Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

577results about How to "Form evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

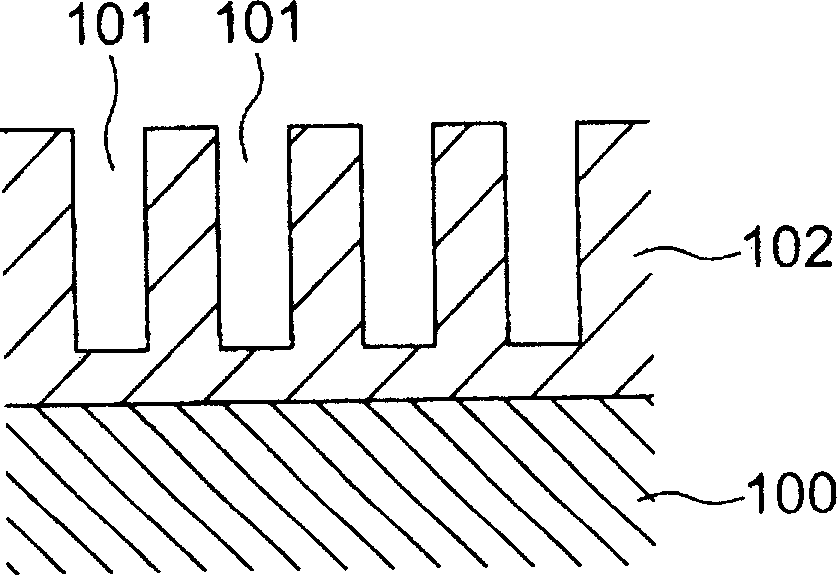

Semiconductor device and method of fabricating semiconductor device with high CMP uniformity and resistance to loss that occurs in dicing

ActiveUS6841880B2Superior resistance to lossForm evenlySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

In the semiconductor device of the present invention, a plurality of dummy patterns are formed in a grid arrangement in the scribe line areas of a wafer, and a plurality of dummy patterns are formed in a diagonally forward skipped arrangement in the chip interior areas of the wafer. Altering the arrangement of dummy patterns in the chip interior areas and scribe line areas in this way enables formation of dummy patterns with greater uniformity in the chip interior areas and enables formation of dummy patterns with greater resistance to loss that occurs when dicing in scribe line areas.

Owner:RENESAS ELECTRONICS CORP

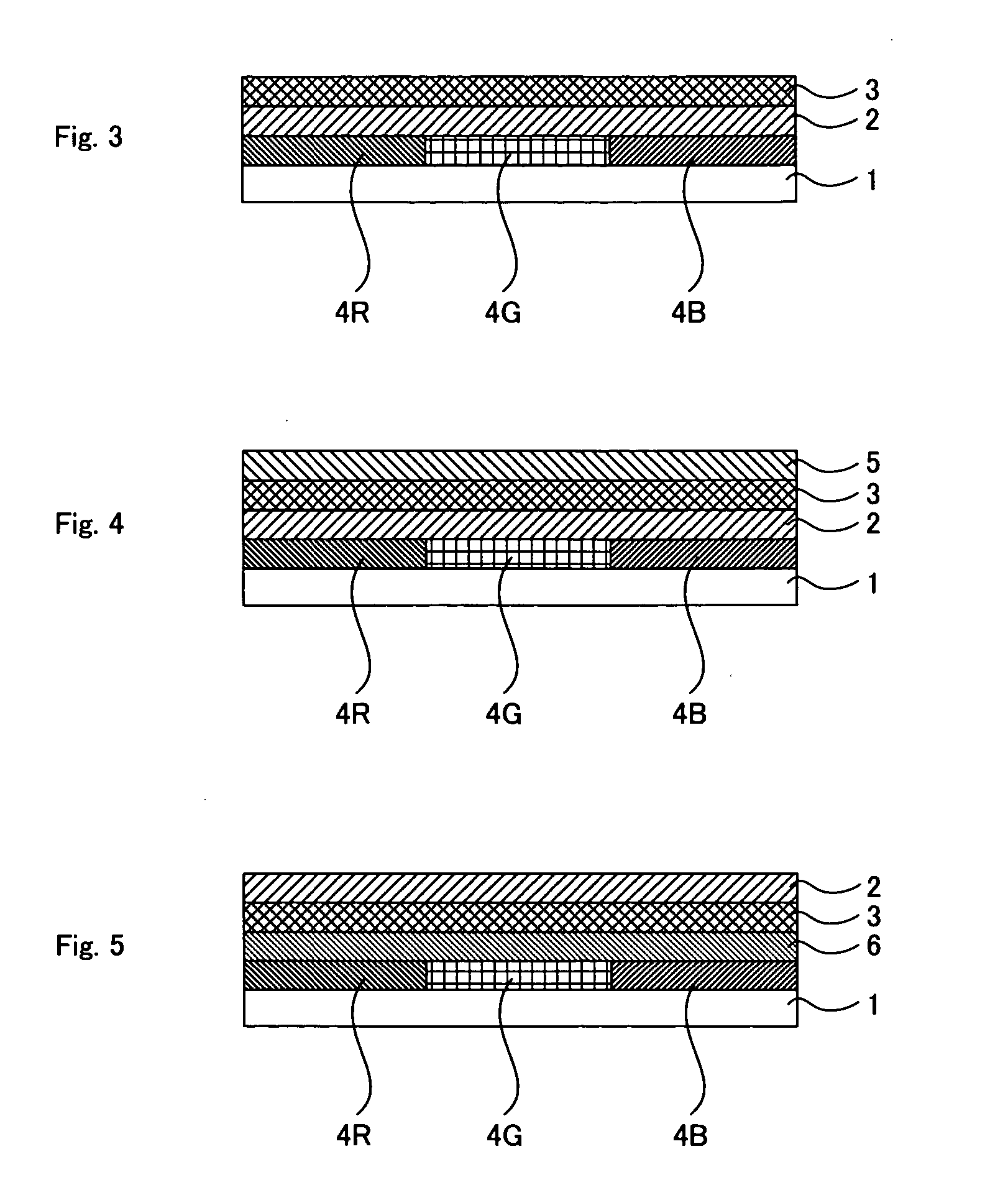

Display device and method of fabricating the display device

InactiveUS6995511B2Form evenlyAvoid discontinuitiesDischarge tube luminescnet screensLamp detailsDisplay deviceEngineering

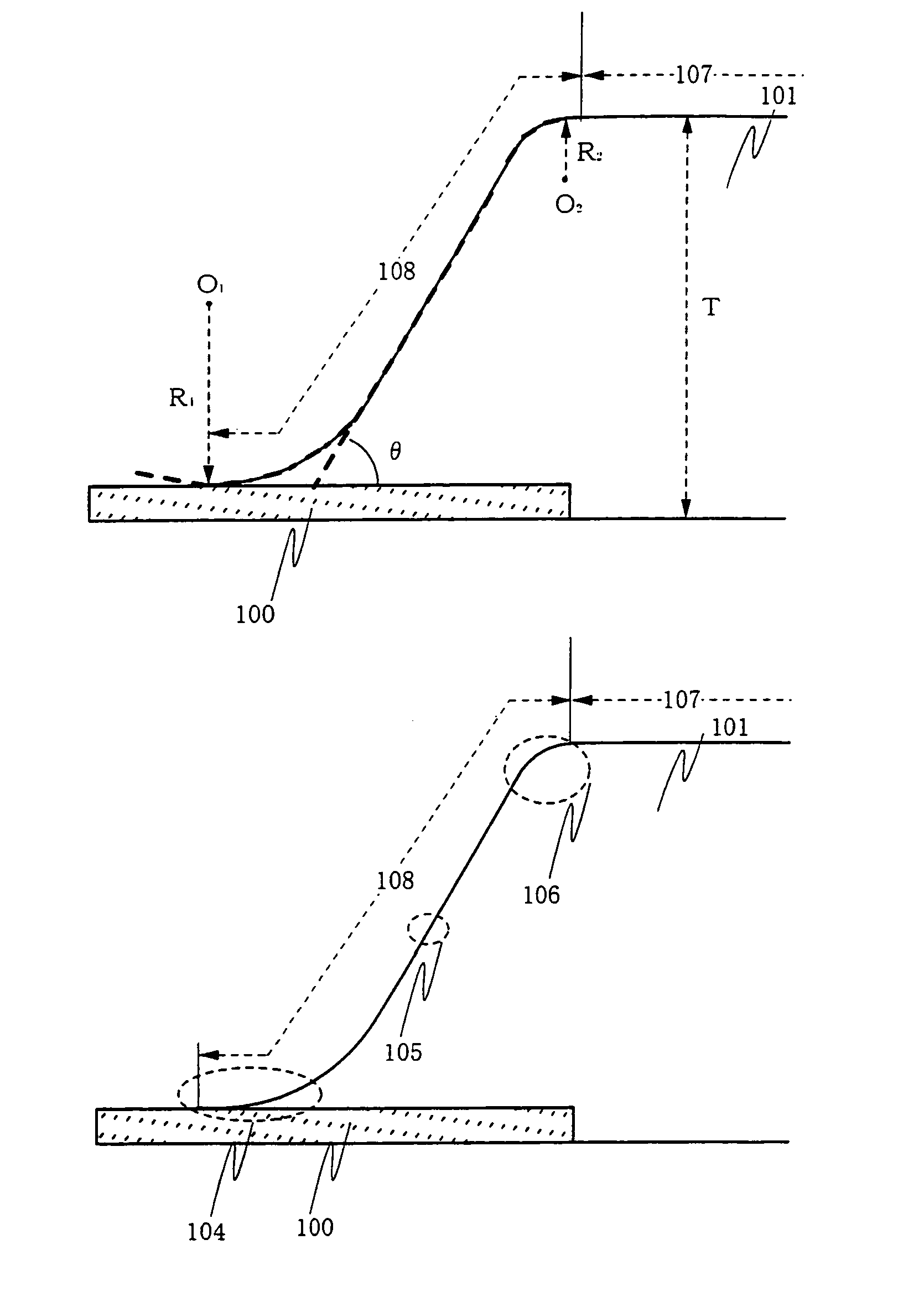

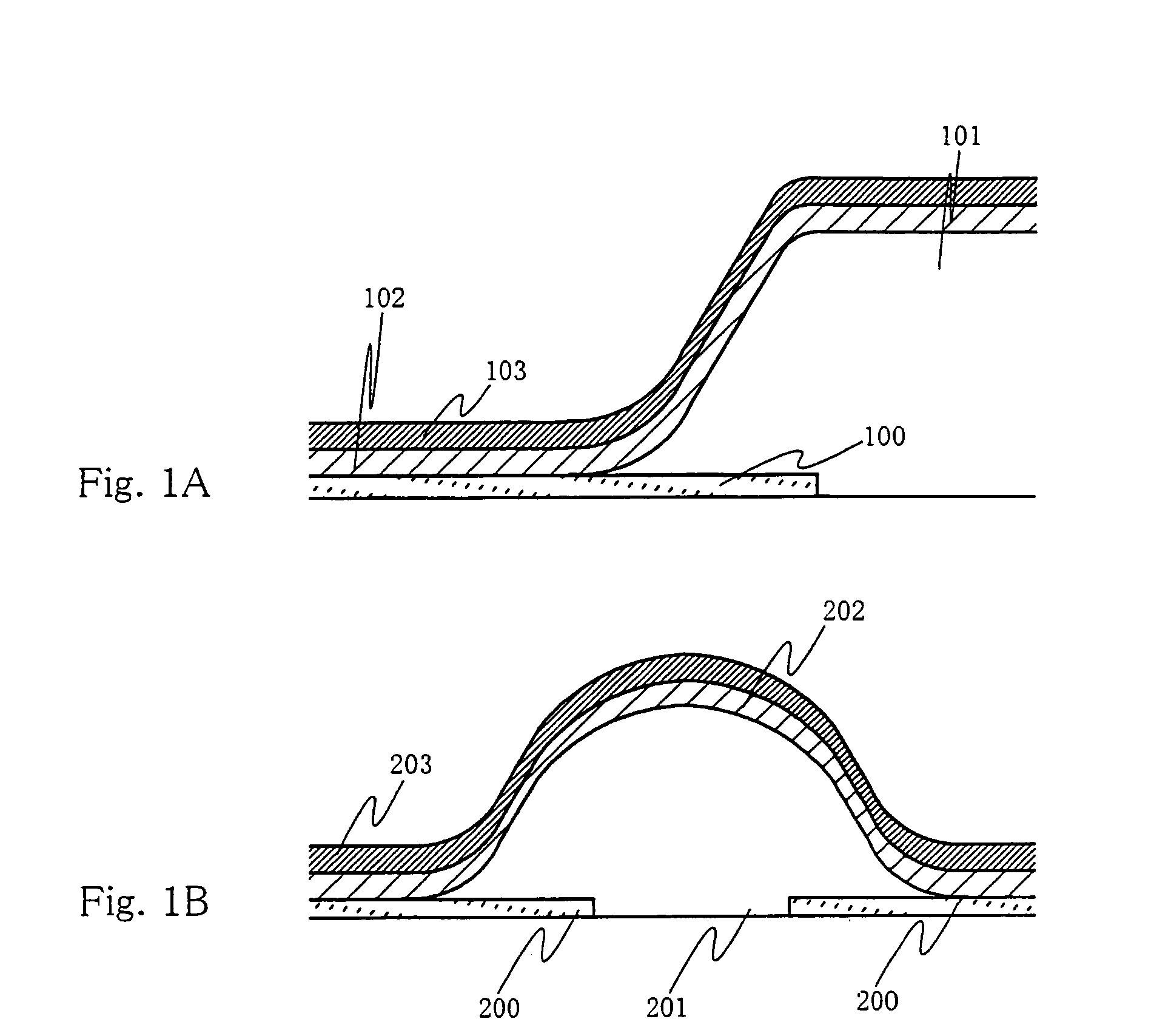

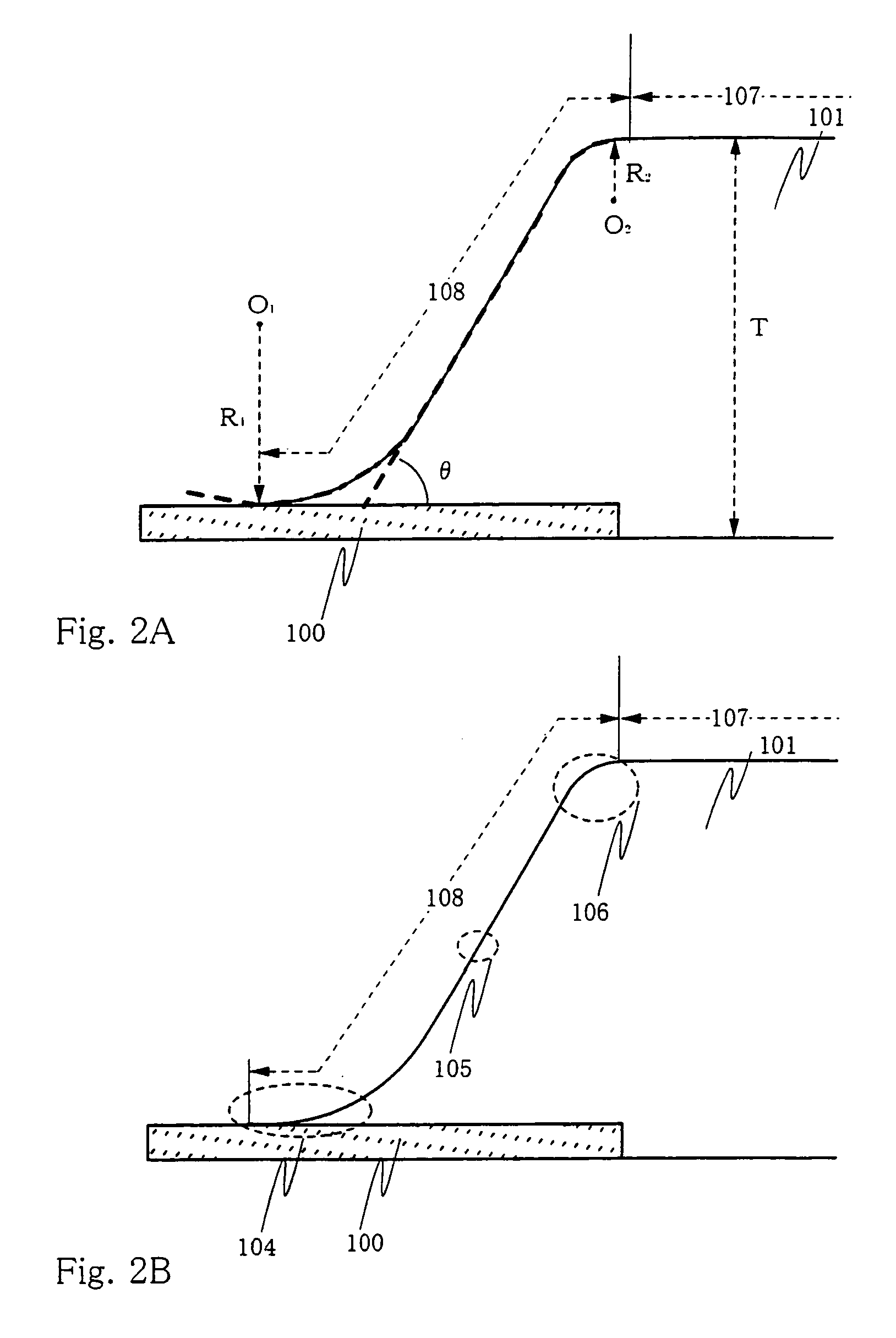

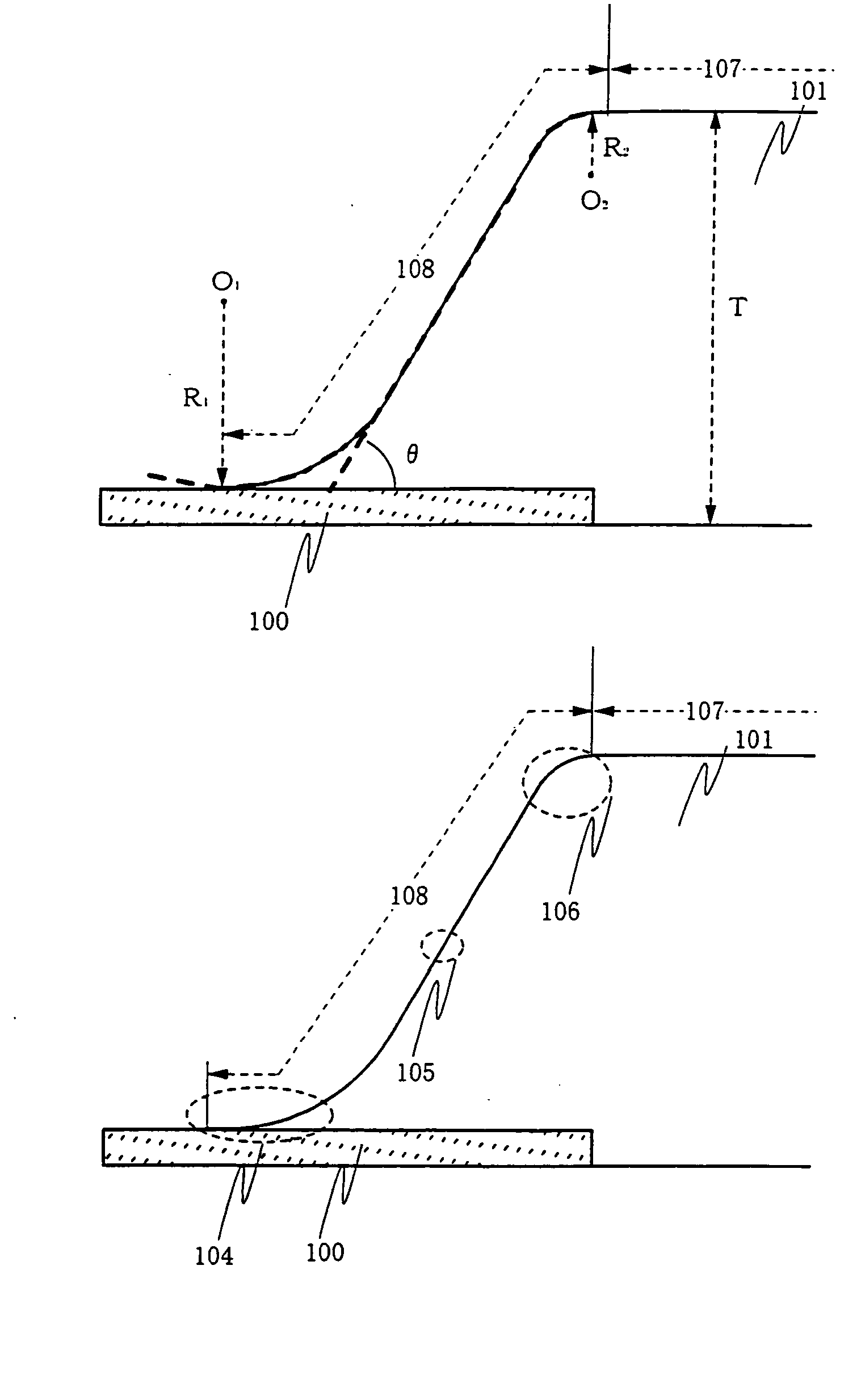

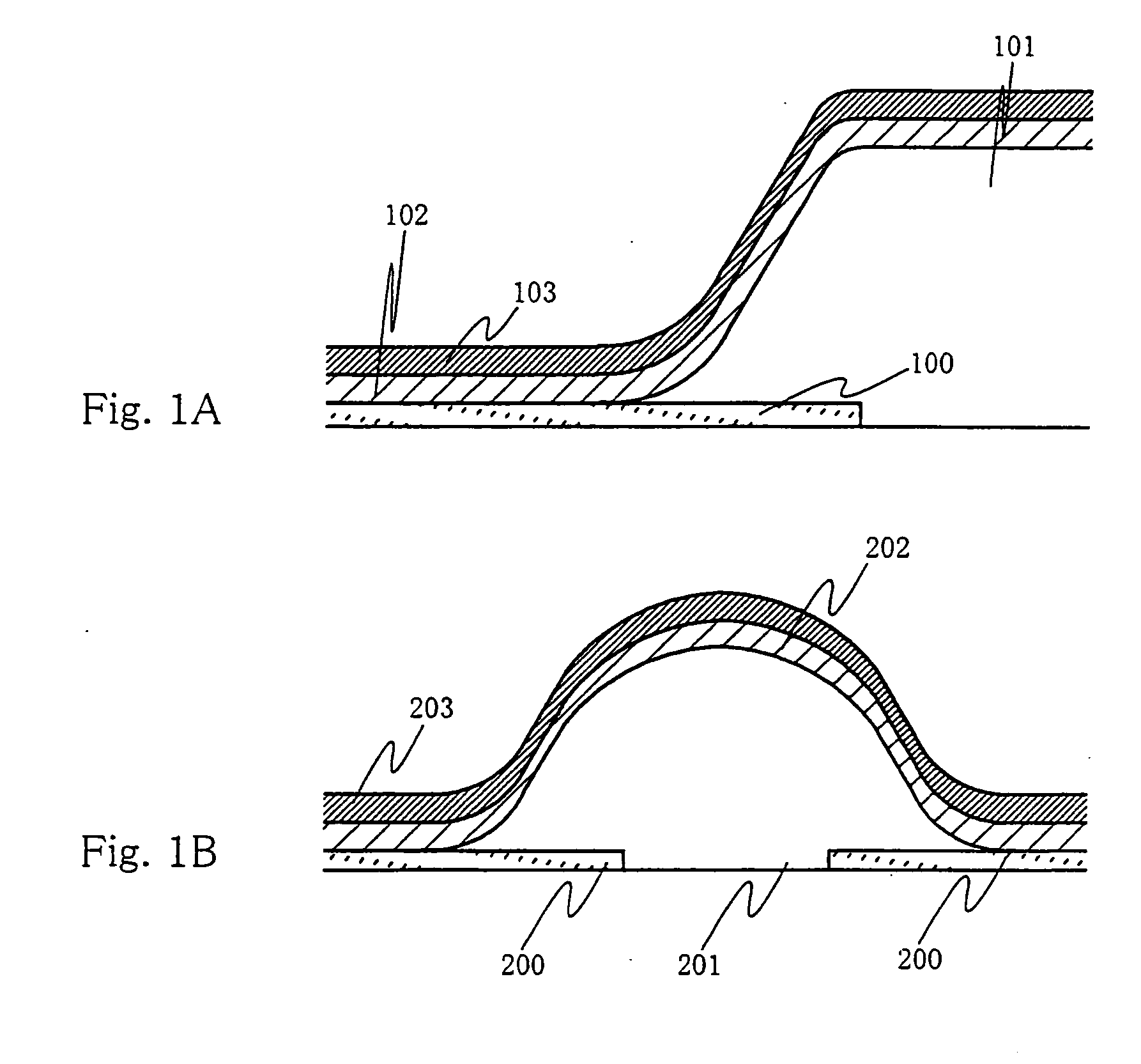

In an EL element having an anode, an insulating film (bump) formed on the anode, and an EL film and a cathode formed on the insulating film, each of a bottom end portion and a top end portion of the insulating film is formed so as to have a curved surface. The taper angle of a central portion of the insulating film is set within the range from 35° to 70°, thereby preventing the gradient of the film forming surface on which the EL film and the cathode are to be formed from being abruptly changed. On the thus-formed film forming surface, the EL film and the cathode can be formed so as to be uniform in thickness, so that occurrence of discontinuity in each of EL film and the cathode is prevented.

Owner:SEMICON ENERGY LAB CO LTD

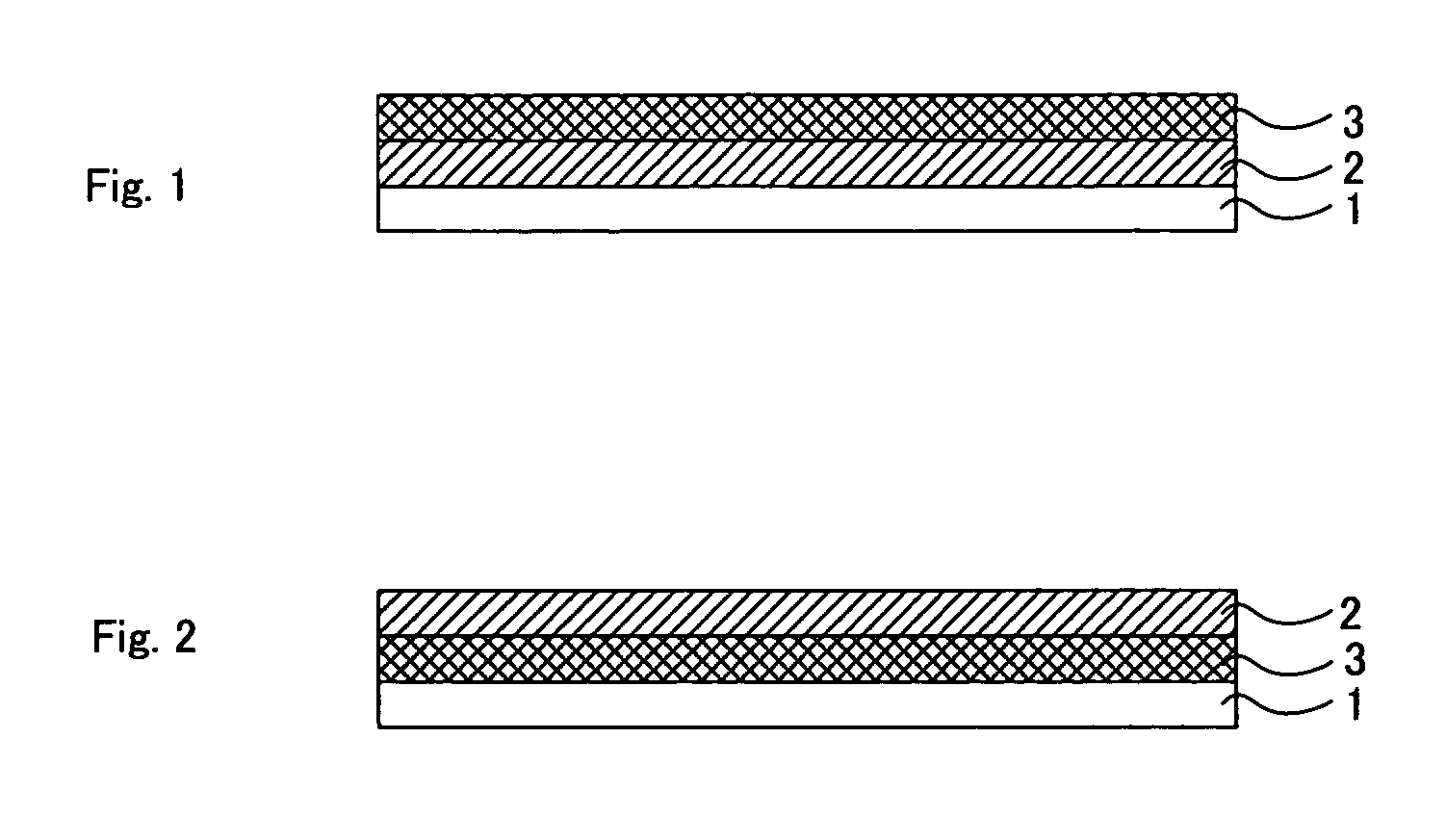

Gas barrier substrate

InactiveUS20050029513A1Quality improvementExcellent gas barrier performanceSolid-state devicesVacuum evaporation coatingMetallurgyGas formation

The main object of the present invention is to provide a gas barrier substrate having a high gas barrier property without a ruggedness, a pin hole or the like in the gas barrier layer. The present invention solves the problem by providing a gas barrier substrate having a base material, a planarization layer formed on the base material, and a gas barrier layer comprising a deposition film formed on the planarization layer.

Owner:DAI NIPPON PRINTING CO LTD

Conductive carbon film based on graphene as well as preparation method and application

InactiveCN101474898AForm evenlySimple processMaterial nanotechnologyCarbon compoundsCarbon filmFilm base

The invention relates to a general conductive carbon film based on Graphene and a preparation method. The method for preparing the carbon film mainly comprises the following steps: (1) preparing water-soluble single-layer or multi-layer grapheme; (2) preparing organic soluble single-layer or multi-layer Graphene; (3) shaping the solution (or dispersion liquid) containing the Graphene in 1 or 2 by methods of spin coating, spraying, soaking or casting and the like to prepare a film based on the single-layer or multi-layer Graphene; and (4) chemically reducing or roasting the film obtained in 3 to prepare the carbon film based on the single-layer or multi-layer Graphene. The method can be used for preparing the carbon film on various matrixes such as steel, glass, ceramics, quartz, carbon materials, organic substances and the like.

Owner:NANKAI UNIV

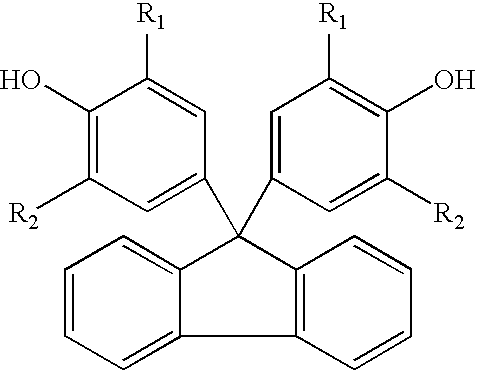

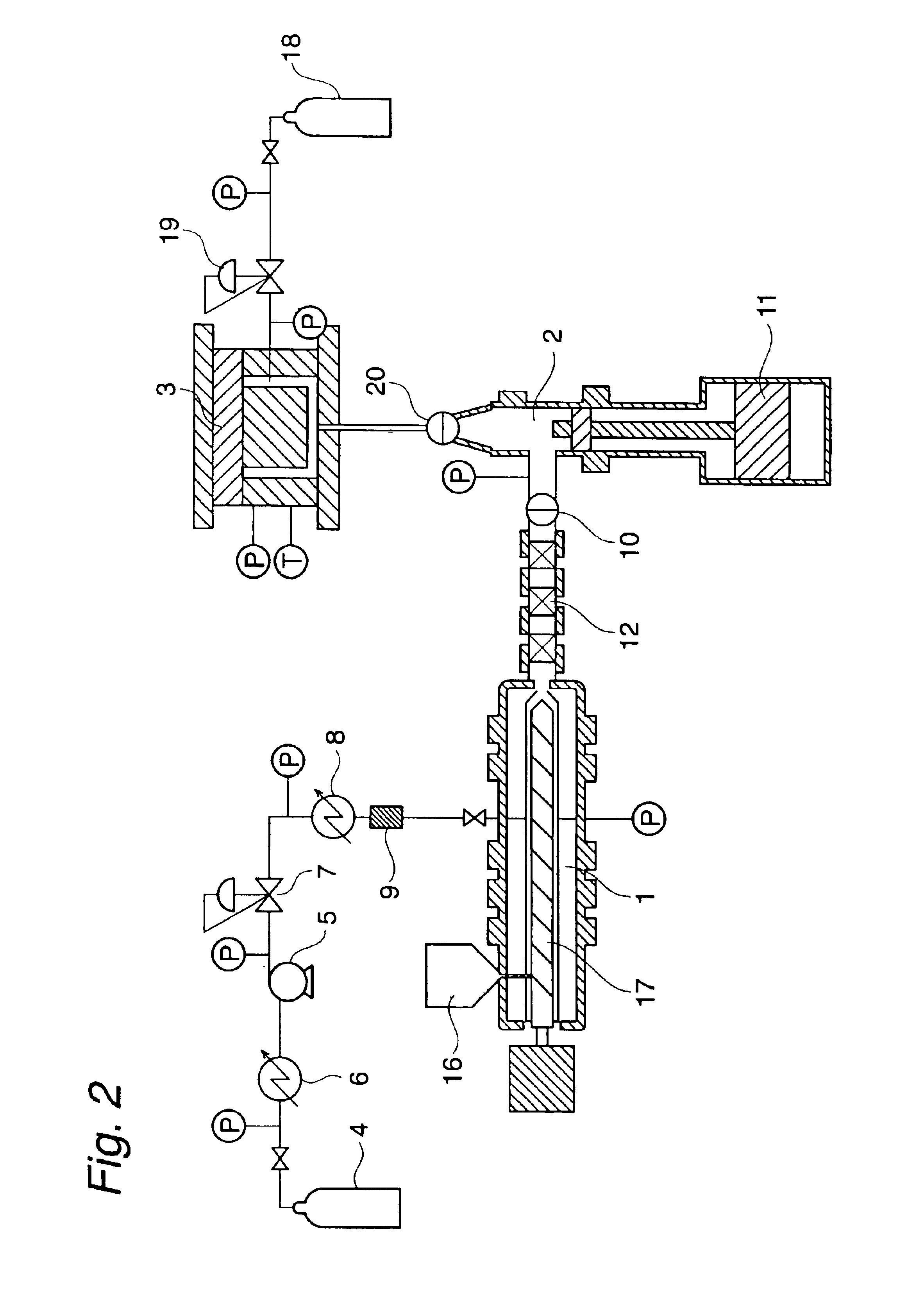

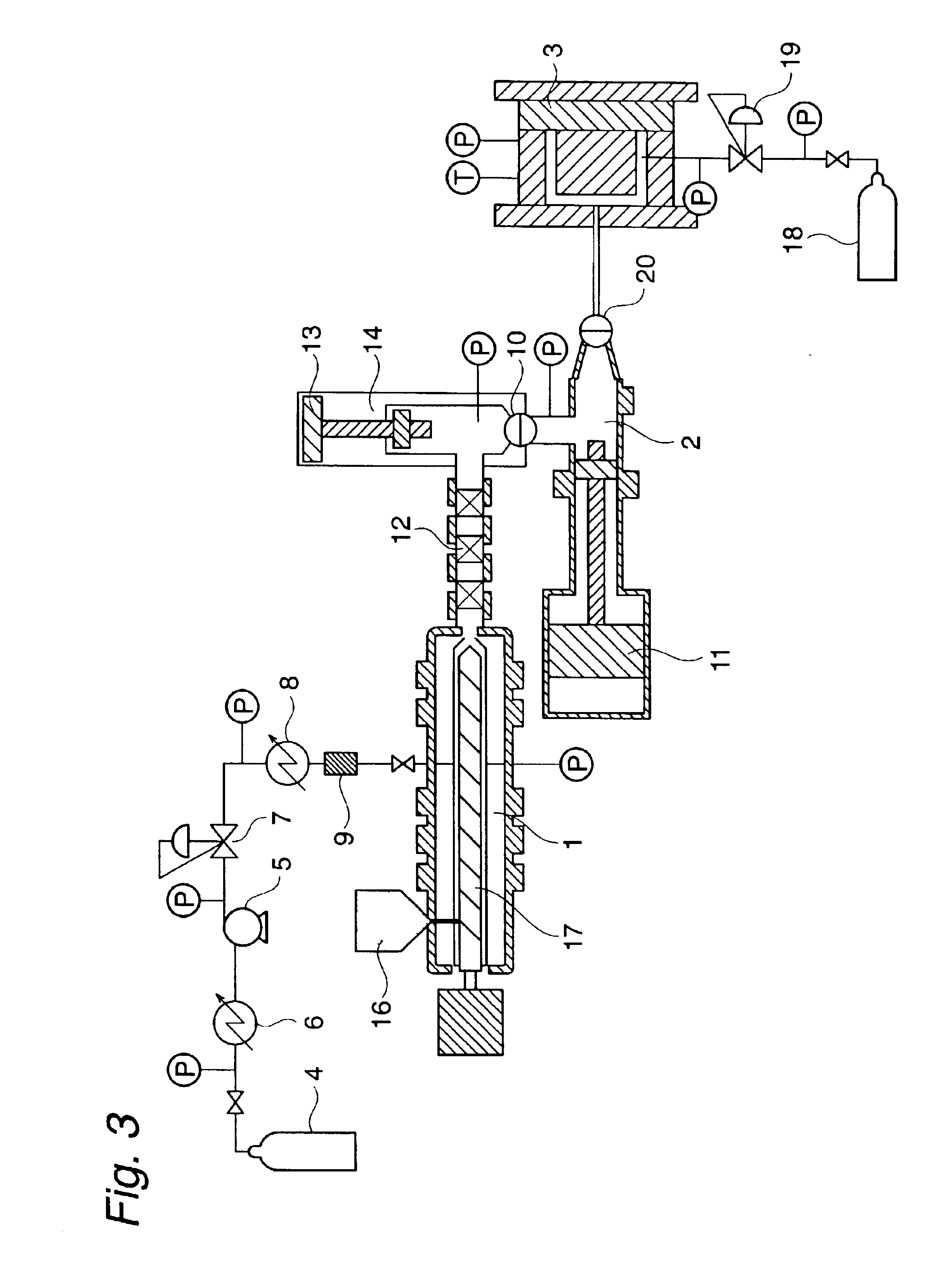

Foam of thermoplastic urethane elastomer composition and process for producing the foam

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

Display device and method of fabricating the display device

InactiveUS20060082300A1Form evenlyAvoid discontinuitiesDischarge tube luminescnet screensLamp detailsDisplay deviceCathode

In an EL element having an anode, an insulating film (bump) formed on the anode, and an EL film and a cathode formed on the insulating film, each of a bottom end portion and a top end portion of the insulating film is formed so as to have a curved surface. The taper angle of a central portion of the insulating film is set within the range from 35° to 70°, thereby preventing the gradient of the film forming surface on which the EL film and the cathode are to be formed from being abruptly changed. On the thus-formed film forming surface, the EL film and the cathode can be formed so as to be uniform in thickness, so that occurrence of discontinuity in each of EL film and the cathode is prevented.

Owner:SEMICON ENERGY LAB CO LTD

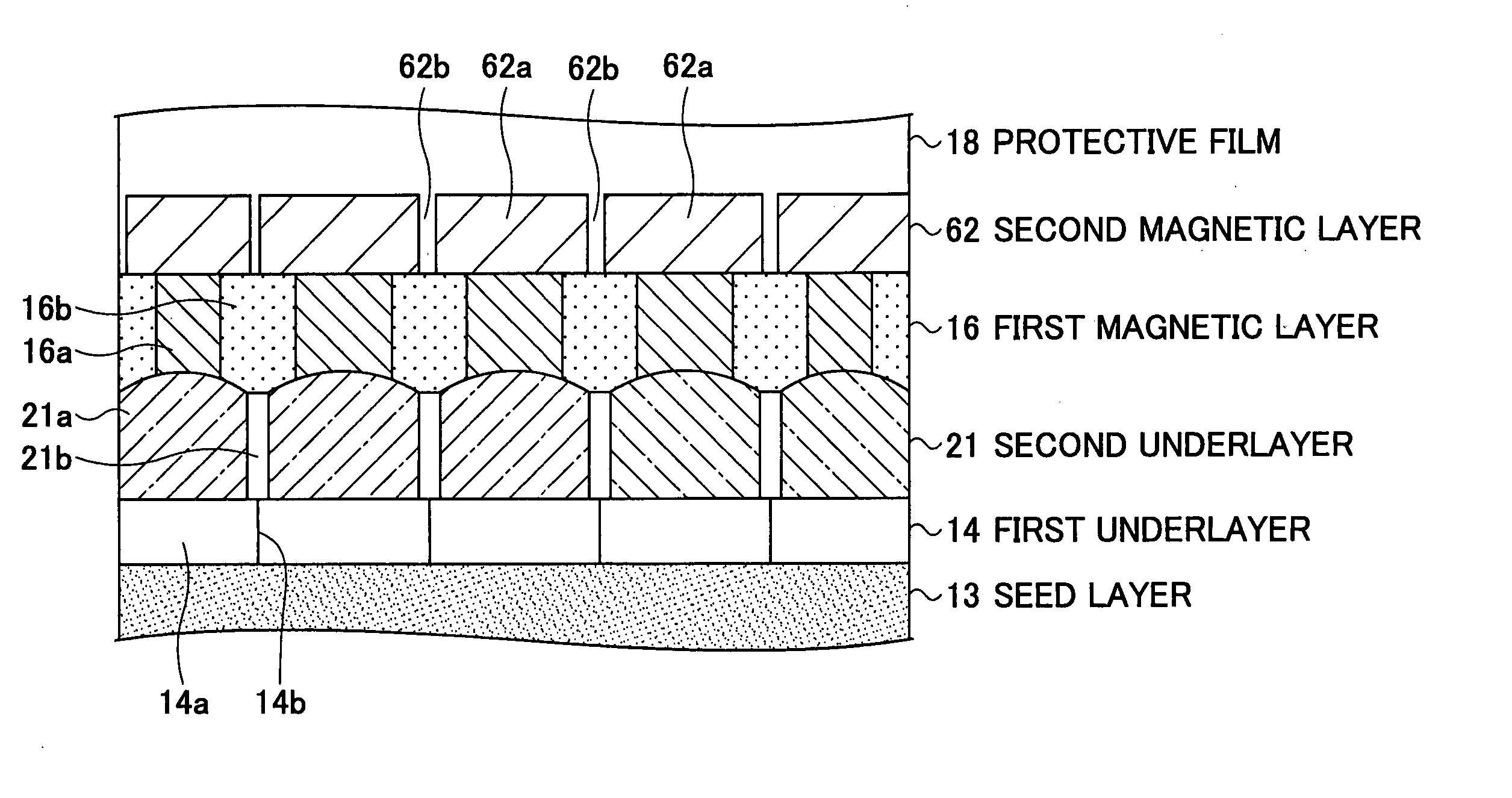

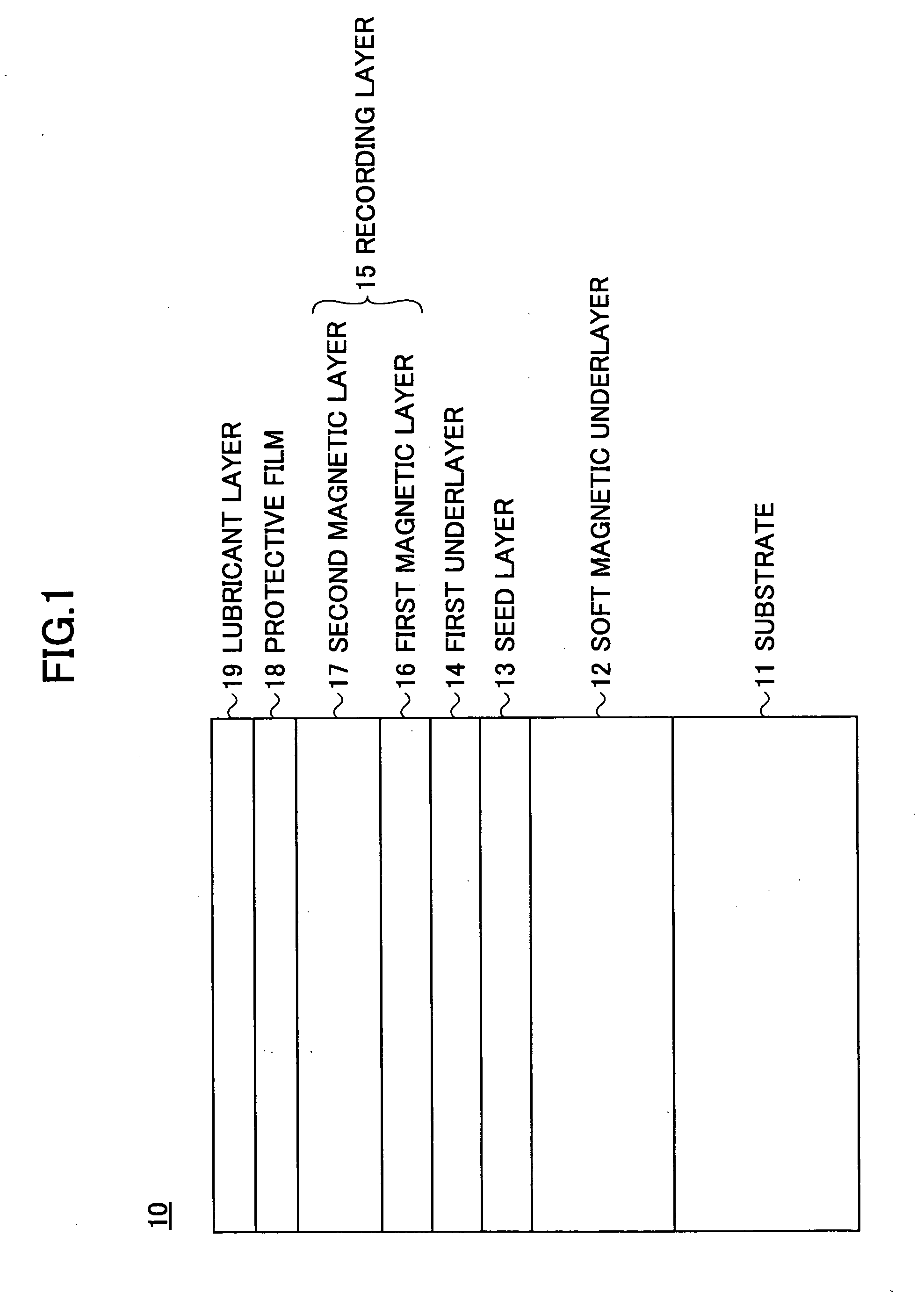

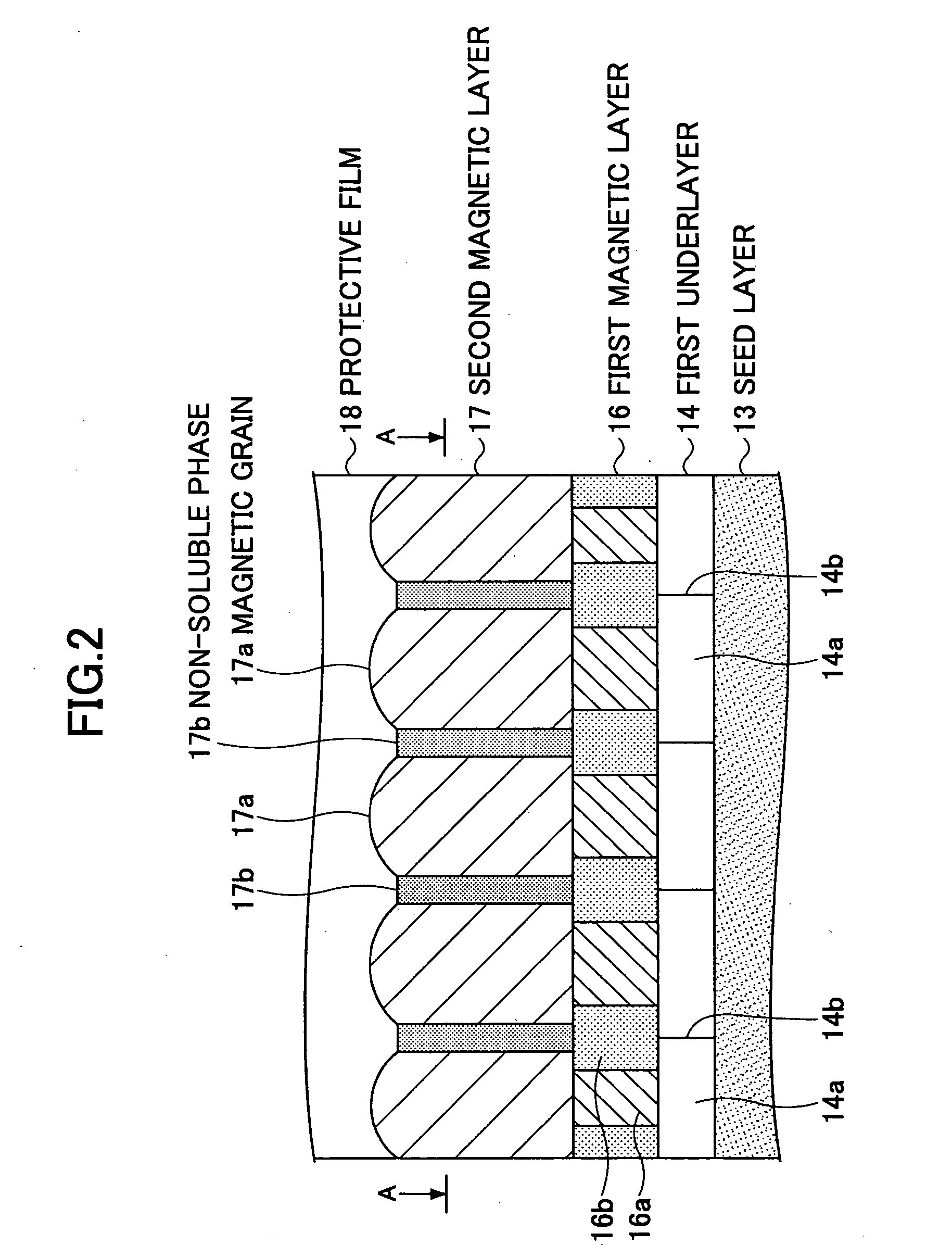

Perpendicular magnetic recording medium, manufacturing method thereof, and magnetic storage device

InactiveUS20060222902A1Medium noise is reducedImprove signal-to-noise ratioVacuum evaporation coatingSputtering coatingHigh densityMagnetic storage

A perpendicular magnetic recording medium for enabling high density recording is disclosed. The perpendicular magnetic recording medium includes a substrate on which a soft magnetic underlayer, a seed layer made of a non-crystalline material, an underlayer made of Ru or an Ru alloy including Ru as a main component, and a recording layer including a first magnetic layer and a second magnetic layer. The first and second magnetic layers include a plurality of magnetic grains having easy magnetization axes in a substantially perpendicular direction with respect to the substrate surface, and first and second nonmagnetic non-soluble phases segregating the magnetic grains of the first and second magnetic layers, respectively. The first magnetic layer includes the first non-soluble phase at a first atomic concentration that is higher than a second atomic concentration of the second non-soluble phase in the second magnetic layer.

Owner:SHOWA DENKO KK

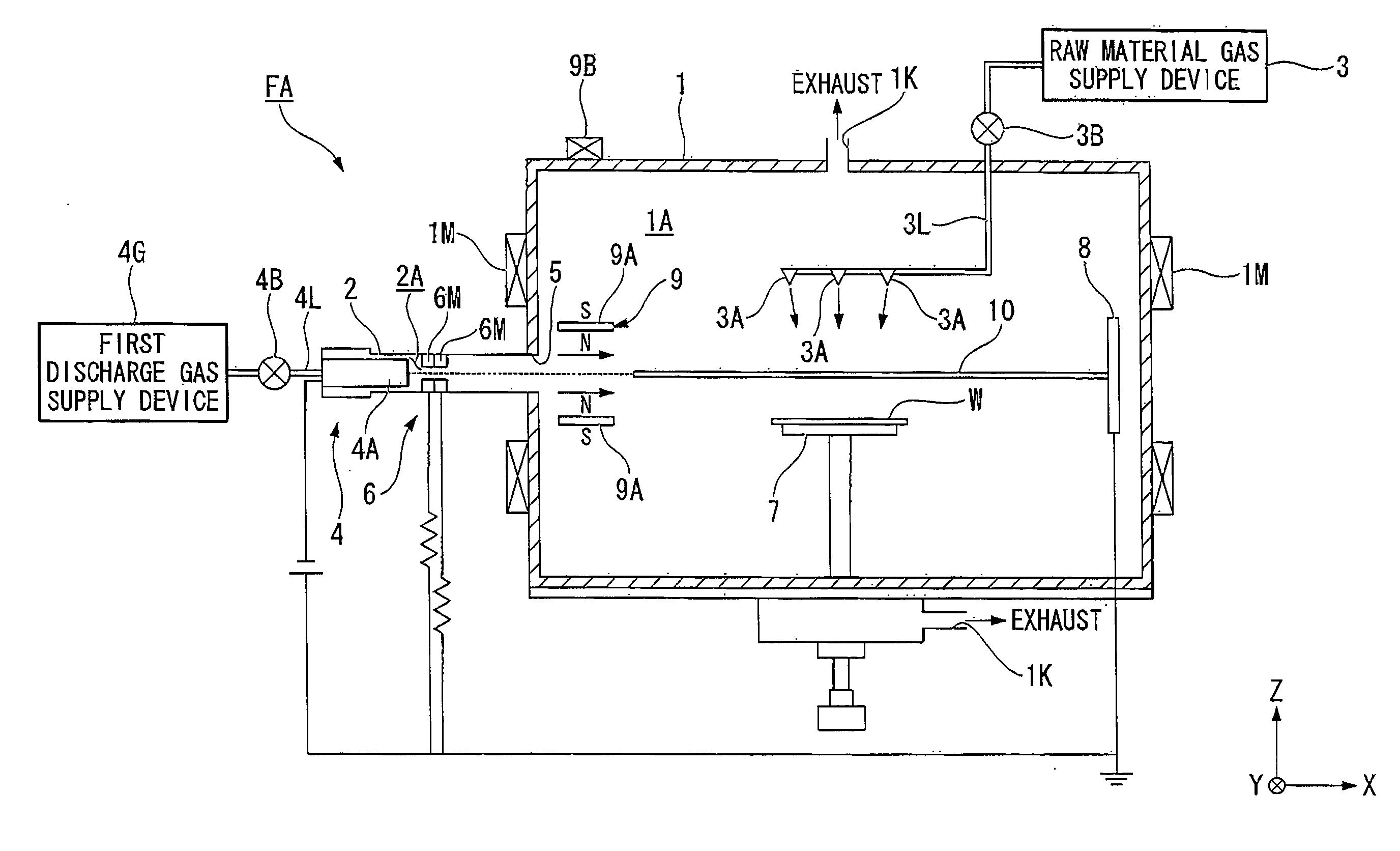

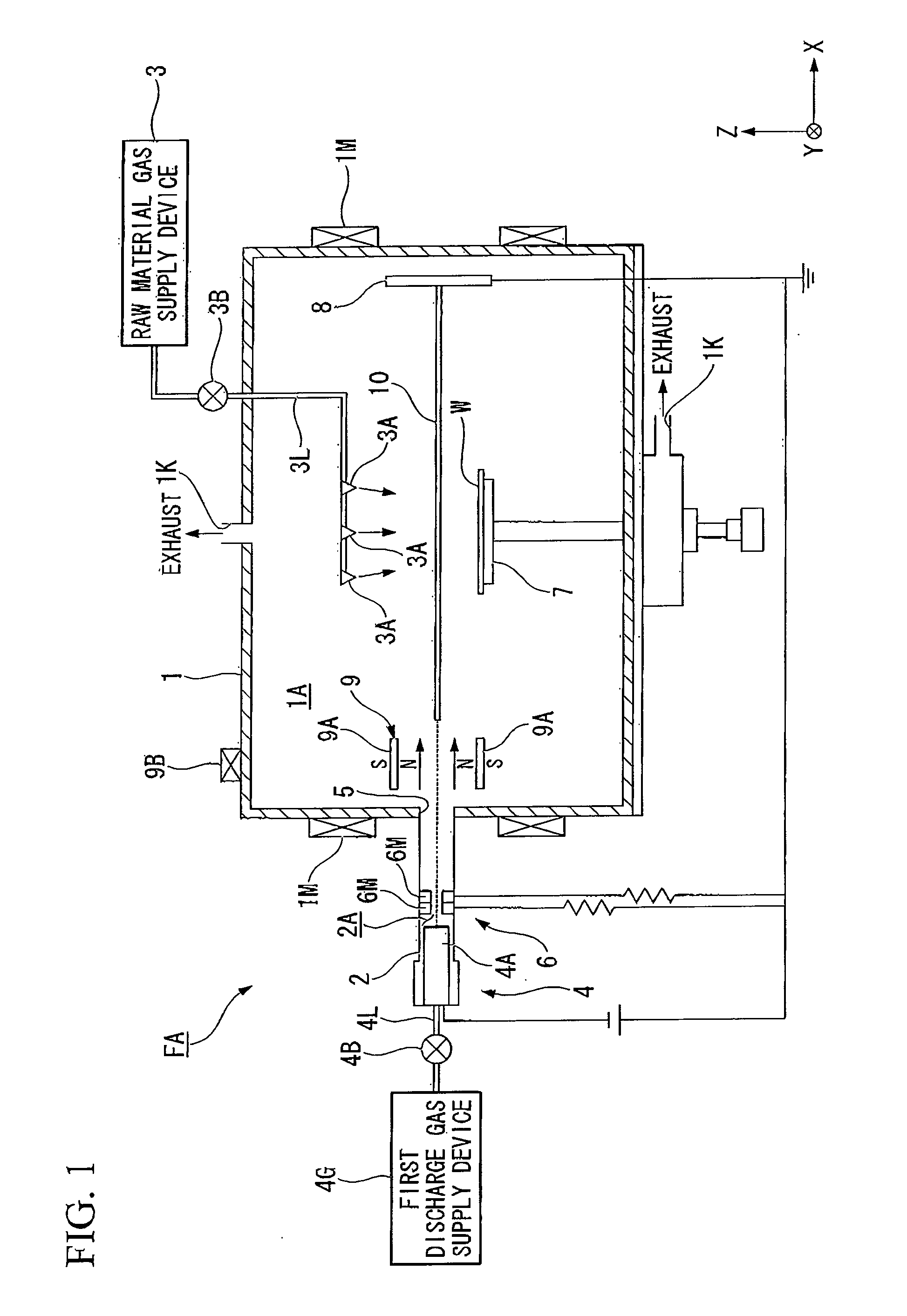

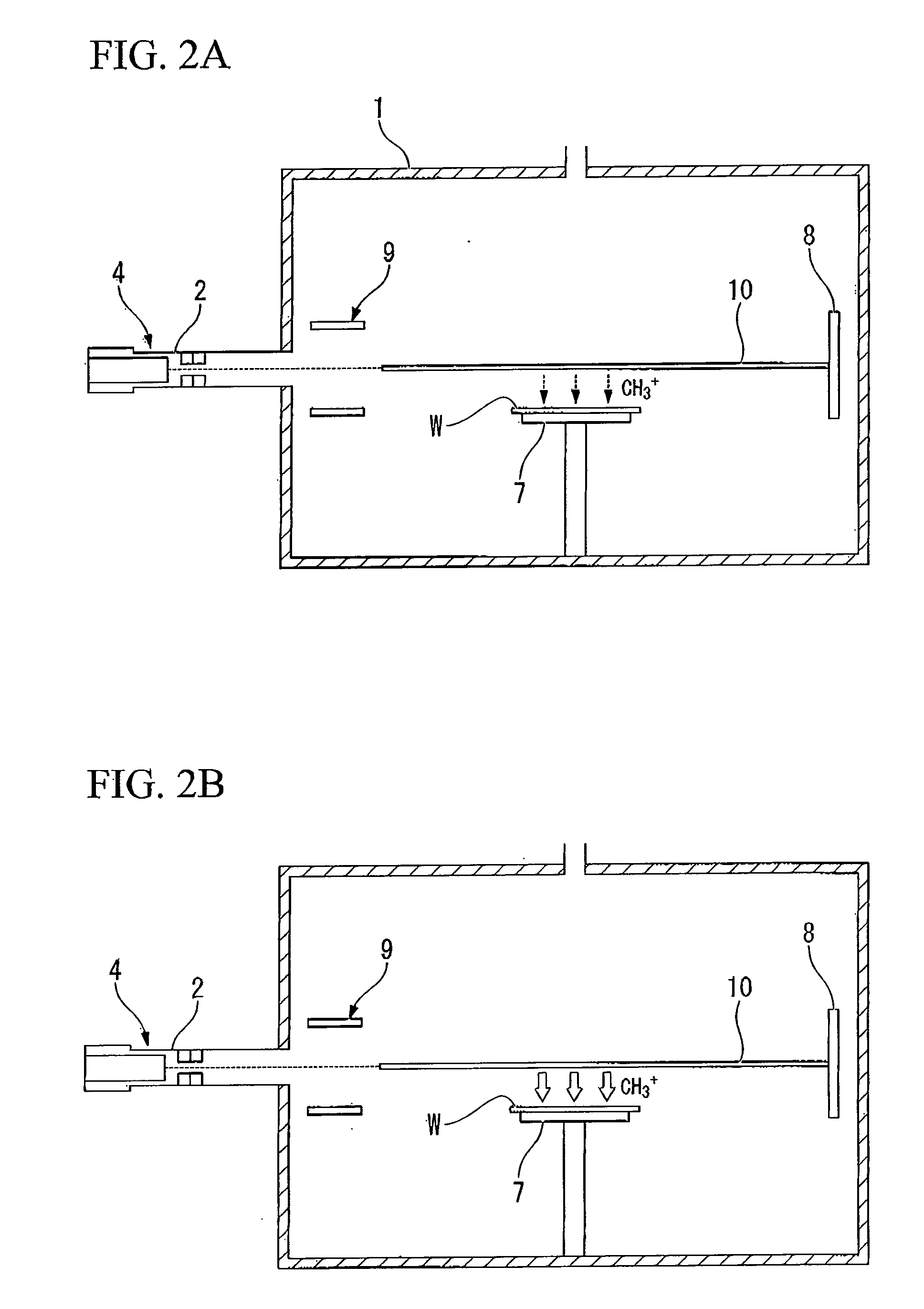

Carbon structure manufacturing device and manufacturing method

InactiveUS20090258164A1Contamination is likelyFormed satisfactorilyMaterial nanotechnologyCarbon compoundsForeign matterProduct gas

This invention relates to a carbon structure manufacturing device, which forms carbon structures on a substrate. This manufacturing device comprises a first chamber, which forms a first space accommodating the substrate; a raw material gas supply device, which supplies raw material gas for formation of the carbon structures to the first space; a second chamber, which forms a second space separate from the first space; a gas supply device, which supplies gas for generation of plasma to the second space; a plasma generation device, which generates plasma in the second space; an aperture, connecting the first space and the second space; and, a plasma introduction device, which introduces plasma generated in the second space into the first space via the aperture; the raw material gas is used to form the carbon structures on the substrate. By means of this manufacturing device, when forming carbon structures on the substrate, the occurrence of contamination, foreign matter, and / or the like on electrodes and / or the like can be suppressed, and carbon structures can be formed satisfactorily over a broad area.

Owner:IHI CORP

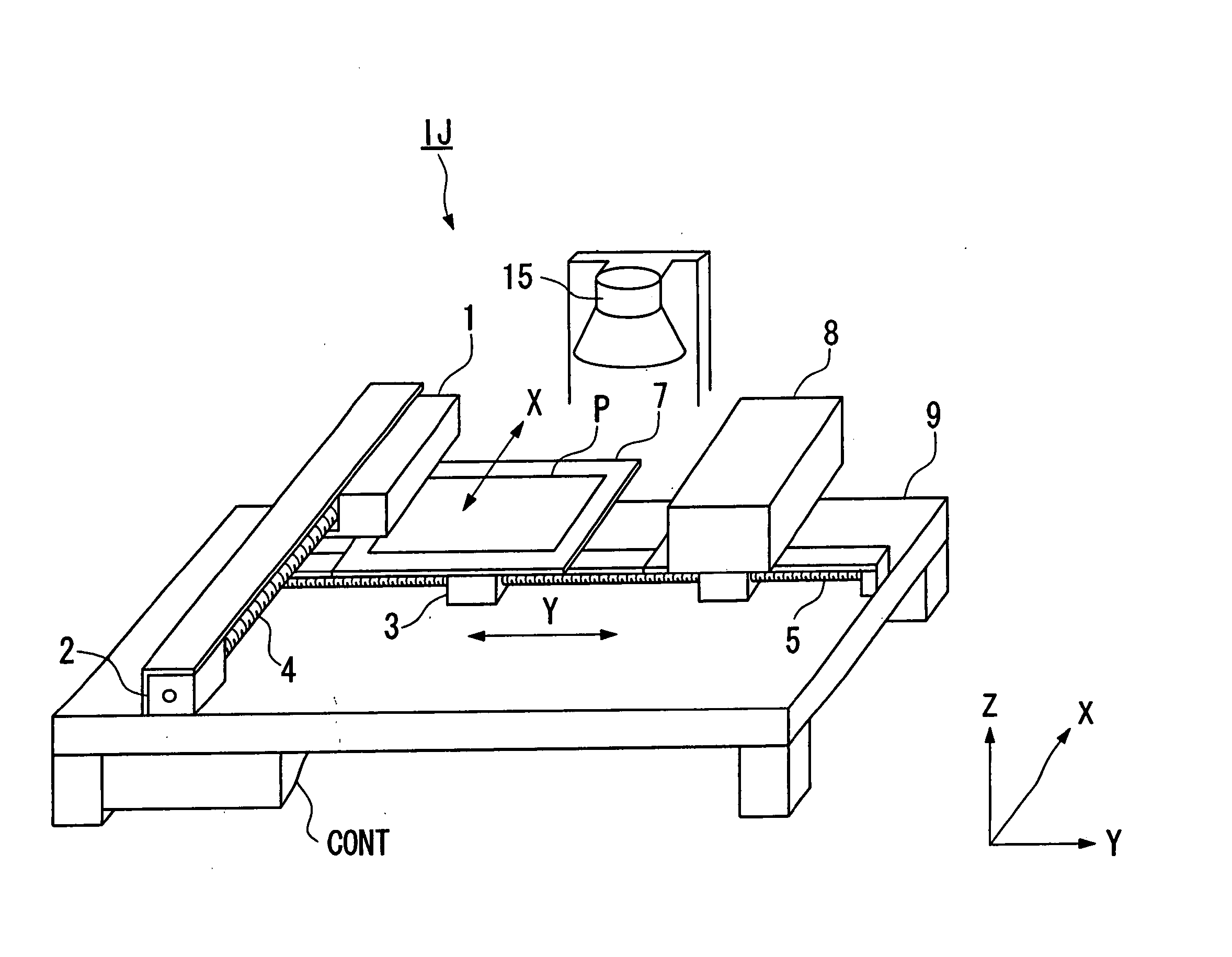

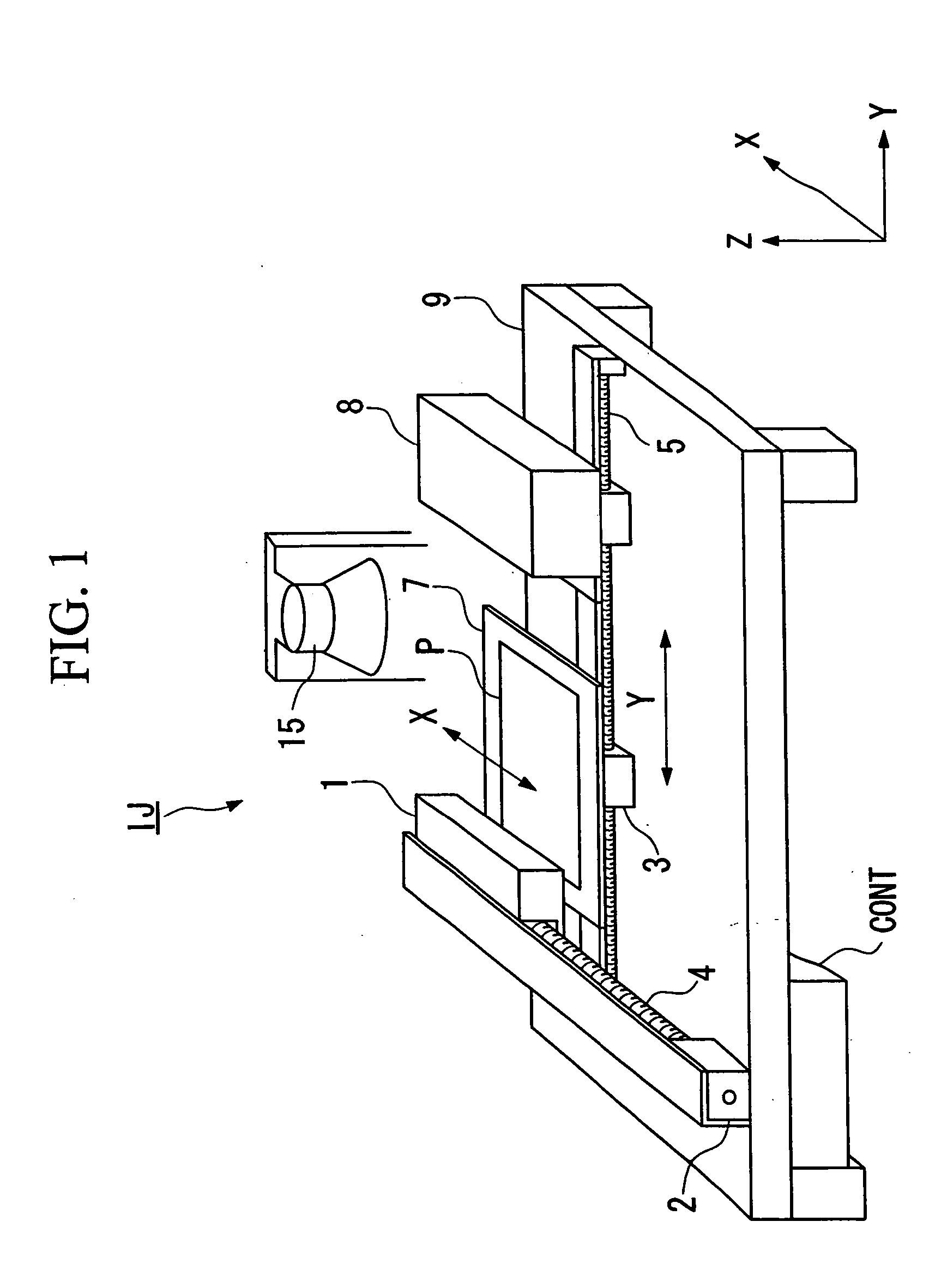

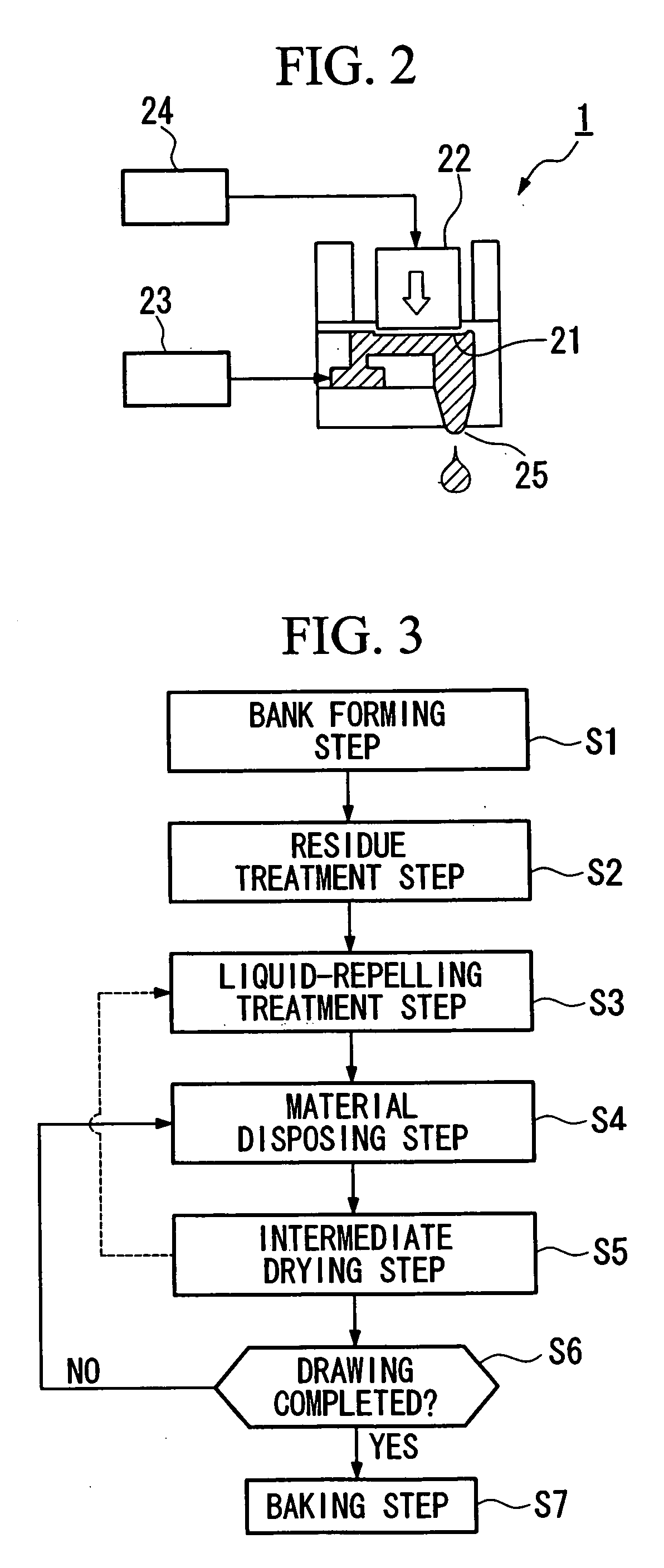

Method for fabricating thin film pattern, method for fabricating device, electro-optical apparatus, and electronic apparatus

InactiveUS20050007398A1Easy to adjustCut surfaceTransistorElectroluminescent light sourcesEngineeringSolvent

A method for fabricating a thin film pattern on a substrate includes a bank forming step of forming banks in a predetermined pattern on said substrate, a first material disposing step of disposing first liquid droplets made of a function liquid between said banks to form a first pattern, a second material disposing step of disposing second liquid droplets made of a function liquid on said first pattern, and an intermediate drying step of removing at least a part of a solvent contained in said first liquid droplets between said first material disposing step and said second material disposing step.

Owner:SEIKO EPSON CORP

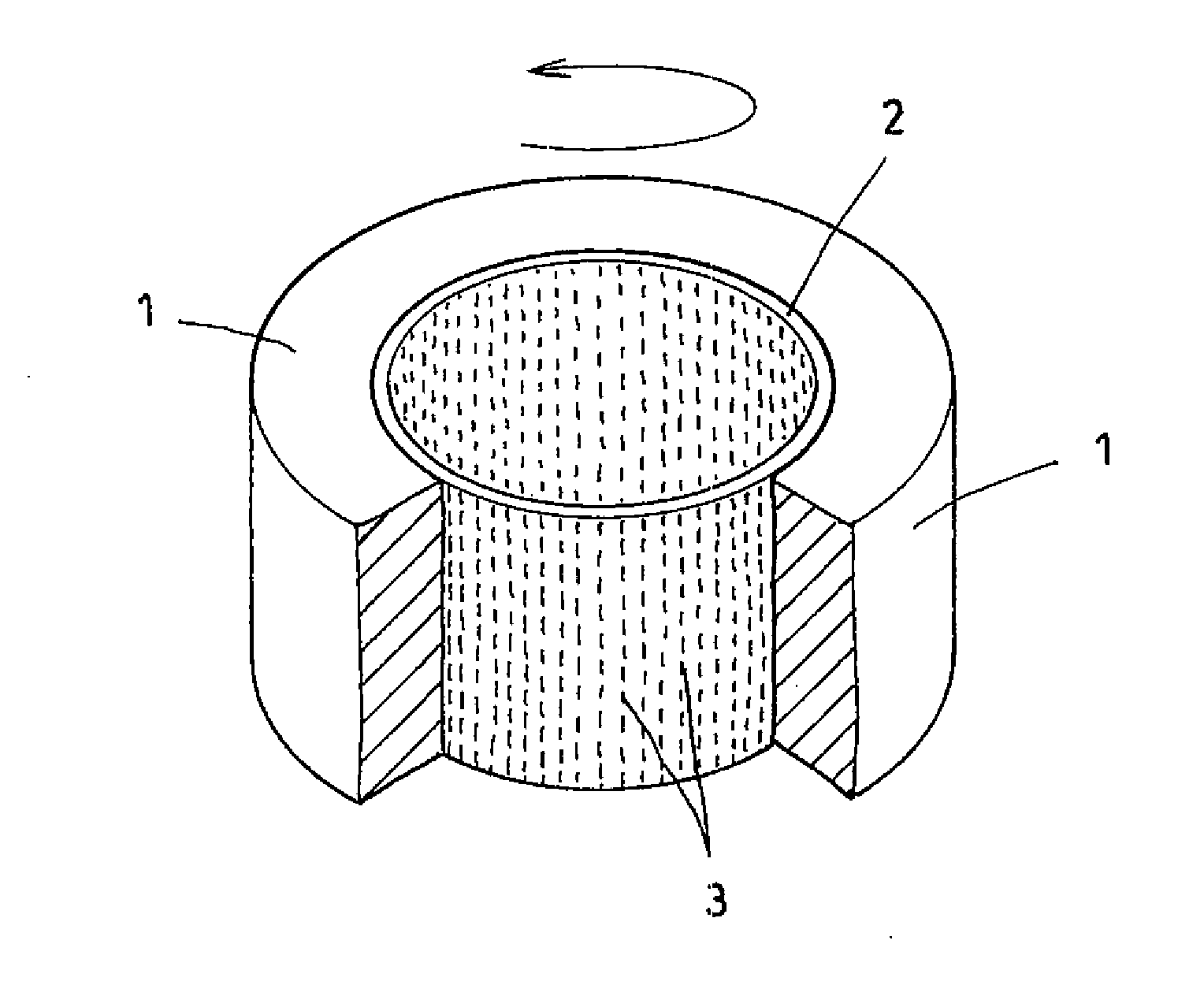

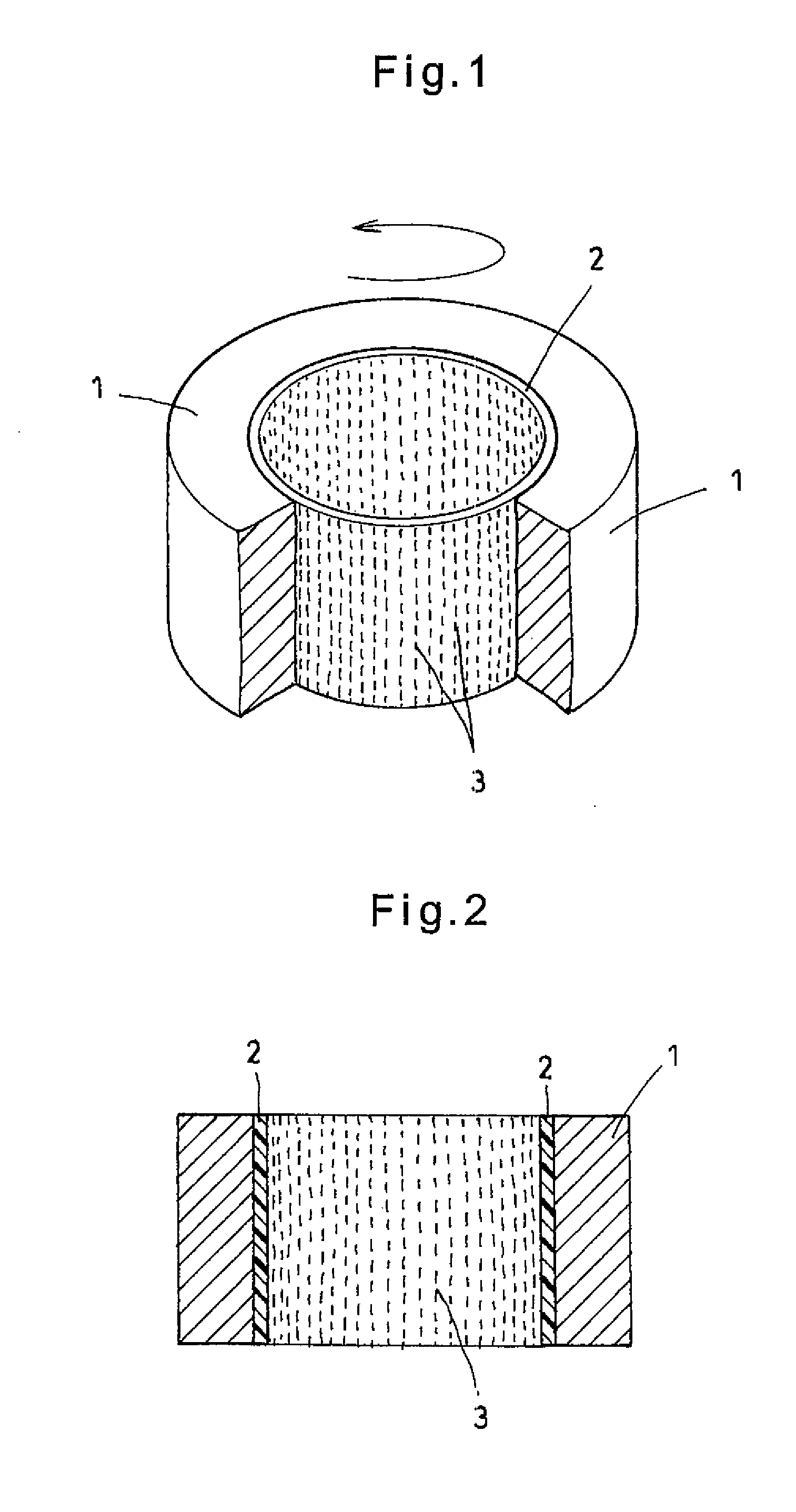

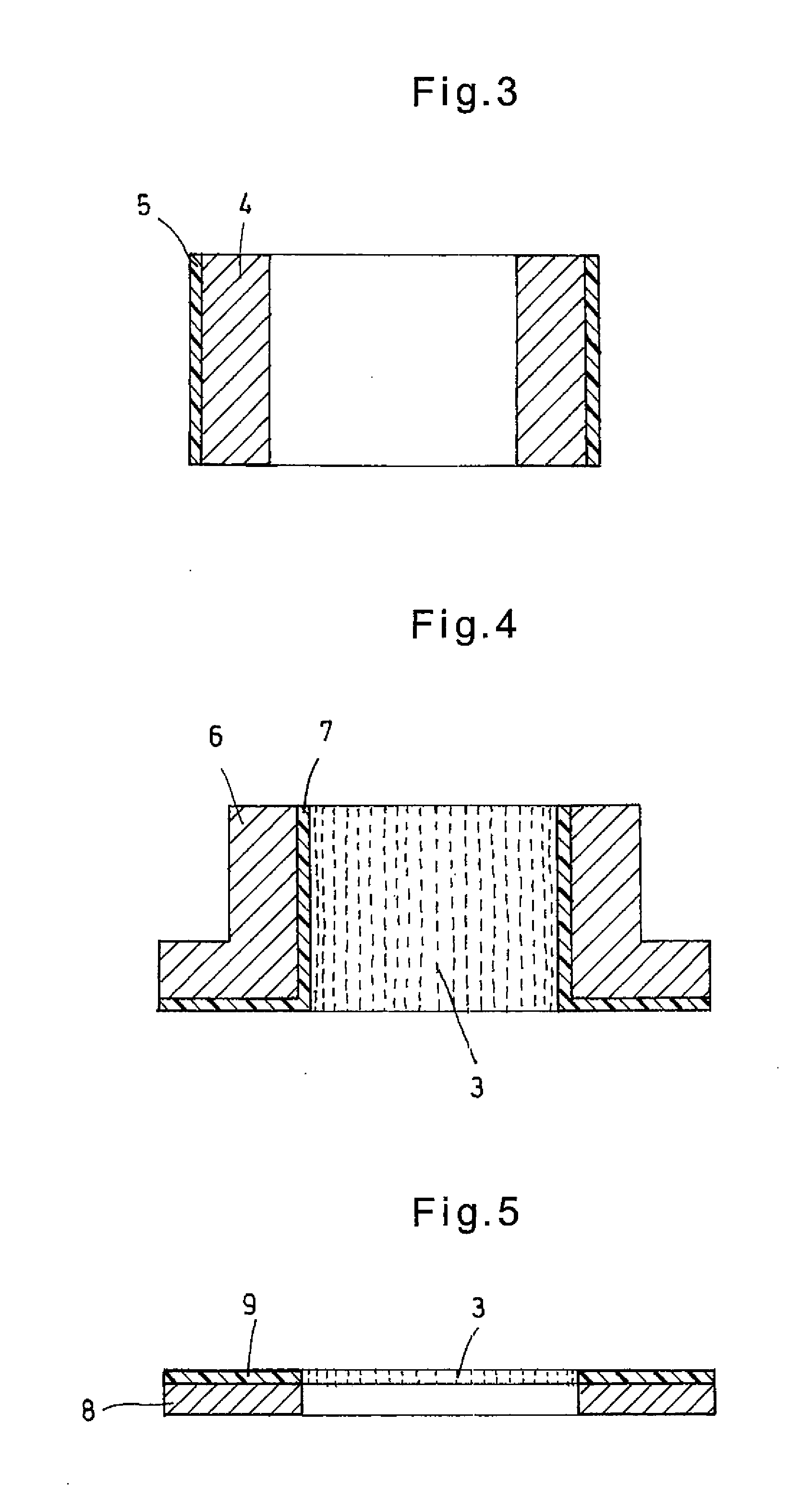

Composite slide bearing

A high-precision slide bearing is provided which includes a substrate of sintered metal and a synthetic resin layer. This bearing can be used e.g. for rotary shafts in compressors of room air-conditioners or in transmissions of motor vehicles and construction machines to support relatively large radial and axial loads. The resin layer is integrally superposed on the radially inner surface of the sintered metal substrate of the slide bearing, which is a cylindrical member. The resin layer is made of a resin composition of an aromatic polyetherketone resin containing a fibrous filler. The fibrous filler are made up of fibers dispersed in the resin layer and oriented such that their length directions intersect the rotational direction of the bearing at angles of 45 to 90 degrees. The resin layer has a thickness of 0.1 to 0.7 mm.

Owner:NTN CORP

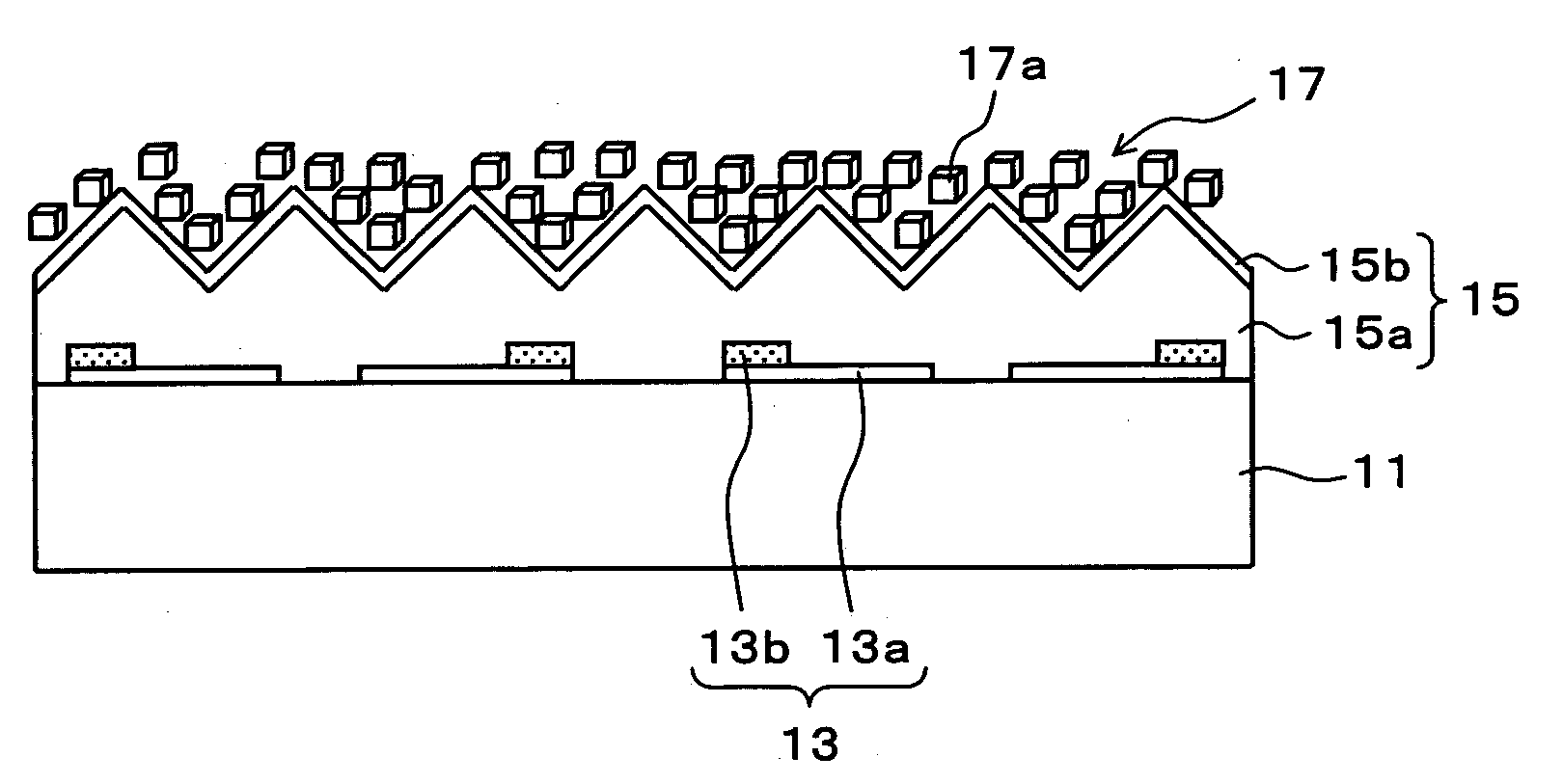

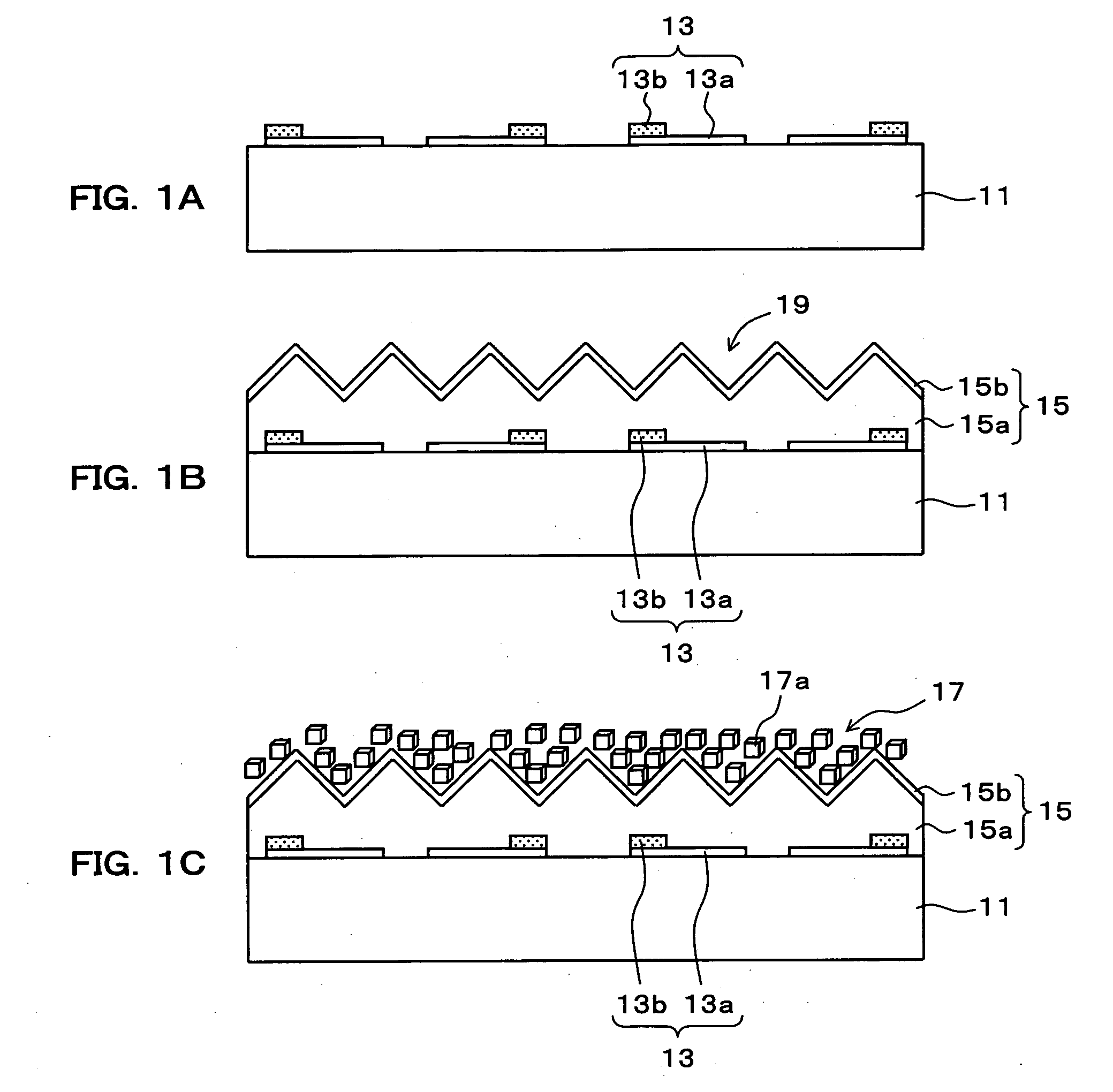

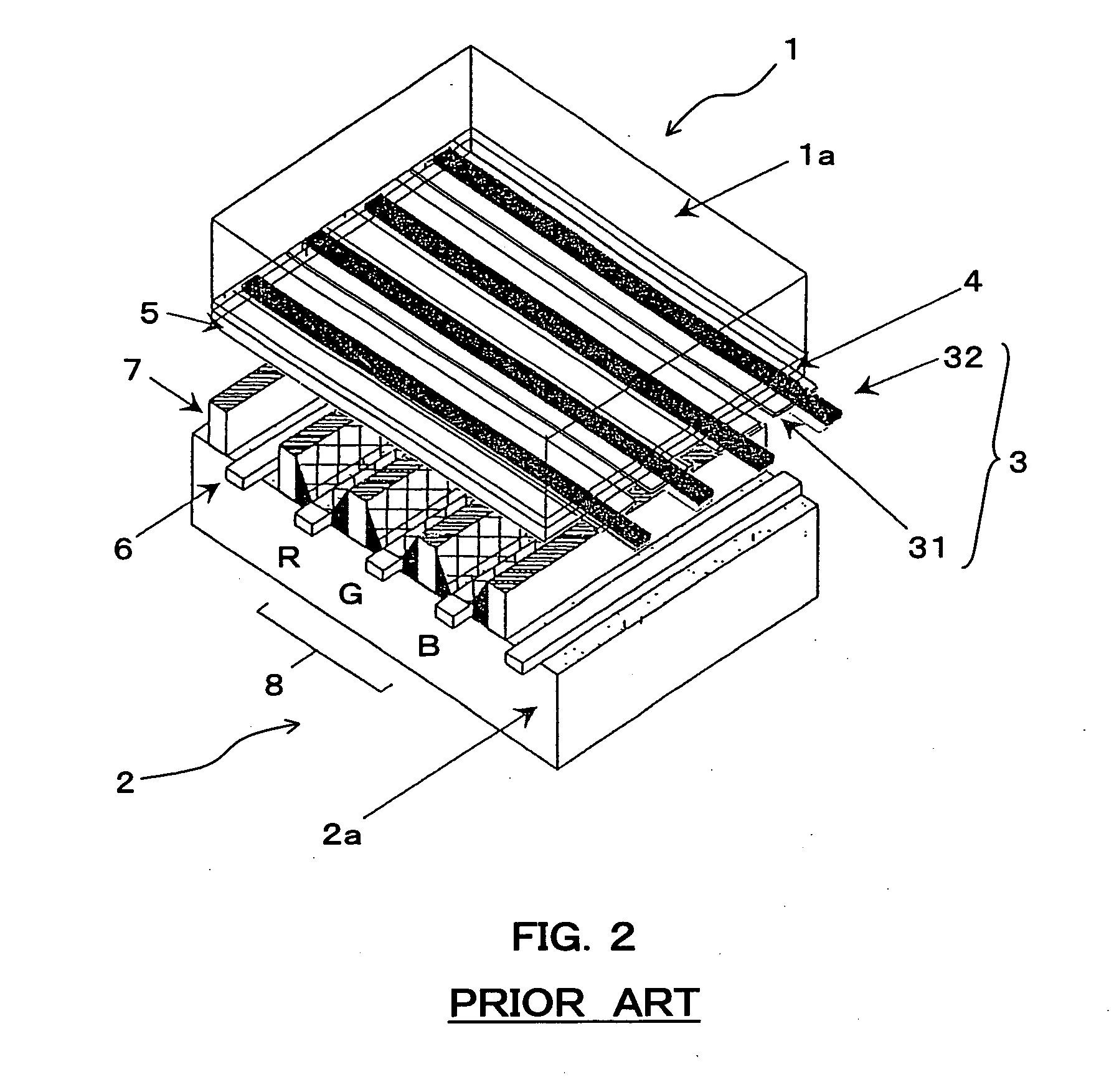

Method for producing substrate assembly for plasma display panel, and plasma display panel

InactiveUS20080049382A1Form evenlyAddress electrodesSustain/scan electrodesRough surfaceOptoelectronics

A method for producing a substrate assembly for a plasma display panel includes the steps of applying a suspension to a dielectric layer covering display electrodes formed on a substrate, the suspension containing a dispersion medium and a large number of magnesium oxide crystals dispersed in the dispersion medium, and thereafter evaporating the dispersion medium to form a layer of the magnesium oxide crystals on the dielectric layer, wherein the dielectric layer has a rugged surface structure having uniformly-dispersed projections and depressions, the rugged surface structure being capable of trapping the magnesium oxide crystals.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

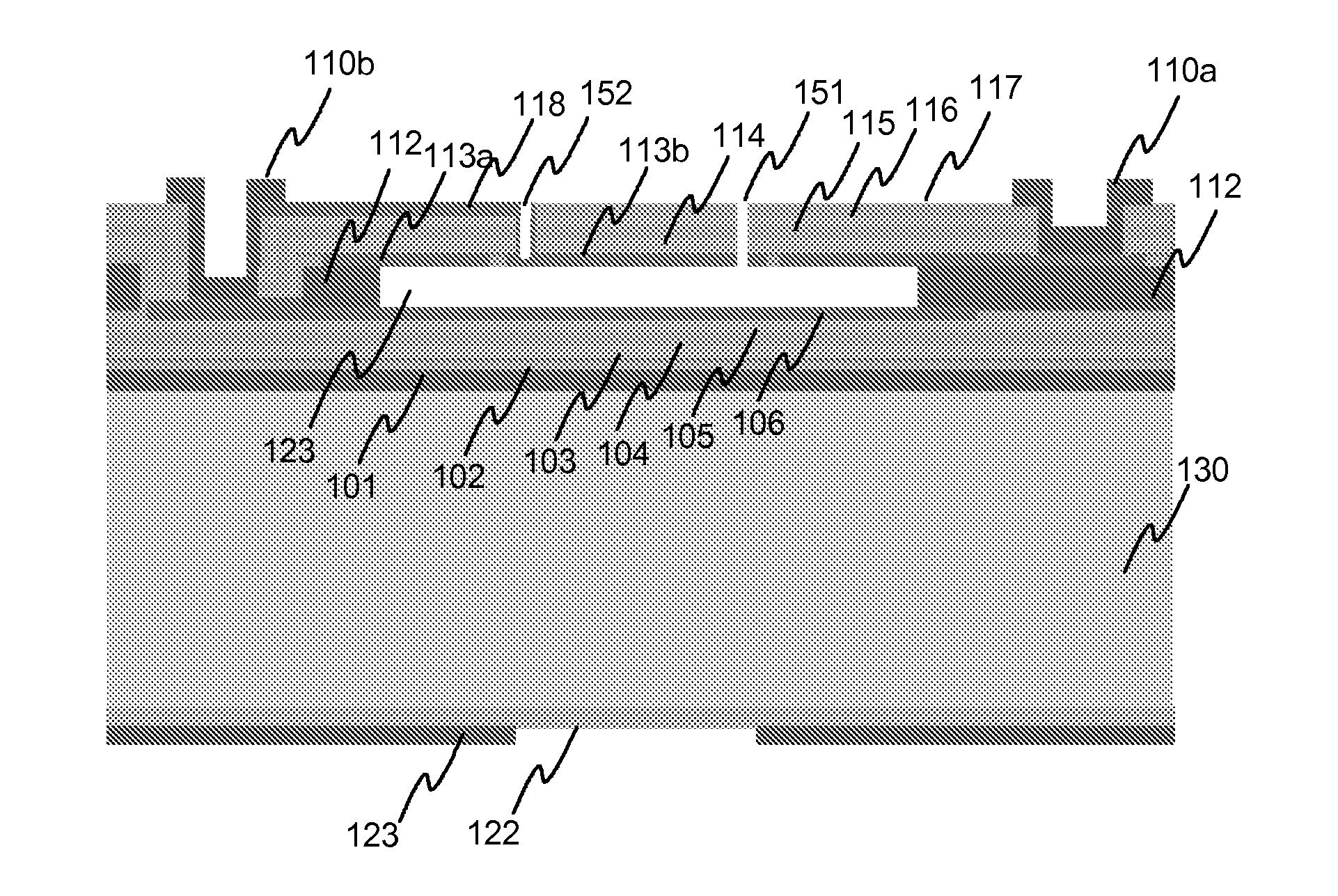

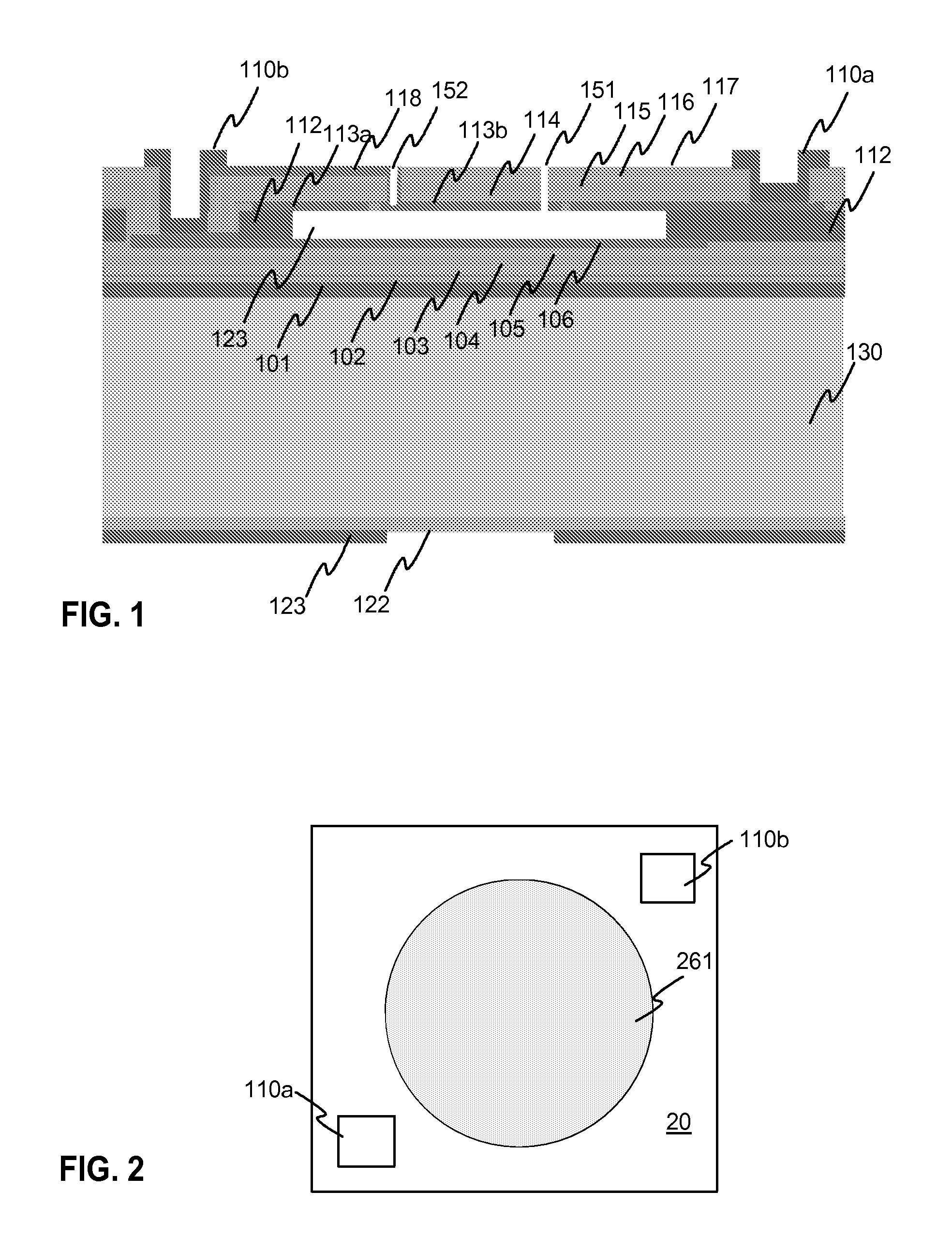

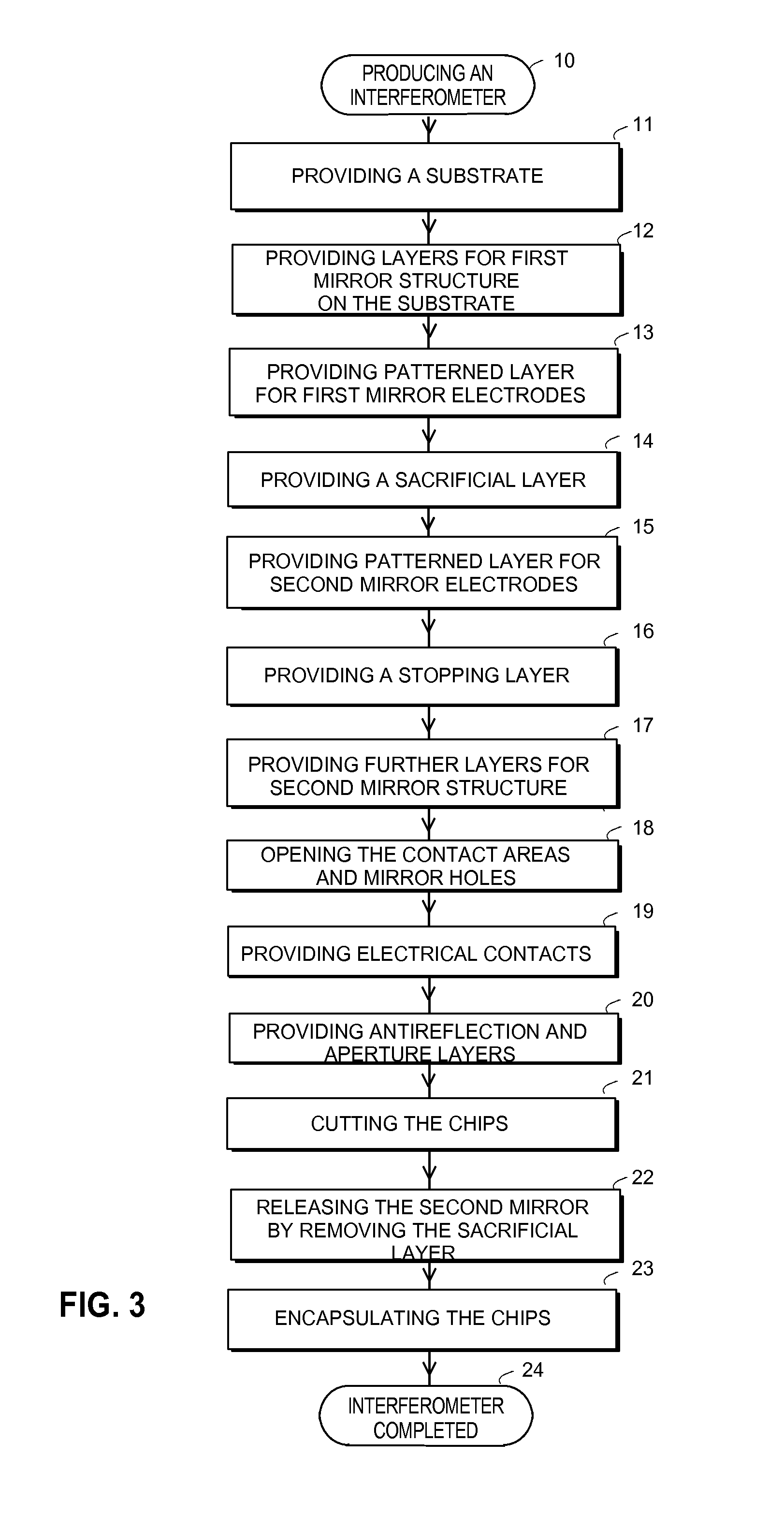

Micromechanical tunable fabry-perot interferometer, an intermediate product, and a method for producing the same

ActiveUS20120050751A1Reduce and avoid useHigh densitySemiconductor/solid-state device manufacturingSpectrum generation using multiple reflectionEtchingSilicon oxide

The invention relates to controllable Fabry-Perot interferometers which are produced with micromechanical (MEMS) technology. Producing prior art interferometers includes a risk of deterioration of mirrors during the etching of the sacrificial layer (123). According to the solution according to the invention at least one layer (103, 105, 114, 116) of the mirrors is made of silicon-rich silicon nitride. In the inventive Fabry-Perot interferometer it is possible to avoid or reduce using silicon oxide in the mirror layers whereby the risk of deterioration of the mirrors is reduced. It is also possible to use mirror surfaces with higher roughness, whereby the risk of the mirrors sticking to each other is reduced.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Method for producing oriented silicon steel with good bottom by low-temperature heating

ActiveCN1978707AGuarantee normal implementationEfficient formationSolid state diffusion coatingFurnace typesHot TemperatureSilicon

The invention supplies a method used to produce orientation silicon steel by low temperature heating. It includes the following steps: heating the plate blank under 1280 degree centigrade; hot rolling; once or double cold rolling to gain finished product sheet thickness; nitriding treatment; decarburizing annealing; coating insulator; high temperature annealing. In the nitriding technology, heating area dew point is controlled at -15-40 degree centigrade. The invention has the advantages of high nitriding efficiency, no influence from the surface oxide film, excellent MgO coat formula which makes the magnesium silicate substrate have good magnetic property, ensure the implementation for the next hot leveling annealing and insulating coating.

Owner:BAOSHAN IRON & STEEL CO LTD

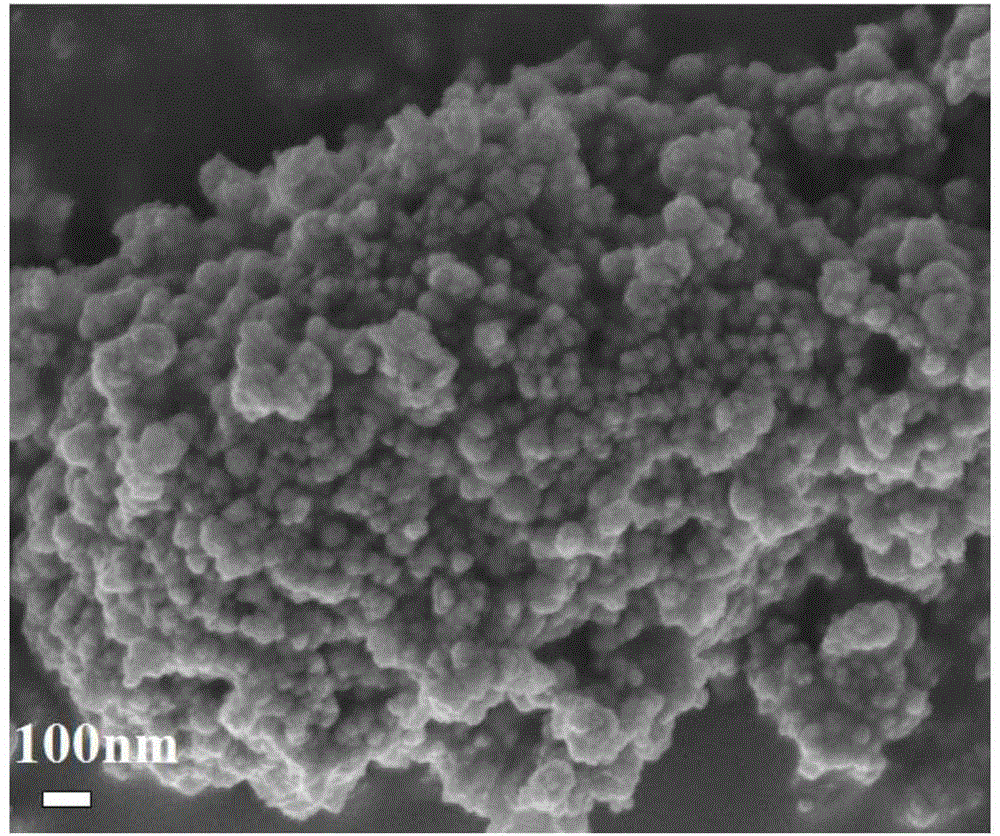

Method for preparing low-carbon olefin catalyst through carbon dioxide hydrogenation

InactiveCN104624194AForm evenlyImprove conversion rateHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMicrowaveHydrogen

The invention relates to a method for preparing a low-carbon olefin catalyst through carbon dioxide hydrogenation. The low-carbon olefin catalyst comprises the following element components: iron, zirconium, potassium and oxygen, the atomic molar ratio of zirconium to iron is (0-1):1, and the atomic molar ratio of iron to potassium is 10:1. The method for preparing the low-carbon olefin catalyst through carbon dioxide hydrogenation comprises the following steps: (1) weighing an iron source and a zirconium sourse, preparing aqueous solution, and marking the prepared aqueous solution as solution A; (2) adding a precipitator into the solution A, stirring, and marking the obtained solution as solution B; (3) carrying out microwave induction on the solution B; (4) centrifuging, filtering and washing reaction products, drying and roasting the obtained sample, and marking the roasted sample as a sample C; (5) weighing a potassium source, dissolving the potassium source in deionized water, impregnating the sample C, drying, and marking the dried sample as a sample D; and (6) carrying out tabletting, pelletizing and hydrogen gas reduction on the sample D, so that a catalyst sample is obtained. The method for preparing the low-carbon olefin catalyst through the carbon dioxide hydrogenation has the advantages that conversion ratio of carbon dioxide raw material is high, selectivity of low-carbon olefin is high, few CH4 and CO byproducts are produced, the catalyst is stable, and powder particles of the obtained catalyst are small and uniform.

Owner:NINGXIA UNIVERSITY

Semiconductor device and method for manufacturing the same

ActiveUS20140103339A1Improve reliabilityStable electrical characteristicsTransistorSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

A semiconductor device formed using an oxide semiconductor layer and having small electrical characteristic variation is provided. A highly reliable semiconductor device including an oxide semiconductor layer and exhibiting stable electric characteristics is provided. Further, a method for manufacturing the semiconductor device is provided. In the semiconductor device, an oxide semiconductor layer is used for a channel formation region, a multilayer film which includes an oxide layer in which the oxide semiconductor layer is wrapped is provided, and an edge of the multilayer film has a curvature in a cross section.

Owner:SEMICON ENERGY LAB CO LTD

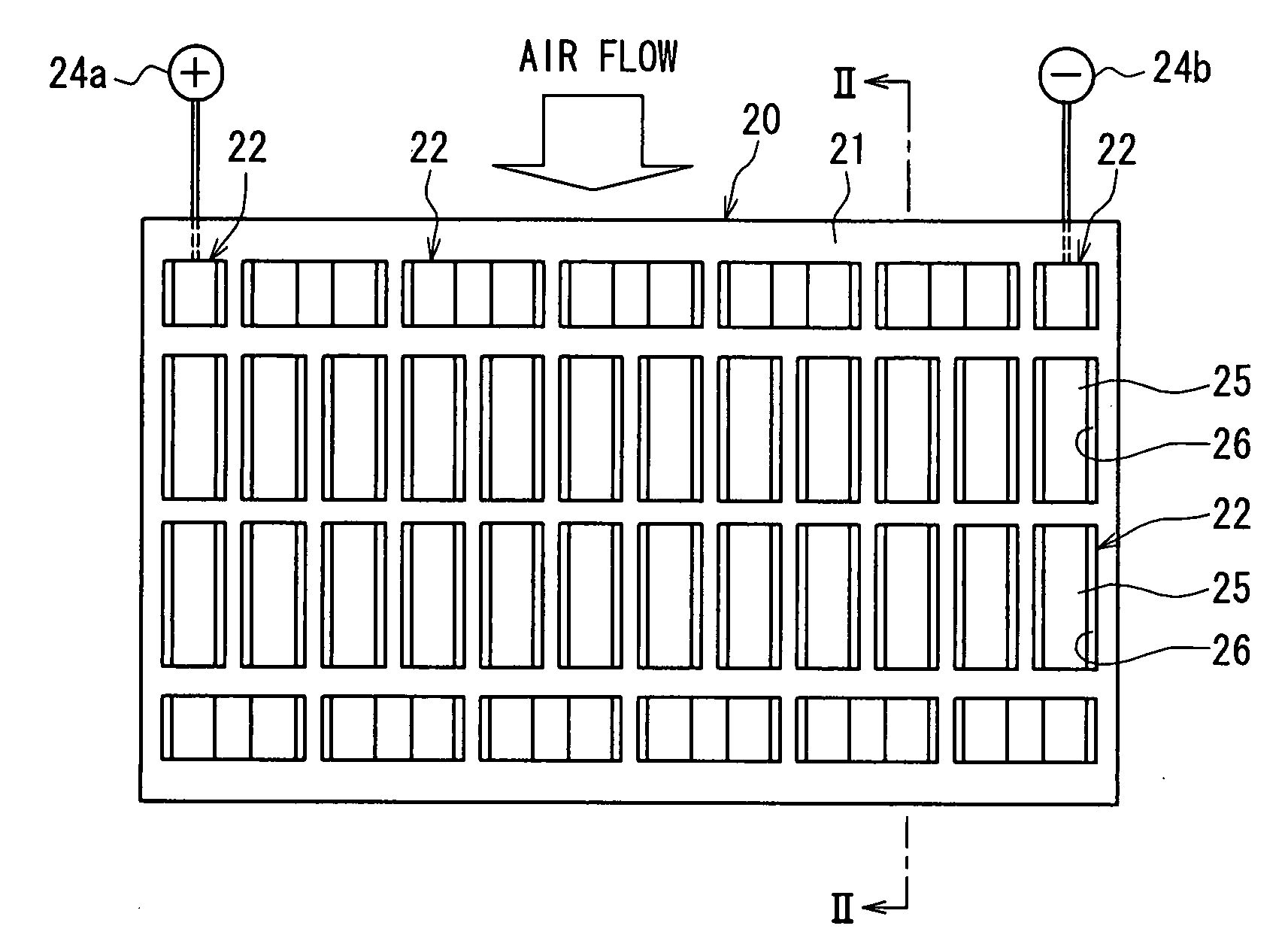

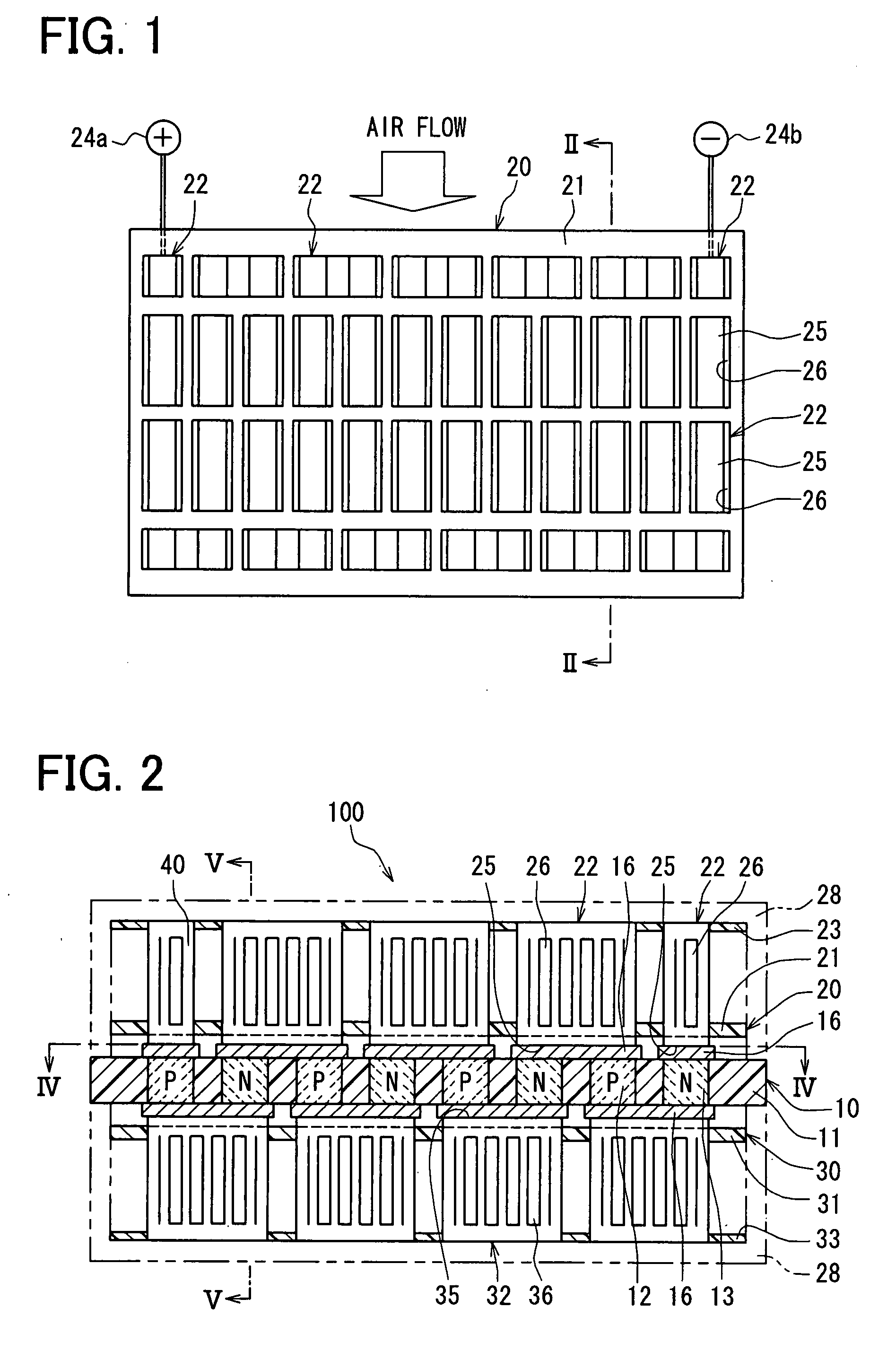

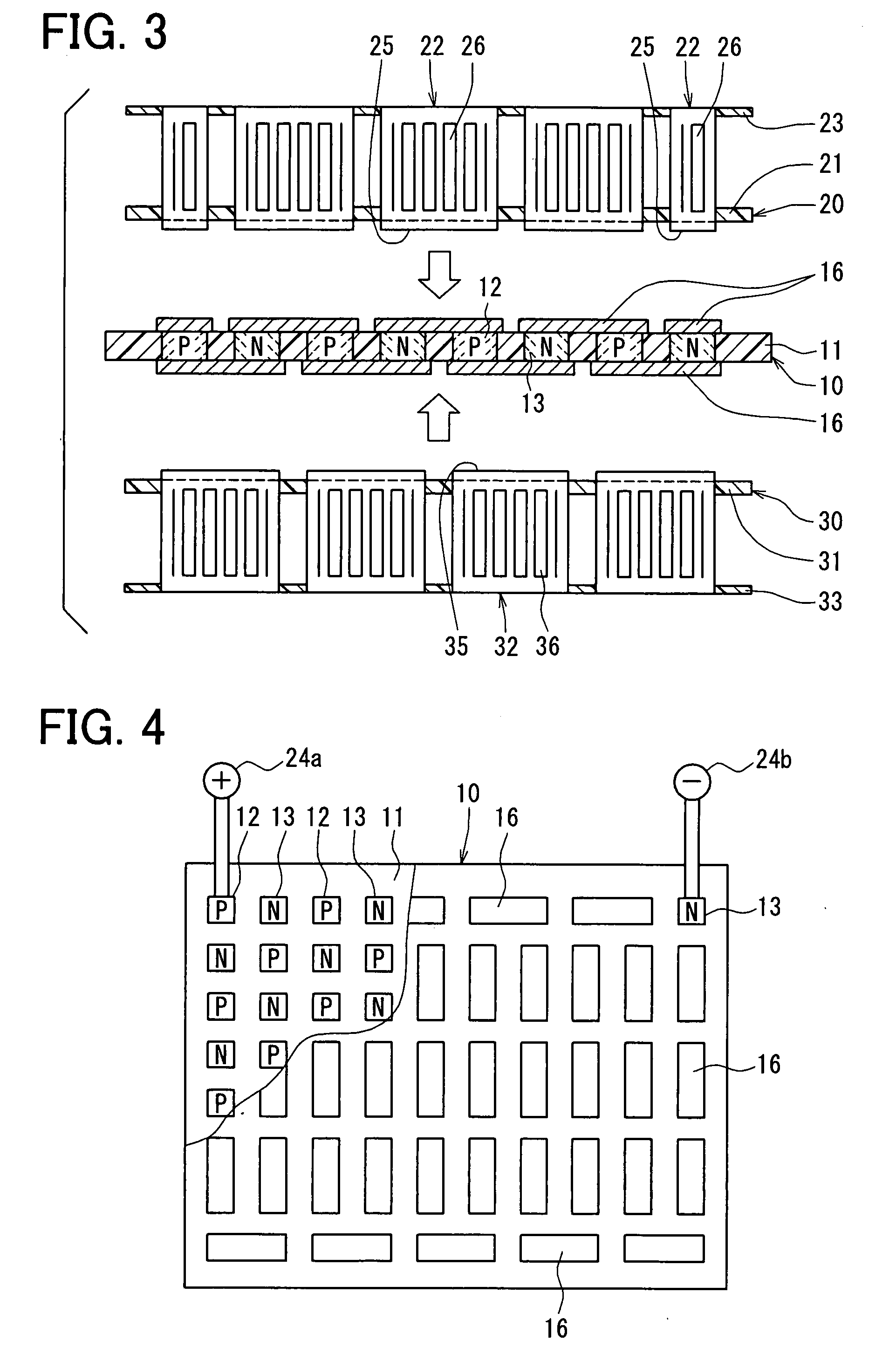

Thermoelectric conversion device and manufacture method of the same

InactiveUS20080000511A1Reduce deteriorationControl migrationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentCooking & bakingEngineering

A thermoelectric conversion device and a manufacture method for the thermoelectric conversion device are provided. The manufacture method includes a joining process for respectively joining heat exchanging members to thermoelectric-element pairs of an thermoelectric element module, an immersion process for immersing the thermoelectric element module and the heat exchanging members in an immersion sink where an melted insulating material is provided, and a baking process for baking an assembly of the thermoelectric element module and the heat exchanging members where the insulating material has been applied in the immersion process so that an insulating film is formed. Thus, an electrical insulation can be provided while a heat-exchanging capacity and an air-blowing capacity are maintained.

Owner:DENSO CORP

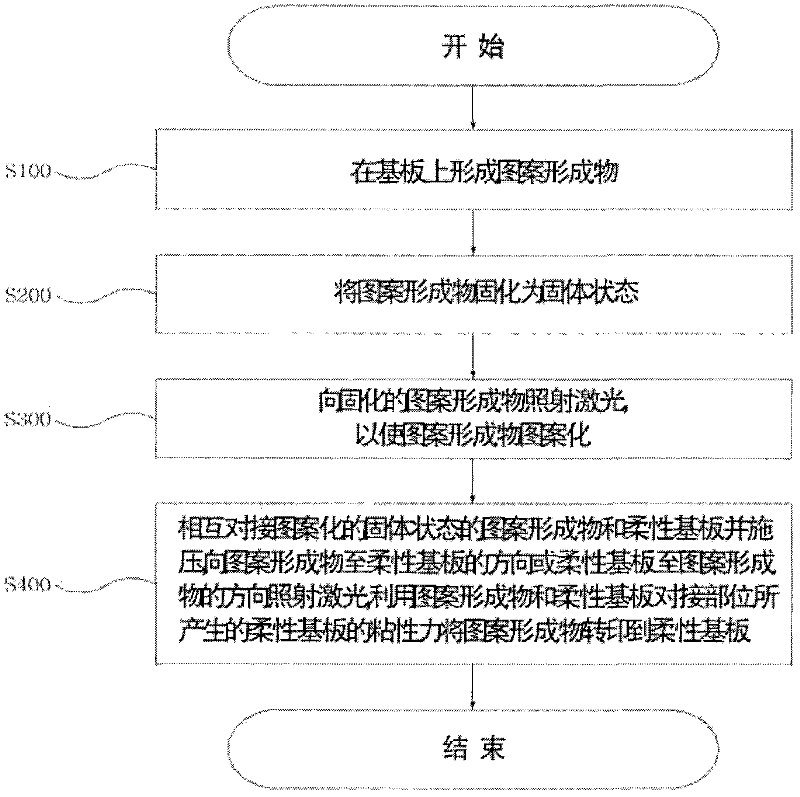

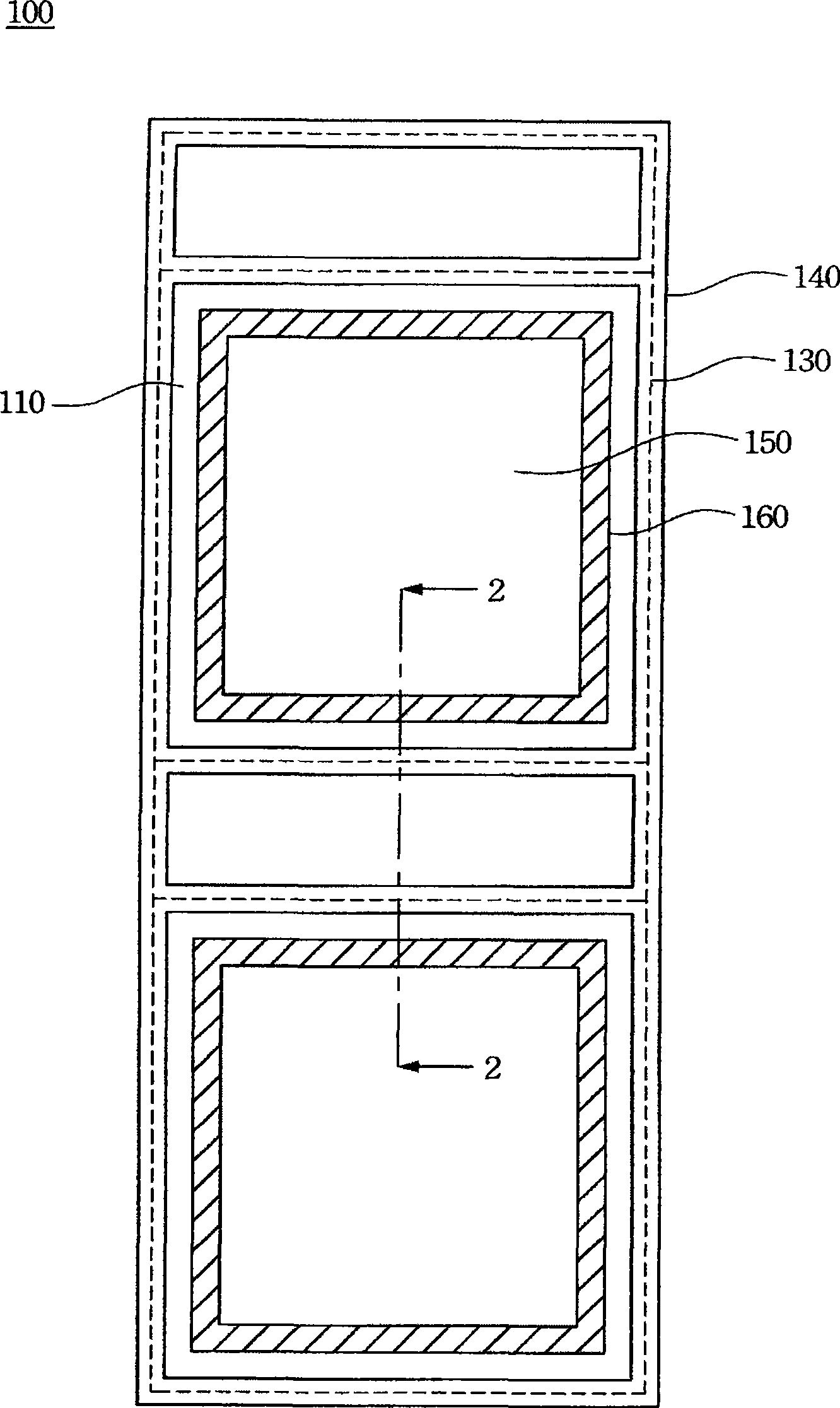

Pattern transfer method and apparatus therefor

InactiveCN102452239AForm evenlyUniform transferTransfer printingDuplicating/marking methodsElectromagnetic shieldingElectronic book

The present invention relates to methods and apparatuses for transferring pattern, a flexible display panel, a flexible solar cell, an electronic book, a thin film transistor, an electromagnetic-shielding sheet, and a flexible printed circuit board applying thereof. A pattern transfer method related to the present invention comprises: a first step of forming a pattern material on a substrate; a second step of hardening the pattern material in the solid state; a third step of patterning the pattern material by irradiating a laser beam to the hardened pattern material in the solid state; and a fourth step of pressing the patterned pattern material in the solid state and a flexible substrate facing each other and transferring the pattern material to the flexible substrate by a viscous force of the flexible substrate occurring in a facing part between the pattern material and the flexible substrate by irradiating the laser beam from the pattern material to the flexible substrate or from the flexible substrate to the pattern material.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method of forming thin film pattern, method of manufacturing device, electro-optical apparatus and electronic apparatus

InactiveUS20050191781A1Suppress generationUniform placementTransistorElectroluminescent light sourcesEngineeringElectronic equipment

A method of forming a thin film pattern by placing a functional liquid on a substrate, includes a bank formation step of forming banks in accordance with the thin film pattern on the substrate, a residue processing step of removing residue between the banks, and a material placement step of placing the functional liquid between the banks removed the residue.

Owner:SEIKO EPSON CORP

Display master blank and use thereof

The invention discloses a display motherboard including a first basal plate, a second basal plate, a plurality of cutting lines and at least one photoresist type supporting material. The second basal plate and the first basal plate are oppositely arranged, and the cutting lines are arranged on the first basal plate and the second basal plate. The cutting lines can distinguish the first basal plate and the second basal plate to be at least one display panel unit. The photoresist type supporting material is arranged between the first basal plate and the second basal plate. The photoresist type supporting material and the cutting lines are superposed, and the photoresist type supporting material takes the shape of a strip and surrounds the edge of the display panel unit. The display motherboard facilitates the smooth formation of rib marks on the basal plates.

Owner:AU OPTRONICS CORP

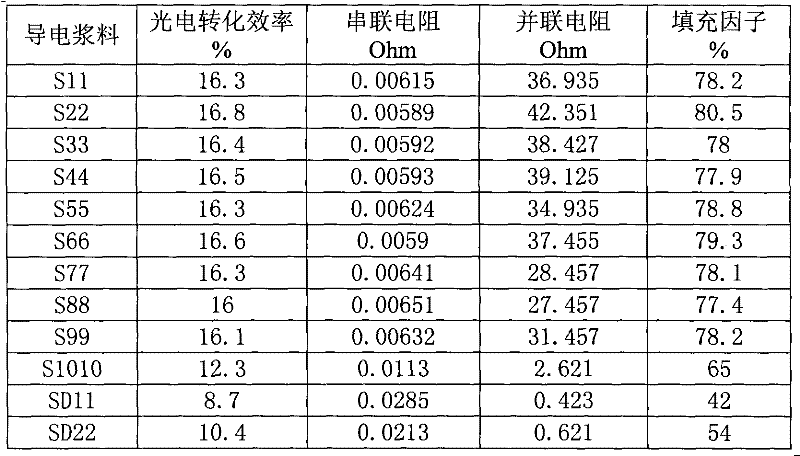

Conductive paste and preparation method thereof

InactiveCN102456427AReduce contact resistanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteSolar battery

The invention provides a conductive paste. The conductive paste contains silver powder, glass powder and an organic carrier, wherein the average particle size of the silver powder is 0.05-0.8mu m, and the glass powder contains a compound of Ag. According to the invention, the super-fine silver powder is used as the main component of the conductive paste provided by the invention, thereby greatly reducing sintering temperature and shortening sintering time; and simultaneously, addition of the compound of Ag in the glass powder is in favor of evenly and rapidly forming a Ag-Si intermetallic compound and reducing a contact resistance between an electrode and a solar substrate. Through using the conductive paste provided by the invention, the energy consumption generated by a solar battery can be effectively reduced, production efficiency is improved, and simultaneously the solar battery plate is ensured to have good photoelectric conversion efficiency.

Owner:BYD CO LTD

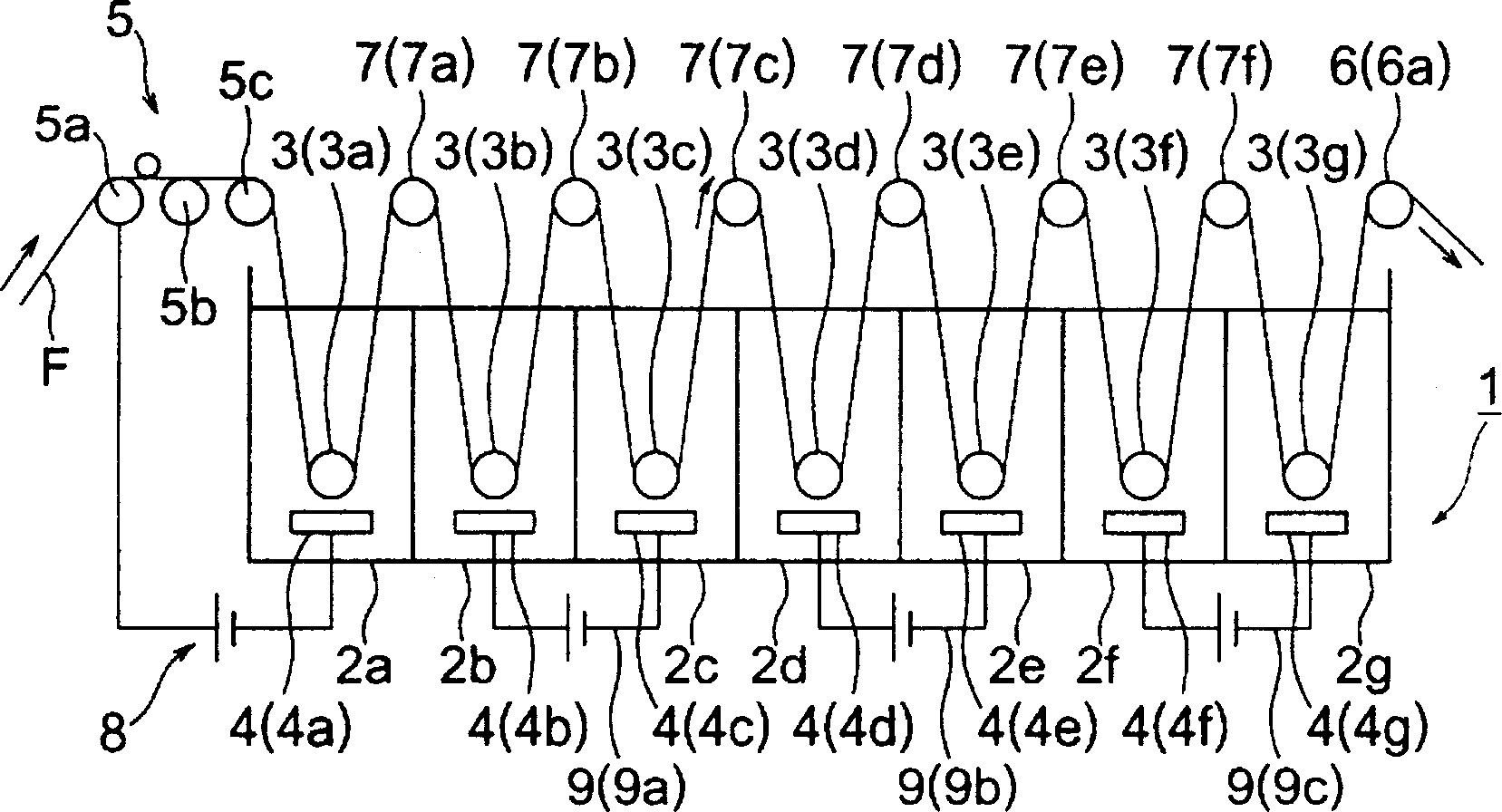

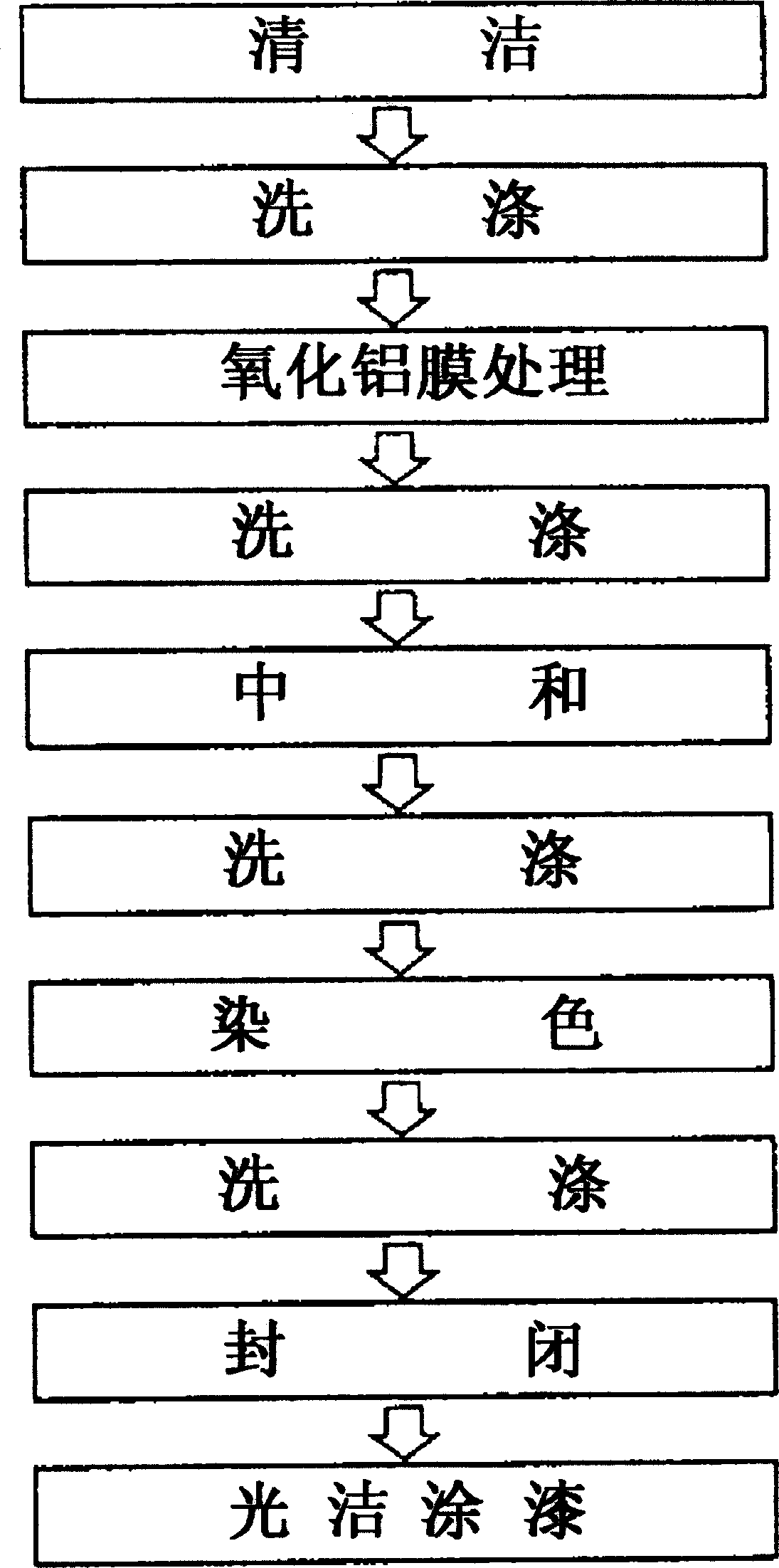

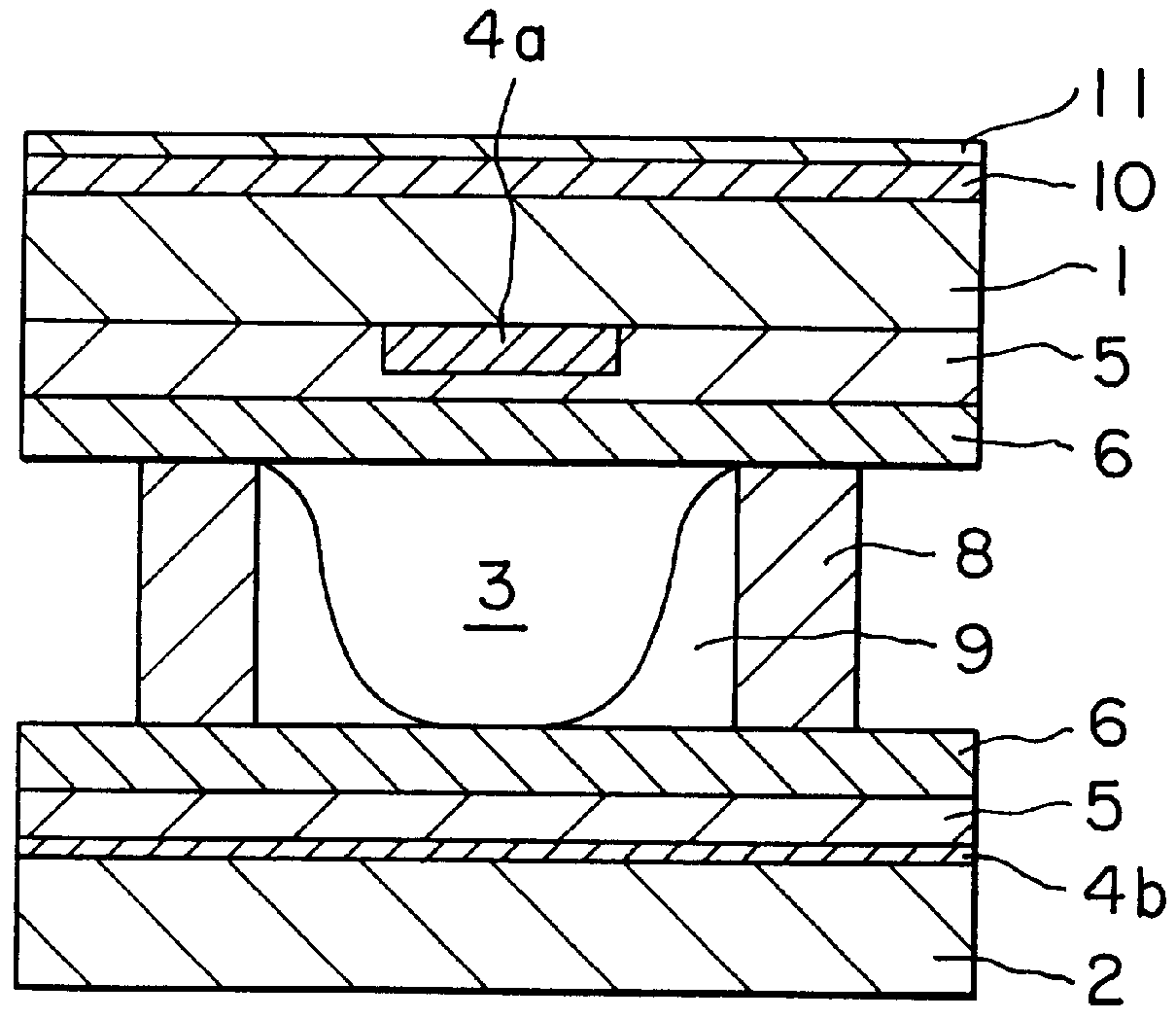

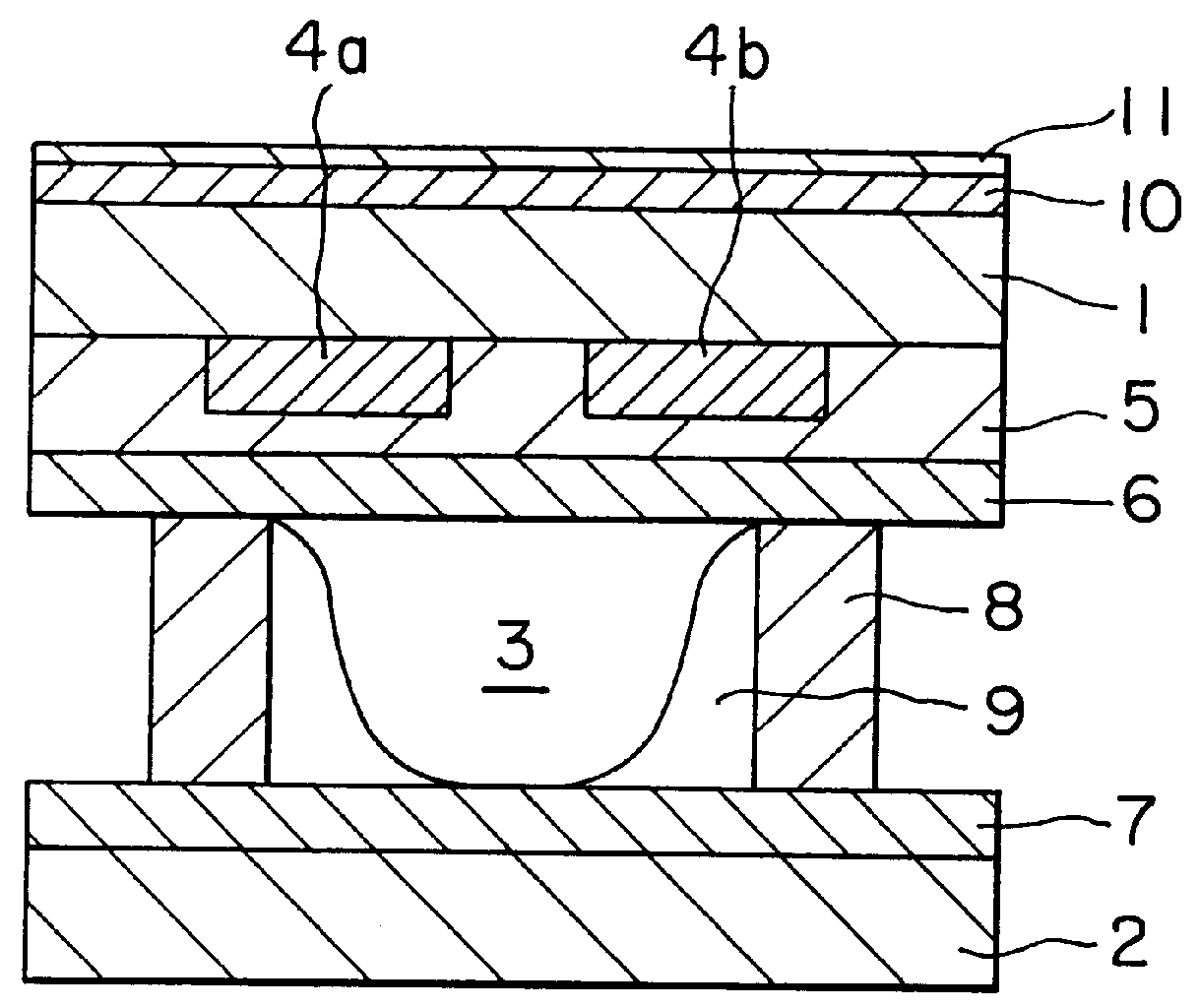

Forming method of anode oxidation film on chain tooth row and its forming equipment

PROBLEM TO BE SOLVED: To form the anodically oxidized films of the row of zip teeth of a fastener chain to arbitrary thicknesses while preventing the defects of energization and contact.SOLUTION: The forming apparatus 1 has an external energizing section 8 for electrically and directly energizing an electrode plate 4a disposed in an electrolyte of a first electrolytic cell 2a and a chain introducing section 5 to each other and a plurality of energizing sections 9 for energizing two sets a pair of adjacent electrode plates 4 within the second and subsequent electrolytic cells 2 to each other across the electrolyte and the fastener chain F. While the fastener chain is successively wrapped around a plurality of rollers 3 and 7 and is transferred zigzag, the tooth trains of the fastener chain are directly energized through the energizing yarn of the fastener chain by the external energizing section. The two sets a pair of the second and subsequent electrode plates are energized to each other in the bath by the energizing sections. The anodically oxidized films having the arbitrary film thicknesses are formed by changing the number of the passage stages to the second and subsequent electrolytic cells, the energizing quantity in the arbitrary electrolytic cells, etc.

Owner:YKK CORP

Sol solution and method for film formation

InactiveUS6149967AImprove stabilityImprove responseGas-filled discharge tubesOther chemical processesDisplay deviceAlternating current

A method for forming a protective layer for a dielectric material in an alternating current type plasma display is provided. In this connection, a coating sol solution is provided which can form a protective layer on a large area substrate without the need to introduce any expensive equipment, the protective layer thus formed being excellent in properties such as strength, adhesion, transparency, and protective properties and capable of being formed by a sol-gel process without use of the conventional vacuum process. The sol solution comprises a dispersion of a precursor to magnesium oxide in a specific form. A method for film formation, using this solution is also provided.

Owner:DAI NIPPON PRINTING CO LTD

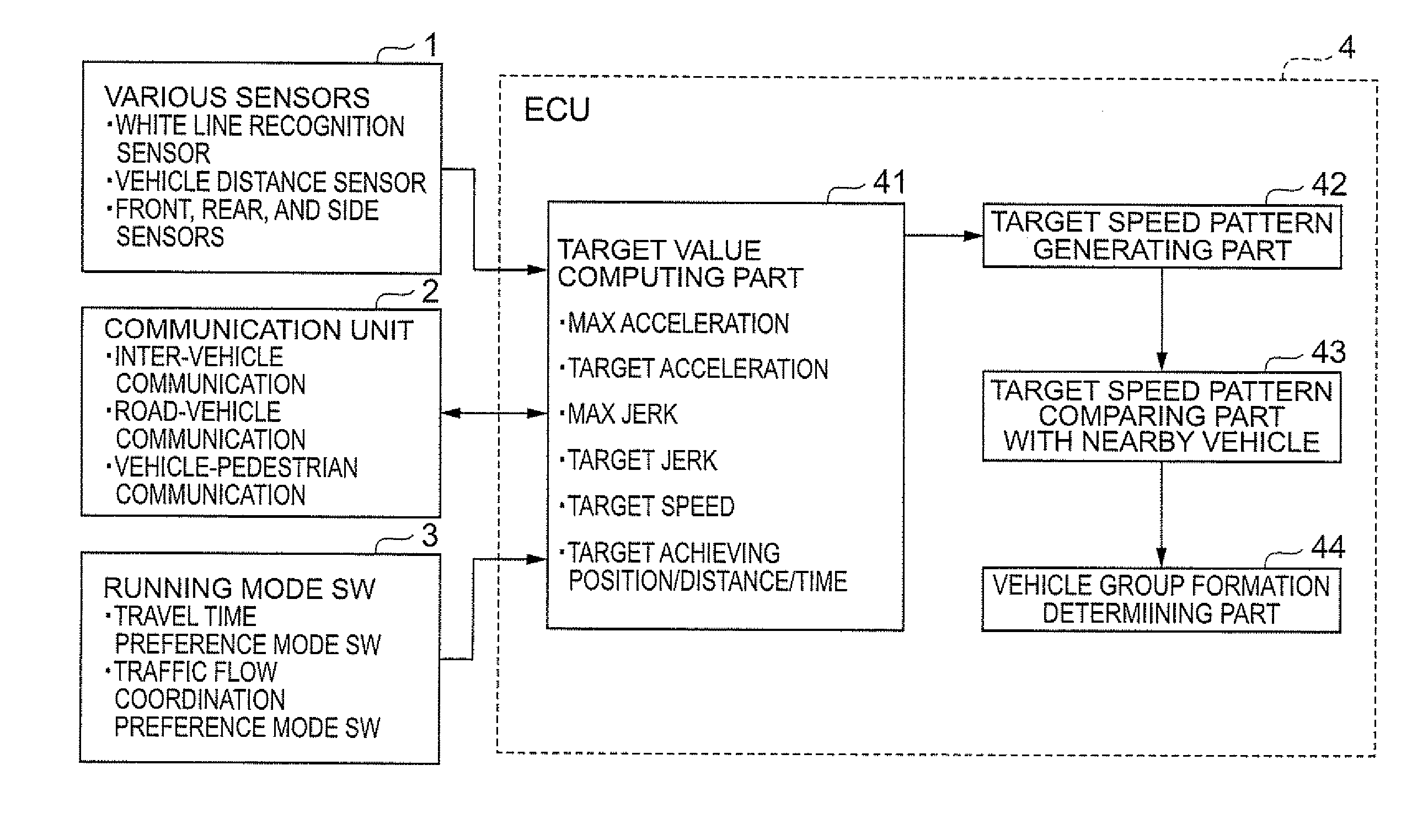

Travel control device

ActiveUS20090271050A1Shorten the timeImprove battery lifeAnalogue computers for vehiclesAnalogue computers for trafficDriver/operatorEngineering

Owner:TOYOTA JIDOSHA KK

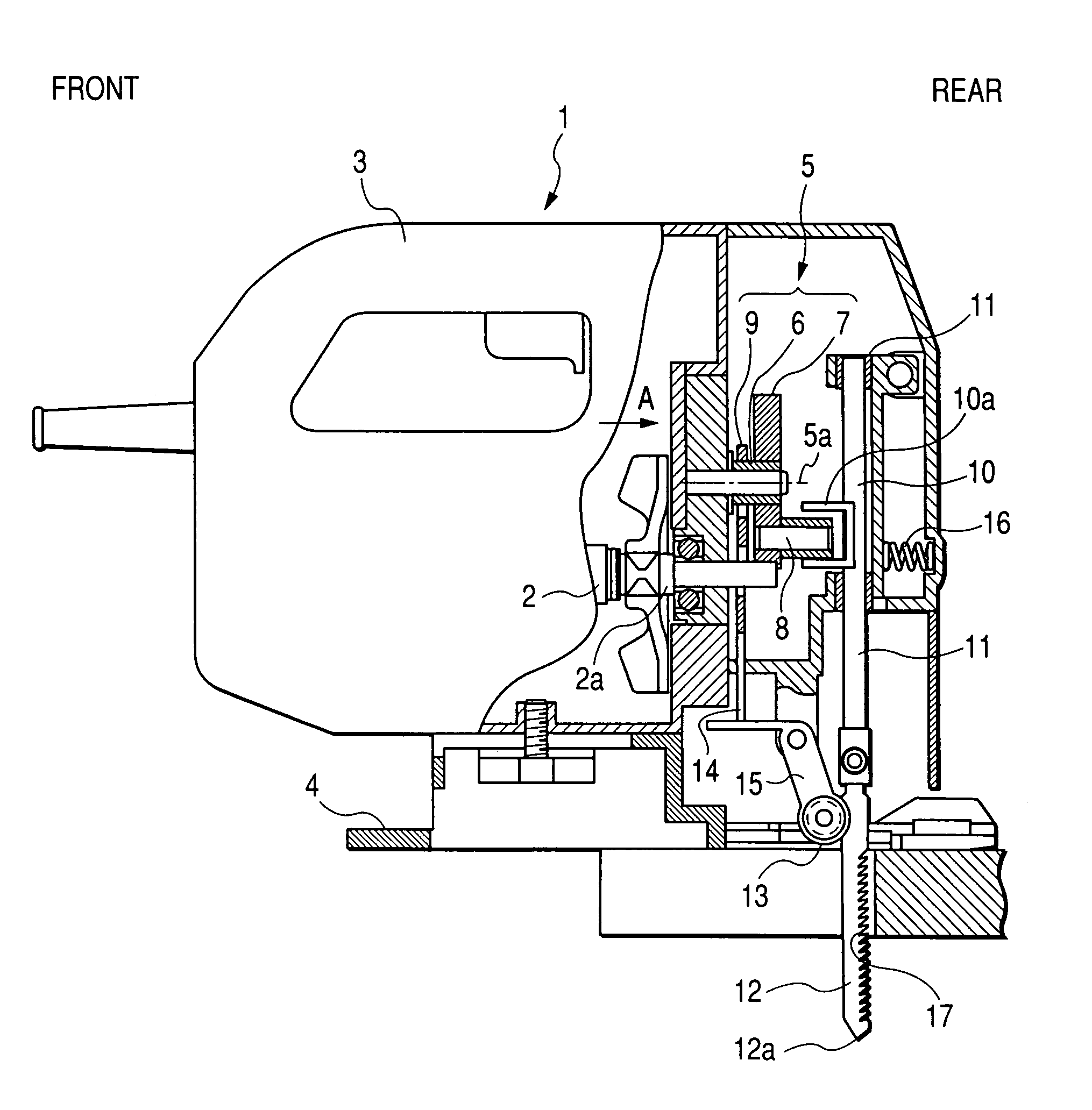

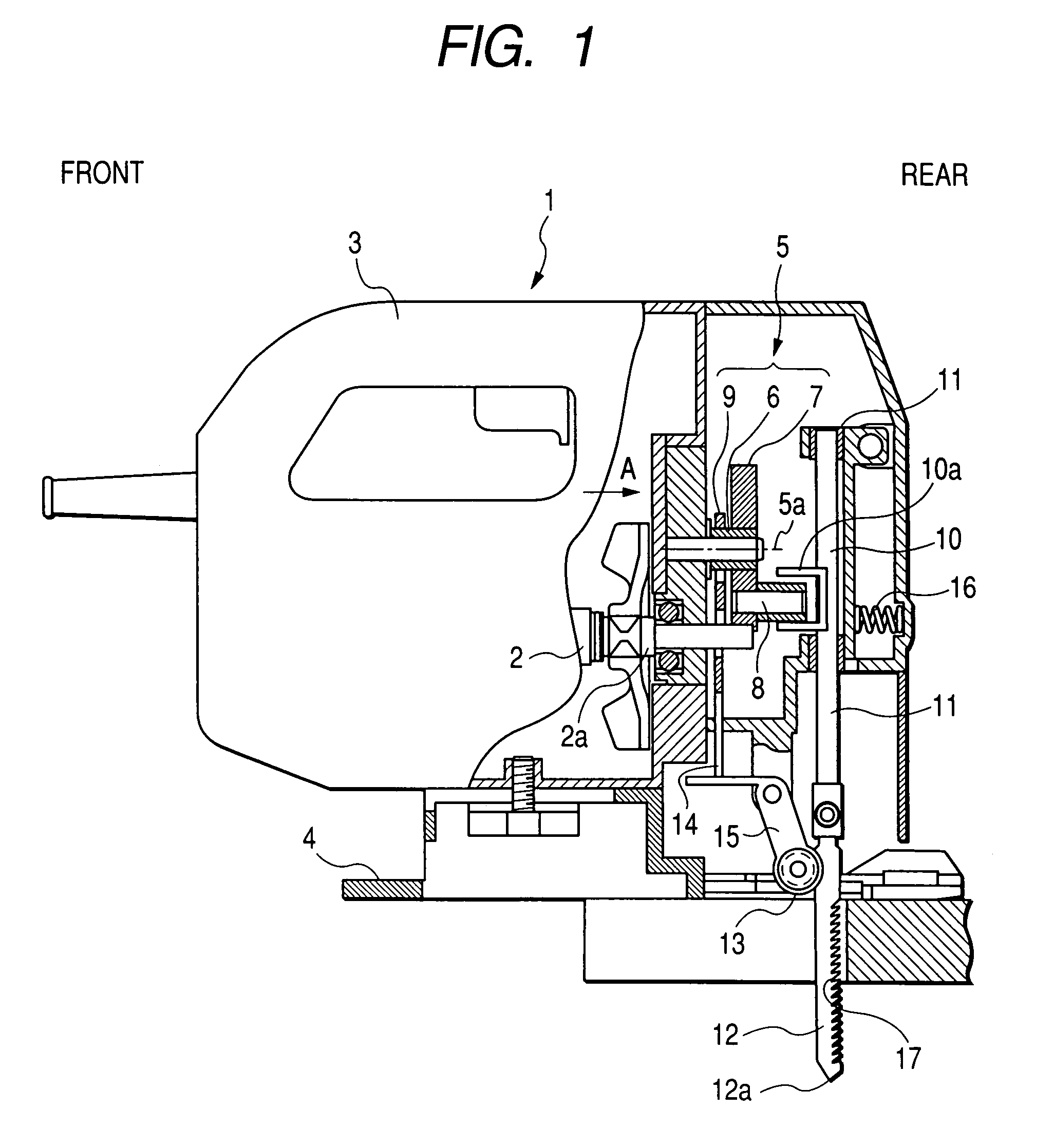

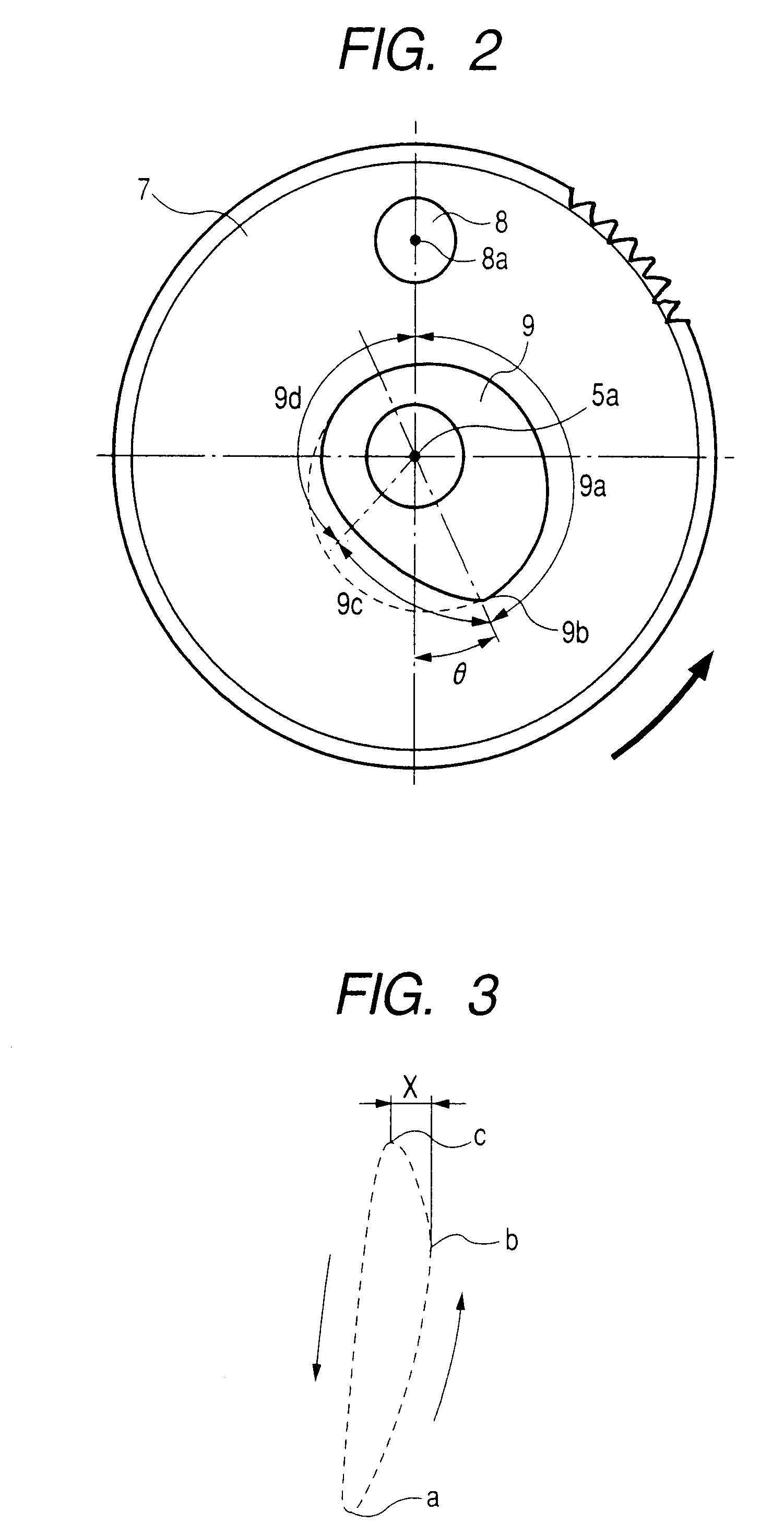

Jigsaw

ActiveUS7350302B2Little vibrationImprove cutting performanceMetal sawing devicesGearingRotational axisClassical mechanics

An outer peripheral surface of a cam has an apex disposed of distance from a rotational axis, a first region adjacent the apex opposite to the direction of rotation that increases in distance from the rotational axis during rotation, and a second region adjacent the apex in the rotational direction that decreases in distance from the rotational axis of the cam with the rotation thereof. The apex is disposed where the phase θ thereof advances by 15 degrees and 55 degrees or less in the rotational direction from a position symmetrical to the rotational axis. The rate of change between the second region and the rotational axis is greater than the rate of change between the first region and the rotational axis. A retreat amount X when a saw blade reaches an uppermost point c from a foremost point is set to 0.8 mm.

Owner:KOKI HLDG CO LTD

Intermittent cutting transferring device

InactiveUS20090320663A1Suppress wrinklesEasy to holdLamination ancillary operationsLaminationMechanical engineeringEngineering

The intermittent cutting transferring device 1 in the present invention is configured to guide the continuum of film sheet 10A between the blade 32 and the stationary glade 32 while the continuum of film sheet 10A is being sucked onto the outer peripheral surface 41 of the lower blade roll 40 by the suction through the suction holes 43 formed in the first region 41A on the outer peripheral surface 41 of the lower blade roll 40. The first region 41A is configured of a suction region 41A-1 in which a plurality of the suction holes are formed and a non-suction region 41A-2 in which suction hole is not formed. And the suction region and the non-suction region 41A-2 are provided alternately in a roll peripheral direction.

Owner:UNI CHARM CORP

Crystallizer protective slag for effectively controlling carbon steel cracks in compact strip production (CSP)

The invention discloses crystallizer protective slag for effectively controlling carbon steel cracks in a compact strip production (CSP). The crystallizer protective slag comprises the following chemical components in percentage by mass: 35 to 38 percent of CaO, 28 to 31 percent of SiO2, 1 to 3 percent of Al2O3, 1 to 2 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 10 to 11.5 percent of F, 9 to 11.5 percent of Na2O, 1.5 to 3.5 percent of MnO, 5 to 8 percent of fixed carbon, and the balance of inevitable trace elements. Through the crystallizer protective slag for controlling the carbon steel cracks in the CSP, the alkalinity is improved by 0.04 to 0.09, the alkalinity is controlled to be 1.20 to 1.25, the constraint that the alkalinity cannot be more than 1.16 in the field is broken, the viscosity is controlled to be 0.08 to 0.09Pa.S, and the melting point is from 1,155 to 1,185 DEG C; capabilities of dissolving and absorbing inclusions are improved, and heat transfer is retarded by reducing a vitreous body, so that an aim of reducing longitudinal cracks is fulfilled; and by adjusting the proportioned carbon and controlling the thickness of a liquid slag layer, bonding steel leakage caused by high crystallization temperature and deteriorated lubricating performance due to over high alkalinity of the protective slag is relieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Trench and via formation in insulating films utilizing a patterned etching stopper film

InactiveUS6268279B1Reduce parasitic capacitanceForm evenlySemiconductor/solid-state device detailsSolid-state devicesConductive materialsSemiconductor

A first interlayer insulating film and an etching stopper film are sequentially formed on a semiconductor substrate with a surface area on which first wiring is formed. The etching stopper film is patterned so as to correspond to a pattern of via hole formed on the first interlayer insulating film and a pattern of forming a second wiring. A second interlayer insulating film is formed on the etching stopped film for forming the second wiring, a wiring trench is formed by etching the second interlayer insulating film. Continuously, the via hole is formed by etching the first interlayer insulating film while having the etching stopper film as a photomask. Conductive materials are laid in the via hole and the wiring trench so that the second wiring connected to the first wiring is formed.

Owner:NEC ELECTRONICS CORP

High-speed feeding and discharging system and method

ActiveCN105059911AFast feeding speedImprove efficiencyControl devices for conveyorsBottles/feedBottle

The invention discloses a high-speed feeding and discharging system, which comprises a control assembly, a bottle collecting net belt, a target platform and a bottle pushing assembly, wherein the target platform and the bottle pushing assembly are respectively located at two sides of the bottle collecting net belt; a bottle feeding end of the bottle collecting net belt is in butt joint with a bottle feeding net belt; the bottle feeding end is provided with a bottle feeding assembly; a bottle stopping assembly is arranged at one end, opposite to the bottle feeding end, of the bottle collecting net belt; the bottle collecting net belt is provided with a detection assembly used for detecting the length of a bottle queue on the bottle collecting net belt; and the detection assembly is connected with the control assembly. The invention also discloses a high-speed feeding and discharging method. When a condition that the length of the bottle queue on the bottle collecting net belt is identical with the length of the target platform is detected, the control assembly stops the transmission of the bottle collecting net belt and the bottle feeding net belt, and the bottle queue on the bottle collecting net belt is pushed towards the bottle stopping assembly, so that after the bottle queue between the bottle feeding assembly and the bottle stopping assembly is in butt joint with a bottle feeding end of the target platform, the bottle queue is pushed onto the target platform by the bottle pushing assembly. The system and the method have the advantage that the feeding speed is improved.

Owner:TRUKING TECH LTD

Continuous large-scale production method for p-aramid nanofiber dispersion liquid

ActiveCN106750265AThe polymerization process went wellForm evenlyMonocomponent polyamides artificial filamentNanofiberChloride

The invention relates to a continuous large-scale production method for p-aramid nanofiber dispersion liquid, and belongs to the technical field of novel polymer materials. A proper aid is added in a process of generating poly-p-phenylene terephthamide (PPTA) through a reaction of p-phenylenediamine and paraphthaloyl chloride, so that the PPTA can directly generate nanofiber instead of random particles under control. Double screws are taken as a main reactor of PPTA polymerization, and an aid damaging molecular molecular aggregation of the PPTA is added into a PPTA polymerization system, so that successful proceeding of a PPTA polymerization process can be ensured on the one hand, interaction between the aid and the PPTA can be accelerated under the strong shear stirring action of a screw element on the other hand, and uniform nanofiber is formed instead of random particles by the PPTA. Moreover, a dispersing process of the nanofiber is finished directly in the screws under the shearing action of the double screws. The method is simple in equipment and is urgent in production links, major reaction and dispersion processes are finished in the double screws, and the production stability and continuity are enhanced greatly.

Owner:山东聚芳新材料股份有限公司

Automatic electrostatic spinning device

InactiveCN101492838AContinuous formationForm evenlyFilament/thread formingNon-woven fabricsAutomatic controlElectrospinning

The invention discloses an automatic electrostatic spinning device. A spinning needle head and a spinning solution feed device are connected with a transversing mechanism; the transversing mechanism is provided with an adjustable lead limit switch for controlling width of non-weaving cloth; the transversing mechanism and a fiber collecting device are respectively connected with a computer control device; the fiber collecting device is provided with a collecting mechanism and a lifting mechanism, and can adjust distance between a receiving electrode and the collecting mechanism by the lifting mechanism, so as to adjust fineness of the non-weaving cloth and set length and thickness of the cloth; transverse speed and collecting speed of the spinning device are matched, so that the non-weaving cloth can be continuously and evenly weaved, and polymer solution can be added during weaving. The automatic electrostatic spinning device is provided with an automatic control device, thereby facilitating weaving, reducing human resource, saving time, and improving production efficiency.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com