Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11367 results about "Water cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water cooling is a method of heat removal from components and industrial equipment. Water may be a more efficient heat transfer fluid where air cooling is ineffective. In most occupied climates water offers the thermal conductivity advantages of a liquid with unusually high specific heat capacity and the option of evaporative cooling. Low cost often allows rejection as waste after a single use, but recycling coolant loops may be pressurized to eliminate evaporative loss and offer greater portability and improved cleanliness. Unpressurized recycling coolant loops using evaporative cooling require a blowdown waste stream to remove impurities concentrated by evaporation. Disadvantages of water cooling systems include accelerated corrosion and maintenance requirements to prevent heat transfer reductions from biofouling or scale formation. Chemical additives to reduce these disadvantages may introduce toxicity to wastewater. Water cooling is commonly used for cooling automobile internal combustion engines and large industrial facilities such as nuclear and steam electric power plants, hydroelectric generators, petroleum refineries and chemical plants. Other uses include cooling the barrels of machine guns, cooling of lubricant oil in pumps; for cooling purposes in heat exchangers; cooling products from tanks or columns; for cooling in HVAC in chillers , and recently, cooling of various major components inside high-end personal computers such as CPUs, GPUs, and motherboards. The main mechanism for water cooling is convective heat transfer.

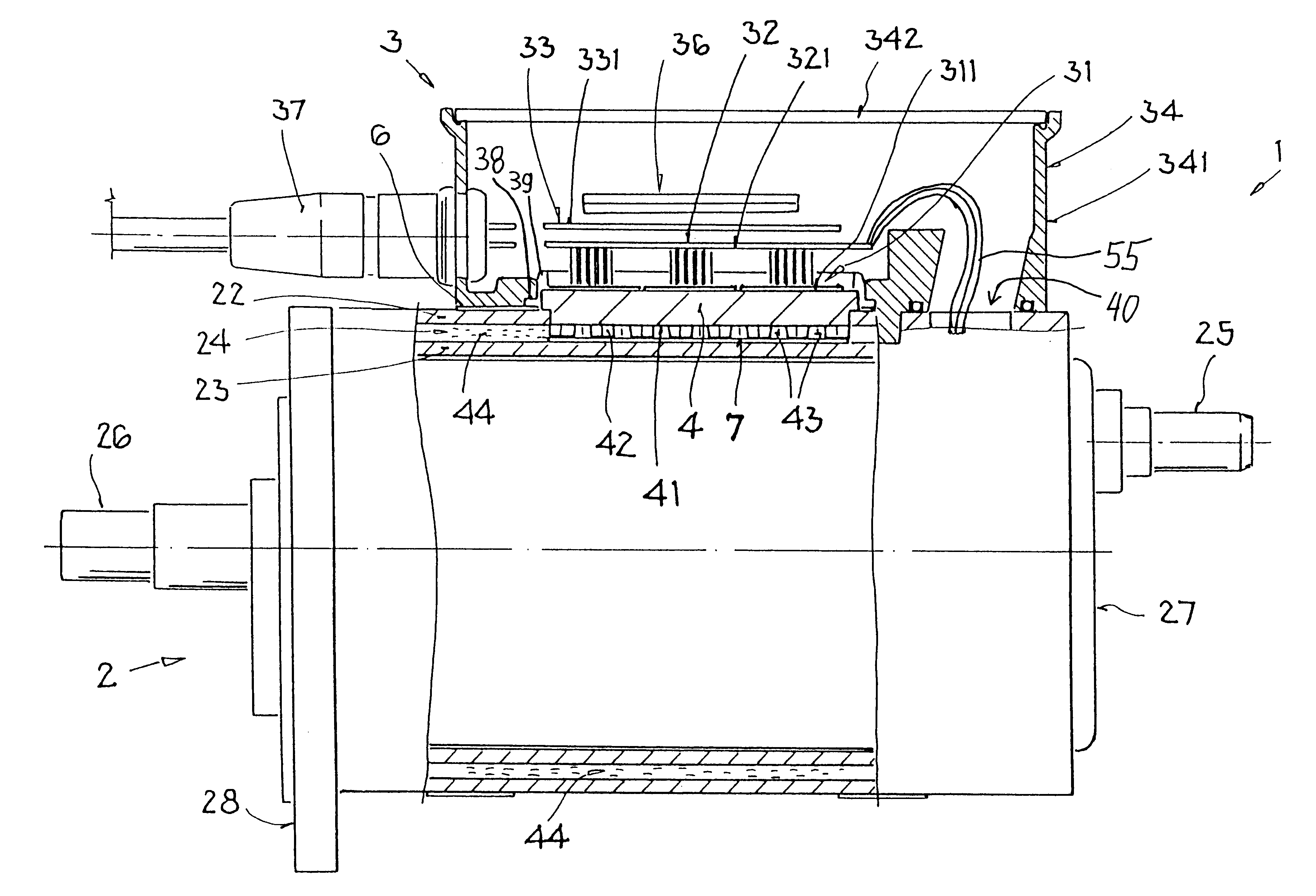

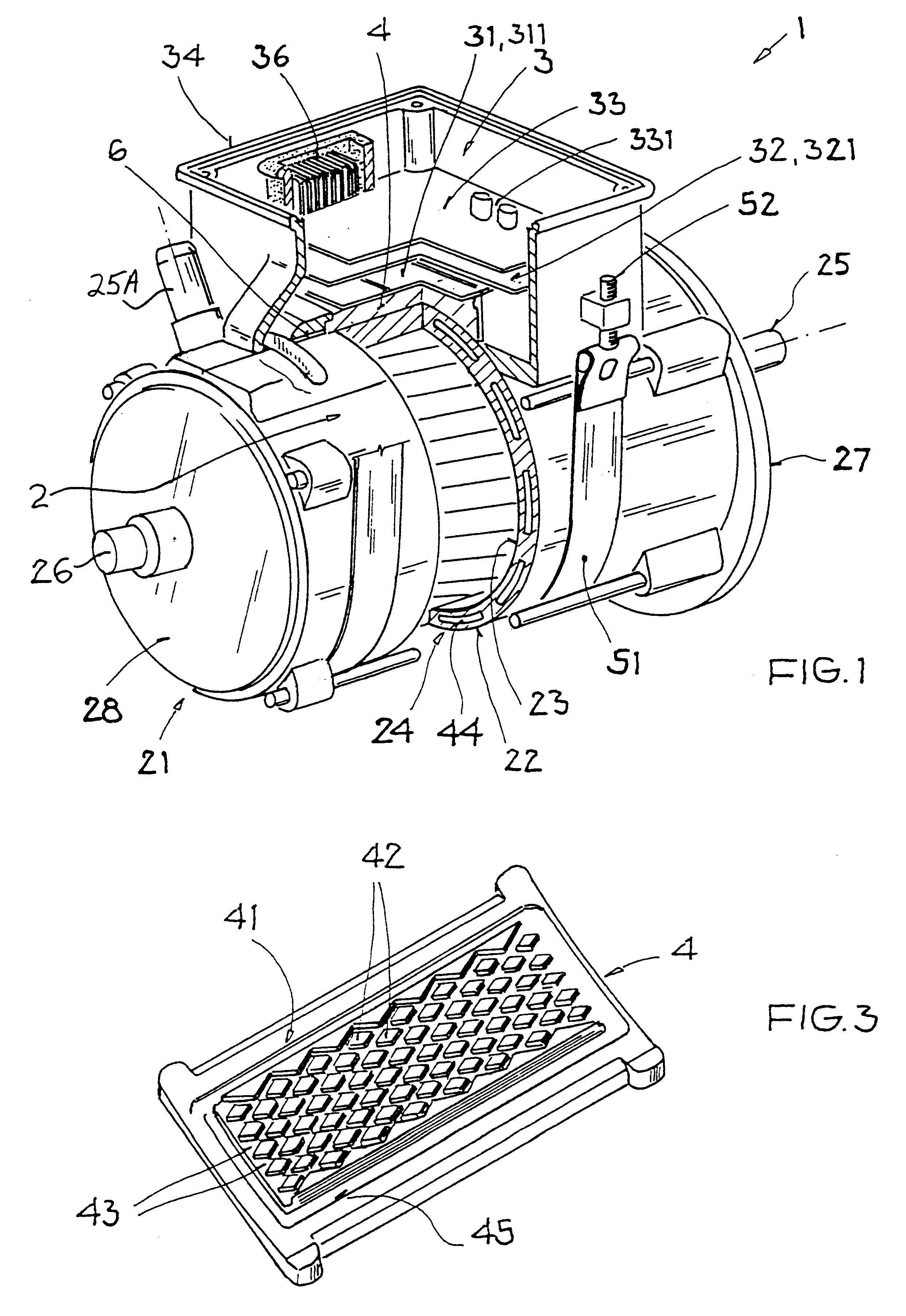

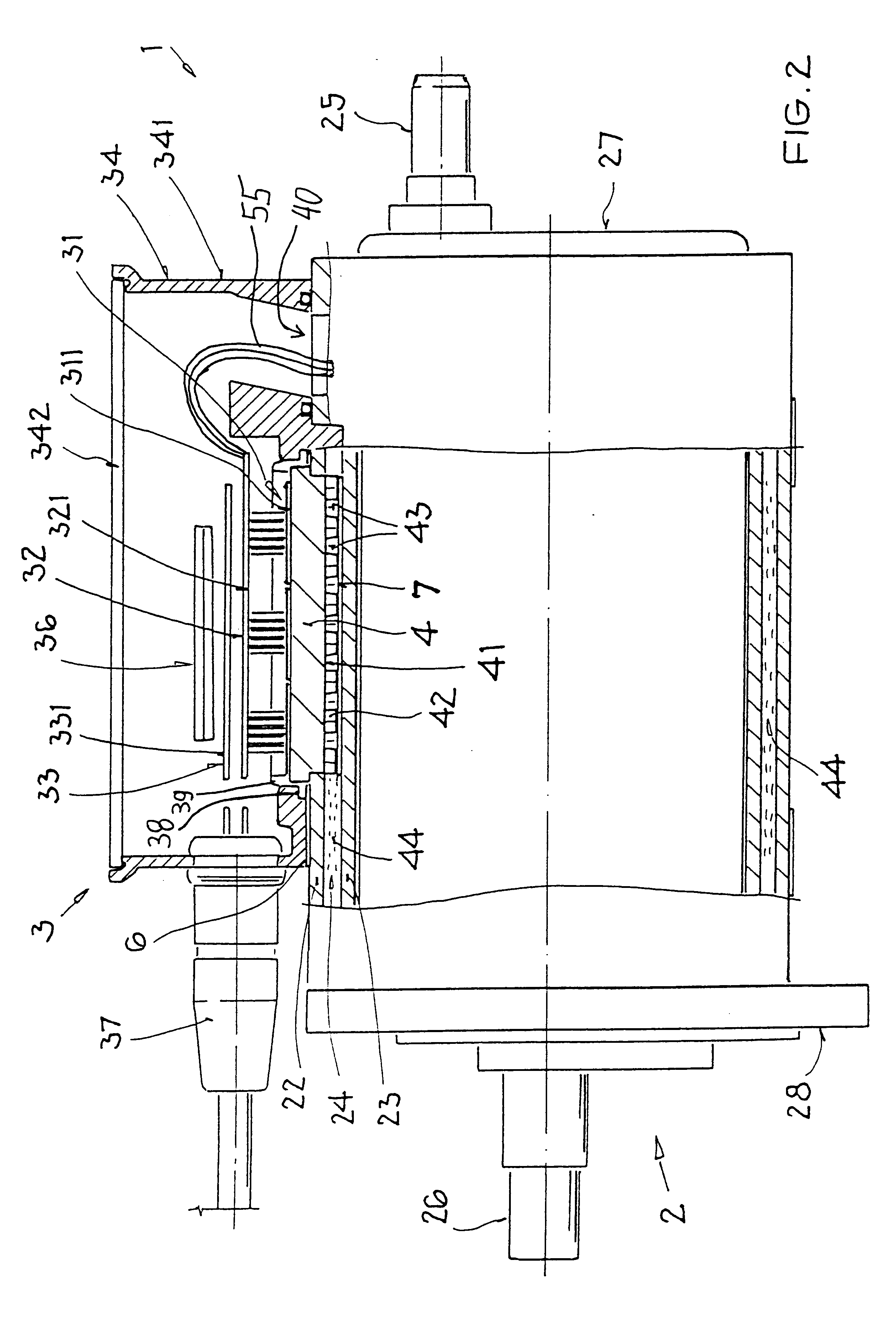

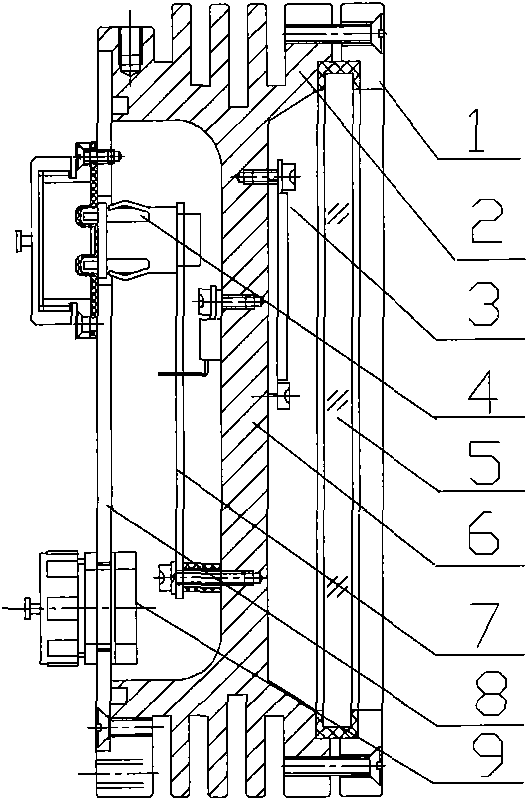

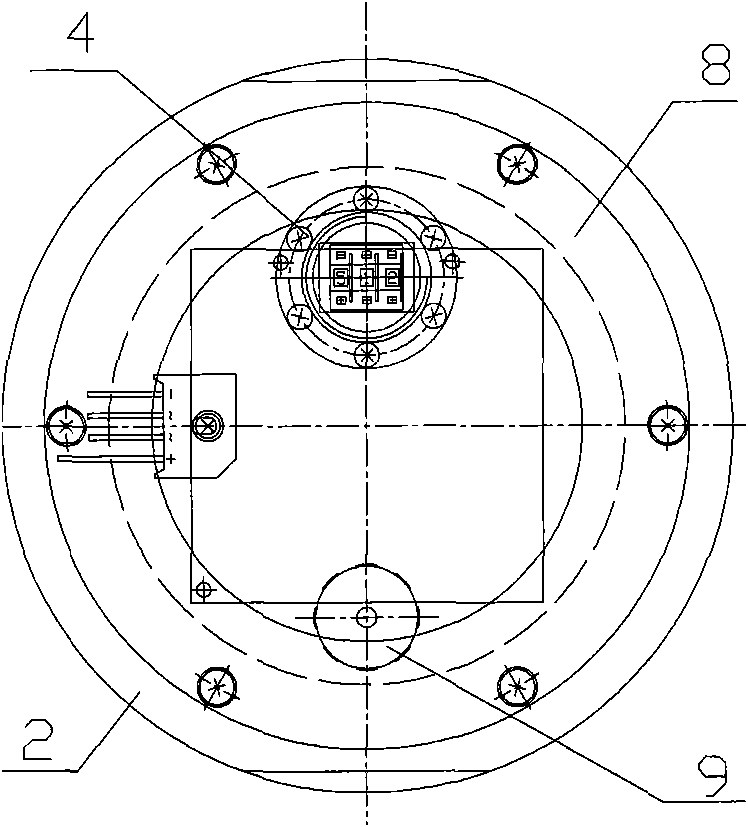

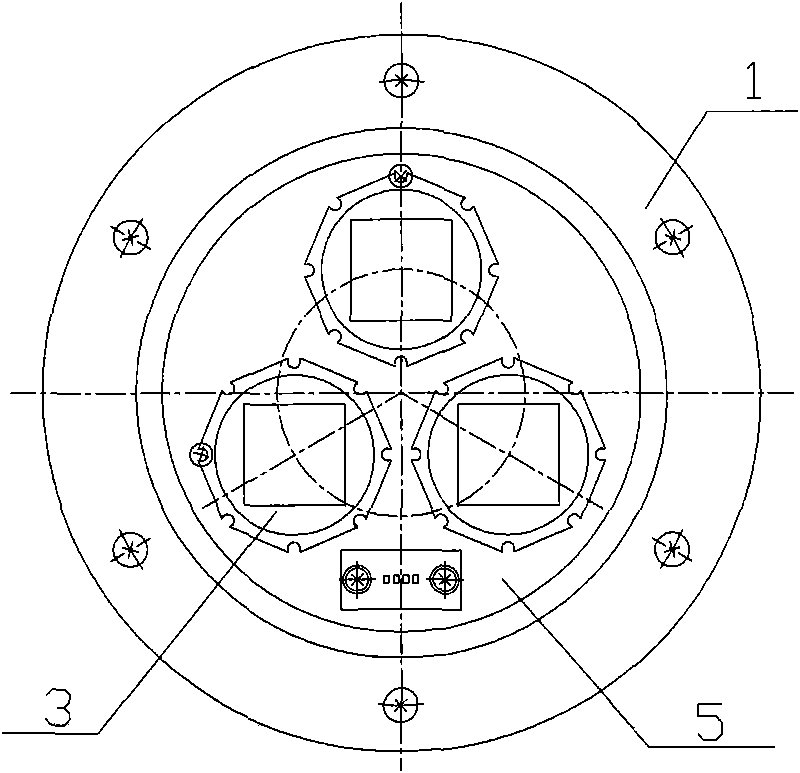

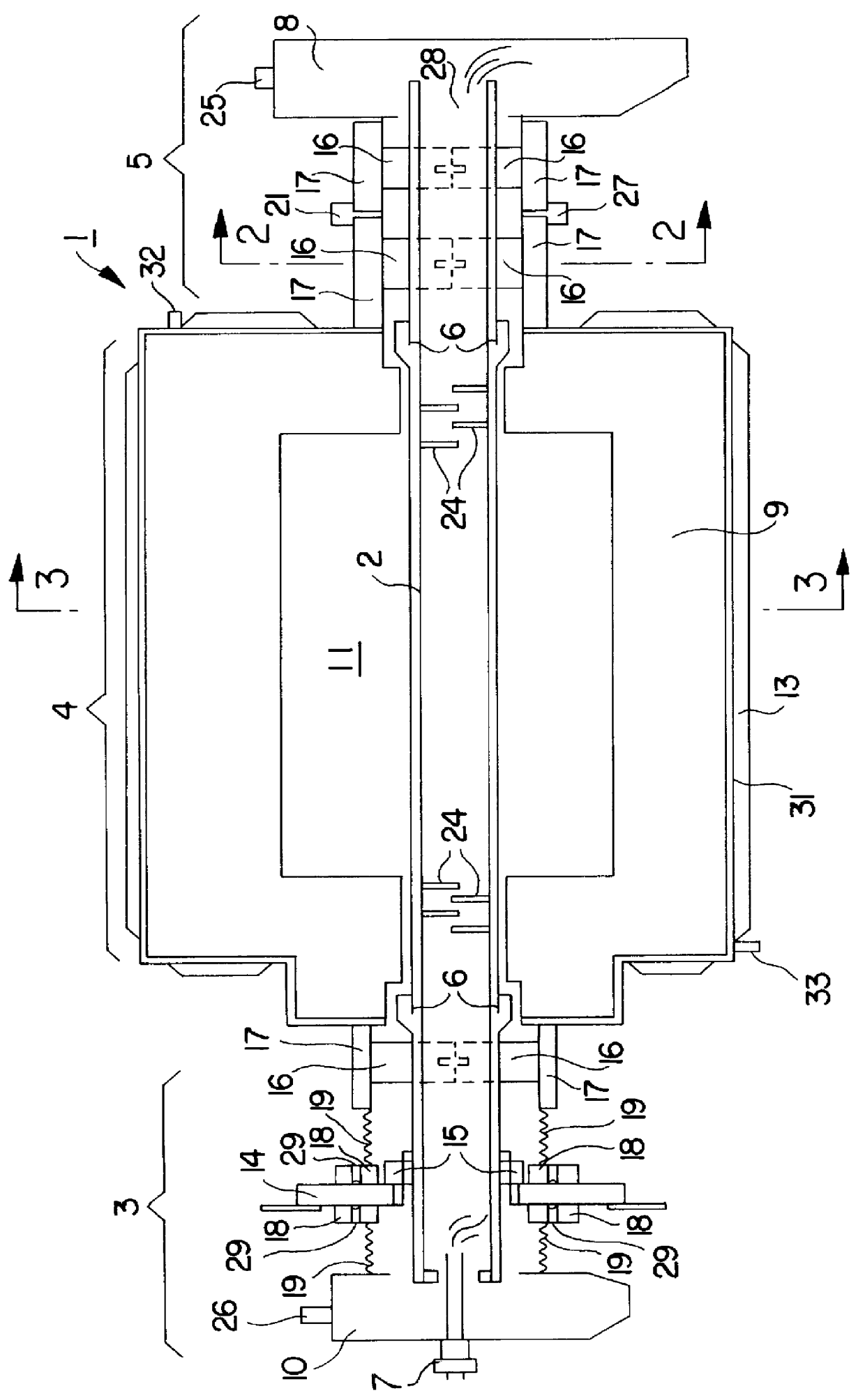

Integrated electric drive unit including an electric motor and an electronic control and monitoring module

InactiveUS6198183B1Small structural installation volumeReduce manufacturing costAssociation with control/drive circuitsMagnetic circuit rotating partsElectricityDouble wall

An electric drive unit includes an electronic control and monitoring module integrally connected to an electric motor. The housing of the electric motor has a double-walled construction to form a water jacket with cooling water passages therein. The electronic module includes at least one high power component that requires cooling. This component is mounted directly on a cooling insert that extends through a recess in the electronic module housing and is inserted in an opening provided in the outer wall of the motor housing. In this manner, the cooling insert is integrated into the water jacket of the motor housing and is directly cooled by the cooling water flowing in the cooling passages. A very compact and reliable construction is achieved, in which the electric motor and the electronic module share a common water cooling circuit. External water hoses and external electrical connections between the electric motor and the electronic module are avoided.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

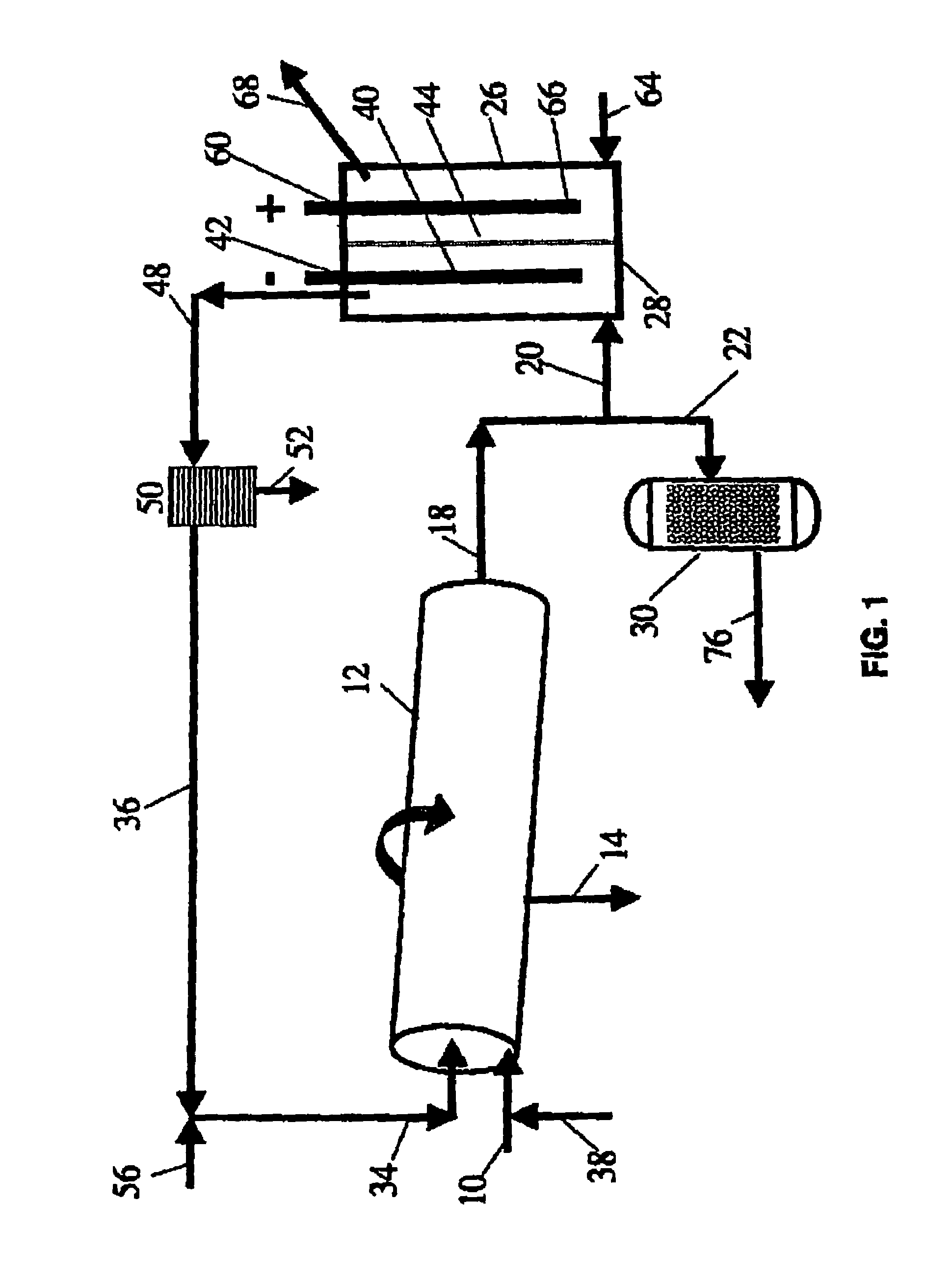

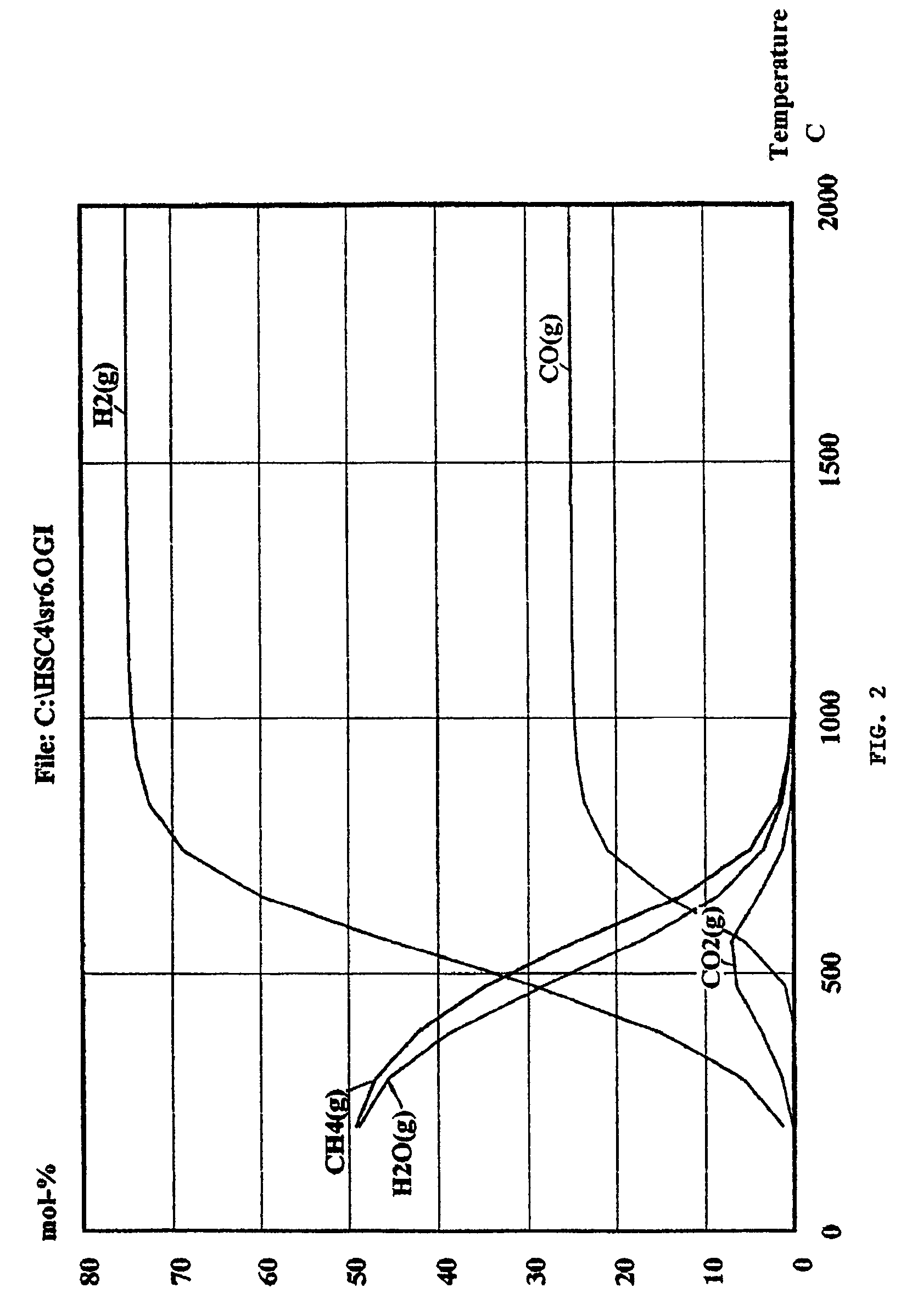

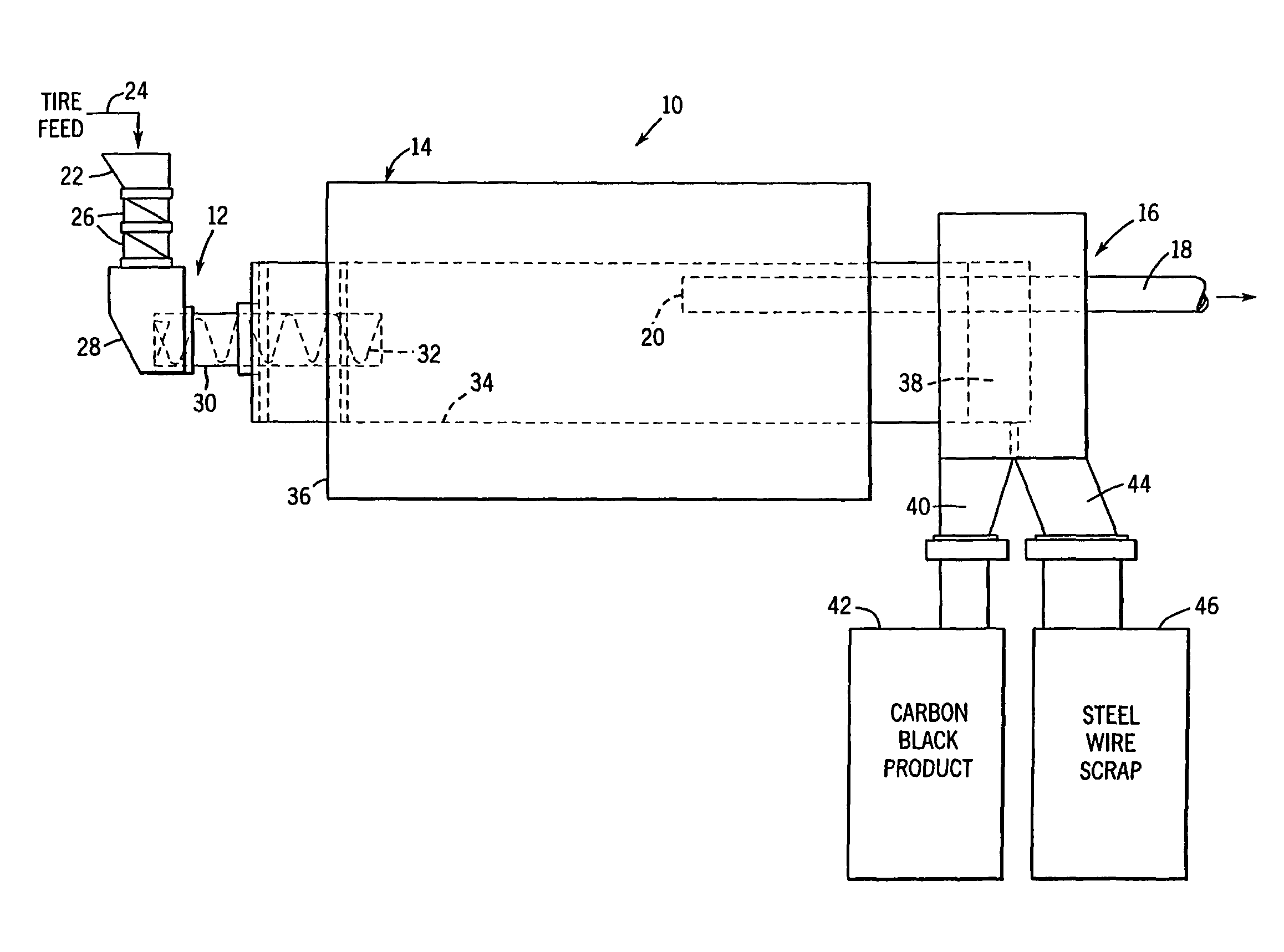

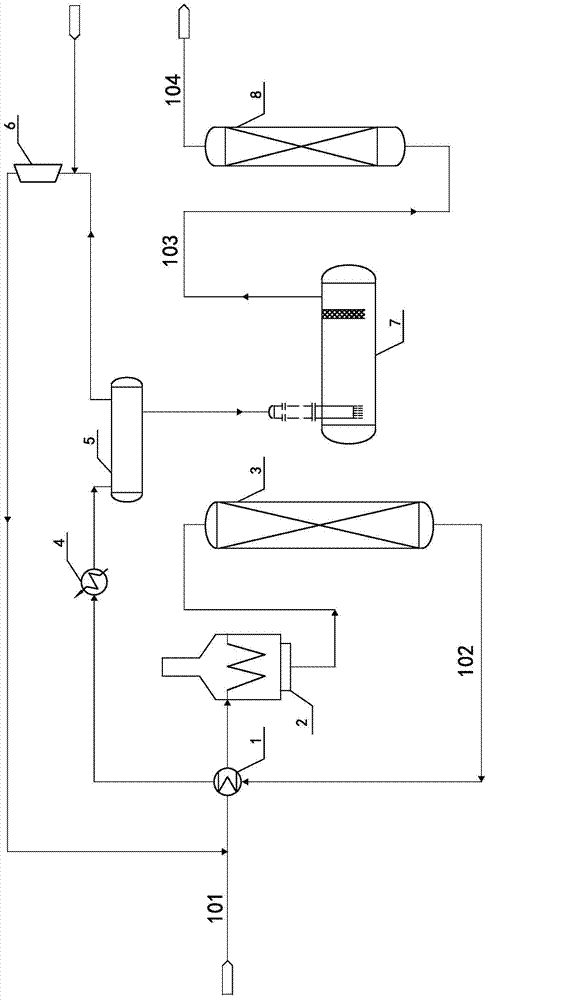

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

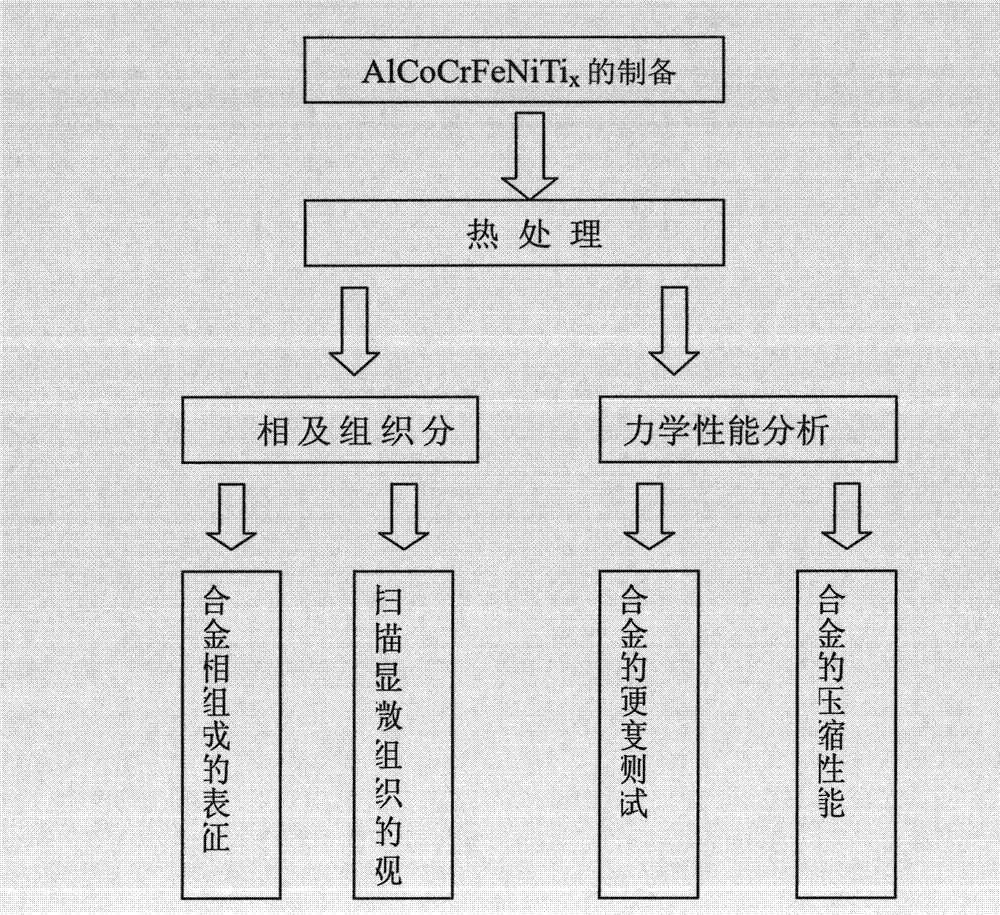

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

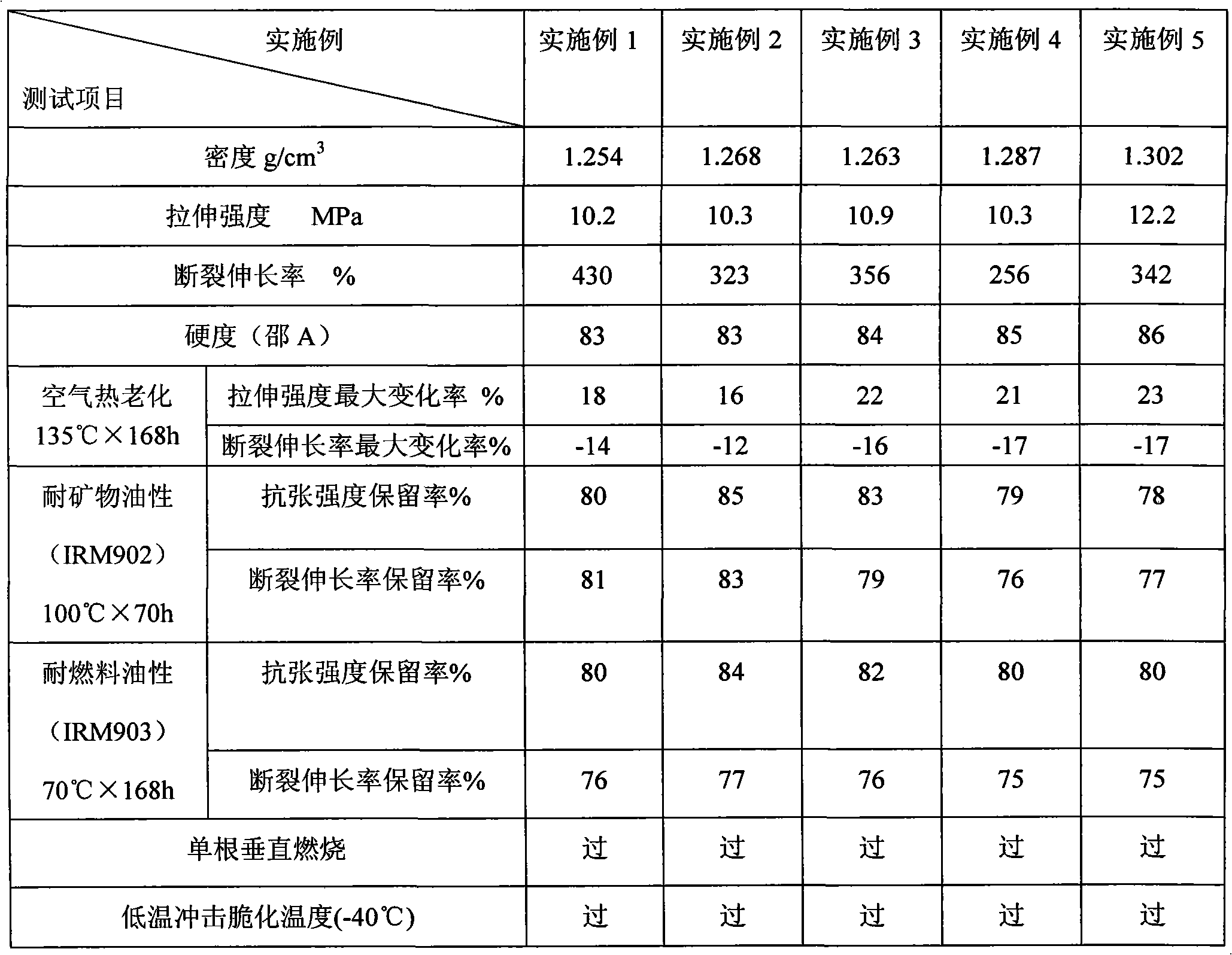

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

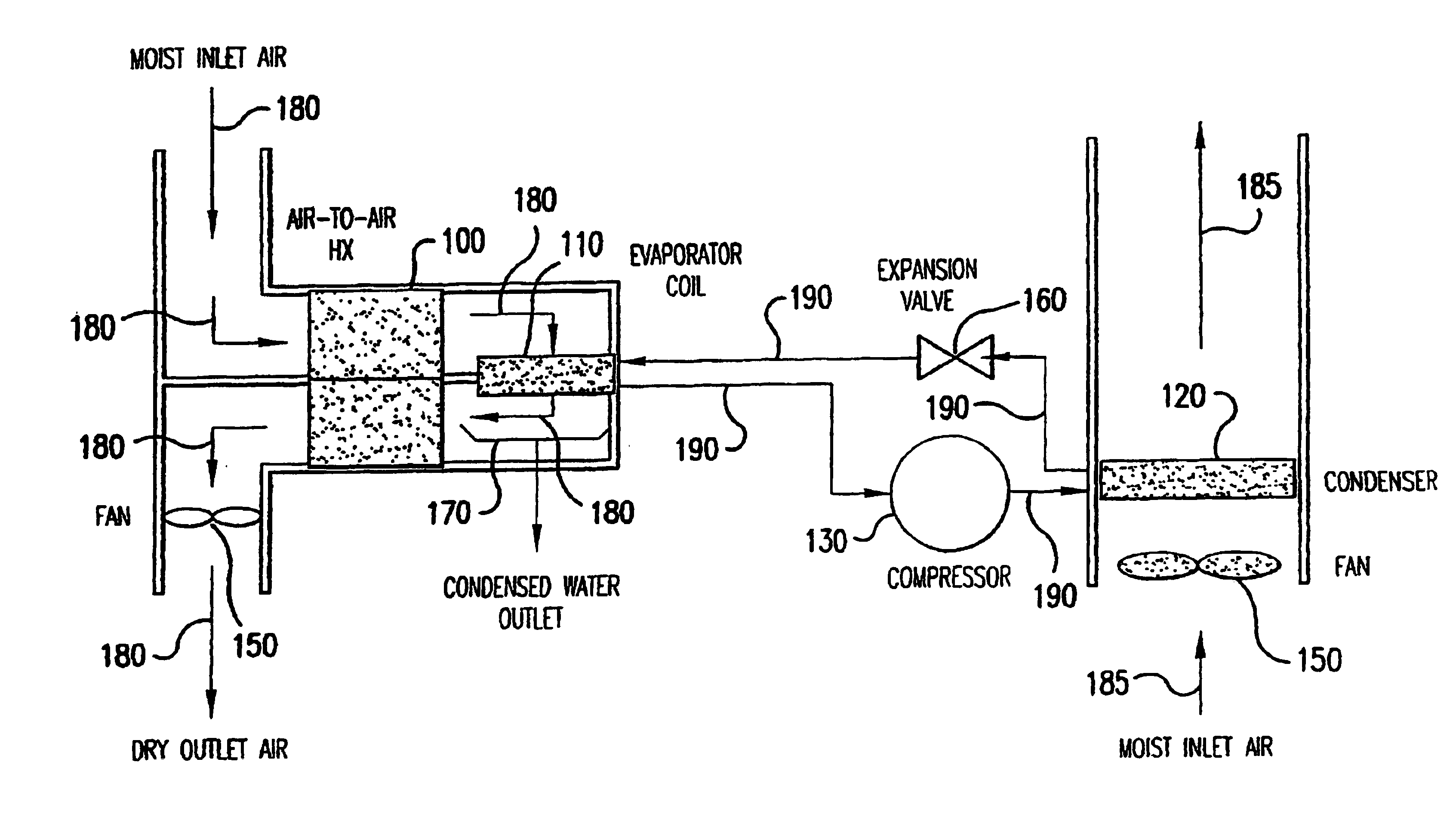

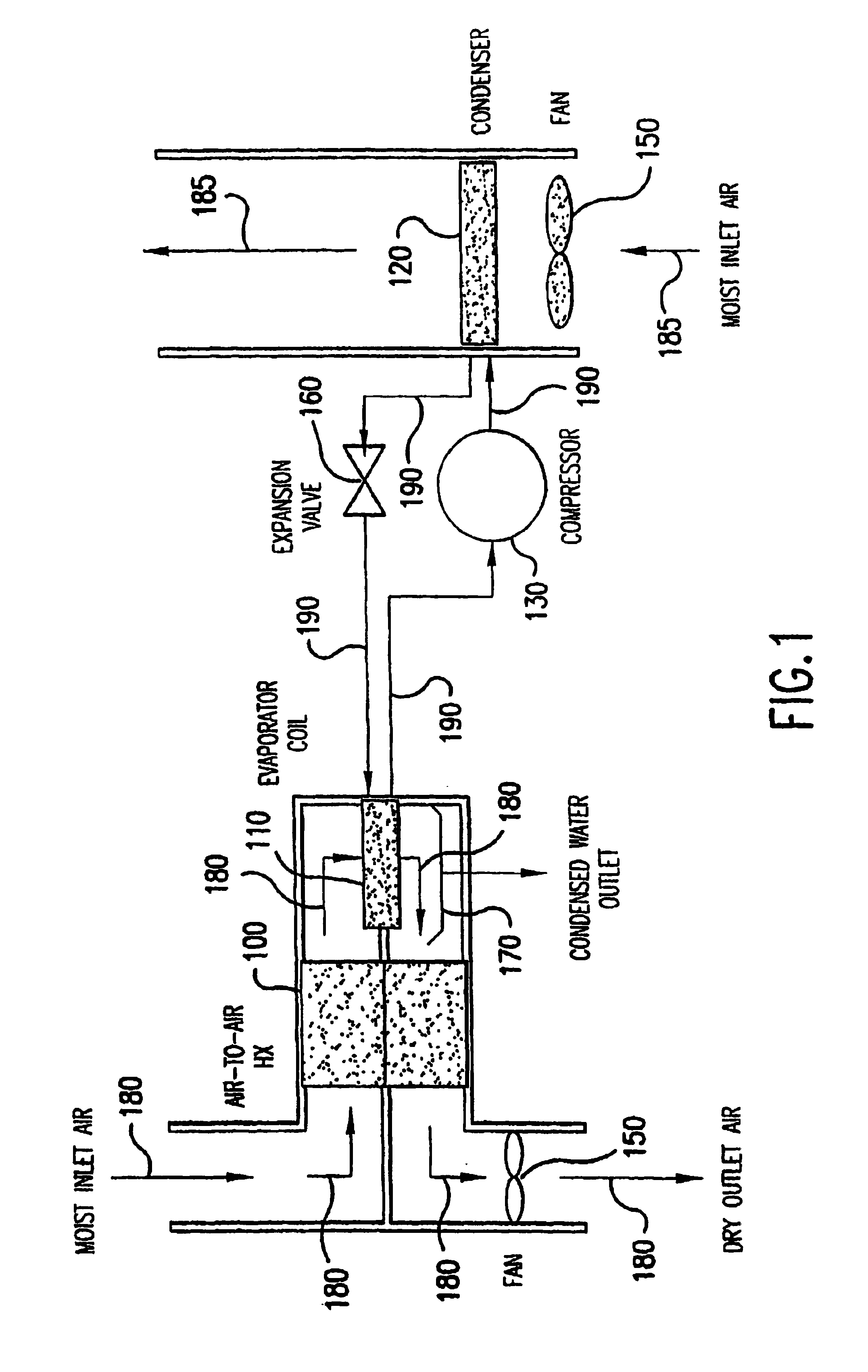

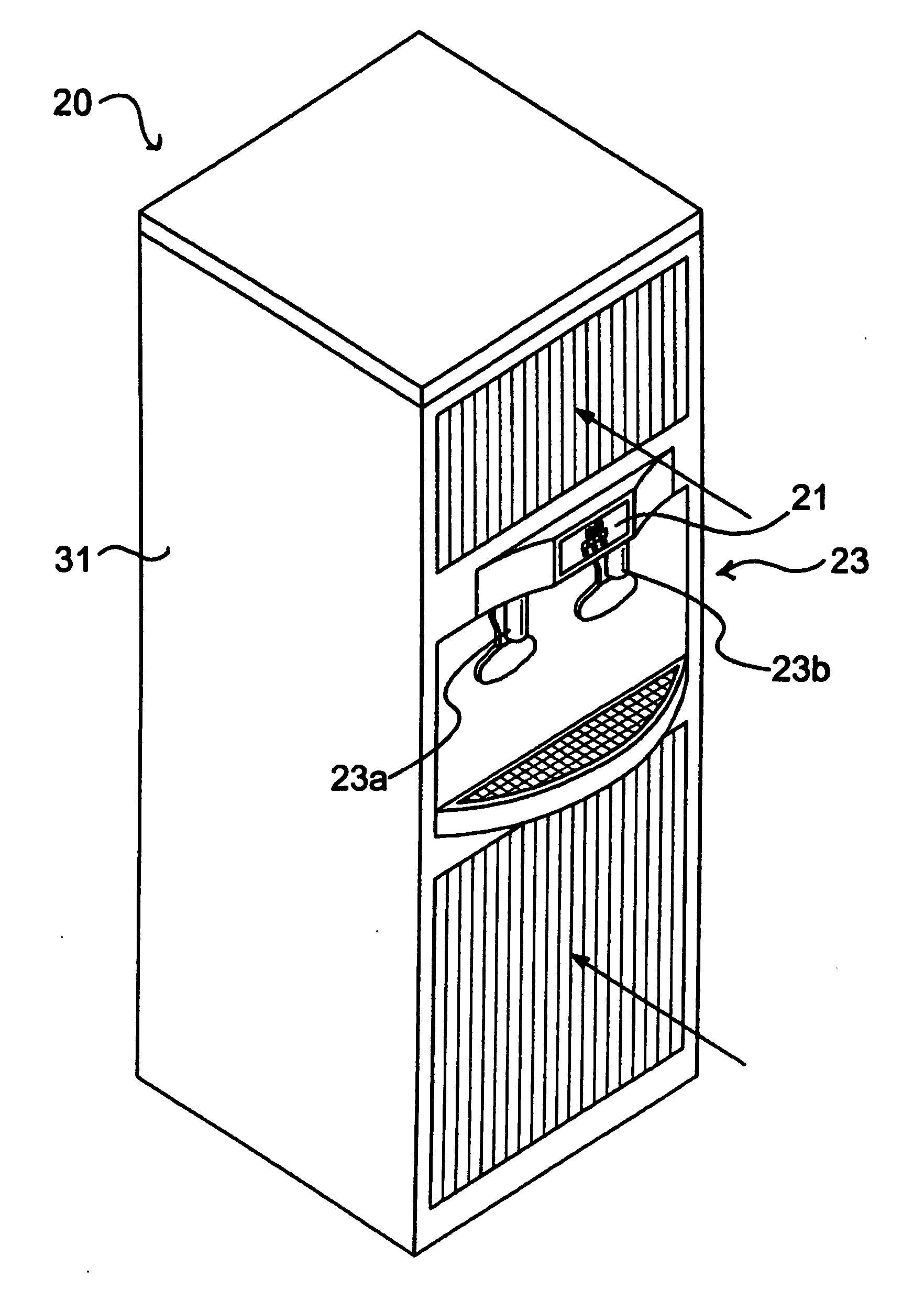

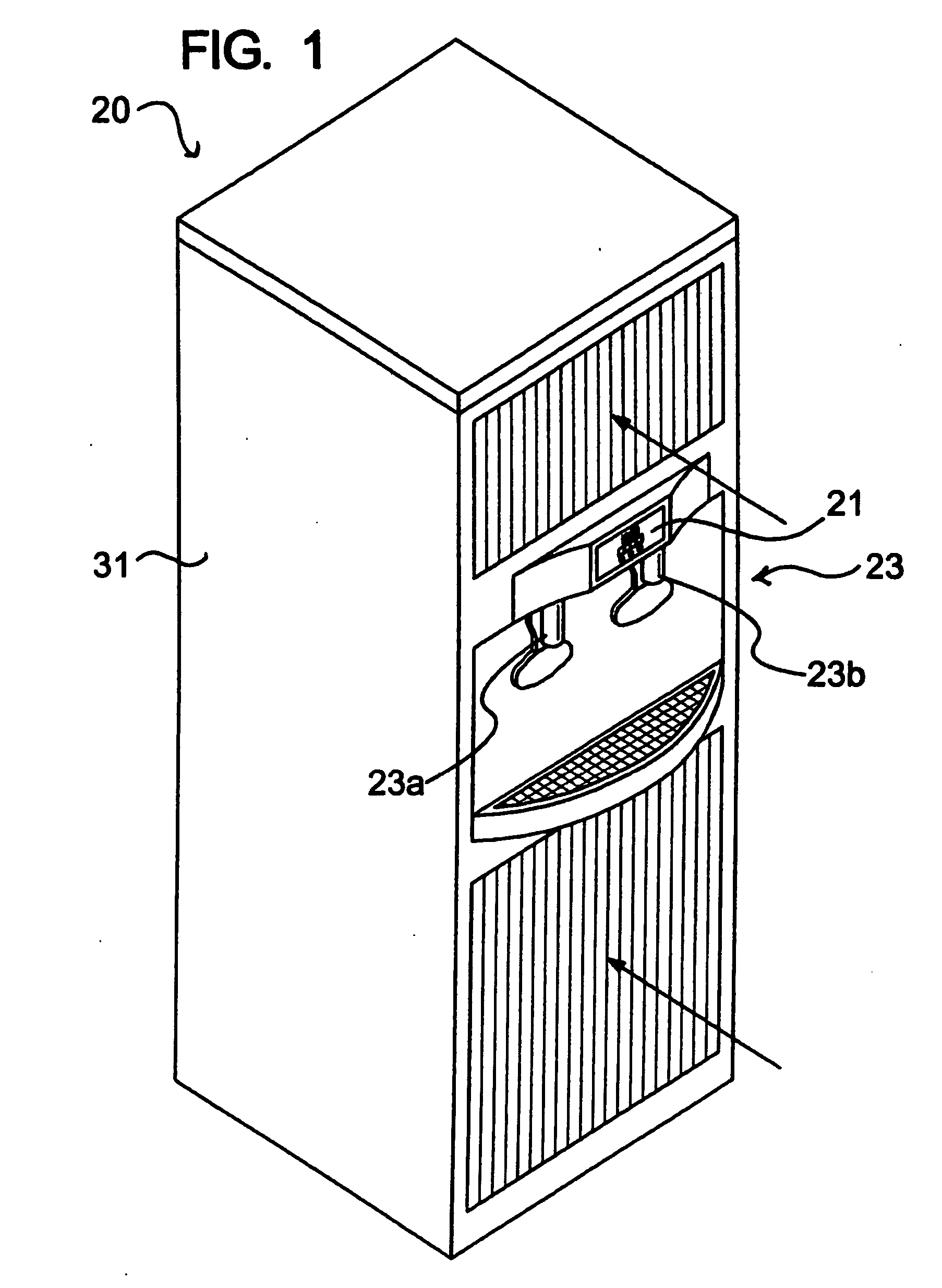

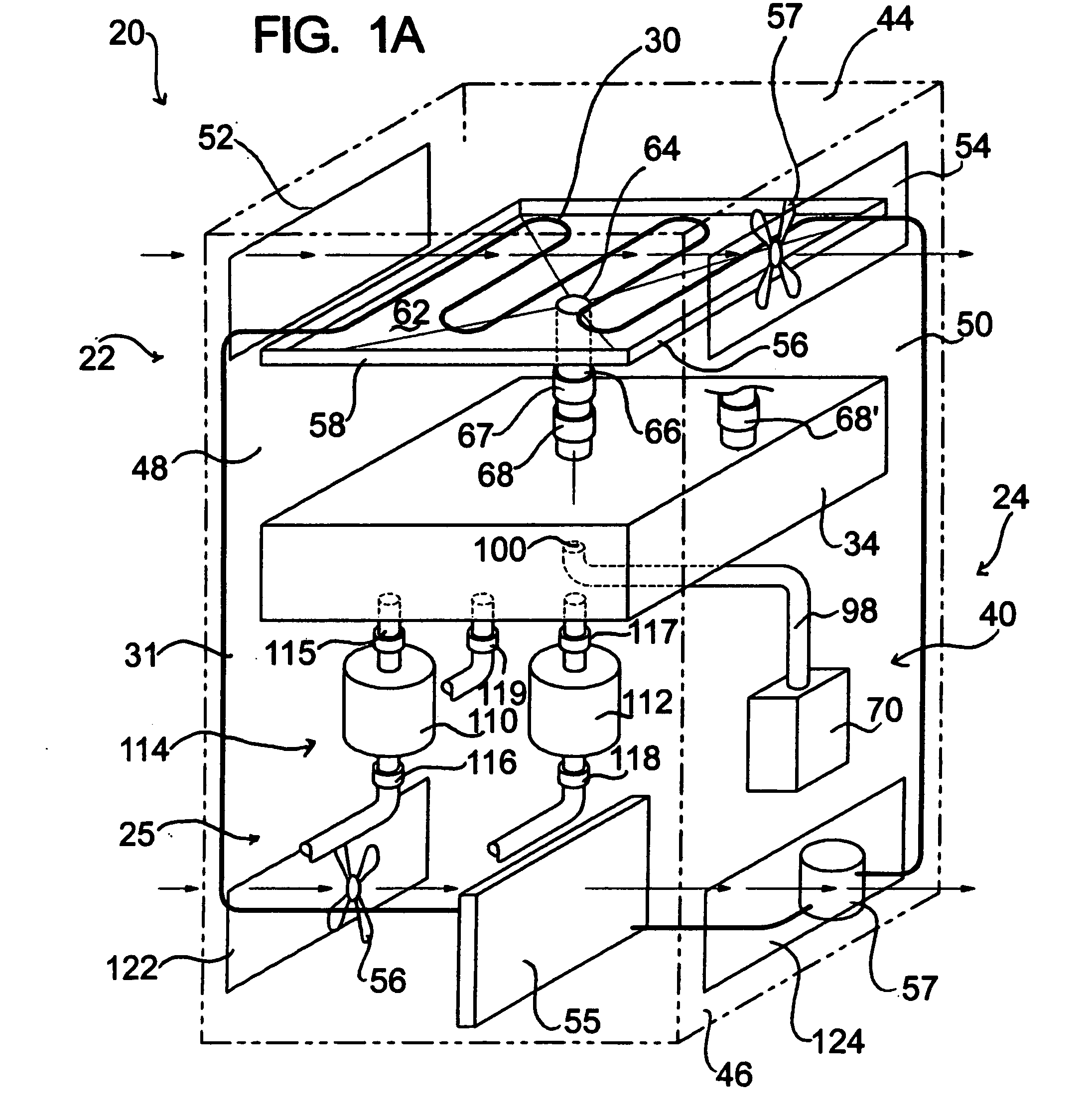

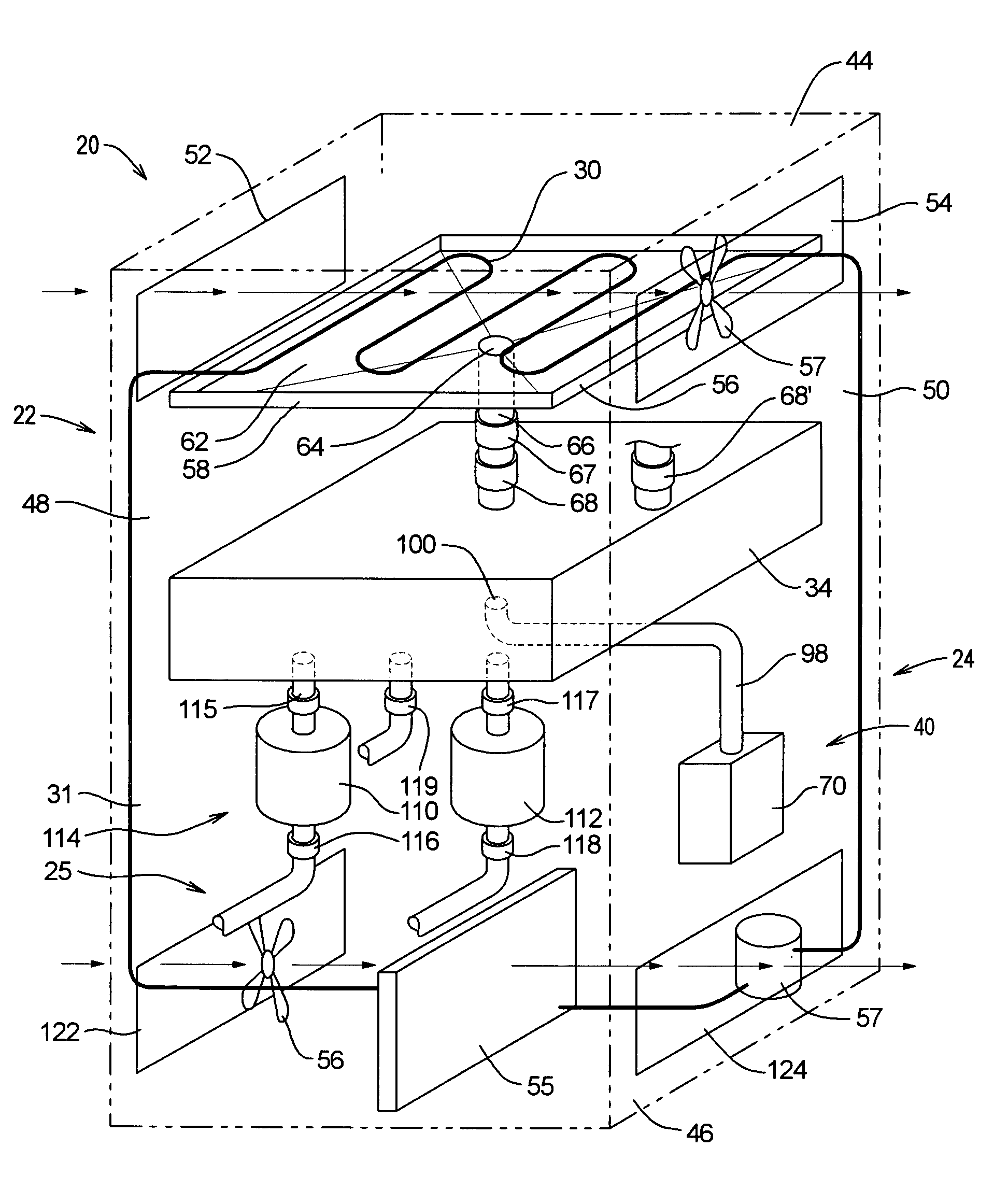

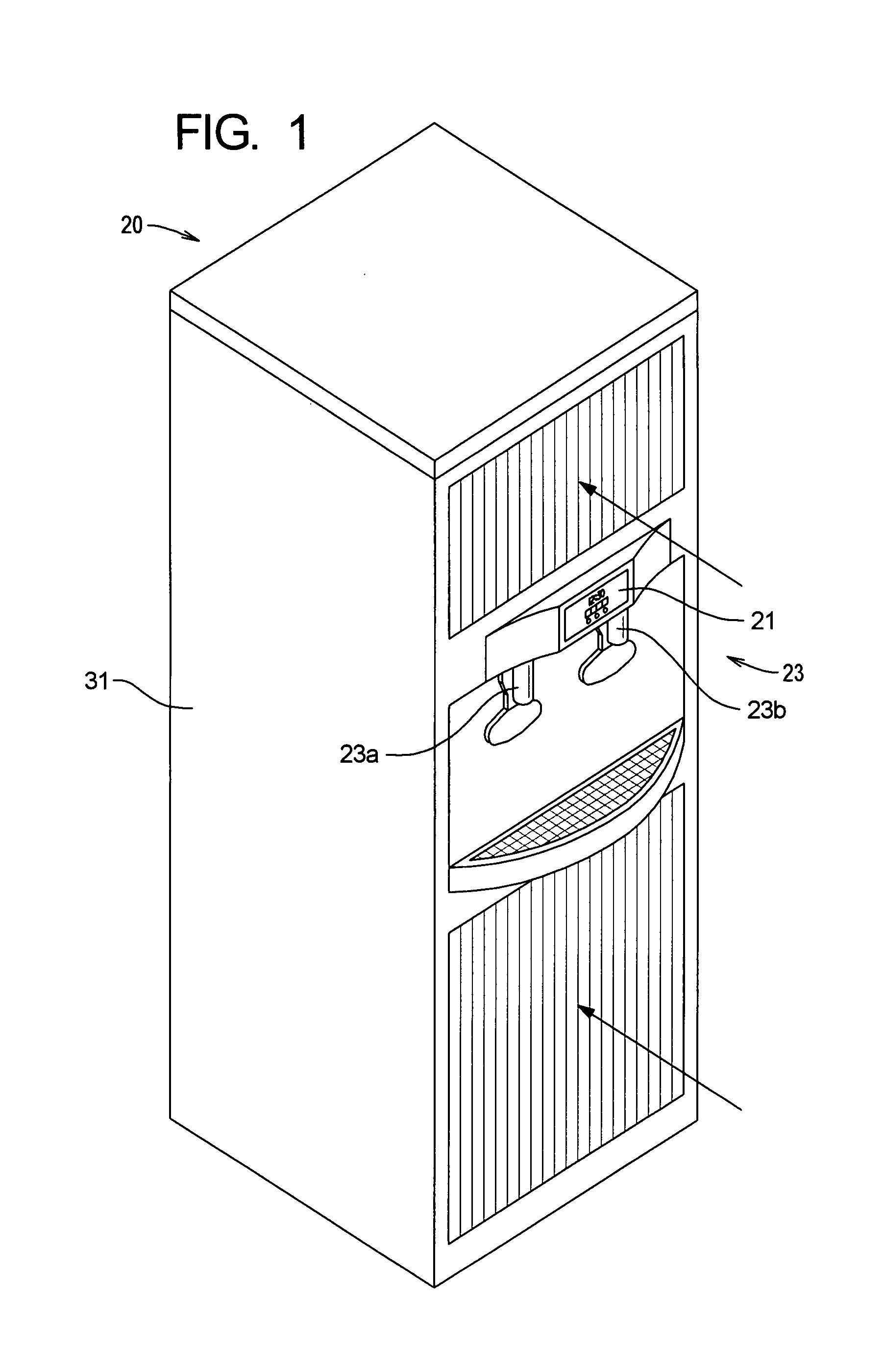

Device for collecting water from air

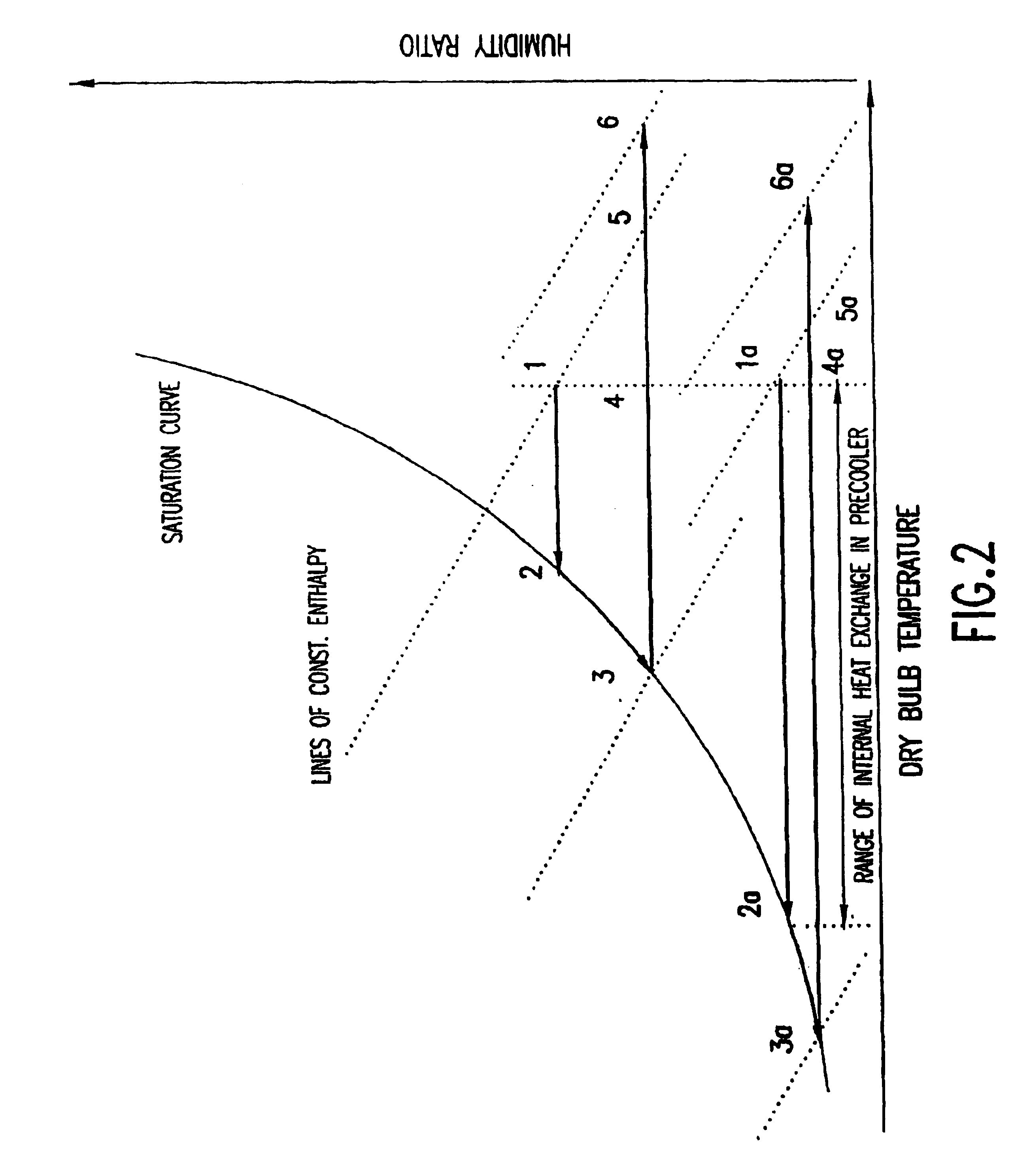

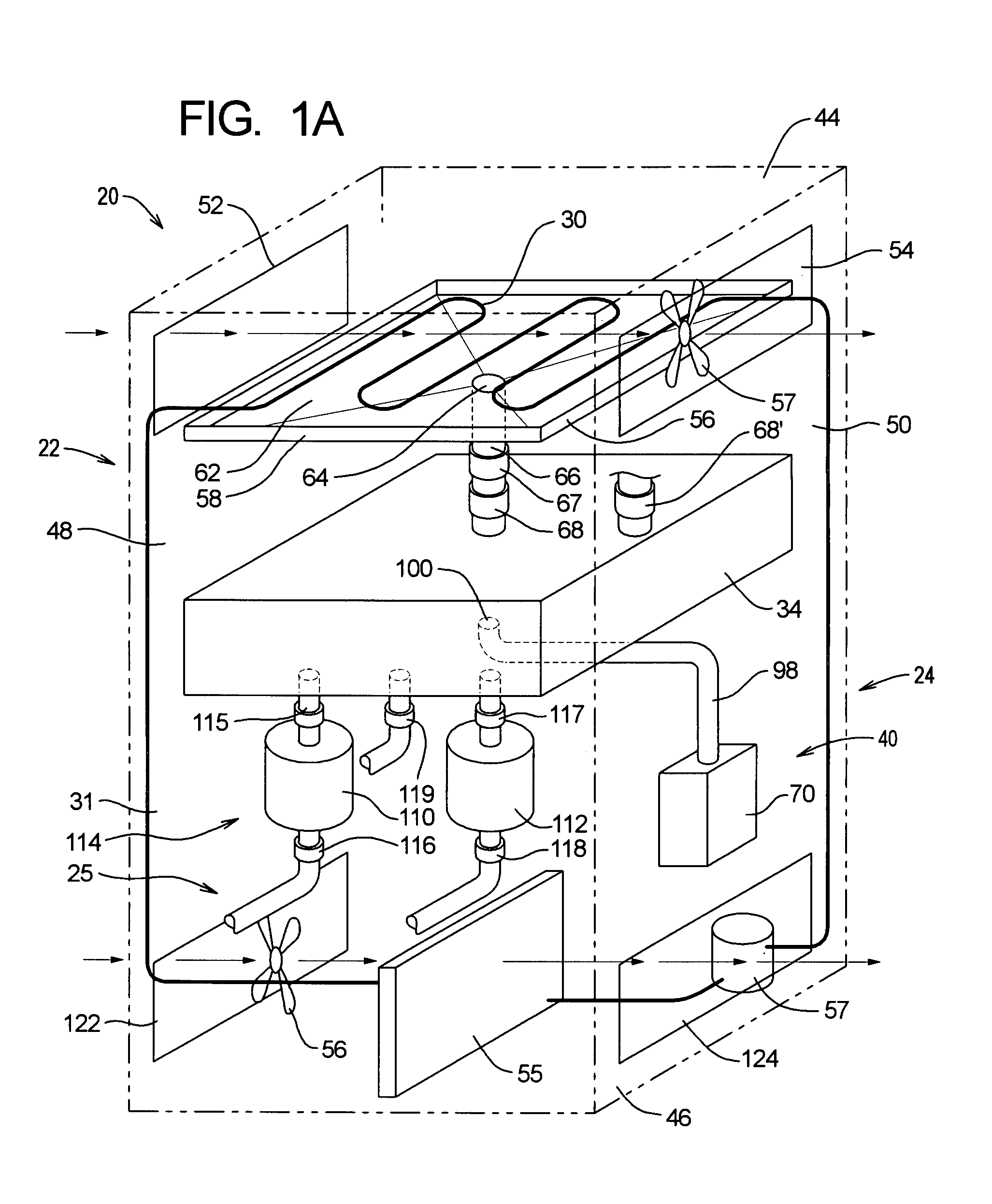

The present invention is directed to a water making device that collects the moisture contained in the atmosphere and condenses it into high purity water. In one embodiment, moist air entering the water making / water cooling system flows across an air filter, then a precooler heat exchanger (where the air stream is cooled to or close to its dew point) and then a water extraction heat exchanger, where the air stream is cooled further and water is extracted. The water that leaves water extraction heat exchanger is collected in a water collection device and passes from there through a primary water filter into a water storage tank. The air stream then passes across a reheat heat exchanger and exhausted to the outside. A water circulation pump extracts water from the water storage tank and circulates the water stream through an evaporator of a vapor compression refrigeration system, where the water stream is chilled, then through the water extraction heat exchanger and precooler, where the incoming air stream is chilled by removing heat to the water stream. The water stream is then circulated through the reheat heat exchanger, where the water stream is again cooled by removing heat to the cool dry air exiting the water extraction heat exchanger. Finally, the cooled water stream is circulated through the water filter to a three way valve, that directs water flow either to a dispenser or back to the water storage tank.

Owner:UNIV OF MARYLAND

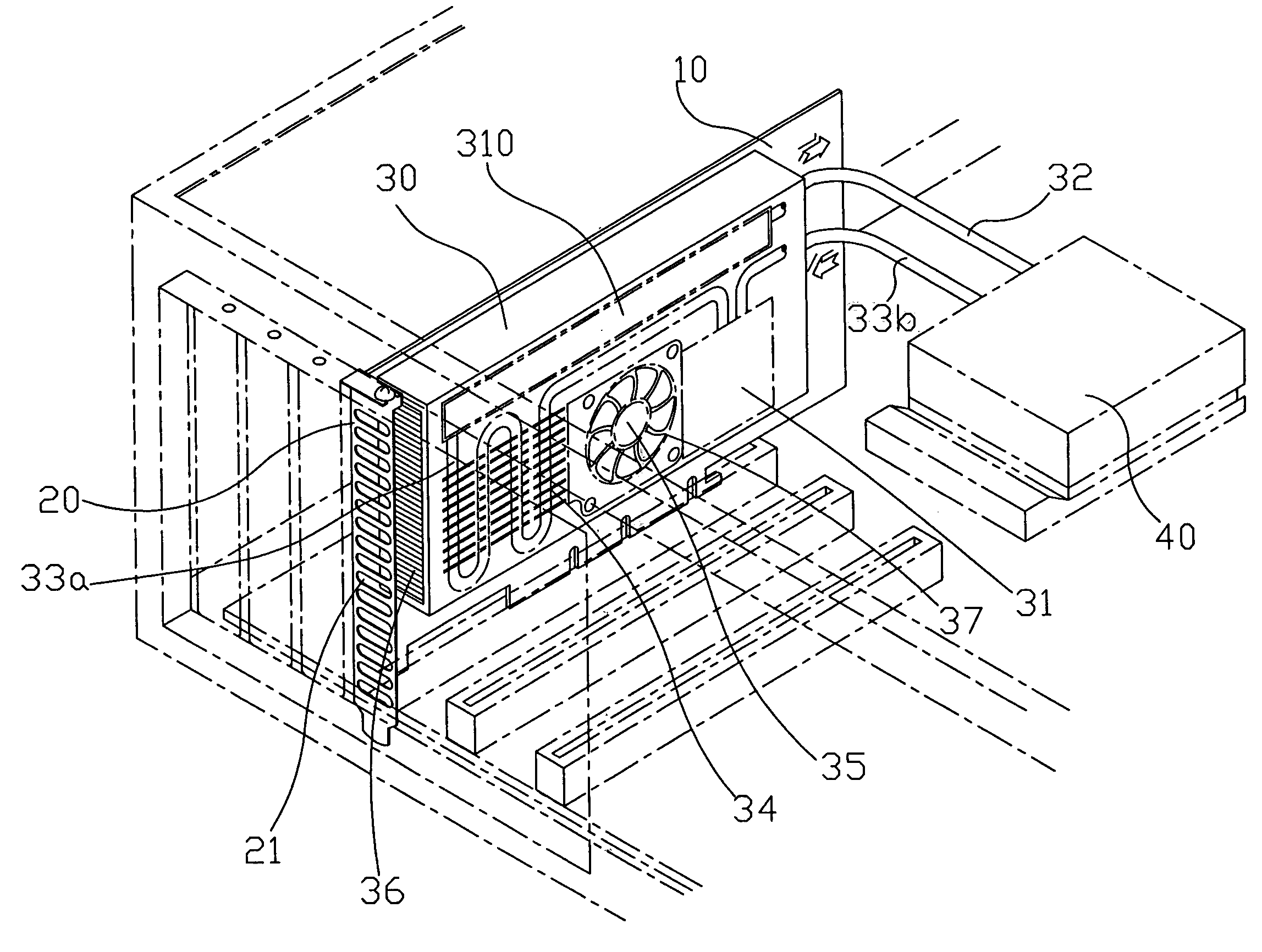

Water-cooler radiator module

InactiveUS6955212B1Reduces possibility of any damage to heat-generatingSave spaceDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectronic component

A water-cool radiator module comes with a supporting part having a shell body; the shell body includes a fan and a water tank; the water tank is connected to a cold water pipe and a hot water pipe; an extended section of the cold water pipe and hot water pipe is connected to a cold waterhead; the shell body includes several radiating holes at one end; such that in an application, the supporting part is inserted into a slot on the computer case and the shell body is mounted onto the slot; the cold water in the cold waterhead of a heat-generating electronic component is circulated to the shell body through the hot water pipe; the fan blows air to radiate heat to the outside through the radiating holes; and the cooled fluid flows from the water tank to the cold waterhead through the cold water pipe.

Owner:ADDA

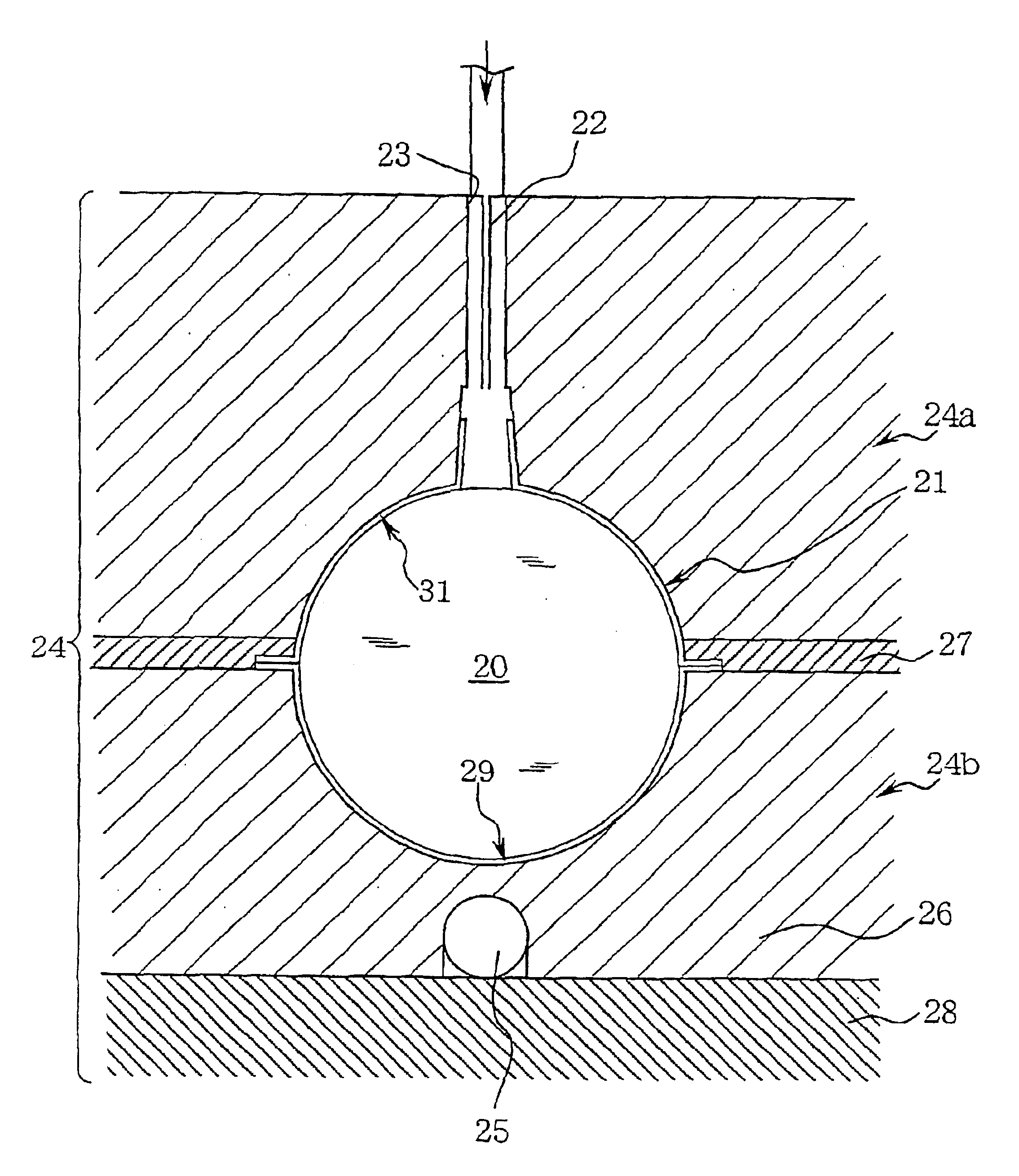

Process and equipment for manufacturing clear, solid ice of spherical and other shapes

InactiveUS6857277B2Less tight contactGood precisionLighting and heating apparatusIce productionEngineeringWater cooling

The process and equipment, according to this invention, for manufacturing clear, solid ice of spherical and other shapes are capable of making clear ice balls and block ice of other shapes in the mold quickly, efficiently, and with effective energy utilization. This process is characterized in the steps of:a) preparing a mold for making ice balls and block ice of other shapes, which comprises an upper mold (24a) made of an insulating material and provided with a vertical injection hole (23) drilled therein and a water-injection nozzle (22) fitted in the hole; and a lower mold (24b) made of a water-freezing block (26) having coolant pipe (25) embedded therein;b) preparing for a domed lid (21a) or the lid of a different shape made of an insulating sheet, said lid (21a) having a shape that fits in with the surface shaped for the upper mold (24a) and being provided with a cylinder for being fitted into the vertical injection hole (23); and a shaped hemispherical cup (21b) of the same insulating sheet, which similarly fits in with the shaped surface of the lower mold (24b);c) assembling both halves of the mold (24) after the lid (21a) and the cup (21b) have been attached tightly to each other and placed in the mold;d) then, keeping the liquid to be frozen cooled at a predetermined temperature and spraying the liquid intermittently in the direction of the water-freezing block (26) that has been cooled to a predetermined freezing temperature;e) repeating the spraying operation to freeze the sprayed liquid in the container (21), layer by layer, until clear ice balls (20) or block ice of other shapes are formed; andf) disassembling the halves of the mold under the ice-releasing effect, which the ice container (21) has on the ice-making mold (24), and immediately taking out We shaped ice balls (20) or the block ice of a different shape.

Owner:SOMURA KATSUZO

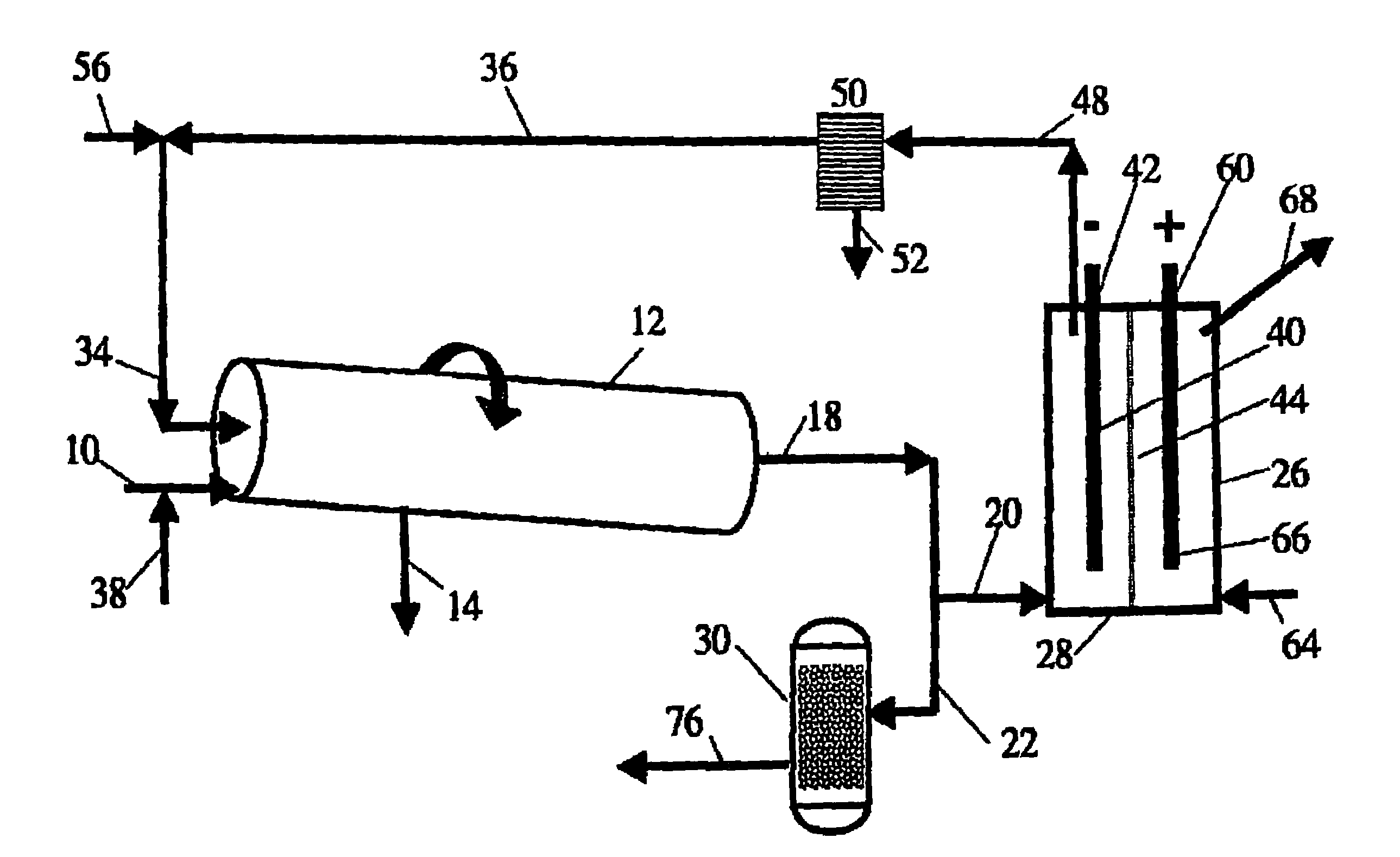

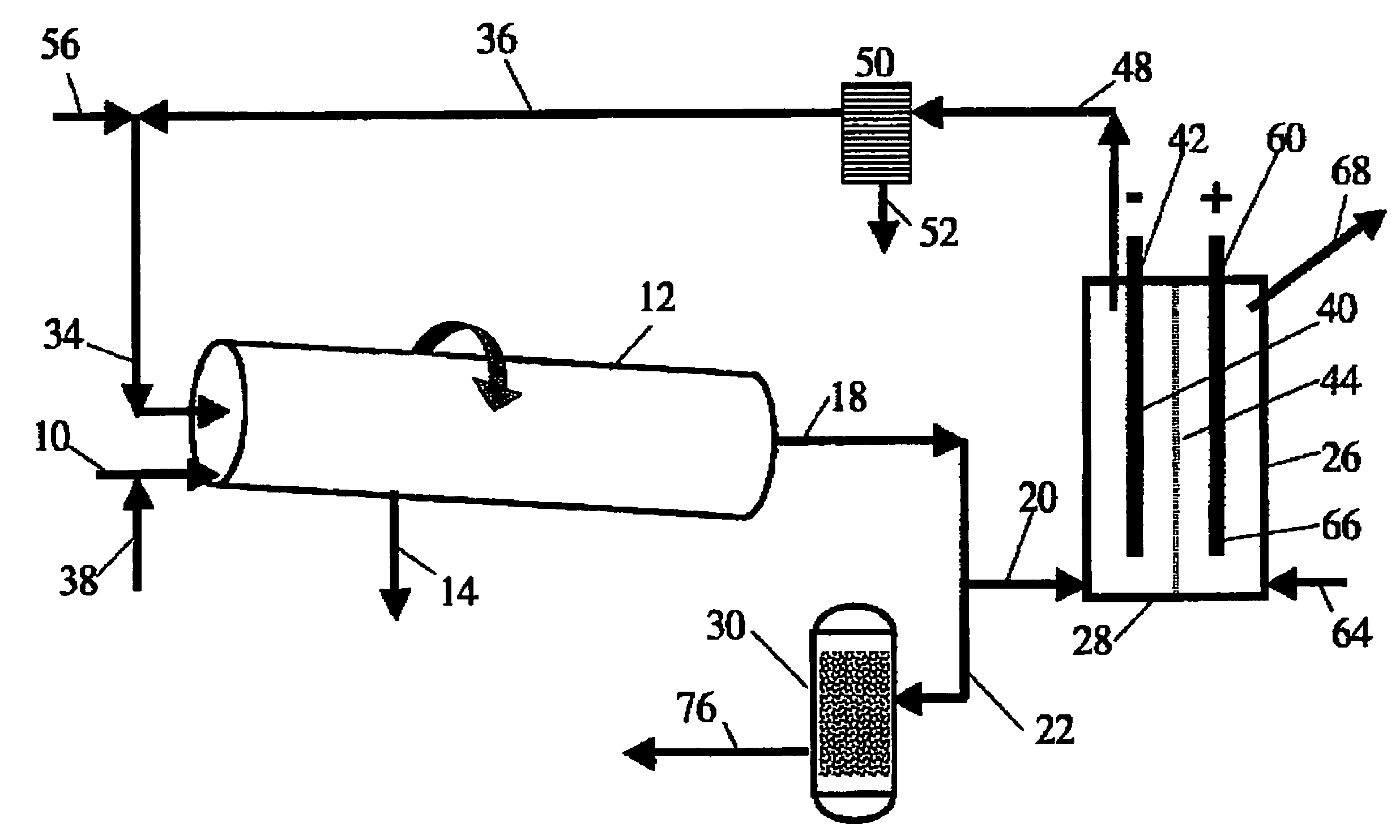

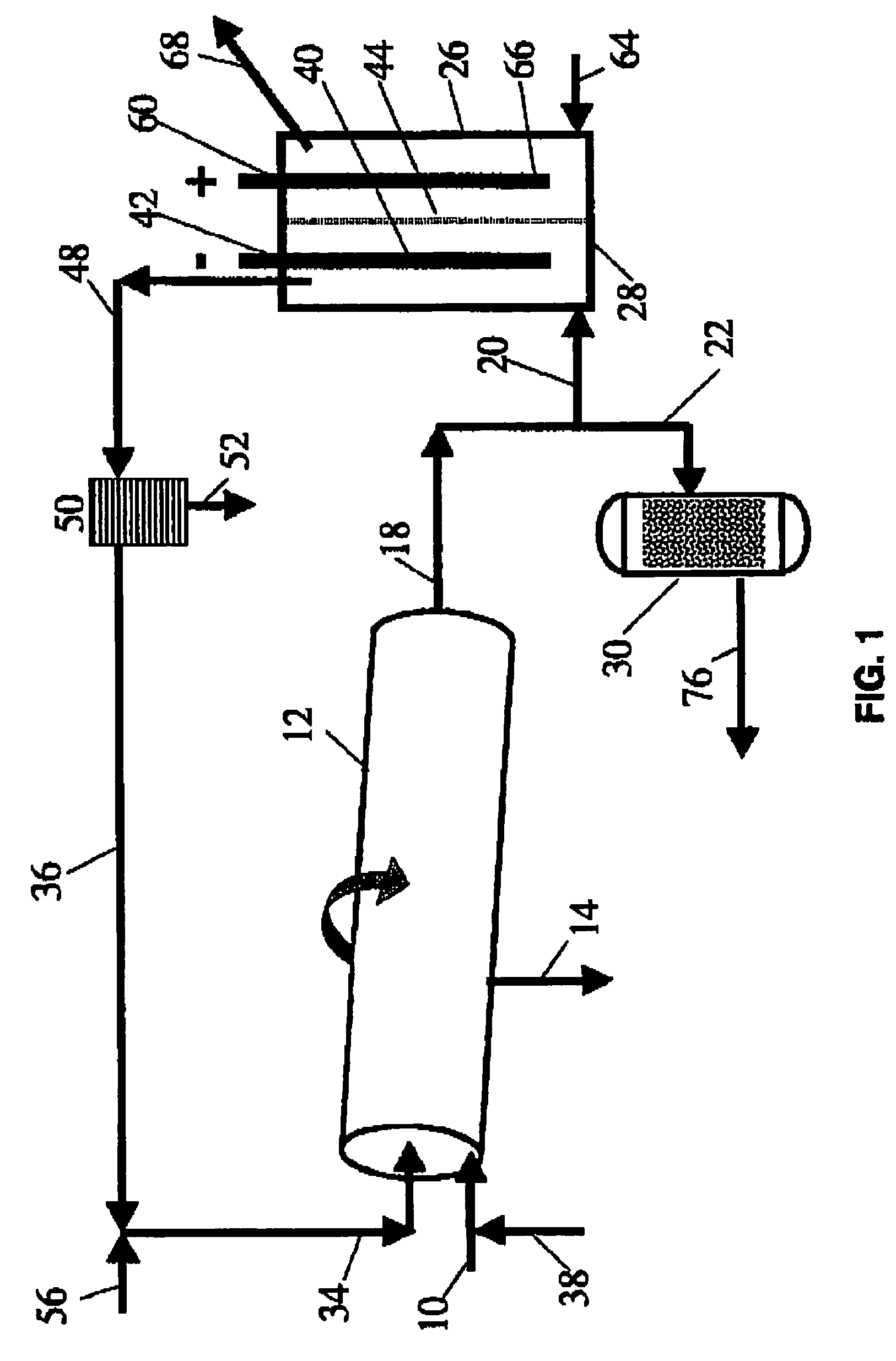

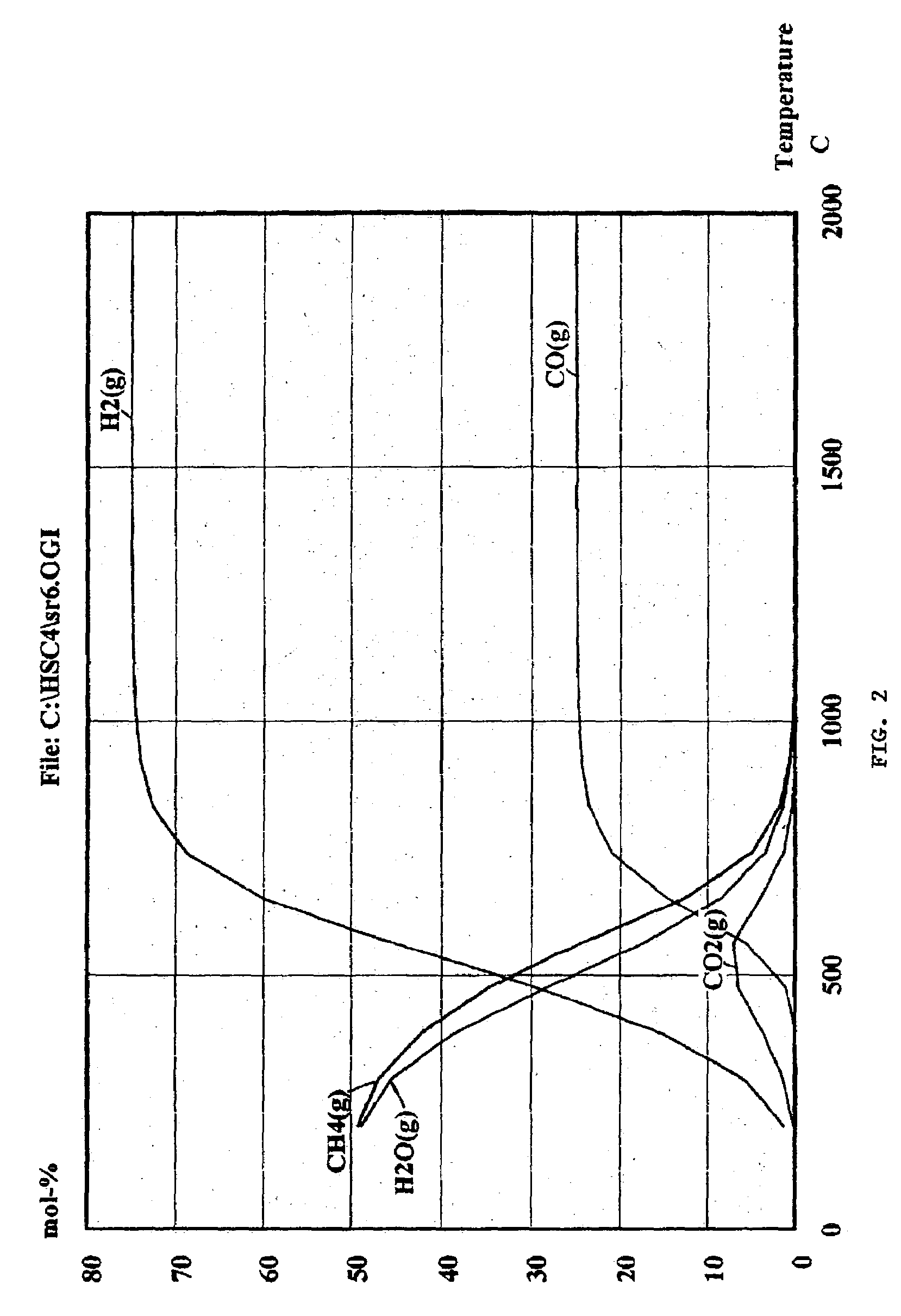

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

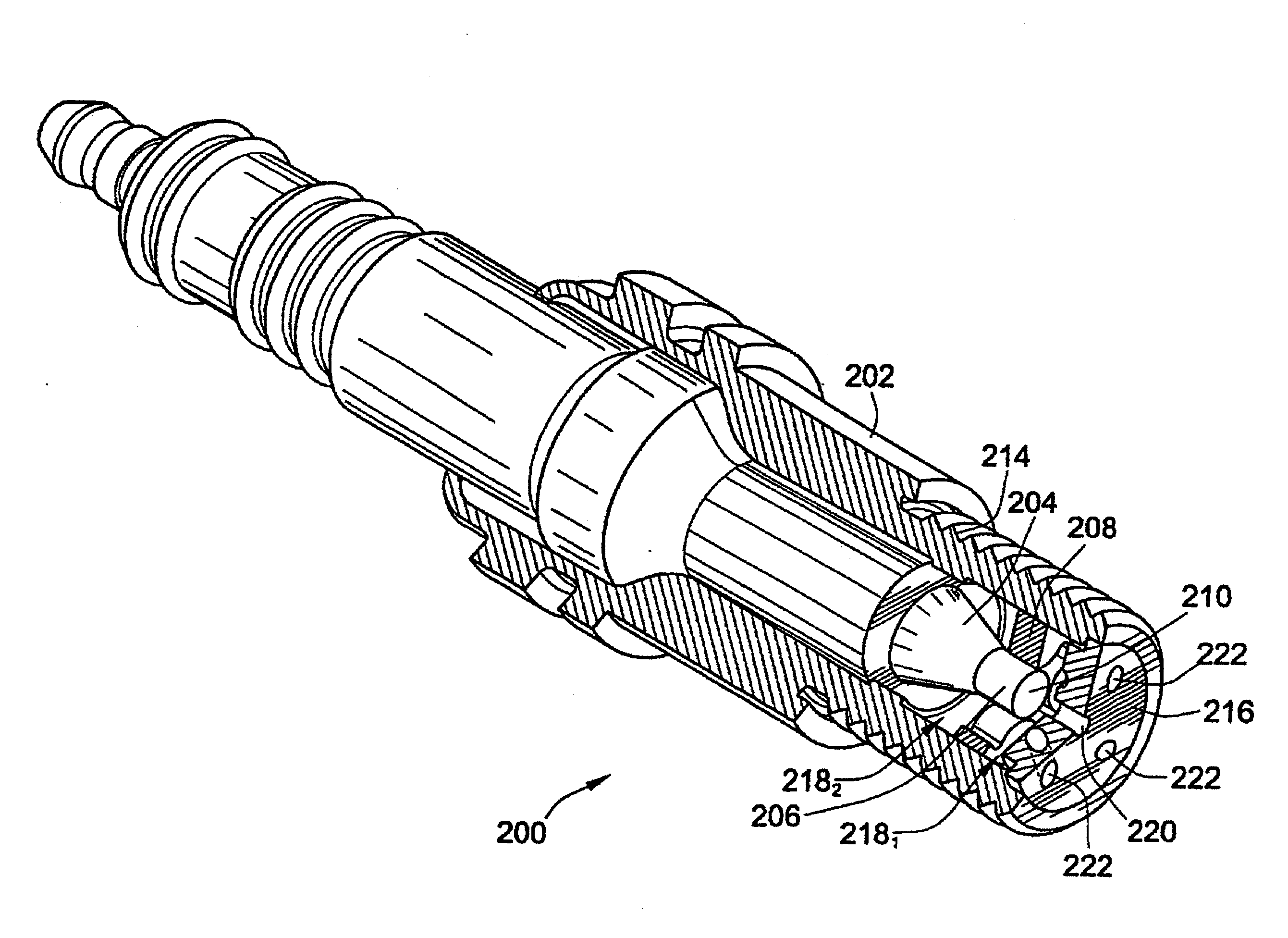

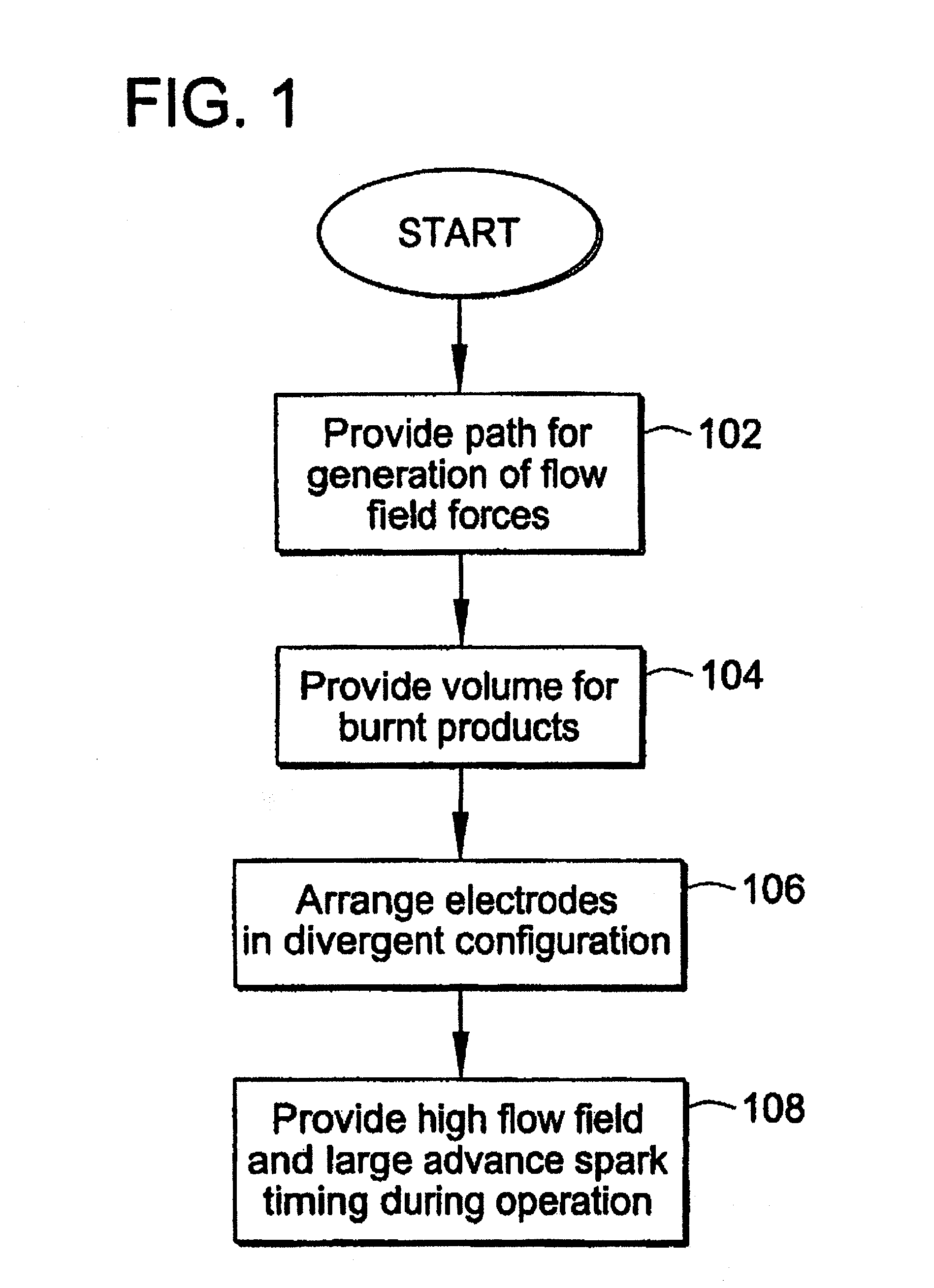

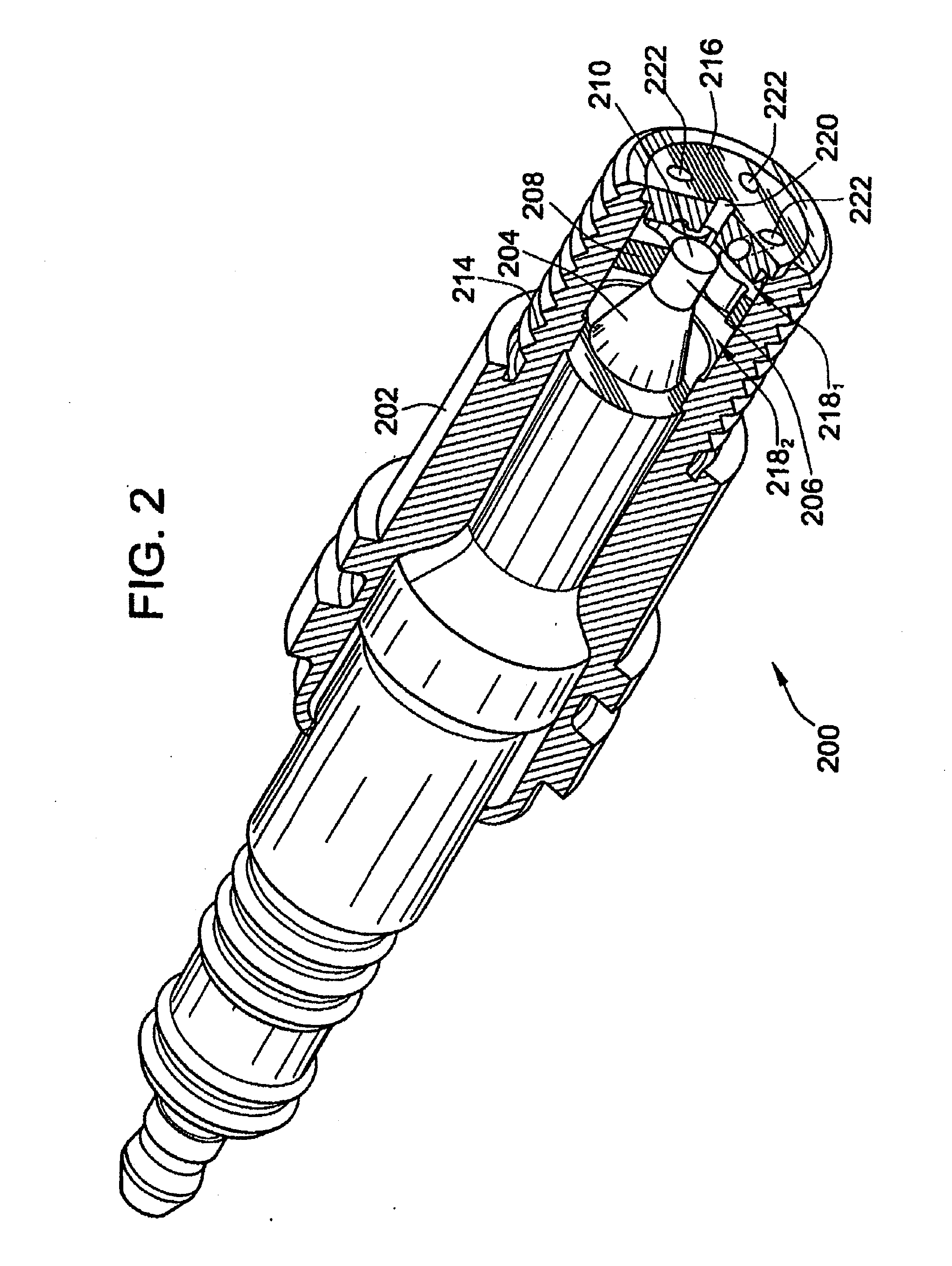

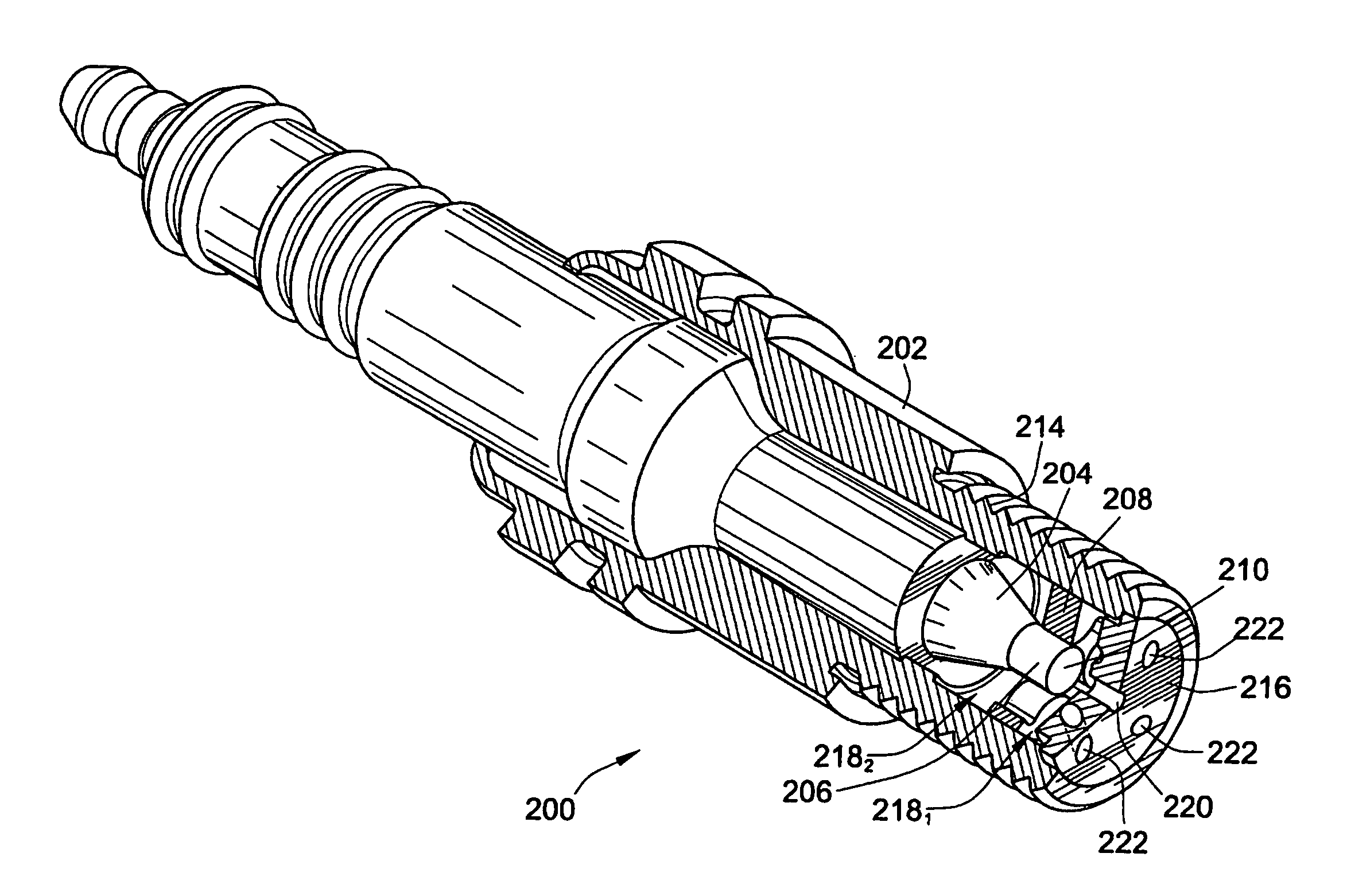

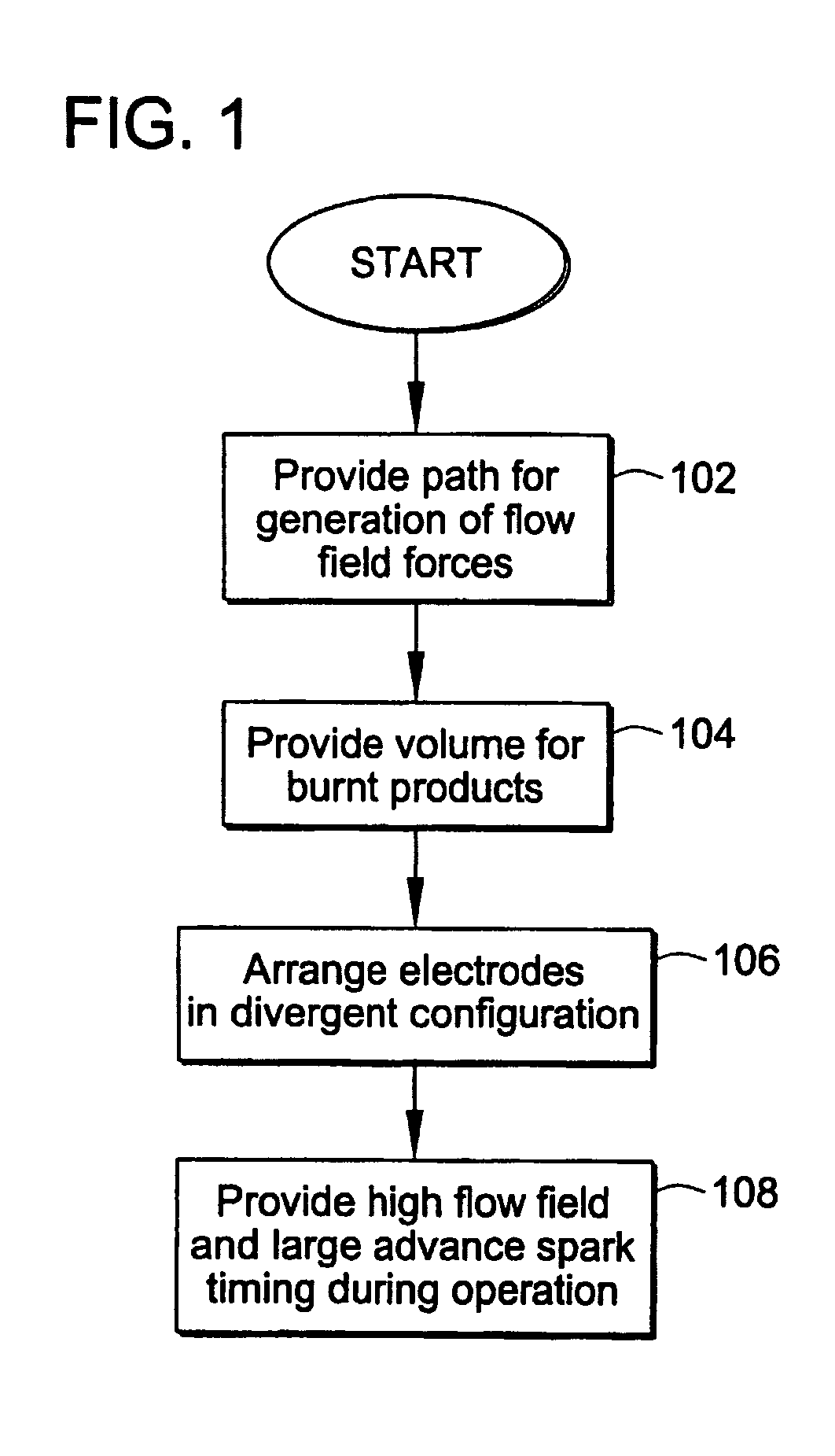

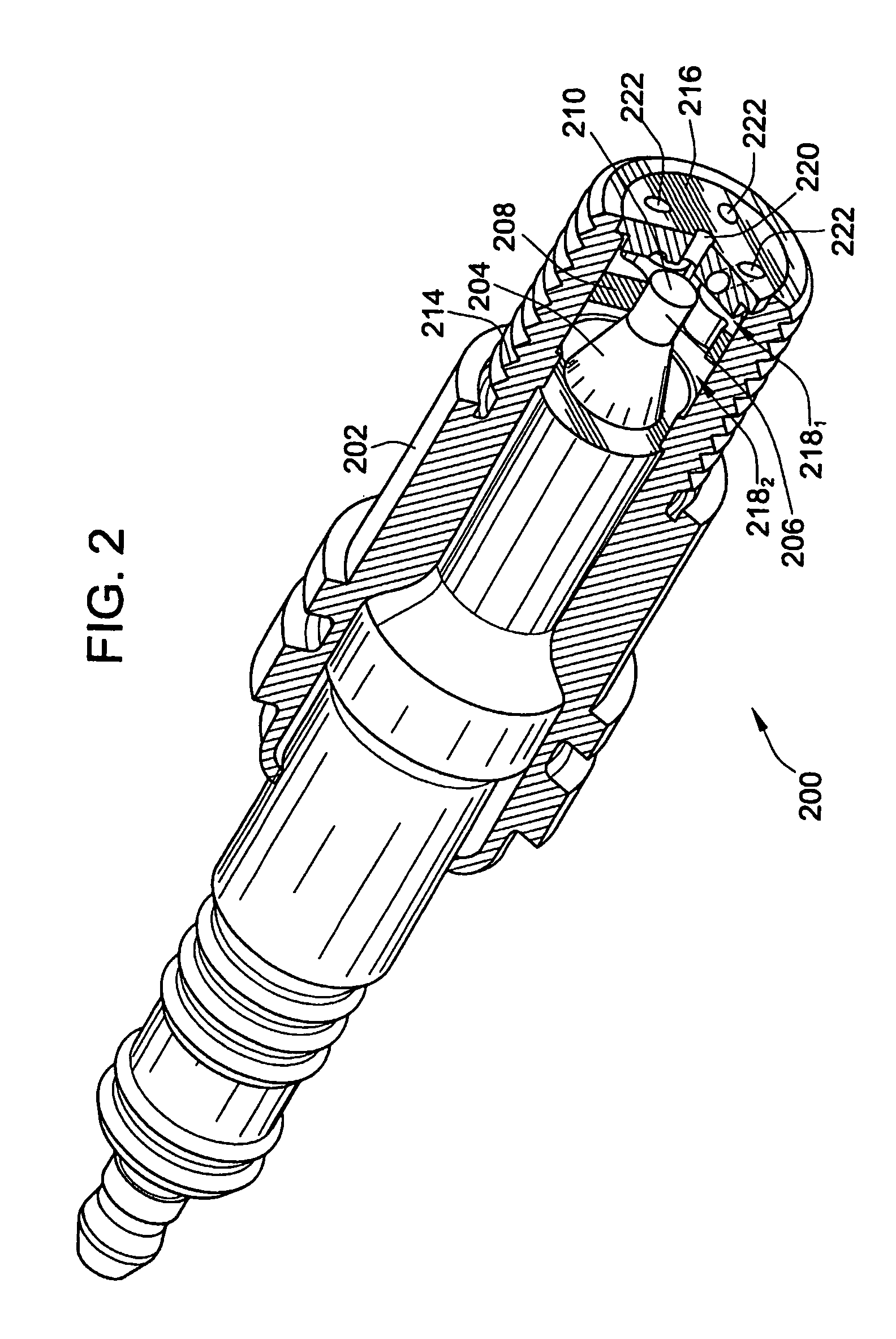

Pre-Chamber Spark Plug

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

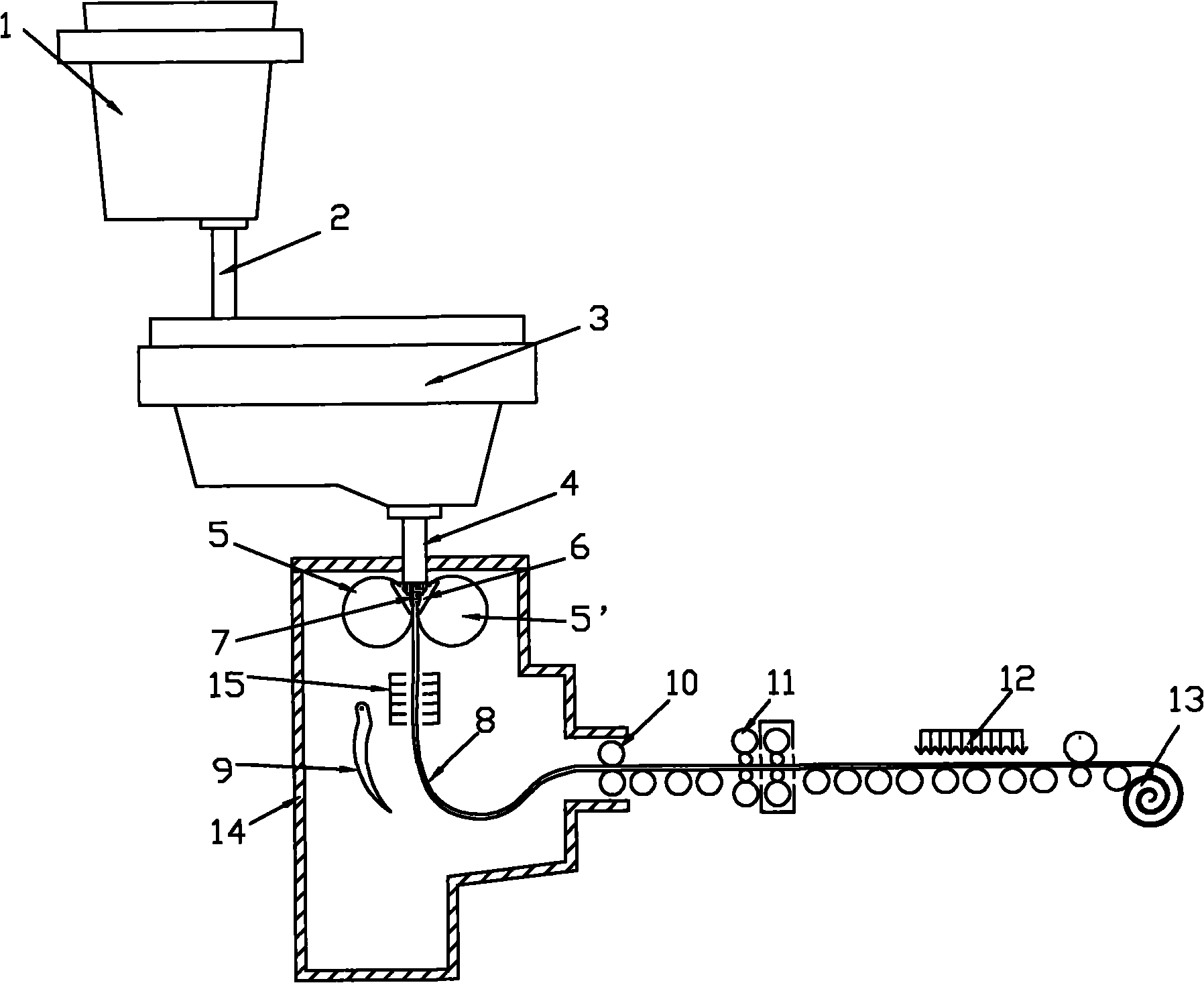

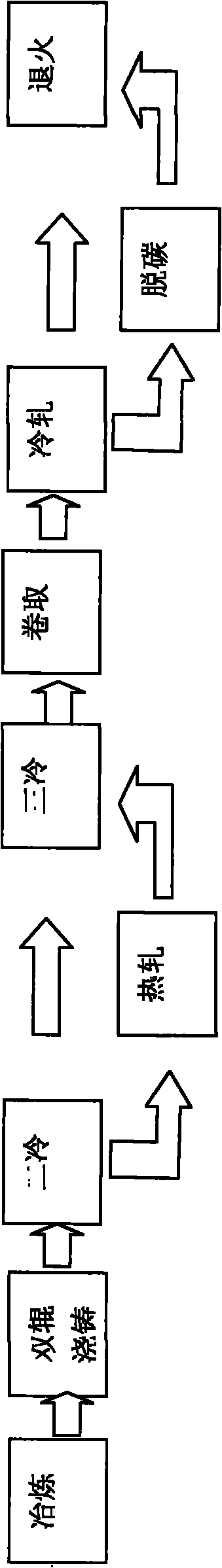

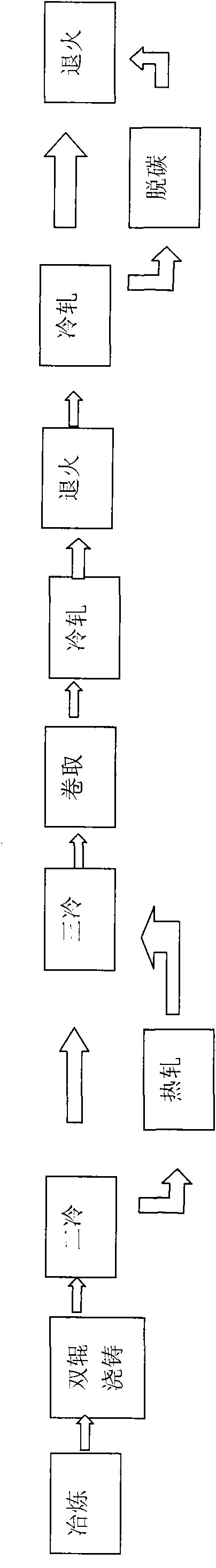

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

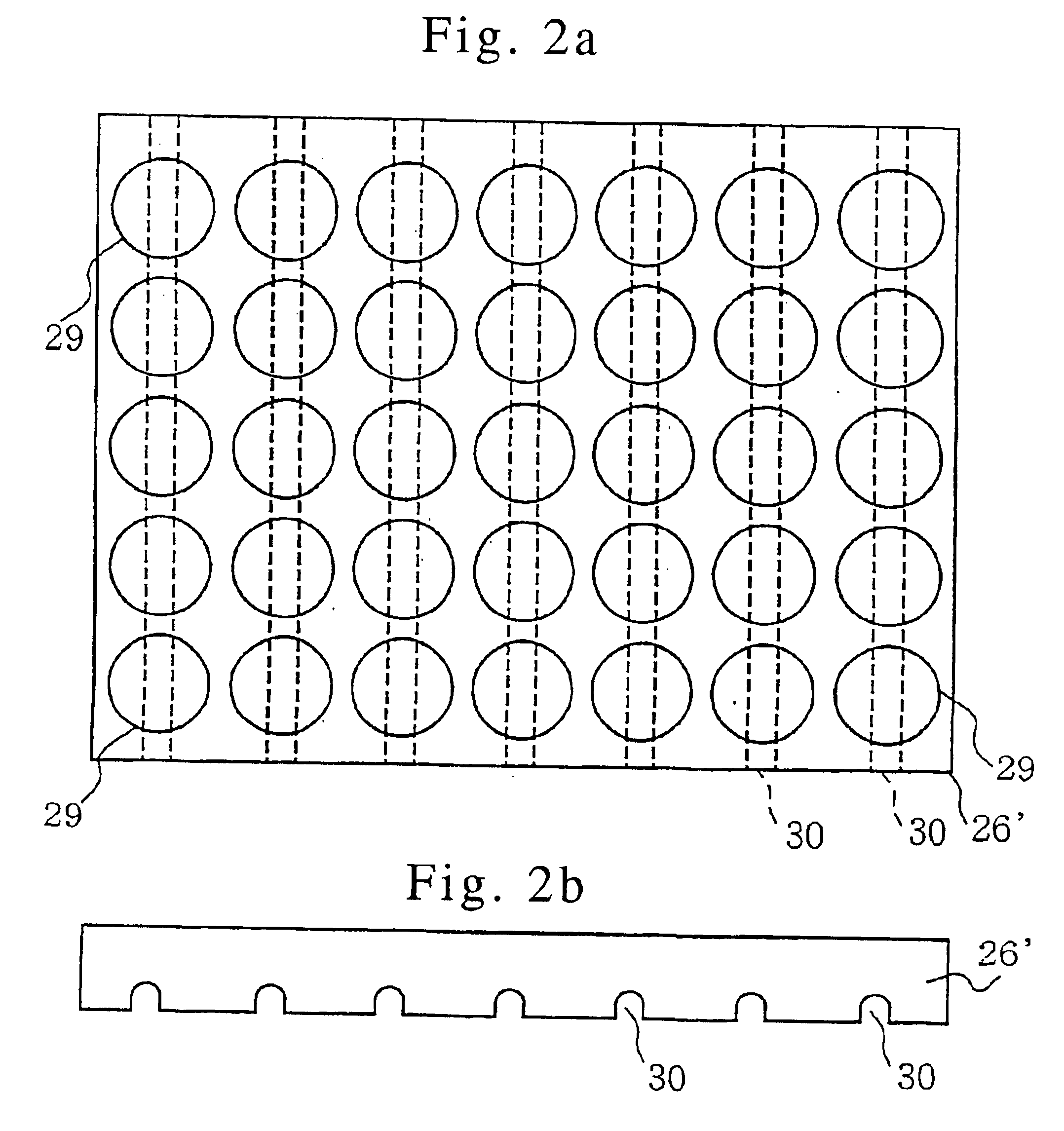

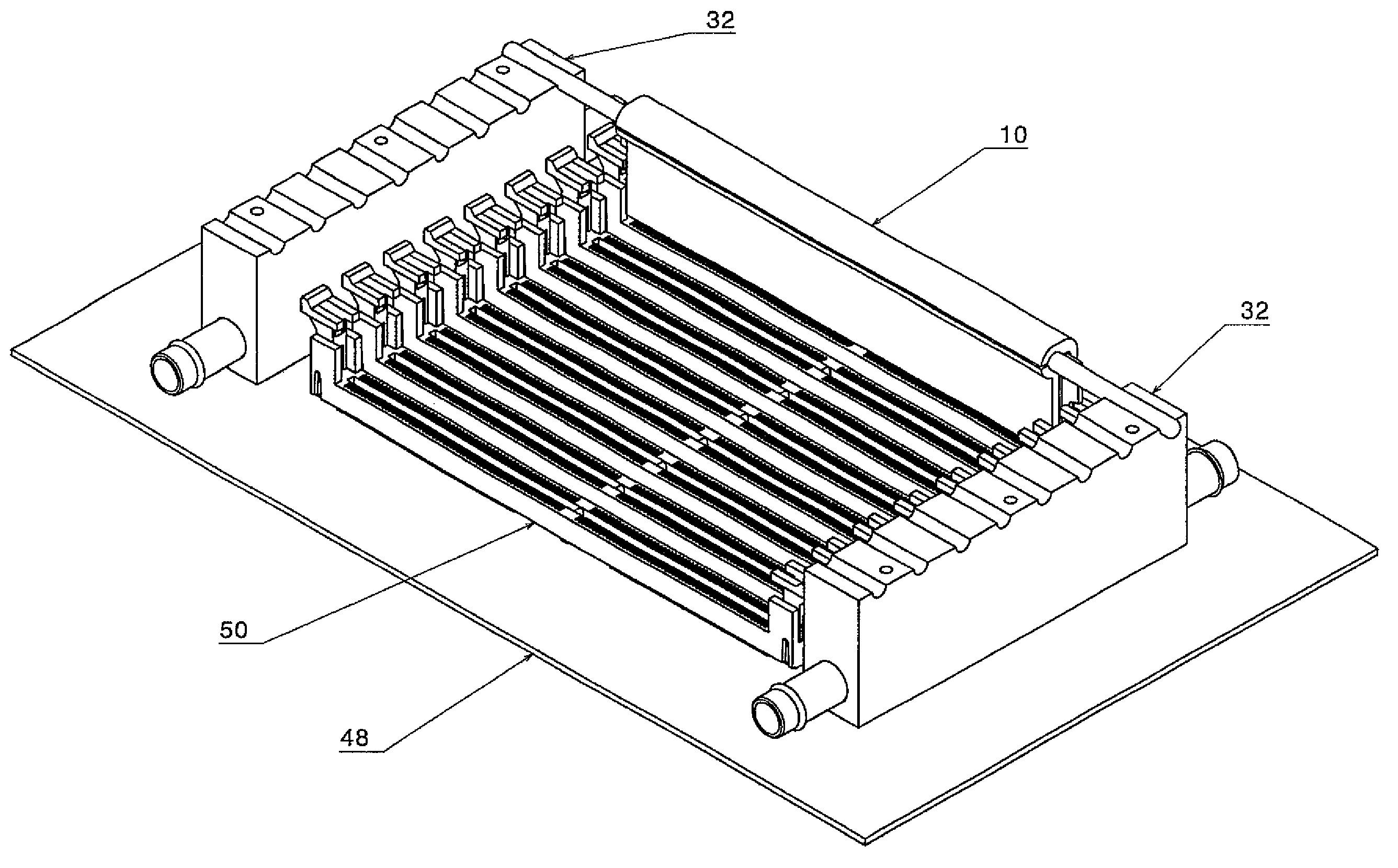

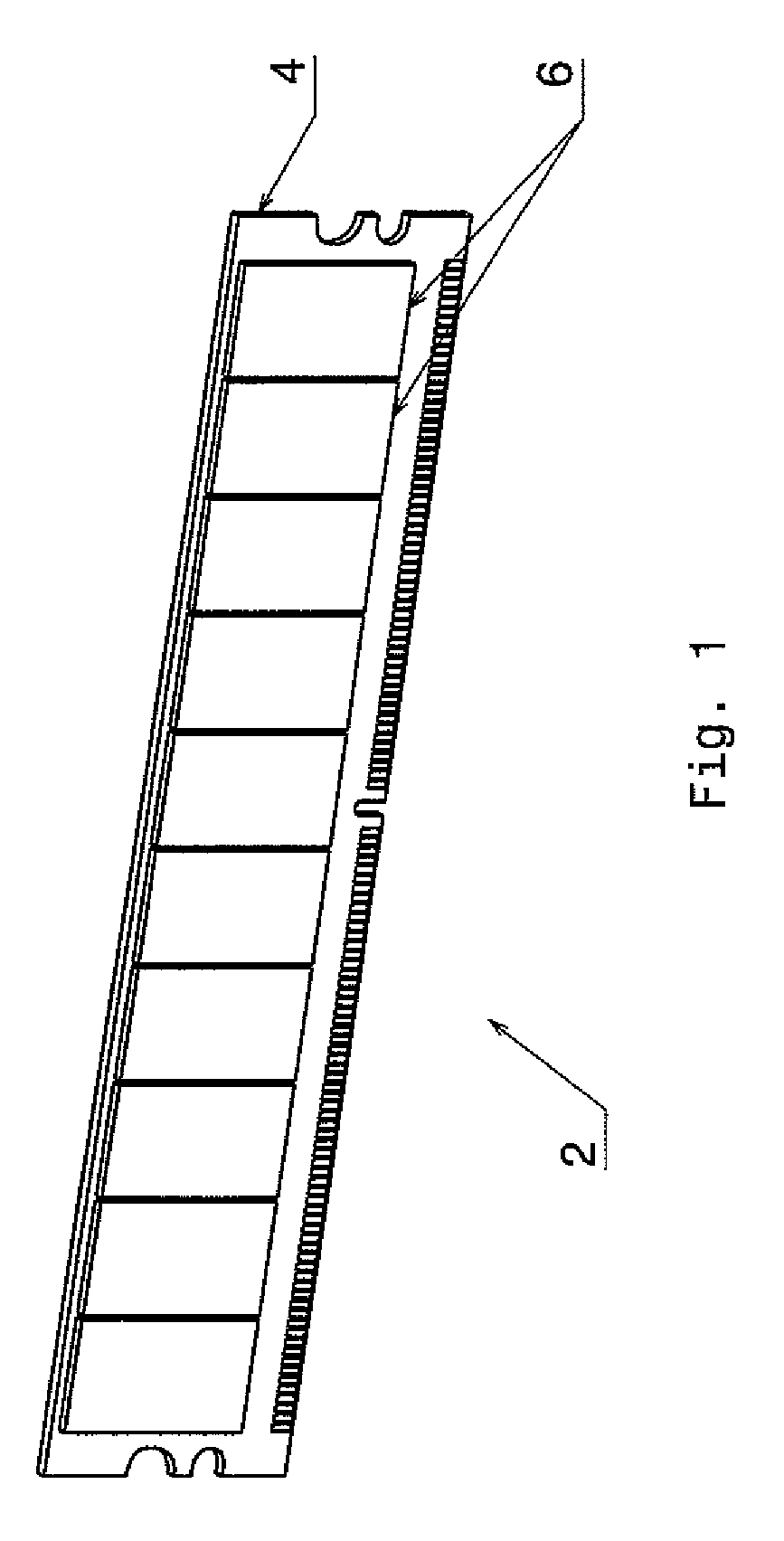

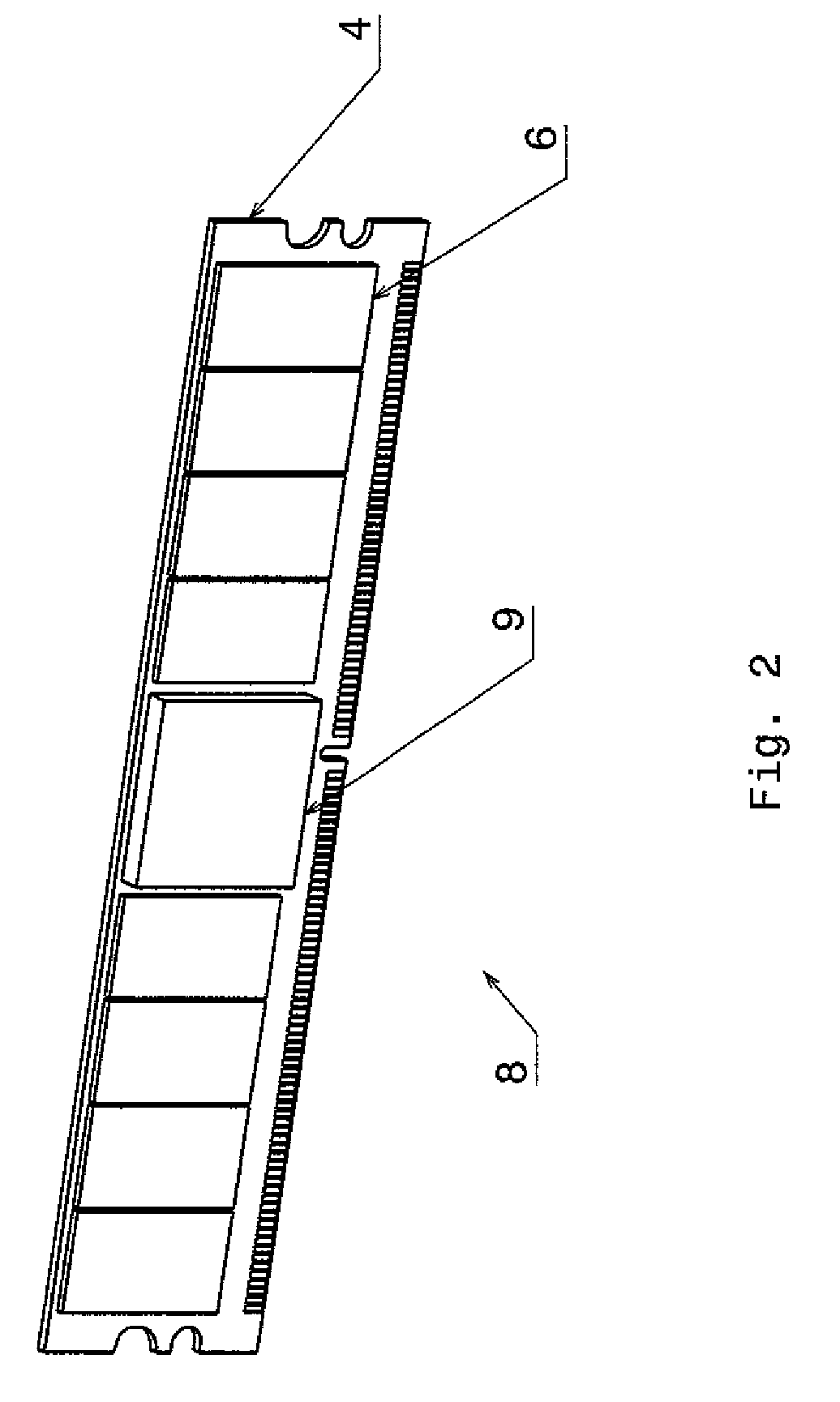

Method and apparatus of water cooling several parallel circuit cards each containing several chip packages

InactiveUS8004841B2Digital data processing detailsSemiconductor/solid-state device detailsWater coolingChip-scale package

A cooling or heat transfer apparatus and method is disclosed for cooling an electronic device. The apparatus includes a heat producing electronic device which may include an electronic circuit card with many heat sources. A heat transfer device is connected to the heat producing electronic device which is thermally communicating with the heat producing device for transferring heat from the heat producing device to the heat transfer device. A heat conduit is connected to the heat transfer device and thermally communicating with the heat transfer device for transferring heat to the heat conduit from the heat transfer device. A cooling housing is connected to the heat conduit and the cooling housing thermally communicating with the heat conduit for transferring heat to the cooling housing from the heat conduit. The apparatus enables the replacement of circuit cards in the field because it eliminates the need to apply thermal-interface materials.

Owner:GLOBALFOUNDRIES INC

Water producing method and apparatus

ActiveUS20060059922A1Lighting and heating apparatusEnergy based wastewater treatmentWorking fluidFilter system

A water producing system adapted to condense water from the air and collected in a storage tank were the water is purified and bacteria is killed. One form of killing the bacteria is utilizing an ozone injection system with a filter system to remove the ozone before the water is dispensed. In one form, a dual fluid circuit is utilized where an operating fluid dumps heat to a second circuit such as a refrigeration cycle and the cooled operating fluid lowers the temperature of a water condensation member.

Owner:DMPG LLC

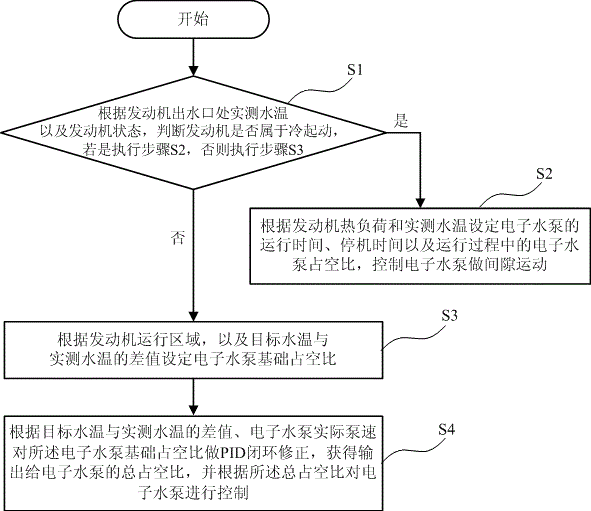

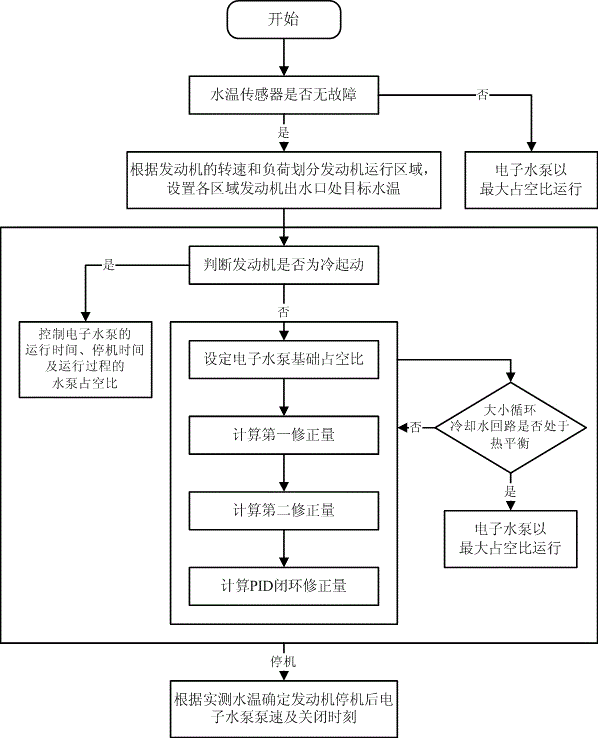

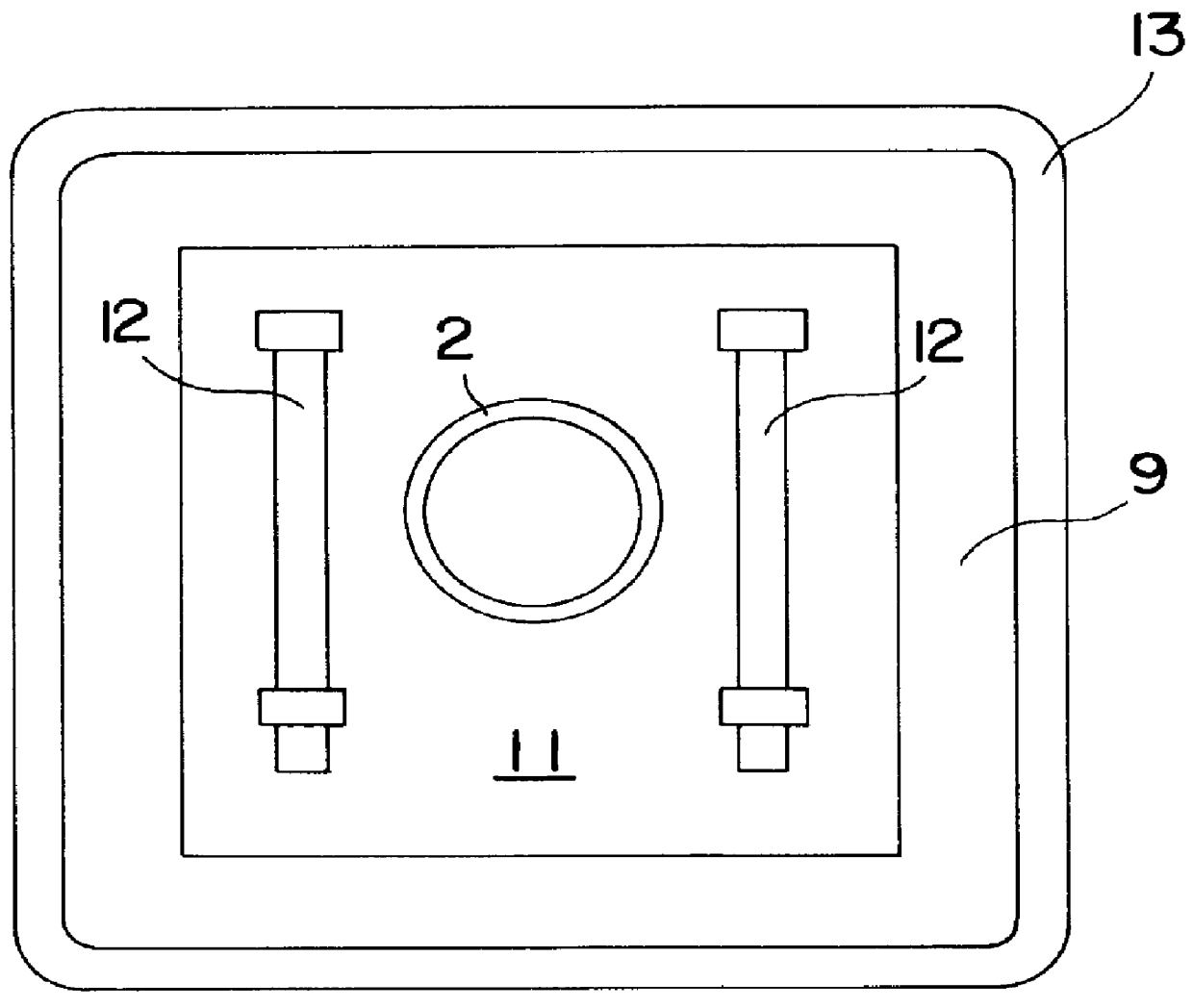

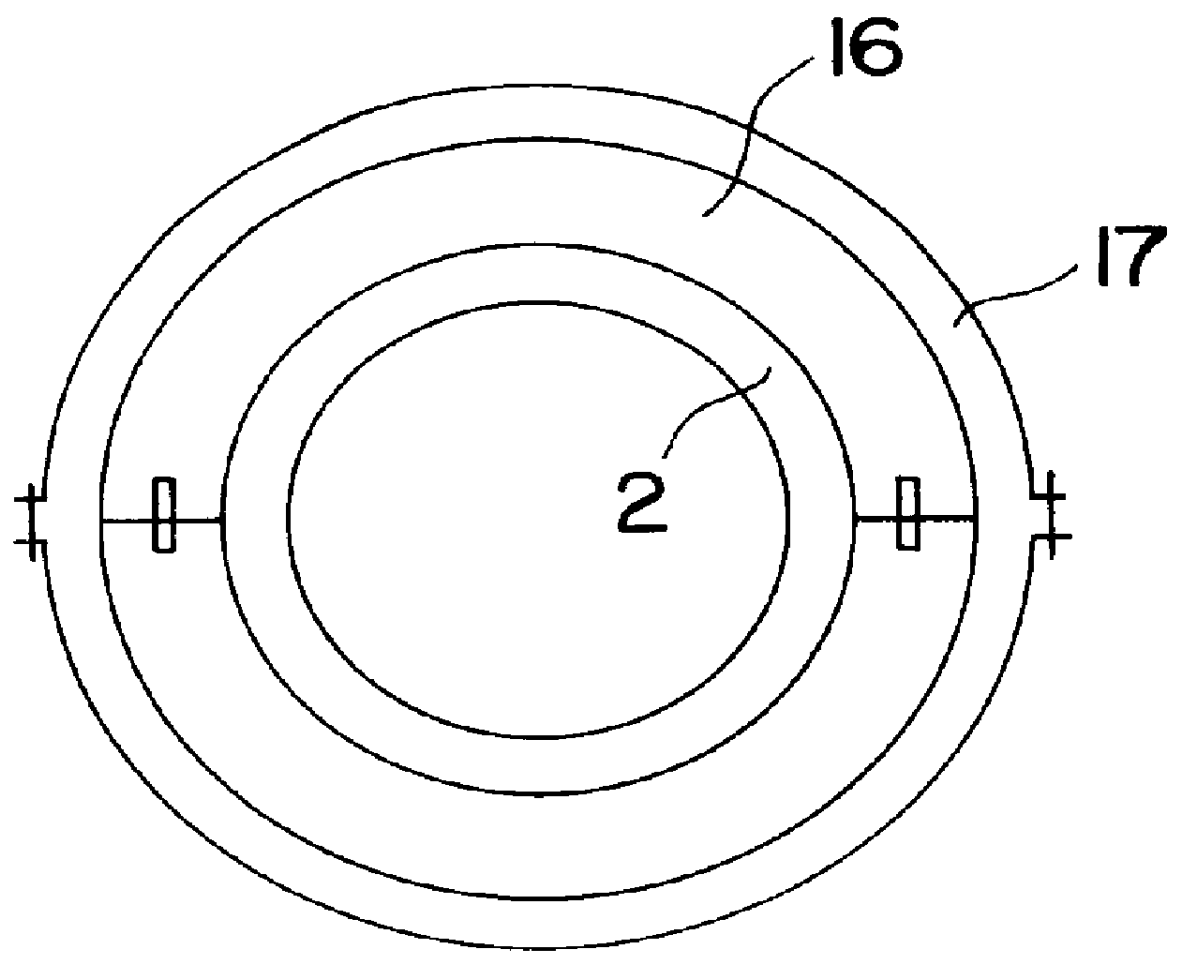

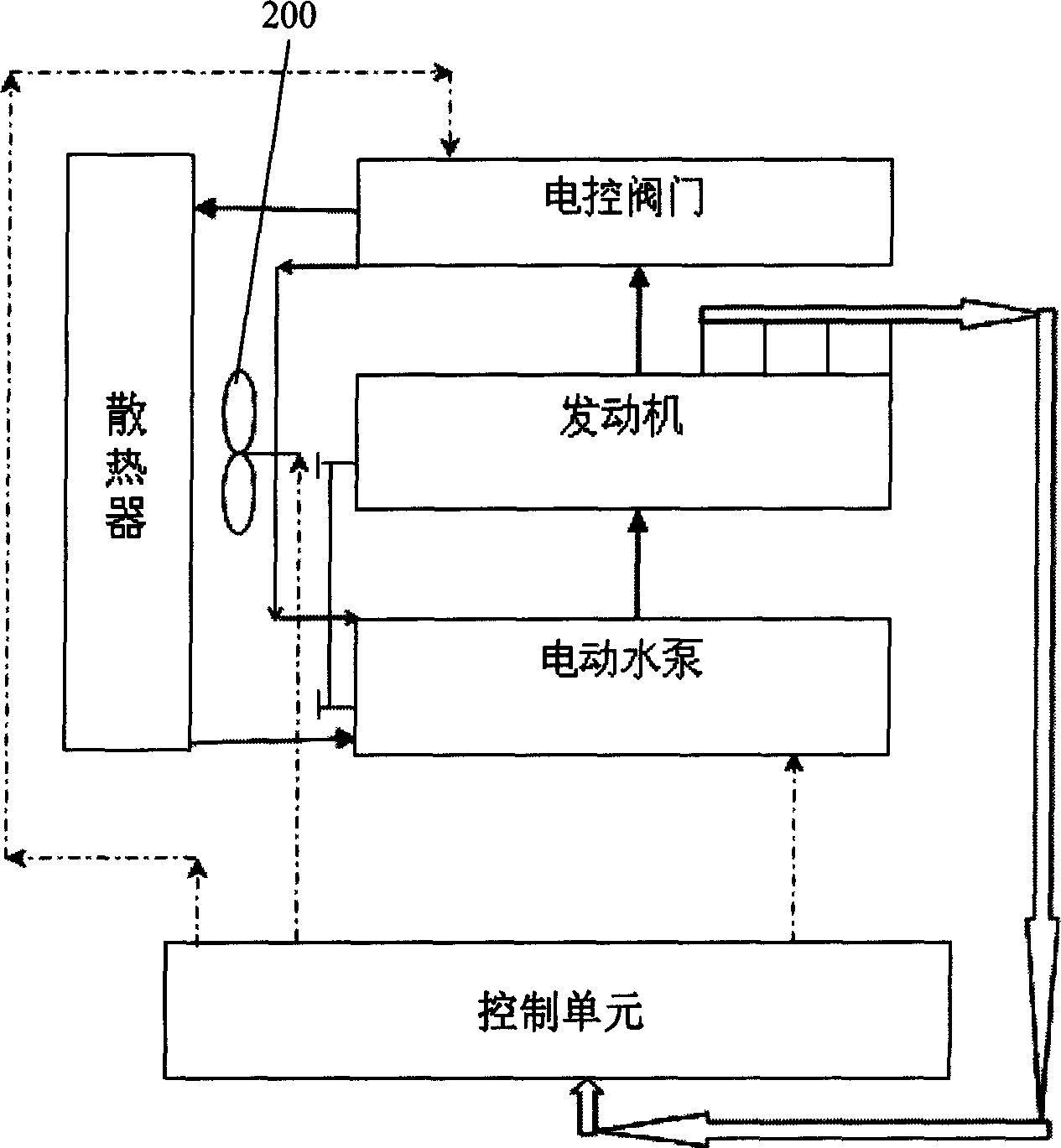

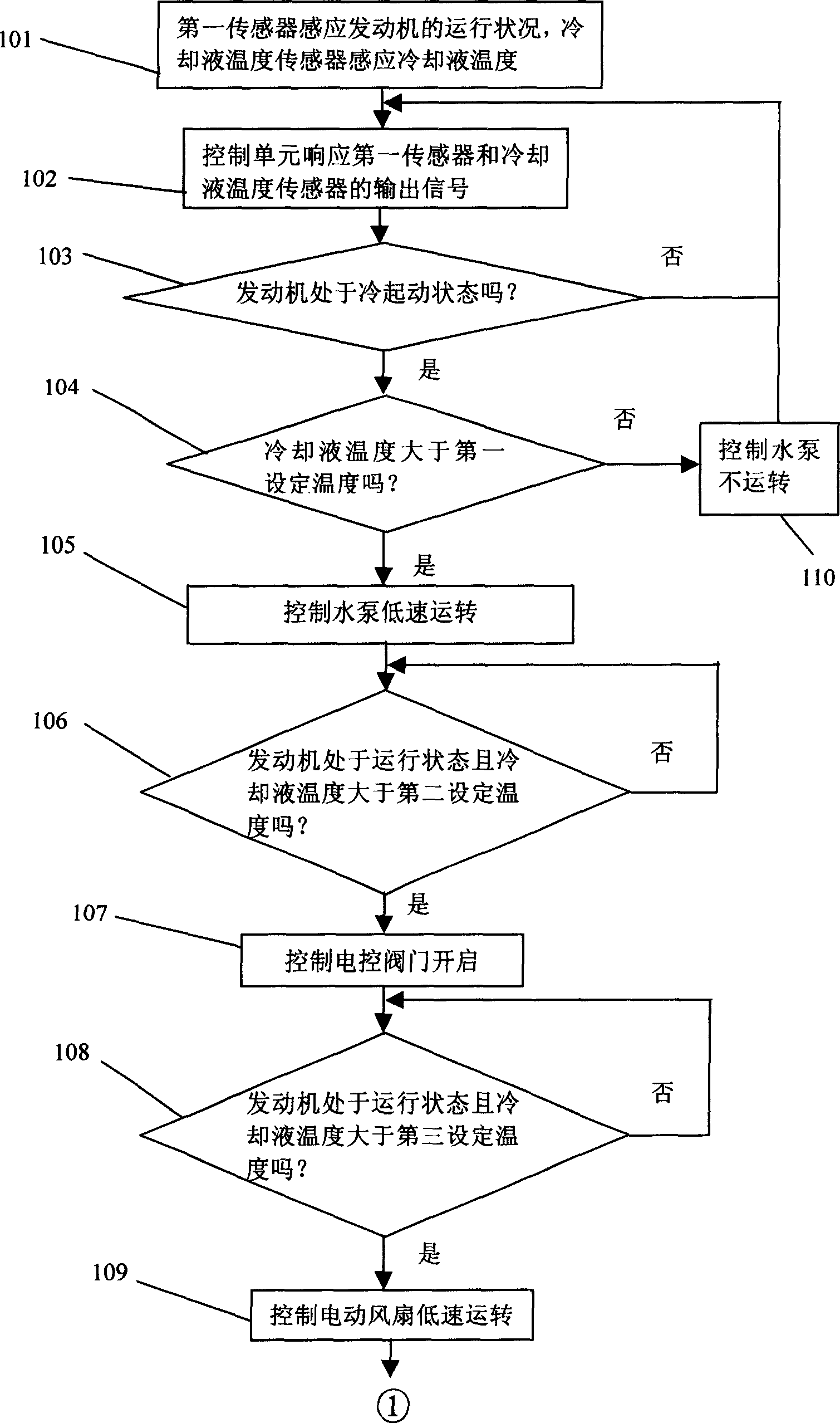

Method and device for controlling electronic water pump of water-cooling system of automobile engine

ActiveCN106246328ALower working temperatureEasy to controlCoolant flow controlMeasurement deviceIntermittent motionStop time

The invention provides a method and device for controlling an electronic water pump of a water-cooling system of an automobile engine. The method comprises the following steps: step S1, judging whether the engine is in a cold start state or not according to actually measured water temperature at a water outlet of the engine and the state of the engine, if the engine is in the cold start state, carrying out step S2, and if the engine is not in the cold start state, carrying out step S3; step S2, setting running time and stopping time of the electronic water pump according to the thermal load and the actually measured water temperature of the engine and duty ratio of the electronic water pump in a running process, and controlling the electronic water pump to carry out intermittent motion; step S3, setting a basic duty ratio of the electronic water pump according to a running region of the engine and difference between target water temperature and the actually measured water temperature; and step S4, carrying out PID closed-cycle correction on the basic duty ratio of the electronic water pump according to the difference between the target water temperature and the actually measured water temperature and actual pump speed of the electronic water pump to obtain total duty ratio output to the electronic water pump, and controlling the electronic water pump according to the total duty ratio. By the method and device for controlling the electronic water pump of the water-cooling system of the automobile engine, warming time can be shortened, and the water temperature control effect is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

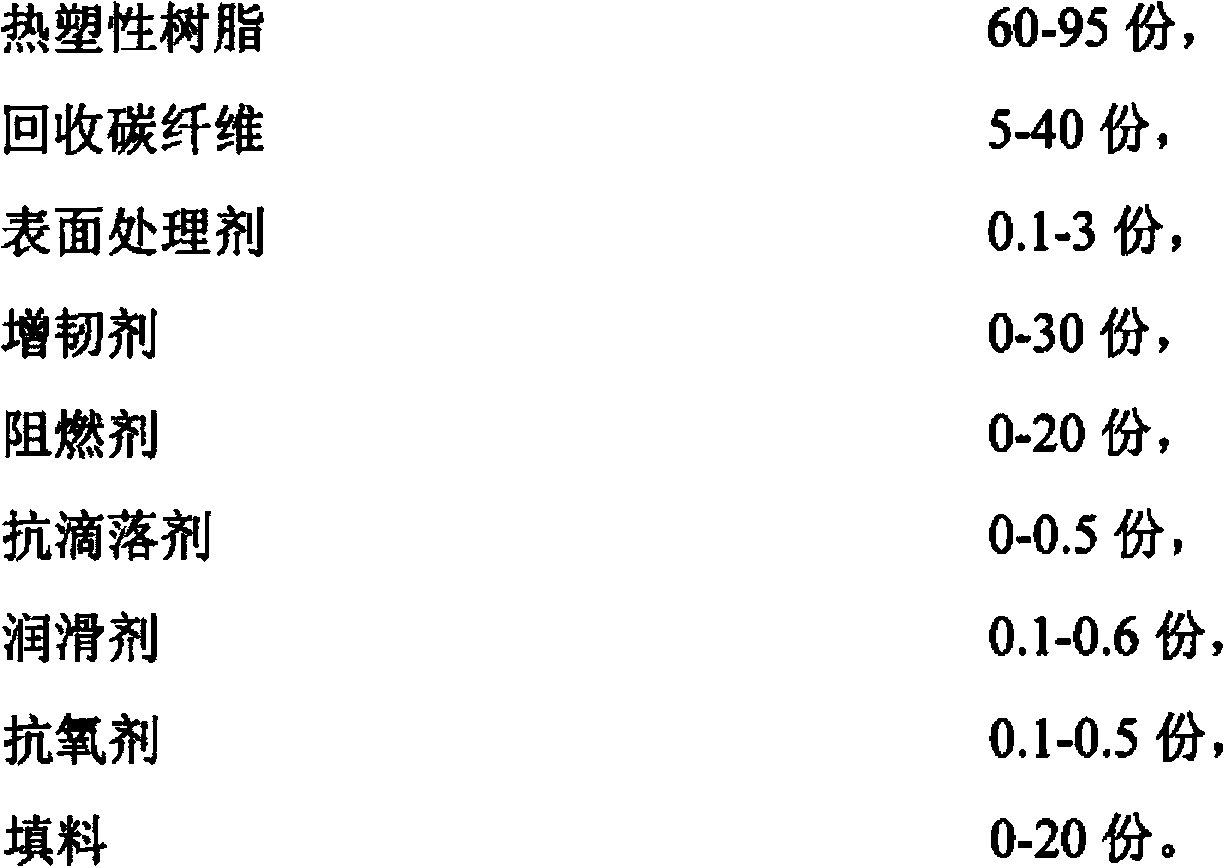

Recycled carbon fiber reinforced thermoplastic resin composite material and preparation method thereof

The invention relates to a recycled carbon fiber reinforced thermoplastic resin composite material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing 5-40 parts of recycled carbon fiber according to a proportion, adding the recycled carbon fiber into a high-speed mixer, adding 0.1-3 parts of surface treating agent, and performing surface treatment on the recycled carbon fiber; (2) weighing 60-95 parts of thermoplastic resin, 0-30 parts of flexibilizer, 0-20 parts of fire retardant, 0-0.5 part of anti-drip agent, 0.1-0.6 part of lubricant, 0.1-0.5 part of antioxidant and 0-20 parts of filler according to the proportion, adding the raw materials into the high-speed mixer, and uniformly mixing the raw materials; (3) adding the uniformly mixed raw materials into a double-screw machine, and performing melt blending, extrusion, water cooling and strand pelletizing to obtain the recycled carbon fiber reinforced thermoplastic resin composite material. Compared with the prior art, the recycled carbon fiber reinforced thermoplastic resin composite material has the advantages of low density, excellent mechanical performance, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

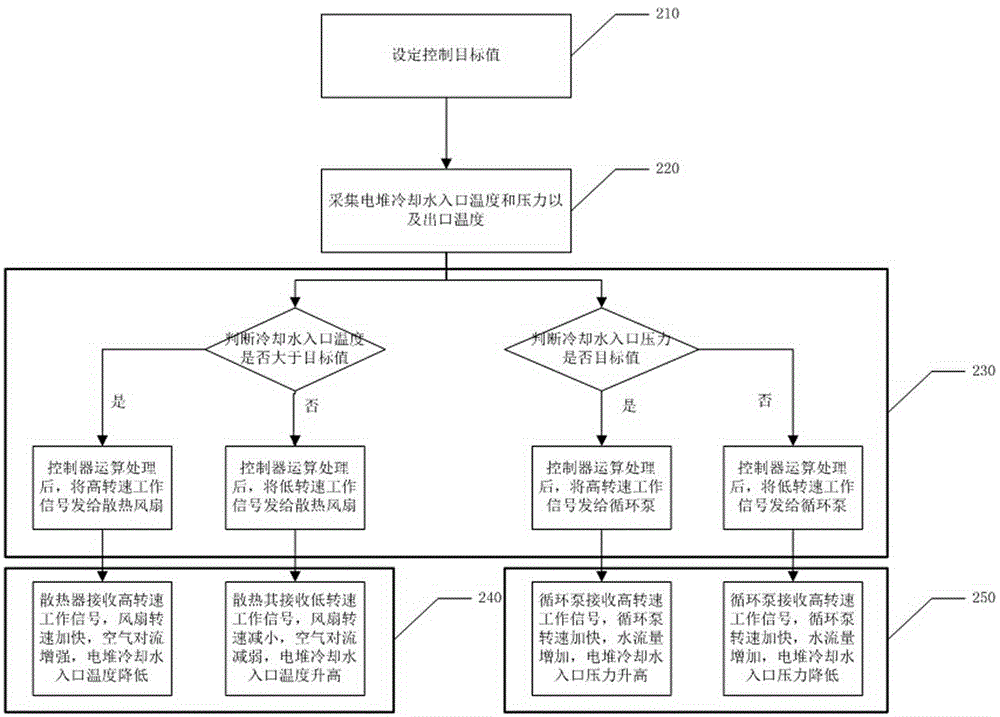

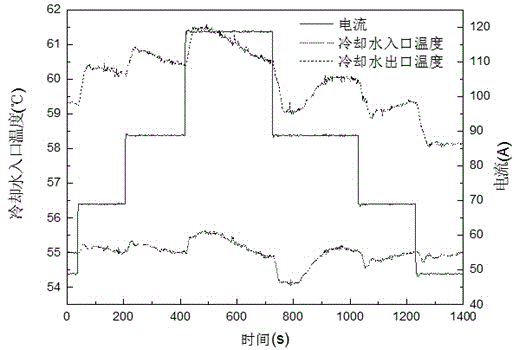

Thermal management system of water-cooling proton exchange membrane fuel cell and control method of thermal management system

ActiveCN104934619AReduce poisonEasy temperature controlFuel cell auxillariesThermal management systemEngineering

The invention provides a simple and effective thermal management system of a water-cooling proton exchange membrane fuel cell and a control method of the thermal management system. The thermal management system mainly comprises an electric pile, a water tank provided with a heating device, a cooling water circulating pump, a radiator, a cooling water pile inlet temperature sensor, a cooling water pile outlet temperature sensor, a cooling water pile inlet pressure sensor and a controller of the thermal management system. The control method following pressure change is provided to overcome the defects of lag, great overshooting, system coupling and the like caused by temperature change tracking in the traditional control strategy. The radiator is mainly used for controlling the cooling water inlet temperature of the pile and mainly controls the rotating speed of a radiator fan according to the cooling water inlet temperature of the pile of the fuel cell; and the cooling water circulating pump is mainly used for controlling the cooling water flow in the whole thermal management system and mainly controls the rotating speed of the circulating pump according to the cooling water inlet pressure of the pile of the fuel cell.

Owner:SOUTHWEST JIAOTONG UNIV

Water producing method and apparatus

ActiveUS7272947B2Lighting and heating apparatusEnergy based wastewater treatmentWorking fluidFilter system

Owner:DMPG LLC

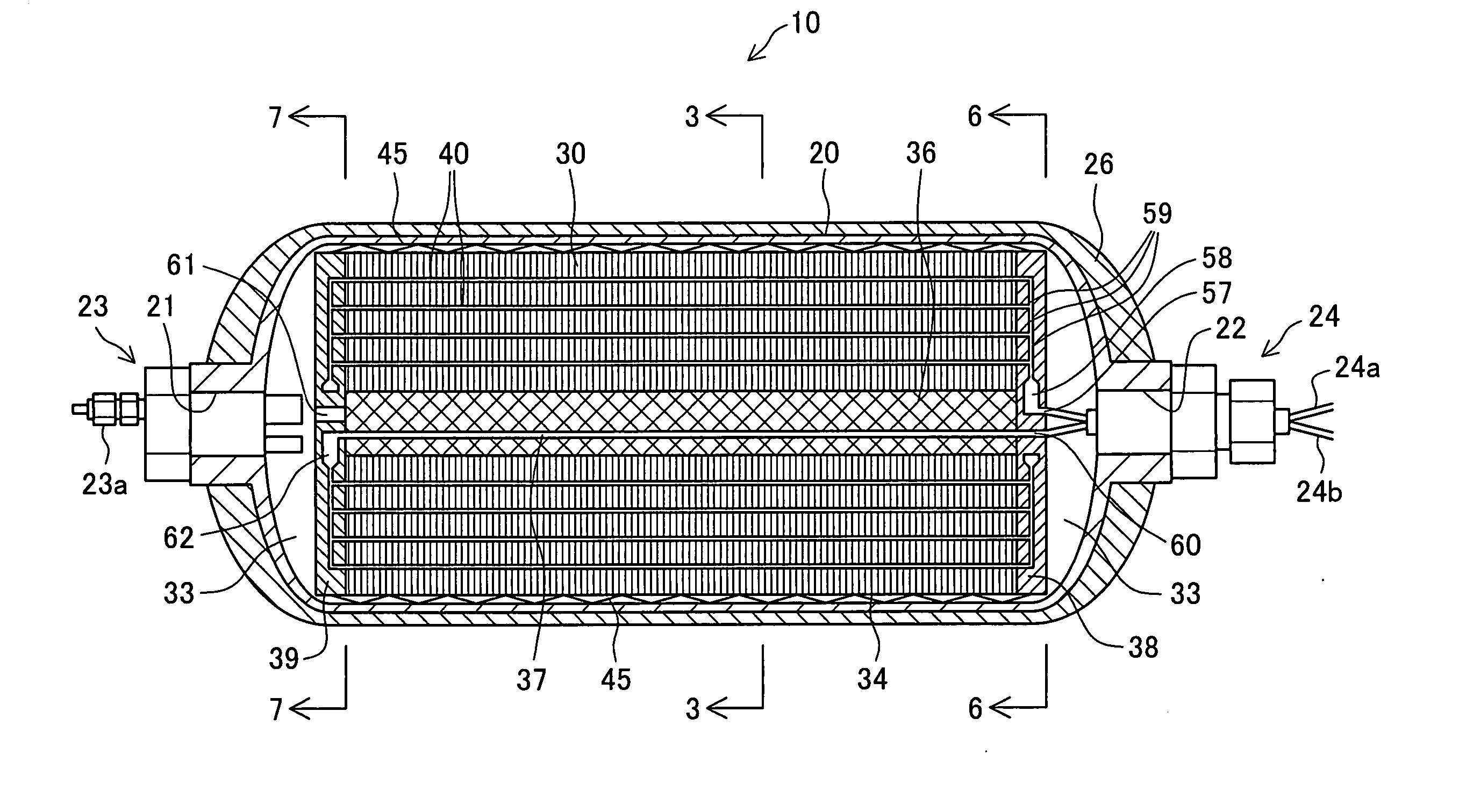

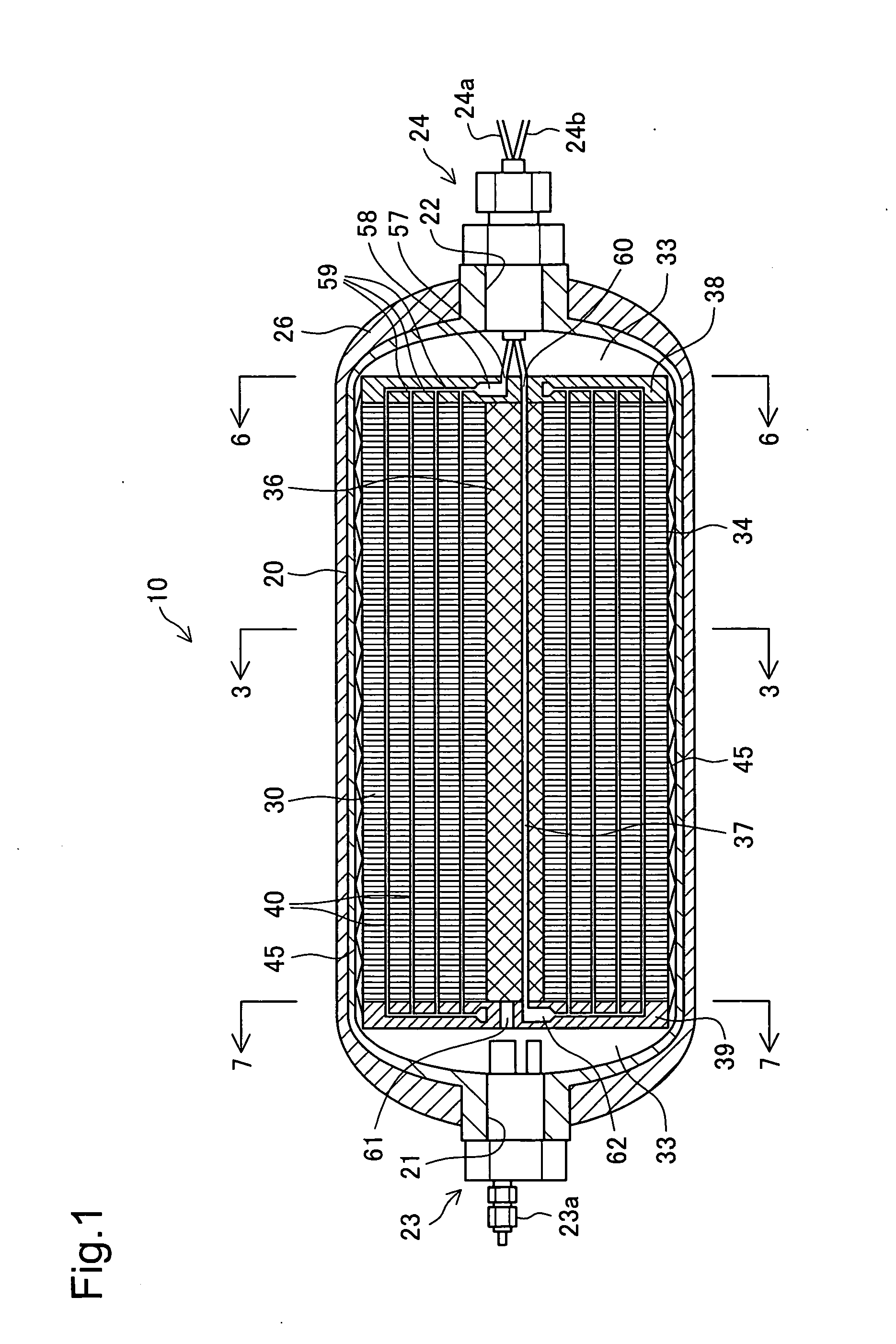

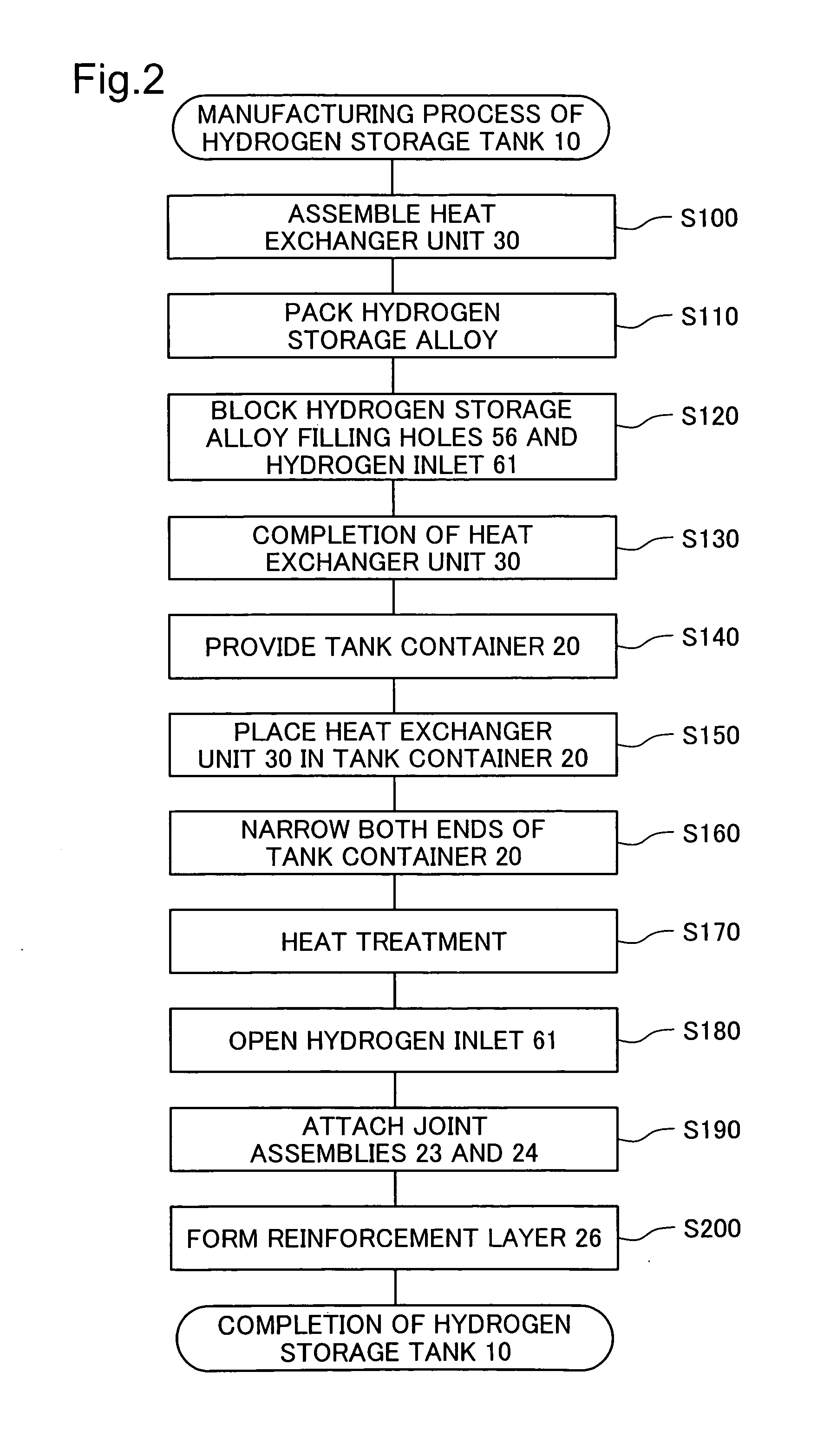

Gas storage tank and method of manufacturing the same

InactiveUS20050000970A1Drawback can be obviatedSufficient performanceReversible hydrogen uptakeCombustion enginesWater coolingHigh pressure

The technique of the invention manufactures a gas storage tank, which includes a gas absorbent / adsorbent and is capable of storing a high-pressure gas. The manufacturing process of a hydrogen storage tank first assembles a heat exchanger unit and packs the particles of hydrogen storage alloy into the heat exchanger unit. The manufacturing process then blocks hydrogen storage alloy filling holes used for packing the hydrogen storage alloy in the heat exchanger unit and attaches a detachable cover member to a hydrogen inlet. The manufacturing process subsequently locates the heat exchange unit filled with the hydrogen storage alloy in a cylindrical tank and narrows both ends of the tank to form joint openings. The manufacturing process then heat-treating the tank under water cooling and detaches the cover member. The manufacturing process attaches joint assemblies to the joint openings and forms a reinforcement layer around the outer circumference of the tank to complete the hydrogen storage tank.

Owner:TOYOTA JIDOSHA KK +1

High-brightness LED underwater energy saving lamp

InactiveCN101608781ARealize direct coolingReduce adverse effectsPoint-like light sourceElectric circuit arrangementsDecreased energyEngineering

The invention relates to a high-brightness LED underwater lamp with low energy consumption and numerically controlled light color. A groove surface of a double-sided groove type lamp housing is provided with one or more LED chips. A transparent cover is arranged on and matched with one side, where an LED is arranged, of the double-sided groove type lamp housing by a rubber sealing ring in a waterproof sealed manner. Another groove cavity of the double-sided groove type lamp housing is internally provided with a control circuit board, a signal end of which is respectively connected with signal ends of one or more LED chips. A wiring terminal is sealed and connected on a sealing cover plate and a lead of the wiring terminal is connected with the signal end of the control circuit board. The sealing cover plate is sealed and matched with the other side of the double-sided groove type lamp housing. The energy saving lamp has the advantages of firstly, not only avoiding unfavorable effect of the control circuit board on the LED chip, but also considerably improving the optical conversion efficiency of the LED chip; secondly, realizing the direct temperature reduction to the LED chip, decreasing energy consumption, improving the optical conversion efficiency of the LED chip and considerably prolonging the service life of the LED chip; and thirdly, realizing the purpose of direct water-cooled temperature reduction.

Owner:杭州亿奥光电有限公司

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

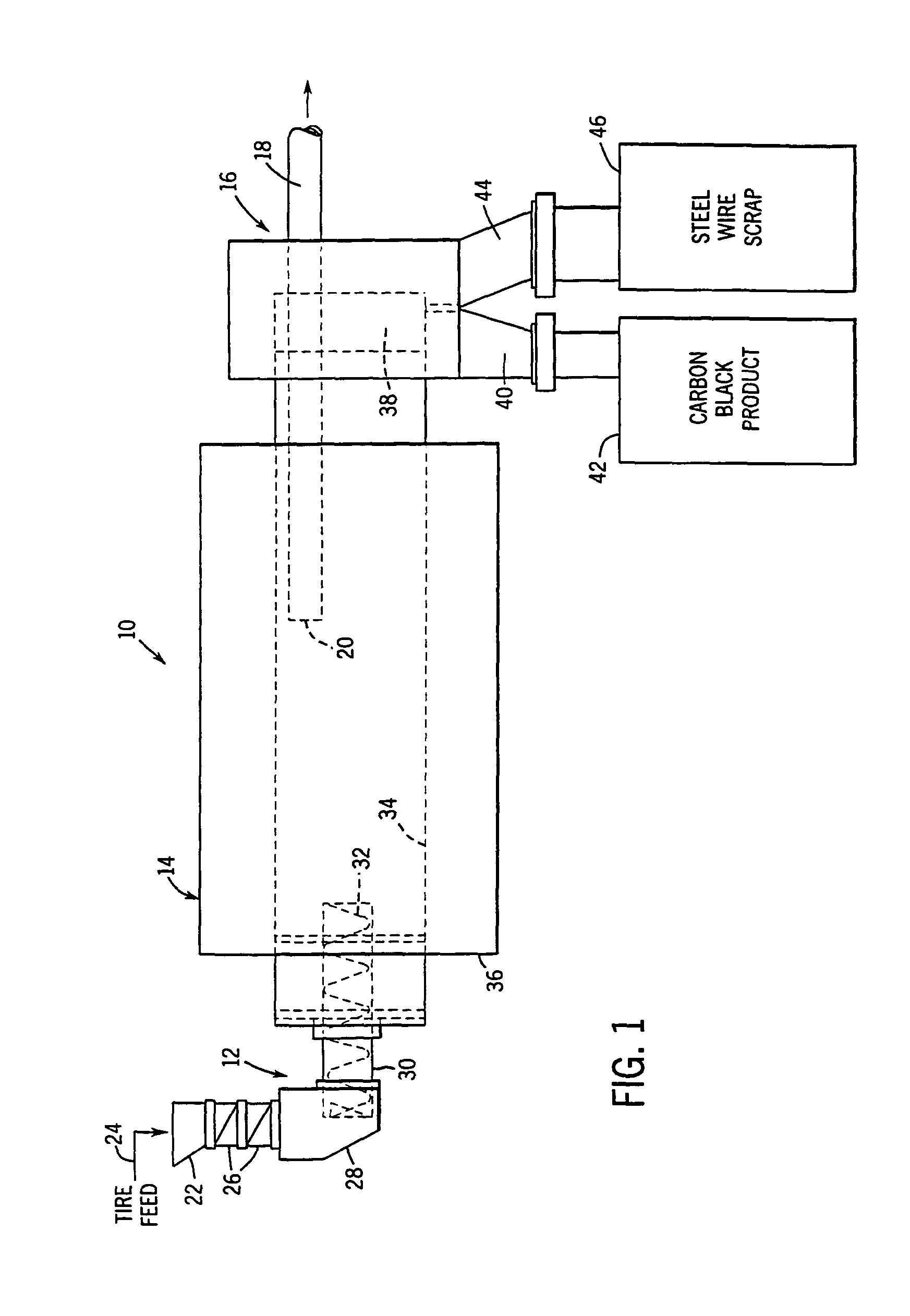

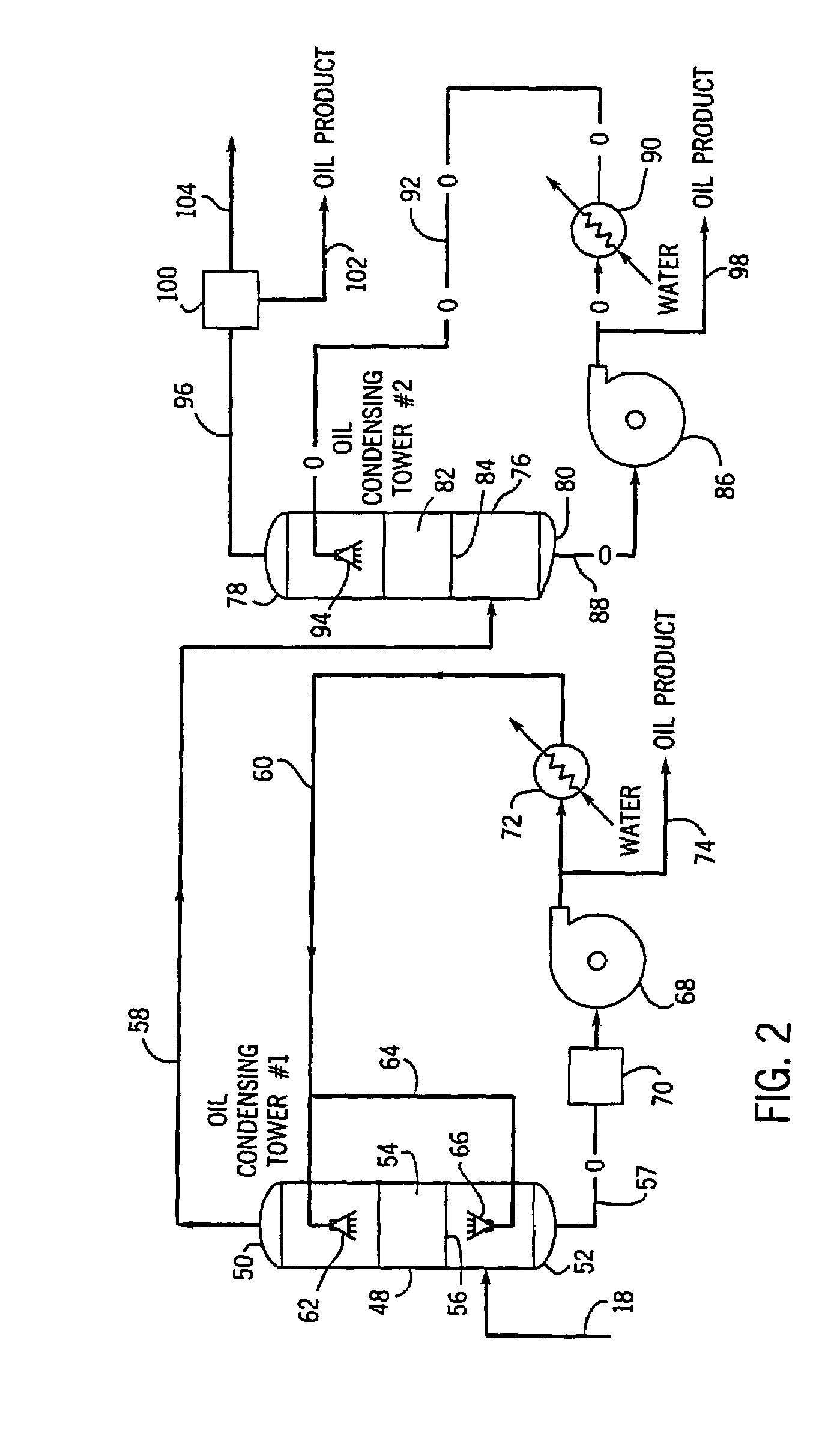

Condensation and recovery of oil from pyrolysis gas

InactiveUS7101463B1Large specific surface areaTemperature controlMultiple-effect/fractional condensationDirect heating destructive distillationWater vaporProduct gas

A system and process for the recovery of oil from the pyrolysis of material containing hydrocarbons such as shredded vehicle tires. The system utilizes a pair of sequentially positioned packed towers to recover at least 95% of the oil contained in the pyrolysis gases. The first packed tower operates above the dew point of the water vapor in the pyrolysis gases to insure that no water is condensed and obtain a primary oil fraction having oil with a high flash point of about 60° C. or greater and a primary vapor fraction containing additional oils, fuel gases and water vapor. The primary vapor fraction is fed to the second packed tower which operates below the dew point of the water vapor to condense the water and oil having a low flash point of 34° C. or below, and provide a secondary vapor fraction containing valuable fuel gases.

Owner:METSO MINERALS IND INC

Pre-chamber spark plug

ActiveUS7659655B2Life maximizationReduce erosionSparking plugsInternal combustion piston enginesElectricityElectrode erosion

Owner:WOODWARD GOVERNOR CO

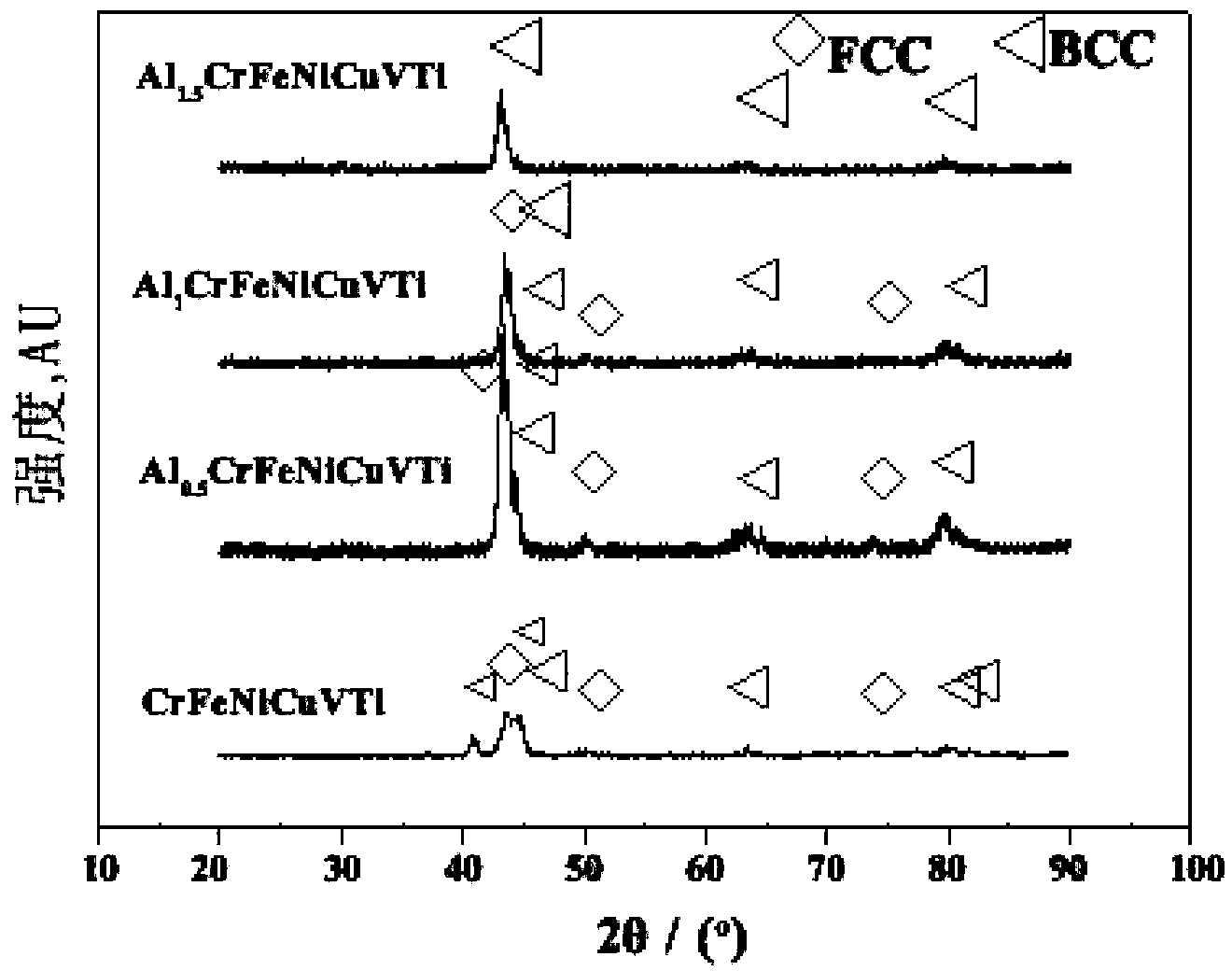

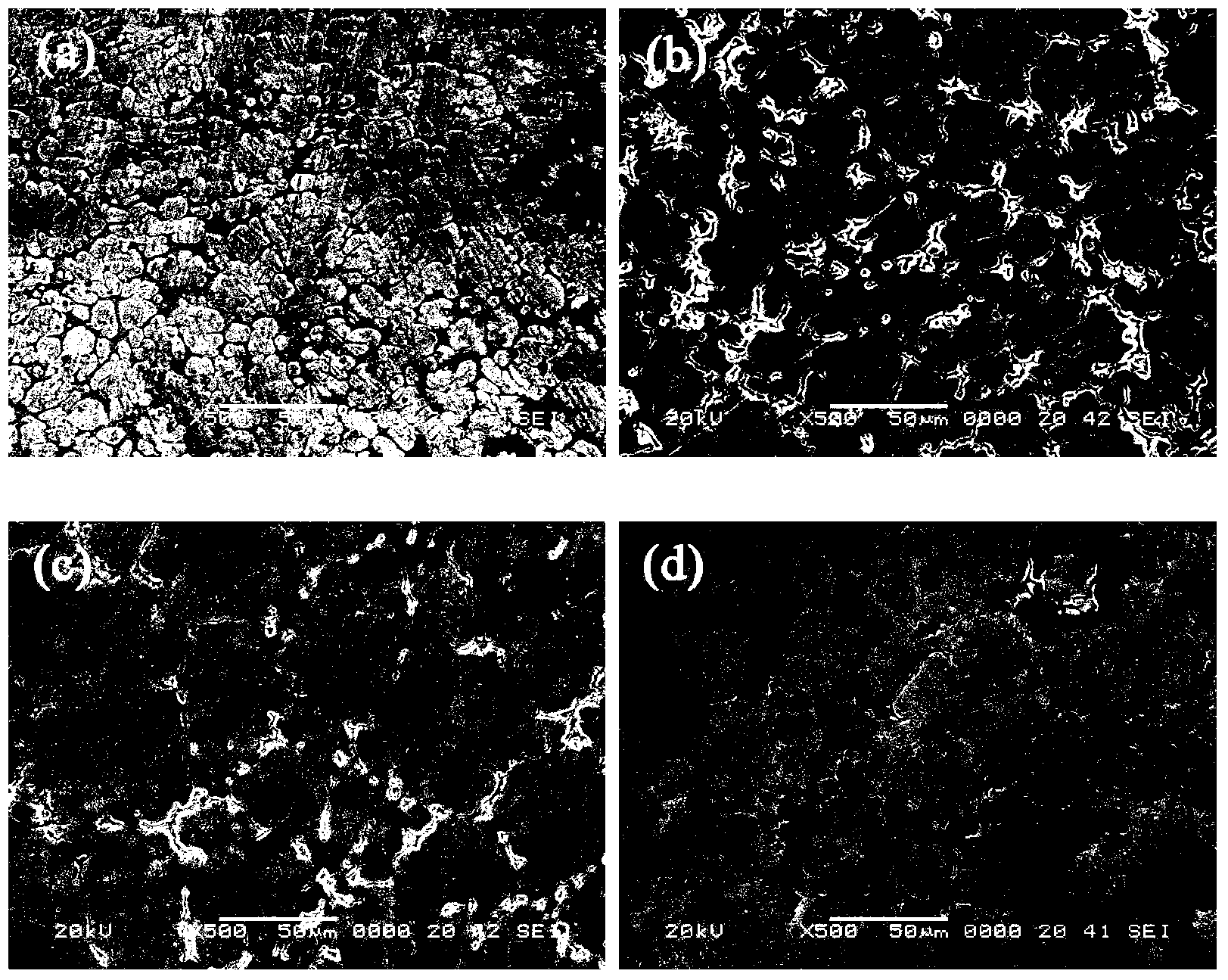

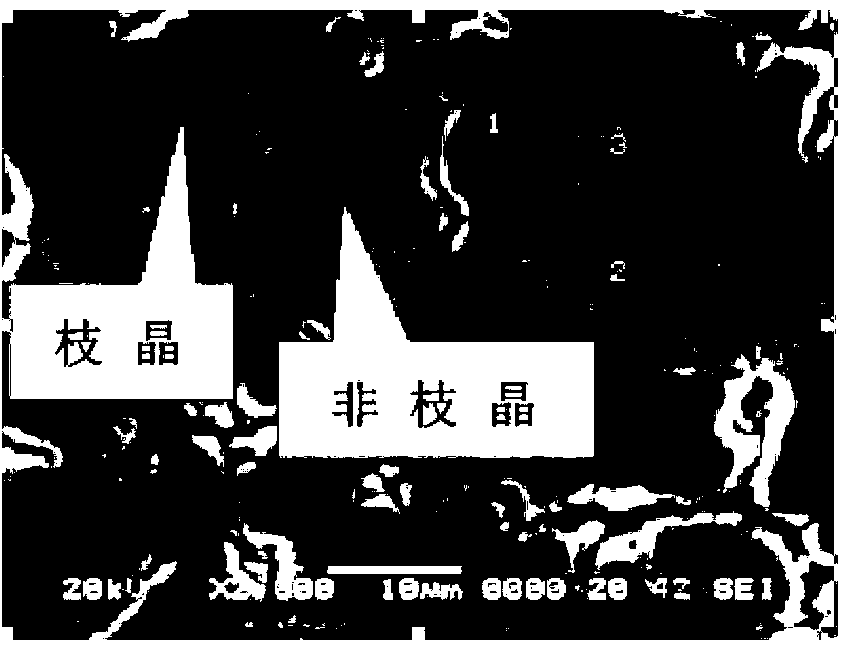

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

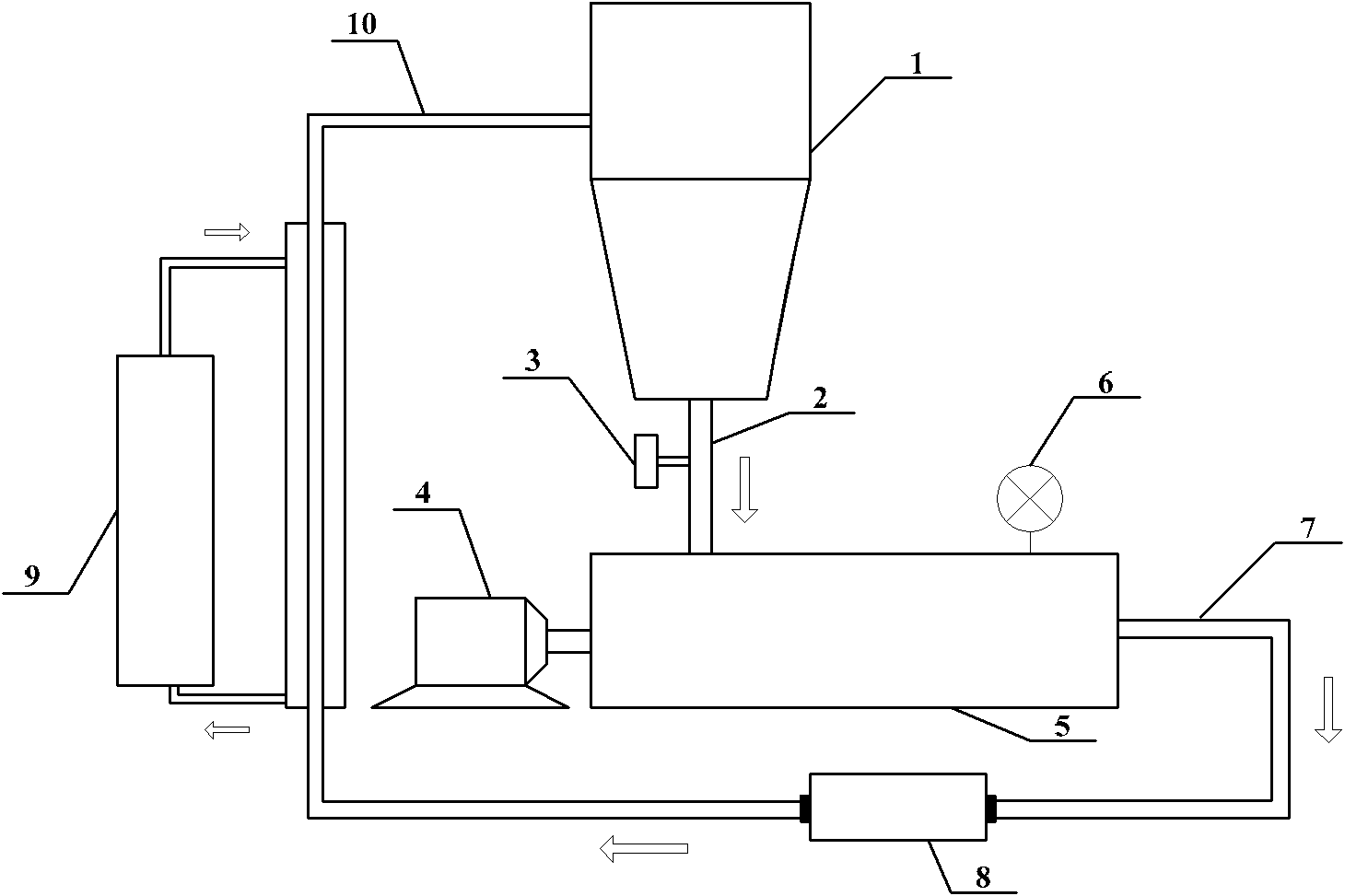

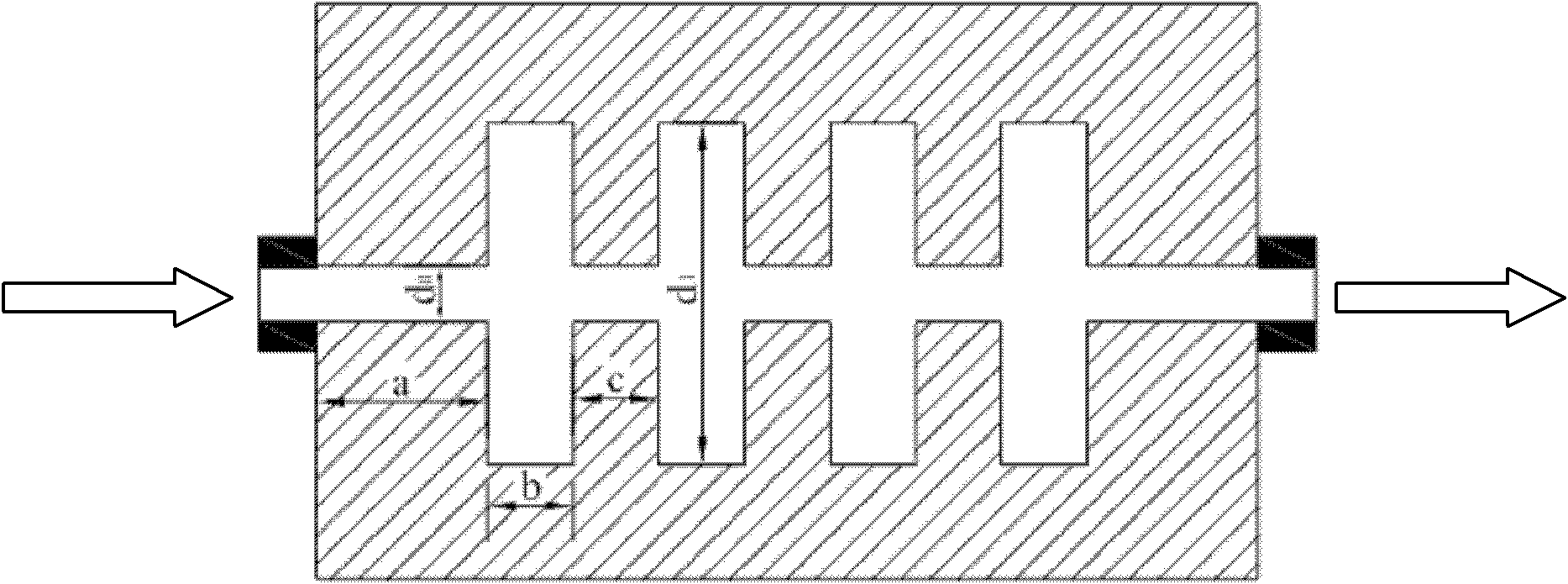

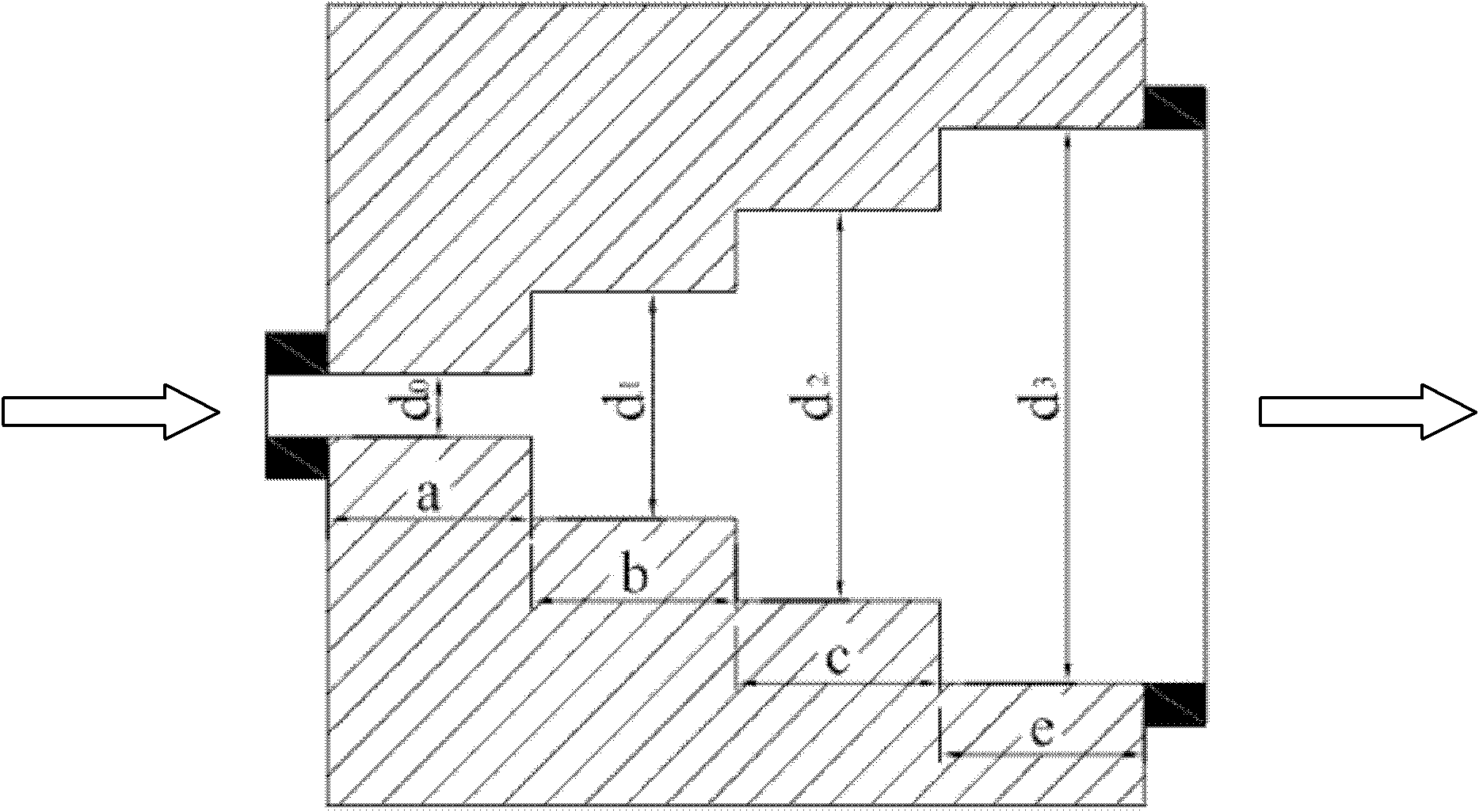

Apparatus and process for preparing graphene by the technology of cavitating jet

Provided is an apparatus and a process for preparing graphene by the technology of cavitating jet. The apparatus comprises a storage tank, a water inlet pipe, a valve, a motor, a plunger pump, a compression gauge, a high pressure pipe, a cavitation generator, a cycle water cooling means and a return line. The outlet of the storage tank is connected with the inlet side of the water inlet pipe, andthe outlet side of the water inlet pipe is connected with the water inlet of the plunger pump; the valve is installed on the water inlet pipe, the plunger pump is driven by the motor, and the operating pressure of the plunger pump is displayed on the compression gauge; the water outlet of the plunger pump is connected with the water inlet of the high pressure pipe, and the water outlet of the high pressure pipe is connected with the water inlet of the cavitation generator; the water outlet of the cavitation generator is connected with the water inlet of the return line, the water outlet of the return line is connected with the inlet of the storage tank, and the cycle water cooling means is installed on the return line. The preparation method comprises seven steps. The conception of the invention is scientific; the process is advanced; production cost is low; no environmental pollution is generated; industrial large scale production can be realized; the apparatus and process provided in the invention have a wide application prospect in the technical field of preparing graphene.

Owner:HUARUIMOSHI DANYANG CO LTD

Steel plate for low temperature pressure container and producing method thereof

InactiveCN101144138AReduce dosageReduce usageRoll mill control devicesFurnace typesChemical industryChemical composition

The present invention relates to a steel plate used for a low temperature pressure vessel and the production method thereof. The steel plate has the main chemical composition content (wt percent) that C is 0.12-0.19 percent, Si is 0.15-0.45 percent, Mn is 1.2-1.6 percent, Nb is 0.015-0.050 percent, Ti is 0.01-0.03 percent, Ni is 0.10-0.35 percent, Al is 0.015-0.050 percent, and P is 0-0.015 percent; S is 0-0.01 percent, and the residual is Fe and inevitable impurity. The present invention uses a new process technology of hot billet steel furnace loading, intermediate billet water cooling, controlled rolling, controlled cooling accelerating, and normalizing, which is easy to be operated, reduces the dosage of the alloying element to the lowest, in particular, largely reduces the use of the precious metal Ni, the transverse impact power of the low temperature toughness 40 below zero is up to 164 J, transverse impact power of 30 below zero is up to 298 J, and CTOD is Delta 0.20 equal to 0.40 mm in the test condition that the temperature is 40 below zero. The cost of the steel type is relatively lower, the hourly output is high, the intensity is moderate, the plasticity is good, the low temperature toughness is high, the welding performance is extremely fine, and thereby the steel type can be widely applied to low temperature vessels for storing and delivering low temperature liquid in various industries and the petroleum and the chemical industry fields.

Owner:SHANDONG IRON & STEEL CO LTD

Manufacturing method for scale shaped metal powder

A process for preparing flaky metal powder used for the environment protection type paint includes mixing the metallic powder with grinding medium, grinding aid and surfactant, and grinding at 20-100 deg.C in a enclosed grinder filled by inertial gas and cooled by water while controlling its rotation speed.

Owner:KUNMING UNIV OF SCI & TECH +1

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

Graphite rotary tube furnace

InactiveUS6042370AMinimizing radiation heat lossStable temperatureRotary drum furnacesCharge supportsRadiative heat lossRadiant heat

A rotary tube furnace suitable for operation in controlled atmospheres at temperatures in the range of 1500 DEG to 2800 DEG comprises a generally horizontal rotatable graphite tube slidably supported on water-cooled split ring graphite bearings. The graphite tube is rotated by means of a stainless steel drive plate and is contained within a flexible atmospheric sealing assembly and enclosure for the containment of a selected atmosphere around and within the tube and allows for the co-current or counter-current flow of gas during operation. Radiation baffles in the interior of the graphite tube inhibit radiant heat loss at the ends of the tube. The graphite tube may be constructed in two or more sections having threaded ends for ease of installation as well as removal or replacement for maintenance purposes. A heating section of the tube is heated by a plurality of graphite electrical heating elements contained within an insulated heating chamber.

Owner:HARPER INT CORP

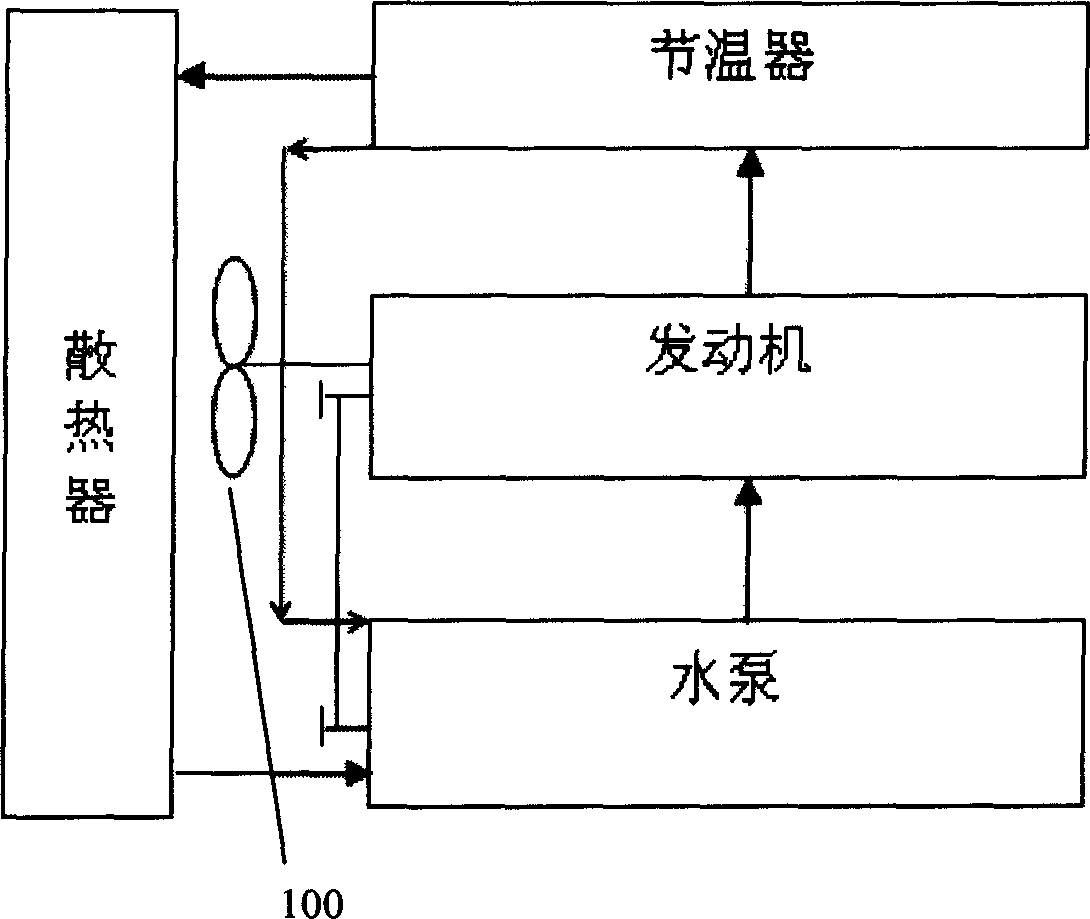

Water cooling system of engine and cooling method thereof

InactiveCN1884804AIncrease starting speedReduce exhaust pollutionLiquid coolingCoolant flow controlLiquid temperatureEngineering

The invention relates to an engine water cooling system and relative cooling method, wherein the first sensor senses the working condition of engine; the cooling liquid temperature sensor senses the temperature of cooling liquid inside the engine; the control unit responds the signals of first sensor and the cooling liquid temperature sensor, to control the electric water pump to operate when the temperature of cooling liquid is higher than the first preset temperature when the engine starts, to drive the cooling liquid to cool the engine, to improve the starting property of engine and the discharging property of heating machine; and the electric controller based on the operation parameter of engine and the temperature of cooling liquid, controls the switch of electric valve, the electric water pump and the rotation speed of electric fan, to control the circulation and the flux of cooling liquid, and the cooling ability of cooling fan, to improve the property of engine.

Owner:BYD CO LTD

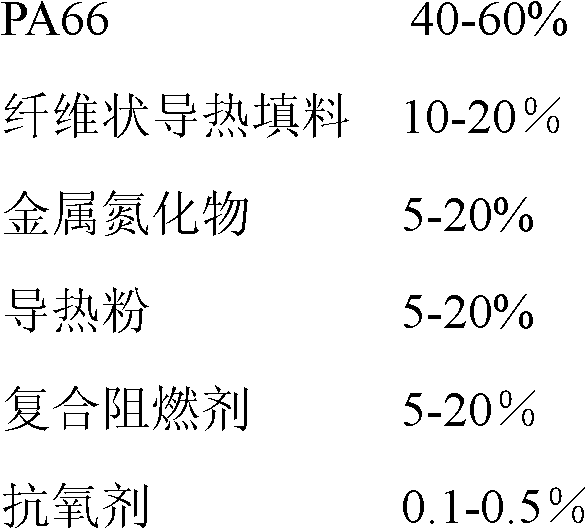

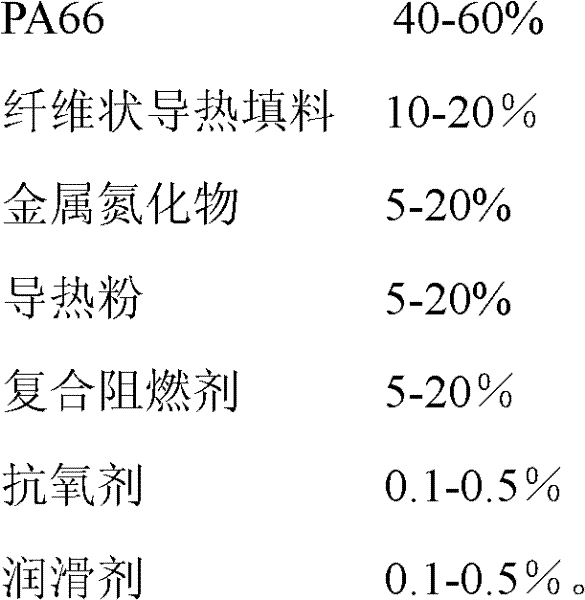

Antiflaming heat-conduction PA66 (Polymide 66) composite material and preparation method thereof

InactiveCN102399442AGuaranteed flame retardant performanceWide range of raw materialsAntioxidantWater cooling

The invention relates to an antiflaming heat-conduction PA66 (Polymide 66) composite material and a preparation method thereof. The antiflaming heat-conduction PA66 composite material comprises the following raw materials by weight ratio: 40-60% of PA66, 10-20% of fibrous heat-conduction padding, 5-20% of metal nitride, 5-20% of heat-conduction powder, 5-20% of composite flame retardant, 0.1-0.5% of antioxidant and 0.1-0.5% of lubricant. The preparation method comprises the following steps of: weighing the raw materials according to the weight ratio; putting all the raw materials in a high-effective mixing machine; mixing for 5-10 minutes; discharging; putting the uniformly-mixed raw materials into a screw compressor; extruding; carrying out water cooling; pelleting; and obtaining the product. The invention has the characteristics of good antiflaming effect, excellent heat-conduction property, easiness for processing and the like.

Owner:SHANGHAI SUNNY

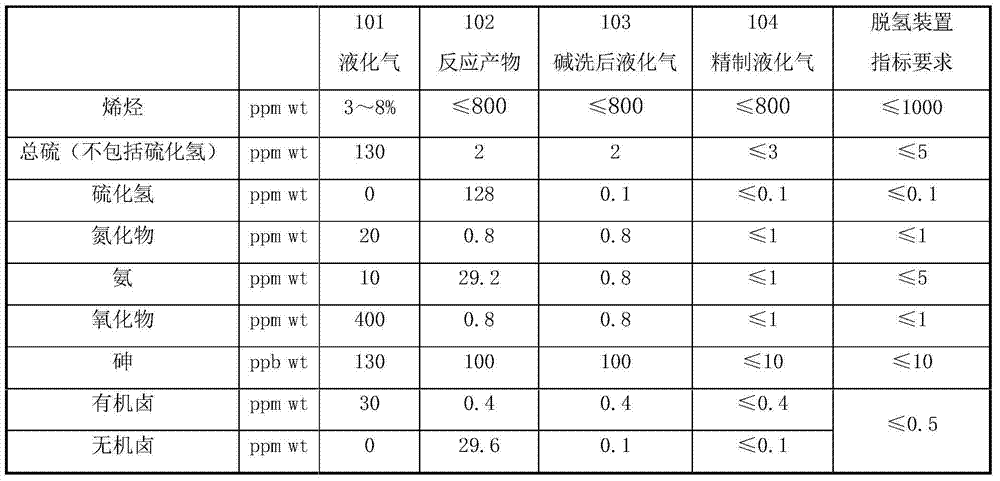

High-temperature hydrogenation and purification process for liquefied gas materials

The invention relates to a purification process of liquefied gas and particularly provides a high-temperature hydrogenation and purification process for liquefied gas materials. The high-temperature hydrogenation and purification process is characterized by comprising the following steps: (1) carrying out heat exchange on raw material liquefied gas and a reactor outlet product in a heat exchanger, heating by a heating furnace to a reaction temperature, then feeding the material into a reactor from the top, carrying out saturation hydrogenation on olefin in the material to obtain alkane, and respectively hydrogenating and converting sulfide, oxide, nitride and halide into hydrogen sulfide, water, ammonia and hydrogen halide; (2) carrying out sufficient heat exchange on the reactor outlet product and the raw material by an efficient heat exchanger, carrying out water cooling by a water cooler and enabling the material to enter a gas-liquid separation tank, compressing a flashing gas phase and fresh hydrogen by a compressor and circulating to the raw material liquefied gas; (3) enabling the flashing liquid phase to enter an alkali washing deposition tank and carrying out fiber membrane alkali washing to remove hydrogen sulfide, ammonia and hydrogen halide; (4) enabling the material which is subjected to the alkali washing to enter a dearsenicator, and removing arsenic and metal to obtain refined liquefied gas. The high-temperature hydrogenation and purification process mainly aims at a project which is very strict in requirement on the impurity content of a catalyst, and is short in flow, small in investment, low in cost and less in solid wastes.

Owner:山东海成石化工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com