Integrated organ and tissue printing methods, system and apparatus

a printing method and tissue technology, applied in the field of organ and tissue printing methods, systems and apparatuses for making tissues in vitro, can solve the problems of low mechanical stability of low viscosity materials being printed, high aspect ratio structures or porous structures that facilitate, and cannot be easily achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

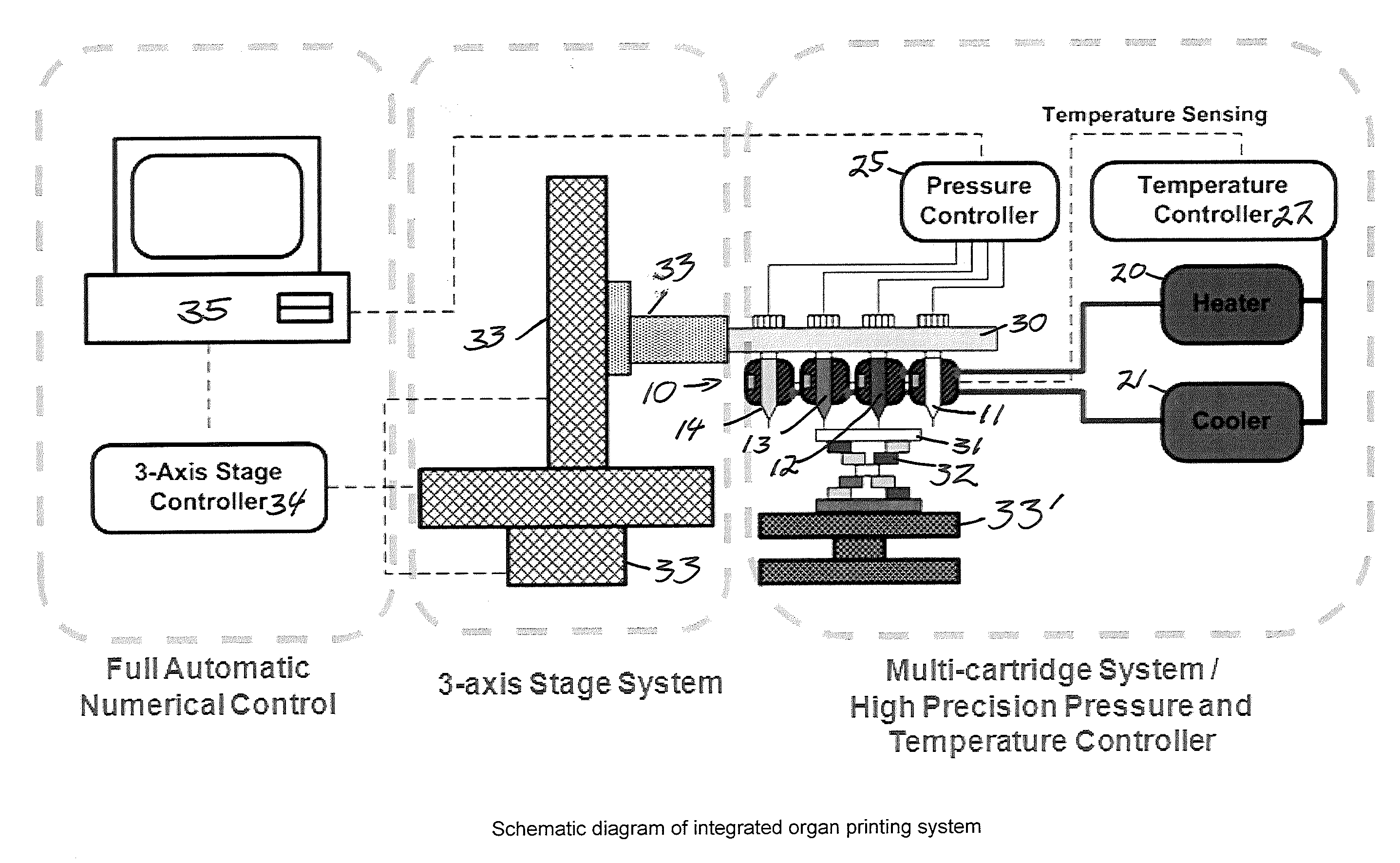

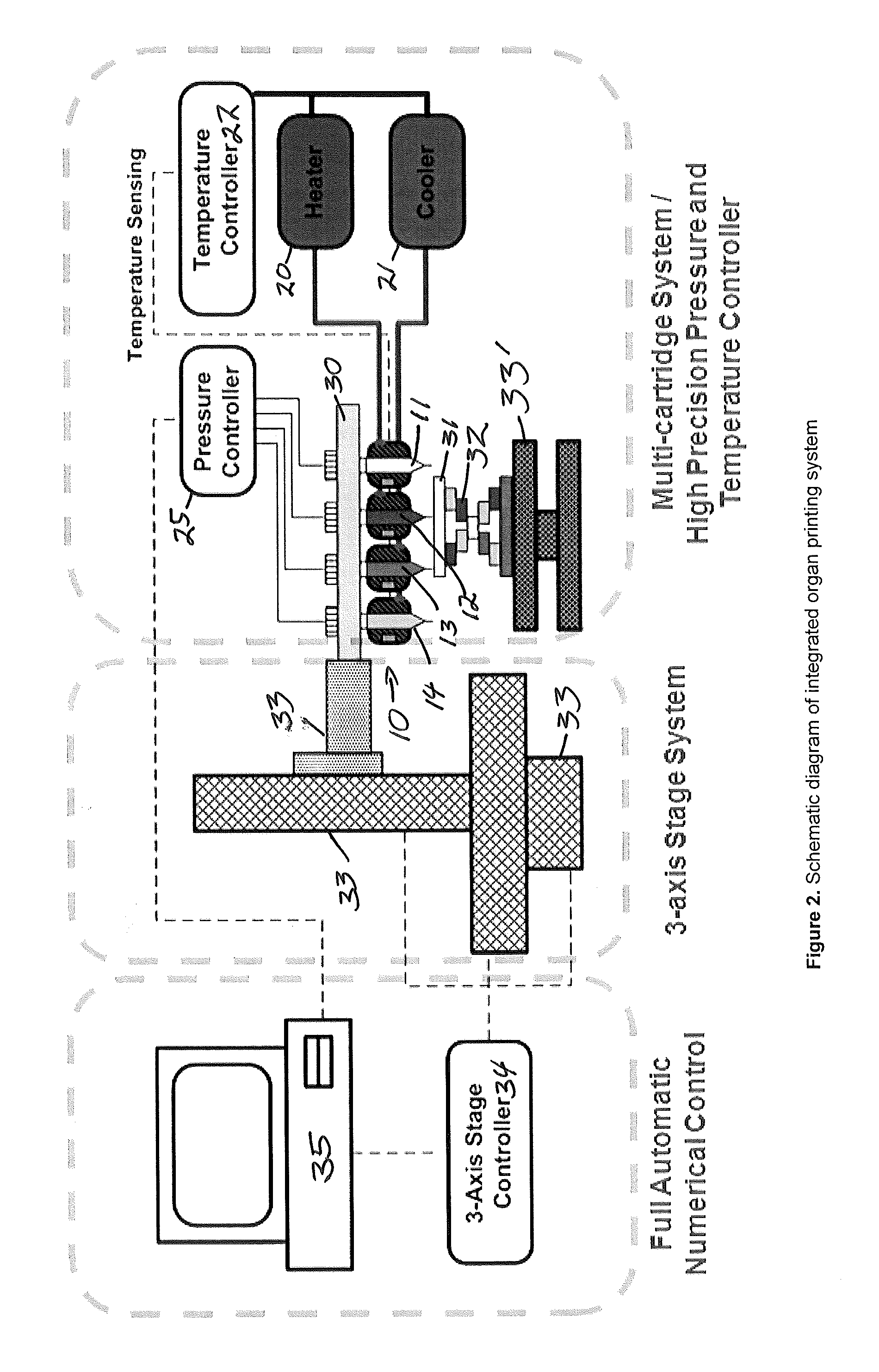

[0096]To engineer tissues, or “tissue engineered constructs” that contain multiple cell types, manual cell placement is not a feasible option. Hence, we have developed a cell delivery method and apparatus that permits accurate placement of multiple cell types, including different cell types, within a common scaffold (in the same region, in different regions, and / or in overlapping regions). In addition, we have developed a system that overcomes the limitation of using a bioprinting system that only allows the use of low viscosity biomaterials.

[0097]Our initial goal was to design a system that can process synthetic and cell mixed natural polymers with the goal of fabrication in the resolution of range of 100-200 microns. This system processes biomaterials such as polycaprolactone and gelatin.

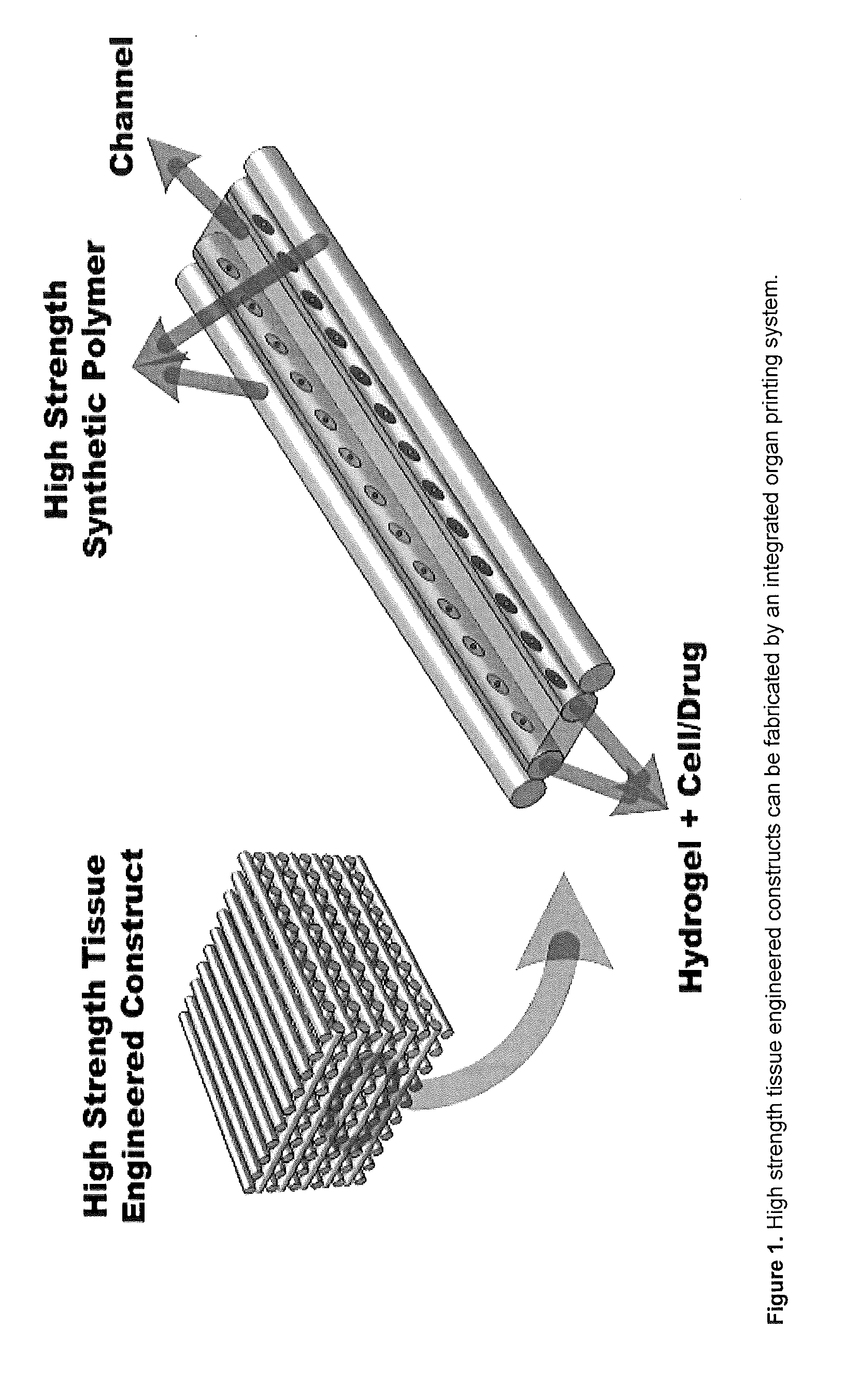

[0098]A schematic of one embodiment of constructs or “tissue engineered constructs” produced by the present invention is shown in FIG. 1. Note that the construct is comprised of multiple layers, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com