Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349 results about "Slicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fields employing interface design skills, slicing is the process of dividing a single 2D user interface composition layout (comp) into multiple image files (digital assets) of the graphical user interface (GUI) for one or more electronic pages. It is typically part of the client side development process of creating a web page and/or web site, but is also used in the user interface design process of software development and game development.

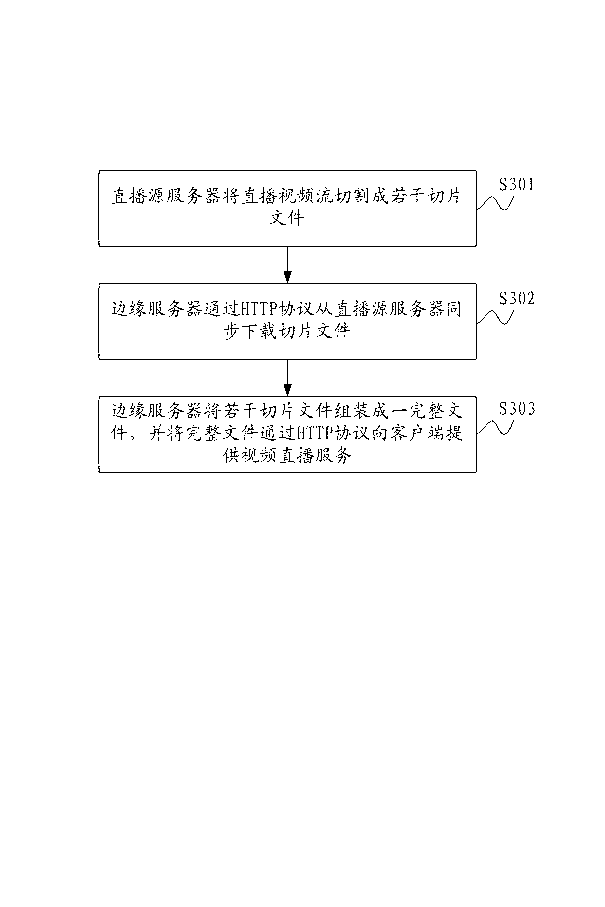

Video live broadcast method and system based on HTTP (Hyper Text Transport Protocol)

InactiveCN102710966AImprove stabilityGuaranteed viewing experienceTransmissionSelective content distributionEdge serverSlicing

The invention provides a video live broadcast method and a system based on an HTTP (Hyper Text Transport Protocol). The video live broadcast method comprises the following steps of: dividing a live video stream into a plurality of slice files by a live source server; synchronously downloading the slice files from the live source server through the HTTP by an edge server; assembling the slice files into a complete file by the edge server; and providing a video live service of the complete file for the client through the HTTP. Therefore, according to the a video live broadcast method and system disclosed by the invention, the stability of the live video stream can be effectively improved, the multi-machine load balance is easily realized and the technical support for late-stage backup or processing of the live video stream is provided.

Owner:百视通网络电视技术发展有限责任公司

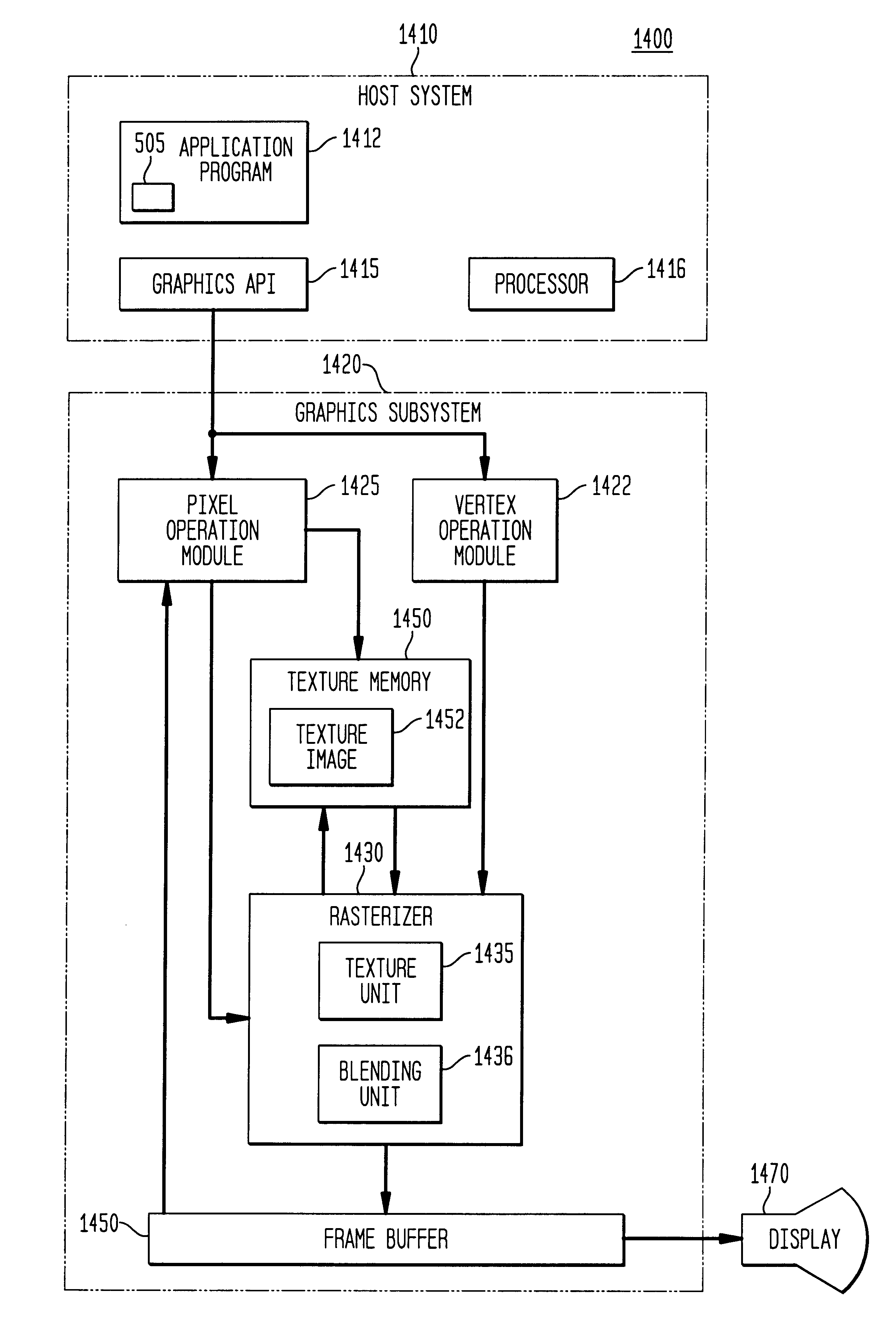

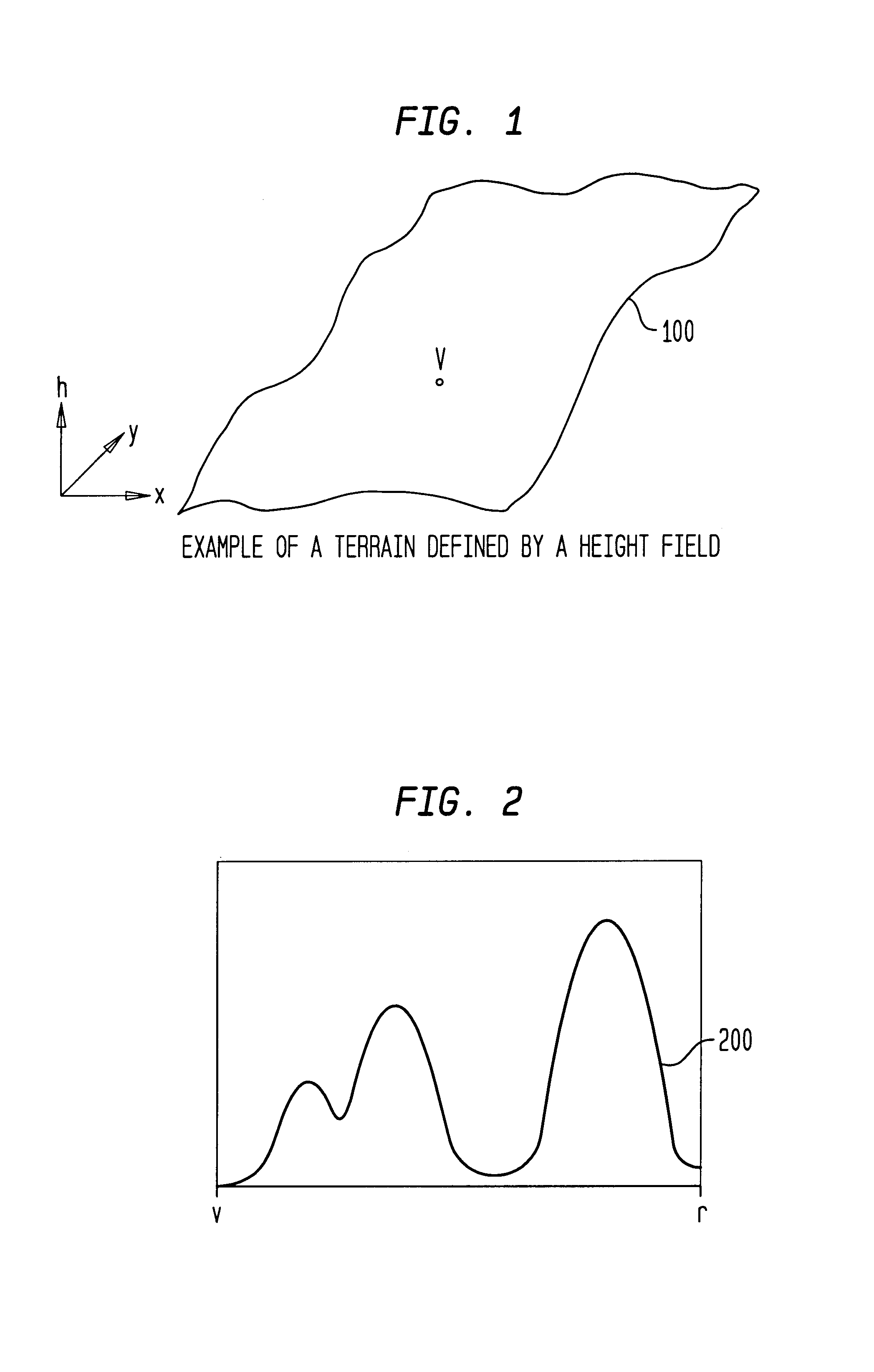

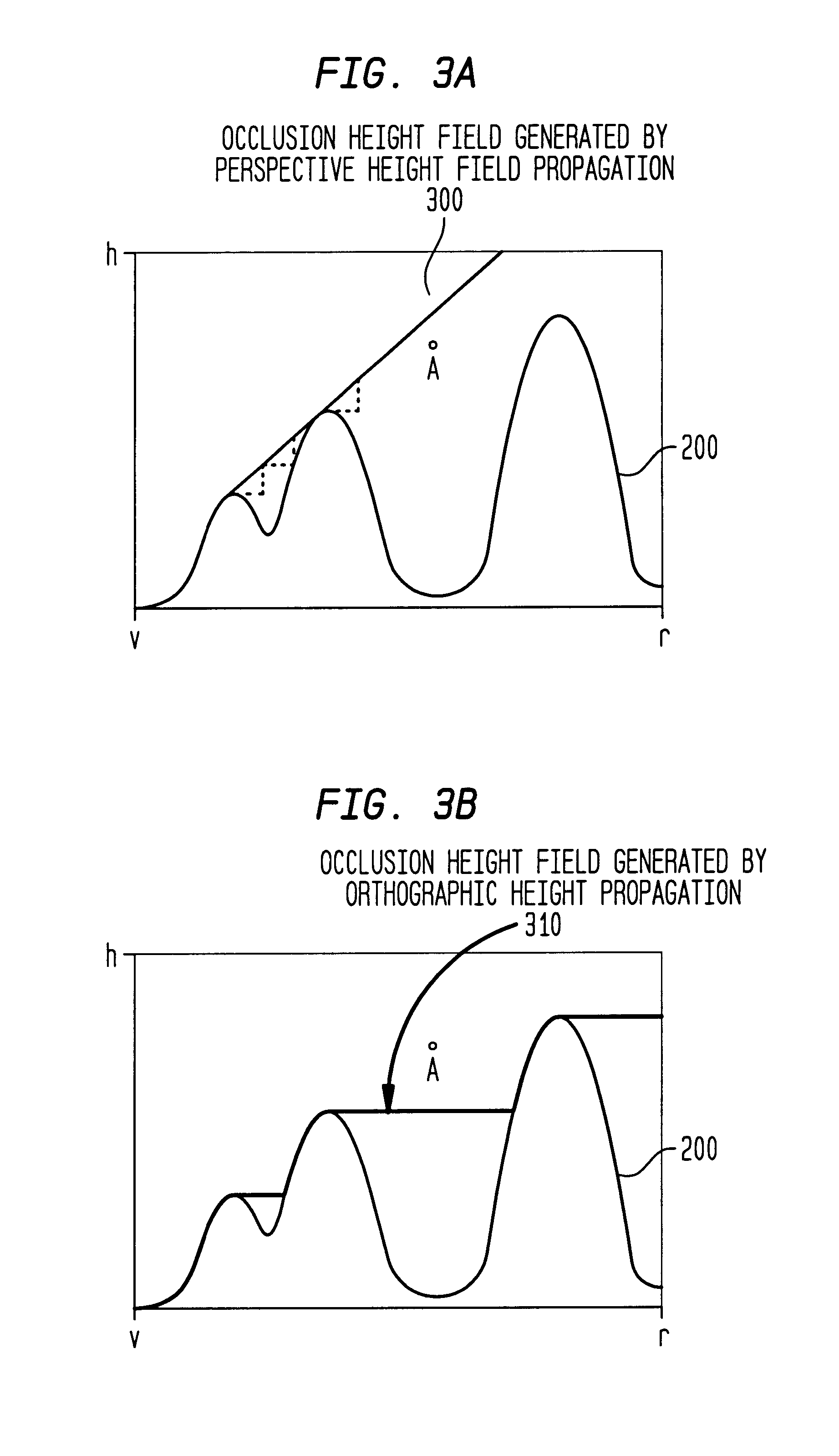

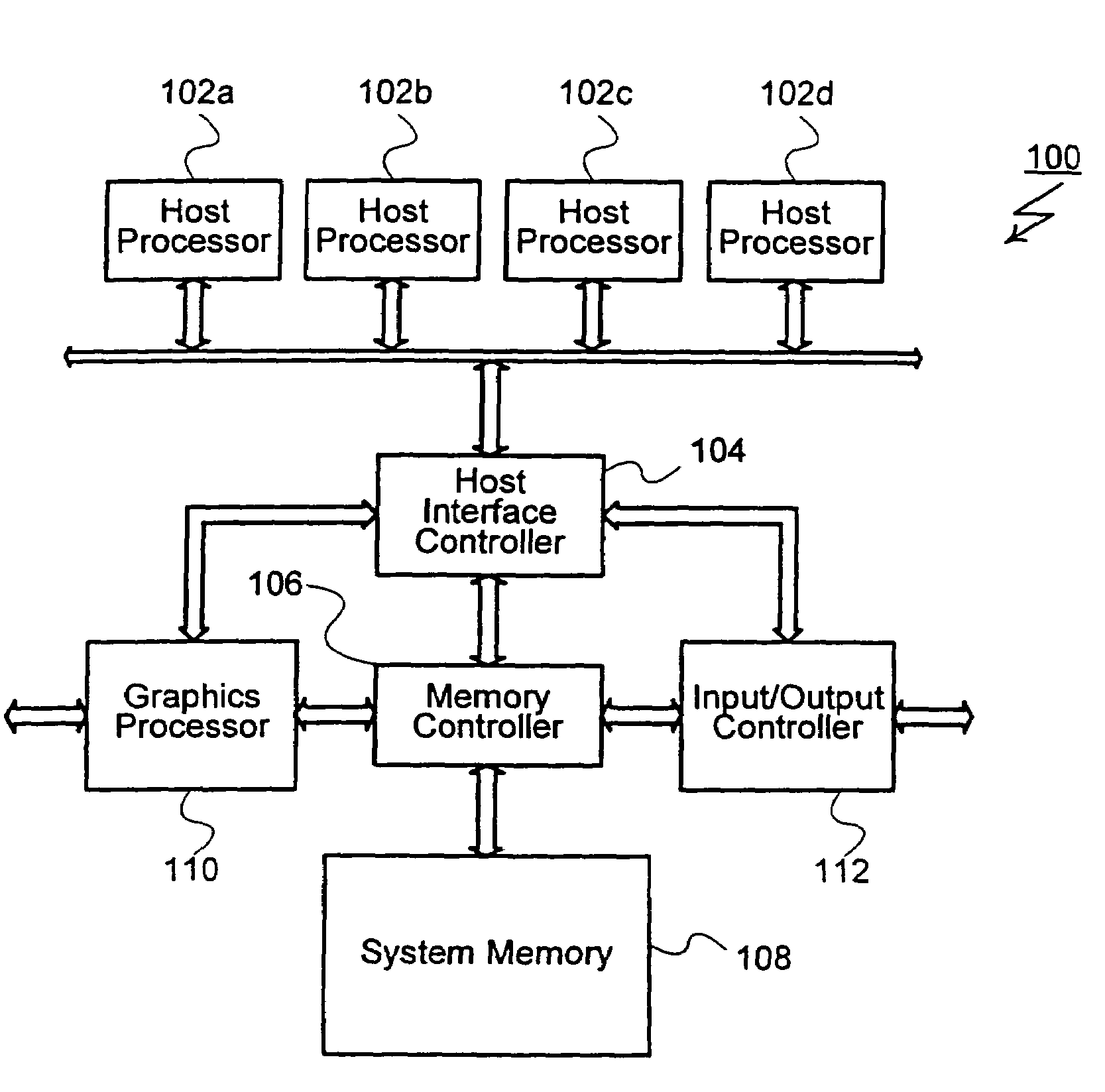

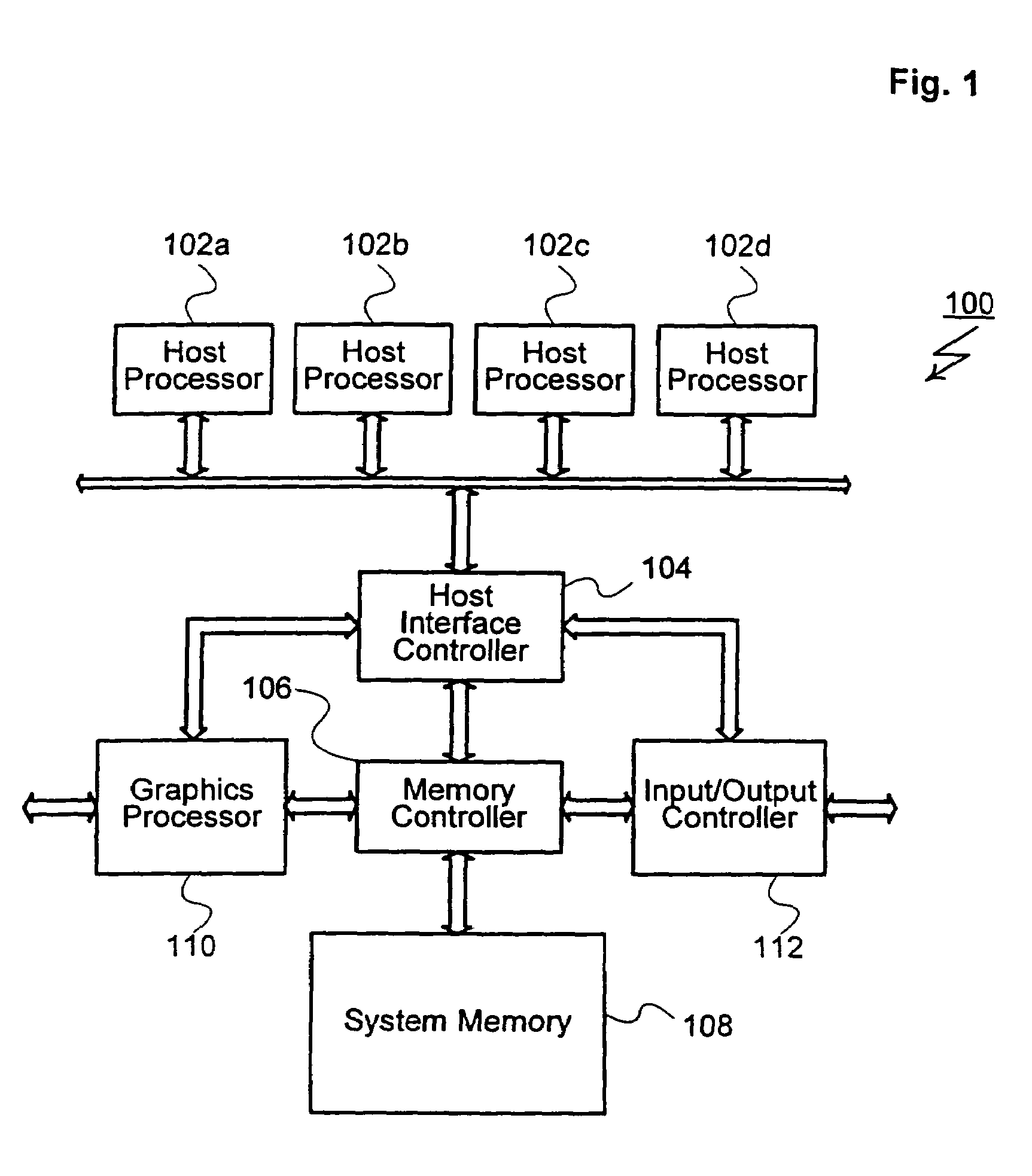

Method, system, and computer program product for visibility culling of terrain

ActiveUS7027046B2Promote reconstructionEasy to adjustCathode-ray tube indicators3D-image renderingTerrainGraphics

A method, system, and computer program product are provided for visibility culling of terrain. A height field is perspective modulated. An occlusion height field is generated based on an orthographic height propagation of the perspective modulated height field. Graphics data is culled based on the generated occlusion height field. Texturing and blending operations can be used to accelerate the perspective modulation. A perspective modulation disk is used to modulate the first height field along radial slices from a viewpoint. Texture from a one-dimensional texture with distance values is mapped to the radial slices to obtain the perspective modulated height field. Generating an occlusion height field can also be carried out using texturing and blending and can be hardware-accelerated. According to a further feature, a shift disk or shift texture is used.

Owner:ACTIVISION PUBLISHING

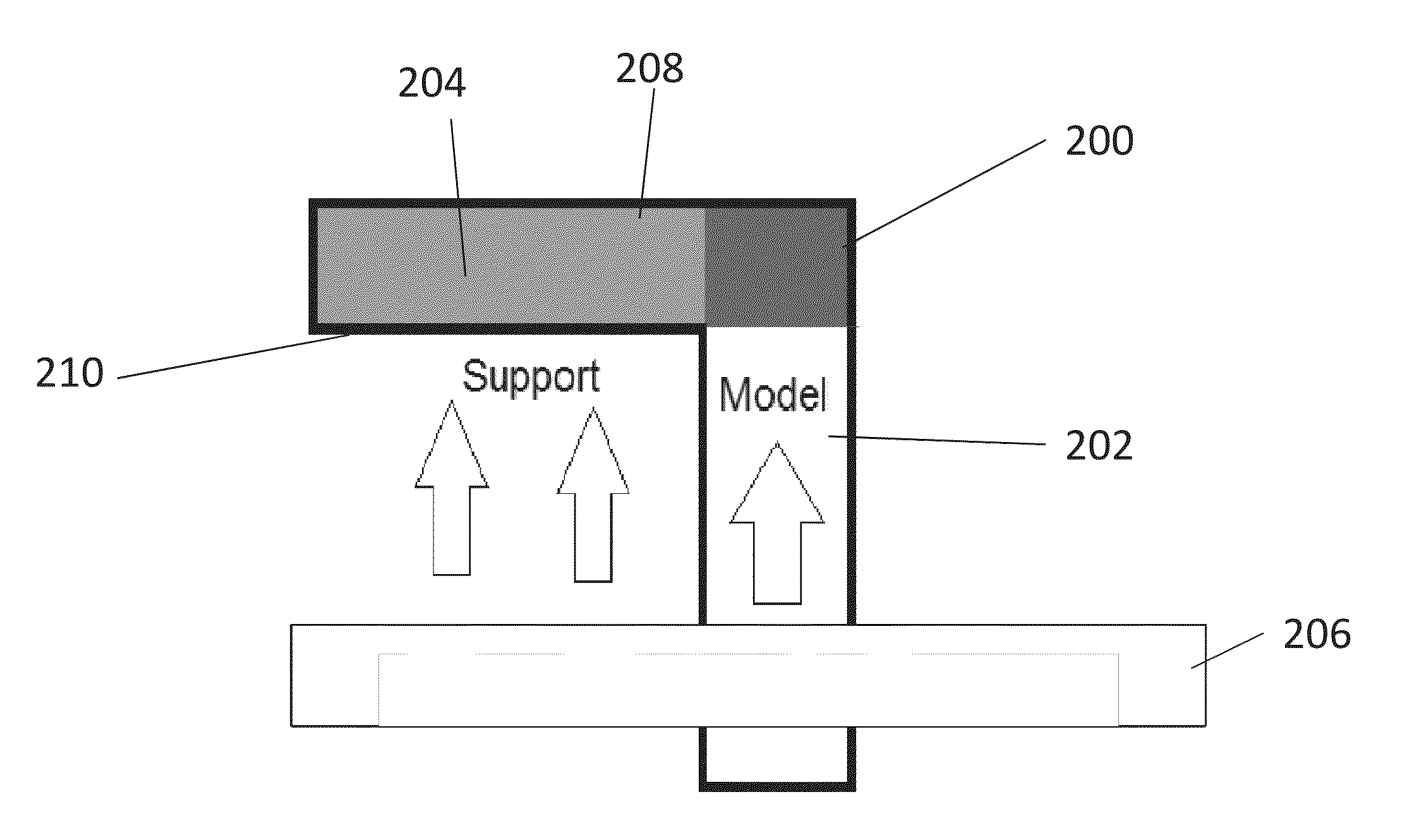

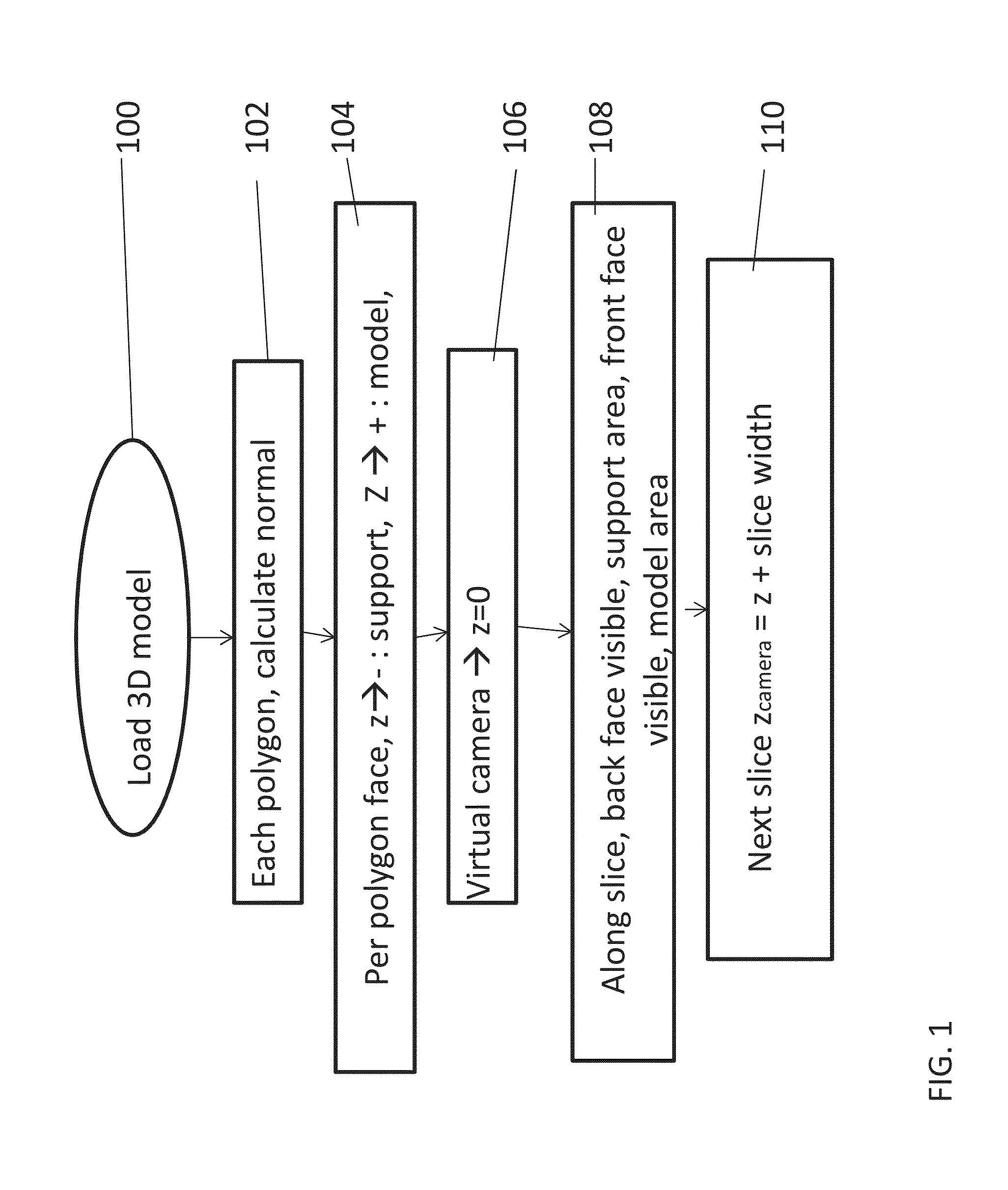

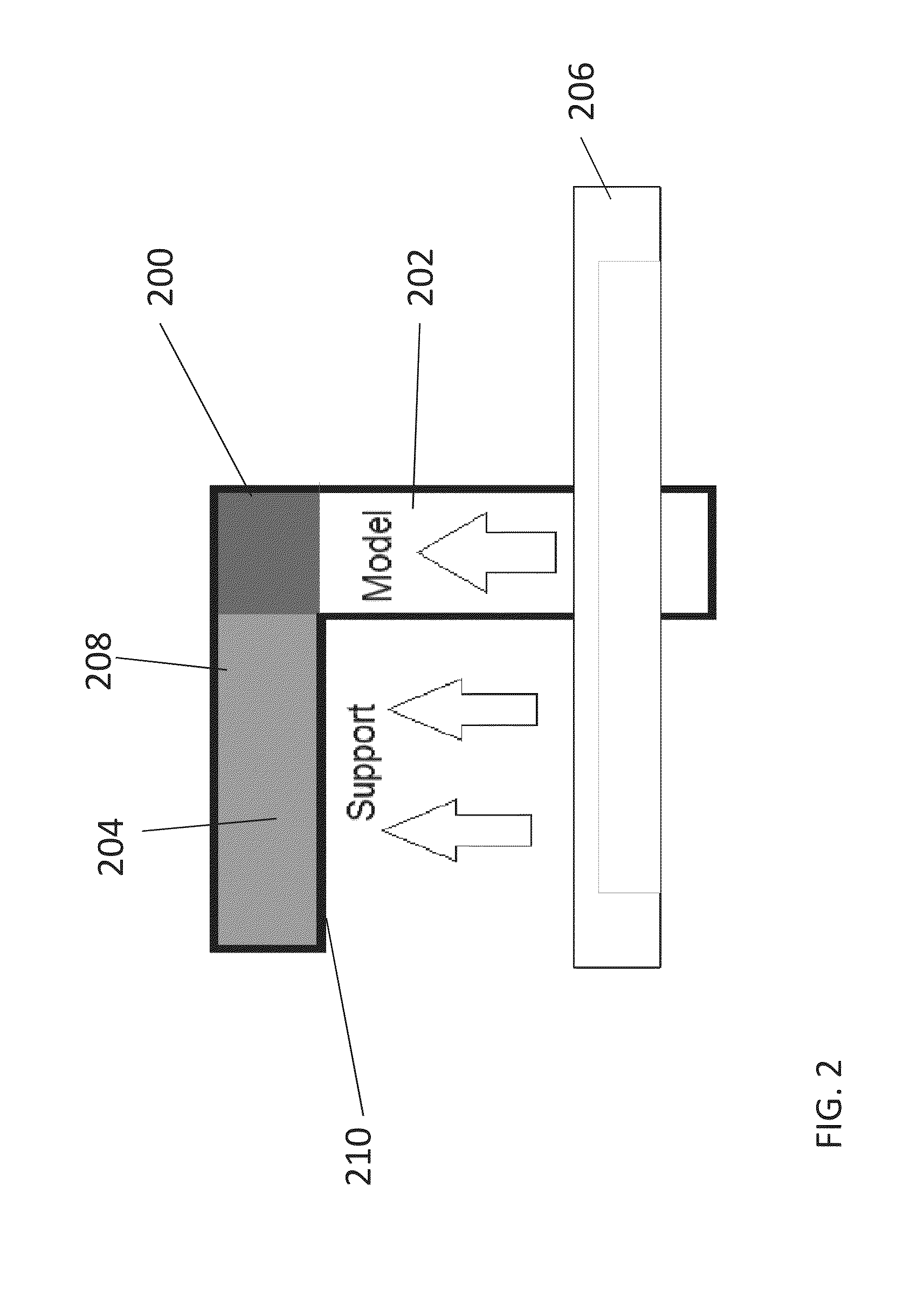

Slicing and/or texturing for three-dimensional printing

A method for slicing a three-dimensional model for printing of a corresponding object by a 3D printer, comprises: obtaining the envelope of the object as polygons, then for each region of a predefined work area within the slicing plane:identifying the closest polygon of said envelope that is positioned above said respective pixel; where no polygon is identified, then marking a corresponding region as a no-print region; if the direction vector of said closest above polygon has a positive component in the Z direction, then marking said corresponding region as a model region; and if the direction vector of said polygon has a negative component in the Z direction, then marking the region as a support region, and printing accordingly. An advantage of the above procedure is that the slicing, and in addition texture mapping, can be efficiently carried out on a graphics card or GPU.

Owner:STRATASYS LTD

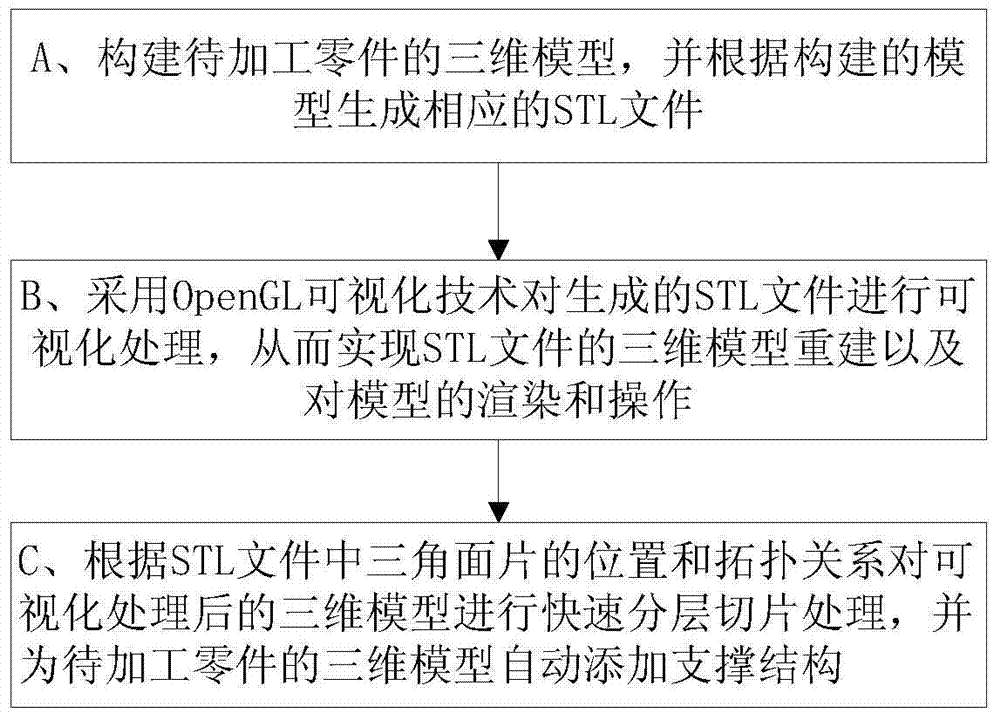

Implementation method based on 3D (Three Dimensional) printing data processing software platform

ActiveCN104504186AOvercome selected deficienciesQuality assuranceSpecial data processing applicationsSelective laser sinteringAutomatic control

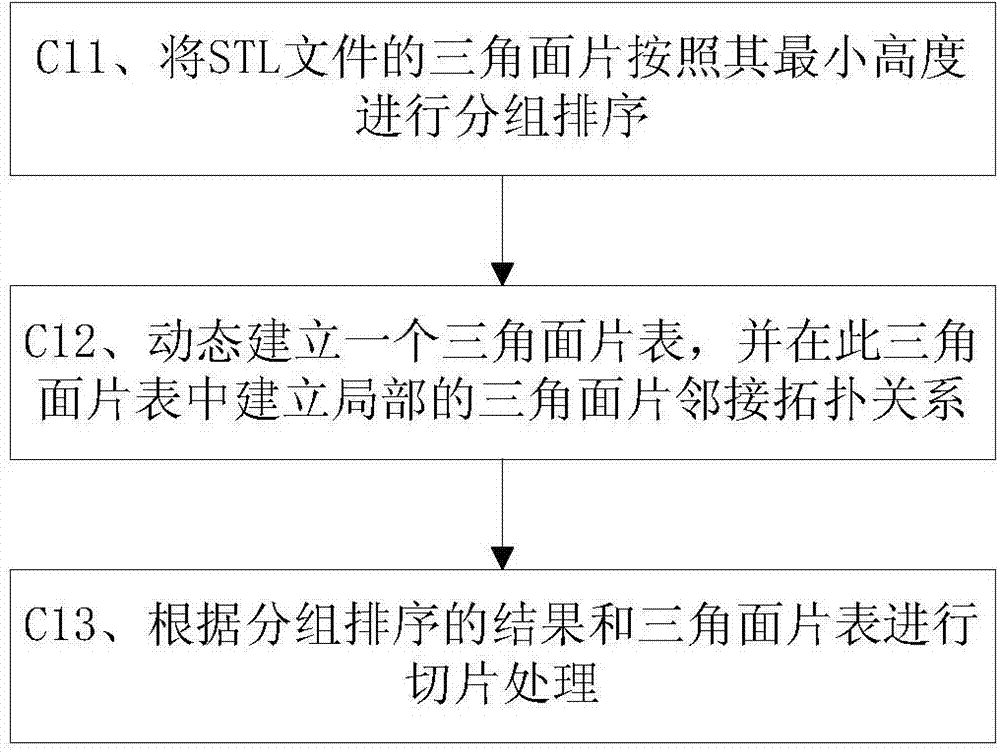

The invention discloses an implementation method based on a 3D (Three Dimensional) printing data processing software platform. The implementation method based on the 3D printing data processing software platform comprises the following steps of establishing a 3D model of a part to be processed, and generating a corresponding STL (Standard Template Library) file according to the established model; adopting an OpenGL visualization technology to carry out visualization processing on the generated STL file; carrying out rapid hierarchical slicing processing on a 3D model subjected to the visualization processing according to the position and the topological relationship of a triangular patch in the STL file, and automatically adding a support structure for the 3D model of the part to be processed; according to the result of hierarchical slicing processing and the characteristics of processing materials, adopting a birth-death element method to simulate a processing process based on SLS (Selective Laser Sintering) and SLM (Selective Maping) technology processes for the part to be processed; carrying out parameter selection and model optimization on the part to be processed according to the simulation result, so that optimal printing parameters and an optimal processing model of the part to be processed are obtained. The implementation method based on the 3D printing data processing software platform has the advantages of high efficiency, low cost and good forming quality, and can be widely applied in the field of automatic control.

Owner:广东健齿生物科技有限公司

Method and apparatus for generating geometric data for use in additive manufacturing

ActiveUS20160370791A1Easy accessEasy and fastProgramme controlAdditive manufacturing apparatusSurface geometryComputer science

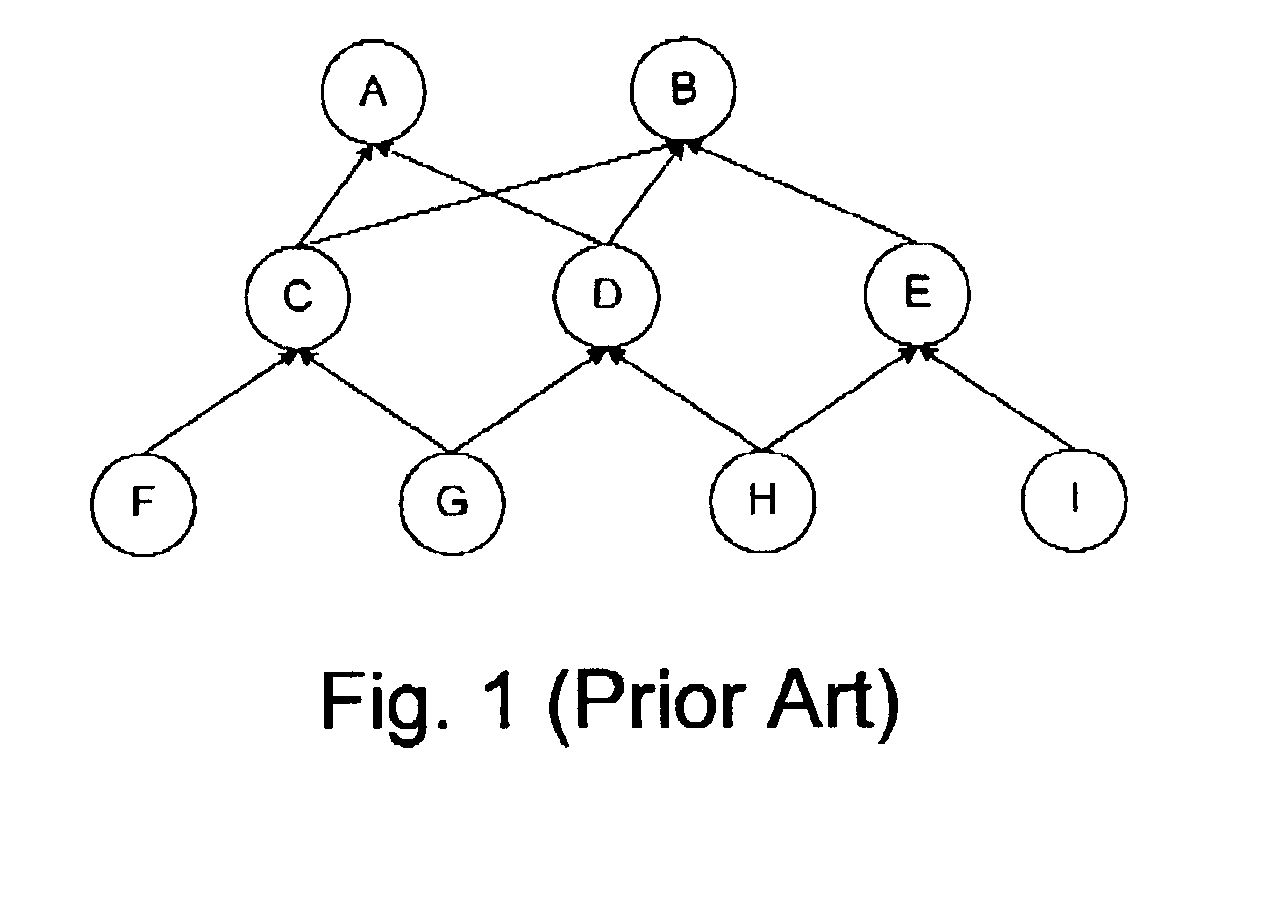

An apparatus and methods for generating geometric data for use in an additive manufacturing process. The apparatus includes a processing unit. The processing unit may be arranged for receiving data defining surface geometry of a plurality of objects to be built together in an additive manufacturing process, providing a user interface that allows a user to define a location of each object within a common build volume and carrying out a slicing operation on at least one of the objects located in the common build volume independently from another one of objects located in the common build volume. The slicing operation determines sections of the at least one object to be built in the additive manufacturing process. In one embodiment, the objects are defined in a hierarchical data structure. Supports for supporting the objects during the build may be defined with reference to a 2-dimensional support cross-section.

Owner:RENISHAW PLC

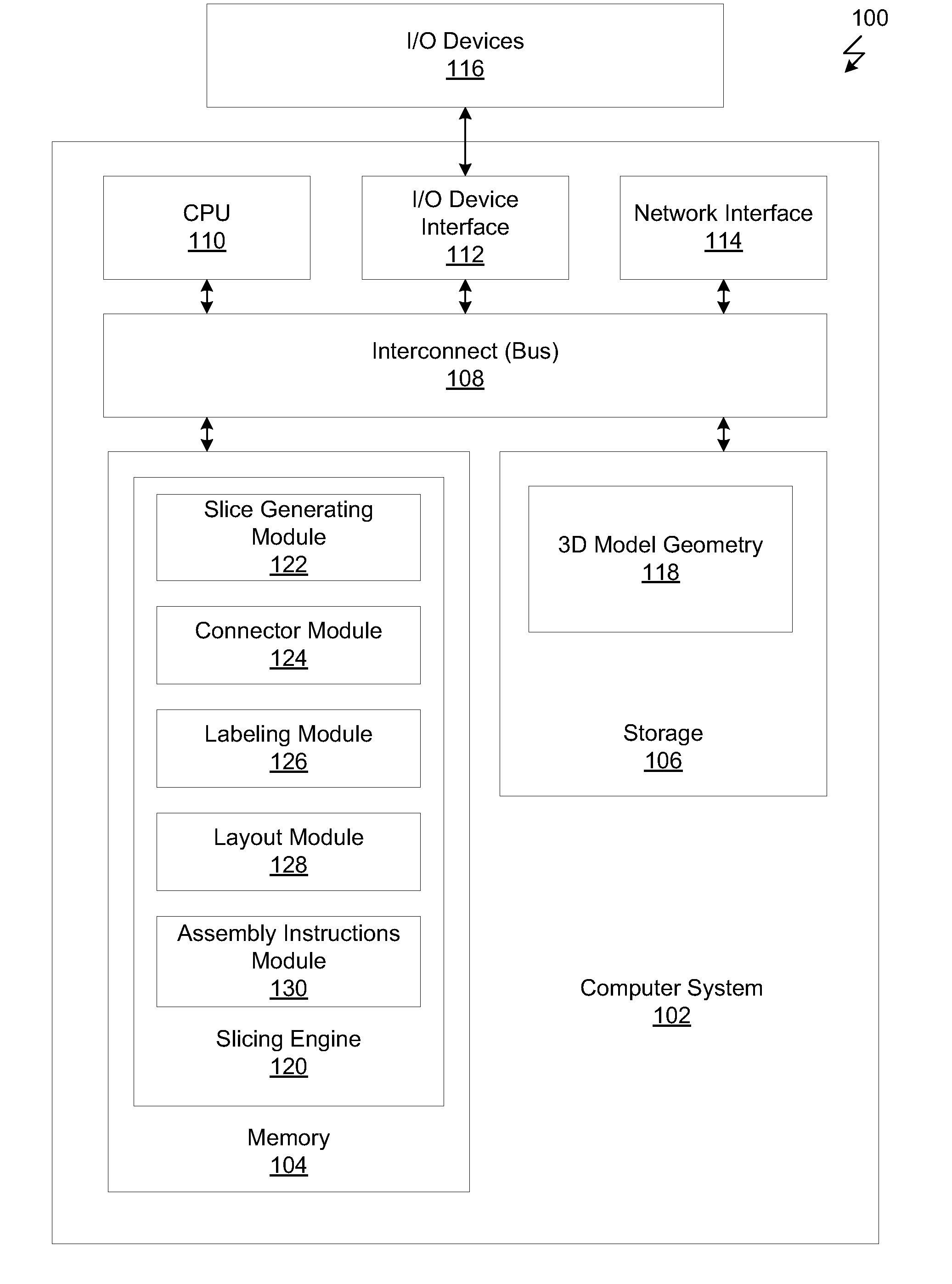

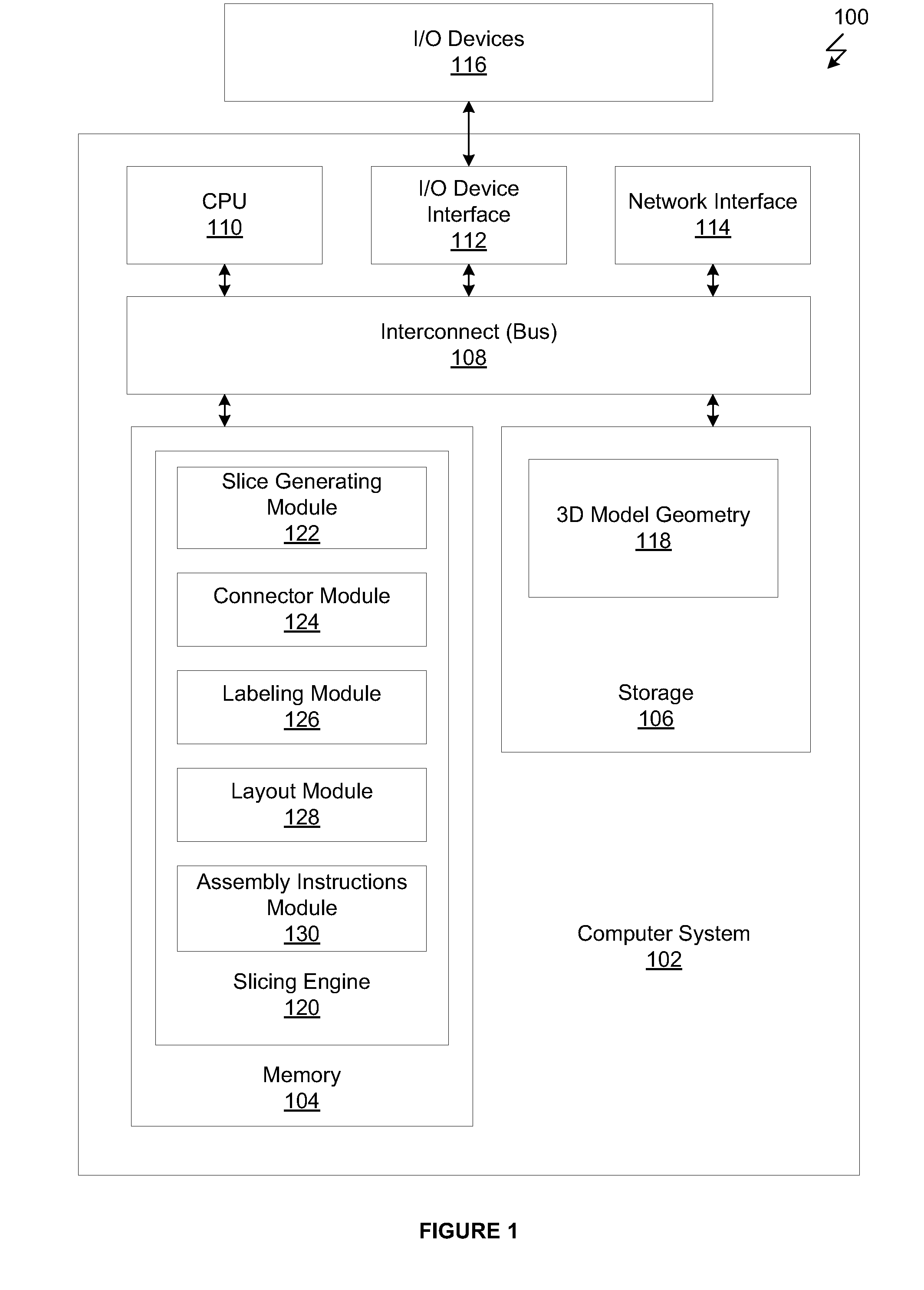

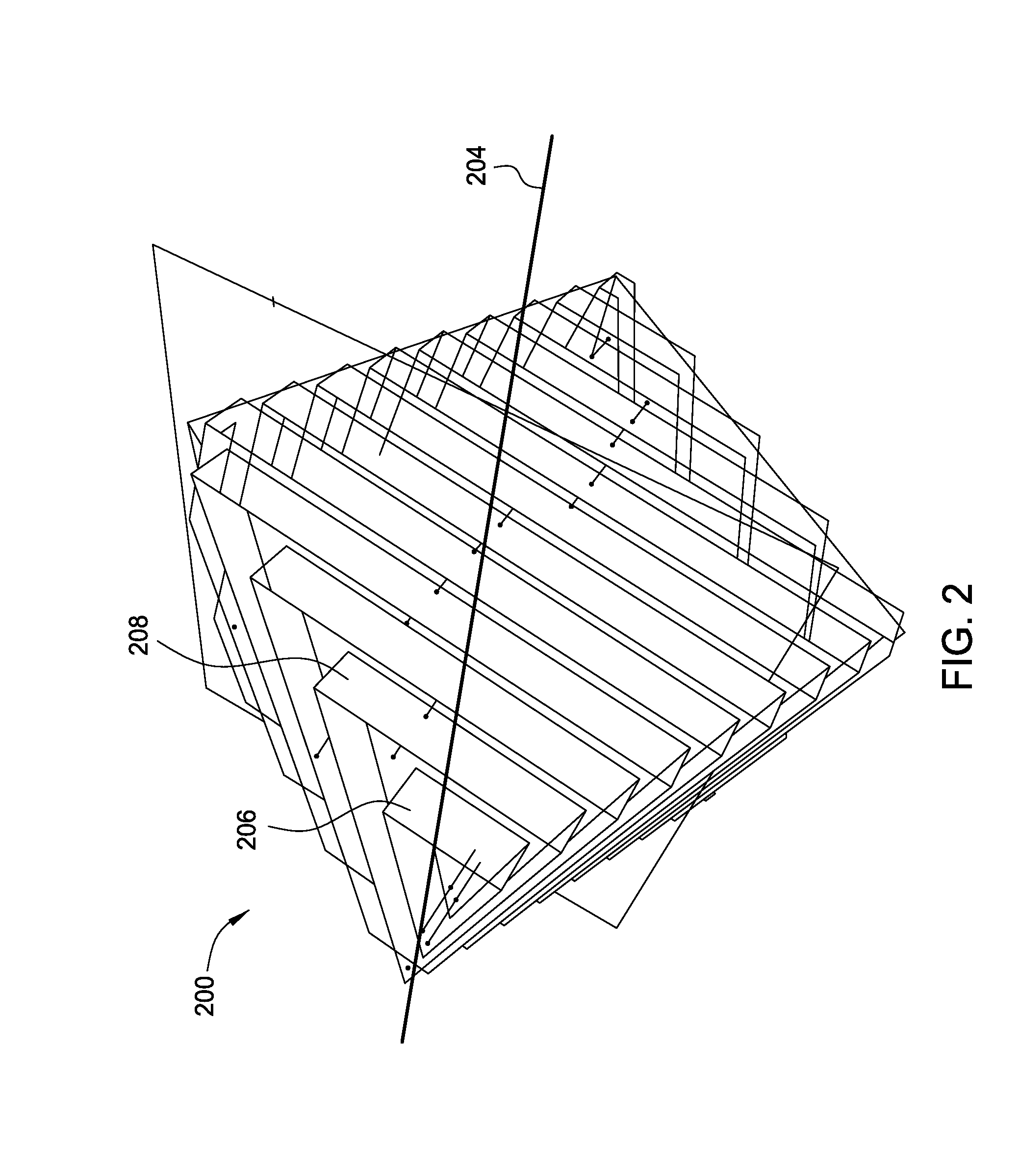

Techniques for slicing a 3D model for manufacturing

One embodiment of the invention is a slicing engine that generates two or more slices of a virtual 3D model given a slice plane. The slicing engine then determines connection points on each of the slices that indicate how the 3D model is to be reconnected by the user when the 3D model is fabricated. The slicing engine also determines an optimized layout for the various slices of the 3D model on fabrication material for minimal use of the material. The user is then able to “print” the layout on the fabrication material via 3D printers, and connect the various printed slices according to the connection points to build a physical representation of the 3D model.

Owner:AUTODESK INC

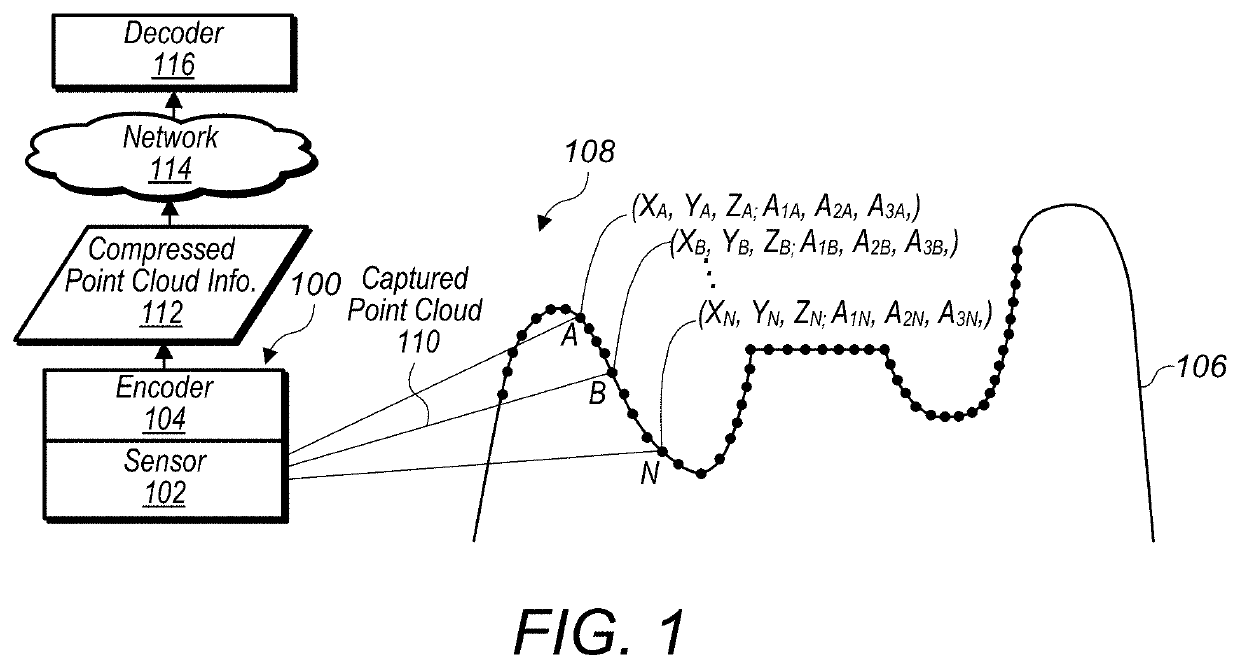

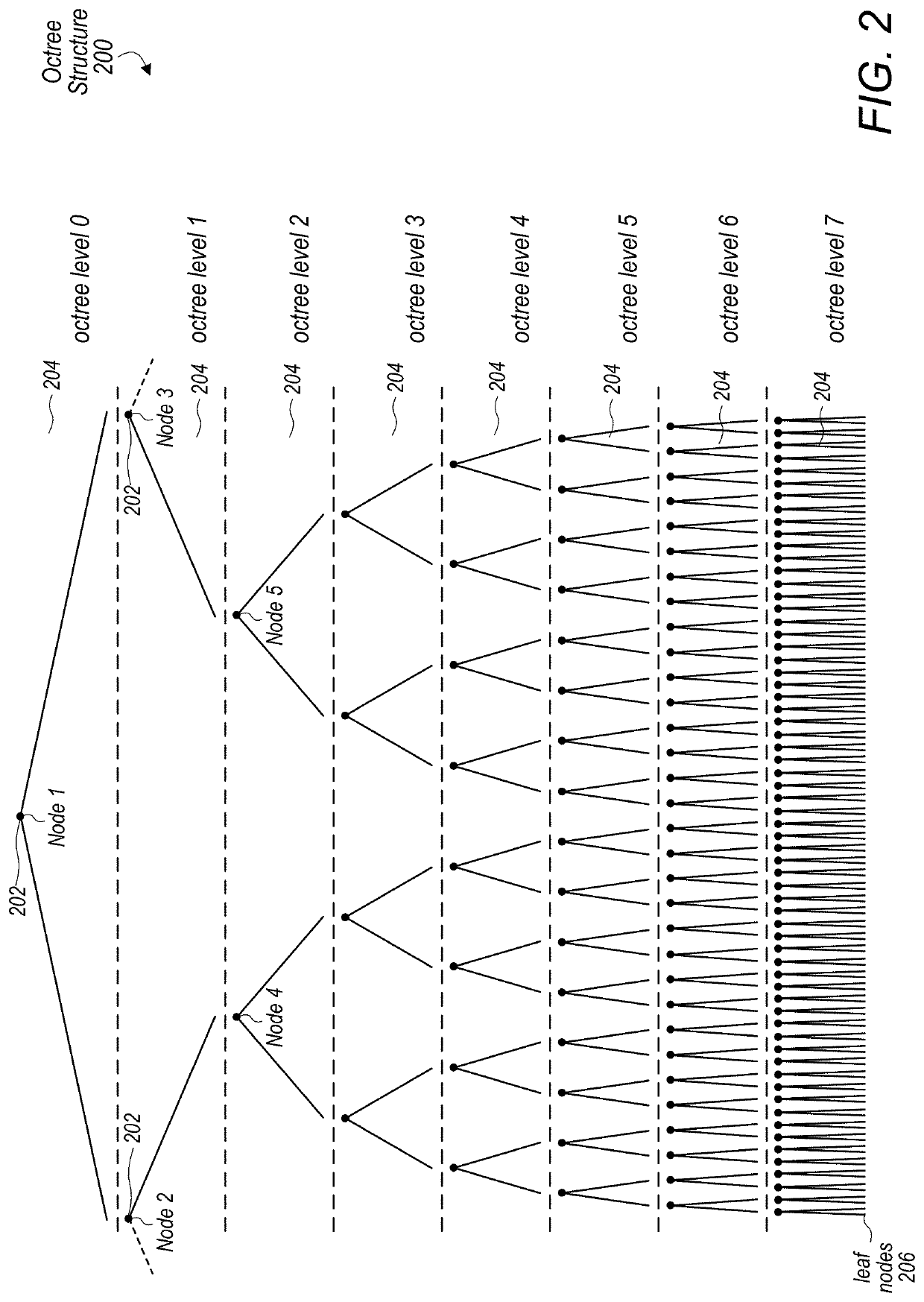

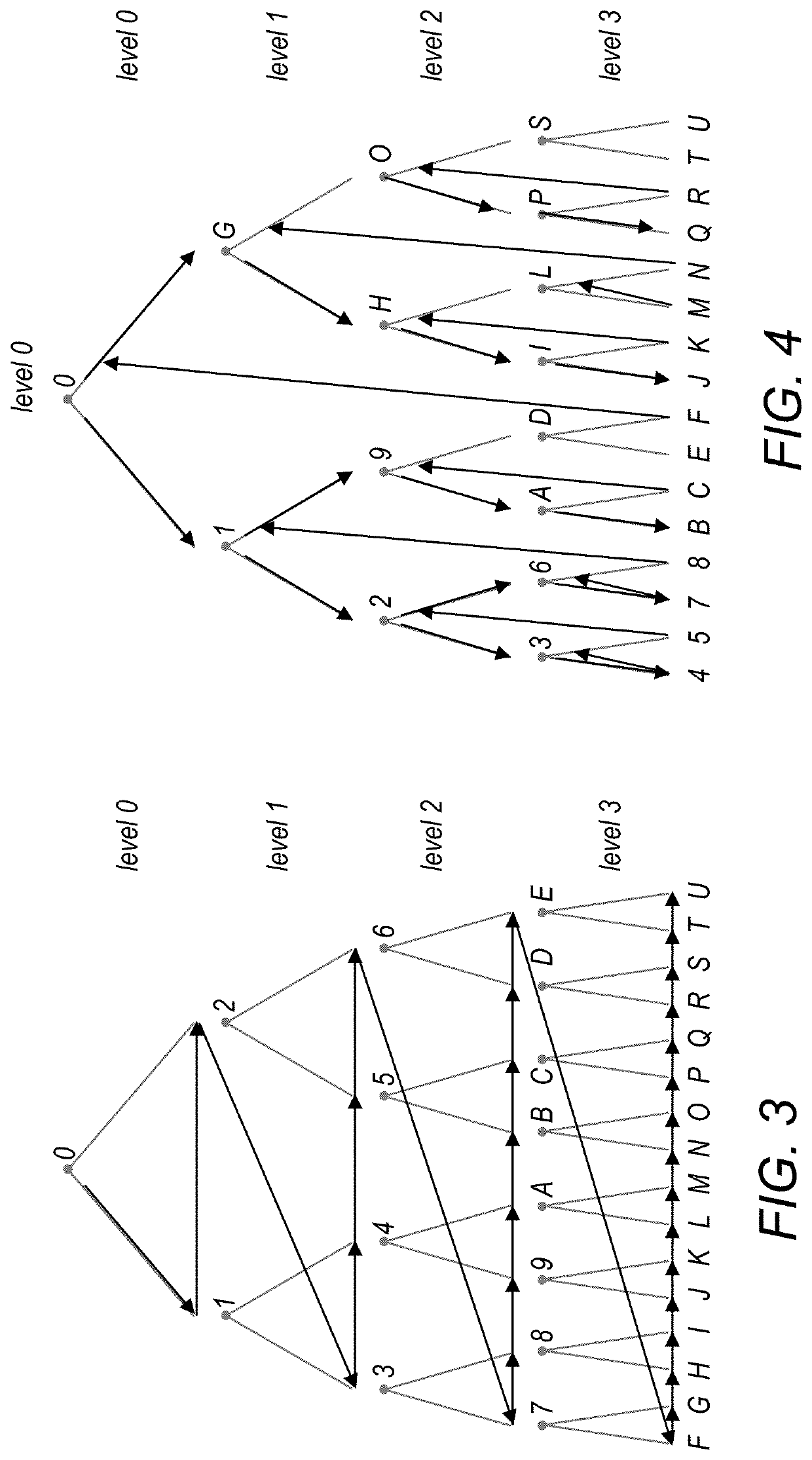

Point Cloud Compression Using Octrees with Slicing

ActiveUS20210407147A1Improve decoding efficiencyReduce memory requirementsImage codingDigital video signal modificationPoint cloudSlicing

An encoder is configured to compress point cloud geometry information using an octree geometric compression technique that utilizes slices corresponding in size to data transmission units. In some embodiments, a subsequent slice may be set to use a re-set entropy context or may be set to use an entropy context saved for a preceding slice. In some embodiments, an entropy context for the preceding slice may be for a slice other than the immediately preceding slice of the subsequent slice being evaluated, such that if the immediately preceding slice is lost in transmission (or if the immediately preceding slice and the subsequent slice are being evaluated in parallel) the subsequent slice's entropy context can still be determined without depending on the immediately preceding slice. A decoder is configured to reconstruct a point cloud based on a bit stream encoded by the encoder.

Owner:APPLE INC

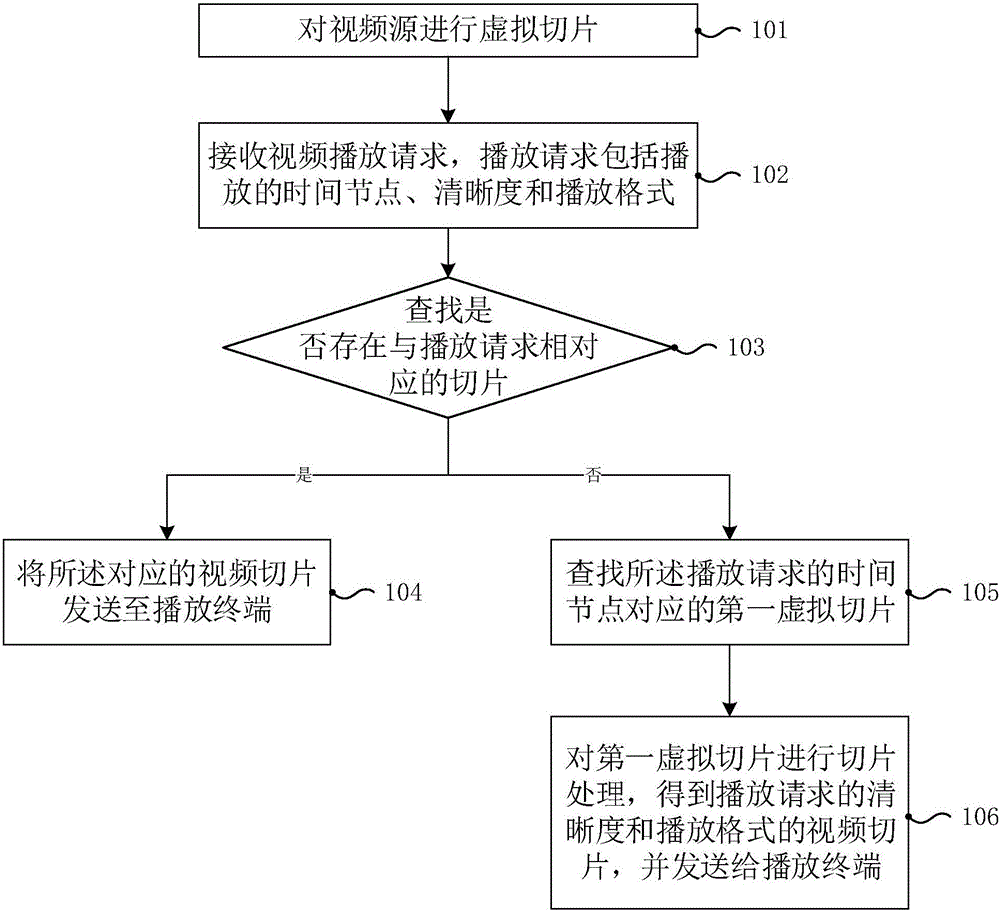

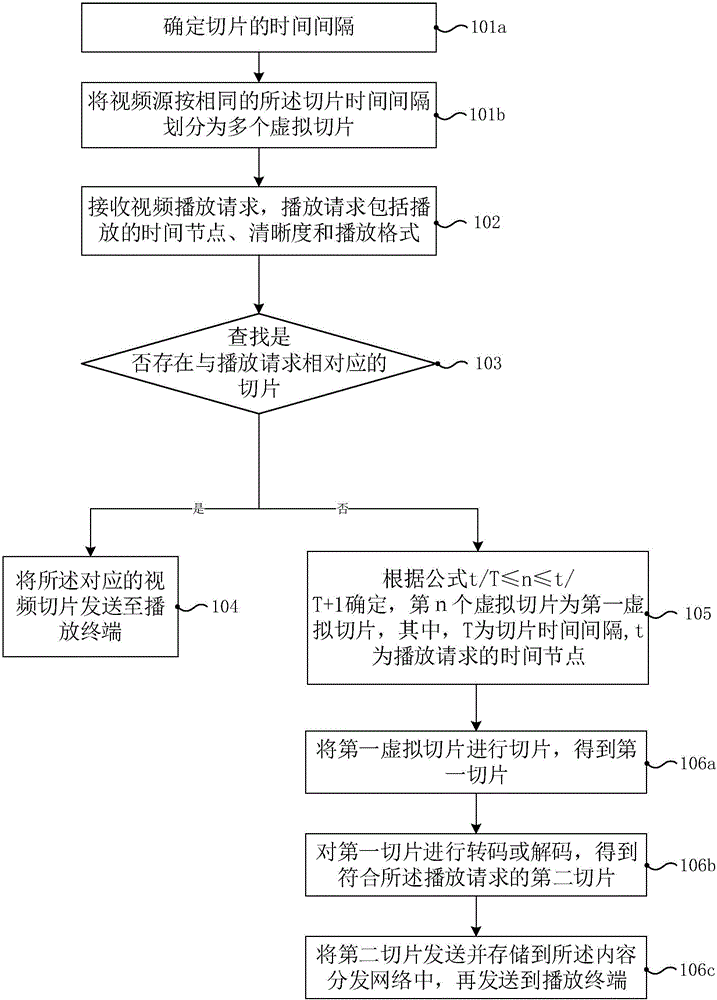

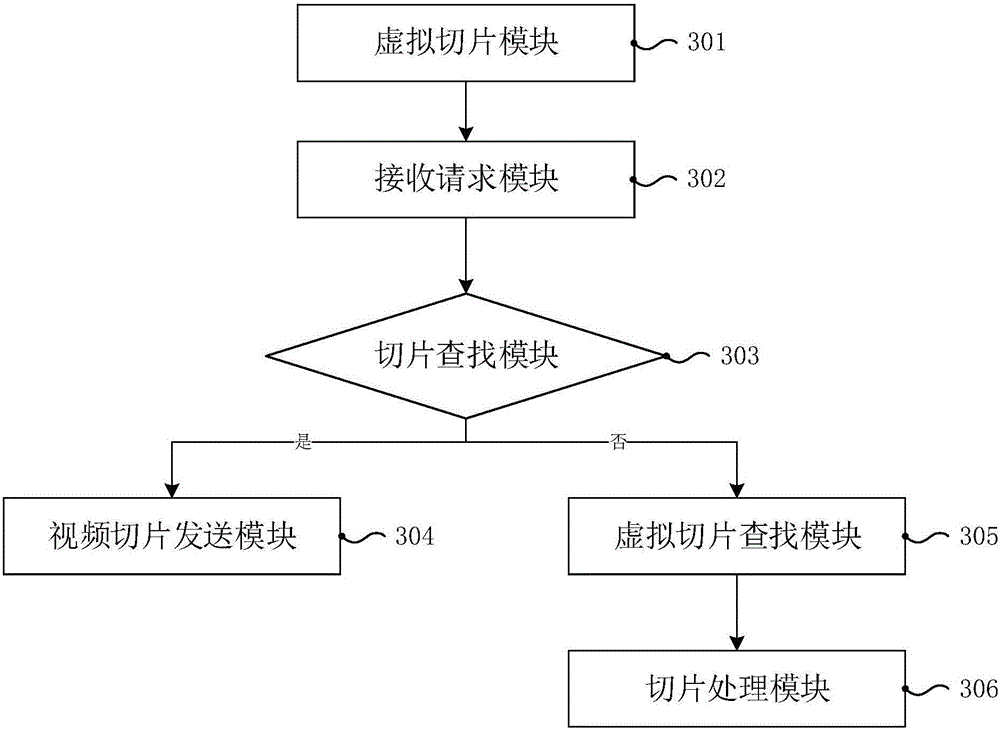

Video playing method and system

InactiveCN105872807AImprove playback efficiencyReduce occupancySelective content distributionVideo serverContent distribution

The invention discloses a video playing method and system. The method comprises the steps that a virtual slice module conducts virtual slicing on a video source; a request receiving module receives a video playing request, wherein the video playing request contains a playing time node, definition and a playing format; a slice search module searches a content distribution network for a video slice corresponding to the playing request; if the video slice corresponding to the playing request exists, a video slice sending module directly sends the corresponding video slice to a playing terminal; otherwise, a virtual search module searches for a first virtual slice corresponding to the time node in the playing request; a slice processing module conducts slicing on the first virtual slice, and a video slice corresponding to the definition and the playing format in the playing request is obtained and sent to the playing terminal. According to the video playing method and system, a virtual slicing mode is adopted, a video is transcoded or decoded in a real-time online slicing mode, and occupation of storage space of a video server is reduced.

Owner:LETV HLDG BEIJING CO LTD +1

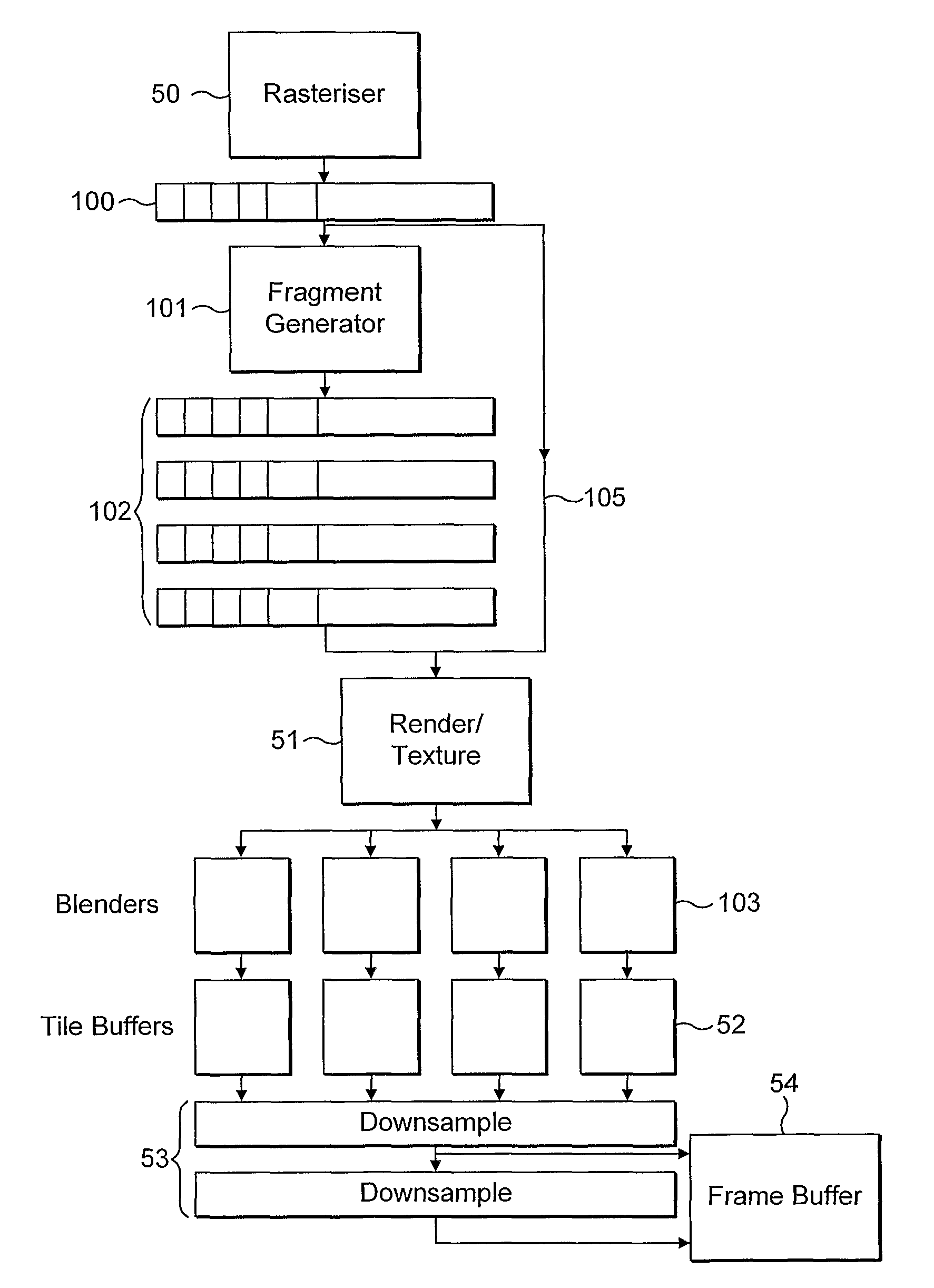

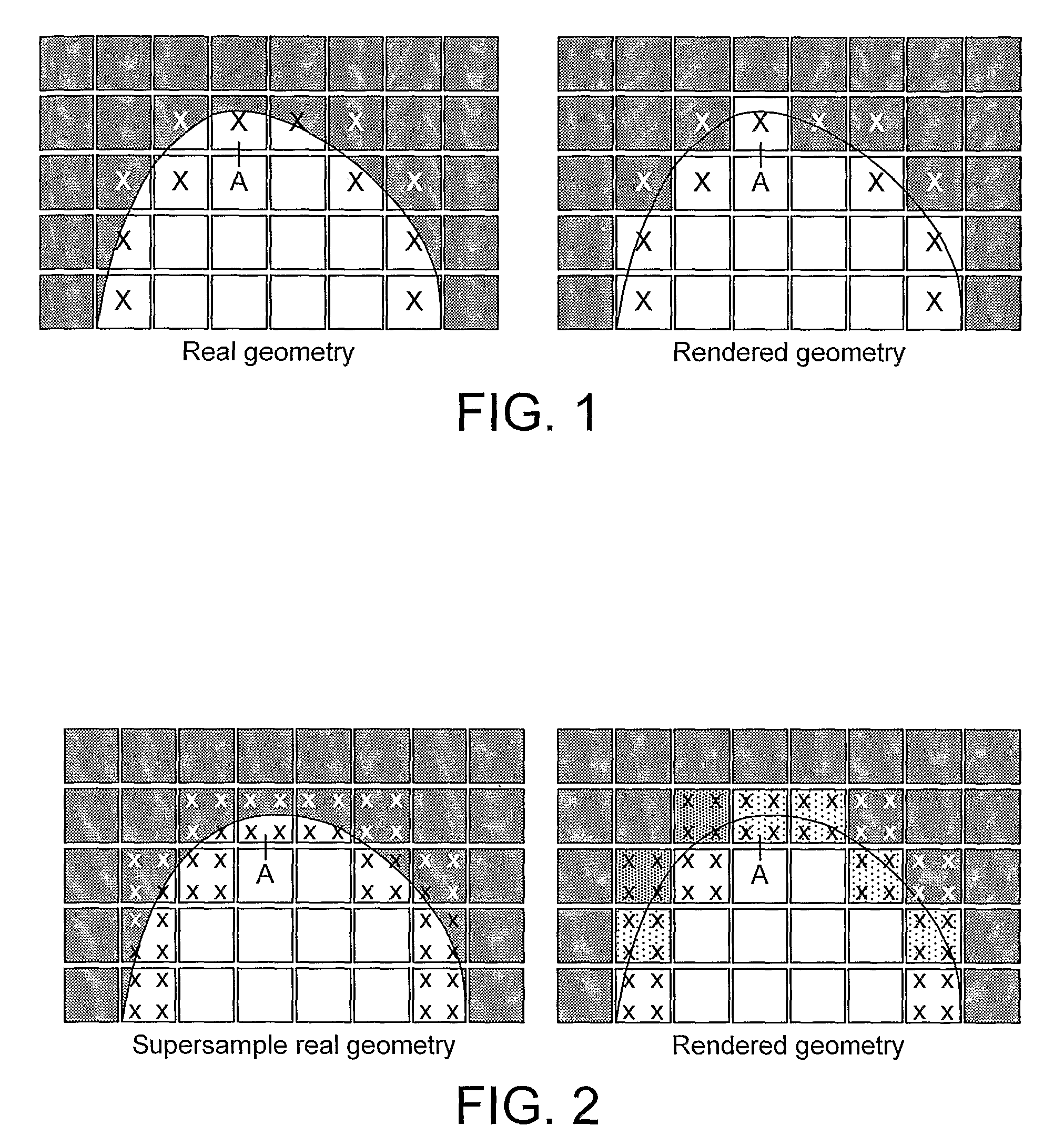

Processing of computer graphics

ActiveUS7920139B2Easy to operateEfficient processingTexturing/coloringCathode-ray tube indicatorsGraphicsDisplay device

A graphics processing platform includes a rasteriser 50 that receives primitives representing an image to be displayed for processing. The rasteriser 50 determines which sets of sampling points of the image include sampling points that are covered by a given primitive, and then generates a fragment for rendering for each set of sampling points found to include a sampling point that is covered by the primitive and passes those fragments to a renderer 51 for rendering. The renderer 51 carries out rendering operations on the fragments that it receives, and stores the rendered fragment data in tile buffers 52. The rendered fragment data is stored in multiple copies in the appropriate sample positions in the tile buffers 52, so as to provide a separate set of fragment data for each individual sample position taken of the image. The data from the tile buffers 52 is input to a downsampling unit 53, and thence output to a frame buffer 54 of a display device 55 for display.

Owner:ARM NORWAY

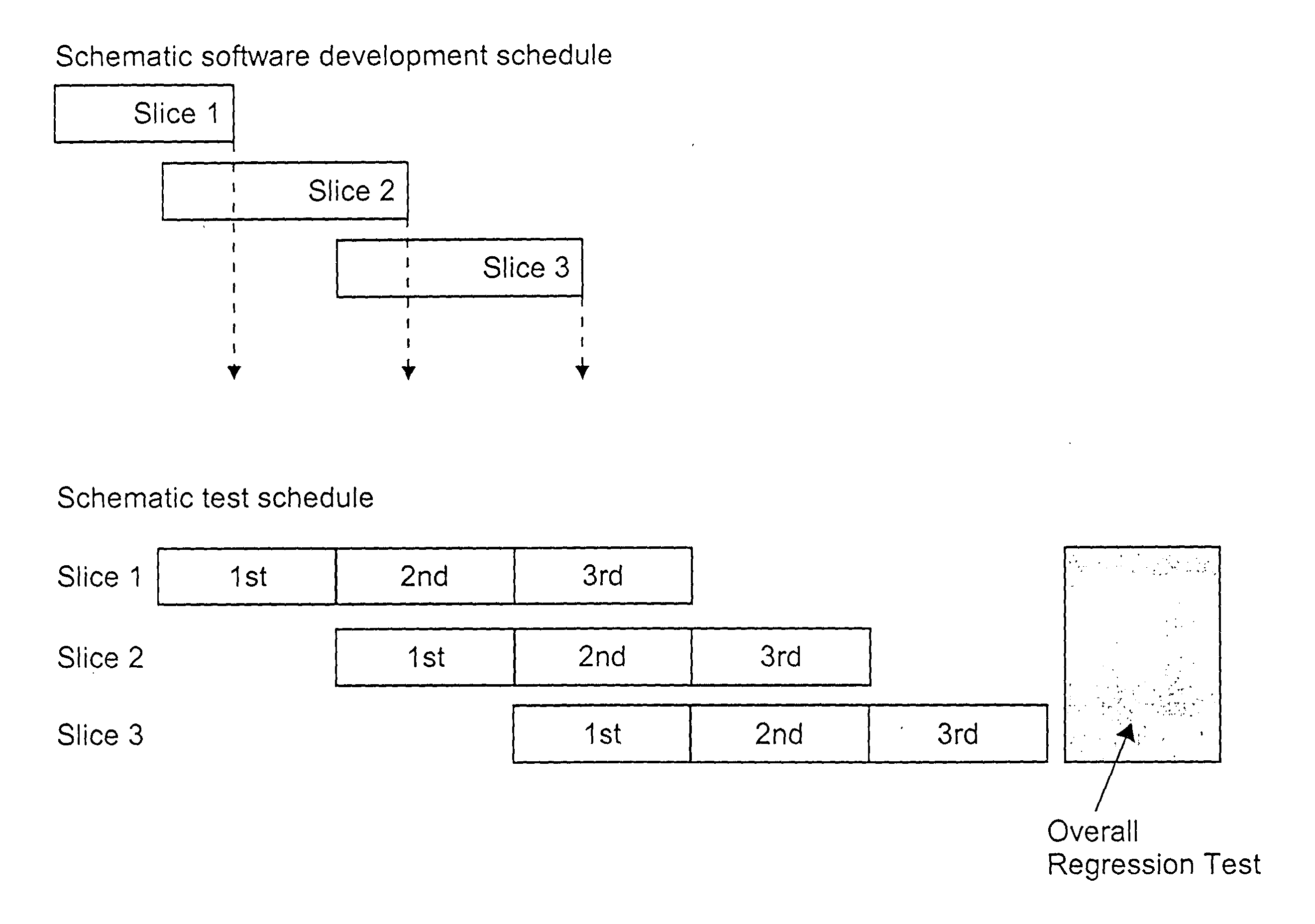

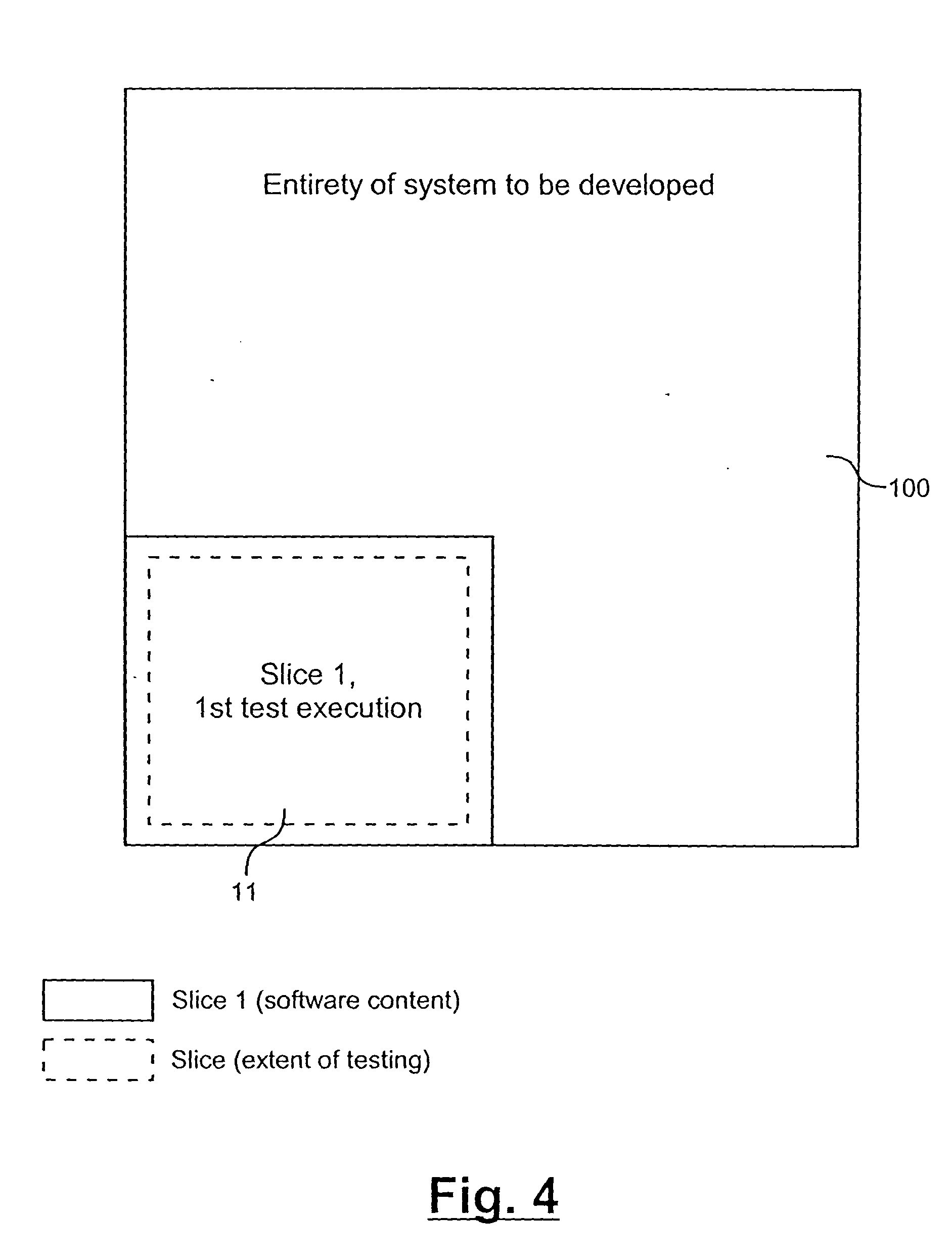

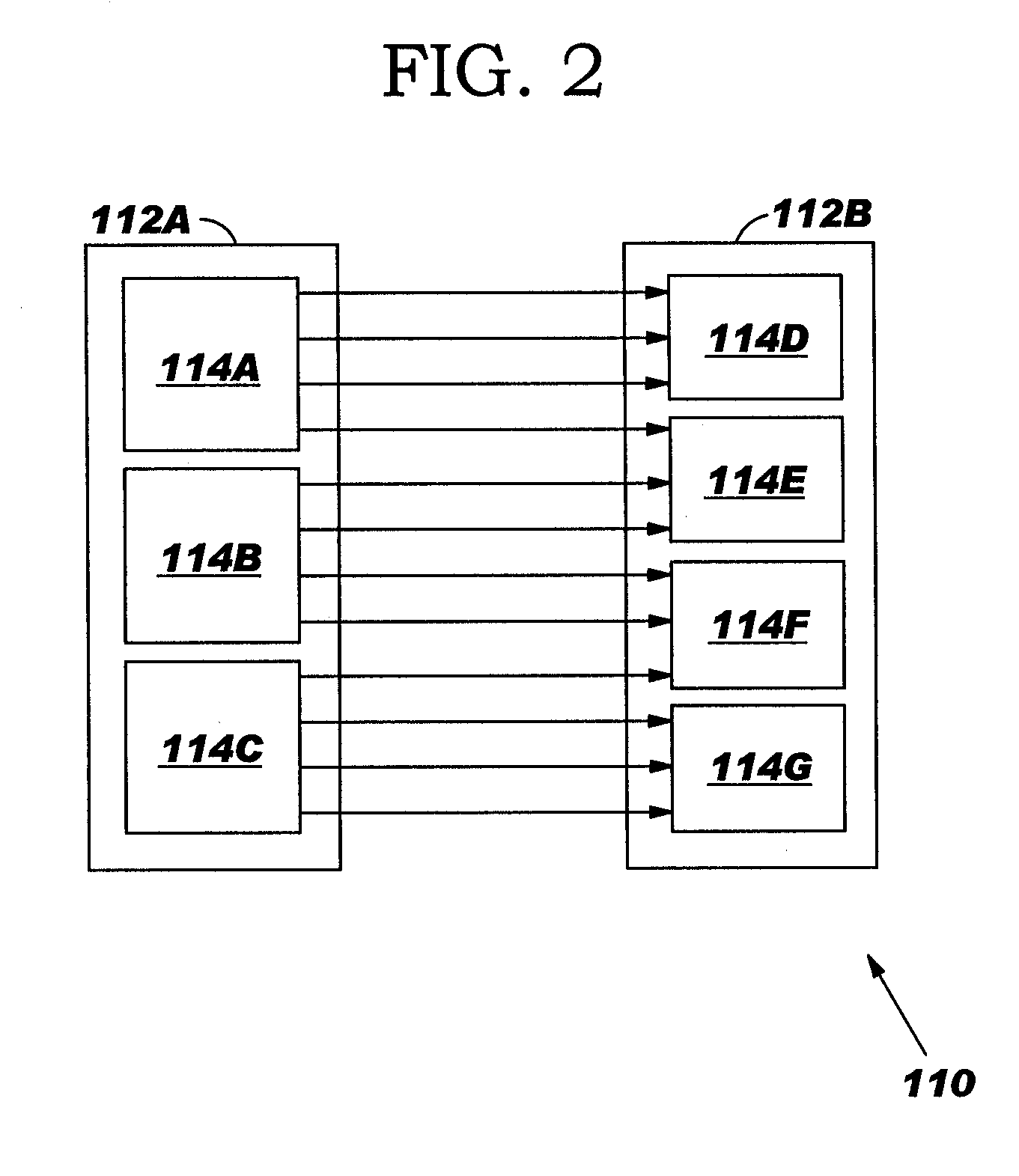

Method of producing a software product

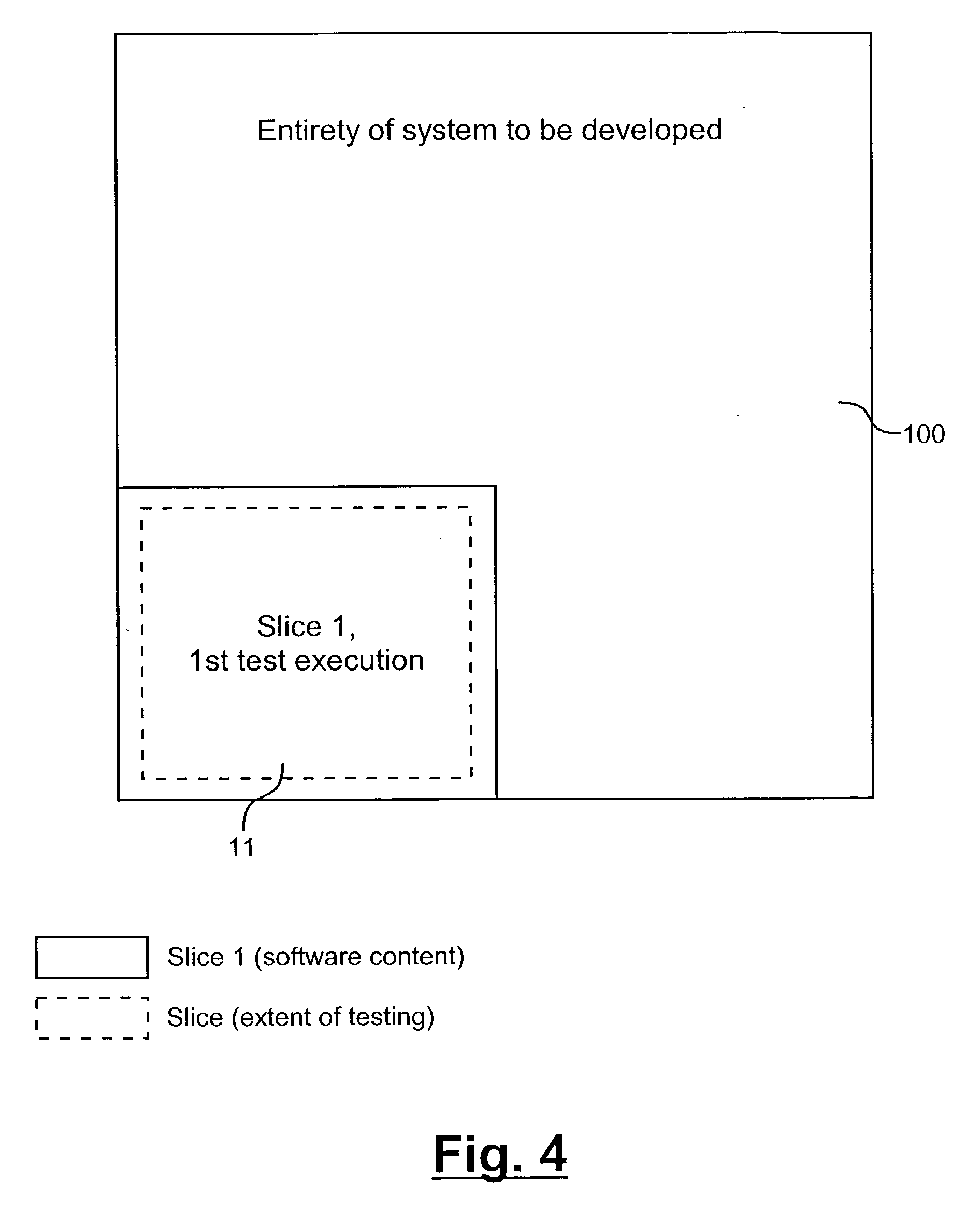

A software product is produced by defining a functional model of the overall software product, designing, based on this functional model, a plurality n of configurations and slices of the software product, wherein a configuration is the entirety or a part of the software product forming an independently testable unit and a slice is a set of functions of the software product constructed together and forming the entirety or part of a configuration. The n slices are independently constructed wherein the first slice forms the first configuration. The seond to n-th configurations are formed by integrating the k-th configuration with the (k+1) slice, wherein k is 1, . . . , n. Subsequently a first to n-th configuration are tested independently. This software development approach allows an integration of the overall systems in parts as early as possible and to gradually increase the number of integrated components in a controlled, but manageable fashion. This allows to achieve a highly efficient use of resources within a short development time.

Owner:ACCENTURE GLOBAL SERVICES LTD

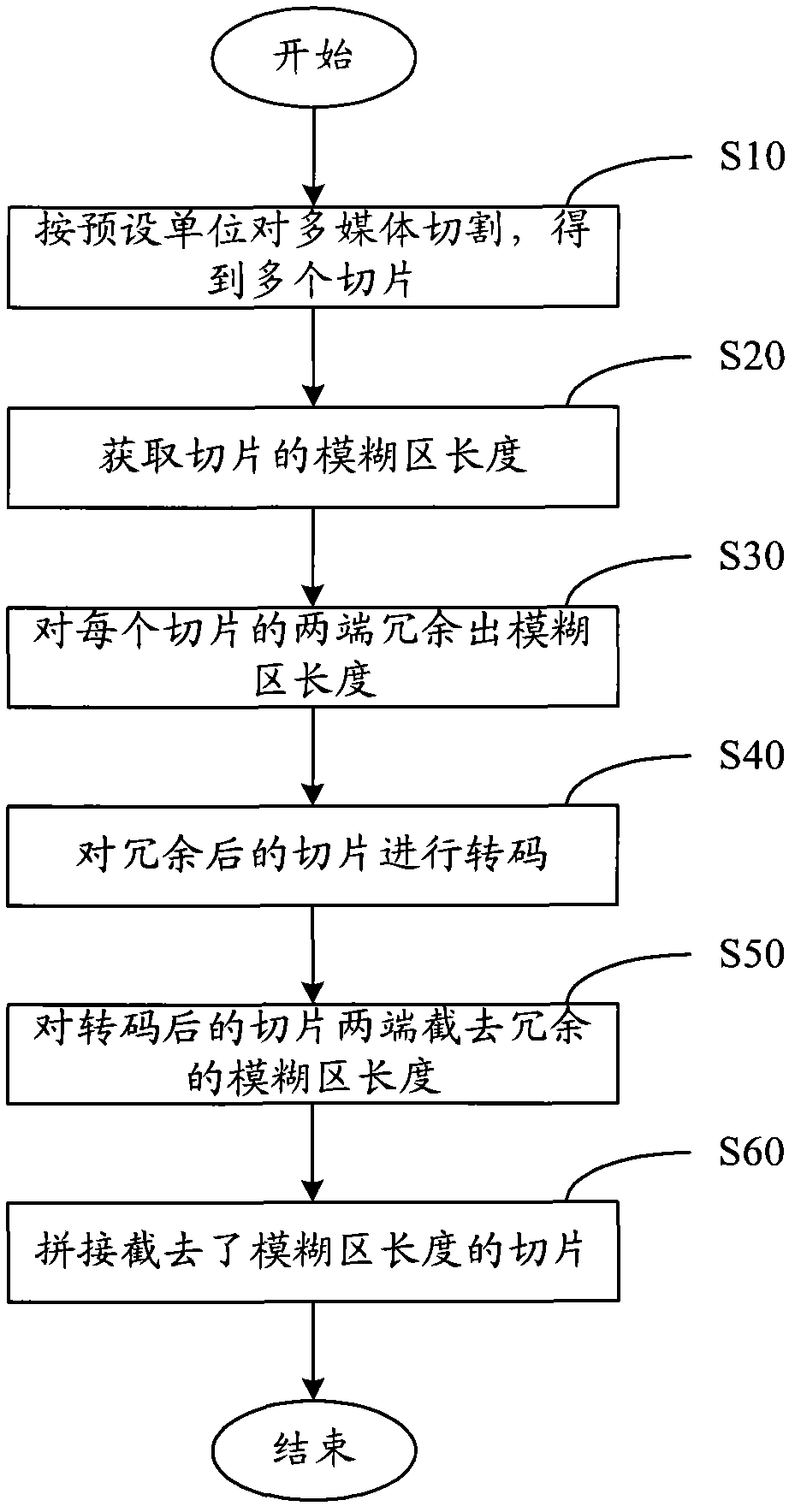

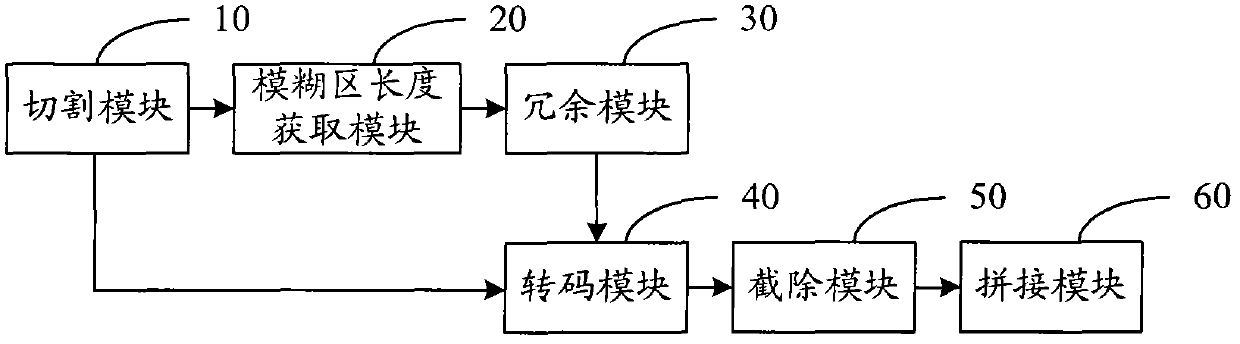

Method and system for transcoding multimedia slices based on overlapping boundaries

ActiveCN101951504AGood effectAchieve the effect of removing the blurred area of the borderPulse modulation television signal transmissionDigital video signal modificationTranscodingSlicing

The invention provides a method for transcoding multimedia slices, which comprises the following steps: slicing a multimedia according to a preset unit so as to obtain a plurality of slices; obtaining a fuzzy-region length of the slice; carrying out redundancy (redundant length: the fuzzy-region length) on the two ends of each slice; transcoding the slices subjected to redundancy; removing the parts (with the fuzzy-region length) of the two ends of the slice subjected to transcoding; and splicing the slice which is removed the parts with the fuzzy-region length. The invention also provides a system for transcoding multimedia slices. The method and the system for transcoding the multimedia slices can remove more boundary fuzzy regions and obtain better multimedia effect in the process of splicing the slices subjected to transcoding.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

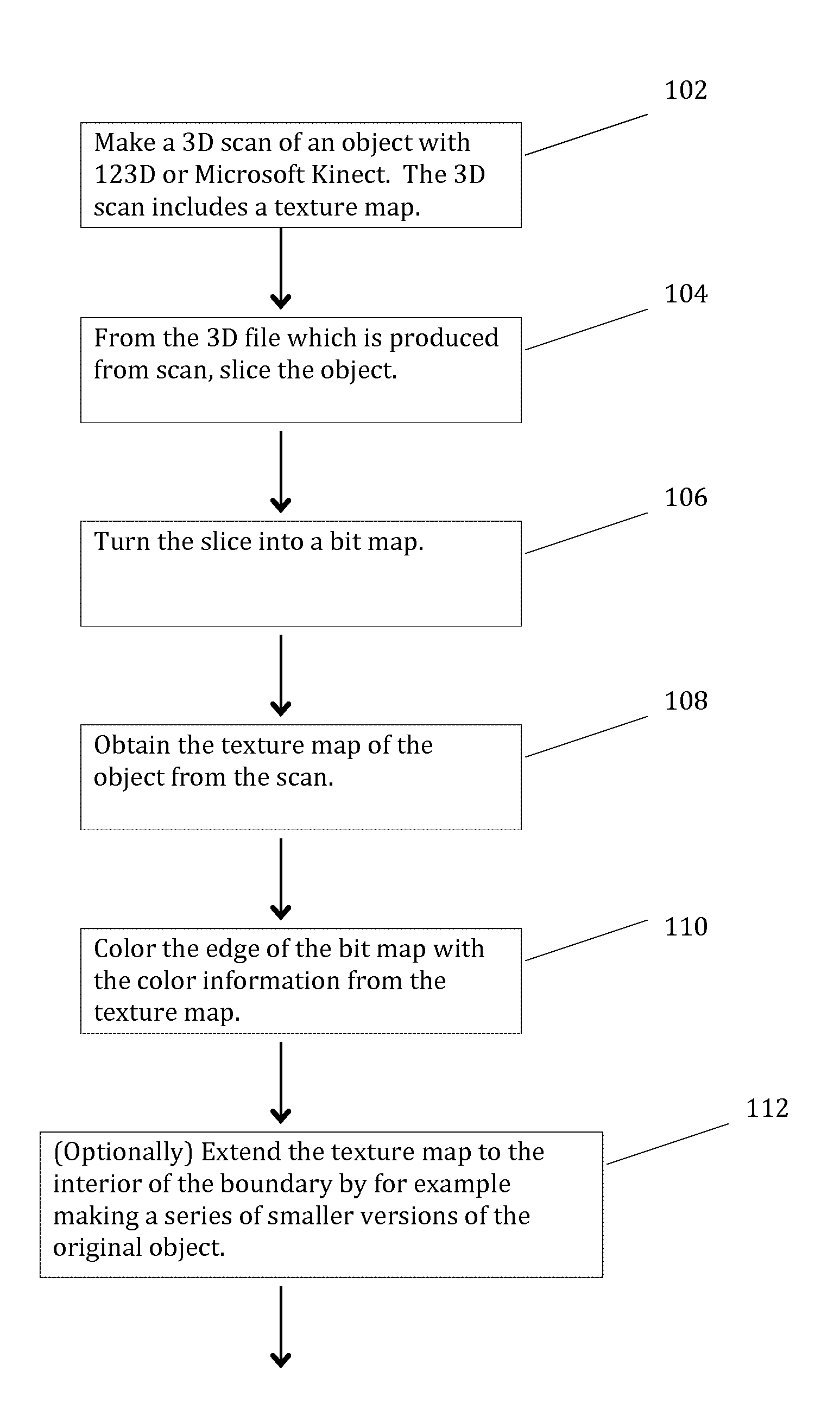

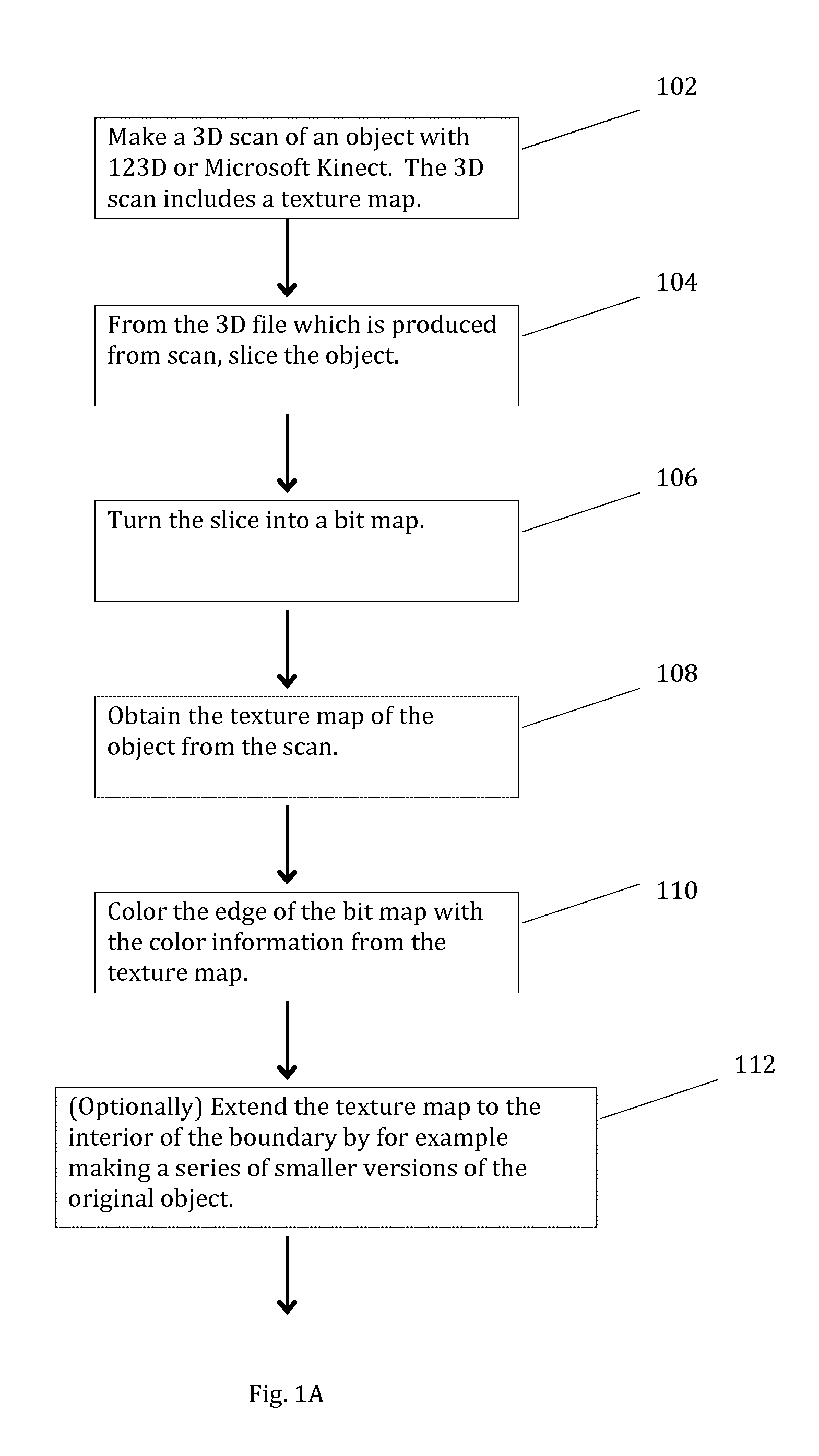

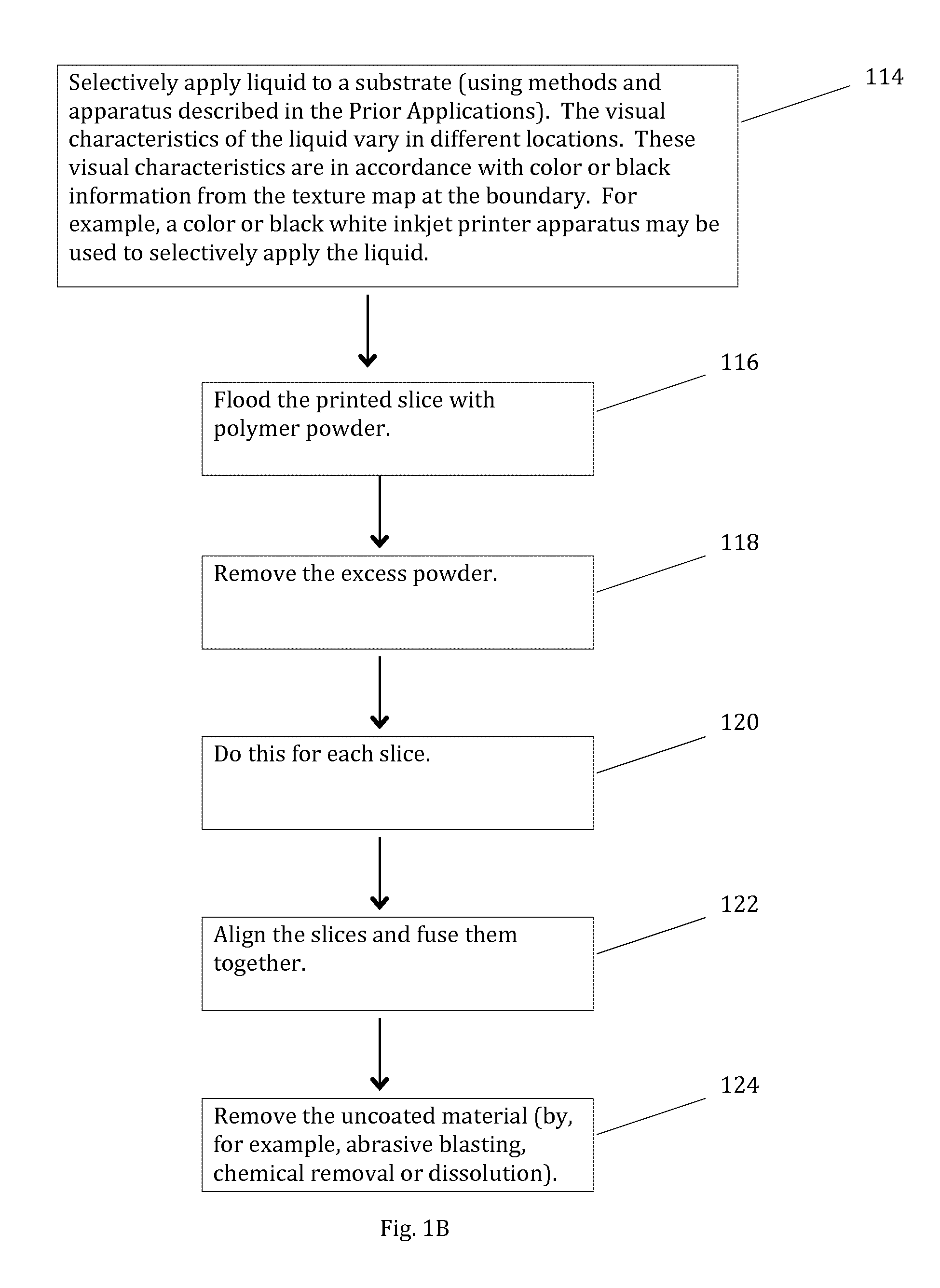

Methods for photosculpture

A 3D object (the “New Object”) is fabricated layer by layer by 3D printing. The shape and relative dimensions of the various parts of the New Object match that of another 3D object (the “Target Object”). In addition, the exterior of the New Object appears to be a photographic likeness of the Target Object. The “photographic” likeness is created by variations in visual characteristics of materials in the layers comprising the New Object, and in particular by variations at or near the surface of the New Object. Thus, the photographic likeness is an integral part of these layers comprising the New Object. An object is scanned, from which a texture map is obtained. A CAD model is sliced into slices (bit maps files) which are then colored by a program with the boundary to match the color or gray scale to color the appropriate pixels, derived from the texture map.

Owner:IMPOSSIBLE OBJECTS INC

Method of producing a software product

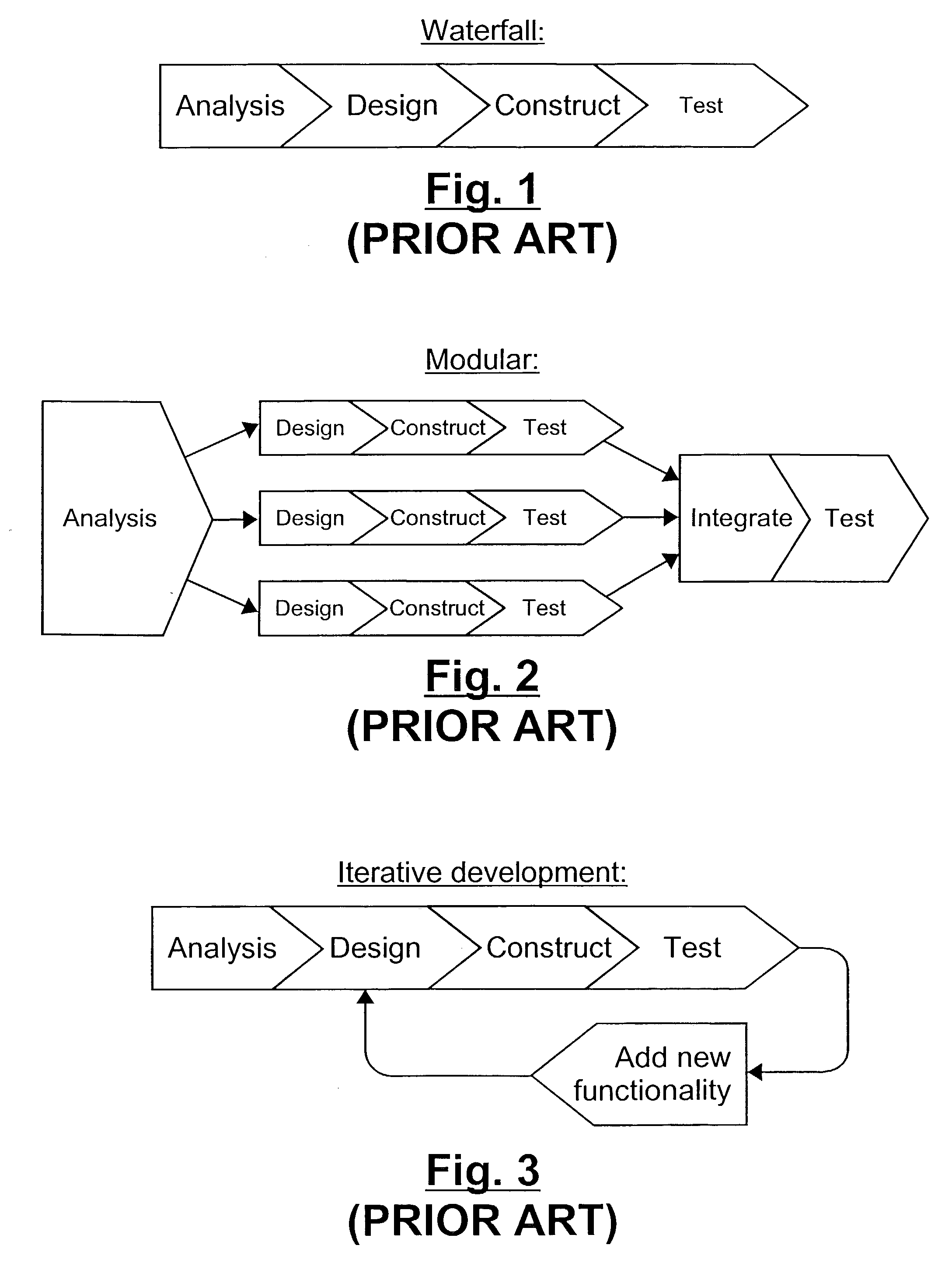

InactiveUS20040073889A1Software testing/debuggingSpecific program execution arrangementsSoftware product lineFeature model

A software product is produced by defining a functional model of the overall software product, designing, based on this functional model, a plurality n of configurations and slices of the software product, wherein a configuration is the entirety or a part of the software product forming an independently testable unit and a slice is a set of functions of the software product constructed together and forming the entirety or part of a configuration. The n slices are independently constructed wherein the first slice forms the first configuration. The seond to n-th configurations are formed by integrating the k-th configuration with the (k+1). slice, wherein k is 1, . . . , n. Subsequently a first to n-th configuration are tested independently. This software development approach allows an integration of the overall systems in parts as early as possible and to gradually increase the number of integrated components in a controlled, but manageable fashion. This allows to achieve a highly efficient use of resources within a short development time.

Owner:ACCENTURE GLOBAL SERVICES GMBH

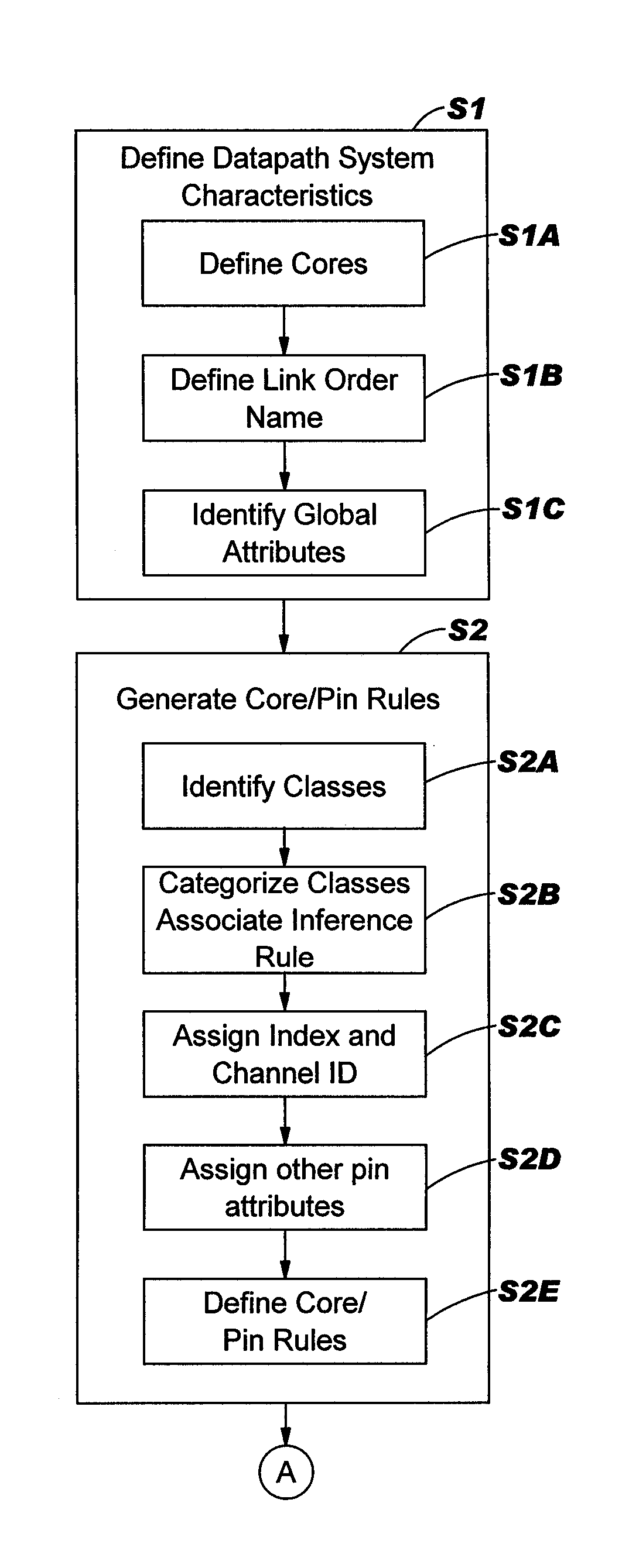

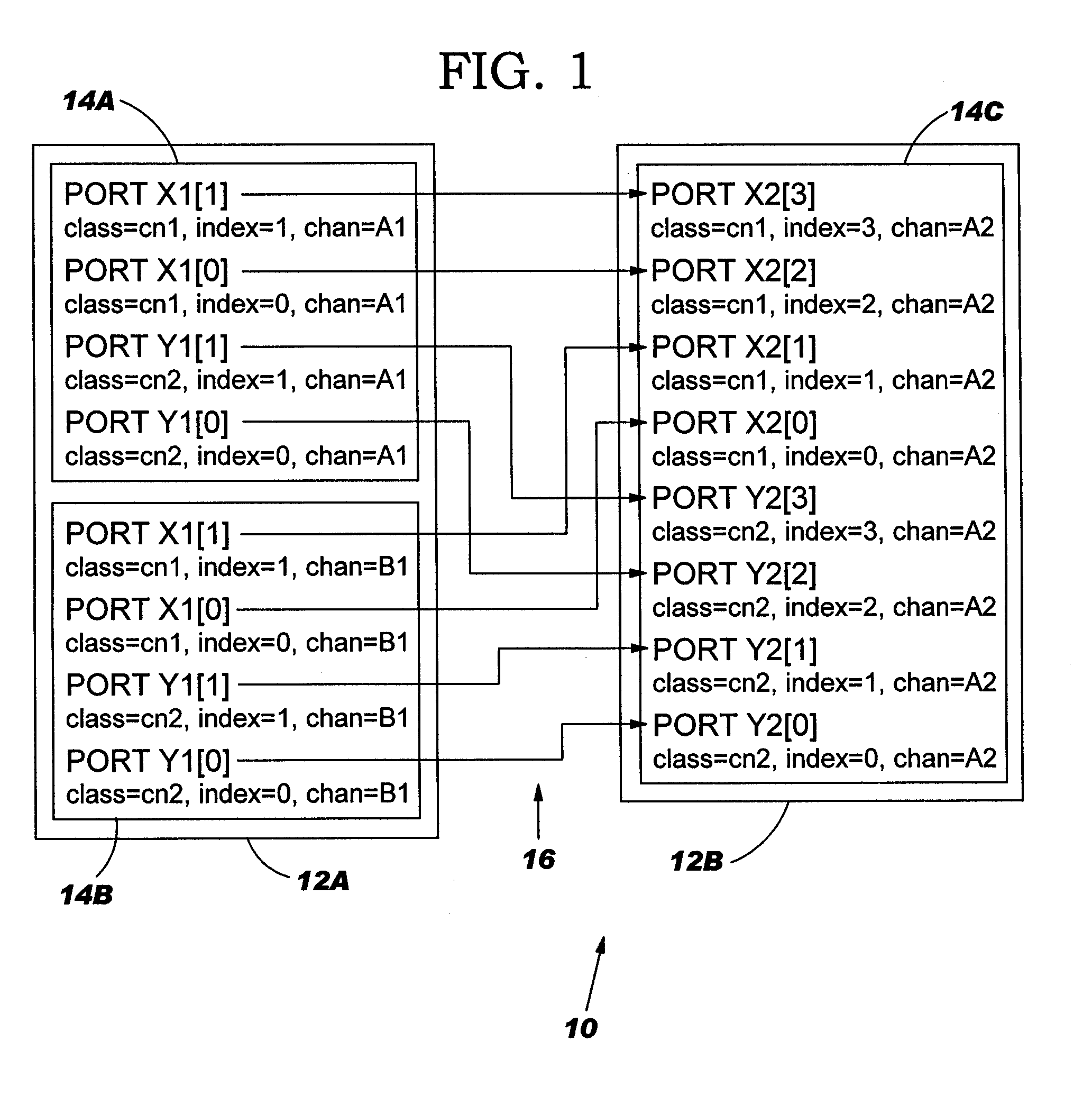

Method, system and program product for building an automated datapath system generating tool

InactiveUS7290238B2Computer aided designSpecial data processing applicationsProgramming languageBit slicing

An automated bit-sliced datapath system generating tool is built so design can be performed at a higher level, and automated generation of the synthesizable HDL representation can be accomplished are disclosed. A method defines datapath system characteristics, defines core / pin rules, and then constructs class-type inference rules that can be used for automatically generating the datapath system. An “orthogonal bundling” technique is used that groups pin by a class, and also by a channel identifier. The class-type inference rule corresponding to each class uses of the following factors to infer appropriate wiring: 1) number and type of pins in the class created by the instantiation of cores by the user; 2) attribute definitions on pins set by library core / pin rules; 3) user selection of “global attributes”; 4) user definition of channel bit order (“link orders”) to imply the order of connection between stages; and 5) user-defined attributes set on pin classes.

Owner:GOOGLE LLC

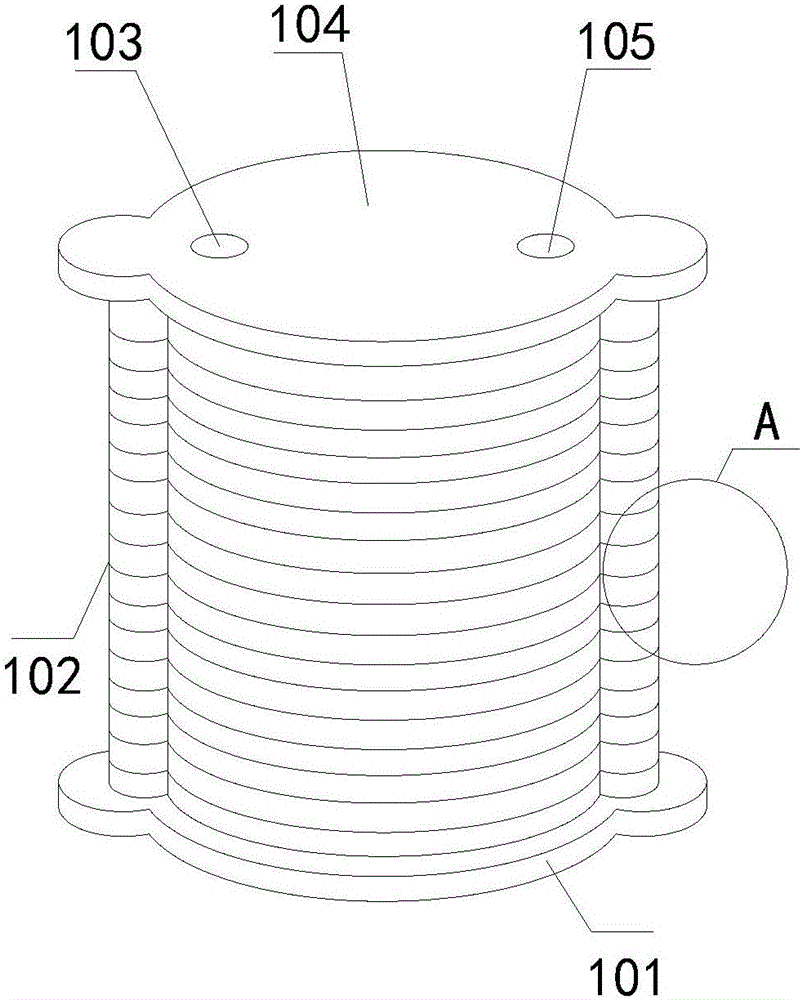

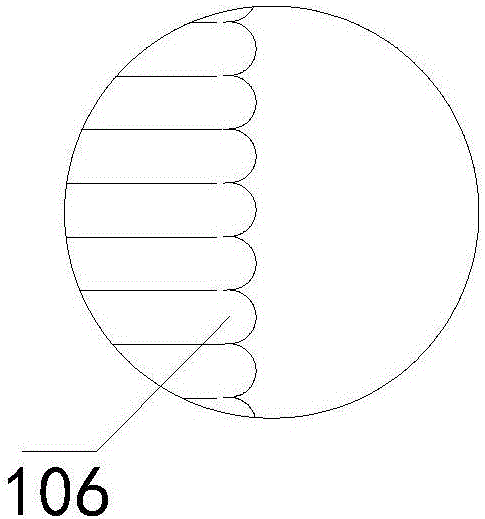

Preparation process and casting mould for cast product based on 3D printing technology

InactiveCN105666750AImprove machining accuracyIncrease productivityAdditive manufacturing apparatusMaterial consumptionProduct base

The invention provides a preparation process and a casting mould for a cast product based on the 3D printing technology, and belongs to the technical field of mould processing. The preparation process comprises the following steps: A, designing a casting mould model by utilizing a three-dimensional software, converting the casting mould model into a STL data format, leading the STL data format into a slicing software to carry out slicing processing, enabling a thickness of a laminate sheet to be 0.01-2mm, and enabling the wall thickness of the casting mould model to be greater than or equal to 0.5mm, thereby obtaining three-dimensional model data of the casting mould; B, leading the three-dimensional model data, obtained in the step A, of the casting mould into 3D printing equipment, carrying out printing and molding, thereby obtaining the casting mould; and C, injecting a fluid raw material into a mould cavity of the casting mould in the step B, thereby obtaining the cast product. The casting mould comprises mould cavity surrounding boards, and a mould cavity defined by the mould cavity surrounding boards, wherein an injection hole and an overflow hole are formed in the top of each mould cavity surrounding board. The preparation process and the casting mould has the advantages such as high processing precision, less material consumption, high production efficiency, simple manufacturing processes, low production cost and the like.

Owner:路文虎

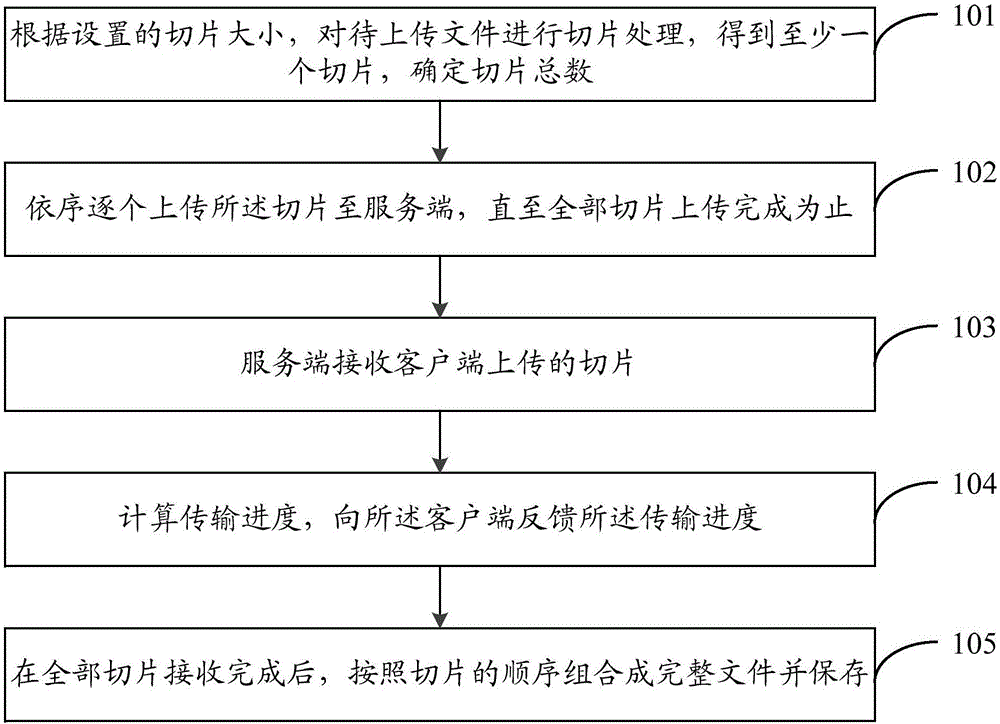

File upload method and system

InactiveCN107528926AUpload implementationAddresses susceptibility to network failuresTransmissionThe InternetData transmission

The invention discloses a file upload method and system, relates to the technology of computer internet, and solves the problems that file uploading is liable to be influenced by the network and then fails. The method comprises the steps that a file to be uploaded is sliced according to the set size of the slice so as to obtain at least one slice, and the total number of slices is determined; and the slices are successively uploaded to a server side one by one until all the slices are completely uploaded. The technical scheme is suitable for data transmission, and file uploading having the breakpoint resume effect can be realized.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Method of encoding a dataset

InactiveUS7007030B2Minimize the numberData processing applicationsDigital data processing detailsData setComputer science

A method of representing a dataset having a plurality of elements characterized by a plurality of relations, the method comprising the following steps. A first step includes, slicing at least a portion of the dataset into a plurality of slices, each of the slices comprises a portion of the plurality of elements. A second step includes, for each element of the plurality of elements, assigning a set of identifiers, each identifier of the set being characterized by a position within the set, the position representing one of the slices. A third step includes, for each element of the plurality of elements, assigning an interval, the interval representing at least one relation of the element to at least one element of the plurality of elements.

Owner:III HLDG 1

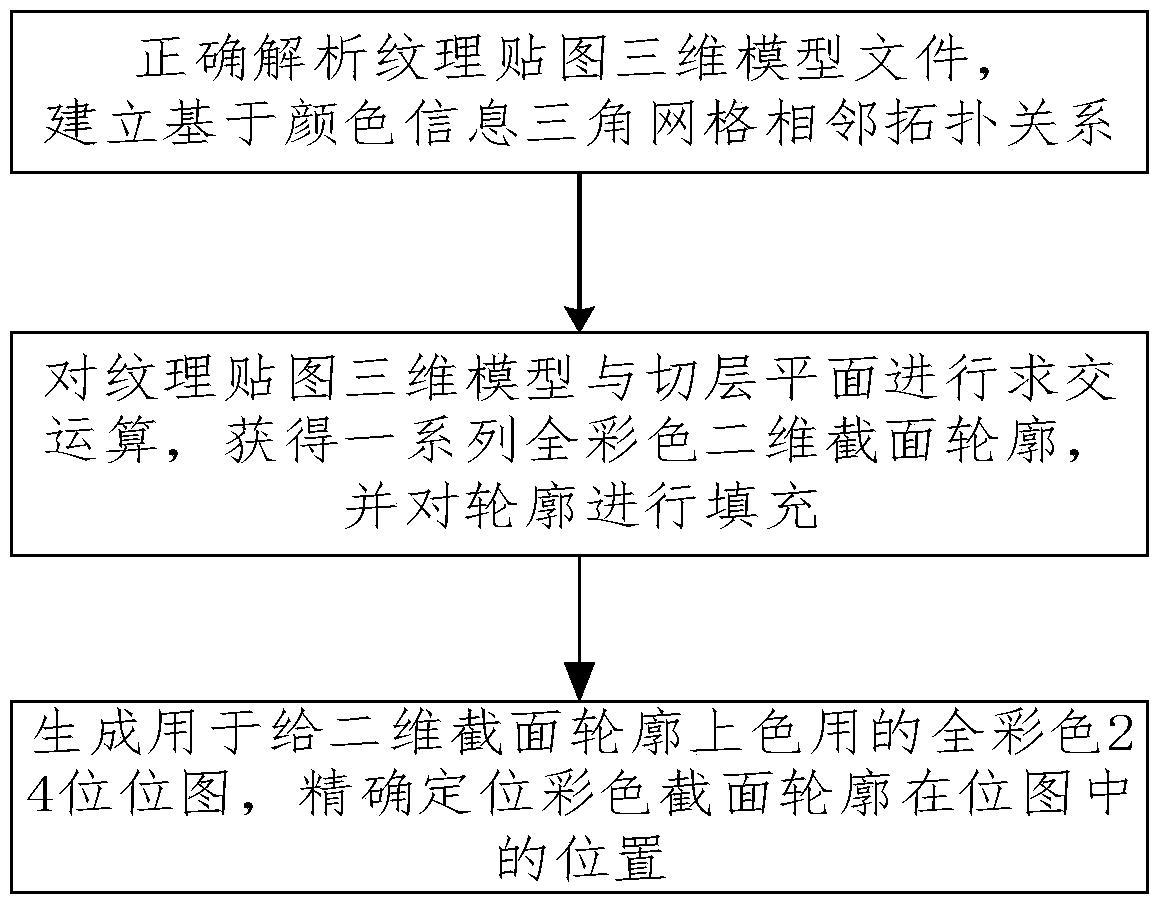

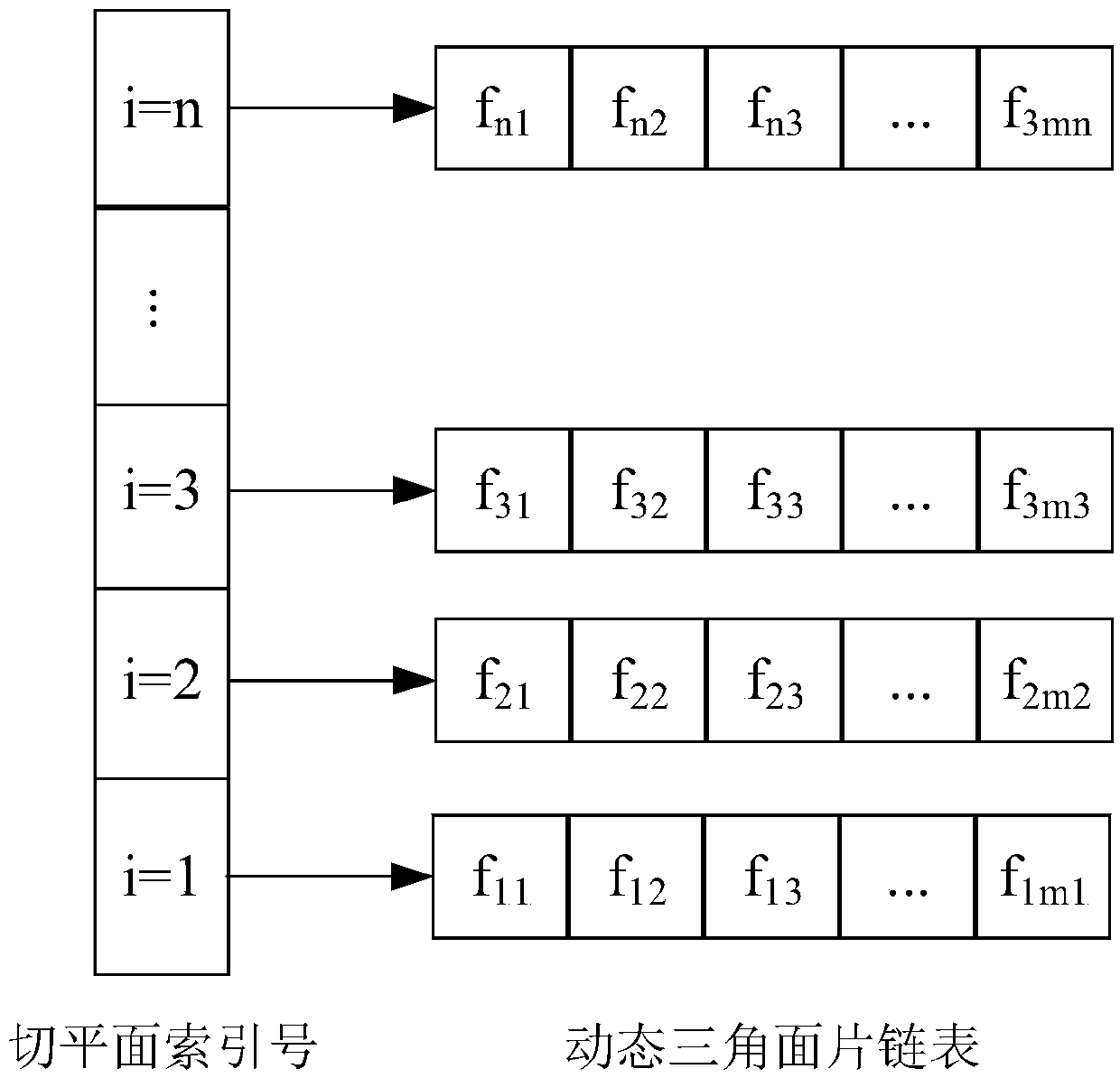

Full-color layered slicing algorithm based on three-dimensional model of texture mapping

ActiveCN110757804AOvercoming the defects of manual coloringMeet printing needsAdditive manufacturing apparatusManufacturing data aquisition/processingAlgorithmSlicing

The invention relates to a full-color layered slicing algorithm based on a three-dimensional model of texture mapping. The full-color layered slicing algorithm based on the three-dimensional model oftexture mapping includes the steps that a three-dimensional model file of texture mapping is analyzed, a triangular mesh adjacent topological relation based on color information is established, and fast query of triangular mesh adjacent information of the color information is realized; the fast intersection operation of color information triangular meshes and a tangent plane is realized, positioncoordinates and texture coordinates of all vertexes in each layer are obtained, the vertexes are connected in sequence to form a full-color two-dimensional contour, and the full-color two-dimensionalcontour is filled; and a full-color bitmap is generated, the position of the full-color contour in the bitmap is precisely located according to the position of a colourless model in a printing platform, the thickness of the contour is increased appropriately, and the function of layer-upon-layer printing and layer-upon-layer coloring is achieved. The full-color layered slicing algorithm based on the three-dimensional model of texture mapping has high slicing efficiency, the surface colors of the model are realistic, the reduction degree is high, the aftertreatment process of coloring the modelis omitted, the requirement for proficiency of operators is greatly reduced, the forming quality of parts is improved, and a real sense of color three-dimensional printing is realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

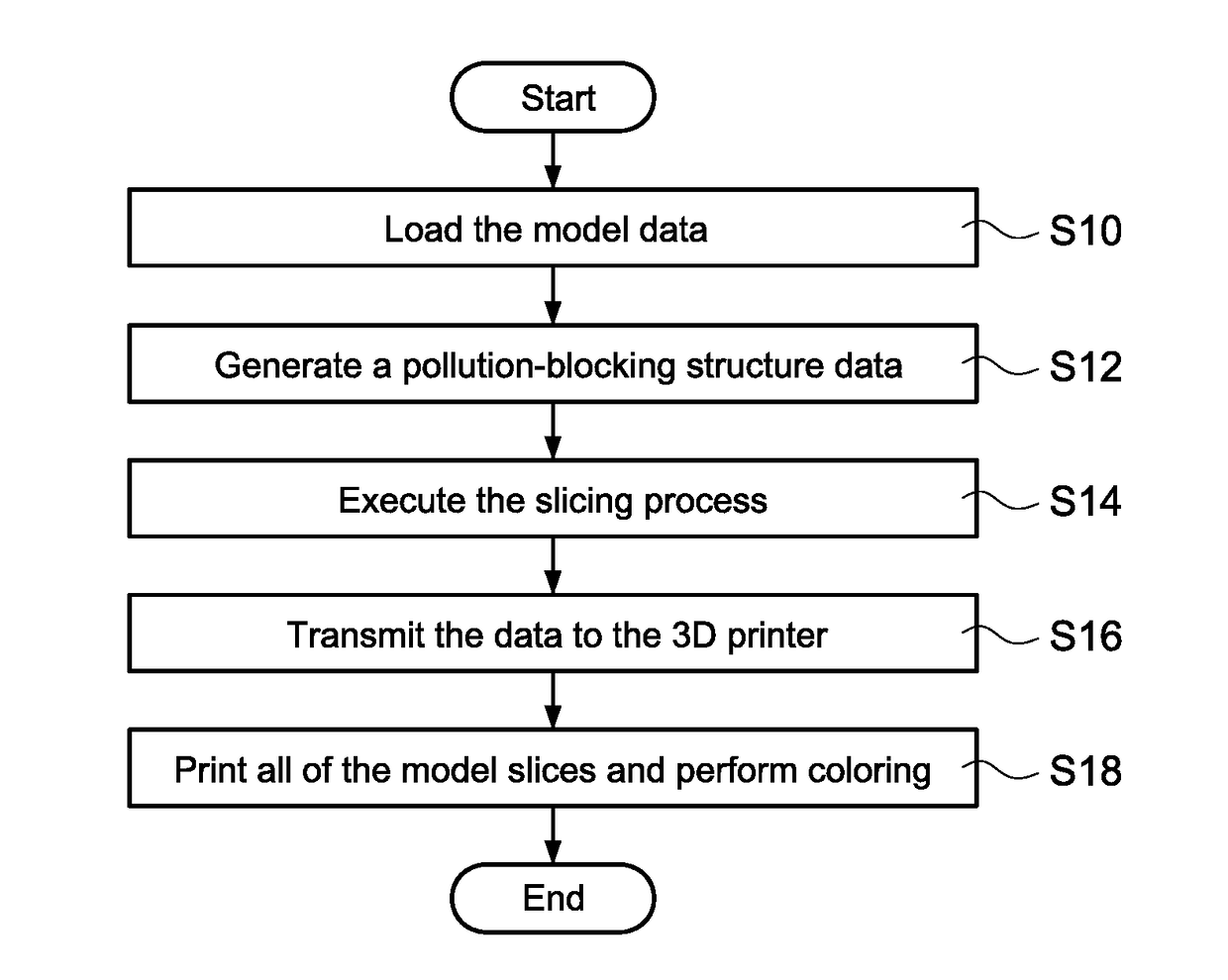

Method of slicing and printing colour 3D model

ActiveUS20180196407A1Improve printing qualityPrevent the ink from being splashedProgramme controlAdditive manufacturing apparatusComputer graphics (images)Spray nozzle

A method of slicing and printing colour 3D model is disclosed. The method includes following steps: loading a model data corresponding to a colour 3D model; adding a pollution-blocking structure next to the colour 3D model; executing a slicing process to the pollution-blocking structure and the colour 3D model for generating a plurality of pollution-blocking slices and a plurality of model slices and configuring colour each of the model slices; and, controlling a modeling nozzle (100) of a multi-colour 3D printer (1) to print the pollution-blocking slices and the model slices layer by layer and controlling a coloring nozzle (102) of the multi-colour 3D printer (1) to color each of the model slices.

Owner:XYZPRINTING +1

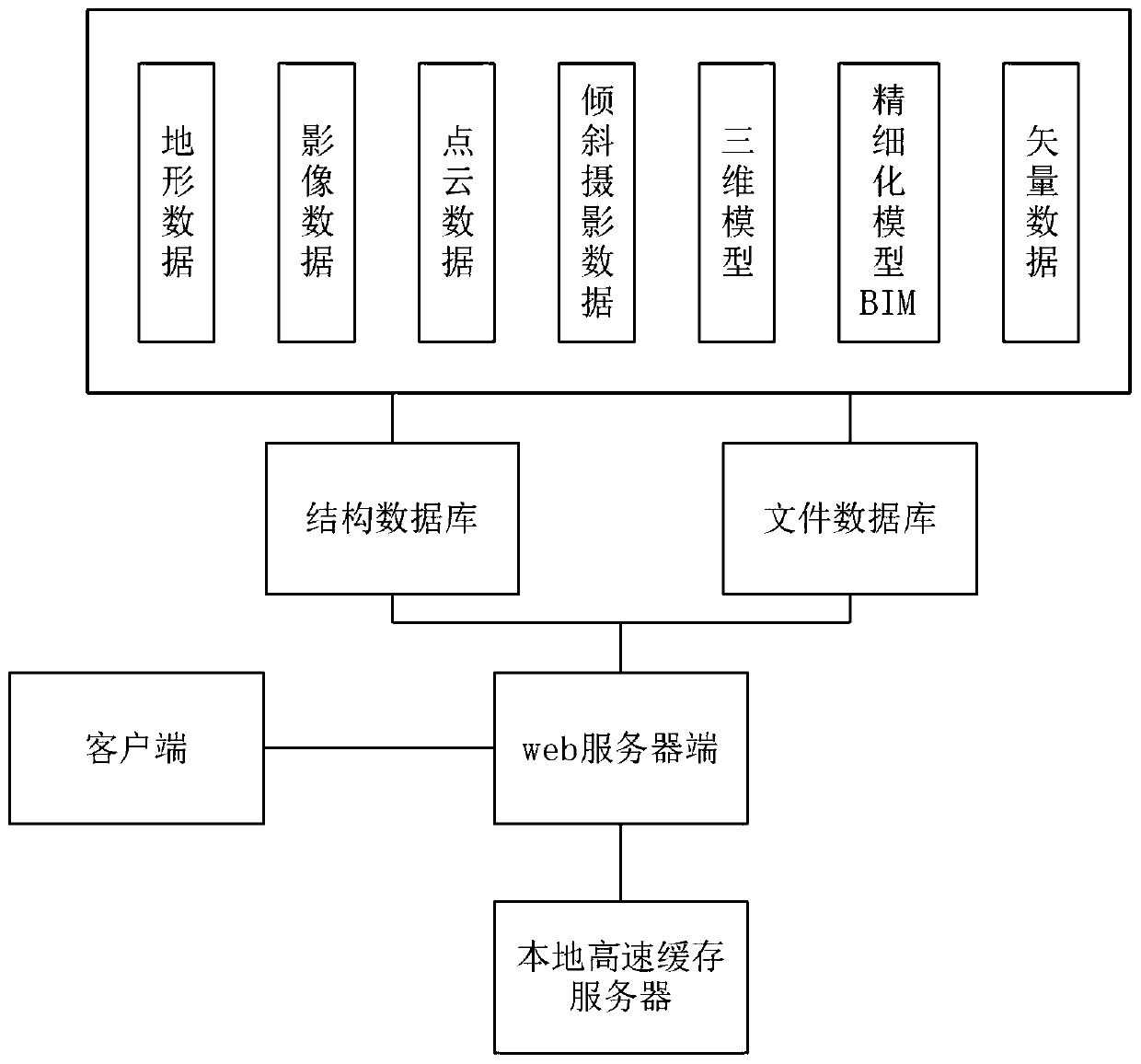

Network geographic information service system based on three-dimensional model tiles

ActiveCN111354084AImprove user experienceImprove loading speedVisual data miningStructured data browsingCache serverDatabase file

The invention discloses a network geographic information service system based on three-dimensional model tiles. The network geographic information service system comprises a client, a structure database, a file database, a web server and a local cache server. The client is connected with the web server; and the web server is connected with the structure database, the file database and the local cache server. Through the slicing technology, various visual data which needs to be displayed and comprises a three-dimensional model is segmented into tiles according to an organization structure; theaddress information is stored in a structure database; the file database is connected and combined with the local cache server during calling, so the three-dimensional model in the view range can be quickly loaded, the loading speed and efficiency of the three-dimensional model are improved, and a user group of the network geographic information service system has better user experience.

Owner:POWER CHINA KUNMING ENG CORP LTD

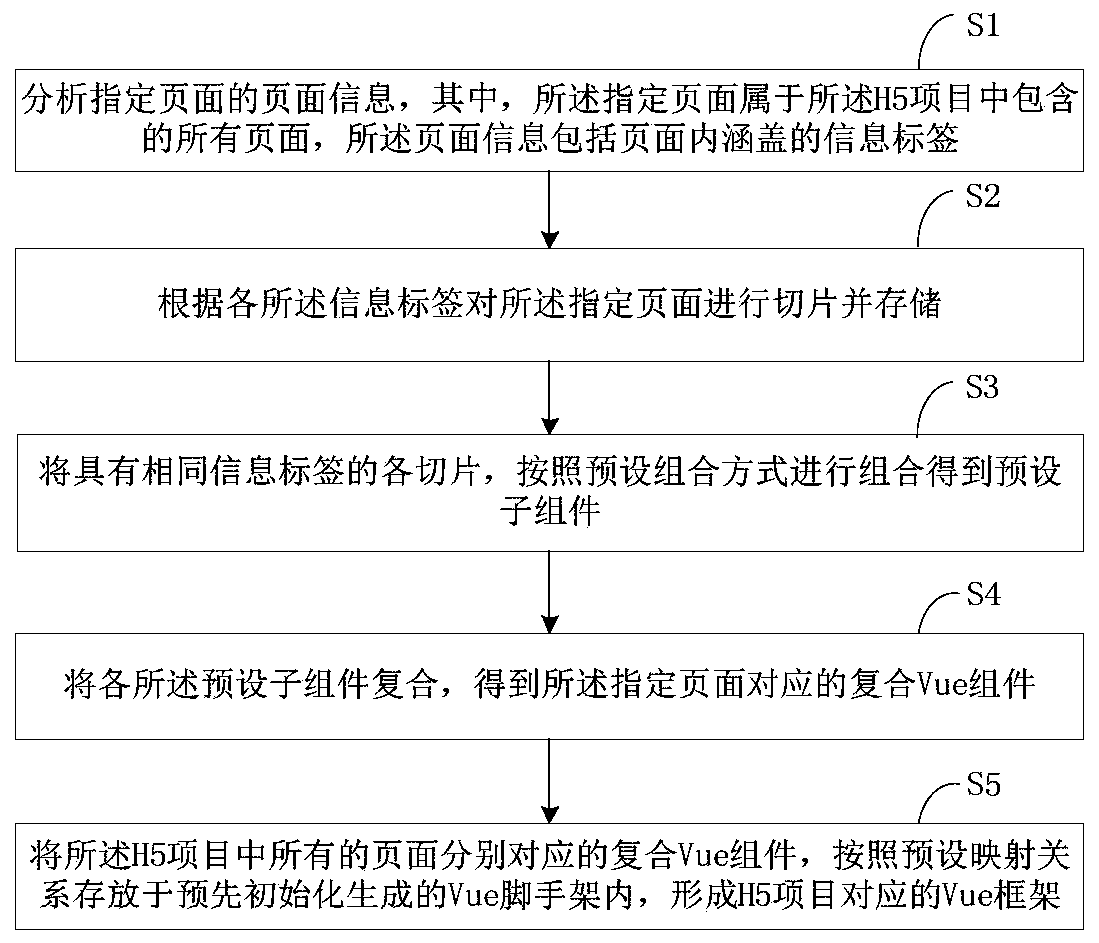

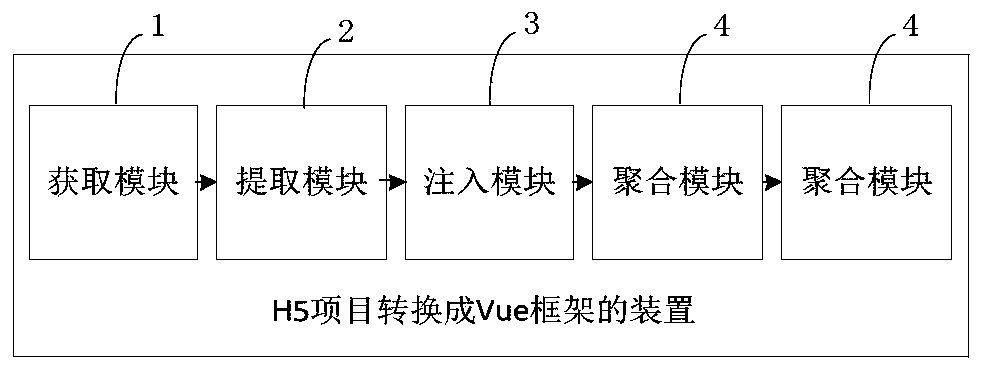

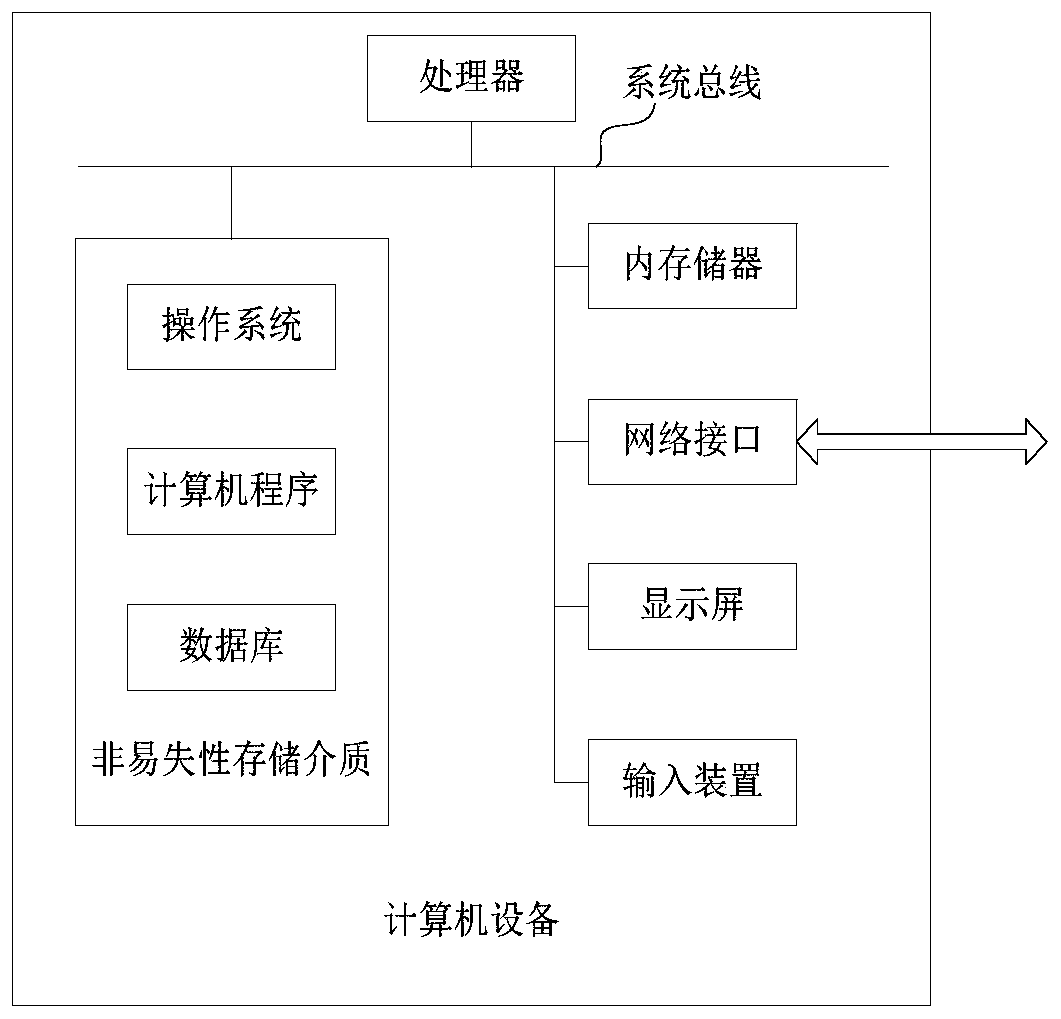

Method and device for converting H5 project into Vue framework and computer equipment

The invention discloses a method and device for converting an H5 project into a Vue framework and computer equipment. The method for converting the H5 project into the Vue framework comprises the steps: analyzing page information of a specified page, wherein the specified page belongs to all pages contained in the H5 project, and the page information comprises information labels contained in the page; slicing and storing the specified page according to each information label; combining the slices with the same information label according to a preset combination mode to obtain a preset sub-assembly; compositing the preset sub-assemblies to obtain a composite Vue assembly corresponding to the specified page; and storing the composite Vue components corresponding to all the pages in the H5 project in a Vue scaffold generated by pre-initialization according to a preset mapping relationship to form a Vue framework corresponding to the H5 project. The method rapidly converts a traditional front-end H5 project into a Vue project, and can reduce the time and labor cost consumed by conversion operation.

Owner:爱云保(上海)科技有限公司

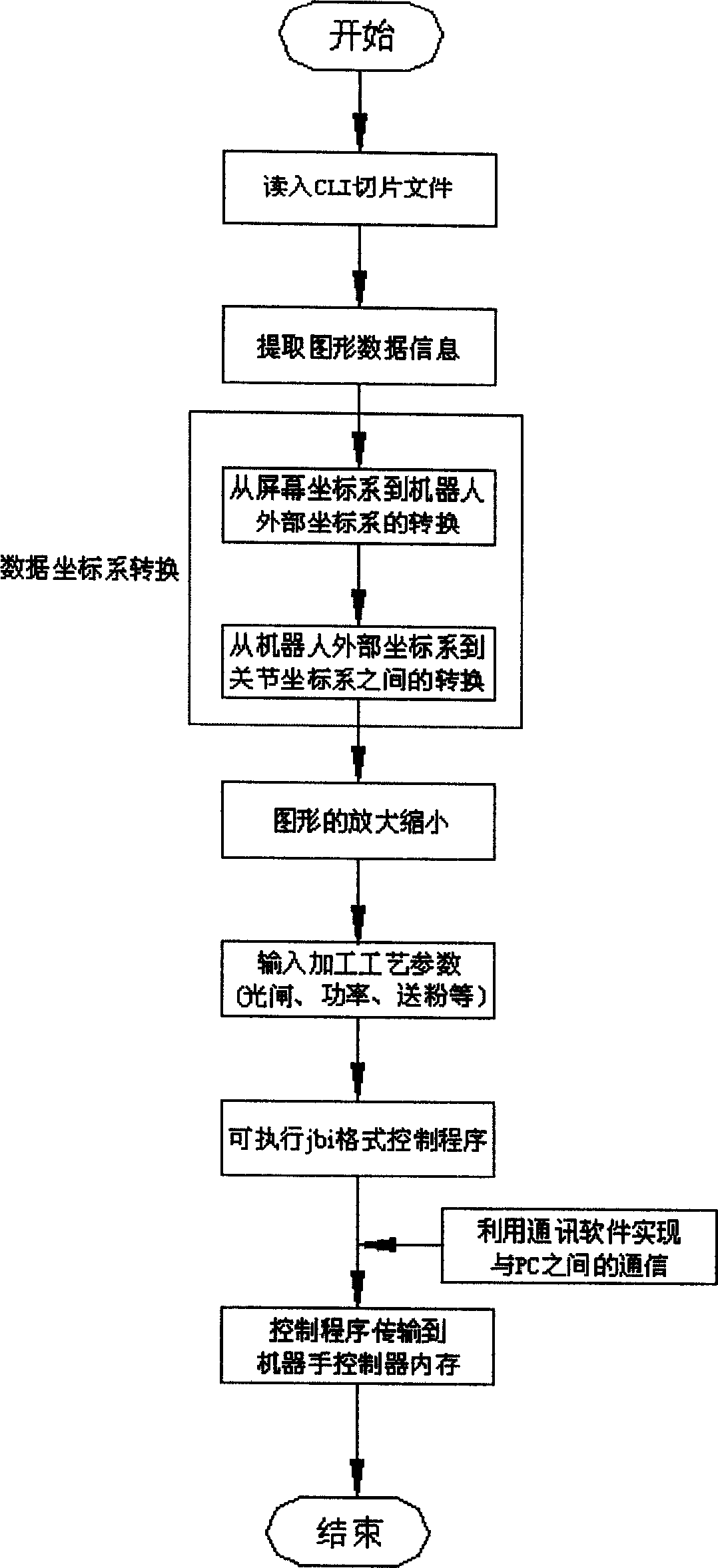

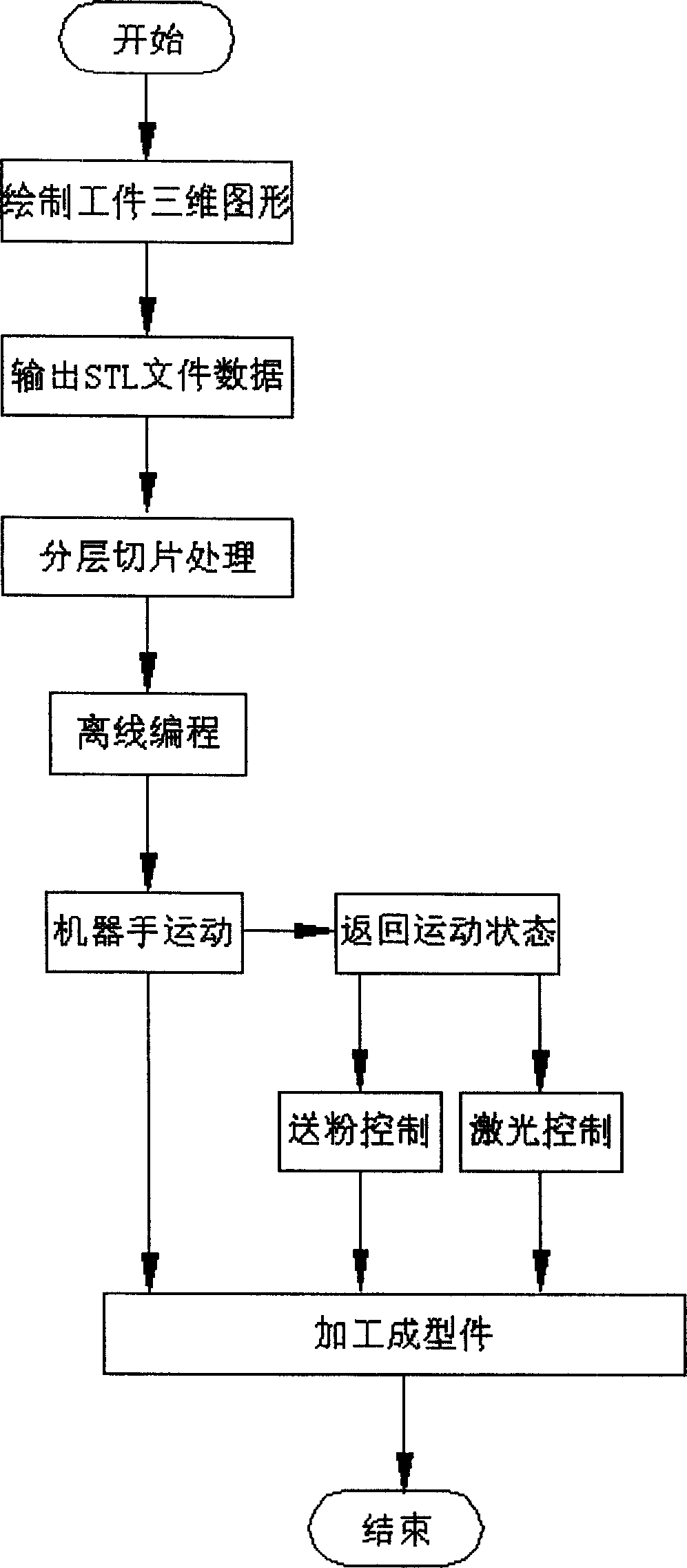

Laser quick forming system and forming method with six shaft machine hand for powder material

The present invention is used to produce workpiece directly based on the 3D model in computer. The system includes computer with fast 3D CAD software, slicing processing software and off-line programming software, computer controlled laser and powder feeder, demonstrating box, six-axis machine hand, machine hand controller and forming worktable. Through off-line programming, the CAD model data in the computer are converted into motion program with forming technological parameters for the machine hand to execute and the six-axis machine hand holding the laser head and powder feeding nozzle is controlled to move on the worktable to realize the fast laser forming of the workpiece with the powder material. By means of the forming system and method of the present invention, it is possible to form various complicated large or small workpiece in high precision effectively.

Owner:BEIJING UNIV OF TECH

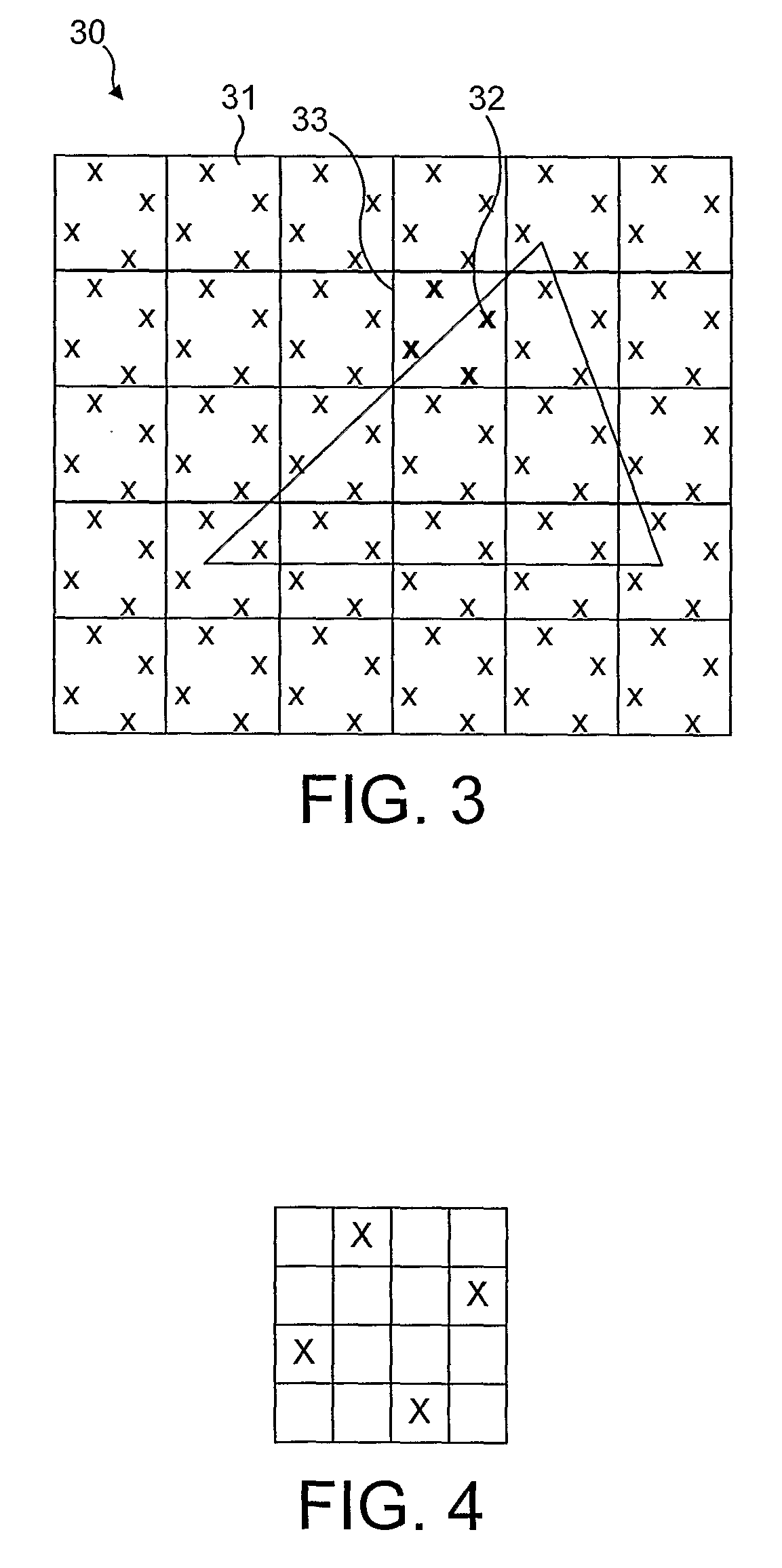

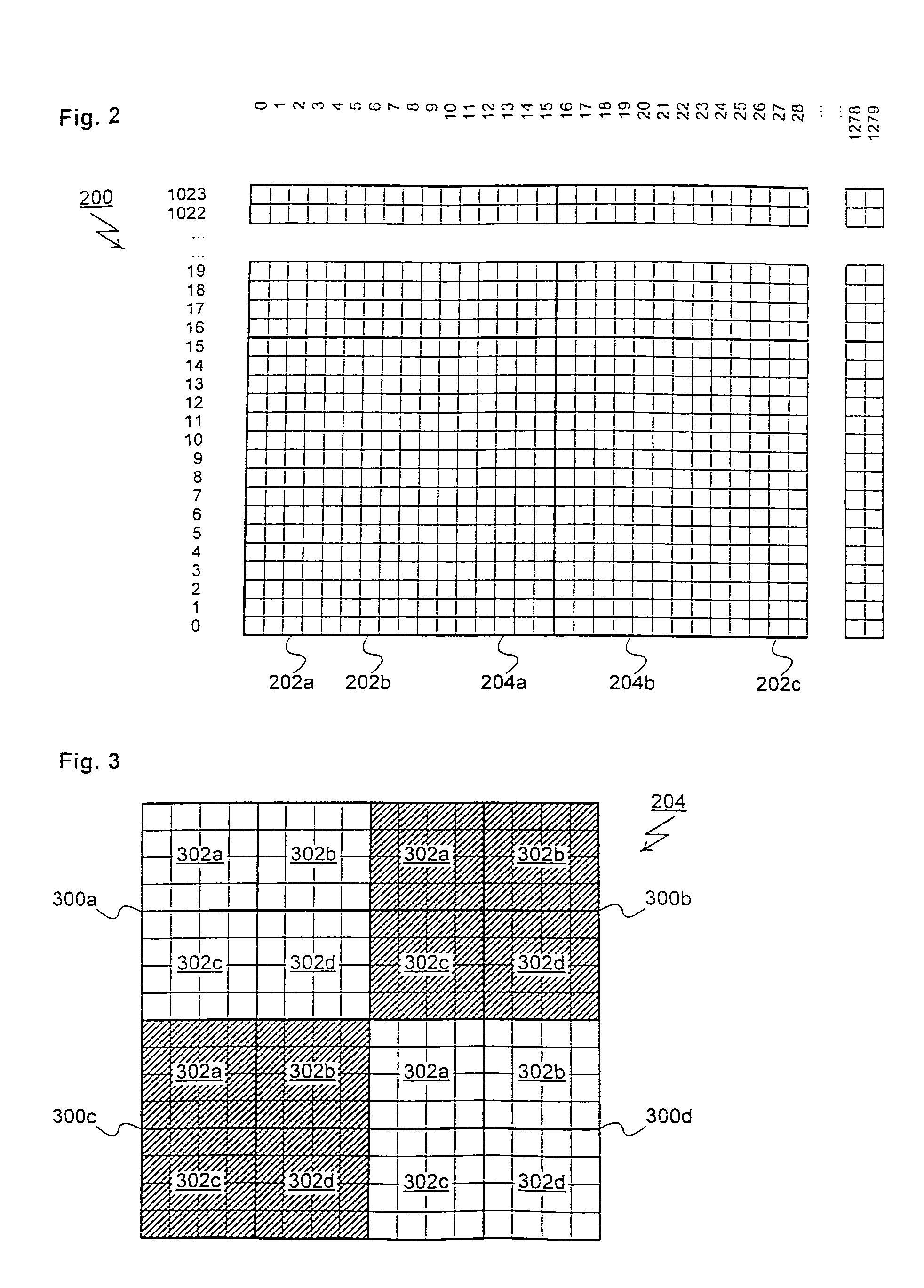

Method and apparatus for rasterizing in a hierarchical tile order

InactiveUS6972768B2Efficiently rasterizedImprove localityDrawing from basic elementsCathode-ray tube indicatorsGraphicsParallel computing

A method and apparatus for efficiently rasterizing graphics is provided. The method is intended to be used in combination with a frame buffer that provides fast tile-based addressing. Within this environment, frame buffer memory locations are organized into a tile hierarchy. For this hierarchy, smaller low-level tiles combine to form larger mid-level tiles. Mid-level tiles combine to form high-level tiles. The tile hierarchy may be expanded to include more levels, or collapsed to included fewer levels. A graphics primitive is rasterized by selecting an starting vertex. The low-level tile that includes the starting vertex is then rasterized. The remaining low-level tiles that are included in the same mid-level tile as the starting vertex are then rasterized. Rasterization continues with the mid-level tiles that are included in the same high-level tile as the starting vertex. These mid-level tiles are rasterized by rasterizing their component low-level tiles. The rasterization process proceeds bottom-up completing at each lower level before completing at higher levels. In this way, the present invention provides a method for rasterizing graphics primitives that accesses memory tiles in an orderly fashion. This reduces page misses within the frame buffer and enhances graphics performance.

Owner:MICROSOFT TECH LICENSING LLC

Manufacturing method of casting mold

InactiveCN111070661AExtended service lifeHigh surface hardnessAdditive manufacturing apparatusFoundry moulding apparatus3d printComputer printing

The invention discloses a manufacturing method of a casting mold. The manufacturing method comprises the steps of 1, designing a casting mold by using three-dimensional mechanical design software; 2,evaluating the size and the shape of the casting mold, and if necessary, carrying out segmentation design; 3, generating a model file which can be accepted by 3D printing slicing software, 4, carryingout slicing processing on the model file by using the 3D printing slicing software, and generating a printing file; 5, printing the casting mold or partitioning by using a 3D printer; 6, if the moldis segmented, assembling each printed block or base plate; and 7, carrying out surface treatment on the casting mold, removing surface defects, conducting gap and pit filling and smooth polishing so as to complete the manufacturing. By means of the casting mold manufactured according to the method, the manufacturing process can be remarkably simplified, the cost is very low, a mold with the relatively complex appearance can be easily manufactured, and the method can become a brand-new choice in mechanical casting mold manufacturing.

Owner:卢建义

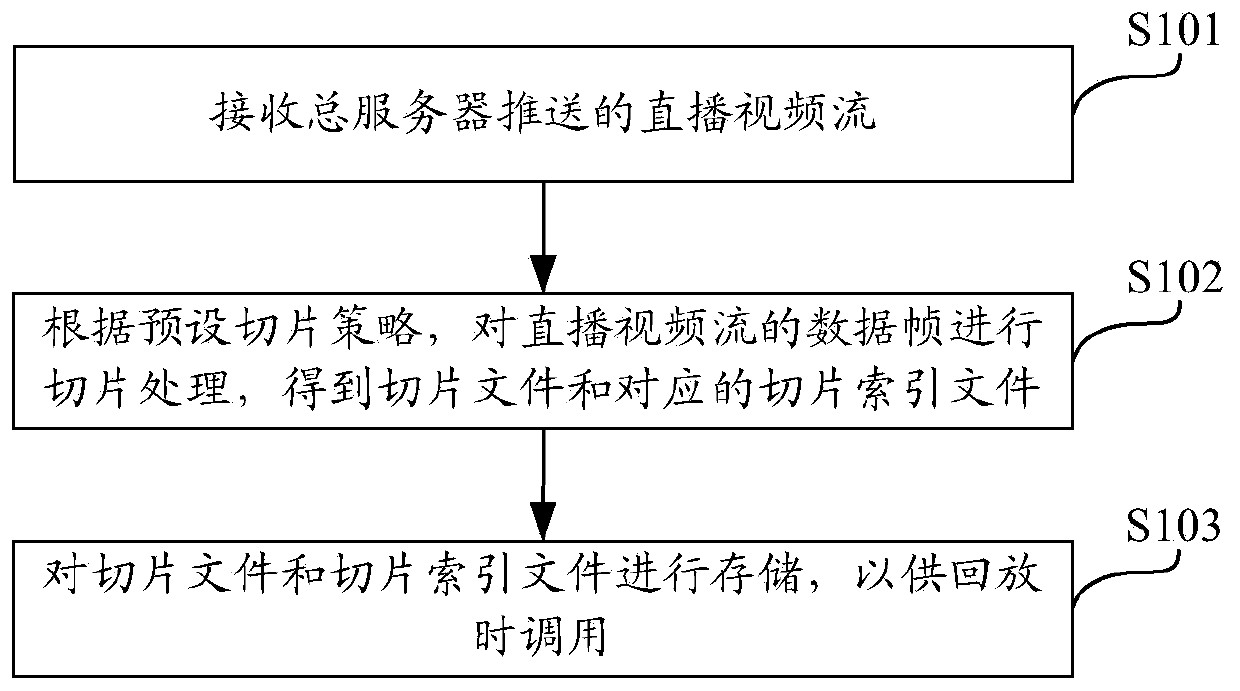

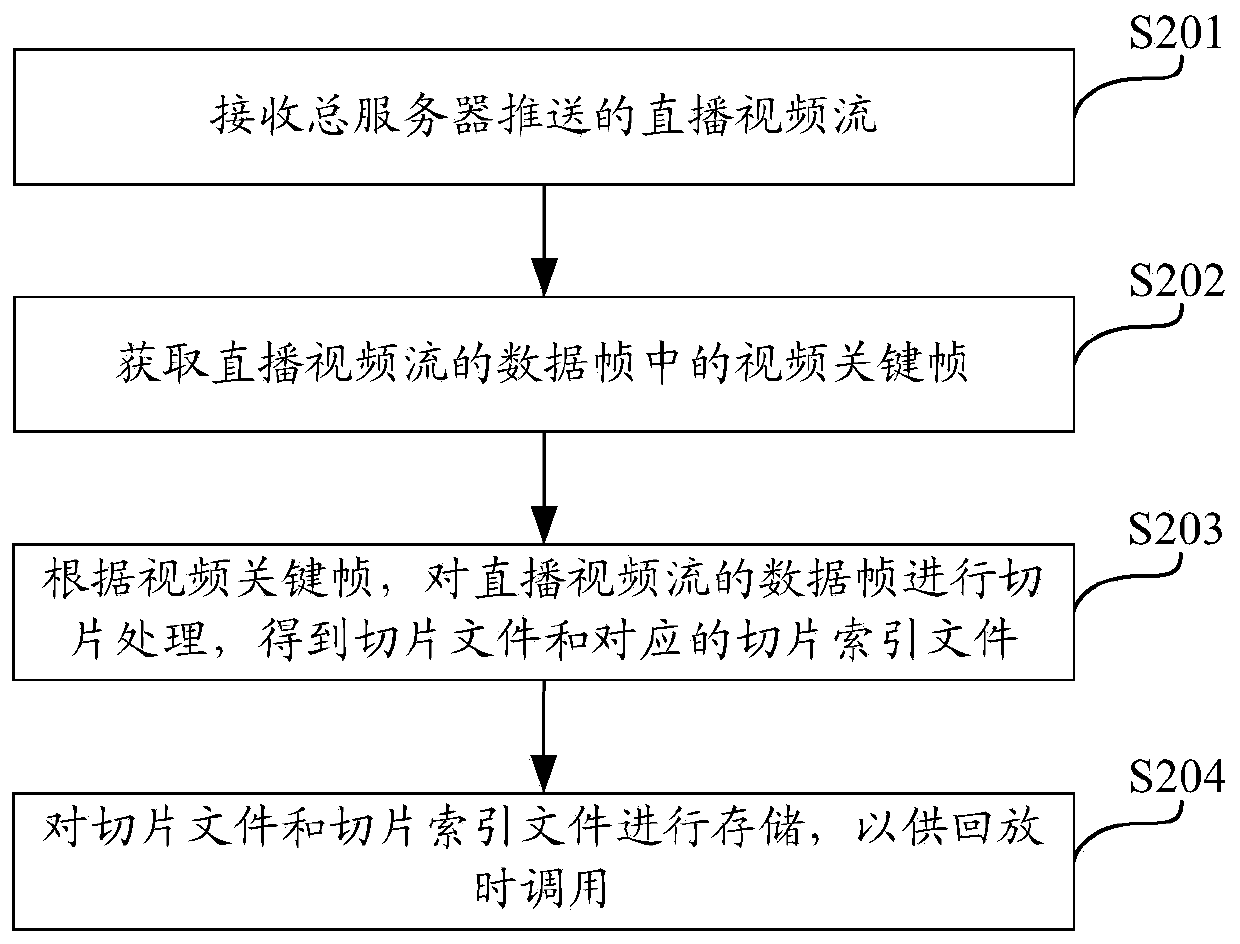

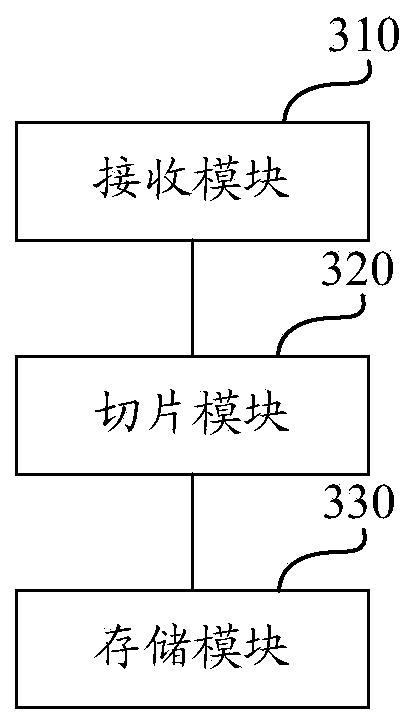

Live video stream playback processing method and device, and computing equipment

PendingCN111447455AShorten the timeImplement real-time playback processingSelective content distributionComputer hardwareSlicing

The invention discloses a live video stream playback processing method and device, computing equipment and a computer storage medium, and the method comprises the steps: receiving a live video streampushed by a main server; slicing the data frame of the live video stream according to a preset slicing strategy to obtain a slicing file and a corresponding slicing index file; and storing the slice file and the slice index file for calling during playback. According to the technical scheme provided by the invention, the time consumed for obtaining the live video stream is effectively reduced, thereal-time playback processing of the live video stream is realized, the playback delay problem is solved, and the user playing experience is improved.

Owner:BEIJING QIHOO TECH CO LTD

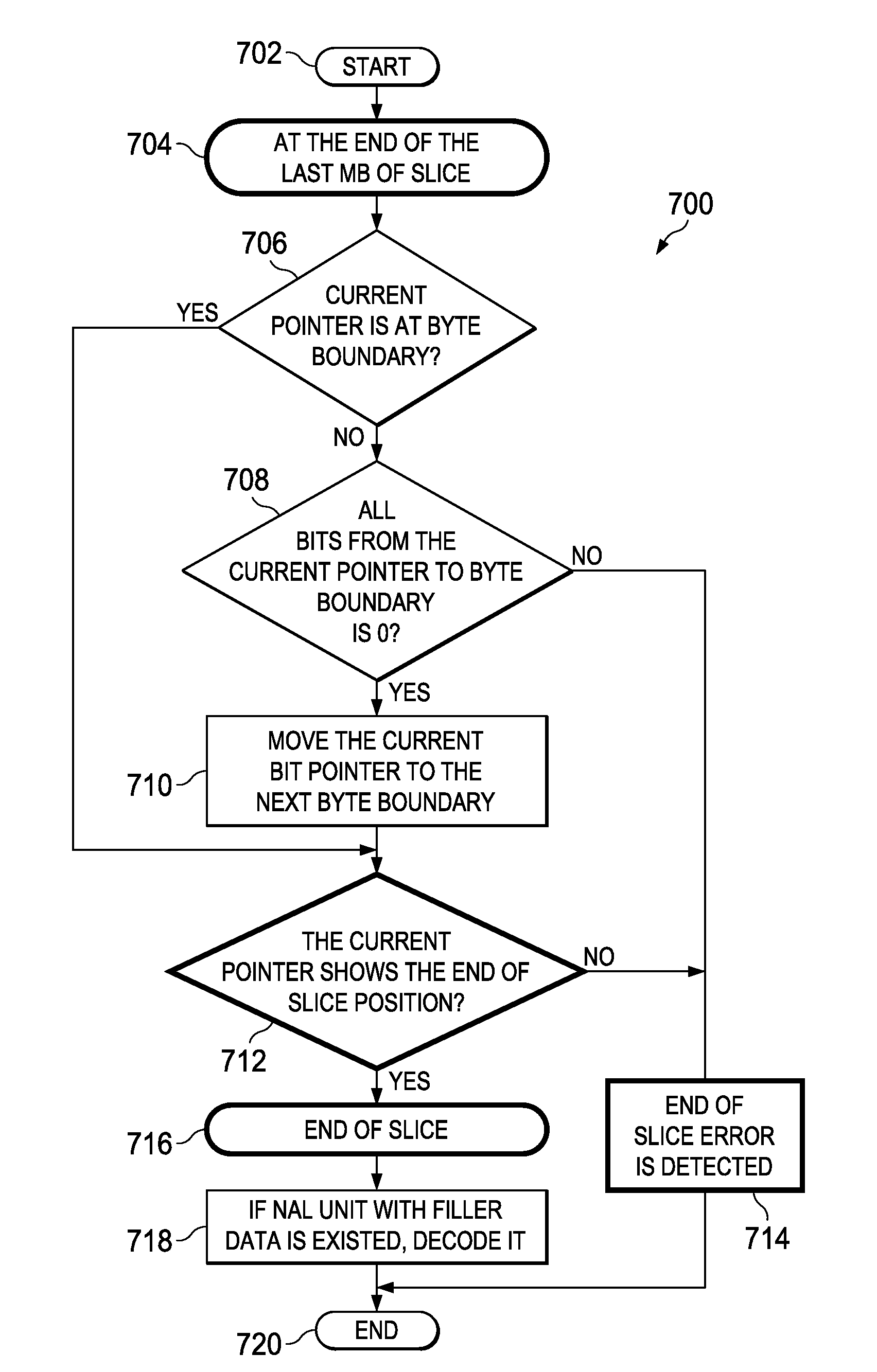

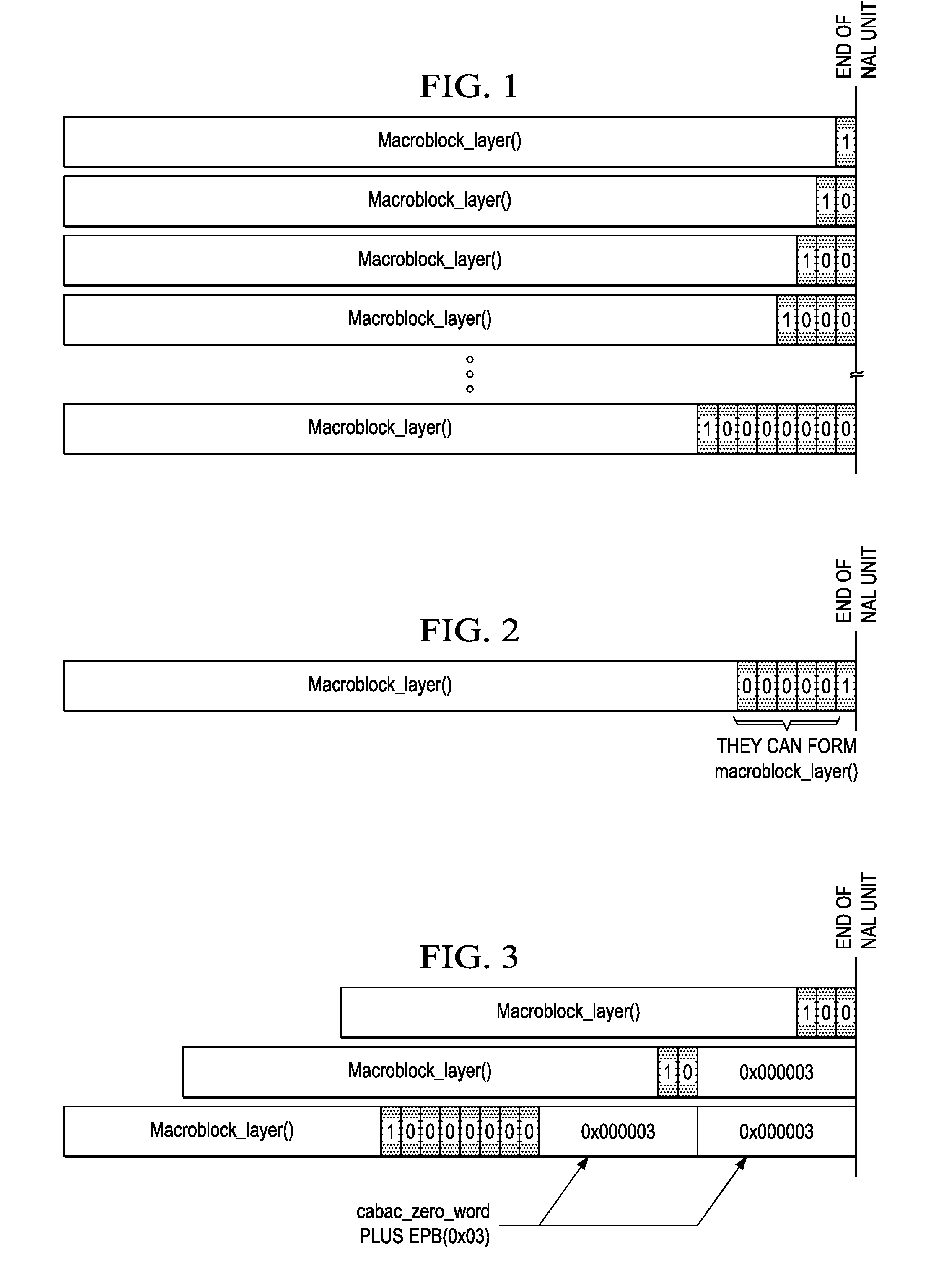

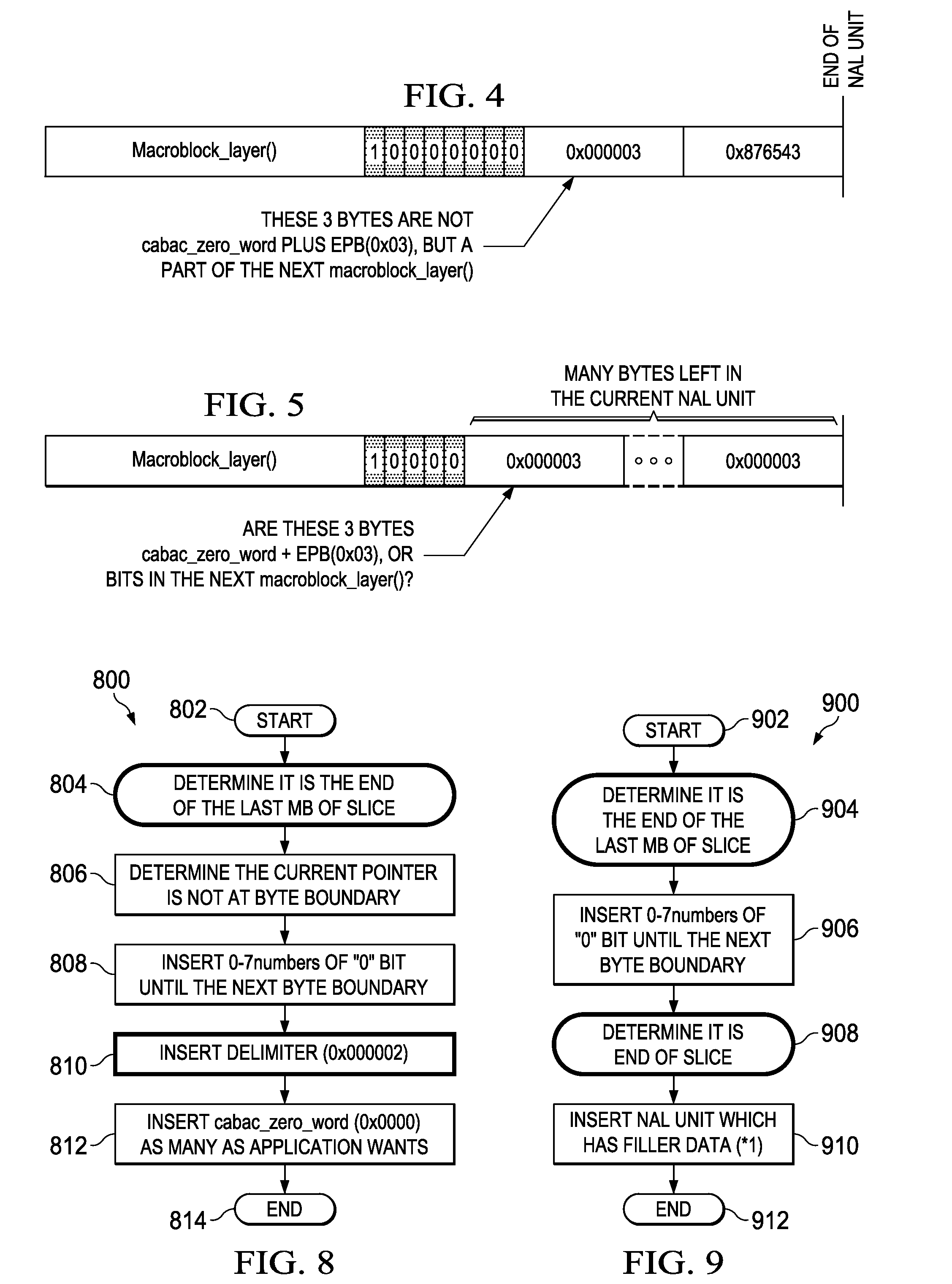

Method and apparatus for error detection in cabac

ActiveUS20120177131A1Color television with pulse code modulationColor television with bandwidth reductionComputer engineeringMacroblock

A method and apparatus for error detection. The method includes decoding slice header when a unit is a NAL unit, decoding a macroblock unit and detecting an end of slice flag setting indicating end of slice, decoding RBSP trailing bits and determining if it is really end of slice; and determining an error occurred when it is not end of slice.

Owner:TEXAS INSTR INC

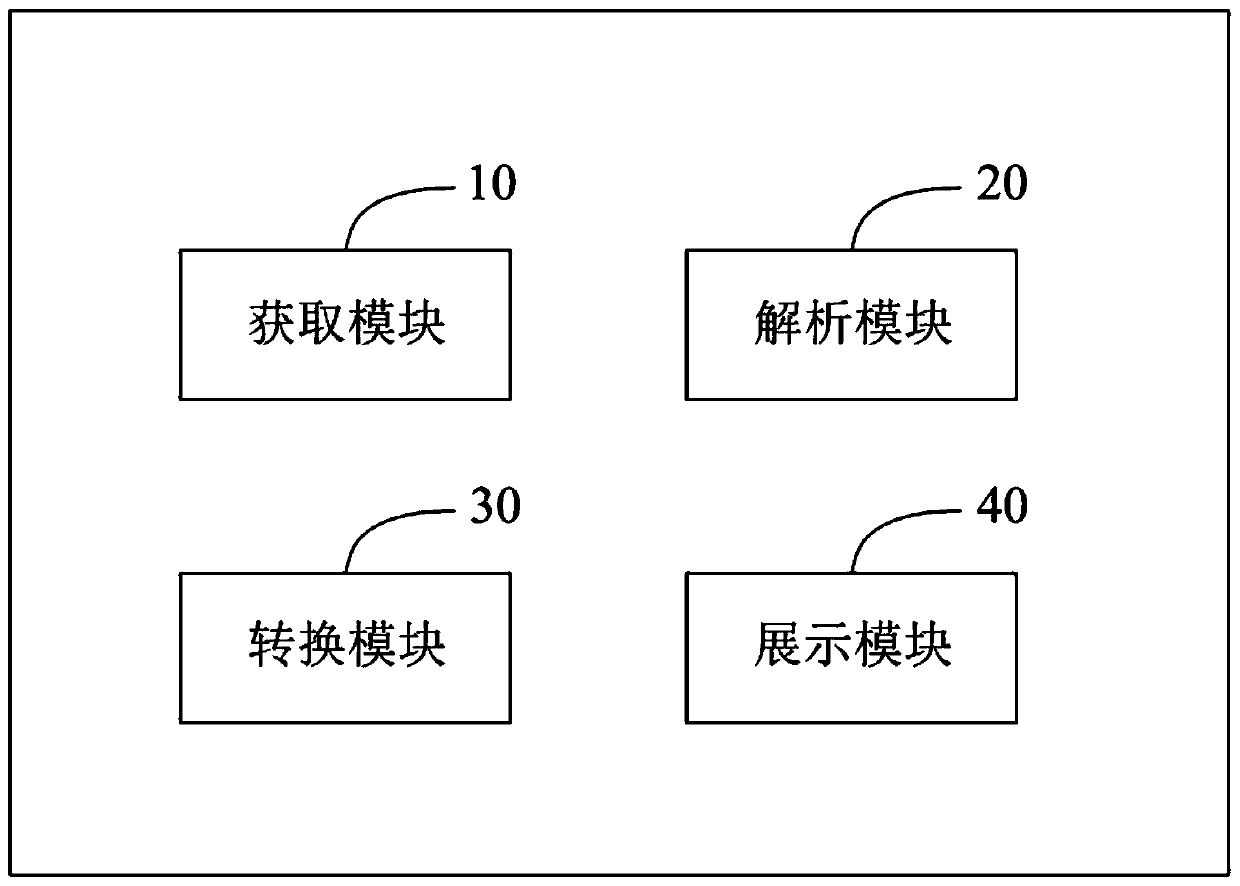

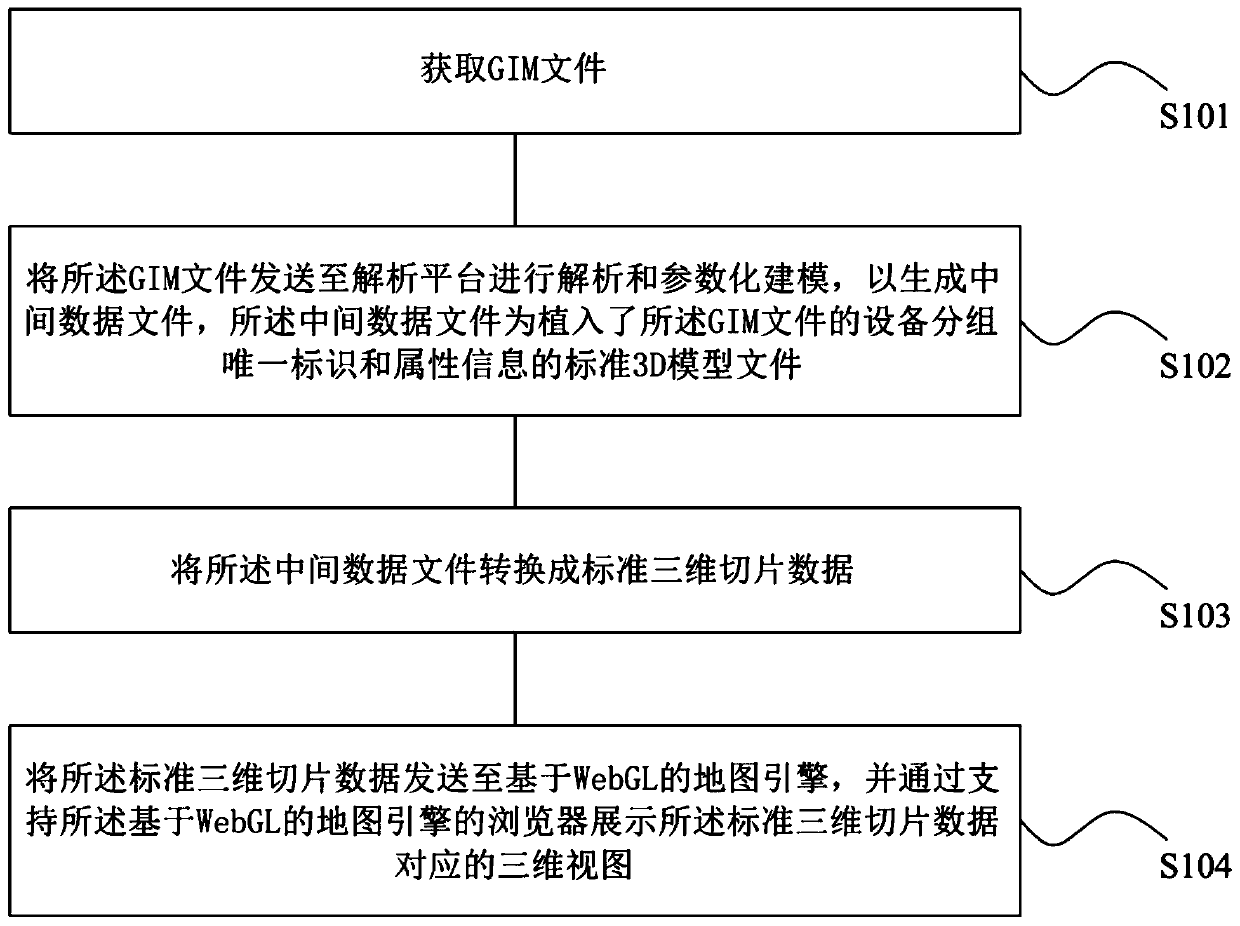

GIM file visualization processing method and system, readable storage medium and computer

ActiveCN111161406AConvenient 3D model preview requirementsGeometric CADSpecial data processing applicationsModelSimSoftware engineering

The invention discloses a GIM file visualization processing method and system, a readable storage medium and a computer. The method comprises the steps of obtaining a GIM file; sending the GIM file toan analysis platform for analysis and parametric modeling to generate an intermediate data file, the intermediate data file being a standard 3D model file implanted with a unique identifier and attribute information of a device group of the GIM file; converting the intermediate data file into standard three-dimensional slice data; and sending the standard three-dimensional slice data to a WebGL-based map engine, and displaying a three-dimensional view corresponding to the standard three-dimensional slice data through a browser supporting the WebGL-based map engine. Through the three-dimensional model preview method and device, a user only needs to upload the GIM file to the server without installing specific three-dimensional design software, three-dimensional model preview of the GIM file can be achieved through the browser, the requirement of the user for three-dimensional model preview of the GIM file is greatly met, and application and popularization of the GIM technology in the power grid industry are facilitated.

Owner:江西博微新技术有限公司

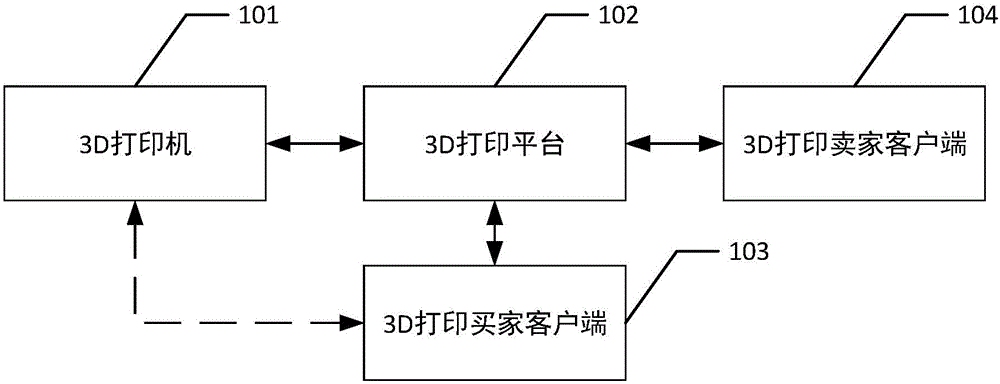

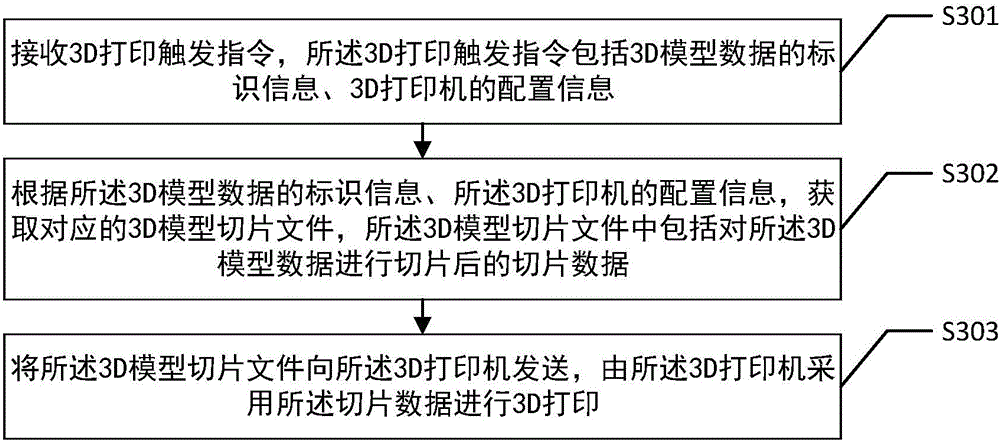

3D printing method and 3D printing device

InactiveCN106113494AImprove conveniencePromote popularizationAdditive manufacturing apparatusComputer graphics (images)3D printing

The invention discloses a 3D printing method and device. The method comprises the following steps that a 3D model slicing file sent by a 3D printing platform is received and comprises slicing data obtained after slicing of 3D model data; the 3D model slicing file is analyzed, and the slicing data are obtained; the slicing data obtained after analyzing are adopted to be subject to 3D printing. According to the scheme in the embodiment, convenience of 3D printing by a user is improved, and application, popularization and the development of the 3D printing technology are facilitated.

Owner:广州紫苑智能科技有限公司

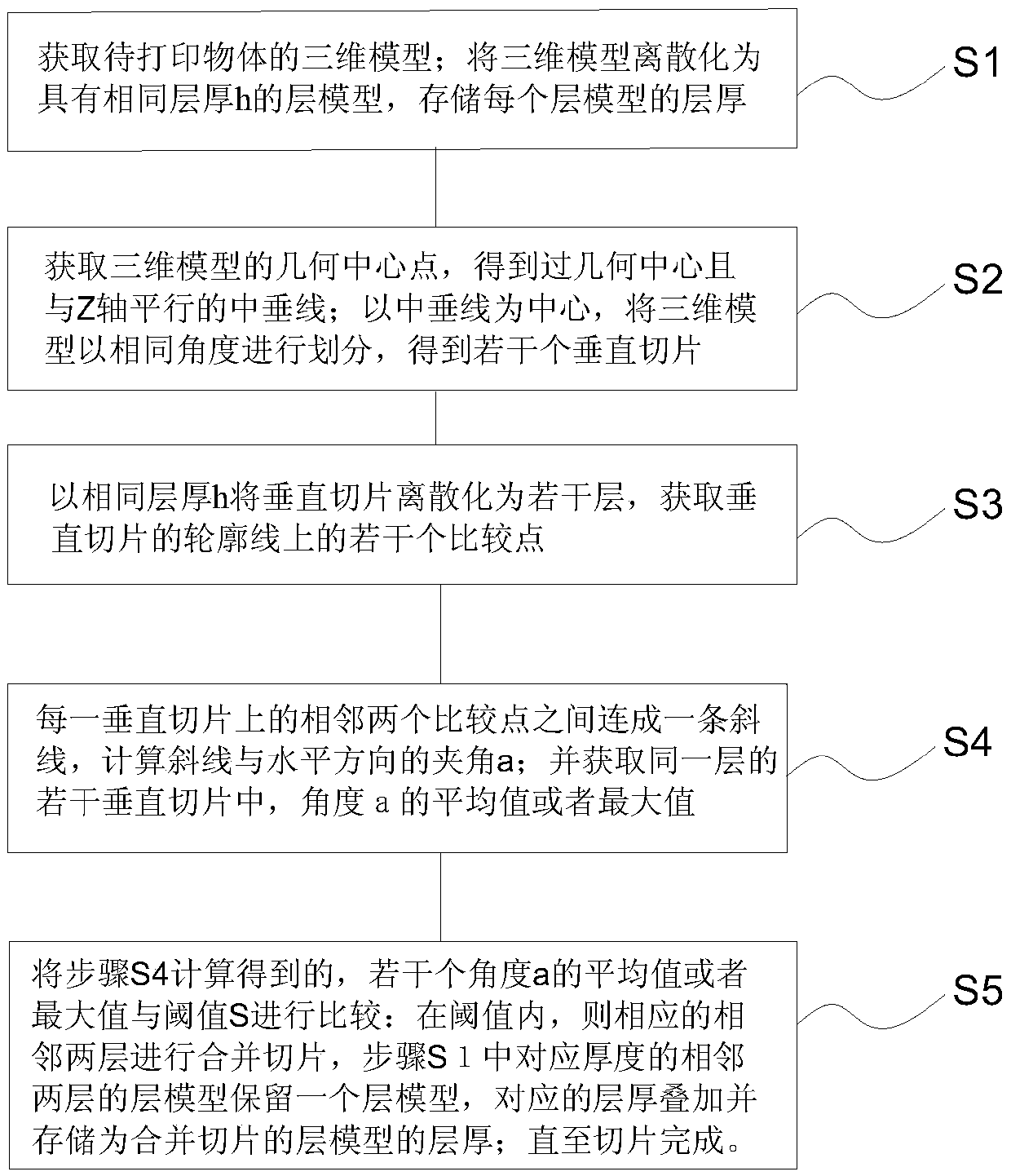

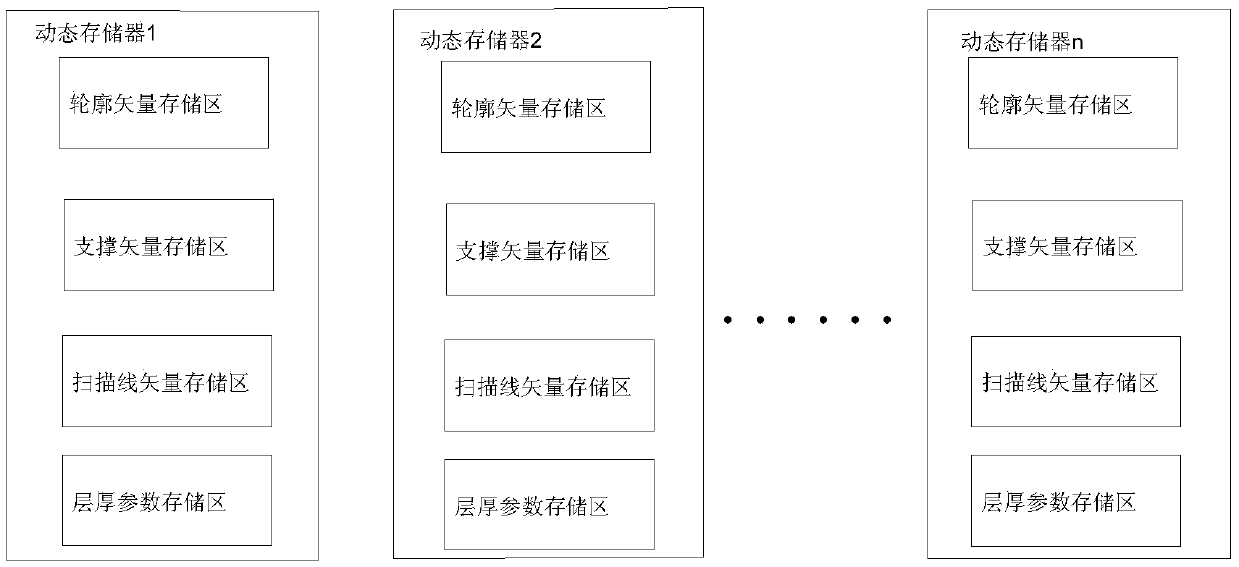

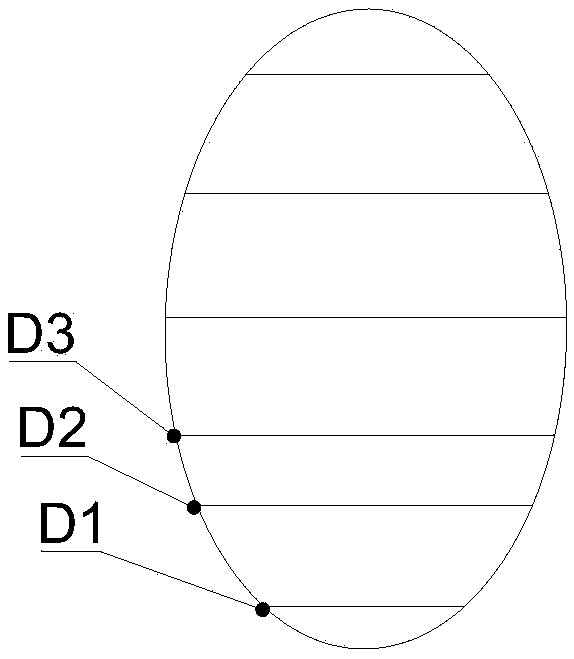

Self-layer-thickness-adaptive slicing method and printing system

ActiveCN109532006AQuality is not affectedDoes not affect printing accuracyAdditive manufacturing apparatus3D object support structuresComputer graphics (images)Layer thickness

The invention provides a self-layer-thickness-adaptive slicing method and a printing system. The self-layer-thickness-adaptive slicing method comprises the steps that a 3D model of a to-be-printed object is acquired; the 3D model is dispersed into d1, d2 to dn layers of models with an identical layer thickness; the midperpendicular of the 3D model is acquired; the 3D model is divided with the sameangle by taking the midperpendicular as the center, so that a plurality of vertical slices are obtained; the vertical slices are dispersed into a plurality of layers with the same layer thickness h,so that a plurality of comparison points on the outlines of the vertical slices are acquired; every two adjacent comparison points on each vertical slice are connected to form a slash, and an includedangle a between each slash and the horizontal direction is calculated; and the angles a are compared with a threshold S, and whether two adjacent layers are combined for slicing or not is determined.By adopting the self-layer-thickness-adaptive slicing method, self-adaptive slicing is performed on the 3D model of the to-be-printed object with different layer thicknesses; and the printing systemis provided for directly printing the self-layer-thickness-adaptive layer models; and printing speed is accelerated on the premise of not affecting printing precision and printing object quality.

Owner:J H TECH ELECTRONICS GZ LTD

Method and device for slicing three-dimensional simulation map

ActiveCN106611056AImprove bindingRegistration process is simpleGeographical information databasesSpecial data processing applicationsThree dimensional simulationUser input

The invention discloses a method and a device for slicing a three-dimensional simulation map. The method comprises the steps of obtaining a geographical coordinate value and a pixel coordinate value of any same position according to a preset three-dimensional simulation map file and a preset remote-sensing image; combining corresponding pixel coordinate values and geographical coordinate values into a registration coordinate file with a preset format; loading the registration coordinate file, receiving slicing parameters input by a user, and obtaining a sliced map and outputting a catalogue file according to the registration coordinate file and the slicing parameters; and running a whole area slicing plug-in to obtain a three-dimensional simulation map sliced file. The method and the device disclosed by the invention can be convenient for the three-dimensional simulation map to combine with a geographical coordinate system, and a registration process is simple; and meanwhile, the three-dimensional simulation map is enabled to generate a map cache; and thus, the slicing efficiency is high.

Owner:GUANGZHOU YIDONG NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com