Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1587results about How to "Improve oil yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

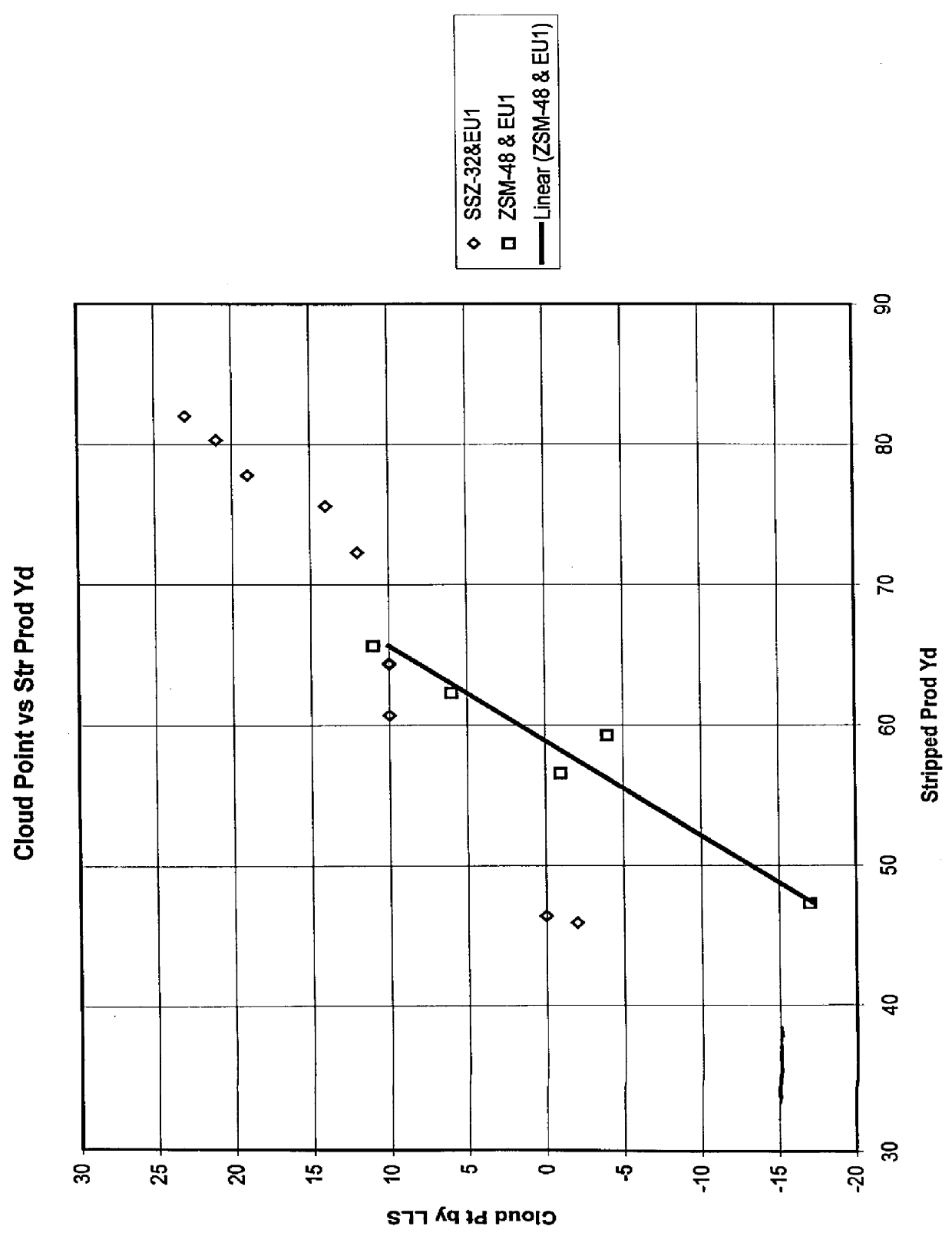

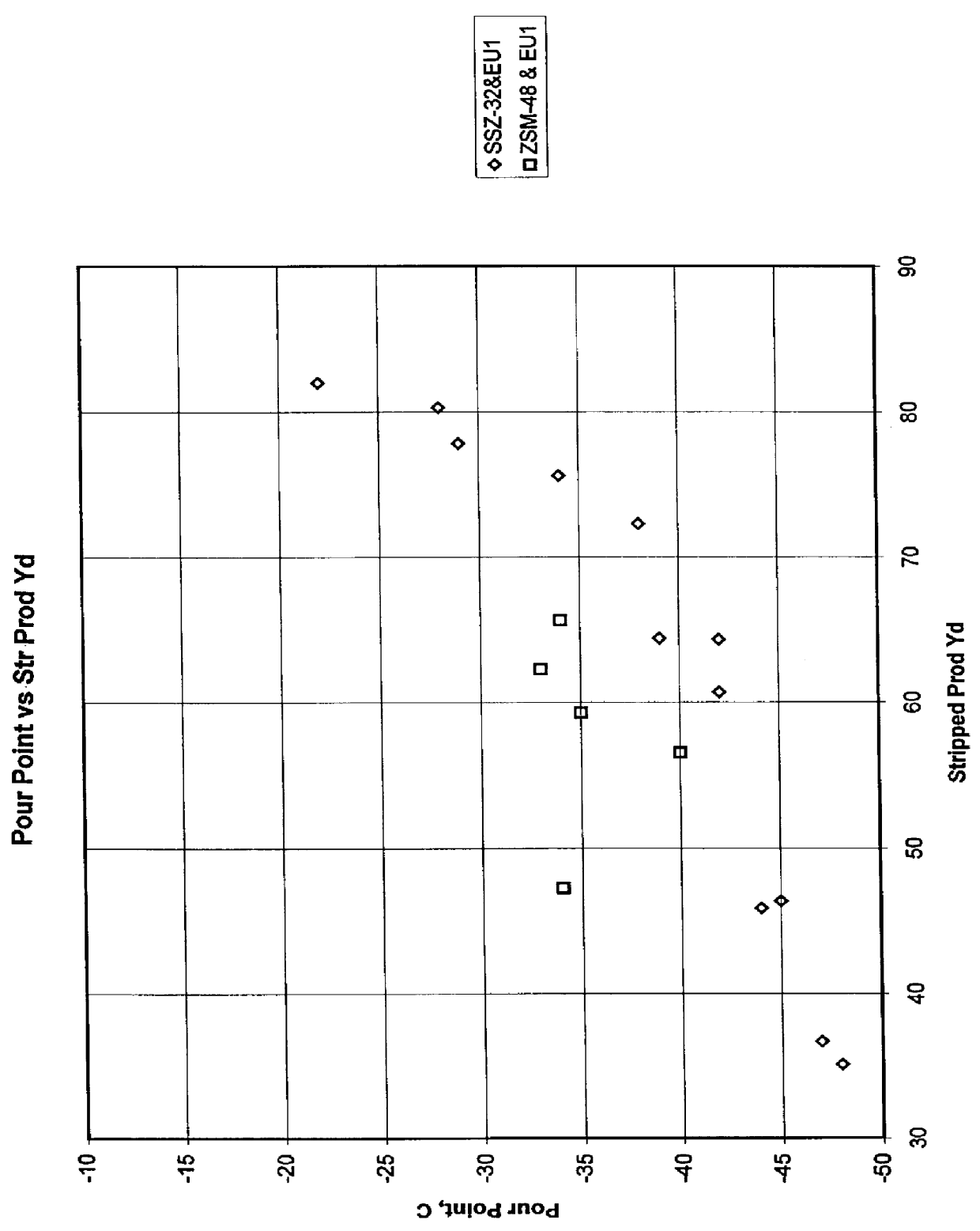

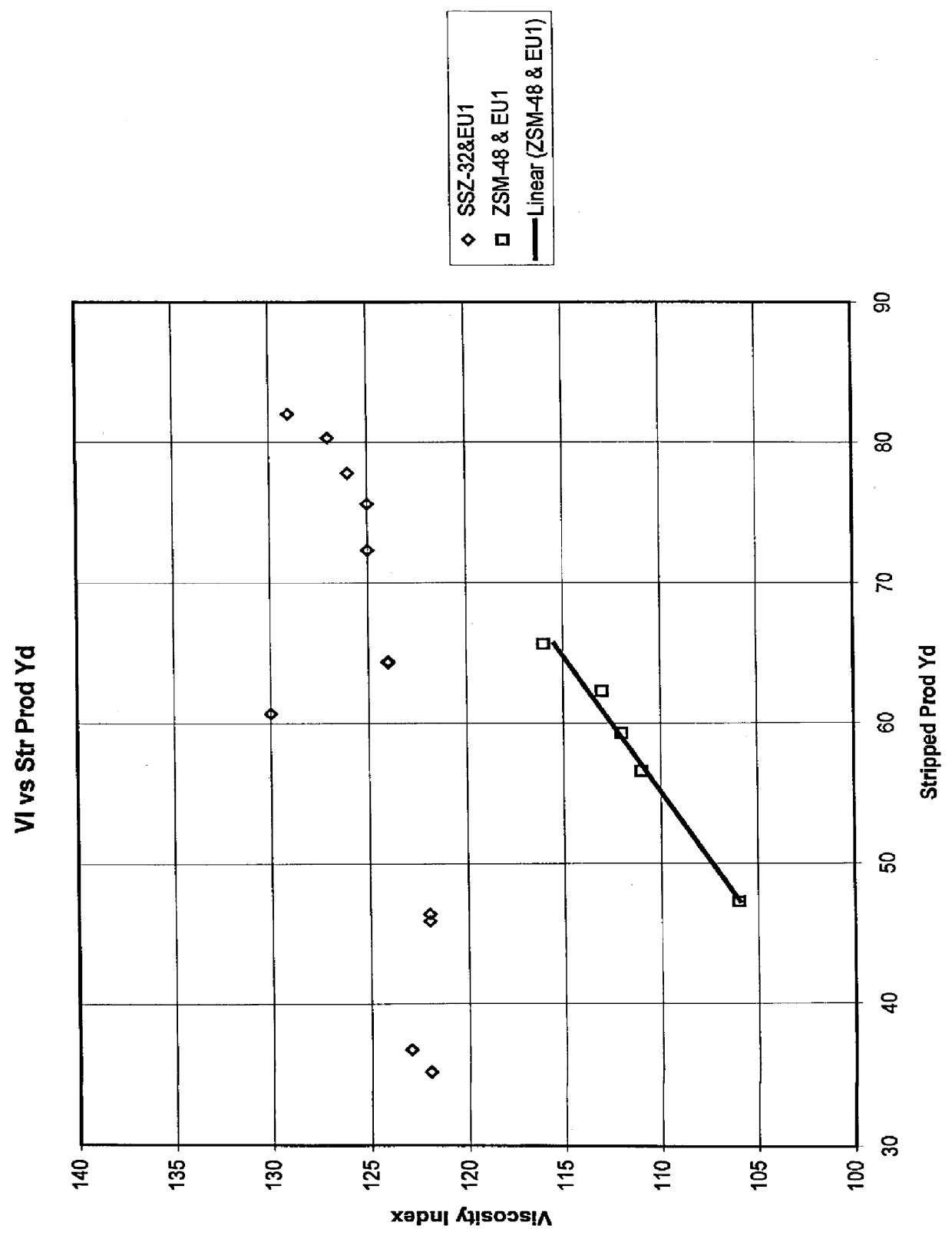

Process for reducing haze point in bright stock

InactiveUS6051129ASuperior lube oil yieldHigh yieldMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenHaze

Owner:CHEVROU USA INC

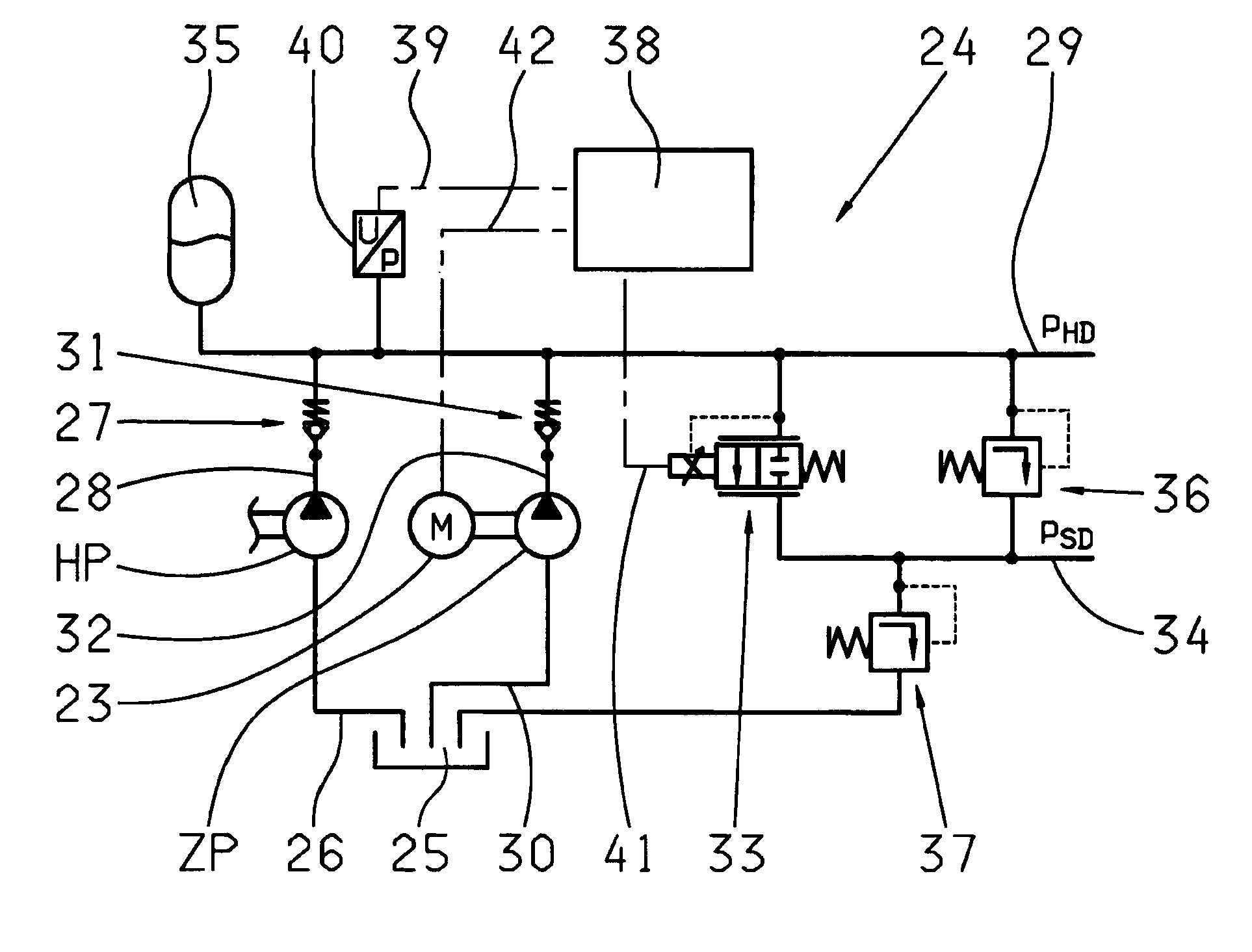

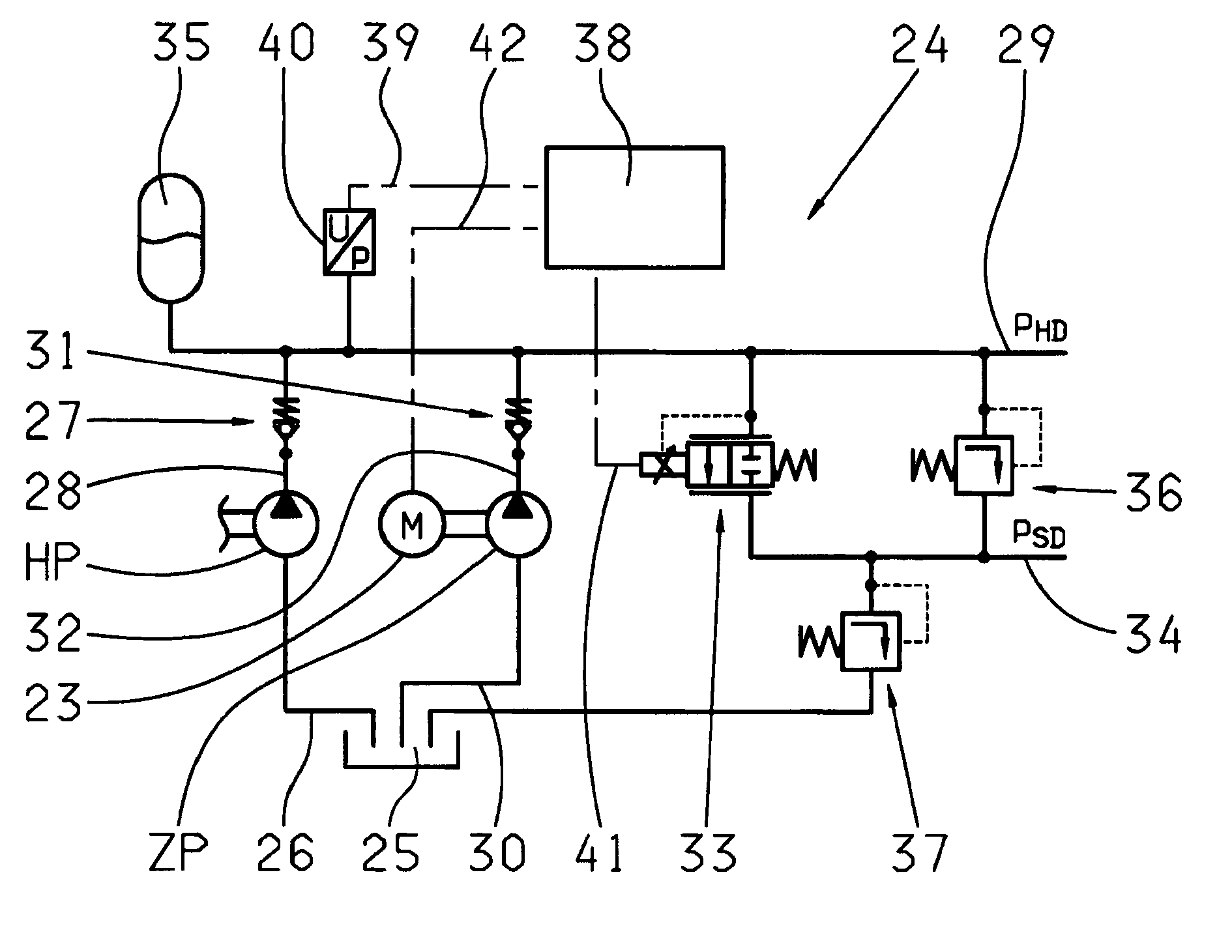

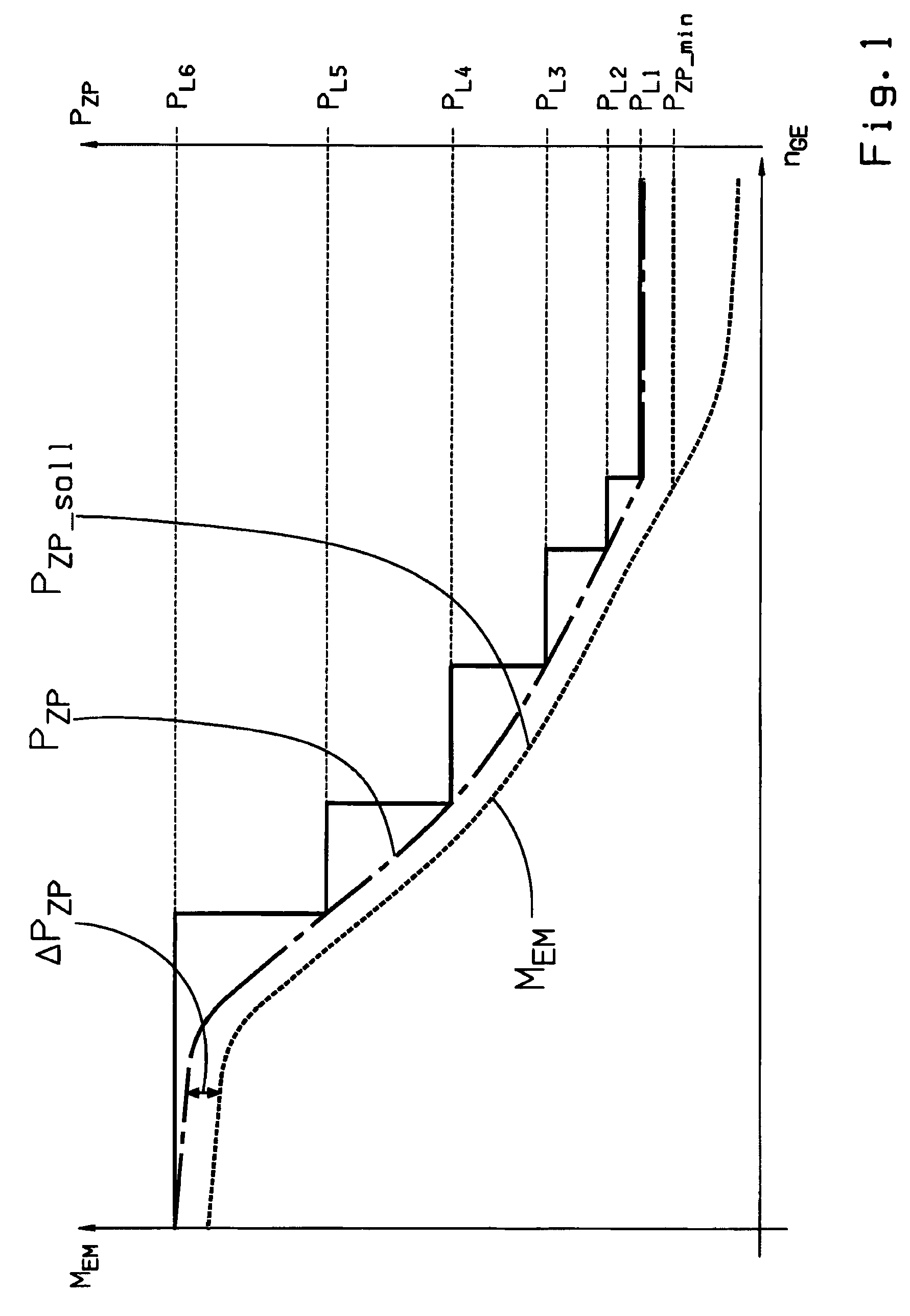

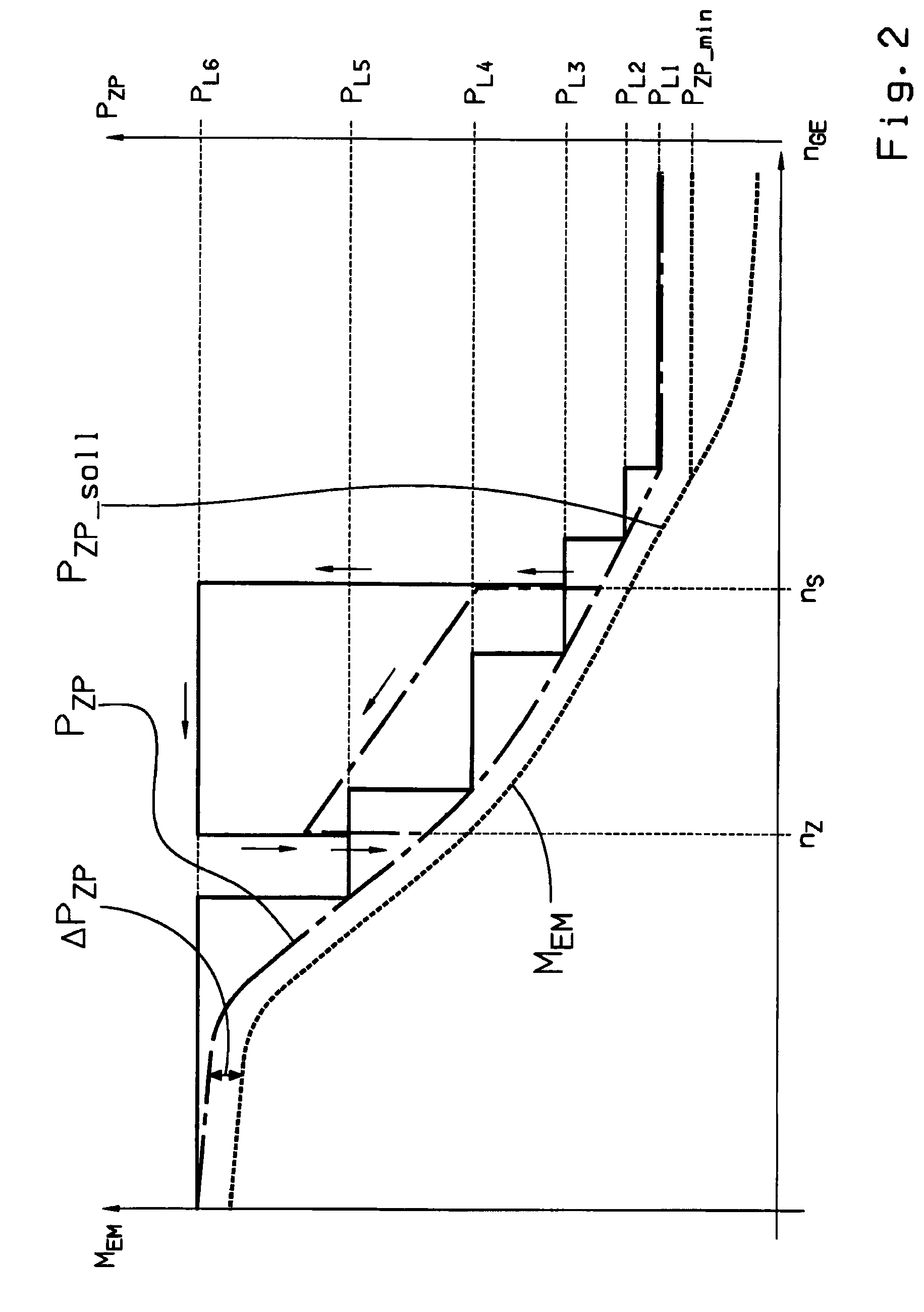

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS20100018808A1Improve accessibilityIncrease installation spaceElectric propulsion mountingGear lubrication/coolingEngineeringInternal combustion engine

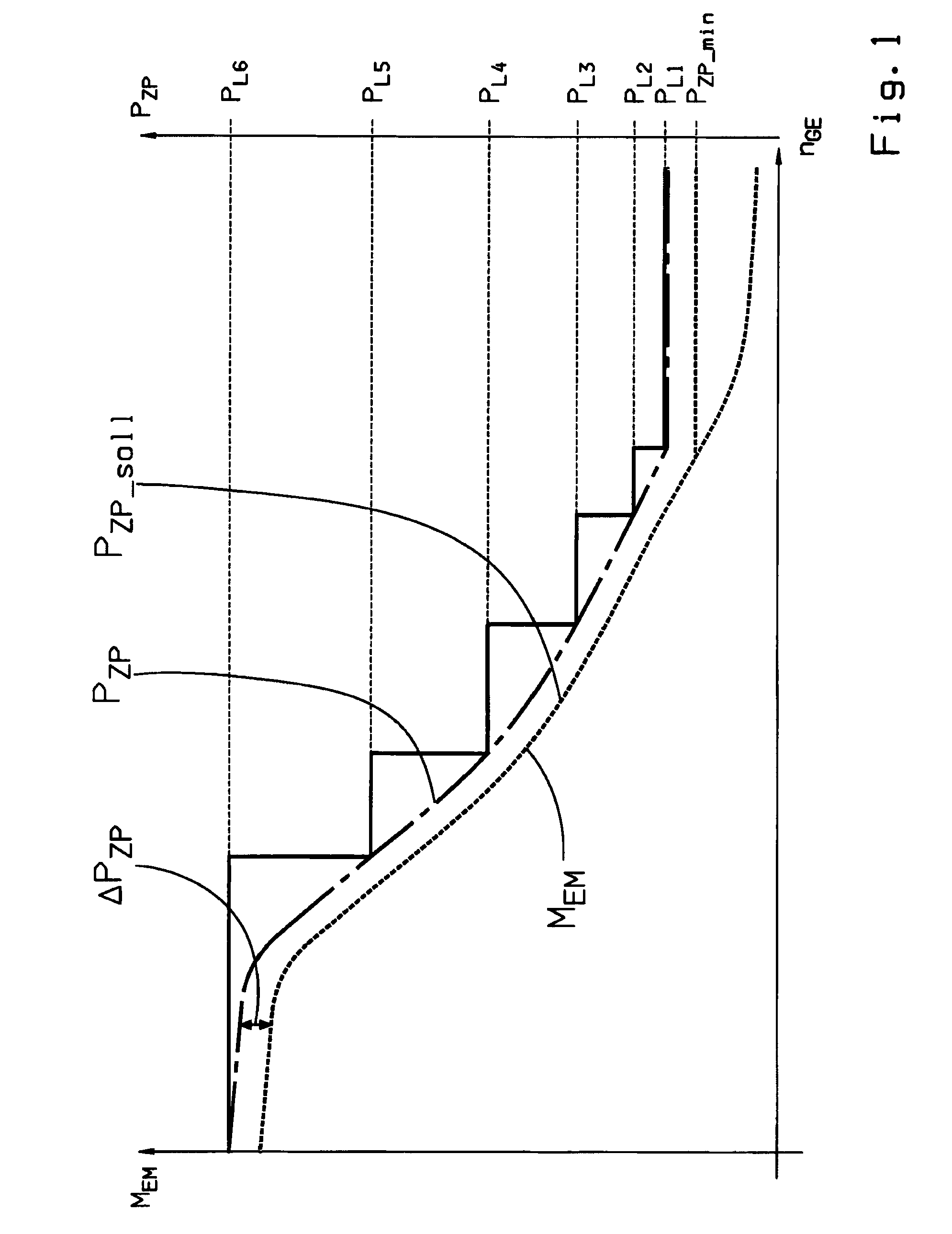

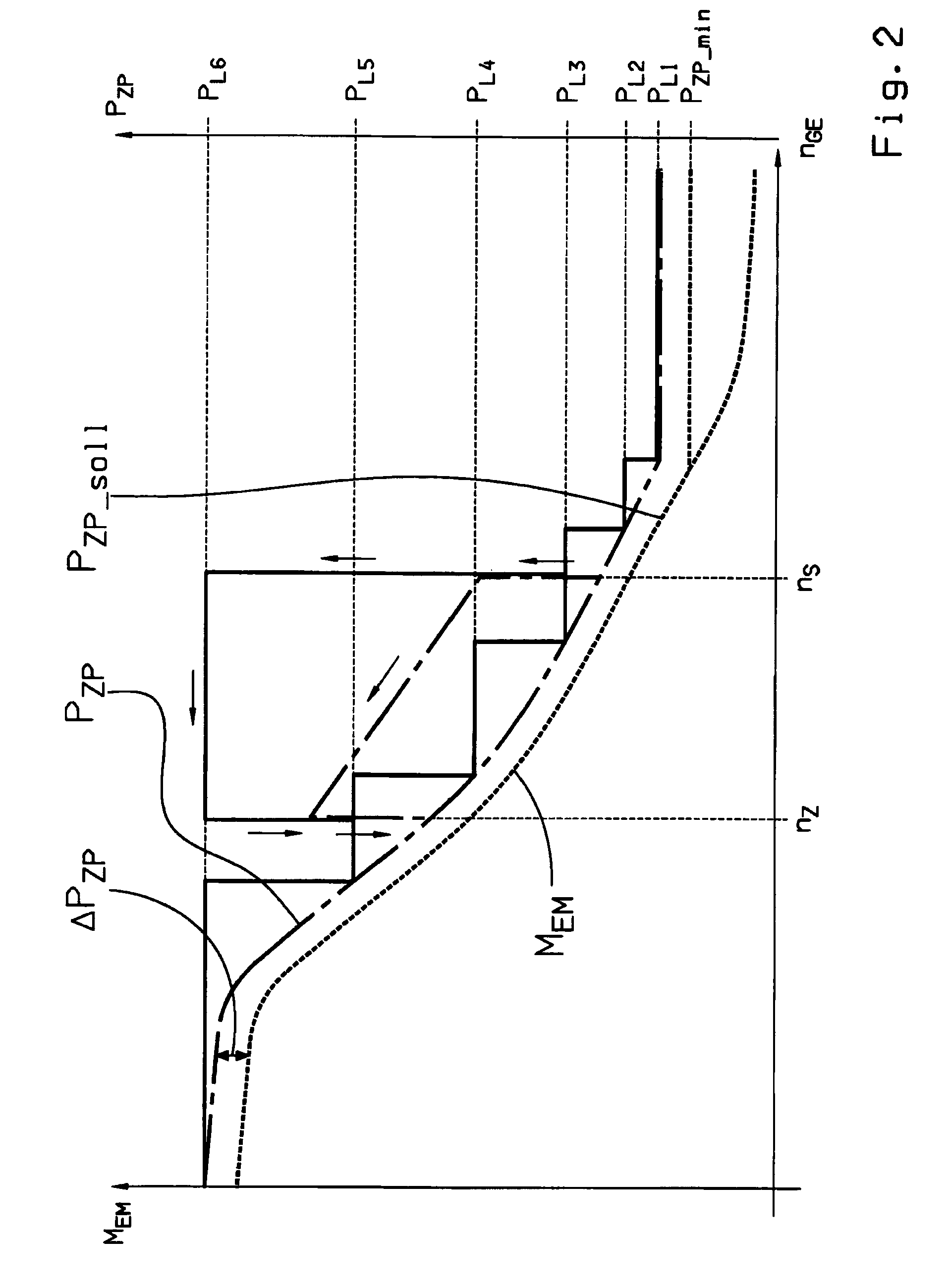

The invention relates to a method for controlling the oil supply device of an automatic planetary transmission, comprising a main oil pump (HP), which is mechanically drivably connected to the drive shaft of an internal combustion engine (VM), and an auxiliary oil pump (ZP) that may be driven via a controllable electric motor, the automatic transmission (ATG) being part of a parallel hybrid powertrain of a motor vehicle having an input shaft (5), which may be connected via a separating clutch (K) to the drive shaft (2) of the internal combustion engine (VM) and is permanently drivably connected to the rotor (4) of an electric machine (EM).In order to achieve an oil supply to the automatic transmission (ATG) as and when needed, it is provided that the current oil requirement (PHD<sub2>—< / sub2>soll) of the automatic transmission is determined as a function of at least one currently captured operating parameter, and that the delivery rate (PZP) of the auxiliary oil pump (ZP) is set, by a correspondingly actuation of the associated electric motor, in the combustion and combined driving mode below a minimum input speed of the main oil pump (HP) and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum input speed of the main oil pump (HP) is set to at least the residual oil requirement exceeding the delivery rate (PHP) of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

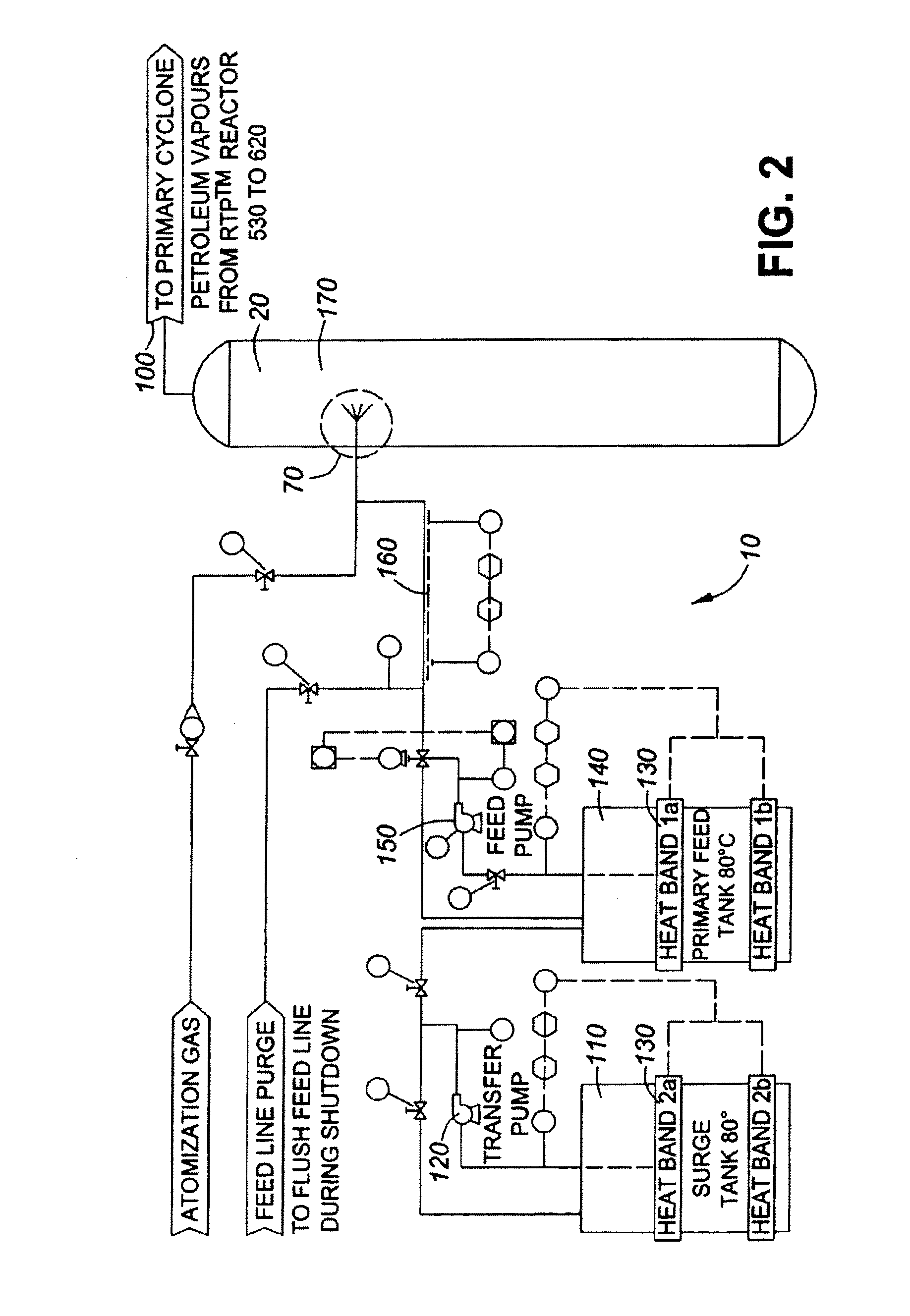

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

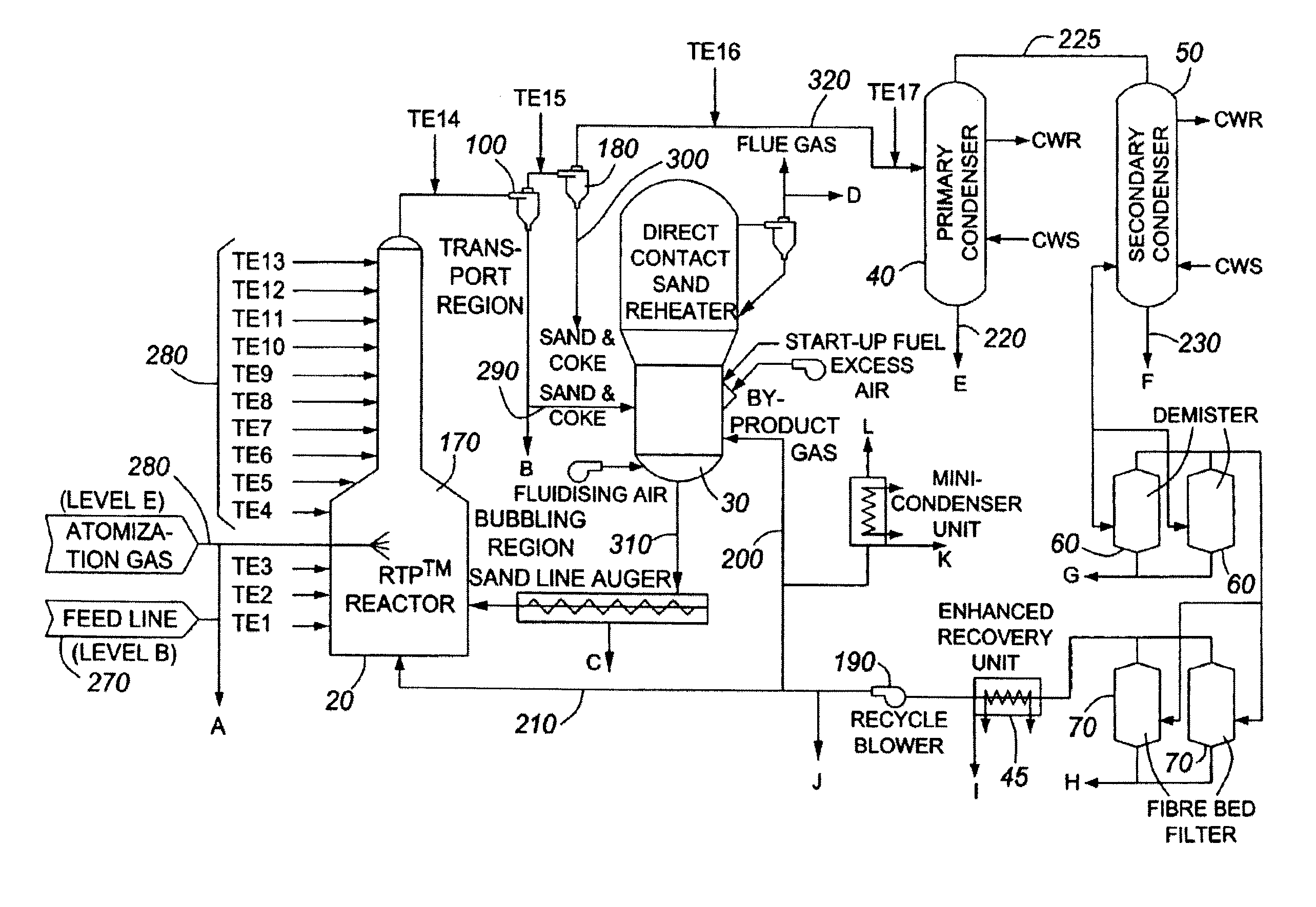

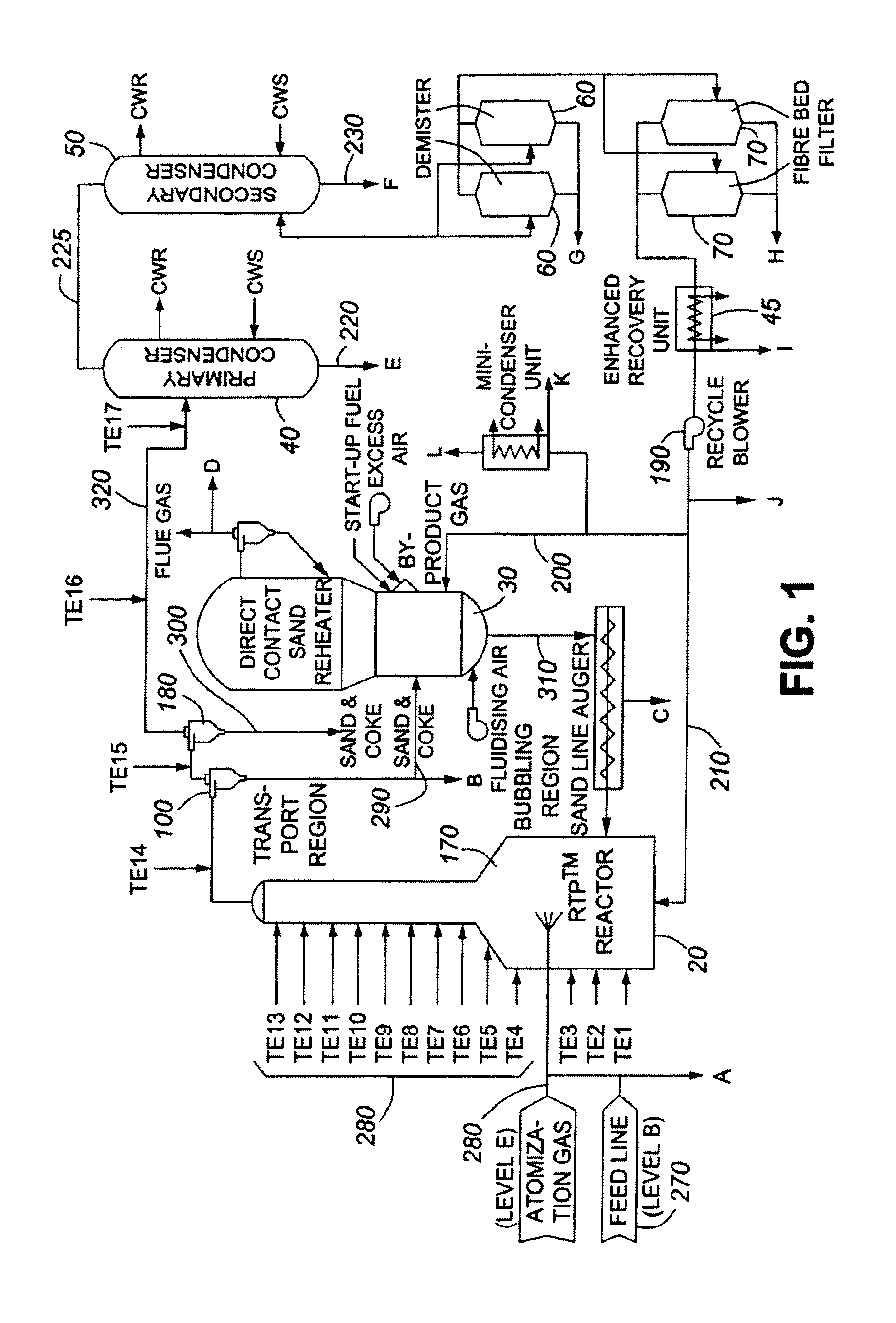

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

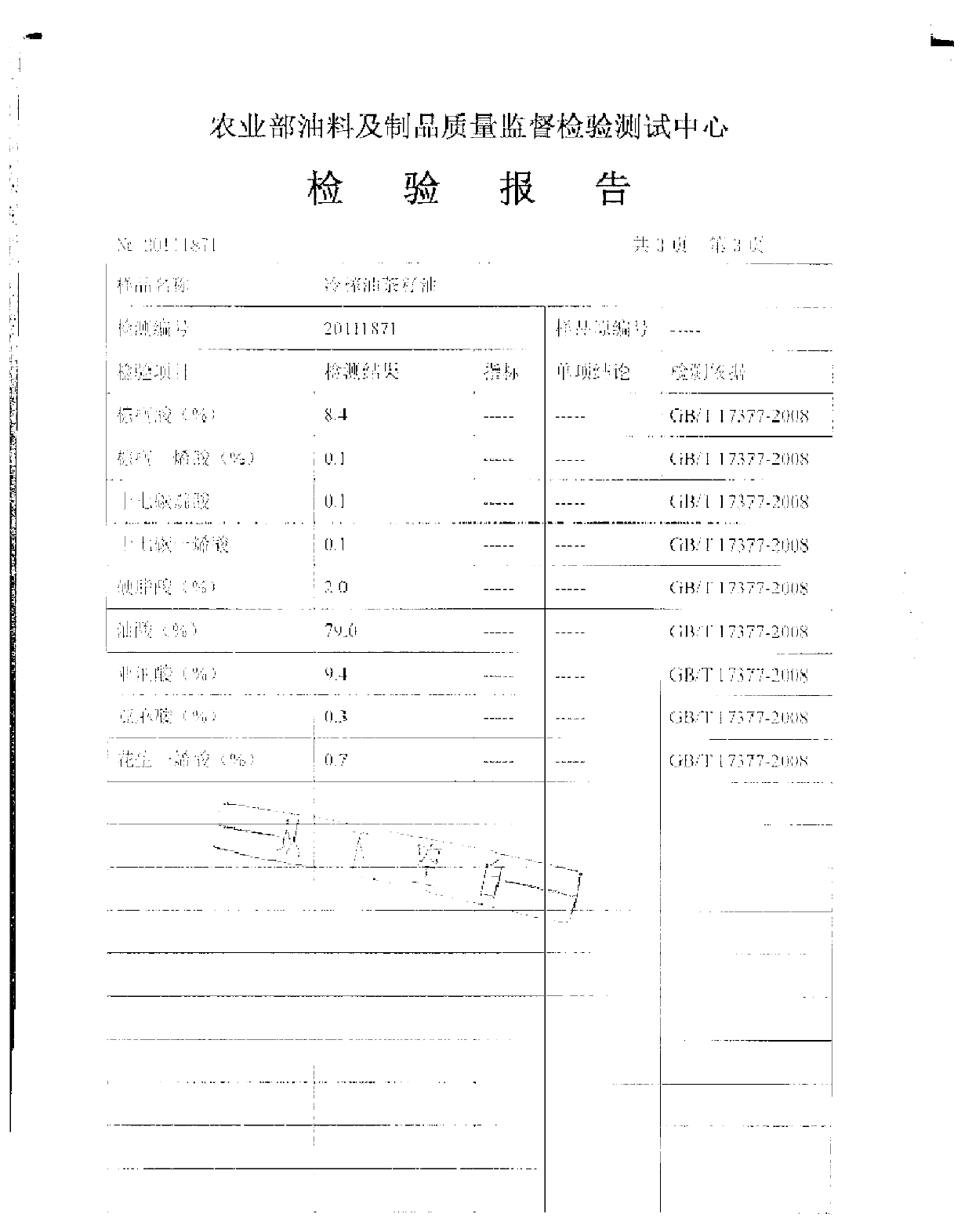

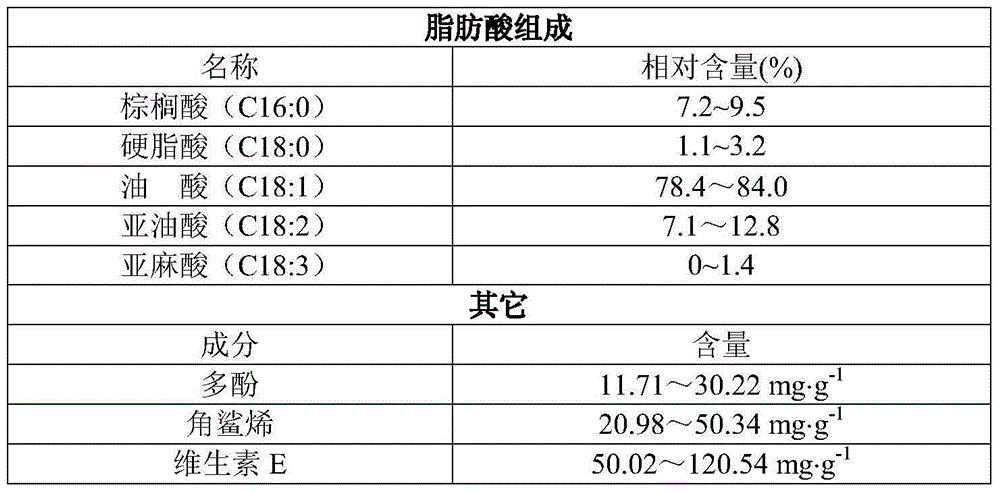

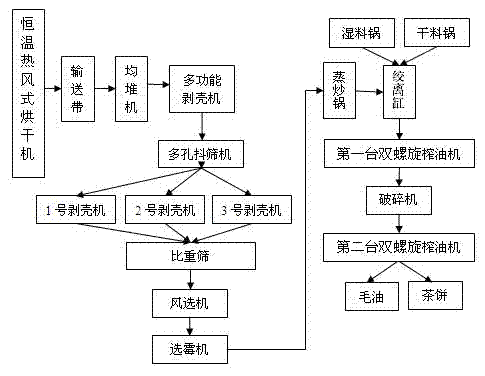

Method for producing low-temperature cold-pressed and refined tea seed oil

InactiveCN103013651AReasonable processStrong maneuverabilityFatty-oils/fats refiningFatty-oils/fats productionChemistryPeroxide value

The invention discloses a method for producing low-temperature cold-pressed and refined tea seed oil, and belongs to the technical field of deep processing of agricultural products. The method for producing the cold-pressed and refined tea seed oil comprises the following main processes of: performing low-temperature storage on screened tea seeds, cleaning, grading, shelling, separating, drying, crushing, pressing at a low temperature, filtering, degumming, decolorizing, deodorizing, winterizing, and packing finished refined oil. By the new technology of low-temperature cold pressing and refining, overheating and excessive chemical treatment of the oil in the conventional processing are avoided, meanwhile, the residue of harmful substances produced in the conventional high-temperature processing is effectively reduced at the same time, the production cost is remarkably reduced, the purely natural property of the oil is kept, and physiological active substances in the oil are kept as much as possible. The tea oil produced by the method is light in color, low in acid value and peroxide value, low in phosphorus content, fragrant and rich in nutrition, and has a long storage period; and a feasible new path is provided for deep processing and utilization of the tea seed oil.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

Generation of plants with altered oil content

InactiveUS20060277630A1Maximize oil contentIncrease valueOther foreign material introduction processesPlant peptidesP PHENOTYPENucleic acid

The present invention is directed to plants that display an altered oil content phenotype due to altered expression of a HIO103.1 nucleic acid. The invention is further directed to methods of generating plants with an altered oil content phenotype.

Owner:EXELIXIS PLANT SCI INC

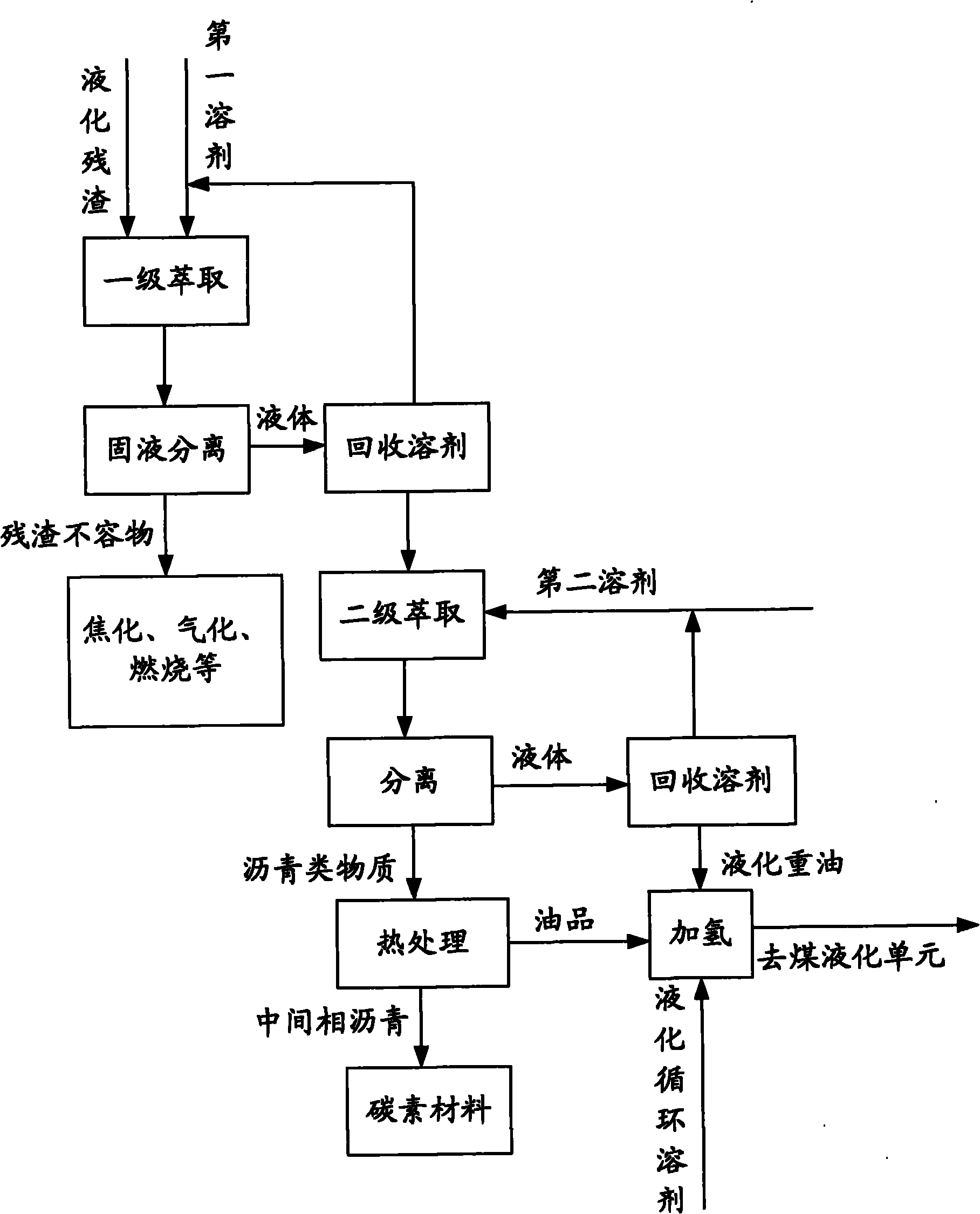

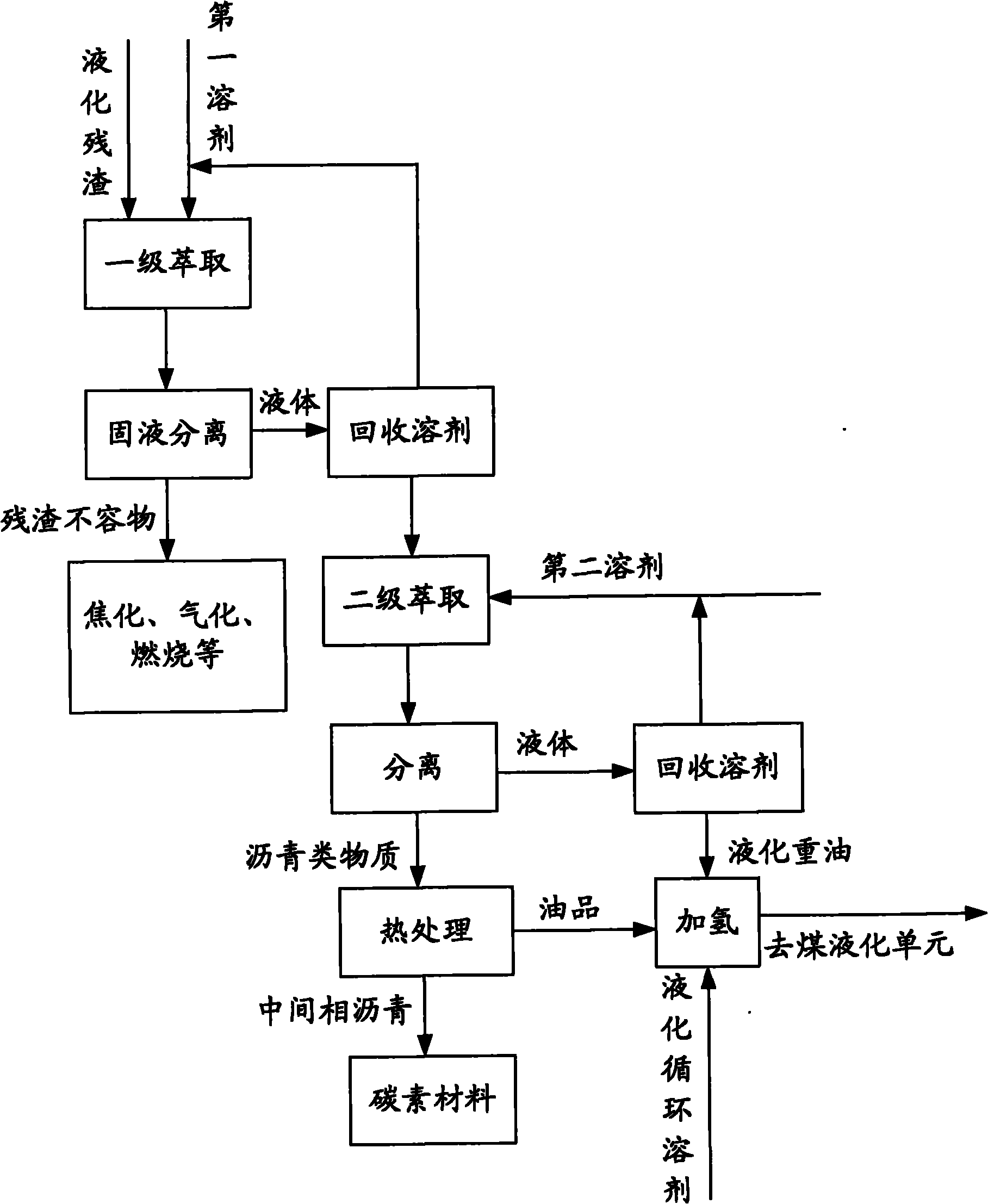

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for extracting and refining paeonia rockii seed oil

InactiveCN101649246AImprove oil yieldNo solvent residueCosmetic preparationsToilet preparationsAdditive ingredientAntioxidant

The invention relates to a method for extracting and refining paeonia rockii seed oil. The method comprises the following steps: collecting seeds, unshelling, baking and frying, carrying out screw press, filtering, deacidifying, degumming, drying, decoloring, deodorizing in vacuum, adding an antioxidant and filling. After solid impurities and residues obtained by the screw press are broken up, ethylacetate is added, then refluxing extraction is carried out, and a solvent is recovered so as to obtain the paeonia rockii seed oil for cosmetics. A two-step method is used for extracting the paeonia rockii seed oil, wherein in the first step: primary pressed oil used for eating is obtained by physical pressing, and the produced paeonia rockii seed oil has higher oil recovery rate and no residual solvents and can be securely eaten; in the second step, the ethyl acetate is adopted for extraction, and ingredients for antioxidation, inflammation resistance, sun block, and the like in the paeonia rockii seed oil can be extracted and used for producing the cosmetics. The invention not only improves the oil recovery rate of paeonia rockii seeds, but also ensures that the effective ingredients in the paeonia rockii seeds are sufficiently utilized.

Owner:兰州牡丹园艺开发公司

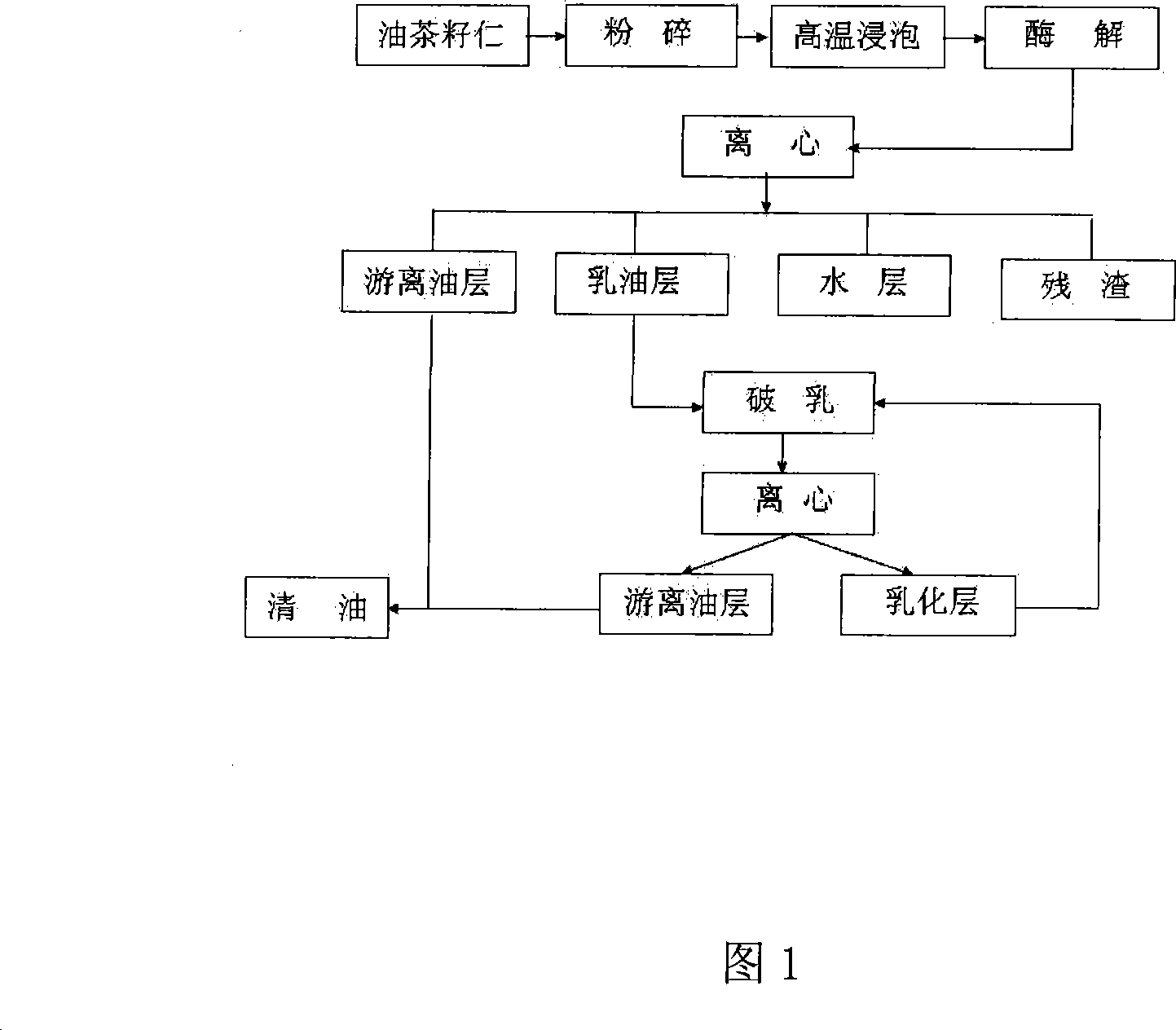

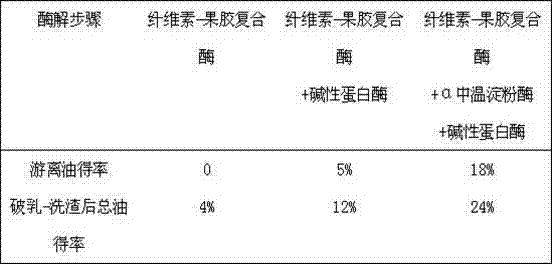

Technique for extracting grease from oil-tea camellia seed by enzyme method

InactiveCN101235399AReduce emulsificationReduce foaming and other problemsFermentationCamellia oleiferaDry weight

The invention relates to an enzymatical extraction process of oil in tea seed oil kernel, which comprises the following steps: firstly, utilizing dried tea seed oil kernel to be raw material, immersing in water in high temperature after disintegrating, stirring in uniform speed under 70-100 DEG C, secondly, enzyme hydrolyzing, adding acid protease which is 0.02-1% dry weight of disintegration samples or mixed enzyme of acid protease / cellulose in 45-55 DEG C to stir in uniform speed, and enzymatic hydrolysis for 2-4 hours, thirdly, separation emulsion breaking processing, directly separating out primary free boiled oil after enzymolysis liquid is centrifuged, getting secondary free boiled oil through centrifuging after missible oil demulsifies, combining the primary free boiled oil and the secondary free boiled oil, and getting the total boiled oil. The invention has the advantages that first, the invention reduces the problem of emulsification, foaming and the like which are faced when a grinding method is utilized to destroy cell structures, second, the invention prevents various enzymes in cells from degrading oil, which has high oil extraction rate to a further disintegrated function to tea seed oil kernel cell, third, the invention increases the treatment to missible oil, which increases free boiled oil yield through demulsifying, centrifuging, stewing to layer and the other modes.

Owner:江西春源绿色食品有限公司

Processing process for rapeseed oil

ActiveCN103666749ALow in phospholipidsReduce crude fiber contentFatty-oils/fats refiningFatty-oils/fats productionFlavorFood safety

The invention discloses a processing process for rapeseed oil. The process comprises the following steps of (1) carefully selecting rapeseeds of the year, drying the rapeseeds in the sun until the water content is 9 to 11 percent, and removing impurities, wherein the oil content of the rapeseeds is 36 to 39 percent; (2) crushing the rapeseeds, and performing flasking to obtain rapeseed flakes; (3) steam-roasting the rapeseed flasks for 70 to 80 minutes by utilizing the natural water of the flasks; (4) placing the steam-roasted rapeseeds in an oil press, and pressing the rapeseeds to extract crude oil at low temperature of 60 to 70 DEG C; (5) filtering the crude oil by using a conventional method, and performing refining to obtain a rapeseed oil finished product. According to the process, the rapeseeds with the oil content of 36 to 39 percent are taken as raw materials, and are subjected to the steps of drying in the sun, steam-roasting, low-temperature pressing and the like, the obtained rapeseed oil is a non-transgenic product, the intrinsic flavor, aroma and nutrient substances of the rapeseed oil are maximally maintained, the oil yield is over 35 percent, the requirements of green processing are met, and the food safety is ensured.

Owner:贵州侗乡生态农业科技发展有限公司

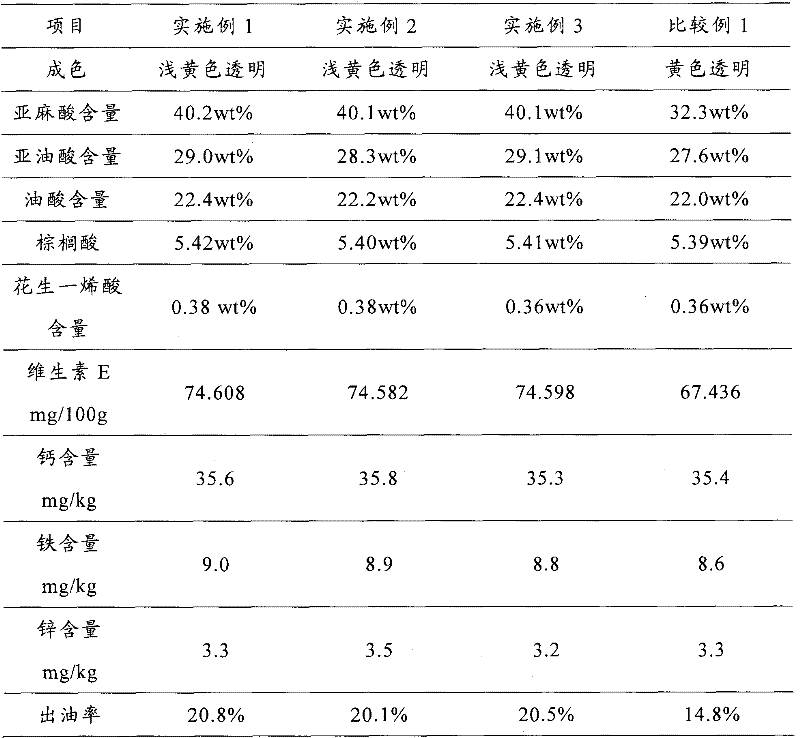

Preparation method of peony seed oil

ActiveCN102071096AImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionAlpha-Linolenic acidPolyunsaturated fatty acid

The invention provides a preparation method of peony seed oil. The oil content in the peony seed oil is above 22%, wherein the content of unsaturated fatty acid can be as high as 90%, and the content of alpha-linolenic acid can be as high as 42.3%, so that the peony seed oil has great development value. The preparation method comprises the following steps: husking, screening, sorting, roasting, stir-frying, pressing, filtering, alkali-refining, hydrating, decoloring, filtering and deodorizing dried and picked peony seeds for getting the peony seed oil, thereby realizing the industrial production of the peony seed oil; and the peony seed oil can be effectively extracted by adopting the steps, and the oil yield of the peony seed oil can be as high as 26-27%.

Owner:HEZE RUIPU PENOY IND TECH DEV

Process for making a lube base stock from a lower molecular weight feedstock in a catalytic distillation unit

InactiveUS6841711B2Sufficient reaction rateImprove oil yieldHydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionCatalytic distillationHydrocarbon

A process for making a lube base stock wherein an olefinic feedstock is contacted with an oligomerization catalyst in a catalytic distillation unit to produce a product having a higher number average molecular weight than the olefinic feedstock. That product is separated zone in the catalytic distillation unit into a light byproduct fraction and a heavy product fraction that includes hydrocarbons in a lube base stock range.

Owner:CHEVROU USA INC

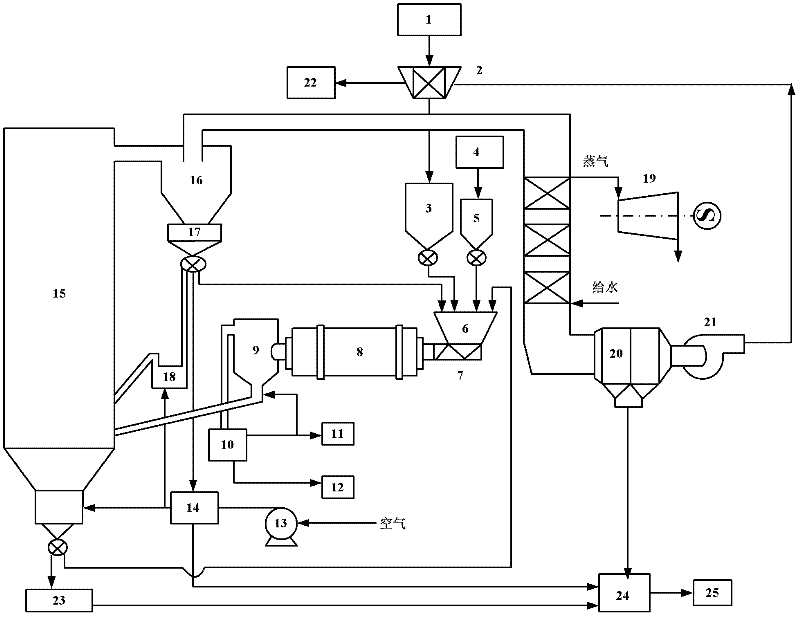

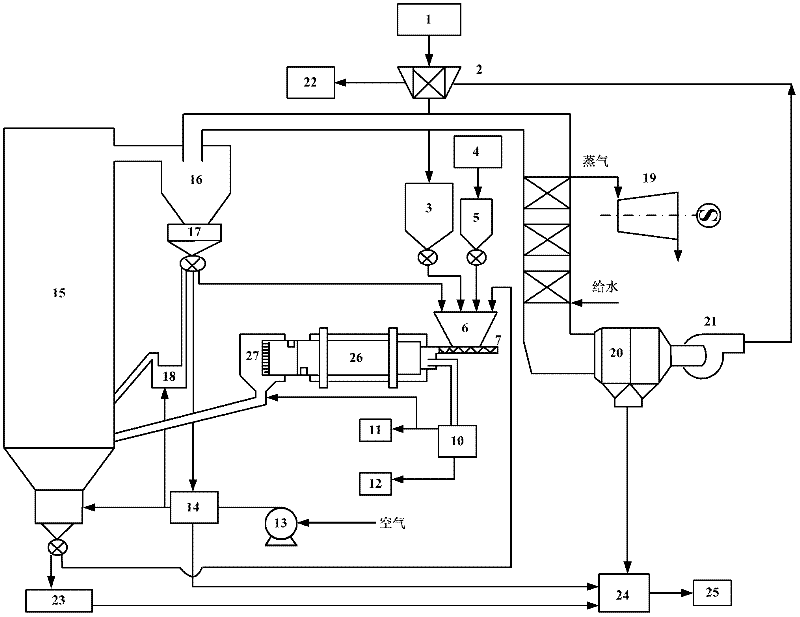

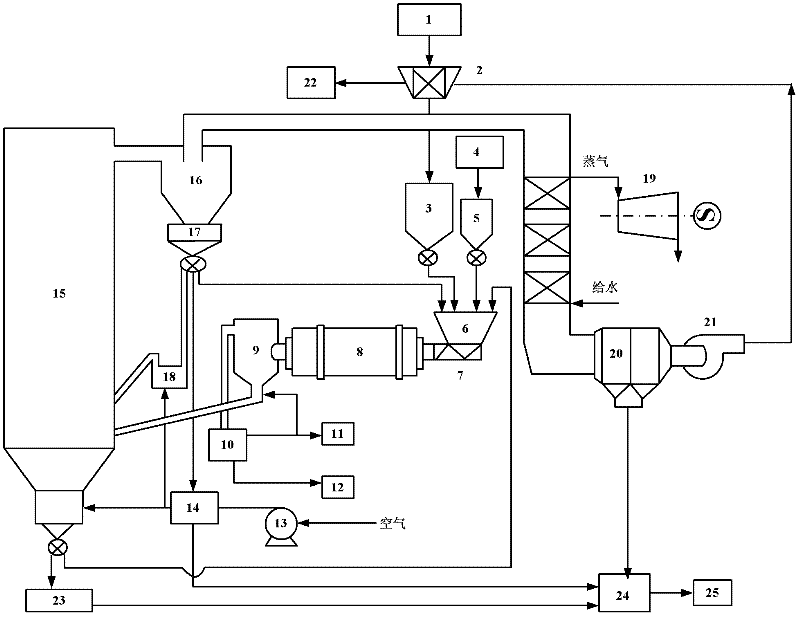

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing tea seed oil in low-temperature cold pressing manner

InactiveCN102965187AHigh mechanical wearReduce oil yieldFatty-oils/fats refiningFatty-oils/fats productionFlavorEngineering

The invention provides a method for preparing tea seed oil in a low-temperature cold pressing manner. The method comprises the following steps of cleaning tea seeds, removing shells and separating, milling oil at normal temperature, washing in water at low temperature, dehydrating under negative pressure, refining at low temperature, filtering for many times, winterizing and dewaxing. The method for preparing the tea seed oil in the low-temperature cold pressing manner, provided by the invention, has the advantages of simple process, low energy consumption and high oil yield; and the prepared tea seed oil has shallow color, high quality and comprehensive nutrition, and also keeps the original flavor of tea oil.

Owner:安徽新世界绿洲茶油有限公司

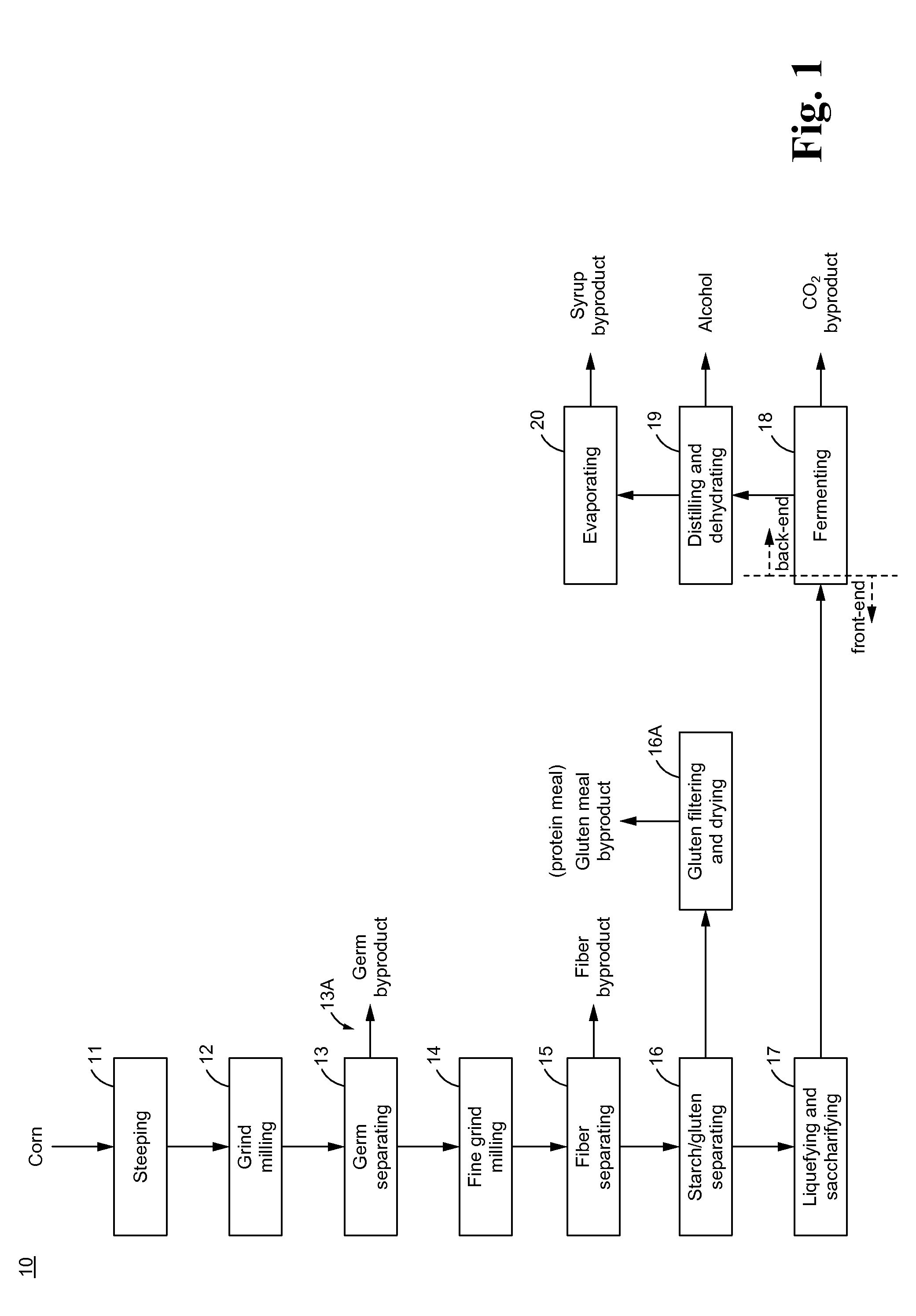

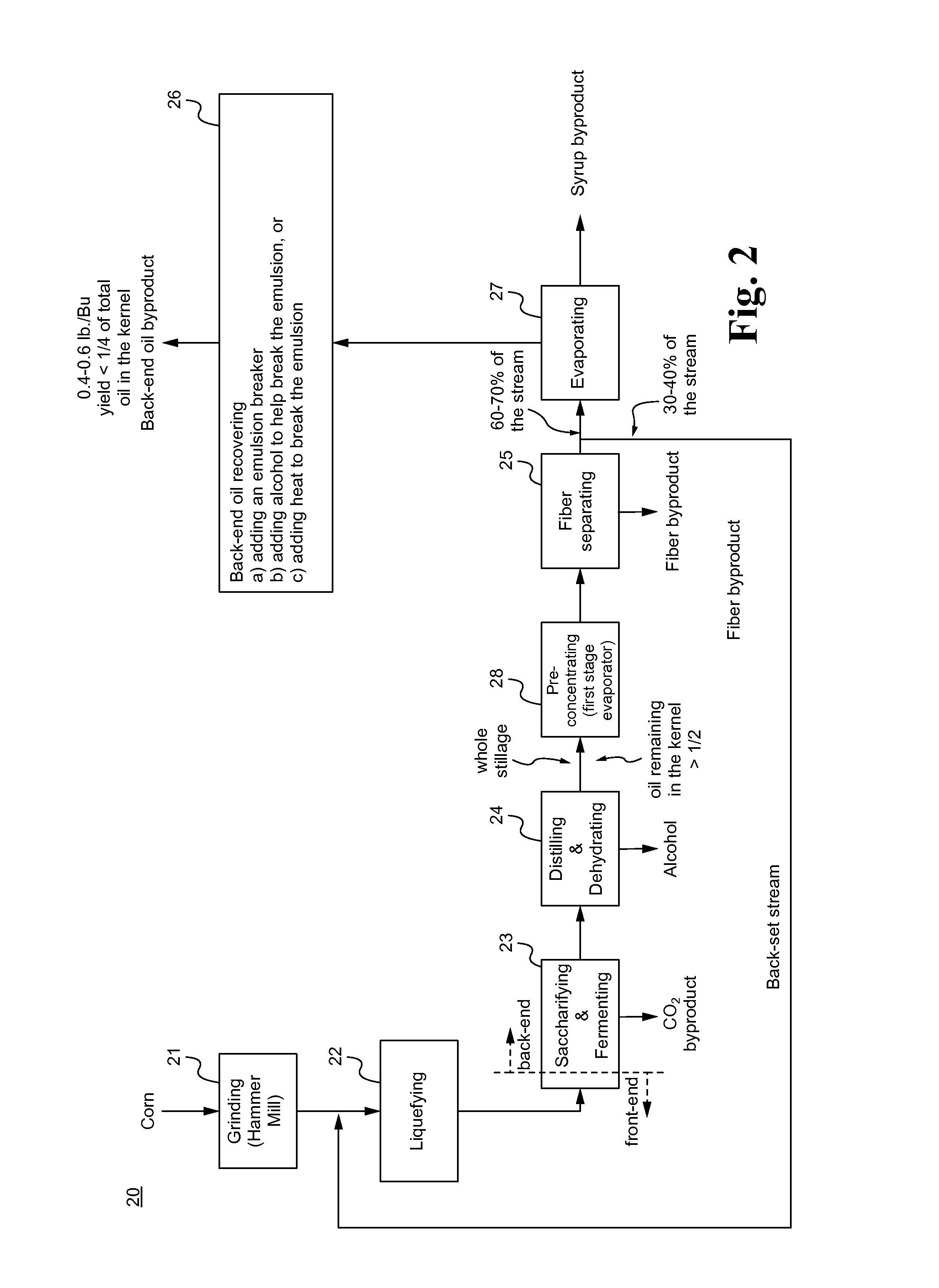

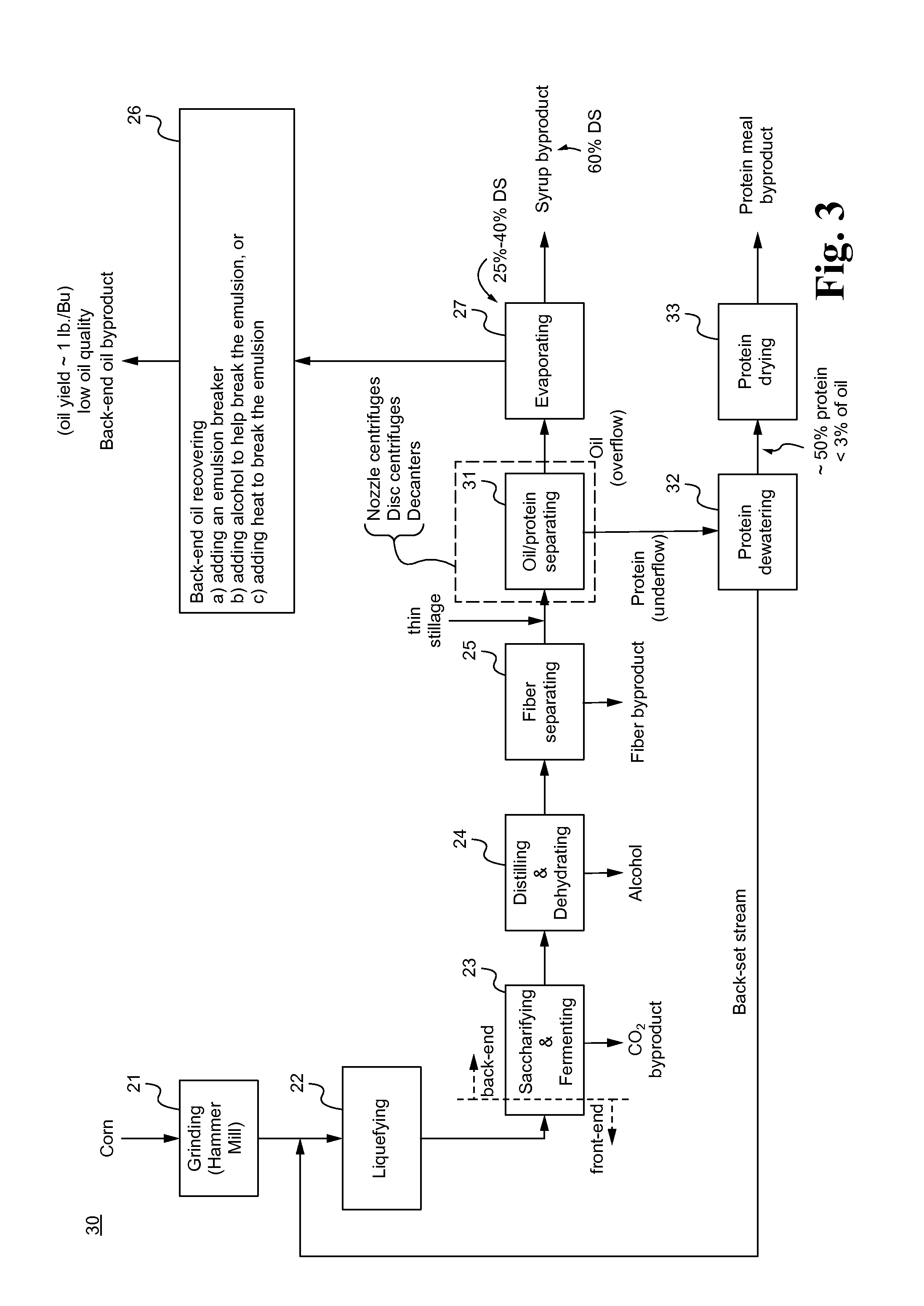

Method of and system for producing oil and valuable byproducts from grains in dry milling systems with a back-end dewater milling unit

ActiveUS20140053829A1High quality of oilHigh capital investmentFatty oils/acids recovery from wasteBioreactor/fermenter combinationsEmulsionChemistry

A method of and system for producing oil and valuable byproducts from grains, such as corn, in dry mills are disclosed. The method and system include dewater milling process after fermenting. Further, the method and system are able to produce oil without evaporating. Moreover, the method and system include one or more of the germ processing units, emulsion processing units, fiber processing units, high value protein producing units, and glycerol and inorganic salt producing units, such that high value byproducts are able to be generated.

Owner:LEE TECH LLC

Method for preparing rice bran oil from rice bran

InactiveCN1935963AImprove stabilityReduced activityFatty-oils/fats productionRice Bran ExtractRice bran oil

The invention relates to rice bran oil preparing method. It includes the following steps: processing the rice bran by micro wave with 800W power, 60s, 60mm height of layer, 7.4% humidity after processing; using supercritical carbon dioxide to extract rice bran oil at 25-60 degree centigrade, 10MPa-40MPa pressure, 15L / h-90L / h rate of CO2 flow for 30-150min. The prepared rice bran oil will not be rancidity and resolved by lipase to increase its stability. The product is easy to store. The rice bran oil yield is 20-22%.

Owner:南京远望富硒农产品有限责任公司 +1

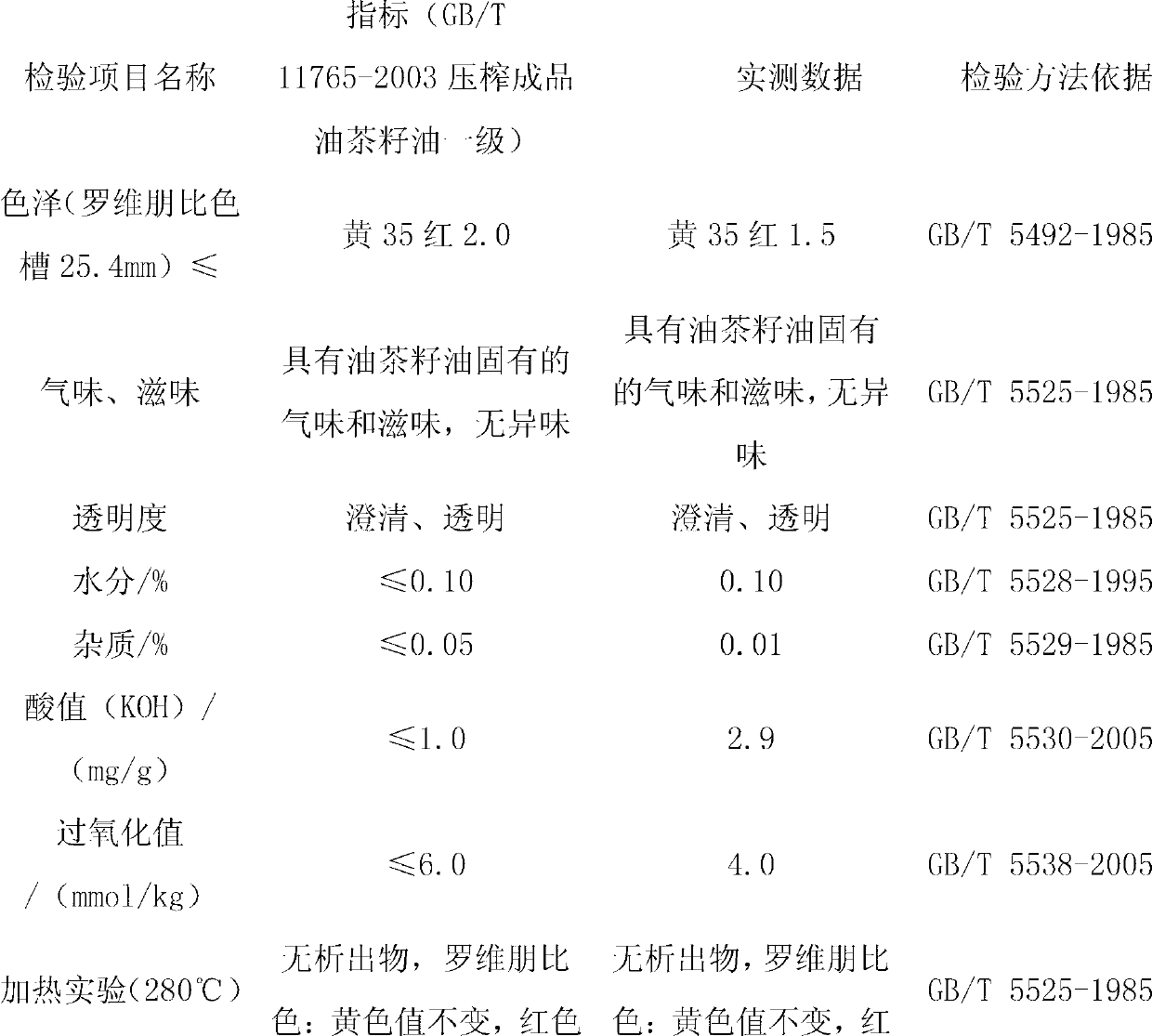

Preparation method of pure camellia oil

ActiveCN101824361AKeep active ingredientsRetain natural flavorFatty-oils/fats refiningFatty-oils/fats productionOil and greaseFlavor

The invention relates to a preparation method of pure camellia oil. Impurities are removed by filtration in a pure physical cold pressing way to obtain the pure camellia oil and the active components of the camellia oil are effectively reserved by a pure physical method without using any chemical agents during oil refining. The invention has light oil color, can obtain the camellia oil fit to a national GB1 1765-2003 pressed tea-seed oil standard without processing processes, i.e. deacidification, decoloration, deodorization, and the like, during the oil refining, reservess the natural flavor and aroma of the camellia oil, and has simple process, low cost and high oil yield.

Owner:广东新大地生物科技股份有限公司

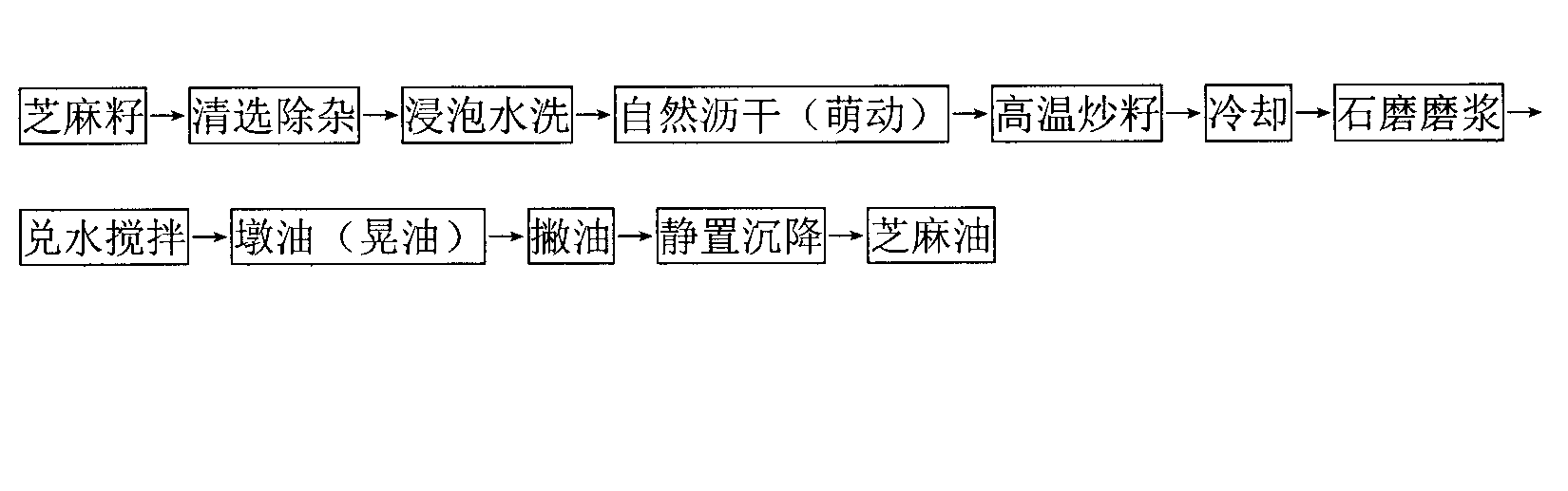

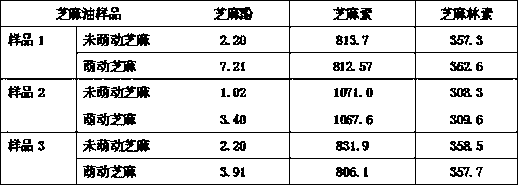

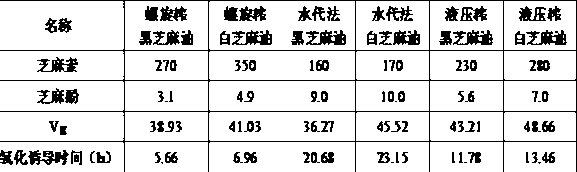

Production process of sesamol-rich fragrant sesame oil

InactiveCN102796609APure fragranceQuality and safetyFatty-oils/fats productionEdible oils/fatsFlavorSesamum

The invention discloses a production process of sesamol-rich fragrant sesame oil. The production process is characterized by comprising the following steps of: cleaning and removing impurities; soaking and washing; naturally draining and germinating; frying seeds at a high temperature; cooling; grinding into pulp with a stone mill; adding water and stirring; turning oil (shaking oil); skimming oil; and standing and settling to obtain a finished product. The production process has the advantages that the defects of high probability of getting burnt during direct roasting of dry sesame and high probability of producing 3,4-benzopyrene after burning are avoided by soaking the sesame with water, draining and then roasting at the high temperature, the sesame seeds are germinated during washing, soaking and drainage of the sesame, the germinated sesame seeds are roasted at the high temperature and then grease is extracted, the sesamol content in the sesame oil is higher than that of the sesame oil extracted from the ungerminated sesame, sesame pulp has high water absorbing speed and high oil yield speed, the obtained sesame oil has better flavor, the content of vitamin E in the sesame oil extracted from the germinated sesame, which is washed and soaked with water and drained, is higher than that of the sesame oil extracted from the ungerminated sesame, and the oil yield is improved by 1-2 percent compared with that in the prior art.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Process for preparing cold-pressed camellia oleosa seed oil by virtue of vacuum microwave enzyme method pretreatment

ActiveCN103981010AImprove qualityPreserve the flavorFatty-oils/fats productionVegetable oilMicrowave

The invention belongs to the field of vegetable oil processing, and particularly relates to a process for preparing cold-pressed camellia oleosa seed oil by virtue of vacuum microwave enzyme method pretreatment. The process comprises the following procedures: (1) picking fruits; (2) removing husks; (3) crushing; (4) adding enzymes; (5) carrying out staged vacuum microwave treatment; (6) carrying out physical cold pressing; (7) drying; (8) filtering. The process disclosed by the invention can be used for pretreating the camellia oleosa seeds by adopting a staged vacuum microwave enzyme method, is moderate in process condition and can be used for greatly enhancing the oil yield of subsequent cold pressing; the prepared camellia oleosa seed oil has good quality and can be used for better preserving the original nutrition and flavor of the camellia oleosa seed oil.

Owner:HUNAN XIANGCHUN AGRI TECH

Method for extracting oil from peony seeds or peony seed dregs

ActiveCN103484235AReduce consumptionNo residueFatty-oils/fats productionEdible oils/fatsEmulsionProtein hydrolysates

The invention discloses a method for extracting oil from peony seeds or peony seed dregs. The method comprises the following steps: (1) pretreatment; (2) enzymolysis; (3) centrifuging; (4) demulsification; (5) dreg washing. Free oil, an emulsion layer, protein hydrolysate and dregs are obtained after enzymatic hydrolysate is centrifuged, wherein the free oil is peony seed oil, and a certain amount of oil can also be recovered after the emulsion layer and the dregs are subjected to demulsification and dreg washing respectively. According to the method, the peony seed oil can be extracted without drying raw materials, the operation is simple, the requirement for equipment is low, the oil yield is high, the oil quality is good, solvent residues and environmental pollution are avoided, and the obtained protein hydrolysate and dregs can also be further used comprehensively.

Owner:TONGLING RUIPU PEONY IND DEV +1

A kind of processing method of peony seed oil

ActiveCN102277229AHigh oil contentReduce moisture contentFatty-oils/fats productionImpurityChemistry

The invention provides a method for processing peony seed oil. The method provided by the invention comprises the following steps of: (a) refrigerating peony seeds at a low temperature in a range of minus 15-minus 2 DEG C for 30-60 days and then storing at a constant temperature for 10-20 days; (b) removing shells of peony fruits which are refrigerated at the low temperature and are stored at theconstant temperature and then removing impurities; and then frying at a temperature in a range of 110-125 DEG C; and (c) pressing the fried peony seeds to obtain the peony seed oil. According to the method provided by the invention, the oil yield of the processed peony seed oil reaches 20%.

Owner:广东金妮宝科技发展有限公司

Method for extracting blueberry seed oil by adopting ultrasonic-assisted aqueous enzymatic method

ActiveCN103897796AImprove oil yieldQuality improvementFatty-oils/fats productionUltrasonic assistedCentrifugation

The invention discloses a method for extracting blueberry seed oil by adopting an ultrasonic-assisted aqueous enzymatic method. The method for extracting the blueberry seed oil by adopting the ultrasonic-assisted aqueous enzymatic method comprises the following steps: carrying out breaking, pulverization and then enzymolysis treatment on blueberry seed taken as raw material, applying certain ultrasonic for assisting extraction in different stages, then carrying out enzyme deactivation and centrifugation, and taking a supernate, so that the blueberry seed oil is obtained. The method for extracting the blueberry seed oil is simple in operation, mild in conditions, high in oil yield, pollution-free, easy for refining, low in production cost and applicable to large-scale production.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for preparing camellia oil

InactiveCN101831352AColor light yellowClear and transparent colorFatty-oils/fats refiningWater dischargeWastewater

The invention discloses a method for preparing camellia oil. The method is implemented by the following steps of: physically de-acidifying degummed crude tea seed oil from which impurities are removed to keep free fatty acid in the crude oil less than 0.4 percent, wherein peroxide and odoriferous substances in the crude oil, in particular the free fatty acid are removed in a physical de-acidifying process; performing alkaline refining and deacidification for ensuring the color and luster of physically de-acidified oil; adding sodium silicate and alkali into the oil in turn respectively; washing and standing the mixture; washing the mixture with water; drying the washed mixture; and de-coloring and deodorizing the dried mixture to obtain refined camellia oil. The method has the characteristics of low consumption of needed auxiliary materials, little waste water discharge, less produced soapstock, short deodorizing time and low production cost.

Owner:黄崇芳

Full-automatic squeezing method of camellia oil

InactiveCN103173278AImprove oil yieldUniform temperatureFatty-oils/fats productionNutrient contentOpen fire

The invention provides a full-automatic squeezing method of camellia oil. The full-automatic squeezing method comprises the following production steps of baking, heaping, husking, steaming and frying, matching the dry humidity of tea kernel and squeezing, wherein the camellia seed does not directly contact with an open fire in a baking step; the temperature for baking the camellia seed is even; no burning smell is generated; the nutritional ingredients in the camellia seed are reserved; no benzo and a few of harmful substances are generated because of burning; a twisted tank with a moisture measurer, a drying pot for containing dried tea seed kernel and a wet material pot for containing the wet tea seed kernel are utilized to match the dry humidity of the tea kernel in the step of matching the dry humidity of the tea kernel; and the moisture measurer is utilized to measure the moisture, so that the work efficiency and effect can be better improved; and specialized technical personnel do not need to be provided. The full-automatic squeezing method of the camellia oil is easier to grasp the full-automatic squeezing mode; the camellia oil yield can be improved by 95%; 8-10 workers can be reduced in each day; and the camellia oil quality is improved by 60%.

Owner:ANHUI YIHONG BIOTECH

Microwave ultrasonic-assisted aqueous enzymatic method for extracting linseed oil

ActiveCN105482890AOvercome extraction solvent contamination and inefficienciesImprove oil yieldFatty-oils/fats productionGlucanaseChemistry

The invention provides a microwave ultrasonic-assisted aqueous enzymatic method for extracting linseed oil. The method comprises the following steps: 1, screening linseed, and carrying out drying and pulverizing sequentially to obtain linseed powder; 2, uniformly mixing any one or more of cellulase, hemicellulase, pectolase and beta-glucanase with protease to obtain a complex enzyme; 3, adding deionized water, the linseed powder and the complex enzyme in a microwave ultrasonic wave combined type reaction kettle for enzymolysis to obtain an enzymatic hydrolysate; 4, performing solid-liquid separation to obtain the linseed oil. The method has the advantages of being high in oil content and extraction efficiency, so that a new effective way is provided for extraction of the linseed oil from the linseed.

Owner:北京民幅农科技有限公司

Method for extracting tea seed oil by using enzymatic hydrolysis method

ActiveCN102061217AHigh purityLight colorFatty-oils/fats productionOil and greaseEnzymatic hydrolysis

The invention discloses a method for extracting tea seed oil by using an enzymatic hydrolysis method, which comprises the following steps of: airing, unshelling, husking and pulverizing tea seeds; carrying out enzymolysis on the tea seeds in the material-liquid ratios of 1:3 to 1:5 at the extraction temperature of 40-60 DEG C for 1-5h with the enzyme quantity of 40-600U under the pH natural condition; centrifugally layering; adding an organic solvent into centrifugal liquid and extracting; and rotating and evaporating to obtain an oil sample. By adopting the scheme, the method has the advantages of low temperature for equipment operation, low energy consumption, high purity of extracted oil, low content of phospholipid, low acid value and low peroxide value, shallow color, low BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) values, easiness of treatment and less pollution, and the oil yield ratio is up to 23.1 percent.

Owner:HUAQIAO UNIVERSITY

Linseed kernel oil and production method thereof

InactiveCN101602978AImprove oil yieldLow residual oil rateFatty-oils/fats productionEdible oils/fatsAlpha-Linolenic acidEdible oil

The invention discloses linseed kernel oil, which is extracted by pretreating and peeling linseed and taking linseed kernel as a raw material. A production method of the linseed kernel oil comprises the following steps: cleaning and drying linseed, separating peel and kernel; crushing, cooking the linseed kernel and squeezing out oil; and filtering and precipitating to obtain a finished product. The invention provides brand new edible oil. The processing technique of the product does not add any chemical reagent and is green and pollution-free, the product has no any chemical pollution, and the processing of the product is not subjected to high temperature, keeps alpha-linolenic acid in the linseed, and enables the content of the alpha-linolenic acid of the product to reach about 60 percent. The content of crude protein in byproduct, namely linseed kernel cake is improved by 10 percent compared with that of linseed cake and reaches about 43 percent, and the anti-nutritional factors are greatly reduced, widen the application of the linseed kernel cake and improve the additional value of processing. The product is novel, and the processing technology is mature, has high oil extraction rate and is easy to popularize.

Owner:高银阁

Production technique of low-temperature pressed rapeseed oil

InactiveCN102952628AEasily brokenImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringRapeseed

The invention discloses a production technique of low-temperature pressed rapeseed oil, wherein rapeseeds are cleaned, subjected to impurity removal, subjected to wall breaking based on freezing treatment and then fried to 60-70% rape to contribute to the oil leaching, a pressing technique is utilized in the invention, and a specially treated adsorbent is used for decoloring. A technique of heating after freezing is utilized in the invention to facilitate the cell disruption of the rapeseeds so as to improve the oil extraction rate, and the oil extraction rate is 5-6% higher than that of a traditional pressing method; and the oil is extracted by the pressing technique in the invention, so that no pollution exists, the purity of the oil product is guaranteed, and the oil is all natural and meets the demands of green food.

Owner:FEIXI RONGXIN GRAIN & OIL

Preparation method of coal-oil slurry coprocessed by coal-oil hydrogenation, coal-oil slurry and its coprocessing method

ActiveCN102732295AReduce dosageImprove conversion rateLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionDecompositionActive component

The invention relates to a preparation method of a coal-oil slurry coprocessed by coal-oil hydrogenation, the coal-oil slurry and its coprocessing method. The preparation method of the coal-oil slurry comprises the following steps of: predispersing FeOOH in a nanometer dimension onto coprocessed coal dust in the presence of an iron-containing main catalyst precursor under the action of a dispersing aid, and mixing the coprocessed coal dust, a sulfur containing auxiliary agent and coprocessed oil to prepare the coal-oil slurry. During the coal-oil coprocessing process, FeOOH undergoes in-situ decomposition and sulfuration to generate a nascent active component. The coal-oil slurry and the coprocessing method have advantages of high conversion rate, high oil yield, small catalyst amount and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS8187151B2Improve oil yieldImprove delivery rateElectric propulsion mountingGear lubrication/coolingElectricityCombustion

A method for controlling the oil supply device of an automatic planetary transmission, having a main oil pump and an auxiliary oil pump. The transmission is part of a parallel hybrid vehicle powertrain. To supply oil to the transmission as needed, the current oil requirement of the transmission is determined depending on at least one current operating parameter. The auxiliary pump delivery rate is set by actuating the electric motor, in the combustion and combined driving mode below a minimum main oil pump input speed and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum main oil pump input speed is set to at least the residual oil requirement exceeding the delivery rate of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com