Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Improved yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

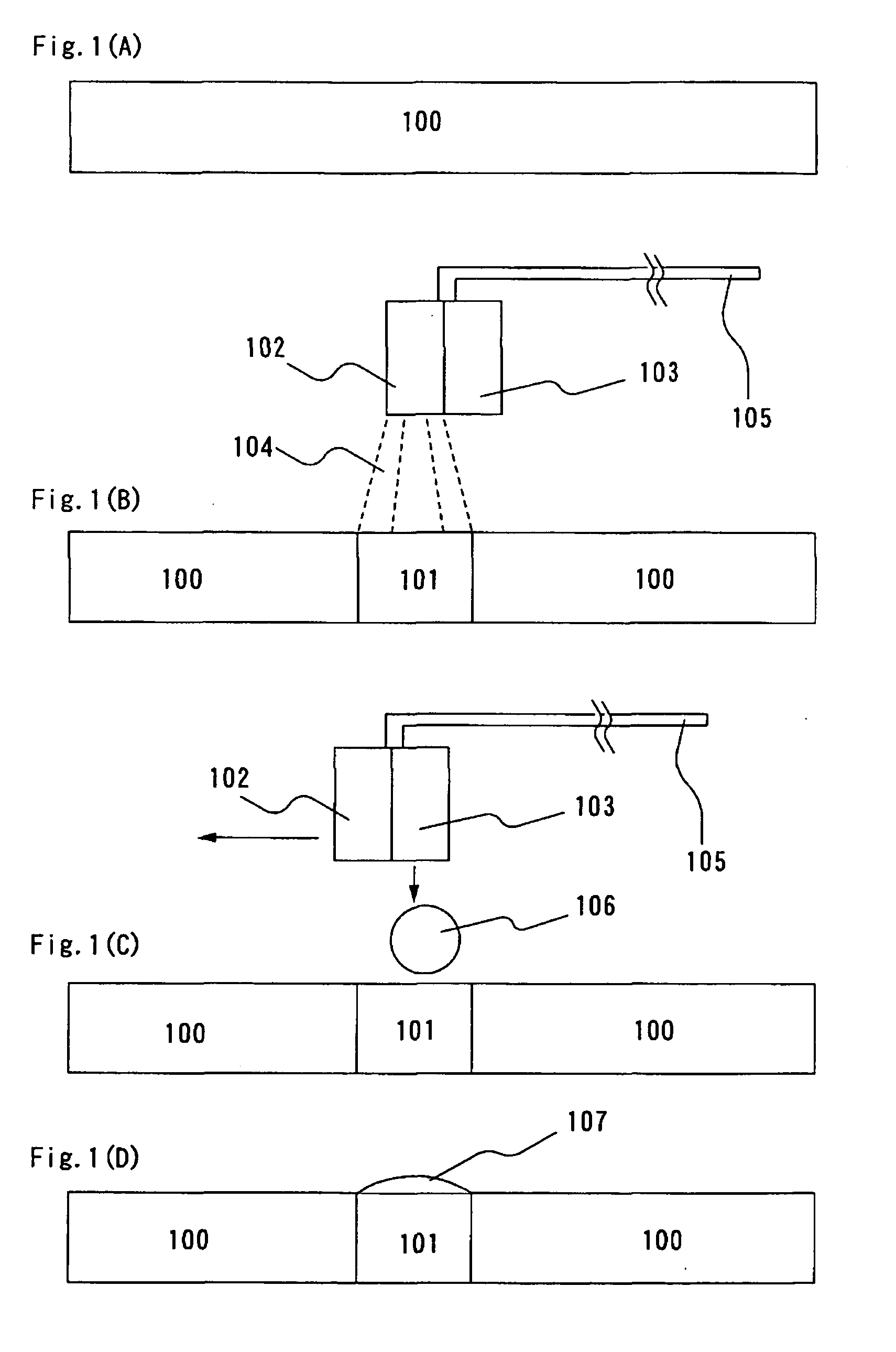

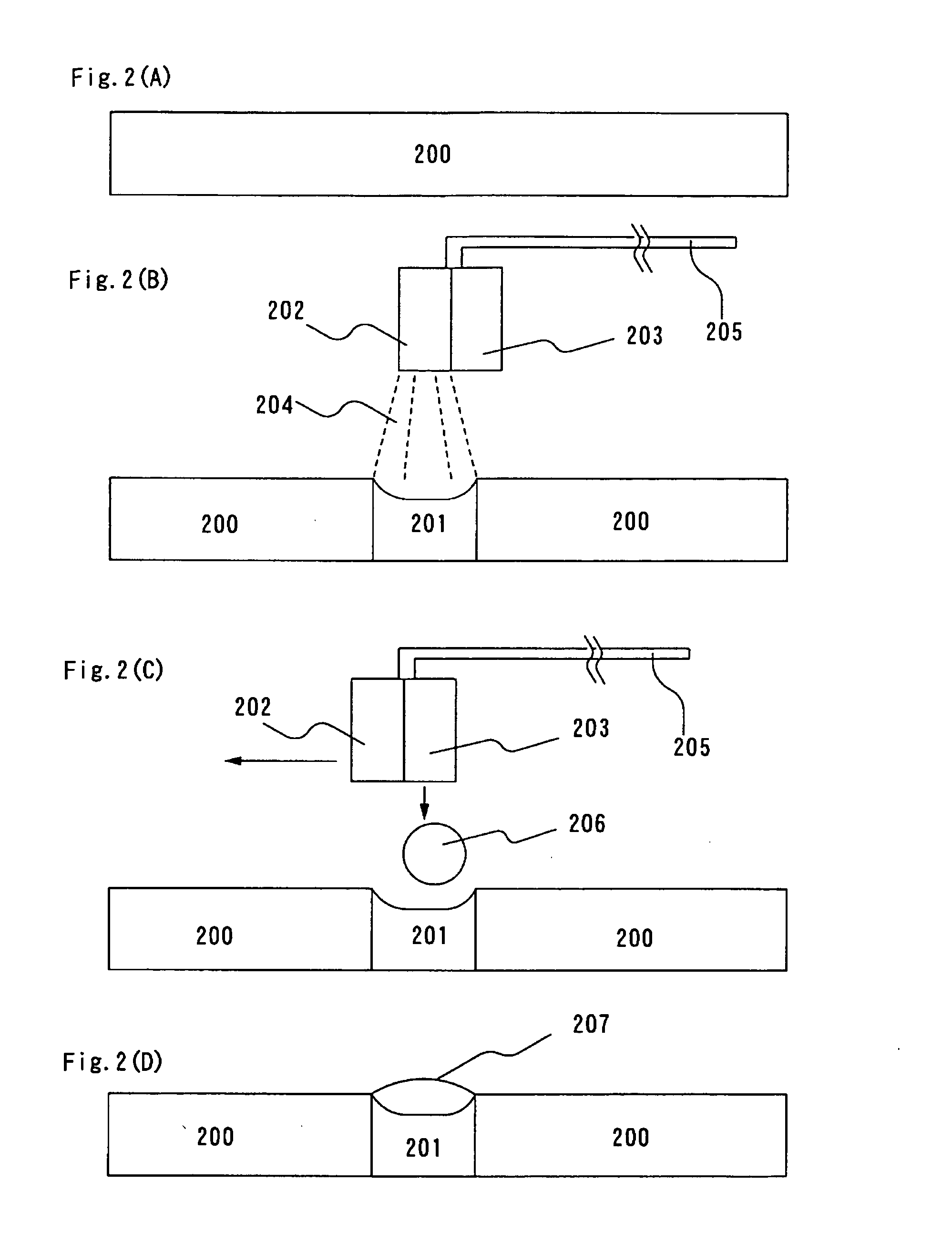

Method for forming pattern and drop discharge apparatus

InactiveUS20050043186A1Process step be reduceImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention is characterized in having a process for forming a pattern by making a substrate having an insulating property, such as a liquid-repellent thin film over a substrate, such as a semiconductor film, selectively have affinity for liquid by plasma generating means 102, and discharging a drop compound to the surface having affinity for liquid by a drop discharging means 103. By putting the region having affinity for liquid, which was selectively formed, between liquid-repellent, a drop after drop landing can be formed without moving the drop landing portion

Owner:SEMICON ENERGY LAB CO LTD

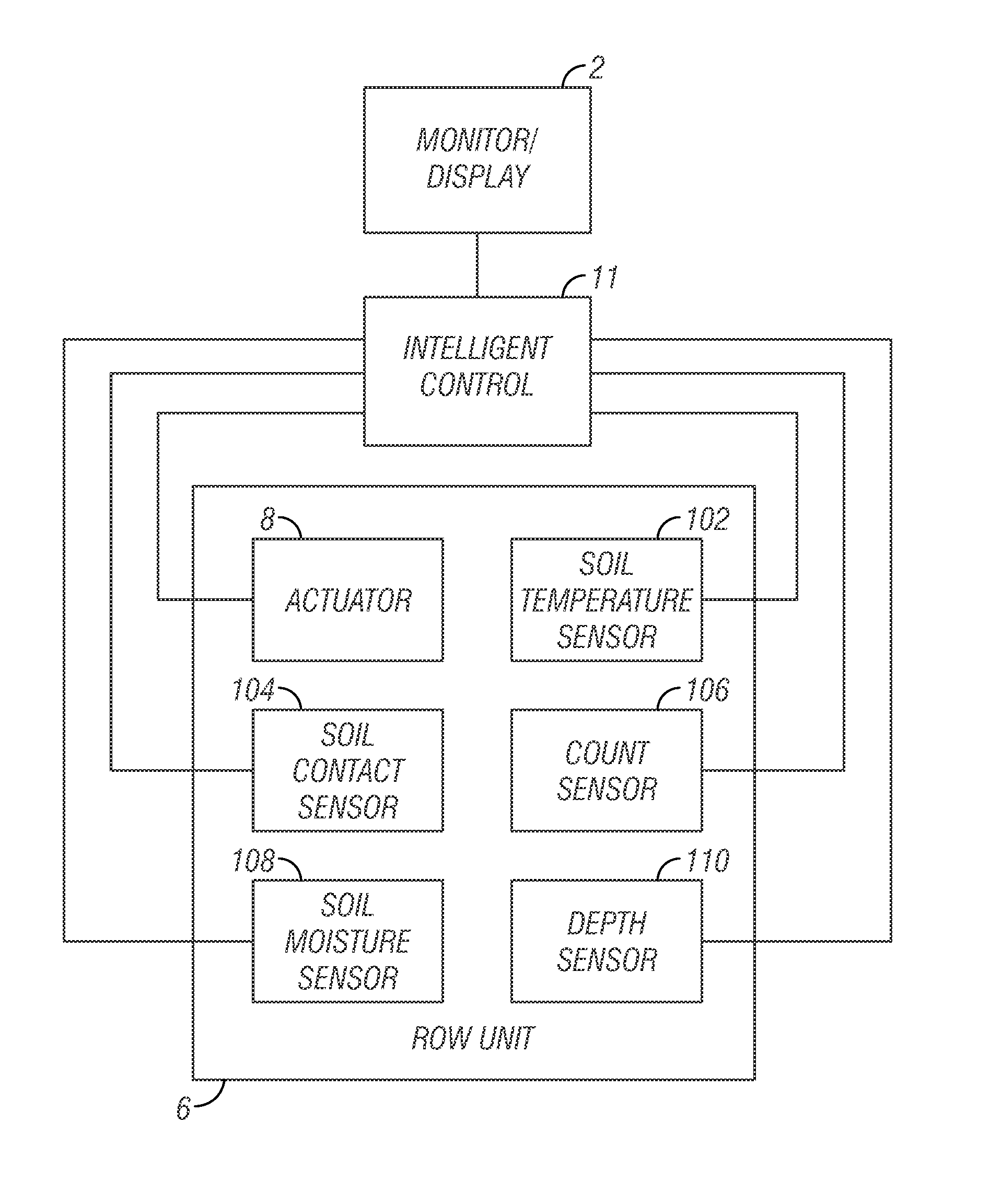

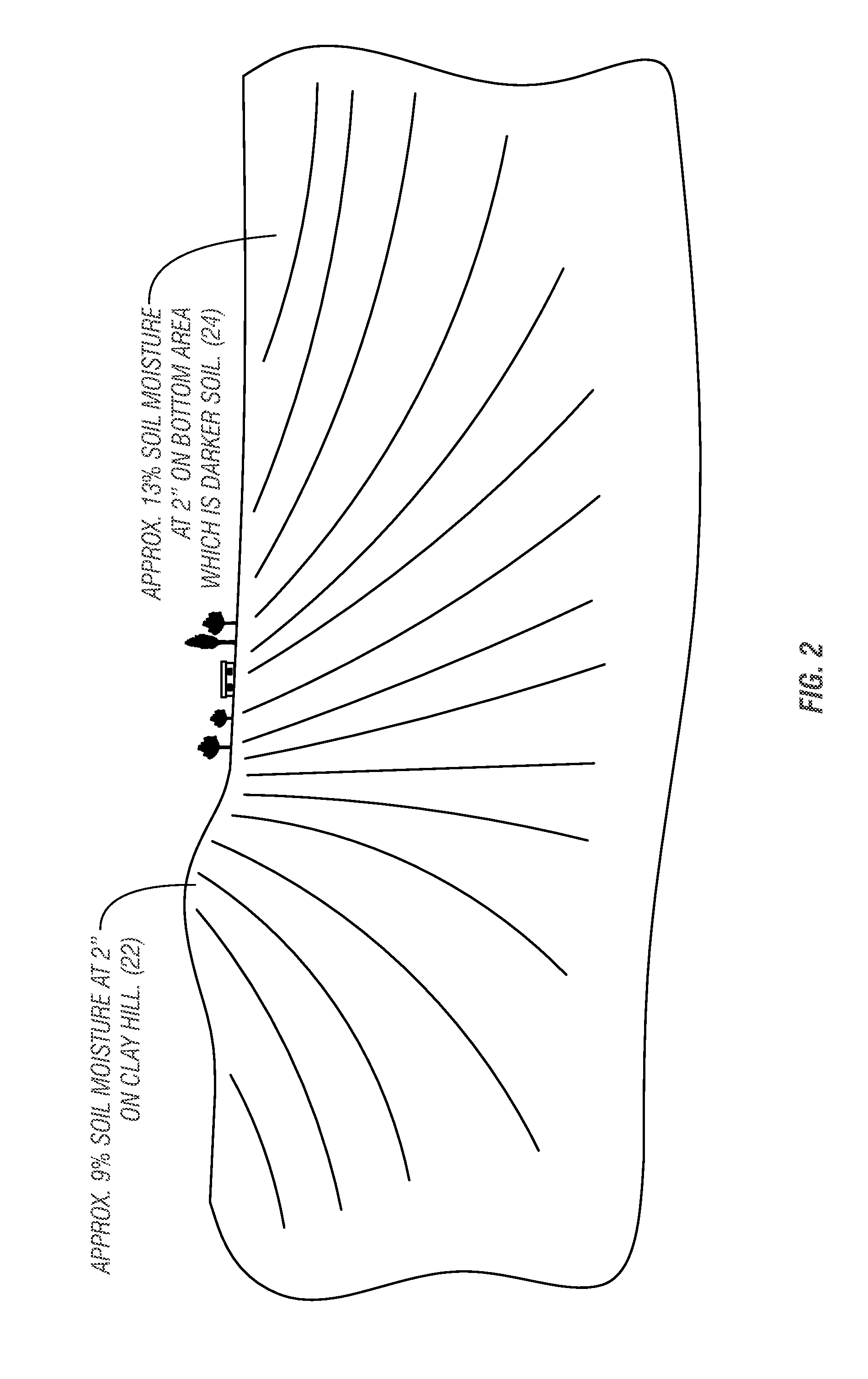

On-the-go soil sensors and control methods for agricultural machines

ActiveUS20140303854A1Improved yieldAutomatically adjustSpadesSoil-working equipmentsAgricultural engineeringTillage

An on-the-go monitor and control means and method for an agriculture machines includes on-the-go soil sensors that can be used to control tillage and seeding depth. On seeder implements, the sensors provide information that affects uniform plant emergence.

Owner:LEADER TECH

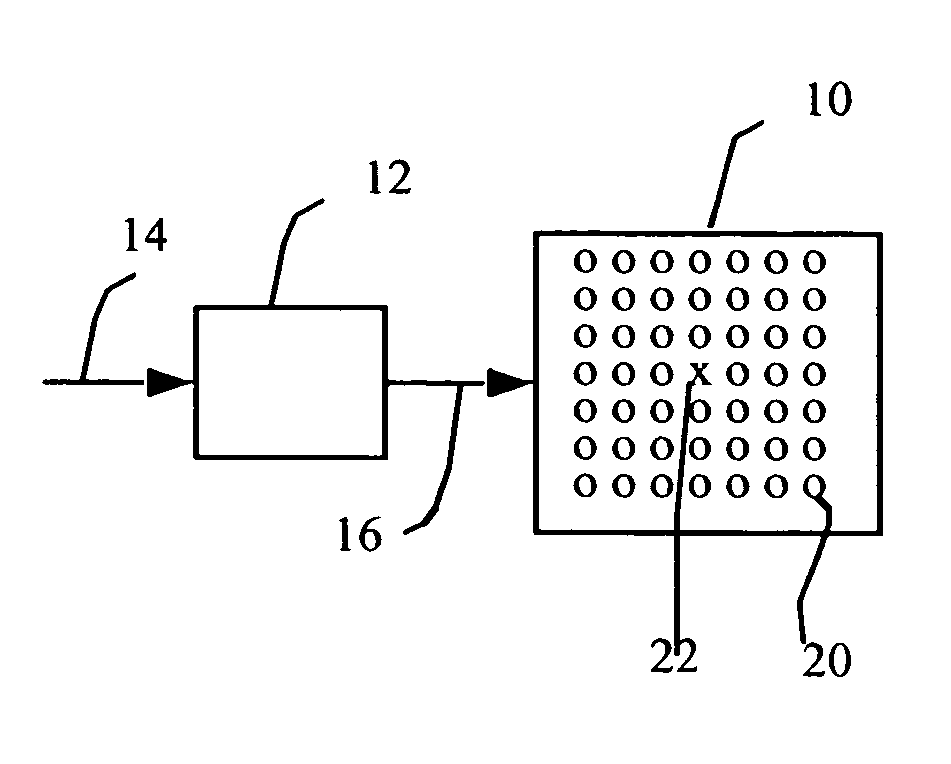

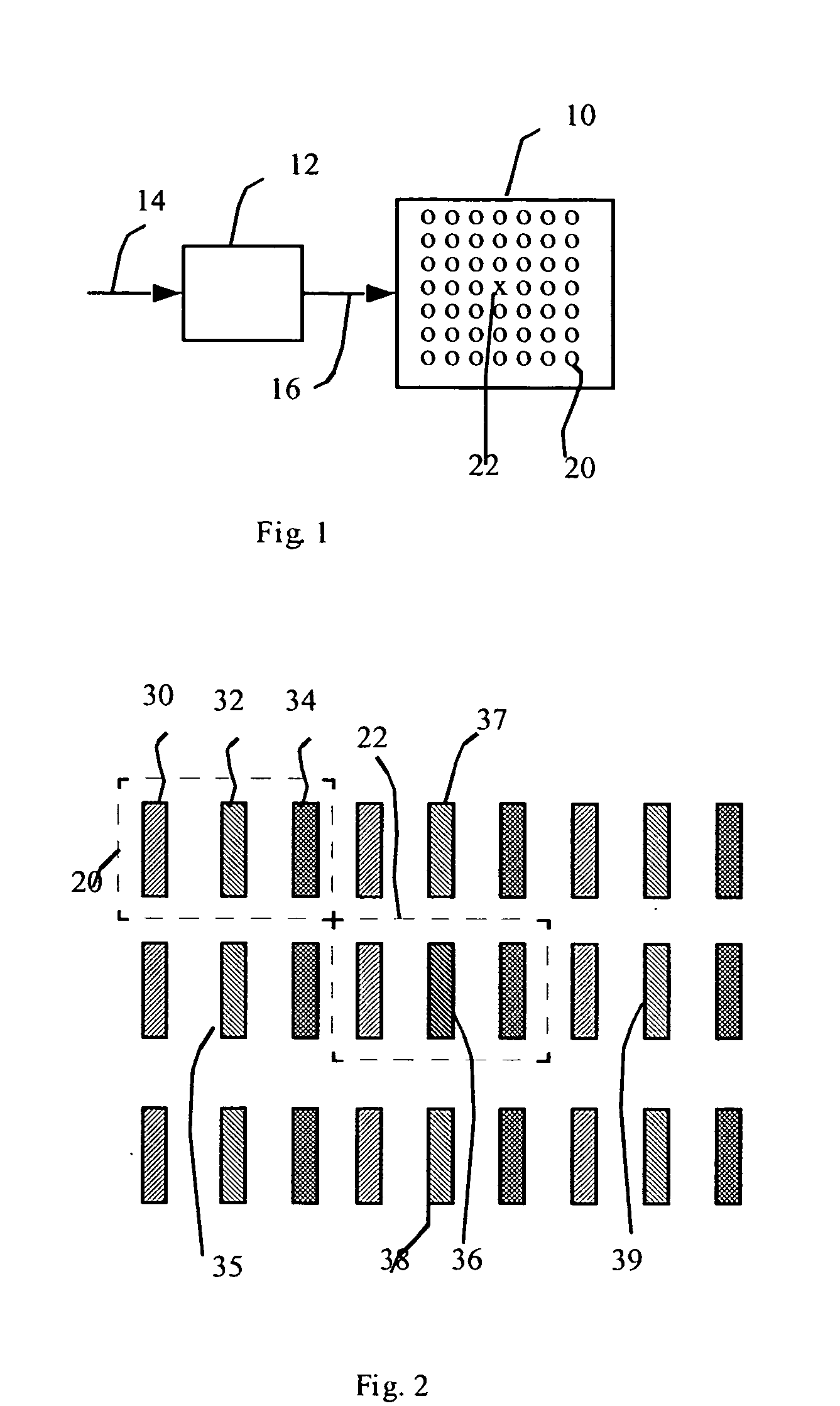

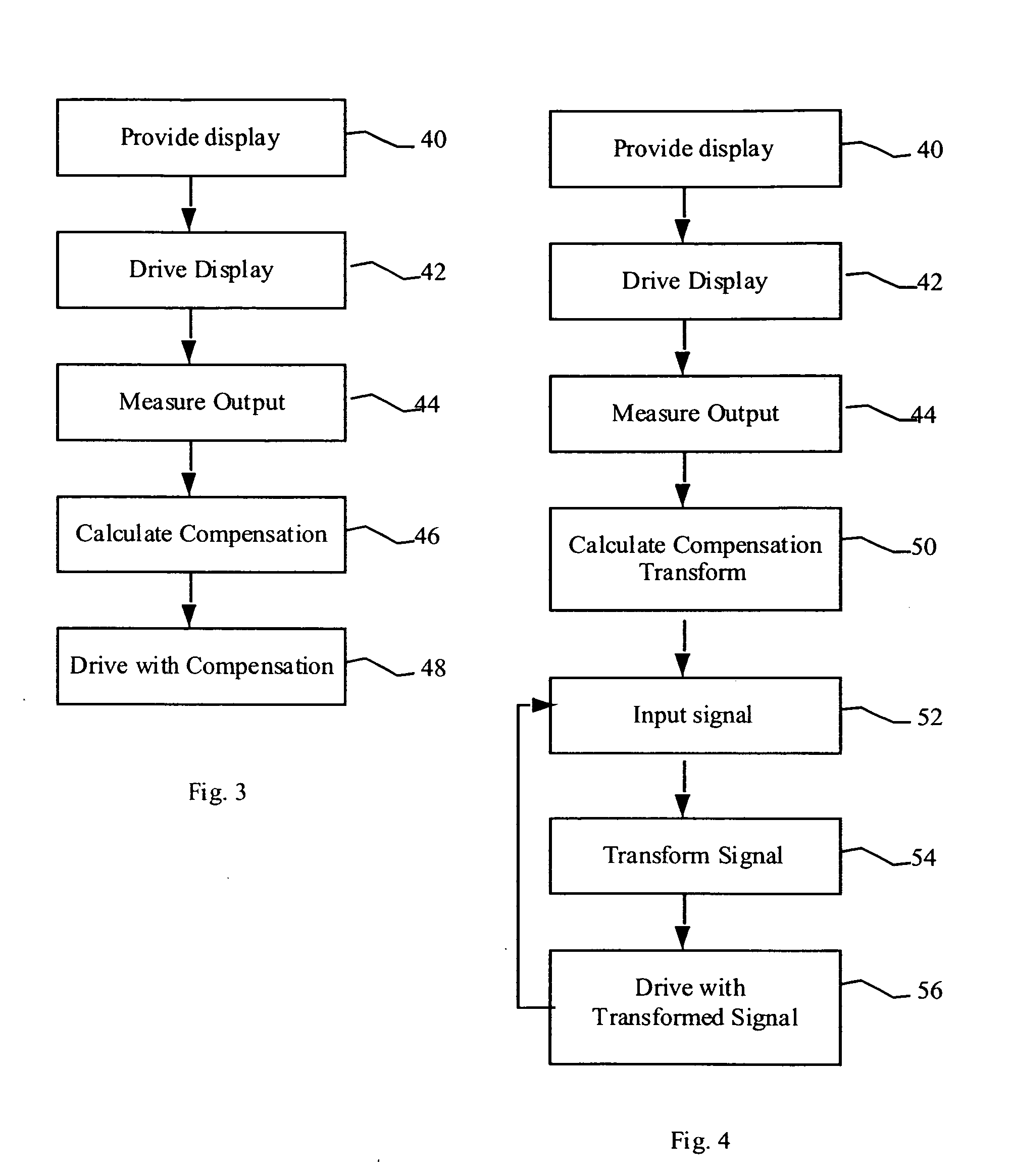

Method and apparatus for defect correction in a display

InactiveUS20060164407A1Improve uniformity and qualityImproved yieldCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceSignal transition

A display device, comprising: a) a display having a plurality of pixels including one or more defective pixel(s) and one or more additional pixel(s); and b) a controller for driving the display pixels and for transforming an input signal into a compensated signal for selectively modifying the output of one or more additional pixel(s) in the display to compensate for the output of the defective pixel(s).

Owner:EASTMAN KODAK COMPAHY

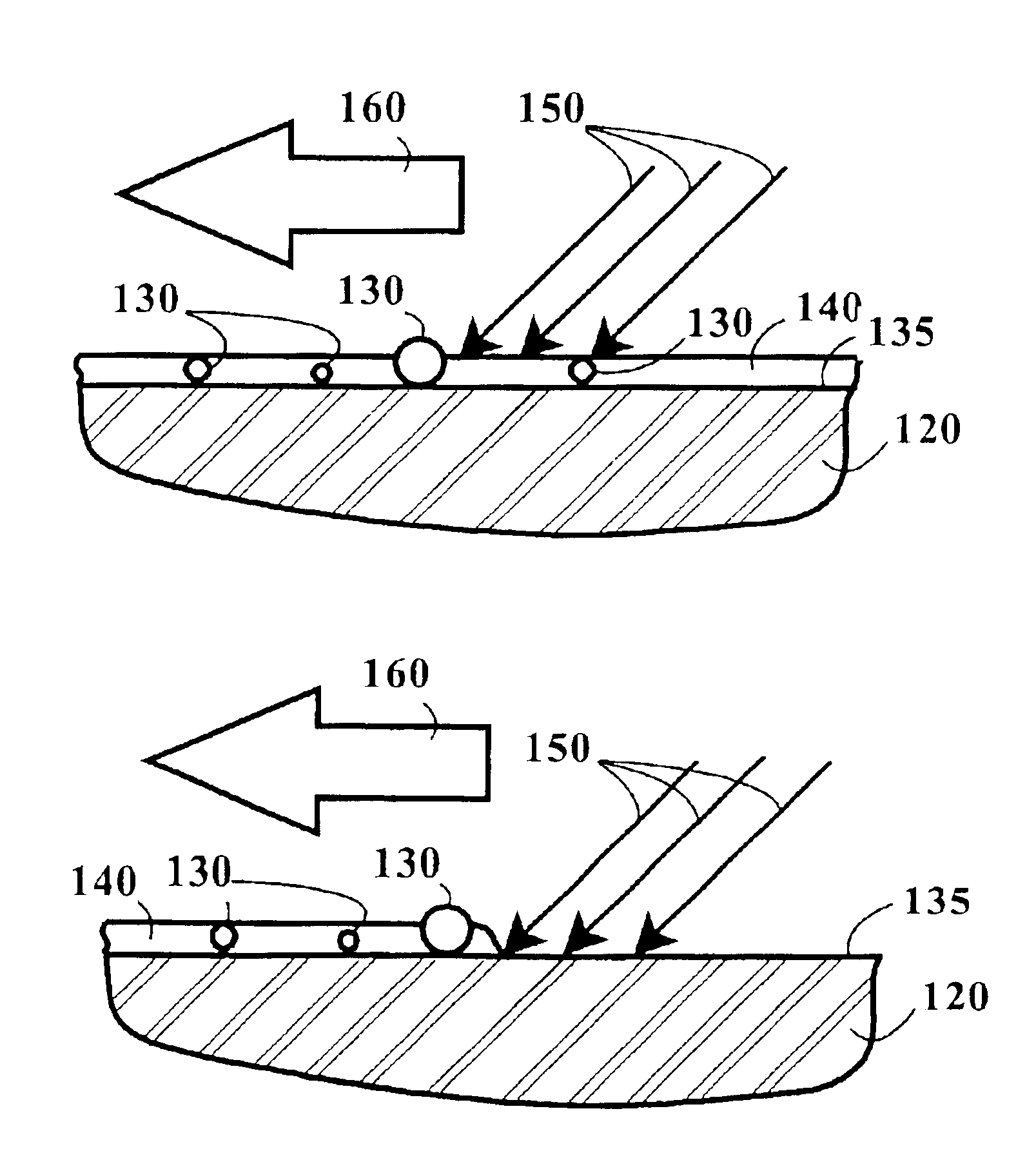

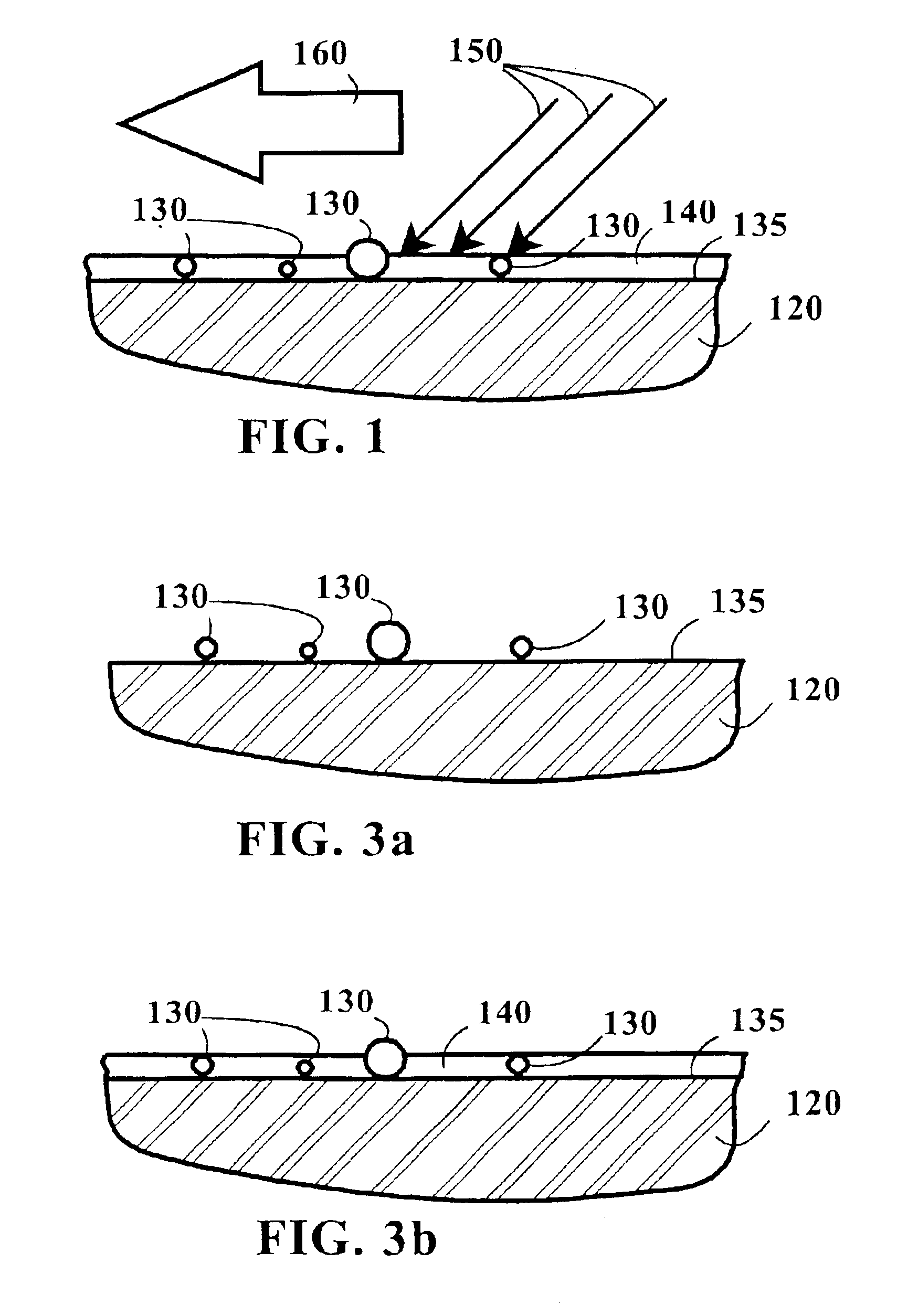

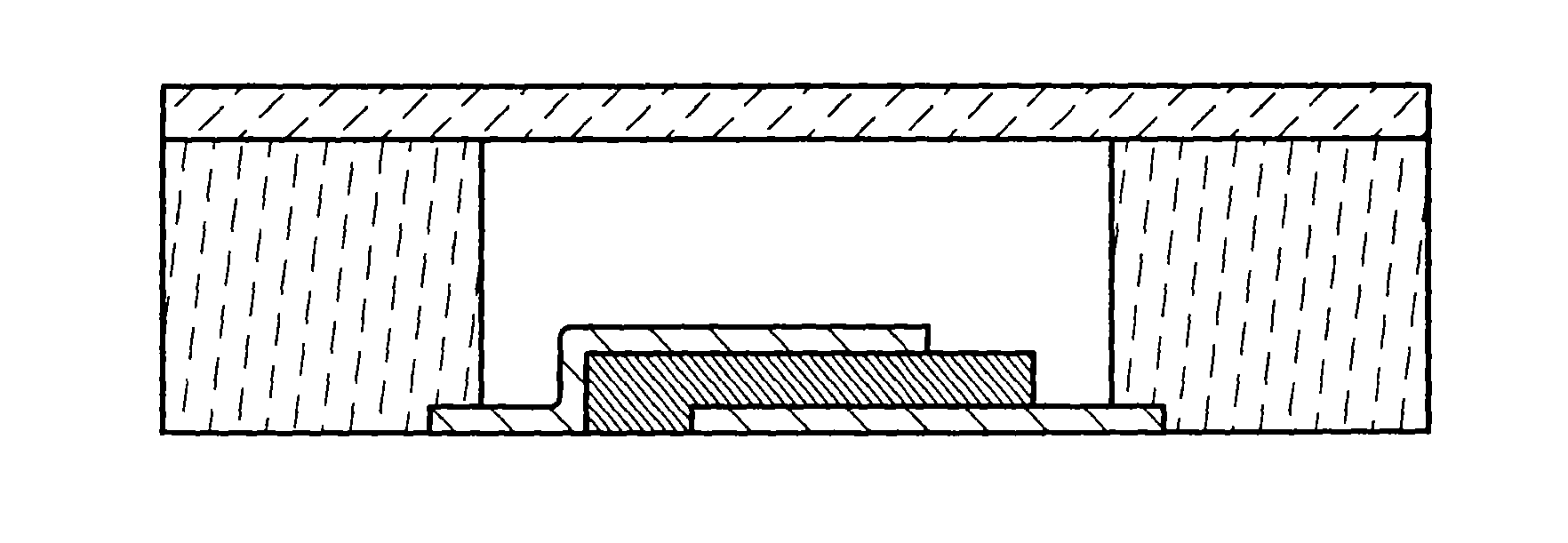

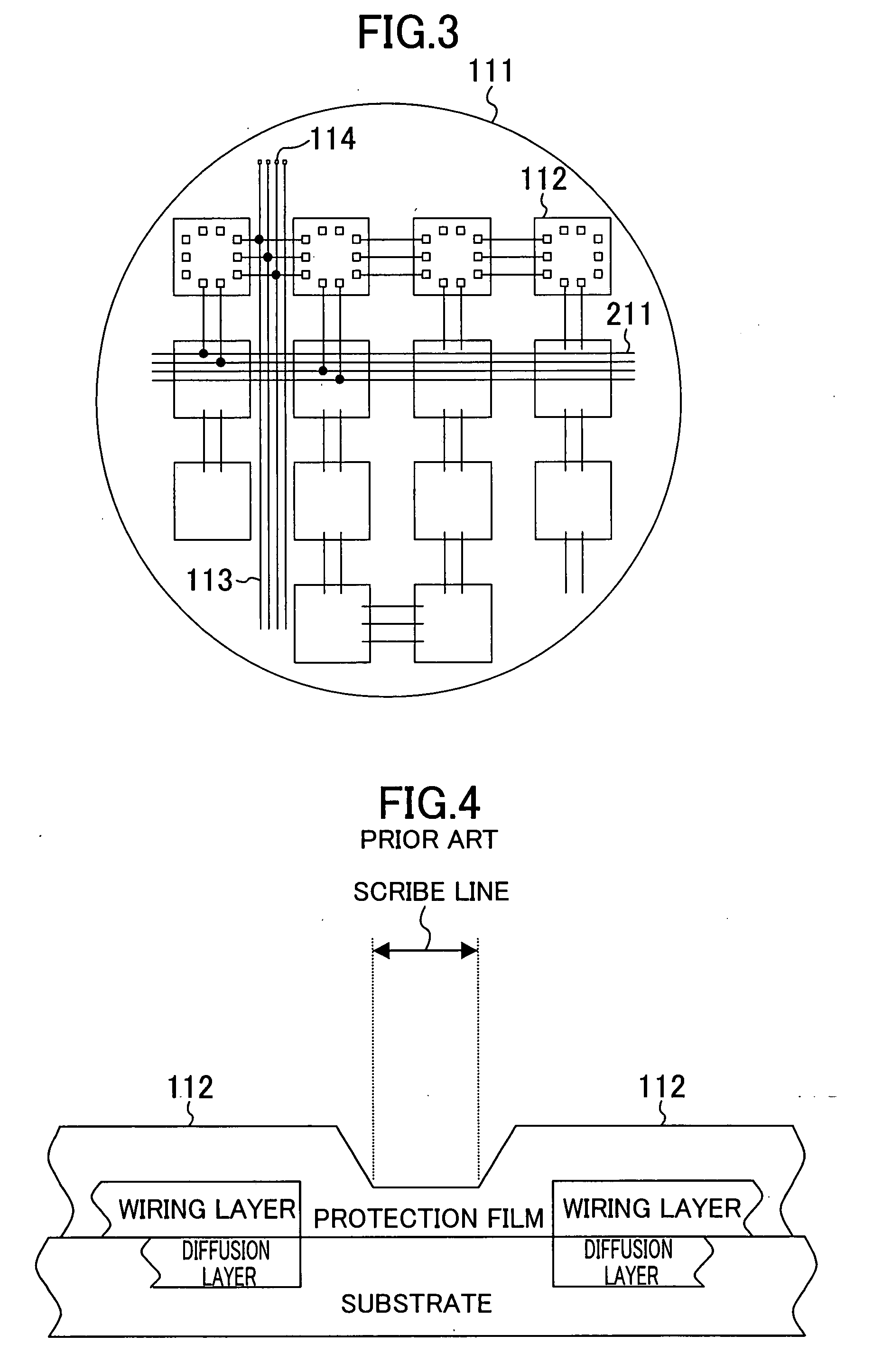

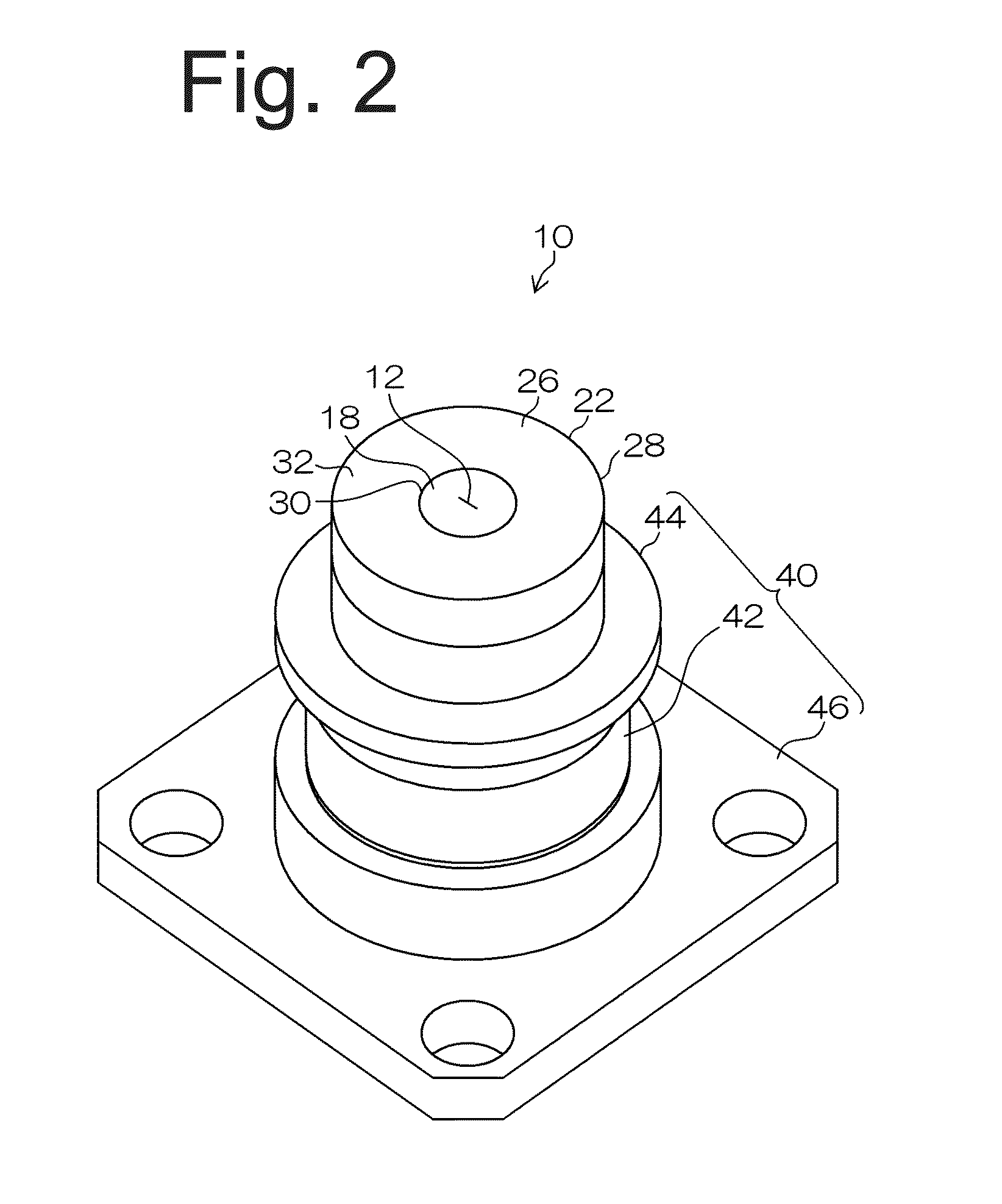

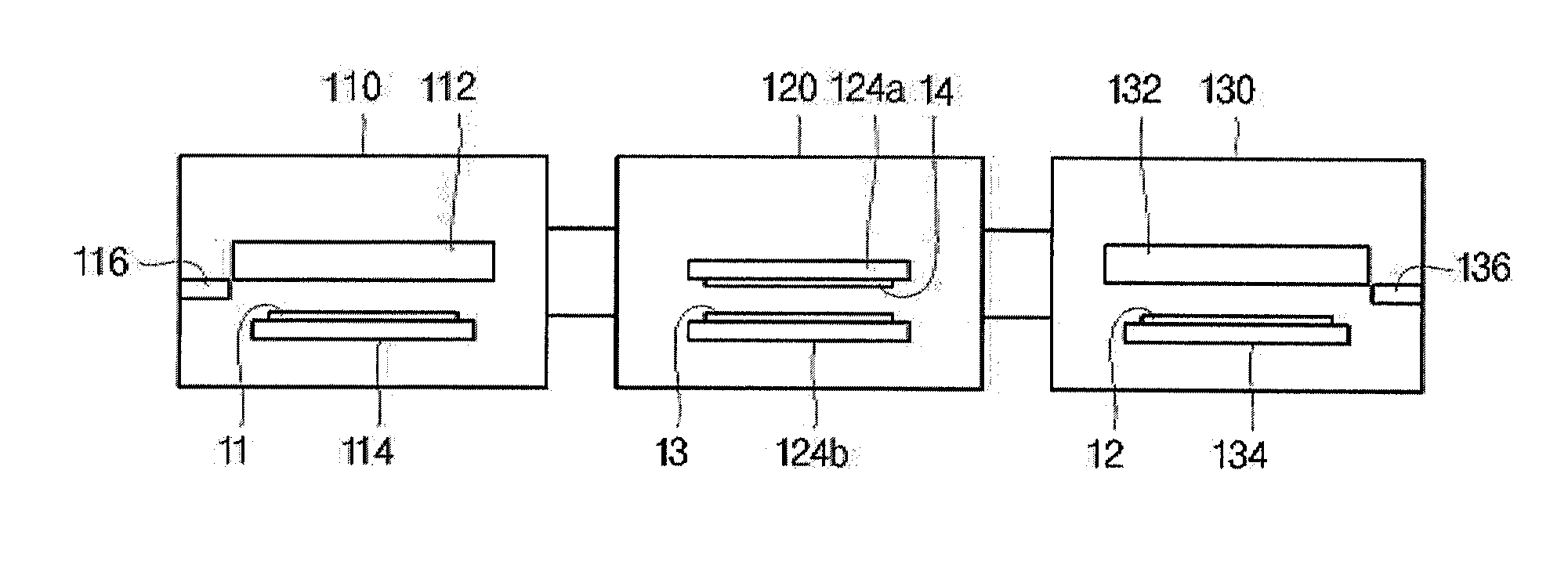

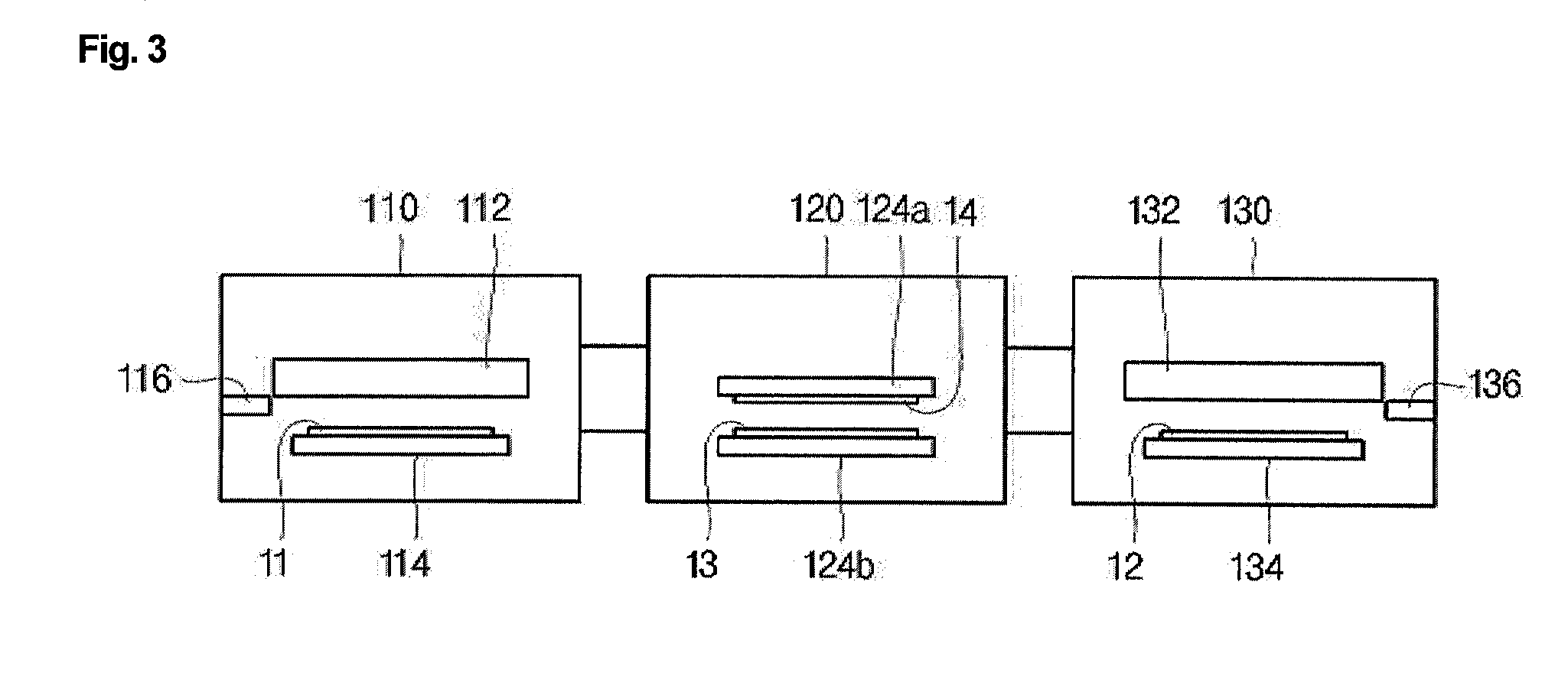

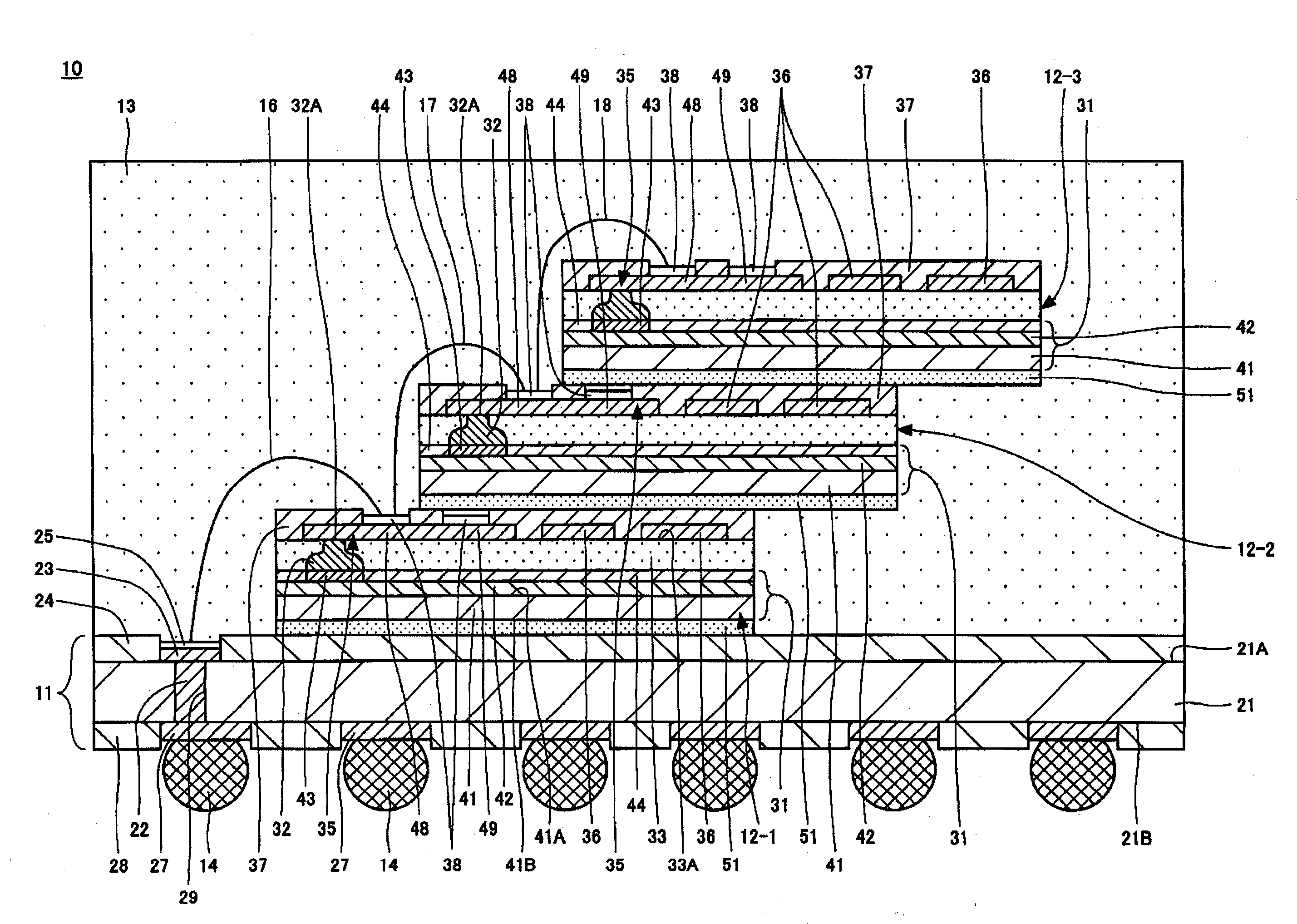

Method for laser cleaning of a substrate surface using a solid sacrificial film

InactiveUS6881687B1Adversely affect functionality and performanceImproved yieldElectrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringData records

An improved semiconductor wafer processing apparatus 10 includes a series of processing stations combined in one form, coupled together by computer-controlled cluster tooling. Wafers are supplied in a pod to an input station 28 which initiates a data record for recording processing results at each station. A sacrificial film 140 is applied to the surface 135 of each wafer. Individual wafers are transferred to a computer-controlled defect-mapping station 14 where particulate defects 130 are identified and their position coordinates recorded. Defect-mapped wafers are transferred to a computer-controlled laser area cleaning station 11 which lifts the defects and sweeps the wafer surface clean, except for stubborn defects. Clean wafers are transferred to a final mapping station 20 or 22, followed by transfer of the wafers to an output station 30. Wafers having remaining stubborn defects are transferred to a second defect-mapping station 16 where stubborn defects are located by coordinates, after which the wafers are transferred to a defect review tool incorporating a scanning electron microscope (SEM-DRT) 24. A SEM image review of stubborn defects includes chemical analysis of the stubborn defects. A laser point-cleaning station 13 lifts and sweeps each stubborn defect individually from the wafer surface. Cleaned wafers are transferred to a third defect-mapping station 18 for recording any stubborn defects remaining, then to a second laser area cleaning station 12 for a final cleaning, followed by transfer of the wafers to a final mapping station 20 or 22 for mapping of any remaining stubborn defects. The accompanying data records are updated followed by transfer of the wafers to an output station 30.

Owner:SEIKO INSTR INC

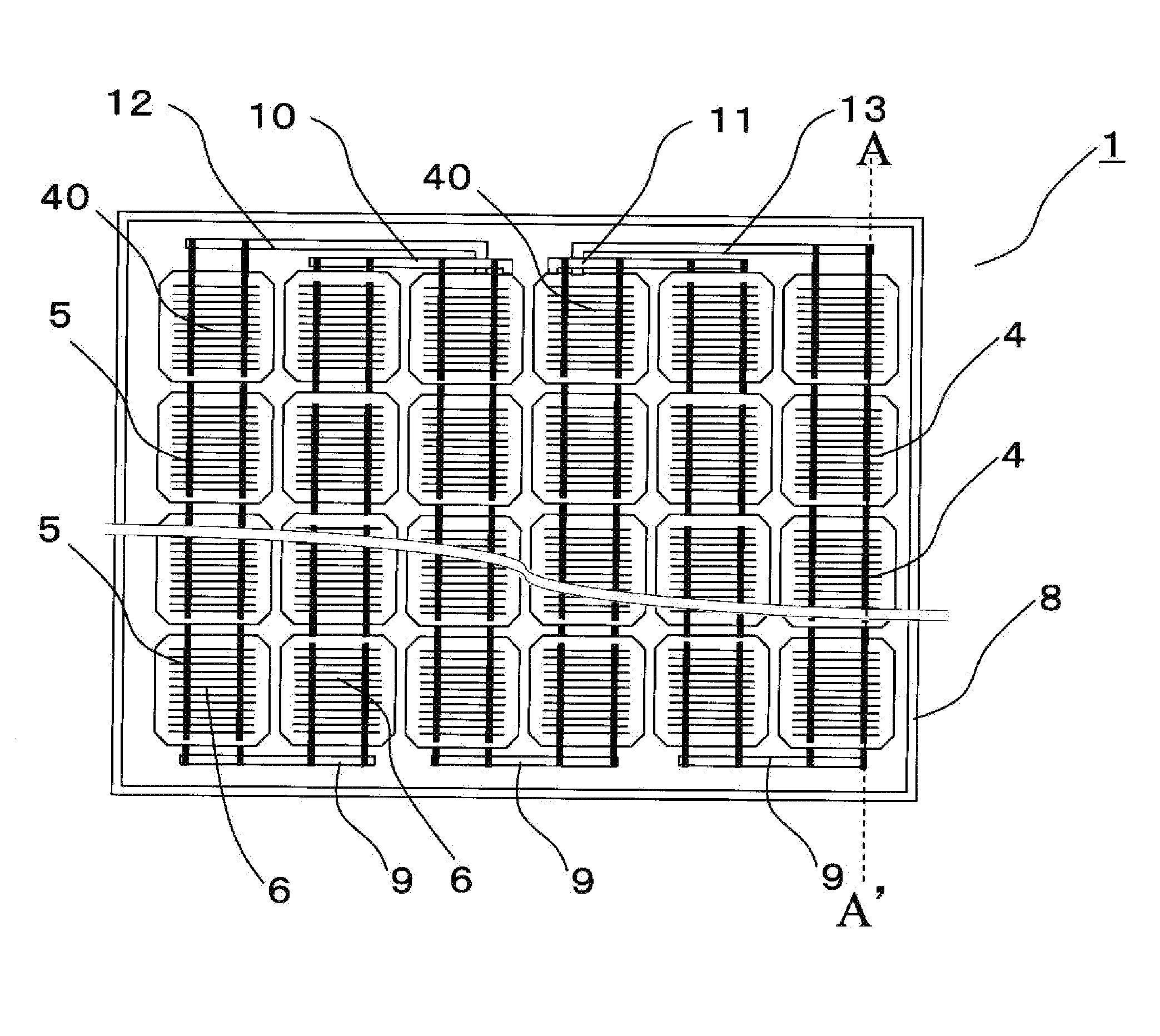

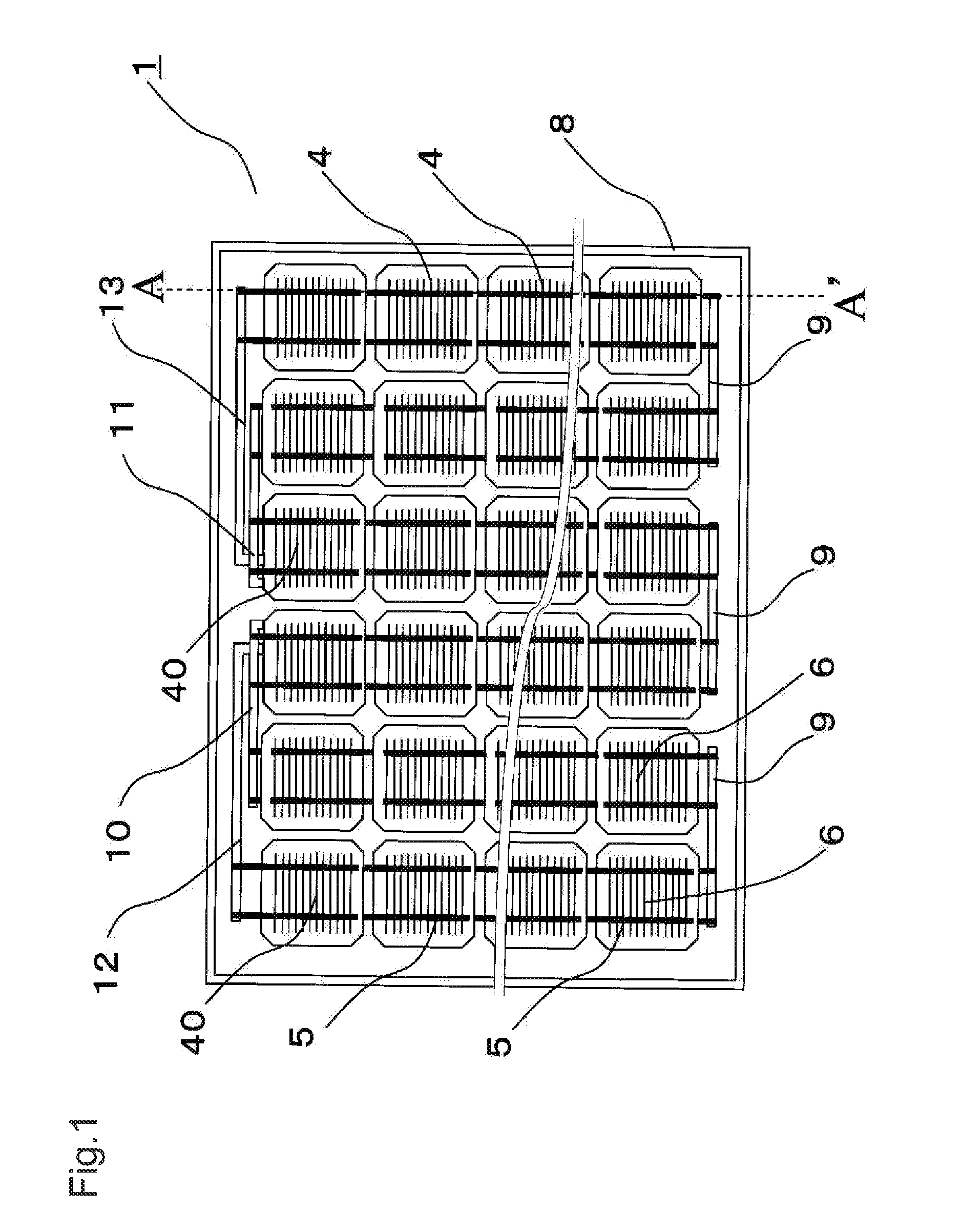

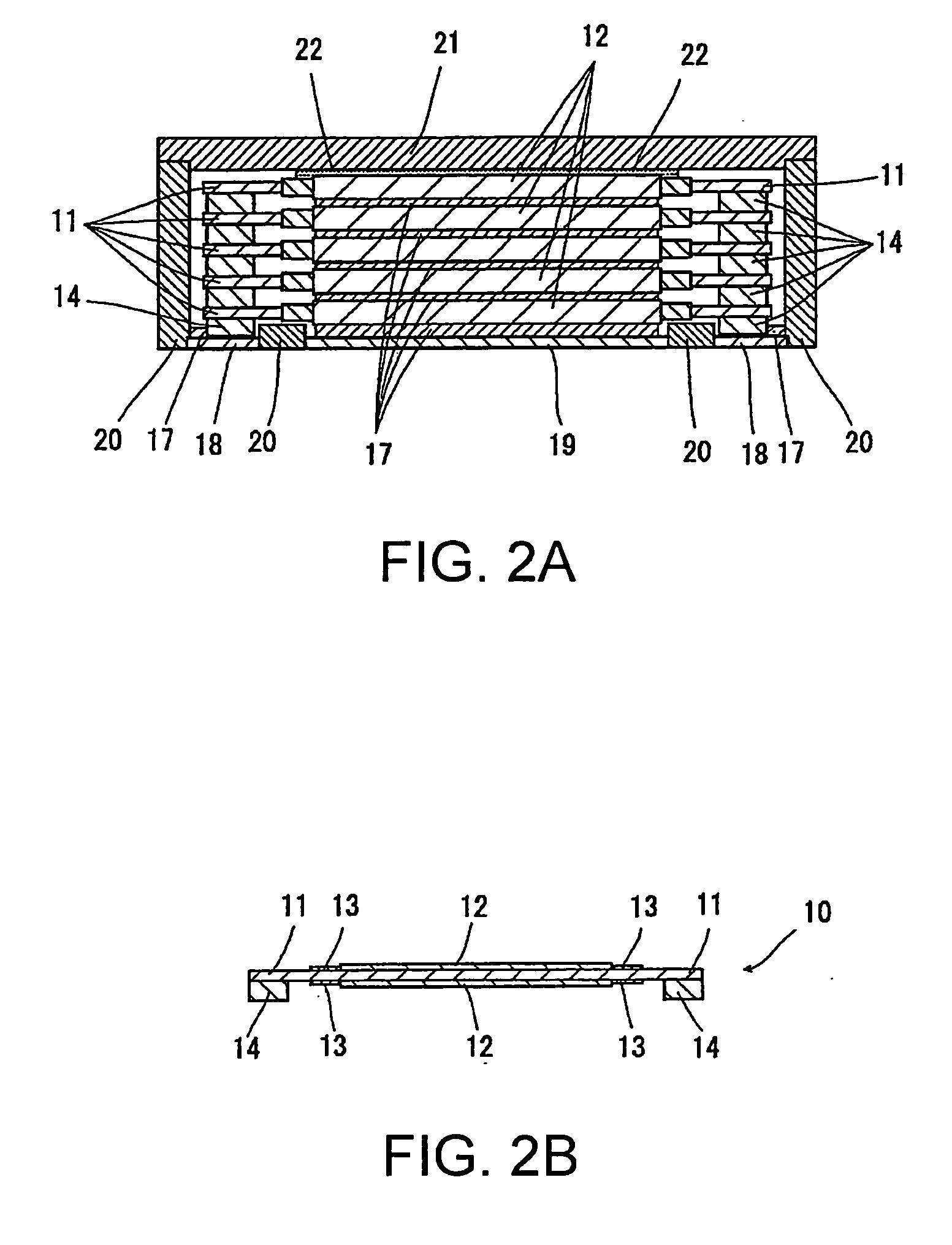

Solar cell and solar cell module

A solar cell includes: an photoelectric conversion body including a first main surface and a second main surface opposed to the first main surface; a first electrode provided on the first main surface; a second electrode provided on the second main surface; a first conductive connection member connected with the first electrode for connecting the solar cell and another solar cell, wherein the first conductive connection member includes a conductive soft layer at an area facing the first electrode, and the first electrode includes a conductive soft layer at an area facing the first conductive connection member; and a first resin adhesive bonding the first conductive connection member to the first electrode in such a manner that the conductive soft layer of the first electrode and the conductive soft layer of the first conductive connection member abut on each other.

Owner:SANYO ELECTRIC CO LTD

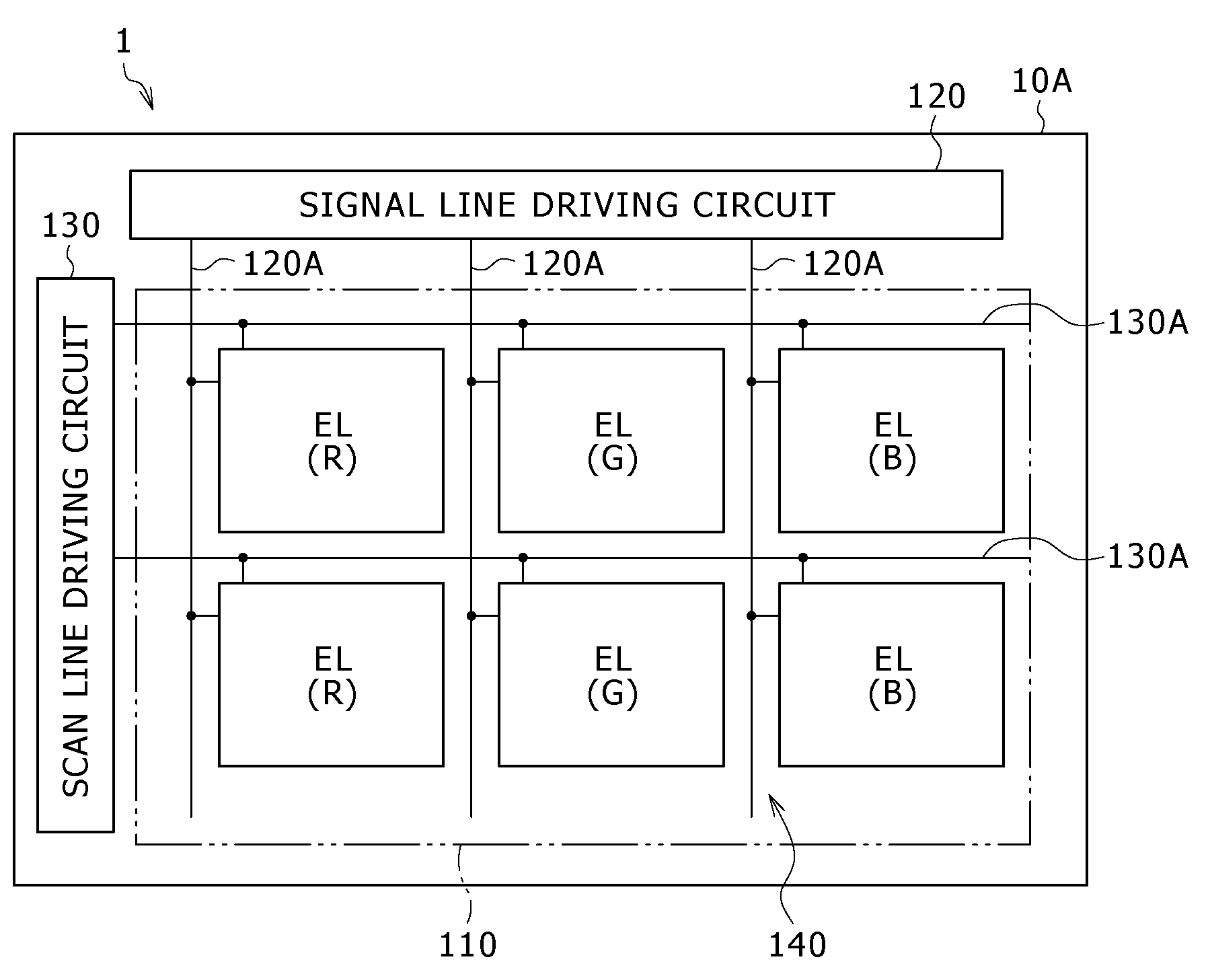

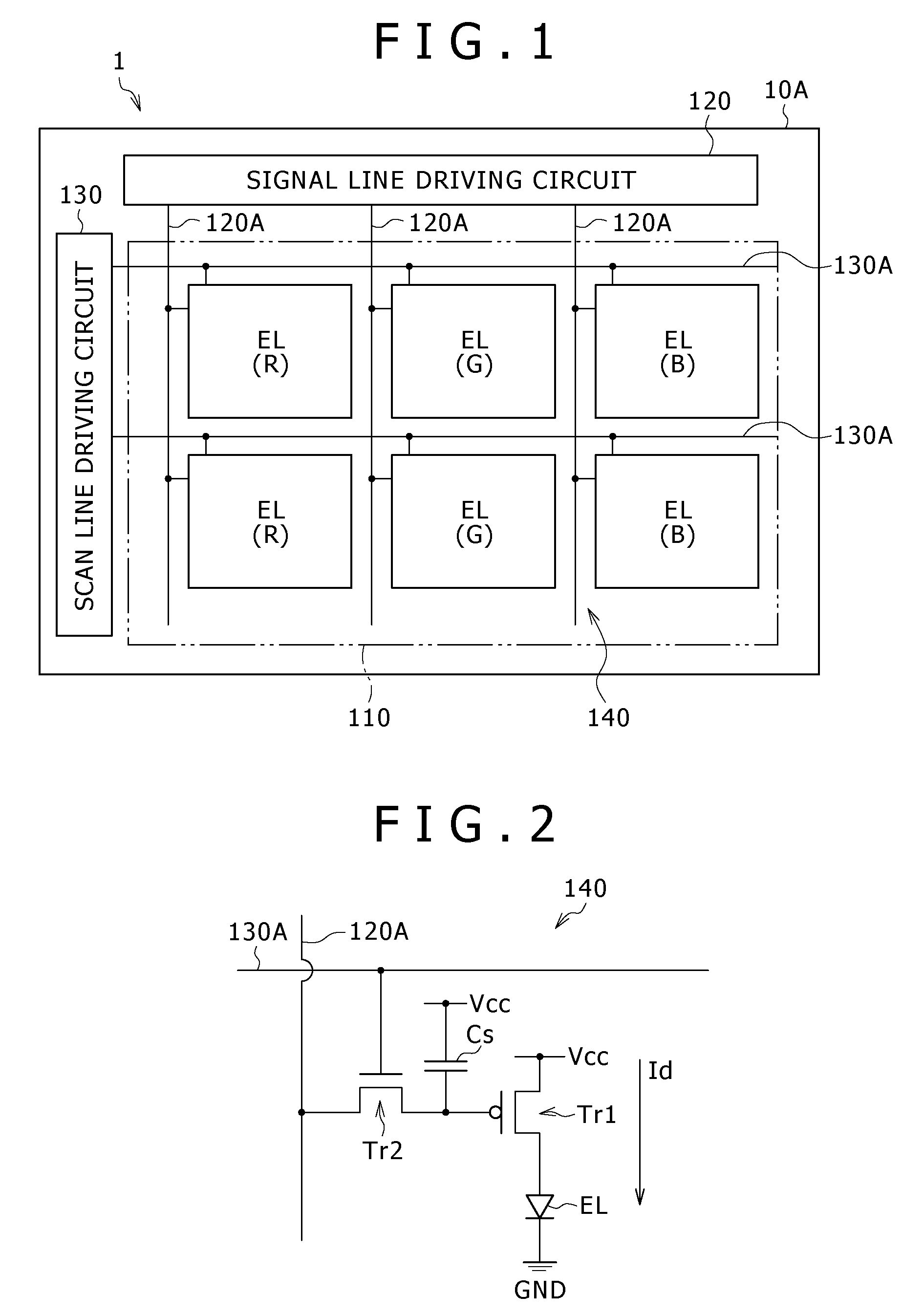

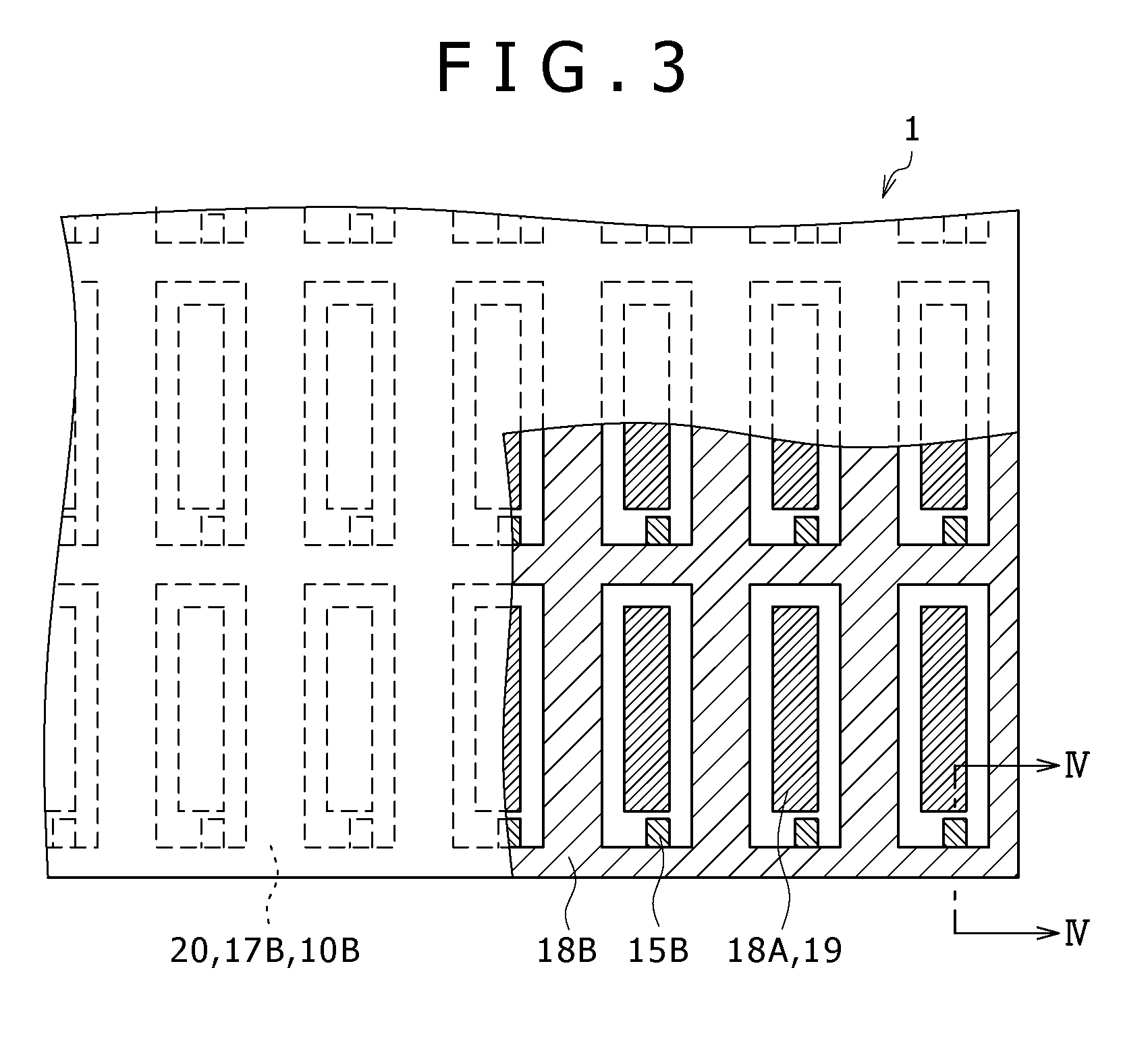

Display device and method for production thereof

ActiveUS20090153046A1Improved yieldDecrease contact resistanceTube/lamp screens manufactureDischarge tube luminescnet screensDriven elementDisplay device

A display device having a plurality of driving elements and wiring parts electrically connected to the driving parts, the display device includes: a plurality of first electrodes which are formed in correspondence to each driving element on the driving elements and the wiring parts; a plurality of light-emitting parts which are each formed on the first electrodes; a common second electrode which is formed from a material that transmits light from the light-emitting part and is formed on the light-emitting parts; auxiliary wiring parts with a lower resistance than the second electrodes; and contact parts which are formed in laminate structure from a plurality of conductive layers and which electrically connect the second electrodes and the auxiliary wirings with each other, with at least the lowermost conductive layer of the conductive layers of the contact parts being in direct contact with the second electrode.

Owner:SONY CORP

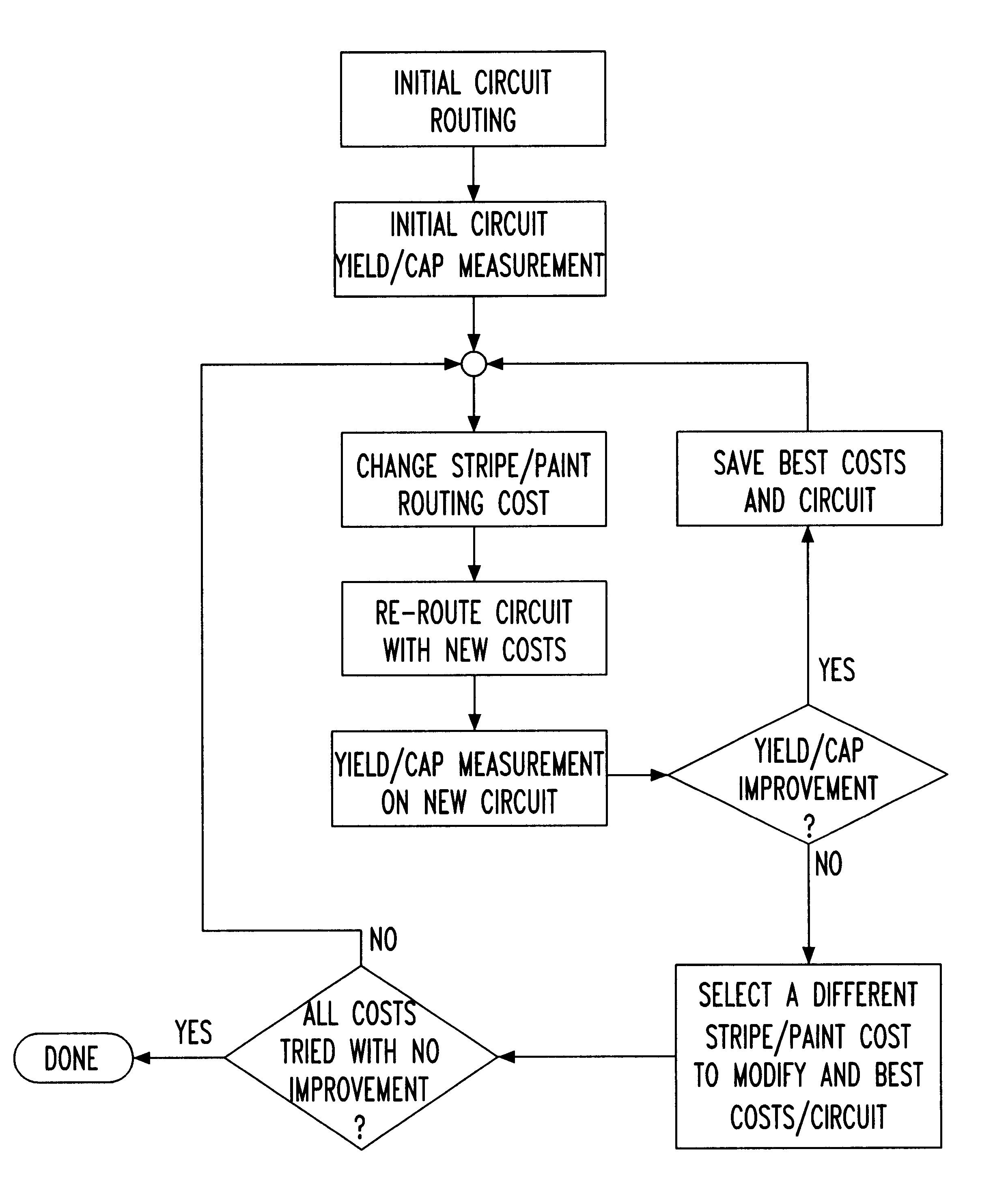

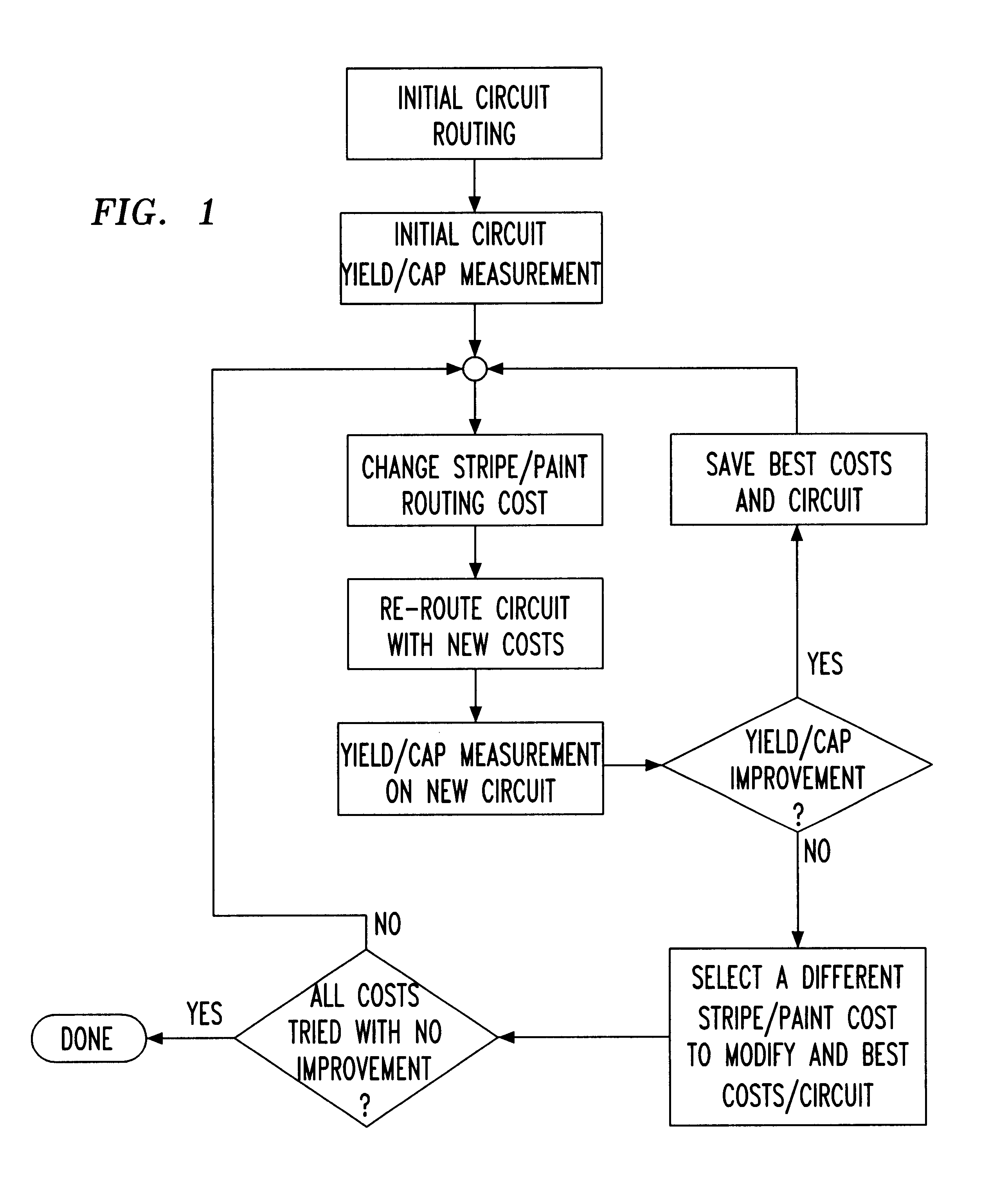

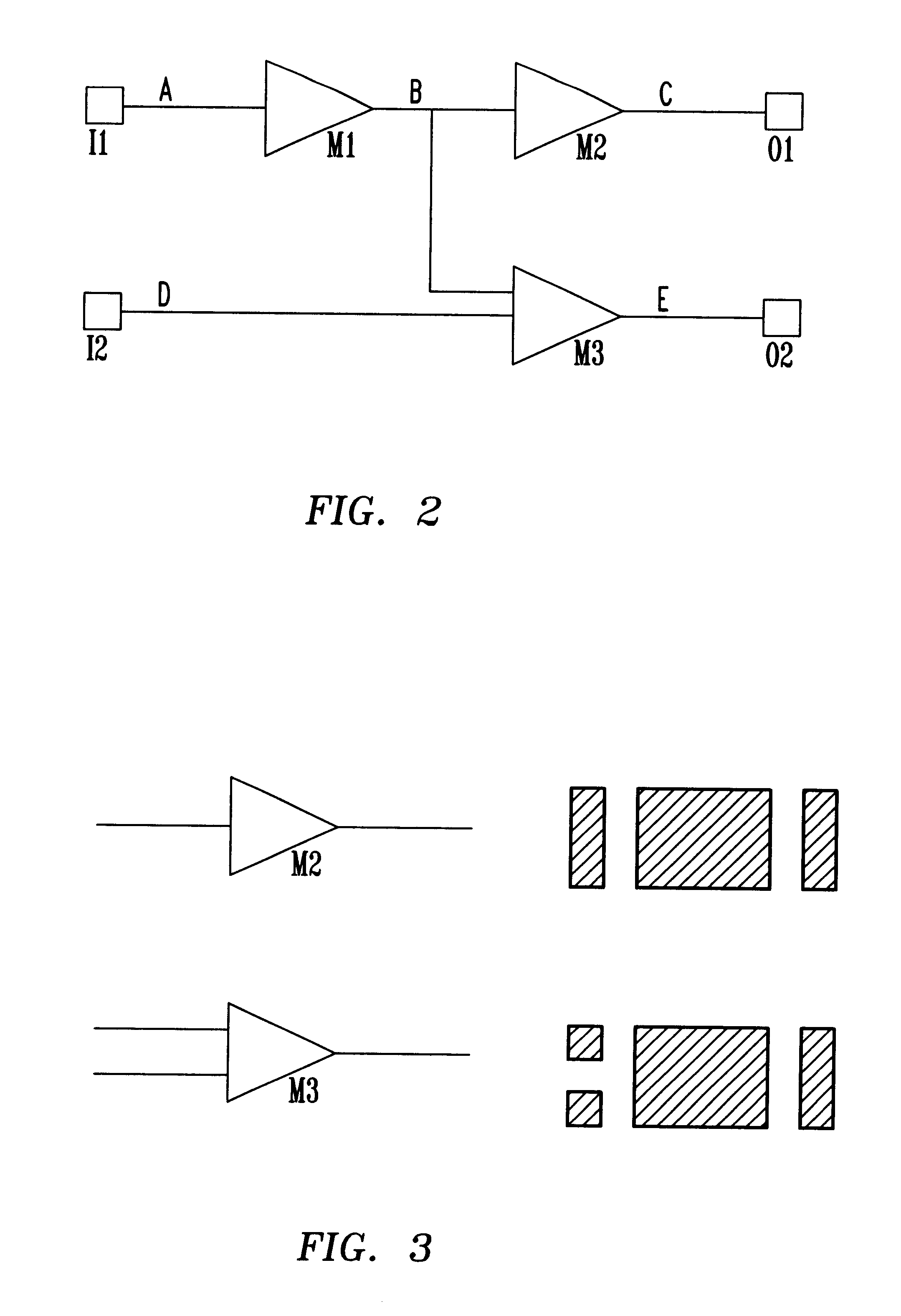

Method for improving wiring related yield and capacitance properties of integrated circuits by maze-routing

InactiveUS6305004B1Improved yieldGood yieldComputer aided designSoftware simulation/interpretation/emulationCapacitanceIntegrated circuit

A method for automatically wiring (i.e., routing) an integrated circuit chip after completing the placement of cells on the chip is described. The method employs a maze routing such that the spacing between the routed wires is increased, while at the same time maintaining control over the total wiring length. The maze routing herein described is modified to improve chip yield, reduce wiring capacitance, limit power consumption and coupled signal noise, all of which are achieved by increasing wire-to-wire spacings.

Owner:IBM CORP

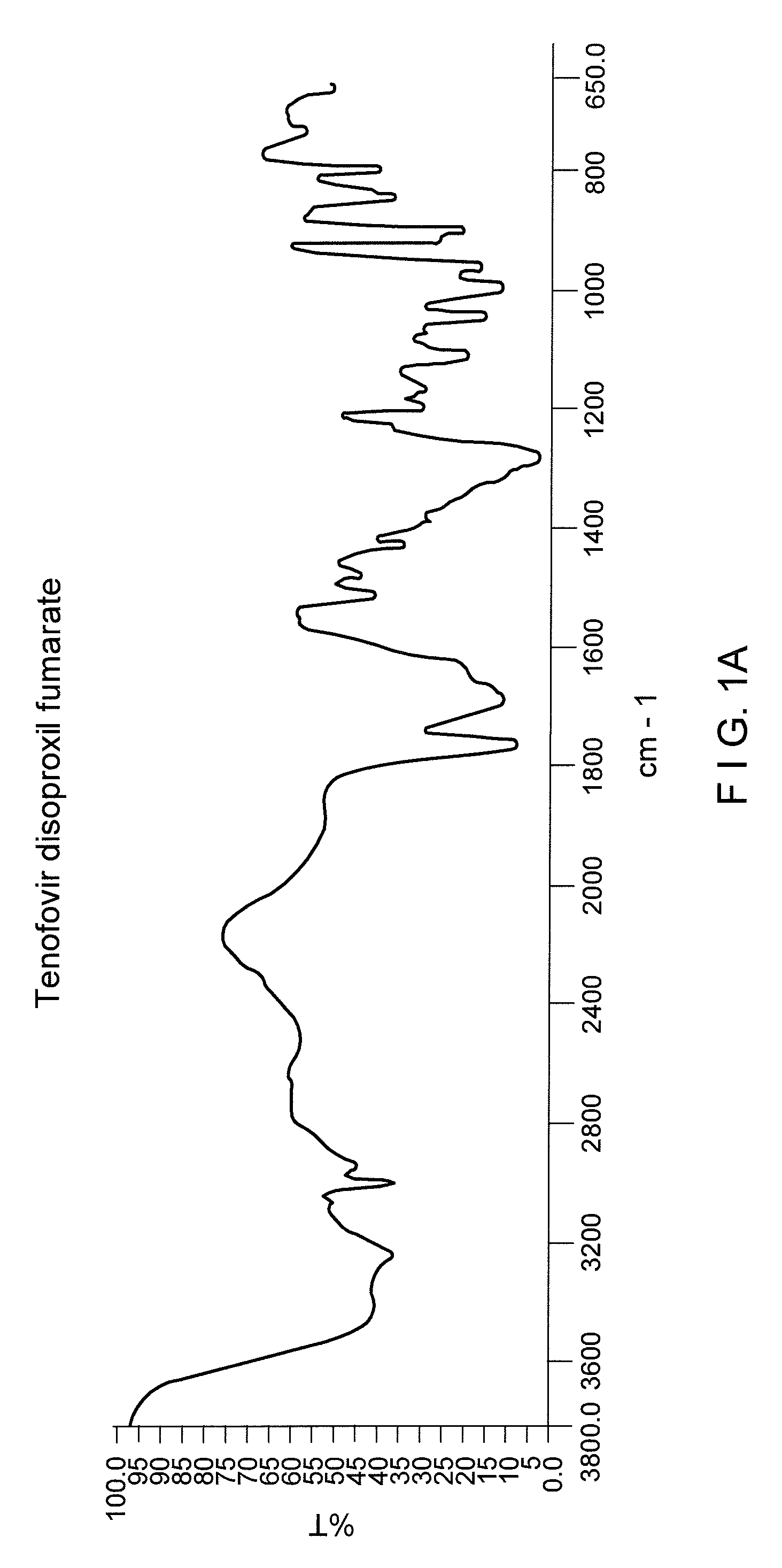

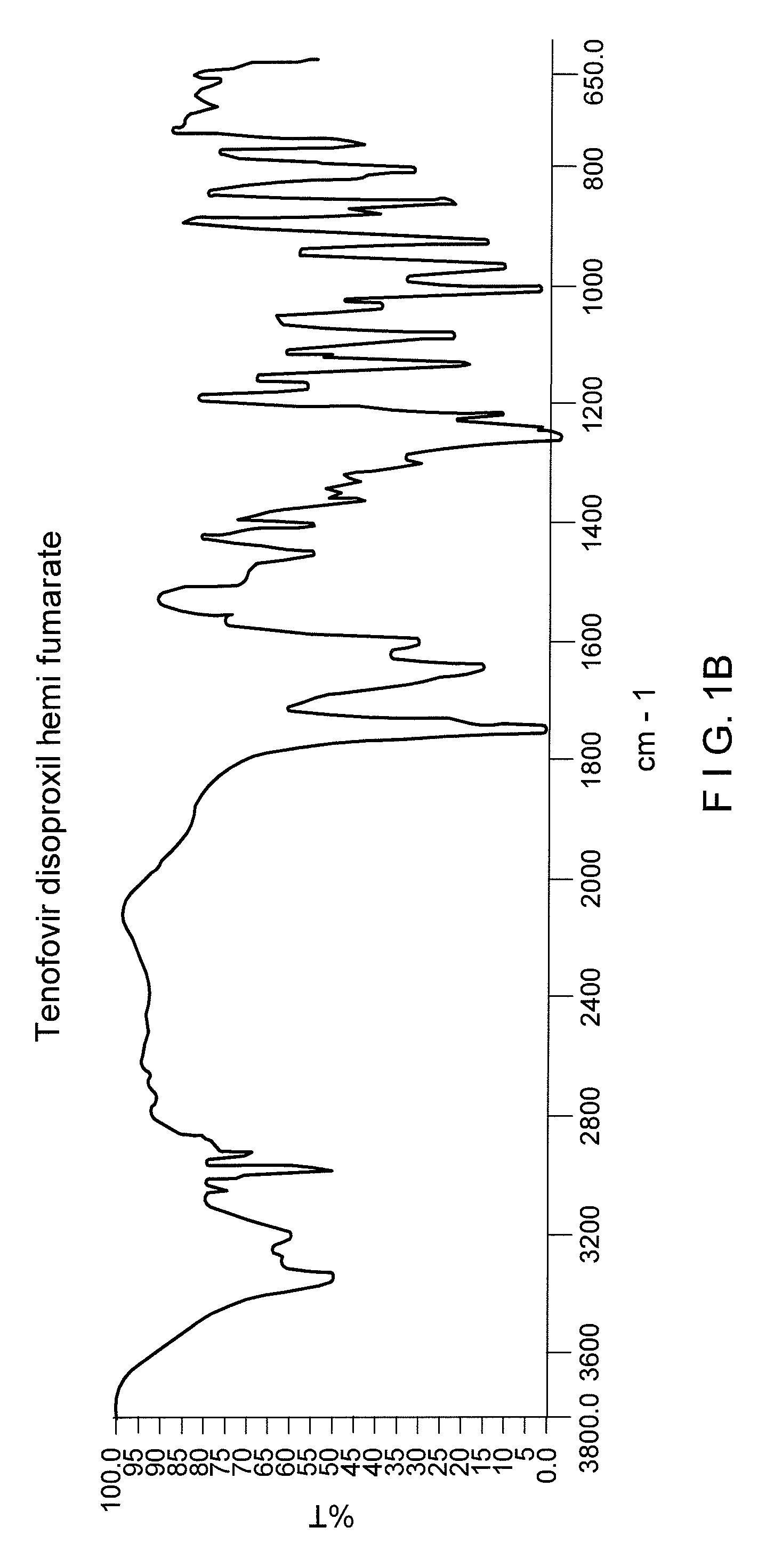

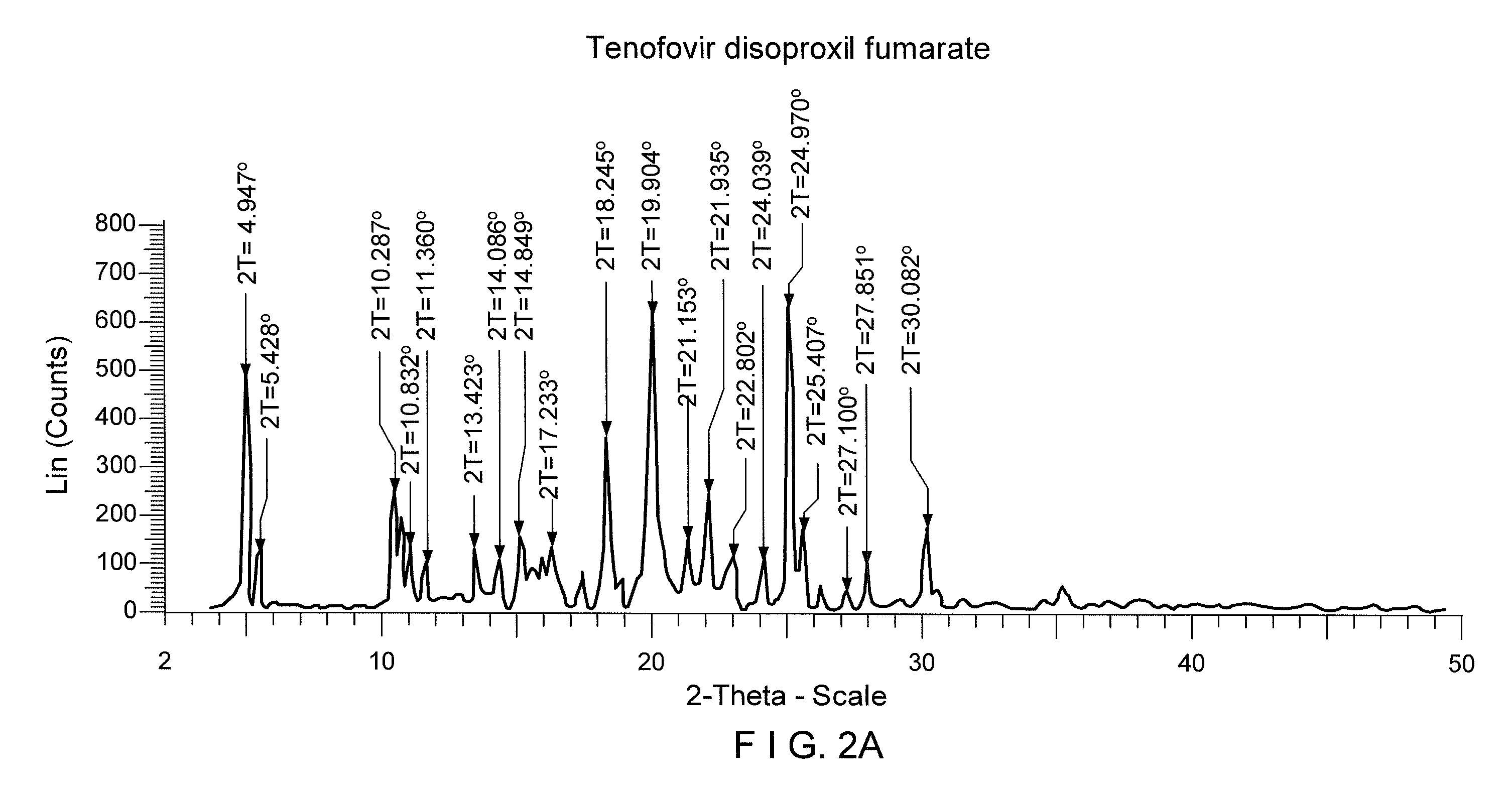

Process for the prepartion of tenofovir

ActiveUS20090286981A1Improved yieldIncrease productionPhosphorus organic compoundsTenofovirMedicinal chemistry

The present invention relates to novel Tenofovir disoproxil hemifumarate salt, which is prepared by dealkylation of Phosphonate esters by using mineral acids followed by esterification and crystallization to give crystalline Tenofovir disoproxil. The Tenofovir disoproxil is further converted to fumarate salts with improved yield.

Owner:MYLAN LAB

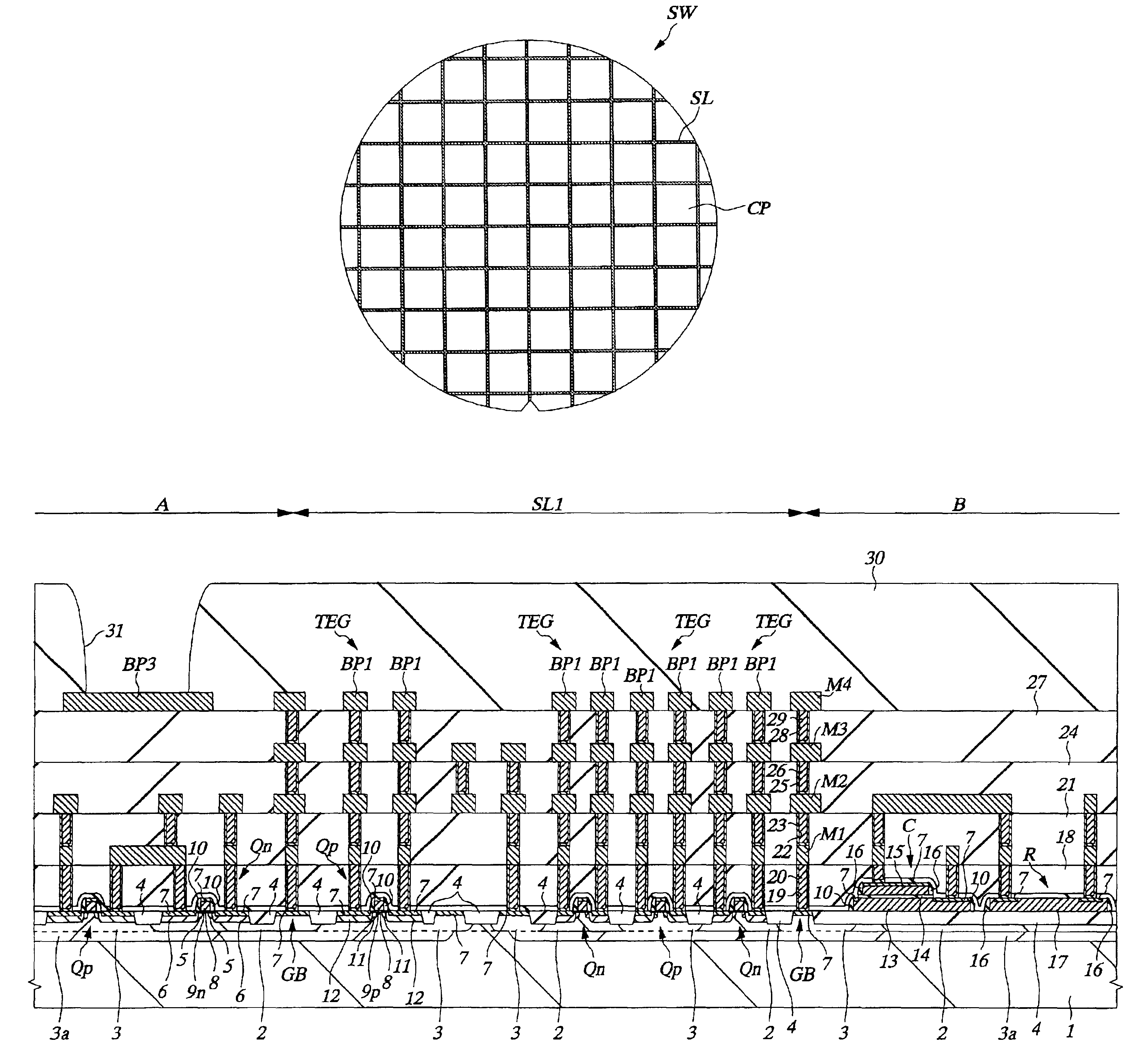

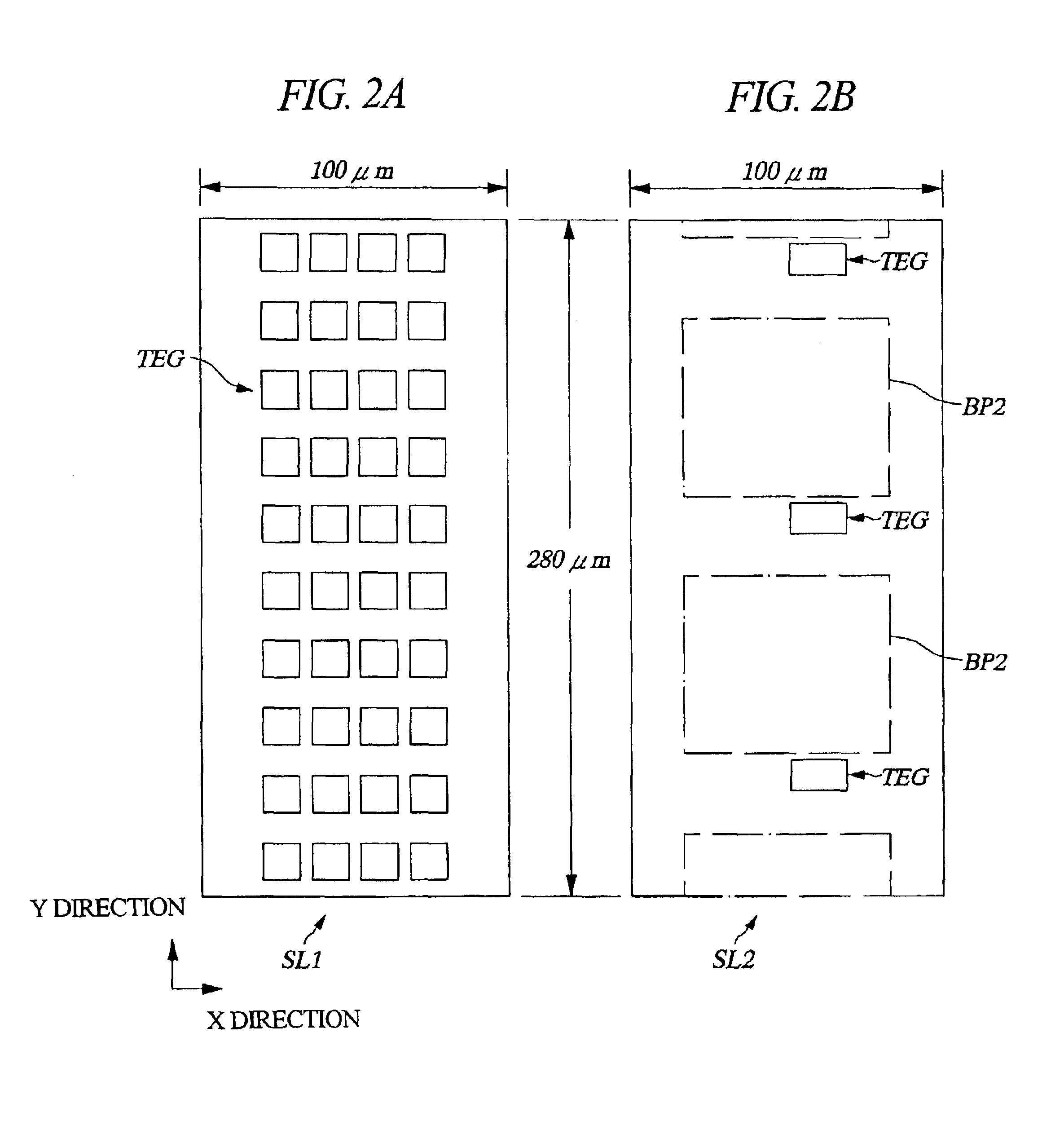

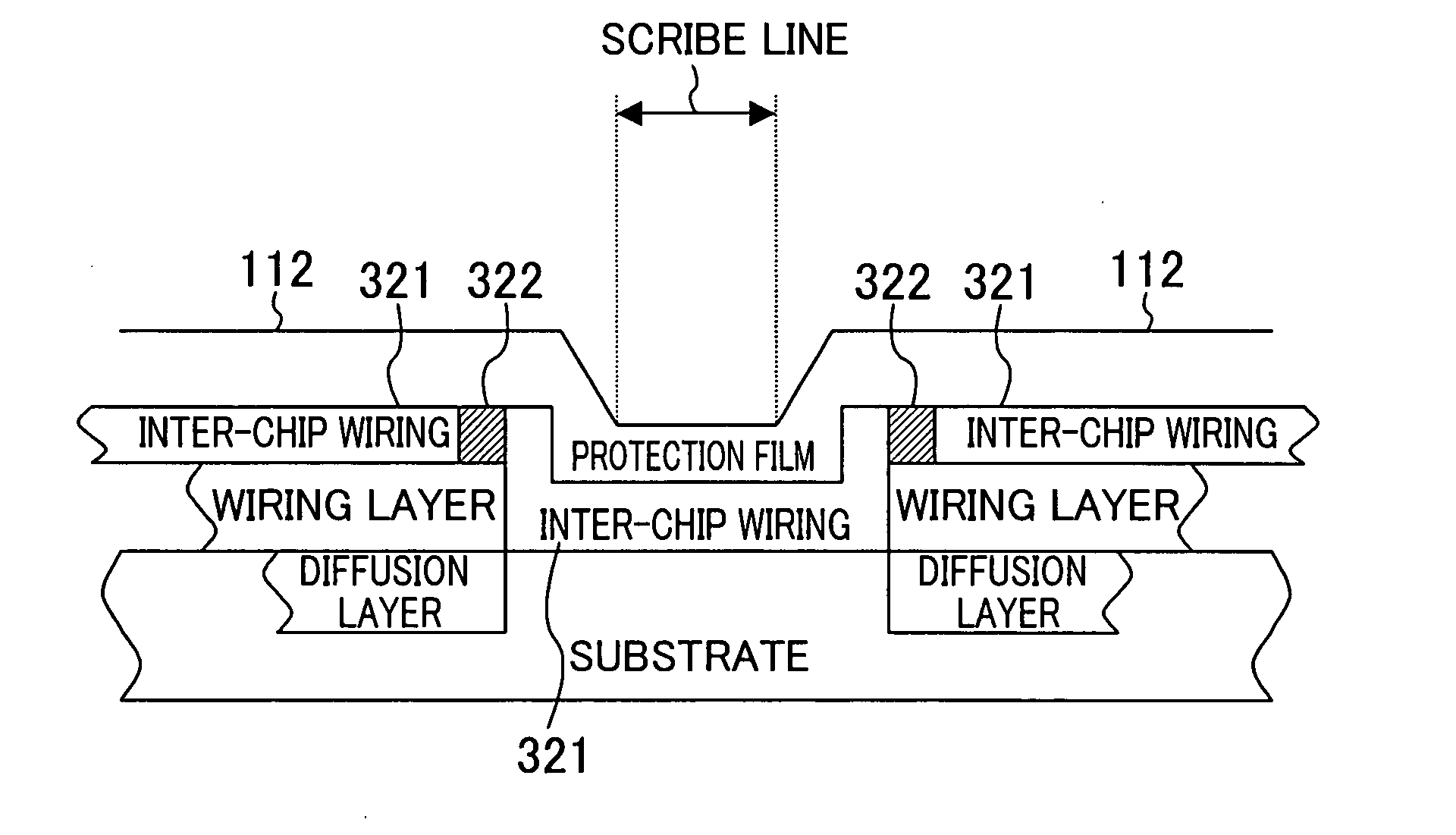

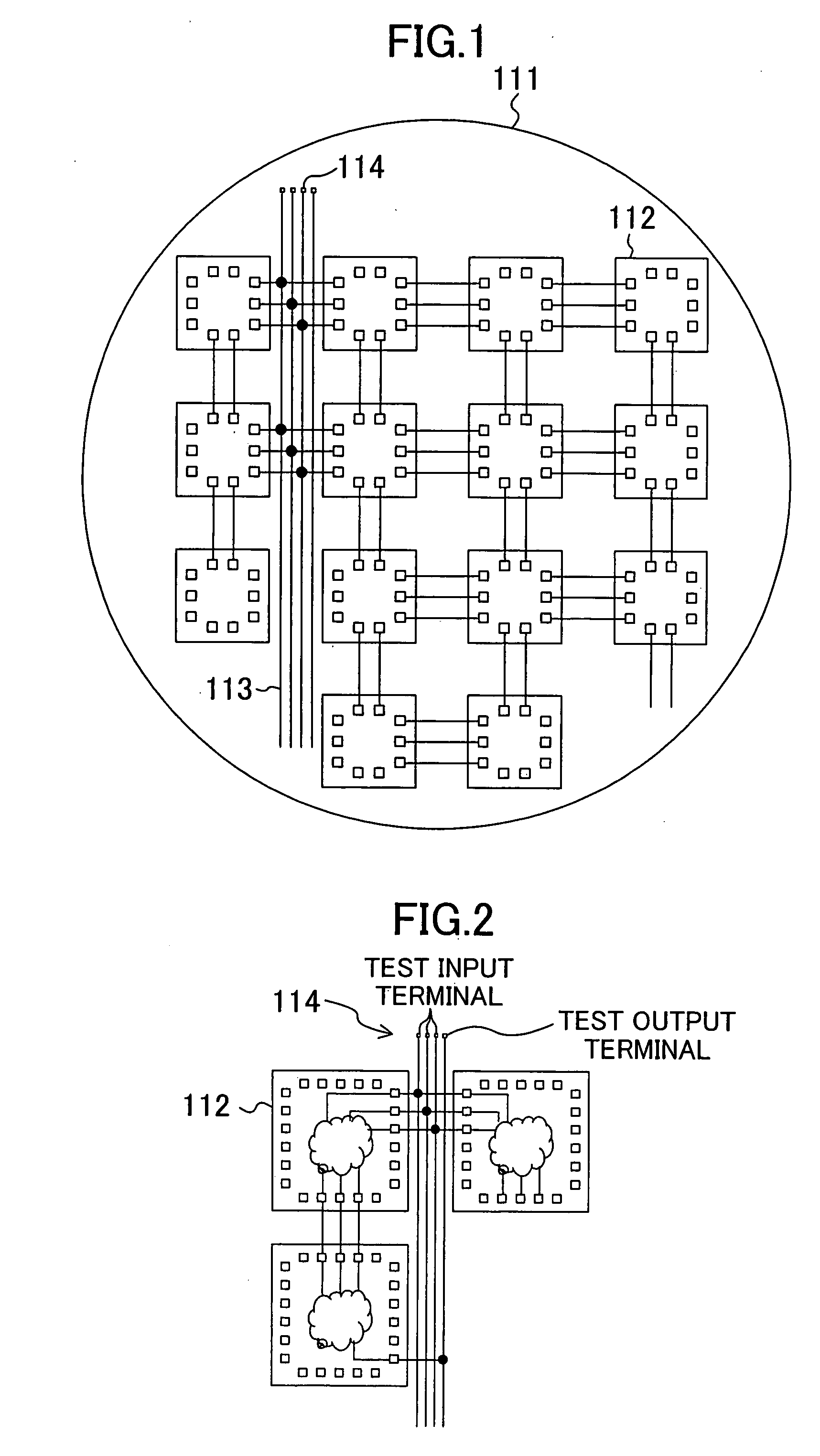

Method of manufacturing a semiconductor device to provide a plurality of test element groups (TEGs) in a scribe region

InactiveUS6881597B2Large amount of dataImproved yieldSemiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringSemiconductor

Disclosed is a technique capable of improving a yield of a semiconductor device by measuring a plurality of TEGs arranged in a scribe region. A first electrode pad connected to each terminal of a TEG is formed as a rectangular, minute, isolated pattern having a side length of about 0.5 μm or shorter and constituted of an uppermost layer wiring on a semiconductor substrate, and therefore, a great number of TEGs can be laid in a first scribe region. The characteristic evaluation or the failure analysis is performed by contacting a nanoprobe having a tip radius of curvature of 0.05 μm to 0.8 μm to the first electrode pad.

Owner:RENESAS ELECTRONICS CORP

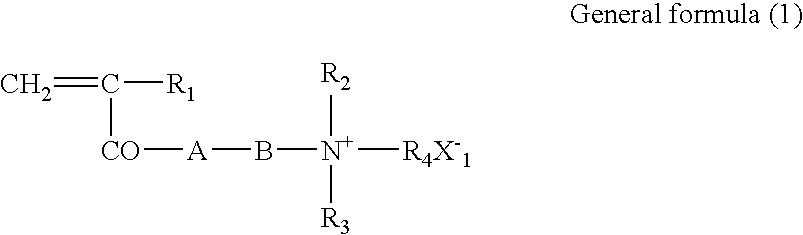

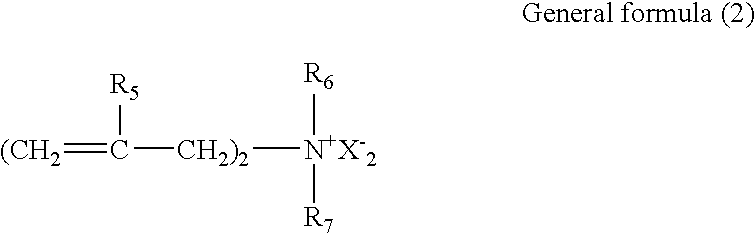

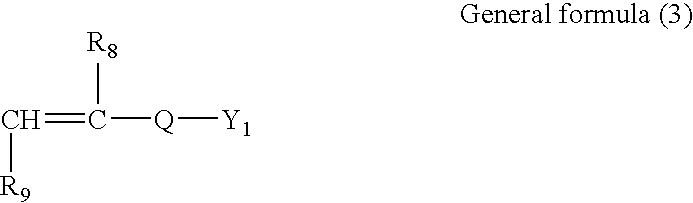

Water-soluble polymer dispersion, process for producing the same and method of use therefor

InactiveUS20060162882A1Marked effectImproved yieldNatural cellulose pulp/paperSpecial paperWater soluble polymersIon

A water-solible polymer dispersion, p process for producing the same and a method of use therefor. In particular, the water-soluble polymer dispersion is one comprising water-soluble polymer fine particles of 100 μm or less diameter having at least one ionic property selected from among cationic, amphoteric, nonionic and anionic properties together with a polyalkyleneimine and / or a product of polyalkyleneimine modification wherein according to necessity an appropriate amount of water-soluble inorganic salt is incorporated. The provided process enables easily performing the production in dispersed form by means of production facilities of low cost. The obtained water-soluble polymer dispersion is excellent in storage stability and exhibits satisfactory fluidity and solubility so as to enable use in papermaking raw material pretreatments added to papermaking raw materials prior to machine operation and also for enhancement of freeness, increase of sizing degree and enhancement yield. Further use can be found in incorporation in an organic sludge or paper mill sludge for flocculation and ensuing drainage.

Owner:HYMO CORPORATION

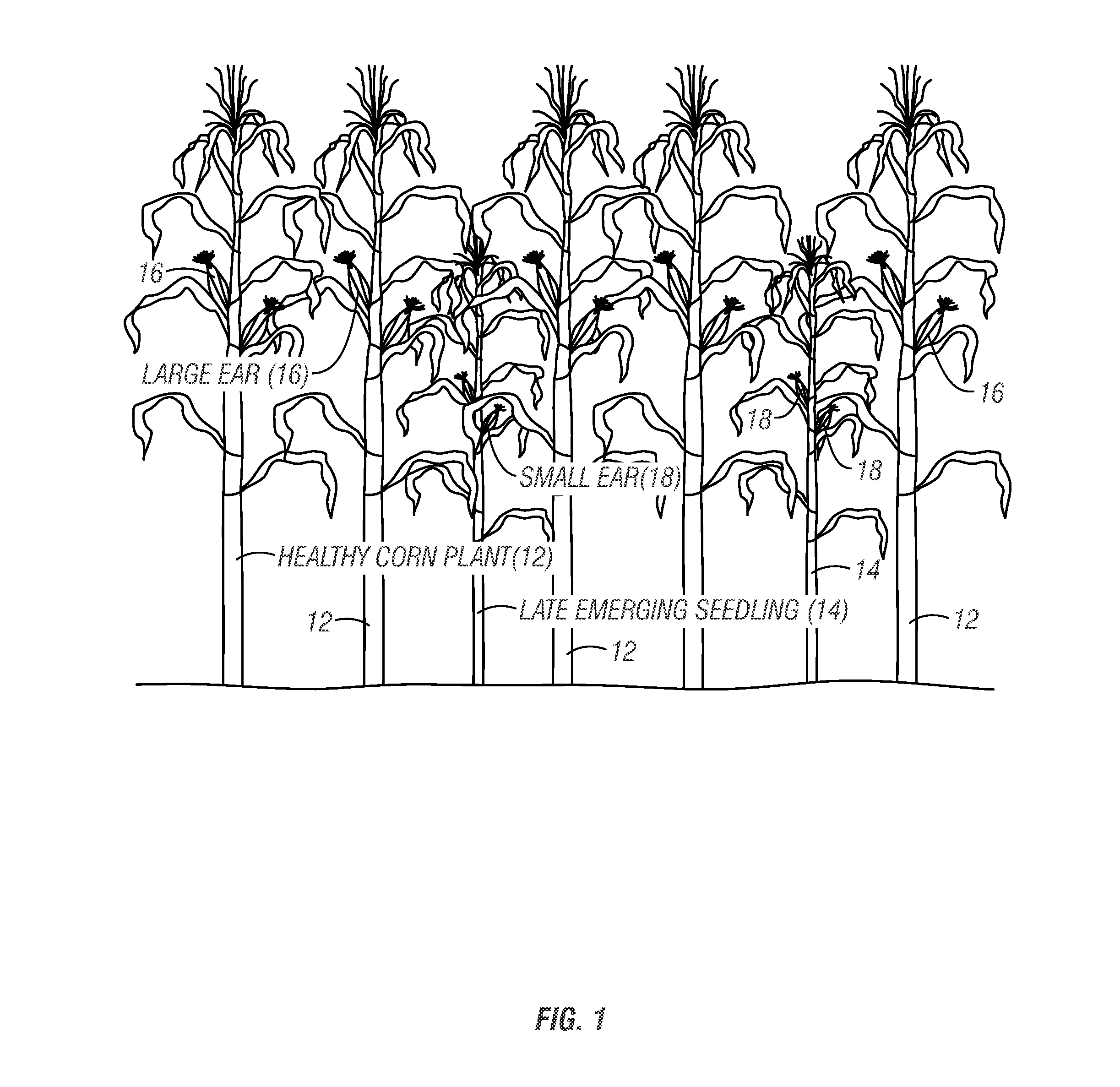

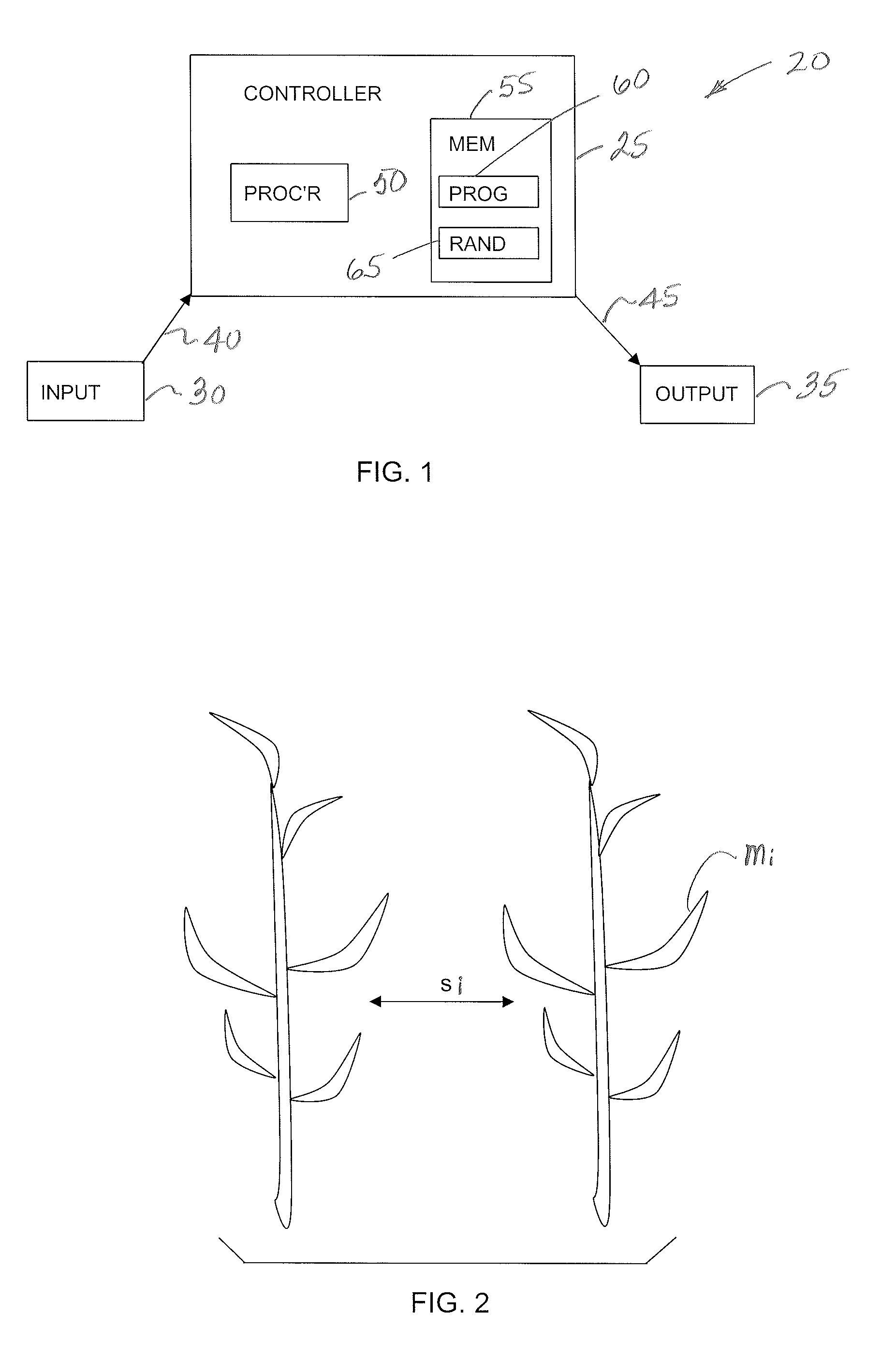

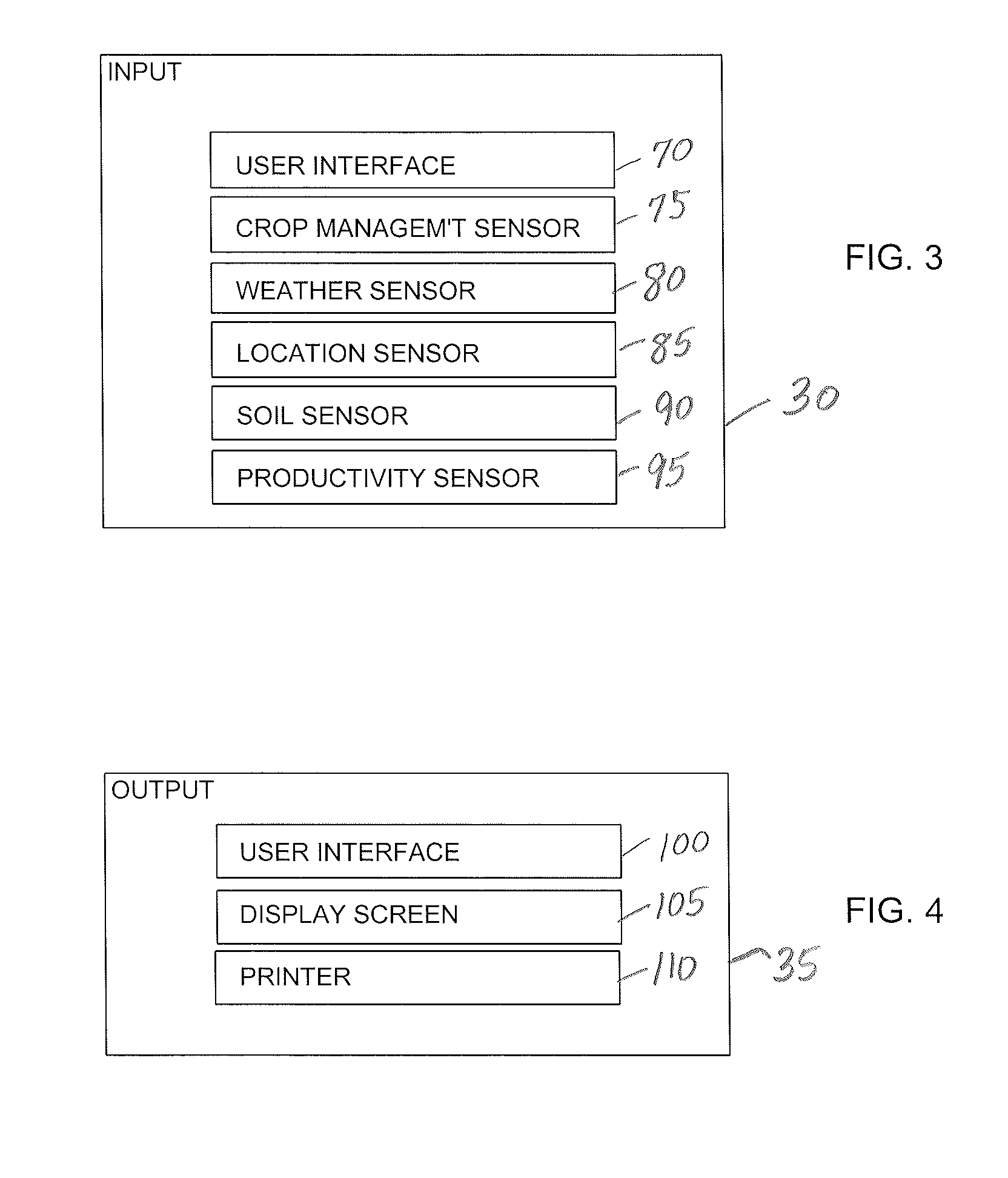

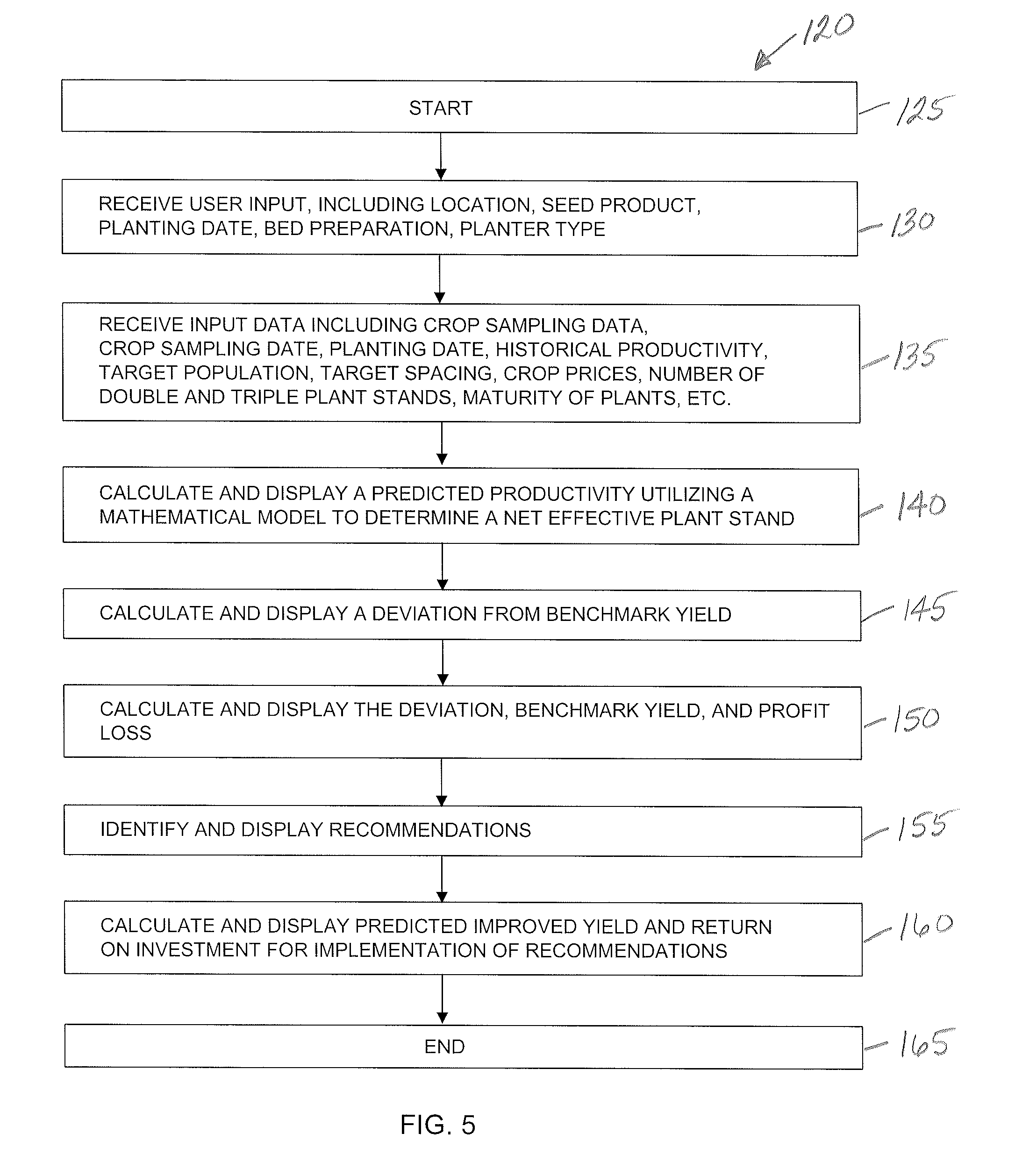

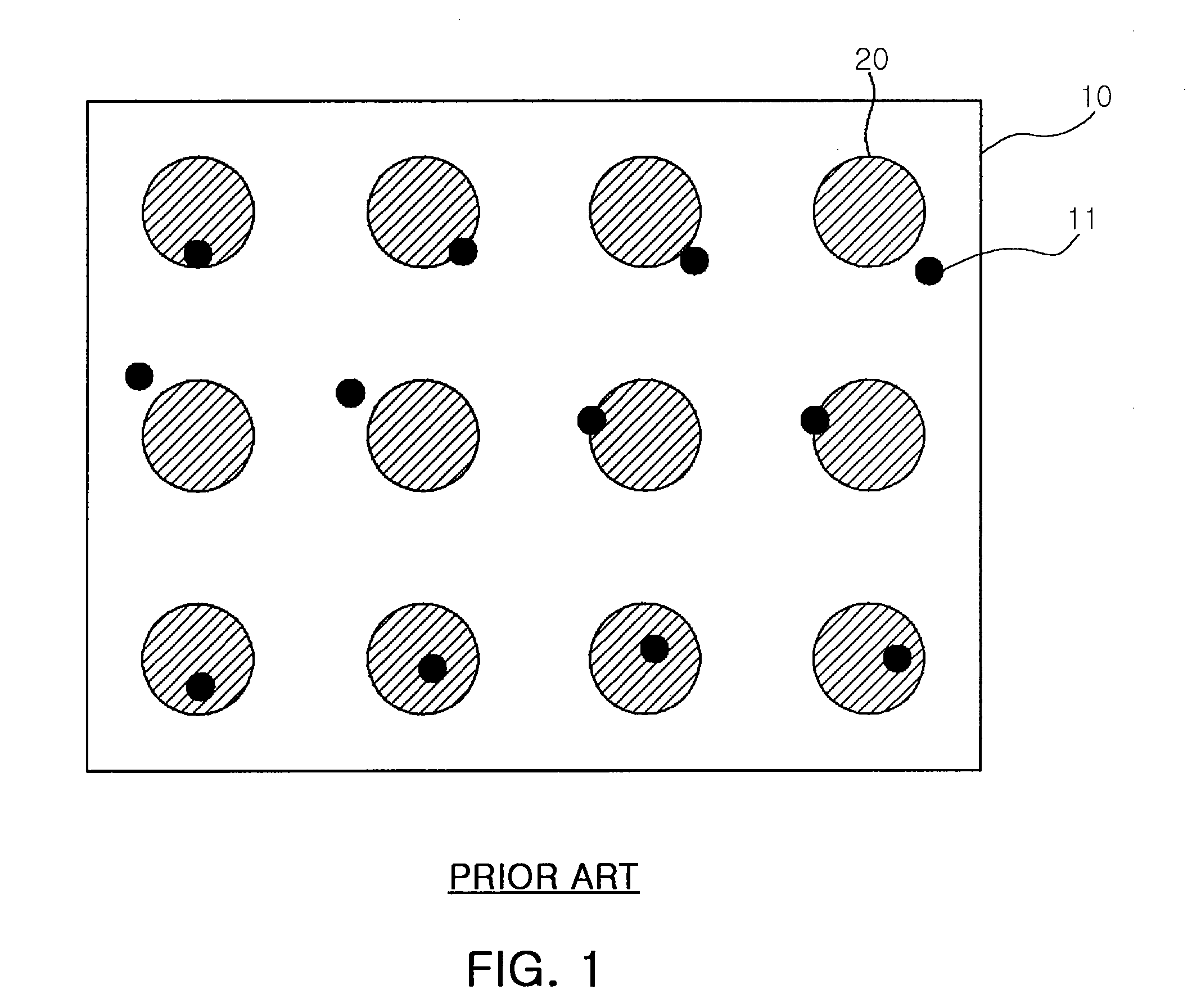

System and method of evaluating crop management

ActiveUS20070255502A1Improved yieldSimple and reliable evaluationAnalogue computers for chemical processesBiological testingPopulationRegion of interest

A method of and system for evaluating performance of a plant population in an area of interest is provided. The method includes the steps of receiving input data from a user, the input data representative of at least one management parameter in the group consisting of: a total plant population in a selected sampling sub-area, a spacing of an individual plant relative to a nearest adjacent plant in the sampling sub-area, and a maturity of the individual plant relative to the nearest adjacent plant in the sampling sub-area. The system analyzes the input data in accordance with a mathematical model having an objective function for predicting a performance of a plant stand represented by a net effective plant population reduced from a benchmark plant population by deduction factors related to at least one of the management parameters.

Owner:BLUE LEAF I P

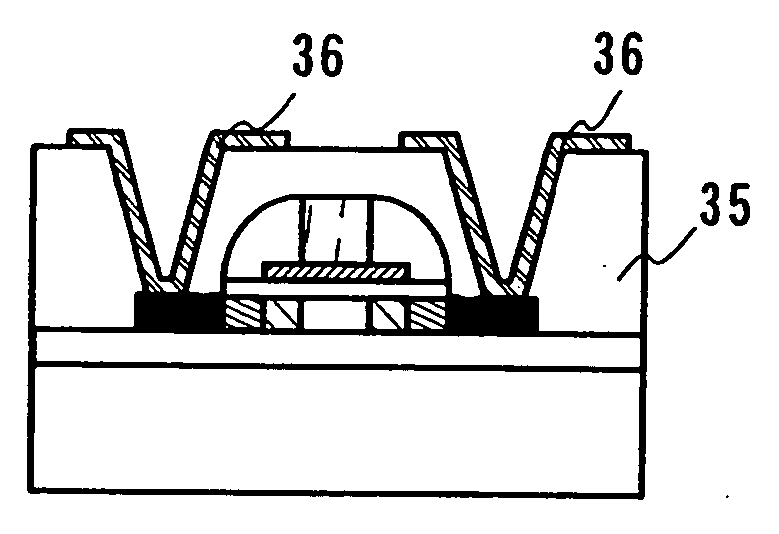

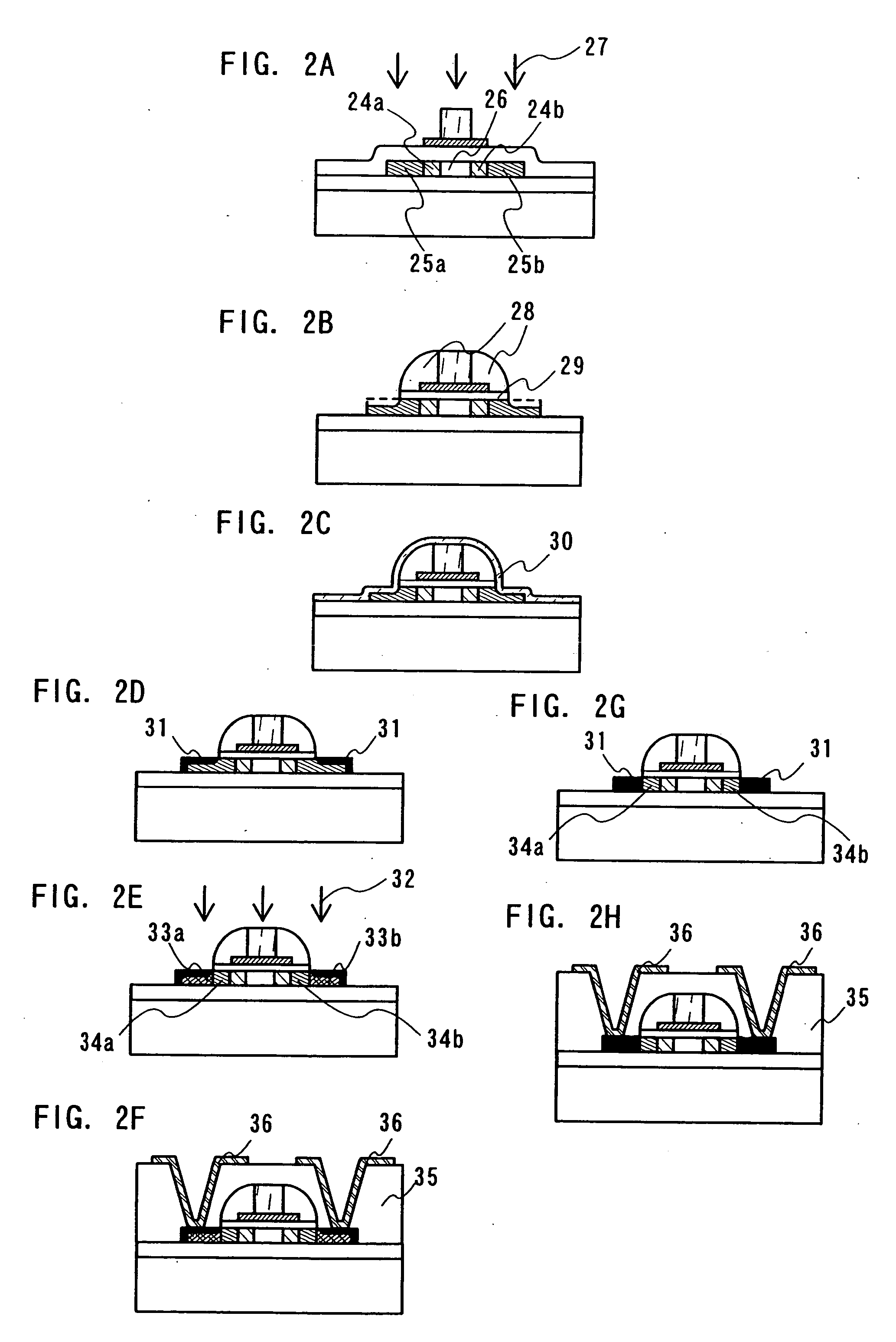

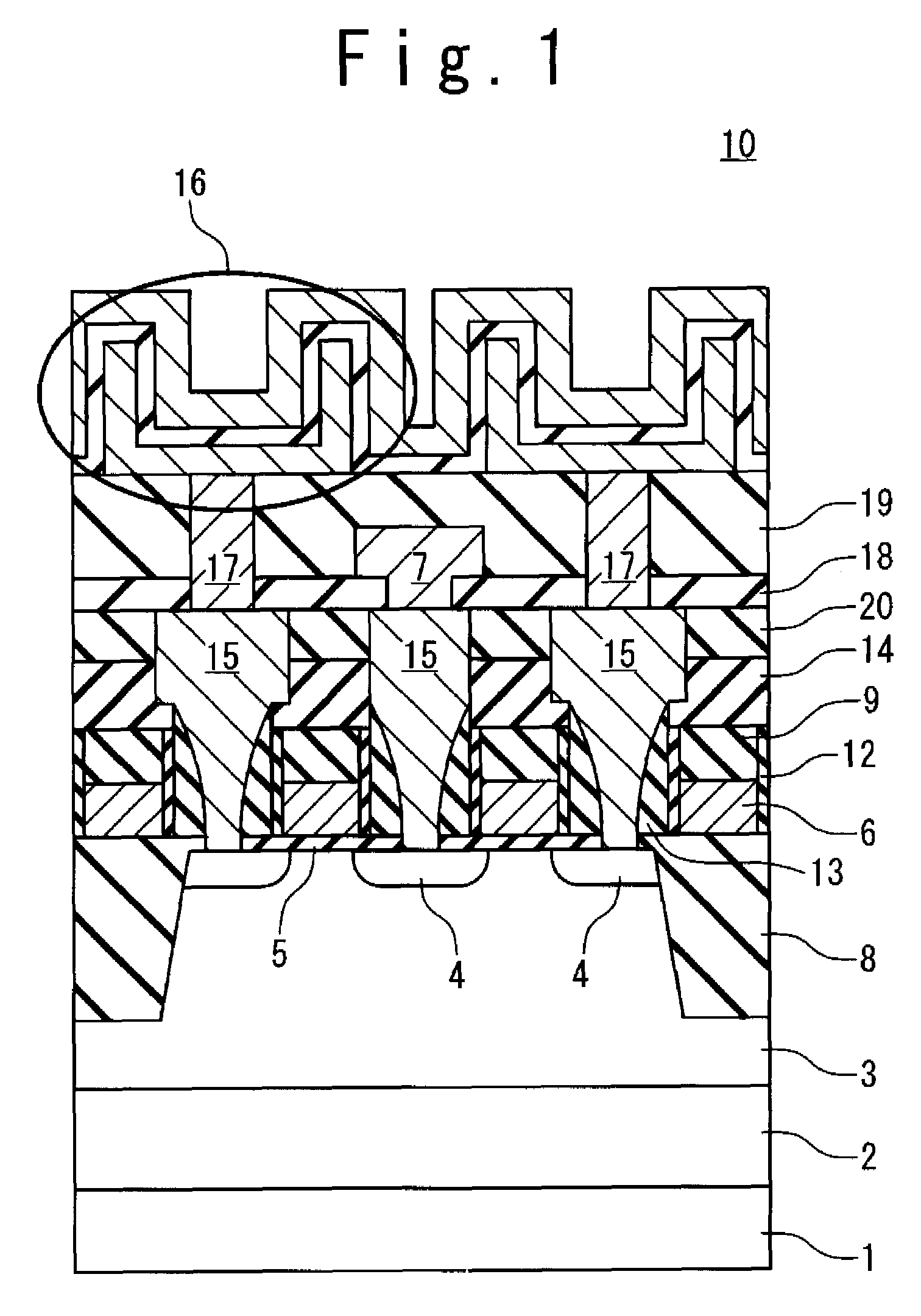

Micro electro mechanical system, semiconductor device, and manufacturing method thereof

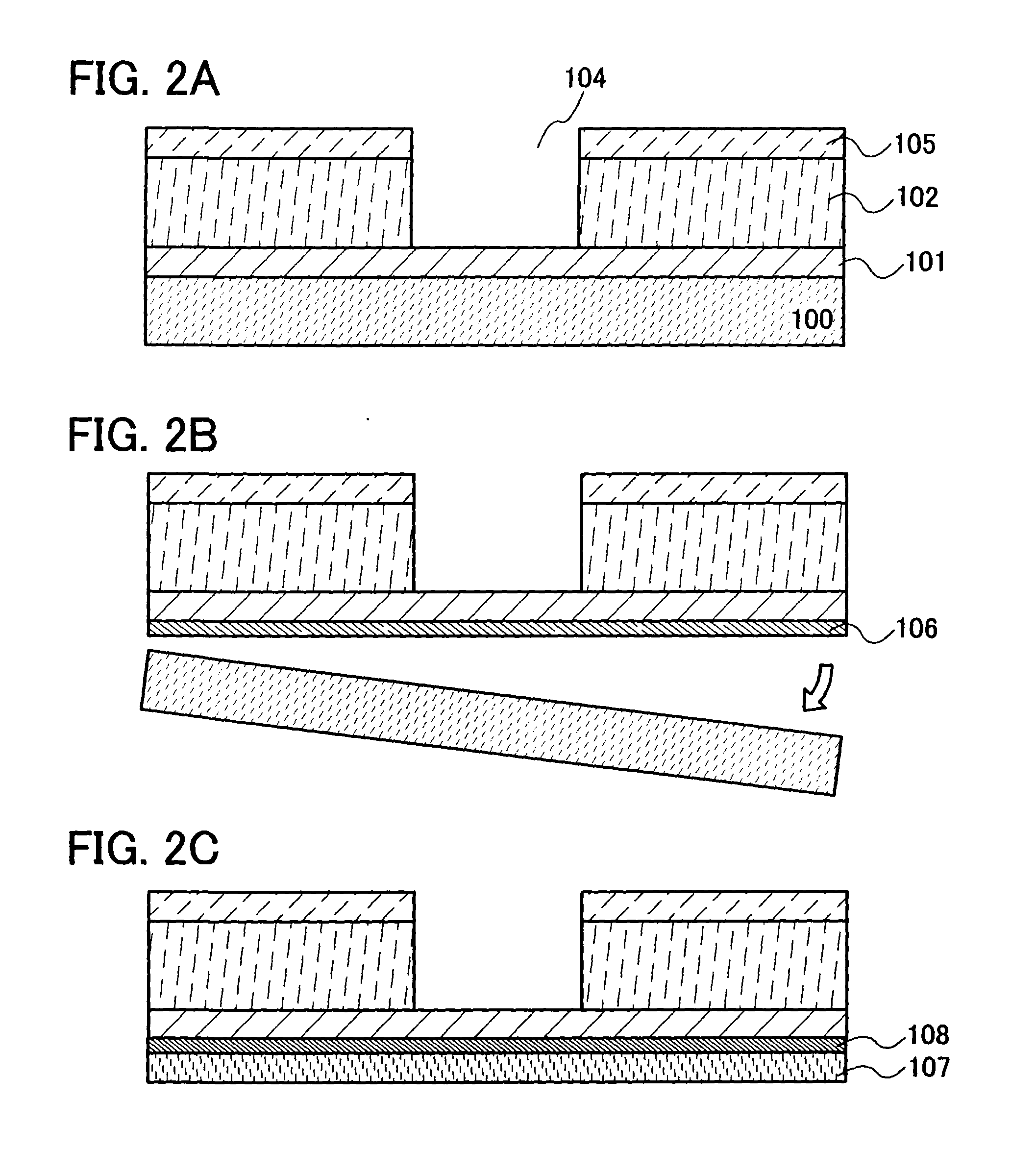

ActiveUS20070152537A1Improved yieldEasy to preparePiezoelectric/electrostrictive device manufacture/assemblyInflated body pressure measurementEngineeringMechanical system

The present invention provides a MEMS and a sensor having the MEMS which can be formed without a process of etching a sacrifice layer. The MEMS and the sensor having the MEMS are formed by forming an interspace using a spacer layer. In the MEMS in which an interspace is formed using a spacer layer, a process for forming a sacrifice layer and an etching process of the sacrifice layer are not required. As a result, there is no restriction on the etching time, and thus the yield can be improved.

Owner:SEMICON ENERGY LAB CO LTD

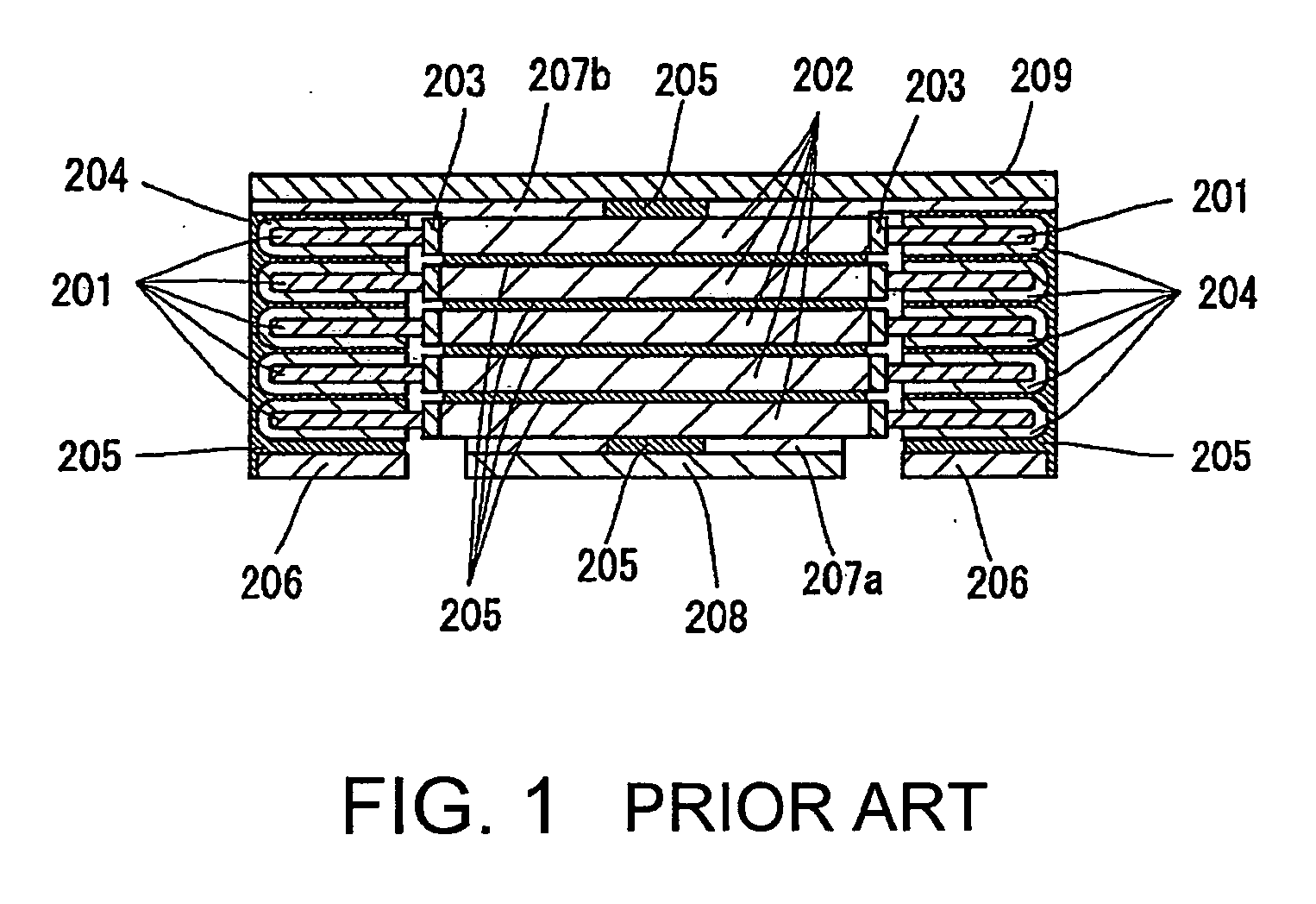

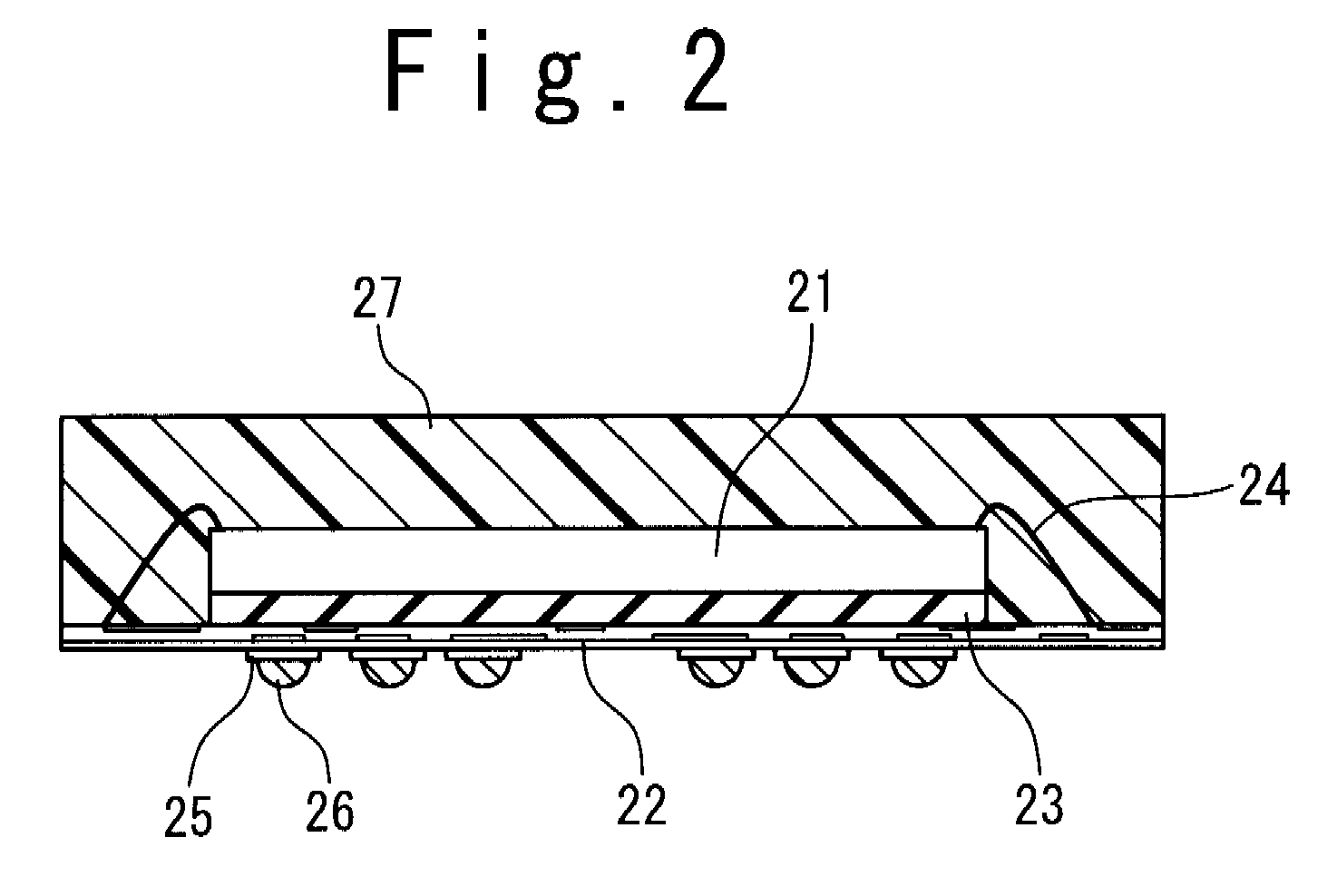

Surface-mount capacitor and method of producing the same

ActiveUS20060087795A1Increase bonding strengthImproved yieldThin/thick film capacitorCapacitor terminalsEngineeringSurface mounting

A surface-mount capacitor includes a multilayer capacitor structure formed by laminating plate-like capacitor elements each having anode lead portions 11 at opposite ends thereof and a cathode portion 12 at the center, an anode terminal 18 connected to each anode lead portion 11 via a strip-like plate 14, and a cathode terminal 19 connected to the cathode portion 12. The anode and the cathode terminals 18 and 19 have a flat shape and are formed on a common plane as a substrate-mounted surface. A mold resin case 20 has a bottom portion filling a gap between the anode and the cathode terminals 18 and 19 and mechanically connecting the anode and the cathode terminals 18 and 19, and side walls substantially perpendicular to the substrate-mounted surface. The anode and the cathode terminals 18 and 19 have upper surfaces exposed on an inner bottom surface of the mold resin case 20 to be connected to the anode lead portions 11 and the cathode portion 12.

Owner:TOKIN CORP

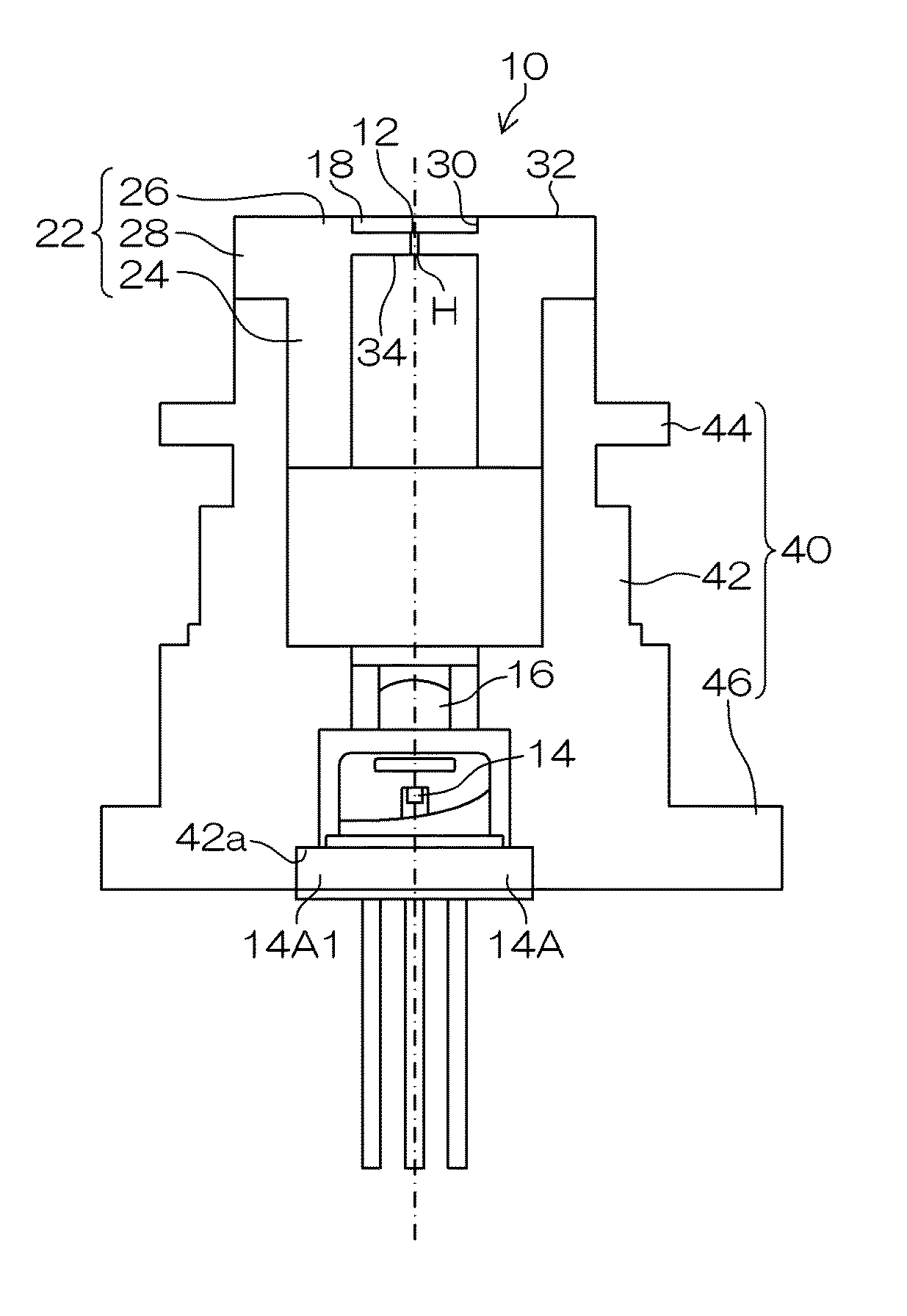

Semiconductor integrated circuit

InactiveUS20070241766A1Cost reductionImproved yieldSemiconductor/solid-state device testing/measurementIndividual semiconductor device testingIntegrated circuitElectricity

A semiconductor integrated circuit includes a wiring capable of connecting a plurality of chips on a wafer and has a configuration which is capable of cutting the wiring electrically and which allows all the chips to be tested at one time. Specifically, an exclusive test circuit region capable of being shared for testing the plurality of chips is formed on the wafer, and a test circuit is removed from each chip. Terminals of the chips and a terminal of the test circuit are connected through a wiring on the wafer or a device outside the wafer to enable a general test to be performed in burn-in.

Owner:PANASONIC CORP

Light emitting device and vehicle lamp

ActiveUS20140160782A1Light incident efficiencyImproved yieldVehicle headlampsPoint-like light sourceEngineeringSemiconductor

A light emitting device can include a head portion including a surface including a convex portion, a back surface on the opposite side, and a through hole penetrating a tip surface of the convex portion and the back surface; a light-transmitting member including a surface and a back surface on the opposite side, the back surface including a first recess to be fitted to the convex portion; an adhesive bonding part of the surface of the head portion around the convex portion to the back surface of the light-transmitting member while the convex portion is fitted to the first recess and the first recess covers the through hole; a semiconductor light emitting element that emits light passing through the through hole for irradiation of the light-transmitting member; and an optical system condensing the light from the semiconductor light emitting element and locally irradiates the light-transmitting member with the light.

Owner:STANLEY ELECTRIC CO LTD

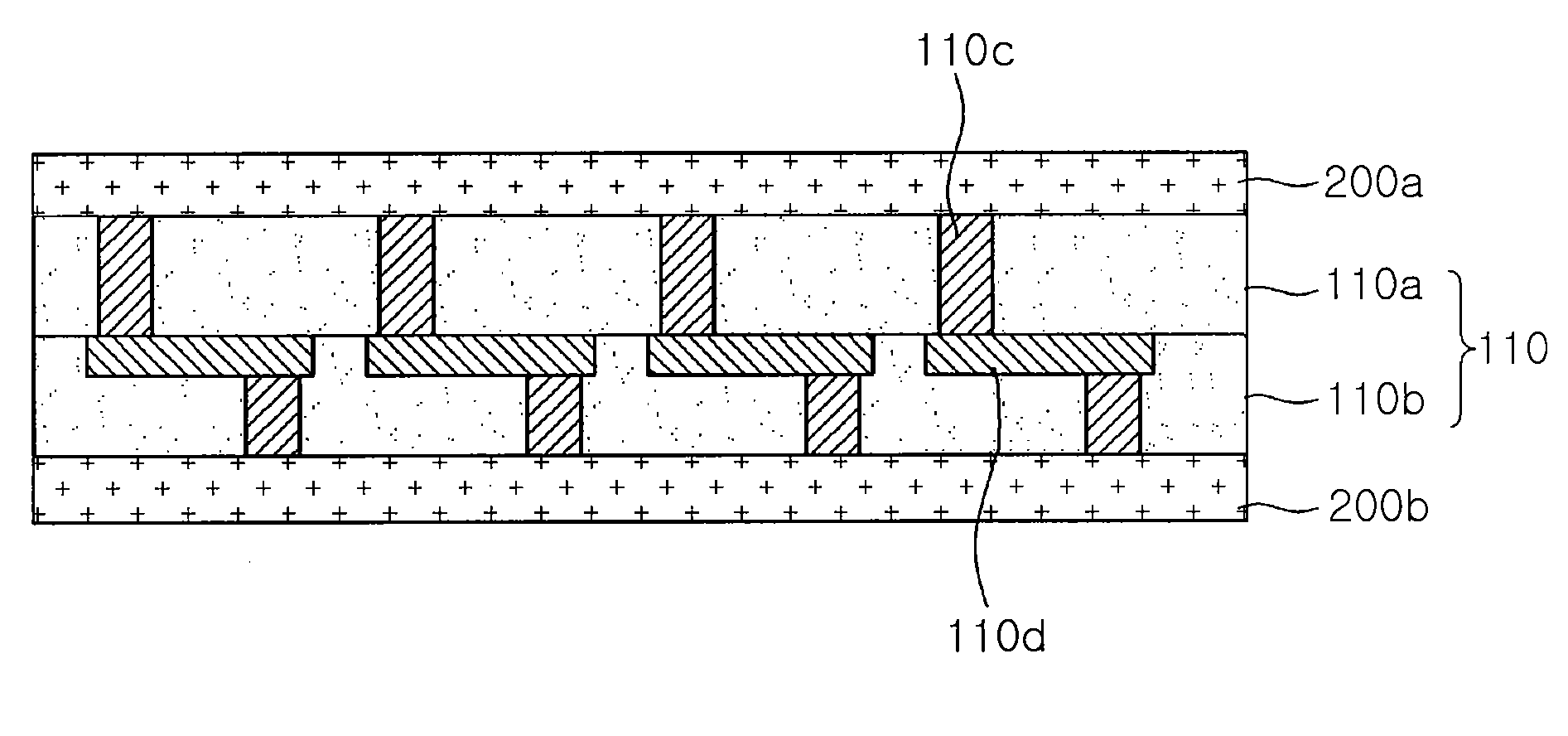

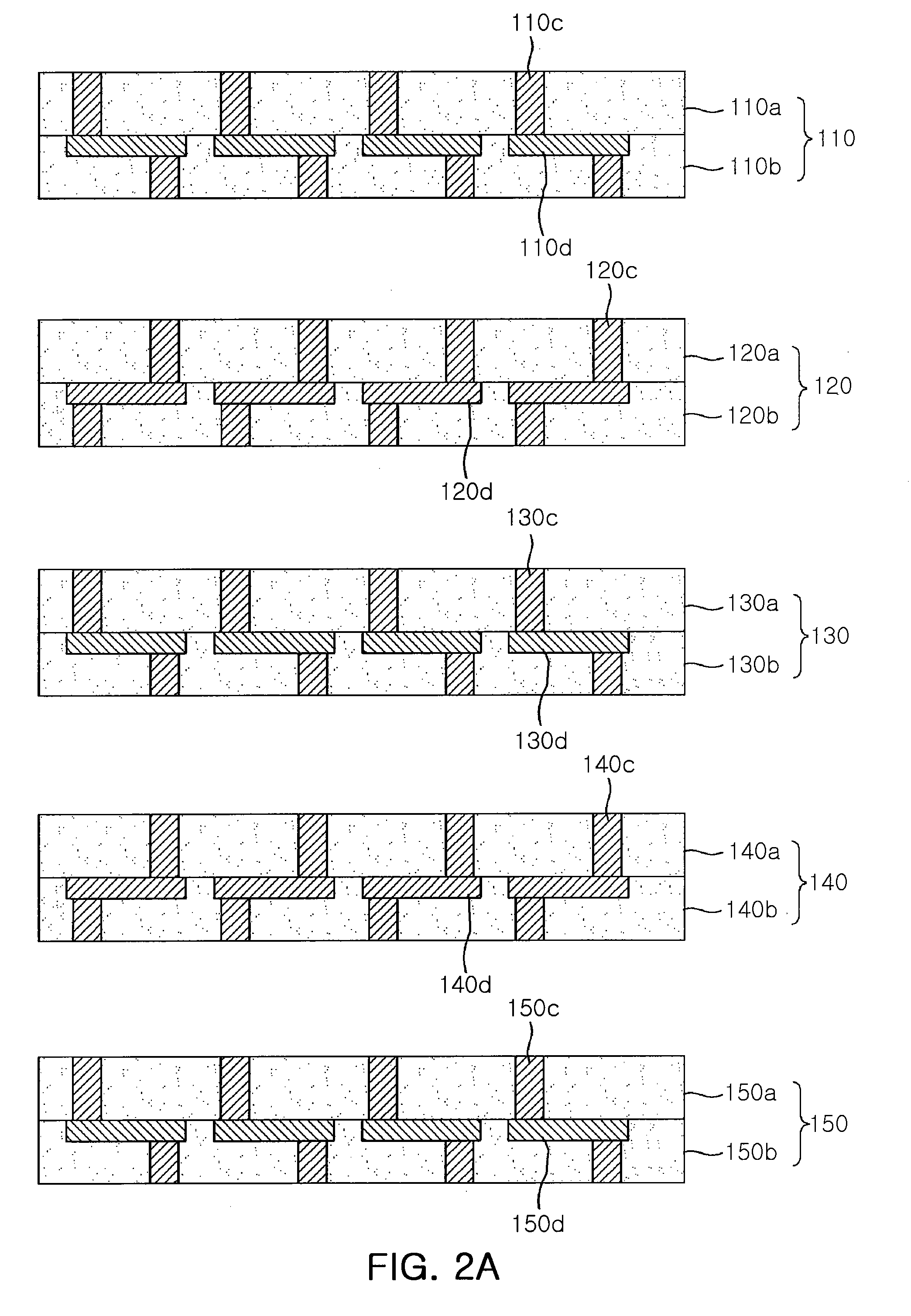

Ceramic multi-layer circuit substrate and manufacturing method thereof

InactiveUS20100059266A1Improved electrical connectionImproved yieldPrinted circuit aspectsCeramic layered productsCeramicElectrode

Provided is a method of manufacturing a ceramic multi-layer circuit substrate. A plurality of ceramic blocks, in each of which one or more ceramic green sheets having via-electrodes are layered one atop the other, are formed and are then fired. The fired ceramic blocks are aligned with each other. One or more bonding green sheets each having bonding electrodes in positions corresponding to the via-electrodes of the ceramic blocks are prepared. Each of the bonding green sheets is interposed between a pair of the ceramic blocks opposing each other. The ceramic blocks and the bonding green sheets are bonded and are then fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Thermosetting die bond film, dicing die bond film and semiconductor device

InactiveUS20110256666A1Improve manufacturing efficiencyImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

The present invention provides a thermosetting type die bond film that can be preferably broken by tensile force. It is a thermosetting type die bond film used for a method of obtaining a semiconductor element from a semiconductor wafer by forming a reforming region by irradiating the semiconductor wafer with a laser beam and then breaking the semiconductor wafer in the reforming region or a method of obtaining a semiconductor element from a semiconductor wafer by forming grooves that do not reach the backside of the semiconductor wafer on a surface thereof and then exposing the grooves from the backside by grinding the backside of the semiconductor wafer, wherein the elongation rate at break at 25° C. before thermal curing is larger than 40% and 500% or less.

Owner:NITTO DENKO CORP

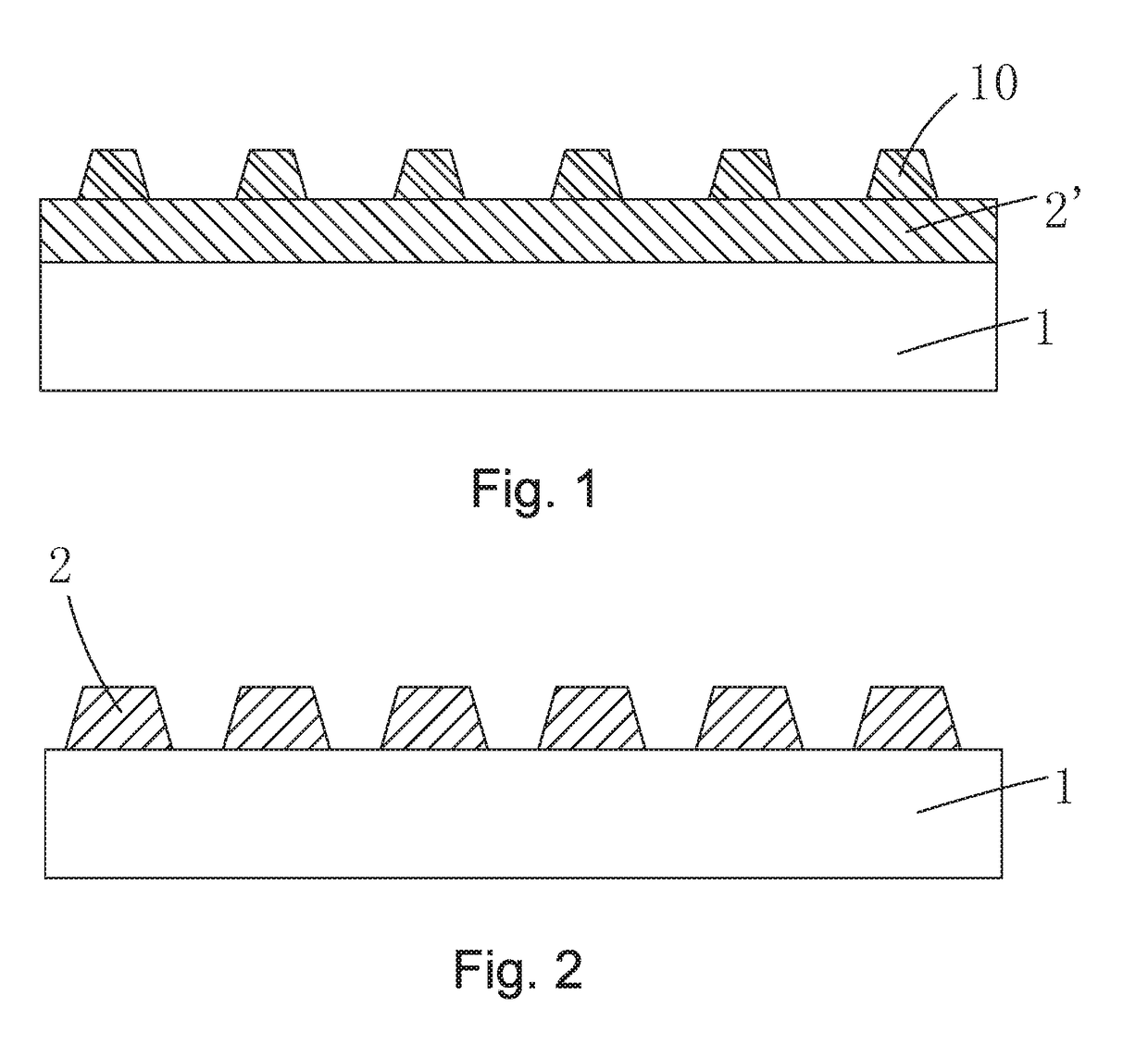

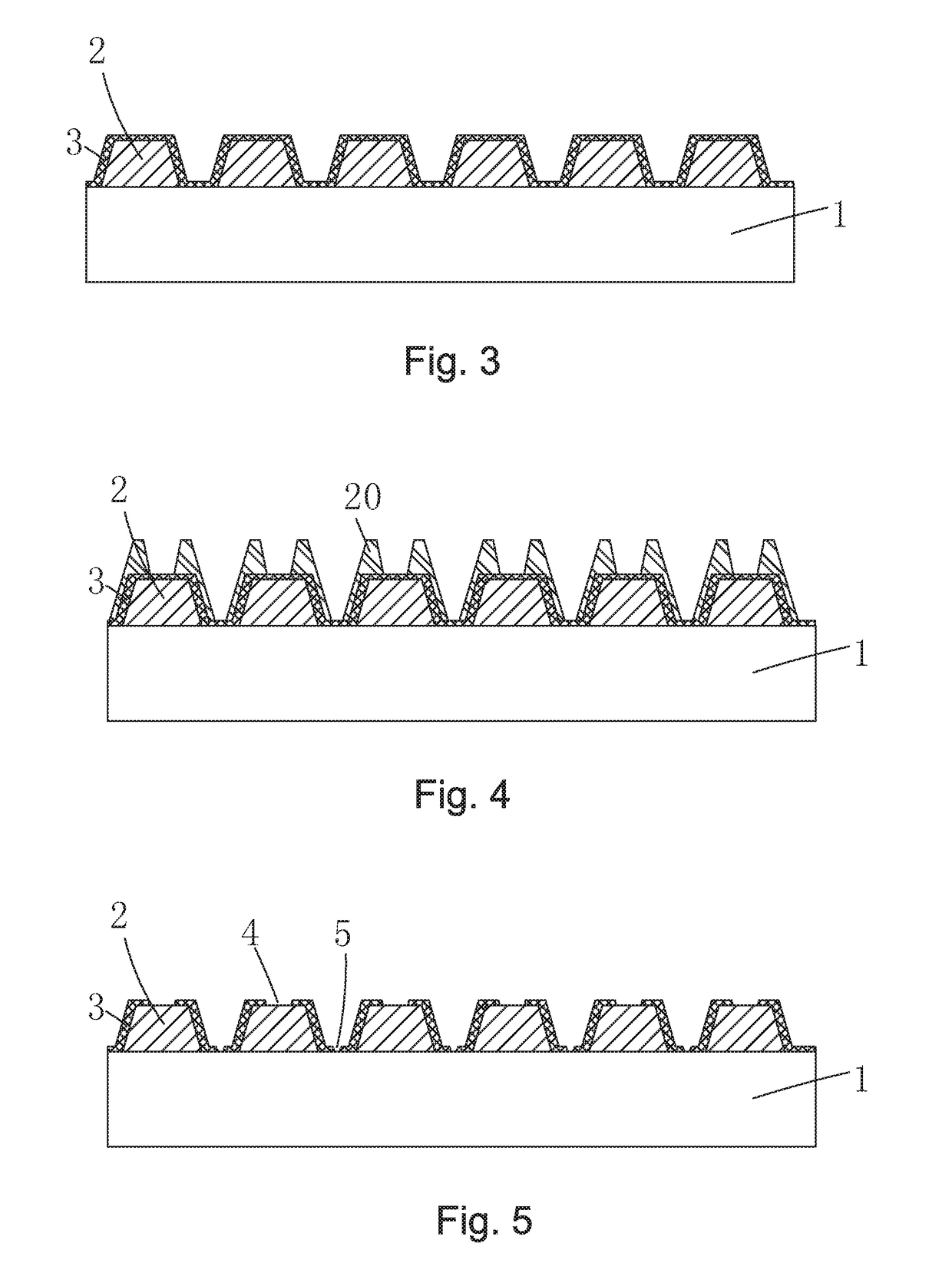

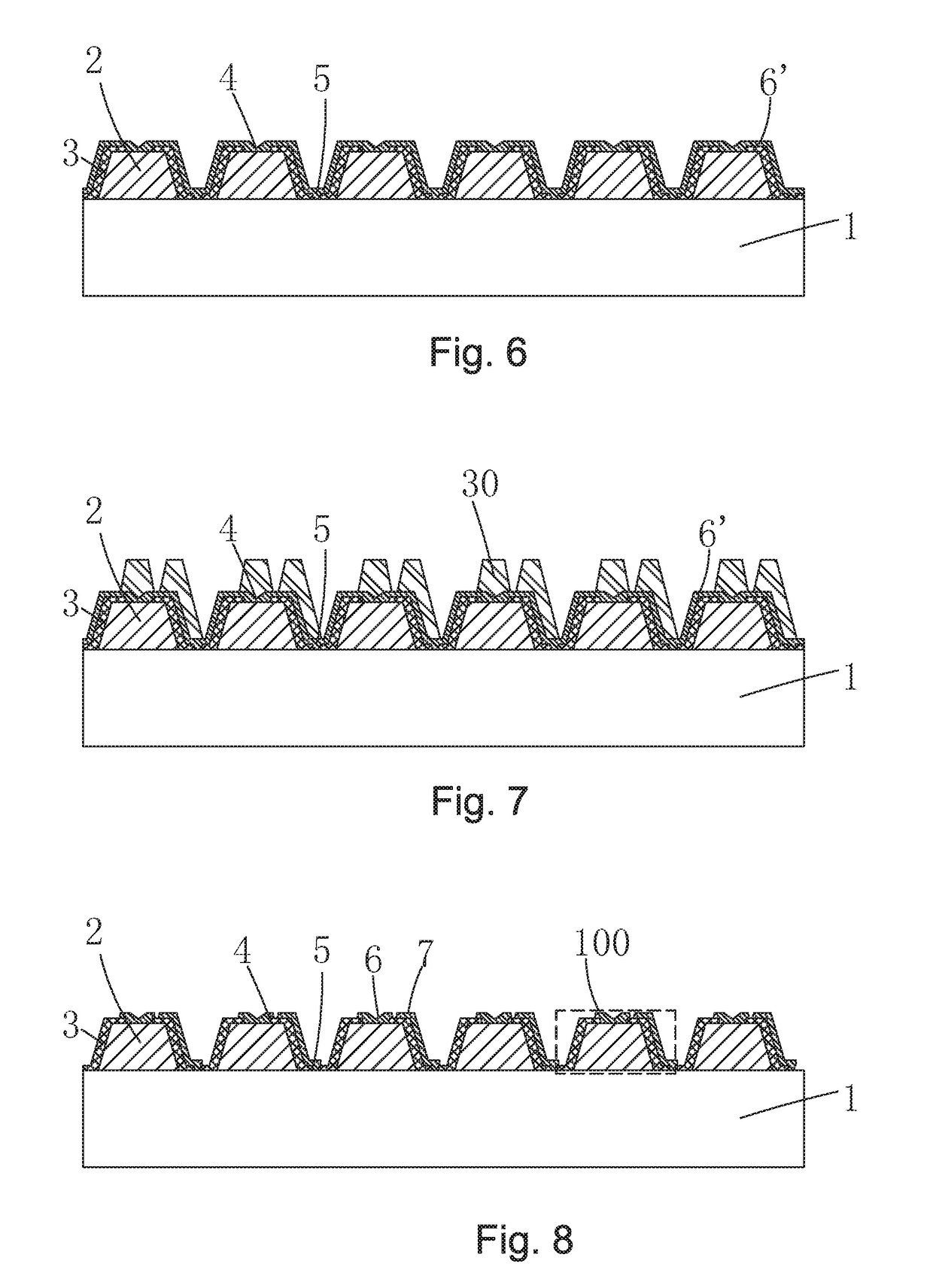

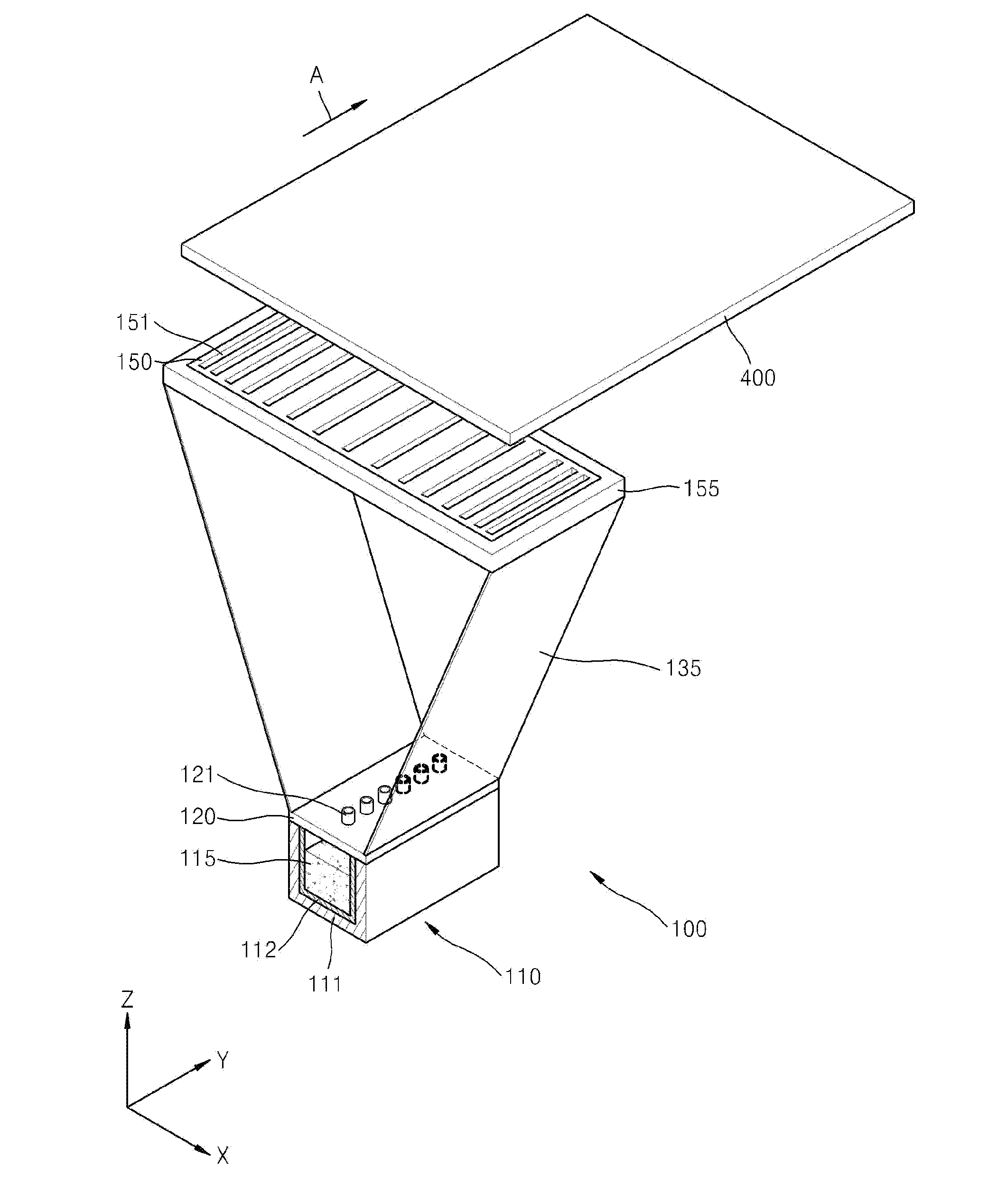

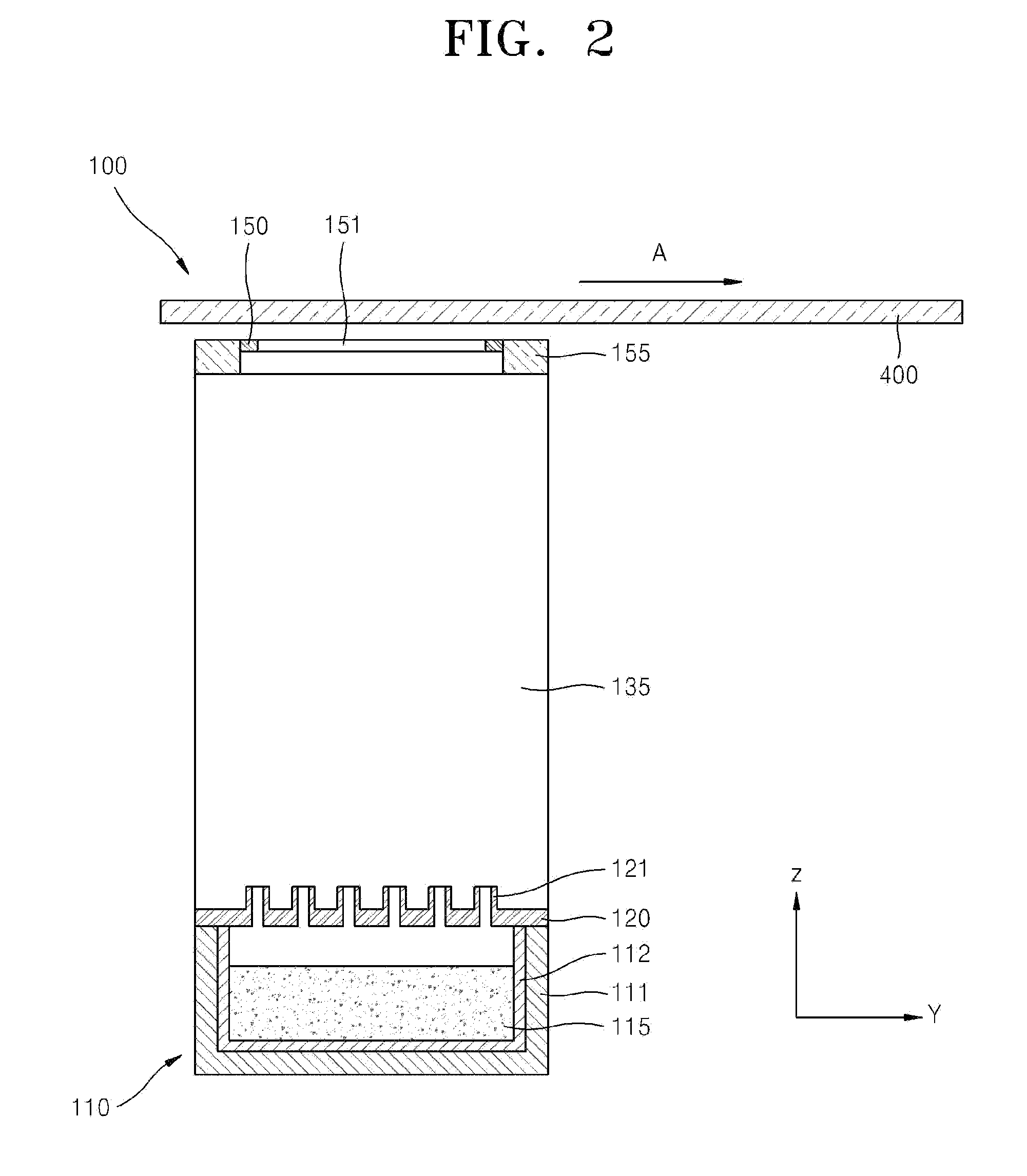

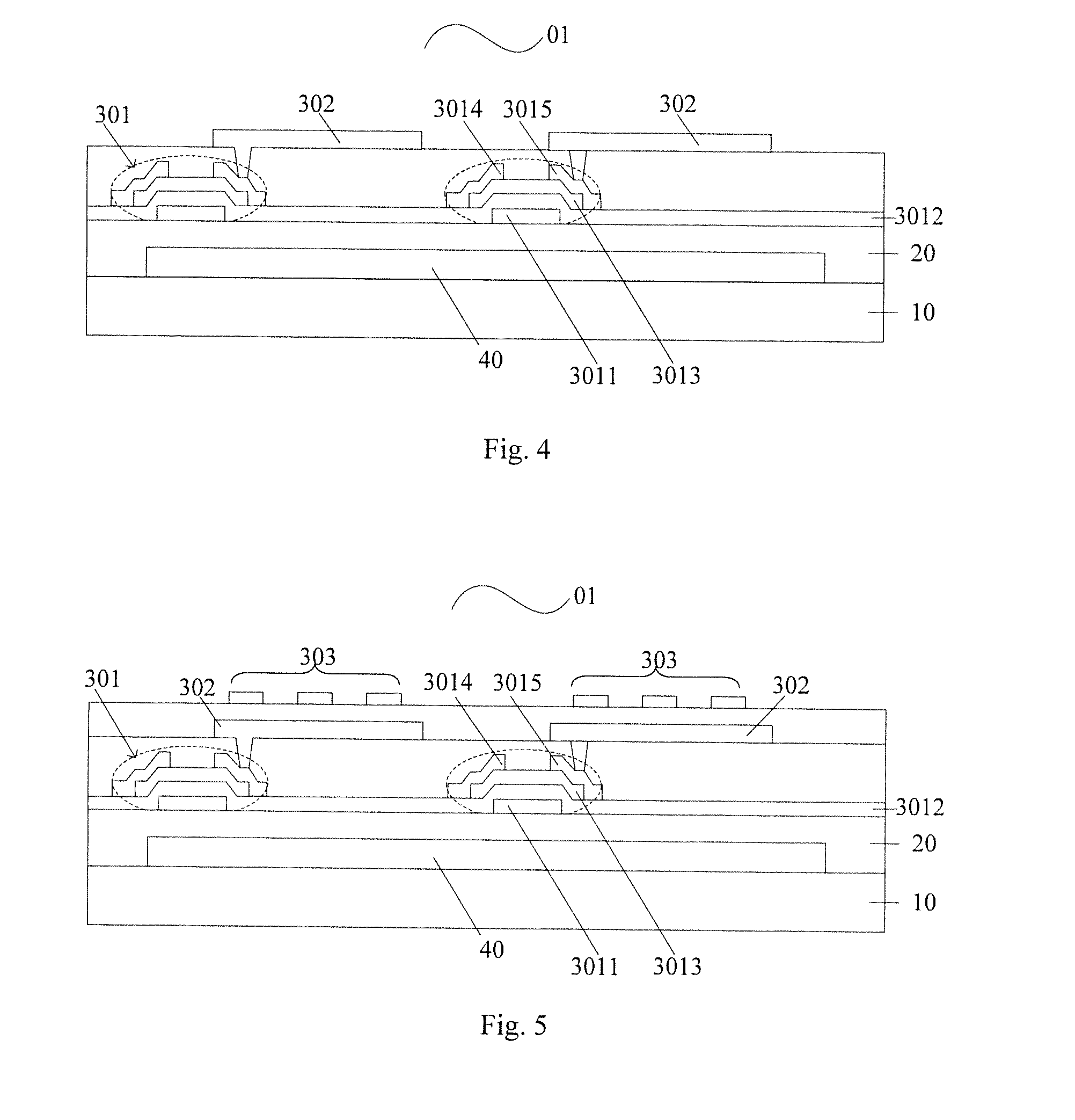

Micro light-emitting-diode display panel and manufacturing method thereof

ActiveUS20180342492A1Reduce difficultyImproved yieldSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringElectrode Contact

The present invention provides a micro light emitting-diode display panel and a manufacturing method thereof. The first electrode contact and the second electrode contact are alternatively disposed on the base substrate of the micro light-emitting-diode display panel, and the first electrode contact and the second electrode contact are respectively connected with the bottom electrode and the connection electrode of the micro light-emitting-diode. The connection electrode is also connected the top electrode of the micro light-emitting-diode, and the micro light-emitting-diodes can be immediately inspected after the micro-light-emitting-diode is transferred, to reduce the difficulty of detection and product repair, and to improve the product yield.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

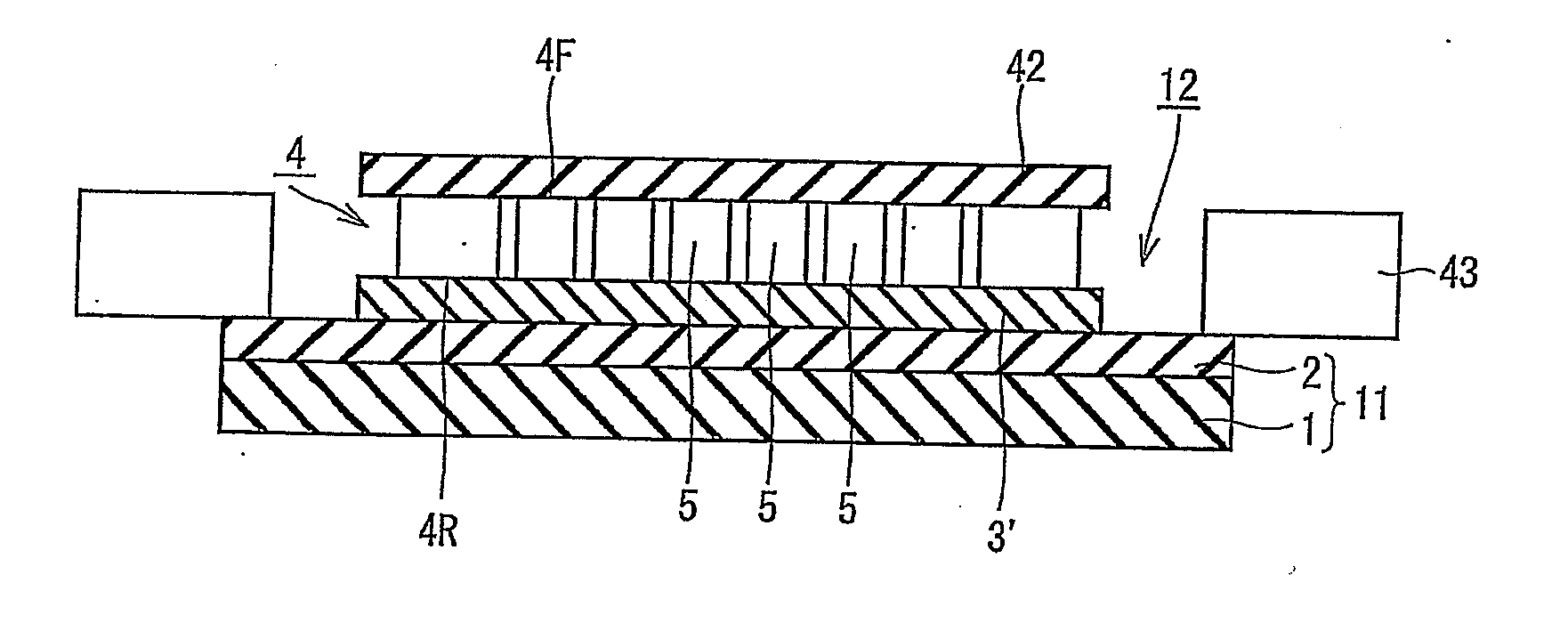

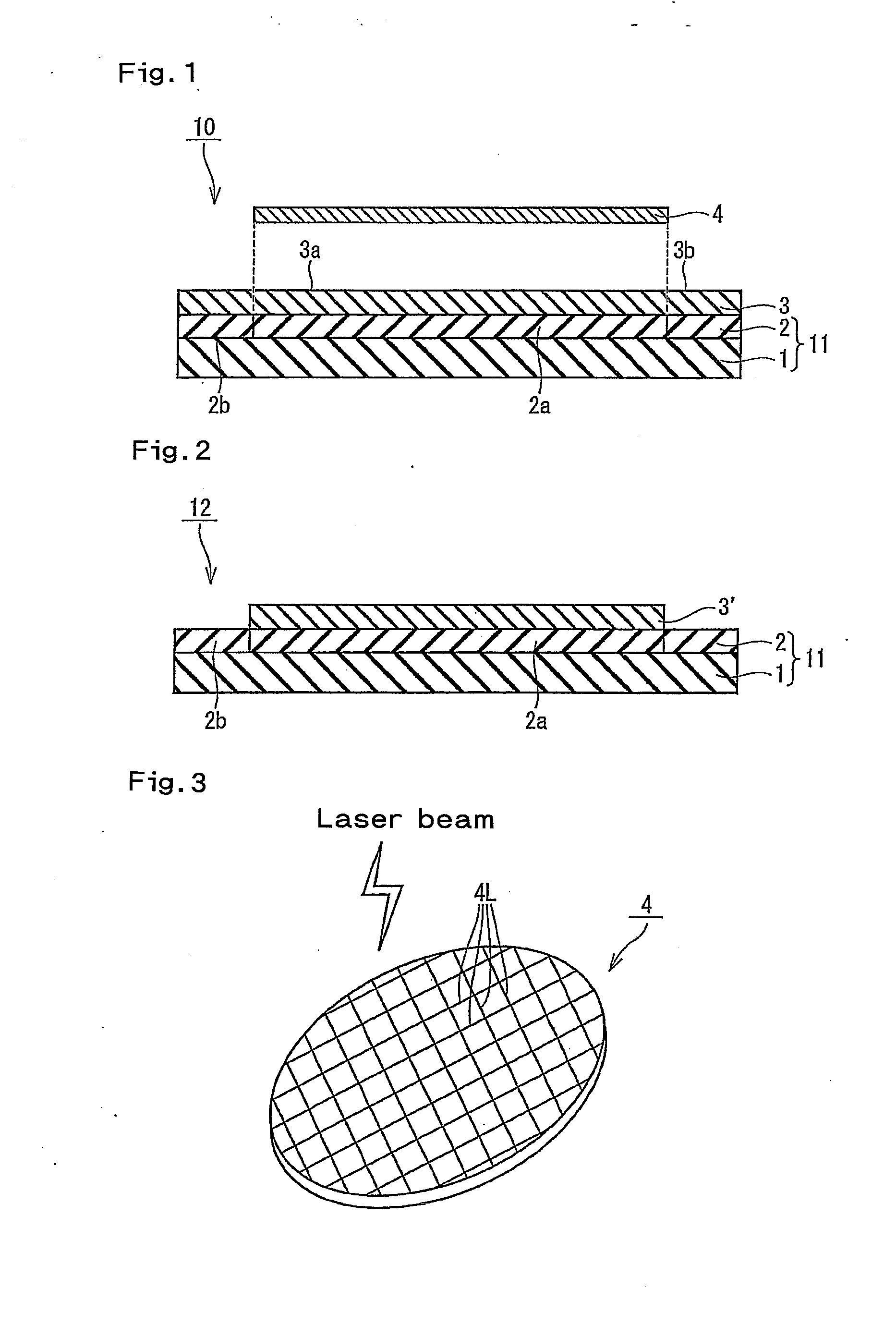

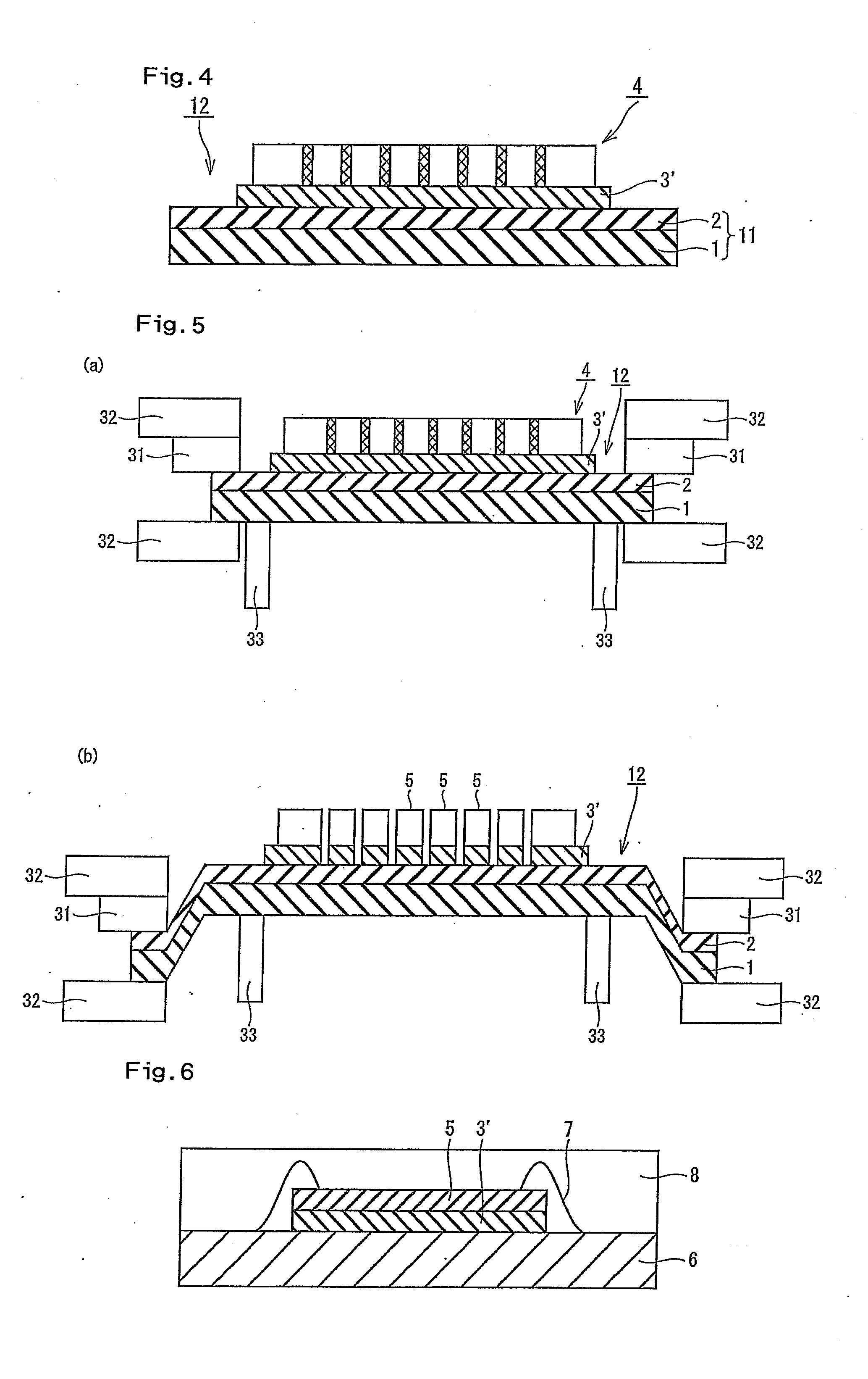

Tension apparatus for patterning slit sheet

InactiveUS20120006259A1Improved yieldImprove manufacturing yieldLiquid surface applicatorsVacuum evaporation coatingTension memberEngineering

A tension apparatus for extending a patterning slit sheet included in a thin film deposition apparatus that can be simply applied to produce large-sized display devices on a mass scale and that improves manufacturing yield. The tension apparatus, wherein a plurality of patterning slits are formed along a first direction in the patterning slit sheet, and distances between adjacent patterning slits are different from each other, includes: a light source disposed to face the patterning slit sheet and irradiating light toward the patterning slit sheet; a tension member combined to at least one end of the patterning slit sheet, and applying a predetermined tensile force on the patterning slit sheet; and a master glass onto which light irradiated from the light source and passed through the patterning slit sheet is projected.

Owner:SAMSUNG DISPLAY CO LTD

Display apparatus

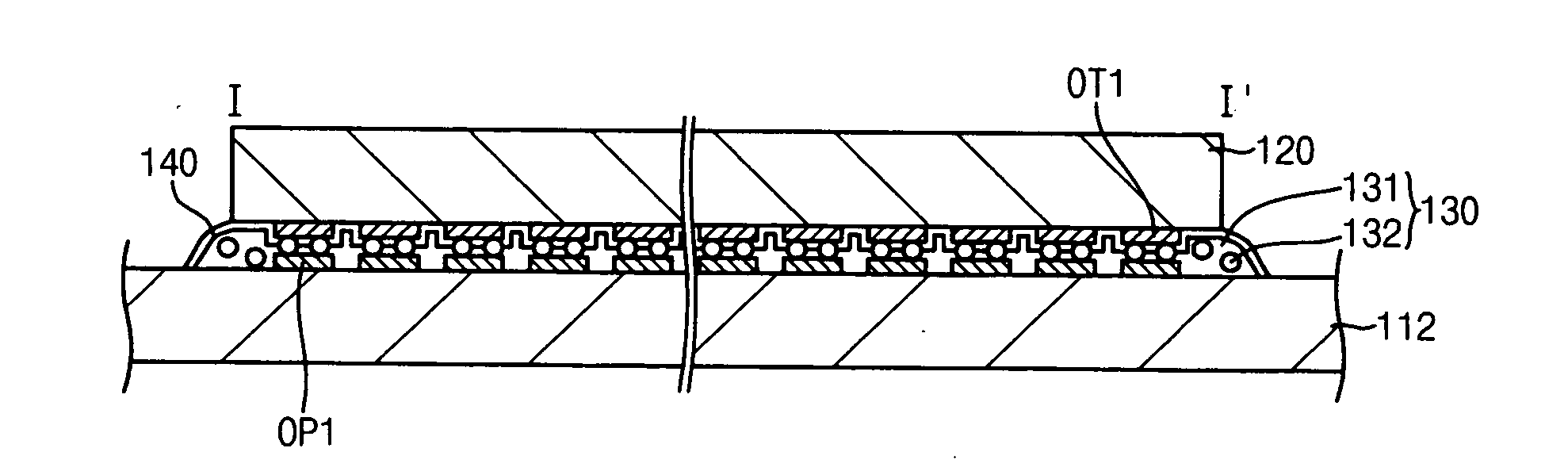

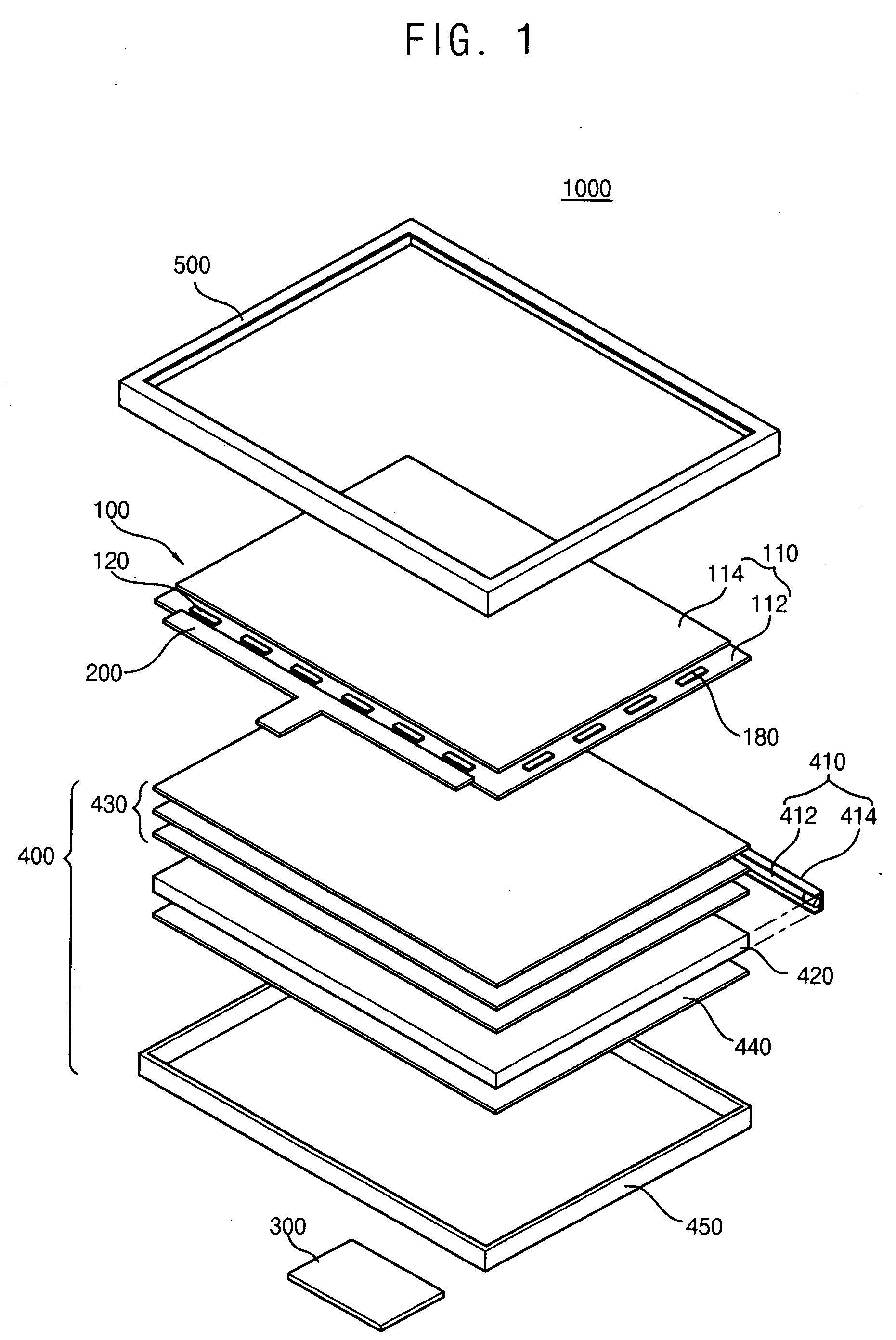

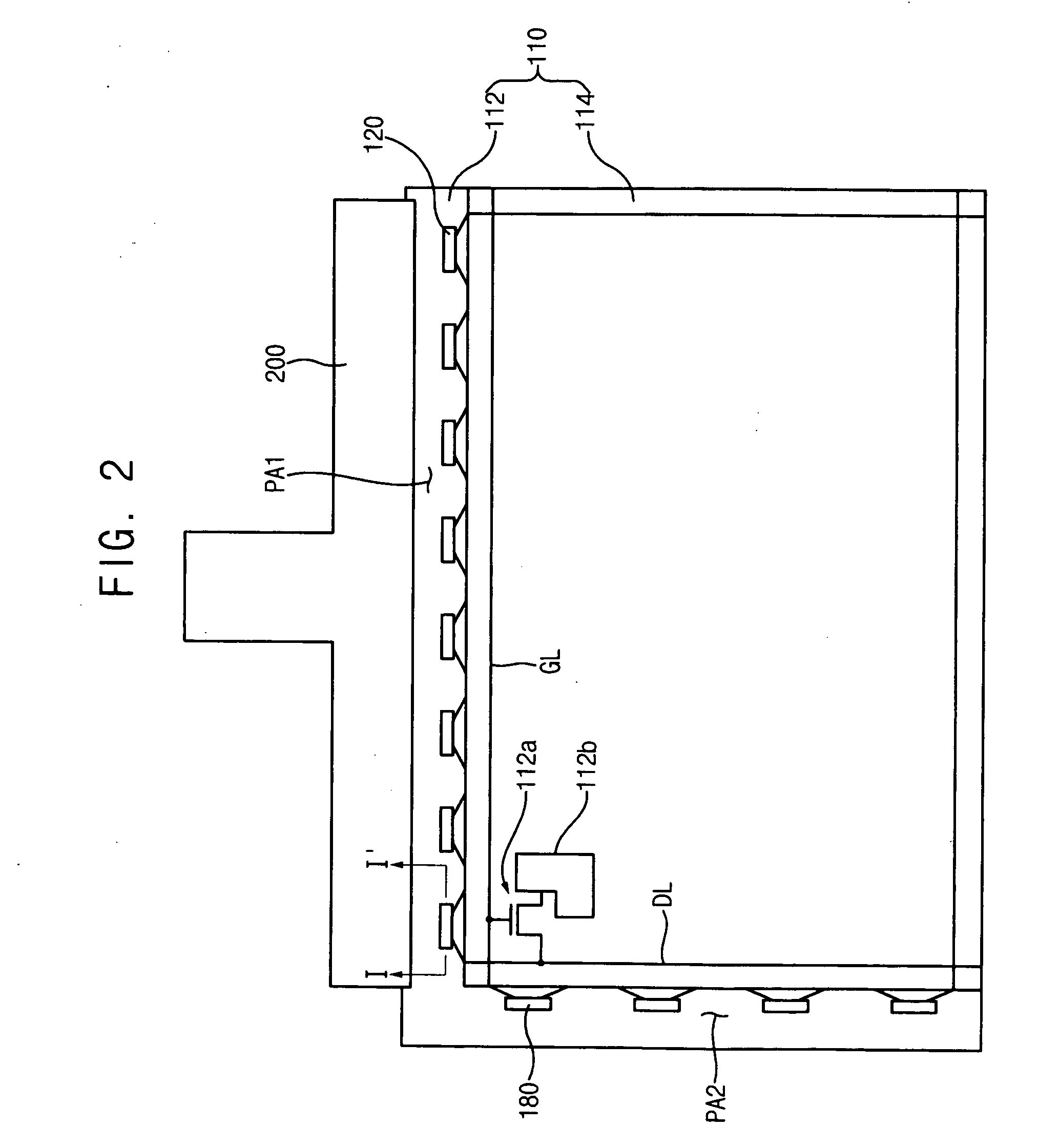

ActiveUS20060163724A1Improved yieldImprove manufacturing yieldSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringSurface plate

In a display apparatus, a display panel receives a driving signal from a driving chip through a pad and displays an image in response to the driving signal. The driving chip includes a terminal outputting the driving signal. The driving chip is mounted on the display panel using the anisotropic conductive film and electrically connected to the display panel. A lubricant layer is formed on a surface of the anisotropic conductive film to prevent an electrical defect in the connection between the driving chip and the display panel. Thus, the display apparatus may have improved yield.

Owner:SAMSUNG DISPLAY CO LTD

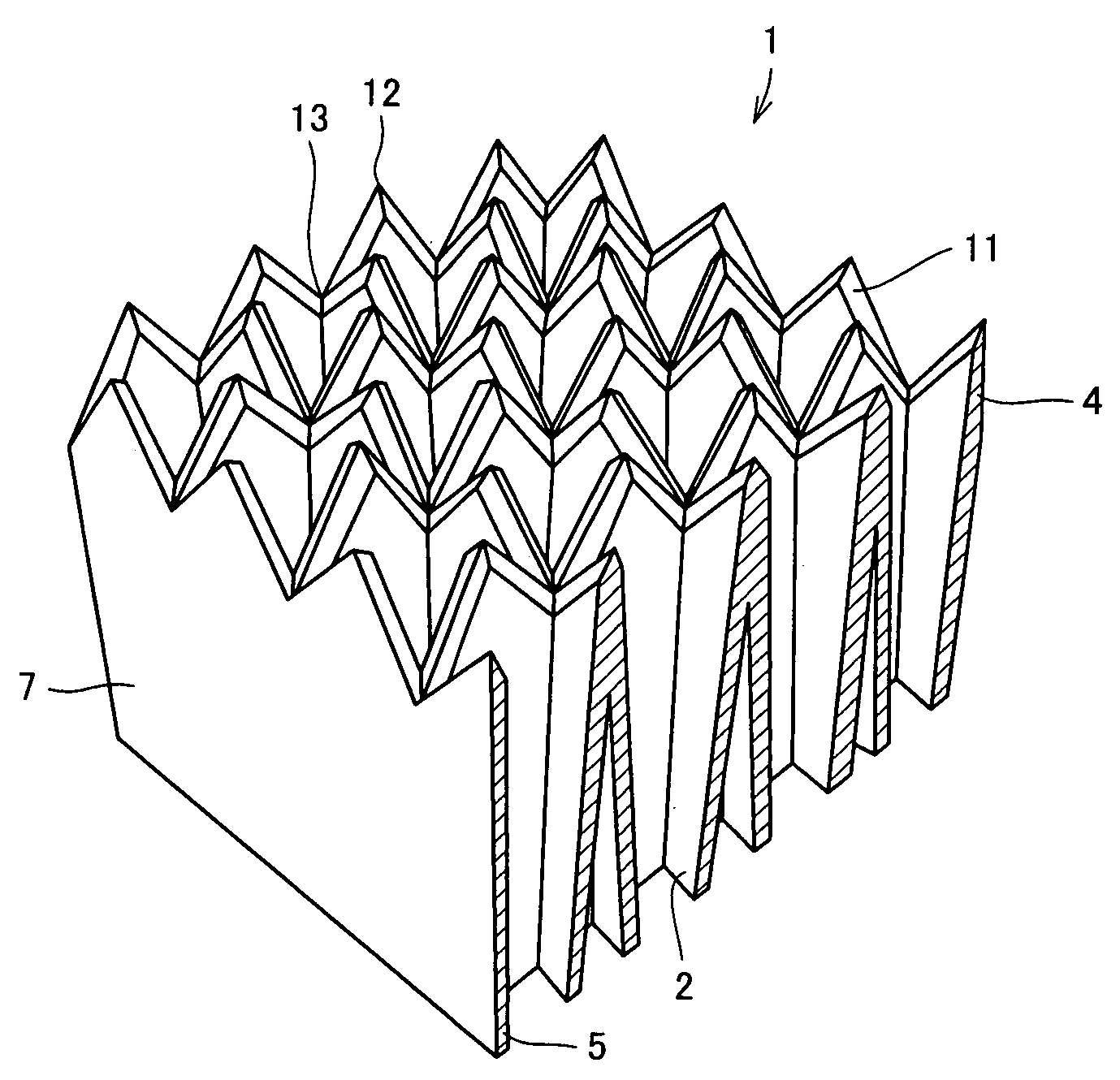

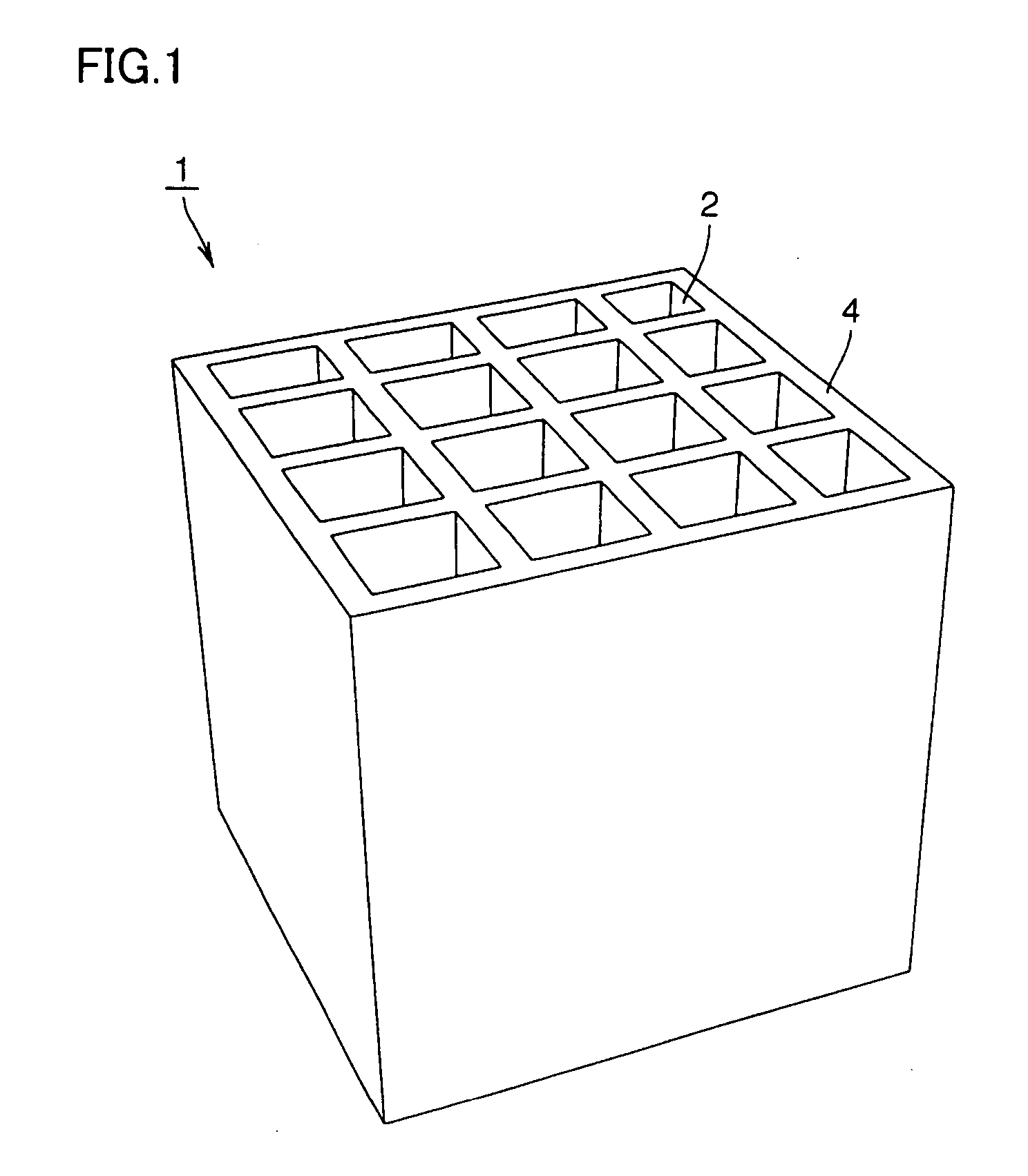

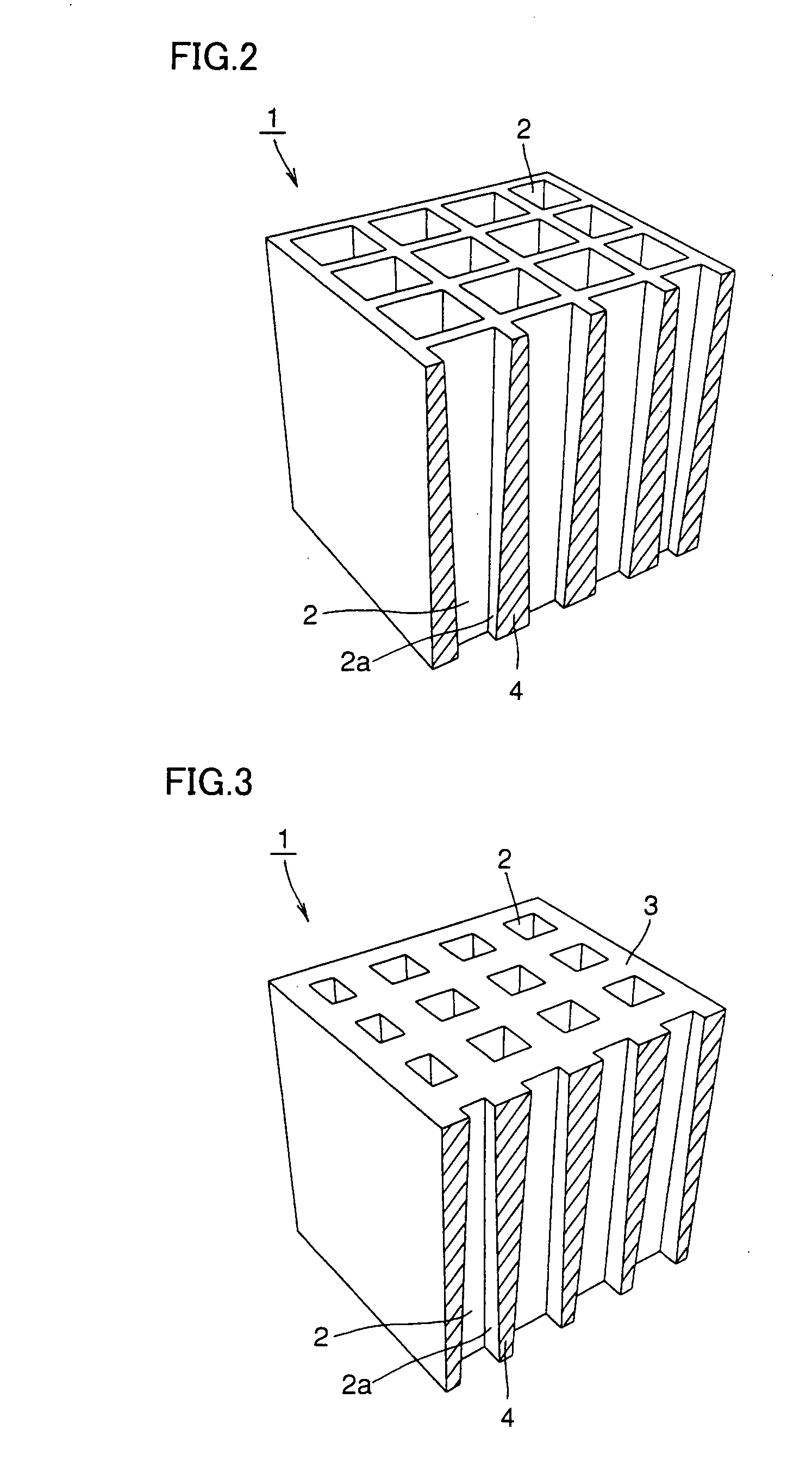

Electromagnetic wave absorption complex, and method of producing the same

InactiveUS20060202882A1Improved yieldSimplify processRadiation/particle handlingMagnetic/electric field screeningEngineeringInjection moulding

An electromagnetic wave absorber is formed by injection-molding a thermoplastic resin blended with approximately 20-60% by volume of soft magnetic material powder, and blended with a molding assistant and a kneading assistant. The electromagnetic wave absorber includes a unit cell having a bore extending from a top face to a bottom face. A portion of the bore located more adjacently to the bottom face than to the top face has a smaller cross-sectional area than the bore at the top face, and a height of the unit cell from the bottom face to the top face is approximately at least 1.2 times and approximately at most 10 times as large as the maximum width of the bore at the top face of the unit cell.

Owner:MIYAGAWA KASEI IND

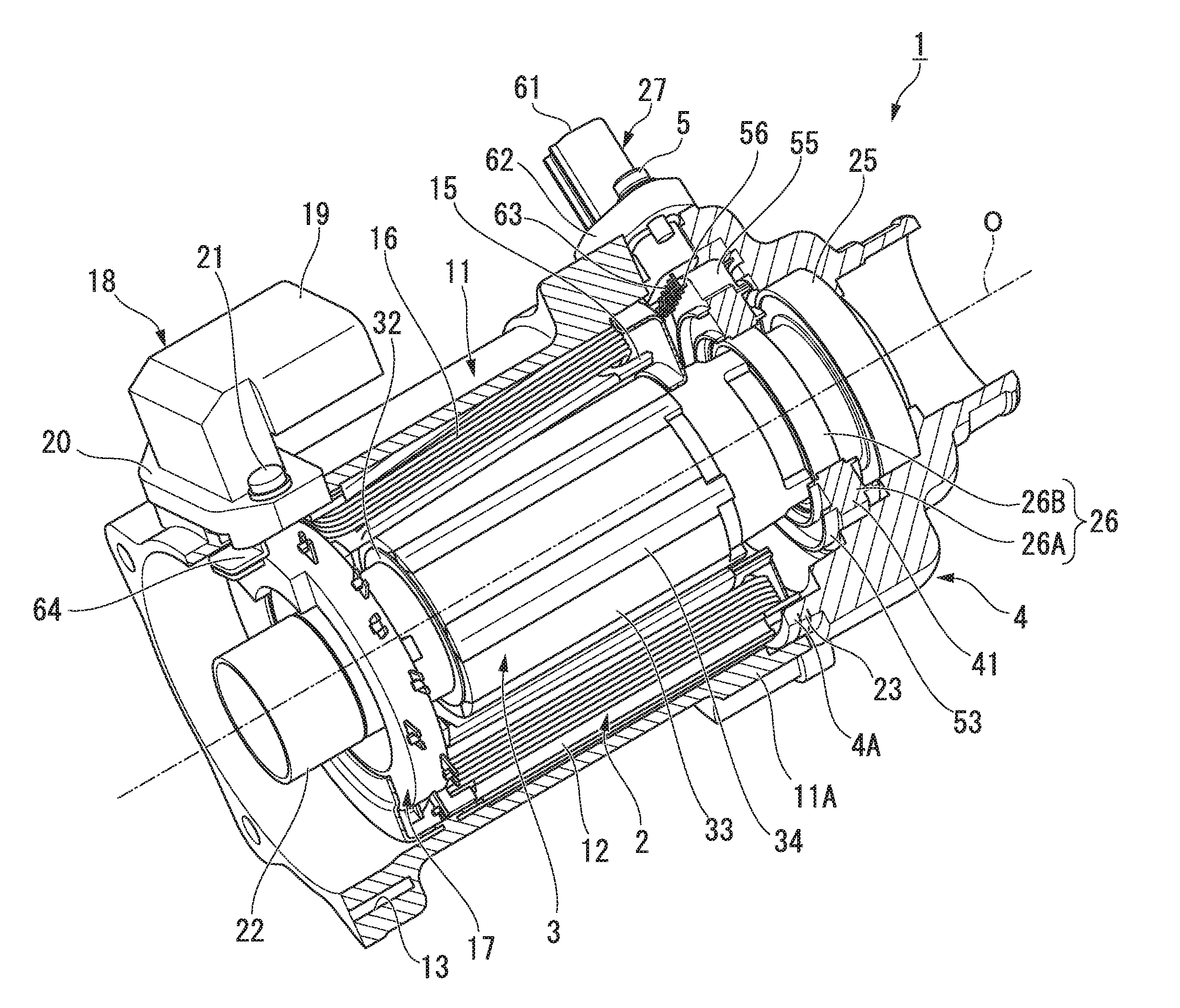

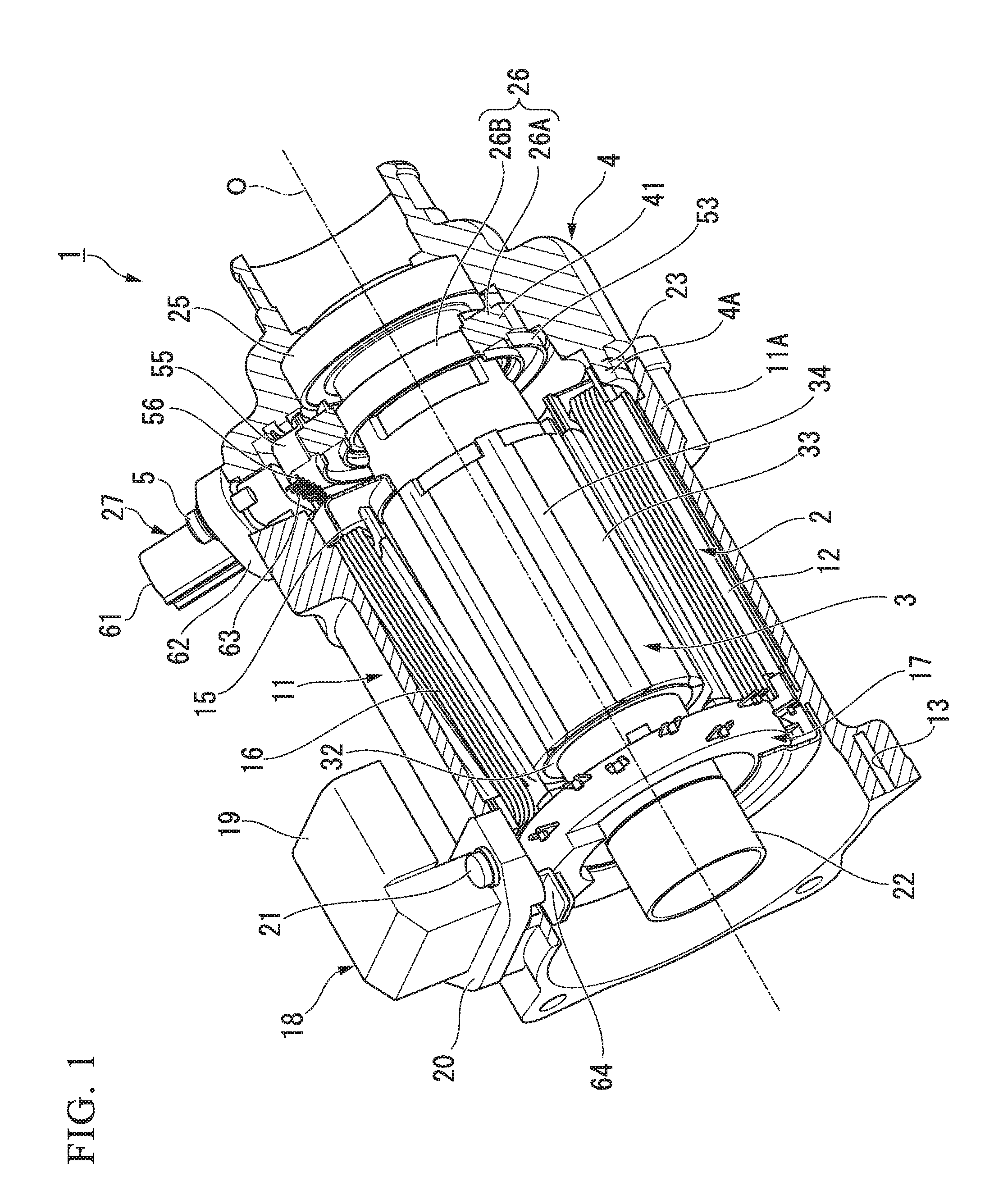

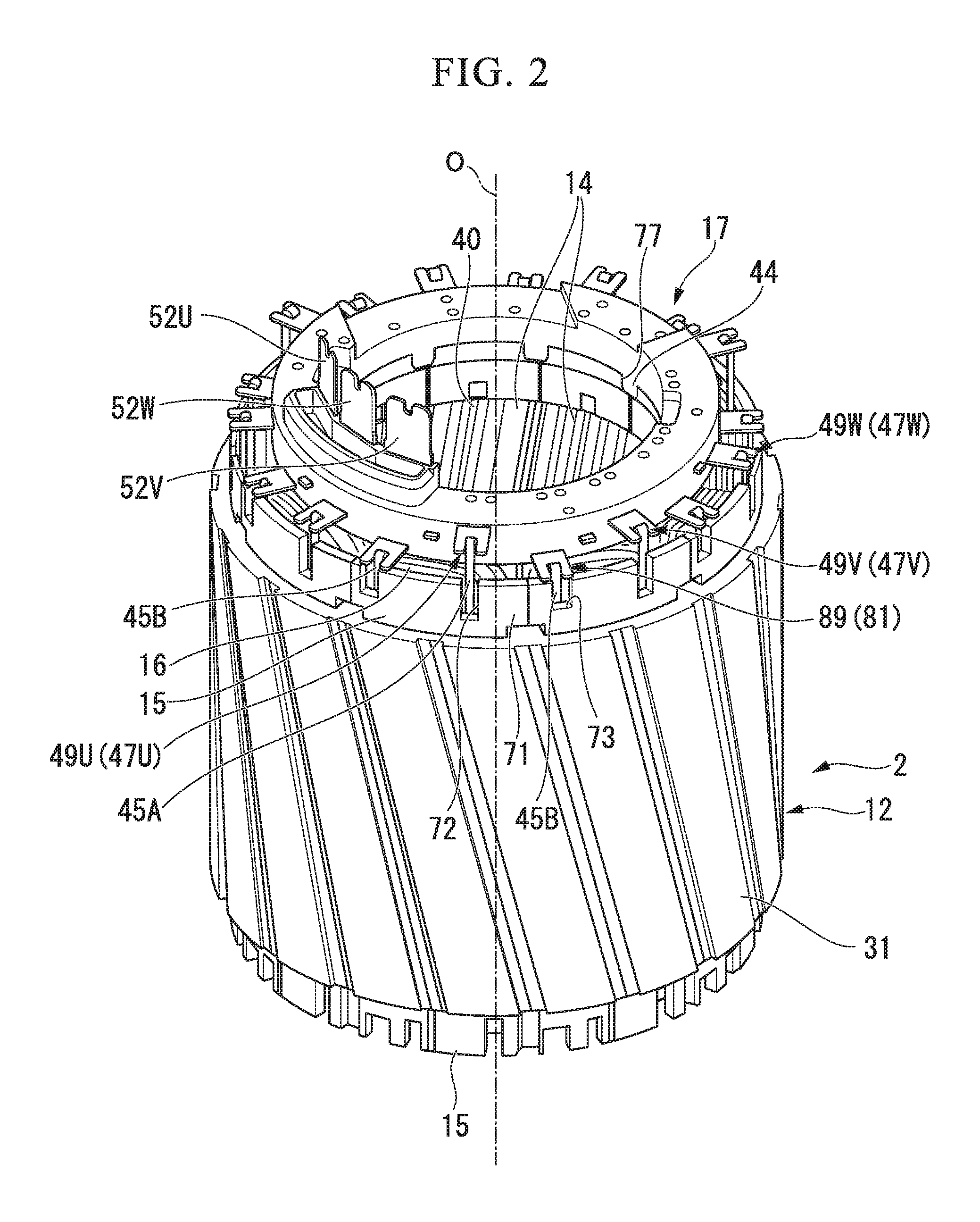

Bus bar unit, method for manufacturing bus bar unit, and brushless motor

InactiveUS20160218578A1Improved yieldDecrease manufacturing costWindings insulation shape/form/constructionManufacturing dynamo-electric machinesElectrical and Electronics engineeringBrushless motors

A bus bar unit is configured to supply power to coils (16) of a plurality of phases, and includes phase bus bars (47U ), (47V), and (47W) which are provided for each phase and are connected to winding start ends of the coils, and a neutral point bus bar (81) which is connected to winding finish ends of the coils, the neutral point bus bar (81) being formed by bending an elongated plate-shaped member such that a width direction of the elongated plate-shaped member and a radial direction of the bus bar unit coincide with each other, and including a plurality of bus bar pieces (82) and a connection portion (83) which connects the bus bar pieces (82) and (82) adjacent to each other, and a width of a deformation portion (85) of the connection portion (83) being narrower than a width of the bus bar piece (82).

Owner:MITSUBA CORP

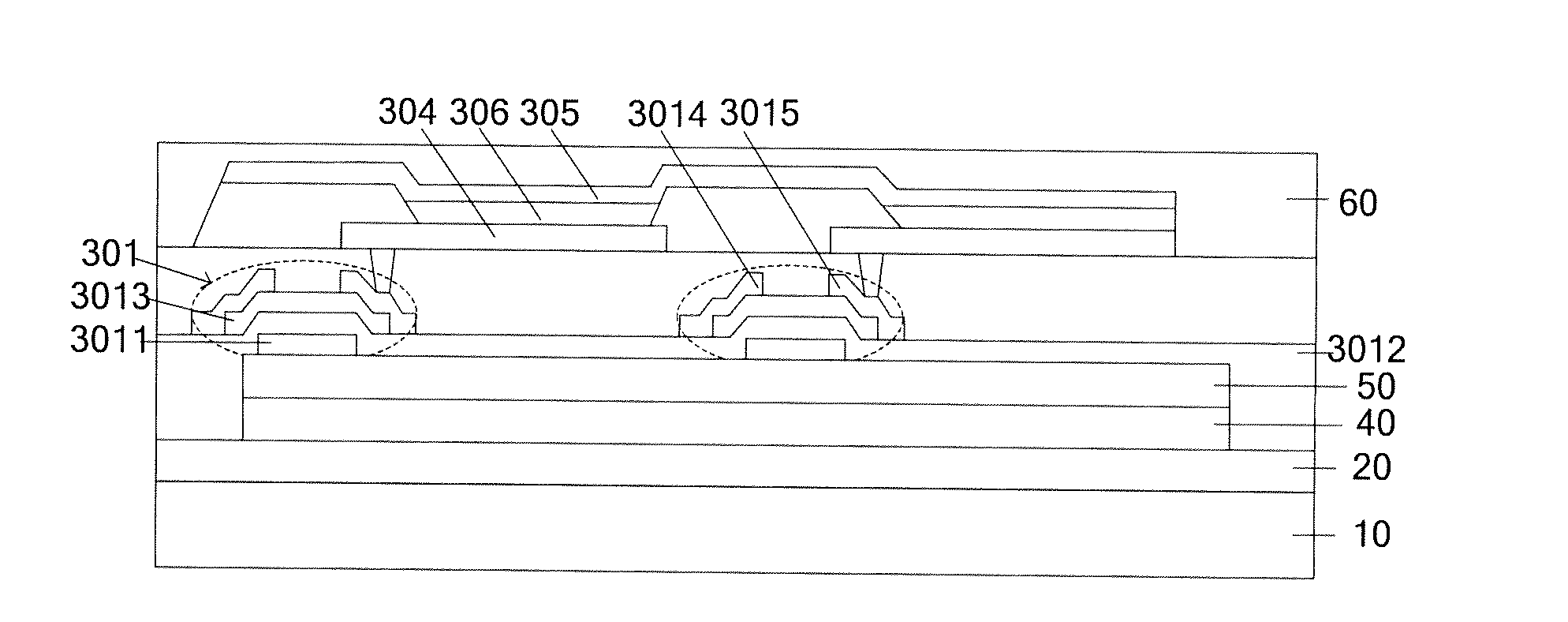

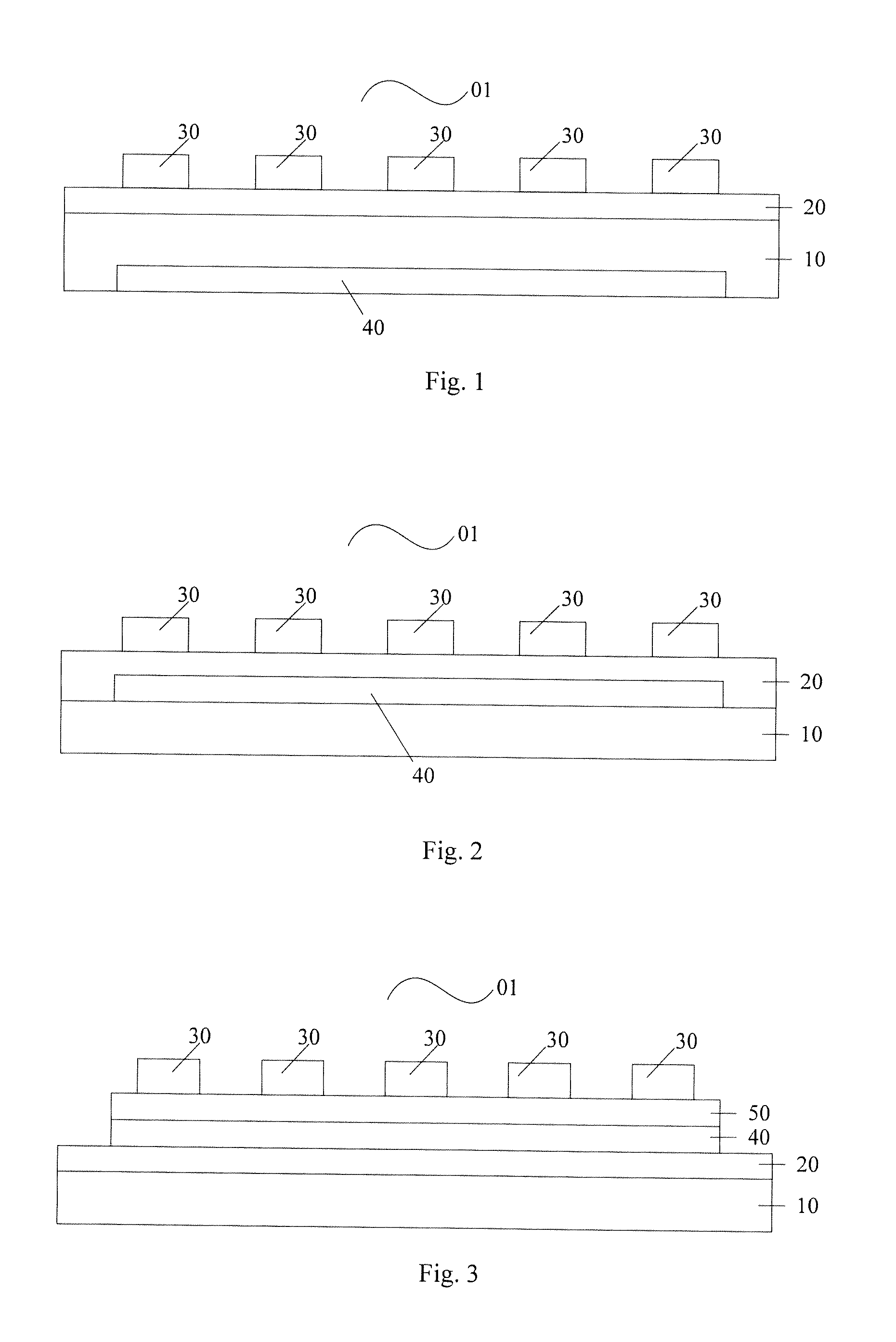

Flexible display substrate and a manufacturing method thereof, as well as a flexible display device

ActiveUS20150333115A1High electron mobility and homogeneityImproved yieldTransistorSemiconductor/solid-state device detailsOxide semiconductorSi substrate

The embodiments of the present invention provide a flexible display substrate and a manufacturing method thereof, as well as a flexible display device, which relate to the technical field of display, and can avoid the performance of the thin film transistor from being influenced by light energy when a flexible substrate is striped from a carrying substrate. The method for manufacturing the flexible display substrate may comprise: forming a flexible substrate on a carrying substrate; forming a first buffer layer on the flexible substrate; forming a plurality of display elements on the first buffer layer, each of the plurality of display elements comprising a thin film transistor and an electrode structure, the thin film transistor comprising a metal oxide semiconductor active layer; stripping the flexible substrate from the carrying substrate, wherein the method further comprises: forming a light absorbing layer before the plurality of display elements are formed.

Owner:BOE TECH GRP CO LTD

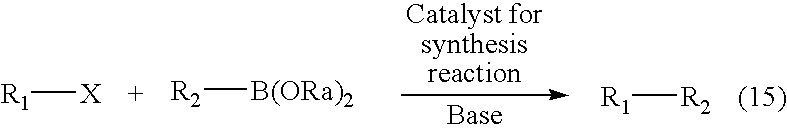

Synthesizing method for compound, and catalyst for synthesis reaction

InactiveUS20050215804A1Improved yieldCost reductionGroup 4/14 element organic compoundsCarboxylic acid nitrile preparationChemistryComposite oxide

A catalyst for synthesis reaction that can allow the cross coupling reaction at an improved yield, and yet can be collected after used for the reaction and recycled, and a synthesizing method for a compound using the same catalyst for synthesis reaction. In the Suzuki cross-couplings given by the following reaction formula (15), palladium containing perovskite-like composite oxide is used as a catalyst for synthesis reaction:

Owner:CAMBRIDGE UNIV TECH SERVICES LTD +1

Nucleotide sequences for transcriptional regulation in corynebacterium glutamicum

InactiveUS7141388B2Enhance productionImproved yieldSugar derivativesBacteriaBacterial genesTranscriptional regulation

The invention relates to isolated polynucleotides from Corynebacterium glutamicum which are useful in the regulation of gene expression. In particular, the invention relates to isolated polynucleotides comprising C.glutamicum promoters which may be used to regulate, i.e., either increase or decrease, gene expression. In certain embodiments, isolated promoter sequences of the present invention regulate gene expression through the use of exogenous or endogenous induction. The invention further provides recombinant vectors and recombinant cells comprising isolated polynucleotides of the present invention, preferably in operable association with heterologous genes. Also provided are methods of regulating bacterial gene expression comprising growth of a recombinant cell of the present invention. In particular, the present invention provides methods to regulate genes involved in amino acid production comprising growth of a recombinant cell of the present invention. In certain embodiments, the present invention provides methods of regulating gene expression in bacteria, particularly Corynebacterium species, especially of the genus Corynebacterium, comprising fermentation growth of a recombinant cell of the present invention, where metabolite concentrations, temperature, or oxygen levels are manipulated to regulate gene expression.

Owner:ARCHER DANIELS MIDLAND CO

Semiconductor device and manufacturing method of the same

InactiveUS20060197088A1Favorable operationImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor

It is an object of the present invention to manufacture a minute TFT having an LDD region through process with the reduced manufacturing steps, and form a TFT having a structure suitable for each circuit. It is also an object of the present invention to secure an ON current even in a TFT having an LDD region. A hat-shaped gate electrode is formed by forming a two-layer gate electrode in which the gate length of a lower layer of the gate electrode is longer than that of an upper layer of the gate electrode. The hat-shaped gate electrode is formed by etching only the upper layer of the gate electrode by making the use of the resist recess width. In addition, silicide is formed in a contact portion of a wiring and a semiconductor film to lower contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

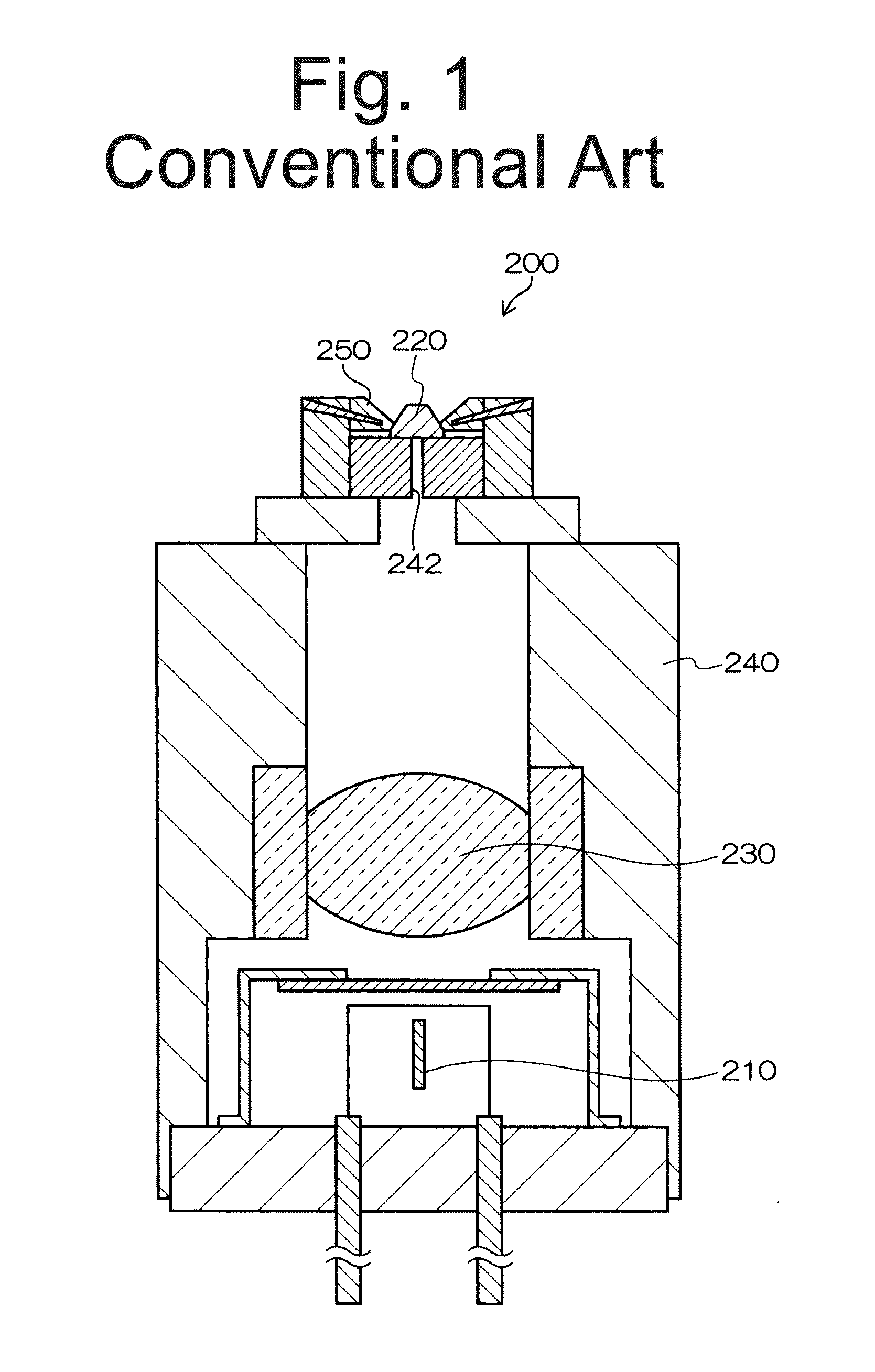

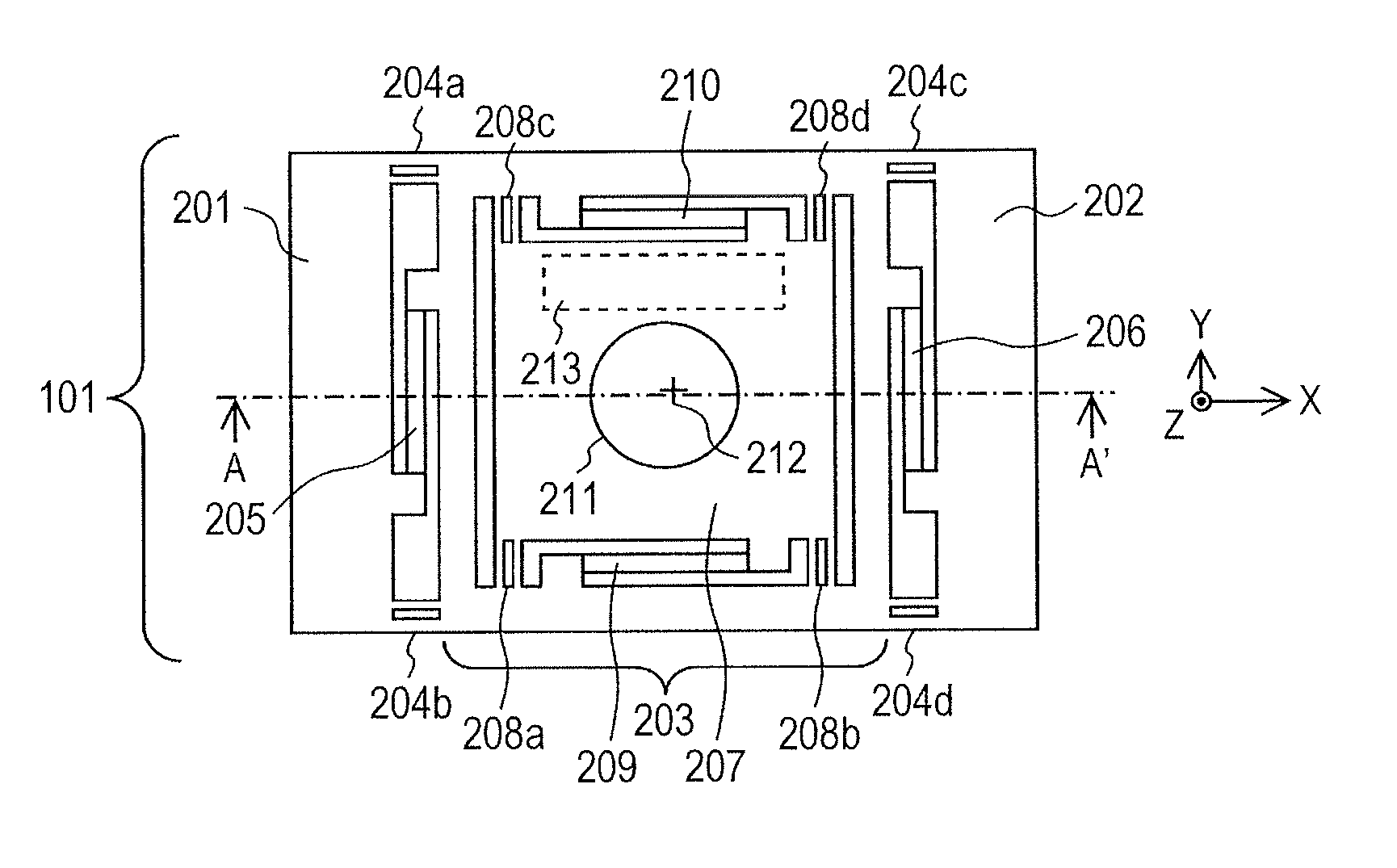

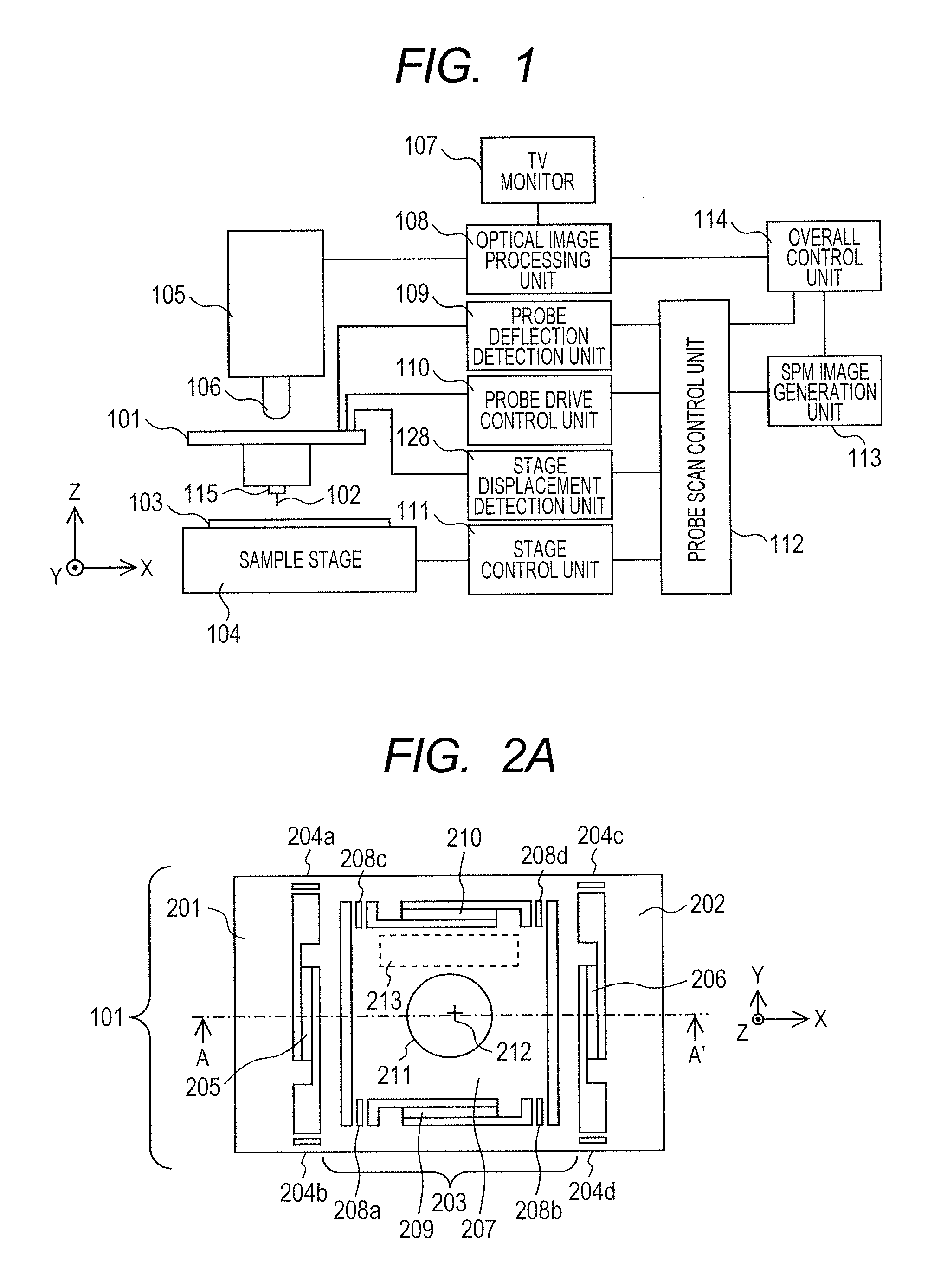

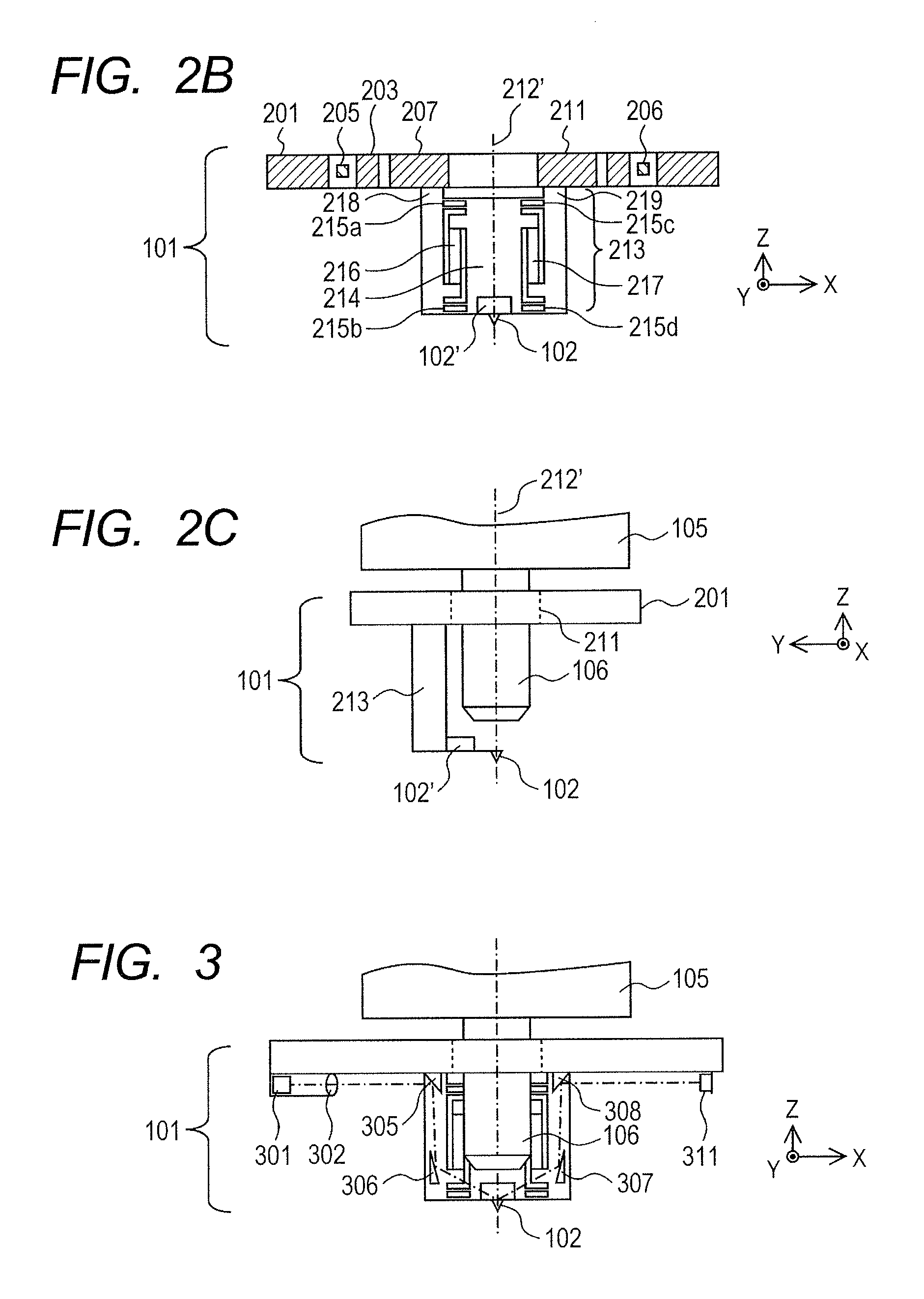

Scanning Probe Microscope and Surface Shape Measuring Method Using Same

ActiveUS20130212749A1High accuracyImproved yieldNanotechnologyScanning probe techniquesPhysicsMicroscope

It has been difficult to highly accurately measure the profiles of samples using scanning probe microscopes at the time when scanning is performed due to scanning mechanism fluctuations in the non drive direction, i.e., vertical direction. The present invention is provided with, on the rear side of a sample stage, a high-accuracy displacement gauge for measuring fluctuation in the non drive direction, i.e., vertical direction, at the time when the sample stage is being scanned in the horizontal directions, and as a result, highly accurate planarity evaluation with accuracy of sample nm-order or less is made possible by correcting sample surface shape measurement results obtained using a probe.

Owner:HITACHI LTD

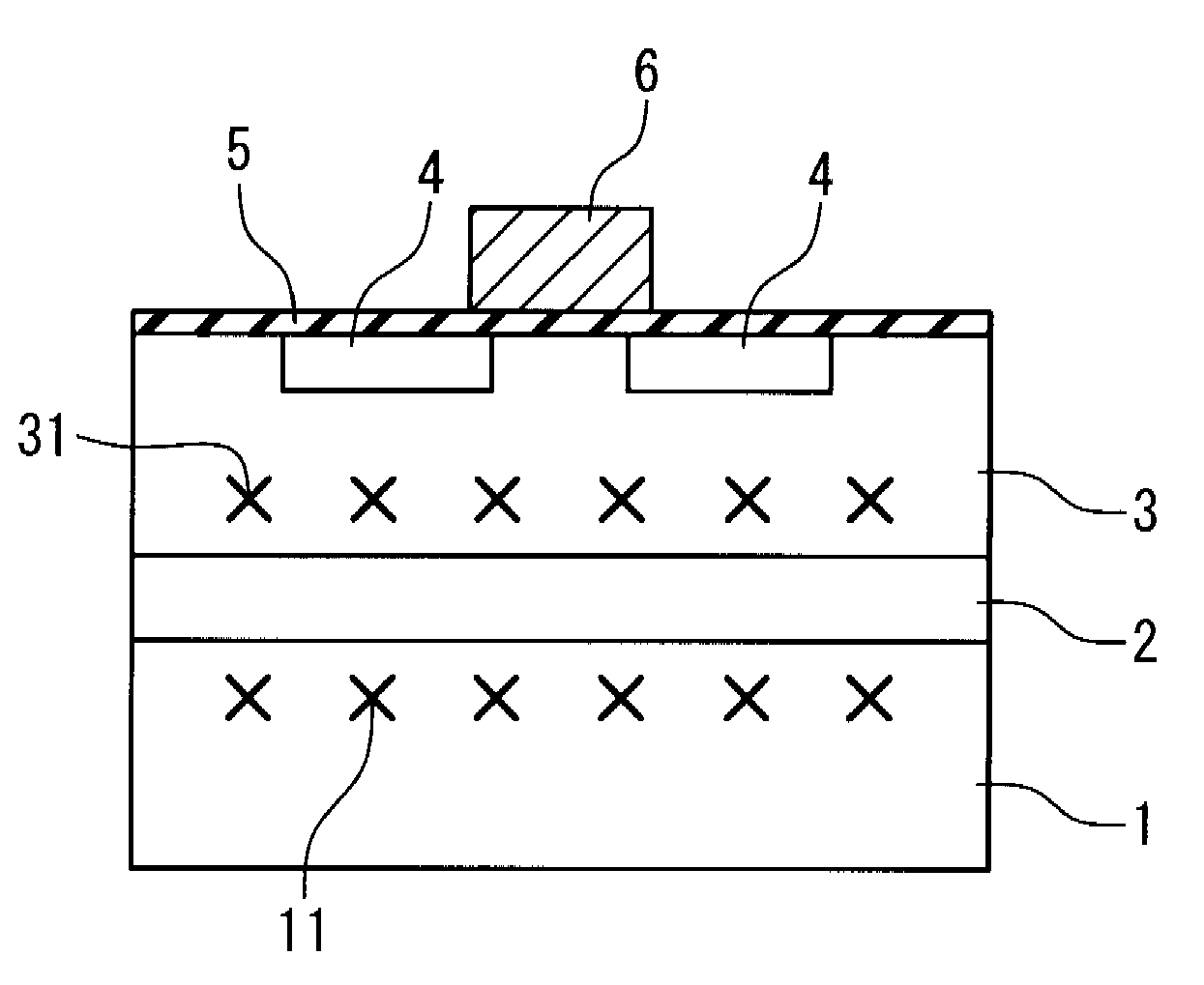

Semiconductor device and method of manufacturing the same

InactiveUS20070207577A1Improved yieldIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingIonHeavy metals

A method of manufacturing a semiconductor device includes: (A) a wafer process; and (B) a bias application process after the wafer process. The wafer process includes: (a) forming a n-type well in a p-type semiconductor substrate; (b) forming a p-type well in the n-type well; and (c) forming a transistor on the p-type well, the transistor having a n-type source / drain diffusion layer. In the bias application process, a forward bias is applied between the p-type well and the n-type well to move heavy metal ions.

Owner:LONGITUDE SEMICON S A R L

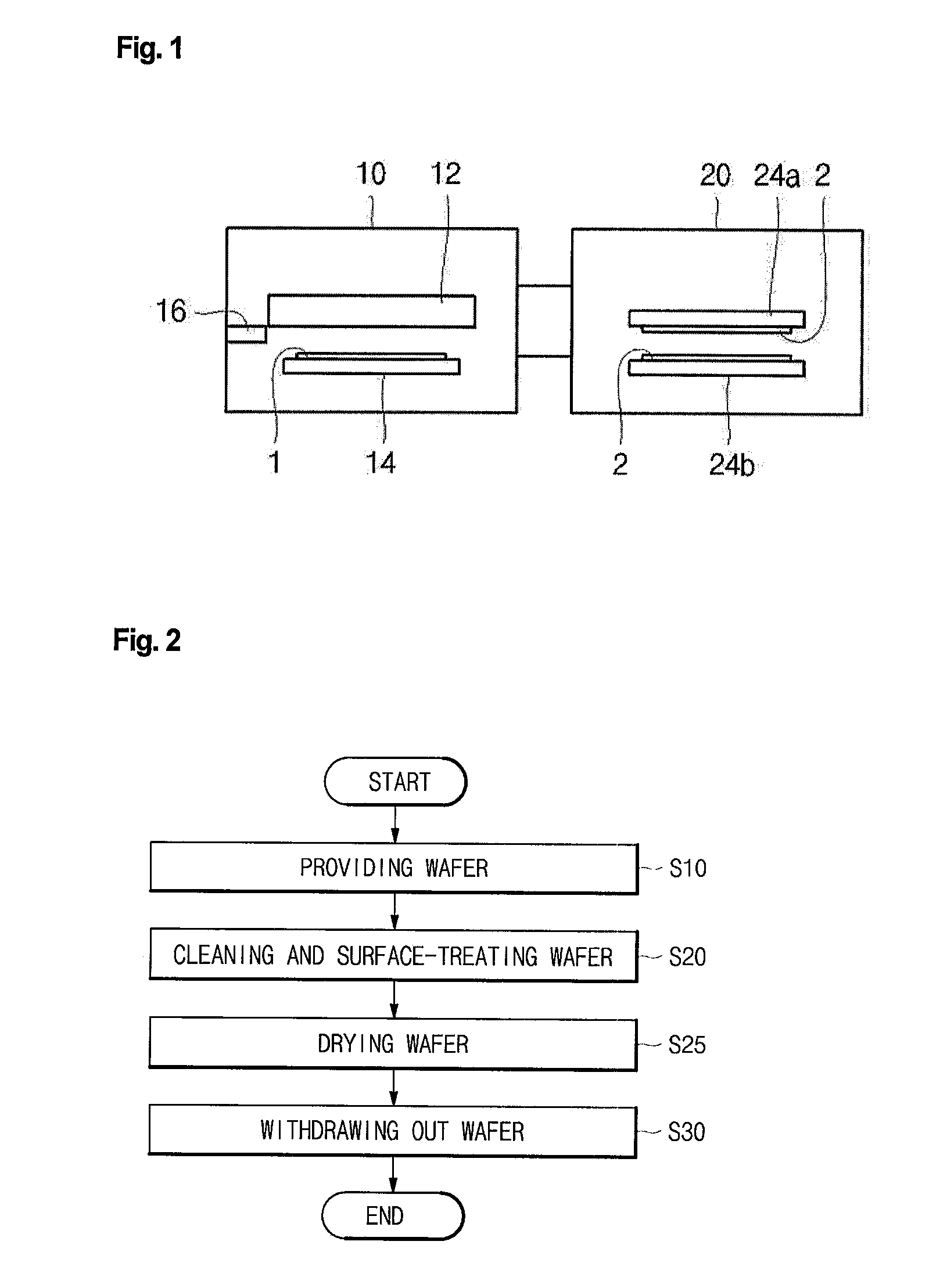

Wafer cleaning method and wafer bonding method using the same

InactiveUS20100261332A1Improved yieldImprove productivitySemiconductor/solid-state device manufacturingElectrostatic cleaningSurface finishingEngineering

The present invention relates to a wafer cleaning and a wafer bonding method using the same that can improve a yield of cleaning process and bonding property in bonding the cleaned wafer by cleaning the wafer using atmospheric pressure plasma and cleaning solution. The wafer cleaning method includes the steps of providing a process chamber with a wafer whose bonding surface faces upward, cleaning and surface-treating the bonding surface of the wafer by supplying atmospheric pressure plasma and a cleaning solution to the bonding surface of the wafer, and withdrawing out the wafer from the process chamber. The wafer bonding method includes the steps of: providing a first process chamber with a first wafer whose bonding surface faces upward; cleaning and surface-treating the bonding surface of the first wafer by supplying atmospheric pressure plasma and a cleaning solution to the bonding surface of the first wafer; withdrawing out the first wafer from the first process chamber and providing a second process chamber with the first wafer; providing a third process chamber with a second wafer whose bonding surface faces upward; cleaning and surface-treating the bonding surface of the second wafer by supplying atmospheric pressure plasma and a cleaning solution to the bonding surface of the second wafer; withdrawing out the second wafer from the third process chamber and providing the second process chamber with the second wafer whose bonding surface faces to the bonding surface of the first wafeη and bonding the bonding surfaces of the first and second wafers to each other.

Owner:LTRIN

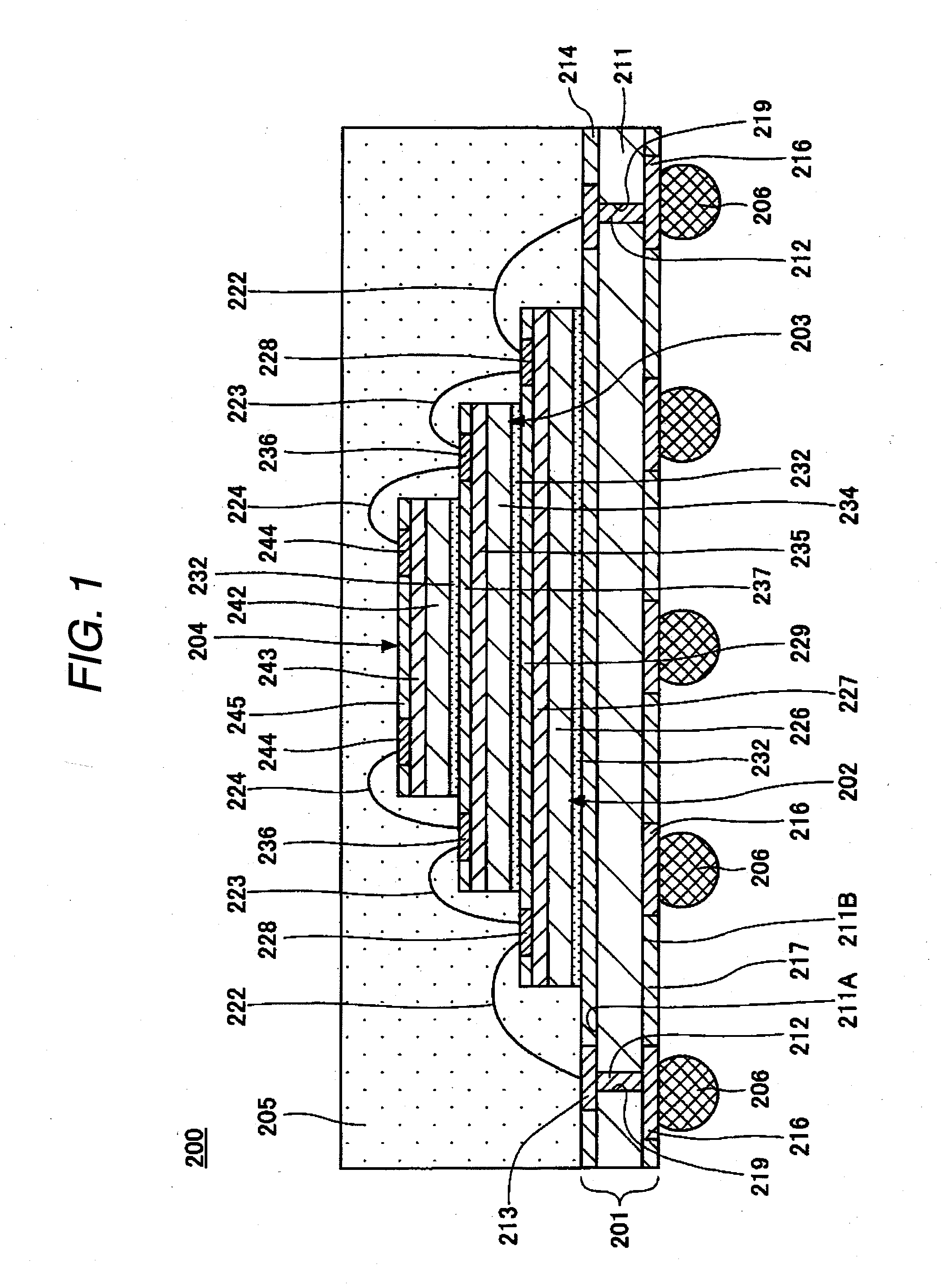

Electronic apparatus and manufacturing method thereof

InactiveUS20090085222A1Improved yieldPrevent be breakSemiconductor/solid-state device detailsSolid-state devicesEngineeringInternal connection

There are provided a plurality of semiconductor apparatuses judged as good items in electrical and functional inspections while having internal connection terminals disposed on electrode pads of semiconductor chips, resin layers which are disposed on surfaces of the semiconductor chips in which the electrode pads are formed and expose the internal connection terminals, and wiring patterns which are disposed on the resin layers and are connected to the internal connection terminals, a wiring substrate on which the plurality of semiconductor apparatuses are stepwise stacked, the wiring substrate electrically connected to the plurality of semiconductor apparatuses, and a sealing resin with which the plurality of semiconductor apparatuses are sealed.

Owner:SHINKO ELECTRIC IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com