Array substrate, chip on film and display device

An array substrate, chip-on-film technology, applied in printed circuits, instruments, electrical digital data processing, etc., can solve the problems of short circuit of adjacent pads, weak binding, deformation of flexible substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

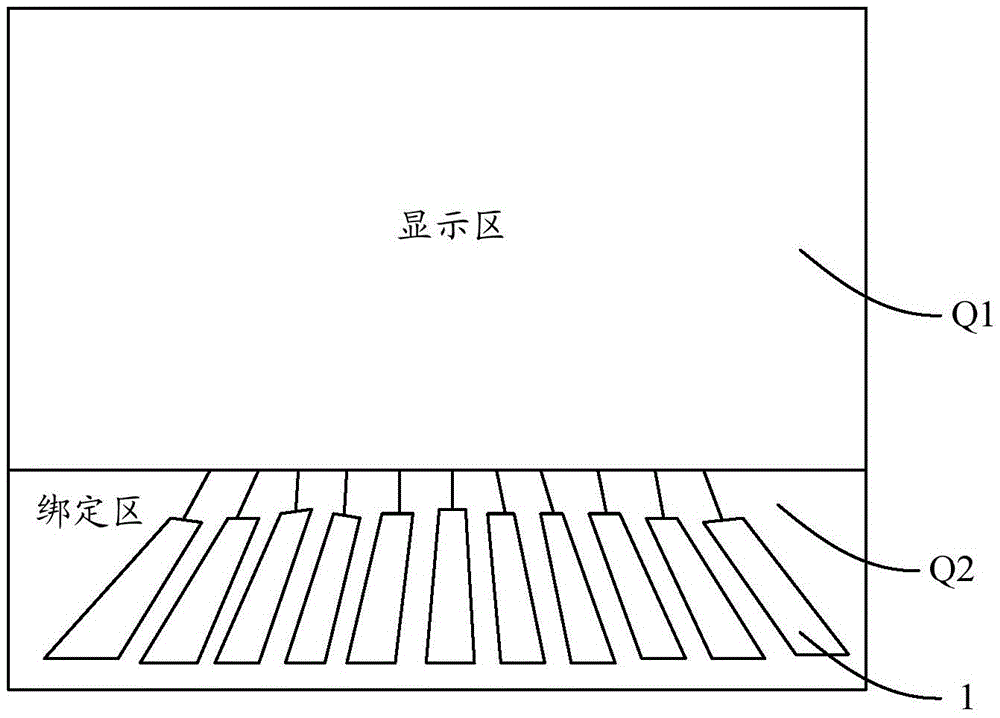

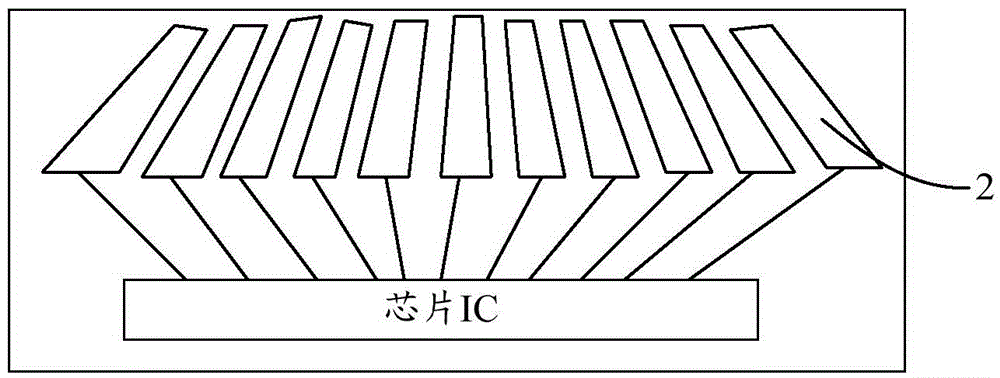

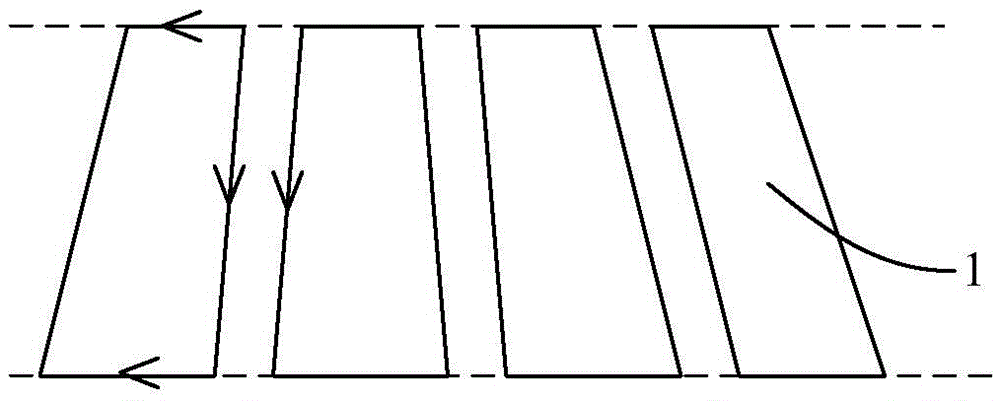

[0027] combine figure 1 and 2 As shown, this embodiment provides a display device including an array substrate and a chip-on-film; wherein, the array substrate has a display area Q1 for display, a binding area Q2 located around the display area Q1, and a binding area Q2 located around the display area Q1. A plurality of first pads 1 are provided, and the plurality of first pads 1 are arranged side by side. Each of the first pads 1 includes a first side and a second side opposite in the row direction, and a third side and a fourth side opposite in the column direction, wherein the first side and The second side edges are arranged non-parallel. It can be understood that the shape of the second pad 2 on the chip on film matches the shape of the first pad 1 on the array substrate. That is to say, each of the second pads 2 also includes a first side and a second side oppositely arranged in the row direction, and a third side and a fourth side oppositely arranged in the column di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com