Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5527 results about "Motor oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Motor oil, engine oil, or engine lubricant is any of various substances comprising base oils enhanced with particularly antiwear additive plus detergents, dispersants and, for multi-grade oils viscosity index improvers. Motor oil is used for lubrication of internal combustion engines. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge (one of the functions of dispersants) and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts.

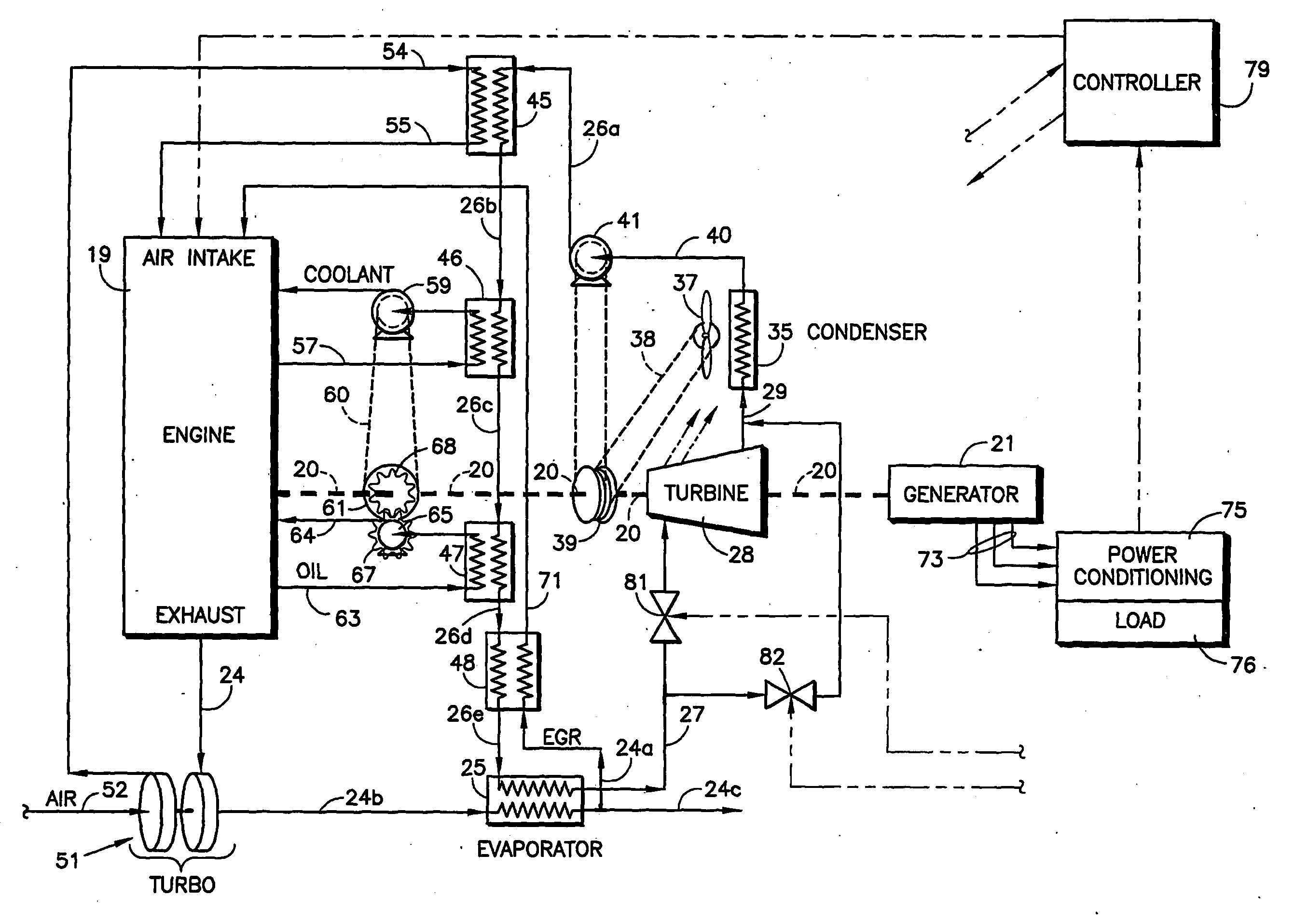

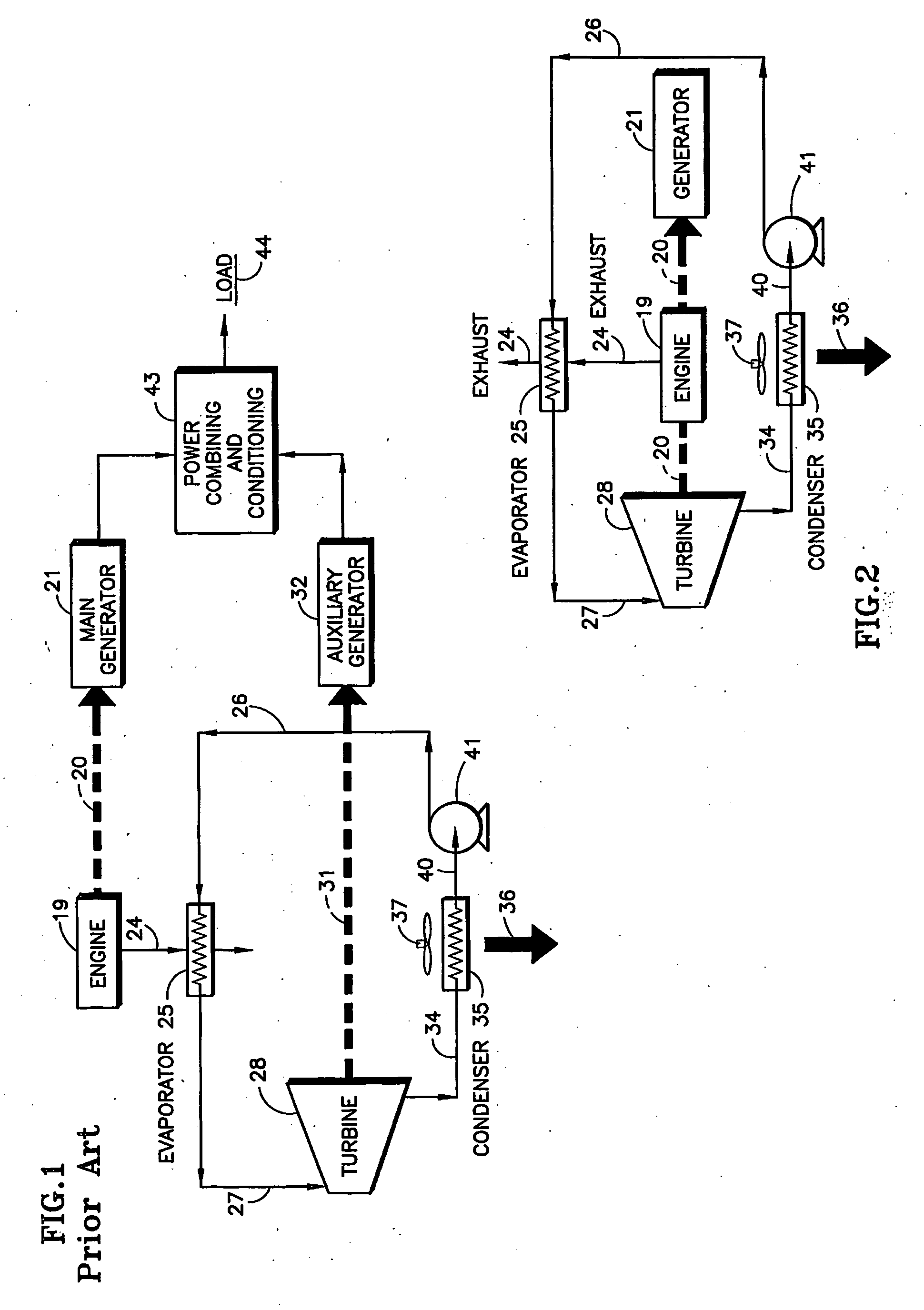

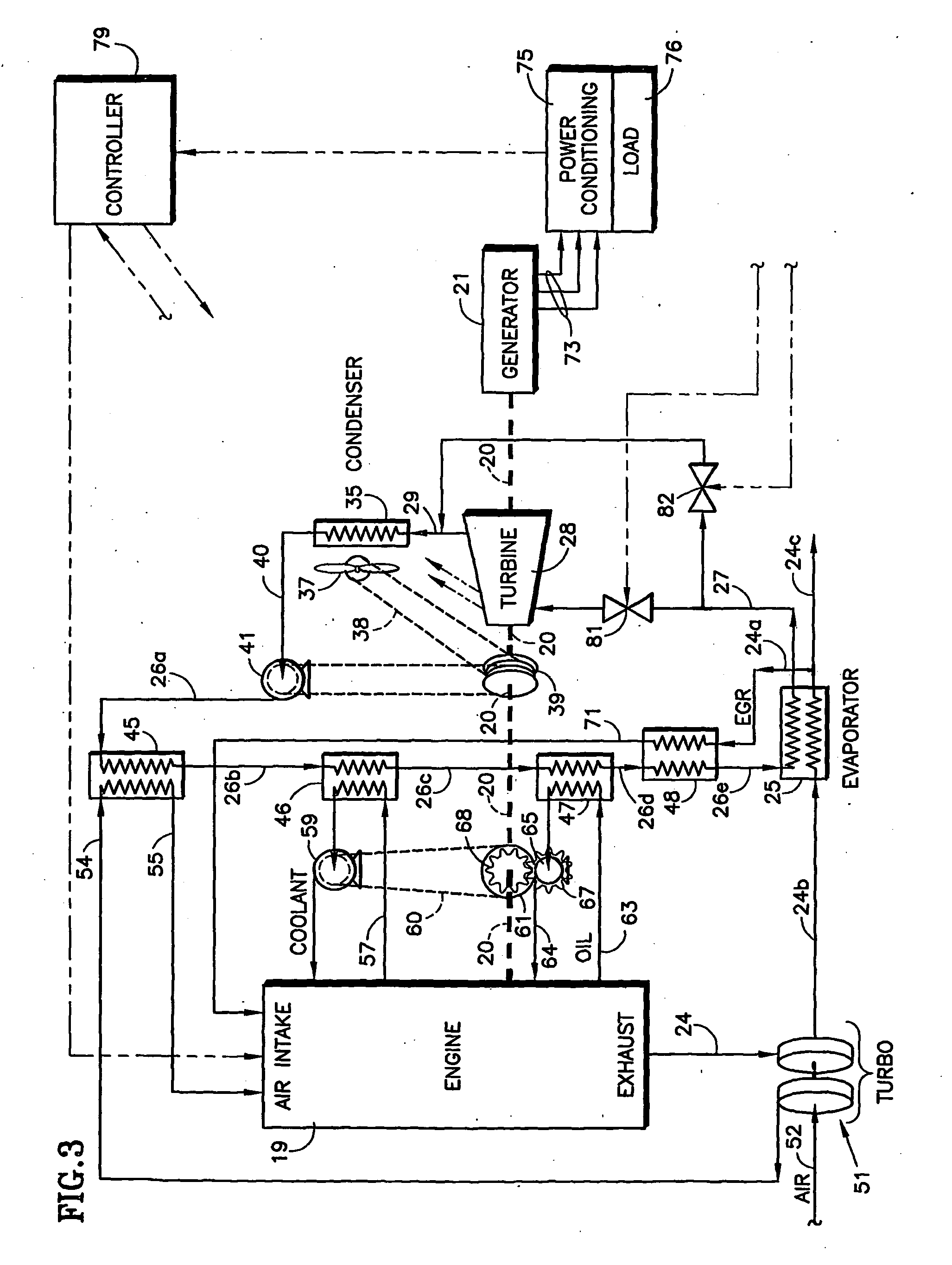

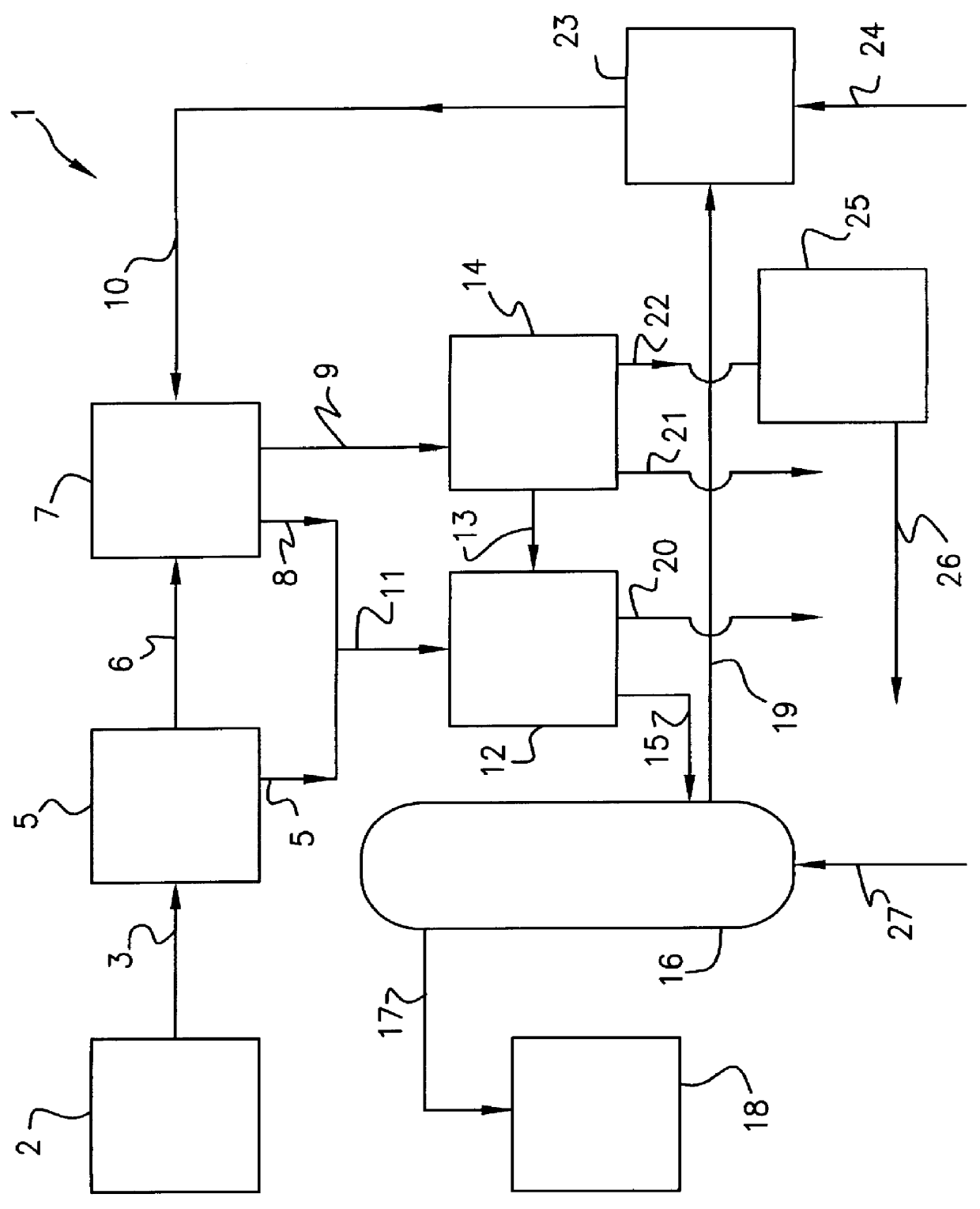

Organic Rankine Cycle Mechanically and Thermally Coupled to an Engine Driving a Common Load

InactiveUS20090211253A1Maximize efficiencyEngine componentsSteam engine plantsPtru catalystOrganic Rankine cycle

The shaft (20) of an engine (19) is coupled to a turbine (28) of an organic Rankine cycle subsystem which extracts heat (45-48, 25) from engine intake air, coolant, oil, EGR and exhaust. Bypass valves (92,94, 96, 99) control engine temperatures. Turbine pressure drop is controlled via a bypass valve (82) or a mass flow control valve (113). A refrigeration subsystem having a compressor (107) coupled to the engine shaft uses its evaporator (45a) to cool engine intake air. The ORC evaporator (25a) may comprise a muffler including pressure pulse reducing fins (121, 122), some of which have NOx and / or particulate reducing catalysts thereon.

Owner:UNITED TECH CORP

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

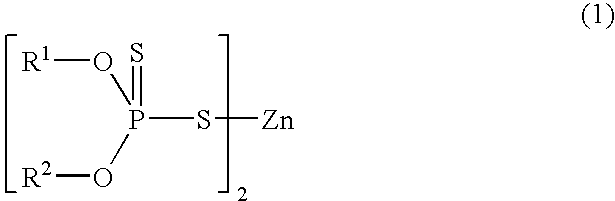

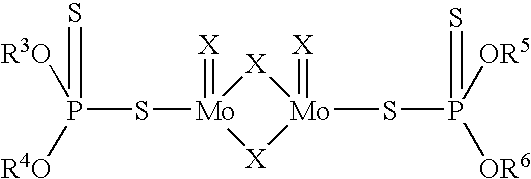

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

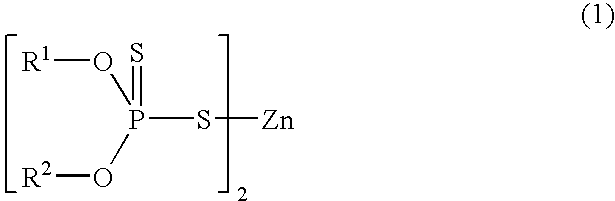

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

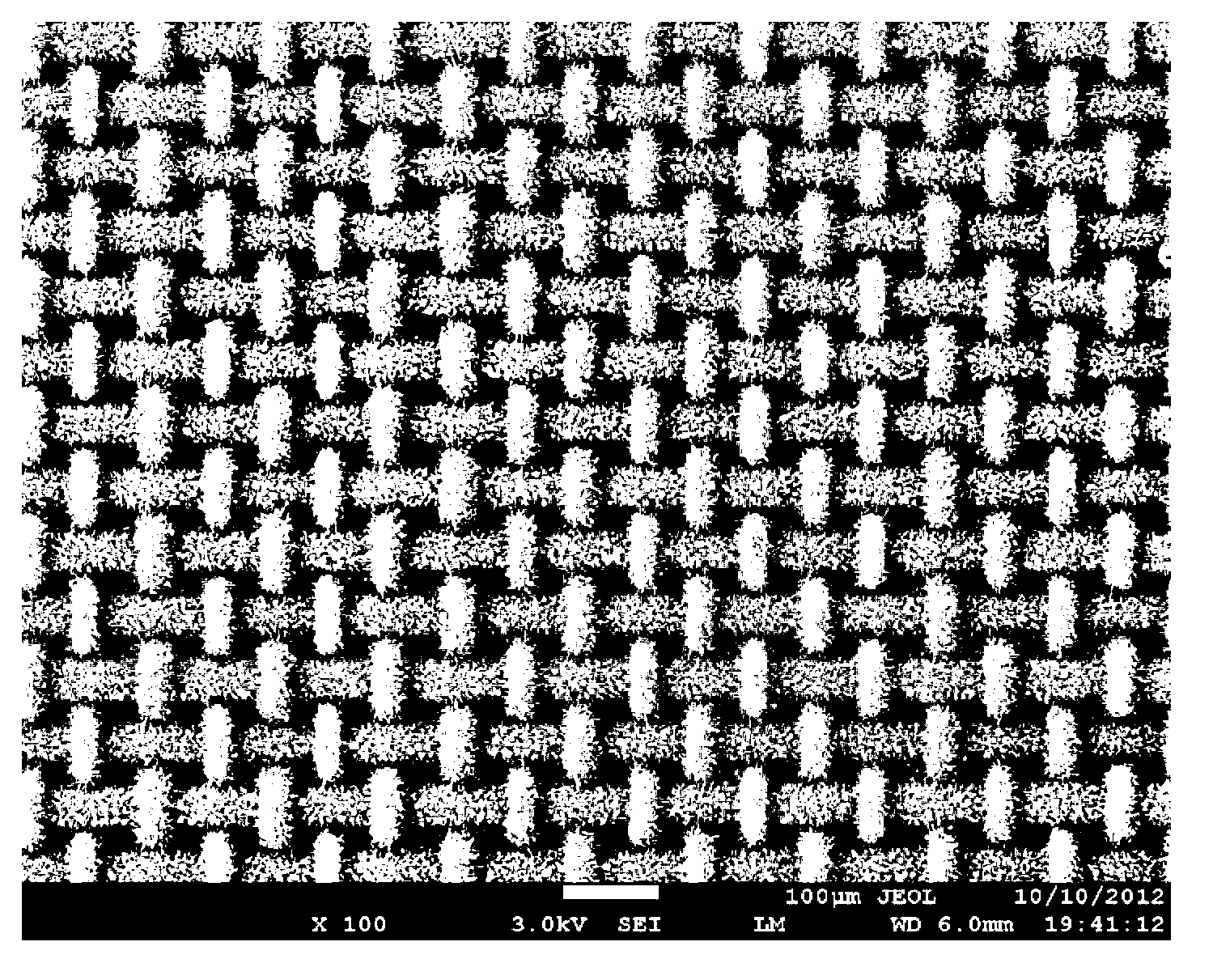

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane having, and its preparation method

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane, and its preparation method. The method comprises the following steps: 1, cleaning a copper mesh, and airing; 2, dissolving an alkaline medium and an oxidant in water, and uniformly stirring to obtain a mixed solution; and 3, dipping the aired copper mesh in the mixed solution, and carrying out an oxidation reaction to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane has the advantages of easily available raw material, low cost, simple equipment and making technology, realization of large-scale preparation, large water flux, fast water-water separation speed, good oil-water separation effect, suitableness for the treatment of sewage containing a large amount of water, very good separation effect on n-hexane, petroleum ether, dichloroethane, benzene, gasoline, diesel oil, kerosene, machine oil, crude oil, animal and plant oil, and the like, easy cleaning, repeatable use, and good stability.

Owner:TSINGHUA UNIV

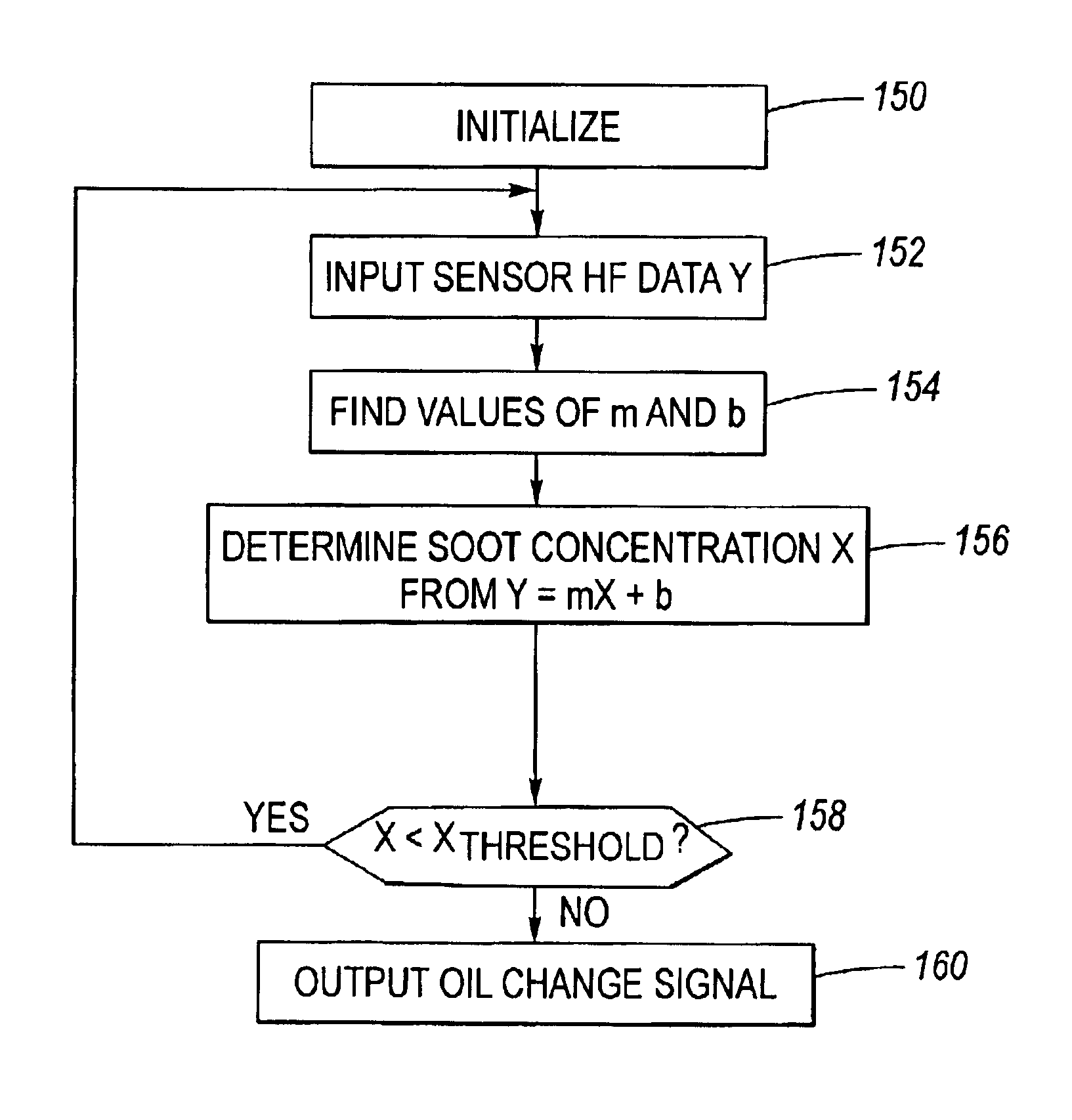

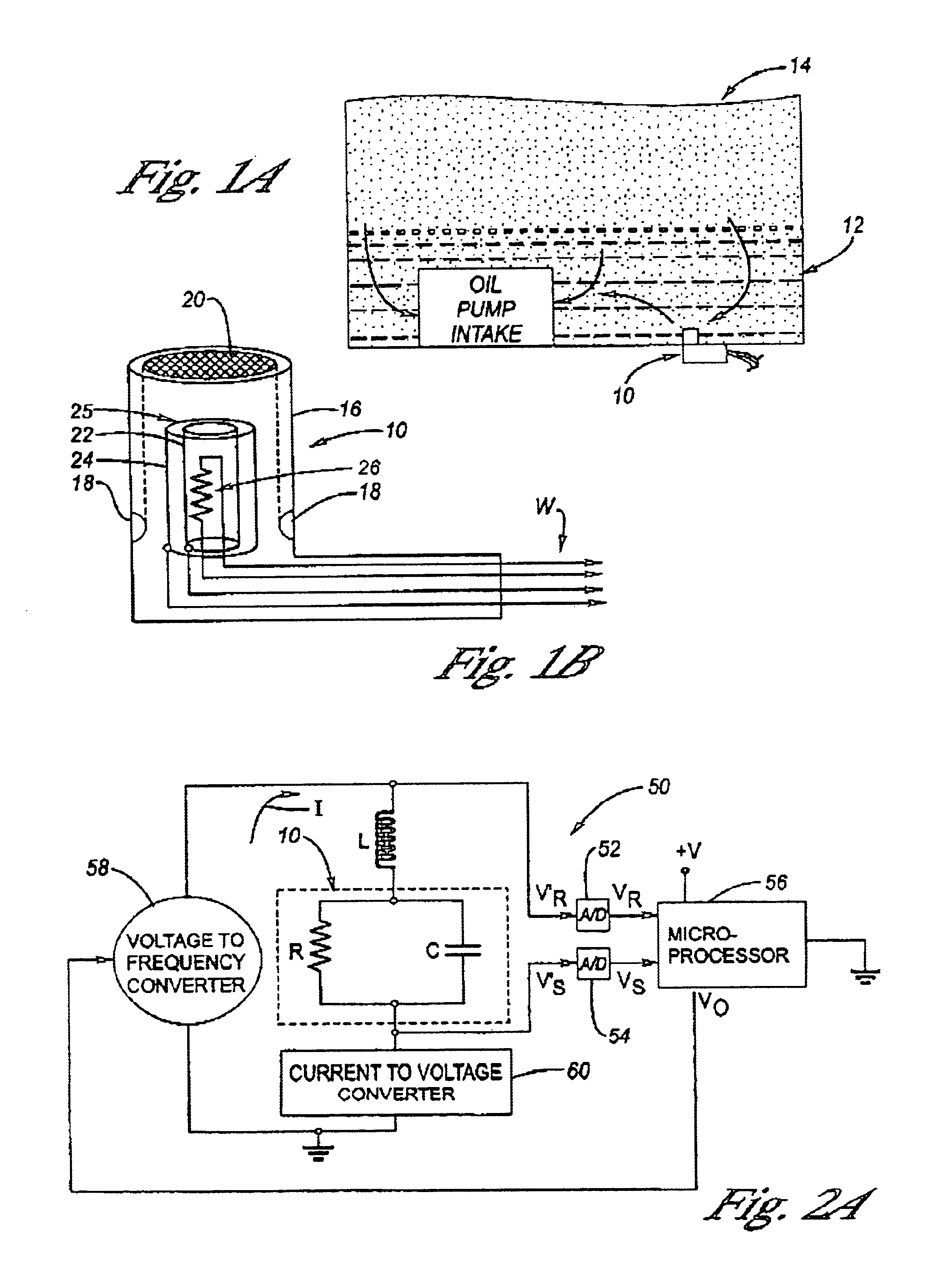

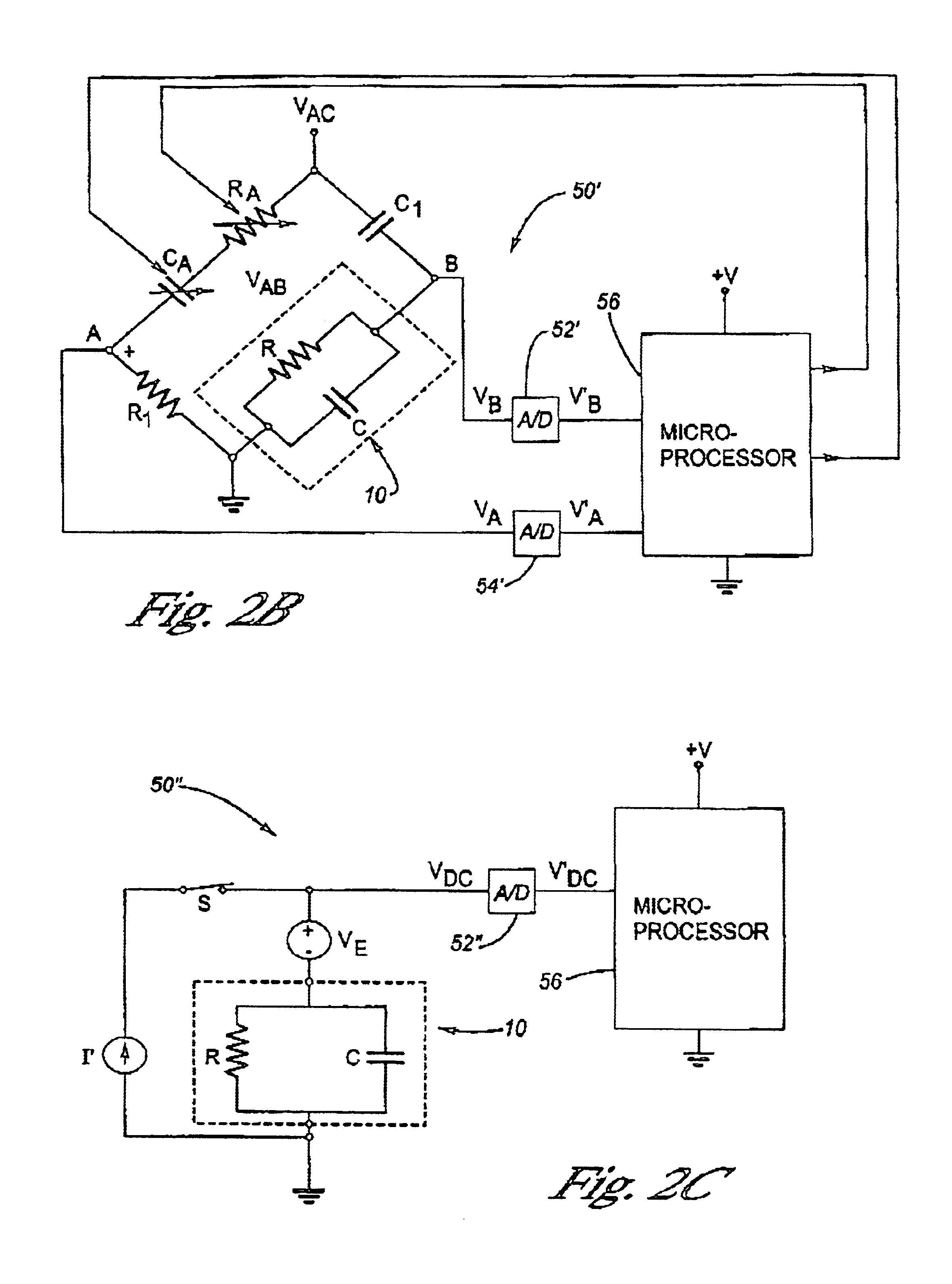

Diesel engine lubricating oil contaminant sensor method

A method by which contaminant (soot) content in Diesel engine oil is determined using electrical conductivity measurements of the Diesel oil at a high frequency, or by which contaminant (soot and / or water and / or anitfreeze) content is determined using the ratio of electrical conductivity measurements of the Diesel oil at a high frequency to the electrical conductivity measurements of the Diesel oil at a low frequency. Both the conductivity ratio and the high frequency conductivity are essentially independent of the brand of oil. High frequency is defined to be above 2 MHz whereas low frequency is defined to be D.C. to about 1 kHz.

Owner:DELPHI TECH INC

Plastic reclamation process

A plastic article or plastic container reclamation process if provided in which plastic containers are divided into relatively large pieces, then washed, agitated and separated using an aqueous solvent to remove residual materials. The residual materials such as motor oil are reclaimed for reuse and the aqueous solvent is regenerated for reuse in the process. Residual materials such as dirt, labels and adhesives from the plastic containers is recovered for recycling or passed to waste for disposal or reuse.

Owner:DOONAN BILLIE ODELL

Working fluid composition for refrigerator machine and refrigerating machine oil

ActiveUS20120132848A1Improve stabilityInhibit deteriorationHeat-exchange elementsLubricant compositionWorking fluidEther

The present invention provides a working fluid composition for a refrigerator machine comprising a base oil comprising an ether-based compound, a carbodiimide compound, and an unsaturated fluorinated hydrocarbon refrigerant. The present invention also provides a refrigerating machine oil comprising a base oil containing an ether-based compound and a carbodiimide compound, the refrigerating machine oil being used together with an unsaturated fluorinated hydrocarbon refrigerant.

Owner:JX NIPPON OIL & ENERGY CORP

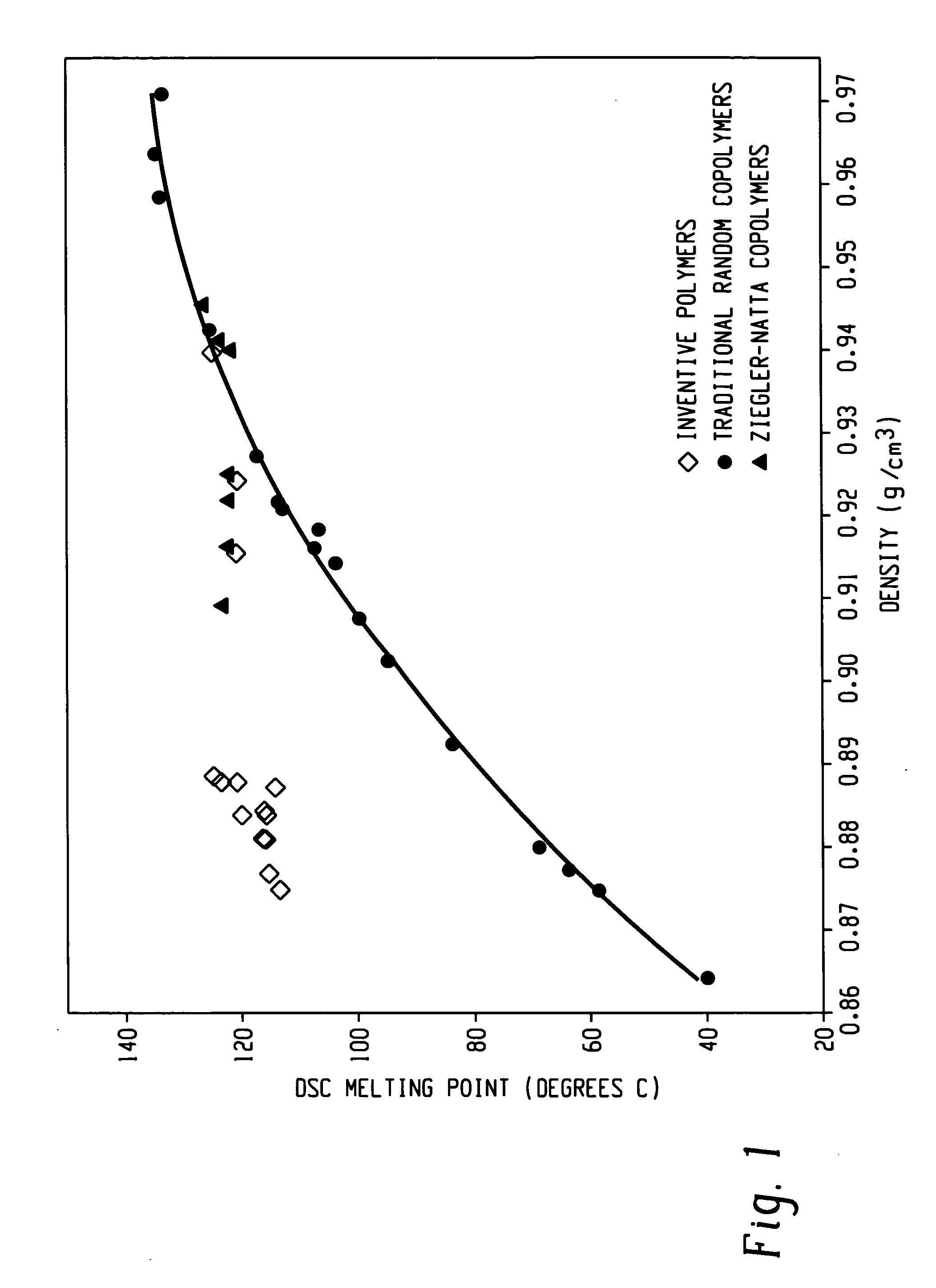

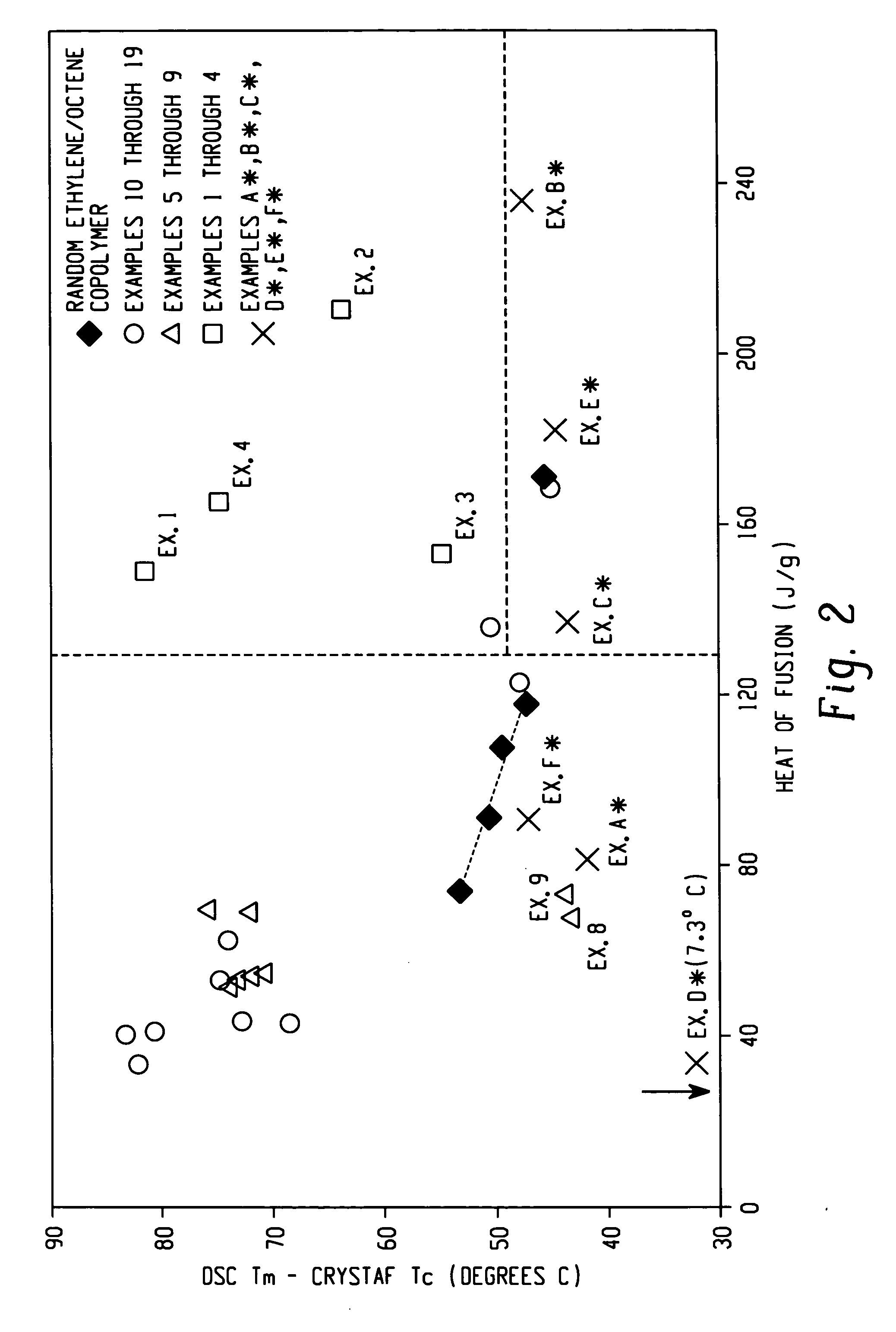

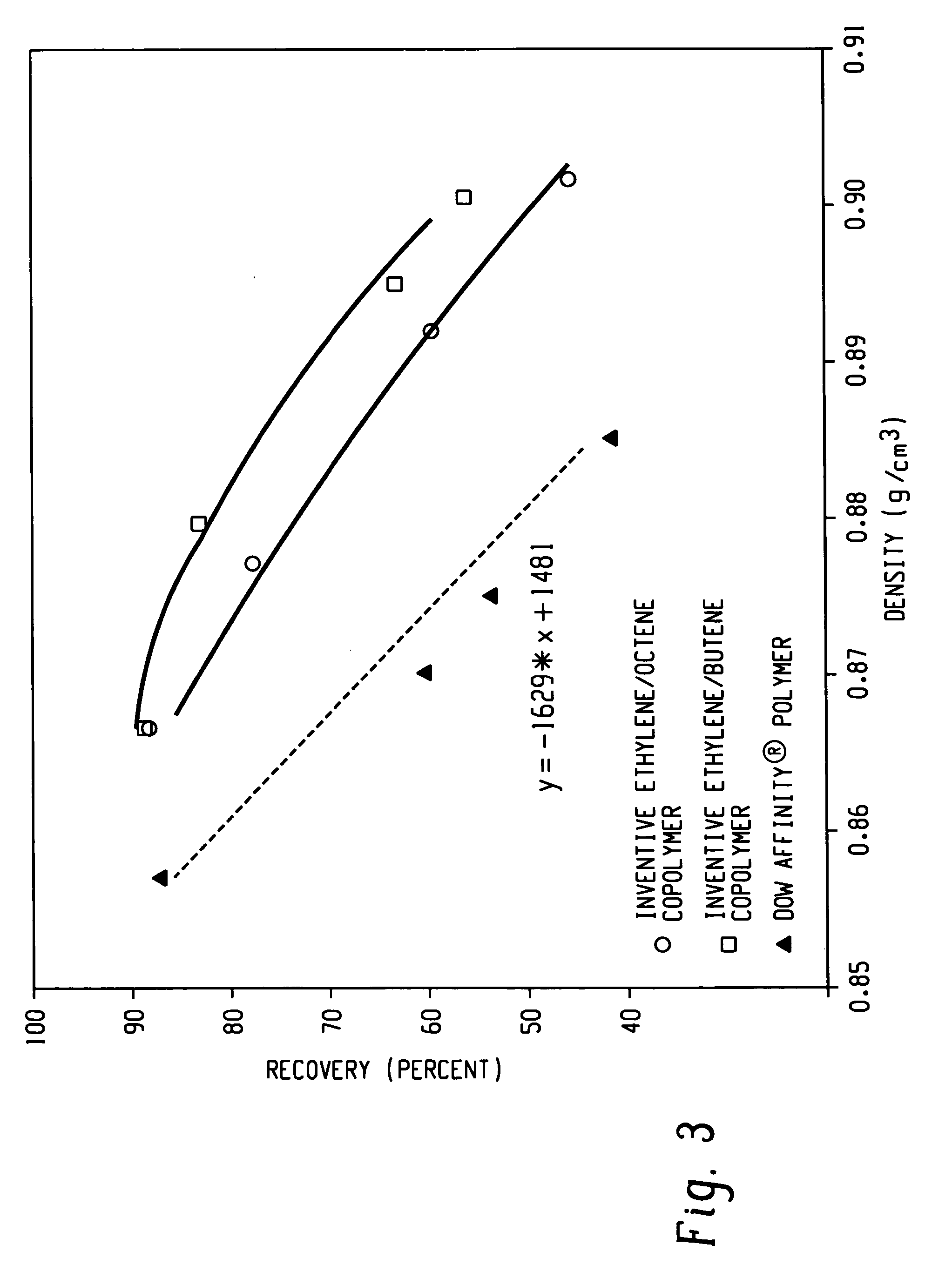

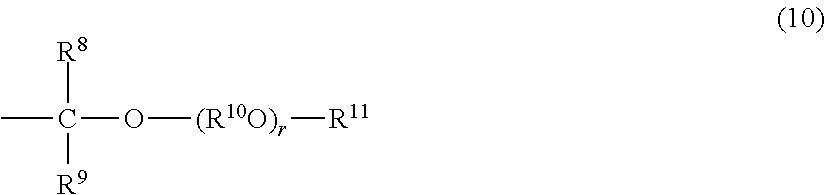

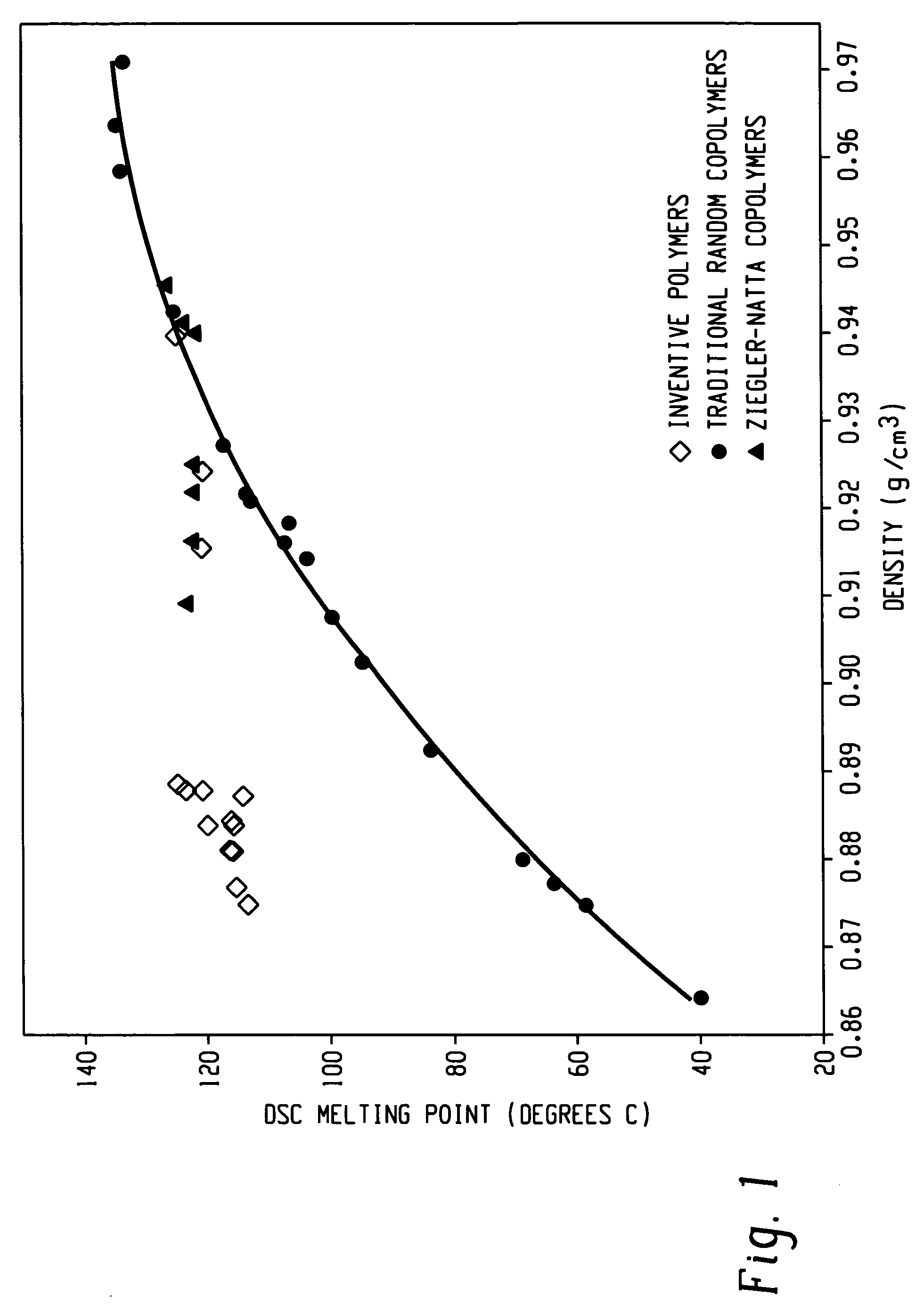

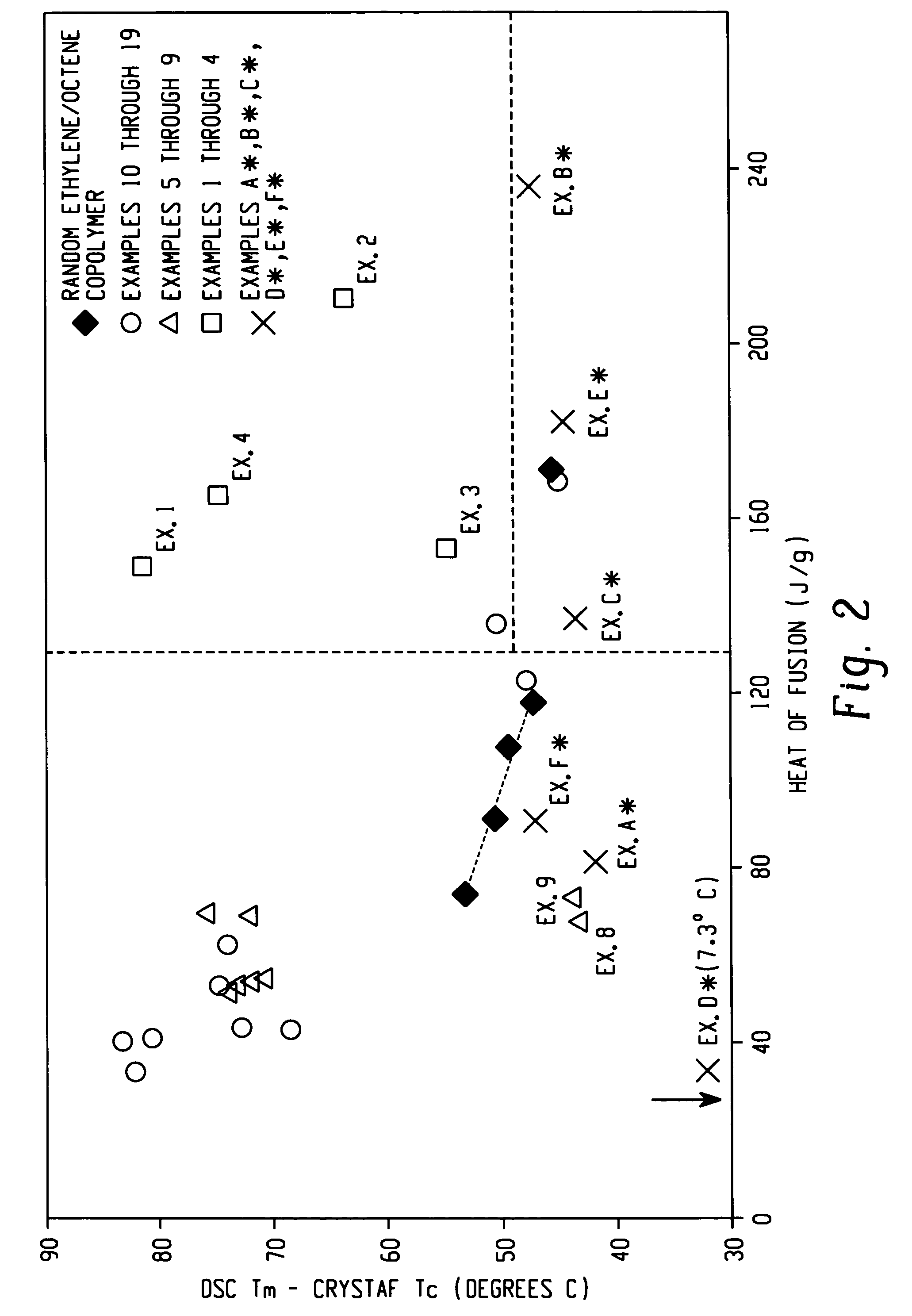

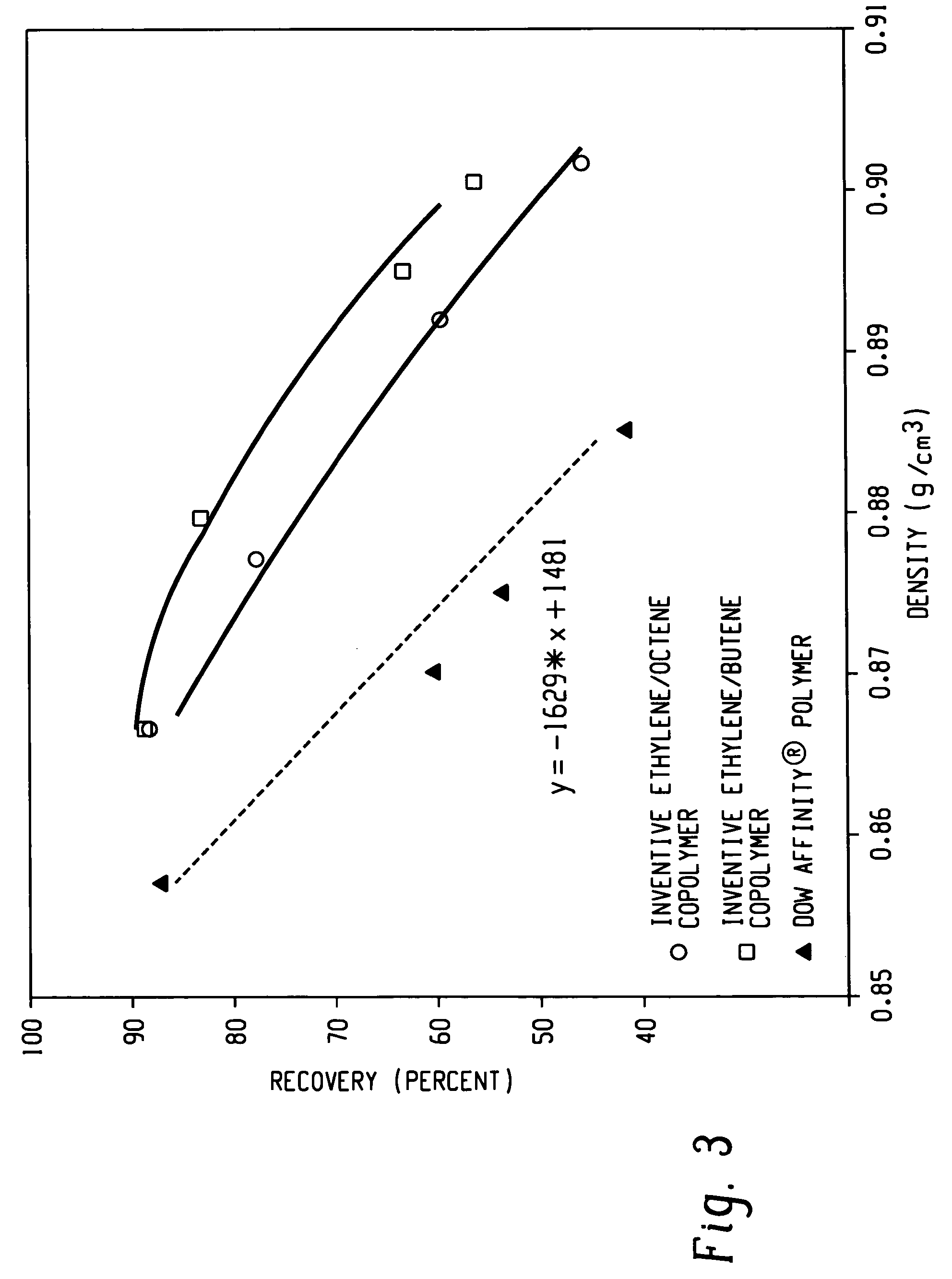

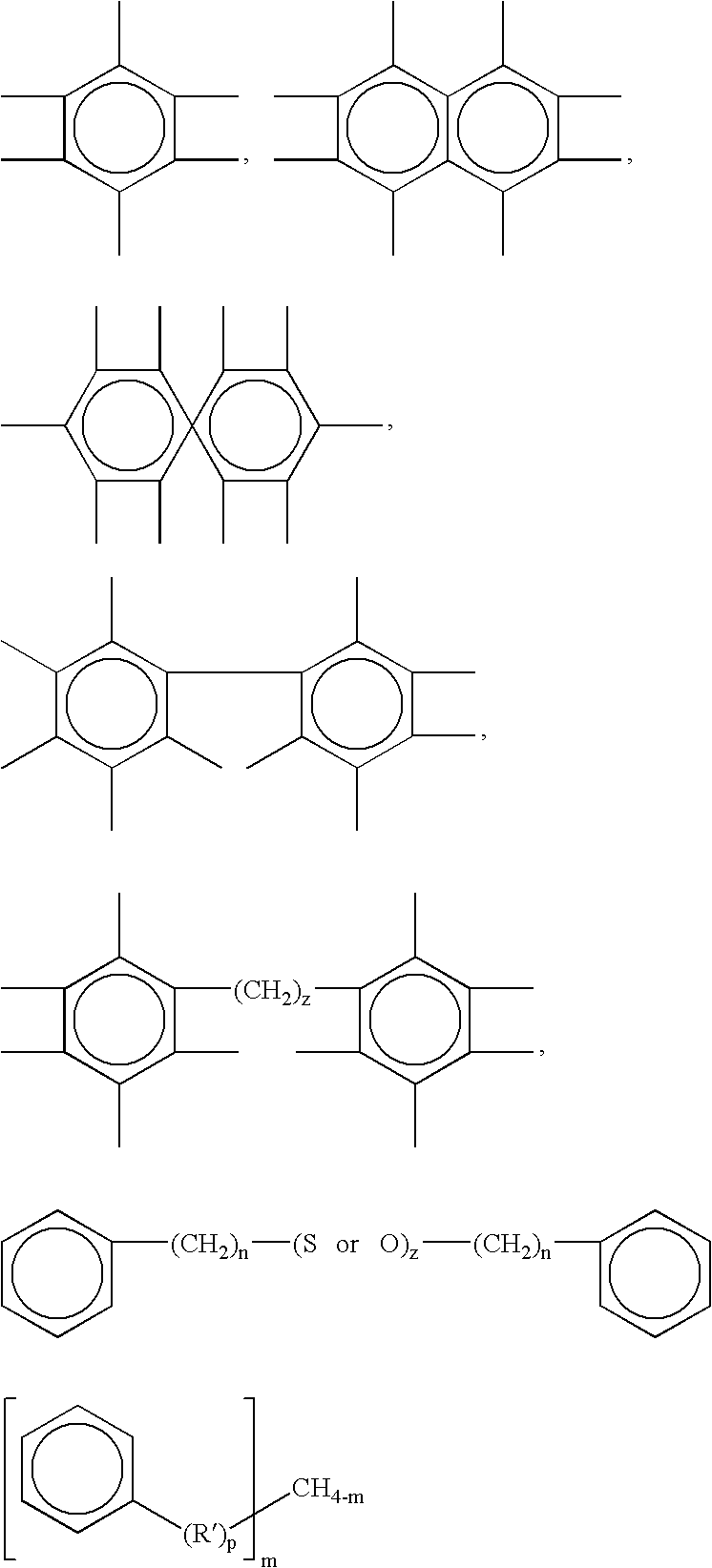

Viscosity index improver for lubricant compositions

A lubricant composition comprises a base oil and a viscosity modifier including an ethylene / α-olefin interpolymer. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block copolymer has a number of unique characteristics disclosed here. Such block copolymers offer the possibility of improved low temperature performance and flexibility in formulating motor oil, gear lubricants and greases, etc.

Owner:DOW GLOBAL TECH LLC

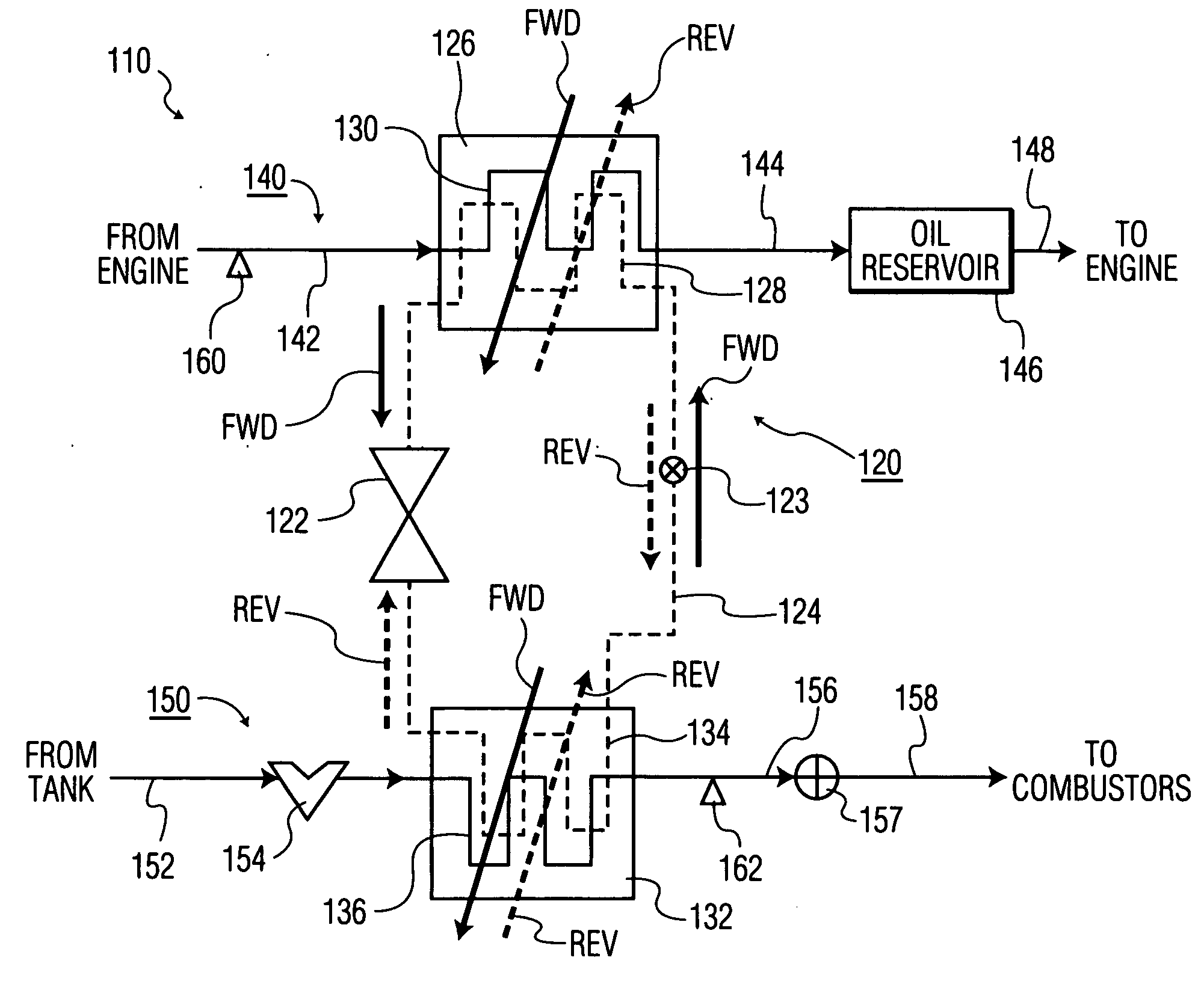

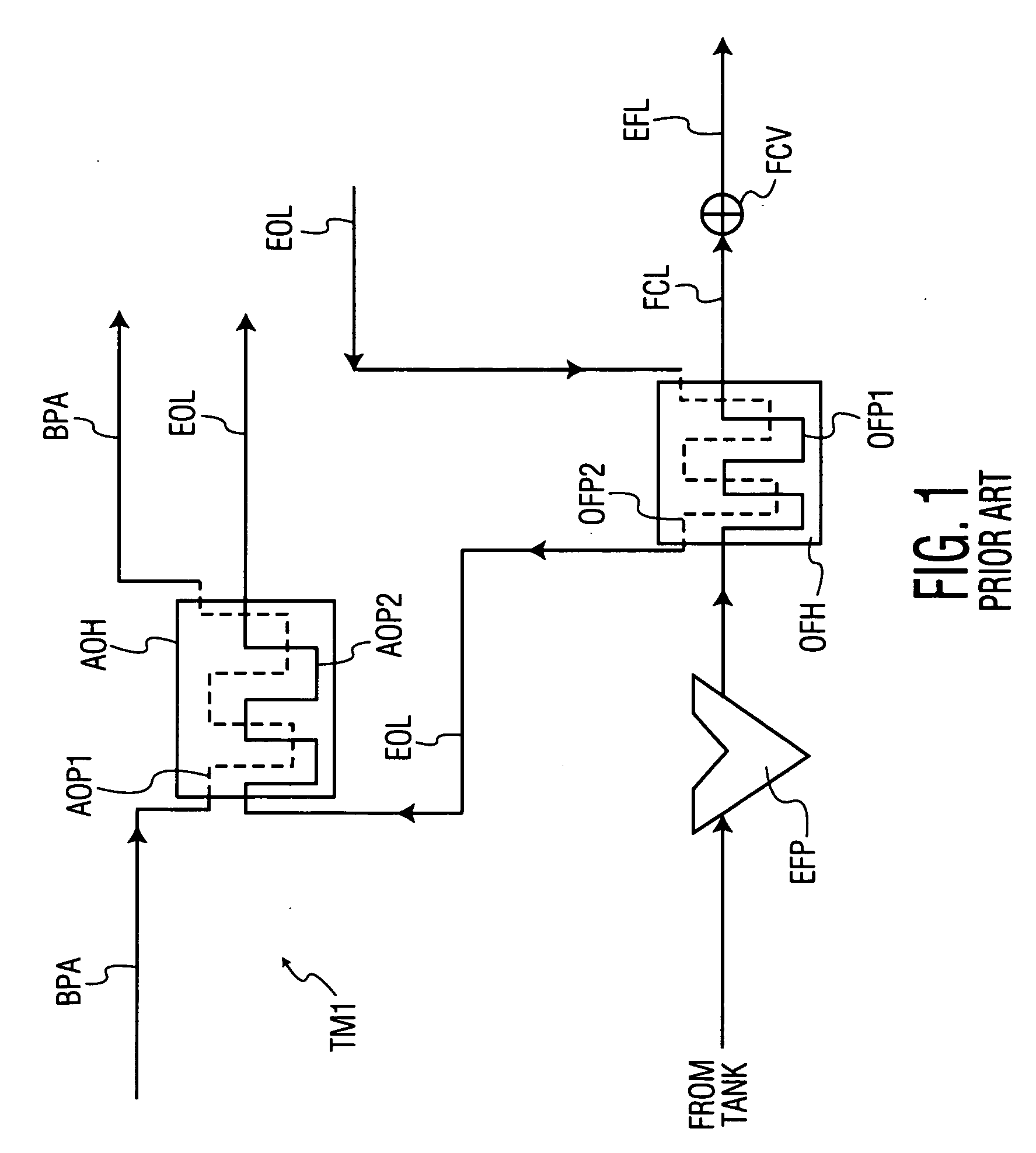

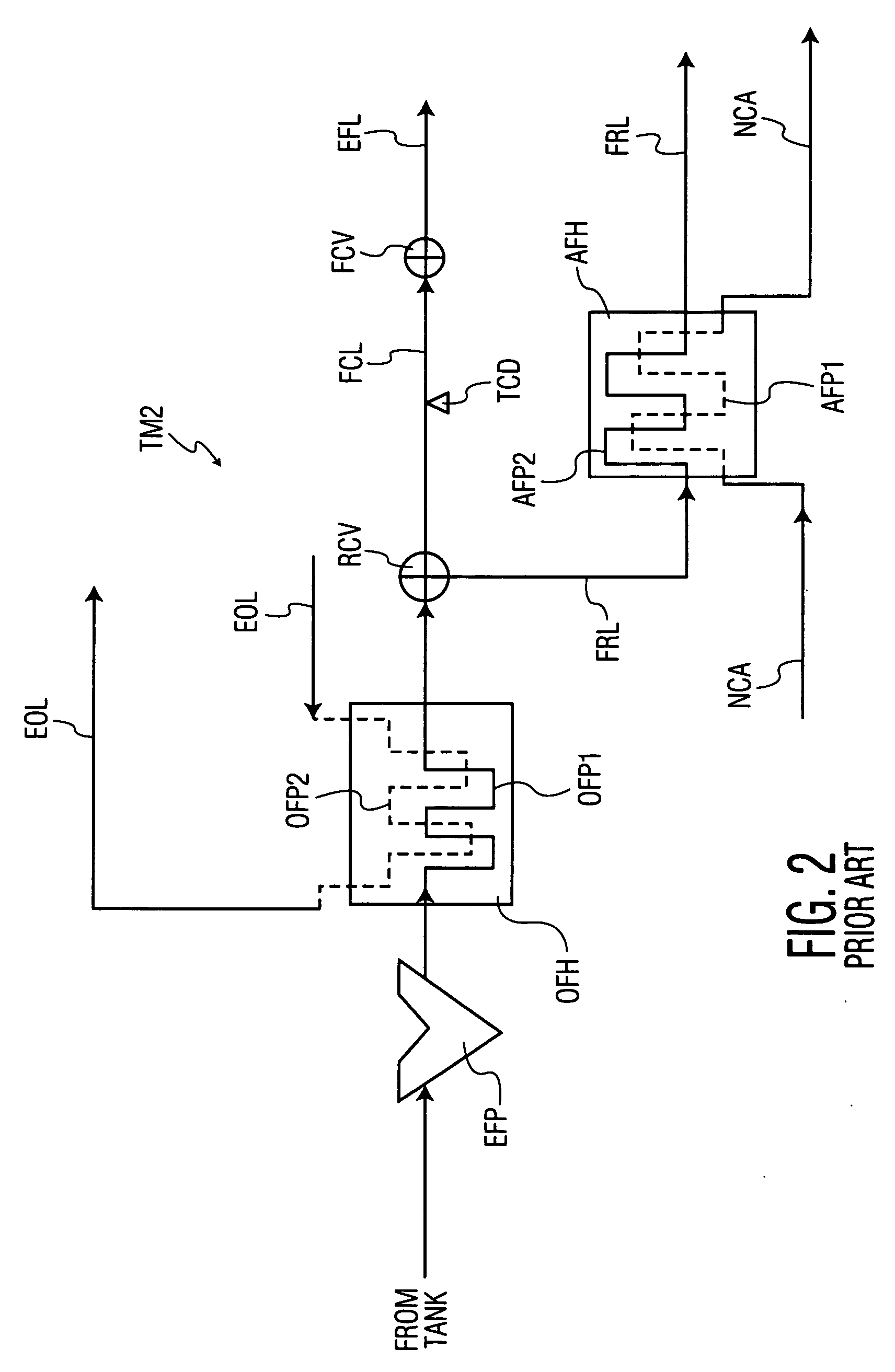

Systems and methods for thermal management in a gas turbine powerplant

InactiveUS20100107603A1Minimize impactReduce coke depositionAnalogue computers for vehiclesTurbine/propulsion engine coolingWorking fluidThermal management system

A thermal management system for a gas turbine powerplant with an engine oil line and an engine fuel line incorporates a heat transfer control module that includes a reversible heat pump with a heat pump compressor for circulating working fluid in forward and reverse directions through a working fluid line of the heat pump. The heat control module also includes a first heat exchanger having a heat exchange path for the working fluid between the compressor and a heat pump expansion valve and another heat exchange path for the engine oil. A second heat exchanger has a heat exchange path for the working fluid between the compressor and the expansion valve and another heat exchange path for the engine fuel. The heat pump can be operated in forward or reverse directions depending on whether heat is to be transferred from the engine oil or the fuel to the heat pump working fluid. In another embodiment an engine oil reservoir located between the first heat exchanger and the engine collects the oil before it is introduced to the engine and thus acts as a heat capacitor for the system.

Owner:PROPULSION GAS TURBINE & ENERGY EVALUATIONS

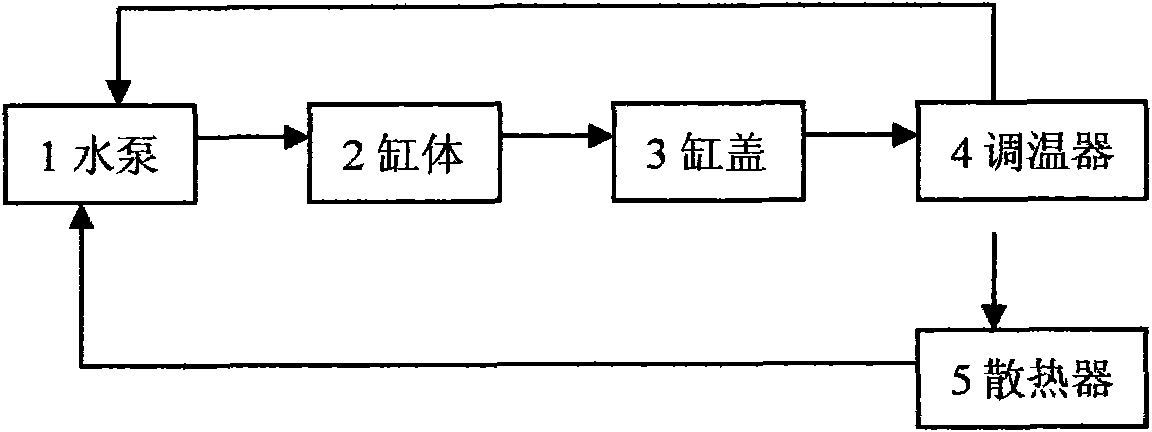

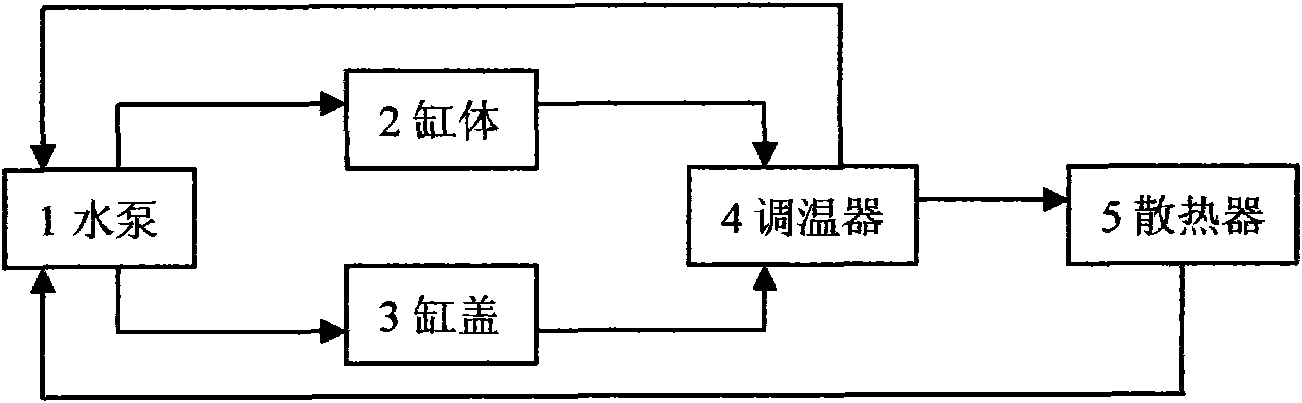

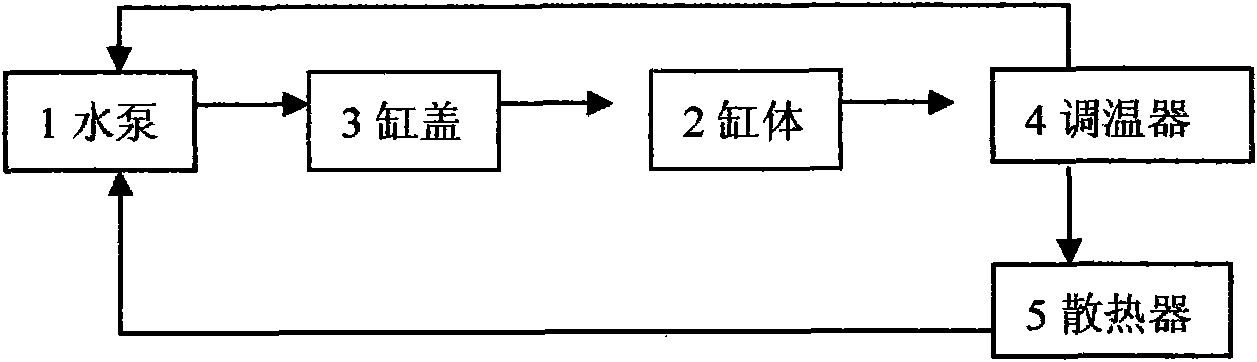

Engine cooling system and cooling method

InactiveCN101655027AReduce the temperatureReduce formationLiquid coolingCoolant flow controlFuel efficiencyEngineering

The invention discloses an engine cooling system and a cooling method. The cooling system comprises a water pump, a double-valve temperature regulator, a machine oil cooler, a water jacket of a cylinder body, a water jacket of a cylinder cover, a water tank radiator and an EGR cooler. The cooling system adopts a water passage circulation as follows: when the engine is started, the water pump begins to work; cooling liquid firstly flows into the machine oil cooler and enters in the water jacket of the cylinder cover to cool the key area of the cylinder cover, and then enters in the water jacket of the cylinder body from a gasket circulating hole of the cylinder cover to cool the cylinder body and the EGR cooler. The cooling liquid in the cooling system firstly cools the cylinder cover to reduce the temperature of the cylinder cover by 10 DEG C to 15 DEG C, enhance aeration efficiency, enlarge air inlet quantity, promote complete combustion, reduce the formation of discharge objects andenhance output efficiency; After cooling the cylinder cover, the cooling liquid enters in the cylinder body for cooling the cylinder body; the higher temperature of the cylinder body can reduce friction, improve fuel efficiency, enhance the output efficiency and reduce peak value pressure and temperature in the cylinder.

Owner:CHERY AUTOMOBILE CO LTD

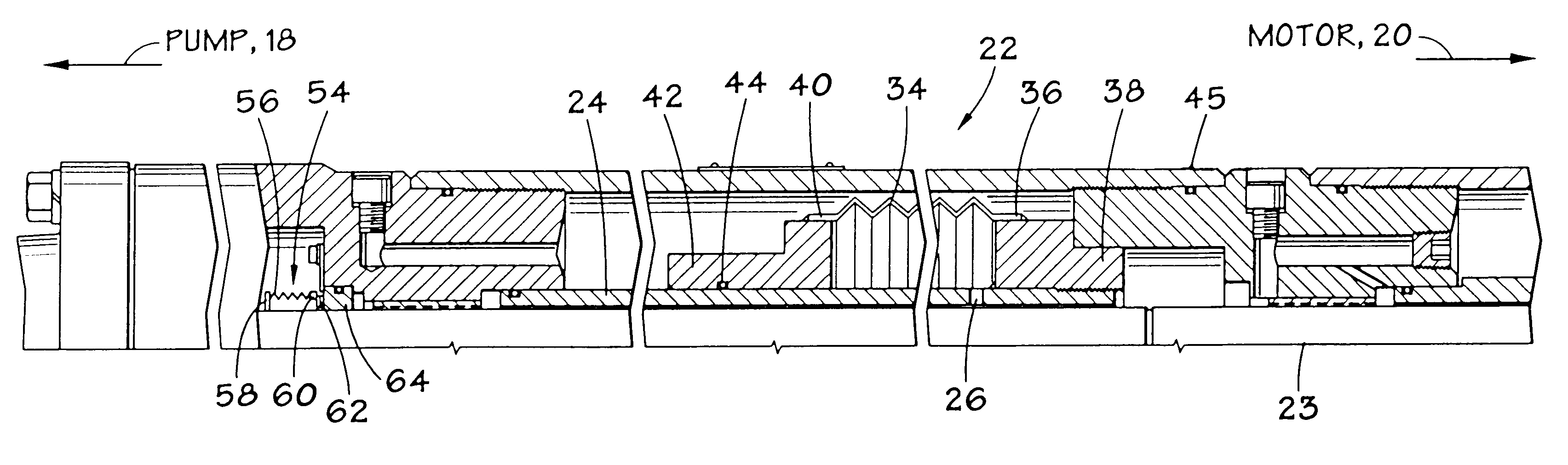

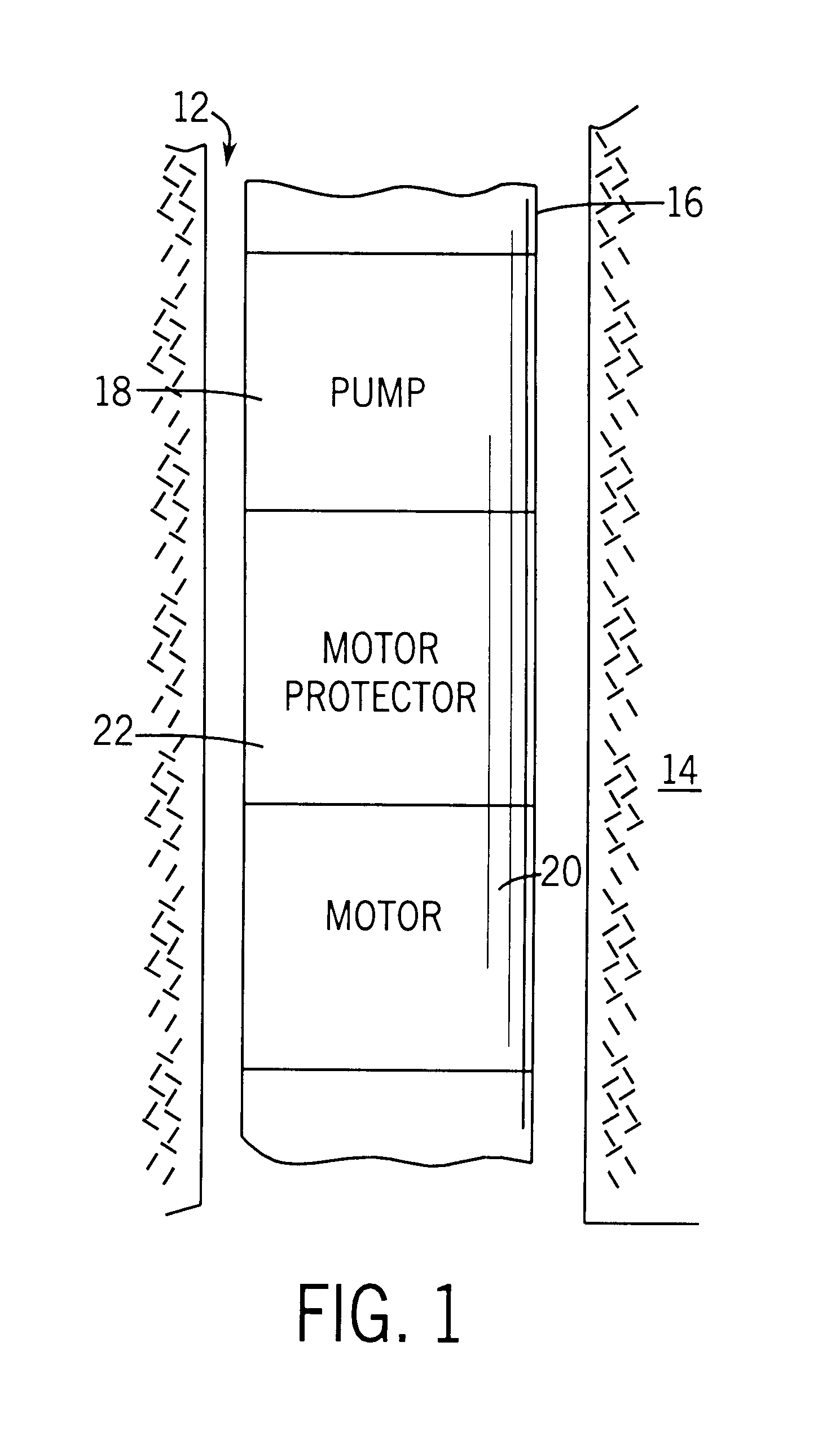

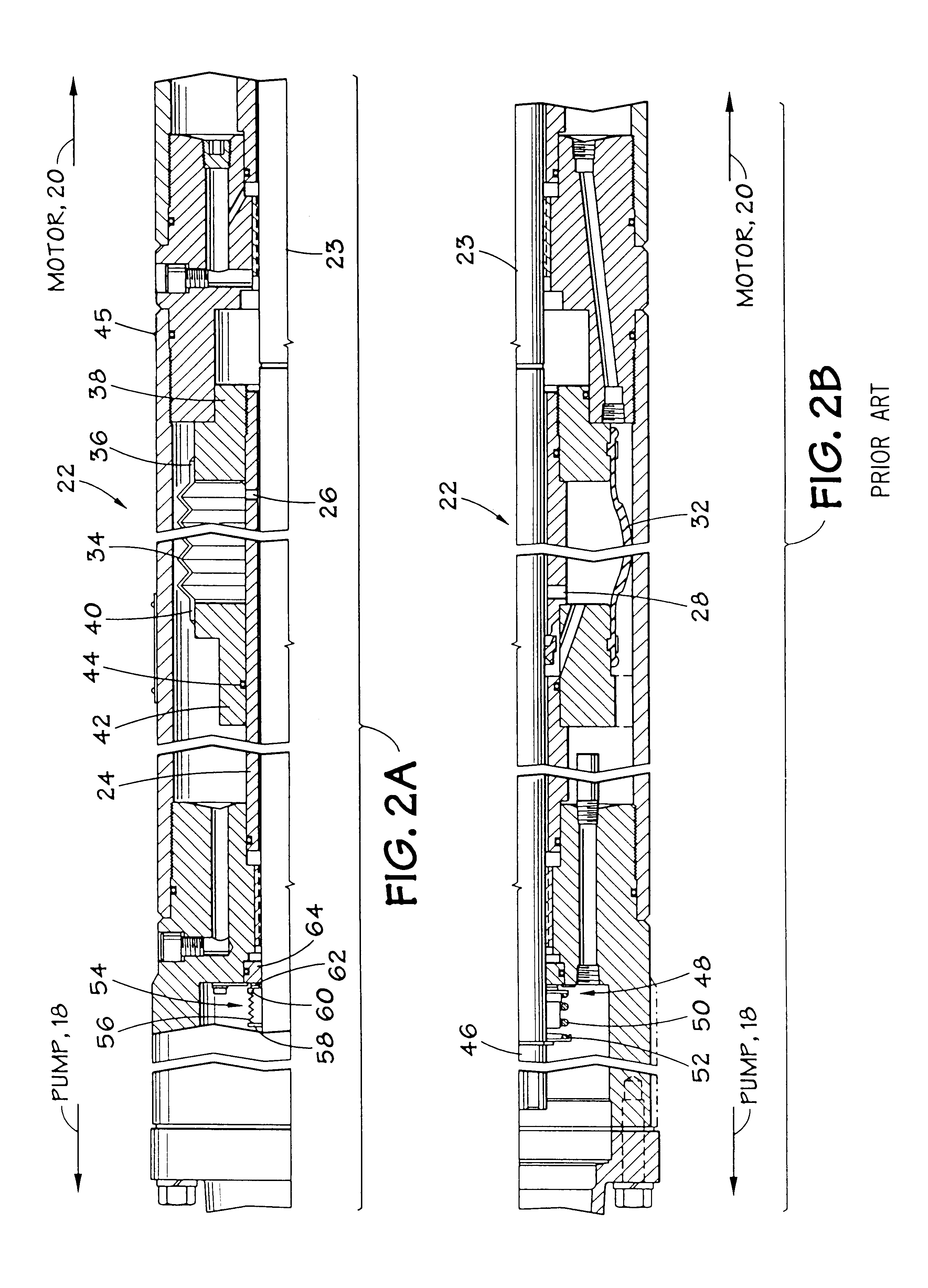

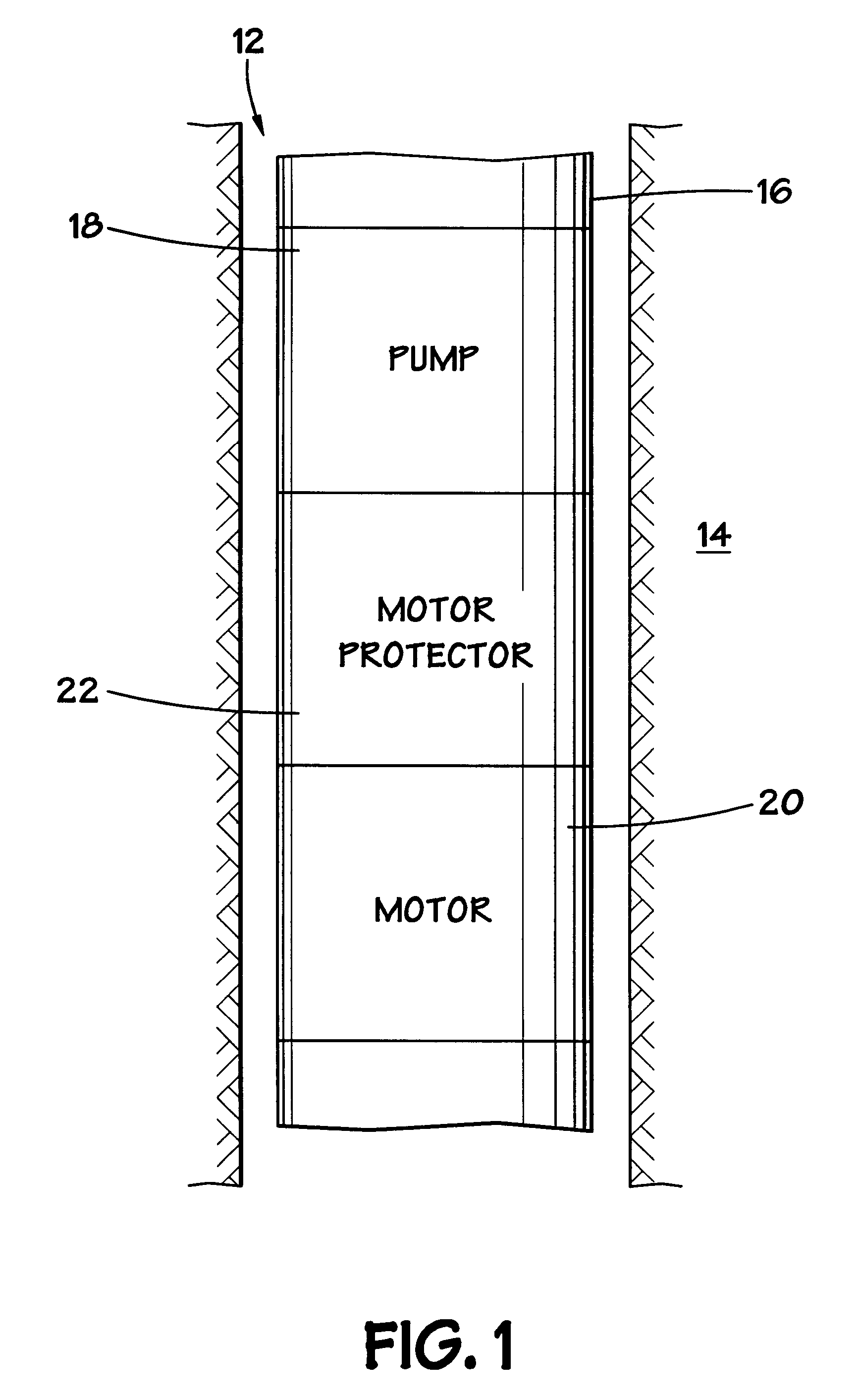

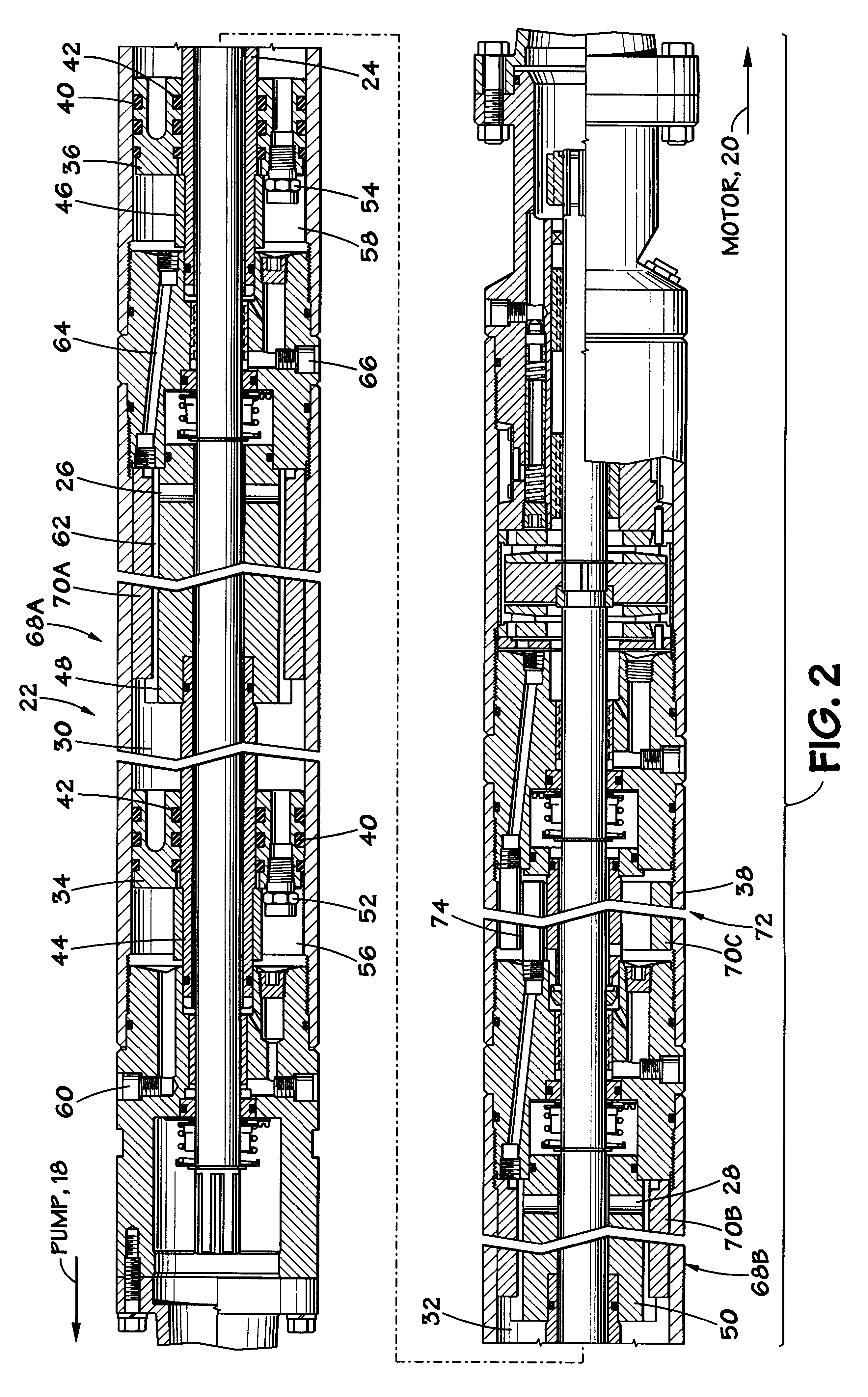

Piston motor protector, and motor and pumping system incorporating the same

A downhole pumping system includes a downhole pump that is coupled to a downhole motor. The downhole motor includes a motor protector that utilizes one or more retractable and extensible pistons, instead of an elastomeric bag, to accommodate motor oil contraction and expansion. The motor protector may also include one or more contamination containment sections for processing contaminants in downhole fluid to reduce contamination of the motor oil.

Owner:CAMCO INT

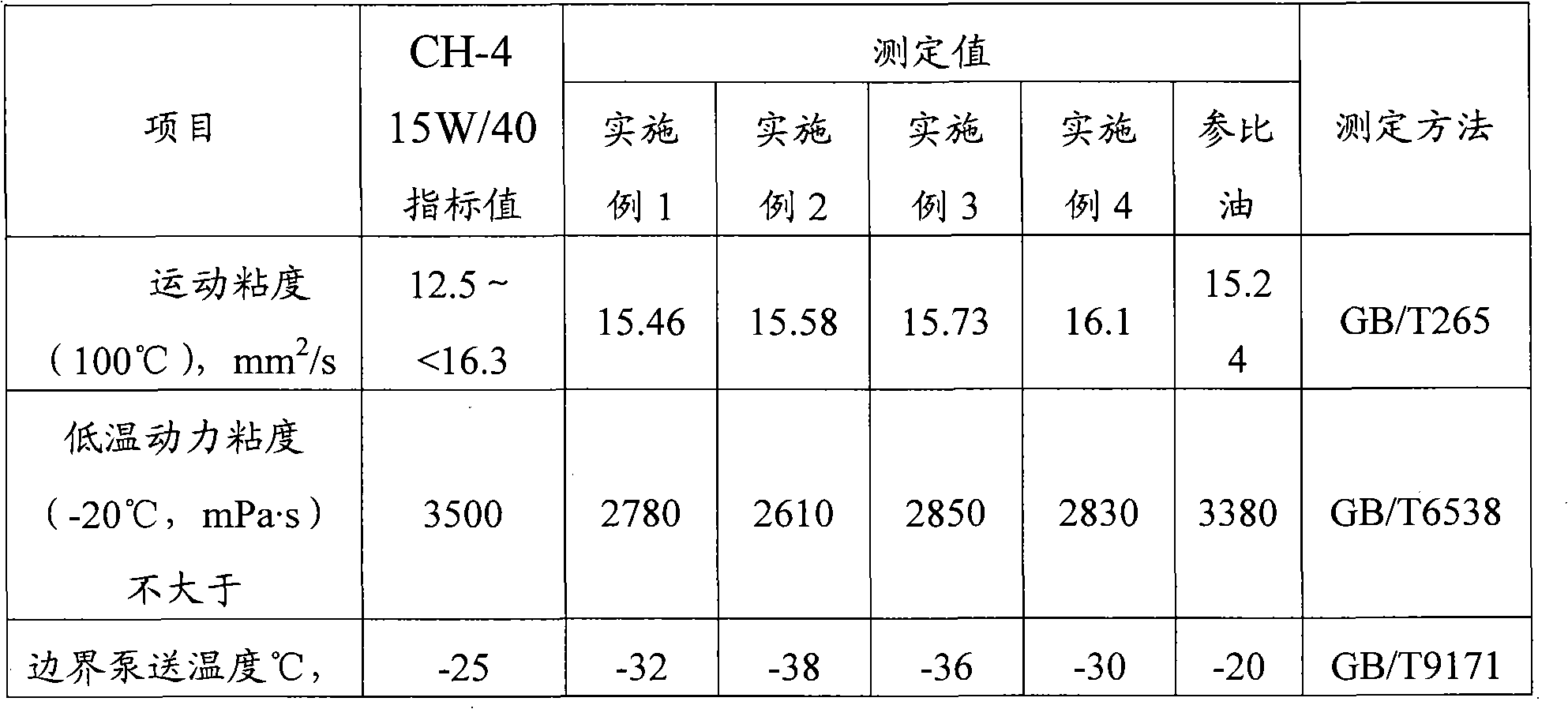

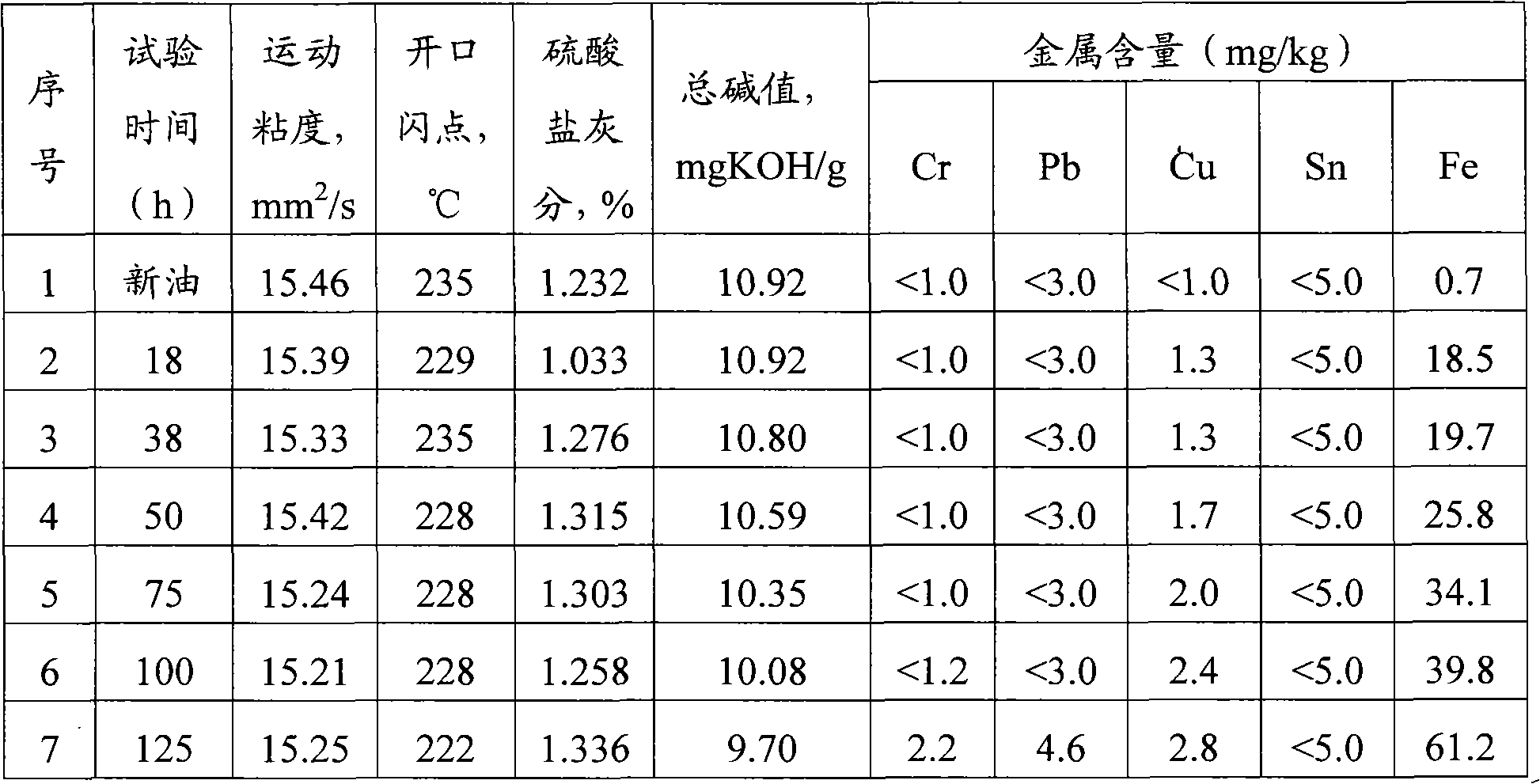

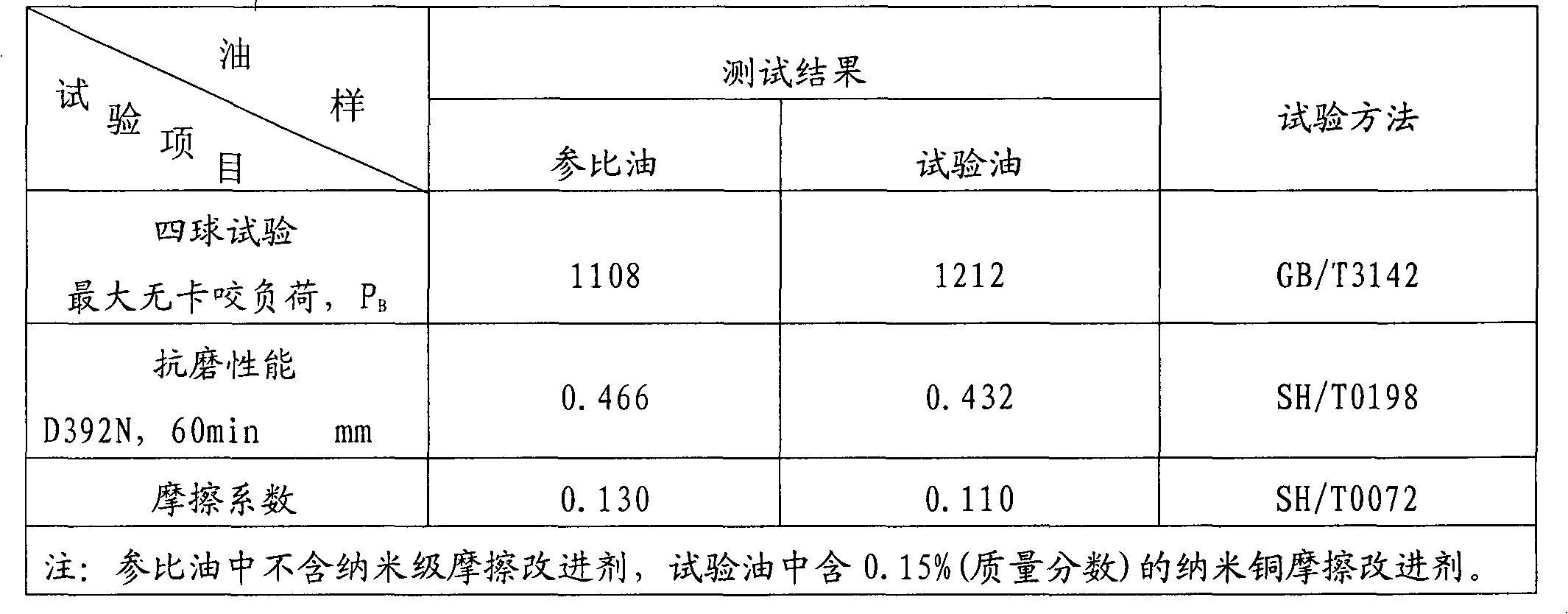

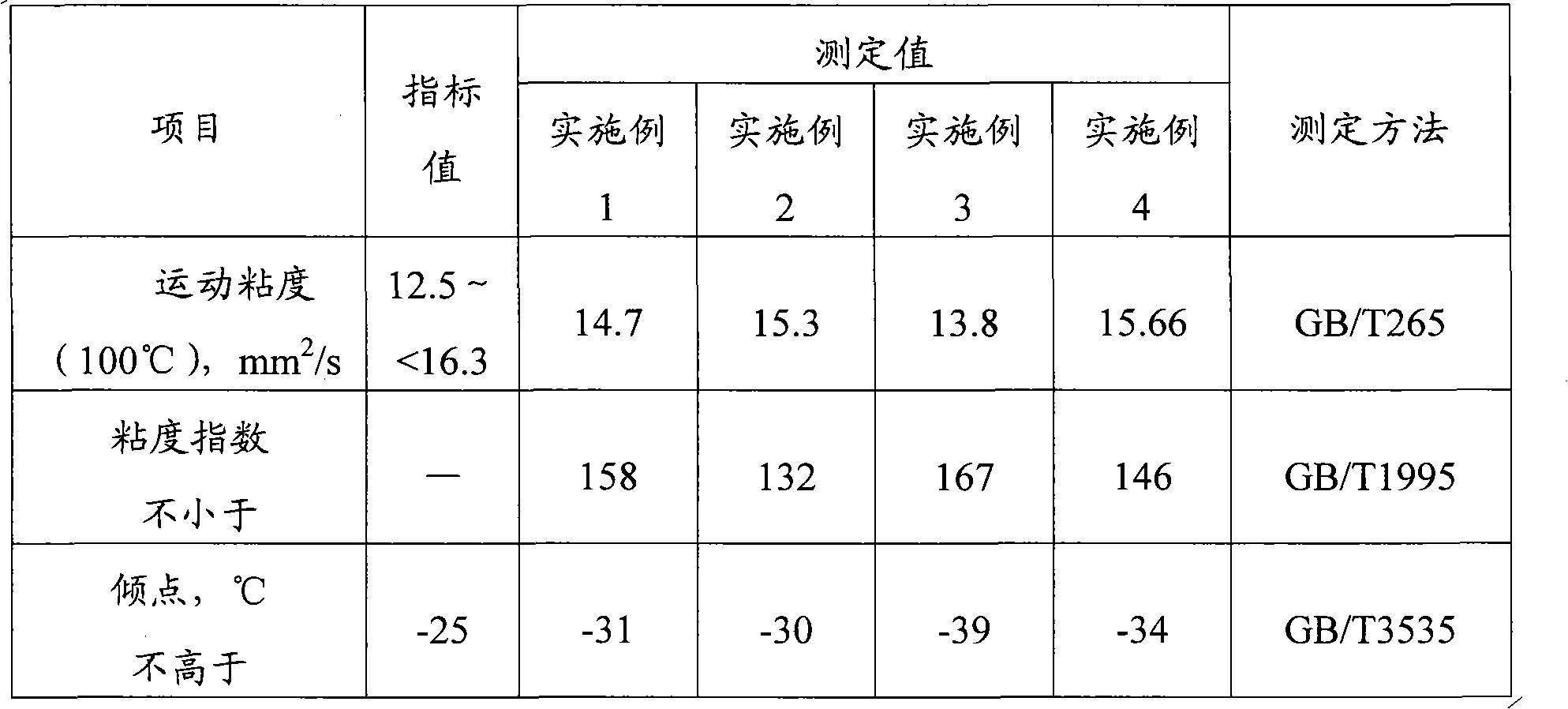

Engine oil of long-service life diesel engine

InactiveCN101851548AImprove lubrication statusExtended service lifeLubricant compositionReducerViscosity index

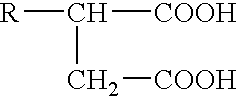

The invention provides engine oil of a long-service life diesel engine, which comprises basic oil and additives, wherein the additives comprise the following ingredients in percentage by weight: 4.0 percent to 6.5 percent of detergent additives, 3.0 percent to 5.5 percent of dispersing agents, 0.2 percent to 0.8 percent of corrosion inhibitors, 0.1 percent to 0.2 percent of antioxidizers, 0.01 percent to 0.15 percent of nanometer wear resistance agents, 5.0 percent to 9.0 percent of viscosity index improving agents, 0.3 percent to 0.5 percent of pour point reducers and the balance of basic oil, wherein the basic oil is semisynthesis composite basic oil consisting of API type III basic oil accounting for 45 percent to 65 percent of the mass percentage of the basic oil and 35 percent to 55 percent of poly-alpha olefin synthesis oil. The engine oil of the diesel engine provided by the invention can adapt to the requirements of various diesel engines, the performance meets the quality requirements of the engine oil of the diesel engine API CH-4, the engine can be ensured to be always in a good lubricating state, the service life of the engine oil is long, the environment pollution is little, and in addition, the cost is low.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

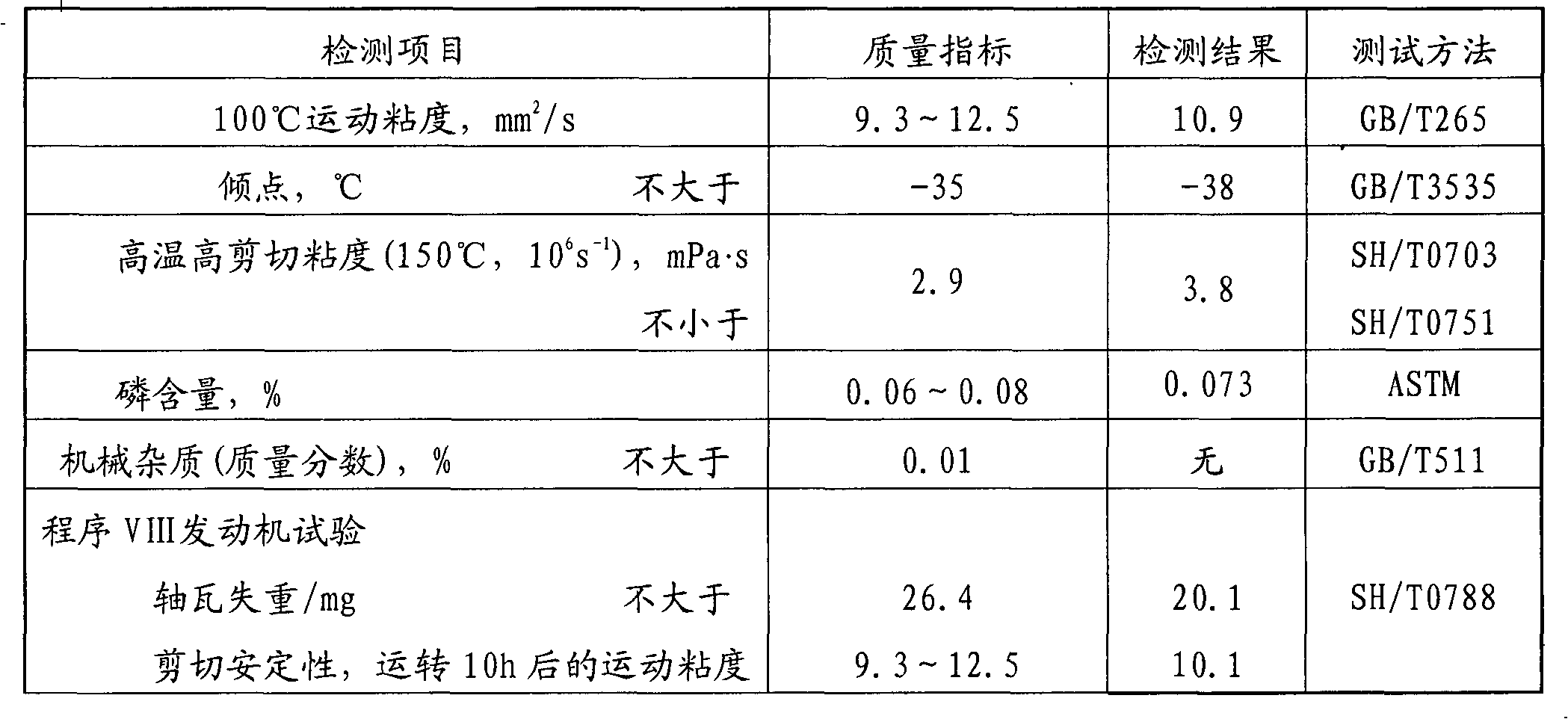

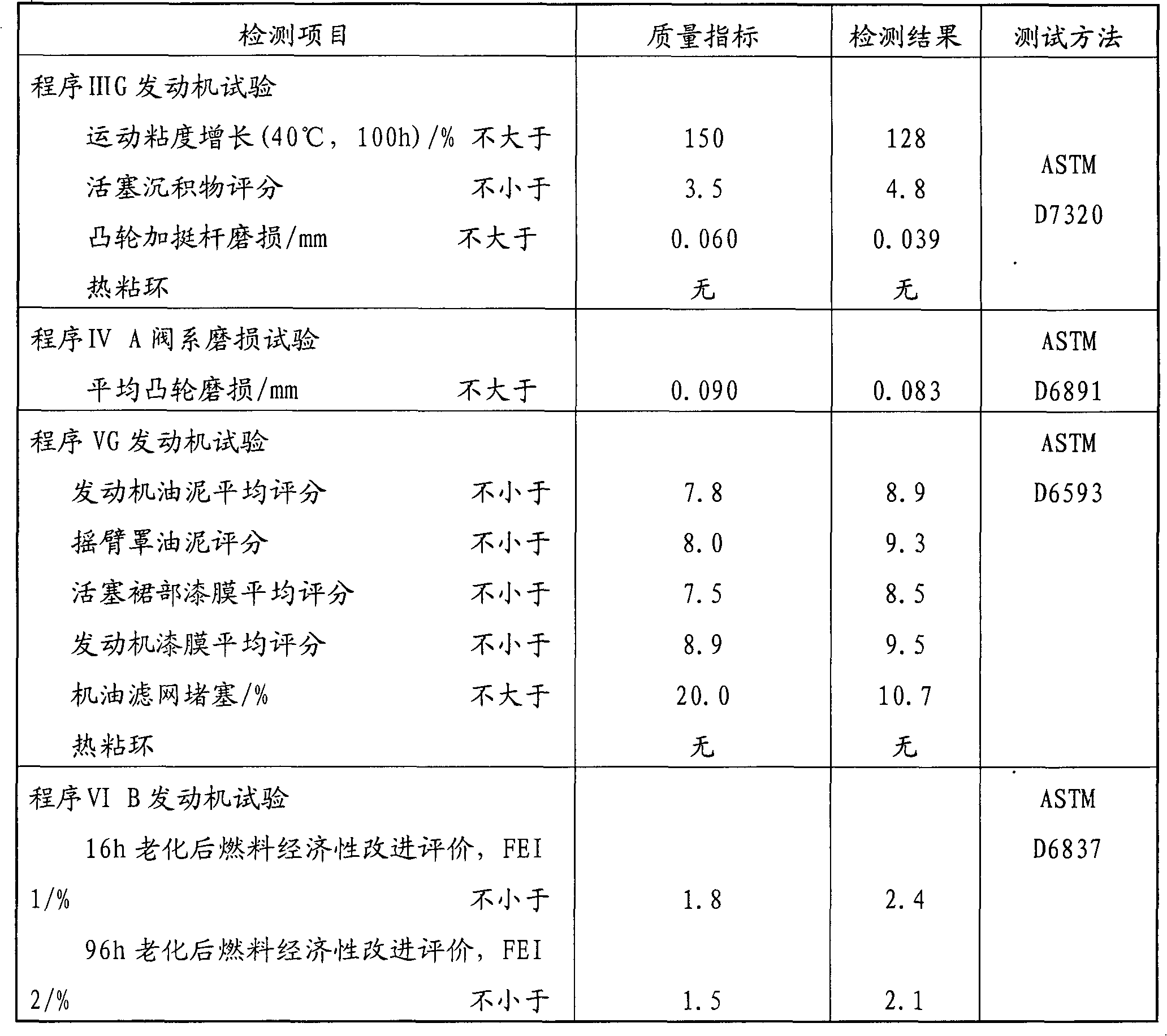

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

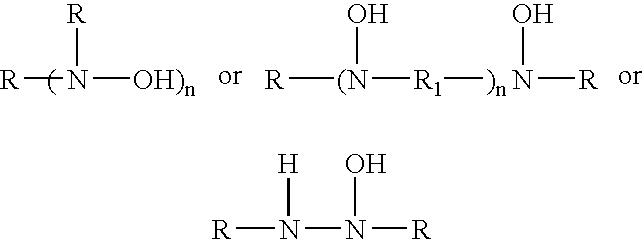

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

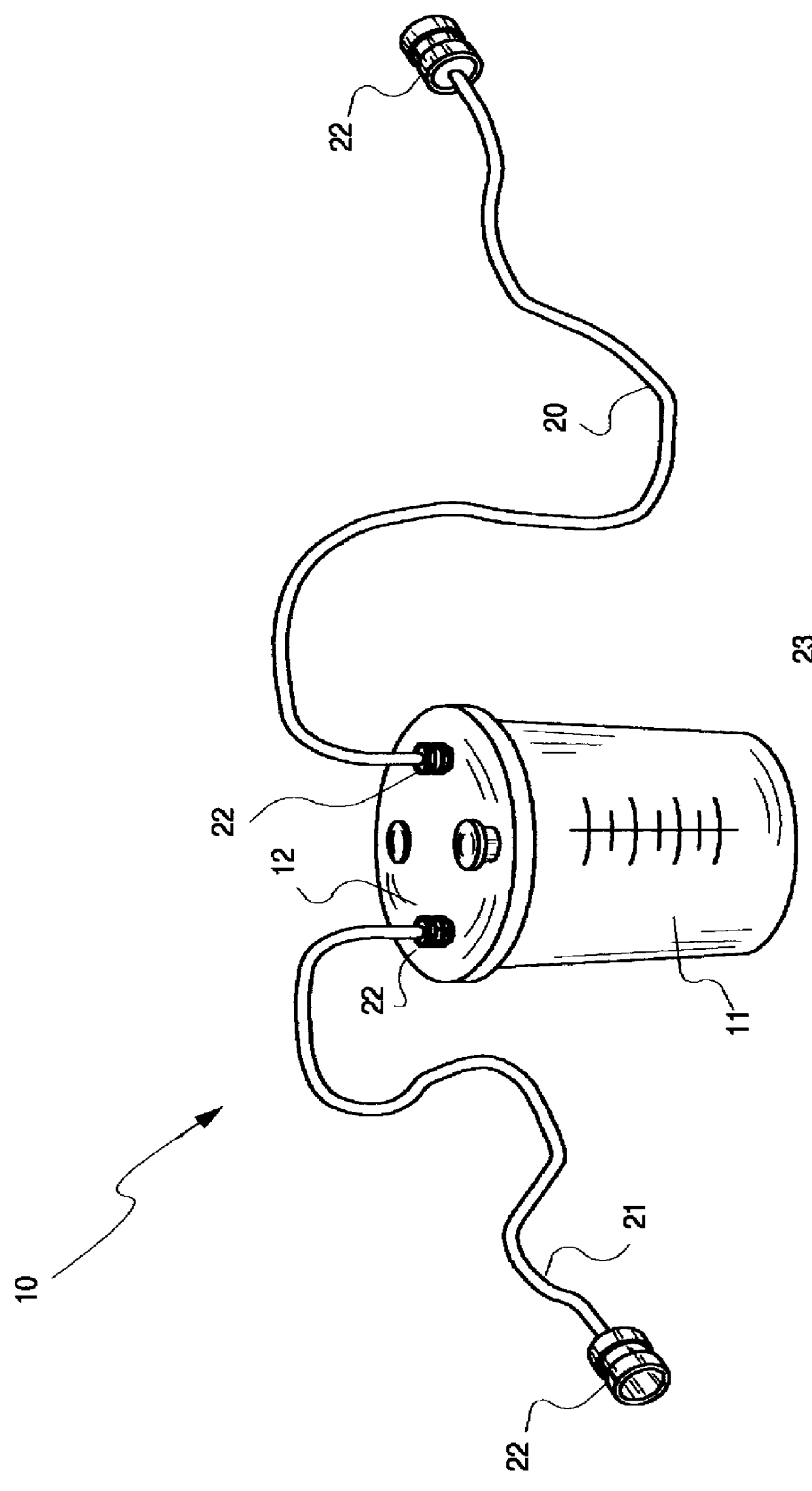

Portable, automatic, oil recovery system

InactiveUS6092390APrevent oil from overflowingPrevent overflowCrankshaftsMachines/enginesEngineeringAir conditioning

A compressor oil recovery device for use in removing oil from compressors typically found on condensing units used in air conditioning or refrigeration applications is disclosed. The device consists of a canister with a lid that contains a vacuum port, a suction port, a drain port, and a vacuum release port. A vacuum hose is connected at one end to the vacuum port and at the other end to an electric vacuum pump. A suction hose is connected at one end to the suction port and at the other end to the gauge manifold of a compressor. Upon activating the vacuum pump, a vacuum is created that draws the compressor oil into the canister where it is collected for disposal.

Owner:GRIFFITH JR DAVID R

Engine oil of long-service life gasoline engine

InactiveCN101851549AImprove lubrication statusExtended service lifeLubricant compositionGasolineReducer

The invention provides engine oil of a long-service life gasoline engine, which comprises basic oil and additives, wherein the additives comprise the following ingredients in percentage by weight: 4.0 percent to 6.0 percent of dispersing agents, 2.5 percent to 4.5 percent of detergent additives, 0.2 percent to 0.8 percent of corrosion inhibitors, 0.1 percent to 0.2 percent of antioxidizers, 0.01 percent to 0.15 percent of nanometer copper wear resistance agents, 5.0 percent to 9.0 percent of viscosity index improving agents, 0.3 percent to 0.5 percent of pour point reducers and the balance ofbasic oil, wherein the basic oil is semisynthesis composite basic oil consisting of API type III basic oil accounting for 40 percent to 65 percent of the mass percentage of the basic oil and 35 percent to 60 percent of poly-alpha olefin synthesis oil. The engine oil can meet the requirements of high-temperature high-speed automobile and motorcycle engines, and can ensure that the engines are always in a good lubricating state, in addition, the service life is long, and the cost is low.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

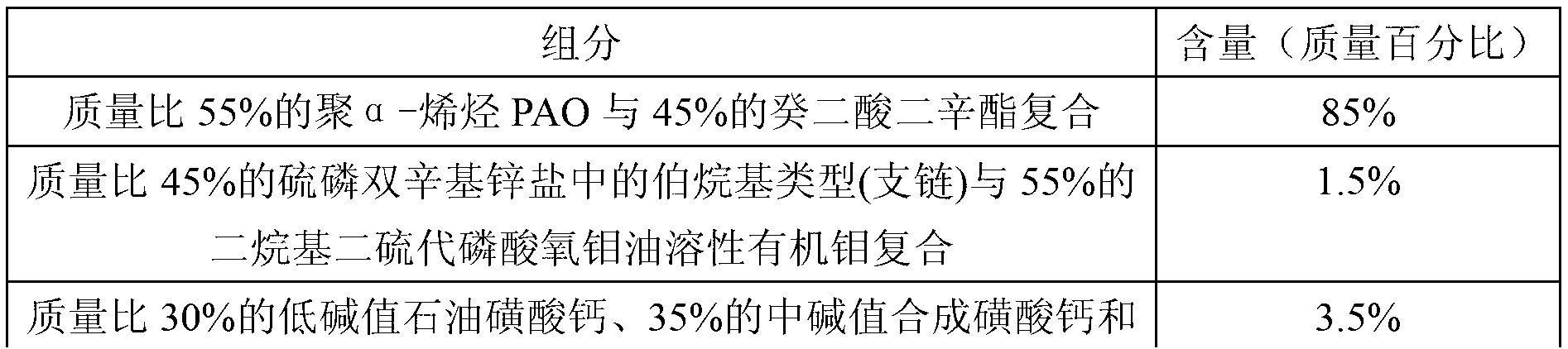

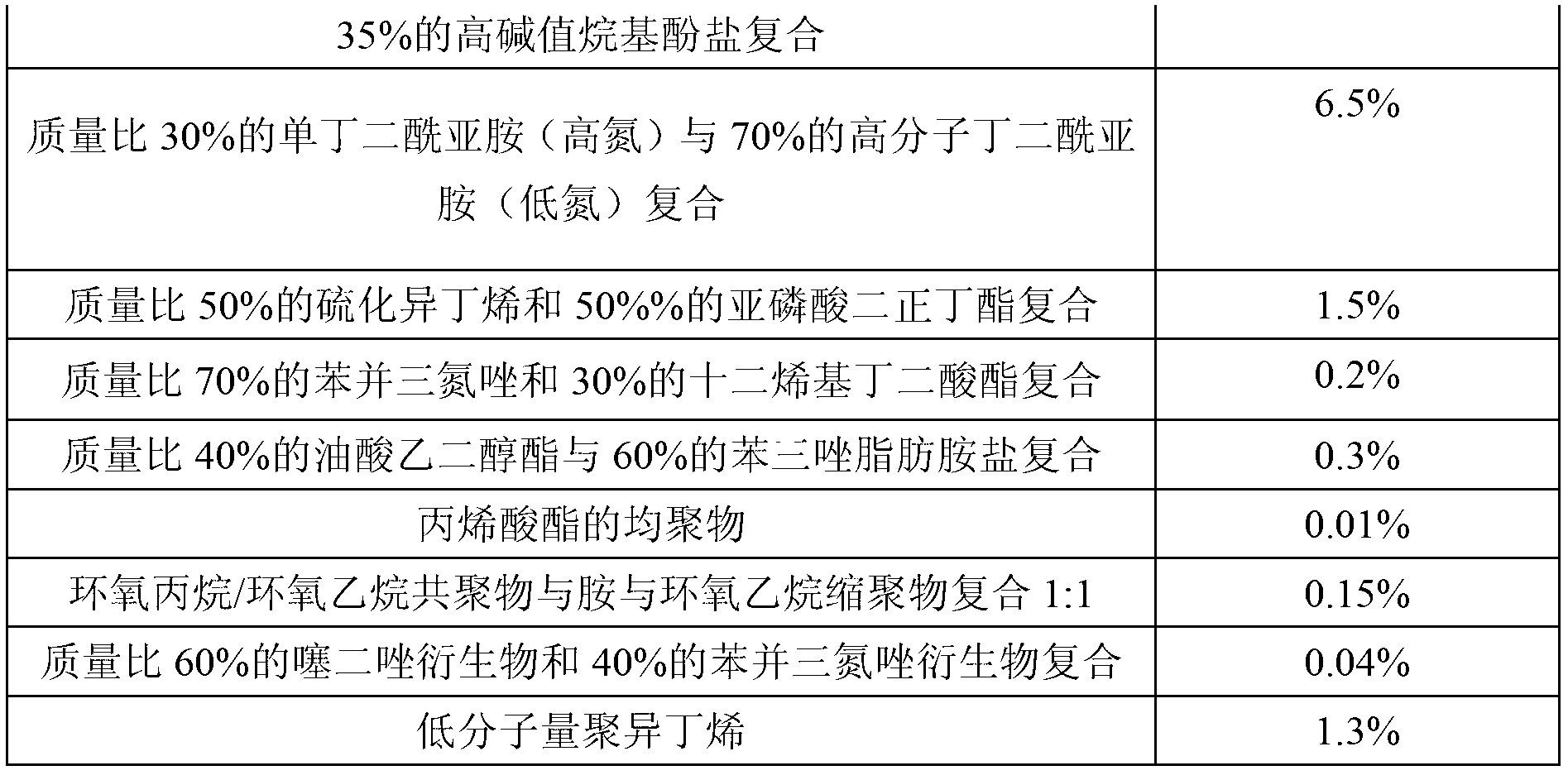

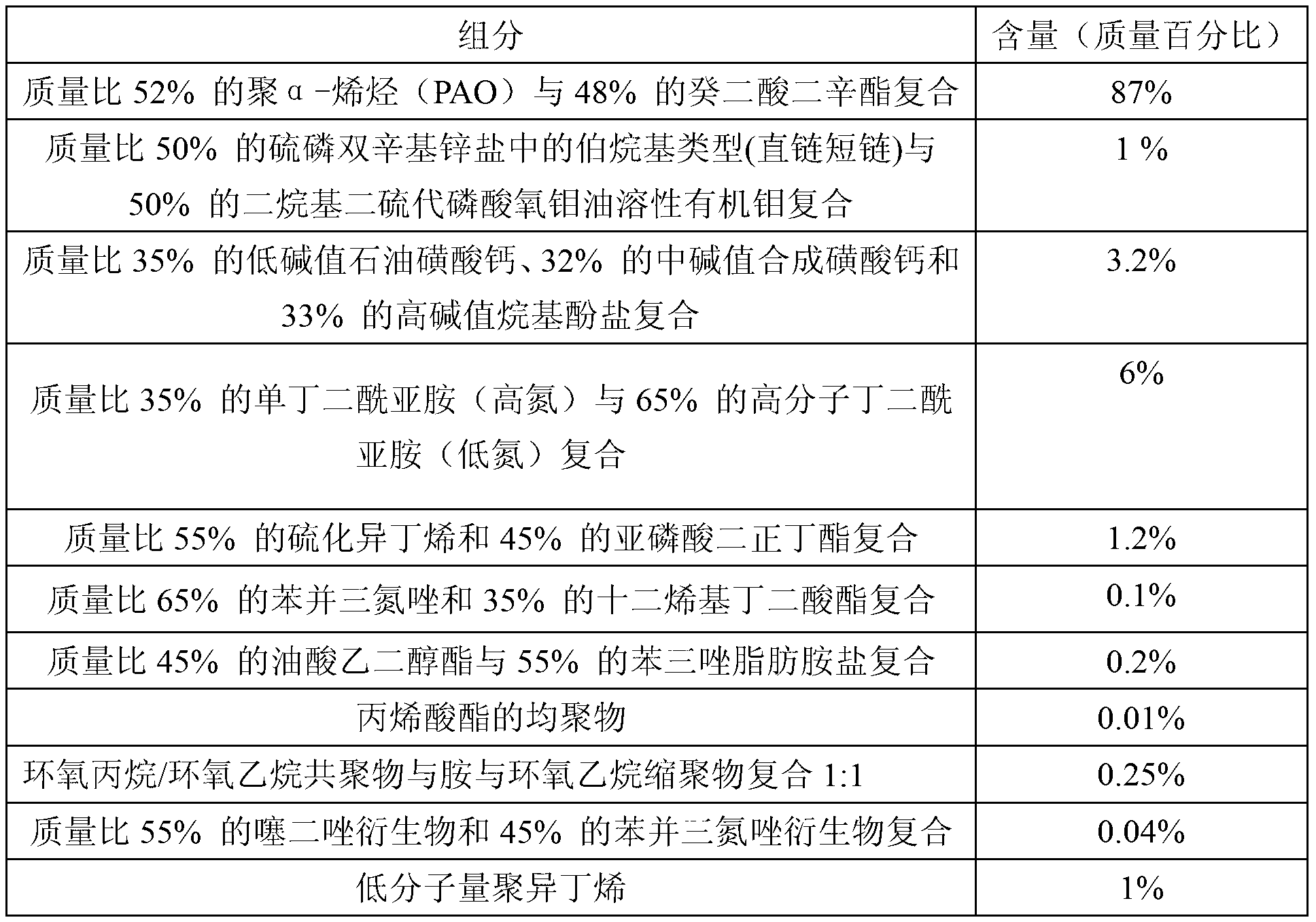

Universal oil composition for environment-friendly energy-saving engineering machinery

The invention discloses a universal oil composition for environment-friendly energy-saving engineering machinery. The universal oil composition comprises the following components according to mass percent: 85%-90% of composite base oil and 15%-10% of other additives. The universal oil composition for the environment-friendly energy-saving engineering machinery adopts a poly-alpha-olefin (PAO) and dioctyl sebacate composition as the base oil, is good in comprehensive performance, can replace diesel engine oil, hydraulic oil, gear oil, hydraulic transmission fluid and other various unit oil used in the engineering machinery, achieves multiple purposes, increases the power of a diesel engine, improves the reliability, the fuel economy and the low-temperature start performance of the diesel engine and the working efficiency and the precision of a hydraulic system, and effectively prolongs the service life and the oil draining period of the hydraulic system, the diesel engine, a gear system, a hydraulic transmission system and other various units.

Owner:GUANGXI UNIV

Engine oil suitable for pluralities of fuel

InactiveCN101418250AHave performance requirementsImprove anti-friction and anti-wear effectAdditivesBase-materialsPhenolDiesel engine

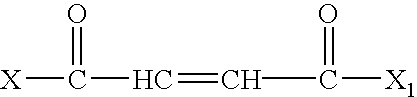

The invention relates to engine oil suitable for multiple fuels, and belongs to the field of engine oil for an automobile. The engine oil comprises the following raw materials in mass portion: 33 to 36 portions of base oil 150SN, 22 to 24 portions of base oil VHVI H350 (type III), 15 to 17 portions of poly alpha-alkene, 2 to 4 portions of ester oil of C8 to C10, 11 to 13 portions of ethylene-propylene copolymer the molecular weight of which is between 63,000 and 108,000 as viscosity index improver, 0.4 to 1.2 portions of zinc dialkyl dithiophosphate as additive for resisting oxidation and corrosion as well as abrasion, 1.1 to 4.8 portions of alkyl phenol calcium and 1.9 to 2.5 portions of calcium sulfonate as detergent, 3.8 to 5.0 portions of polyisobutene succimide as dispersant, and 0.001 to 0.003 portion of methyl silicone oil as antifoaming agent. The engine oil meets performance requirements of automobile and engine manufacturers at home and abroad on gasoline engine oil and sedan diesel engine oil.

Owner:CHANGCHUN YONGCHANG PETROCHEM

Emulsified fuels and engine oil synergy

InactiveUS7413583B2Emission reductionReduces soluble organic fraction fractionNon-fuel substance addition to fuelEngine operationsParticulatesNitrogen oxide

Owner:THE LUBRIZOL CORP

Air compressor oil composition

ActiveCN101724489AImprove anti-coking performanceImprove wear resistanceAdditivesBase-materialsTert butyl phenolFoaming agent

The invention relates to an air compressor oil composition, which comprises the following components in percentage by weight: 1.5 to 5 percent of antioxidant, 0.03 to 0.5 percent of ashless antirust agent, 0.01 to 0.5 percent of metal deactivator, 0.01 to 1 percent of ashless antiwear agent, 0.001 to 0.01 percent of anti-foaming agent and the balance of base oil, wherein the base oil is prepared by mixing poly alpha-olefin with ester oil in a weight ratio of 7-9:3-1 or mixing hydrogenated oil with the ester oil in the weight ratio of 7-9:3-1; and the antioxidant is the mixture of dialkylaniline, high-molecular thioether phenol and 4,4-methylenedi(2,6-di-tert-butyl phenol) in the weight ratio of 1:0.1-10:0.1-10. The air compressor oil composition has the advantages of excellent high-temperature anti-oxidation stability, anti-carbon deposition property, abrasive resistance, obvious energy-saving effect, good cost performance and low cost.

Owner:PETROCHINA CO LTD

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS20030158048A1Reduce friction and wearLow sulfurOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Refining used motor oil through successive hydrotreating processes

ActiveUS20150361356A1Economical efficiency can be improvedAvoid accumulationTreatment with hydrotreatment processesLubricating oils distillationHydrogenGasoline

A method for refining used motor oil using two or more hydrotreating reactors arranged in series. The used motor oil may be vacuum distilled to produce an unrefined gasoil. The unrefined gasoil may then be hydrotreated in a first hydrotreating reactor with hydrogen operated at a temperature ranging from approximately 245° C. to approximately 260° C. to produce a hydrotreated gasoil. The hydrogen may comprise a mixture of fresh hydrogen and recycled hydrogen recovered from the last of the two or more hydrotreating reactors. The hydrotreated gasoil may then be hydrotreated in one or more additional hydrotreating reactors operated at temperatures ranging from approximately 260° C. to approximately 330° C. to produce a refined gasoil. The first hydrotreating reactor may remove a substantial portion of metallic impurities from the unrefined impurities, while the one or more additional hydrotreating reactors remove a substantial portion of heteroatom impurities from the unrefined gasoil.

Owner:AIR PROD & CHEM INC

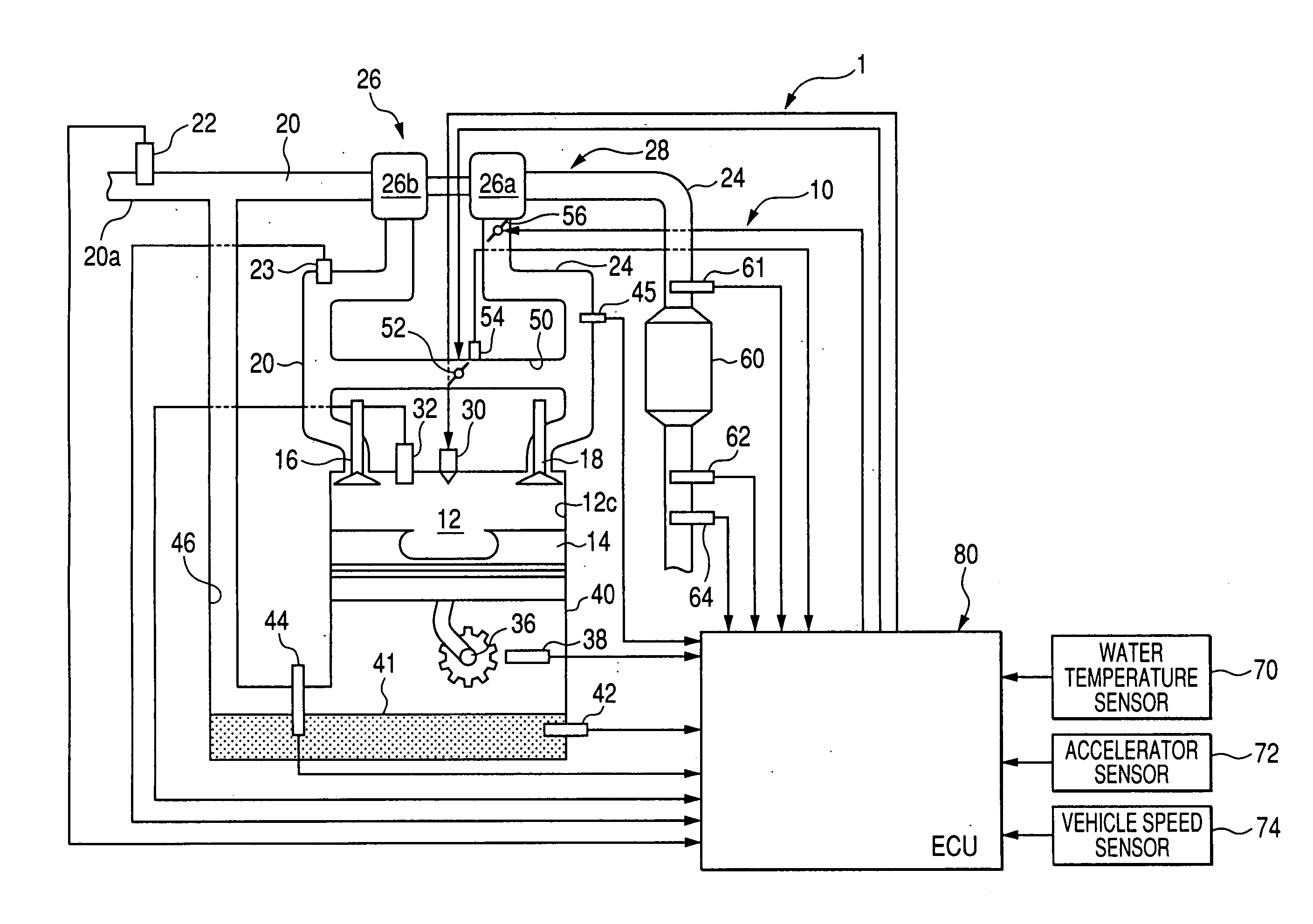

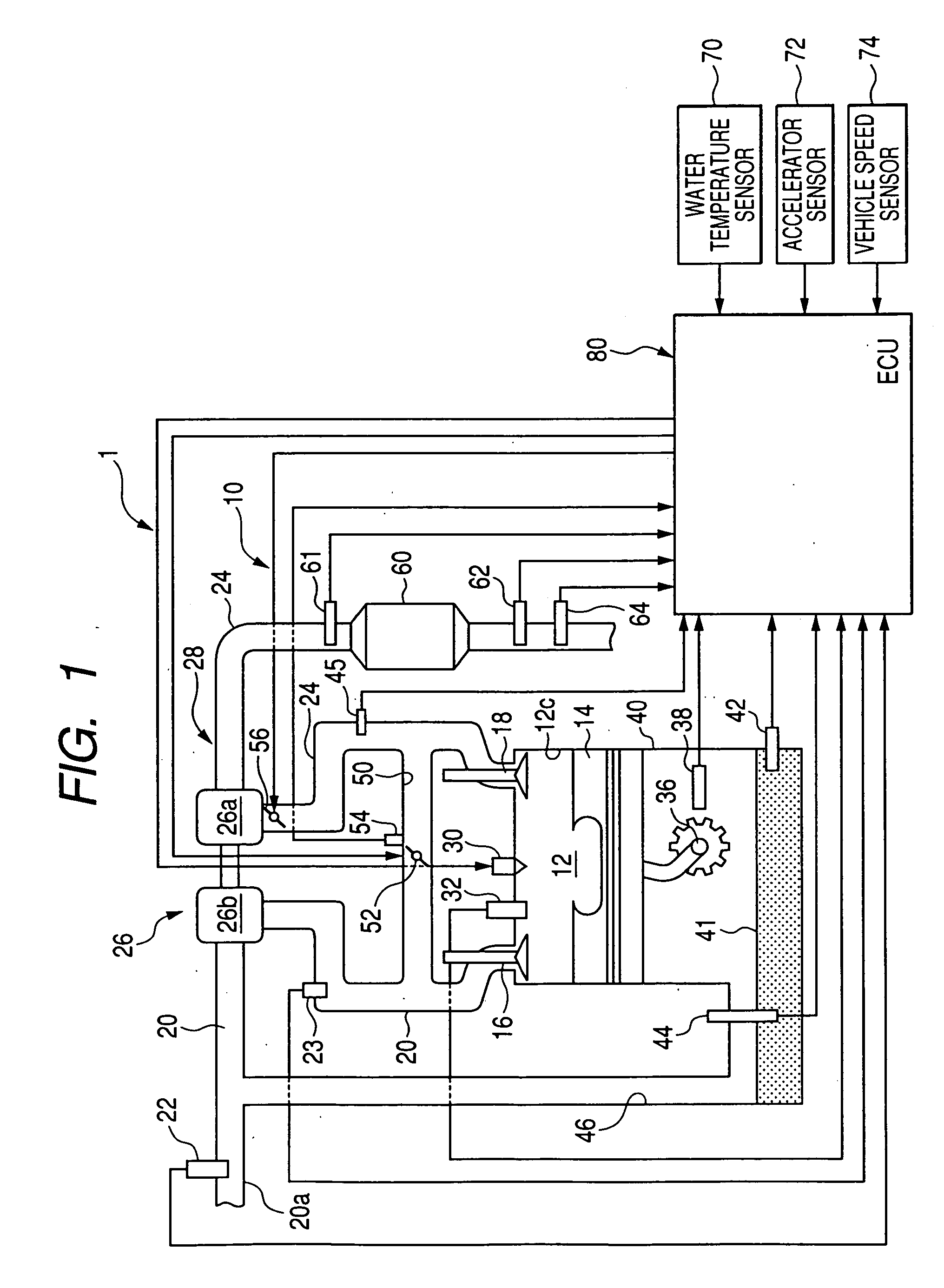

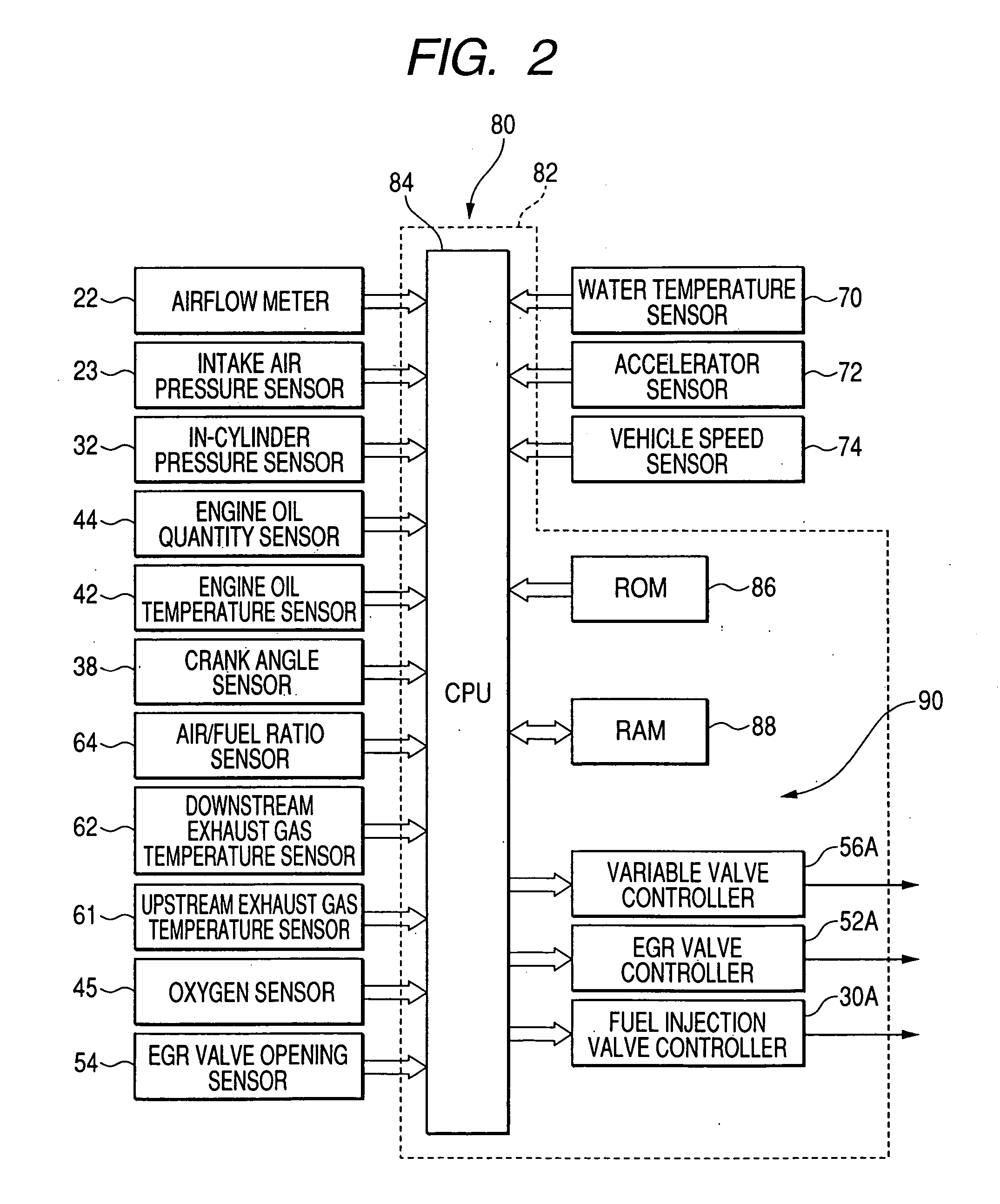

Engine control system and engine control method

InactiveUS20070156322A1Avoid lubricationSimple wayAnalogue computers for vehiclesElectrical controlControl systemEngineering

An engine control system and an engine control method are disclosed wherein a combustible component quantity of intake air, reflecting combustible components in a crankcase of an engine, is calculated on the basis of a deviation between basic injection quantity for a target rotational speed to be attained and an actual injection quantity during operation to perform idling stabilizing control. A ratio of the combustible components mixed to engine oil is calculated on the basis of the combustible component quantity of intake air and a temperature of engine oil. During a status of the engine with a given temperature of engine oil and the mixing ratio of the combustible components in engine oil, a fuel injection affect eliminating operation is executed.

Owner:DENSO CORP

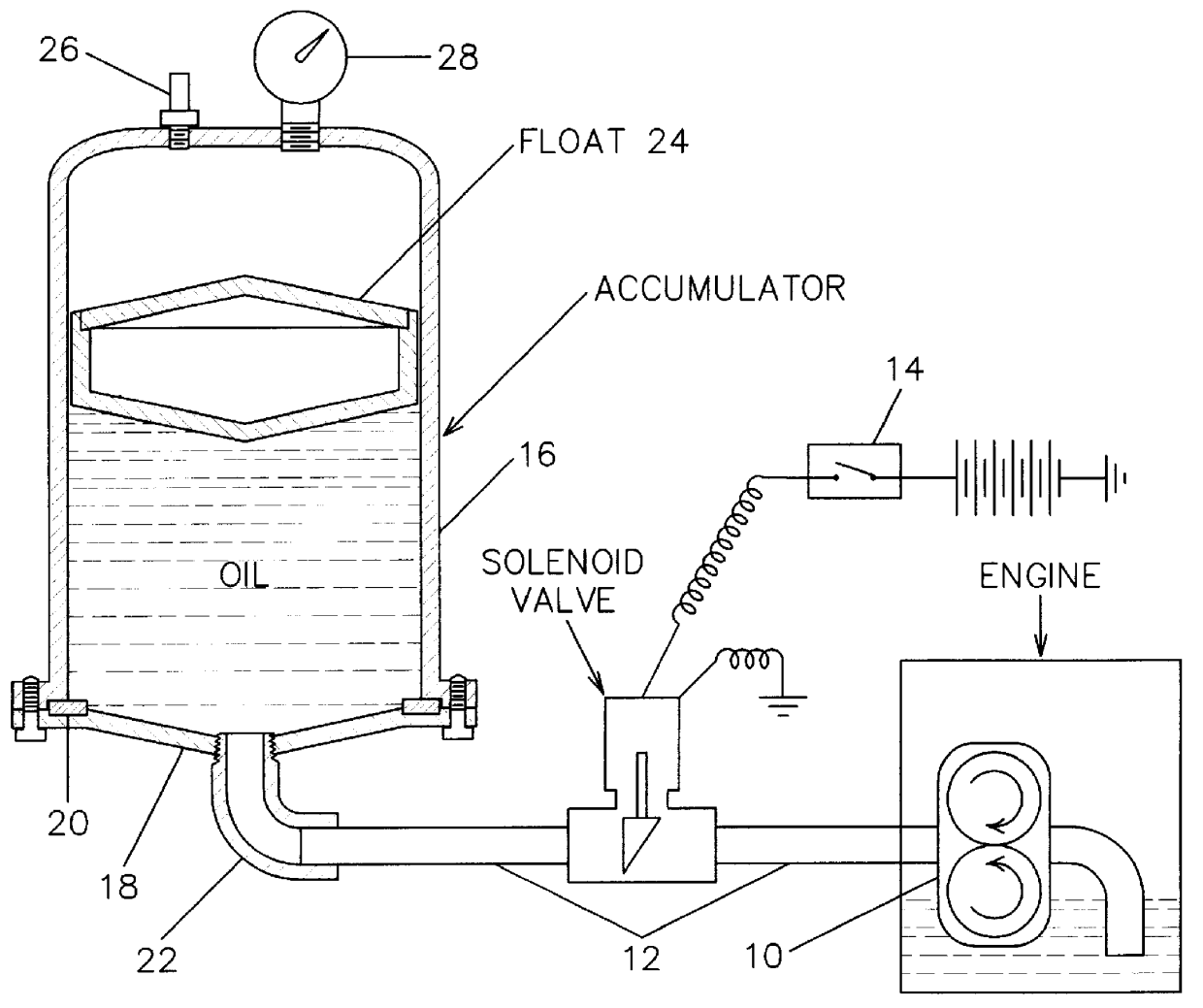

Engine-pressurized prestart oiler

InactiveUS6148789AEasy to modifyMinimal modificationLubrication of auxillariesLubricant conduit arrangementsAutomatic controlSolenoid valve

An engine-pressurized prestart oiler for an engine having pressure lubrication is provided, which rapidly lubricates critical engine bearing surfaces prior to the starting sequence. An accumulator for storing oil and pressurized air contains an air-oil separation float, which essentially fills the internal cross-sectional area and prevents absorption of the air. Discharge and recharge of the accumulator is preferably implemented by a normally closed solenoid valve. Discharge is controlled either manually by a switch or automatically by circuitry containing ignition-off time and accumulator pressure comparators, a starter interrupter, and a prestart oiling timer. Recharge is automatic, as the solenoid valve allows oil flow whenever the engine oil pressure sufficiently exceeds the accumulator pressure. A conduit connects the accumulator, solenoid valve, and engine, connecting to the engine either at the oil pressure sensor port or through an adaptor installed between the oil filter and the oil filter mount.

Owner:JOHNS RALPH HOWARD

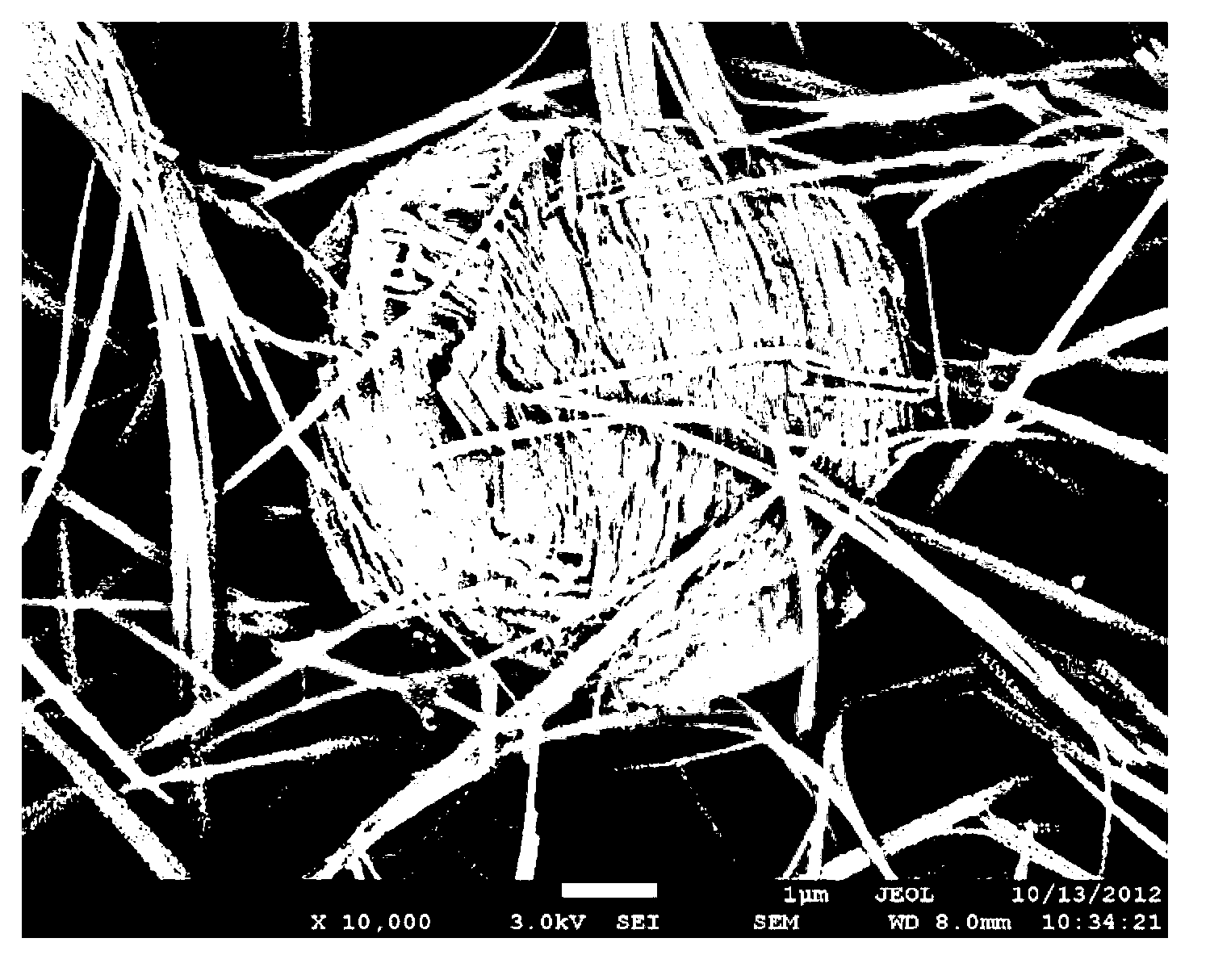

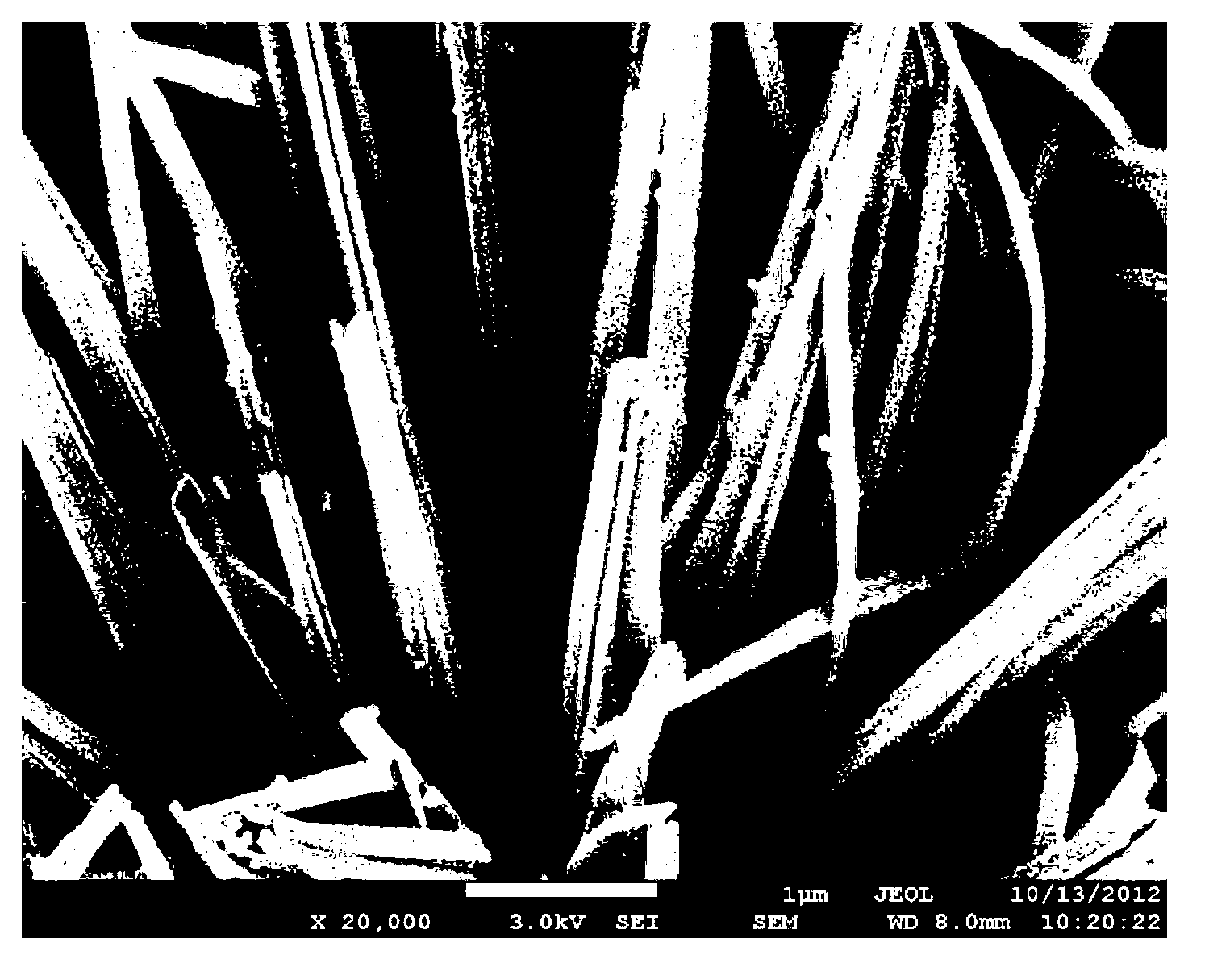

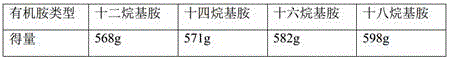

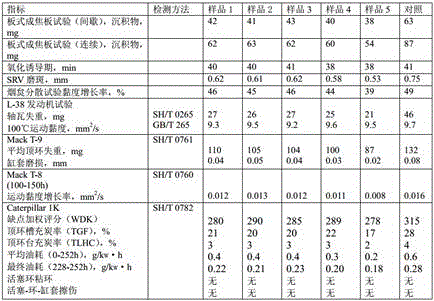

Modified graphene oxide, engine lubricating oil and application thereof

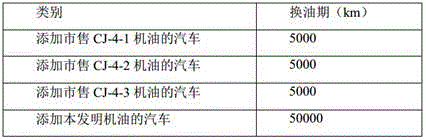

The invention discloses a graphene oxide modifying method and application thereof in engine lubricating oil. The method comprises the following steps: firstly preparing graphene oxide (GO) by adopting an improved Hummers process, and modifying the graphene oxide with long-chain fatty amine and organic silicon to obtain modified graphene derivative; and secondly, taking the modified graphene oxide as A), and compounding a friction modifier with a metal cleaning agent B), a metal corrosion inhibitor C), a complex antioxidant, an anti-foaming agent, a viscosity index improver, synthetic ester base oil and base oil, so that the engine lubricating oil added with the graphene oxide modifying agent is obtained. The method disclosed by the invention has the advantages that abrasion of an engine is greatly reduced by adding the graphene oxide modifying agent, so that oil draining period of automobile engine oil is prolonged to 50000 kilometers from 5000 kilometers, and fuel oil can be saved by 7-10% in the aspect of fuel economy.

Owner:江苏悦尔科技有限公司

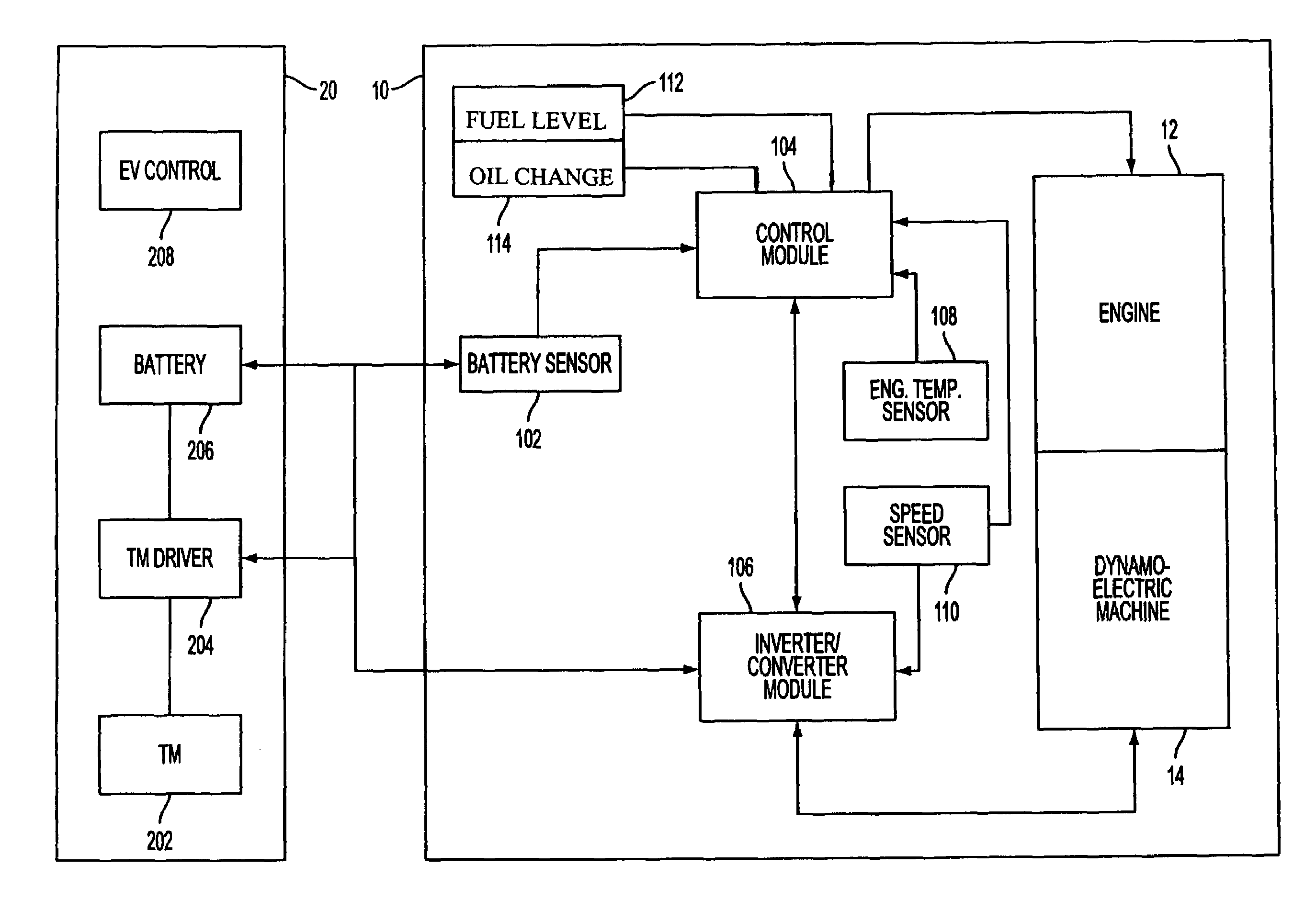

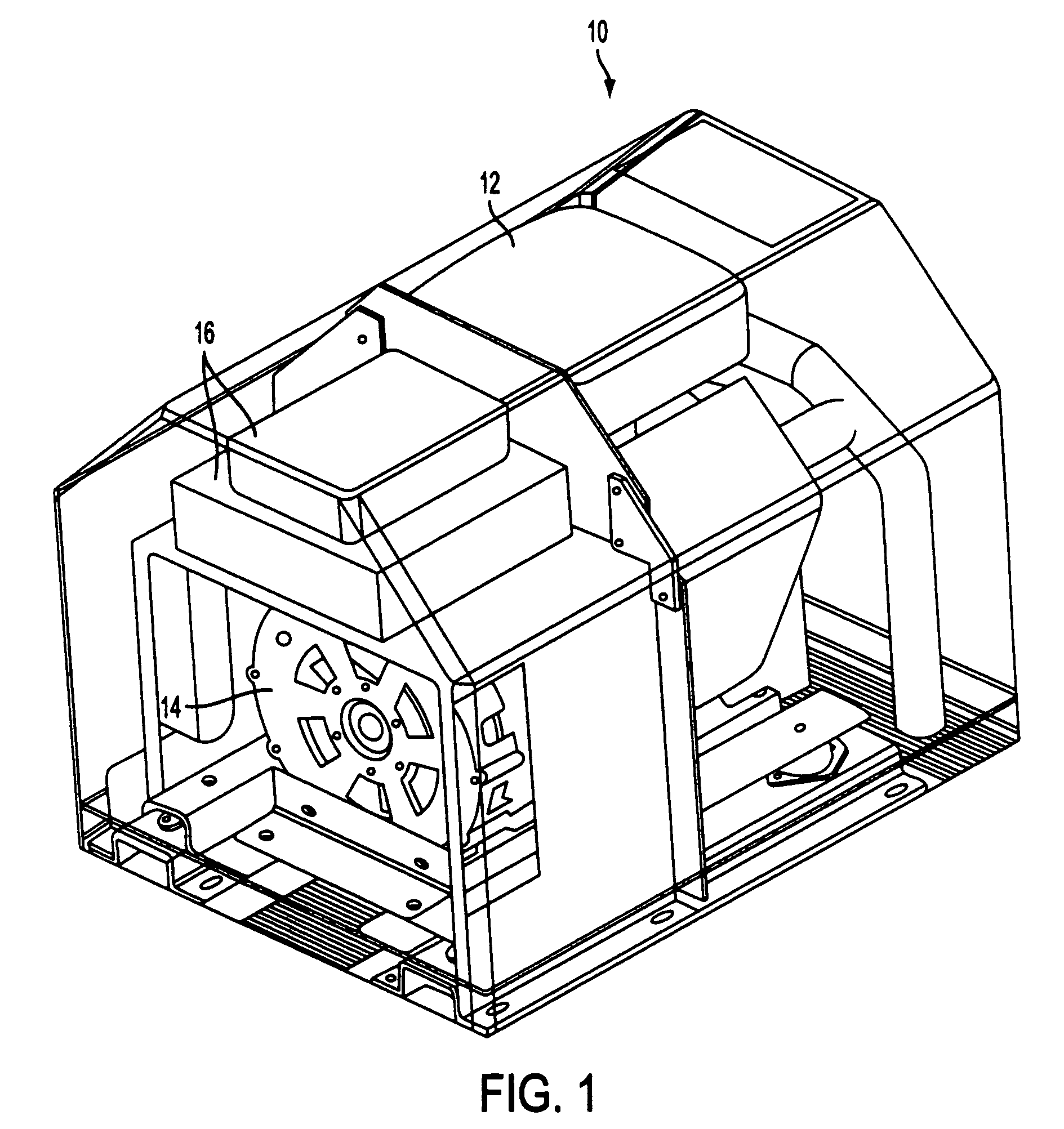

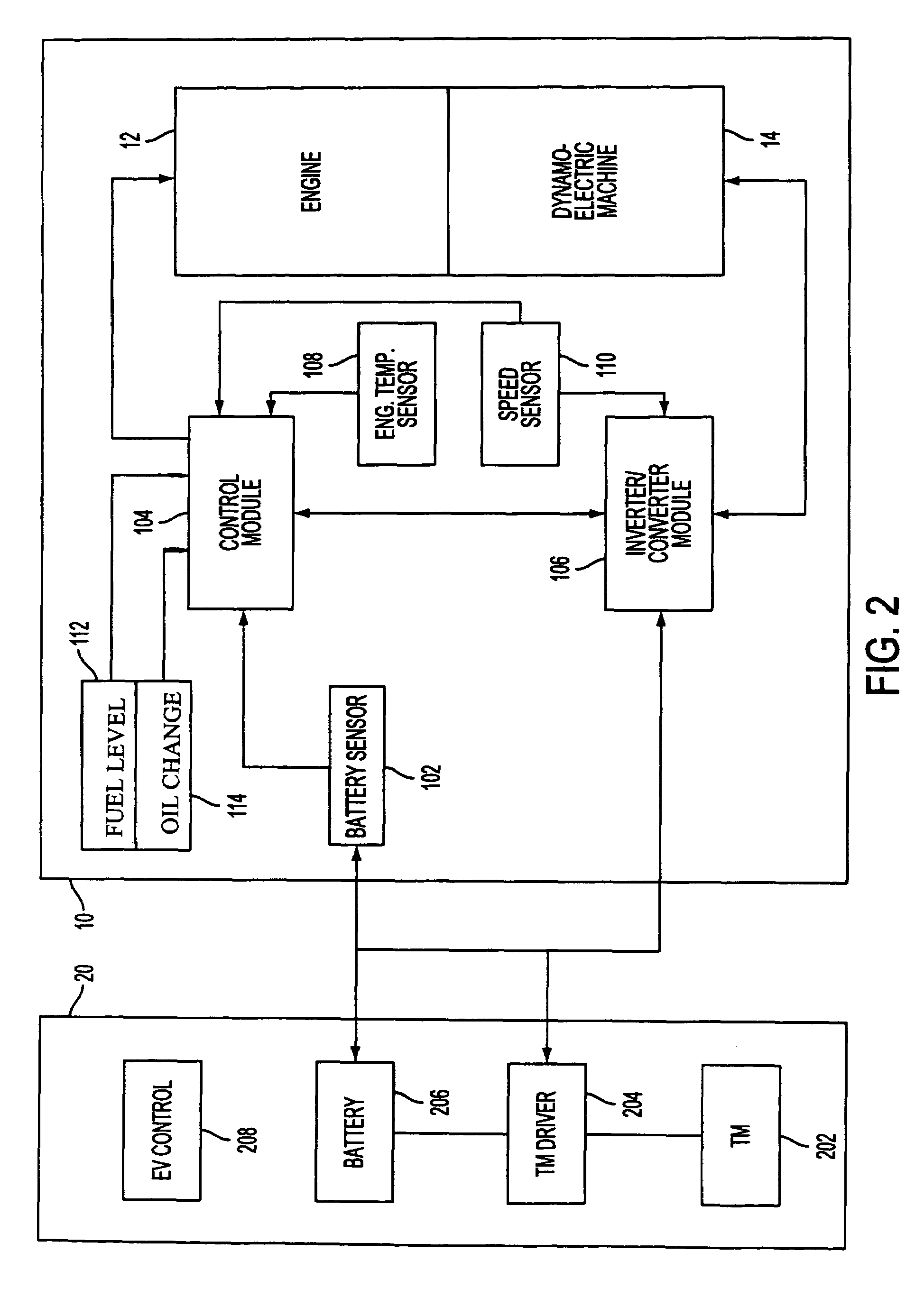

Sensorless fuel level and oil change indicators

InactiveUS7259664B1Digital data processing detailsOptical signallingElectric power systemElectric vehicle

Sensorless fuel level and oil change indicators are provided in a range extender for an electric vehicle. The range extender includes an engine, and an electric generating device driven by the engine to generate electric power supplied to the vehicle. The fuel level is calculated based on the generated power. The oil change indicator indicates that the oil should be changed when the number of engine rotor revolutions exceeds a threshold value. The electric generating device may be a dynamoelectric machine coupled to the engine by a shaft to operate as a motor for starting the engine. In response to prescribed engine conditions, the dynamoelectric machine is switched to operate as a generator driven by the engine to generate the electric energy.

Owner:BLUWAV SYST LLC

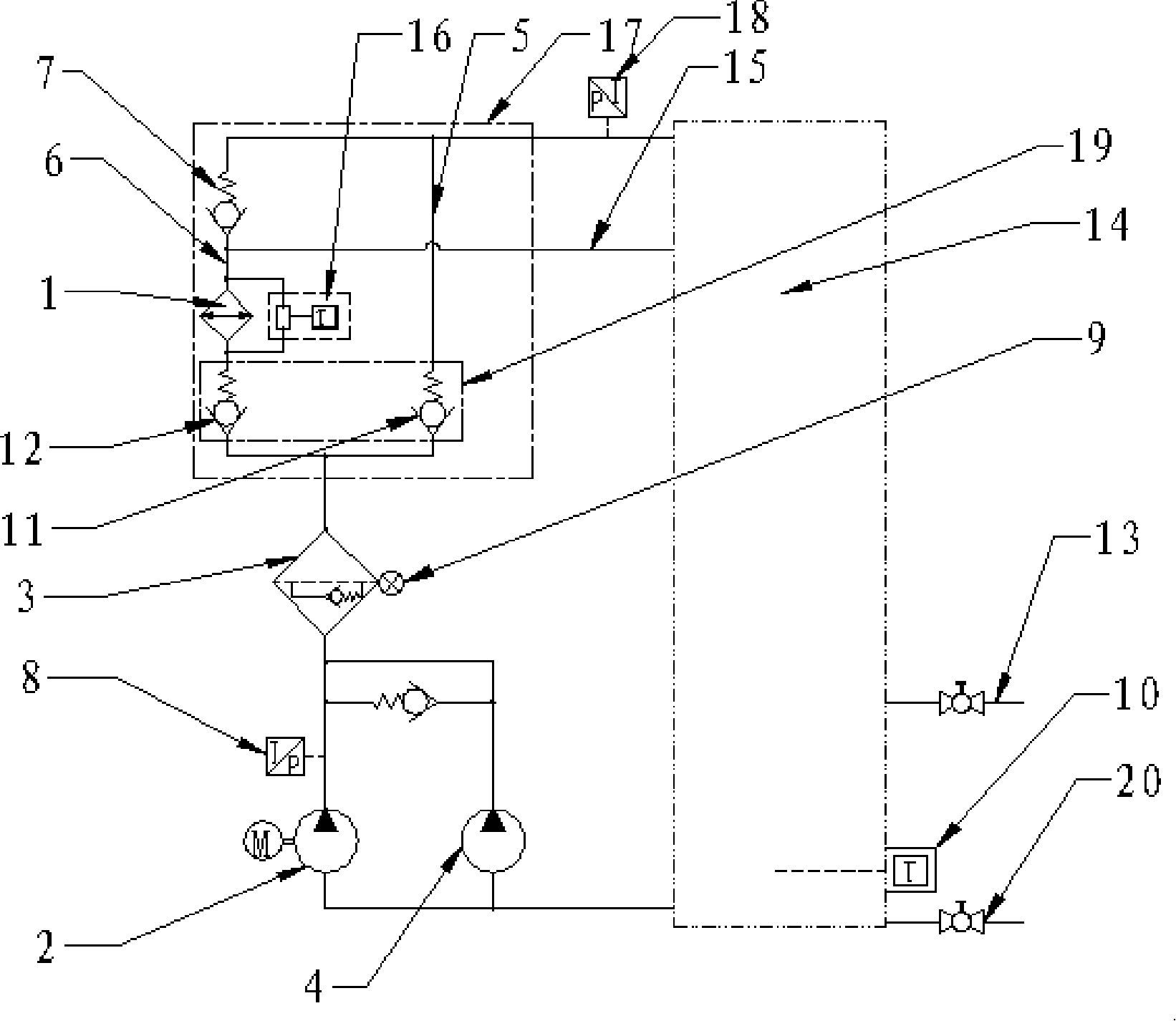

Low temperature wind-driven generator speed increasing engine oil lubrication system

ActiveCN101196176AExtended service lifeImprove protectionGear lubrication/coolingMachines/enginesWind drivenFiltration

The invention discloses a low temperature type wind power generator accelerator oil lubricating system being able to start up under the condition of low temperature. The lubricant in the system enters an electric pump and a mechanical pump after being heated by a heater; the outlets for the electric pump and the mechanical pump are both connected to an oil filtration device; the oil filtration device is communicated with the accelerator via a pipeline system configured with an oil cooling device; the pipeline system comprises a normative open passage and a startup passage connected in parallel; the oil cooling device is positioned on the normative open passage. The normative open passage and the startup passage can switch automatically via a startup one-way valve and a normative open one-way valve; an ultra low pressure one-way valve on the normative open passage is able to provide accident protection for a high-speed axle of the accelerator; a pressure sensor can control the motor of the electric pump via a control circuit, so that the electric pump can supply oil to the system on demand. Therefore, the invention, which enhances the reliability and service life of equipment, can be best applied for the wind power generator system in harsh cold region.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Enhanced deposit control for lubricating oils used under sustained high load conditions

Engine lubricating oils used under sustained high load conditions, such as high speed diesel or stationary natural gas engines, can have their deposit control properties enhanced by the addition to such engine oils of a minor amount of one or more neutral / low TBN or mixture of neutral / low TBN and overbased / high TBN alkali and alkaline earth metal salts of alkyl salicylates, or alkyl phenolate, a minor amount of one or more of an organo molybdenum complex in an amount sufficient to provide 25 wt. ppm to 2000 wt. ppm elemental molybdenum in the final lubricant composition.

Owner:CARTWRIGHT STANLEY JAMES

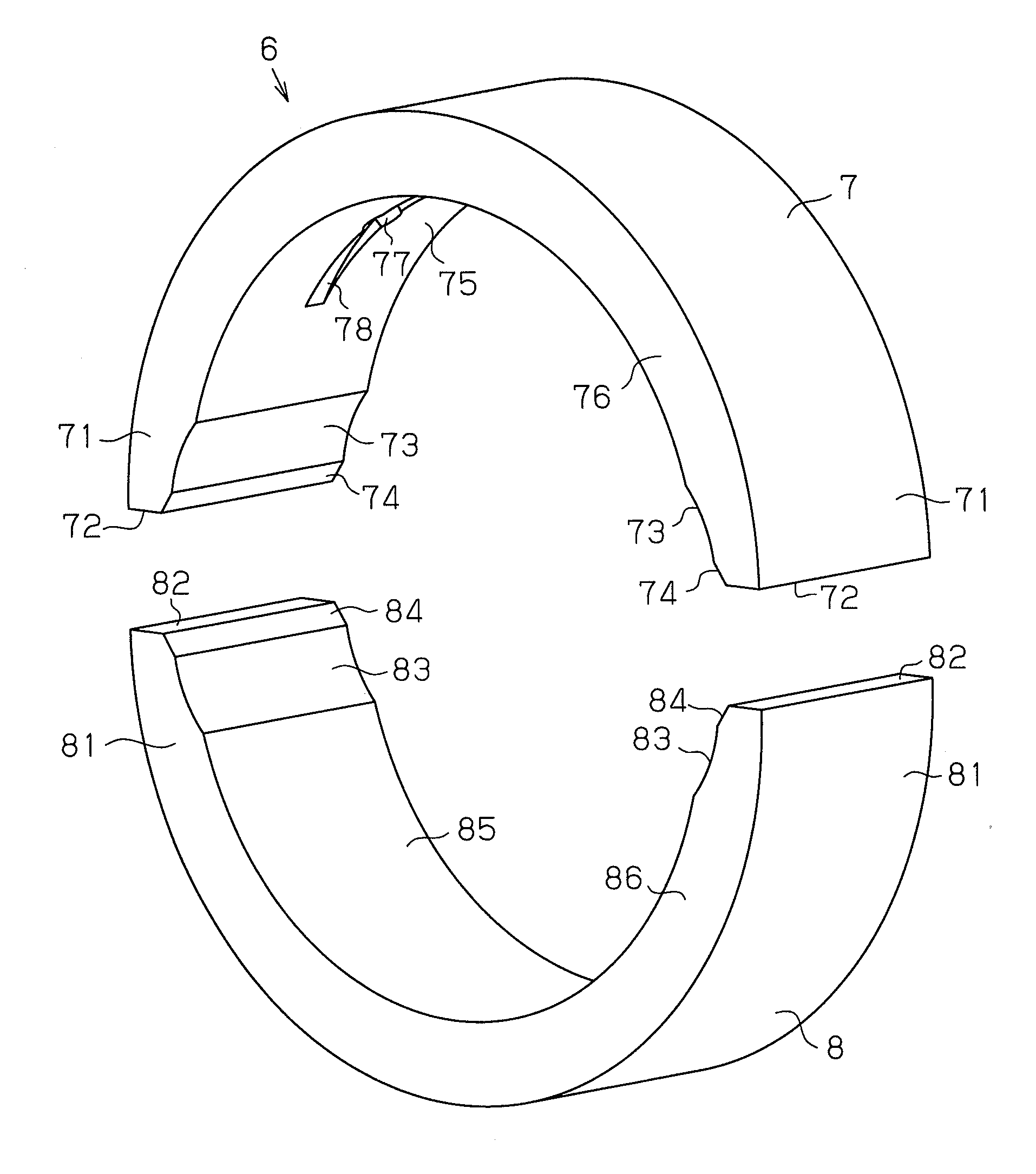

Slide bearing

ActiveUS20100046869A1Reduces amount of lubricantAvoid damageCrankshaftsConnecting rod bearingsEngineeringMechanical engineering

A crank bearing is disclosed that includes a semicircular upper bearing and a semicircular lower bearing, which can be split from each other. The upper bearing includes a first oil passage for introducing engine oil from the outside to a gap between the crank bearing and a crank journal, and a second oil passage for permitting the engine oil to flow in the circumferential direction of the crank bearing. The first oil passage includes an inner circumference opening, which is open to the inner circumference of the main bearing. The upper bearing includes a non-undercut portion in which no oil passage is formed on the trailing side of the inner circumference opening in the rotational direction of the crank journal. A chamfer oil passage for discharging the engine oil in the second oil passage to the outside from the axial direction of the crank bearing is provided in at least one of the lower bearing and a region on the proceeding side of the circumference opening in the rotational direction of the crank journal.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com