Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "API gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

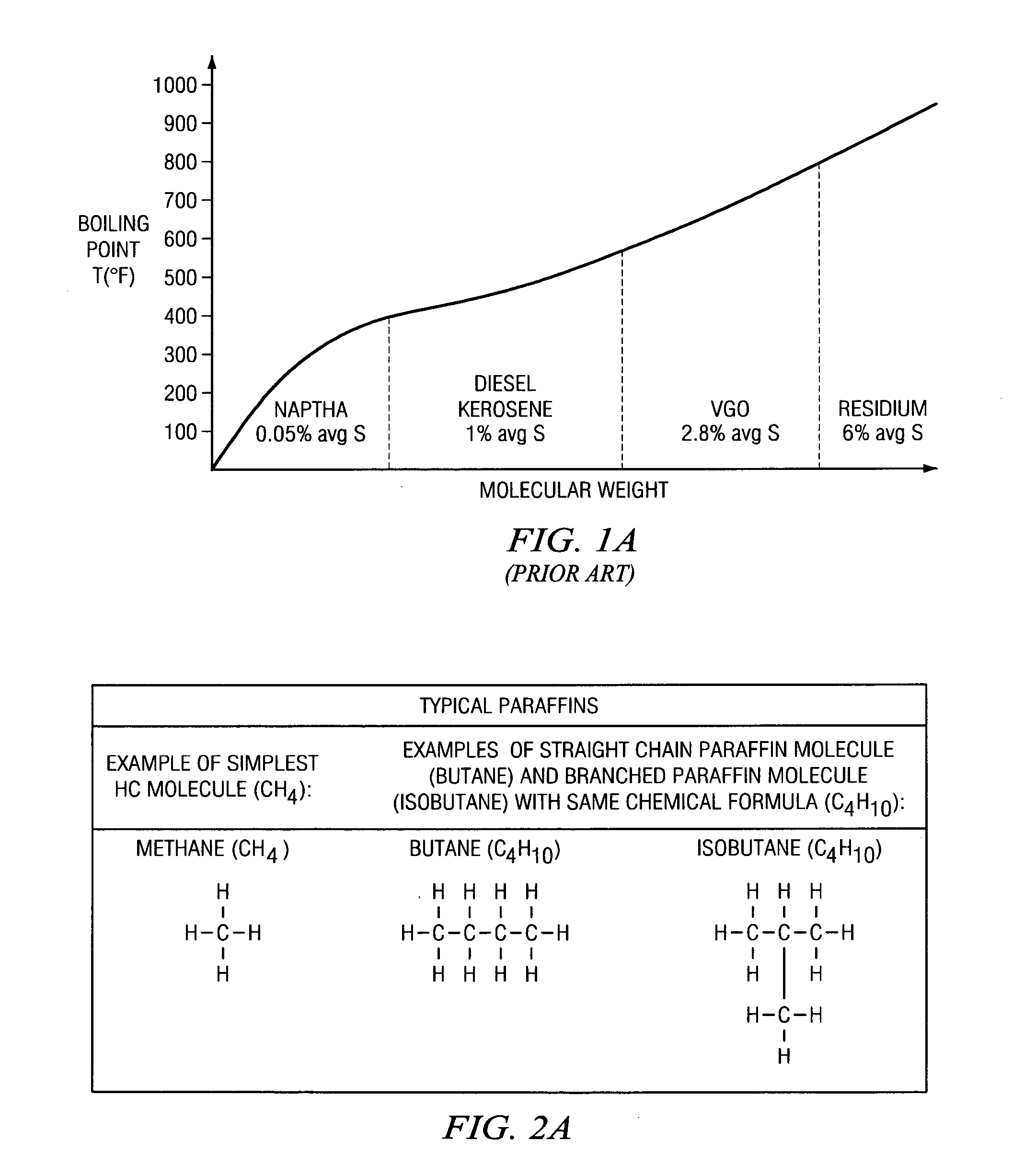

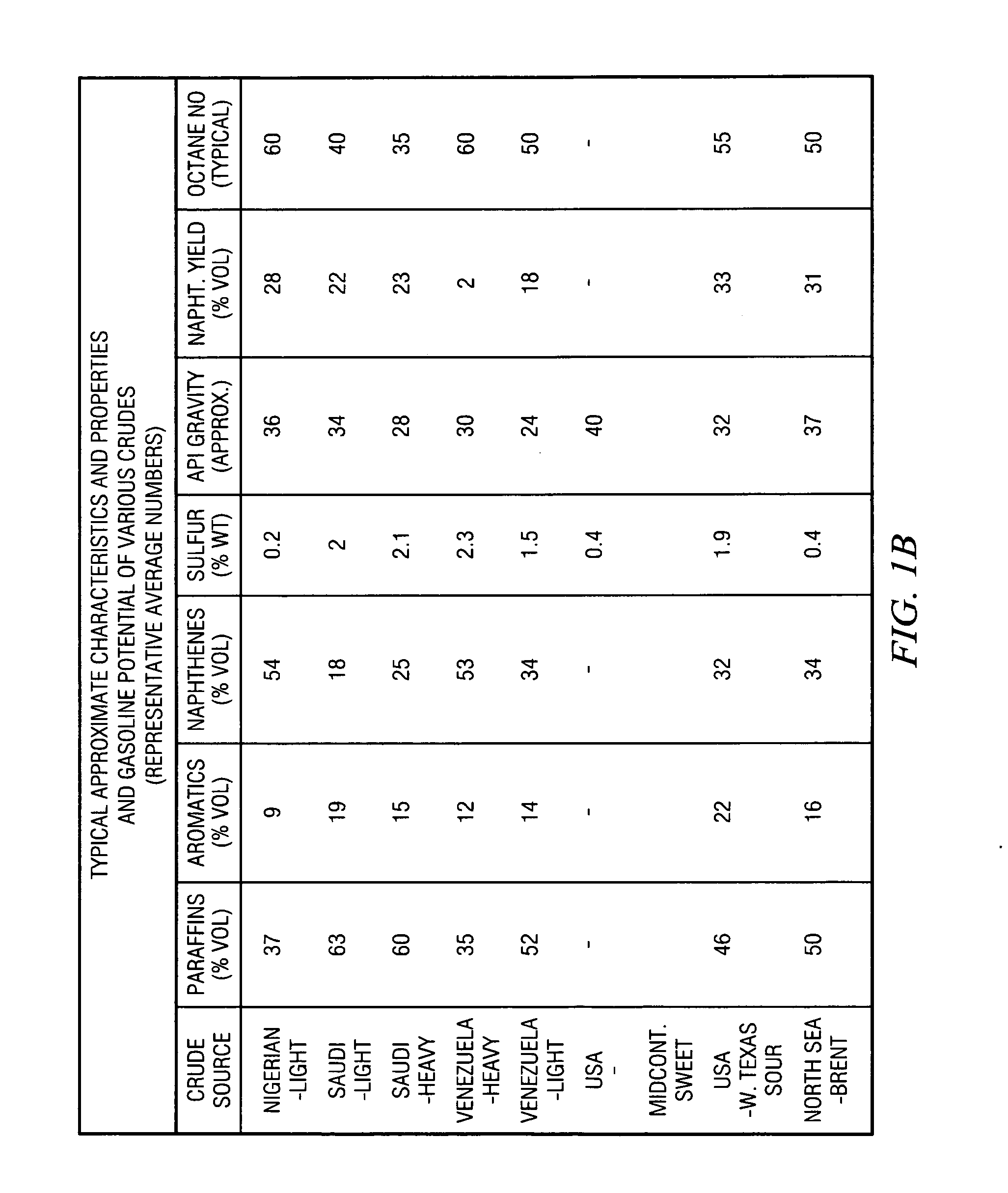

The American Petroleum Institute gravity, or API gravity, is a measure of how heavy or light a petroleum liquid is compared to water: if its API gravity is greater than 10, it is lighter and floats on water; if less than 10, it is heavier and sinks.

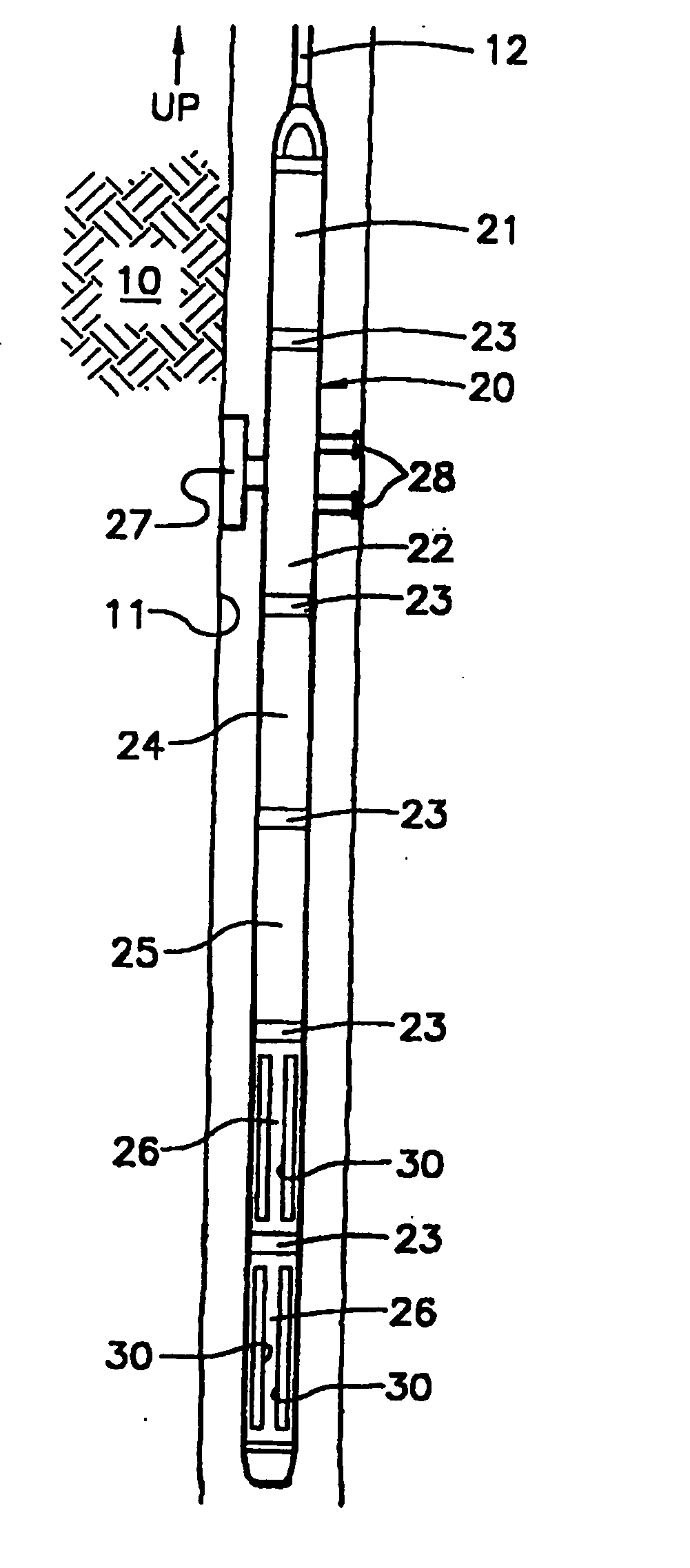

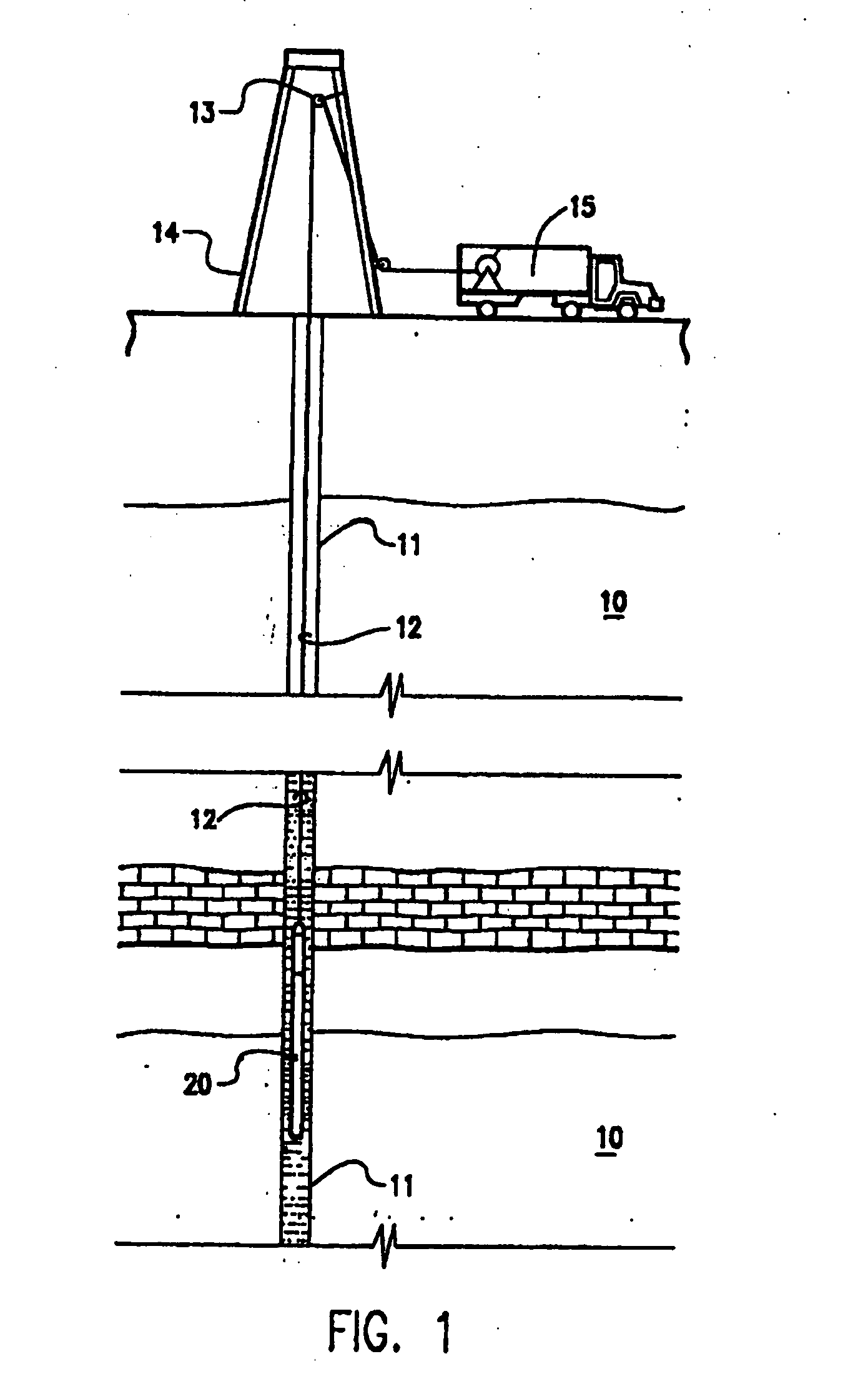

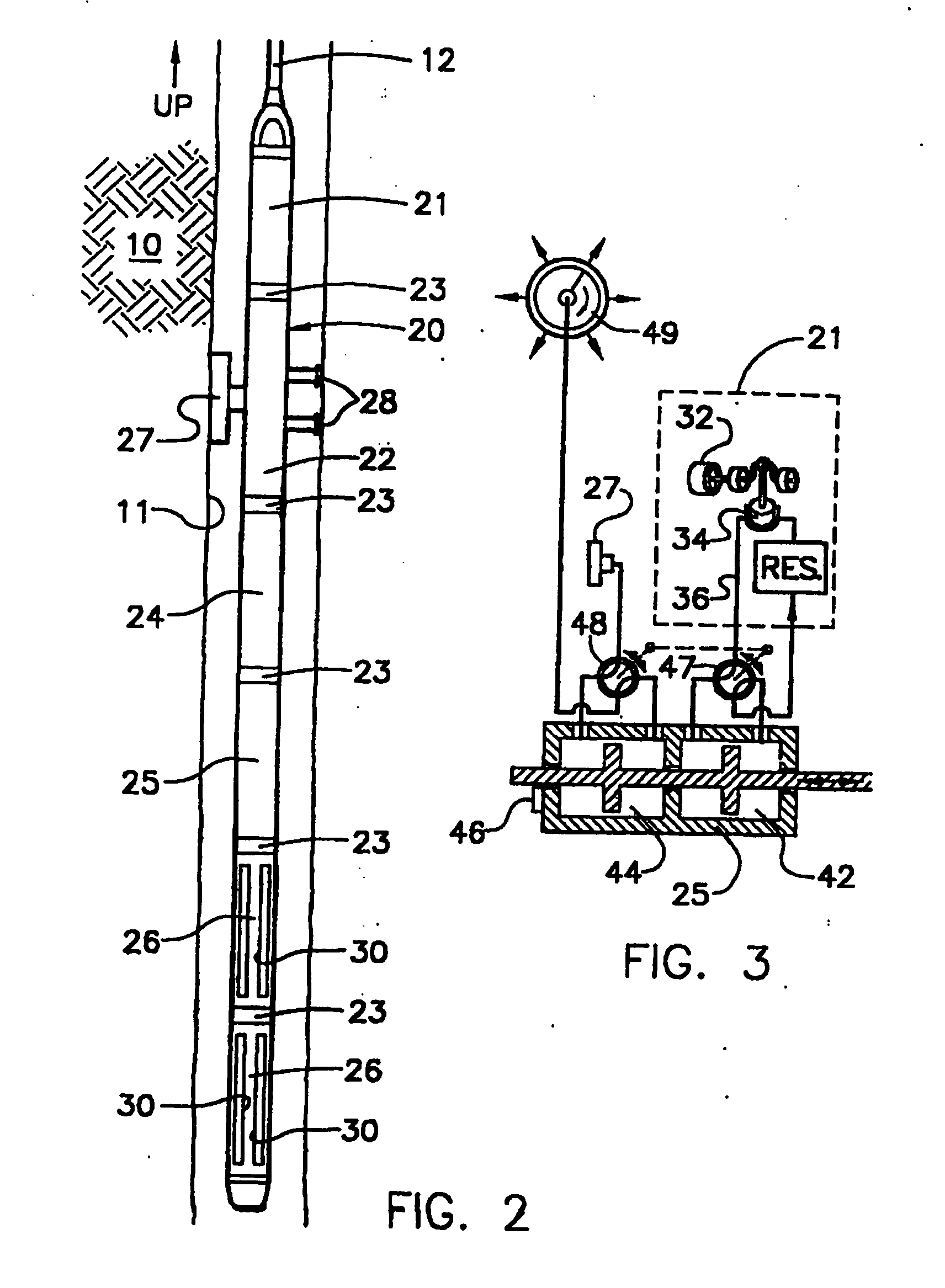

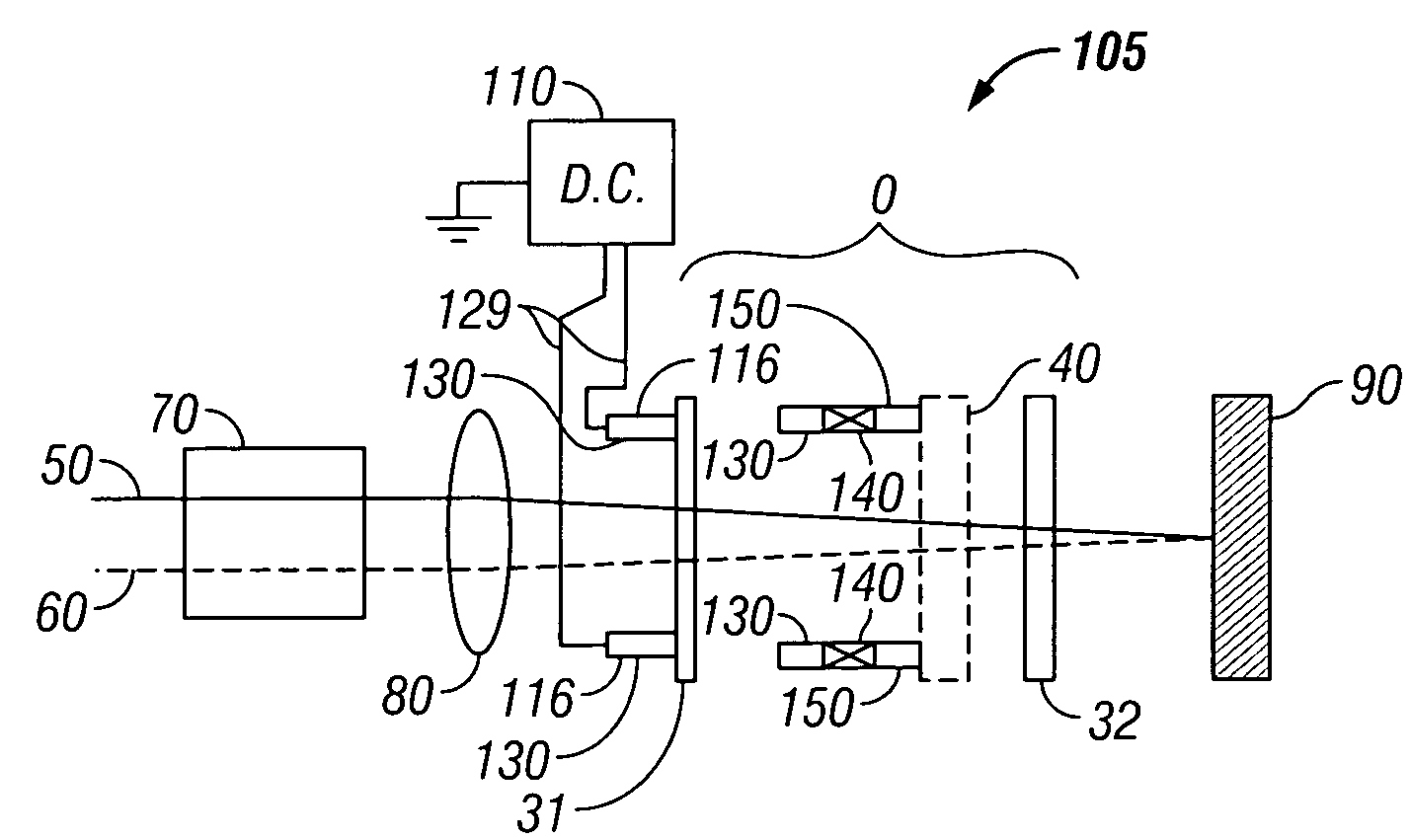

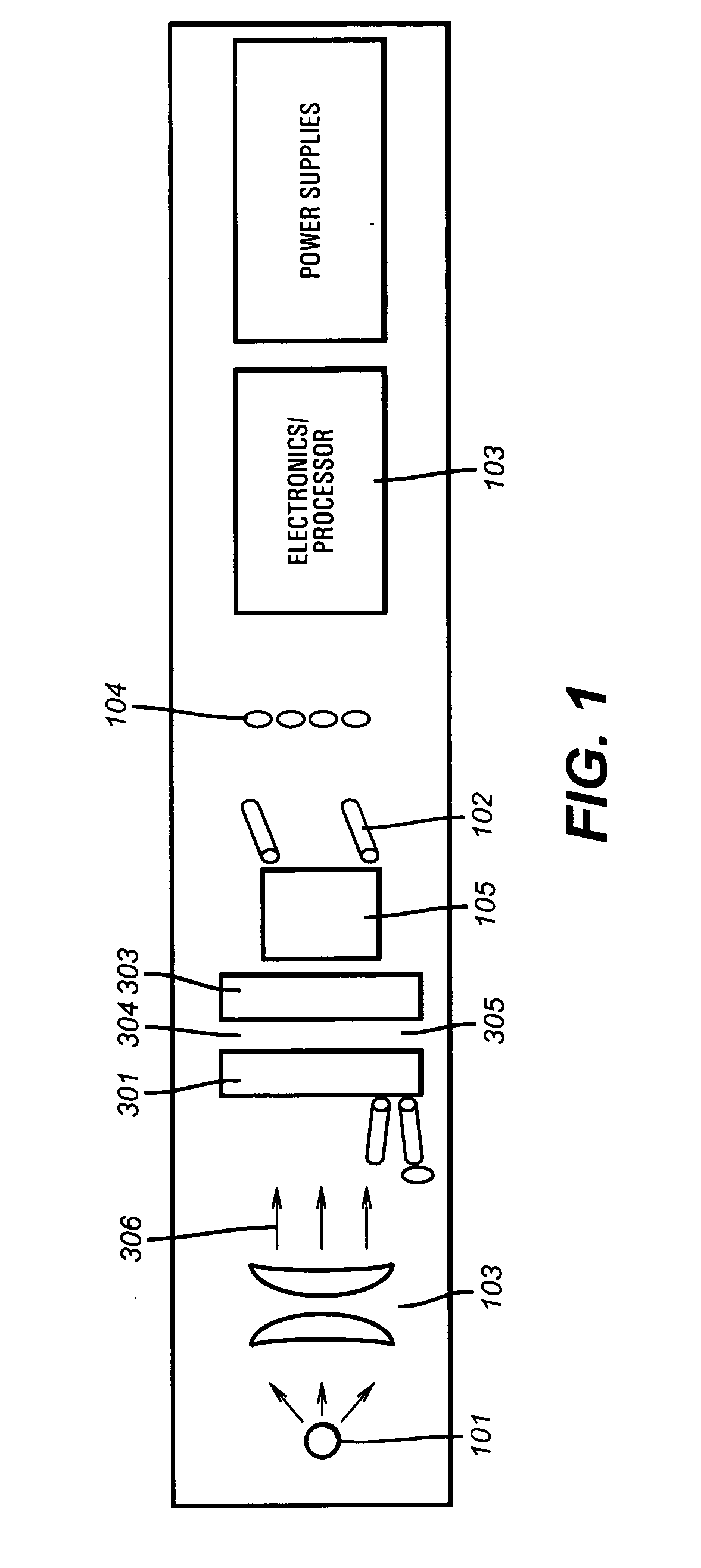

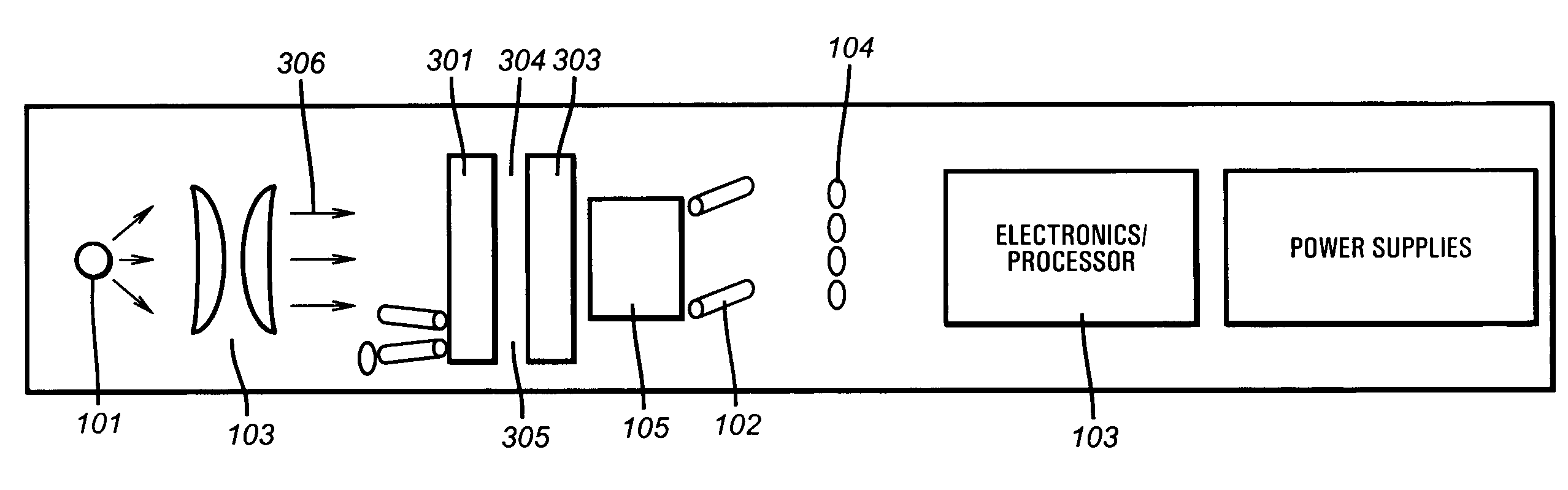

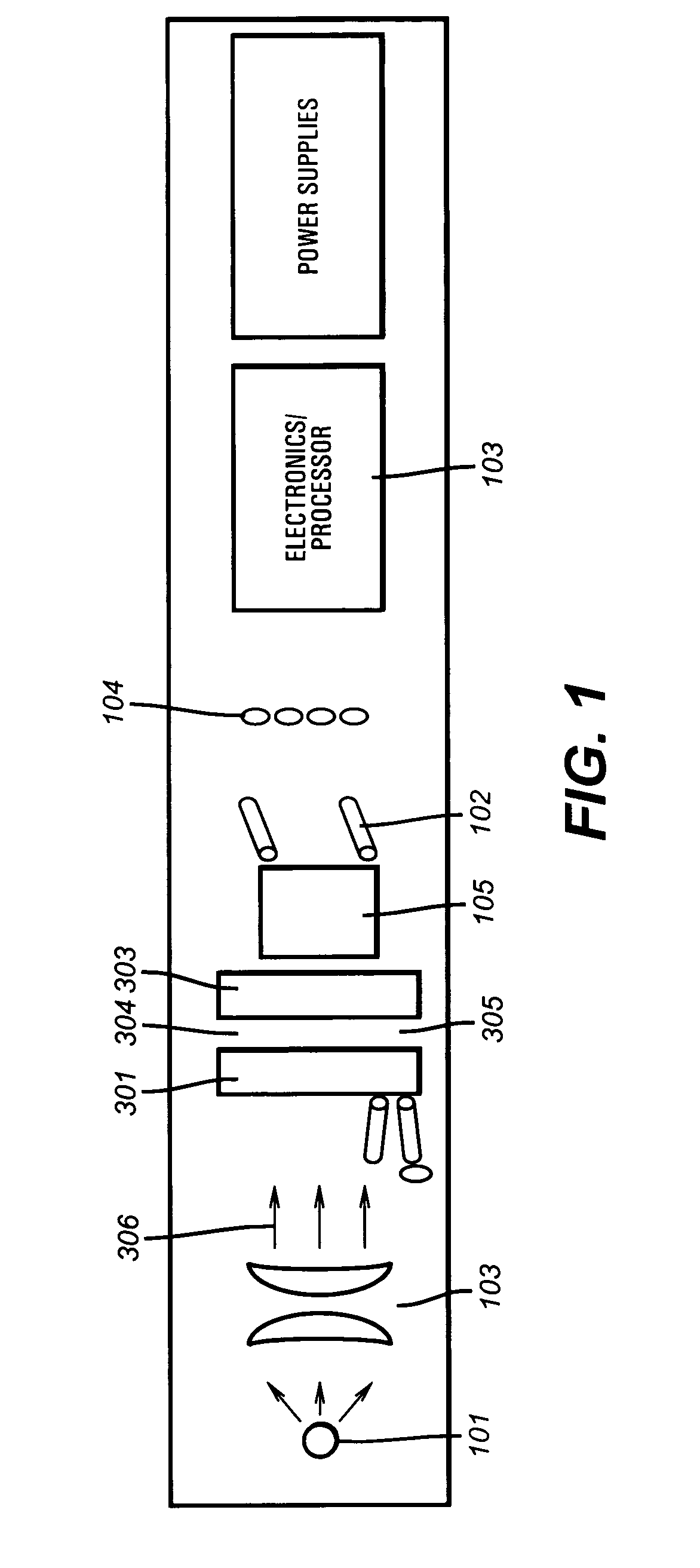

Method and apparatus for a downhole spectrometer based on electronically tunable optical filters

ActiveUS20050099618A1High resolution spectroscopyEasy to analyze and useRadiation pyrometrySurveyGas oil ratioAPI gravity

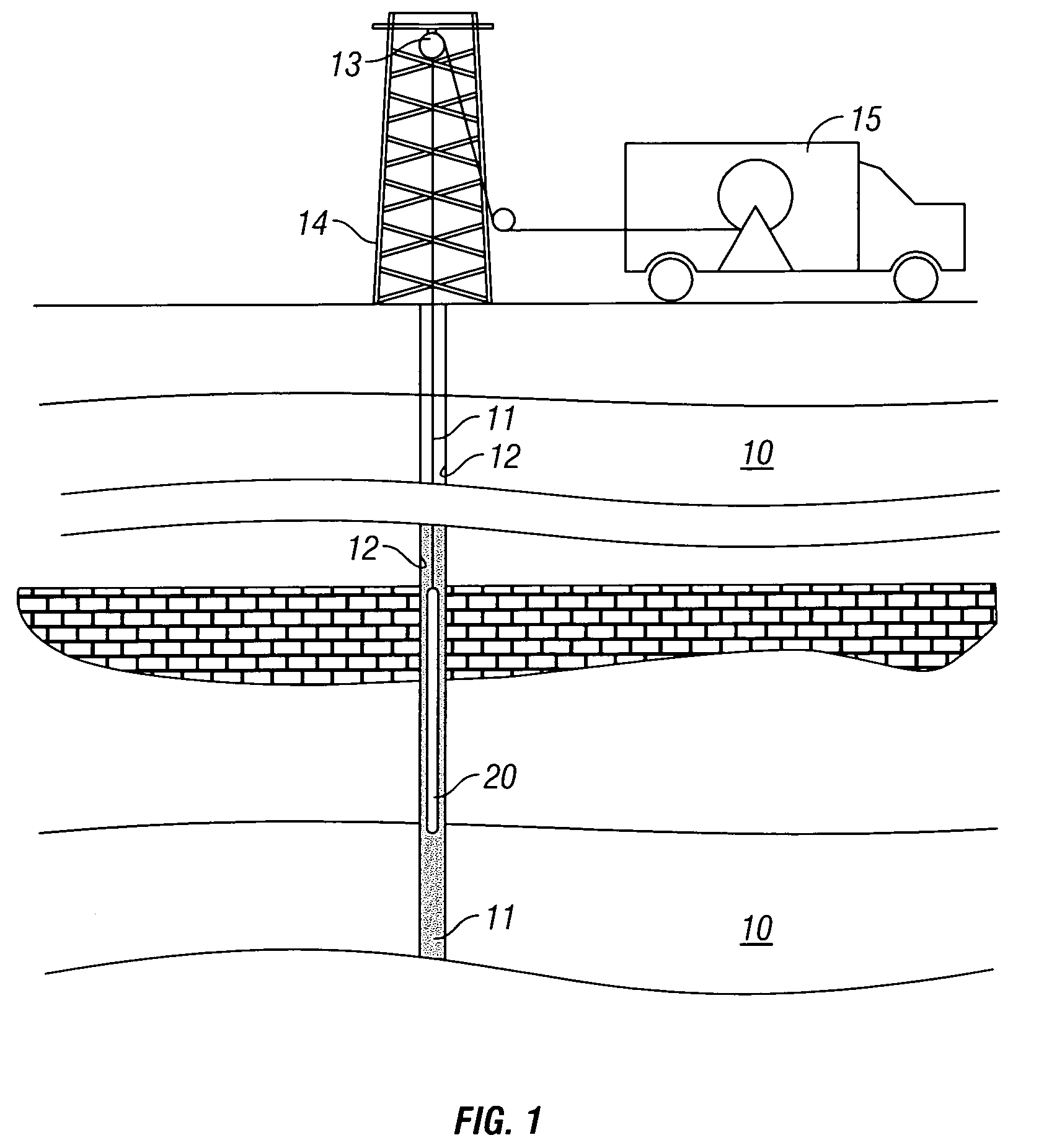

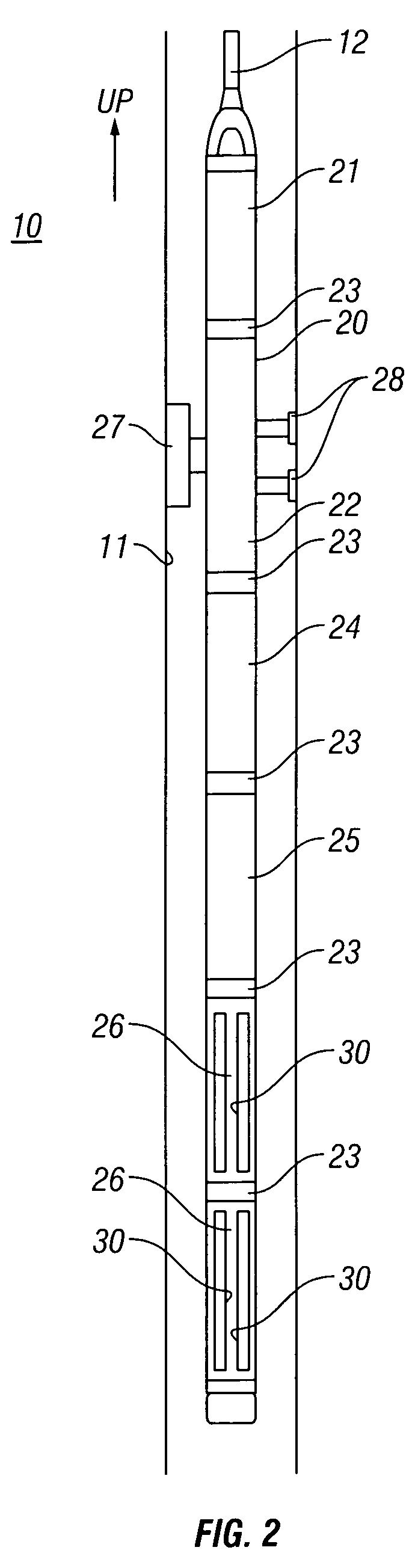

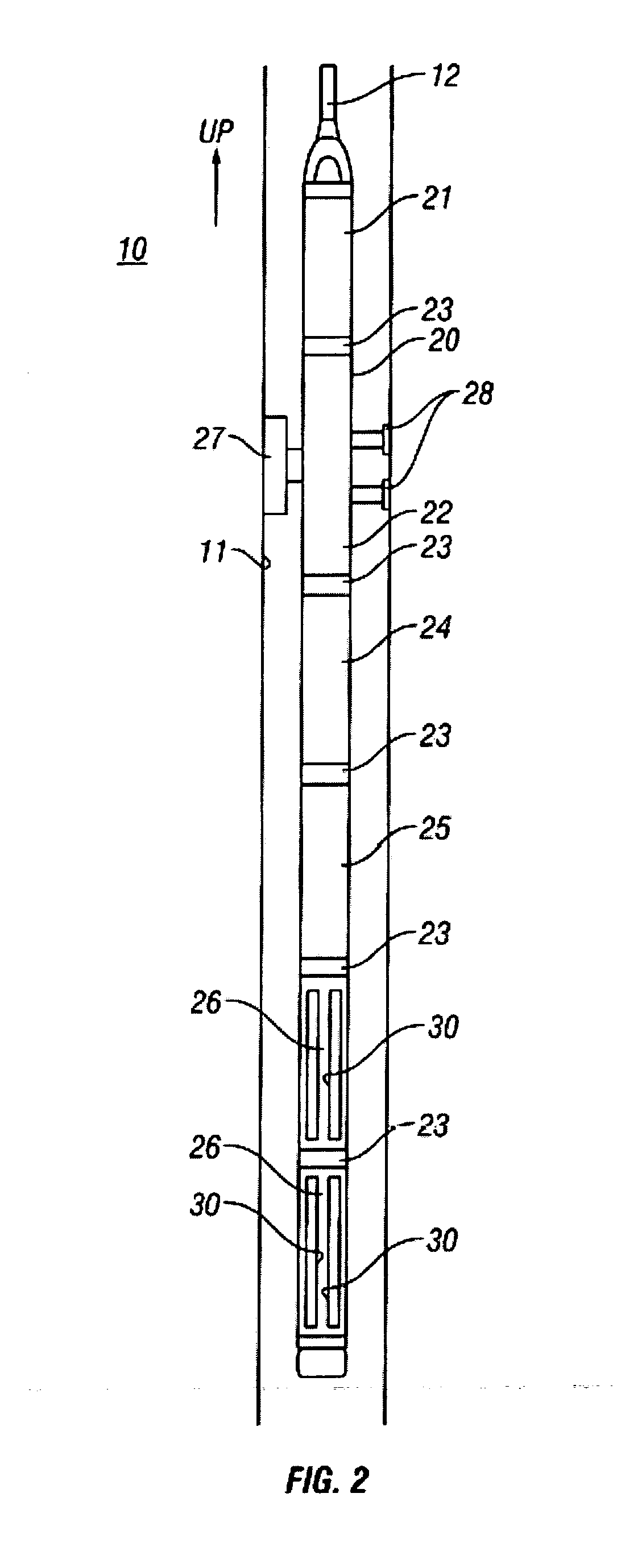

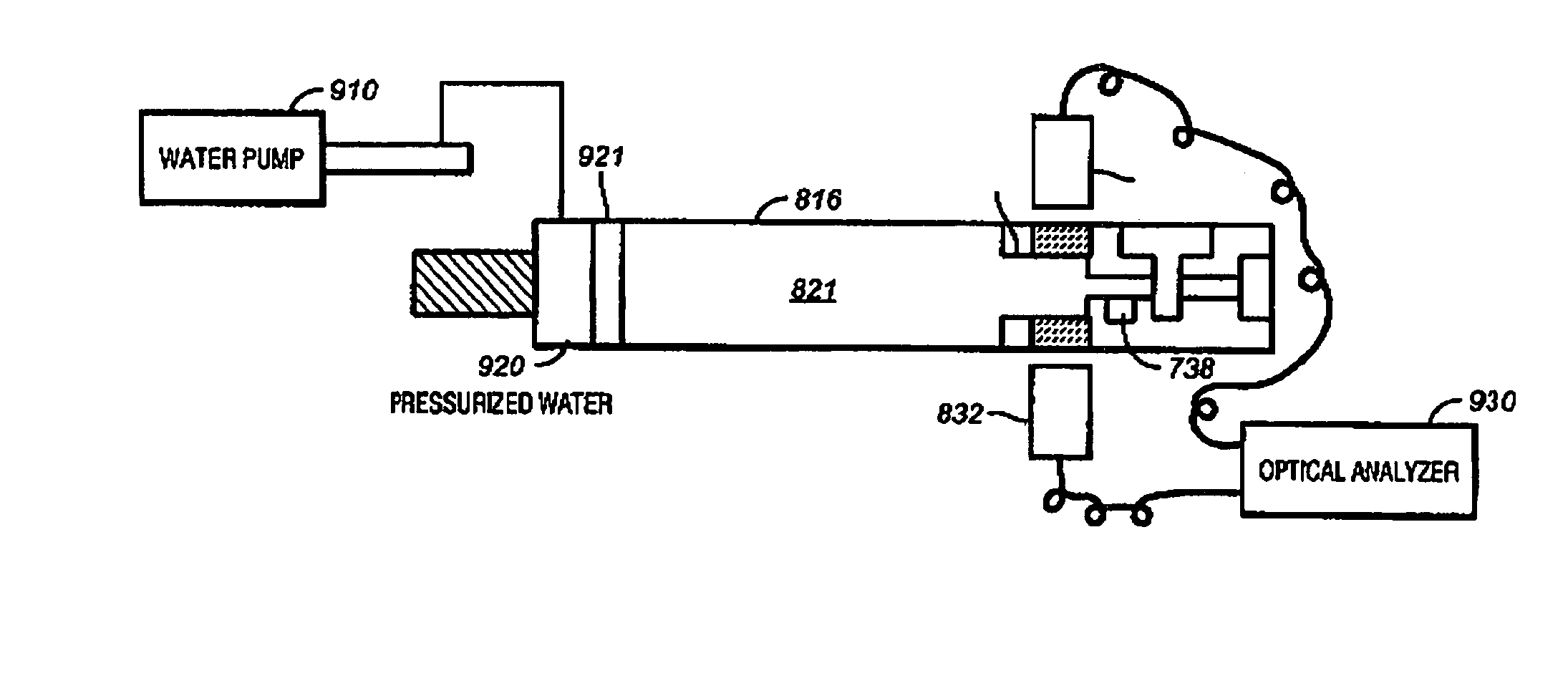

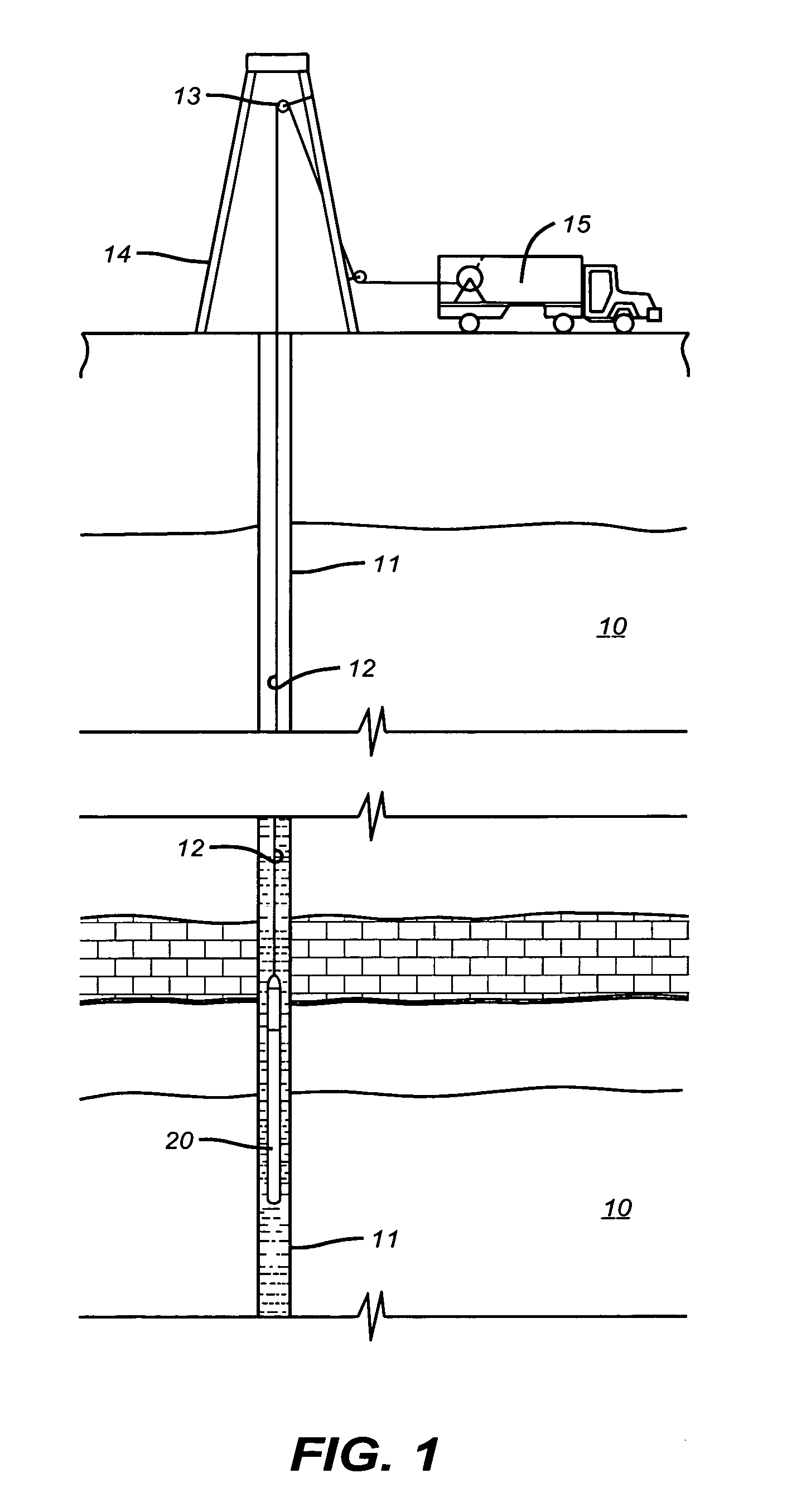

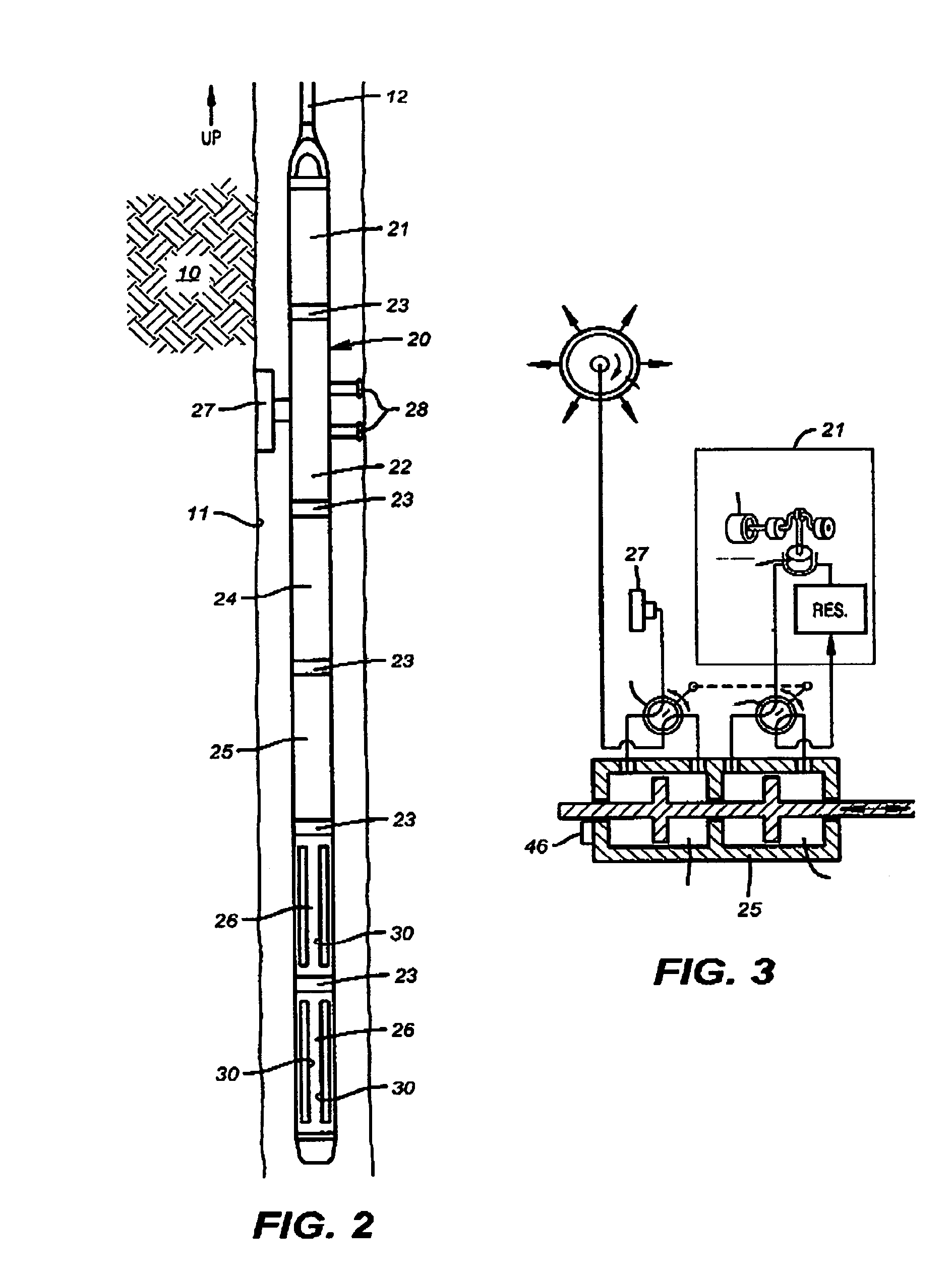

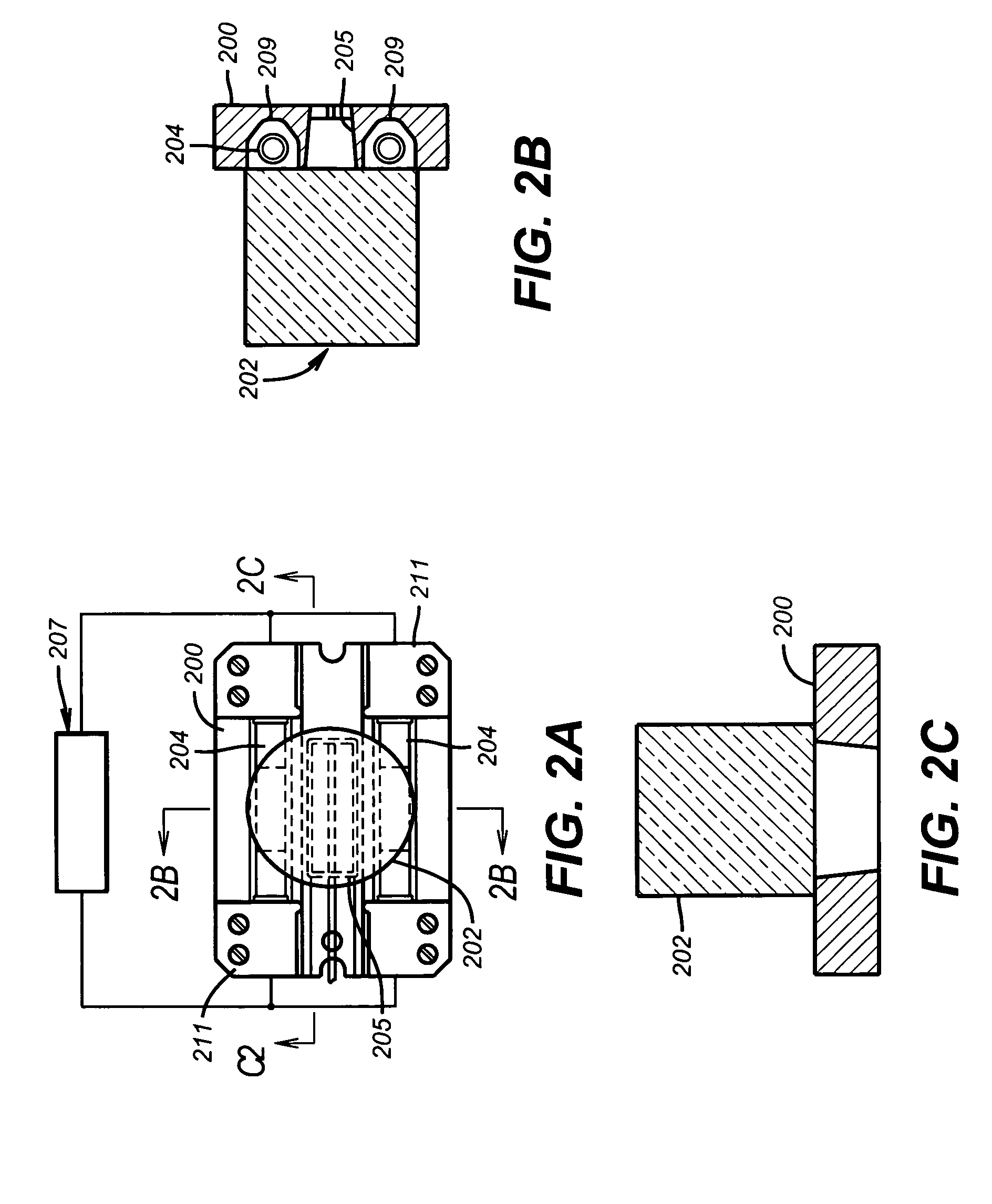

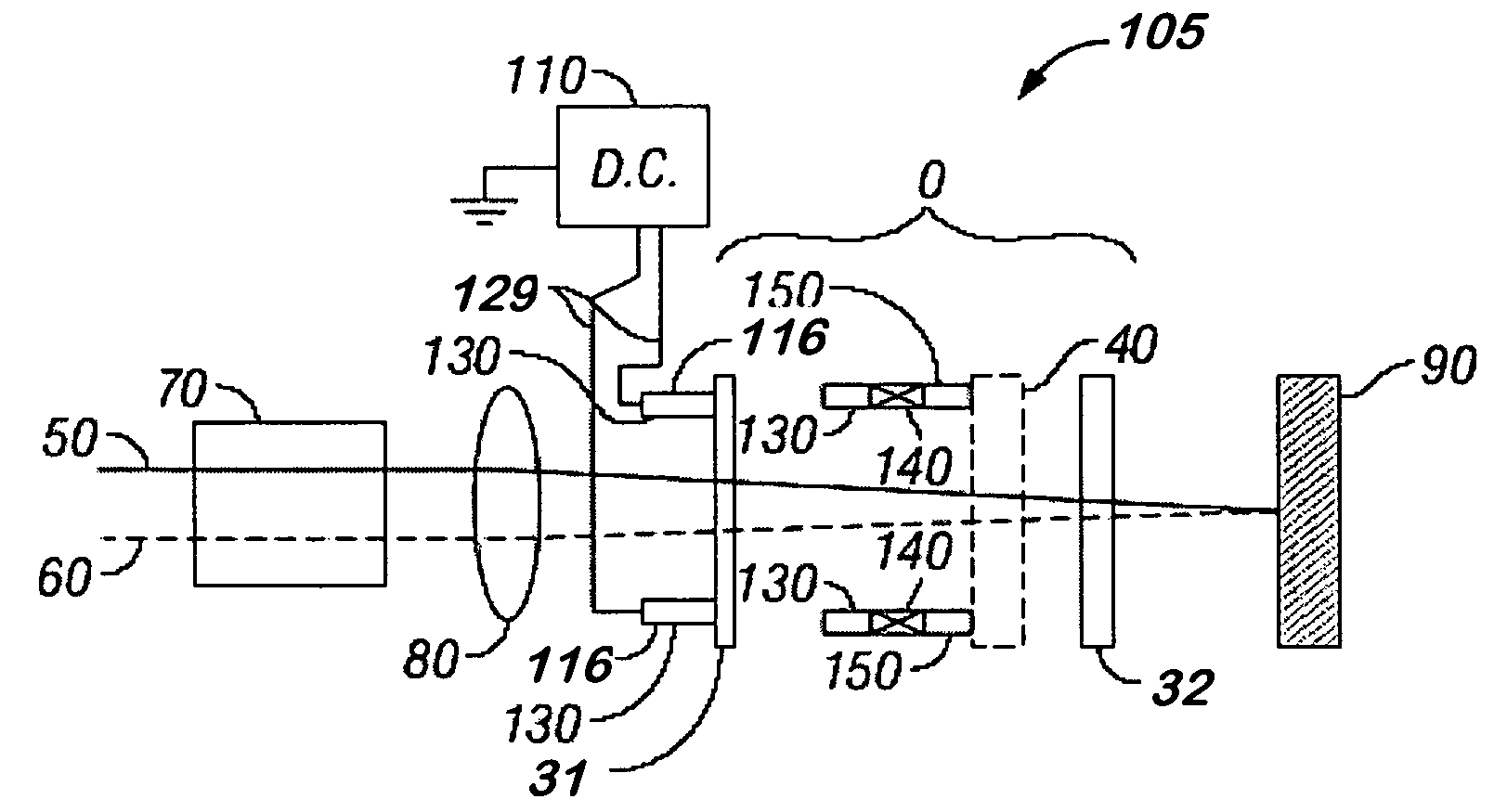

The present invention provides an apparatus and method for high resolution spectroscopy (approximately 10 picometer wavelength resolution) using a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES INC

Method and apparatus for a tunable diode laser spectrometer for analysis of hydrocarbon samples

The present invention provides an down hole apparatus and method for ultrahigh resolution spectroscopy using a tunable diode laser (TDL) for analyzing a formation fluid sample downhole or at the surface to determine formation fluid parameters. In addition to absorption spectroscopy, the present invention can perform Raman spectroscopy on the fluid, by sweeping the wavelength of the TDL and detecting the Raman-scattered light using a narrow-band detector at a fixed wavelength. The spectrometer analyzes a pressurized well bore fluid sample that is collected downhole. The analysis is performed either downhole or at the surface onsite. Near infrared, mid-infrared and visible light analysis is also performed on the sample to provide an onsite surface or downhole analysis of sample properties and contamination level. The onsite and downhole analysis comprises determination of aromatics, olefins, saturates, gas oil ratio, API gravity and various other parameters which can be estimated by correlation, a trained neural network or a chemometric equation.

Owner:BAKER HUGHES INC

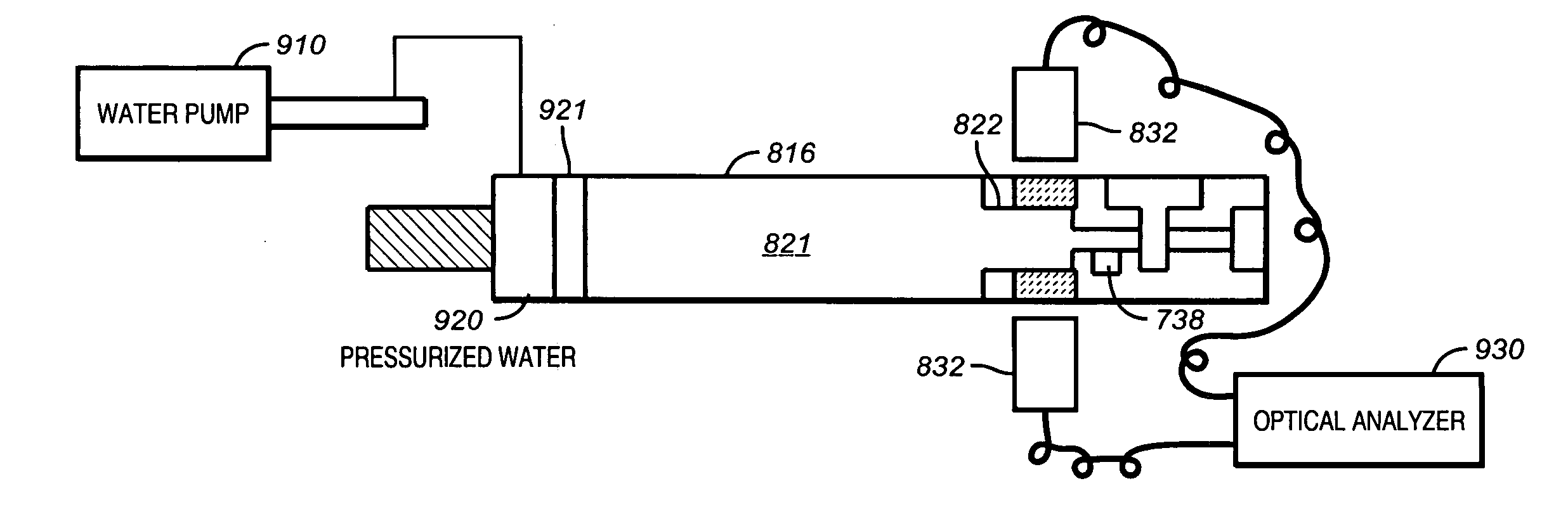

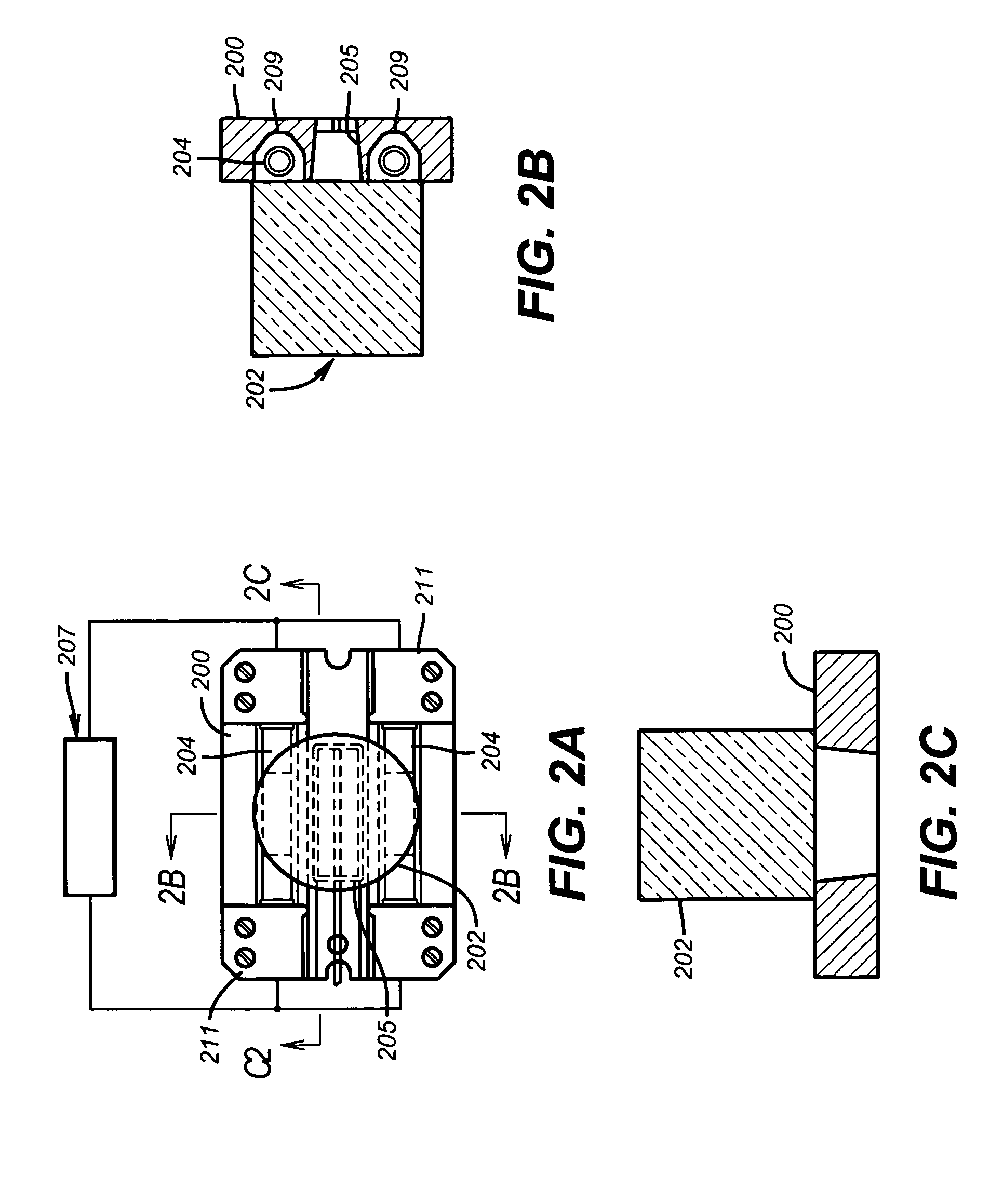

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

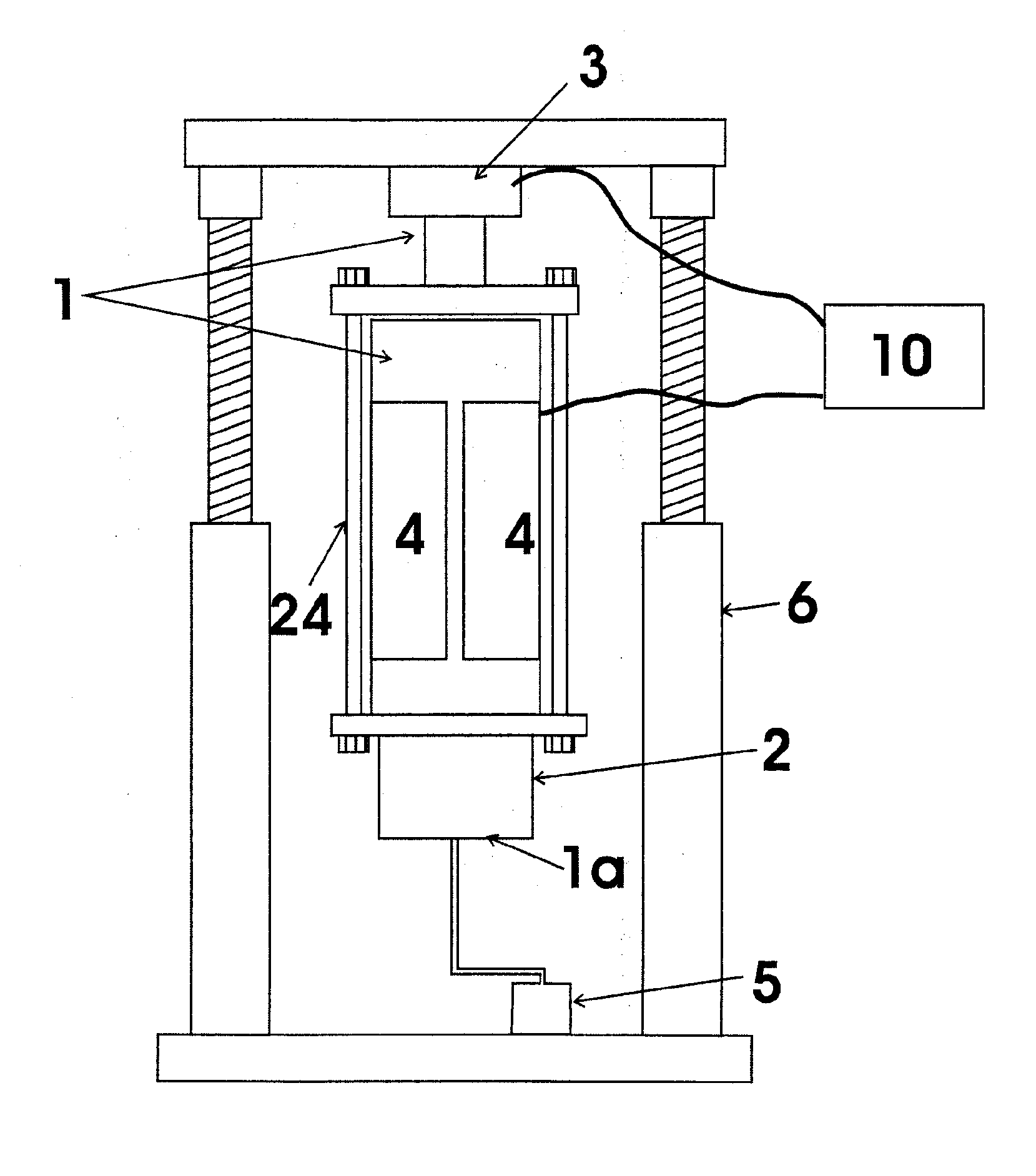

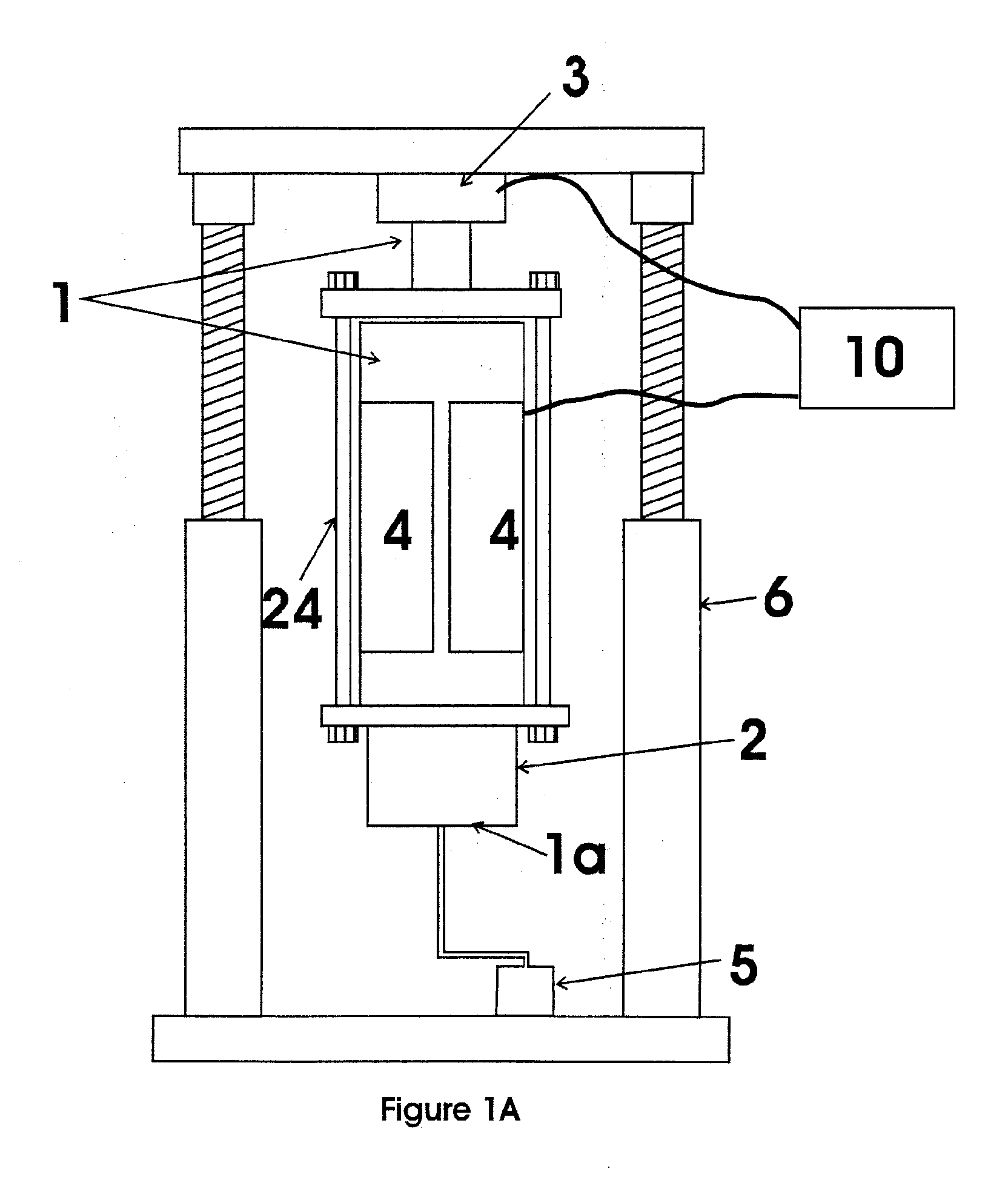

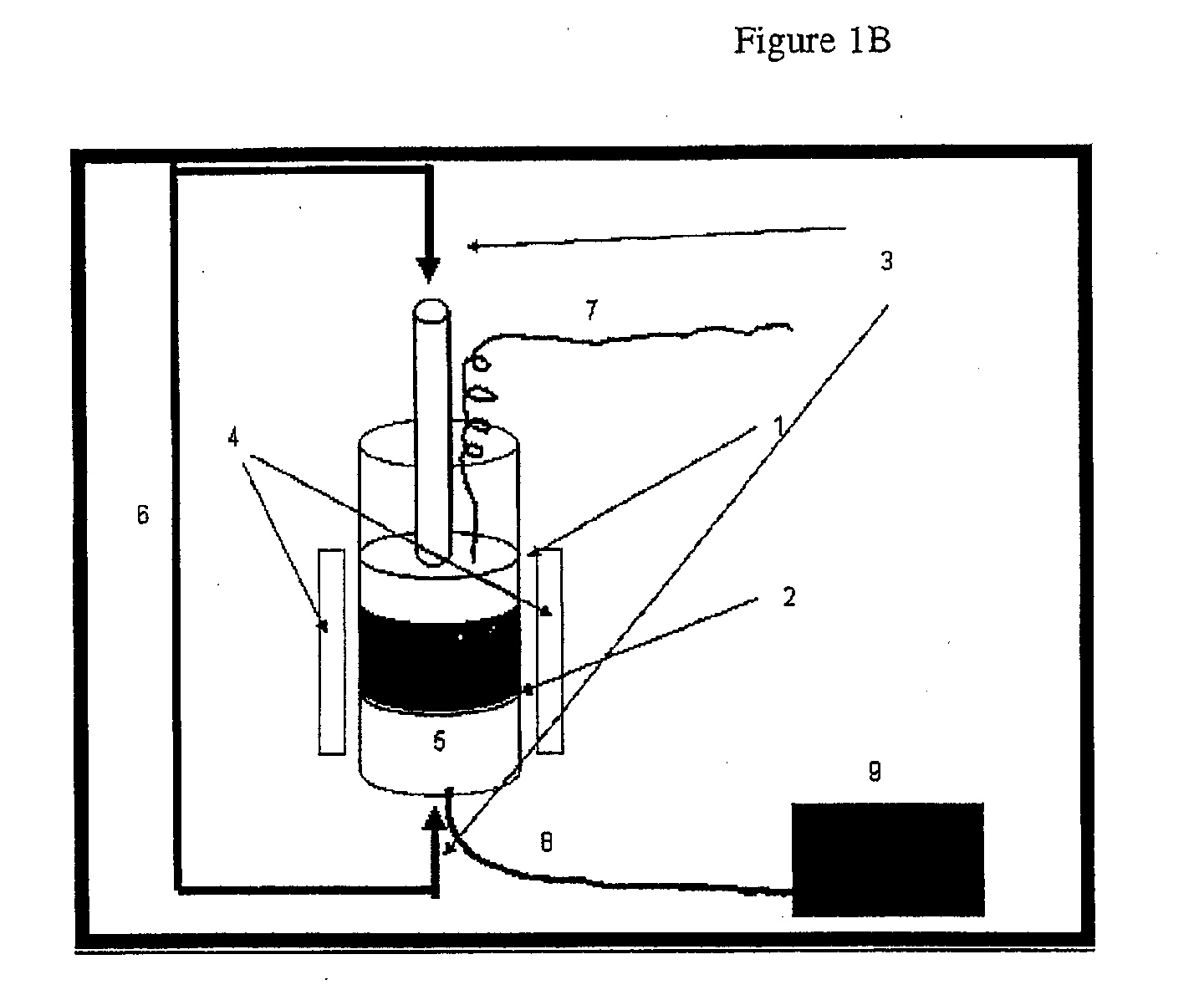

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

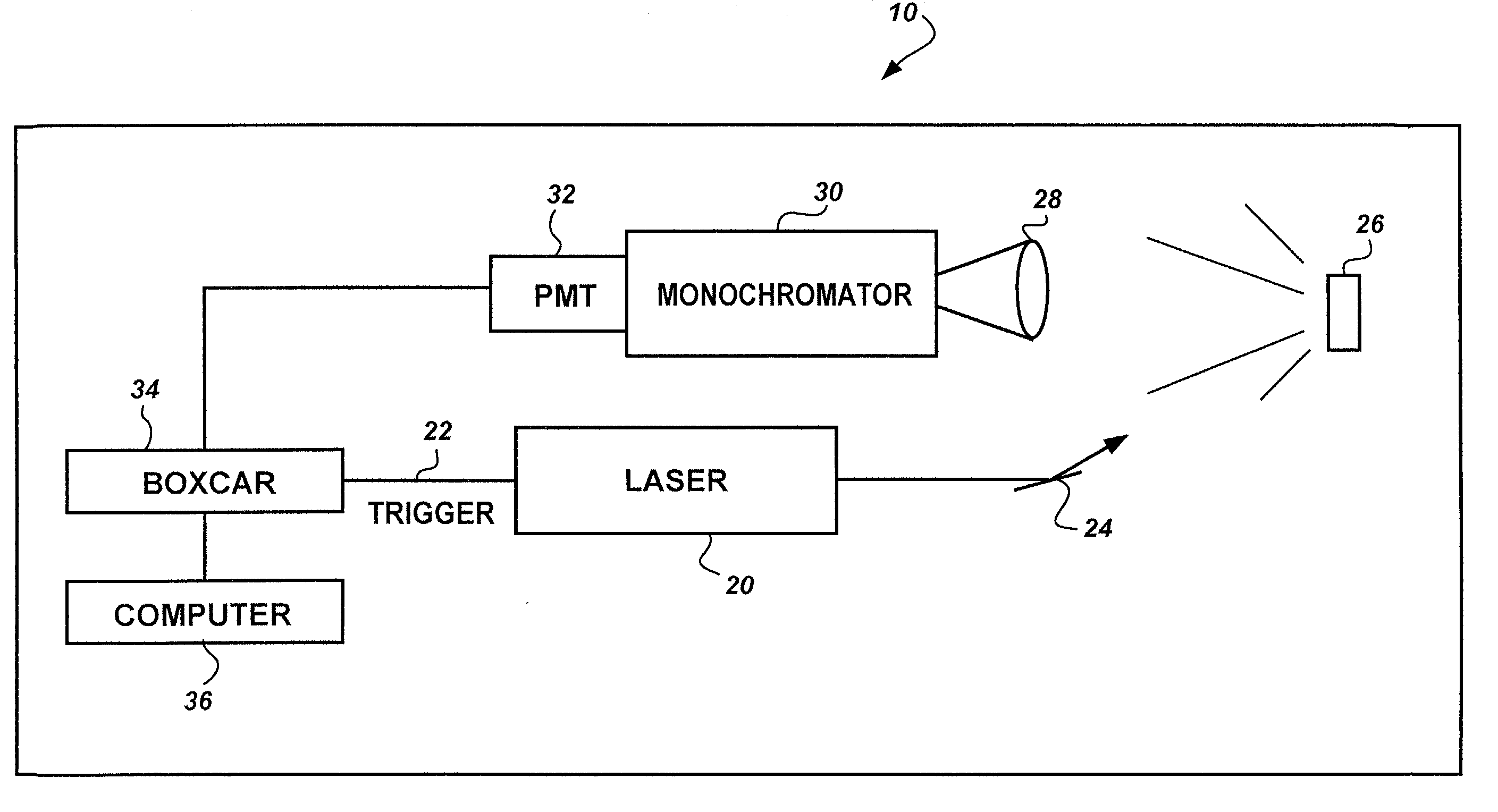

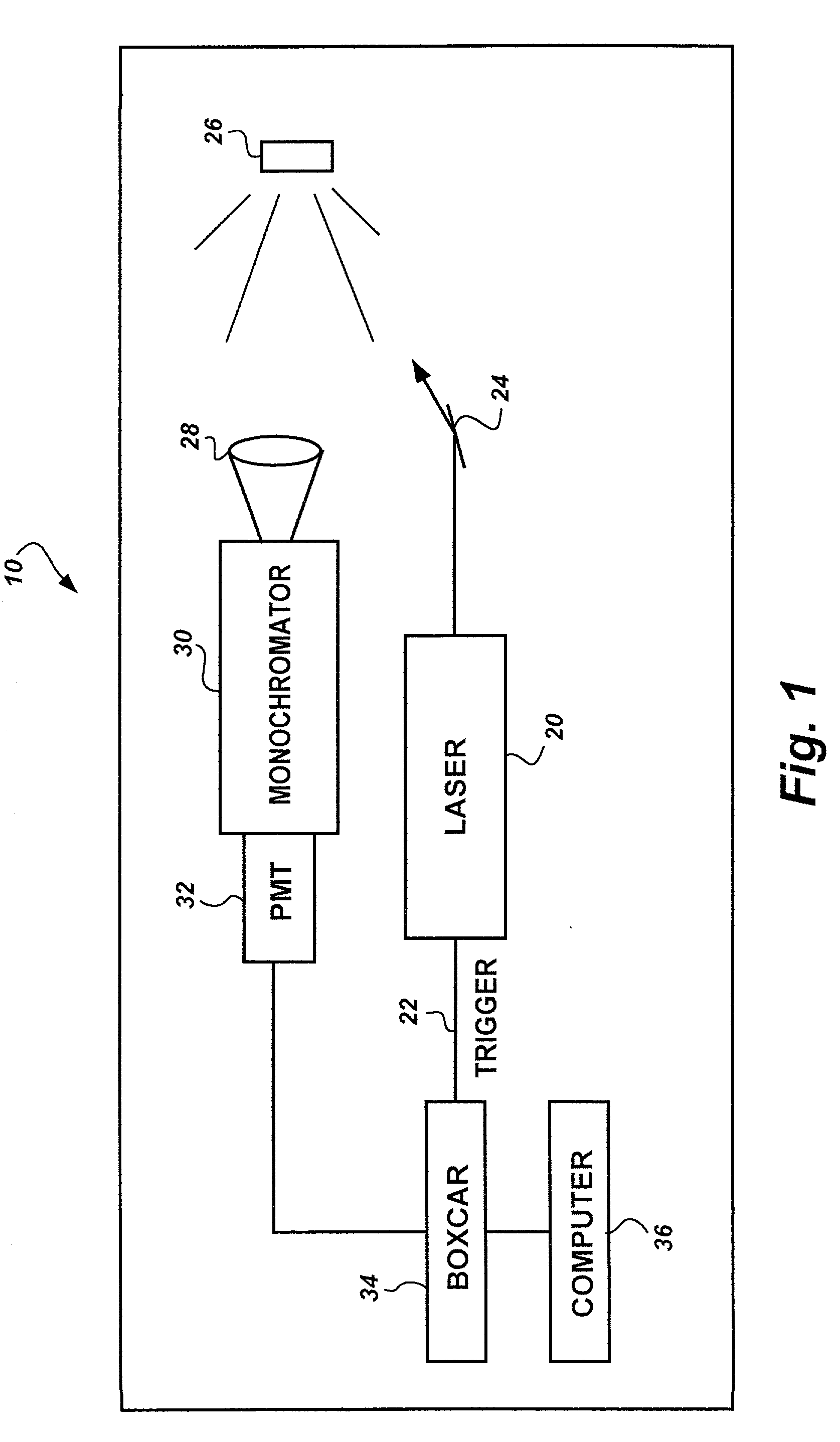

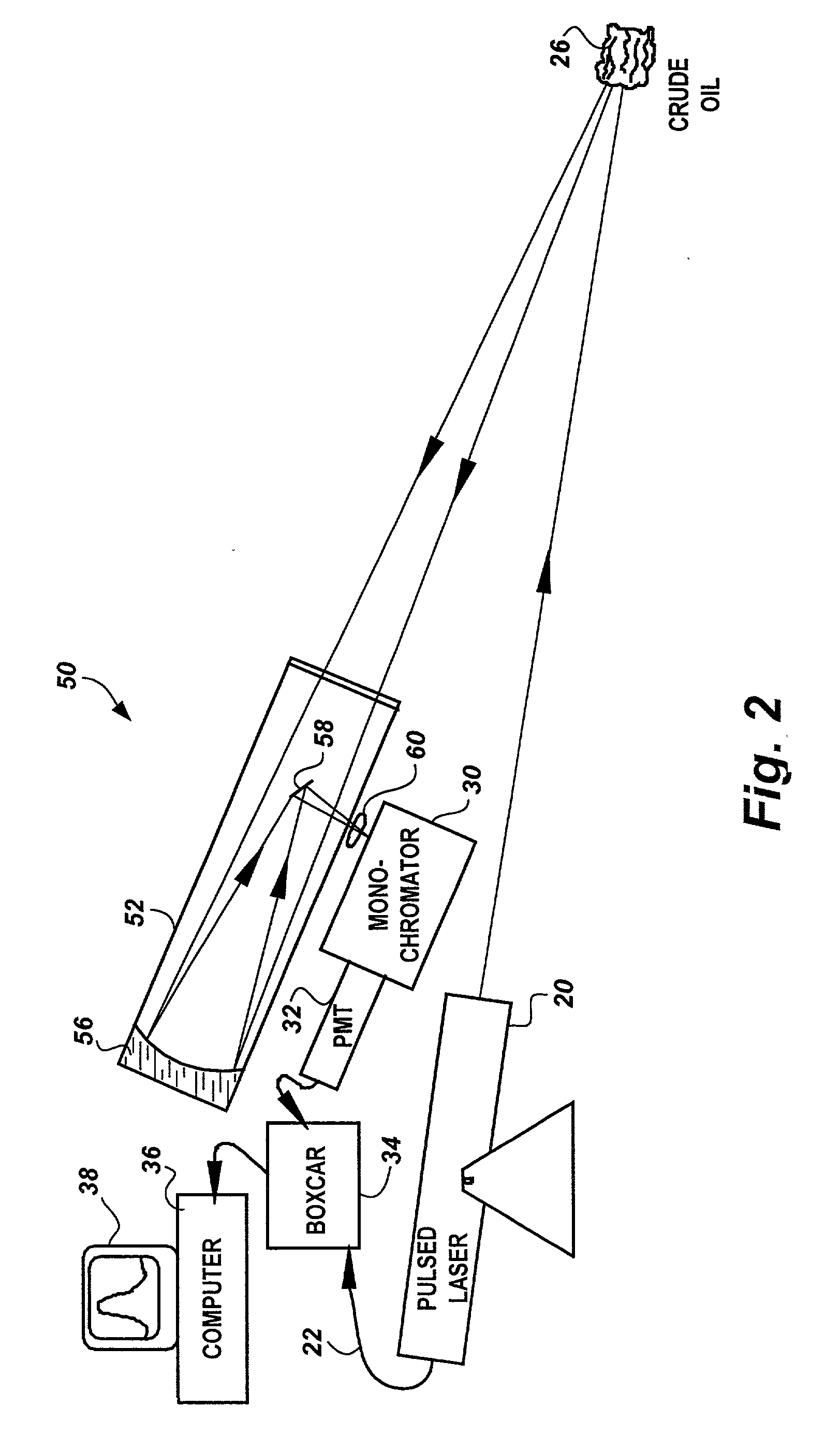

Method for characterization of petroleum oils using normalized time-resolved fluorescence spectra

A method based on time-resolved, laser-induced fluorescence spectroscopy for the characterization and fingerprinting of petroleum oils and other complex mixtures. The method depends on exciting the wavelength-resolved fluorescence spectra of samples using ultraviolet pulsed laser radiation, measuring them at specific time gates within the temporal response of the excitation laser pulse, and comparing them in terms of their shapes alone without taking into account their relative intensities. The method provides fingerprints of crude oils without resorting to any kind of approximation, for distinguishing between closely similar crude oils of the same grade, and is useful in remote and non-remote setups, along with applications in fingerprinting blended and non-blended crude oils using different ultraviolet excitation wavelengths. Applications include estimating °API gravity of crude oils and monitoring degradation of mineral oils.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

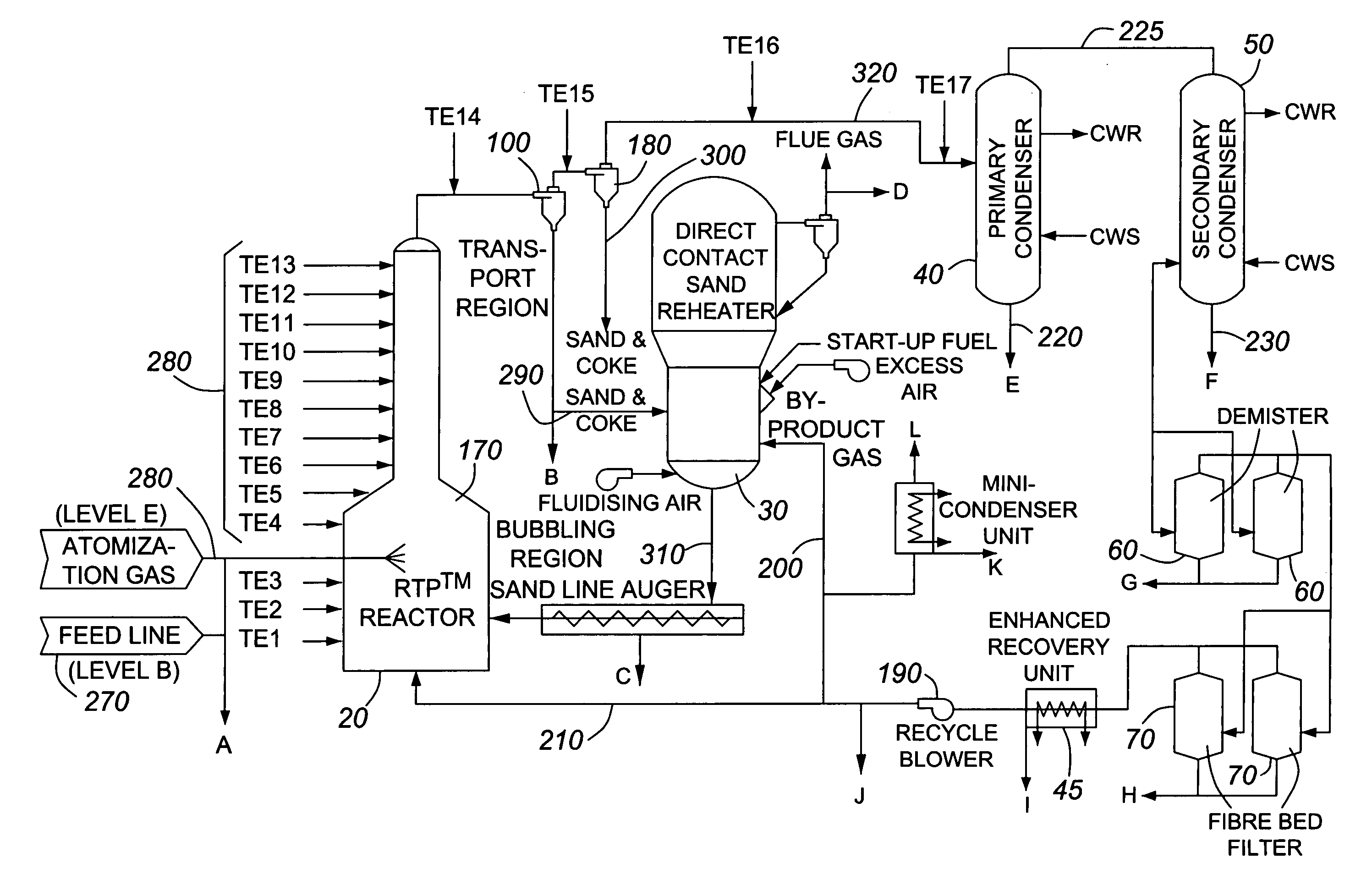

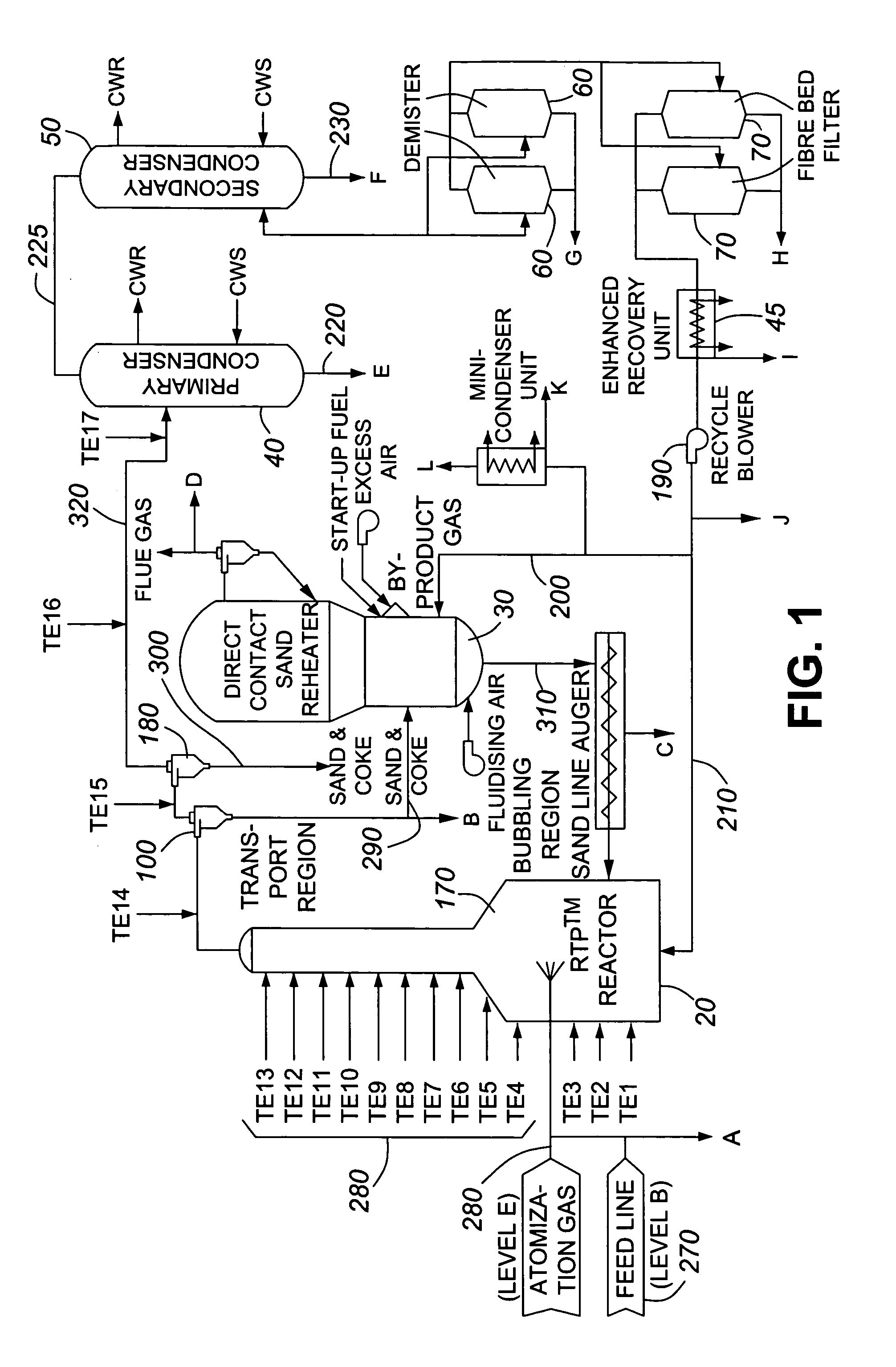

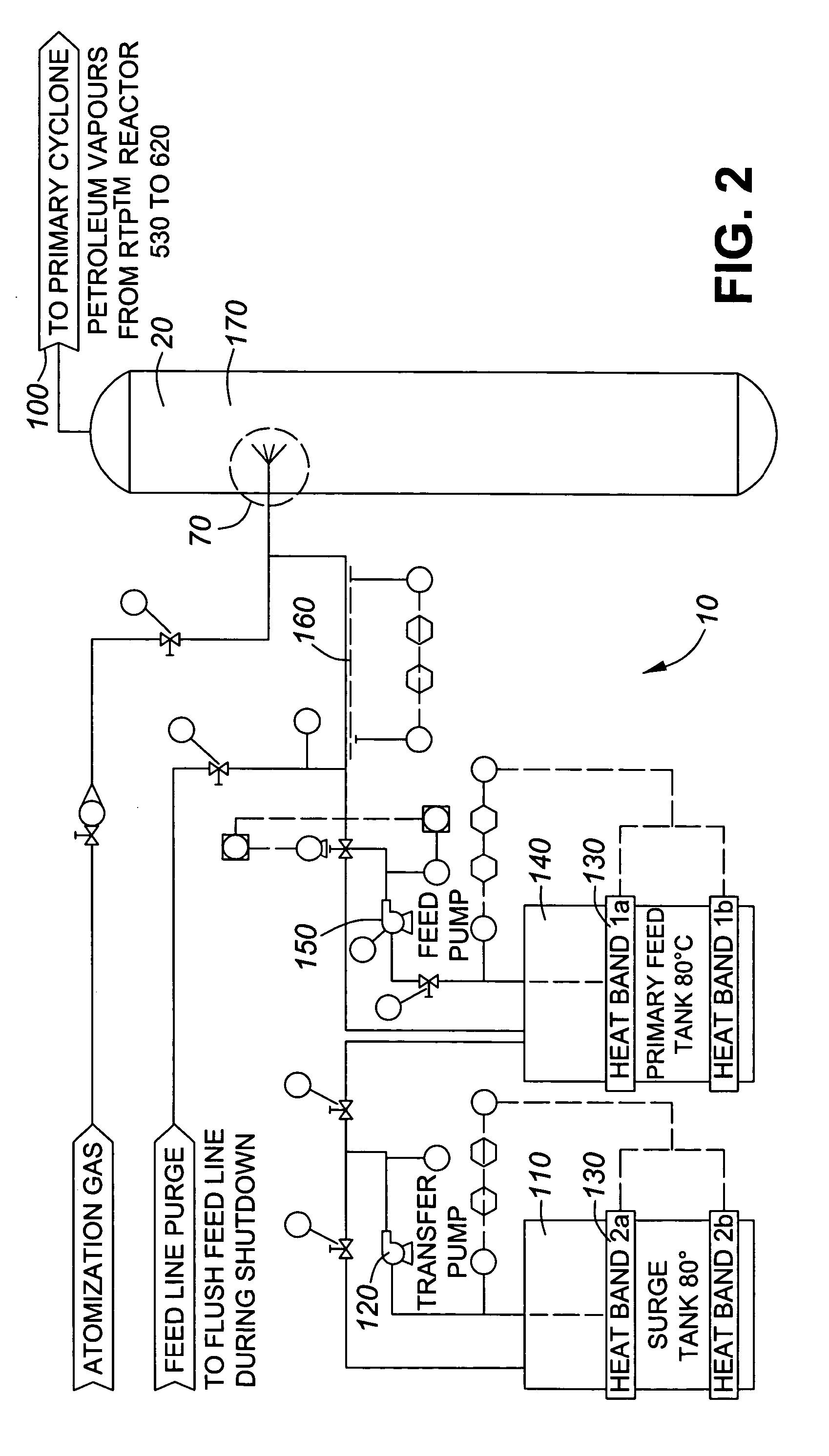

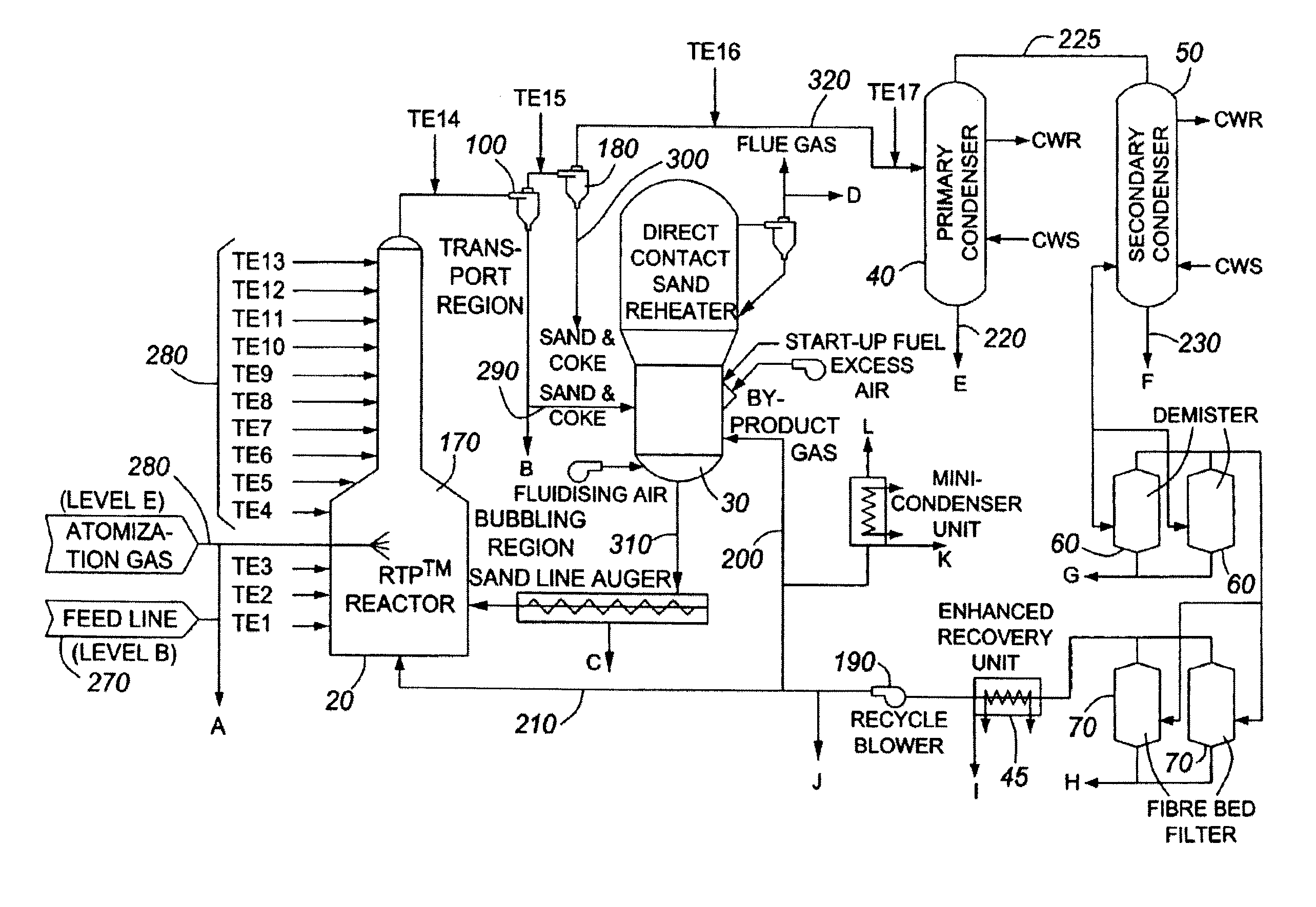

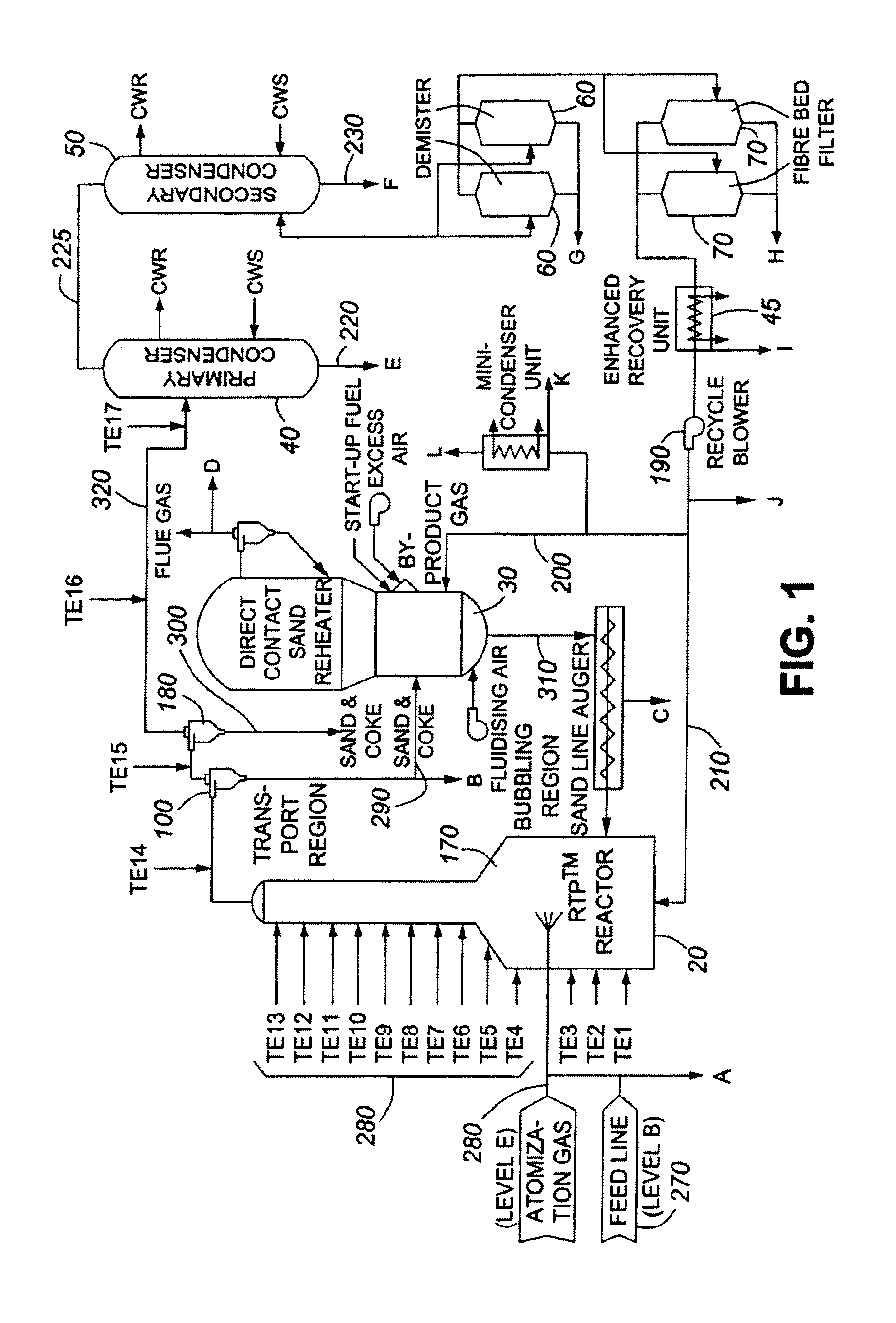

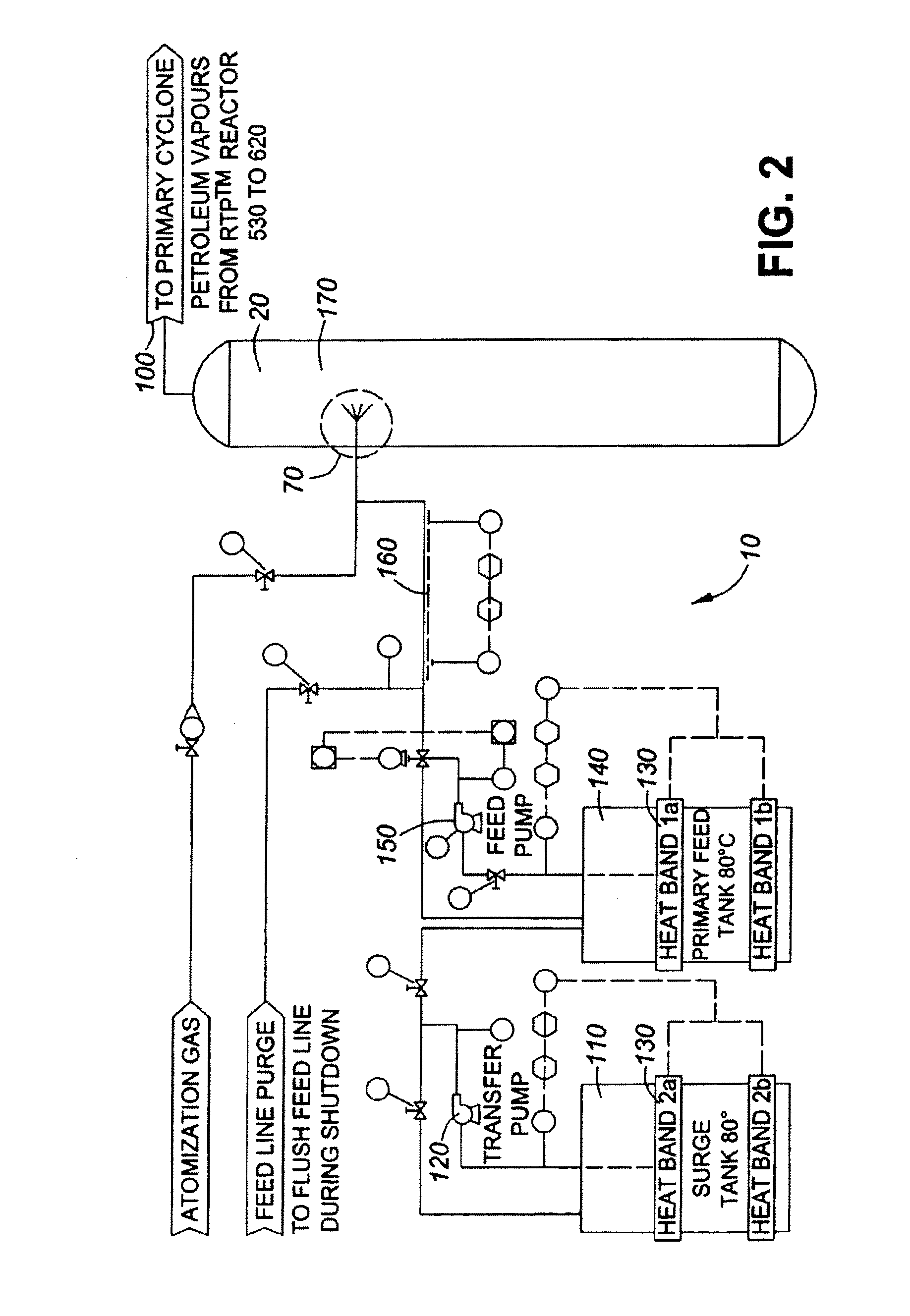

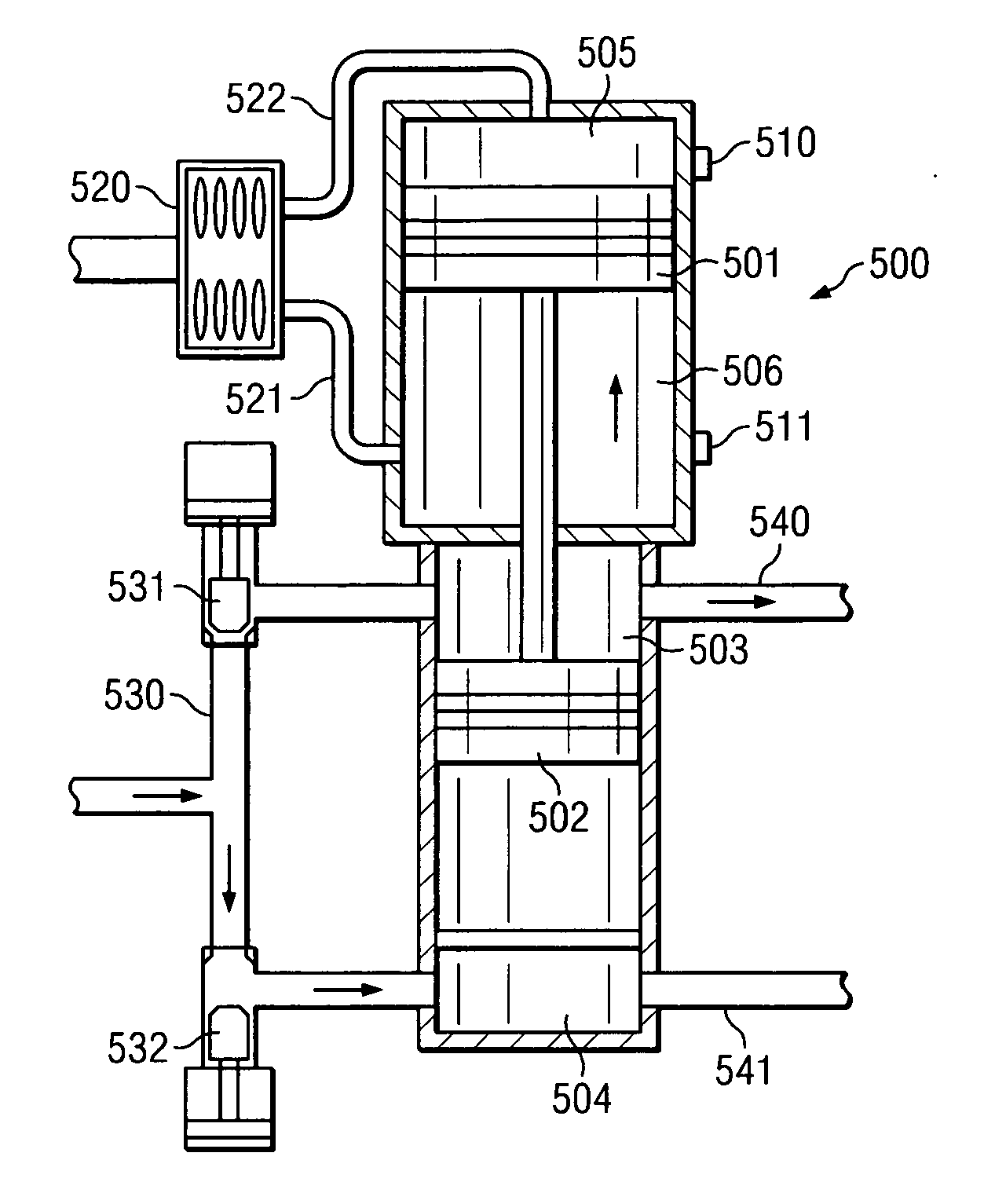

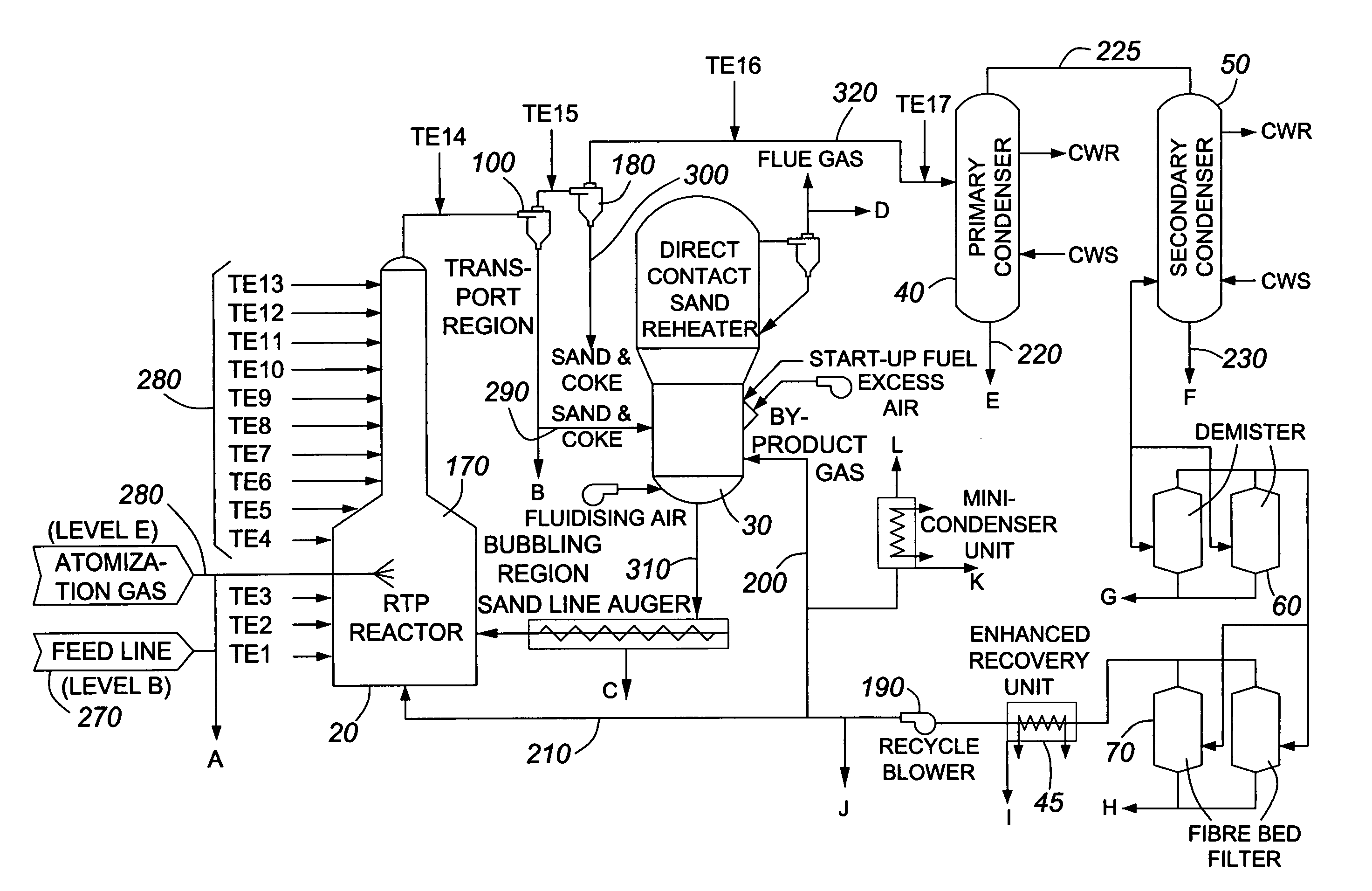

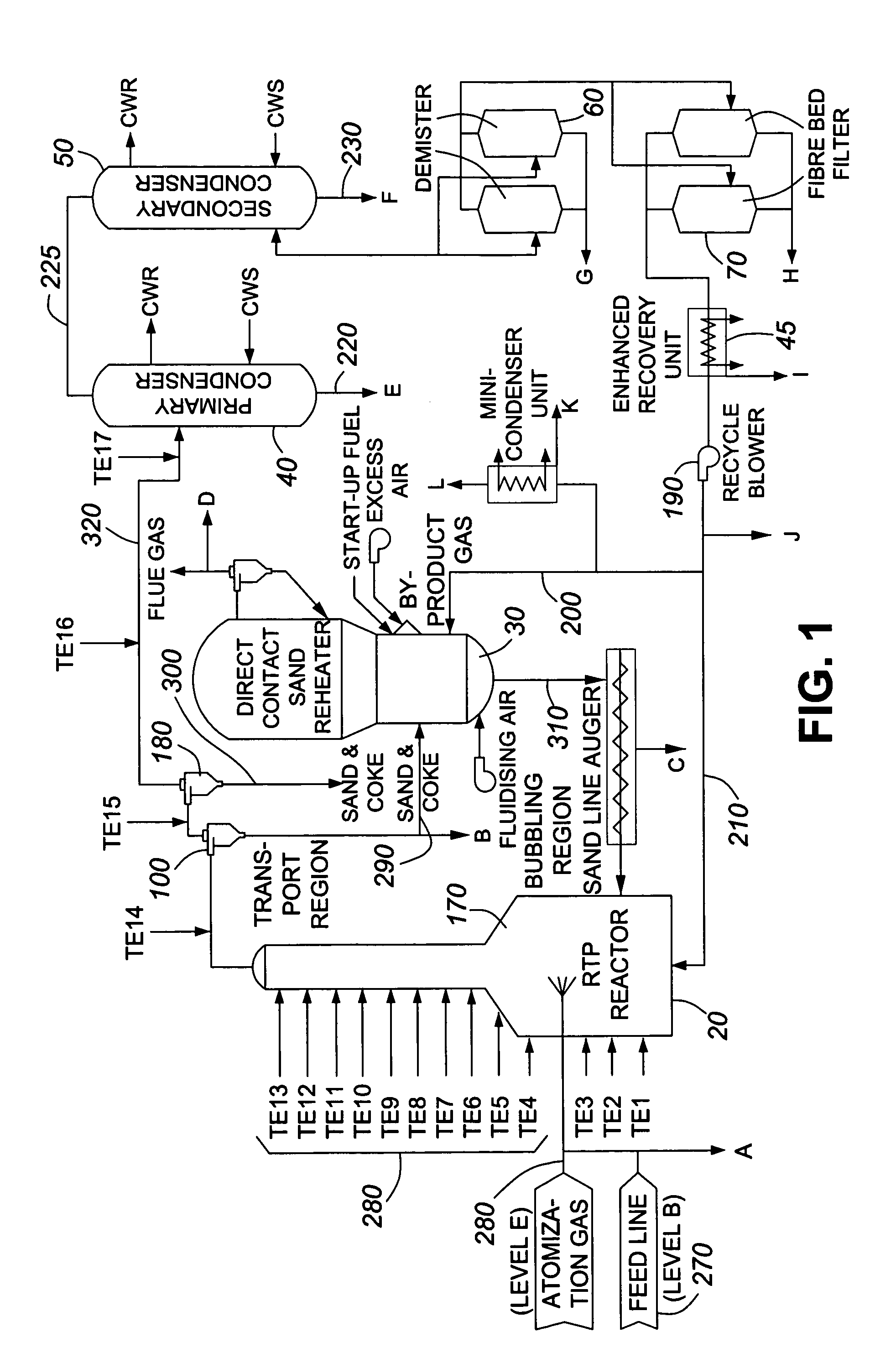

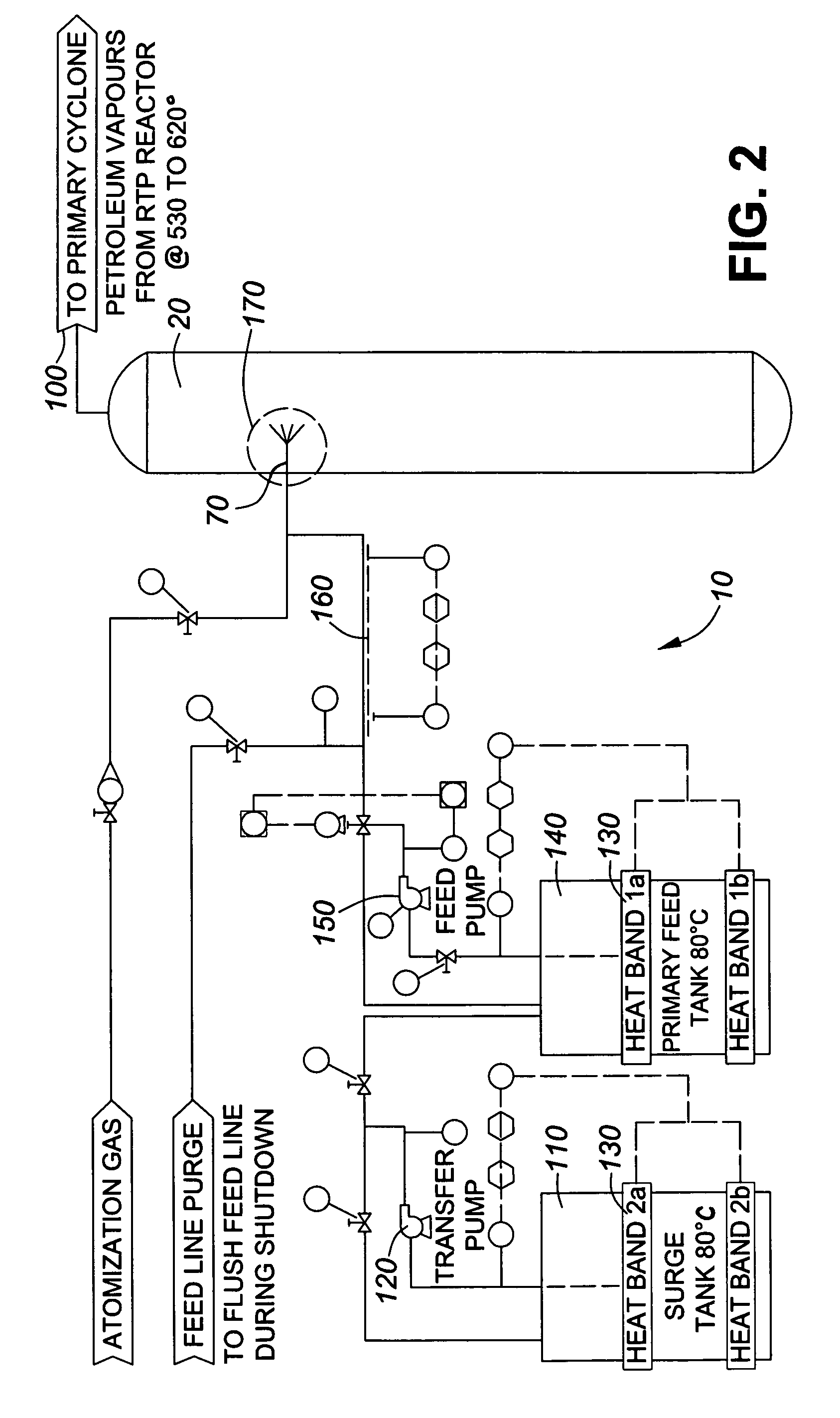

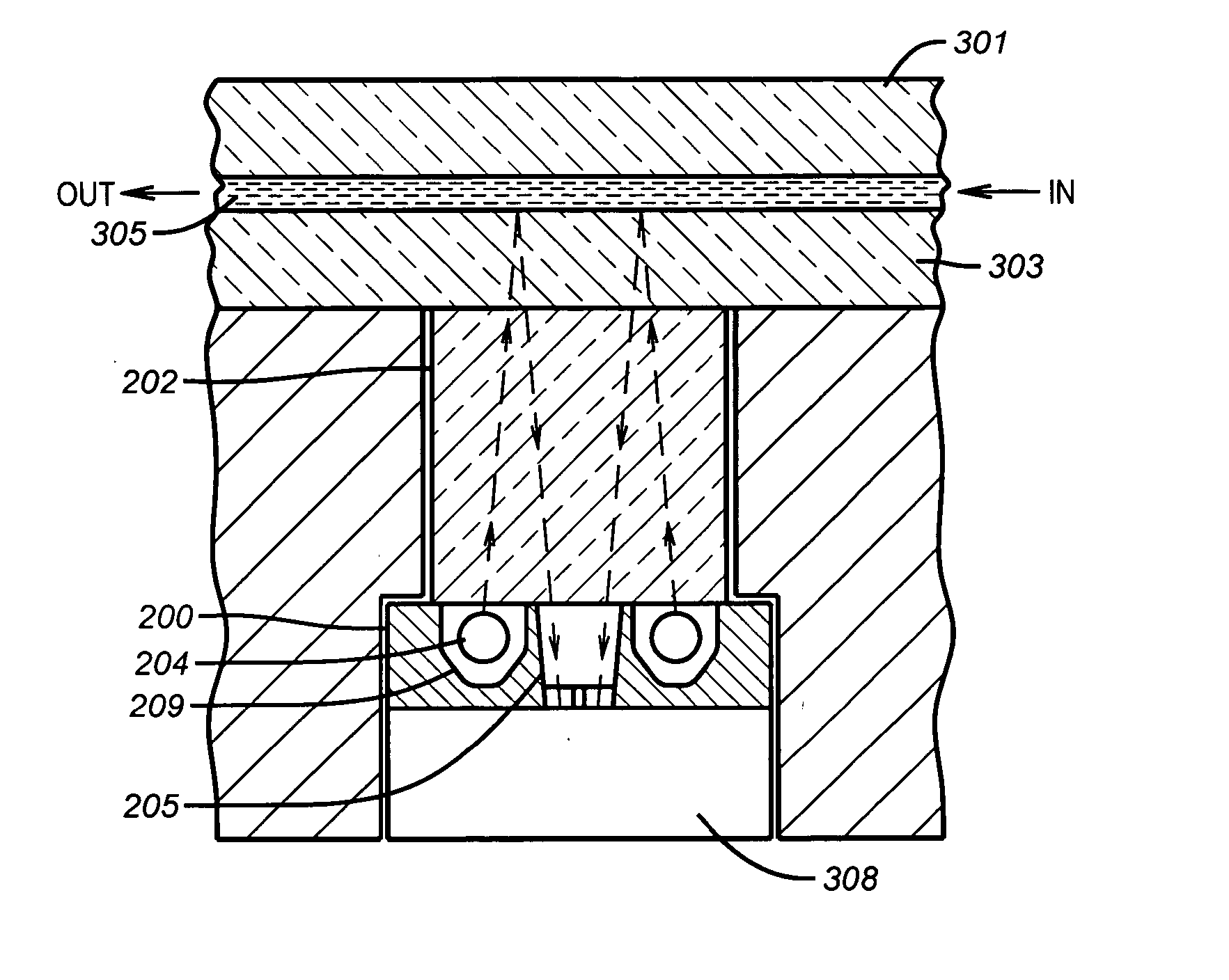

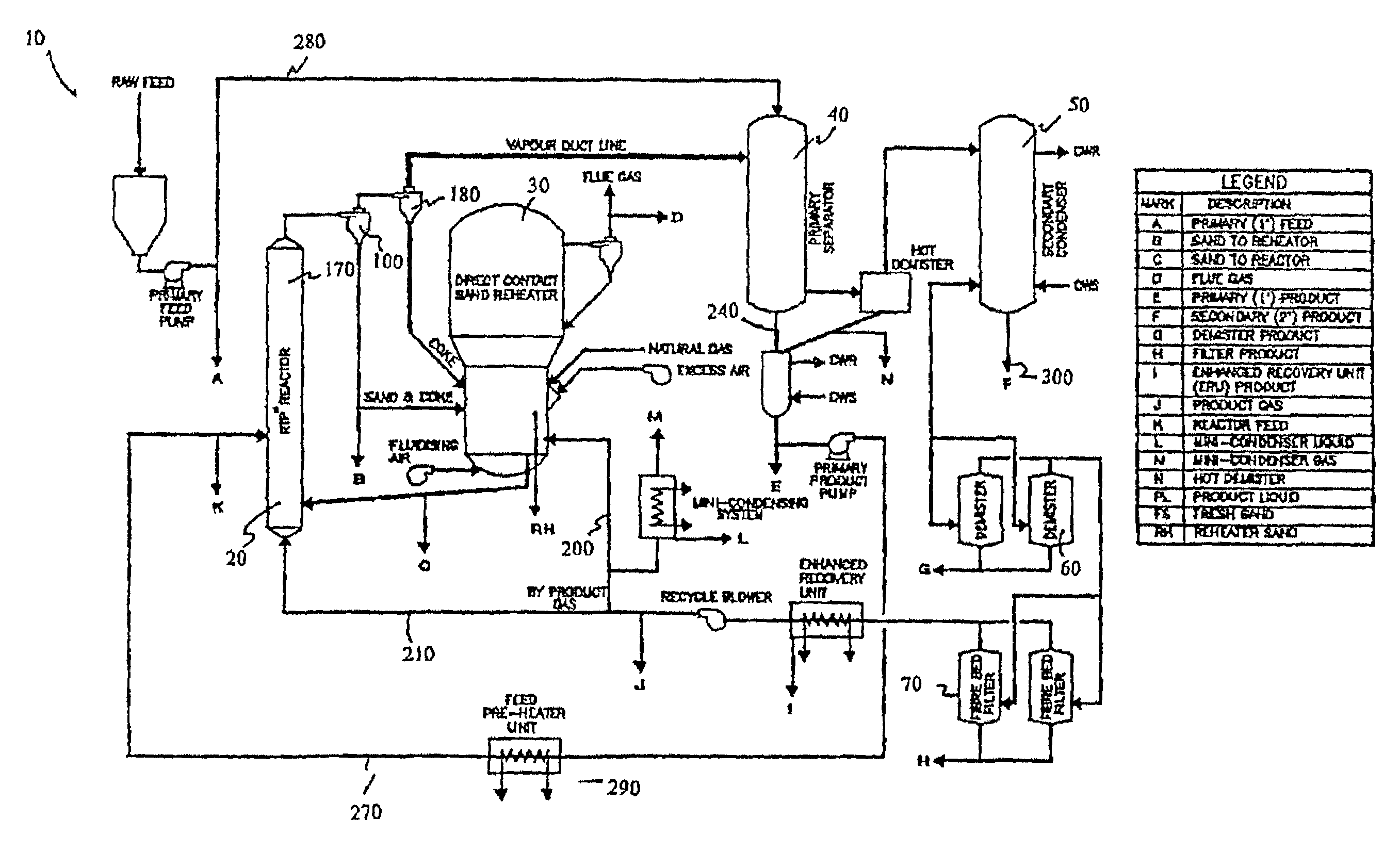

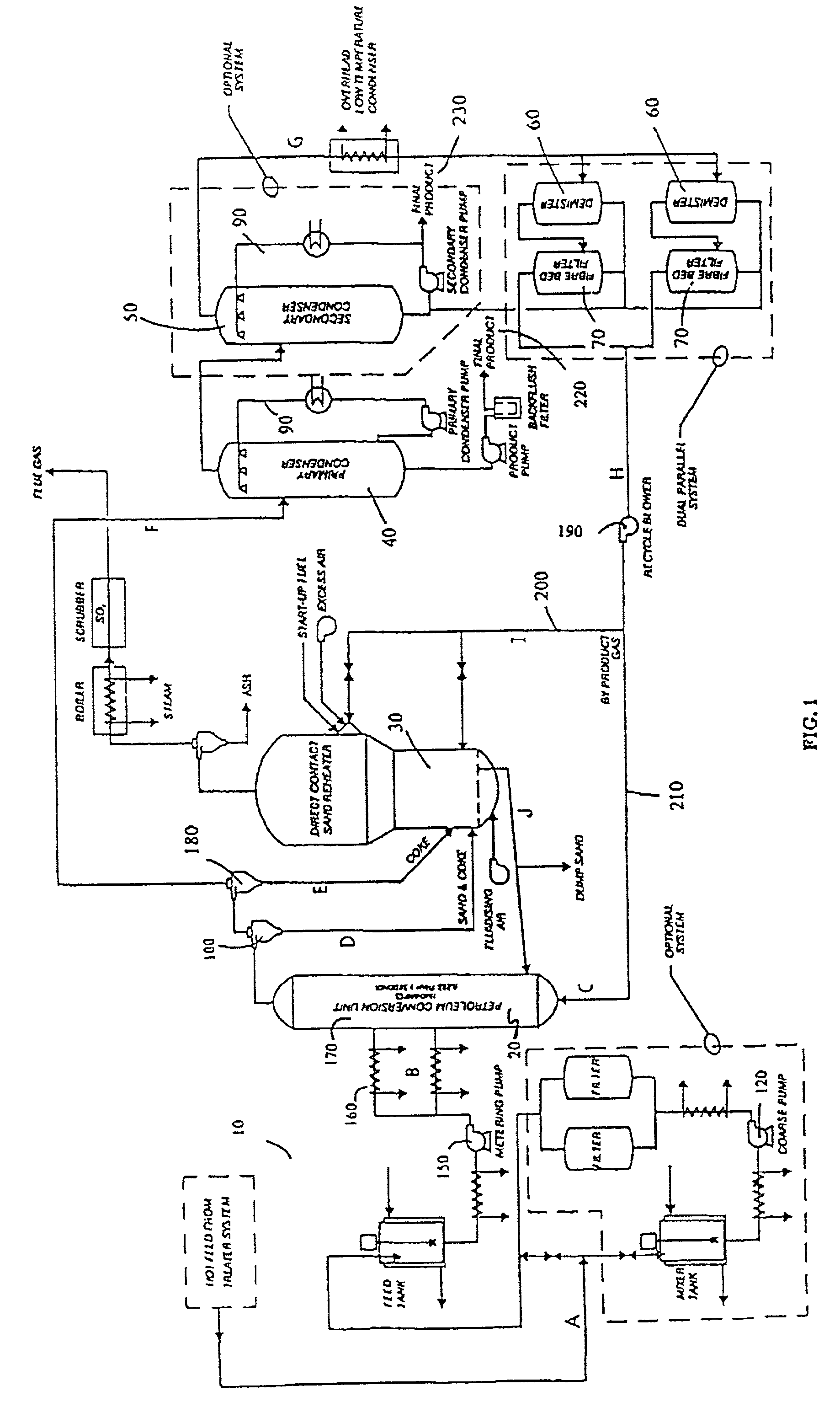

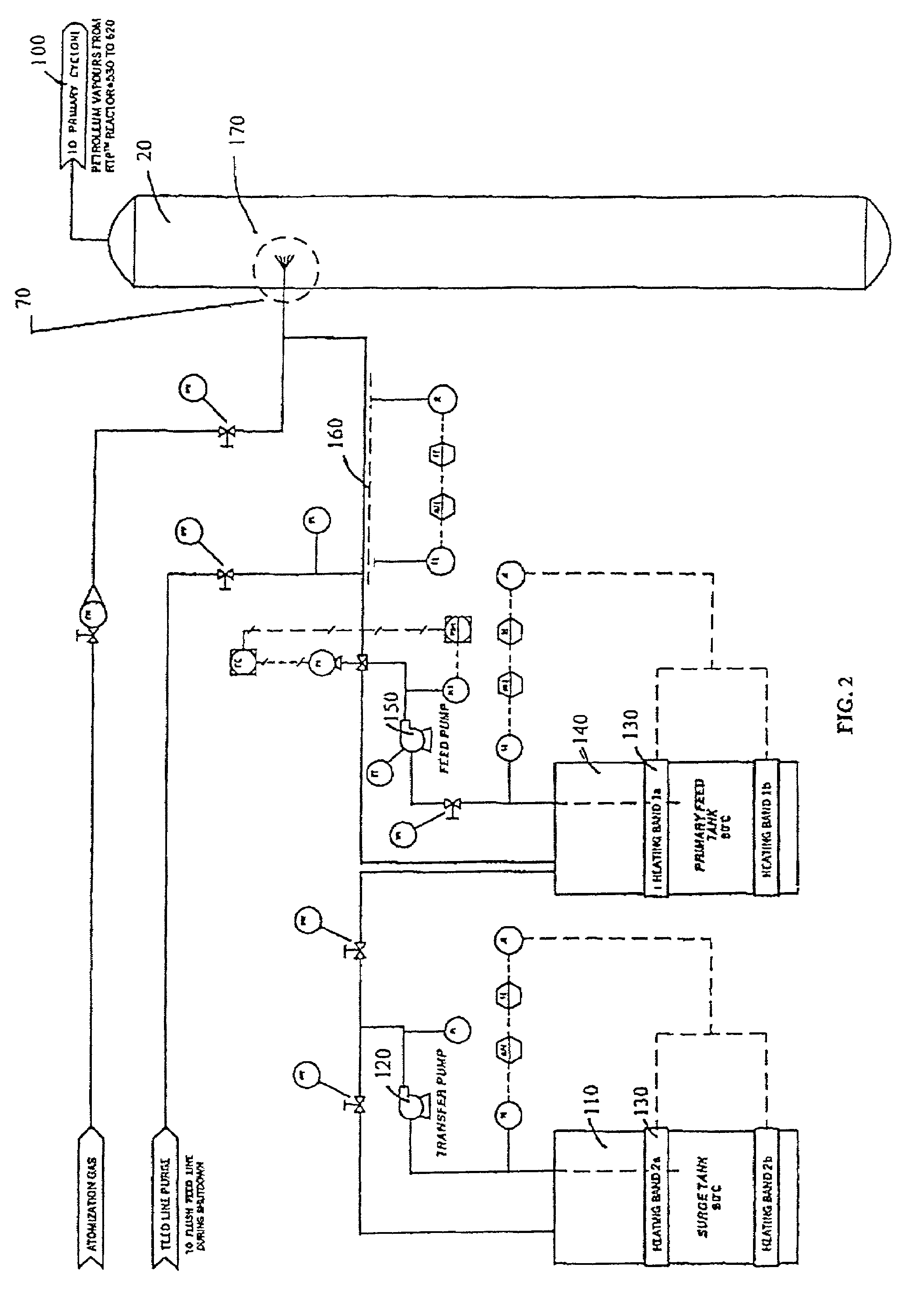

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

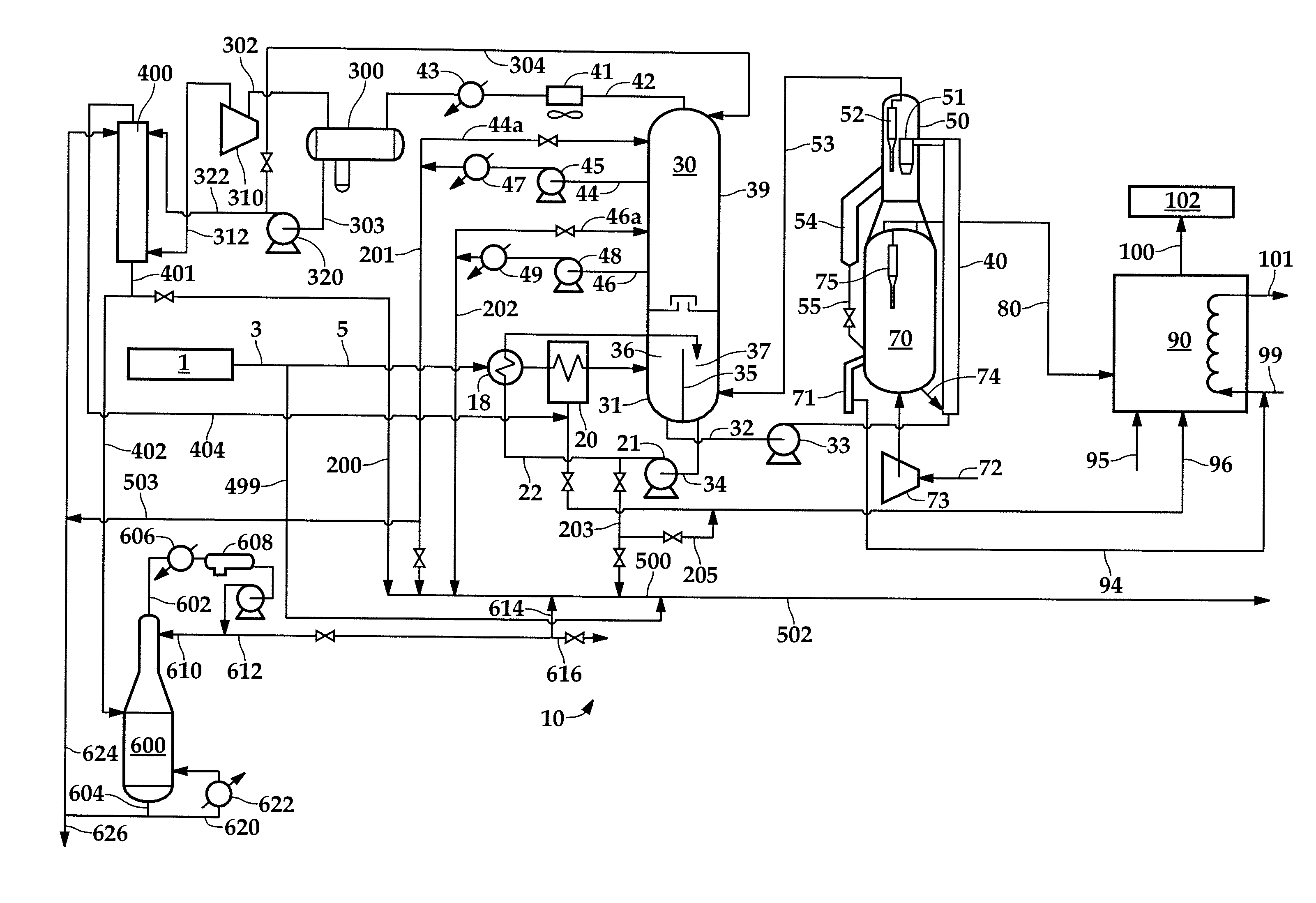

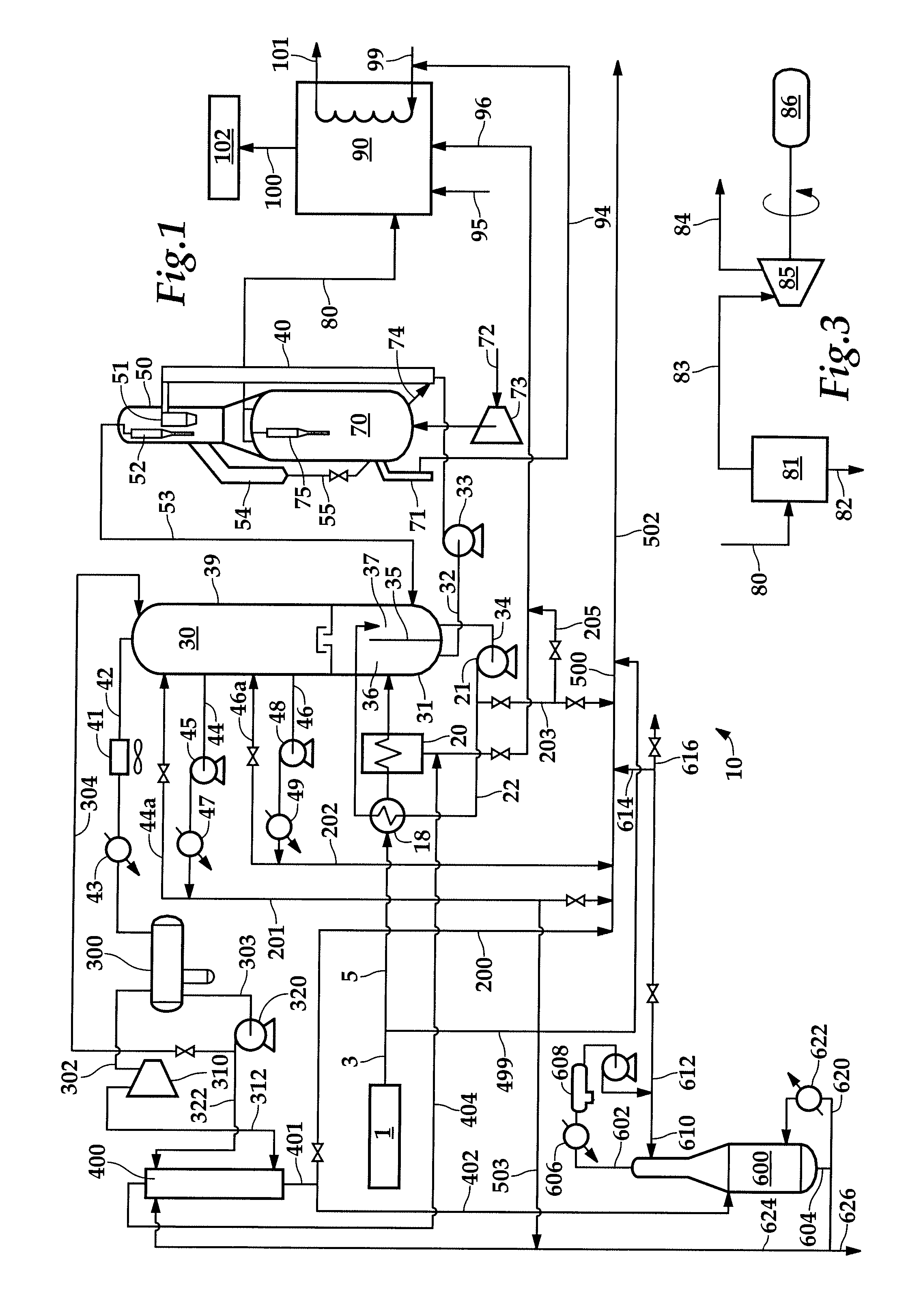

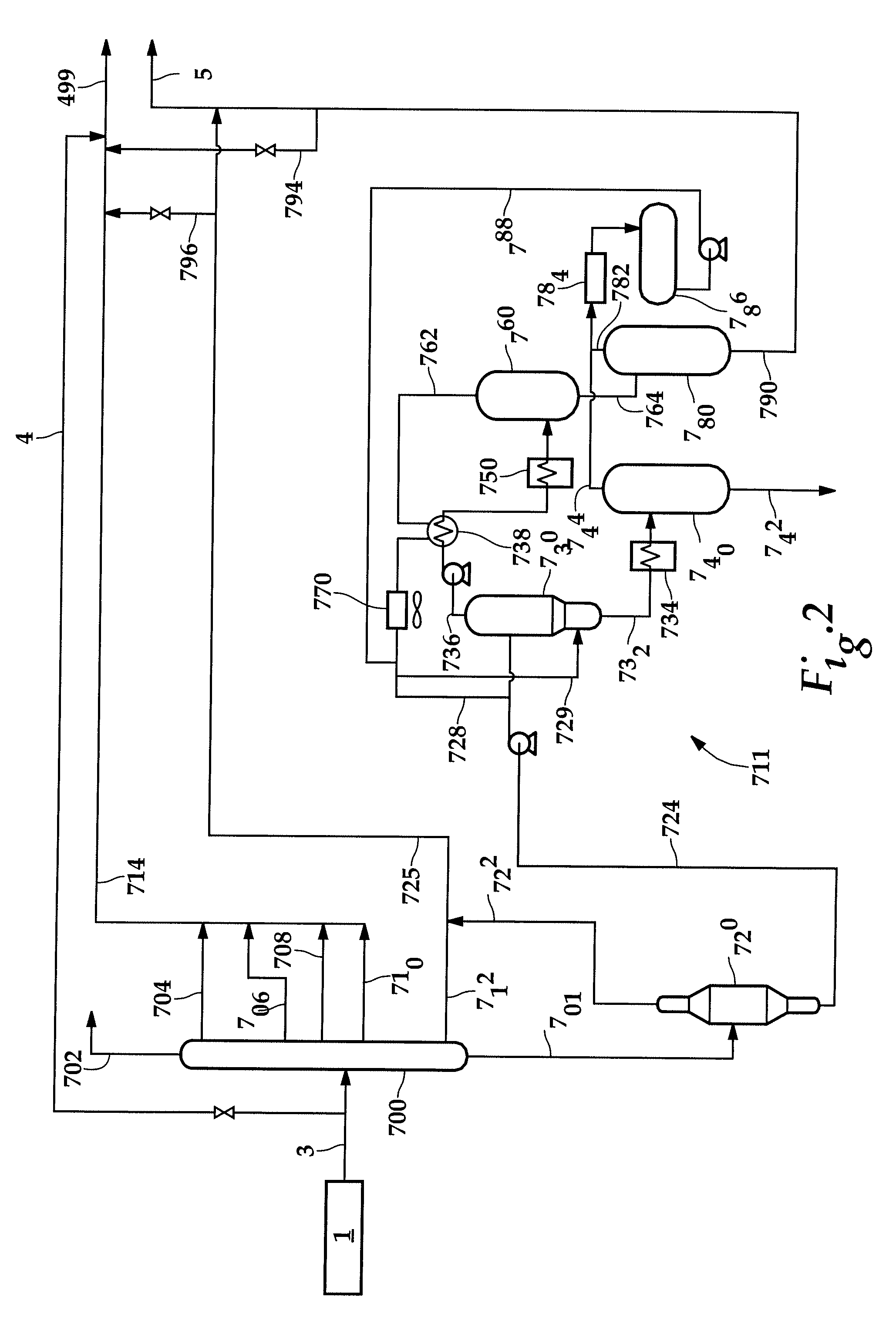

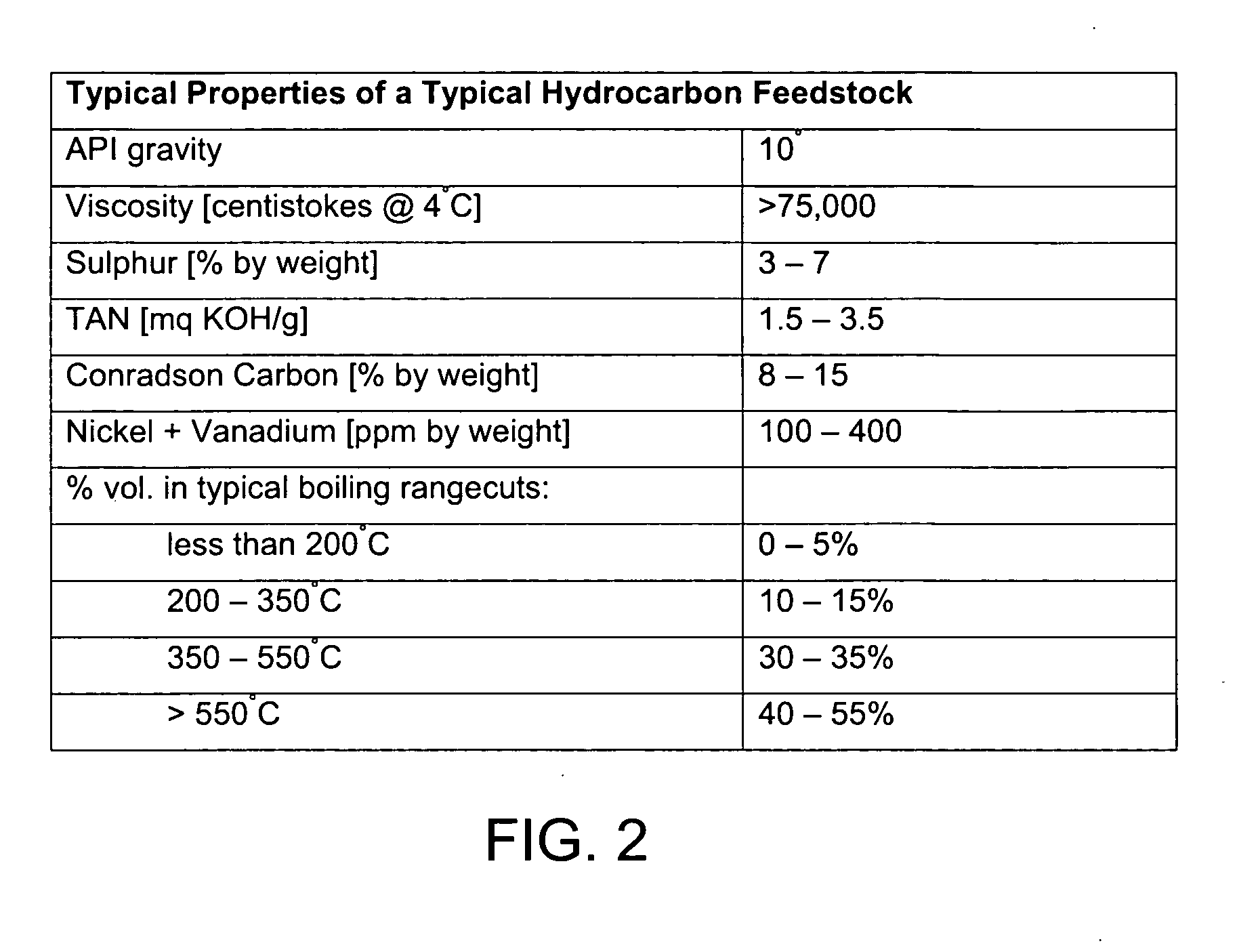

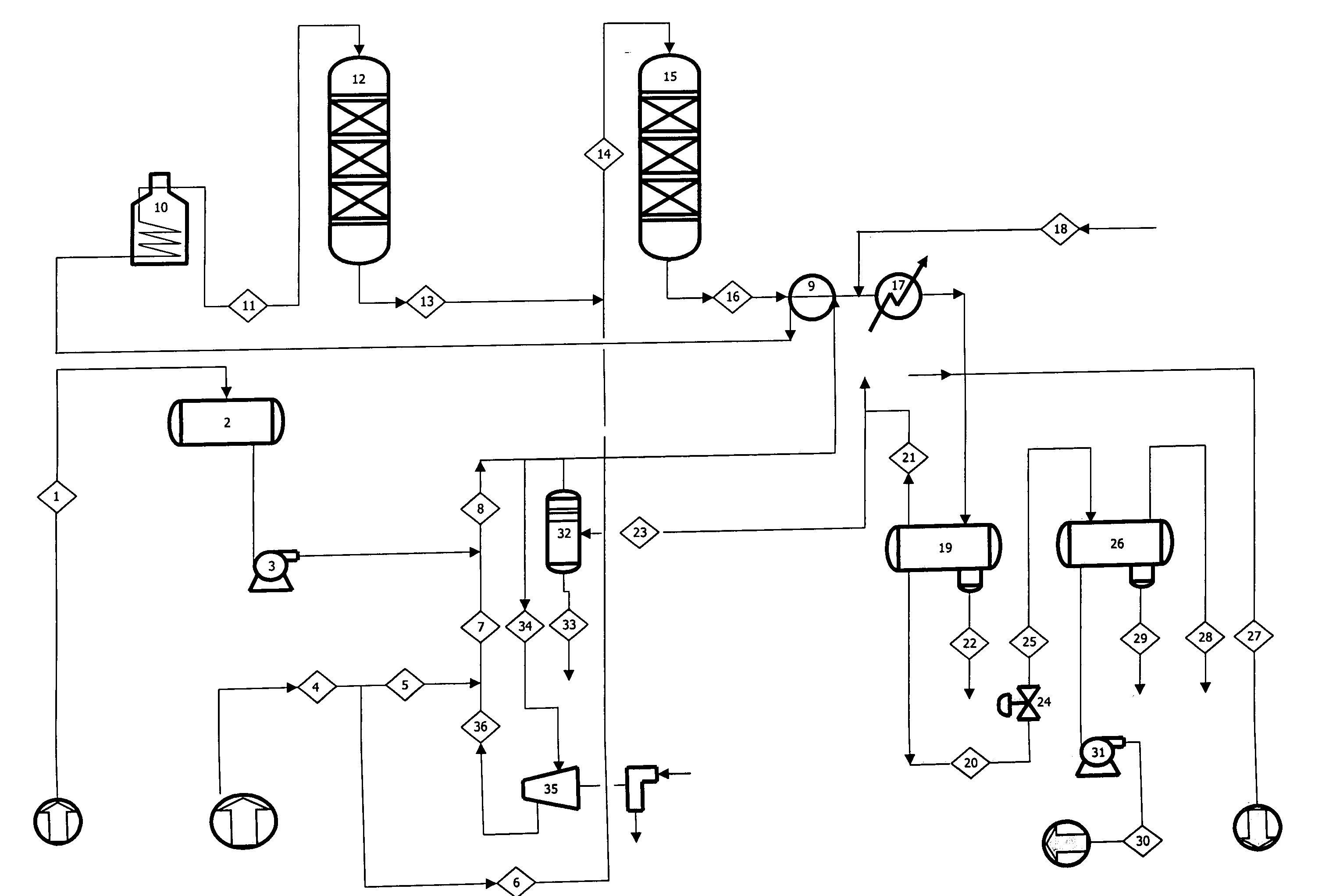

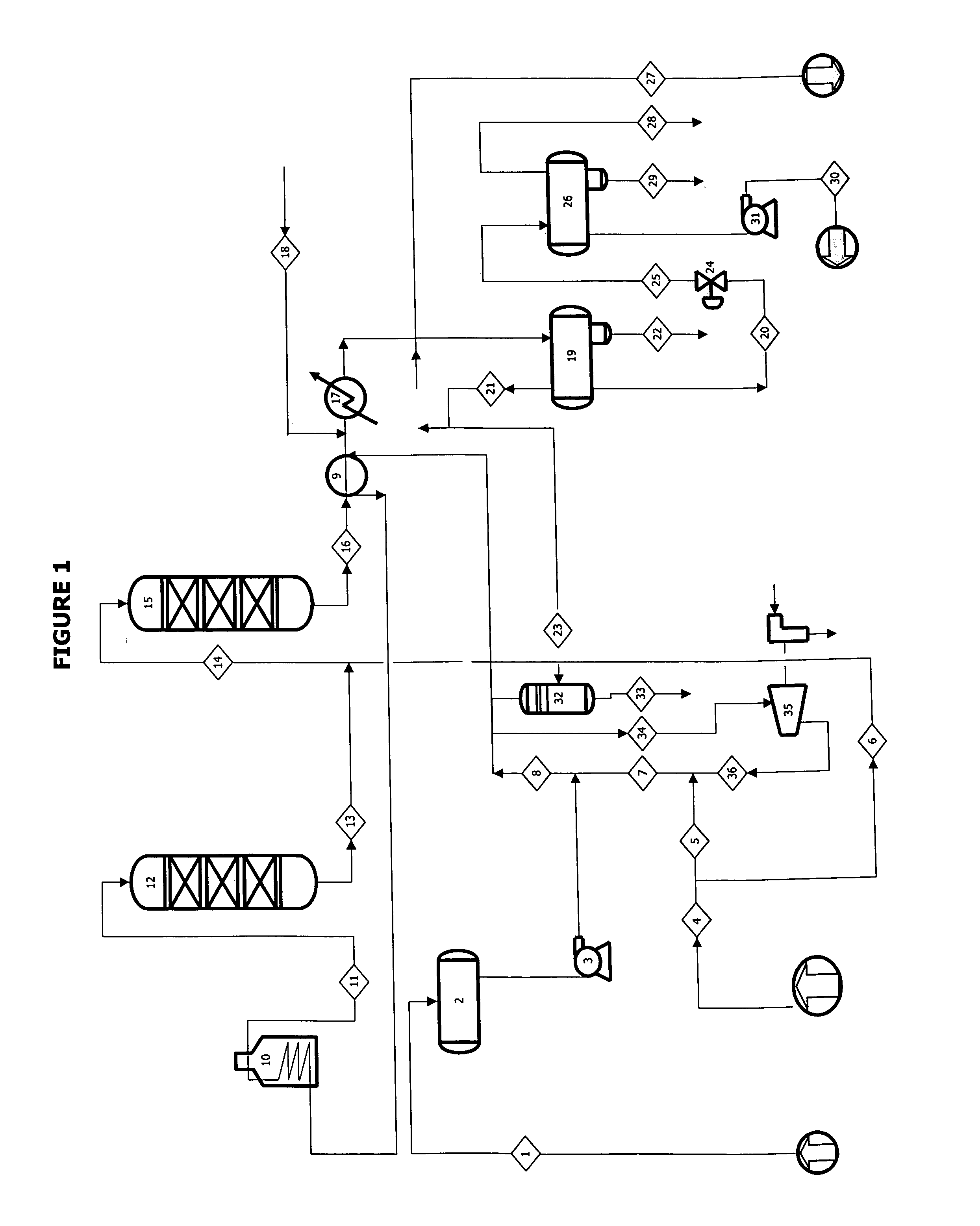

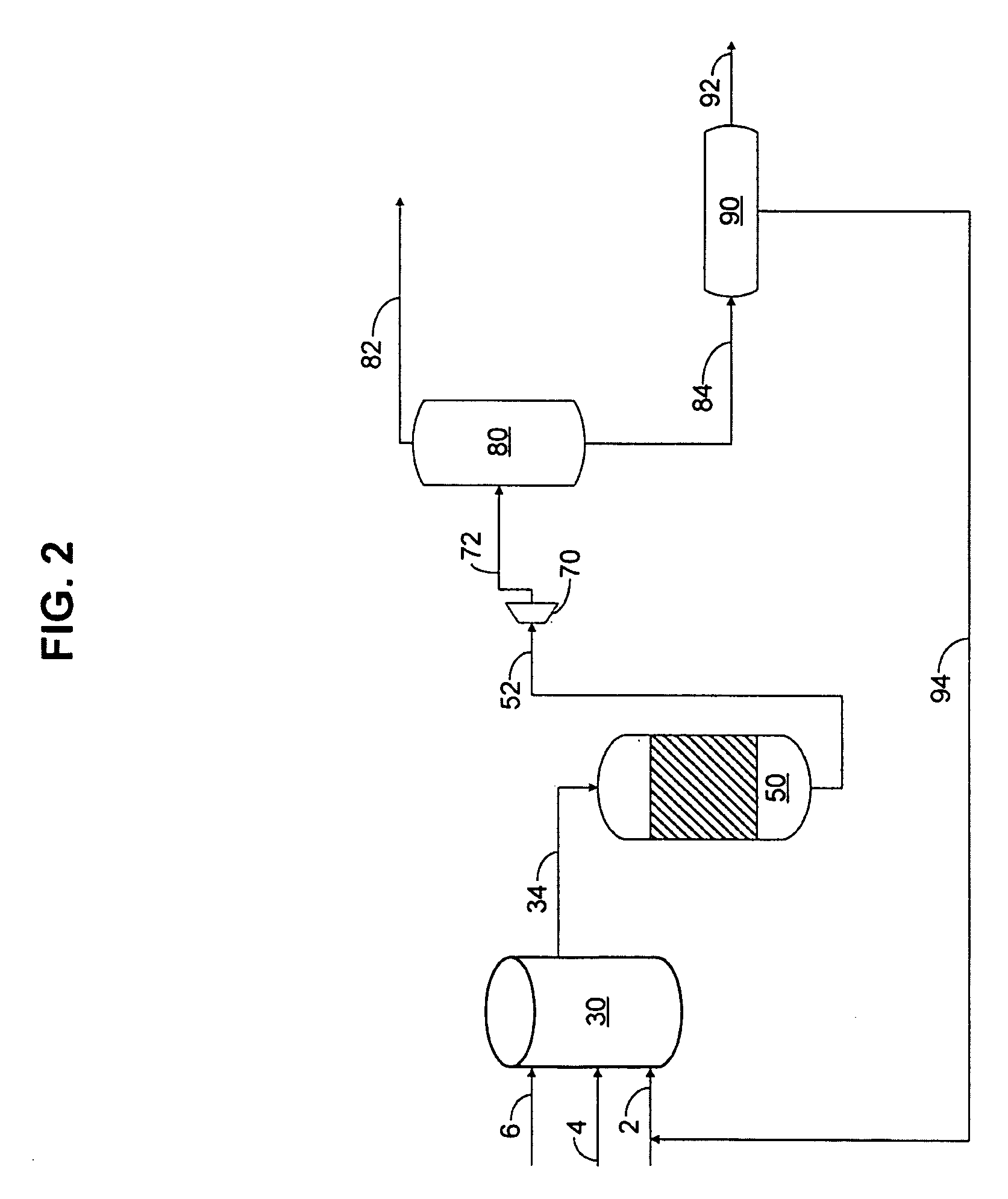

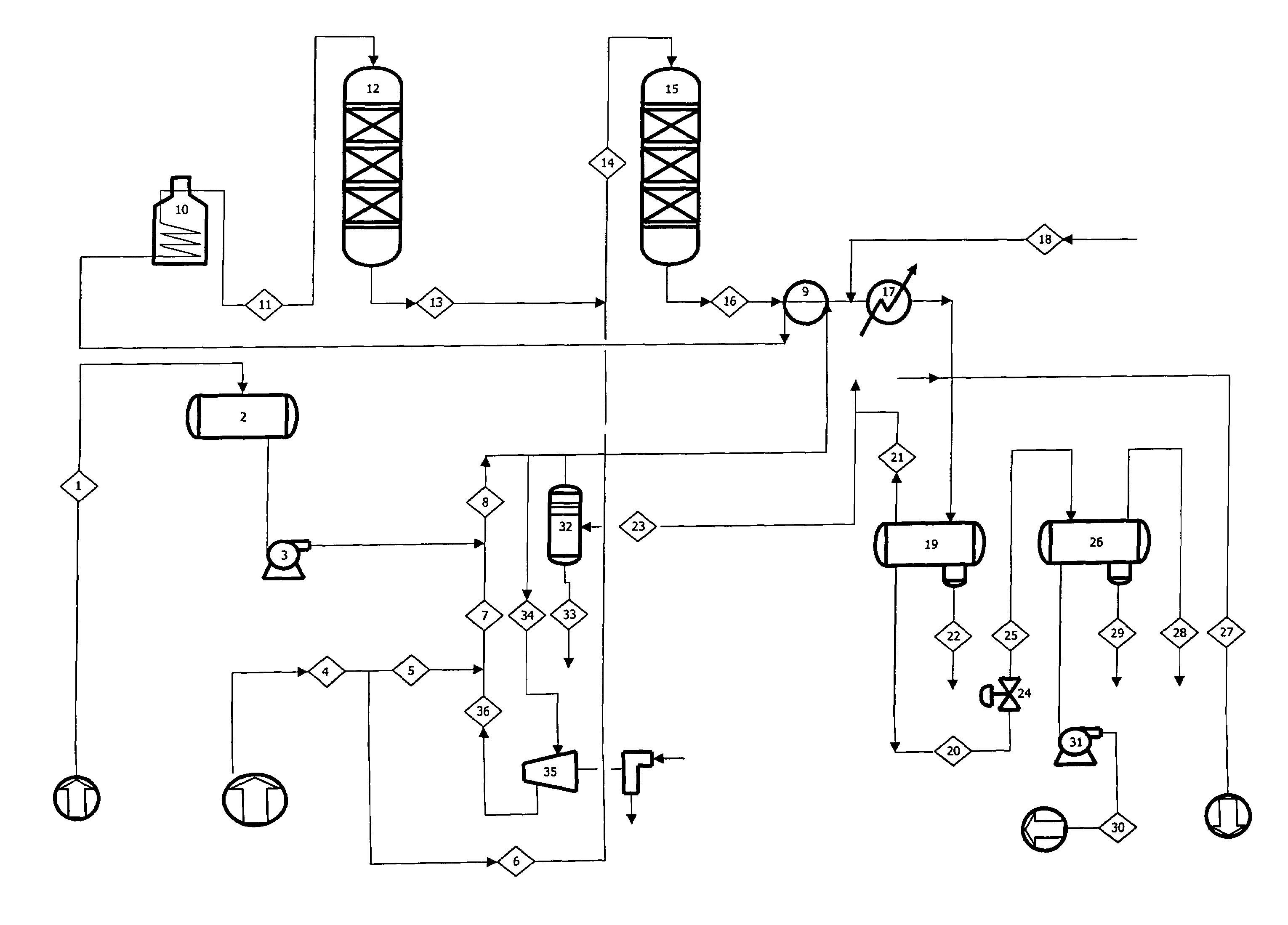

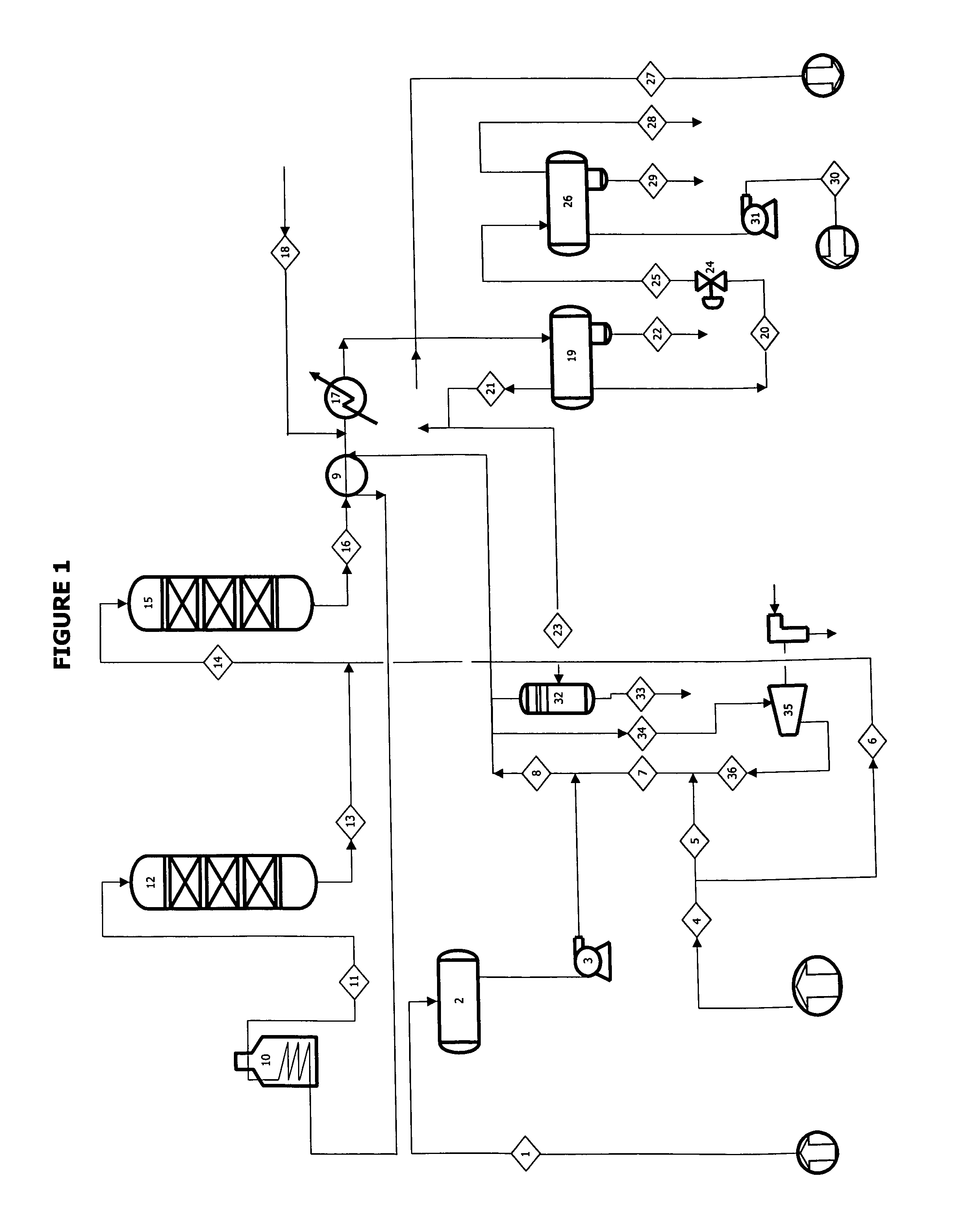

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Method and apparatus for a downhole spectrometer based on electronically tunable optical filters

The present invention provides an apparatus and method for high resolution spectroscopy (approximately 10 picometer wavelength resolution) using a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES HLDG LLC

Process and apparatus for improving flow properties of crude petroleum

A process for improving flow properties of crude may include processing a first crude stream, which may in turn include cracking the first crude stream with fresh catalyst to form a cracked stream and spent catalyst, and then mixed with an unprocessed second stream. The spent catalyst may be regenerated to form fresh catalyst, which may then be recycled. At least part of the cracked stream may be mixed with a second crude stream. A ratio of the second crude stream to the first crude stream may be between about 0.5:1 and about 9:1. A ratio of part of the cracked stream to add to the second crude stream may be selected to achieve a API gravity of at least about 18. The first crude stream may be heated and stripped before being cracked.

Owner:UOP LLC

Light source for a downhole spectrometer

ActiveUS20070013911A1Material analysis by optical meansSpectrum generation using multiple reflectionAPI gravityGas oil ratio

The present invention provides an apparatus and method for high resolution spectroscopy using a narrow light beam source such as a superluminescent diode (SLD) and a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The SLD and TOF have a matching etendue. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES INC

Method and apparatus for a tunable diode laser spectrometer for analysis of hydrocarbon samples

The present invention provides an down hole apparatus and method for ultrahigh resolution spectroscopy using a tunable diode laser (TDL) for analyzing a formation fluid sample downhole or at the surface to determine formation fluid parameters. In addition to absorption spectroscopy, the present invention can perform Raman spectroscopy on the fluid, by sweeping the wavelength of the TDL and detecting the Raman-scattered light using a narrow-band detector at a fixed wavelength. The spectrometer analyzes a pressurized well bore fluid sample that is collected downhole. The analysis is performed either downhole or at the surface onsite. Near infrared, mid-infrared and visible light analysis is also performed on the sample to provide an onsite surface or downhole analysis of sample properties and contamination level. The onsite and downhole analysis comprises determination of aromatics, olefins, saturates, gas oil ratio, API gravity and various other parameters which can be estimated by correlation, a trained neural network or a chemometric equation.

Owner:BAKER HUGHES INC

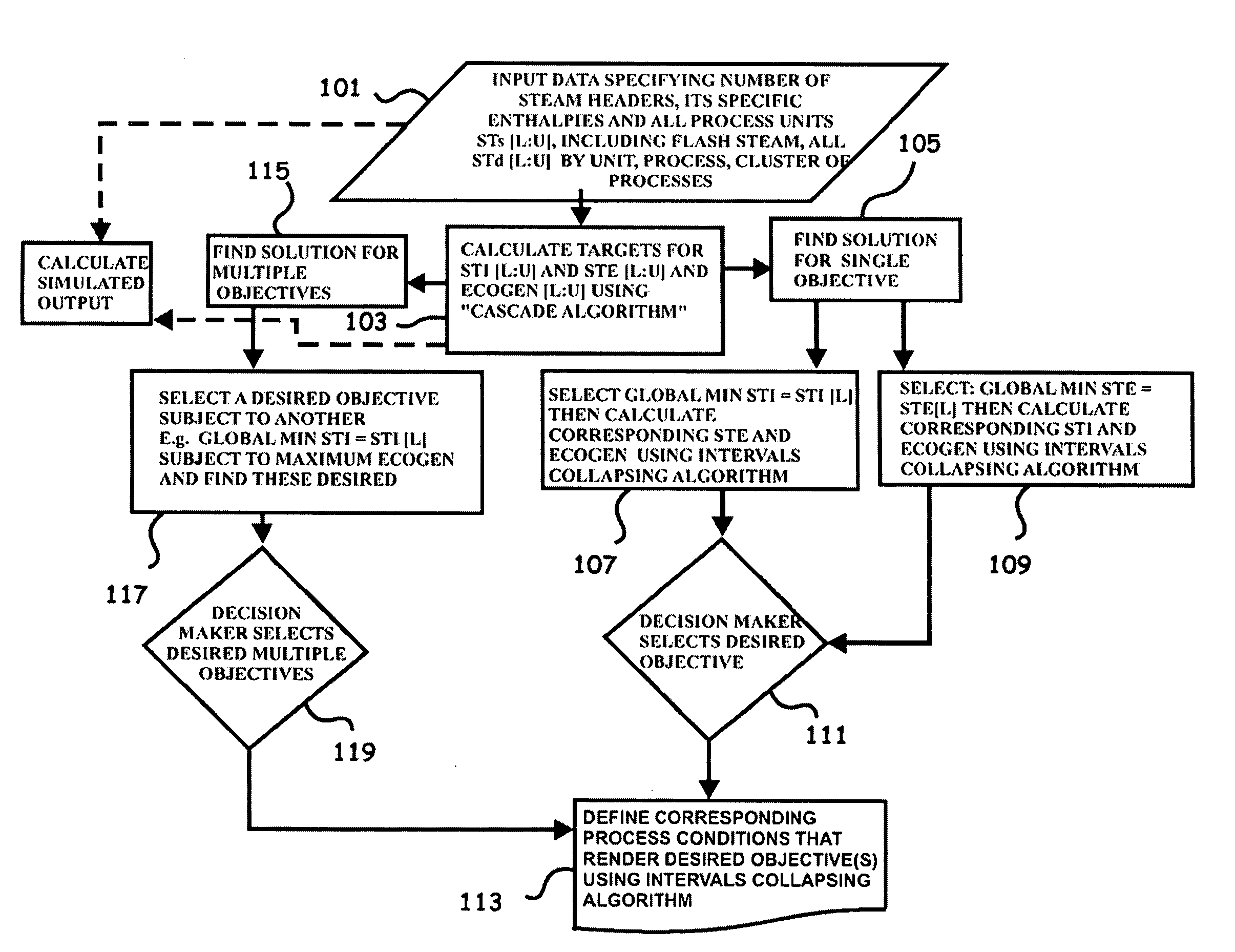

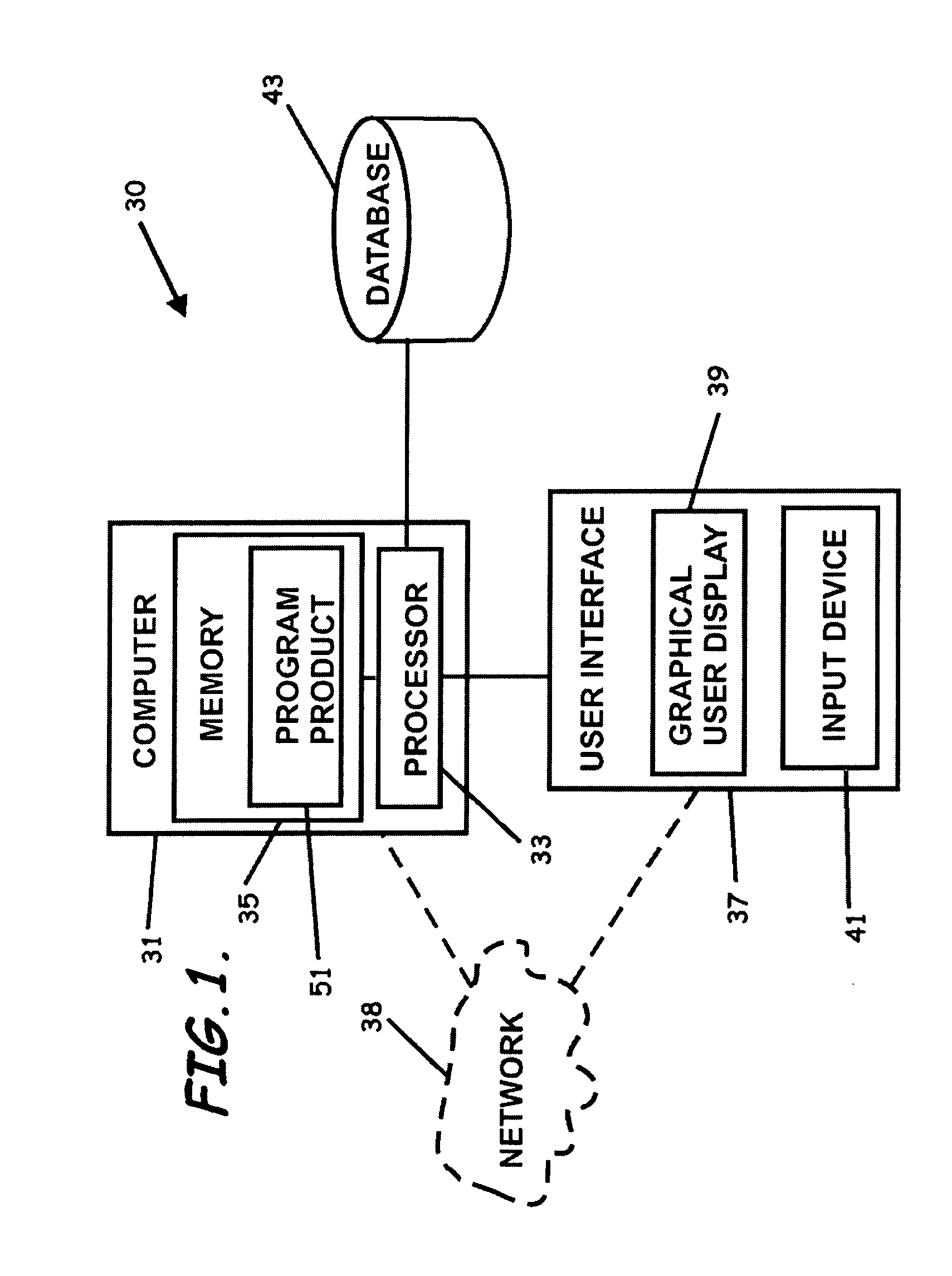

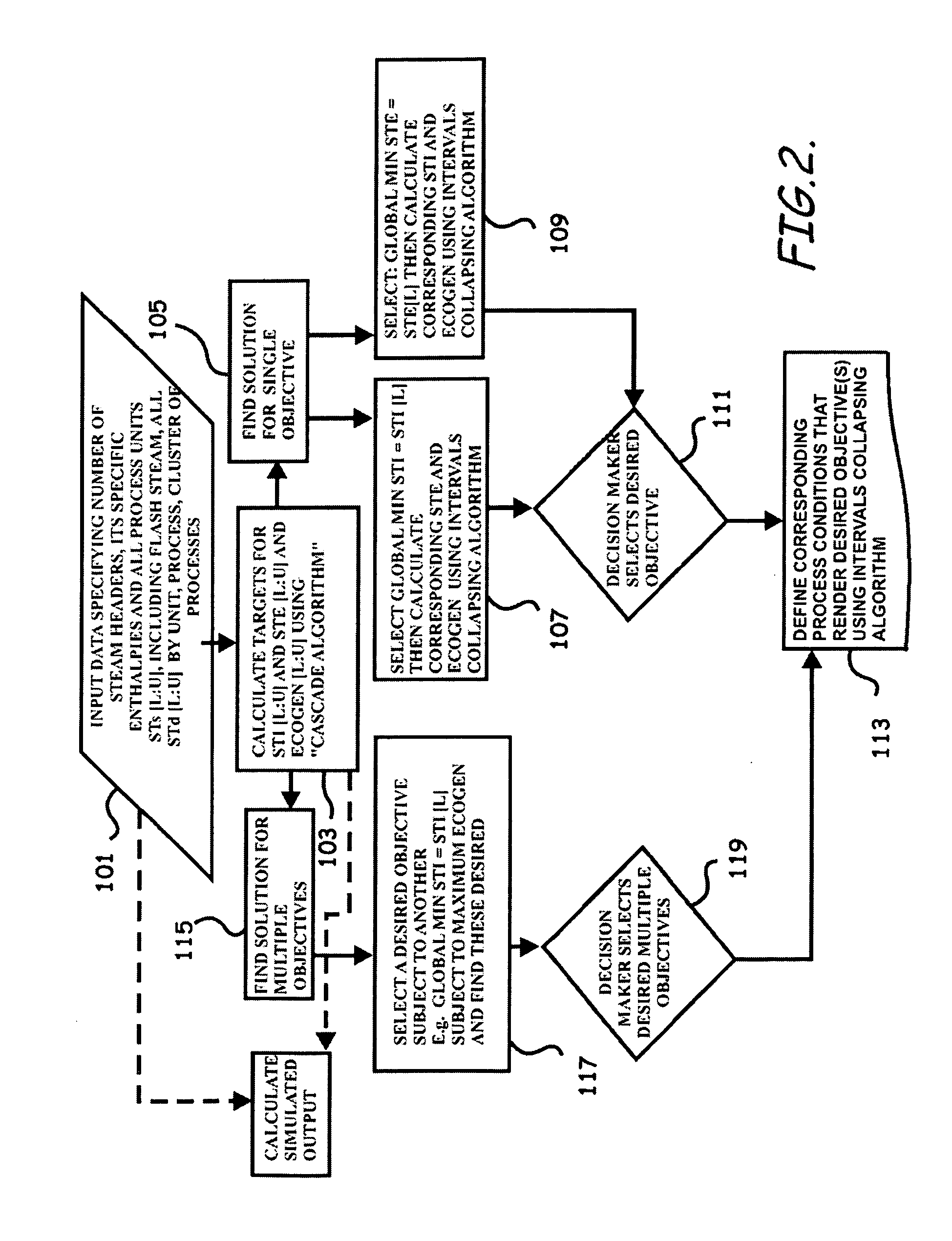

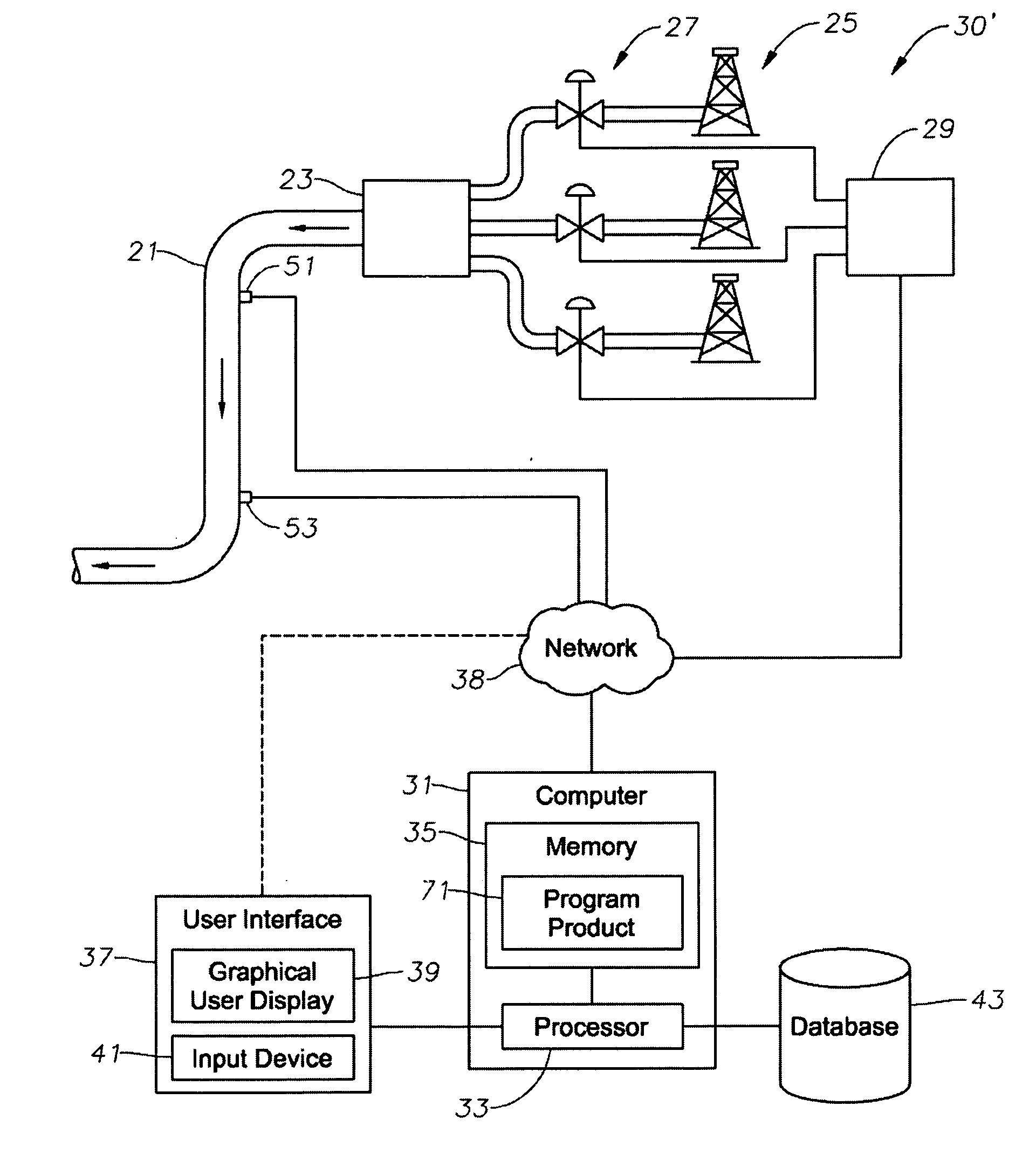

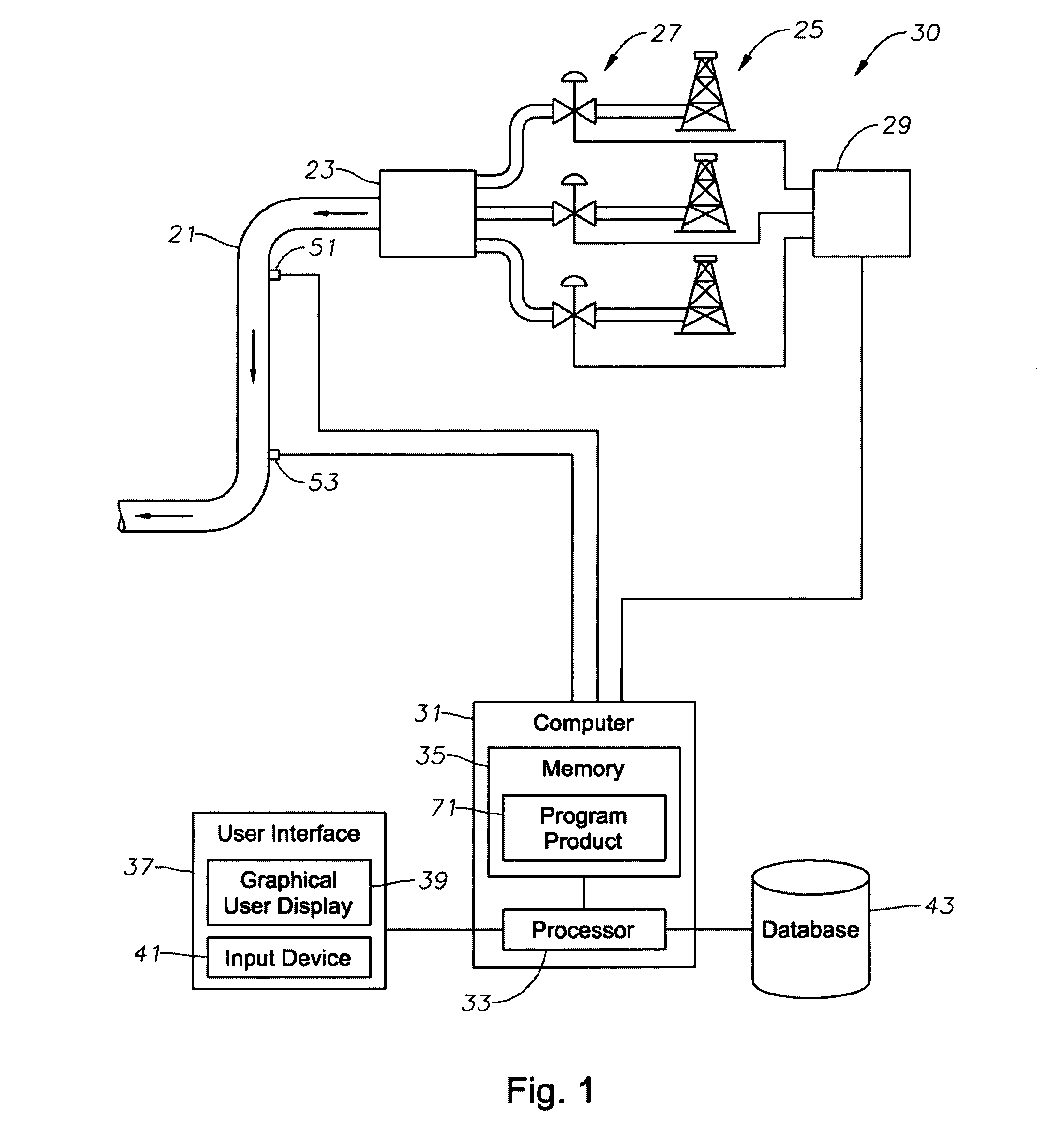

System, Program Product, and Related Methods for Global Targeting of Process Utilities Under Varying Conditions

UndeterminedUS20080257413A1Overcome deficienciesComputer controlPipeline systemsStream flowAPI gravity

Systems, program product, and methods to estimate and manage flowing fluid characteristics of a fluid stream flowing through a pipeline in real-time, are provided. A system can include a vertically oriented extent of a pipeline for transporting crude oil, a pair of spaced vertically apart sensors or sensor assemblies connected to a bypass line interfaced with or positioned across the vertically oriented extent of the pipeline to obtain pressure and temperature readings of the crude oil flowing through the pipeline, a controller in communication with the pair of sensors or sensor assemblies, and crude oil analysis and management program product stored in the memory of the controller and adapted to determine or estimate density, specific gravity, and API gravity of the crude oil to thereby manage flowing fluid characteristics of the crude oil.

Owner:SAUDI ARABIAN OIL CO

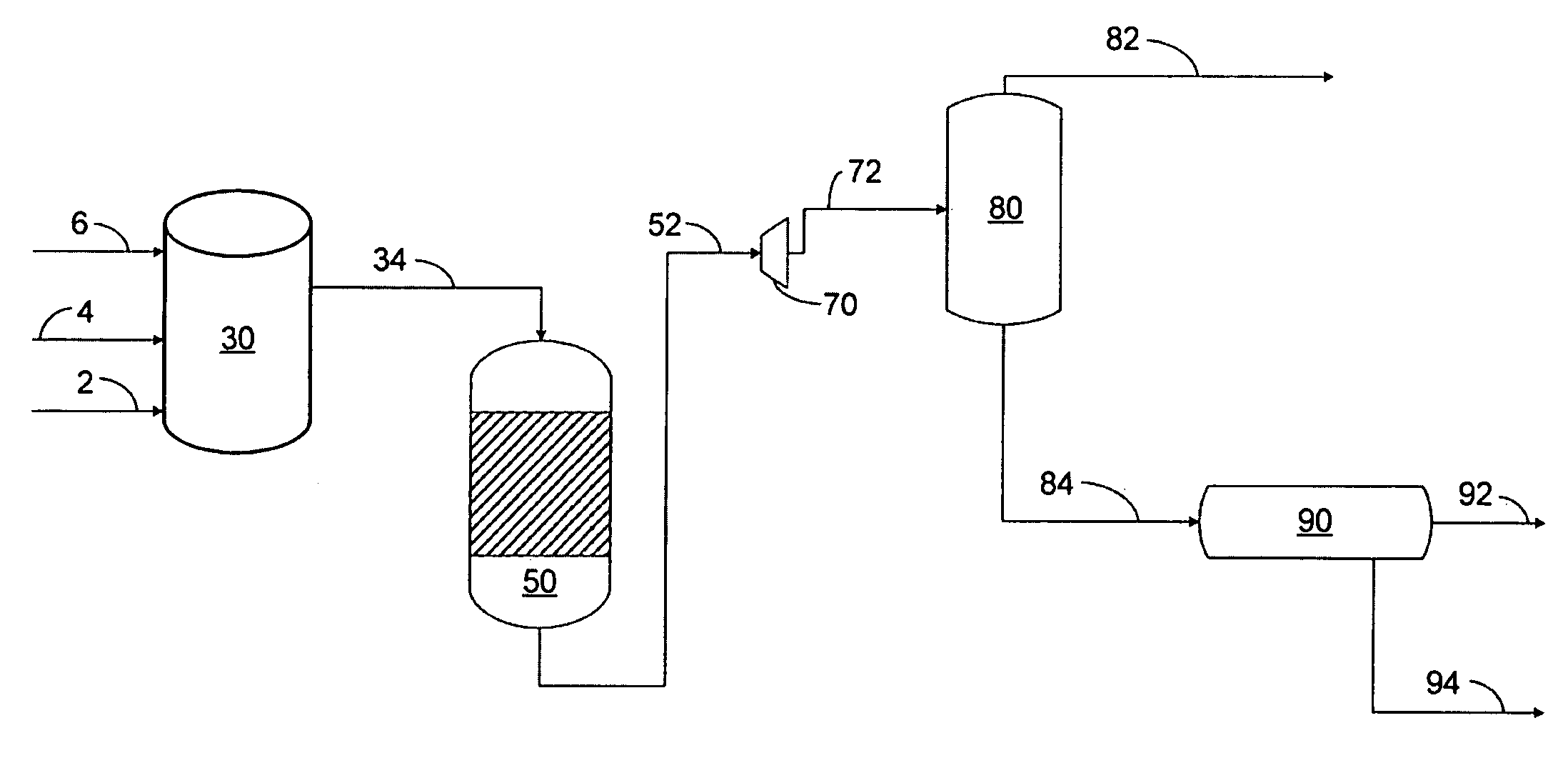

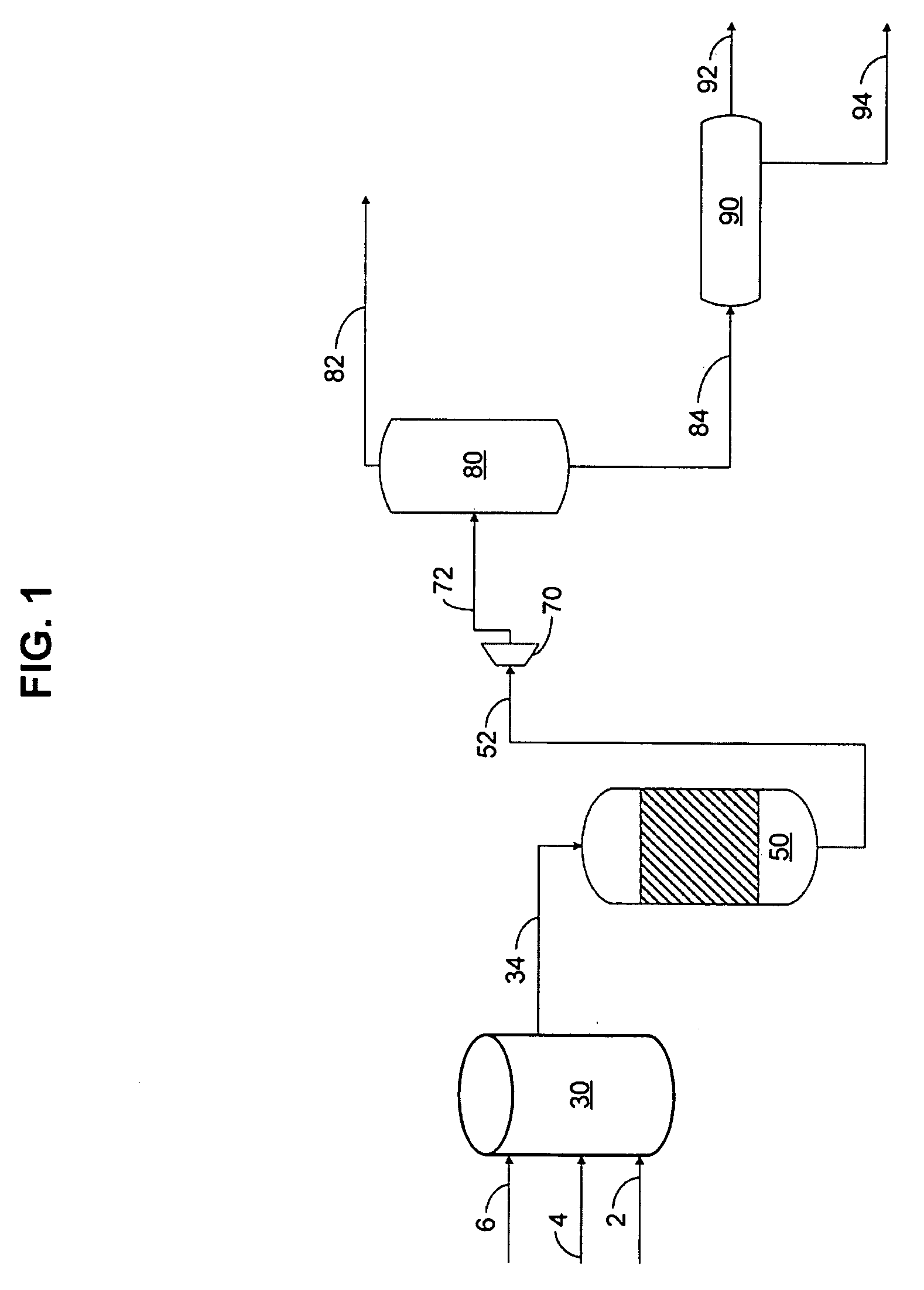

Methods and Systems for Producing Reduced Resid and Bottomless Products from Heavy Hydrocarbon Feedstocks

InactiveUS20080230440A1Cost controlReduce operating costsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyParticulatesLiquid product

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, collecting a gaseous and liquid product mixture comprising a mixture of a light fraction and a heavy fraction from the product stream, and using a vacuum tower to separate the light fraction as a substantially bottomless product and the heavy fraction from the product mixture.

Owner:IVANHOE HTL GASOLINEEUM

System for improving crude oil

InactiveUS20060231462A1Increase heightEnhancing crude oilThermal non-catalytic crackingSemi-permeable membranesAPI gravityFiltration

Crude oil can be refined through a filtration media. Cavitation bubbles having localized areas of very high temperatures and pressures may be created thereby causing several physical and chemical phenomena, including thermal cracking of carbon-carbon bonds as the crude moves through the flux cartridge membrane. Heavy hydrocarbons are residues are thereby cracked into smaller lowering boiling molecules having a higher API gravity. Once the relatively smaller hydrocarbons pass through the flux cartridge membrane into the flux cartridge, the effluent can be routed to a second separator annulus. It should also be pointed out that lighter hydrocarbons formed can volatilize and special provisions may be needed to efficiently capture these gases.

Owner:LJC TECH

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Asphalt composition and method

A paving asphalt composition for improving the durability and longevity of asphalt road surfaces is disclosed. The paving asphalt composition includes asphalt base stock, heavy residuum of re-refined motor oil, and a chemical modifier. The heavy residuum of re-refined motor oil preferably has an API gravity of at least about 12, a kinematic viscosity greater than about 400 centistokes at 140 DEG F., a flash point greater than about 400 DEG F. and a mass loss less than about 3%. The paving asphalt composition may also include a polymer. A method of forming the paving asphalt composition and a method of paving roads are also disclosed.

Owner:CROWN ASPHALT DISTRIBUTION L L C

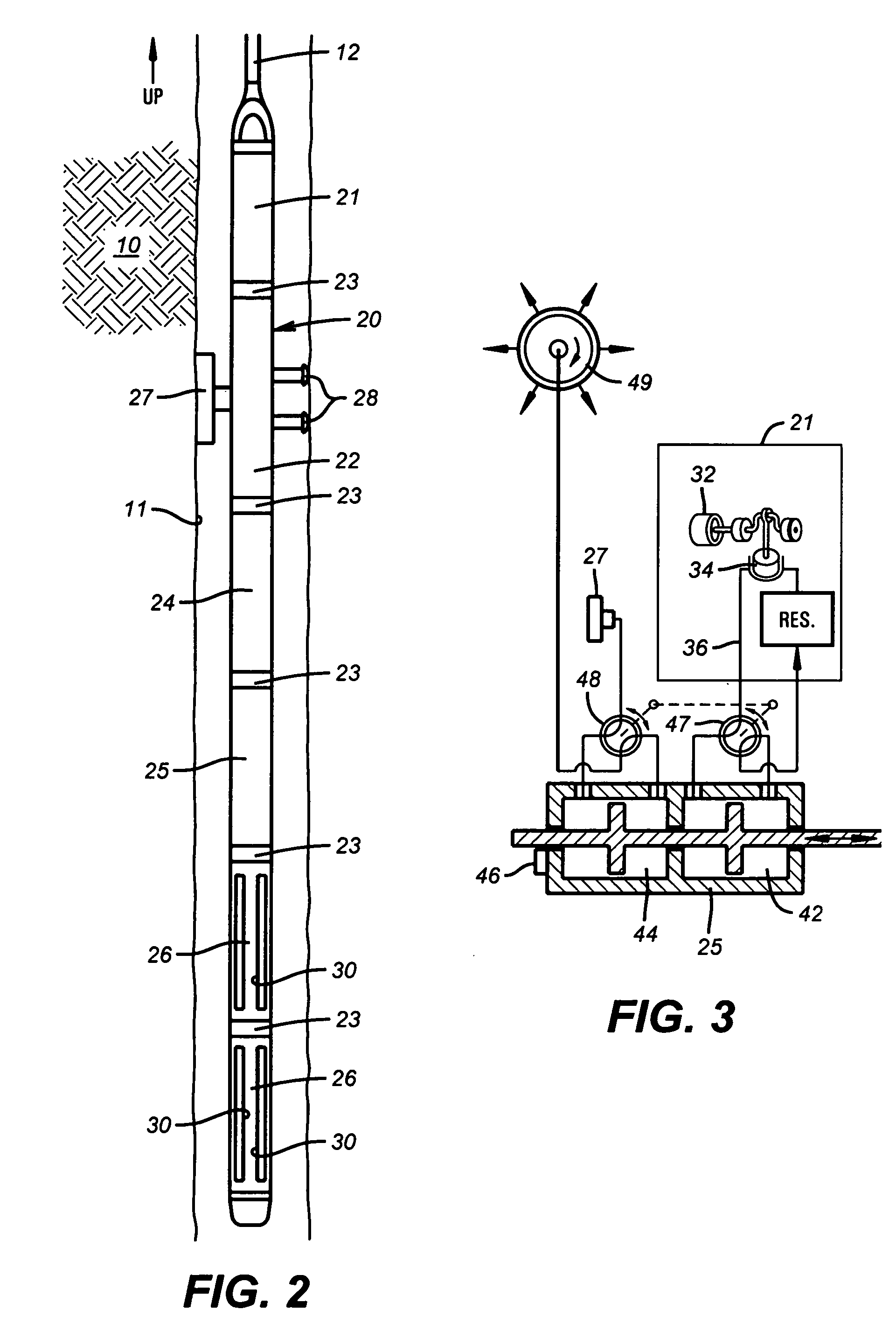

Method and apparatus for a downhole fluorescence spectrometer

ActiveUS20040104355A1Raman/scattering spectroscopyRadiation pyrometryAPI gravityFluorescence spectrometry

The invention comprises an apparatus and method for simple fluorescence spectrometry in a downhole environment using a UV light source and UV fluorescence to determine a parameter of interest for a sample downhole. The UV light source illuminates the fluid, which in turn fluoresces light. The fluoresced light is transmitted back towards the UV light source and through the pathway towards an optical spectrum analyzer. API gravity is determined by correlation the wavelength of peak fluorescence and brightness of fluorescent emission of the sample. Asphaltene precipitation pressure is determined by monitoring the blue green content ratio for a sample under going depressurization.

Owner:BAKER HUGHES INC

Method and apparatus for a downhole fluorescence spectrometer

InactiveUS7084392B2Easy to measureQuantify OBM filtrate contaminationRadiation pyrometryRaman/scattering spectroscopyAPI gravityFluorescence spectrometry

Owner:BAKER HUGHES HLDG LLC

Method for monitoring feeds to catalytic cracking units by near-infrared spectroscopy

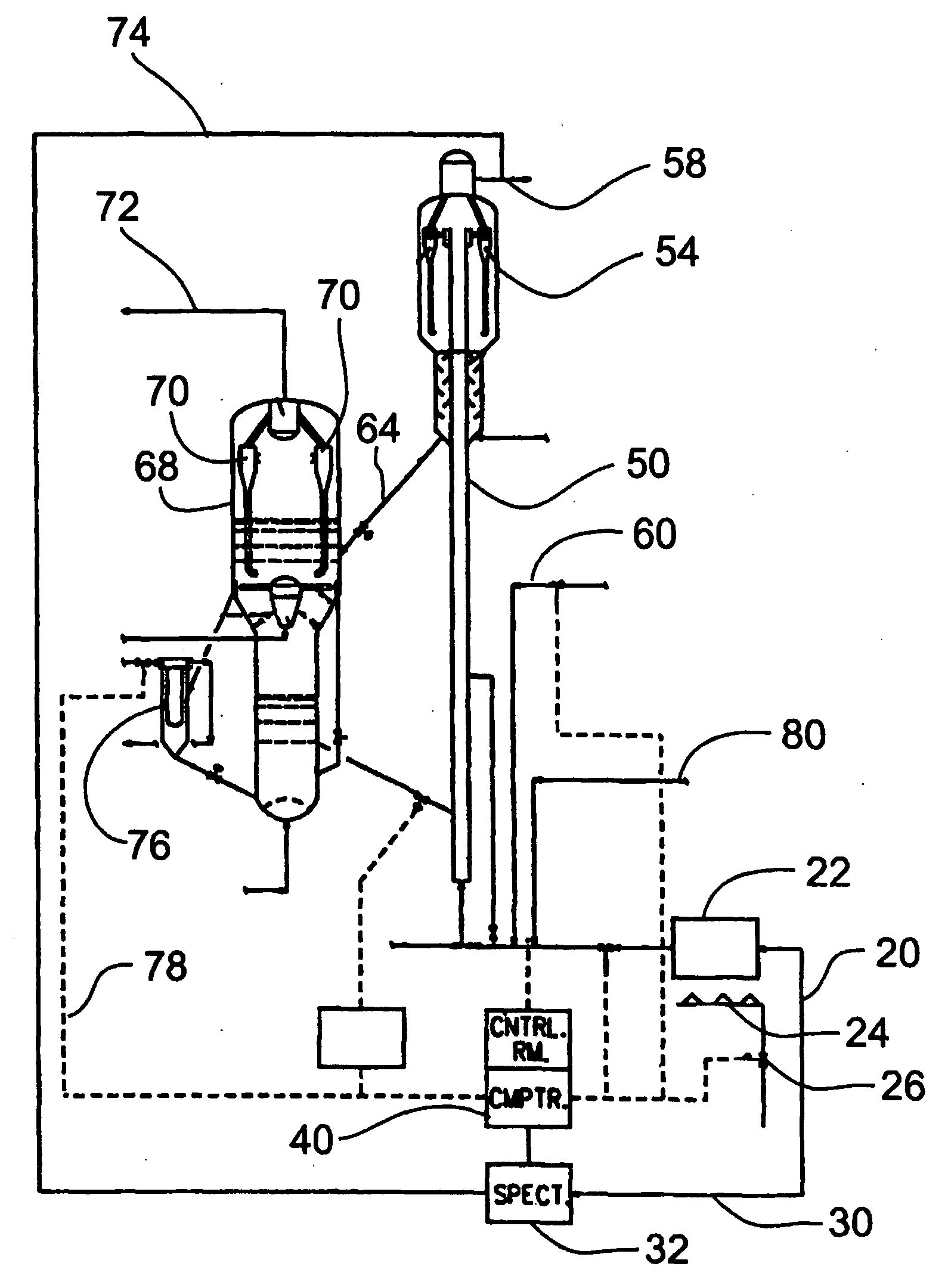

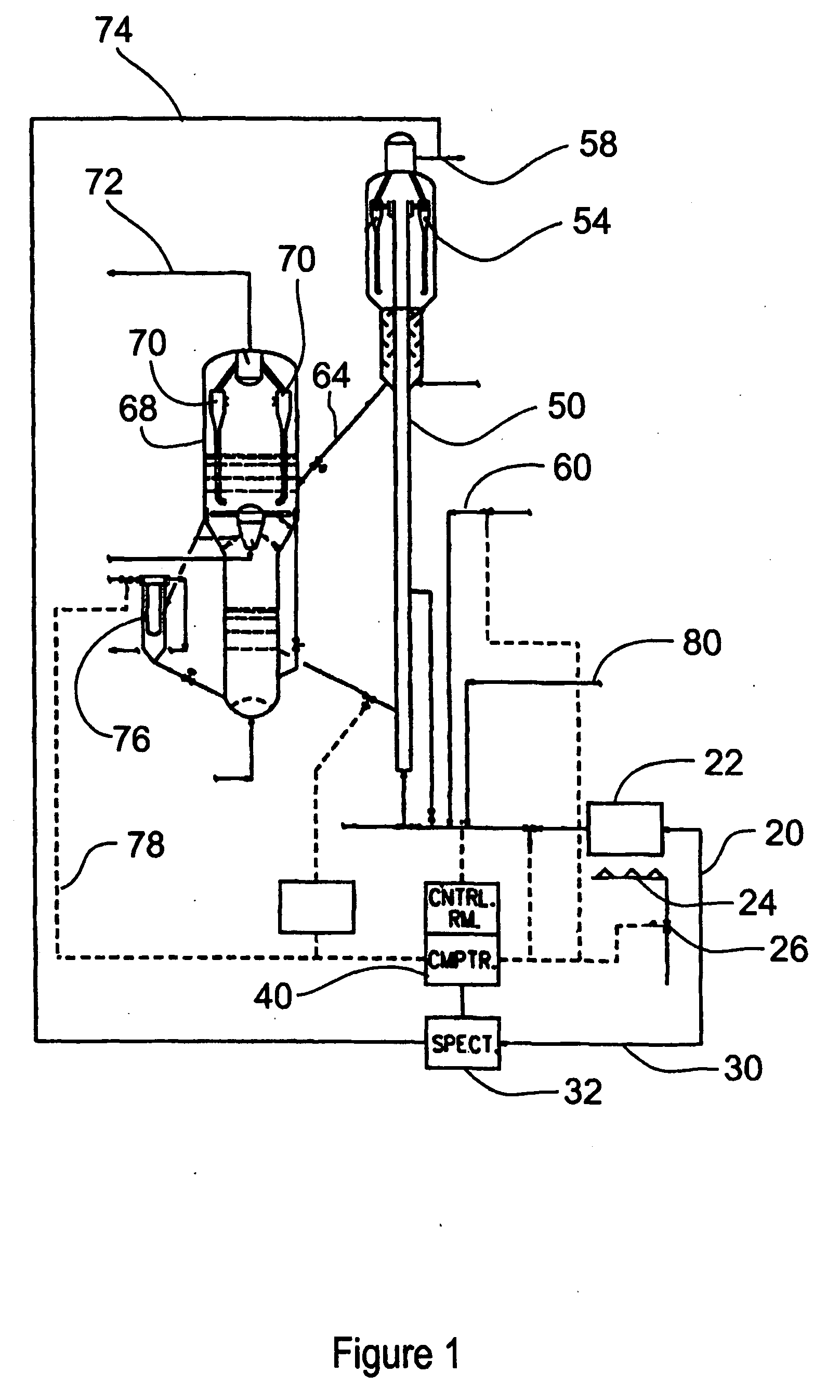

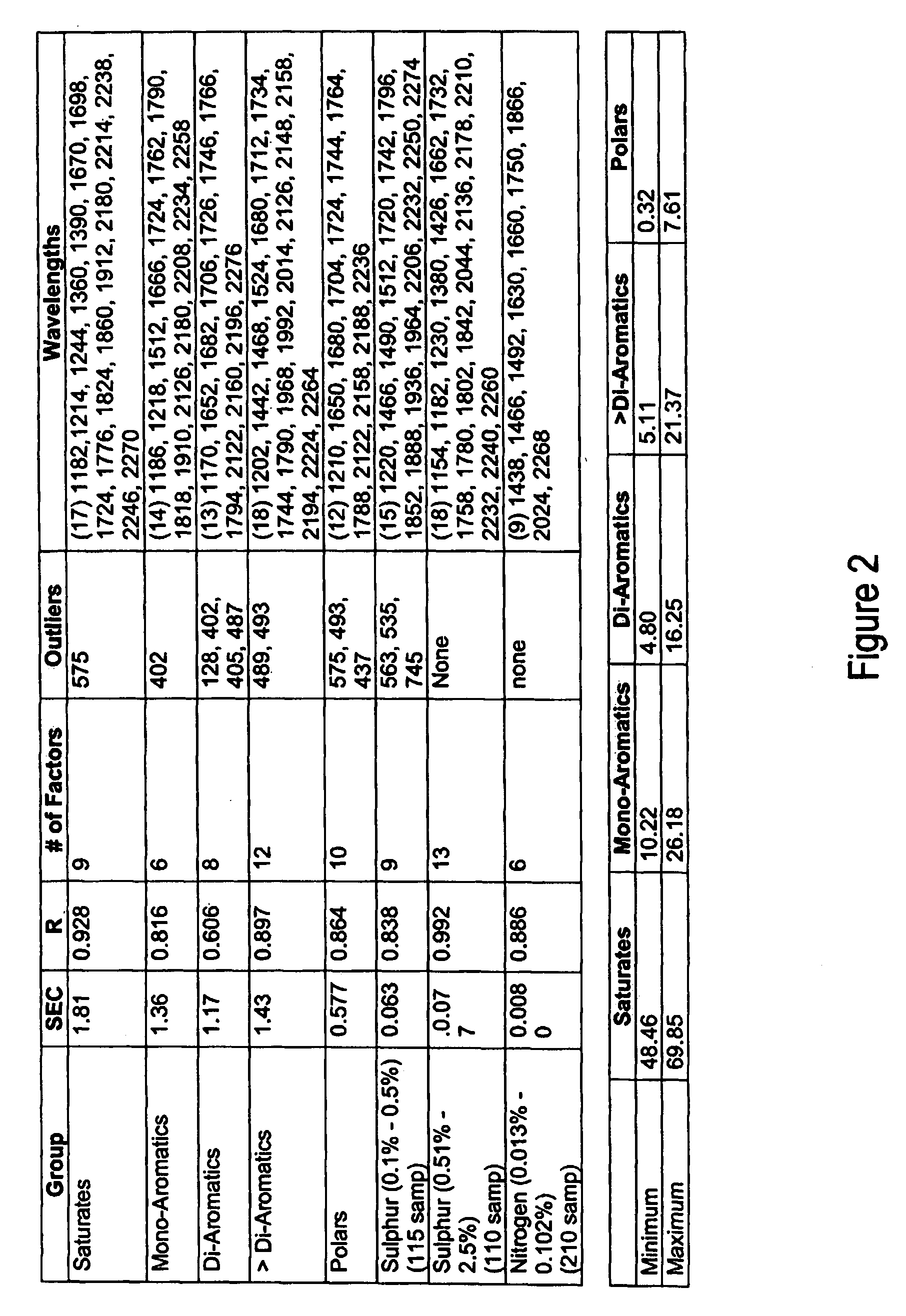

InactiveUS20070212790A1Monitor the FCC feed stocks quality more quickly and efficientlyMaterial analysis by optical meansBiological testingInfraredDistillation

A monitoring of catalytic cracking processing is provided which uses near infrared (NIR) analysis to characterize cracking feeds, intermediates and products for chemical and physical properties such as saturates, monoaromatics, diaromatics, triaromatics, tetraaromatics, polar aromatics, total aromatics, thiophenes, distillation points, basic nitrogen, total nitrogen, API gravity, total sulfur, MCRT and % coker gasoil and the resulting characterization thereof. The NIR results can be used in FCC simulation software to predict unit yields and qualities.

Owner:MARATHON PETROLEUM

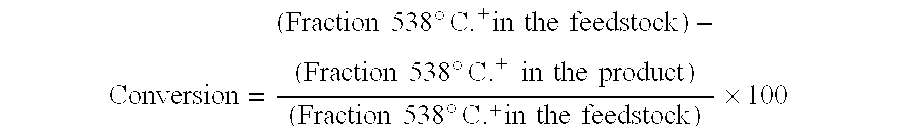

Products produced form rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS7270743B2Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

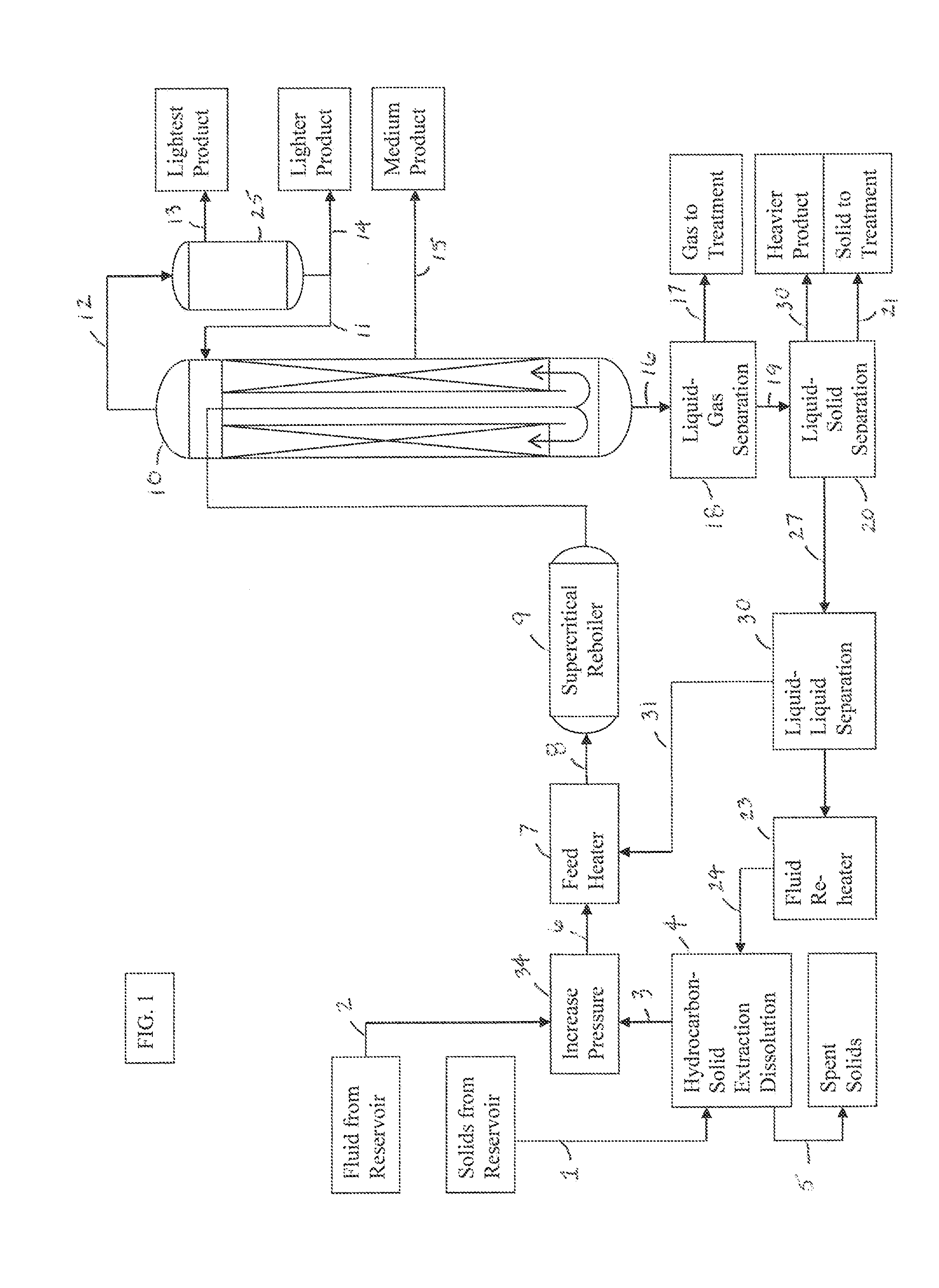

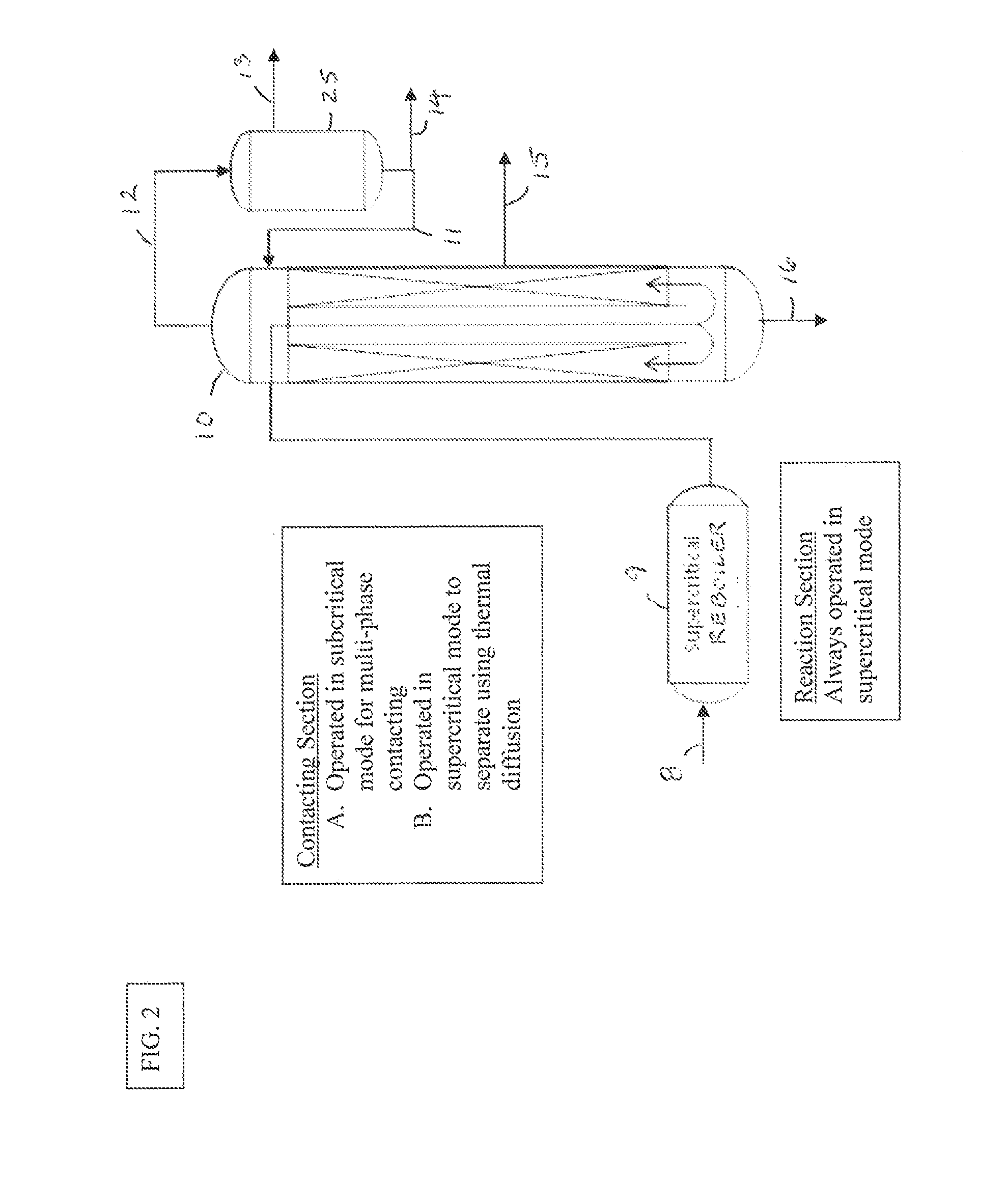

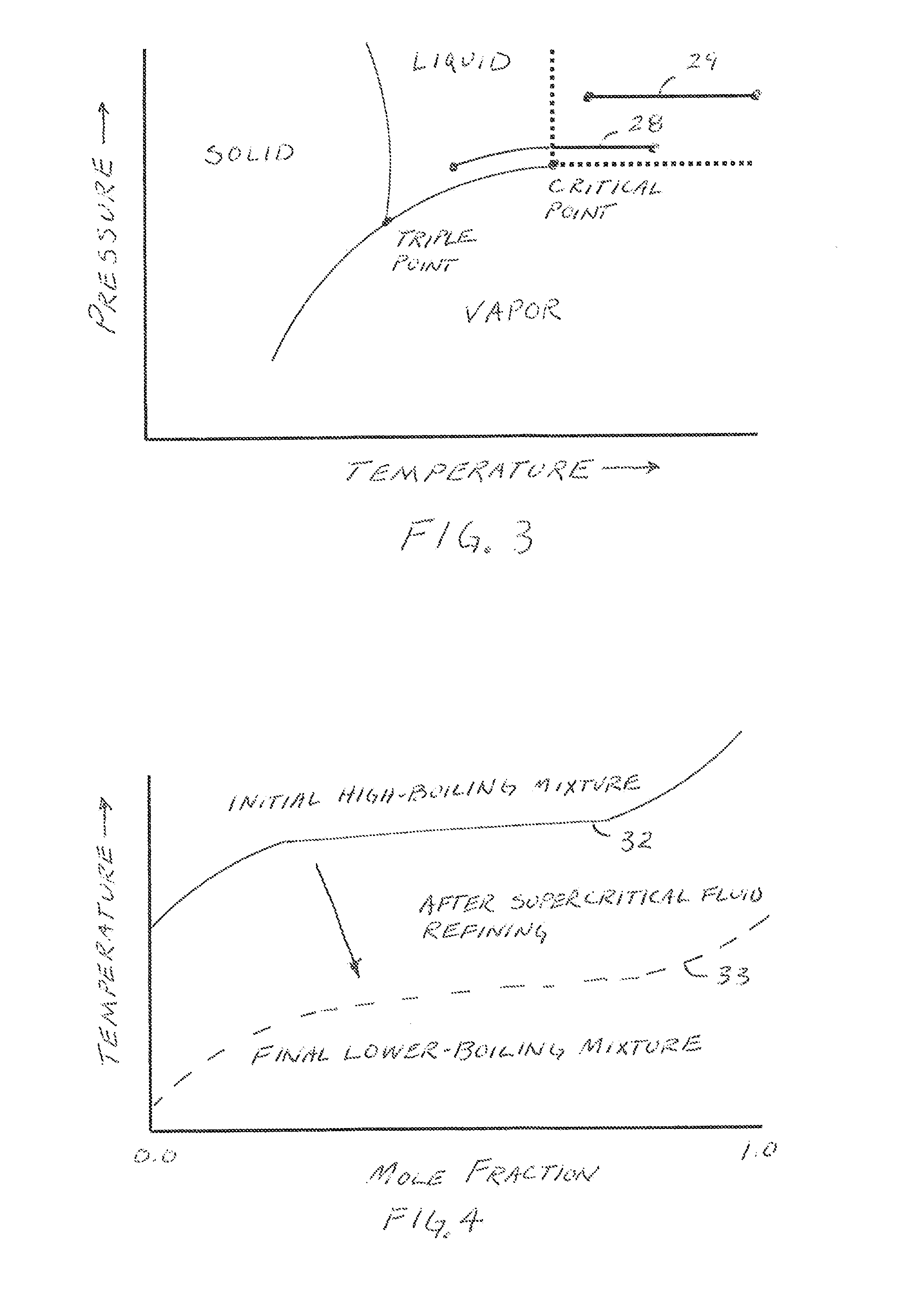

Using supercritical fluids to refine hydrocarbons

ActiveUS20110163011A1Light weightImprove securityRefining by water treatmentLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesAPI gravity

This is a method to reactively refine hydrocarbons, such as heavy oils with API gravities of less than 20° and bitumen-like hydrocarbons with viscosities greater than 1000 cp at standard temperature and pressure using a selected fluid at supercritical conditions. The reaction portion of the method delivers lighter weight, more volatile hydrocarbons to an attached contacting device that operates in mixed subcritical or supercritical modes. This separates the reaction products into portions that are viable for use or sale without further conventional refining and hydro-processing techniques. This method produces valuable products with fewer processing steps, lower costs, increased worker safety due to less processing and handling, allow greater opportunity for new oil field development and subsequent positive economic impact, reduce related carbon dioxide, and wastes typical with conventional refineries.

Owner:HEAVY OIL SOLUTIONS INC

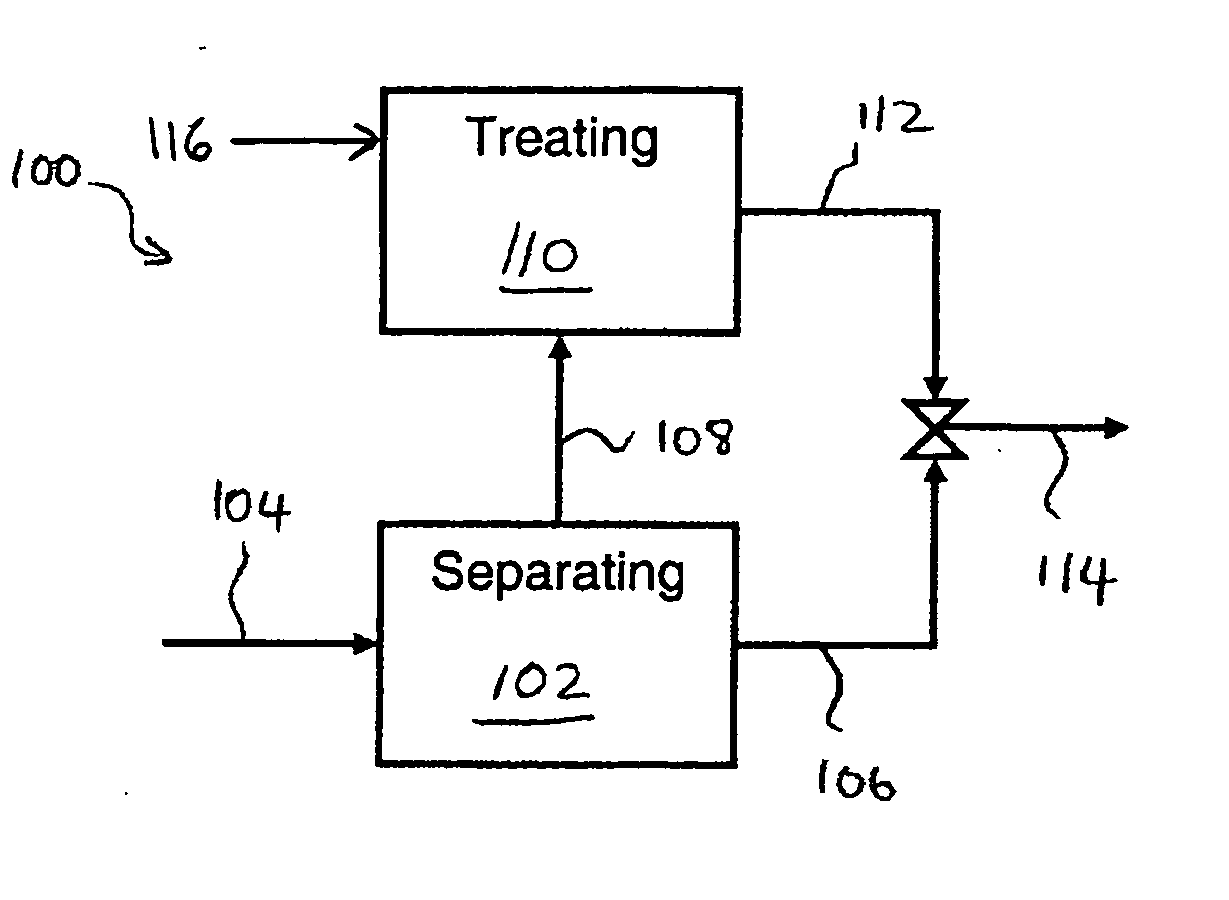

Process for treating a heavy hydrocarbon feedstock and a product obtained therefrom

InactiveUS20070108098A1Thermal non-catalytic crackingCatalytic crackingAPI gravityPipeline transport

A process for treating a heavy hydrocarbon feedstock is disclosed. The process involves separating the feedstock into a residue component and a light component, the residue component having a lower API gravity than the light component and treating at least a portion of the light component to produce a synthetic transport diluent suitable for combining with at least a portion of the residue component to produce a product which meets applicable criteria for pipeline transport.

Owner:STATOIL CANADA

Light source for a downhole spectrometer

ActiveUS7511819B2Material analysis by optical meansSpectrum generation using multiple reflectionAPI gravityGas oil ratio

The present invention provides an apparatus and method for high resolution spectroscopy using a narrow light beam source such as a superluminescent diode (SLD) and a tunable optical filter (TOF) for analyzing a formation fluid sample downhole and at the surface to determine formation fluid parameters. The SLD and TOF have a matching etendue. The analysis comprises determination of gas oil ratio, API gravity and various other fluid parameters which can be estimated after developing correlations to a training set of samples using a neural network or a chemometric equation.

Owner:BAKER HUGHES INC

Process for the catalytic hydrotretment of heavy hydrocarbons of petroleum

ActiveUS20070187294A1Large capacityImprove propertiesTreatment with plural serial cracking stages onlyRefining with metalsAPI gravityHydrodesulfurization

Two-stage low pressure catalytic hydrotreatment of heavy petroleum hydrocarbons having a high content of contaminants (metals and asphaltenes), is conducted under operating conditions with low-pressure, in a fixed bed or ebullated bed reactor to limit the formation of sediments and sludge in the product and obtain a hydrotreated hydrocarbon of improved properties, with levels of contaminants, API gravity and distillates within the ranges commonly reported in the feedstocks typical to refining schemes. A hydrotreatment catalyst, whose principal effect is the hydrodemetallization and the hydrocracking of asphaltenes of the heavy hydrocarbons of petroleum is used in the first stage, and the second reaction stage employs a hydrotreatment catalyst for a deeper effect of hydrodesulfurization of the heavy petroleum hydrocarbon whose content of total sulfur is reduced to a level required for its treatment in the conventional refining process or for its sale as a hydrocarbon of petroleum with improved properties.

Owner:INST MEXICANO DEL GASOLINEEO

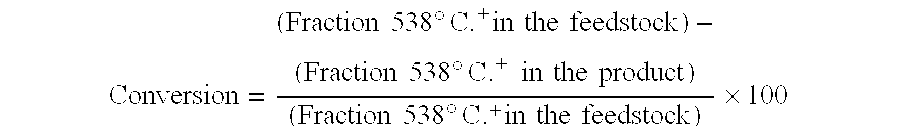

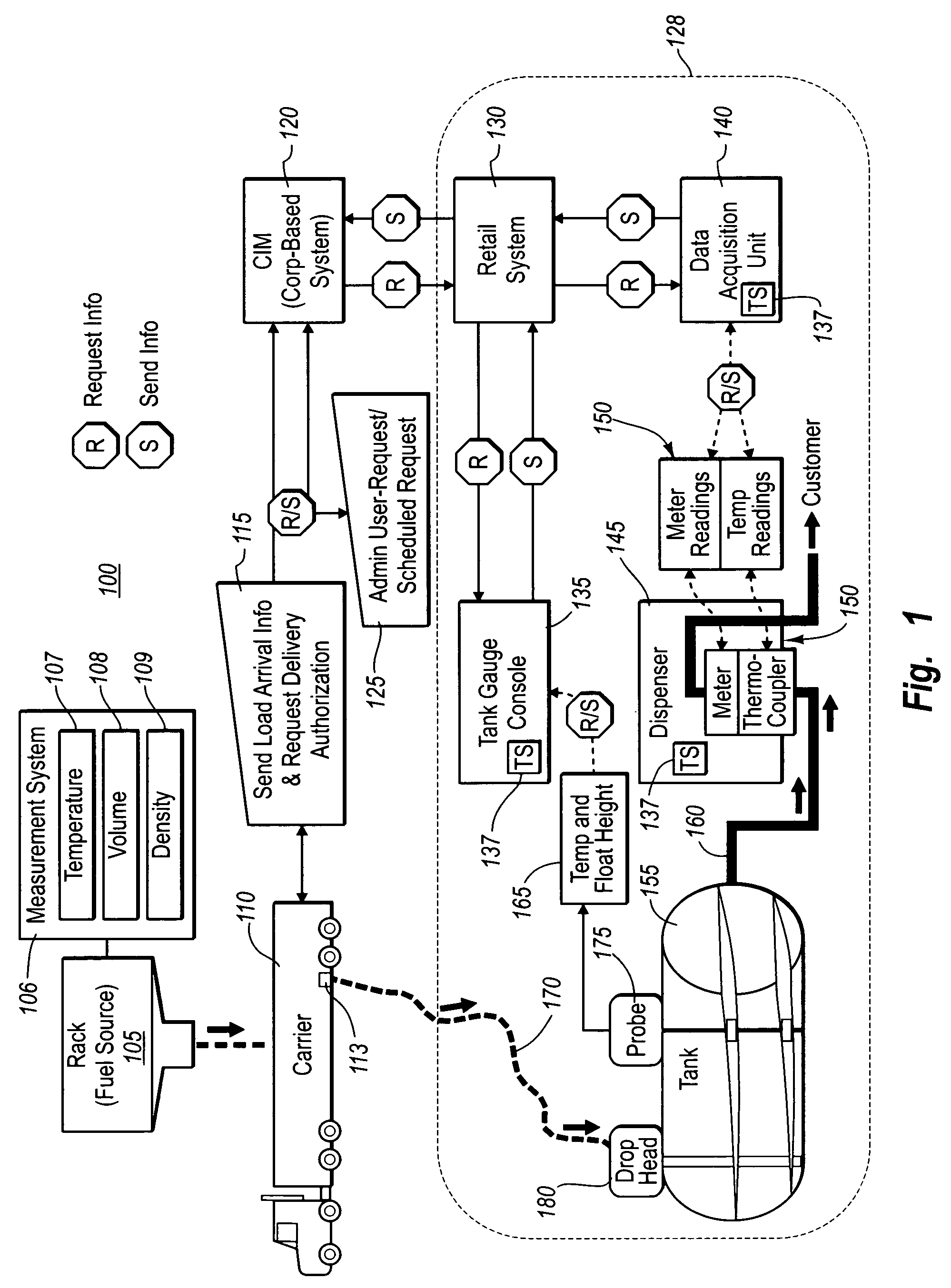

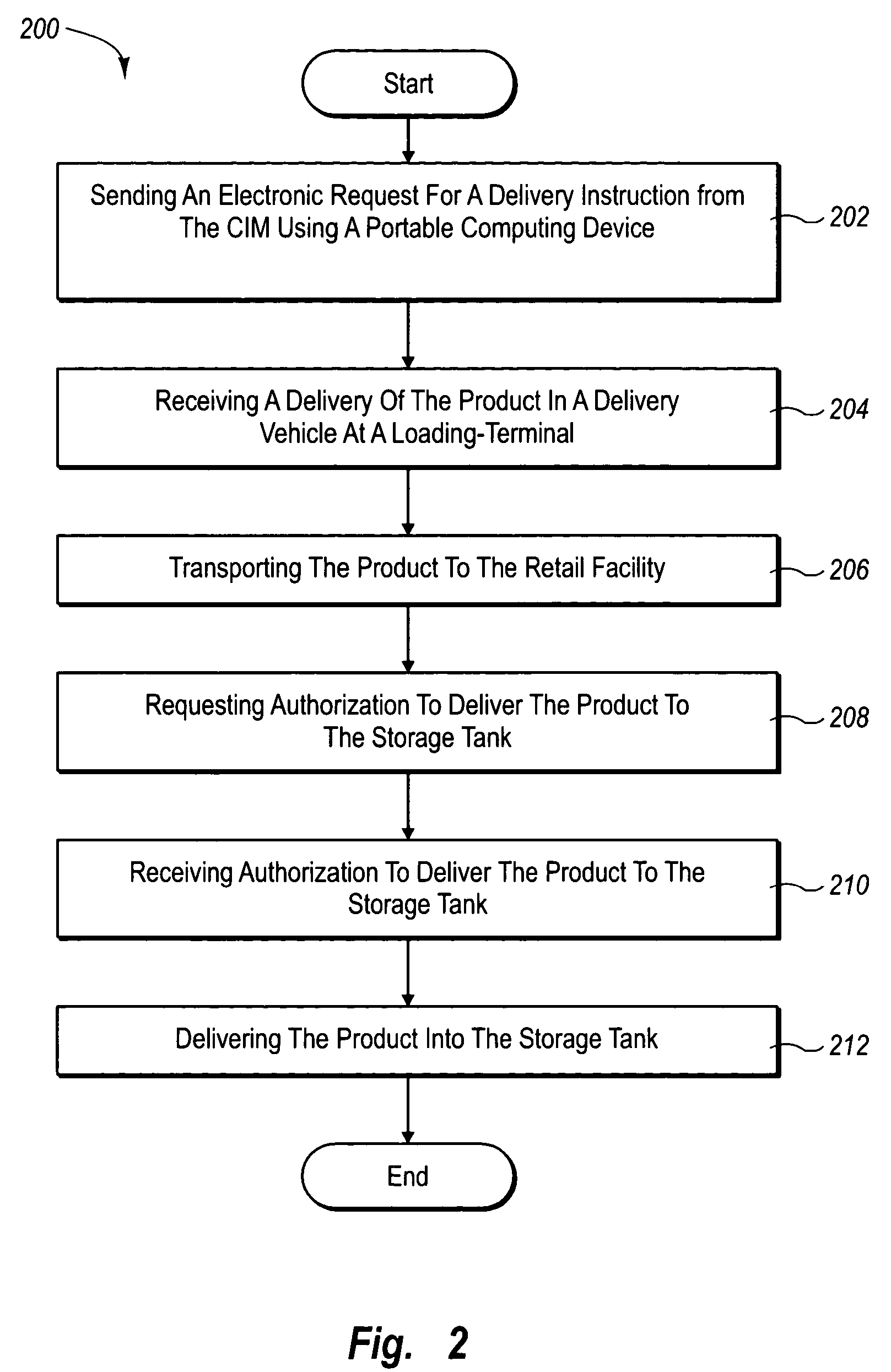

Balancing net inventory using a dynamic expansion coefficient of liquid product relative to temperature changes

InactiveUS7536264B2Block deliveryFlow interruptionTesting/calibration apparatusLevel controlLiquid productAPI gravity

Disclosed are methods, systems, and computer program products for balancing net inventory using a dynamic expansion coefficient of liquid product relative to the temperature changes with density. The method can include receiving an API gravity report that includes a measurement of a specific gravity and a temperature of the product reported at a rack. Utilizing the API gravity report, the method can include maintaining correct densities of the liquid product by utilizing a plurality of expansion coefficients to dynamically convert a gross volume measurement to a net volume measurement for transactions of liquid product in a tank and at a dispenser in order to maintain a net perpetual book balance.

Owner:PILOT TRAVEL CENTS LLC

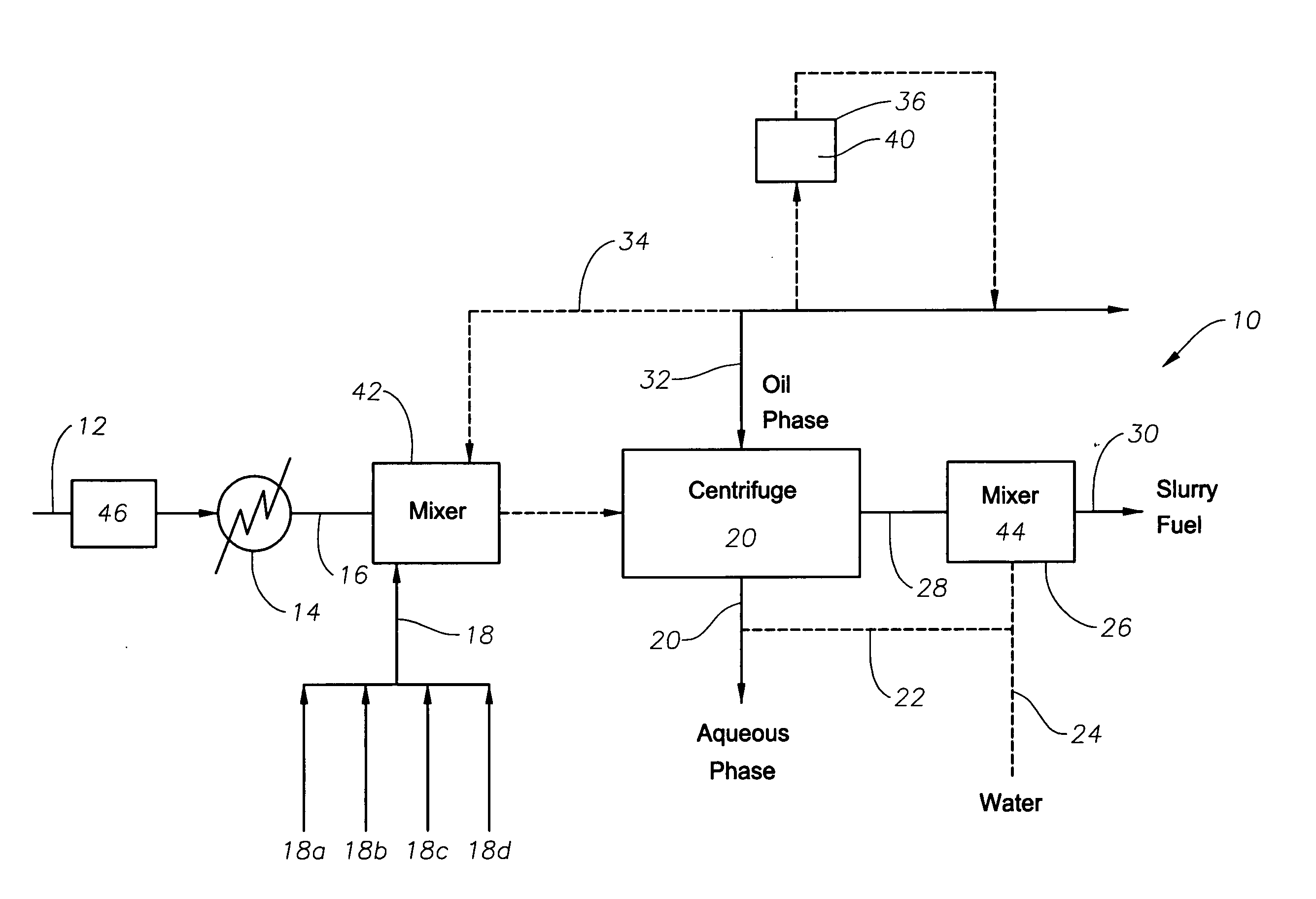

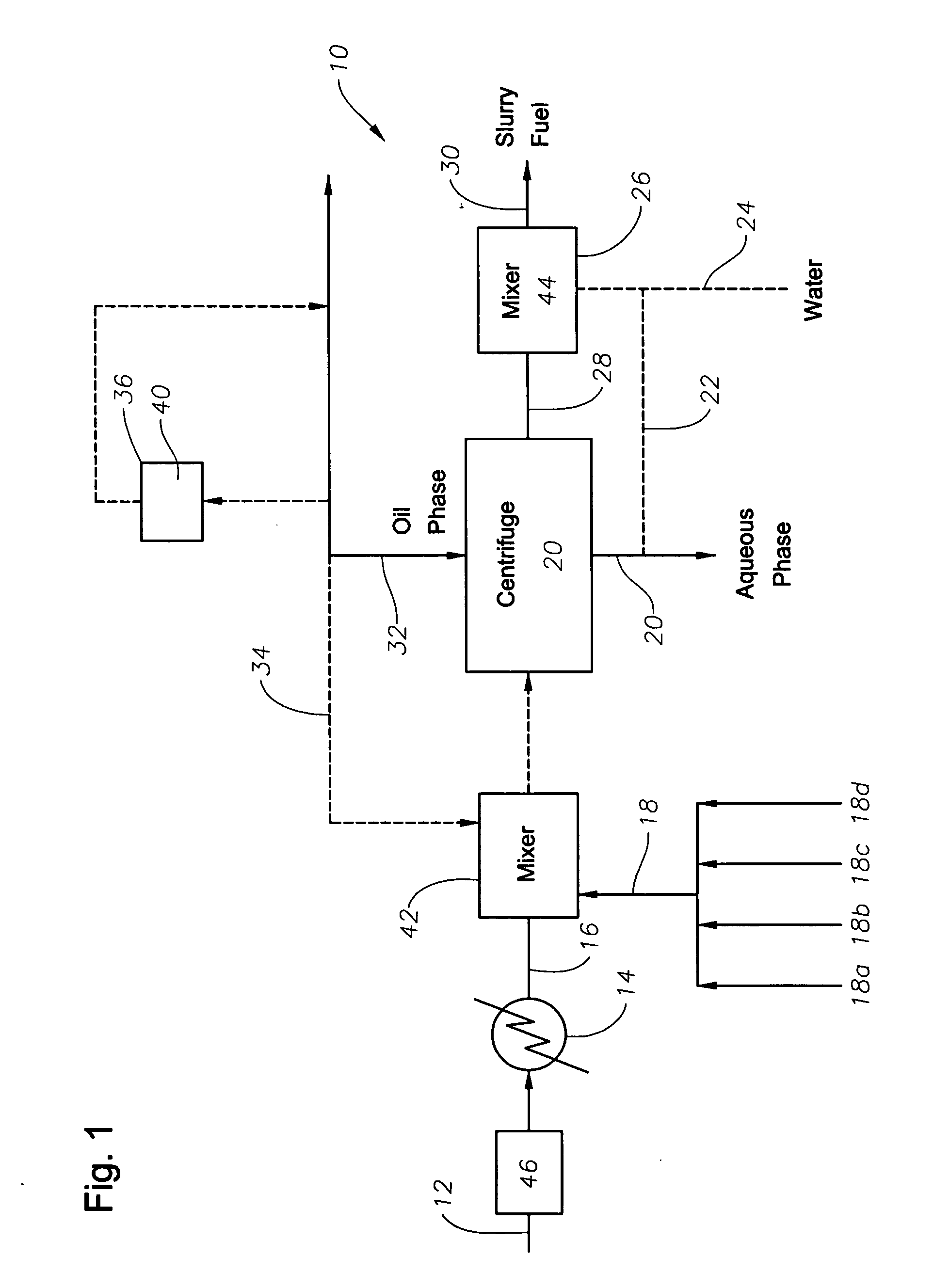

Method for utilizing hydrocarbon waste materials as fuel and feedstock

ActiveUS20060070912A1Low costDewatering/demulsification with mechanical meansRefining by heating/coolingFiberCarbon fibers

The fuel properties of petroleum hydrocarbon waste having an API gravity varying from about 5 to 30 are improved by heating the hydrocarbon to a temperature of about 35° C. to 90° C. and mixing the heated hydrocarbon stream with a suitable solvent to reduce the viscosity of the hydrocarbon, which is then separated by a centrifuge to obtain an aqueous phase stream, an oil phase stream, and a separated solids stream. The oil phase stream has a viscosity range of about 250 centipoise (cP) to about 1000 cP. The oil phase stream is utilized in a refinery, while a slurry fuel is prepared with the separated solids stream and aqueous phase stream as a feedstock for road asphalt, a fuel for a combustor, or a fuel for a gasification process. The oil phase stream is used for fuels and feedstock for making carbon fiber.

Owner:SAUDI ARABIAN OIL CO

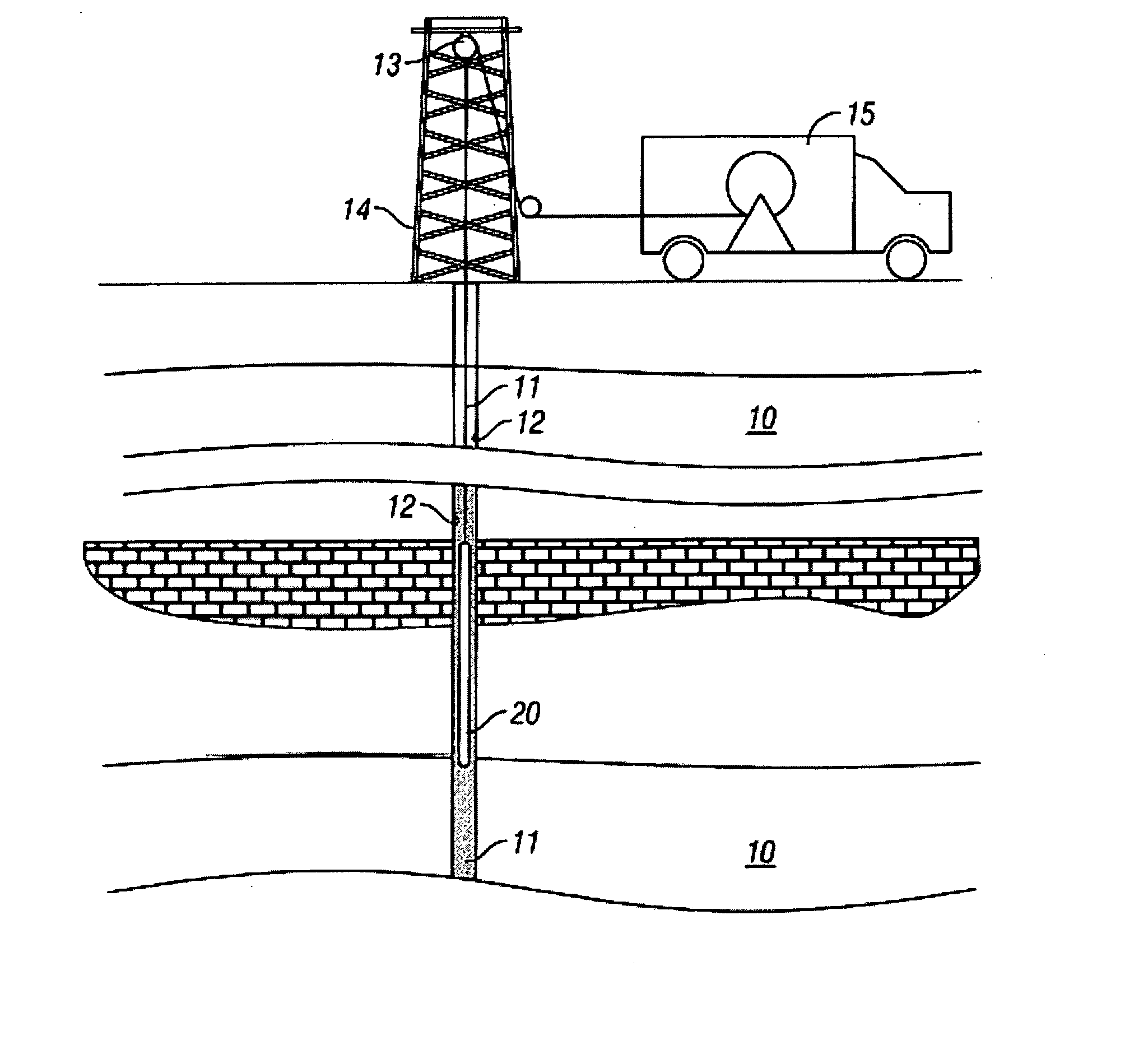

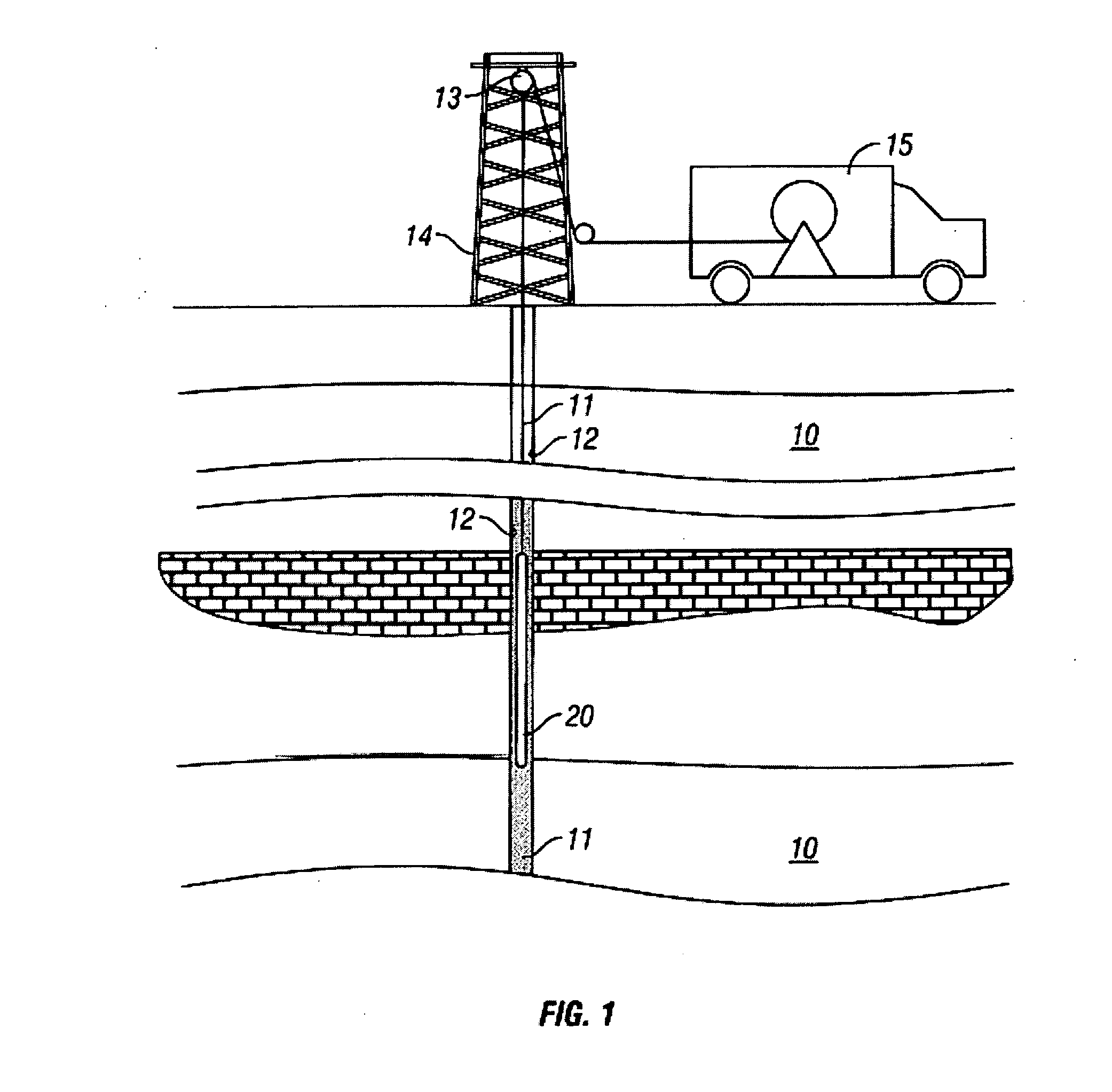

Method and apparatus for obtaining heavy oil samples from a reservoir sample

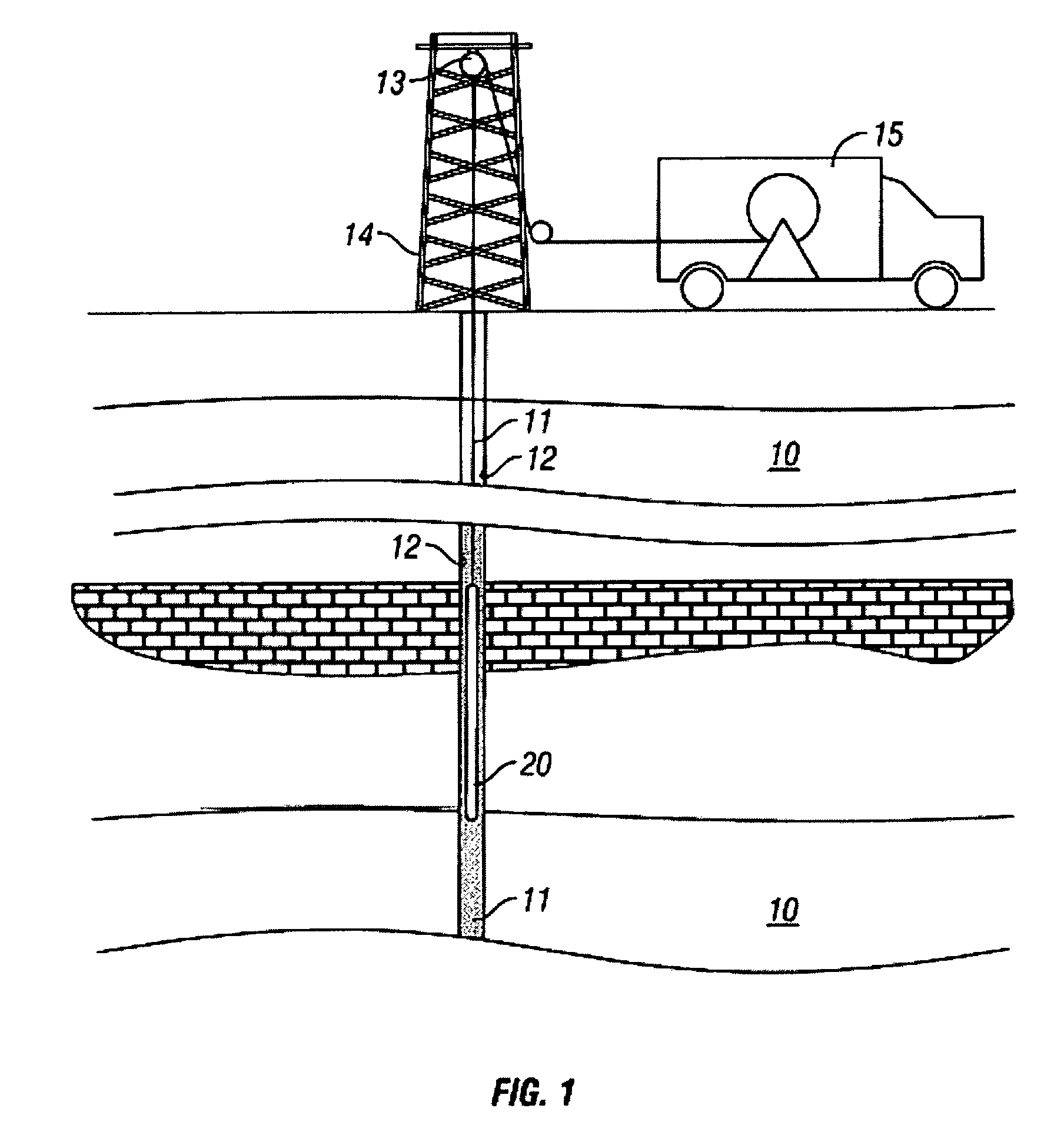

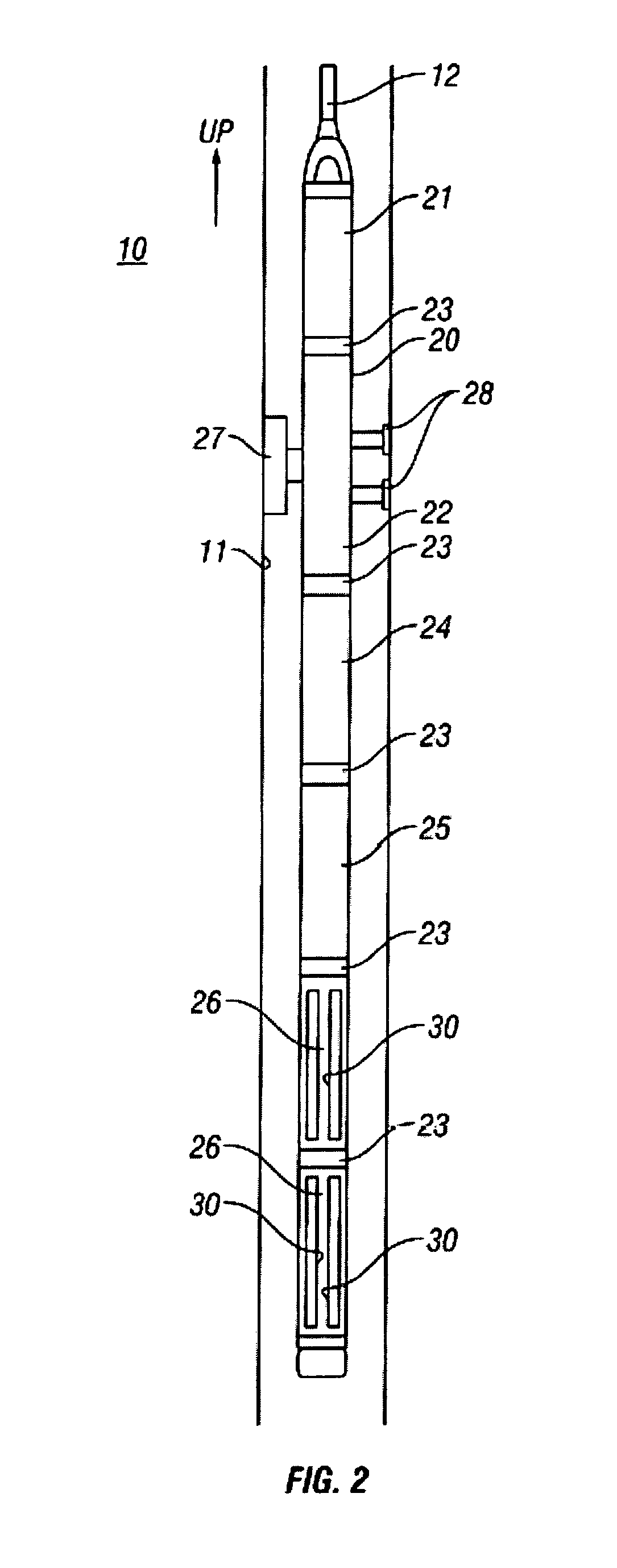

ActiveUS20100089132A1Quality improvementEasy accessFlow propertiesLiquid hydrocarbon mixture productionAPI gravityFuel oil

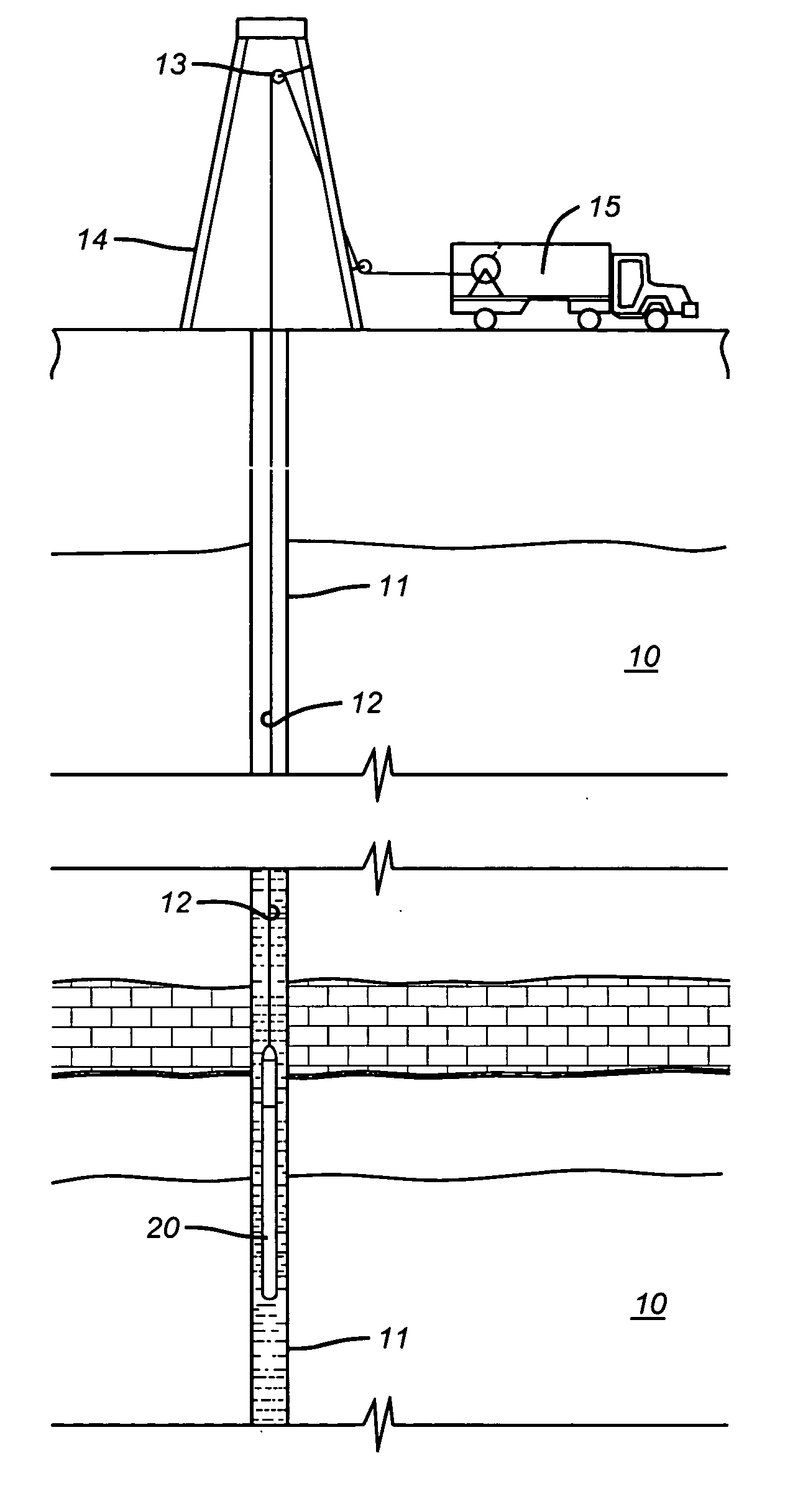

The invention relates to an apparatus and method to obtain a bitumen or heavy oil sample from an oil reservoir sample, such as a core sample, to enable measurement of physical properties such as viscosity, API gravity, or chemical properties such as sulphur content of the obtained bitumen or heavy oil sample. The analyses performed on the samples obtained in accordance with the invention are effective in assisting oil field operators in making timely drilling and production decisions at the oil reservoir or for routine laboratory extraction of oils and bitumens. The invention also permits the collection of samples from simulated thermal recovery operations and also allows the collection of bitumens and oils for online analysis of live oil physical properties.

Owner:SCHLUMBERGER TECH CORP

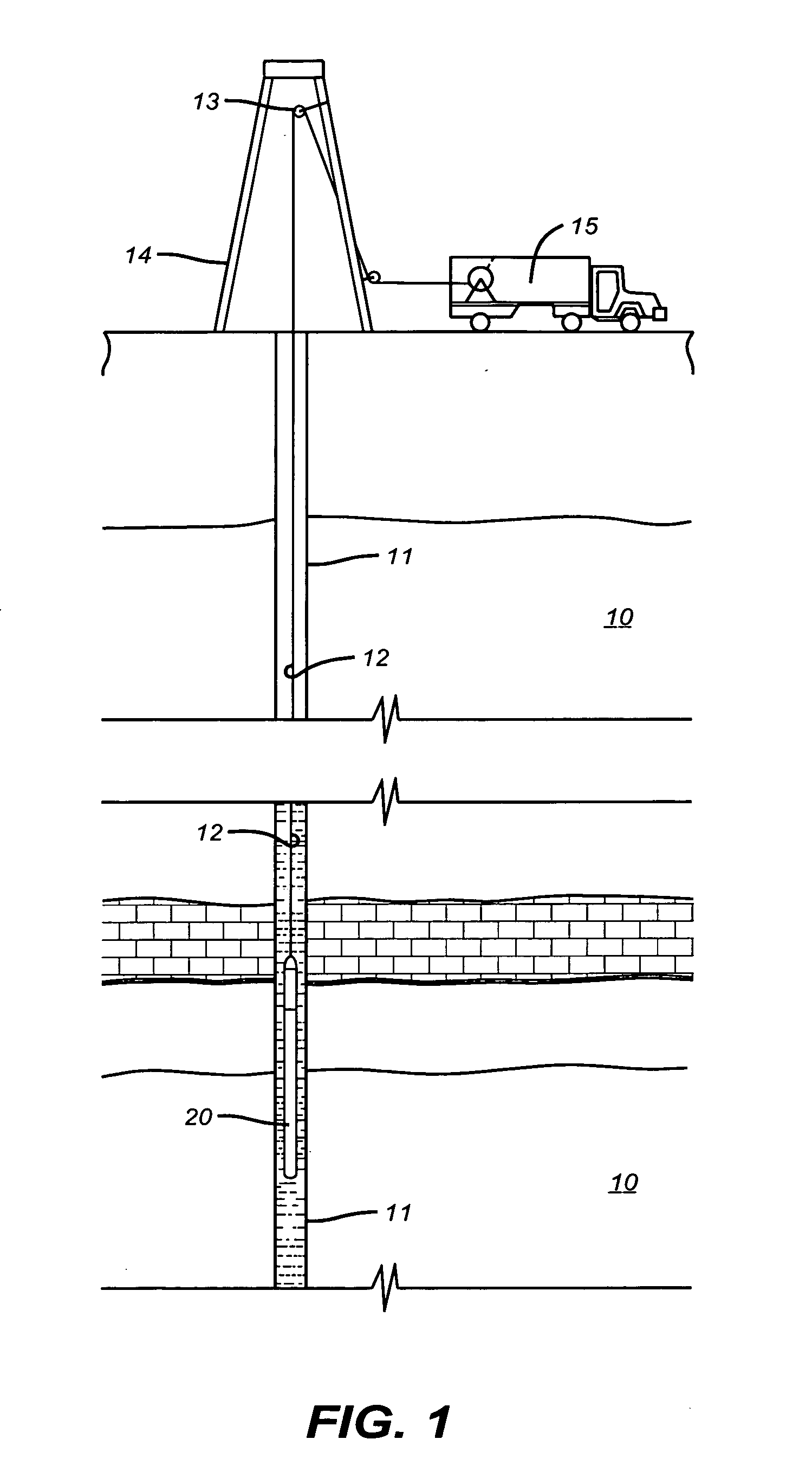

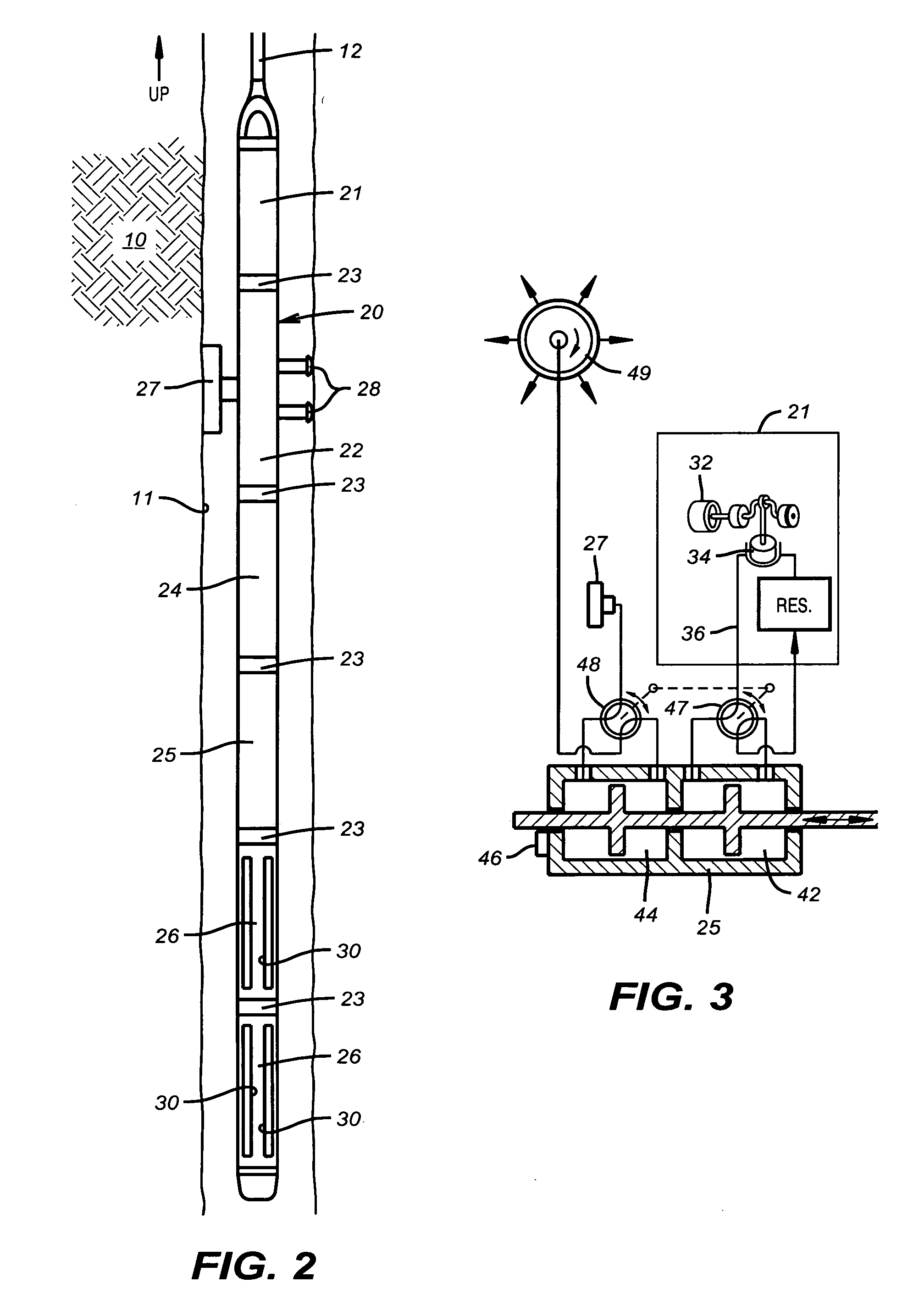

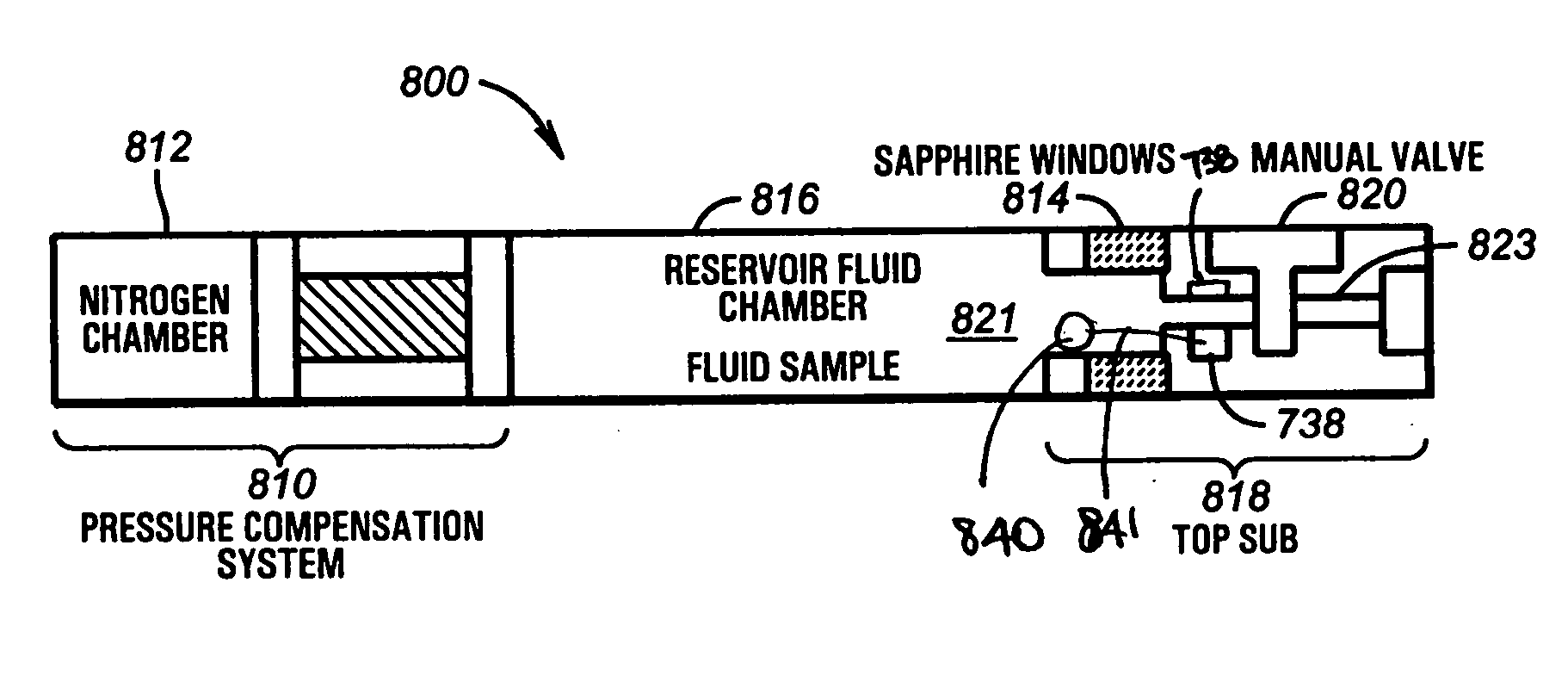

Method and apparatus for a continuous data recorder for a downhole sample tank

ActiveUS20040216521A1Reduce pressureFormat has been changedSurveyEarth material testingSmall sampleAPI gravity

The present invention provides an apparatus and method for continuously monitoring the integrity of a pressurized well bore fluid sample collected downhole in an earth boring or well bore. The CDR continuous by measures the temperature and pressure for the down hole sample. Near infrared, mid infrared and visible light analysis is also performed on the small amount of sample to provide an on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation a flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is overpressured or supercharged to obviate adverse pressure drop or other effects of diverting a small sample to the CDR.

Owner:BAKER HUGHES INC

System, program product, and related methods for estimating and managing crude gravity in flowlines in real-time

ActiveUS20090312964A1Flow propertiesSpecific gravity by measuring pressure differencesStream flowAPI gravity

Systems, program product, and methods to estimate and manage flowing fluid characteristics of a fluid stream flowing through a pipeline in real-time, are provided. A system can include a vertically oriented extent of a pipeline for transporting crude oil, a pair of spaced vertically apart sensors or sensor assemblies connected to the vertically oriented extent to obtain pressure and temperature readings of the crude oil, a controller in communication with the pair of sensors or sensor assemblies, and crude oil analysis and management program product stored in the memory of the controller and adapted to determine or estimate density, specific gravity, and API gravity of the crude oil to thereby manage flowing fluid characteristics of the crude oil.

Owner:SAUDI ARABIAN OIL CO

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

Process for the catalytic hydrotreatment of heavy hydrocarbons of petroleum

ActiveUS7651604B2Large capacityImproved propertyTreatment with plural serial cracking stages onlyRefining with metalsSludgeSulfur

Two-stage low pressure catalytic hydrotreatment of heavy petroleum hydrocarbons having a high content of contaminants (metals and asphaltenes), is conducted under operating conditions with low-pressure, in a fixed bed or ebullated bed reactor to limit the formation of sediments and sludge in the product and obtain a hydrotreated hydrocarbon of improved properties, with levels of contaminants, API gravity and distillates within the ranges commonly reported in the feedstocks typical to refining schemes. A hydrotreatment catalyst, whose principal effect is the hydrodemetallization and the hydrocracking of asphaltenes of the heavy hydrocarbons of petroleum is used in the first stage, and the second reaction stage employs a hydrotreatment catalyst for a deeper effect of hydrodesulfurization of the heavy petroleum hydrocarbon whose content of total sulfur is reduced to a level required for its treatment in the conventional refining process or for its sale as a hydrocarbon of petroleum with improved properties.

Owner:INST MEXICANO DEL GASOLINEEO

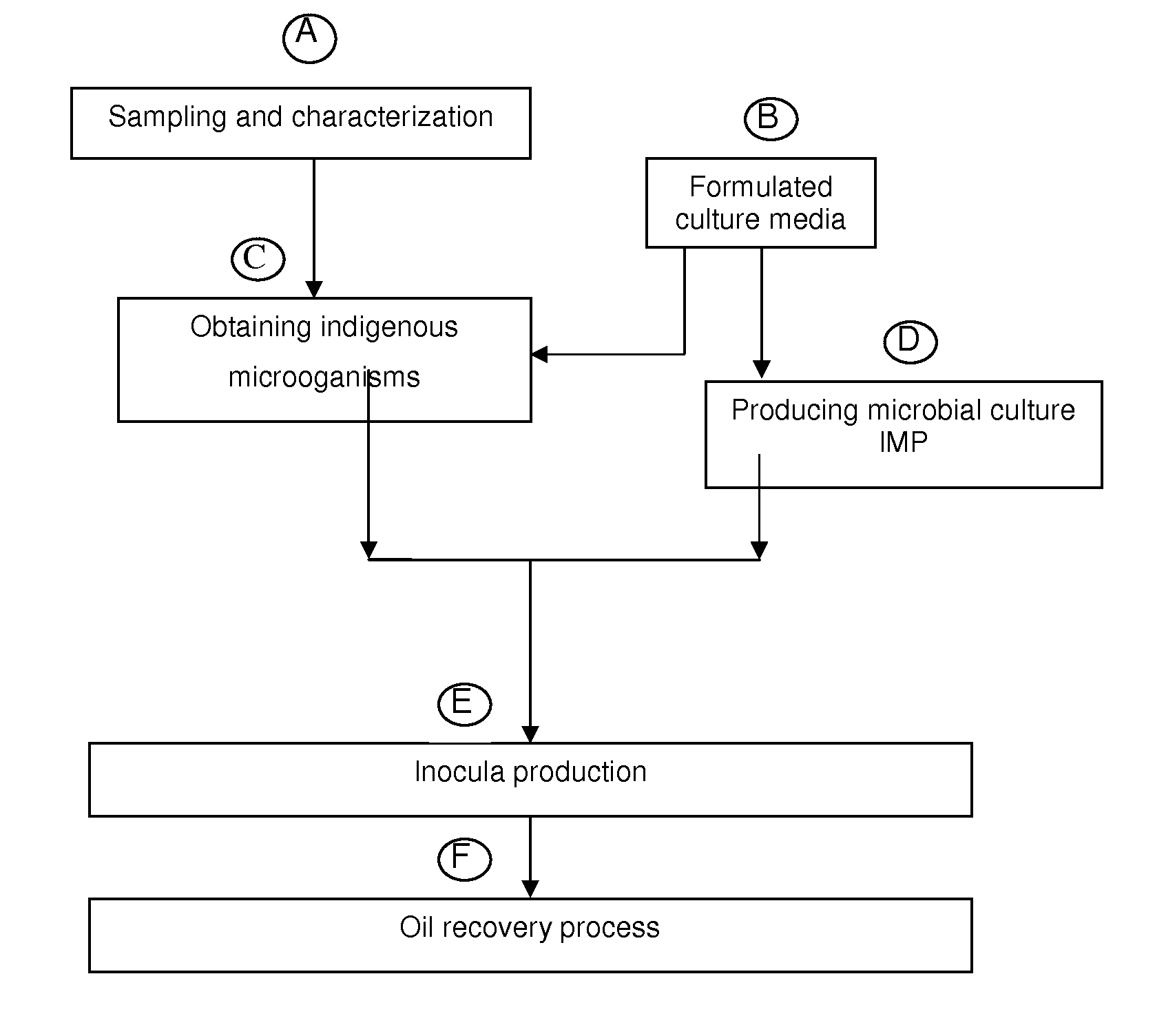

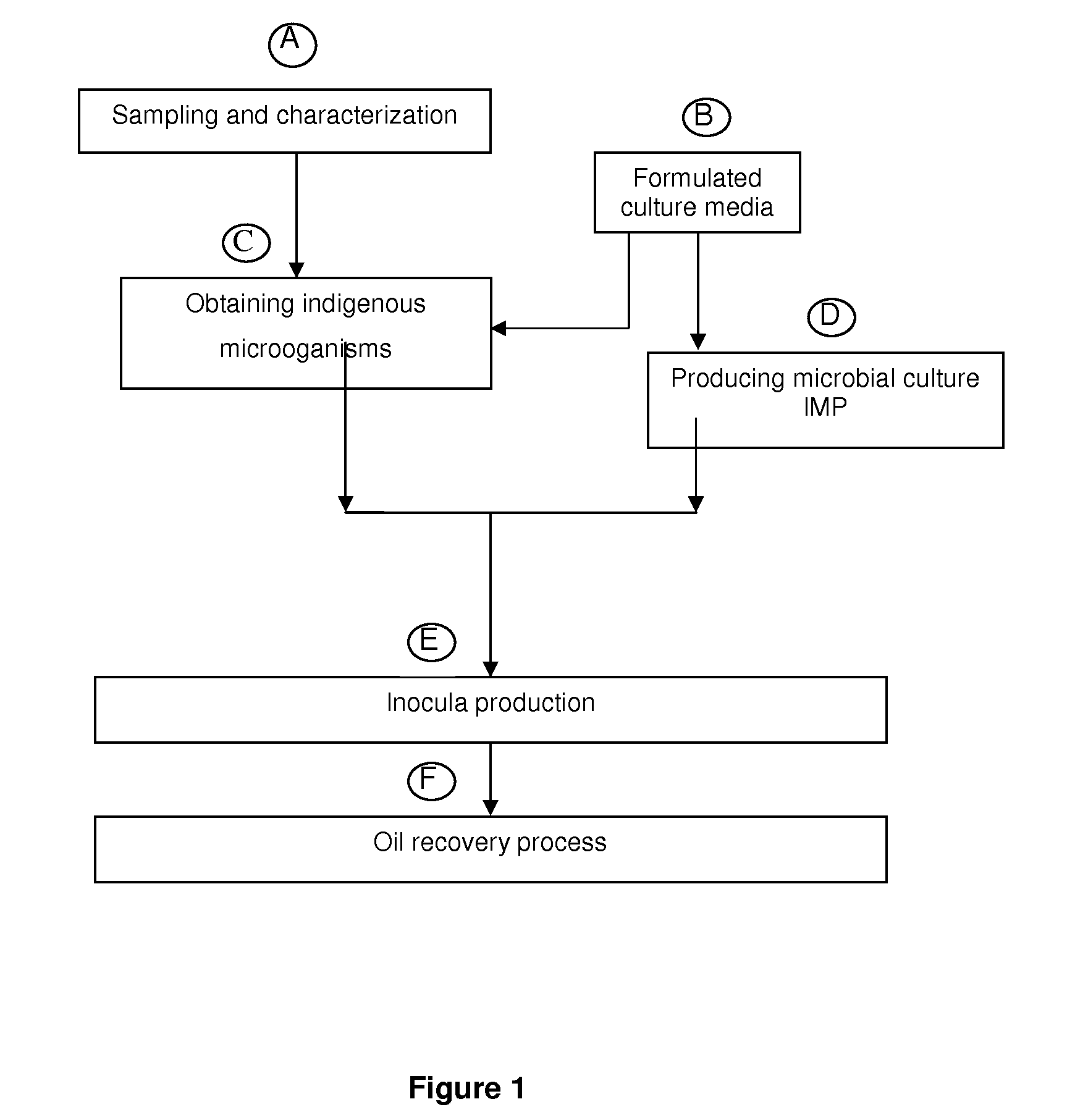

Biotechnological process for hydrocarbon recovery in low permeability porous media

ActiveUS20110146973A1Enhanced overall recoveryImprove mobilityFluid removalDrilling compositionMetaboliteAPI gravity

The present invention refers to a biotechnological process that enhances oil recovery of a 14 to 25 API Gravity oil contained in carbonate-containing and / or clayey sandstone porous rock systems with low permeability (7 to 100 mD), thus focused to petroleum wells associated to zones with low recovery factor. The process utilizes the indigenous extremophile microorganisms activity from the oil reservoir and an IMP culture, as well as its metabolites (gases, acids, solvents and surfactants), which improve oil mobility and are able to develop at 60 to 95° C. temperatures, 7 to 154.6 Kg / cm2 (100 to 2,200 psi) pressures and NaCl content from 5,000 to 45,000 ppm, in anaerobic conditions. The biotechnological process of the present invention includes: indigenous microorganisms sampling, collecting and characterization from the reservoir; formulation of culture media; selection, enrichment, activation and preservation of such microorganisms, as well as biostimulation (indigenous microorganisms) and bioaugmentation (IMP culture) to increase the metabolite production, useful for oil recovery in a porous media impregnated with oil in carbonate-containing and / or clayey sandstone porous systems, with one or several cycles and confinement periods from 5 to 10 days, to increase oil recovery. Experimental tests show that the biotechnological process of the present invention supplies an oil recovery increase up to 30%, additional to that obtained in secondary recovery processes.

Owner:INST MEXICANO DEL GASOLINEEO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com