Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5947 results about "Water repellent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

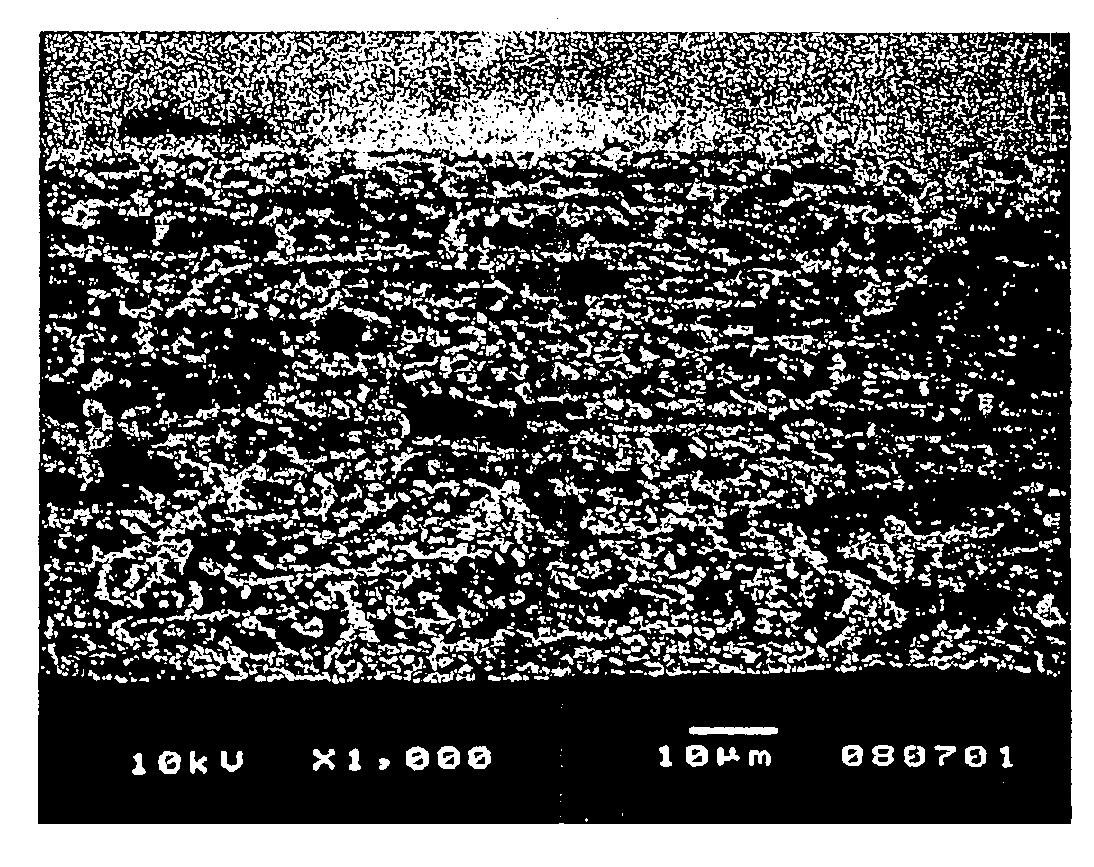

Process for producing detachable dirt- and water-repellent surface coatings

ActiveUS7083828B2Good removal effectSimple wayFouling preventionSolid waste managementWaxSurface structure

Process for producing detachable dirt- and water-repellent surface coatings on articles, wherein during the coating process, hydrophobic particles are applied to the surface of the articles, thus generating a surface structure with elevations on that surface of the articles that has dirt- and water-repellent properties, which comprises suspending the hydrophobic particles in a solution of a silicone wax in a highly volatile siloxane, and applying this suspension to at least one surface of an article, and then removing the highly volatile siloxane.

Owner:EVONIK DEGUSSA GMBH

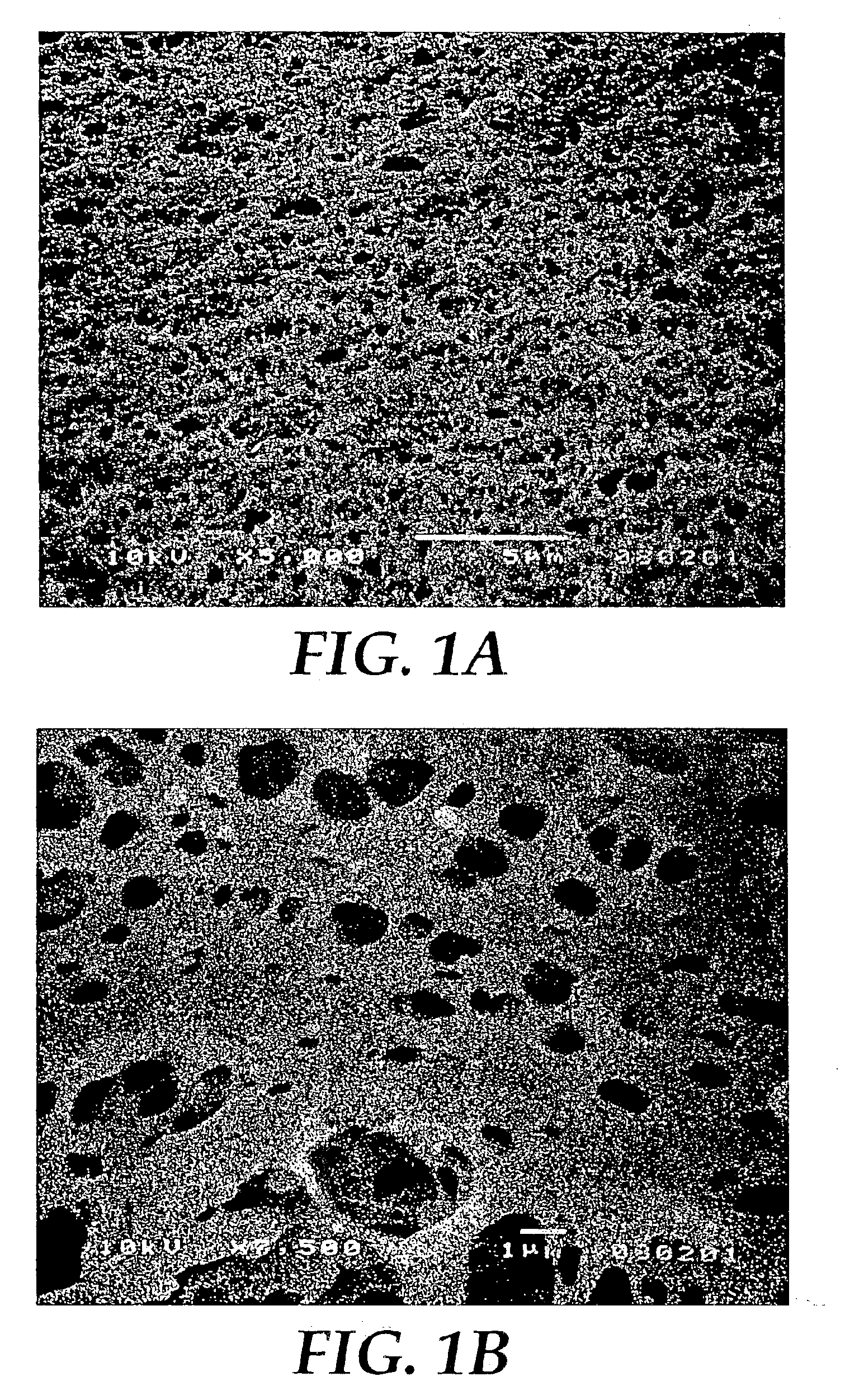

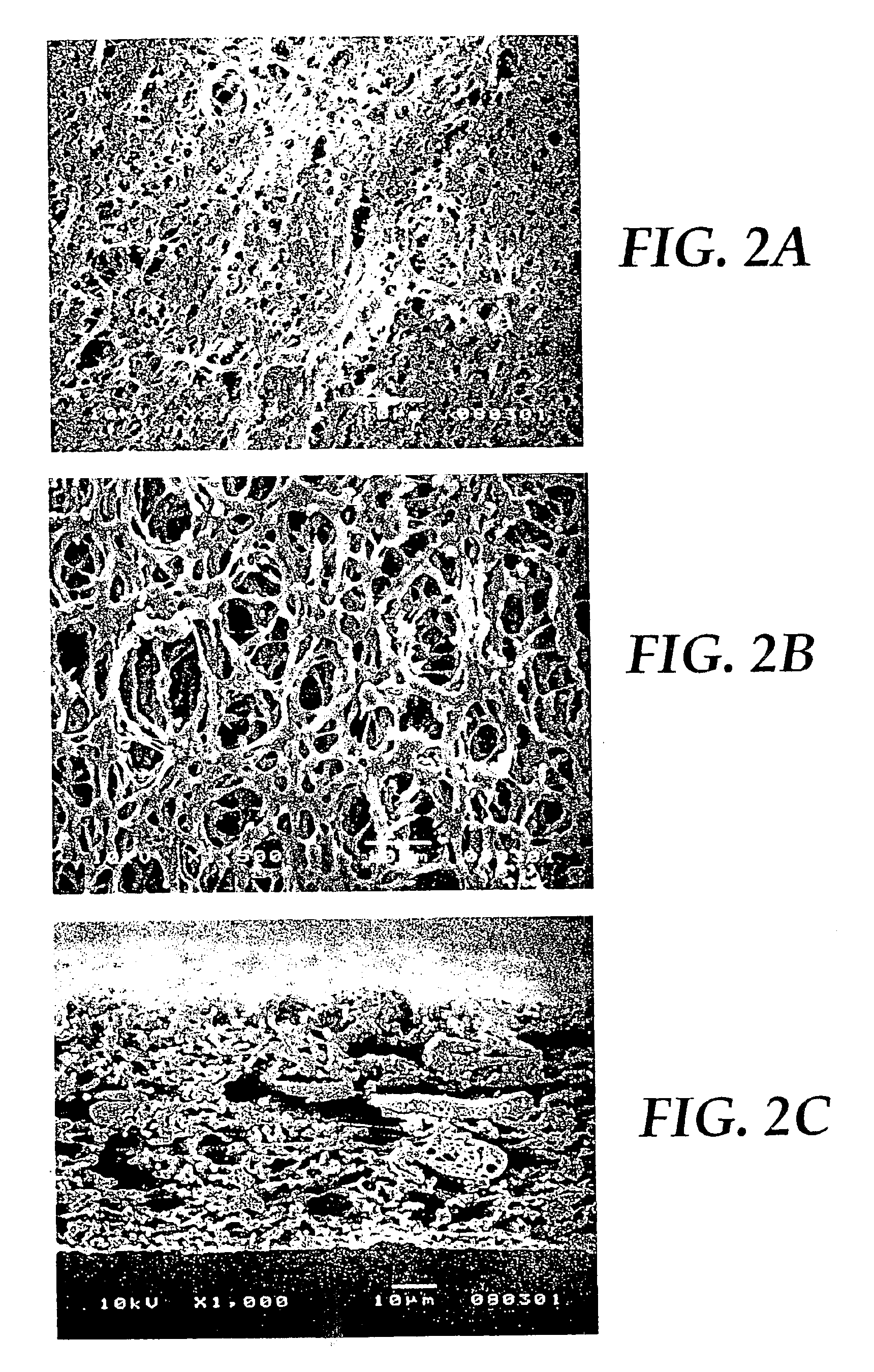

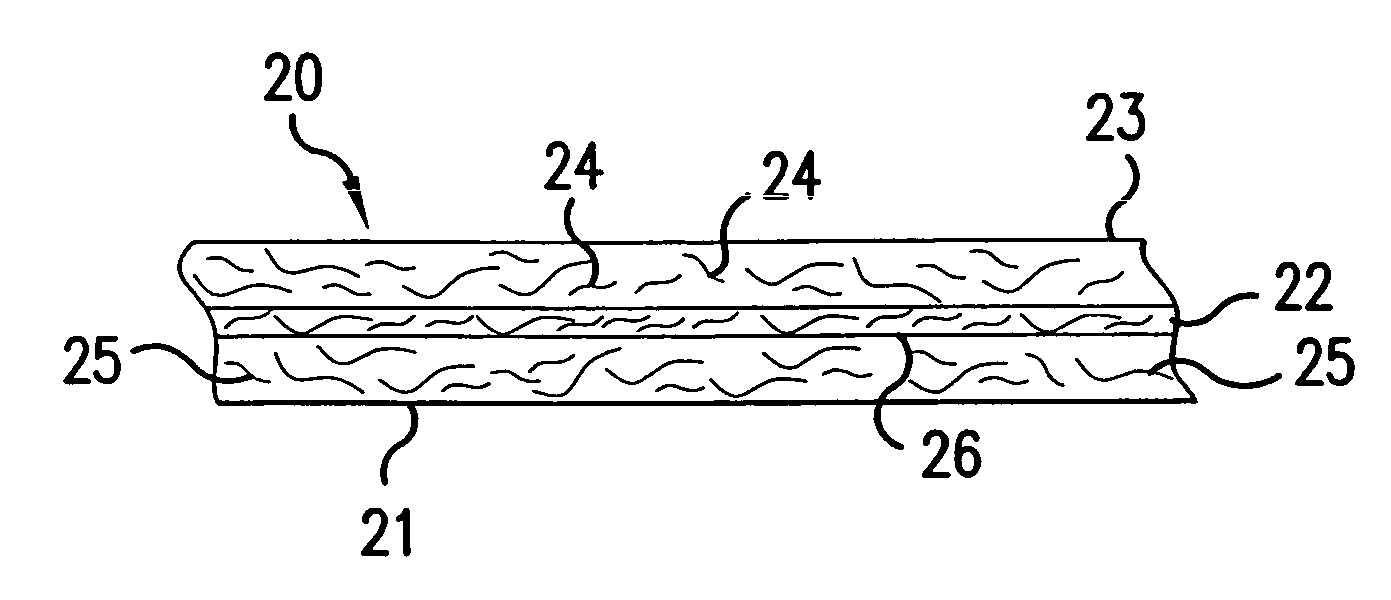

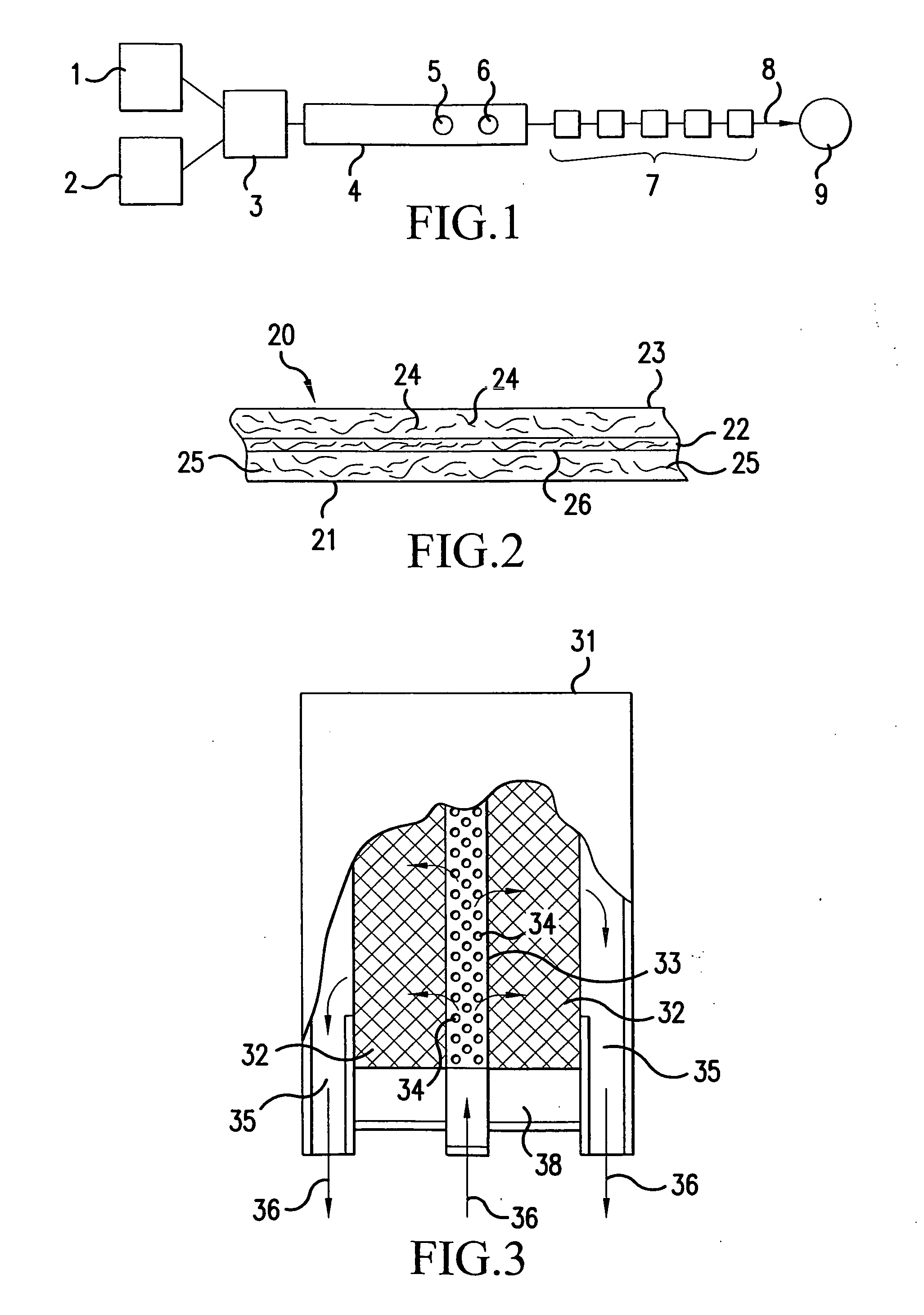

Hydrophobic membrane materials for filter venting applications

The present invention relates to filtration media having both hydrophobic (water-repellent) properties. The filtration media are produced using a fluorothermoplastic material, such as a terpolymer of tetrafluoroethylene, vinylidene fluoride, and hexafluoropropylene. The invention also relates to methods of preparing such filtration media using casting solution phase inversion.

Owner:PALL CORP

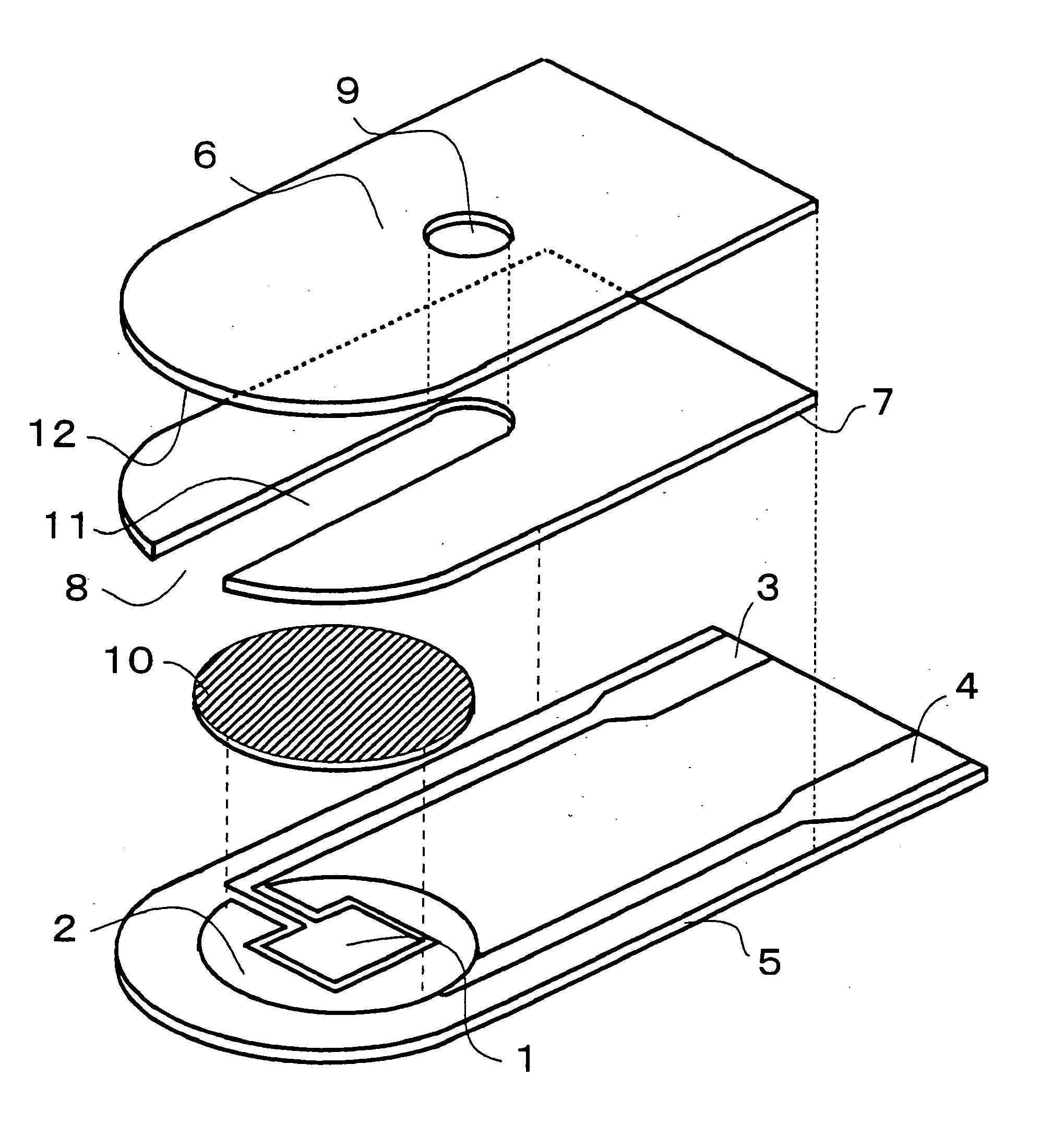

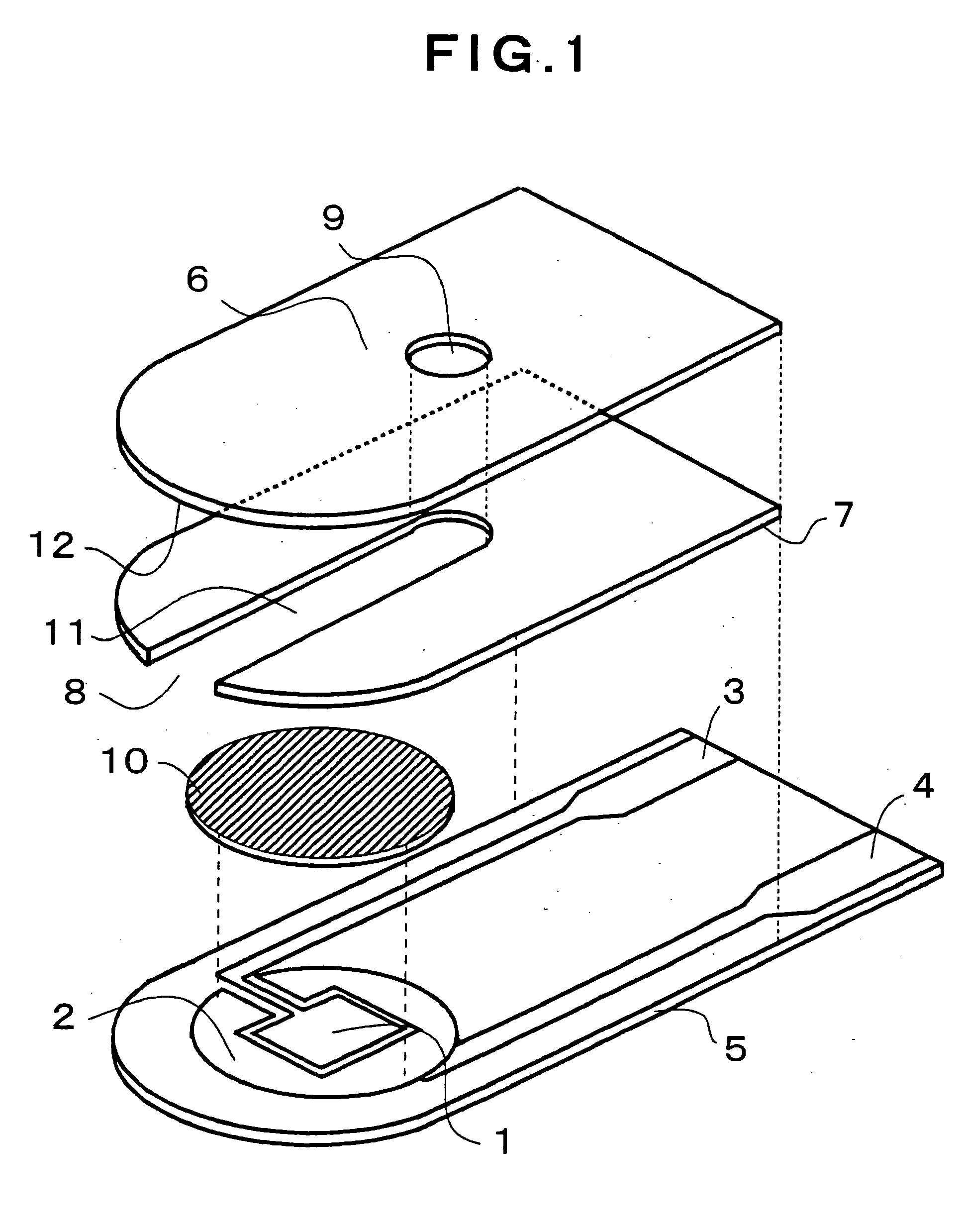

Biosensor

InactiveUS20050036906A1High measurement accuracyImmobilised enzymesBioreactor/fermenter combinationsFree energiesWater repellent

A biosensor for analyzing specific components in an introduced liquid sample by reaction of the liquid sample with a reagent comprises a cavity into which the liquid sample is introduced, an air hole communicating from the cavity to outside, and a water repellent part having a water repellency at 43 mN / m or less in surface free energy and provided to at least a portion around the outlet of the air hole. By the water repellent part around the air hole, the liquid sample can be prevented from flowing out through the air hole, thereby achieving a high-accuracy measurement.

Owner:PANASONIC CORP +1

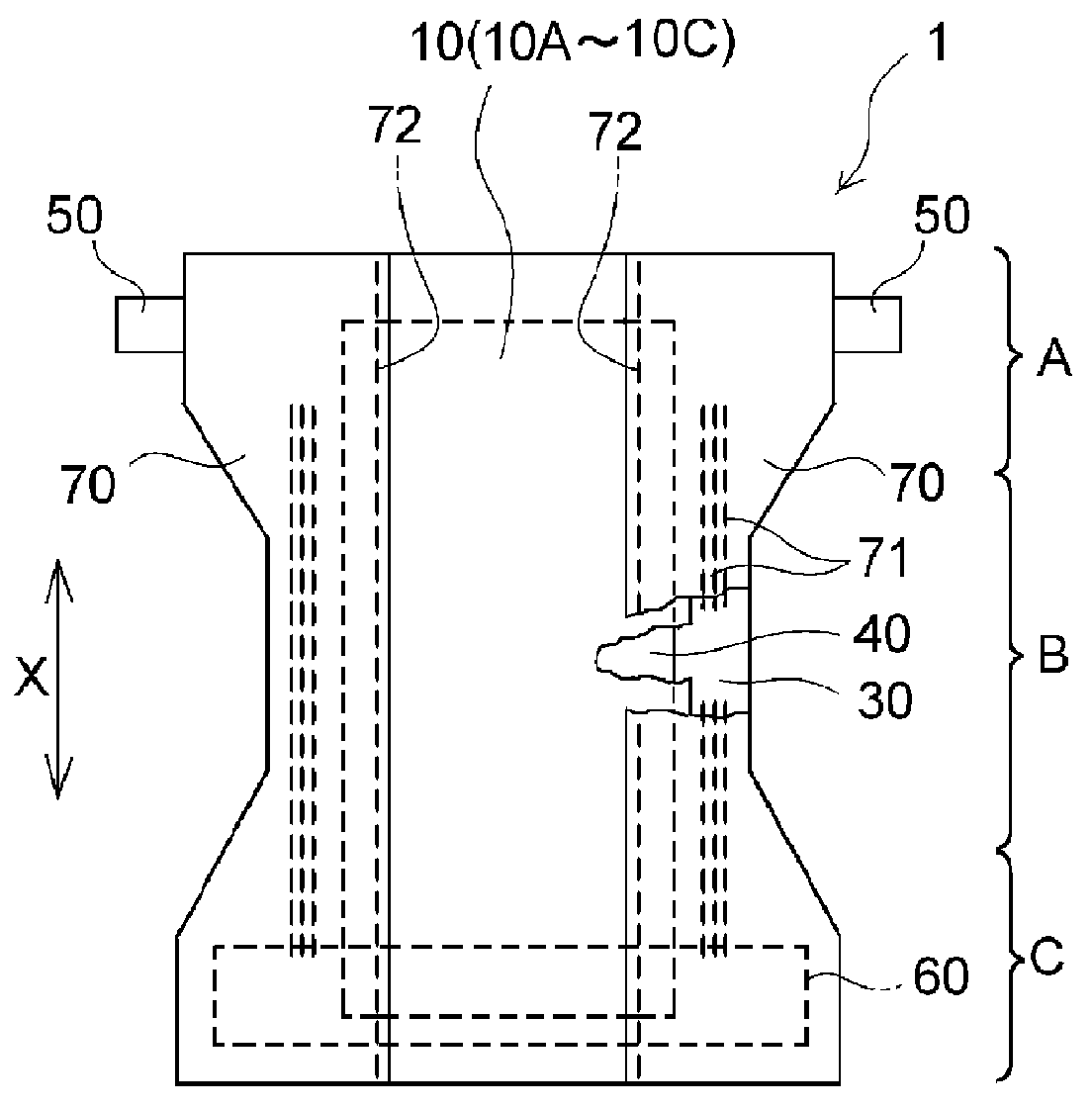

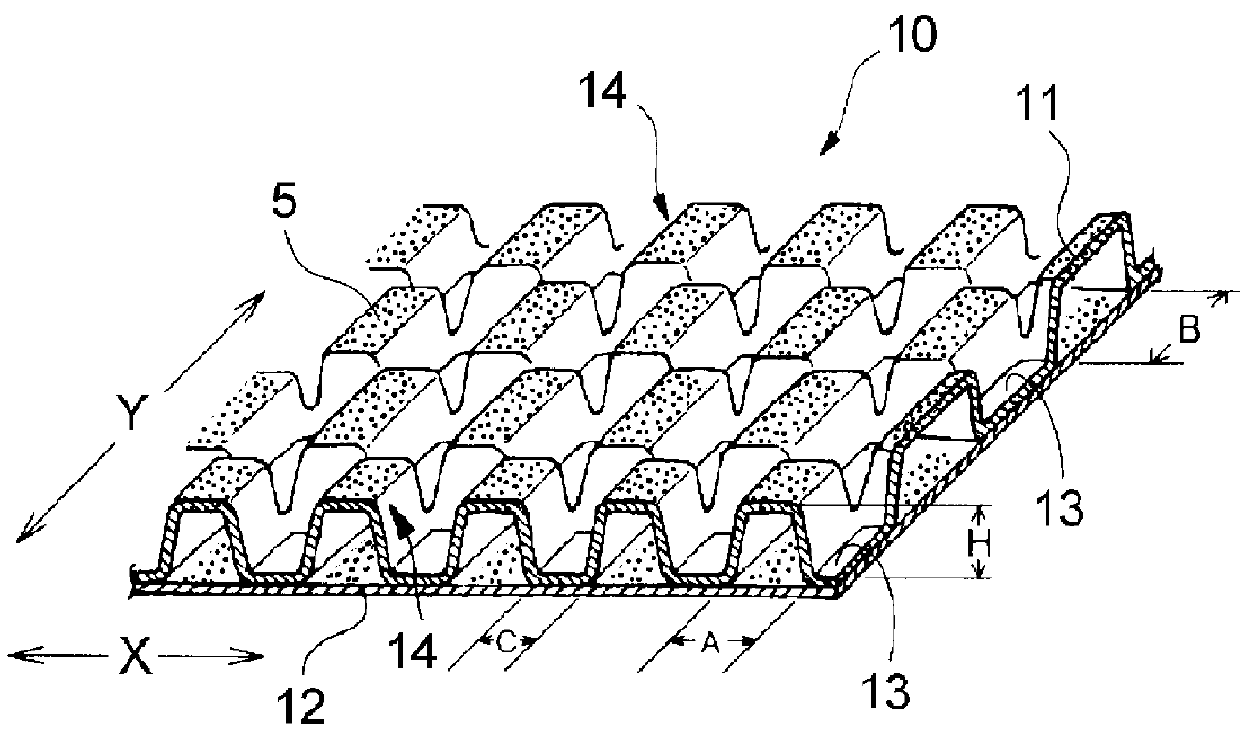

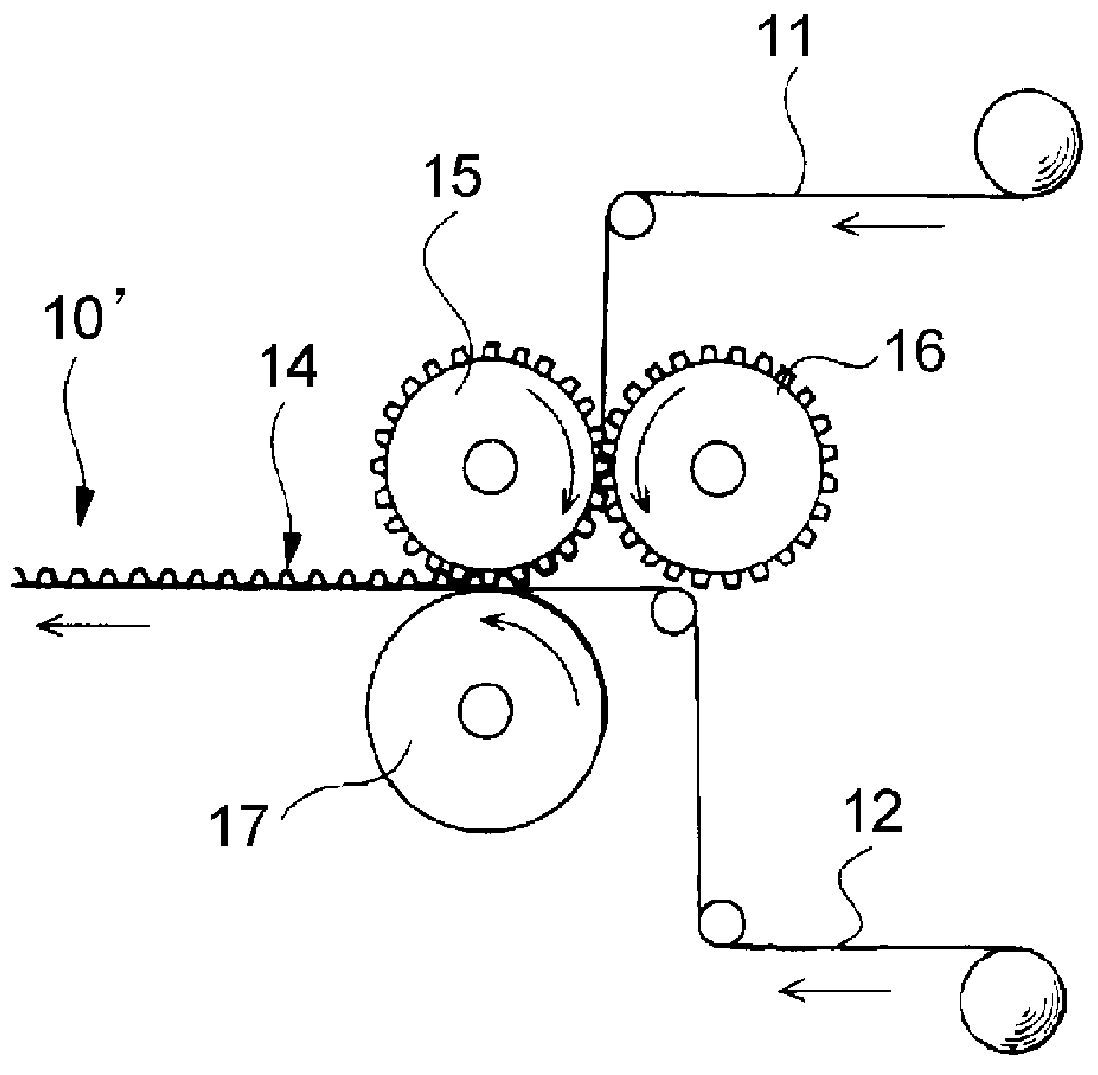

Absorbent article

An absorbent article includes a liquid permeable topsheet (10), a liquid impermeable or water repellent backsheet, and an absorbent member interposed between these sheets. The topsheet (10) is formed of a nonwoven sheet having high density portions (13A) and low density portions (14A). Each high density portion (13A) and each low density portion (14A) are different in density from each other. The high density portions (13A) and the low density portions (14A) are arranged in planar directions of the topsheet (10). The low density portions (14A) have a larger amount of a skin care agent (5) applied thereto than the high density portions (13A).

Owner:KAO CORP

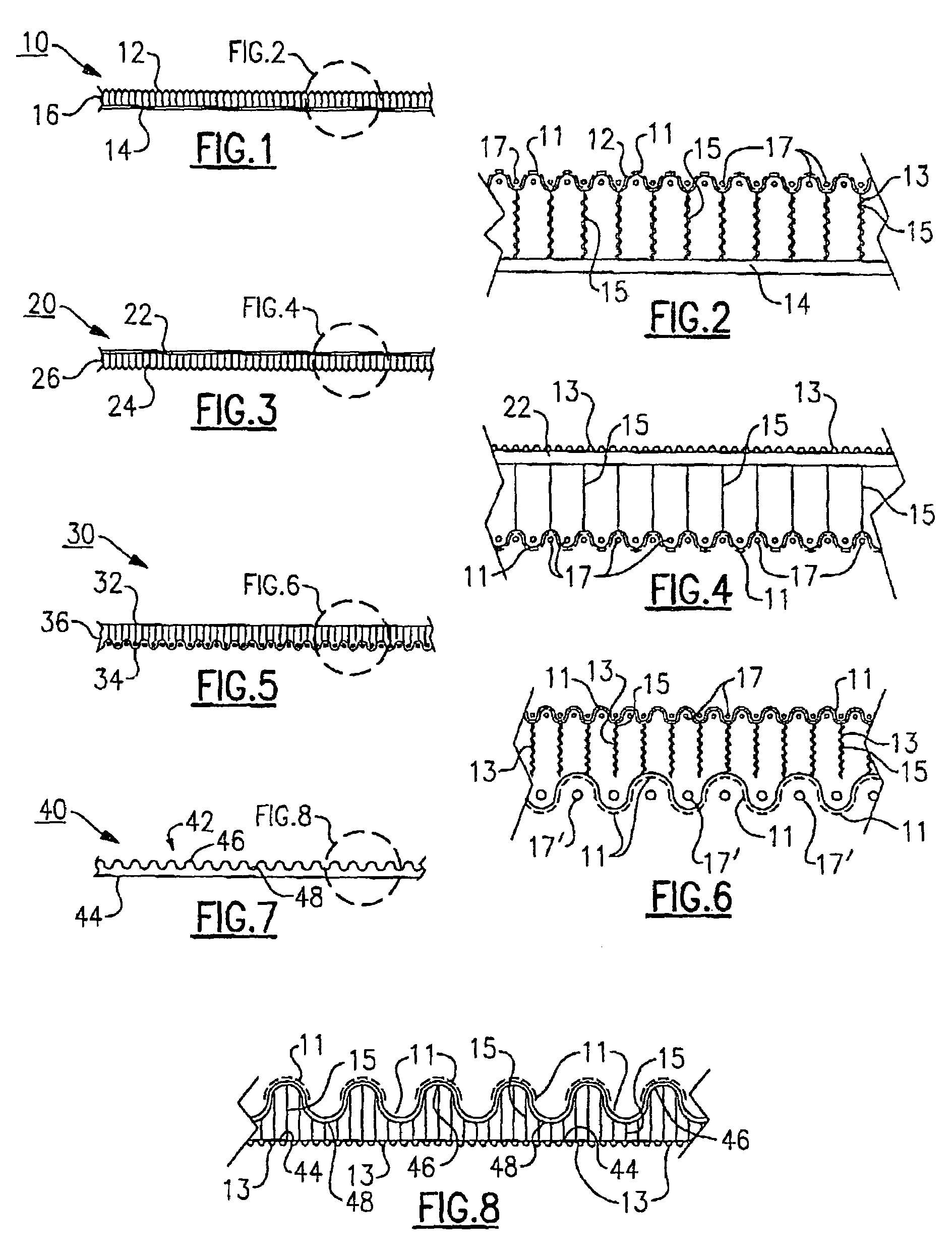

Moisture management system

InactiveUS7169720B2Efficient evaporationReduce capacityOrnamental textile articlesInsolesEngineeringWater repellent

Owner:ETCHELLS MARC D +2

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

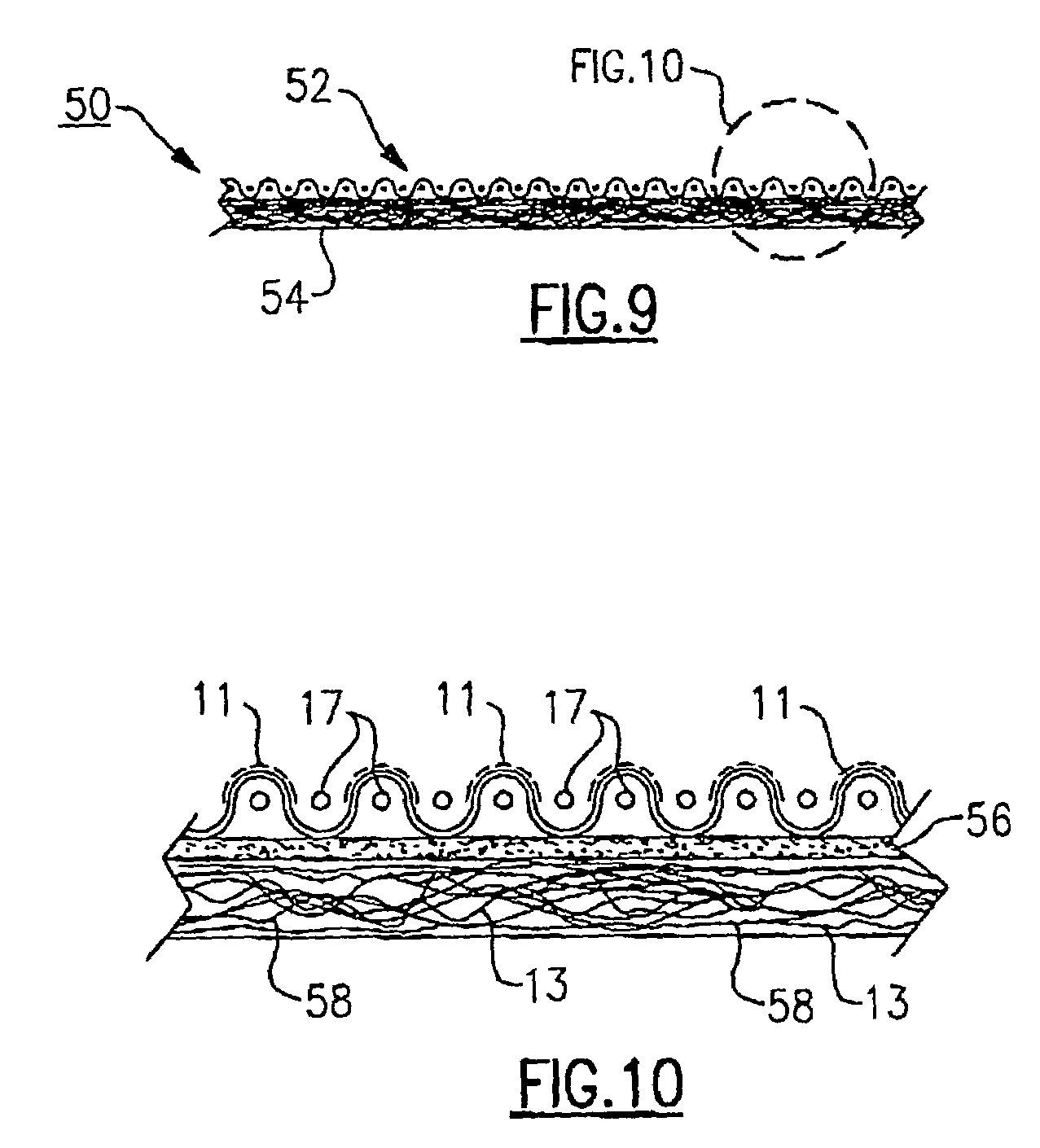

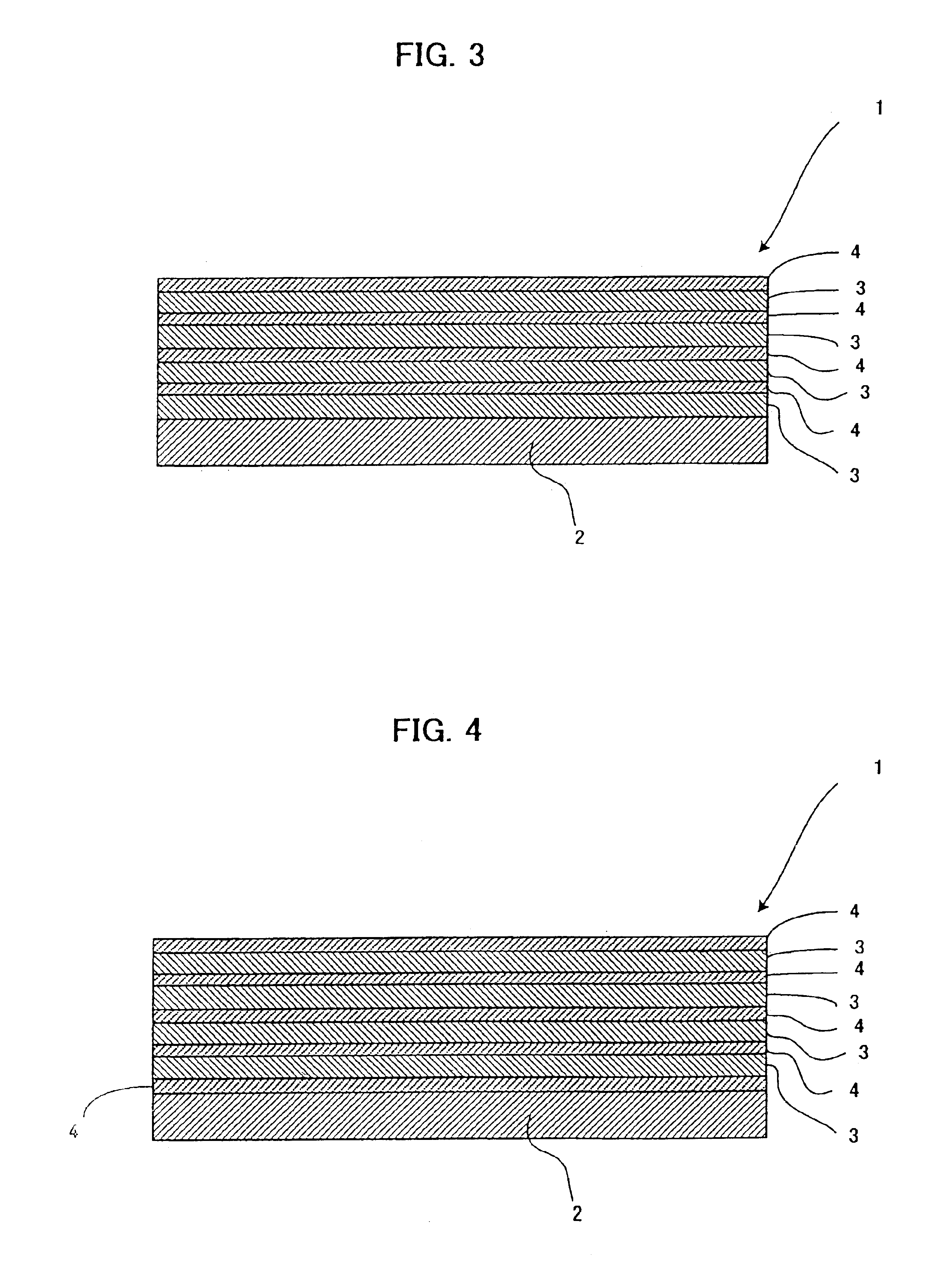

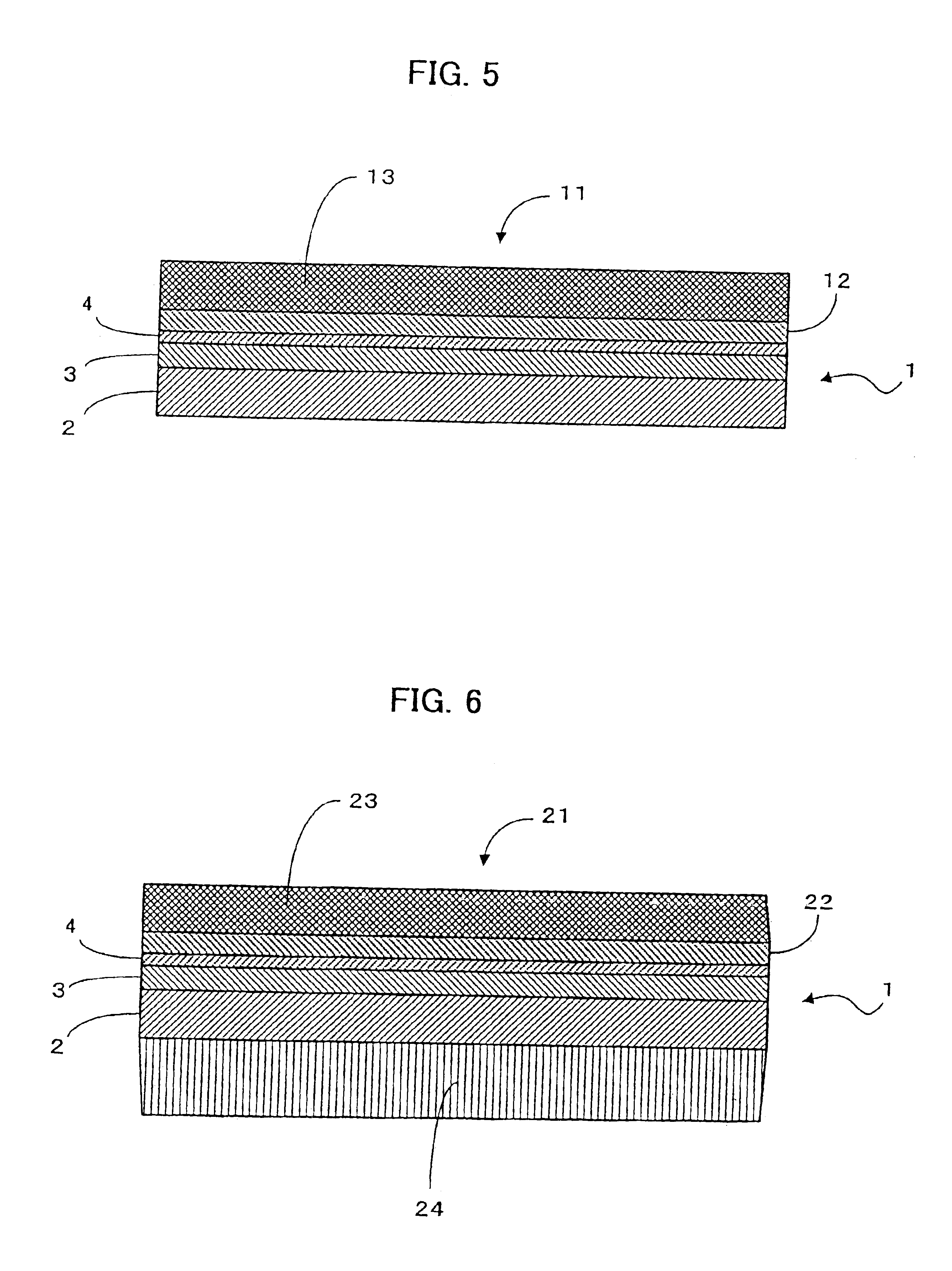

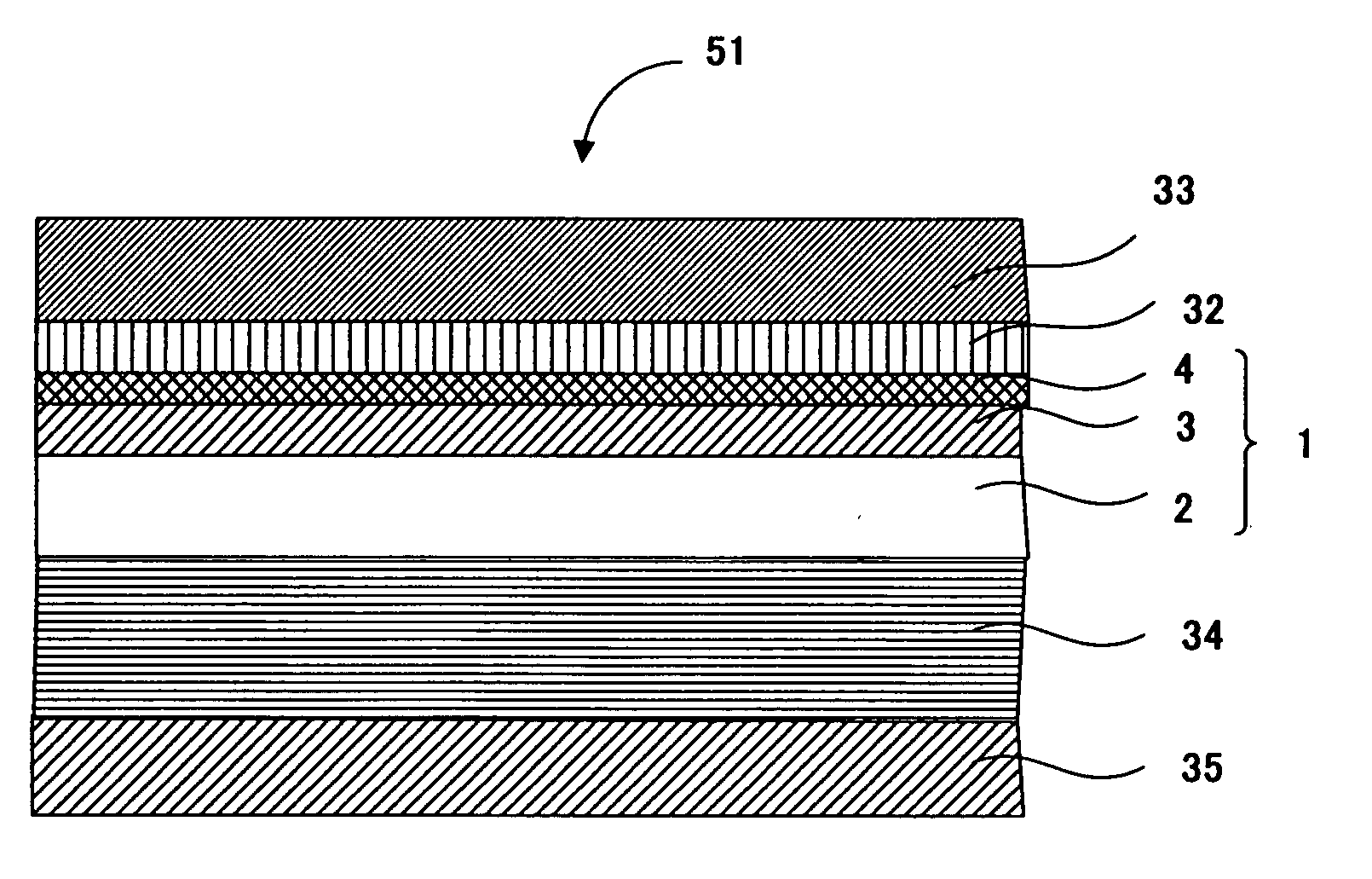

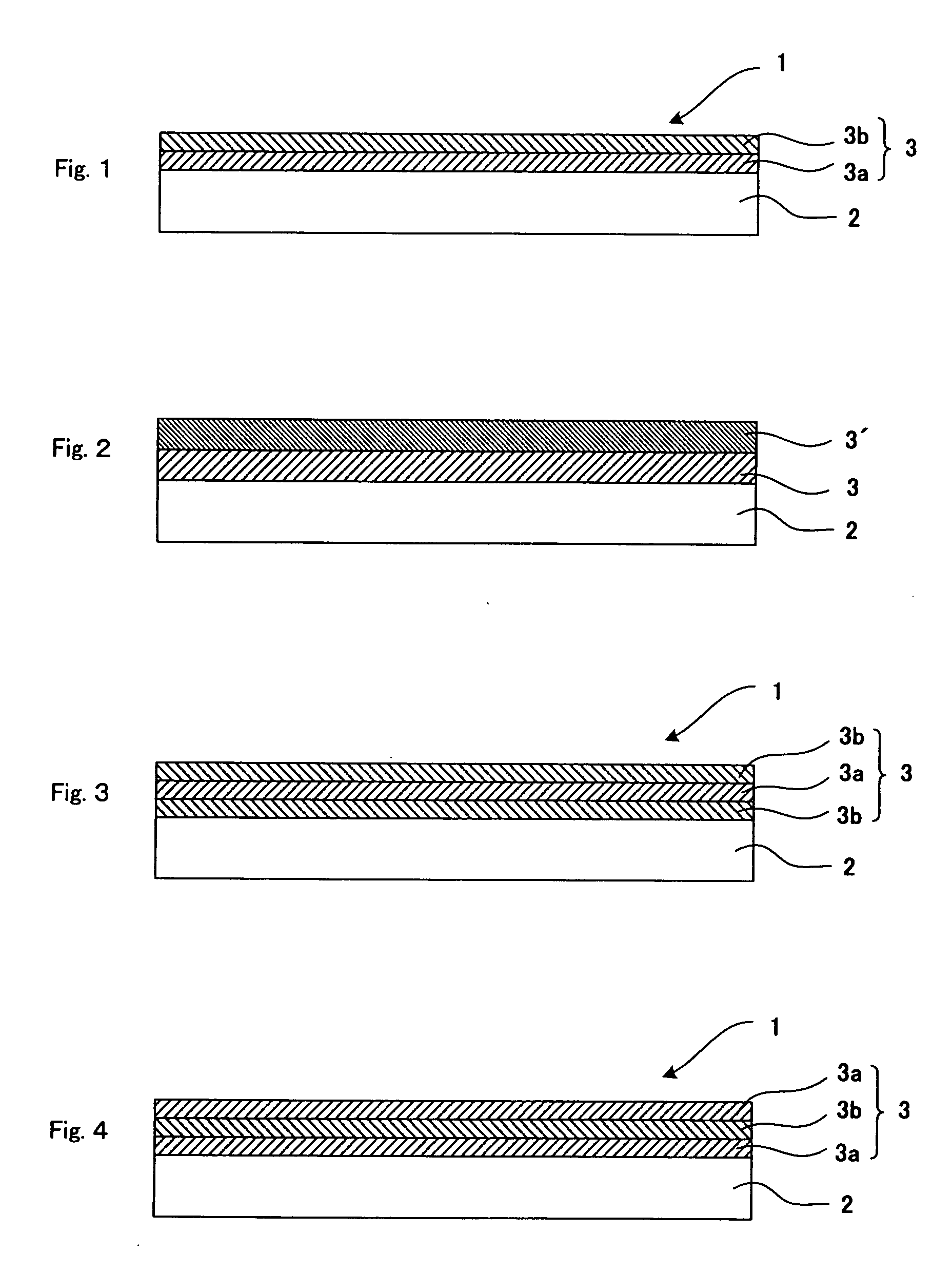

Gas barrier film

InactiveUS6905769B2Excellent gas barrier propertiesGood weather resistanceFlexible coversWrappersProduct gasWater repellent

It is an object of the present invention to provide a gas barrier film improved in gas barrier characteristics by decreasing the adsorbent of the surface of a gas barrier layer to water and the like. The present invention attains the above object by providing a gas barrier film comprising a substrate, a gas barrier layer which is a vacuum deposition film, formed on one surface or both surfaces of the above substrate, and a water-repellent layer which is a film having water repellency, formed on the above gas barrier layer.

Owner:DAI NIPPON PRINTING CO LTD

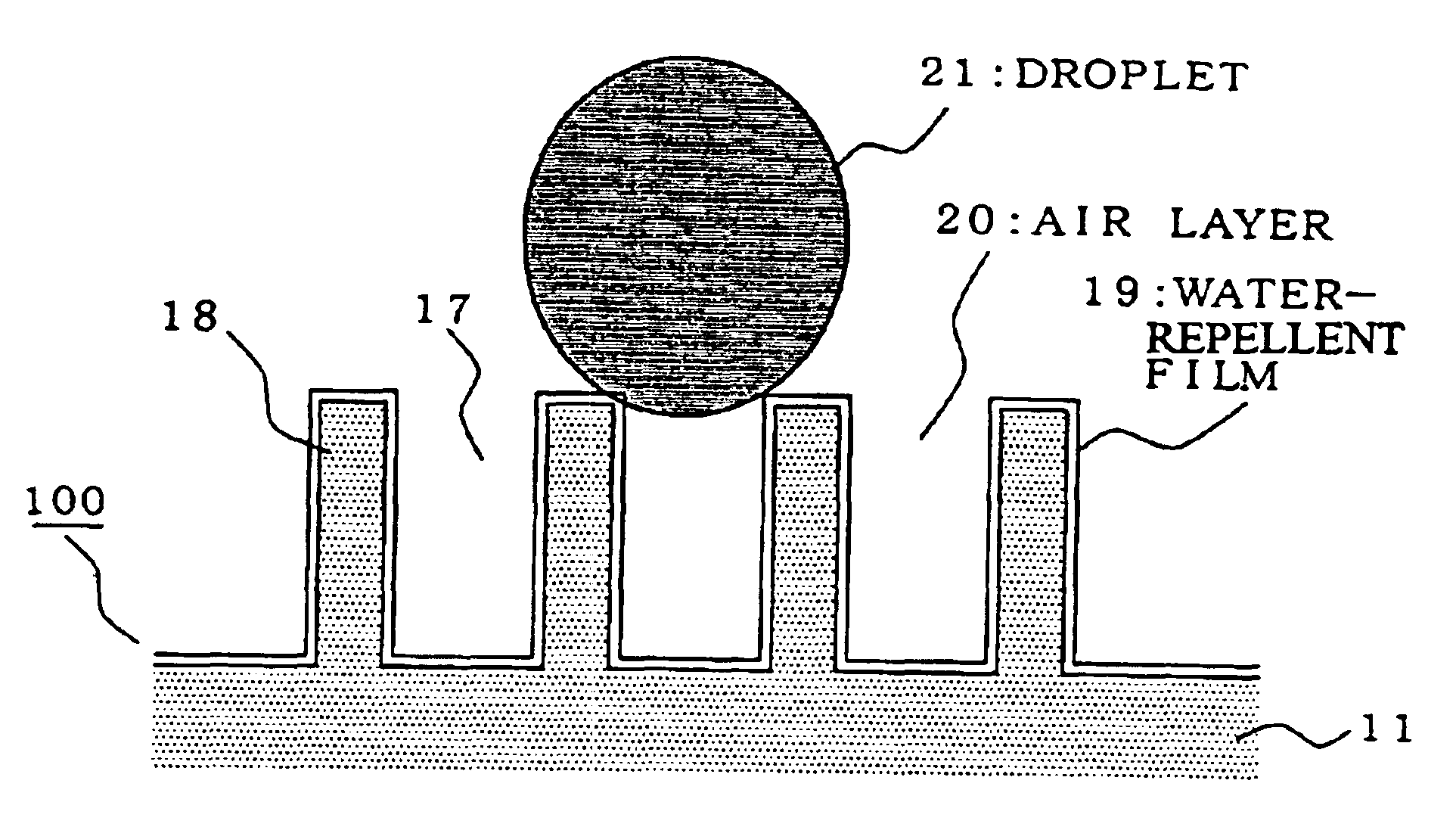

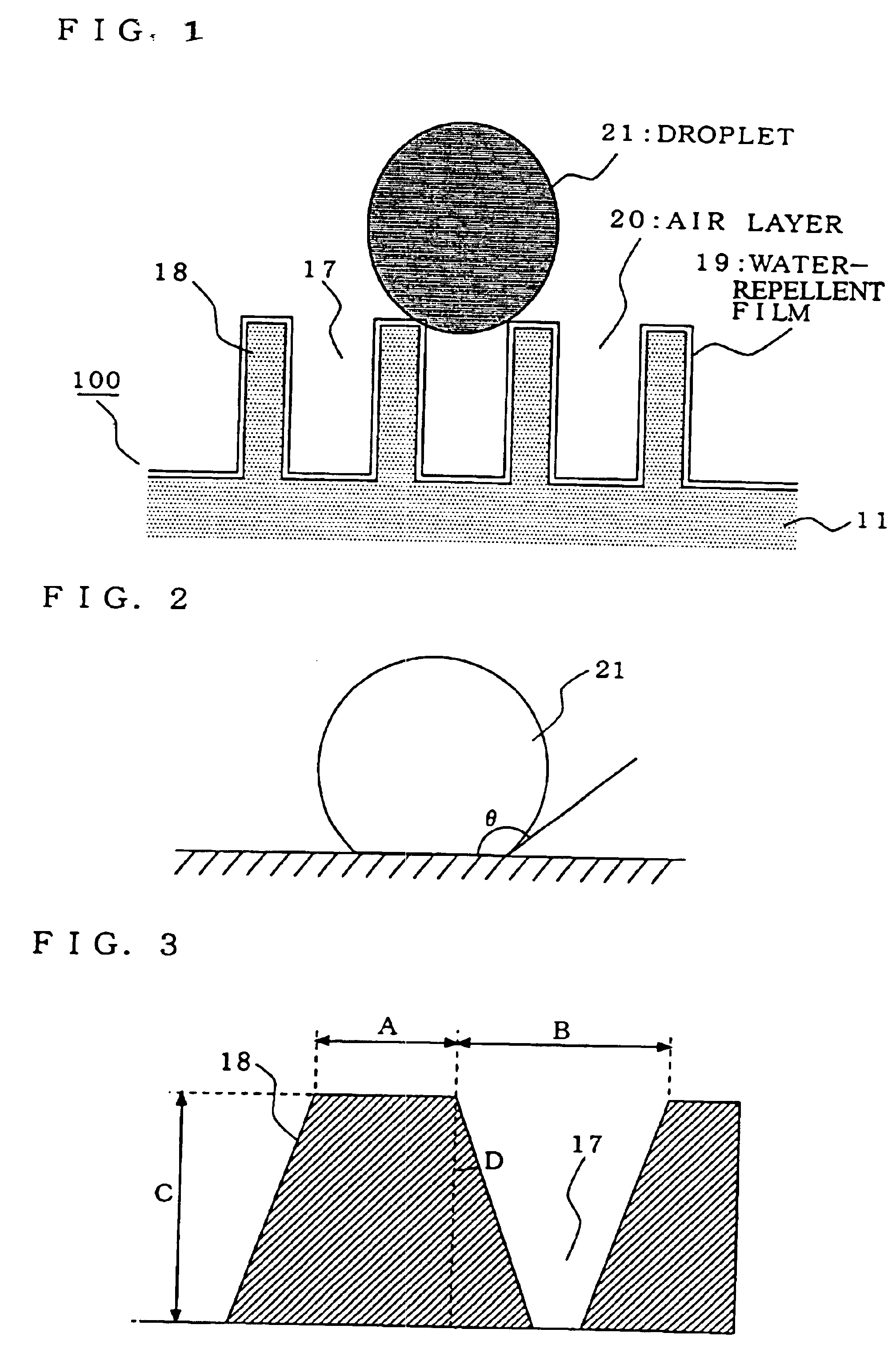

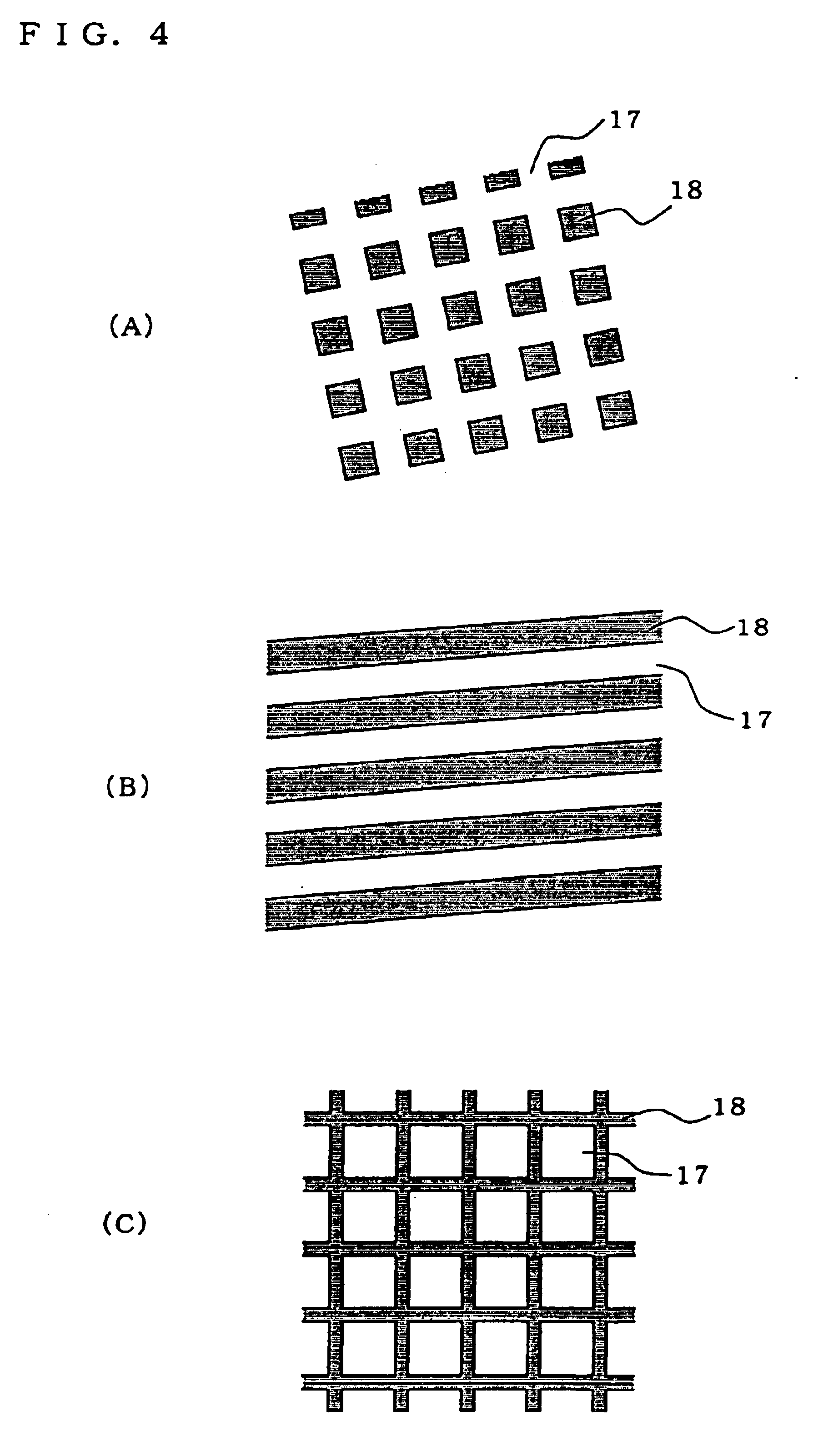

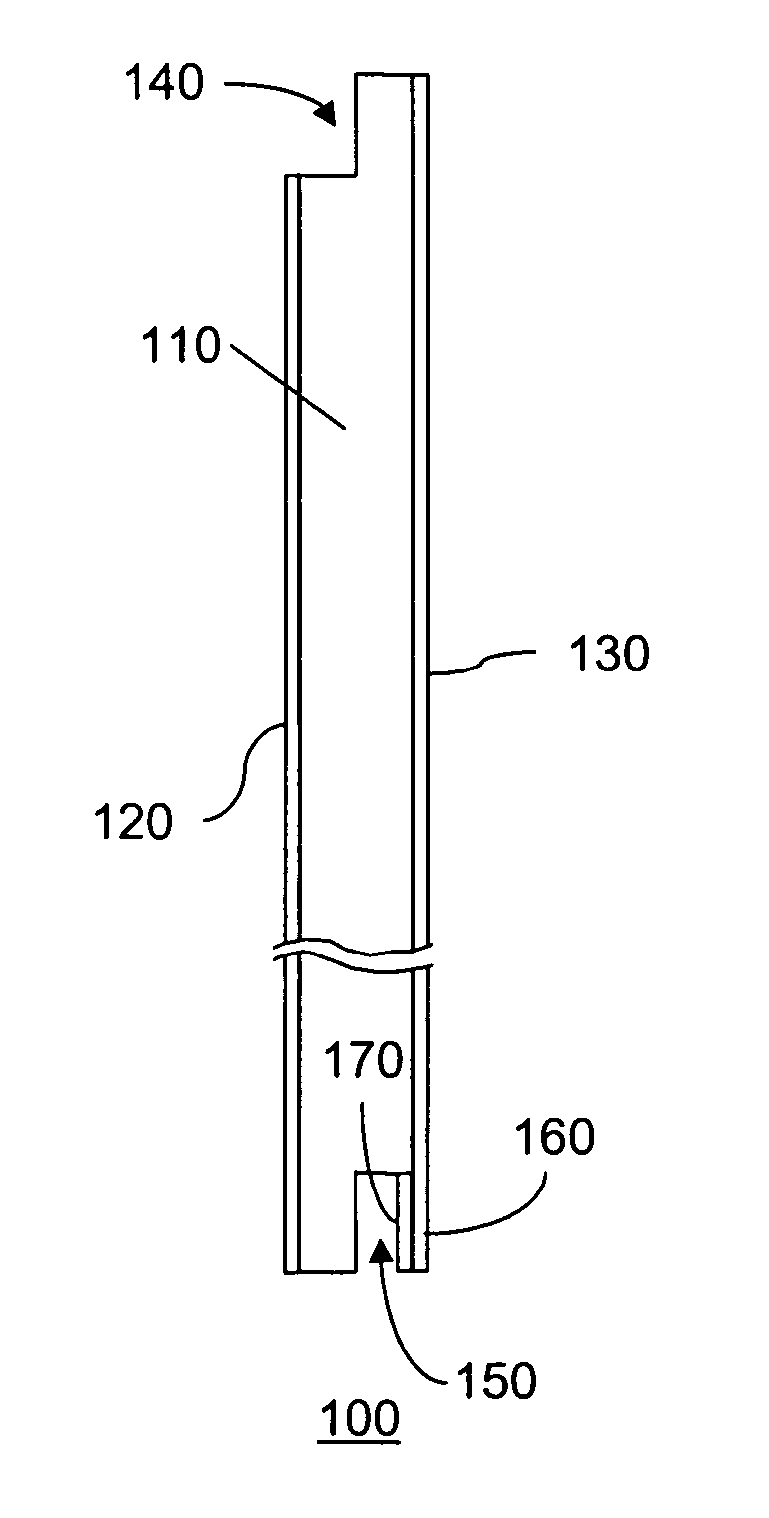

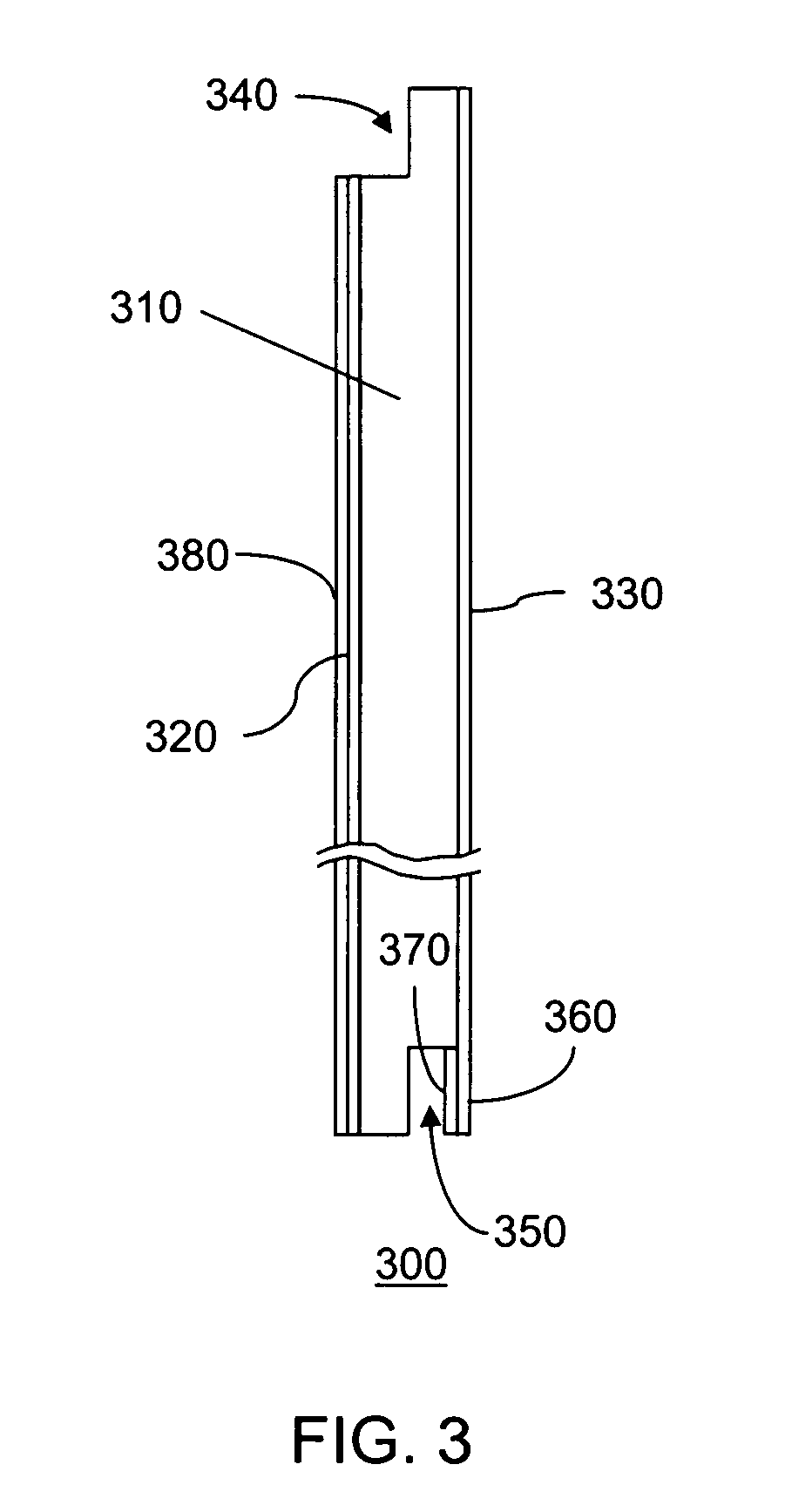

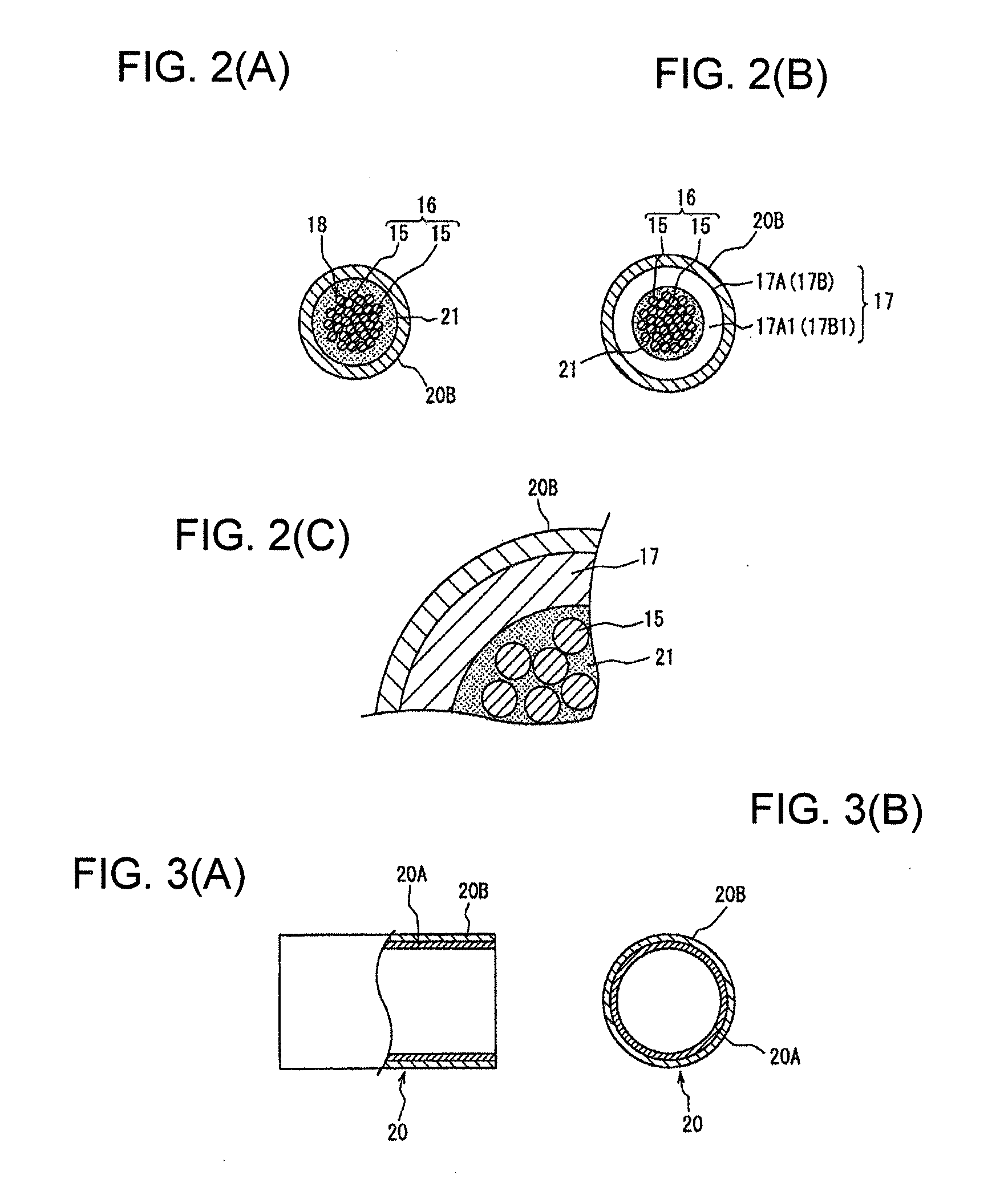

Structural member superior in water repellency and method for manufacturing the same

InactiveUS6764745B1Synthetic resin layered productsRecord information storageBiomedical engineeringWater repellent

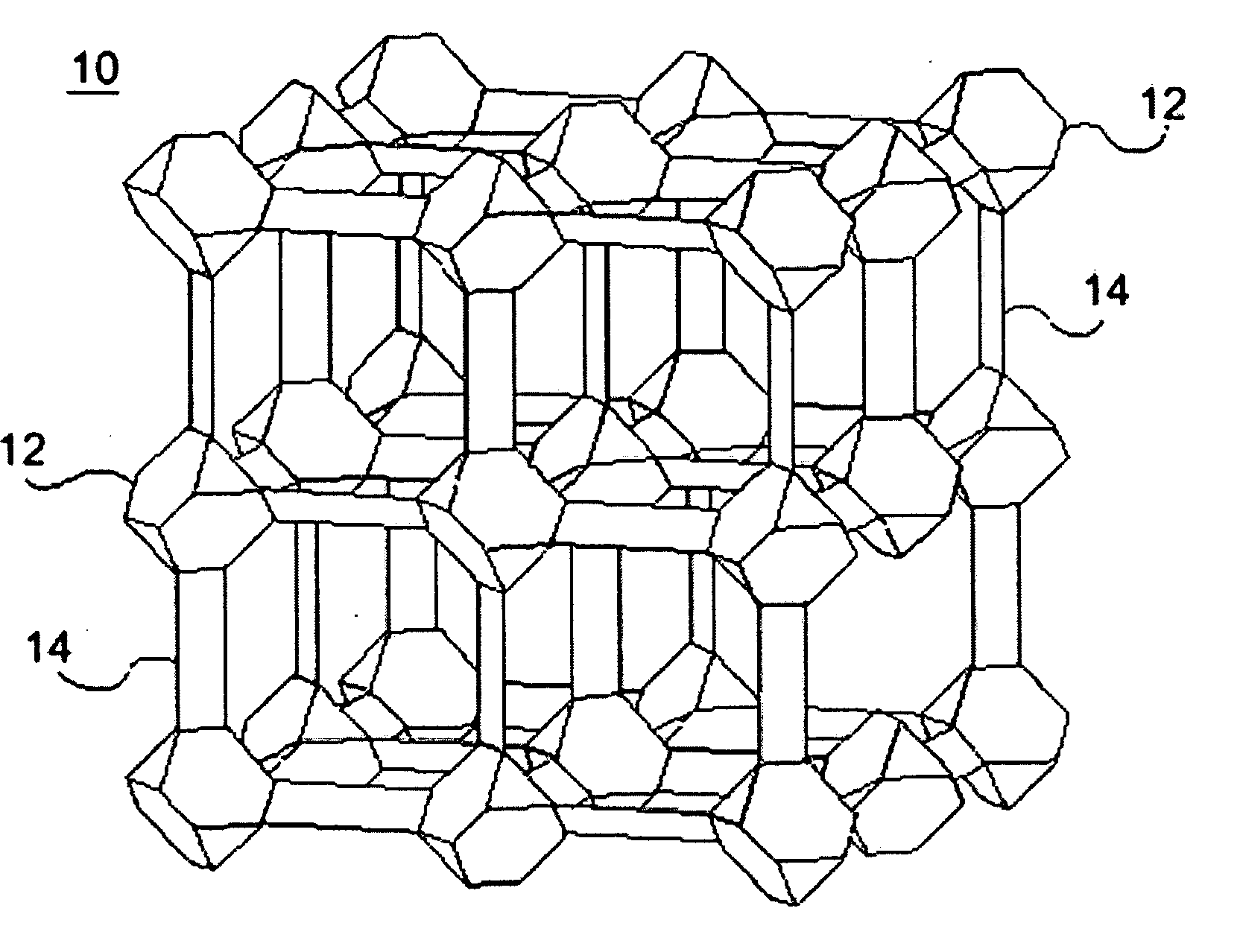

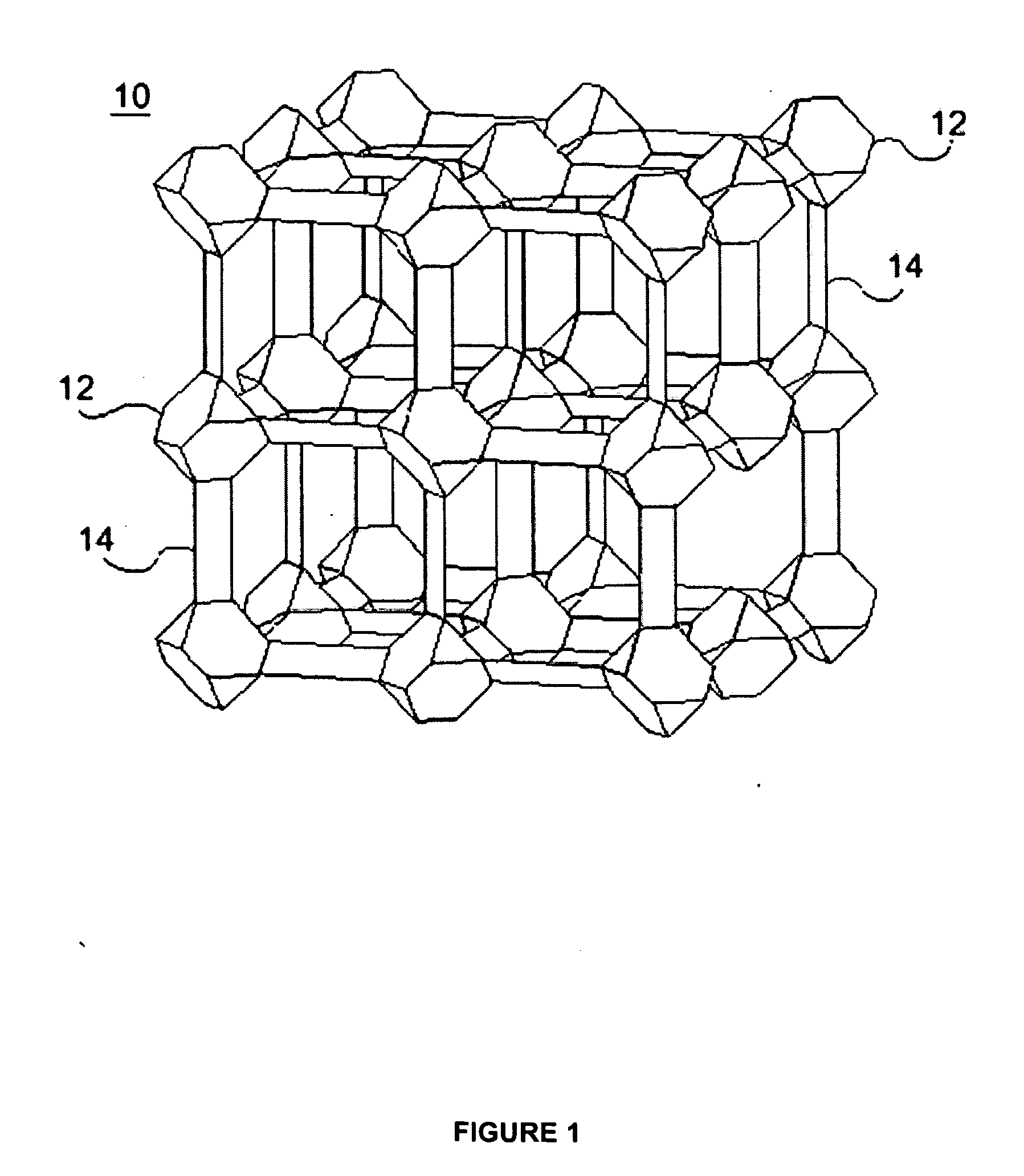

A structural member in which a super water-repellent function and high durability and scratch assistance can be obtained; and a method of manufacturing such a structural member. A water-repellent structure (100) consisting of appropriate irregularities comprising protrusion portions (18) uniform in height is formed on an external surface. The irregularities (17 and 18) have such dimensions that any droplet should not fall in a recess portion and the droplet is in contact with an air layer (20) in the recess portion (17).

Owner:SEIKO EPSON CORP

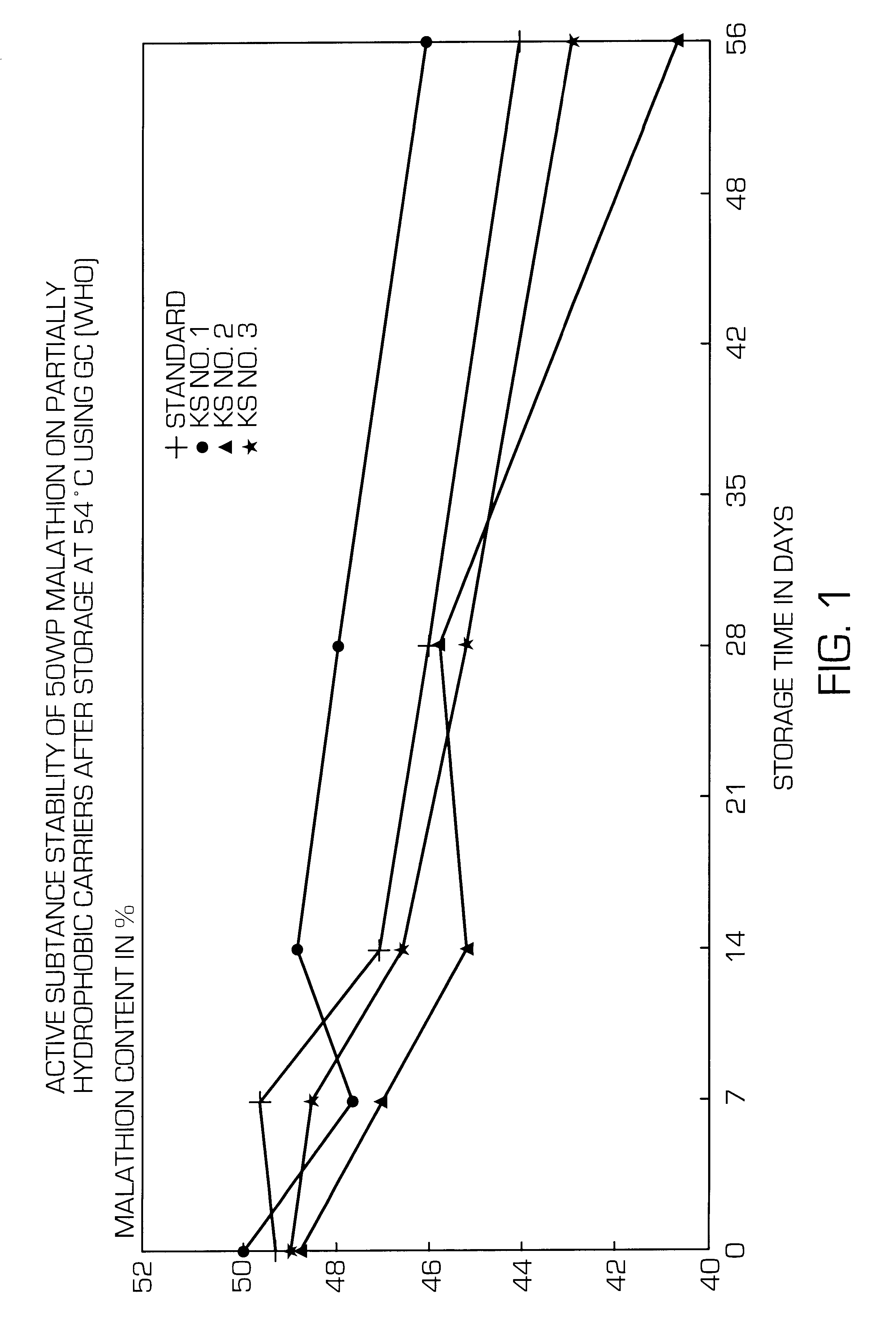

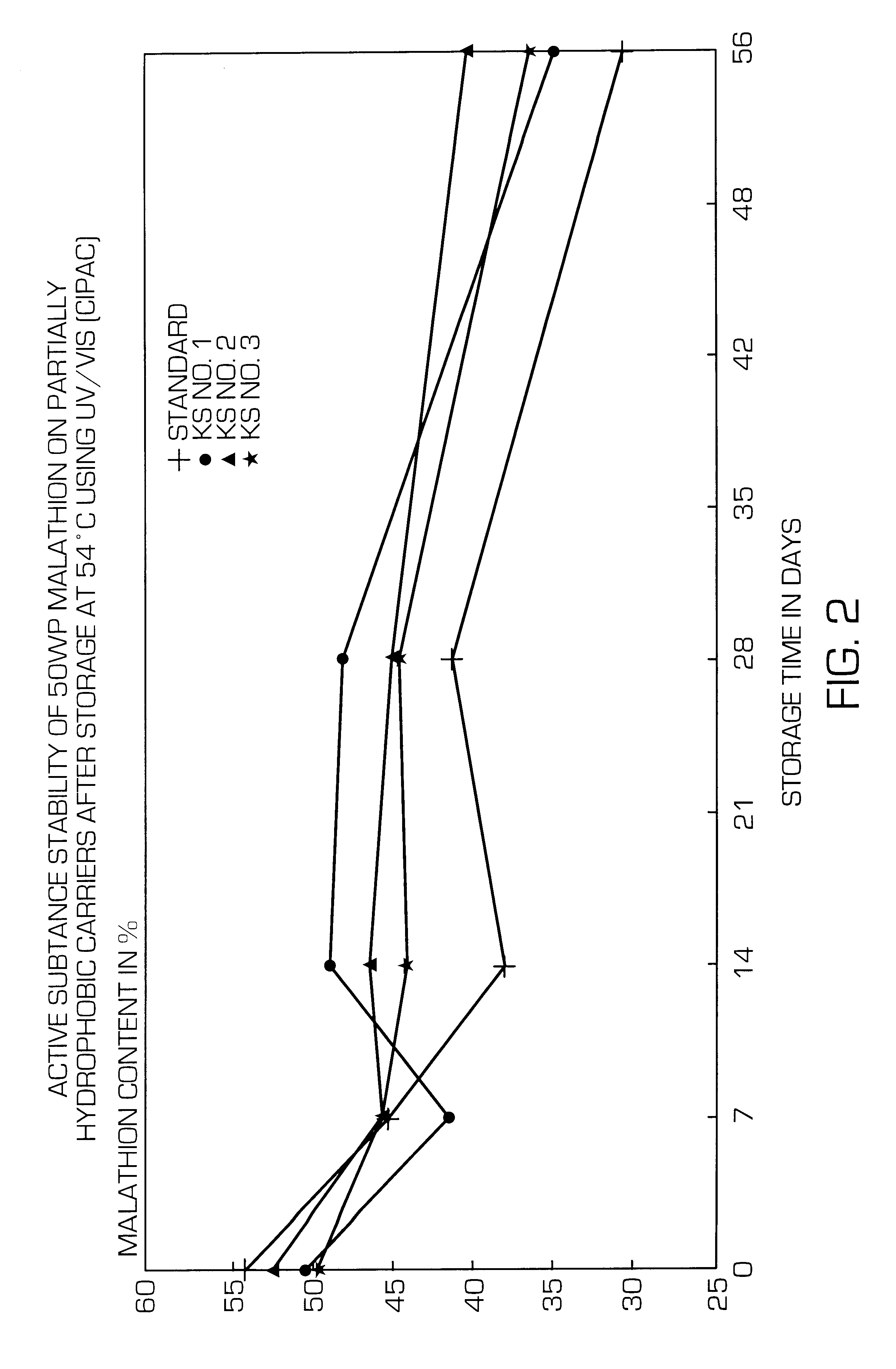

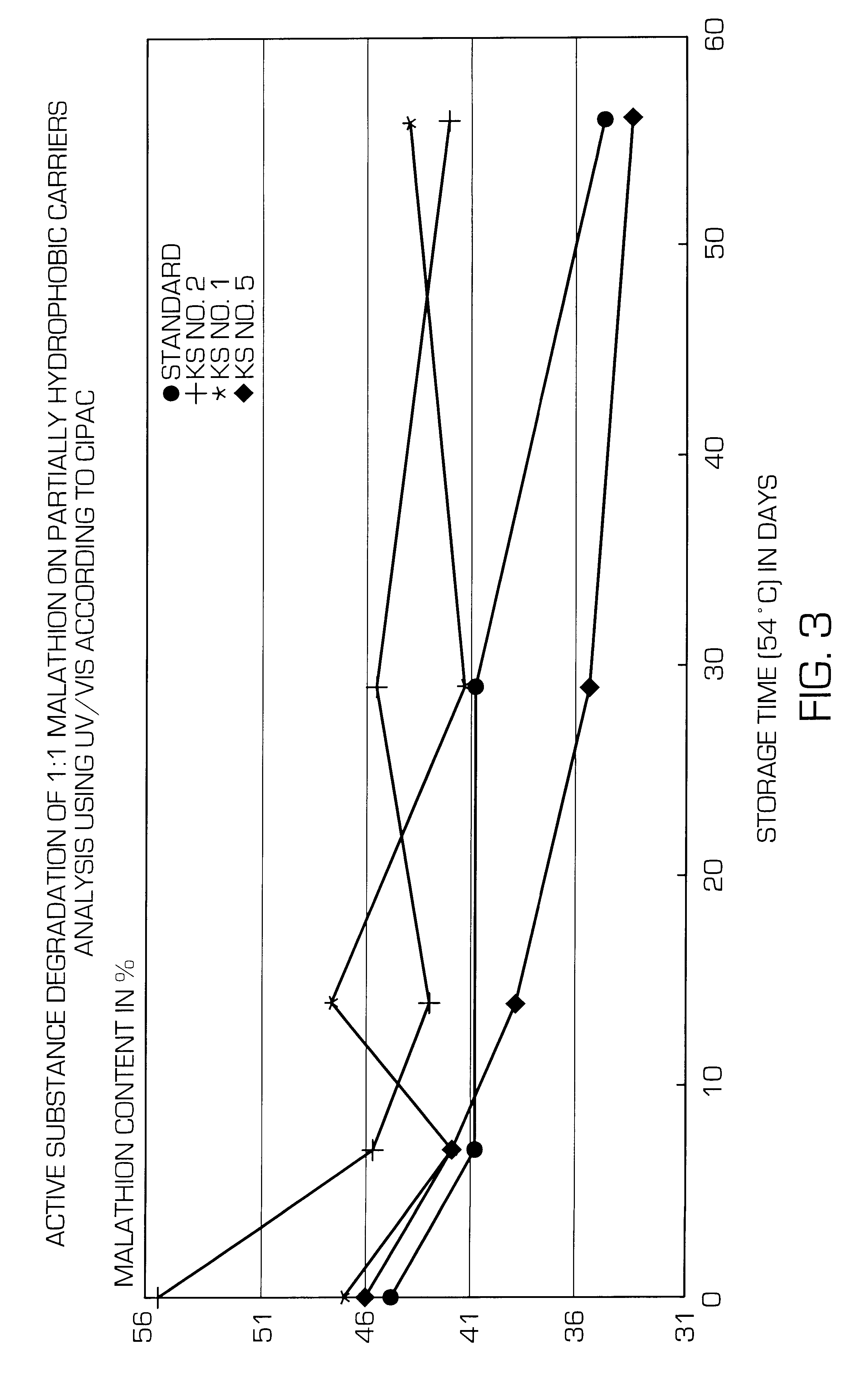

Partially hydrophobic precipitated silicas

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

High efficiency fuel filter

InactiveUS20060277877A1Improve efficiencyImprove tear resistanceCombination devicesDispersed particle filtrationGlass fiberEpoxy

Provided is a composite fuel filter material which comprises (A) a support layer made of wet laid cellulose and / or synthetic fibers, (B) a barrier layer having wet laid glass fibers for providing increased efficiency to the filter material, (C) a thermosetting bonding agent dispersed through the composite and in an amount sufficient for bonding the composite into a strong, tear resistant and pleatable material, and (D) a water repellant agent dispersed in the composite for removing and coalescing water dispersed in a fuel to be filtered. In a preferred embodiment for a diesel fuel filter, the glass fibers have an average diameter of about 0.1 to 2.0 microns and the thermosetting bonding agent is an epoxy resin in the composite in an amount of between 1 and 5% by weight. A filter efficiency of at least 90% or even 99% can be achieved, along with a water removal of 90 to 99.9%. Preferably, the barrier layer has a small amount of synthetic fibers therein and an interface between the support layer and the barrier layer is mechanically interlocked.

Owner:LYDALL INC

Finishing of textile fibers, tissues and fabrics

InactiveUS7056845B2Improve the level ofImprove functional propertiesOther chemical processesPhysical treatmentTextile fiberEngineering

A method is provided for the application of a finishing layer to a textile support material. A water repellent or oil repellent layer, a so-called finishing layer, is applied to a textile support material selected from the group of fibers, tissues, and fabrics. The water repellent or oil repellent finishing layer comprises at least two water repellent or oil repellent components wherein a first component comprises one or more dispersants and a second component comprises one or more dispersed phases or colloids, and wherein the dispersant and the dispersed phase are present in the gel state.

Owner:SCHOELLER TEXTIL

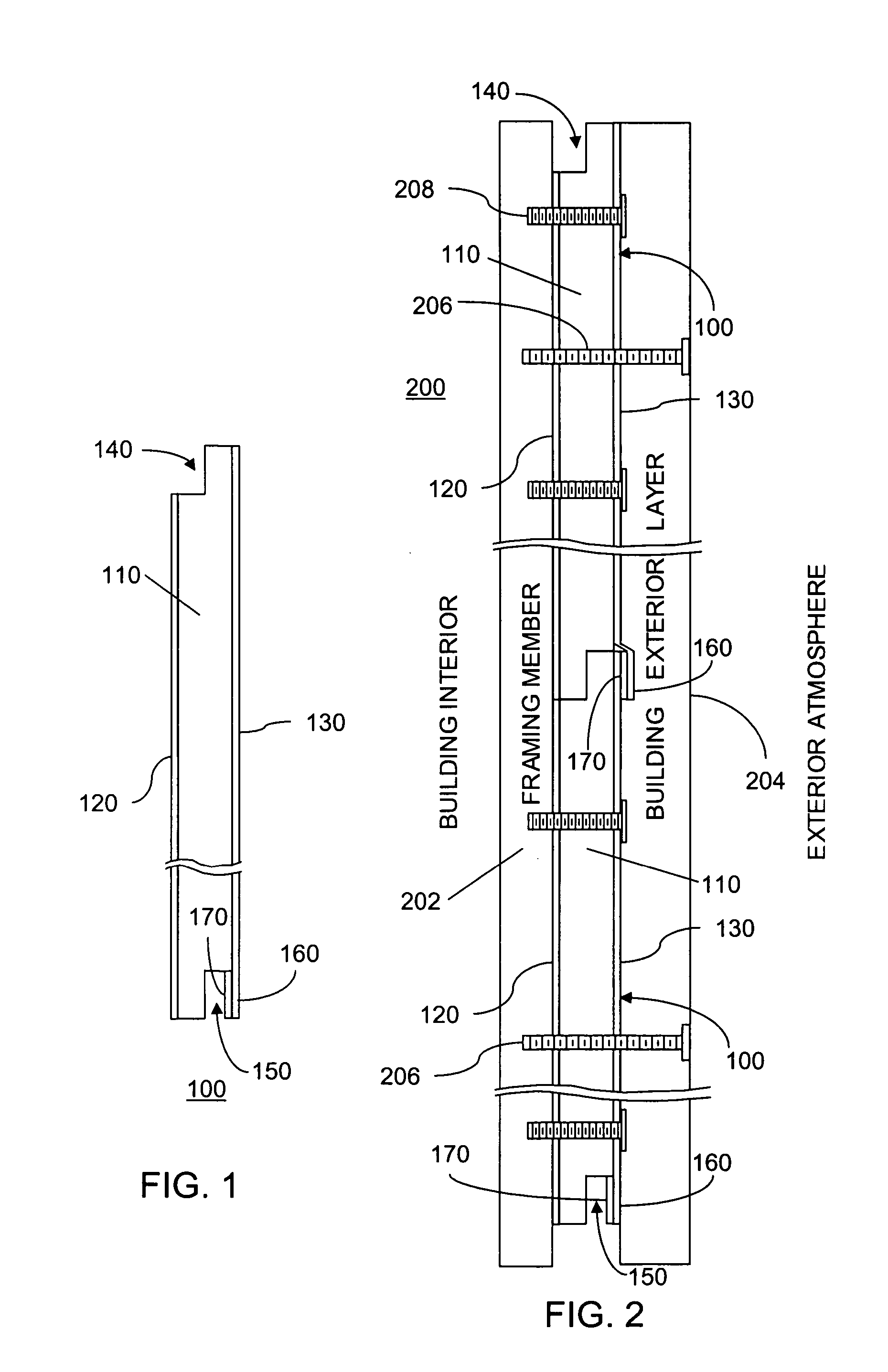

Insulation board with air/rain barrier covering and water-repellent covering

A product comprises: a mineral fiber insulation board which is resistant to liquid water-penetration and has first and second major surfaces, a facing material, which is resistant to air infiltration and liquid water-penetration, laminated to the first major surface of the insulation board, the facing material being permeable to water vapor, and an interior facing laminated to the second surface of the insulation board with an adhesive, so that the second major surface with the interior facing and adhesive thereon is resistant to liquid water-penetration, thereby to form a unitary building exterior envelope product.

Owner:CERTAINTEED CORP

Method for preparing floride-free super-hydrophobic cotton fabric

InactiveCN101397754AMeet the requirementsWide variety of sourcesVegetal fibresSilicon dioxideMechanical property

The invention provides a preparation method of fluoride-free super-hydrophobic cotton fabrics, pertaining to the technical field of water repellent finishing of cotton fabrics. The preparation method is characterized in that the concrete steps comprise: 3ml to 6ml of ammonia water with a mass concentration of 25wt percent to 28wt percent is added into 50ml to 100ml of ethanol and stirred. 5ml to 6ml of N-tetraethyl silicate is added in a dropwise manner and aged for 30min to 80min to obtain silica sol; the cotton fabric is immersed in the silica sol, dipped and rolled, and then dried at 60 DEG C to 100 DEG C for 1min to 5min; and the cotton fabric is immersed in alkane siloxane hydrolyzate, dried at room temperature and roasted for 30min to 120min in an oven which is preheated to 120 DEG C to 160 DEG C. The preparation method is environmentally-friendly, convenient and effective and meets the requirements of ecotypic textiles; the preparation method has wide sources of raw materials and the contact angle of the prepared cotton fabrics and water dripping exceeds 150 degrees and the prepared cotton fabrics have super-hydrophobic performance and does not influence the physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

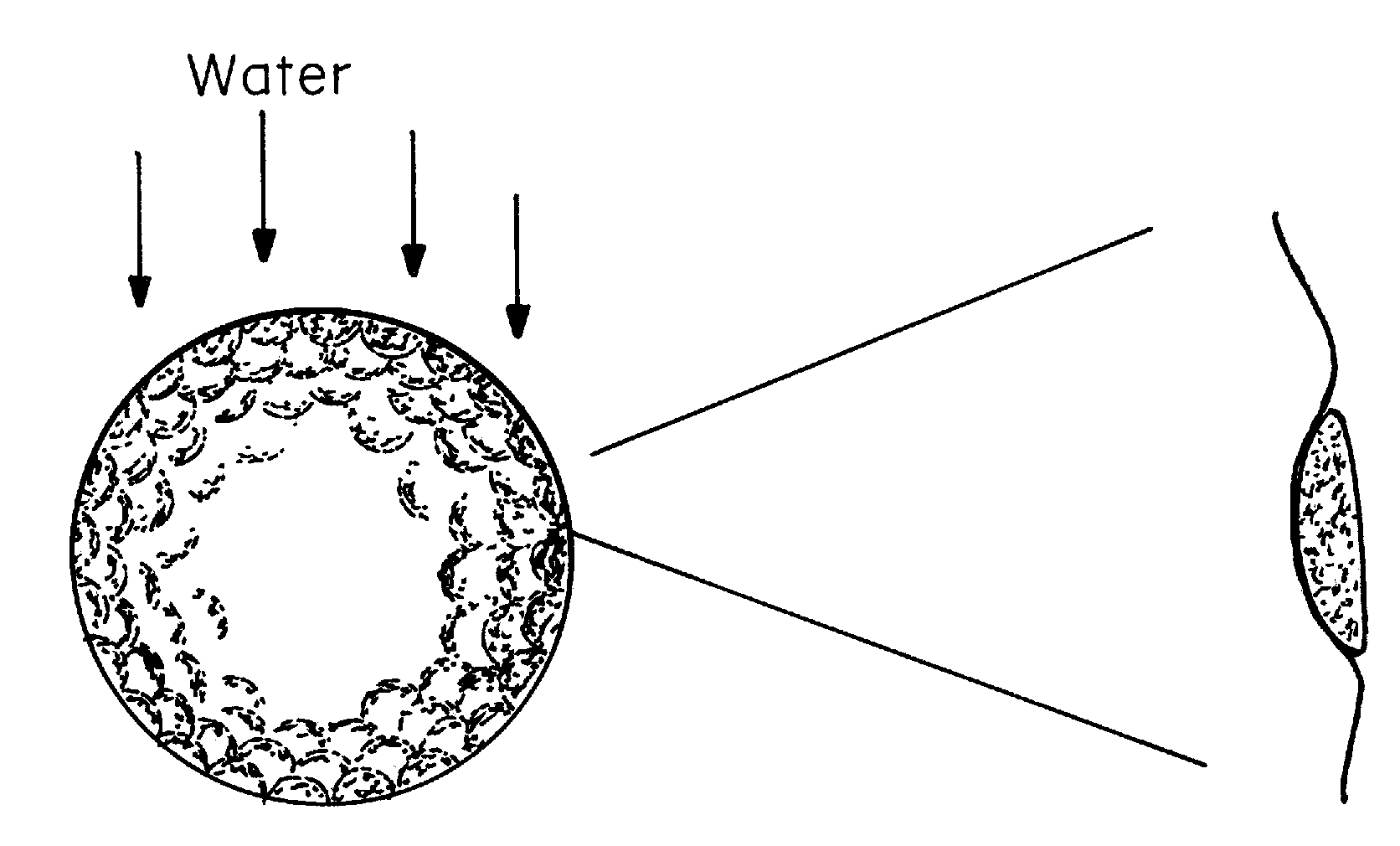

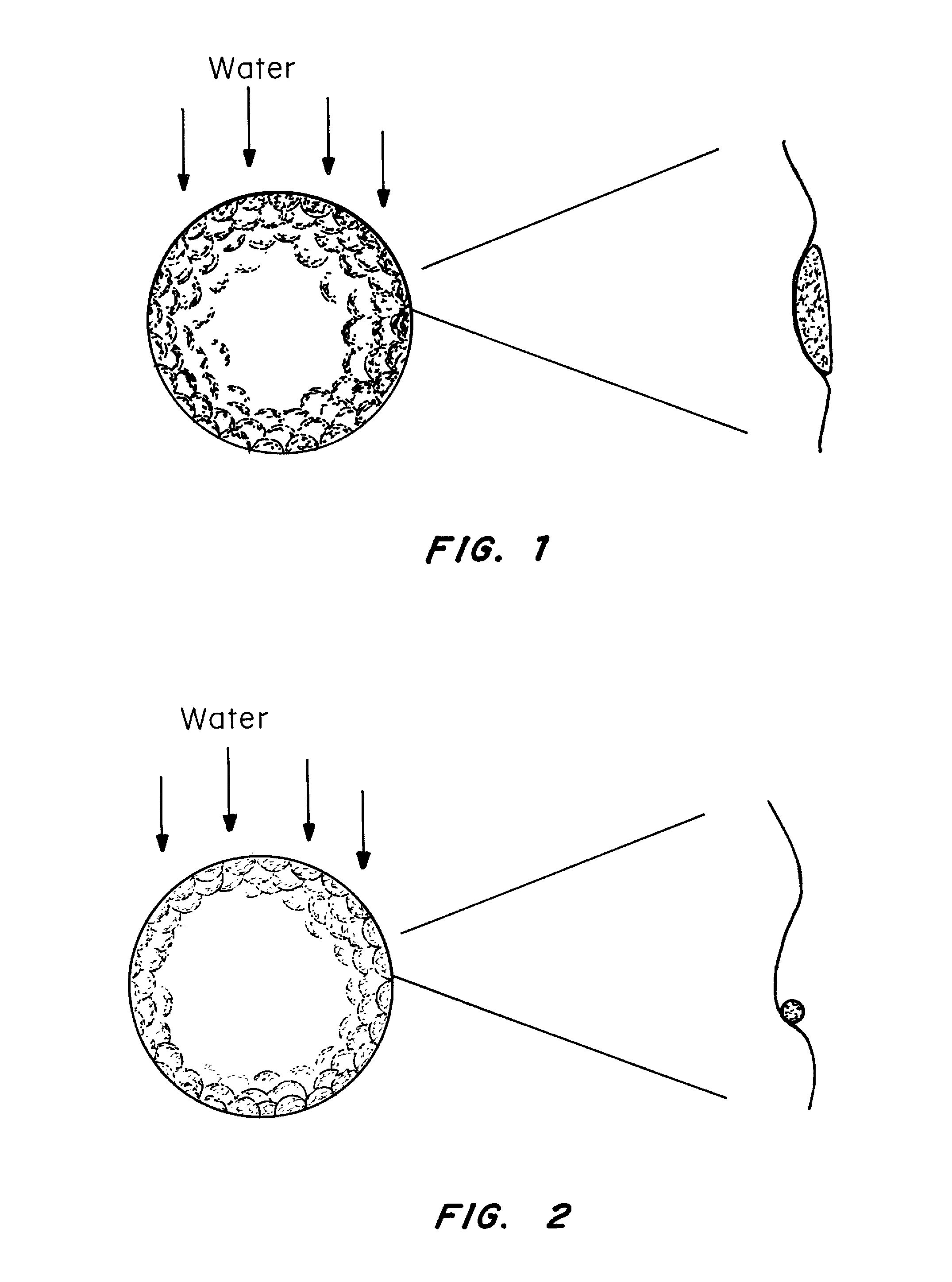

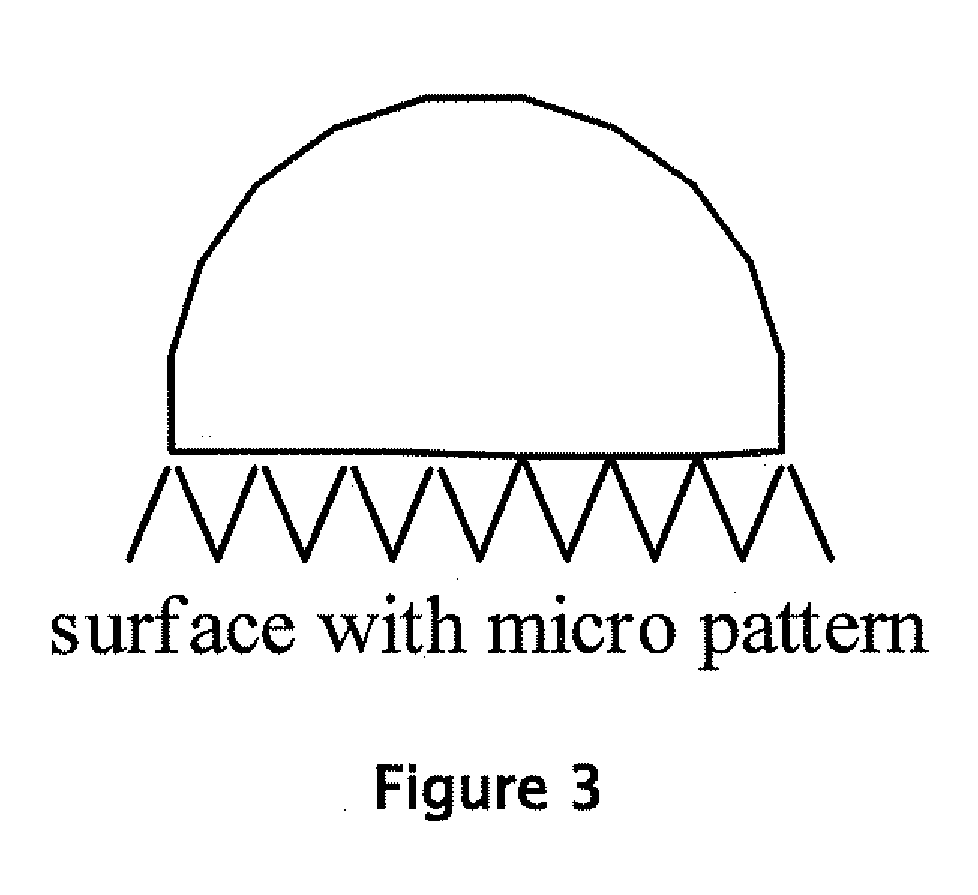

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

Super-light foam cement concrete and preparation method thereof

The invention discloses a super-light foam cement concrete and a preparation method thereof. The super-light foam cement concrete comprises the following raw materials by weight parts: 9-36 parts of dead burnt magnesium oxides, 9-32 parts of dihydric phosphates, 0.5-7 parts of adjustable solidification agents, 6-25 parts of light burnt magnesium oxides, 0.5-7 parts of sulfur-containing components, 1-25 parts of industrial slag powder, 1-20 parts of kieselguhrs, 0.3-3.9 parts of waterproof agents, 0.2-1.7 parts of foam stabilizing agents, 1.0-8.9 parts of foaming agents and 25-90 parts of water. The preparation method of the high-performance super-light foam cement concrete comprises the following steps of: metering raw materials; preparing the slurry containing the foam stabilizing agents; uniformly mixing the foaming agents; pouring and standing by; foaming and expanding; coagulating and curing; and naturally maintaining. The super-light foam cement concrete has the advantages of light weight, high strength, heat preservation and insulation, stable volume, low production cost, energy-saving property, no environmental pollution, and the like. The super-light foam cement concrete is simple in production process and is especially suitable for the heat-insulating material of external building wall, roof and floor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

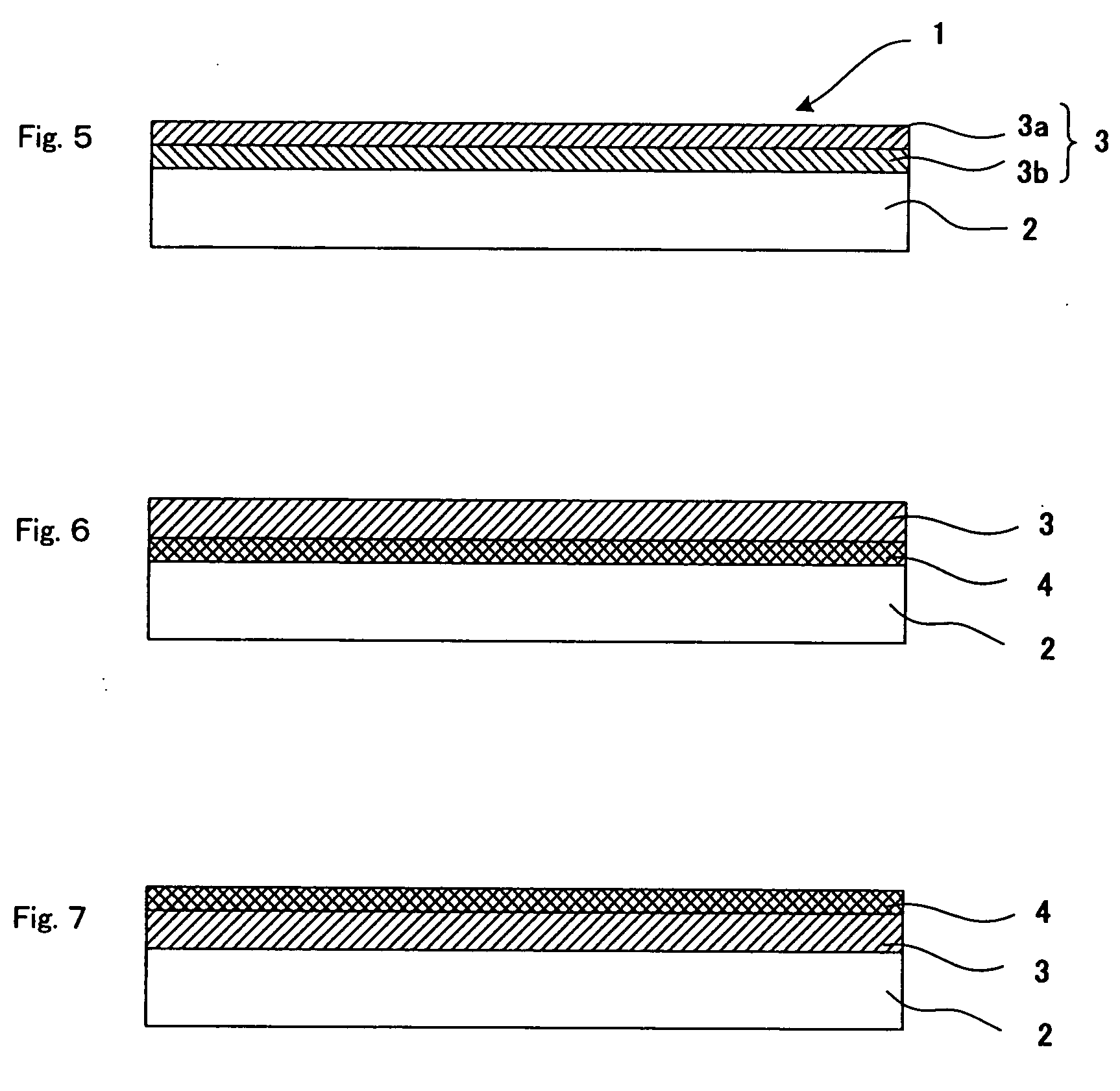

Barrier film

InactiveUS20080050567A1Improve water vapor barrier performanceImprove barrier propertiesNatural mineral layered productsChemical vapor deposition coatingCarbide siliconSilicon oxide

The main object of the present invention is to provide a barrier film having an extremely high barrier property and a good transparency, a laminated material using the above-mentioned barrier film, a packaging container, and an image display medium. The above-mentioned object is achieved by providing a barrier film comprising a base material film and a barrier layer deposited on at least one side surface of the base material film, wherein the barrier layer comprises a water repellent layer and a dense layer, the water repellent layer is a silicon oxide carbide film having the atomic percent of Si:O:C in a range of 100:40 to 120:80 to 160, and the thickness in a range of 2 to 300 nm, and the dense layer is a silicon oxide carbide film having the atomic percent of Si:O:C in a range of 100:100 to 200:5 to 100, and the thickness in a range of 5 to 300 nm.

Owner:DAI NIPPON PRINTING CO LTD

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

Manufacturing method of aerated concrete

ActiveCN101823864AIncreased durabilityExcellent mechanical propertiesSolid waste managementCeramicwareCalcium hydroxideFoaming agent

The invention discloses a manufacturing method of aerated concrete, which comprises the following steps of: preparing liquid feed liquid; precuring; mixing an amorphous silicon material and water to prepare amorphous silicon material slurry; then mixing the amorphous silicon material slurry, the liquid feed liquid, a crystalline silicon material, one of calcined lime or calcium hydroxide or lime milk, dihydrate gypsum or semi-hydrated gypsum, ordinary portland cement, feldspar materials, strength intensifier, calcined lime digestion regulator, bubble regulator, lubrication tackifier, water repellent, a foaming agent and water; stirring the mixture at the speed of between 800 and 1,500rpm for 3 to 7 minutes to prepare foam slurry; and performing standing curing and still kettle curing to prepare the aerated concrete. The product obtained by the manufacturing method has the characteristics of light weight, high strength, flame retardance, heat preservation, heat insulation, hydrophobic property, long service life, impact resistance, small shrinkage, and the like; moreover, the material sources are wide, and the products are simple and convenient to process and manufacture.

Owner:吴智深 +2

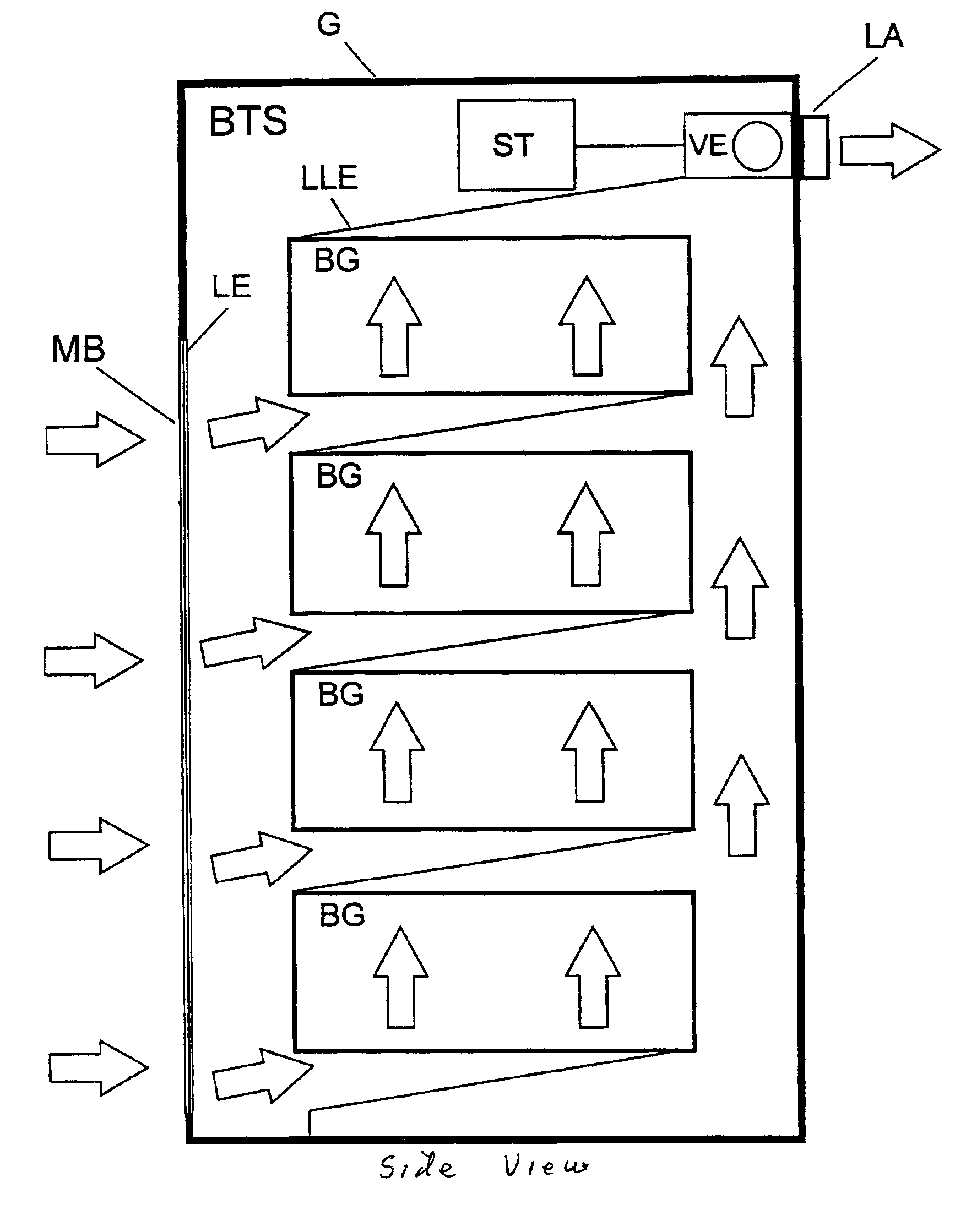

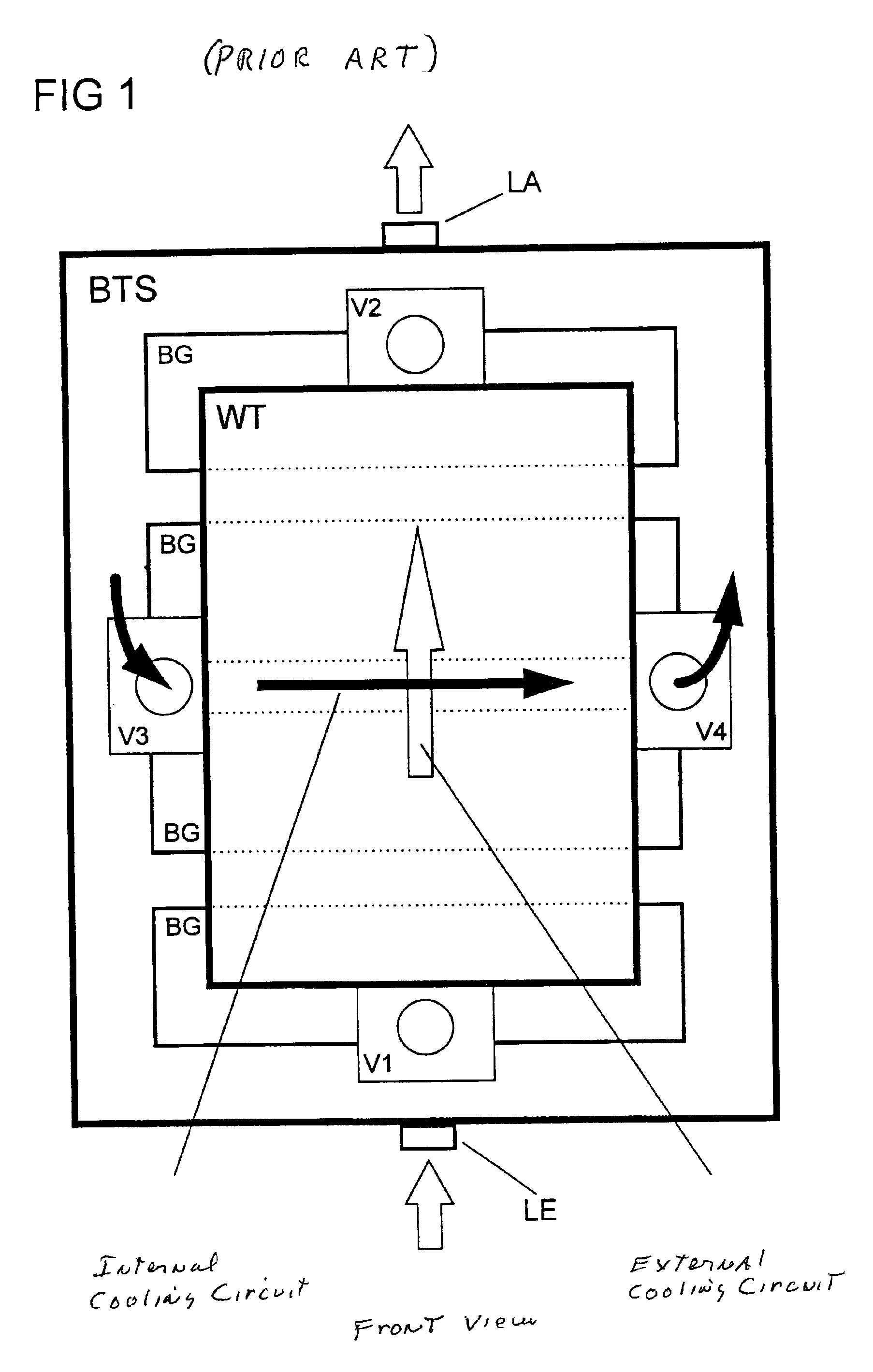

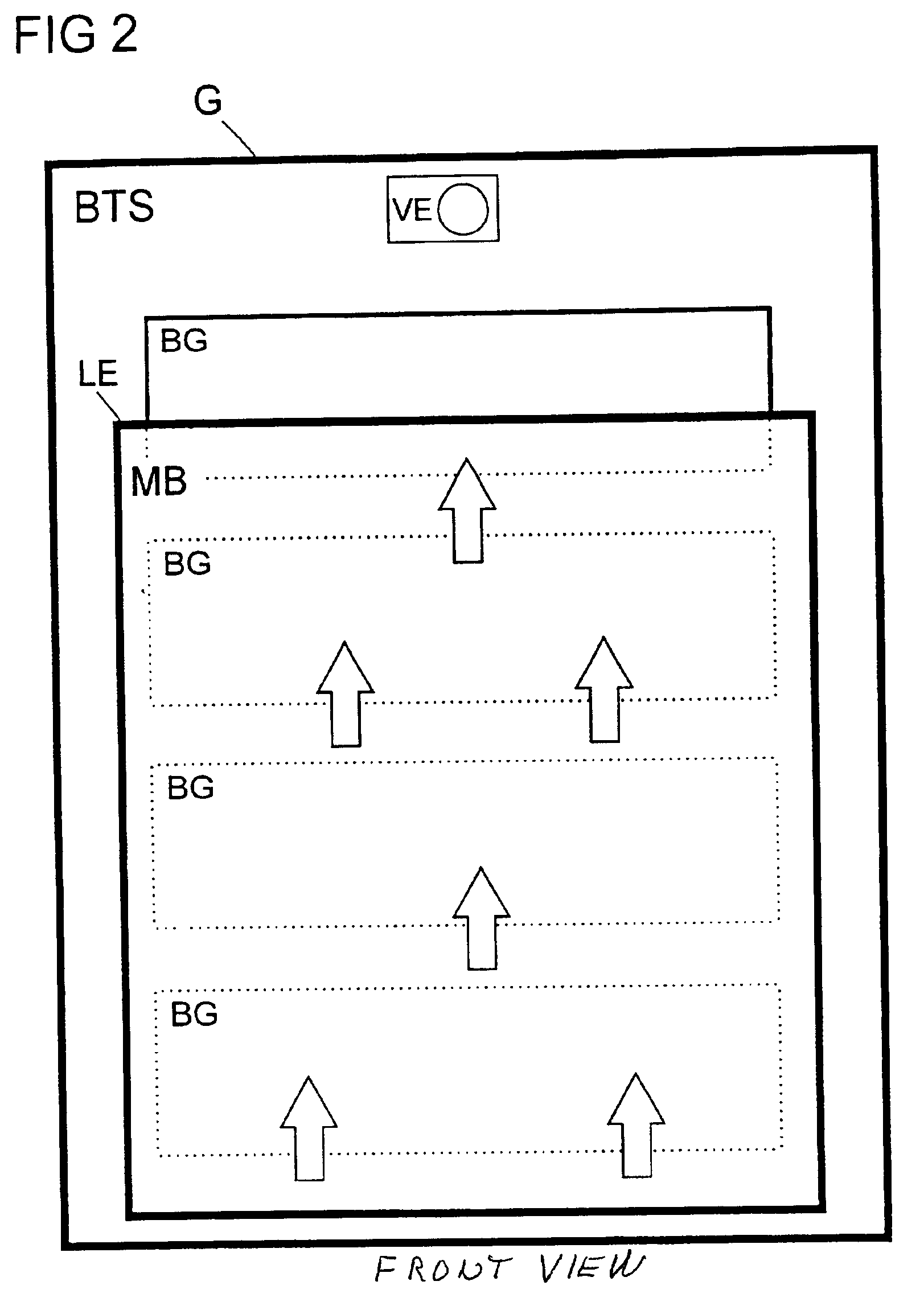

Cooling device for electrical subassemblies

InactiveUS6885554B1Easy constructionEasy to cleanCombination devicesIsotope separationAccess networkFiltration

The invention relates to an arrangement for cooling electrical subassemblies arranged in a housing, in particular for use in base stations of a mobile radio system or access network system. The arrangement has at least one water-repellent membrane filter, in each case arranged in an air inlet of the housing, for the surface filtration of dirt particles from cooling air flowing in for cooling electrical subassemblies, as well as at least one cooling device to build up an airflow and to lead the filtered cooling air, heated because of flowing through the subassemblies, out of the housing through at least one air outlet.

Owner:SIEMENS AG +1

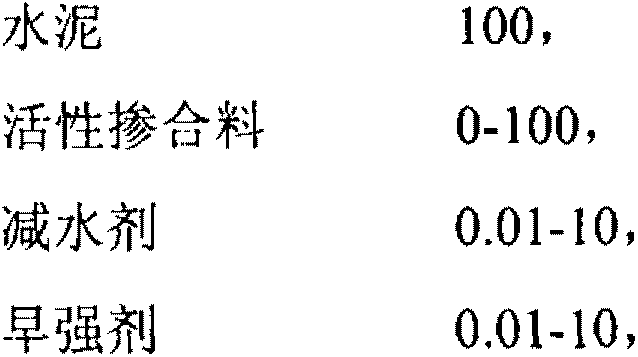

Cement-based shrinkage-free wall hole-penetrating blocking material and preparation method and construction method

ActiveCN103159440AGuaranteed tightnessPrevent infiltrationBuilding material handlingBuilding insulationsEtherFree wall

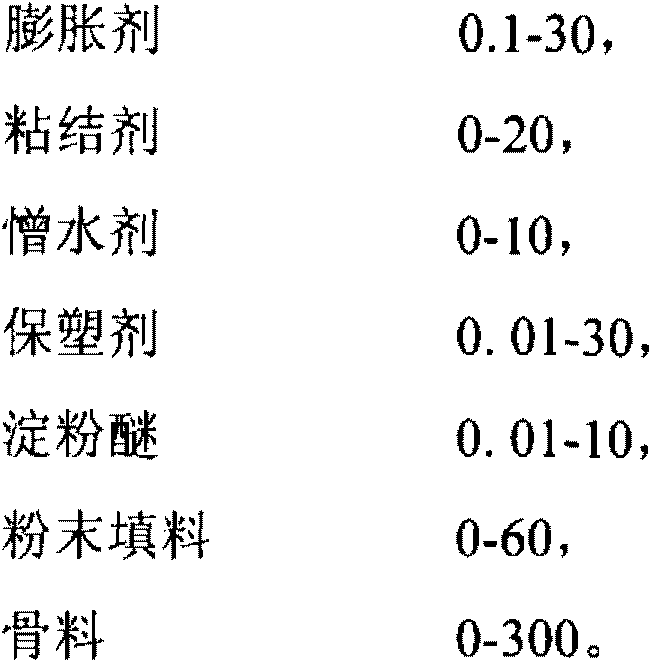

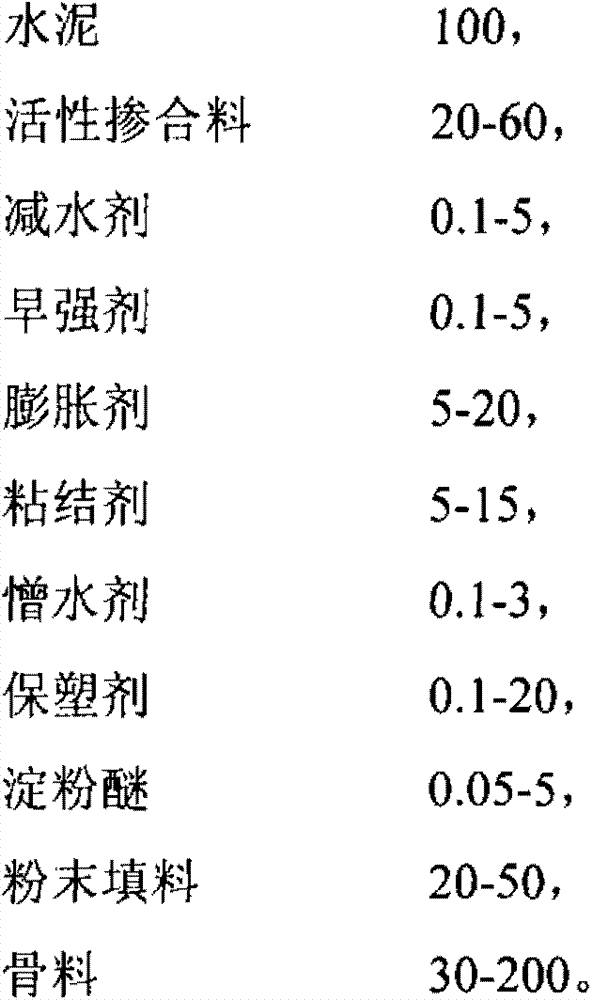

The invention relates to cement-based shrinkage-free wall hole-penetrating blocking materials and a preparation method and a construction method. The materials comprise, by weight, 100 cement, 0-100 active admixture, 0.01-10 water reducing agent, 0.01-10 early strength agent, 0.1-30 expanding agent, 0-20 adhesion agent, 0-10 water repellent, 0.01-30 plastic retaining agent, 0.01-10 starch ether, 0-60 power filler and 0-300 aggregate. Compared with the prior art, the cement-based shrinkage-free wall hole-penetrating blocking materials have the advantages of being good in construction performance, and long in operational time. New mixing slurry has good plasticity, adhesive power and anti-falling performance, a caulking gun or a caulking machine can be used for pressing, injecting or sealing holes, a flowing phenomenon cannot appear even big holes are filled, and the big holes can be filled until the big holes are full and until reaching the deep hole, and completely sealed, and the sealing materials can fully come into play.

Owner:杭州固特建筑加固技术工程有限公司

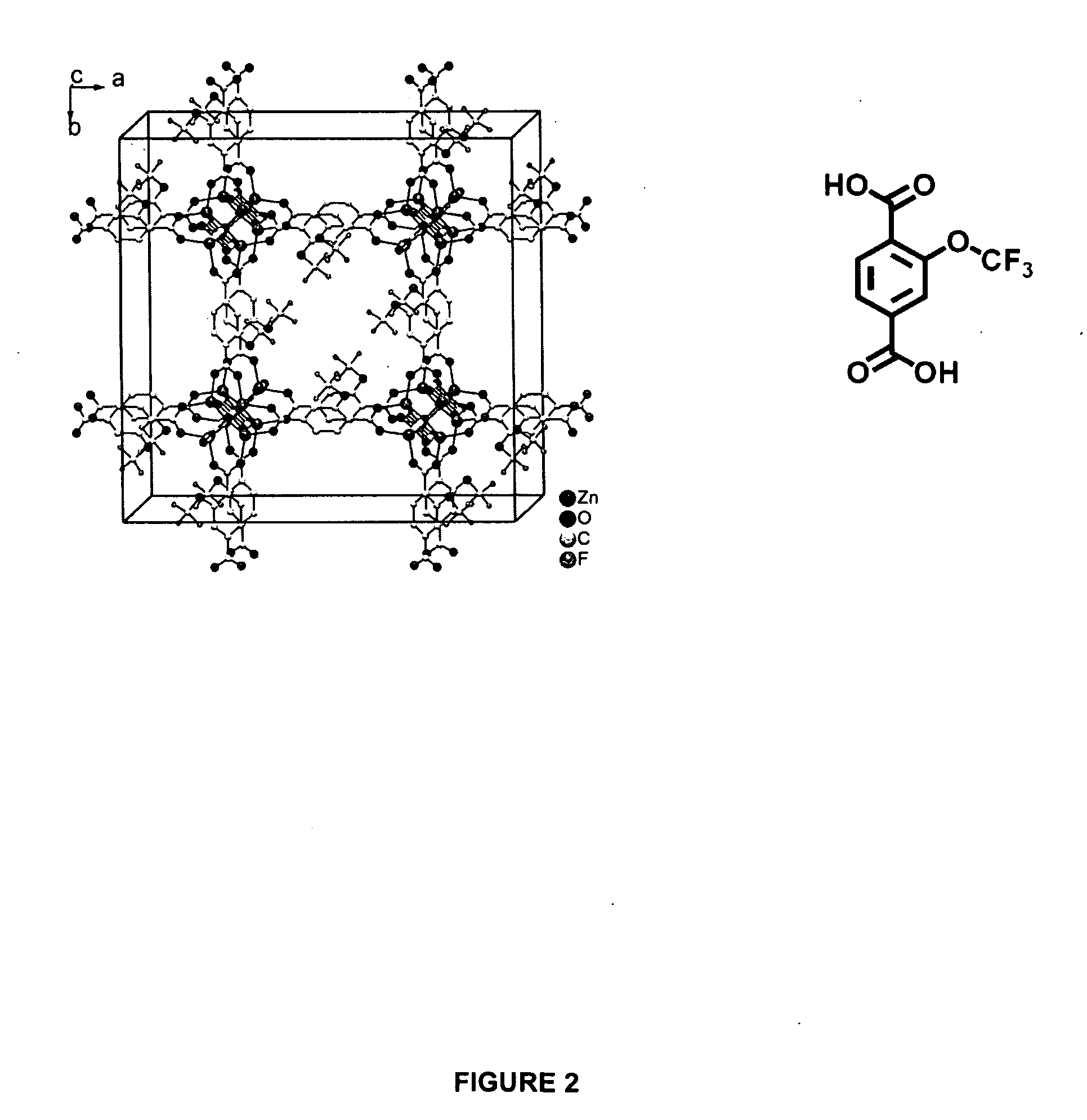

Water repellent metal-organic frameworks, process for making and uses regarding same

ActiveUS20100075123A1Improve stabilityImproved MOF stabilityGroup 8/9/10/18 element organic compoundsLayered productsWater vaporSorbent

Microwave assisted synthesis may be used to produce water-repellent metallic organic frameworks (MOFs) molecules. The water-repellent MOFs contain non-polar functional groups, such as a trifluoromethoxy group, which has a strong water repellent effect. The water-repellent MOF, when exposed to water vapor for one week does not result in a significant X-ray power pattern change. The water-repellent MOFs may be suitable as an adsorbent in many industrial applications, such as gas chromatography.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

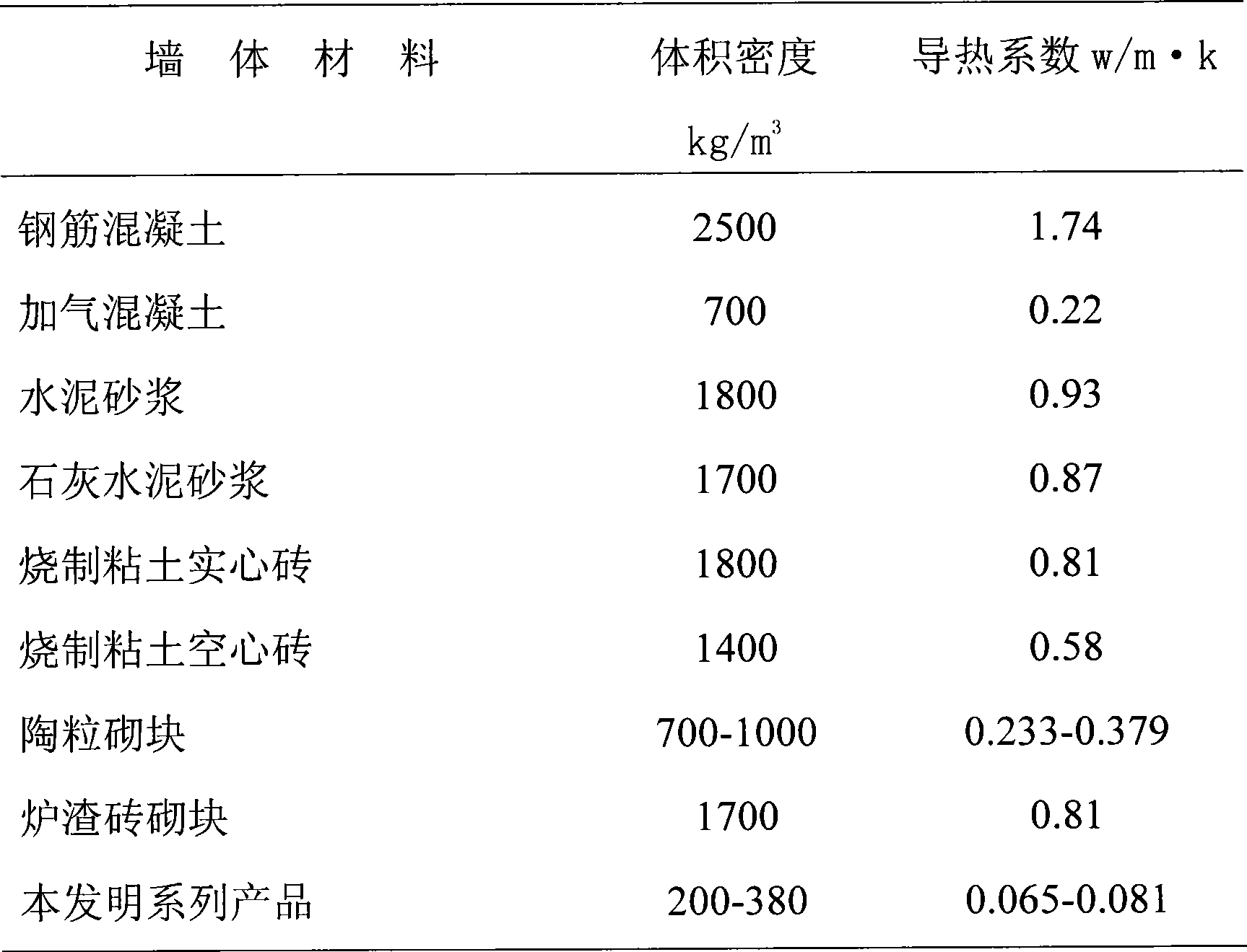

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Method for preparing product with one-way moisture-conducting function

ActiveCN101962885AExcellent unidirectional moisture transfer performanceFeel coolTextile treatment by spraying/projectingVegetal fibresHydrophilizationEngineering

The invention relates to a method for preparing a product with a one-way moisture-conducting function. The method comprises the following steps of: 1) performing hydrophilization pretreatment on a textile; and 2) spraying water repellent finishing agent-containing working solution on one face of the treated textile, so that liquid drops with diameter of 0.1 to 2mm and spacing of 0.1 to 2mm are formed on the face of the textile and the product with the one-way moisture-conducting function is obtained. Fabrics prepared by the method has the advantages of greatly reducing the using amount of a plurality of resources such as water, energy and the like and solving the environmental problems of pollution discharge and the like, along with the one-way moisture-conducting property.

Owner:CHINA TEXTILE ENG SOC +3

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

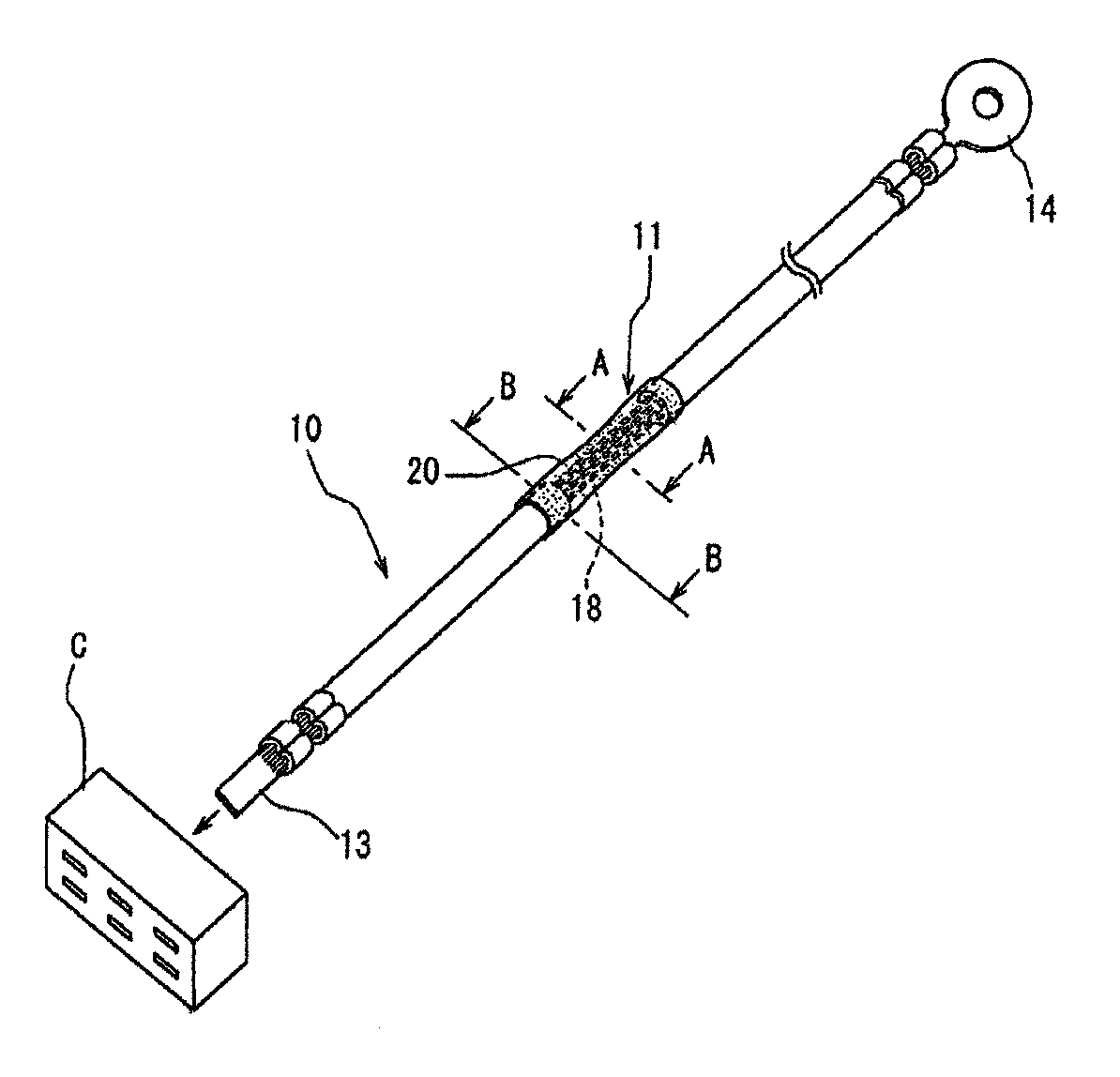

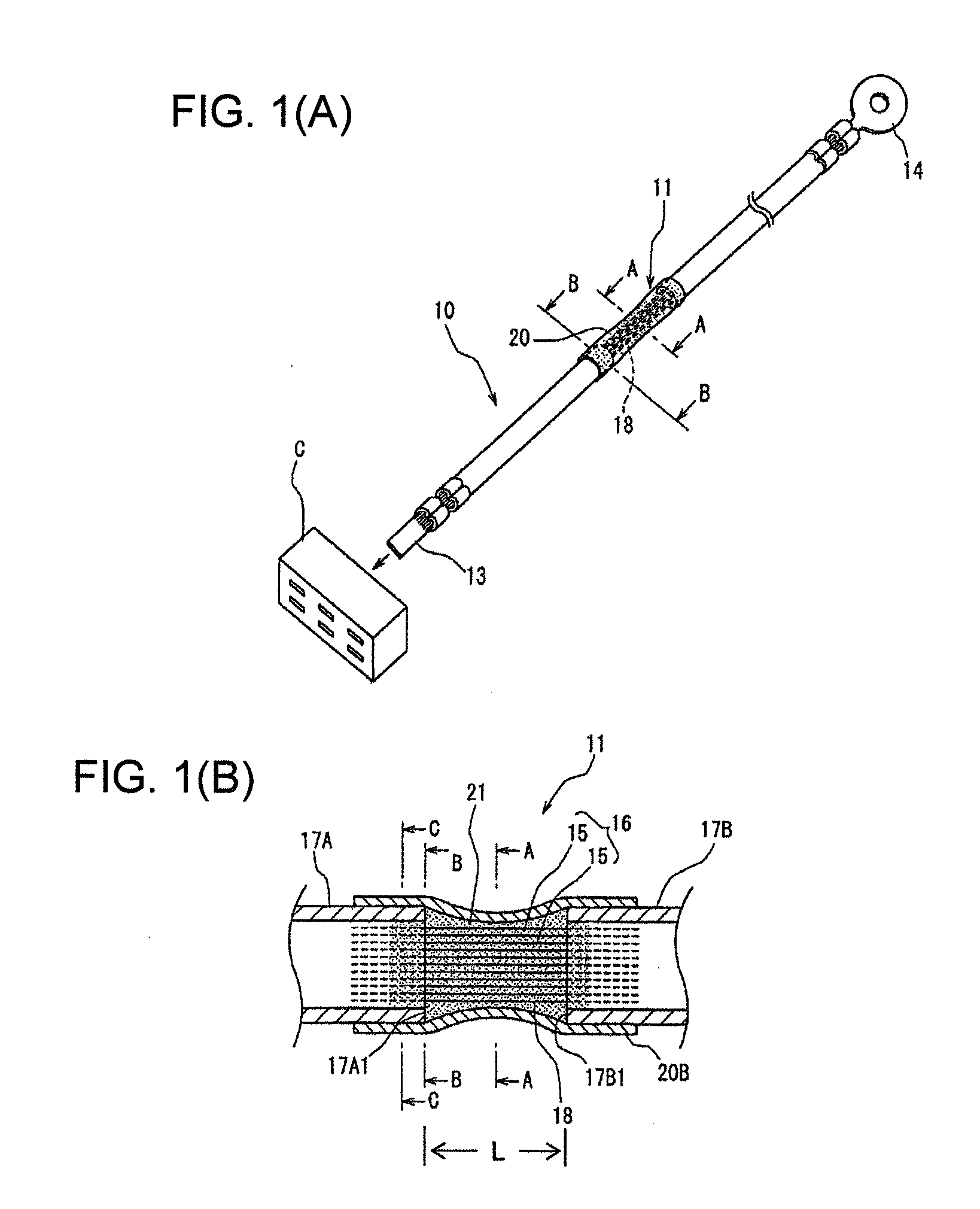

Waterproofing method for wire and wire having waterproof part formed by the waterproofing method

InactiveUS20110048762A1Water penetration into a connector can be more reliably preventedPrevent water penetrationSoldering apparatusInsulated cablesEngineeringHot melt

A waterproofing method is provided for a wire to be arranged in a water susceptible area of a vehicle. An insulating coating layer is removed in a lengthwise intermediate part of the wire to expose a core. A heat shrinkable tube with an inner layer made of a hot-melt waterproofing agent is mounted on the exposed core section and parts of the insulating coating layer adjacent to the exposed core section and heated. As a result, the hot-melt waterproofing agent of the inner layer is melted and infiltrates into clearances between strands of the exposed core section. In addition, negative pressure is introduced into the inside of the insulating coating layer from an end of the wire, thereby sucking the waterproofing agent into the inside of the insulating coating layer to infiltrate the waterproofing agent also between the strands of the core inside the insulating coating layer.

Owner:SUMITOMO WIRING SYST LTD

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

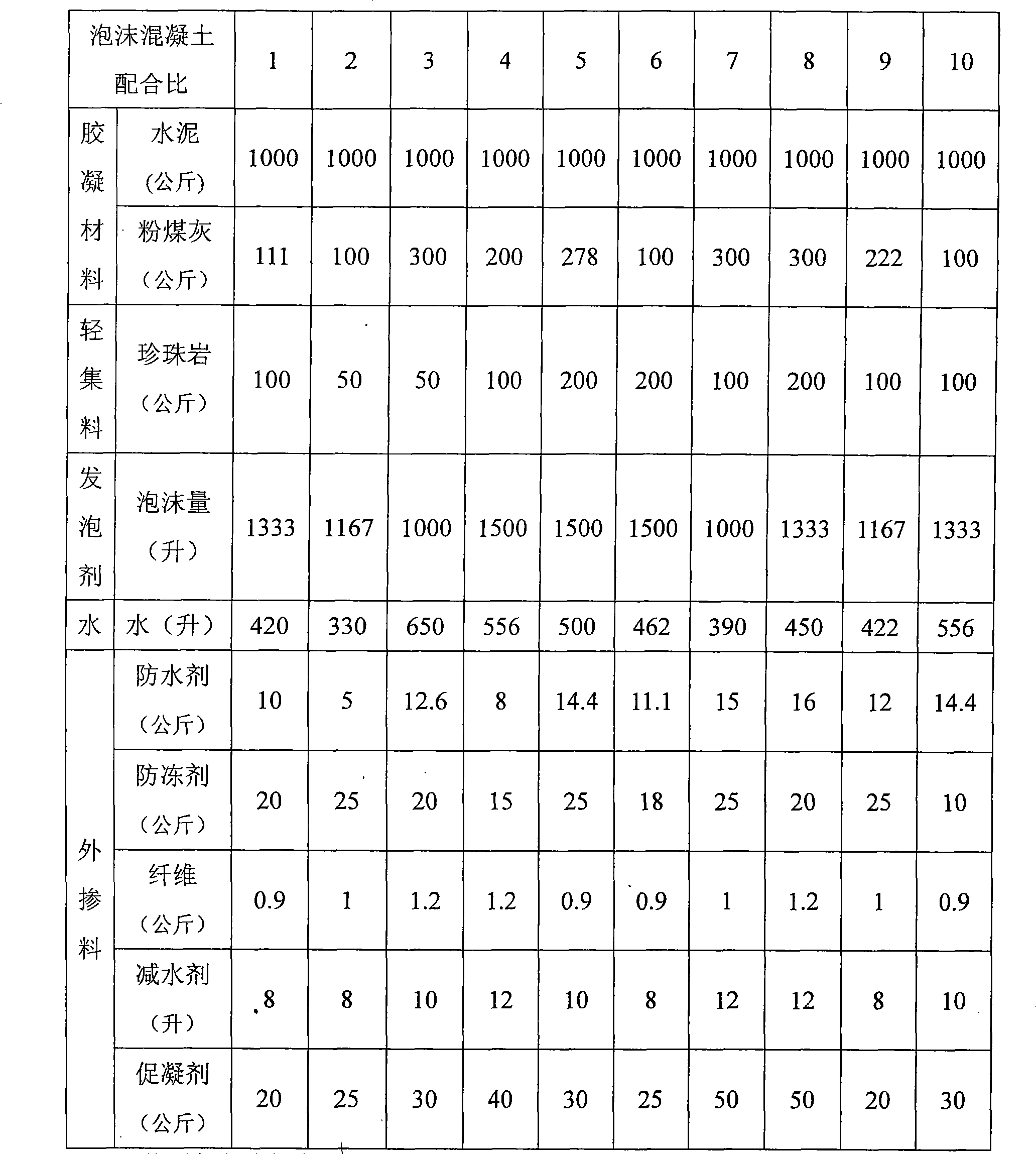

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

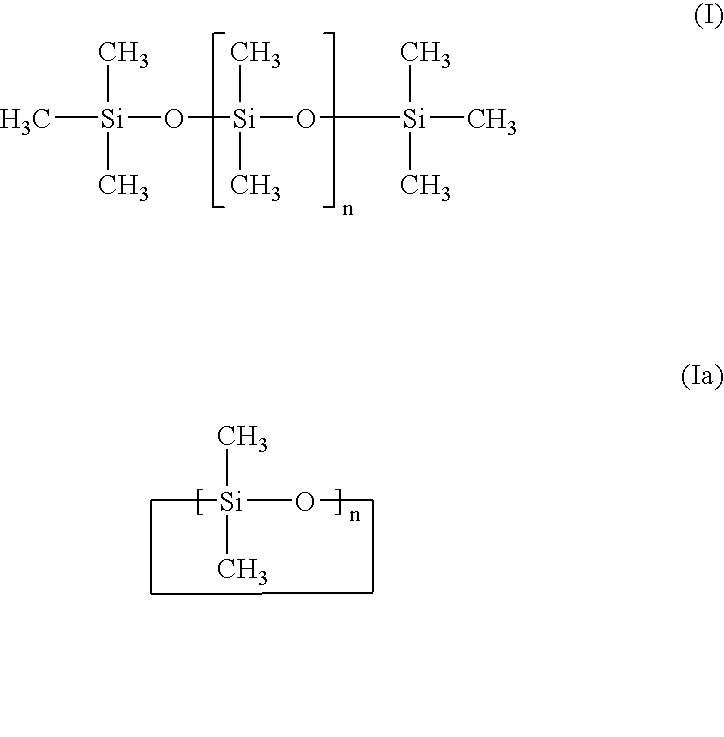

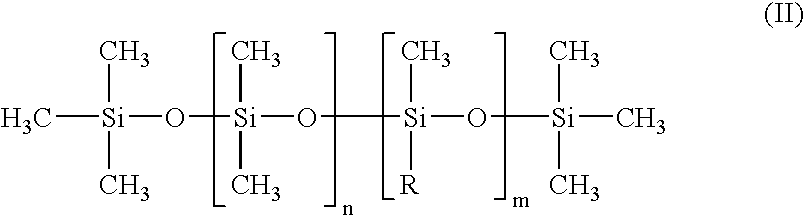

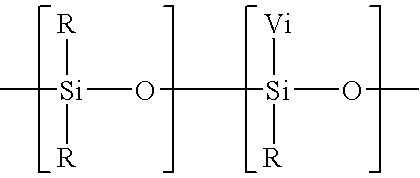

Silicone resin composition for water repellent coating

Resinous composition comprising: (A) 100 weight parts of (R2SiO2 / 2)w(RSiO3 / 2)x(SiO4 / 2)y(O1 / 2R<1>)z wherein R is selected from the group consisting of monovalent hydrocarbon groups having 1 to 10 carbon atoms, R<1 >is selected from the group consisting of the hydrogen atom and saturated hydrocarbon groups having from 1 to 6 carbon atoms, w is a number from 0 to 0.2, x is a number from 0.4 to 0.9, y is a number from 0.1 to 0.6, z is a number from 0.1 to 0.5, and (w+x+y)=1; (B) 20 to 150 weight parts of an alcohol-based solvent; (C) 100 to 1000 weight parts of a solvent selected from the group consisting of hydrocarbon-based solvents and polydimethylsiloxanes described by the formula Me3SiO(Me2SiO)nSiMe3, wherein Me is the methyl group and n has a value of 0 or 1; (D) 1 to 100 weight parts of a coupling agent selected from the group consisting of alkoxysilanes and silane coupling agents; (E) 0.1 to 20 weight parts of a condensation catalyst, and (F) 0.1 to 20 weight parts of a polyoxyalkylene-modified silicone.

Owner:DOW CORNING TORAY SILICOME CO

Comfortable and quick-drying type fabric with difference between inner layer and outer-layer of hydrophily and hydrophobicity and production method thereof

ActiveCN1831233AImprove hydrophobicityImprove hydrophilicityFibre treatmentDyeing processEngineeringMoisture

The invention discloses a comfortable, quick drying fabric whose inner and outer layers have hydrophilic and hydrophobic properties, respectively, and the producing method thereof, characterized by that: one side of the fabric is hydrophobic and made by applying water repellent assistant onto the fabric using coating or printing technique, where the region with the water repellent assistant is a water repellent region accounting for 50%-99% of the total area of the hydrophobic side, and the rest of the hydrophobic side is a hydrophilic region accounting for 1%-50% of the total area of the hydrophobic side; and the other side of the fabric is hydrophilic without the water repellent assistant. And water and sweat can be quickly transmitted to the hydrophilic side, so as to have an one-way water transmitting effect, and the clothing made of the fabric is comfortable to wear and quick to dry when absorbing moisture.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Water repellent compositions for wood preservatives

InactiveUS7264886B2Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:VIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com