Antiflaming heat-conduction PA66 (Polymide 66) composite material and preparation method thereof

A composite material and thermally conductive filler technology, applied in the field of PA66 composite materials, can solve the problems of difficult production and processing, many links, and high cost, and achieve the effects of excellent processing performance, wide range of raw materials, and high-efficiency flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0027] A preparation method of flame-retardant and heat-conducting PA66 composite material, comprising the following steps:

[0028] (1) Prepare materials according to the components and contents in Table 1 and Table 3.

[0029] (2) Put the above raw materials into a high-efficiency mixer and mix for 10 minutes, then melt, knead, extrude, cool, dry, pelletize and pack through a twin-screw extruder. The used twin-screw extruder barrel has a temperature of 245 to 265°C in each subregion, and the number of revolutions of the screw is 300 rpm. The flame retardancy is tested according to the UL-94 standard, and the thermal conductivity is tested according to the GB / T 3135-2005 standard. See Table 2 and Table 4.

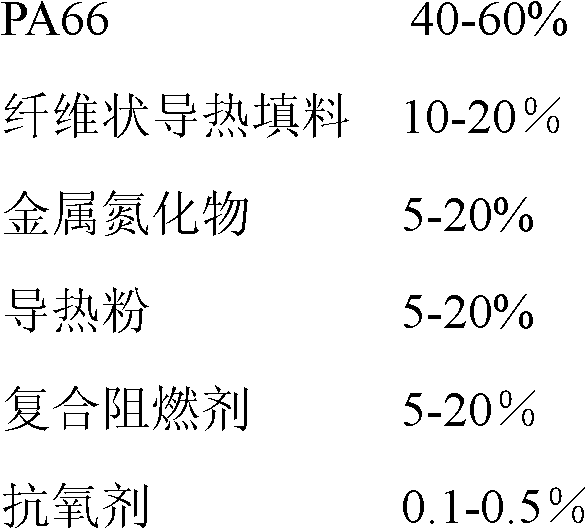

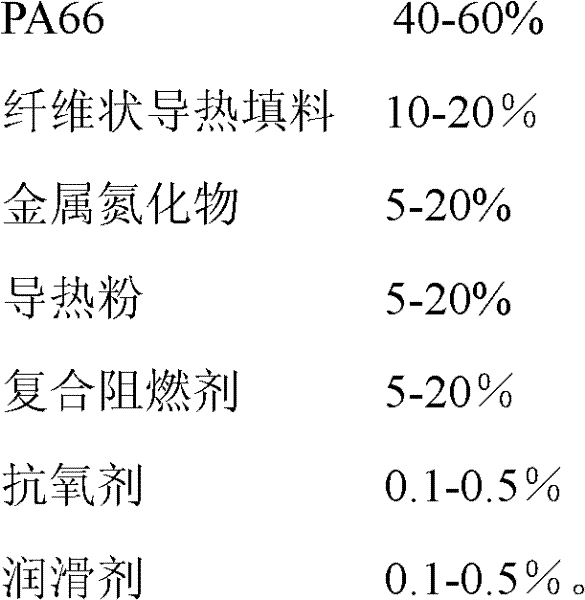

[0030] Table 1

[0031] components

[0032] Table 2

[0033] performance

[0034] table 3

[0035] components

[0036] Table 4

[0037] performance

[0038] From Table 2 and Table 4, it can be seen that the flame retardancy of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com