Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4711 results about "Material supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

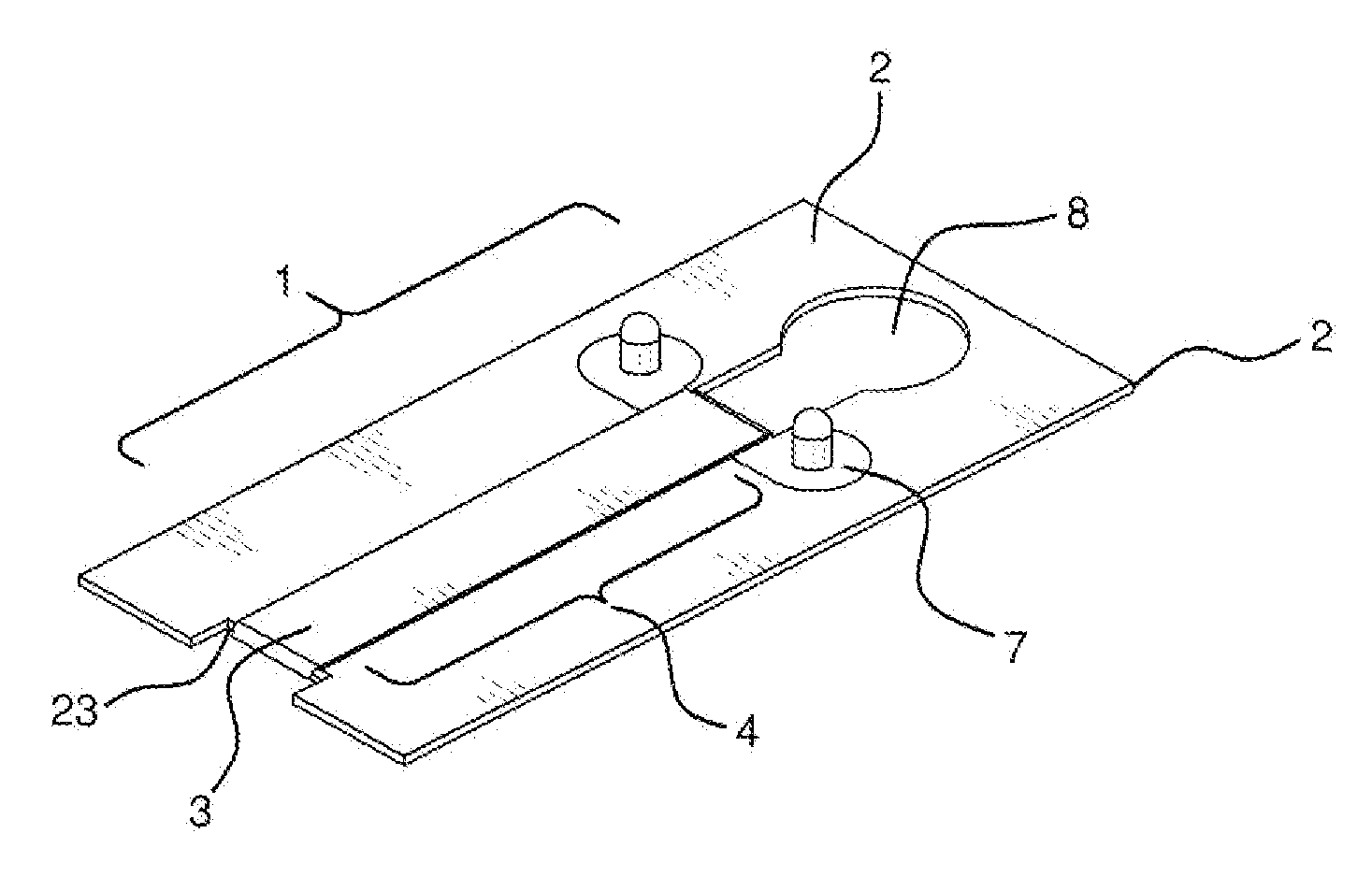

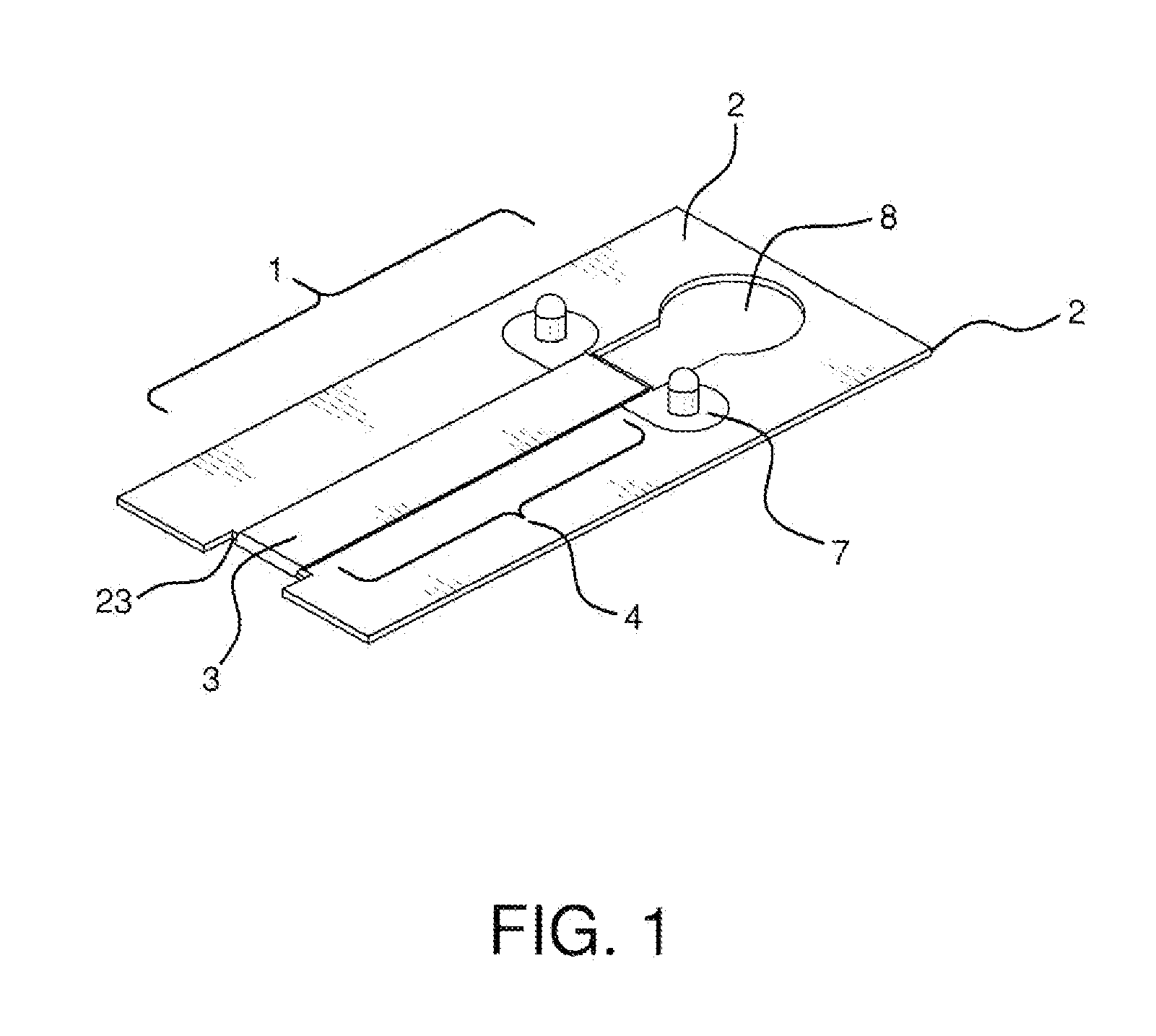

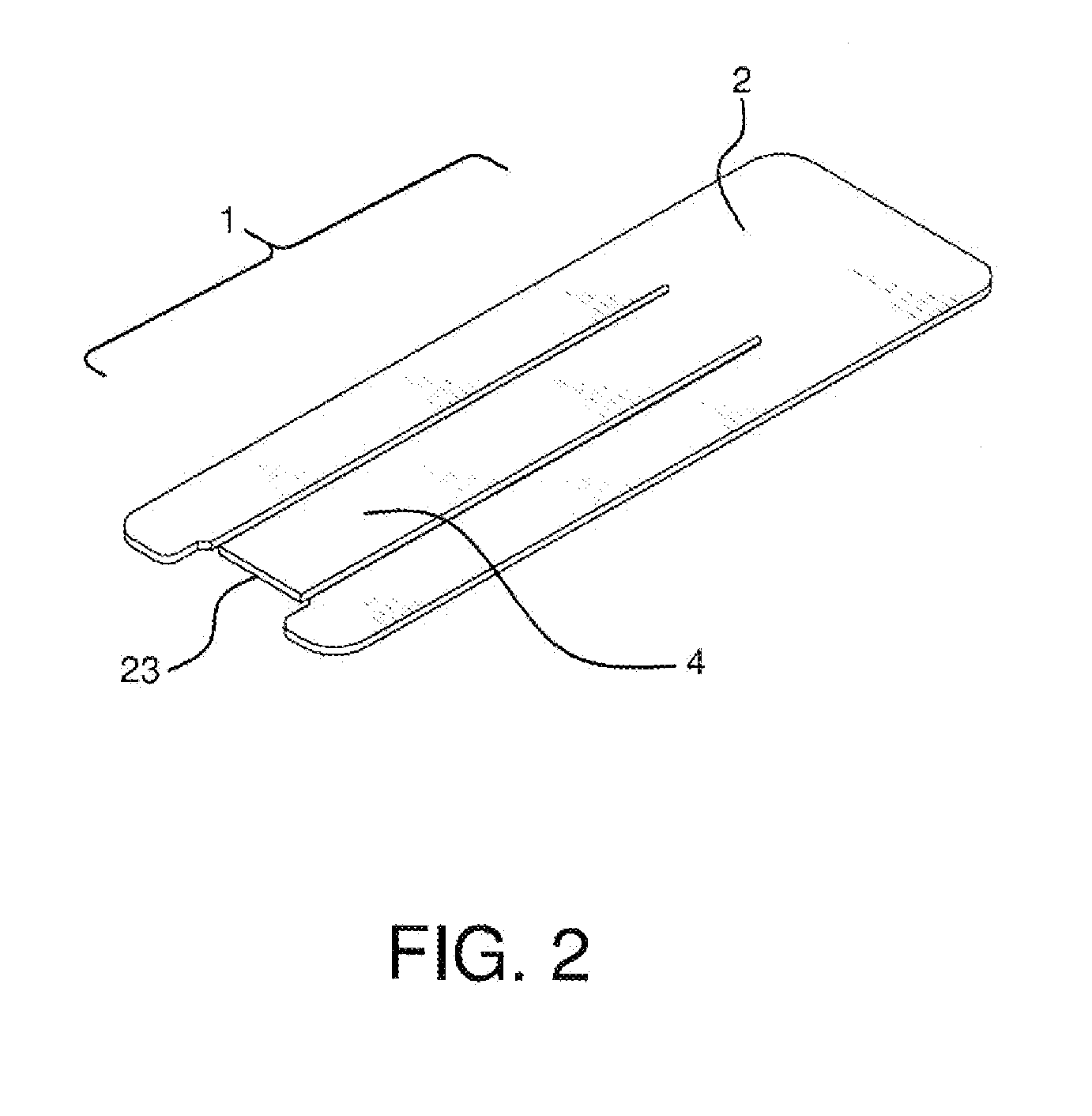

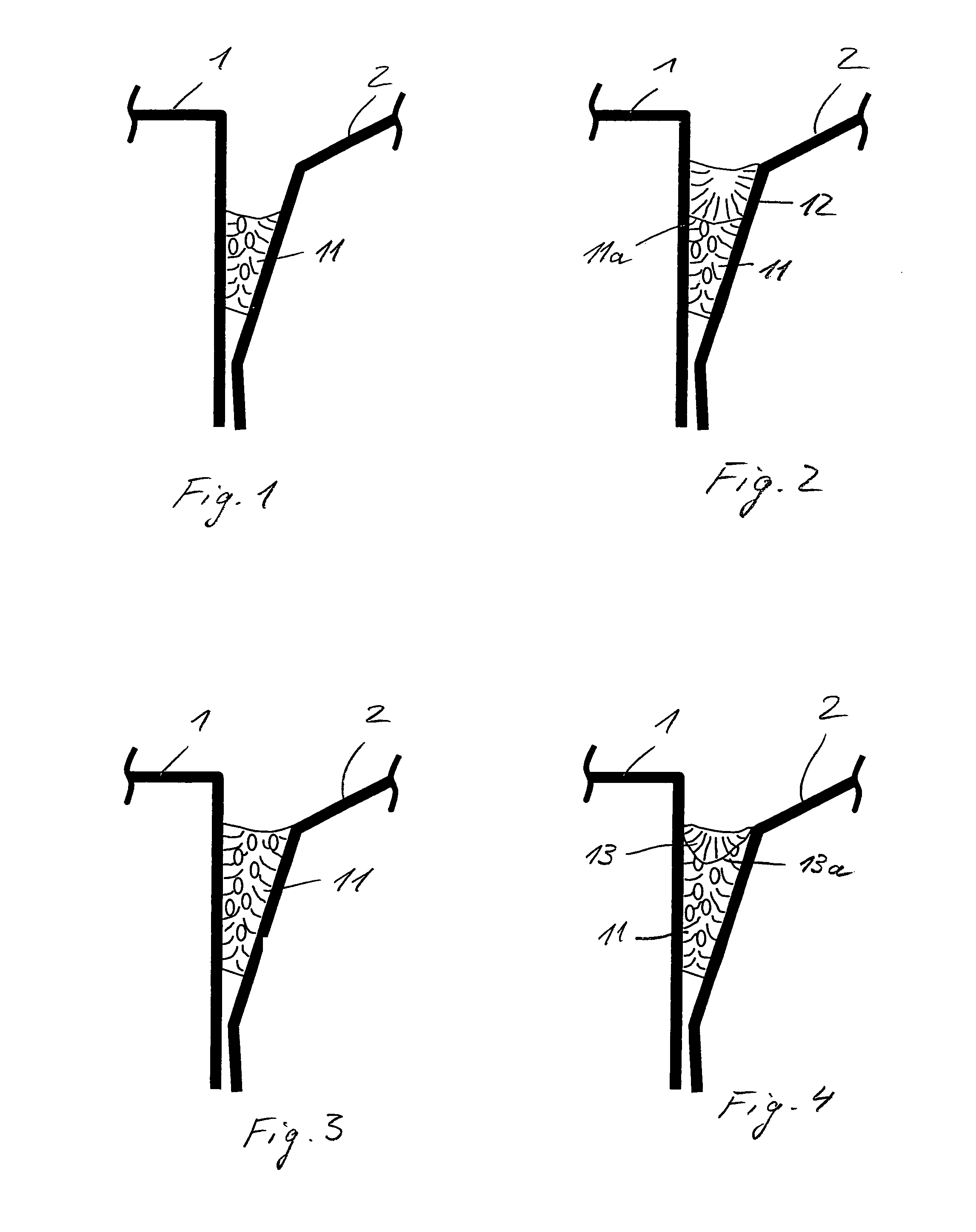

Apparatus for Supplying Surgical Staple Line Reinforcement

InactiveUS20120289979A1Accurately and successfully positionedMaintain strengthSurgical staplesWound clampsSurgical stapleMaterial supply

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

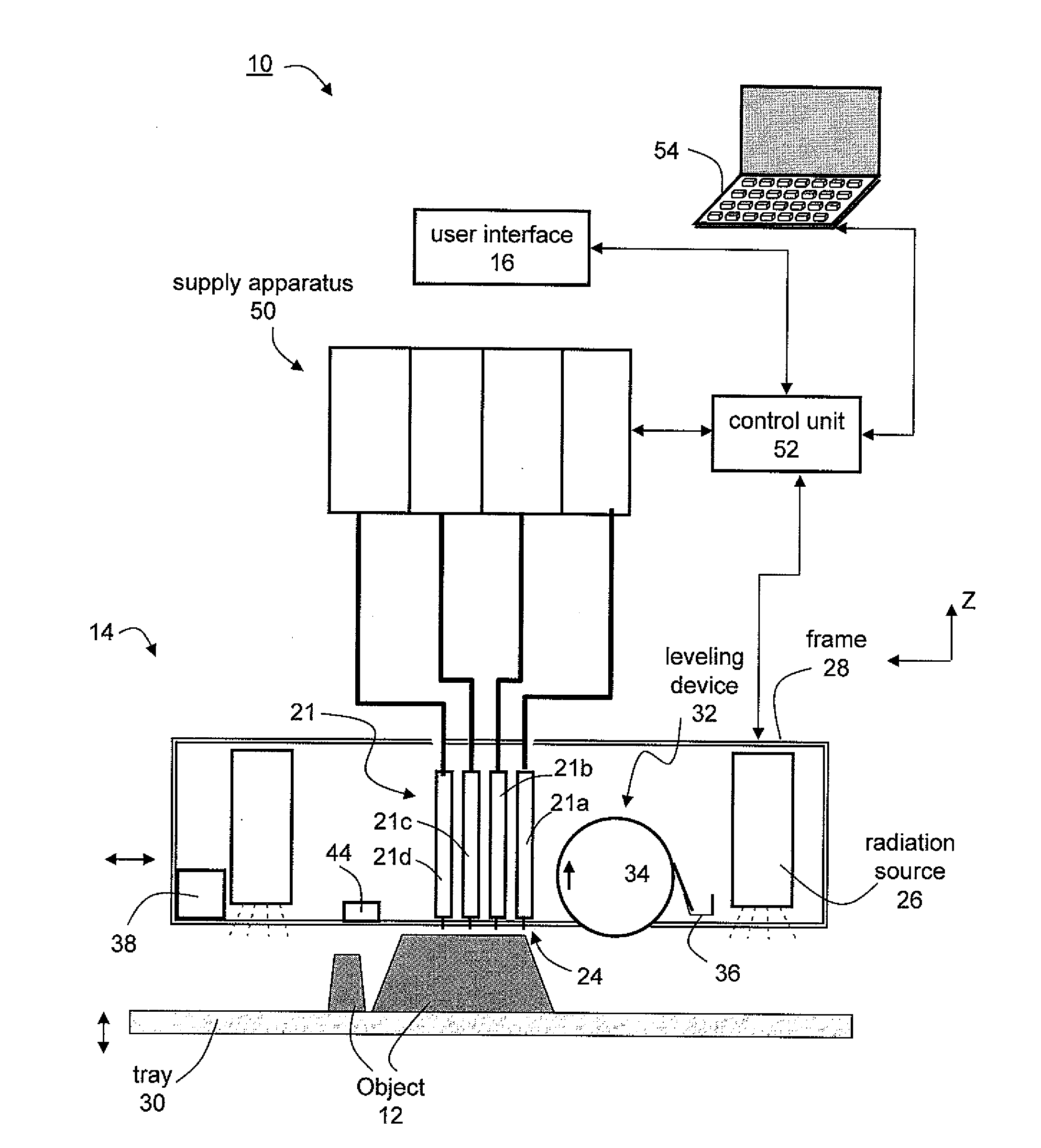

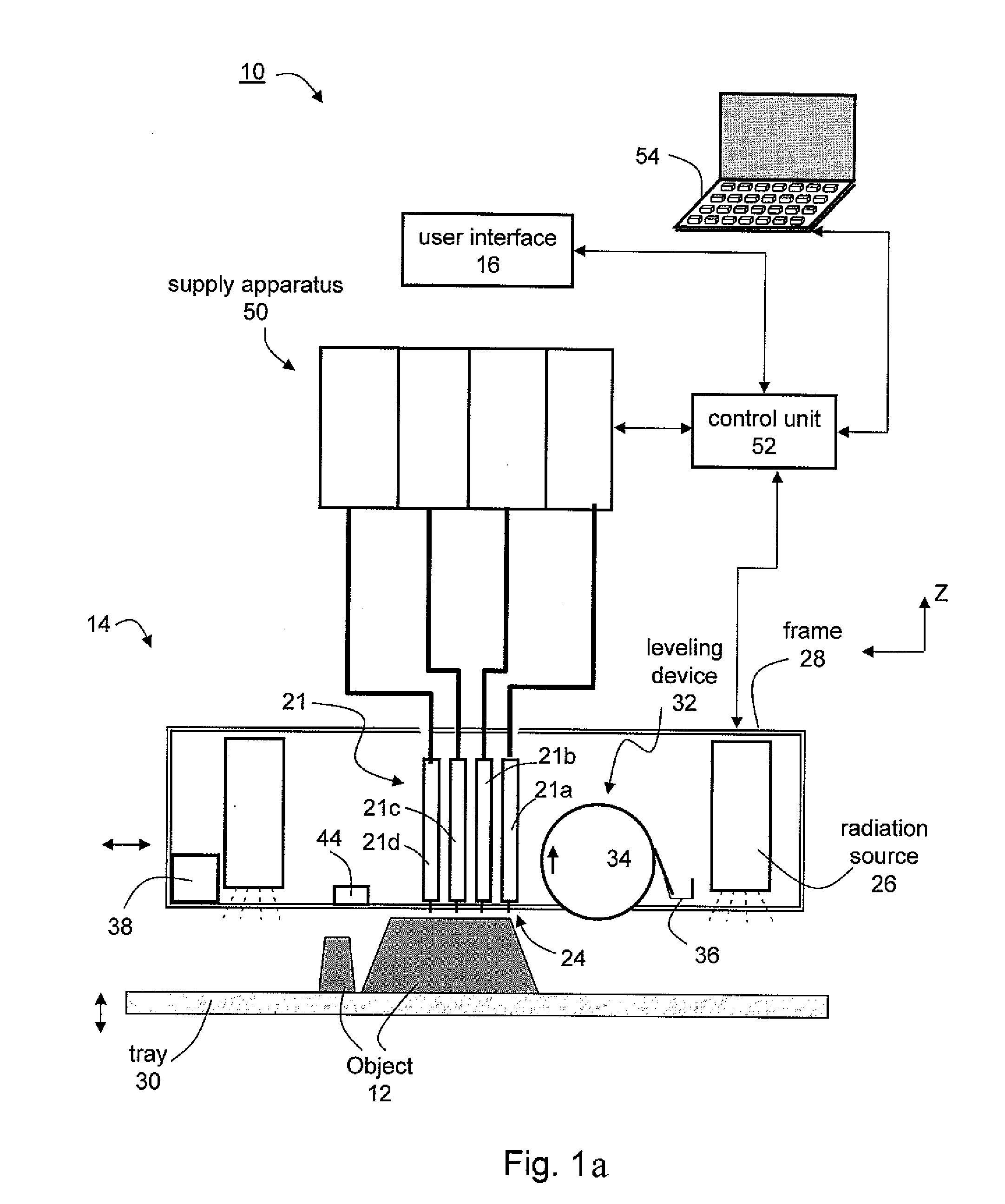

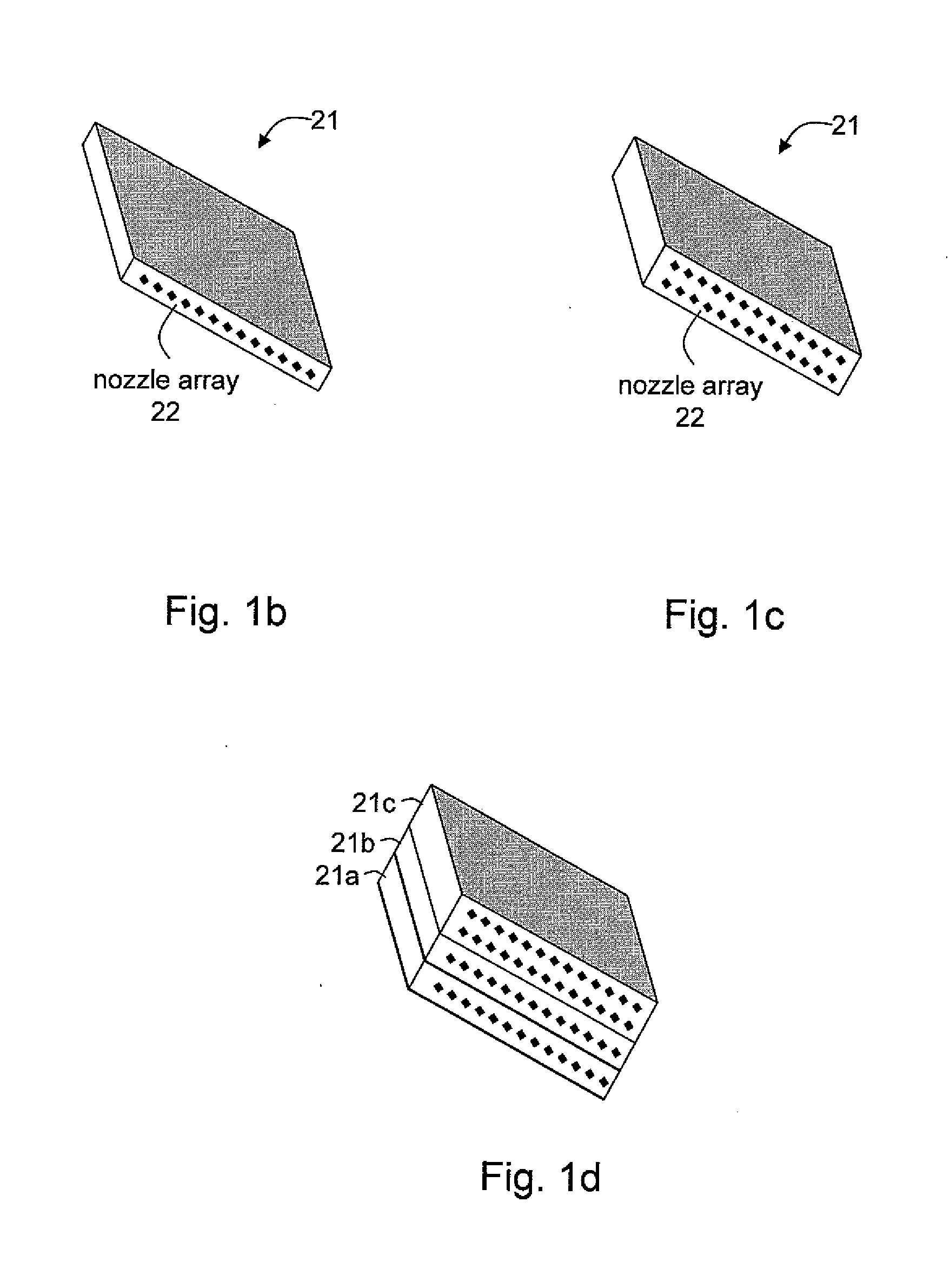

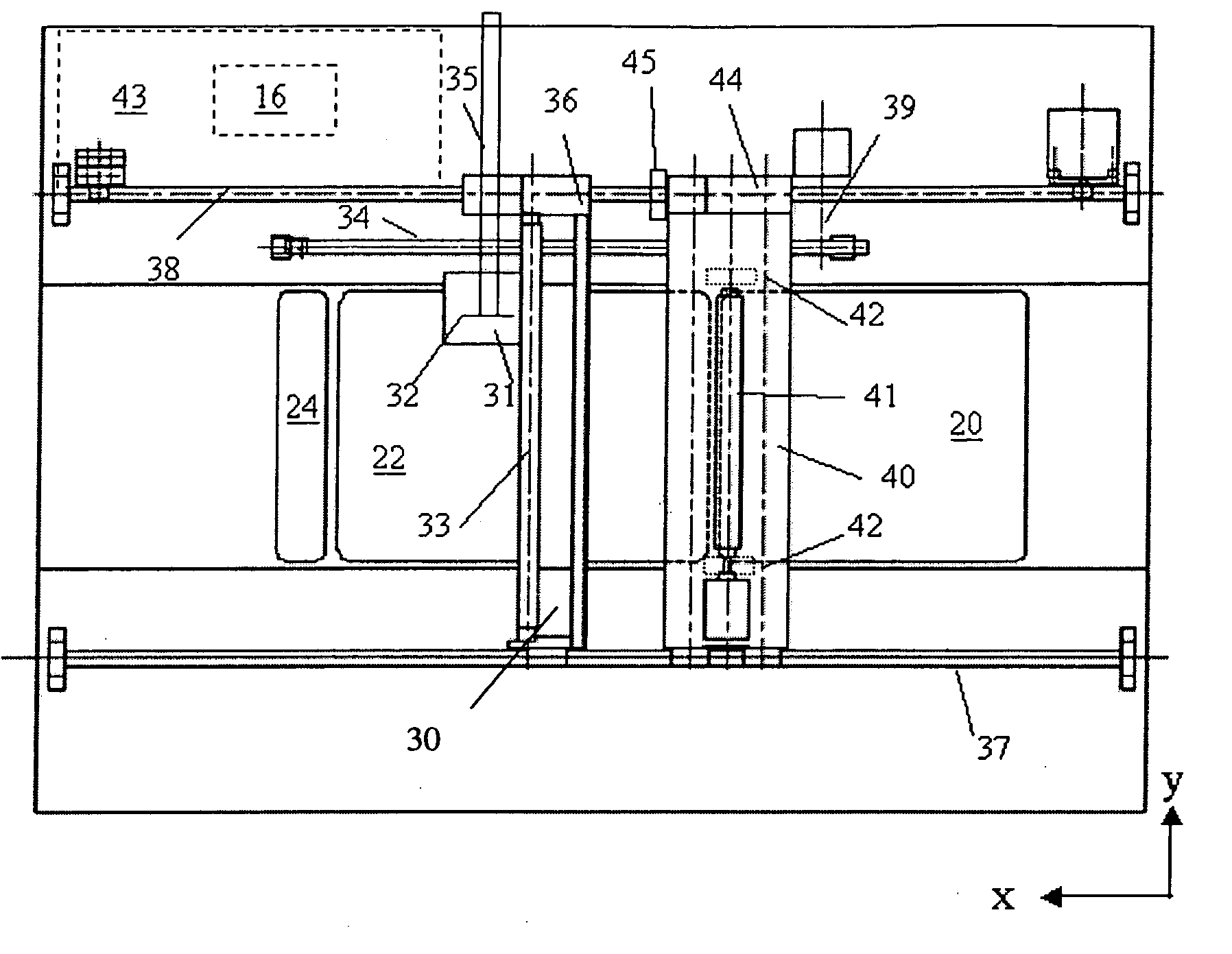

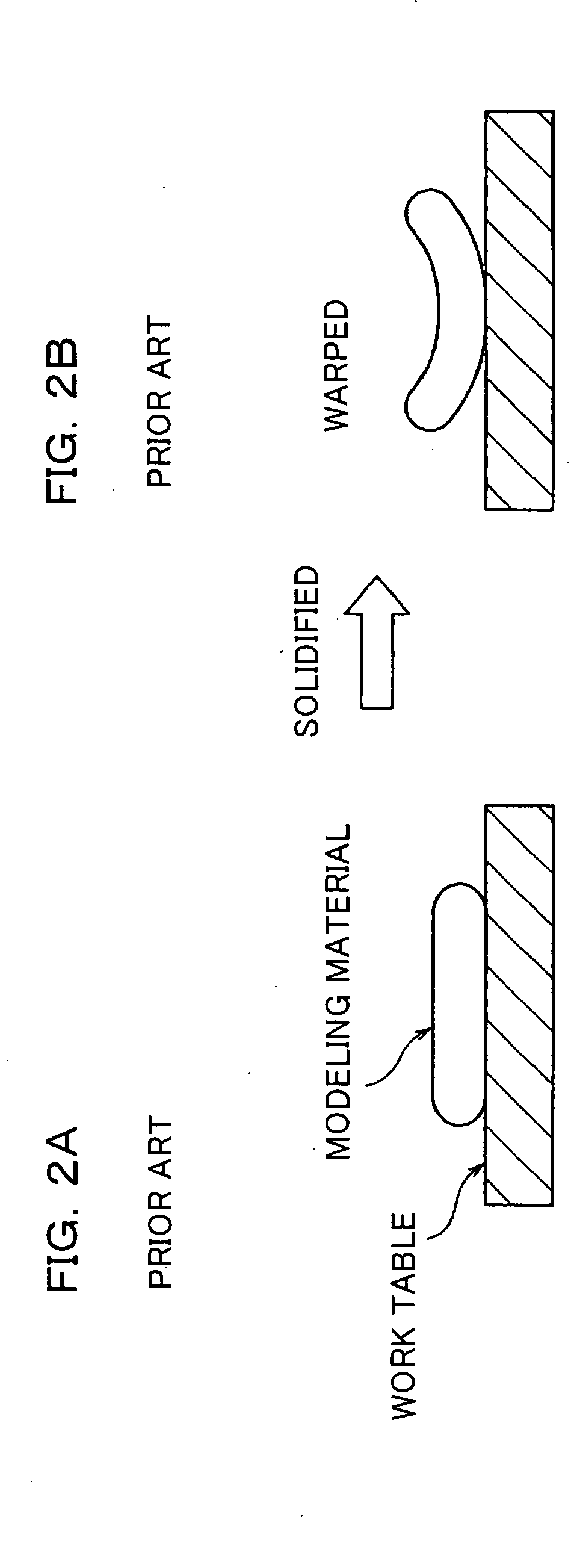

Solid freeform fabrication using a plurality of modeling materials

InactiveUS20100191360A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeMaterial supply

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:OBJET GEOMETRIES

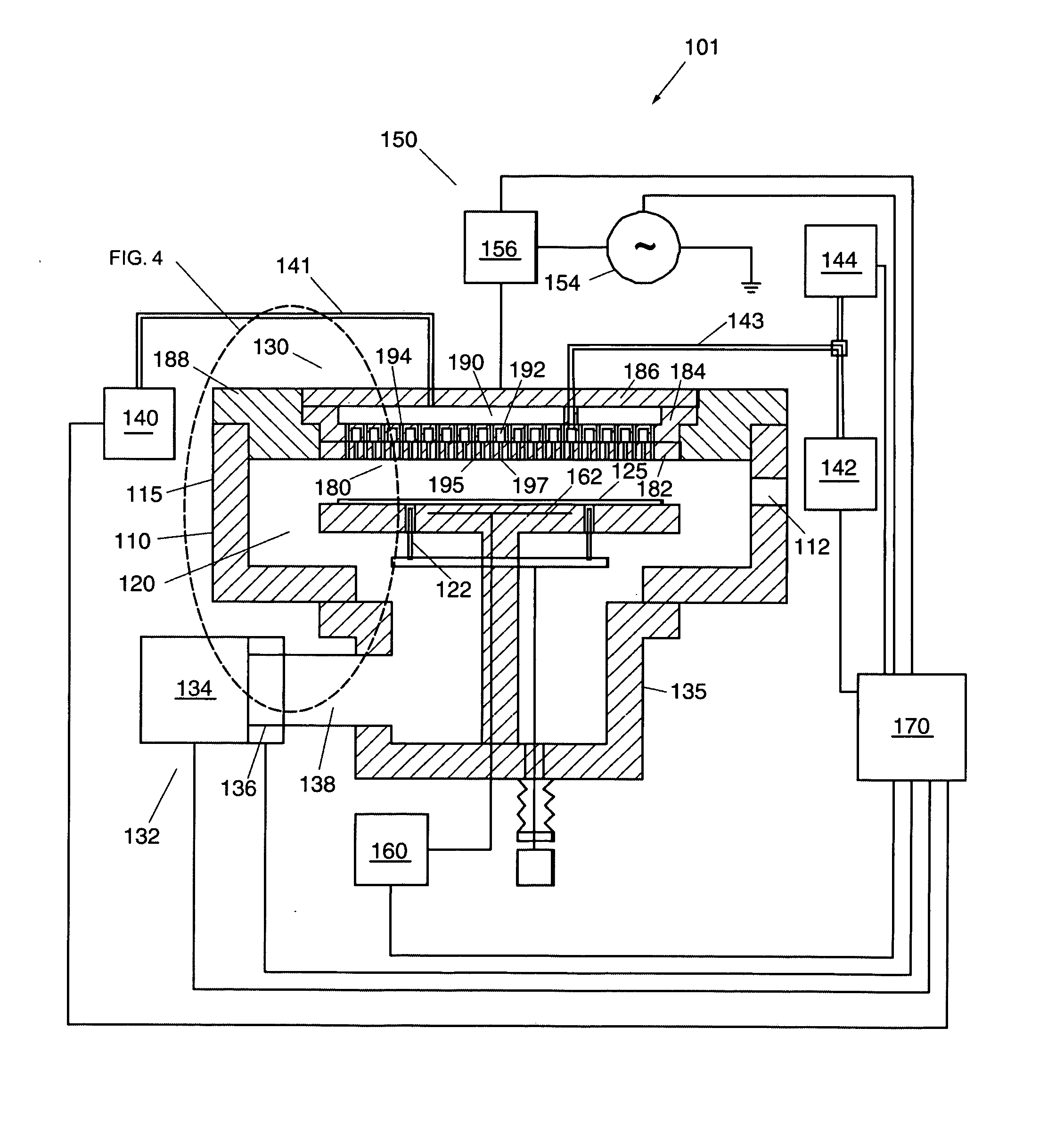

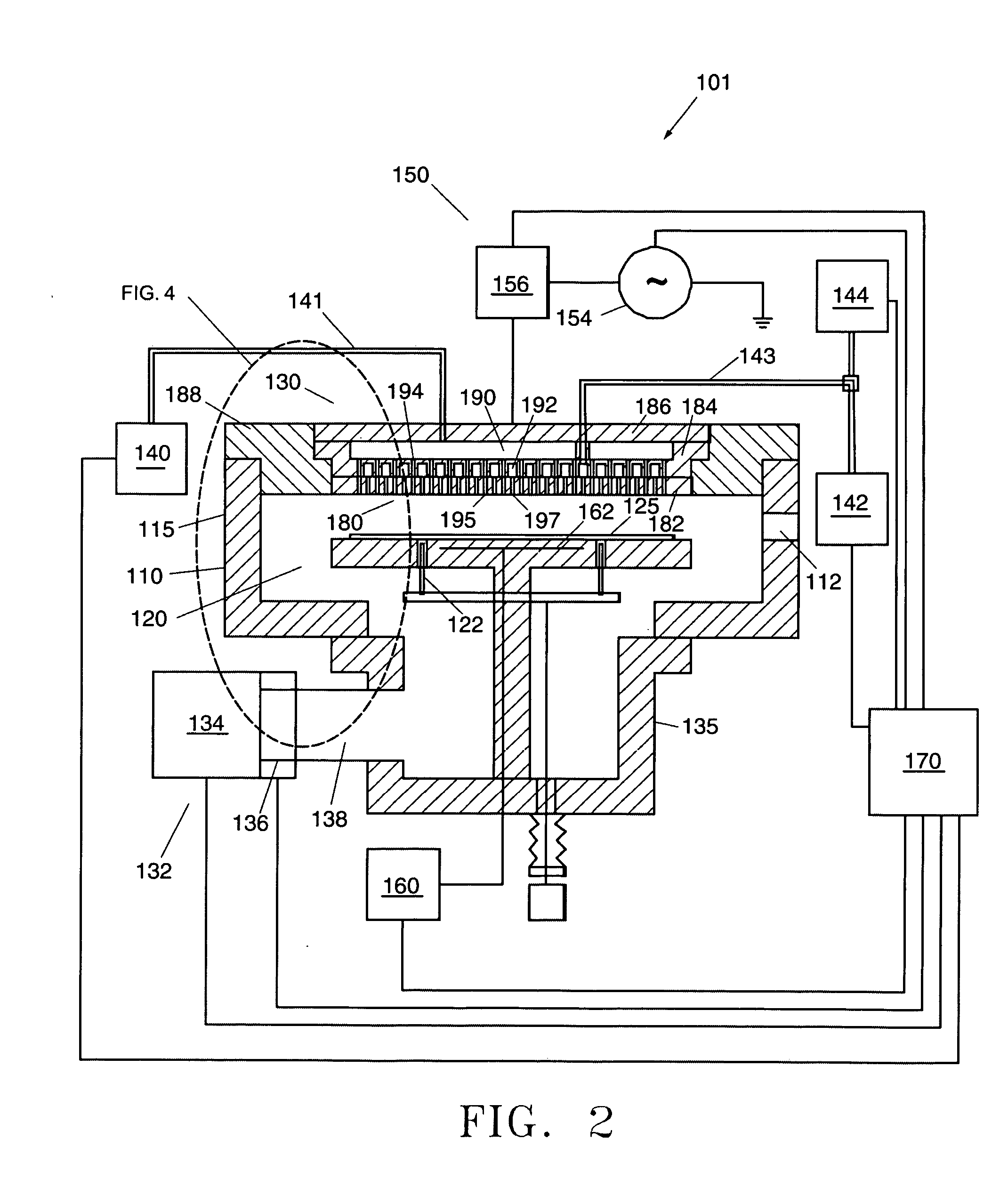

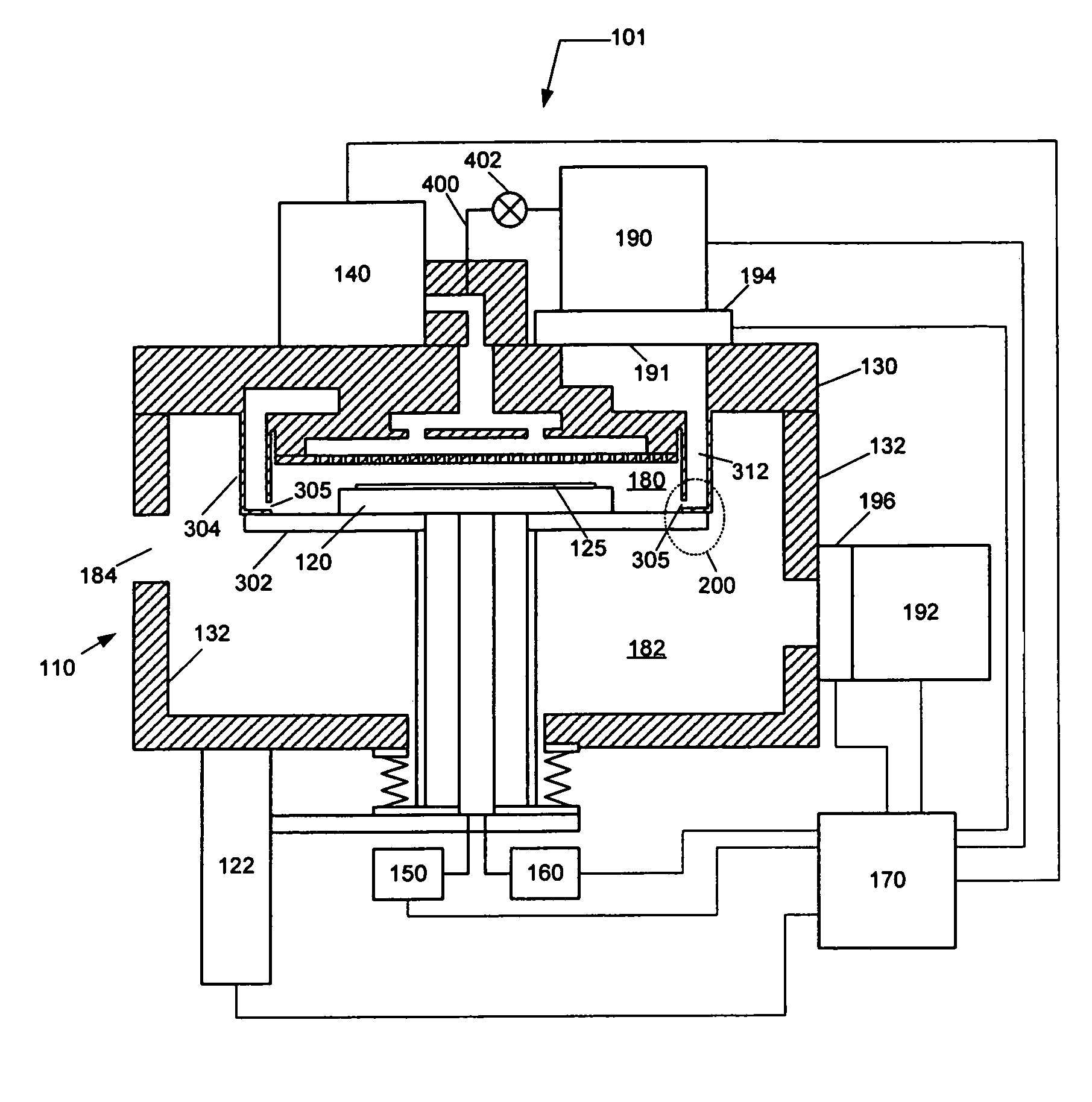

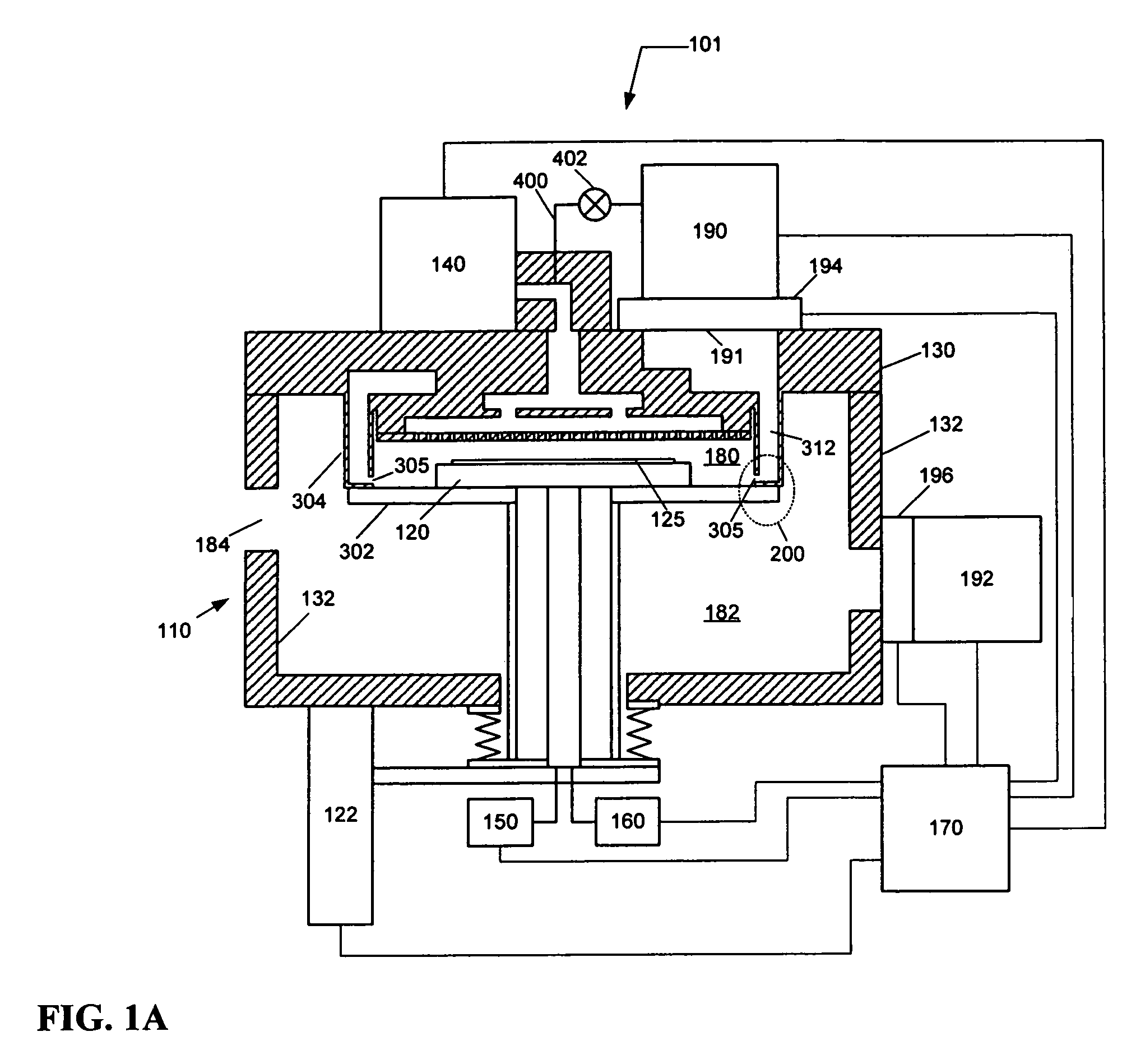

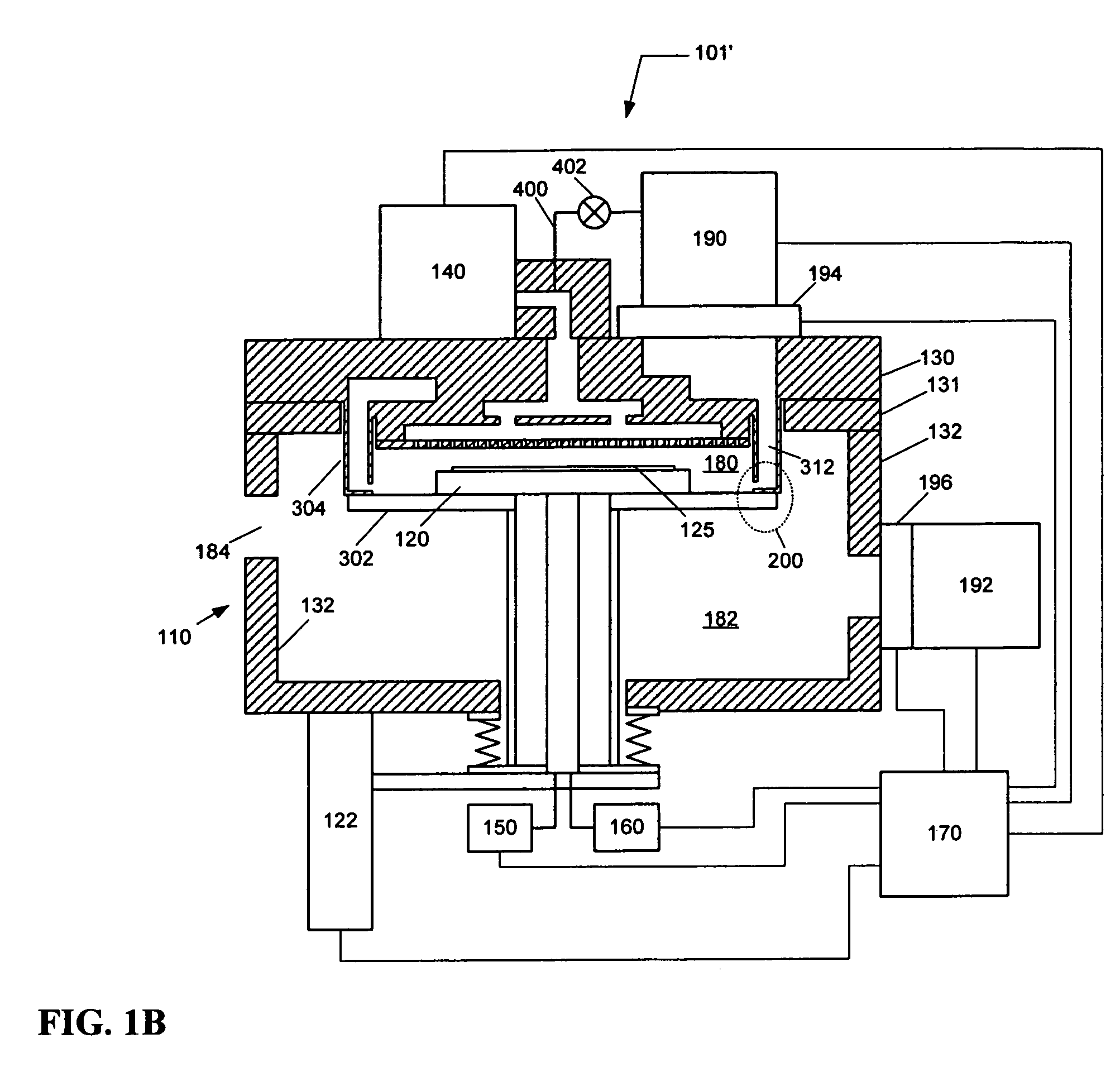

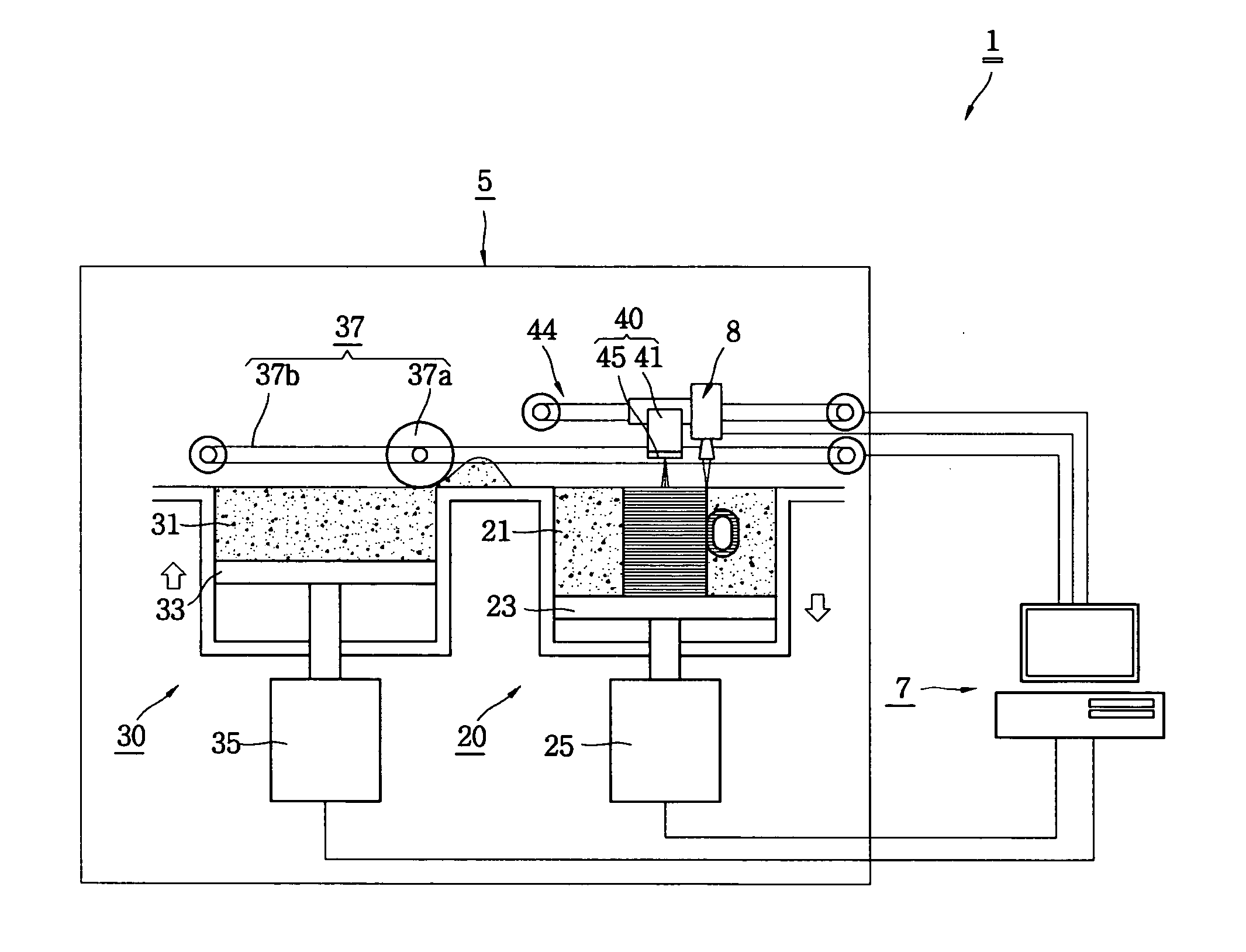

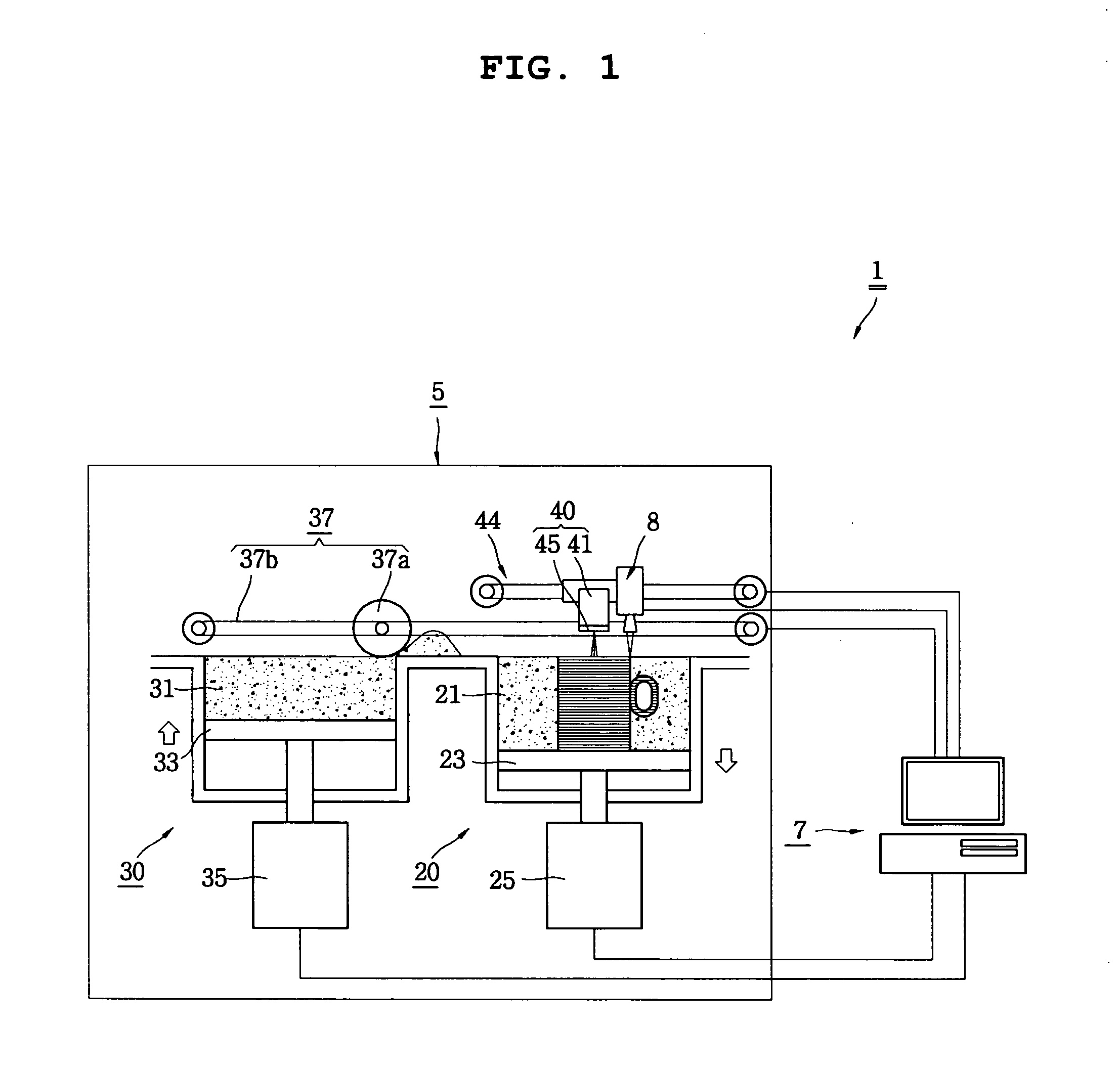

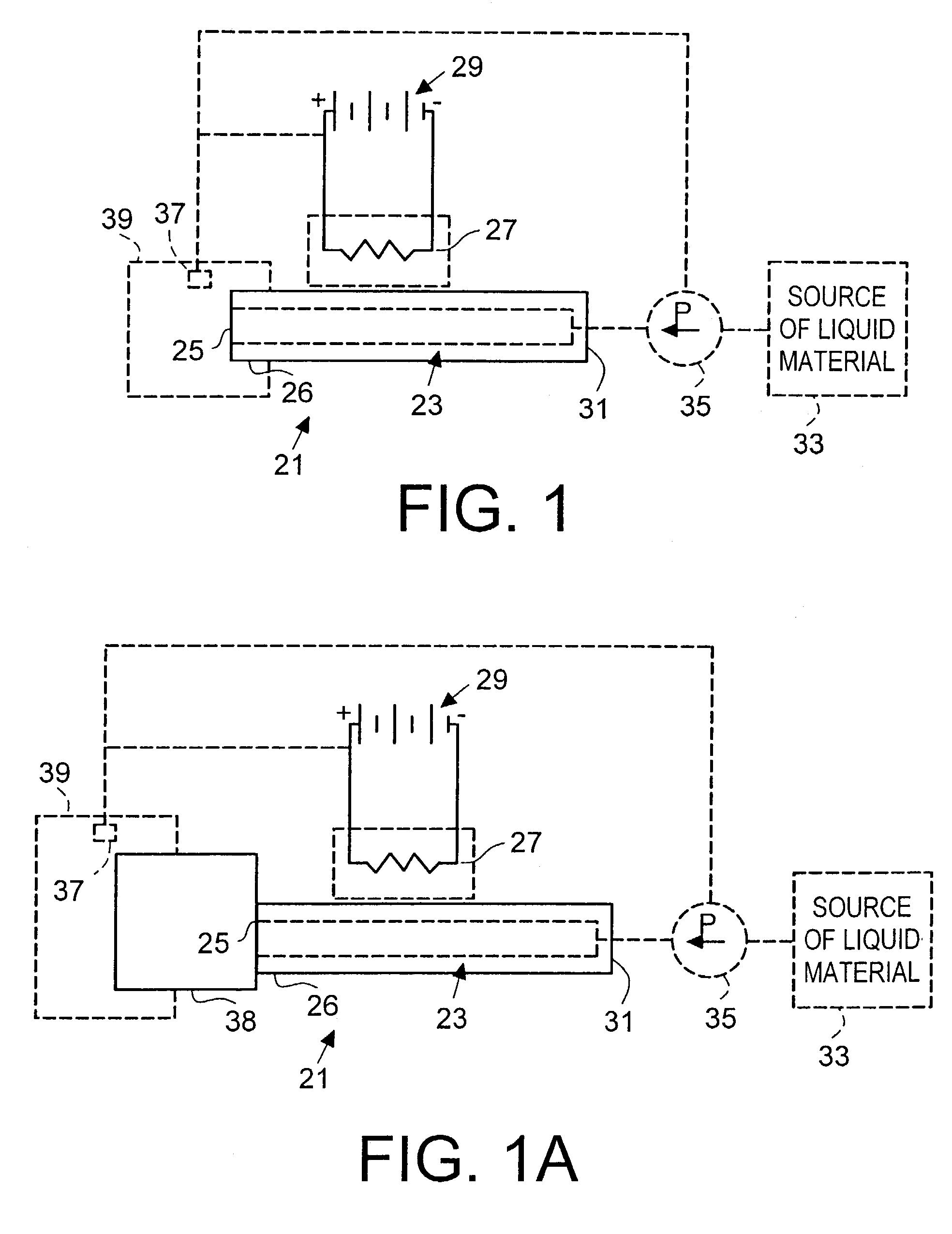

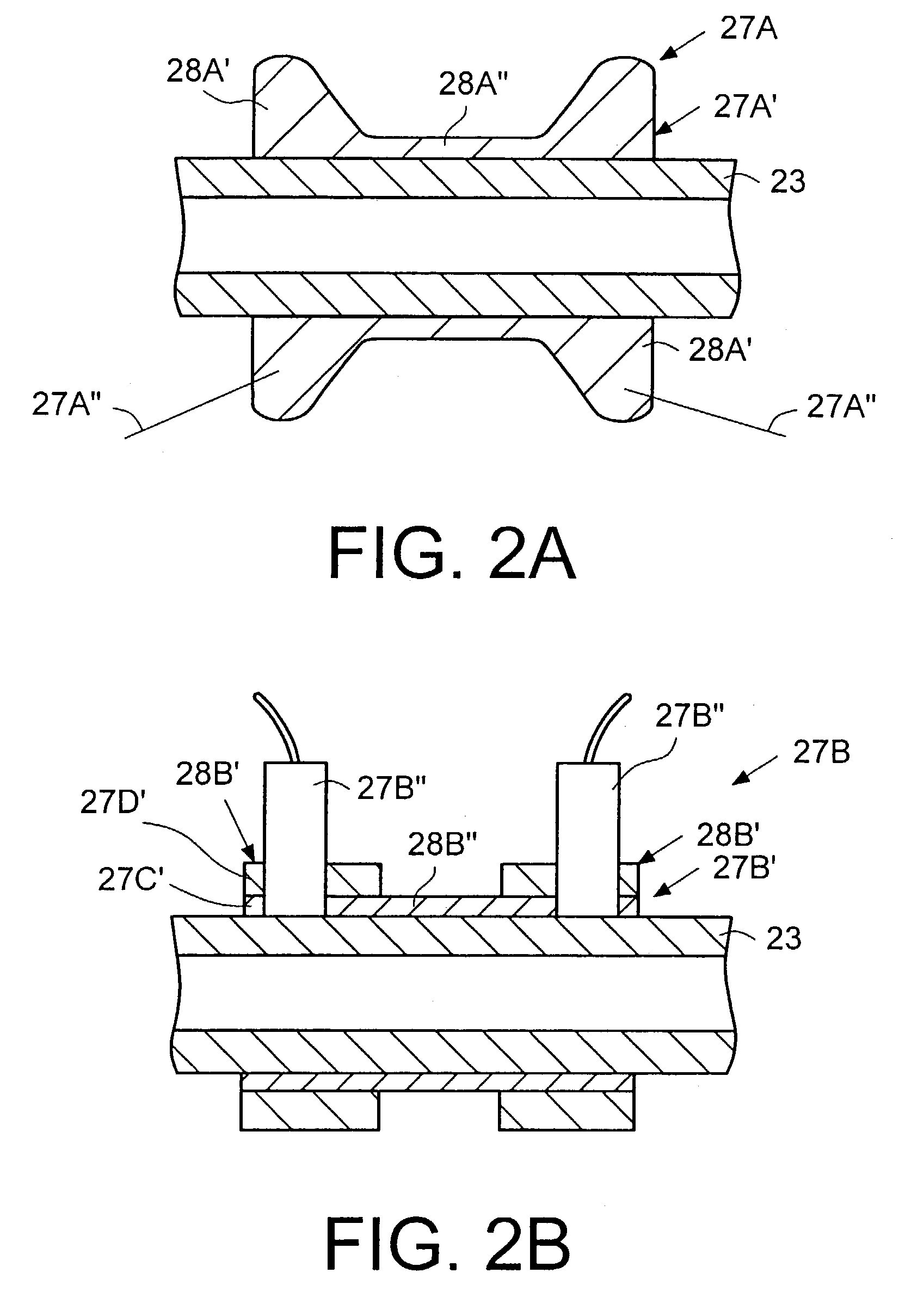

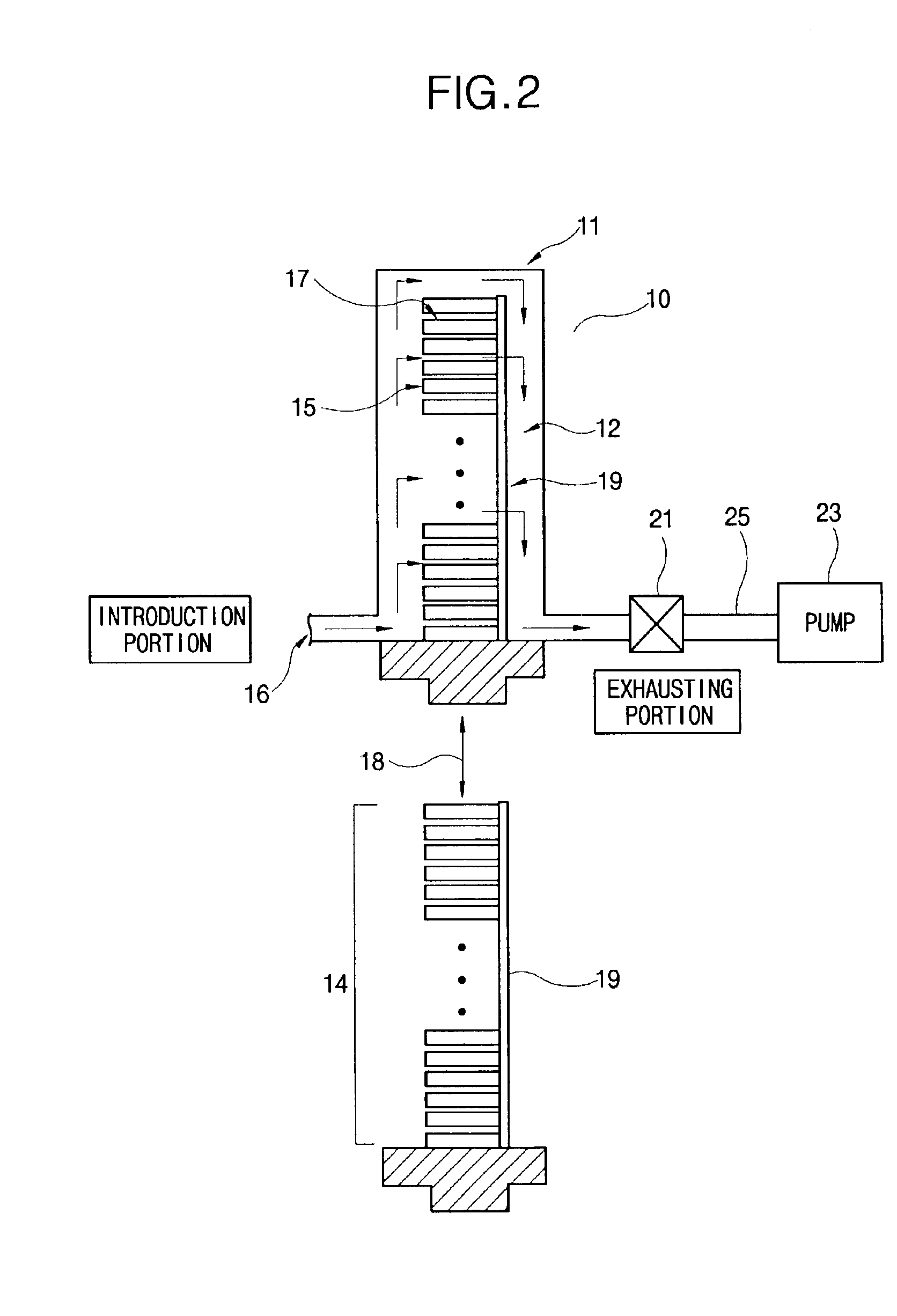

Plasma enhanced atomic layer deposition system

InactiveUS20060213437A1Reduce pollutionReduce decreaseChemical vapor deposition coatingEngineeringMaterial supply

A plasma enhanced atomic layer deposition (PEALD) system includes a processing chamber defining an isolated processing space within the processing chamber, and a substrate holder provided within the processing chamber and configured to support a substrate. A first process material supply system is configured to supply a first process material to the processing chamber, a second process material supply system is configured to supply a second process material to the processing chamber and a power source is configured to couple electromagnetic power to the processing chamber. A contaminant shield is positioned along a periphery of the substrate holder and configured to impede external contaminants that permeate the chamber from traveling to a region of the substrate holder, wherein the film is formed on the substrate by alternatingly introducing the first process material and the second process material.

Owner:TOKYO ELECTRON LTD

Exhaust system for a vacuum processing system

InactiveUS7670432B2Reduce pollutionEasy transitionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

A method, computer readable medium, and system for treating a substrate in a process space of a vacuum processing system is described. A vacuum pump in fluid communication with the vacuum processing system and configured to evacuate the process space, while a process material supply system is pneumatically coupled to the vacuum processing system and configured to supply a process gas to the process space. Additionally, the vacuum pump is pneumatically coupled to the process supply system and configured to, at times, evacuate the process gas supply system.

Owner:TOKYO ELECTRON LTD

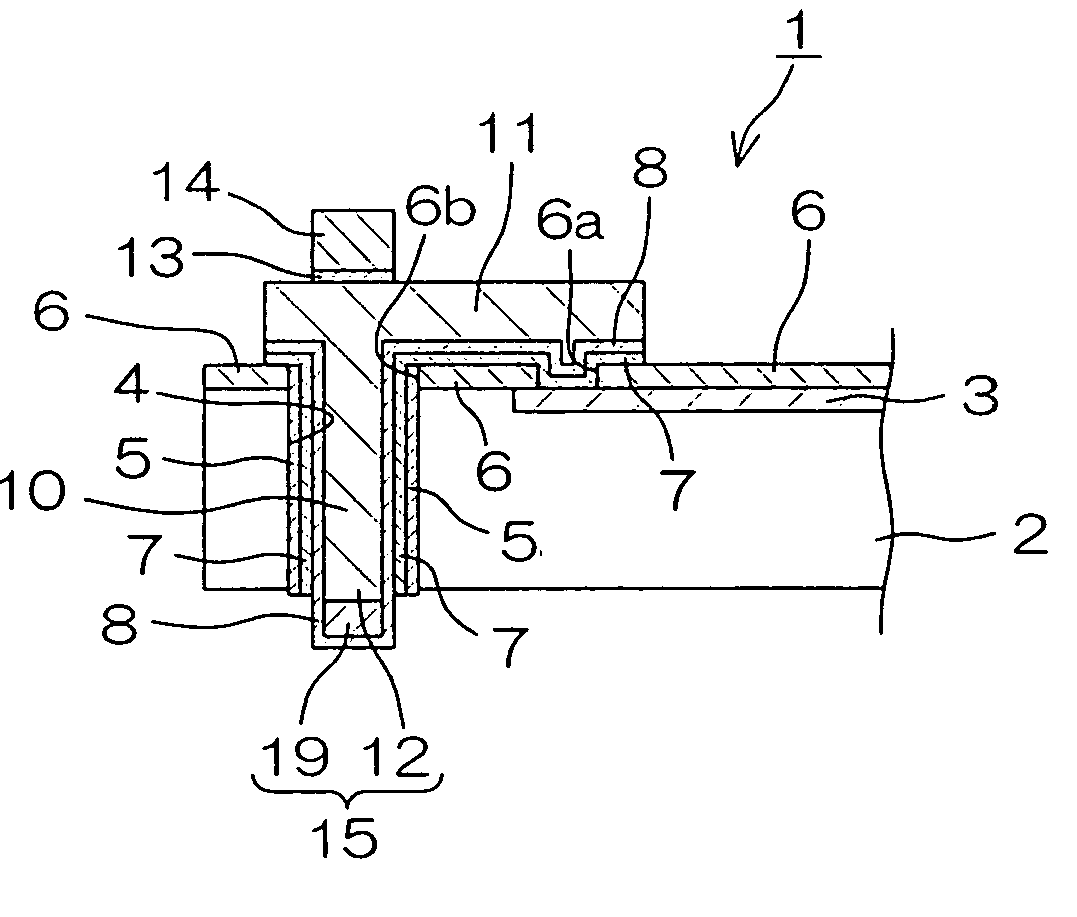

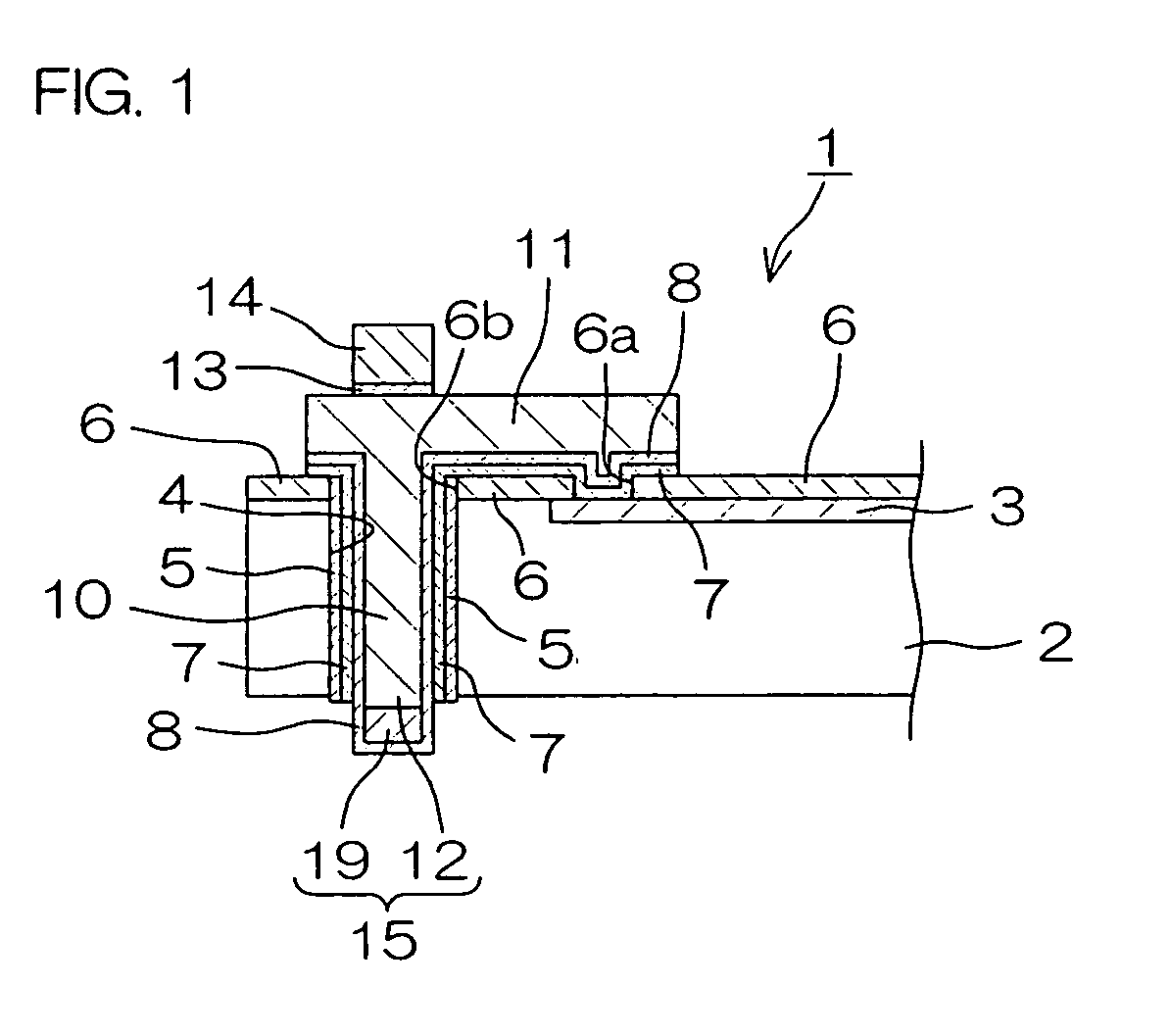

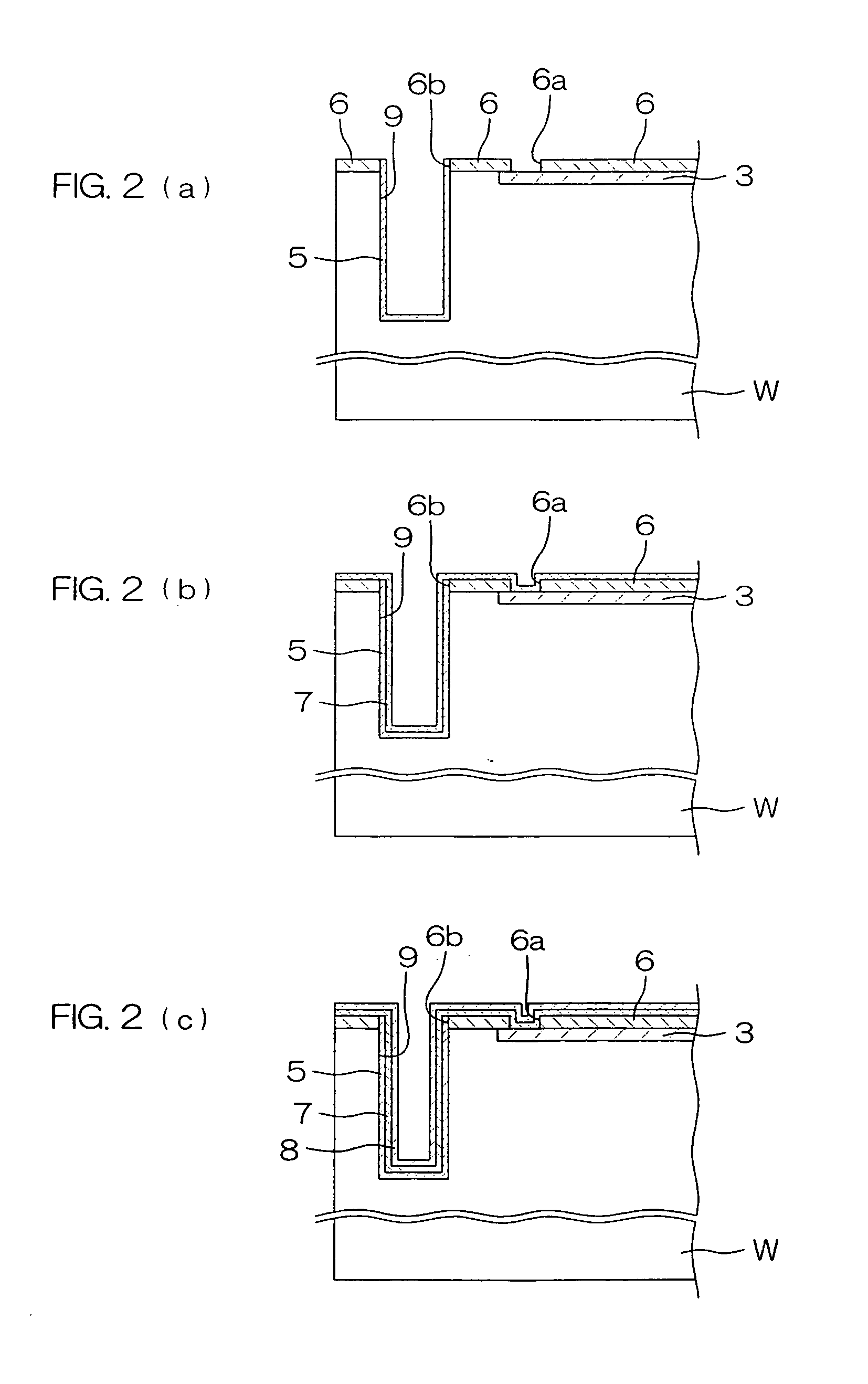

Semiconductor chip and manufacturing method for the same, and semiconductor device

ActiveUS20050151228A1Improve reliabilityThe connection is tight and firmSemiconductor/solid-state device detailsSolid-state devicesDevice formSemiconductor chip

The invention provides a semiconductor chip manufacturing method including the steps of: forming a concave portion extended in the thickness direction of a semiconductor substrate which has a front surface and a rear surface and has a function device formed on the front surface, from the front surface; forming an oxidation preventive film made of an inert first metal material by supplying the first metal material onto the inner wall surface of the concave portion; supplying a second metal material containing a metal which is oxidized more easily than the first metal material to the inside of the concave portion after the step of forming the oxidation preventive film; electrically connecting the second metal material supplied to the inside of the concave portion and the function device; and thinning the semiconductor substrate so that the thickness thereof becomes thinner than the depth of the concave portion by removing the semiconductor substrate from the rear surface while leaving the oxidation preventive film.

Owner:KIOXIA CORP +3

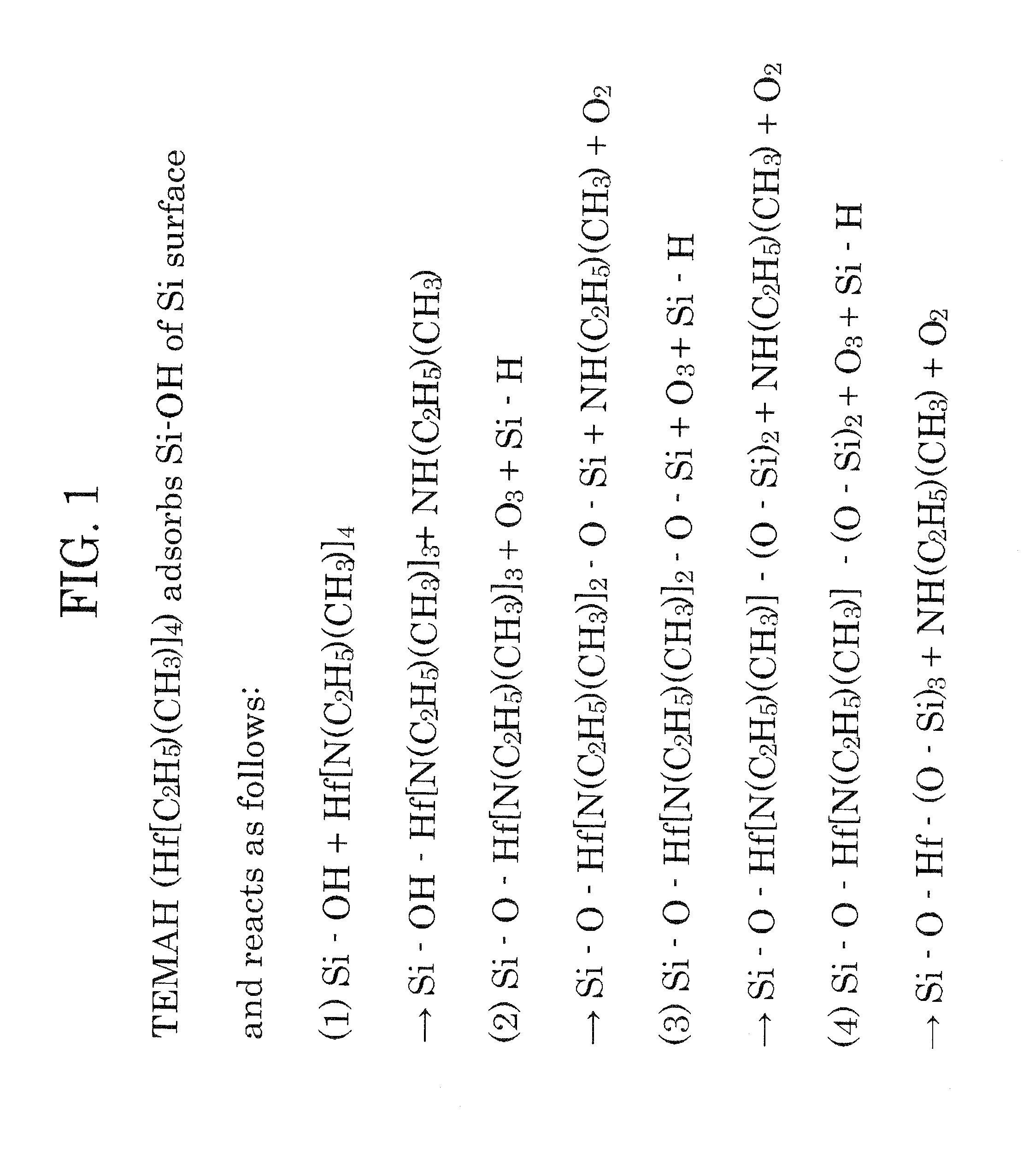

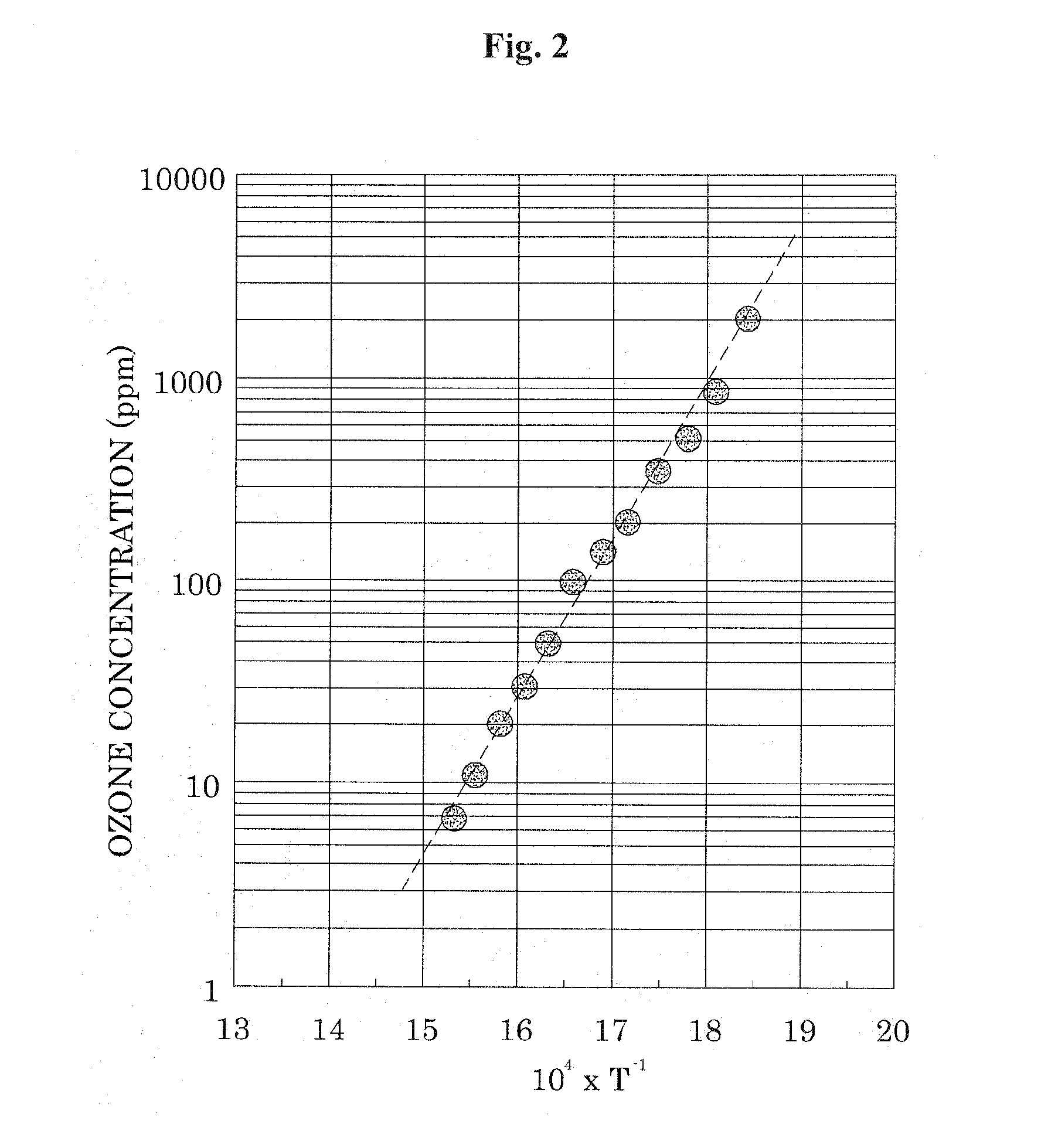

Method of manufacturing semiconductor device and substrate processing apparatus

InactiveUS20100087069A1Improved coverage characteristicImprove load effectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDecompositionUltraviolet lights

The coverage characteristics or loading effect of an oxide film can be improved without having to increase the supply amount or time of an oxidant. There is provided method of manufacturing a semiconductor device. The method comprises loading at least one substrate to a processing chamber; forming an oxide film on the substrate by alternately supplying a first reaction material and a second reaction material containing oxygen atoms to the processing chamber while heating the substrate; and unloading the substrate from the processing chamber, wherein the forming of the oxide film is performed by keeping the substrate at a temperature equal to or lower than a self-decomposition temperature of the first reaction material and irradiating ultraviolet light to the second reaction material.

Owner:KOKUSA ELECTRIC CO LTD

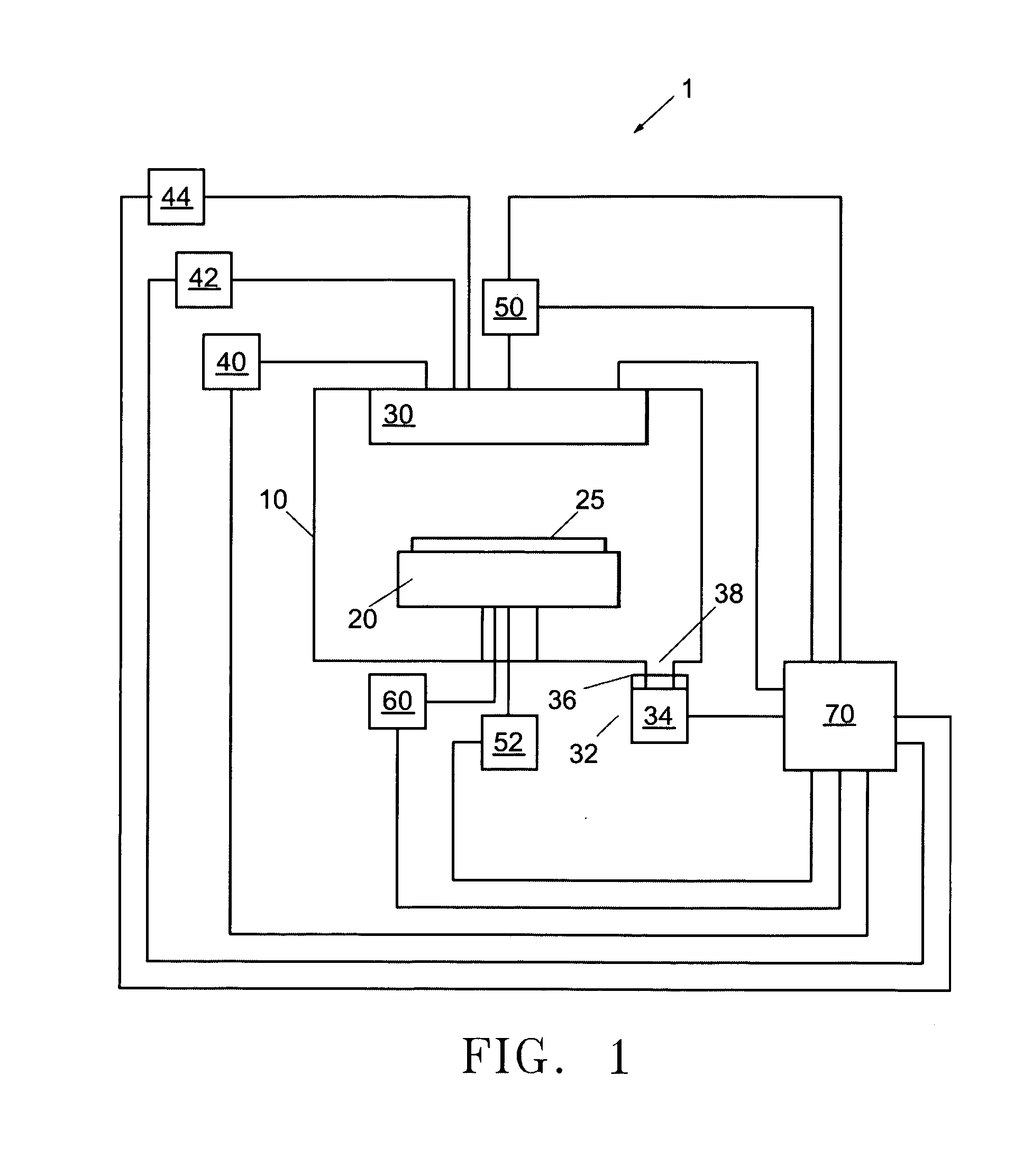

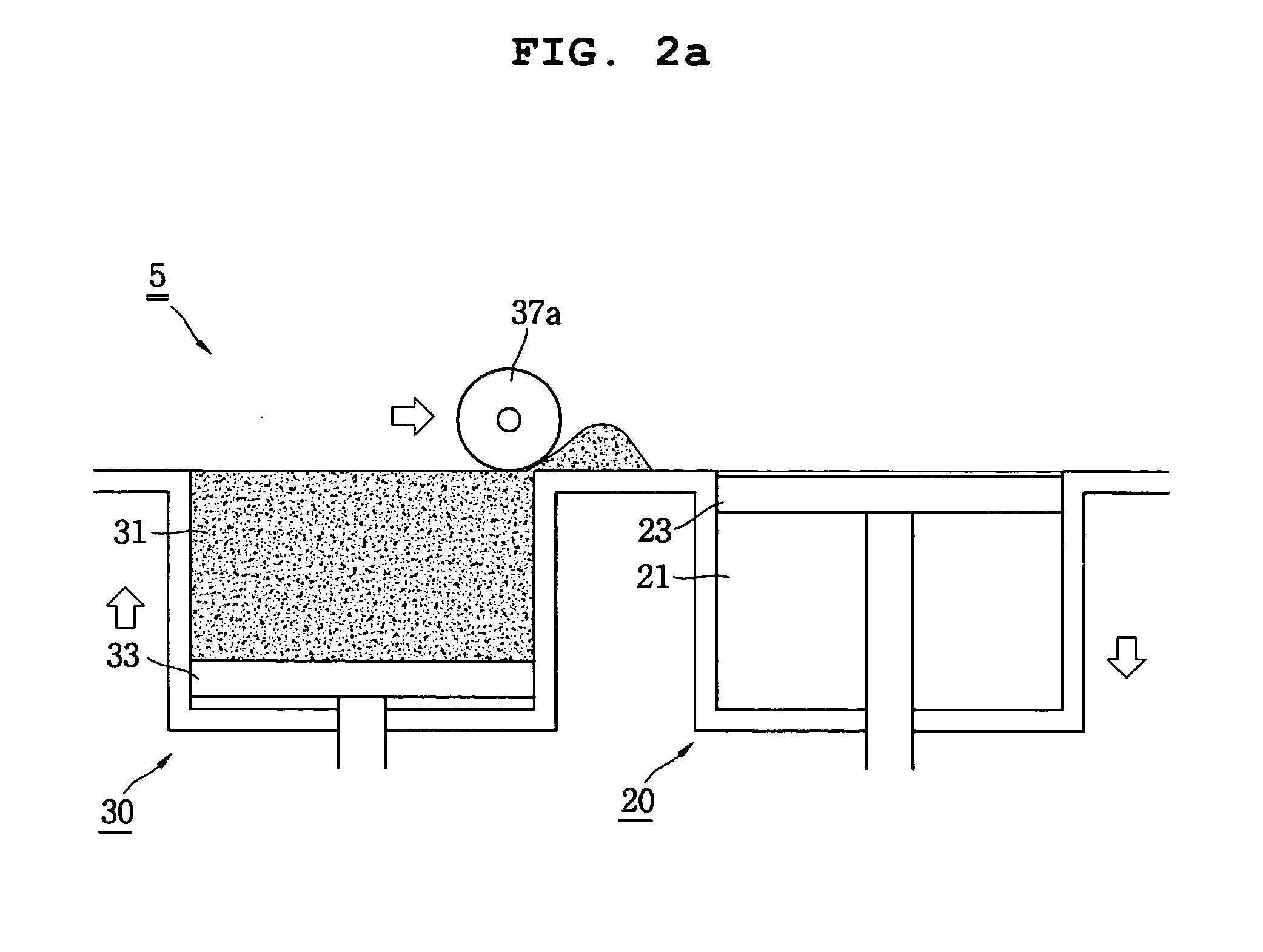

Three-dimensional printing prototyping system

InactiveUS20060099287A1Shorten the time periodLow viscosityConfectionerySweetmeatsEngineeringMaterial supply

The present invention relates to a three-dimensional printing prototyping system which includes a prototyping chamber having a prototyping table capable of moving up and down by a predetermined range, a material containing chamber containing a powder material and having a material supply table capable of moving up and down by a predetermined range, and a material supplying means for supplying the powder material contained in the material containing chamber to the prototyping table as much as a sectional thickness corresponding to divided section data of a three-dimensional prototype to be prototyped. The system of the present invention comprises a printing head for injecting a photocuring adhesive material to a region, corresponding to the sectional data, on the powder material supplied to the prototyping table; a curing device for photocuring at least the region on which the adhesive material is injected; and a control computer for controlling the printing head and the curing device such that the adhesive material is injected and cured, respectively, on the region corresponding to the divided section data of the three-dimensional prototype. According to the present invention, a period of time required in curing a three-dimensional prototype can be remarkably shortened and the three-dimensional prototype with its superior solidity can be obtained.

Owner:KOREA INST OF MACHINERY & MATERIALS

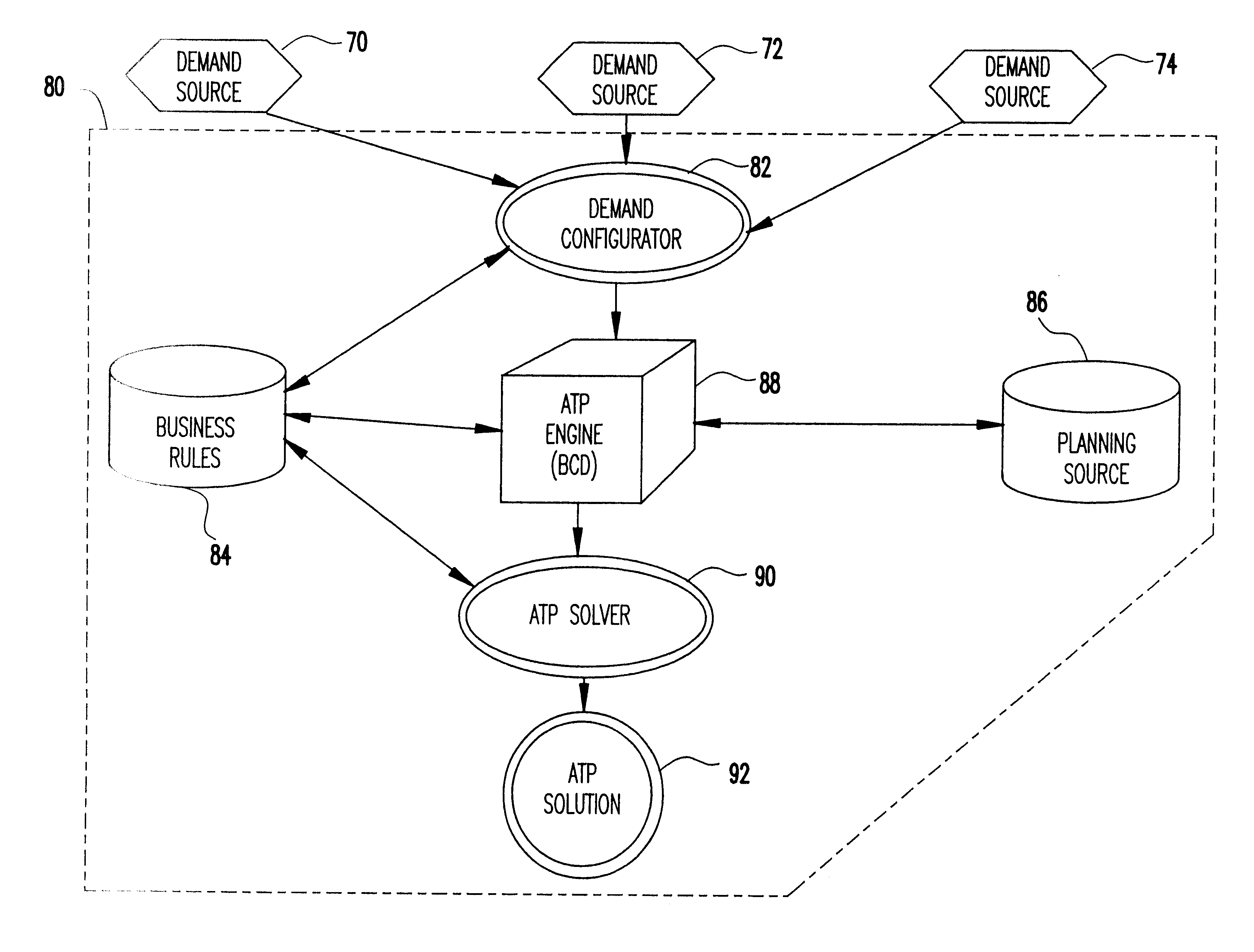

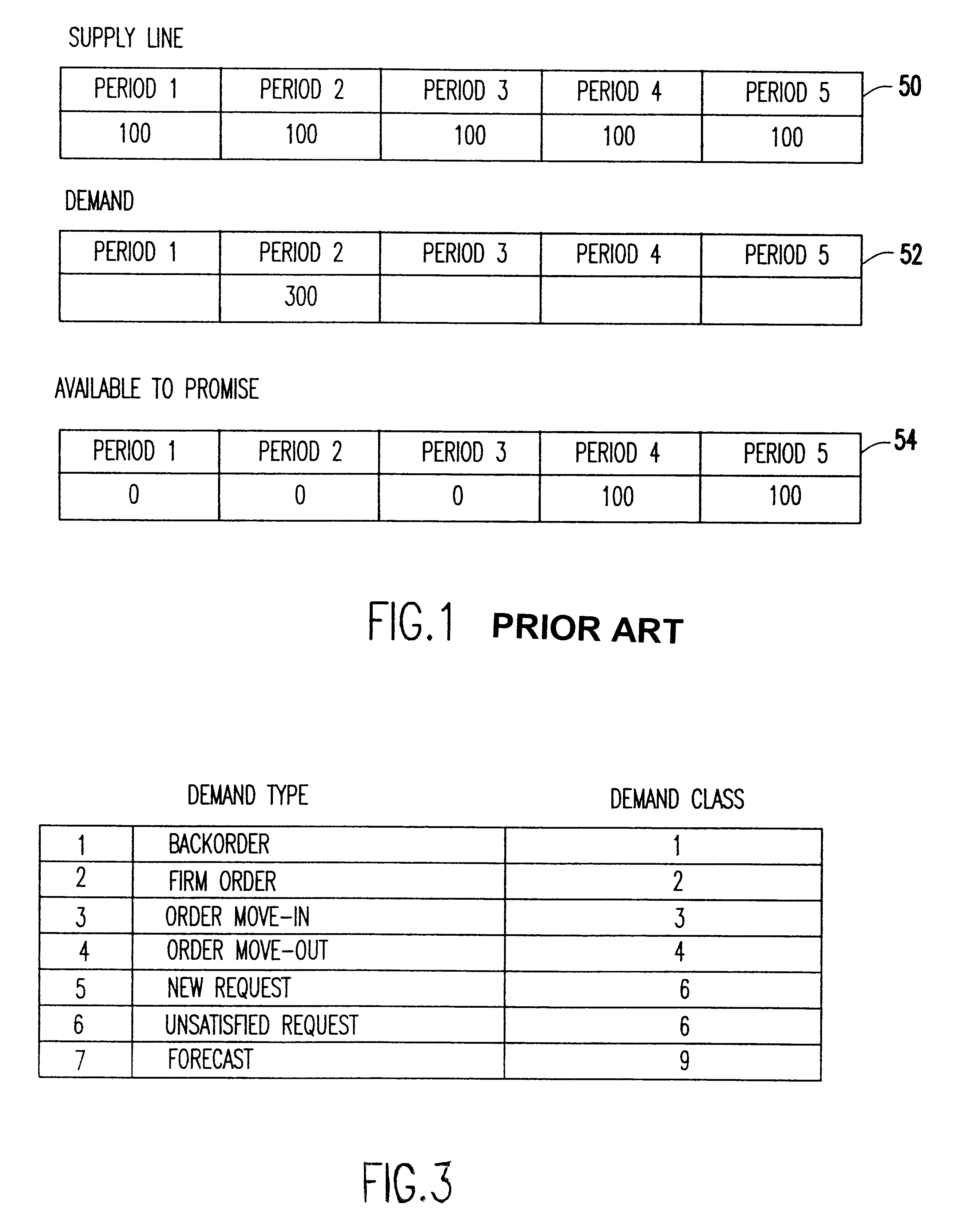

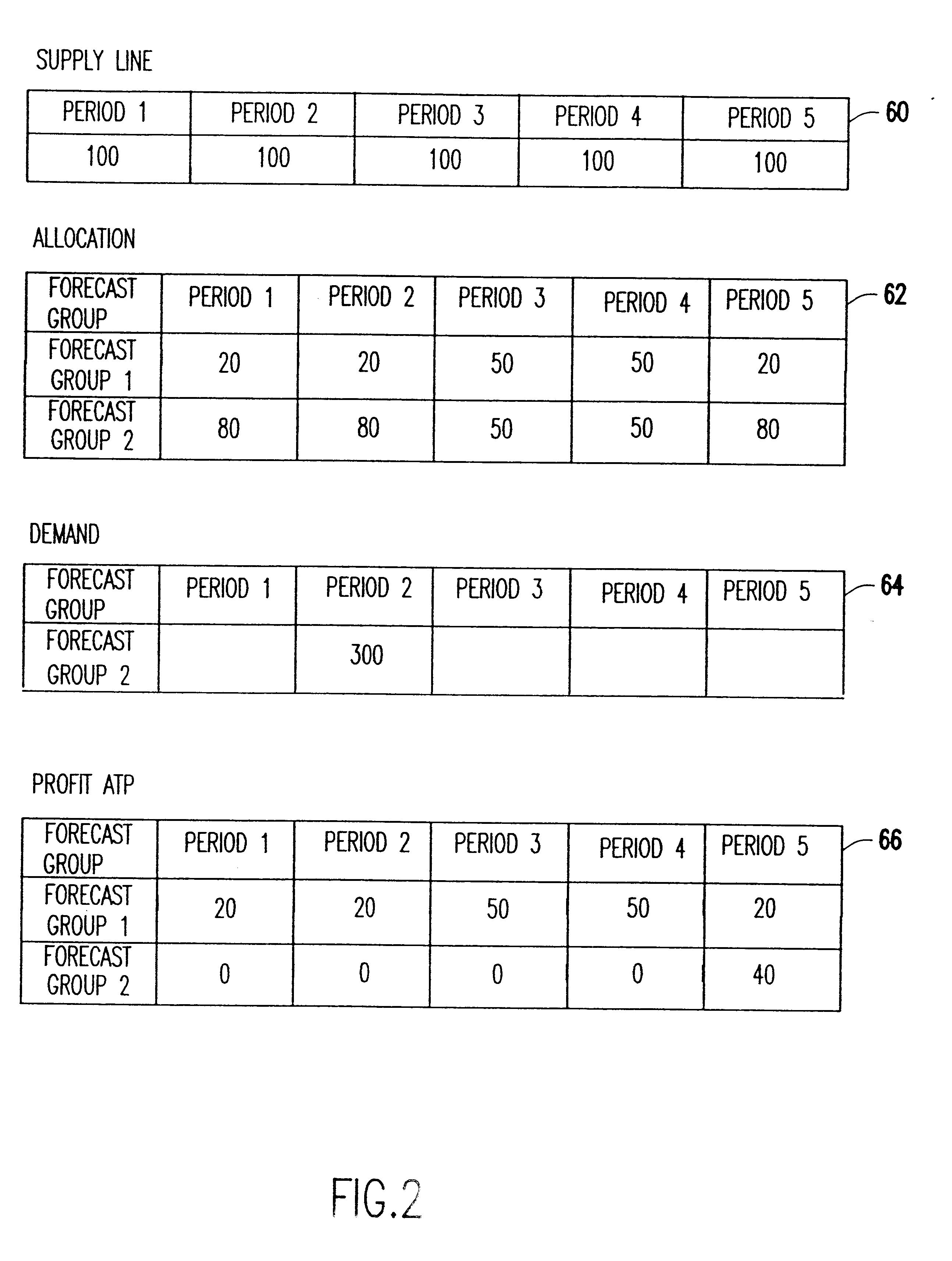

Regenerative available to promise

InactiveUS6463345B1LogisticsSpecial data processing applicationsOrder management systemWorking environment

A computer implemented Availability Checking Tool enabling tool users to execute within a common work environment, from common enterprise data, and considering assets and demands across multiple order management systems and manufacturing facilities within boundaries established by manufacturing specifications and process flows and business policies. The tool receives orders from multiple demand sources or ordering systems. Tool users can easily maintain a synergistic relationship between multiple ordering systems. A demand configurator coordinates product requests based on information from the demand source according to certain rules and priorities assigned to the product requests. A material resource engine manipulates data from the demand configurator and the rules to provide material supply information. A solver manipulates the material supply information from the resource engine and the rules to provide optimized product availability information. Thus, customer business rule level definitions are supported to provide the tool users with the power to micro-manage, optimally, enterprise assets and demands.

Owner:INT BUSIESS MACHINES

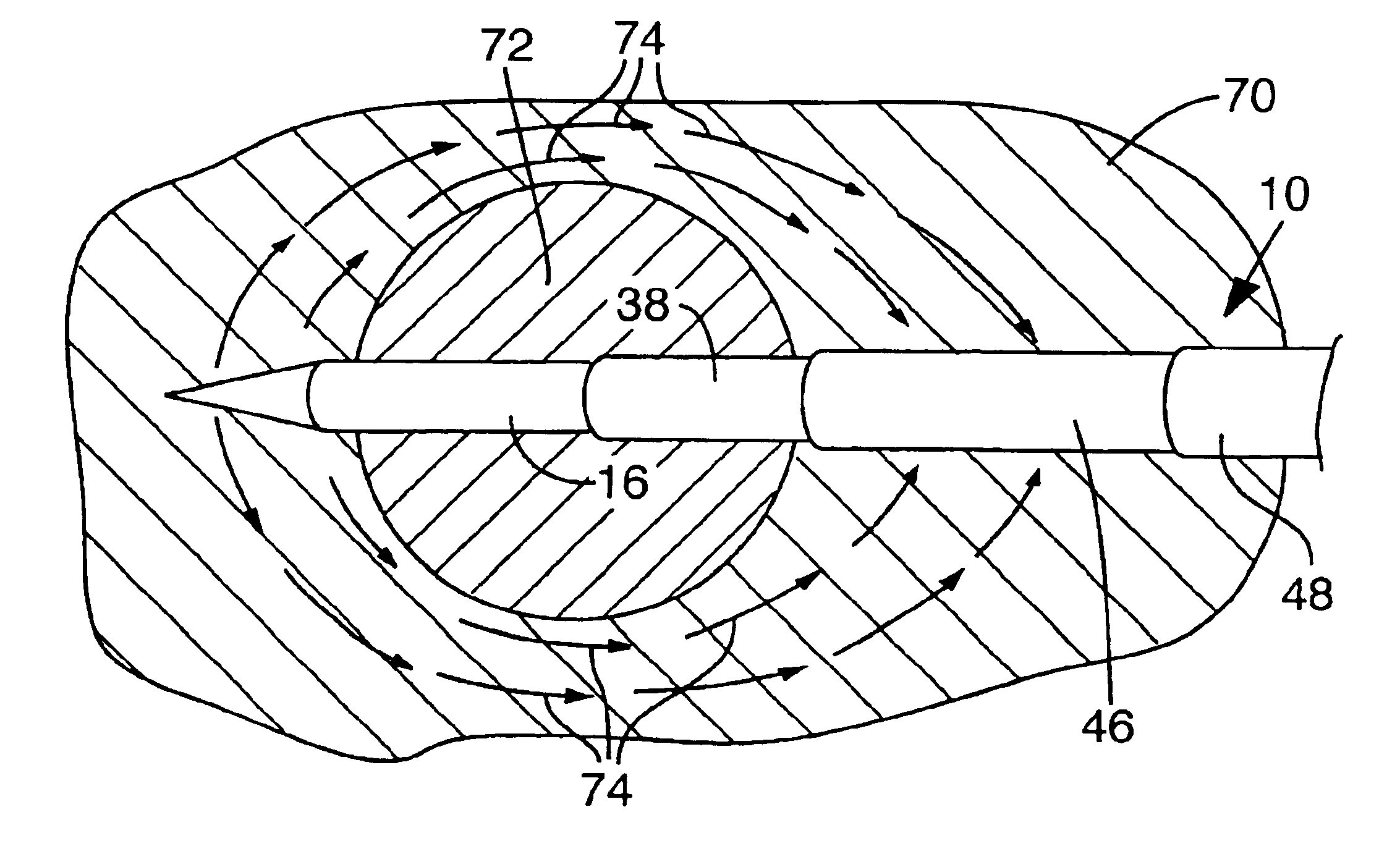

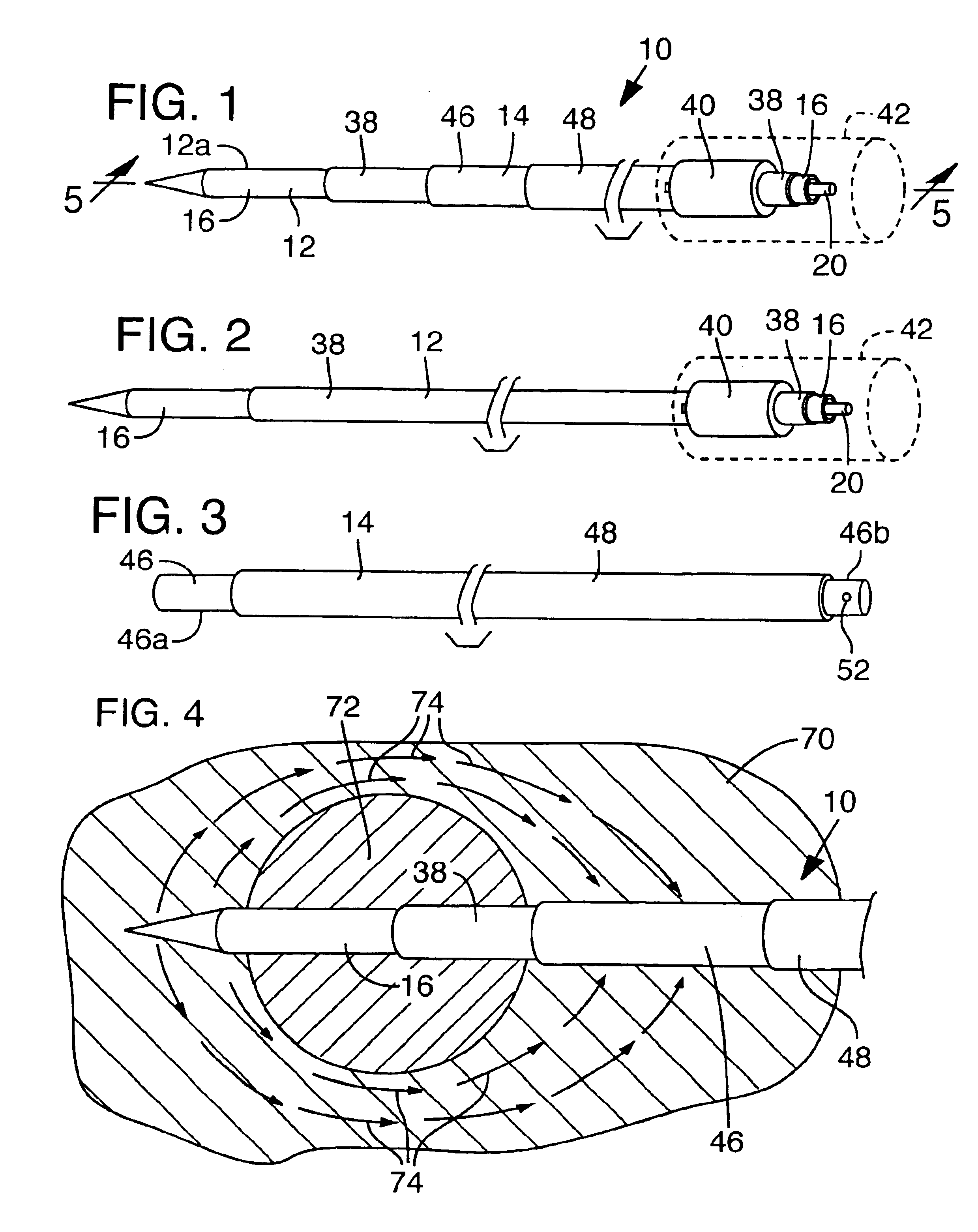

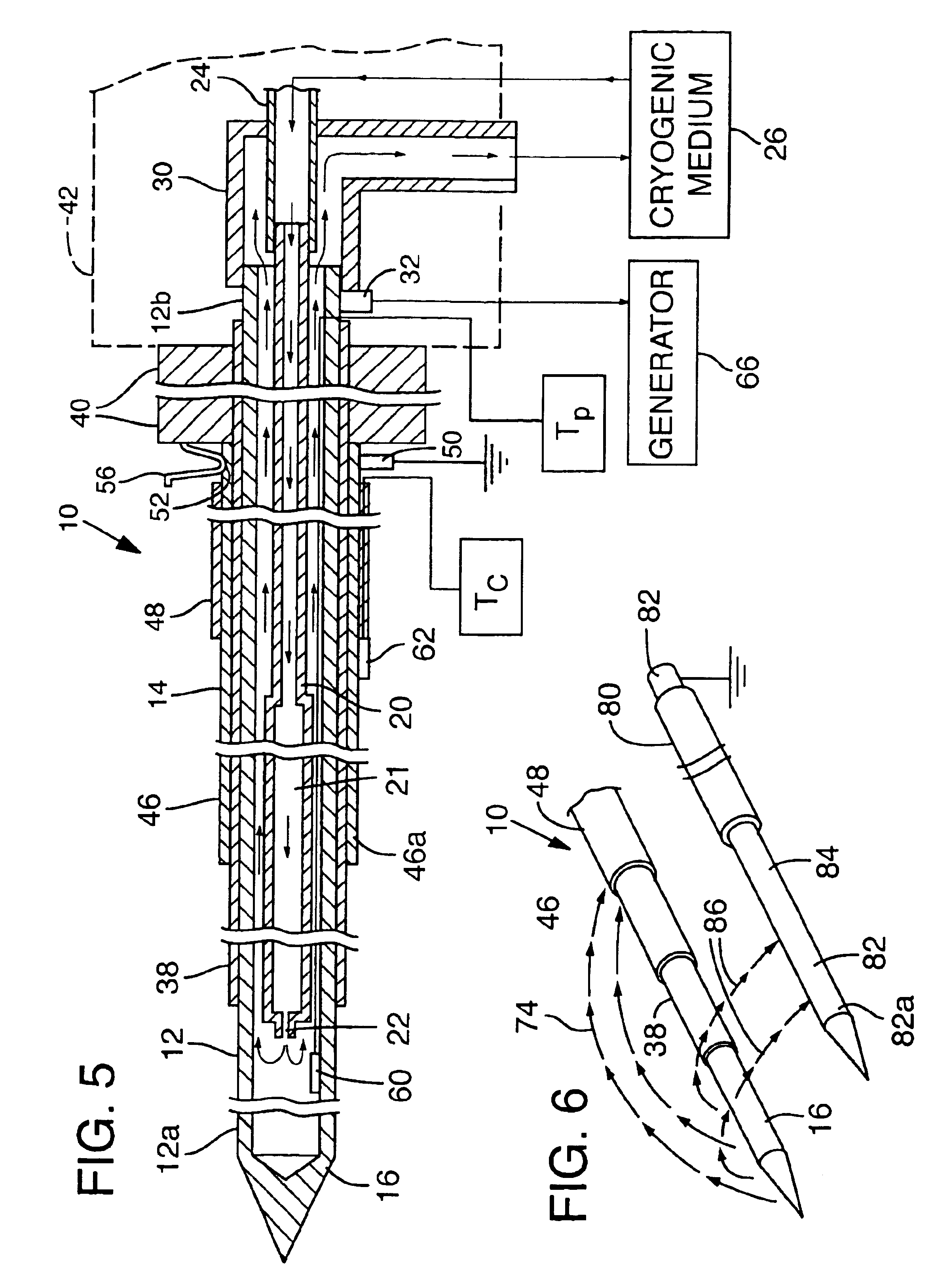

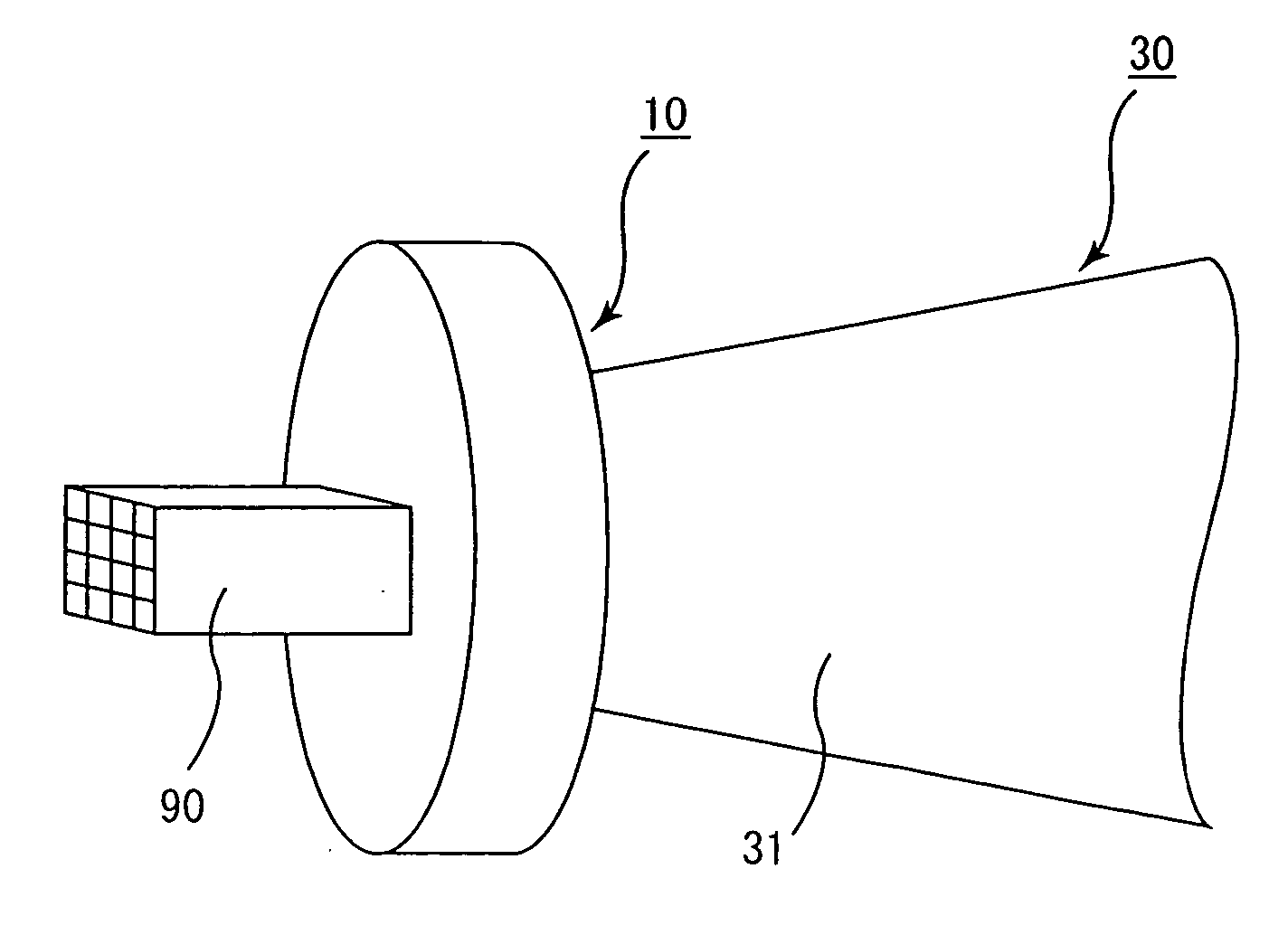

Cryo-surgical apparatus and method of use

Cryosurgical apparatus includes an elongate cryoprobe having a cooling portion and an electrically conductive first portion in the region of the cooling portion. A removable sheath having an electrically conductive second portion is received on the cryoprobe with its electrically conductive second portion spaced from the electrically conductive first portion of the cryoprobe. Electrical insulation is interposed between the first portion and the second portion. Coolant material supplied to the cryoprobe produces tissue freezing in the region of the cooling portion. Electromagnetic energy supplied to either the first portion or the second portion, while the other of such first portion or second portion is connected to ground, provides selective heating in tissue surrounding an iceball produced by the cooling portion to control the configuration of the iceball.

Owner:ERBE ELEKTROMEDIZIN GMBH

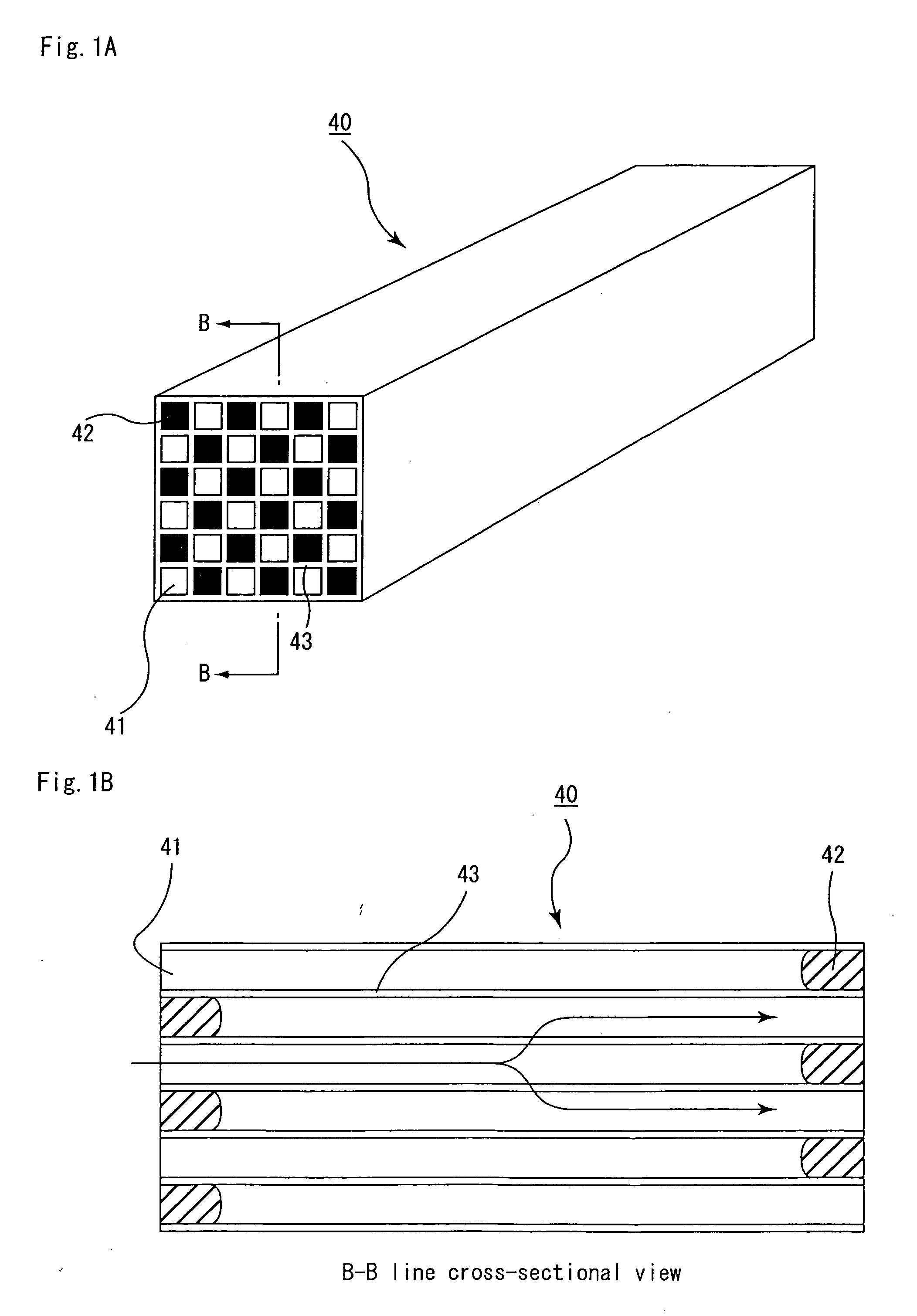

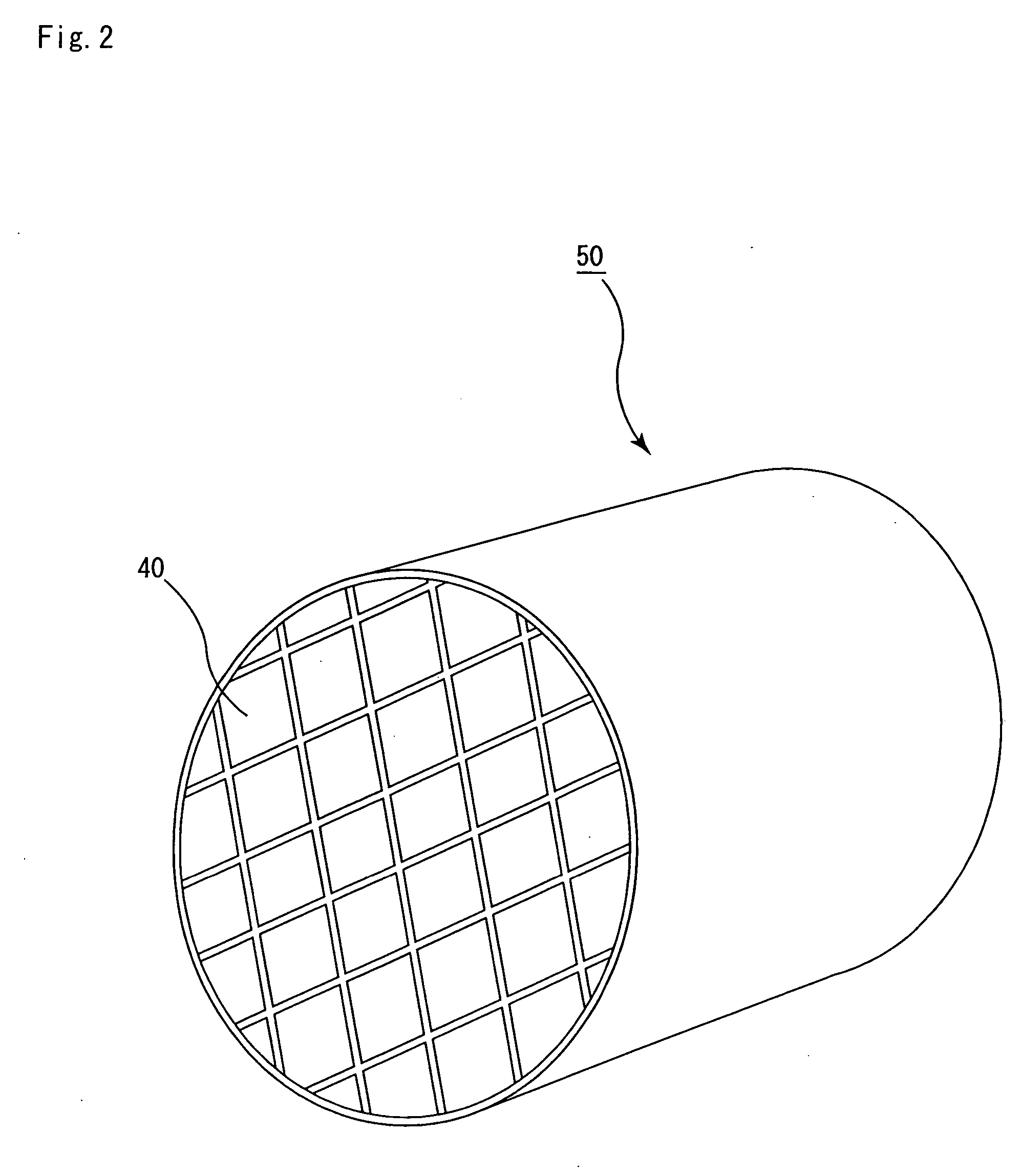

Die for extrusion-molding and method for manufacturing porous ceramic member

A die for extrusion-molding in accordance with the present invention comprises: a molding groove part, a material supplying part, and an outer frame for fixing a die main body comprising the molding groove part and the material supplying part to the front end of an extrusion-molding apparatus, wherein the die main body has a form in which the plate-shaped molding groove part smaller than the material supplying part is provided at almost the middle of the plate-shaped material supplying part such that it protrudes from the material supplying part, the outer frame comprises: a die holding part which is provided such that it covers the material supplying part around the molding groove part; and a peripheral part which is provided near the die holding part, and supposing that the thickness of the molding groove part is X, the thickness of the material supplying part is Y, and the thickness of the die holding part of the outer frame is Z, these X, Y and Z are allowed to satisfy the inequalities (1) about 3≦X≦about 6, (2) about 5≦Y≦about 10, (3) about 3.5≦Z≦about 8.5, (4) about 0.8<Y / X<about 2.5, and (5) about 1<Z / X<about 2.

Owner:IBIDEN CO LTD

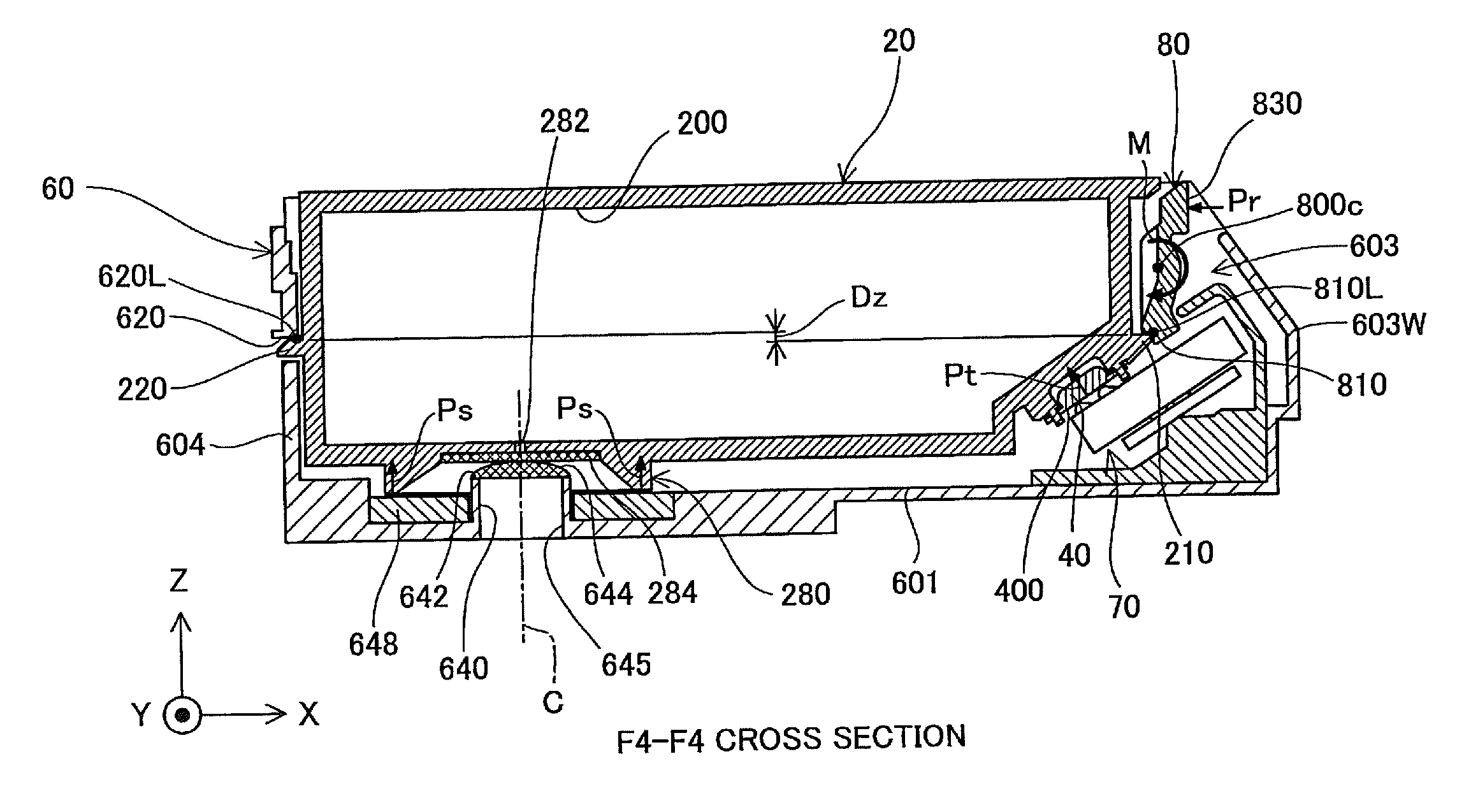

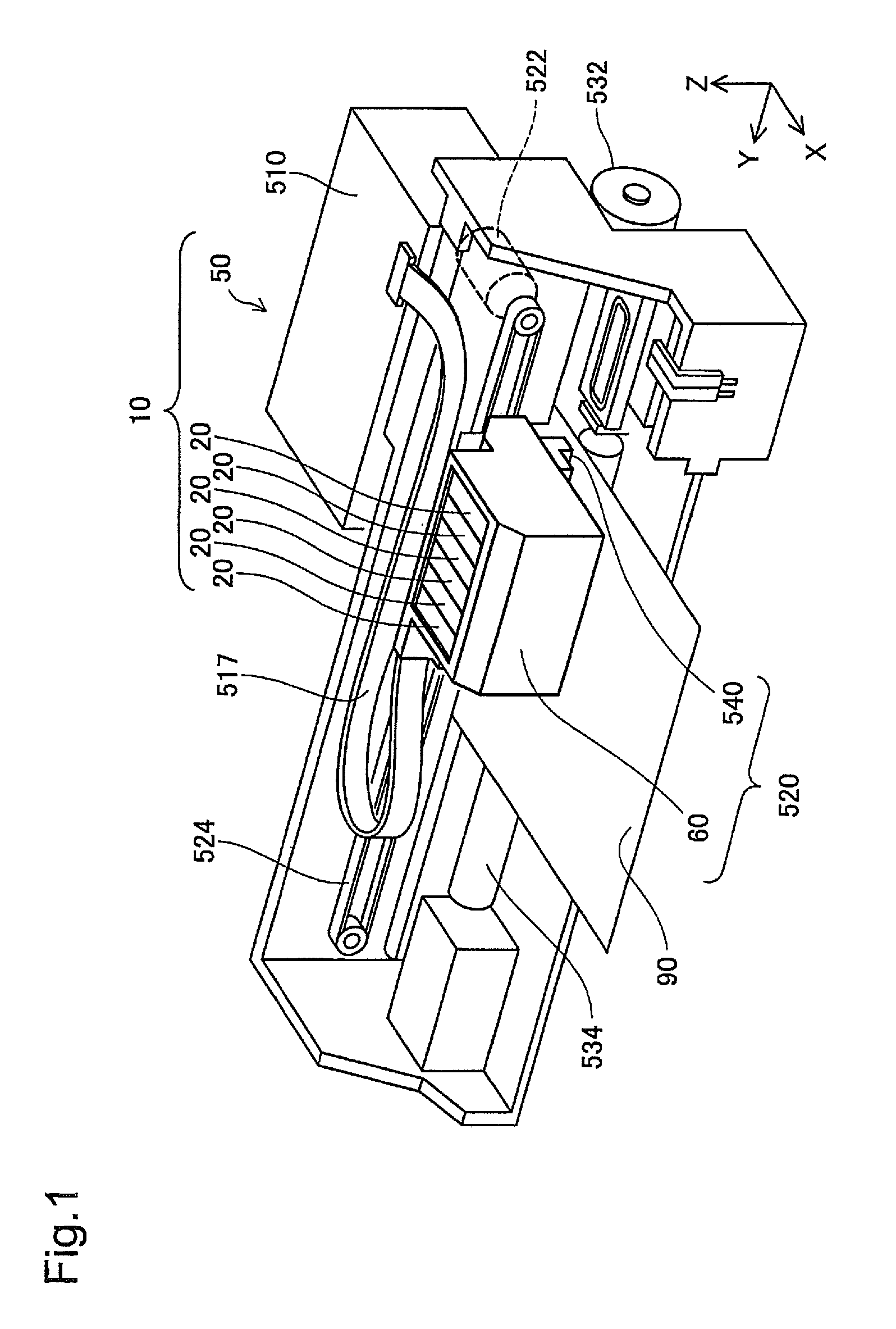

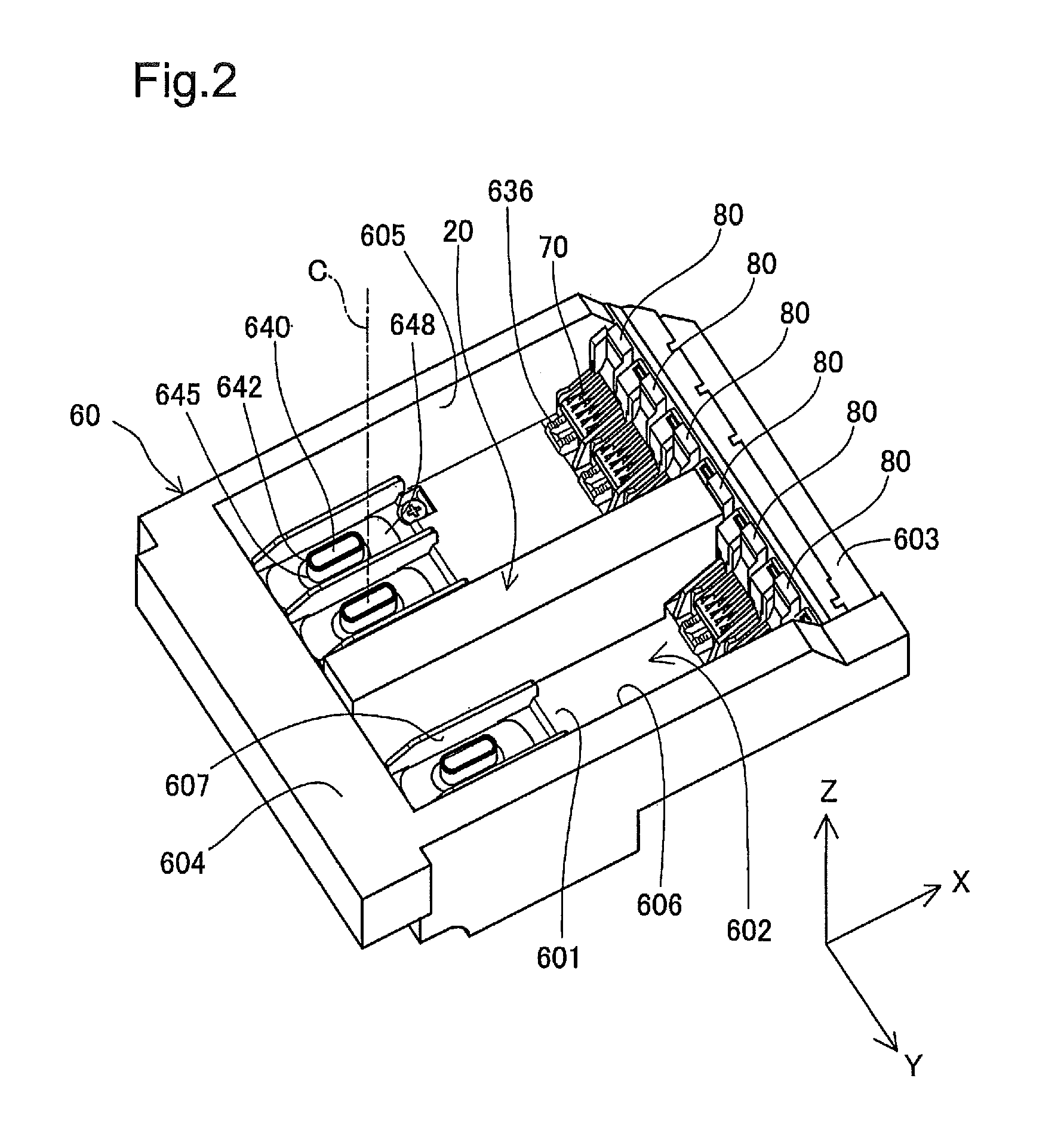

Cartridge and printing material supply system

ActiveUS8297738B1Reliable electrical connectionReduces poor continuityOther printing apparatusLeading edgeEngineering

A cartridge comprises an ink supply structure, a terminal bearing structure, and a first restriction portion. The terminal bearing structure has terminals arranged in a terminal plane which is neither parallel nor perpendicular to a plane defined by a mounting direction leading edge of the ink supply structure, so that the contact portions of the terminals receive a force in a direction opposite from the mounting direction. An engagement portion of the first restriction portion is provided at a position adjacent to the terminal bearing structure.

Owner:SEIKO EPSON CORP

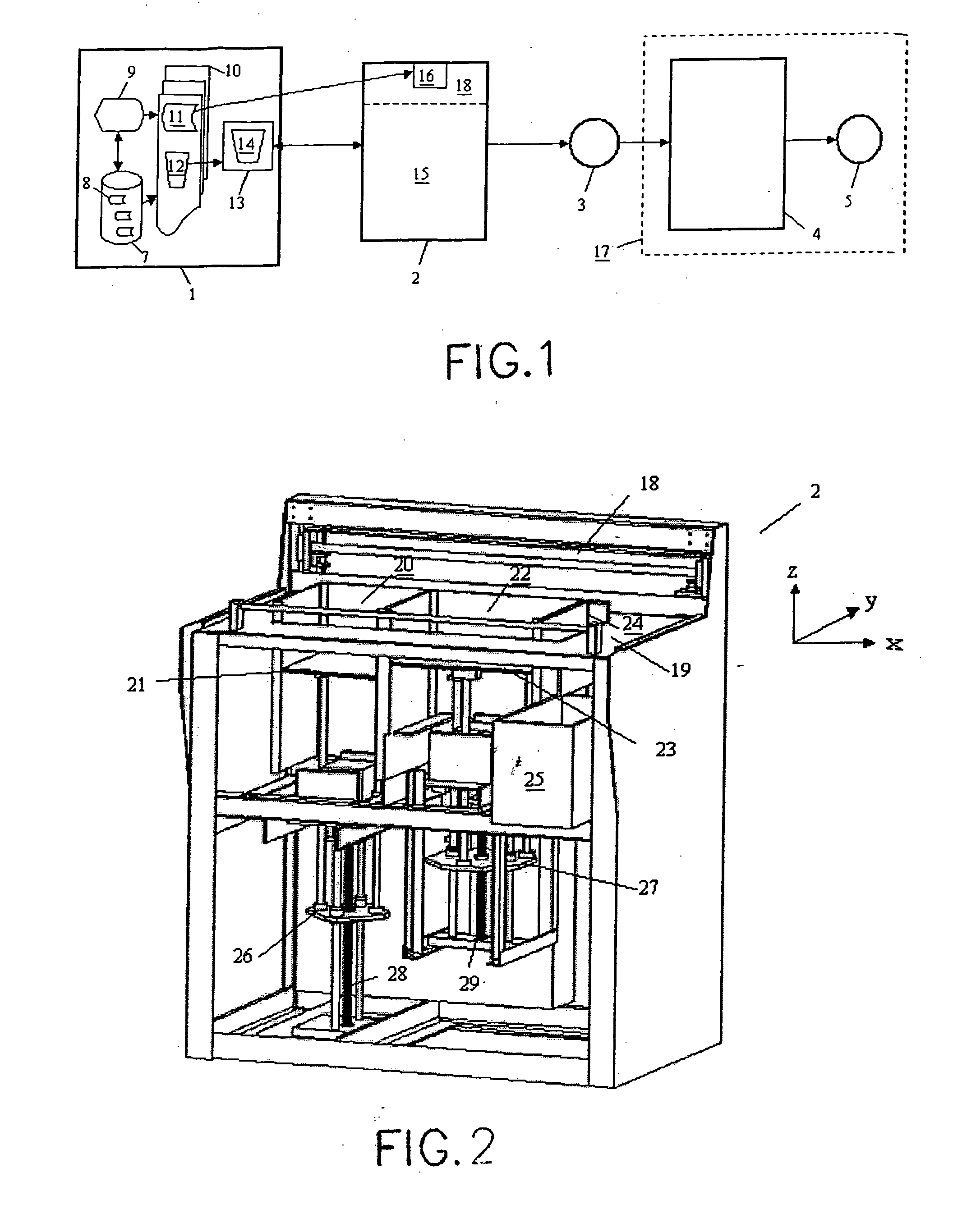

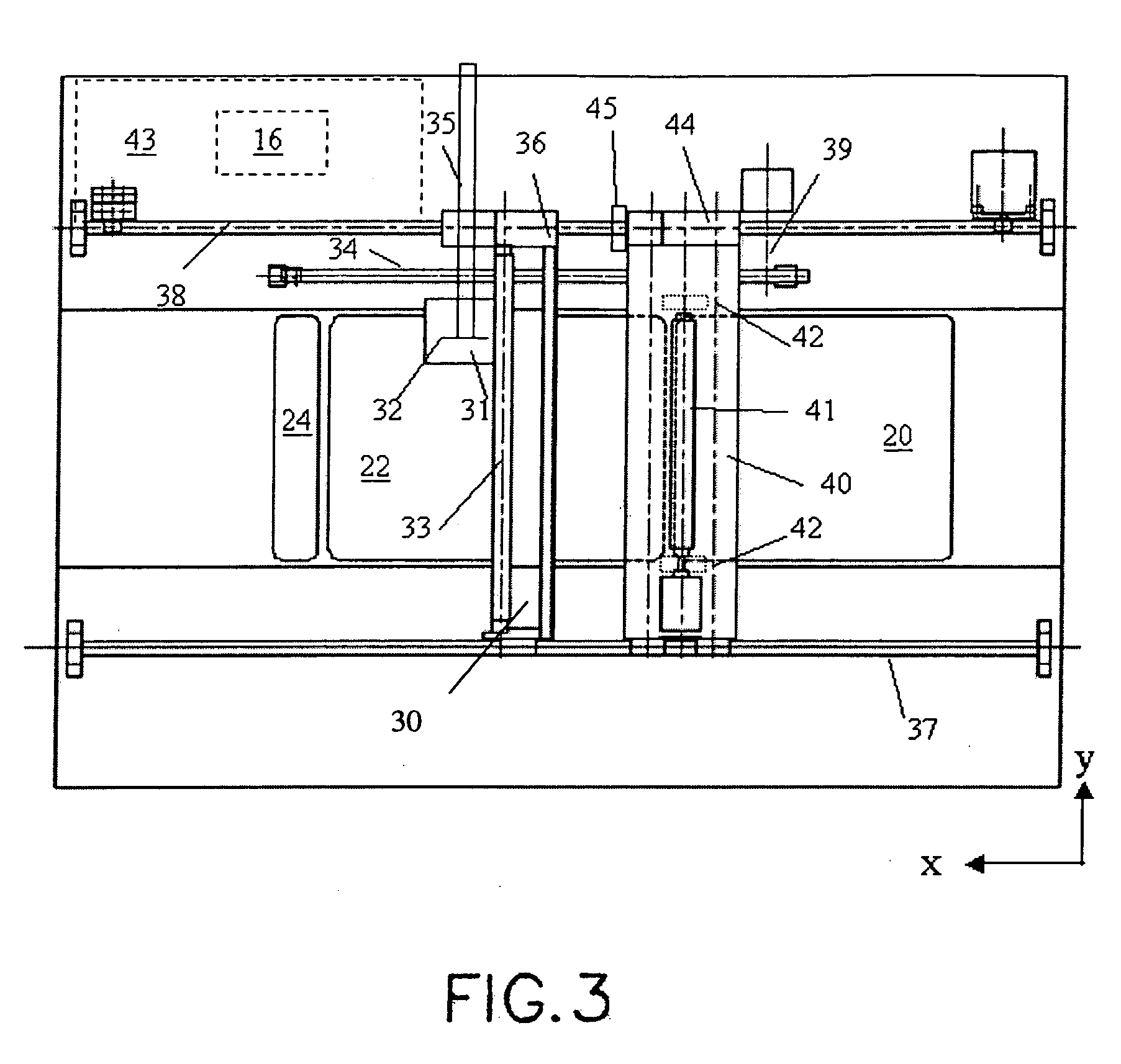

Method and apparatus for rapid prototyping using computer-printer aided to object realization

InactiveUS20050225007A1Shorten the timeIncrease printing speedConfectionerySweetmeatsComputer printingObject store

This invention applies a new computer and printer integrated technology to aid forming physical objects rapidly, and the method and apparatus are disclosed to satisfy the market requirements for a quick, reliable, safe, and inexpensive operation. The invention coverts a virtual object stored in the storage device of computer through software that slices the virtual object into many layers. The cross-section of the first layer is sent to a printer or a plotter, and the contour domain is printed or plotted by the printer or plotter. The fluid (not limited to binder) in the printer head is coated onto a layer of uniform distributed porous material which allows the powder and fluid to combine with each other; however, the combining process can be either a natural or an artificial process to enhance the binding force between the fluid and powder. After the first layer is finished, the second layer of powder is uniformly distributed on the first layer, and the contour printing process is repeated. As the printing process is repeated until all slicing layers of the model are finished, the object is stacked layer by layer sequentially. The physical object can be obtained after all the unglued powders are removed. The above-mentioned printing process not only produces monochrome objects, but also produces color objects. The machine includes components of a printer or plotter and its interface card, and x-z axis traversal driven mechanism. The operation platforms include a material supply chamber, a constructing chamber at which powder material is combined with solution, and a recycling hole. A slicing algorithm control software is used to calculate the cross-sectional contour, and the manufacture process is controlled by software and hardware interfaces.

Owner:NAT CHENG KUNG UNIV

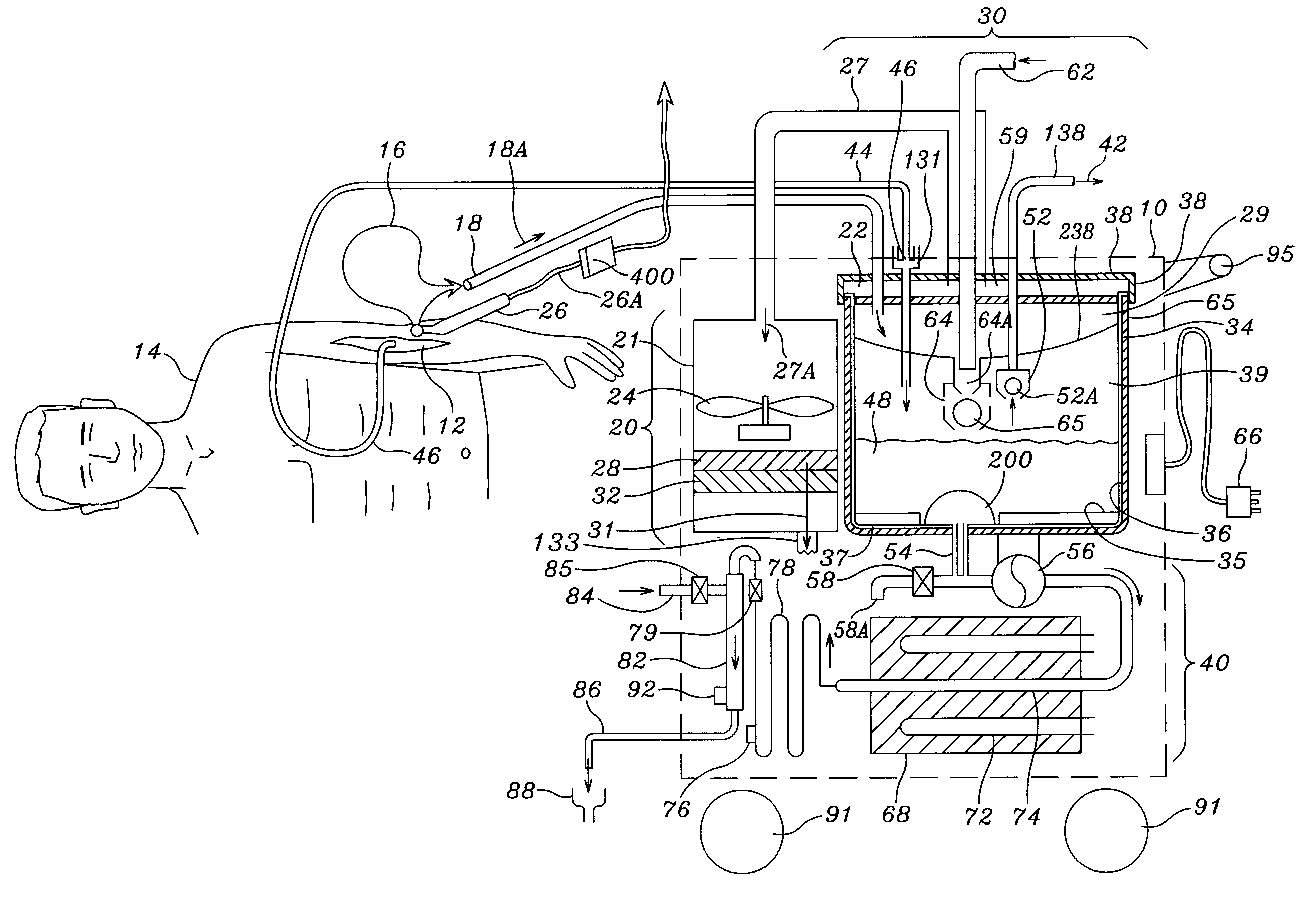

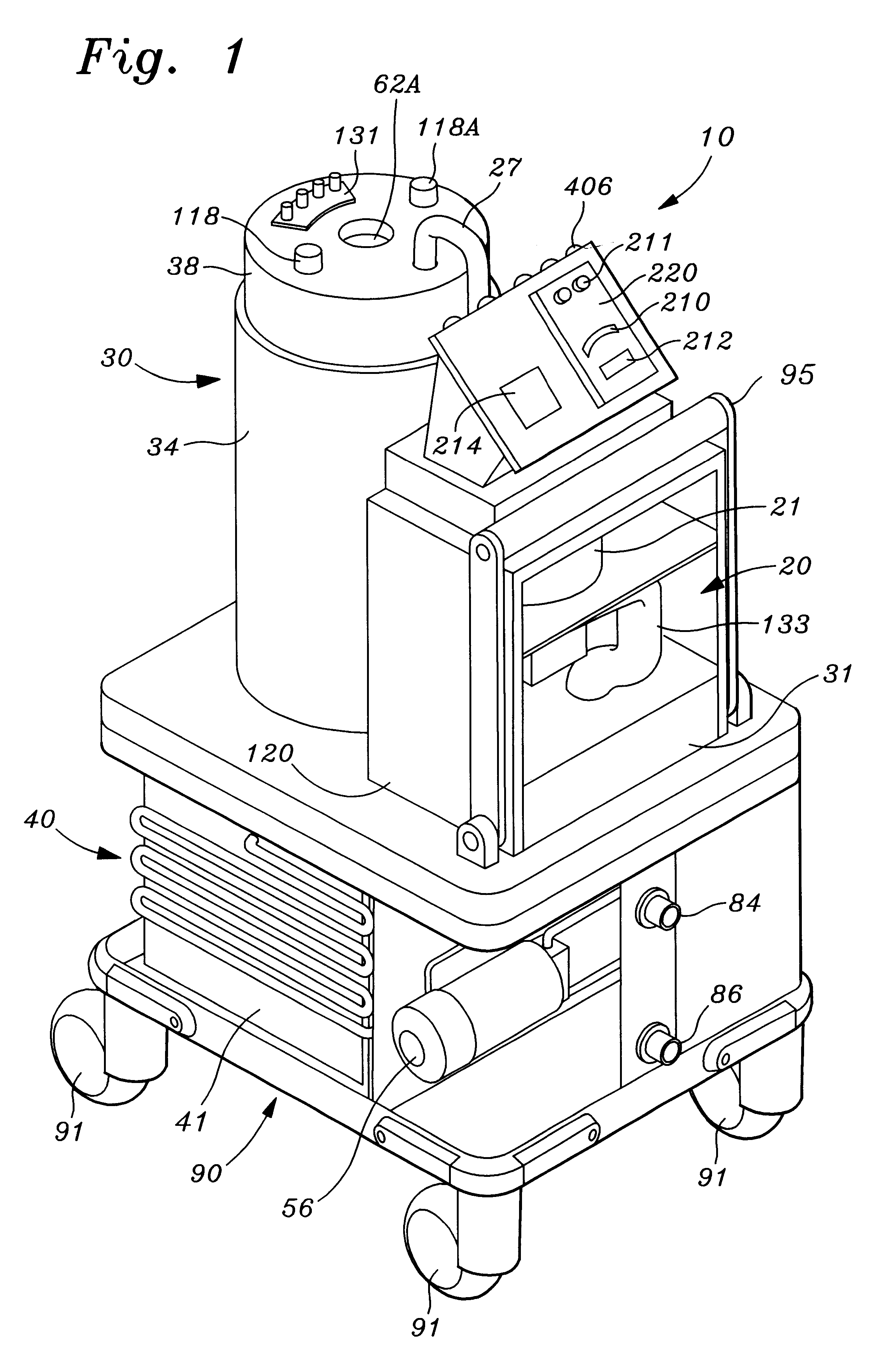

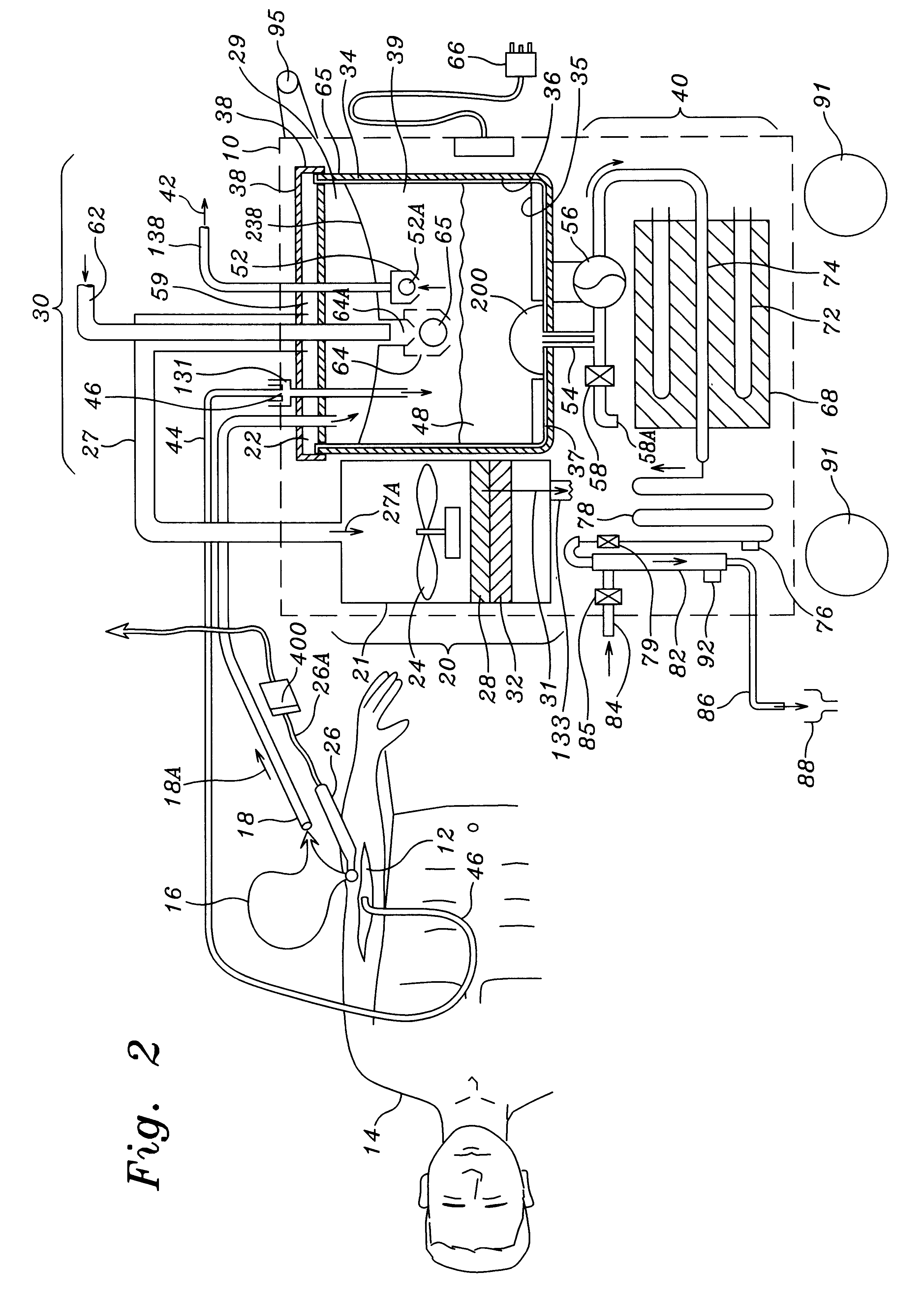

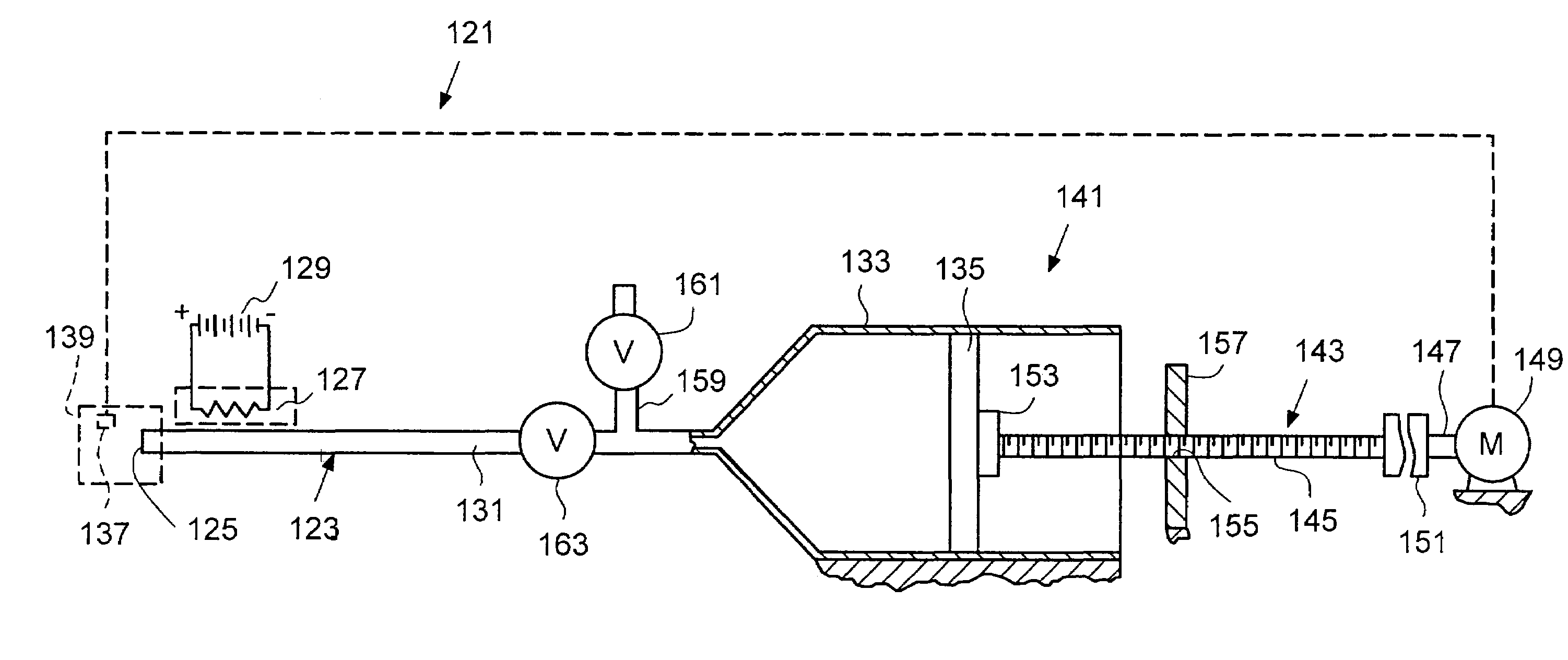

Surgical waste liquid and smoke disposal system

InactiveUS6180000B1Quickly and easily and efficiently maintain integrity of surgical siteLow efficiencyLiquid separation auxillary apparatusCombination devicesLiquid wasteCollection system

A waste liquid and smoke disposal system which combines the functions of a smoke extraction system and a waste (typically, liquid) collection system, typically in, but not limited to, a surgical environment. The smoke extraction system and the liquid waste collection system are connected to supply the waste materials collected thereby to a waste treatment (e.g. decontamination and / or sterilization) and disposal system. In a preferred embodiment, the waste treatment system includes a plurality of heat exchanger units for efficient controlling of the temperature of the waste material during the waste treatment process. These three systems are all combined into a integrated system wherein the treated waste can be safely returned to the ambient. In one embodiment, the system is provided as a cart-mounted apparatus to provide mobility.

Owner:STRYKER CORP

Method and apparatus for generating an aerosol

InactiveUS7128067B2Improve scalabilityOrganic active ingredientsOther heat production devicesEngineeringMaterial supply

An aerosol is formed by supplying a material in liquid form to a flow passage and heating the flow passage such that the material volatizes and expands out of an open end of the flow passage. The volatized material combines with ambient air such that volatized material condenses to form the aerosol. An apparatus and method for generating such an aerosol are disclosed wherein the apparatus may include an electrically conductive sleeve at an open end of the flow passage, an electrically conductive flow passage and / or a spacer chamber. The volatilized material may contain a volatilized solute and vehicle such that the resulting aerosol particle sizes of the solute and the vehicle are either different or the same.

Owner:PHILIP MORRIS USA INC

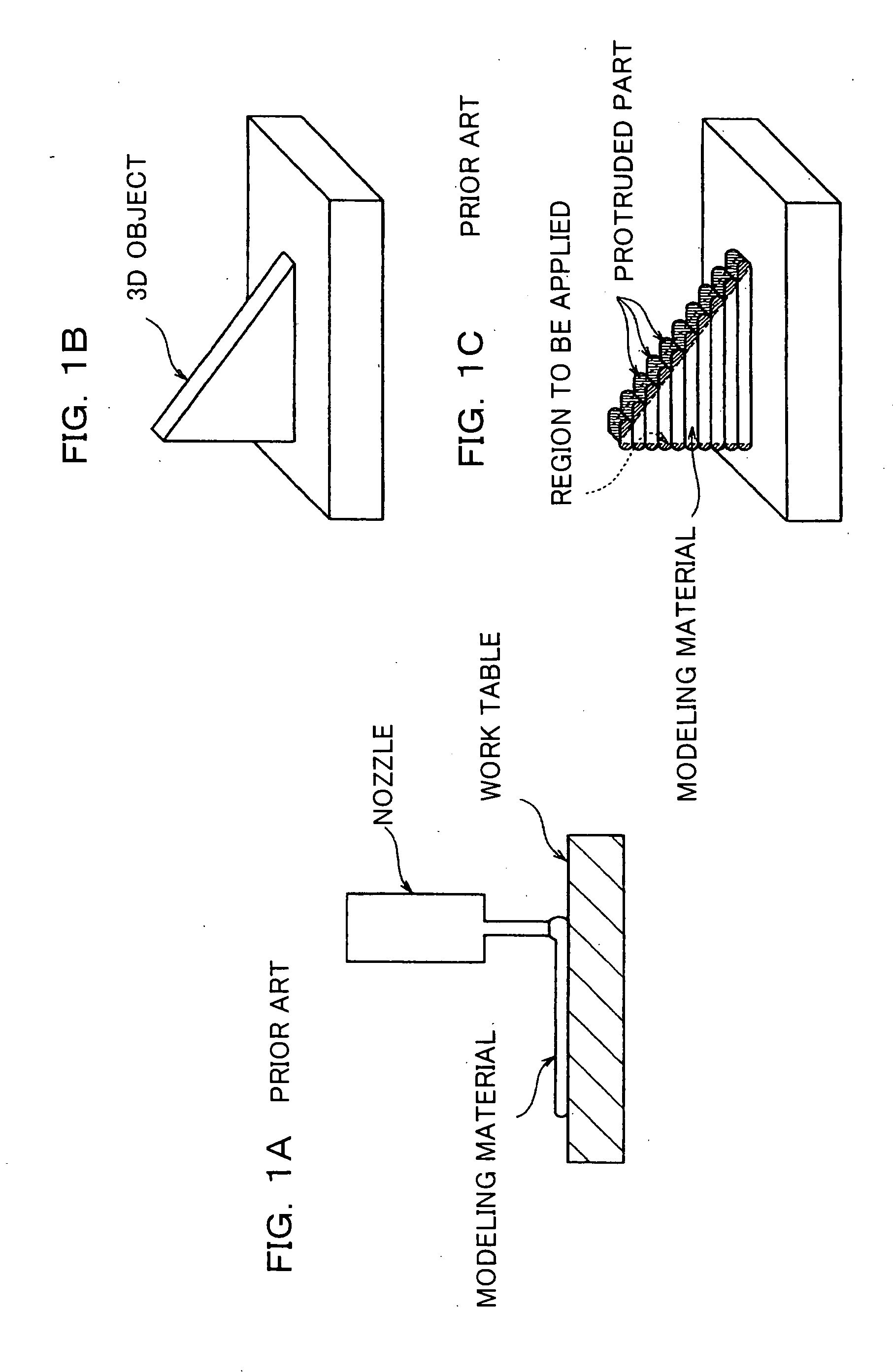

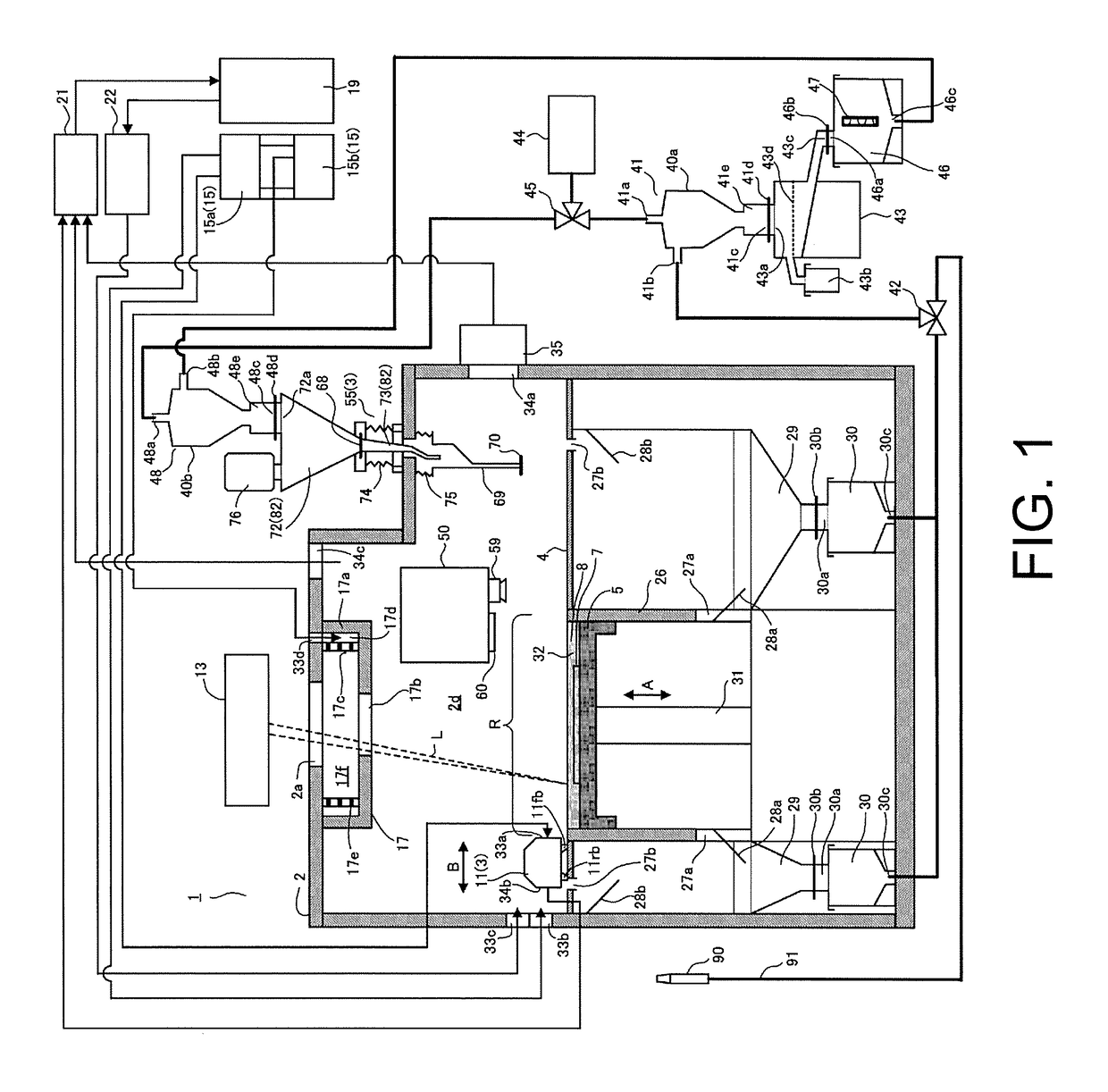

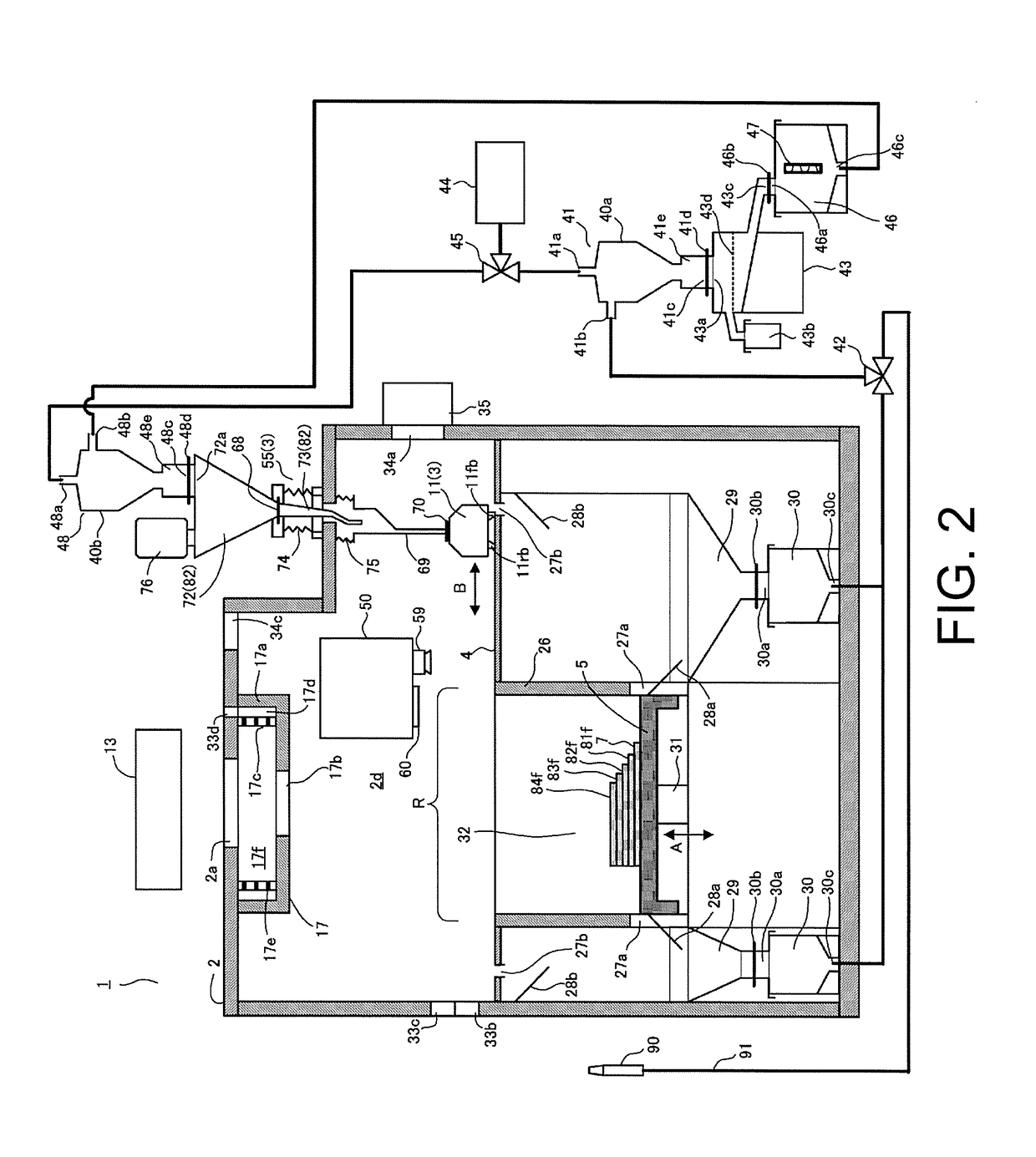

3D modeling device and 3D modeling method for supplying material with high precision

A 3D modeling device performs repeatedly a step of cutting a subsidiary material layer formed of a subsidiary material and cutting a modeling material layer formed of a modeling material. The 3D modeling device comprises at least one of a subsidiary material supplying device which discharges the subsidiary material drop by drop from an outlet positioned apart from a region in which the subsidiary material is to be applied at a predetermined distance, and a modeling material supplying device which discharges the modeling material drop by drop from an output positioned apart from a region in which the modeling material is to be applied at a predetermined distance. Since the material can be applied with high precision, a high-quality 3D molded object is provided.

Owner:ROLAND DG CORP

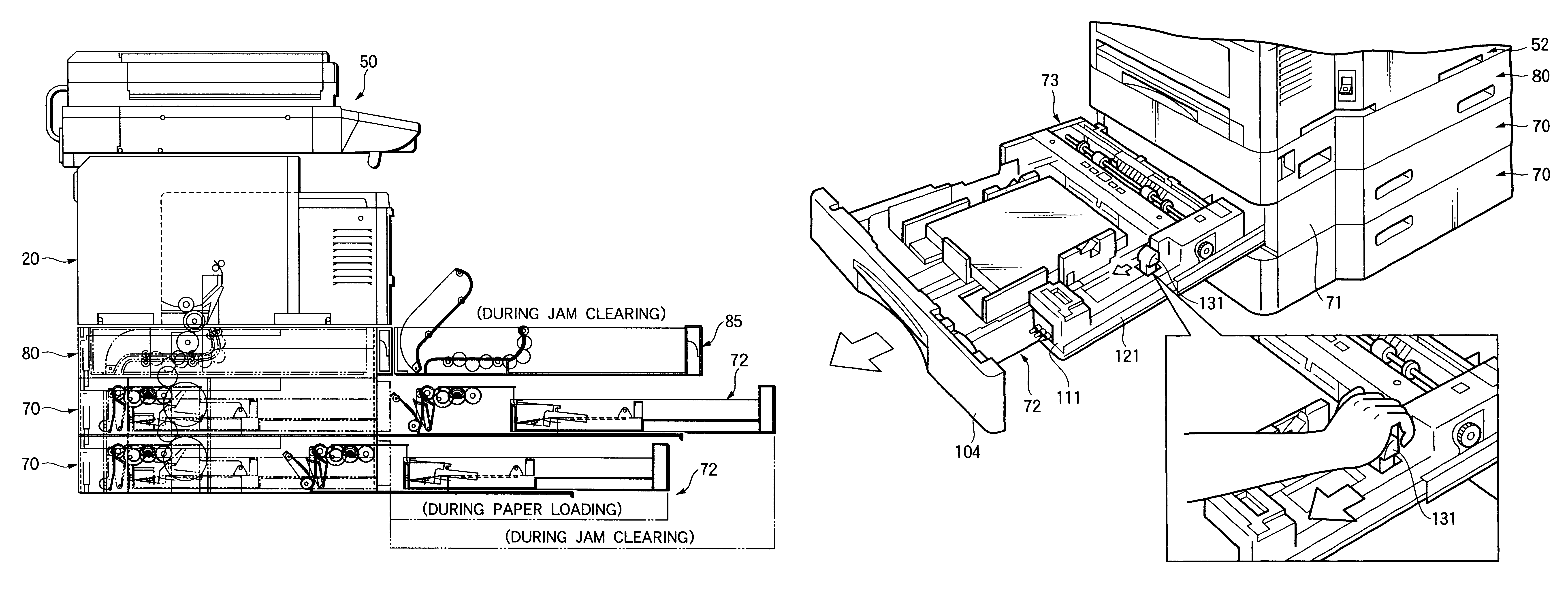

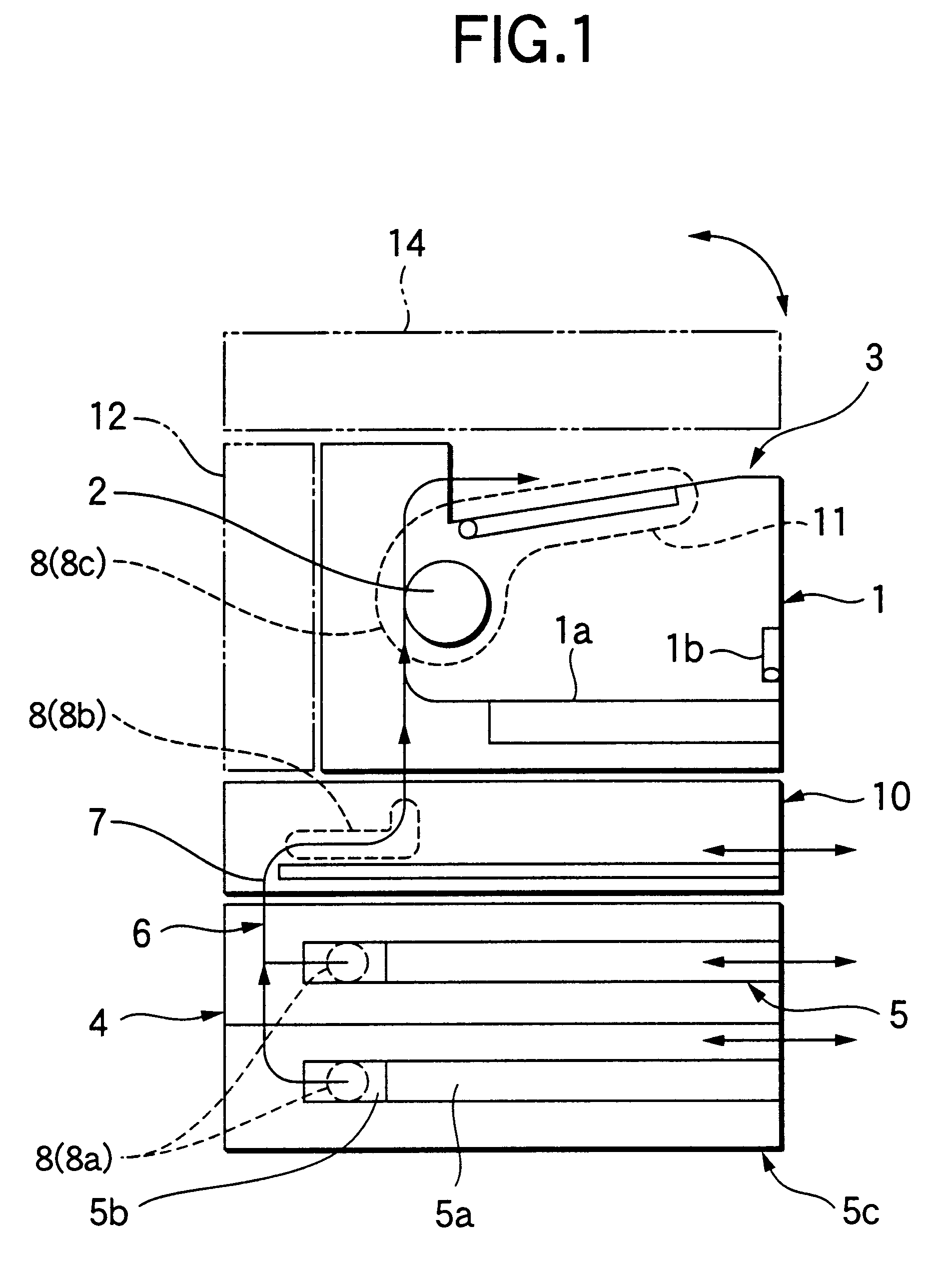

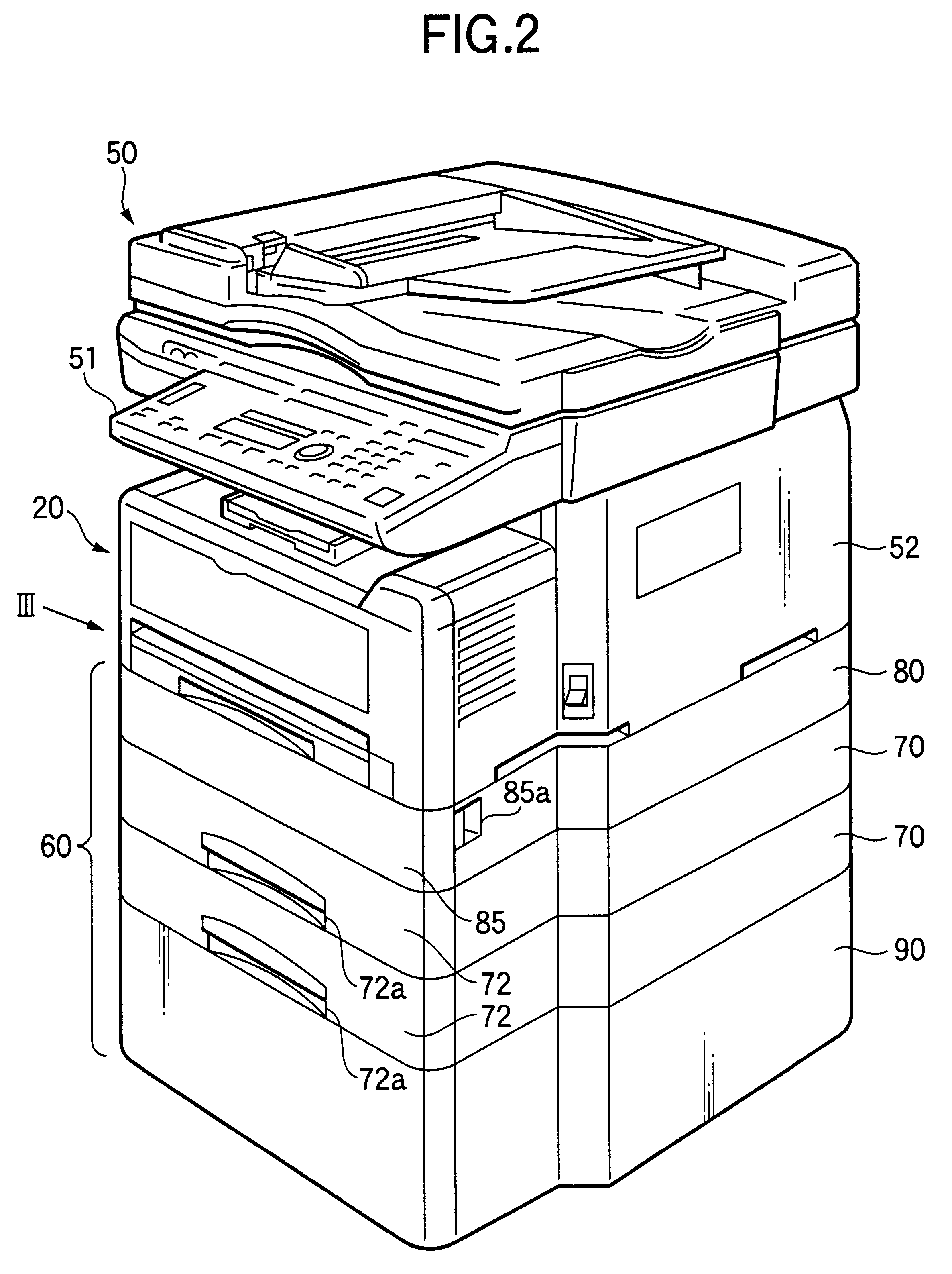

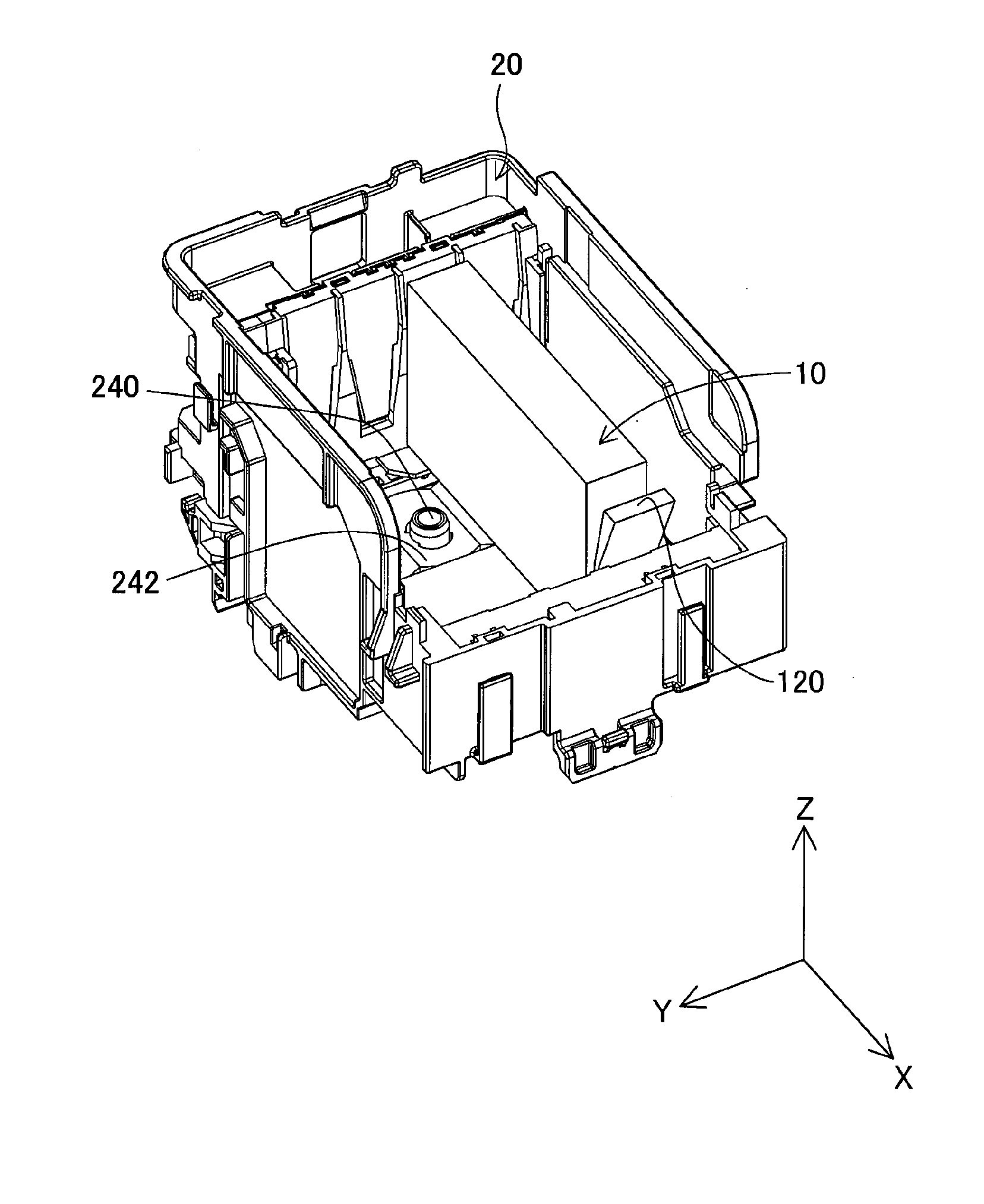

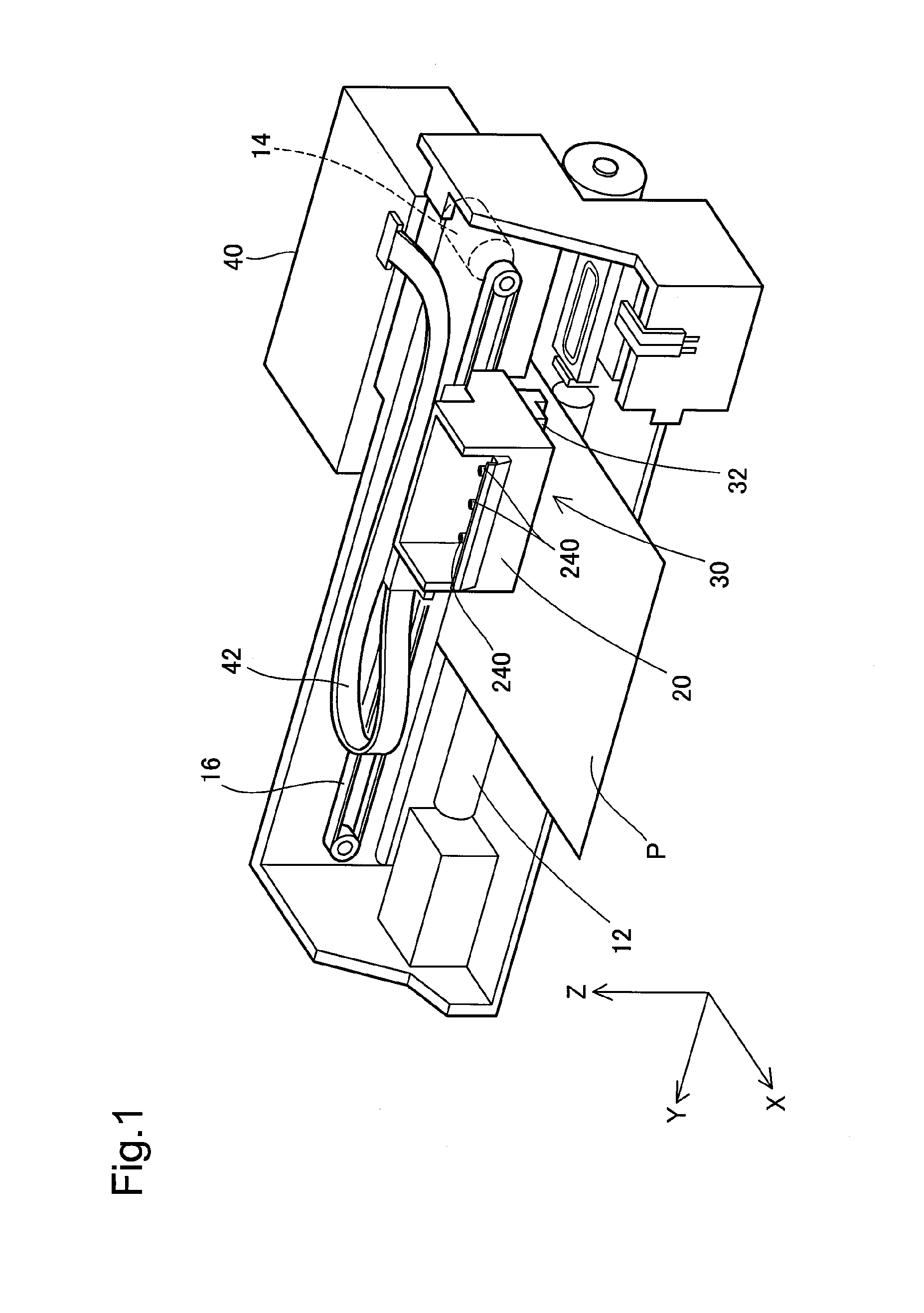

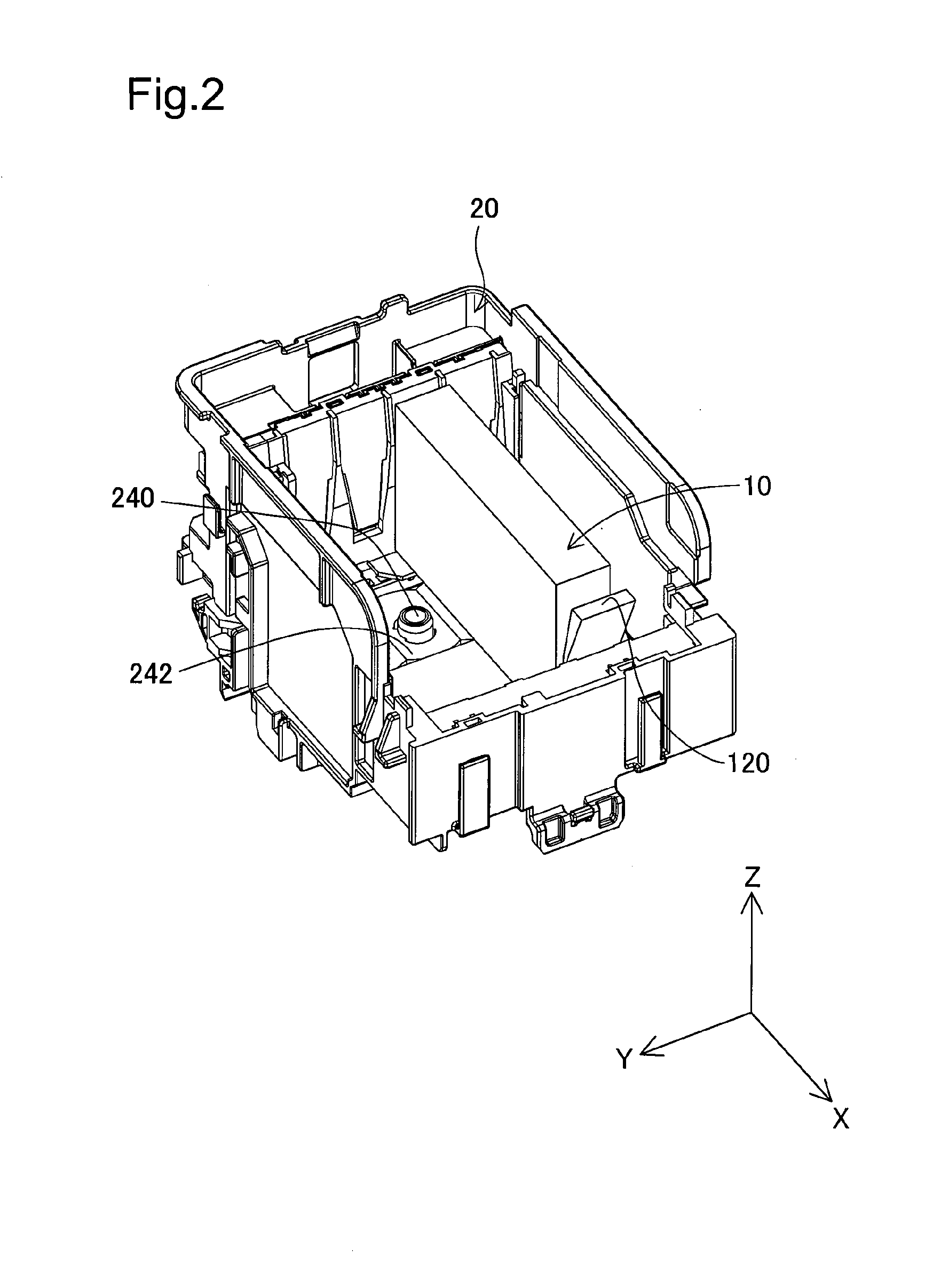

Image forming apparatus and sheet feeder

InactiveUS6674983B2Increase the areaEasy to disassembleElectrographic process apparatusArticle feedersImage formationMaterial supply

An image forming apparatus and sheet feeder in which a recording-material transporting system is provided for transporting to an image forming section recording material supplied from a recording-material supplying section and for subsequently guiding the recording material to a recording-material discharging section. A portion of the transporting path is arranged on a rear side of the apparatus body located on an opposite side to the user operation side. At least either one of the recording-material supplying section and the recording-material transporting system is provided with a jam clearing section for allowing recording material jammed in the recording-material transporting system to be both accessed from and cleared on the user operation side without need to open any access panels on the side portions or rear portion of the apparatus body. As a result the apparatus may be located without reserving space for opening a side or rear access portion.

Owner:FUJIFILM BUSINESS INNOVATION CORP

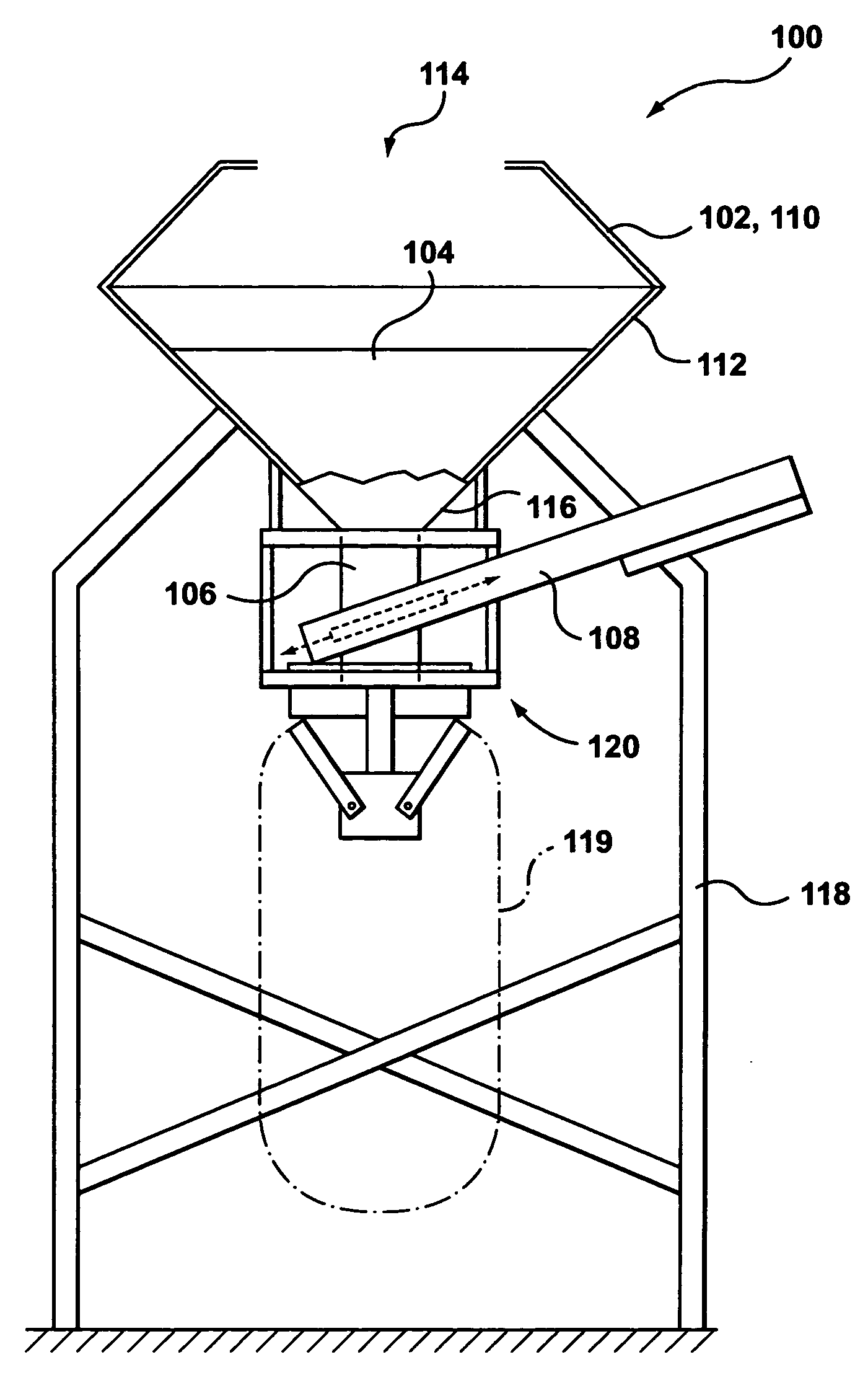

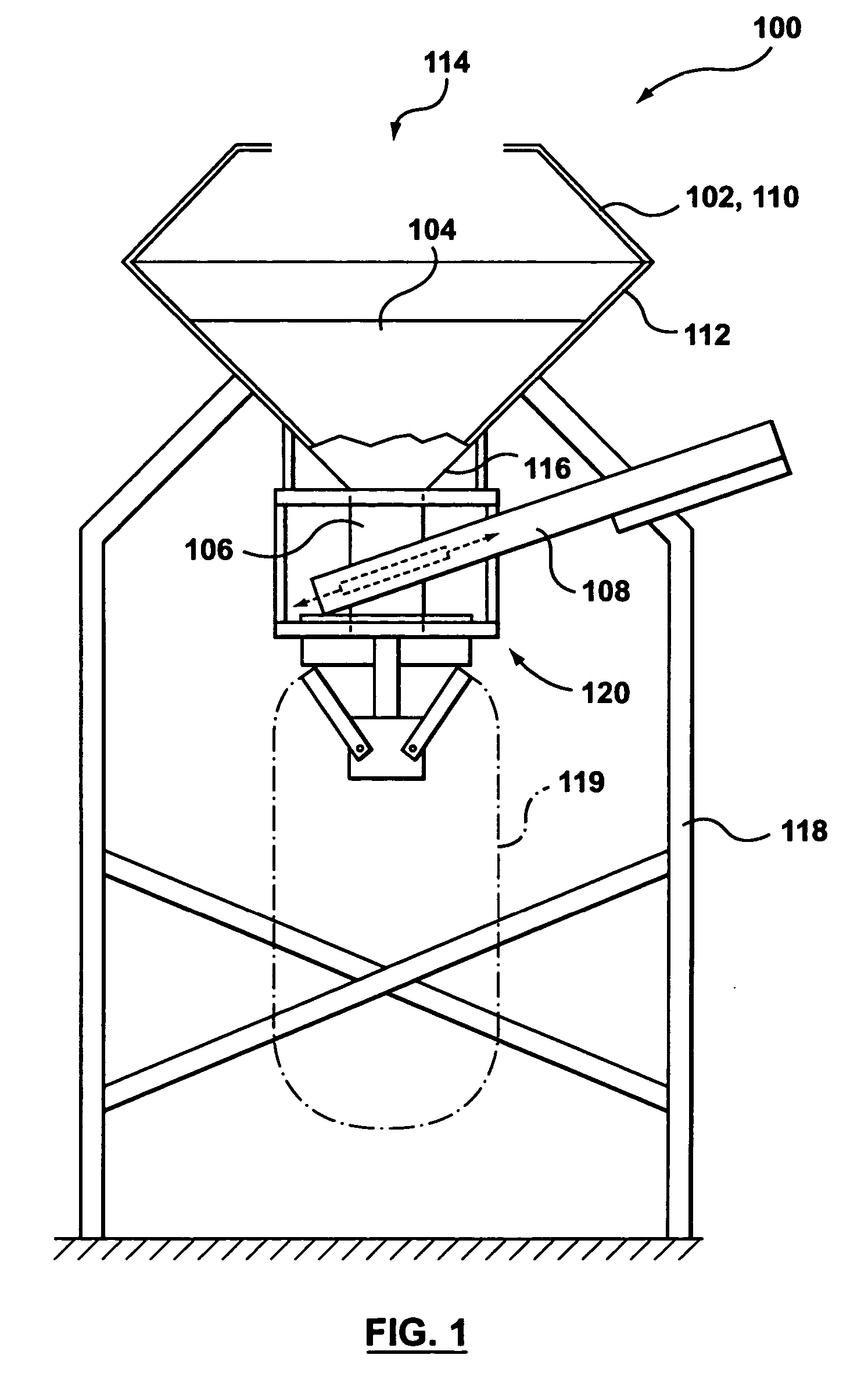

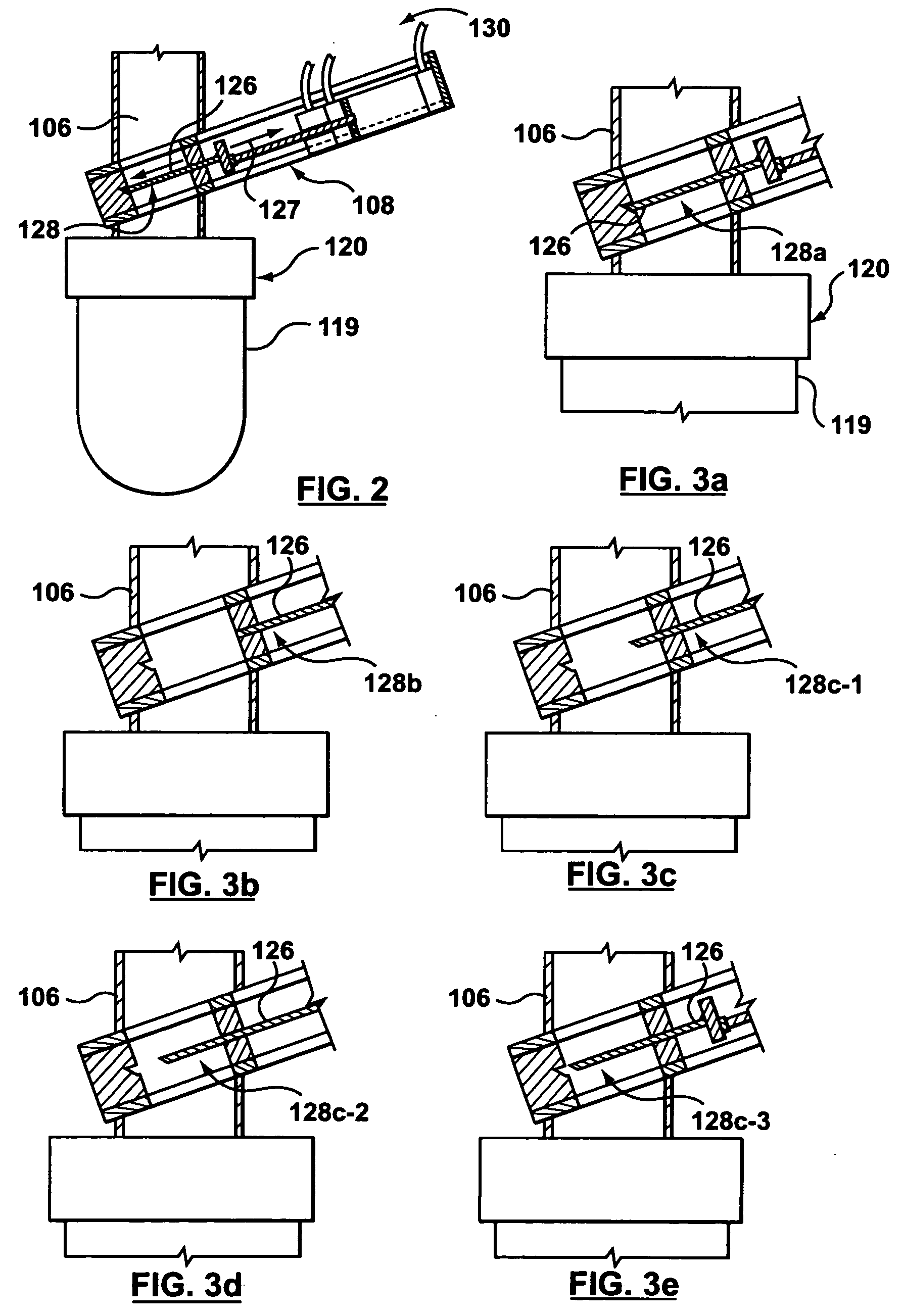

Product dispensing apparatus

A product dispensing apparatus for filling a container with product material has an enclosure for holding a supply of product material, a discharge outlet in the enclosure, and a gate device mounted adjacent the discharge outlet for controlling the flow of material through the outlet. The gate device is provided with a plate slidable across the discharge outlet between a fully closed position wherein the plate completely covers the discharge outlet and a maximum open position wherein the plate is generally clear of the discharge outlet and one or more partially open positions located between the maximum open and fully closed positions. The gate device is further provided with an actuator having a driven member connected to the plate for moving the plate among the closed, maximum open, and partially open positions, and stopping means adjacent the actuator for stopping the plate at the partially open positions.

Owner:INDAL PROCESS INNOVATIONS

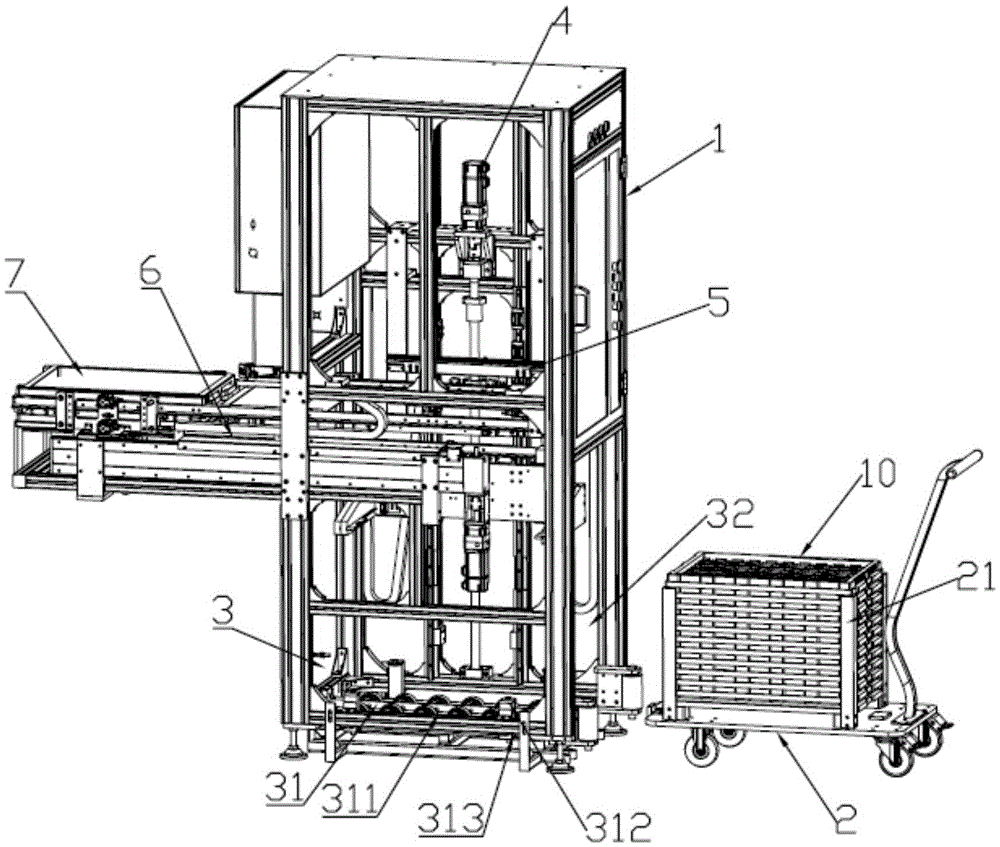

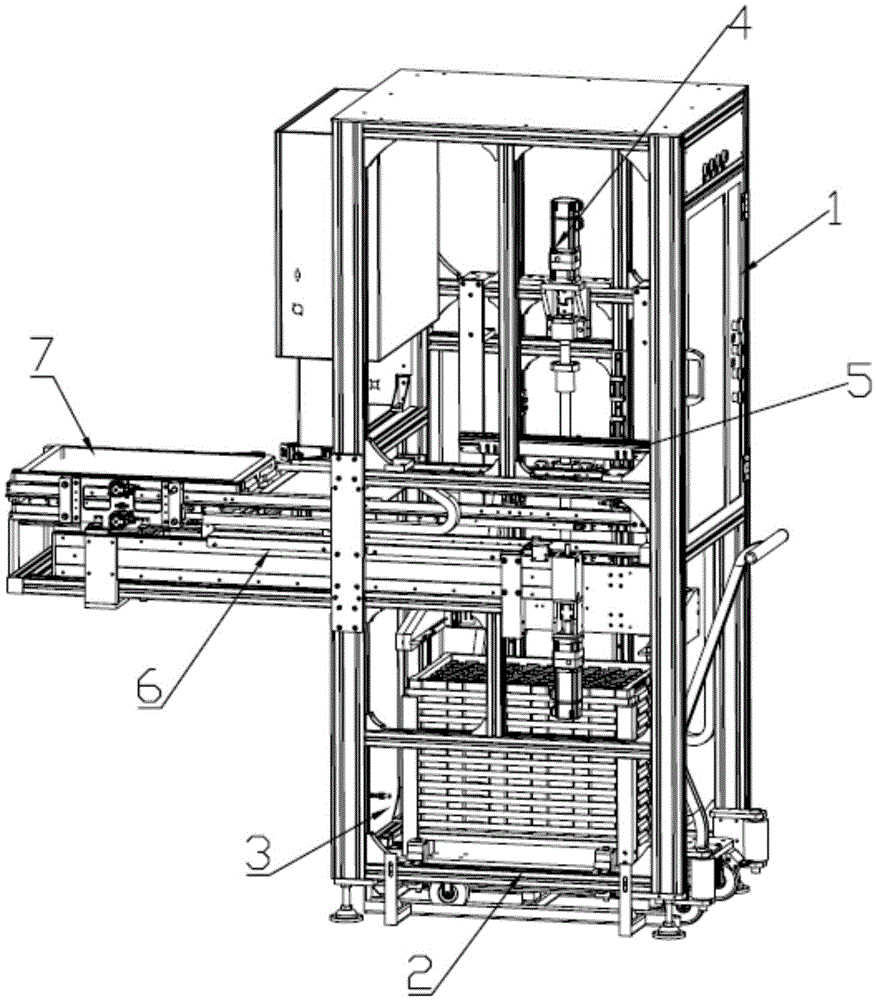

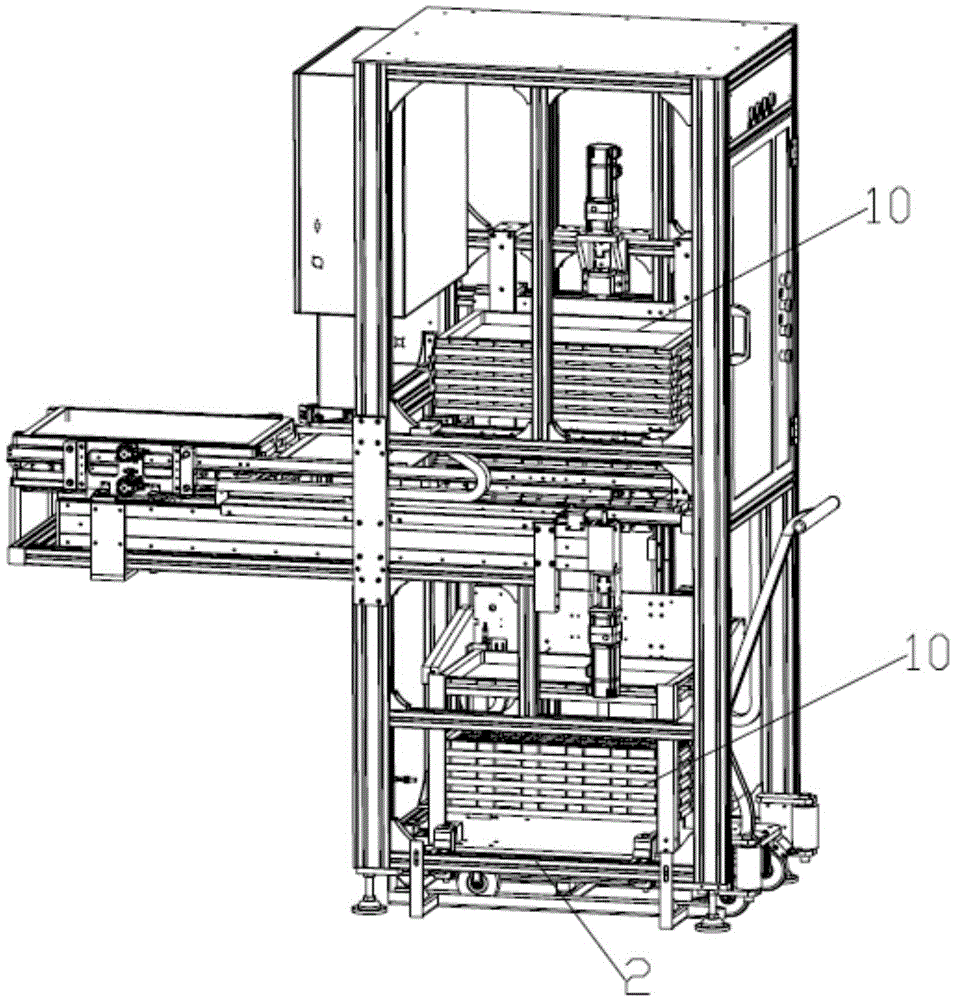

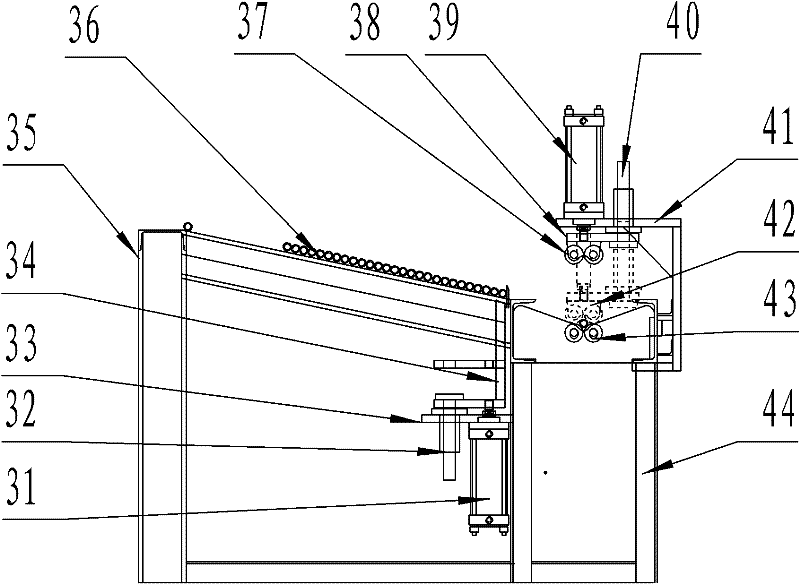

Tray type automatic supply and retraction equipment

InactiveCN105621110AFully automatedRealize intelligenceConveyorsStacking articlesButt jointEngineering

The invention discloses tray type automatic supply and retraction equipment. The equipment comprises a frame and multiple supply cars; a loading area is formed under the frame; a car positioning mechanism is arranged in the loading area; a supply car feed port is formed in one side surface of the loading area in the X direction; and after the support cars enter the loading area from the supply car feed port, the car positioning mechanism locks and positions the supply cars. The frame is provided with a tray hoisting mechanism in the Z direction in an area above the loading area; three layers of tray lifting mechanisms are symmetrically spaced on two sides of the Y direction of the middle part of the frame; a tray carrying mechanism in the X direction is arranged corresponding to two layers of tray lifting mechanisms on the lower side; and a butt joint equipment taking area is formed on the outer side of the tray carrying mechanism. The tray type automatic supply and retraction equipment divides a tray into a mother tray and son trays; for materials with different shapes, only the corresponding son trays need to be replaced, so that the replacement is convenient, and the resource is saved; and a robot is matched to clamp the materials so as to realize the material supply automation and intelligence more efficiently, more accurately and more quickly.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

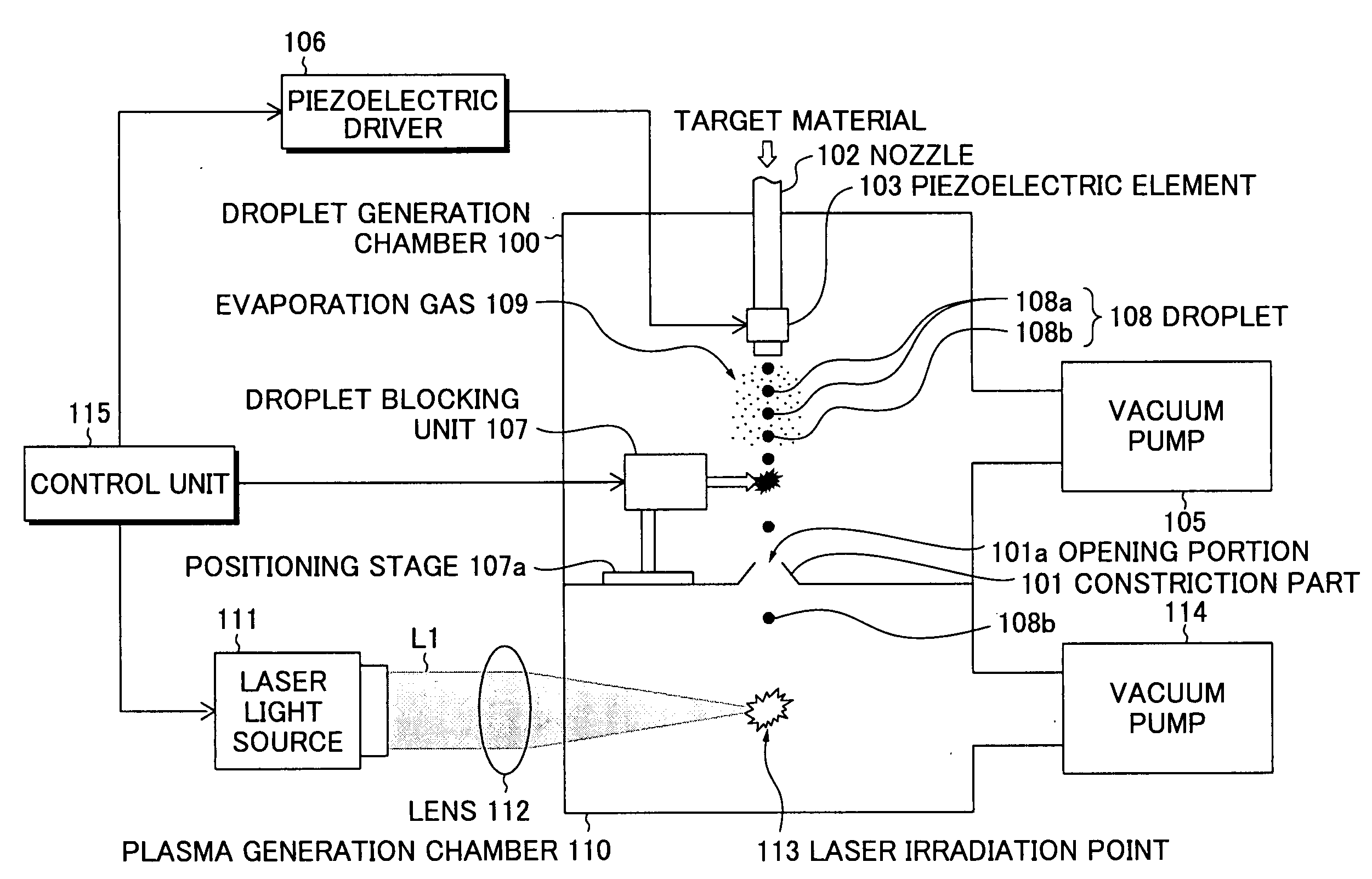

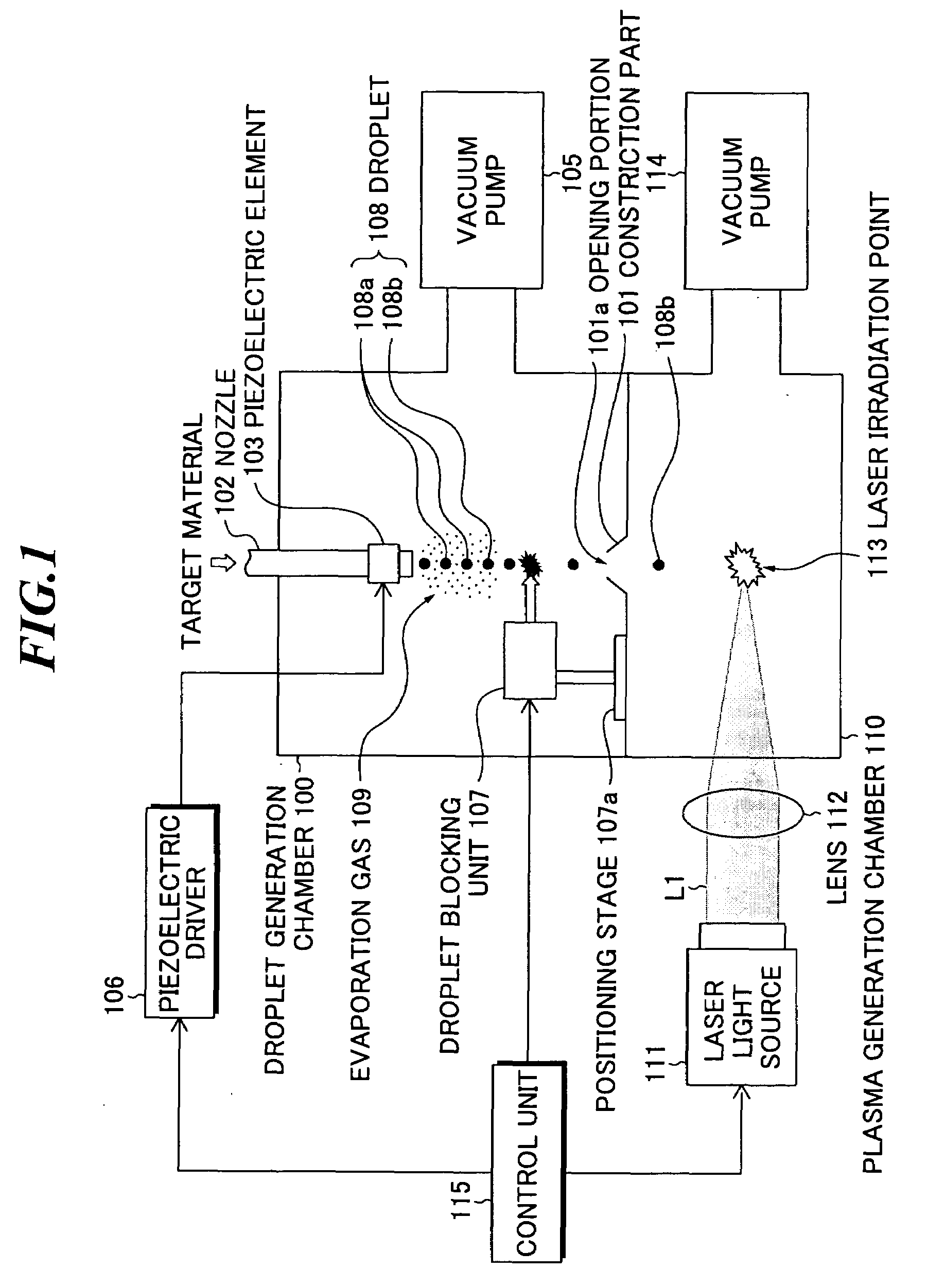

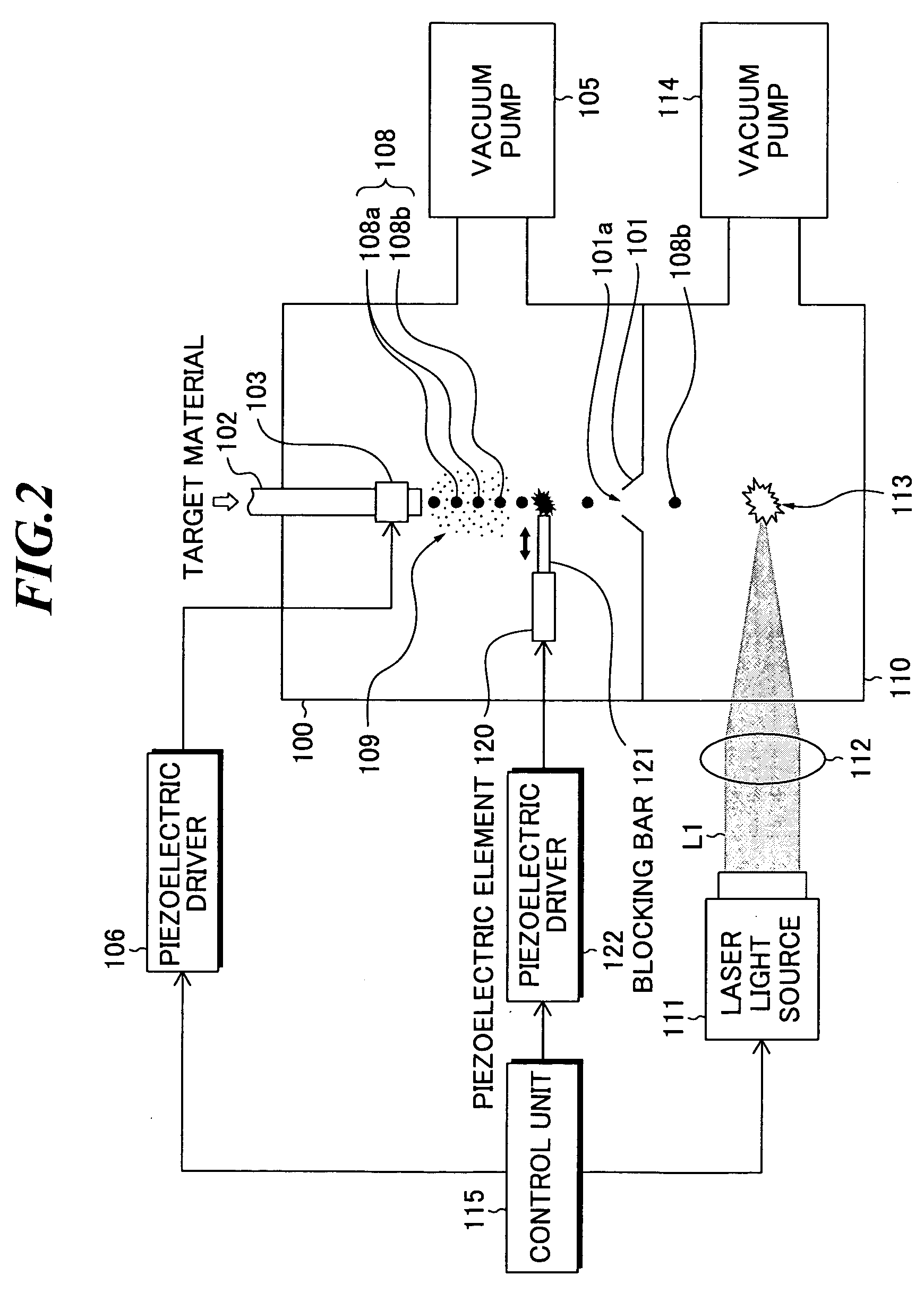

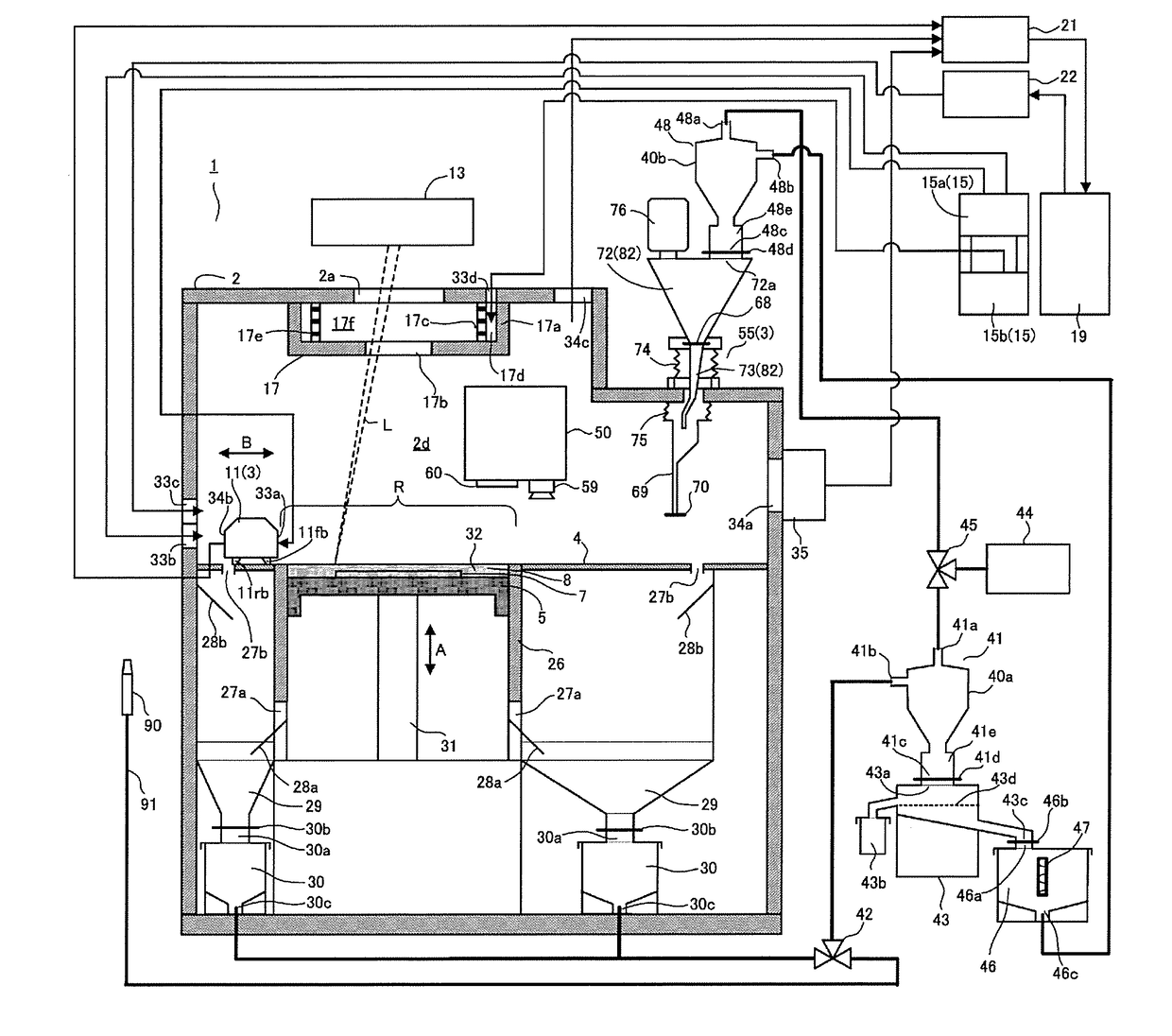

Extreme ultra violet light source device

ActiveUS20070170377A1Improve of cleannessDegree of improvementRadiation pyrometryPhotometryUltravioletLaser light

An EUV (extreme ultra violet) light source device in which a degree of vacuum or cleanness in a plasma generation chamber is improved while the construction is simplified. The device includes: a first chamber; a second chamber connected to the first chamber through an opening portion; a target supplier that supplies a target material into the first chamber; a droplet generating unit that generates droplets of the target material of molten metal repetitively dropping based on the target material supplied by the target supplier; a blocking unit that prevents the droplets of the target material generated by the droplet generating unit from passing through the opening portion; control unit that controls the blocking unit to operate at predetermined timing; a laser light source; and an optical system that leads a laser beam to the droplets of the target material introduced into the second chamber.

Owner:GIGAPHOTON

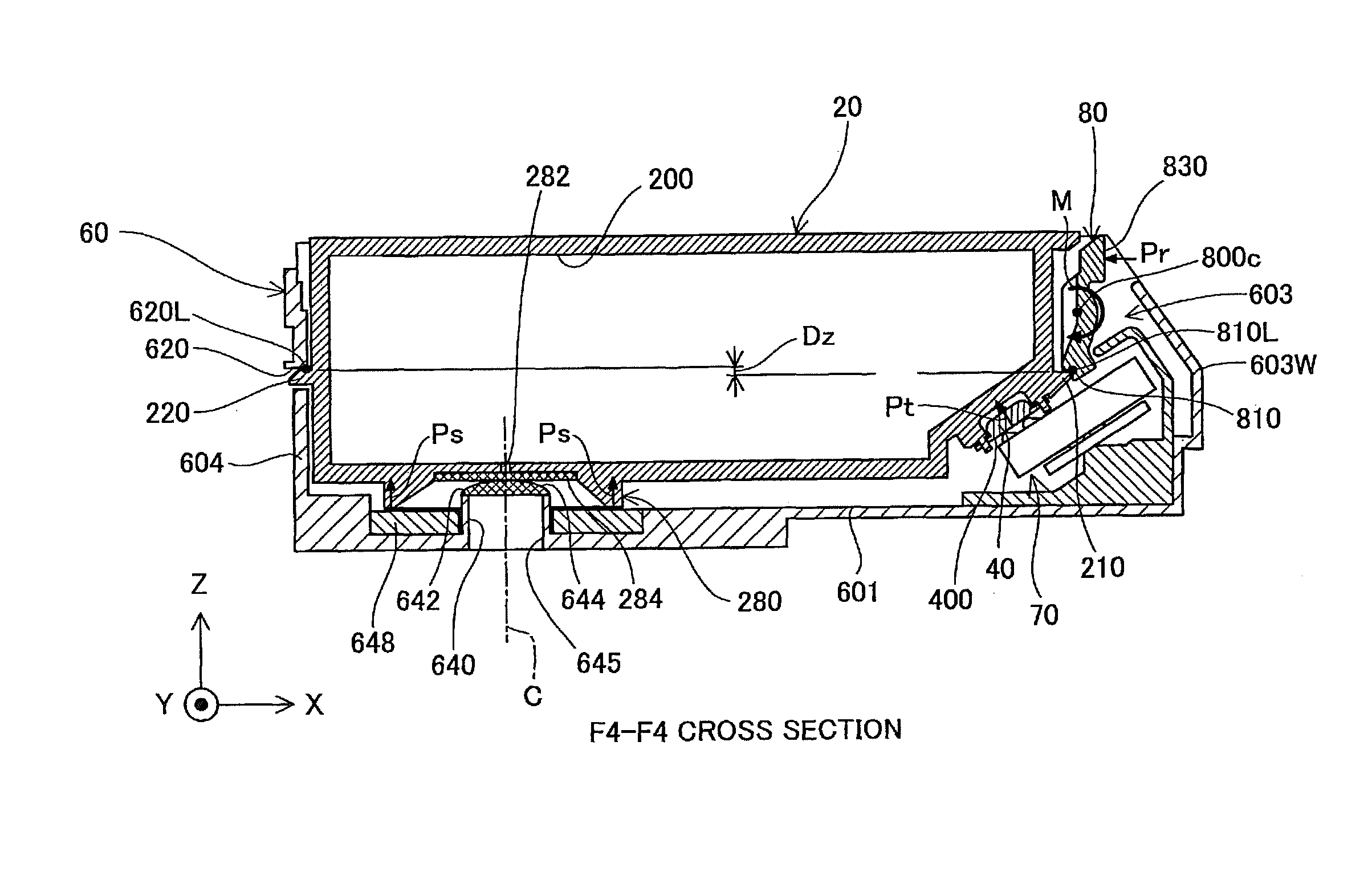

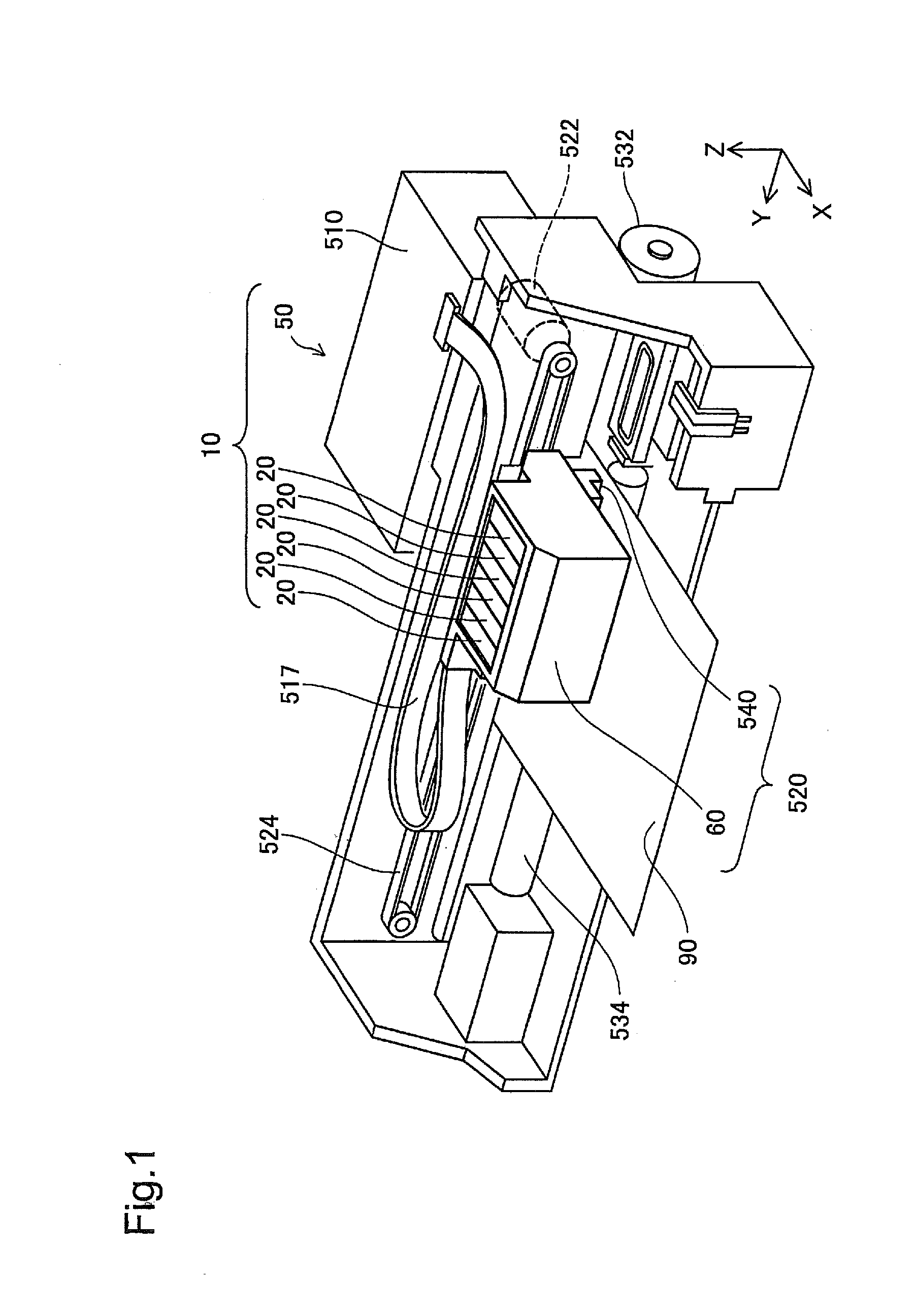

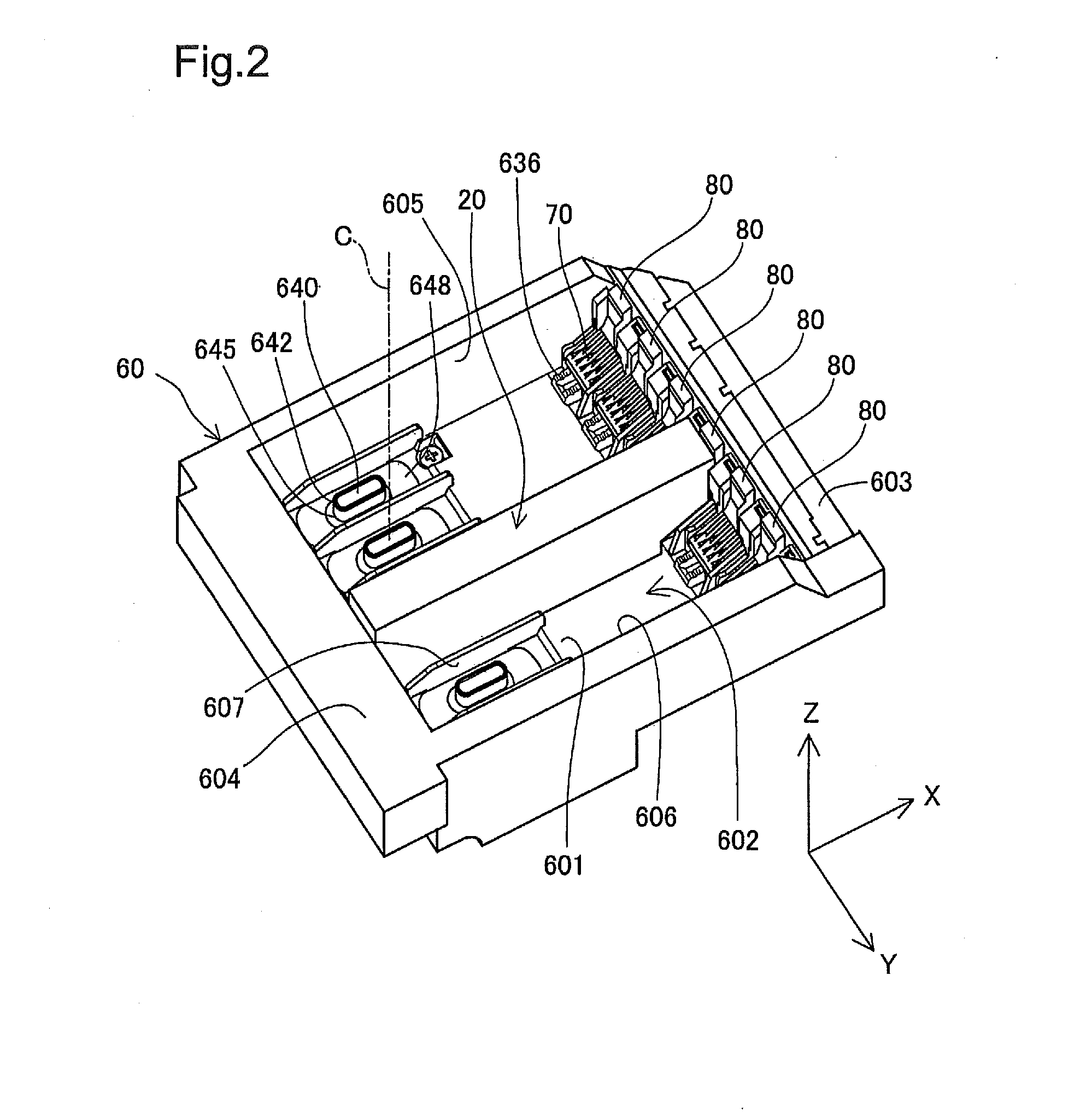

Printing material cartridge and printing material supply system

ActiveUS20120056955A1Reduce the likelihood of failureReduce the possibilityPrintingAcute angleEngineering

A printing apparatus has a cartridge attachment section including a terminal block having apparatus-side terminals disposed on its inclined surface, and a printing material supply pipe. Among the apparatus-side terminals, one apparatus-side ground terminal located on their center in Y direction is protruded to a greater height than the other plural apparatus-side terminals. A printing material cartridge has a circuit board, a printing material supply port, and a board mount portion that is inclined at an acute angle relative to a plane extended from an opening face of the printing material supply port. The circuit board is arranged such that one cartridge-side terminal on the circuit board comes into contact with the apparatus-side ground terminal prior to the other cartridge-side terminals in the process of attachment of the printing material cartridge to the cartridge attachment section. This arrangement enables the printing material cartridge to be attached in an adequate correct orientation or alignment to the printing apparatus. This arrangement also reduces the possibility of failure caused by application of a high voltage to the circuitry of the printing material cartridge.

Owner:SEIKO EPSON CORP

Sectional meter shut-off and agricultural implement having sectional meter shut-off

ActiveUS8141504B2Fertiliser distributersAgriculture and animal husbandary industrySeederMaterial supply

An assembly for selectively supplying particulate material to an air seeder, an agricultural implement able to selectively supply and dispense particulate material into the ground and a method of selectively dispensing particulate material into the ground are provided. The assembly has at least one supply receptacle for receiving particulate material from a source and a metering roller for supplying the material to an air seeder. The assembly is operative to selectively supply the material to the air seeder and prevent the material from being supplied to the air seeder. The implement can use the assembly to selectively supply particulate material to ground engaging openers where the particulate material will be dispensed into the ground. Particulate material can be selectively supplied to the implement when it is desired to have the particulate material dispensed into the ground and then prevented from being supplied to the implement when it is not desirable.

Owner:ONE PASS IMPLEMENTS

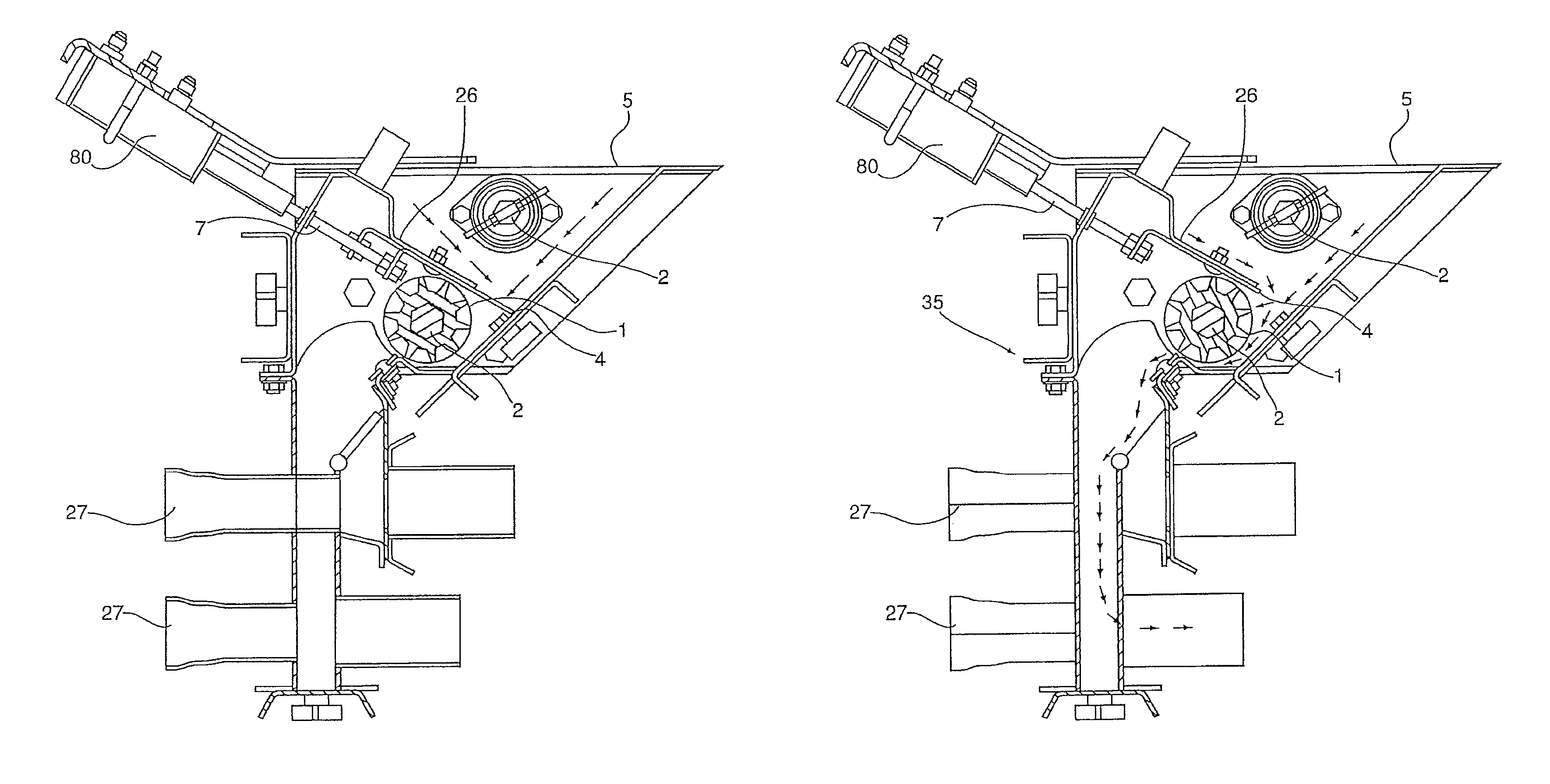

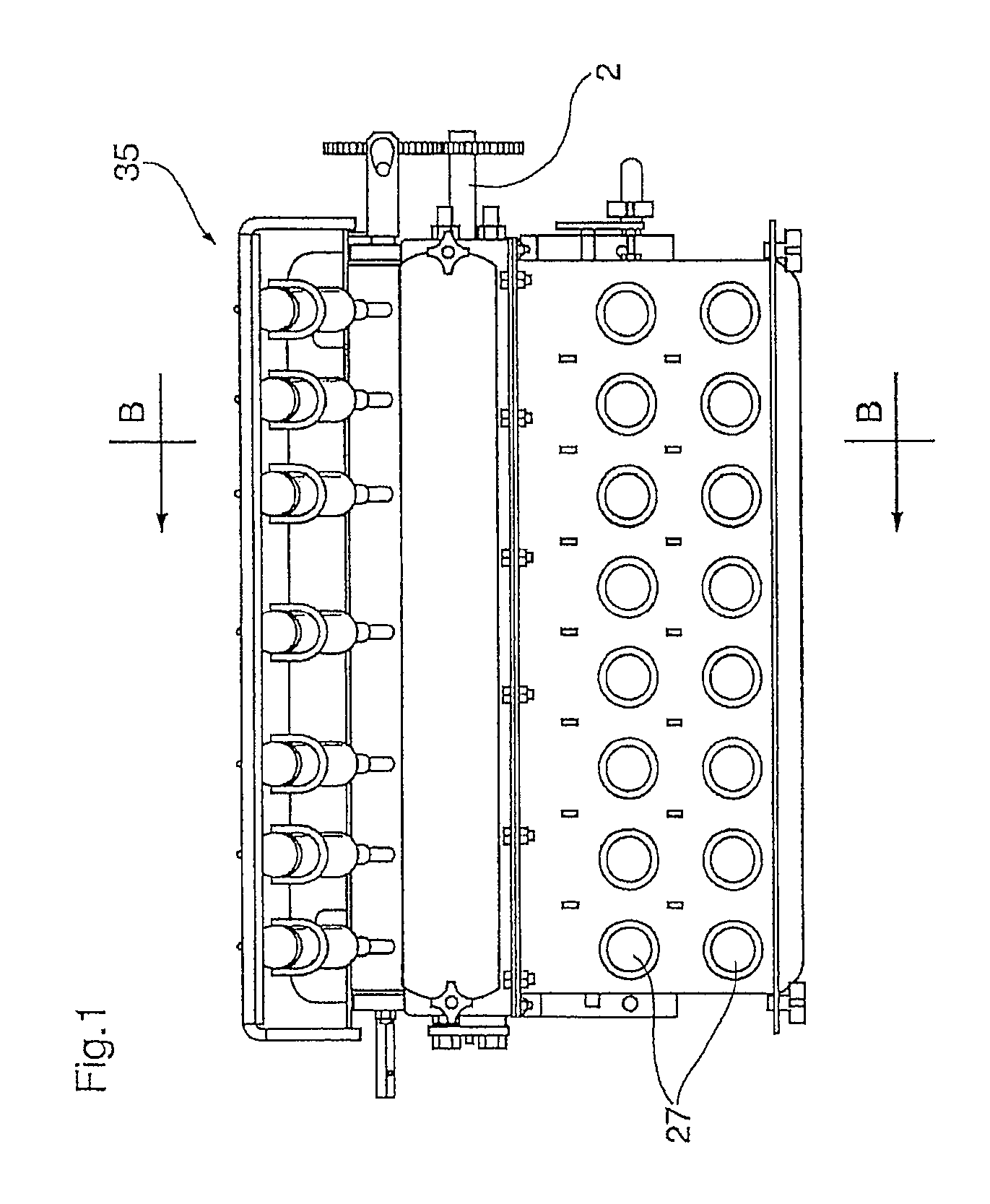

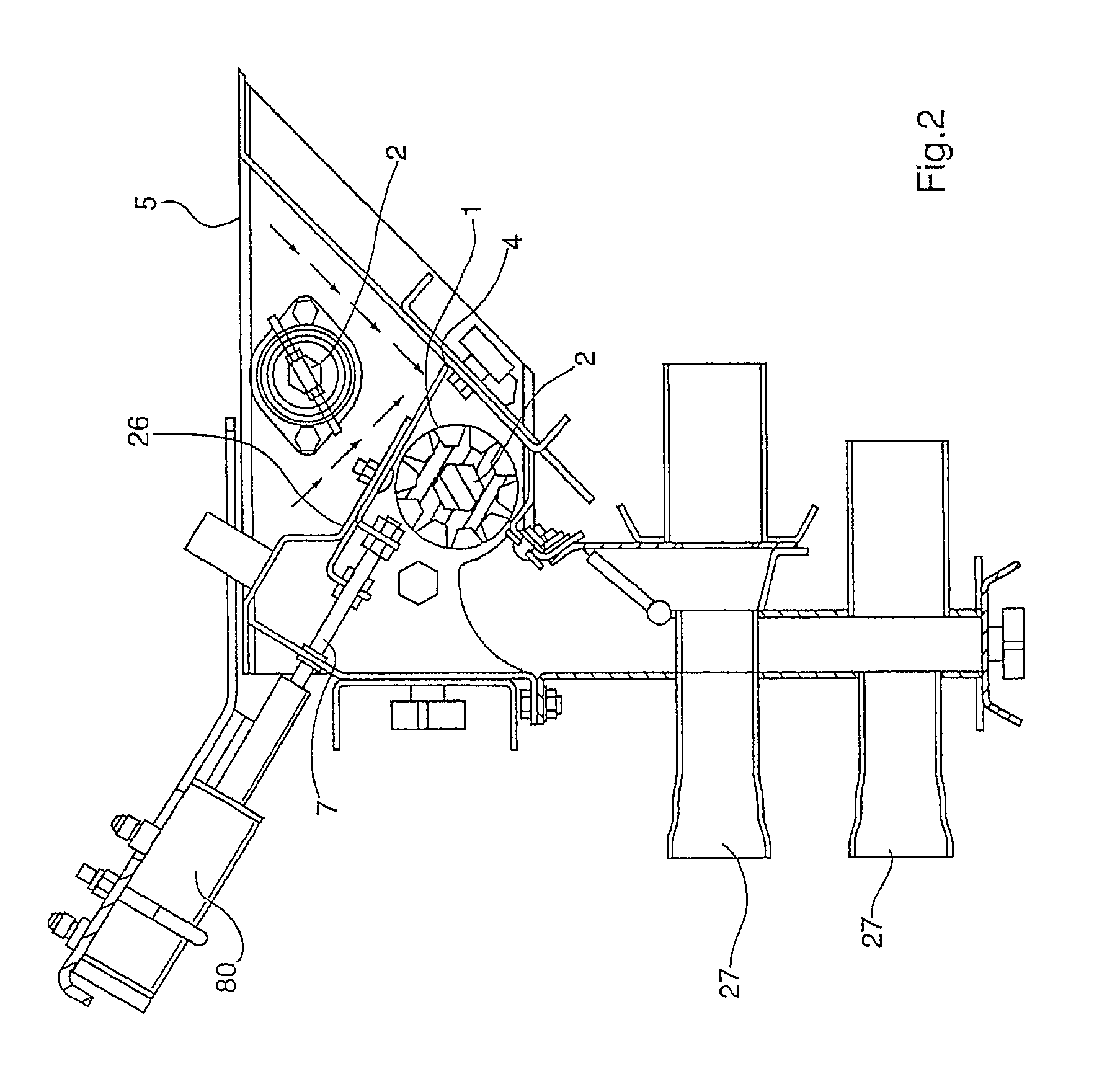

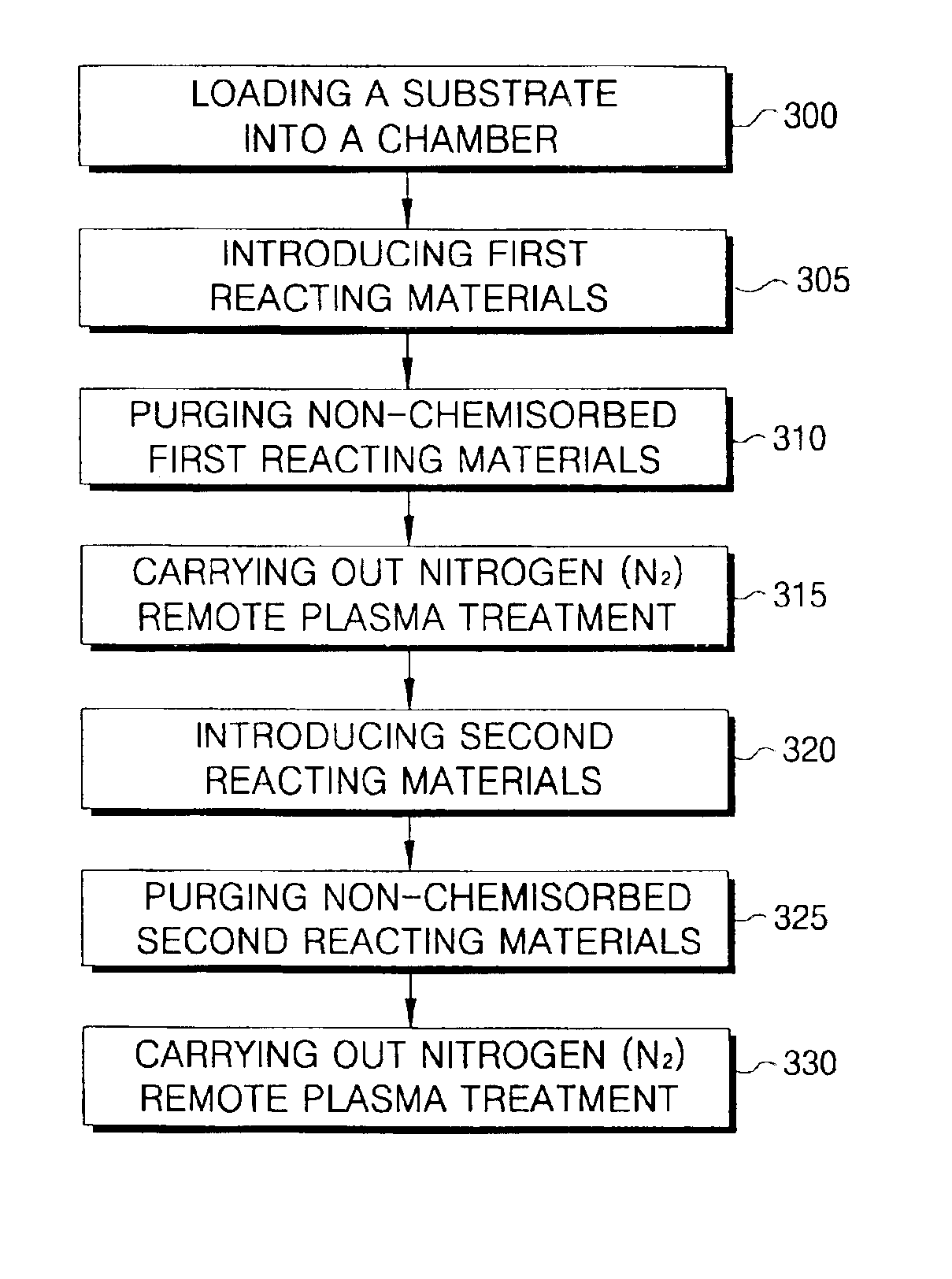

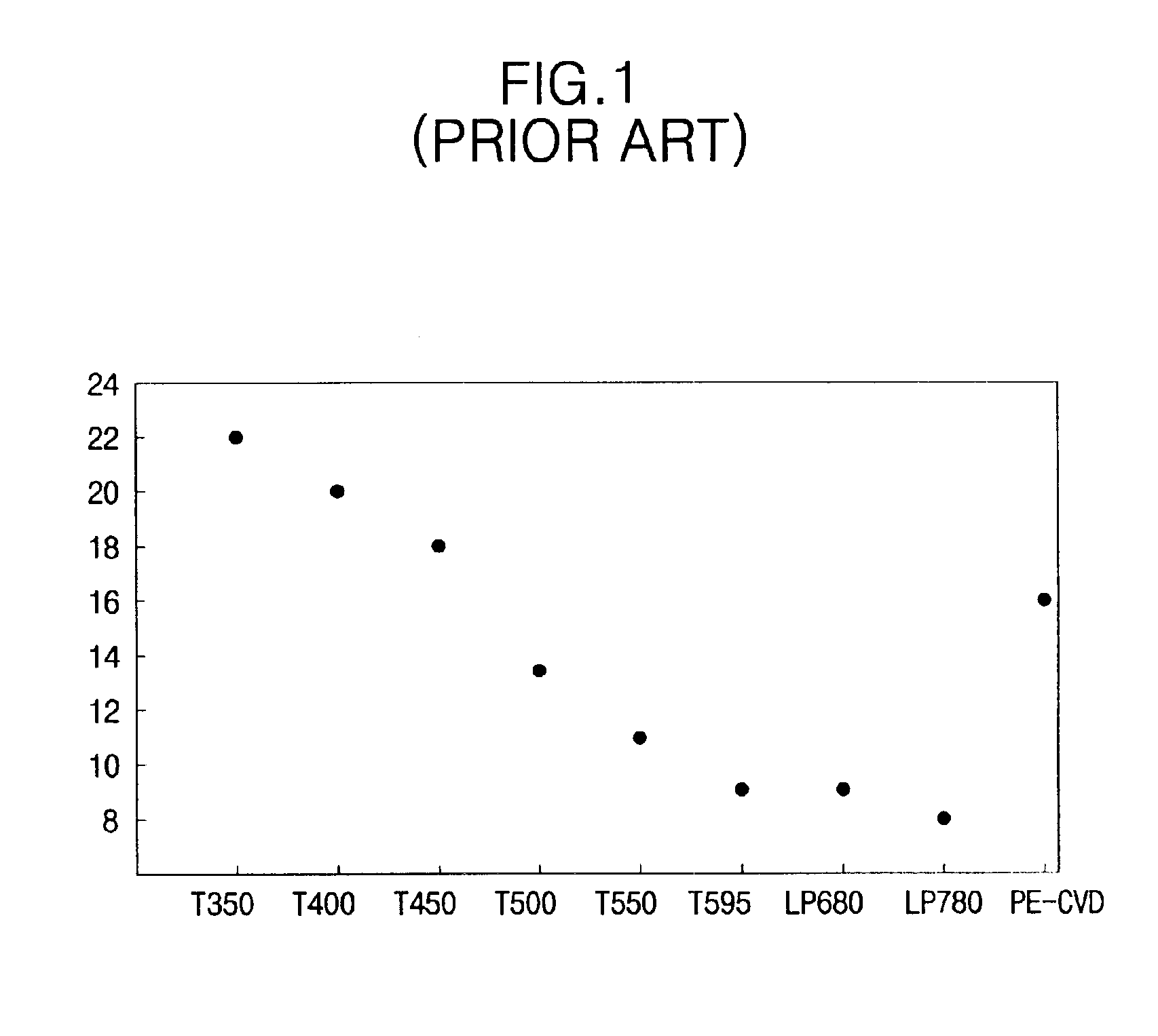

Method of forming a thin film with a low hydrogen content on a semiconductor device

InactiveUS6933245B2Reduce hydrogen contentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaChemisorption

A method of forming a thin film with a low hydrogen contents is provided by positioning a substrate inside a processing chamber, and supplying reacting materials into the chamber, chemisorbing a portion of the reacting materials onto the substrate. Then, a nitrogen (N2) remote plasma treatment is performed to reduce the hydrogen content of thin film layer formed by chemisorption of the reacting materials on the substrate. Accordingly, a thin film is formed having a low hydrogen content, since the hydrogen bonds in the thin film layer formed by chemisorption of the reacting materials are removed.

Owner:SAMSUNG ELECTRONICS CO LTD

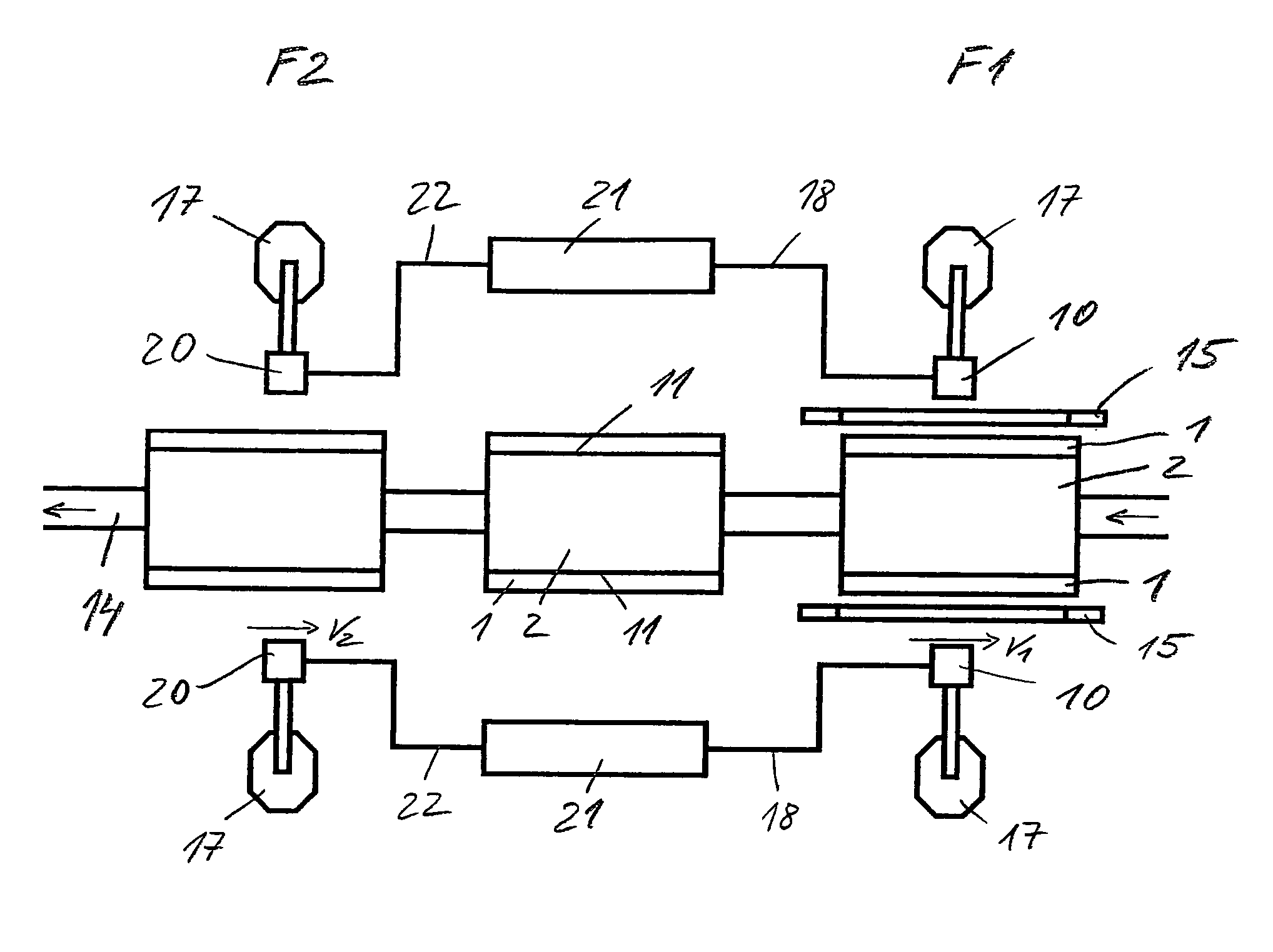

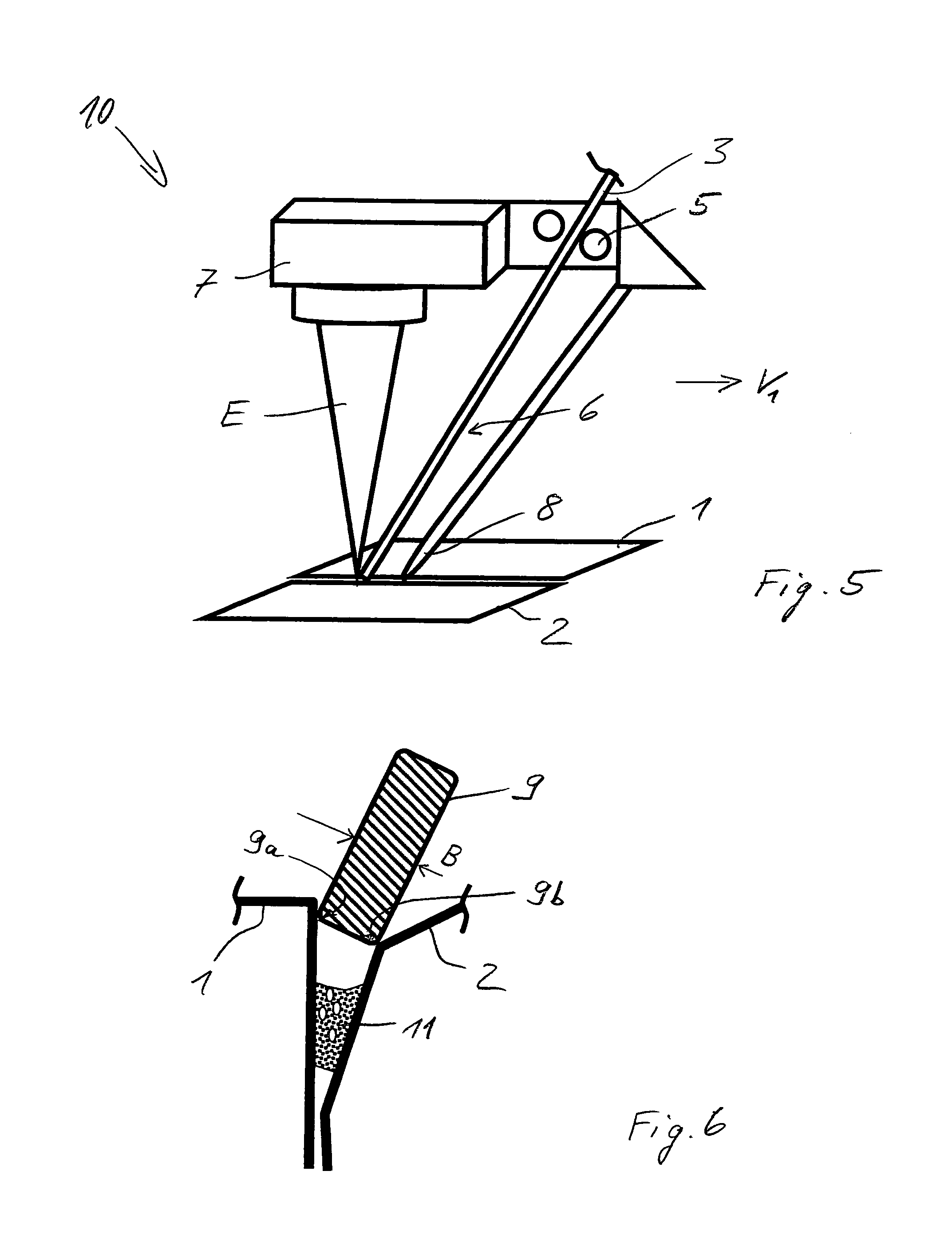

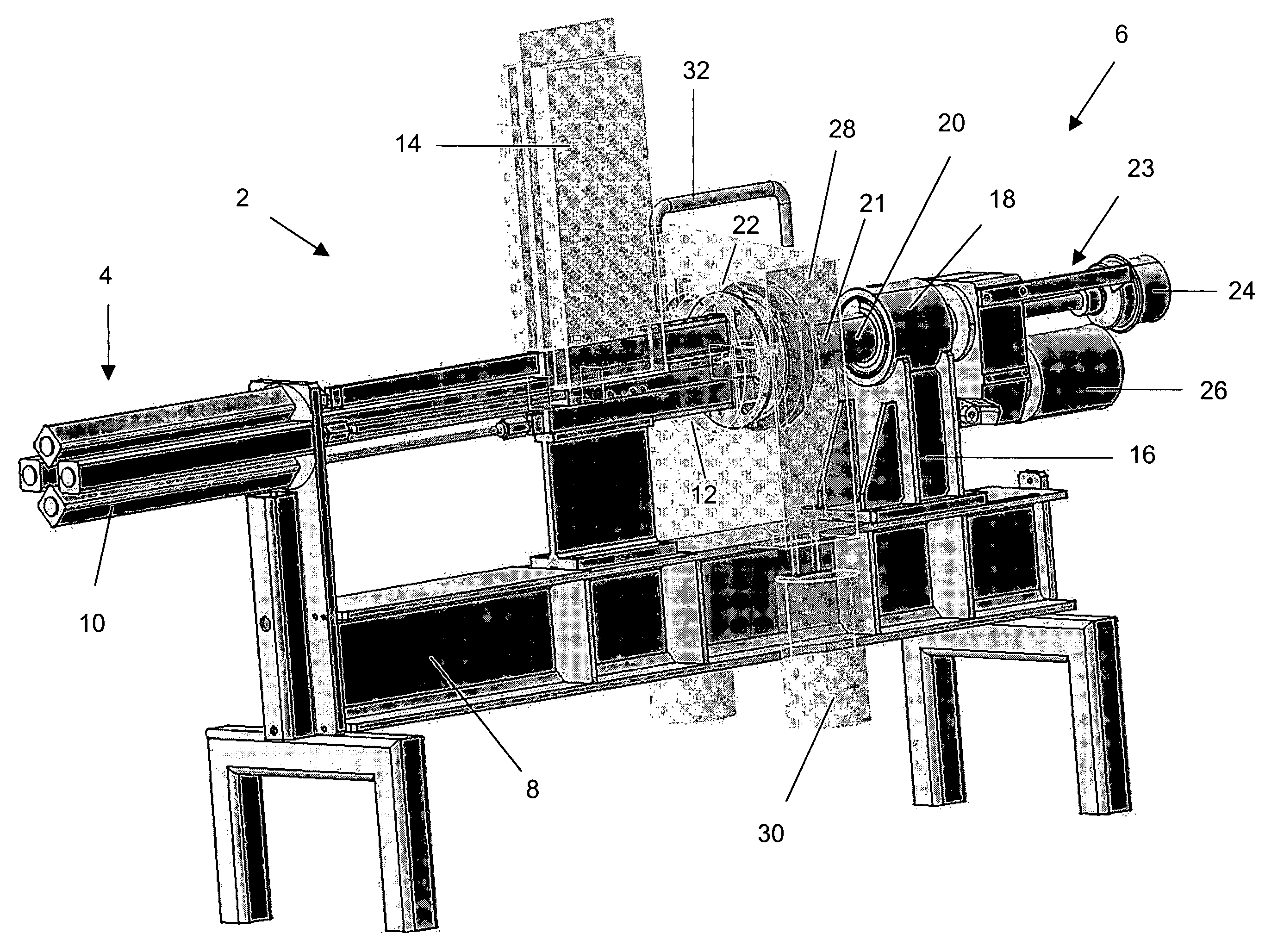

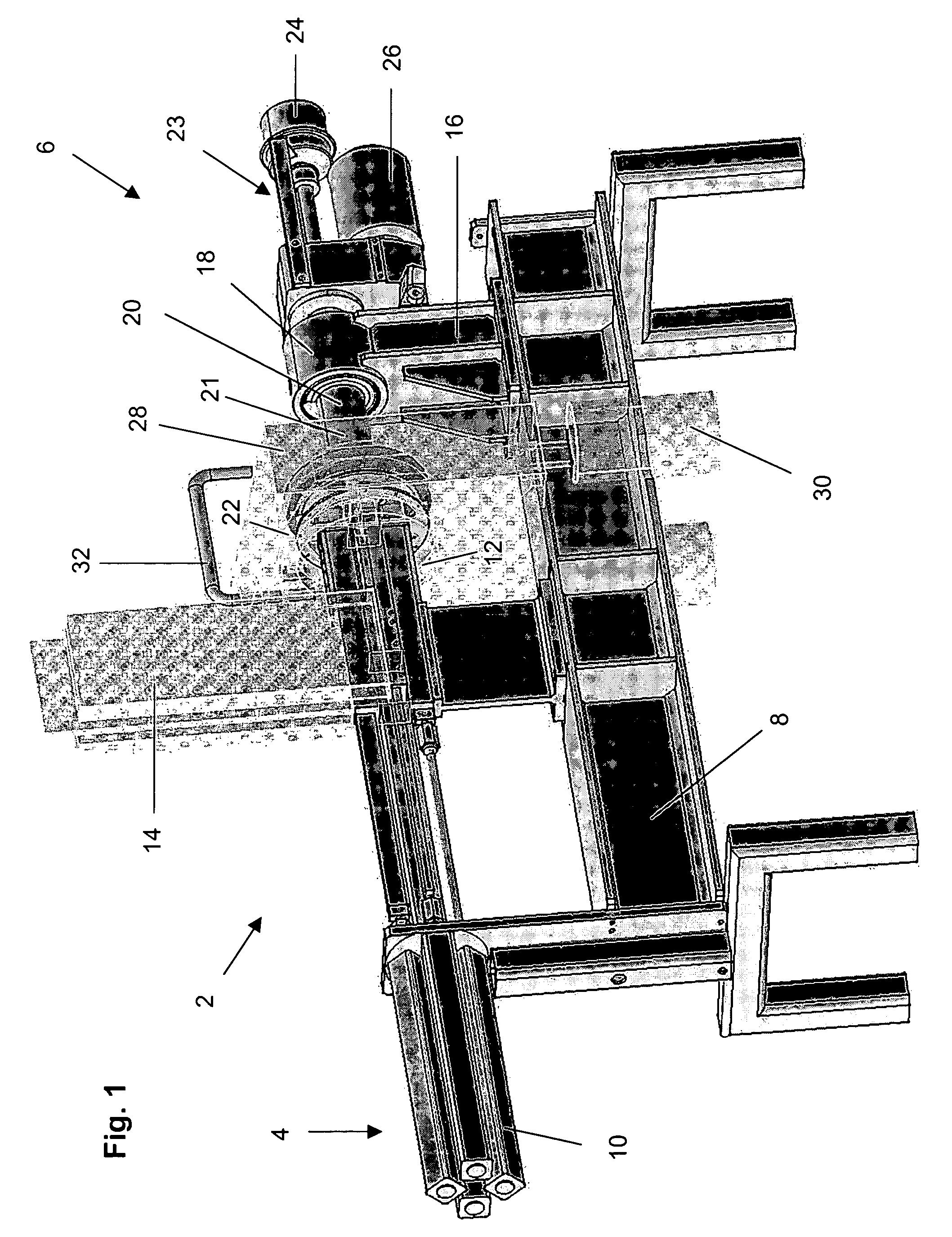

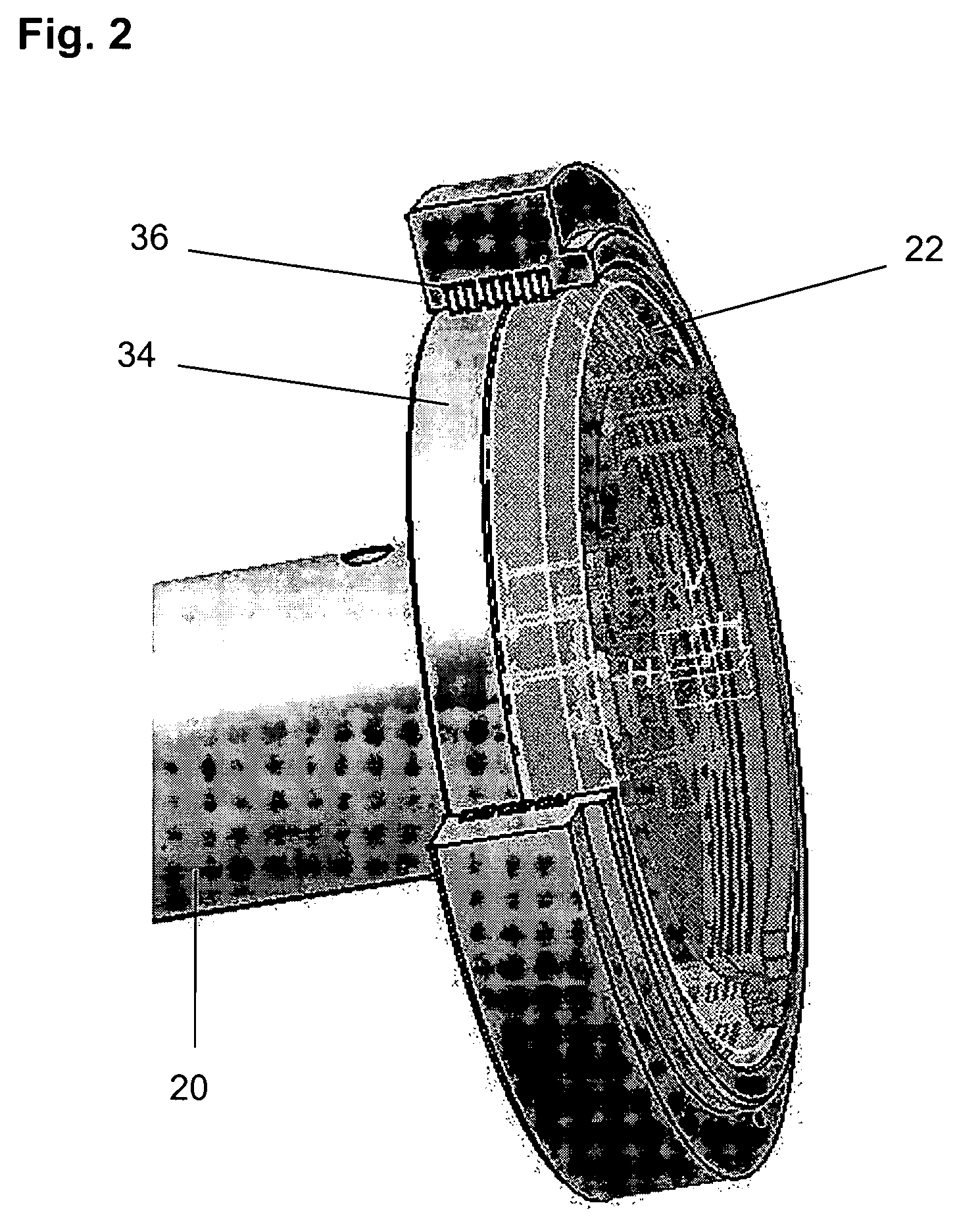

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

Cartridge and printing material supply system

A cartridge comprises an ink supply structure, a terminal bearing structure, and a first restriction portion. The terminal bearing structure has terminals arranged in a terminal plane which is neither parallel nor perpendicular to a plane defined by a mounting direction leading edge of the ink supply structure, so that the contact portions of the terminals receive a force in a direction opposite from the mounting direction. An engagement portion of the first restriction portion is provided at a position adjacent to the terminal bearing structure.

Owner:SEIKO EPSON CORP

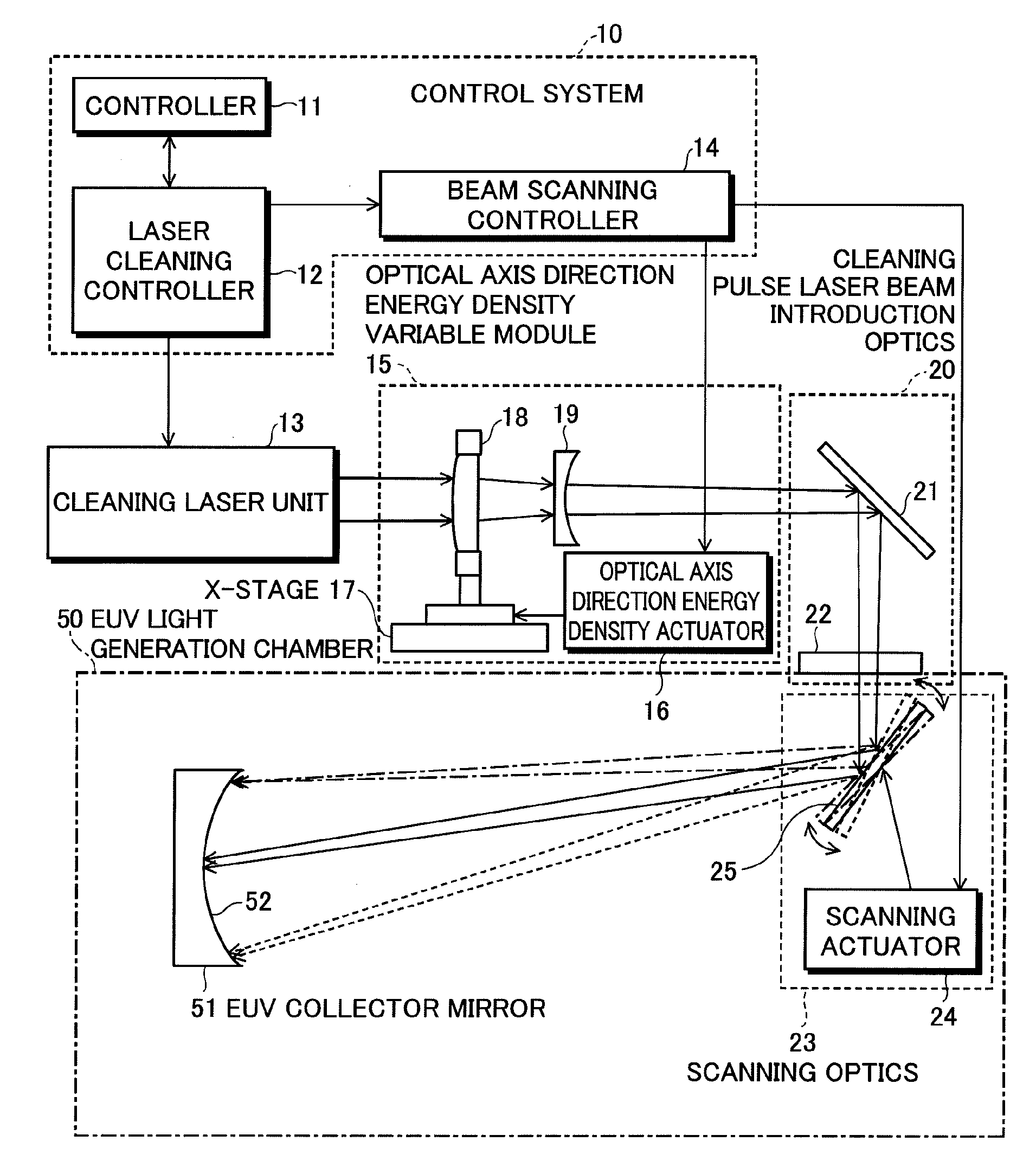

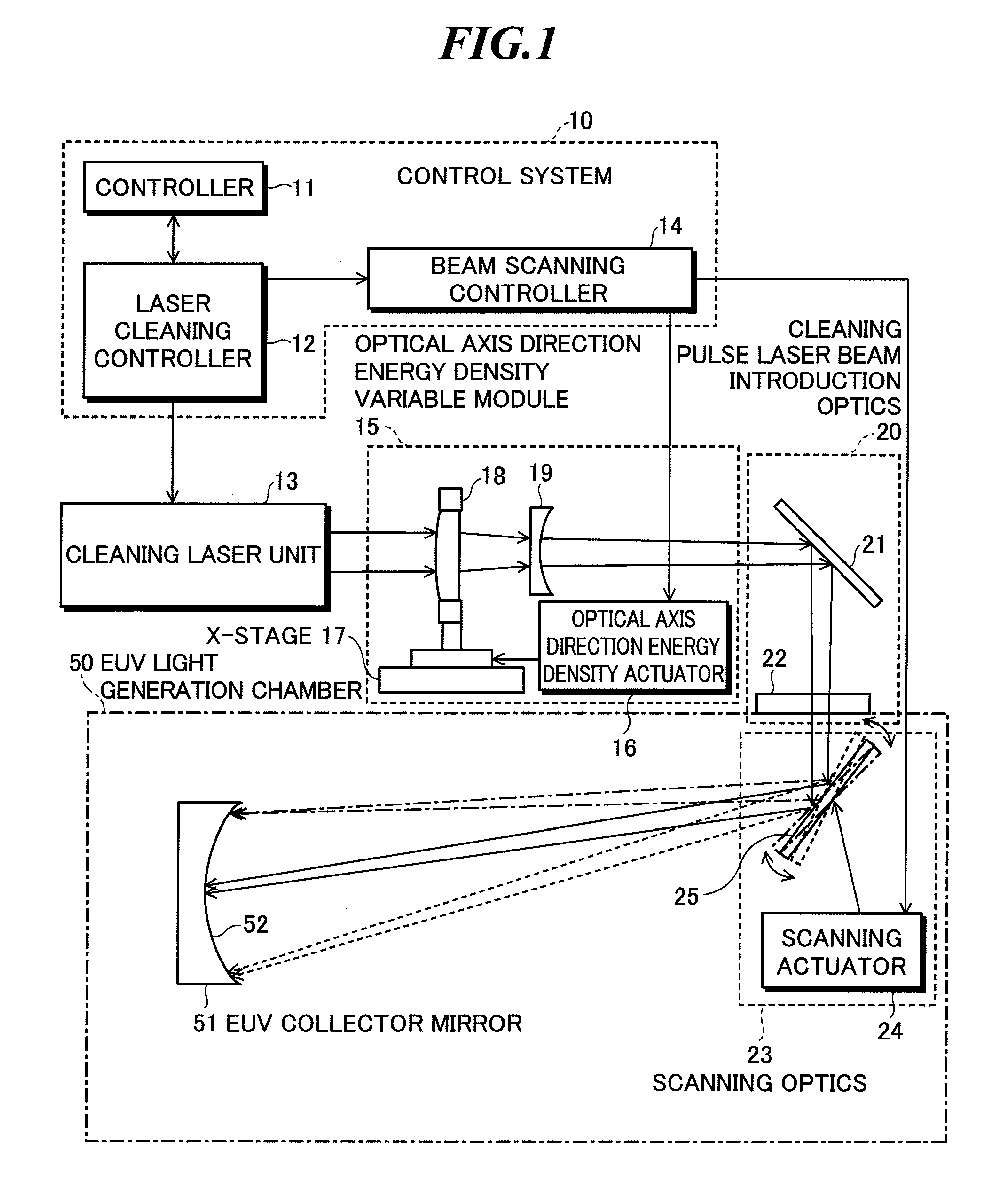

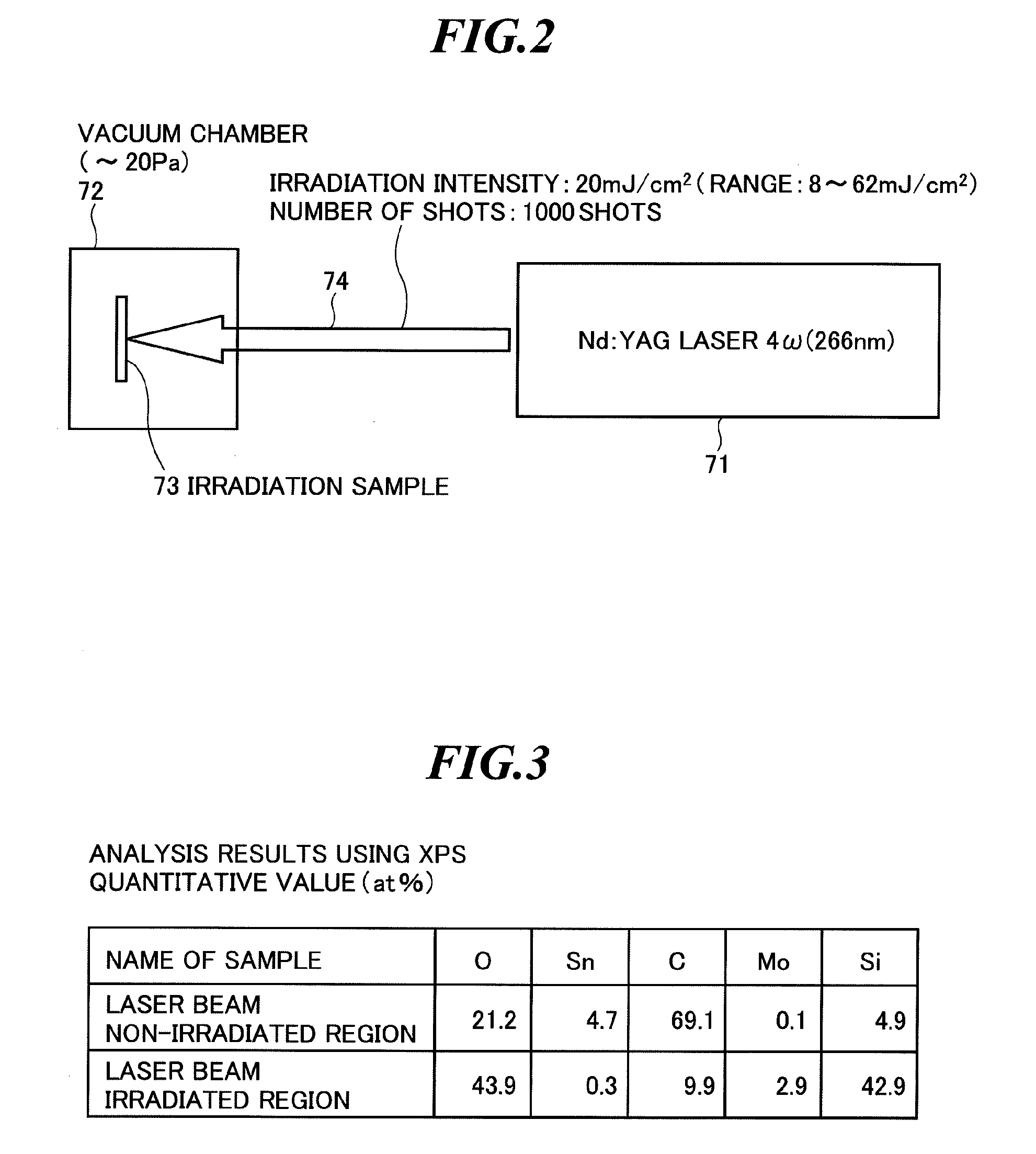

Extreme ultraviolet light source apparatus and cleaning method

InactiveUS20100192973A1Eliminate adhesionEfficient removalSimulator controlPhotomechanical apparatusLight beamPulsed laser beam

An extreme ultraviolet light source apparatus that can eliminate debris adhering to a component such as optical elements provided within a chamber. The extreme ultraviolet light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target material supply unit for supplying a target material into the chamber; a driver laser unit for irradiating the target material with a driver pulse laser beam to generate plasma; a cleaning laser unit for emitting a cleaning pulse laser beam; and a control unit for controlling an irradiation position of the cleaning pulse laser beam emitted from the cleaning laser unit so as to irradiate a component provided within the chamber with the cleaning pulse laser beam to remove debris adhering to a surface of the component.

Owner:GIGAPHOTON

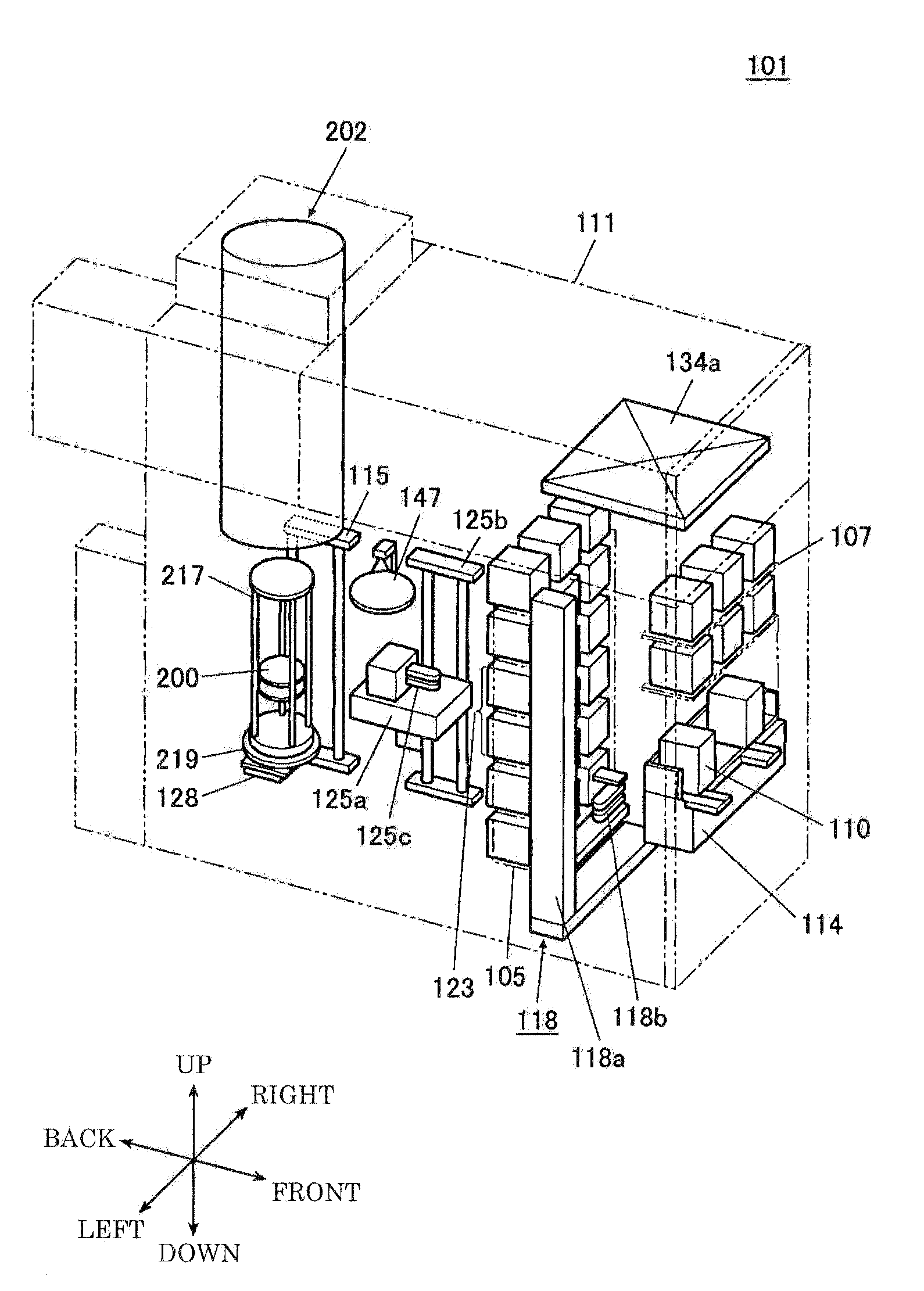

Three-dimensional printer

ActiveUS20170348771A1Form evenlyLong automationManufacturing enclosuresManufacturing material handlingMaterial supplyRetaining wall

A three-dimensional printer (1) includes a material supply device (3) that supplies material powder to a table which is movable vertically, a powder retaining wall (26) that surrounds the table and retains the material powder, a material-recovery bucket (30) that accommodates excess material powder and impurities discharged from the powder retaining wall, an impurity removing device (43) that removes the impurities from the material powder, and a material drying device (47) that dries the material powder. The material powder from which the impurities have been removed and which has been dried is returned and recycled to the material supply device.

Owner:SODICK CO LTD

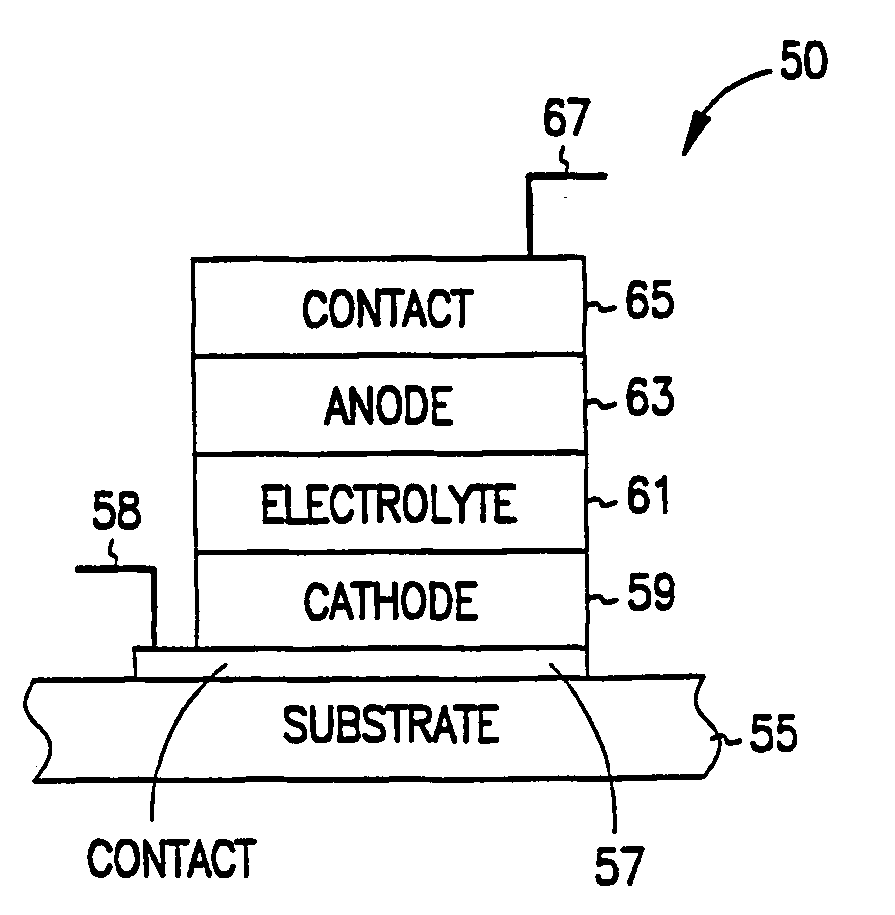

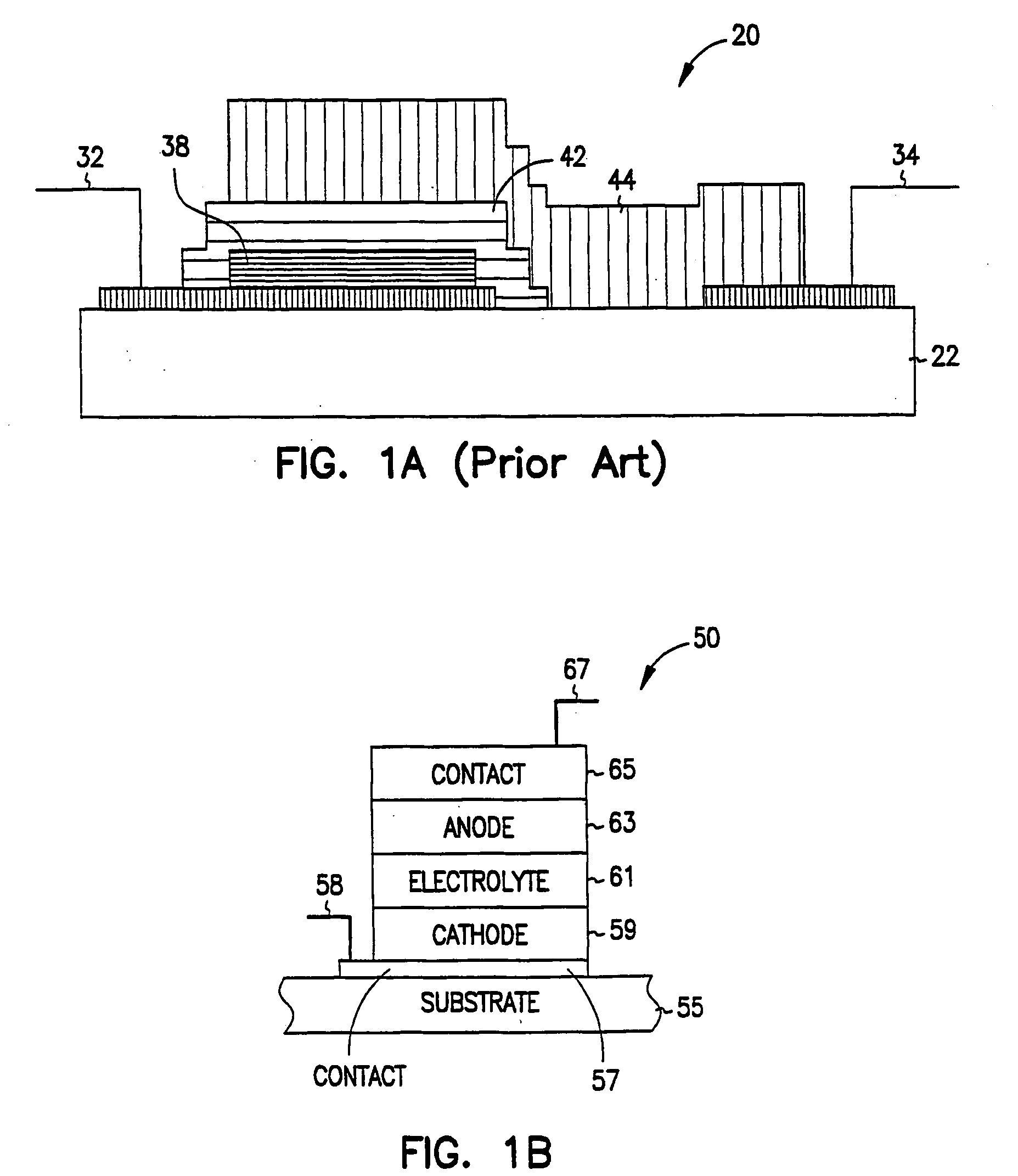

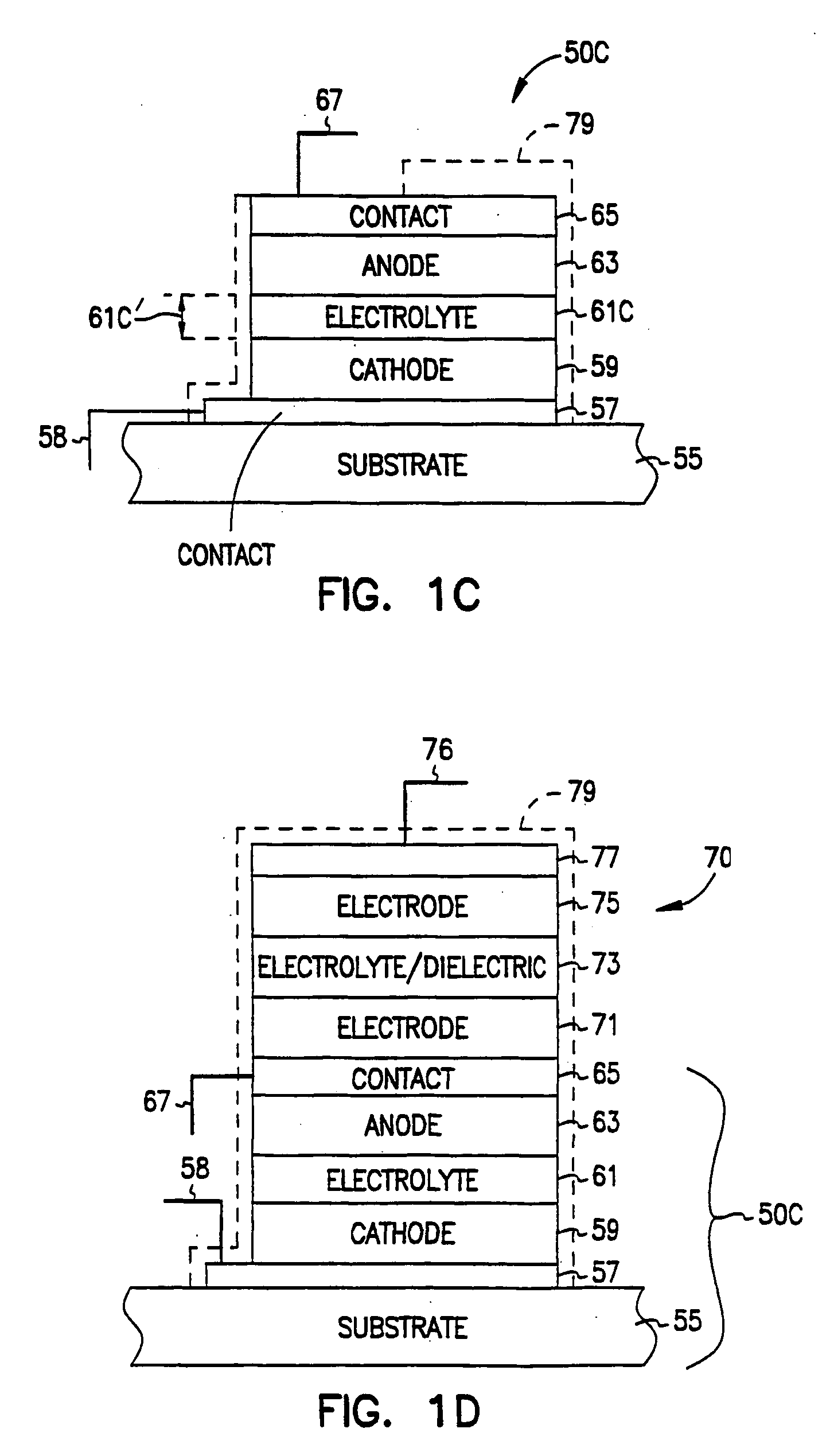

Method of continuous processing of thin-film batteries and like devices

A method of making a thin-film device including a substrate-supply station that supplies a substrate. The substrate has a first layer on the substrate. Also described is a method and device for depositing a second layer onto the first layer, wherein energy supplied to the second layer aids in layer formation without substantially heating the substrate. Some embodiments include depositing a photovoltaic cell. In some embodiments, the substrate is a flexible material supplied from a roll. Some embodiments include attaching an integrated circuit to the substrate and operatively coupling the integrated circuit to charge the battery from the photovoltaic cell.

Owner:CYMBET CORP

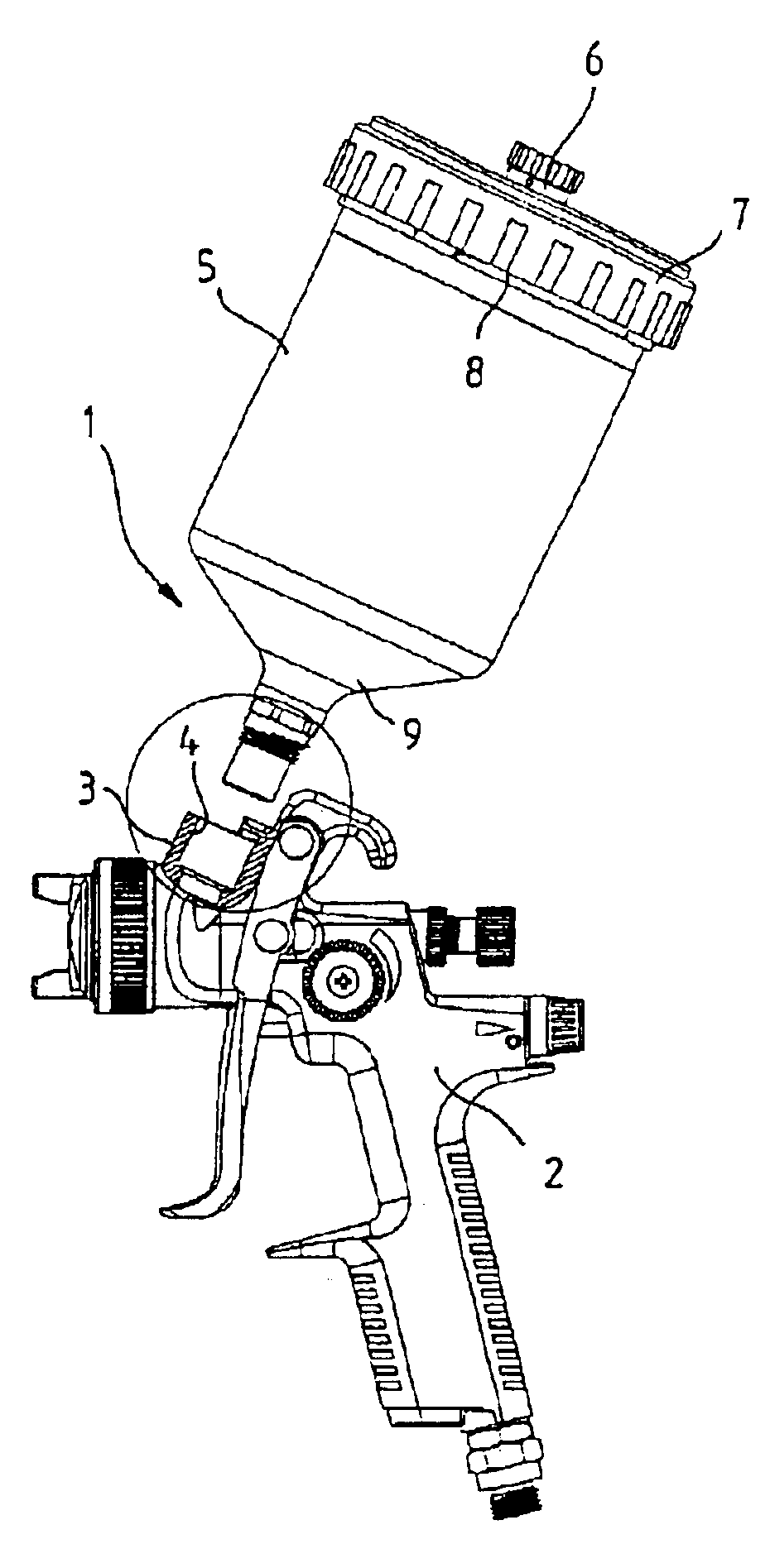

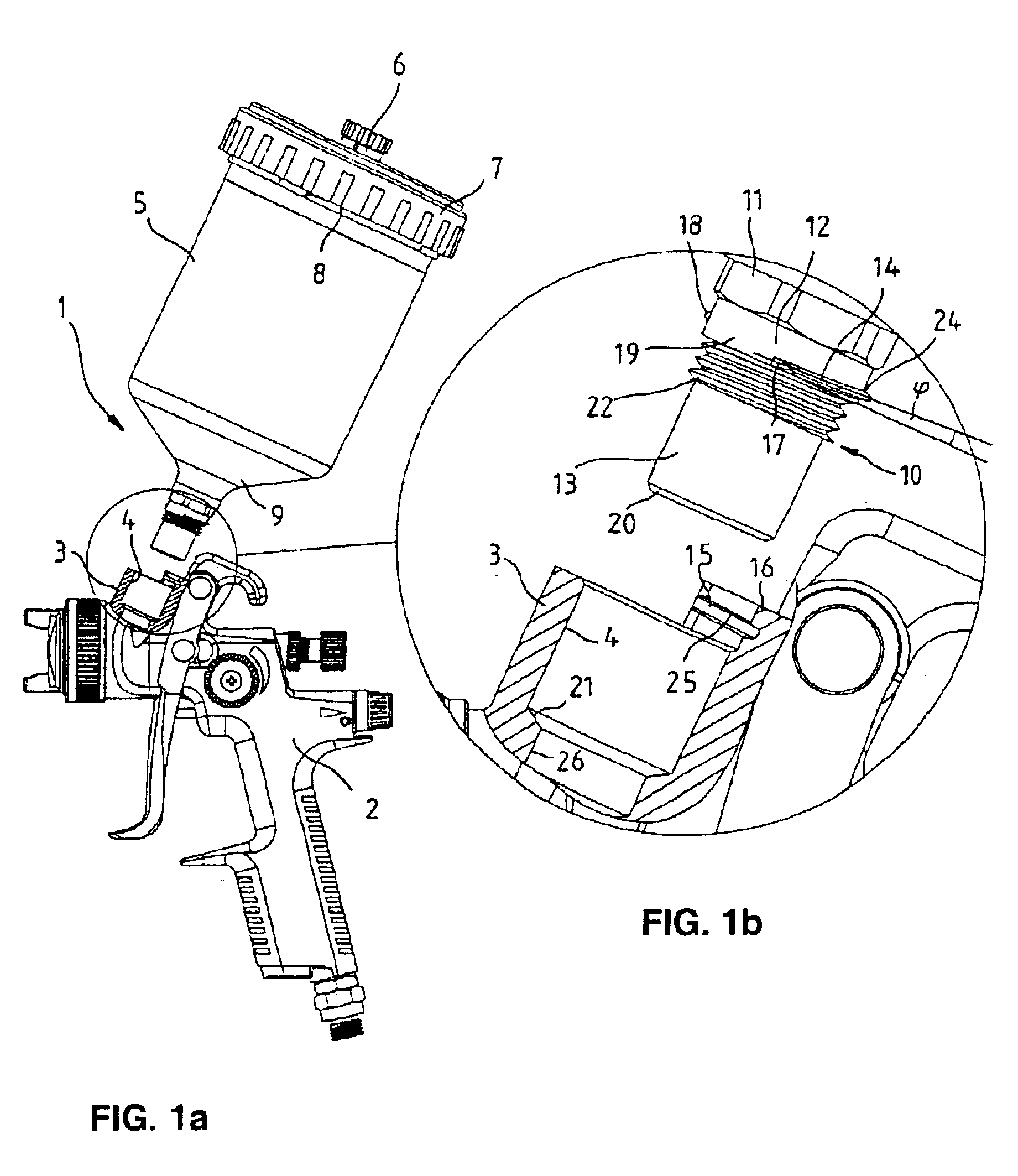

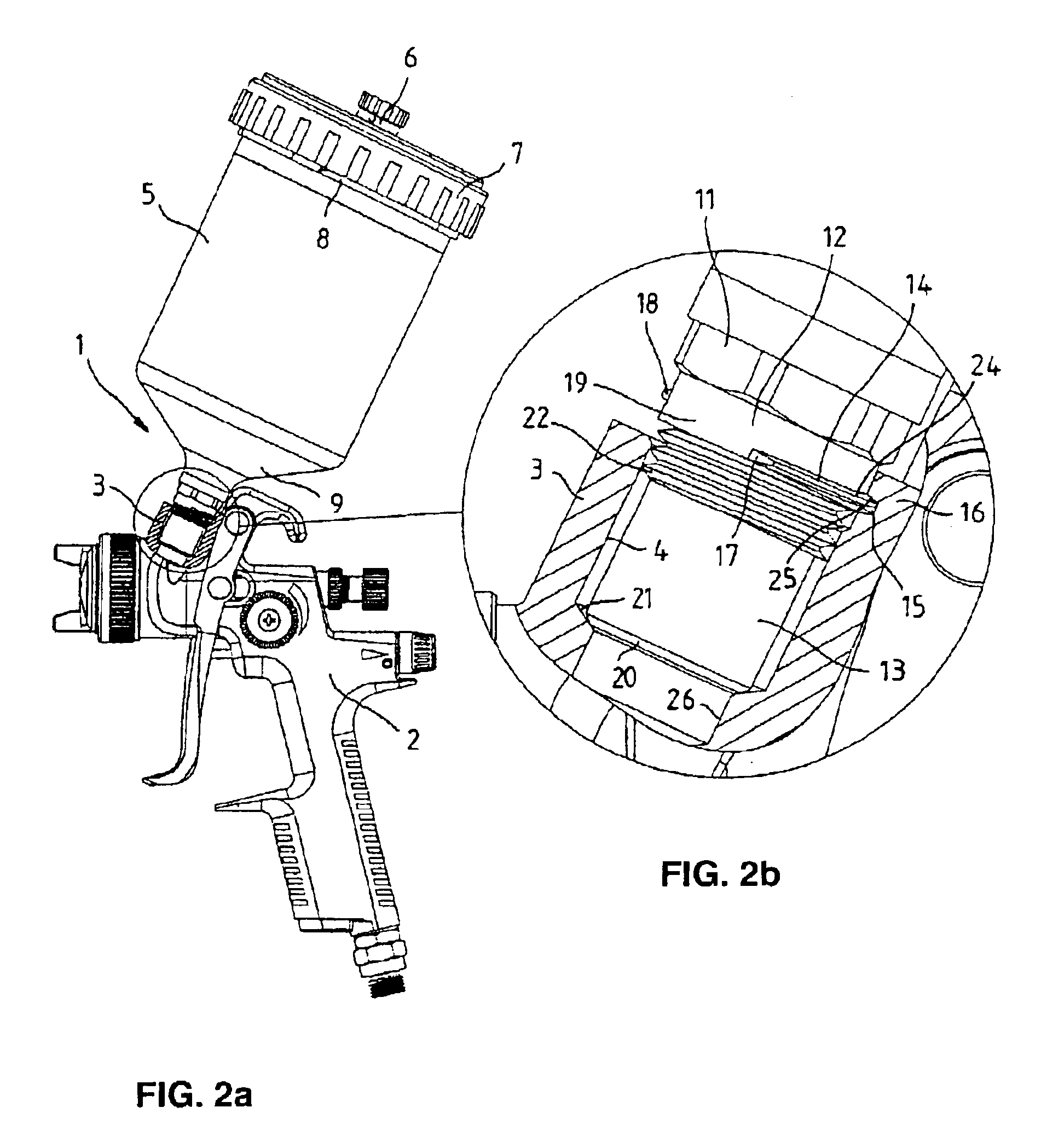

Paint spraying gun

A paint spraying gun with a gun body and a material supply device that are connected to one another by a screw-wedge connection. The screw-wedge connection includes a screw-wedge element that is arranged on the circumference of an essentially hollow-cylindrical connecting part of the material supply device, and a corresponding counter element on the gun body. The connection is inexpensively manufactured and easily handled. The screw-wedge element extends in an arc over more than half of the circumference of the connecting part with the ends of the screw-wedge element being peripherally spaced from one another. The counter element is an arcuate projection arranged on one side of and above a receiving bore of the gun body.

Owner:SATA GMBH & CO KG

Method and device for thermal ablative pyrolysis of biomass

InactiveUS7438785B2Available heating surfaceWithdrawal of pyrolysis products is moreover simplifiedCombustible gas coke oven heatingSolid waste disposalProcess engineeringMaterial supply

Owner:PYTEC THERMOCHEM ANLAGEN

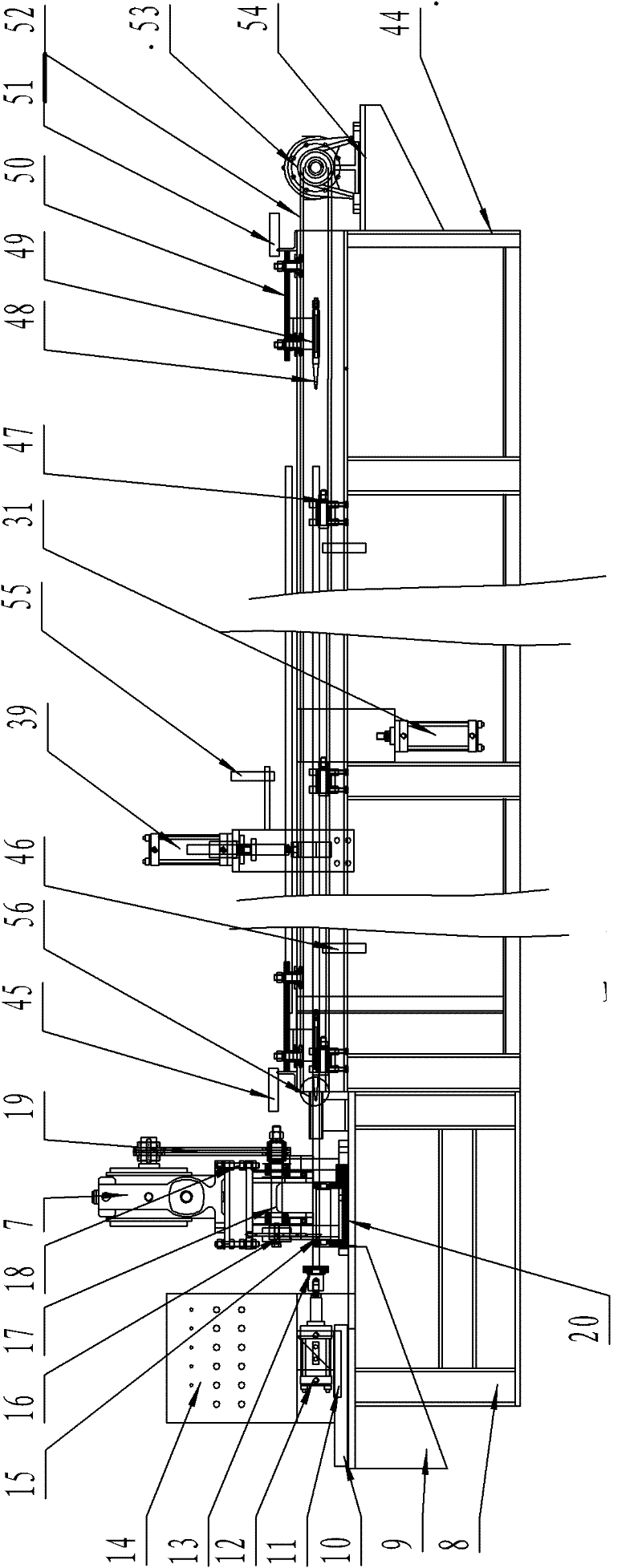

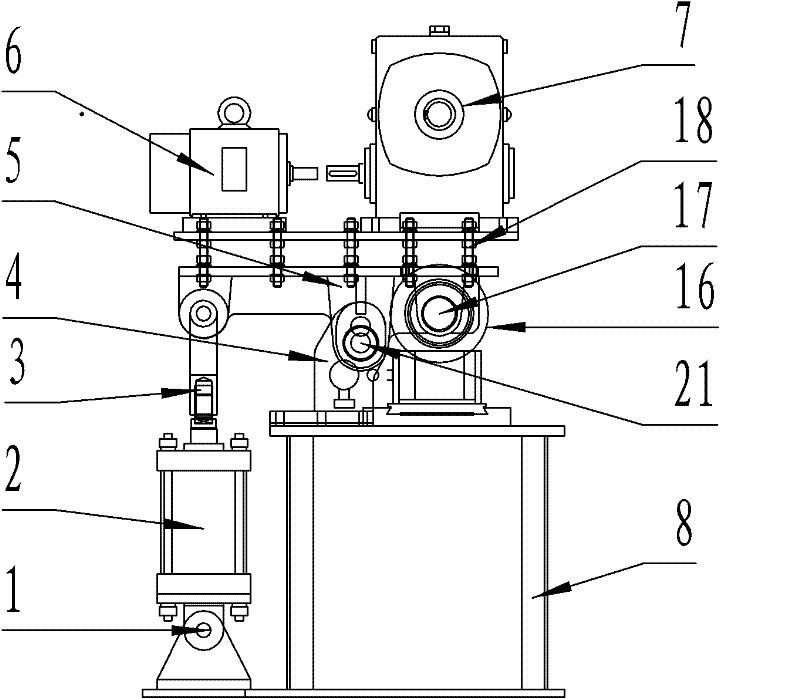

Automatic blanking machine for steel pipes

ActiveCN102126045AExact lengthFully automatedTube shearing machinesShearing machine accessoriesElectrical controlSlide plate

The invention discloses an automatic blanking machine for steel pipes, belongs to the field of cutting-off equipment of the steel pipes and particularly relates a steel pipe cutting-off device with a mechanical automatic material supply device and a cutting-off device. The automatic blanking machine for the steel pipes is characterized by mainly comprising a fixed scale cutting-off system, a steel pipe conveying system and an electrical control system, wherein the steel pipe conveying system and the electrical control system are connected with the fixed scale cutting-off system, wherein the fixed scale cutting-off system comprises a steel pipe fixed scale device mounted on a transverse sliding track at the left end of a lathe bed and the cutting-off device mounted on the lathe bed, a front positioning sliding plate is mounted on a front positioning sliding plate seat fixed on the transverse sliding track of the steel pipe fixed scale device, a steel pipe fixed scale cylinder is arranged on the sliding plate, a steel pipe fixed scale detection switch is arranged at the front end of the cylinder, and the steel pipe conveying pipe comprises a steel pipe storage device and a steel pipe feed device. The automatic blanking machine for the steel pipes has the beneficial effects of realizing automation of supply, compression and fixed scale cutting-off of the steel pipes, not only improving the working efficiency and reducing the labor intensity, but also ensuring the precise length of the steel pipes which are cut off, and being suitable for being used in occasions which need to cut the steel pipes into steel pipe sections with equal length.

Owner:济南玛钢钢管制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com