Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8466results about "Manufacturing data aquisition/processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

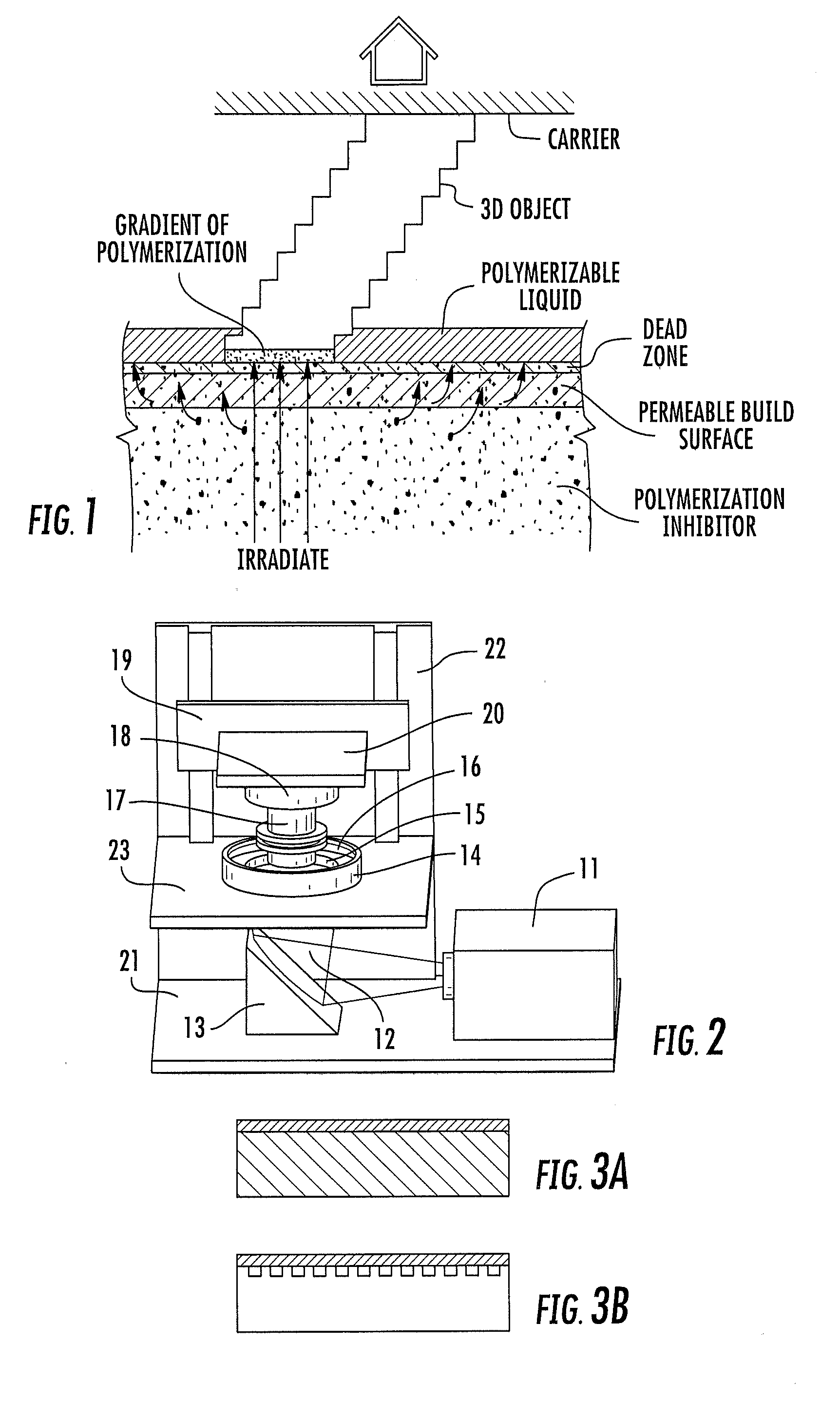

Continuous liquid interphase printing

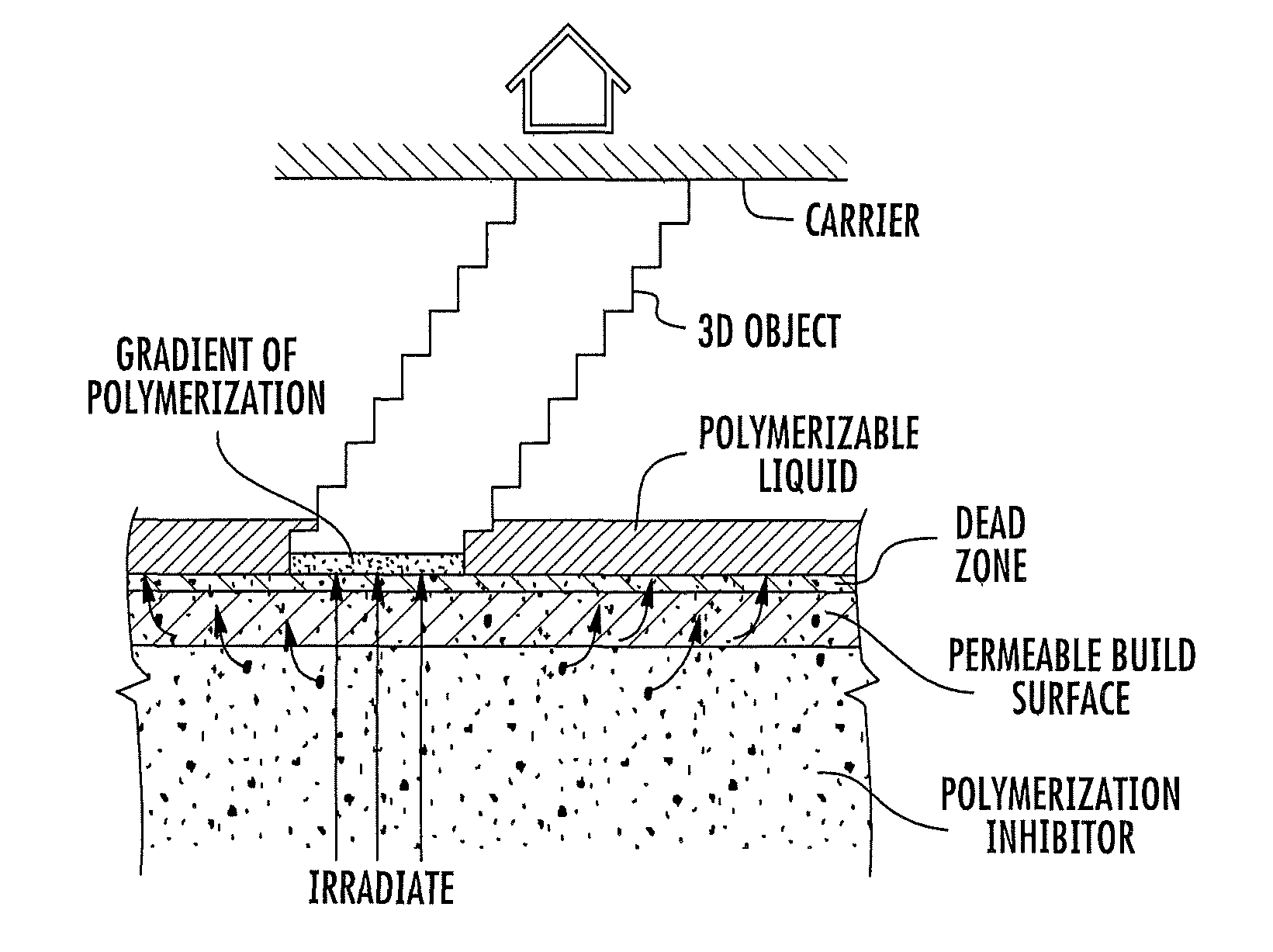

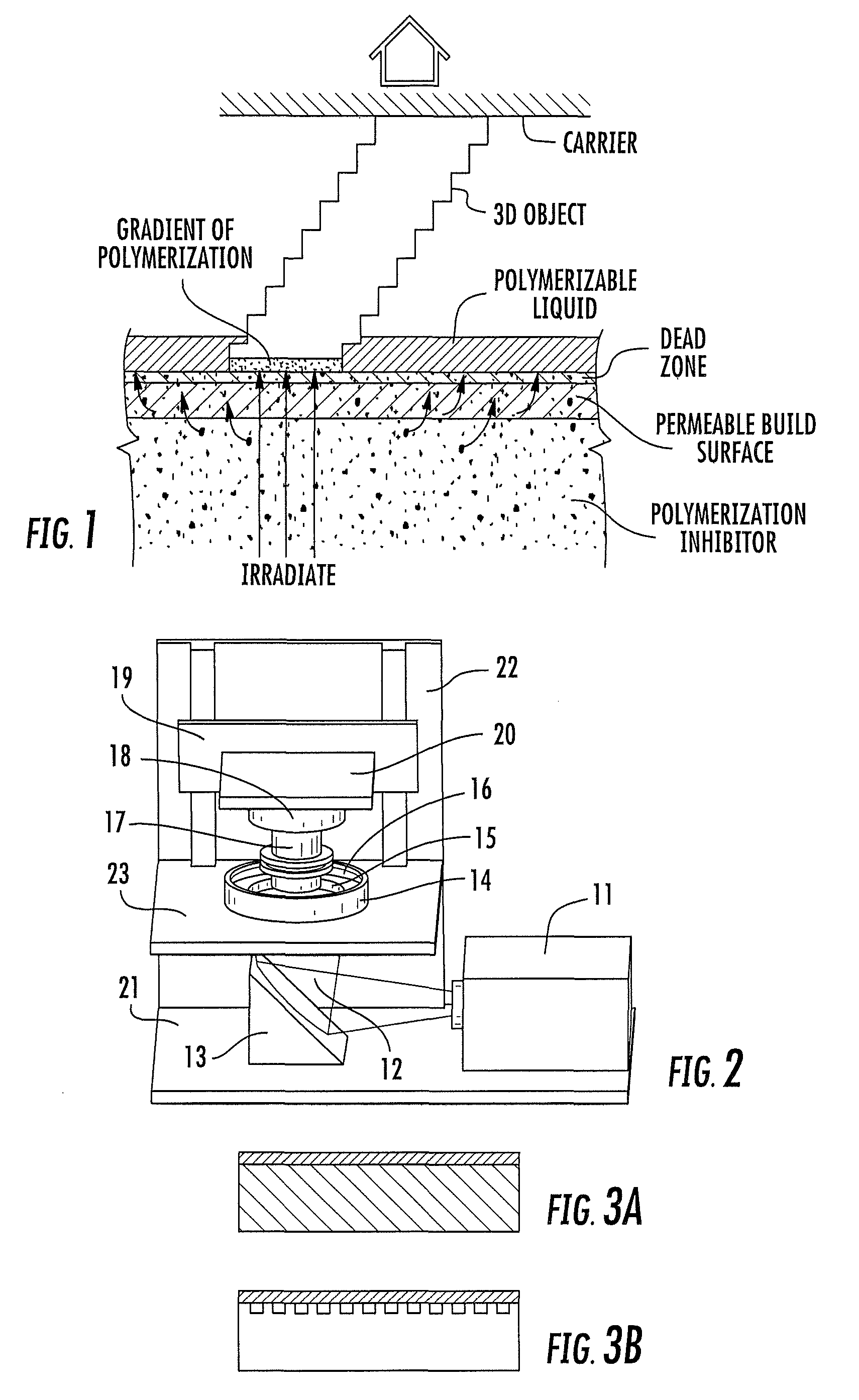

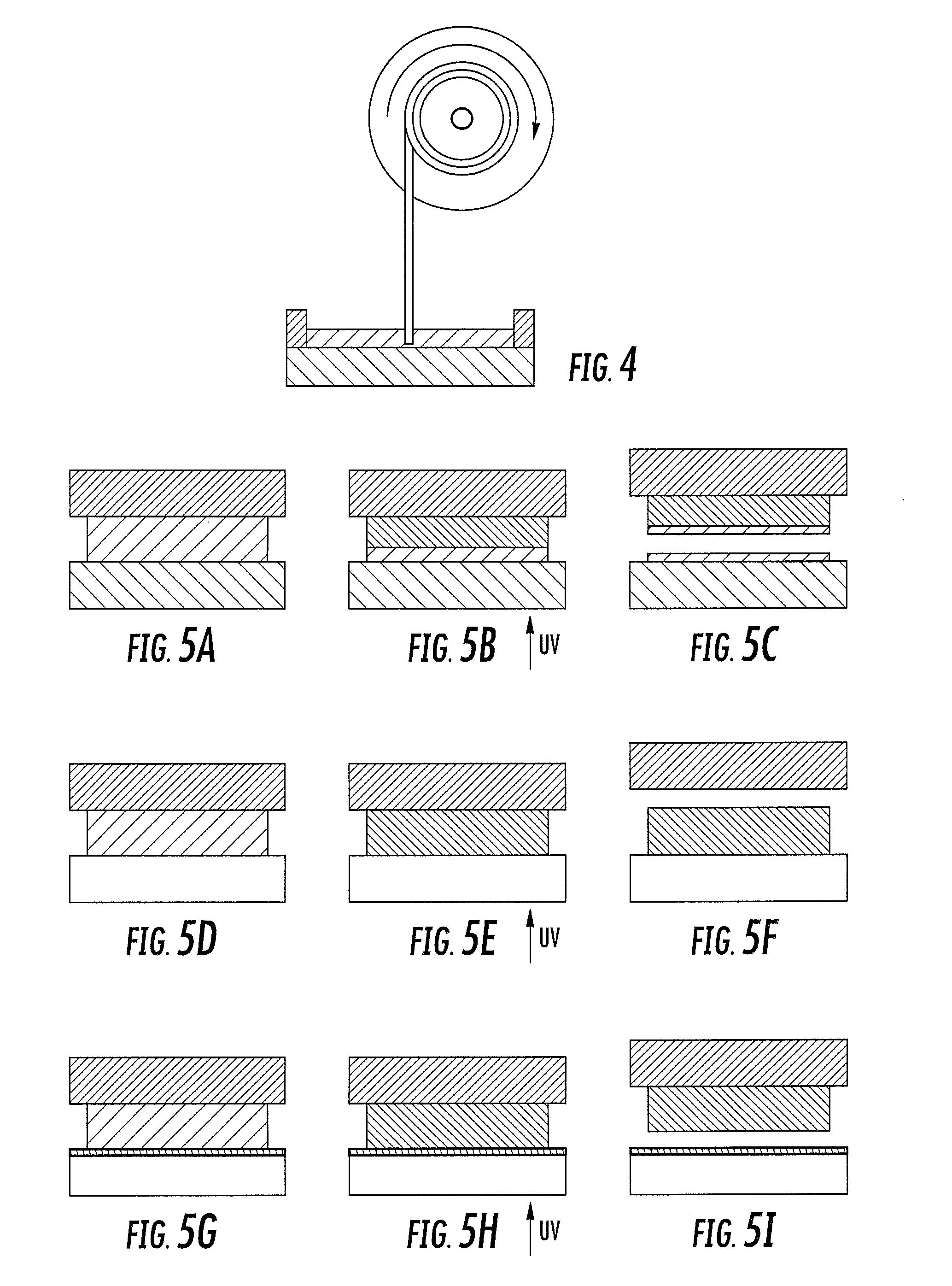

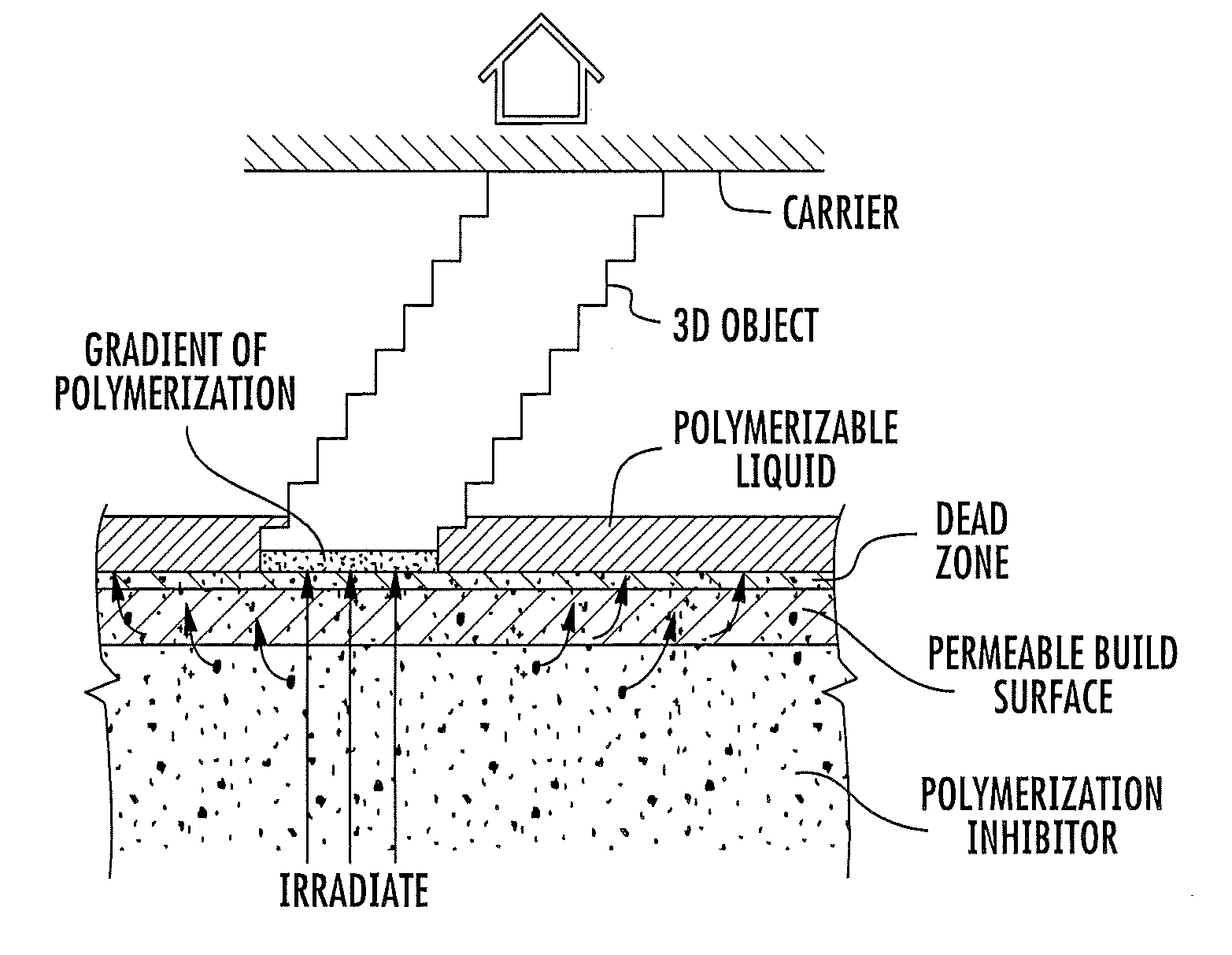

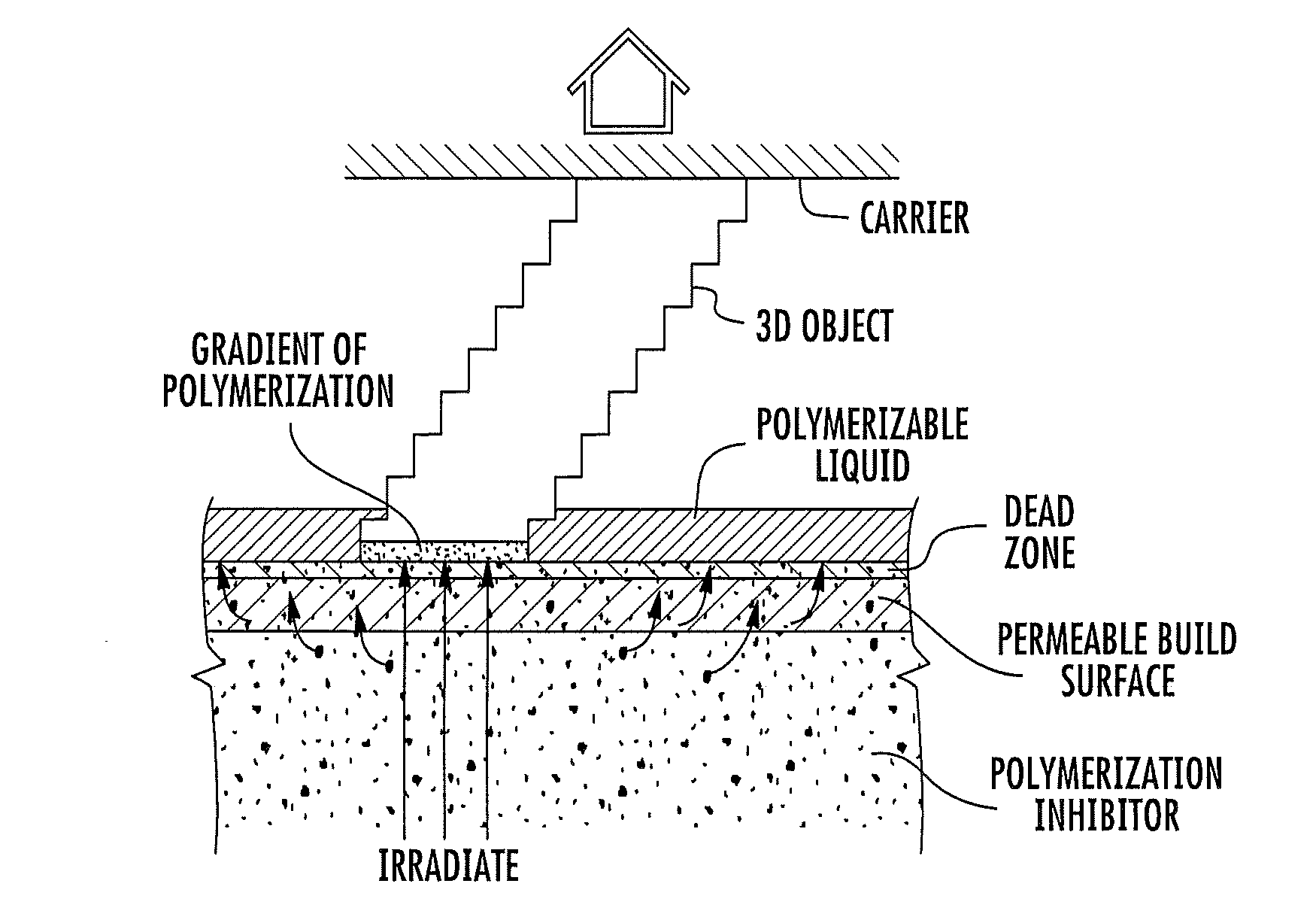

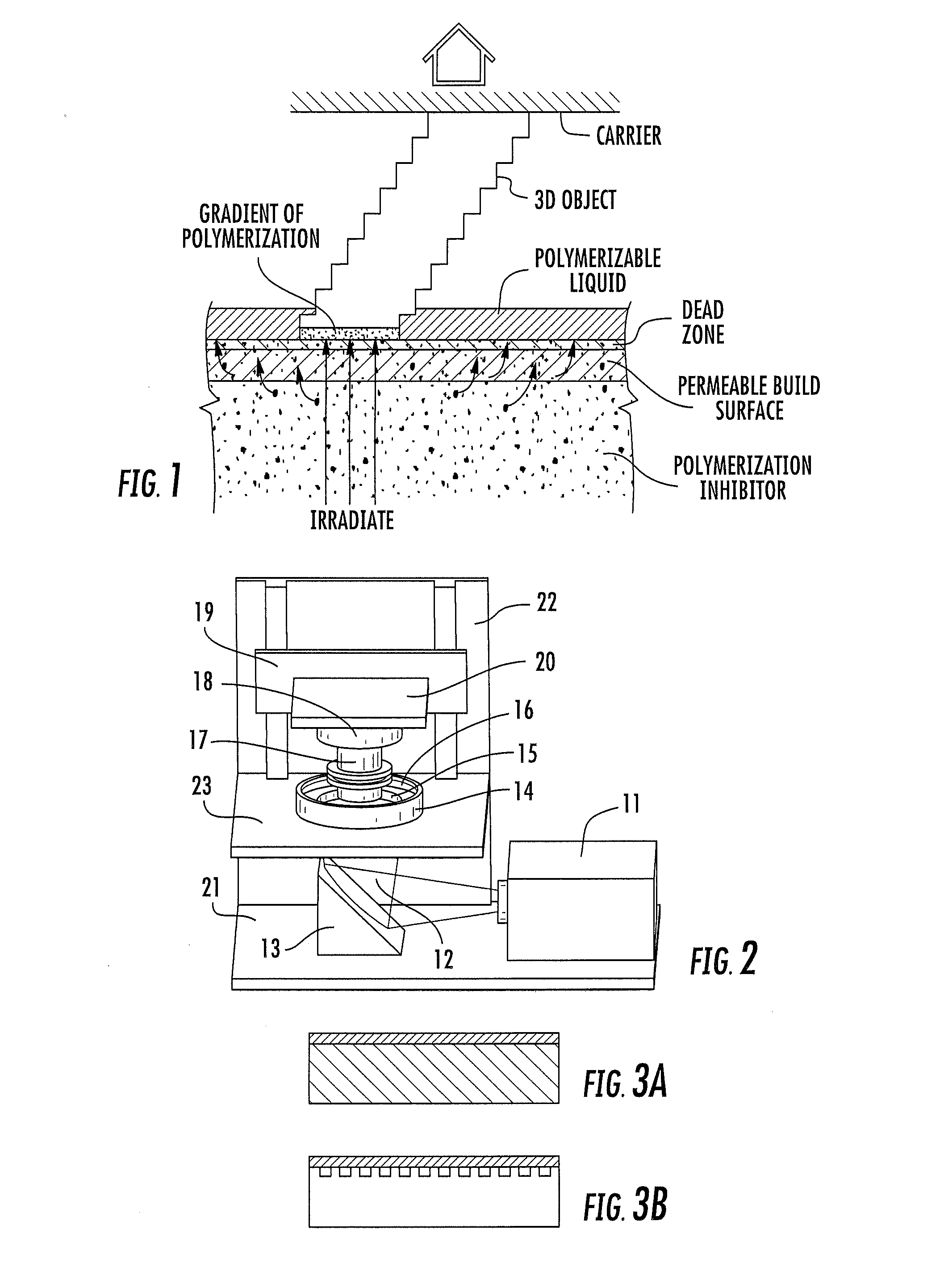

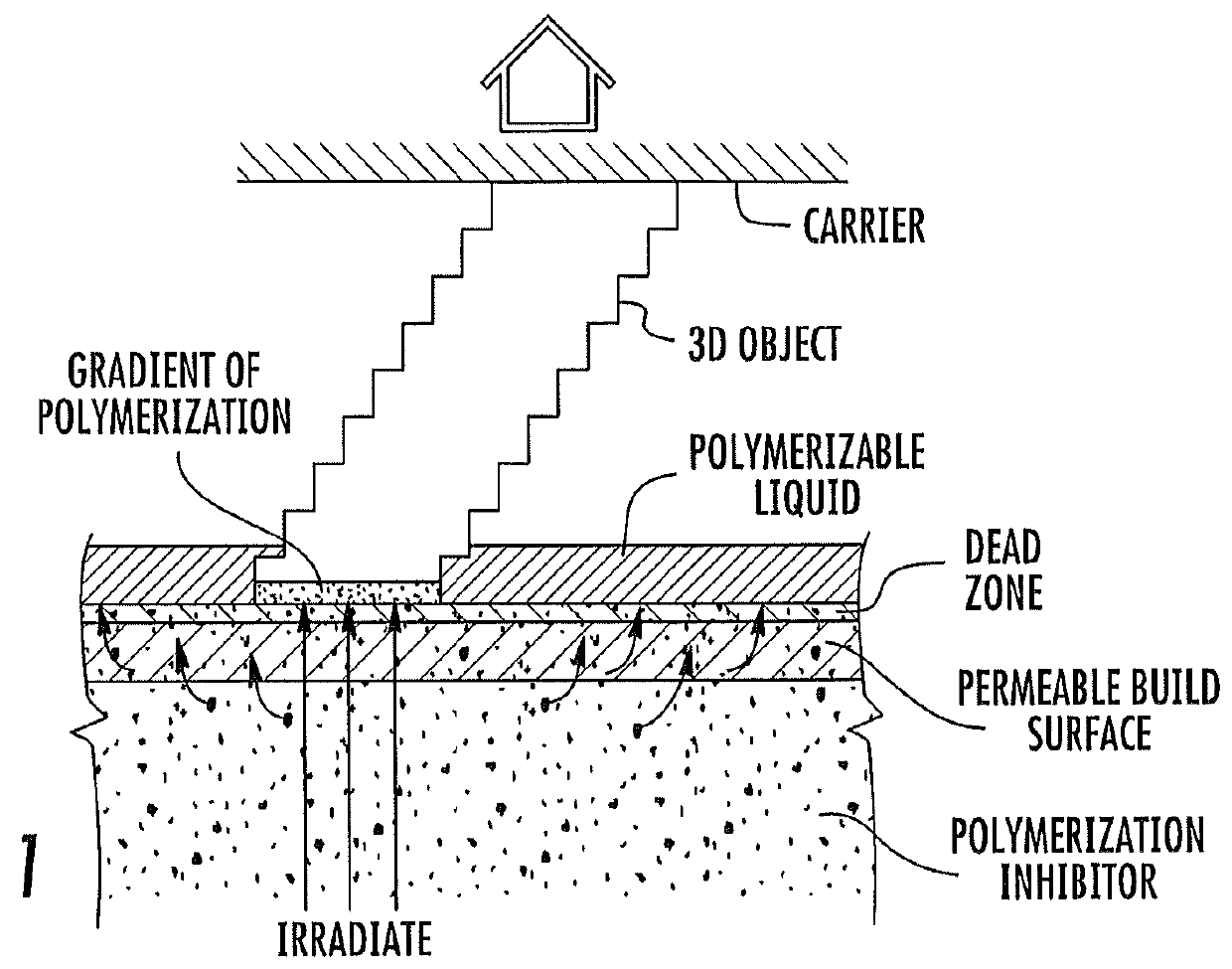

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

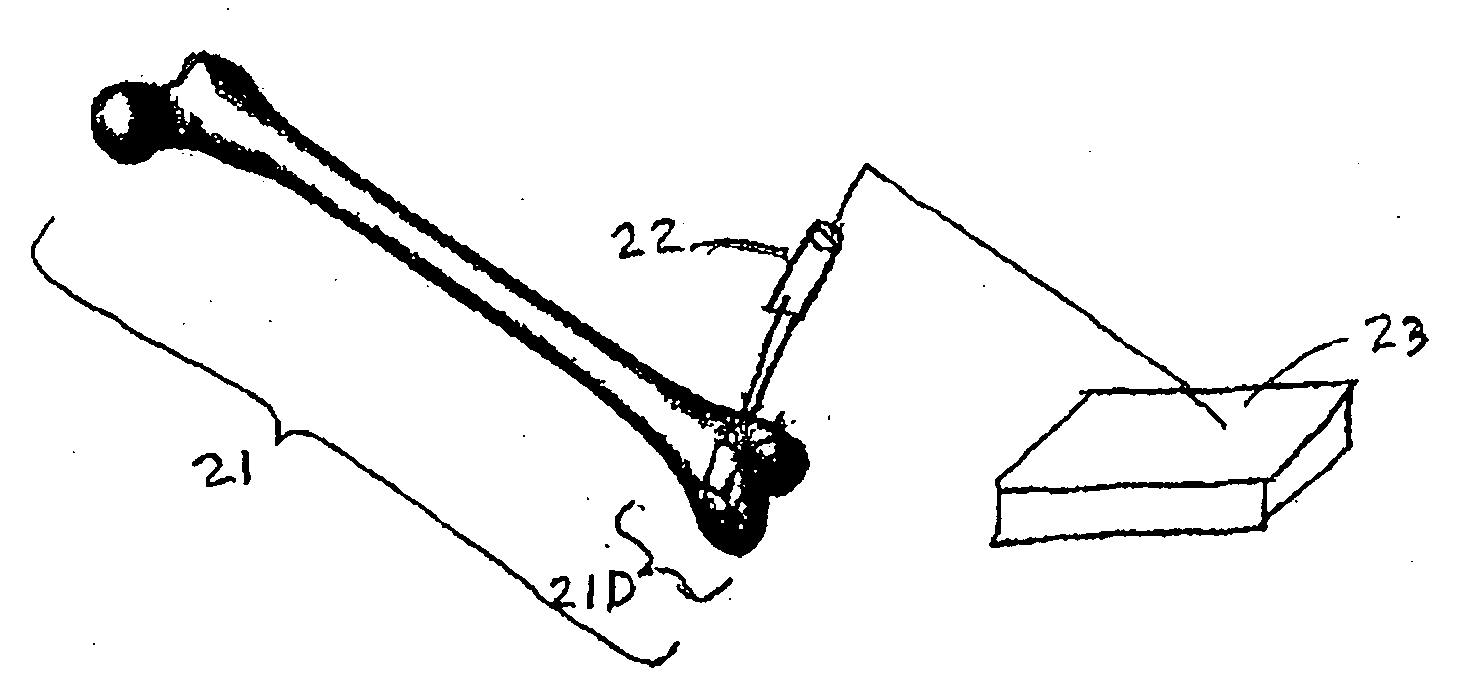

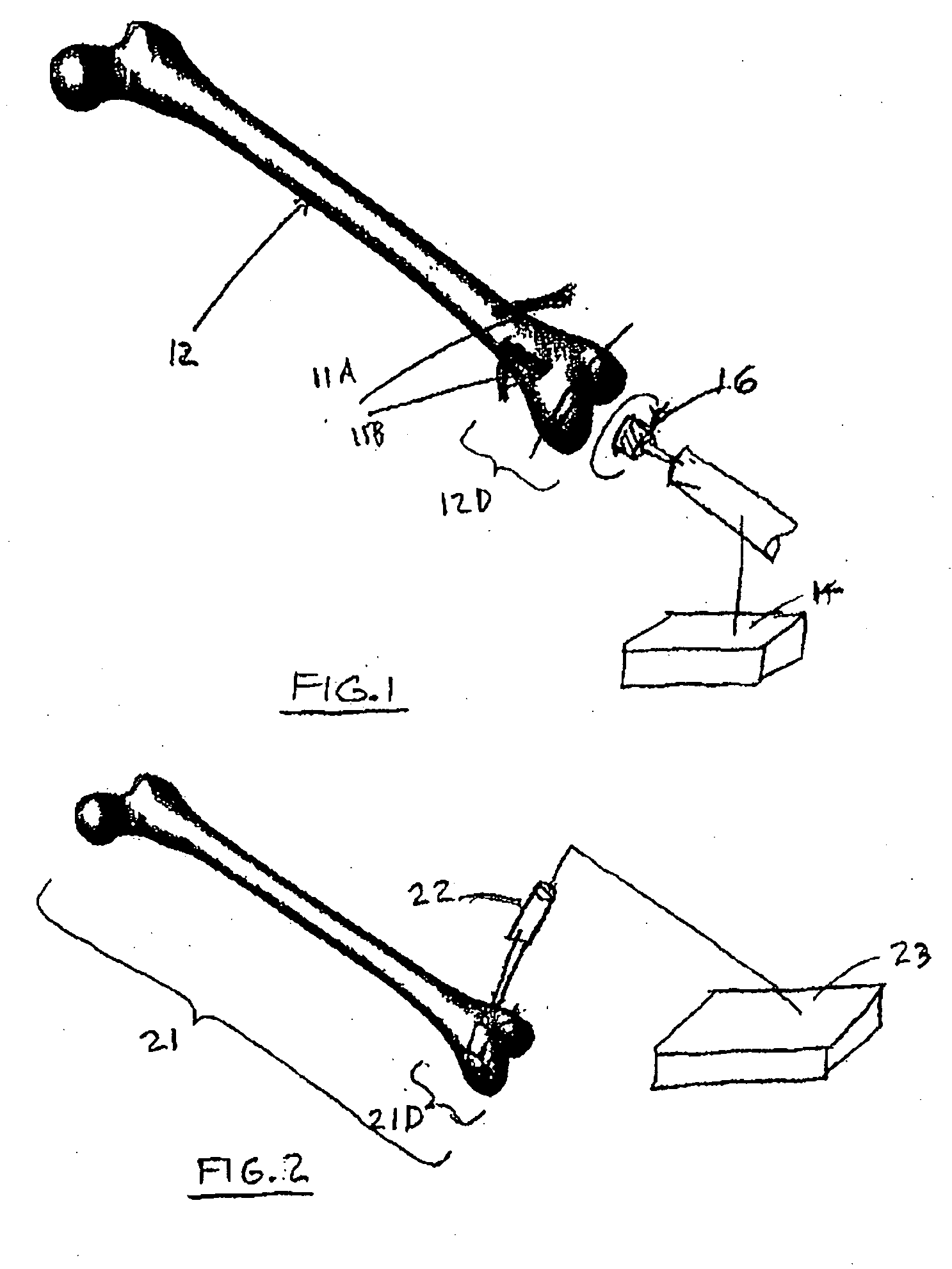

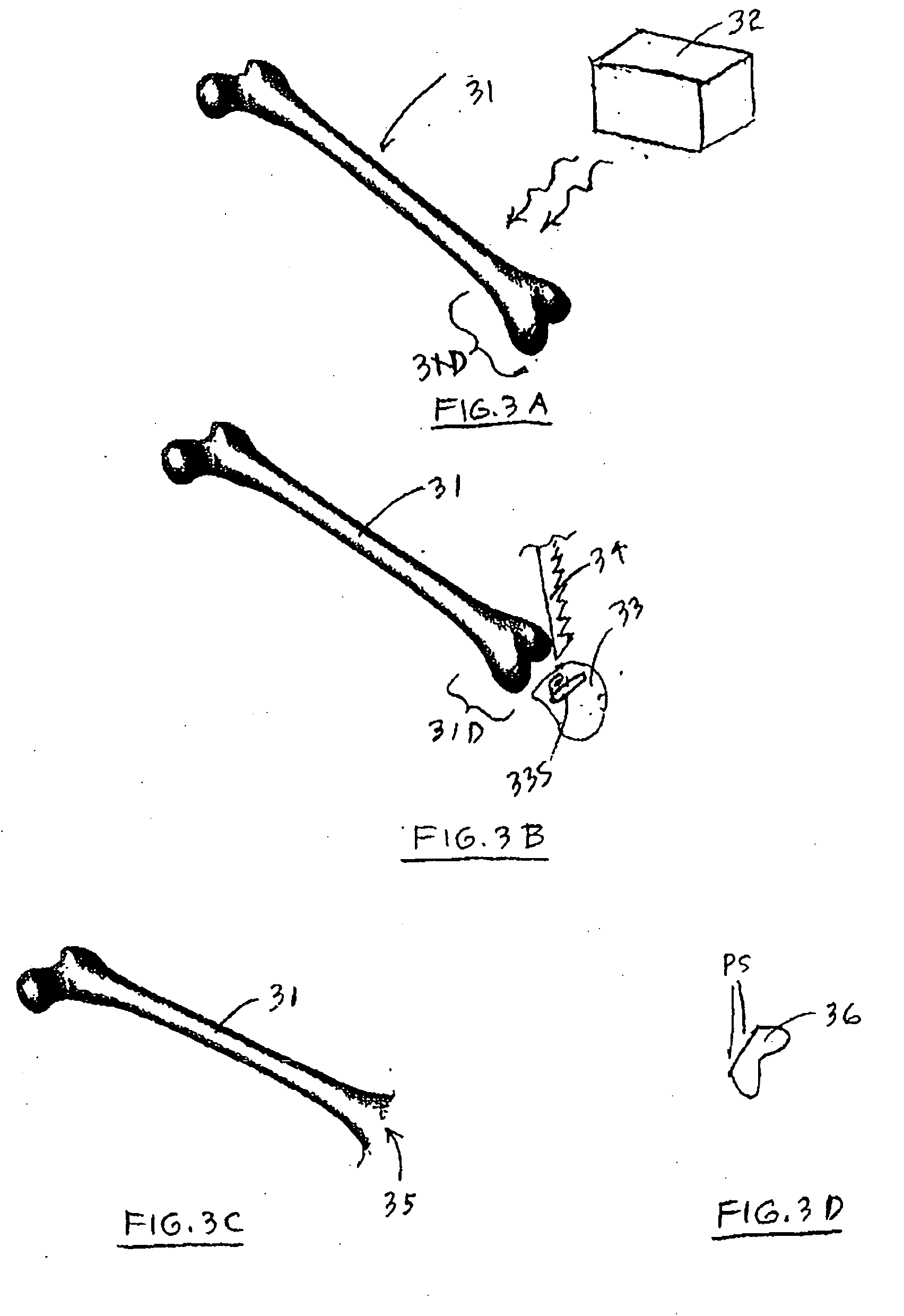

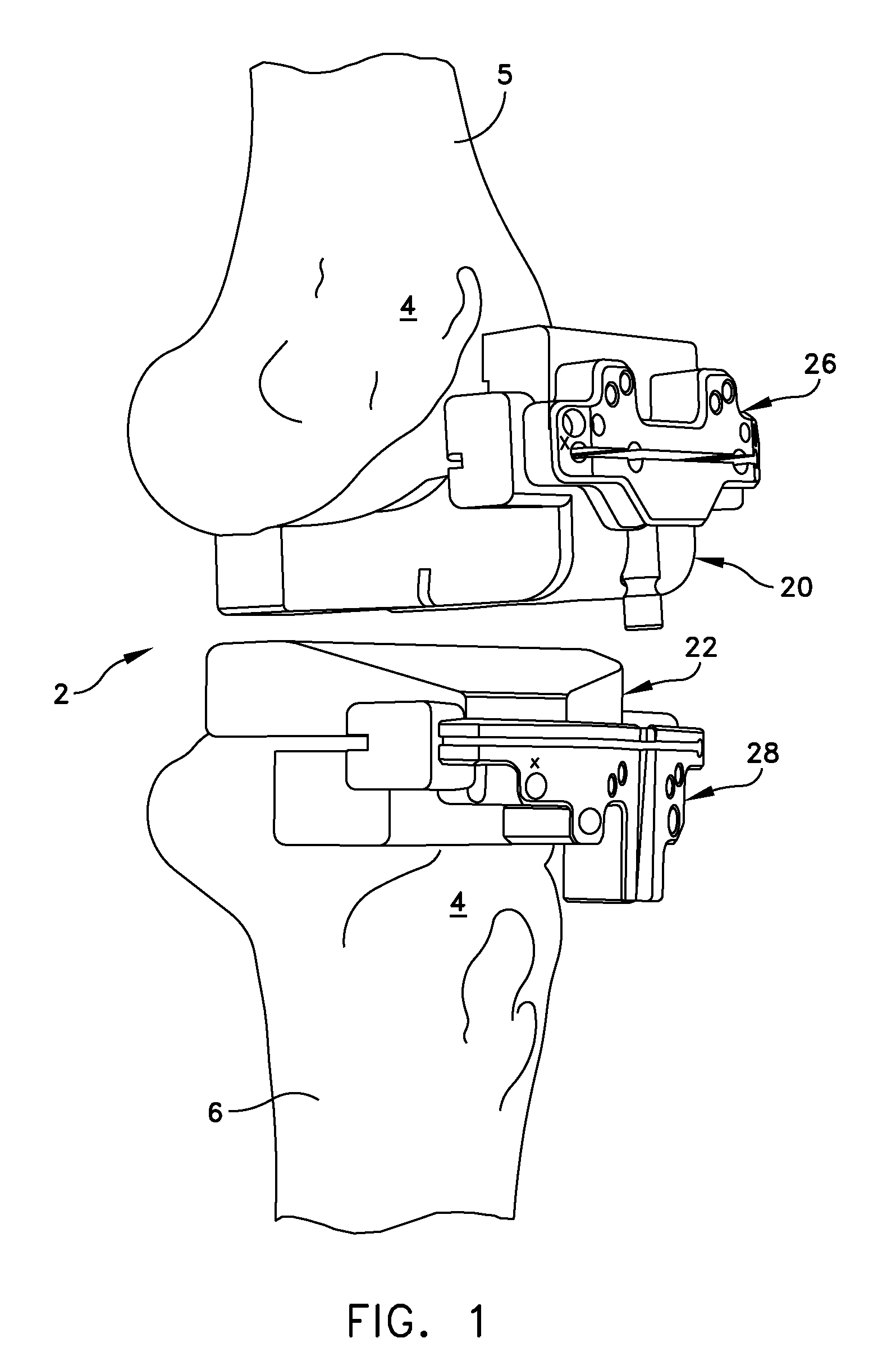

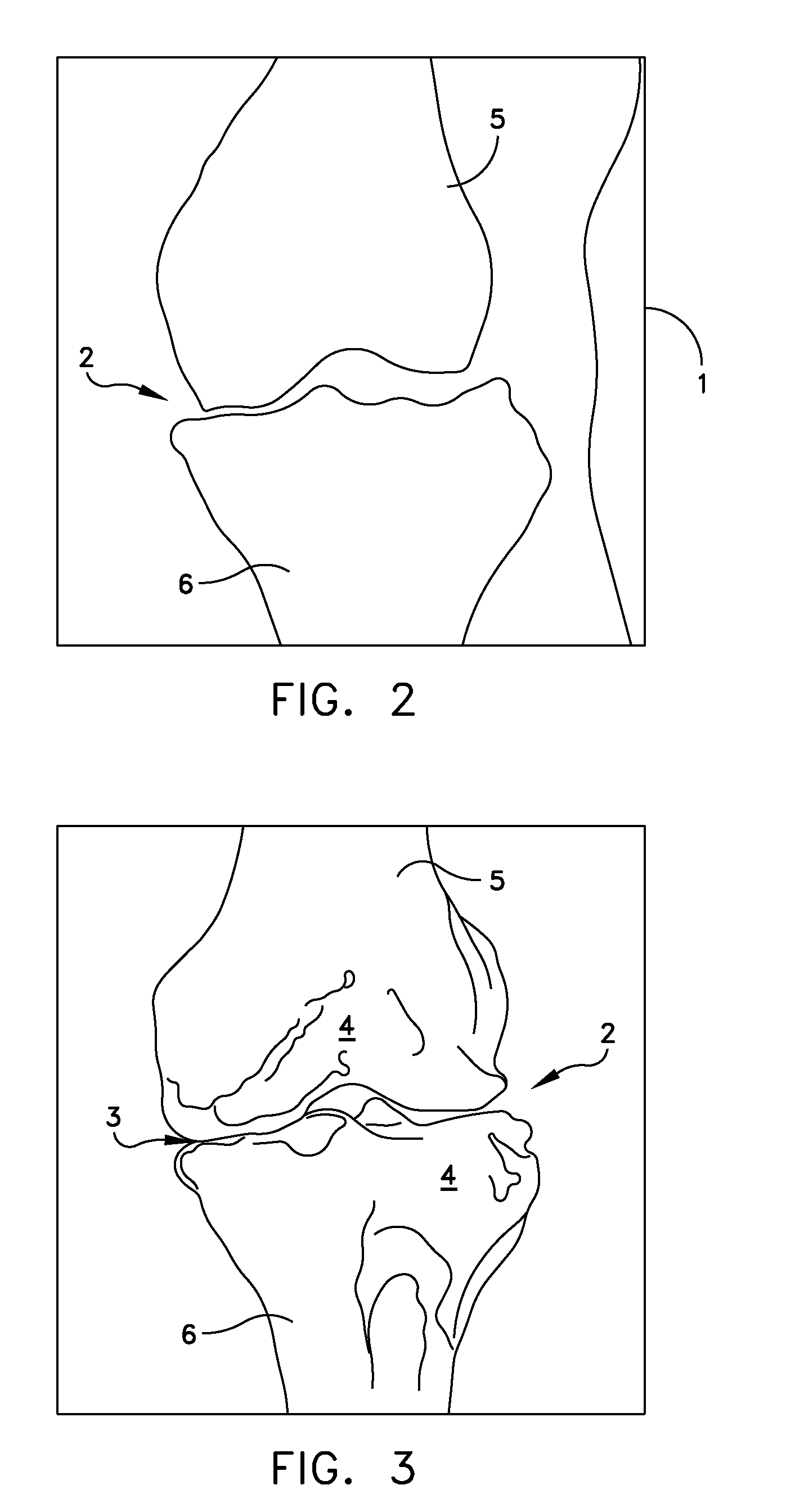

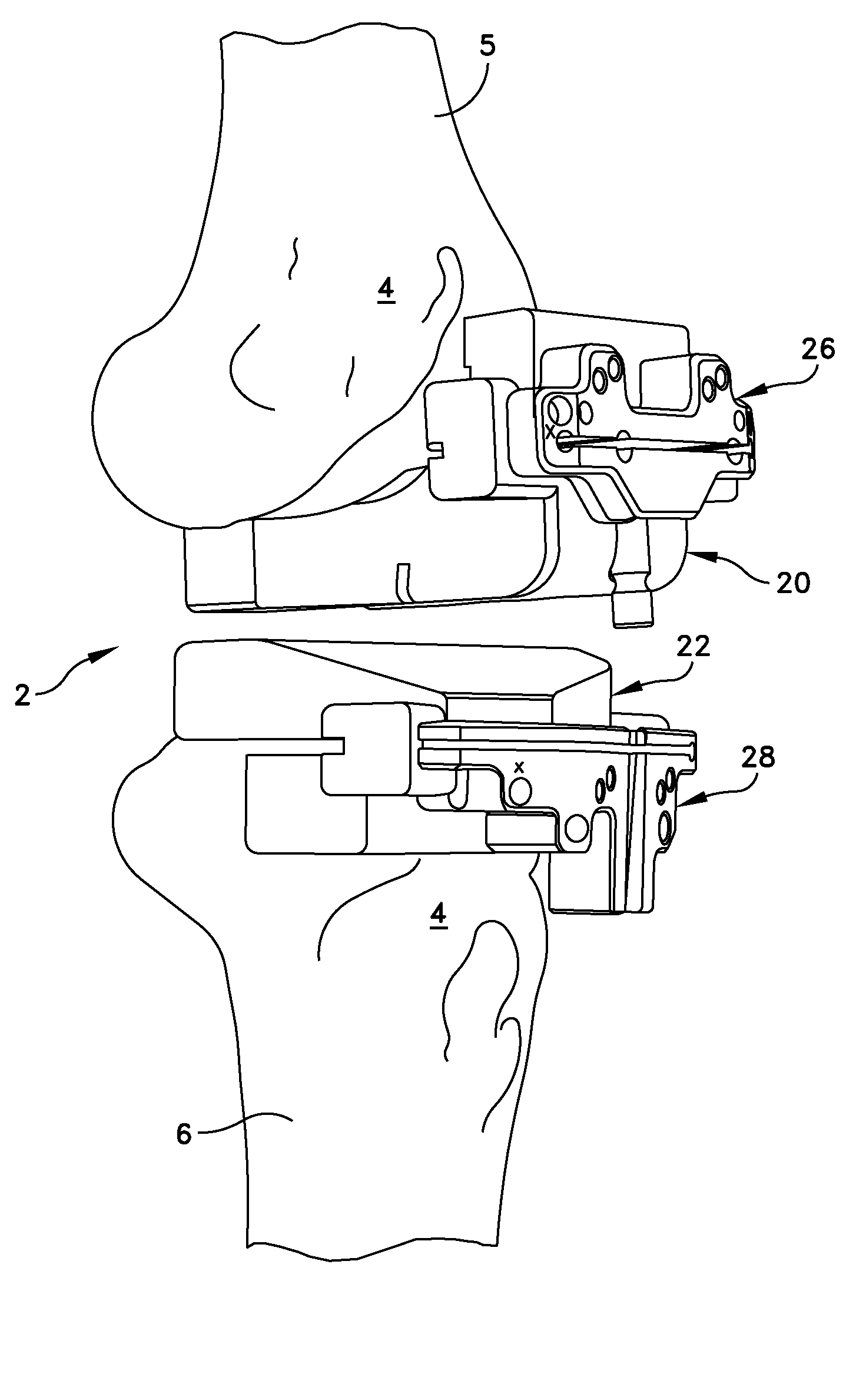

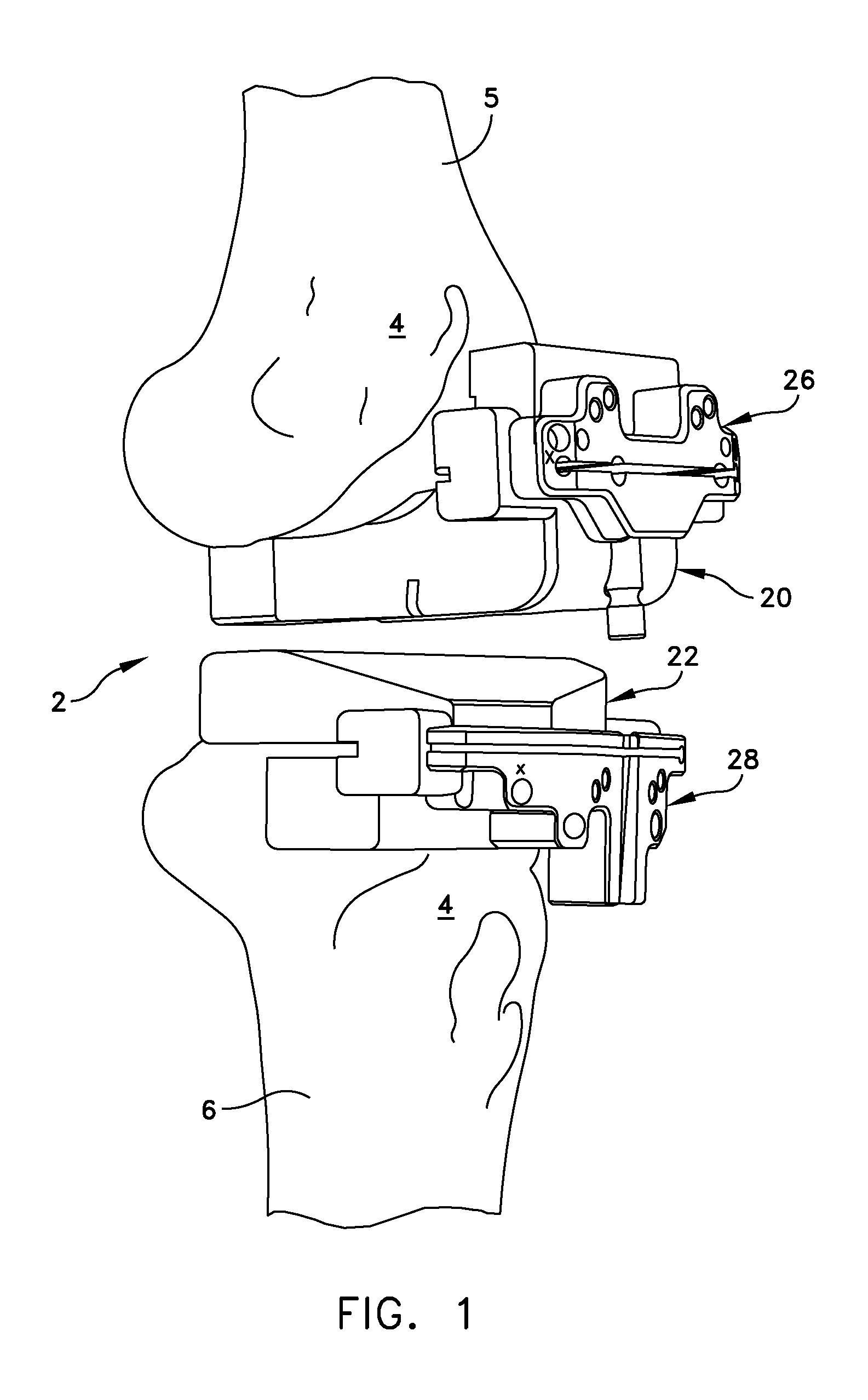

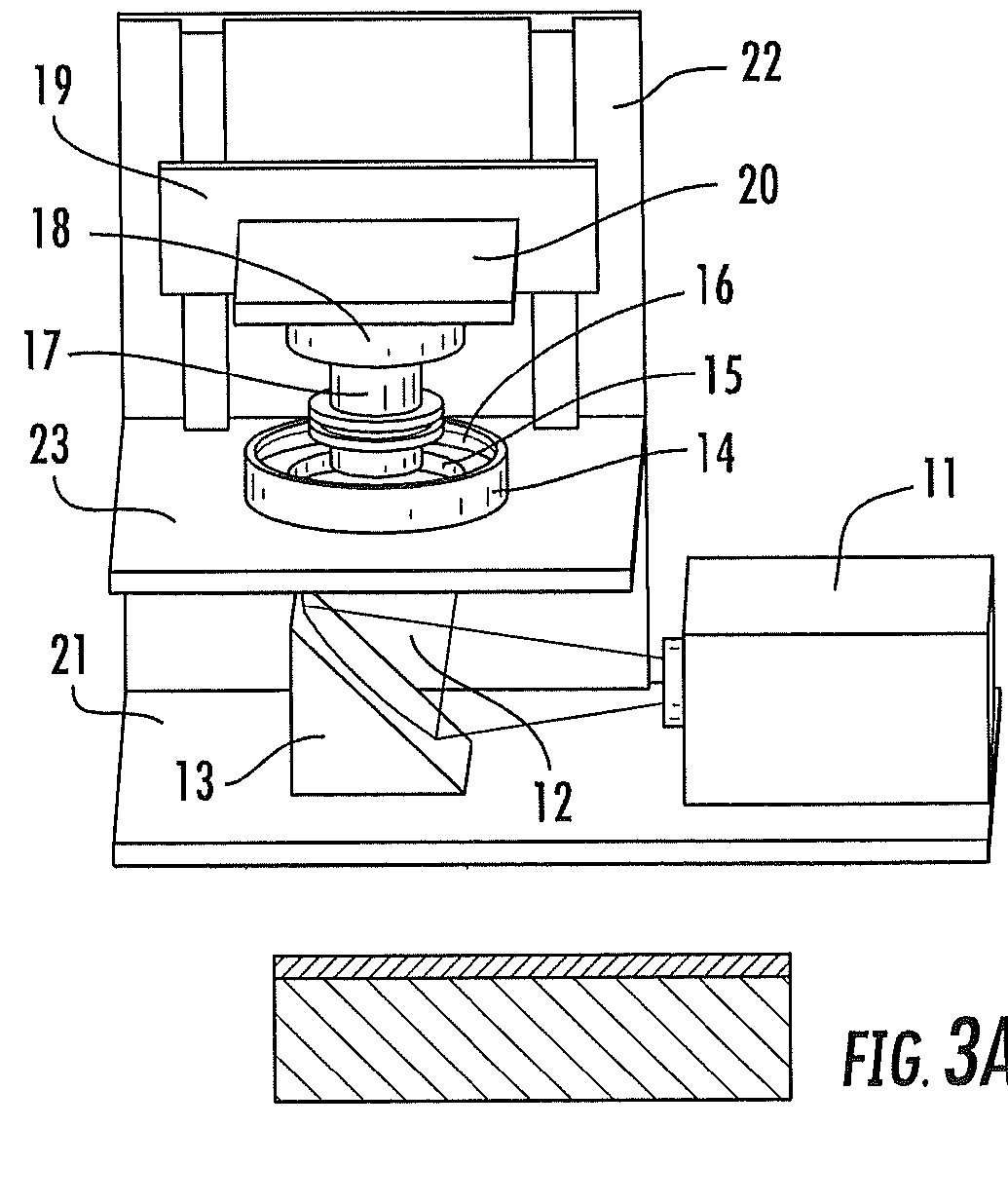

Total joint arthroplasty system

ActiveUS20090131941A1Precise alignmentImprove visualizationMedical simulationProgramme controlJoint arthroplastyTotal hip arthroplasty

A method and system for performing a total joint arthroplasty procedure on a patient's damaged bone region. A CT image or other suitable image is formed of the damaged bone surfaces, and location coordinate values (xn,yn,zn) are determined for a selected sequence of bone surface locations using the CT image data. A mathematical model z=f(x,y) of a surface that accurately matches the bone surface coordinates at the selected bone spice locations, or matches surface normal vector components at selected bone surface locations, is determined. The model provides a production file from which a cutting jig and an implant device (optional), each patient-specific and having controllable alignment, are fabricated for the damaged bone by automated processing. At this point, the patient is cut open (once), the cutting jig and a cutting instrument are used to remove a selected portion of the bone and to provide an exposed planar surface, the implant device is optionally secured to and aligned with the remainder of the bone, and the patient's incision is promptly repaired.

Owner:HOWMEDICA OSTEONICS CORP

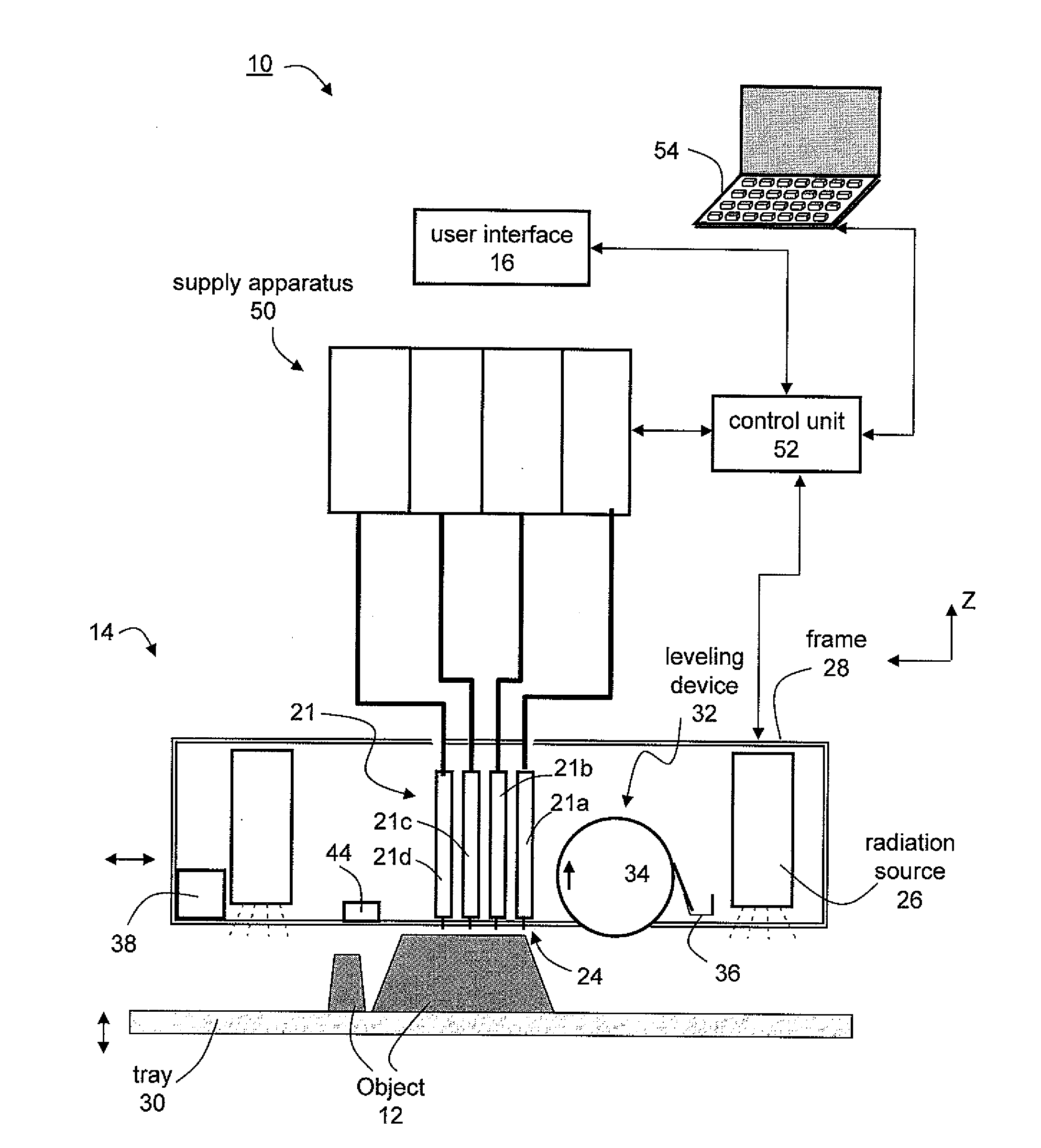

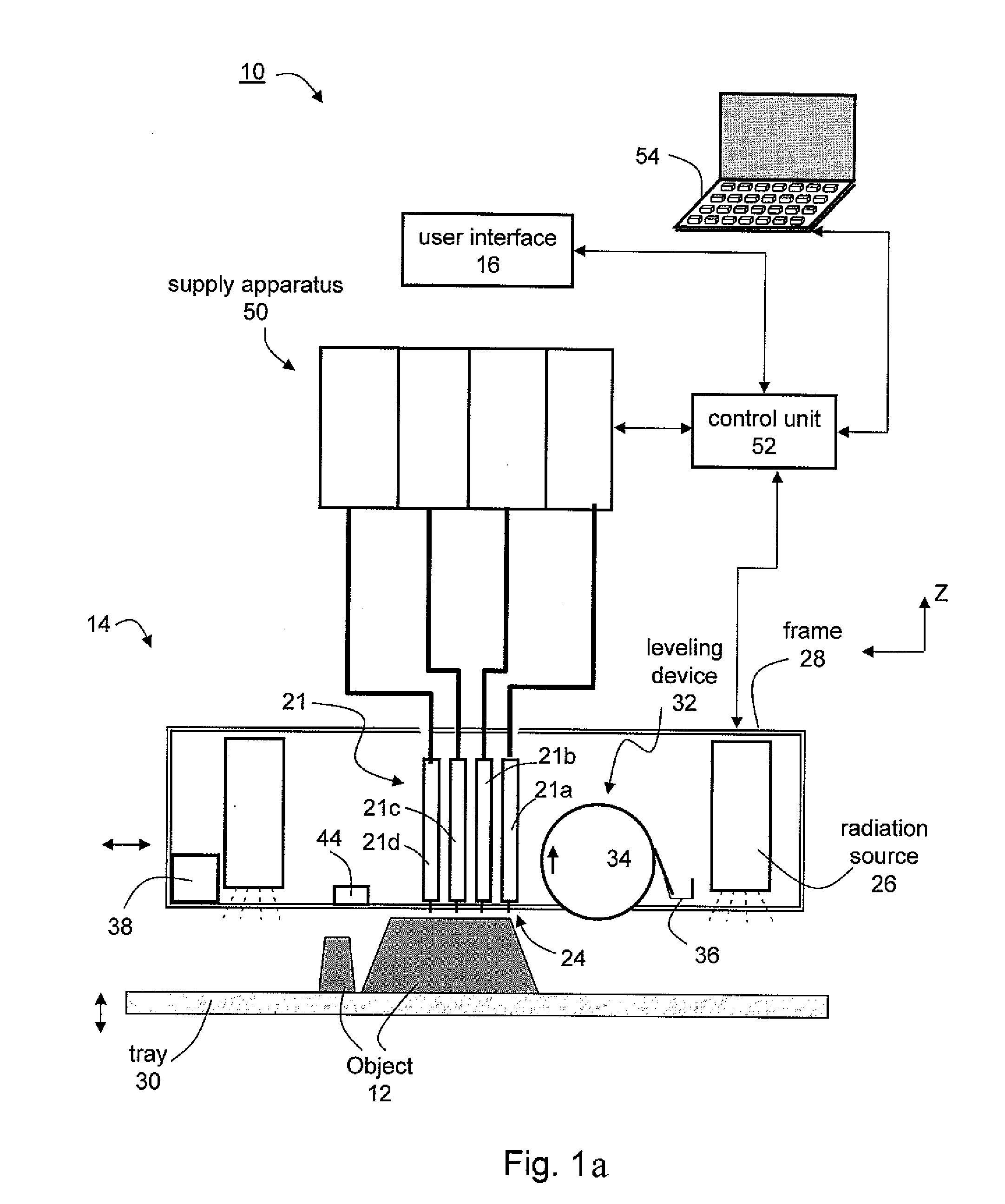

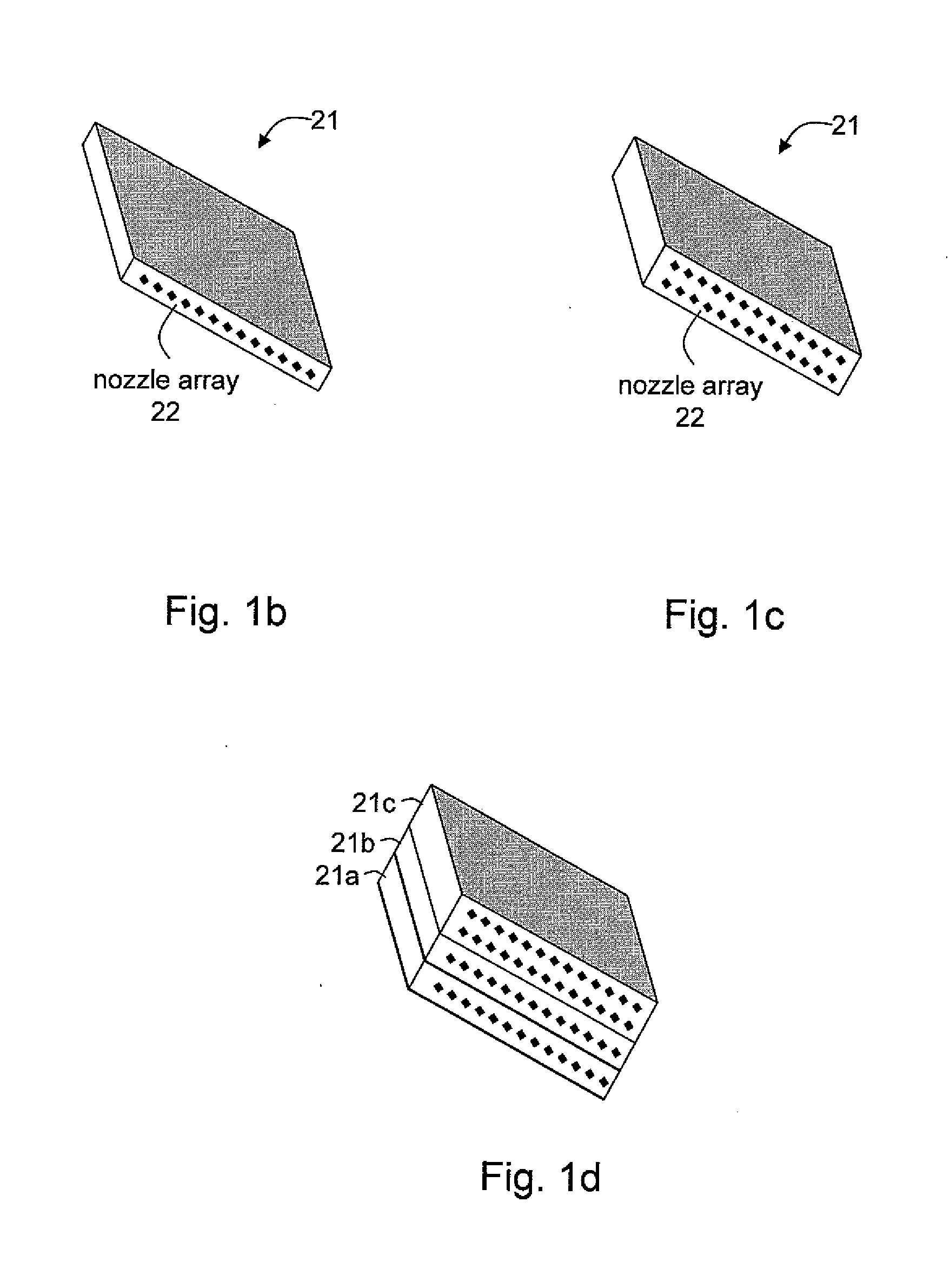

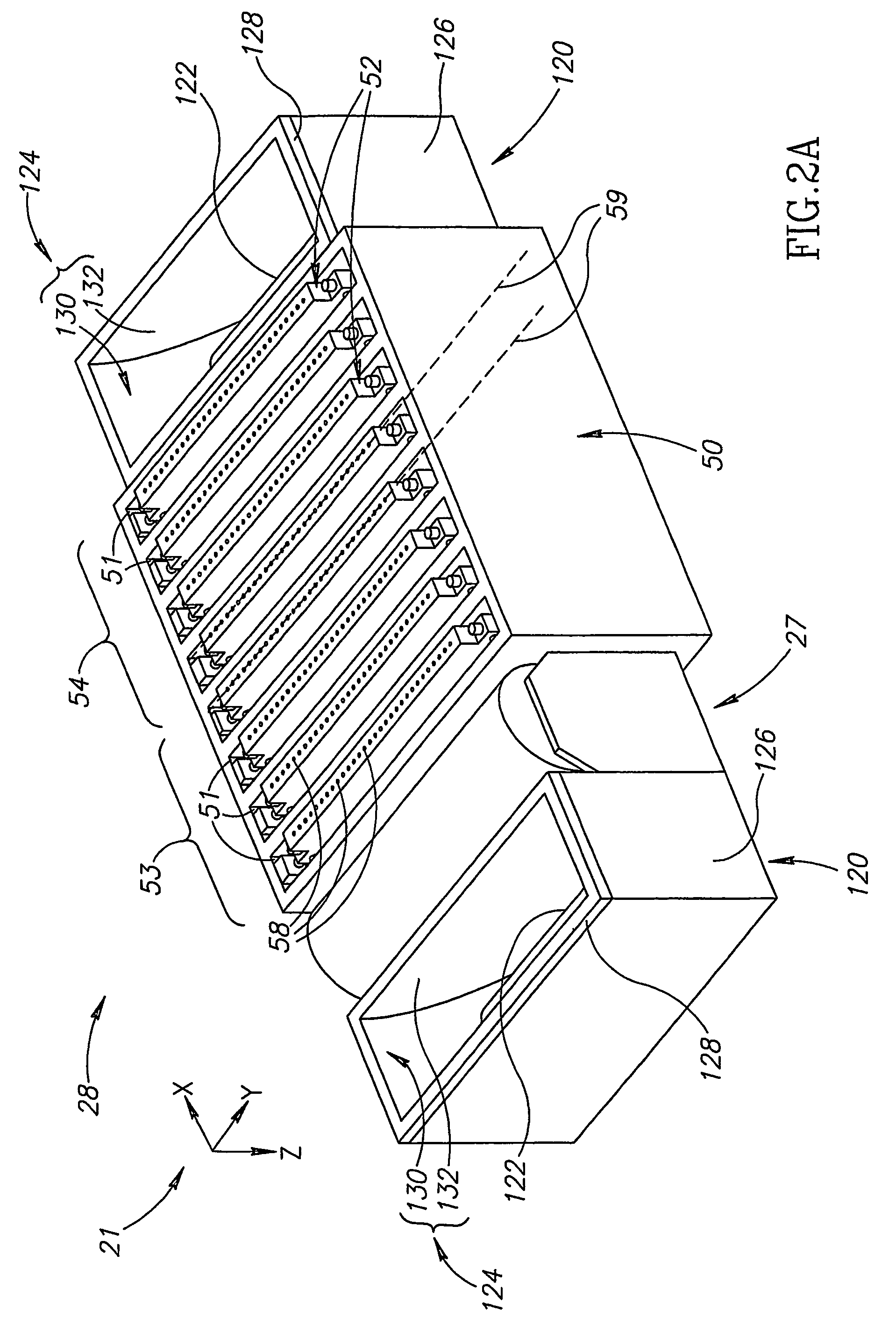

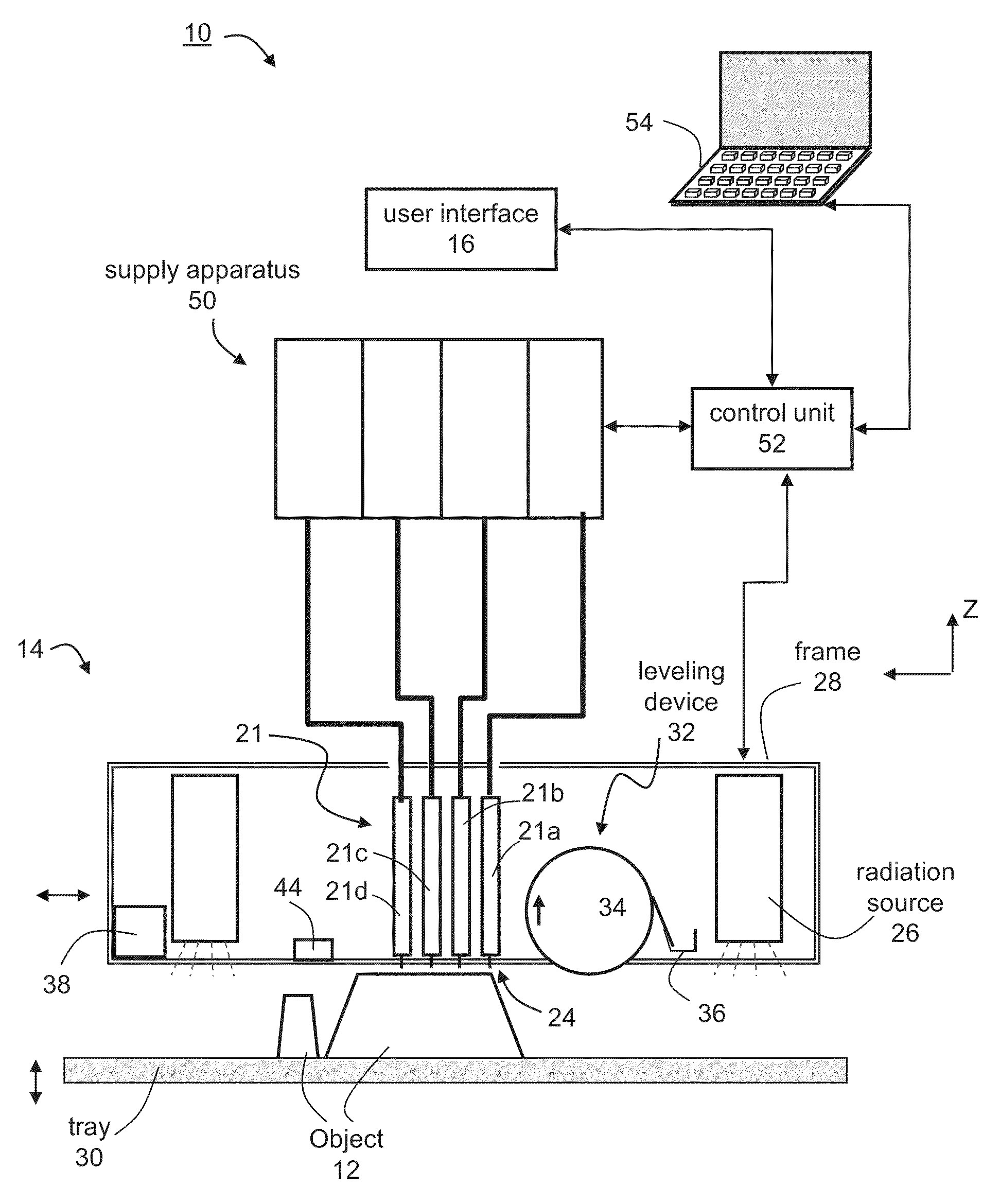

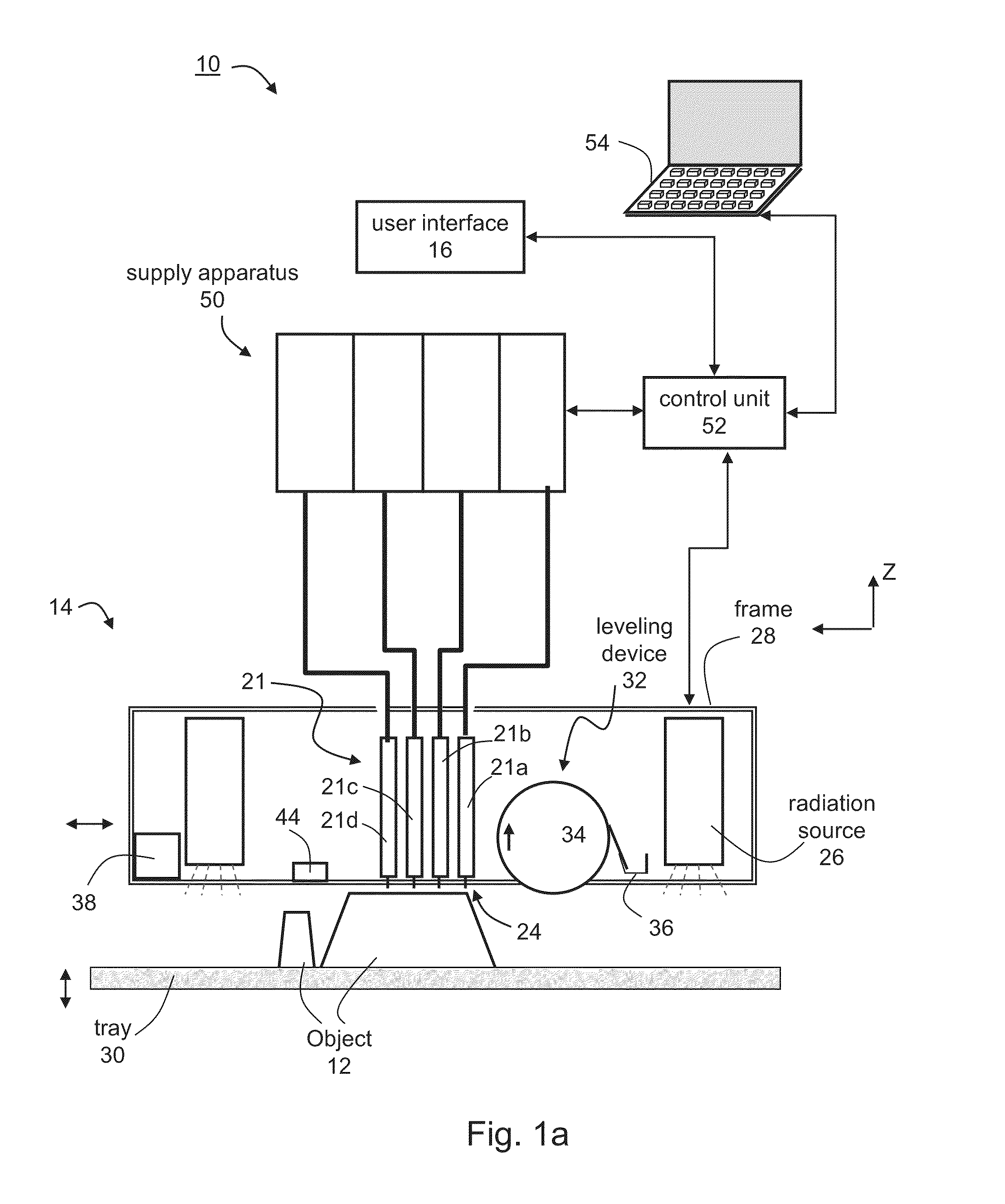

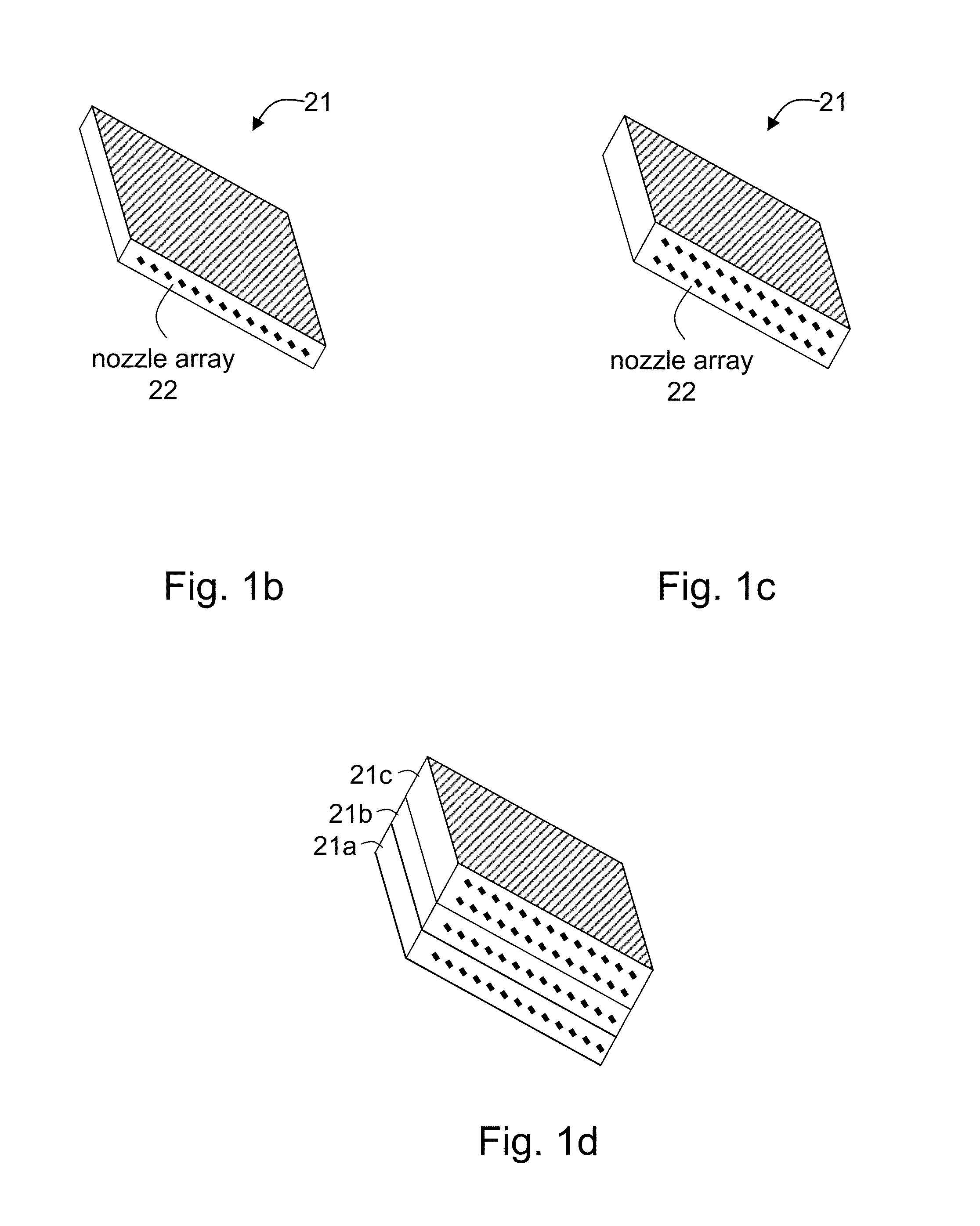

Solid freeform fabrication using a plurality of modeling materials

InactiveUS20100191360A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeMaterial supply

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:OBJET GEOMETRIES

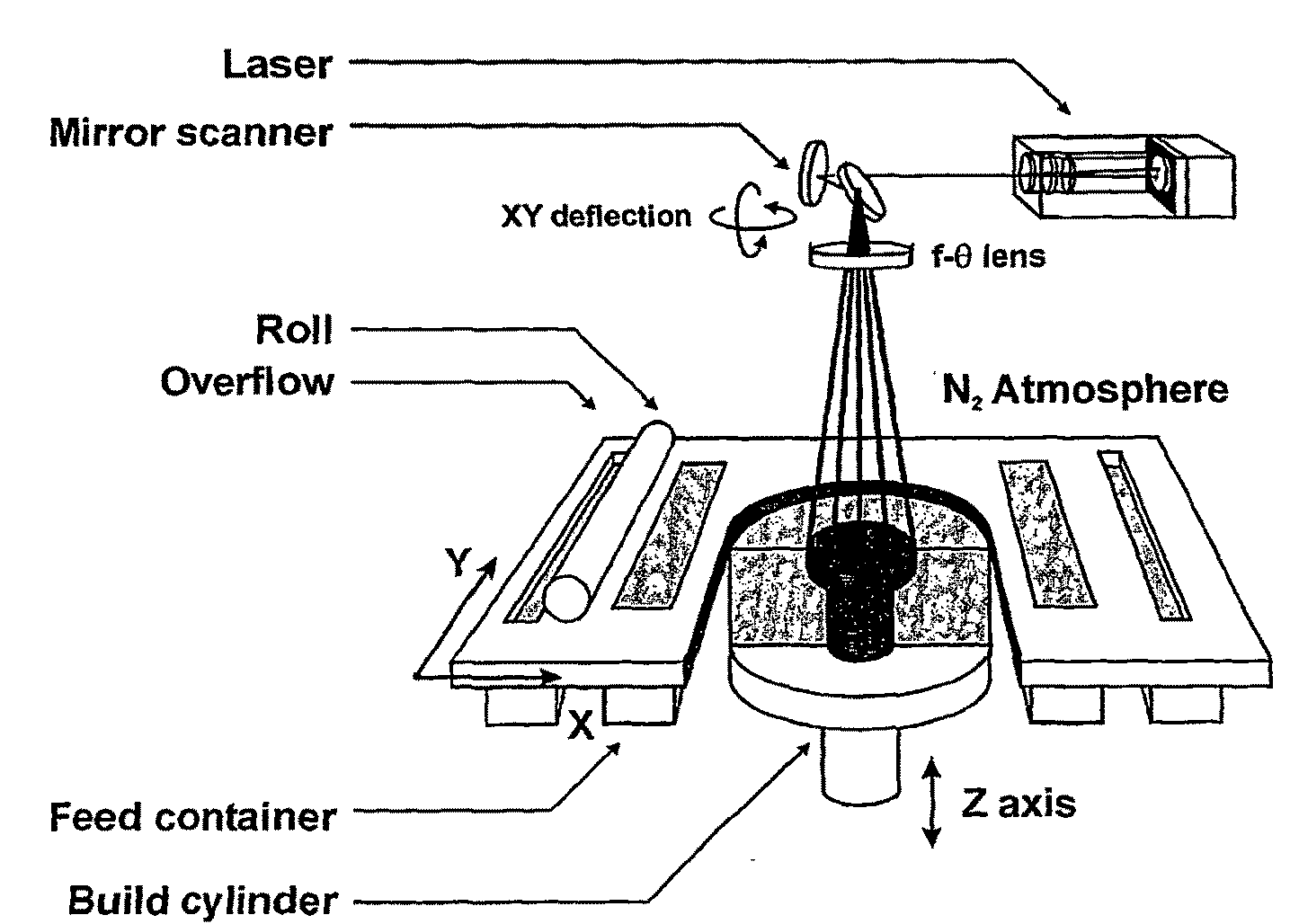

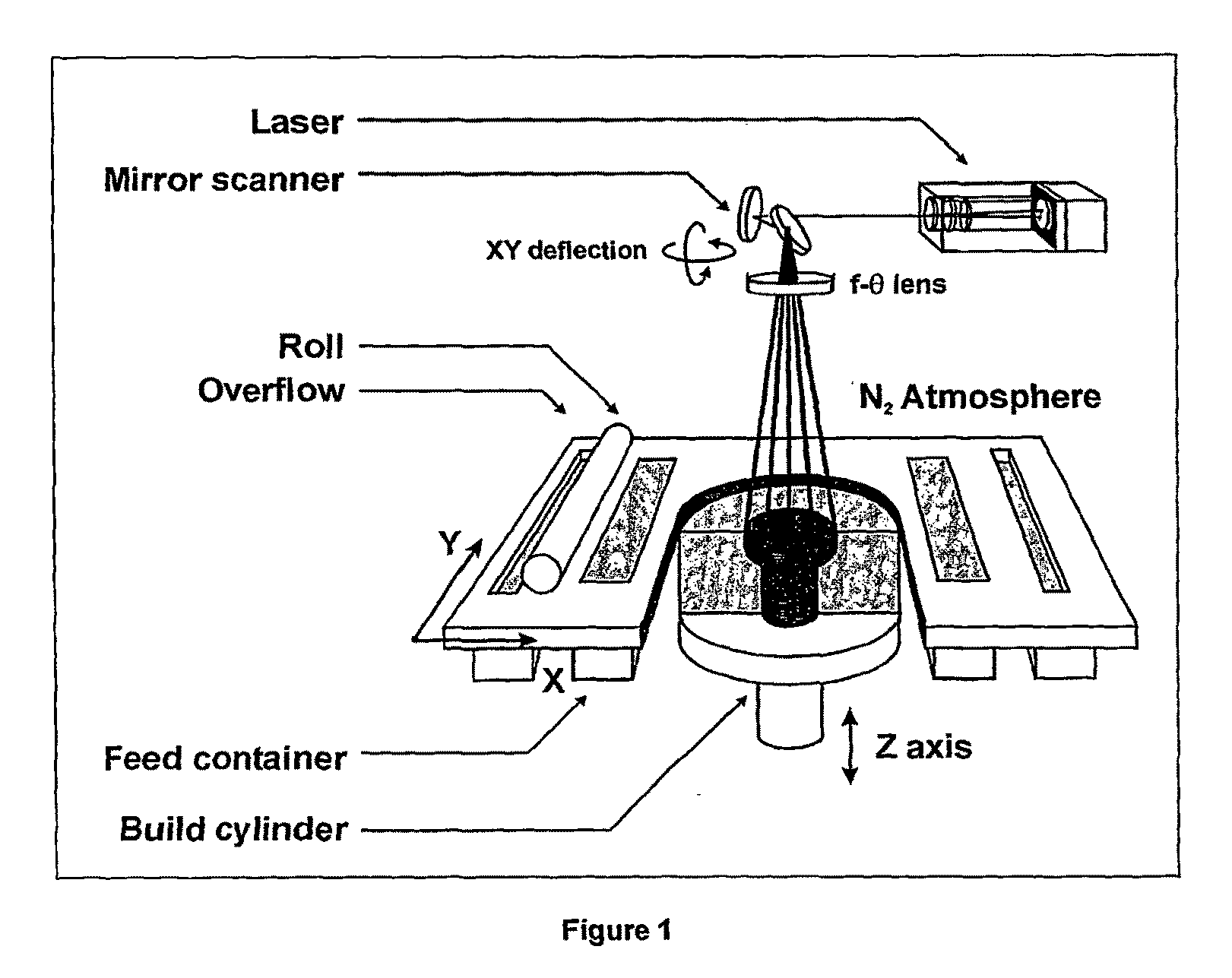

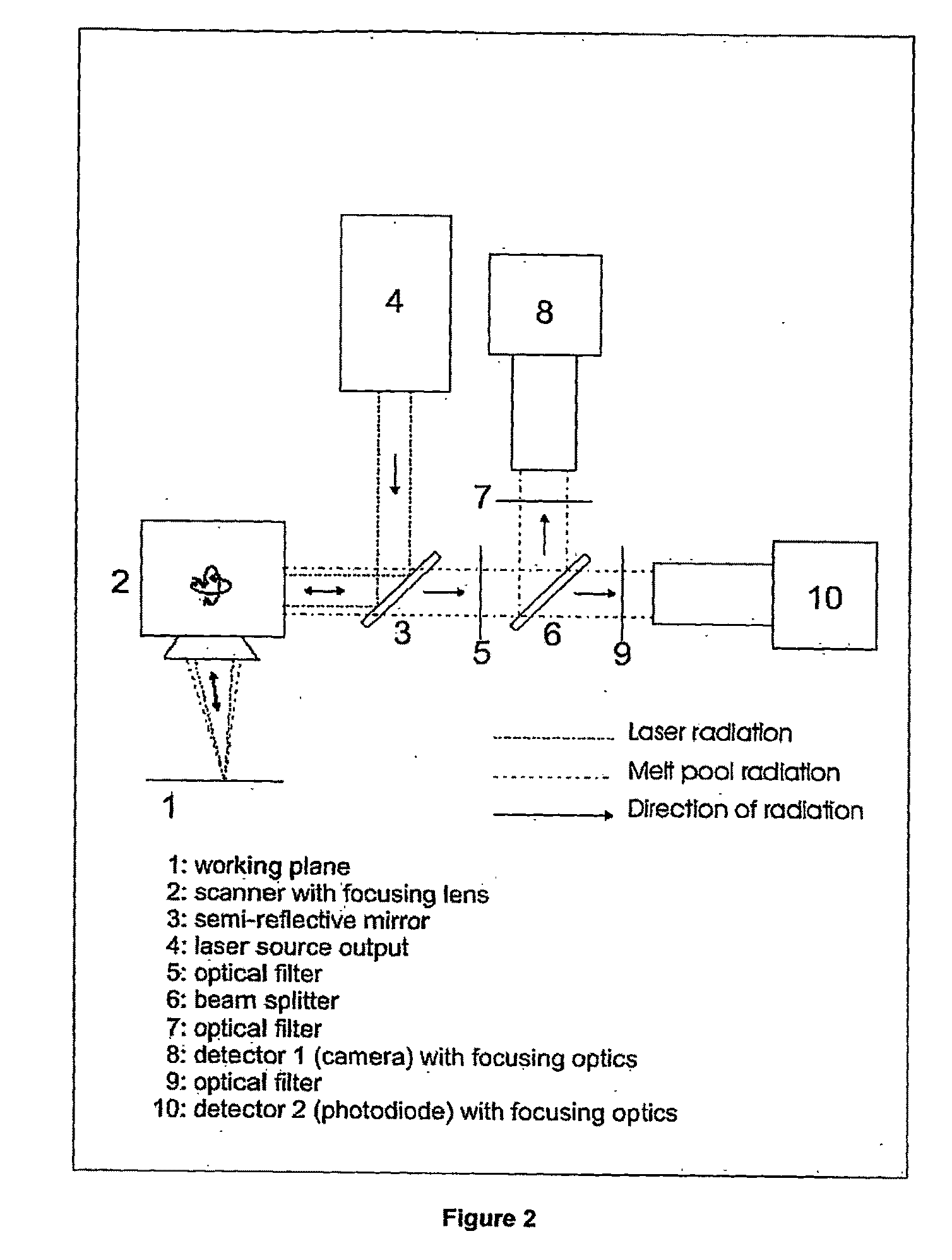

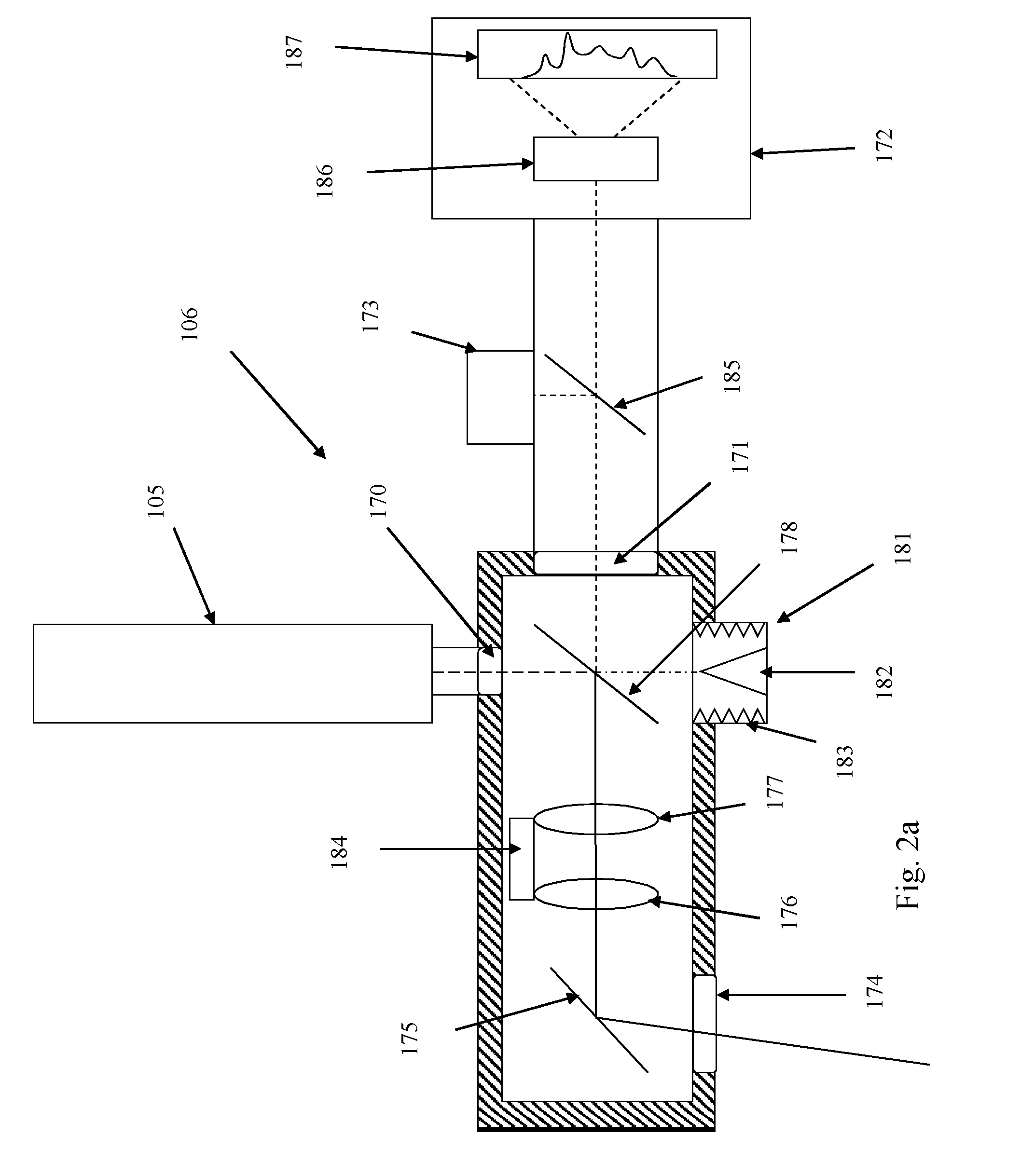

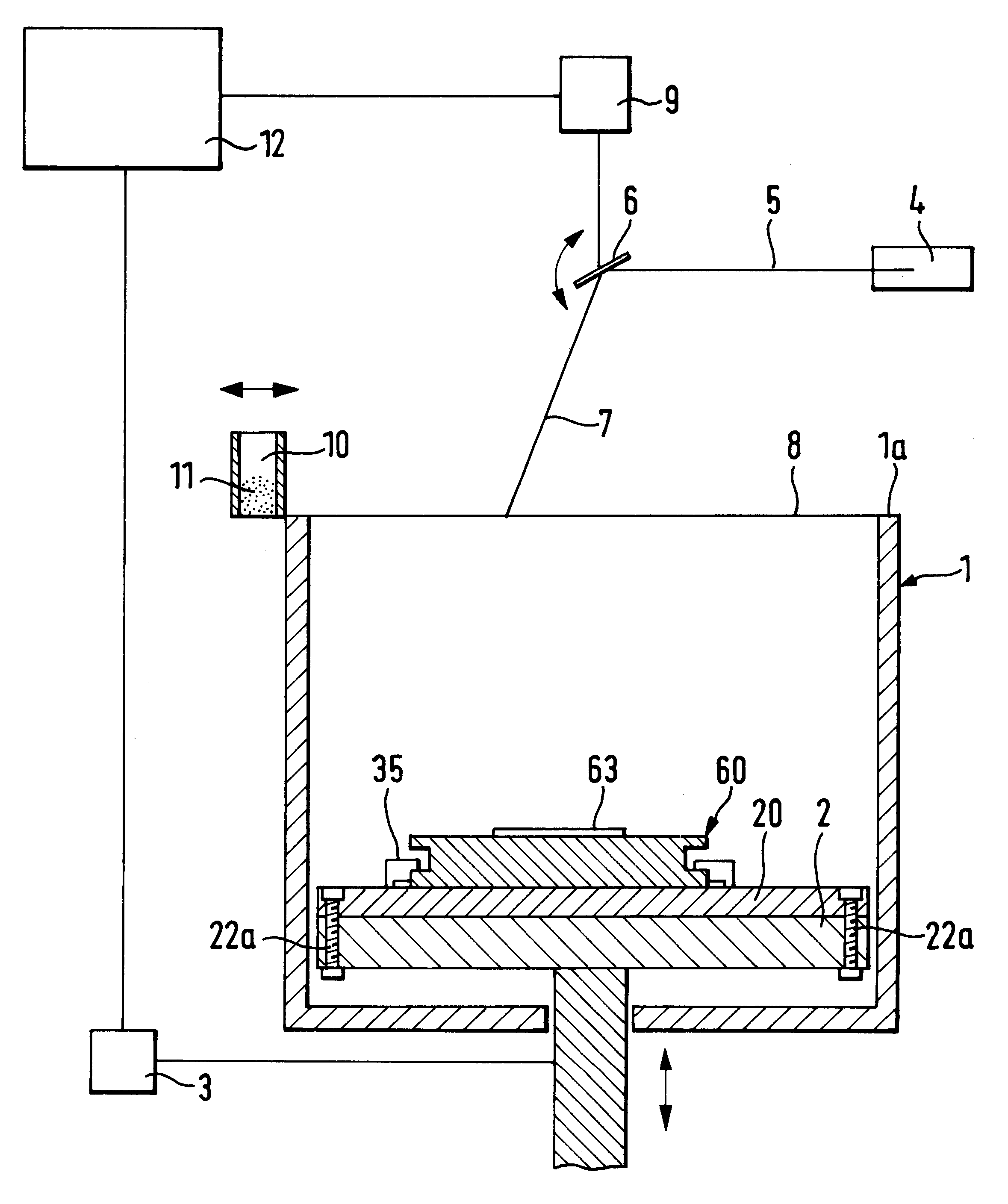

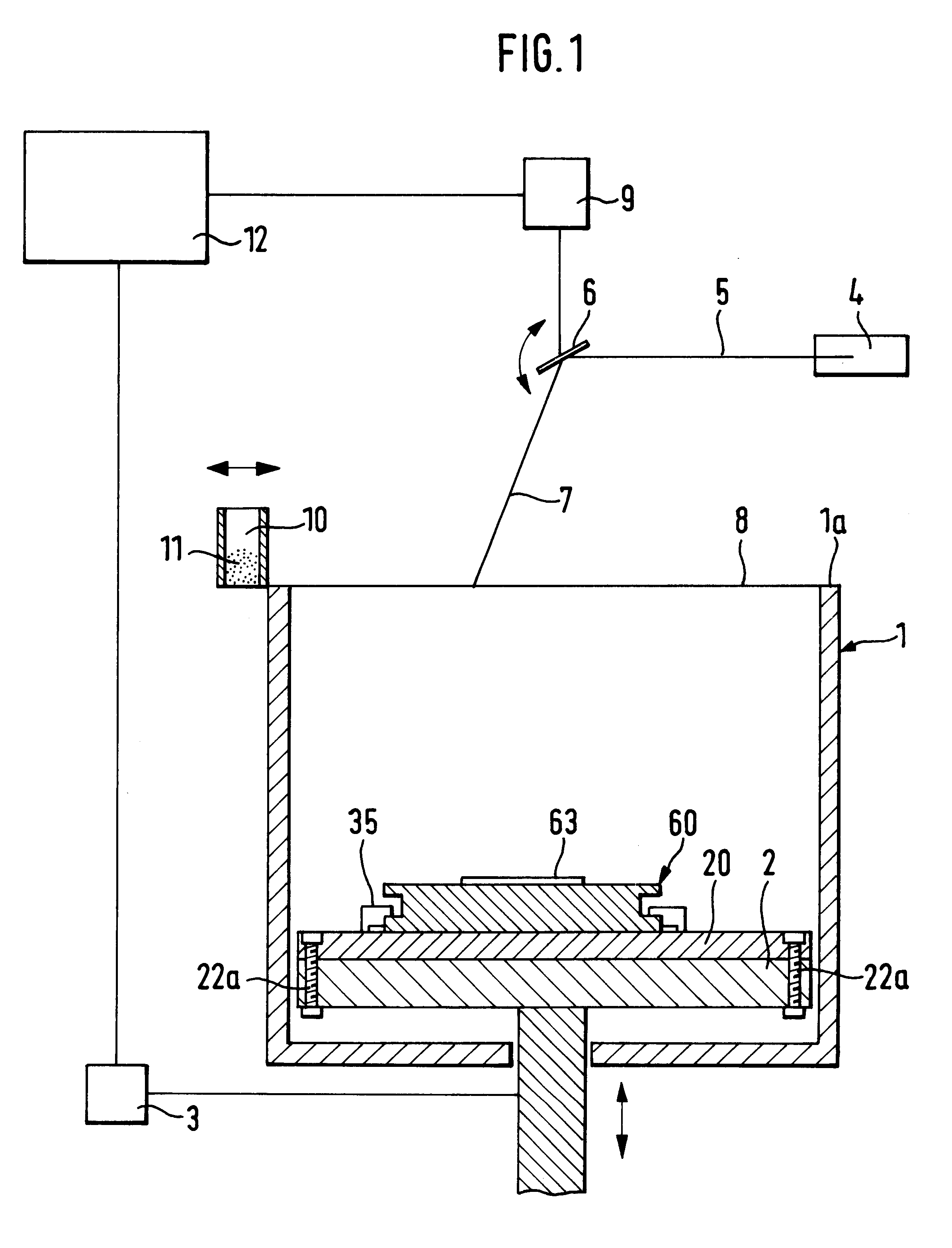

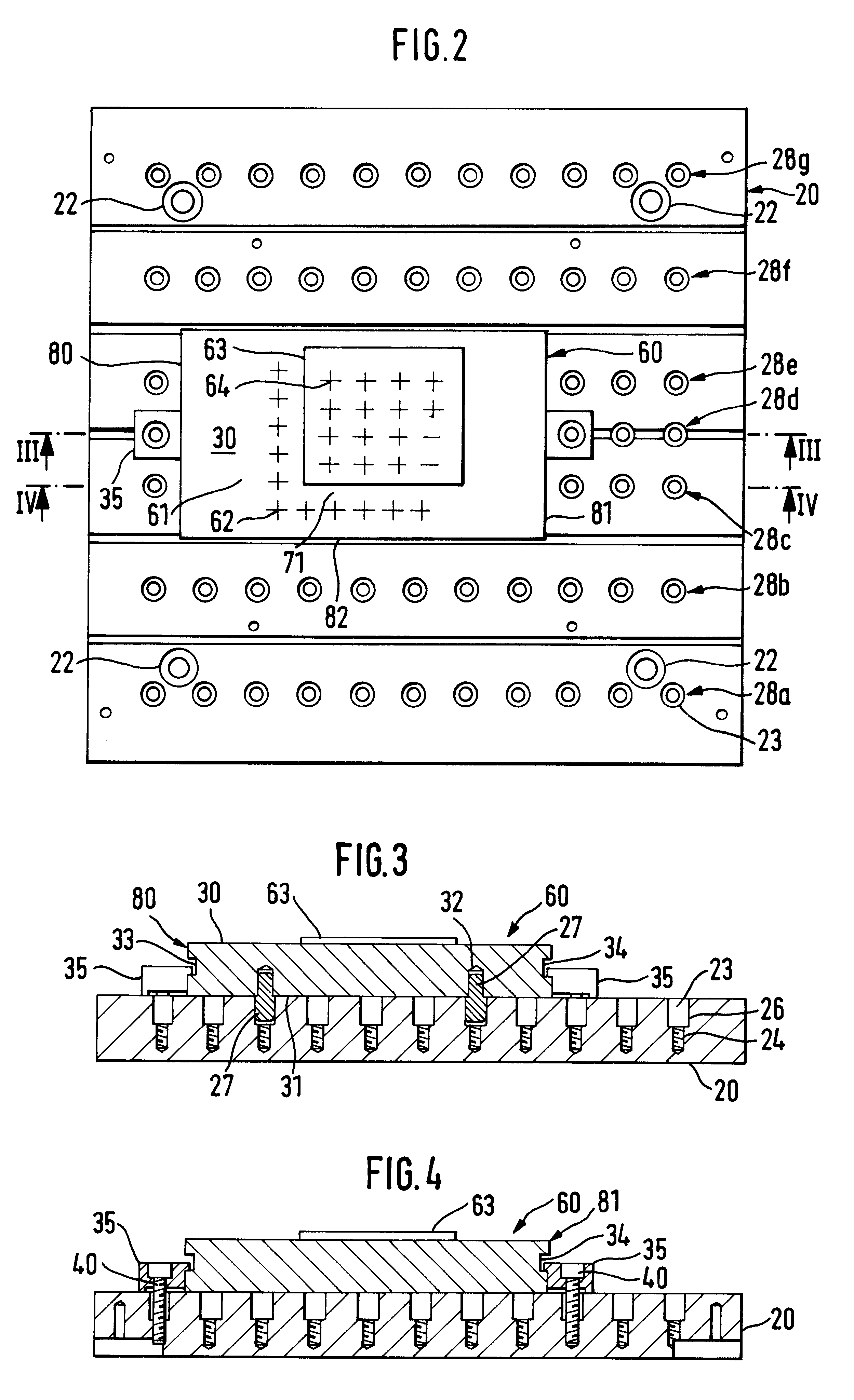

Procedure and apparatus for in-situ monitoring and feedback control of selective laser powder processing

InactiveUS20090206065A1Quality improvementReduce spectral distortionAdditive manufacturing apparatusIncreasing energy efficiencyControl systemFeedback controller

The present invention relates to a method and a device to monitor and control the Selective Laser Powder Processing. A Selective Laser Powder Processing device comprising a feedback controller to improve the stability of the Selective Laser Powder Processing process is presented. A signal reflecting a geometric quantity of the melt zone is used in the feedback controller to adjust the scanning parameters (e.g. laser power, laser spot size, scanning velocity, . . . ) of the laser beam (4) in order to maintain the geometric quantity of the melt zone at a constant level. The signal reflecting the geometric quantity of the melt zone can also be displayed in order to monitor the Selective Laser Powder Processing process. The present invention allows for the production of three-dimensional objects from powder material and improves the state of the art by compensating variations of the border conditions (e.g. local heat conduction rate) by a feedback control system based on a geometric quantity of the melt zone resulting in e.g. a lower amount of dross material when overhang planes are scanned.

Owner:KRUTH JEAN PIERRE +1

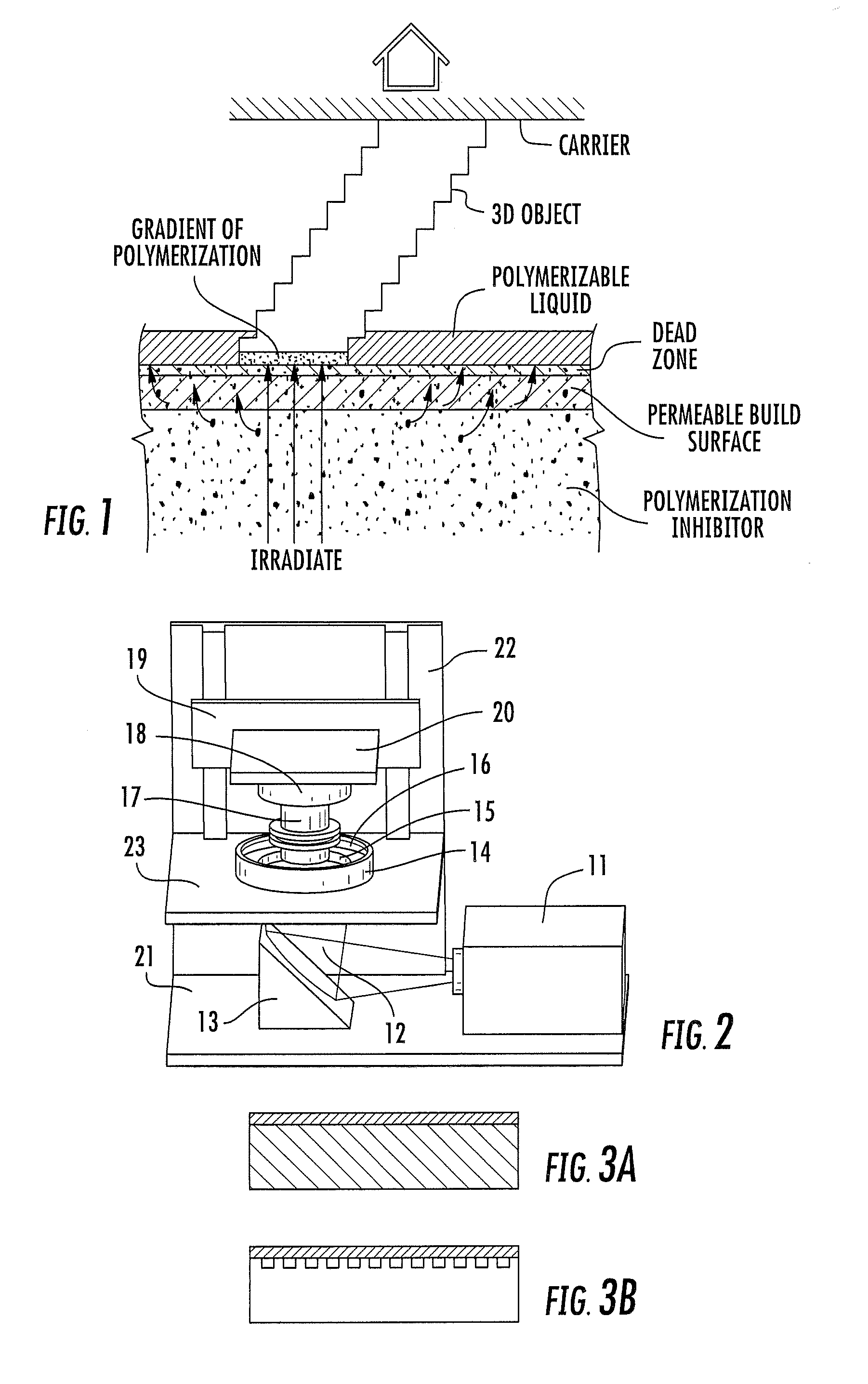

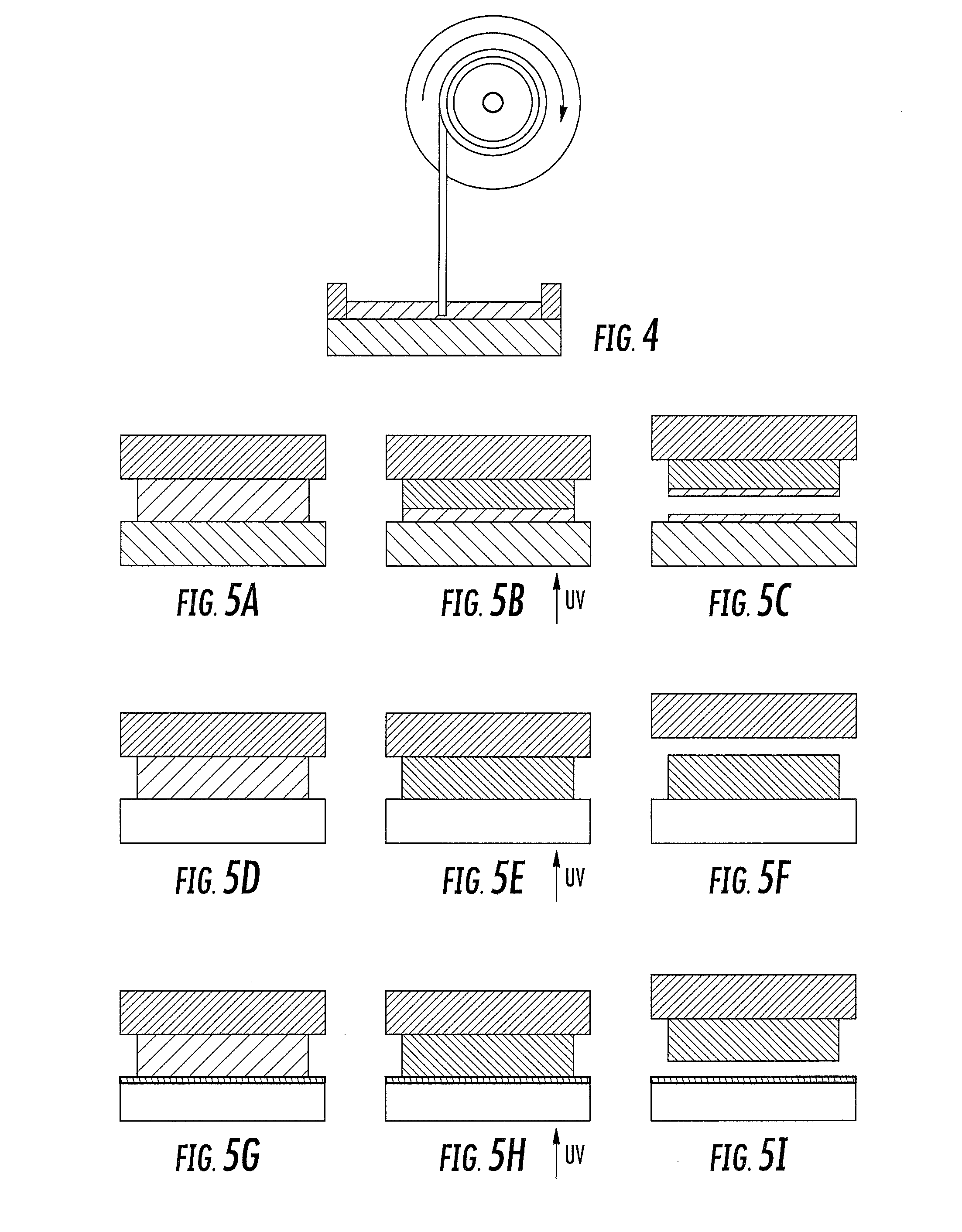

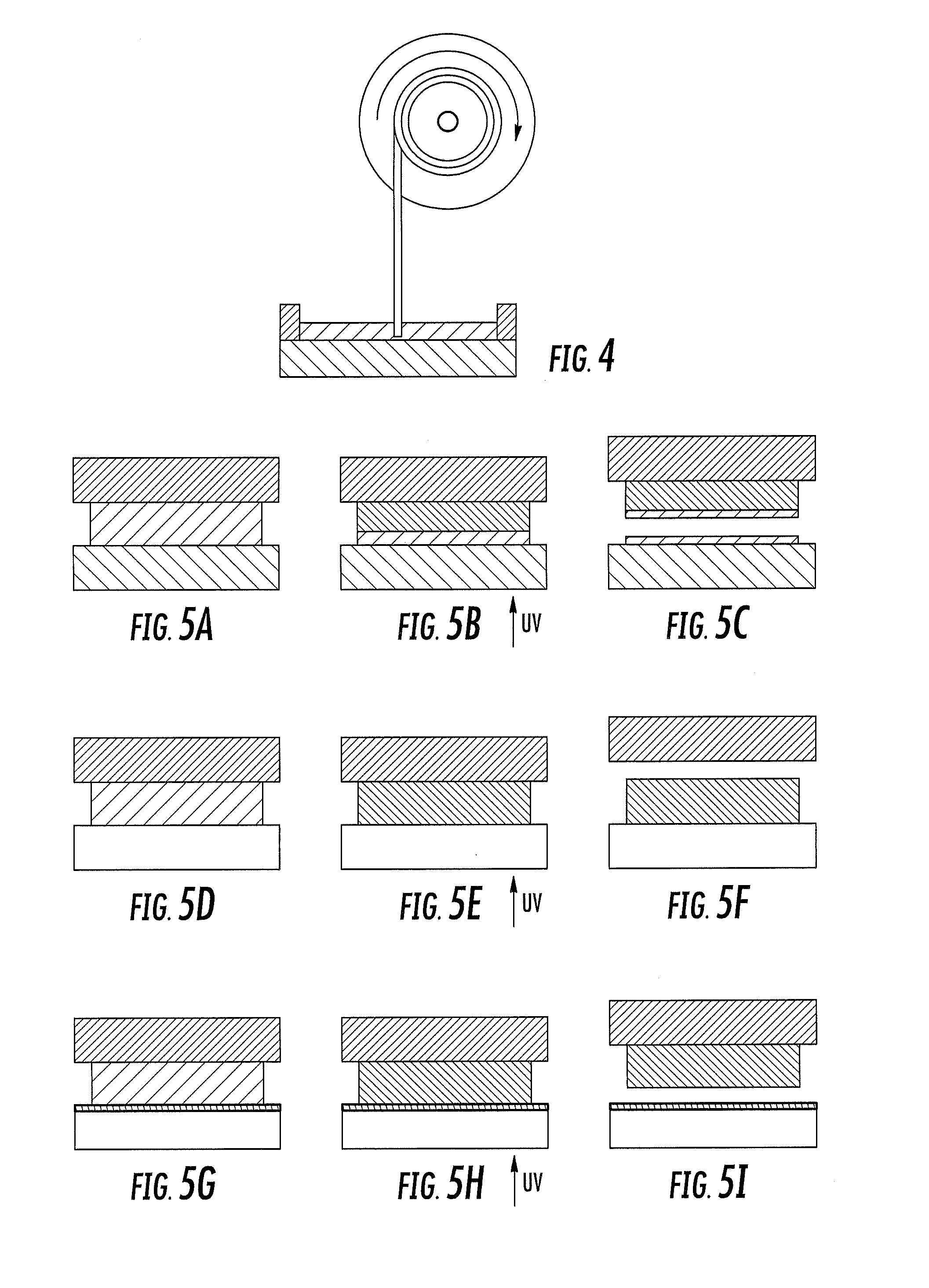

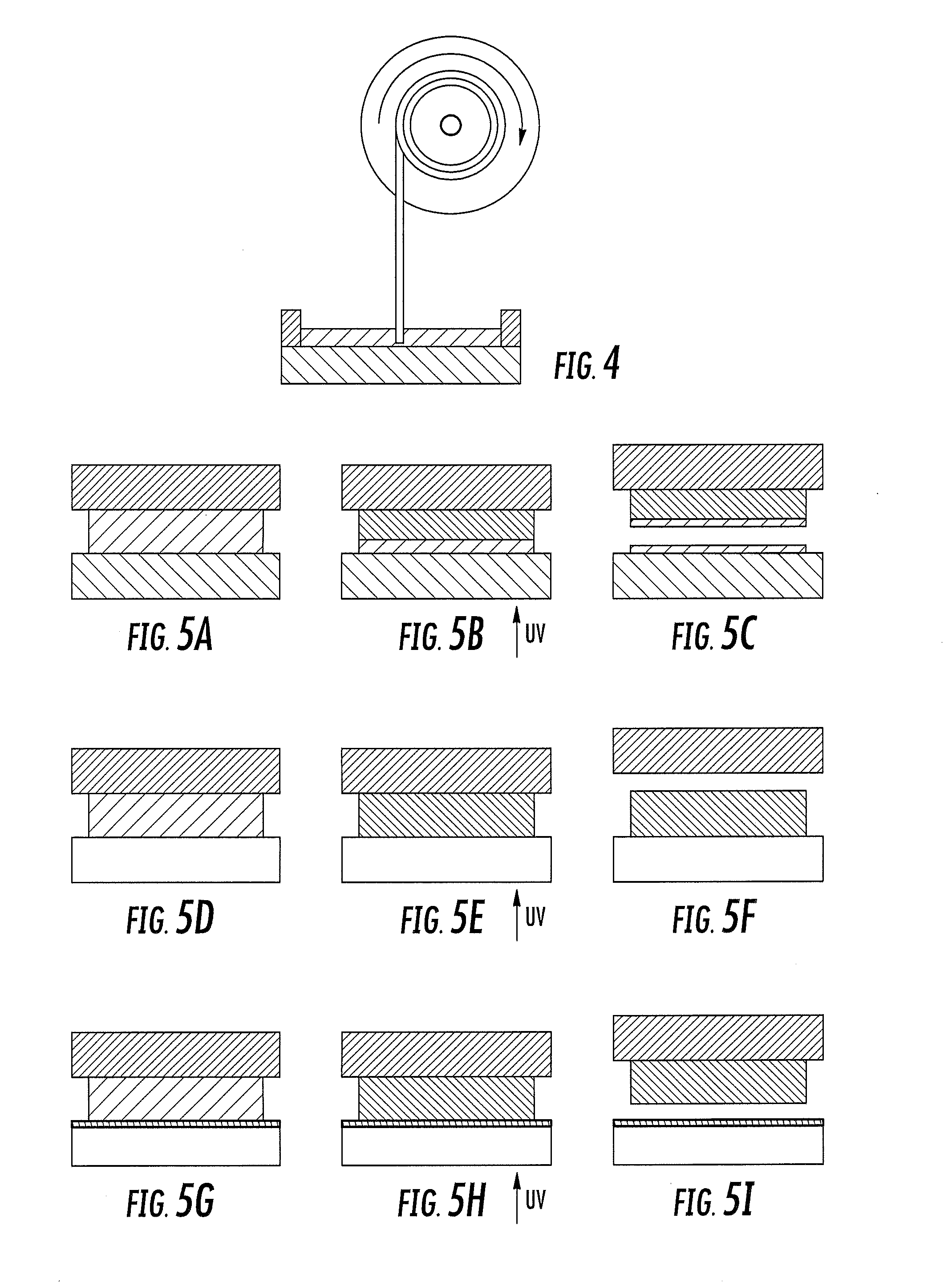

Method and apparatus for three-dimensional fabrication with feed through carrier

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquid contacting the build surface; (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface; (e) wherein the carrier has at least one channel formed therein, and the filling step is carried out by passing or forcing the polymerizable liquid into the build region through the at least one channel. Apparatus for carrying out the method is also described

Owner:CARBON INC

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

Rapid prototyping apparatus

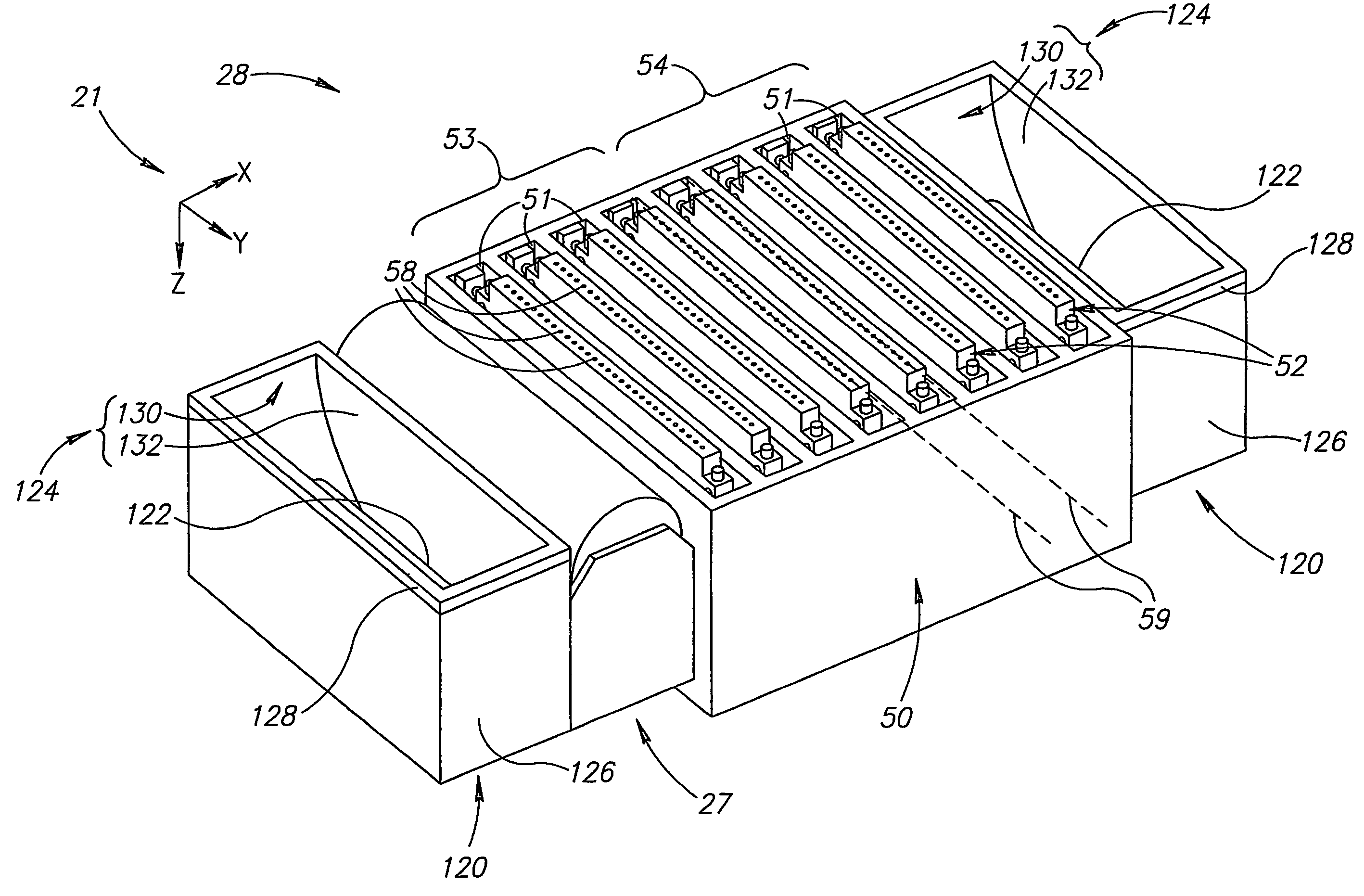

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

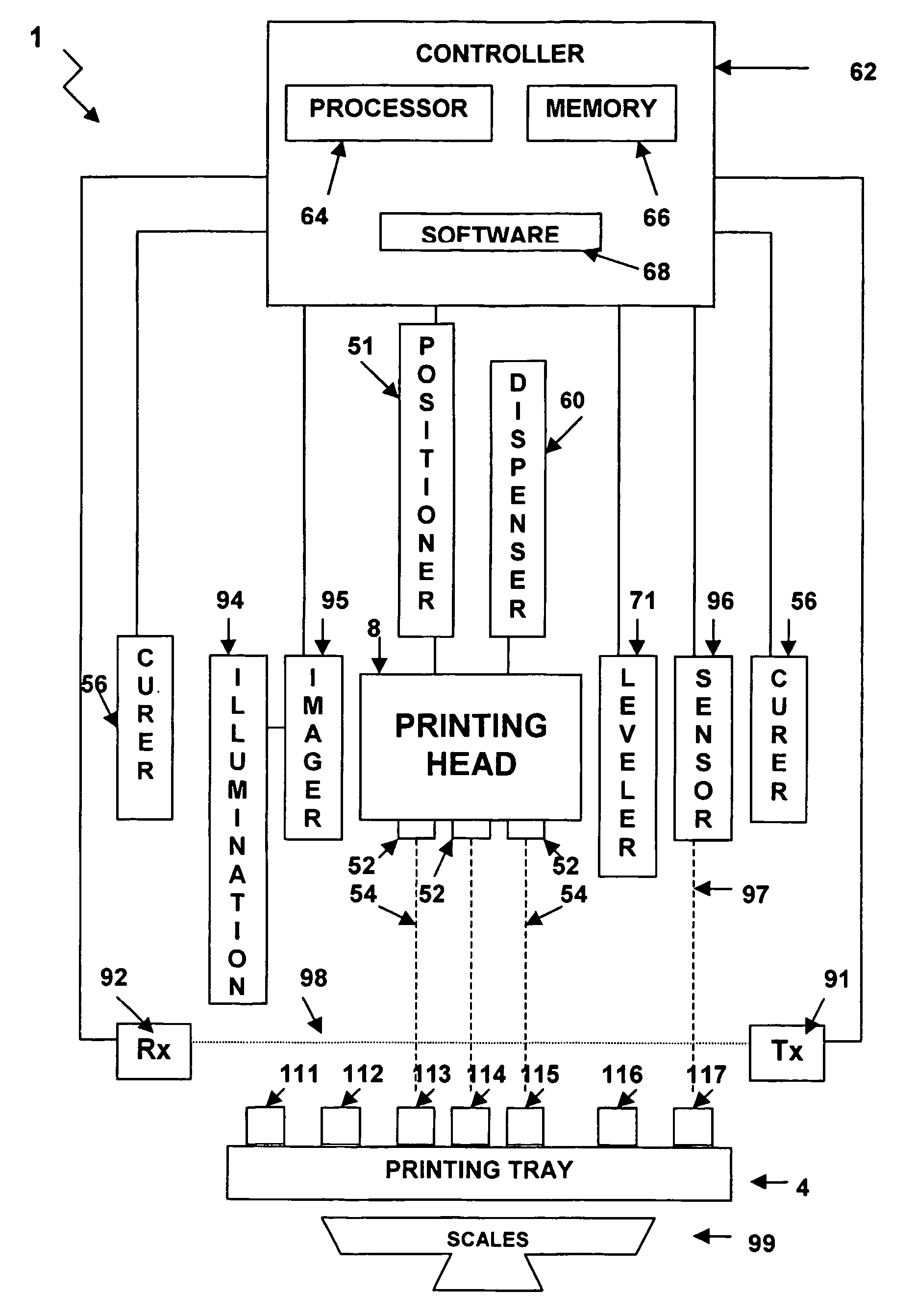

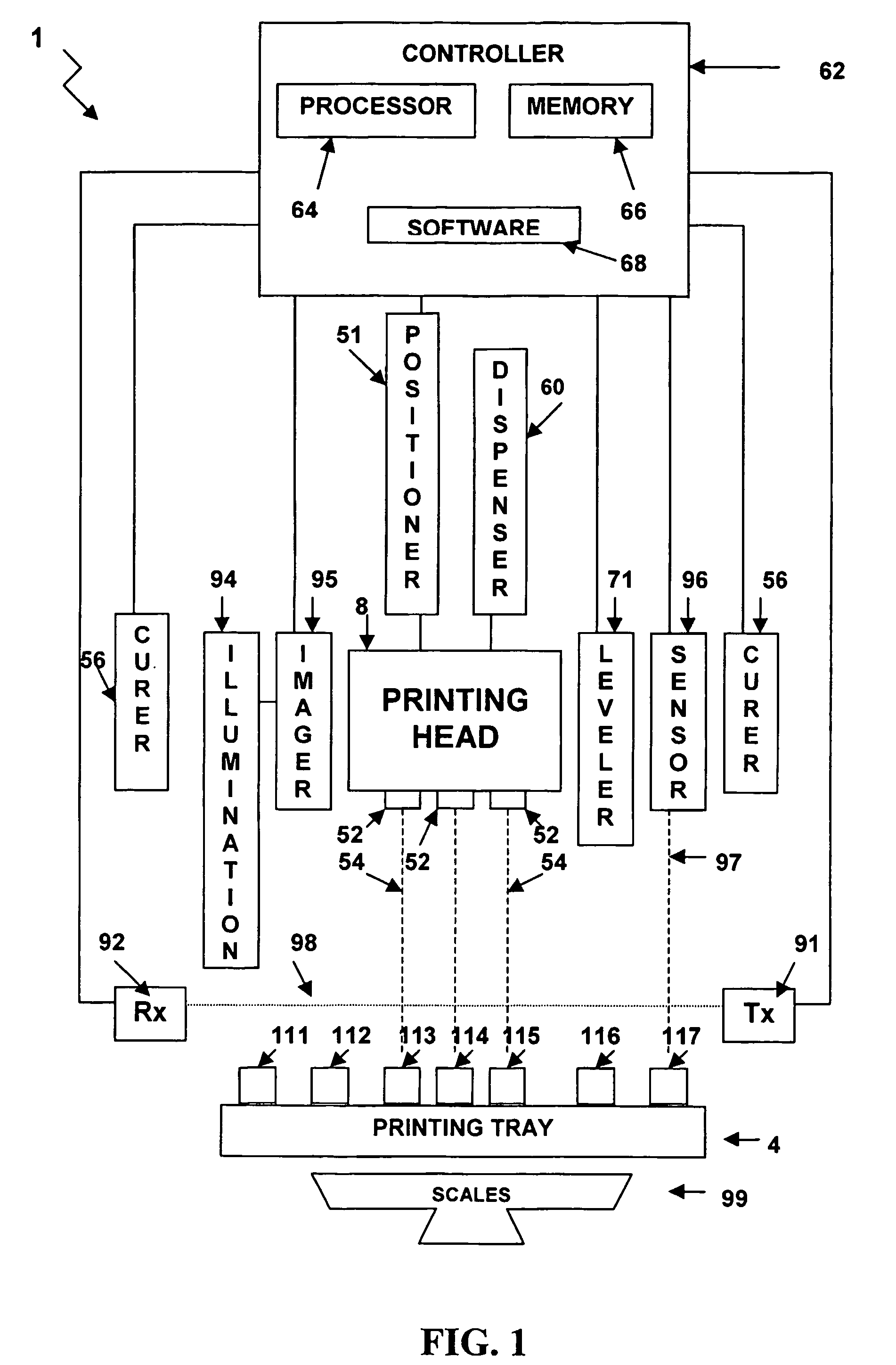

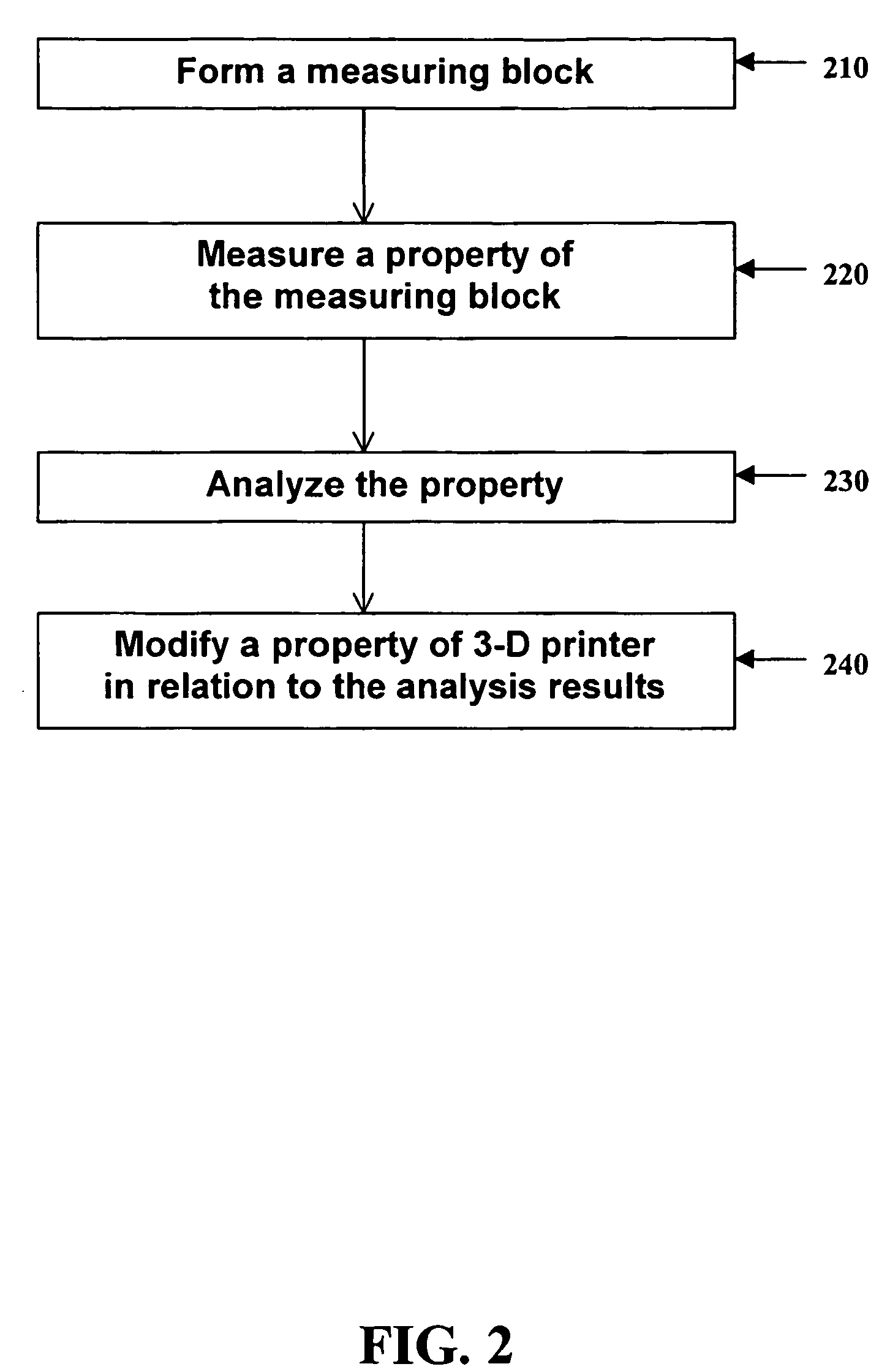

Device, system and method for calibration in three-dimensional model printing

InactiveUS20060111807A1Additive manufacturing apparatus3D object support structuresEngineeringThree dimensional model

Owner:OBJET GEOMETRIES

Continuous liquid interphase printing

A method of forming a three-dimensional object, comprises providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid while concurrently advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof, the gradient of polymerization zone comprising the polymerizable liquid in partially cured form. Apparatus for carrying out the method is also described.

Owner:CARBON INC

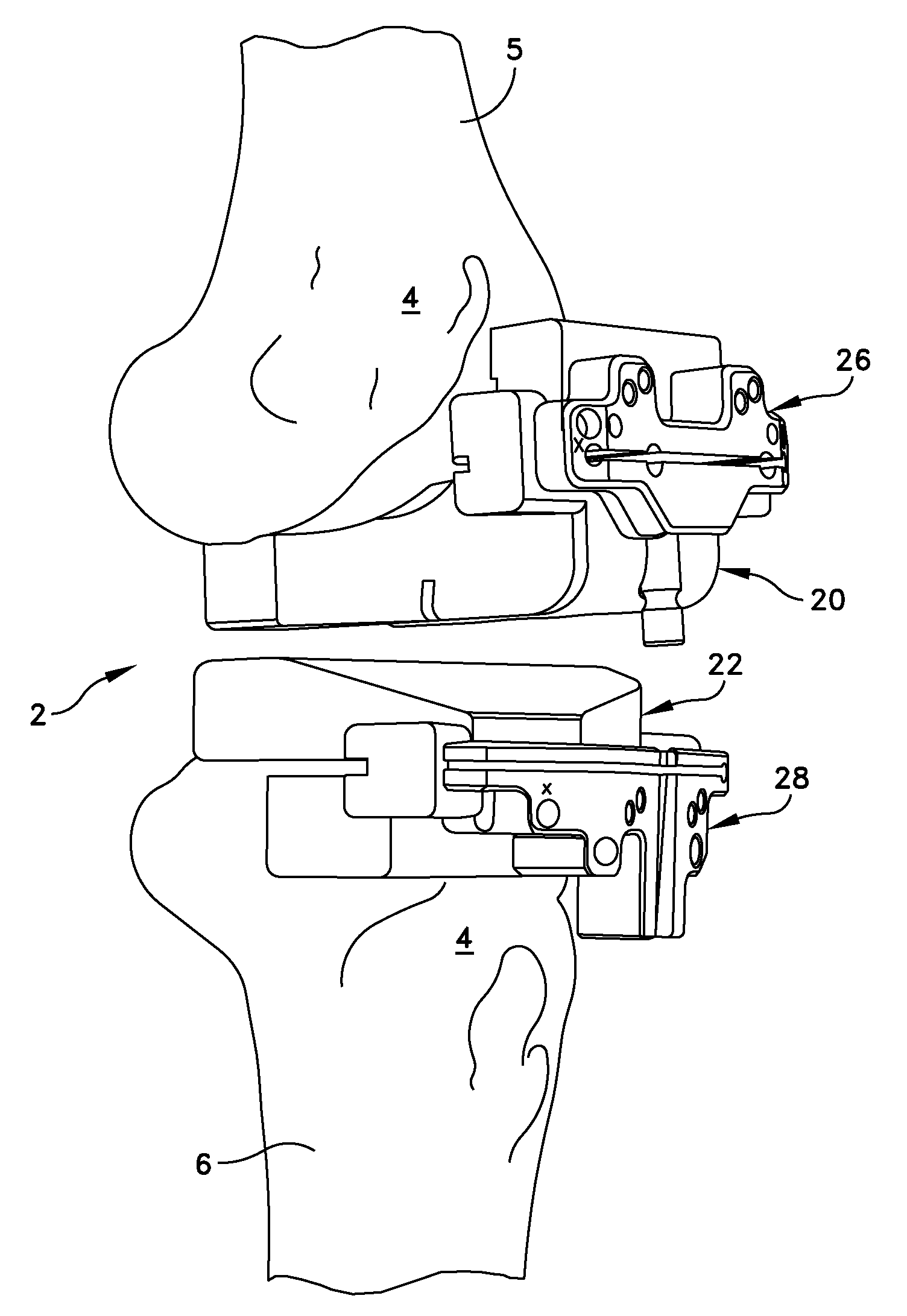

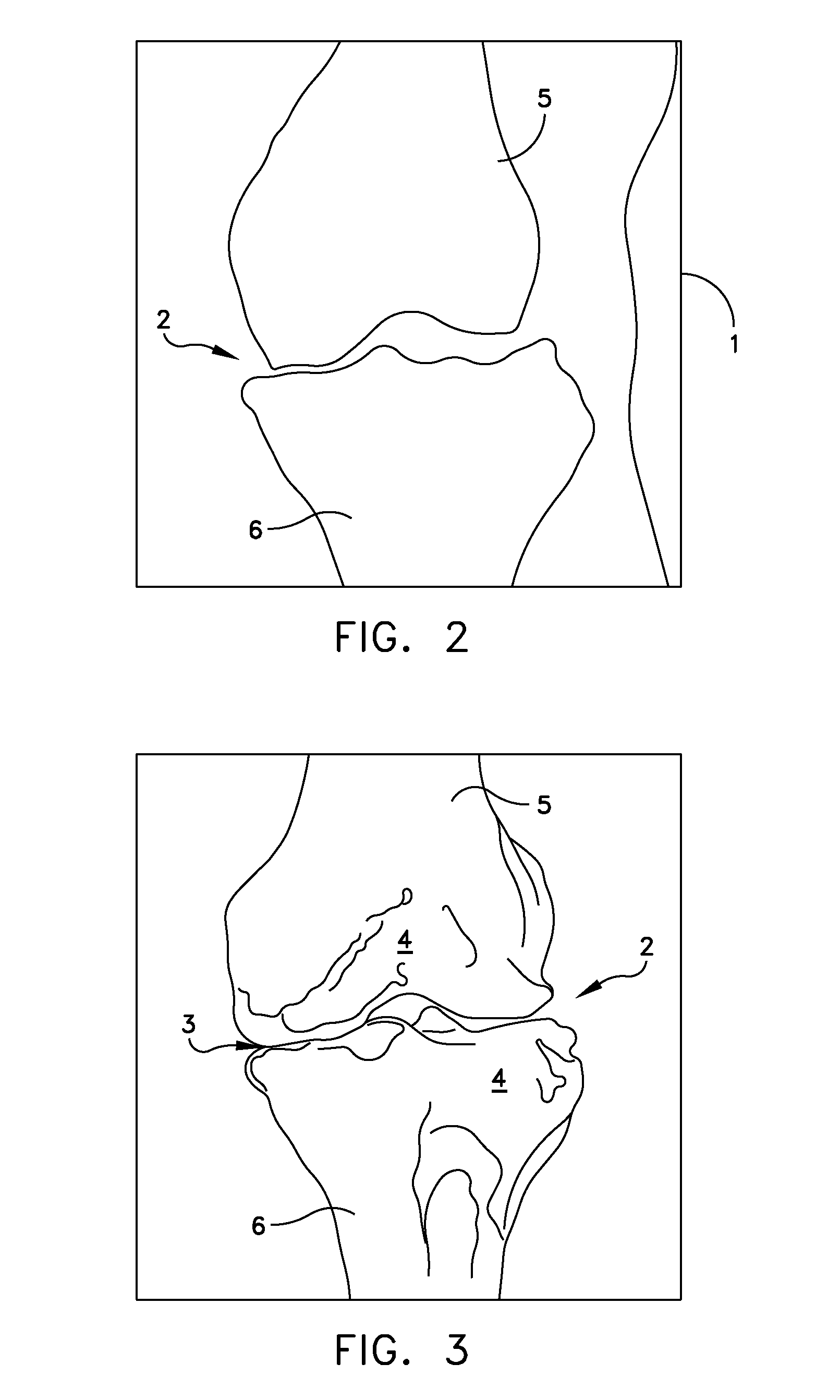

Method For Forming A Patient Specific Surgical Guide Mount

A resection guide locator includes a bone engagement portion with surfaces that are complementary to the surface topographies of a bone to be resected during surgery. A housing includes a socket defined by a resilient annular wall that is sized and arranged so to accept a resection guide by press-fit to thereby position and hold the resection guide within the socket. The resection guide is maintained in a predetermined, preferred position while the surfaces are releasably locked in position on the bone. A method is disclosed for forming and using the resection guide locator.

Owner:MICROPORT ORTHOPEDICS HLDG INC

Patient Specific Surgical Guide Locator and Mount

A resection guide locator includes a bone engagement portion with surfaces that are complementary to the surface topographies of a bone to be resected during surgery. A housing includes a socket defined by a resilient annular wall that is sized and arranged so to accept a resection guide by press-fit to thereby position and hold the resection guide within the socket. The resection guide is maintained in a predetermined, preferred position while the surfaces are releasably locked in position on the bone. A method is disclosed for forming and using the resection guide locator.

Owner:MICROPORT ORTHOPEDICS HLDG INC

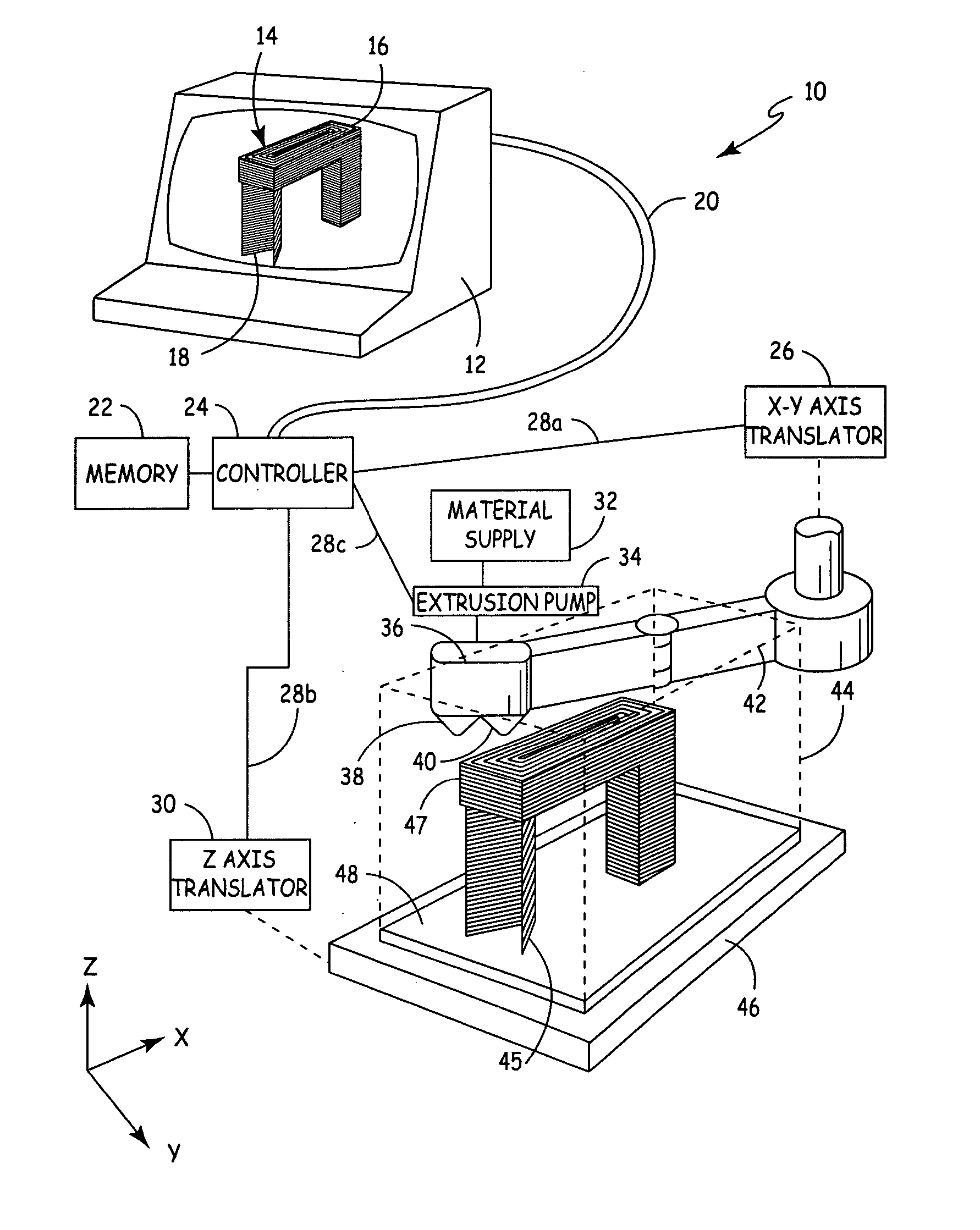

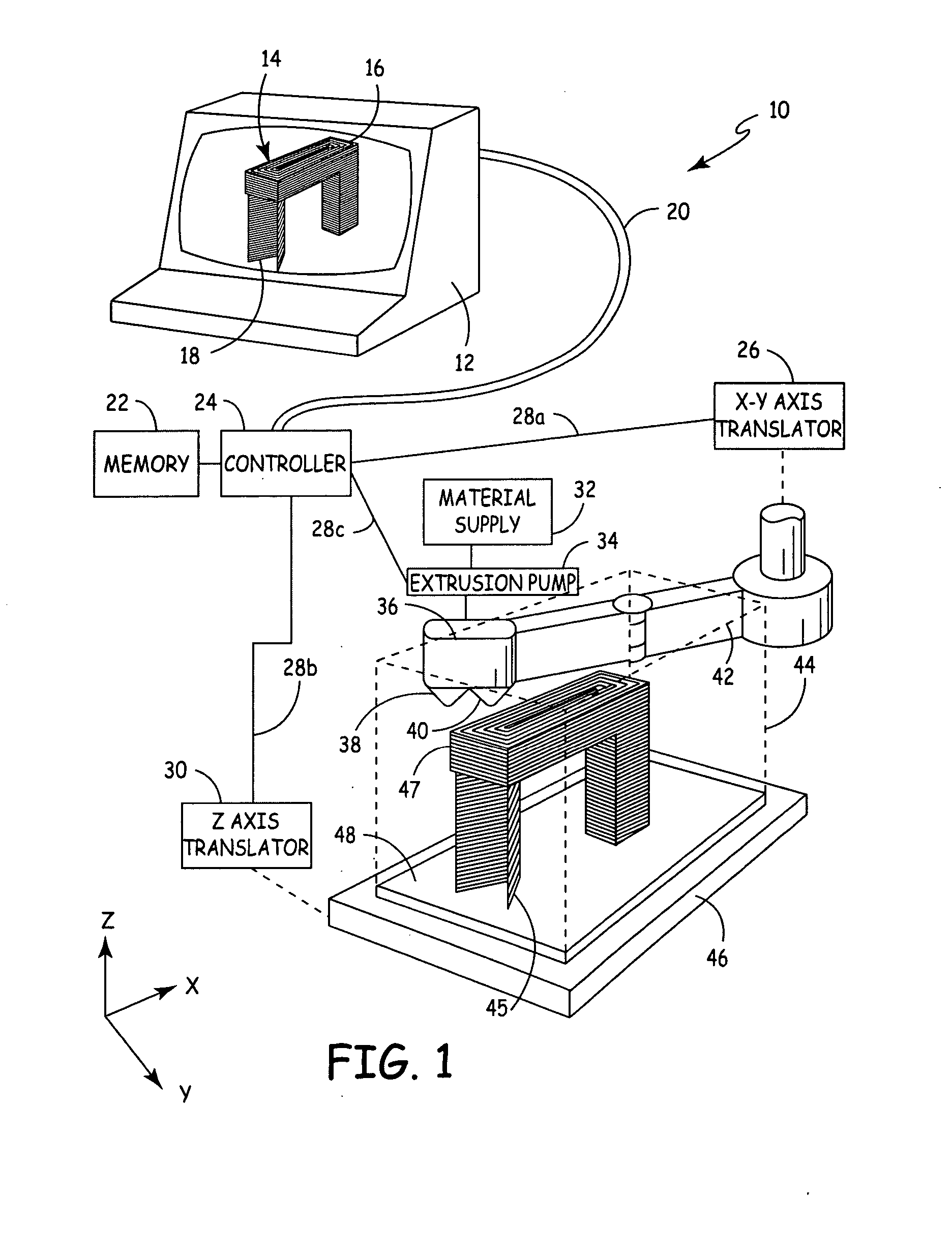

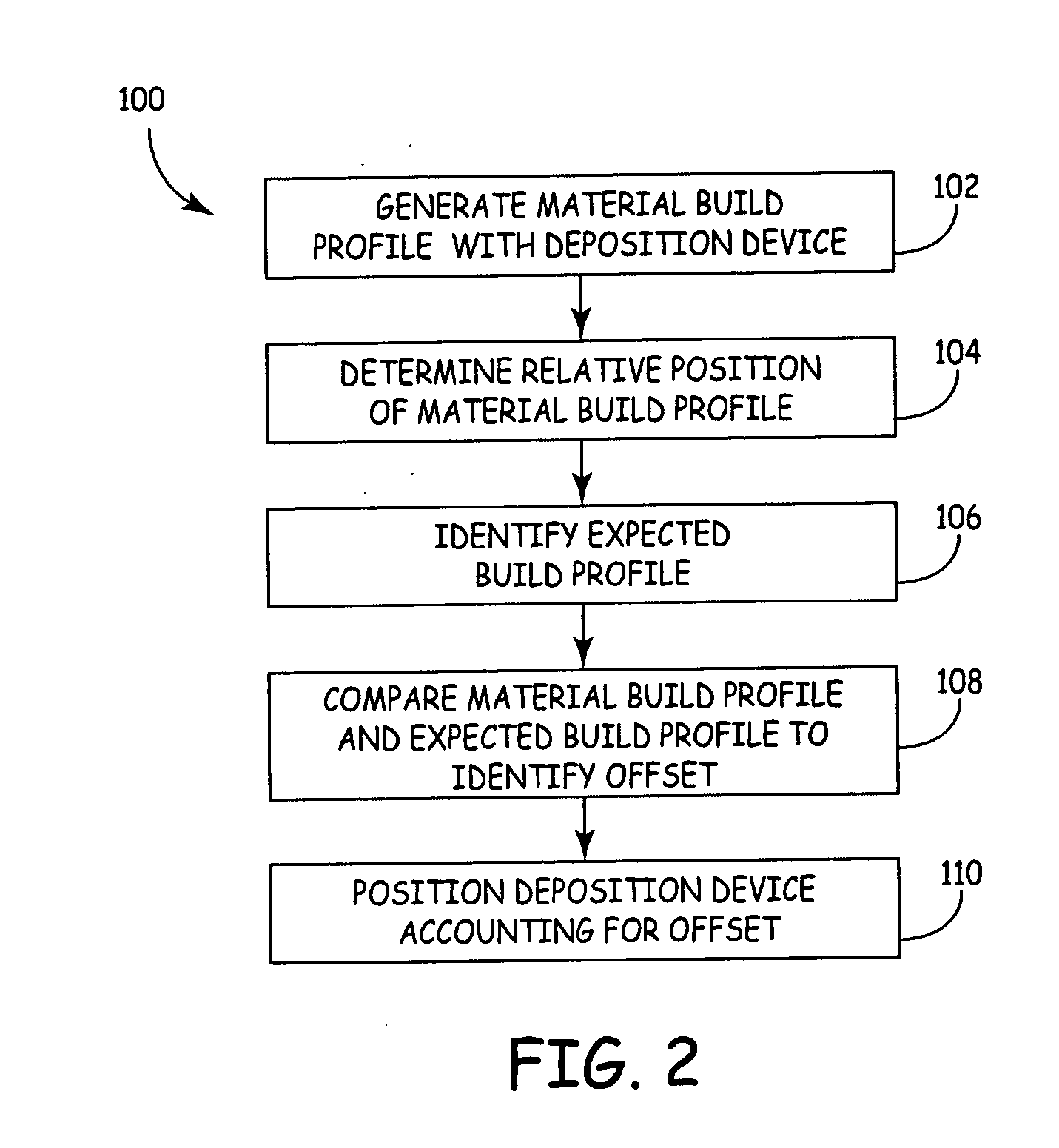

Auto tip calibration in an extrusion apparatus

The present invention is a method for performing a calibration routine of a deposition device in a three-dimensional modeling machine that deposits a material to build up three-dimensional objects as directed by a controller on a substrate mounted on a platform. The method comprises generating a material build profile, which represents a three-dimensional structure at defined locations. A relative position of the material build profile is then determined. An expected build profile is identified and then compared to the determined relative position of the material build profile to identify any difference which represents an offset. The modeling system then positions the deposition device based upon the offset.

Owner:STRATSYS INC

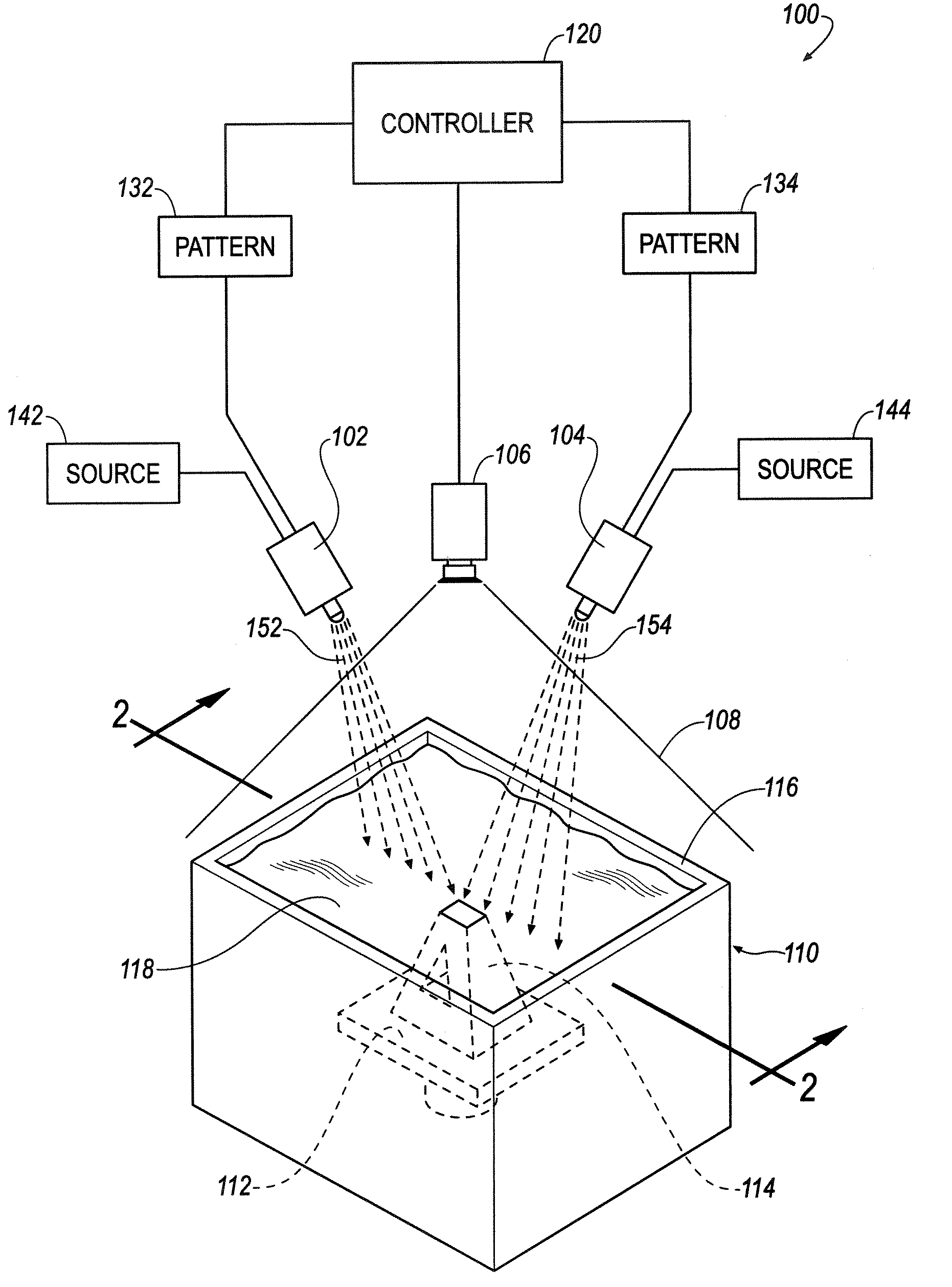

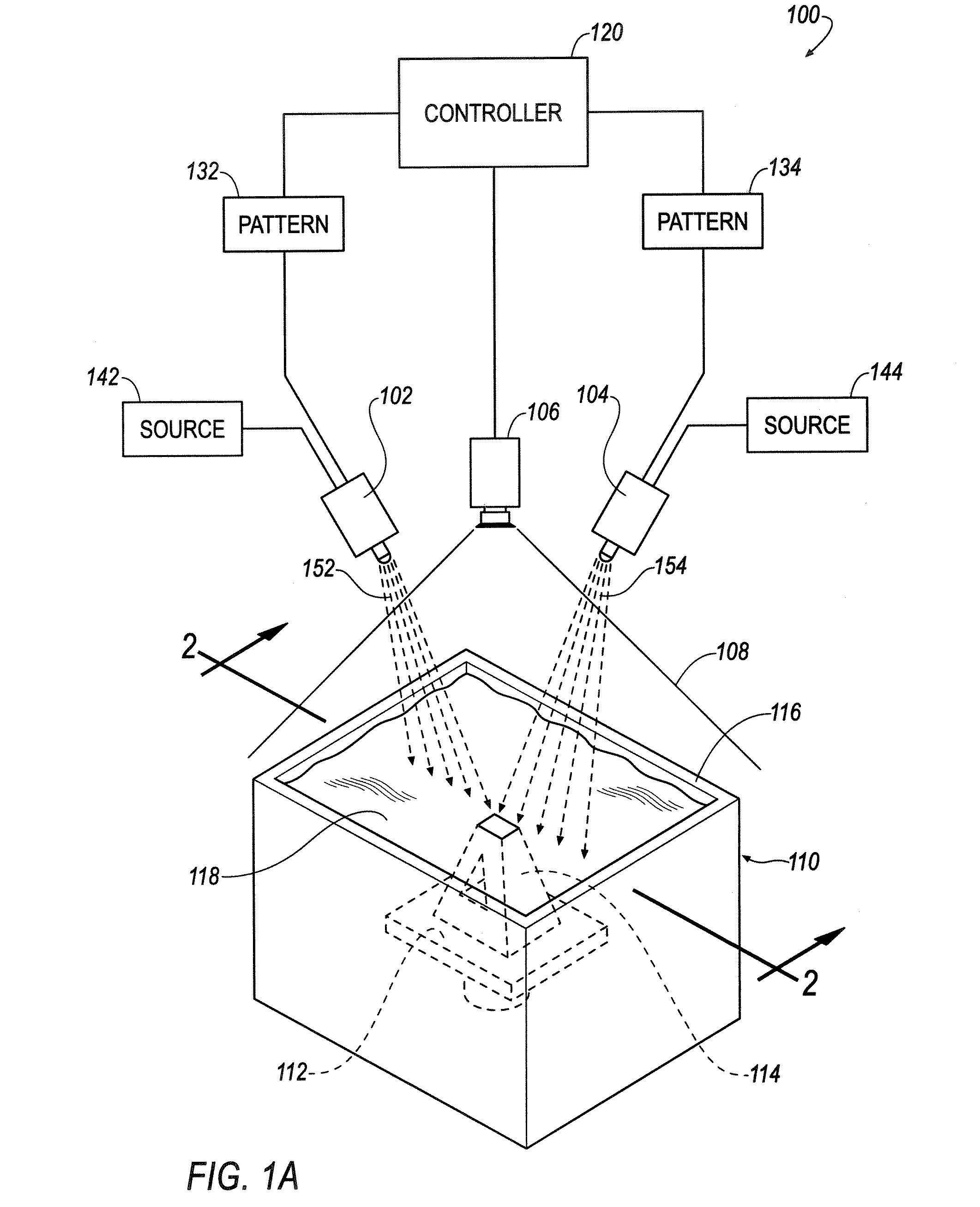

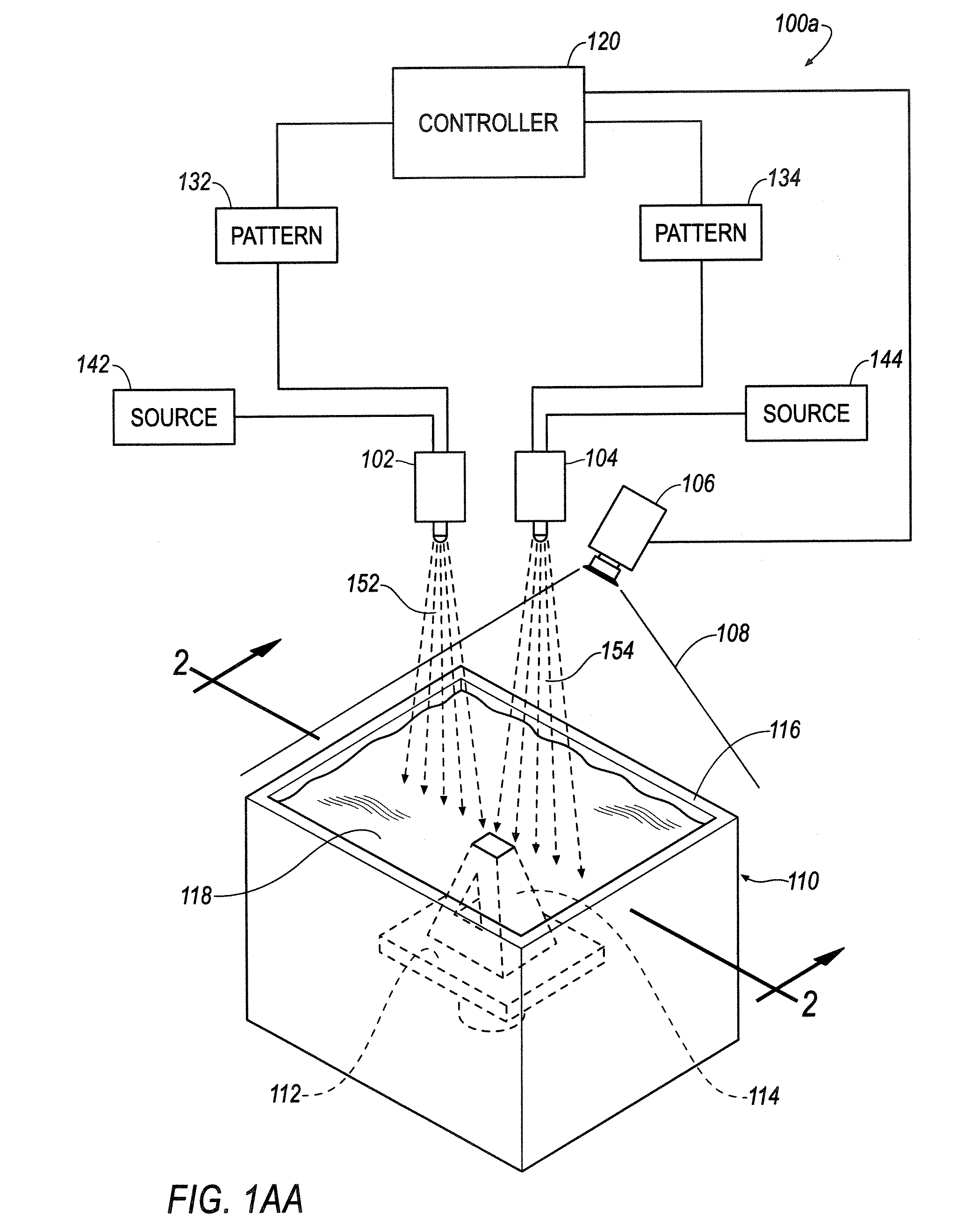

System and Method for Manufacturing

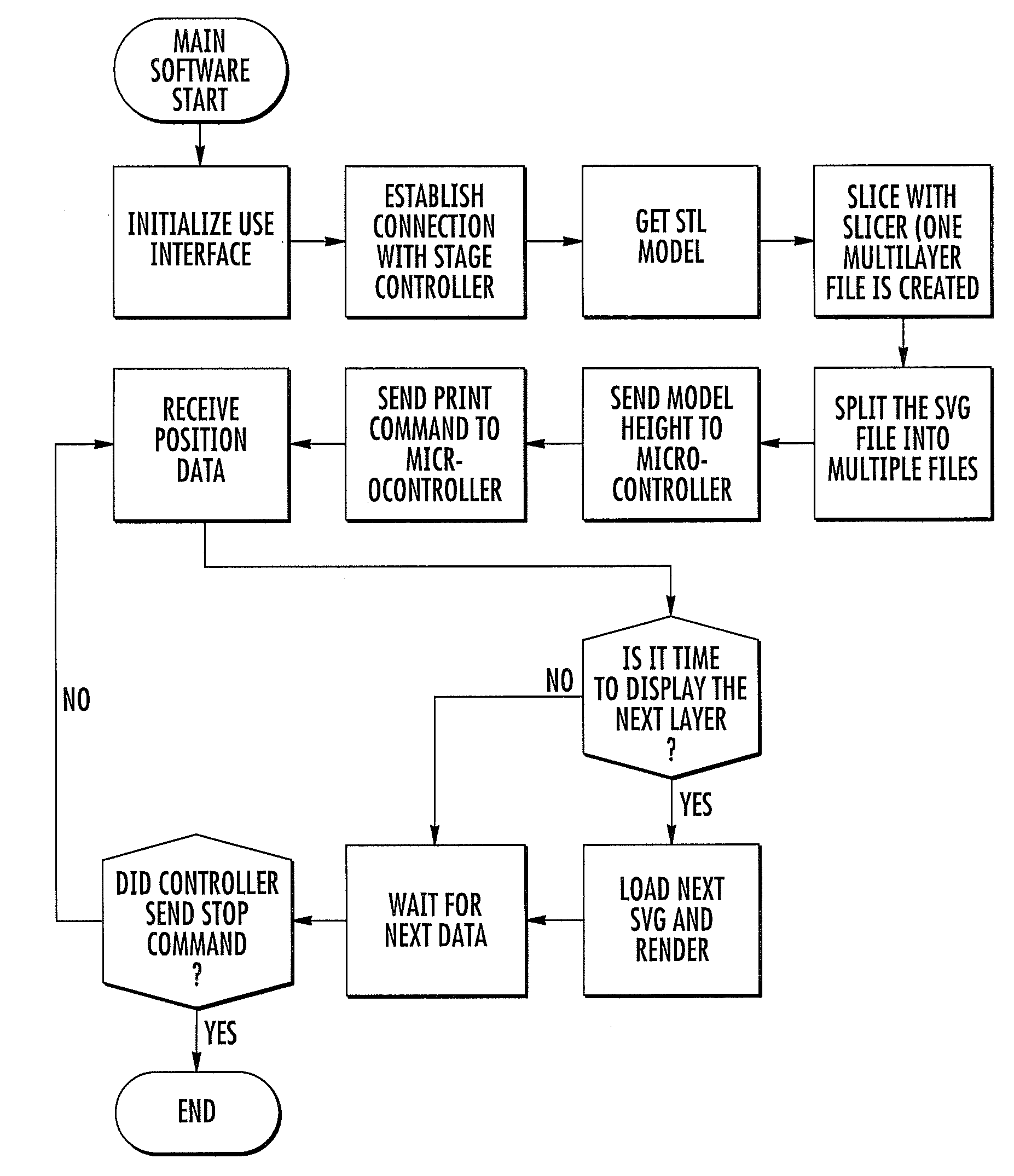

ActiveUS20100125356A1Image enhancementAdditive manufacturing apparatusComputer graphics (images)Reactive material

A method includes receiving a predetermined object pattern representing a portion of a three-dimensional object, modifying the predetermined object pattern to correct for geometric distortion of a pattern generator, and generating the modified pattern using the pattern generator. The generated pattern interacts with a reactive material to form the portion of the three-dimensional object defined by the predetermined object pattern.

Owner:GLOBAL FILTRATION SYST

Method and apparatus for monitoring electro-magnetic radiation power in solid freeform fabrication systems

Owner:STRATASYS LTD

Additive manufacturing apparatus and method

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

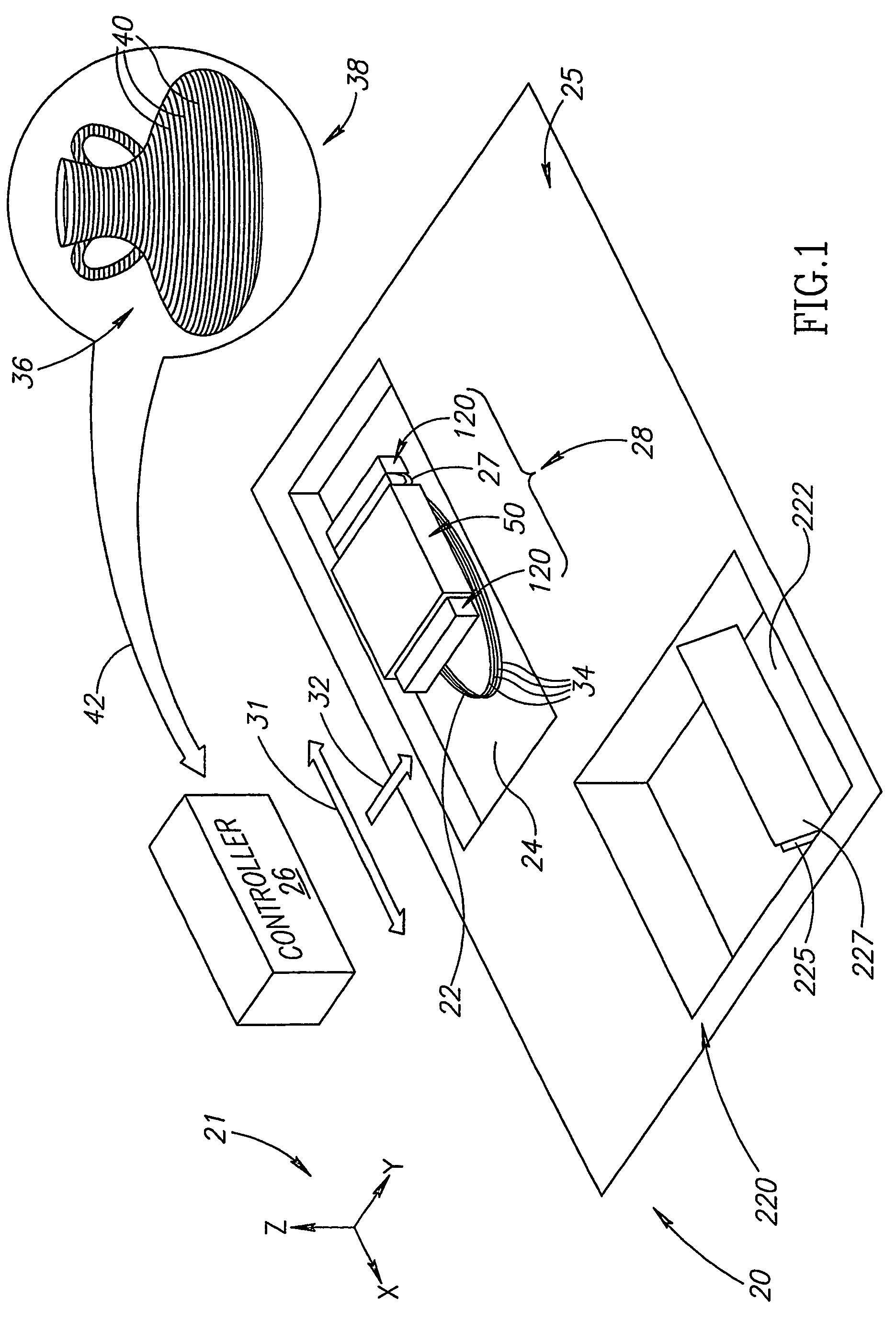

Solid freeform fabrication using a plurality of modeling materials

ActiveUS9031680B2Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:STRATASYS LTD

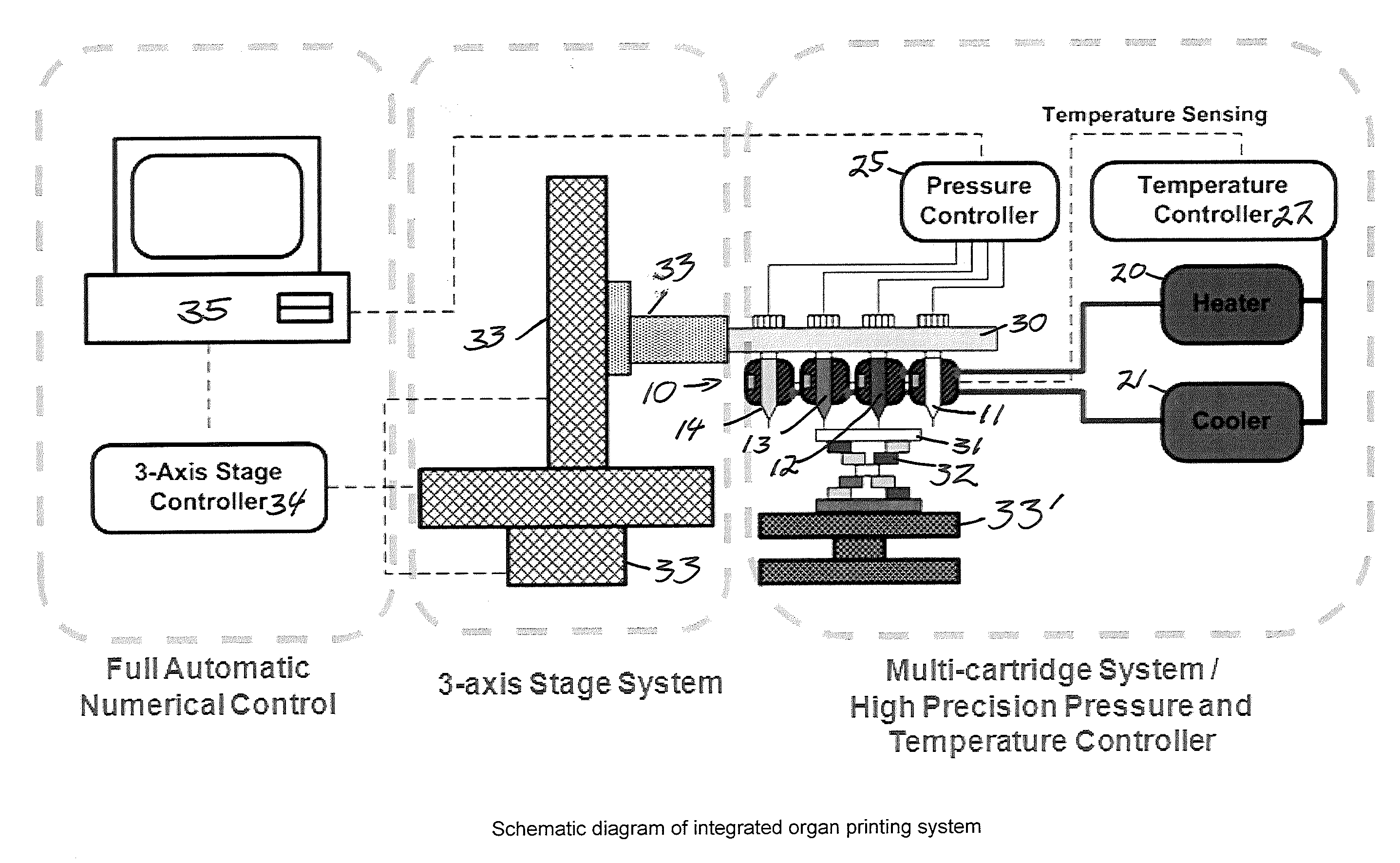

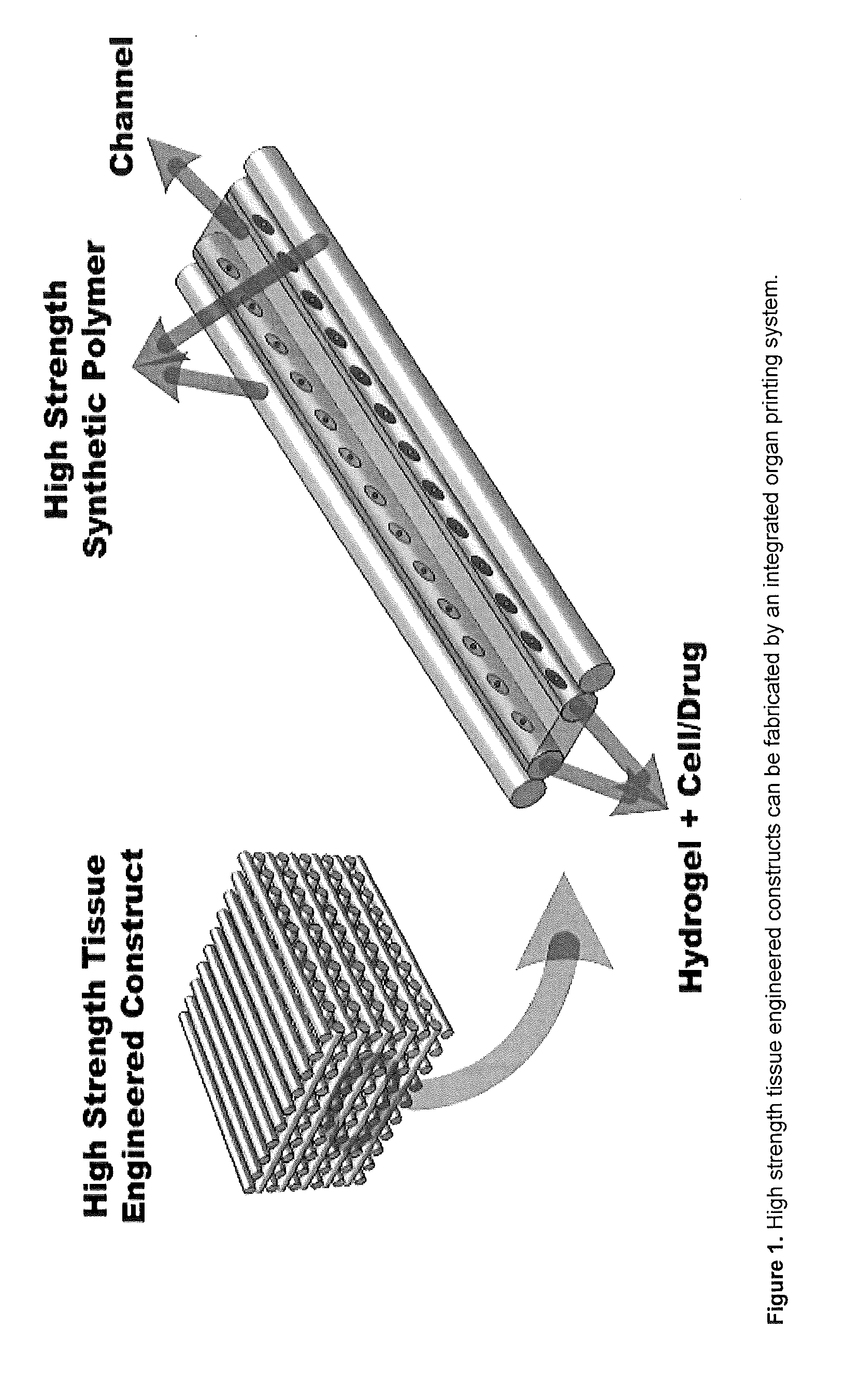

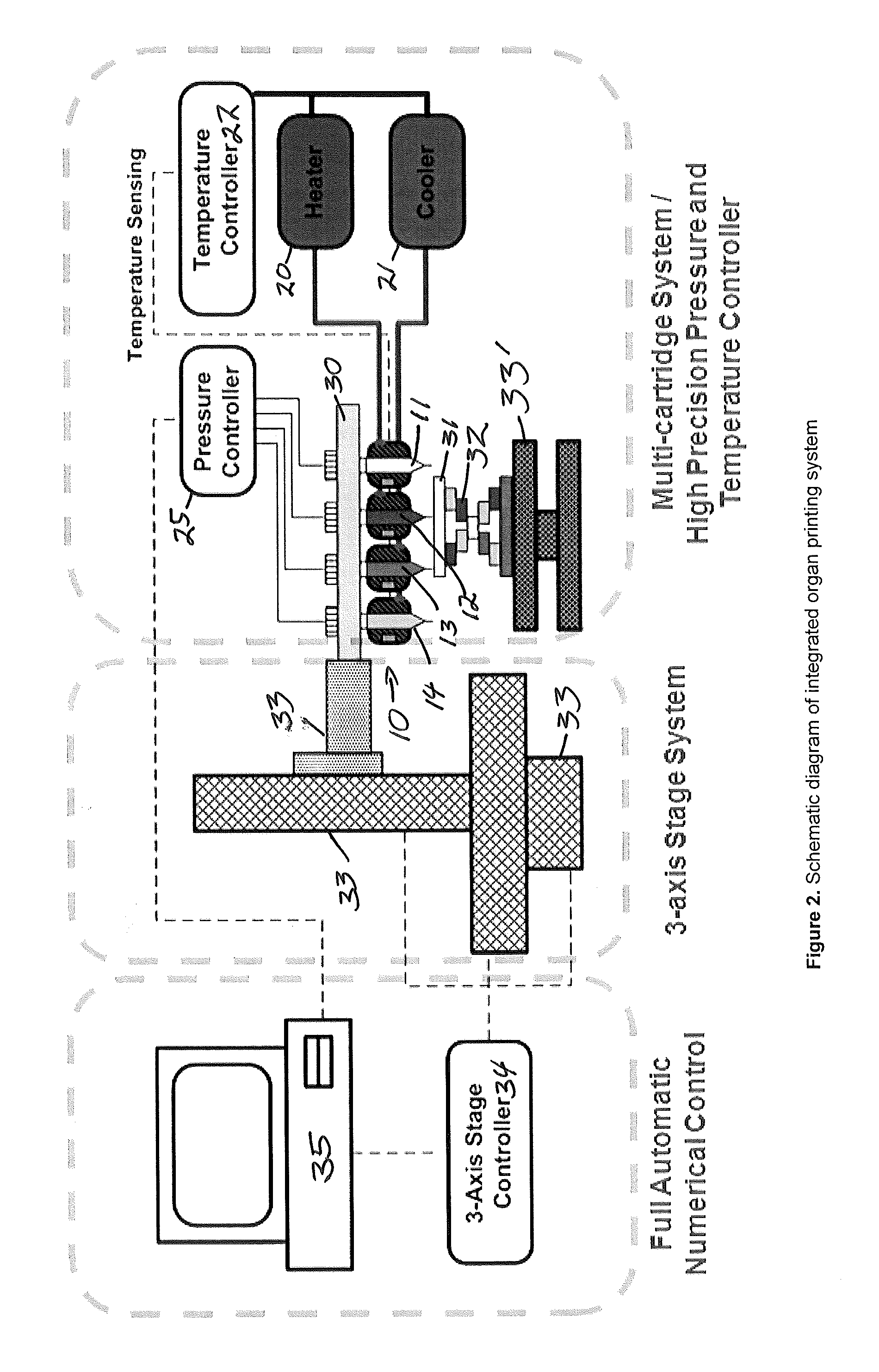

Integrated organ and tissue printing methods, system and apparatus

InactiveUS20120089238A1Additive manufacturing apparatusPretreated surfacesLiving cellBiomedical engineering

A method of making an organ or tissue comprises: (a) providing a first dispenser containing a structural support polymer and a second dispenser containing a live cell-containing composition; (b) depositing a layer on said support from said first and second dispenser, said layer comprising a structural support polymer and said cell-containing composition; and then (c) iteratively repeating said depositing step a plurality of times to form a plurality of layers one on another, with separate and discrete regions in each of said layers comprising one or the other of said support polymer or said cell-containing composition, to thereby produce provide a composite three dimensional structure containing both structural support regions and cell-containing regions. Apparatus for carrying out the method and composite products produced by the method are also described.

Owner:KANG HYUN WOOK +3

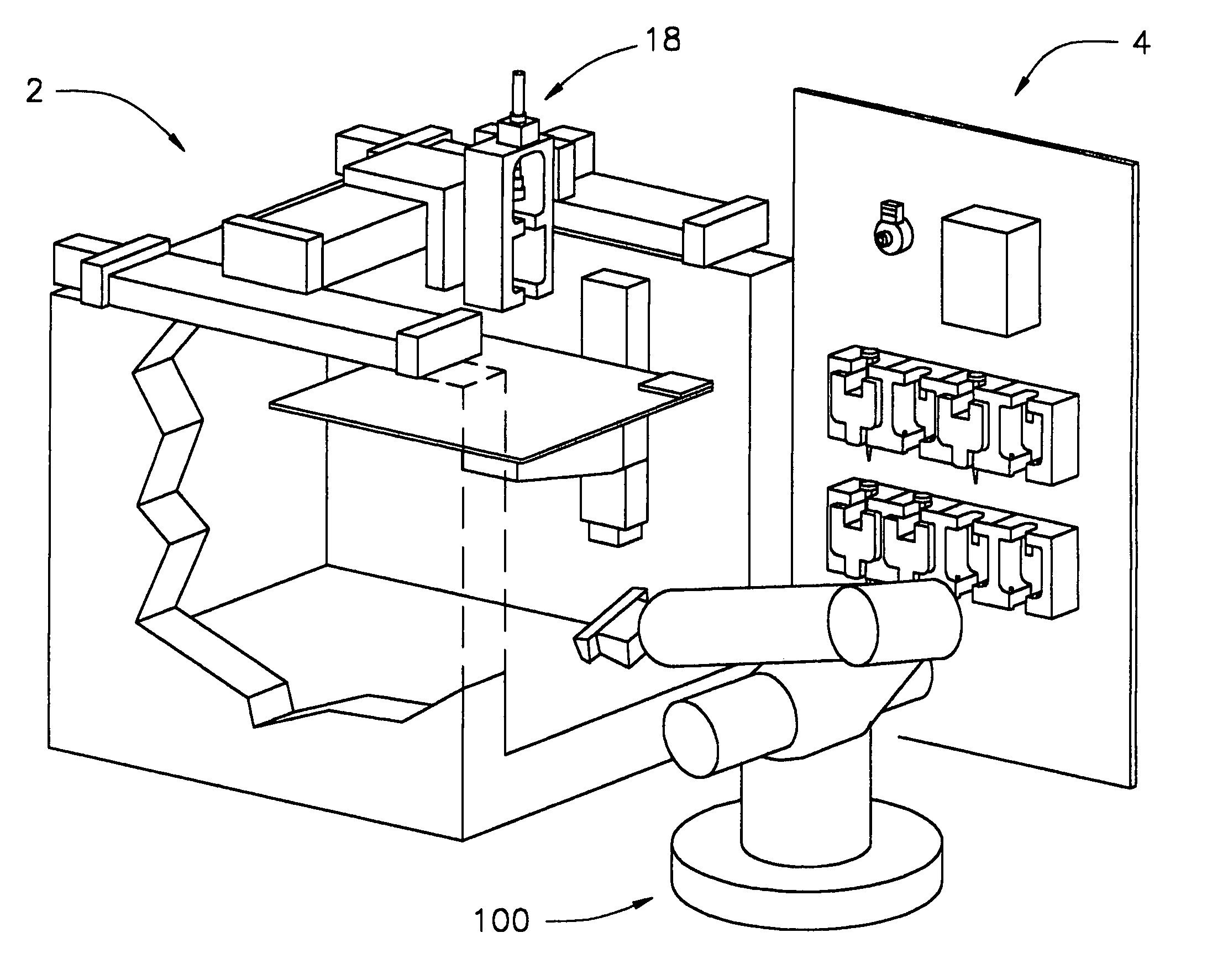

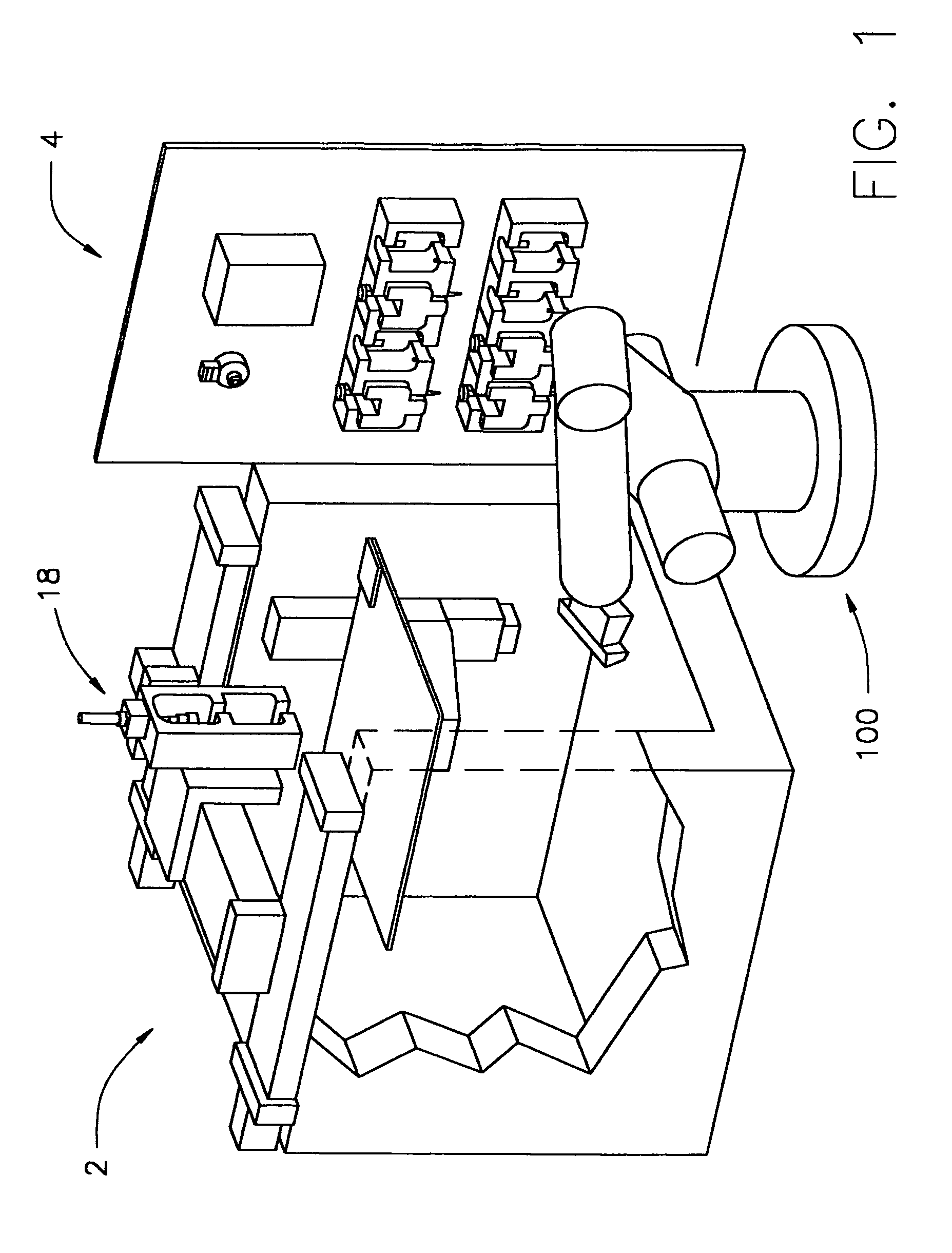

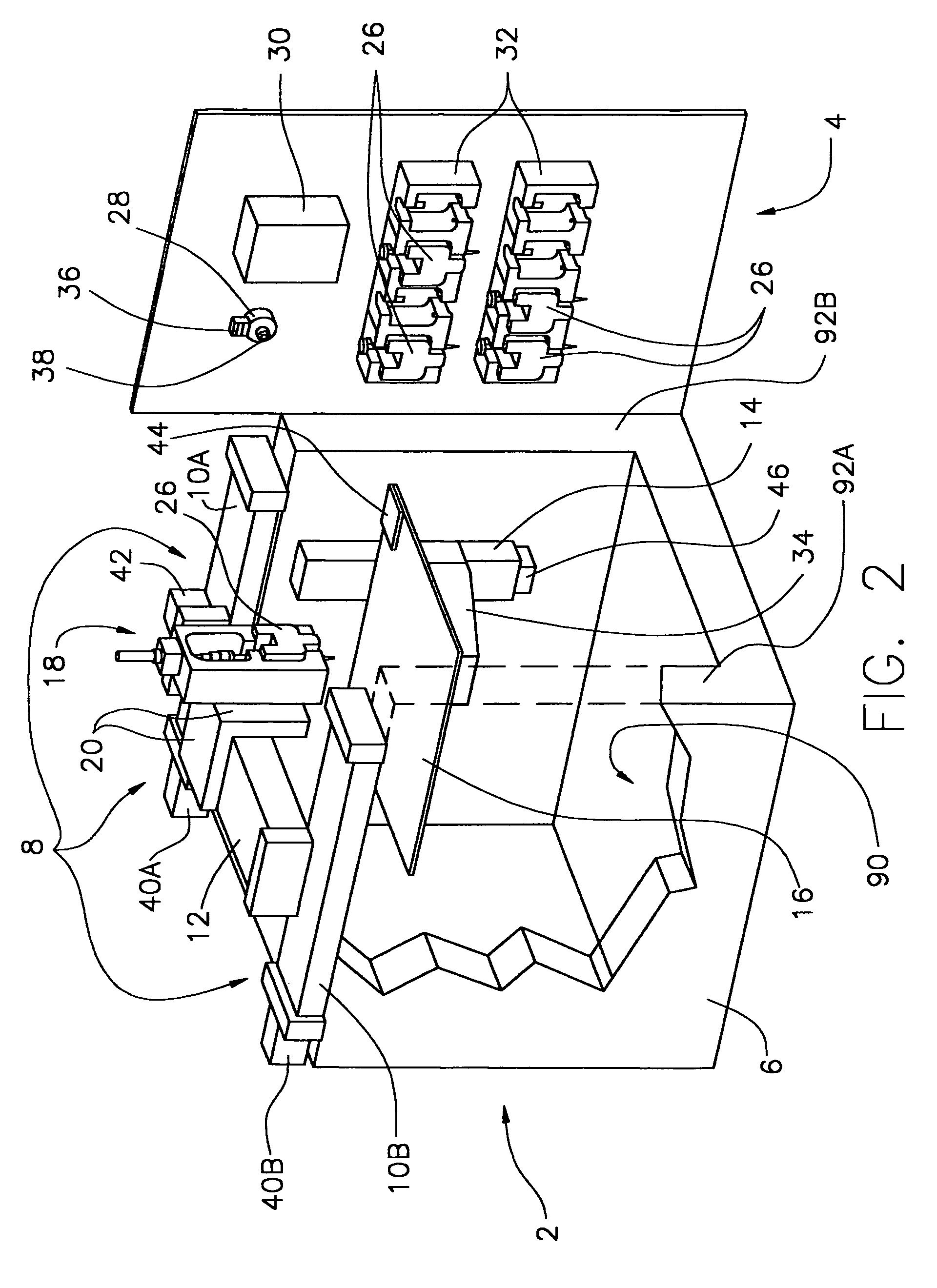

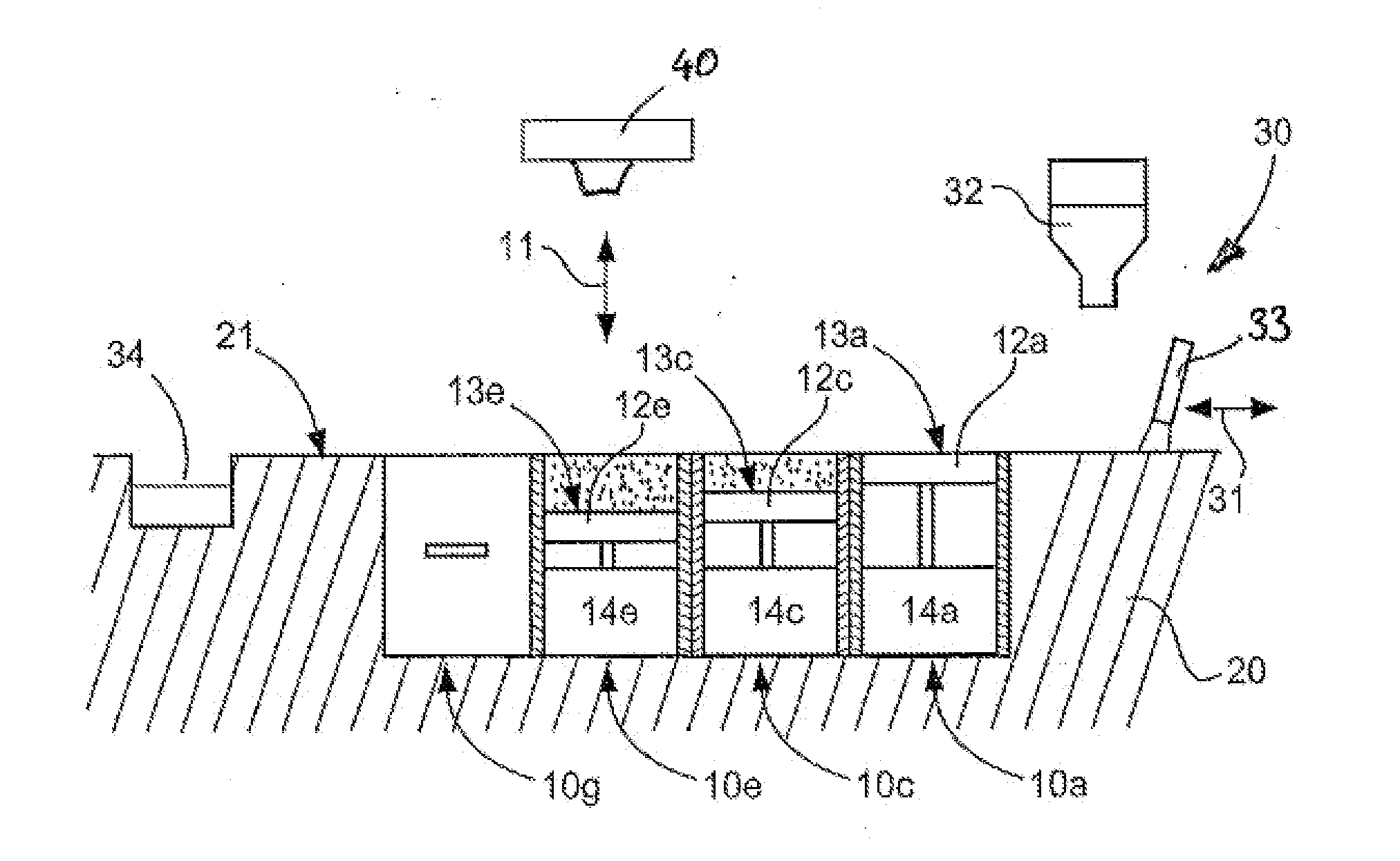

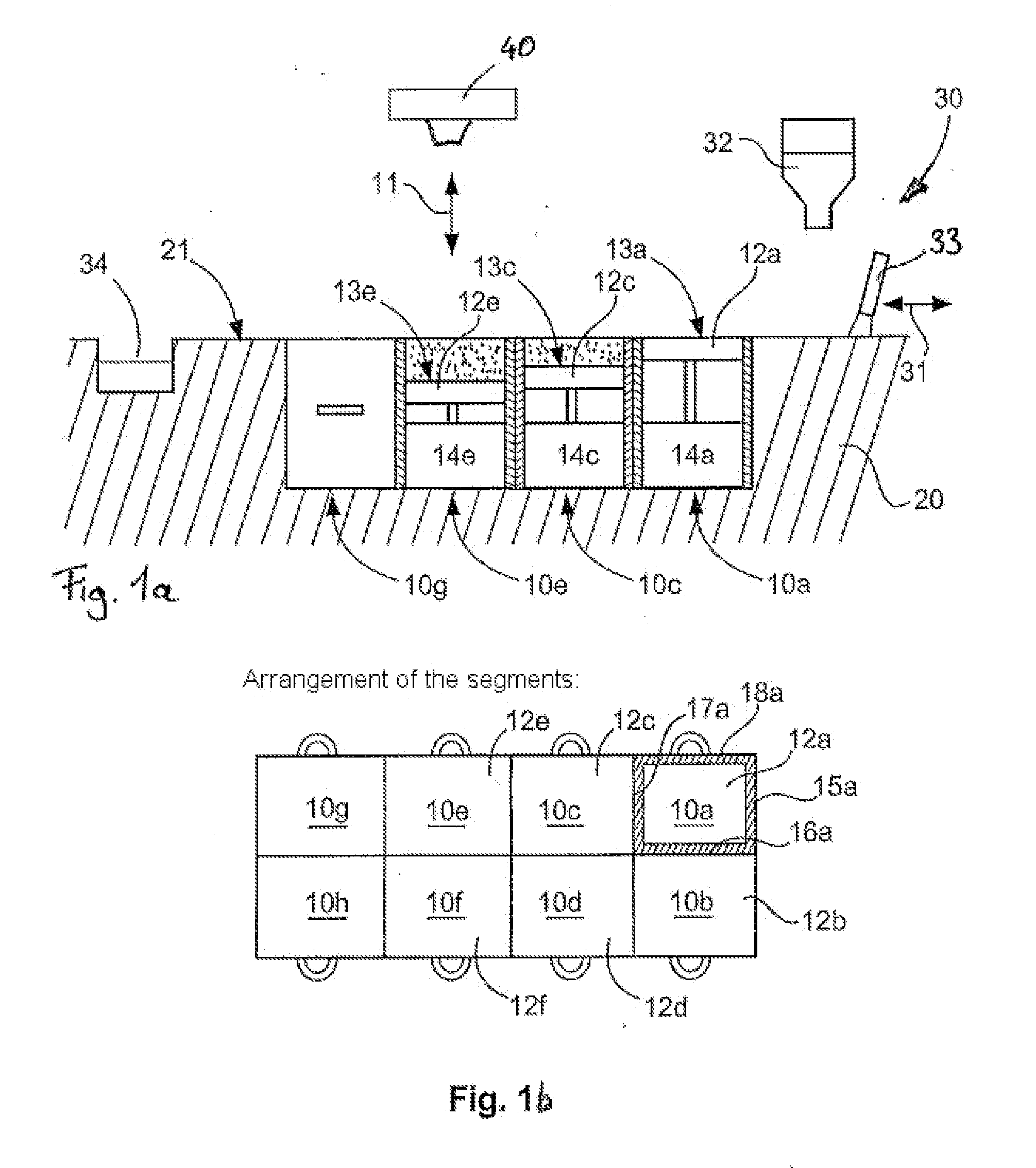

Modular fabrication systems and methods

ActiveUS7625198B2Improve throughputAdapt to a wide rangeLiquid surface applicatorsConfectioneryEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

Continuous liquid interphase printing

ActiveUS9360757B2Low viscosityFacilitate re-fillingManufacturing platforms/substratesManufacturing heating elementsEngineeringMechanical engineering

A method of forming a three-dimensional object is carried out by providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; filling the build region with a polymerizable liquid; irradiating the build region through the optically transparent member to form a solid polymer from the polymerizable liquid and advancing the carrier away from the build surface to form the three-dimensional object from the solid polymer, while also concurrently with the irradiating and / or advancing steps: (i) continuously maintaining a dead zone of polymerizable liquid in contact with the build surface, and (ii) continuously maintaining a gradient of polymerization zone between the dead zone and the solid polymer and in contact with each thereof. The gradient of polymerization zone comprises the polymerizable liquid in partially cured form (e.g., so that the formation of fault or cleavage lines between layers of solid polymer in the three-dimensional object is reduced). Apparatus for carrying out the method is also described.

Owner:CARBON INC

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

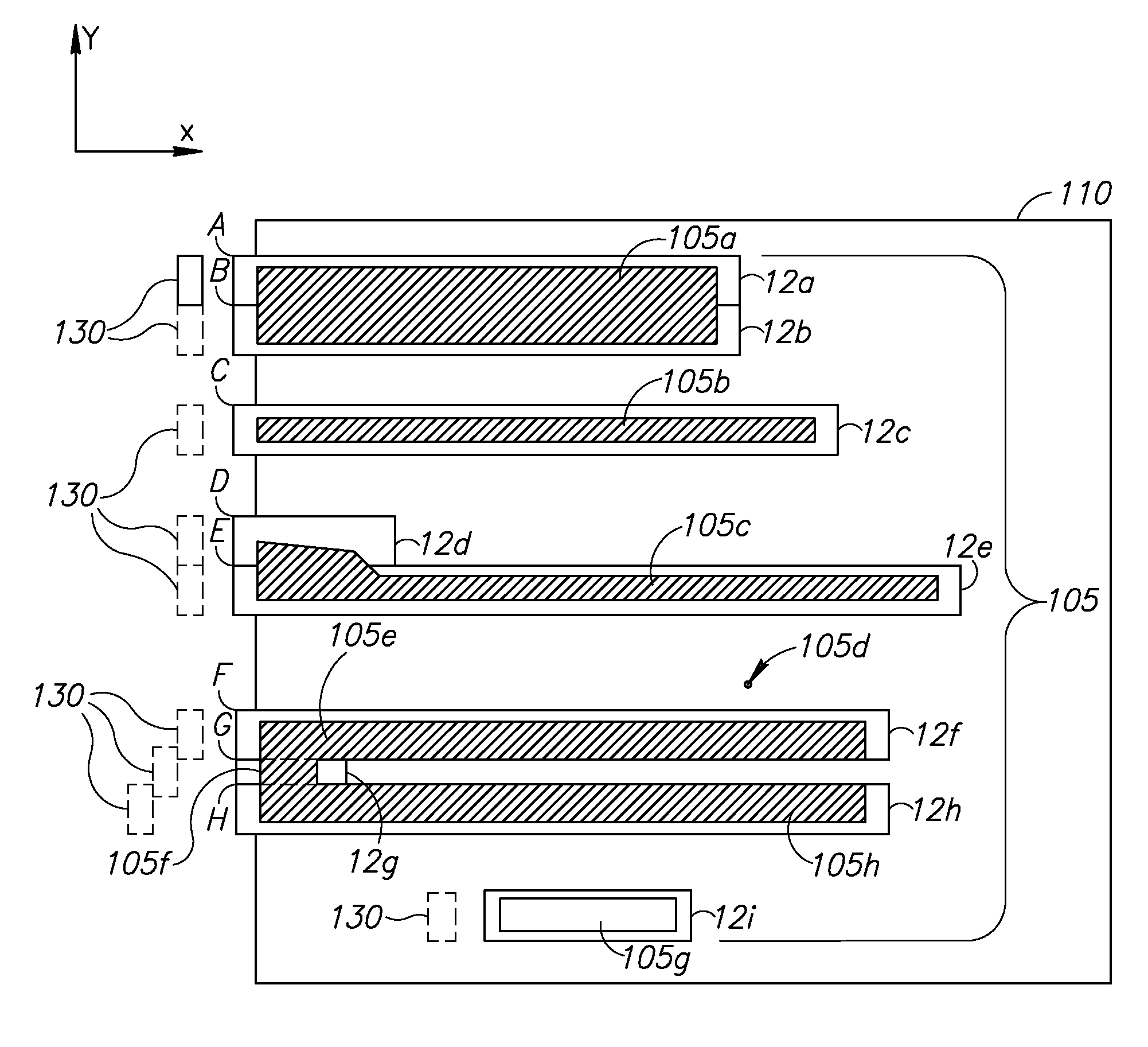

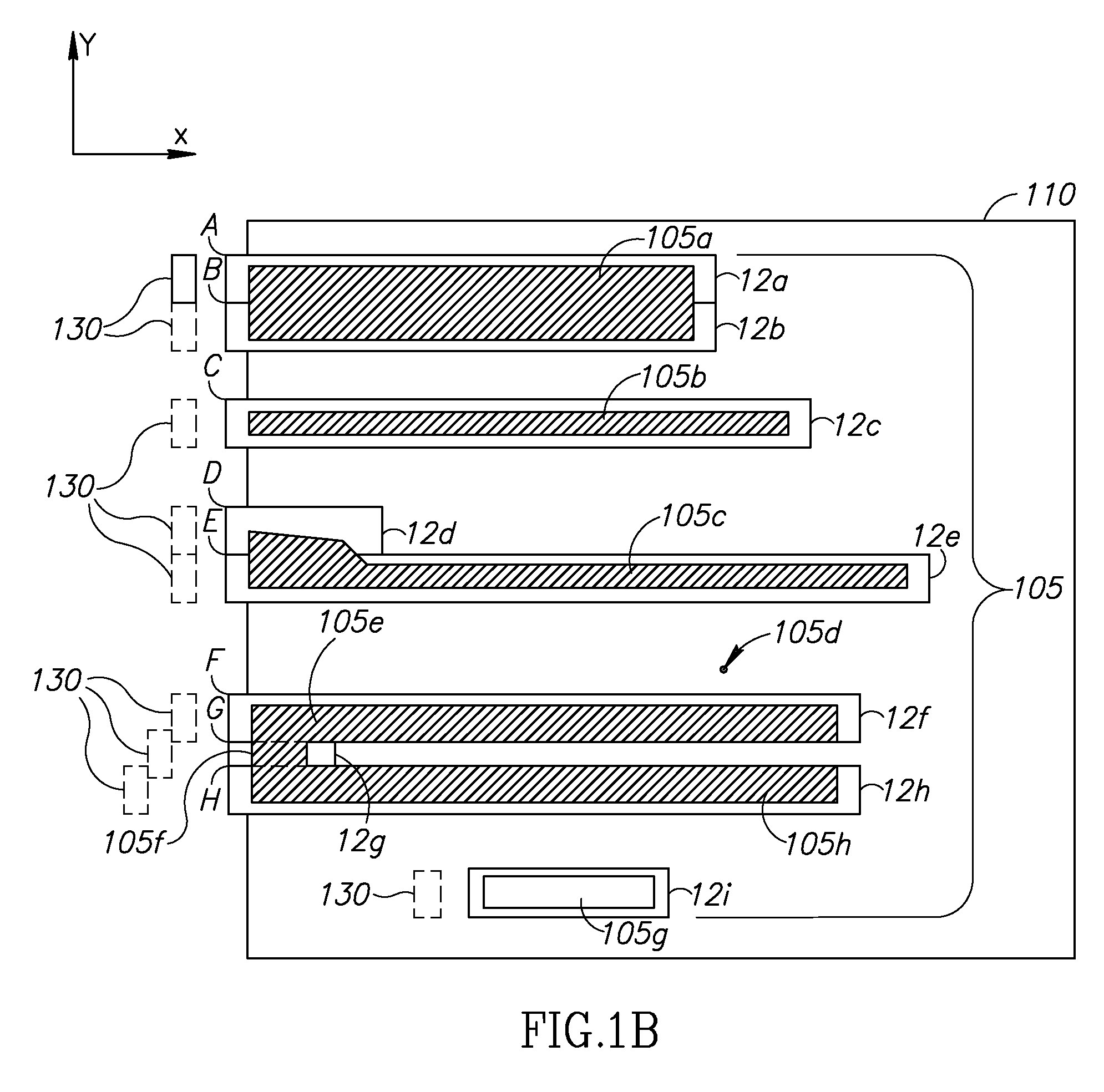

Method and apparatus for optimizing a scanning plan in three-dimensional printing

ActiveUS7962237B2Additive manufacturing apparatusPower drive mechanisms3 dimensional printingComputer science

Embodiments of the present invention may include a method for printing three-dimensional objects, layer by layer utilizing an optimized scheme of predefined passes for each layer based on considerations related to both throughput and quality of printing. Embodiment of the invention may include generating a scanning plan for a layer such that the accumulated length for all the scanning passes in the layer is minimized. The optimization scheme may be performed based on image data parameters, such as sizes, locations, dimensions and shapes of the imaged areas of the layer.

Owner:STRATASYS LTD

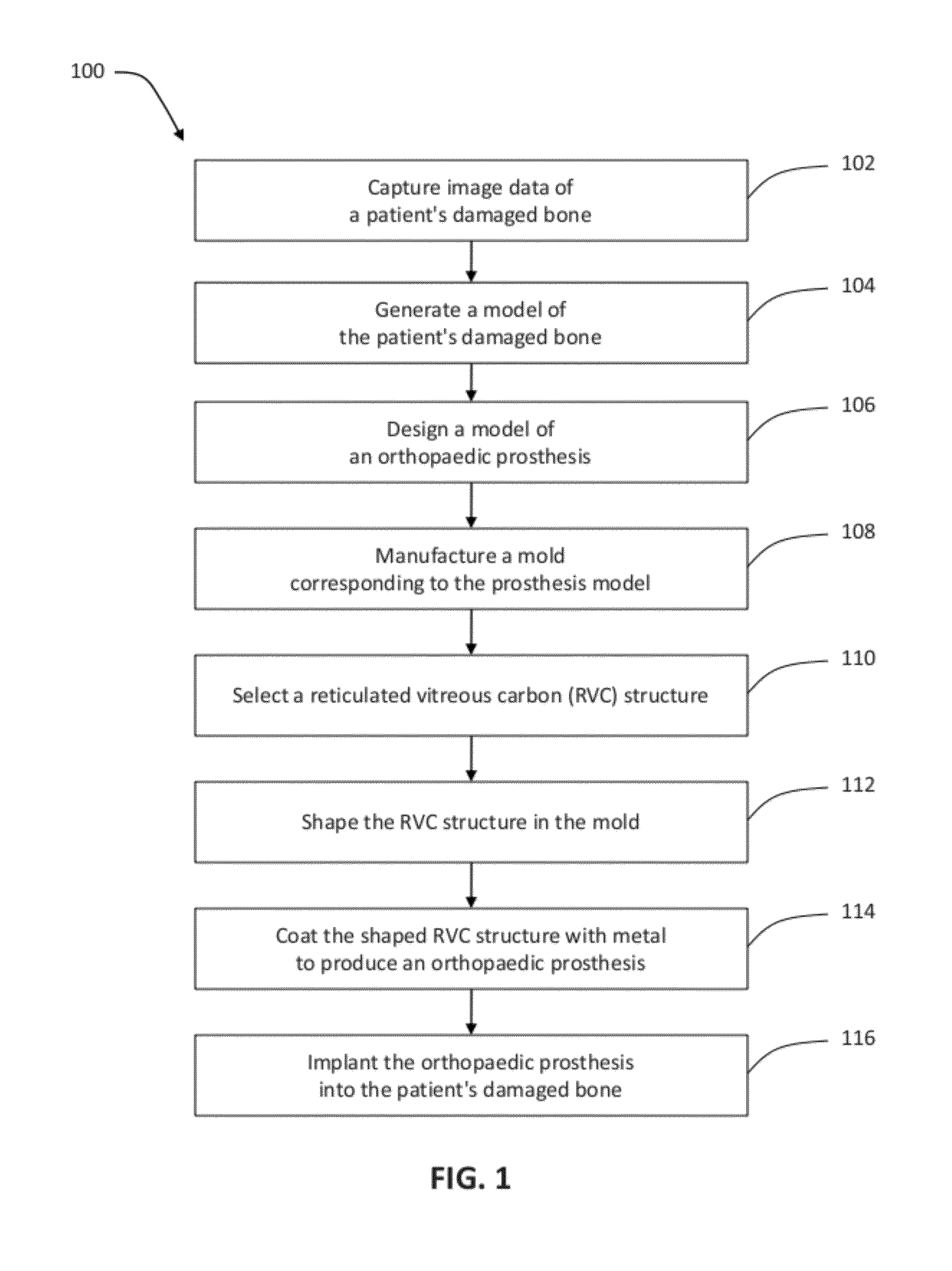

Patient-specific manufacturing of porous metal prostheses

ActiveUS20120310364A1Low efficiencyAvoid substantially changing porosityImpression capsPretreated surfacesProsthesisPlastic surgery

A patient-specific porous metal prosthesis and a method for manufacturing the same are provided. The orthopaedic prosthesis may be metallic to provide adequate strength and stability. Also, the orthopaedic prosthesis may be porous to promote bone ingrowth.

Owner:ZIMMER INC

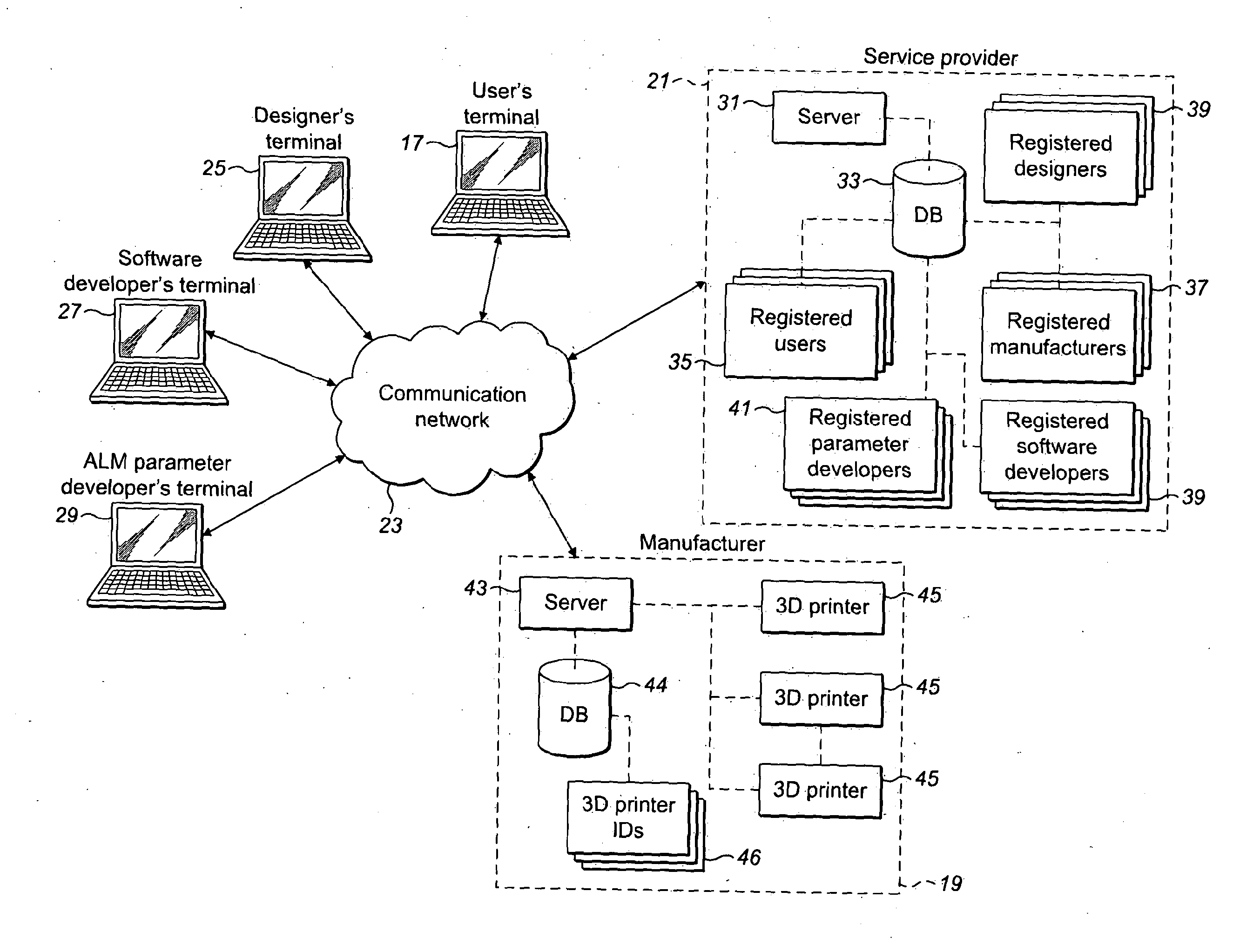

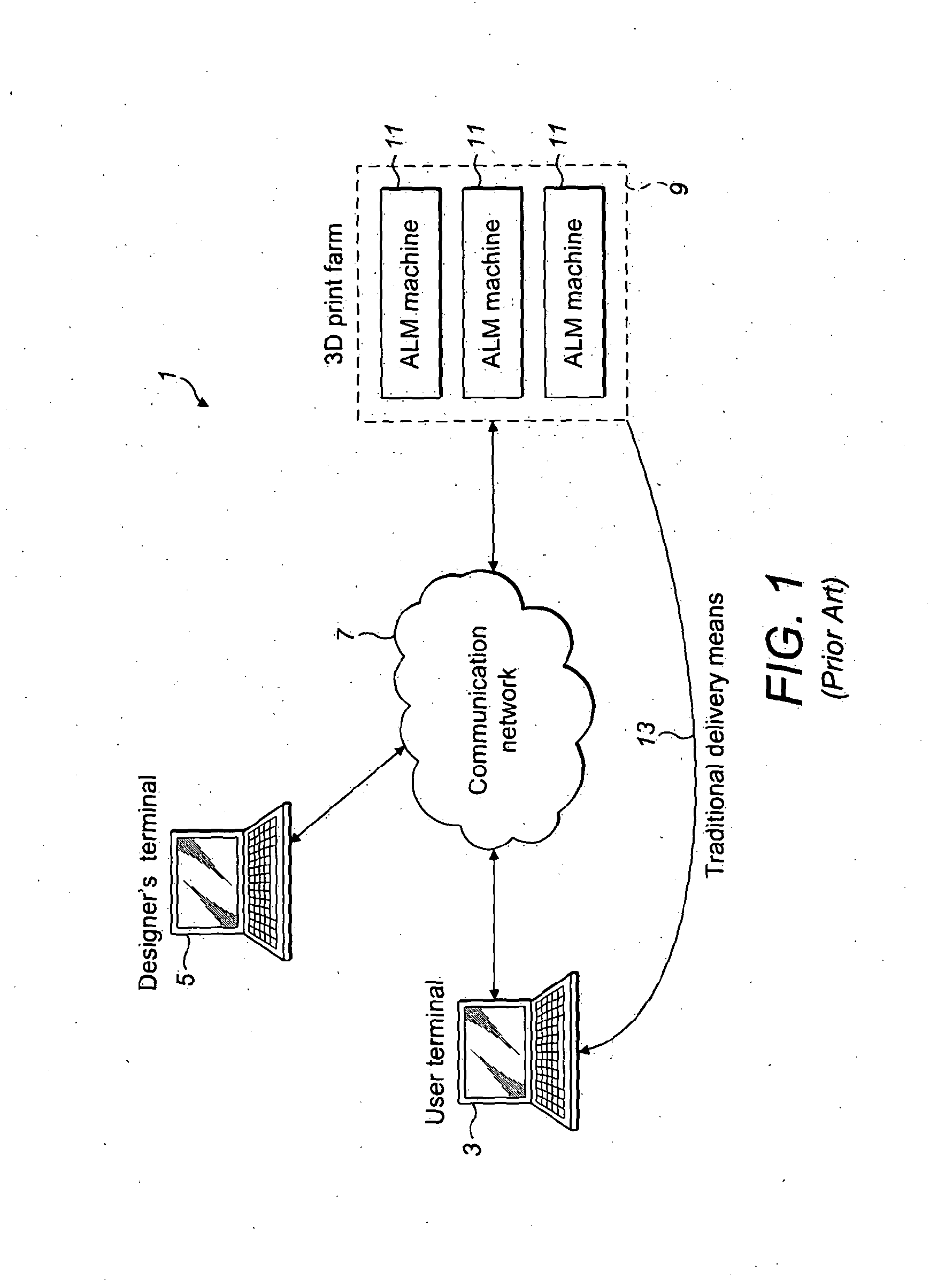

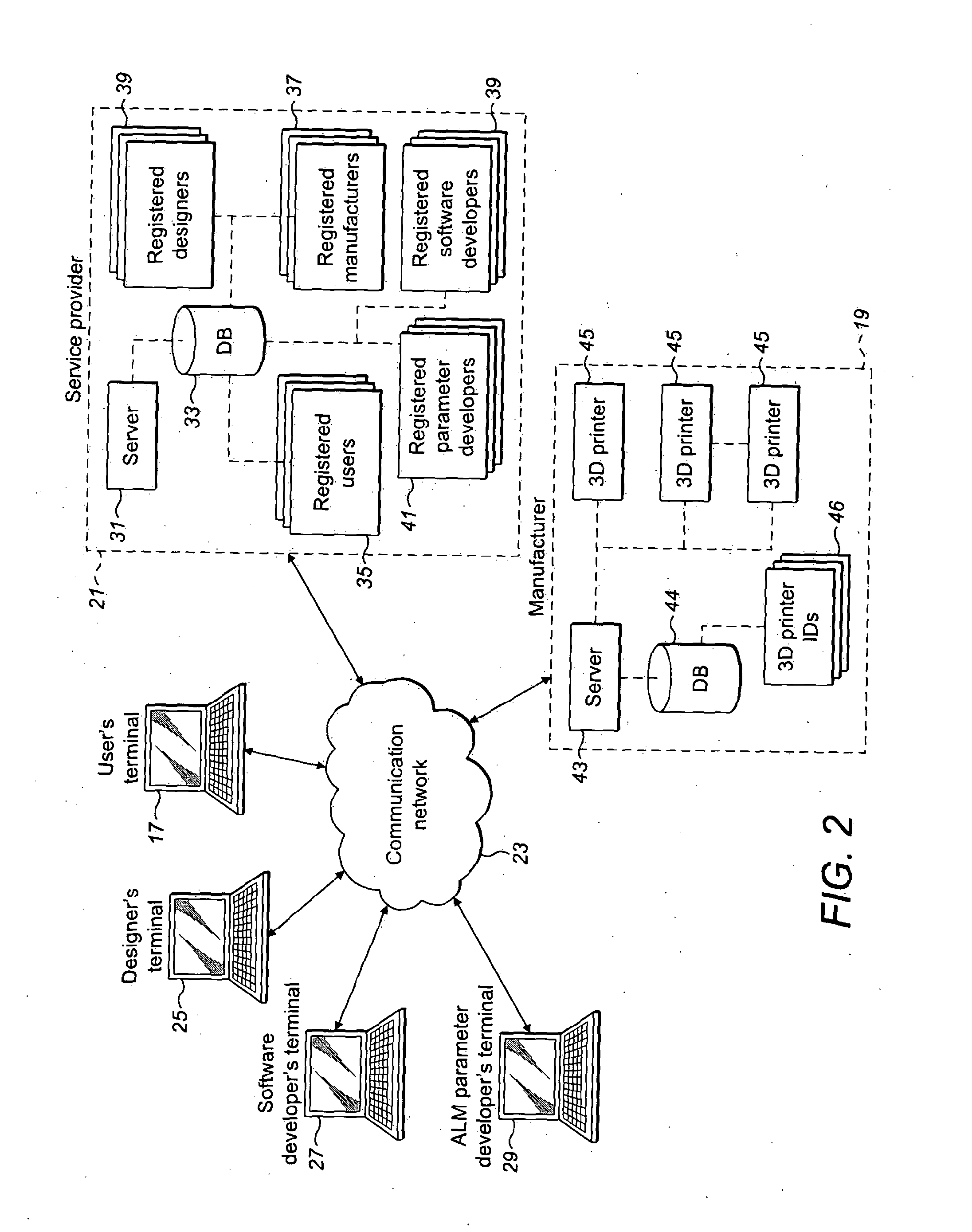

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

Method of calibrating an apparatus for producing a three-dimensional object, calibration apparatus and method and apparatus for producing a three-dimensional object

InactiveUS6483596B1Simple methodEnhanced radiationPretreated surfacesElectrical measurementsElectromagnetic radiationRapid prototyping

The invention refers to a method for calibrating the control of a radiation device producing electromagnetic radiation or particle radiation in a rapid prototyping system. The method comprises the steps of arranging a calibration plate at a defined position in the rapid prototyping system, the calibration plate having an upper side with a first region and a second region separate from the first region, the first region being provided with optically detectable reference marks and the second region having a medium which is sensitive to the radiation of the radiation device, producing a test pattern by exposing said medium to said radiation at predetermined desired positions defined by position coordinate data, digitizing the first region of the calibration plate with the reference marks thereon and the second region of the calibration plate having the test pattern, comparing the digitized reference marks and the digitized test pattern and calculating and providing correction data for the control of the radiation device on the basis of the comparison.

Owner:EOS ELECTRO OPTICAL SYST

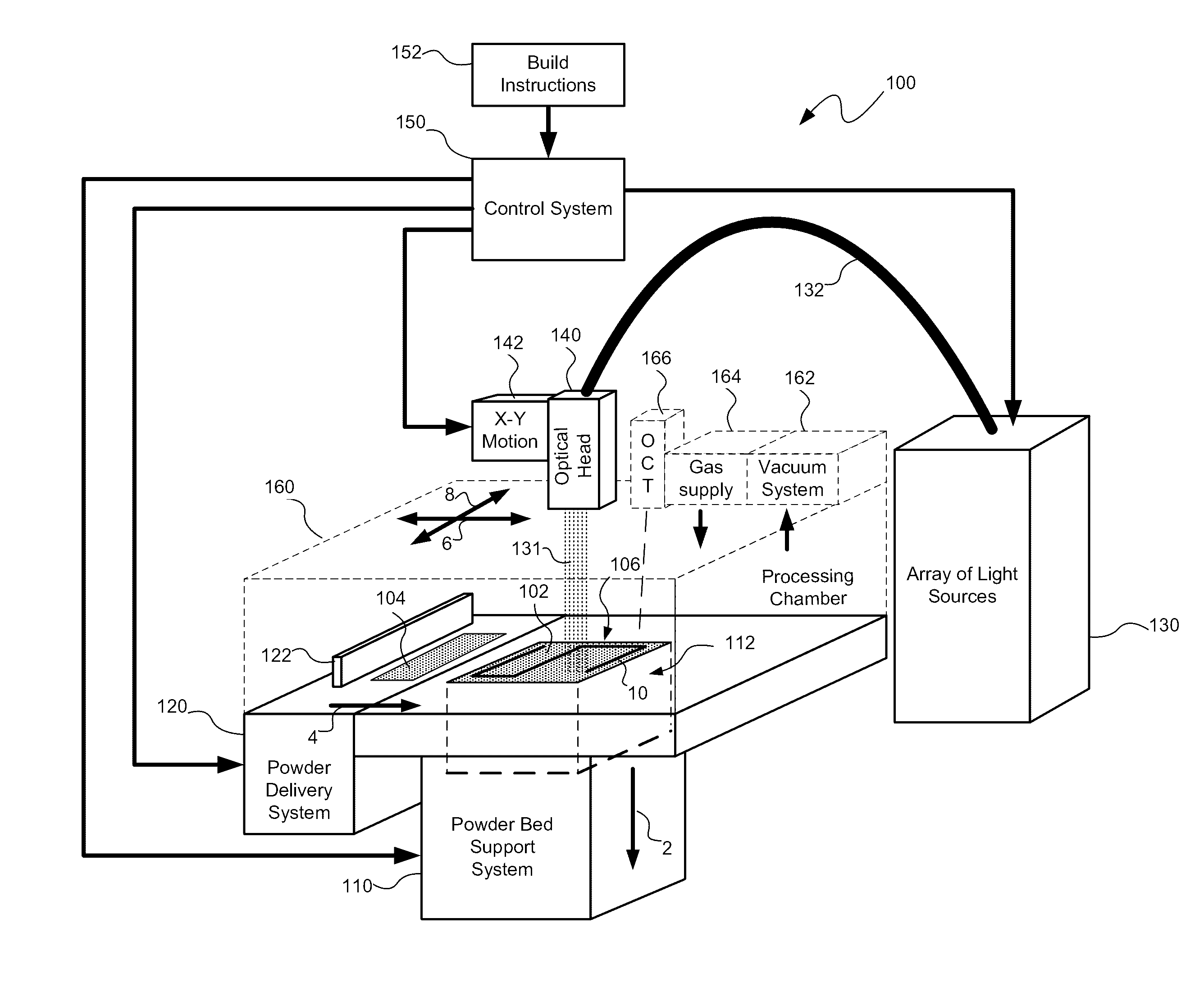

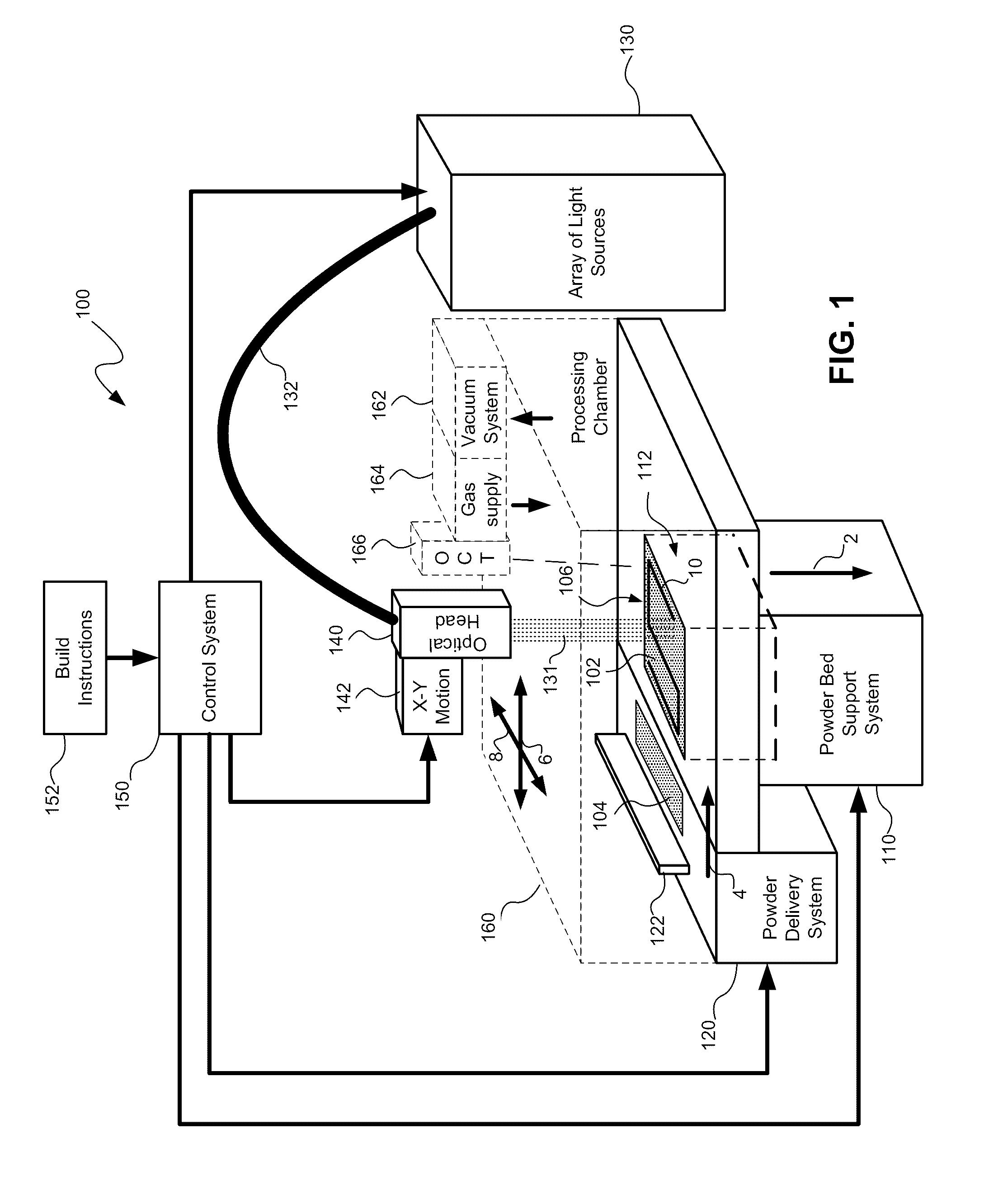

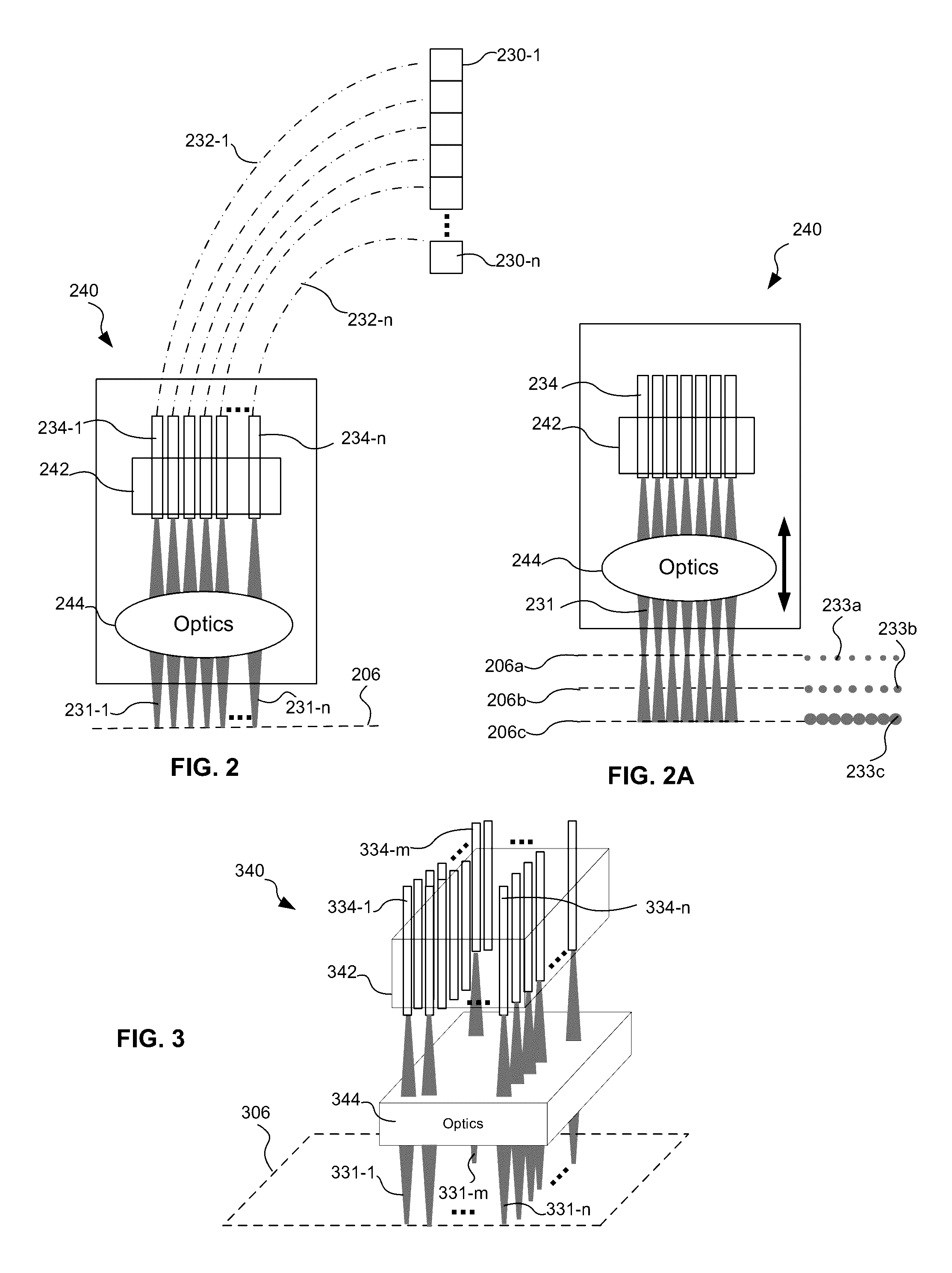

Multiple beam additive manufacturing

Systems and methods for multiple beam additive manufacturing use multiple beams of light (e.g., laser light) to expose layers of powder material in selected regions until the powder material fuses to form voxels, which form build layers of a three-dimensional structure. The light may be generated from selected light sources and coupled into an array of optical fibers having output ends arranged in an optical head in at least one line such that multiple beams are sequentially directed by the optical head to the same powder region providing multiple beam sequential exposures (e.g., with pre-heating, melting and controlled cool down) to fuse the powder region. The multiple sequential beams may be moved using various techniques (e.g., by moving the optical head) and according to various scan patterns such that a plurality of fused regions form each build layer.

Owner:IPG PHOTONICS CORP

Method and Apparatus for Additive Mechanical Growth of Tubular Structures

InactiveUS20160031155A1High strengthEliminate needLiquid surface applicatorsManufacturing driving meansAdditive layer manufacturing3D printing

Owner:CONTINUOUS COMPOSITES INC

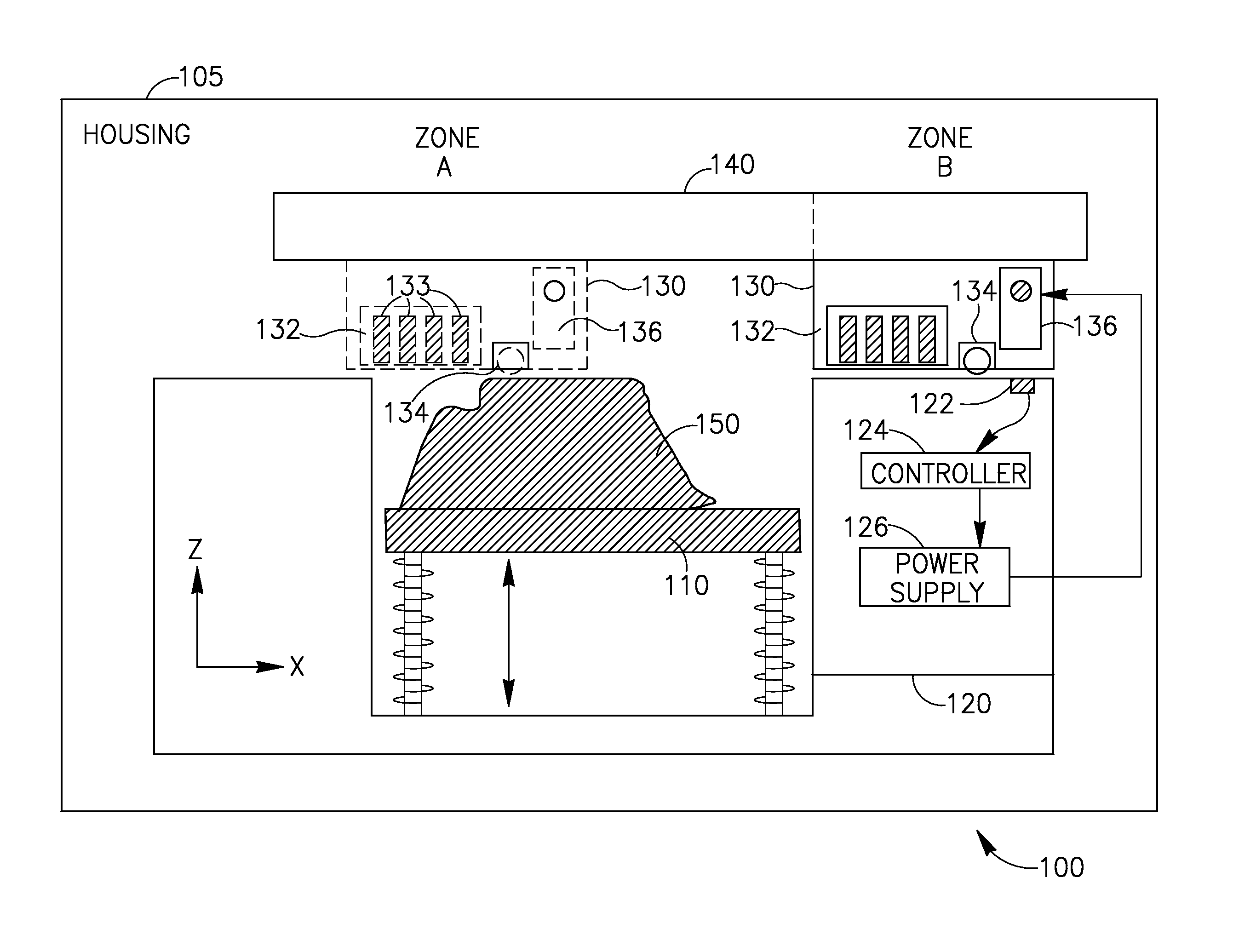

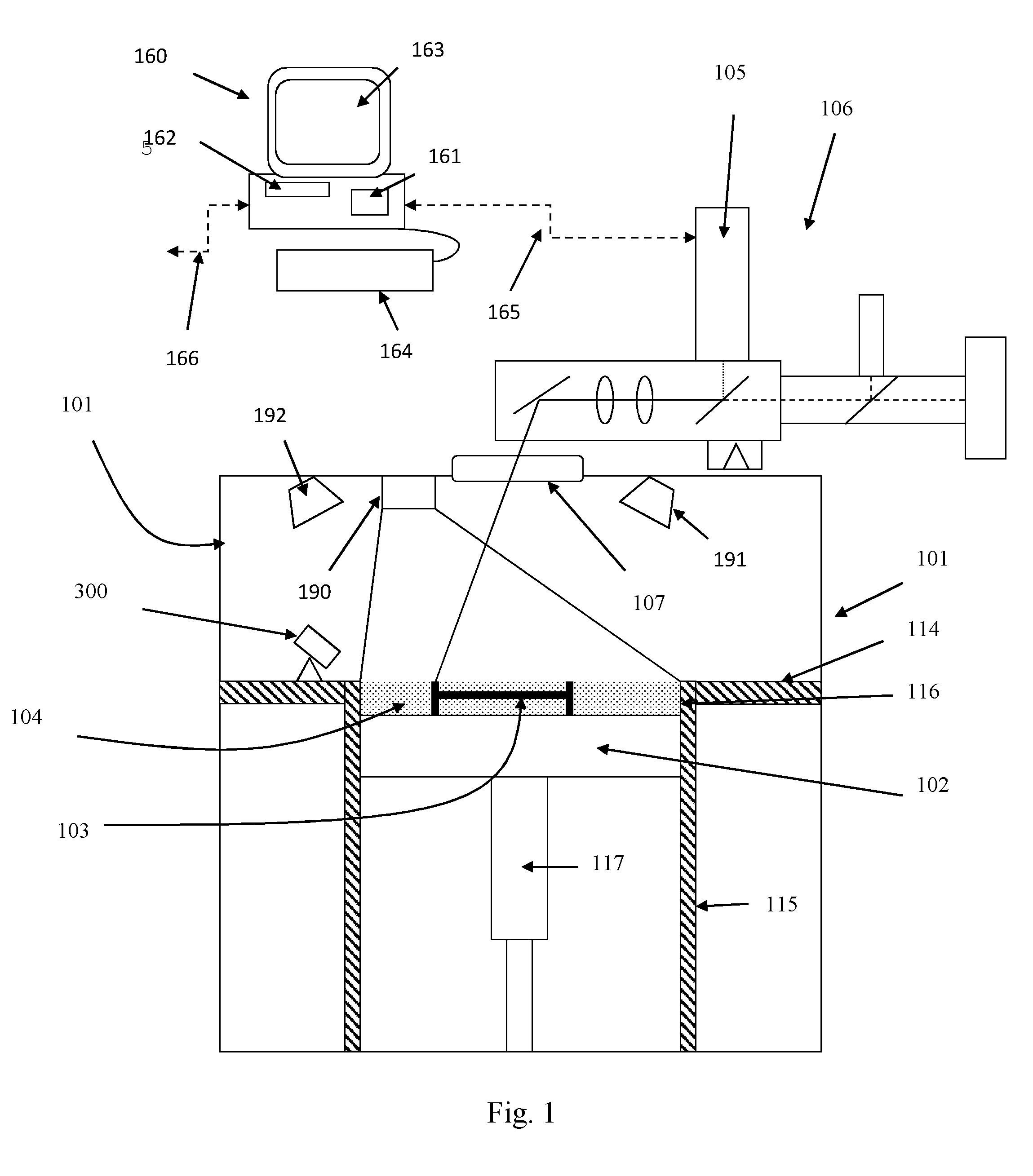

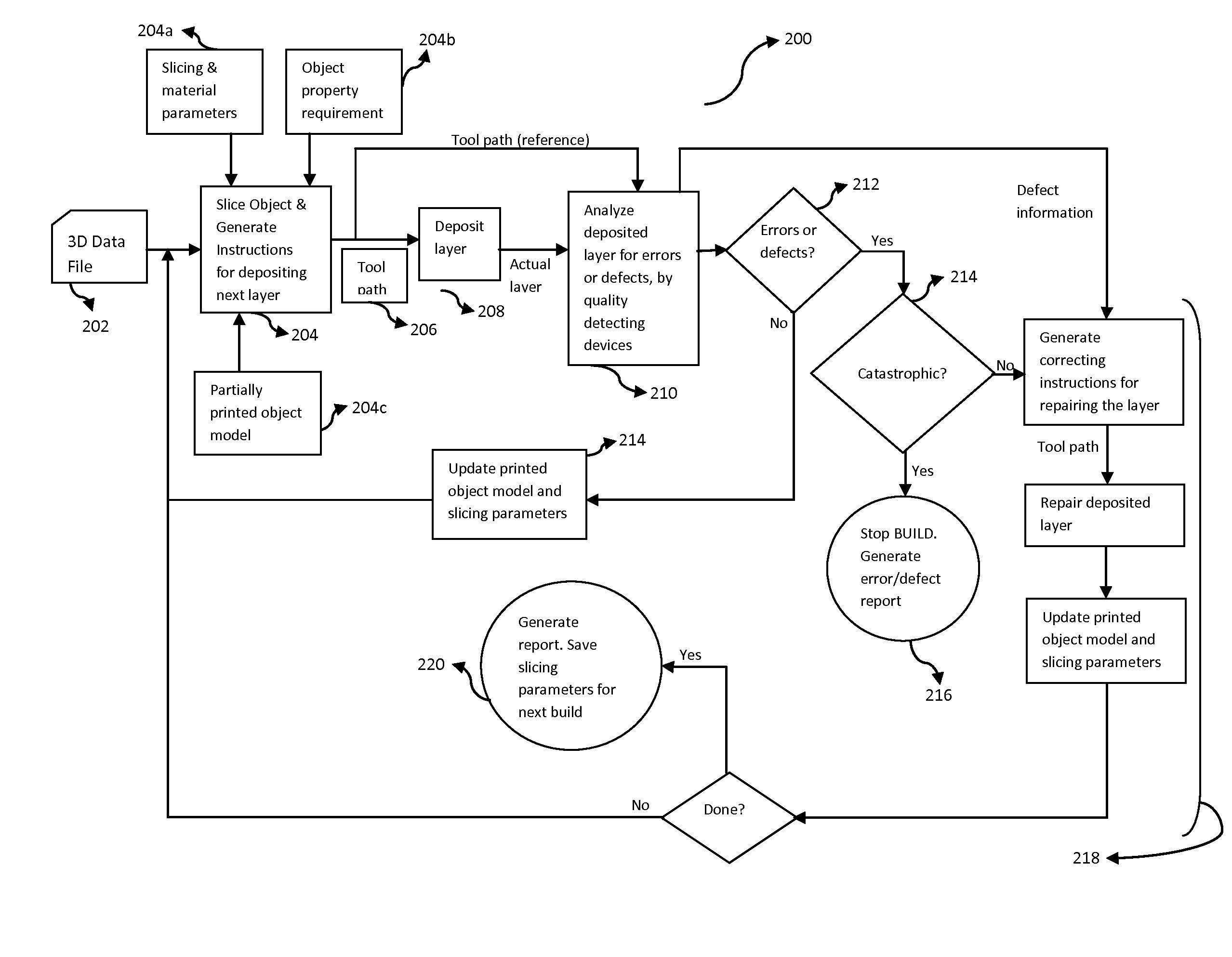

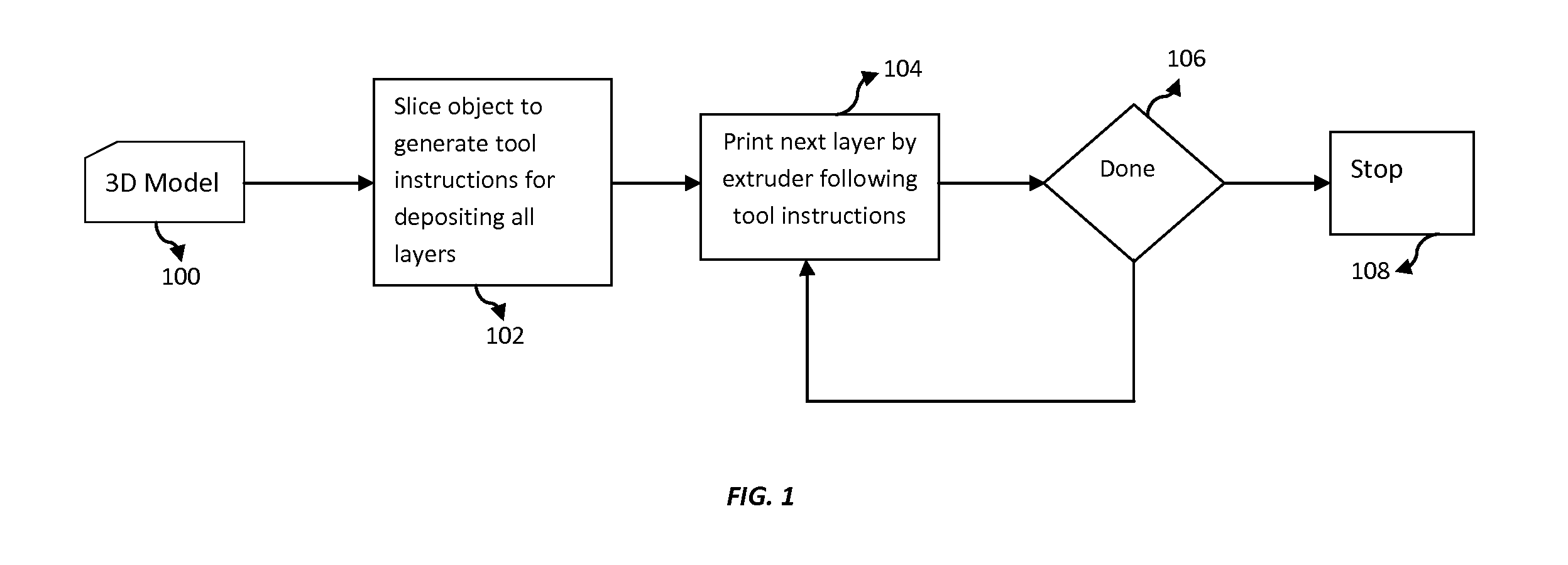

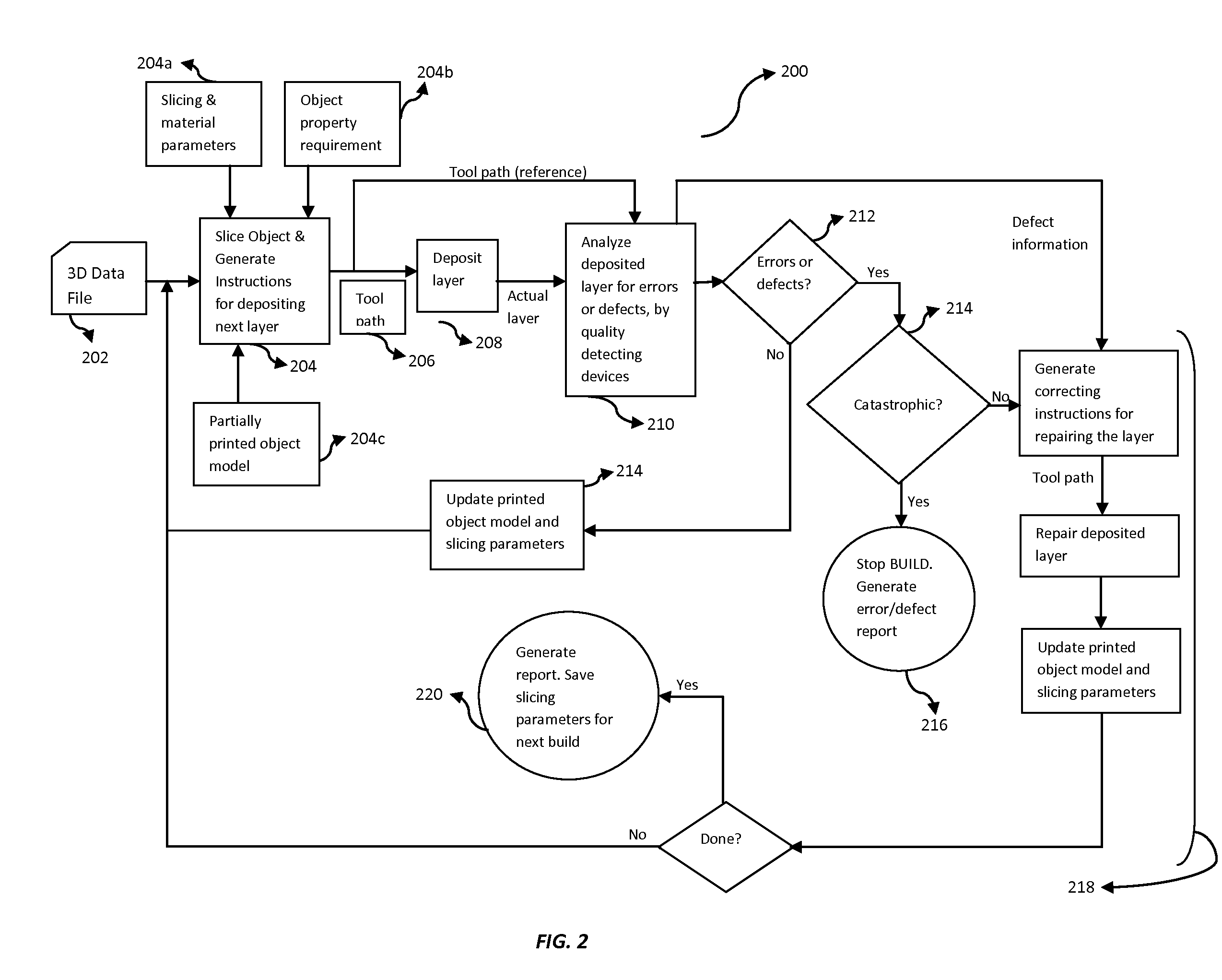

Method to monitor additive manufacturing process for detection and in-situ correction of defects

ActiveUS20160236414A1Minimize presenceProgramme controlAdditive manufacturing apparatusStructural geometryEngineering

The present invention provides a system and a method for real time monitoring and identifying defects occurring in a three dimensional object build via an additive manufacturing process. Further, the present invention provides in-situ correction of such defects by a plurality of functional tool heads possessing freedom of motion in arbitrary planes and approach, where the functional tool heads are automatically and independently controlled based on a feedback analysis from the printing process, implementing analyzing techniques. Furthermore, the present invention provides a mechanism for analyzing defected data collected from detection devices and correcting tool path instructions and object model in-situ during construction of a 3D object. A build report is also generated that displays, in 3D space, the structural geometry and inherent properties of a final build object along with the features of corrected and uncorrected defects. Advantageously, the build report helps in improving 3D printing process for subsequent objects.

Owner:AREVO INC

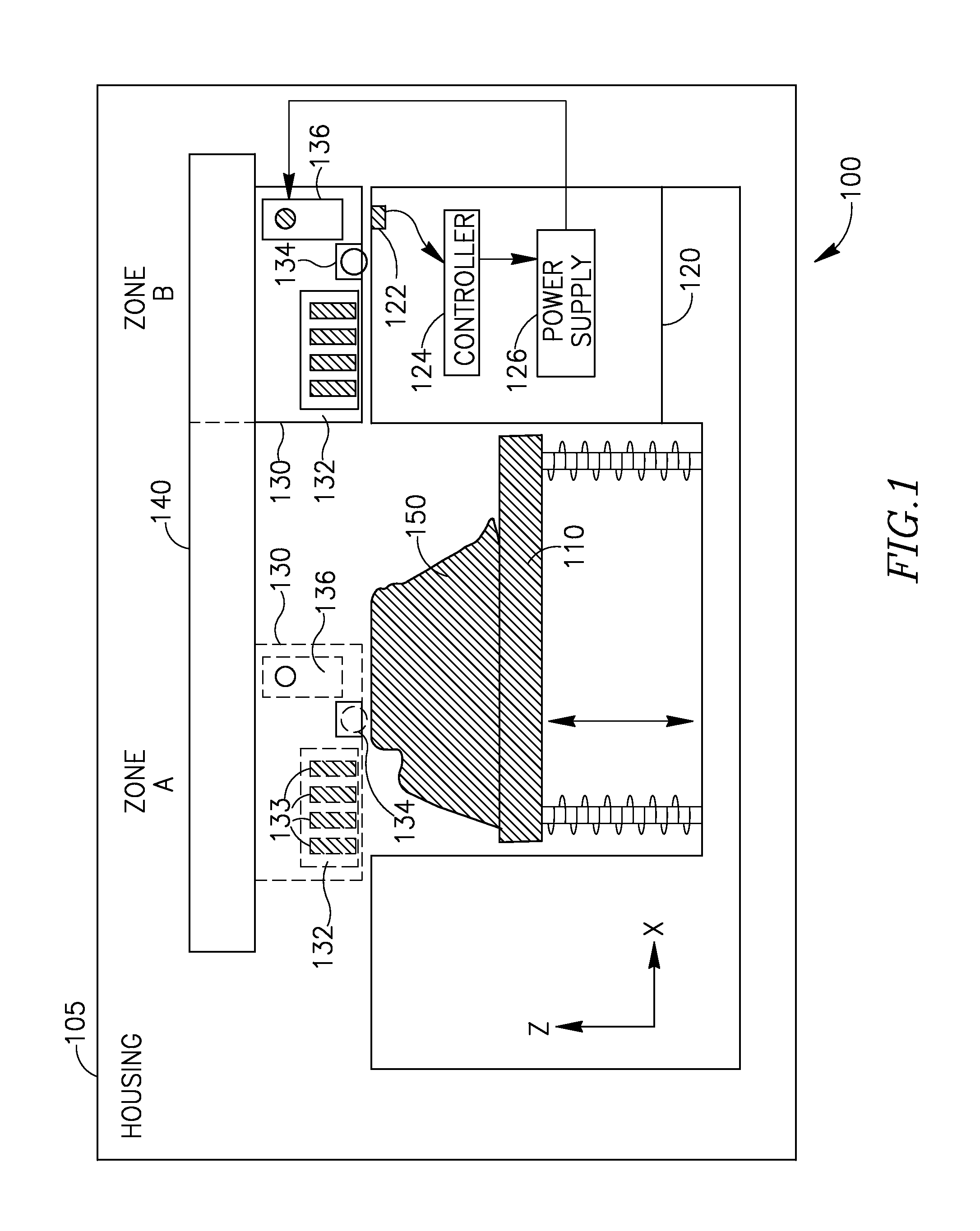

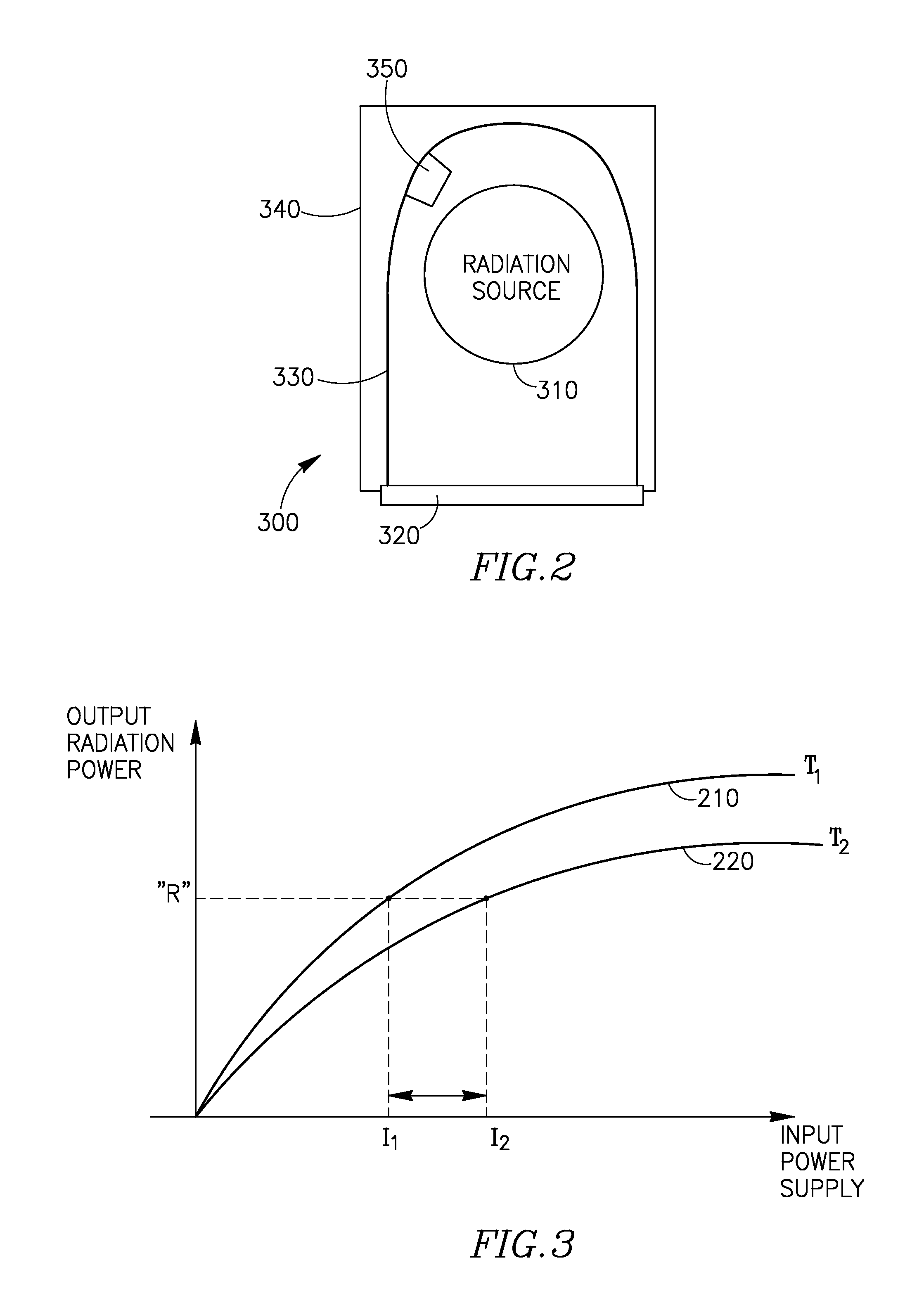

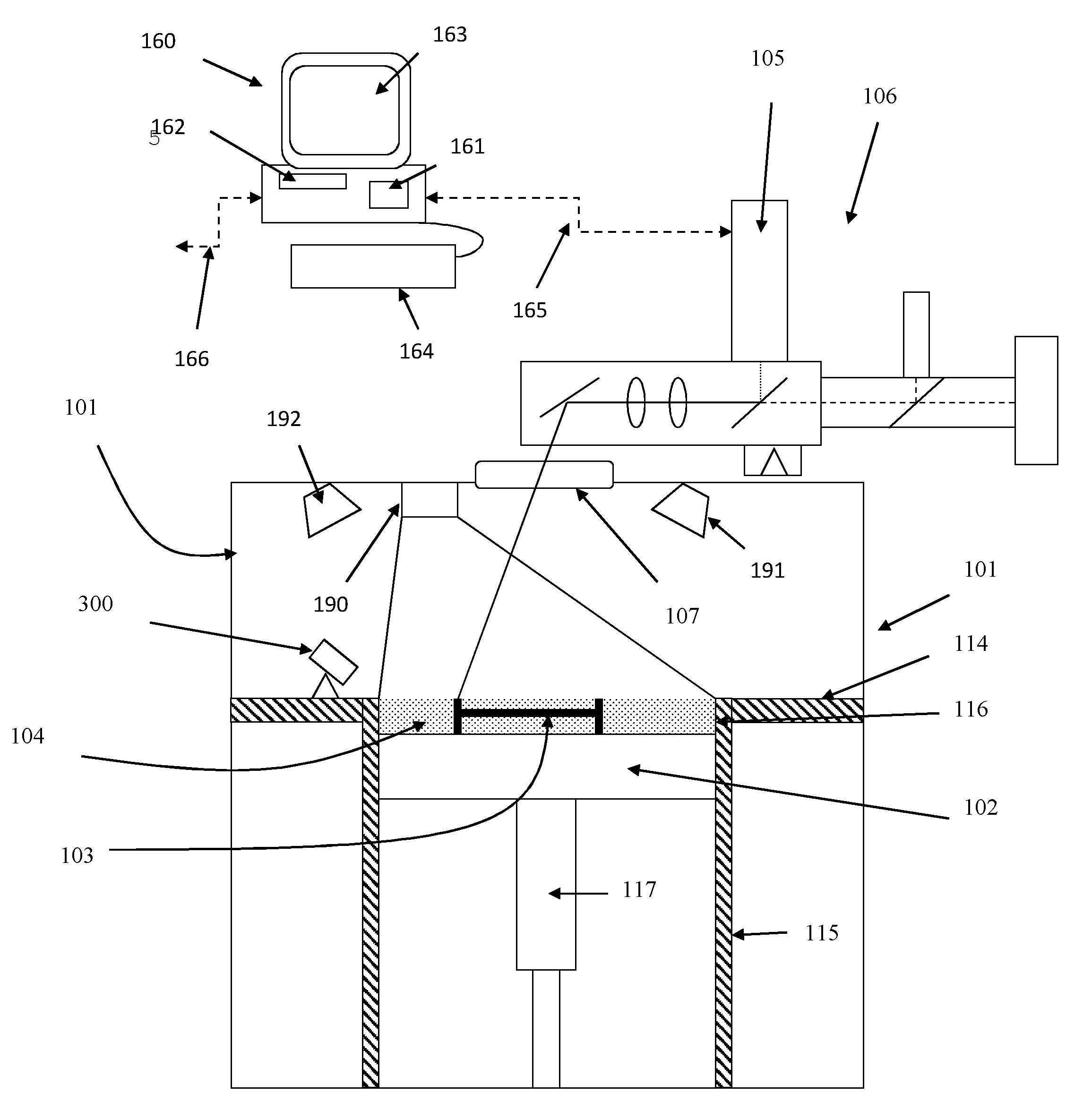

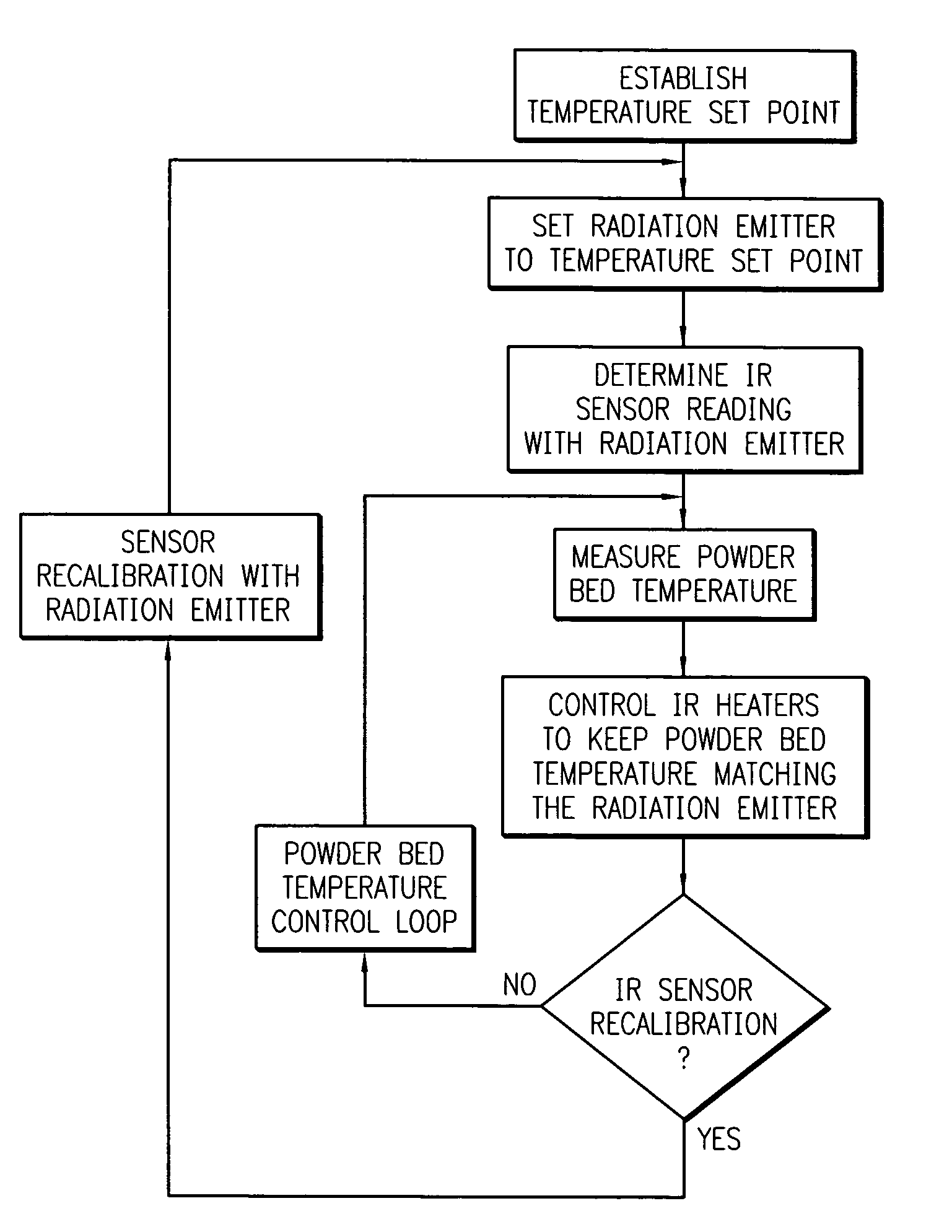

Continuous calibration of a non-contact thermal sensor for laser sintering

ActiveUS6930278B1Accurate monitoringHighly consistent mechanical propertyAdditive manufacturing apparatusIncreasing energy efficiencyAcousticsLaser

An apparatus and a method of using the apparatus wherein a radiation emitter is positioned adjacent a sensor apparatus within a process chamber in a laser sinter system that emits radiation to the sensor apparatus and a calibration apparatus receives readings from the sensor apparatus to compare temperature sensings received from the sensor apparatus with set emission signals from the radiation emitter to adjust the temperature sensings to calibrate the sensor apparatus during the forming of a three-dimensional article. The calibration is done repeatedly during the build process of the three-dimensional article.

Owner:3D SYST INC

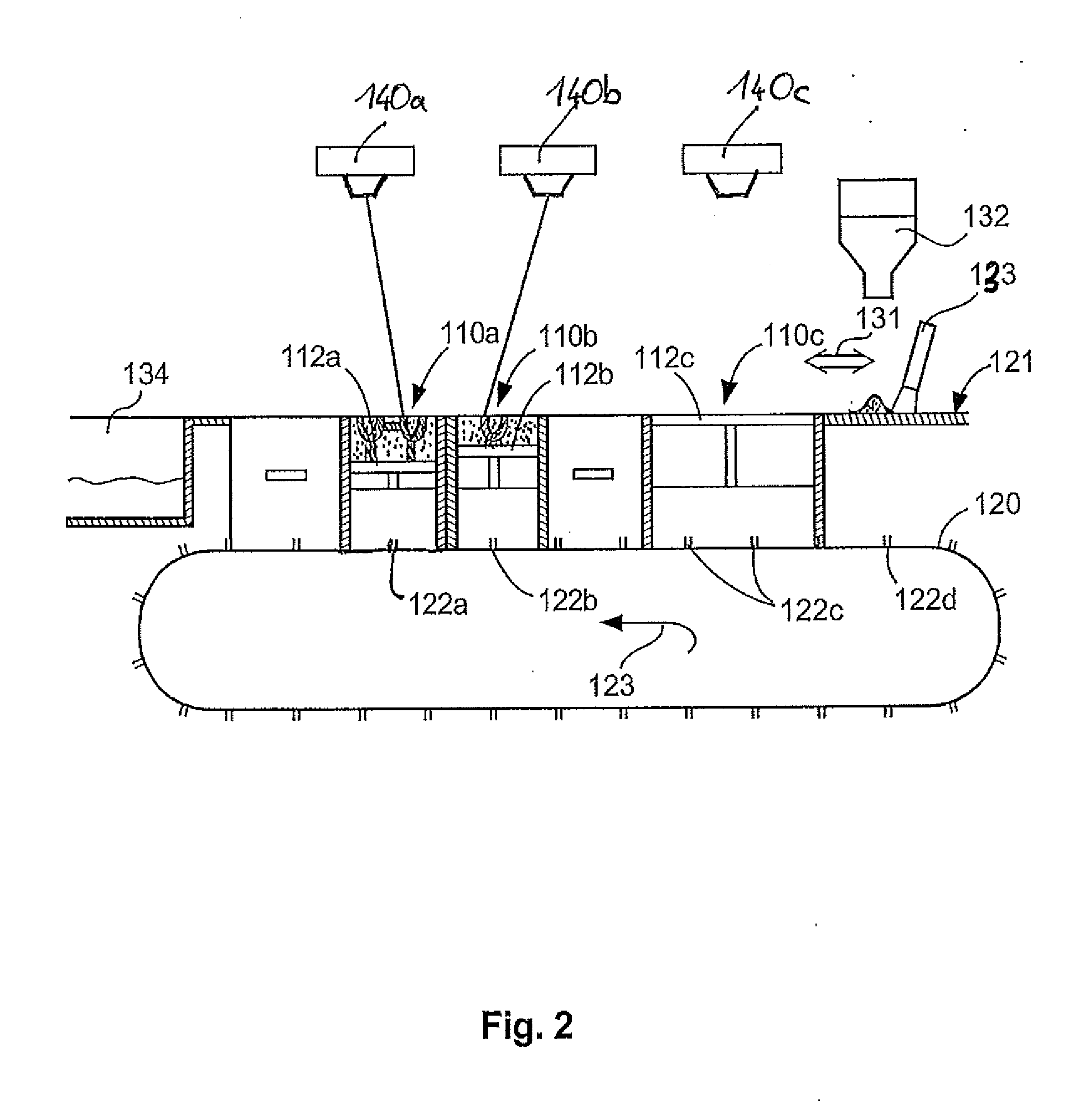

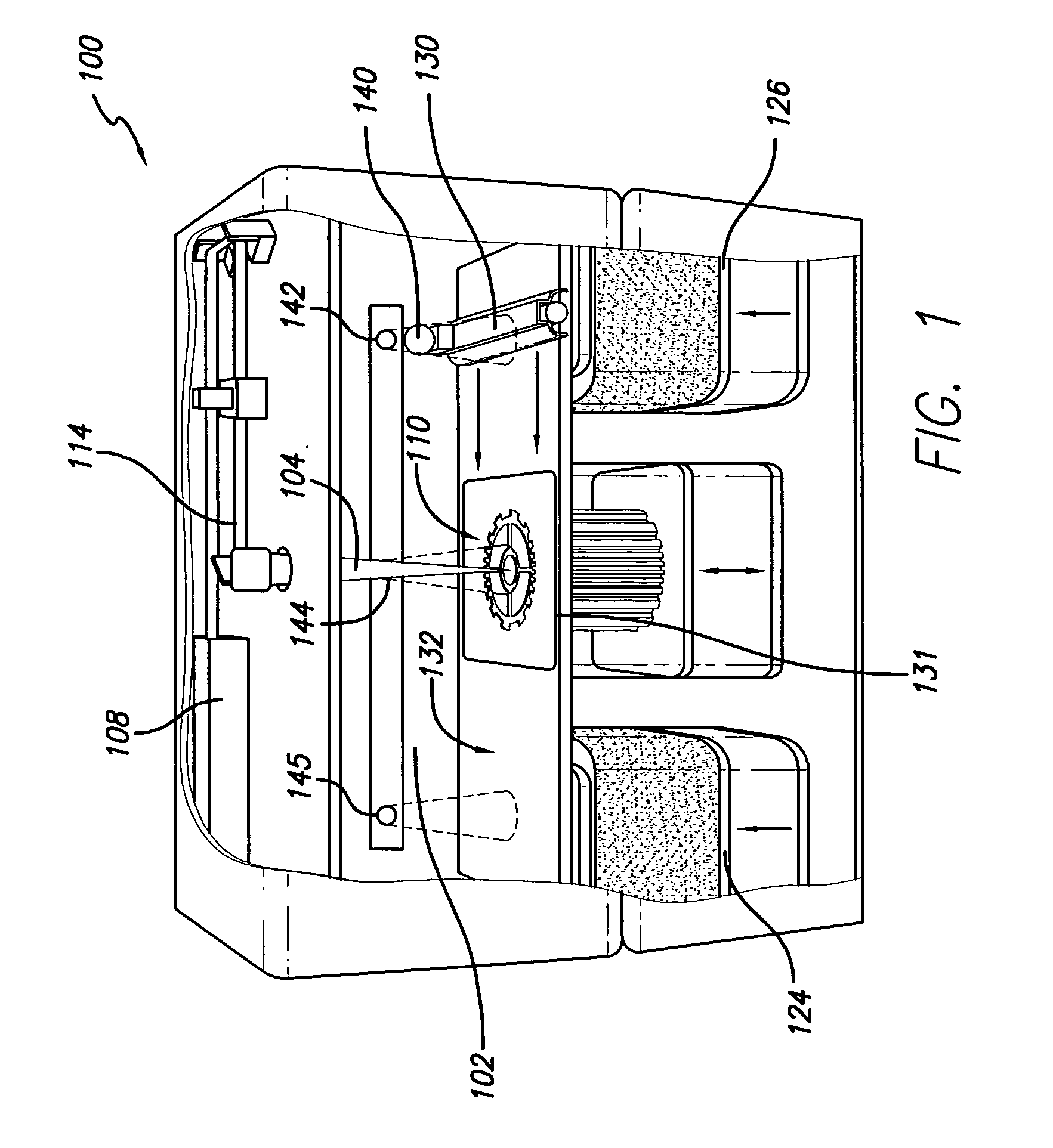

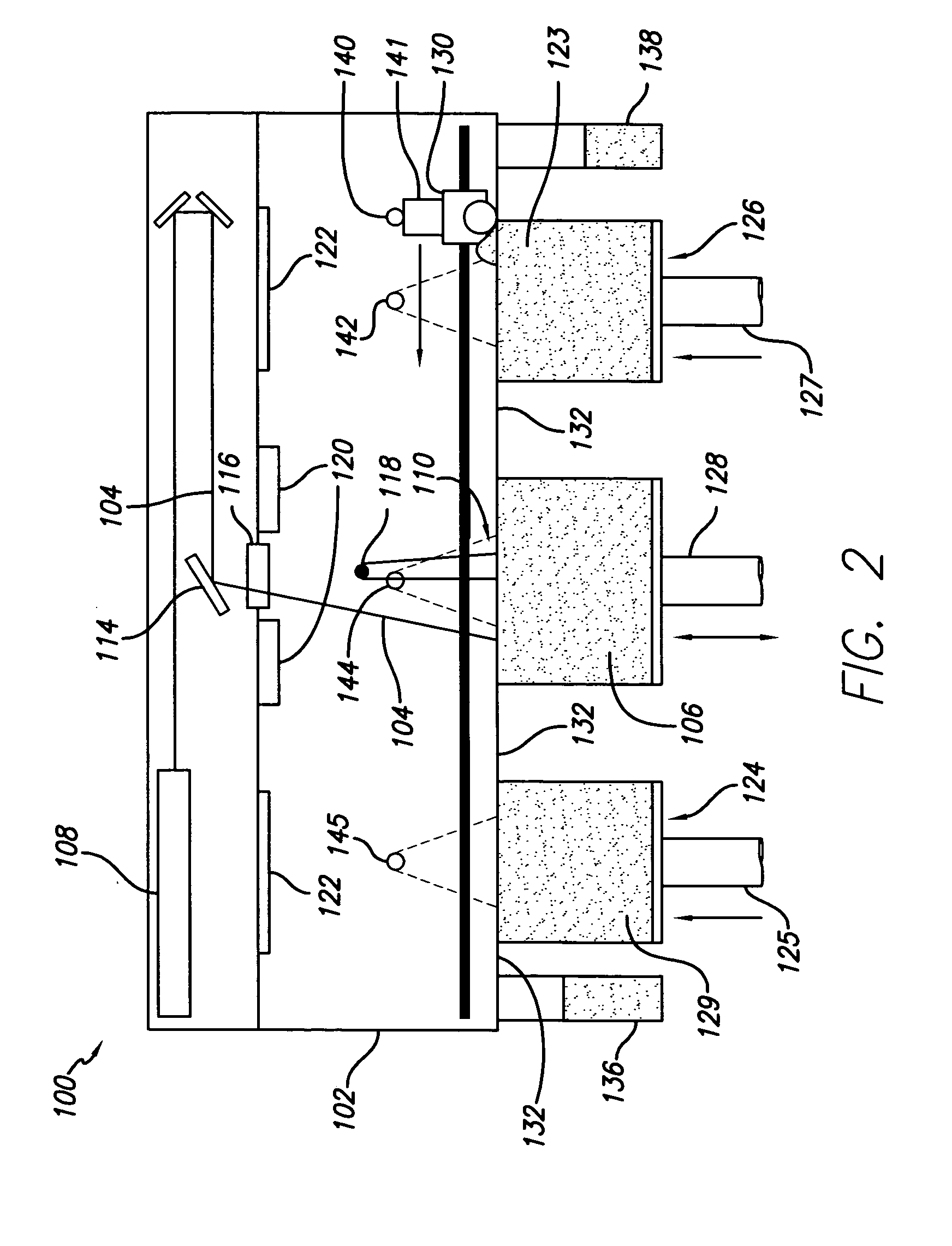

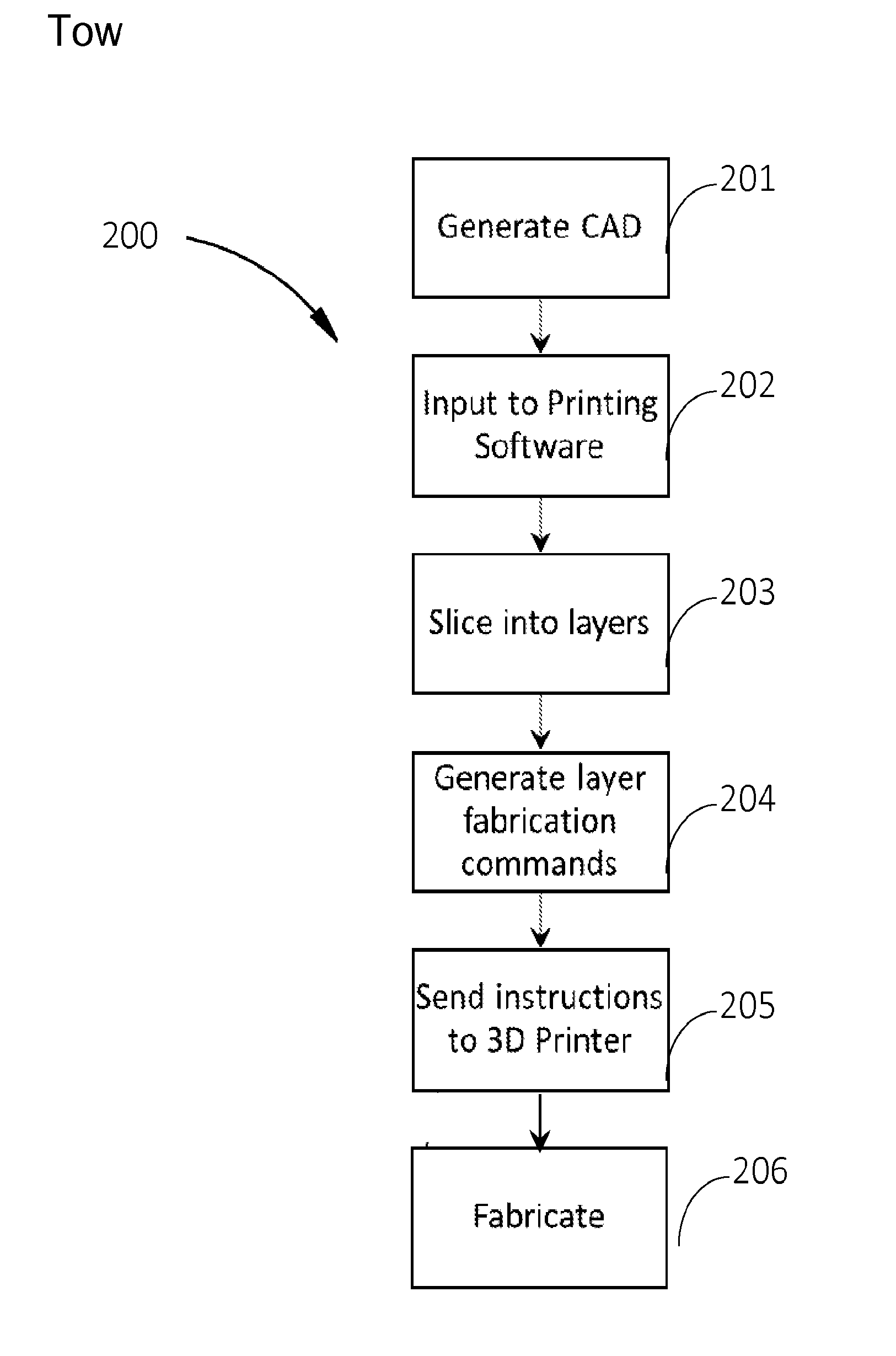

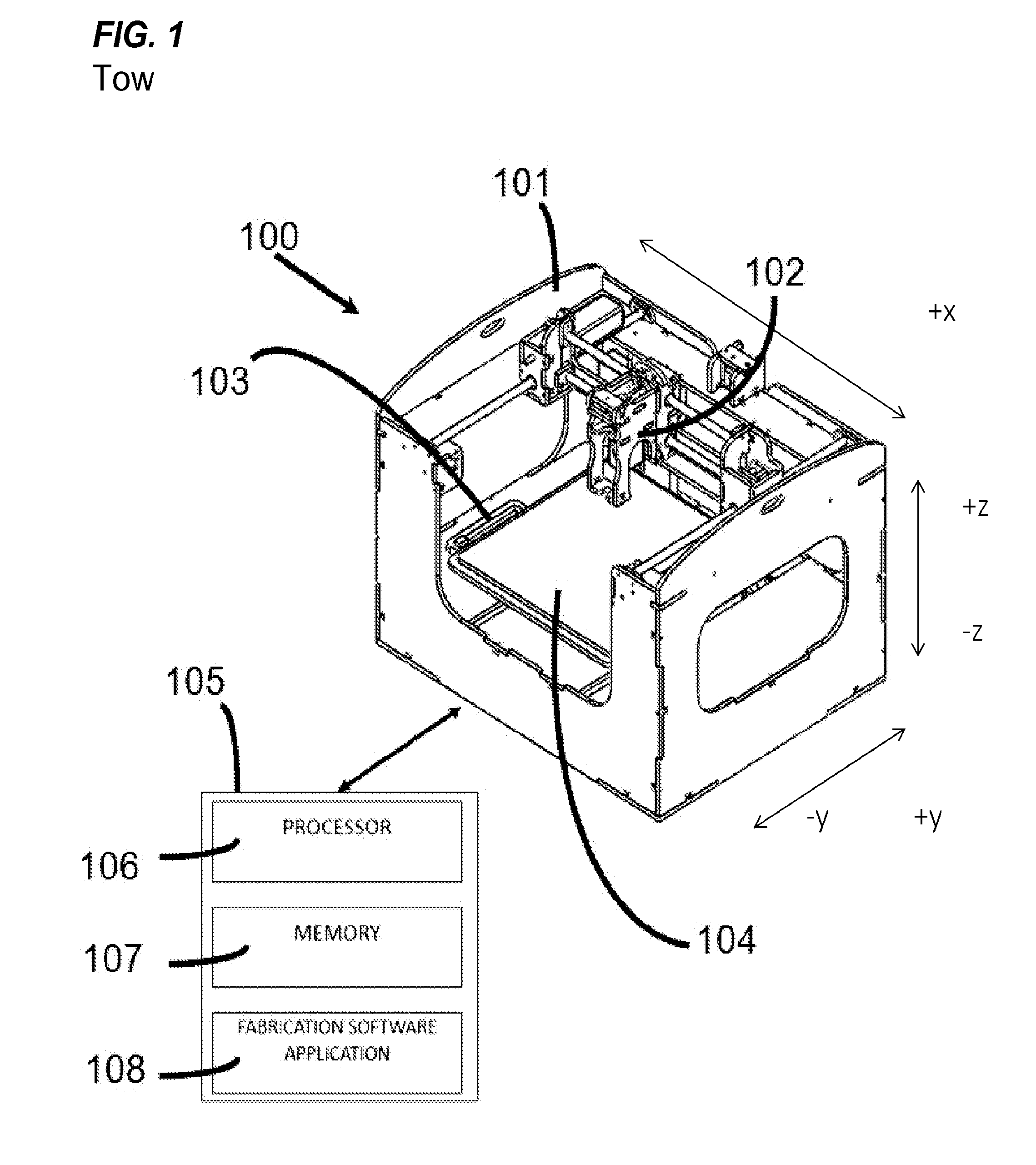

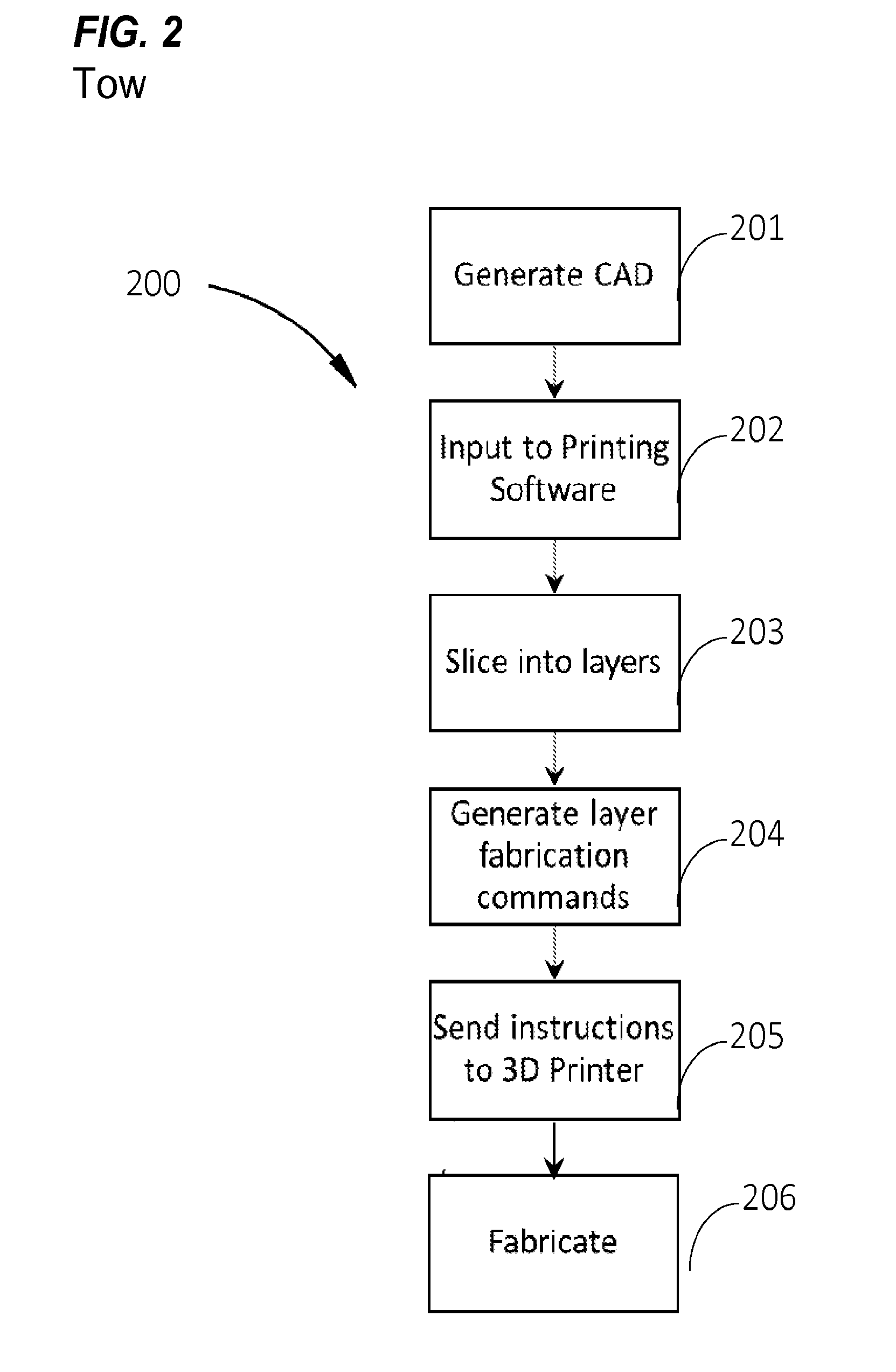

Systems and methods for manufacturing of multi-property anatomically customized devices

InactiveUS20150165690A1Increase productionOvercomes shortcomingAdditive manufacturing apparatusComputer controlMulti materialEngineering

Systems and methods for using a three dimensional fabrication device, like a 3D Printer, for novel automation and additive manufacturing techniques in manufacturing medical devices such as orthotics, customized for a particular person. The systems and methods may use a plurality of work surfaces on the three dimensional fabrication device. The systems and methods may use a plurality of materials or a plurality of fabrication tools and processes to manufacture the customized product.

Owner:TOW ADAM P

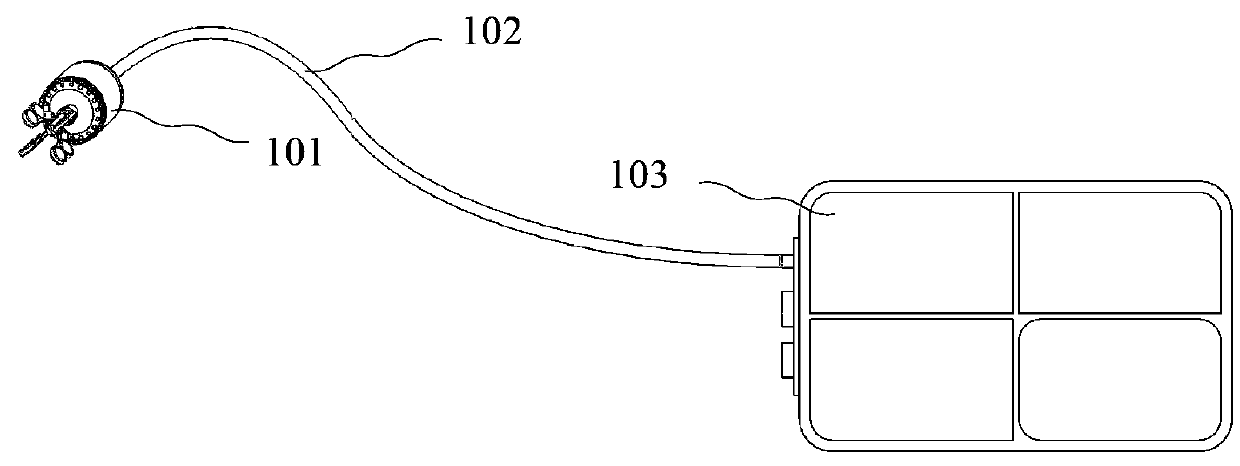

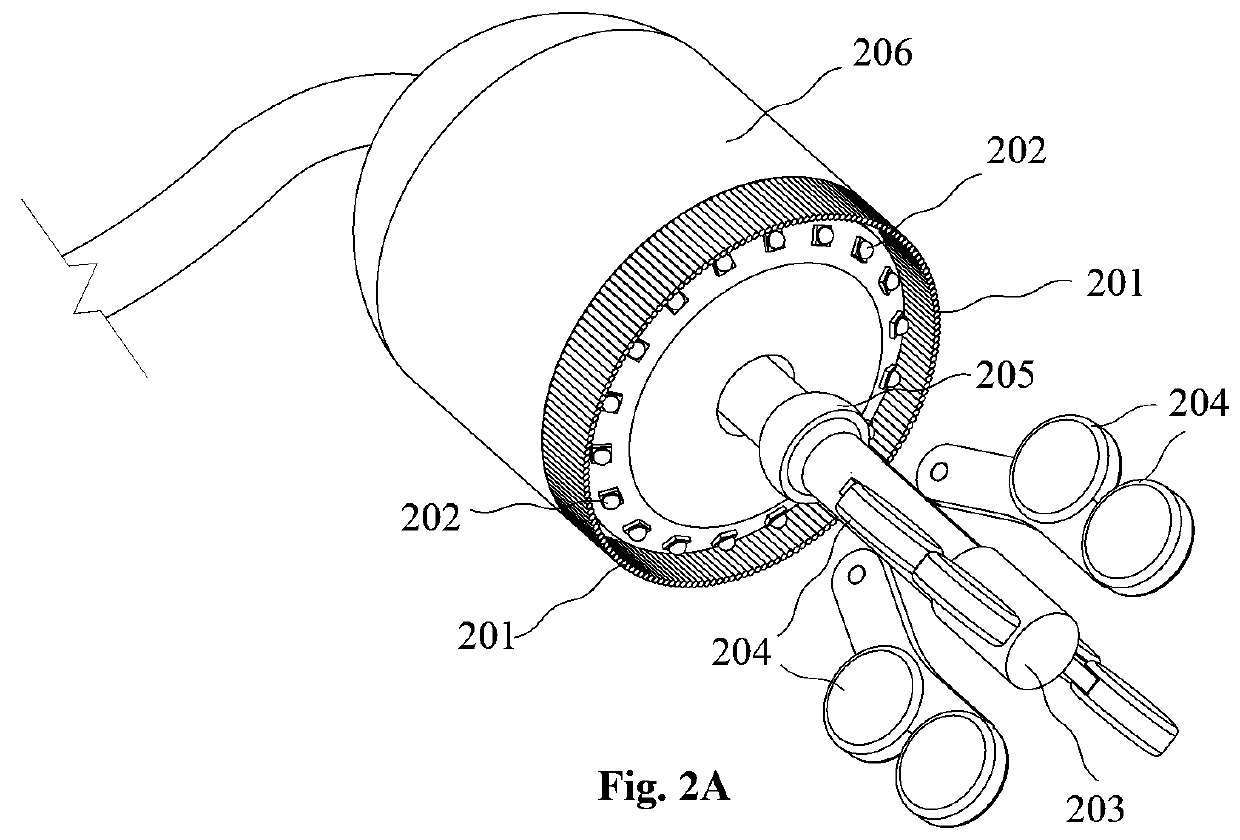

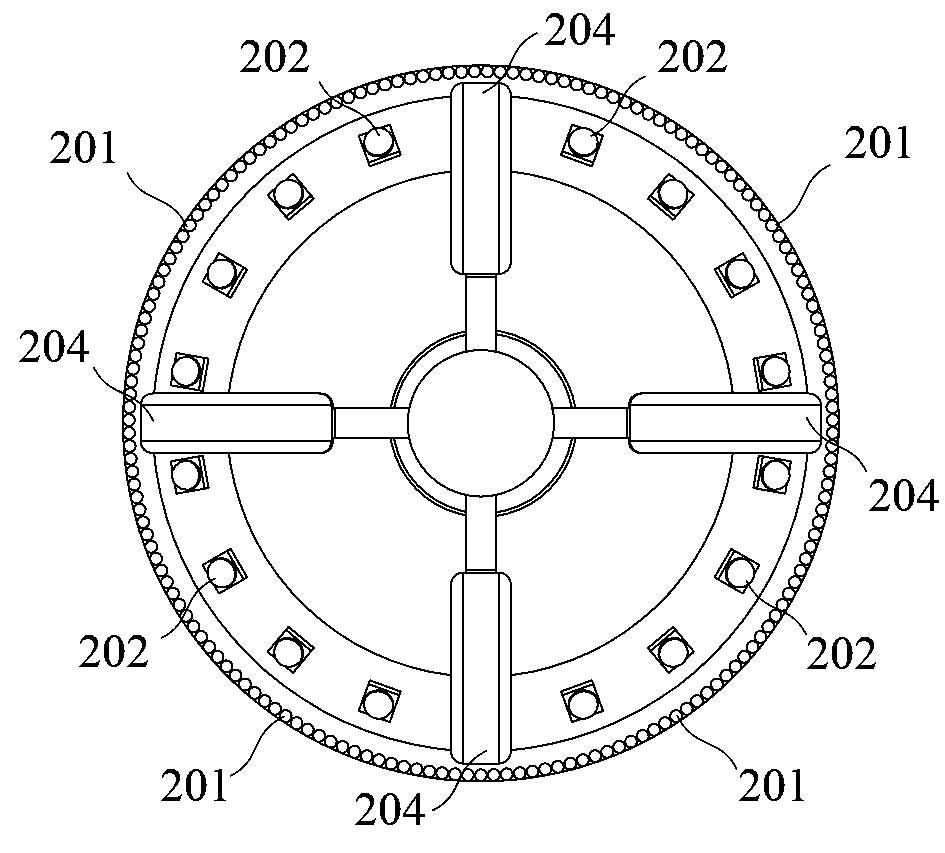

Impression scanning for manufacturing of dental restorations

ActiveUS20090220916A1Simplify the scanning processAvoiding time-consume and costlyDental implantsImpression capsImpressions materialsDental restoration

The present invention relates to a method for obtaining an accurate three-dimensional model of a dental impression, said method comprising the steps of, scanning at least a part of an upper jaw impression and / or a lower jaw impression, obtaining an impression scan, evaluating the quality of the impression scan, and use the impression scan to obtain a three-dimensional model, thereby obtaining an accurate three-dimensional model of the dental impression.

Owner:3SHAPE AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com