Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

210results about How to "Easy to oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Thin hot-rolled pickled steel with good formability and production method thereof

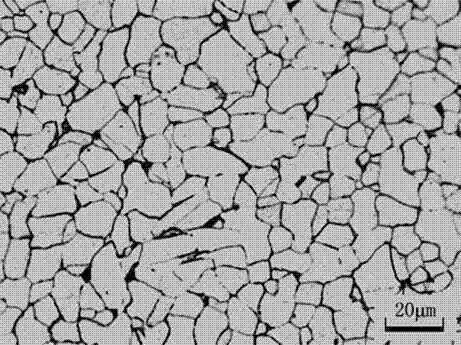

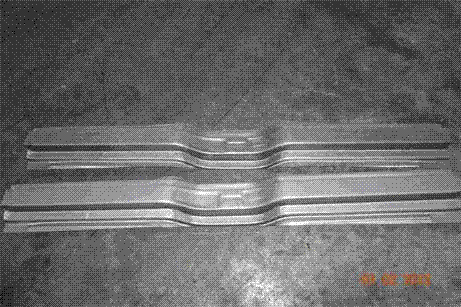

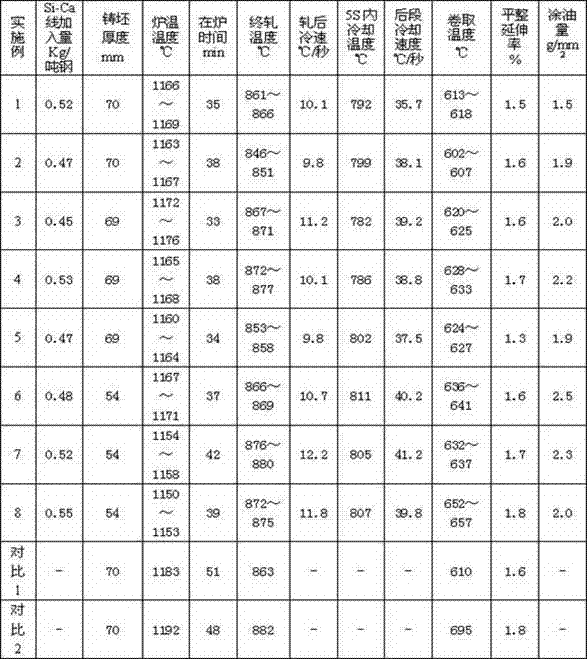

ActiveCN102787270AReduce the difficulty of productionImprove surface qualityMetal rolling arrangementsChemical compositionHigh pressure water

The invention relates to a thin hot-rolled pickled steel with good formability, which comprises the following chemical components by weight percent (wt%): 0.04-0.07% of C, 0.10-0.30% of Si, 0.41-0.60% of Mn, 0.025% of P or less, 0.012% of S and 0.010-0.030% of Als. The preparation method of the thin hot-rolled pickled steel with good formability comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water, controlling rolling, cooling by laminar flow, curling, pickling by acid levelling and finishing adopting static oil removal. The produced hot-rolled pickled steel which has the tensile strength of 370MPa or higher and the thickness of 1.8 mm or lower, is low production difficulty and good in surface quality and is convenient to weld, oil and paint. In addition, the thin hot-rolled pickled steel has the advantages of good punch formability, high forming size accuracy, short production cycle, high yield and low cost.

Owner:武汉钢铁有限公司

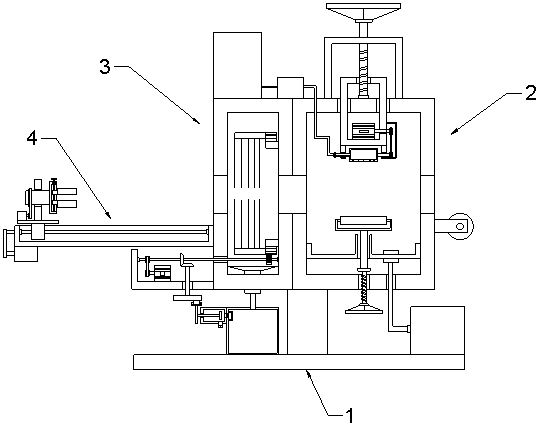

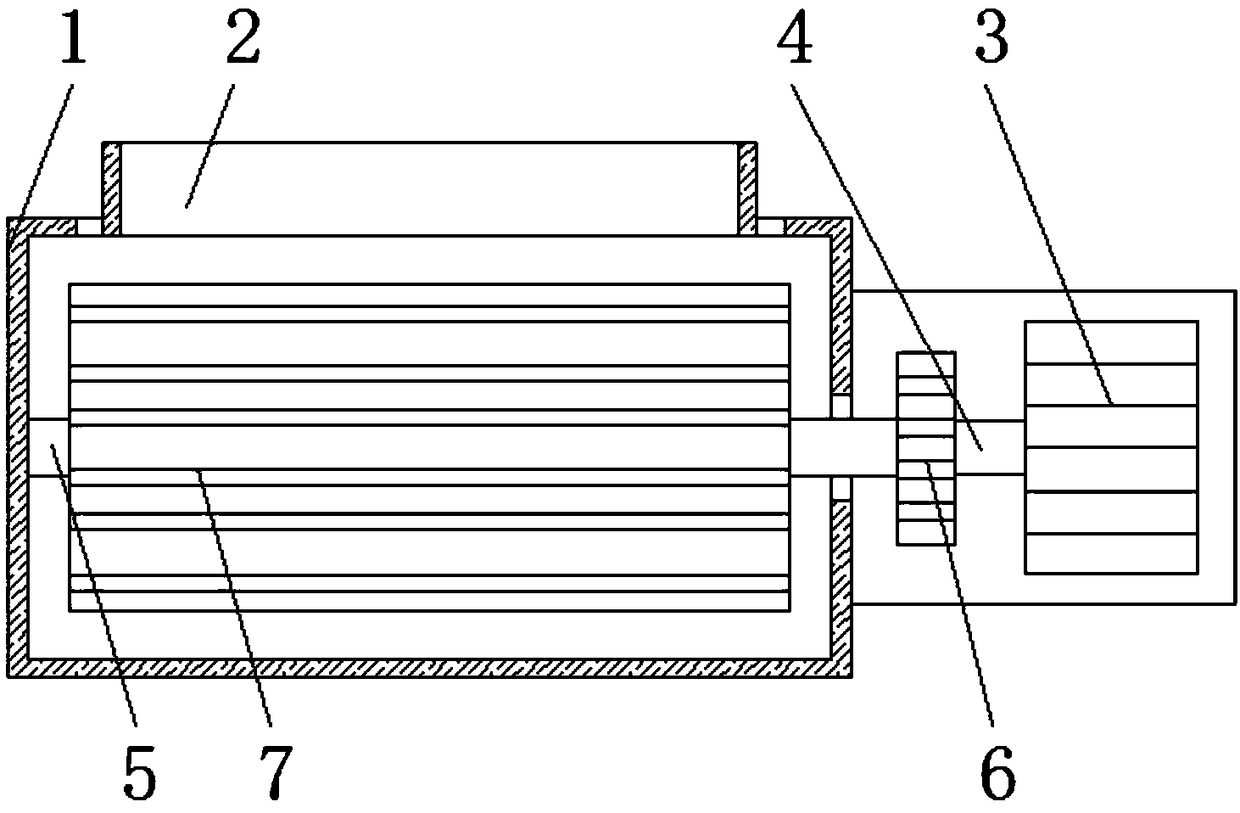

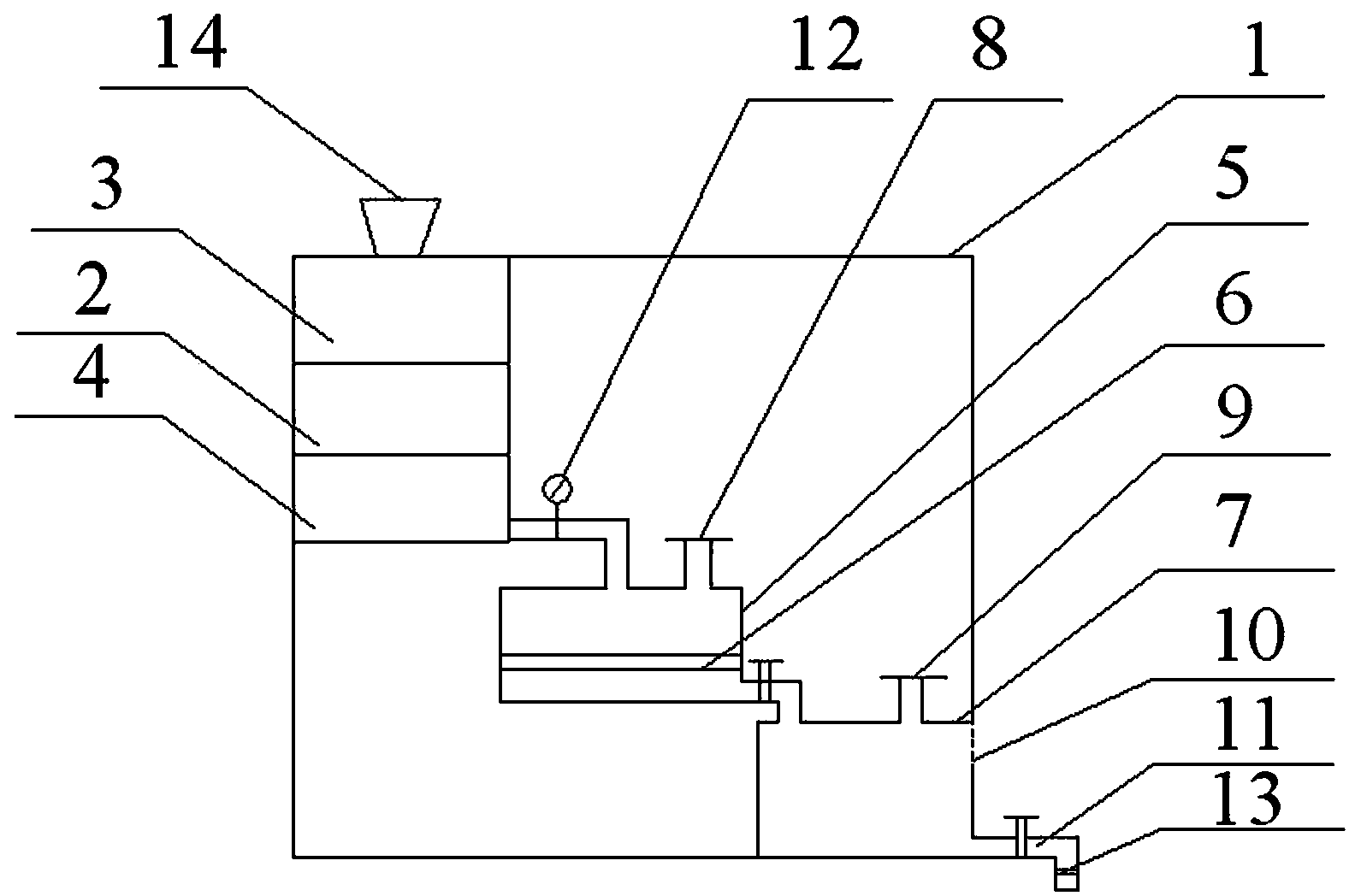

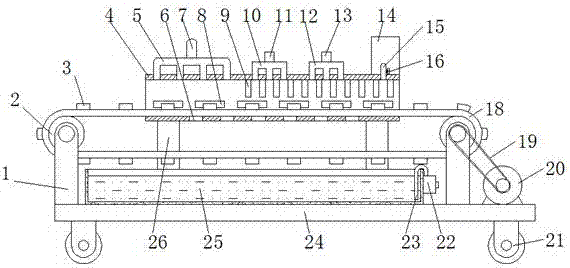

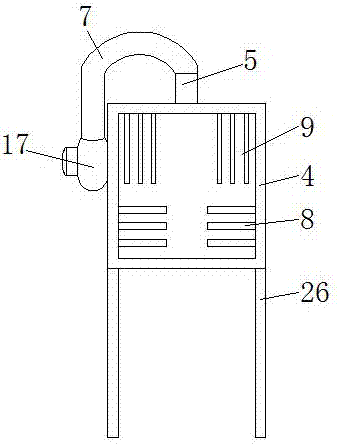

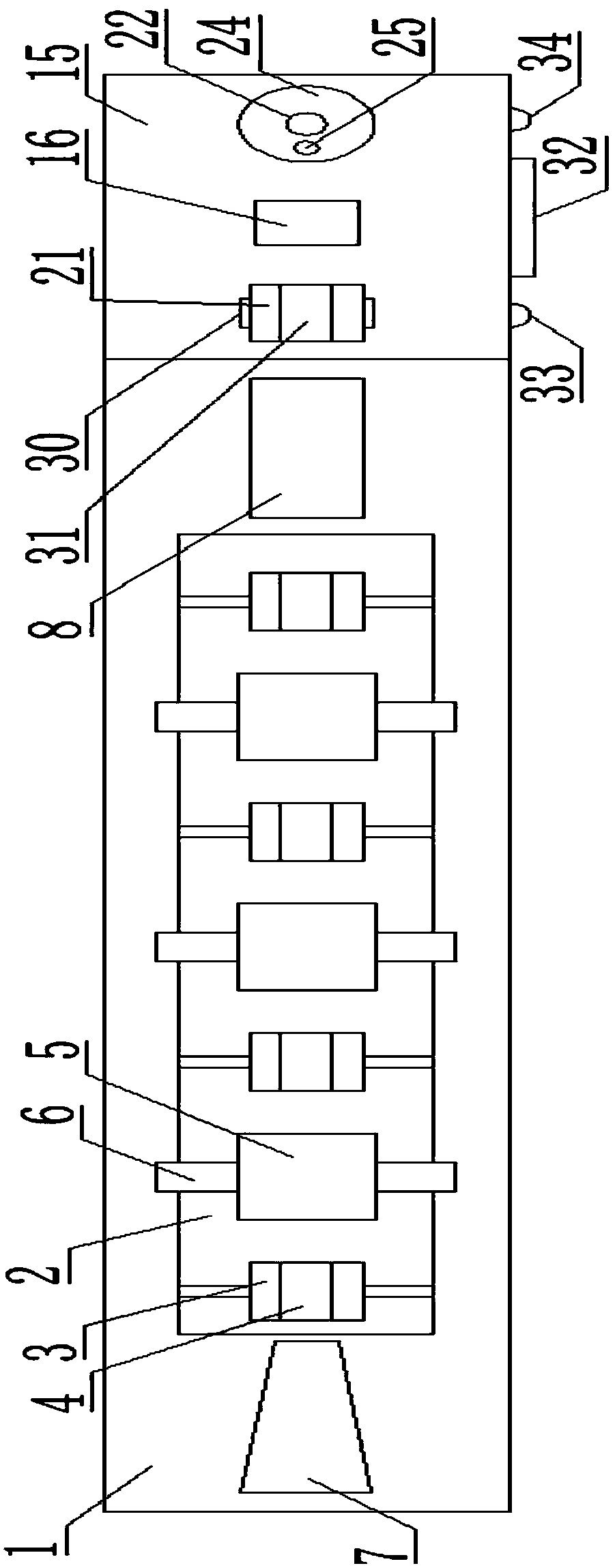

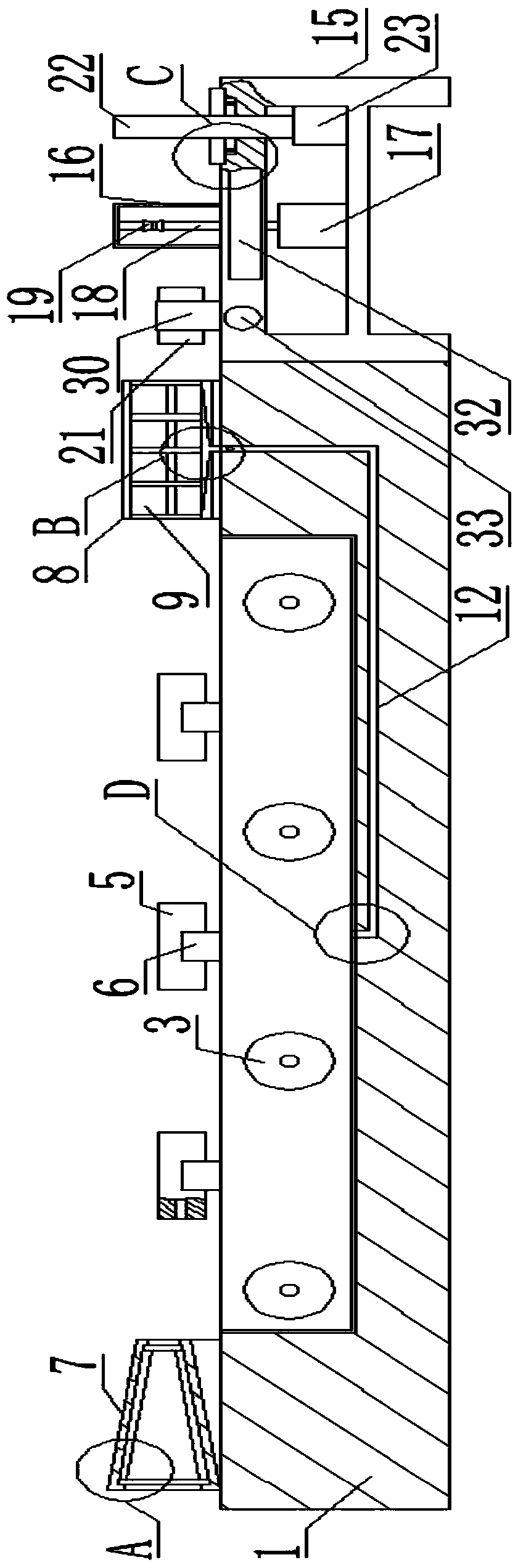

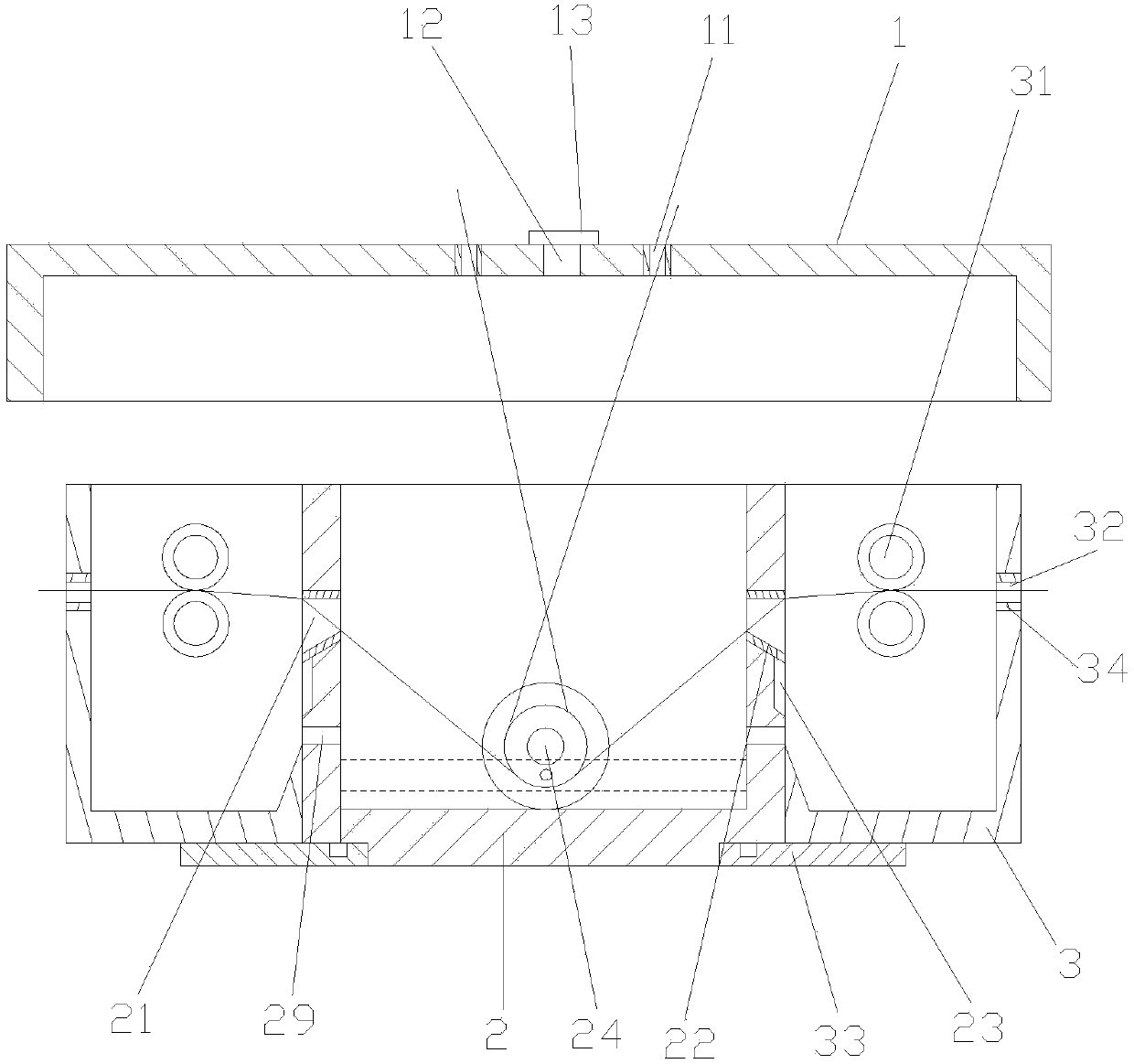

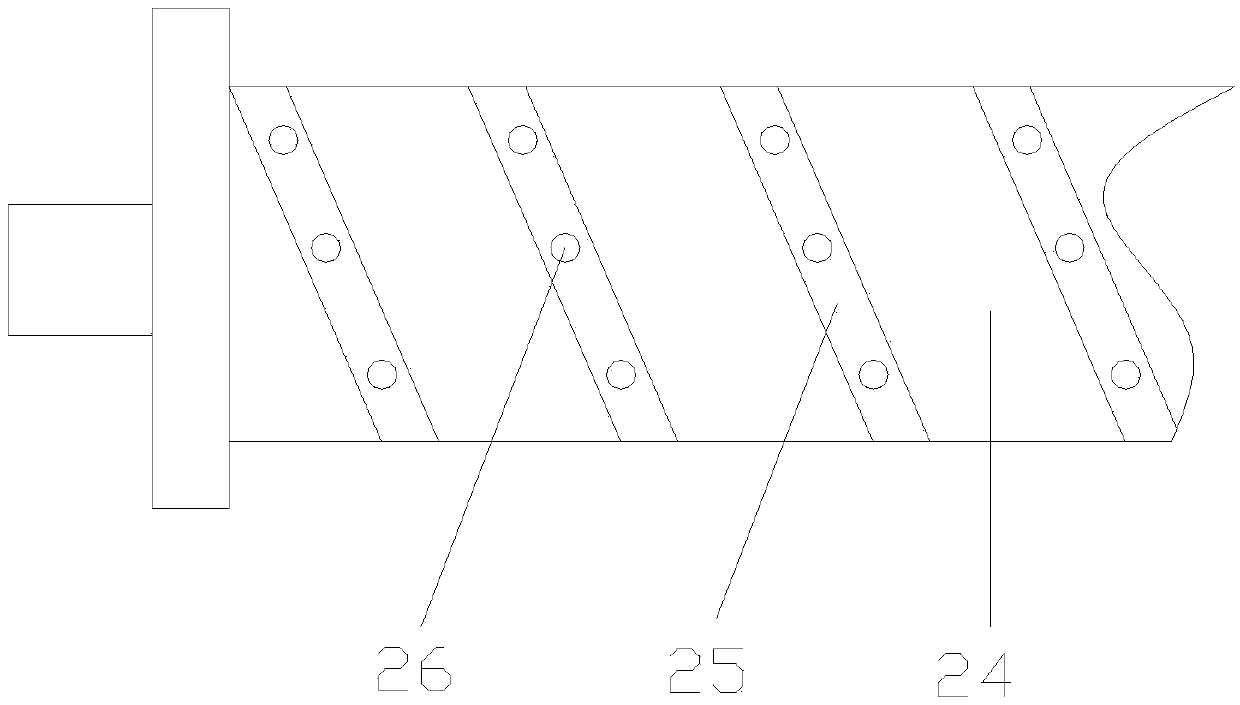

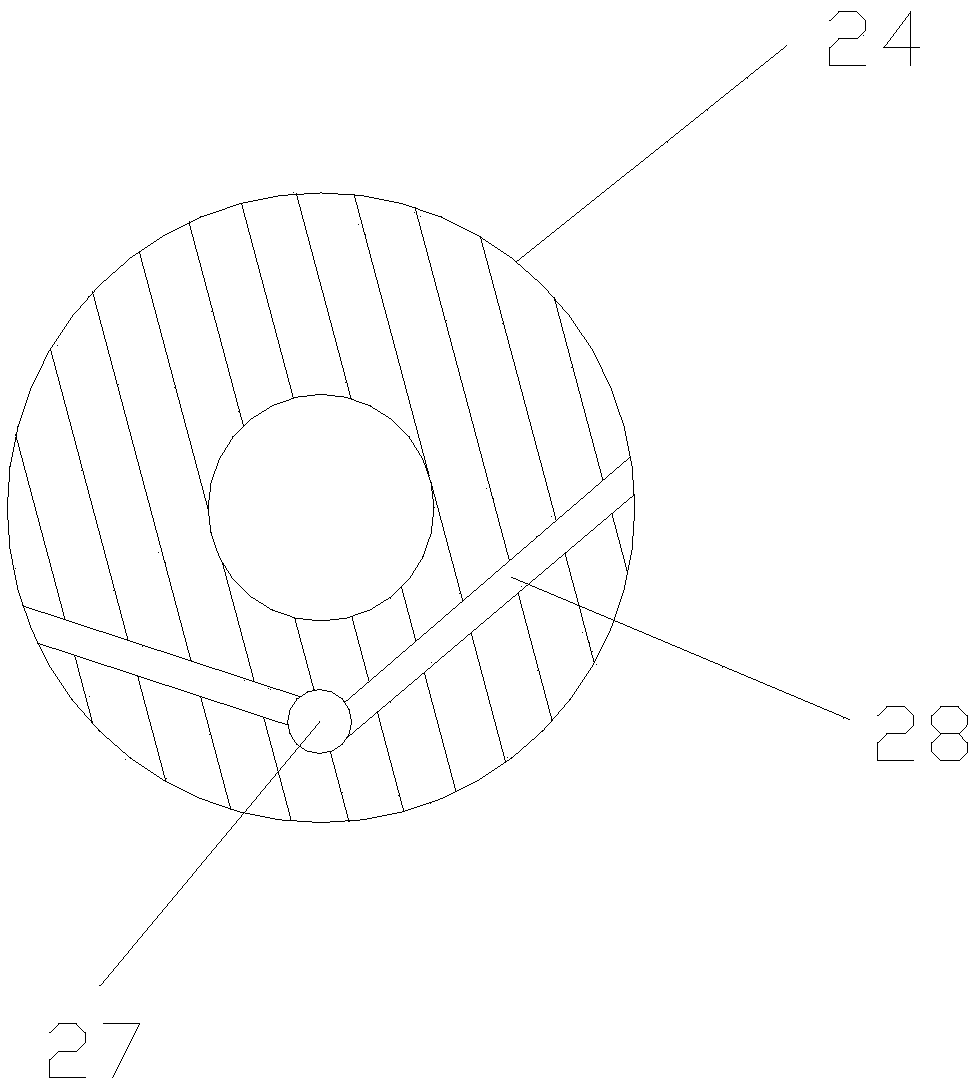

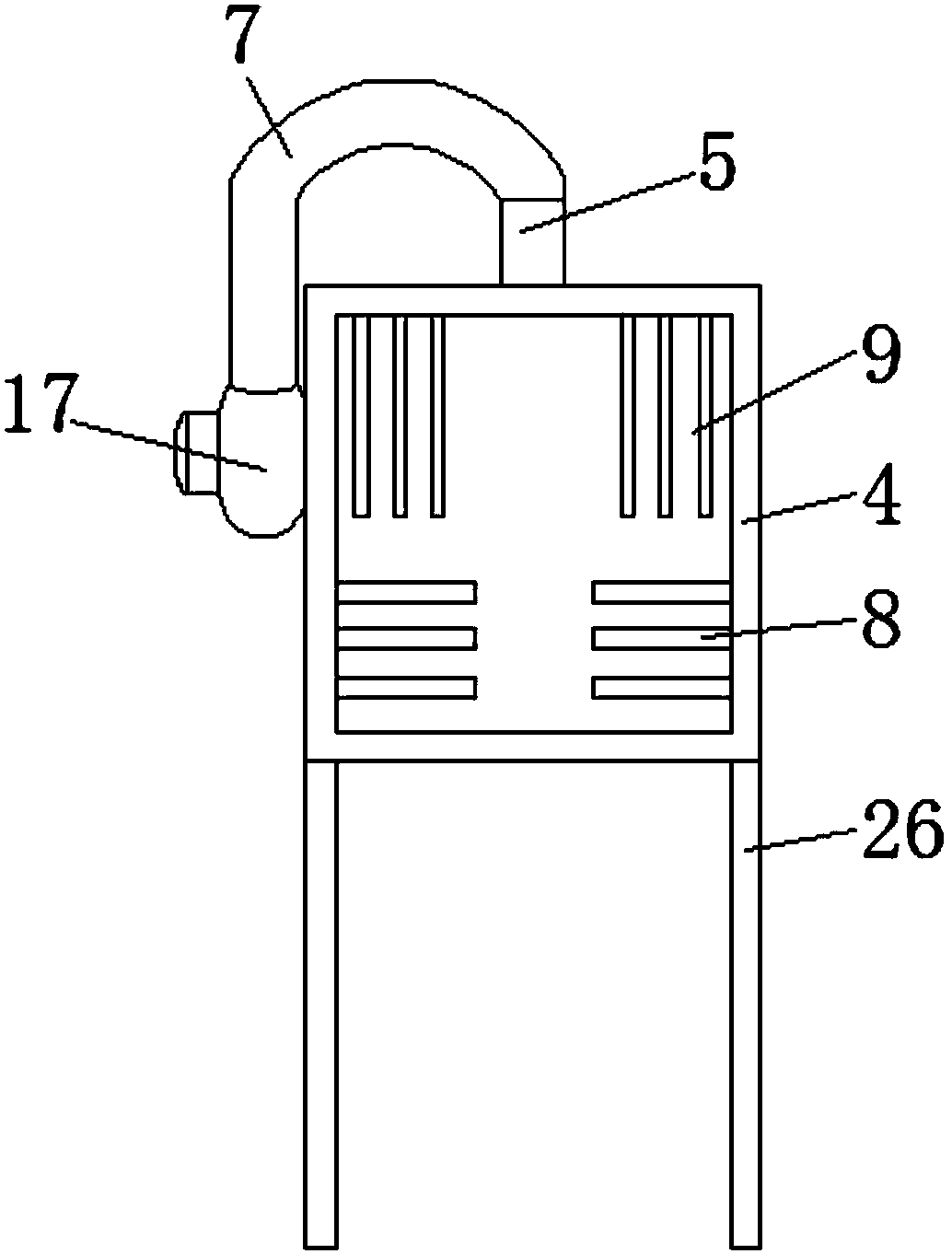

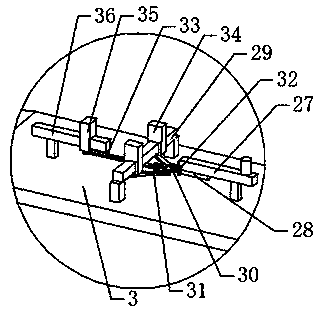

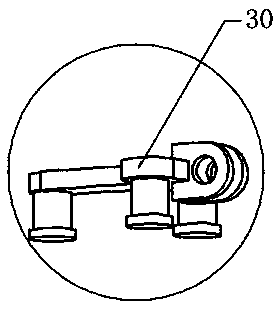

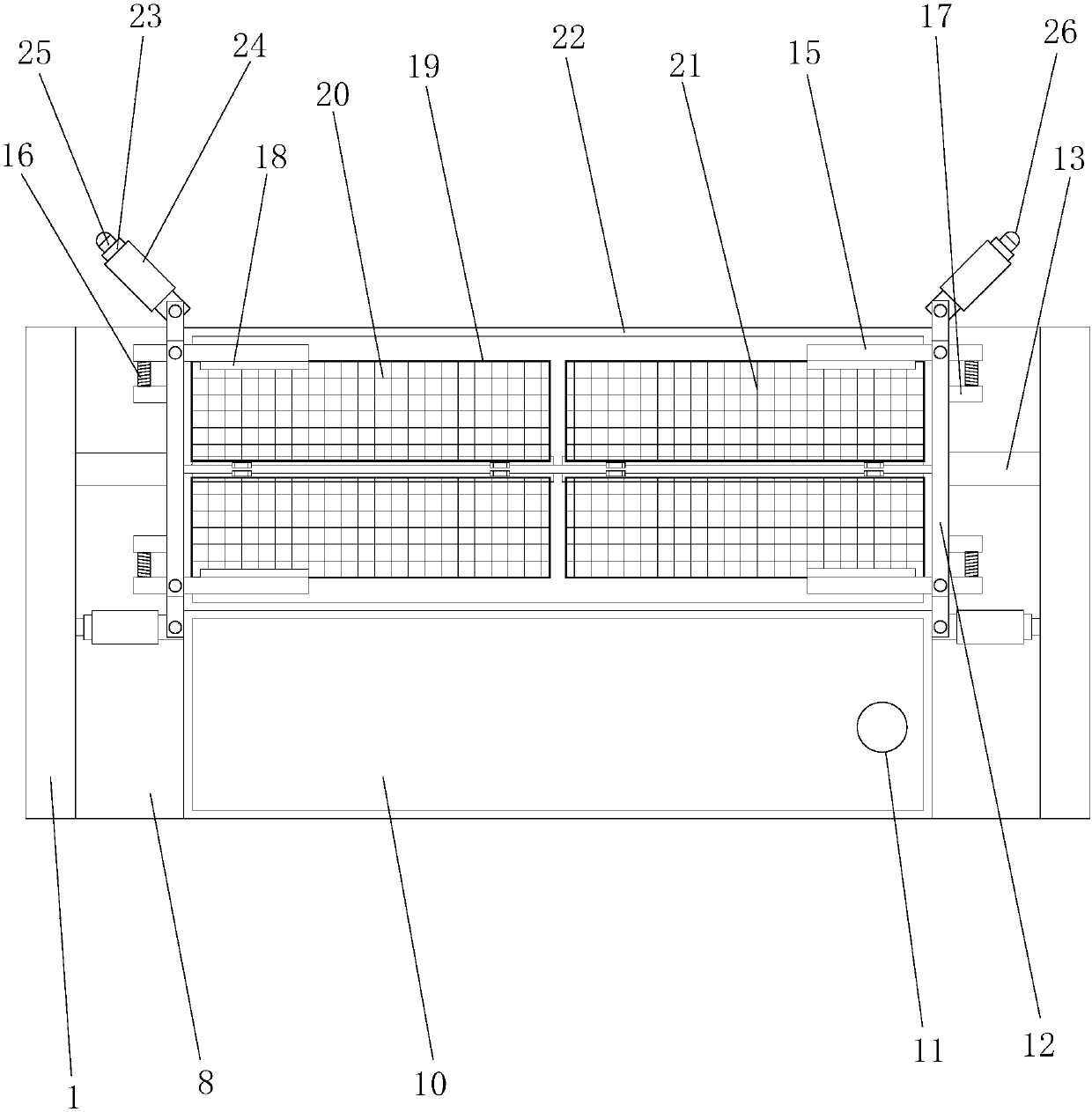

Steel pipe mechanical-oiling equipment

InactiveCN109550640AReduce dosageEfficient dust removalLiquid surface applicatorsCoatingsArchitectural engineeringFuel tank

The invention discloses steel pipe mechanical-oiling equipment which comprises a base, an oiling mechanism, a dust removing mechanism and a feeding mechanism, wherein the oiling mechanism comprises anoiling tank which is fixedly connected with the base; an oiling roll is arranged in the oiling tank; uniformly-distributed overflow holes are formed in the circumferential surface of the oiling roll;the dust removing mechanism comprises a dust removing tank; and a ring-shaped brush is arranged in the dust removing tank. The steel pipe mechanical-oiling equipment disclosed by the invention has the beneficial effects that through the arrangement of the hollow oiling roll provided with the overflow holes as well as a spreading roll capable of rising and falling, the surface of a steel pipe canbe uniformly coated with anti-rust oil, thereby improving the oiling quality when the consumption of the anti-rust oil is reduced; and through the arrangement of the ring-shaped brush, a dust collecting hood and a dust collecting tank which communicates with a suction piston cylinder, the efficient dust removing operation on the to-be-oiled steel pipe can be achieved, thereby guaranteeing the oiling quality; and through the arrangement of a rotating cylinder and a sliding frame which are equipped with a clamping mechanism, the steel pipe can be rotated when fed, thereby facilitating the oilingoperation on the circumferential surface of the steel pipe.

Owner:HUNAN UNIV OF SCI & ENG

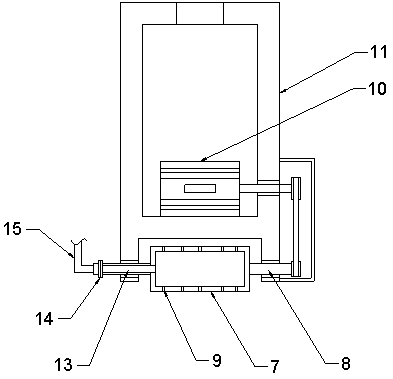

Preparation method of hot-rolled acid-washing high-strength steel for automobile carriage

The invention relates to a preparation method of hot-rolled acid-washing high-strength steel for an automobile carriage. The hot-rolled acid-washing high-strength steel comprises the following major ingredients in percentage by weight: 0.07 percent to 0.1 percent of C, at most 0.05 percent of Si, 1.5 percent to 1.9 percent of Mn, at most 0.015 percent of P, at most 0.01 percent of S, at most 0.005 percent of N, 0.1 percent to 0.2 percent of Mo, 0.04 percent to 0.06 percent of Nb, 0.15 percent to 0.2 percent of Ti, 0.02 percent to 0.04 percent of Al, 0.001 percent to 0.004 percent of B, 0.002 percent to 0.01 percent of Ca and the balance of Fe and inevitable impurities, Ti / B is greater than or equal to 35, and the carbon equivalent Ceq is smaller than or equal to 0.45 percent. The preparation method has the advantages that the ingredients are simple, the production process is simple, the tempering or hardening and tempering treatment is not needed after hot rolling, the surface qualityis good, the obdurability, the welding performance and the cold forming performance are excellent, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

Full-degradable disposable tableware and production method thereof

The invention relates to fully-degraded disposable tableware and a manufacturing method thereof, in particular to the fully-degraded disposable tableware manufactured by taking vegetable fibers and vegetable starch as main raw materials and a manufacturing method. The fully-degraded disposable tableware is sanitary and nontoxic and is manufactured by utilizing underutilized vegetable fibers in the nature through a simple manufacturing process. After being used, the fully-degraded disposable tableware can be treated in the same mode as that of the leftover, and not only can be used as animal feeding stuffs, but also can be used as organic fertilizers to be naturalized so as to achieve a virtuous cycle of obtaining from the nature and serving for the nature truly. Moreover, the fully-degraded disposable tableware brings more convenient life style, and is good for constructing a conservation-minded society.

Owner:闫羽

Fine fertilizer application method for flue-cured tobaccos K326

ActiveCN104041234AQuality improvementReduce churnFertilising methodsHorticulture methodsChemical compositionPotassium

The invention discloses a fine fertilizer application method for flue-cured tobaccos K326. Fine fertilizer application for the flue-cured tobaccos K326 is realized by measuring the alkali-hydrolyzale nitrogen content, the effective phosphorous content and the effective potassium content, calculating the using amount of nitrogen, and then calculating the using amount of phosphorous and the using amount of potassium according to a fertilizer application ratio to finally obtain the amount of nitrogen, phosphorous and potassium fertilizers by a base fertilizer and topdressing combination mode, so that a certain yield of high-quality tobaccos can be obtained. According to the fine fertilizer application method, the most economic fertilizer application amount can be calculated, so that loss of redundant nutrients can be reduced, and the cost can be lowered to a certain extent; on the premise that the yield and the quality of the flue-cured tobaccos K326 are not affected, a requirement on the growth of the flue-cured tobaccos K326 is met under the least using amount of nitrogen, phosphorous and potassium. The tobaccos obtained by the method provided by the invention are high in quality; chemical components in the tobaccos are coordinated; the flue-cured tobaccos are fresh in color, mesophyll tissues are dense, leaves are high in toughness, the oil content is large, and requirements of a cigarette enterprise can be met.

Owner:HONGTA TOBACCO GRP +1

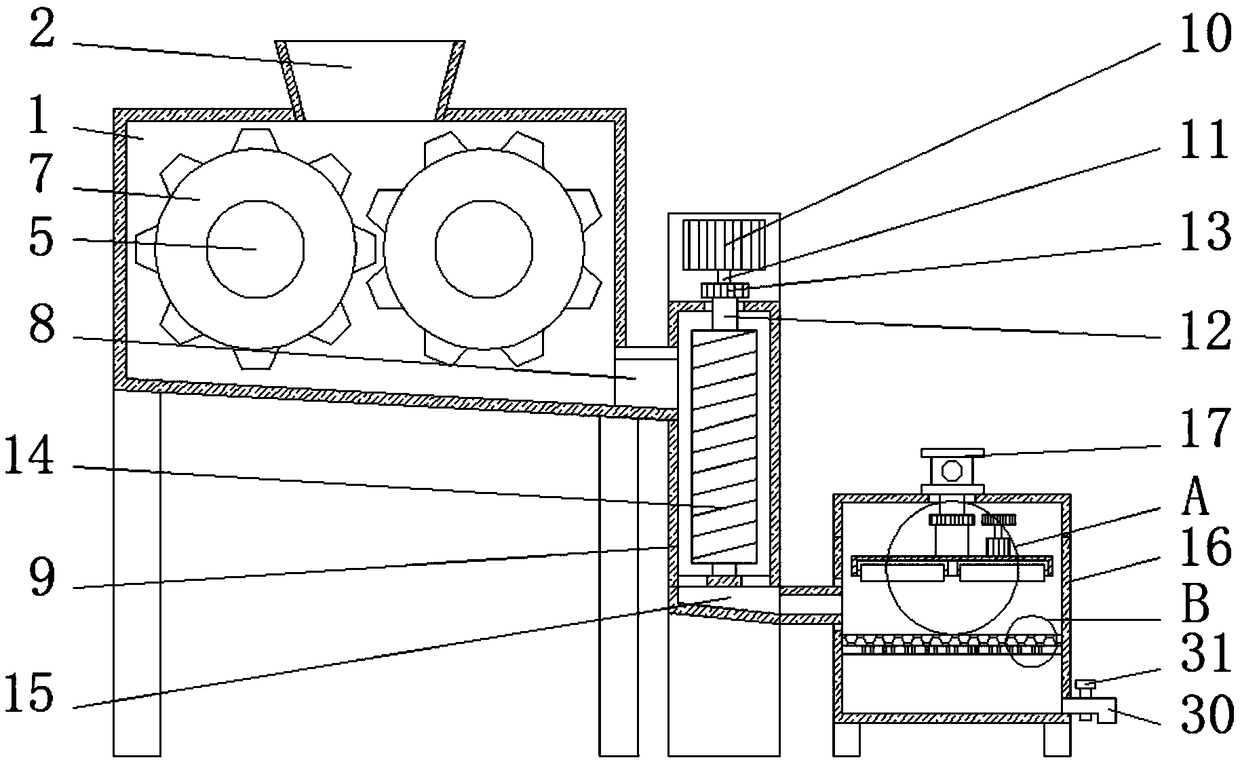

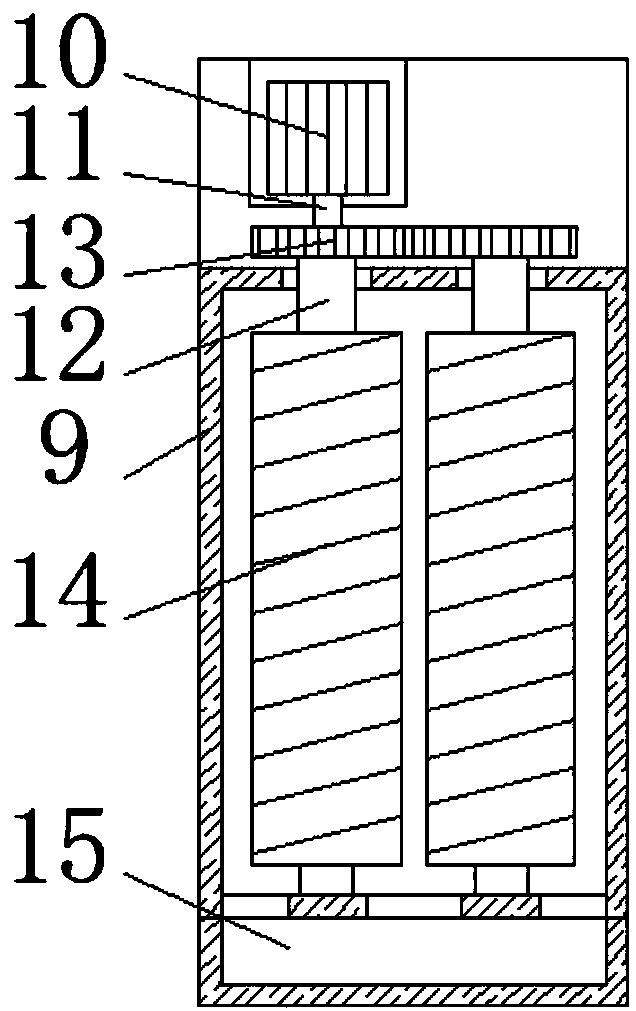

Edible oil presser with convenient graded pressing

InactiveCN109177281AImprove purityImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionEdible oilEngineering

The invention discloses an edible oil presser with convenient graded pressing. The edible oil presser comprises a first pressing box, a second pressing box, a third pressing box and an oil outlet pipe. A feed hopper is arranged on the upper side of the first pressing box, the second pressing box is arranged on the right side of the first pressing box, and a second motor is arranged on the upper side of the second pressing box. The third pressing box is arranged on the right side of the second pressing box, and a hydraulic cylinder is arranged on the upper side of the third pressing box. A third gear is arranged at the upper end of a fixing rod, a third motor is arranged on the upper side of a moving block, and a third rotating rod is arranged on the inner side of the moving block. A filterscreen is arranged below the moving block, and the oil outlet pipe is arranged on the right side of the third pressing box. According to the edible oil presser with convenient graded pressing, a first connecting shaft drives a squeezing block to rotate through a first rotating rod, the squeezing block is made to grind materials, the hardness of the materials can be conveniently lowered, and the size of the materials is smaller.

Owner:安徽茗峰机械制造股份有限公司

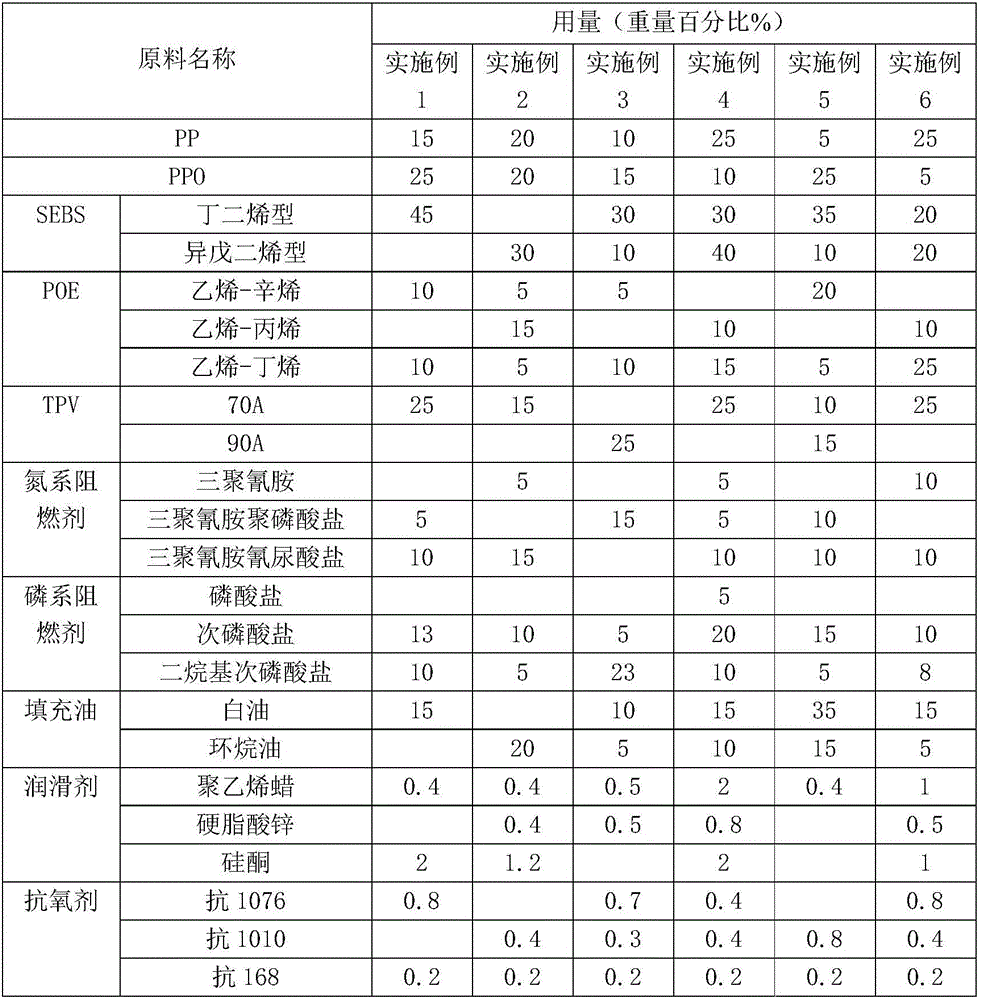

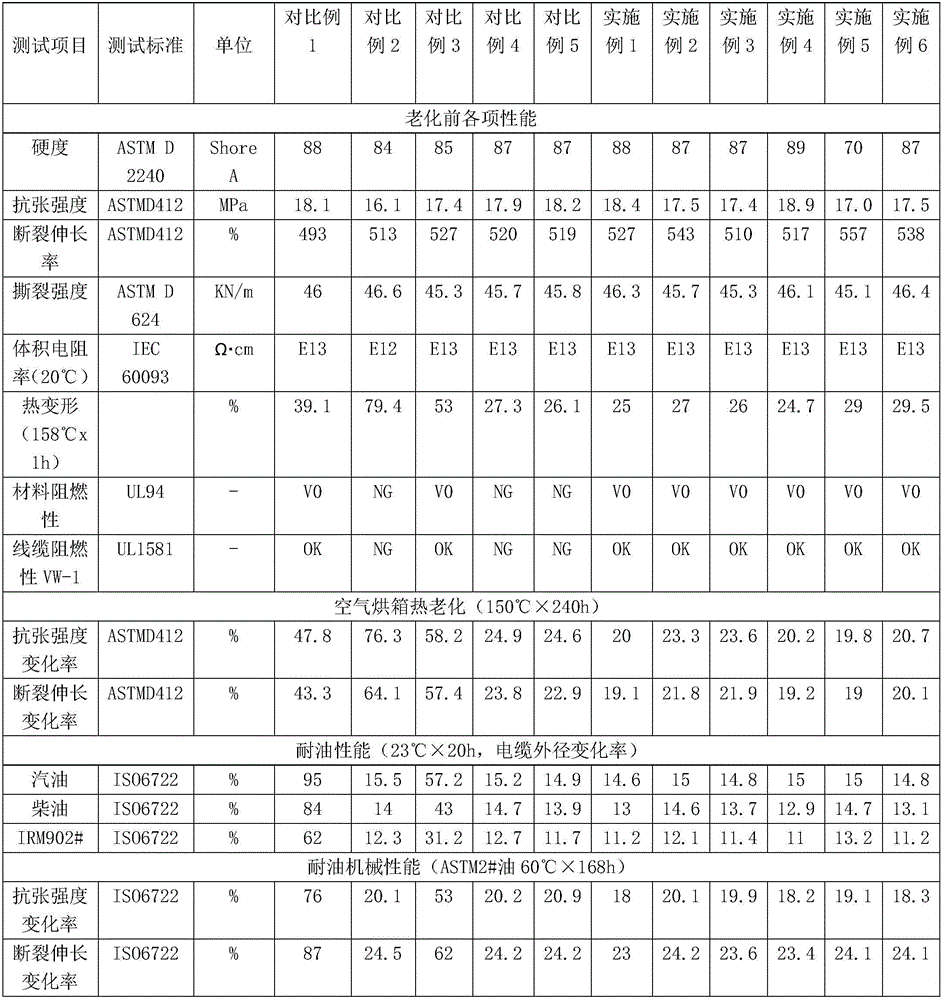

Halogen-free flame-retardant TPE cable material with heat resistance and oil resistance and preparation method of cable material

InactiveCN106366547AEasy to processGood physical propertiesPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to a halogen-free flame-retardant TPE cable material with heat resistance and oil resistance and a preparation method of the cable material. The halogen-free flame-retardant TPE cable material is prepared from, by weight, 30-70 parts of styrene series thermoplastic elastomer, 5-25 parts of polyolefin elastomer, 5-25 parts of oil resistant resin modifier, 5-25 parts of heat resistant resin modifier, 5-25 parts of heat resistant and oil resistant resin modifier, 25-55 parts of fire retardant, 5-50 parts of extending oil, 1-5 parts of lubricating agent and 0.2-0.5 part of antioxidant. The cable material has excellent heat resistance, oil resistance, ageing resistance and combination property, and is suitable for isolation and sheathing materials used for a vehicle-mounted charging line or a charging pile charging line of an electric automobile.

Owner:SUZHOU HENGLI COMM MATERIAL

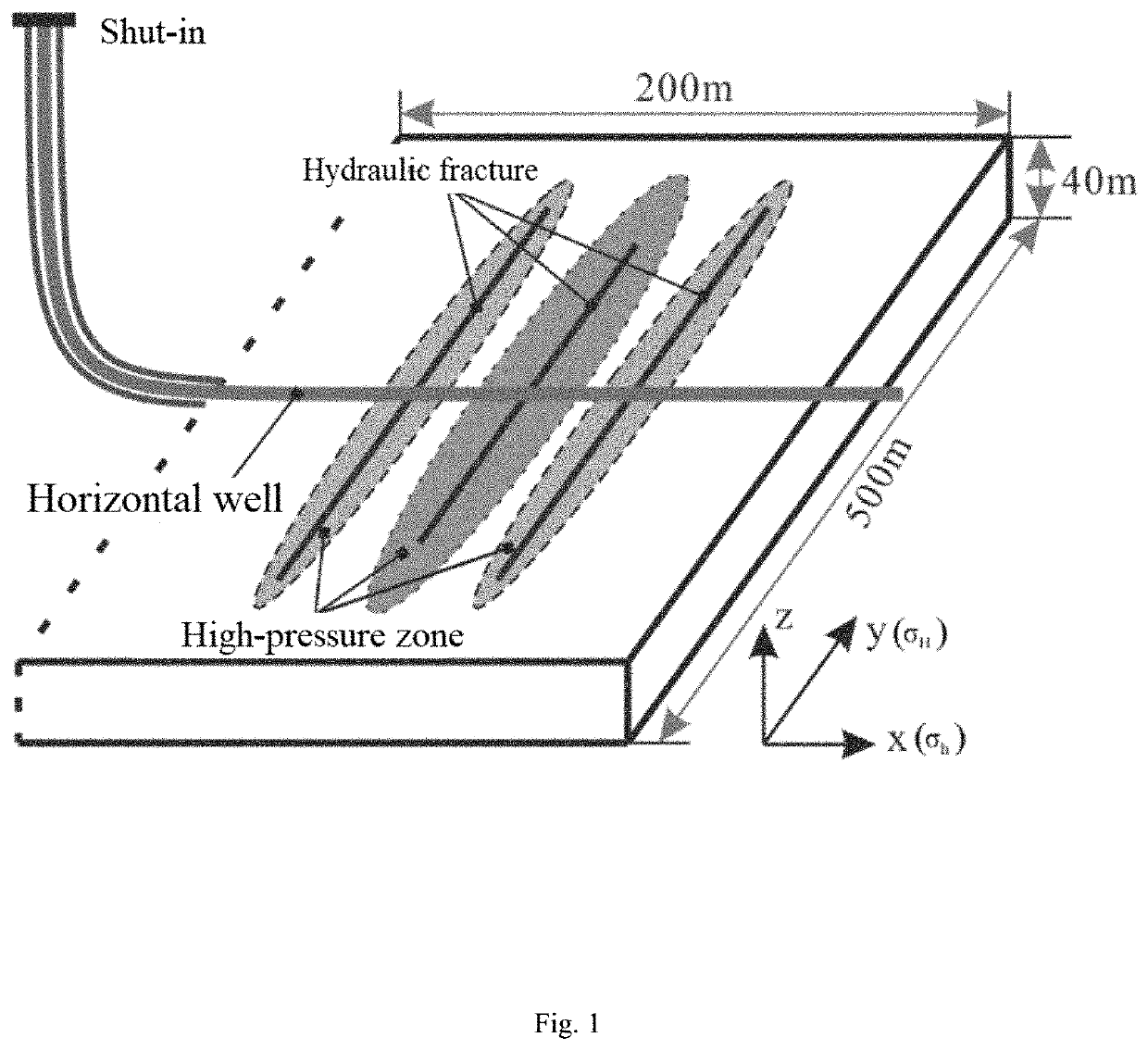

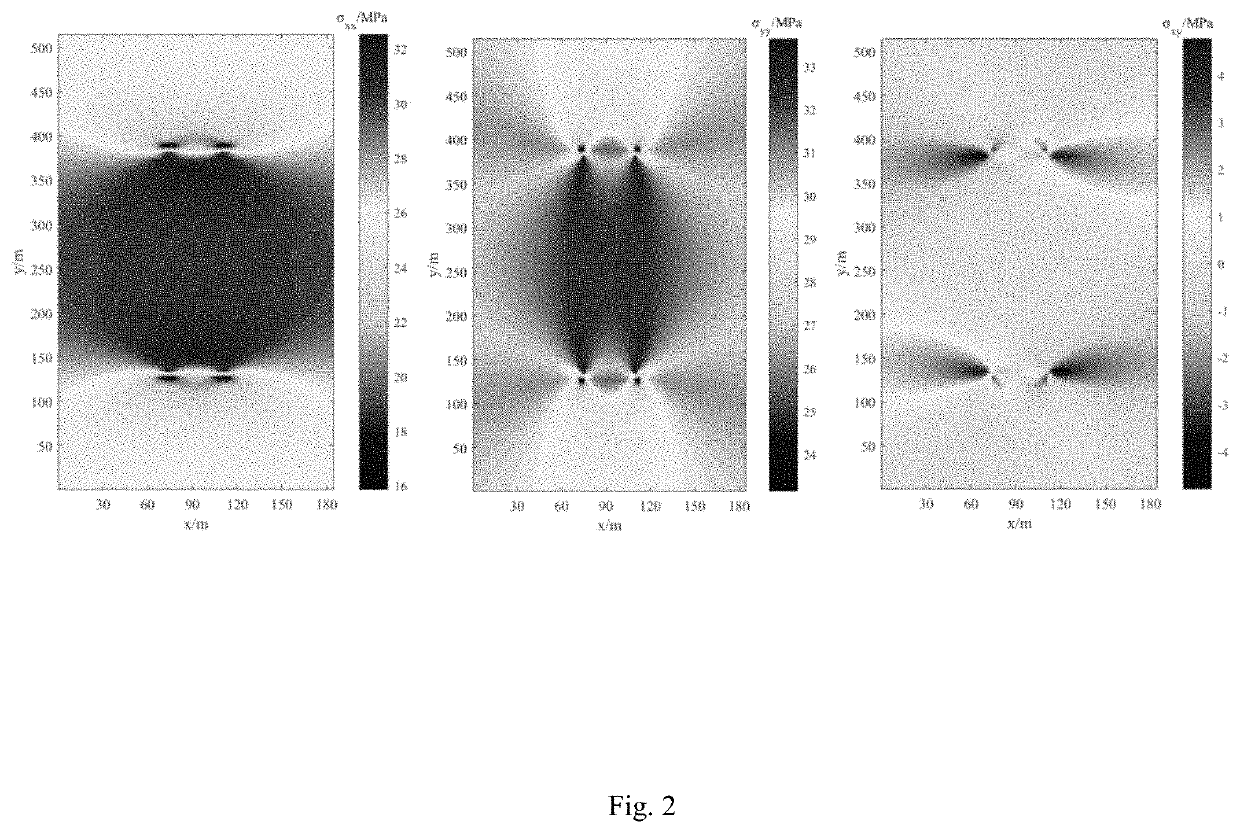

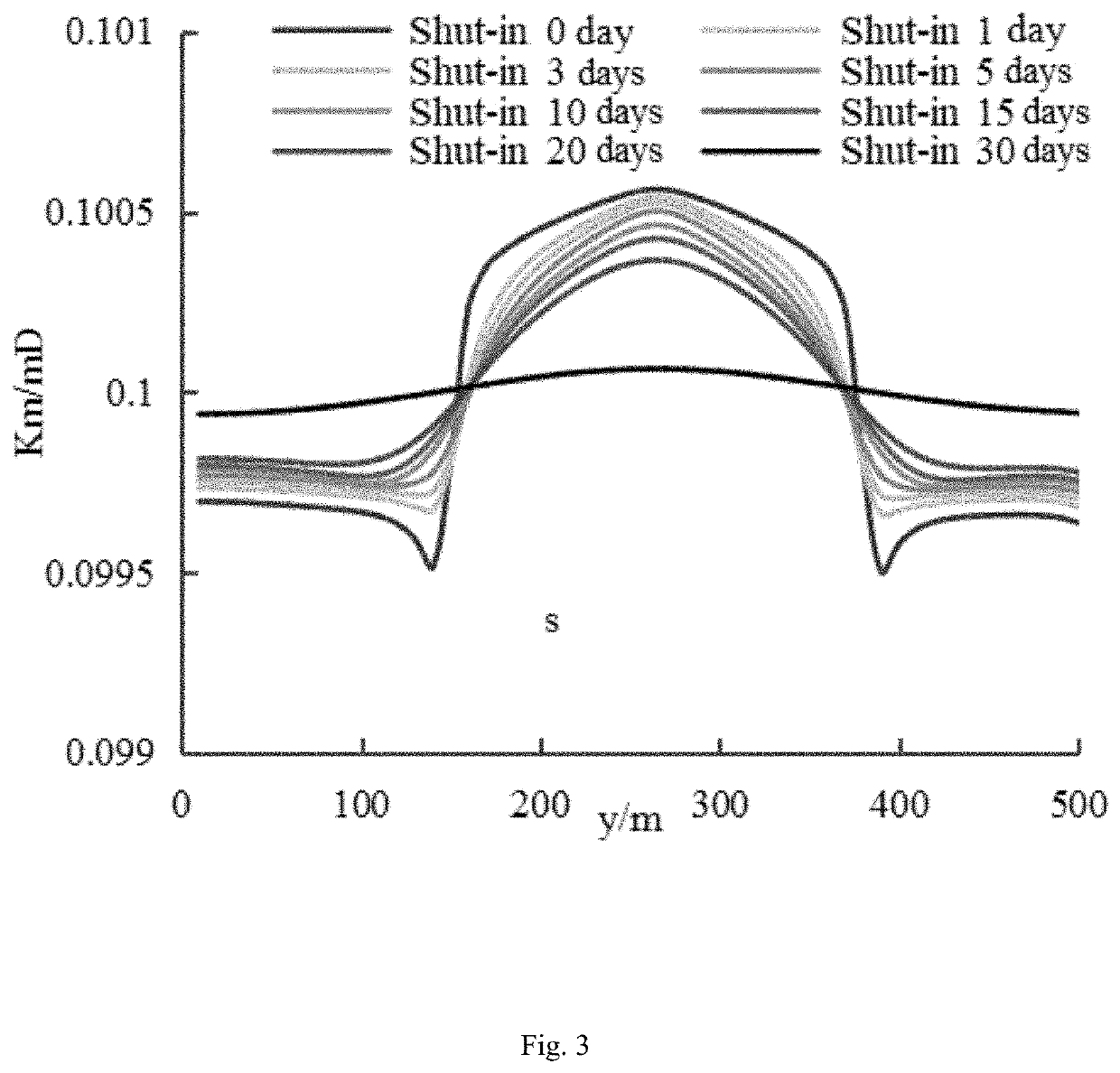

Method for predicting the optimal shut-in duration by coupling fluid flow and geological stress

ActiveUS20200332655A1Accurate predictionEasy to oilForecastingFluid removalTight oilFluid solid coupling

The invention discloses a method for predicting the optimal shut-in duration by coupling fluid flow and geological stress, comprising the following steps: determine basic parameters; obtain the fracture length, fracture width and reservoir stress distribution based on the basic parameters; calculate the oil saturation, pore pressure, and permeability and porosity after coupling change in different shut-in durations on the basis of the principle of fluid-solid coupling; take the oil saturation, pore pressure, and permeability and porosity obtained in Step 3 as initial parameters and calculate the production corresponding to different shut-in time on the basis of the productivity model; finally select the optimal shut-in time based on the principle of fastest cost recovery. The present invention can accurately predict the optimal shut-in duration after fracturing to improve the oil and gas recovery ratio in tight oil and gas reservoirs with difficulty in development and low recovery.

Owner:SOUTHWEST PETROLEUM UNIV

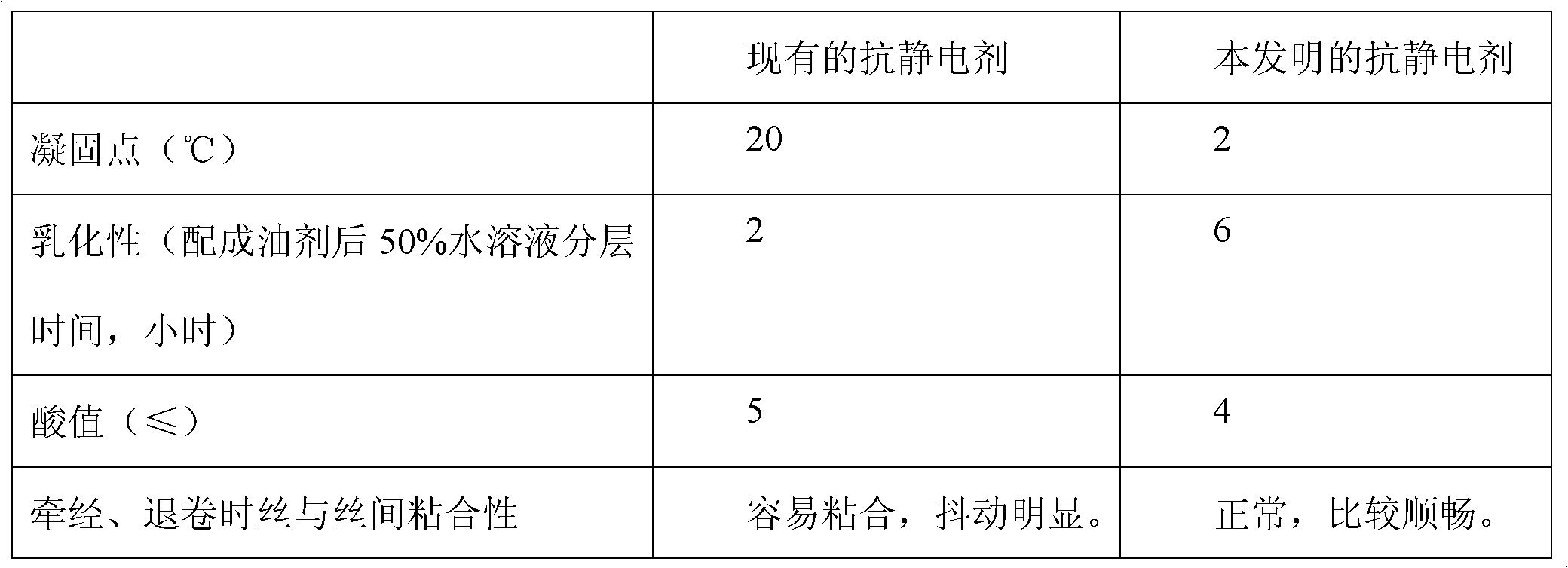

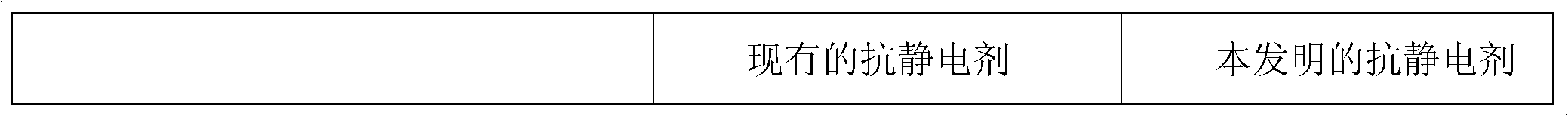

Antistatic agent for polyester elasticizing oiling agent and manufacturing method thereof

InactiveCN102182059ALow costImprove conductivityFibre typesPhosphorus organic compoundsPolyesterAlcohol

The invention discloses an antistatic agent for a polyester elasticizing oiling agent. The antistatic agent comprises the following components in part by weight: 30 to 40 parts of fatty alcohol, 10 to 12 parts of ethylene oxide, 40 to 50 parts of phosphorus pentoxide, 1 to 3 parts of potassium hydroxide and 2 to 5 parts of deionized water. The manufacturing method comprises the follow steps of: firstly, synthesizing the fatty alcohol and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether; secondly, synthesizing the fatty alcohol-polyoxyethylene ether and the phosphorus pentoxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate; thirdly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester; and fourthly; and fourthly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester and the potassium hydroxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester sylvite. The antistatic agent produced by the method has the advantages of high efficiency, low cost, strong frost resistance, easiness in emulsification and capability of meeting series of requirements of post-processing such as elasticizing.

Owner:TONGXIANG HENGLONG CHEM CO LTD

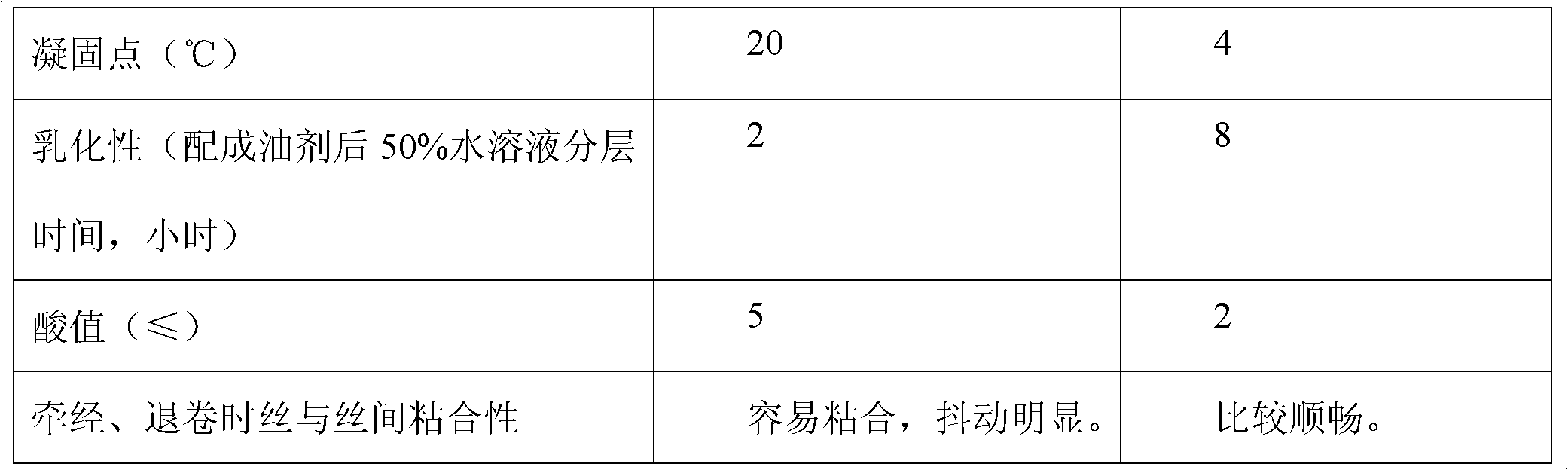

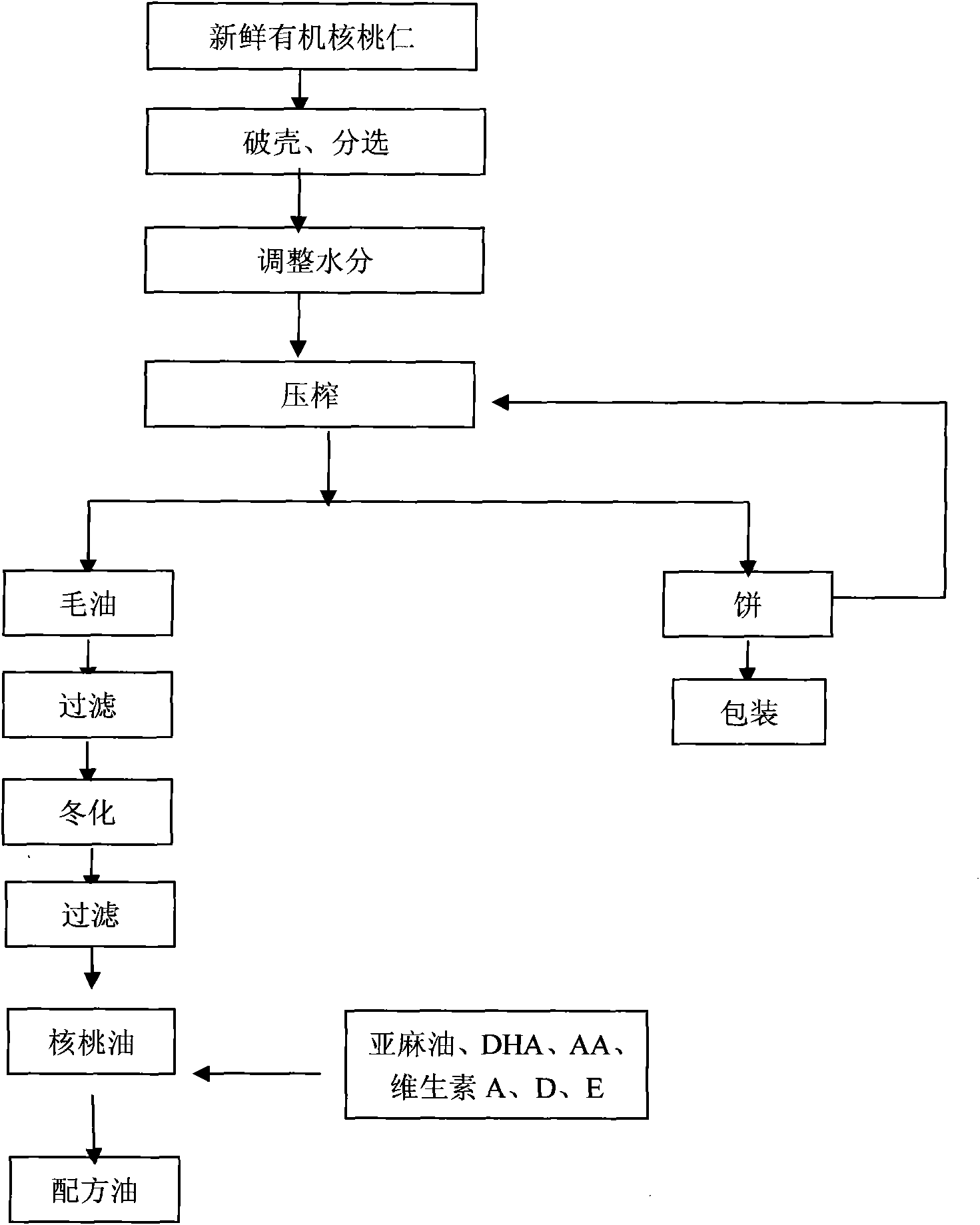

Method for preparing walnut oil and formulated product taking walnut oil as stroma

The invention relates to a method for preparing walnut oil and a formulated product taking walnut oil as stroma. The method mainly comprises the steps: crushing shell, sorting, squeezing, filtering I, winterization and filtering II; wherein, the squeezing process comprises: cakes made of walnut meat are evenly mixed with the walnut meat according to the mass ratio of 1:0.5-5, the mixture is squeezed to obtain crude oil and secondary cakes; the obtained secondary cakes are continuously recycled for use in the squeezing process when oil is made the next time, and then the obtained third-time cakes are used in the next time of oil making process; the process is repeatedly carried out in this way, so that the aim of recycling the cakes can be achieved; every 100g of the formulated product contains 79-99.8g of walnut oil, 0.1-20g of flax seed oil, 0.01-0.5g of DHA, 0.01-1.0g of AA, 300-900mug of vitamin A (based on retinol equivalent), 5-10mug of vitamin D and 4-7mg of vitamin E (based on da tocopherol). The method saves energy and reduces the production cost.

Owner:SANMARK CORP

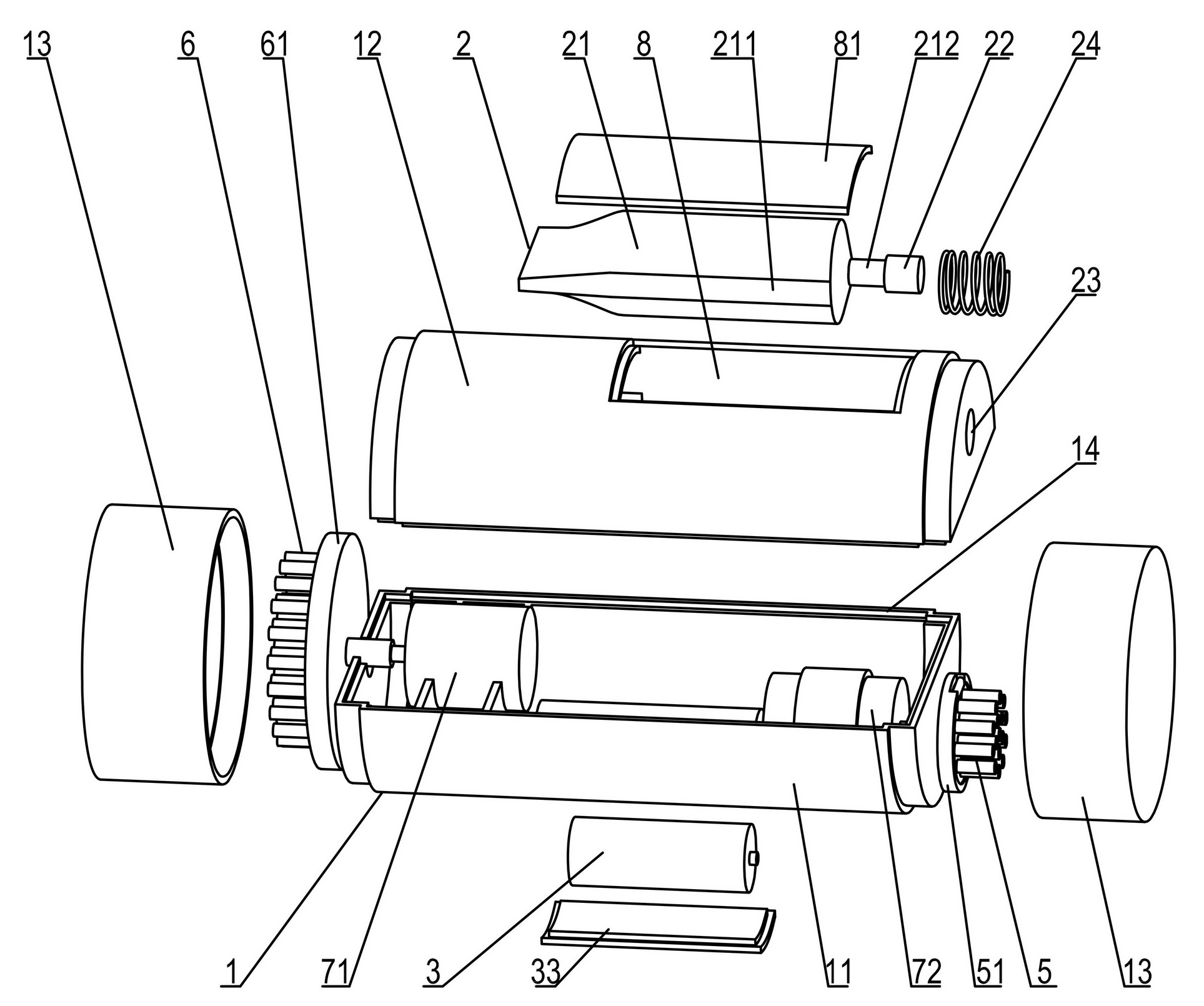

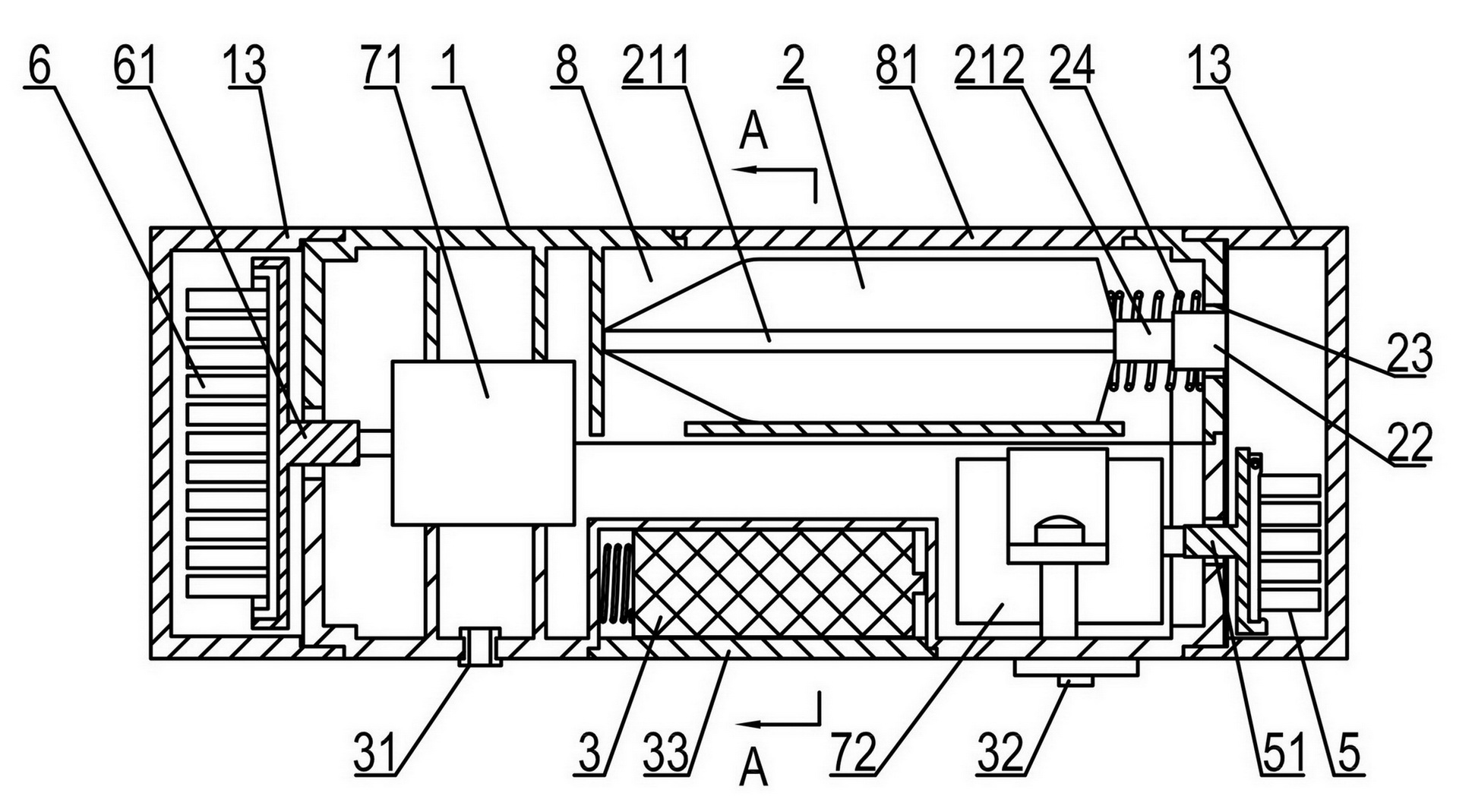

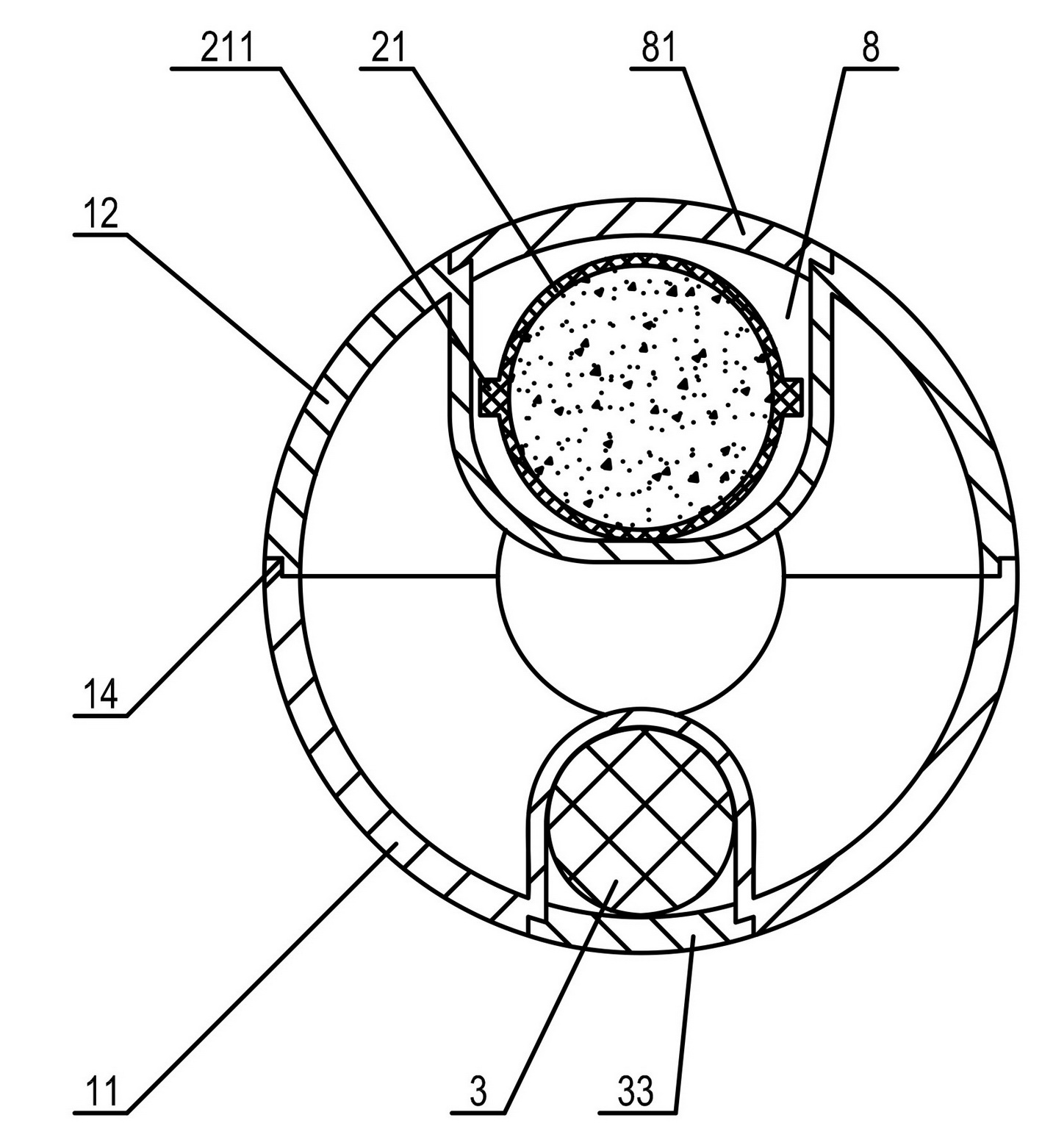

Electric shoe polisher

The invention discloses an electric shoe polisher comprising a body, shoe polish, a brush head, a switch and a power element, wherein the brush head comprises a polish applying brush head and a polishing brush head respectively arranged at both ends of the body; the power element comprises a direct current geared motor which is arranged in the body and is used for driving the polish applying brush head and a direct current motor which is used for driving the polishing brush head; a direct-current power supply arranged in the body is respectively connected with the direct current geared motor and the direct current motor by the switch; and a polish bin body for accommodating the polish is arranged in one side of the body. In the invention, the polish applying brush head and the polishing brush head are respectively arranged at both ends of the body, which can obviously improve the polish applying effect and the polishing effect; the polish is integrated in the body, which facilitates the storage, the carrying and the use of the shoe polisher; moreover, the electric shoe polisher has simple integral structure and convenient use, thereby being suitable for cleaning and maintaining leather shoes in household life and on travel.

Owner:郑南海

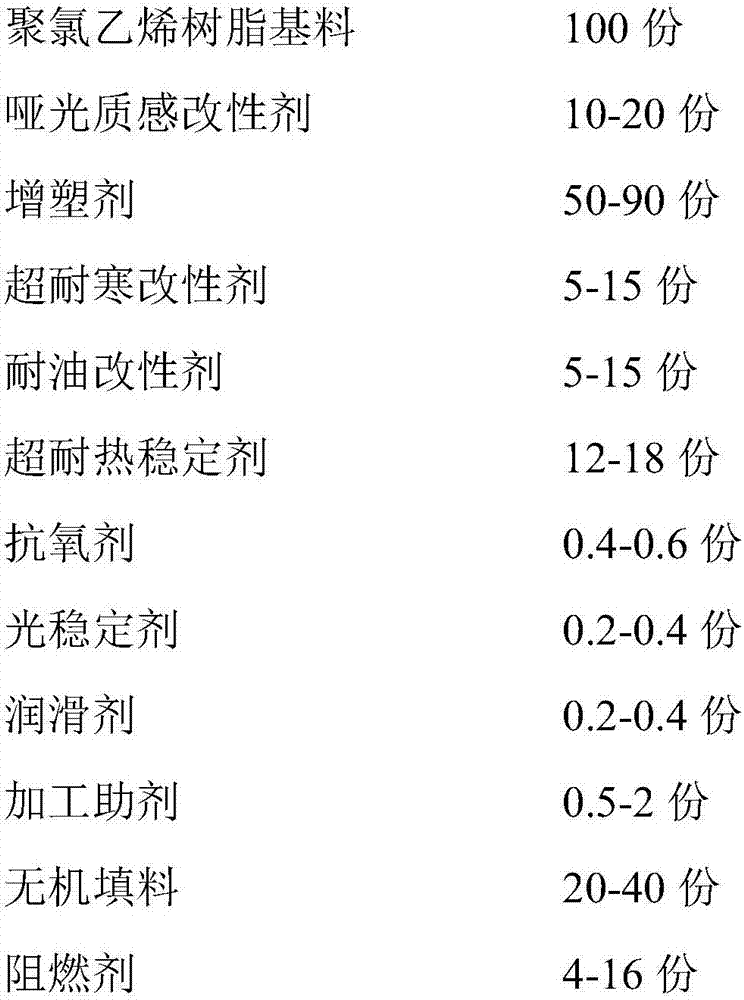

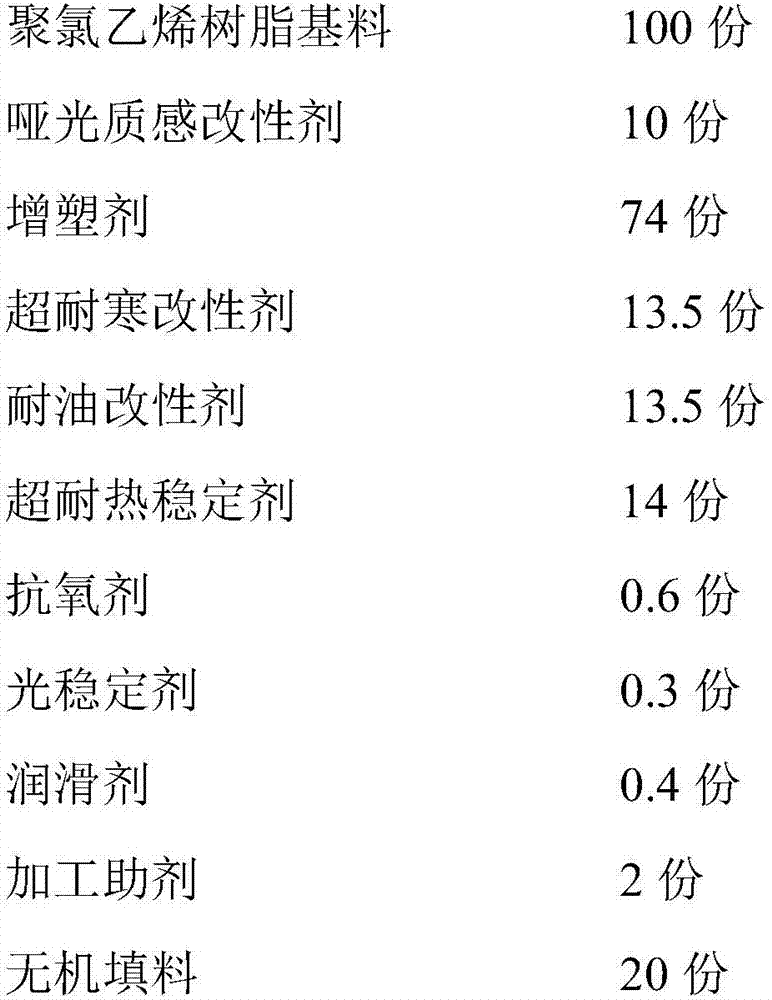

Polyvinyl chloride elastomer cable material for charging pile cables and preparation method thereof

InactiveCN107266829AGood processing performanceHigh strengthPlastic/resin/waxes insulatorsPlasticizerResin matrix

The invention discloses a polyvinyl chloride elastomer cable material for charging pile cables. The polyvinyl chloride elastomer cable material comprises the following components by weight: charging cable with PVC elastomer cable material, by weight comprises the following components: 100 parts of polyvinyl chloride resin matrix, 10-20 parts of a matte texture modifier, 50-90 parts of a plasticizer, 5-15 parts of a super cold-resistant modifier, 5-15 parts of an oil-proof modifier, 12-18 parts of a super heat-resistant stabilizer, 0.4-0.6 part of an oxidant, 0.2-0.4 part of a light stabilizer, 0.2-0.4 part of a lubricant, 0.5-2 parts of a processing aid, 20-40 parts of inorganic filler, and 4-16 parts of a flame retardant. The polyvinyl chloride resin matrix is composed of 0-70 parts of polyvinyl chloride resin with ultra-high molecular weight and 30-100 parts of gel polyvinyl chloride resin. The polyvinyl chloride elastomer cable material for charging pile cables provided by the invention has the characteristics of high tensile strength, high tear strength, a heat resistant grade up to 125DEG C, a cold-resistant grade of -50DEG C, good aging resistance, good resistance to gasoline and machine oil, a flame retardant level up to VW-1 for V0 level flame retardant cable, low VOC, and high-grade surface matte texture, etc.

Owner:SUZHOU HENGLI COMM MATERIAL

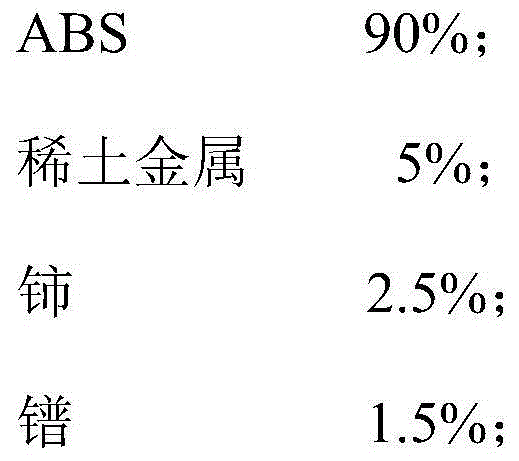

Oil-saving combustion-supporting core and preparation method thereof

The invention relates to the technical field of oil-saving combustion-supporting materials and preparation methods thereof and in particular relates to an oil-saving combustion-supporting core and a preparation method thereof. The oil-saving combustion-supporting core comprises the following components in percentage by weight: 20-95 percent of plastics and 5-80 percent of rare metals. The preparation method comprises the following steps: (1) performing tension molding; (2) extruding the master batch; (3) performing spraying plastics to form threads; and (4) winding the threads into the curled oil-saving combustion-supporting core. Compared with the prior art, the oil-saving combustion-supporting core disclosed by the invention has the advantages that the plastics are taken as a base material, rare metals are uniformly dispersed in the plastics, and the combustion-supporting core is prepared into a loose curled shape by virtue of the steps, has excellent shrinkage performance and is conveniently arranged in an oil-saving flame-retardant device; when fuel oil passes through the oil-saving combustion-supporting core, the volatilization performance is accelerated, the odor of the fuel oil is reduced, the contact area is large, the penetration rate is high, the combustion efficiency is improved, the fuel oil is saved, the power is further greatly improved, and the emission amount of waste gas is reduced; and moreover, according to the preparation method, the steps are simple, large-scale industrial production and application can be realized, and the product cost is effectively reduced.

Owner:东莞市车宝节能科技有限公司

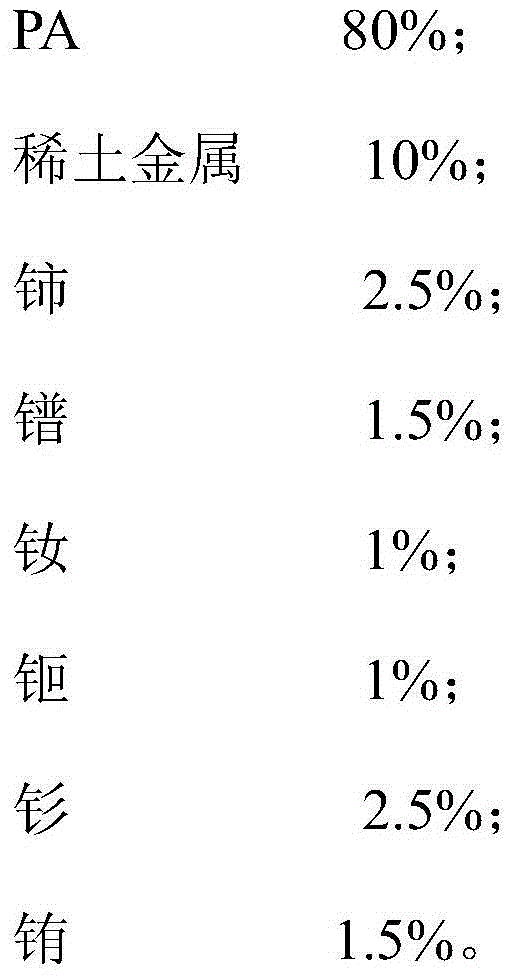

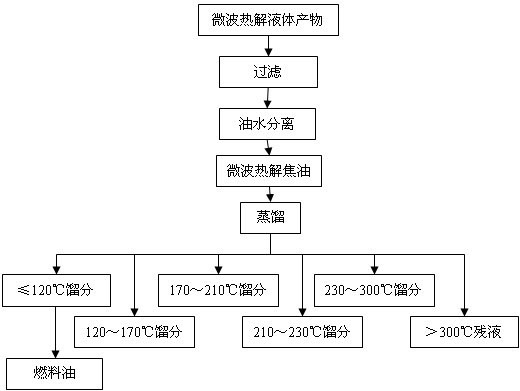

Method for preparing fuel oil by performing microwave cracking on garbage

InactiveCN102559233AEasy to operateImprove resource utilizationLiquid hydrocarbon mixture productionTarFuel oil

The invention discloses a method for preparing fuel oil by performing microwave cracking on garbage. The method comprises the following steps of: 1) pretreating garbage to obtain structured garbage suitable for microwave cracking; 2) performing microwave cracking on the garbage; 3) discharging cracked gas generated by cracking, spraying by using water and cooling, separating out liquid and gas, and filtering liquid to remove impurities; and 4) separating out tar and water from the liquid subject to the impurity removal by using an oil water separator, and distilling the tar at normal pressure to obtain oil with different distillation ranges, wherein the fraction with the distillation range of less than 120 DEG C is the prepared fuel oil. The garbage is treated by microwave heating, so that the garbage is cracked at a high temperature and recovered to prepare the fuel oil. The method is simple to operate and high in resource utilization ratio. The obtained fuel oil has the same index requirement as the standard 2# fuel and high oil quality, can obviously reduce environmental pollution caused by the garbage and realizes harmless treatment on the garbage.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Peony seed oil for puerperae and preparation method

ActiveCN103815053AGood for healthReasonable nutritional contentEdible oils/fatsMicrowavePanax notoginseng extract

The invention relates to blend oil, particularly to peony seed oil for puerperae and a preparing method. The blend oil provided by the invention includes the following components in parts by weight: 15-30 parts of peony seed oil, 69.5-84.9 parts of soybean oil and 0.1-0.5 part of sanchi extract. The blend oil is prepared completely according to requirements of puerperae, is complete and reasonable in nutritional ingredients, very good in mouthfeel, and benefits to human health. The preparation method for the blend oil, provided by the invention, includes the following steps: freezing peony seeds soaked in water, smashing the seeds at a low temperature and microwave vacuum drying the peony seeds. According to the blend oil and the preparing method, extraction of peony seed oil is facilitated, loss of effective constituents is reduced, and the oil extraction rate is improved.

Owner:杨盼盼

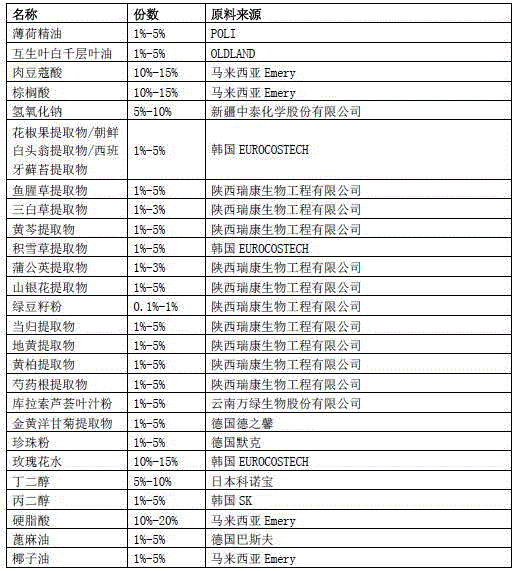

Composition used for cleaning skin and preparation method thereof

PendingCN105796462ARelieves Seborrheic AlopeciaRelieve itchingCosmetic preparationsToilet preparationsHouttuyniaButanediol

The invention discloses a composition used for cleaning the skin.The composition is prepared by mixing rose flower water, coconut oil, butanediol, propylene glycol, castor oil, myristic acid, palmitic acid, sodium hydroxide, stearic acid, Chinese prickly ash fruit extract / pulsatilla cernua extract / tillandsia usneoides extract, heartleaf houttuynia herb extract, Chinese lizardtail rhizome or herb extract, radix scutellariae extract, Asiatic pennywort herb extract, herba taraxaci extract, flos lonicerae extract, mung bean powder, radix angelica sinensis extract, radix rehmanniae extract, cortex phellodendri extract, peony root extract, aloe barbadensis leaf juice powder, chrysanthellum indicum extract, pearl powder, mint oil and melaleuca alternifolia leaf oil.The composition is prepared from pure Chinese herbs, can remove dirt caused by external factors and grease generated by the skin, has a significant relieving effect on closed comedos, blackheads, whiteheads and acne, has the effects of diminishing inflammation, relieving itching, removing acne and effectively relieving seborrhoeic alopecia and pruritus, and has no toxic or side effect as no additive is used.

Owner:无锡简玺生物科技有限公司

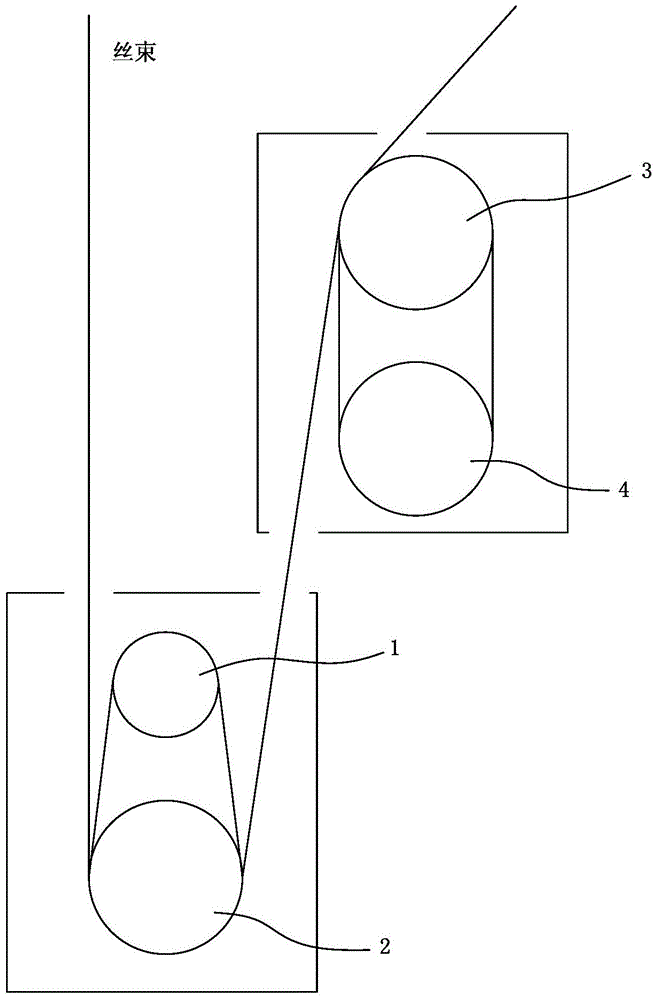

Production process of nylon-6 coarse-denier high-strength yarns

InactiveCN104695033AReduced drawabilityPromote crystallizationArtificial thread manufacturing machinesFilament manufactureBreaking strengthYarn

A production process of nylon-6 coarse-denier high-strength yarns includes slicing, melting, metering, spinning, cooling, oiling, pre-interlacing, drafting and setting, main interlacing, and winding. In the slicing step, nylon-6 slices 2.8 to 3.2 in viscosity are selected. Melting is performed at the temperature of 270 DEG C to 280 DEG C. In the spinning step, pore diameter of a spinneret plate is 0.36mm, pore length is 1.08 mm, and initial pressure of a component is 135 bars to 142 bars. In the oiling step, oil resistant to high temperature, anti-static and high in cohesion is adopted. The nylon-6 slices of specific viscosity are used, the temperature of the melting step is adjusted, and a melt pipe, a spinning component, an oiling device, pre-interlacing and drafting and setting are modified, and the nylon-6 coarse-denier high-strength yarns up to 6.2Cn / dtex in breaking strength are produced.

Owner:QUANZHOU TIANYU CHEM FIBER WEAVING IND

Integral half-coupling cleaning device

InactiveCN106944384AWash thoroughlyImprove cleaning efficiencyDrying gas arrangementsCleaning using toolsSewerageDrive motor

The invention discloses an integral half-coupling cleaning device, and relates to the technical field of coupling machining. The integral half-coupling cleaning device comprises a baseplate; a driving motor is mounted on the baseplate; support plates are respectively welded at the front part and the back part of two sides of the upper surface of the baseplate; transmission rollers are respectively mounted on the tops of the two support plates on the same one side of the baseplate; a conveying belt is sleeved between the two transmission rollers; cylindrical rubber blocks are thermoplastically formed on the outer side surface of the conveying belt at equal intervals; one end of one transmission roller is connected with an output shaft of the driving motor through a transmission belt; and four supporting plates are welded on the upper surface of the baseplate, and are all positioned on the inner sides of the support plates. The integral half-coupling cleaning device integrates such functions as washing liquid spraying, brushing, flushing, airing and sewage collection as a whole, greatly improves the production and machining efficiency of half-couplings, is more thorough in cleaning of the half-couplings, and is convenient to oil the half-couplings.

Owner:李光

Production technology of nuts

The invention discloses a production technology of nuts. The technology comprises the steps of A raw material selection; B, annealing; C, pickling and phosphatizing; D, drawing; E, cold heading forming; F, tapping; G, surface finishing: a finished product nut is placed into a cleaning pond which contains a cleaning solution to be cleaned and remove rust, and then drying and spraying process are conducted on the finished product nut; H, packaging and outbound delivery. The technology has the advantages that the method is simple and reasonable, the production speed is fast, the production efficiency is effectively improved, the production cost is reduced, the processing sequences of the nut is simplified by adopting the cold heating forming method, the processing cost is reduced, and the processing speed and accuracy are improved.

Owner:嘉兴市兆丰五金科技股份有限公司

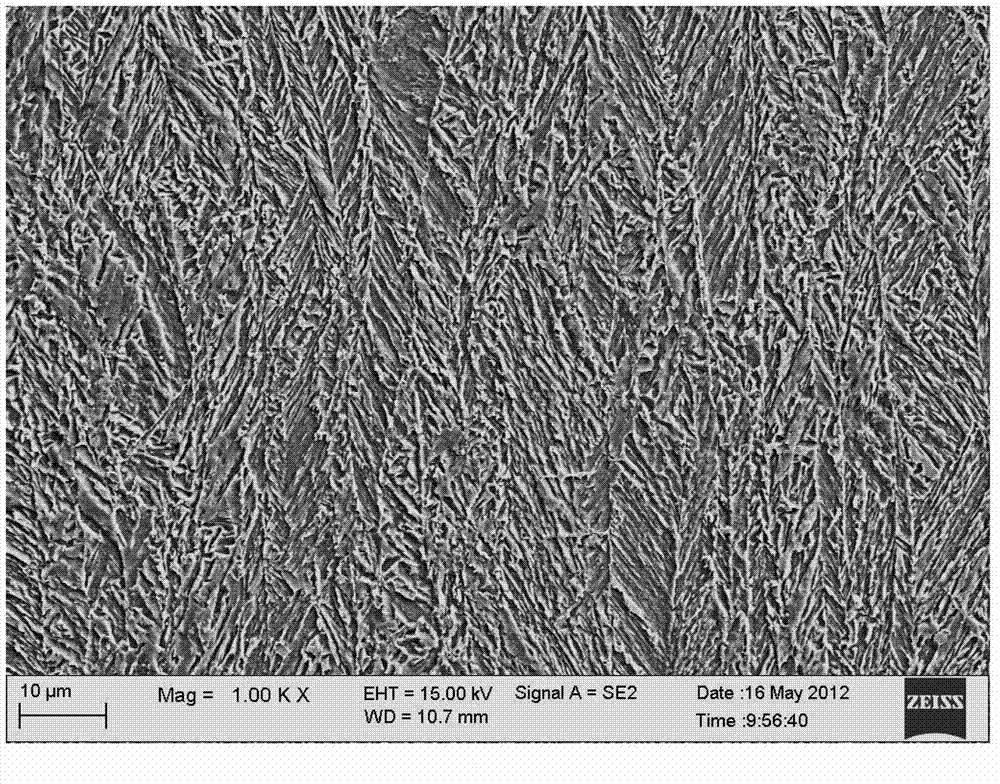

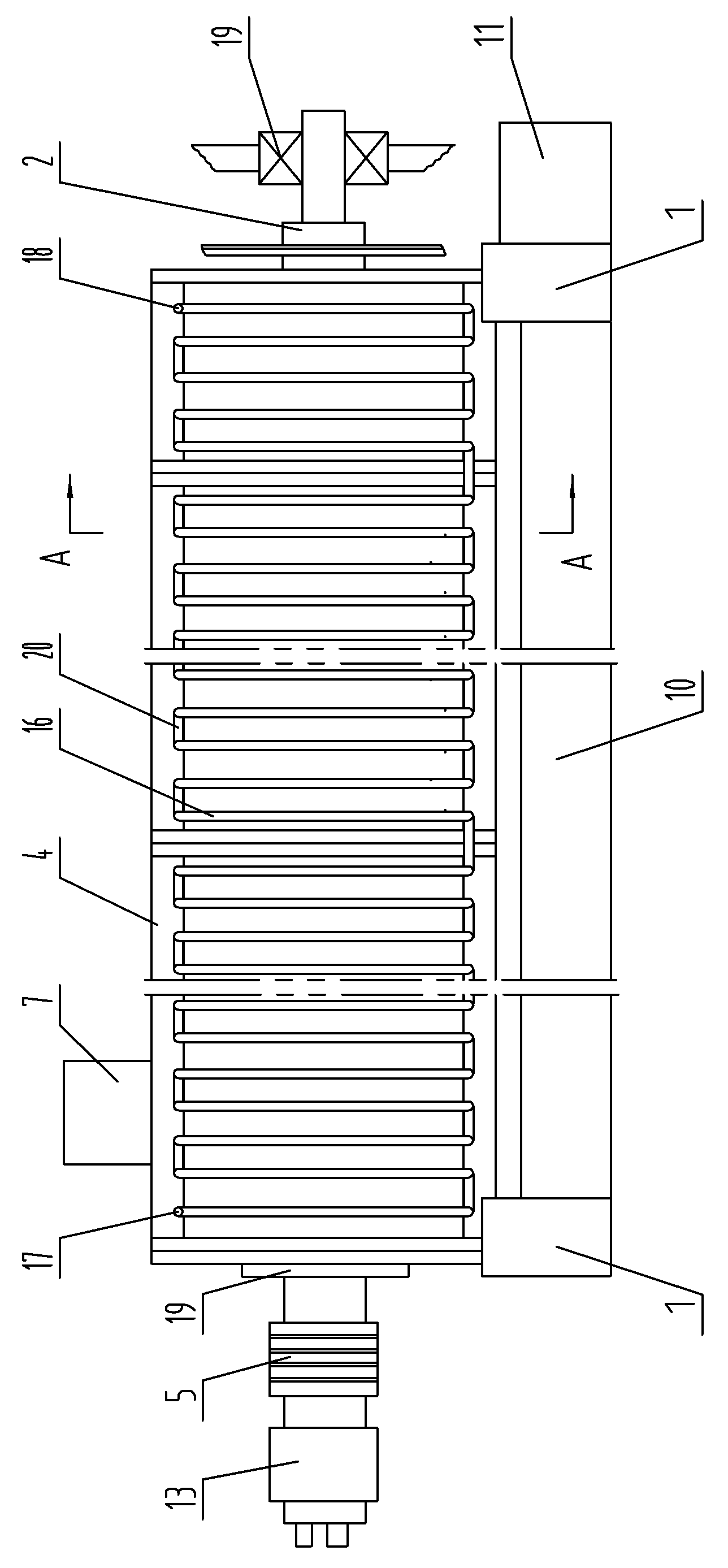

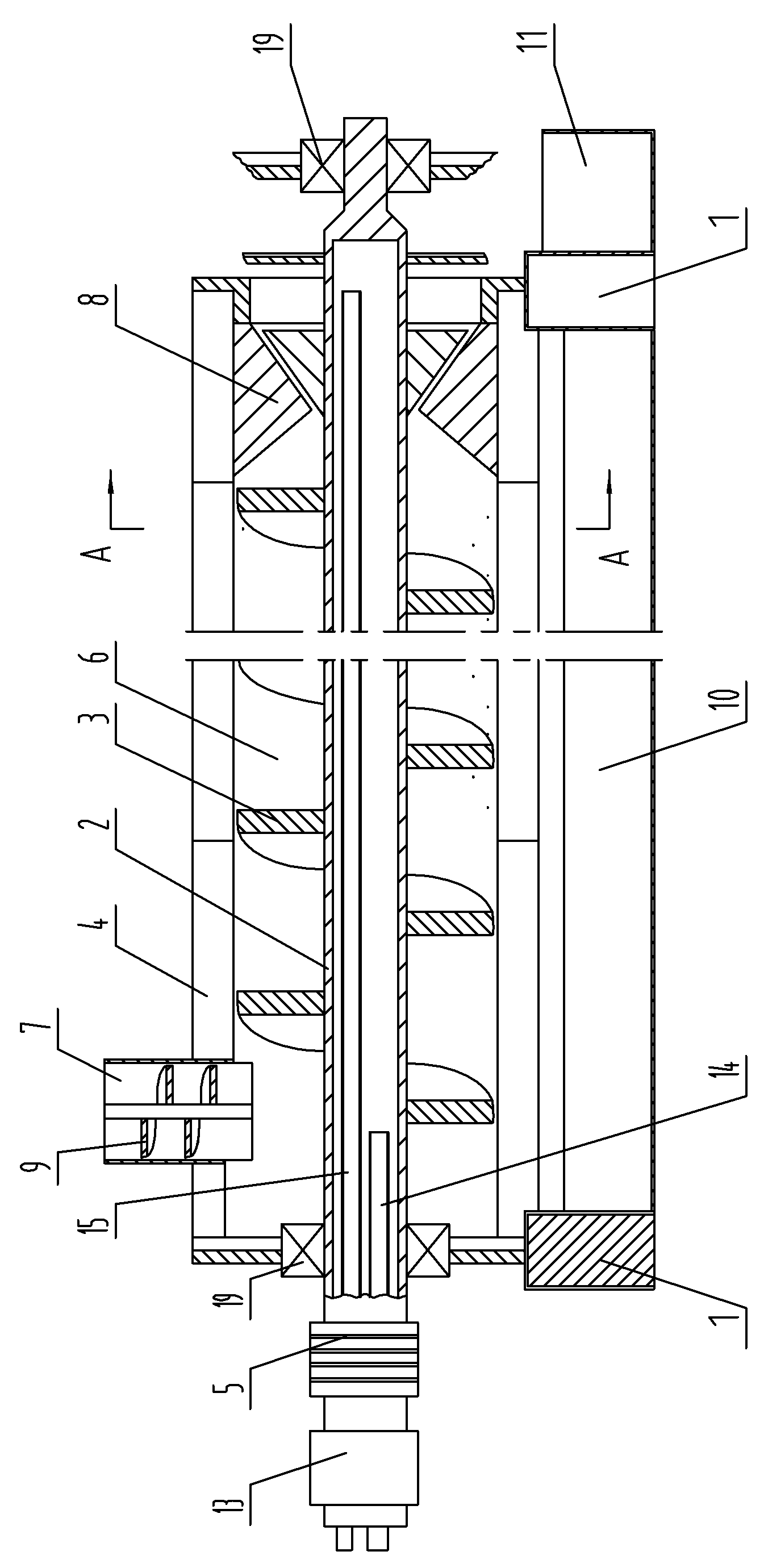

Twin-screw oil press with cooling device

The invention relates to a screw oil press, in particular to a twin-screw oil press with a cooling device. The twin-screw oil press comprises a rack, wherein a hollow pressing shaft is arranged above the rack; the pressing shaft is fixedly provided with a plurality of spiral blades; a pressing row is sleeved out of the blades; the pressing row consists of two half-cylinders; one end of the pressing shaft is provided with a transmission mechanism; a pressing row cavity is formed between the pressing row and the blades; one end of the pressing row cavity is communicated with a material inlet arranged above the upper side; the other end of the pressing row cavity is provided with a cake outlet adjusting mechanism; the material inlet is provided with a spiral feeding mechanism; an oil collection tank is arranged on the middle part of the rack and below the pressing row; the side of the rack corresponding to the cake outlet adjusting mechanism is provided with a cake collection tank; and the oil press further comprises a pressing shaft cooling device and a pressing row cooling device. With the adoption of the oil press, the temperature in a peanut oil pressing process is controlled effectively, and the condition that the cake temperature in the peanut oil pressing process is not higher than 60 DEG C is ensured, so that the condition that the modification of peanut protein and the loss of micro beneficial components is avoided, the quality of cold-press peanut oil is guaranteed; besides, the oil yield is high and the power consumption is low, thereby the twin-screw oil press is beneficial to development and promotion.

Owner:郑州鼎盛机械设备有限公司 +3

Efficient heat-setting spinning thread processing machine with uniform oil

The invention discloses an efficient heat-setting spinning thread processing device with uniform oil, which comprises a shell, wherein a first groove is arranged on the shell; an oil roller, a heatingplate and a support rod are arranged inside the first groove; a dust removal channel and an oil return channel are arranged on the two sides of the first groove. A first sponge ring, an oil outlet, an oil tank and an oil return pipe are installed on the oil return channel. A second sponge ring and an electrostatic precipitator are arranged inside the dust removal channel. A winding base is arranged at one side of the shell. A lead frame, a hydraulic cylinder, a telescopic rod, a lead wheel and a tension sensor are arranged on the winding base. Directional wheels and winding rods are arrangedon both sides of the lead frame. A variable speed motor, a clamp and a pressure sensor are arranged on each winding rod. The efficient heat-setting spinning thread processing device with uniform oil not only can improve oil uniformity and work efficiency, but also has the advantages of simple structure, low labor intensity, saving oil, good winding effect, long service life and convenient use.

Owner:湖州织里凯狄酷娃服饰有限公司

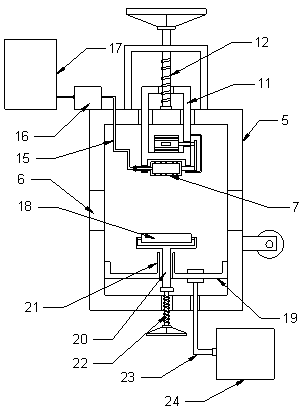

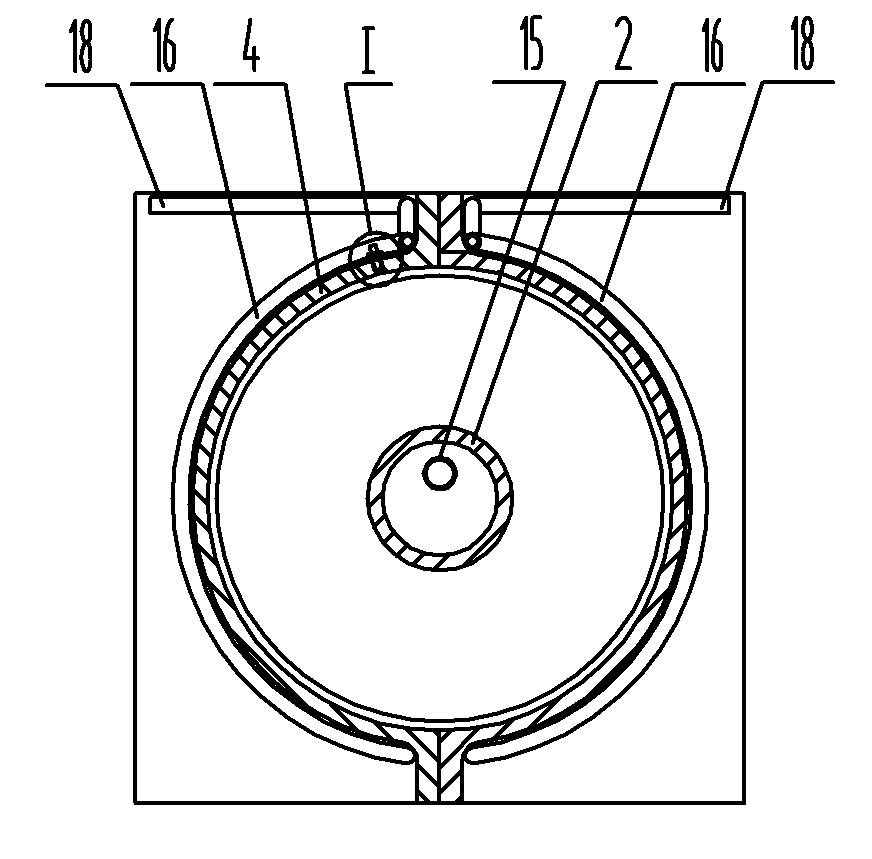

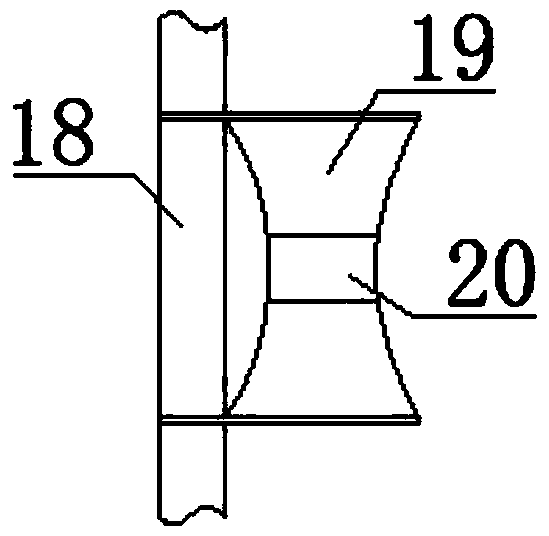

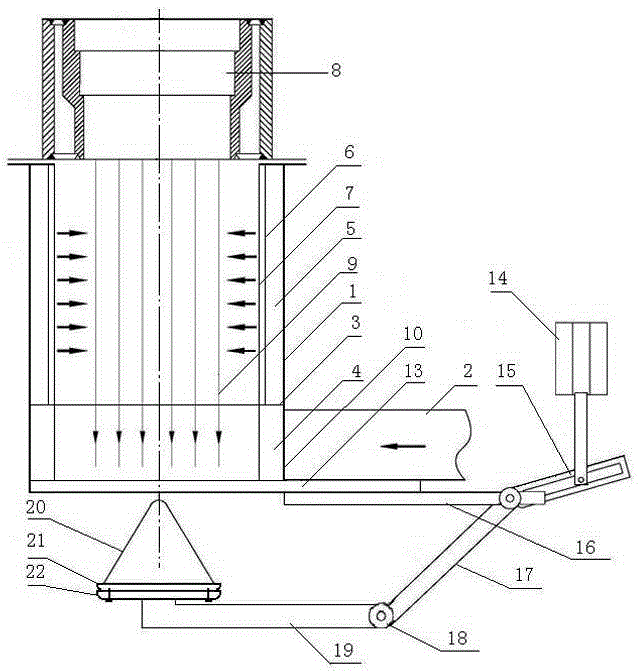

Outer ring-blowing cooling and center oiling device for composite spinning

InactiveCN104611776AImprove energy efficiencyReduce wind speedFilament/thread formingPush and pullCold air

An outer ring-blowing cooling and center oiling device for composite spinning comprises an outer shell, a cold air input pipeline, a cold air flow guide plate, an air distribution air flue, a ring-blowing air flue, a ring-blowing plate, a ring-blowing net, an oiling unit, a moving unit and a circulating oiling unit. A cold air inlet is formed in the lower end of the outer shell, the cold air input pipeline is connected with the cold air inlet, the cold air flow guide plate is horizontally installed above the cold air inlet, the air distribution air flue is arranged below the cold air flow guide plate, the ring-blowing plate is installed in the outer shell, the ring-blowing air flue is formed due to the distance between the ring-blowing plate and the outer shell, a plurality of air distribution holes are formed in the cold air flow guide plate, the ring-blowing net is installed in the ring-blowing plate, and a spun silk falling and cooling channel is arranged in the ring-blowing net; the oiling unit comprises a conical cover, an oiling plate and an oil receiving plate, an oiling lip is arranged on the periphery of the oiling plate, a distance fine tuning mechanism is arranged between the oiling plate and the conical cover, the circulating oiling unit determines oil supply amount by controlling the rotation speed of a variable-frequency oil pump, and the moving unit is pushed and pulled through a pneumatic pushing and pulling device so that the oiling unit can be moved to enter or exit.

Owner:海兴材料科技有限公司

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS7169842B2High-temperature and pressure resistanceHigh tensile strengthSynthetic resin layered productsPaper coatingElastomerPolyvinyl acetate

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

High-efficiency energy-saving cleaning and oil applying device for chain parts

InactiveCN108273796AEasy to cleanShorten cleaning and oiling cycleSpraying apparatusCleaning using liquidsCleansing AgentsMachining

The invention discloses a high-efficiency energy-saving cleaning and oil applying device for chain parts. The device comprises a primary cleaning tank, the outer wall of the top end of one side of theprimary cleaning tank is fixedly connected with a clean water flushing tank through a rotary power box, the clean water flushing tank is fixedly connected with an oil applying tank through a rotatingconnecting box, and the middle position of inner walls on the two sides of the primary cleaning tank is connected with a material loading device in a sliding mode; one end, away from the primary cleaning tank, of the material loading device penetrates through the clean water flushing tank and the oil applying tank and extends to the outside of the oil applying tank; and fixed supporting sliding rods are arranged between the primary cleaning tank and the clean water flushing tank and between the clean water flushing tank and the oil applying tank. The invention relates to the technical field of chain production and machining equipment. According to the device, a cleaning and oil applying process of the chain parts is independently carried out in three steps, so that a cleaning agent can berepeatedly used, rust-proof oil can be timely collected, the cleaning effect of the device on the chain parts is improved, the cleaning and oil applying period of the chain parts is shortened, and the purposes of energy conservation and environmental protection are achieved at the same time.

Owner:湖州众诚链传动制造厂

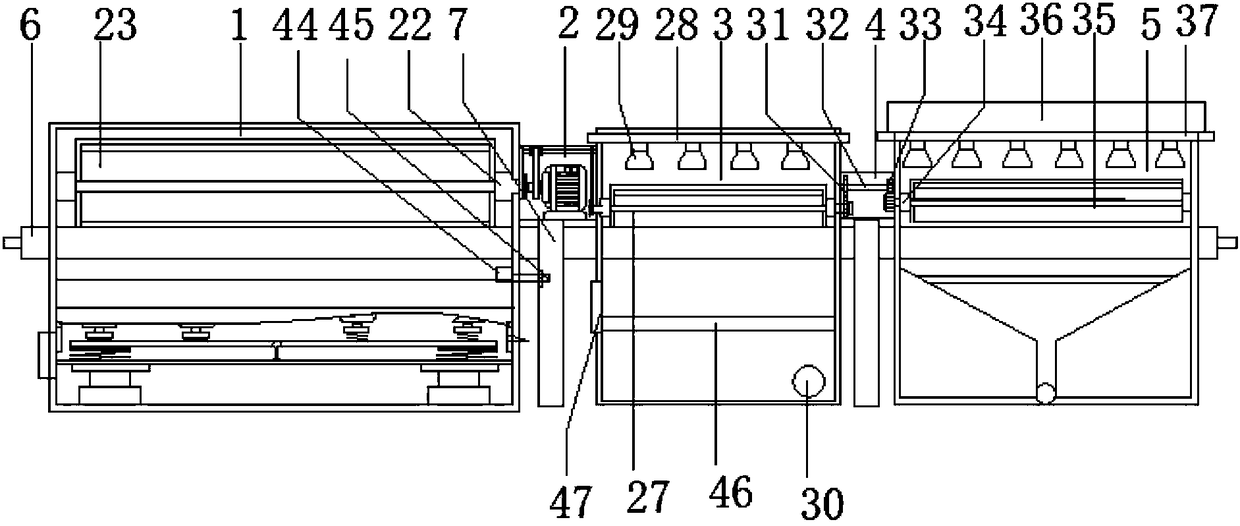

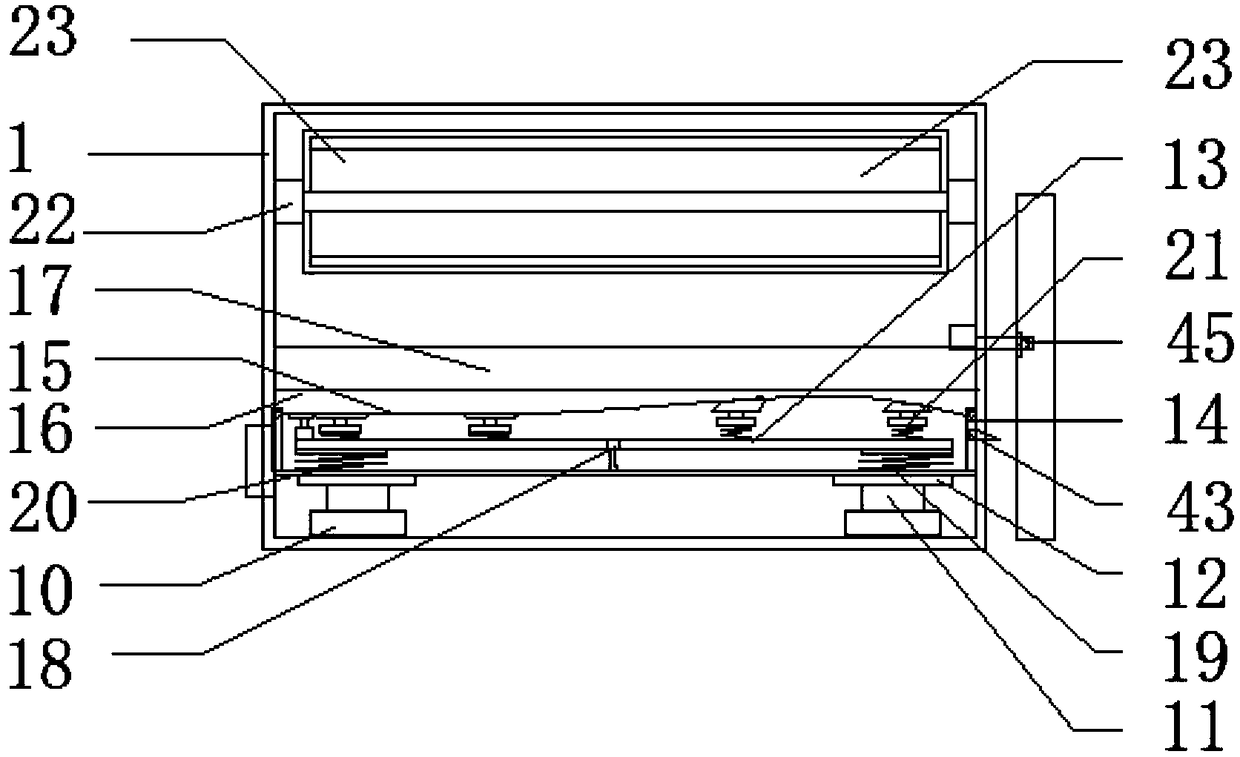

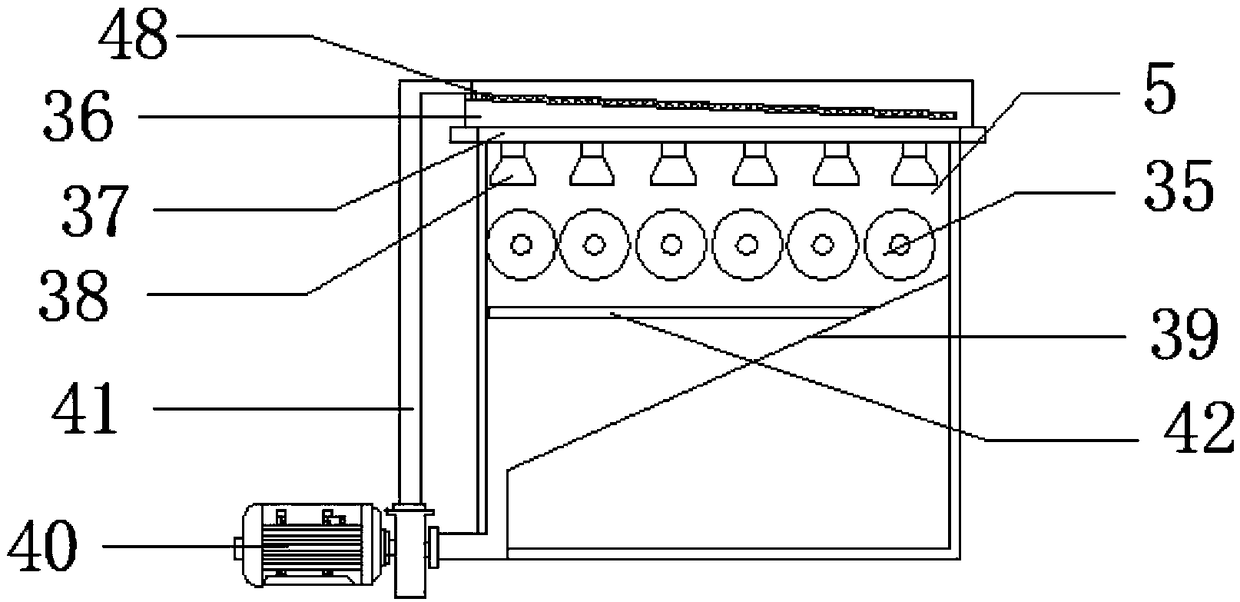

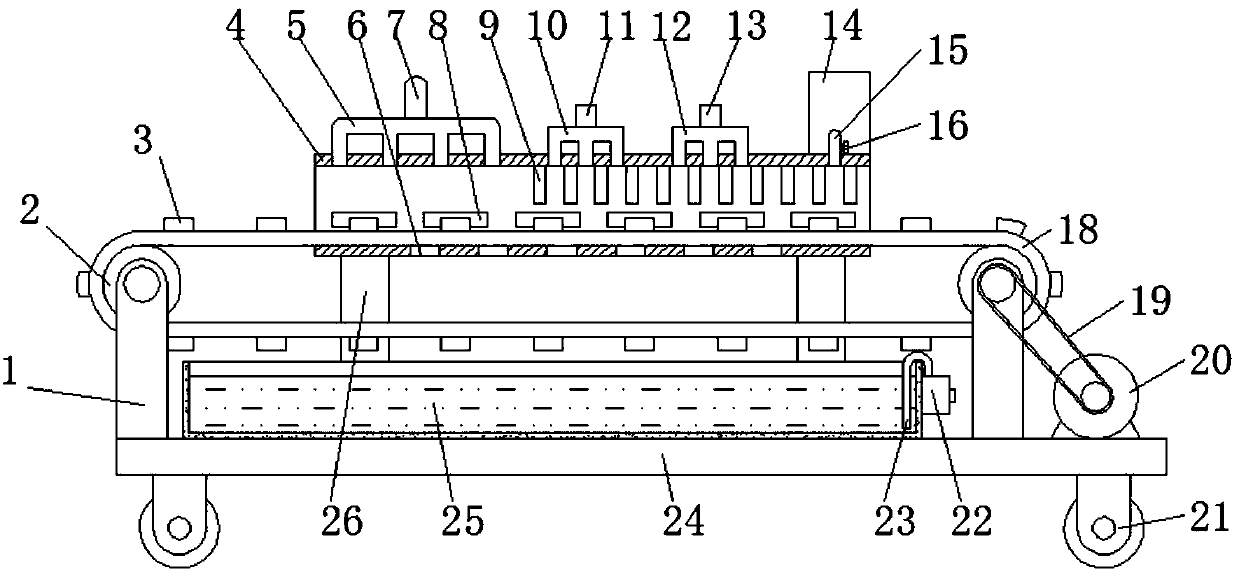

Double-row silk thread oiling device

InactiveCN108677419AAvoid entanglementTightly woundLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsInlet channelFuel tank

The invention discloses a double-row silk thread oiling device. The double-row silk thread oiling device comprises an oil cover and an oiling box; oil overflowing boxes are arranged on the two sides of the oiling box; two rows of entrance holes which are distributed in a staggered way are formed in the oil cover; threading holes are formed in the two sides of the oiling box correspondingly; the bottom surface of each threading hole is an inclined surface; the lowest end of each inclined surface faces towards each oil overflowing box; a flow guide groove is formed at the bottom end of the outerside of each threading hole; an oiling roller is arranged in the oiling box; a spiral winding groove is formed in the surface of the oiling roller; a plurality of oil outlet holes are formed in the surface of the winding groove; an oil inlet channel capable of running through axially is formed in the end face of the oiling roller; the oil inlet channel is communicated with the oil outlet holes through an oil groove; a pair of extruding rollers are arranged in the oil overflowing box; and outgoing holes are formed in the two outer sides of the oil overflowing box. The double-row silk thread oiling device has the characteristics of oiling uniformly and improving silk thread quality, and also has the characteristics of large quantity of oiling silk threads, insusceptibility to winding and intersecting, low pollution and low cost.

Owner:HUZHOU ZHUOHAO SILK CO LTD

Integrated half coupling cleaning device

InactiveCN107812725AImprove cleaning efficiencyGood limit effectDrying gas arrangementsDrying machines with progressive movementsSewerageDrive motor

The invention discloses an integrated half coupling cleaning device, and relates to the technical field of coupling processing. The integrated half coupling cleaning device comprises a bottom plate, wherein a driving motor is installed on the bottom plate, support plates are respectively welded on the front part and the back part of both sides of the upper surface of the bottom plate, driving rollers are respectively installed on the tops of the two support plates located on the same side of the bottom plate, the two driving rollers are sleeved with a conveying belt, cylindrical rubber blocksare formed on the outer side surface of the conveying belt at equal intervals in a thermoplastic mode, one end of one driving roller is connected with an output shaft of a driving motor by virtue of adriving belt, four supporting plates are welded on the upper surface of the bottom plate, and the four supporting plates are respectively located on the inner sides of the support plates. According to the integrated half coupling cleaning device, the functions of spraying washing liquid, brushing, flushing, airing and collecting sewage are integrated, so that the production machining efficiency of half couplings is improved, the half couplings are thoroughly cleaned, and oil is conveniently applied to the half couplings.

Owner:寿炬烽

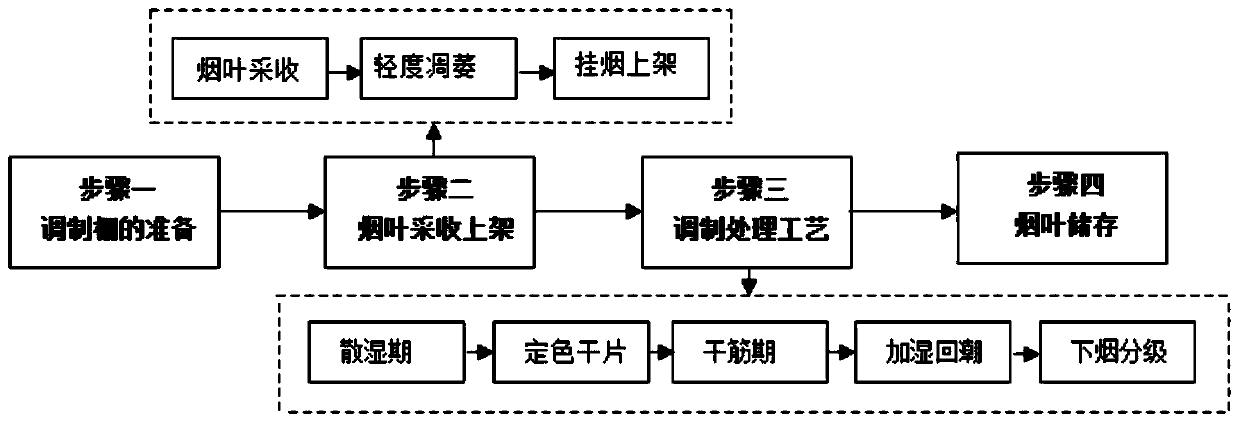

Preparation method of cyan cigar coating tobacco

The invention discloses a preparation method of cyan cigar-coated tobacco, and the cyan cigar-coated tobacco prepared by the preparation method disclosed by the invention has the characteristics that(1) the color of the tobacco is changed from light yellow green, light cyan, cyan to dark cyan, the oil content of the tobacco is better, the integrity is good, the veins are finer, and the leaves aresmooth, and the use conditions of the cigar-coated tobacco are met; (2) through sensory quality identification, the cyan cigar-coated tobacco is good in aroma quality, sufficient in aroma amount, soft and fragrant in aroma, small in irritation and low in miscellaneous gas amount, has unique fruity faint scent, has slight pepper flavor, wood flavor and grey tobacco ash, and meets the use requirements of products; and (3) the tobacco leaves are added into the product formula design, the cyan cigar-coated tobacco prepared by the method is used as the product cigar coating, the appearance meets the design requirement, the fresh and wood fragrance is brought to the whole new formula, the cigar coating tobacco leaves with new colors are provided for the production of domestic cigars, and the product style is enriched.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

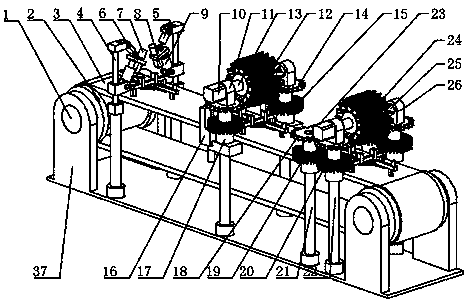

Automatic shoeshine applying robot

The inVention proVides an automatic shoeshine applying robot. The robot comprises a transmission part, a cleaning part, a shoeshine applying part, a uniformly spreading part and a clamping part; the transmission part comprises belt wheels, a transmission shaft, a belt and a machine base; the cleaning part comprises a cleaning gear, a first side brush head, a second side brush head, a first gear shaft, a second gear shaft, a cleaning motor, a cleaning front brush head, a cleaning brush head shaft and a cleaning motor rack; the shoeshine applying part comprises a shoeshine applying motor, a shoeshine applying motor rack, a shoeshine applying front brushing head, a front brush head shaft, a shoeshine applying gear, a side shoeshine applying brush head, a shoeshine extruding deVice and a shoeshine applying gear shaft; the uniformly spreading part comprises a buffing shaft and a buffing brush head. According to the robot, a belt is adopted as an operating rail of a leather shoe, the leathershoe is clamped tightly on the belt through the clamping deVice, operations of cleaning and shoeshine applying are conducted on the leather shoe by adopting multiple kinds of brush heads, operationsof buffing and shoeshine uniformly spreading are conducted on the leather shoe through the cooperation of multiple hydraulic cylinders, the shoe applying efficiency is greatly improVed, and manpower is liberated.

Owner:山东艾兰药业有限公司

Turnover barbecue

ActiveCN107854001AEasy to removeGrill evenlyClimate change adaptationRoasting apparatusEngineeringCharcoal

The invention provides a turnover barbecue which comprises two vertical side plates, a platform plate, a strip-shaped charcoal oven and a turnover frame. Movable slide grooves are correspondingly formed in the opposite inner sides of the two vertical side plates; the strip-shaped charcoal oven is transversely mounted on the platform plate; the turnover frame comprises two strip-shaped face plates,a center shaft and four steel mesh clamping units, and the four steel mesh clamping units are used for clamping foods; the center shaft is transversely fixed to positions between the two strip-shapedface plates; a support shaft is arranged on the outer side of each strip-shaped face plate; slide rollers are arranged on shaft heads of the support shafts; the two slide rollers are embedded in themovable slide grooves in the two vertical side plates; the four steel mesh clamping units are mounted on the center shaft. The turnover barbecue has the advantages that the turnover frame can be integrally turned over, and accordingly the turnover barbecue is beneficial to uniformly barbecuing the front and back surfaces of the foods; the turnover frame can move out to reach a position above the strip-shaped charcoal oven, accordingly, oil brushing, turnover and ingredient scattering operation and the like can be facilitated, and the barbecue efficiency can be effectively improved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com