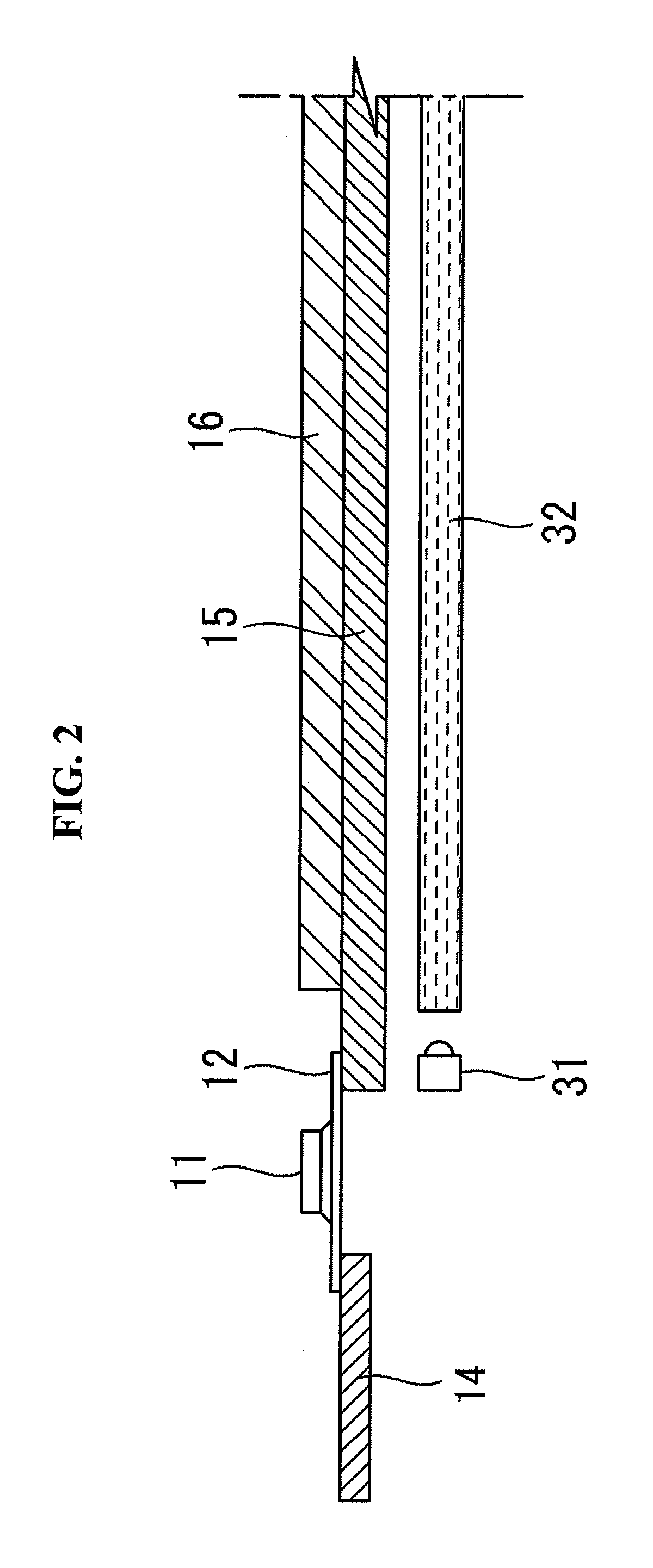

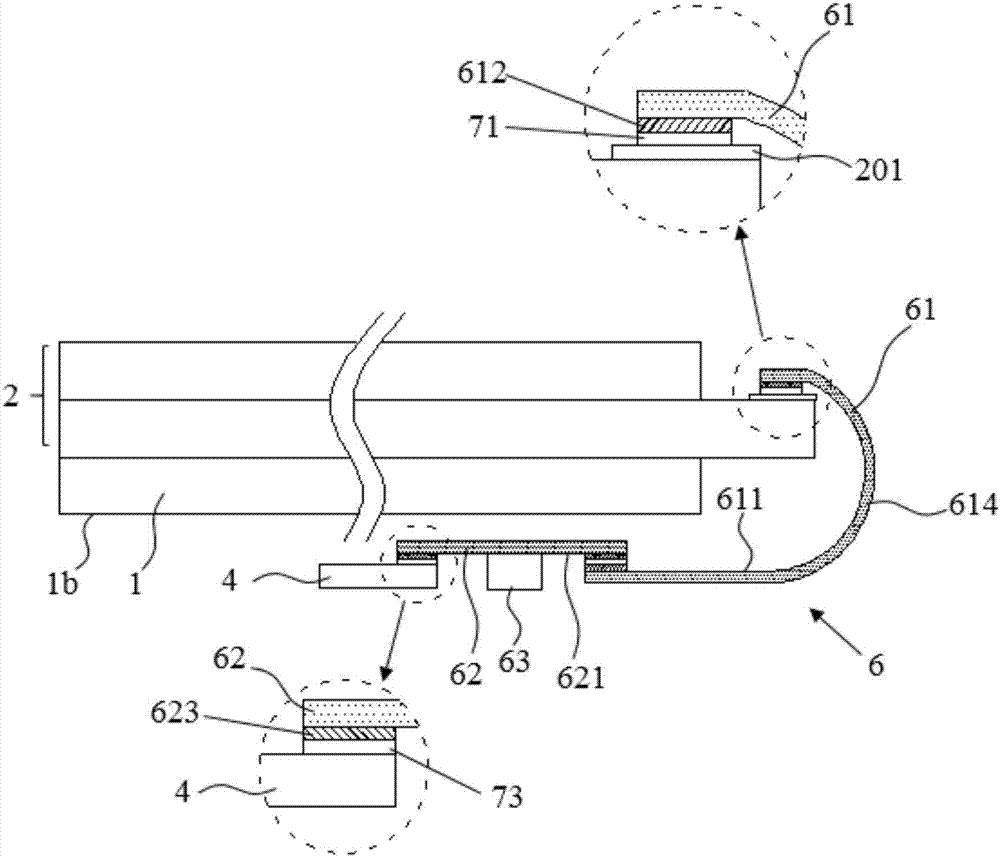

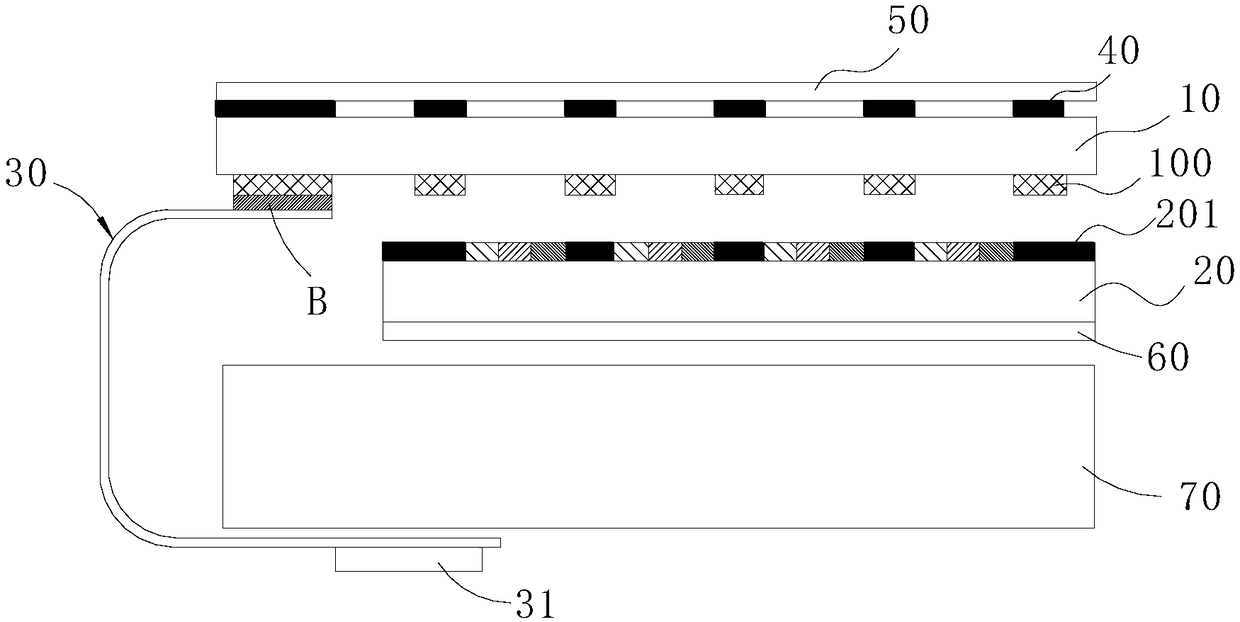

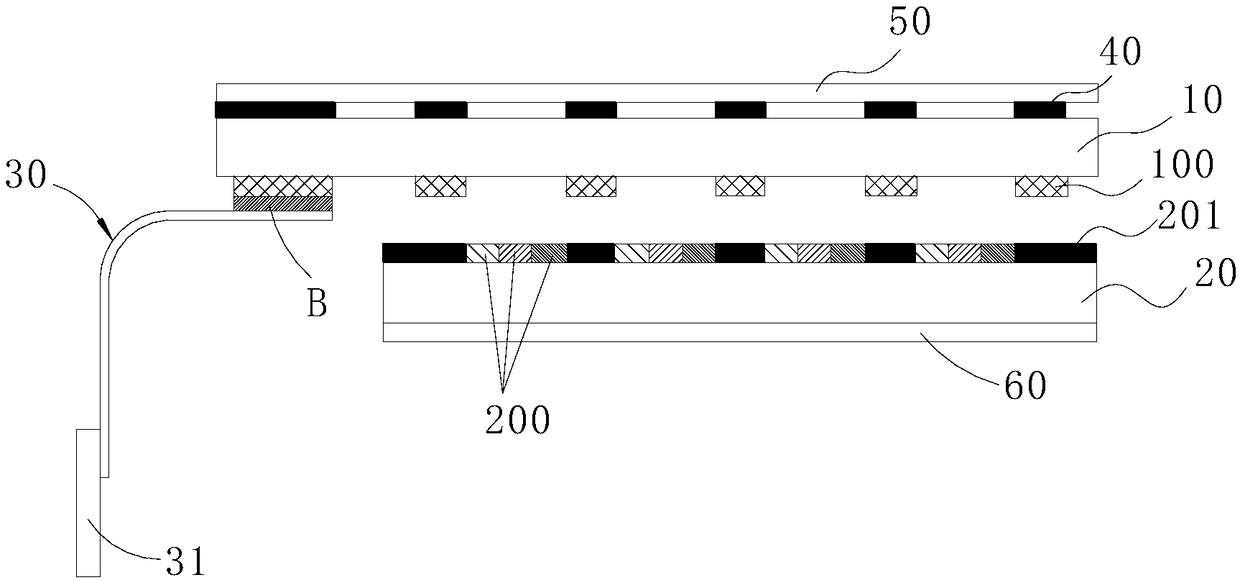

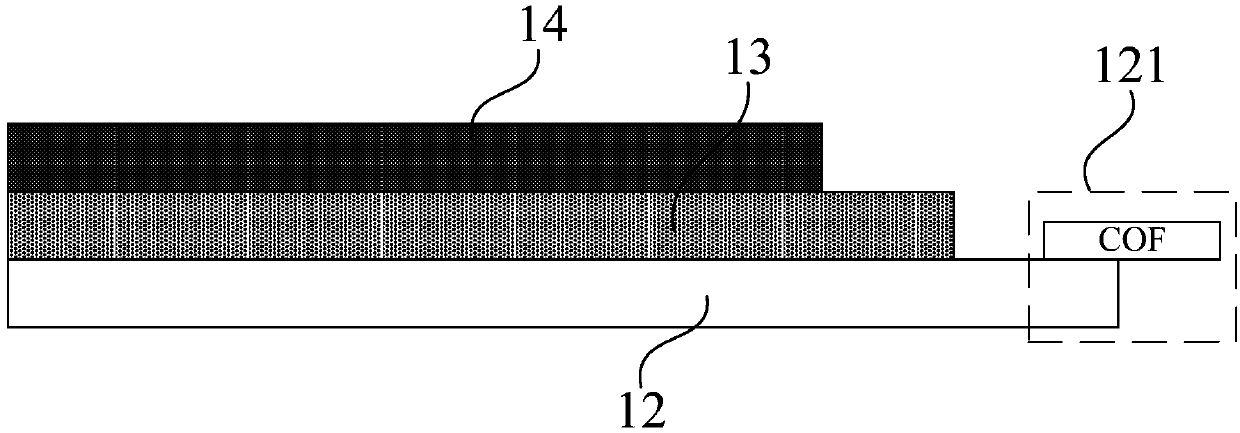

Touch panel-integrated liquid crystal display device

ActiveUS20110141042A1Reduce in quantityFirmly connectedNon-linear opticsInput/output processes for data processingChip on filmLiquid-crystal display

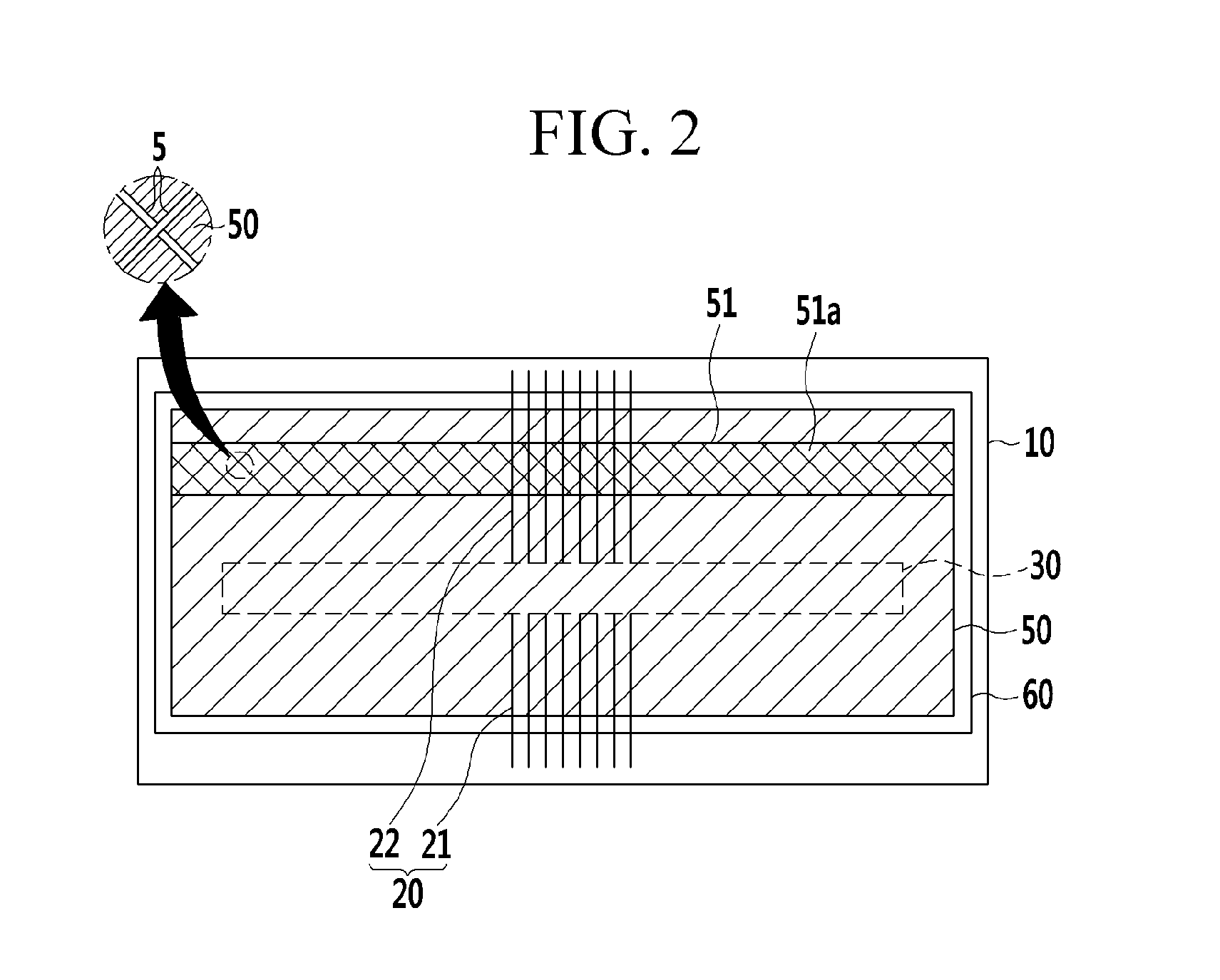

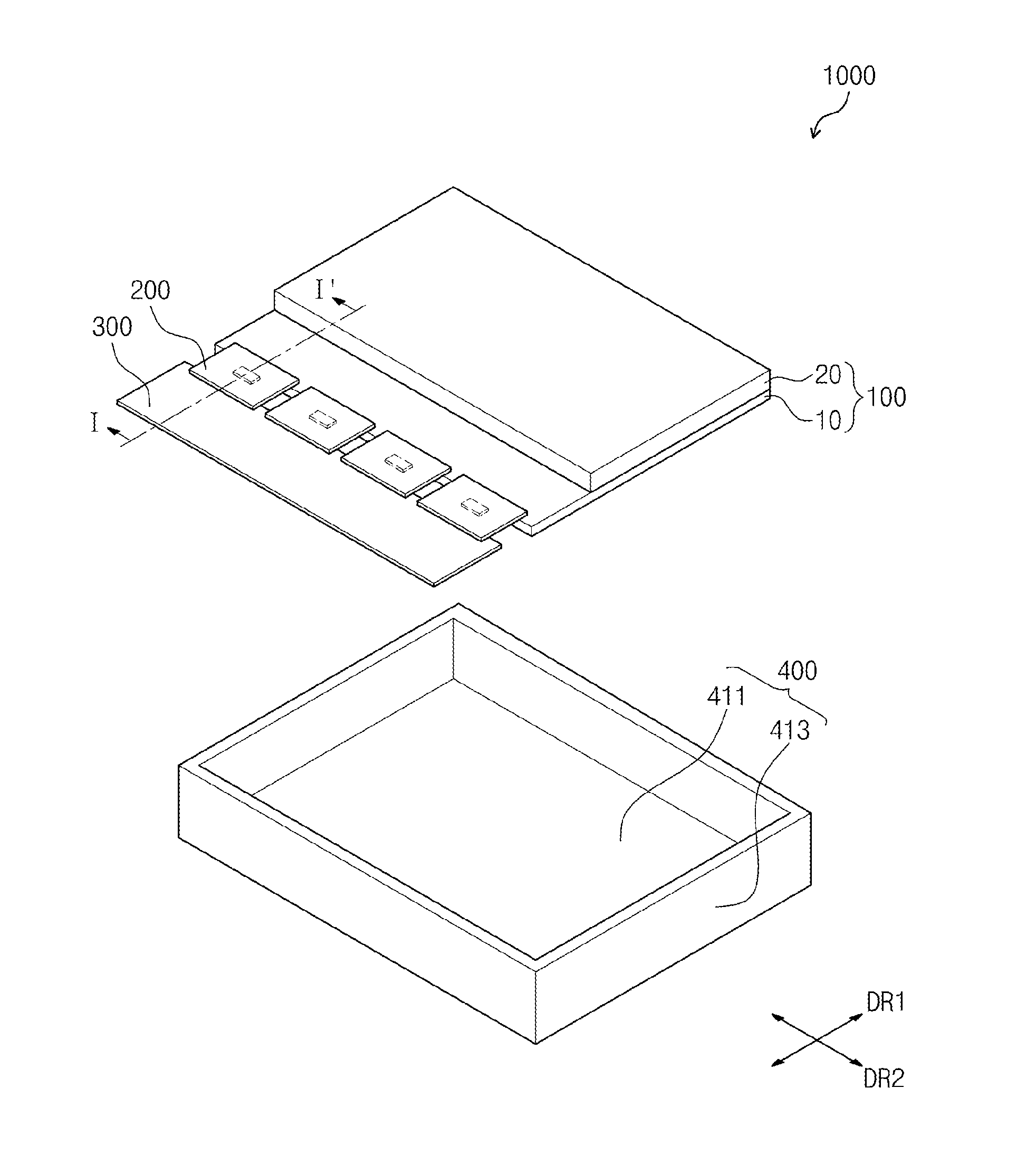

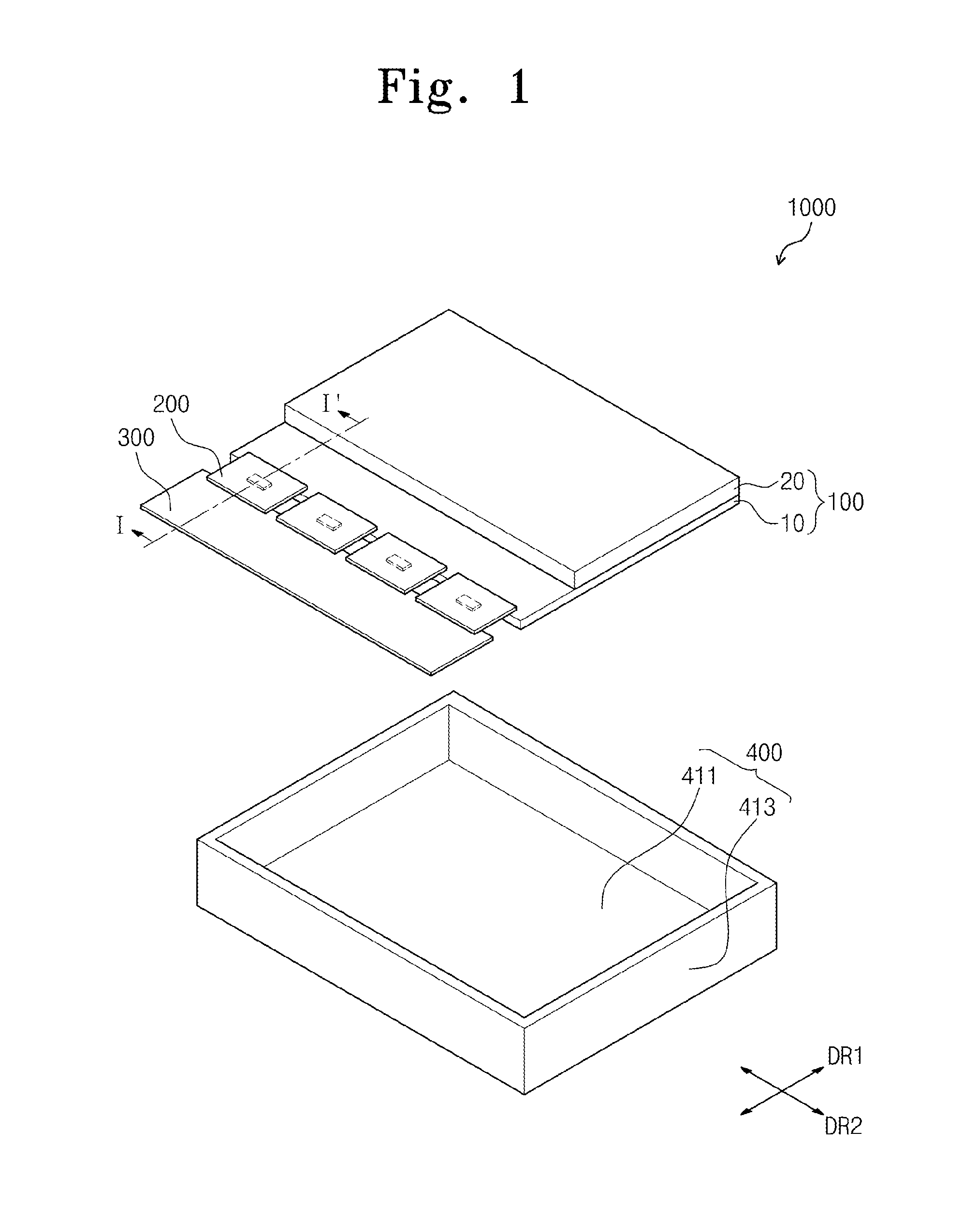

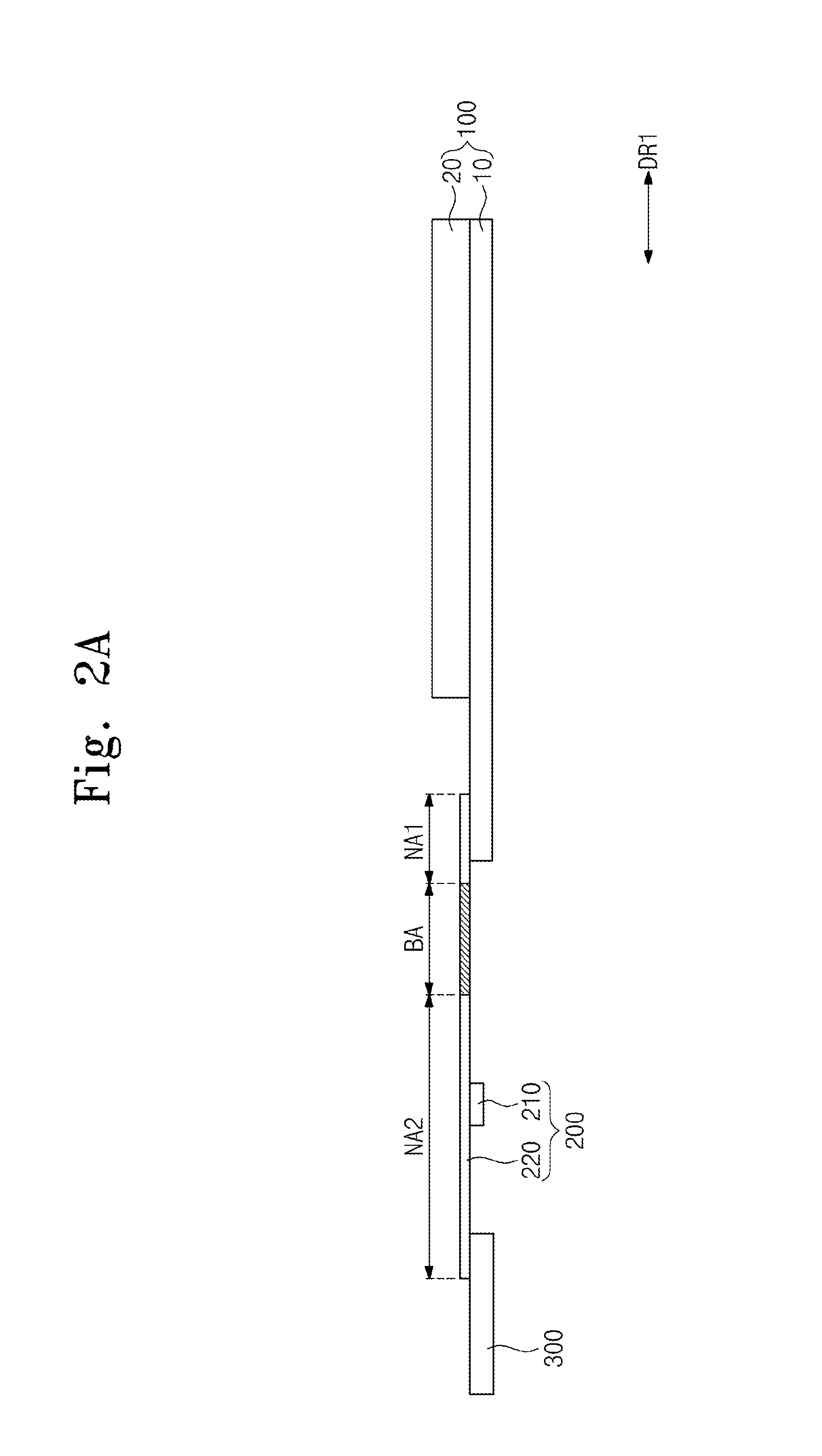

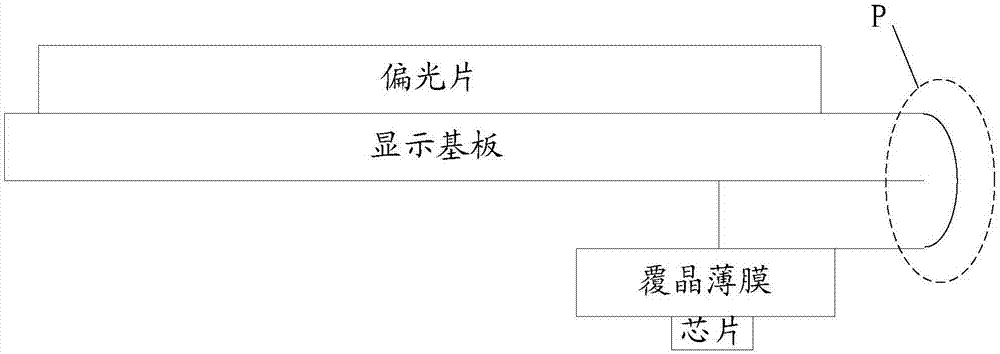

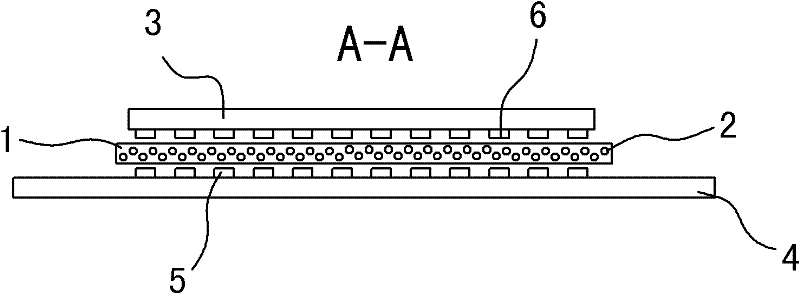

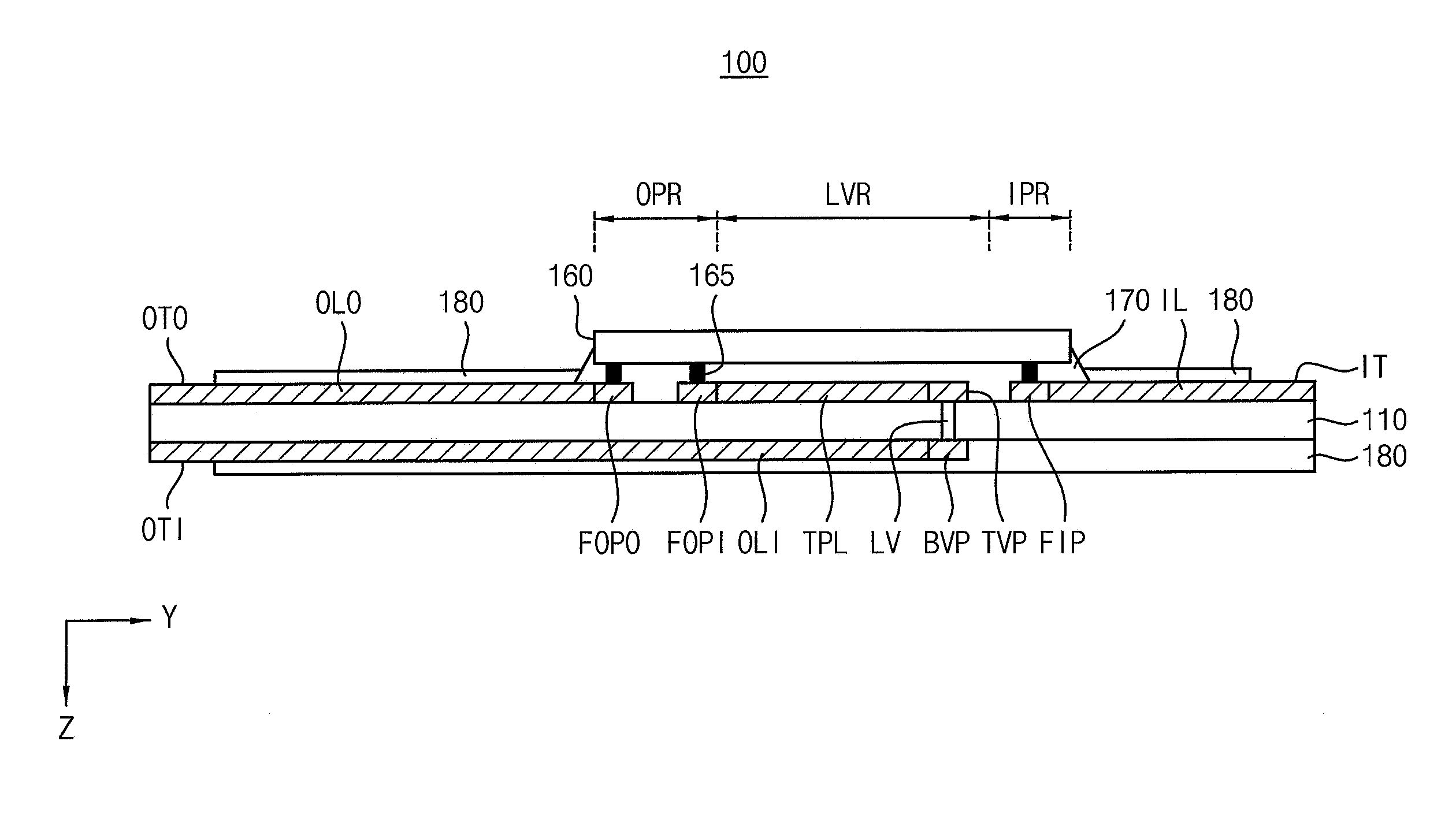

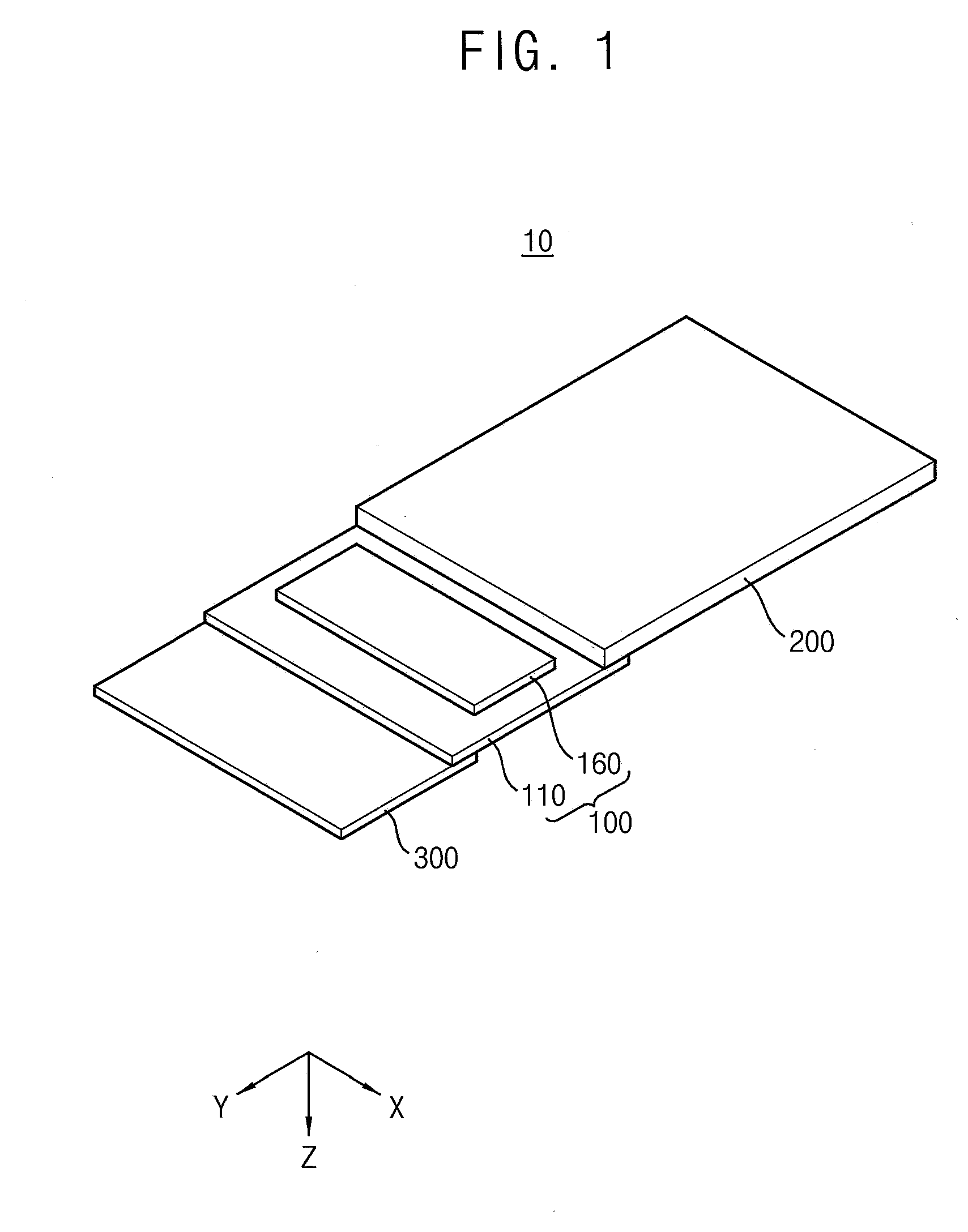

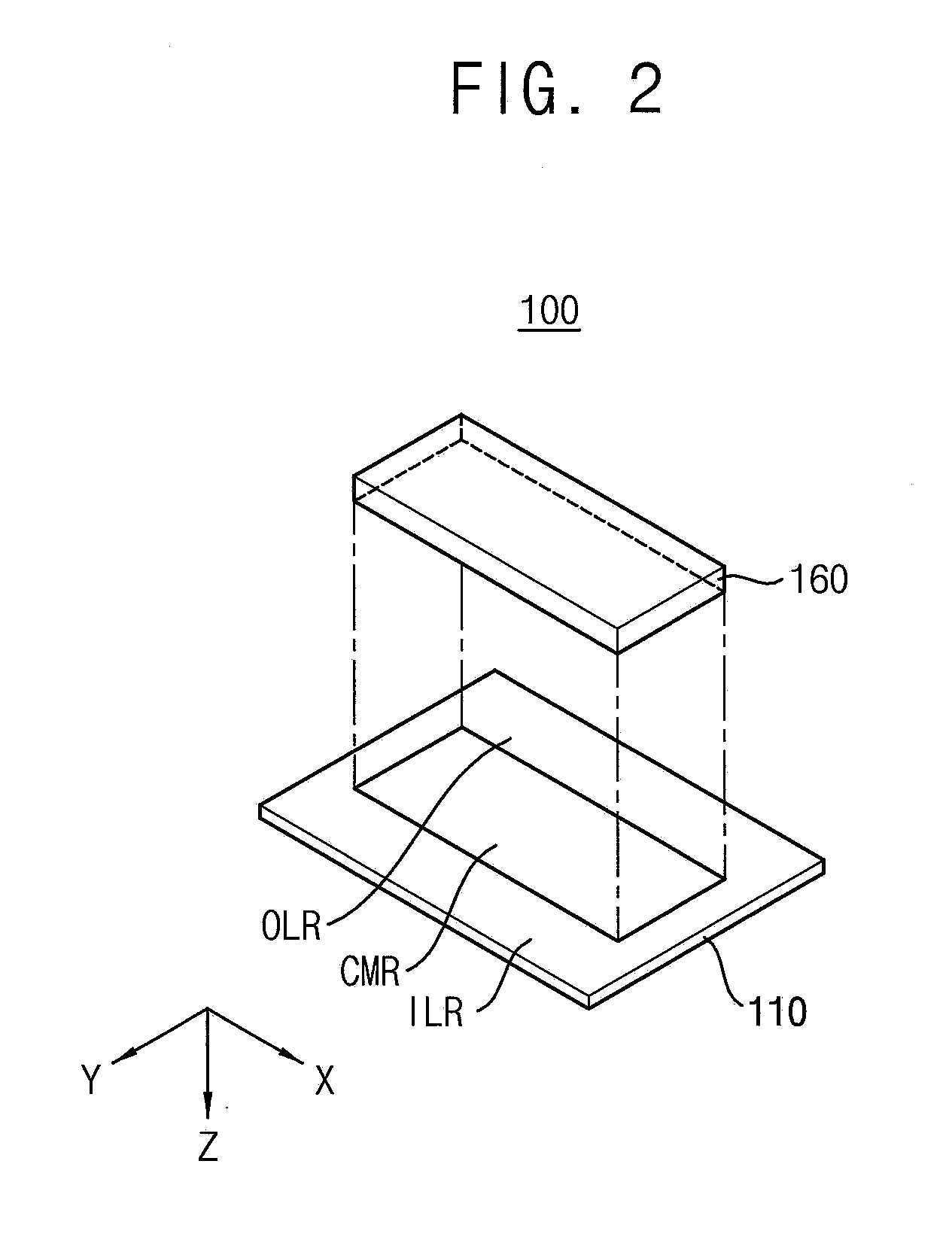

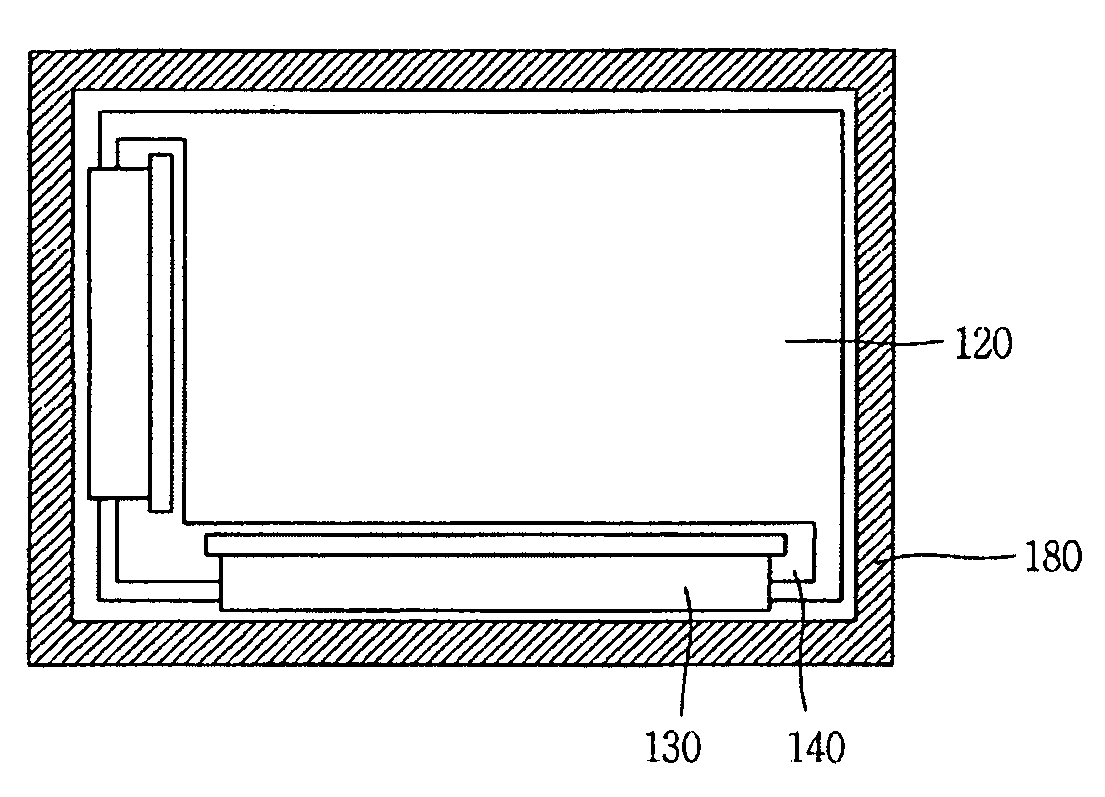

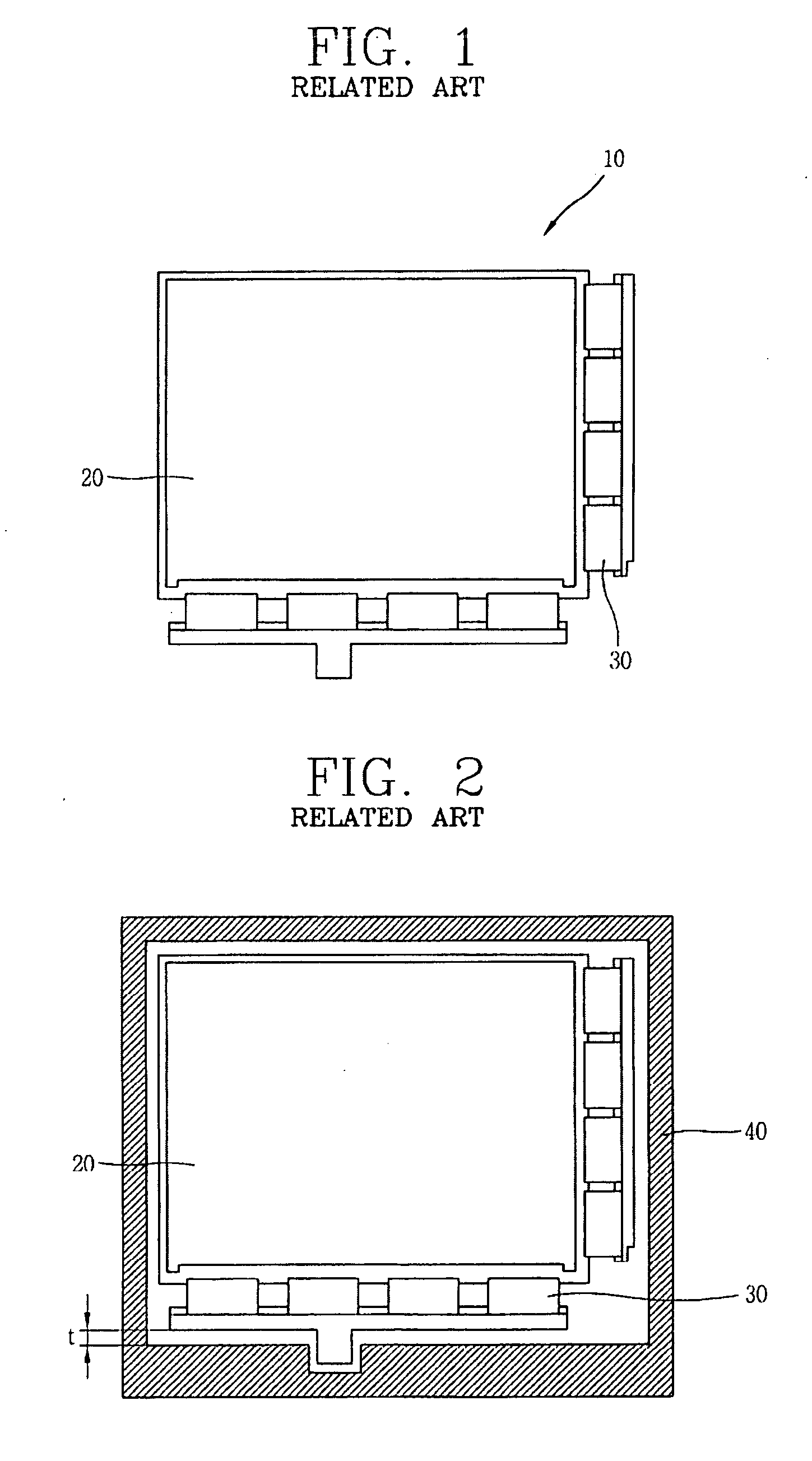

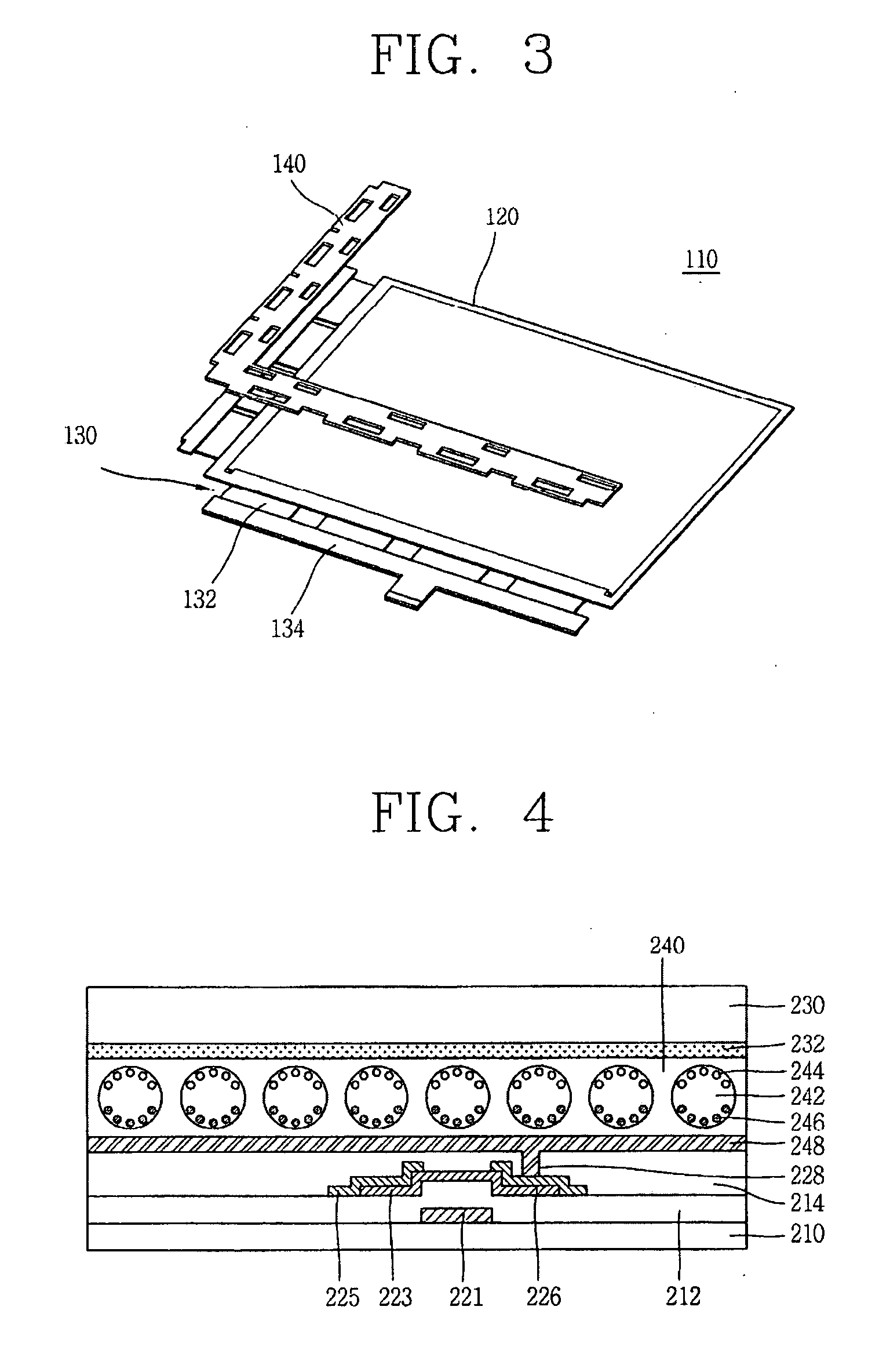

A liquid crystal display device includes a liquid crystal panel comprising a first substrate and a second substrate, a seal pattern arranged in the edge provided between the first and second substrates, and a liquid crystal layer, a plurality of first electrodes and second electrodes crossing each other and arranged in the seal pattern on an outer surface of the second substrate, a pad electrode for the touch panel partially overlapping the seal pattern on the outer surface of the second substrate, a pad electrode for the liquid crystal panel arranged at the outside of the seal pattern on the first substrate, a chip-on-film (COF) connected to the pad electrode for the liquid crystal panel, a printed circuit board for driving the liquid crystal panel, connected to the chip-on-film, a routing line to connect the pad electrode for the touch panel to the first electrodes and the second electrodes on the outer surface of the second substrate, and a flexible printed cable connected to pad electrodes for the touch panel, to receive driving signals of the first and second electrodes, the flexible printed cable connected to the printed circuit board.

Owner:LG DISPLAY CO LTD

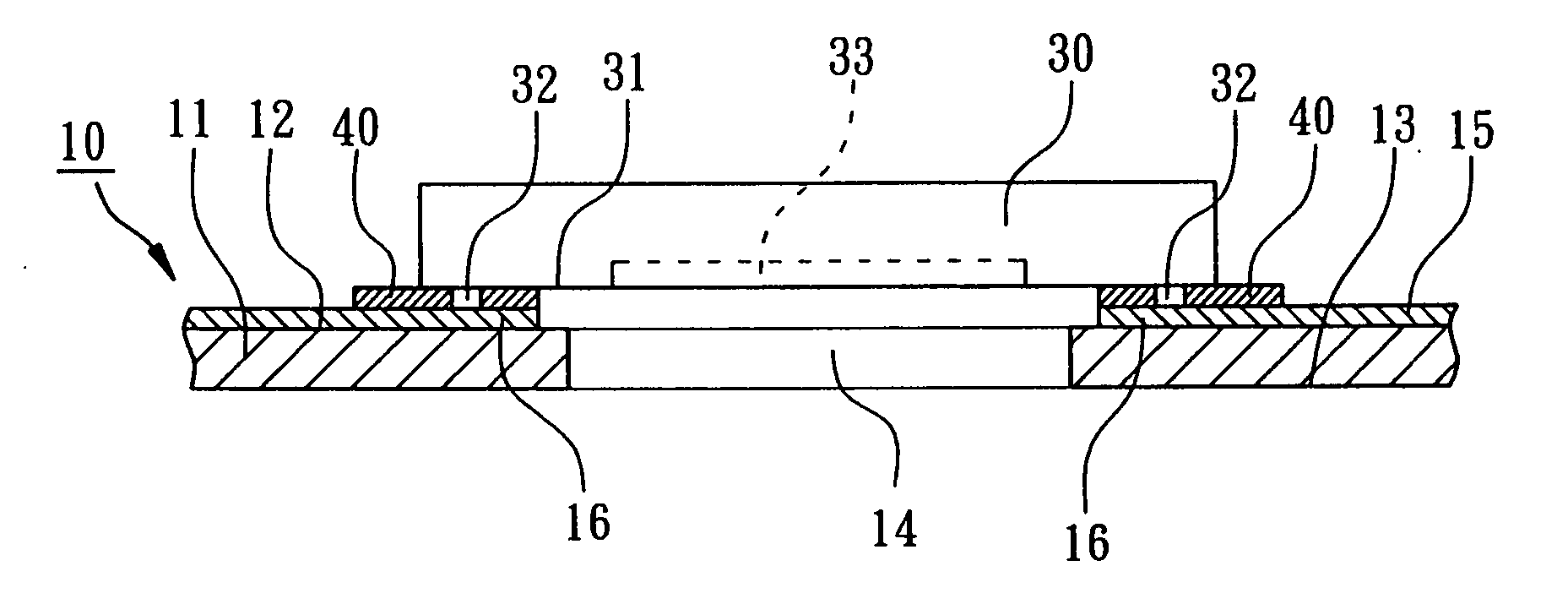

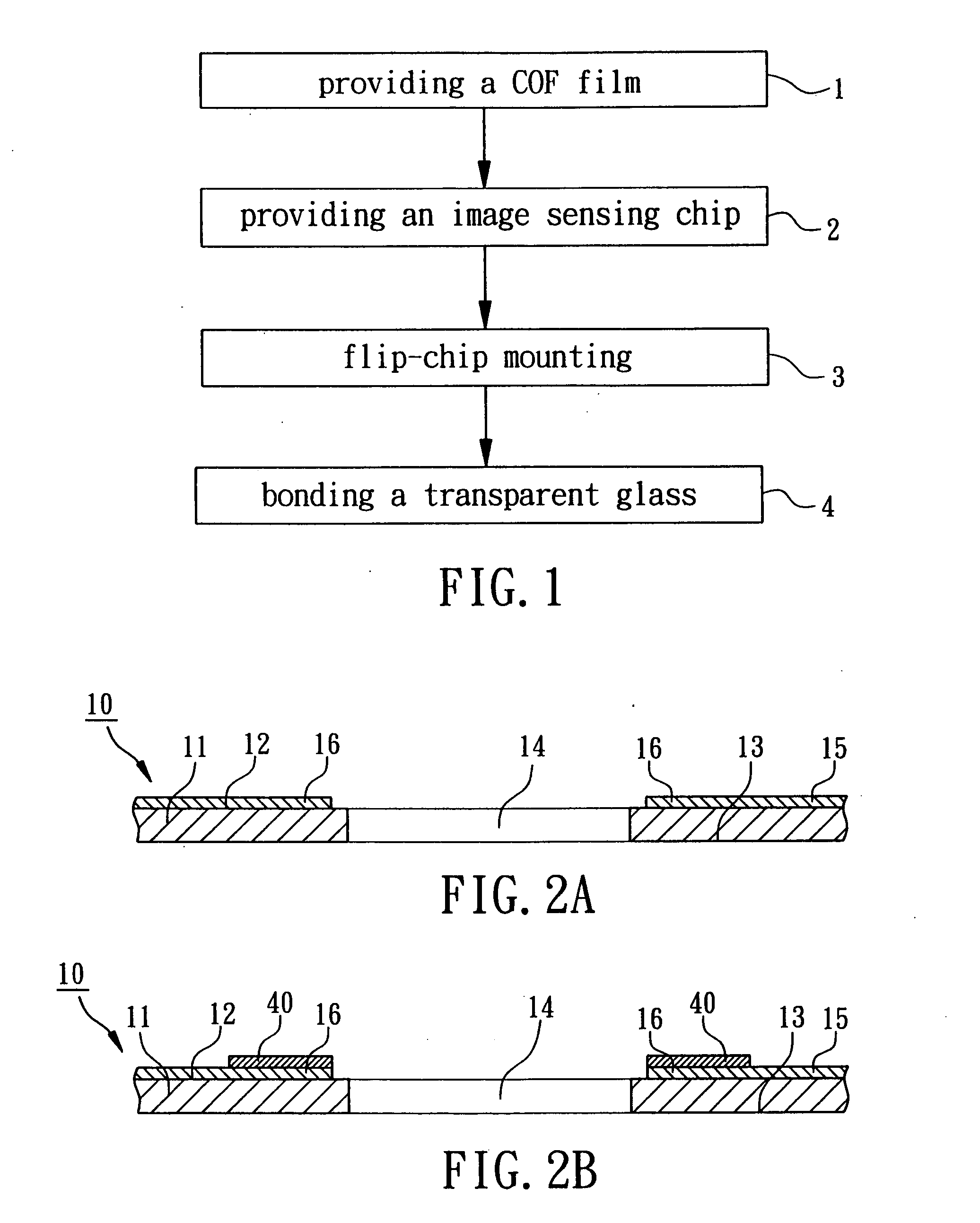

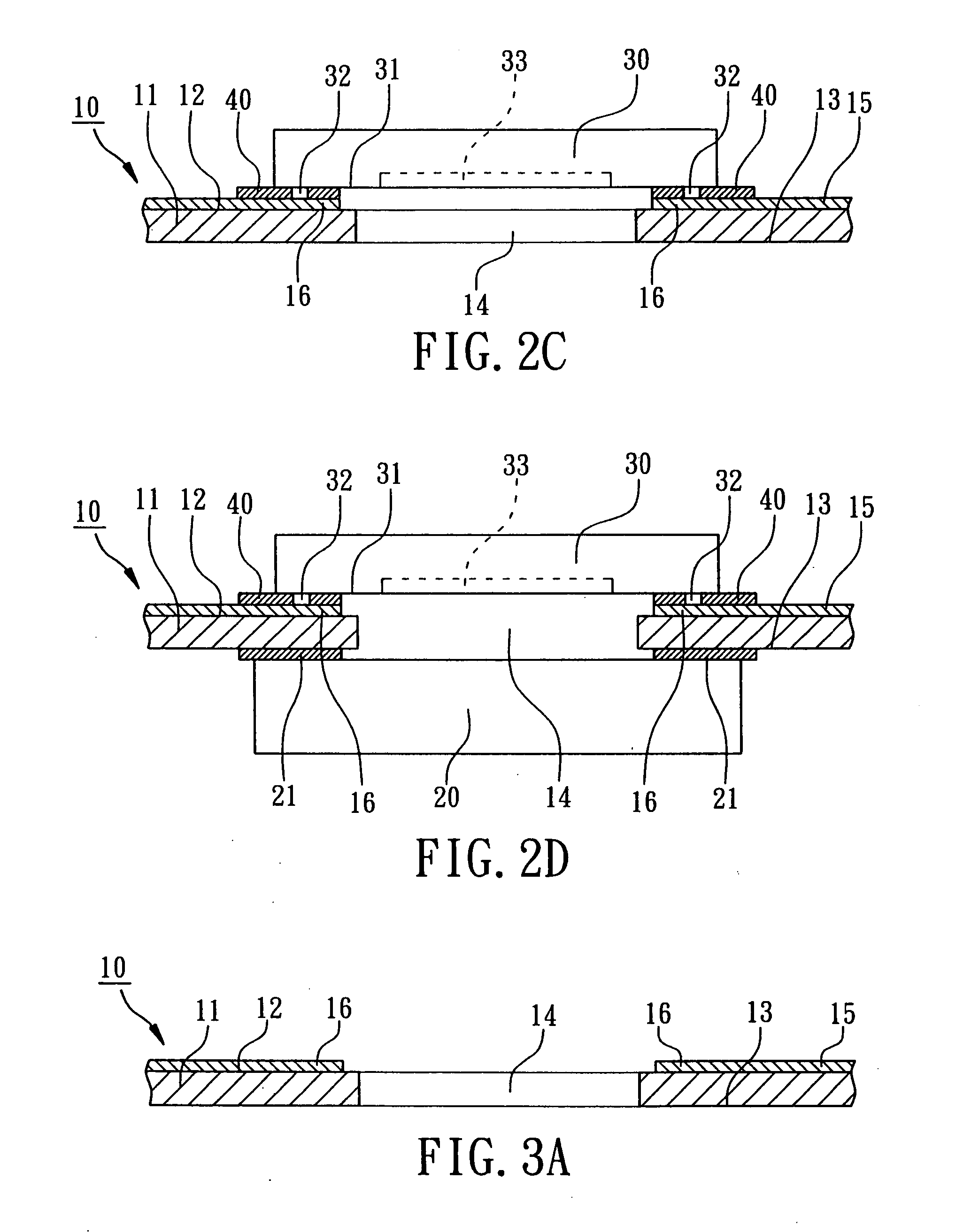

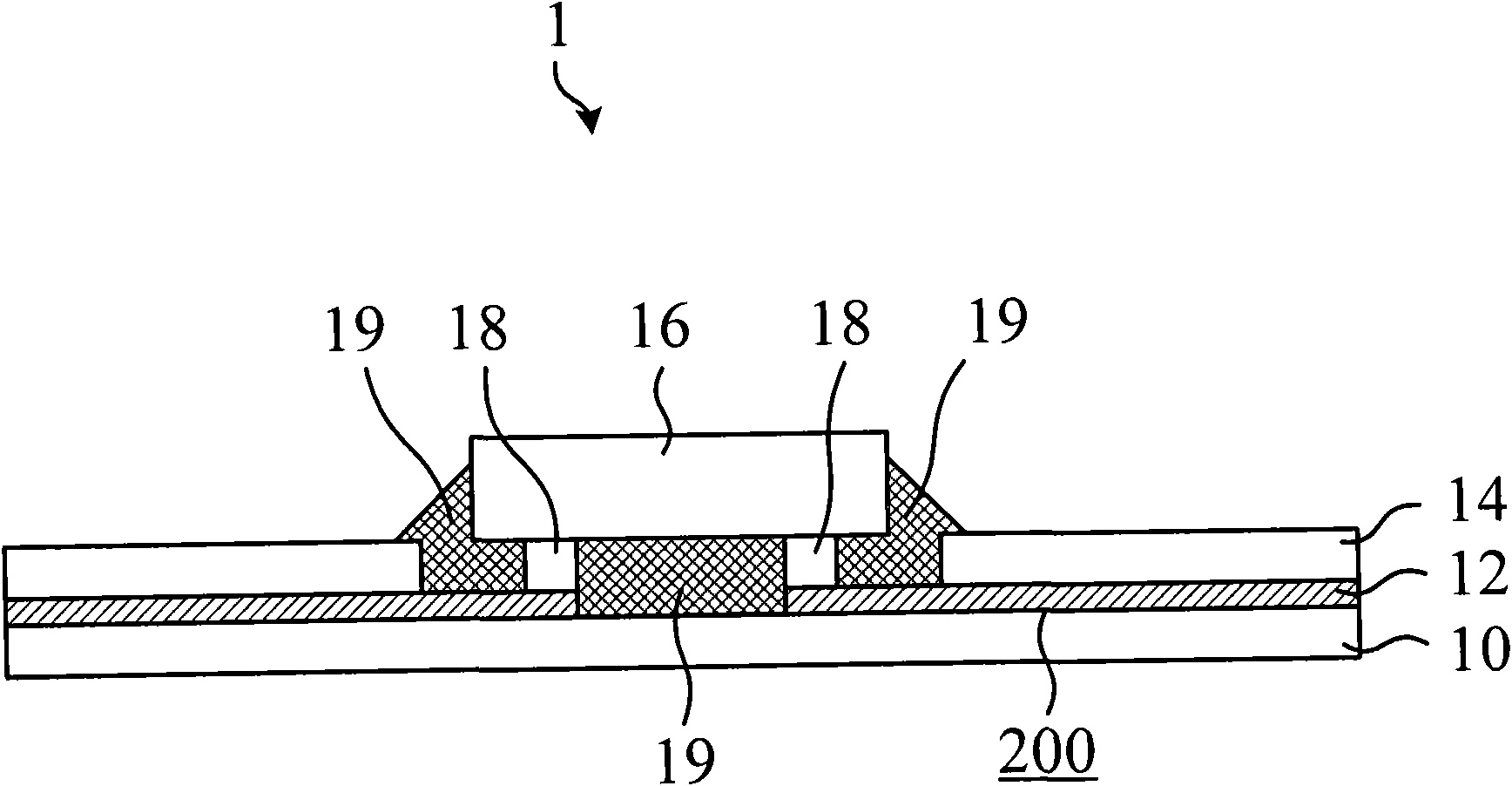

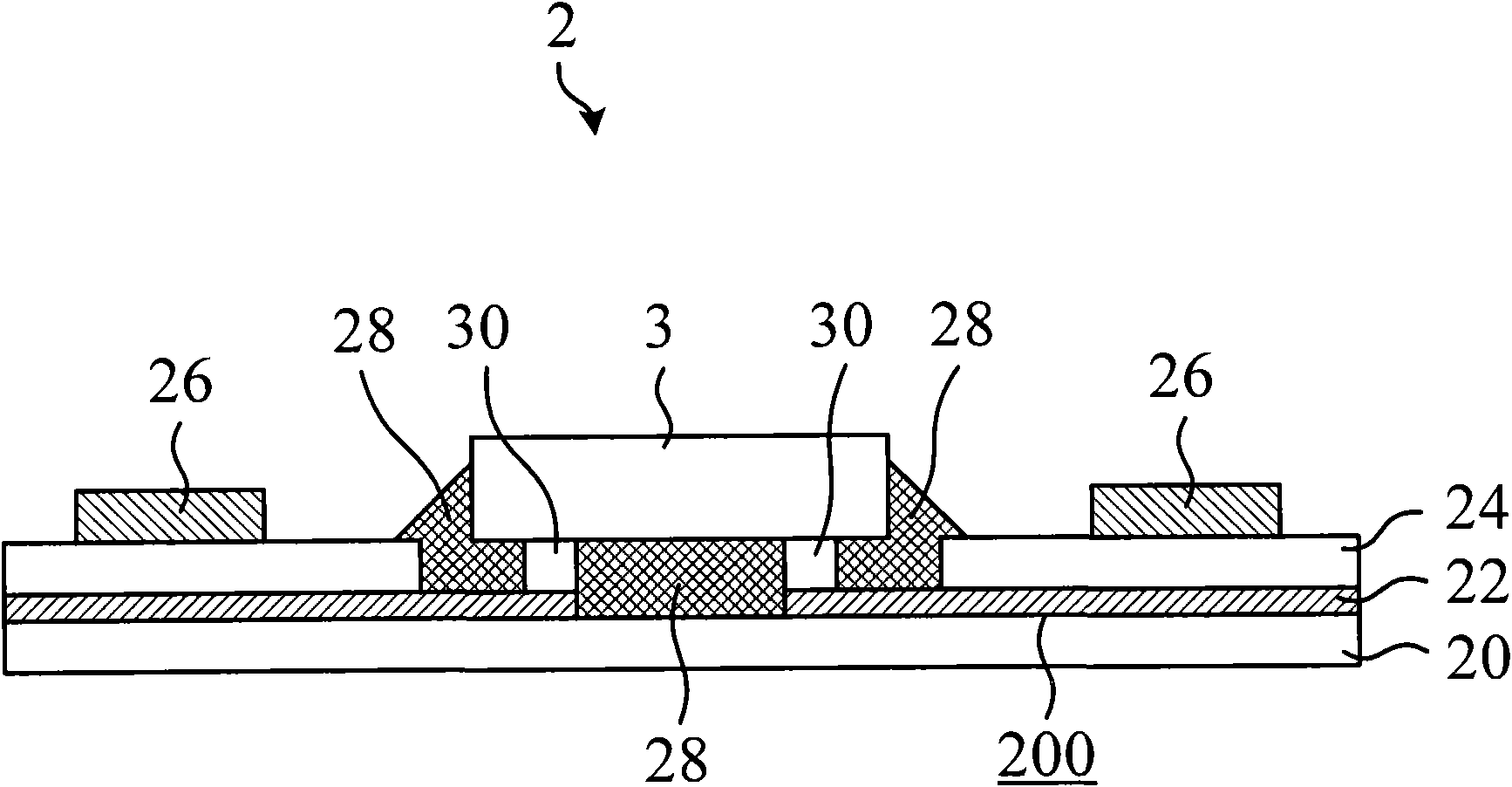

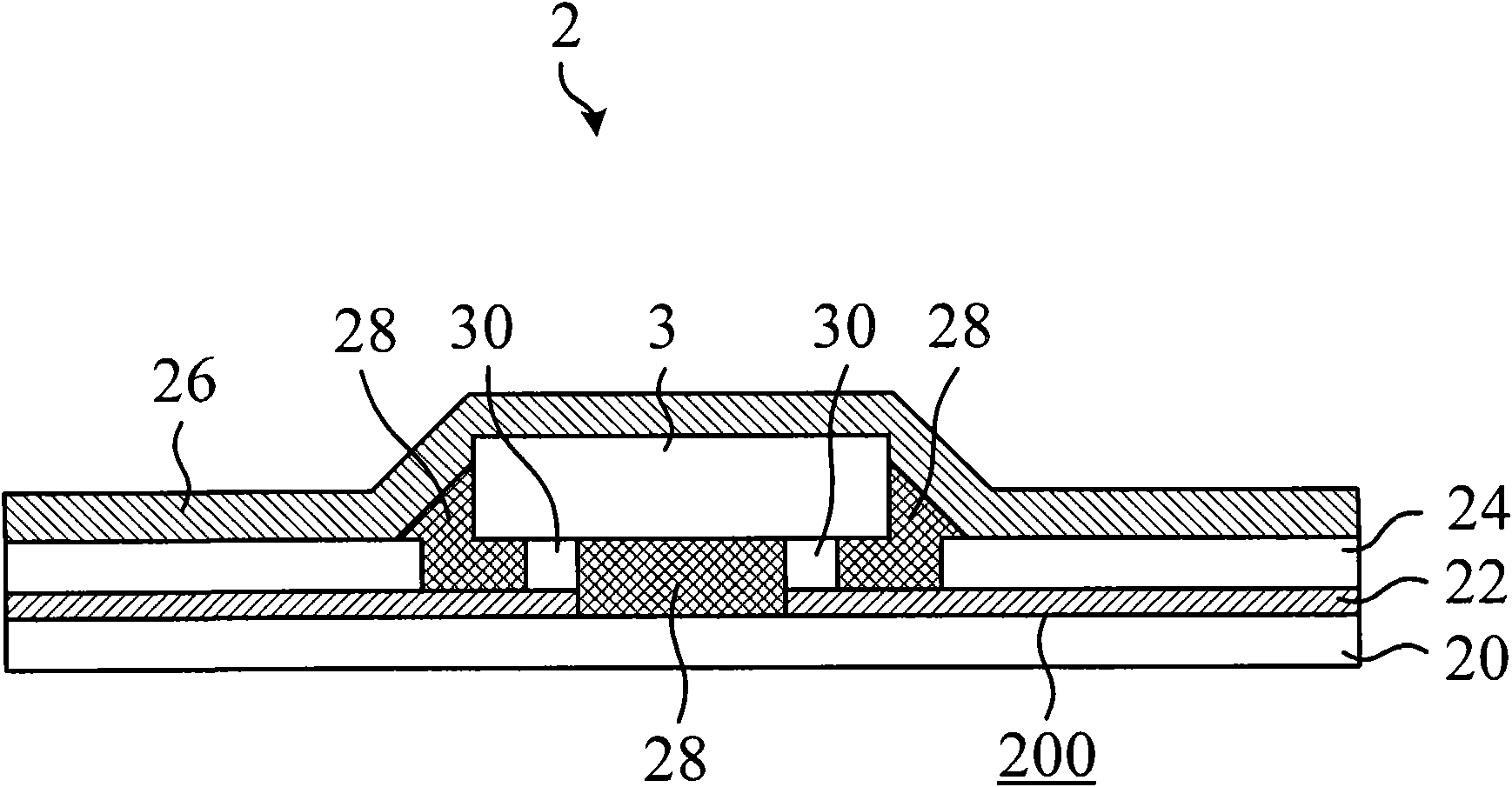

Chip-on-film package for image sensor and method for manufacturing the same

InactiveUS20050104186A1Simplify filling materialWell formedSemiconductor/solid-state device detailsSolid-state devicesChip on filmFilling materials

A chip-on-film (COF) package and method for image sensor has been disclosed. According to the method a COF film with opening is provided. The COF film has an upper surface, a lower surface and at least an opening. An image sensing chip is flip-chip mounted on the upper surface of the COF film. A transparent glass is bonded to the lower surface of the COF film. The opening is clipped by the transparent glass and the image sensing chip to form a hermetic space. The active surface of the image sensing chip includes an image sensing region toward the transparent glass through the opening and is sealed in the hermetic space by a limited filling material in order to prevent the image sensing region of the image sensing chip from contamination by means of COF tape packaging method.

Owner:ADVANCED SEMICON TECH

Chip on film and display device including the same

InactiveUS20140118969A1Minimizing electromagnetic interferenceReduce tensionCircuit bendability/stretchabilityMagnetic/electric field screeningChip on filmDisplay device

A chip on film according to an exemplary embodiment includes: a driving film, a wire layer formed on a first surface of the driving film, a driving chip connected to the wire layer, and an electromagnetic wave blocking layer formed on a second surface of the driving film, in which a mesh portion may be formed on a portion of the electromagnetic wave blocking layer.

Owner:SAMSUNG DISPLAY CO LTD

Chip-on-film package and display device having the same

ActiveUS20140319523A1Avoid defectsInhibit deteriorationSemiconductor/solid-state device testing/measurementStatic indicating devicesChip on filmDisplay device

A chip-on-film package includes a base film, a test line, and an integrated circuit chip. The base film includes a bent area in which a bending occurs. The test line is disposed on the base film, and at least a portion of the test line is overlapped with the bent area. The integrated circuit chip is disposed on the base film and includes a first terminal and a second terminal. The first terminal is connected to one end of the test line to output a first signal and the second terminal is connected to the other end of the test line to receive a second signal. The integrated circuit chip detects whether a crack occurs in the bent area based on a difference value in signal characteristics.

Owner:SAMSUNG DISPLAY CO LTD

Chip assembly

ActiveUS20080284014A1Improve electrical performanceReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesChip on filmExternal circuit

A chip assembly includes a semiconductor chip, a bump and an external circuit. The semiconductor chip includes a semiconductor substrate, a transistor in and on the semiconductor substrate, multiple dielectric layers over the semiconductor substrate, a metallization structure over the semiconductor substrate, wherein the metallization structure is connected to the transistor, and a passivation layer over the metallization structure, over the dielectric layers and over the transistor. The bump is connected to the metallization structure through an opening in the passivation layer, wherein the bump includes an adhesion / barrier layer and a gold layer over the adhesion / barrier layer. The external circuit can be connected to the bump using a tape carrier package (TCP), a chip-on-film (COF) package or a chip-on-glass (COG) assembly.

Owner:QUALCOMM INC

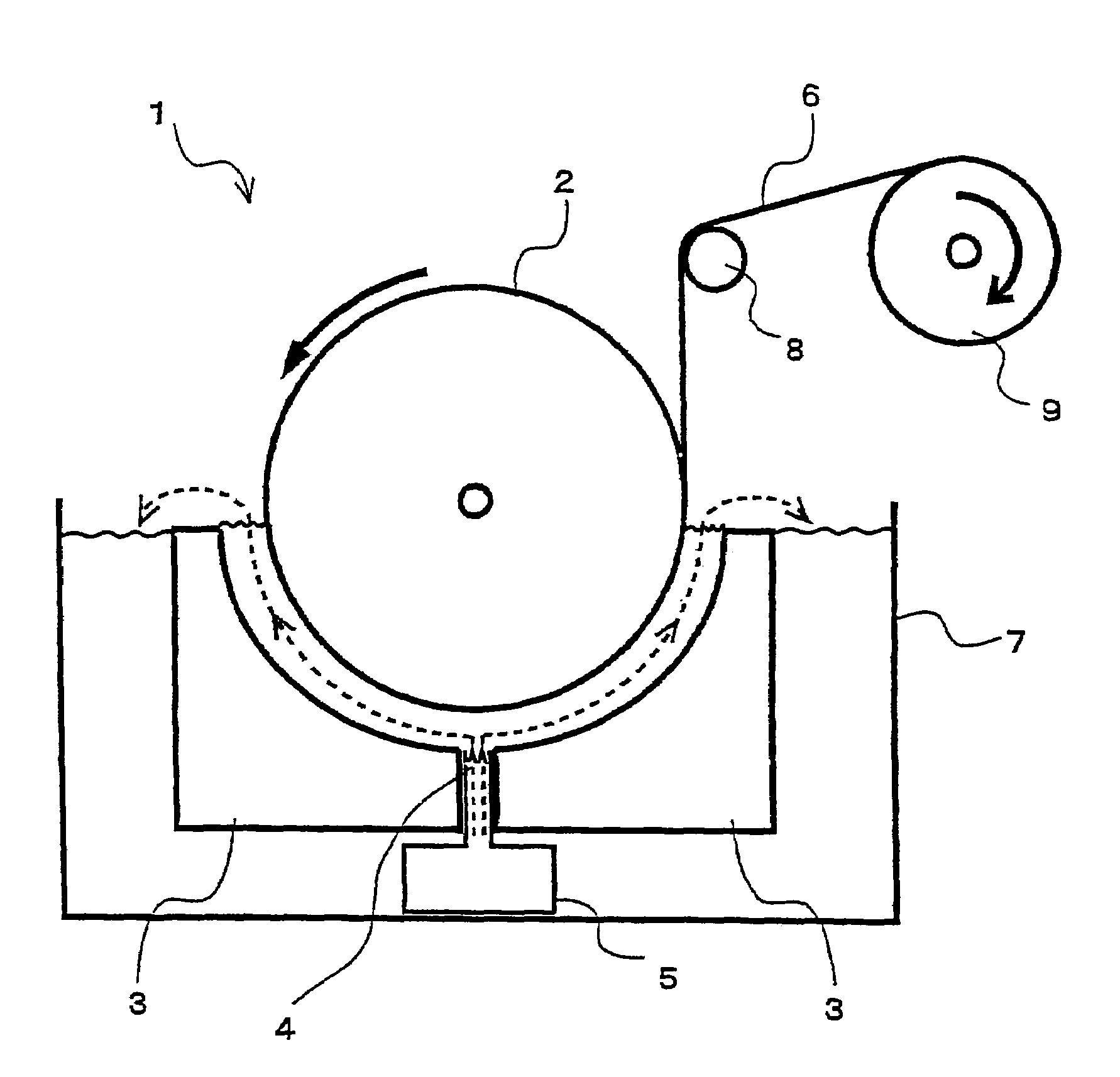

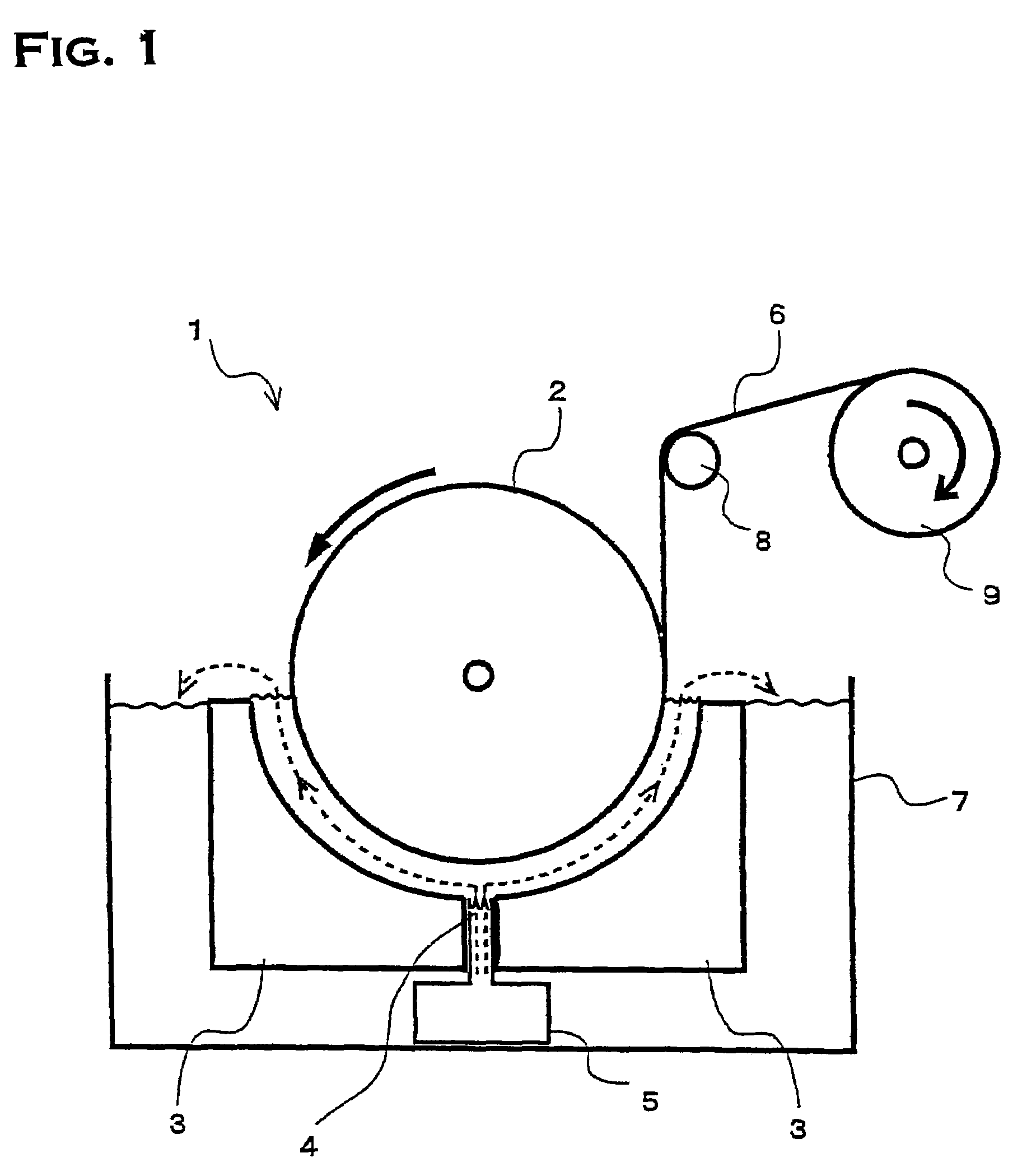

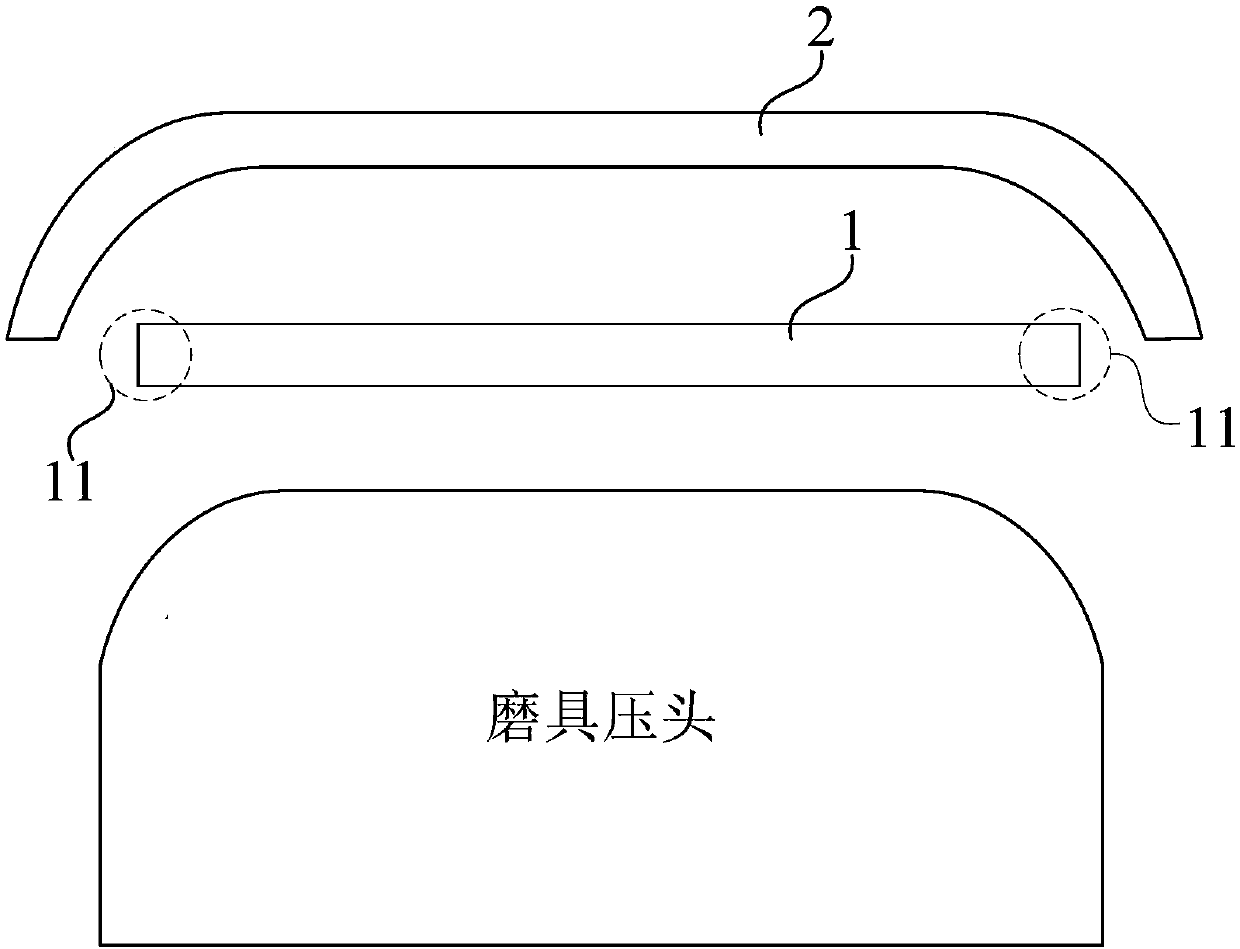

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS20050048306A1Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

An object of the present invention is to produce an ultra-thin copper foil with a carrier which has few pinholes and small surface roughness and which has an the thickness of less than 5 μm, and to produce the method of producing the foil, and further to produce a printed circuit board for fine pattern, a multilayer printed circuit board and a chip on film circuit board by using the ultra-thin copper foil with a carrier. The present invention provides an ultra-thin copper foil with a carrier produced by stacking a peeling layer and an ultra thin copper foil in order on the surface of a carrier copper foil which is made smooth so that the mean surface roughness of at least one side is Rz of 0.01 to 2.0 μm by the chemical polishing, the electrochemical dissolution, or the smoothing plating processing method independently, combining two or more, or further combining the mechanical polishing.

Owner:FURUKAWA ELECTRIC CO LTD

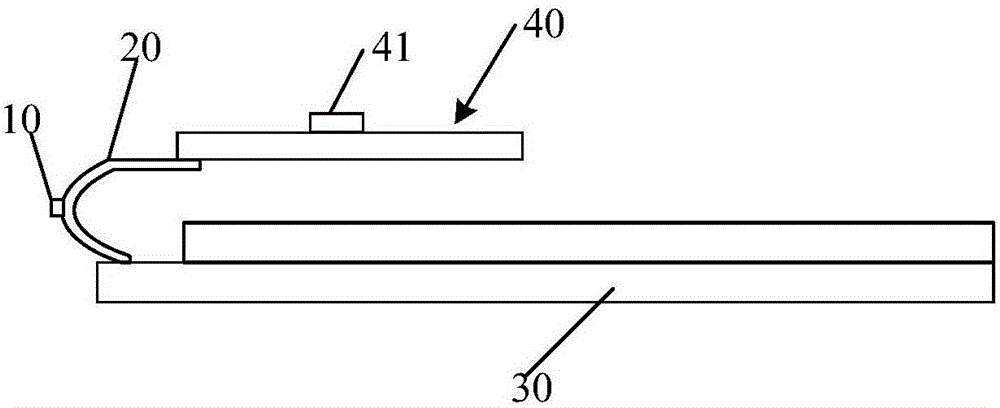

Display device

ActiveUS20150230331A1Smooth dischargeRobust designPrinted circuit aspectsHigh voltage circuit adaptationsChip on filmDisplay device

Provided is a display device including: a display panel; a chip on film (COF) coupled to the display panel; a flexible printed circuit board (FPCB) coupled to the chip on film, the flexible printed circuit board including a plurality of conductive layers and a plurality of insulating layers, the insulating layers being interposed between the conductive layers or being located at opposite sides of the flexible printed circuit board; and a protecting sheet at one side of the display panel and including a conductive region. One of the insulating layers at one side of the flexible printed circuit board is an opening region of the one of the insulating layers and exposes a corresponding one of the conductive layers to at least partially contact the conductive region.

Owner:SAMSUNG DISPLAY CO LTD

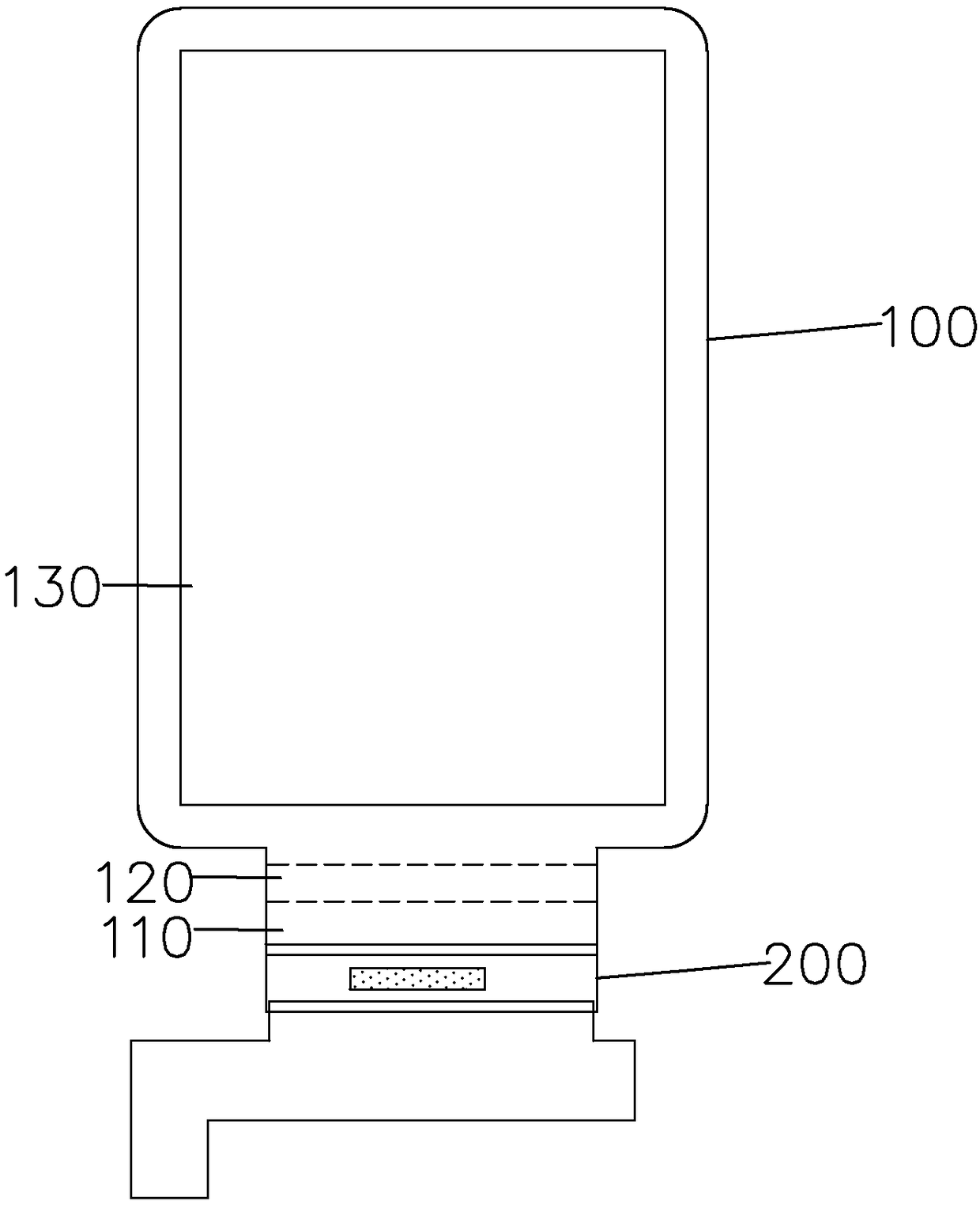

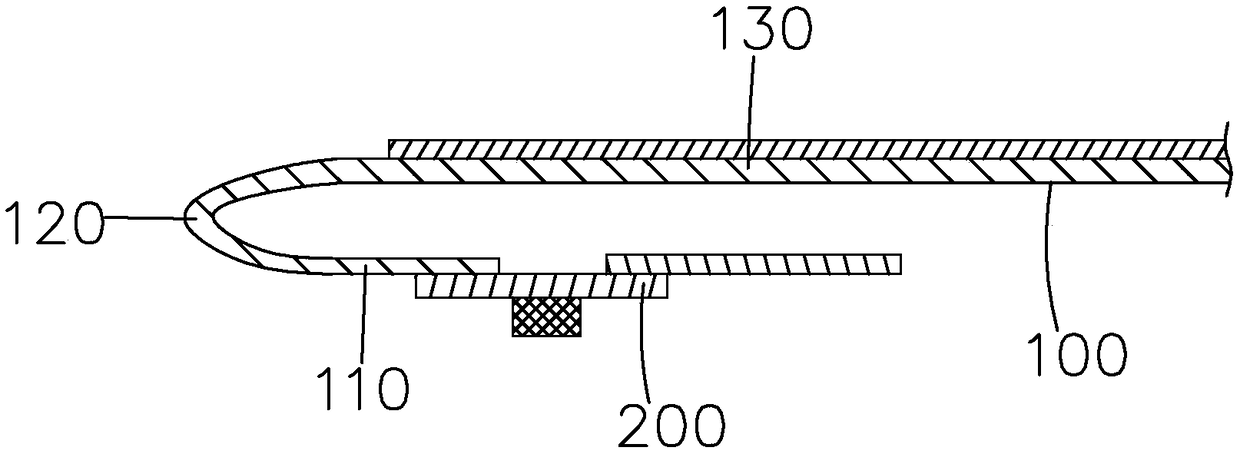

Touch screen panel active matrix organic light emitting diode display device

ActiveUS20130016049A1Reduce thicknessAvoid damageSolid-state devicesPrinted circuitsChip on filmEngineering

A touch screen panel Active Matrix Organic Light Emitting Diode (AMOLED) display device for decreasing the thickness of a mobile terminal and improving a degree of freedom in design is provided. The touch screen panel AMOLED display device includes a flexible AMOLED disposed on the bottom of a window, and a Chip-On-Film (COF) film connected to the flexible AMOLED and coupled with a flexible AMOLED driver Integrated Circuit (IC). Therefore, the thickness of the touch screen panel AMOLED display device may be decreased, and damage of the AMOLED due to an external shock may be prevented. Additionally, separation of the flexible AMOLED driver IC from a mounting surface may be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

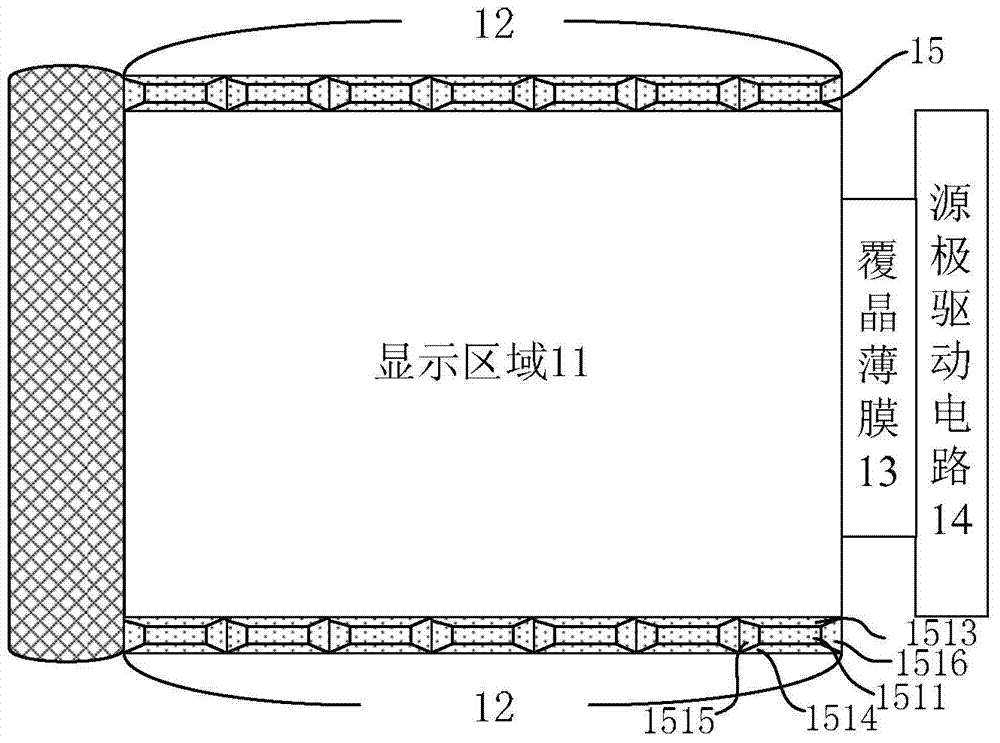

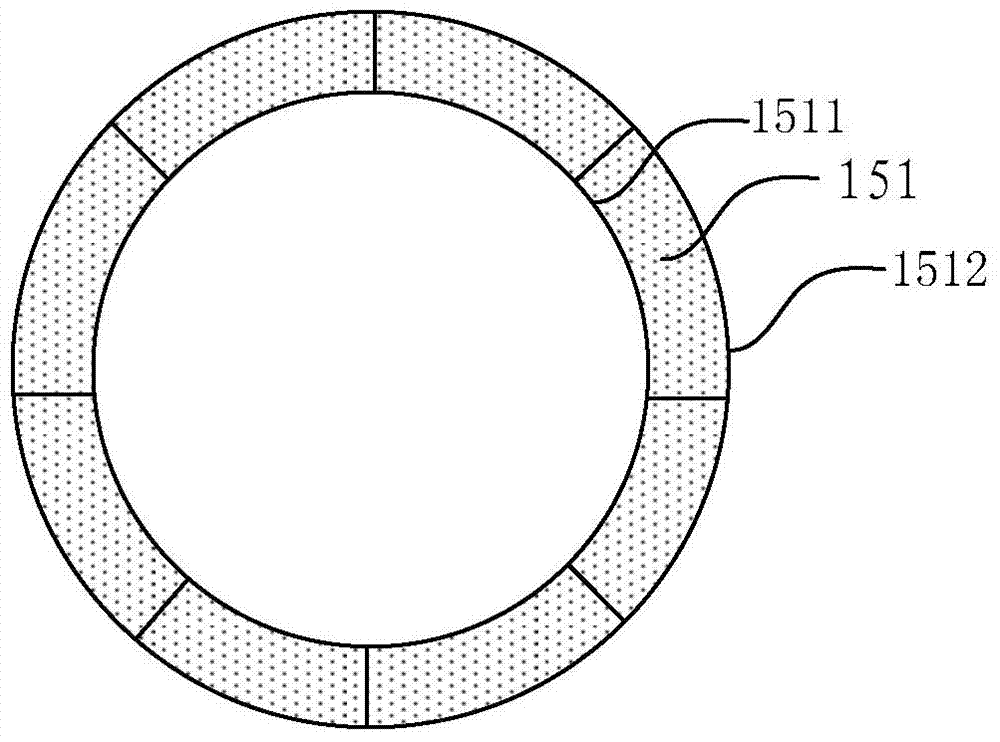

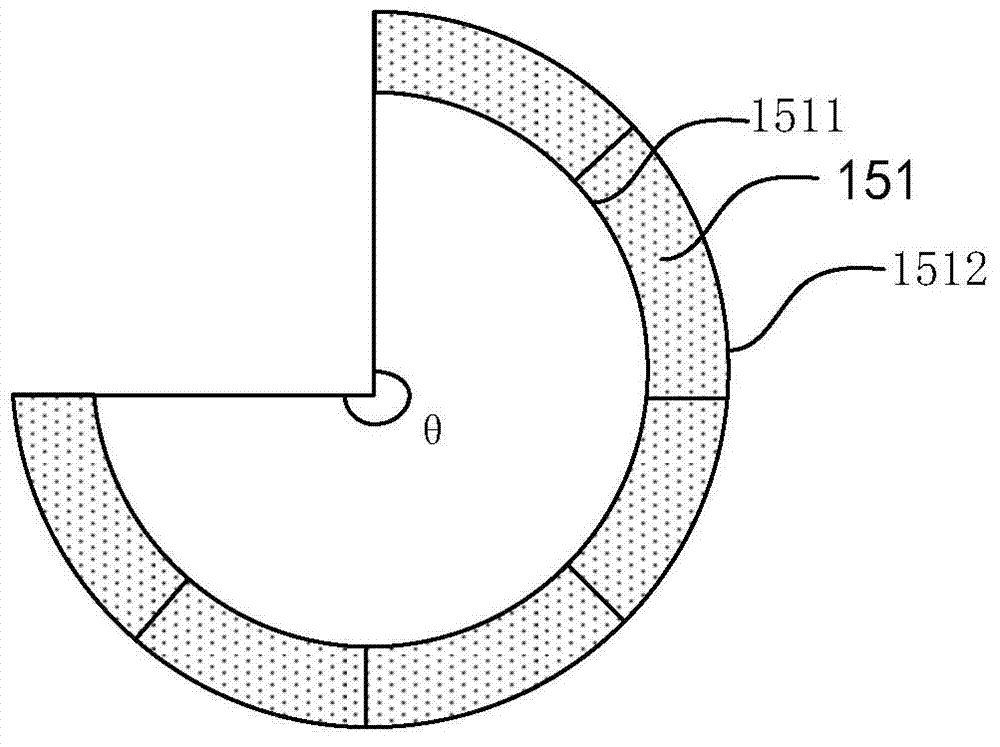

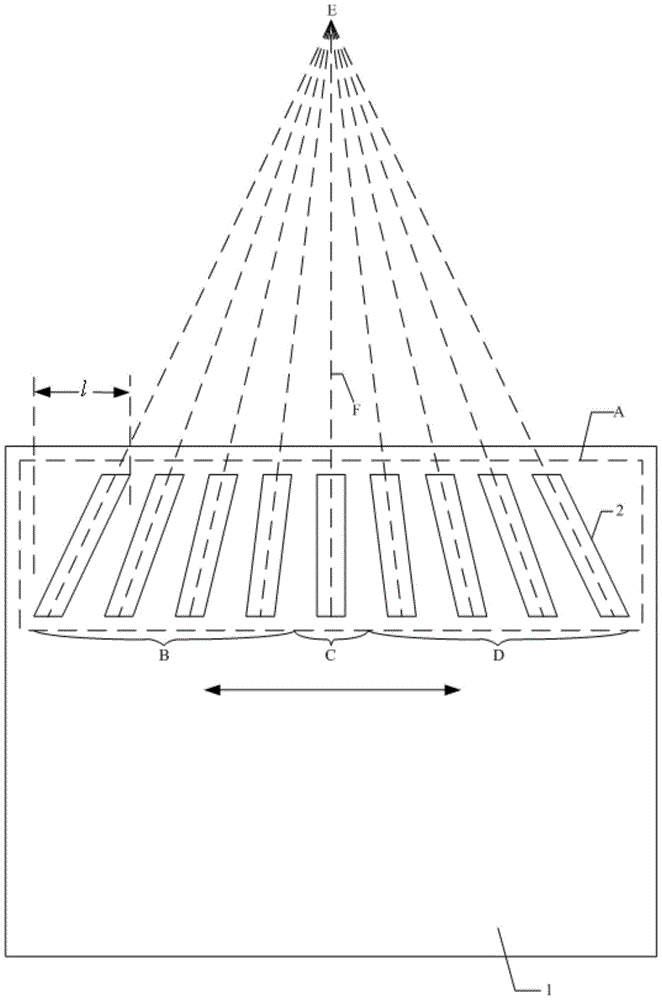

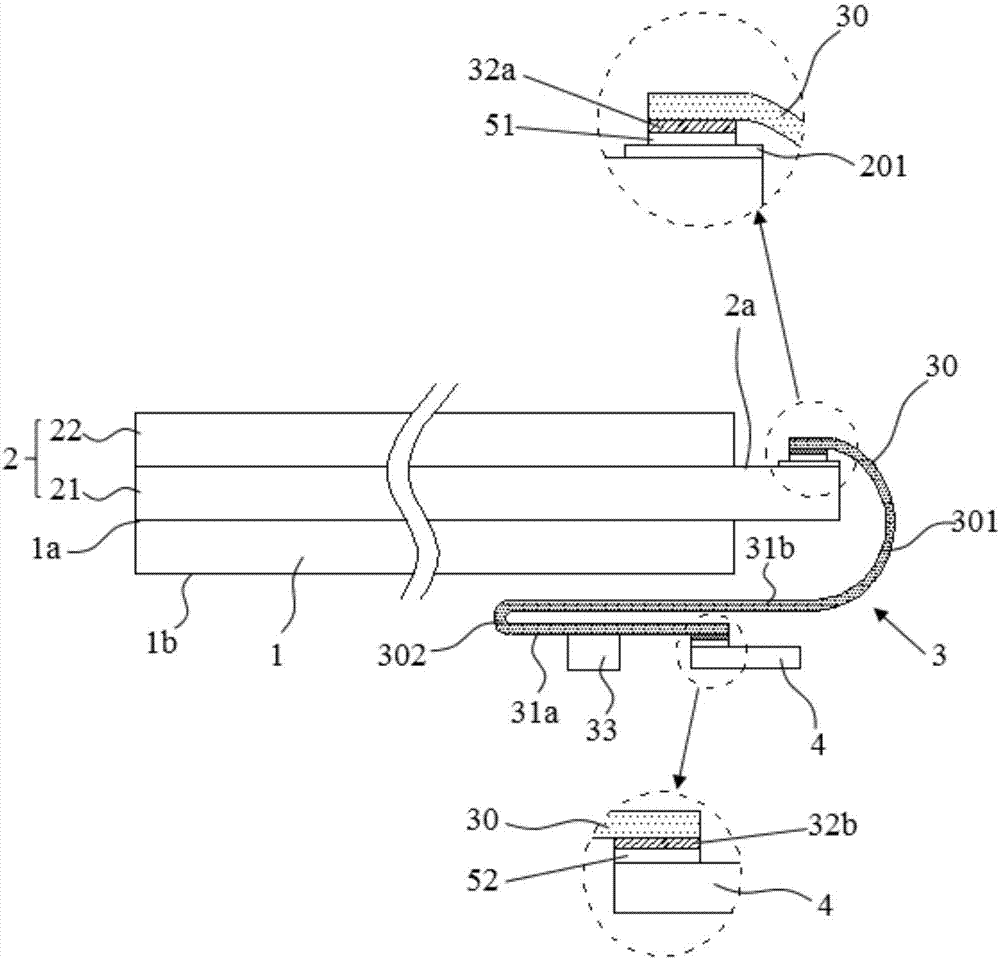

Flexible display panel and driving method thereof, and display apparatus

ActiveCN104851369AControllable radius of curvatureReduce power consumptionSolid-state devicesElectric analogue storesIsosceles trapezoidChip on film

The embodiments of the invention, which belong to the field of the display technology, provide a flexible display panel and a driving method thereof, and a display apparatus. The bending curvature radius of the flexible substrate can be controlled and the power consumption is reduced. The flexible display panel comprises a pixel region, gate drive circuit regions, and a source electrode drive circuit connected with the pixel region by a chip on film. In addition, the flexible display panel also includes curvature adjusting units arranged at the two sides of the pixel region. The curvature adjusting units are formed by a plurality of isosceles-trapezoid-shaped platforms, wherein the lower surfaces of the isosceles-trapezoid-shaped platforms are successively connected; the isosceles-trapezoid-shaped platforms contain upper surfaces, lower surfaces, first waist surfaces, second waist surfaces, third waist surfaces, and fourth waist surfaces, wherein the first waist surfaces and the second waist surfaces are opposite to each other and the third waist surfaces and the fourth waist surfaces are opposite to each other. When the display panel is bent, the third waist surface of one isosceles-trapezoid-shaped platform is in contact with the fourth waist surface of the adjacent isosceles-trapezoid-shaped platform; and the upper surface of the isosceles-trapezoid-shaped platform is connected with the upper surface of the adjacent isosceles-trapezoid-shaped platform. According to the embodiments of the invention, the flexible display panel and the driving method thereof, and the display apparatus are used for manufacturing display equipment.

Owner:BOE TECH GRP CO LTD

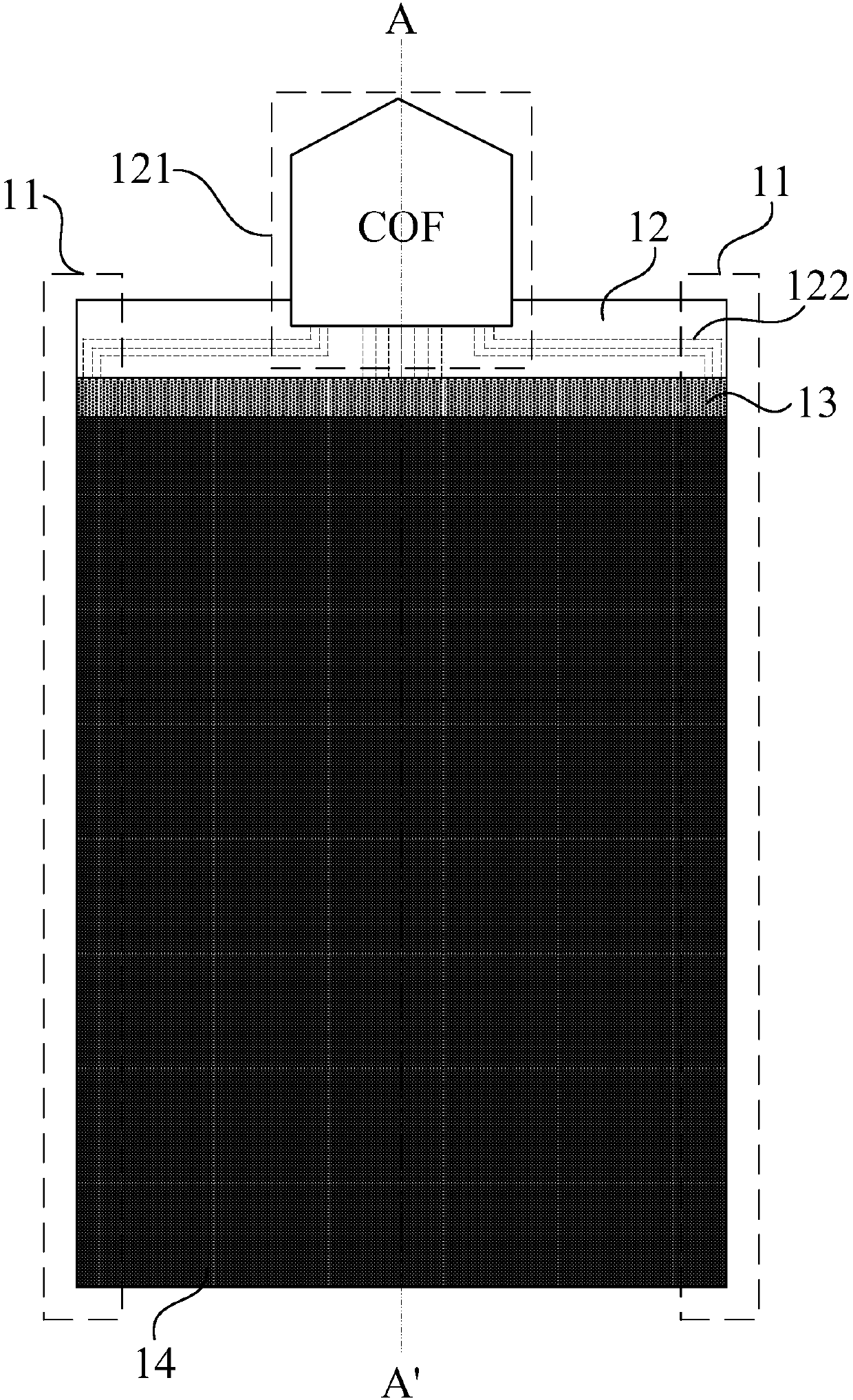

Display panel and manufacturing method thereof, and display device

ActiveCN107039377ANarrow bezelGuaranteed surface contactDigital data processing detailsSemiconductor/solid-state device detailsChip on filmAdhesive

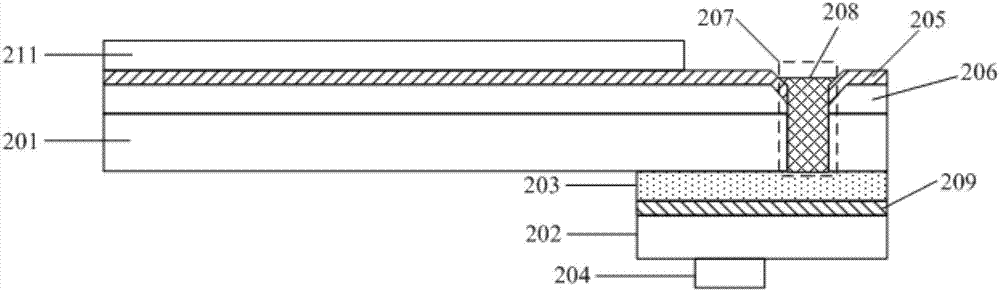

The invention discloses a display panel and a manufacturing method thereof, and a display device. After a chip on film is adhered by adhesive to a side away from the display surface of a display substrate, signal lines around the display surface of the display substrate can be connected with connecting terminals arranged on the chip on film through a conductive material arranged in connecting holes which at least penetrate through the display substrate, the signal lines and an insulating layer. Thus, a connecting terminal bending process is omitted, there is no connecting terminal bending area around a display panel, and the display panel has a narrower bezel. Moreover, as the insulating layer is provided with multiple depressions around the connecting holes, the conductive material can be in contact with the surfaces of the signal lines in the depressions, the contact area of the conductive material and the signal lines is increased, hole drilling and conductive material filling failure are prevented, and the yield of the product is improved.

Owner:BOE TECH GRP CO LTD +1

Alignment method for attaching chip or flexible circuit board to circuit substrate

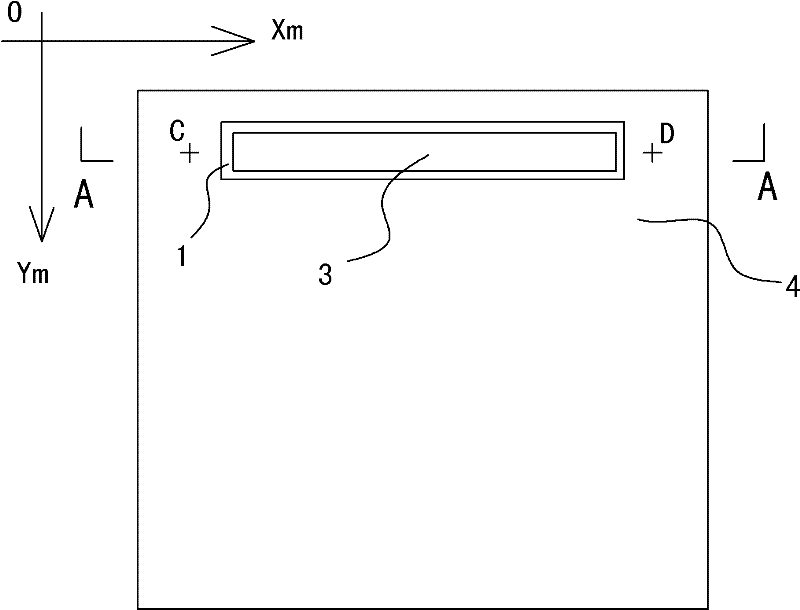

ActiveCN102164460AImprove alignment accuracyGuaranteed alignmentPrinted circuit assemblingSemiconductor/solid-state device testing/measurementChip on filmImaging processing

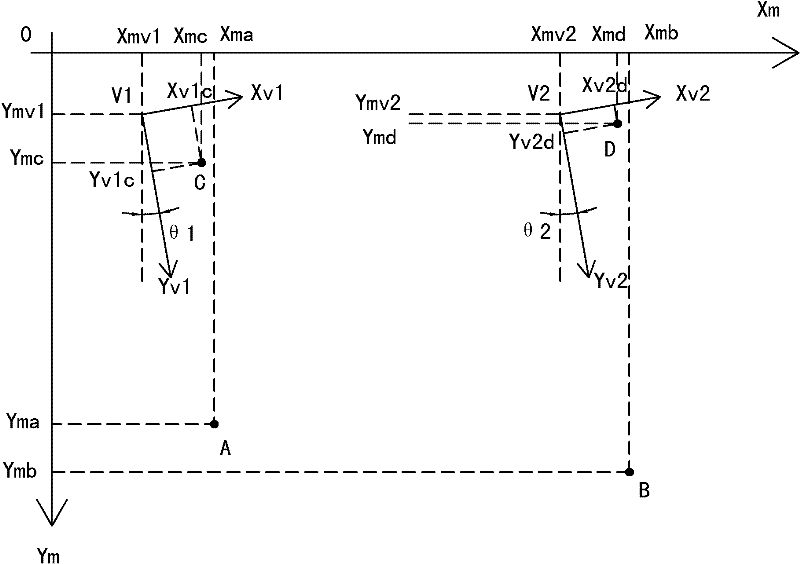

The invention discloses an alignment method for attaching a chip or a flexible circuit board to a circuit substrate, which is characterized by comprising the following steps of: designing two identification points on the circuit substrate in advance; after the circuit substrate is transferred to a framing table board and positioned, shooting images of the two identification points by using a camera, converting the images of the two identification points into position coordinates of an image coordinate system by using an image processing system; converting image coordinates of the two identification points into mechanical coordinate values of a mechanical coordinate system by using a relationship between the image coordinate system and the mechanical coordinate system; finding out an X-directional offset, a Y-directional offset and a deflection angle around a Z axis between the actual positions of the two identification points and a target position through calculation; and finally adjusting the two identification points to the target position by using an X-directional movement mechanism, a Y-directional movement mechanism and a rotating mechanism around the Z axis, so that the chip or the flexible circuit board is aligned with a conducting terminal of the circuit substrate. By the invention, the alignment precision of a chip on glass (COG), a film on glass (FOG) and a chip on film (COF) is greatly improved.

Owner:苏州凯蒂亚半导体制造设备有限公司

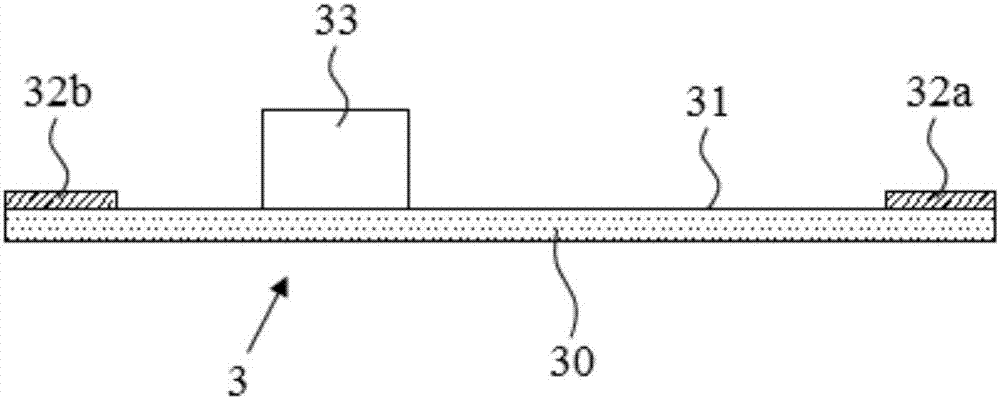

Chip on film and display device

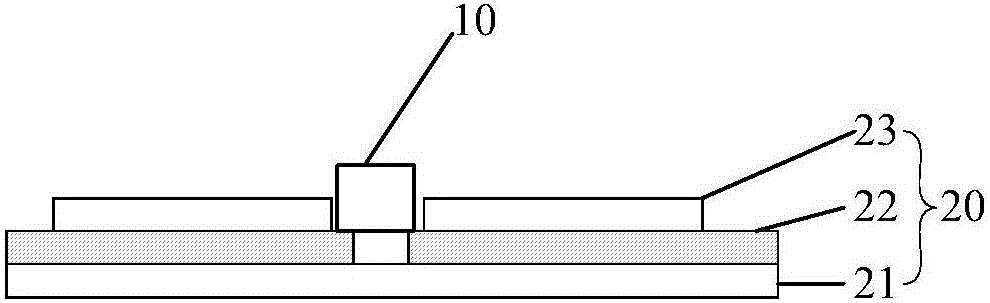

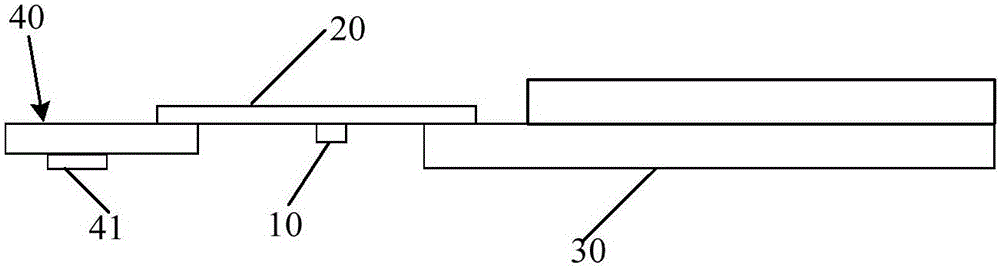

InactiveCN105826353AThe overall thickness is thinReduce crushSolid-state devicesSemiconductor devicesChip on filmFlexible circuits

The present invention provides a chip on film. The chip on film comprises a flexible circuit board, and the flexible circuit board includes a conductive layer consisting of a first binding zone located at the first end of the conductive layer and a second binding zone located at the second end of the conductive layer; the first binding zone is configured to bind a display substrate, and the second binding zone is configured to bind a printing circuit board, wherein the first binding zone and the second binding zone are respectively located at two opposite surfaces of the conductive layer. Correspondingly, the present invention further provides a display device. The chip on film and the display device are able to reduce the whole thickness of the display device and prevent the chip on the chip on film from being extruded.

Owner:BOE TECH GRP CO LTD

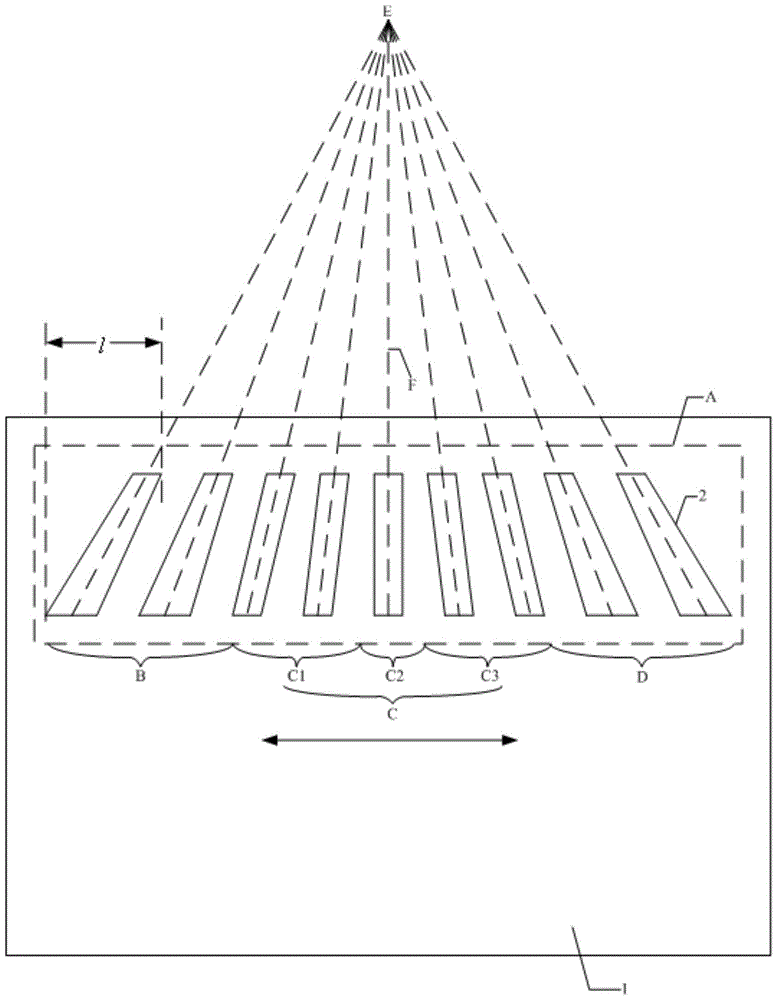

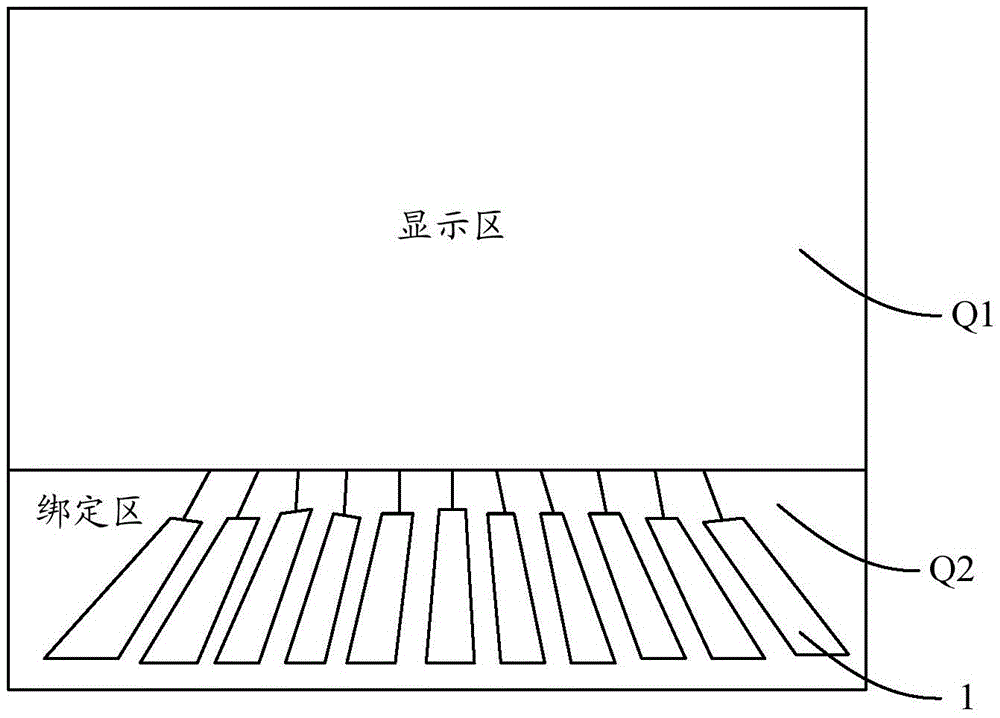

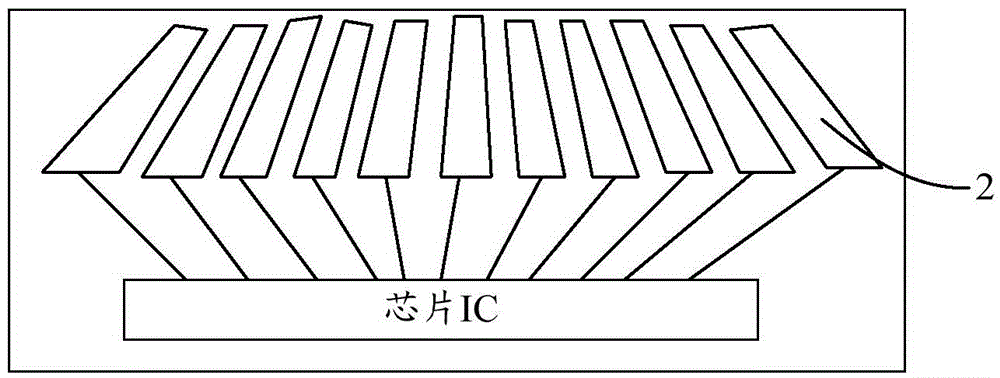

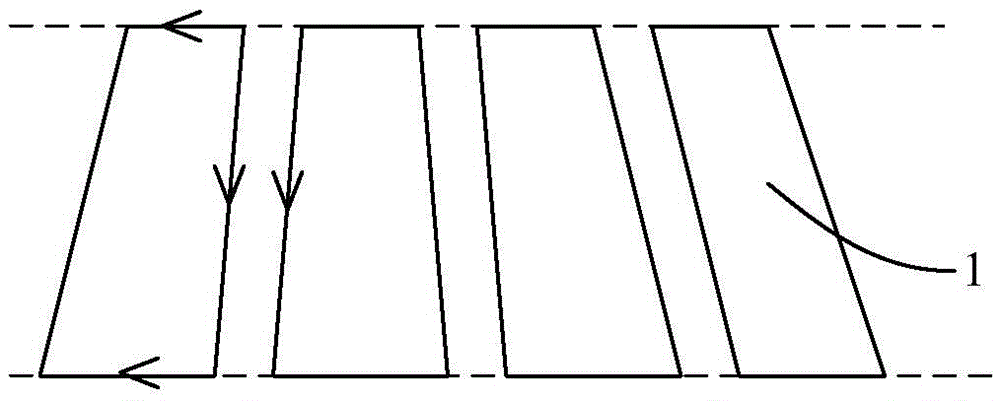

Flexible display panel, display device and binding method for flexible display panel

ActiveCN105513499AAchieve correct alignmentImprove yieldSemiconductor/solid-state device detailsSolid-state devicesChip on filmDisplay device

The invention discloses a flexible display panel, a display device and a binding method for the flexible display panel. The flexible display panel comprises a plurality of fanout leads, wherein the fanout leads are arranged in a fanout region along the first direction; virtual extension lines of the fanout leads in a side region of the fanout region are at least intersected at a first intersection point in a reference line vertical to the first direction; a chip on film comprises a plurality of output pads which are arranged along the first direction and correspond to the fanout leads one by one; and virtual extension lines of the output pads corresponding to the fanout leads in the side region are at least intersected at a second intersection point in the reference line. When the size of the flexible display panel changes along the first direction, the included angles between the virtual extension lines of the output pads and the fanout leads, which are in one-to-one correspondence, and the reference line are the same, so that correct alignment of the output pads and the fanout leads is achieved by adjusting the relative positions of the flexible display panel and the chip on film in the direction vertical to the first direction and then binding the flexible display panel and the chip on film, and the binding yield and the reliability are improved.

Owner:BOE TECH GRP CO LTD

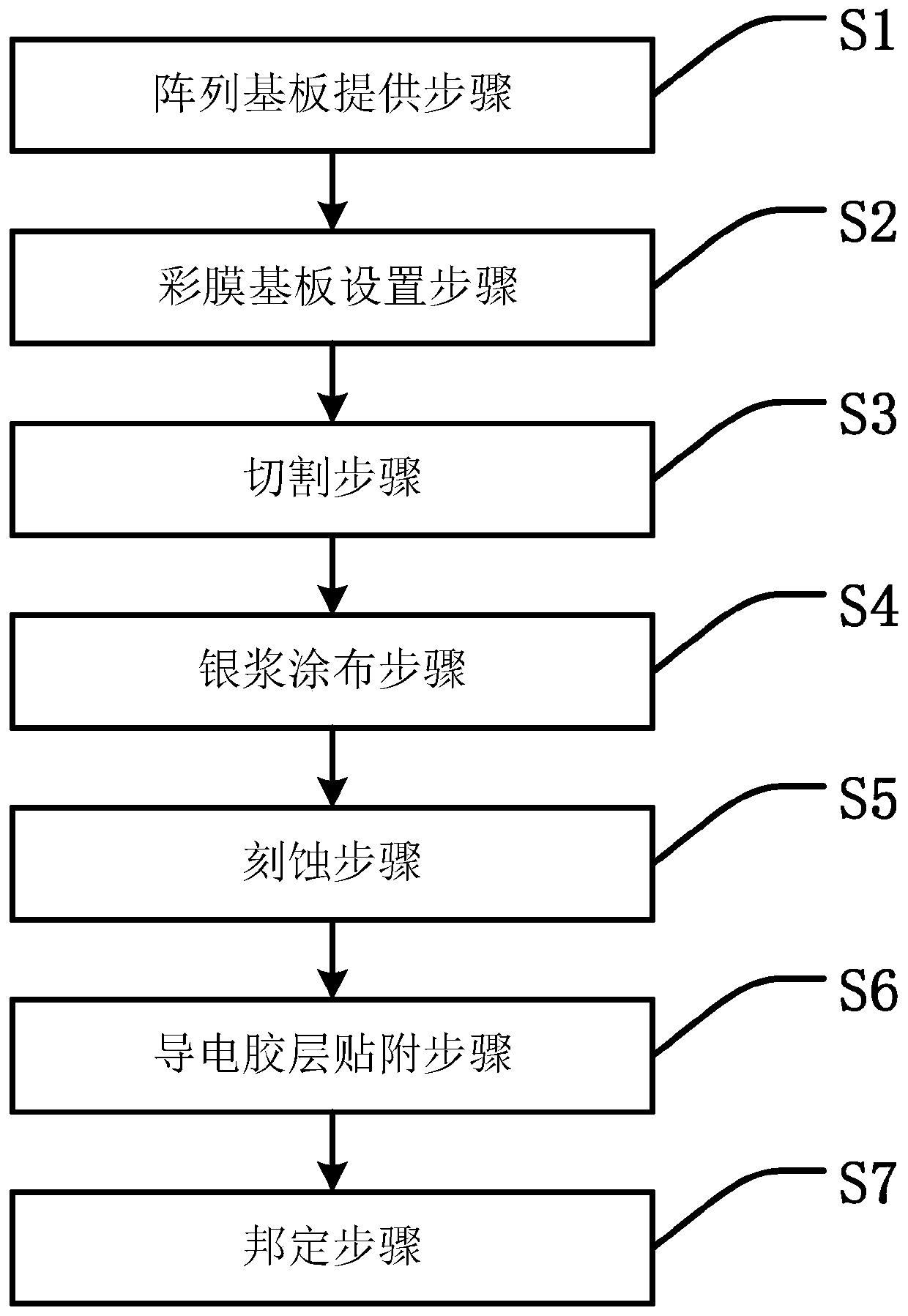

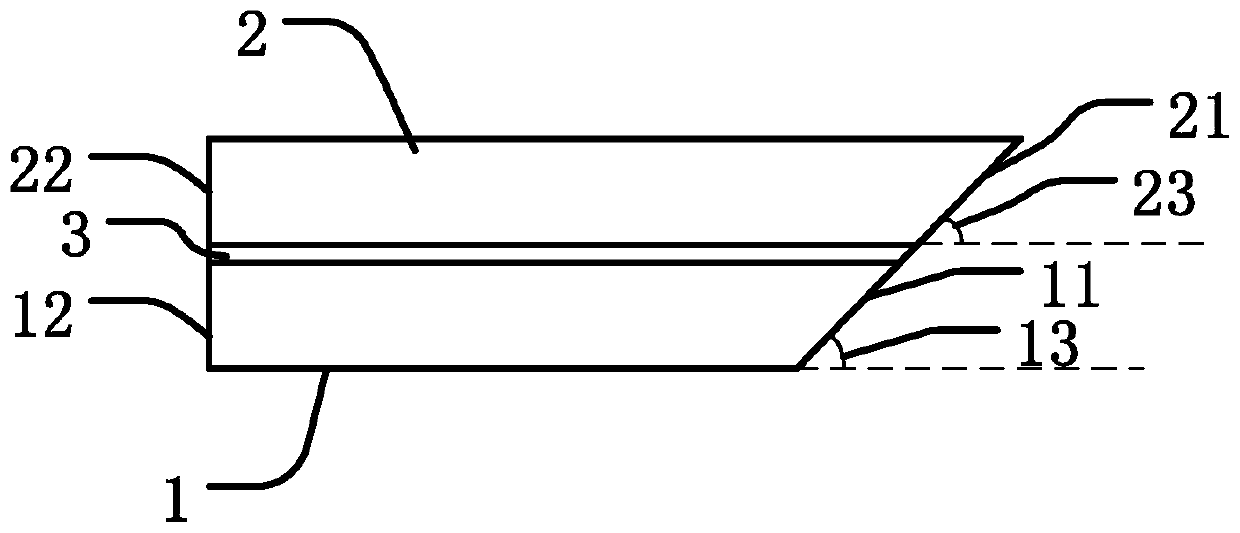

Display panel and display device

ActiveCN107247373AConducive to narrow borderReduce areaPrinted circuit groundingSemiconductor/solid-state device detailsChip on filmDisplay device

The invention discloses a display panel and a display device, and belongs to the field of display technologies. The display panel comprises electrically conductive adhesion bodies, a chip on film, an electrically conductive layer, a first substrate and a second substrate. The first substrate is opposite to the second substrate, the chip on film is adhered at a step region of the first substrate, and the electrically conductive layer is positioned on the side, which is far away from the first substrate, of the second substrate; the chip on film comprises a grounding bonding pad, and the grounding bonding pad is arranged on the side, which is far away from the first substrate, of the chip on film; the electrically conductive adhesion bodies are electrically connected with the electrically conductive layer and are electrically connected with the grounding bonding pad. According to the technical scheme, the display panel and the display device have the advantages that the grounding bonding pad is arranged on the side, which is far away from the first substrate, of the chip on film, accordingly, the occupied area of the step regions can be reduced while static electricity is prevented, and frames of the display panel can be advantageously narrowed.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

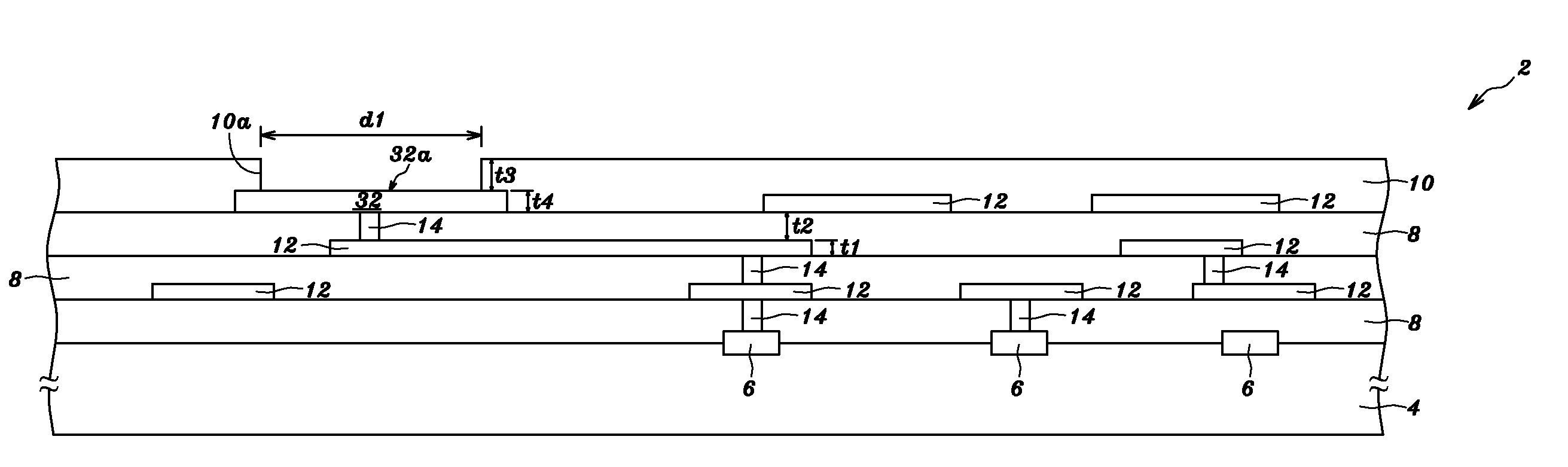

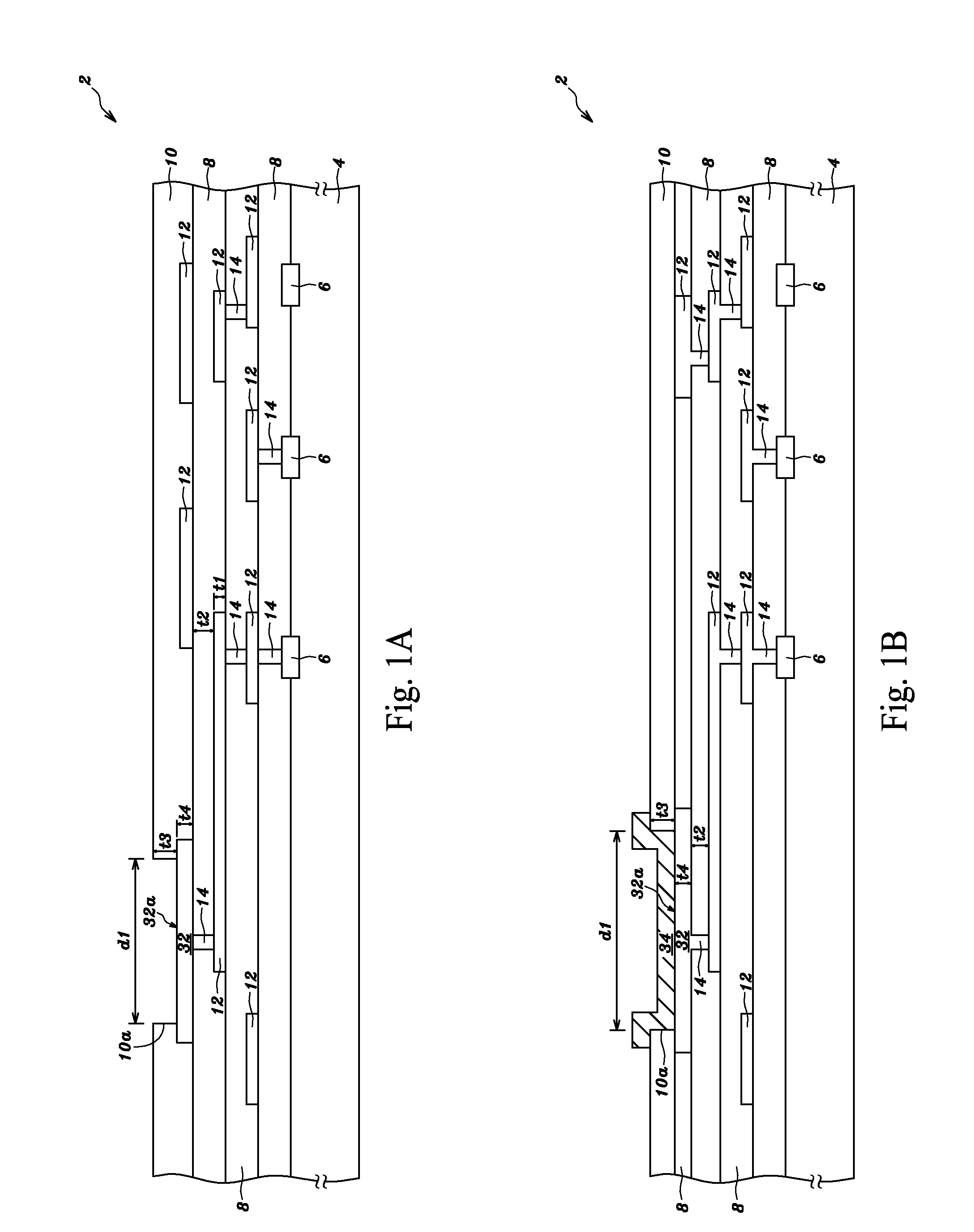

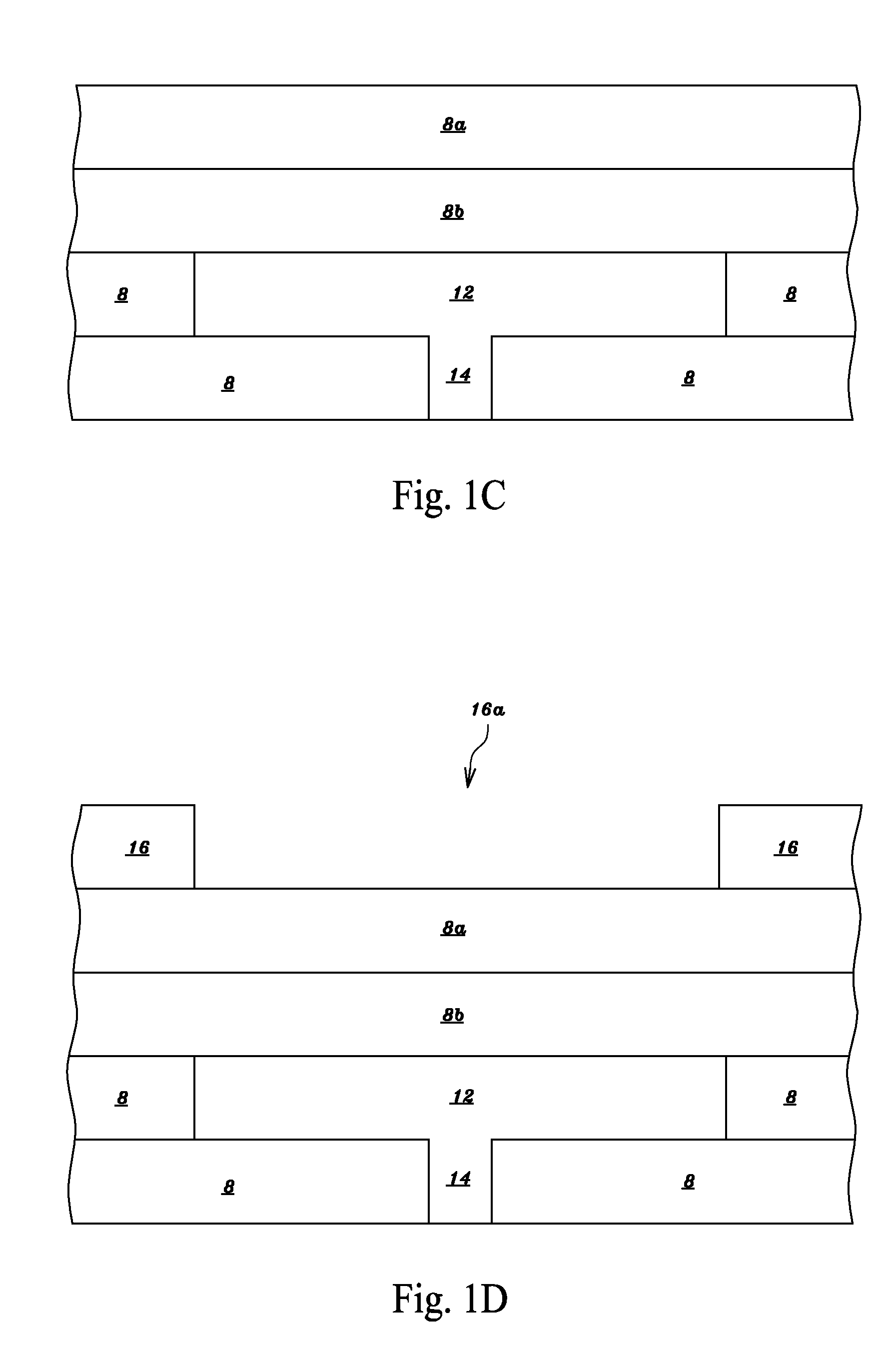

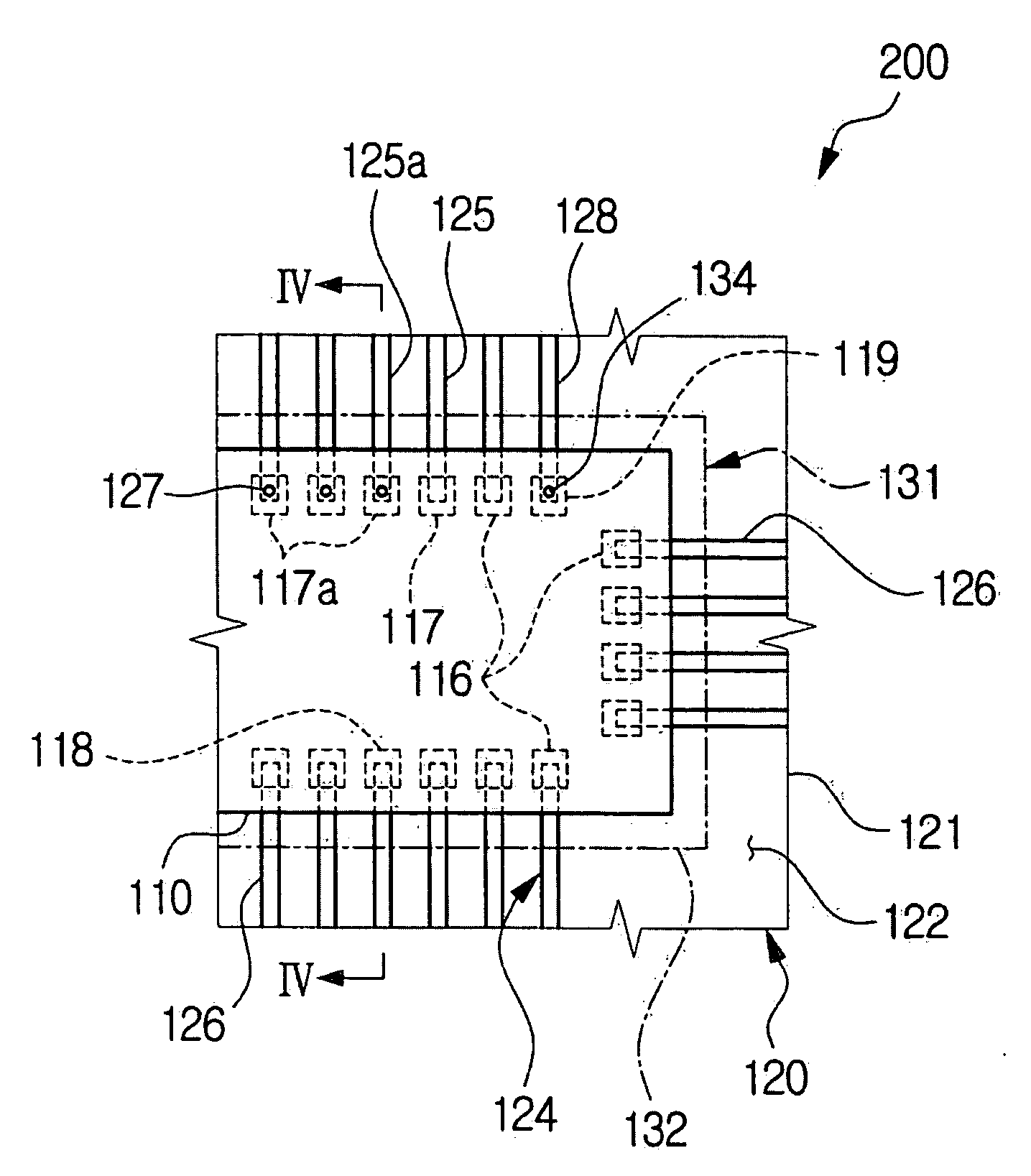

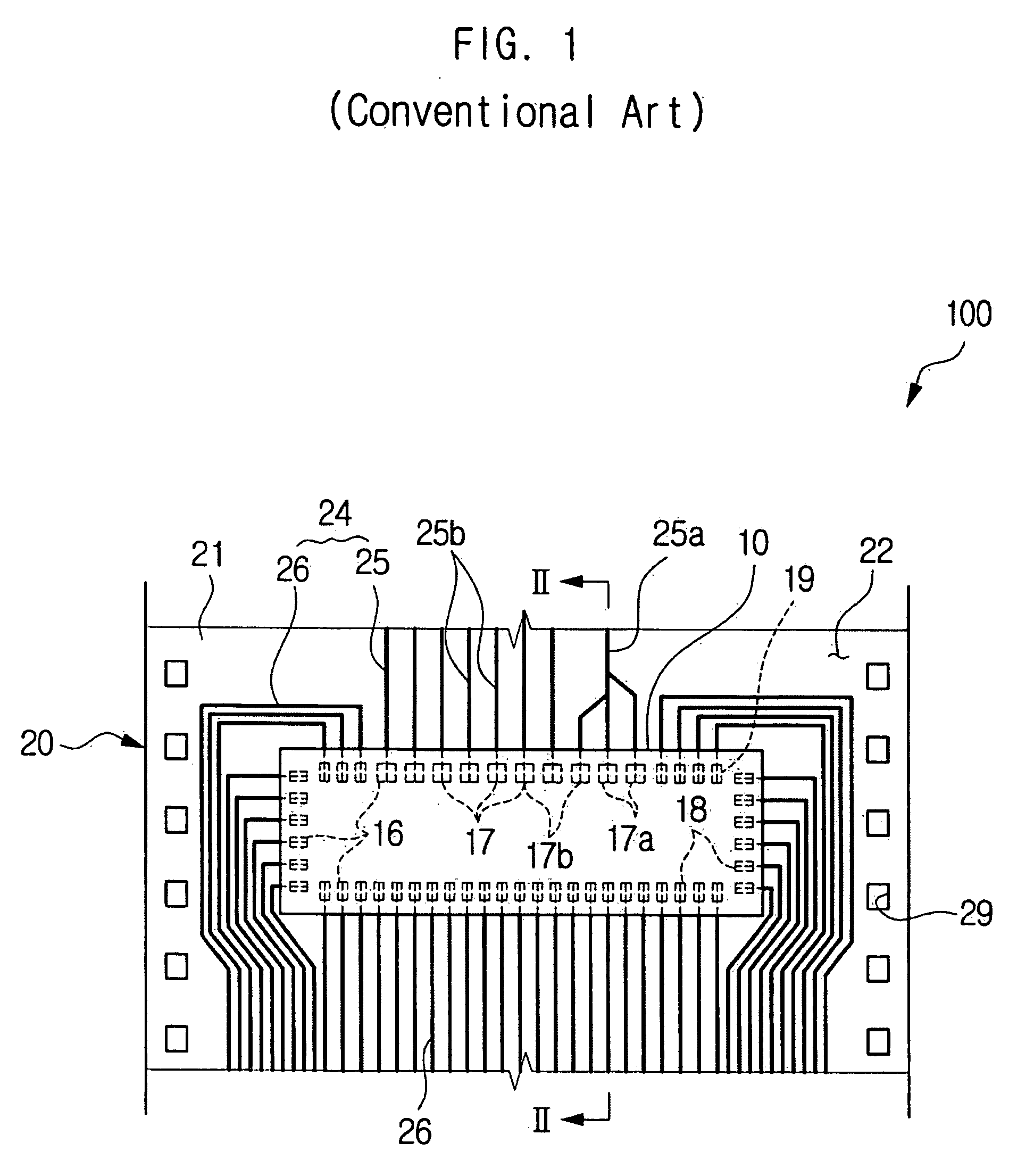

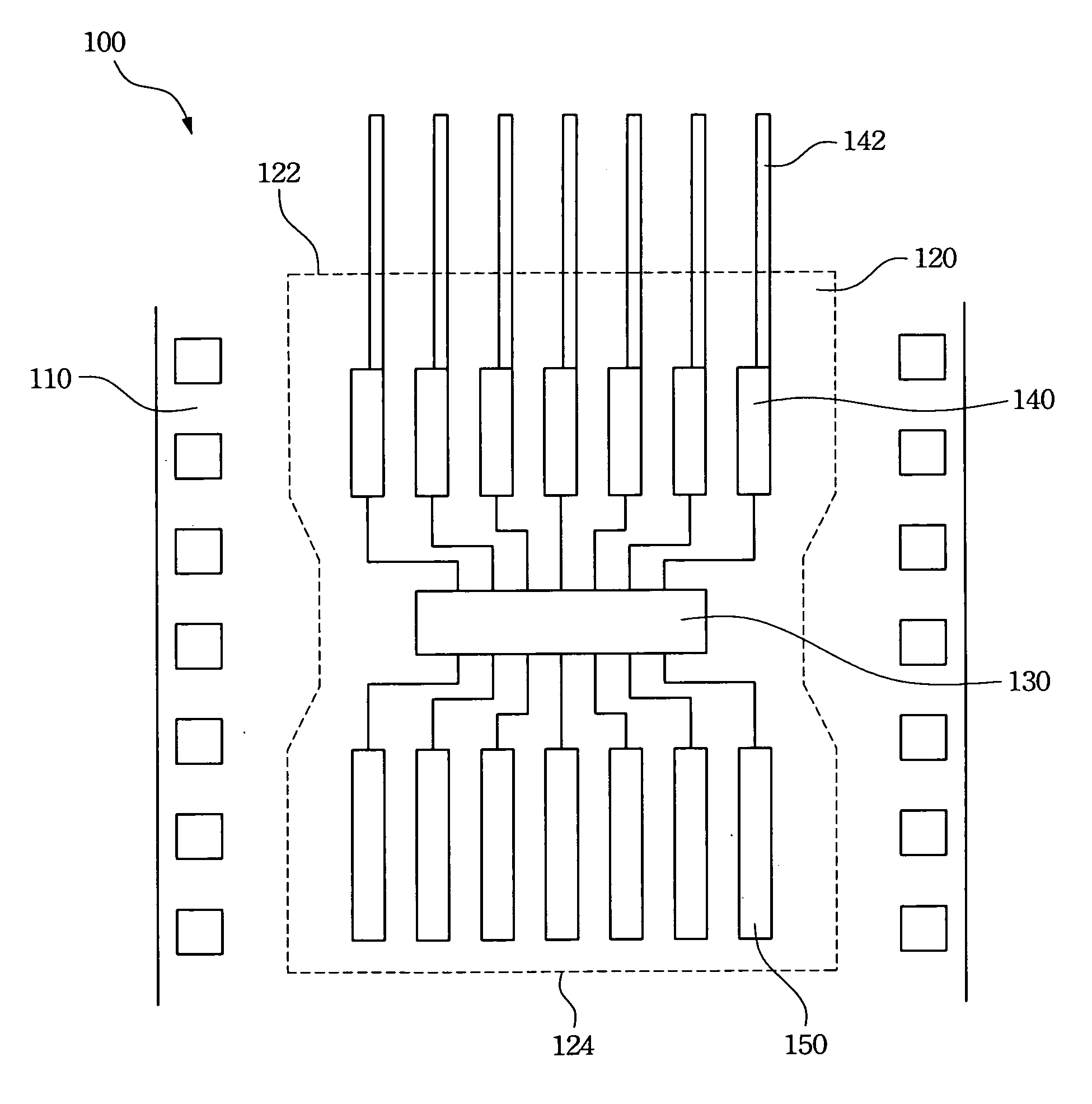

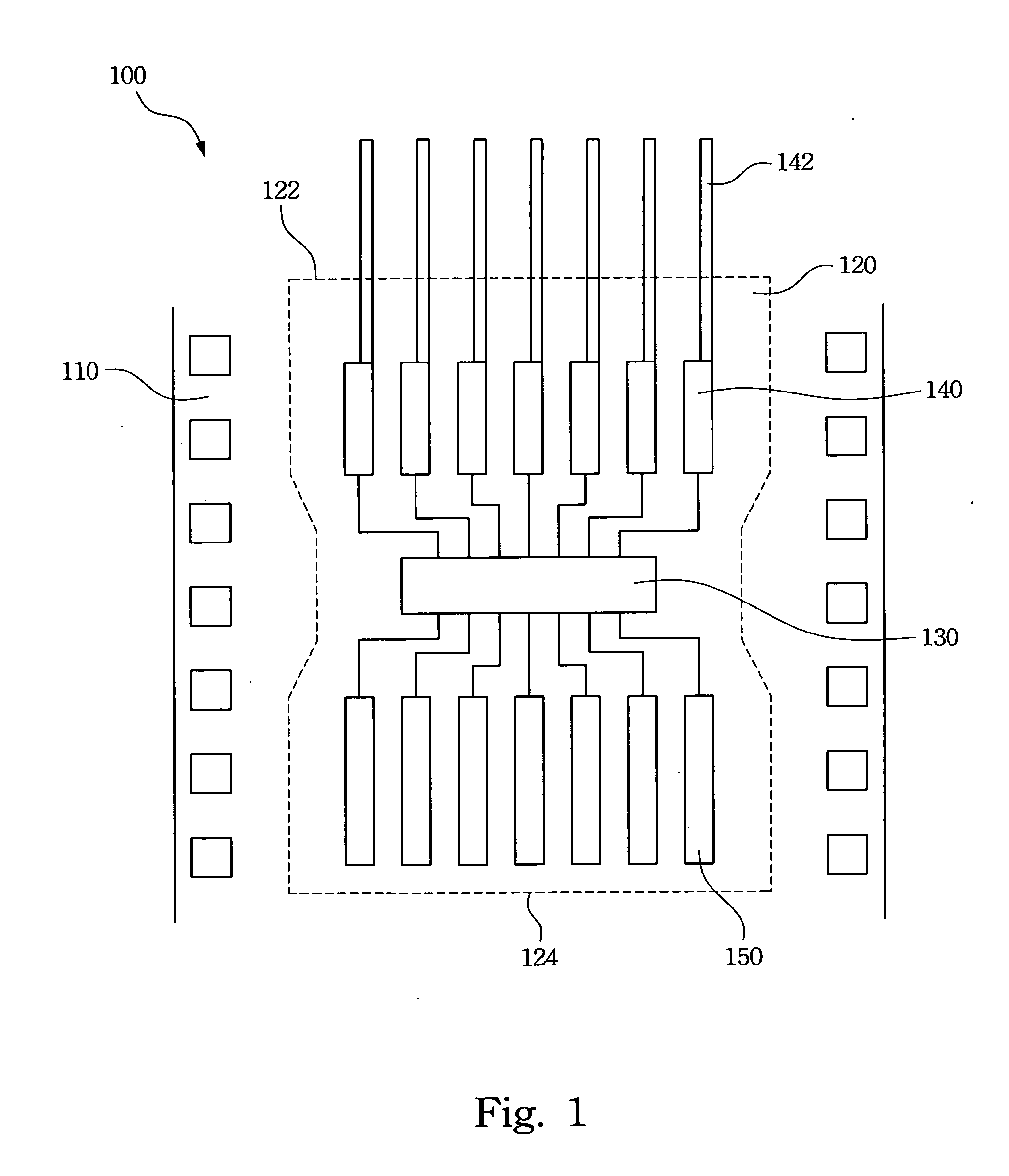

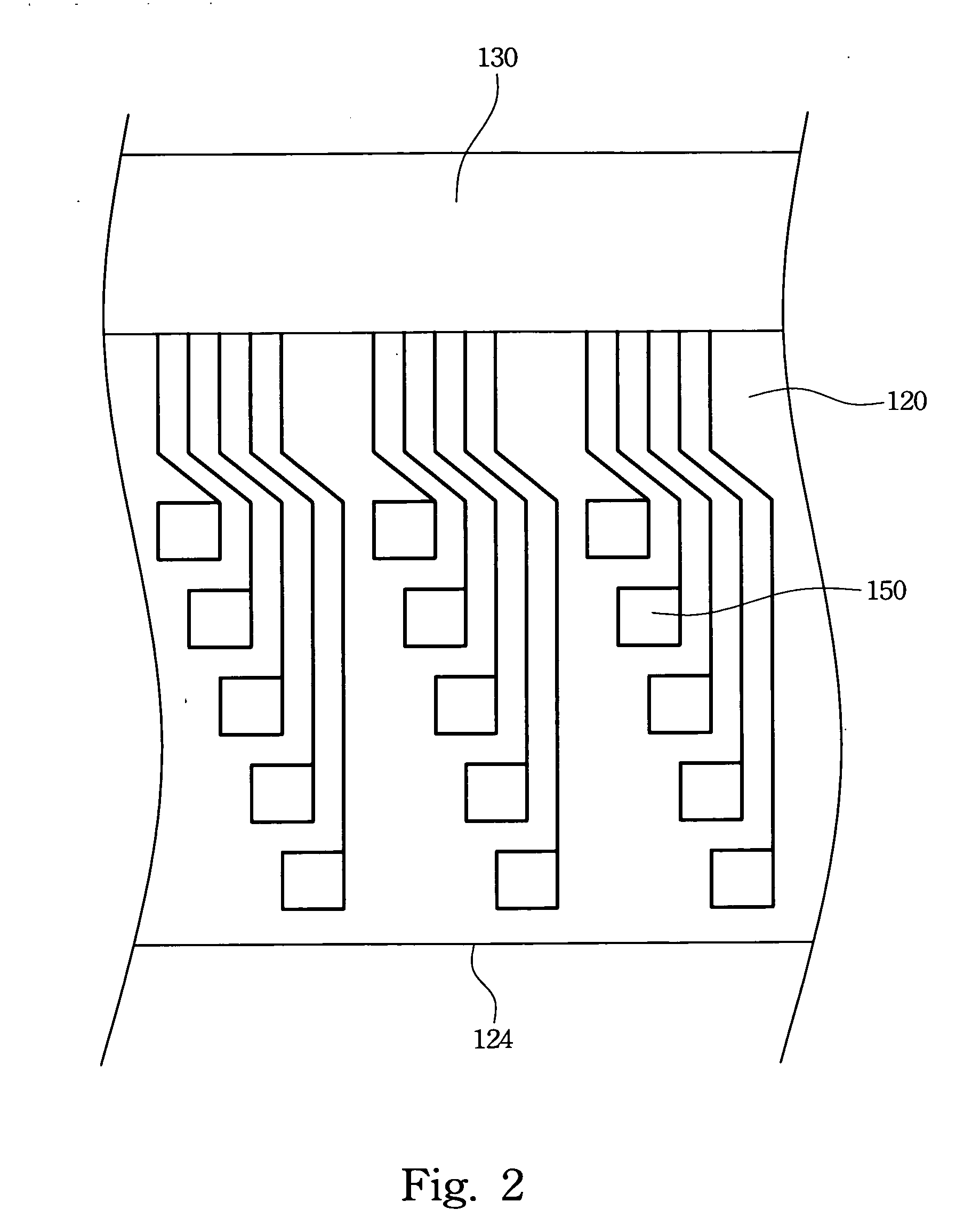

Tape wiring substrate and chip-on-film package using the same

ActiveUS20070013056A1Semiconductor/solid-state device detailsCross-talk/noise/interference reductionChip on filmSemiconductor chip

A chip-on-film package may include a tape wiring substrate, a semiconductor chip mounted on the tape wiring substrate, and a molding compound provided between the semiconductor chip and the tape wiring substrate. The tape wiring substrate may include a film having upper and lower surfaces. Vias may penetrate the film. An upper metal layer may be provided on the upper surface of the film and include input terminal patterns and / or output terminal patterns. The input terminal patterns may include ground terminal patterns and / or power terminal patterns. A lower metal layer may be provided on the lower surface of the film and include a ground layer and / or a power layer. The ground layer and the power layer may cover at least a chip mounting area.

Owner:SAMSUNG ELECTRONICS CO LTD

Chip-on-film package and display device including the same

ActiveUS20160218053A1Small sizeImprove productivitySemiconductor/solid-state device detailsSolid-state devicesChip on filmDisplay device

A chip-on-film (COF) package includes a base film, a semiconductor chip mounted on a chip mounting region of a top surface of the base film, a plurality of top inner output conductive patterns, a plurality of bottom inner output conductive patterns and a plurality of landing vias. The top inner output conductive patterns are formed on the top surface of the base film and respectively connected to chip inner output pads formed on a bottom surface of the semiconductor chip. The bottom inner output conductive patterns are formed on a bottom surface of the base film. The landing vias are formed to vertically penetrate the base film and to respectively connect the top inner output conductive patterns and the bottom inner output conductive patterns. The landing vias are arranged within the chip mounting region to form a two-dimensional shape.

Owner:SAMSUNG ELECTRONICS CO LTD

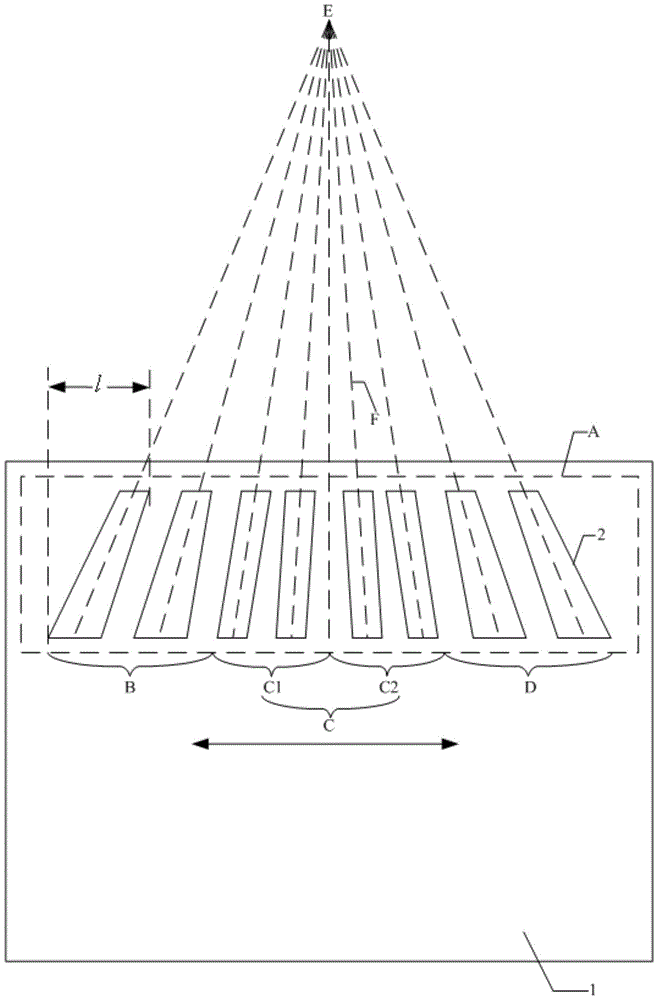

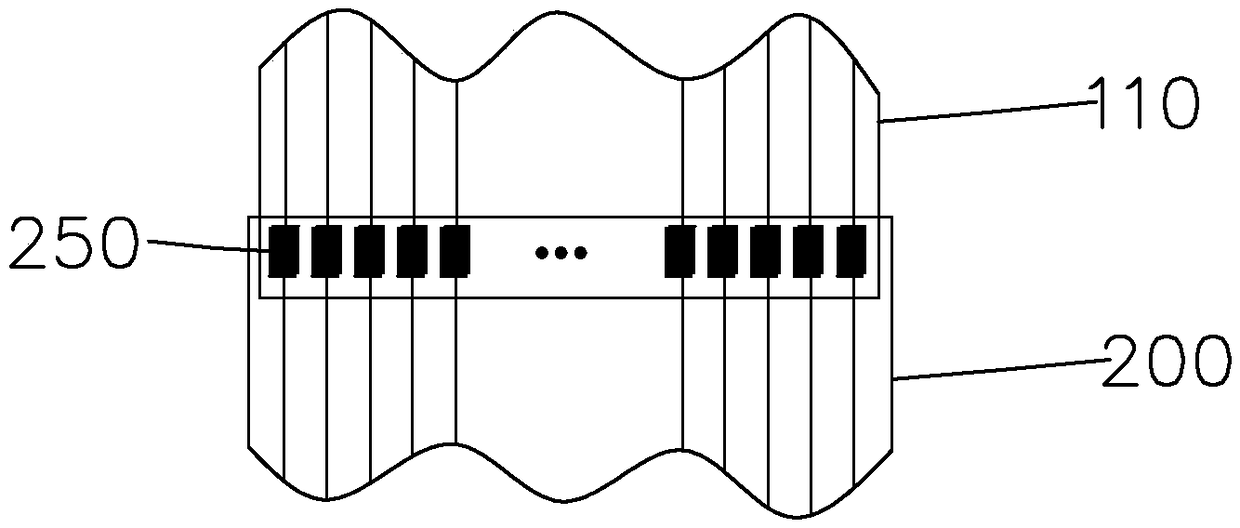

Chip on film, flexible display panel and display device

ActiveCN105720028AAvoid misalignmentImprove bonding yieldStatic indicating devicesSemiconductor/solid-state device detailsChip on filmDisplay device

The invention discloses a chip on film, a flexible display panel and a display device. When a swelling amount of a middle area in a binding area of the flexible display panel is smaller than swelling amounts of areas on both sides, input pad distances in the middle area are smaller than input pad distances in the areas on both sides. In the chip on film disclosed by the invention, output pads positioned in different areas are set into different shapes, namely, the output pads in the middle area are set into shapes to occupy small space while the output pads in the areas on both sides are set into shapes to occupy relatively large space, so that the chip on film can adapt to deformation at different positions in the binding area of the flexible display panel; a compression joint area between the chip on film and the binding area of the flexible display panel is increased; the problem of misalignment between the output pads of the chip on film and input pads in the binding area of the flexible display panel is solved; and a binding yield between the chip on film and the flexible display panel is increased.

Owner:BOE TECH GRP CO LTD

Liquid crystal display

ActiveUS20100265225A1Small sizePreventing defective orientation of liquid crystalsCathode-ray tube indicatorsNon-linear opticsChip on filmChIP-on-chip

A liquid crystal display is disclosed. The liquid crystal display includes a liquid crystal display panel including an upper substrate, a lower substrate, a liquid crystal layer between the upper substrate and the lower substrate, and m×n liquid crystal cells (where m and n are a positive integer) arranged in a matrix format according to a crossing structure of m / 2 data lines and 2n gate lines, a plurality of chip on films (COFs) on which source driver integrated circuits (ICs) supplying a data voltage to the data lines are mounted, a printed circuit board (PCB) connected to input terminals of the COFs, and a gate drive circuit directly mounted onto the lower substrate, the gate drive circuit supplying a gate pulse to the gate lines.

Owner:LG DISPLAY CO LTD

Flexible display device

ActiveCN109377890AHigh resolutionGuaranteed binding accuracyCircuit bendability/stretchabilitySolid-state devicesChip on filmFlexible display

The invention provides a flexible display device. The flexible display device comprises a flexible display panel and chip on film bound to the flexible display panel, the flexible display panel is divided into a display area, a binding area and a bending area, the chip on film comprises a main body part and two expansion binding parts vertically arranged at the two ends of one side edge of the main body part respectively, multiple connection pins are arranged on the side edge, adjacent to the two expansion binding parts, of the main body part and the two expansion binding parts, and the chip on film is bound to the binding area of the flexible display panel through the connection pins. The flexible display device has the advantages that by changing the shape of the chip on film, the two ends of one side of the main body part are additionally provided with the expansion binding parts, the edge of the side, only corresponding to the binding area, of existing chip on film is provided withthe connection pins, the edges of the three sides, corresponding to the binding area, of the existing chip on film are provided with the connection pins, under the situation of ensuring the binding precision and not increasing the width of the binding area, the number of the connection pins can be increased correspondingly, thereby being conductive to high-resolution-ratio display of the flexibledisplay device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Array substrate, chip on film and display device

ActiveCN105529339AConvenient bindingSemiconductor/solid-state device detailsPrinted circuit aspectsChip on filmDisplay device

The invention provides an array substrate, a chip on film and a display device and belongs to the technical field of display. The display device provided by the invention comprises the array substrate and the chip on film, wherein the array substrate comprises a plurality of first bonding pads which are arranged side by side; the chip on film comprises a plurality of second bonding pads which are arranged side by side; the array substrate is bound to the second bonding pads of the chip on film through the first bonding pads; each first bonding pad comprises a first side, a second side, a third side and a fourth; each first side and each second side are oppositely arranged in a column direction; each third side and each fourth side are oppositely arranged in the column direction; the first side and the second side of each first bonding pad are not arranged in parallel; and each second bonding pad and the bound first bonding pad have the same structure. The array substrate, the chip on film and the display device can be applied to a flexible display panel.

Owner:BOE TECH GRP CO LTD

Electrophoretic display device and packing structure thereof

InactiveUS20100013756A1Avoid it happening againQuick assemblyStatic indicating devicesSemiconductor/solid-state device detailsChip on filmElectrophoresis

An electrophoretic display device includes: an electrophoretic display panel; a COF (Chip On Film) attached to at least one side of the display panel and having a driving element mounted thereon; and a support frame installed on a rear surface of the electrophoretic display panel, wherein the COF is attached to the support frame through a double-sided tape.

Owner:LG DISPLAY CO LTD

Liquid display device

ActiveCN108008584AReduce the impactAvoid performance degradationNon-linear opticsChip on filmLiquid-crystal display

The invention discloses a liquid display device. The liquid display device comprises a back light module, a liquid crystal panel and a chip on film, wherein the backlight module is composed of a lightemitting surface and a back surface opposite to the light emitting surface; the liquid crystal panel is arranged on the light emitting surface of the backlight module, and the front surface of the liquid crystal panel, which backs to the backlight module, is provided with a signal binding end; the chip on film is composed of a flexible circuit board, a binding unit and a driving chip, the bindingunit and the driving chip are arranged on the first surface of the flexible circuit board, the flexible circuit board is electrically connected to the signal binding end through the binding unit andis bent to extend towards the back surface of the backlight module; in the part of the flexible circuit board which is bent to extend towards the back surface of the backlight module, the first surface of the flexible circuit board comprises a first area back to the backlight module, and the driving chip is connected inside the first area. The liquid display device can reduce influence of heat generated by the backlight module on the driving chip, thereby improving the reliability of the driving chip.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

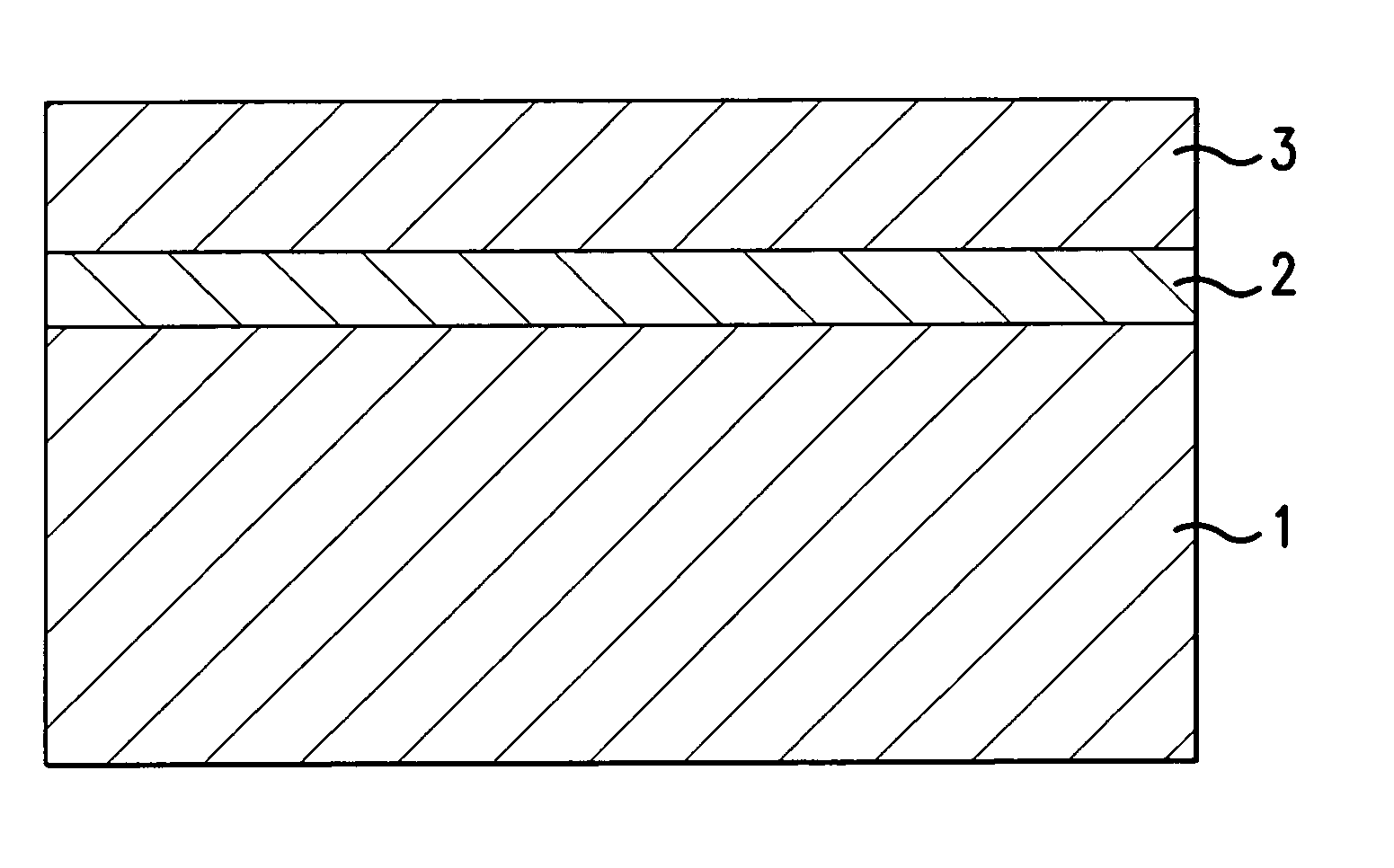

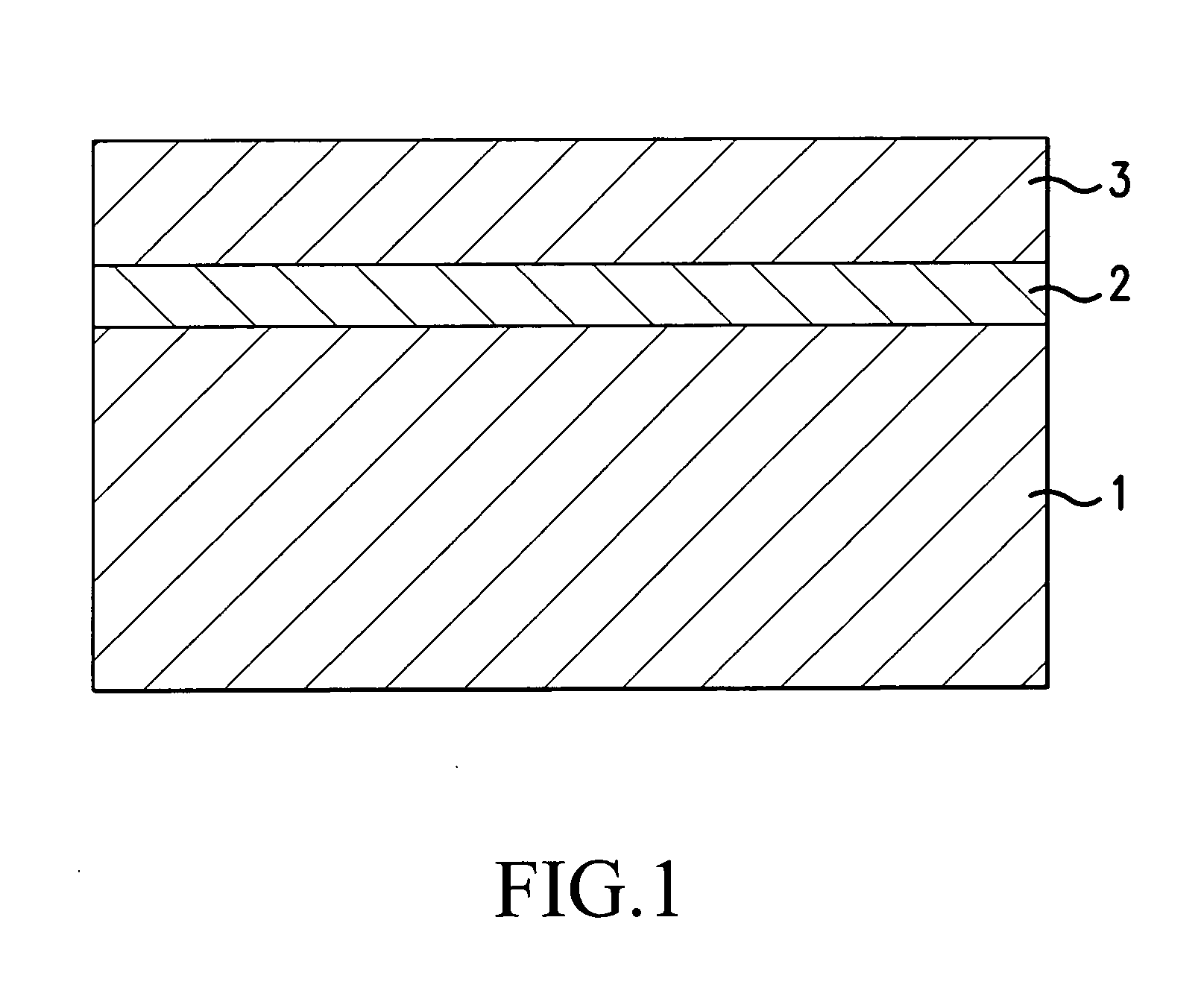

Flexible printed wiring board for chip-on flexibles

InactiveUS6984456B2More adhesiveReduce adhesionThermometers using material expansion/contactionPrinted circuit secondary treatmentElectrical resistance and conductanceChip on film

There is provided a flexible printed wiring board including an insulating layer having a high optical transmittance, a high adhesion strength and a high migration resistance, and suitable for a chip on film (hereafter referred to as COF). In a flexible printed wiring board for COF, having an insulating layer on which a conductive layer of an electrodeposited copper foil is laminated, and an optical transmittance of 50% or more of the insulating layer in the etched region when a circuit is formed by etching said conductive layer, electrodeposited copper foil was made to have a rust-proofing layer of a nickel-zinc alloy on the adhering surface to be adhered to the insulating layer; the surface roughness (Rz) of the adhering surface was made to be 0.05 to 1.5 μm, and the specular gloss was made to be 250 or more when the incident angle is 60°.

Owner:MITSUI MINING & SMELTING CO LTD

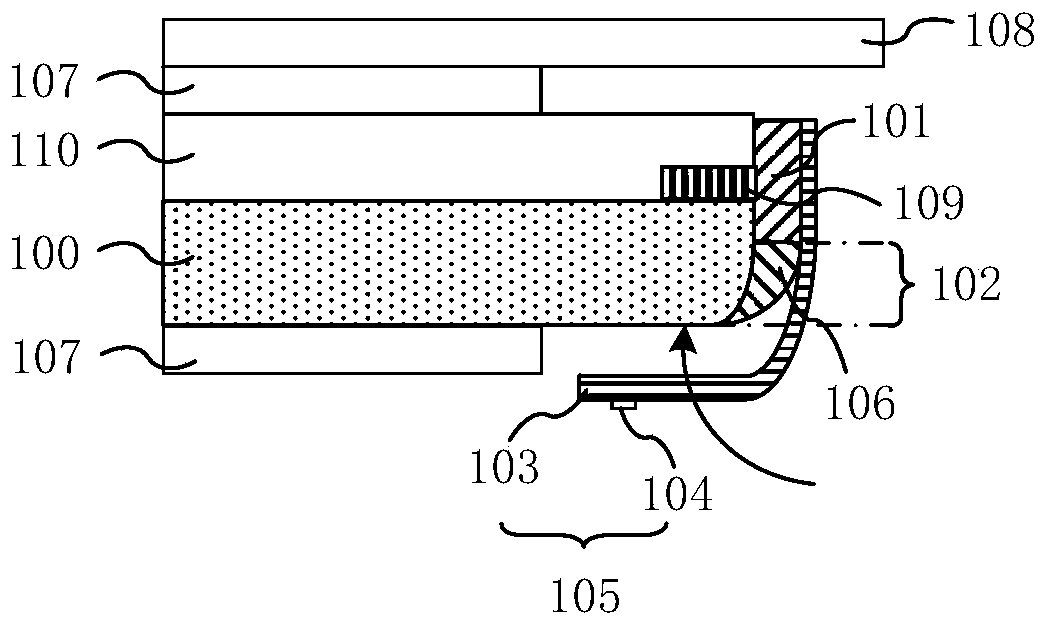

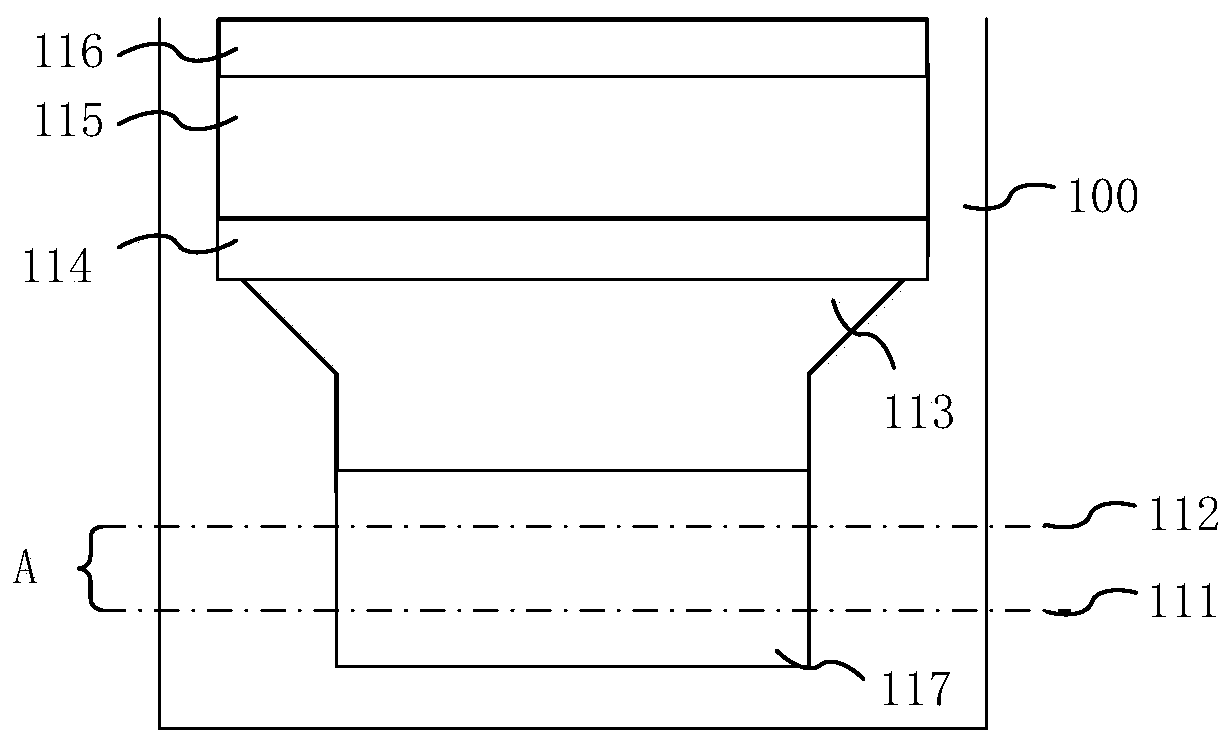

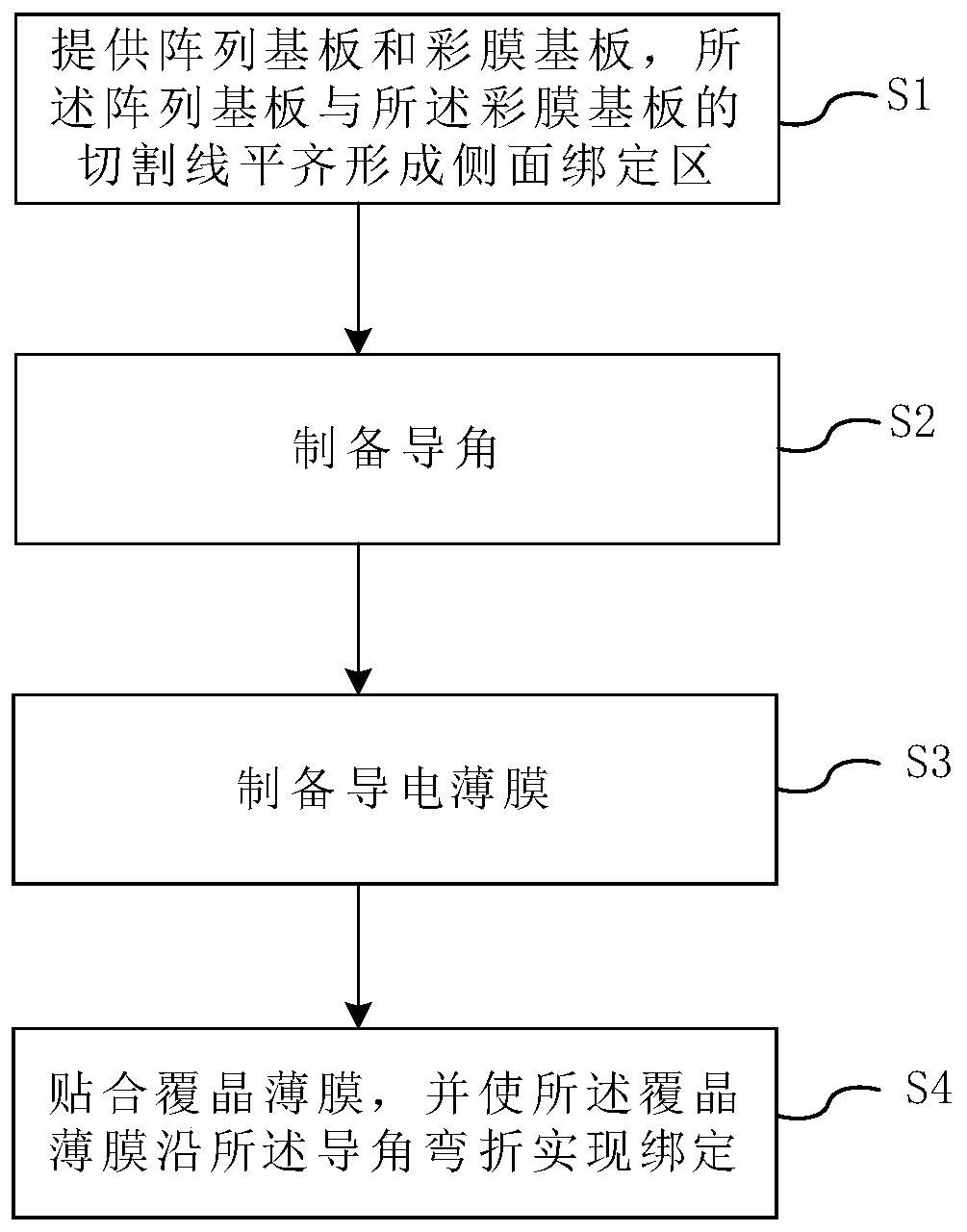

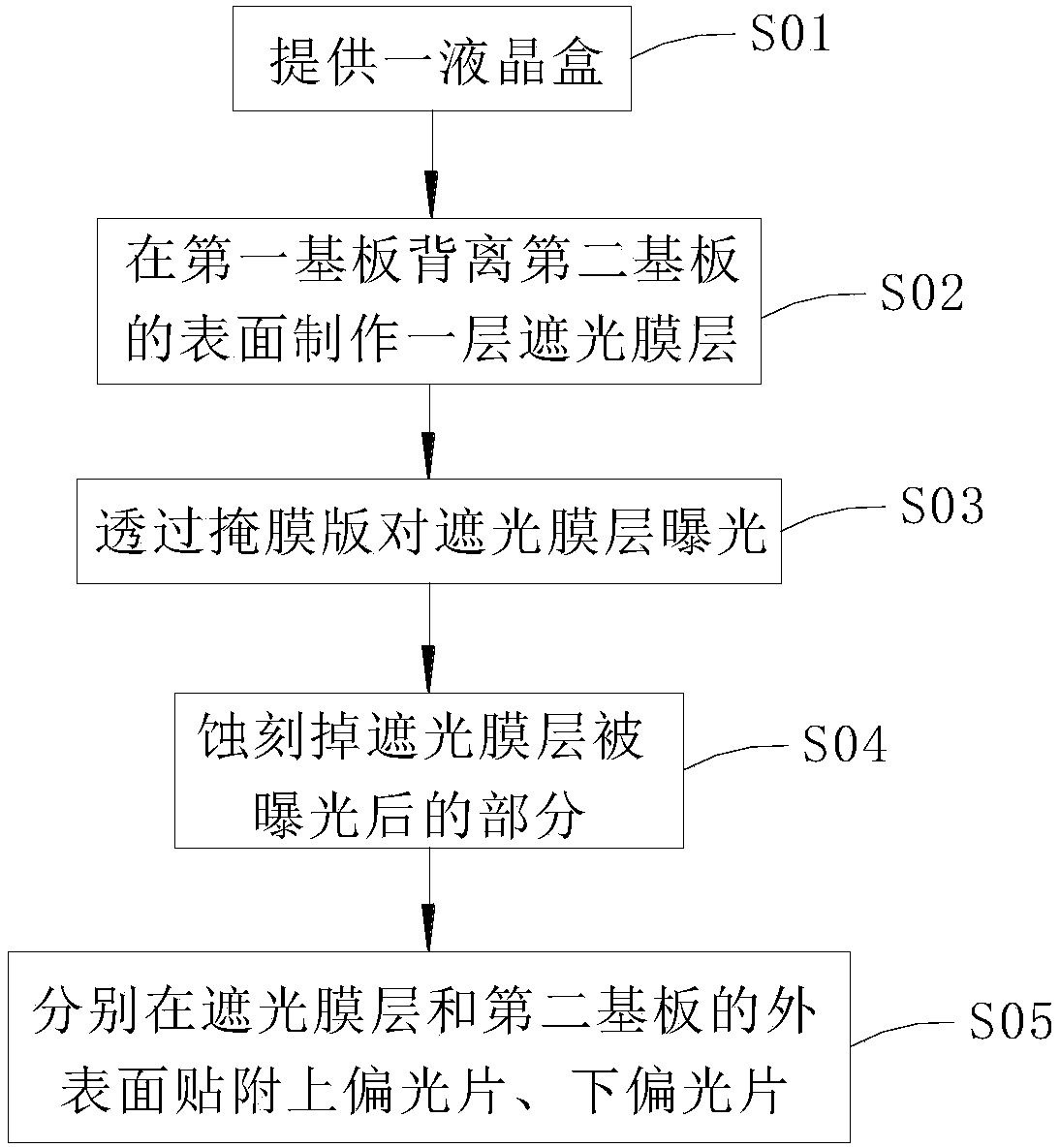

Display panel and preparation method thereof and display device

InactiveCN110579916AReduce border widthReduce the risk of susceptibility to disconnectionNon-linear opticsChip on filmDisplay device

The invention provides a display panel and a preparation method thereof and a display device. Conductive films are arranged at the end parts of an array substrate and a color film substrate of which the sides are flush with each other. A lead angle is formed at the edge, corresponding to the color film substrate or the array substrate, of a binding area. A chip on film is attached to the conductive film, and the chip on film is bent along the lead angle to realize binding. Therefore, the border width of the display panel is reduced, and the risk of line breakage easily occurring in the borderarea of the display panel is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Chip on film structure

ActiveUS20090153791A1Reduce widthSemiconductor/solid-state device detailsPrinted circuit aspectsChip on filmLiquid-crystal display

The chip on film structure for a liquid crystal display is disclosed. The chip on film structure includes a film substrate, a driver chip disposed on the film substrate, a plurality of the input pad, and a plurality of output pads. The input pads and the output pads are disposed on two opposite sides of the driver chip, and are electrically connect to the driver chip respectively. Each input pad comprises an extending portion extending from the input pads to a first cutting edge respectively, and a width of the extending portion is thinner than a width of the input pad, and the extending portions are cut along the first cutting edge.

Owner:AU OPTRONICS CORP

Chip on film packaging structure and chip on film packaging method

ActiveCN101626010AHigh folding resistanceSemiconductor/solid-state device detailsSolid-state devicesState of artChip on film

The invention discloses a chip on film packaging structure, which comprises a flexible substrate, a lead layer, an insulating layer and an elastic layer. The flexible substrate has a surface; the lead layer is formed on the surface and is provided with a plurality of leads; the insulating layer is formed on the lead layer; and the elastic layer is formed on the insulating layer and corresponds to at least one of the leads. When the flexible substrate is bent under the action of an external force, the elastic layer can buffer the deformation of the corresponding lead. Therefore, the rupture, caused by over deformation, of the corresponding lead can be avoided. The invention also provides a chip on film packaging method, which can improve the folding endurance of the chip on film packaging structure so as to solve the problem of the prior art.

Owner:RAYDIUM SEMICON

Display panel, manufacturing method thereof and display device

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

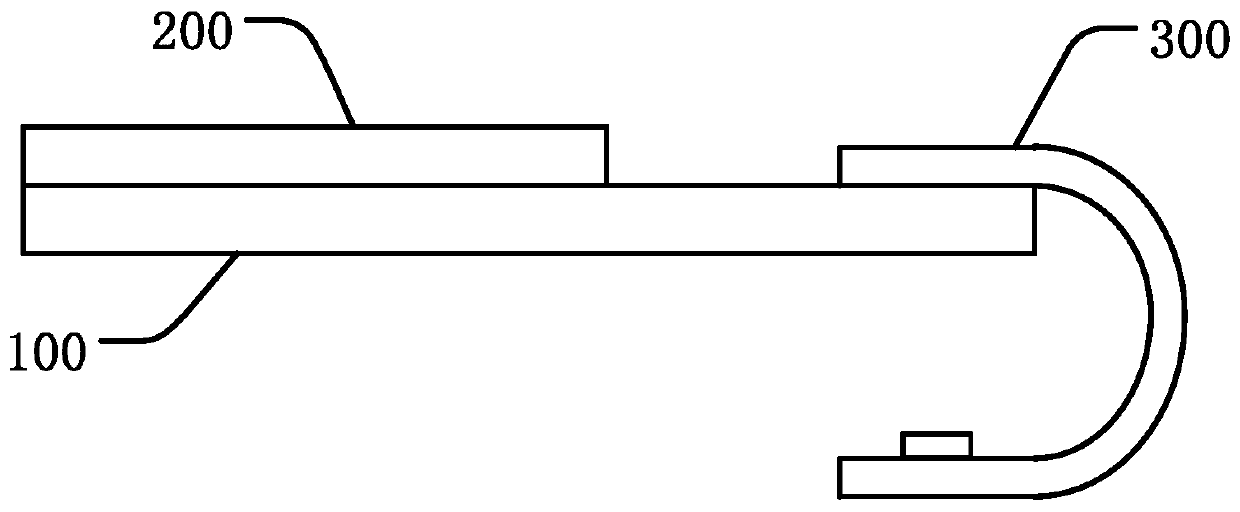

Display panel and preparation method thereof

ActiveCN110277018AReduce border widthIncrease the screen ratioIdentification meansChip on filmColor film

The invention provides a display panel and a preparation method thereof. The display panel comprises an array substrate, a color film substrate and a chip-on-film; a first oblique face is arranged at the edge of one side of the array substrate; the color film substrate is arranged on the surface of one side of the array substrate; a second oblique face is arranged at the edge of one side of the color film substrate and is in the same plane together with the first oblique face; and the chip-on-film is bound to the first oblique face and the second oblique face. The preparation method of the display panel comprises the following steps: providing of the array substrate, arranging of the color film substrate, cutting and binding. The display panel and the preparation method thereof have the technical effects that the thickness of a lower frame of the display panel is decreased, and the screen-to-body ratio is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method of producing ultra-thin copper foil with carrier, ultra-thin copper foil with carrier produced by the same, printed circuit board, multilayer printed circuit board and chip on film circuit board

InactiveUS7223481B2Small surface roughnessThermometers using material expansion/contactionSolid-state devicesChip on filmSurface roughness

Owner:FURUKAWA ELECTRIC CO LTD

Organic light emitting display panel

ActiveCN109524433ASolve the problem of abnormal display or even failure to light upSolid-state devicesSemiconductor/solid-state device manufacturingChip on filmPolarizer

The embodiment of the invention discloses an organic light emitting display panel which comprises an array substrate, a polarizer formed above the array substrate, and a binding region formed on the array substrate along one side of a first direction, wherein bending regions are formed on the binding region along two sides of a second direction, a covering layer covers the bending regions, and thefirst direction is perpendicular to the second direction. According to the technical solution provided by the embodiment of the invention, the problem of display failure of the display panel caused by the breakage of metal film layers in the bending regions at two sides of a chip on film of the display panel easily caused by the 3D bonding of an existing curved display screen can be solved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com