Process for producing caprolactam and nylon 66 salt copolymer slice

A caprolactam, production process technology, applied in the production process field of caprolactam and nylon 66 salt copolymer chips, can solve the problems of poor low temperature performance, need to be further improved, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

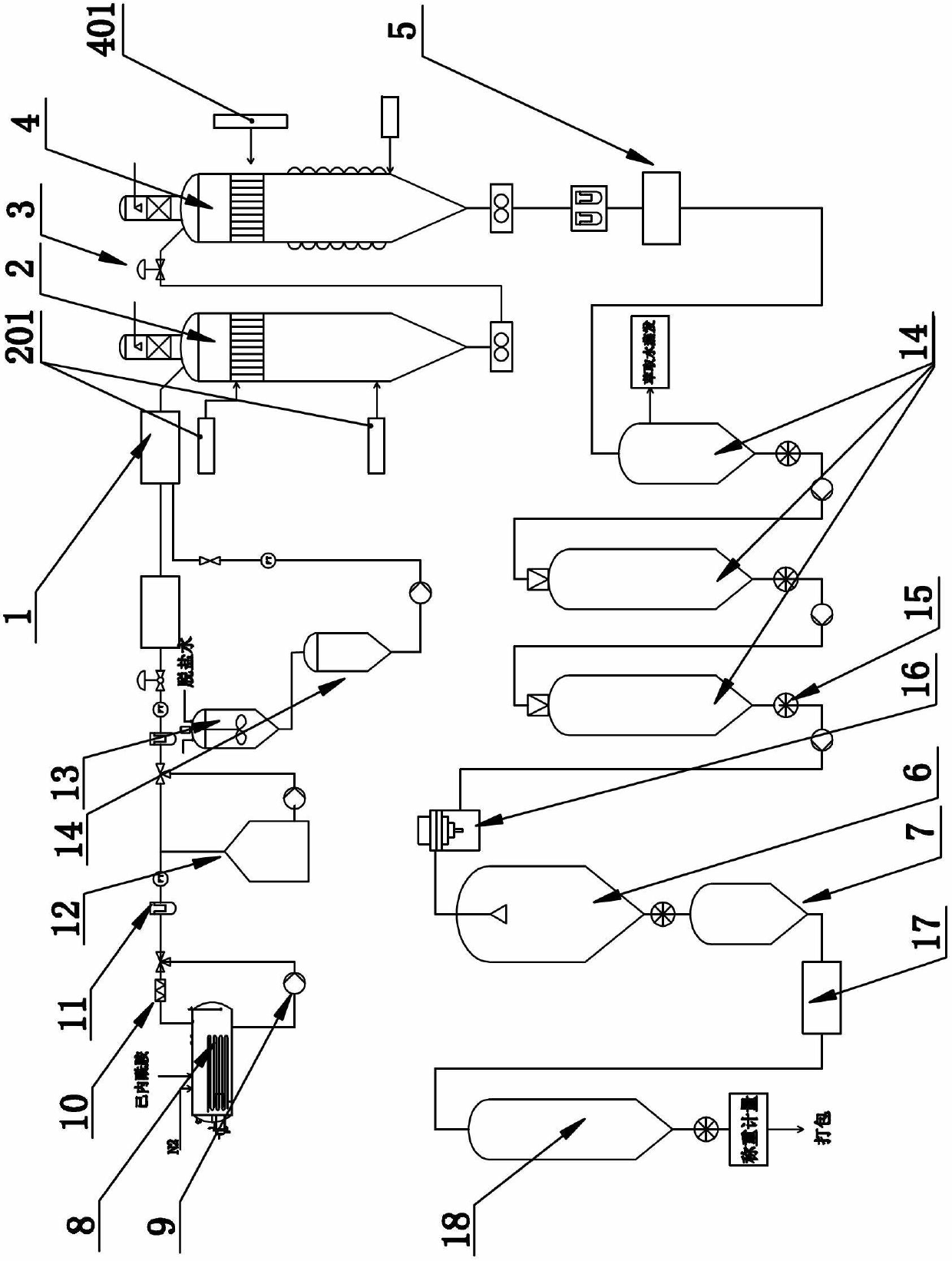

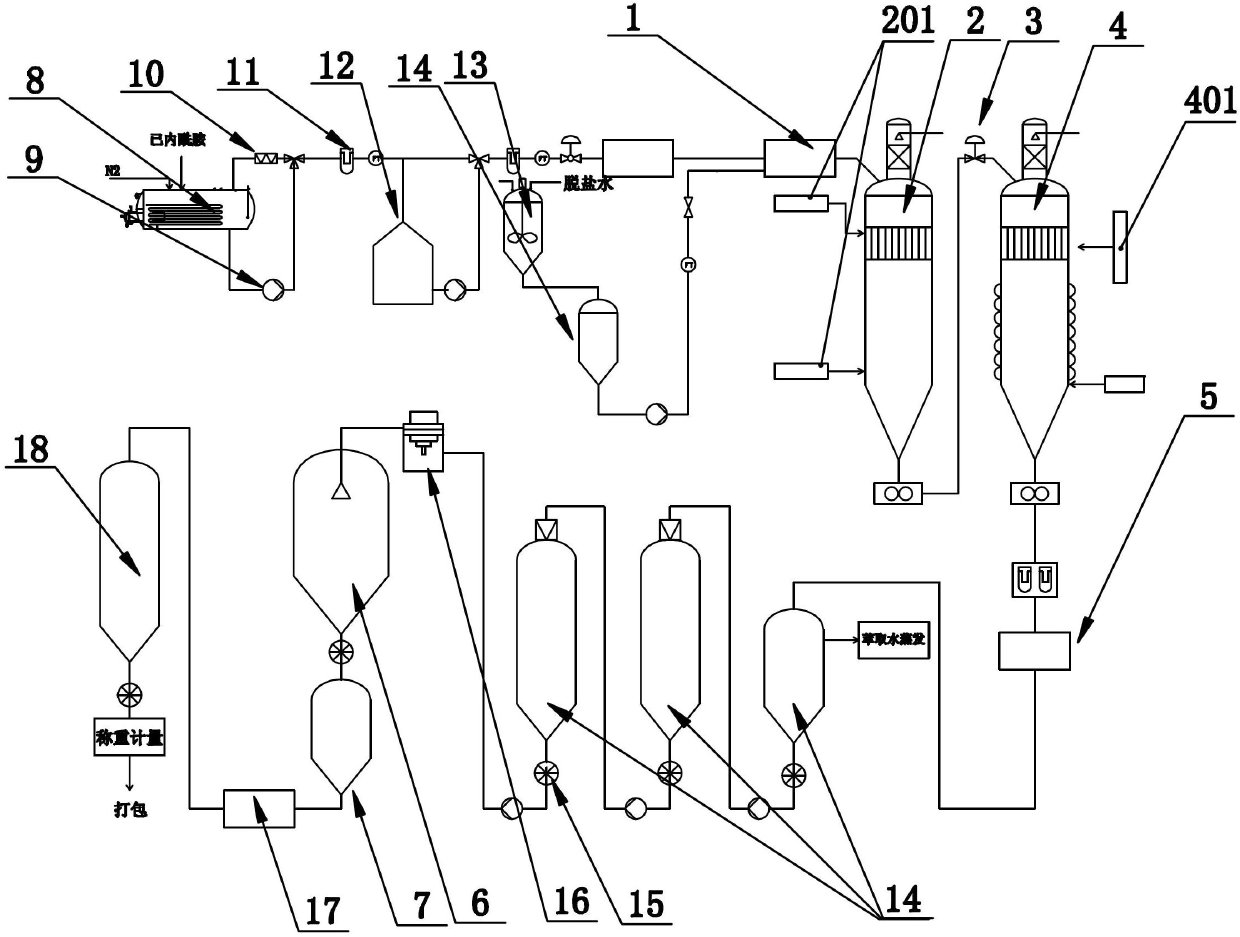

[0020] See attached figure 1 , the production process of caprolactam and nylon 66 salt copolymer chip disclosed in the present invention, comprises the following steps: 1), the preparation of raw material: prepare caprolactam melt, the aqueous solution of nylon 66 salt and additive respectively; 2), make The raw material that step 1) makes enters mixer 1 and mixes, and mixer 1 can be static mixer or dynamic mixing chamber; 3), the material that will be mixed through step 2) enters pre-polymerization tower 2, caprolactam in water Accelerate ring opening under the action of nylon 66 salt and perform addition and partial polycondensation reaction respectively to obtain the melt of low molecular weight caprolactam and nylon 66 salt copolymer, and remove excess water in the pre-polymerization tower 2; 4 ), after the melt of the low-molecular-weight caprolactam and nylon 66 salt copolymer obtained in step 3) is sloughed off residual moisture through the film former 3, enters the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com