Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1480 results about "Failure analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure, often with the goal of determining corrective actions or liability. According to Bloch and Geitner, machinery failures reveal a reaction chain of cause and effect… usually a deficiency commonly referred to as the symptom…”. failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing (NDT) methods (such as industrial computed tomography scanning) are valuable because the failed products are unaffected by analysis, so inspection sometimes starts using these methods.

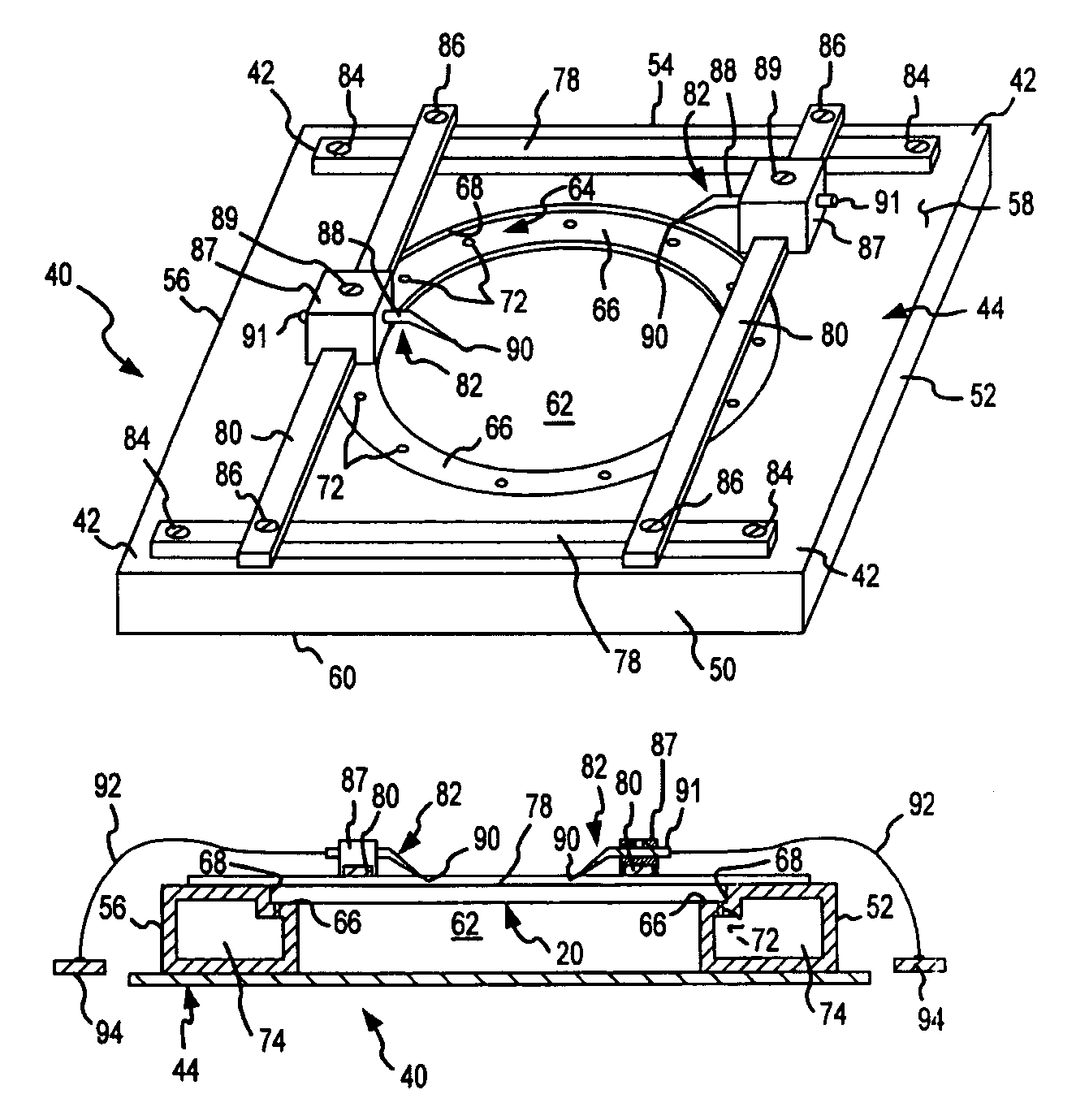

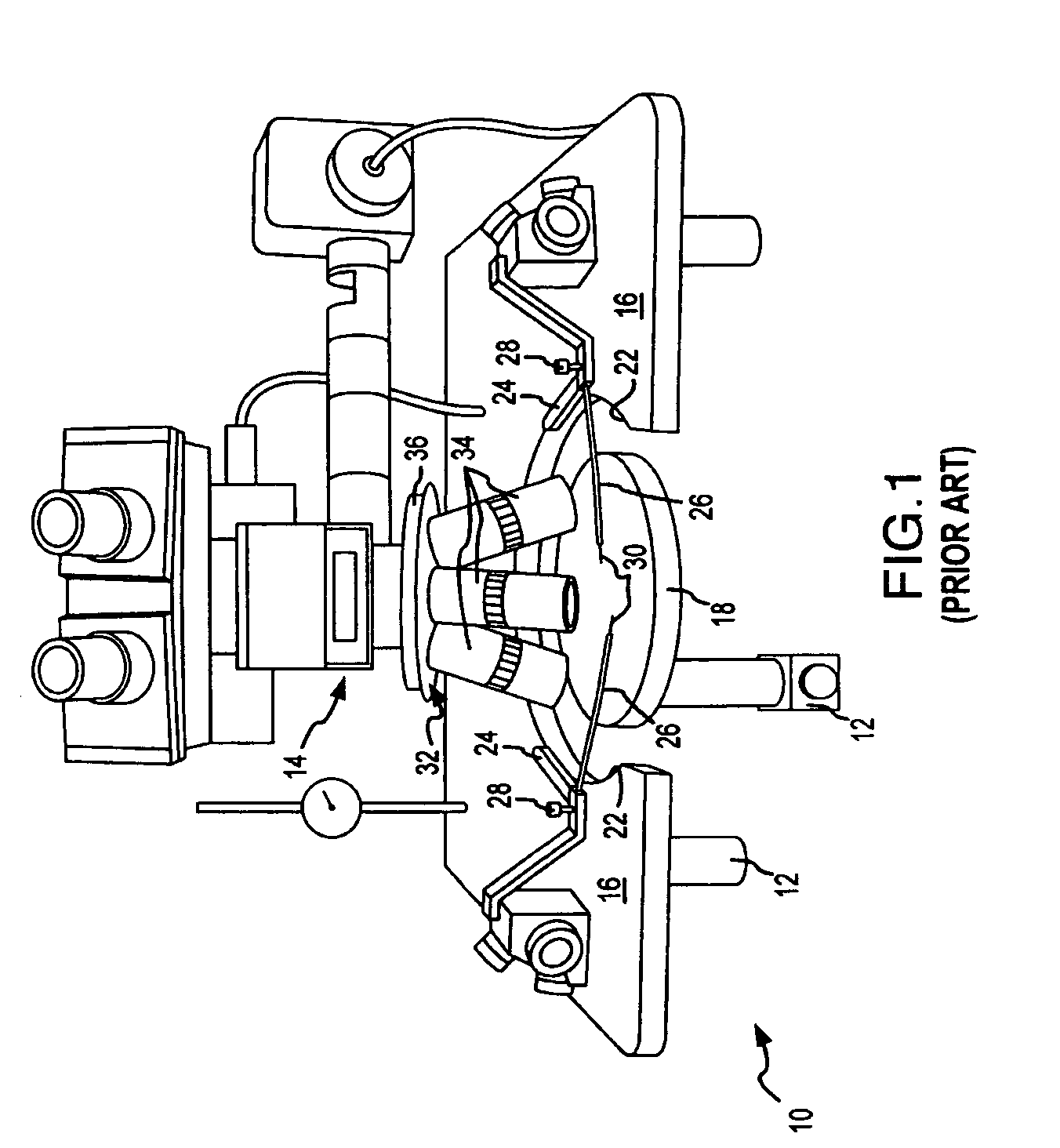

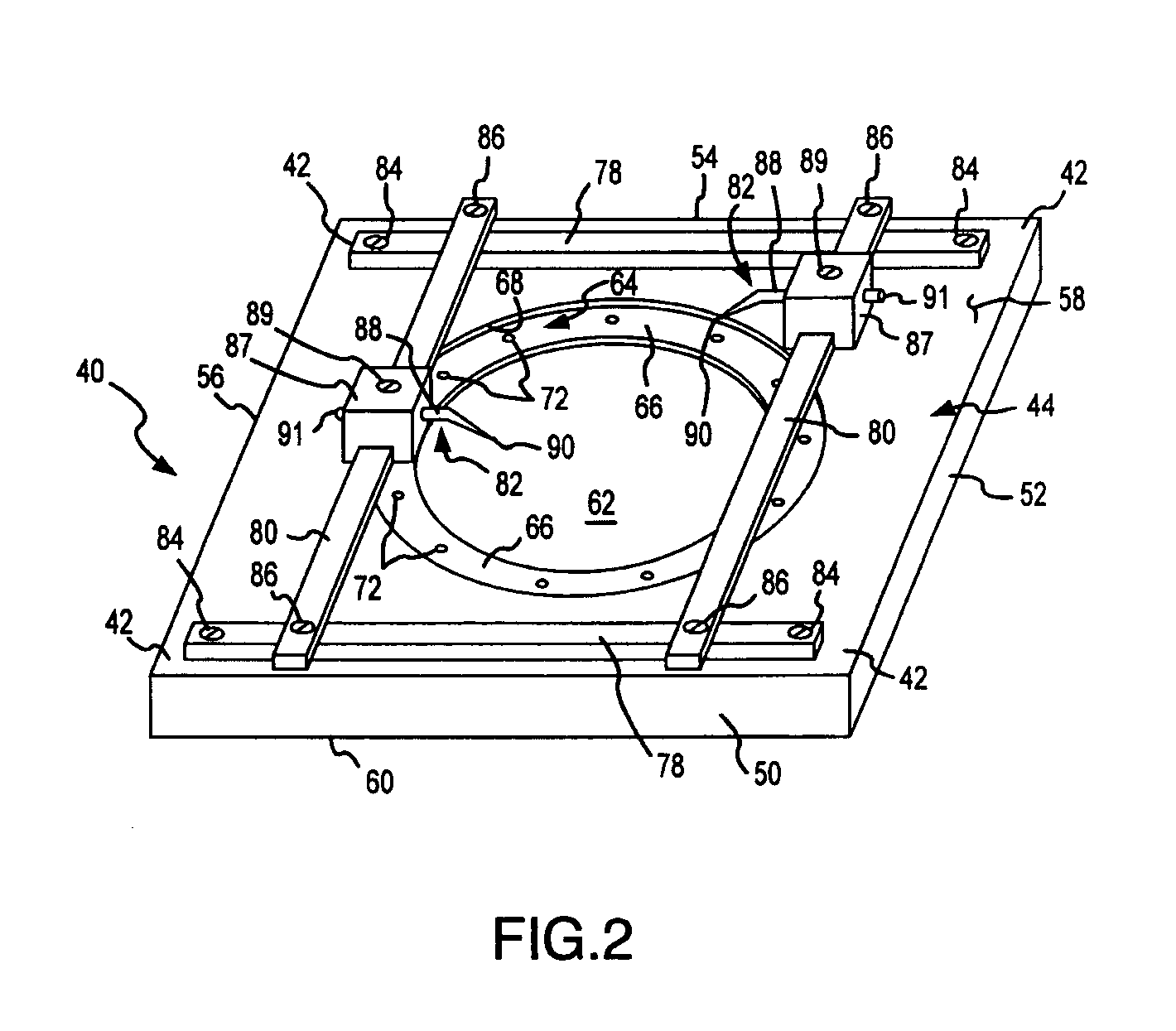

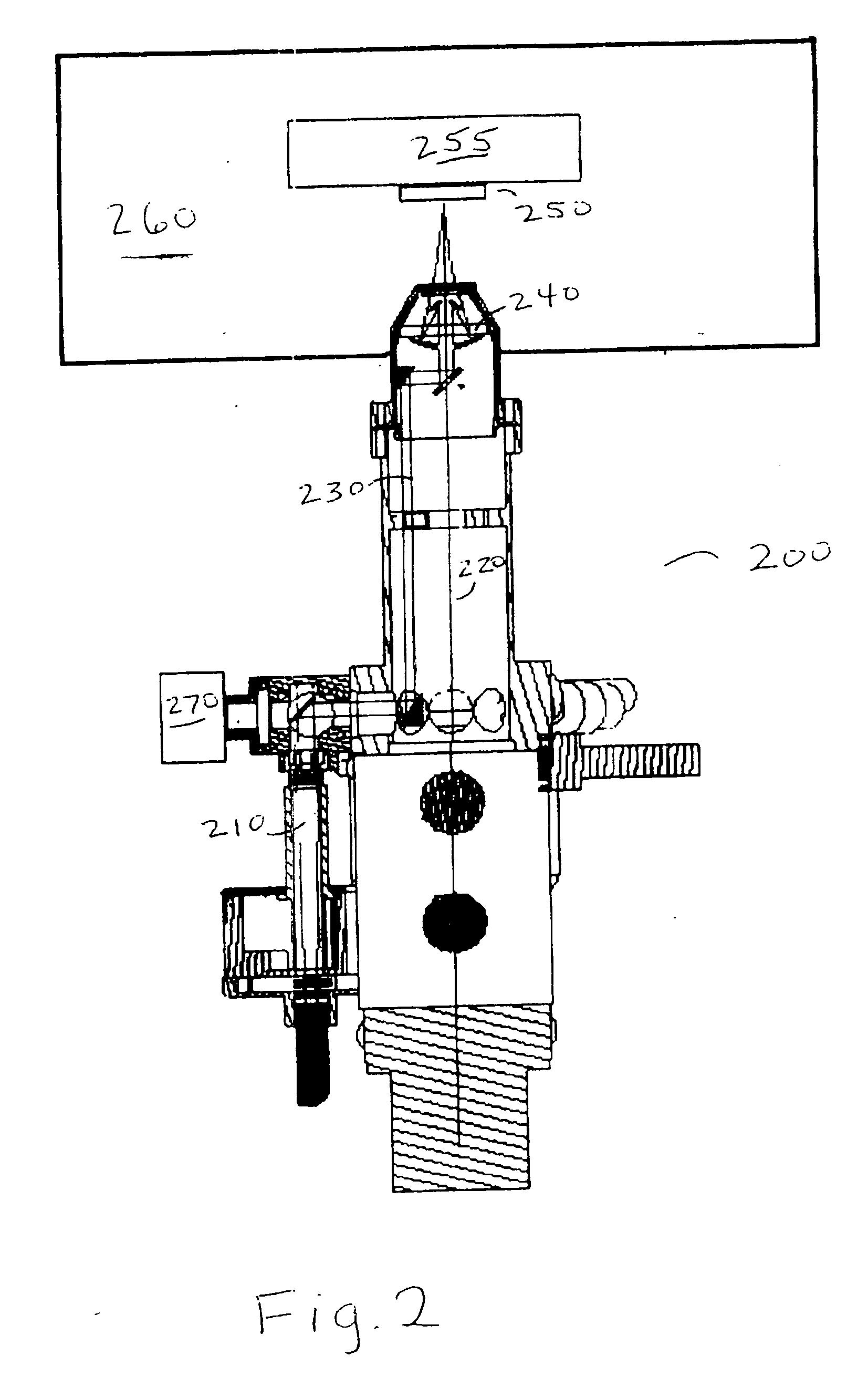

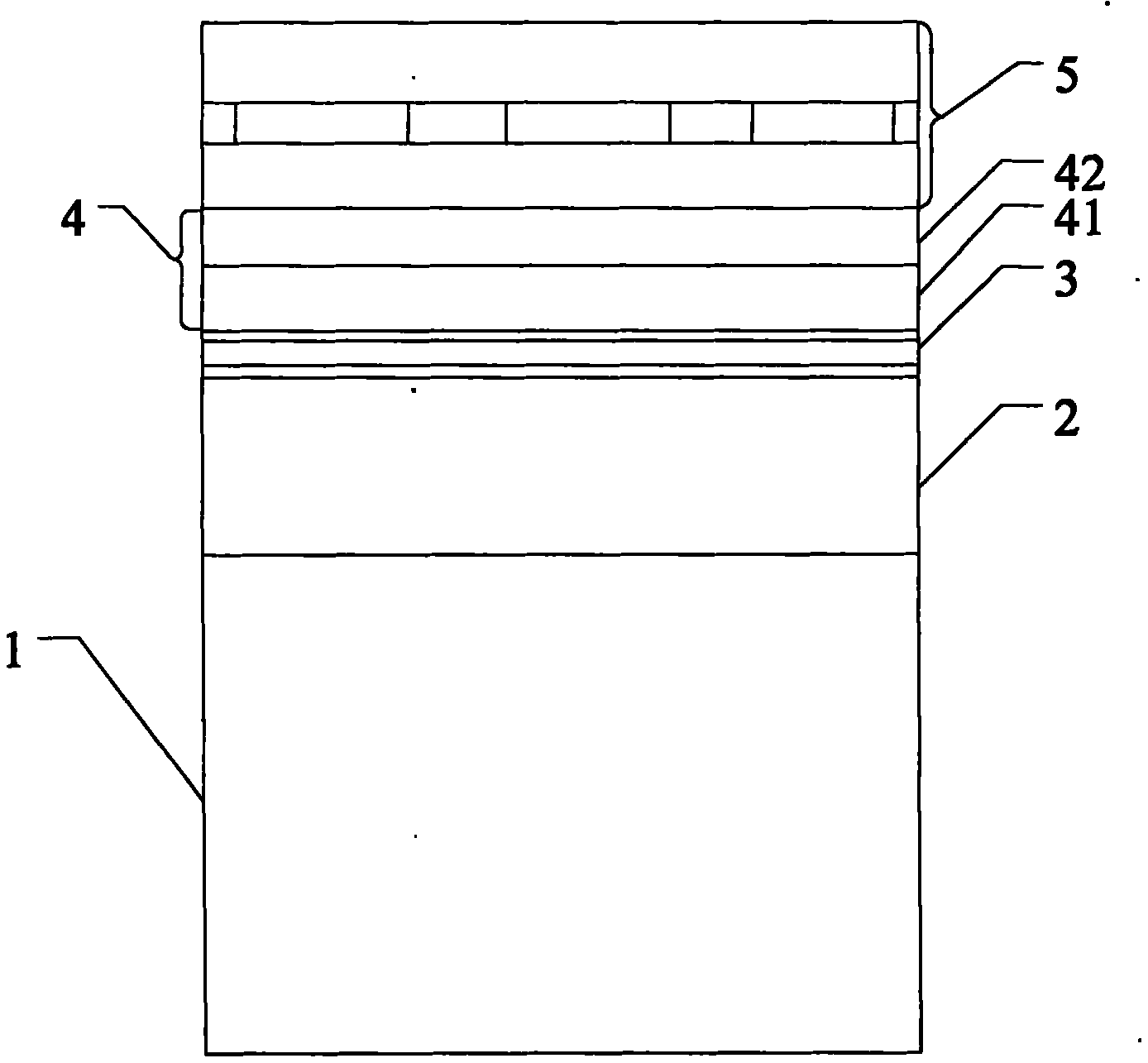

Method for probing a semiconductor wafer

InactiveUS6927079B1Avoid difficultyShorten the timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWaferingEngineering

A semiconductor wafer is placed into a probe fixture with a front side of the wafer facing up. Power and signal probes are then placed on an integrated circuit (IC) formed on the front side of the wafer. The probe fixture is retained at a test station either in a upright or an inverted position for testing and optical failure analysis. The probe fixture includes a position adjustment mechanism to locate the entire probe above the wafer and to more precisely position a tip of the probe on the IC. Optical failure analysis techniques are performed on the front side or the back side of the wafer while the wafer is retained in the test fixture and the probes are connected to the IC.

Owner:BELL SEMICON LLC

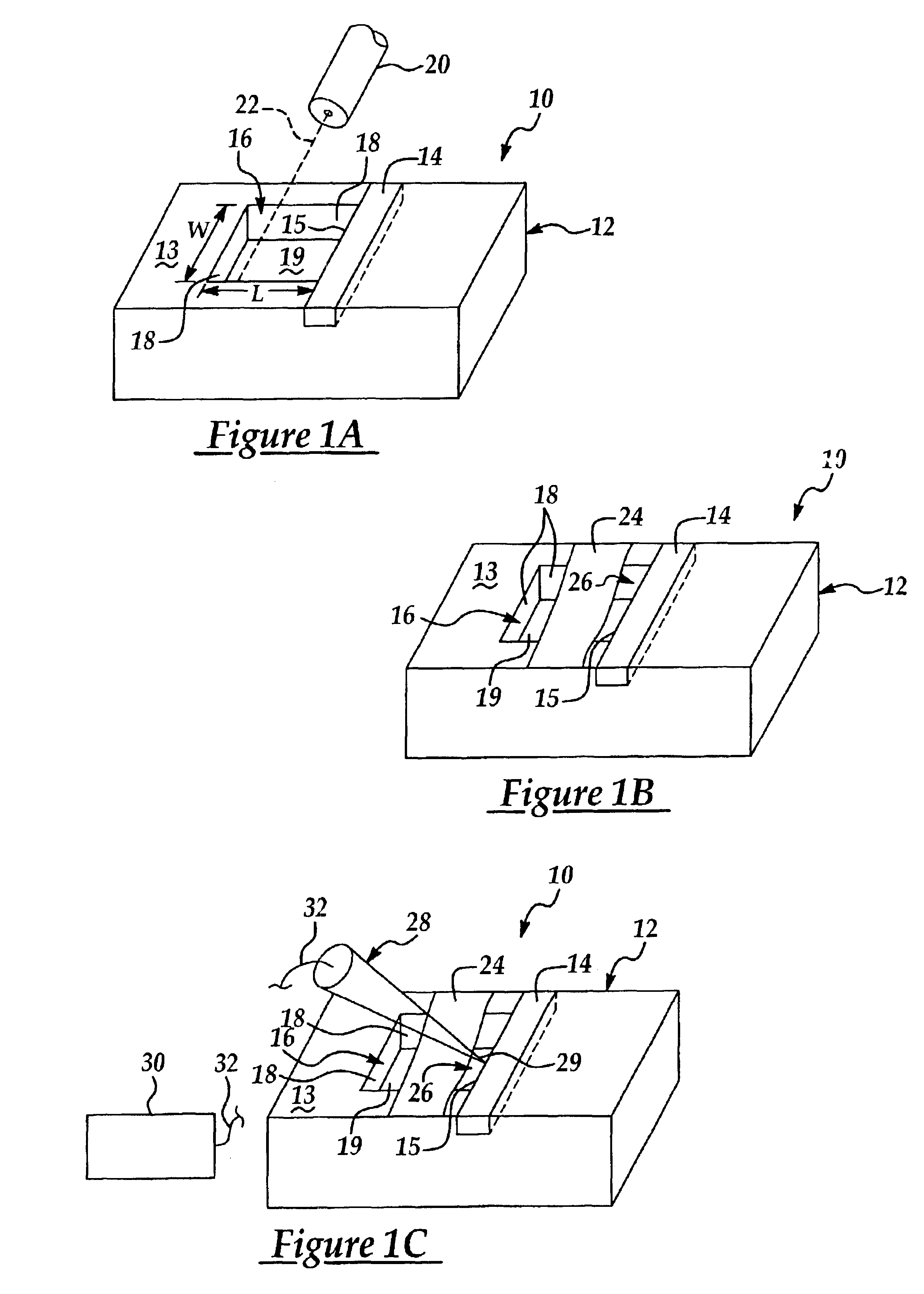

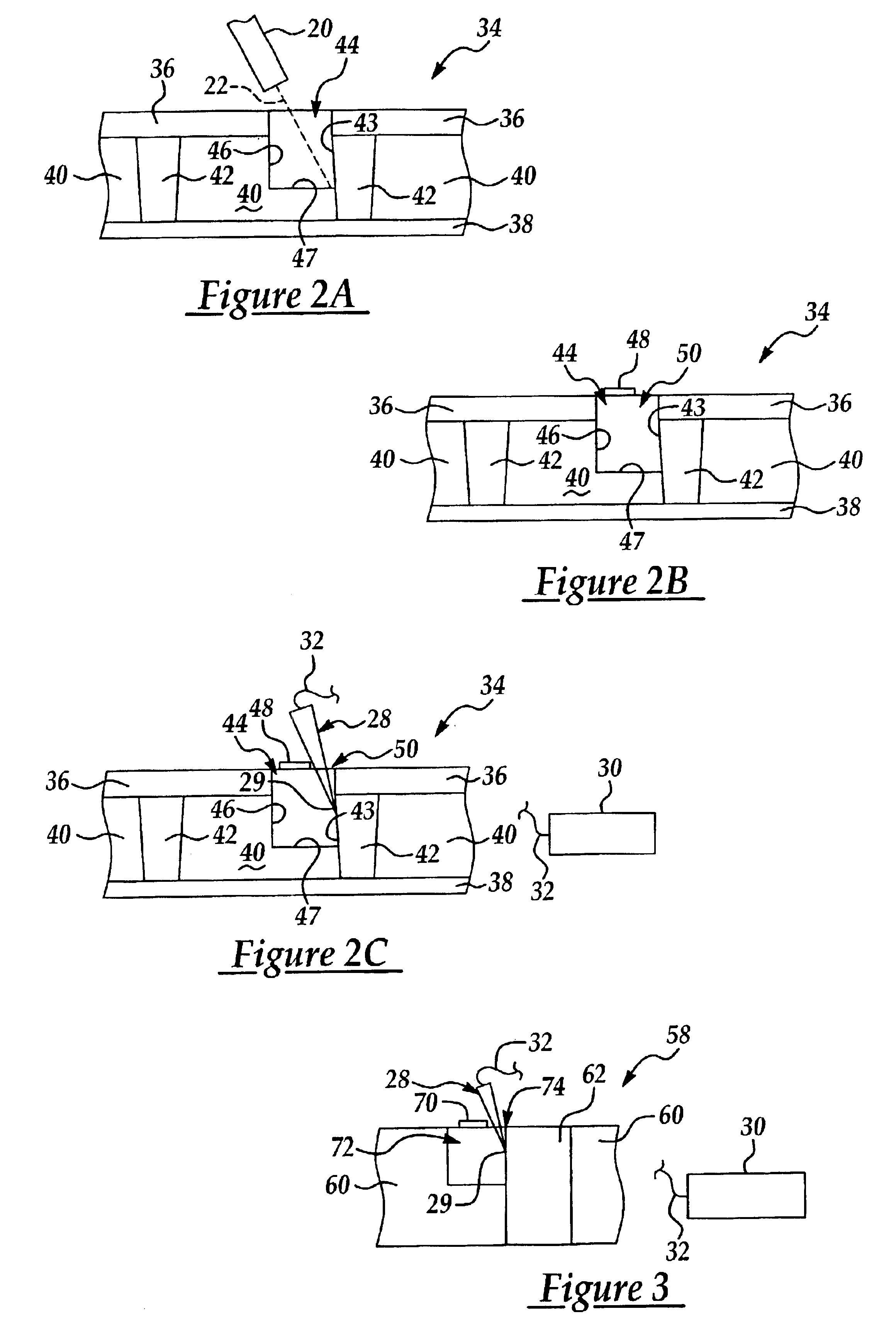

Probing of device elements

InactiveUS6902941B2Reduce contact resistanceAvoid Particle ContaminationSemiconductor/solid-state device testing/measurementElectronic circuit testingDielectricElectricity

A new and improved method for the probing of integrated circuits (ICs) and is particularly suitable for probing various elements of an IC for failure analysis or other electrical testing and / or measurement of the IC. The method includes providing a probe access trench in the IMD (intermetal dielectric) or other substrate adjacent to the circuit element to be tested and then providing direct electrical contact between the test probe and the sidewall of the element through the trench, during the testing process. Such direct electrical contact between the test probe and the sidewall of the element prevents excessively high contact resistance which may otherwise occur in the use of a probing pad between the test probe and the element.

Owner:TAIWAN SEMICON MFG CO LTD

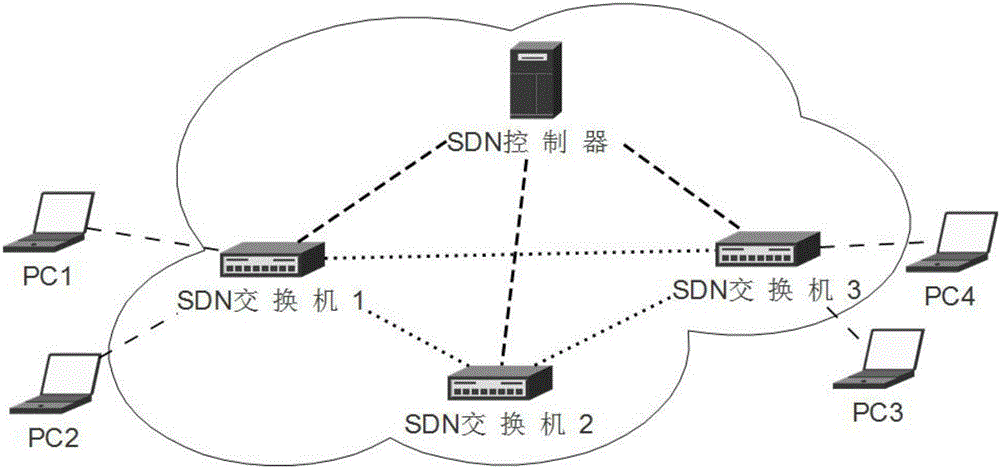

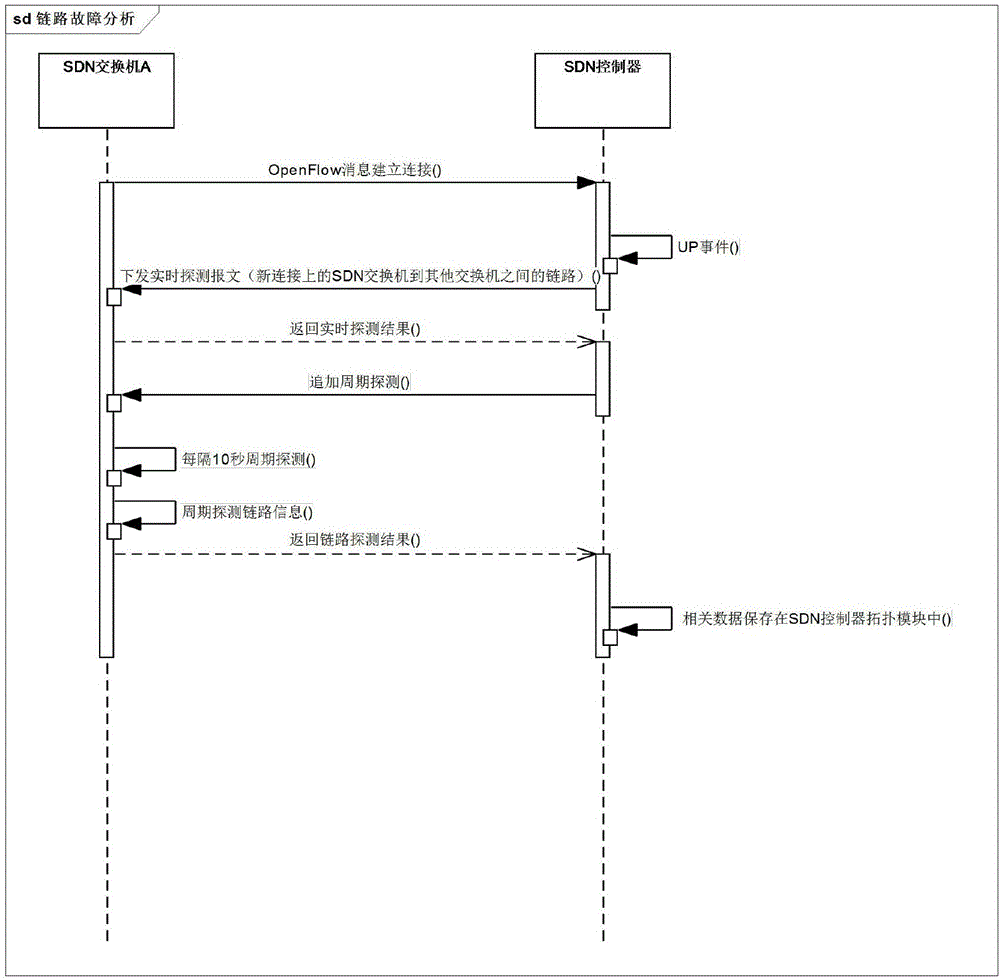

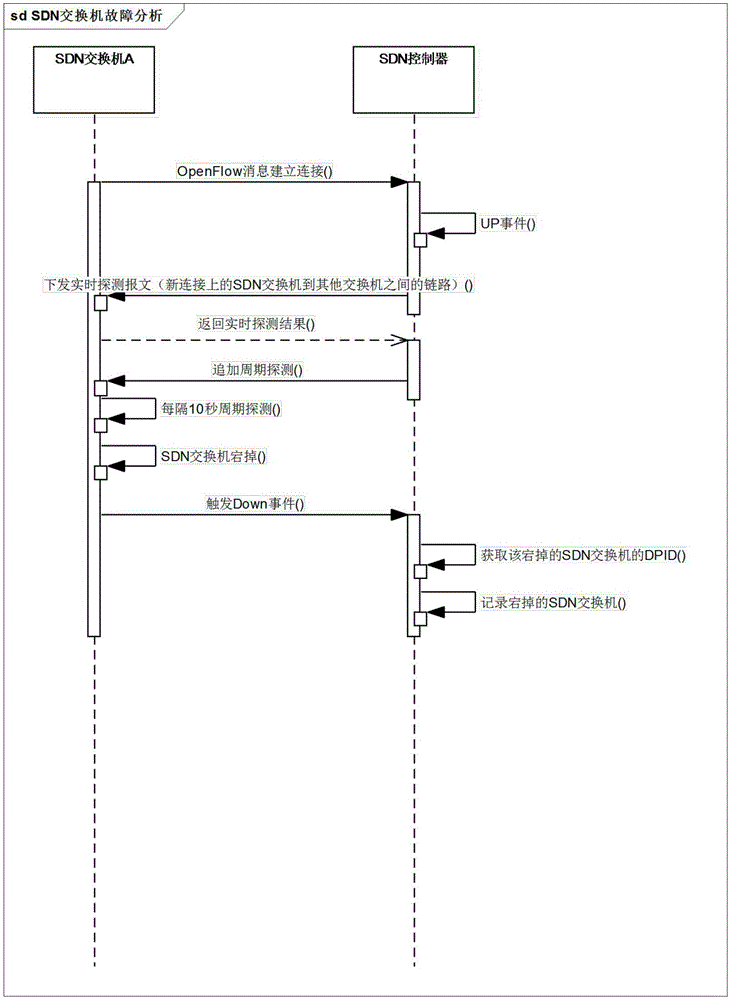

System and method for realizing automatic network failure analysis based on SDN technology

ActiveCN106130766AAdaptableStrong reliabilityData switching networksFailure analysisNetwork topology

The invention relates to a system and a method for realizing automatic network failure analysis based on SDN technology. The system comprises one SDN controller and multiple SDN switches. The SDN controller realizes real-time detection and cycle detection of each link in network topology, and monitors states of the SDN switches in real time and maintains the global network topology. The SDN controller comprises an OpenFlow module, an OpenFlow extension module, an event module, a topology module and a detection module. The detection module comprises a real-time detection module and a cycle detection module. With the system and the method, the whole network can be monitored, and network failure analysis is realized.

Owner:WUHAN GREENET INFORMATION SERVICE

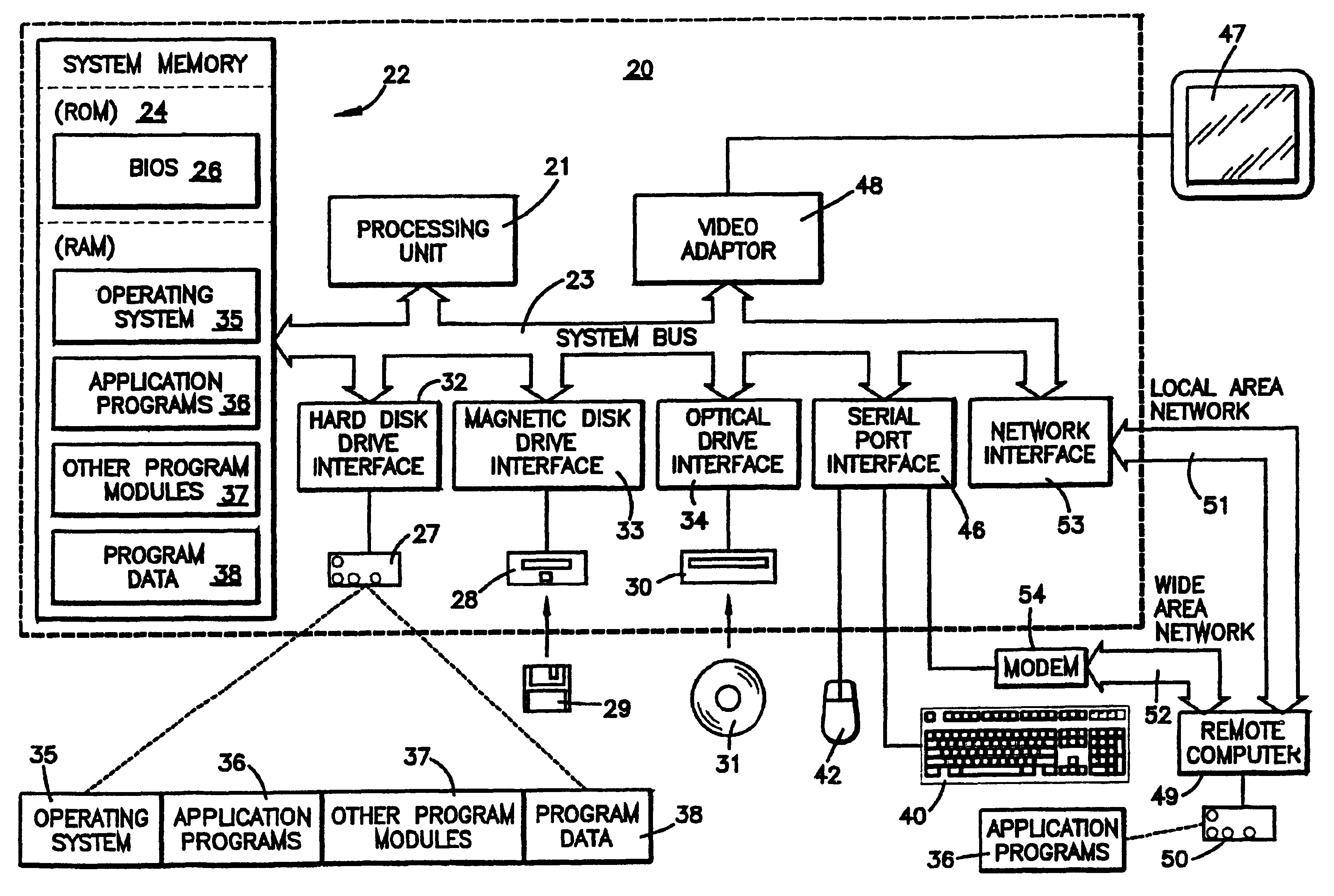

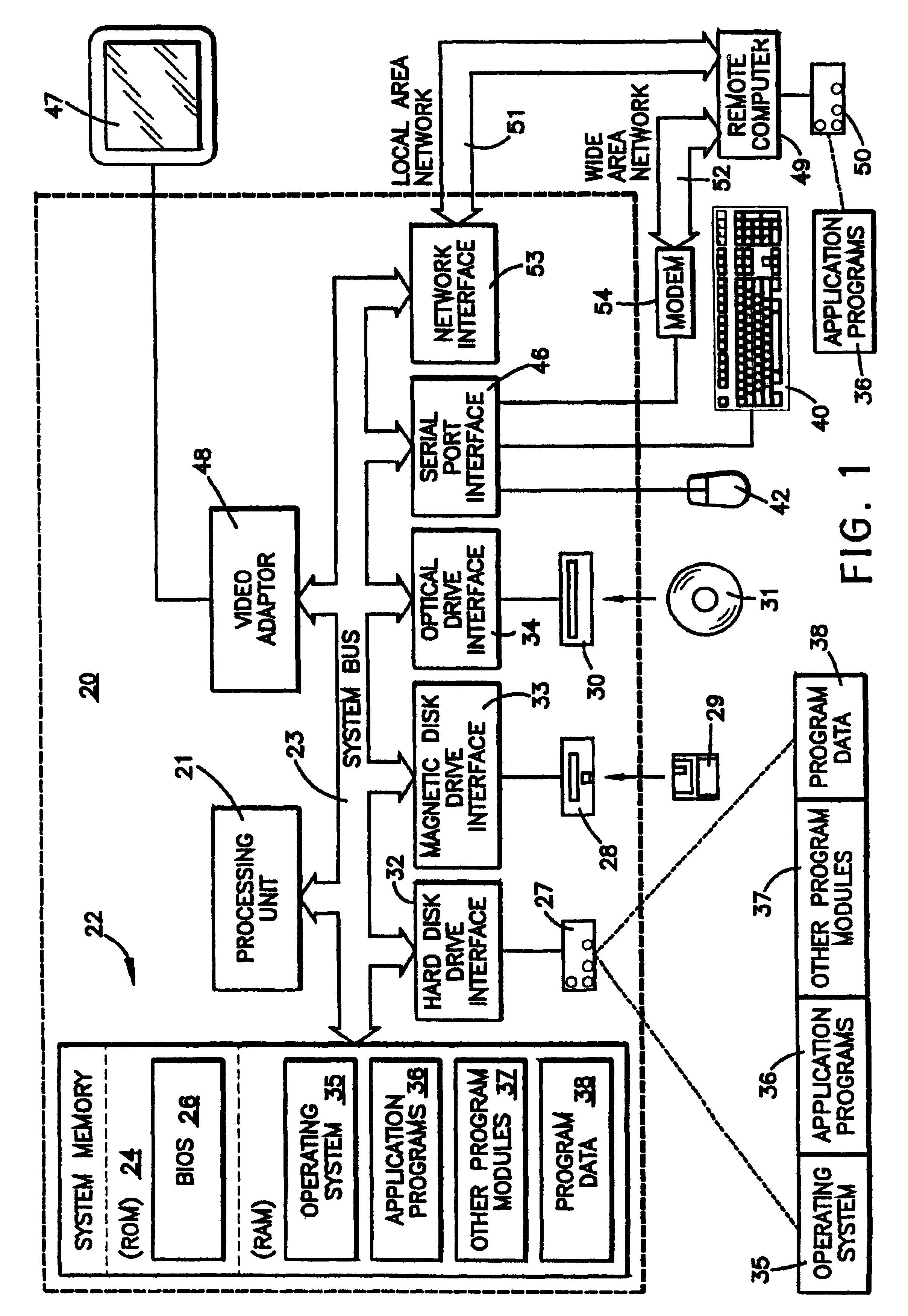

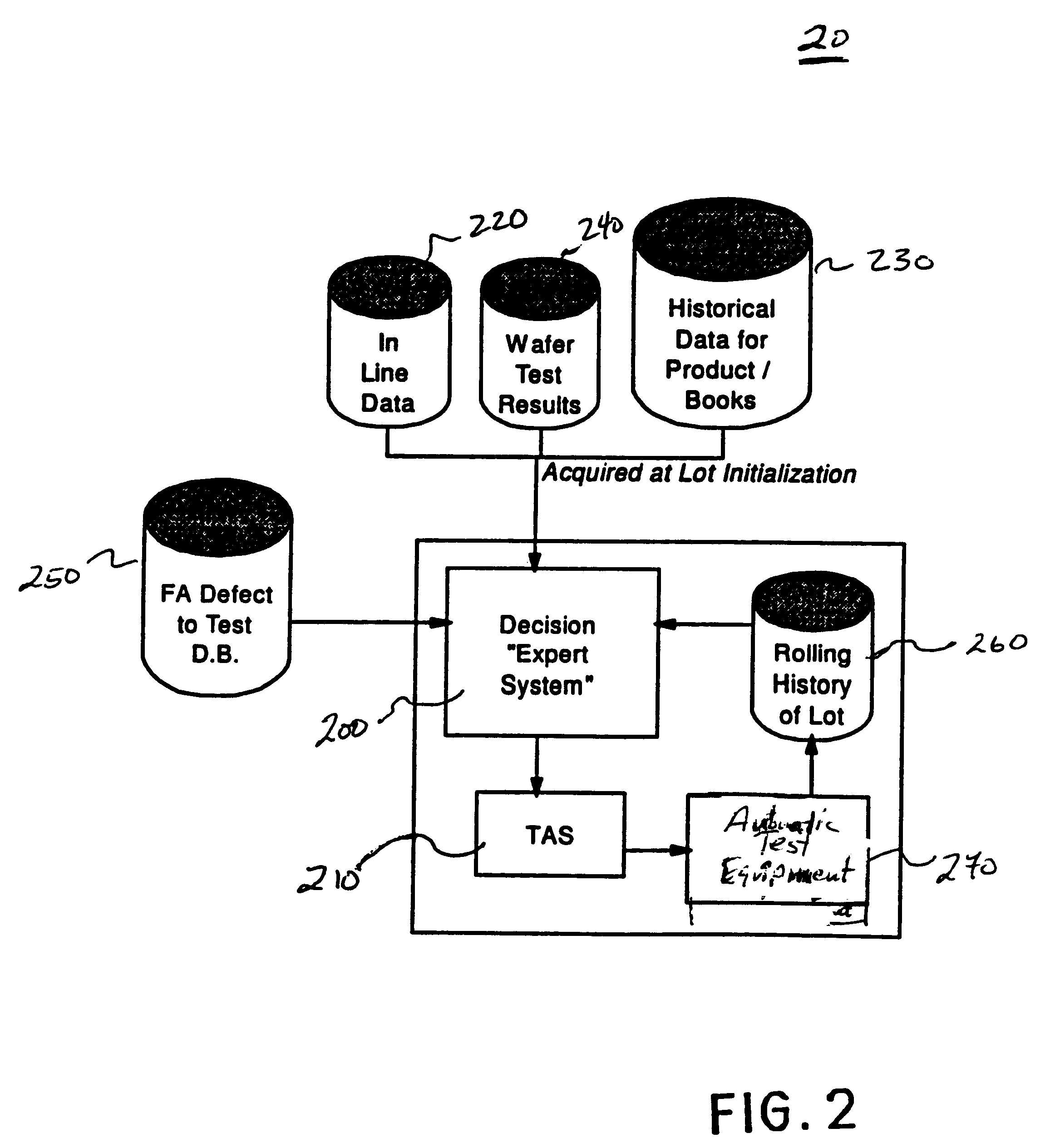

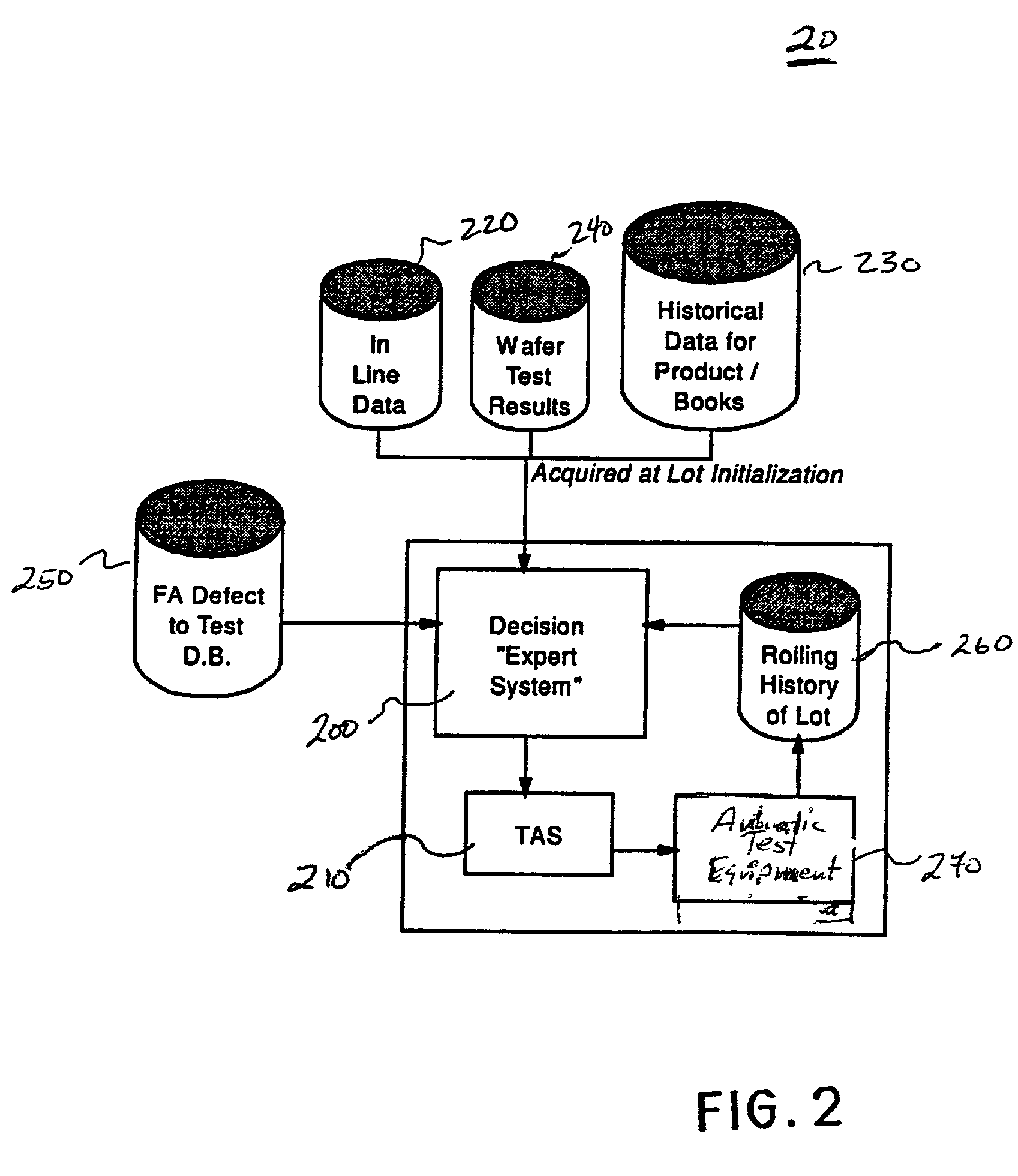

Method for test optimization using historical and actual fabrication test data

InactiveUS6618682B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingQuality levelWafer fabrication

A method and system are provided that minimize wafer or package level test time without adversely impacting yields in downstream manufacturing processes or degrading outgoing quality levels. The method provides optimization by determining, a priority, the most effective set of tests for a given lot or wafer. The invention implements a method using a processor-based system involving the integration of multiple sources of data that include: historical and realtime, product specific and lot specific, from wafer fabrication data (i.e., process measurements, defect inspections, and parametric testing), product qualification test results, physical failure analysis results and manufacturing functional test results. These various forms of data are used to determine an optimal set of tests to run using a test application sequence, on a given product to optimize test time with minimum risk to yield or product quality.

Owner:CADENCE DESIGN SYST INC

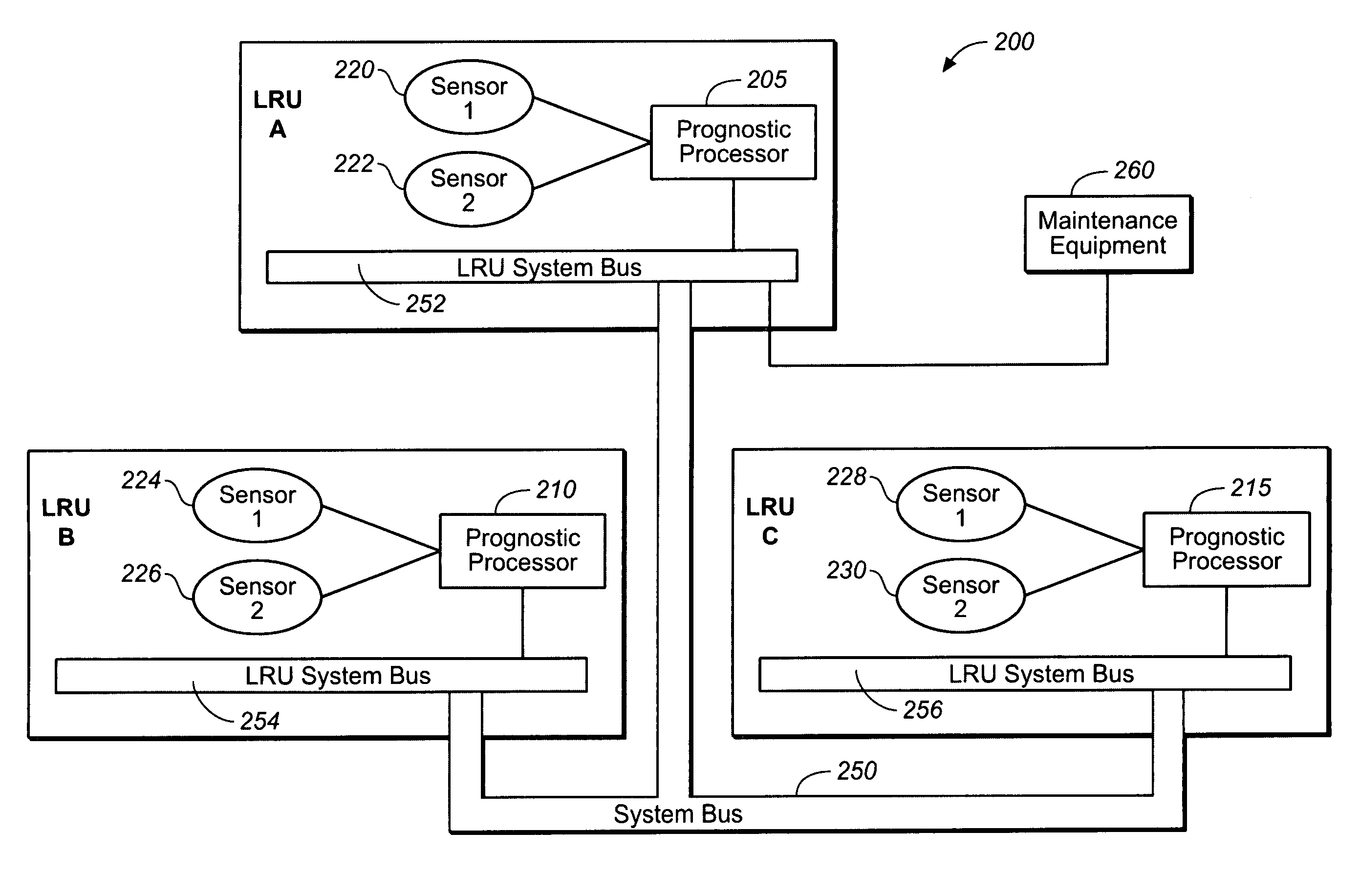

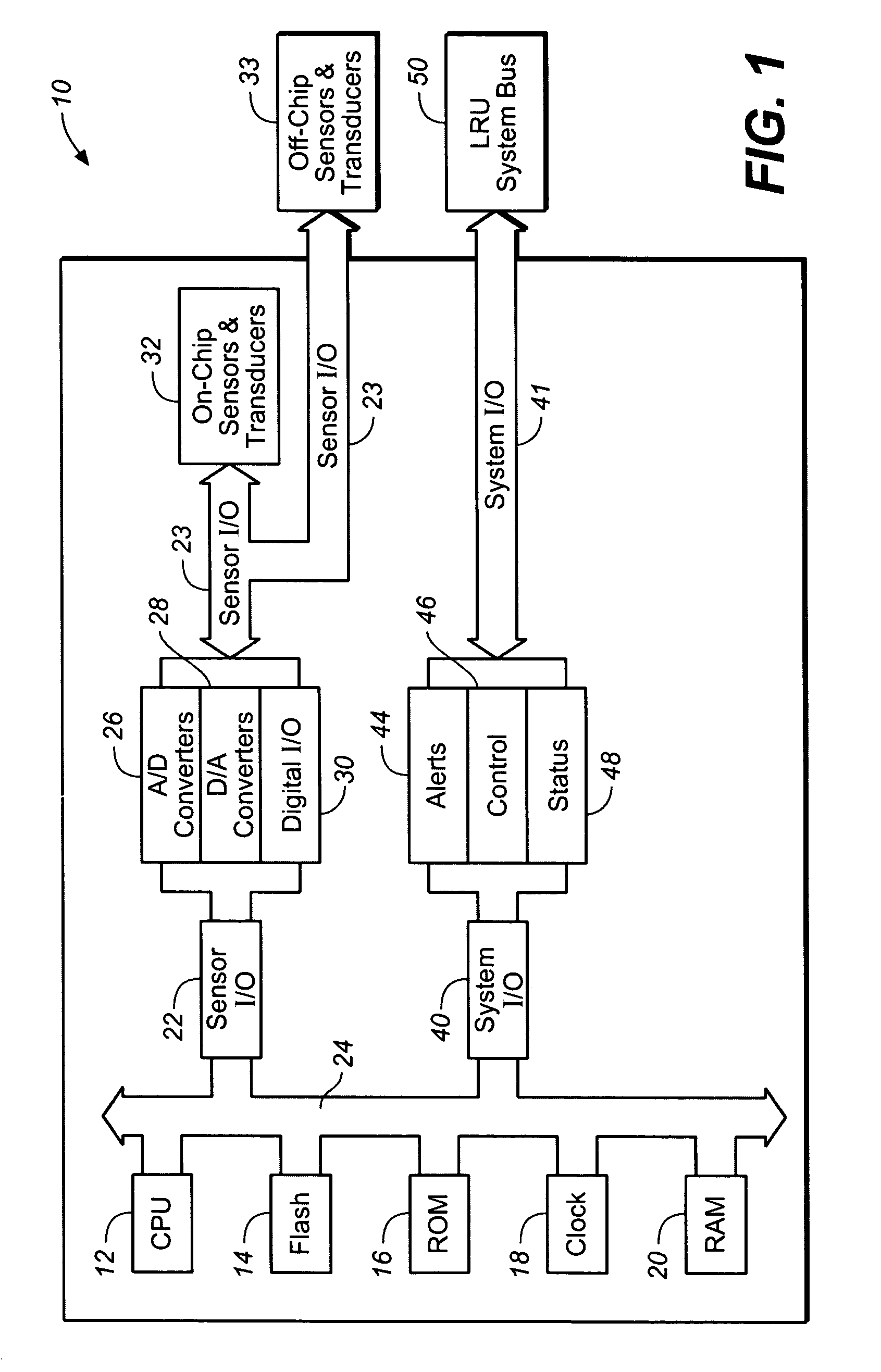

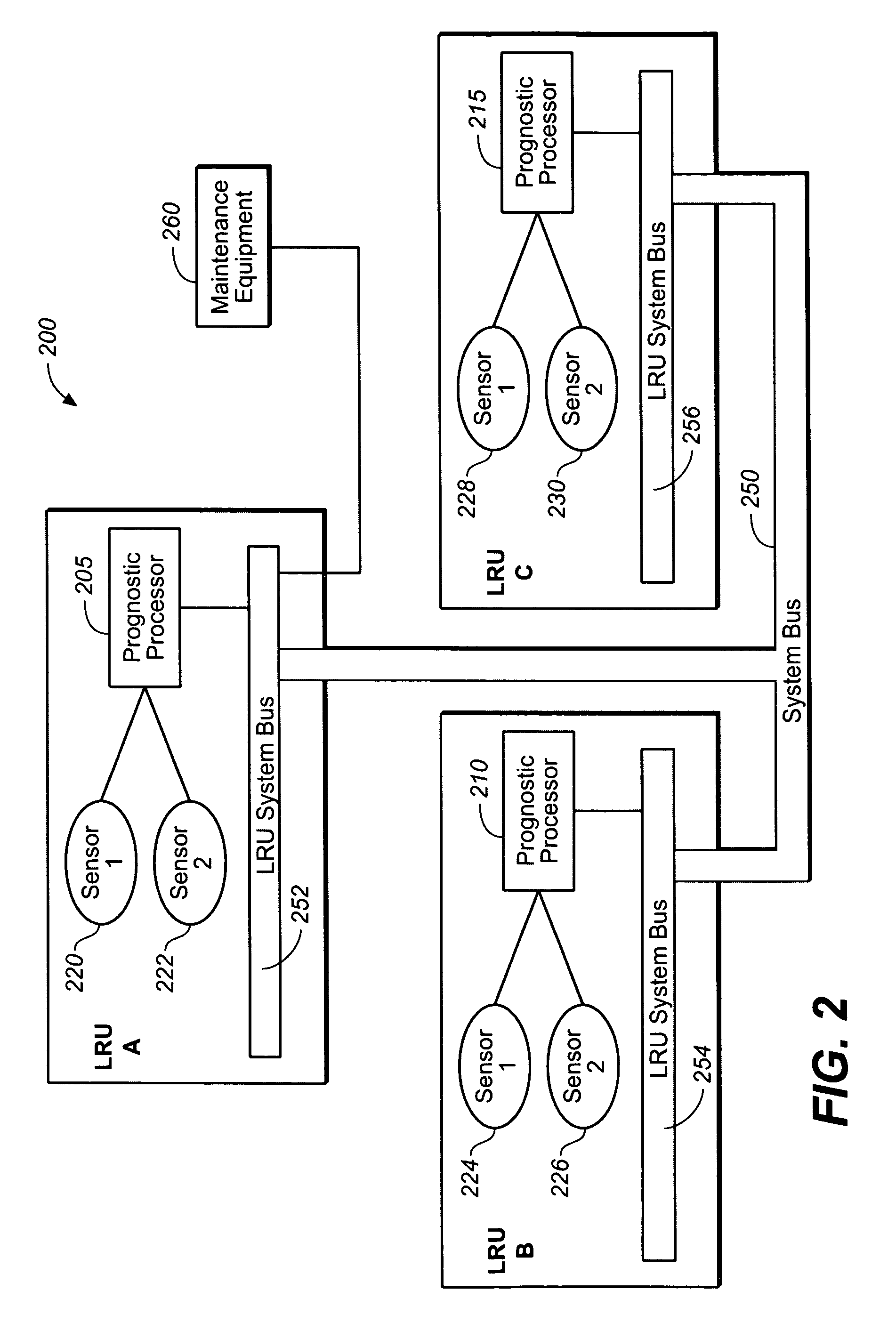

Prognostic processor system for real-time failure analysis of line replaceable units

ActiveUS7509537B1Electronic circuit testingTesting/monitoring control systemsModeling softwarePredictive failure analysis

A prognostic processor for predicting machine failure in avionics electronics comprises prognostic capabilities in a single integrated circuit, with a processor, volatile and non-volatile memory, clock, on-chip and off-chip sensors and transducers, A / D converters, a common I / O interface adapted to be employed in a network of similar prognostic processors, and predictive Failure Analysis (FA) model software, which may be distributed throughout the network. The FA software employs a log file history, with the log file history storing data collected by the prognostic processor, real-time execution of a predictive model, with the ability to update the FA model with data from field failures. The prognostic processor network supports hierarchical processing to work with multiple prognostic processors. The prognostic processor system is applicable to FA monitoring of a wide range of avionics electronic equipment, in particular, Line Replacement Units (LRUs).

Owner:ROCKWELL COLLINS INC

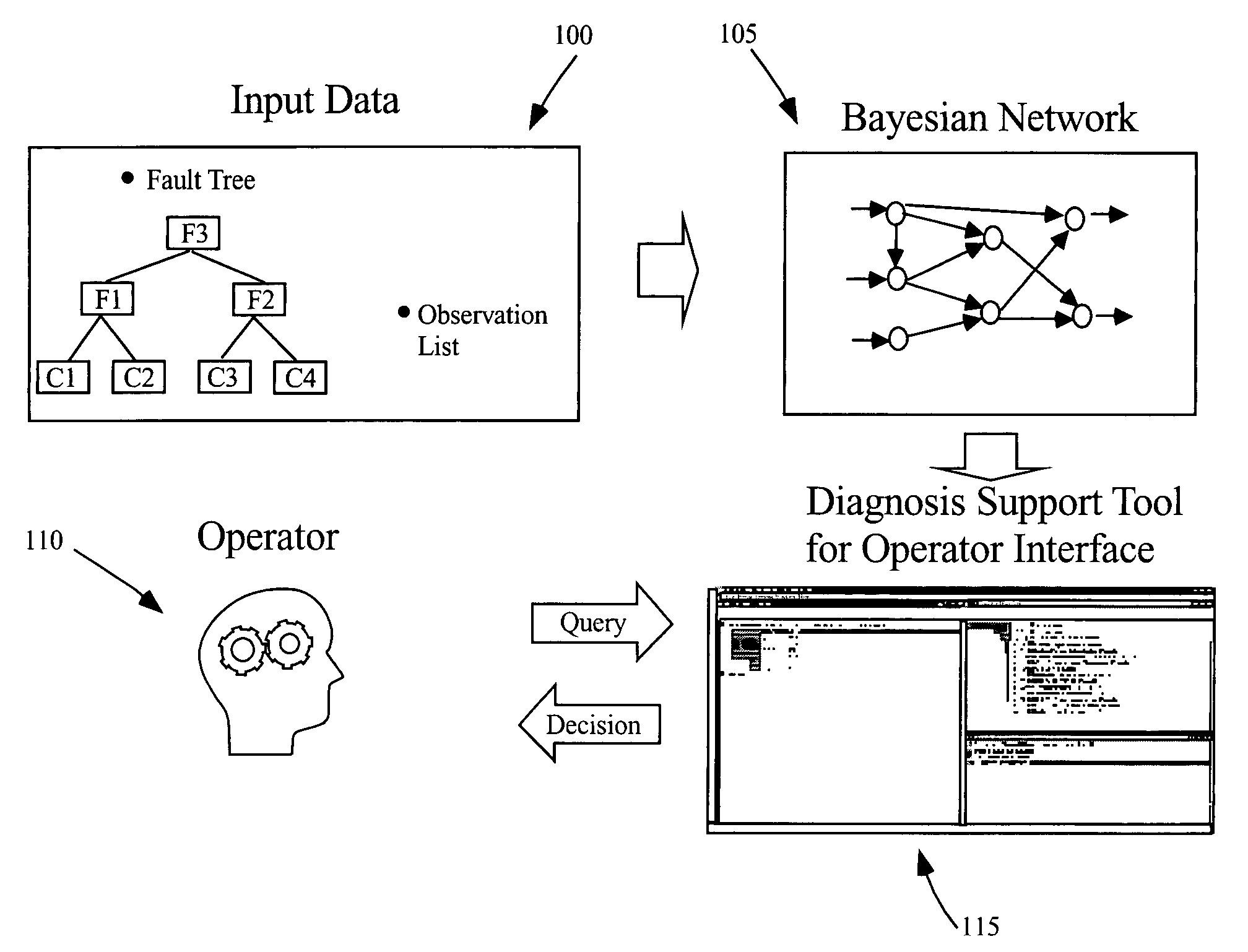

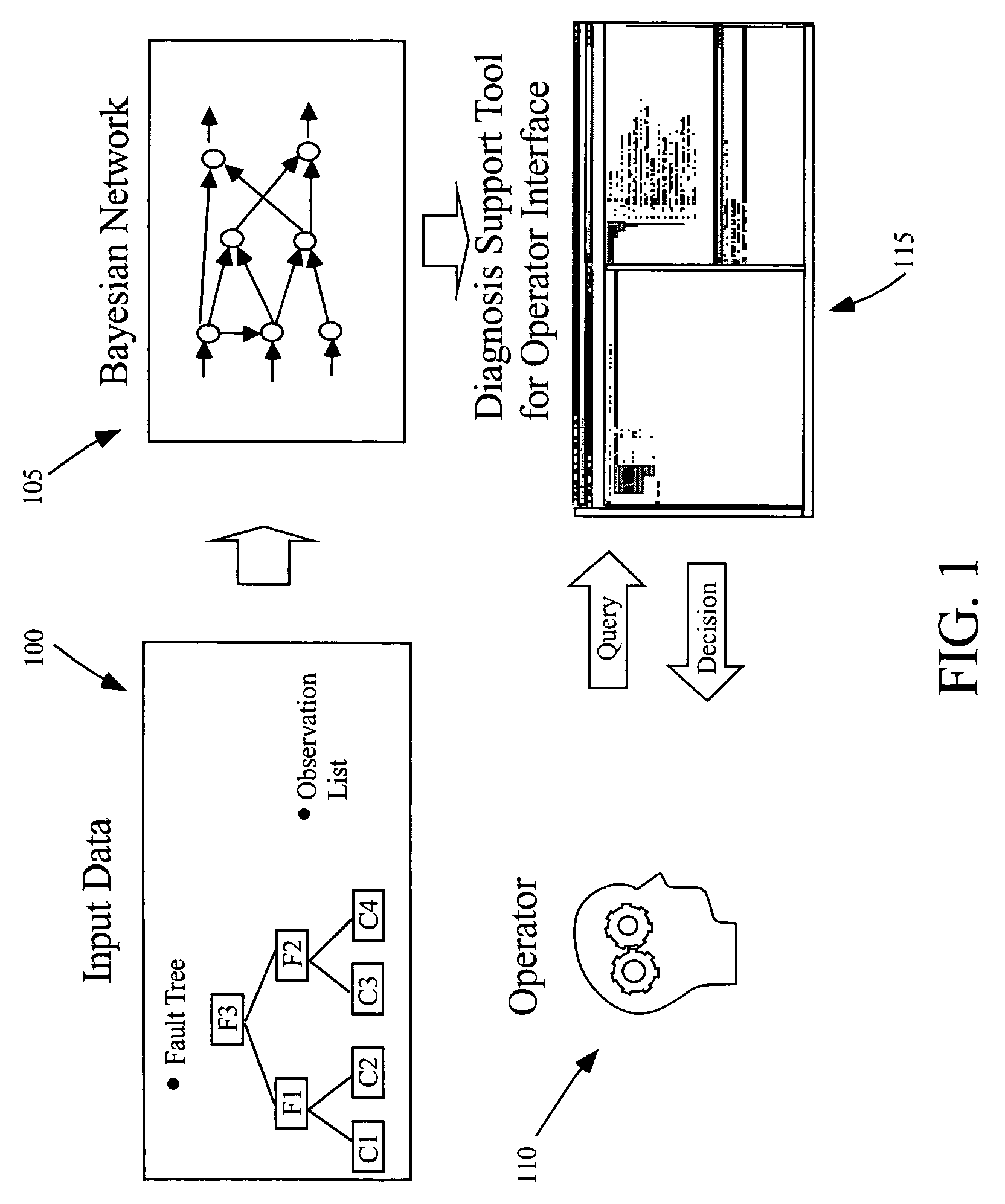

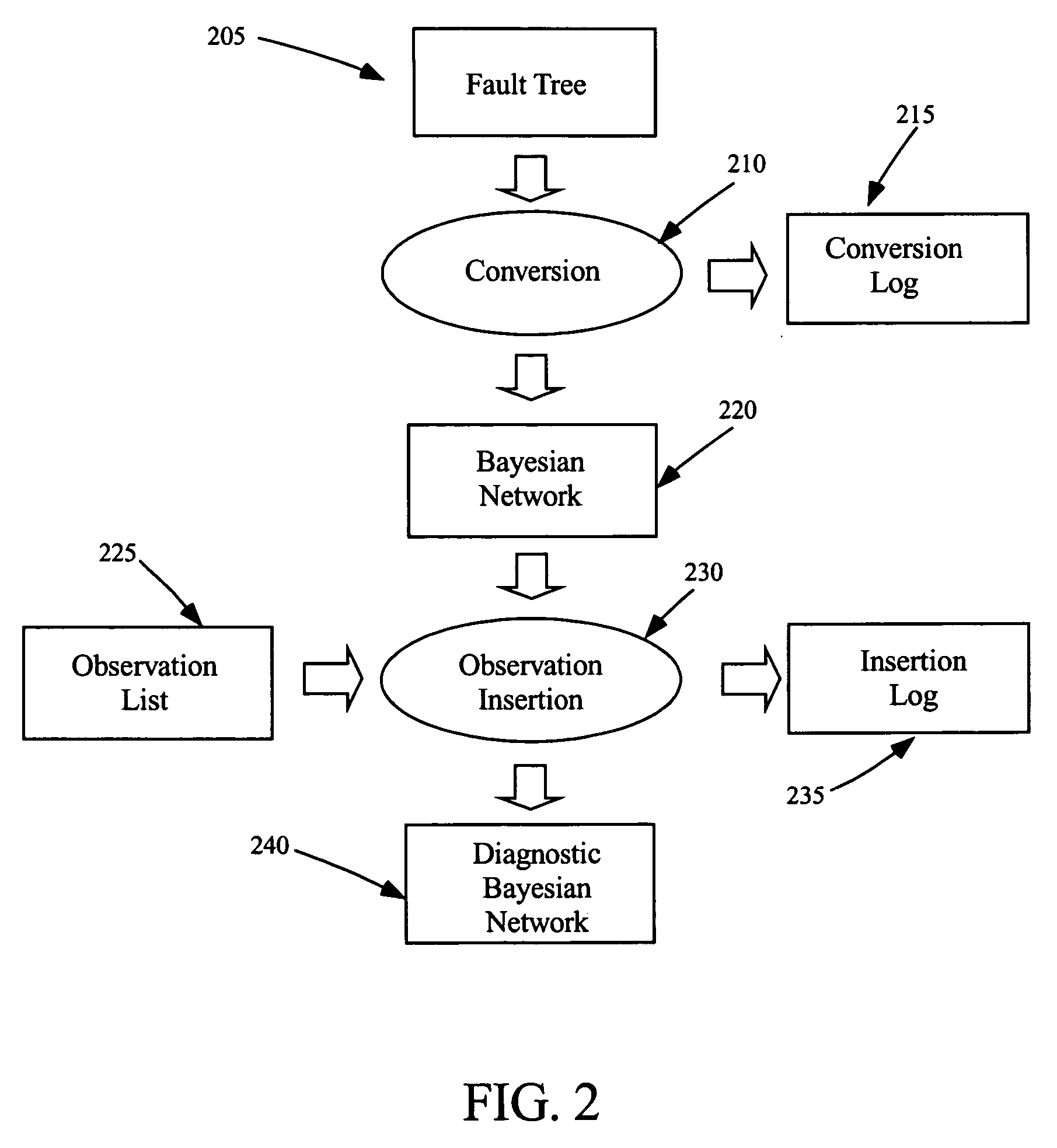

Automatic generation of baysian diagnostics from fault trees

InactiveUS20050160324A1Early detection of failureRapid return to serviceError detection/correctionProbabilistic networksFailure analysisDependability

Fault trees are automatically converted to Bayesian networks for assisting in system reliability, failure analysis and diagnostics by using information from the fault tree structure to create the Bayesian network structure, creating parameters of the Bayesian network using information from the fault tree, obtaining information about observation nodes for the Bayesian network from a list of observations that augments information contained in the fault tree, and inserting the observation nodes into the Bayesian network. The fault tree is pre-processed into an intermediate format prior to conversion that may include adding reliability values from a separate text document when the fault tree is in such format that requires it.

Owner:THE BOEING CO

Integration of photon emission microscope and focused ion beam

InactiveUS20060012385A1Vacuum gauge using ionisation effectsFault location by increasing destruction at faultPhoton emissionIon beam

An integrated FIB / PEM apparatus and method for performing failure analysis on integrated circuits. In-situ failure analysis is enabled by integrating Photon Emission Microscopy into a Focused Ion Beam system, thereby improving throughput and efficiency of Failure Analysis. An iterative method is described for identifying and localizing fault sites on the circuit.

Owner:DCG SYST

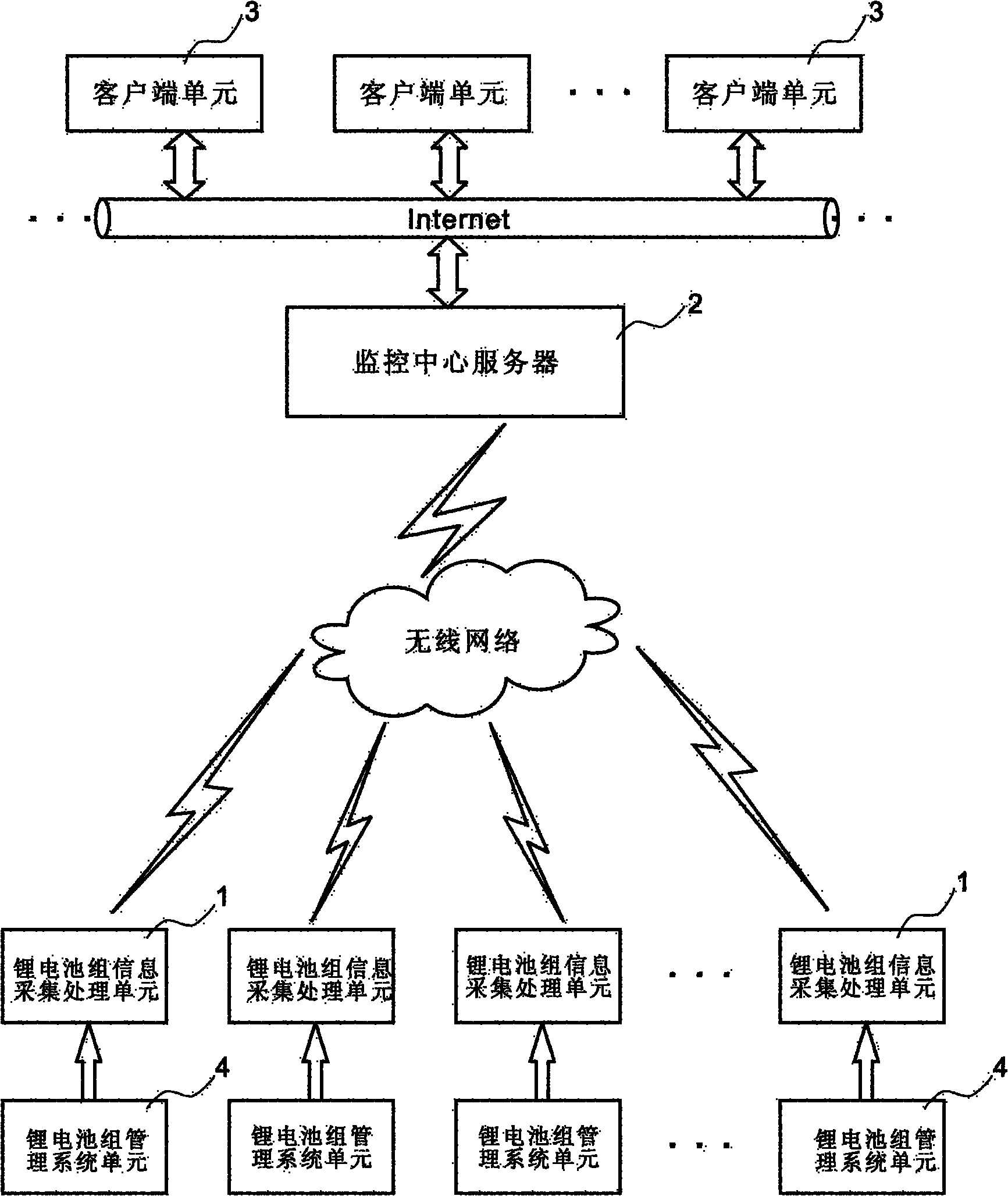

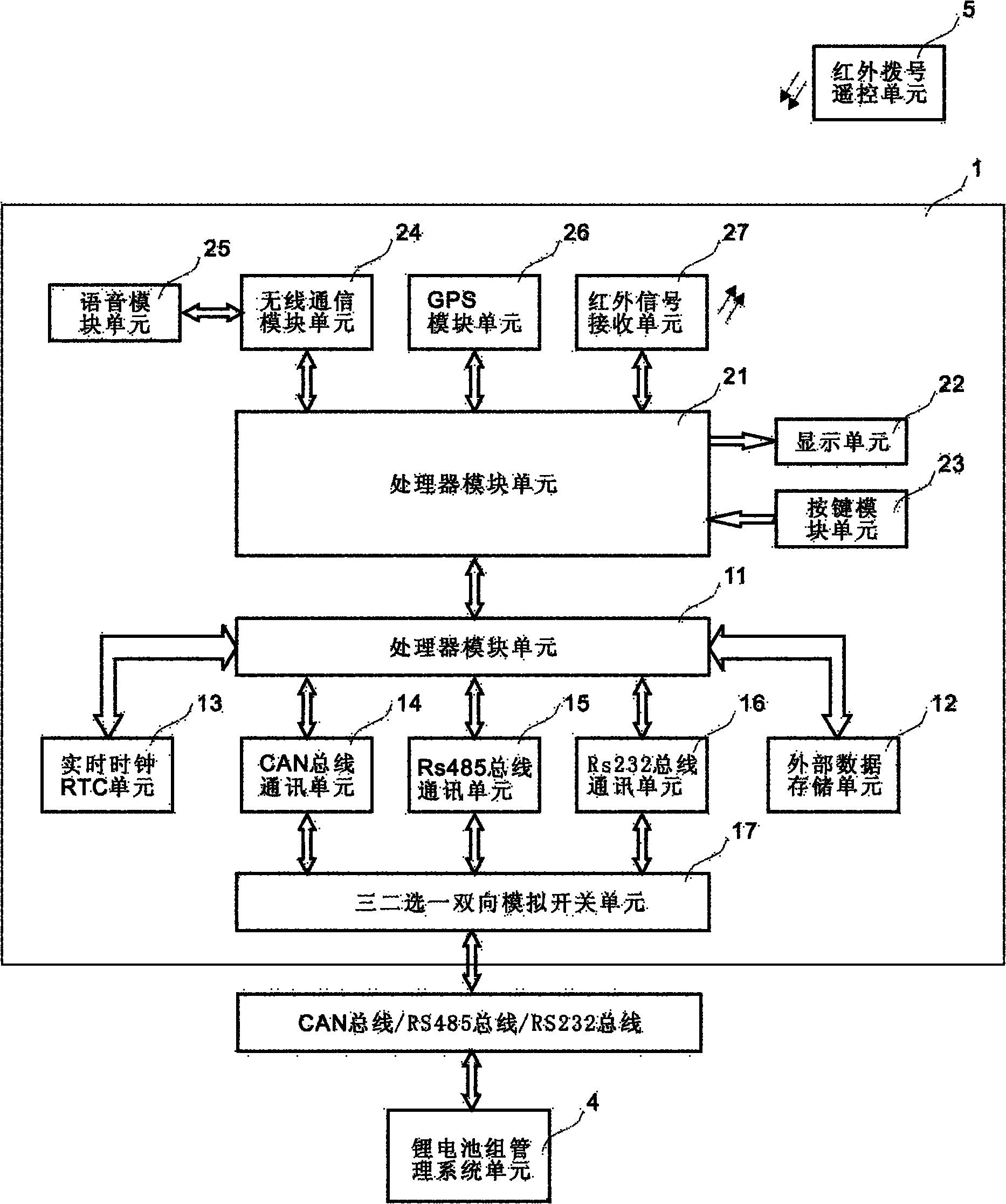

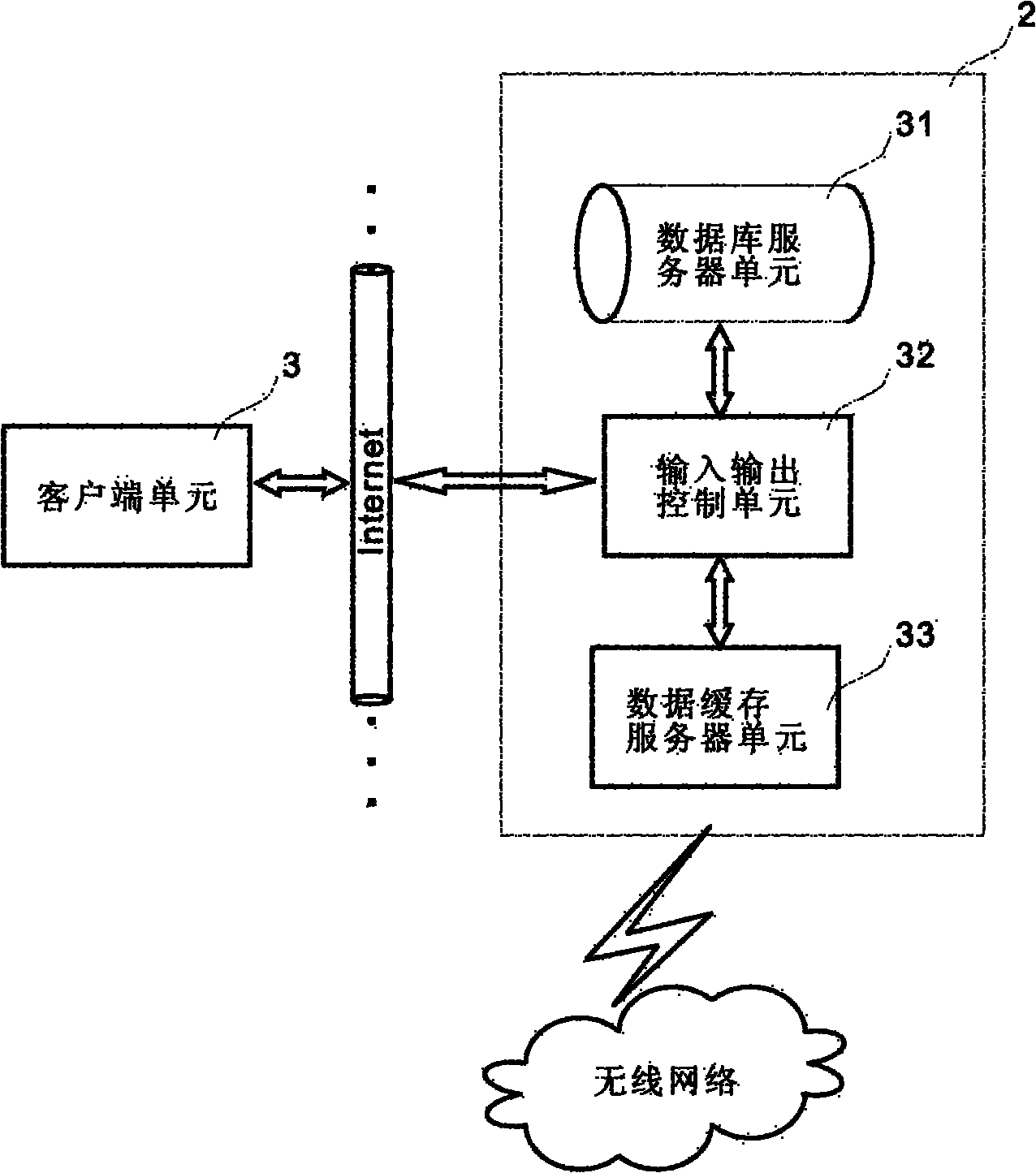

Remote monitoring system for lithium battery pack

InactiveCN102142186AReliable dataAvoid Unrecoverable FailuresTransmission systemsElectrical testingData acquisitionState of charge

The invention discloses a remote monitoring system for a lithium battery pack. The remote monitoring system comprises a lithium battery pack management system unit, a lithium battery pack information collecting and processing unit, a monitoring center server unit and a client unit, wherein, voltage, current, temperature, state of charge and fault information of the lithium battery pack is monitored and collected by the lithium battery pack management system unit in real time and then is transferred into the lithium battery pack information collecting and processing unit for data processing; then the processed data is transmitted to the monitoring center server unit through a wireless network so as to be stored; and the client unit is connected with the monitoring center server unit through Internet. The remote monitoring system can be used for solving the problems of the lithium battery pack such as low data collection efficiency, poor fault early-warning real-time property and shortage of failure analysis data in the prior art.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

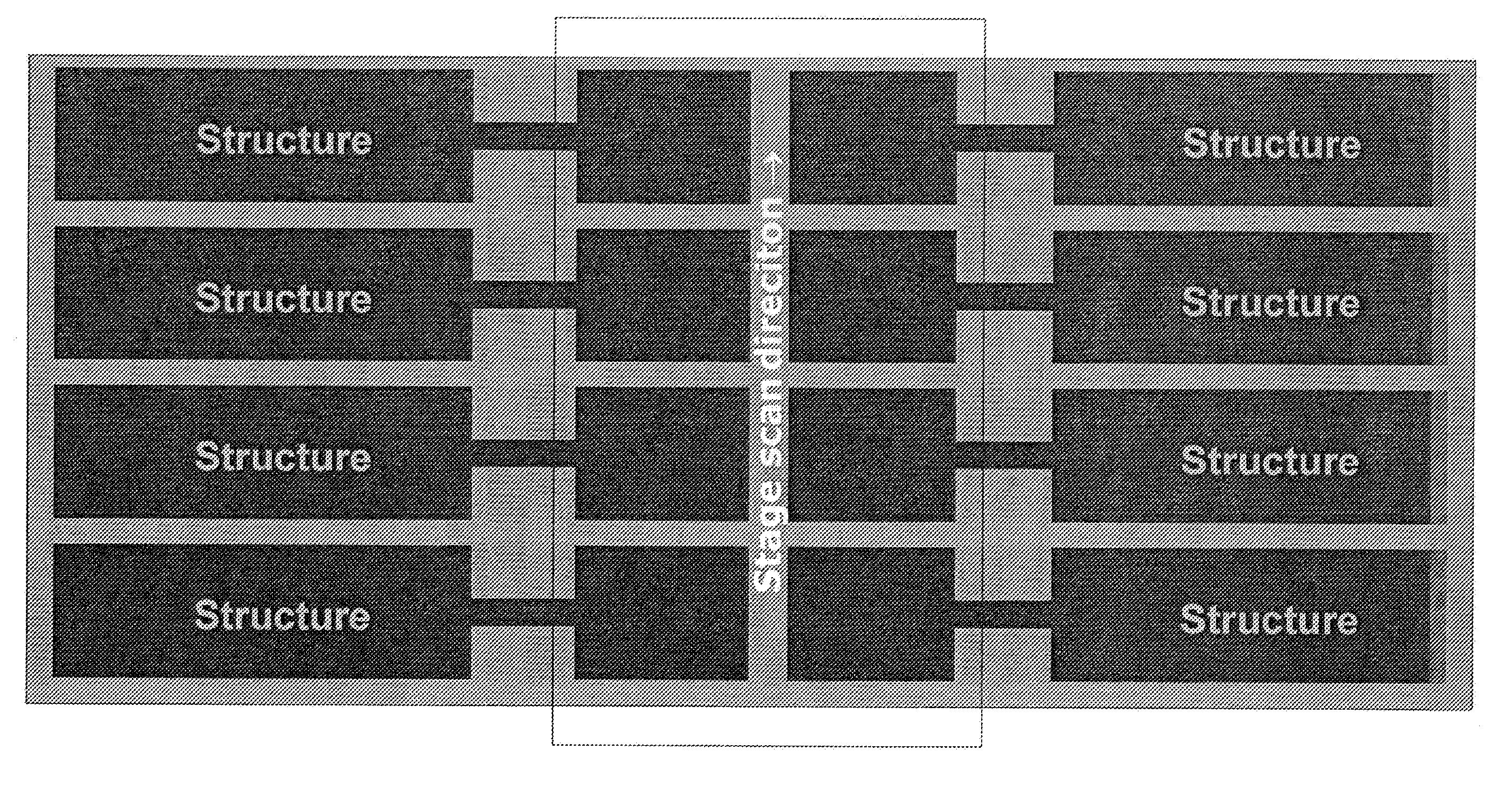

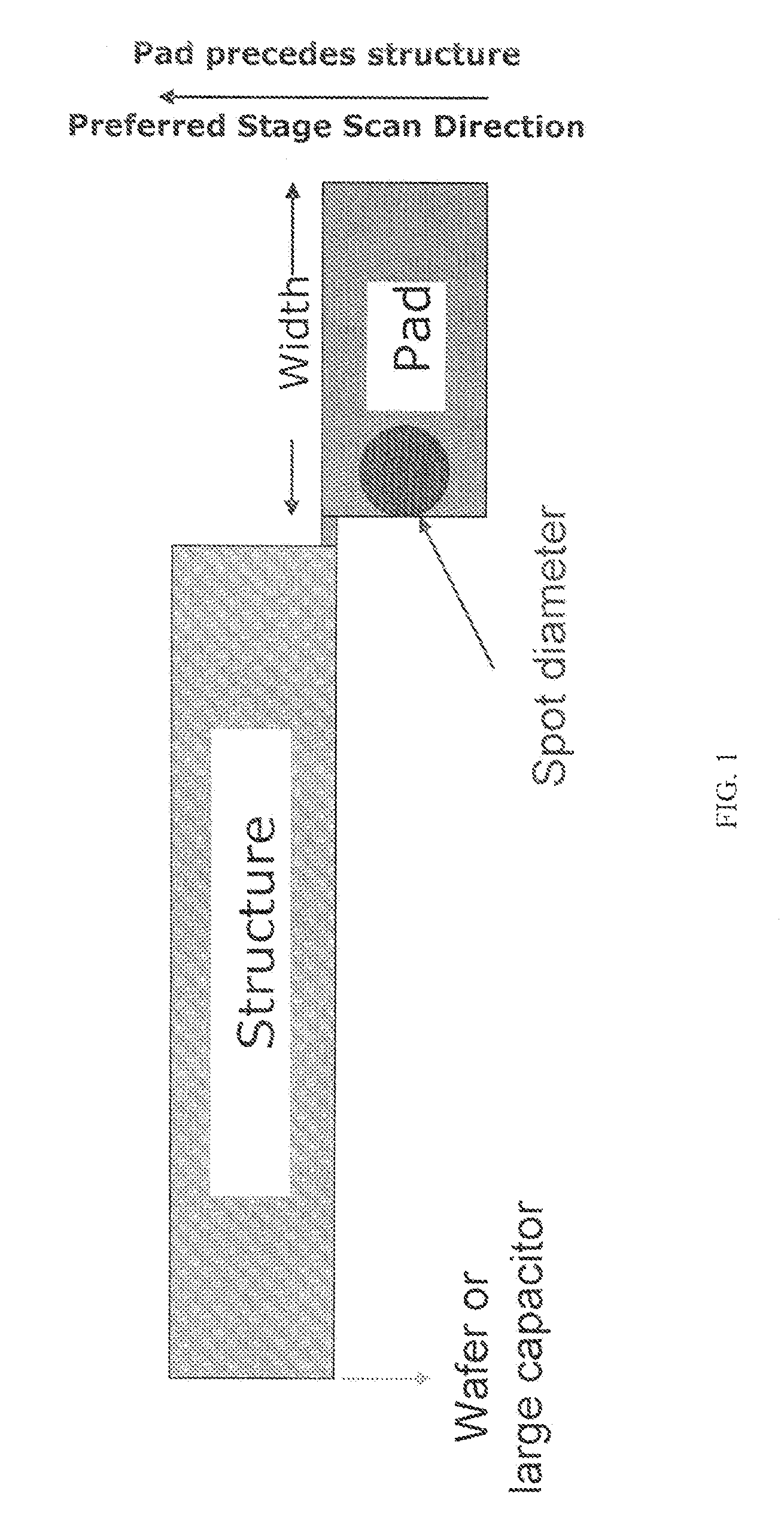

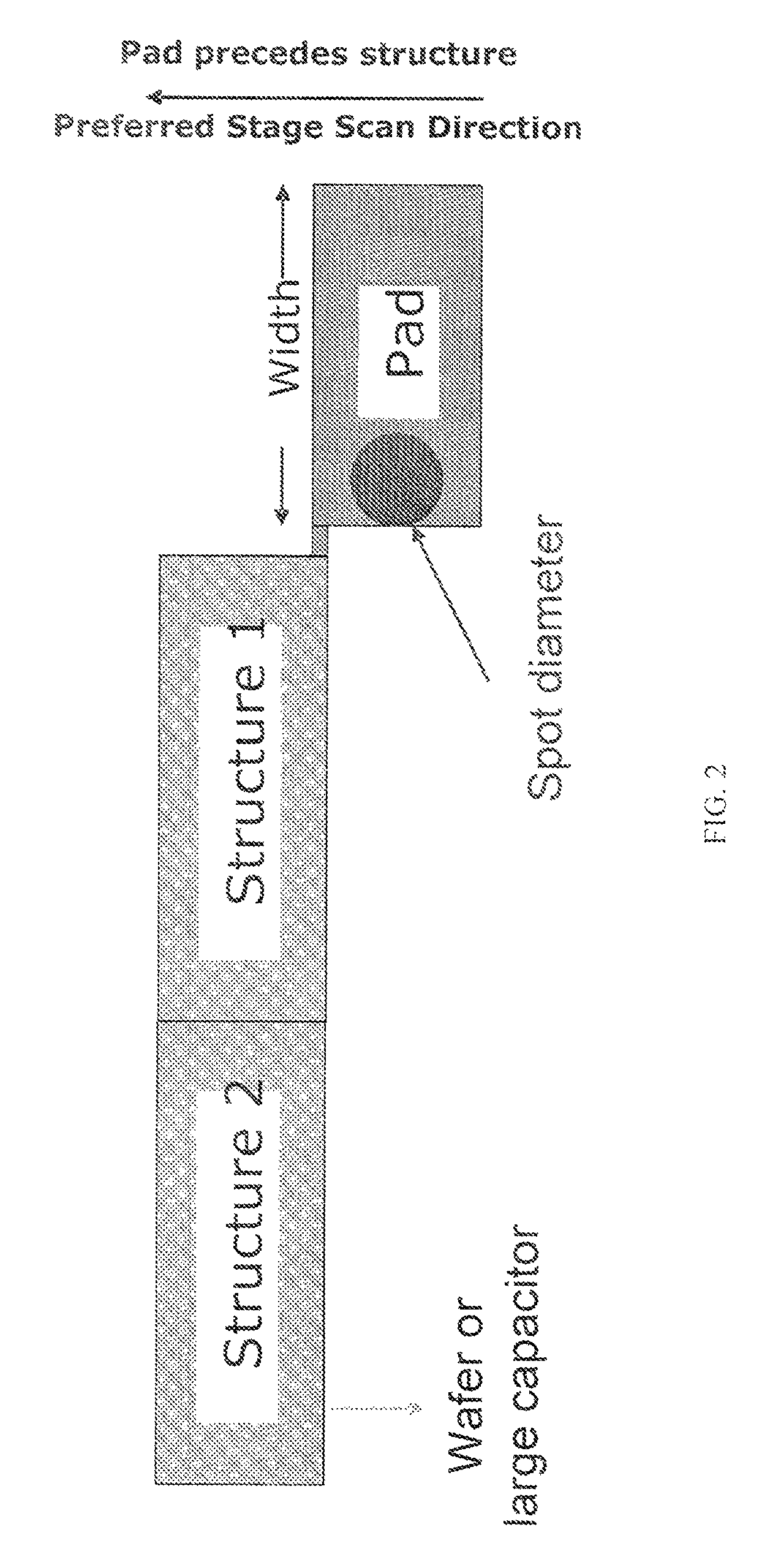

Apparatus and method for test structure inspection

ActiveUS7902849B2Semiconductor/solid-state device testing/measurementElectric discharge tubesElectrical resistance and conductanceRoot cause

Herein are described layouts of test structures and scanning methodologies that allow large probe currents to be used so as to allow the detection of resistive defects with a resistance lower than 1 MΩ while at the same time allowing a sufficient degree of localization to be obtained for root cause failure analysis. The detection of resistances lower than 1 MΩ nominally requires a probe current greater than 1 micro ampere for detection on an electron beam inspection system.

Owner:APPL MATERIALS ISRAEL LTD

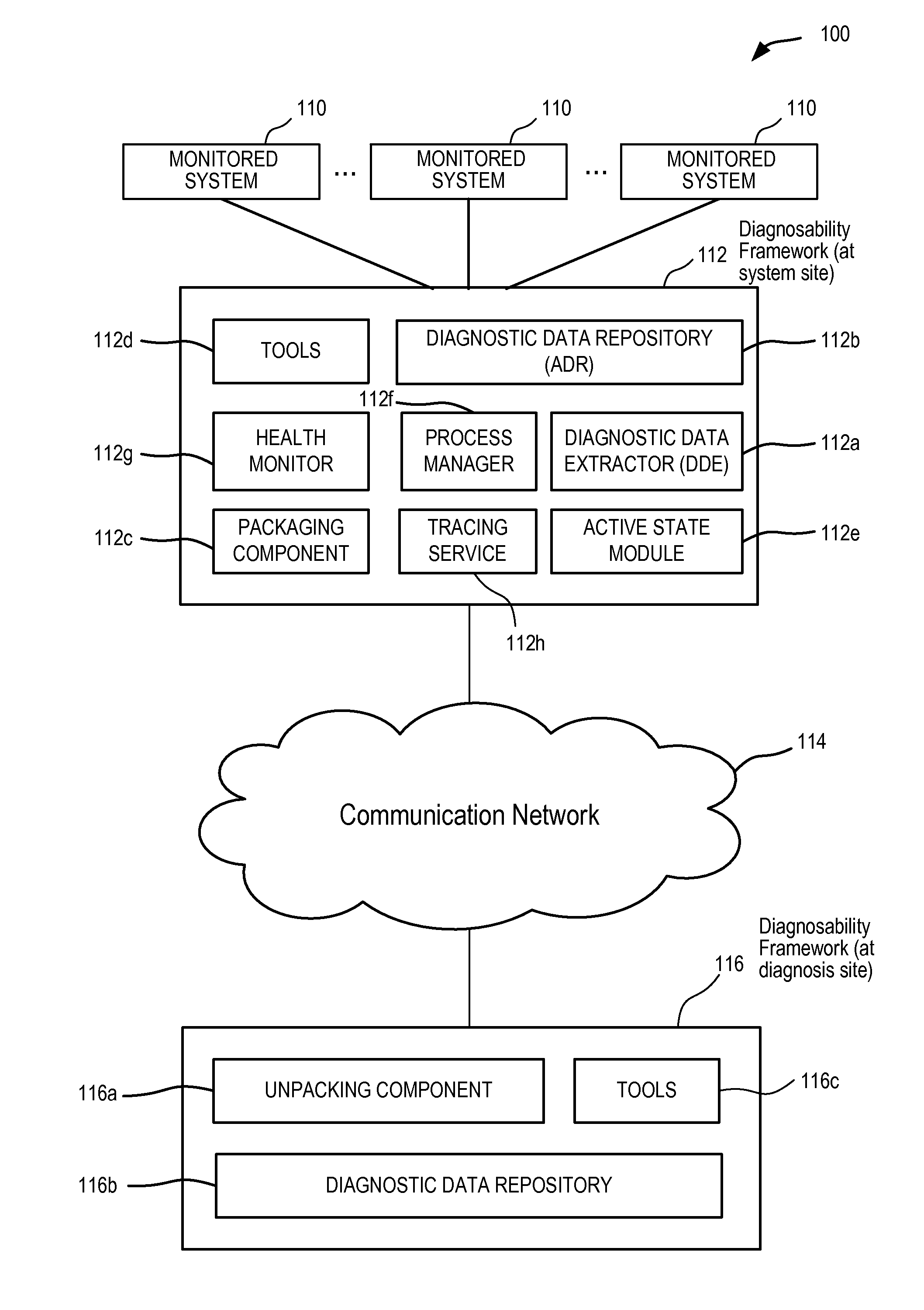

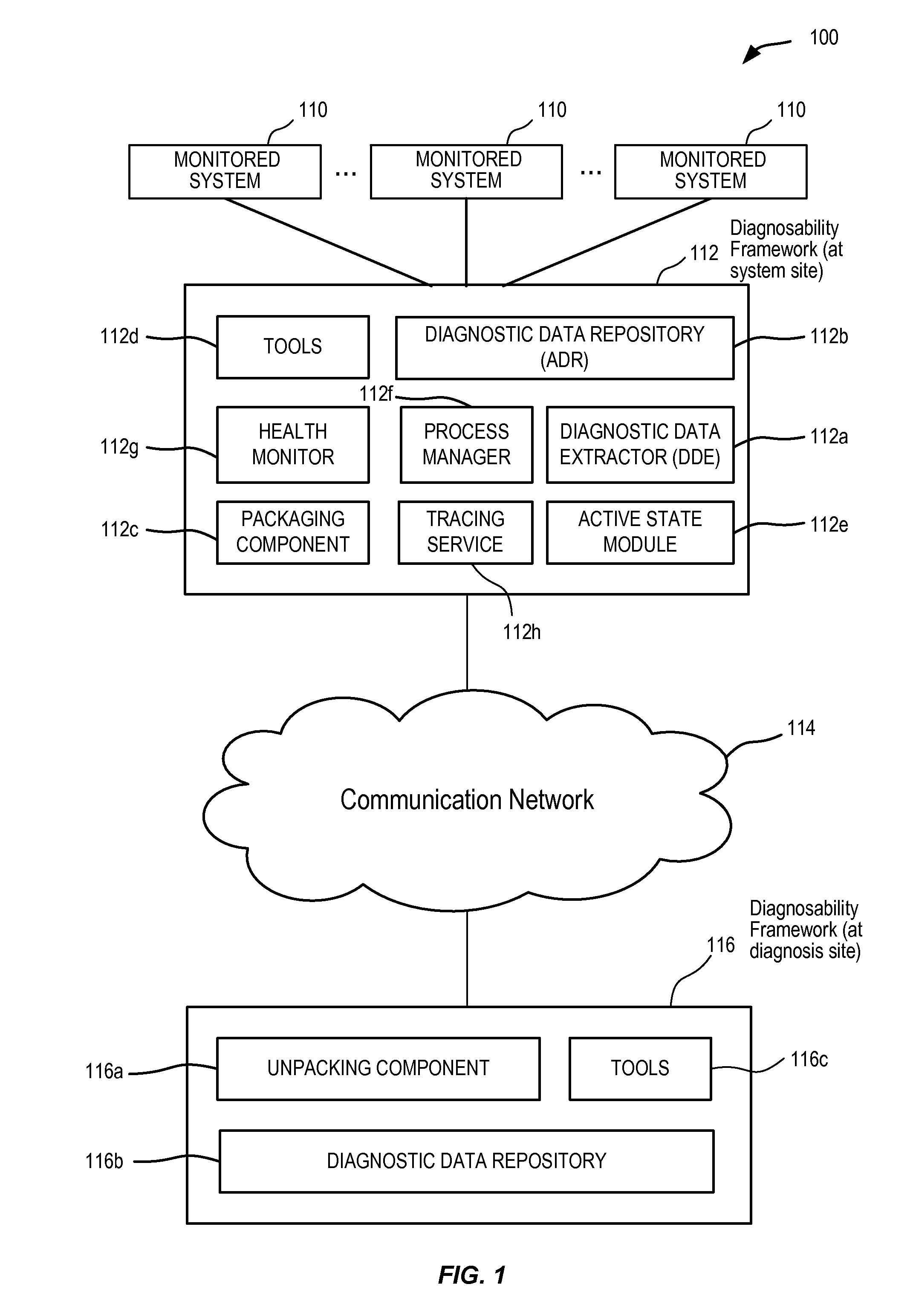

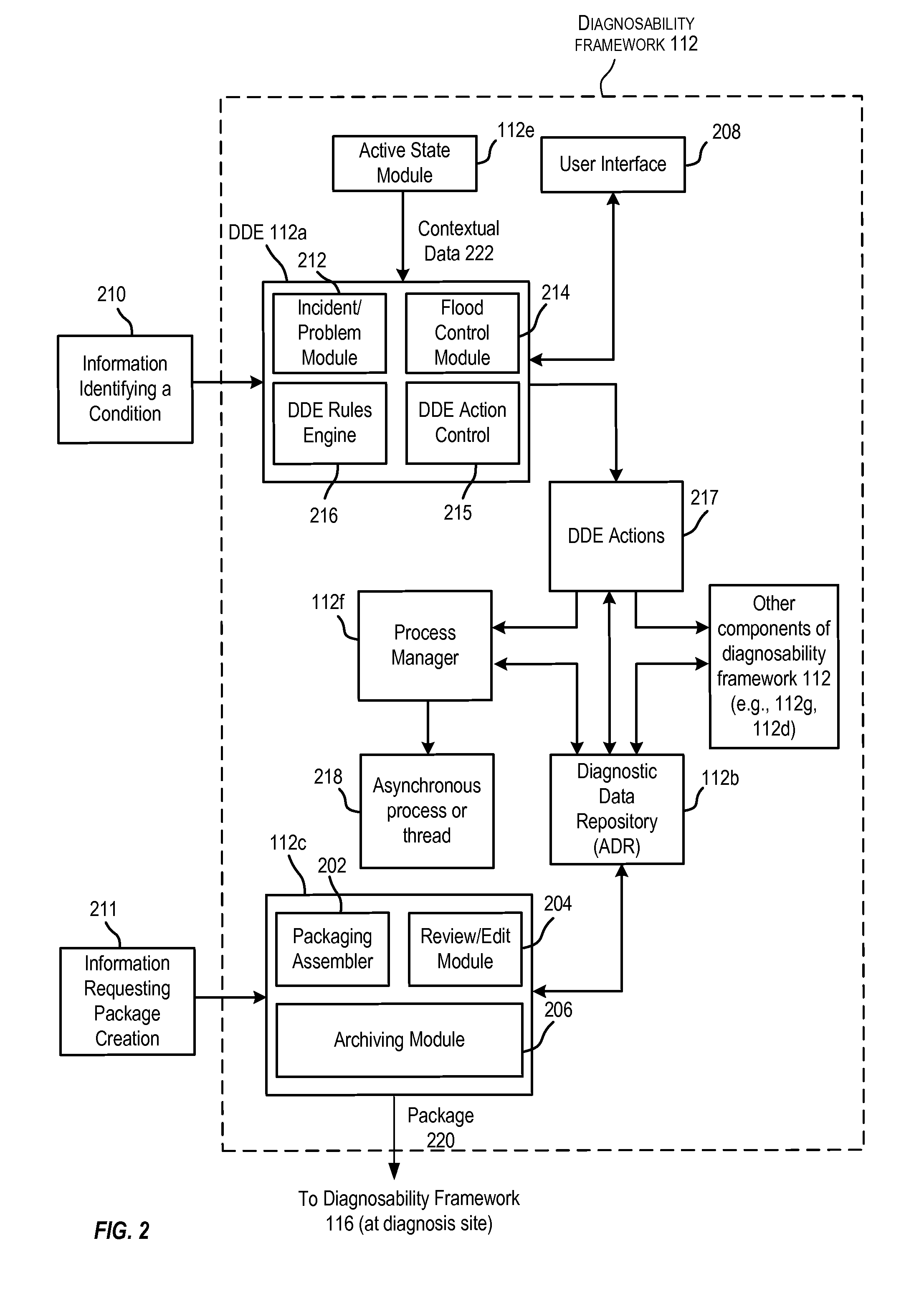

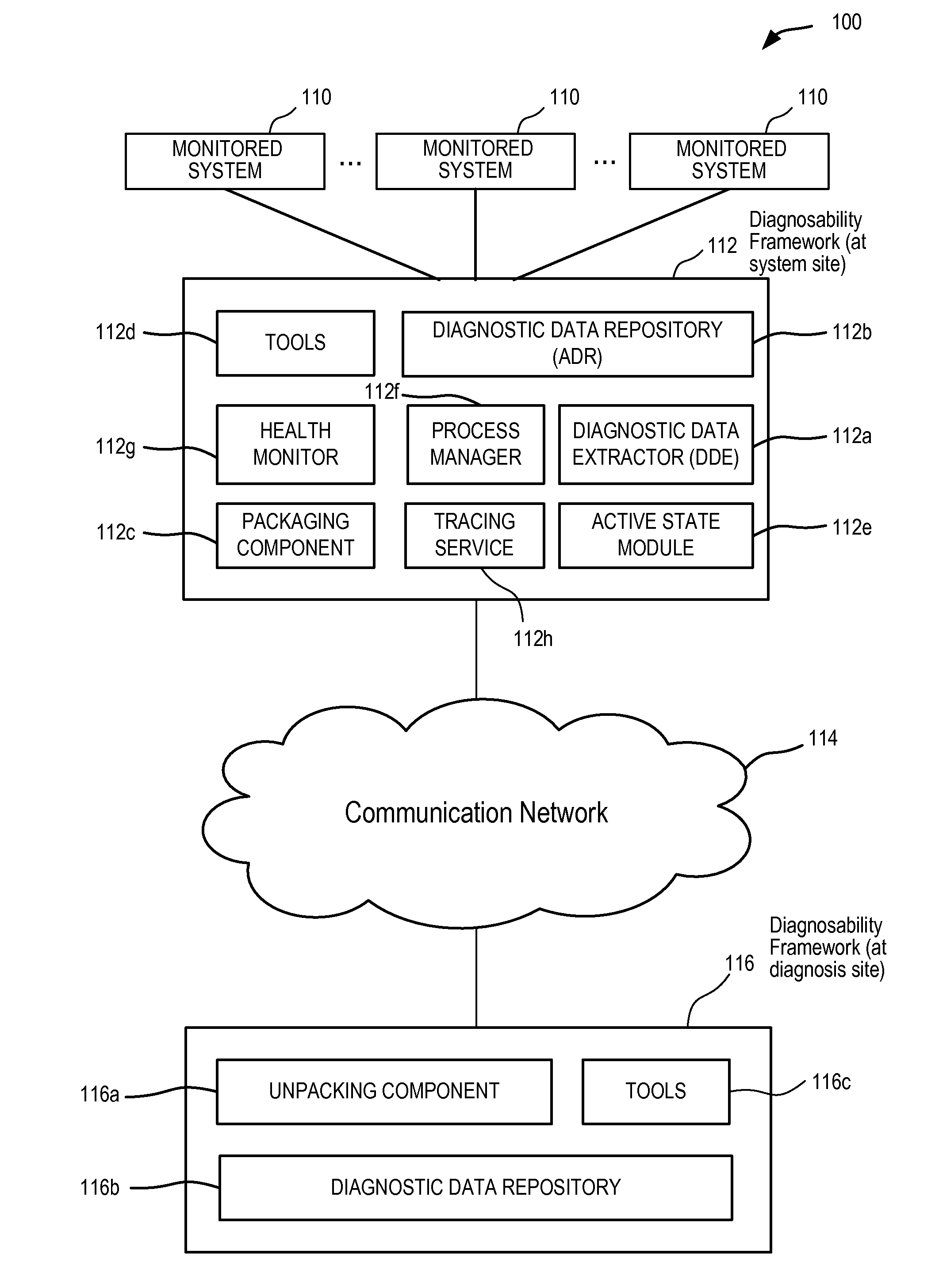

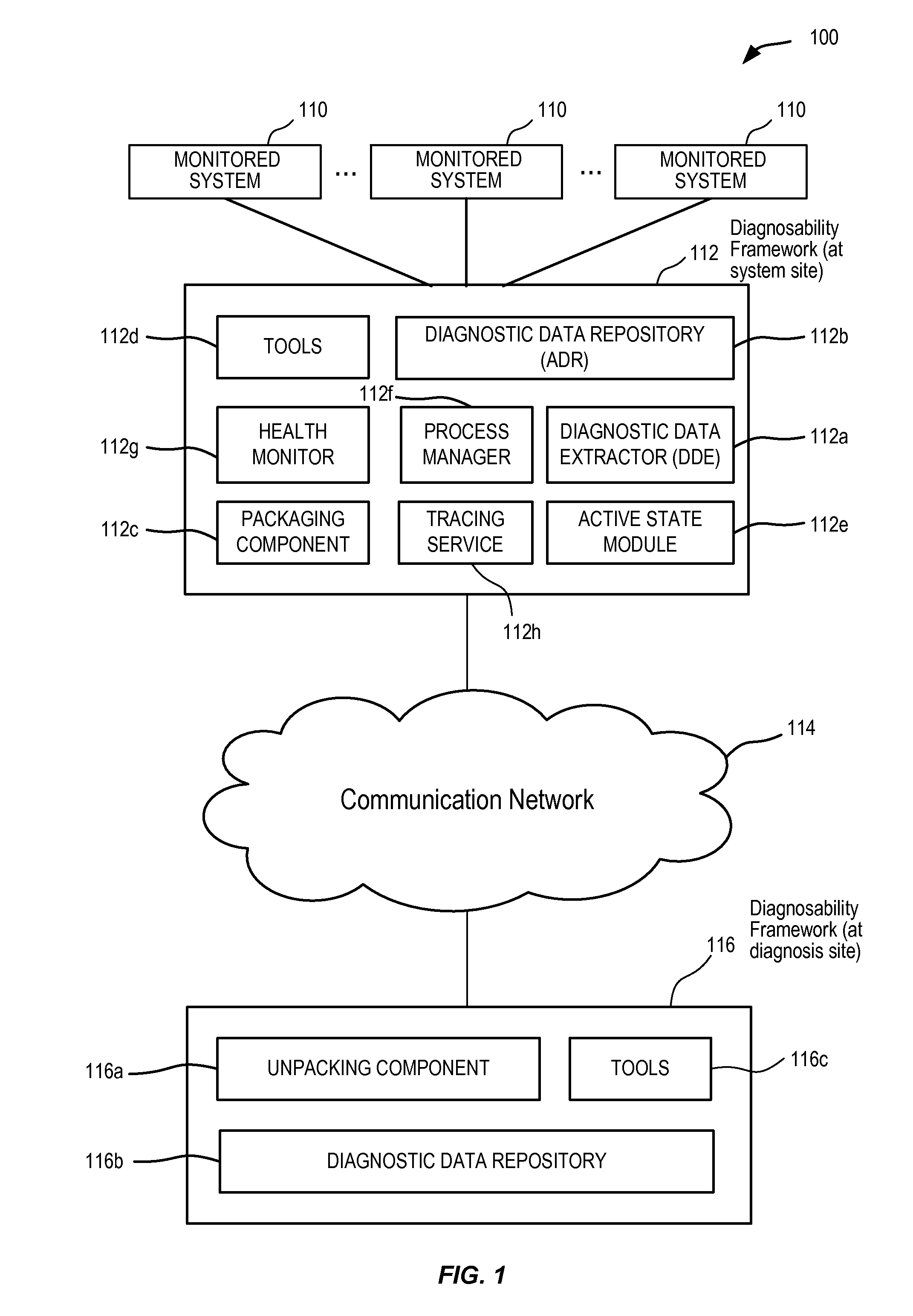

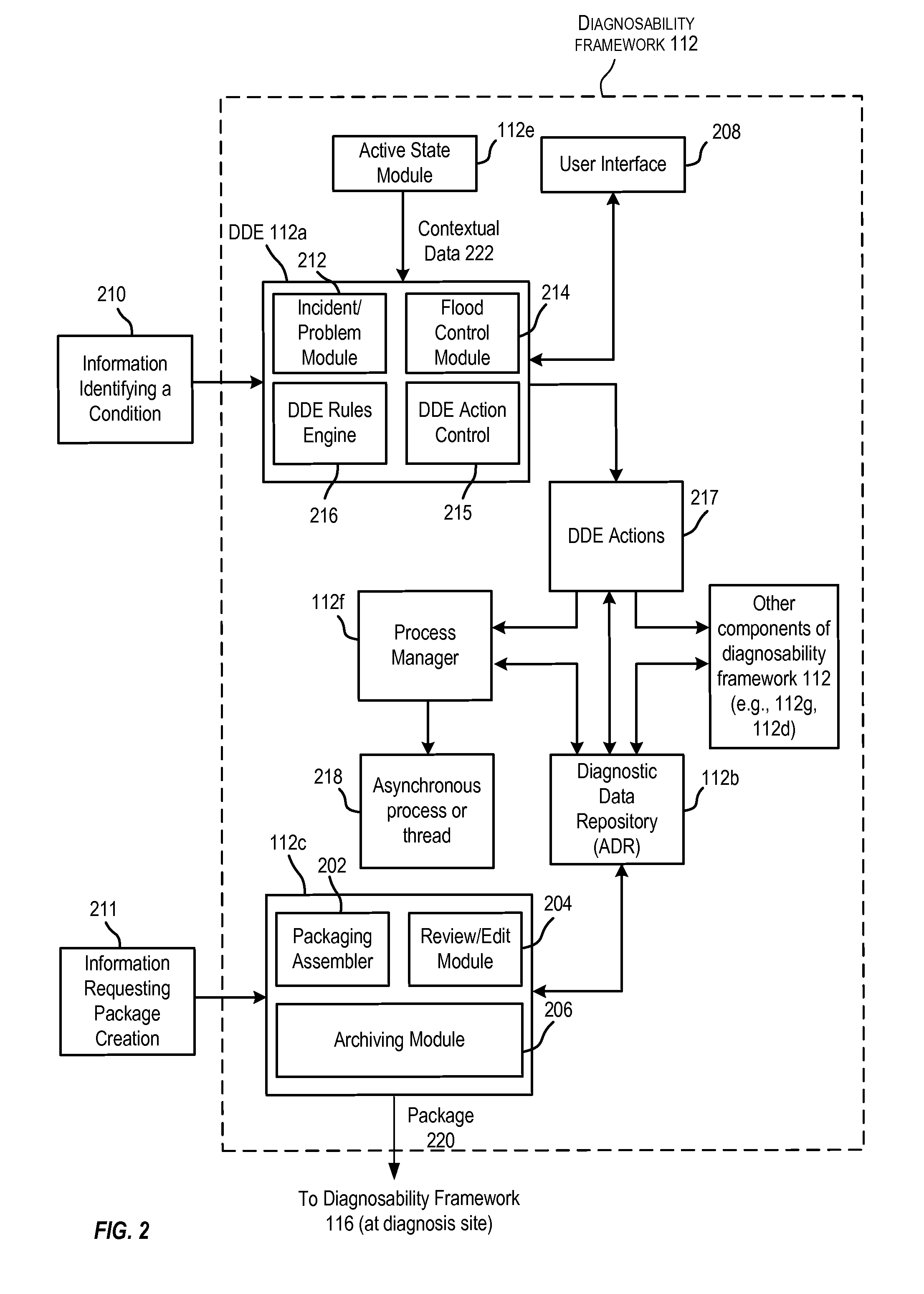

Diagnosability system

ActiveUS7937623B2Shorten the timeError detection/correctionTransmissionDiagnostic dataMonitoring system

A diagnosability system for automatically collecting, storing, communicating, and analyzing diagnostic data for one or more monitored systems. The diagnosability system comprises several components configured for the collection, storage, communication, and analysis of diagnostic data for a condition detected in monitored system. The diagnosability system enables targeted dumping of diagnostic data so that only diagnostic data that is relevant for diagnosing the condition detected in the monitored system is collected and stored. This in turn enables first failure analysis thereby reducing the time needed to resolve the condition detected in the monitored system.

Owner:ORACLE INT CORP

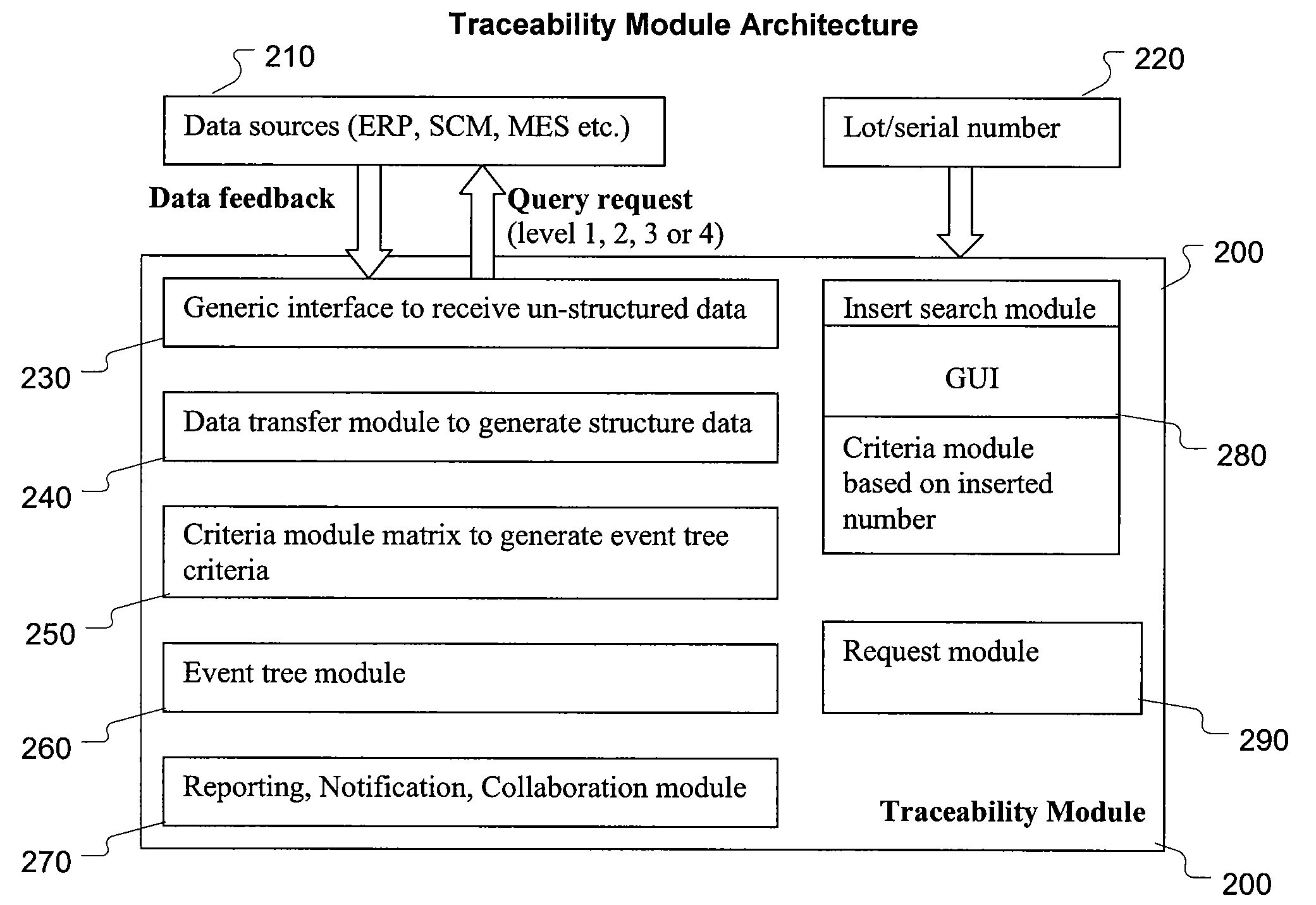

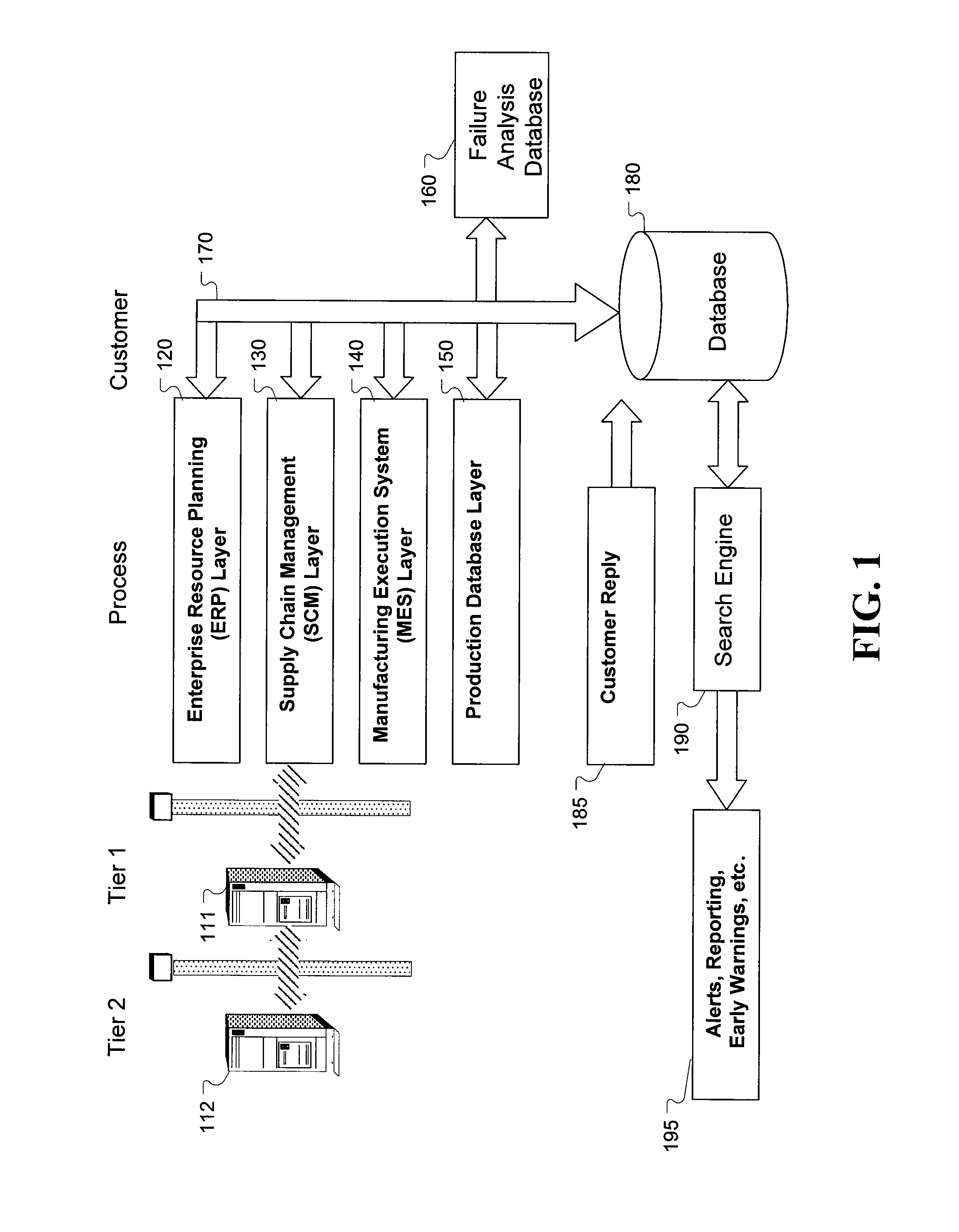

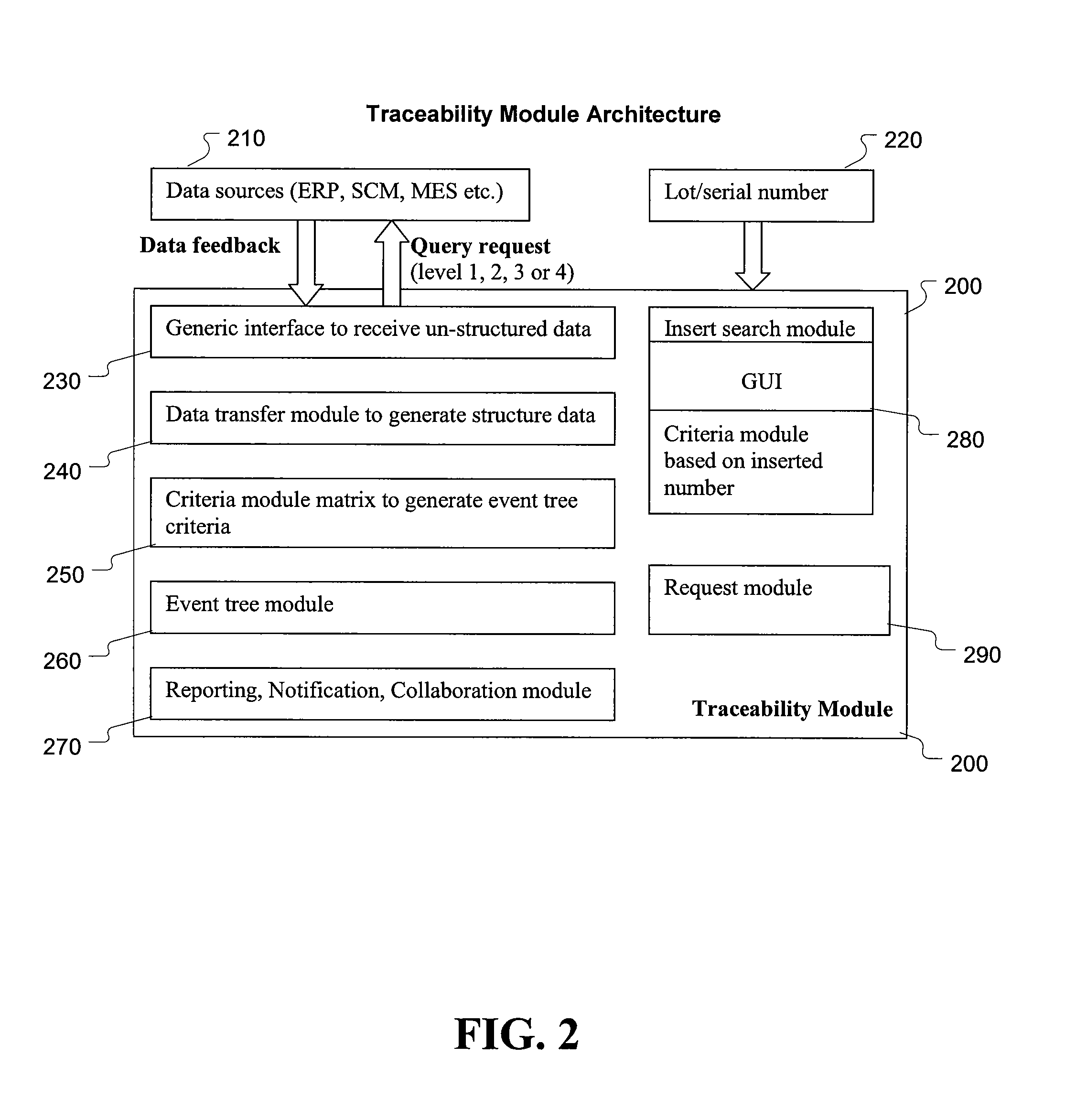

Search engine to improve product recall traceability activities

InactiveUS20090254535A1Avoid damageIncrease costWeb data indexingDigital data processing detailsTime rangeHuman search engine

The present invention provides an improved method of handling product recall activities through traceability. One embodiment of the present invention involves gathering data in a multi-layered database architecture containing supply, process, test, and customer layers. The data is supplied to a traceability module which contains a search engine to link and access the data. The search engine enables a search by part number, lot number, serial number, time stamp, and date / time frame. A traceability analysis is generated from the search, allowing failure analysis of the data. This analysis is performed through an event list over the entire supply, manufacturing, and customer data, facilitating backward and forward traceability of parts and components of the parts. This failure analysis further facilitates automatic response such as automatic warning and automatic recall to manufacturers and customers.

Owner:IBM CORP

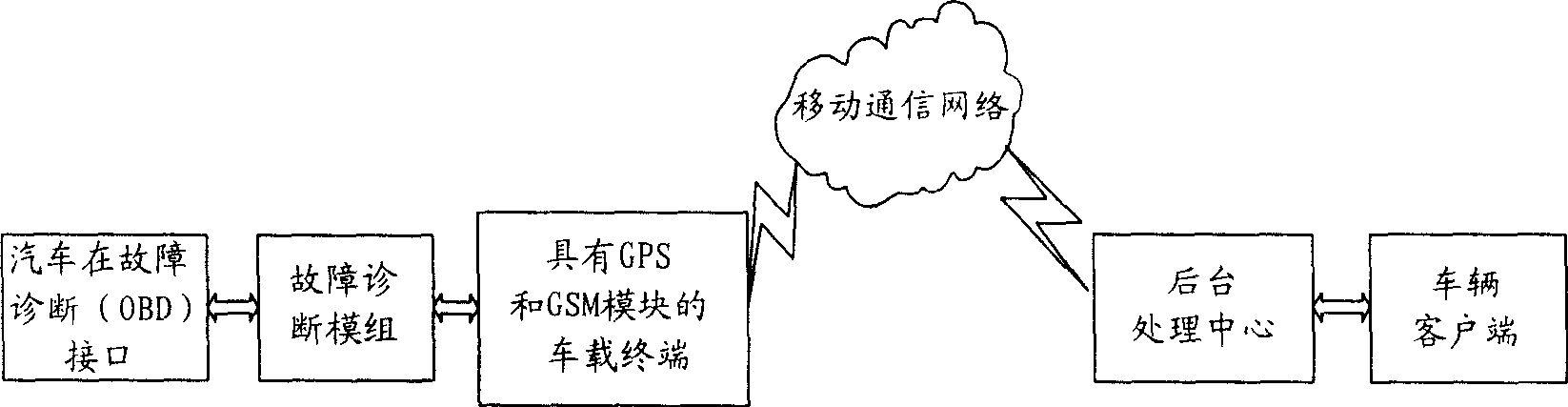

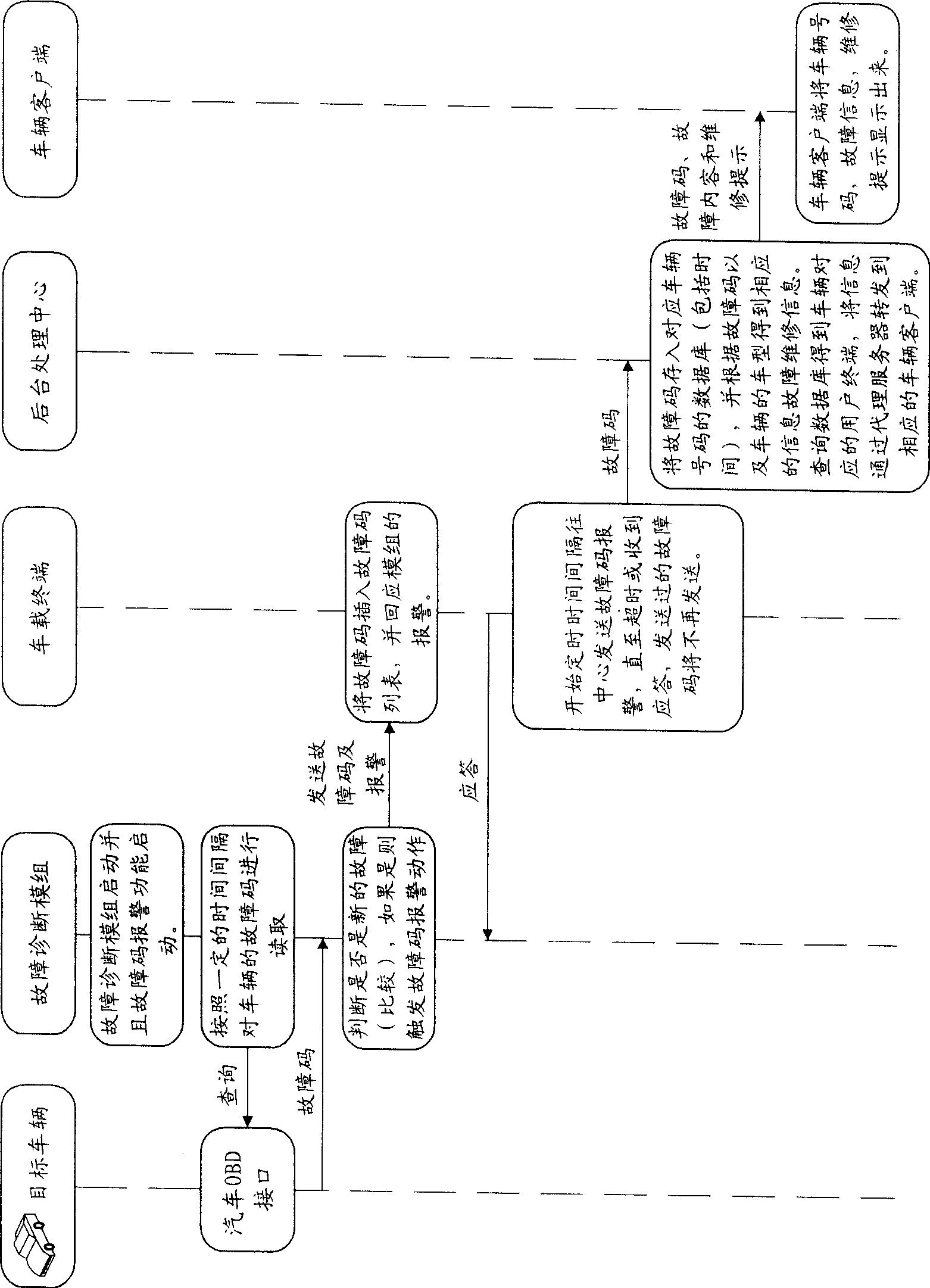

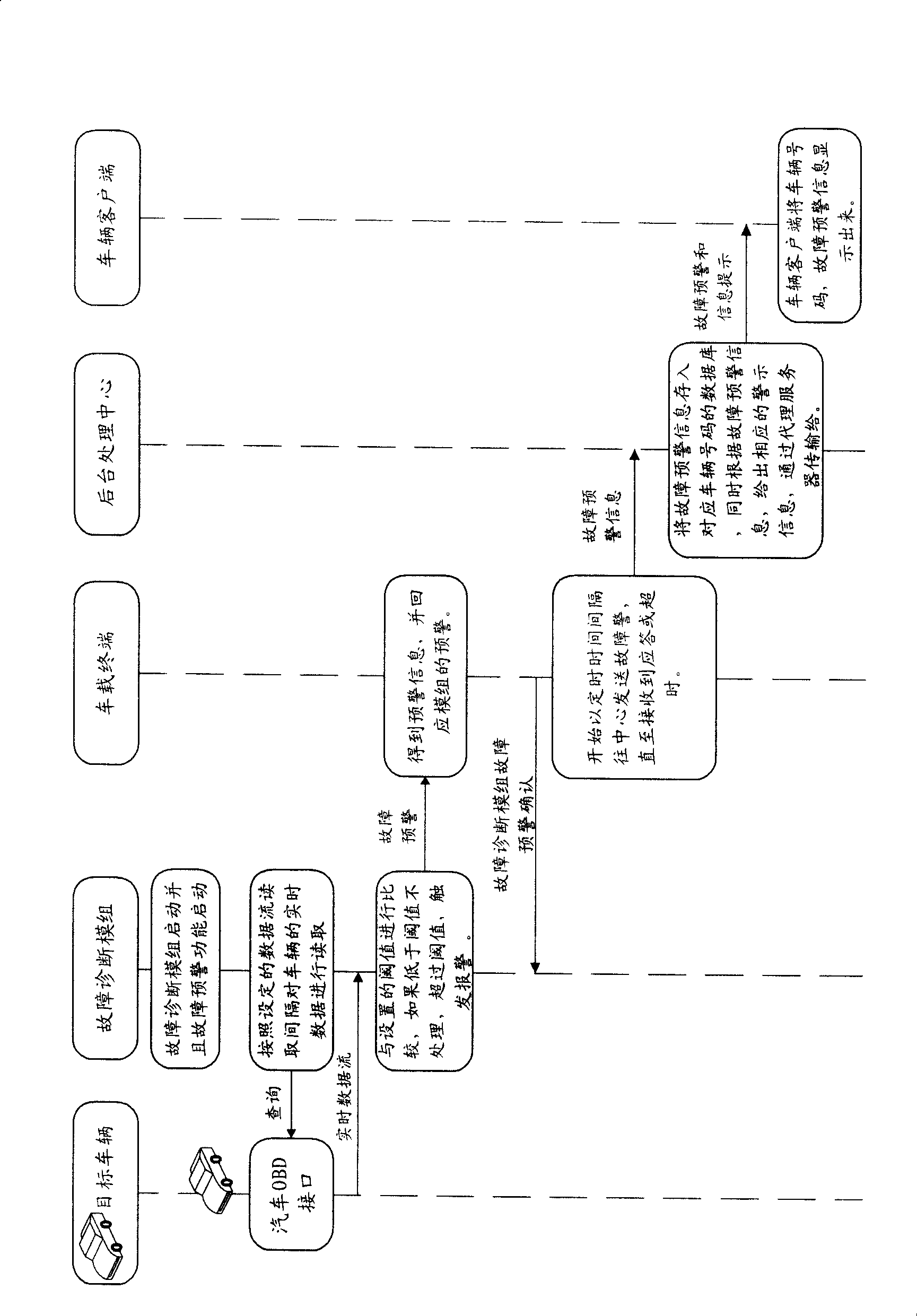

Method for implementing real-time vehicle remote fault analysis through GPS positioning and mobile communication

The present invention relates to a method for realizing real-time remote malfunction analysis of vehicle through GPS positioning and mobile communication. When a failure code is generated or a certain data flow exceeds the preset threshold value, warning information is generated and is transmitted to the vehicle-mounted terminal with GPS positioning and mobile communication functions through serial-port communication. The vehicle-mounted terminal can transmit the warning information transmitted by the present failure analysis module and present vehicle position to a background processing center through mobile communication network. The background processing center transmits the failure information and position information through a proxy server and displays the interface of vehicle client. The invention breaks through the wired mode of traditional hand-holding vehicle failure diagnostic device, real-time monitors the vehicle condition with the mobile communication network, and transmits the failure information to the background processing center and vehicle client.

Owner:XIAMEN YAXON NETWORKS CO LTD

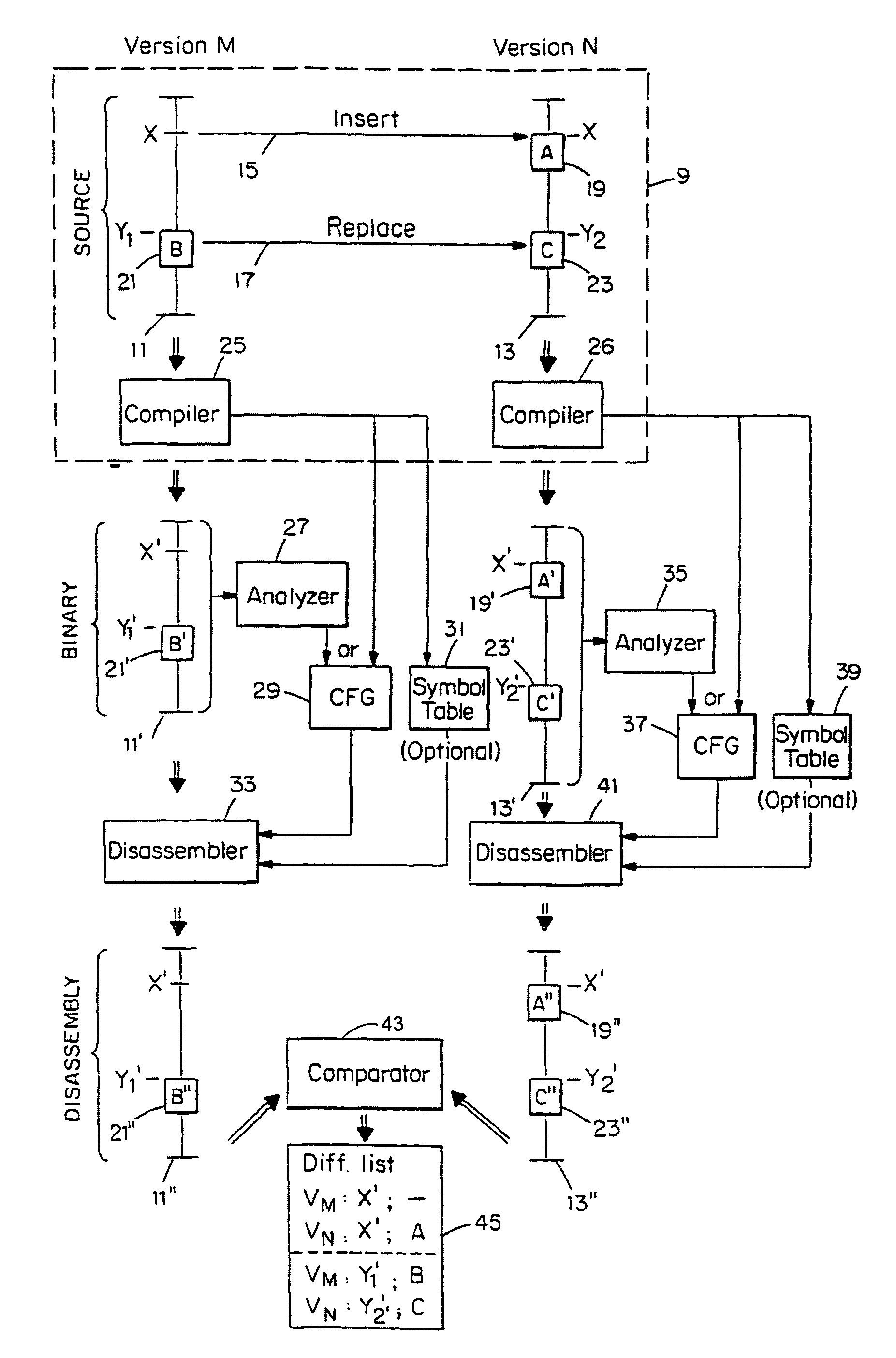

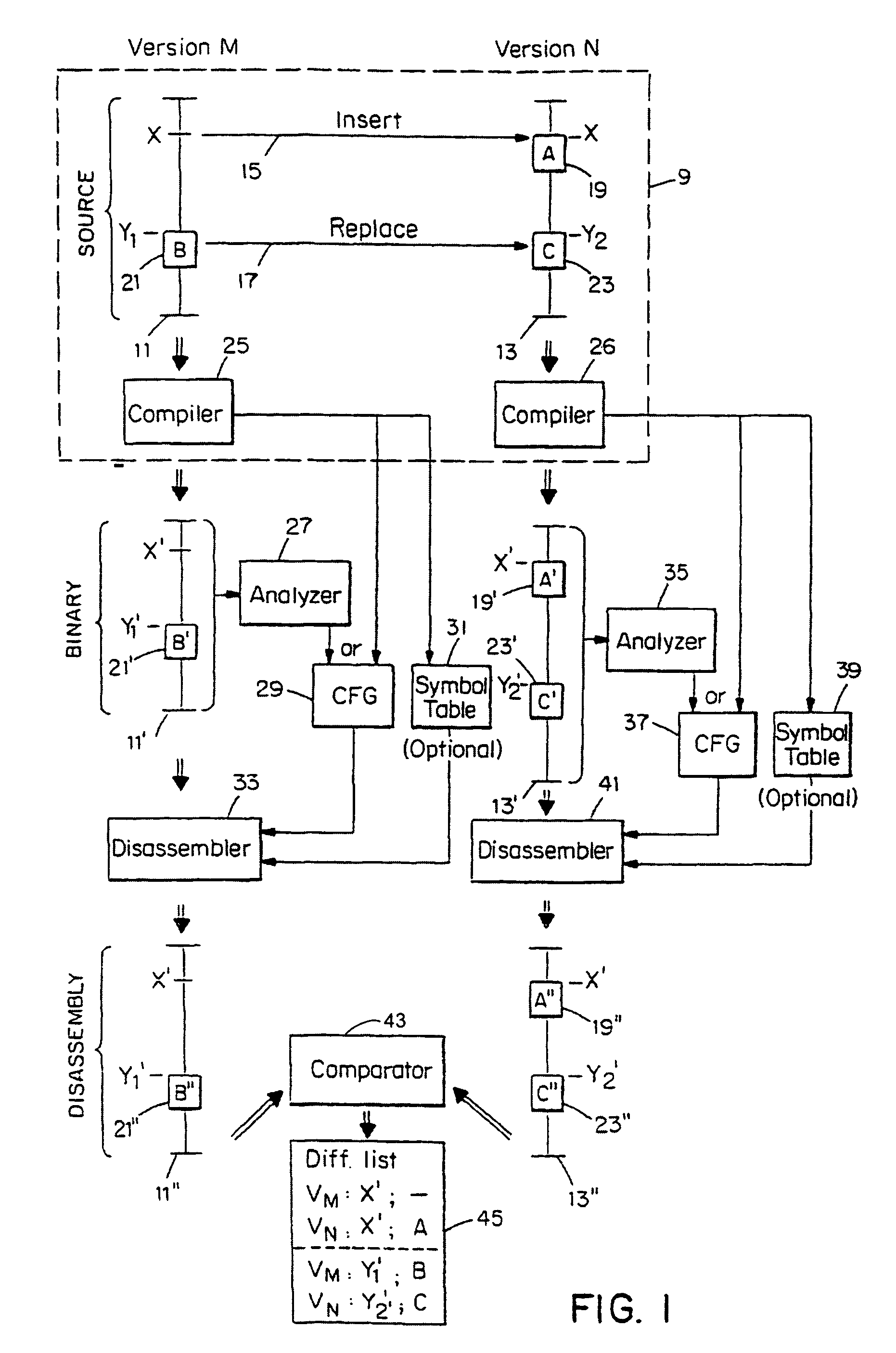

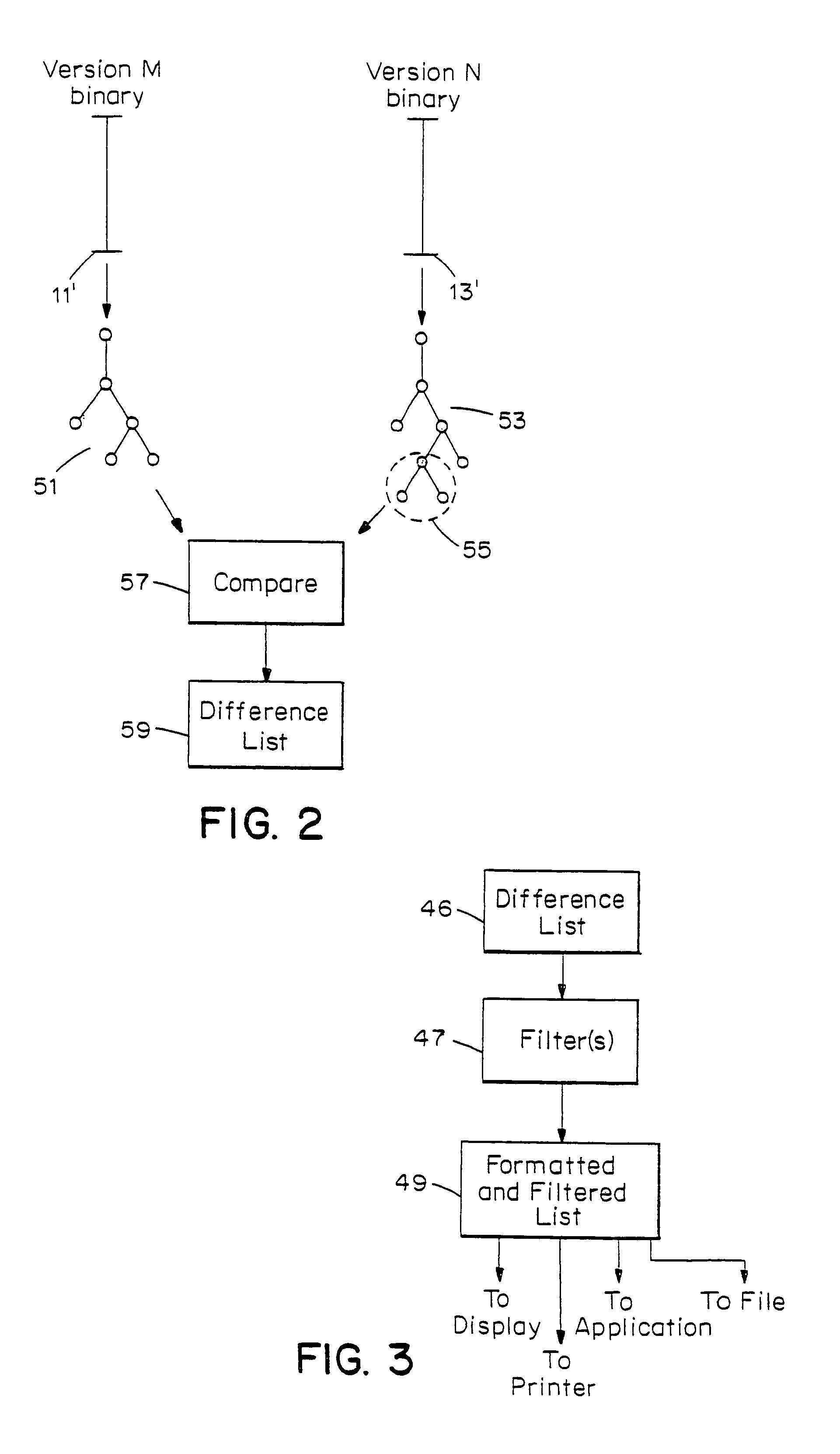

Method for determining the degree to which changed code has been exercised

InactiveUS7296261B2Find exactlyVersion controlSpecific program execution arrangementsControl flowDifference list

A method for determining changed code in a second program binary relative to a first or baseline program binary, where the second program is a different version of the first program, includes translating, responsive to symbol tables and / or control flow representations, machine addresses of both program binaries to symbols. The first and second program binaries are disassembled using the translated symbols. Differences between the two resulting disassemblies are determined, and a list of the differences is created. Differences between the program binaries can be determined by textually comparing the disassemblies, or alternatively, by determining the differences between the control flow representations of the programs. The list of differences can be presented to a user, or alternatively, can be passed to another process for further processing, such as test coverage analysis, code change analysis, or failure analysis, among other analyses.

Owner:CA TECH INC

Diagnosability system

ActiveUS20090106278A1Shorten the timeHardware monitoringTransmissionDiagnostic dataMonitoring system

A diagnosability system for automatically collecting, storing, communicating, and analyzing diagnostic data for one or more monitored systems. The diagnosability system comprises several components configured for the collection, storage, communication, and analysis of diagnostic data for a condition detected in monitored system. The diagnosability system enables targeted dumping of diagnostic data so that only diagnostic data that is relevant for diagnosing the condition detected in the monitored system is collected and stored. This in turn enables first failure analysis thereby reducing the time needed to resolve the condition detected in the monitored system.

Owner:ORACLE INT CORP

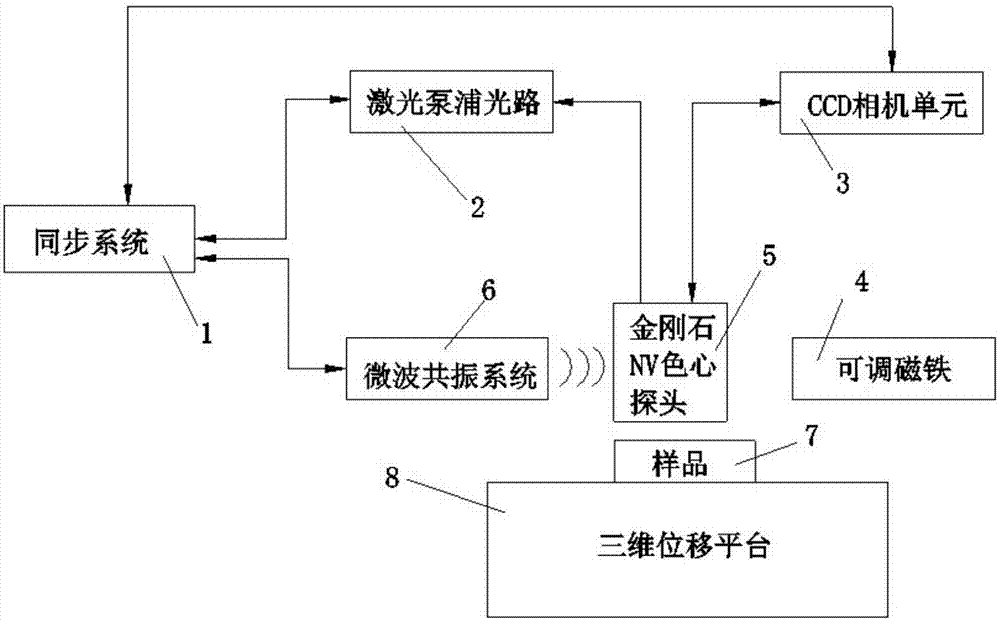

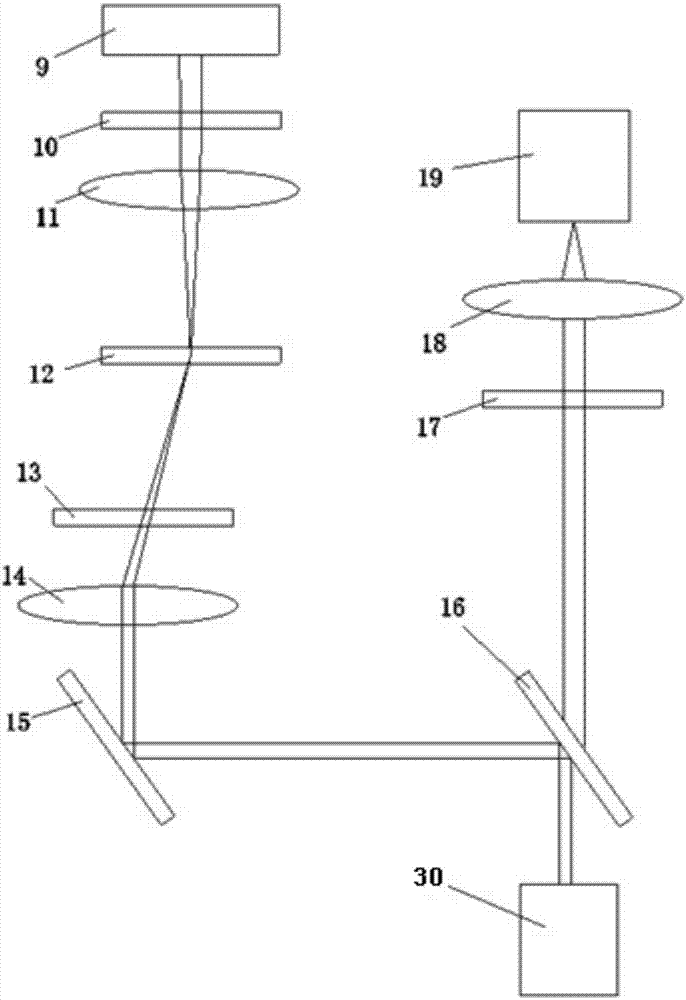

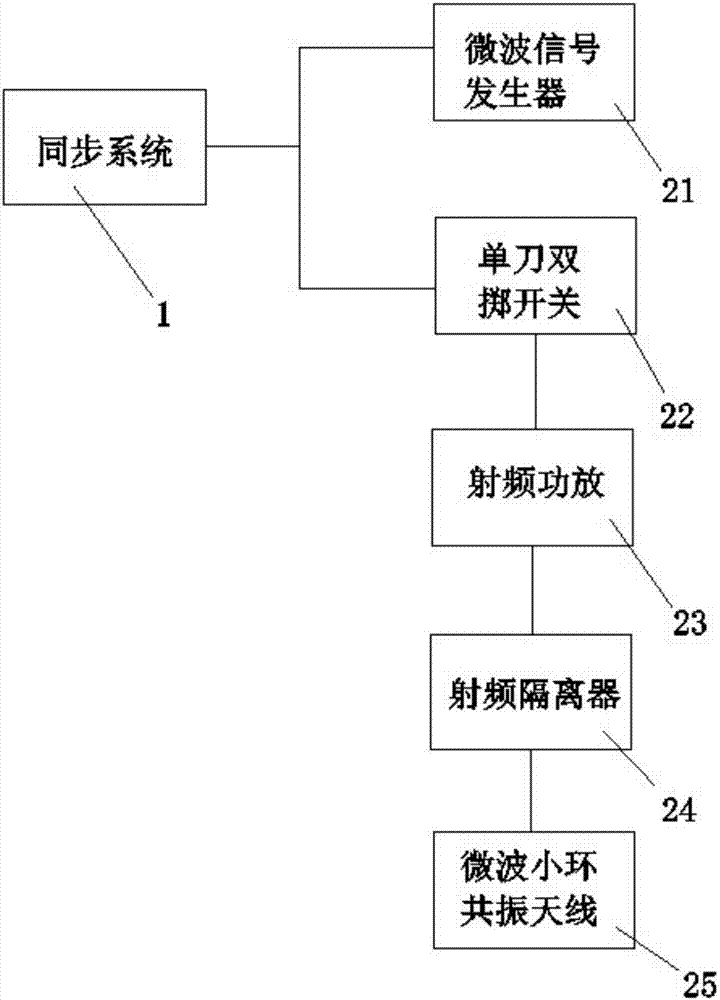

Electromagnetic field near-field imaging system and method based on pulsed light detection magnetic resonance

InactiveCN107356820ASimple structureLow costAnalysis using nuclear magnetic resonanceElectromagentic field characteristicsHigh resolution imagingSingle crystal

The invention discloses an electromagnetic field near-field imaging system and method based on pulsed light detection magnetic resonance. The system consists of a laser pump optical path, a microwave source, a diamond NV color-center probe, a CCD camera unit, a synchronization system, a displacement scanning platform, control software and a data analysis imaging system. In the system, a large diamond single crystal containing the NV color-center is used as a detection unit, a static magnetic field is used to split a magnetic resonance peak of the diamond NV color-center into eight peaks, the eight resonance peaks correspond to four crystal axis directions <111>, <1-11>, <-111>, <11-1> of a diamond lattice structure, by measuring the Rabi frequency of each resonance peak, the strength of a circularly polarized microwave field perpendicular to the corresponding crystal axis direction is obtained, and through comprehensive calculation of the microwave field strengths in the four directions, the strength and direction of a microwave vector are then reconstructed. Through the microwave near-field high-resolution imaging of a local region of a microwave chip under measurement, the quantitative data can be provided for the failure analysis of the chip.

Owner:南京昆腾科技有限公司

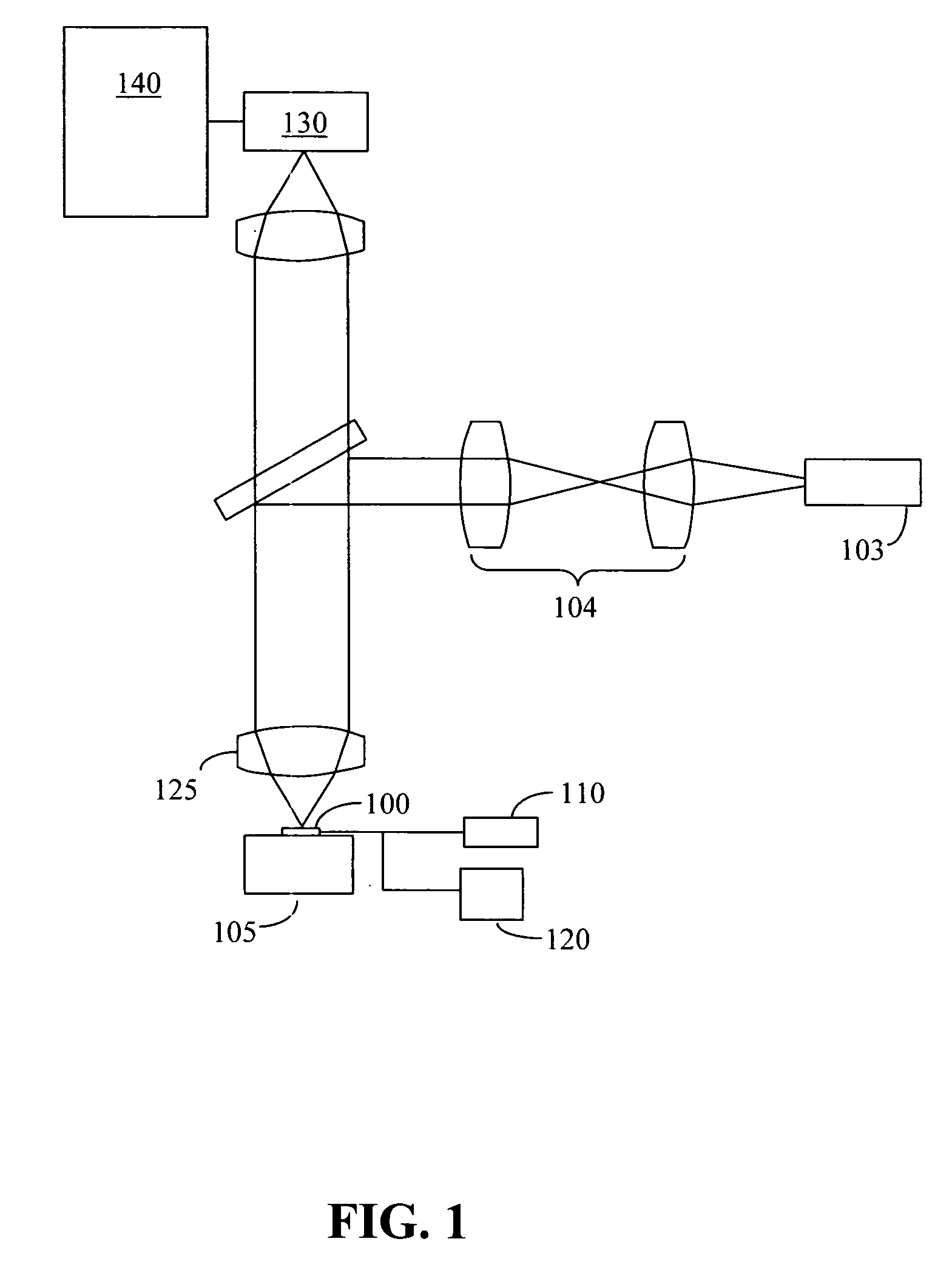

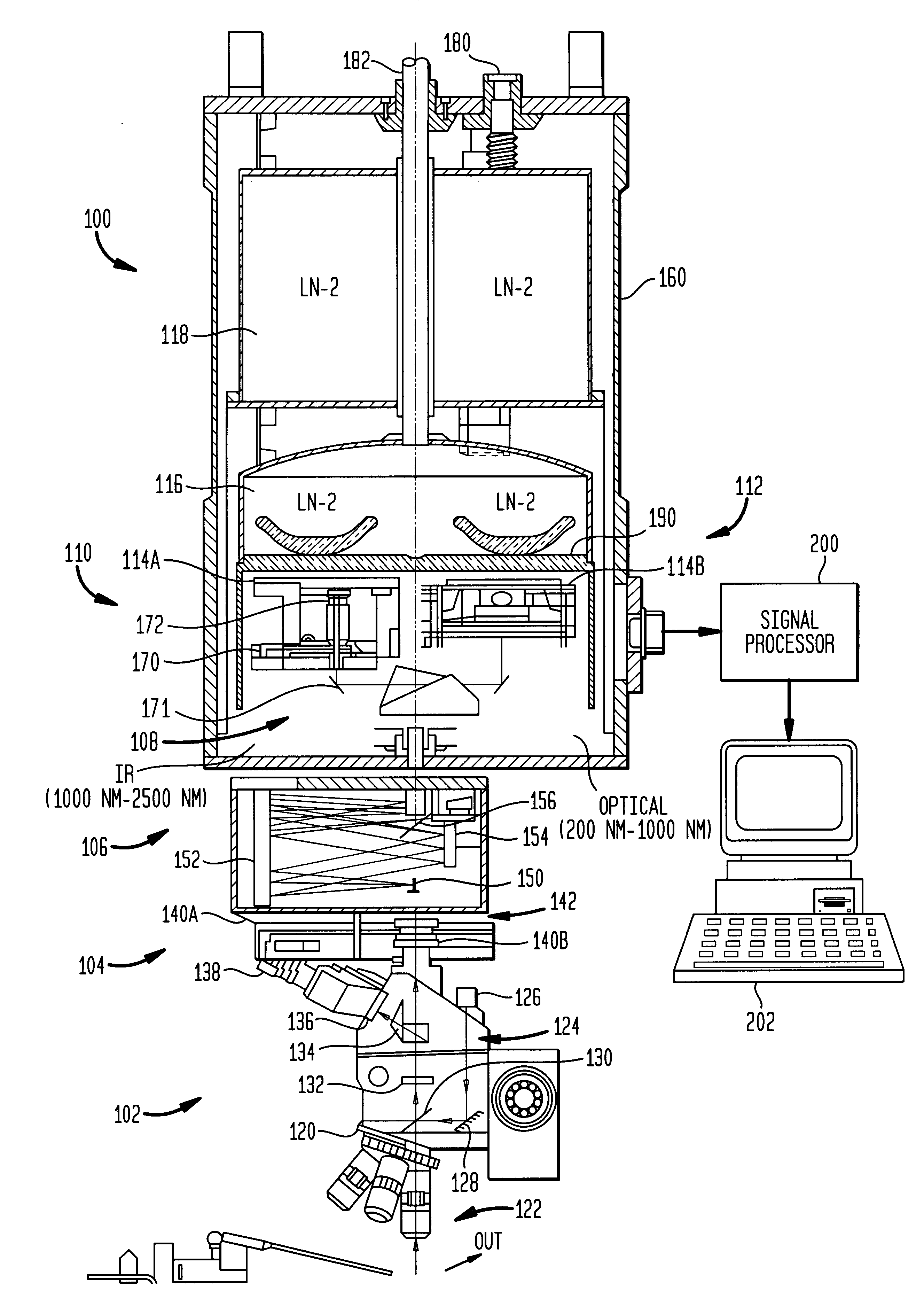

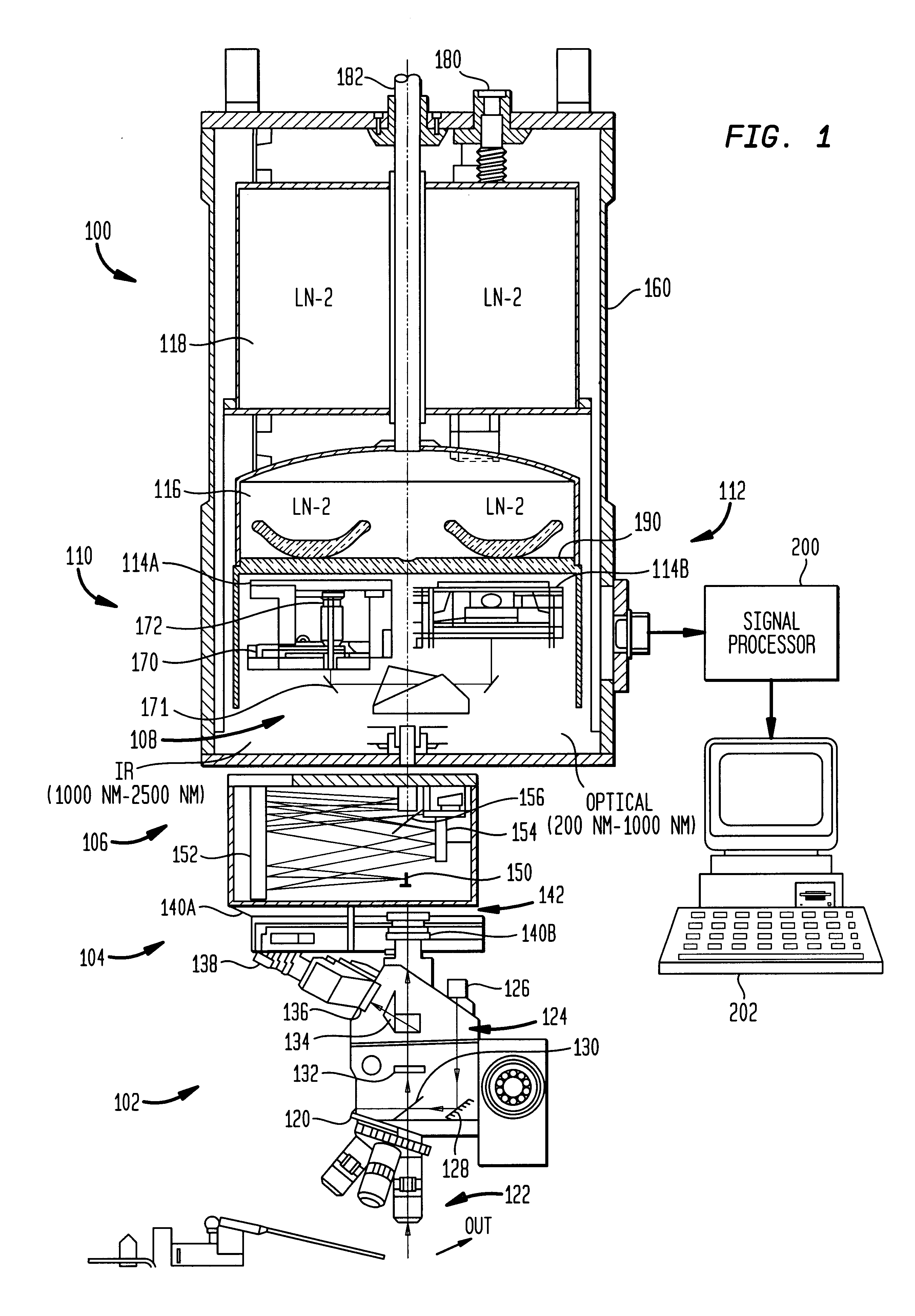

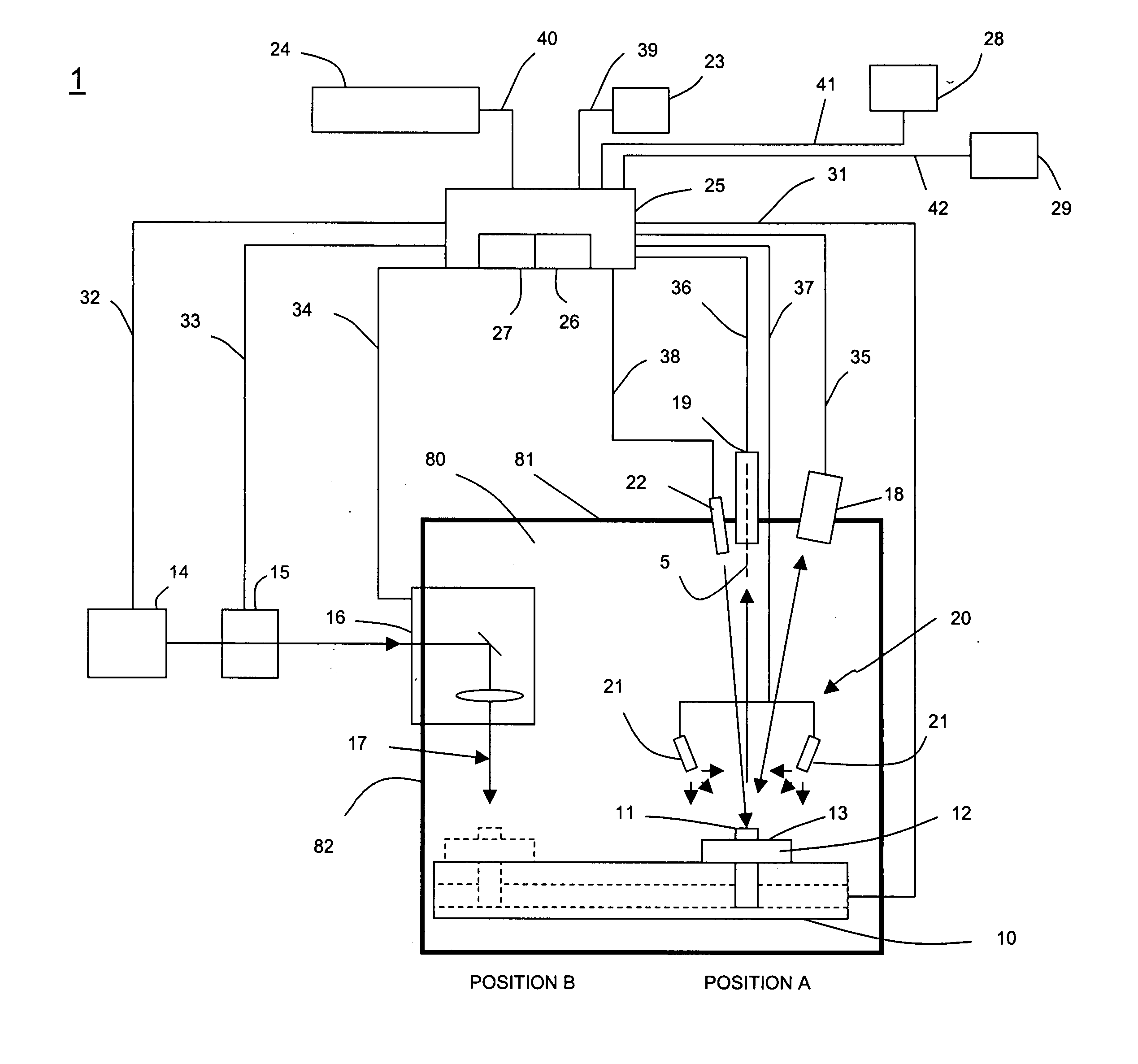

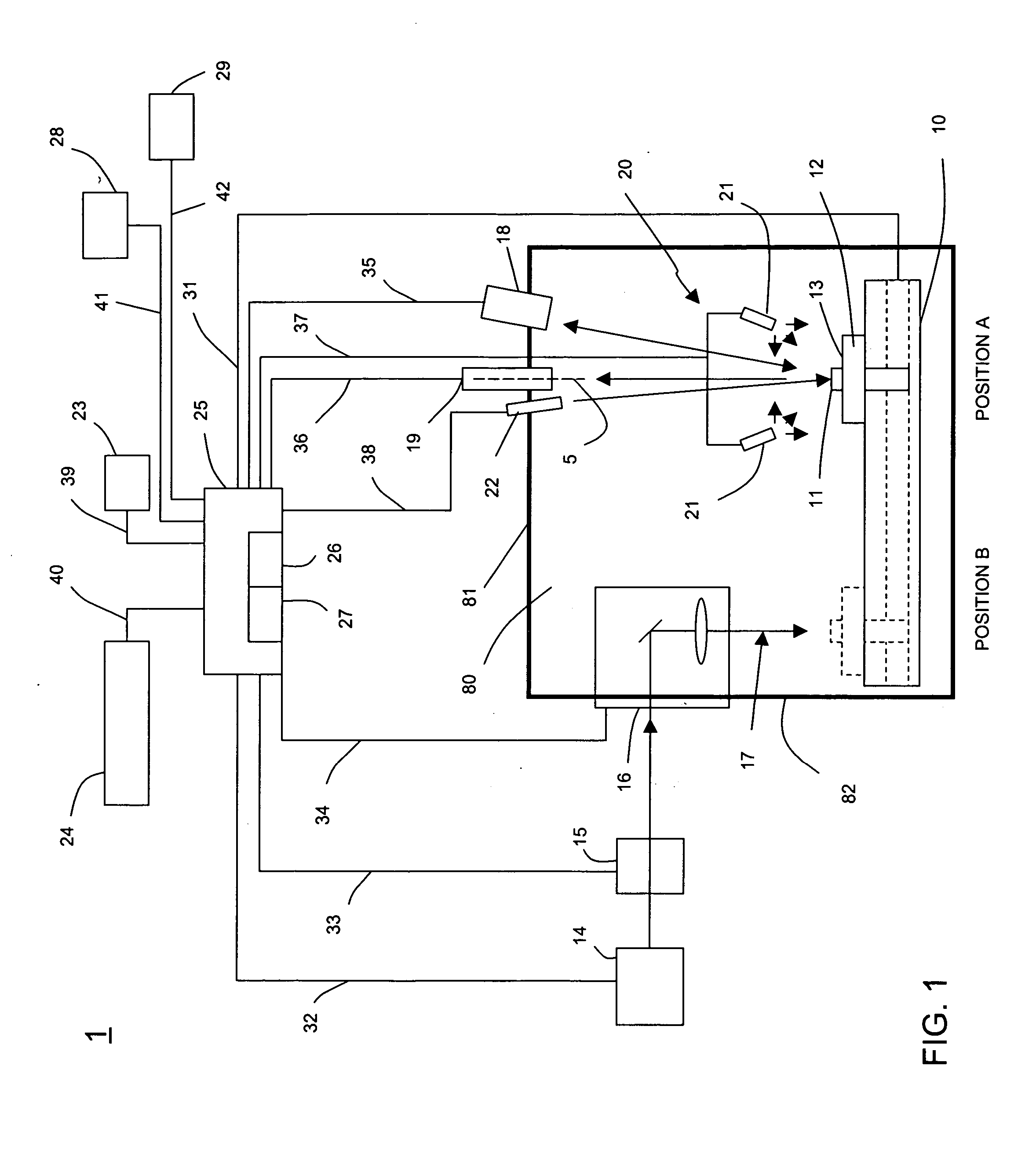

Multiwavelength imaging and spectroscopic photoemission microscope system

InactiveUS6222187B1Wide of electromagnetic emissionReduce the temperatureEmission spectroscopyRadiation pyrometryBeam splitterSpectrograph

A multiwavelength imaging and spectroscopic photoemission microscope system (100) which simultaneously provides images in a broad range of the electromagnetic spectrum, such as between 200 nm-1000 nm (optical or visible light) and 1000 nm-500 nm (infrared light). The multiwavelength imaging and spectroscopic photoemission microscope system comprises a microscope (102), a spectrometer (106), a beam splitter (108), a first spectrum focal plane array (110) including an appropriate photodiode (114A), a second spectrum focal plane array (120) including an appropriate photodiode (114B), and a cryogenic vessel (160) to maintain relevant portions of the system at a very low temperature. The invention may be used in failure analysis of integrated circuits and in semiconductor and low temperature physics.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

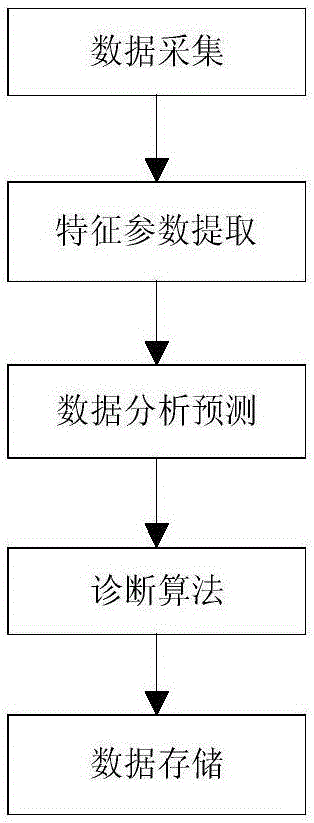

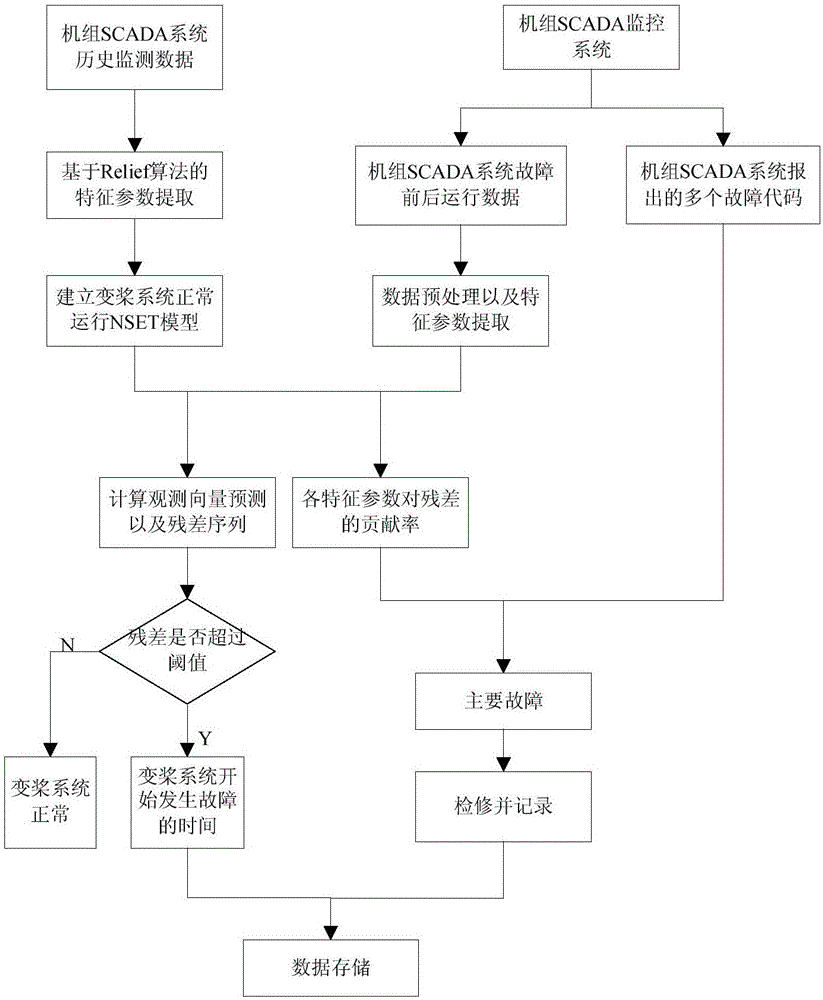

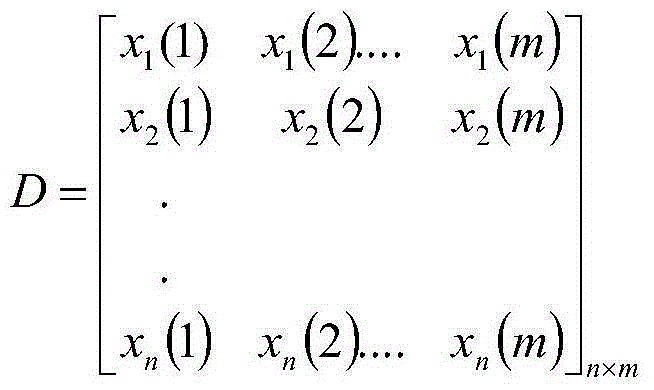

State monitoring and failure diagnosis method for wind generating set variable pitch system

The invention discloses a state monitoring and failure diagnosis method for a wind generating set variable pitch system. The method includes the steps that 1, in data collection, operation parameters related with the operation state of the variable pitch system are extracted from a wind generating set SCADA system; 2, according to feature parameter extraction, a Relief algorithm is utilized for extracting effective feature parameters of the variable pitch system; 3, in data analysis and prediction, historical data during normal operation of the variable pitch system are screened out to establish a health model of a fan and calculate the prediction value of a real-time signal and the difference between an actual output value and the prediction value; 4, according to a diagnosis algorithm, the operation state of the fan is judged according to residual error information transmitted by the step 3, and the main failure reason of the variable pitch system is found according to a corresponding diagnosis rule and the contribution rate of residue errors; 5, according to data storage, real-time data, prediction data and the diagnosis result are stored to facilitate failure analysis at the later period and provided as reference data for modifying the failure diagnosis rule.

Owner:北京中恒博瑞数字电力科技有限公司

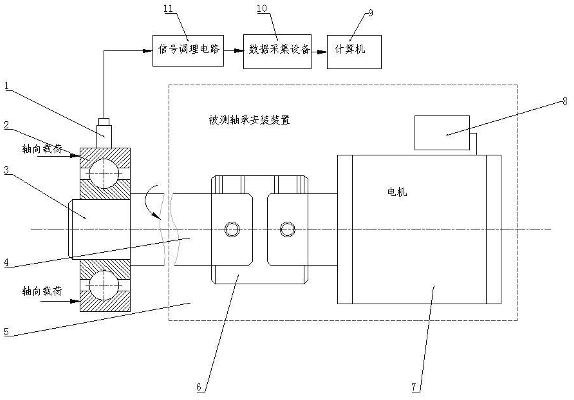

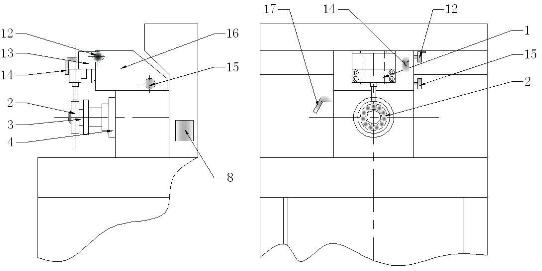

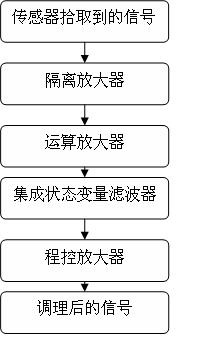

Device and method for vibration measurement and failure analysis of rolling bearing

InactiveCN102183366AAccurate measurementImprove anti-interference abilityVibration measurement in solidsMachine bearings testingVibration measurementSignal conditioning circuits

The invention relates to a device and method for vibration measurement and failure analysis of a rolling bearing. The device comprises a detected bearing mounting device, a speed sensor, a signal conditioning circuit, a data collection device and a computer, wherein a detected bearing is mounted on a mandrel of the detected bearing mounting device; a vibration rod of the speed sensor is arranged on a middle plane of an outer cylindrical surface of an outer ring of the detected bearing with prescribed pressure, the measurement direction is along the radial direction of the bearing and vertical to the axis of the bearing, and the signal conditioning circuit and the data collection device are connected to the computer; the speed sensor measures radial vibration speed signals of the outer ring of the bearing, the picked bearing radial vibration speed signals are converted into corresponding electric signals which are processed by the signal conditioning circuit and then transferred to the data collection device which carries out A / D conversion of the conditioned signals to convert the conditioned signals into digital signals capable of being processed by the computer, and finally the computer carries out analysis and processing of the digital signal. The device and the method are applicable to production test and user acceptance of finished bearings by laboratories and bearing manufacture factories.

Owner:SHANGHAI UNIV

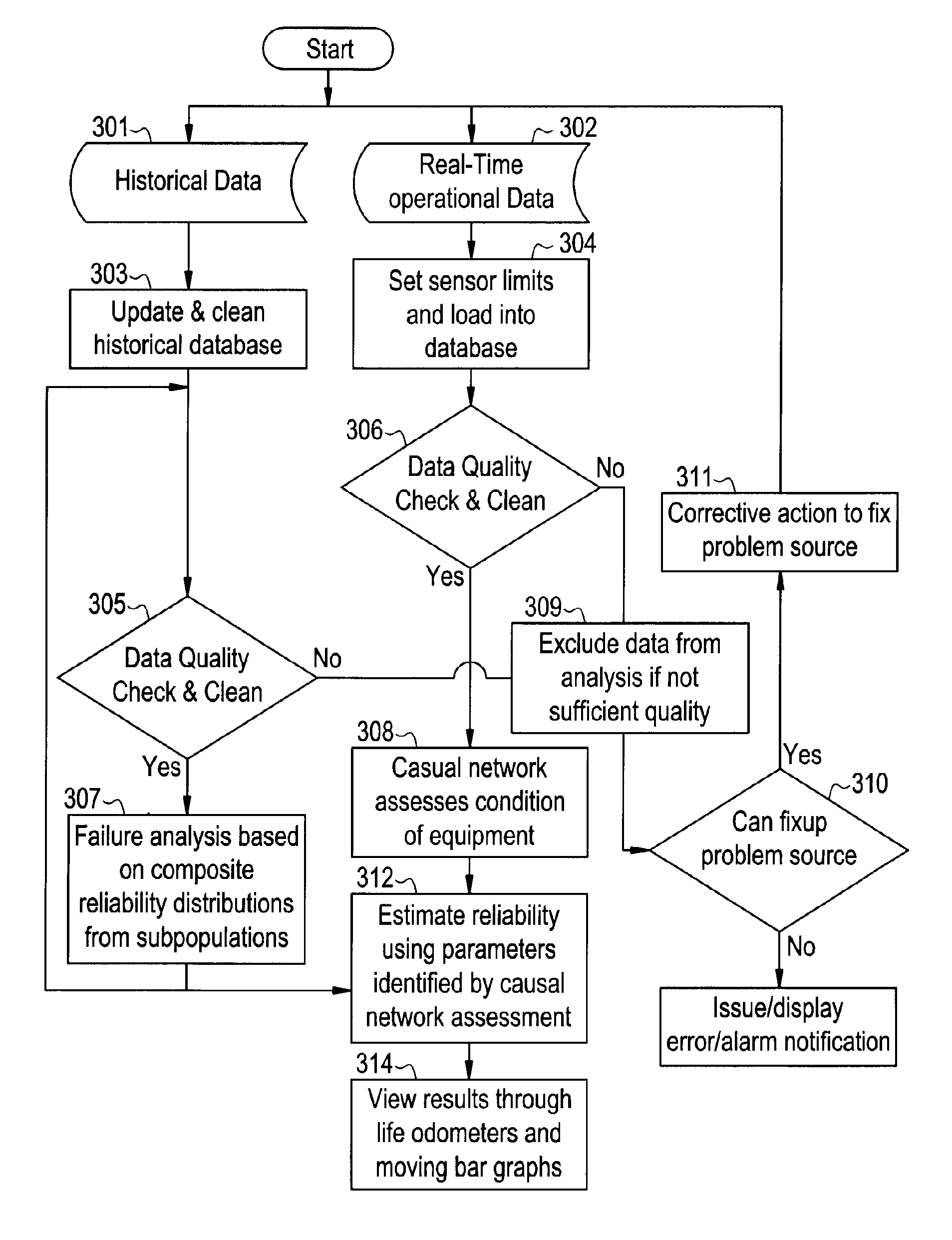

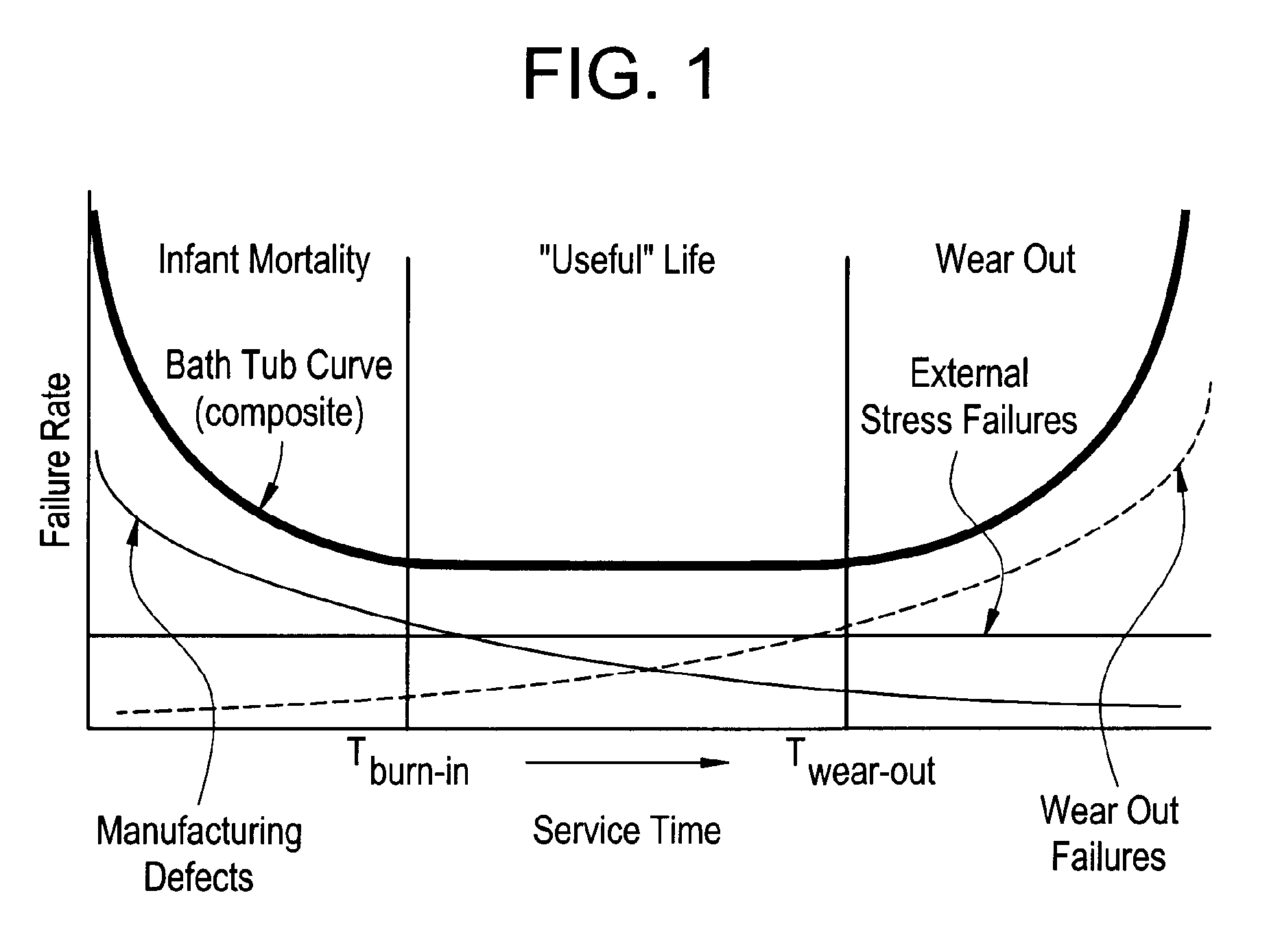

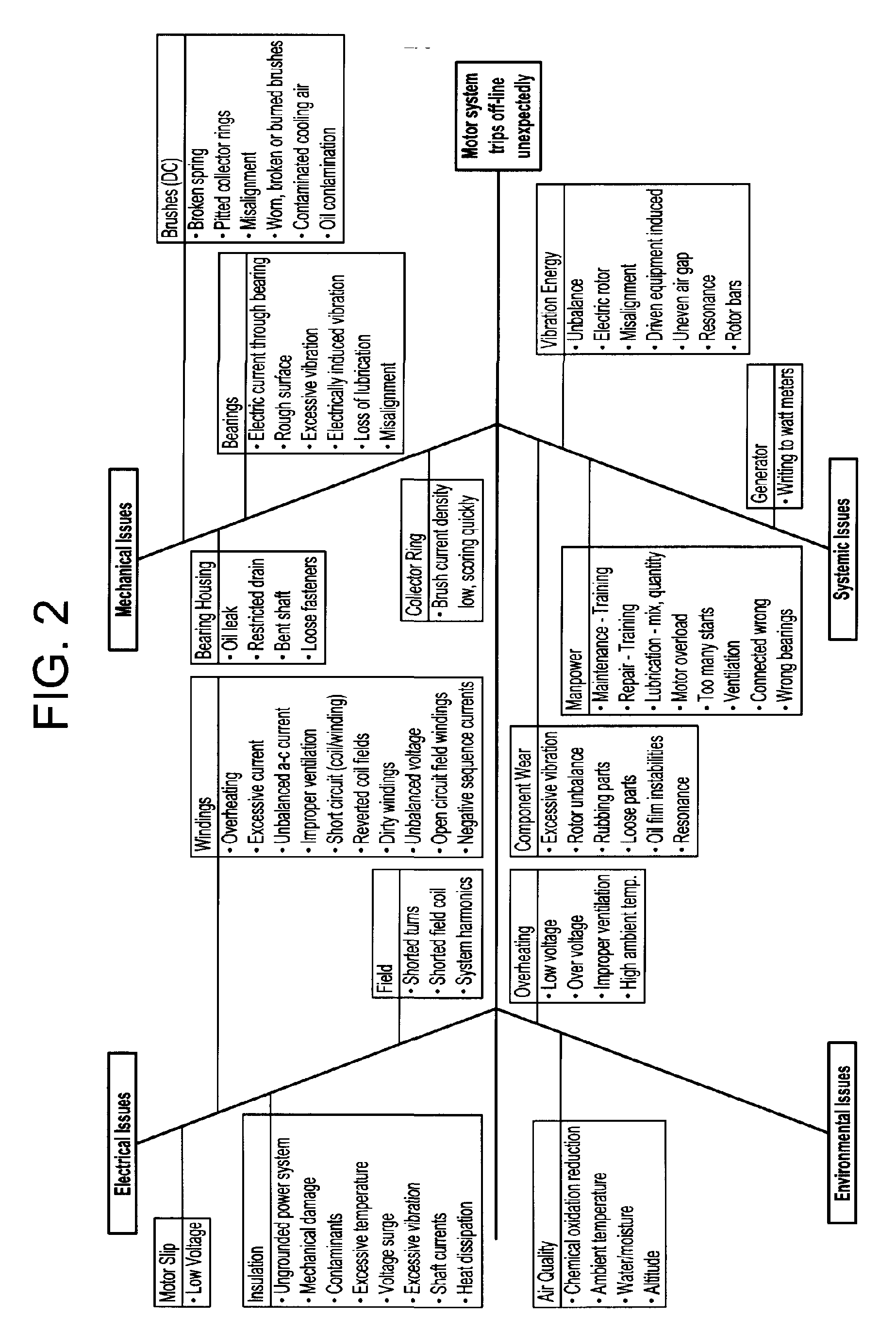

Method and system for predicting remaining life for motors featuring on-line insulation condition monitor

A method for determining reliability and a remaining time before failure with statistical confidence for a motor system includes acquiring historical motor data in a computer system, obtaining operational parameter data, uploading the operational parameter data to the computer system, performing failure analysis, developing a causal network, and performing an integrated causal network and reliability analysis of the motor system. The historical motor data corresponds to the motor system. The operational parameter data is obtained from sensors at the motor system. The sensors include a tan delta sensor. The failure analysis is performed based on a composite of reliability probability distributions corresponding to predetermined sub-populations of historical motor system failure causes. The causal network is developed for modeling reliability of one or more motor system components and assessing motor system component condition based on the causal network. Results from the performing failure analysis are integrated with results from the assessing motor system component condition based on the causal network to compute a quantitative value for a time remaining before failure with an ascertained statistical confidence.

Owner:GENERAL ELECTRIC CO

Method for test optimization using historical and actual fabrication test data

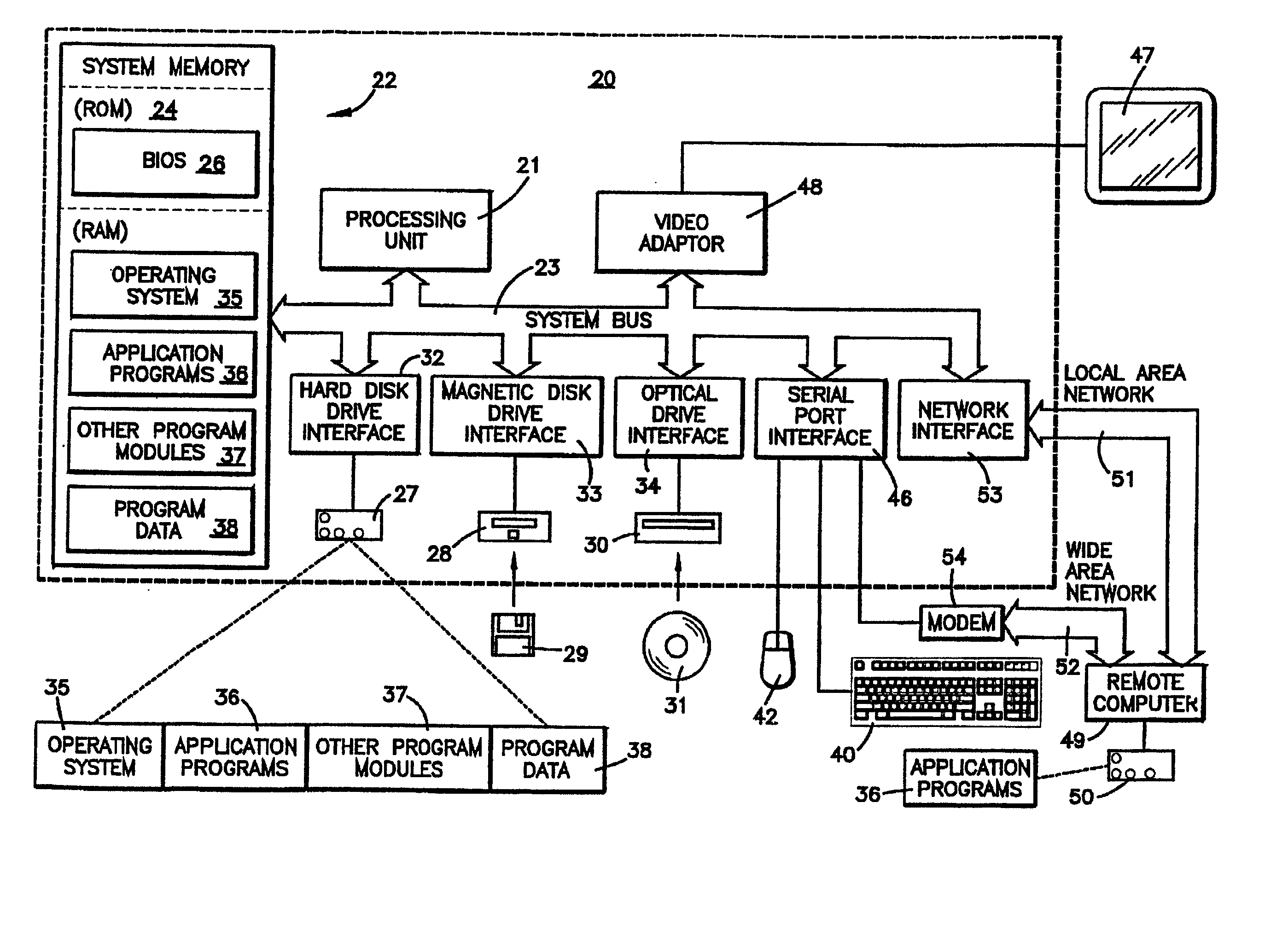

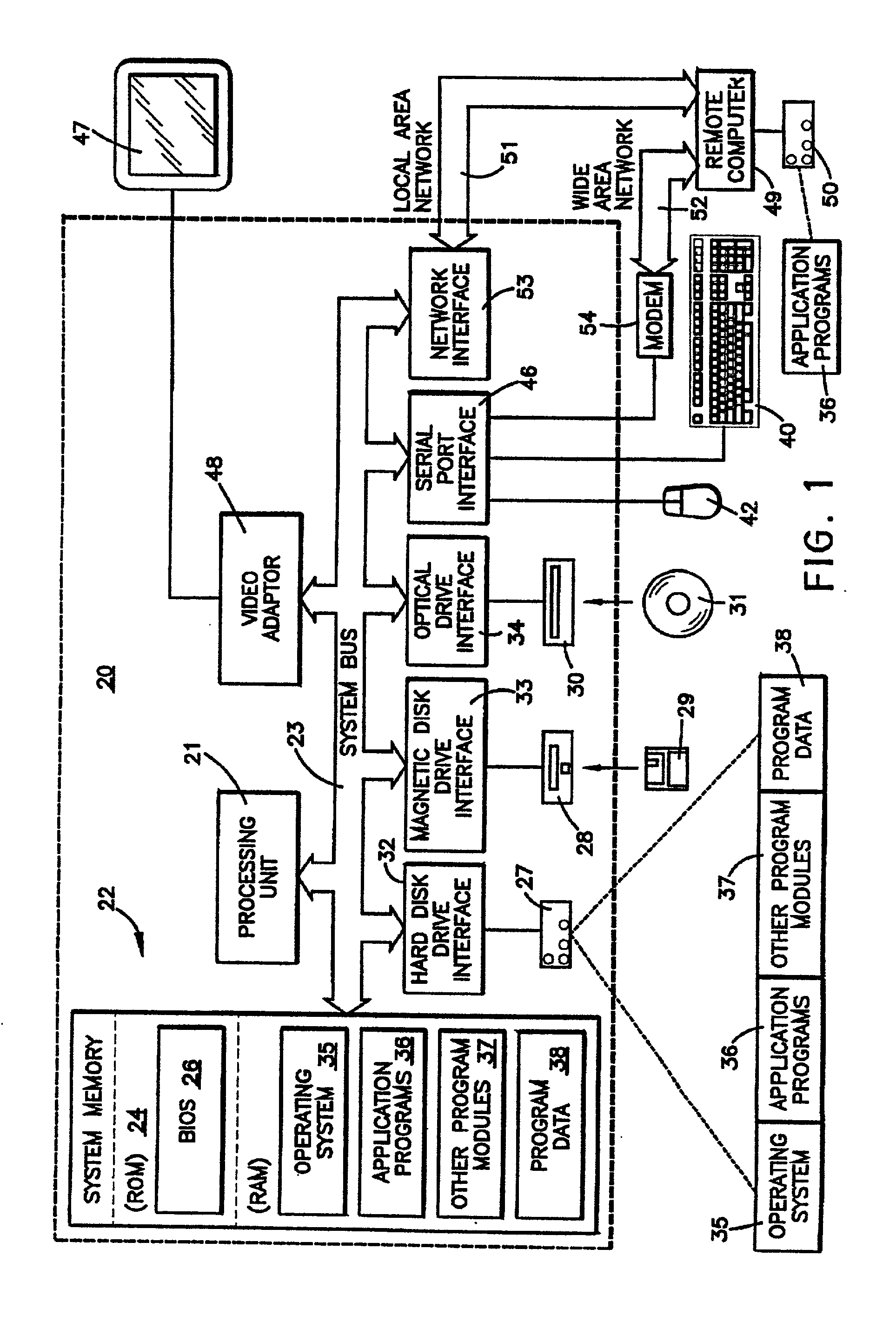

InactiveUS20020155628A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingQuality levelWafer fabrication

A method and system are provided that minimize wafer or package level test time without adversely impacting yields in downstream manufacturing processes or degrading outgoing quality levels. The method provides optimization by determining, a priority, the most effective set of tests for a given lot or wafer. The invention implements a method using a processor-based system involving the integration of multiple sources of data that include: historical and realtime, product specific and lot specific, from wafer fabrication data (i.e., process measurements, defect inspections, and parametric testing), product qualification test results, physical failure analysis results and manufacturing functional test results. These various forms of data are used to determine an optimal set of tests to run using a test application sequence, on a given product to optimize test time with minimum risk to yield or product quality.

Owner:CADENCE DESIGN SYST INC

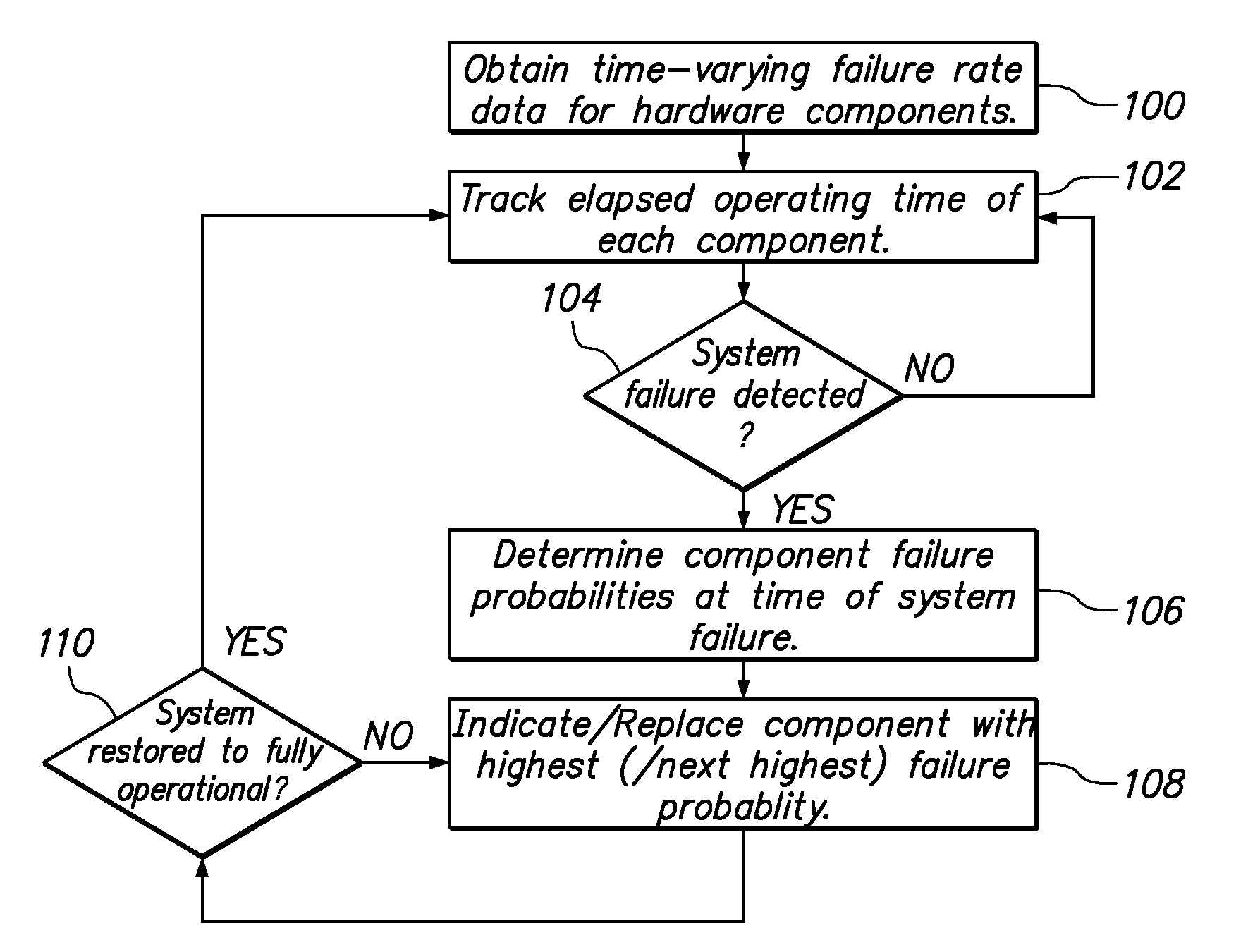

Failure Analysis Based on Time-Varying Failure Rates

Failure analysis method and apparatus using failure rate data in coordination with the power on hours to more efficiently resolve computer system failures without occupying system memory or processor bandwidth. In response to a system failure, a baseboard management controller (BMC) notes the time of failure and the elapsed operating time of system components. In response to a failure of the computer system, the BMC accesses industry standard failure rate data correlating the elapsed operating time with the probability of failure for each component. By cross-referencing the time of failure with the failure rate data, the BMC automatically determines the probability of failure of each component at the time of failure of the computer system. The BMC generates a component replacement list identifying the component that currently has the highest probability of failure.

Owner:LENOVO GLOBAL TECH INT LTD

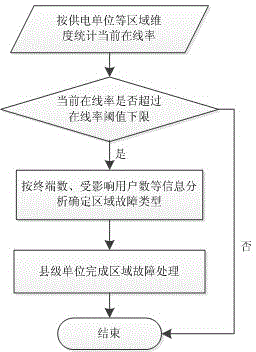

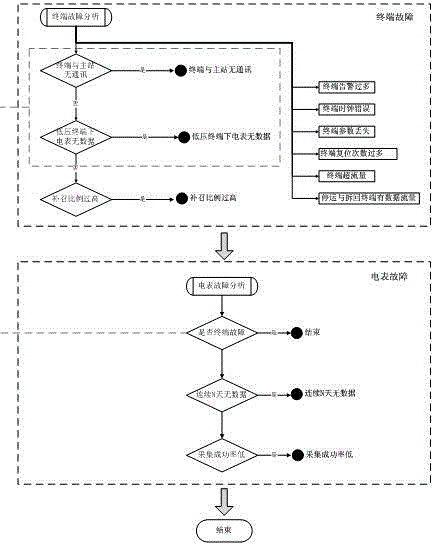

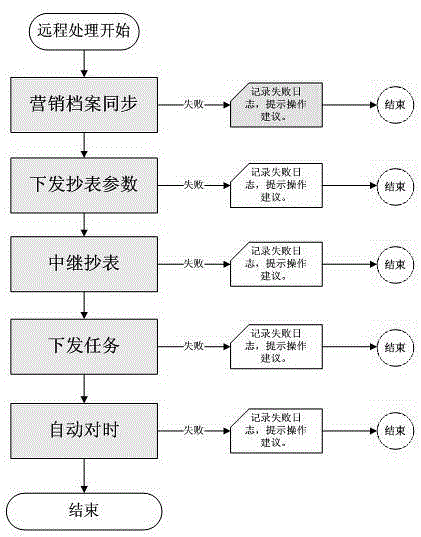

Acquisition failure analyzing and processing method of electricity utilization information acquisition operating and maintaining system

InactiveCN104360208ASmart Fault AnalysisIntelligent handlingElectrical testingProcessing InstructionPrimary station

The invention relates to an acquisition failure analyzing and processing method of an electricity utilization information acquisition operating and maintaining system. The acquisition failure analyzing and processing method comprises region failure discovery and analysis and equipment failure discovery and analysis, wherein the region failure discovery and analysis comprises the following steps: 1, counting terminal online rate per hour, if a statistical value is lower than a normal period terminal online rate threshold, forming failure grouping; 2, analyzing region failures according to a number of terminals, a number of affected uses and valid user number information by counting the terminal online rate and a communication operator influence degree; 3, determining a failure order of severity according to a failure scale and a failure range, showing a failure region distribution condition on a GIS (Geographic Information System) graph. The equipment failure discovery and analysis comprises the following step of discovering and analyzing a terminal failure and an electricity meter failure. The acquisition failure analyzing and processing method of the electricity utilization information acquisition operating and maintaining system comprises the following steps: synchronizing a newest file of a marketing system to an electricity utilization information acquisition system by a main station, and sending a processing instruction out. The acquisition failure analyzing and processing method of the electricity utilization information acquisition operating and maintaining system can be used for monitoring the failure and intelligently analyzing and processing the failure.

Owner:STATE GRID CORP OF CHINA +2

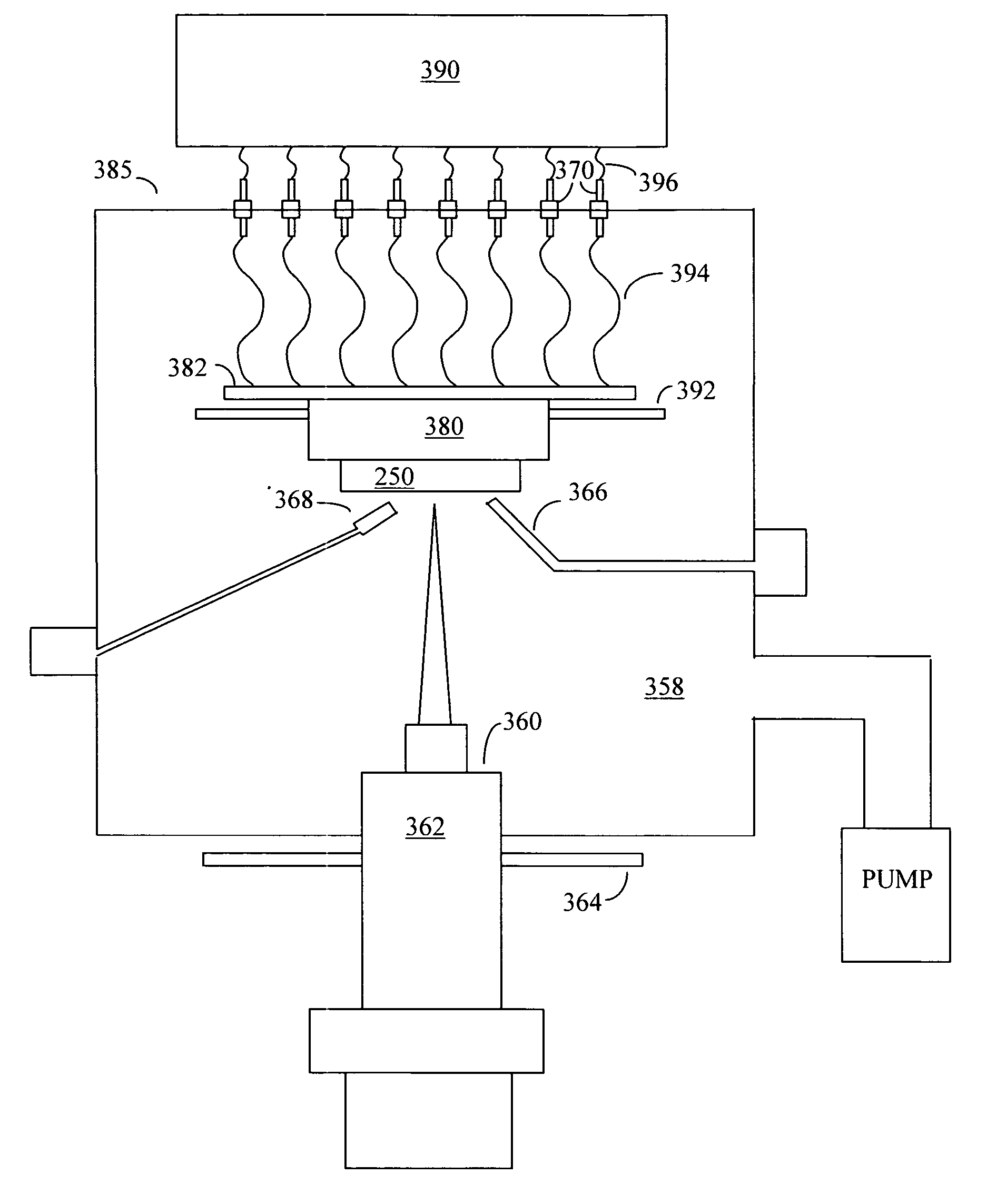

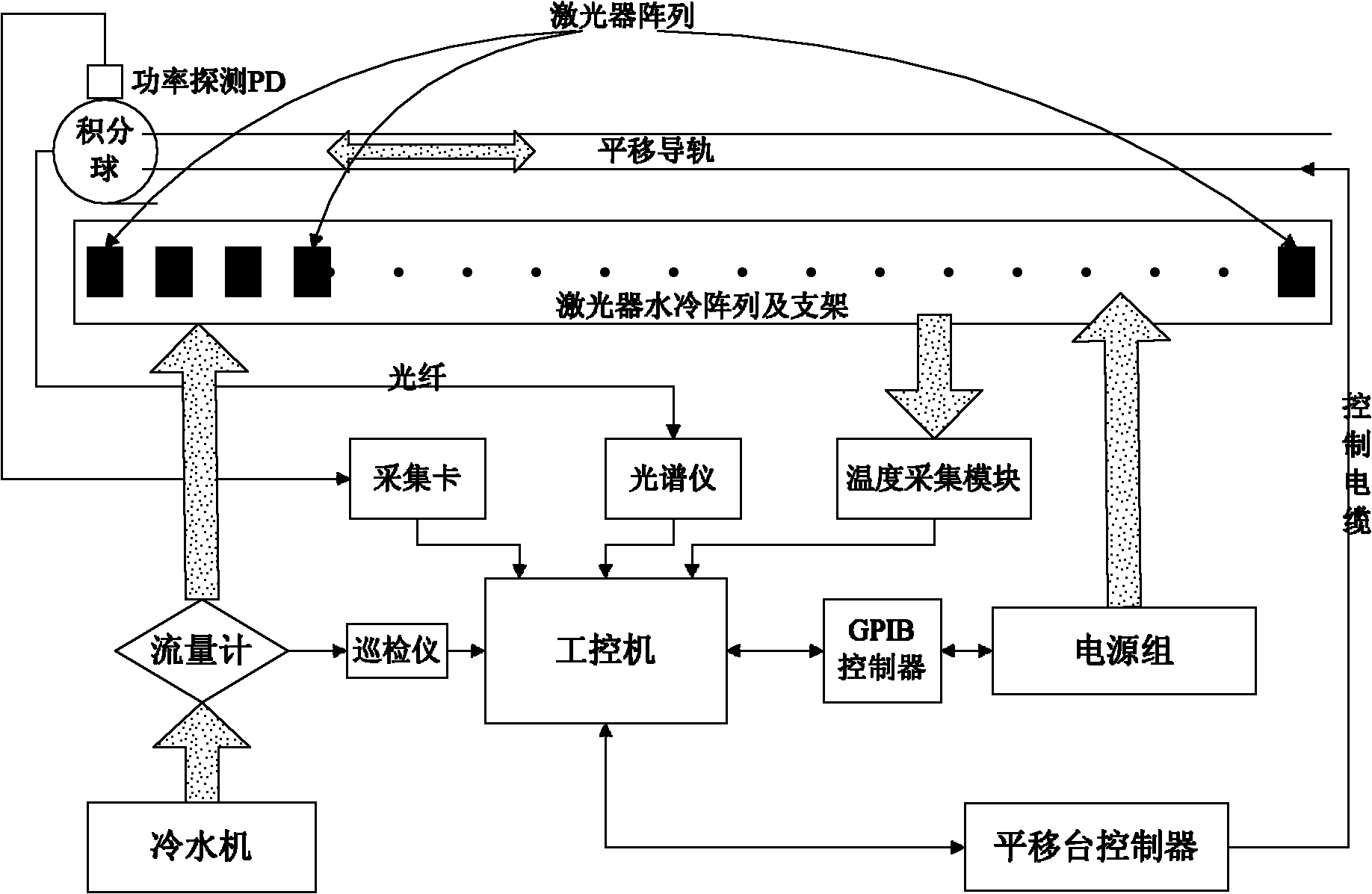

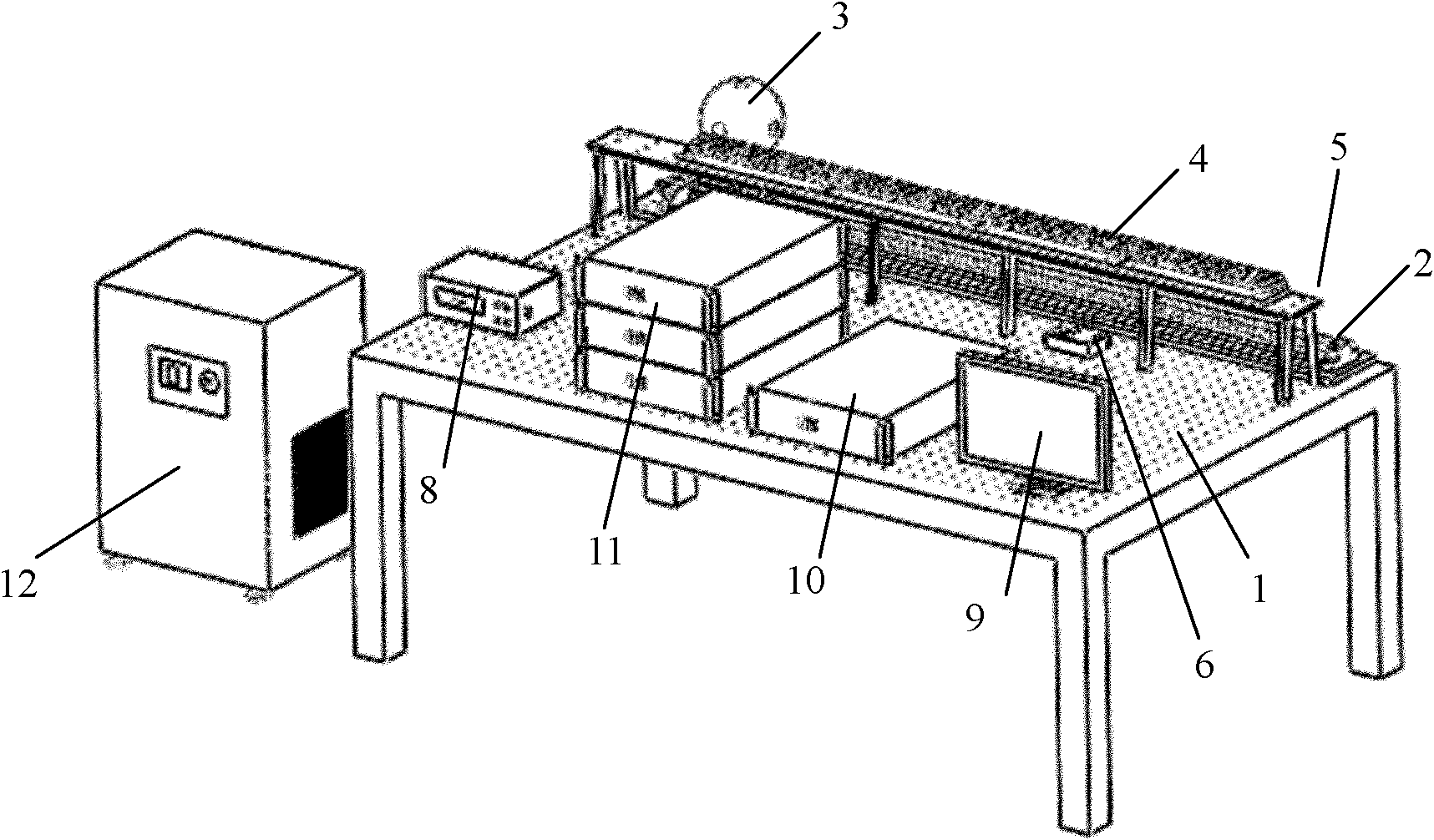

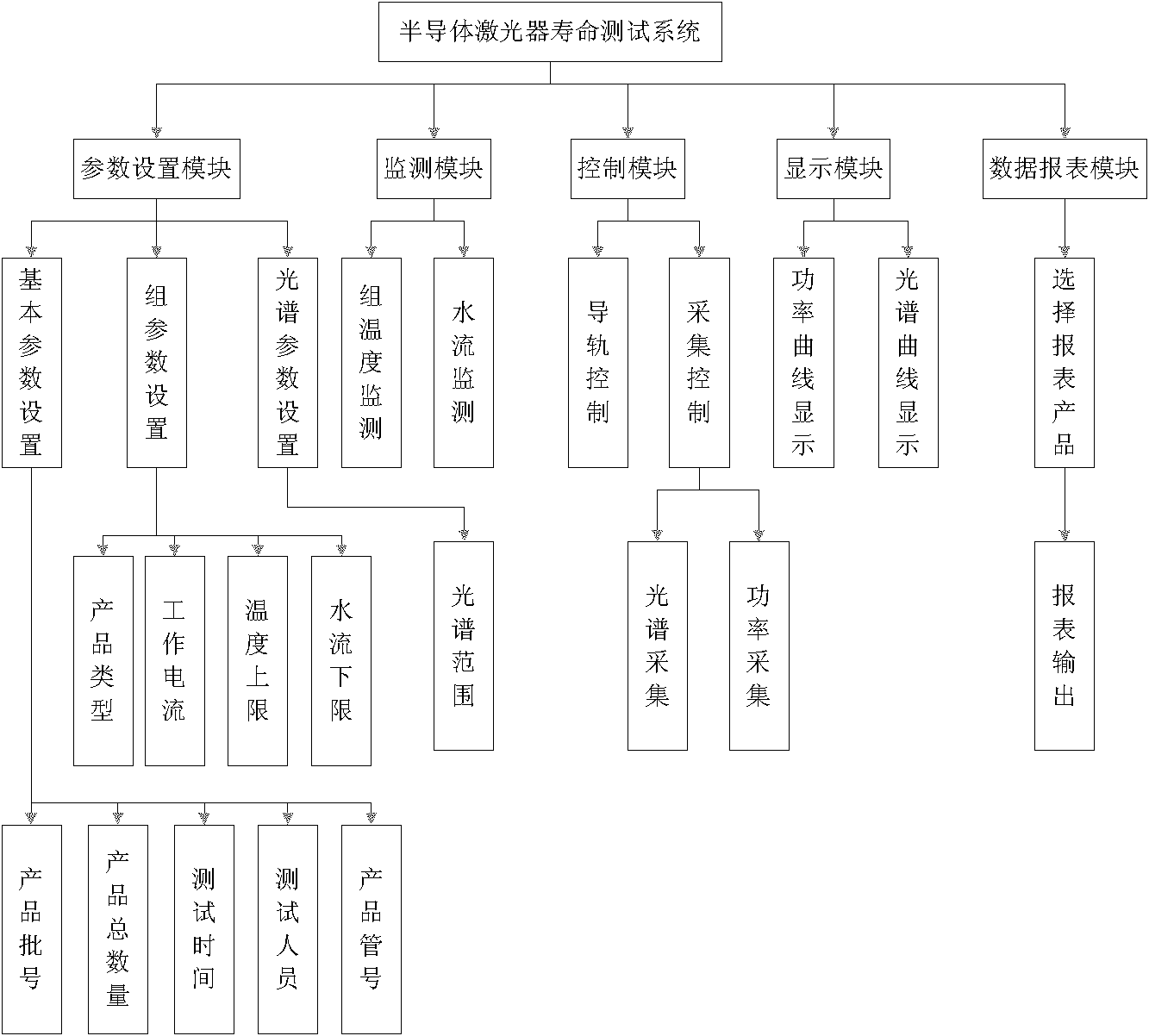

Device for testing life of semiconductor laser

ActiveCN102062675AImprove test efficiencyAchieve multi-functionalitySpectrum investigationPhotometrySpectrographPower detector

The invention discloses a device for testing life of a semiconductor laser, comprising an optical platform, wherein the optical platform is provided with parallel guide rails and a laser water cooling array; the parallel guide rails are provided with electric translation tables; an integrating sphere and a PD (Power Detector) are fixed on the electric translation tables; the integrating sphere isconnected with a spectrograph through an optical fiber; the spectrograph is connected to an industrial personal computer; the PD is connected with the industrial personal computer through a collecting card; a temperature collecting module is arranged at the side of the laser water cooling array and connected with the industrial personal computer; the electric translation tables are connected witha translation table controller through controlling a cable; and the translation table controller is connected to the industrial personal computer. By the system, automatic parameter tests can be carried out on laser products with different packaging types, powers and numbers. The power and the spectral information of the laser products are automatically collected and recorded in the processing ofworking, the report printing data can be automatically carried out to form a test report, and therefore, the basis for failure analysis and research of the laser products is provided.

Owner:FOCUSLIGHT TECH

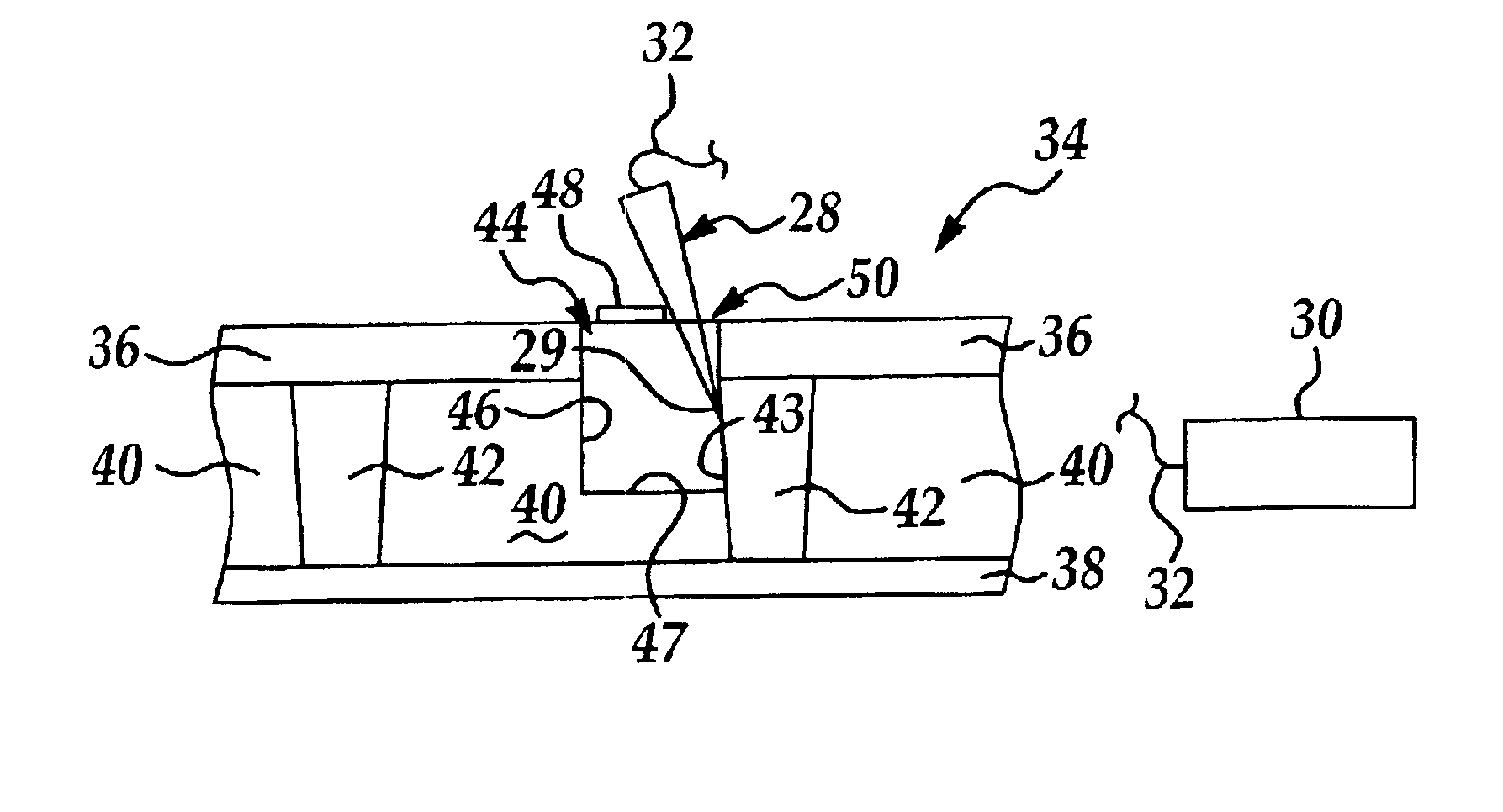

Semiconductor failure analysis tool

InactiveUS20070075050A1Semiconductor/solid-state device testing/measurementSolid-state devicesMaterial removalAnalysis tools

Systems and methods for removing material from a packaged electronic device of the type encapsulated with a protective material that forms an outer surface of the device. An exemplary system includes a stage for placing the device in a first position for receiving laser radiation to remove the material by ablation, and for placing the device in a second position for viewing one or more features along the outer surface of the device. An optical system is configured to provide an exterior image, including one or more features along an exposed surface of the device, while the device remains in the second position. A viewing system displays a captured image of the device, including one or more features interior to the protective surface, overlayed with the exterior image for simultaneous viewing of both images so that a position of a first feature present in the captured image can be viewed in relation to a position of a second feature in the exterior image. The combination of the first feature position and the second feature position can be used to define a region of the device for material removal with a laser. In an associated method a captured image of the device is provided, the image including one or more features interior to the protective surface. One or more features along the outer surface of the device are viewed with an optical system while the device remains on a stage, the optical system providing an exterior image. The captured image is combined with the exterior image for simultaneous viewing so that the position of a first feature present in the captured image can be viewed in relation to the position of a second feature in the exterior image. A region is defined for decapsulation based on the position of the first feature relative to the position of the second feature.

Owner:CONTROLLED SEMICON

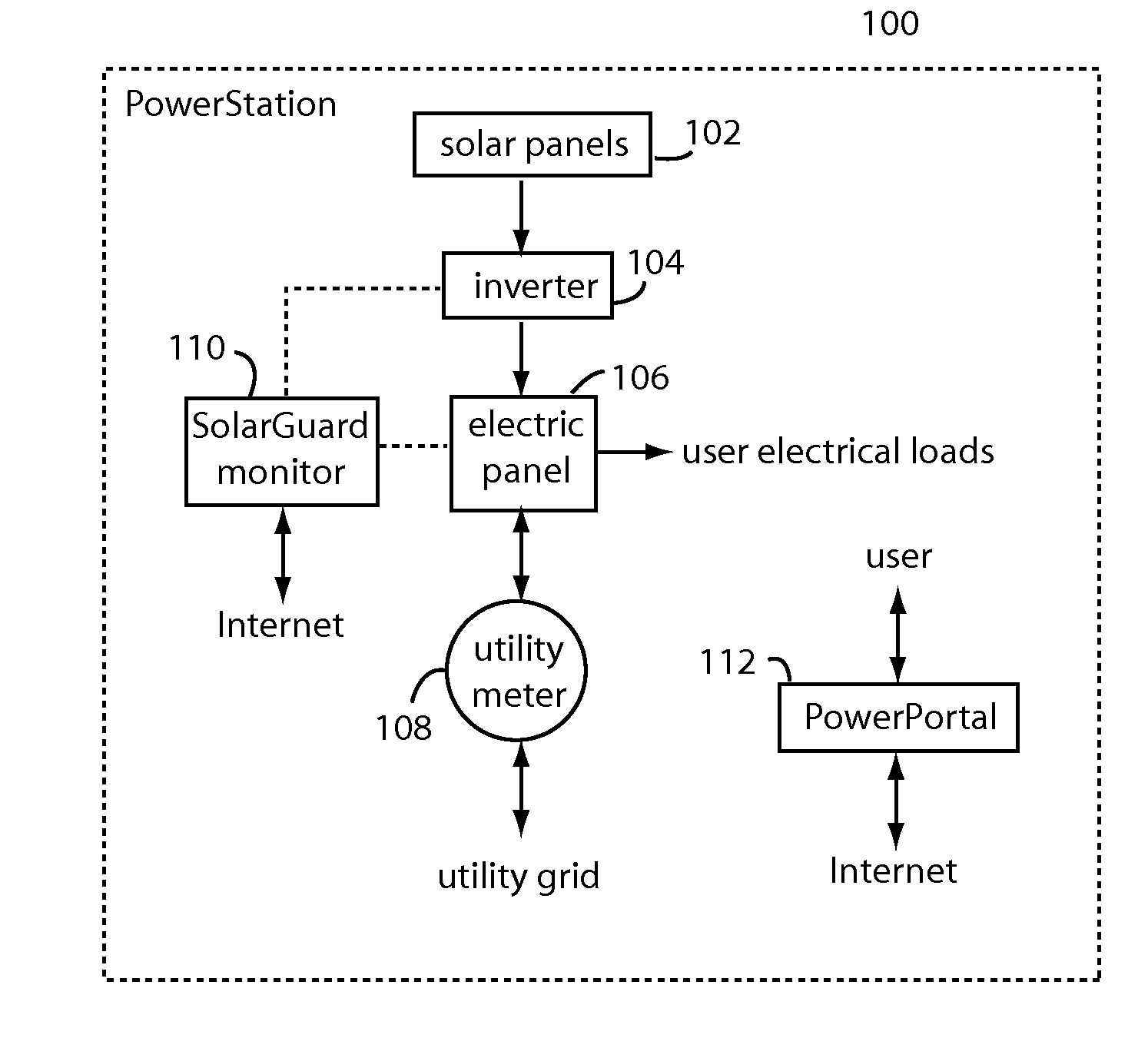

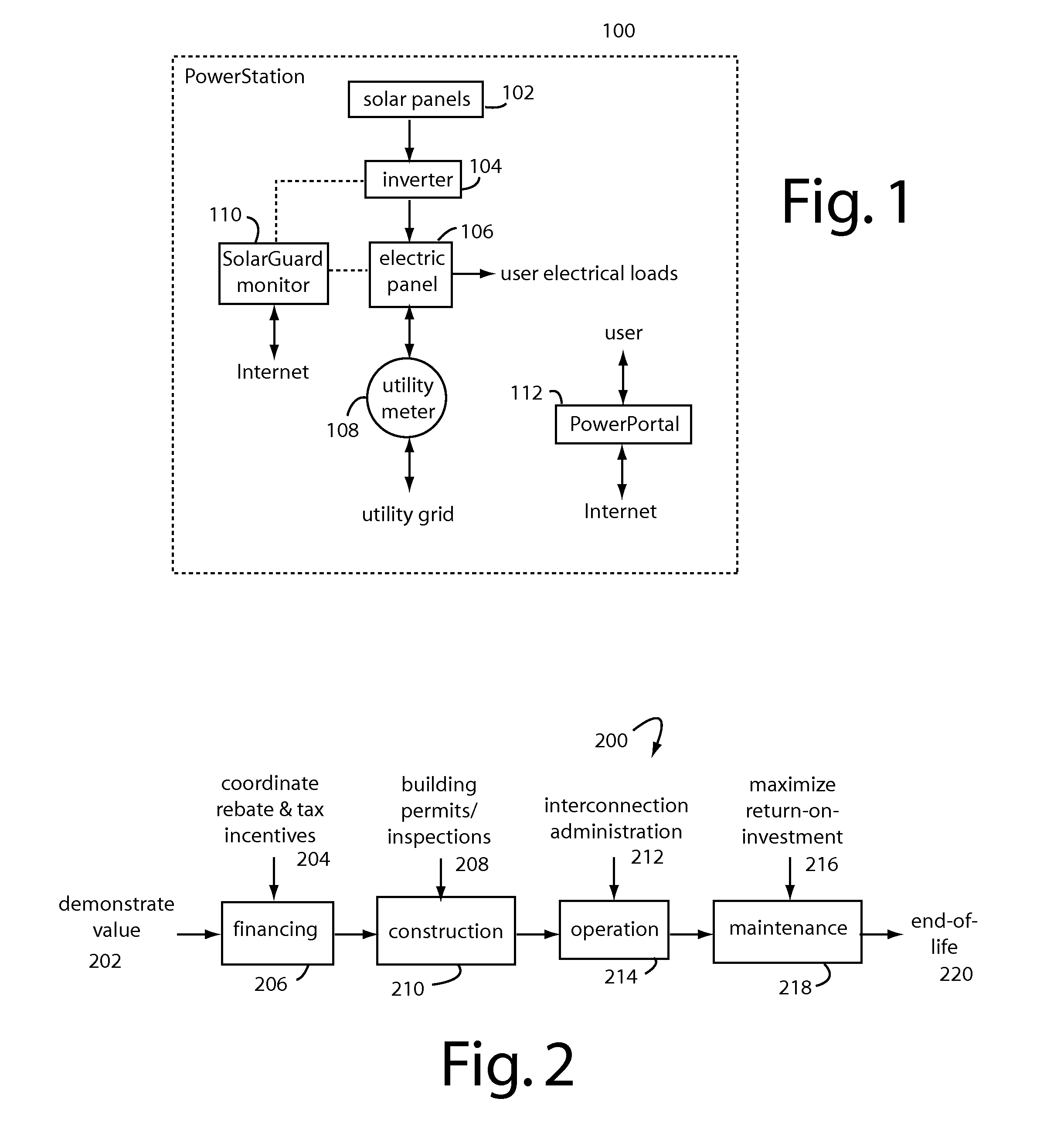

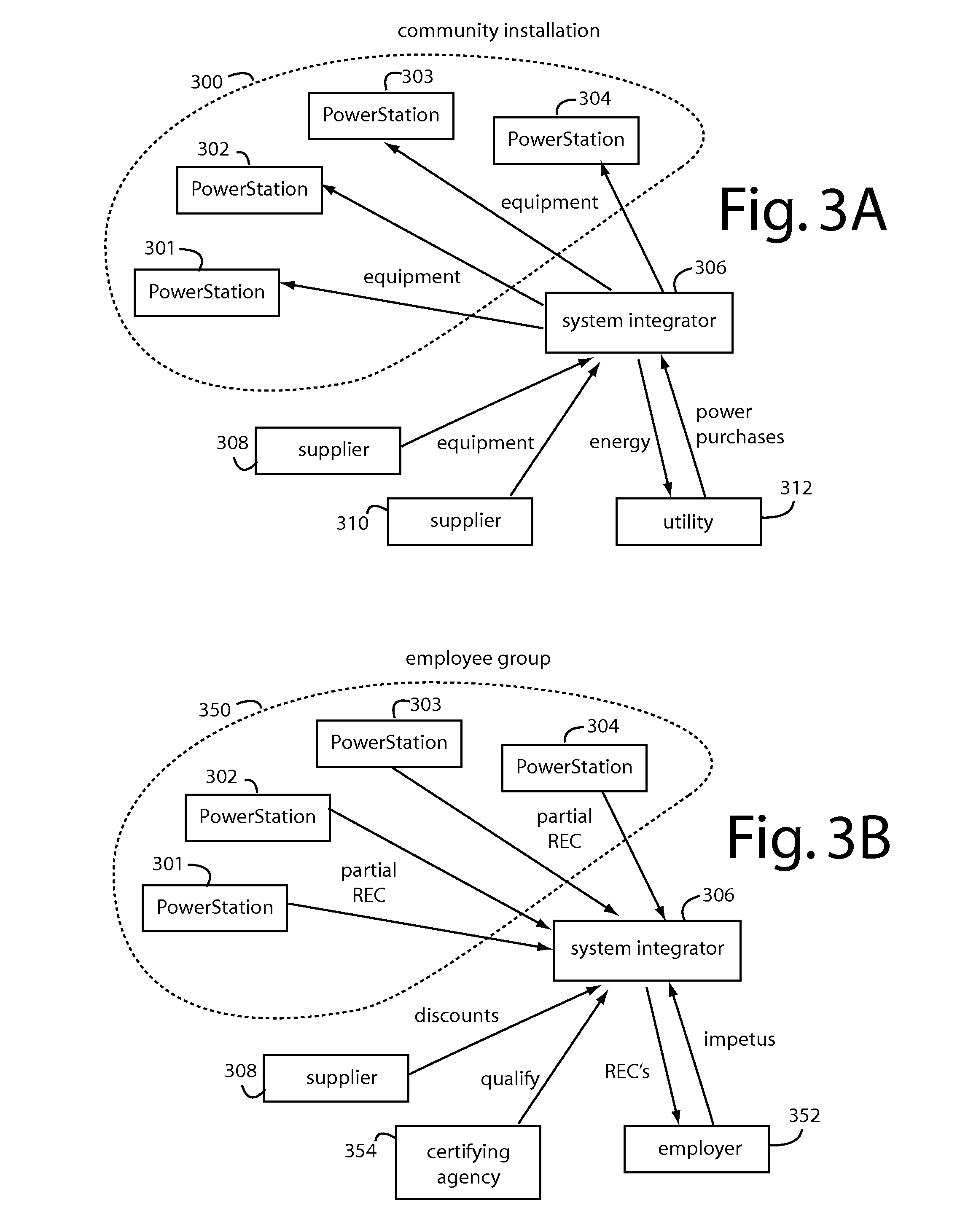

Renewable energy system business tuning

InactiveUS20100010939A1Improve efficiencyImprove economyElectric devicesSpecial tariff metersDemographic dataEngineering

A business tuning system collects streams of informational reports from remote renewable energy systems. A database holds the information and associates it with a particular renewable energy business operation. A pre-processor semi-structures the information into failure analyses, sales histories, performance results, regional trends, seasonal trends, and demographics. A data mining processor provides for knowledge discovery and prediction from semi-structured information related to said particular renewable energy business operation.

Owner:SOLARCITY

Method for analyzing chip failure

ActiveCN102253325AImprove work efficiencySave time and costOptically investigating flaws/contaminationContactless circuit testingEngineeringFailure analysis

The invention provides a method for analyzing chip failure, which is used for detecting defect characteristics of a chip grid and comprises the following steps: removing most of a substrate and an active region of a chip to be subjected to failure analysis through mechanical grinding; removing the remained substrate and active region of the chip through wet etching; removing most of a gate oxide layer of the chip through dry etching, wherein the remained gate oxide layer is used for protecting a first polysilicon layer of the grid; and detecting whether the defect characteristics exist on thefirst polysilicon layer or not. By utilizing the method provided by the invention, the chip can be accurately stripped to the bottom of the first polysilicon layer of the grid, the accurate size parameters of the bottom of the first polysilicon layer can be measured, the working efficiency can be greatly improved, and the time can be saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

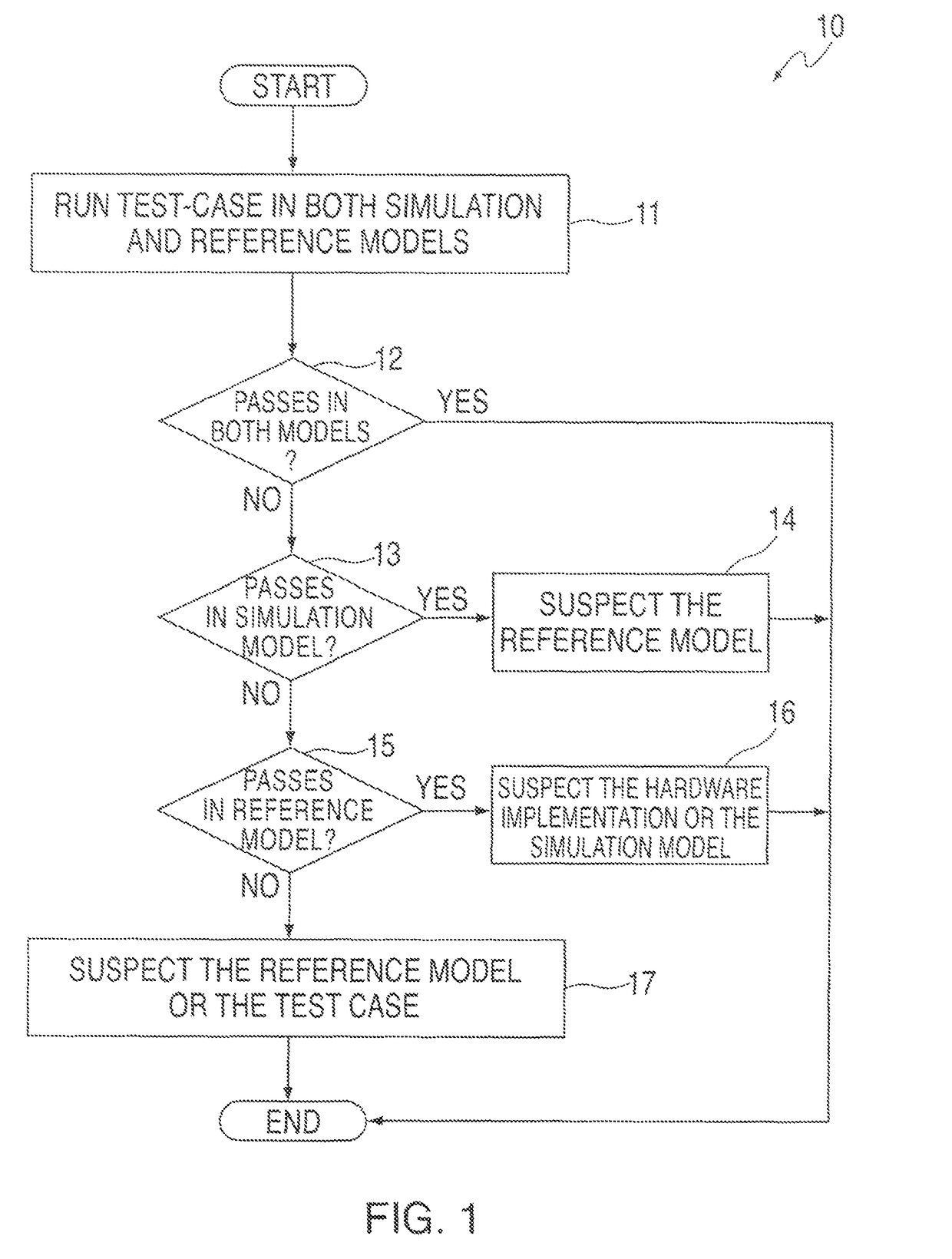

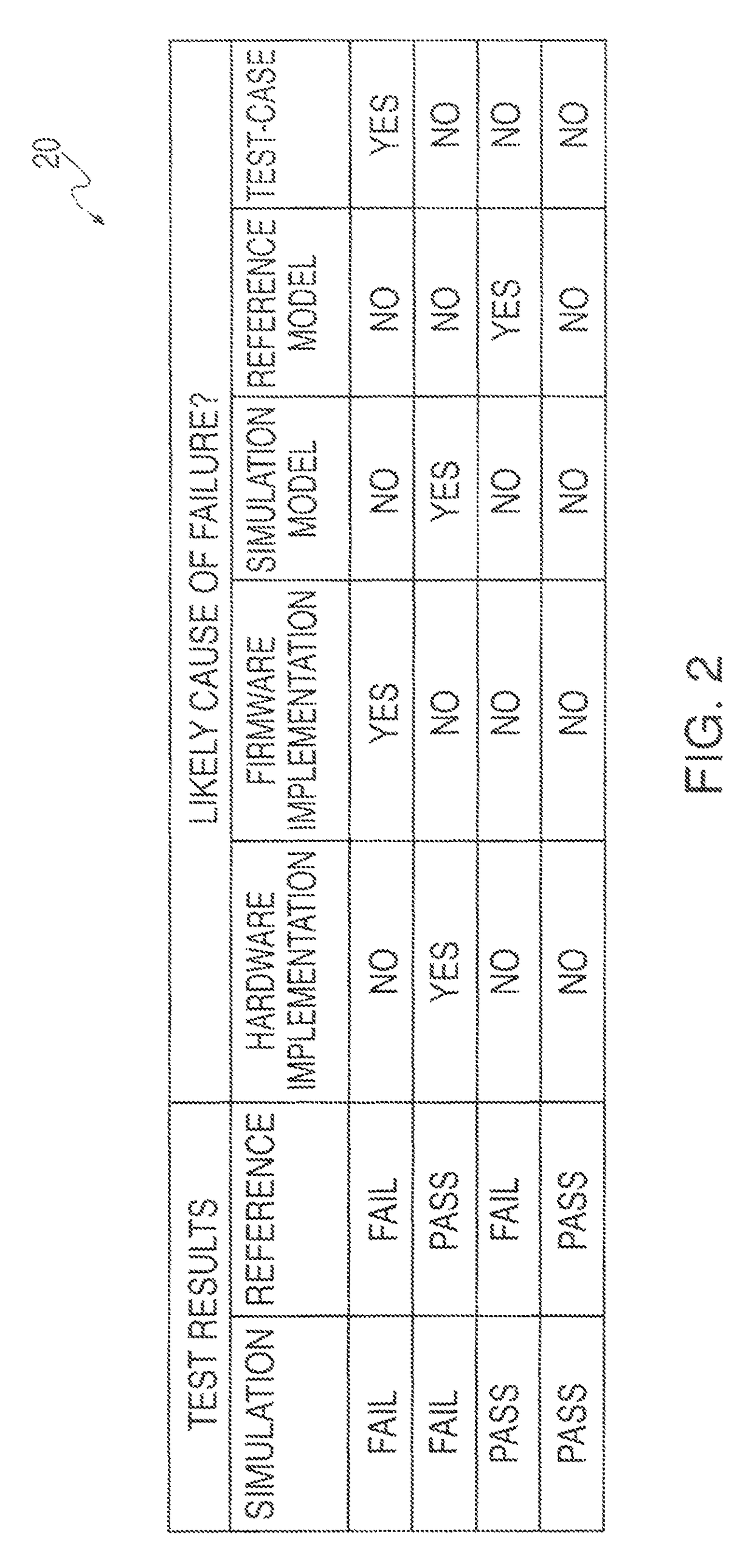

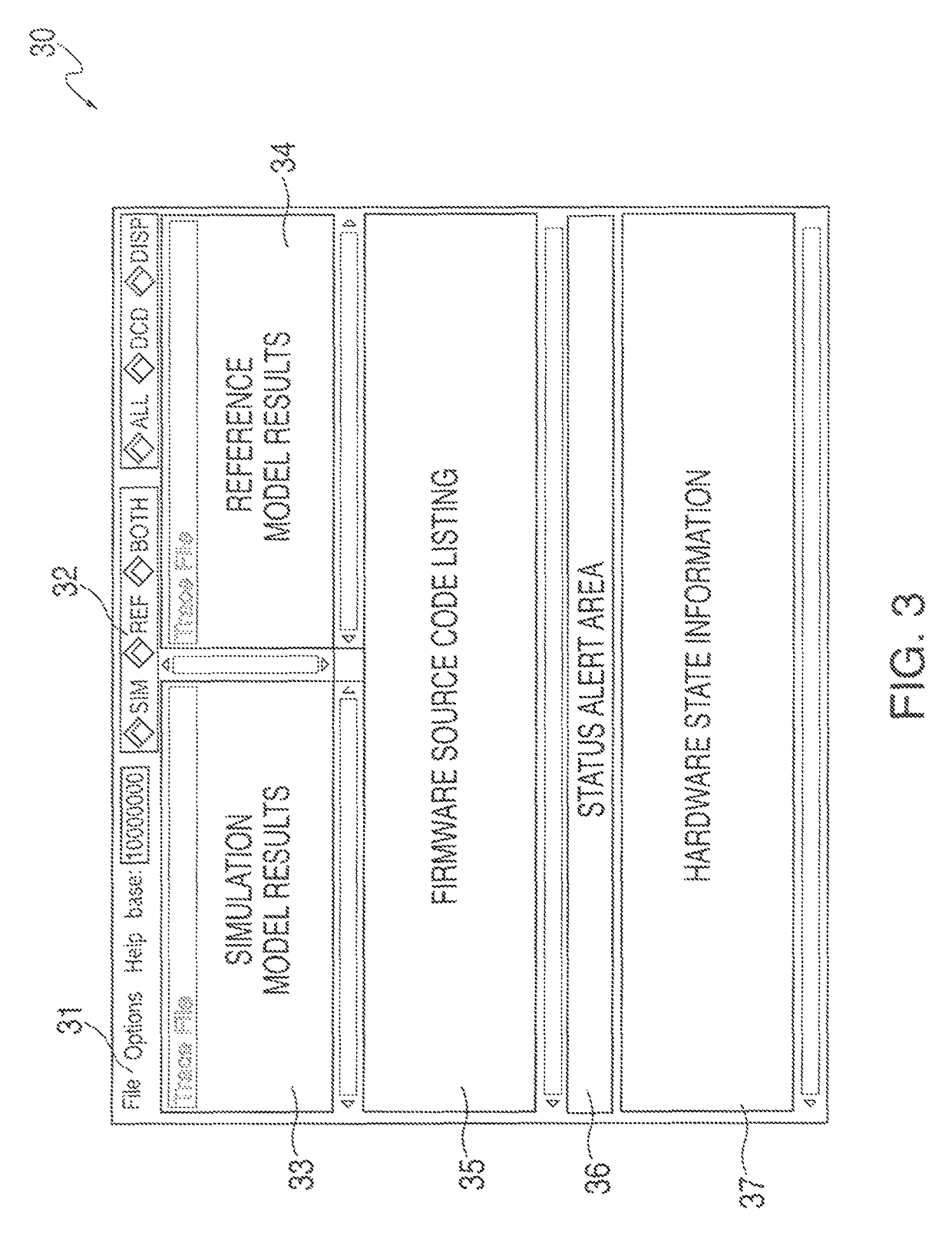

Method, system and computer program product for failure analysis implementing automated comparison of multiple reference models

InactiveUS7908518B2Error detection/correctionSpecific program execution arrangementsReference modelComputerized system

Owner:INT BUSINESS MASCH CORP

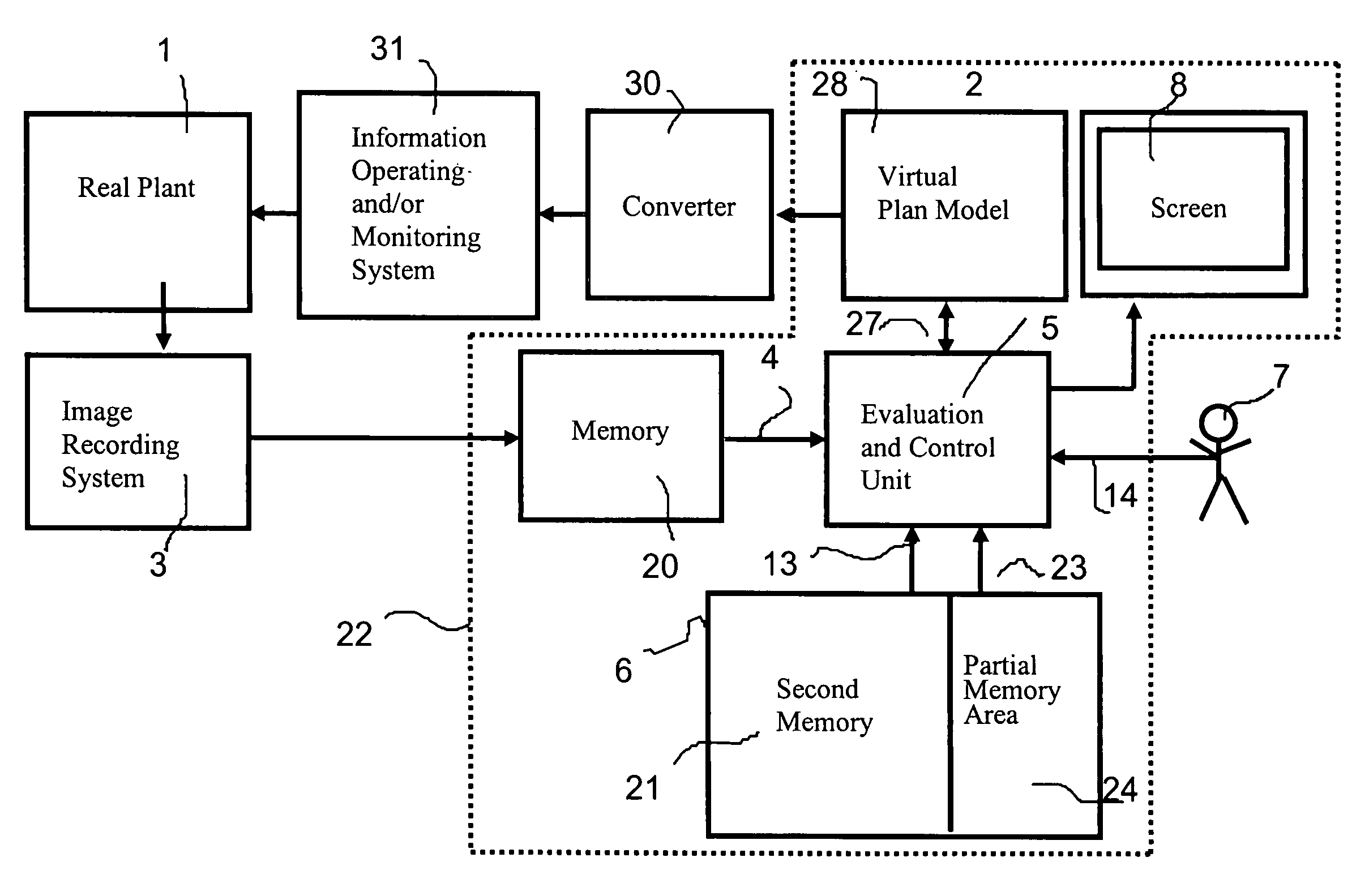

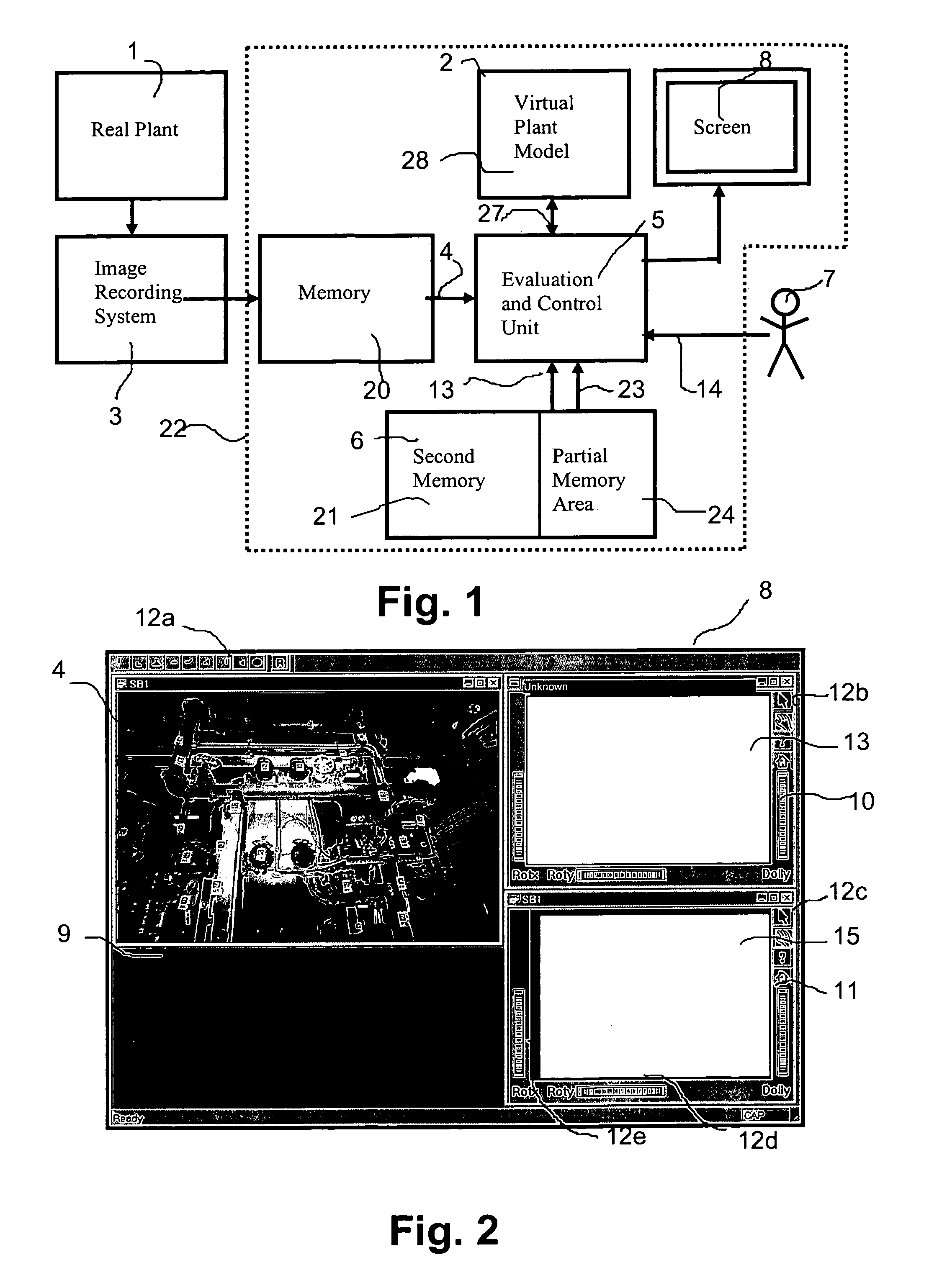

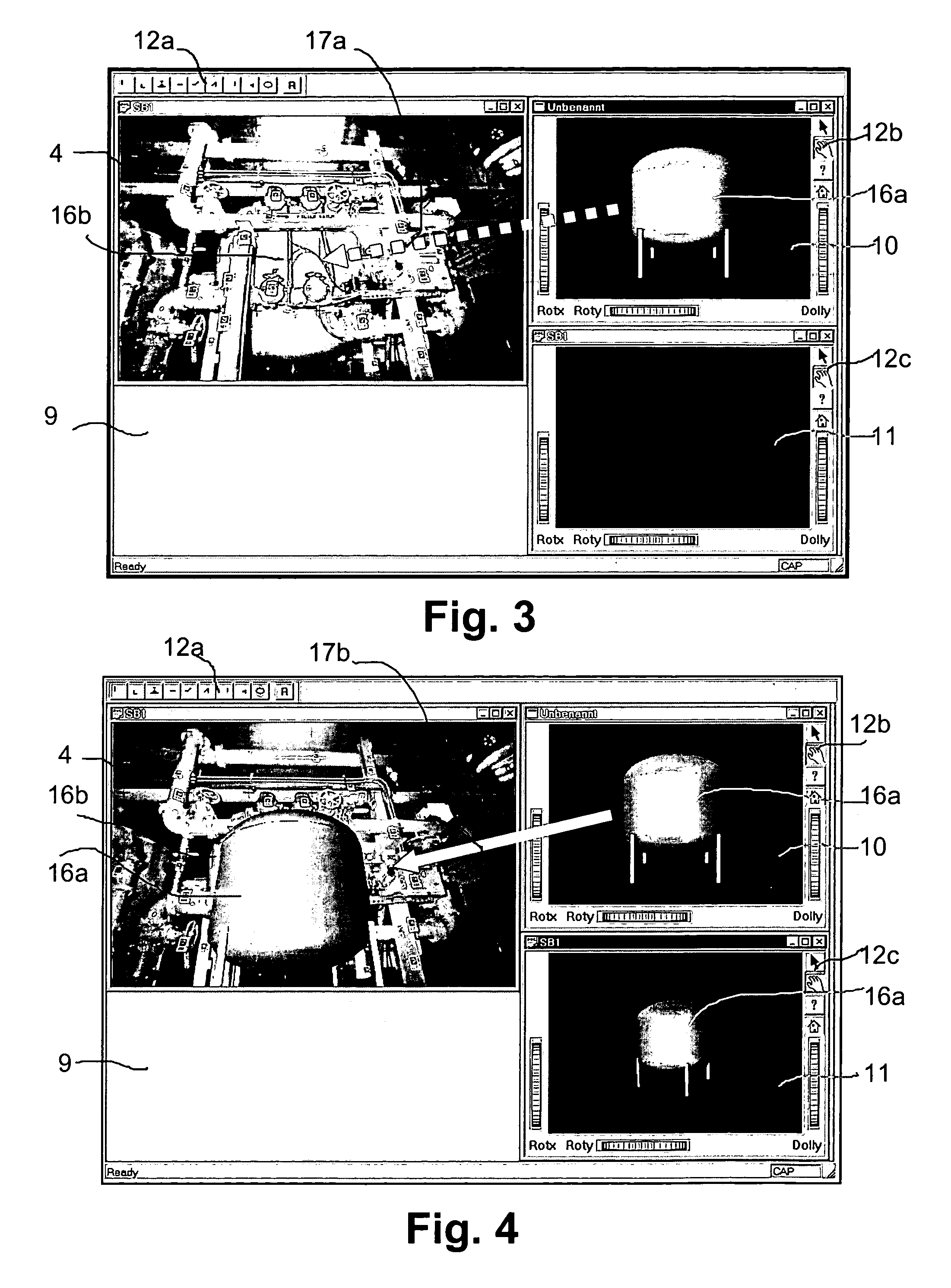

Device and method for generating a virtual model of an installation

InactiveUS7054793B2Simple wayEasy to installComputer controlSimulator controlImaging analysisSimulation

The invention relates to a method and a device for generating a virtual installation model (2) as an image of a real installation (1). As a database therefor, digital picture data (4) representing pictures of a real installation (1) on the one hand and installation components (13) of a component library (6) on the other hand are used. The data of the installation components as well as the digital picture data (4) of the real installation (1) is evaluated by means of an image analysis (5). Based on this analysis, the identified installation components (13) are assigned to the virtually generated installation model (2). The virtual image of the real installation thus created serves to document the actual structure of the installation / facility, to simplify failure analysis, e.g., in areas that are difficult to access, and / or to operate and monitor the installation / facility. In addition to geometric data, functional data, etc. of the installation components are also stored.

Owner:SIEMENS AG

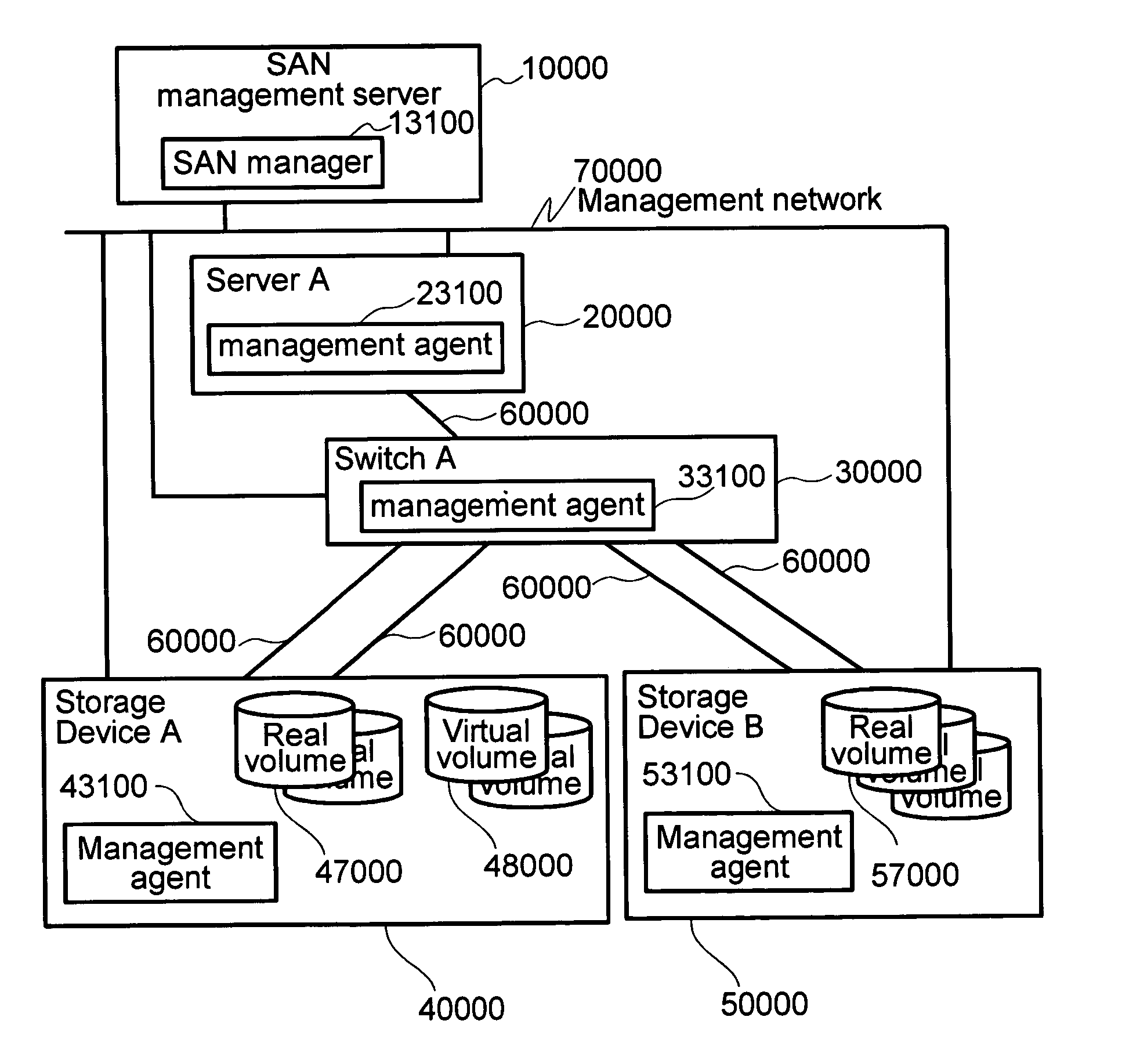

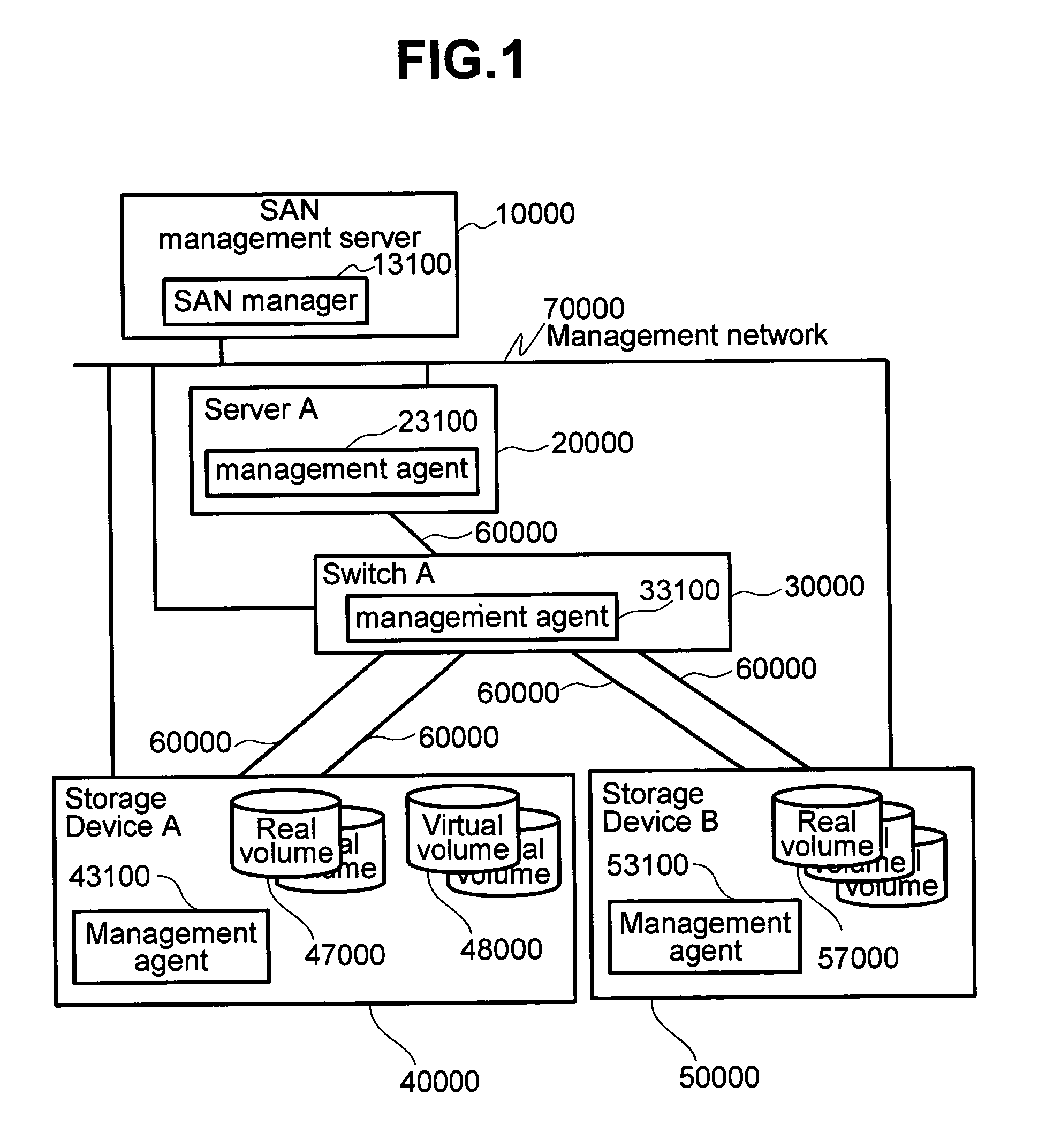

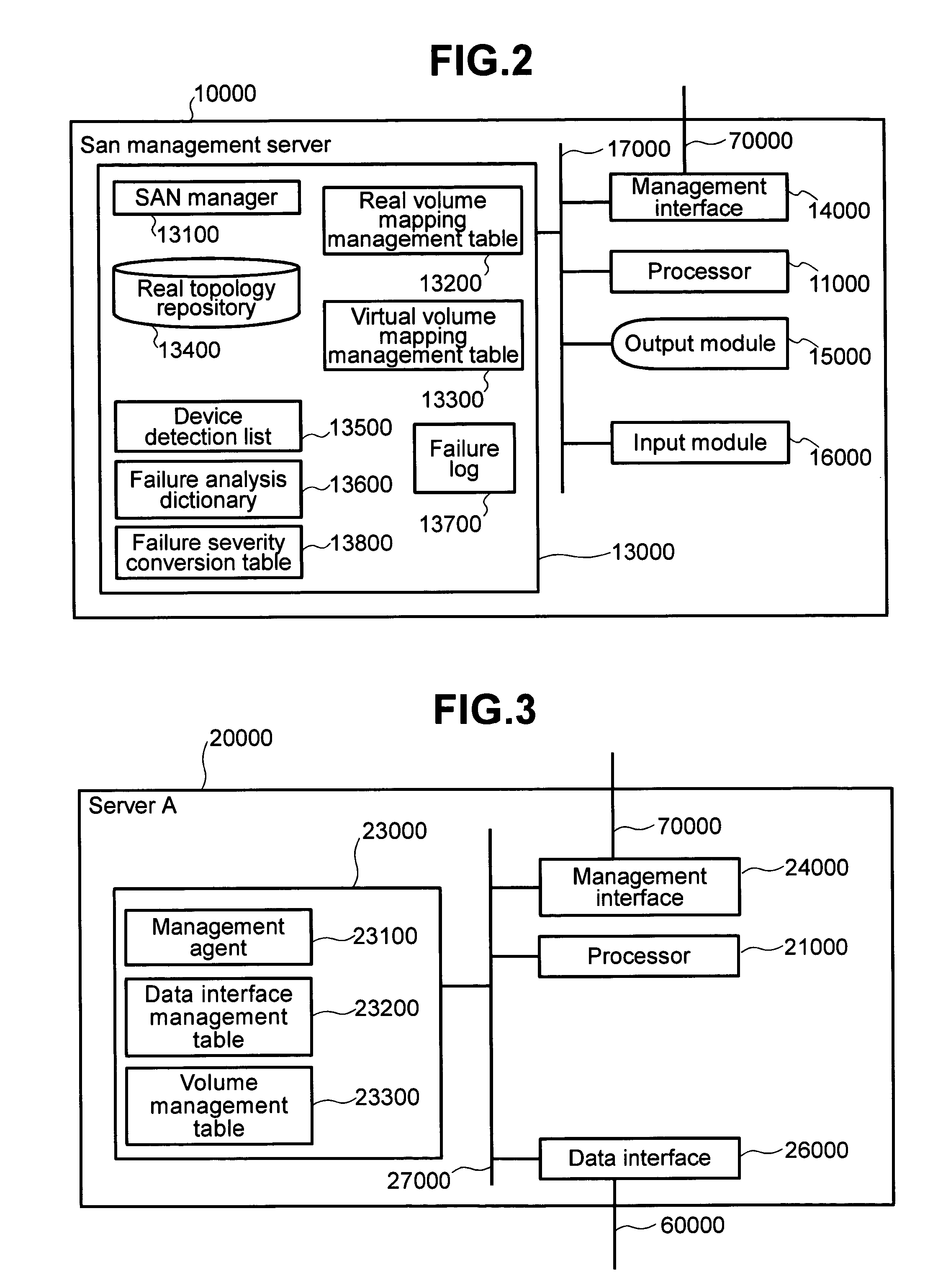

Failure information management method and management server in a network equipped with a storage device

InactiveUS7076688B2The degree of freedom becomes largerIncrease management costsInput/output to record carriersFault responseFailure analysisDevice failure

Owner:HITACHI LTD

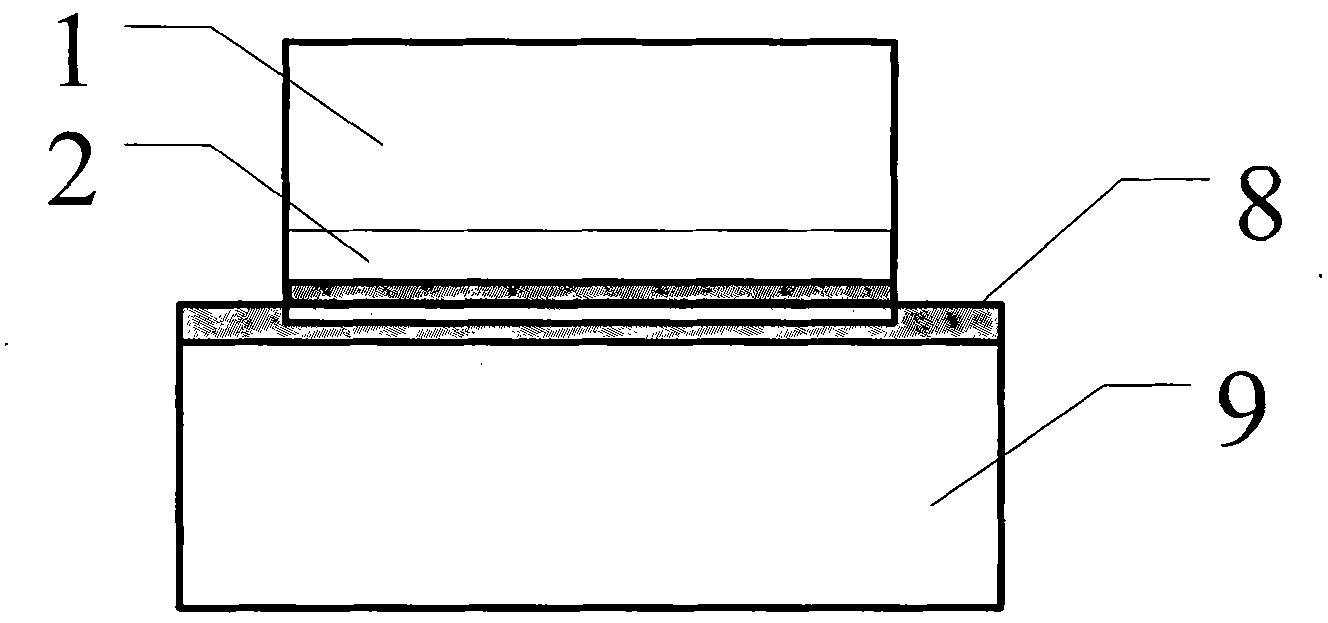

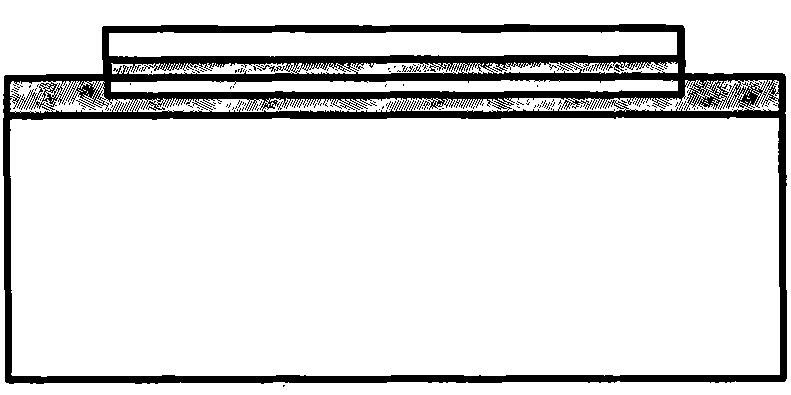

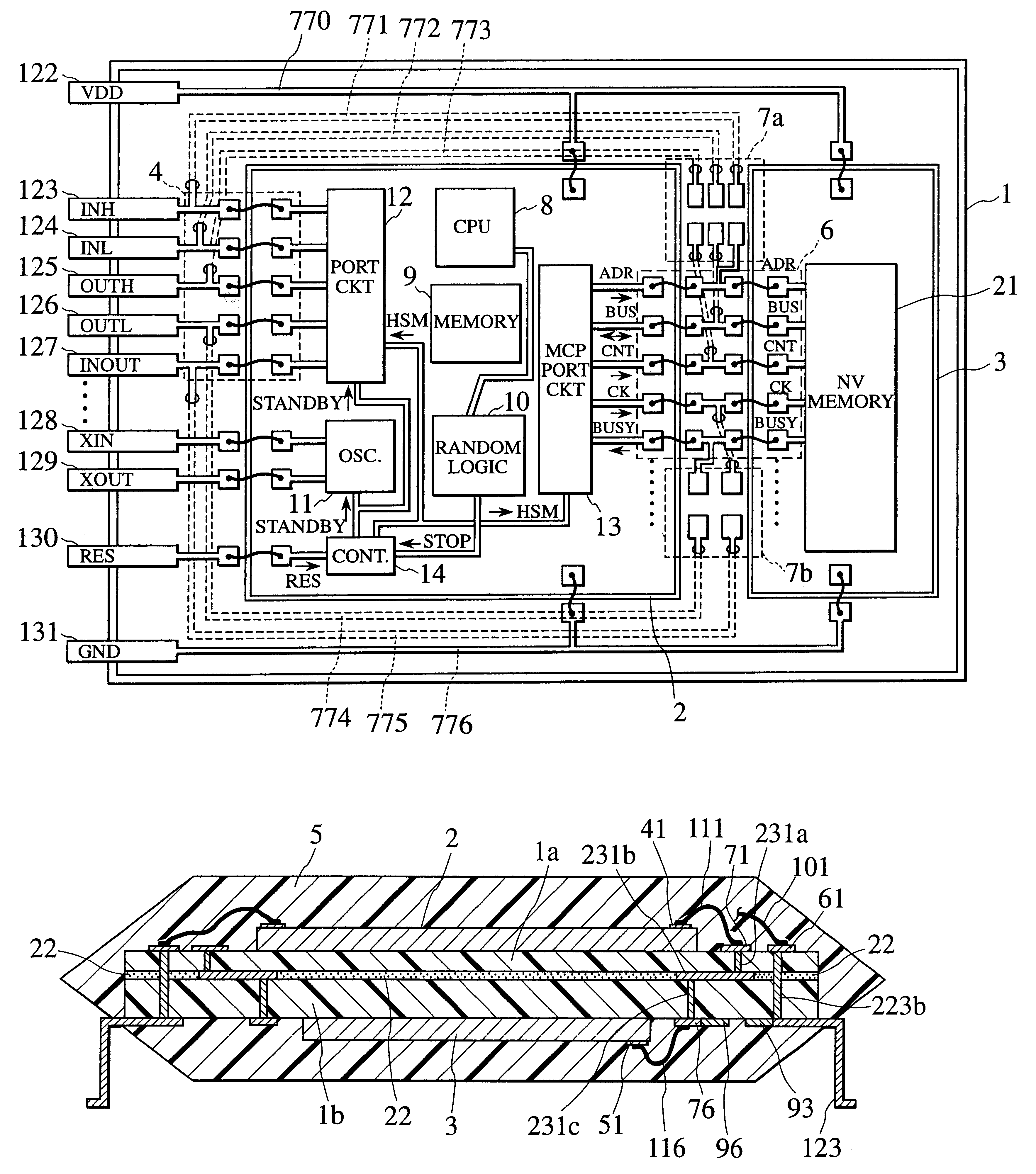

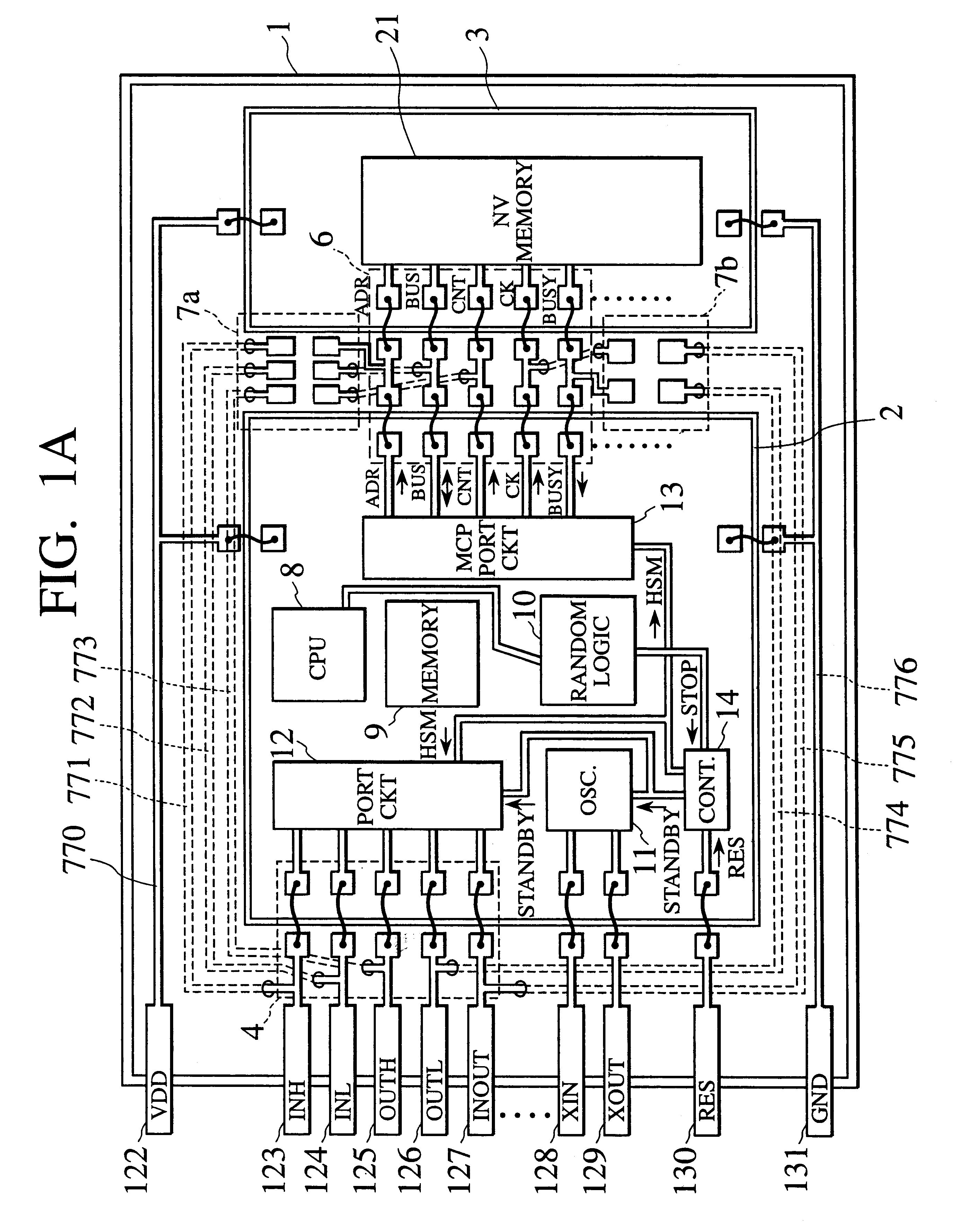

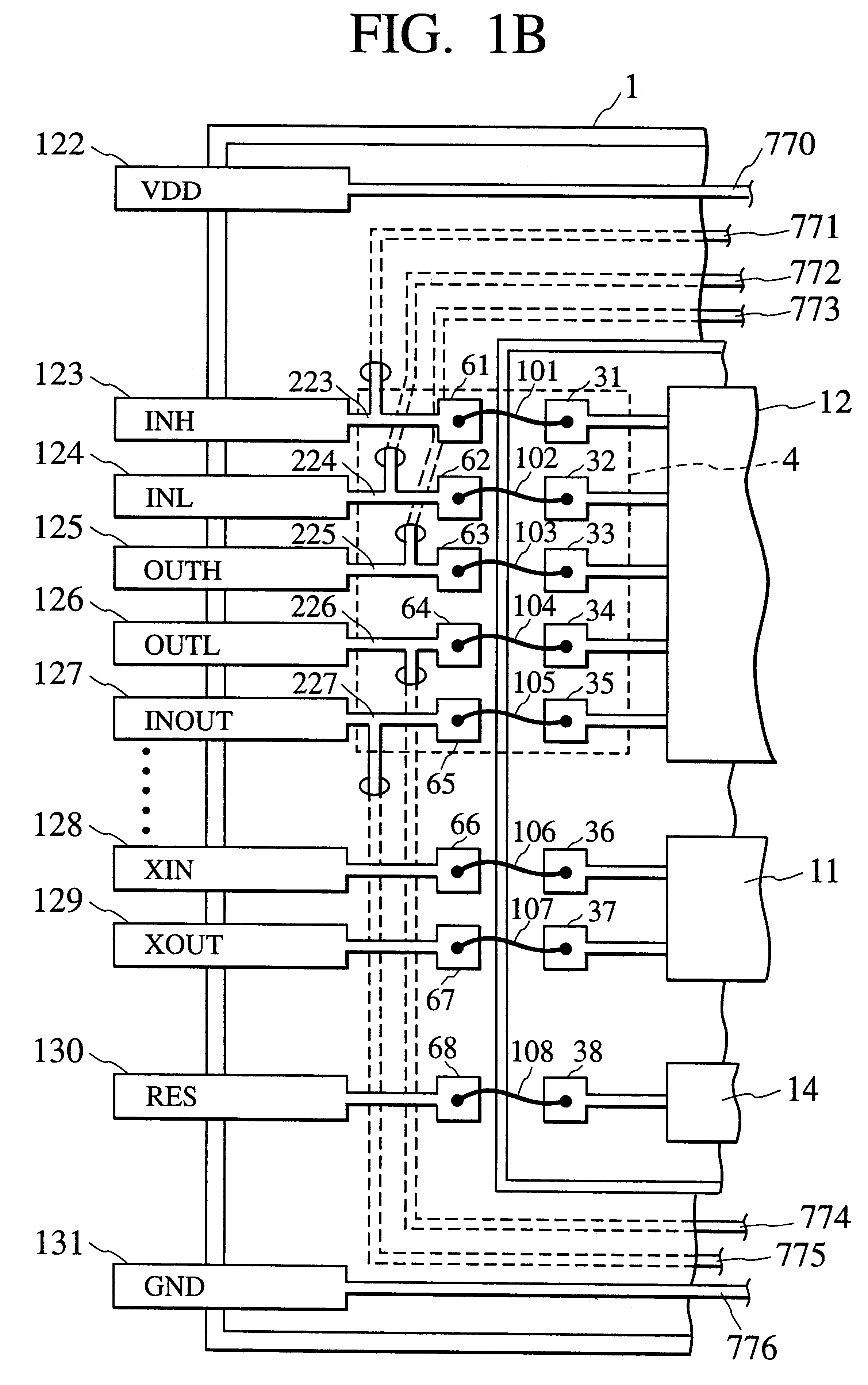

Multi chip package (MCP) applicable to failure analysis mode

InactiveUS6255729B1Easy to analyzeShort timeSemiconductor/solid-state device testing/measurementElectronic circuit testingSemiconductor chipEngineering

An MCP has an MCP substrate, first and second semiconductor chips mounted on the MCP substrate, MCP leads connected to perimeter of the MCP substrate. MCP terminal wires disposed on the MCP substrate connect the MCP leads to the first semiconductor chip. Interface signal wires disposed on the MCP substrate connect the first and second semiconductor chips to each other. The MCP further has first and second extra bonding pads. The first extra bonding pad electrically connects to the interface signal wires. The second extra bonding pad electrically connects to the MCP leads. The second extra bonding pad is arranged near the first extra bonding pad. The first and second extra bonding pads are designed to be electrically isolated from each other in a normal usage condition. However, the first and second extra bonding pads are electrically connected to each other when failure analysis is required. Outputs from the port circuit and the MCP port circuit are inhibited by a control circuit mounted on the first semiconductor chip, so that a signal can be exchanged between the second semiconductor chip and an external circuit without using the first semiconductor chip. In this manner, the first and second extra bonding pads are electrically connected to each other, so that the second semiconductor chip can be analyzed, electrically independently of the first semiconductor chip.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com