Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2758 results about "Gas barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

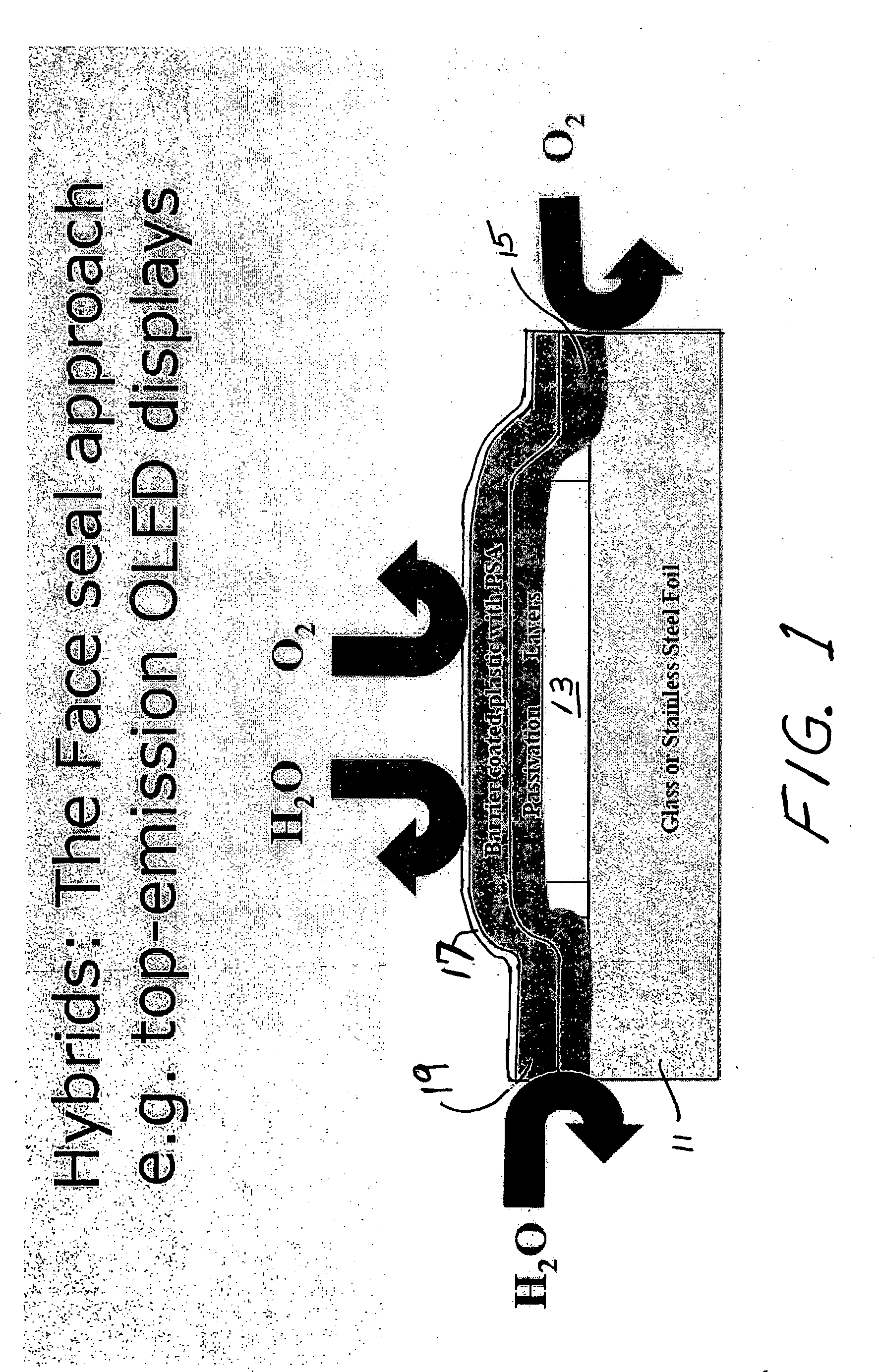

Gas Barrier. Gas barriers are technological solutions able to reduce or slow down the passage of gases and vapors. The typical function of blocking or reducing the gas migration is to protect what is stored on the other side of the barrier.

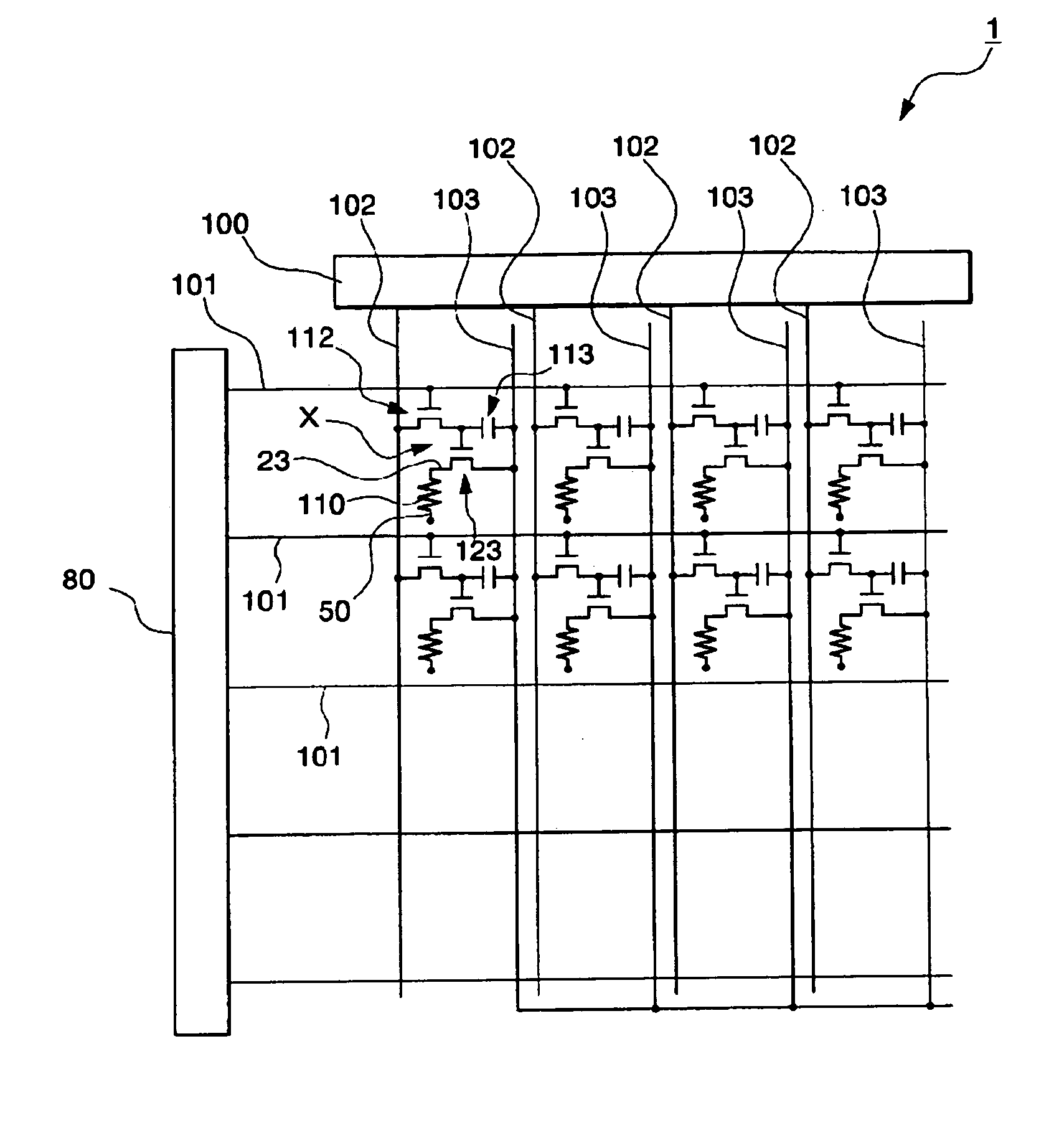

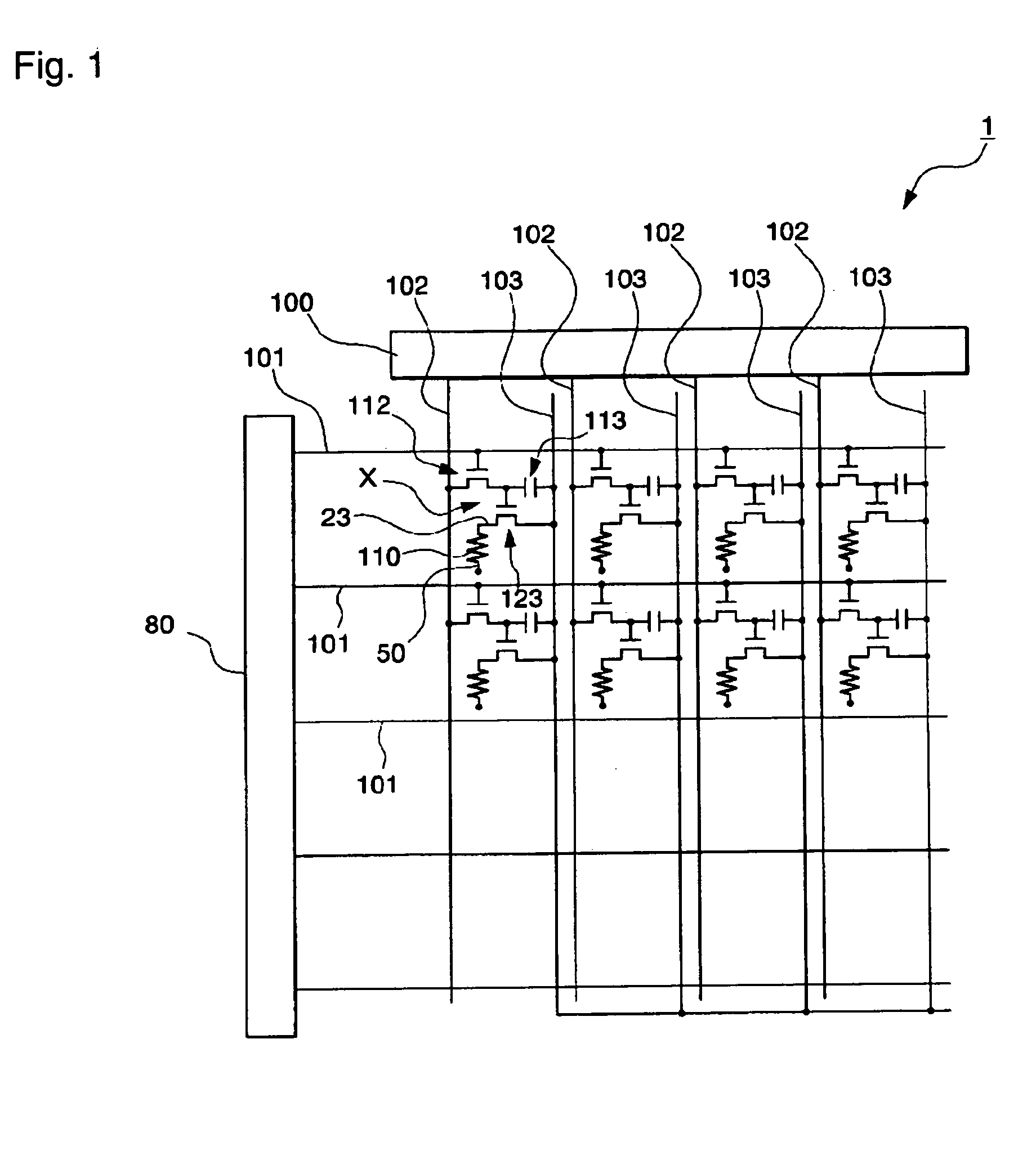

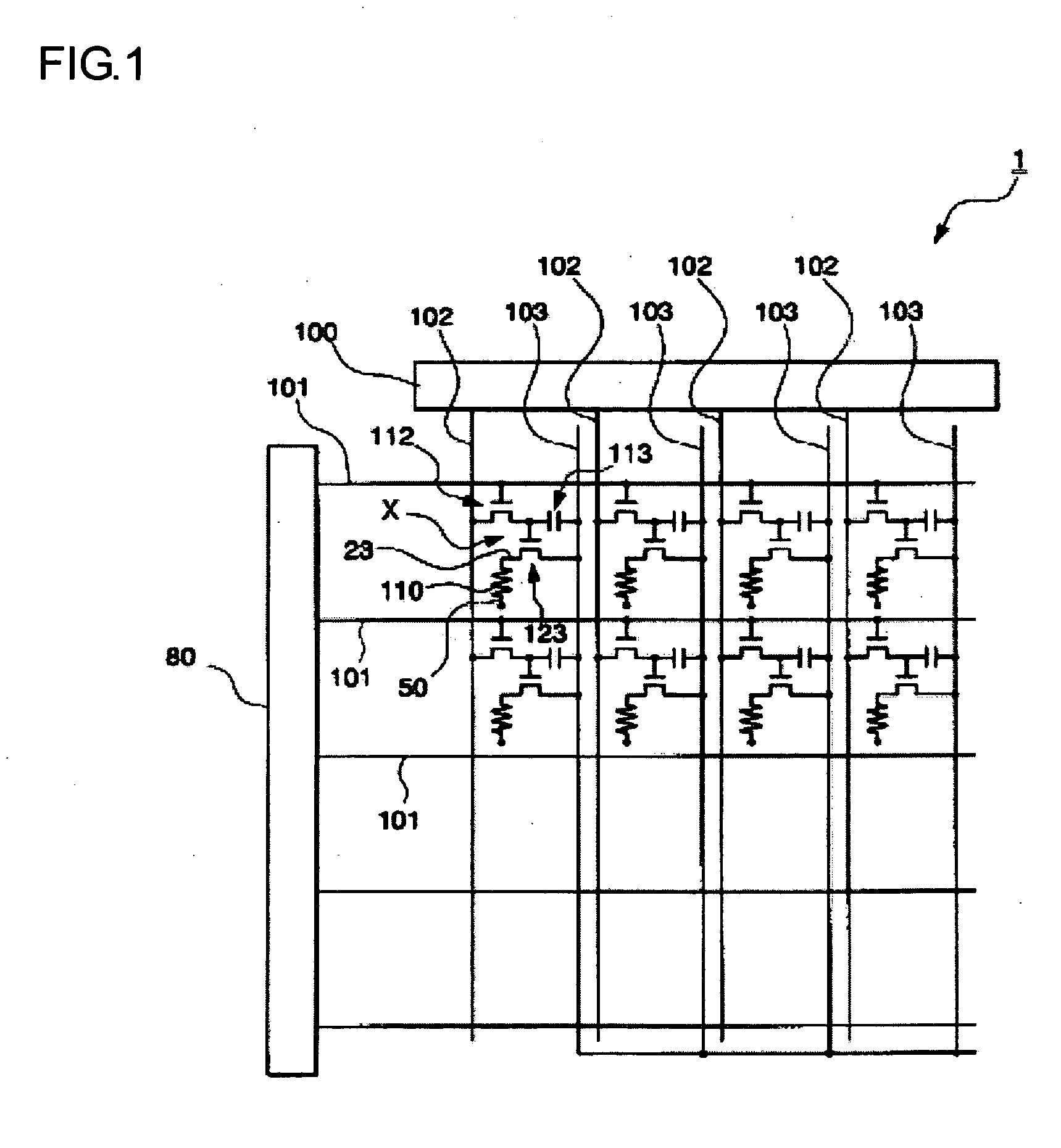

Structure with transistor

ActiveUS20080258139A1Improve mobilityOn/off ratio highSemiconductor/solid-state device manufacturingSemiconductor devicesLiquid-crystal displayDisplay device

A structure with a transistor is disclosed comprising a substrate, a gas barrier layer on the substrate, and a transistor on the gas barrier layer. The transistor can include an oxide semiconductor layer. The oxide semiconductor layers can comprise In—Ga—Zn—O. A display, such as a liquid crystal display, can have such a structure.

Owner:TOPPAN PRINTING CO LTD

Method for fabrication of transparent gas barrier film using plasma surface treatment and transparent gas barrier film fabricated thereby

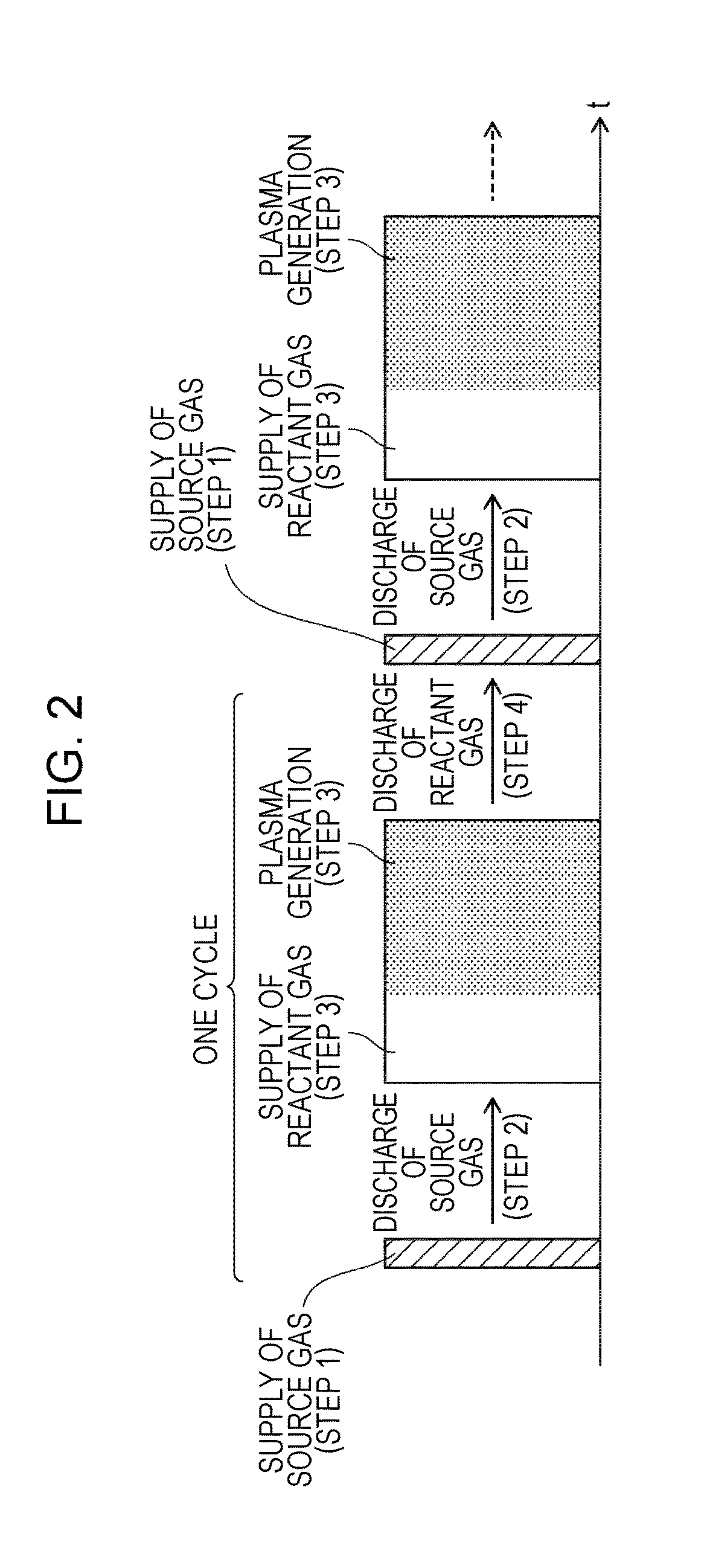

InactiveUS20100285319A1Excellent gas barrier performanceEconomical and simple methodSynthetic resin layered productsPretreated surfacesOptoelectronicsInorganic layer

The present invention relates to a method of fabricating a transparent gas barrier film by using plasma surface treatment and a transparent gas barrier film fabricated according to such method which has an organic / inorganic gradient interface structure at the interface between an organic / inorganic hybrid layer and an inorganic layer. Since the method of the present invention is capable of fabricating a gas barrier film by plasma surface treatment instead of deposition under high vacuum, it can mass-produce a transparent gas barrier film with excellent gas barrier properties in an economical and simple manner. Further, since the transparent gas barrier film fabricated according to the method of the present invention shows excellent gas barrier properties and is free of crack formation and layer-peeling phenomenon, it can be effectively used in the manufacture of a variety of display panels.

Owner:KOREA INST OF SCI & TECH

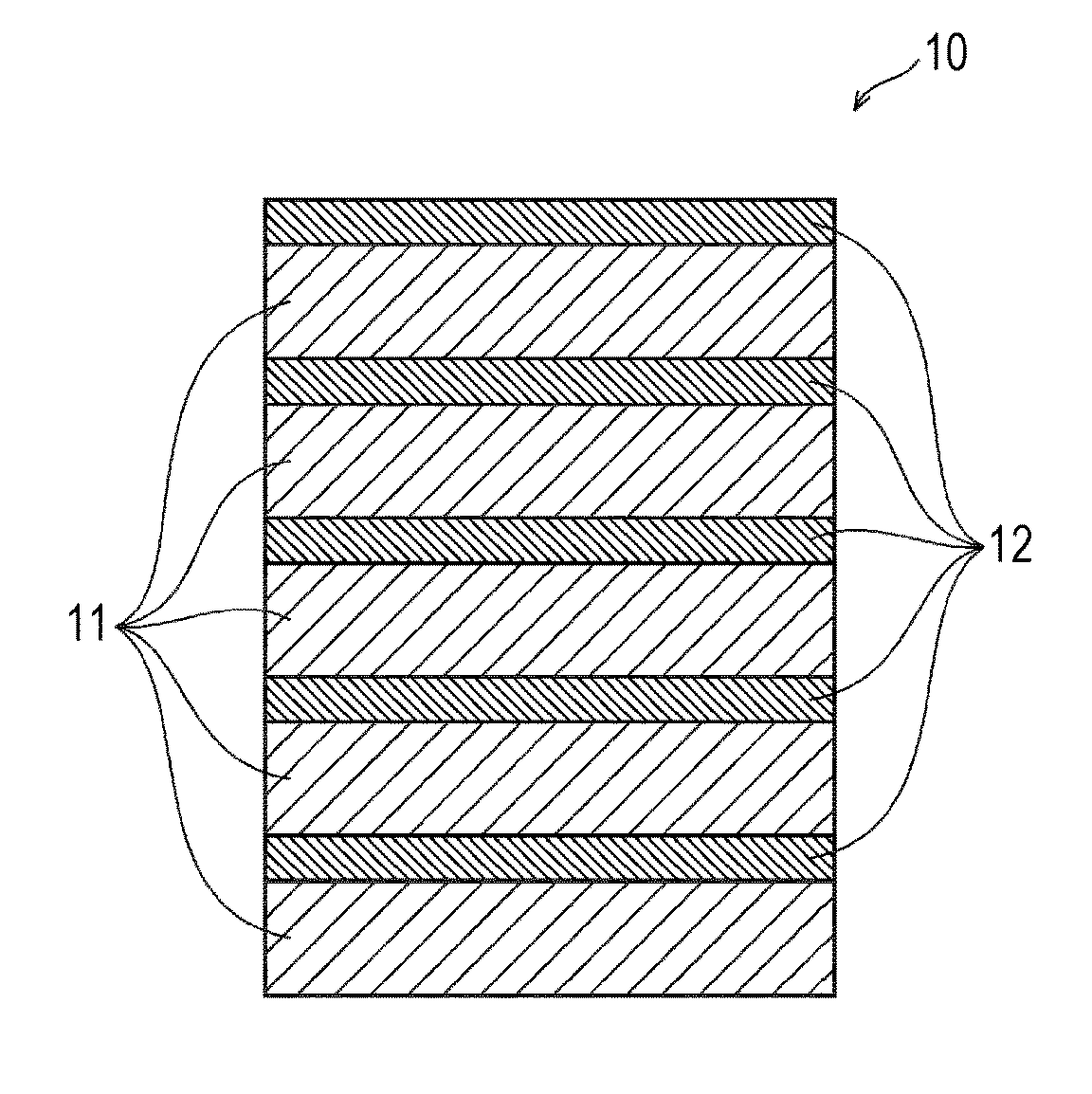

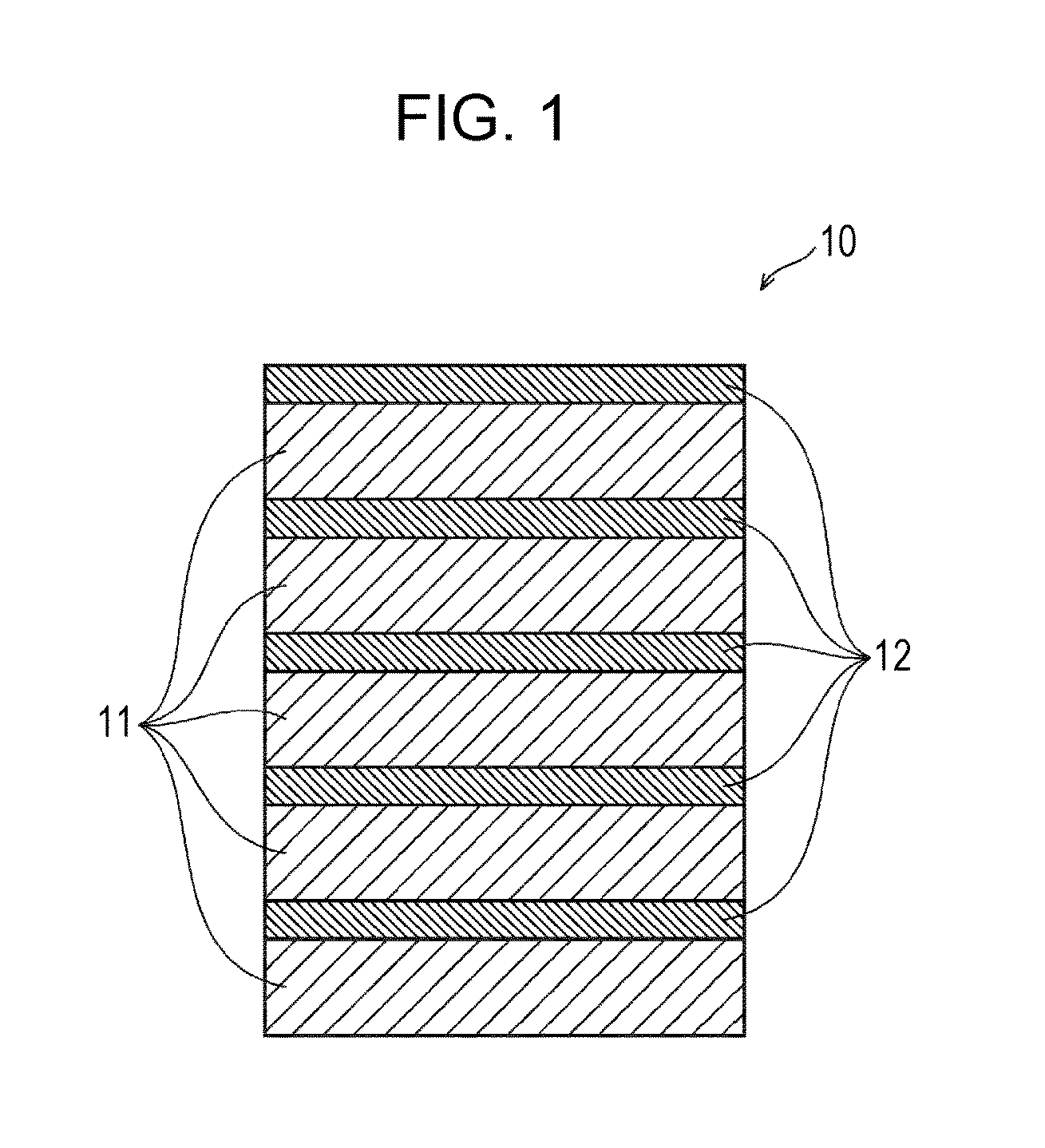

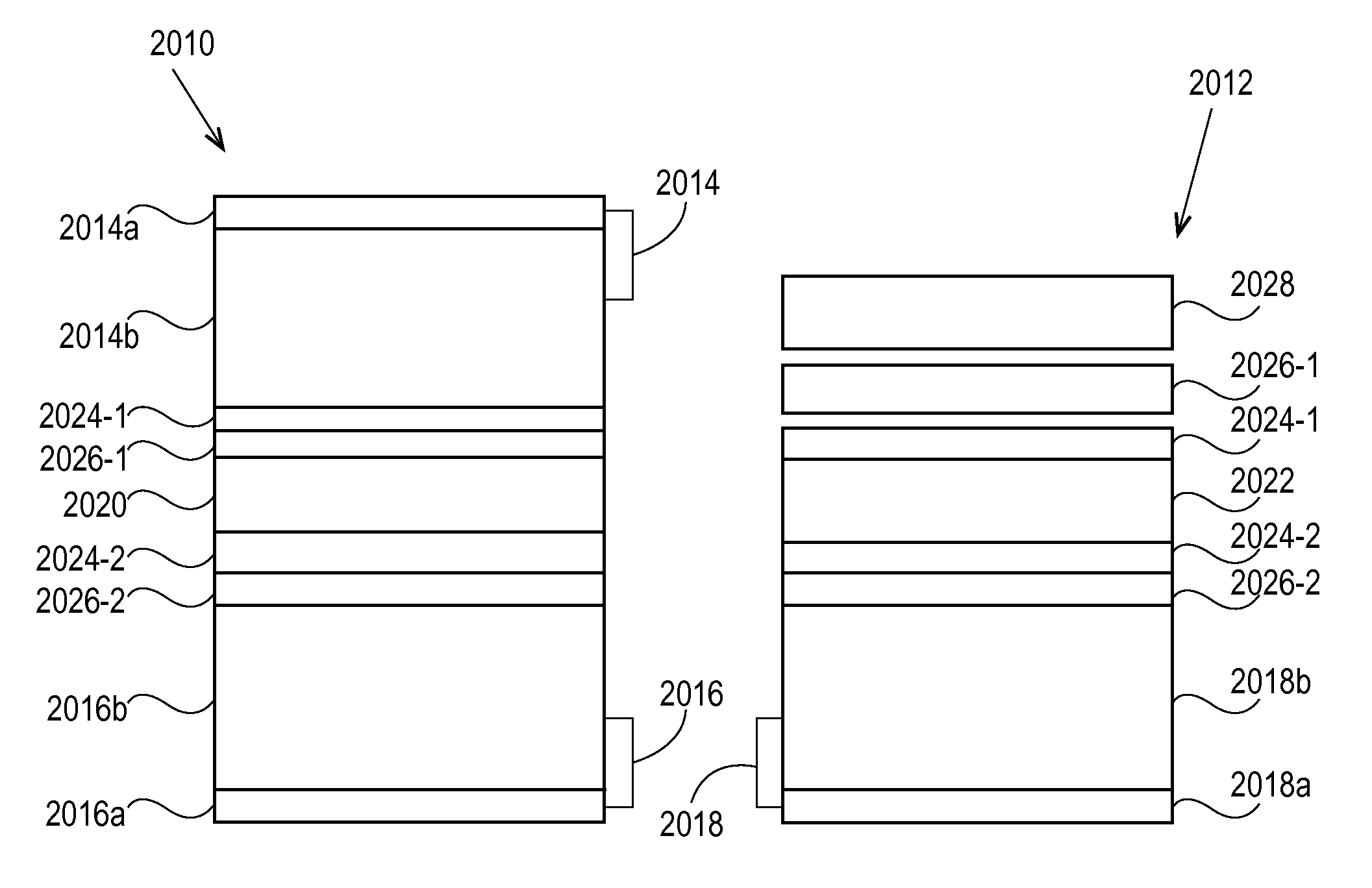

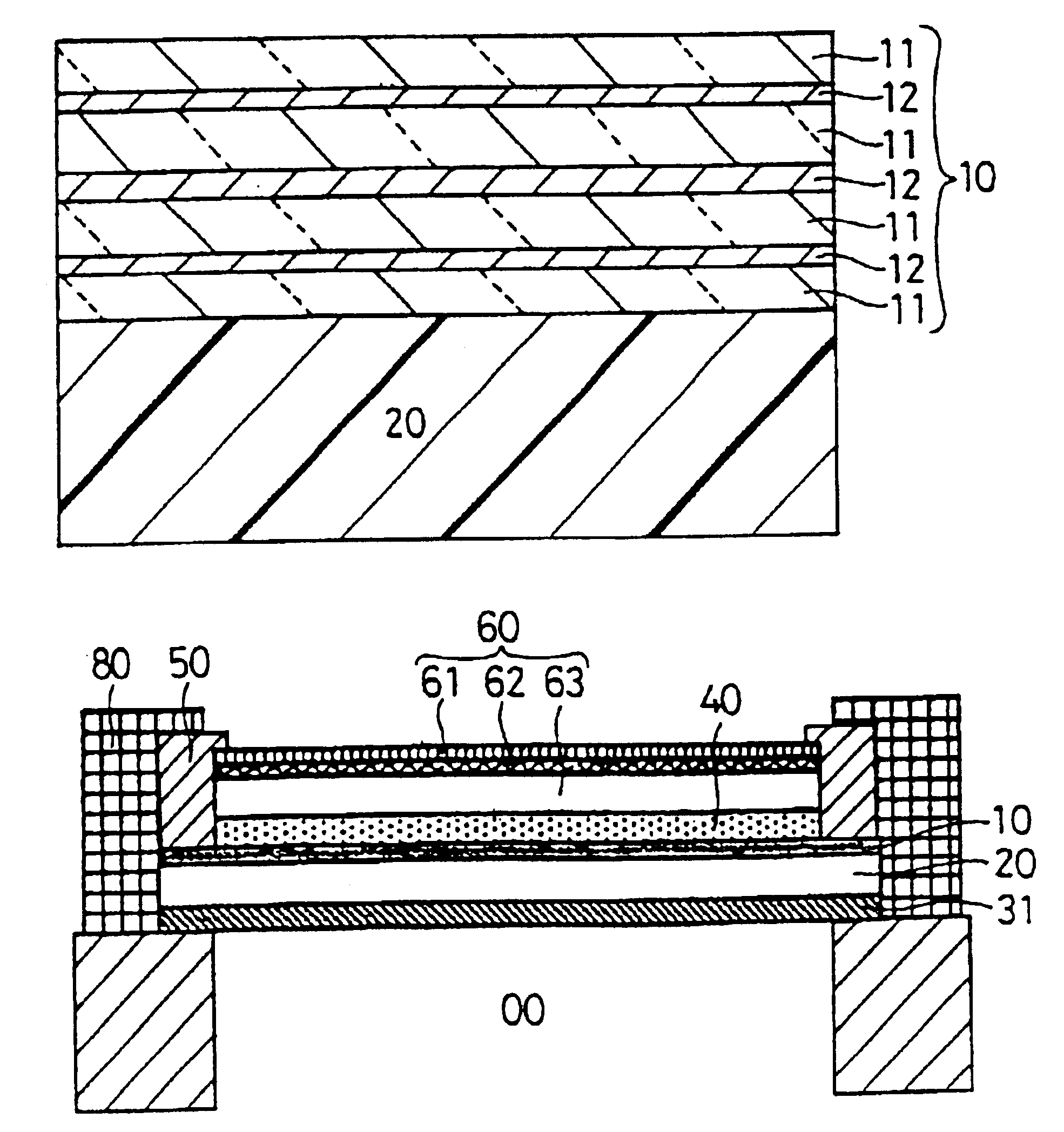

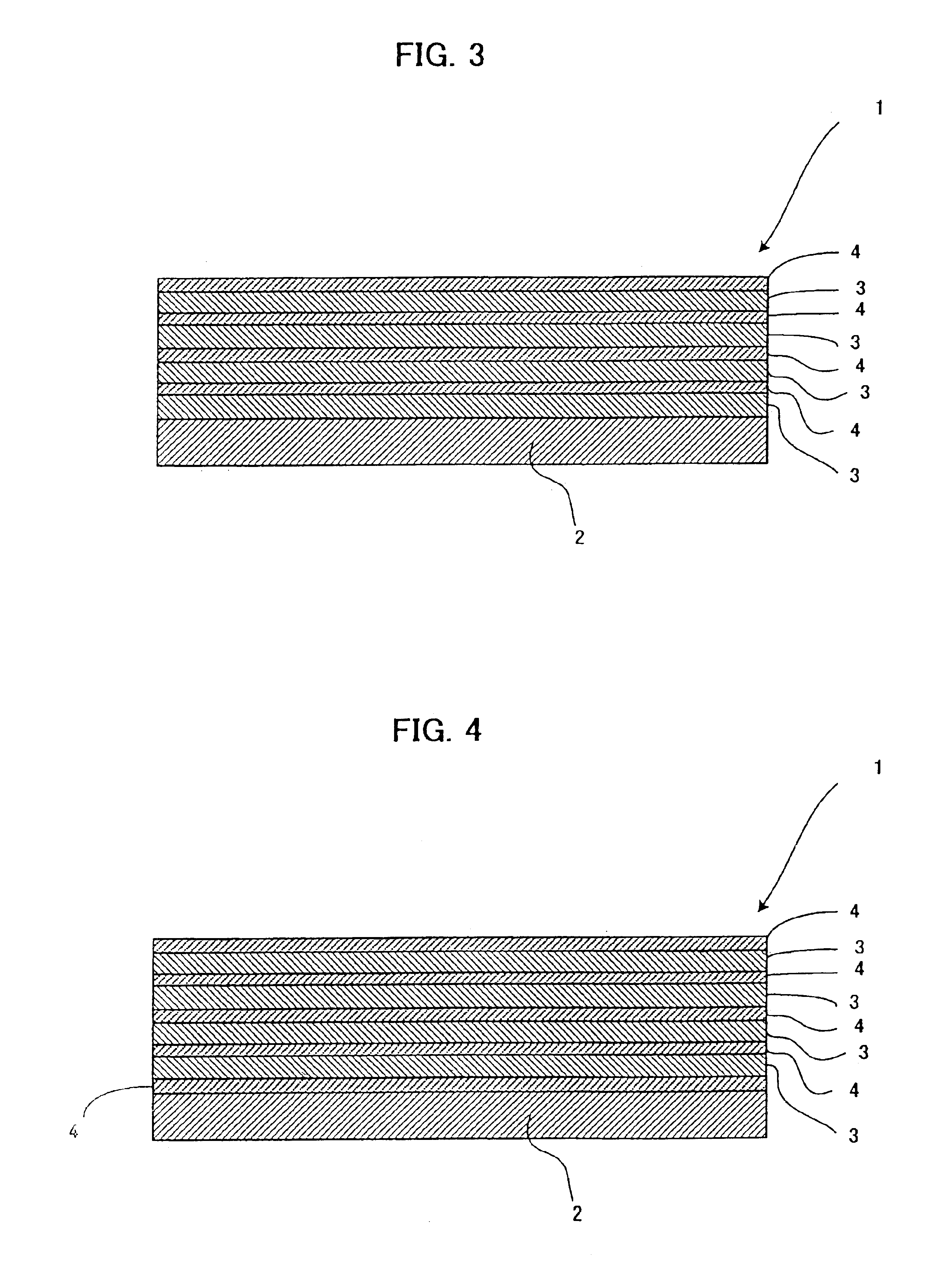

Gas barrier film, film substrate provided with gas barrier film, and electronic device including the film substrate

ActiveUS20150343741A1Excellent gas barrier performanceIncrease resistanceLayered productsRecord information storageThin membraneElectric devices

A gas barrier film includes two or more first barrier layers each made of a first inorganic material and one or more second barrier layers each made of a second inorganic material different from the first inorganic material. Each of the two or more first barrier layers and each of the one or more second barrier layers are alternately stacked. The first inorganic material comprises aluminum oxide. Each of the two or more first barrier layers has a thickness of 3 nm or more. The total thickness of the two or more first barrier layers is 20 nm or less. The two or more first barrier layers and the one or more second barrier layers are formed by atomic layer deposition.

Owner:SAMSUNG DISPLAY CO LTD

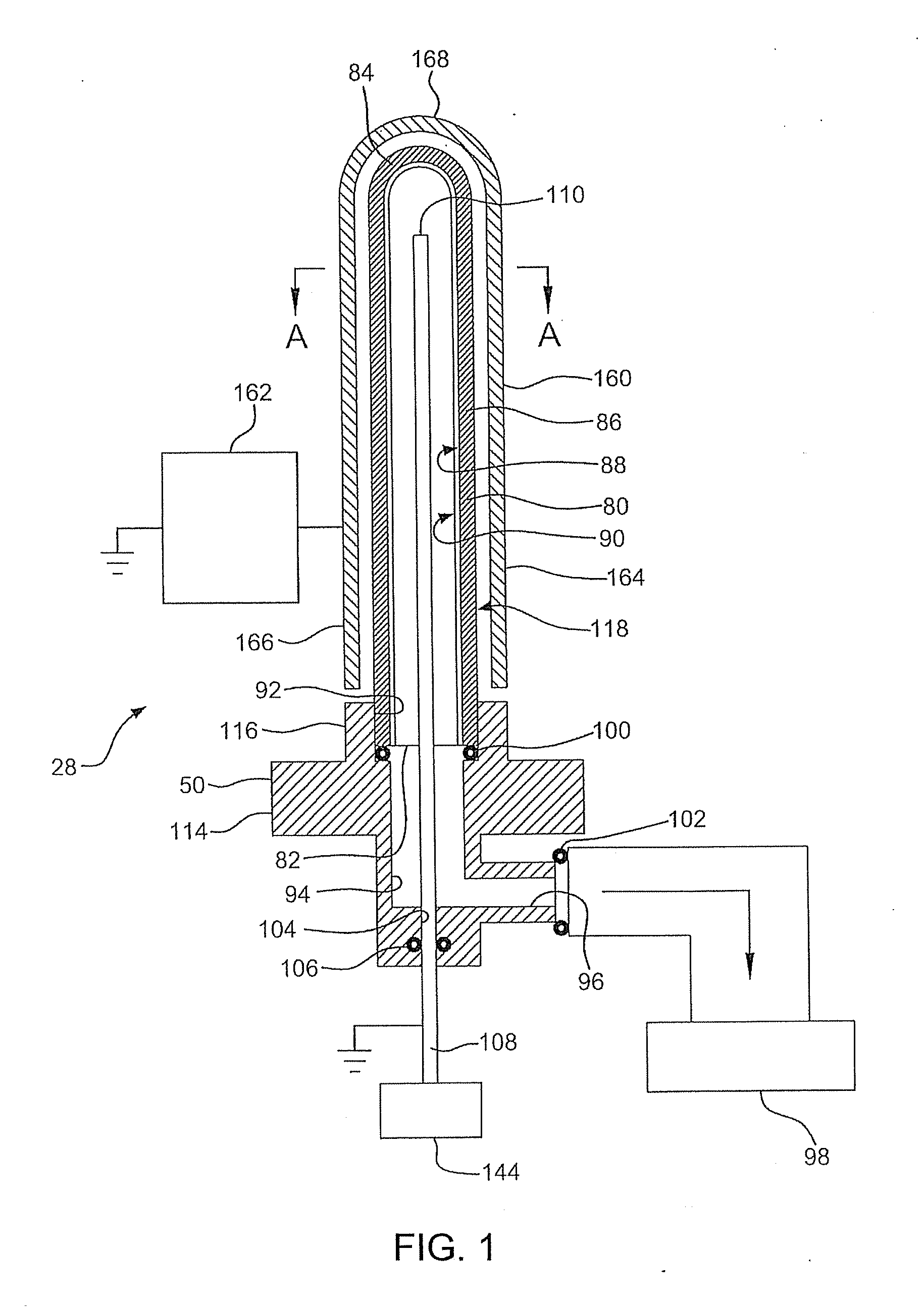

Methods for controlling formation of deposits in a deposition system and deposition methods including the same

InactiveUS20060216416A1Avoid contactChemical vapor deposition coatingProcess engineeringReaction chamber

A method for controlling parasitic deposits in a deposition system for depositing a film on a substrate, the deposition system defining a reaction chamber for receiving the substrate and including a process gas in the reaction chamber and an interior surface contiguous with the reaction chamber, includes flowing a buffer gas between the interior surface and at least a portion of the process gas to form a gas barrier layer such that the gas barrier layer inhibits contact between the interior surface and components of the process gas.

Owner:CREE INC

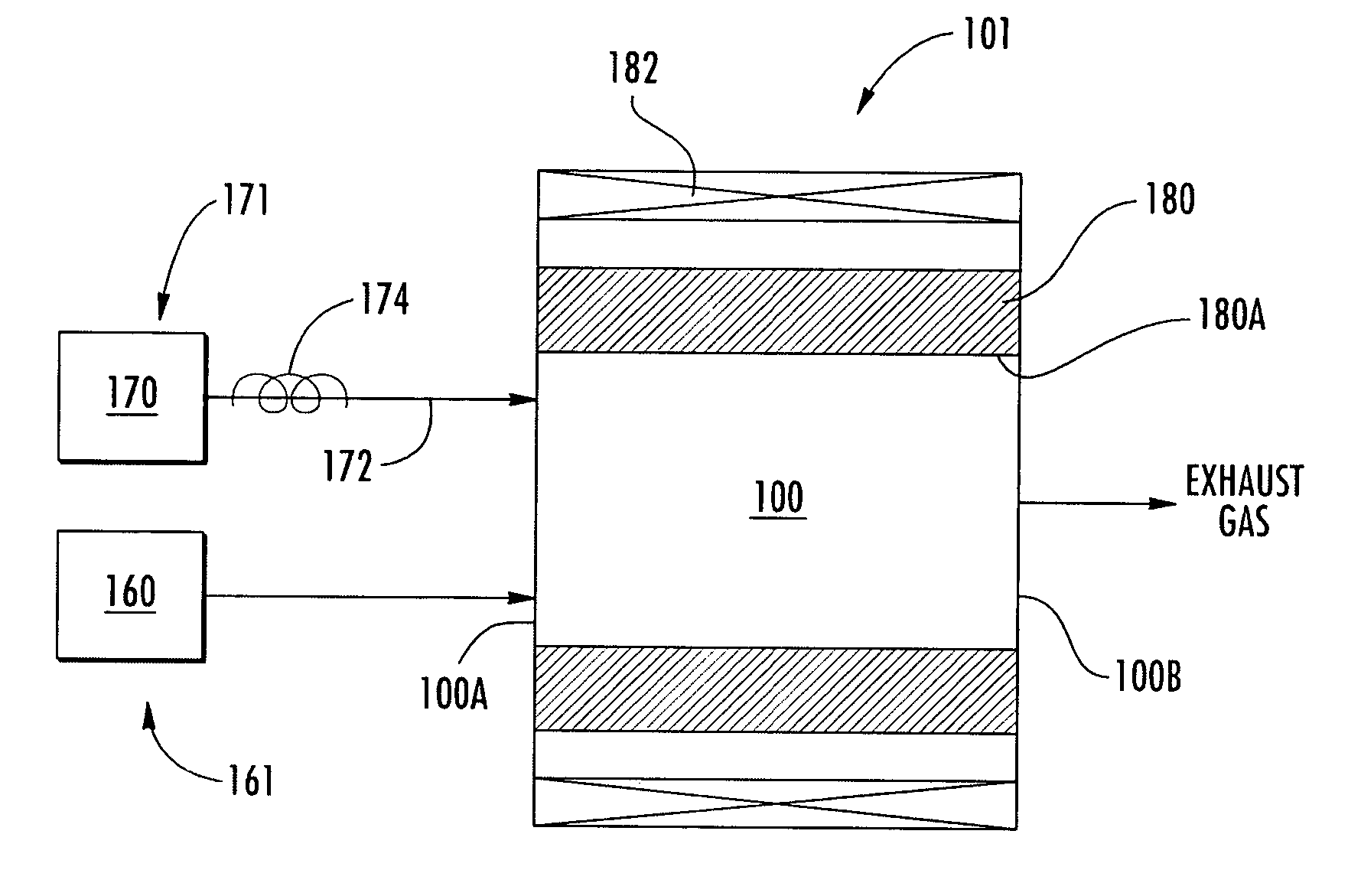

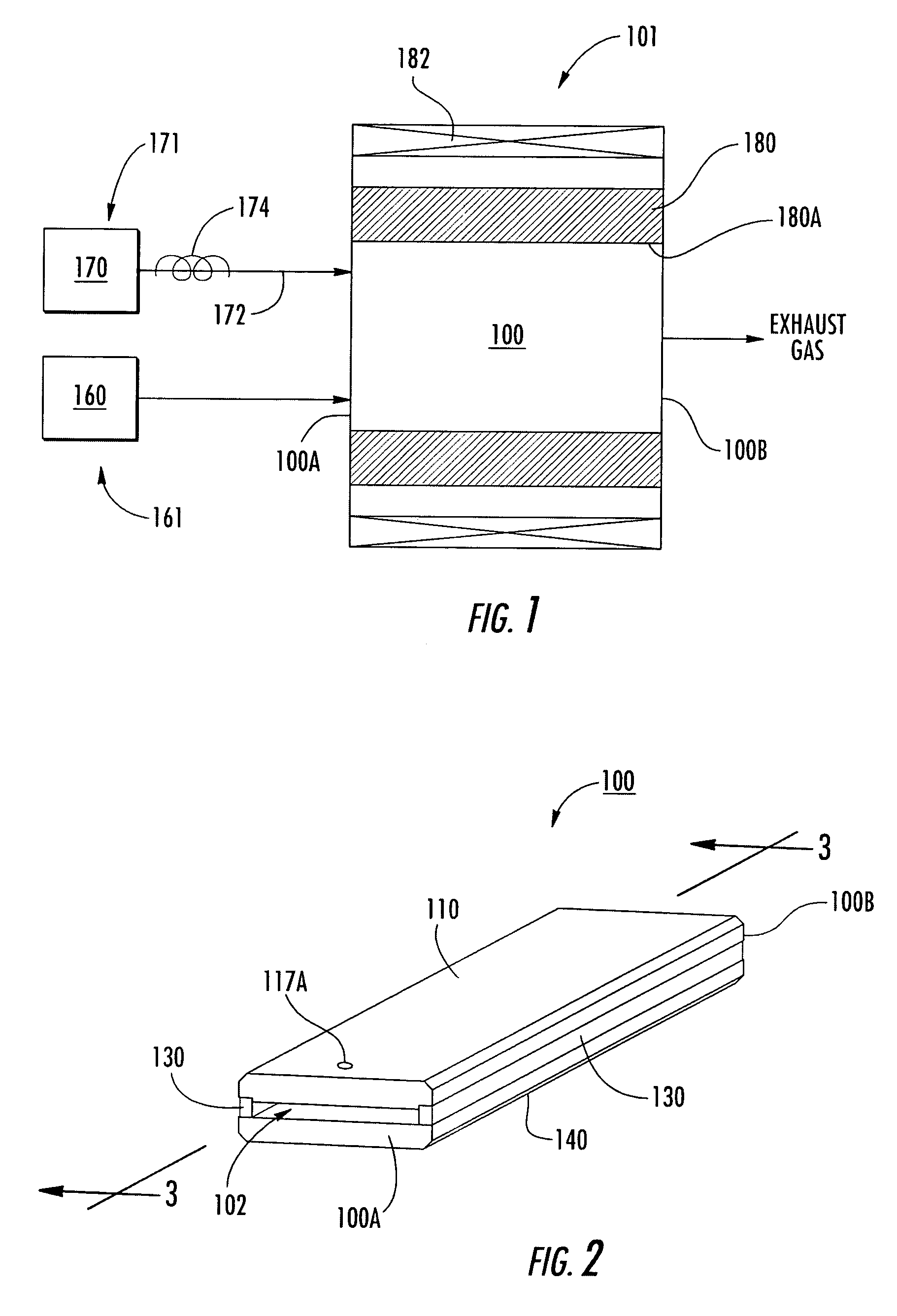

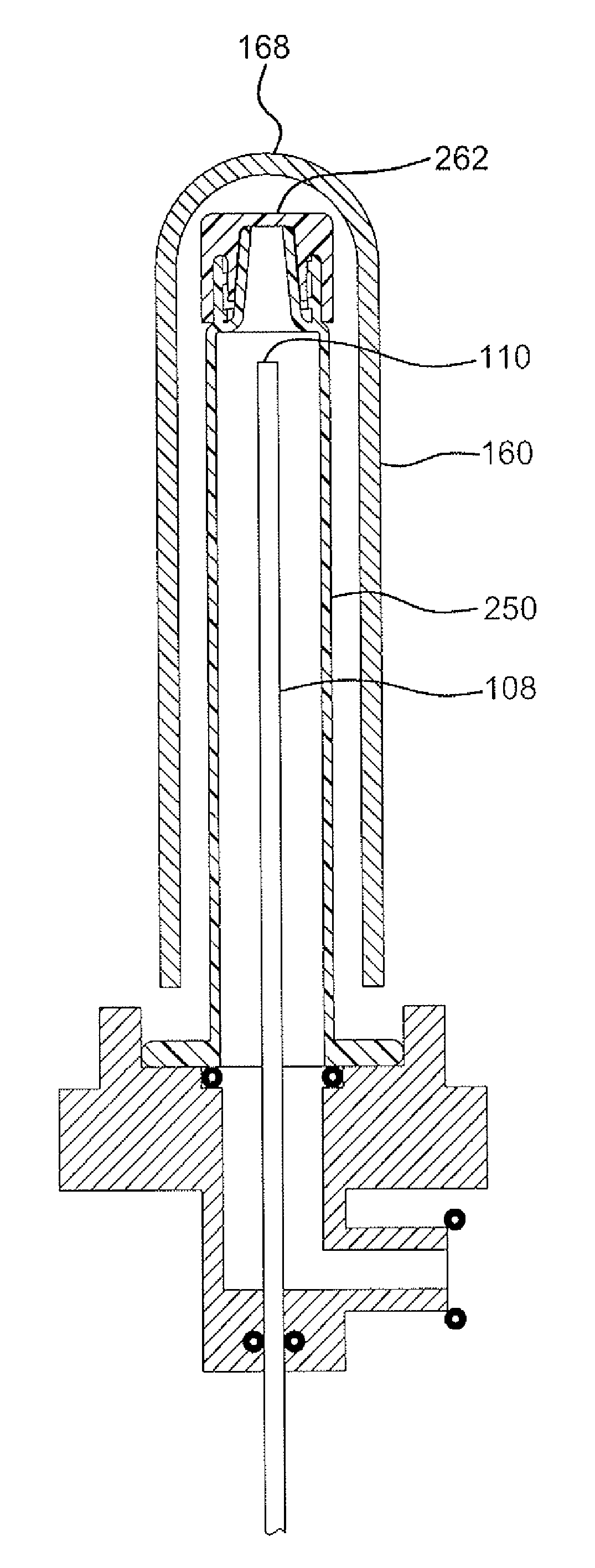

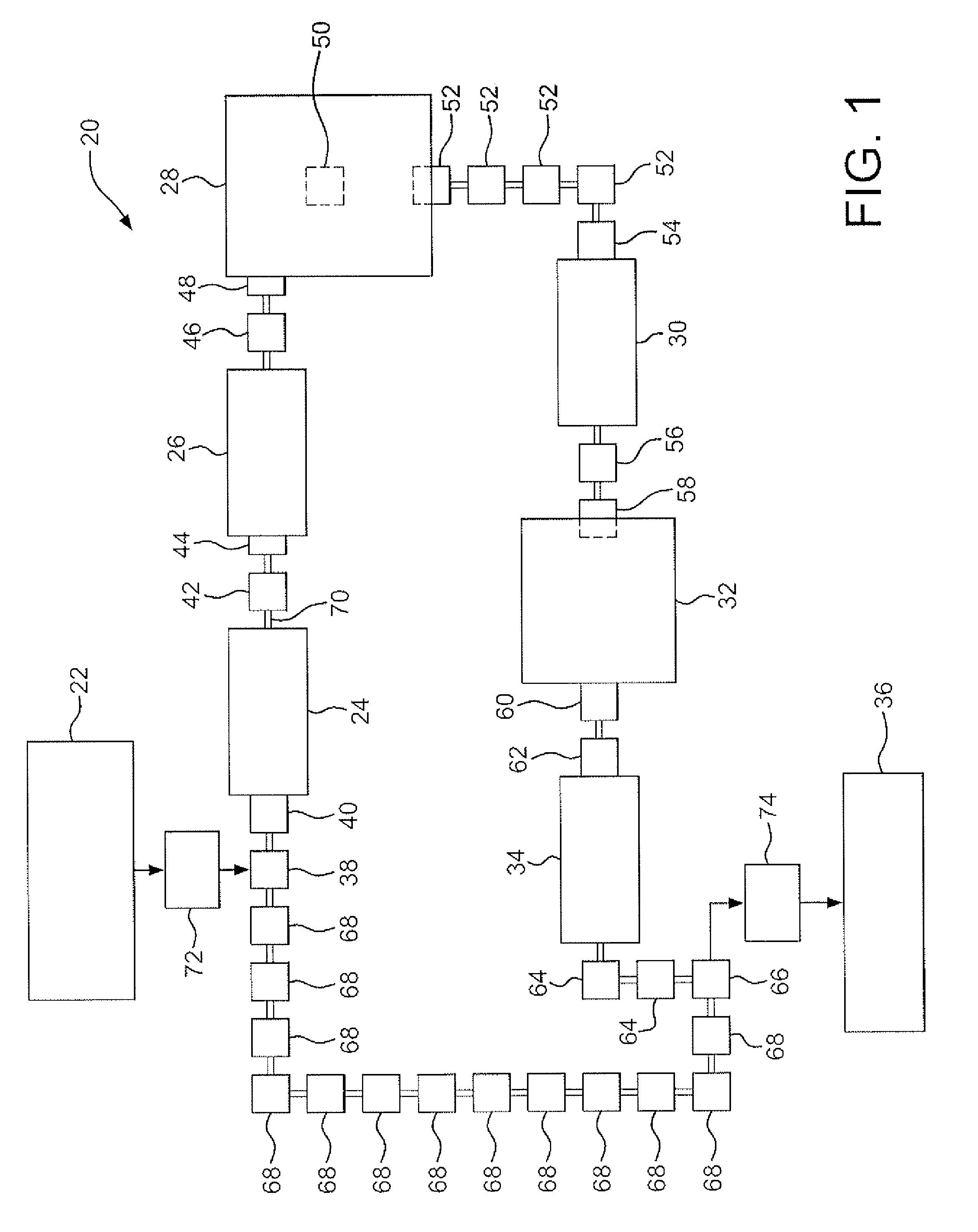

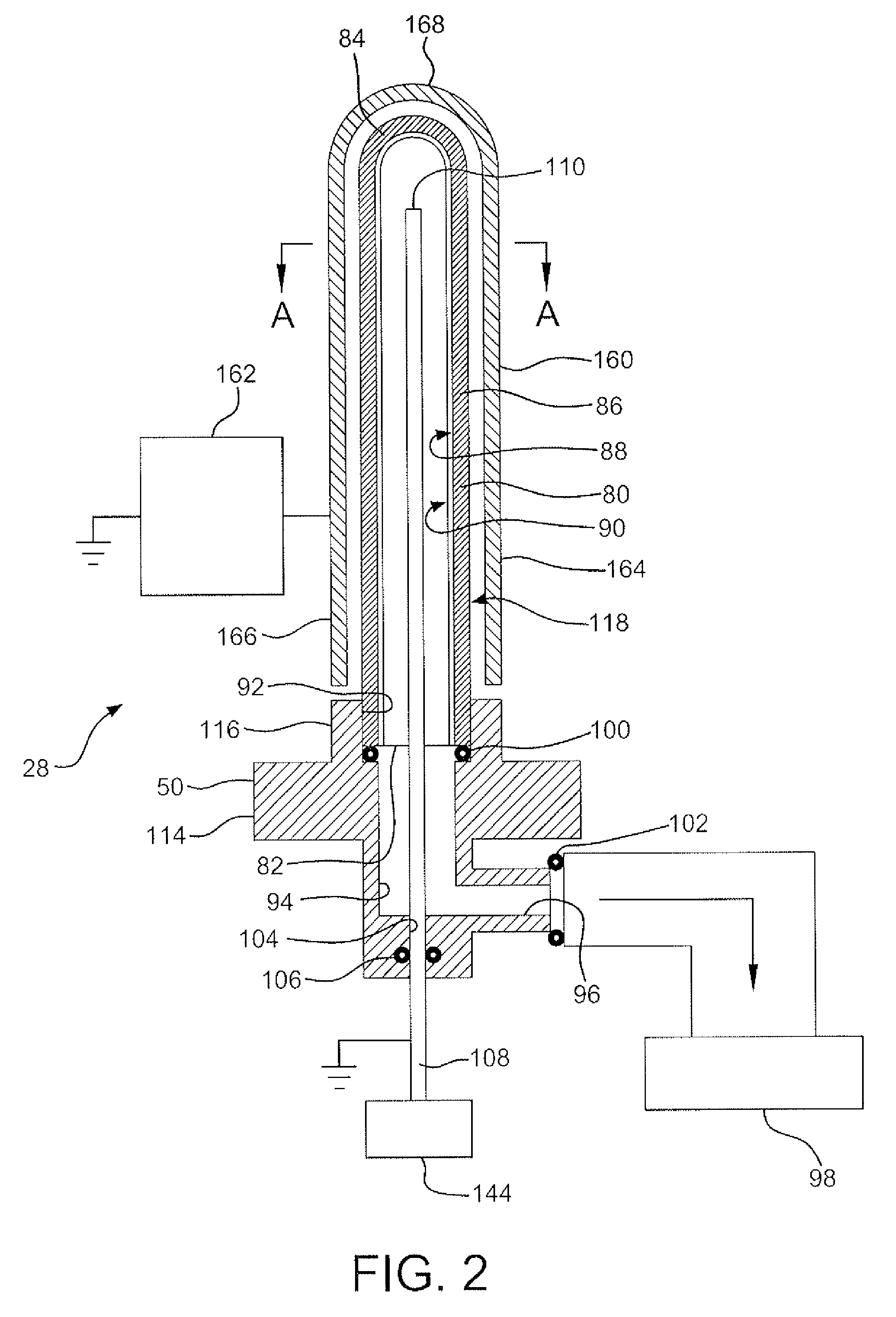

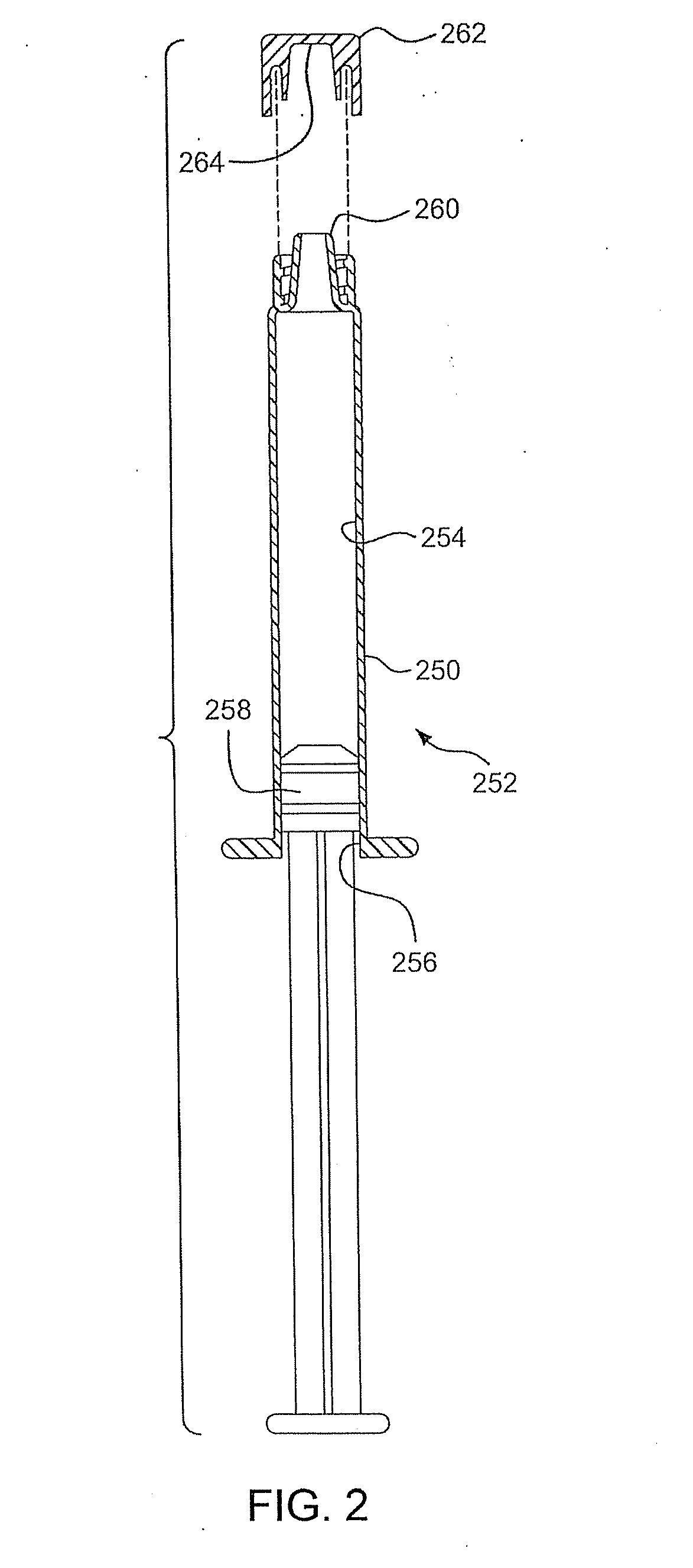

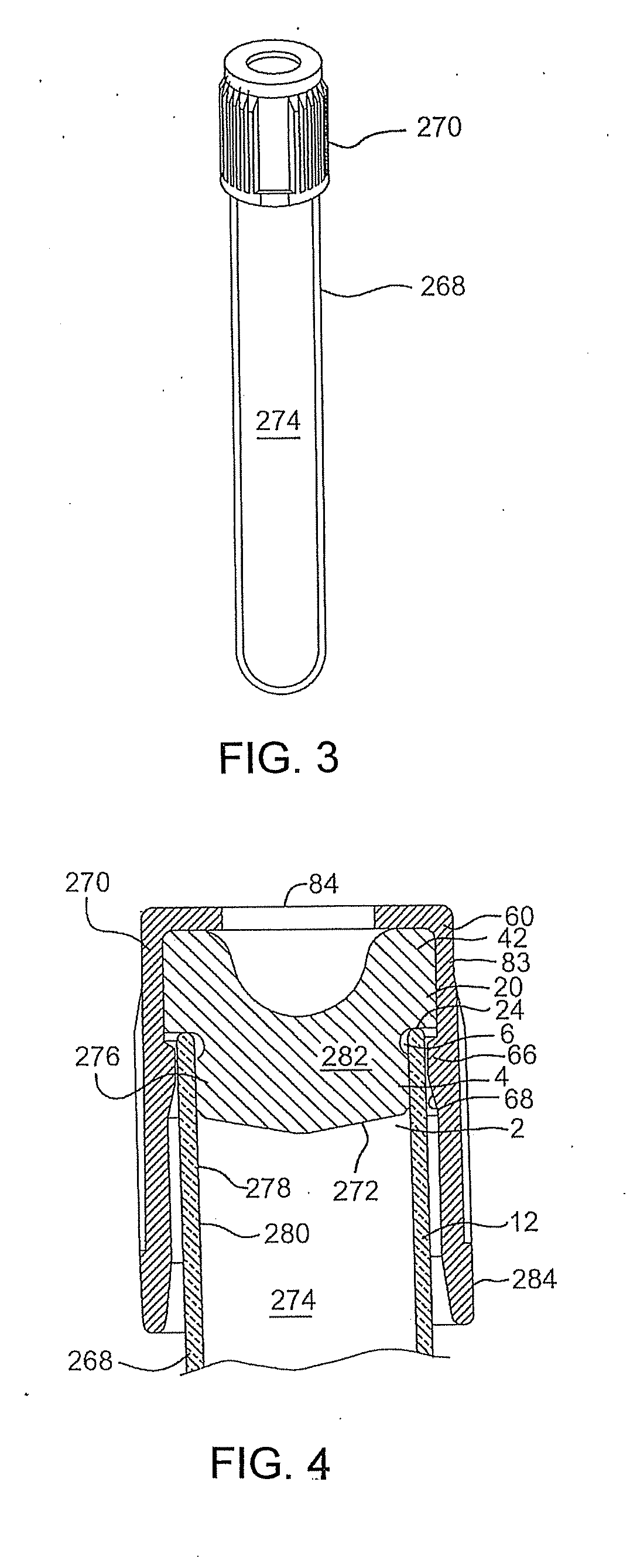

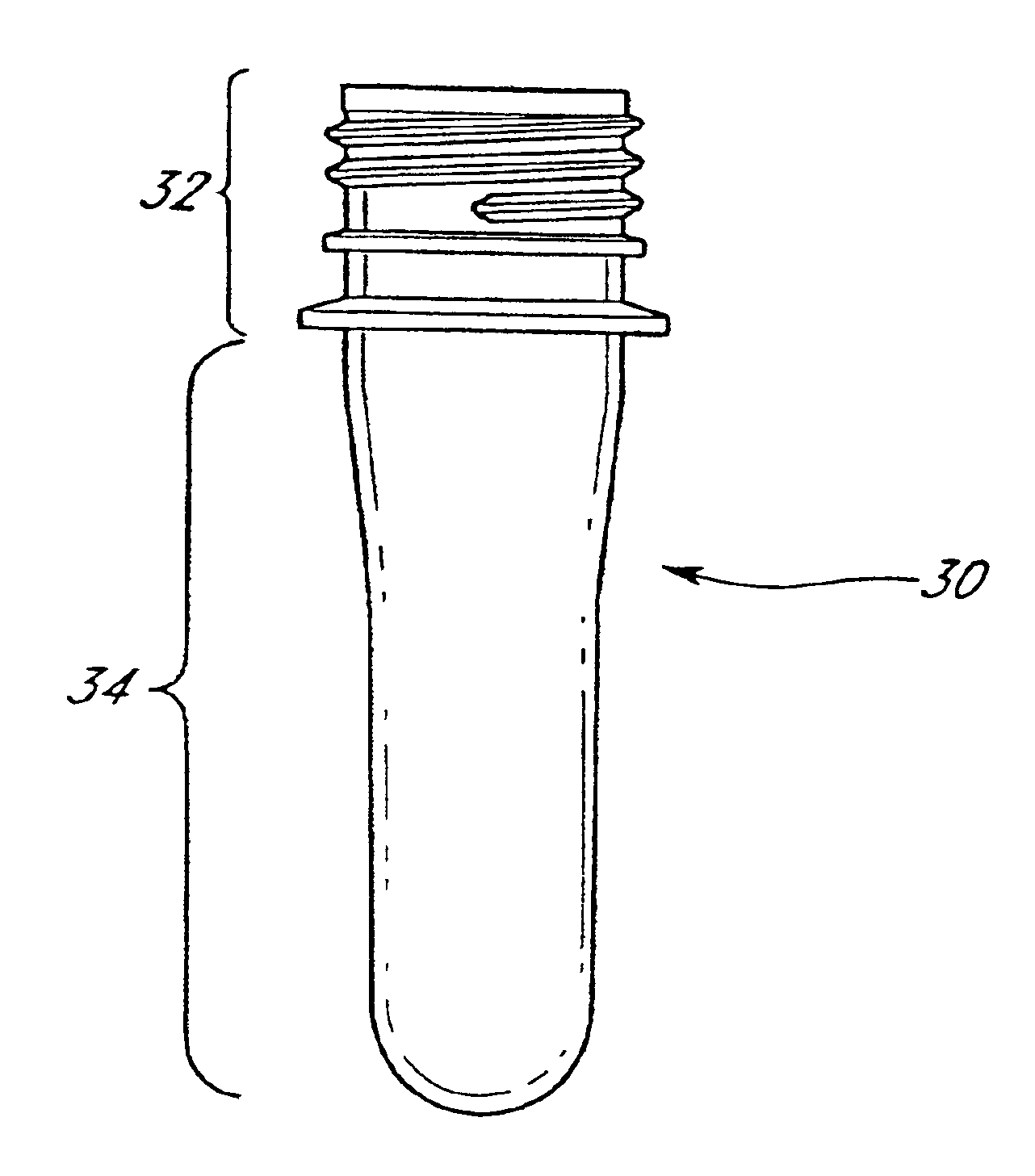

Vessel, coating, inspection and processing apparatus

ActiveUS7985188B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingMarine engineeringProduct gas

Methods for processing a vessel, for example to provide a gas barrier or lubricity, are disclosed. First and second PECVD or other vessel processing stations or devices and a vessel holder comprising a vessel port are provided. An opening of the vessel can be seated on the vessel port. The interior surface of the seated vessel can be processed via the vessel port by the first and second processing stations or devices. Vessel barrier, lubricity and hydrophobic coatings and coated vessels, for example syringes and medical sample collection tubes are disclosed. A vessel processing system and vessel inspection apparatus and methods are also disclosed.

Owner:SI02 MEDICAL PRODS

Flexible Materials for Flexible Containers

ActiveUS20130337244A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

Flexible Materials for Flexible Containers

ActiveUS20130294711A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:THE PROCTER & GAMBLE COMPANY

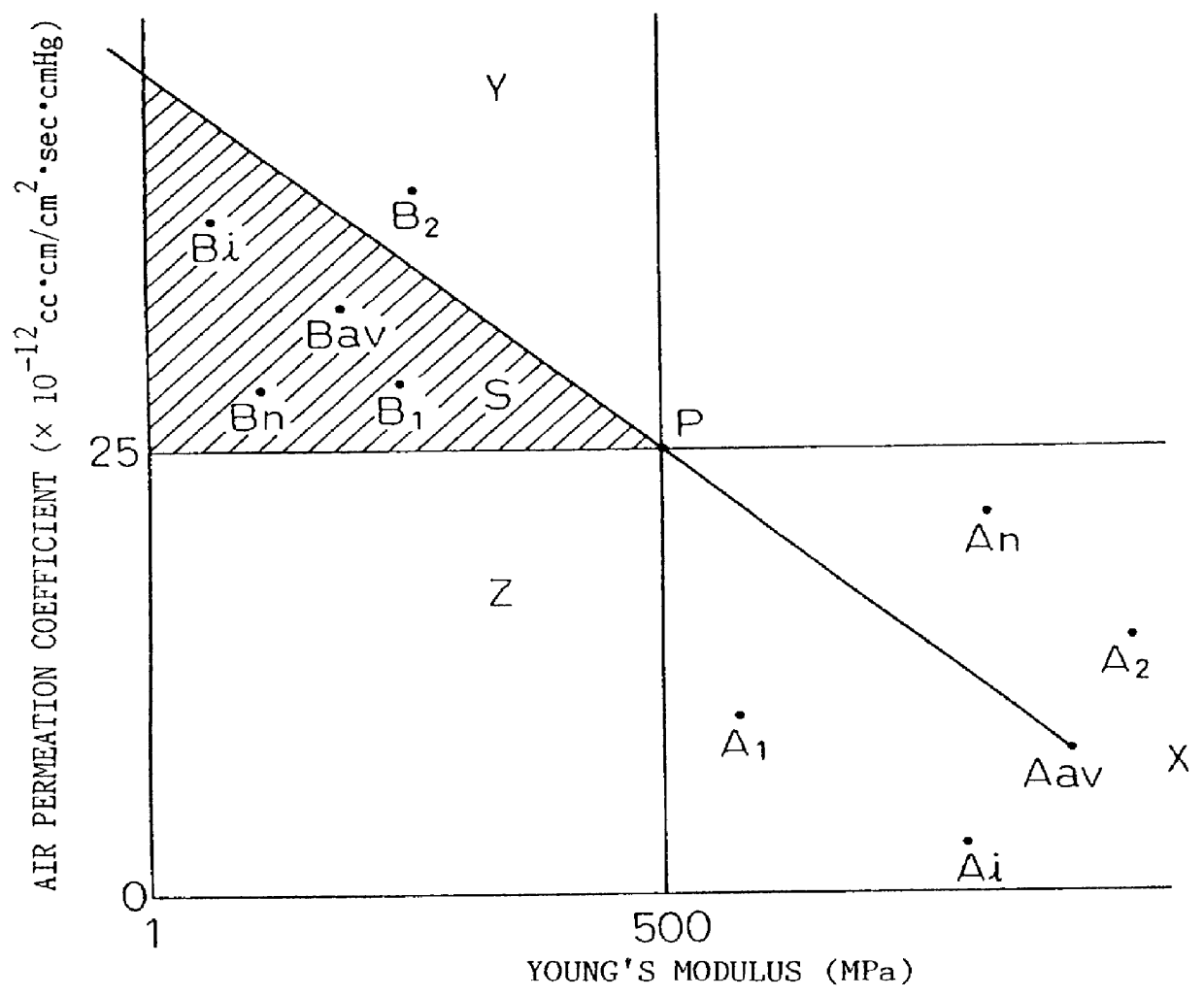

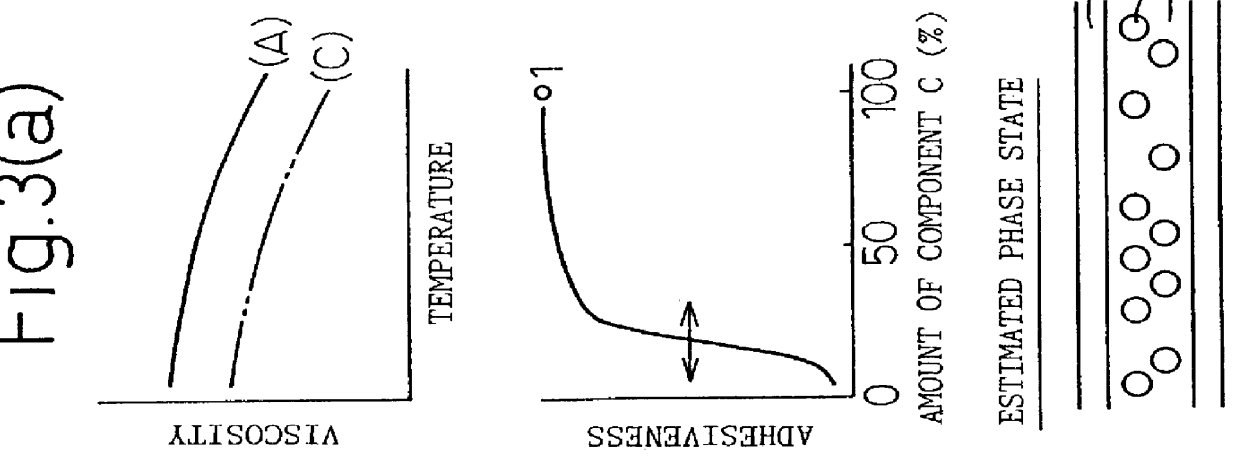

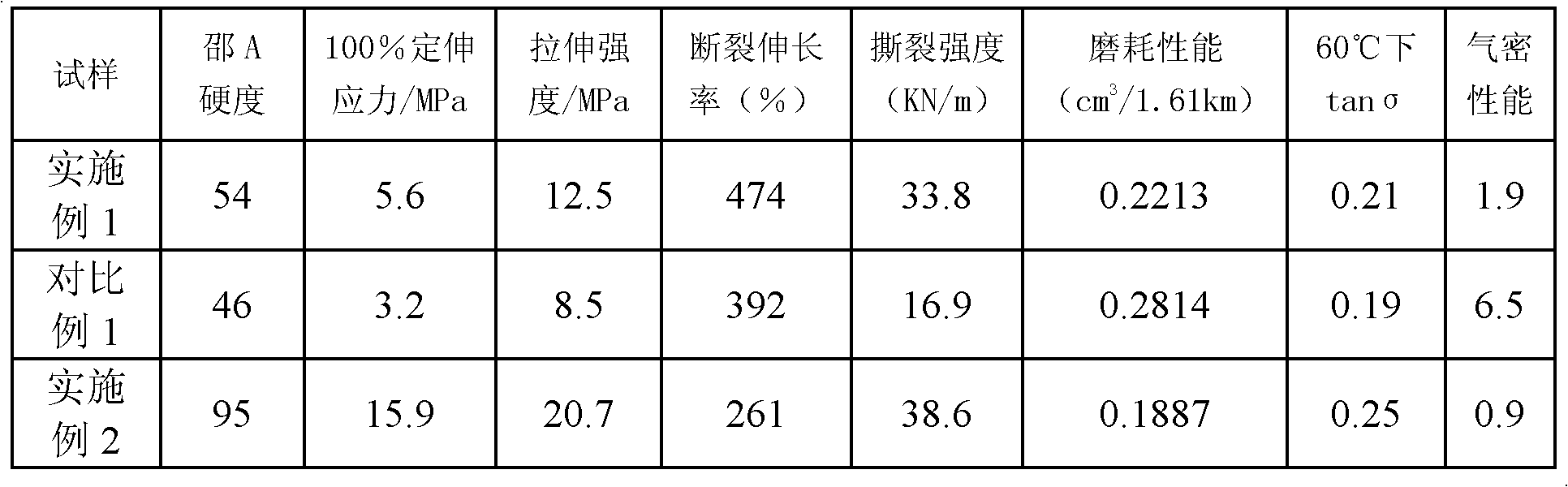

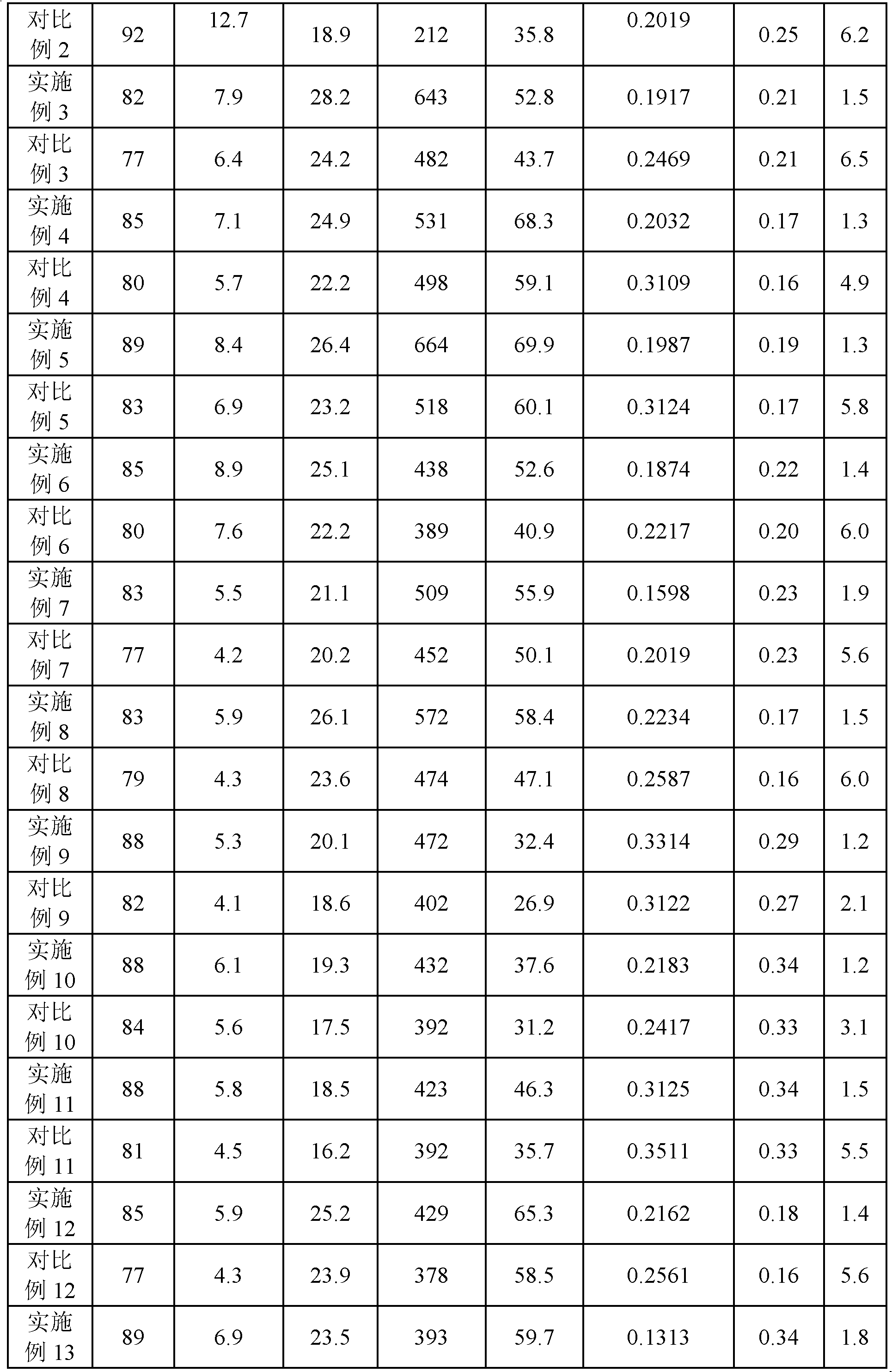

Pneumatic tire made by using lowly permeable thermoplastic elastomer composition in gas-barrier layer and thermoplastic elastomer composition for use therein

InactiveUS6062283AHigh elastomer ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

PCT No. PCT / JP97 / 01514 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 45489 PCT Pub. Date Dec. 4, 1997A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:YOKOHAMA RUBBER CO LTD

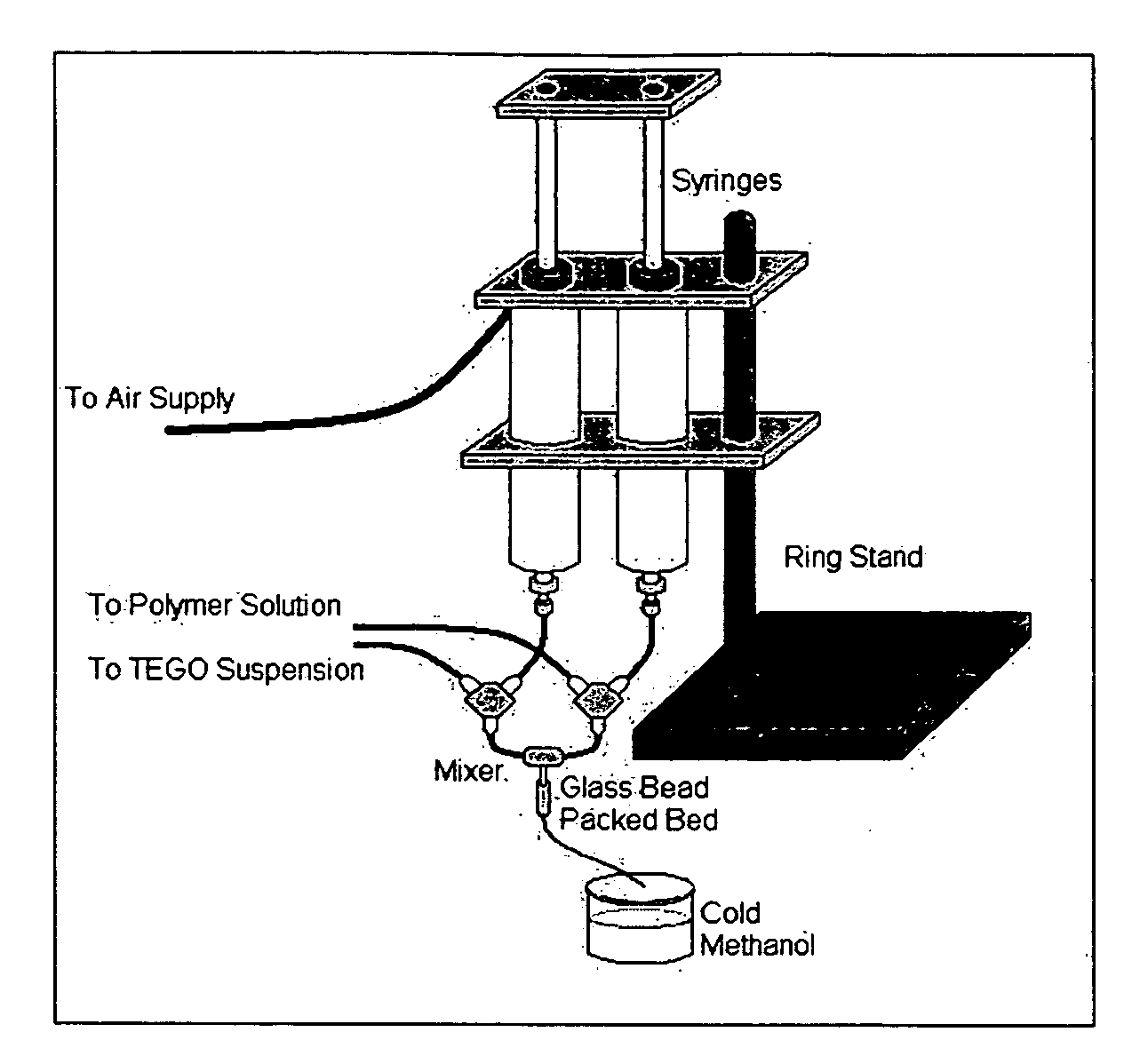

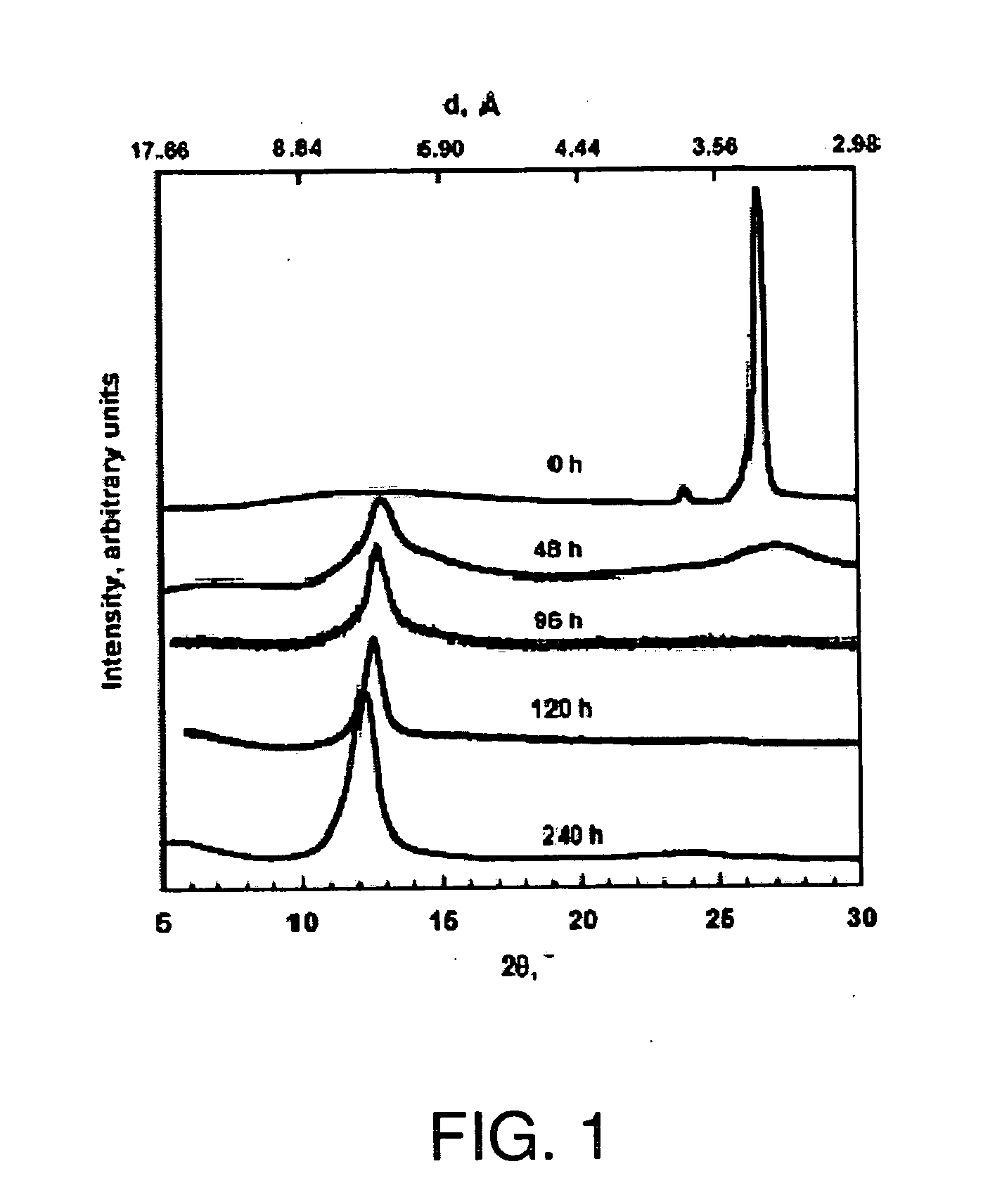

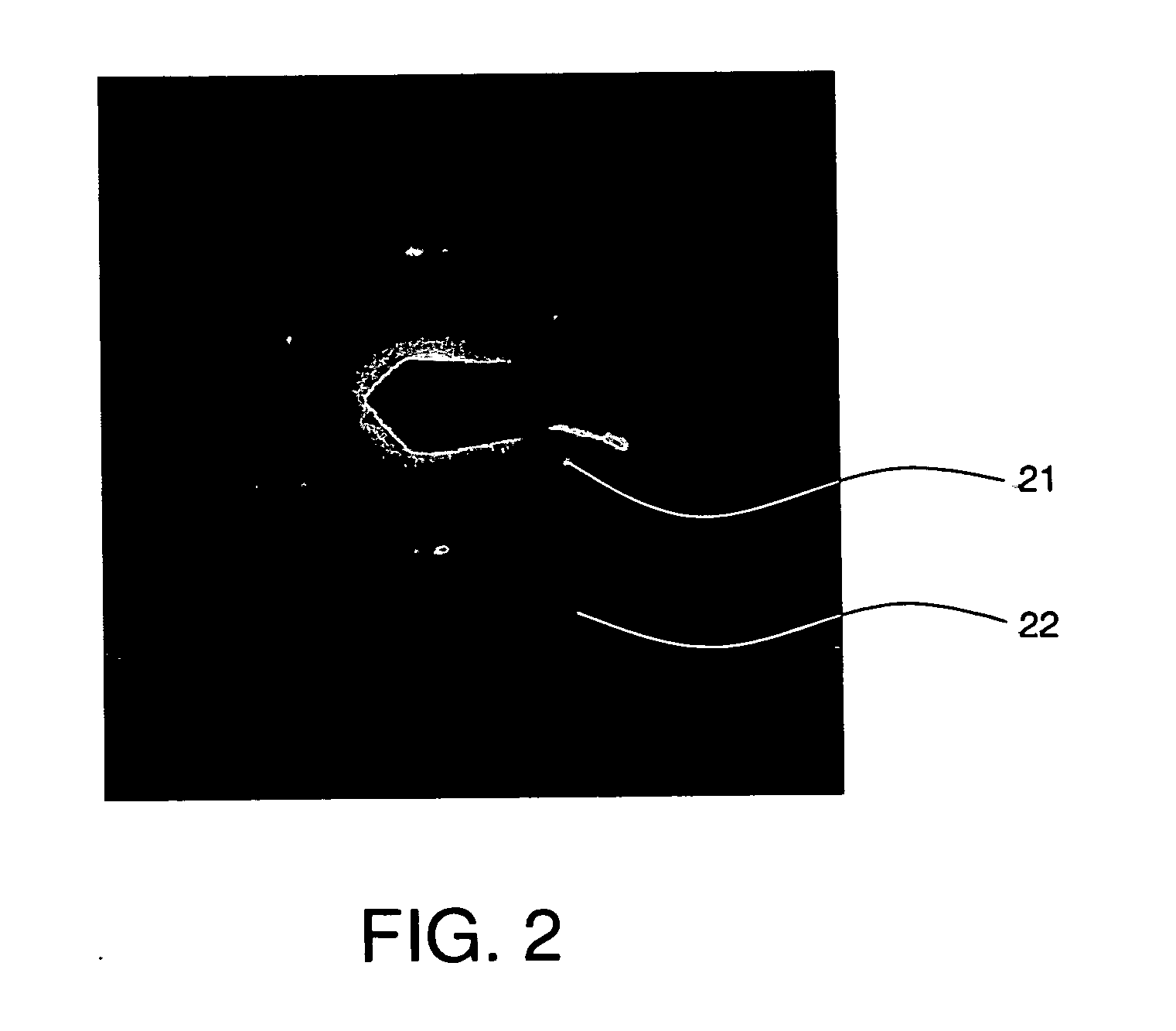

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

Vacuum insulating material and device using the same

Vacuum heat insulator comprising a laminated core made of a plurality of sheets of inorganic fibers having 10 μm or smaller in diameter and a certain composition including SiO2 as a main component, Al2O3, CaO, and MgO, a gas barrier enveloping member, and an absorbent. The vacuum heat insulator is characterized by having at least one groove formed therein after fabrication of the vacuum heat insulator. Further, the vacuum heat insulator is characterized by using inorganic fiber core of which a peak of distribution in fiber diameter lies between 1 μm or smaller and 0.1 μm or larger, and not containing binding material for binding the fiber material. Electronic apparatuses use the vacuum heat insulator. With use of the vacuum heat insulator, electronic and electric apparatuses superior in energy saving and not to present uncomfortable feeling to the user can be provided.

Owner:PANASONIC CORP

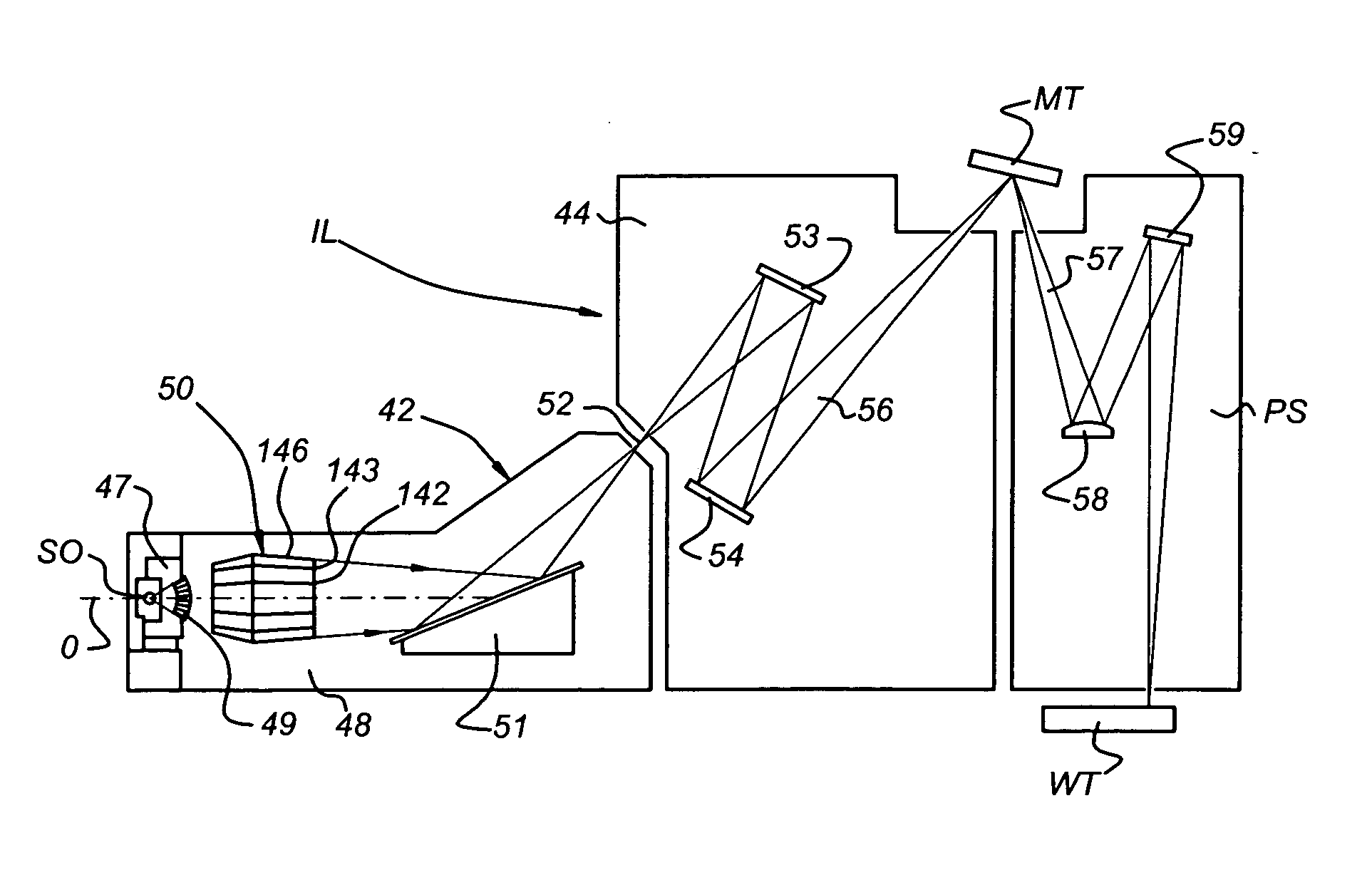

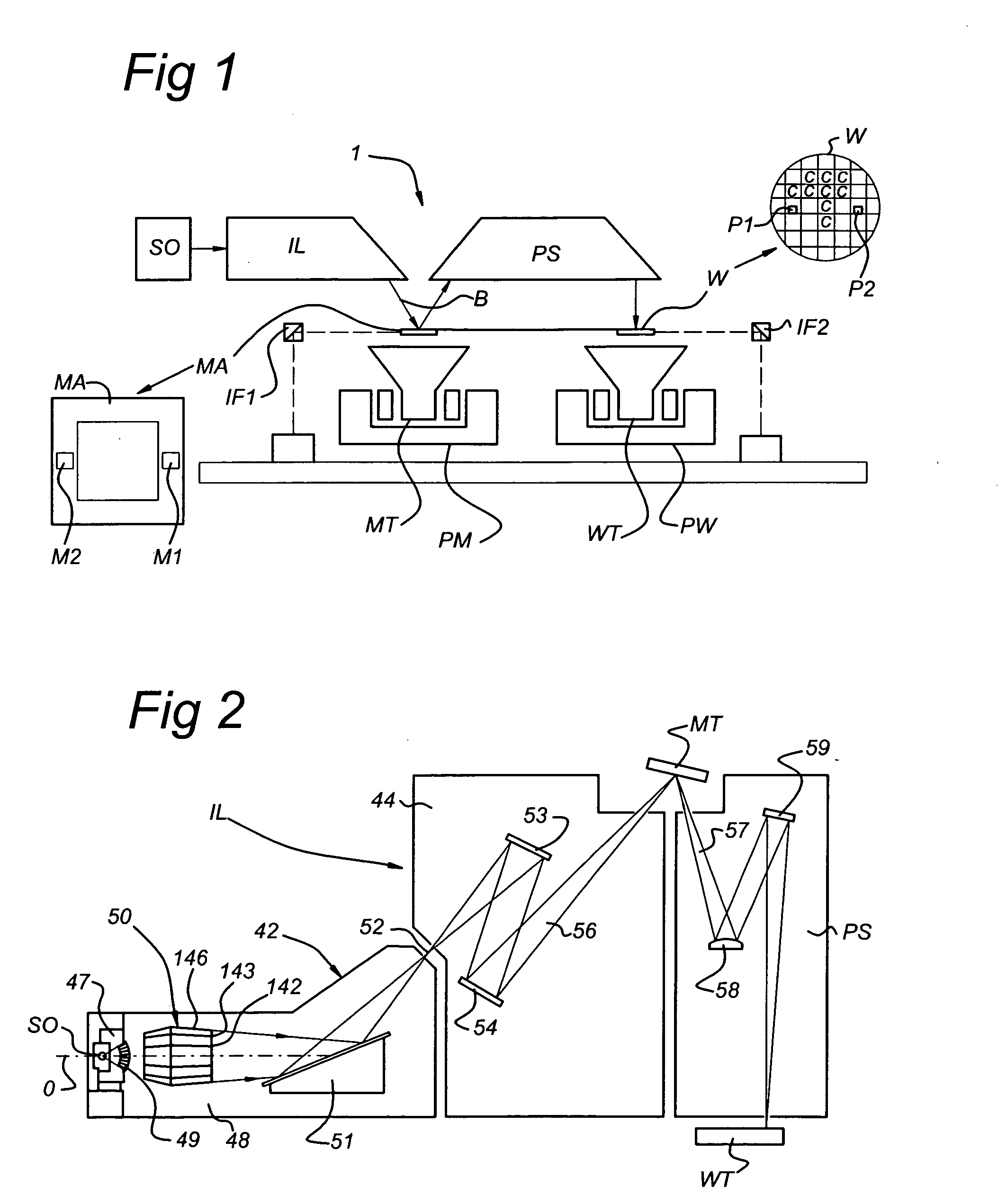

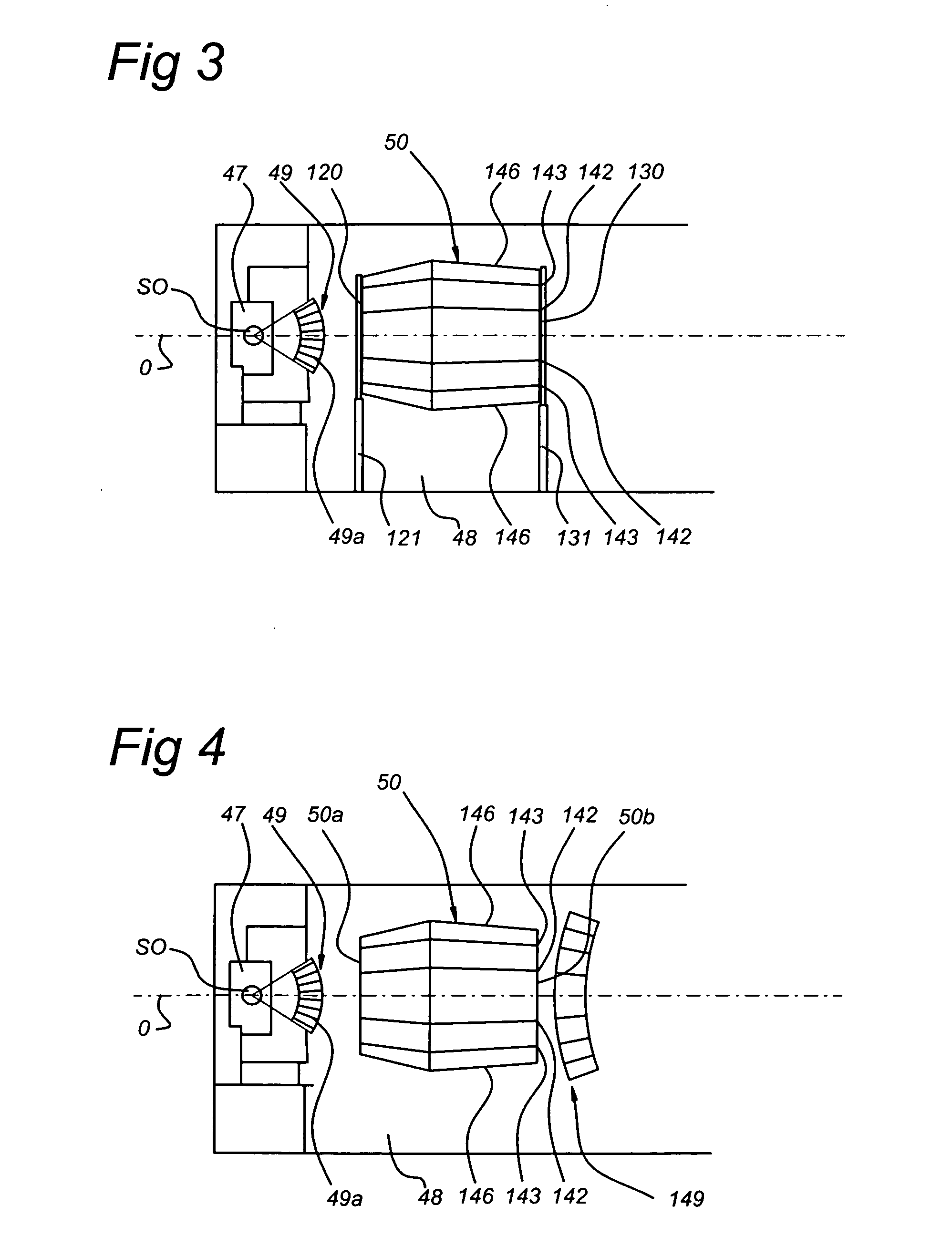

Method for removal of deposition on an optical element, lithographic apparatus, device manufacturing method, and device manufactured thereby

A method for removal of deposition on a radiation collector of a lithographic apparatus includes providing a gas barrier to an end of a radiation collector, thereby providing a radiation collector enclosure volume; providing a gas to the enclosure volume, the gas selected from a halogen containing gas and a hydrogen containing gas; and removing at least part of the deposition from the radiation collector. A lithographic apparatus includes a radiation collector; a circumferential hull enclosing the radiation collector; a gas barrier at an end of the radiation collector, thereby providing a radiation collector enclosure volume. The radiation collector is enclosed by the circumferential hull and the gas barrier. An inlet provides a gas to the radiation collector enclosure volume and an outlet removes a gas from the radiation collector enclosure volume.

Owner:ASML NETHERLANDS BV

Gas barrier substrate

InactiveUS20050029513A1Quality improvementExcellent gas barrier performanceSolid-state devicesVacuum evaporation coatingMetallurgyGas formation

The main object of the present invention is to provide a gas barrier substrate having a high gas barrier property without a ruggedness, a pin hole or the like in the gas barrier layer. The present invention solves the problem by providing a gas barrier substrate having a base material, a planarization layer formed on the base material, and a gas barrier layer comprising a deposition film formed on the planarization layer.

Owner:DAI NIPPON PRINTING CO LTD

Gas barrier

InactiveUS20070135552A1Improved resistance to water vapor transmissionSmall sizeMaterial nanotechnologyPolymer scienceSealant

Nanoparticles of amorphous aluminum oxynitride or silicon oxynitride having a very high aspect ratio are used to fill polymeric materials to provide products that have an extremely low WVTR / OTR. Such products are particularly effective for incorporation into organic light-emitting devices or the like which are susceptible to degradation from moisture and / or oxygen. Pressure sensitive and / or thermosetting adhesives filled with such particles create excellent sealants. Polymeric sheets or films made from resin in which these nanoparticles are dispersed, or intimately associated with, before extrusion exhibit very low WVTR / OTR.

Owner:GENERAL ATOMICS

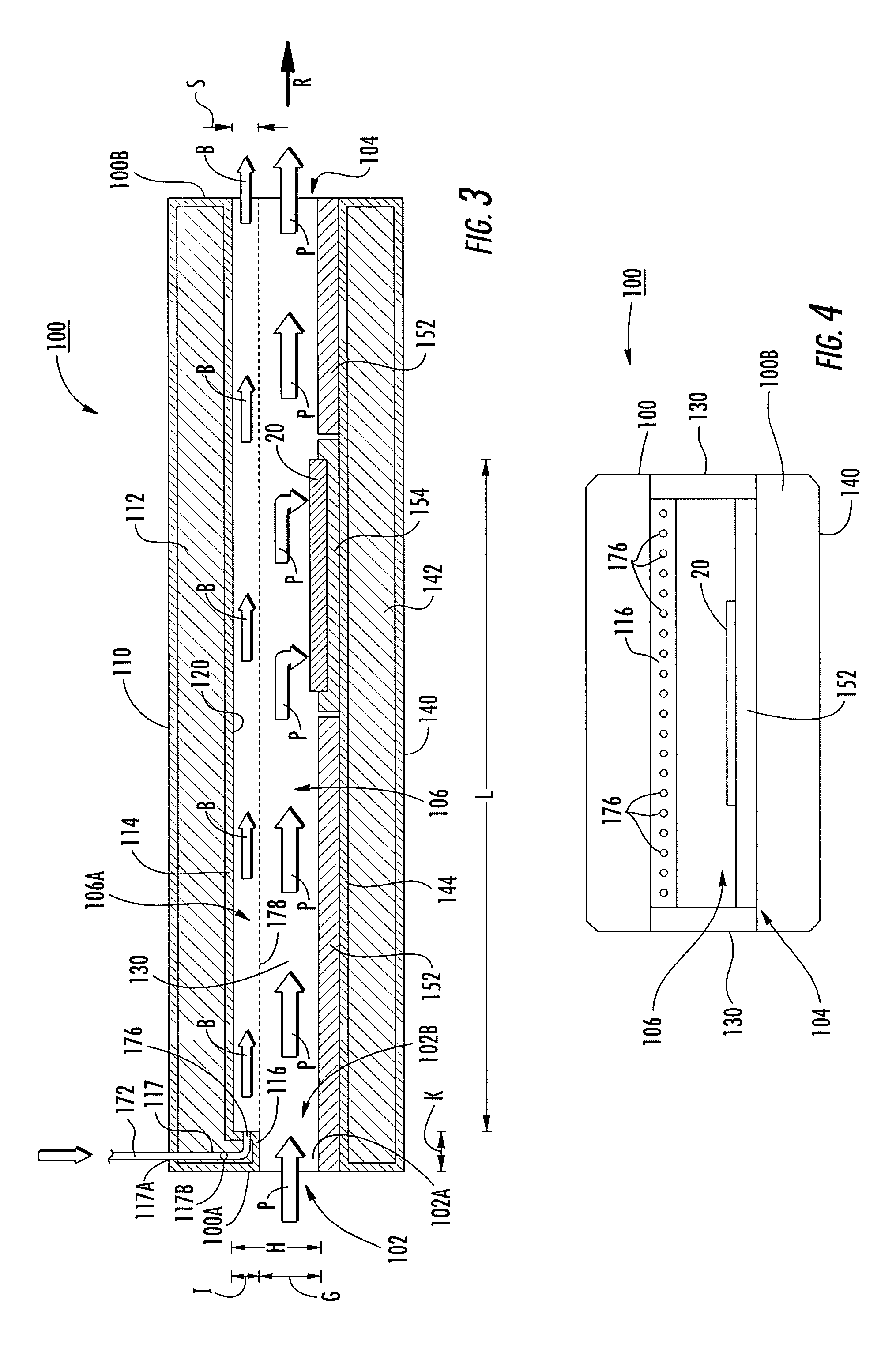

Vessels, contact surfaces, and coating and inspection apparatus and methods

ActiveUS20120252709A1Reduce transmission of fluidReduce transmissionInfusion syringesBearing componentsProduct gasSurface barrier

Methods for processing a contact surface, for example to provide a gas barrier or lubricity or to modify the wetting properties on a medical device, are disclosed. First and second PECVD or other contact surface processing stations or devices and a contact surface holder comprising a contact surface port are provided. An opening of the contact surface can be seated on the contact surface port. The interior contact surface of the seated contact surface can be processed via the contact surface port by the first and second processing stations or devices. contact surface barrier, lubricity and hydrophobic coatings and coated contact surfaces, for example syringes and medical sample collection tubes are disclosed. A contact surface processing system and contact surface inspection apparatus and methods are also disclosed.

Owner:SI02 MEDICAL PRODS

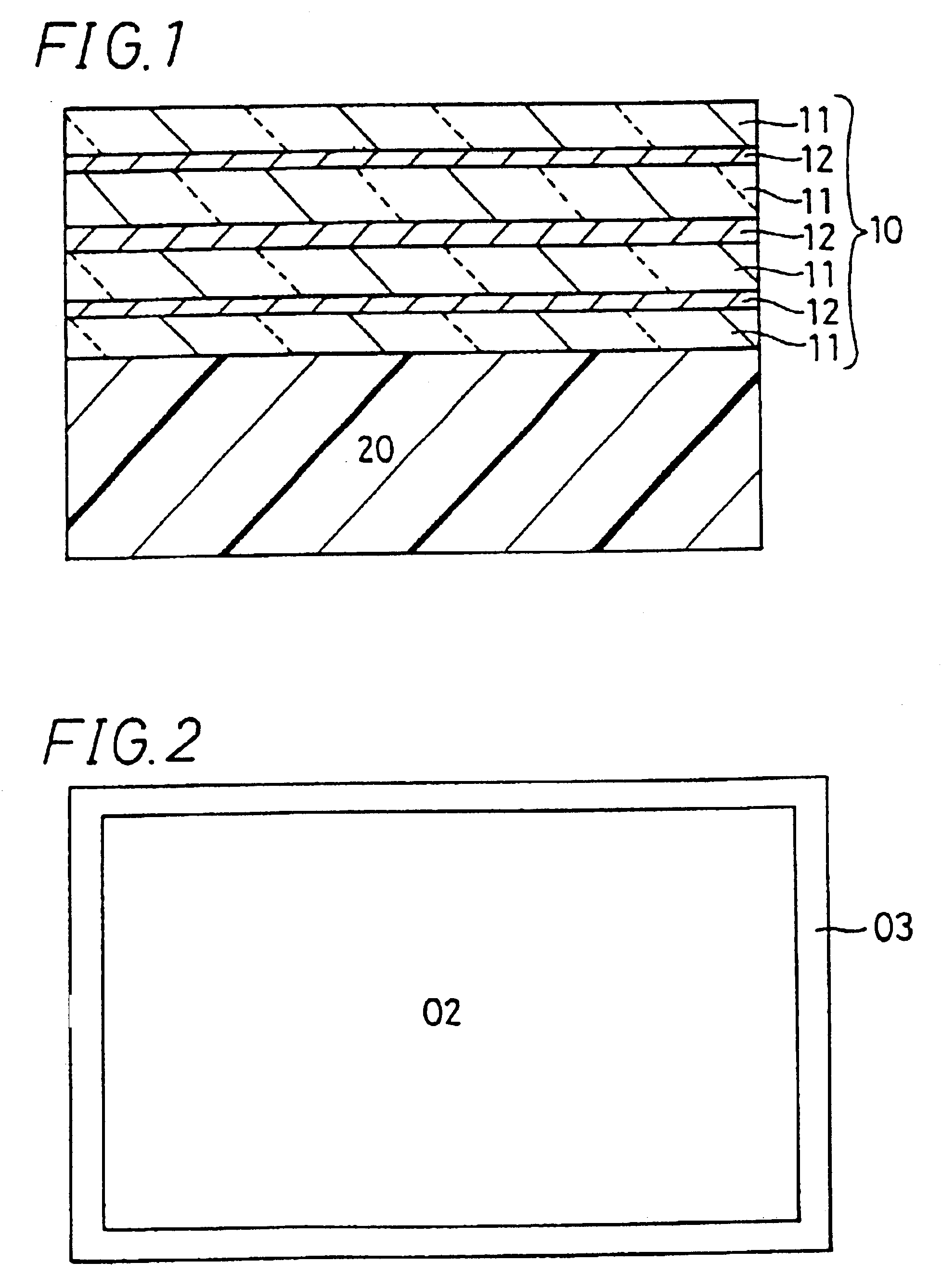

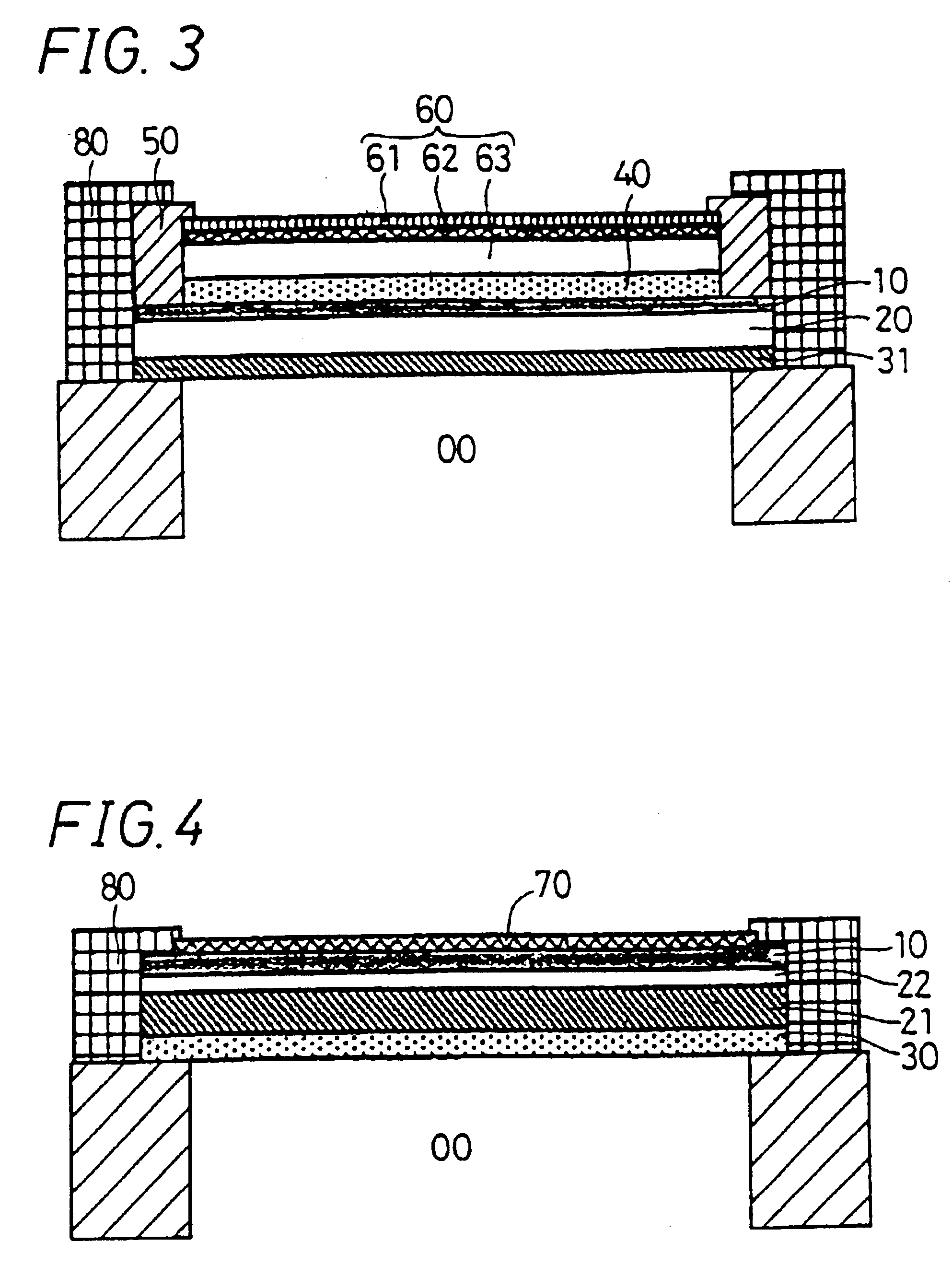

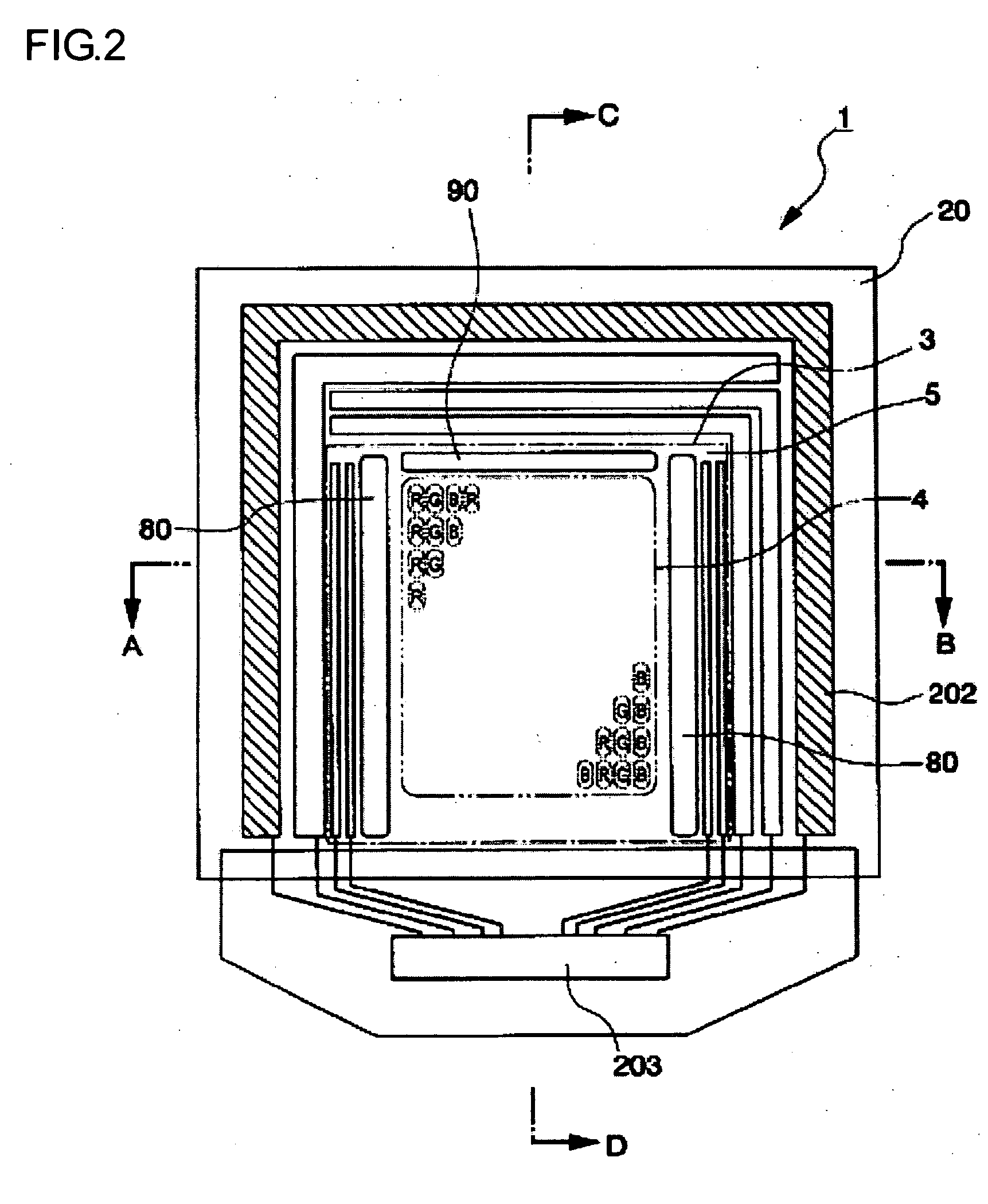

Filter for displaying, display unit and production method therefor

InactiveUS20030156080A1High color purityGood colorMagnetic/electric field screeningStatic indicating devicesDisplay deviceCopper foil

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

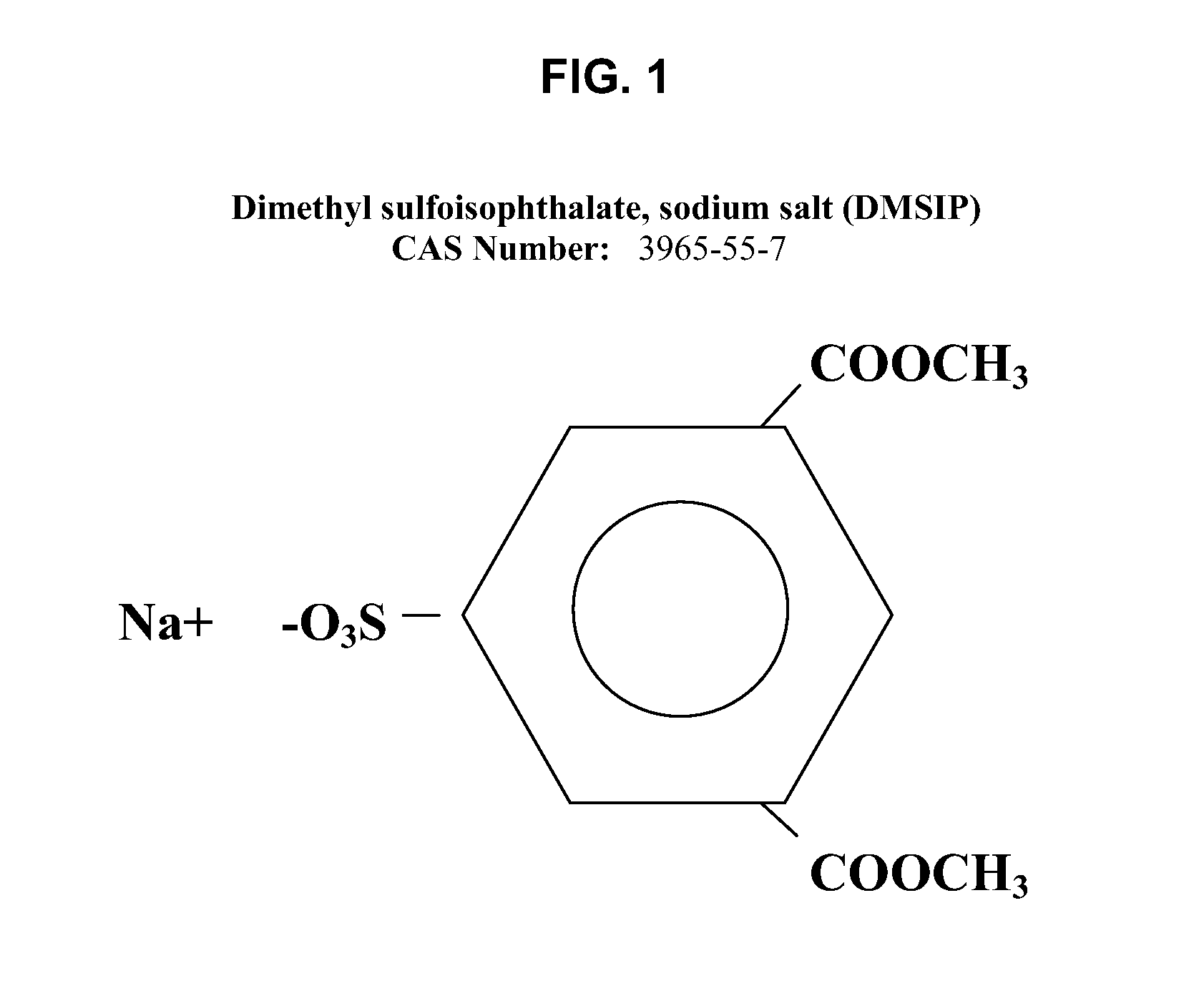

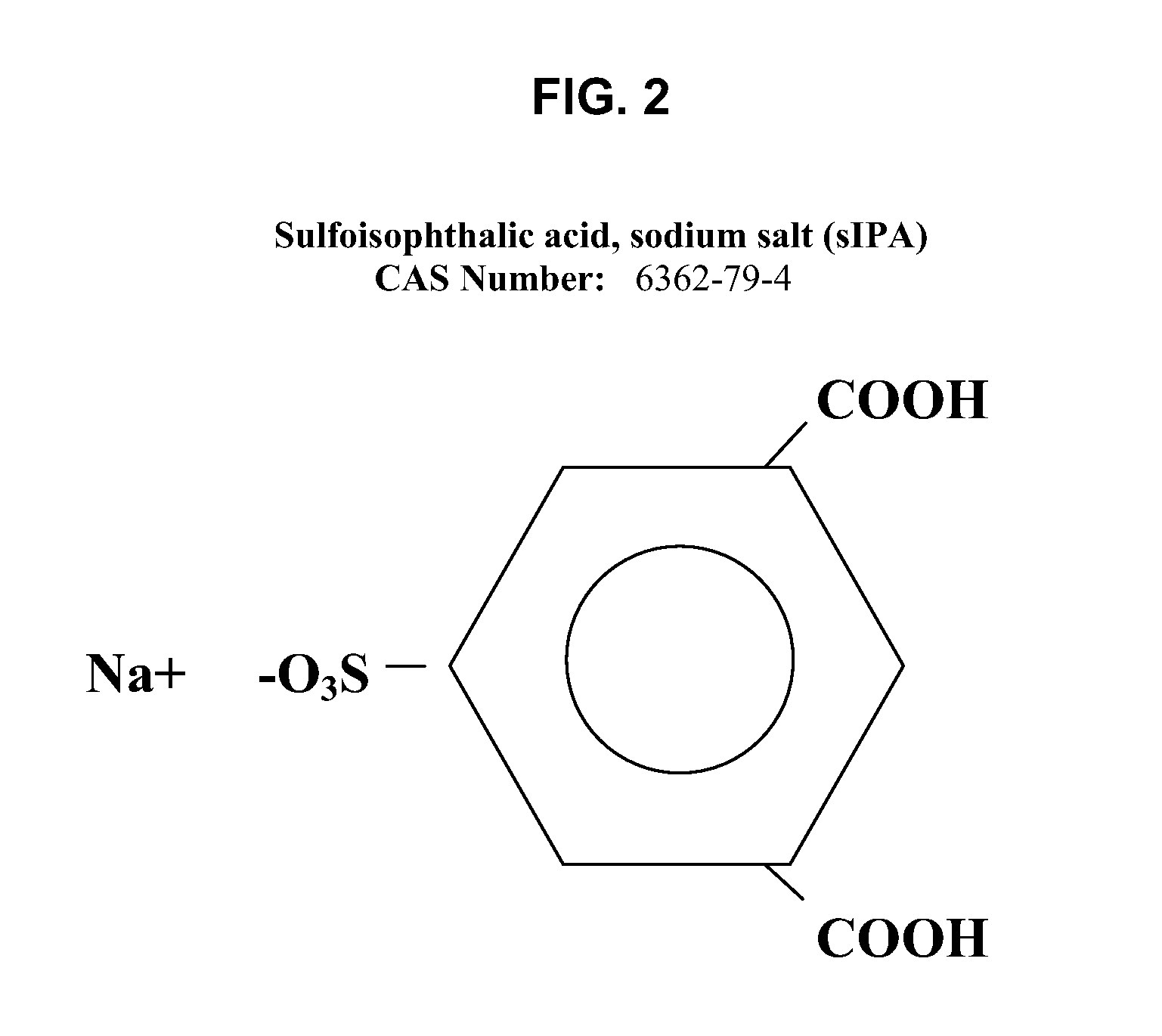

Polyamide-Polyester Polymer Blends and Methods of Making the Same

InactiveUS20080009574A1Superior polyamide-polyester barrier blendsEasy to recycleImpression capsDentistry preparationsPolyesterPolymer science

The present invention relates to polyamide-polyester barrier blends that possess improved gas barrier, clarity, and organoleptic properties, as well as containers (e.g., bottles), sheets, and films formed from such barrier resins. The invention further relates to polyamide-compatible polyethylene terephthalate resins that are useful in forming these improved polyamide-polyester polymer blends. The invention still further relates to cost-effective recycling of articles formed from polyamide-polyester polymer blends.

Owner:WELLMAN INC

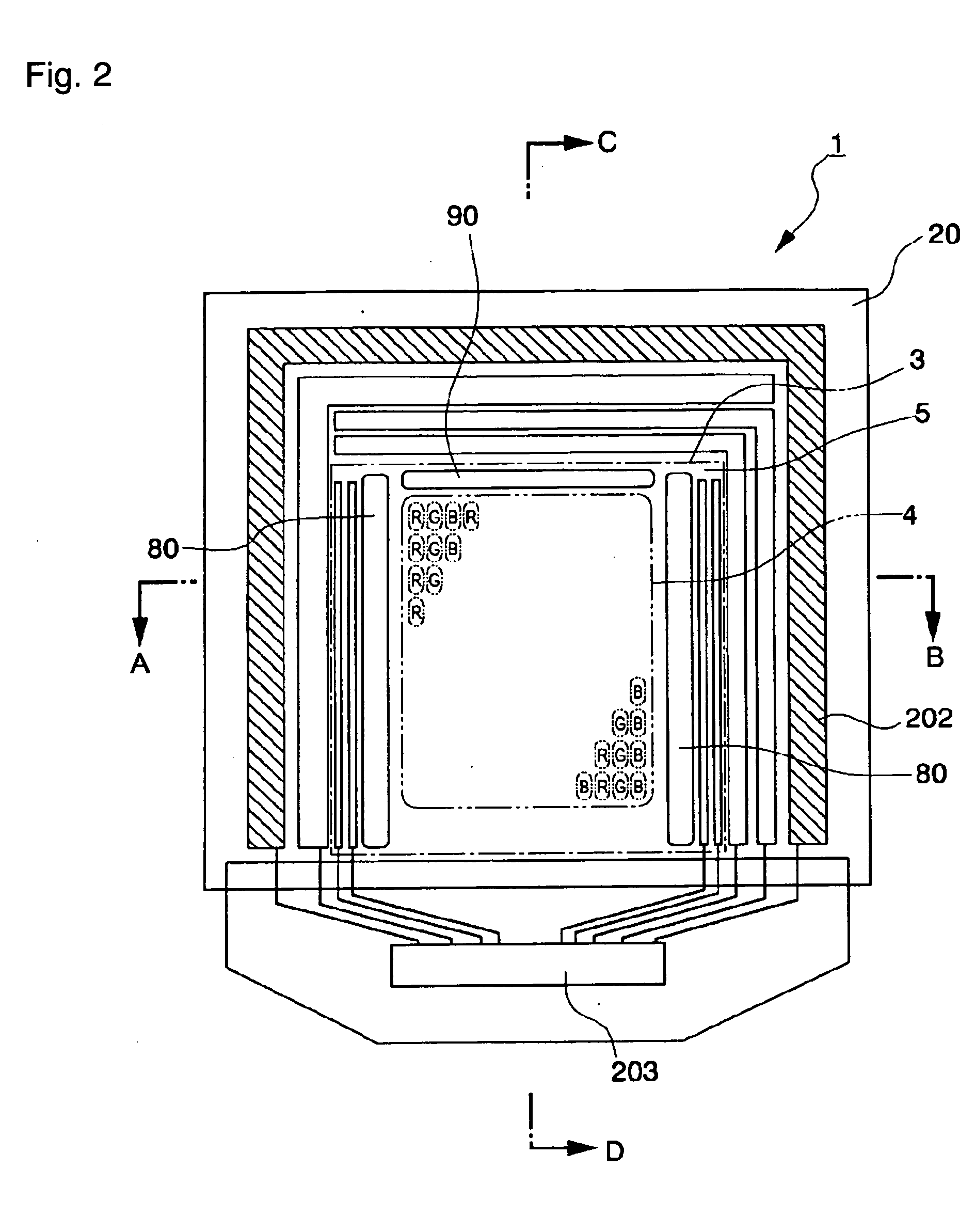

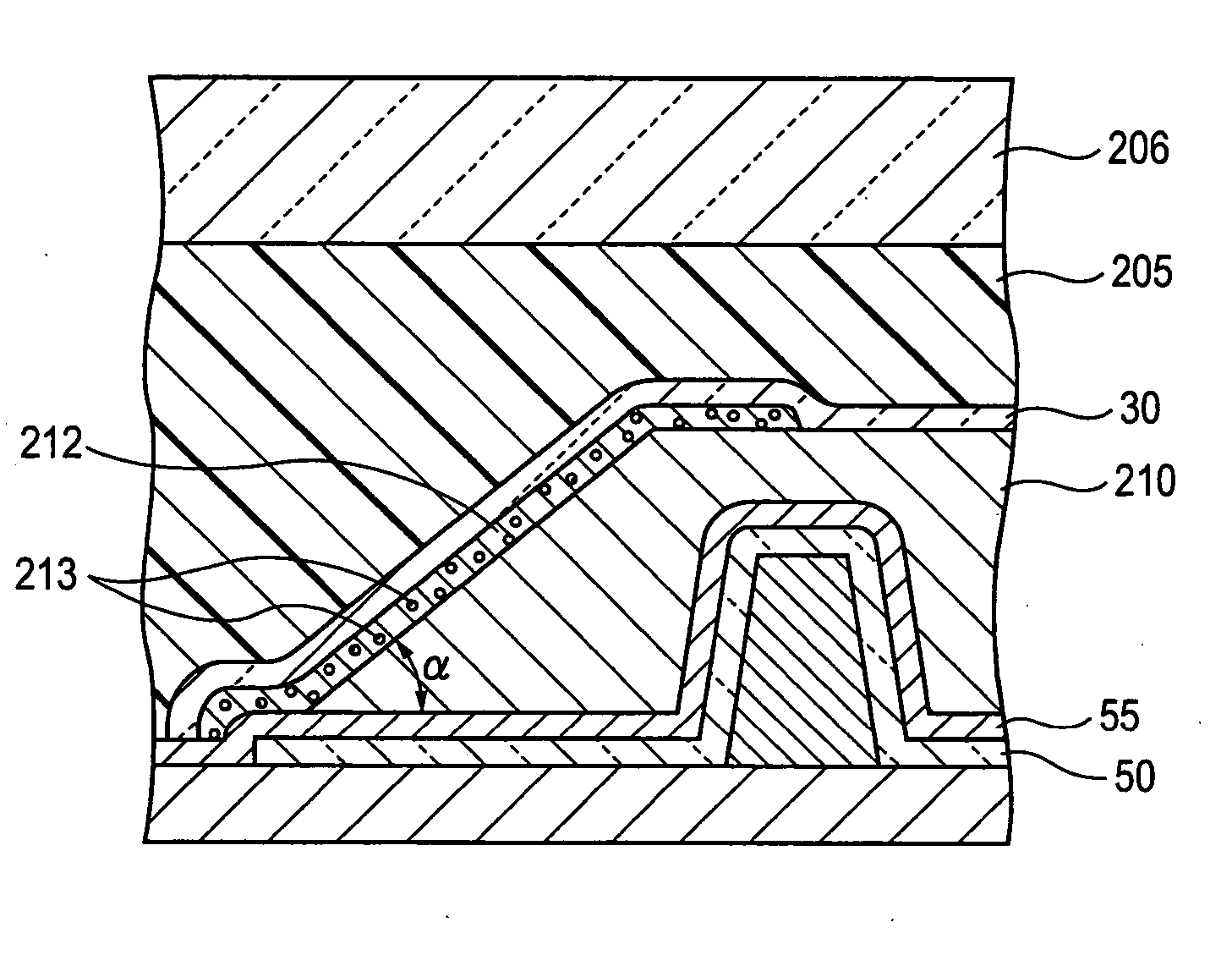

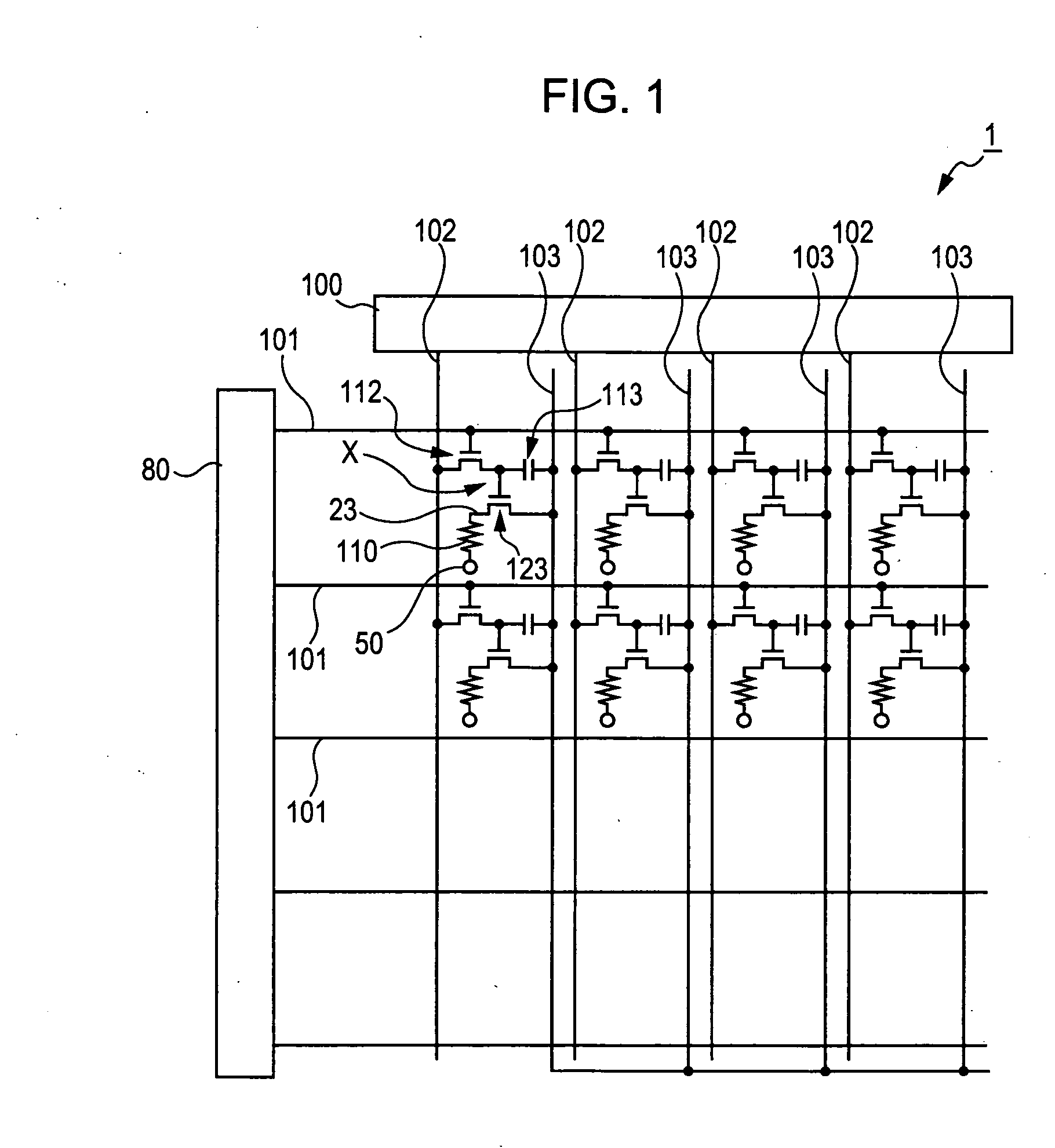

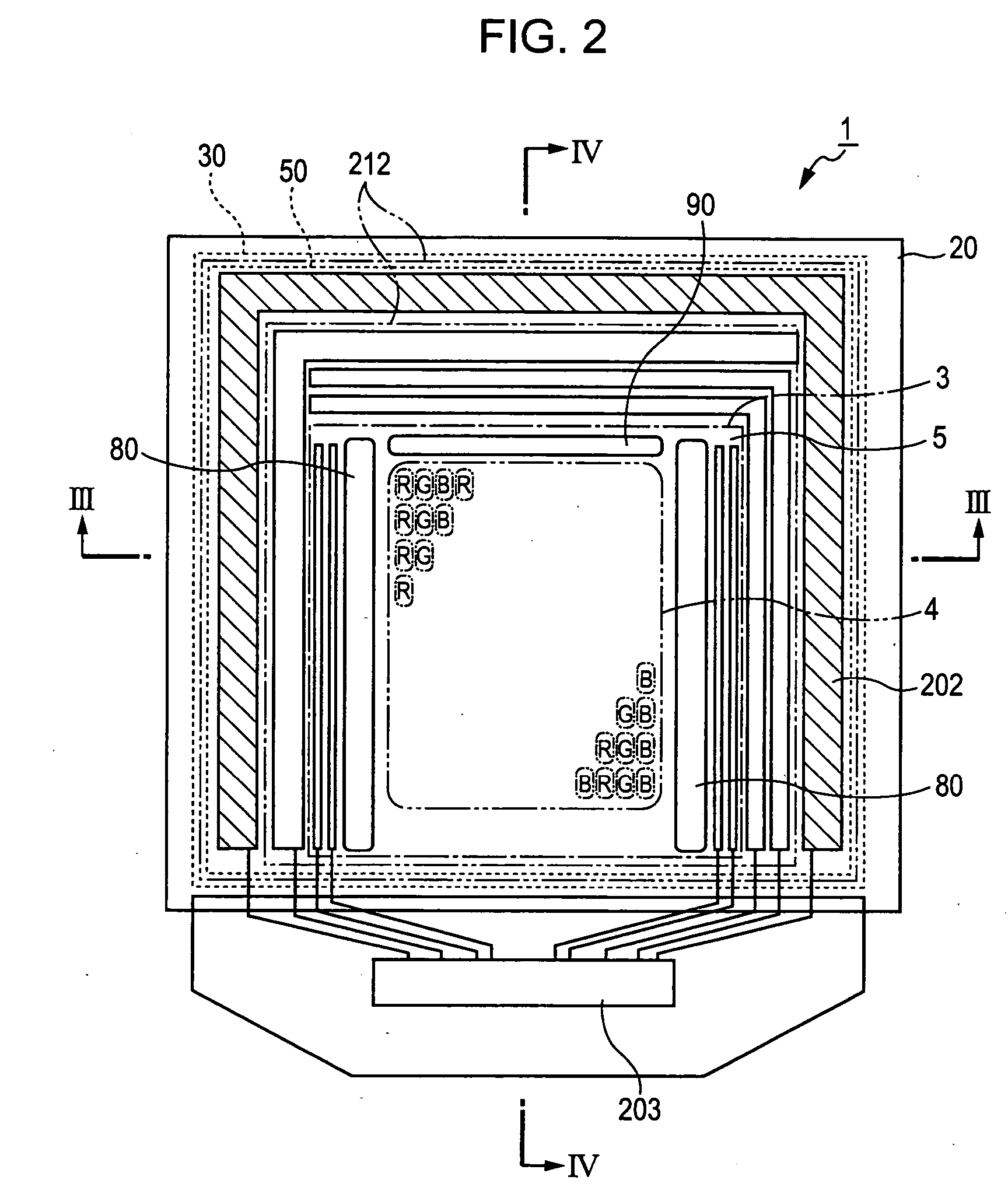

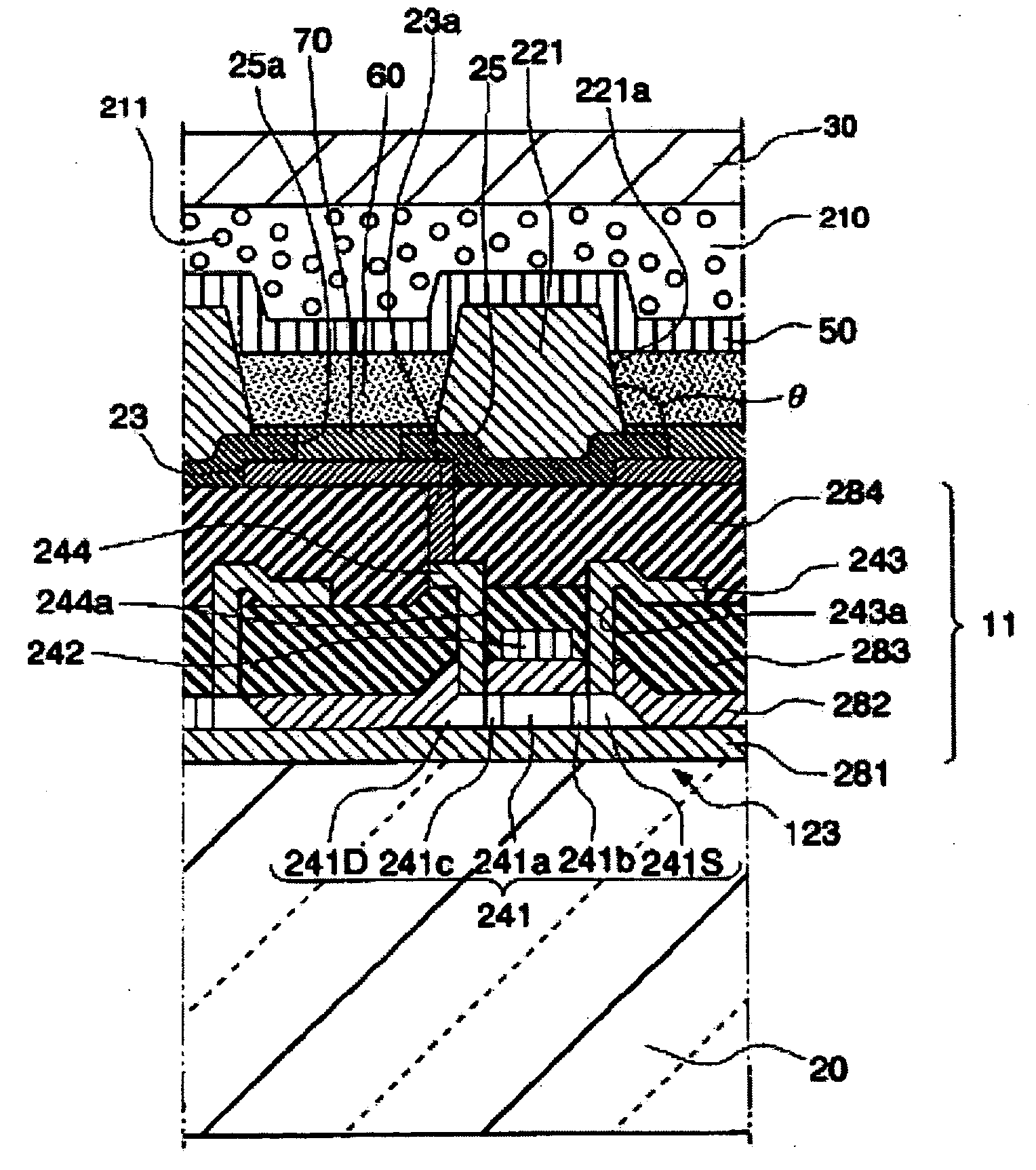

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS20040212759A1Reduced or prevented from being deterioratedQuality improvementElectroluminescent light sourcesSolid-state devicesUltravioletEngineering

Owner:SEIKO EPSON CORP

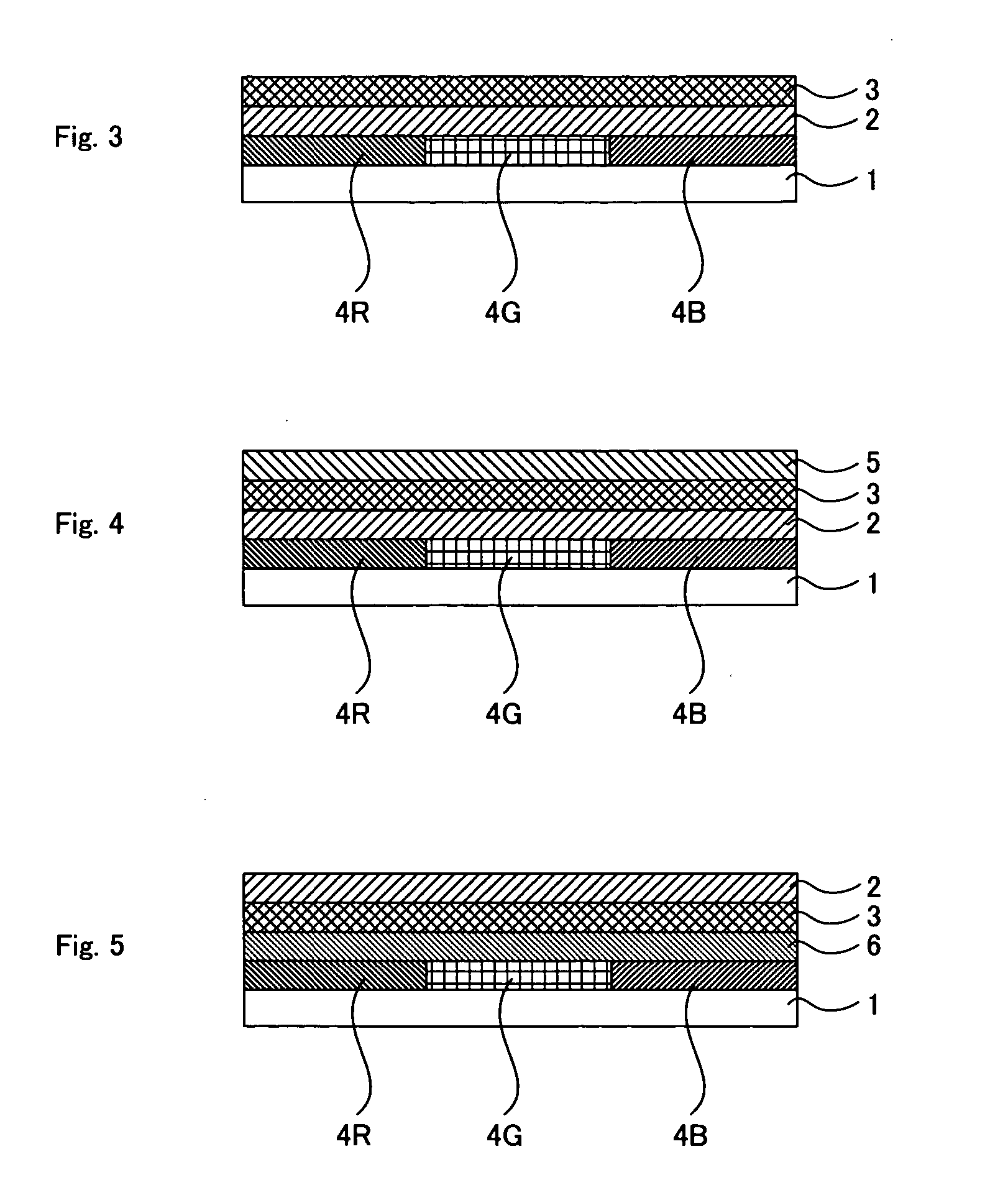

Light-emitting device, method for manufacturing light-emitting device, and electronic apparatus

ActiveUS20060158111A1Prevent moisture penetrationPrevent penetrationDischarge tube luminescnet screensLayered productsEngineeringProtection layer

A light-emitting device includes a base; a plurality of first electrodes; a partition having a plurality of openings located at positions corresponding to the first electrodes; organic functional layers each arranged in the corresponding openings; a second electrode covering the partition and the organic functional layers; an organic buffer layer covering the second electrode; a gas barrier layer covering the organic buffer layer; and an intermediate protective layer, disposed between the organic buffer layer and the gas barrier layer, having an elasticity which is greater than that of the organic buffer layer and which is less than that of the gas barrier layer. These layers and electrodes are arranged on or above the base.

Owner:SEIKO EPSON CORP

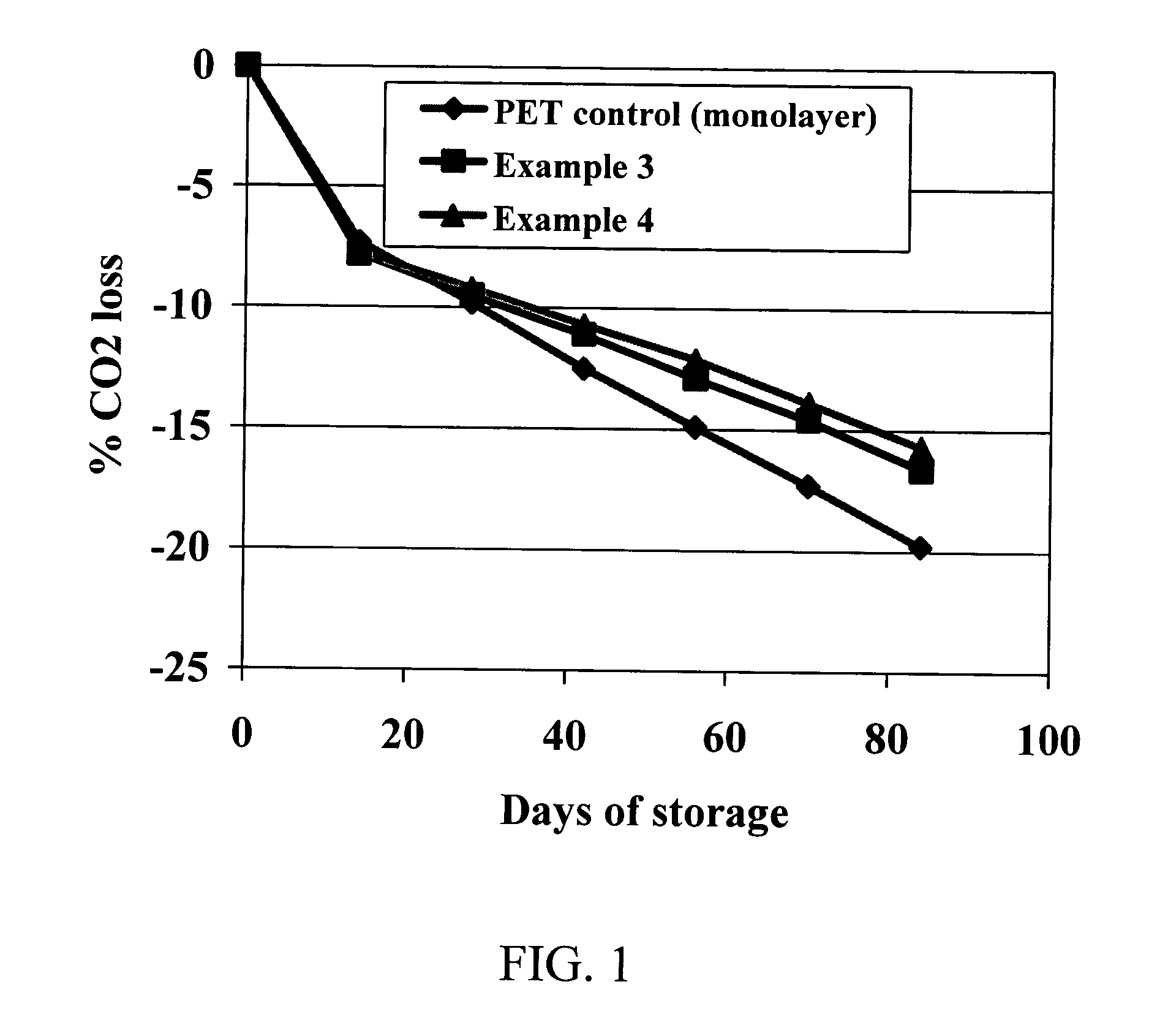

Delamination-resistant, barrier polyamide compositions for 3-layer pet beverage bottles

Gas barrier polyamide compositions exhibiting a low crystallization rate and good coinjection stretch blow moldability with polyethylene terephthalate (PET) to enable the fabrication of clear, high barrier multilayer PET bottles that have a long shelf life.

Owner:HONEYWELL INT INC

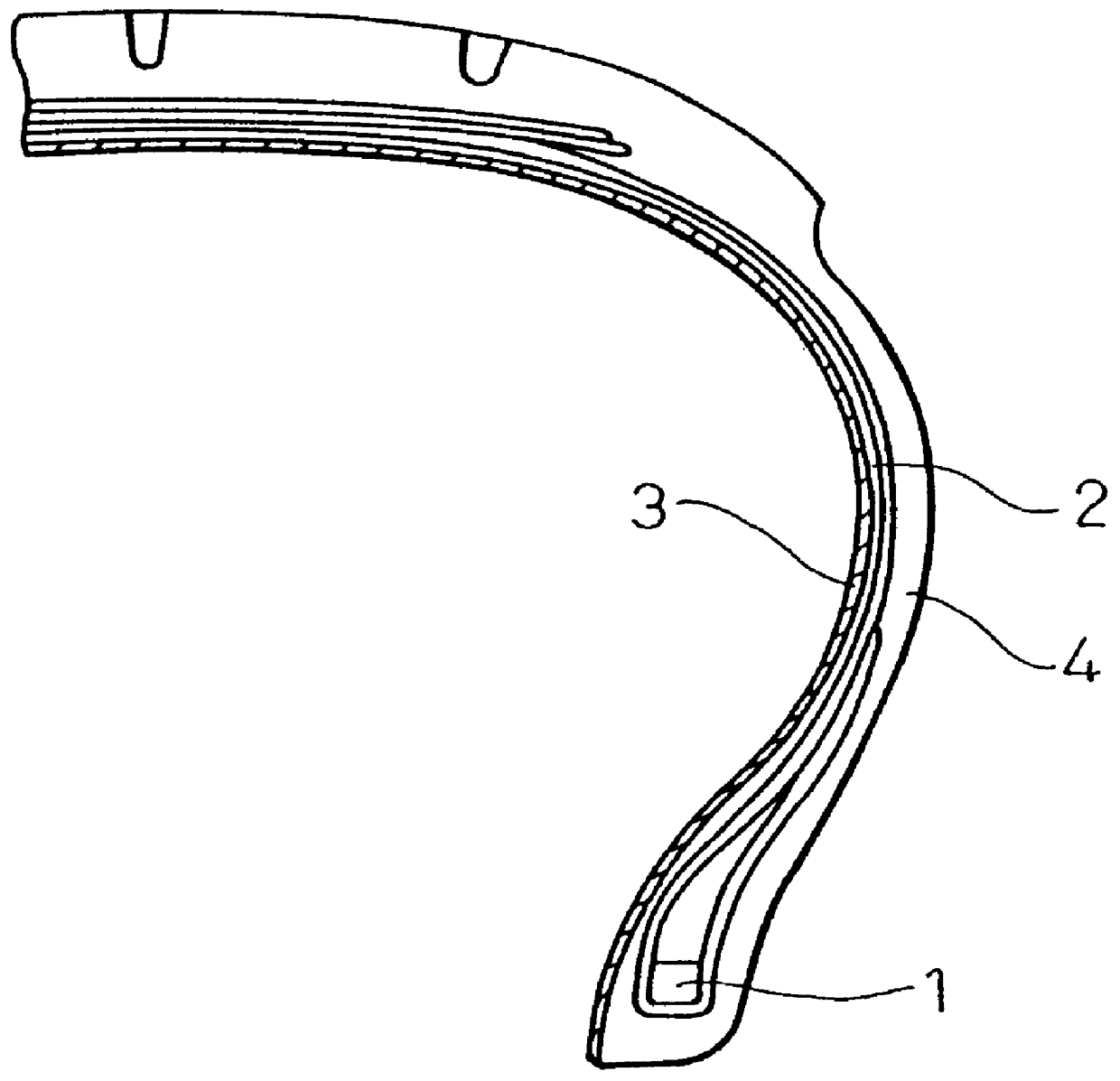

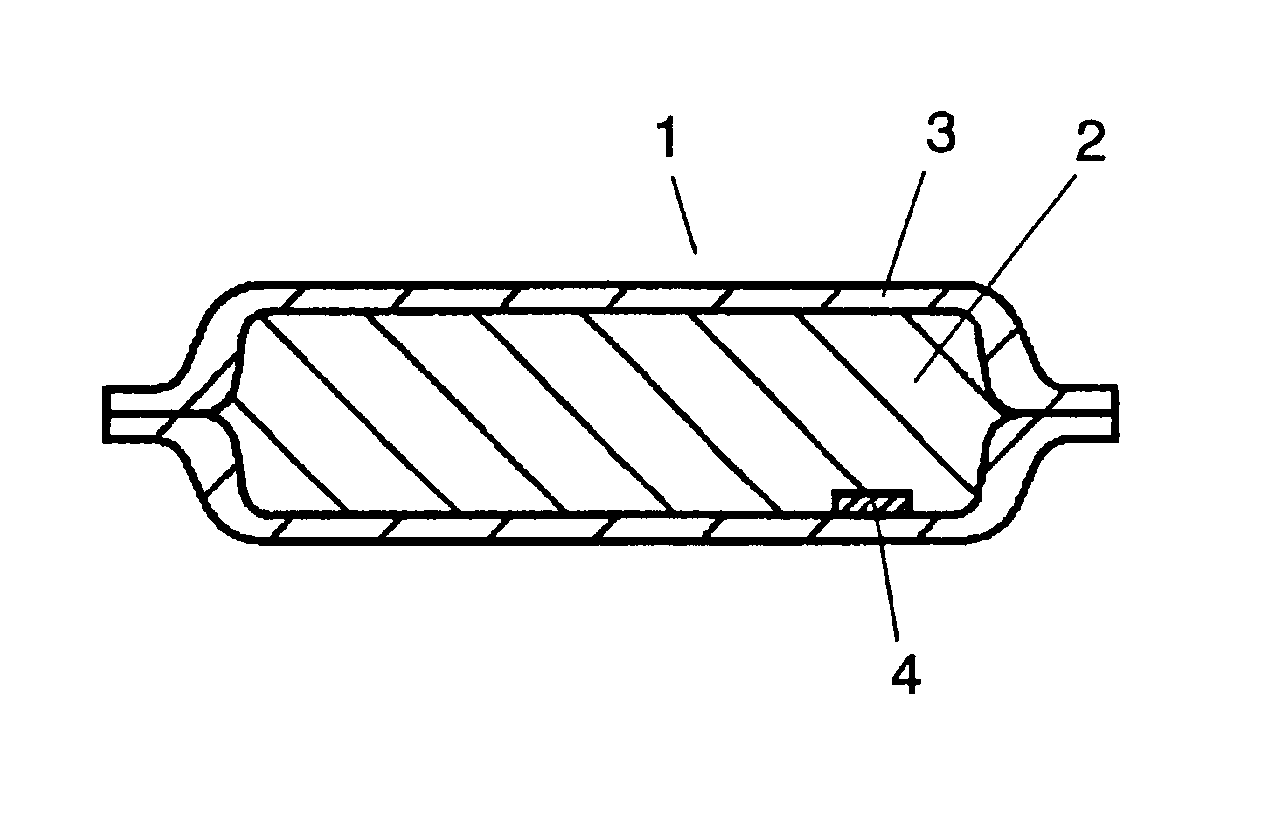

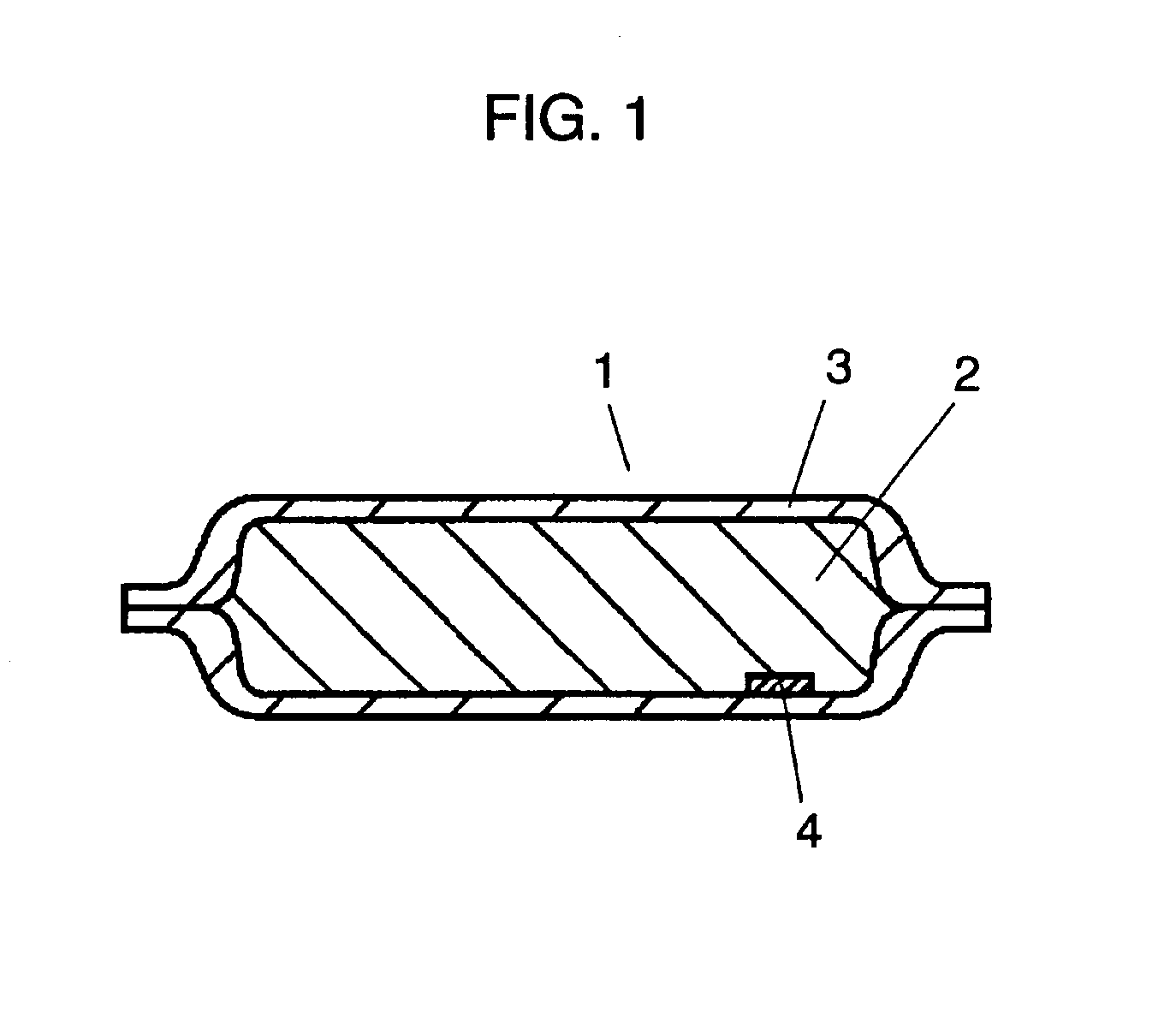

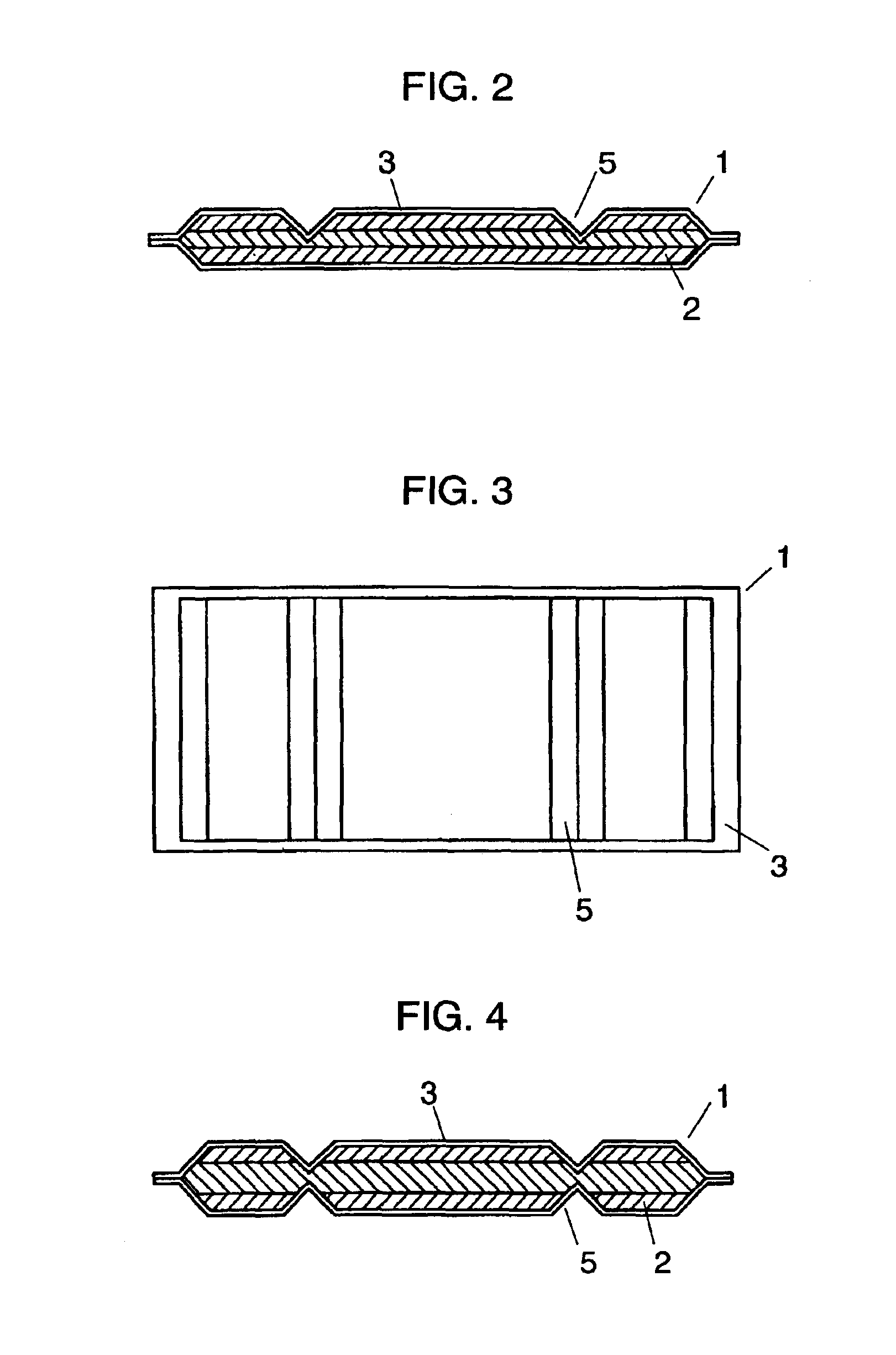

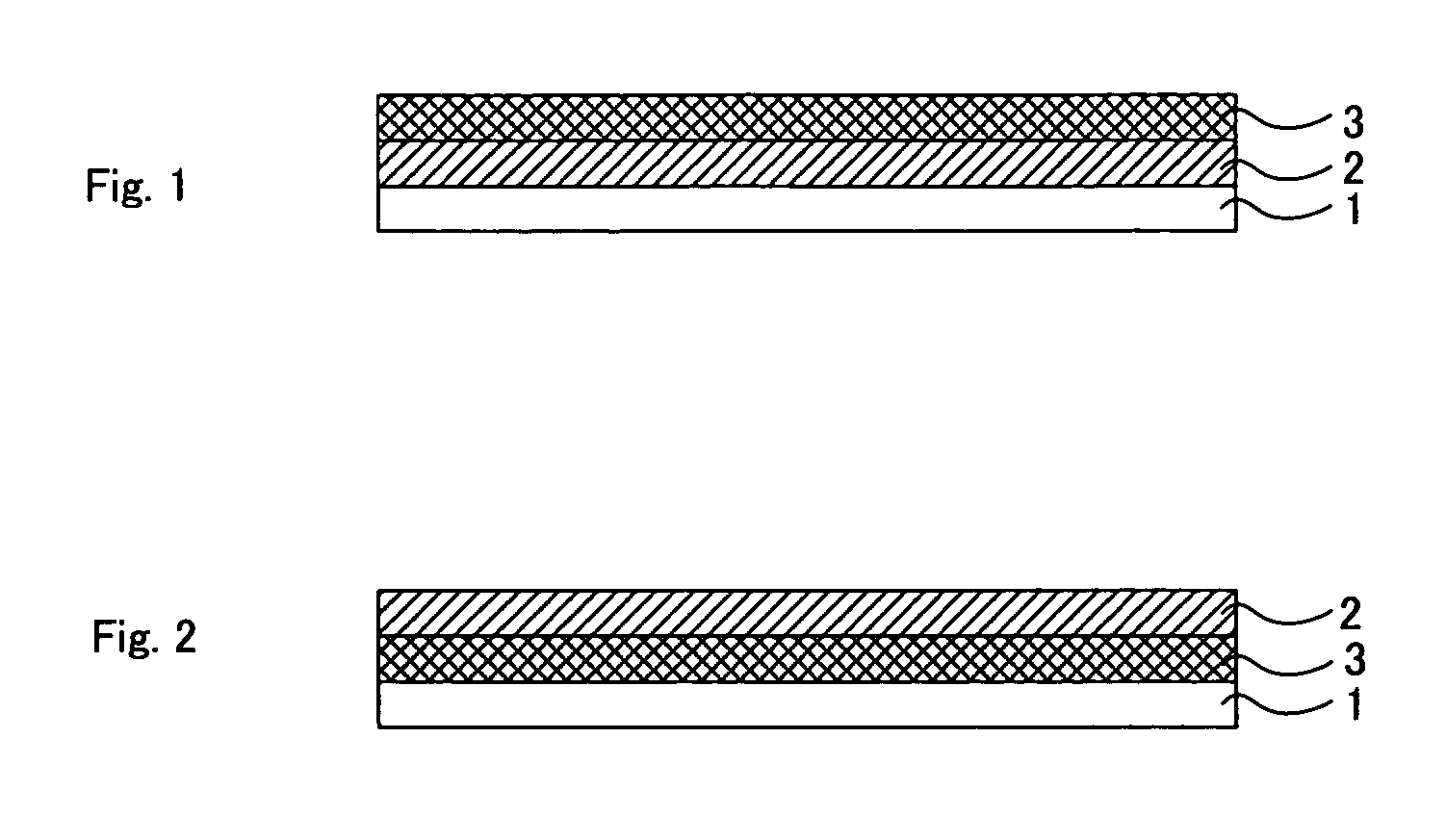

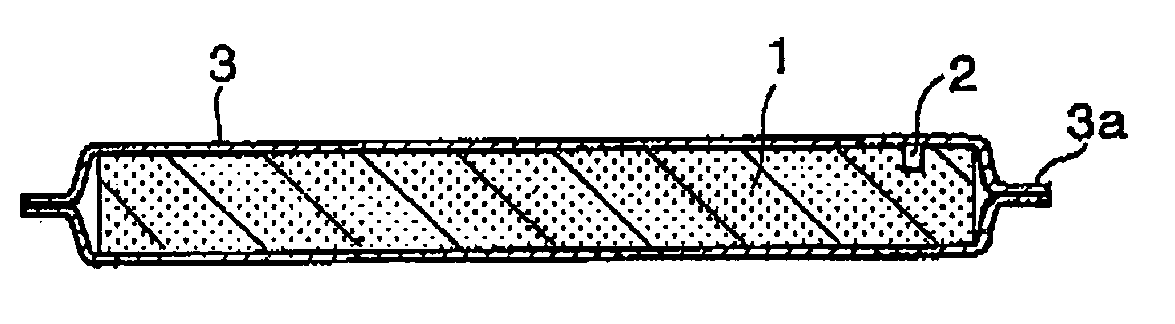

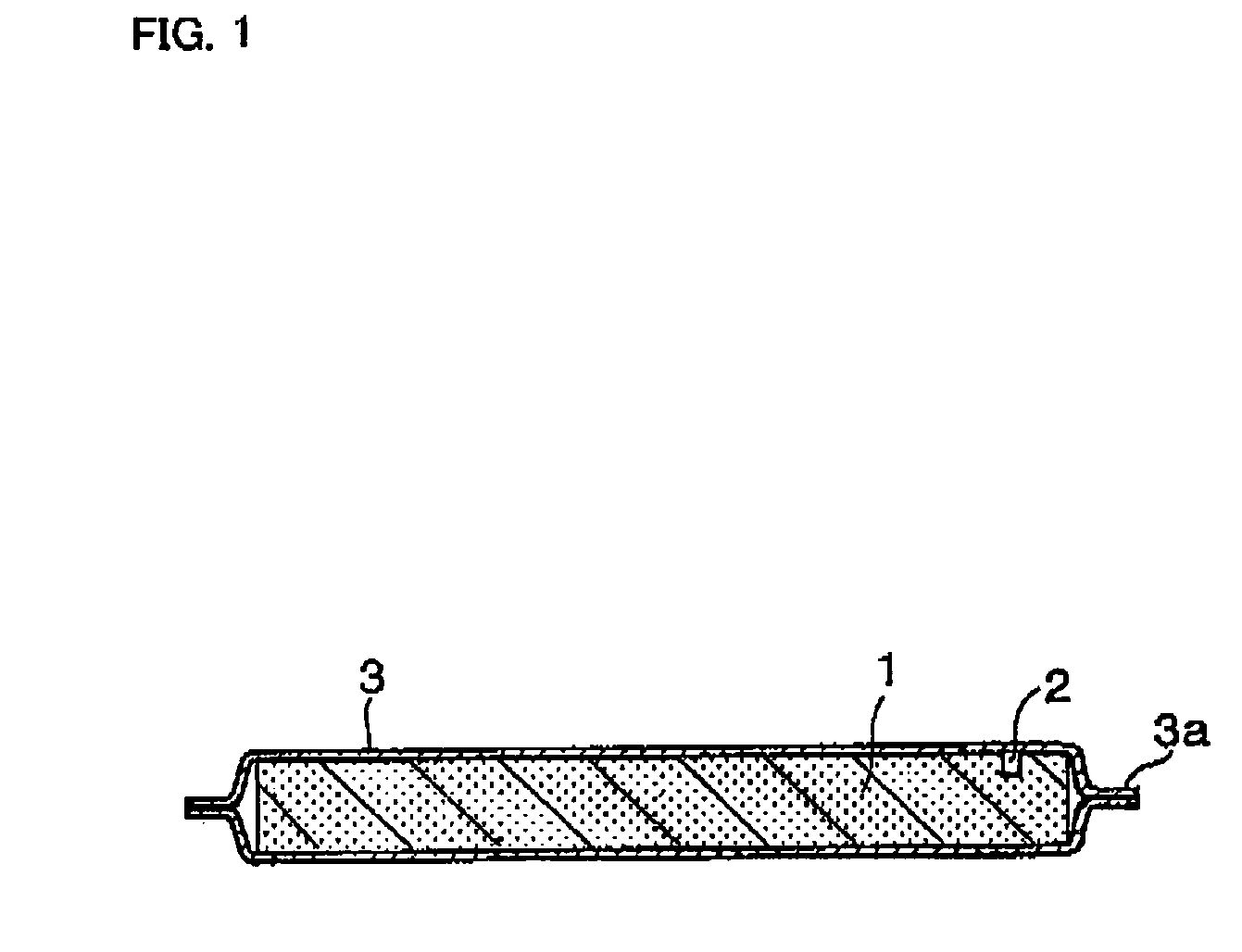

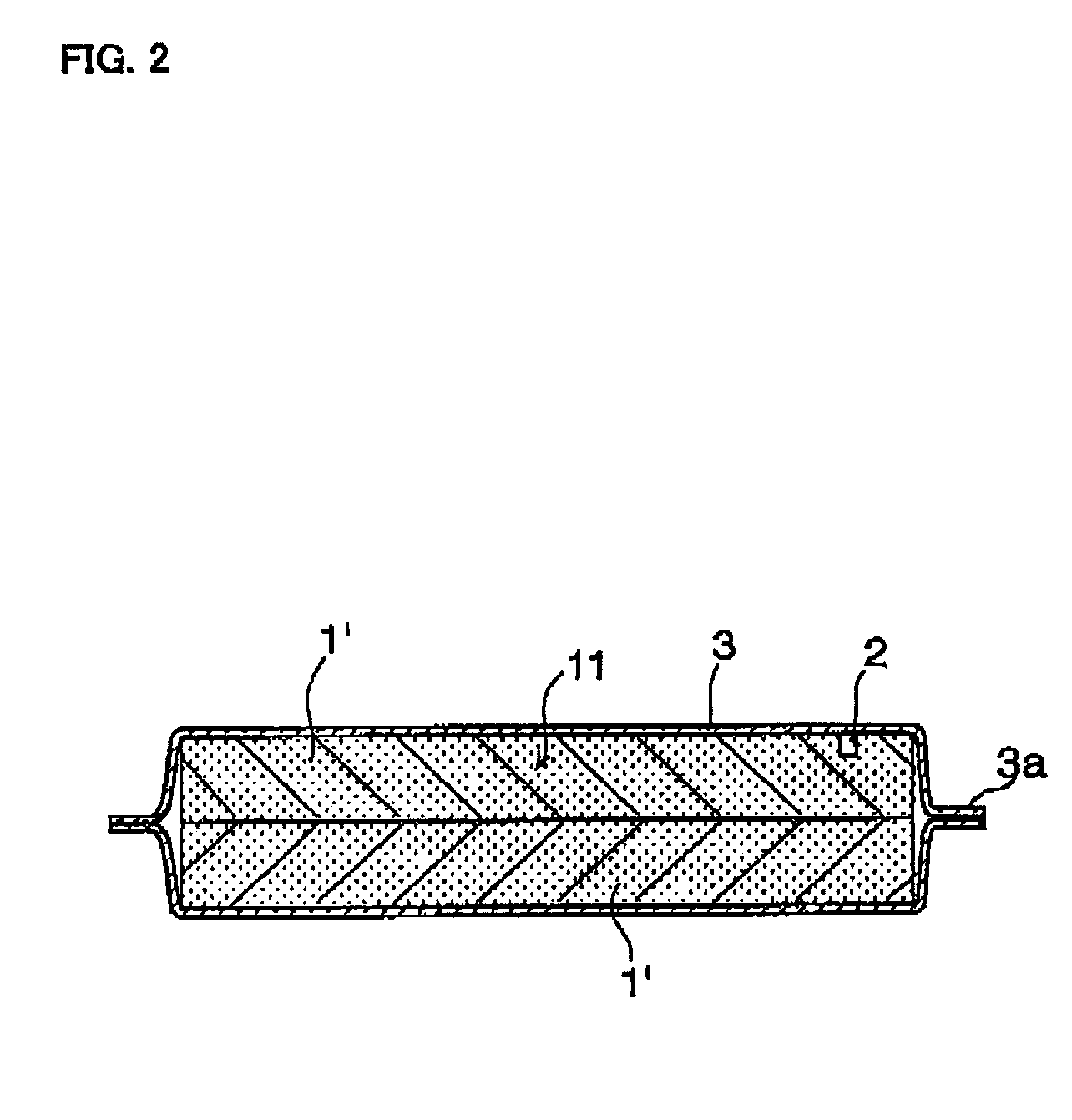

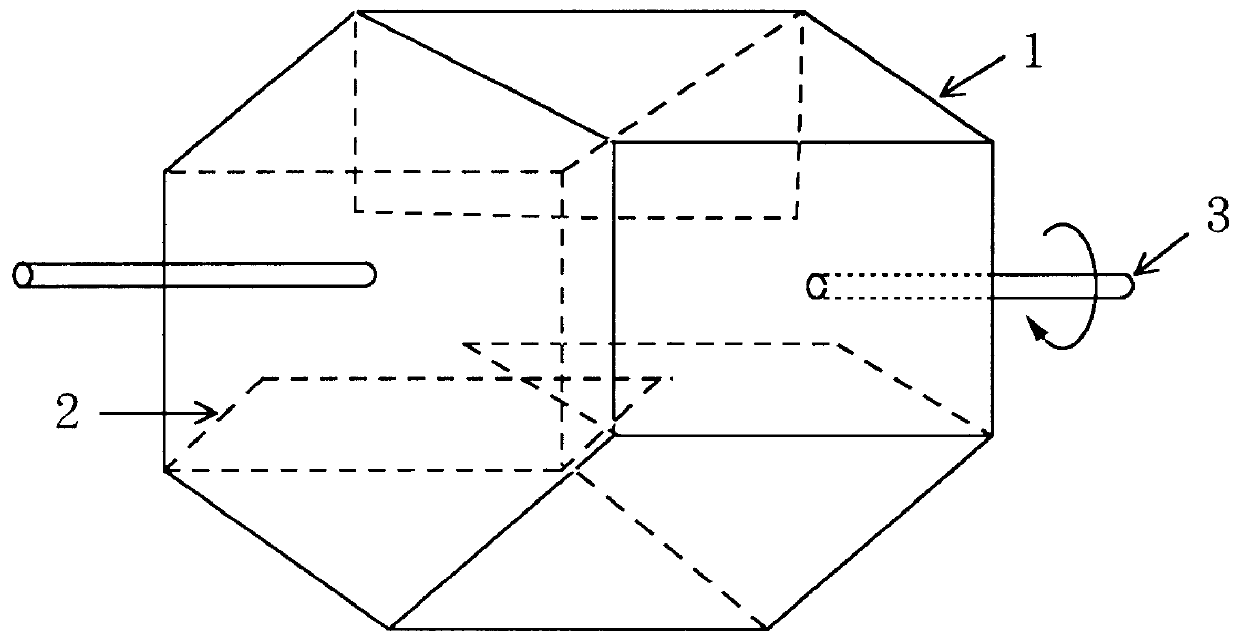

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

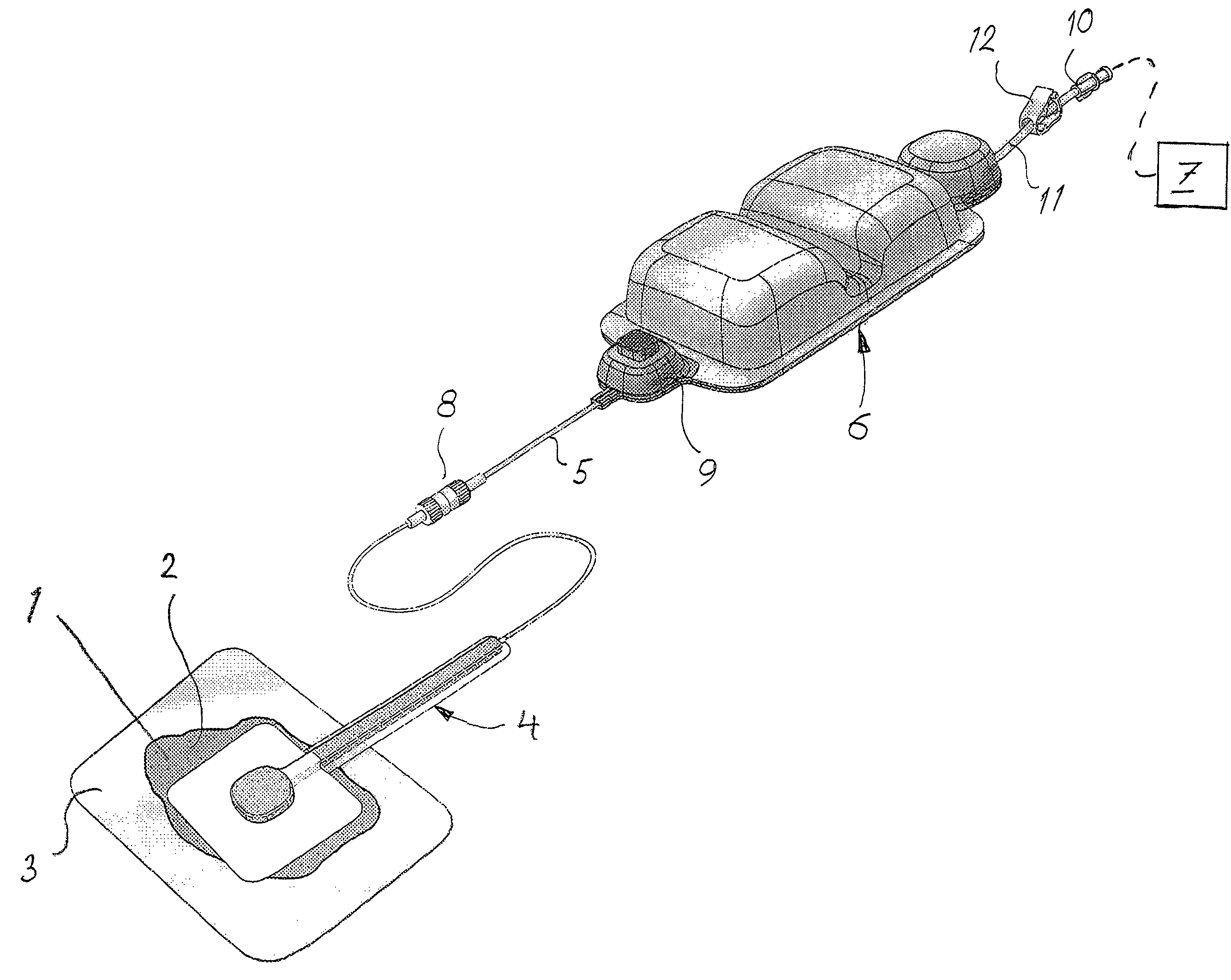

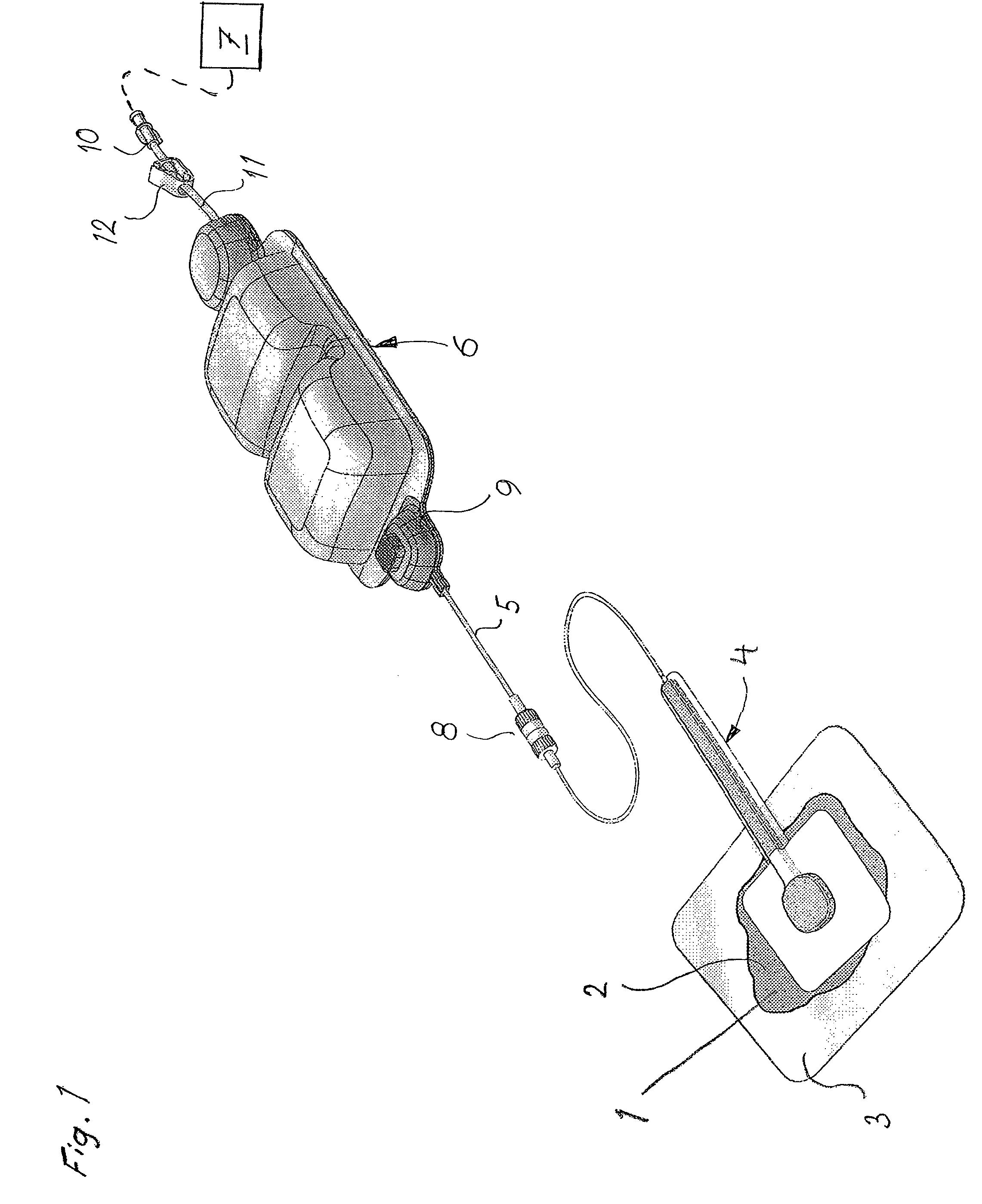

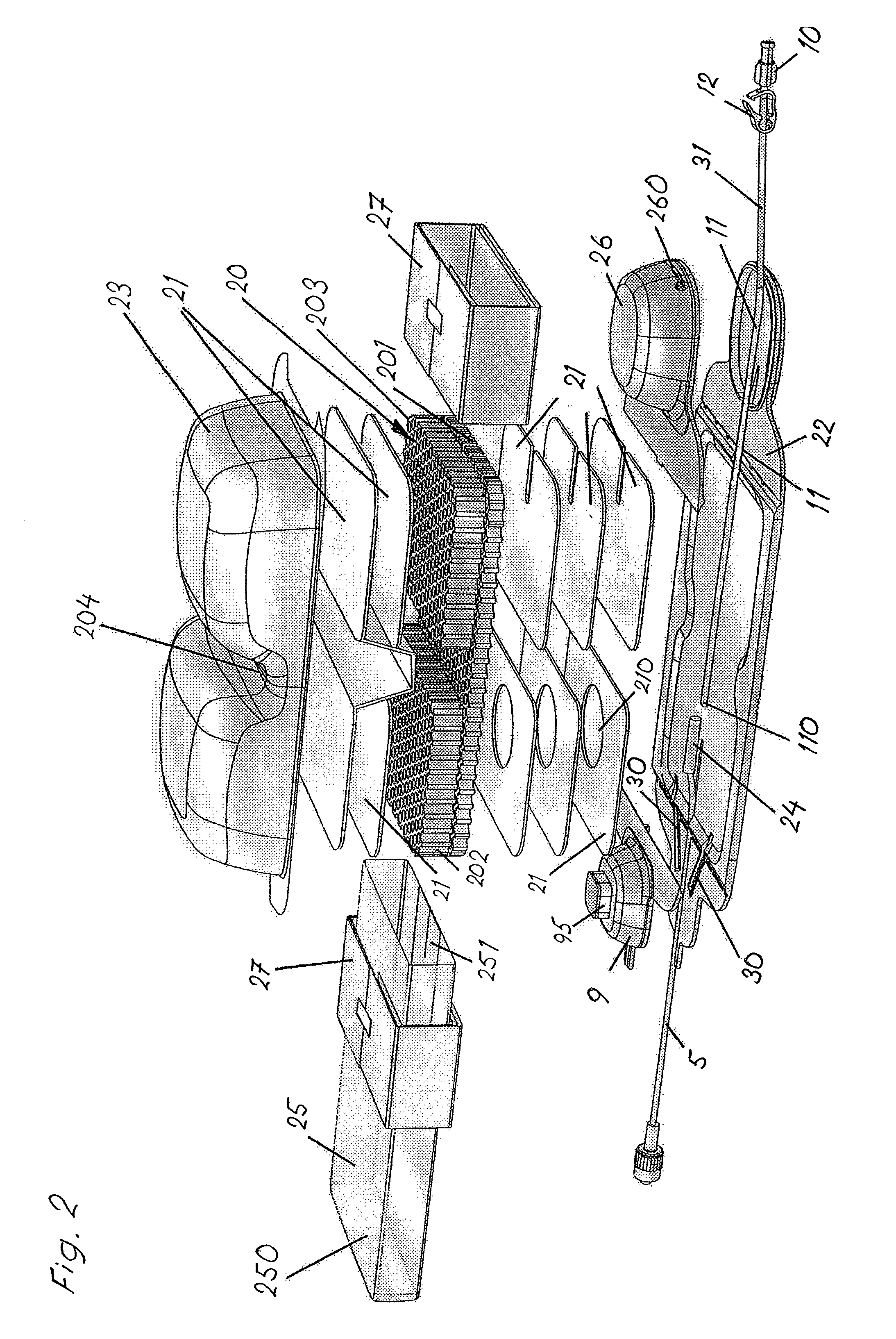

Device for treatment of wound using reduced pressure

ActiveUS8382731B2Reduce pressureKeep the pressureSurgeryMedical devicesLiquid diffusionCompressible material

Provided is a device for treatment of wounds using reduced pressure, which includes a pump, a gas barrier cover, a first compressible material which expands after compression, and a second material capable of absorbing wound fluids several times its own weight. The first and second materials are arranged inside the cover and form a reservoir connected to the pump. The device also includes an inlet for connecting the reservoir with a wound, a wound pad to be arranged in the wound cavity, and a sealing covering the wound and the wound pad. A third material with high liquid spreading capability is arranged around at least a major part of the first material, and the second material is in the form of at least one layer arranged outside the third material and separated from the first material by the third material.

Owner:MOLNLYCKE HEALTH CARE AB

Display filter, display apparatus, and method for production of the same

InactiveUS6965191B2Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDisplay deviceEngineering

The display filter is constituted by laminating a transparent adhesive layer (C) 31 containing dye, a polymer film (B) 20, a transparent electrically conductive layer (D) 10, a transparent adhesive layer (E) 40, and a functional transparent layer (A) 60 having an anti-reflection property, a hard coat property, a gas barrier property, an antistatic property and an anti-fouling property sequentially in this order, adhered on a display area 00; on this occasion, the transparent electrically conductive layer (D) 10 is grounded to a ground terminal of the display via an electrode 50 and an electrically conductive copper foil adhesive tape 80.

Owner:MITSUI CHEM INC

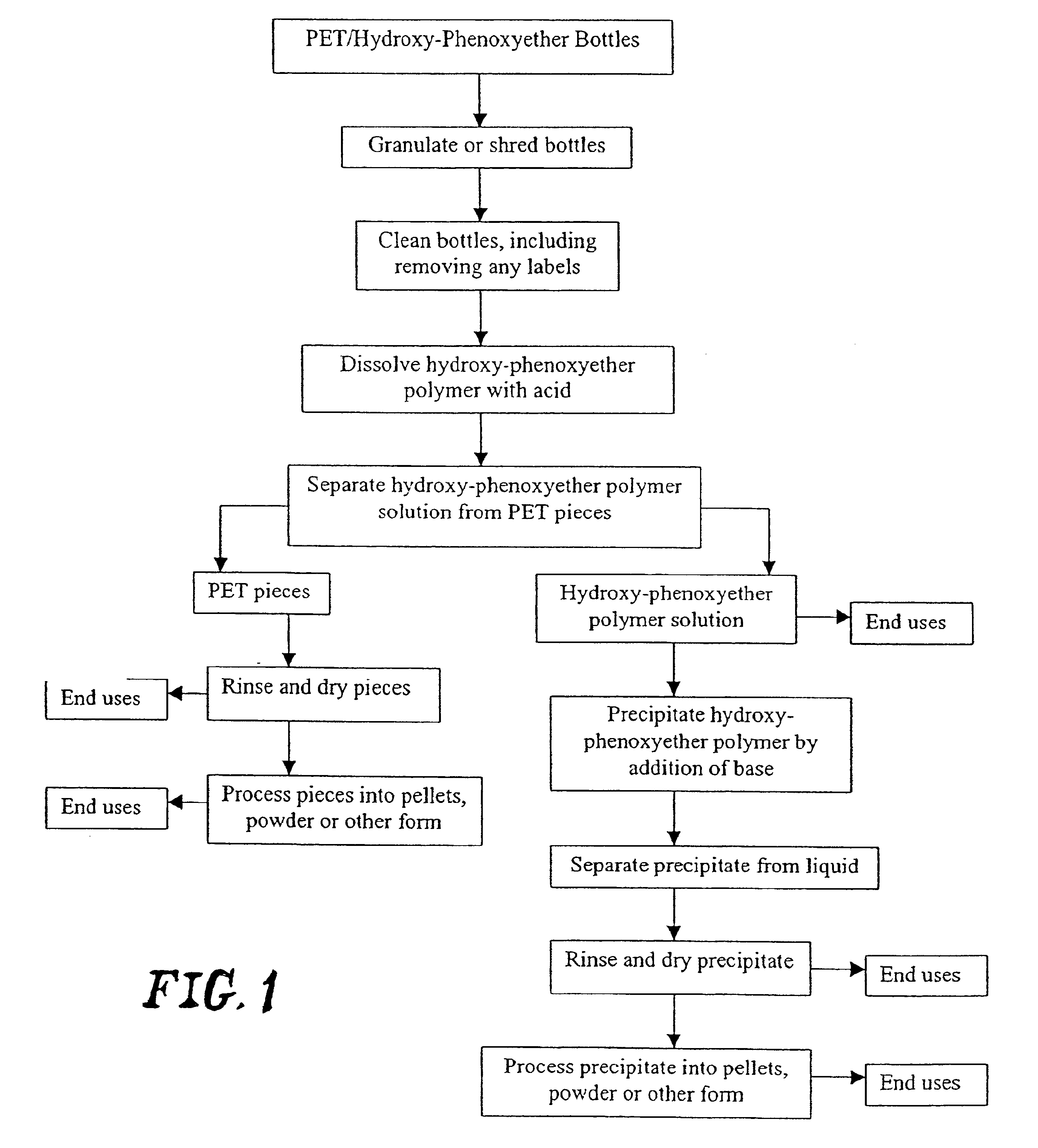

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS6808820B2Reduce the amount requiredMaintain good propertiesSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

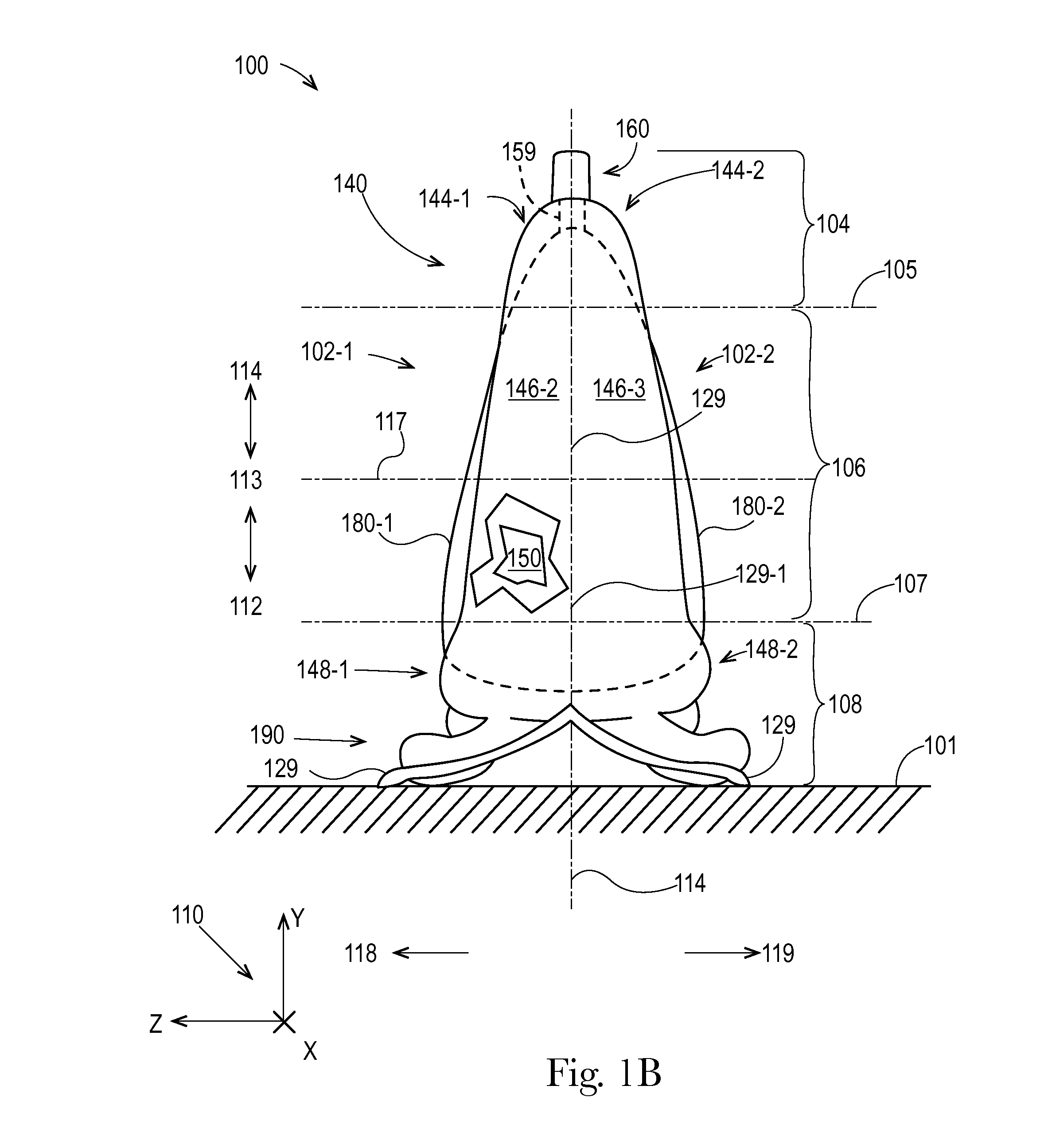

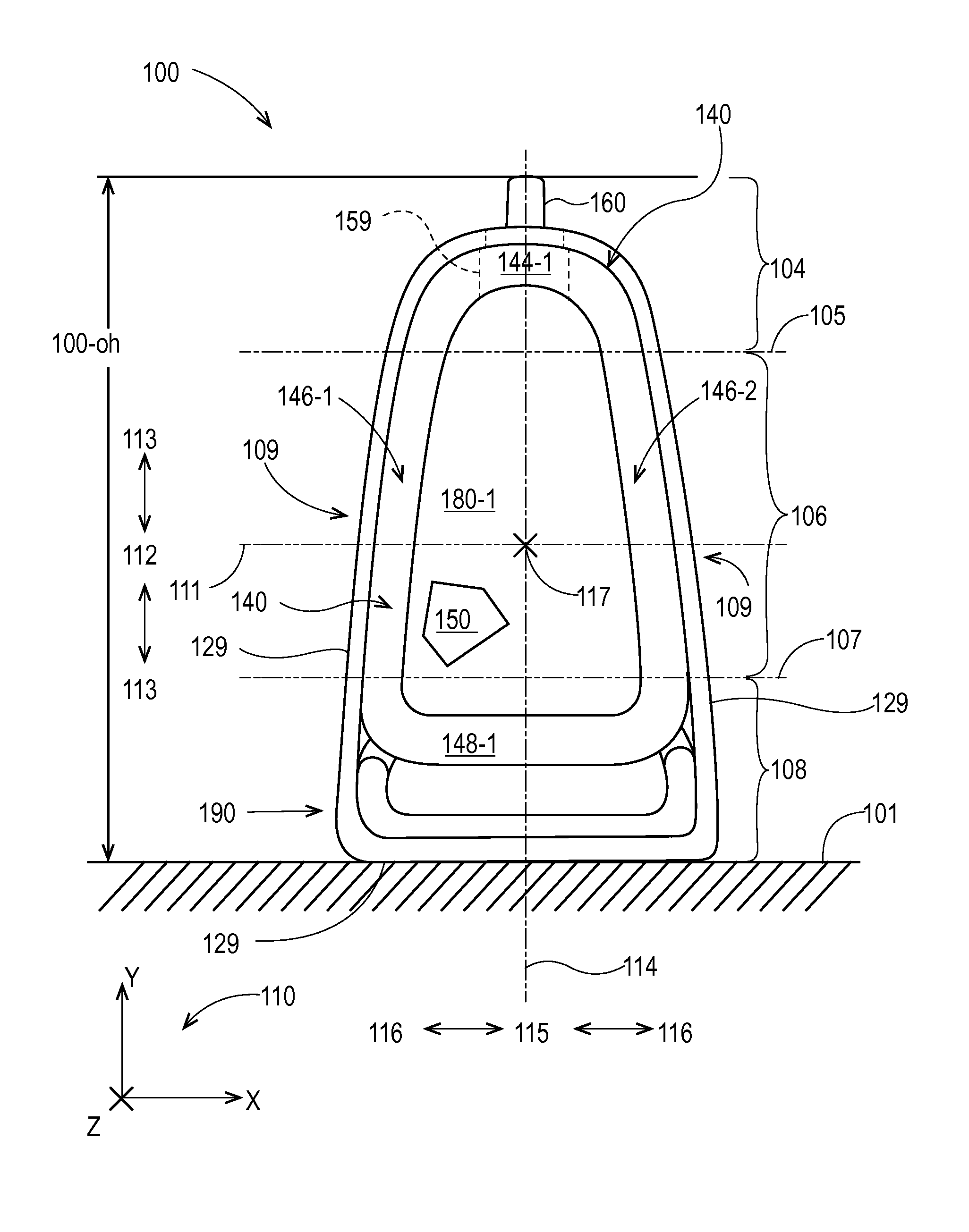

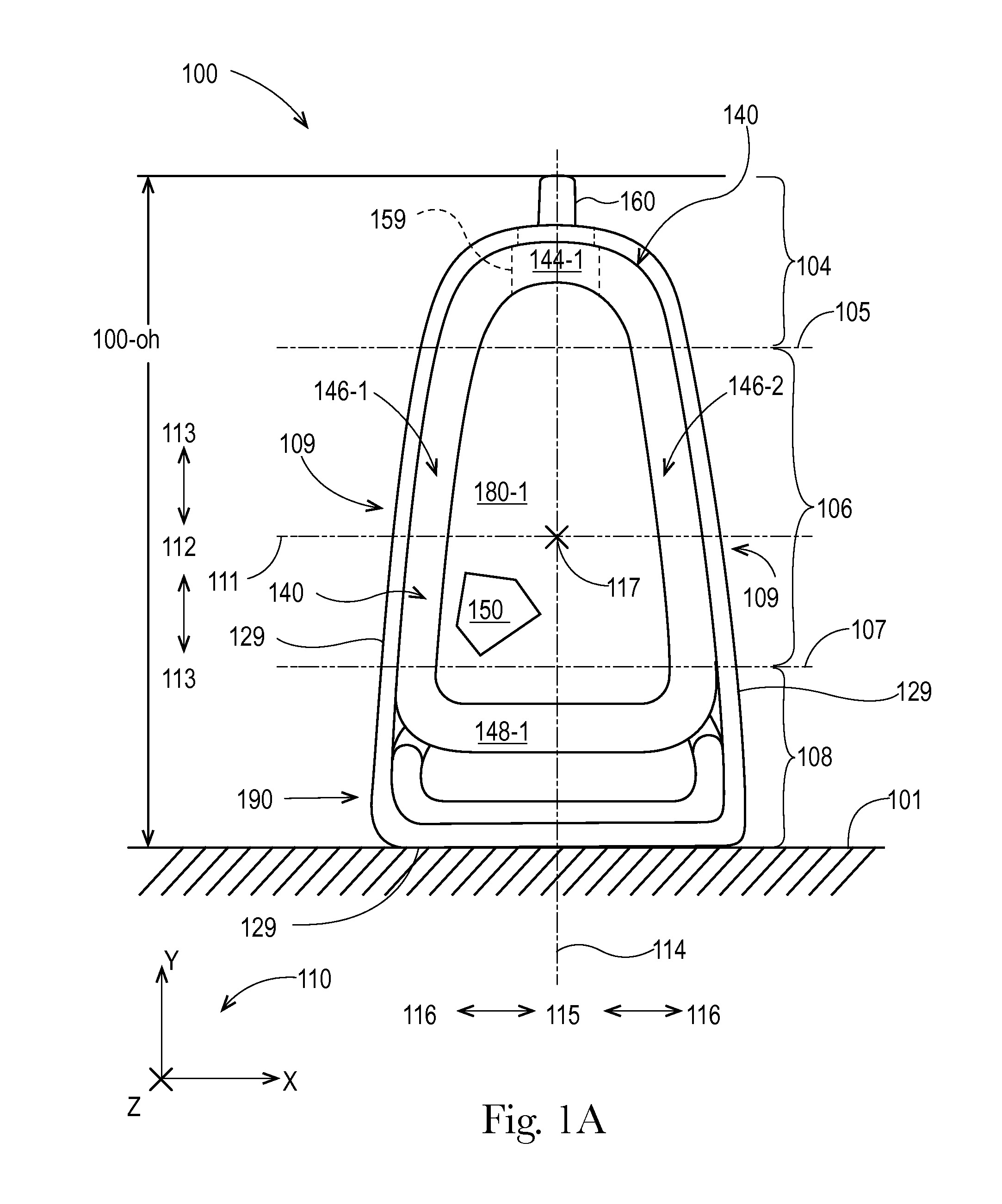

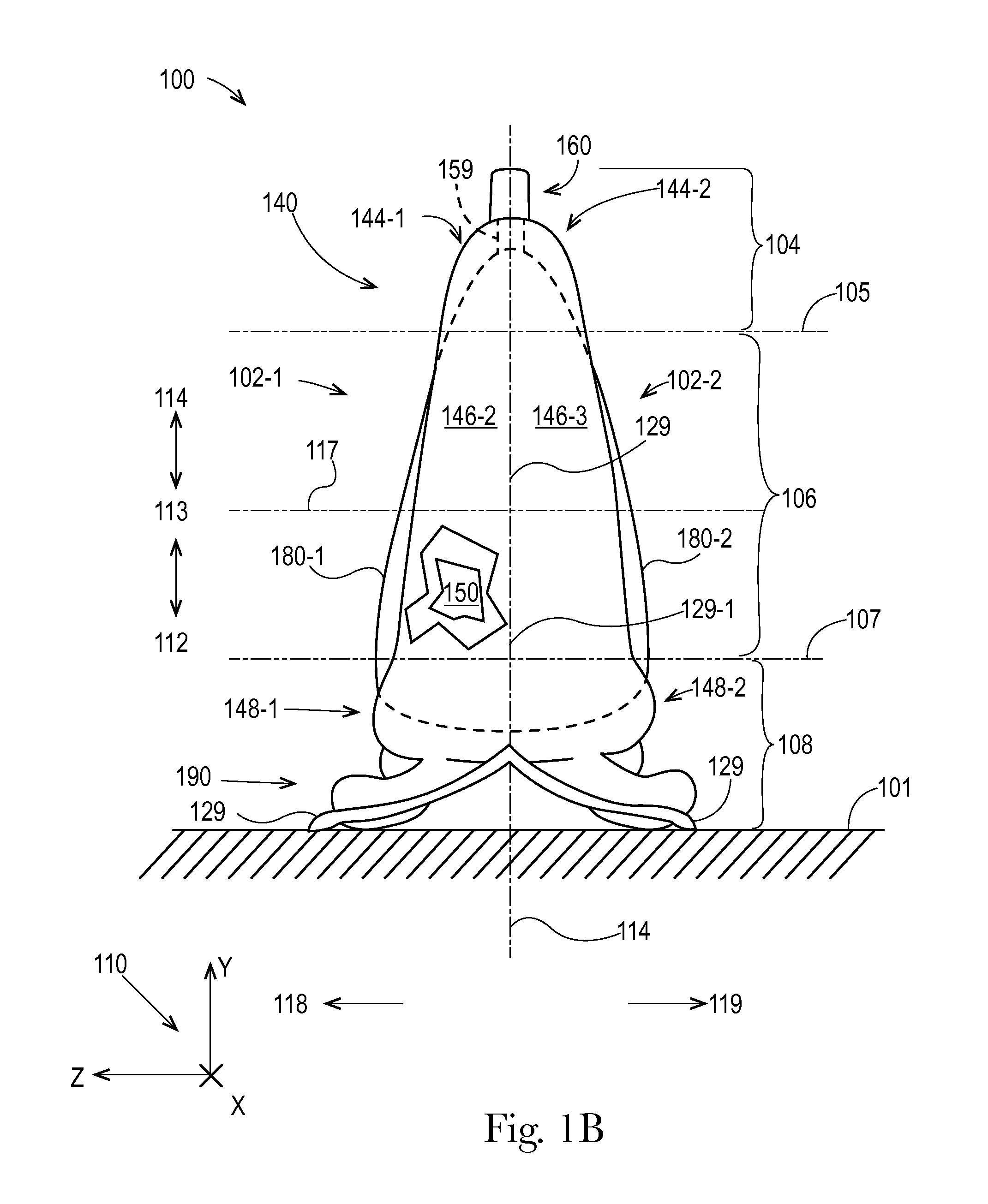

Flexible materials for flexible containers

ActiveUS9469088B2Less-expensiveImprove the decorative effectDomestic containersCoatingsMechanical engineeringGas barrier

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

Electro-optical device, manufacturing method of the same, and electronic apparatus

ActiveUS20050110020A1Avoid crackingPrevent peelingTransistorElectroluminescent light sourcesStress concentrationEngineering

Owner:SEIKO EPSON CORP

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Gas barrier film

InactiveUS6905769B2Excellent gas barrier propertiesGood weather resistanceFlexible coversWrappersProduct gasWater repellent

It is an object of the present invention to provide a gas barrier film improved in gas barrier characteristics by decreasing the adsorbent of the surface of a gas barrier layer to water and the like. The present invention attains the above object by providing a gas barrier film comprising a substrate, a gas barrier layer which is a vacuum deposition film, formed on one surface or both surfaces of the above substrate, and a water-repellent layer which is a film having water repellency, formed on the above gas barrier layer.

Owner:DAI NIPPON PRINTING CO LTD

Heat-shrinkable multi-layer film

InactiveUS6146726AImprove sealingLow-temperature sealabilityWrappers shrinkageShrinkage connections1-OcteneCLARITY

The invention provides a heat-shrinkable multi-layer film comprising at least a thermoplastic resin layer as the outermost layer (A), a gas barrier resin layer as a core layer (B) and a sealing resin layer as the innermost layer (C), and optionally an adhesive layer between the individual layers, wherein (1) the sealing resin layer of the innermost layer (C) is a layer formed of a resin material (b) comprising a linear ethylene-1-octene copolymer (a) obtained by using a constrained geometry catalyst and having an 1-octene content not lower than 1 wt. % but lower than 20 wt. % and a density higher than 0.885 g / cm3 but not higher than 0.960 g / cm3, and (2) an intermediate layer (D1) formed of at least one resin (c) selected from the group consisting of polyamide resins, thermoplastic polyester resins and ethylene copolymer resins is provided between the outermost layer (A) and the core layer (B). The film has excellent sealing properties, clarity, mechanical strength, stretchability and bag-making property.

Owner:KUREHA KAGAKU KOGYO KK

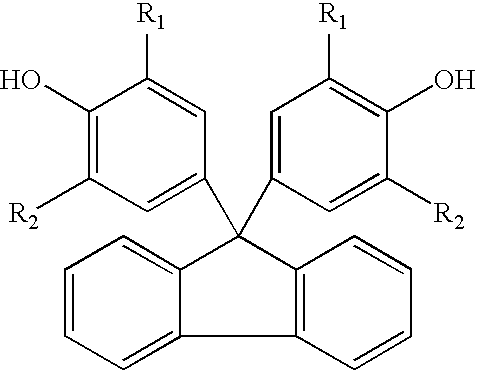

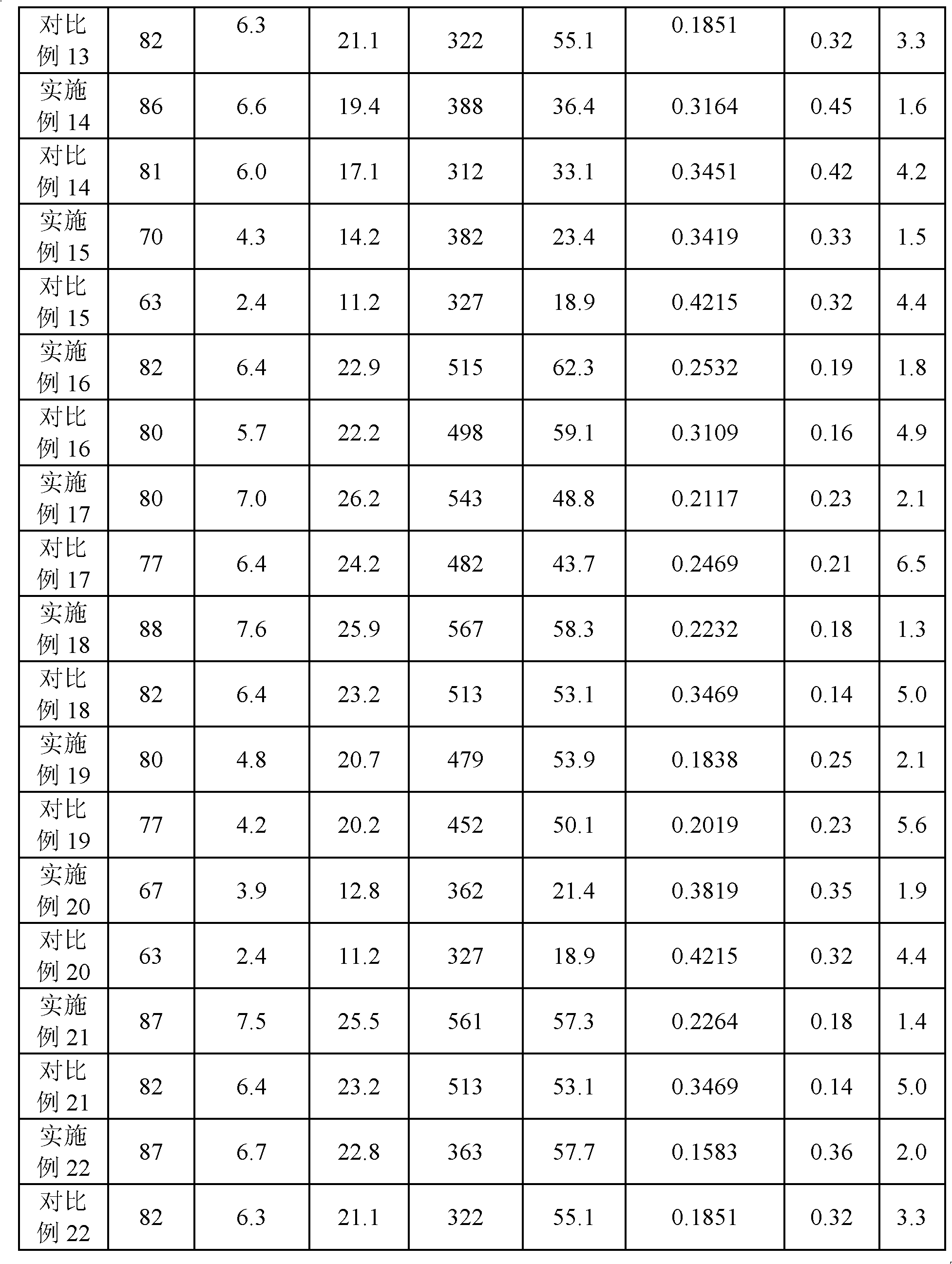

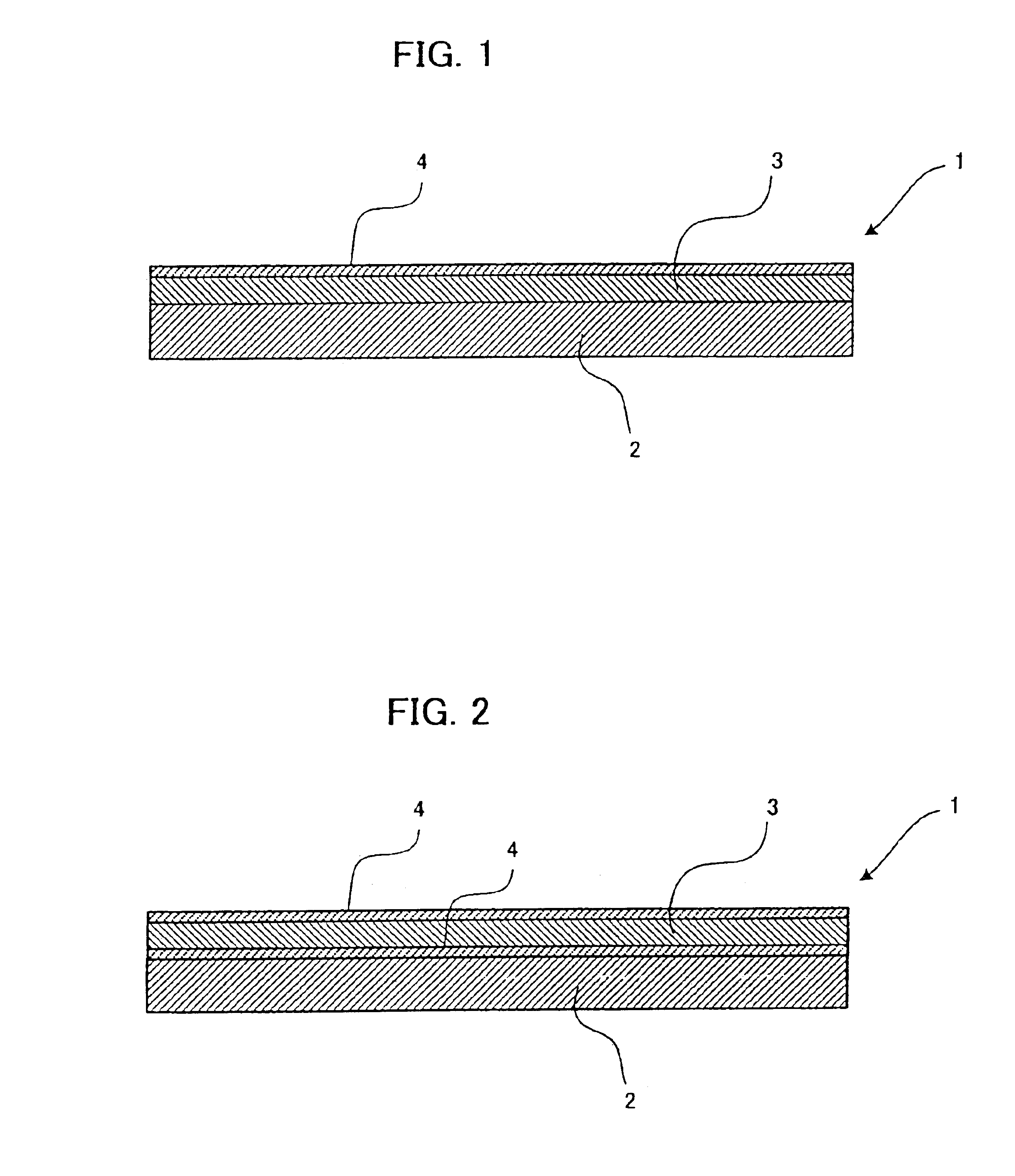

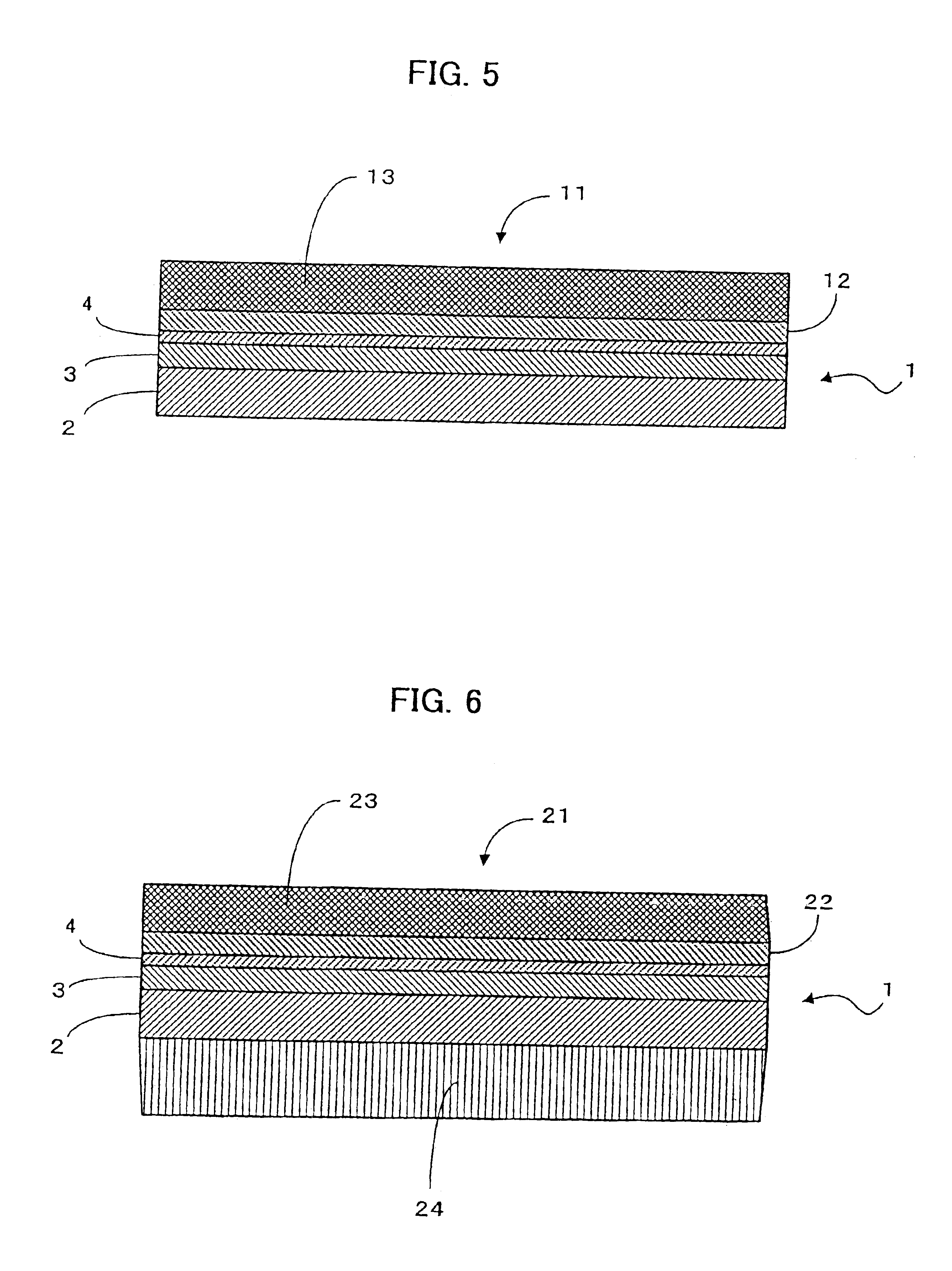

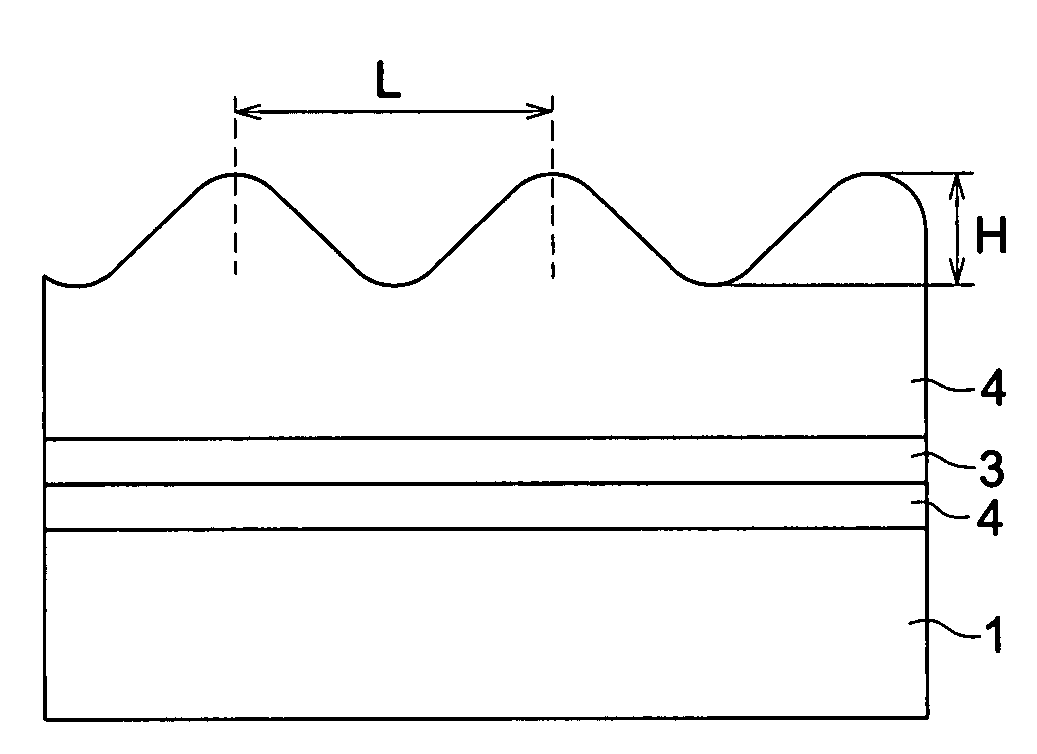

Resin Film Substrate for Organic Electroluminescence and Organic Electroluminescence Device

InactiveUS20080176041A1Low costExcellent gas barrier performanceSynthetic resin layered productsSolid-state devicesConvex structureOrganic electroluminescence

Disclosed is a low-cost resin film substrate for organic electroluminescence which comprises a gas barrier layer having high gas barrier properties while being improved in light taking-out efficiency. Also disclosed is an organic electroluminescence device using such a resin film substrate. Specifically disclosed is a resin film substrate for organic electroluminescence comprising at least one gas barrier layer on a resin film. This resin Film substrate is characterized in that the surface of the outermost layer on the side having the gas barrier layer has a concavo-convex structure for diffracting of diffusing light.

Owner:KONICA MINOLTA INC

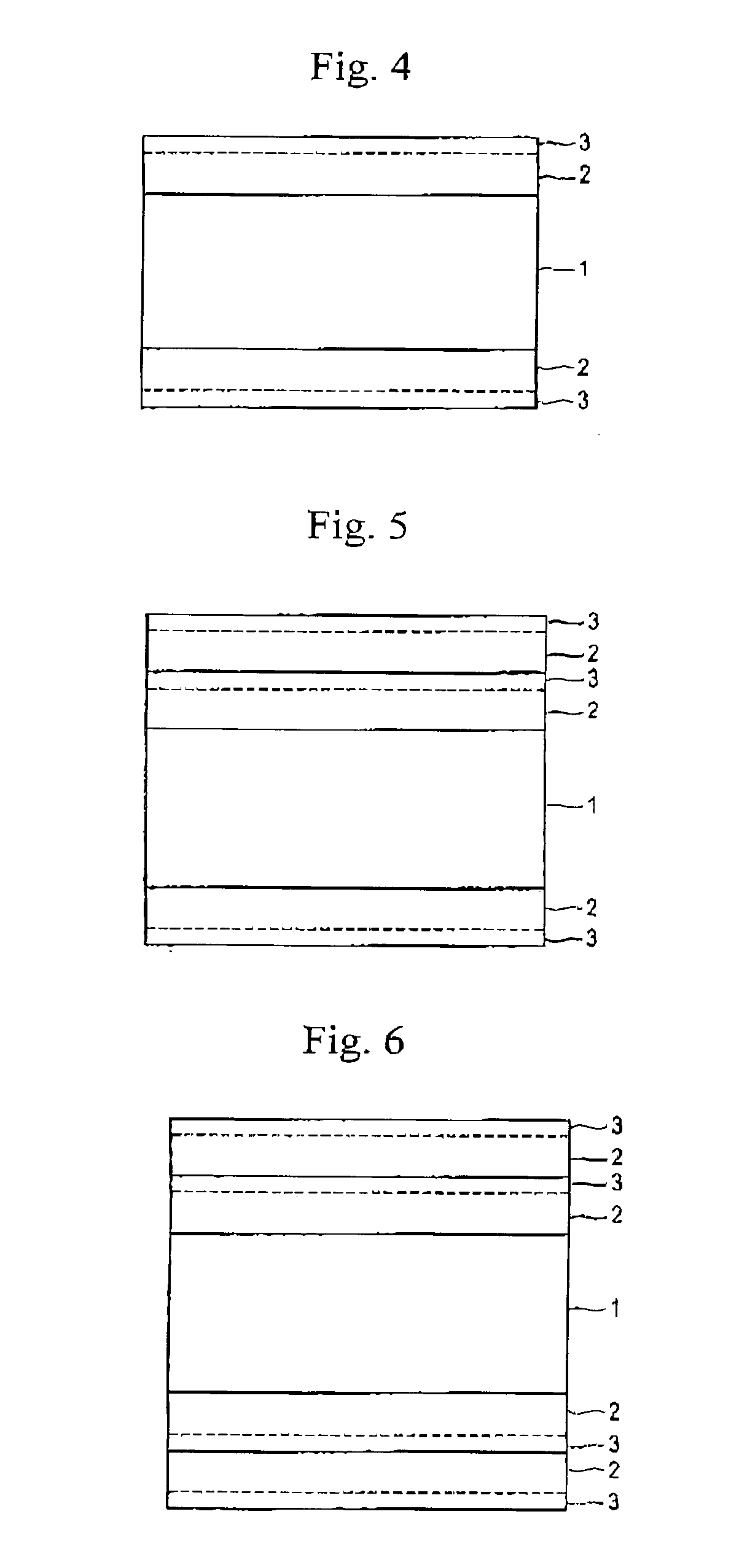

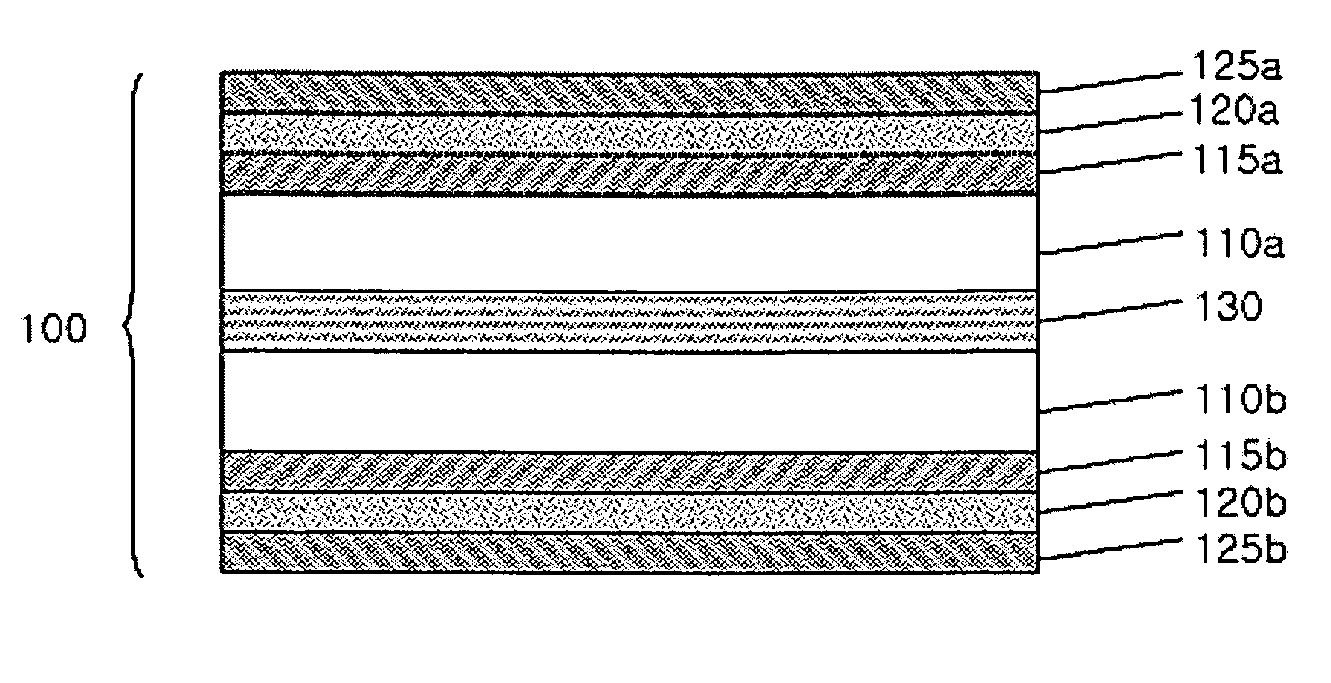

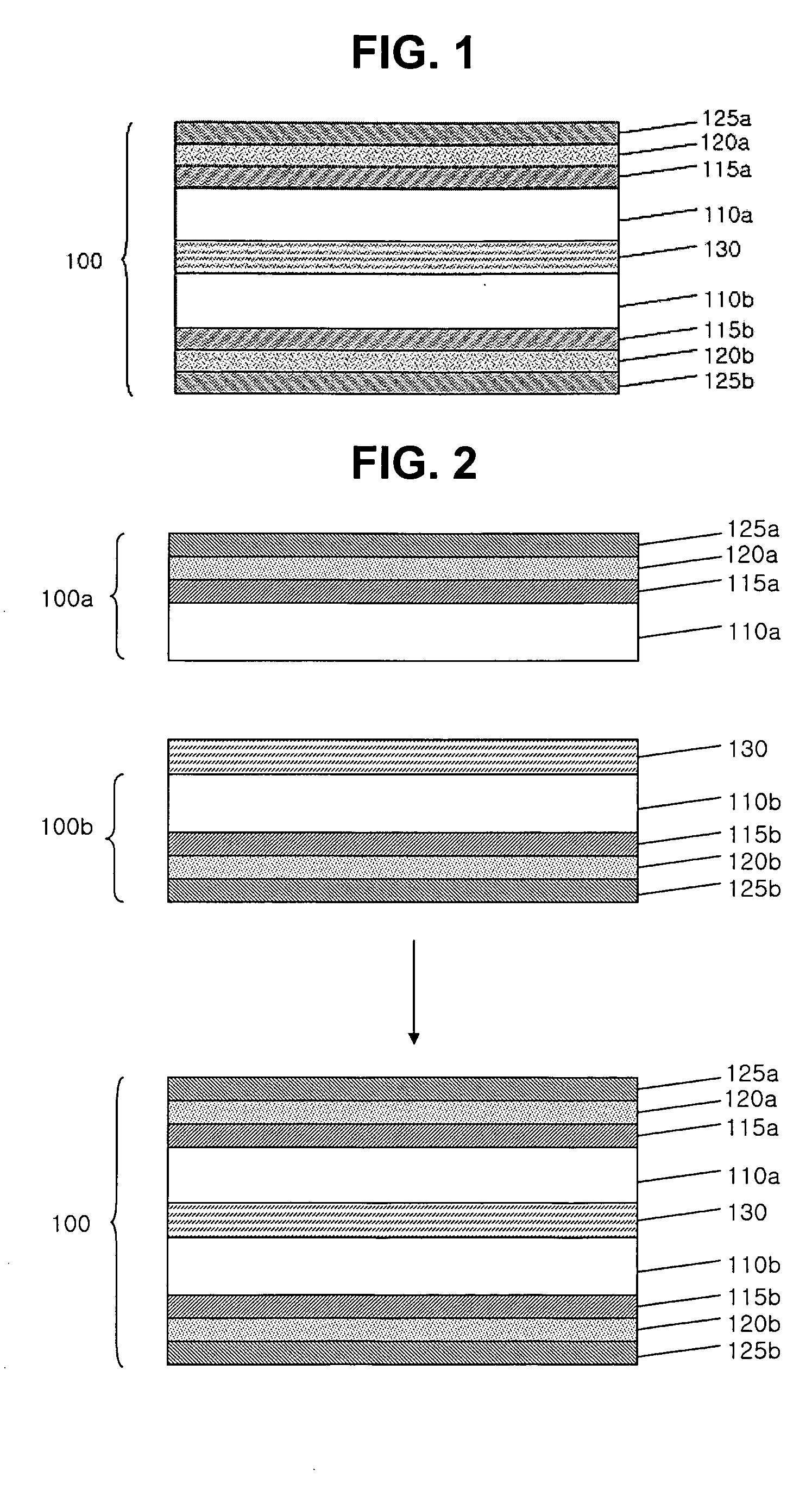

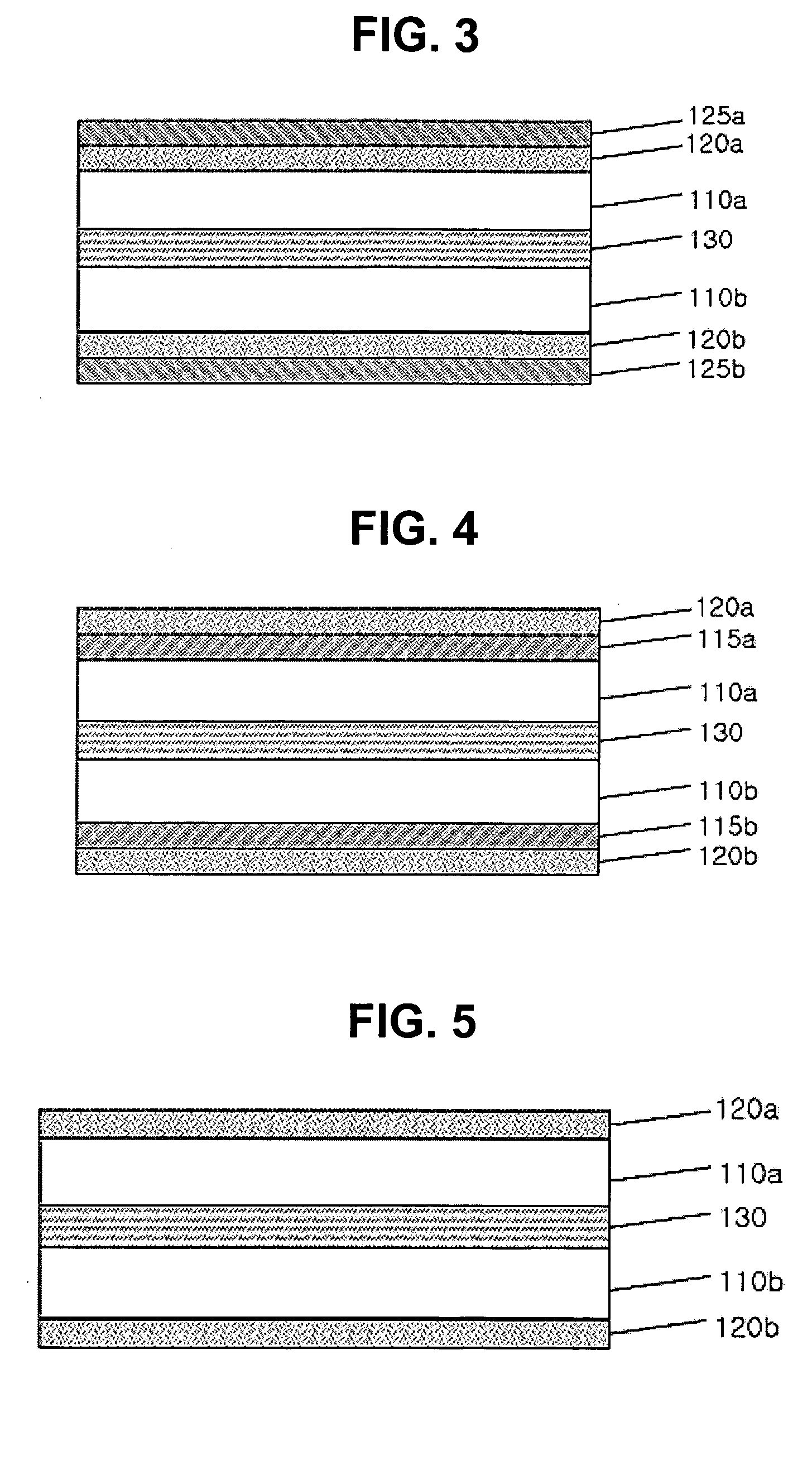

Plastic substrate having multi-layer structure and method for preparing the same

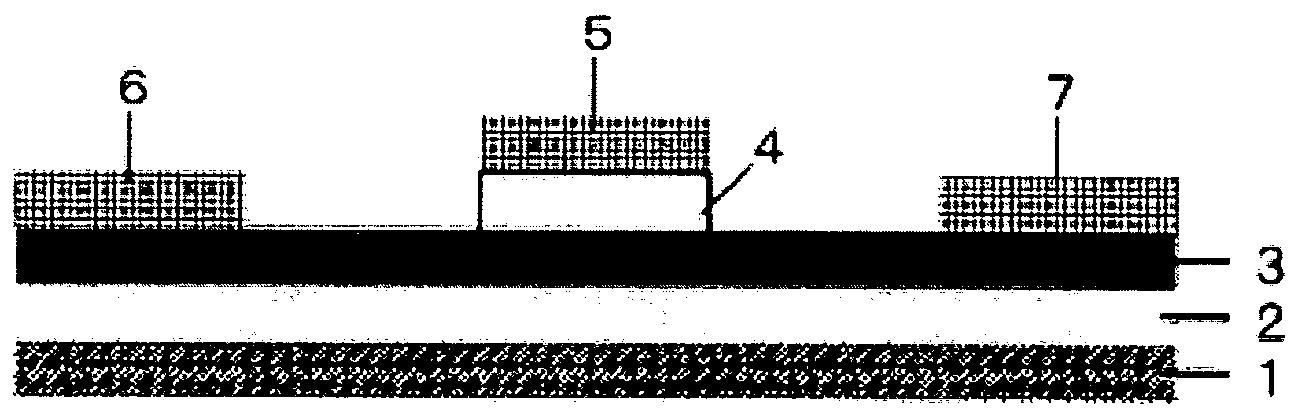

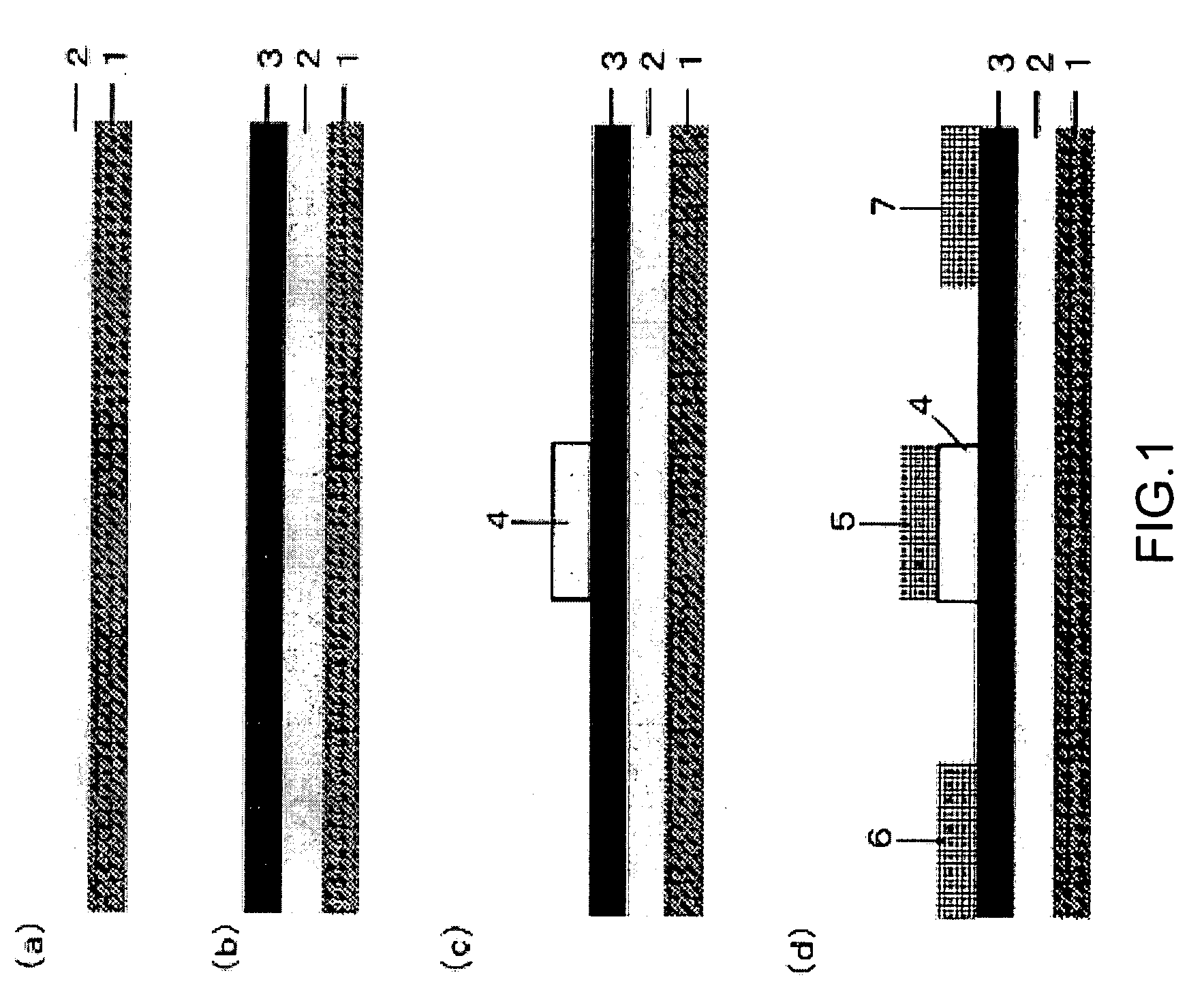

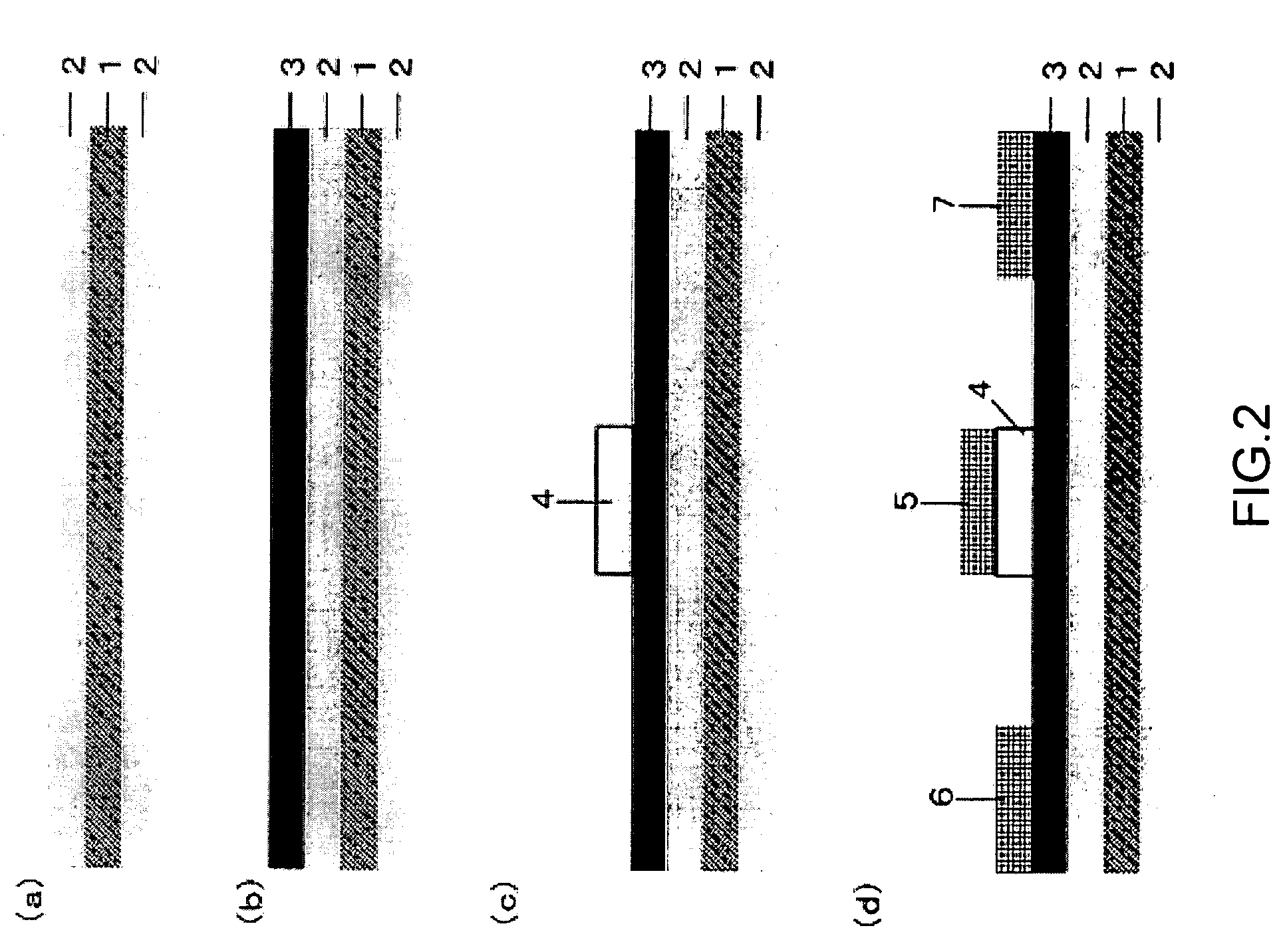

ActiveUS20050175831A1Small coefficientGood dimensional stabilityFinal product manufactureSolid-state devicesDisplay deviceEngineering

The present invention relates to a plastic substrate having a multi-layer structure and a method for preparing the same. The plastic substrate of the present invention comprises plastic films attached to each other, and a first buffering layer of an organic-inorganic hybrid, a layer of gas barrier, and a second buffering layer of an organic-inorganic hybrid which are stacked on both sides of the plastic films in an orderly manner, each layer forming a symmetrical arrangement centering around the plastic films. Because the plastic substrate of the present invention has a small coefficient of thermal expansion, excellent dimensional stability, and superior gas barrier properties, it can replace the brittle and heavy glass substrate in display devices. Also, it can be used for a variety of packaging or container materials in applications requiring superior gas barrier properties.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com