Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "Enhance haze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intermediate film for laminated glass and laminated glass

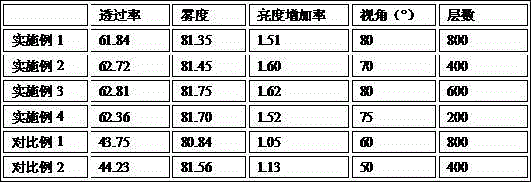

InactiveUS6673456B1High transparencyEnhance hazeSynthetic resin layered productsGlass/slag layered productsWeather resistanceTransmittance

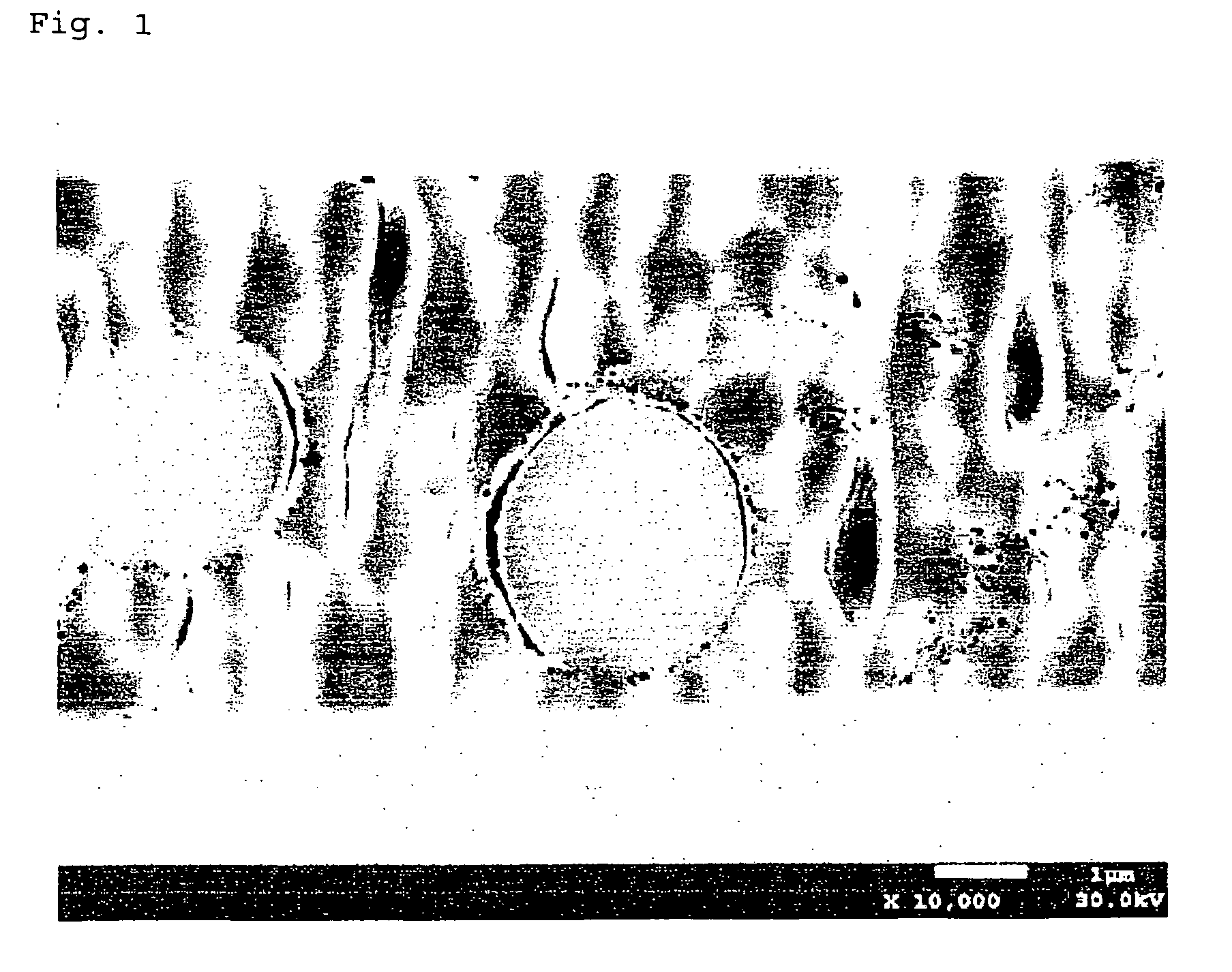

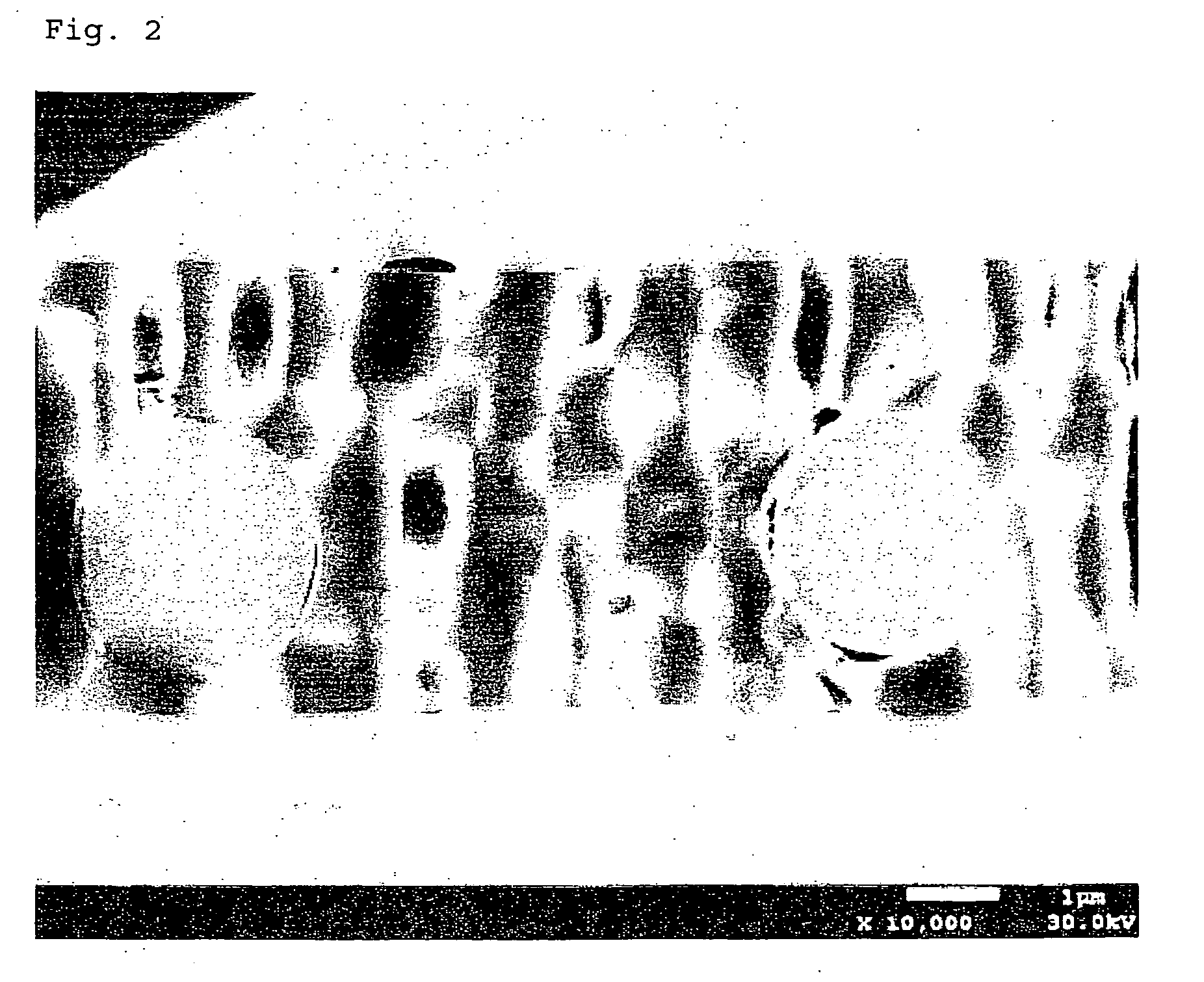

The object of the present invention is to provide an interlayer film for laminated glass which exerts excellent heat insulation or electromagnetic wave transmittance and which is suitable for producing a laminated glass having excellent fundamental performance characteristics required for the laminated glass, such as transparency, especially good haze, appropriate bond strength between an interlayer film and glass, penetration resistance, impact absorption, weather resistance, and so on. Also, the object of the present invention is to provide a laminated glass produced by using the above-mentioned interlayer film. These objects are realized by the interlayer film for laminated glass comprising an adhesive resin, wherein the average particle diameter of tin-doped indium oxide and / or antimony-doped tin oxide is ranging from 0 to 80 nm, and the number of the tin-doped indium oxide or antimony-doped tin oxide particles with a particle diameter of not less than 100 nm are dispersed not more than 1 per 1 mum<2>, and also, by a laminated glass produced by interposing said interlayer film for laminated glass between at least a pair of glass sheets having a visible light transmittance rate (Tv) of not less than 65% in the light rays of 380 to 780 nm, a solar radiation transmittance rate (Ts) in the light rays of 300 to 2500 nm of not more than 80% of the mentioned visible light transmittance rate (Tv), the haze value (H) of up to 1.0% and electromagnetic wave shield (DeltadB) of not more than 11 dB in the wavelength of 10 to 2000 MHz.

Owner:SEKISUI CHEM CO LTD

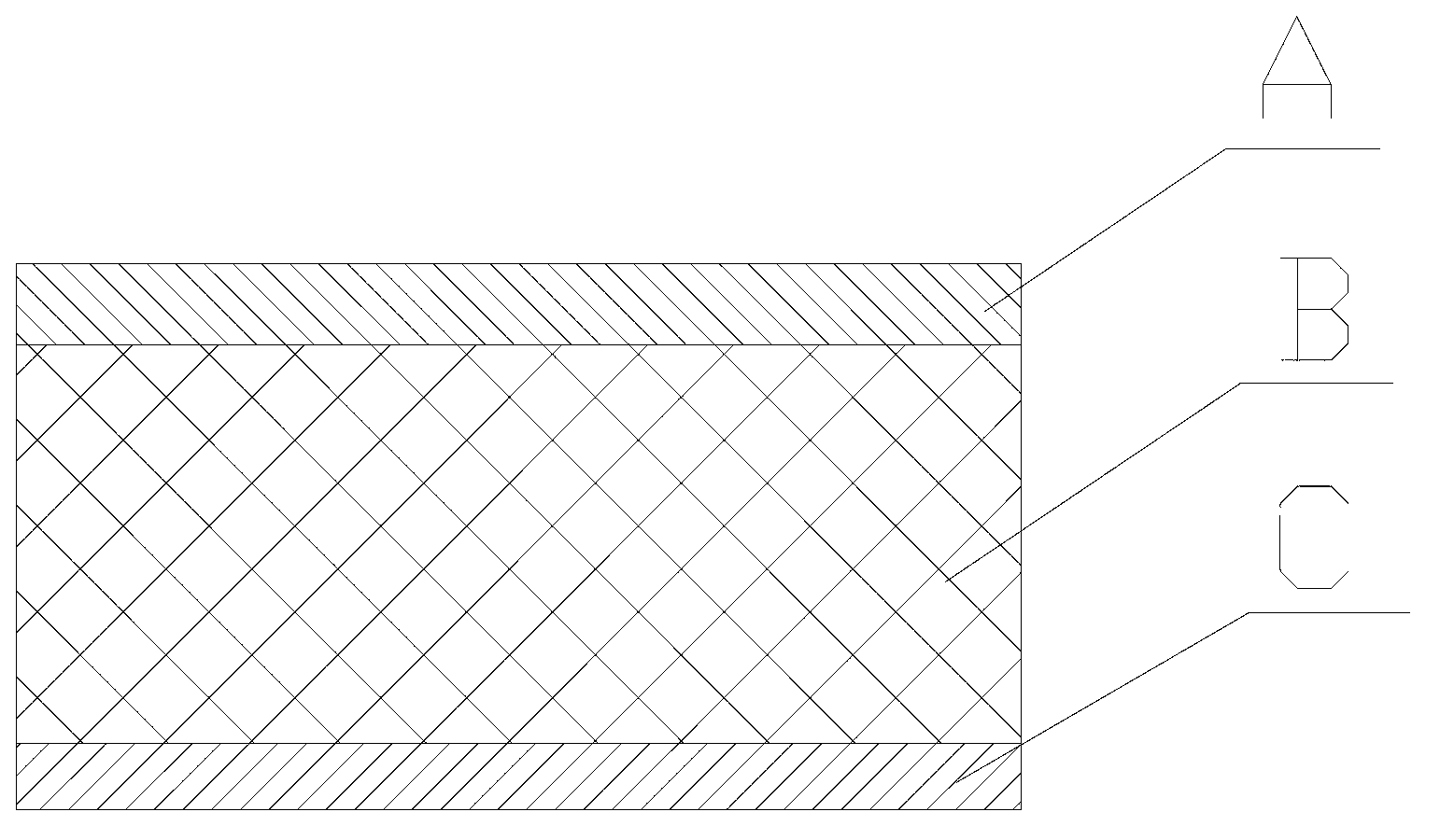

Pressure sensitive adhesive (PSA) laminates

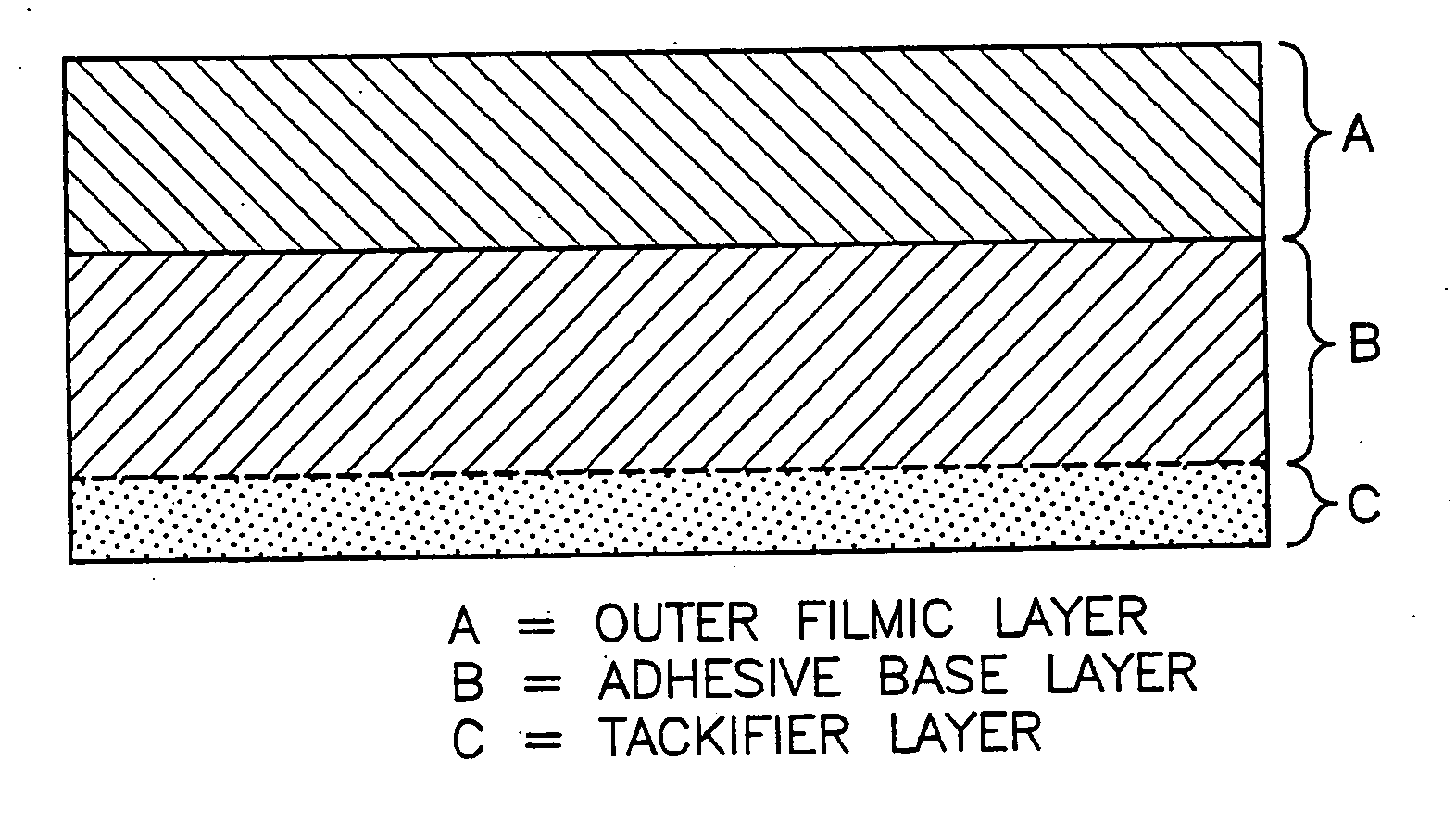

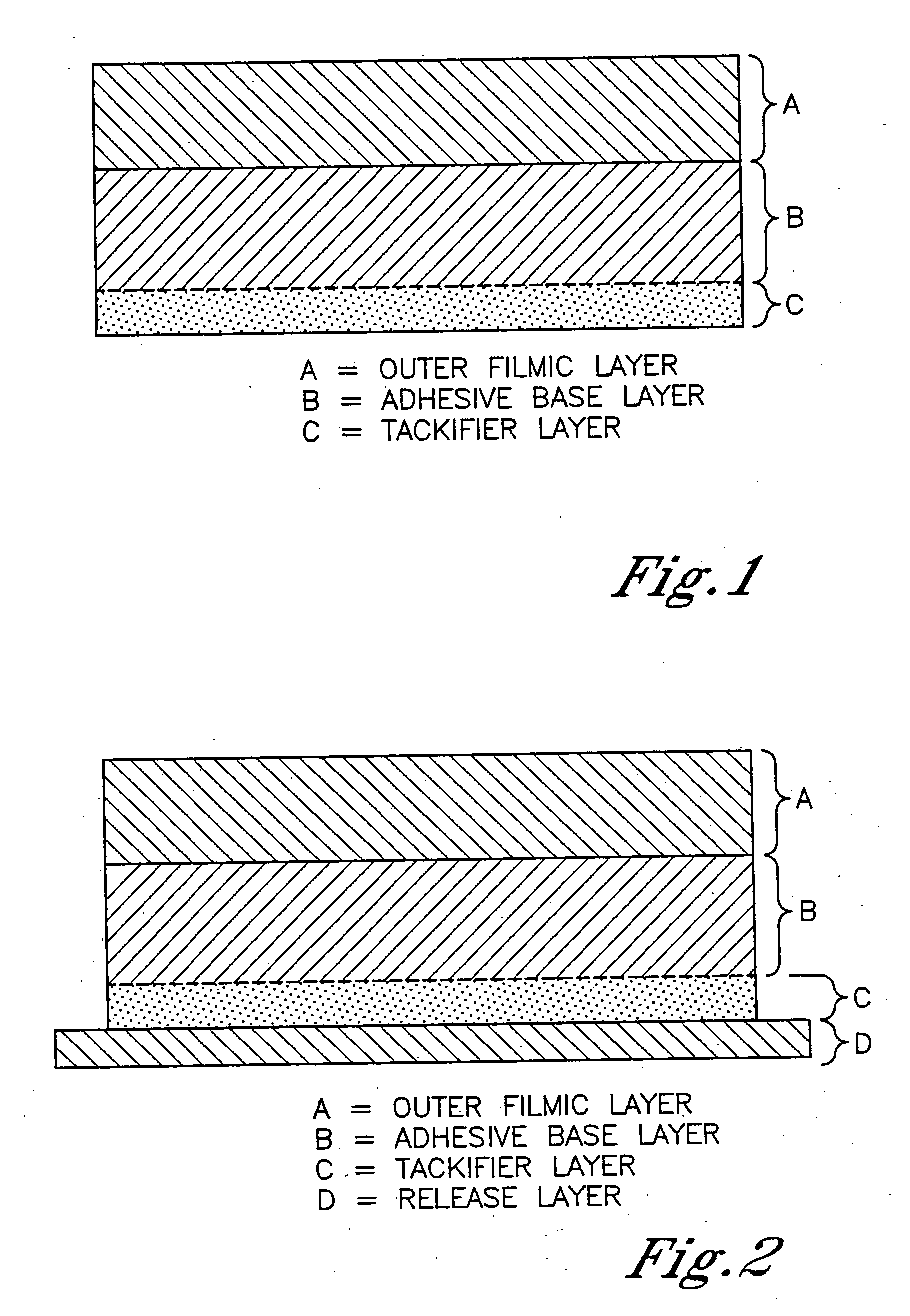

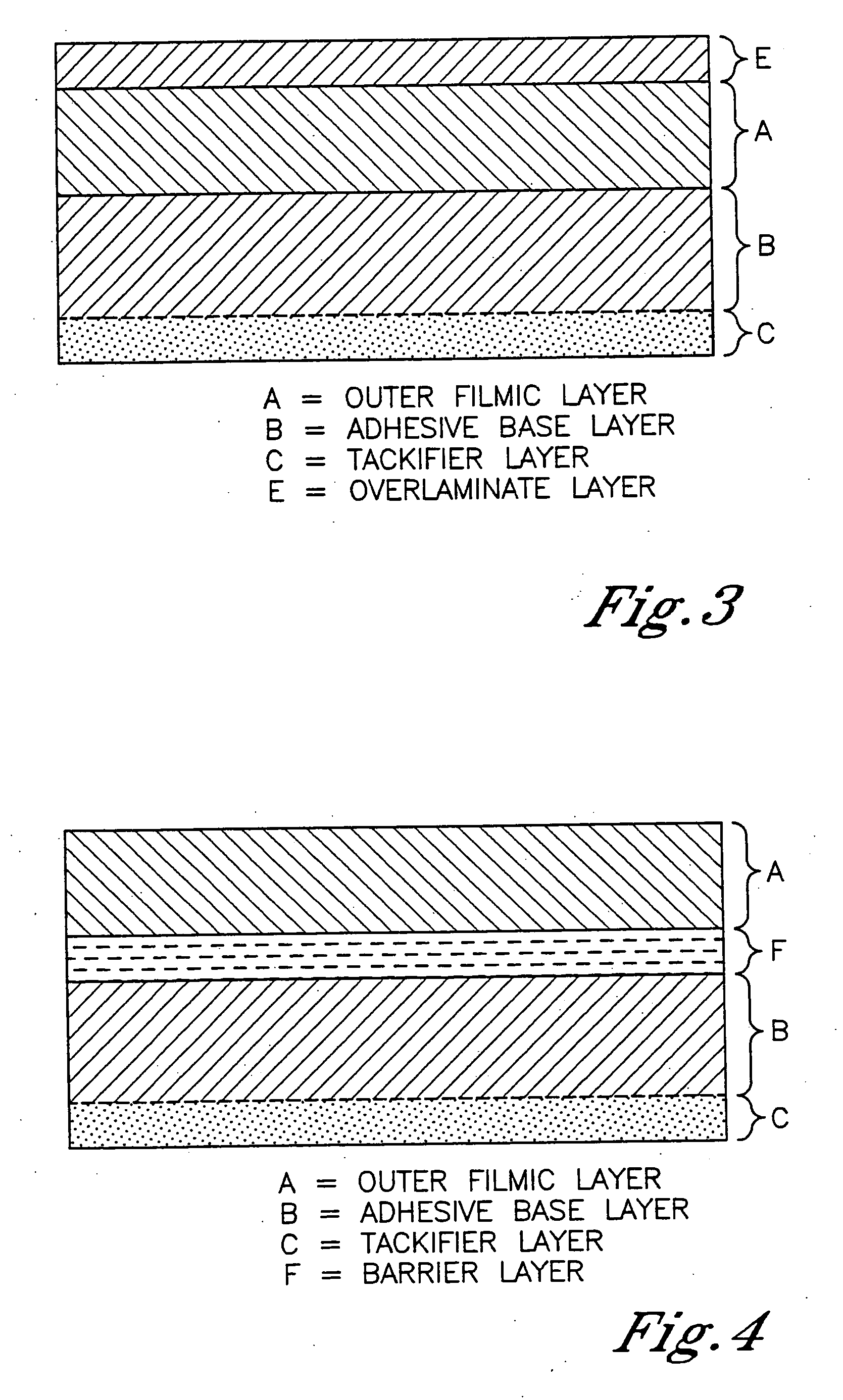

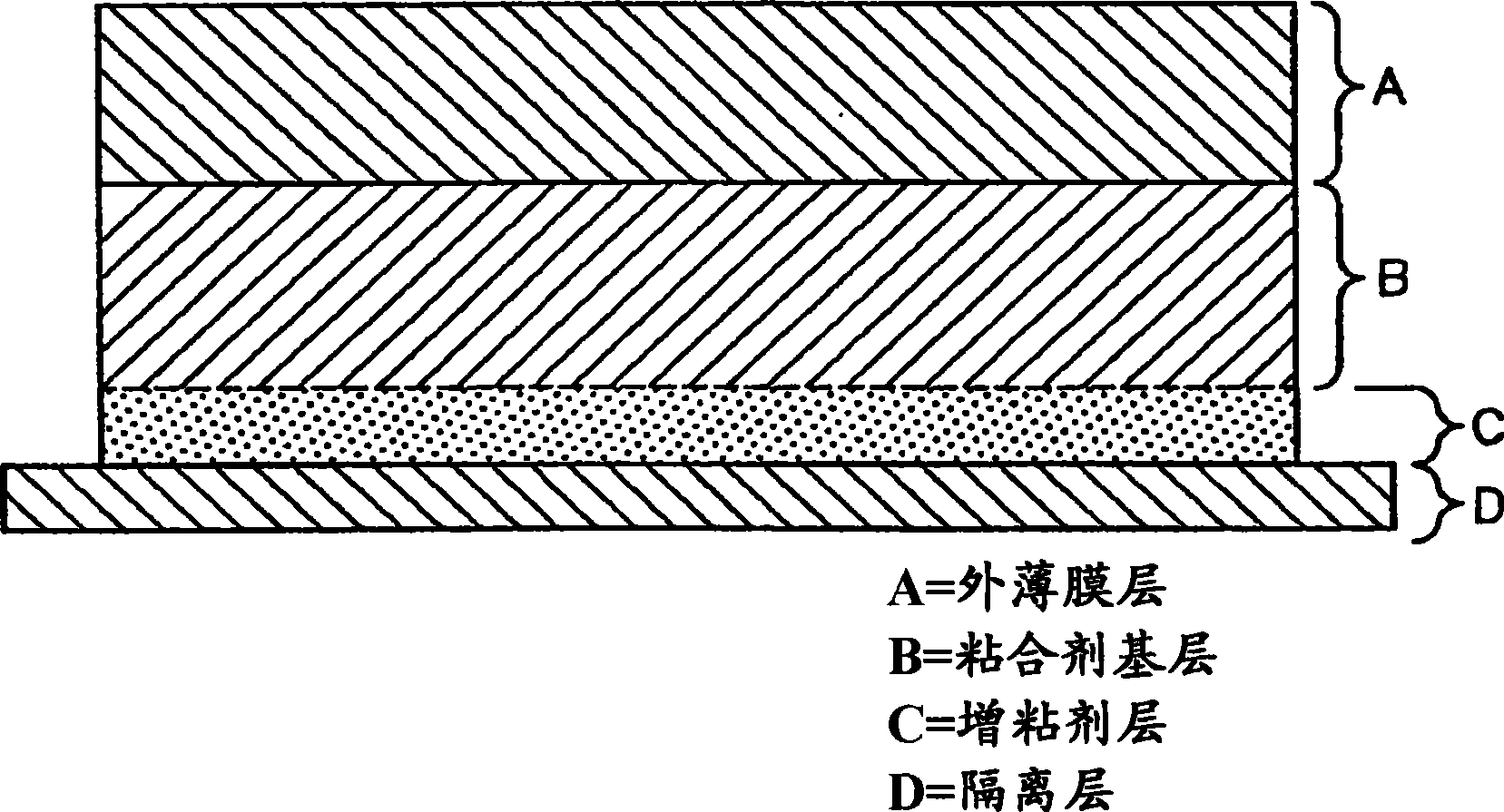

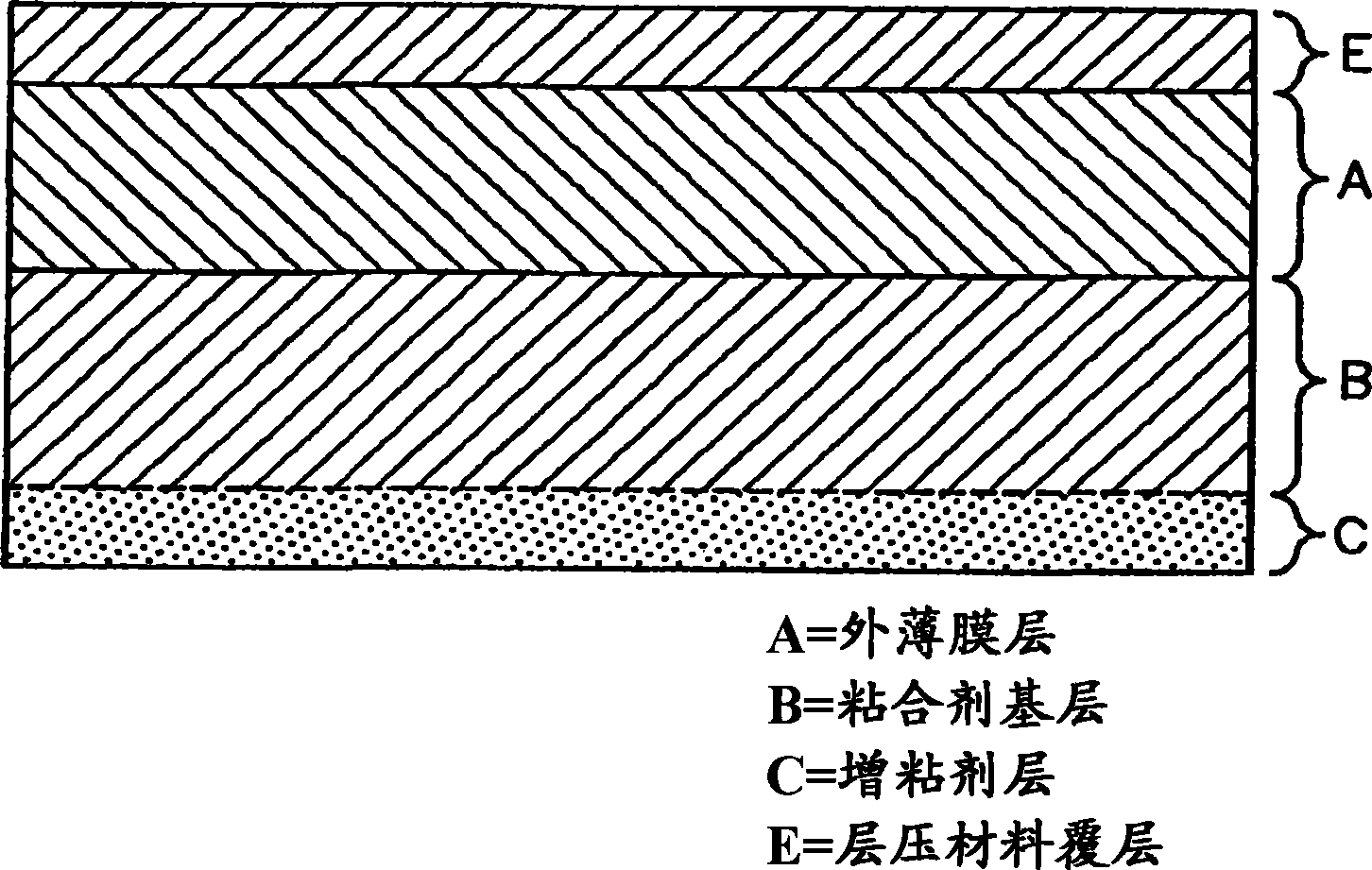

InactiveUS20070231571A1High cohesive strength polymerImprove cohesive strengthFlat articlesThin material handlingTackifierPolymer

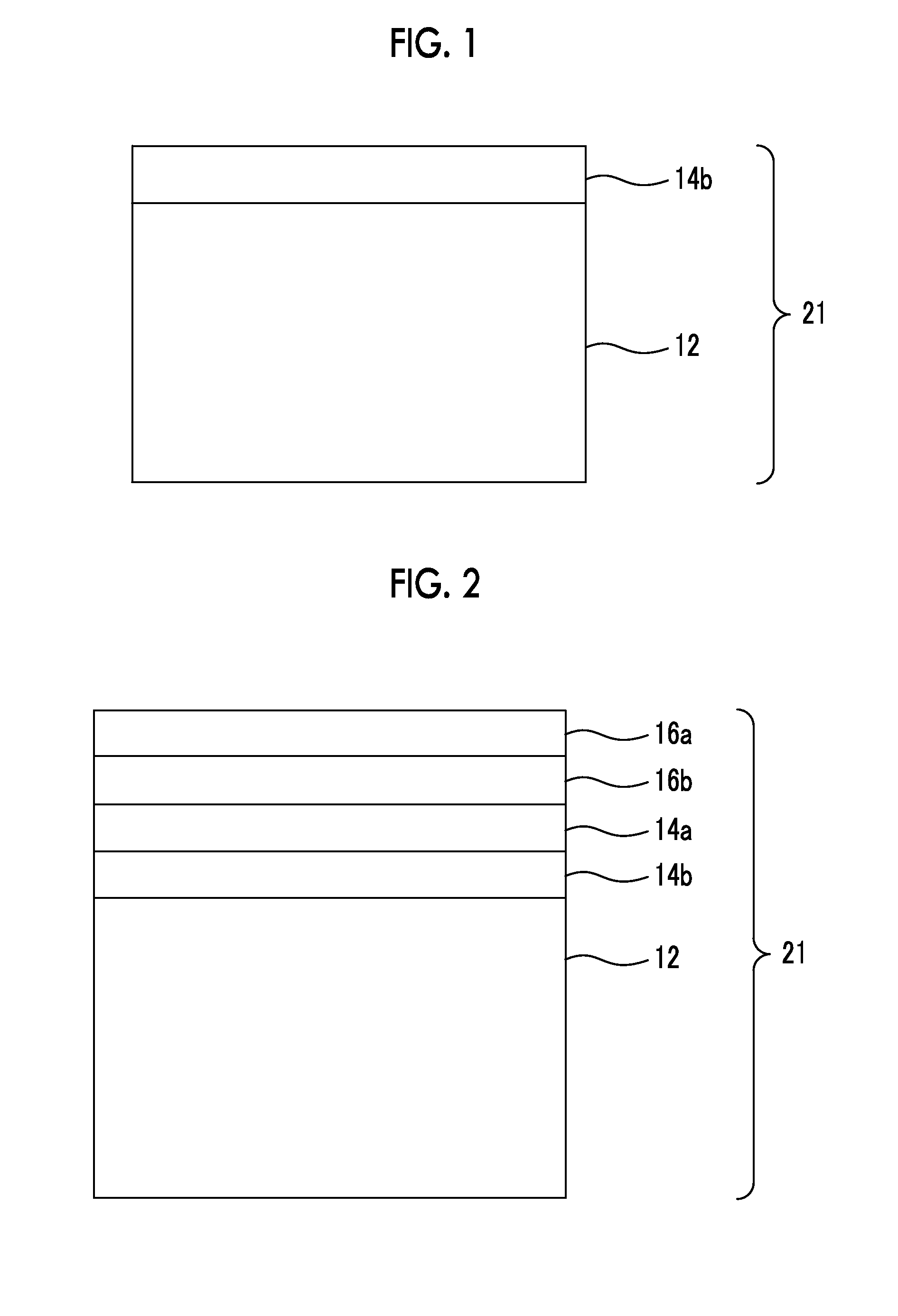

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

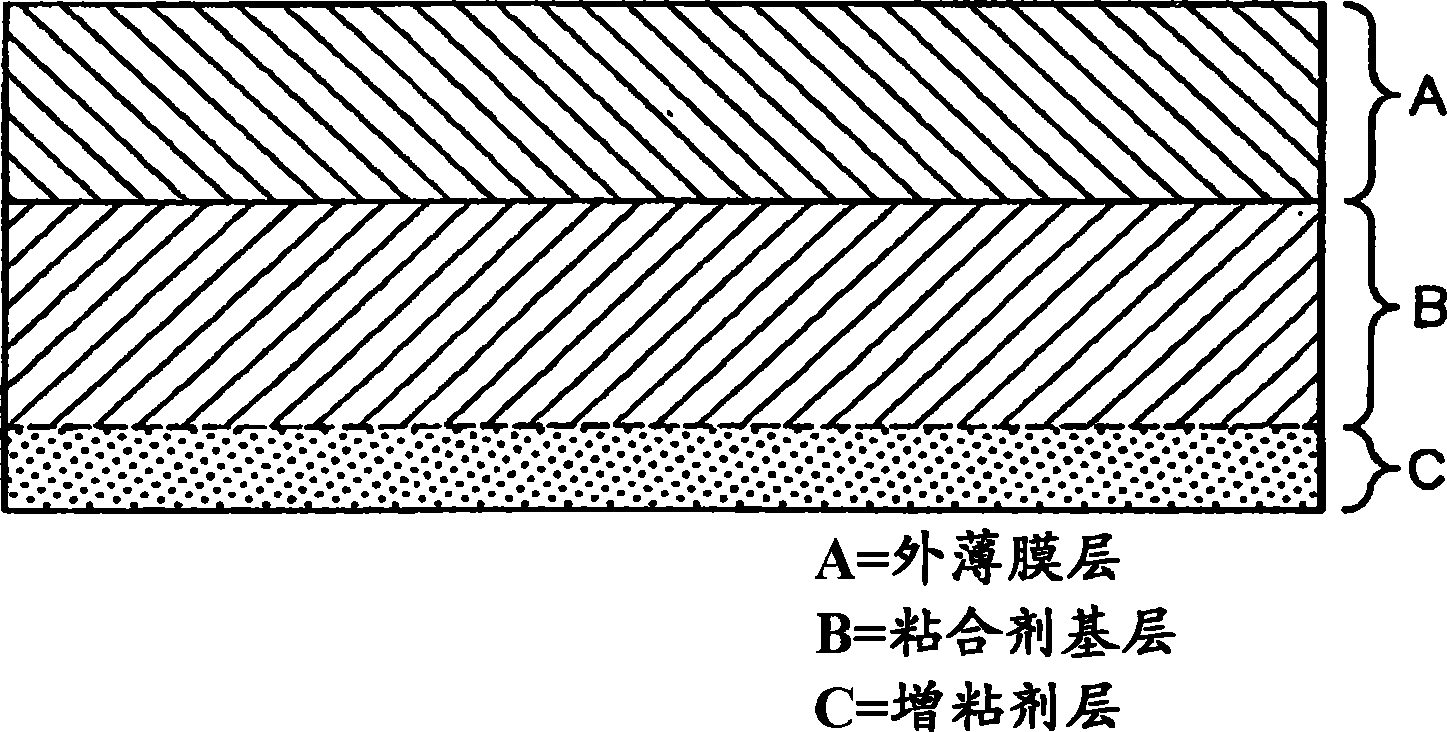

Pressure sensitive adhesive (psa) laminates

InactiveCN101454416AManufacturing Method ImprovementsCoating temperature is lowFlat articlesThin material handlingPolymer scienceTackifier

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

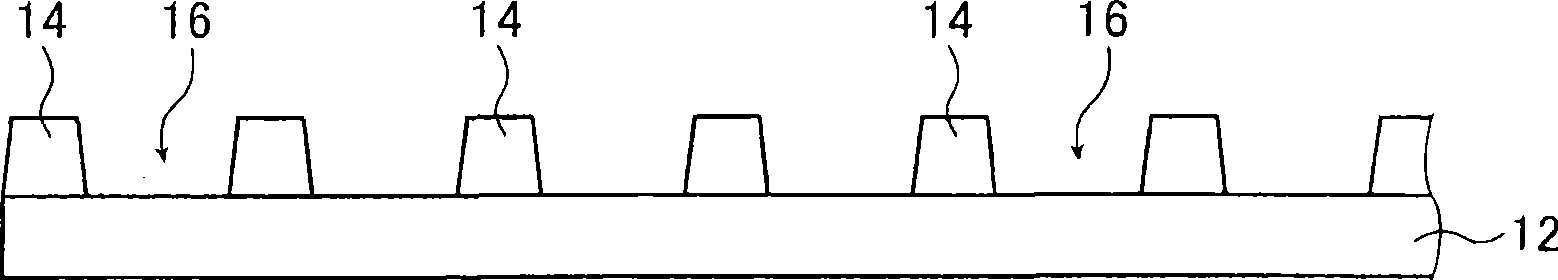

Interlayer film for laminated glass and laminated glass

InactiveUS20050181220A1Improve insulation effectImprove transmittanceCeramic layered productsGlass/slag layered productsIndiumGlass sheet

The object of the present invention is to provide an interlayer film for laminated glass which exerts excellent heat insulation or electromagnetic wave transmittance and which is suitable for producing a laminated glass having excellent fundamental performance characteristics required for the laminated glass, such as transparency, especially good haze, appropriate bond strength between an interlayer film and glass, penetration resistance, impact absorption, weather resistance, and so on. Also, the object of the present invention is to provide a laminated glass produced by using the above-mentioned interlayer film. These objects are realized by the interlayer film for laminated glass comprising an adhesive resin, wherein the average particle diameter of tin-doped indium oxide and / or antimony-doped tin oxide is ranging from 0 to 80 nm, and the number of the tin-doped indium oxide or antimony-doped tin oxide particles with a particle diameter of not less than 100 nm are dispersed not more than 1 per 1 μm2, and also, by a laminated glass produced by interposing said interlayer film for laminated glass between at least a pair of glass sheets having a visible light transmittance rate (Tv) of not less than 65% in the light rays of 380 to 780 nm, a solar radiation transmittance rate (Ts) in the light rays of 300 to 2500 nm of not more than 80% of the mentioned visible light transmittance rate (Tv), the haze value (H) of up to 1.0% and electromagnetic wave shield (ΔdB) of not more than 10 dB in the wavelength of 10 to 2000 MHz.

Owner:SEKISUI CHEM CO LTD

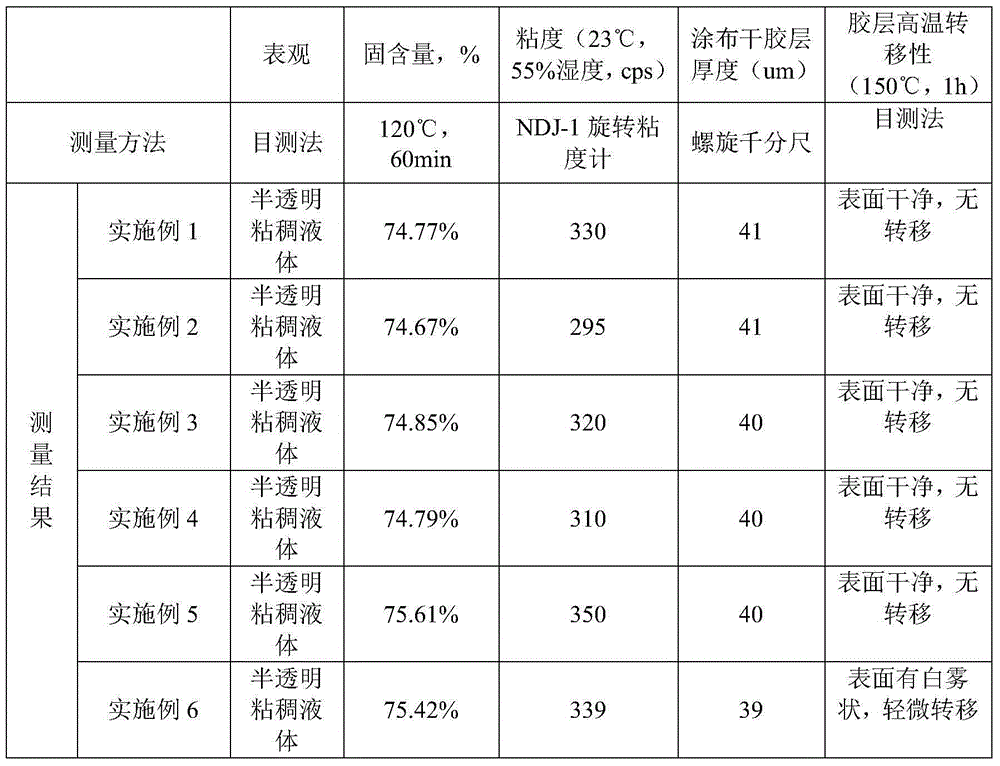

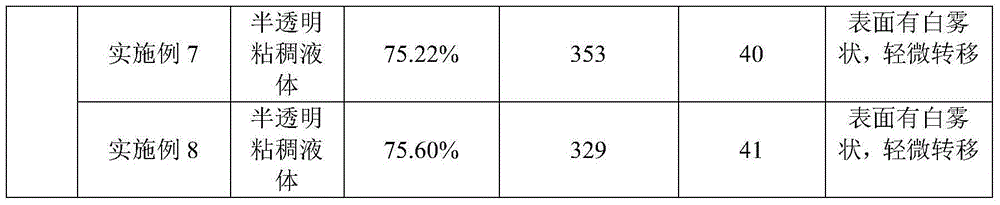

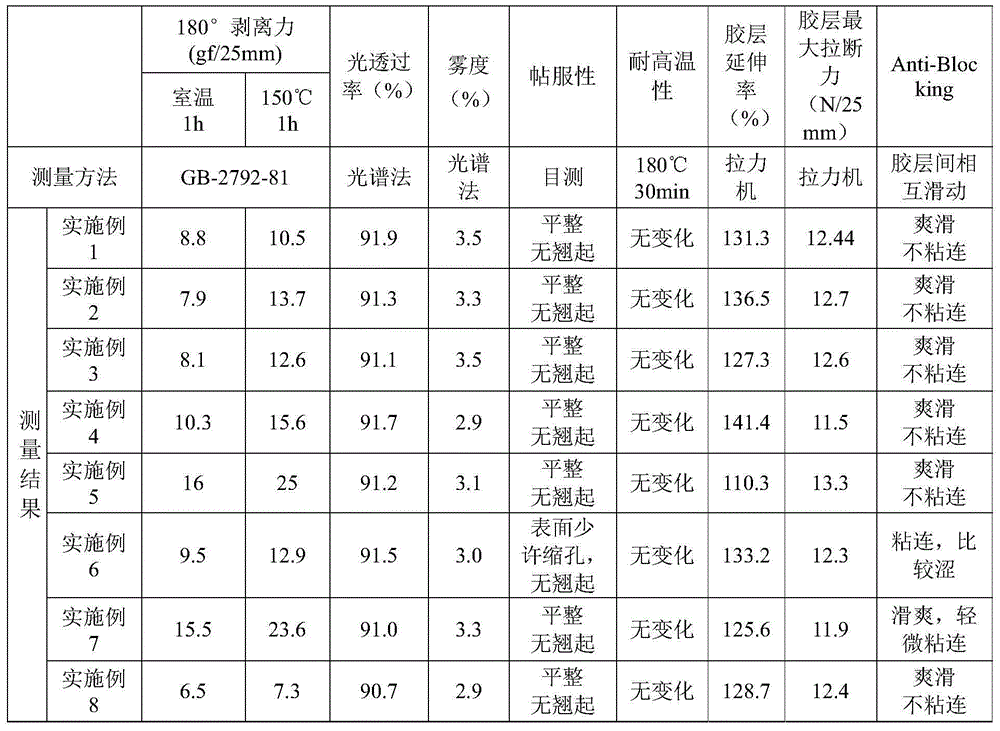

Peelable glue coating composition and peelable glue coating as well as preparation method and application of peelable glue coating

The invention provides a peelable glue coating composition and a peelable glue coating as well as a preparation method and an application of the peelable glue coating. The peelable glue coating composition comprises the following components in parts by weight: 80-120 parts of an acrylate type oligomer, 8-20 parts of a dilutive monomer, 0.1-1.5 parts of a peeling force modifying agent, 2-12 parts of a triggering agent and 30-50 parts of an organic solvent. The peelable glue coating composition is relatively high in transparency and relatively high in light transmittance and relatively low in haze after film formation. Meanwhile, a coating formed by curing the peelable glue coating composition is relatively high in high temperature resistance and relatively high in peelability. By the high temperature resistance, the coating is good in adhesion property on the surface of a functional hardened layer, and the problems of air bubbles and warping can be effectively improved. By the peelability, the problem of glue layer residues caused during peeling of the coating can be reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

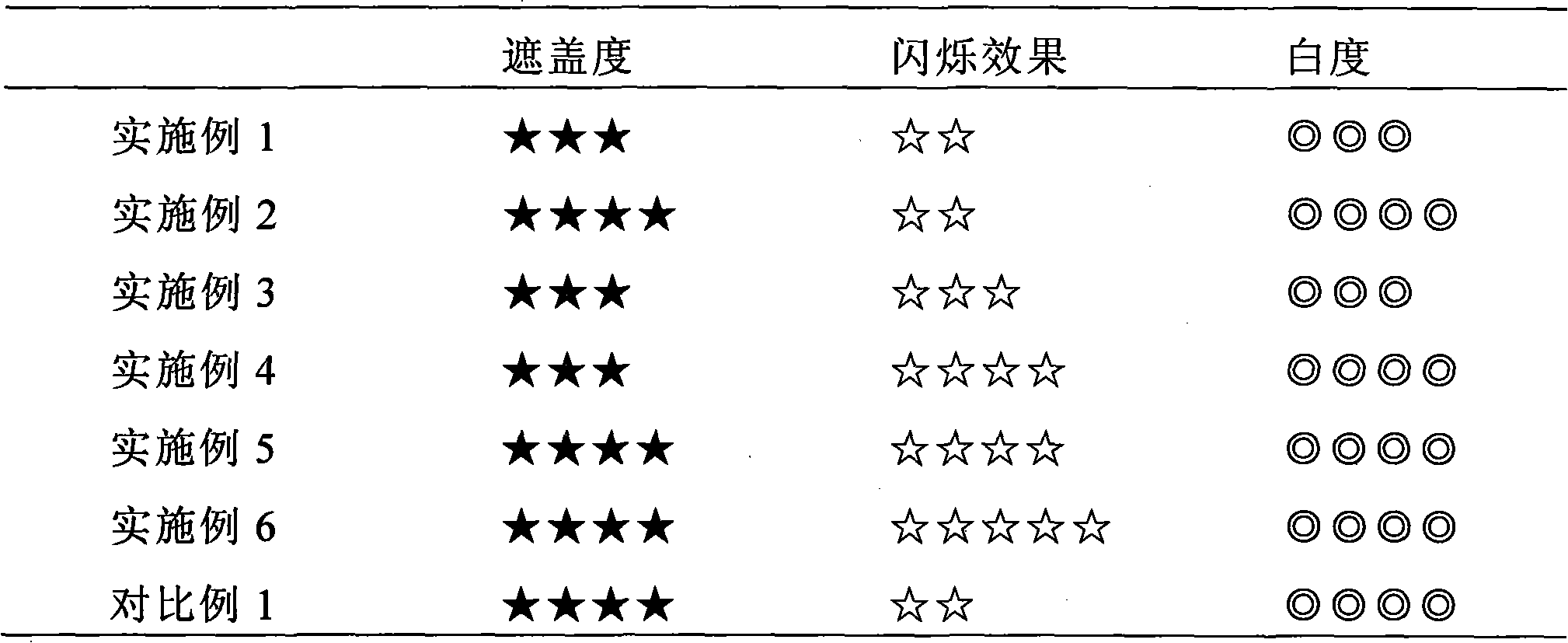

Aesthetic resin for improving white blink effect and preparation method thereof

The invention relates to an aesthetic resin for improving white blink effect and a preparation method thereof. The aesthetic resin comprises 100 weight portions of resin matrix, 0.1-5.0 weight portions of white pigment, 0.1-2.0 weight portions of pearlescent pigment, 0-0.5 weight portions of cross-linked polymer, 0.1-3.0 weight portions of lubricant, 0.1-1.0 weight portions of anti-oxidant, and 0.001-0.15 weight portions of fluorescent brightener. The preparation method comprises the following steps: stirring and mixing the raw materials in a high speed mixer, then putting the mixed raw materials in a double screw extruder, under the conveying, shearing and mixing of the screws, melting and compounding the materials, then carrying out extrusion, pulling, cooling, and dicing on the materials to obtain the product. Compared with the prior art, the disadvantages of poor blink effect of present white aesthetic resin under the conditions of high whiteness and high-cover ratio are overcome, thus the apparent effect of the white aesthetic resin is greatly enhanced, the feasibility of a white blink free-spraying scheme is increased, and the market potential in the fields of automobile, household appliance, consumer electronics and the like is raised.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

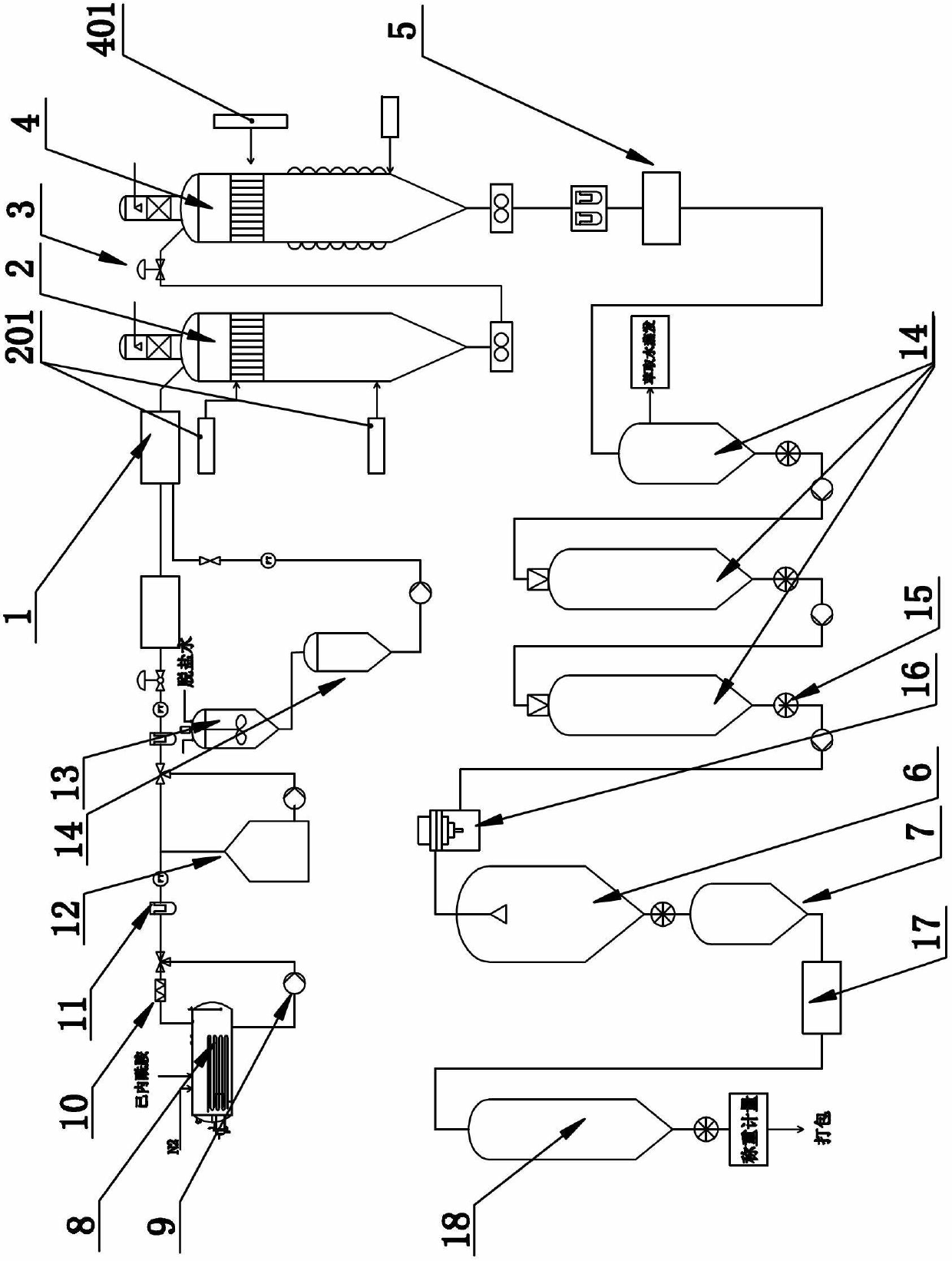

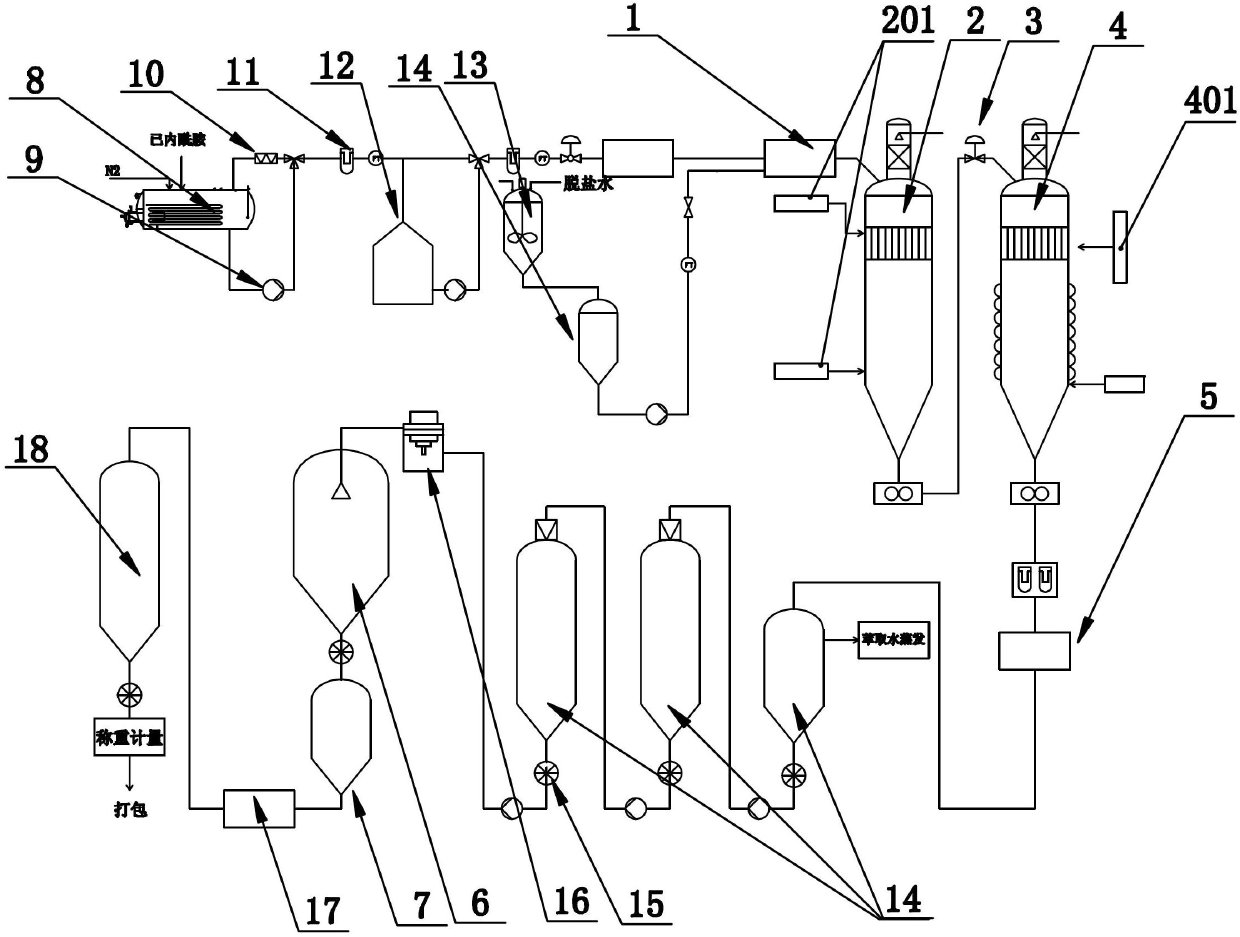

Process for producing caprolactam and nylon 66 salt copolymer slice

The invention relates to a process for producing a caprolactam and nylon 66 salt copolymer slice. The process comprises the following steps of: 1) preparing raw materials, namely respectively preparing caprolactam melt, a nylon 66 salt aqueous solution and an additive; 2) mixing the raw materials prepared in the step 1) in a mixer; 3) reacting the raw materials mixed in the step 2) in a pre-polymerization tower; 4) reacting the materials treated in the step 3) in a post-polymerization tower for reaction; 5) slicing the materials prepared in the step 4); 6) extracting the slices prepared in the step 5); 7) drying the extracted slices in the step 6); and 8) cooling the slices dried in the step 7), thus obtaining the caprolactam and nylon 66 salt copolymer slice finished product. According to the technical scheme, the caprolactam and nylon 66 salt copolymer slice has the characteristics of outstanding tensile strength, anti-impact strength and anti-puncturing strength, high gas isolation performance, high heat resistance, high mist degree, high glossiness, low temperature performance, flexibility, high transparency, high printablility and the like.

Owner:浙江华建尼龙有限公司

Anti-glare material and optical layered product

InactiveUS20090233048A1Highly visible and quality displayReduce in quantityLayered productsRecord information storageSlope angleComposite material

Owner:TOMOEGAWA CO LTD

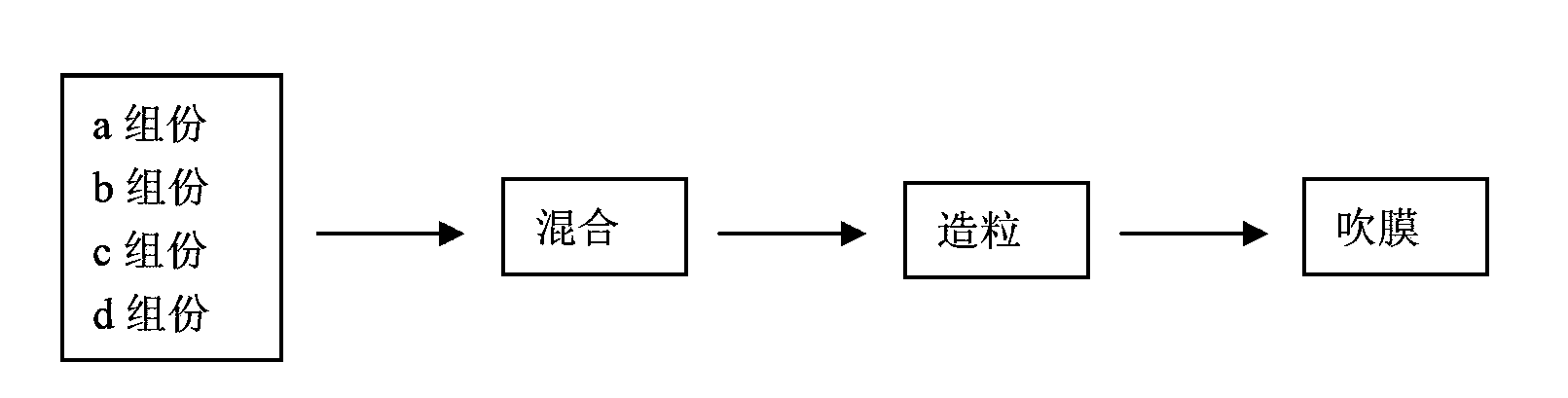

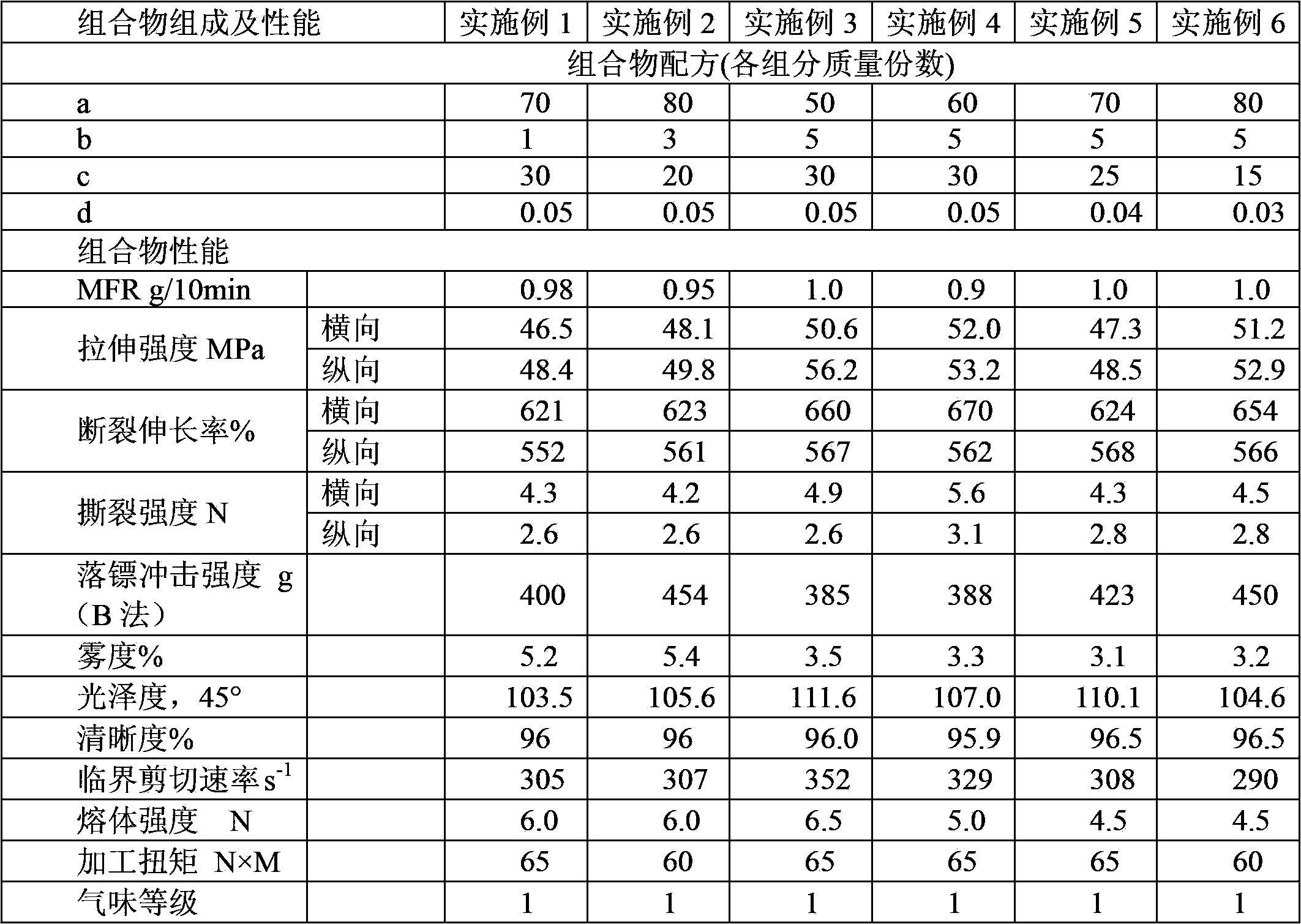

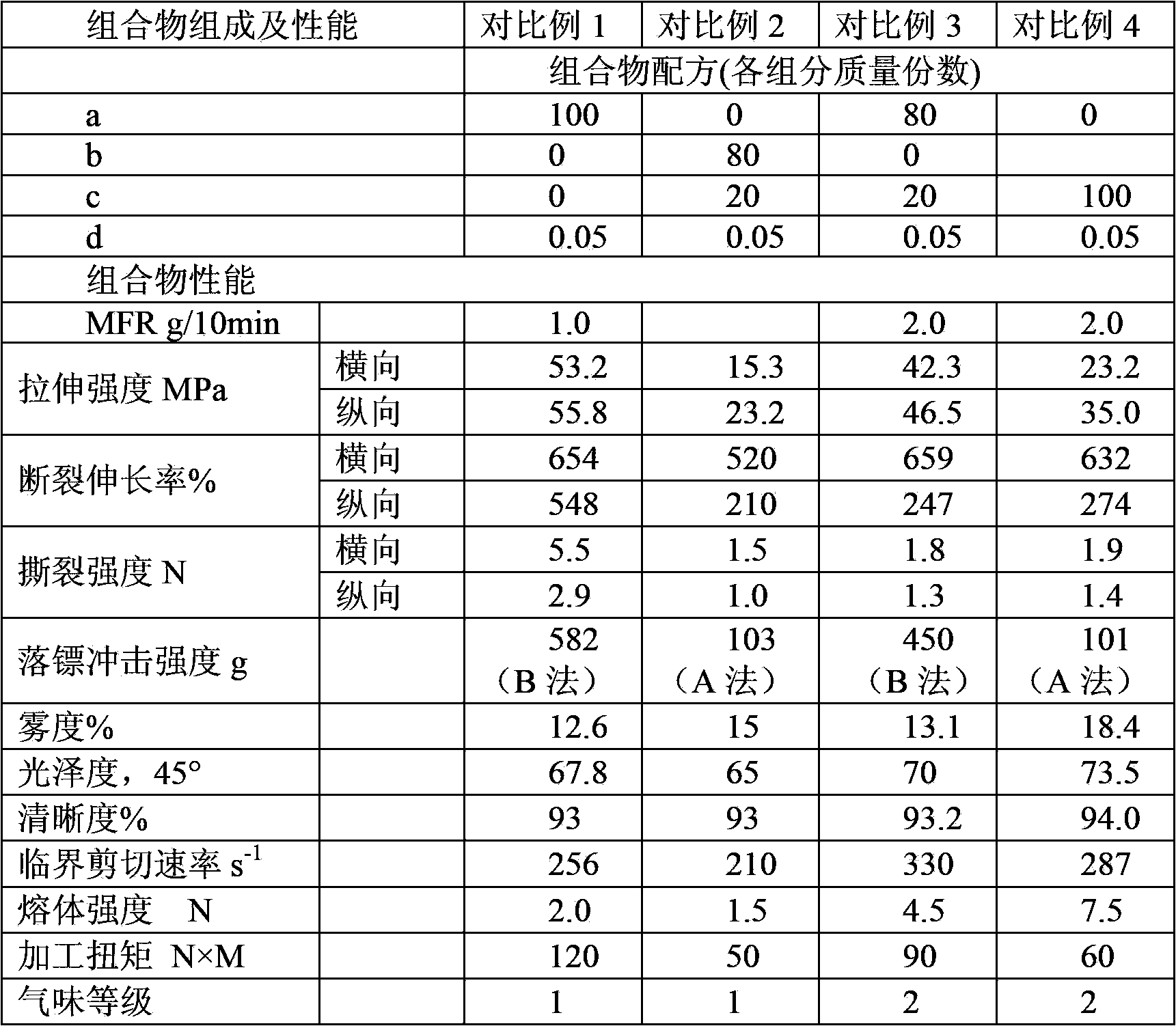

Highly-transparent polyethylene composition and preparation method thereof

The invention relates to a polyethylene composition, specifically to a highly-transparent polyethylene composition and a preparation method thereof. The highly-transparent polyethylene composition comprises a matrix resin and a processing auxiliary agent, wherein the matrix resin is prepared by co-mixing first mLLDPE, second mLLDPE and high pressure LDPE. The composition has characteristics of good strength, good flexibility, good processability, good aging resistance, low odor, excellent gloss, excellent impact strength, excellent tensile strength and excellent tear strength, can be used for preparing composite package films with excellent comprehensive performances, and can be provided for avoiding phenomena such as scratch, puncture and breaking by external force due to insufficient performances such as tear resistance and the like during the use process. In addition, after the mLLDPE resin and the normal resin are blended, the thickness of the film is reduced, the comprehensive performance is excellent, the product cost is reduced, and the processability of the composition is improved.

Owner:CHINA PETROLEUM & CHEM CORP

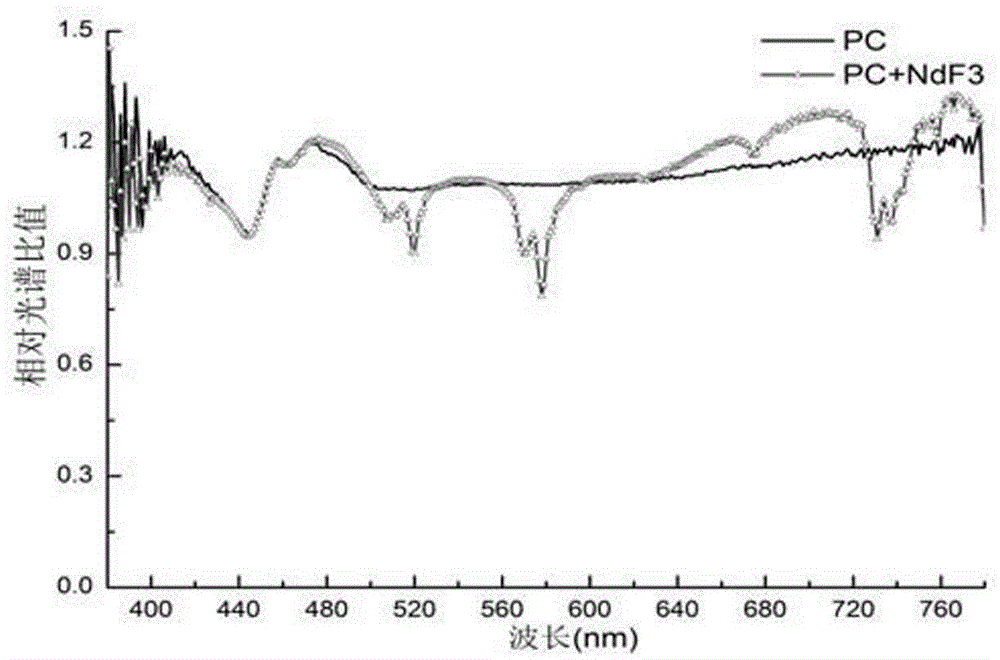

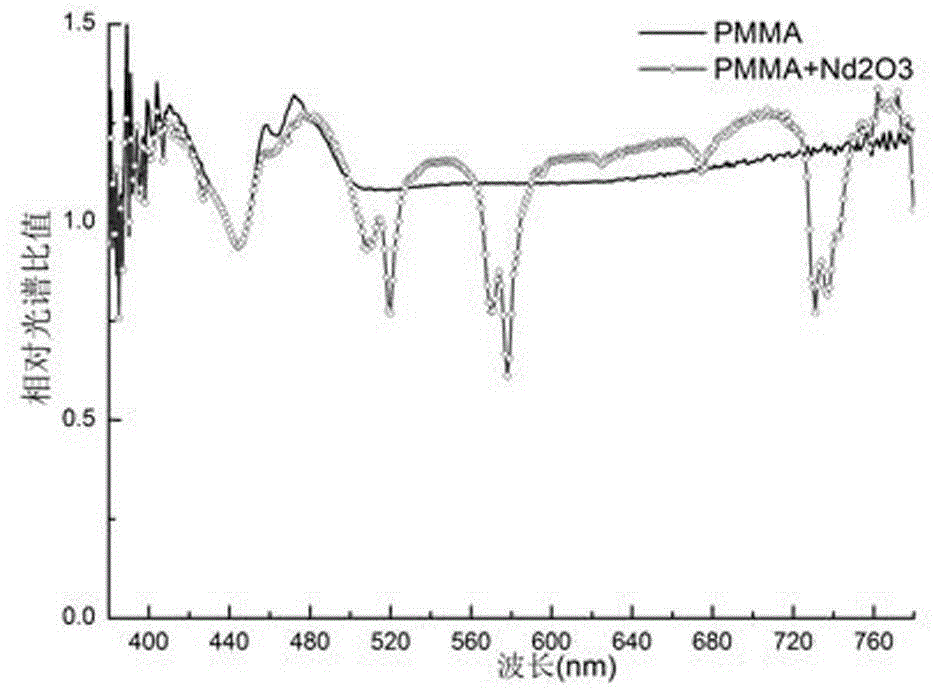

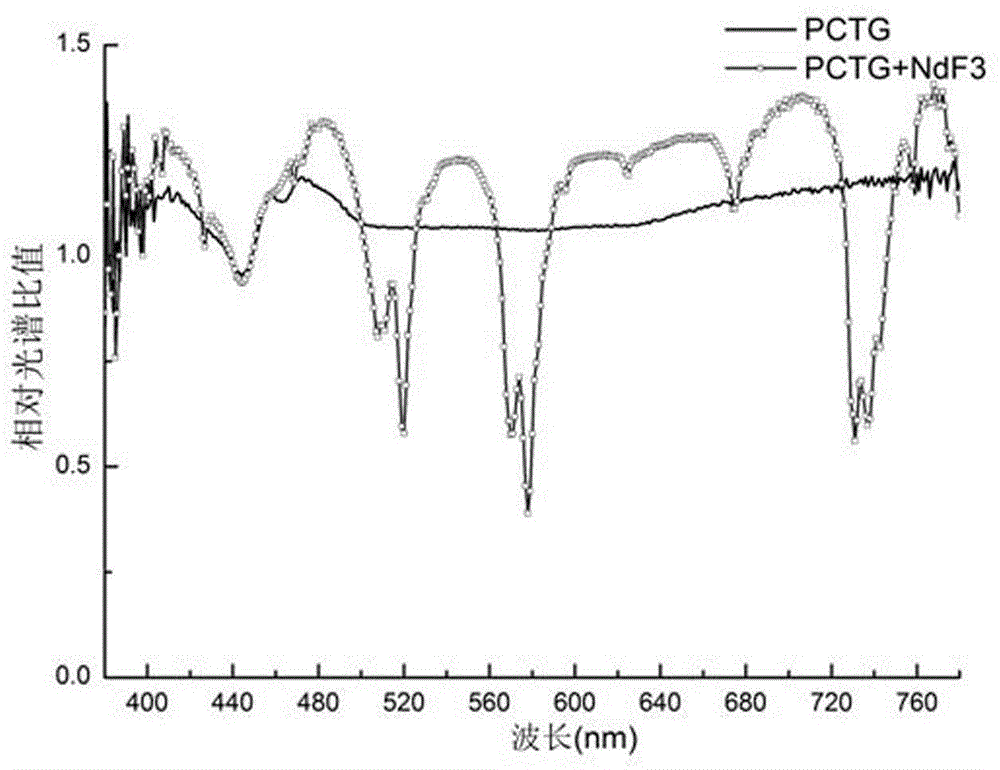

LED material for filtering yellow light and preparation method thereof

ActiveCN104650568AHigh light transmittanceExcellent optical properties such as hazePhysical chemistryOptical transmittance

The invention relates to the technical field of high-molecular materials and particularly relates to an LED material for filtering yellow light and a preparation method thereof. The LED material for filtering yellow light is prepared from the following raw materials in parts by mass: 60-100 parts of a base material, 1-13 parts of a yellow light filtration aid, 0.1-1.0 part of a light diffusing agent, 0.1-0.8 part of an antioxidant, 0.2-0.4 part of a dispersant DP310 and 2-26 parts of deionized water, wherein the yellow light filtration aid is one or more than one of neodymium fluoride, neodymium oxide, neodymium chloride and neodymium nitrate. The LED material for filtering yellow light, prepared by the method disclosed by the invention, is excellent in optical performances such as yellow light filtration property, light transmittance and haze and can be used for effectively filtering and eliminating yellow light generated by an LED lamp so as to relieve the fatigue of eyes and preventing the eyes from damages of yellow light. The preparation method of the LED material is simple in process, convenient to operate and control, stable in quality, high in yield, high in production efficiency and low in production cost.

Owner:DONGGUAN ZOYO ELECTRONICS TECH CO LTD

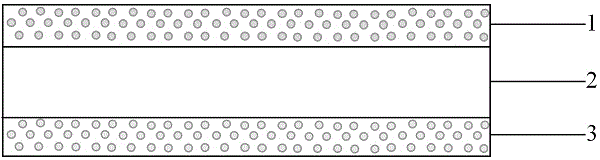

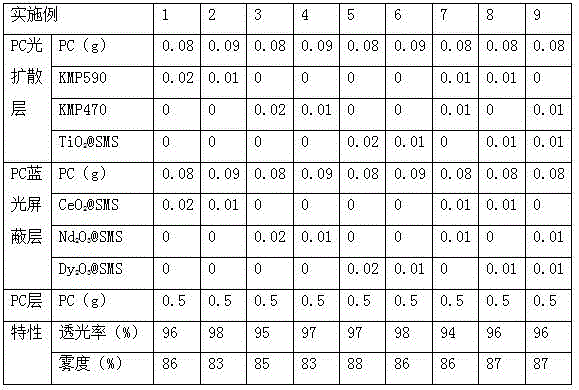

Photodiffusion film with blue light shielding function

InactiveCN103955016AHigh hazeModerate light transmittanceDiffusing elementsOptical filtersManufacturing technologyTransmittance

The invention relates to a photodiffusion film with a blue light shielding function. The photodiffusion film is composed of a base material layer, a photodiffusion layer and a blue light shielding layer, wherein the two surfaces of the base material layer are provided with the photodiffusion layer and the blue light shielding layer respectively. According to the photodiffusion layer, organic silicon resin spherical micro-powder is evenly dispersed in base materials, the thickness of the organic silicon resin spherical micro-powder is 5% - 20% of the thickness of the whole film, and the weight of the organic silicon resin spherical micro-powder is 0.5% - 2% of the total weight of the photodiffusion layer. According to the blue light shielding layer, blue light shielding particles are evenly dispersed in the base materials, the thickness of the blue light shielding particles is 5% - 20% of the thickness of the whole film, and the weight of the blue light shielding particles is 0.5% - 2% of the total weight of the blue light shielding layer. The photodiffusion film has the advantages of being high in haze, moderate in light transmittance, and good in stability of haze and light transmittance and has a blue light shielding function. Solutions are not used during photodiffusion film manufacturing, and therefore environmental friendliness is realized. Meanwhile, manufacturing technology is simple, price is low, application prospects are good, and market value is high.

Owner:SHANGHAI UNIV

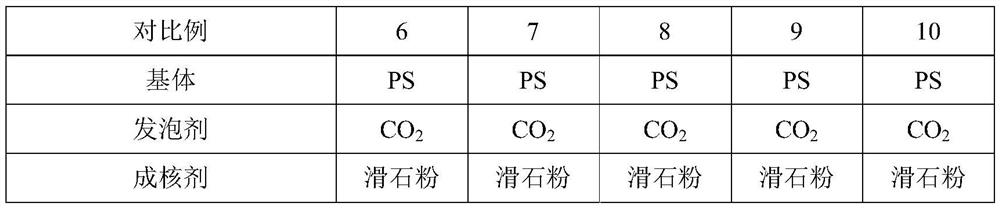

Foaming light diffusion plate and preparation method and application thereof

ActiveCN112646282AGood optical performanceReduce quality problemsDiffusing elementsPoint lightFoaming agent

The invention relates to the field of diffusion plates, in particular to a foaming light diffusion plate and a preparation method and application thereof. Compared with a chemical foaming agent, supercritical fluid is used for foaming to prepare the light diffusion plate, residues of toxic substances cannot be caused, meanwhile, the prepared light diffusion plate has excellent optical performance by controlling the introduction rate of the supercritical fluid, gathered point light sources can be homogenized, and the light diffusion plate has excellent haze; the maximum haze can reach 99.6%, the soft and uniform lighting effect can be achieved, meanwhile, the high light transmittance is achieved, the maximum light transmittance can reach 52.6%, and too high light loss cannot be caused; besides, the mass of the light diffusion plate is effectively reduced, the usage amount of raw materials is reduced, the production cost is reduced, meanwhile, the better mechanical strength is maintained, and the light diffusion plate has good impact resistance, smoothly passes an IK03 test and is wide in application prospect.

Owner:常州奥智高分子集团股份有限公司

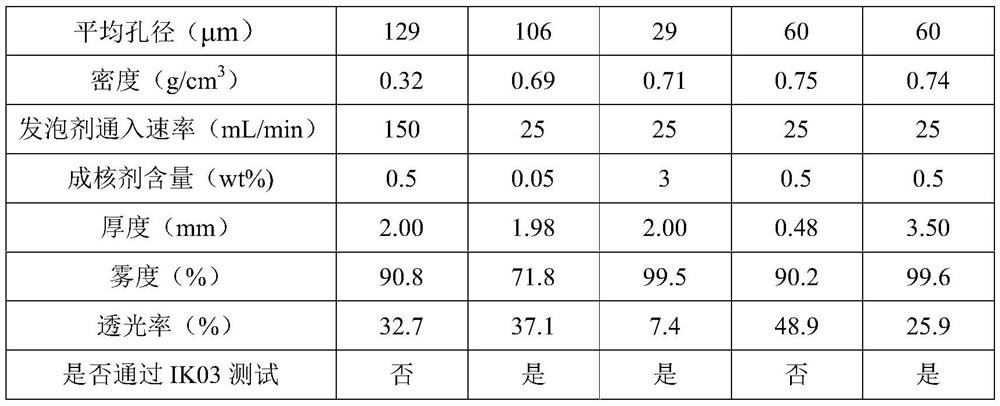

Highly transparent polyethylene shrink film and film blowing technology thereof

ActiveCN104175676AEnhance hazeHigh glossSynthetic resin layered productsPolymer scienceThin membrane

The invention relates to the technical field of shrink films, in particular to a highly transparent polyethylene shrink film and a film blowing technology. The highly transparent polyethylene shrink film consists of three films, namely an outer layer, a middle layer and an inner layer; the outer layer comprises 0%-20% of LDPF, 79%-99% of MPE, and 1%-5% of a nucleating agent in percentage by weight; the melt index of LDPE in the outer layer is greater than or equal to 2g / 10min, and the melt index of MPE is greater than or equal to 1g / 10min; the middle layer comprises 60%-80% of MDPE, 10%-20% of LDPE and 10%-20% of HDPE in percentage by weight; the melt index of MDPE in the middle layer is smaller than or equal to 0.5g / 10min, the melt index of LDPE is smaller than or equal to 0.5g / 10min, and the density of HDPE is greater than or equal to 0.960g / cm<3>; and the composition of the raw material of the inner layer and the composition of the raw material of the outer layer are the same. The highly transparent polyethylene shrink film has the haze of 7%, the light transmittance of greater than or equal to 92%, and the glossiness of 75%, so that the haze is good, the glossiness is good, and a printed pattern is more attractive and clearer when the highly transparent polyethylene shrink film is used for printing. The film blowing technology is stable in condition, precise in temperature and high in production efficiency.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

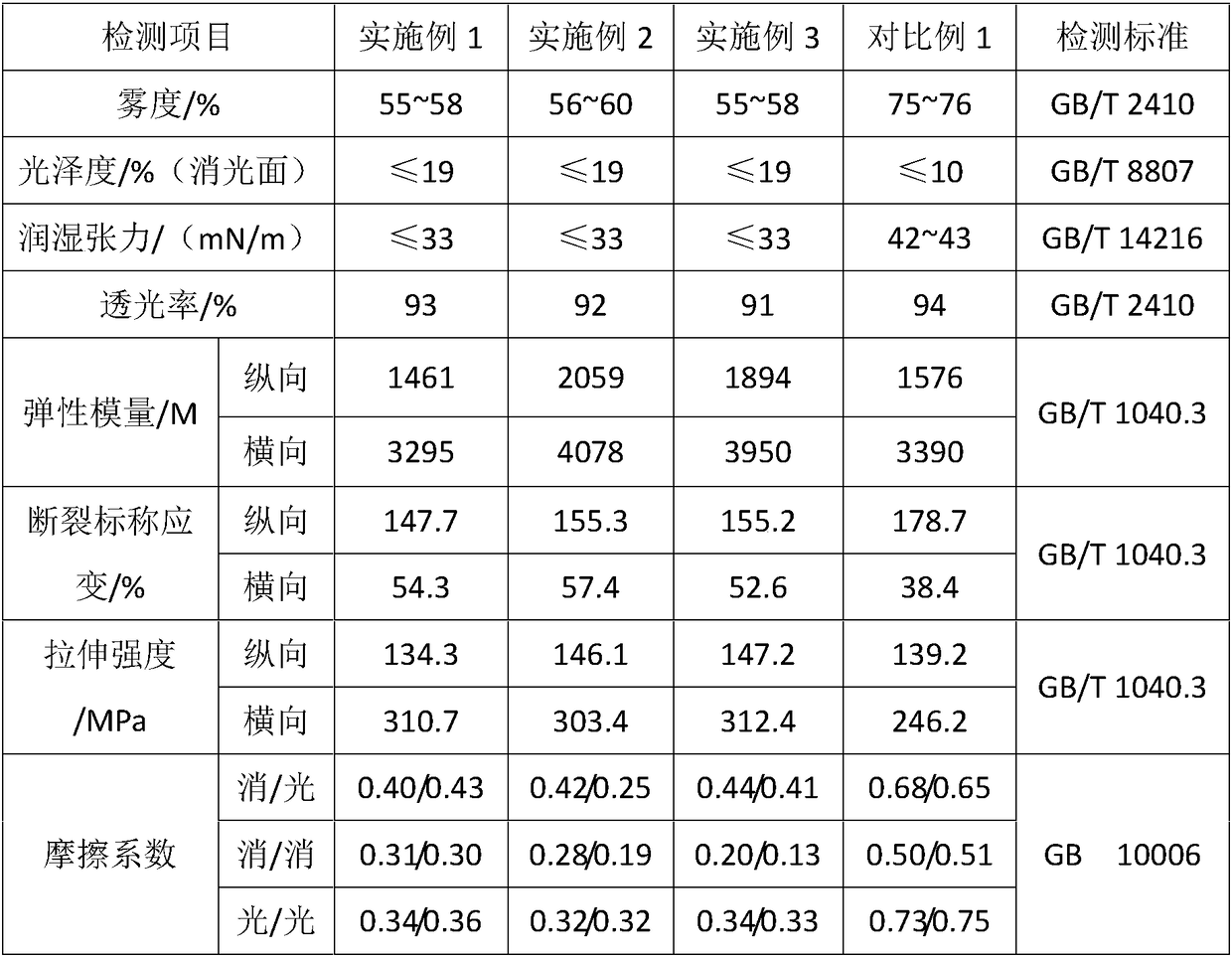

BOPP matting transfer film for coating transfer and preparation method thereof

InactiveCN109228591AAvoid stickingGuaranteed stabilitySynthetic resin layered productsLaminationMasterbatchSurface layer

The invention discloses a BOPP matting transfer film for coating transfer. The BOPP matting transfer film for coating transfer sequentially comprises an upper surface layer, an upper core layer, a lower core layer and a lower surface layer, wherein the upper surface layer is an anti-adhesive layer; the upper core layer is a polypropylene layer; both the lower core layer and the lower surface layerare transfer layers; each transfer layer comprises the following components in percent by weight: 80-88% of matting transfer masterbatch, 4.0-8.0% of an antistatic agent, 4.0-6.0% of a slipping agentand 4.0-6.0% of an anti-adhesion agent. The BOPP matting transfer film is directly prepared by a four-layer coextrusion and biaxial stretching method. The BOPP matting film for coating transfer is uniform in matting layer surface roughness, stable in matting effect and good in transfer effect, and can be applied to transfer of leather textiles.

Owner:ANHUI GUOFENG PLASTIC

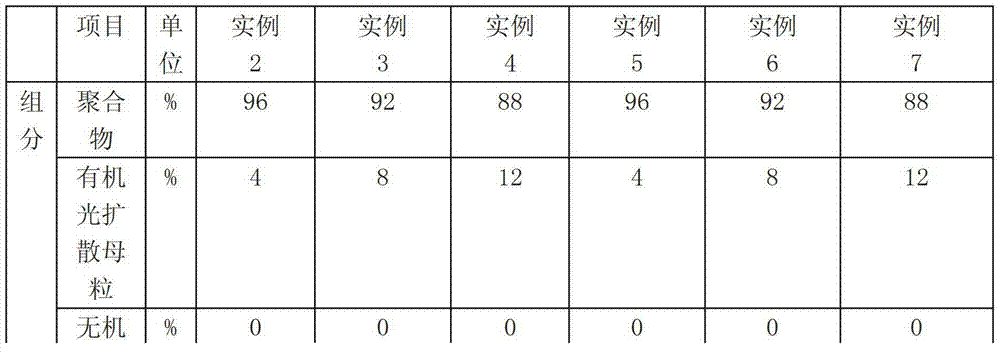

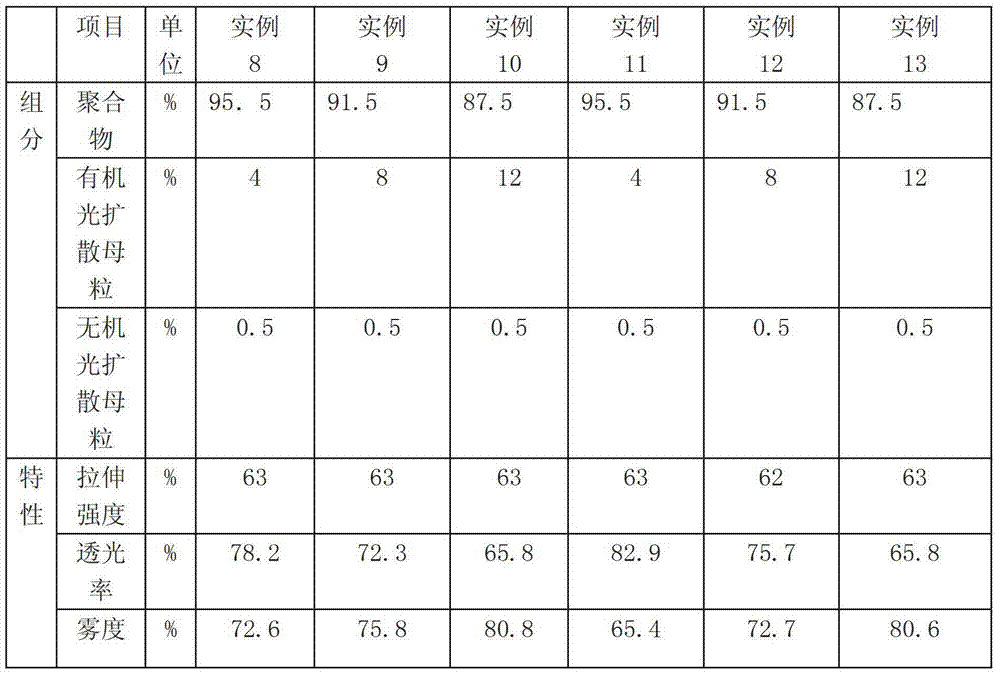

Photodiffusion composite and preparation method thereof

The invention discloses a photodiffusion composite. The photodiffusion composite is characterized by comprising the following raw materials by weight: 87.5 to 96% of polycarbonate, 4 to 12% of organic photodiffusion master batch and 0 to 0.5% of inorganic photodiffusion master batch, wherein the organic photodiffusion master batch comprises, by weight, 90% of polycarbonate and 10% of a photodiffusing agent 1, and the inorganic photodiffusion master batch comprises, by weight, 90% of polycarbonate and 10% of a photodiffusing agent 2. The invention also discloses a preparation method for the photodiffusion composite. According to the invention, the method of addition of the master batch is employed, so the problem of nonuniform dispersion of the photodiffusing agents is overcome, and the photodiffusion composite has high light transmittance and haze; and addition of a small amount of the inorganic photodiffusion master batch enables the haze of the composite to be improved.

Owner:SHANGHAI UNIV

Infrared light-reflecting film and production method thereof

InactiveUS20120223272A1Reduce oxygen concentrationImprove responseLiquid crystal compositionsLayered product treatmentOrganic solventMonomer

A method of producing an infrared light-reflecting film includes a coating step of coating a polymerizable liquid crystal composition including a polymerizable cholesteric liquid crystal compound (A), a chiral agent having an HTP of 50 μm−1 or less (B), a monofunctional monomer (C), and an organic solvent (D) on a substrate, an alignment step of aligning the polymerizable cholesteric liquid crystal compound by heating to form a cholesteric liquid crystal phase, and an irradiation step of irradiating the polymerizable liquid crystal composition with actinic radiation to fix the cholesteric liquid crystal phase and form an infrared light-reflecting layer, wherein the amount of a residual solvent after the alignment step is controlled to 0.20 g / m2 or more.

Owner:FUJIFILM CORP

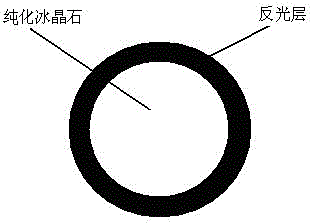

Light-transmitting inorganic light diffusion agent and preparation method thereof

InactiveCN104059246ALarge luminous surfaceLess light lossInorganic pigment treatmentPhysicsPotassium feldspar

The invention discloses a light-transmitting inorganic light diffusion agent which is characterized by comprising the following components by weight percent: 85%-94% of cryolite, 3%-8% of pyrophyllite, 2%-5% of kaolin, 0.5%-1% of potassium feldspar and 0.2%-1% of brucite. A fluidized bed is coated with cryolite, a powdery material is mixed with heated hot air in a rotational-flow dynamic calcining furnace, the specific surface of the cryolite is instantly calcined and molten and is spheroidized, and the surface of cryolite is covered with a reflection layer, so that cryolite has good light transmitting and reflectivity. The light diffusion agent is high in micro-particle sphericity and good in flowing dispersity, can be used at a high temperature of 800 DEG C or above, has excellent high temperature resistance, has a reflectivity different from most transparent resins, can be uniformly dispersed in resin so that a point light source is changed into an area light source, light transmitting and dodging effects are achieved, and therefore high light transmittance is ensured and good haze is achieved.

Owner:江门市金德丰塑业科技有限公司

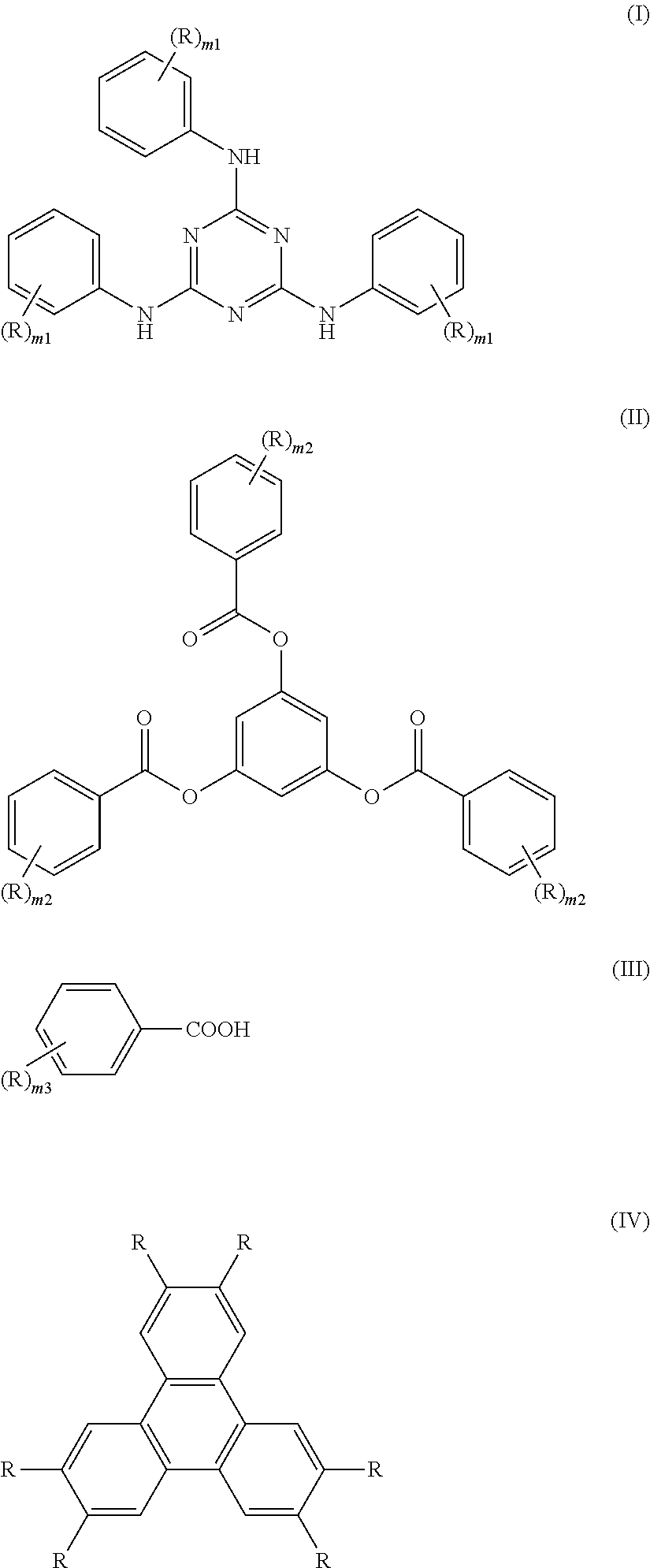

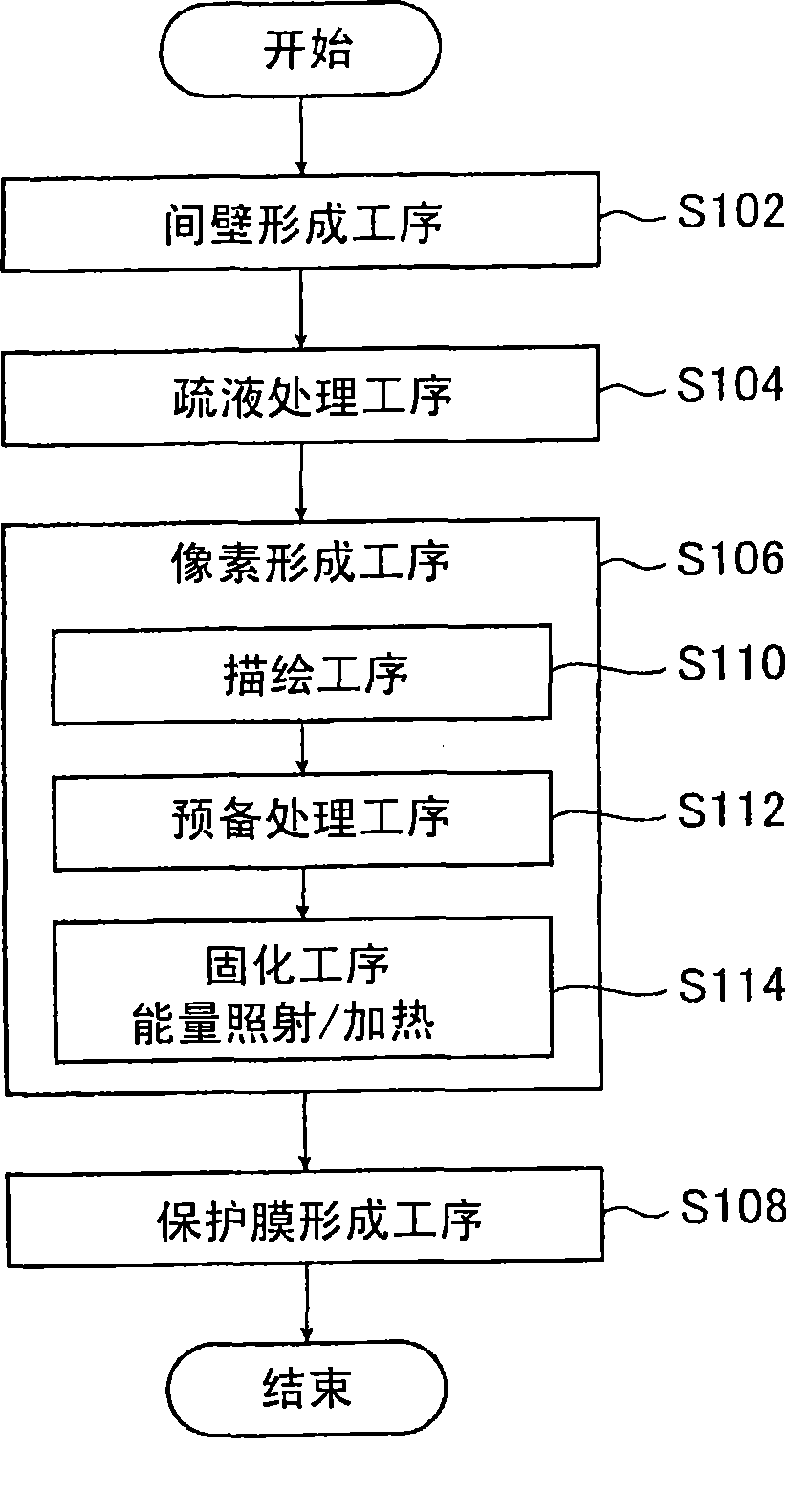

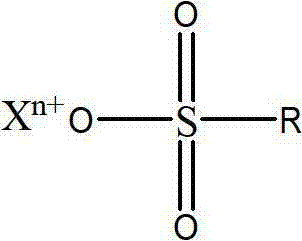

Print ink for ink jet, color filter, manufacturing method thereof, liquid display device using the color filter and image display element

The invention provides an ink for manufacturing a colour filter having excellent light resistance or heat resistance, a colour filter manufactured by the ink, a manufacturing method of the colour filter and an image display. It is characterized in that the ink comprises a compound represented by formula (1) and a solvent, in which the content of the compound is 1-20 mass percent, the content of the solvent is 30-90 mass percent, and the boiling point of the solvent ranges in 130-280 degrees centigrade; in the formula (1), Za and Zb each independently represent -N=, or -C(R8)=; R1 to R5 and R8 each independently represent a hydrogen atom or a substituting group; R6 and R7 each independently represent a hydrogen atom, alkyl, alkenyl, aryl or heterocyclyl; R2 and R3, R3 and R6, R4 and R5, R5 and R7, and / or R6 and R7 are mutually bondable for independently forming a 5-, 6- or 7-membered ring, respectively.

Owner:FUJIFILM CORP

Film material for PE coated paper

Disclosed is a film material for PE coated paper. Raw material formula of the film material is composed of 71.2-90.8% of a polymer, 0.2-1.2% of a lubricant and 9-27.6% of a fogging filler, wherein the polymer is selected from the group consisting of polyethylene, polypropylene, PVC and PET; and the filler is solid particles with the particle size being 3-20 micrometers. A fogging-surface release film with stable release force and good pressure-sensitive adhesive surface fogging effect can be produced, thus reaching low reflection effect of transfer adhesive surface. The production technology is simple, equipment investment cost is low and equipment is convenient to operate.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Reflection polarization brightening diffusion composite film

ActiveCN104316986ANo polarizing effectReduce processDiffusing elementsSynthetic resin layered productsDiffusionComposite film

The invention discloses a reflection polarization brightening diffusion composite film which comprises a base film, a first adhesive layer formed on the surface of the base film and a second adhesive layer on the other surface of the base film. A first mist layer is arranged on the first adhesive layer, a second mist layer is arranged on the second adhesive layer, the first mist layer and the second mist layer has uneven surfaces, the first mist layer is provided with a fine mist face with the roughness as 13-17mum and a coarse mist face with the roughness as 25-30 mum, and the fine mist face of the first mist layer is connected with the first adhesive layer. The second mist layer is provided with a fine mist face with the roughness as 13-17mum and a coarse mist face with the roughness as 25-30 mum, the fine mist face of the second mist layer is connected with the second adhesive layer, and the first mist layer and the second mist layer are non-stretching isotropic films. The brightness of the film is improved by over 50% compared with a common prism film, the view angle is increased, and the flow of the base film can be shielded, and the requirement of a backlight module is met.

Owner:昆山乐凯锦富光电科技有限公司

Method for synthesizing superfine silver nanowires through light triggering conducted in aqueous solution

ActiveCN106563812ASmall sizeControl diameterMaterial nanotechnologyTransportation and packagingSeed crystalMaterials science

The invention discloses a method for synthesizing superfine silver nanowires through light triggering conducted in an aqueous solution. The method comprises the steps of heating a mixed solution of sodium citrate and polyvinylpyrrolidone, so that the mixed solution has reducibility; adding a silver nitrate solution, and meanwhile conducting illumination with blue light to trigger nucleation; then screening seed crystals with hydrogen peroxide as an etching agent, so that small silver nanowire seed crystals high in purity are obtained; and conducting three cycles of continuous growth, so that the superfine silver nanowires with the diameter ranging from 8 nm to 20 nm and the length ranging from 1 micron to 30 microns are obtained. By means of the method, the blank of silver nanowires with the diameter ranging from 10 nm to 20 nm is filled up; the superfine silver nanowires prepared through the method are quite suitable for being used for preparing transparent conducting thin films; and the haze situation caused by the large diameter of a nanowire can be effectively improved. Compared with a traditional polyhydric alcohol method, the method is easy to operate and short in experimental cycle.

Owner:SOUTHEAST UNIV

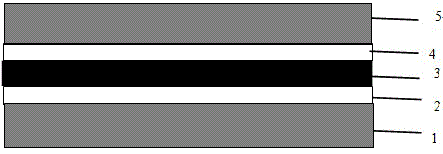

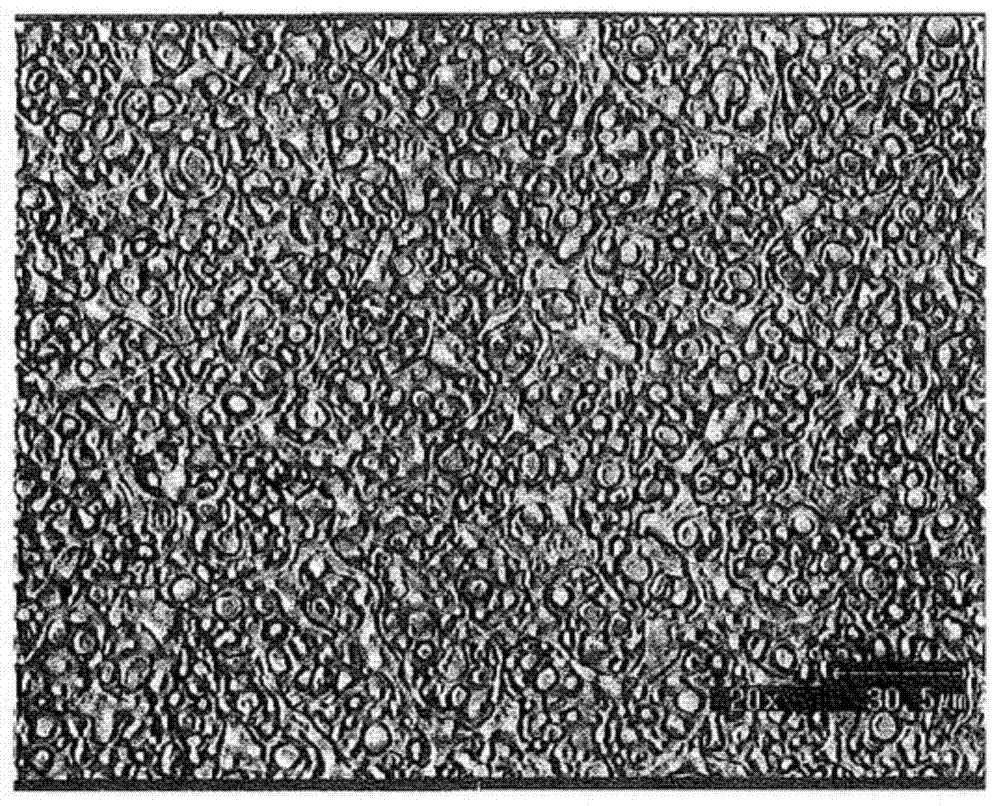

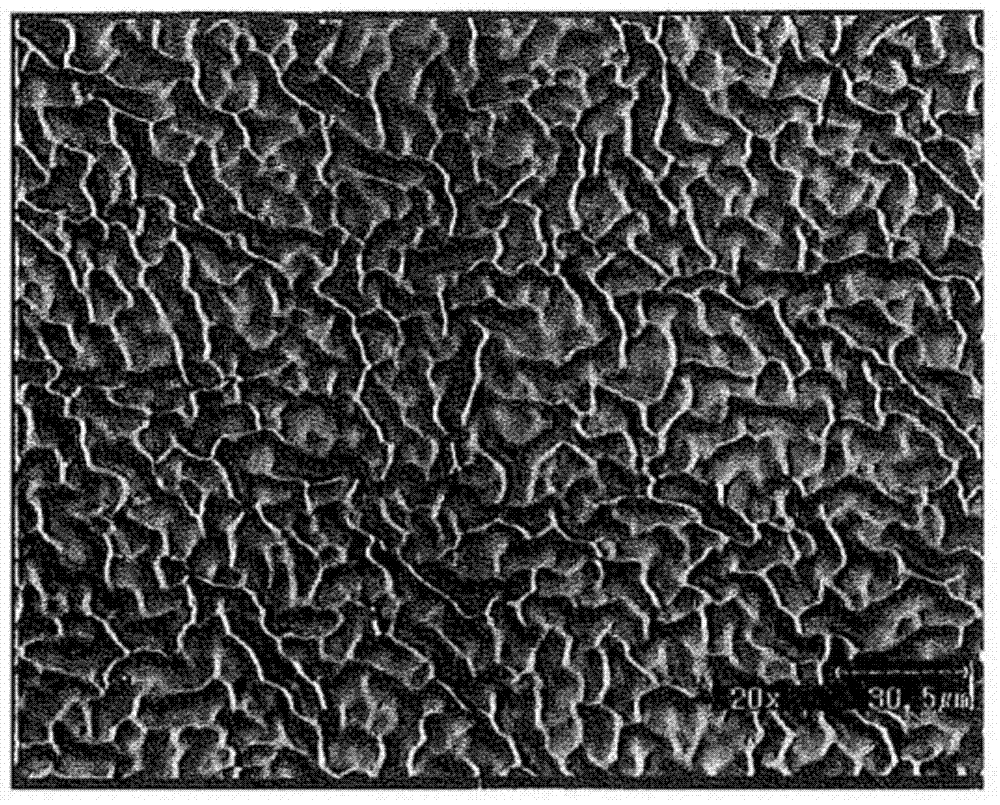

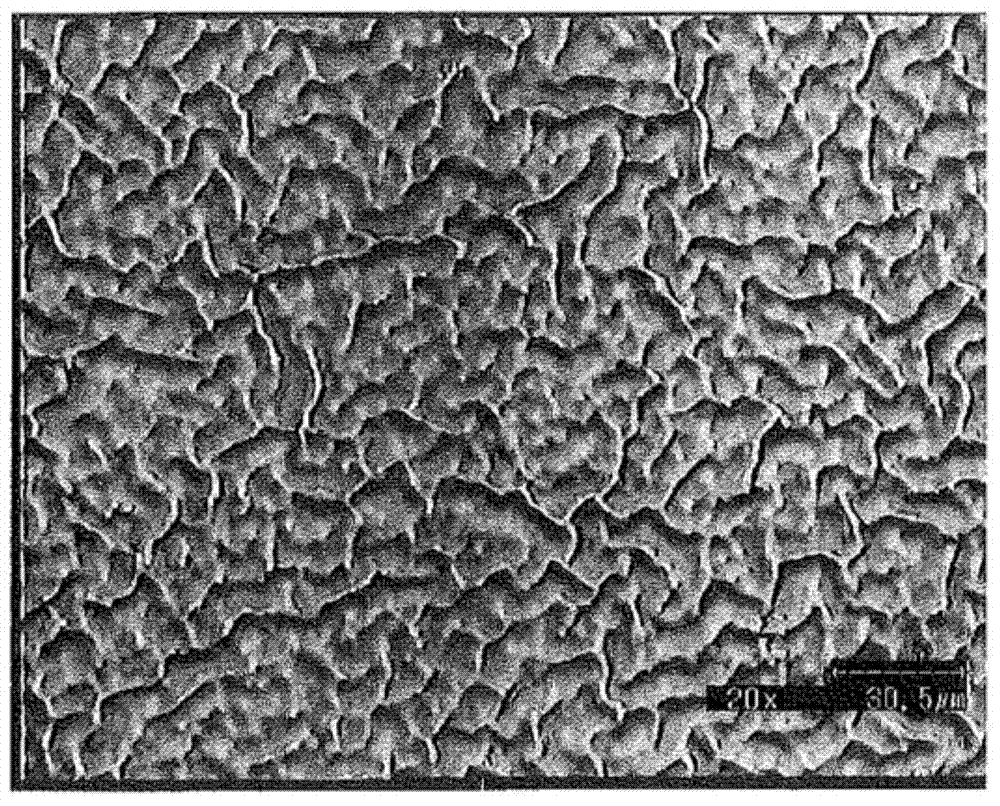

Anti-dazzle film and manufacturing method therefor

ActiveCN103777255ASuppress blurEnhance hazeDiffusing elementsSolid-state devicesSquare MillimeterMeasuring instrument

The invention provides an anti-dazzle film with good balance between haze and clearness. When the anti-dazzle film is arranged on a highly-fine display device, the anti-dazzle property can be improved, dazzle can be greatly inhibited, and character indistinction can be prevented. Long and thin projection parts of a total length of greater than 100[mu]m are formed on the surface of an anti-dazzle layer of the anti-dazzle film when various resin constituents are separated from each other. More than one the abovementioned long and thin projection parts exist in every one square millimeter on the surface of the anti-dazzle layer. The abovementioned long and thin projection parts form a joint continuous phase structure, and the average diameter of meshes of the joint continuous phase structure is around from 1[mu]m to 70[mu]m. The anti-dazzle film has a transmission image definition of 70-100%, a haze of 10-40% and a total light transmissivity of 70-100%. The transmission image definition is detected using a mapping measuring instrument of an optical slit 0.5mm wide.

Owner:DAICEL CHEM IND LTD

Anti-static polyester film and preparing method thereof

The invention relates to an anti-static polyester film and a preparing method thereof. The anti-static polyester film comprises a structure layer A, a structure layer B and a structure layer C. The layer B is a middle core layer and is made of a super bright polyester chip. The layer A is an upper surface layer anti-static layer and is made of an anti-static anti-blocking polyester chip and a super bright polyester chip. The layer C is a lower surface layer anti-static layer and is made of an anti-static anti-blocking polyester chip and a super bright polyester chip. Modified synthetic PET materials containing organic metal positive ions and silicon dioxide are selected as anti-static anti-blocking additives, a special production technology is used for changing the structure of a BOPET polyester film and the overall crystallization rate of a production process and the crystallinity of final products, accordingly, polyester molecular structures are changed, the effects of good glossiness, normal haze and static resistance are achieved, and meanwhile good opening performance is achieved.

Owner:福建百宏高新材料实业有限公司

Matte release paper

InactiveCN102619142AEnhance hazeImprove bonding fastnessSurface covering paperCoatings with pigmentsPolymer sciencePolyethylene terephthalate glycol

The invention relates to matte release paper, comprising a substrate, wherein coating material is coated on the surface of at least one side of the substrate, raw material formula of the coating material comprises 71.2-90.8% of polymer, 0.2-1.2% of lubricating agent and 9-27.6% of fogging filler; the polymer is selected from polyethylene, polypropylene, PVC (polyvinyl chloride) and PET (polyethylene terephthalate); and the filler is solid particles with particle size of 3-20 microns. According to the invention, the matte release paper with stable release force and a pressure sensitive adhesive surface having a good haze effect can be produced, thus an adhesive moving surface can achieve low reflective effect. The matte release paper has the advantages that the production process is simple, equipment investment cost is low and operation is easy to carry out.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

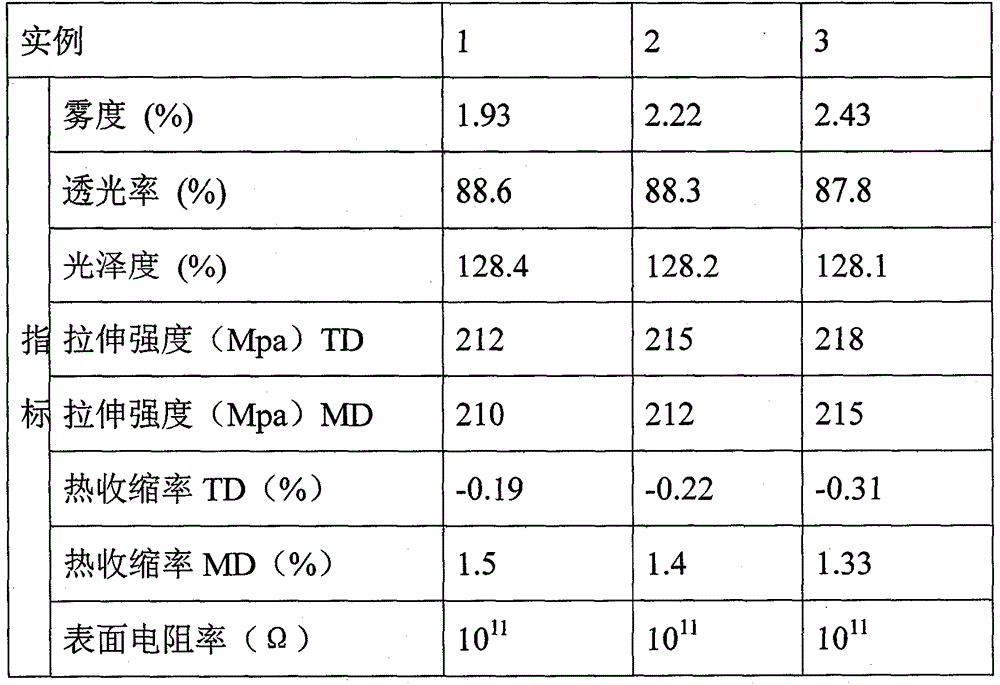

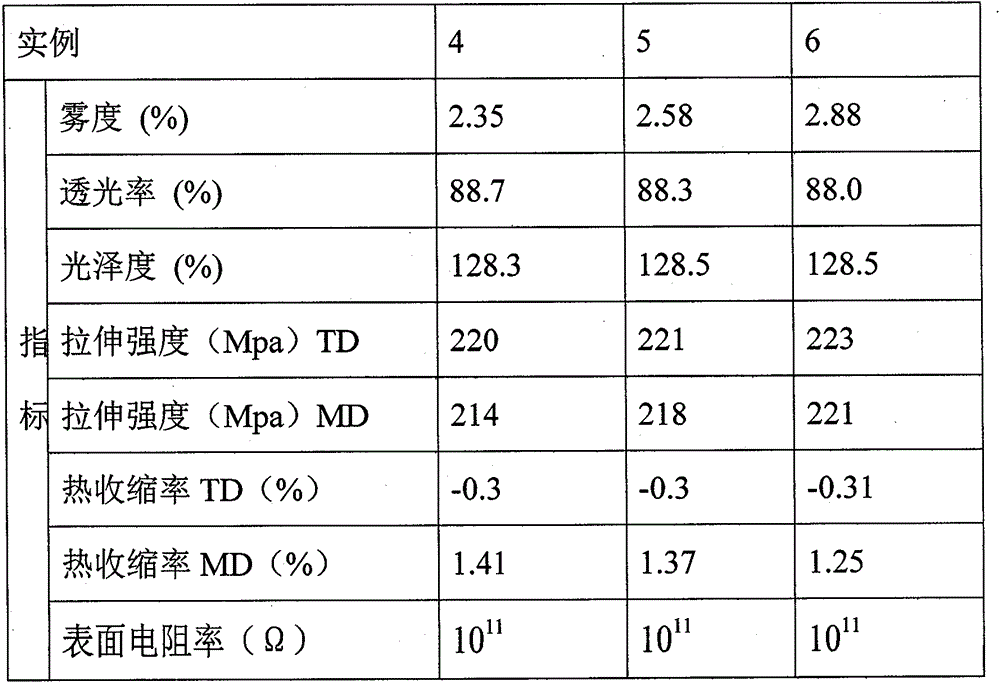

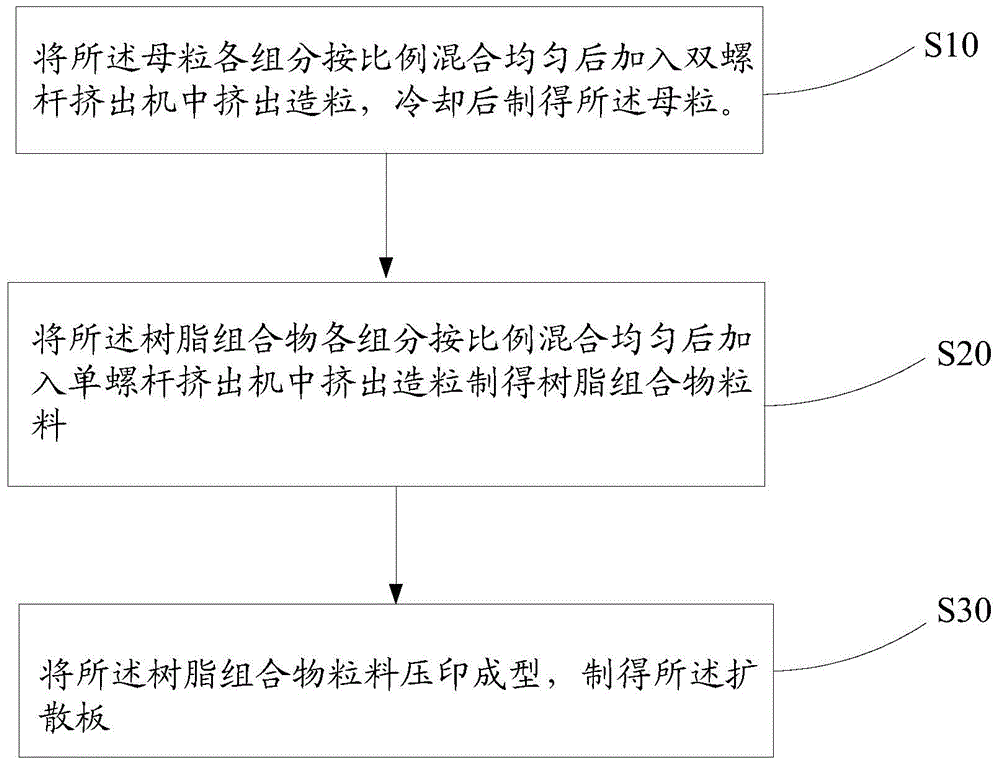

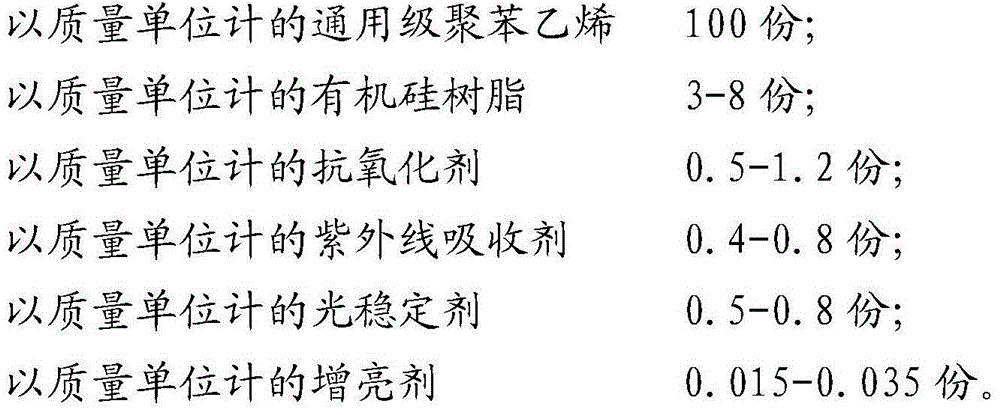

Master batches, resin composition, diffusion plate and preparation method of diffusion plate

The invention discloses master batches, a resin composition, a diffusion plate and a preparation method of the diffusion plate, wherein the resin composition comprises the following component in parts by mass: 100 parts of general polystyrene, 18-30 parts of the master batches, 5-10 parts of high-impact polystyrene, 2-3 parts of polypropylene and 0.02-0.025 part of mineral oil. The master batches comprise the following components in parts by mass: 100 parts of general polystyrene, 3-8 parts of organic silicon resin, 0.5-1.2 parts of an antioxidant, 0.4-0.8 part of an ultraviolet absorbent, 0.5-0.8 part of a light stabilizer, 0.015-0.03 part of mineral oil and 0.015-0.035 part of a brightening agent. The diffusion plate prepared by using the resin composition is high in light source utilization ratio, and the product is anti-bending and good in shielding property and has high brilliance and a relatively good shielding effect.

Owner:REGENCY OPTICS ELECTRON CORP

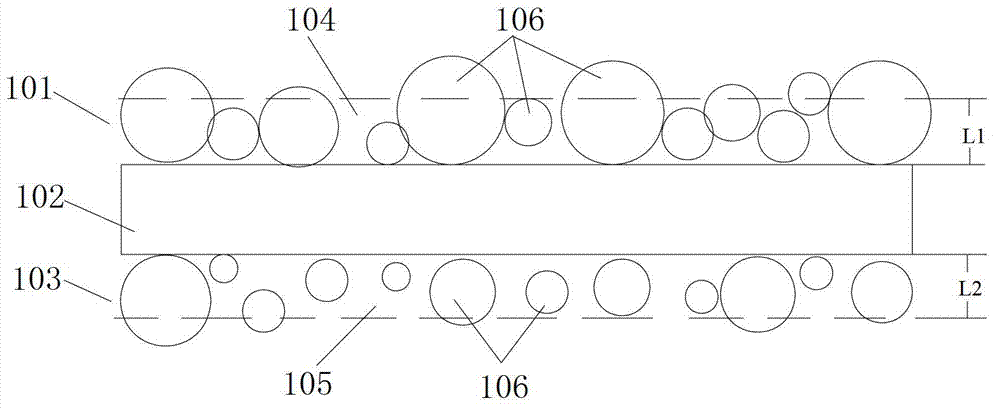

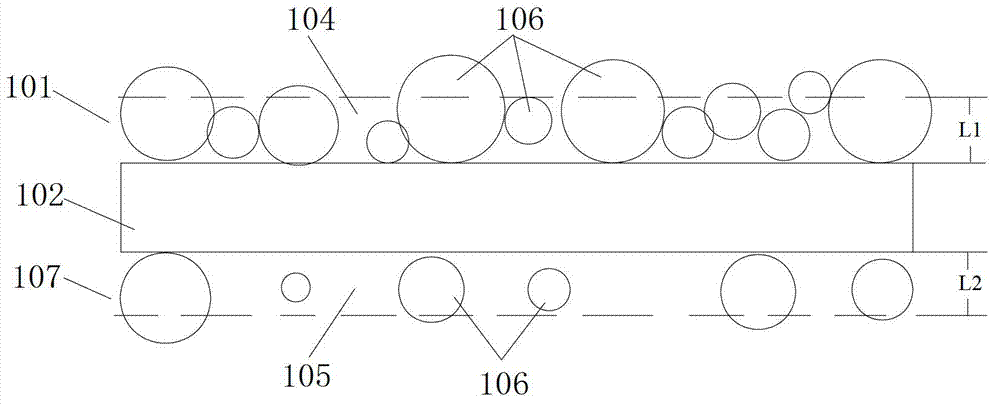

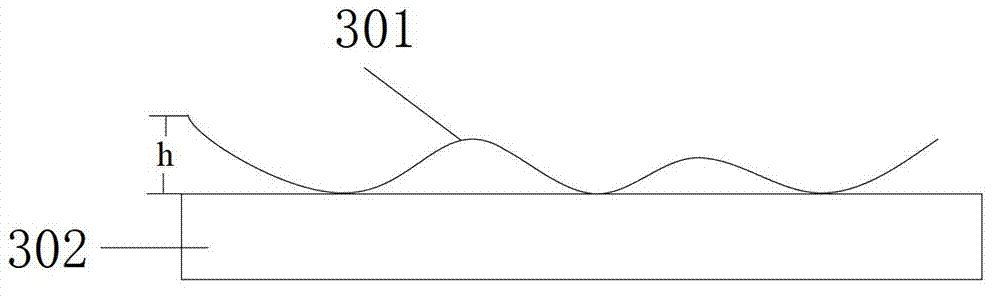

Warping-resistant optical thin film, preparation method thereof and display device using optical thin film

ActiveCN102928900AHigh light transmittanceEnhance hazeDiffusing elementsNon-linear opticsDisplay deviceOptical thin film

The invention relates to the technical field of optical thin films, in particular to a warping-resistant optical thin film, a preparation method thereof and a display device using the optical thin film, and aims to overcome the defects that a film surface of the conventional diffusion film is easy to warp, and raised grains are generated. The optical thin film comprises a transparent base plate; one side of the transparent base plate is provided with an upper diffusion coating, and the other side of the transparent base plate is provided with a lower diffusion coating; the thickness of the upper diffusion coating is 1 to 50 mu m; and the absolute value of the difference between the thickness of the lower diffusion coating and the upper diffusion coating is less than or equal to 3 mu m. The provided warping-resistant optical thin film has the advantages of the conventional diffusion film; the coatings of the film are low in shrinkage percentage; the warping phenomena can be reduced obviously; the preparation method is simple and easy to operate; and the optical thin film is used as the diffusion film in the display device, a good screen effect can be achieved, and shadows can be avoided.

Owner:NINGBO EXCITON TECH

Three-layer medical liquid medicament packaging film and preparing method thereof

ActiveCN103009733AAdapt to wideLow Particle DissolutionFlexible coversWrappersElastomerProduction line

The invention discloses a three-layer medical liquid medicament packaging film which has a composite structure with three layers A, B and C, wherein the layer A forms the outer surface of the film and comprises the ingredients of homo-polypropylene or a mixture of homogeneous propylene and SEBS (Thermoplastic Elastomer); the layer B comprises the ingredients of polypropylene random copolymer, SEBS, POE (Polyolefin Elastomer), mPE (Metallocene Polyethylene) or the mixture of two or more than two of the materials; the layer C forms the inner surface of the film and comprises the ingredients of polypropylene random copolymer and / or a mixture of ethylene-propylene-butene terpolymer and SEBS, wherein the SEBS is 8-24wt% in weight percent. The medical liquid medicament packaging film has comprehensive properties of excellent weather resistance, good heat sealability, high transparency, high tenacity, high barrier property and the like, and has wide adaptability to a full-automatic filling sealing production line in the pharmacy process.

Owner:安徽双津实业有限公司

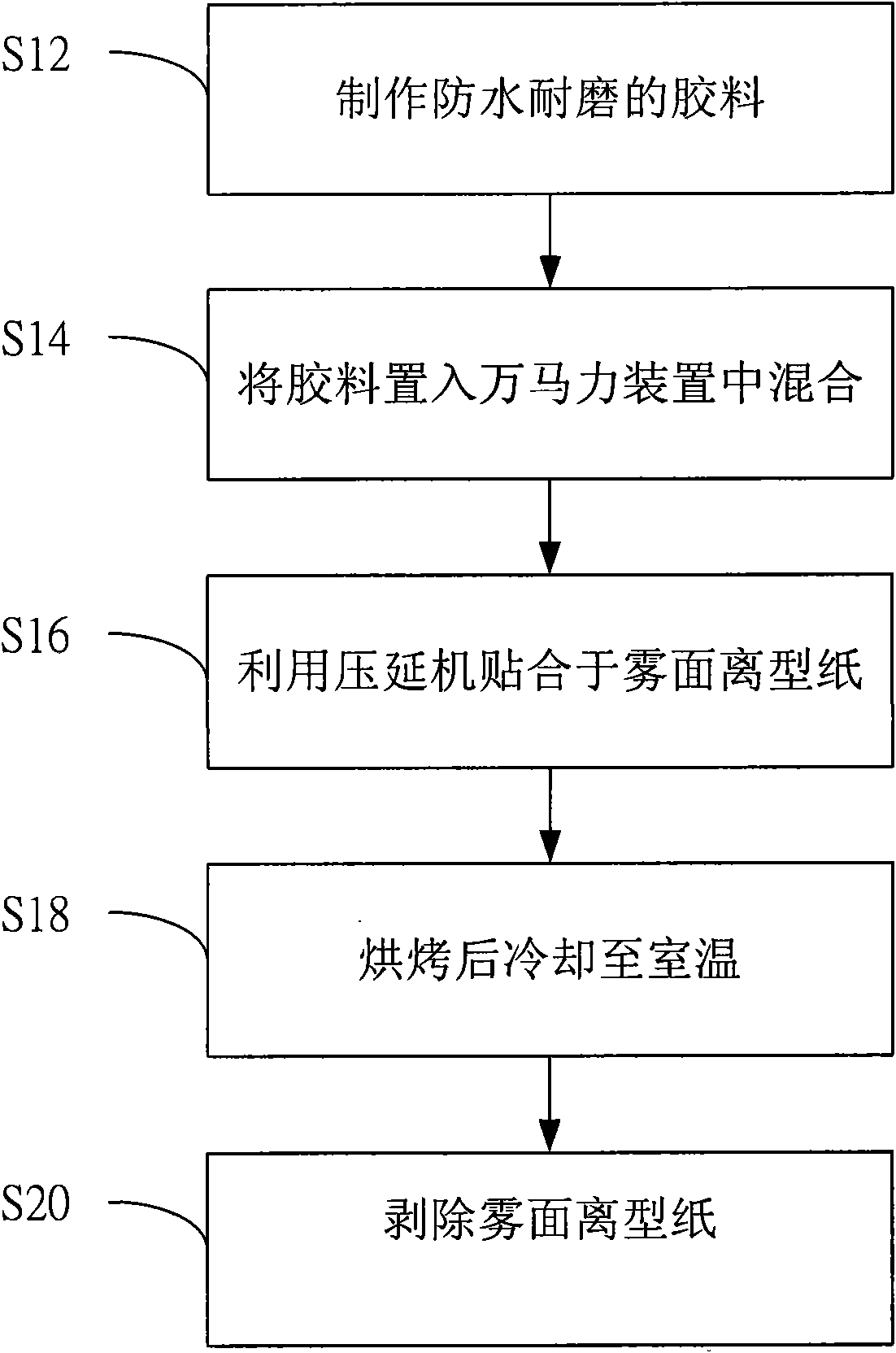

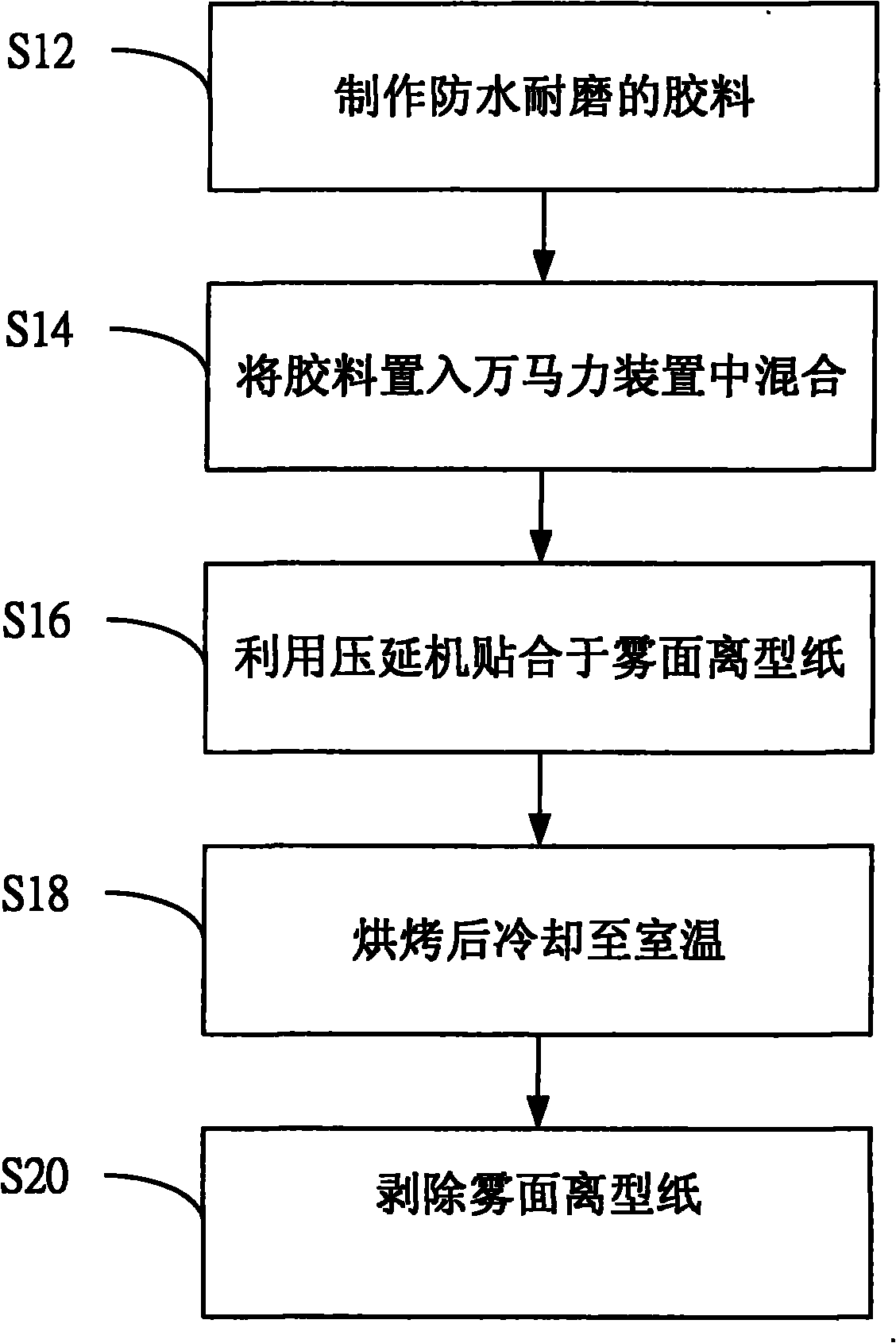

Production method of thermoplastic elastomer film

The invention provides a production method of a thermoplastic elastomer film. The production method comprises mixing 100 parts of thermoplastic polymer sizing material, 20-30 parts of coloring cake and 5-8 parts of other additives to obtain a sizing material, sufficiently stirring the sizing material in a device with ten thousand horsepower to obtain uniformly mixed sizing material, affixing the sizing material to matte release paper, baking, cooling to room temperature, and stripping the matte release paper to obtain the thermoplastic elastomer film.

Owner:FORMOSAN RUBBER GRP

Light-diffusion environment-friendly and inflaming retarding polycarbonate based composition for LED (Light-Emitting Diode) illumination and preparation method thereof

ActiveCN102731985AImprove mechanical propertiesEasy to processPoint-like light sourceSemiconductor devices for light sourcesAntioxidantOptical transmittance

The invention discloses a light-diffusion environment-friendly and inflaming retarding polycarbonate based composition for LED (Light-Emitting Diode) illumination and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight of: 50-90 parts of diphenol A aromatic polycarbonate A, 1-40 parts of diphenol A aromatic polycarbonate B, 0.005-2 parts of light dispersant A, 0.05-1 part of light dispersant B, 0.01-2 parts of fire retardant, 0-2 parts of antioxidant A, 0-2 parts of antioxidant B and 0-2 parts of antioxidant C. The composition disclosed by the invention has excellent mechanical property and machining performance, has higher light transmittance and haze, and has a good inflaming retarding effect.

Owner:SINOPLAST NEW MATERIAL

High-viscosity polyvinyl butyral and preparation method thereof

InactiveCN107022041AIncrease the degree of acetalizationStable structurePolyvinyl butyralPolymer science

The invention discloses high-viscosity polyvinyl butyral. The high-viscosity polyvinyl butyral is prepared from the following raw materials in parts by weight: high-polymeric polyvinyl alcohol, low-polymeric polyvinyl alcohol, pure water, ammonium sulfate, n-butanal and concentrated hydrochloric acid. The invention also discloses a preparation method of the high-viscosity polyvinyl butyral. The preparation method comprises the following steps: preparing a polyvinyl alcohol solution; adding n-butanal and concentrated hydrocholoric acid into the polyvinyl alcohol solution, thus obtaining primary high-viscosity polyvinyl butyral; and washing the primary high-viscosity polyvinyl butyral with pure water until the pH of the washing solution is 7, and then drying to obtain the high-viscosity polyvinyl butyral finished product. The high-polymeric polyvinyl alcohol and the low-polymeric polyvinyl alcohol of different polymerization degrees are adopted to prepare the high-viscosity polyvinyl butyral together with the pure water, the ammonium sulfate, the n-butanal and the concentrated hydrochloric acid, so that not only is the obtained product stable in structure and high in degree of acetalization, good in transparency and haze, but also the process is simple, easy in preparation and suitable for being popularized.

Owner:CHENGDU YULONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com