Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

430results about How to "Improve anti-coking performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Catalyst for dehydrogenation of propane for preparing propylene and preparation method thereof

ActiveCN101972664BHigh propane conversionExcellent anti-coke performanceMolecular sieve catalystsHydrocarbonsChemistryMolecular sieve

The invention discloses a catalyst, which is carried by an AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework, for dehydrogenation of propane for preparing propylene. In the catalyst, the AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework is used as a carrier, platinum-group element metal is used as a main catalyst, IVA-group, IA-group or IIA-group element metal is used as an auxiliary agent, and high-temperature-resistant inorganic oxide is used for forming an adhesive. A multi-step dipping method is used in the preparation of the catalyst, namely the alkaline metal auxiliary agent is dipped, so that the acidity and alkalinity of the catalyst and the types of cations in pores of the molecular sieve are effectively modulated by cation exchange technology, and the platinum-group element metal is dipped. The catalyst has superior anti-carbon deposit performance, high propane conversion rate under the reaction conditions of high temperature and low pressure, propylene selectivity and reaction stability.

Owner:CHINA PETROLEUM & CHEM CORP

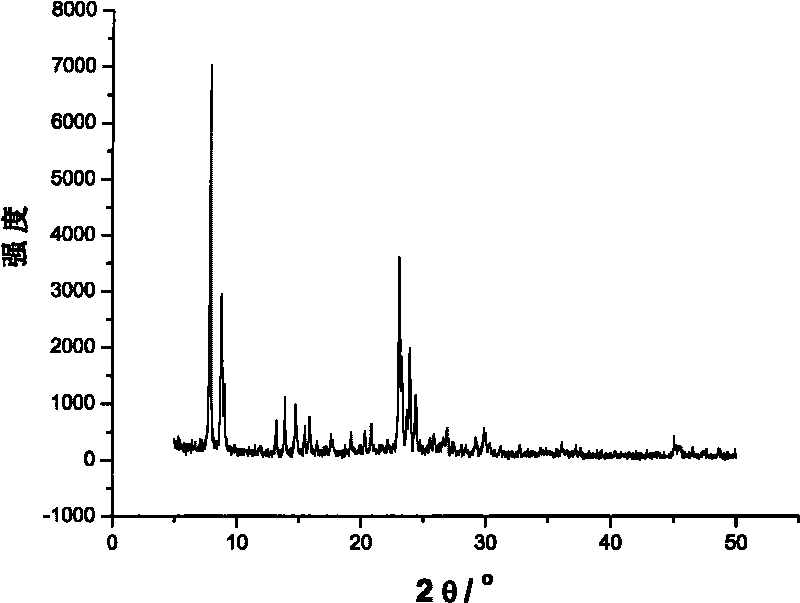

Mesopore and micropore compound ZSM-5 zeolite material

ActiveCN101723403AImprove diffusivityImprove anti-coking performancePentasil aluminosilicate zeoliteTolueneAromatic hydrocarbon

The invention relates to a mesopore and micropore compound ZSM-5 zeolite material and mainly aims to solve the problem that the ZSM-5 zeolite material cannot contain mesopores and micropores at the same time, the problem that inactivation speed is high when the ZSM-5 zeolite material is used in the reactions such as toluene disproportionation and the like in the prior art. To solve the problems existing in the prior art, the invention adopts a technical scheme that: in the mesopore and micropore compound ZSM-5 zeolite material, the molar ratio of SiO2 to Al2O3 is 15 to 500, and the material has 0.5 to 0.6 nanometer micropores and 5 to 100 nanometer mesopores, and the pore volume of the mesopores is 1 to 10 times that of the micropores. The mesopore and micropore compound ZSM-5 zeolite material can be applied to the industrial production of conversion and treatment of aromatic hydrocarbons, such as toluene disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

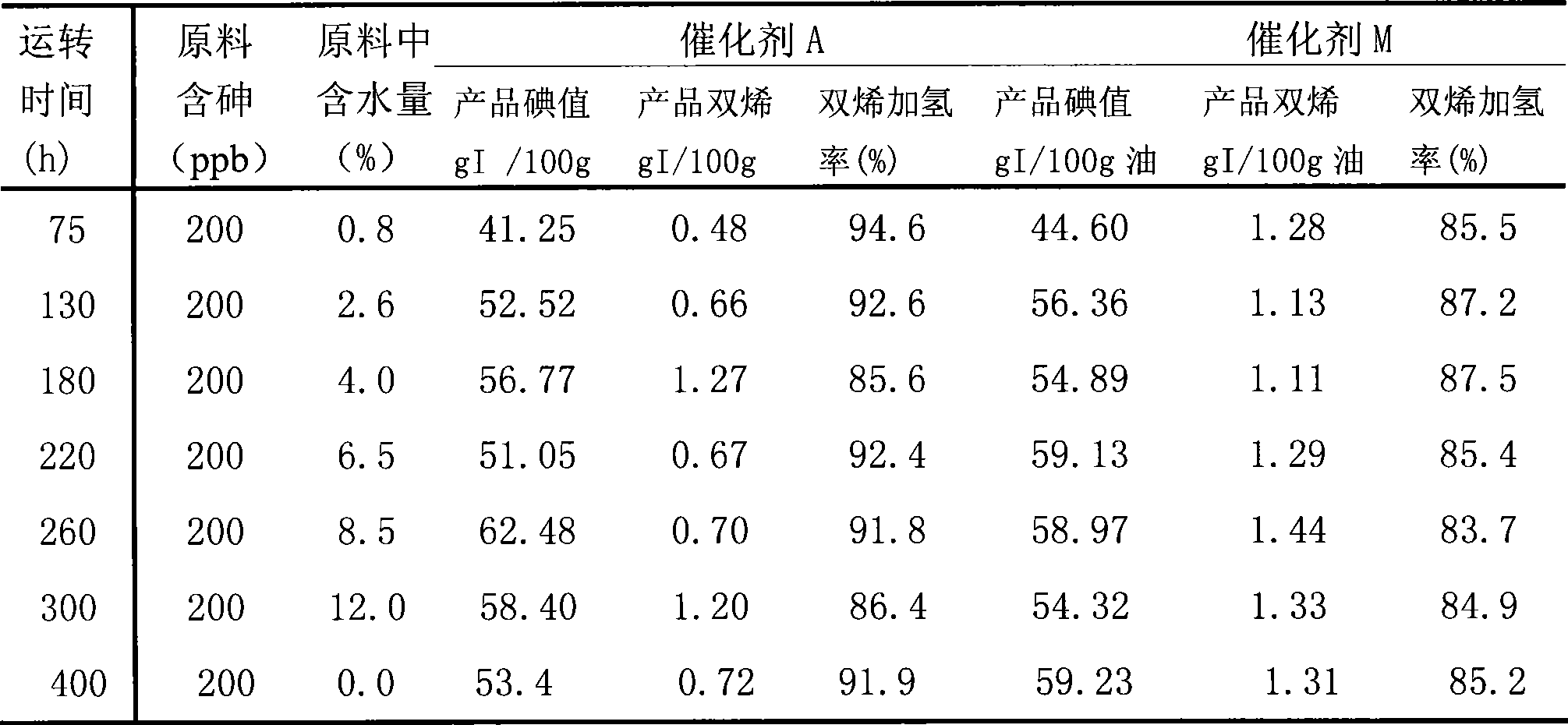

Selectively hydrogenating catalyst and preparation method thereof

ActiveCN101433845AStable physical propertiesActiveMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationPalladiumMetal

The invention provides an unsaturated hydrocarbon selective hydrogenation catalyst and a preparation method thereof. The catalyst uses alumina as a carrier and palladium as an active ingredient, and is characterized by comprising the following components by weight percentage: 0.1 to 1.0 percent of the palladium, 0.3 to 8.0 percent of a rare earth metal, 0.1 to 5.0 percent of alkaline-earth metal, and 0 to 3.0 percent of fluorine which can also be contained in the catalyst, based on the total weight of the catalyst. The catalyst carrier is theta or mix-crystal type Al2O3, and the priority is given to the theta crystal type. In the invention, the catalyst palladium is preferably distributed in a secondary outer layer of the catalyst. The catalyst has certain impurity resistance and coking resistance, is applicable to a section of selective hydrogenation process in full distillate cracked gasoline and unsaturated hydrocarbon selective hydrogenation process in other distillate oils.

Owner:PETROCHINA CO LTD

Hydro-conversion catalyst for heavy oil and residual oil and its preparing process

The present invention belongs to the field of heavy oil and residual oil hydrotransforming technology. The heavy oil and residual oil hydrotransforming catalyst has siliceous alumina carrier, relatively strong acidity and especially protonic acid amount higher than that in available residual oil hydrotransforming catalyst. The siliceous alumina carrier is prepared through one colloid forming process, during and after which silicon is added to make alumina possess more strong acid centers and ideal pore structure. The catalyst of the present invention is used in the hydrotransforming treatment of heavy oil, residual oil and other inferior oil material.

Owner:CHINA PETROLEUM & CHEM CORP +1

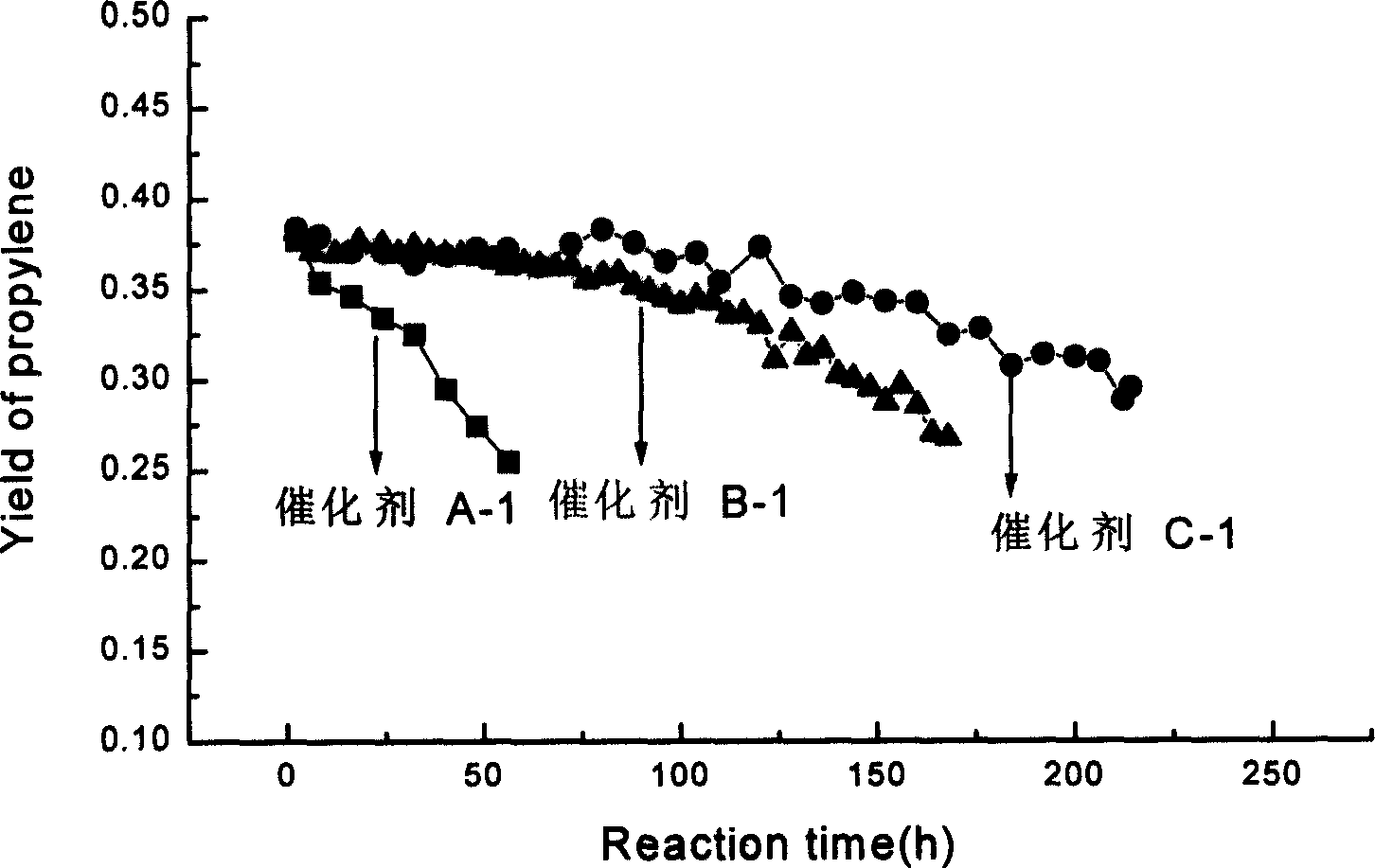

Method for producing propene for C4 and more olefin catalytic cracking

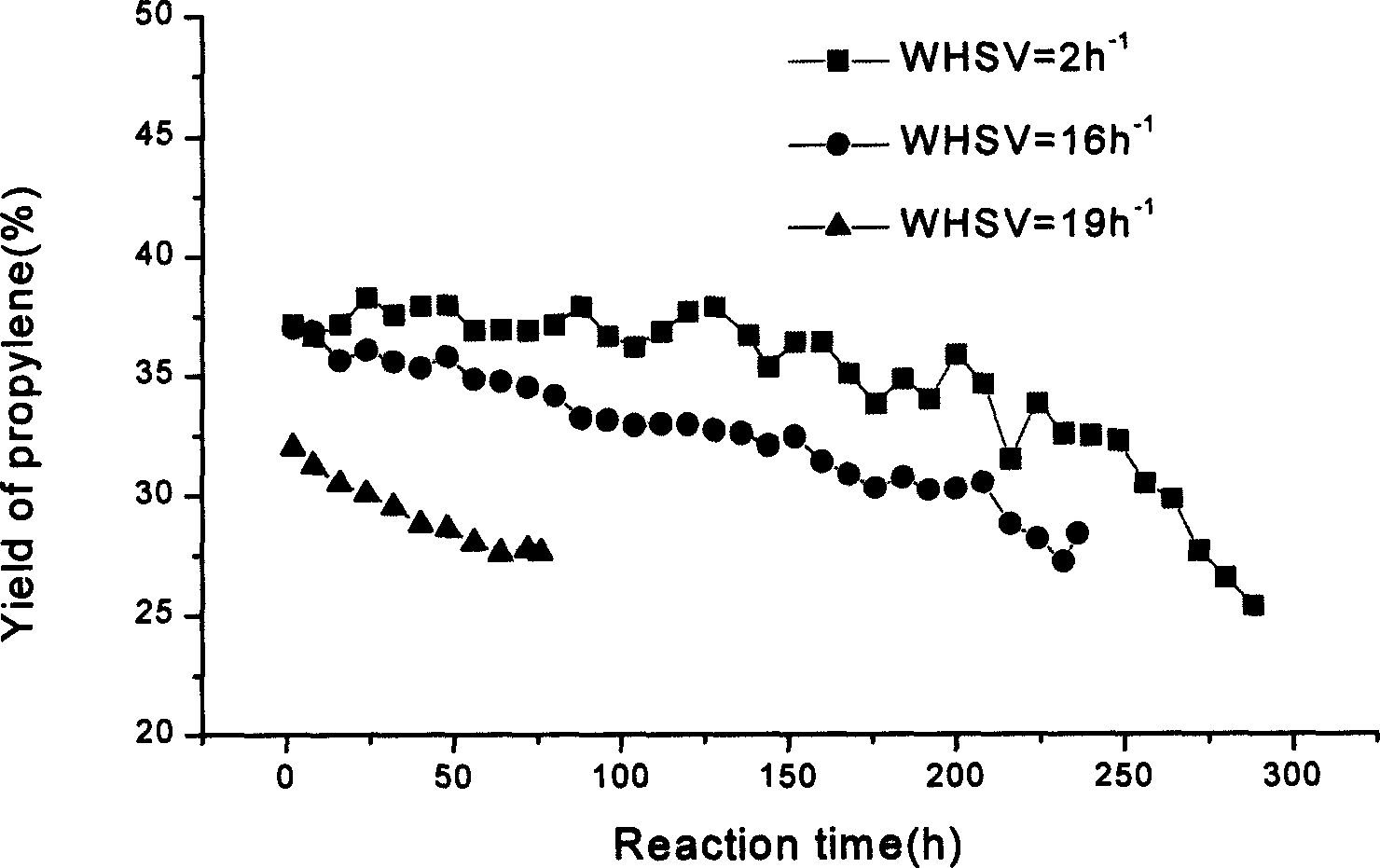

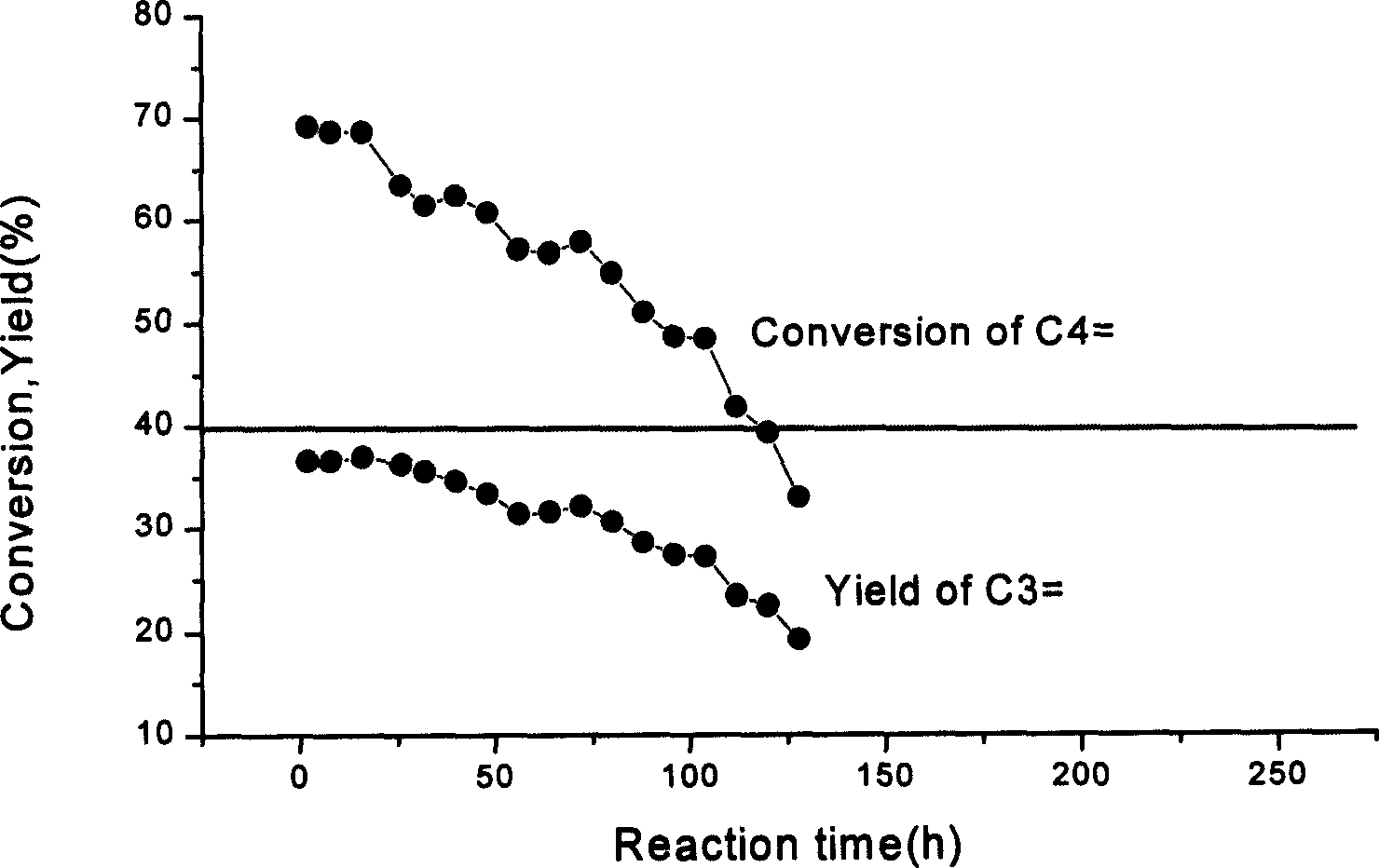

ActiveCN1611472AIncreased diffusion resistanceSize diffusion resistanceChemical recyclingHydrocarbon by hydrocarbon crackingMolecular sieveAluminium

The invention relates to a kind of method for manufacturing propylene by catalytic cracking alkene of no less than tetra carbon, which mainly solves the short catalyst regeneration period problem and the stability problems uninvolved in previous technique. The invention uses minor crystalline grain and molecular sieve with high silicon-aluminium ratio as the catalyst for catalytic cracking with alkene that no less than tetra carbon to manufacture propylene. According to the technique scheme that described above, the invention can solve the problems mentioned above excellently, and can be used in industrial production of manufacturing propylene by catalytic cracking with alkene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular sieve catalyst for preparing low-carbon olefin and preparation method thereof

ActiveCN101628242ATotal pressure is smallSimplify production stepsMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh activity

The invention provides a molecular sieve catalyst for preparing low-carbon olefin, and the catalyst comprises the following raw materials by parts by weight: 30-93.7 parts of Na-ZSM-5 zeolite, 5-40 parts of bonding agent, 0.1-10 parts of modifier of mixed elements, 1-15 parts of hole structure regulator and 0.1-5 parts of extrusion assistant, and the modifier of the mixed elements is a soluble substance containing one or a plurality of elements of B, P, La, Ca, Mg, Sr, Zn, Cu, Mn, Cd, Ga and In. The invention further provides a prepration method of the catalyst. The molecular sieve catalyst adopts the extrusion assistant and adds an appropriate amount of hole structure regulator, thereby improving product strength and hole structure, effectively improving diffusion performance of the catalyst and further improving selectivity of the low-carbon olefin. The catalyst has the advantages of appropriate strength, high hydrothermal stability, high activity and high selectivity of propylene.

Owner:DATANG INT CHEM TECH RESINST

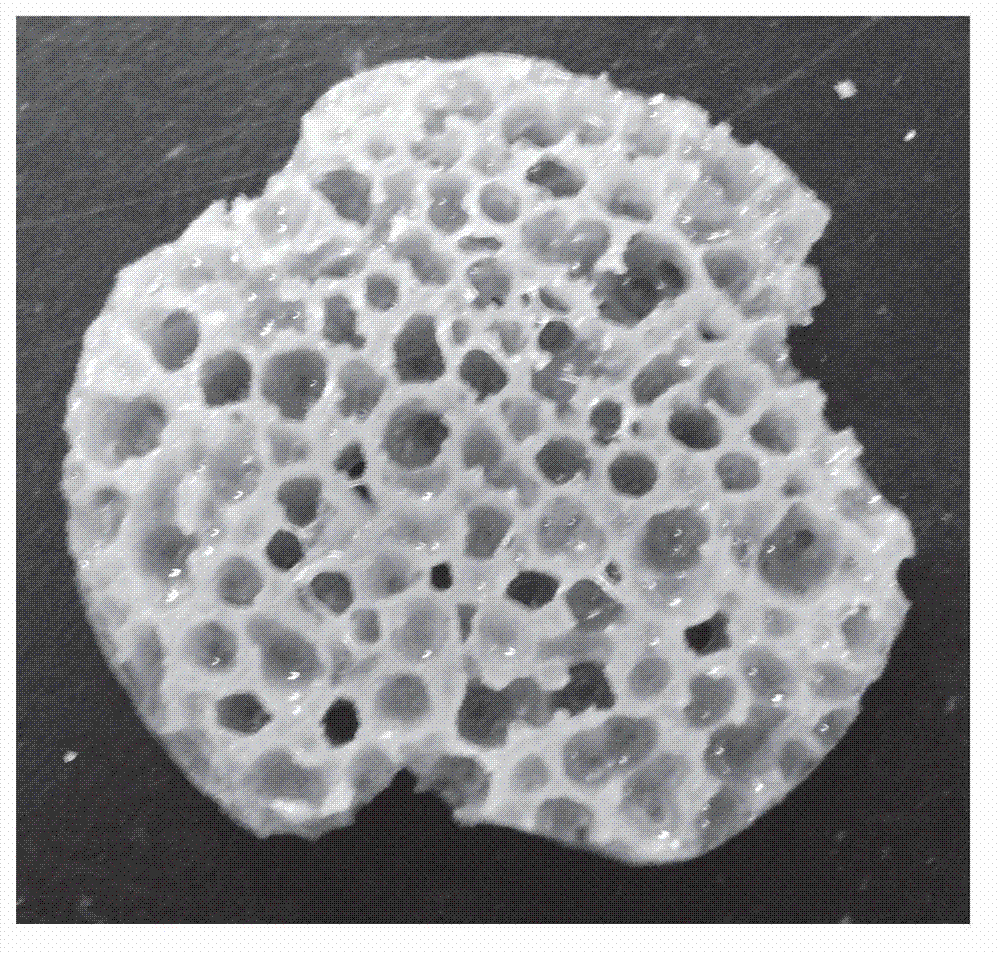

Preparation method of multi-stage pore channel beta molecular screen

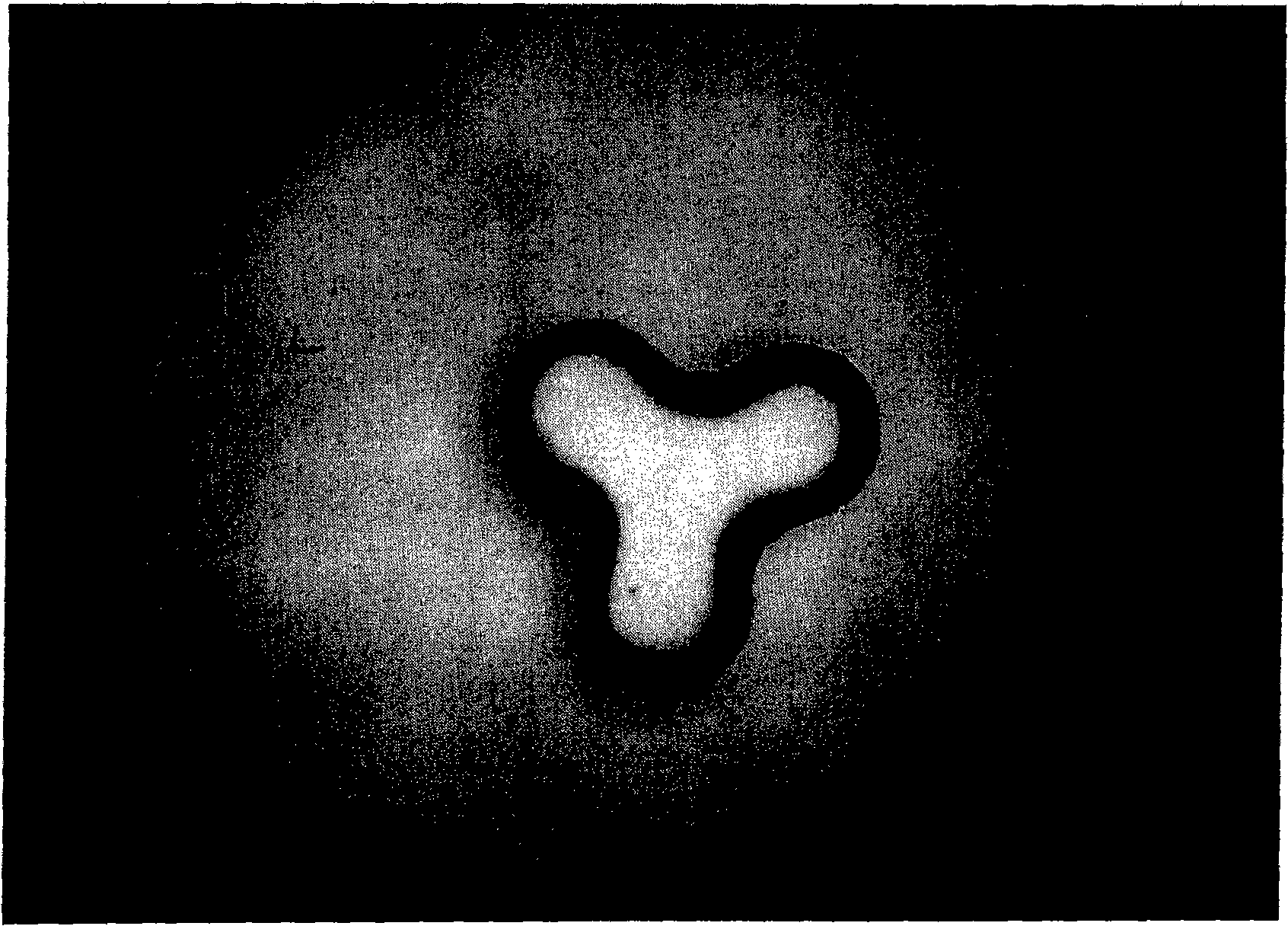

ActiveCN102826565AAvoid lostLower synthesis costMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveHoneycomb

A preparation method of a multi-stage pore channel beta molecular screen belongs to the technical field of preparation of a multi-stage pore channel molecular screen. The preparation method is as follows: synthesizing the multi-stage pore channel beta molecular screen in one step by pseudo solid phase aluminosilicate; the molecular screen comprises a honeycomb-shaped structure or a plurality of particles in the size of 5micron to 60micron, the honeycomb-shaped structure or particles are polymerized by small crystal particles of a nano-level molecular screen, and the size of the small crystal particles of the nano-level molecular screen is 10nm to 100nm; and the aperture of one of meso pores formed by the polymerization of the small crystal particles of the nano-level molecular screen is 3nm to 45nm, and the aperture of a micro-pore is 0.6nm to 0.8nm. A second template agent is not in need during the synthesis process, so that the synthesis cost is reduced and the synthesis step is simplified; and in addition, the filtering is not in need after the crystallization is finished, therefore, the yield of the molecular screen is greatly enhanced.

Owner:BEIJING UNIV OF CHEM TECH

Air compressor oil composition

ActiveCN101724489AImprove anti-coking performanceImprove wear resistanceAdditivesBase-materialsTert butyl phenolFoaming agent

The invention relates to an air compressor oil composition, which comprises the following components in percentage by weight: 1.5 to 5 percent of antioxidant, 0.03 to 0.5 percent of ashless antirust agent, 0.01 to 0.5 percent of metal deactivator, 0.01 to 1 percent of ashless antiwear agent, 0.001 to 0.01 percent of anti-foaming agent and the balance of base oil, wherein the base oil is prepared by mixing poly alpha-olefin with ester oil in a weight ratio of 7-9:3-1 or mixing hydrogenated oil with the ester oil in the weight ratio of 7-9:3-1; and the antioxidant is the mixture of dialkylaniline, high-molecular thioether phenol and 4,4-methylenedi(2,6-di-tert-butyl phenol) in the weight ratio of 1:0.1-10:0.1-10. The air compressor oil composition has the advantages of excellent high-temperature anti-oxidation stability, anti-carbon deposition property, abrasive resistance, obvious energy-saving effect, good cost performance and low cost.

Owner:PETROCHINA CO LTD

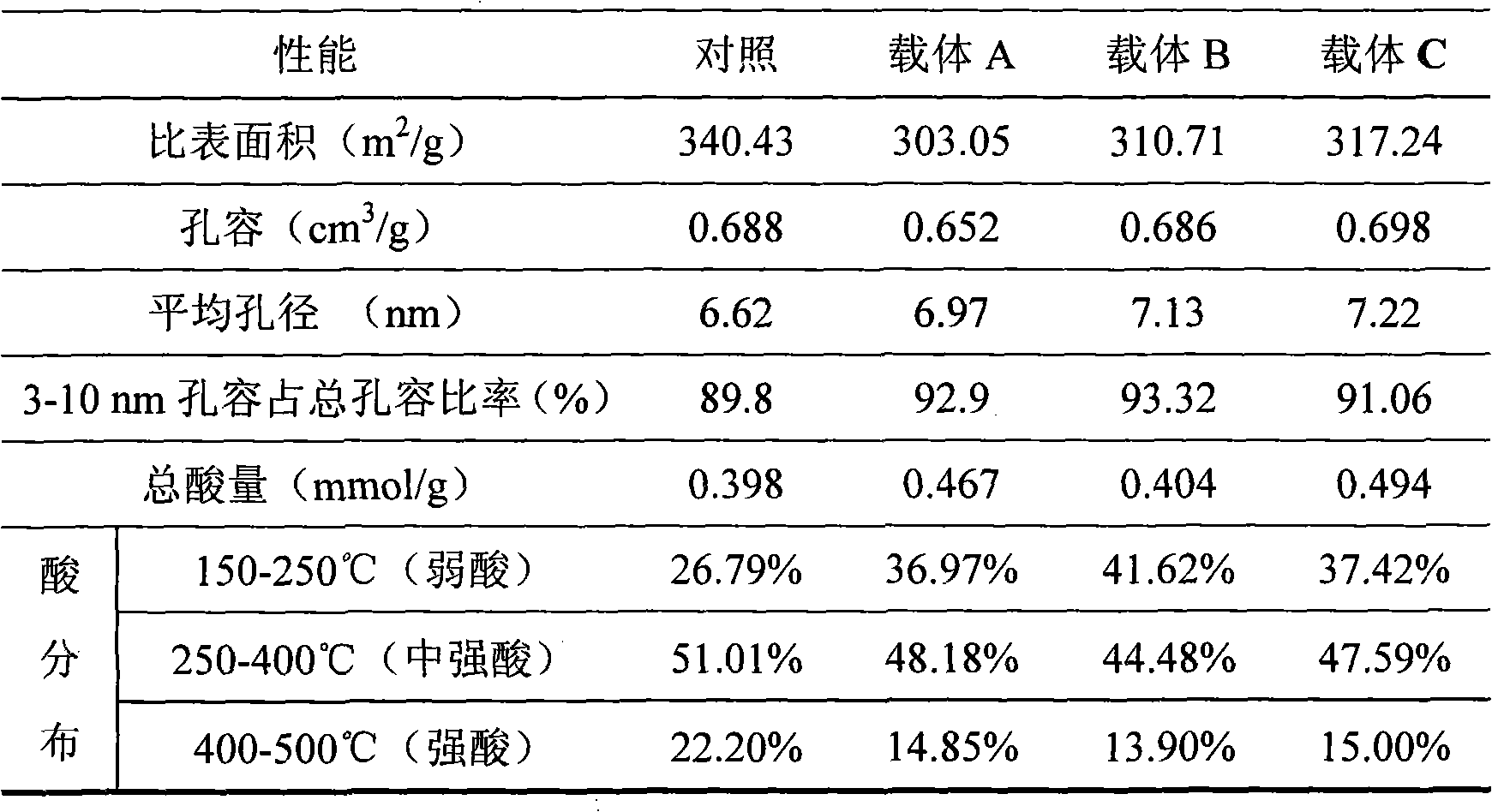

Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

InactiveCN101327454ALarge specific surface areaLarge hole volumeCatalyst carriersCatalyst activation/preparationOil processingModified carbon

The present invention discloses a modified carbon-covered alumina support with a core-shell structure and a preparation method thereof. The modified carbon-covered alumina support of the present invention is a granule with the core-shell structure. A shell of the core-shell structure is alumina deposited with carbon, and an inner core of the core-shell structure is an industrial alumina support. The modified carbon-covered alumina support of the present invention has the advantages of high specific surface area, large pore volume, high mechanical strength, and the like; the aperture distribution is more concentrated; total acid quantity is increased obviously, and strong acid quantity is reduced; the modified carbon-covered alumina support can be directly used as a catalyst during certain processes and is more applicable to be used as a catalyst support, in particular as a hydrogenation treatment catalyst support during petroleum processing course.

Owner:EAST CHINA UNIV OF SCI & TECH

High-temperature chain oil and preparation method thereof

InactiveCN101117609AHigh temperature thermal oxidation performanceReduce evaporation lossAdditivesPentaerythritolEvaporation

The present invention discloses high temperature chain oil, the components and the contents are: high temperature antioxygen 1 to 5 percent, extreme pressure / anti-wear agent 1 to 10 percent, corrosion inhibitor 0.01 to 0.5 percent, and high temperature detergent dispersant 1 to 20 percent, the rest is base oil; the components and the contents of the base oil (weight ratio) are: dipentaerythritol ester 50 to 90 percent, and aromatic ester 10 to 50 percent. The preparation is as follows: the dipentaerythritol ester and the aromatic ester are mixed together according to the above ratio to prepare the base oil, a certain volume of the high temperature antioxygen, the extreme pressure anti-wear agent, the high temperature detergent dispersant and the corrosion inhibitor is added into the base oil, then the base oil is heated to 80 to 100 DEG C, and is agitated at the constant temperature for 0.5 to 1 hour, and is filtrated, thus the product is got. The present invention is characterized in that the coking volume can be obviously reduced, the anti-high temperature coking performance and the high temperature detergency performance can be improved, the product can be used under the 280 DEG C high temperature condition, the evaporation loss is little, and the coking volume is little, the lubrication performance and the high temperature detergency and dispersing performance is good.

Owner:中国石油天然气股份有限公司大连润滑油研究开发中心

Aluminium oxide carrier containing magnesium and phosphor and preparing method

InactiveCN101069853AStrong anti-coking abilityHigh activityMetal/metal-oxides/metal-hydroxide catalystsLarge poreChemistry

The present invention discloses an aluminium oxide carrier which contains magnesium and phosphorus, also can contain potassium and its preparation method. The magnesium, phosphorus and potassium can be added in the process of preparation. Said carrier is low in acidity and has large pore volume and large specific surface area. The catalyst prepared by using said carrier has the features of strong anti-coking property and good stability.

Owner:林方 +3

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

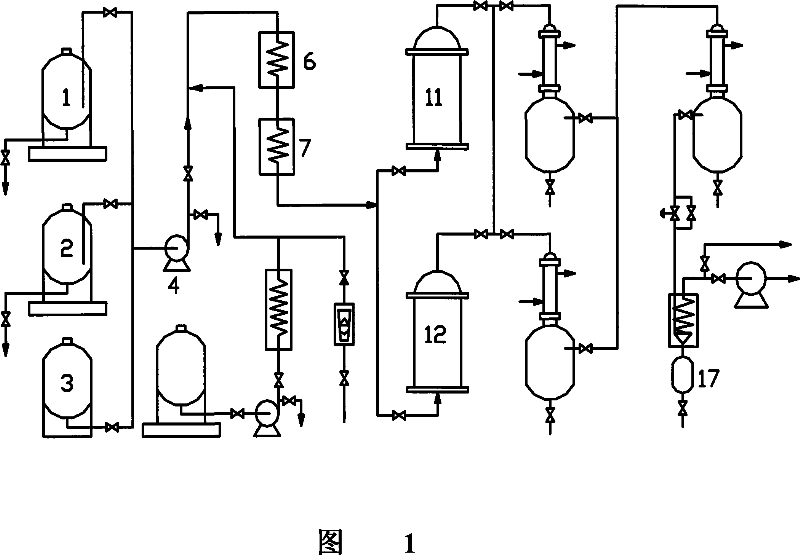

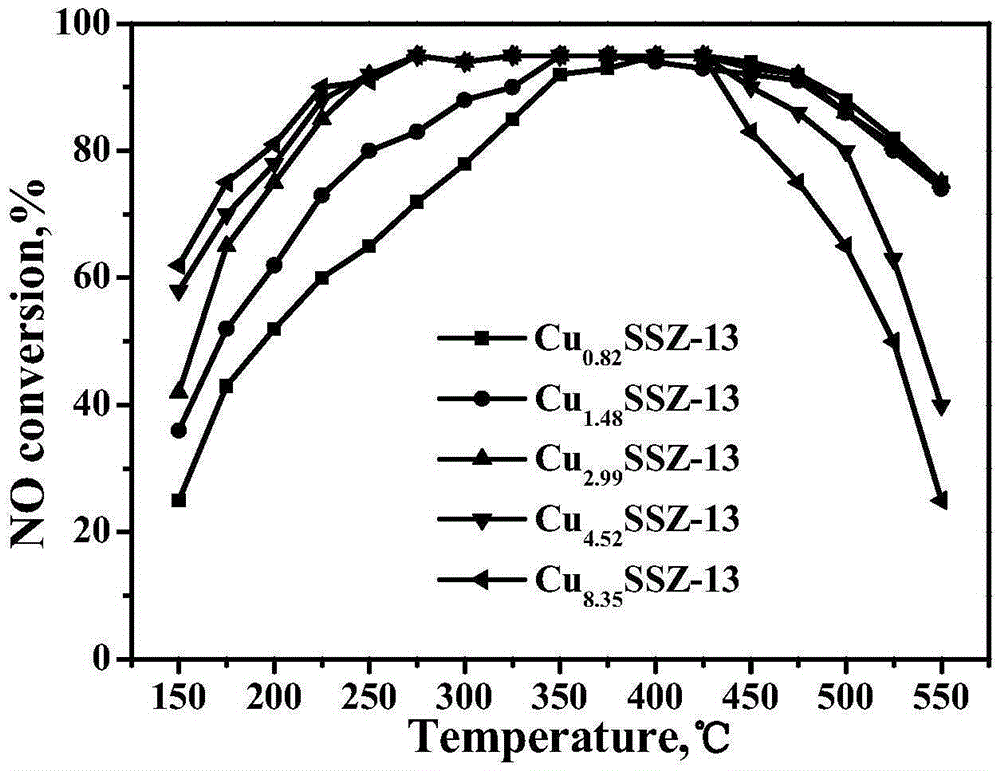

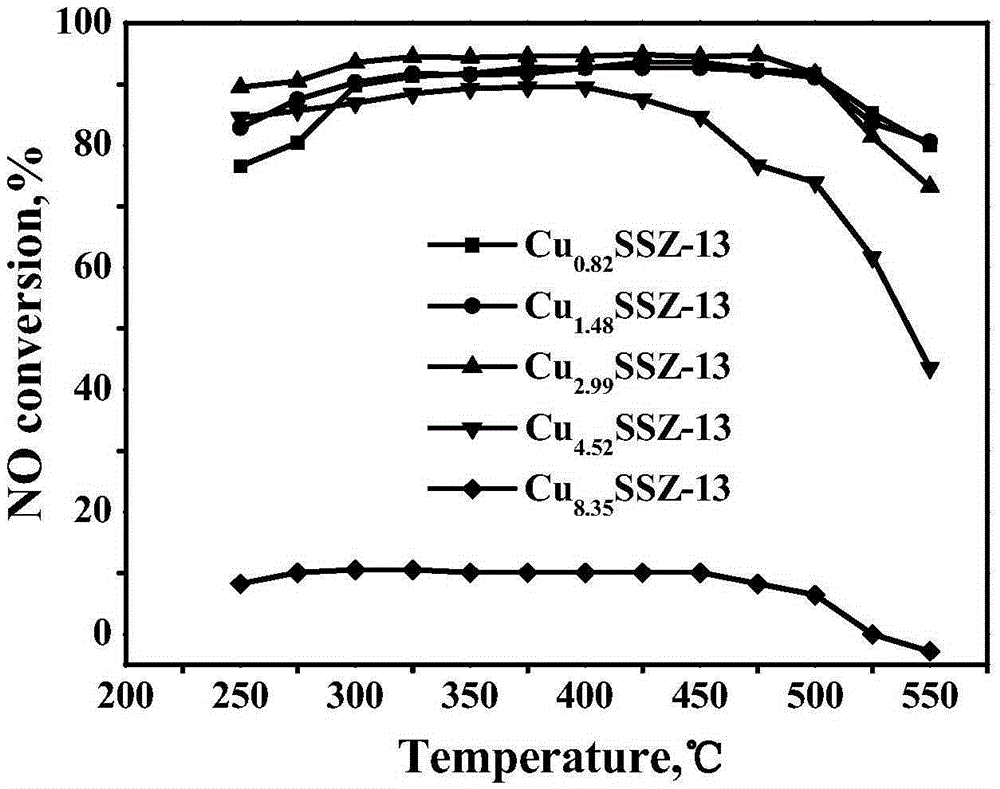

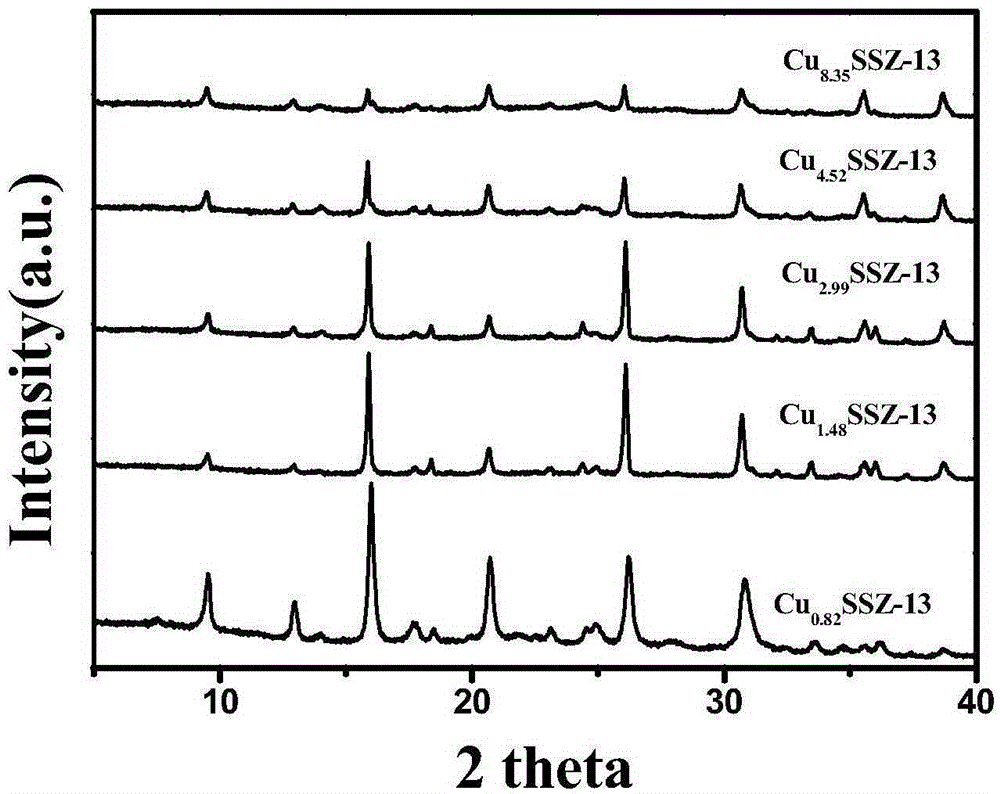

Preparation method and use of Cu-SSZ-13 molecular sieve based catalyst

InactiveCN106179472AHigh crystallinityGood catalytic activityMolecular sieve catalystsInternal combustion piston enginesIon exchangeIon

The invention provides a preparation method of a Cu-SSZ-13 molecular sieve based catalyst. The preparation method comprises the following steps of adding sodium aluminate, sodium hydroxide, a silica solution, copper sulfate, tetraethylenepentamine and an organic template agent to deionized water, and performing stirring so as to obtain gel; and performing a reaction in a reaction kettle, then performing cooling, performing centrifugal filtration, performing washing, performing drying, and performing calcining so as to obtain the Cu-SSZ-13 molecular sieve based catalyst. The method disclosed by the invention is simple in technology, low in cost, energy-saving, and environmentally-friendly. Use of a copper salt solution ion exchange and calcining technology many times is avoided, and the defect that a conventional technology needs performing later-period ion exchange so as to reduce content of active components is overcome. The silica alumina ratio of the Cu-SSZ-13 molecular sieve based catalyst prepared by the method disclosed by the invention is adjustable within the range of 7.9- 26.7, and the percentage by mass of copper is in the range of 0.47 -8.6wt%, excellent NH3-SCR catalytic activity, water thermal stability, alkali metal poisoning resistance and noble metal poisoning resistance can be kept in a wide-temperature window.

Owner:HUAZHONG UNIV OF SCI & TECH

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-coking resistance selective-hydrogenation catalyst

ActiveCN104096573AReduced activityImprove anti-coking performanceHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsChemistryActive component

The invention discloses a preparation method of a high-coking resistance selective-hydrogenation catalyst. The high-coking resistance selective-hydrogenation catalyst utilizes carriers which mainly comprise alumina, have bimodal hole distributed structures and contain double active components of Pd and Ni. In catalyst preparation, the coking resistant ingredient Ni in a form of microemulsion enters into a large hole of the carrier and the active ingredient Pd is mainly distributed on the carrier surface and especially in a small hole of the carrier. The coking resistant ingredient Ni is mainly distributed in the large hole of the carrier so that a catalyst surface coking degree is greatly reduced and the hydrogenated saturated compound can be gradually diffused out of the catalyst channels and thus channel blocking is avoided and a catalyst service life is greatly prolonged. The high-coking resistance selective-hydrogenation catalyst is especially suitable for C2 and C3 fraction hydrogenation, obviously reduces a green oil generation amount and catalyst coking, prolongs a catalyst service life and improves economic benefits of device operation.

Owner:PETROCHINA CO LTD

Core-shell structure catalyst, and preparation method and application thereof

InactiveCN104226312AHigh activityExtended service lifeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationNanoparticle

The invention relates to a core-shell structure catalyst. Nanometer particles of a metal active component and nanometer particles of an assistant are used as a core, and a carrier and the assistant are used as a shell. The core-shell structure catalyst disclosed by the invention is wrapped by the shell layer, a micro-environment is formed in the closed interior of the shell layer, and in a catalytic reaction process, local high concentration is formed in an inner cavity usually by accumulation of reactants, so that the reaction is promoted to be relatively efficiently performed, and the integral activity of the catalyst is improved. In addition, in multiple liquid phase reactions, the shell layer can prevent active species in the micro-environment inside from outwards losing, and thus the service life of the catalyst is prolonged. In addition, for certain organic matter catalytic reactions, the shell layer can prevent carbon deposit in a reaction process, and the carbon deposit-resisting property of the catalyst is improved; meanwhile, after one layer of stable matter coats the surface of certain nanometer particles which are likely to agglomerate and inactivate to form the core-shell structure, the agglomeration trend of the nanometer particles is greatly weakened, and the stability of the catalyst is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

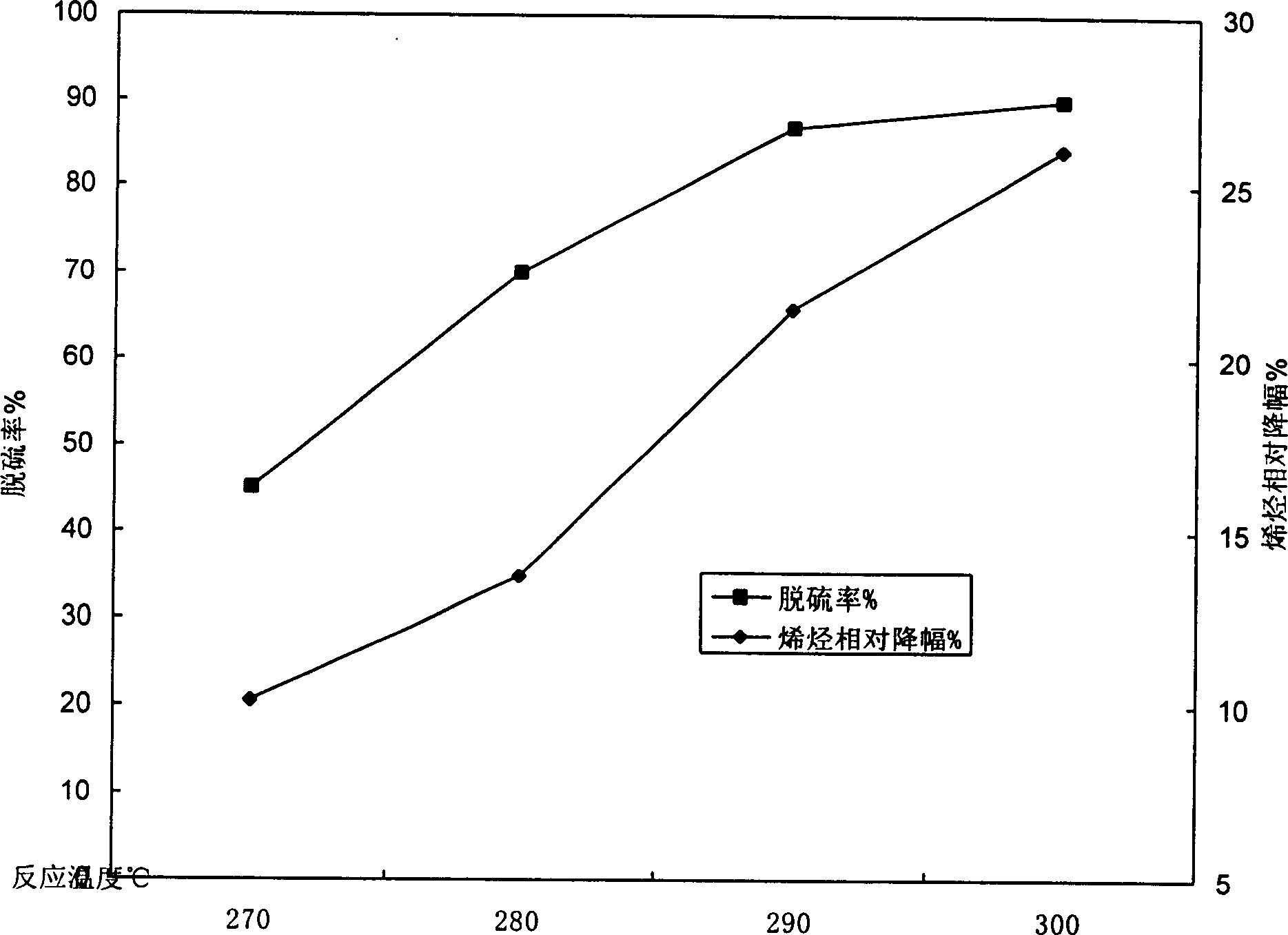

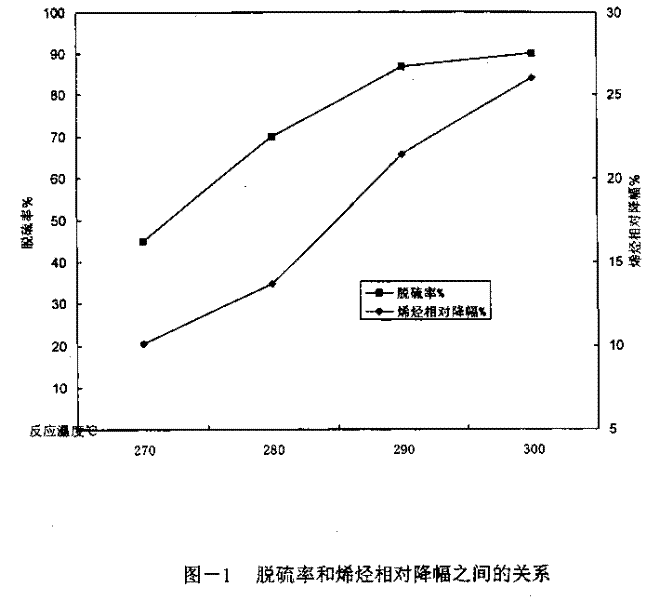

Gasoline hydrogenation catalyst, its prep. and application in lowering olefin by desulfurization

InactiveCN1448471AImprove anti-coking performanceHigh activityRefining to eliminate hetero atomsLiquid productActive component

The gasoline hydrogenating catalyst includes the components of carrier with TiO2 in 20-90 wt%; active component A of VIII metal oxide in 0.1-8 wt%; active component B of VIB metal oxide in 1-13 wt%; and adhesive in the rest content. After being pre-sulfurized, the catalyst of the present invention is used to process FCC gasoline in condition of mild hydrogenation and exhibits very high hydrodesulfurization activity and selectivity. Compared with traditional hydrogenation catalyst, the catalyst of the present invention has less loss of gasoline octane number and higher liquid product yield, up to 99 wt%, in the condition of same hydrodesulfurization level.

Owner:BEIJING HAISHUNDE TITANIUM CATALYST

Octane value recovering catalyst and its use

InactiveCN1458235AImprove stabilityImprove anti-coking performanceRefining to eliminate hetero atomsAdhesiveHydrodesulfurization

The present invention discloses a kind of octane number restoring catalyst and its preparation and application. The catalyst has nickel oxide / ZSM-5+Beta as main component and alumina adhesive, and has a total acid amount of 0.31-0.65 mmol / g, L acid amount of 0.30-0.60 mmol / g and B acid amount of 0.03-0.06 mmol / g. The preparation process of the catalyst includes first loading active metal onto thecarrier and then hydrothermal treatment. The catalyst of the present invention is applied in the selective hydrogenating and desulfurizing of gasoline and has powerful carbon deposition resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

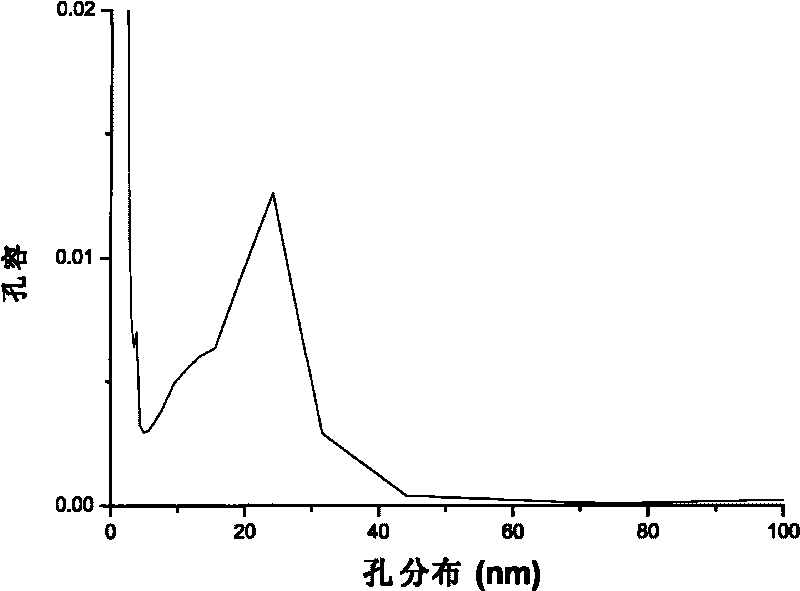

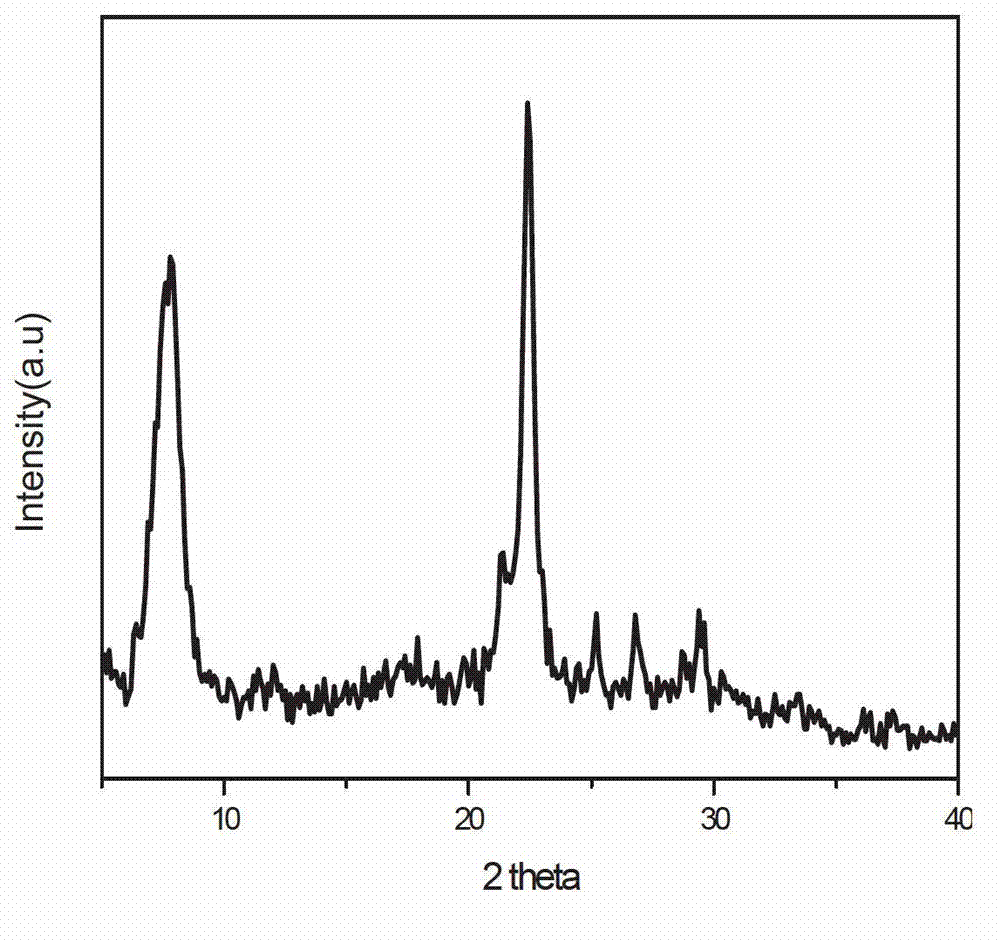

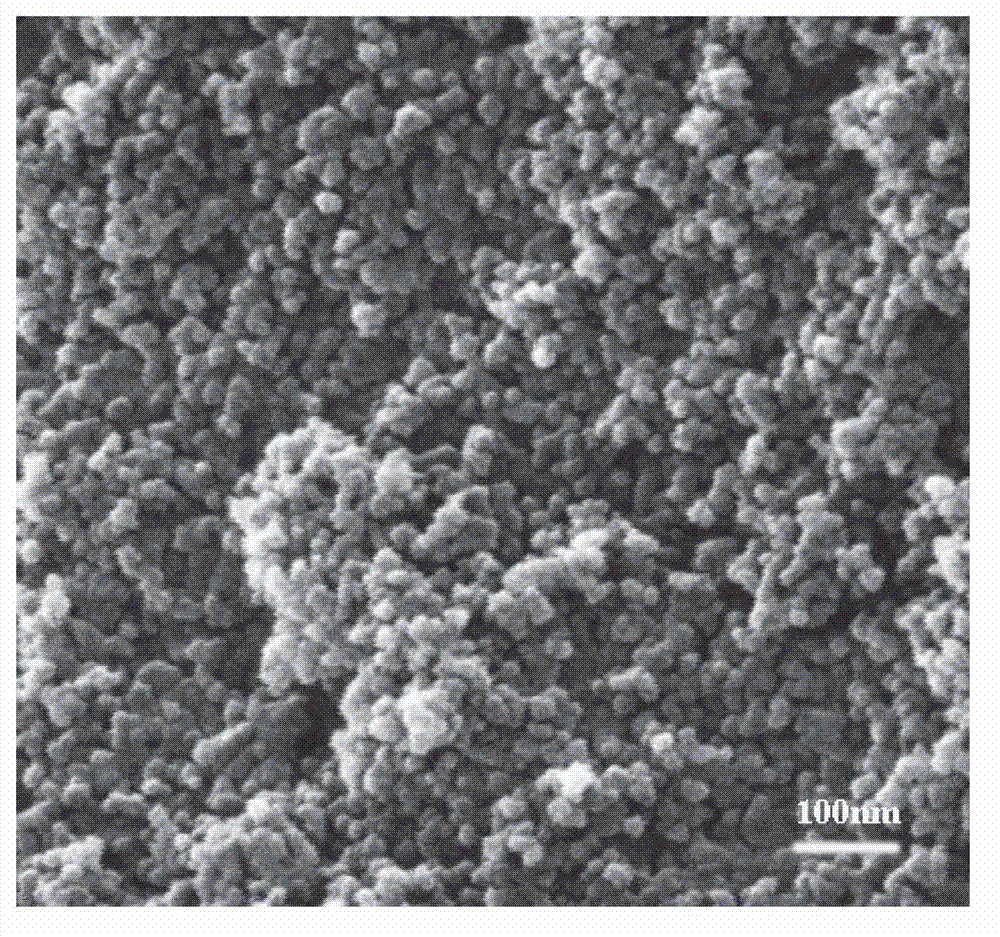

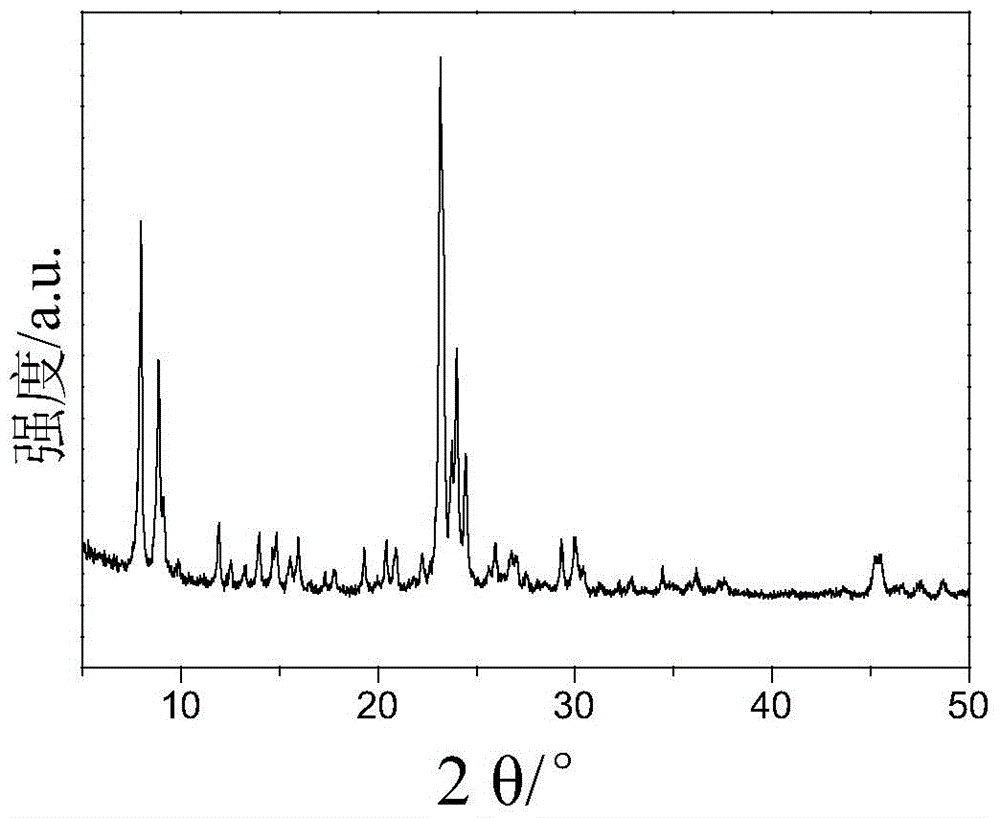

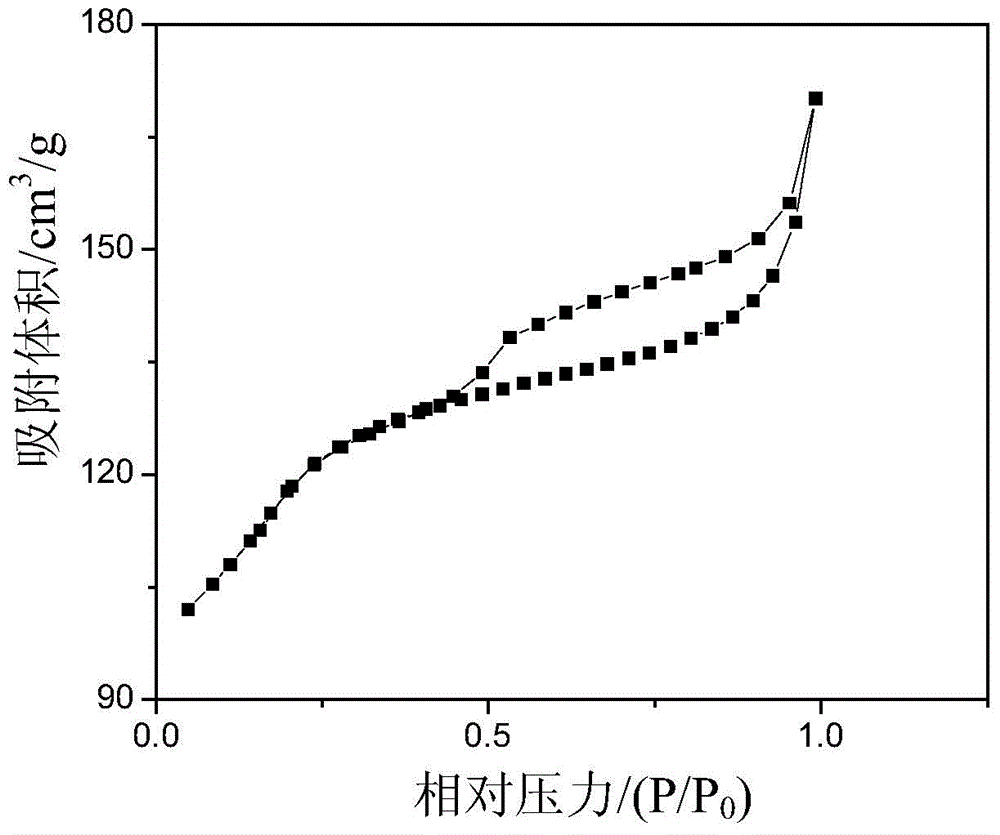

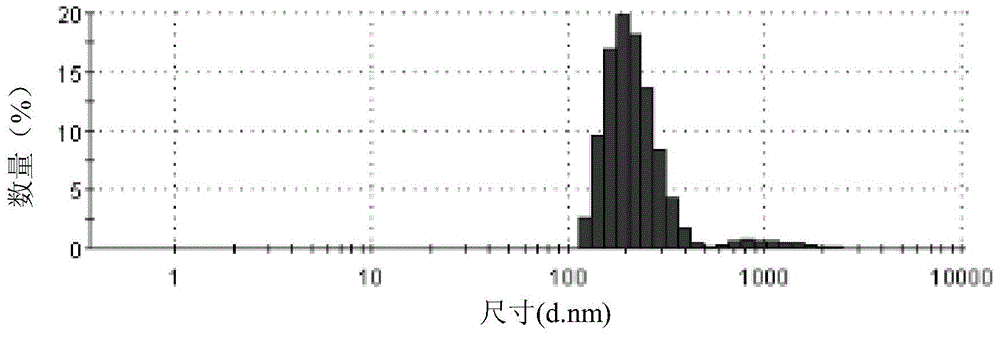

Nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application

ActiveCN104525245APropylene selectivity is highLong catalyst lifeMaterial nanotechnologyMolecular sieve catalystsMolecular sieveCrystallite

The invention provides a nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application thereof. The catalyst is aggregated by small grains with particle sizes of 20-100 nm to an aggregation state with a particle size of 200-2000 nm, the aggregation state forms the catalyst, the specific surface area of the catalyst is 350-420 m<2> / g, and the pore volume of the catalyst is 0.25-0.35 cm<3> / g. According to the invention, a mesoporous-microporous composite nanocrystalline accumulation state ZSM-5 molecular sieve is directly synthesized; under the condition of adding no second template, a solid silicon source is pretreated to generate different degrees of depolymerization, the material ratio of the synthesis system is further adjusted, a sodium salt is added to adjust the growth speed in a crystallization process of the molecular sieve, and meanwhile, a two-stage crystallization method is adopted to promote the generation of a crystal nucleus at a low temperature and promote the growth of a crystal at a high temperature, so as to synthesize a serial grain aggregation state ZSM-5 molecular sieve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Petroleum resin hydrogenation catalyst and preparation method thereof

ActiveCN103386302AImprove anti-coking performanceImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh activityChemistry

The invention provides a petroleum resin hydrogenation catalyst and a preparation method thereof. The petroleum resin hydrogenation catalyst comprises an Al2O3 carrier, a precious metal Pd loaded on the Al2O3 and an assistant element oxide. The catalyst provided by the invention has high activity, and the steeping depth of active metals in the catalyst is controllable; and the preparation method of the catalyst is simple and suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

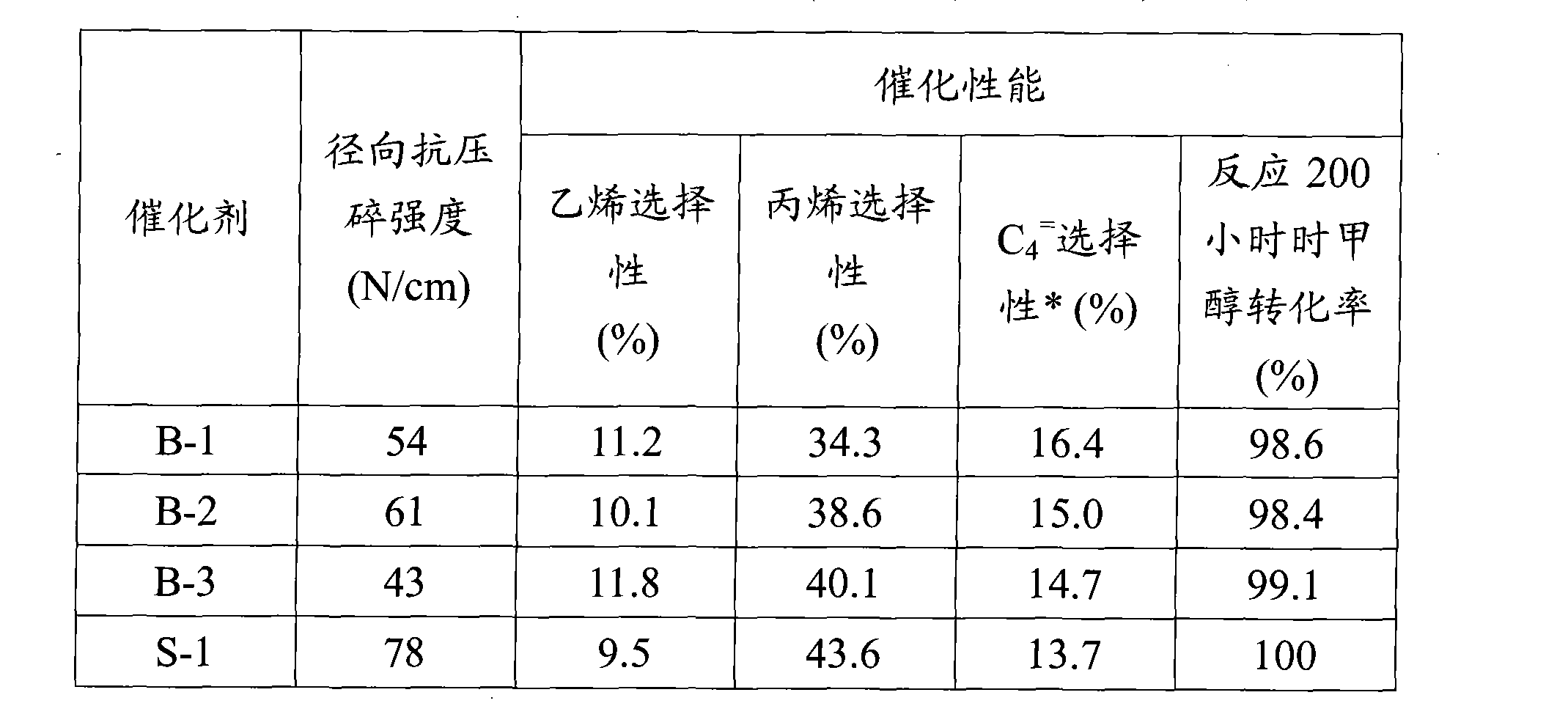

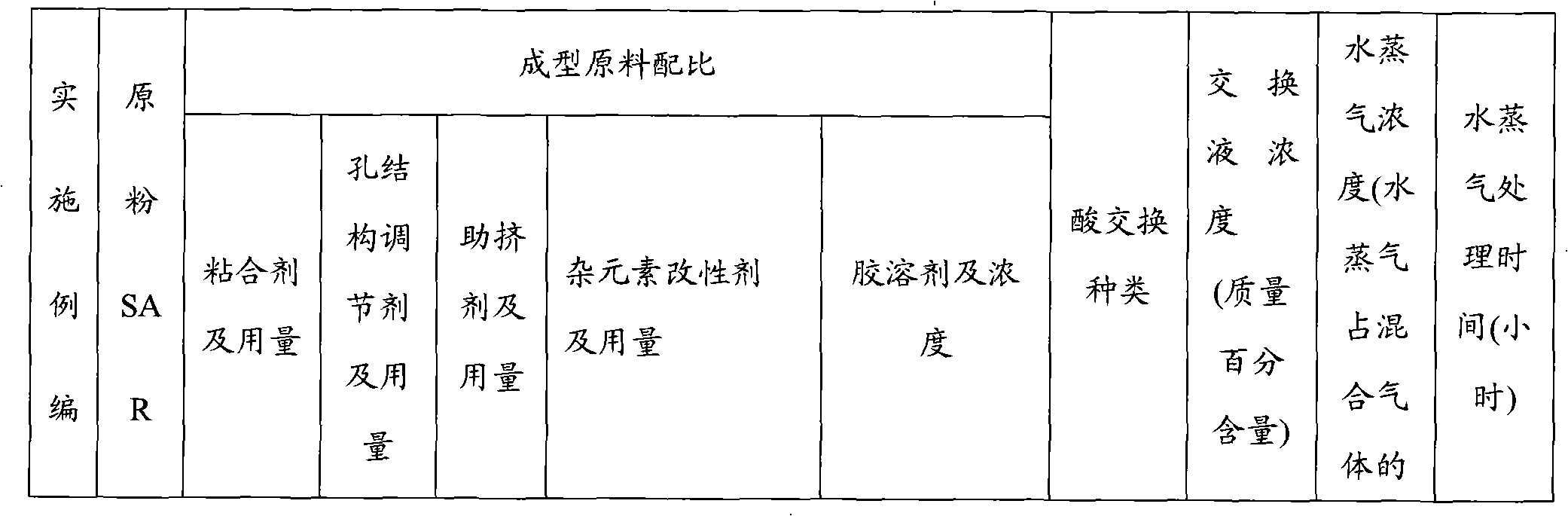

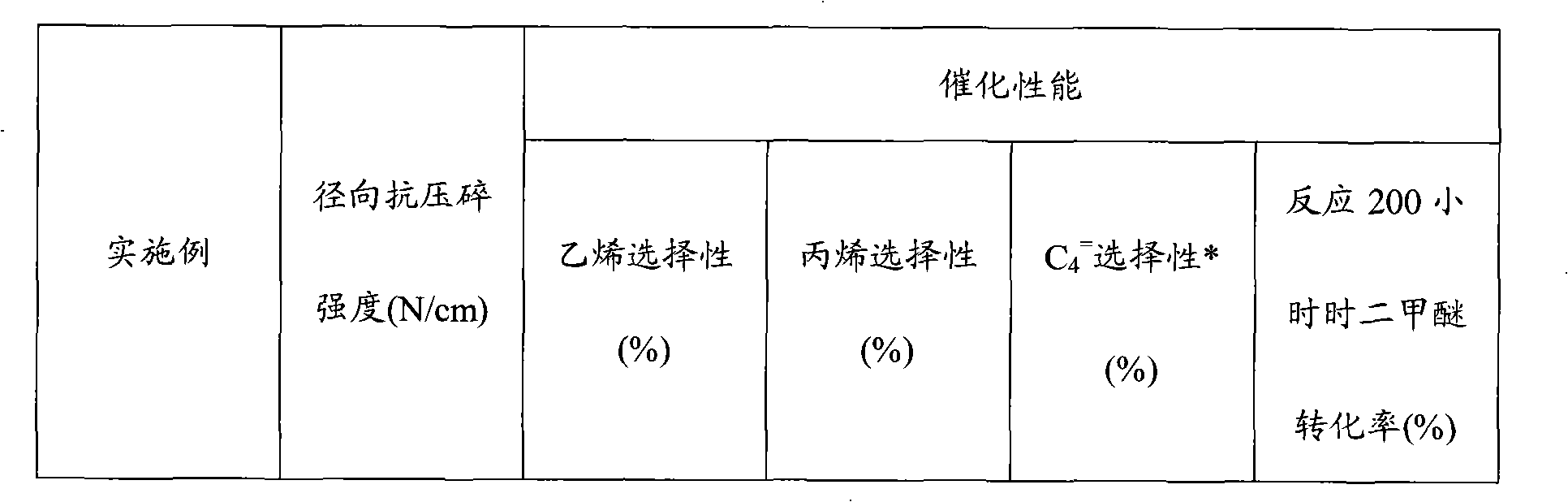

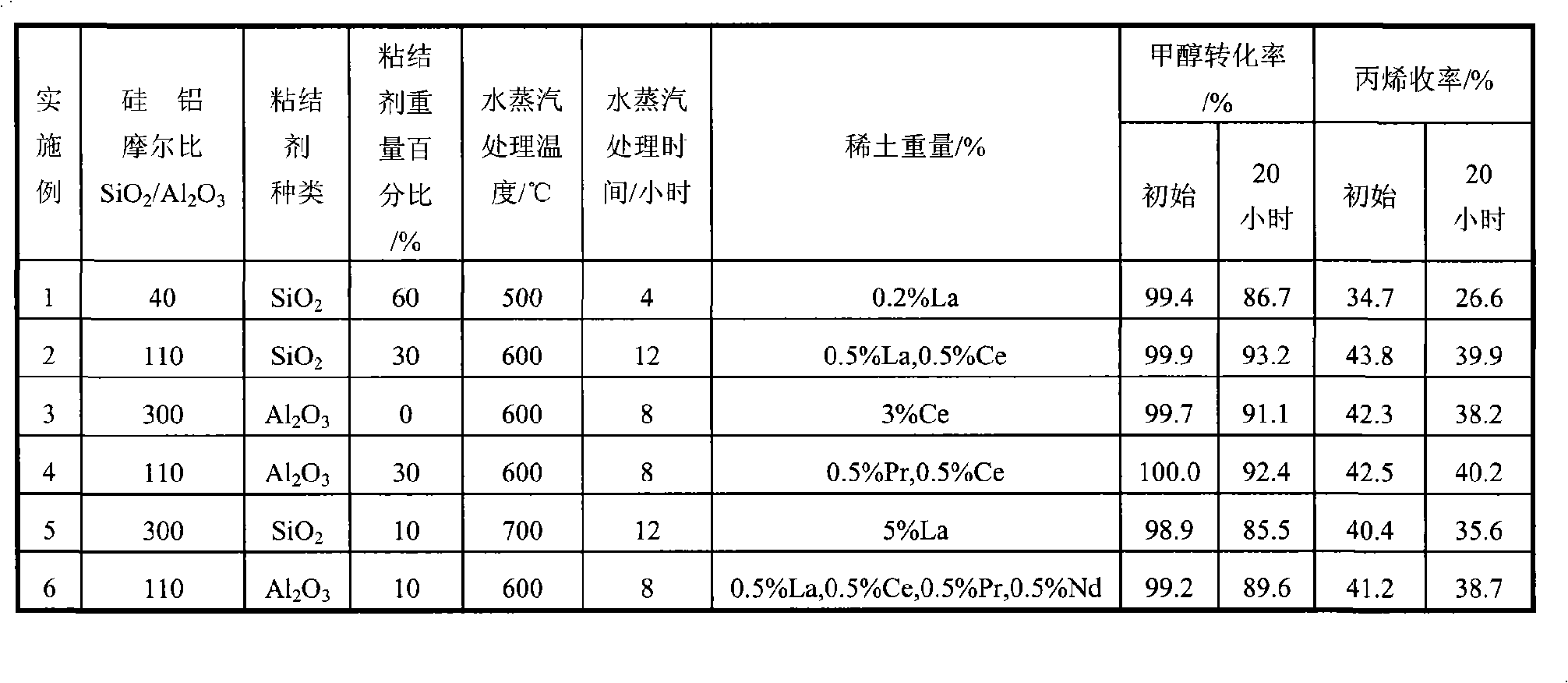

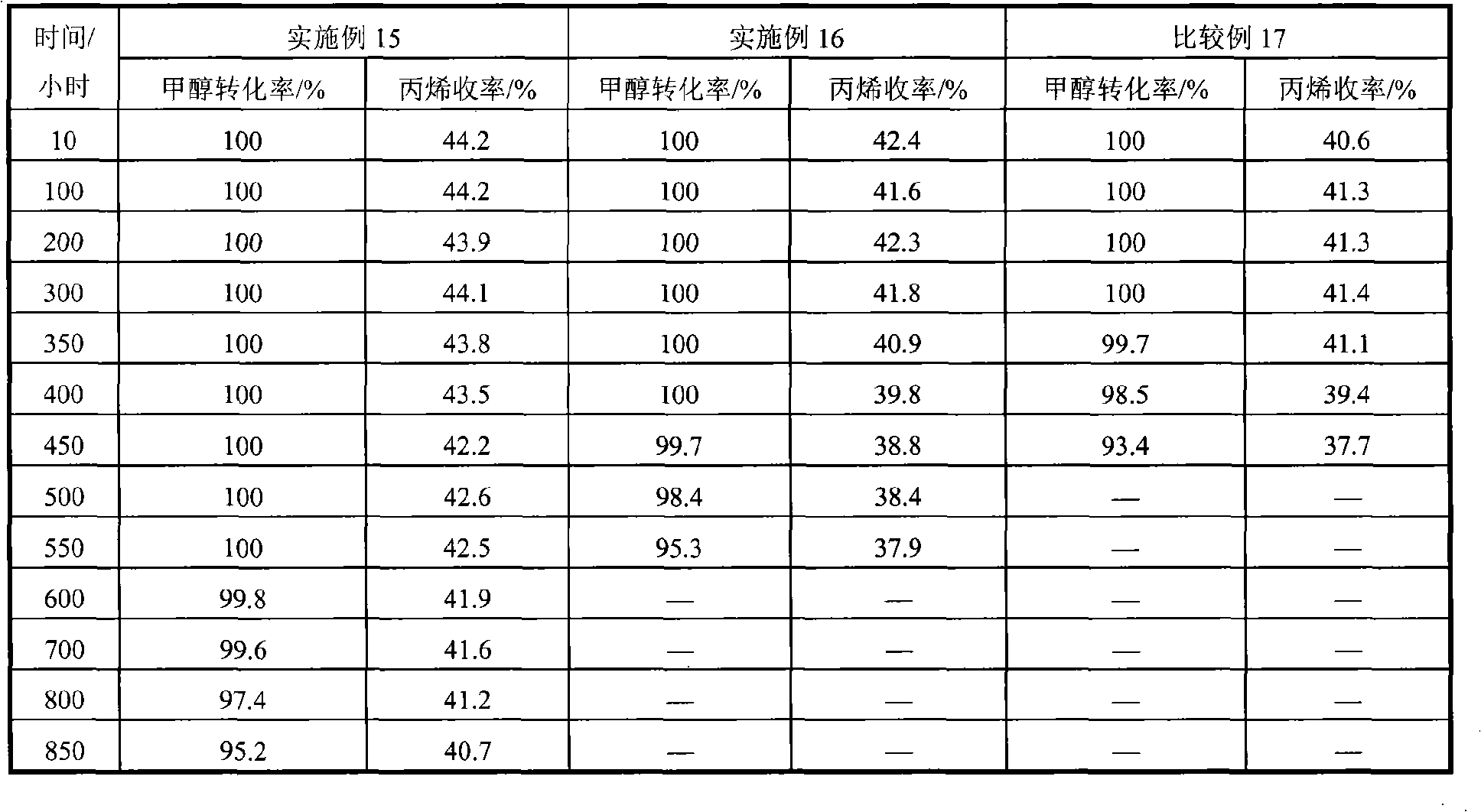

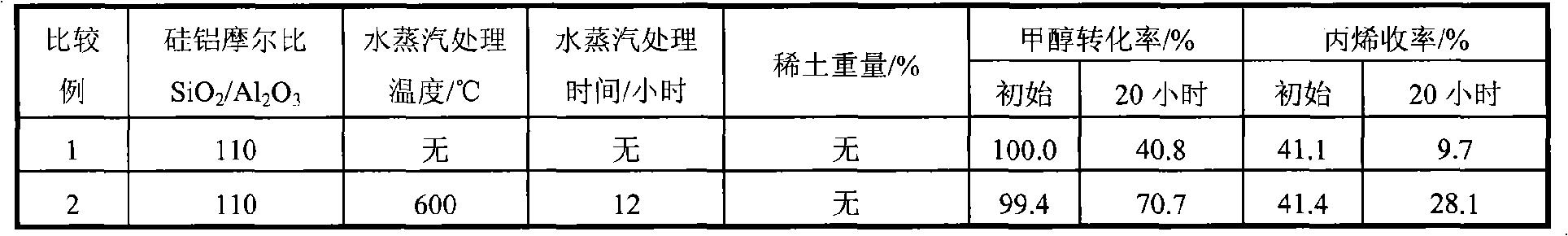

High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

ActiveCN101279281AStay acidicImprove anti-coking performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCerium nitratePhosphoric acid

The present invention relates to a high stability molecular sieve catalyst for preparing propylene by being converted from methanol and a preparation method thereof which mainly solve the problems of poor molecular sieve stability and water thermal stability as well as easy coking and deactivation in the prior art. The present invention adopts the technical proposal of adopting the molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 25 to 99.9 percent as well as at least one caking agent from SiO2, clay and Al2O3 to extrude, tablet or spray ball to shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol, phosphoric acid or acetic acid under a temperature of 20 to 90 DEG C; then using 0.1 to 5 percent of at least one liquor selected from lanthanum, cerium nitrate or chloride calculated by weight percentage to treat for 4 to 8 hours under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid, phosphoric acid and maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing vulcanized dehydrogenation catalyst

ActiveCN101898138AImprove activity stabilityHigh selectivityCatalyst activation/preparationHydrocarbonsPolymer scienceWater vapor

The invention discloses a method for preparing a vulcanized dehydrogenation catalyst. The method comprises the following steps of: preparing an La and Sn-containing aluminum oxide carrier; dipping dehydrogenation active ingredients; performing vapor dechlorination process; and injecting a sulfur-containing compound and drying the carrier to obtain the dehydrogenation catalyst. The dehydrogenation catalyst prepared by the method has the advantages of high activity stability, long service life, high regeneration and the like when used for propane dehydrogenation and is particularly applicable to a technological process for preparing the propane by the propane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

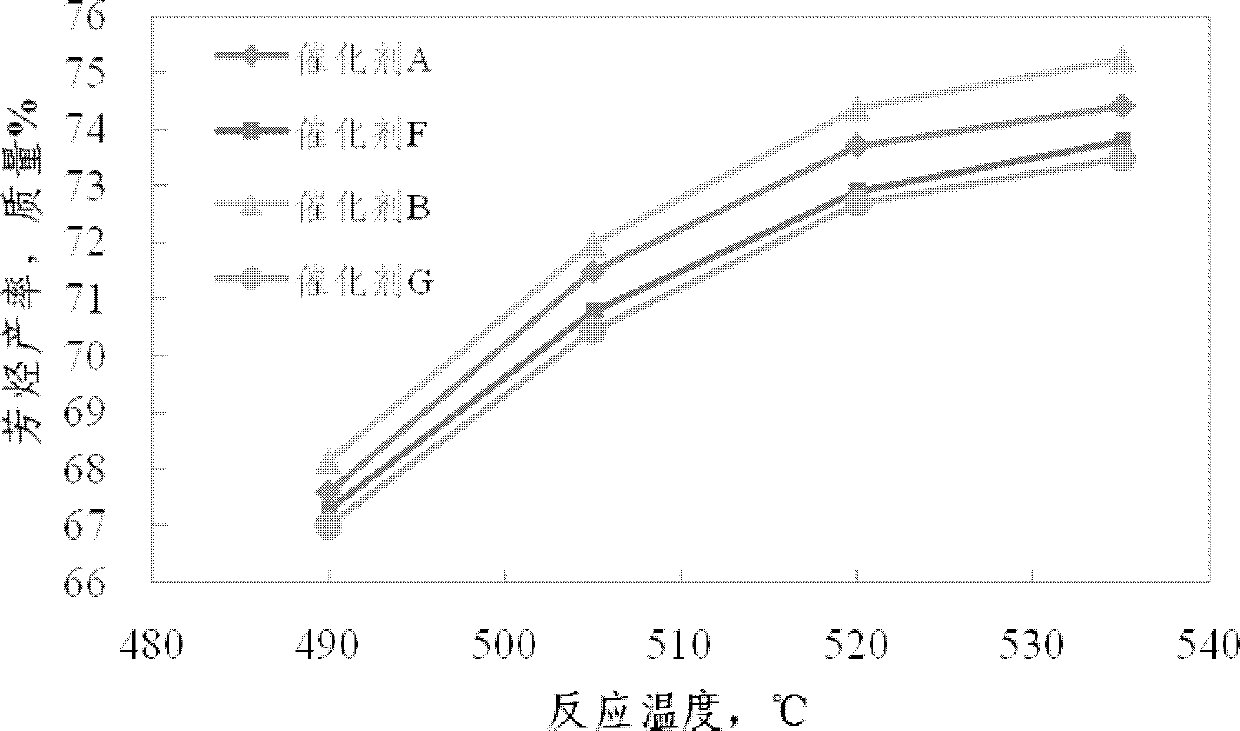

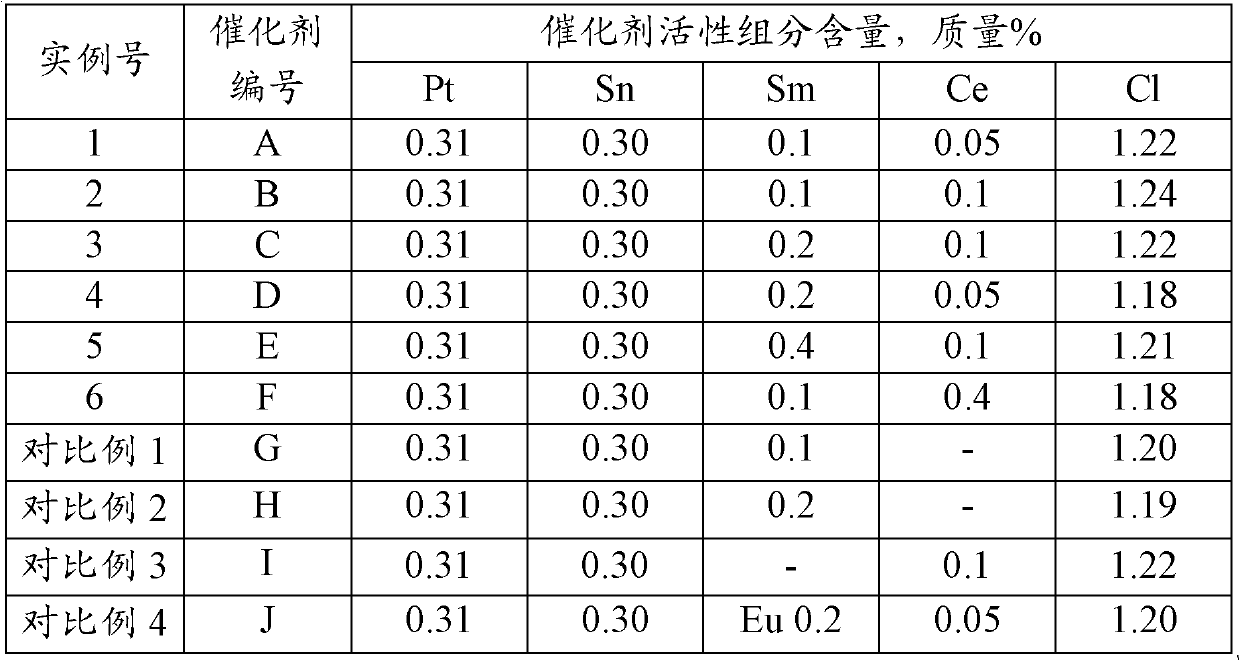

Multimetal reforming catalyst and preparation and applications thereof

ActiveCN103372454AHigh selectivityImprove anti-coking abilityPhysical/chemical process catalystsNaphtha reformingHalogenHigh selectivity

The invention relates to a multimetal reforming catalyst. The multimetal reforming catalyst comprises a high-temperature-resistant inorganic oxide carrier and the following components calculated on the basis of the carrier: 0.01-2.0% by mass of VIII metal, 0.01-5.0% by mass of IVA metal, 0.01-3.0% by mass of Sm, 0.01-3.0% by mass of Ce, and 0.1-5.0% by mass of halogen. The catalyst has good activity stability and high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

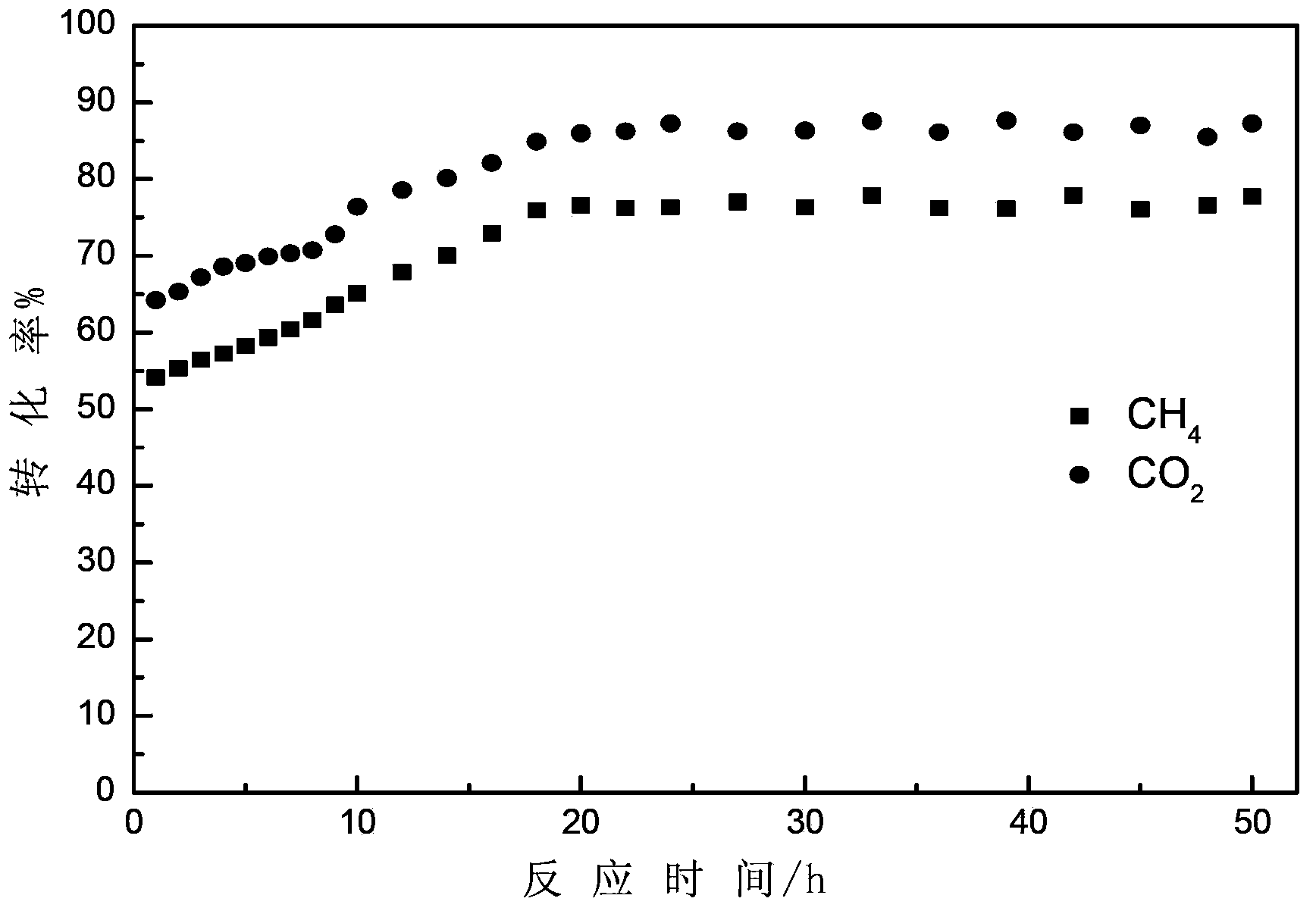

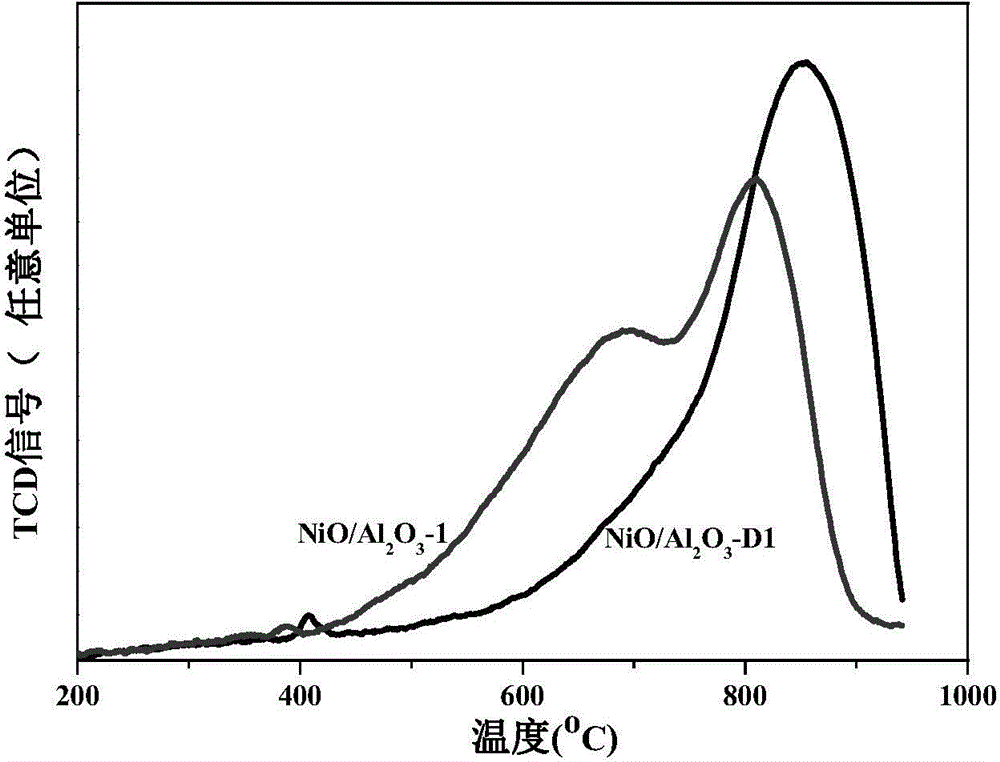

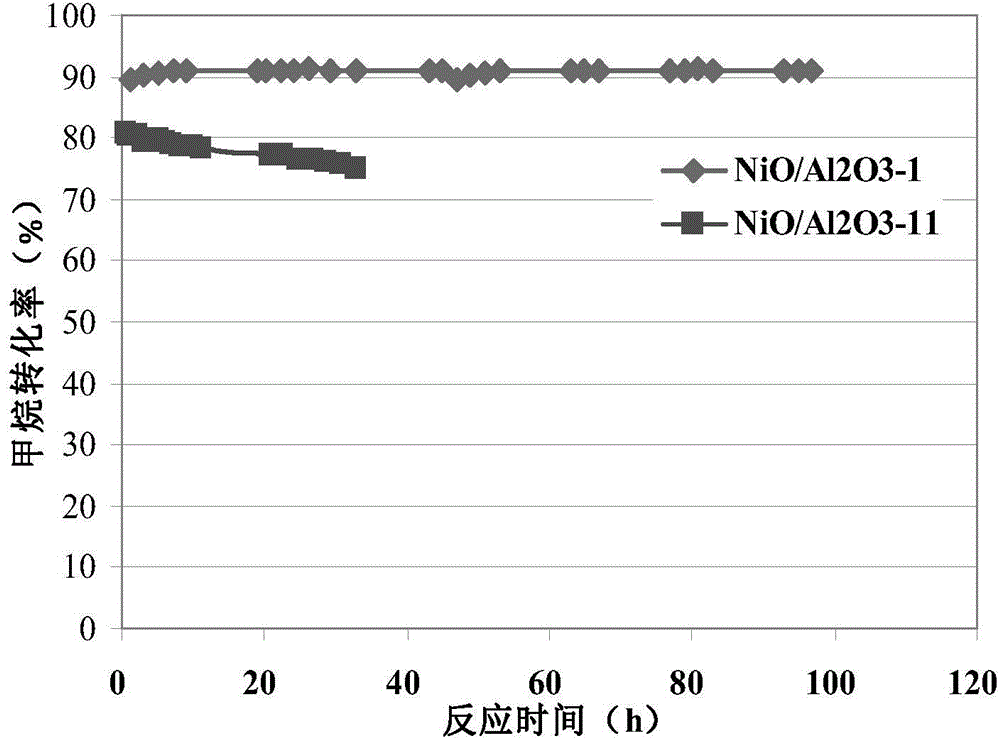

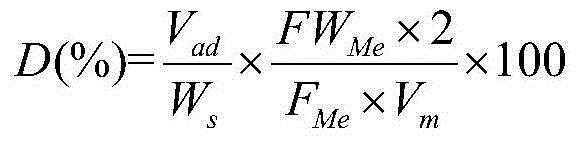

Novel nano composite methanation catalyst and preparation method thereof

ActiveCN104043454AHigh surface uniformityGood dispersionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationAlumina composite

The invention discloses a novel nano composite methanation catalyst and a preparation method thereof. The preparation method comprises the following steps: adding a tetrabutyl titanate and ethyl alcohol mixed solution dropwise into an ethyl alcohol and nitric acid mixed water solution at room temperature, and hydrolyzing tetrabutyl titanate so as to obtain sol; drying the sol to form gel, and forging to obtain nano TiO2 powder; mixing pseudo-boehmite and deionized water to obtain a turbid liquid, and adding nitric acid to obtain semitransparent sol gama-AlOOH; adding the nano TiO2 powder into the semitransparent sol gama-AlOOH, drying overnight, and baking to obtain TiO2 / gama-Al2O3 nano powder as a methanation catalyst carrier; dipping a nickel nitrate solution on the methanation catalyst carrier, drying, and forging to obtain a NiO / TiO2 / Al2O3 catalyst; and dipping an additive on the carrier, thereby obtaining a NiO-M / TiO2 / Al2O3 catalyst. According to the invention, nanoscale titanium oxide and a nanoscale aluminum oxide composite material act as the carriers, and NiO acts as an active component, so that the novel nano composite methanation catalyst is prepared.

Owner:HUANENG CLEAN ENERGY RES INST +1

Middle hole ZSM-5 zeolite microsphere and preparation method thereof

InactiveCN102001678AImprove effective utilizationImprove adsorption capacityPentasil aluminosilicate zeolitePorosityMicrosphere

The invention relates to a middle hole ZSM-5 zeolite microsphere and a preparation method thereof, which belong to the field of inorganic nonmetallic materials and catalyst preparation. The middle hole ZSM-5 zeolite microsphere is characterized by belonging to a microsphere with intracrystalline middle holes and intercrystalline middle holes and being formed by nanometer zeolites with the intracrystalline middle holes through self aggregation; the diameter of the microspheres is between 4mum and 8mum, the diameter of the nanometer zeolite grain is between 15nm and 50nm, and the diameter of the intracrystalline middle holes is between 3nm and 8nm. The microsphere is synthesized in the hydrothermal crystallization system by using nanometer silicon dioxide with the silanized surface as raw materials. The zeolite microsphere combines the advantages of the nanometer zeolite and the middle hole zeolite, overcomes the defect of difficult separation of the nanometer zeolite in the synthesis and use process and has uniform size, good sphericity degree, high hydrothermal stability and mechanical strength. The porosity of the middle holes can be regulated through changing the mol proportioning ratio of the organic silane coupling agents and silicon dioxide. The use of spherulization agents is avoided, the preparation process is simplified, and the preparation cost is reduced.

Owner:TAIYUAN UNIV OF TECH

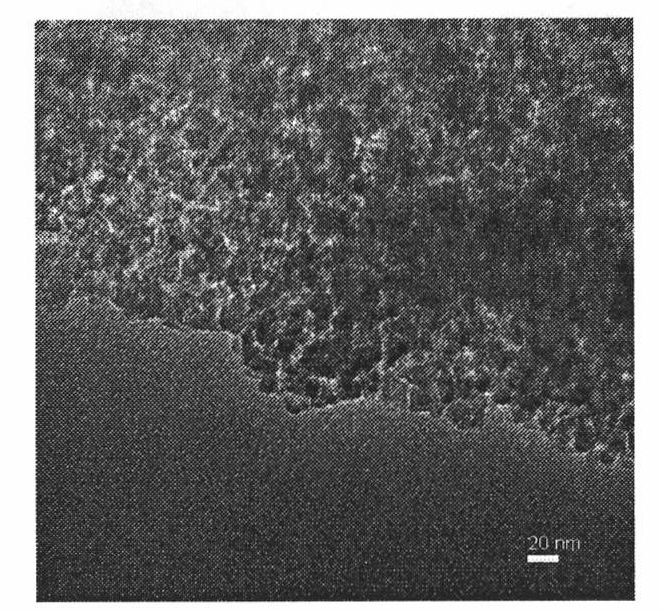

Method for preparing Ni base catalyst for methane portion oxidation synthesis gas

InactiveCN101693203AImprove anti-coking performanceImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsChemical industryFree cooling

The invention relates to a method for preparing Ni base catalyst for methane portion oxidation synthesis gas, which belongs to the technical field of natural gas chemical industry. The method is characterized in that the method comprises adopting a water hot method to prepare the carrier ZrO2 of Ni base catalyst, and adopting high-temperature thermal treatment to prepare ZrO2 carrier. The ZrO2 is placed in a Muffle furnace, and the temperature reaches 850 DEG C in the temperature rise speed of 4 DEG C / min in air, the ZrO2 is roasted for 8h under the temperature, thereby getting high-temperature thermal-treatment ZrO2. Ni / ZrO2 prepared by the technical method is catalyst, and has excellent stability and carbon accumulation resistance property in methane portion oxidation synthesis gas. As comparison, a water hot method is used to prepare ZeO2, the prepared Ni / ZrO2 catalyst has unstable performance and is easy to accumulate carbon in the methane portion oxidation synthesis gas reaction, although the traditional precipitation method which is used to prepare ZrO2 catalyst conducts thermal treatment under given temperature, the prepared Ni / ZrO2 catalyst is also easy to accumulate carbon.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

Preparation method for catalyst for dehydrogenation of low-carbon alkane

ActiveCN104549248AReduce recrystallization rateAvoid growing upHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkanePotassium nitrate

The invention discloses a preparation method for a catalyst for dehydrogenation of a low-carbon alkane. The preparation method comprises the following steps: (1) performing immersion treatment on an inorganic oxide carrier with an aqueous solution of potassium nitrate, and then performing program heating drying treatment to obtain a treated inorganic oxide carrier; (2) dissolving chloroplatinic acid in an organic solvent, adjusting the pH value to obtain a chloroplatinic acid immersion liquid, immersing the carrier obtained by the step (1) with the chloroplatinic acid immersion liquid, performing program heating drying treatment, roasting, washing, drying and dewatering to obtain the catalyst for the dehydrogenation of the low-carbon alkane. According to the method, hydrothermal dechlorination is not required to be performed; the preparation method for the catalyst is simplified; the aggregation and growth of Pt particles are avoided; the energy consumption is reduced; the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922BEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

Owner:CHINA PETROLEUM & CHEM CORP +1

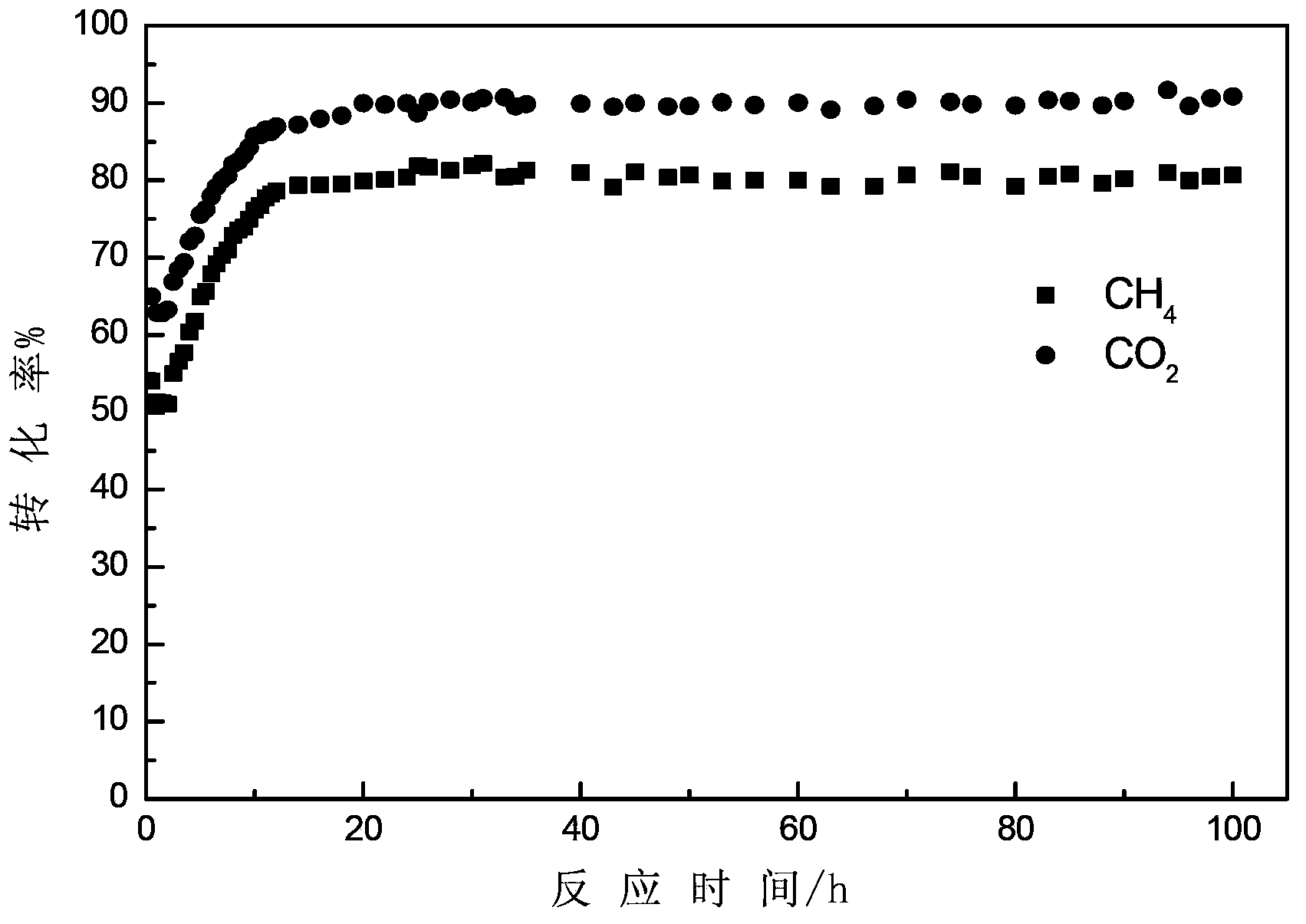

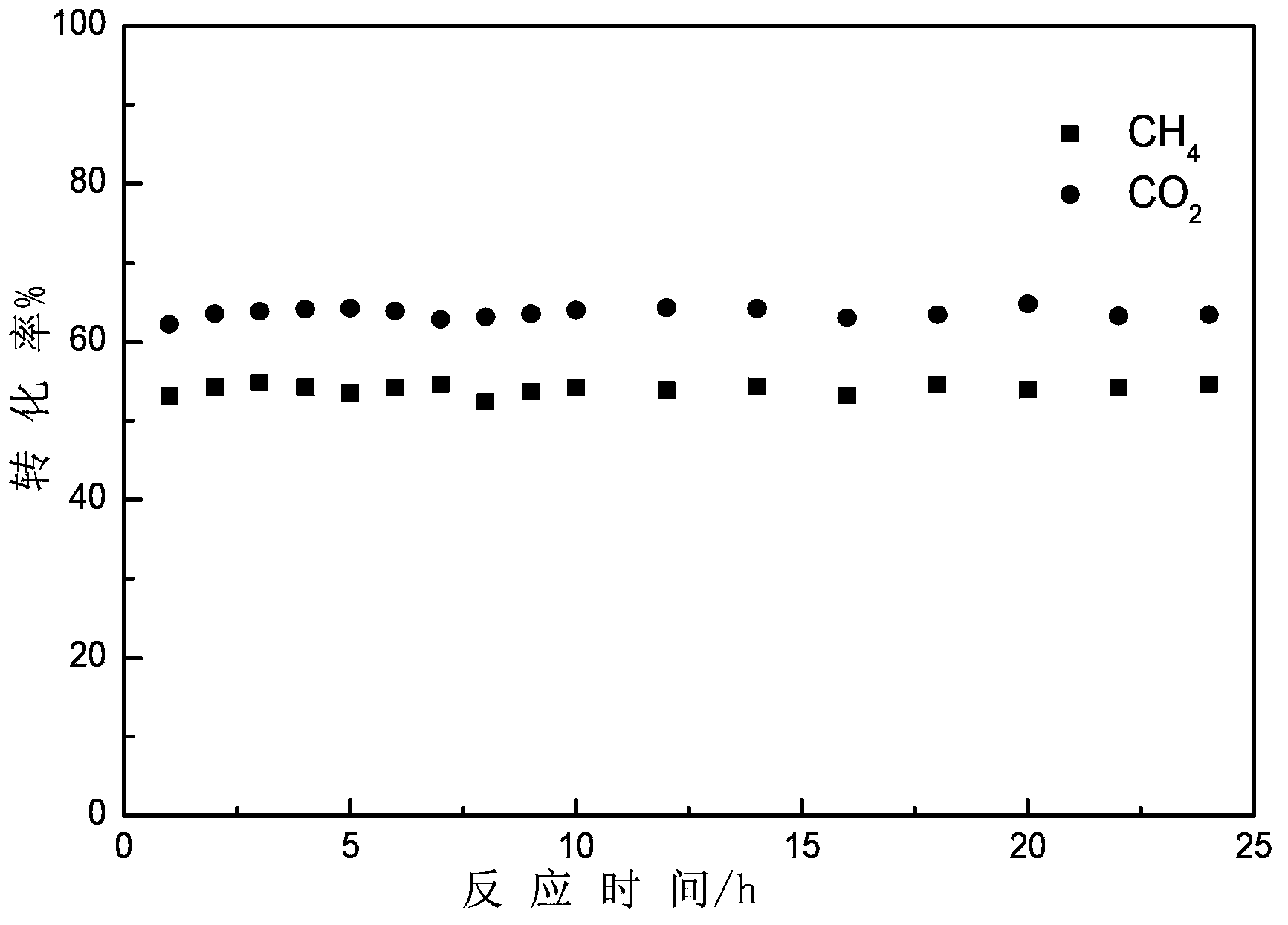

Catalyst carrier and supported catalyst and their preparation methods and use and method for producing synthetic gas through dry reforming of methane

ActiveCN105562113ASimple processReduce manufacturing costHydrogenCatalyst carriersSolventCatalyst support

The invention relates to a preparation method of a catalyst carrier, a preparation method of a supported catalyst, the supported catalyst, a use of the supported catalyst and a method for producing synthetic gas through dry reforming of methane through the supported catalyst. According to the preparation method of the catalyst carrier, a sale carrier precursor such as pseudo-boehmite as a raw material is used, a carrier modification assistant is directly added into a glue solvent such as a dilute nitric acid solution, simultaneously, a pore forming agent and an extrusion aid are added into the solution, the mixture is mixed and is extruded to form strips and the strips are dried and roasted. The carrier is roasted once so that the carrier has excellent texture properties, has a large specific surface area and is conducive to active metal uniform dispersion. The carrier carries an active metal Ni to form the supported catalyst and the supported catalyst is used for a methane dry reforming catalytic reaction. Compared with the same type of the existing catalyst, the supported catalyst has higher catalytic activity and better resistance to carbon deposition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com