Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

413 results about "Alumina composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

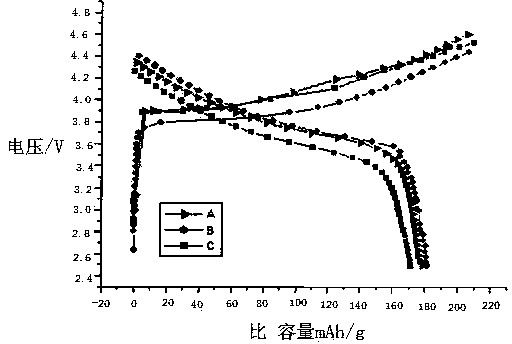

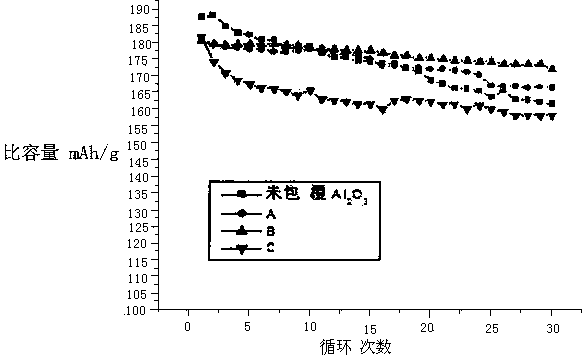

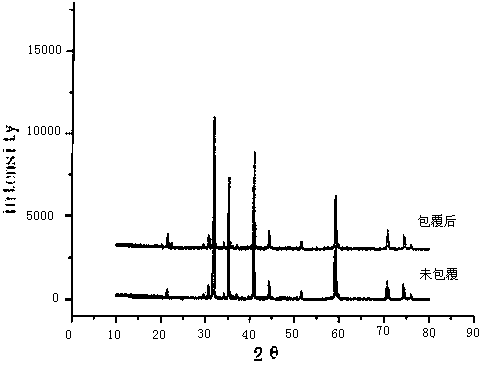

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

Yttria-alumina composite oxide films, laminated bodies having the same, a method for producing the same, and corrosion resistant members and films

InactiveUS6858332B2Improve corrosion resistanceLong period of timeLiquid surface applicatorsRecord information storageFilm baseX-ray

An object of the invention is to provide an yttria-alumina composite oxide film wherein peeling-off of the film from a substrate may be prevented. An intermediary layer is provided on a substrate containing at least one of alumina and yttria-alumina composite oxide as a main component. In the intermediary layer, a ratio (Y / A) of a molar ratio Y of yttria to a molar ratio A of alumina is not smaller than 0.1 and not larger than 0.9. An yttria-alumina composite oxide film is formed on the intermediary layer. A ratio (YAG (420) / M) of a peak intensity YAG (420) of a (420) plane of a garnet phase to a maximum peak intensity M of crystal phases other than the garnet phase is 2.5 or more in the yttria-alumina composite oxide film based on an X-ray diffraction measurement.

Owner:NGK INSULATORS LTD

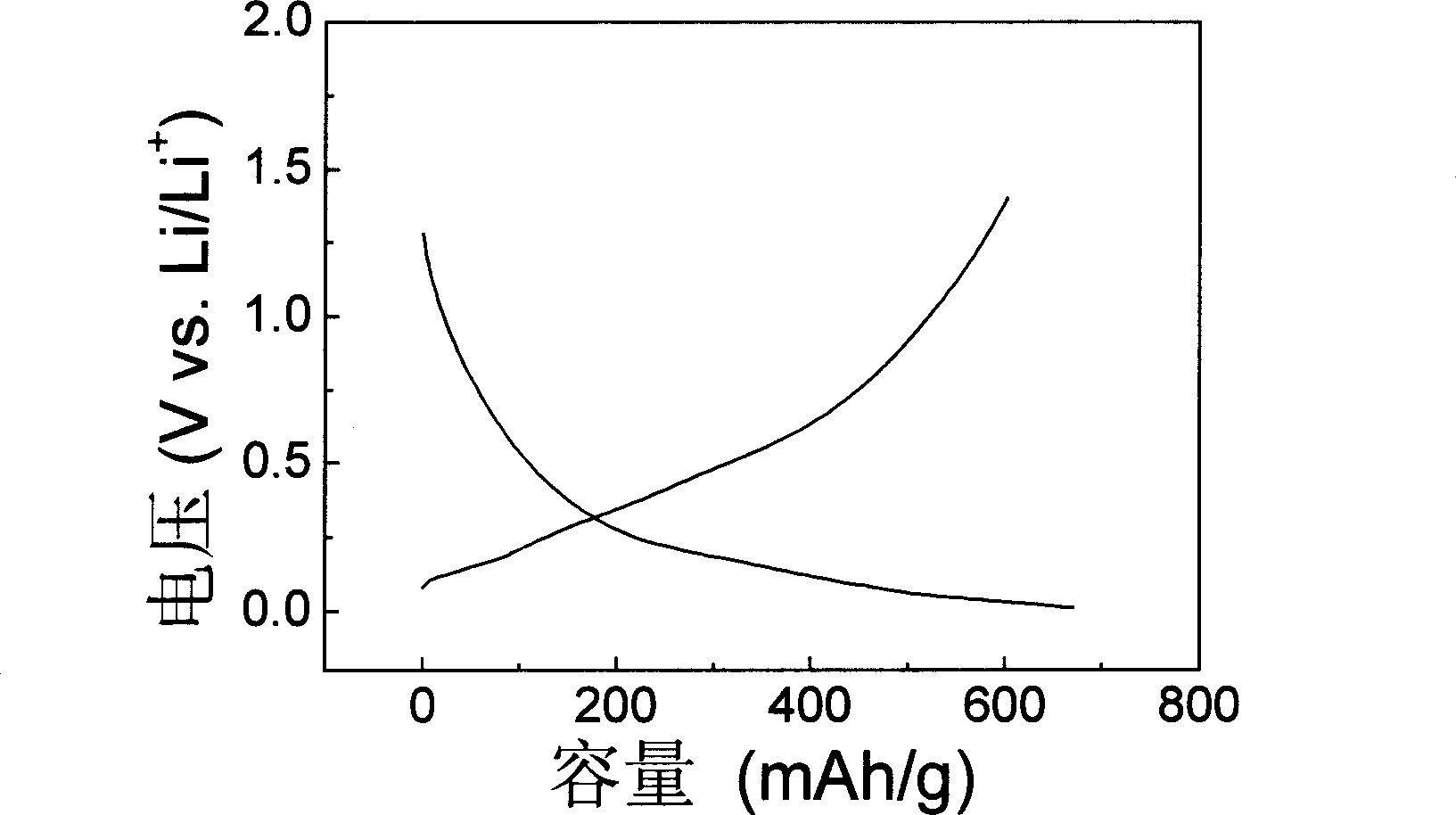

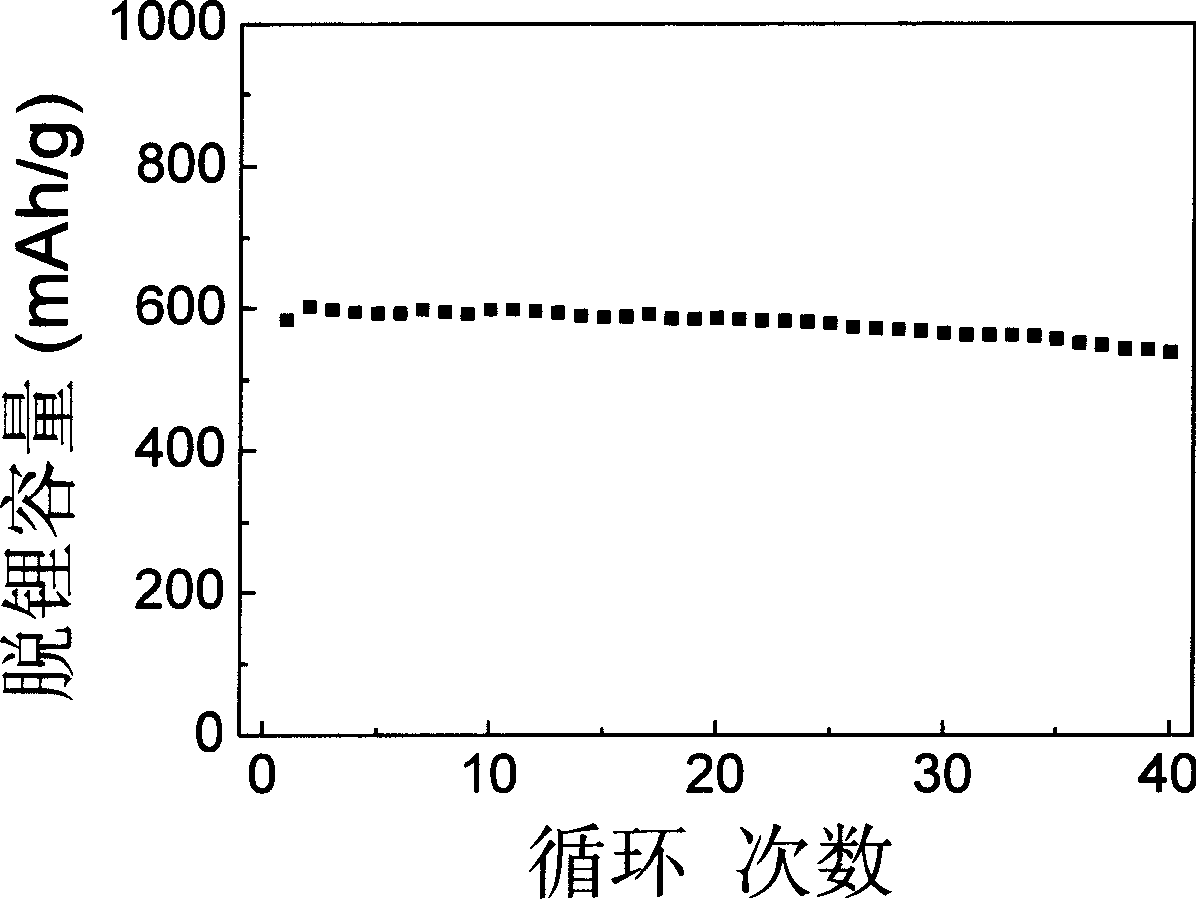

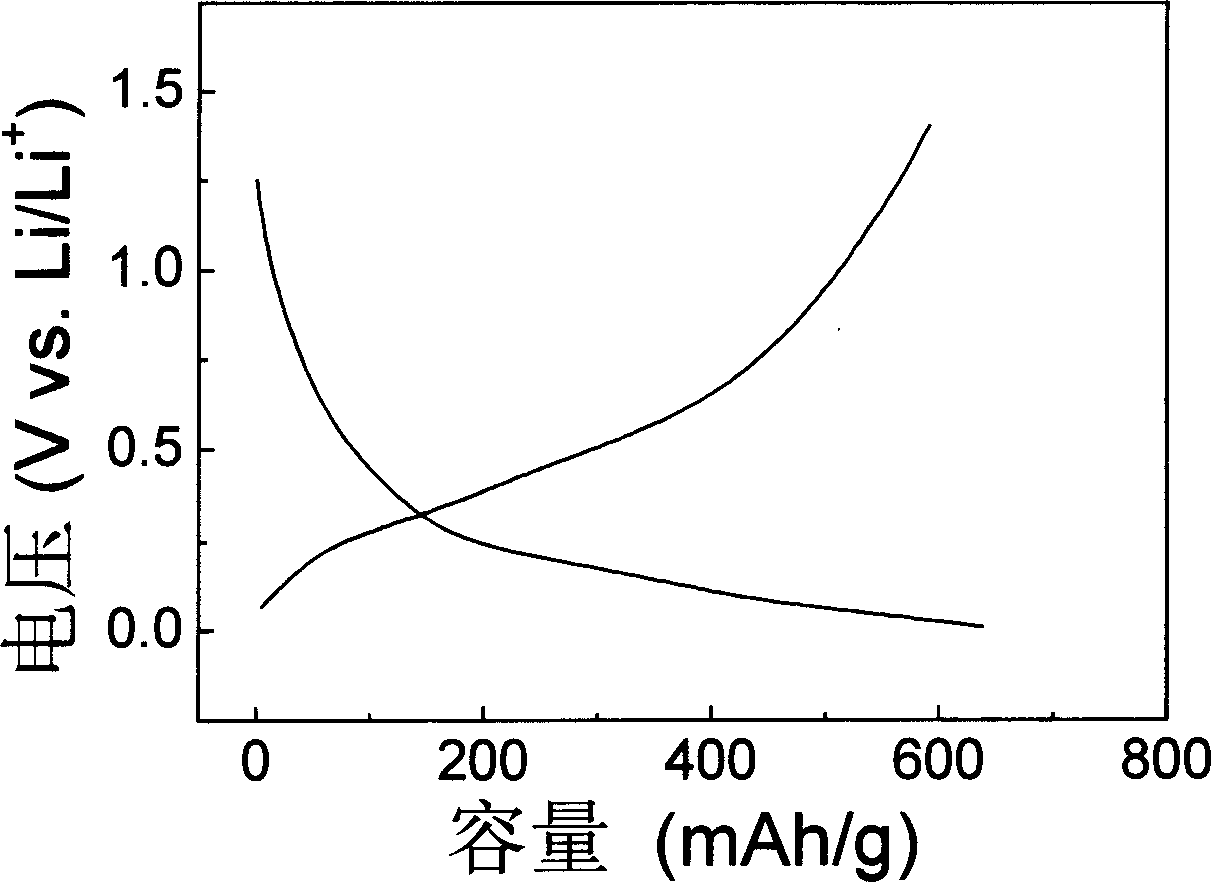

Preparation method for composite negative electrode material of lithium ion battery

InactiveCN1909266AIncrease capacityImprove cycle stabilityNanostructure manufactureElectrode manufacturing processesCarbon compositesHigh energy

The invention relates to a method for preparing the composite cathode of lithium battery, wherein said cathode material is formed by silicon / copper / carbon; said silicon has nanometer porous structure; the nanometer silicon / alumina composite, nanometer silicon / alumina / copper composite, and nanometer silicon / alumina / copper / carbon composite, with high disperse degree, is obtained by high-energy grinding; then adding hydrochloric acid; removing alumina, and over alumina, to obtain said composite cathode. And the inventive method uses hydrochloric acid to remove the inactive alumina and over aluminum, to improve specific capacity of composite; and the treatment of hydrochloric acid makes the silicon with nanometer porous structure, to adsorb the volume change when embedding lithium, to buffer volume effect, improve the structure stability. And the reversible capacity of said cathode material can reach 580mAh .g-1; in the first 35 cycles, the average capacity damage of each cycle is 0.1%.

Owner:SHANGHAI JIAO TONG UNIV

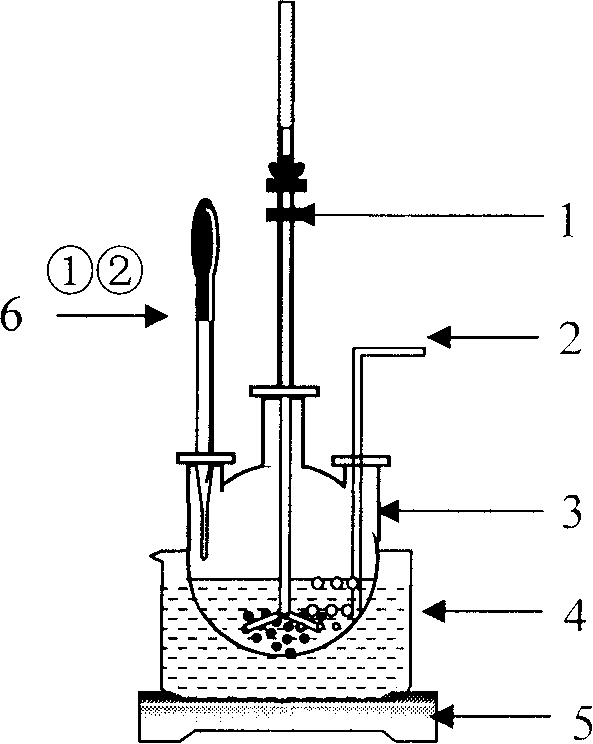

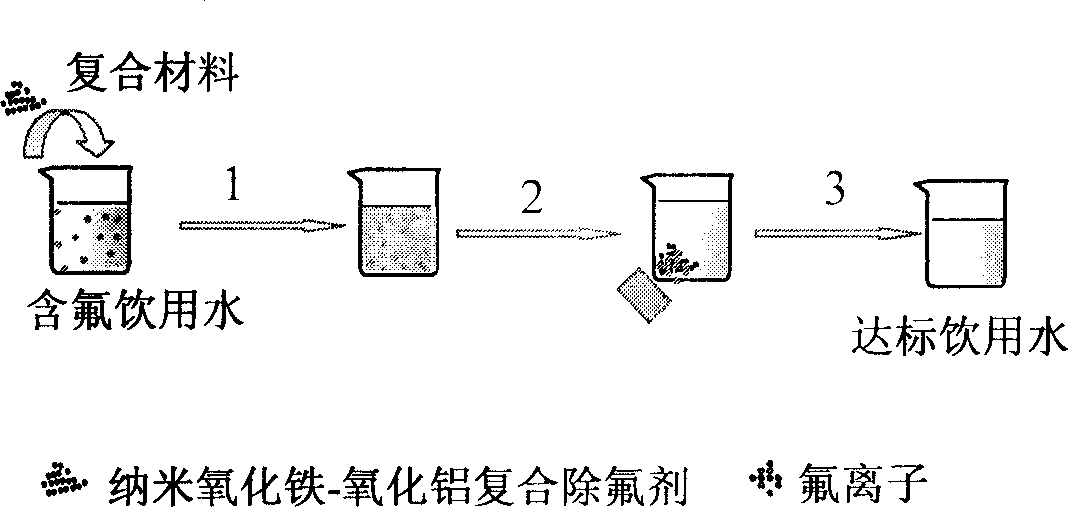

Preparing and applications of ferric oxide-alumina compound nanophase defluoridation material

InactiveCN101229504AReduce dosageImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentAlumina composite

The invention pertains to the field of chemical analysis test equipment, relating to a novel composite material of nano iron oxide-alumina which is used as an sorbent for removing fluoride from water to remove the fluoride from the large amount of drinking water; the fluorin content after the treatment is lower than the content of national standard; compared with the traditional defluorinating agent, the invention has the advantages of simple structure, low cost, high sorption capacity and fast removing speed. As a novel magnetic nano material, the defluorinating agent can realize the separation of extraction agent and base solution under the condition of external magnetic field. The surface of the nano iron oxide is coated with a layer of Al(OH)3; F<-> and Al<3+> in the water to form a complex compound which settles down to realize the effect of defluorination; 1L of water sample only consumes the defluorinating agent of 0.1g; to high fluorin content water with concentration of 20mg / L, the concentration after defluorination can be less than 1mg / L, which can well meet requirement with the reproducibility of analysis result RSD being less than 7 percent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

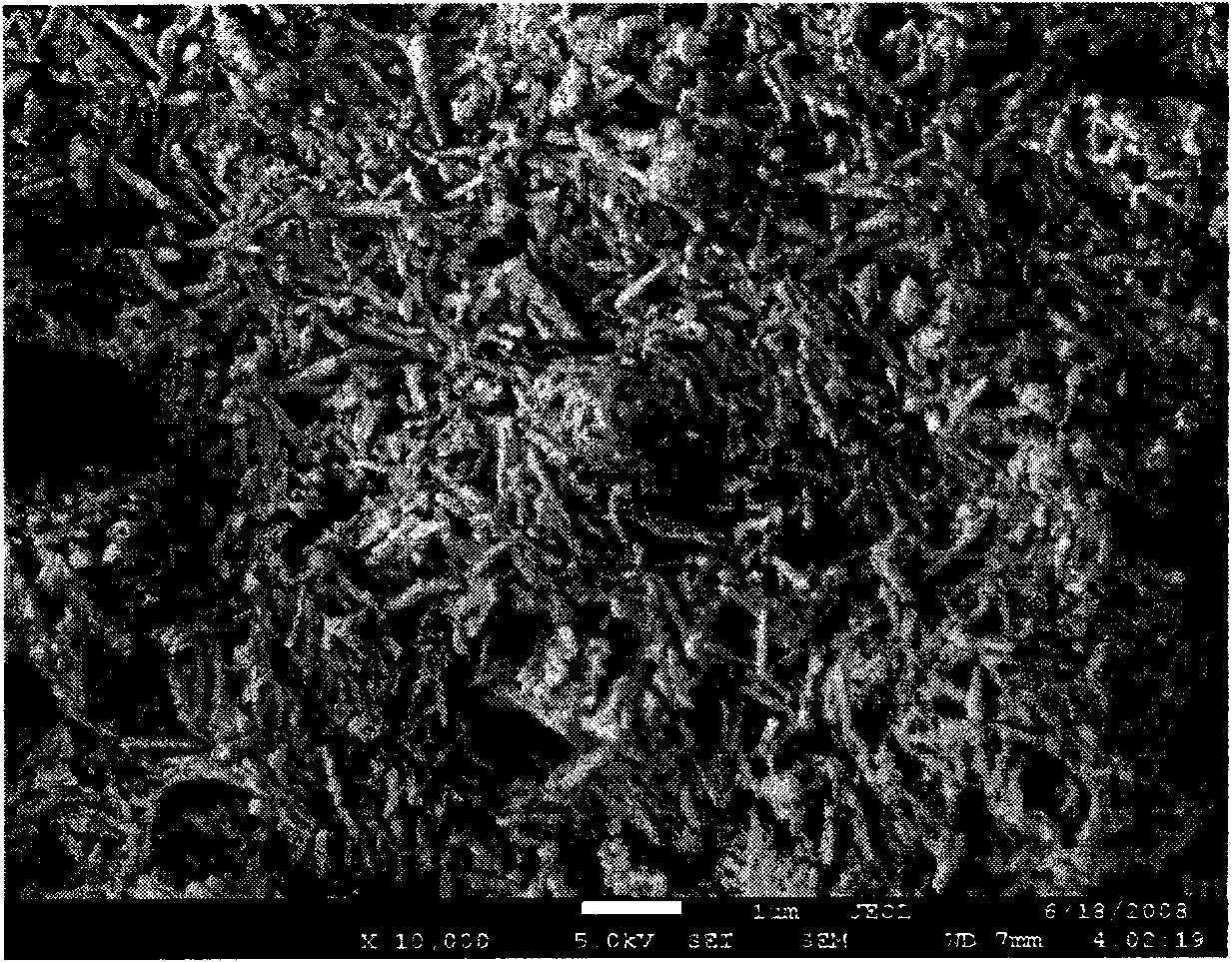

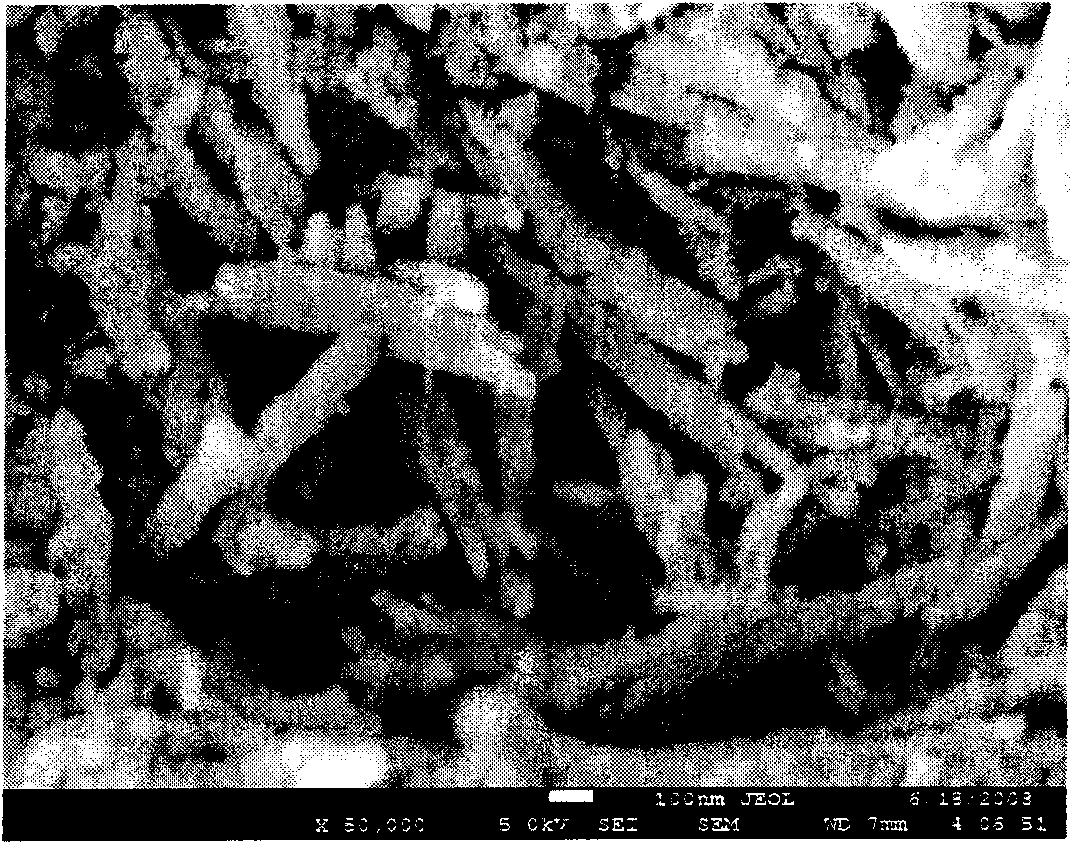

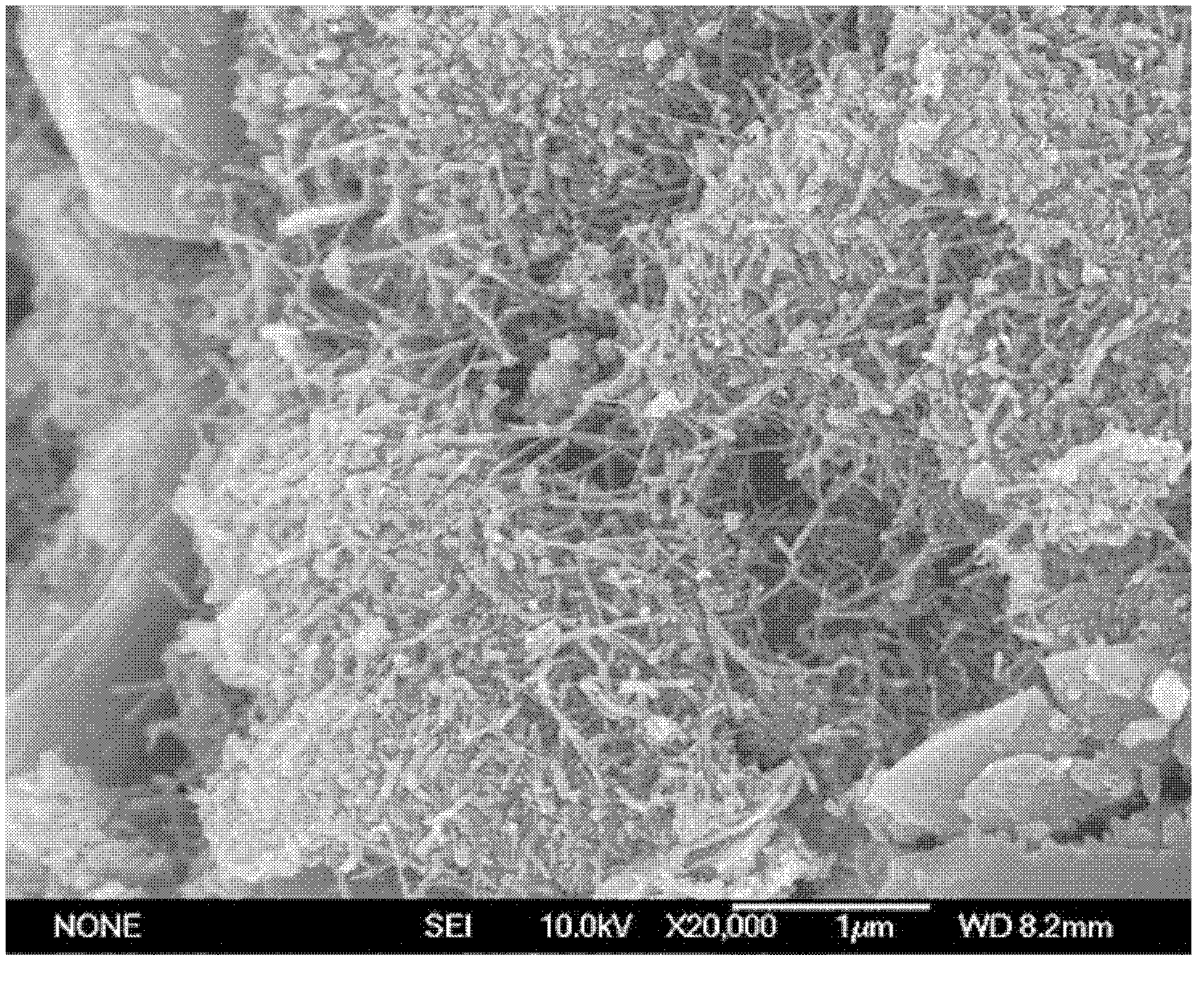

Silica-alumina composite carrier and method for preparing same

The invention discloses a silica-alumina composite carrier and a method for preparing the same. The composite carrier is prepared from a silicon hydroxide-aluminum hydroxide gel serving as a raw material by using a super-solubility micelle method. Because the gel contains a surfactant and hydrocarbon components, silica nanoparticles and alumina nanoparticles formed after dehydration of polymerized silicon hydroxide and aluminum hydroxide still have rod-like basic structures after shaping and roasting, and the nanoparticles are disorderly stacked into a frame structure. The composite carrier has large pore volume, large aperture, high porosity, large orifices on outer surface and high pore penetrability, and particularly for high molecules, the carrier can prevent a catalyst from becoming inactivated due to blockage of the orifices, contribute to increasing the deposition of impurities and prolong the operating period of the catalyst because the carrier does not have orifices similar to ink bottle-shaped orifices. The composite carrier can be used in catalytic reactions comprising high molecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-dimensional fiber prefabricated member reinforced aluminum oxide composite material and preparation method thereof

The invention discloses a three-dimensional fiber prefabricated member reinforced aluminum oxide composite material and a preparation method thereof. The three-dimensional fiber prefabricated member reinforced aluminum oxide composite material comprises a three-dimensional fiber prefabricated member and aluminum oxide, wherein the aluminum oxide uniformly fills pores of the three-dimensional fiber prefabricated member and is physically combined with the three-dimensional fiber prefabricated member, the aluminum oxide is alpha-Al2O3 ceramics, and the porosity of the three-dimensional fiber prefabricated member reinforced aluminum oxide composite material is 9 percent to 16 percent. The preparation method comprises: (1) immersing; (2) drying; (3) carrying out the heat treatment; (4) repeating an immersion-drying-heat treatment process of the step (1) to (3). The three-dimensional fiber prefabricated member reinforced aluminum oxide composite material has the advantages of low porosity, high compactness, high stability and excellent mechanical performance. The preparation method is high in preparation efficiency; and moreover, the compactness and the mechanical performance of the prepared composite material are remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

High-alumina structure heat-insulation integrated composite brick and preparation method

The invention discloses a high-alumina structure heat-insulation integrated composite brick and a preparation method. The high-alumina structure heat-insulation integrated composite brick comprises a heavy working layer adopting compact bauxite chamotte as main raw material and a high-strength light heat-insulation layer adopting alumina hollow ball, aluminum-magnesium hollow ball, corundum hollow ball, hollow micro-sphere, light ceramic particle or the mixture of the above materials as a skeleton material, and is formed by compounding the heavy working layer and the light heat-insulation layer in a vibration pressurizing way or a mechanical formation way, and the length ratio of the heavy working layer and the light heat-insulation layer is 1 to 5: 2 to 1. The high-alumina structure heat-insulation integrated composite brick overcomes the weakness that the high-alumina brick for rotary kiln has large heat conduction coefficient or overcomes the weakness that the heat-insulation layer of the present high-alumina composite brick has low strength and is easy to break. The invention provides the structure heat-insulation integrated composite brick with good abrasion resistance, high refractoriness, good structural strength and good heat-preserving and heat-insulation performance.

Owner:ZHEJIANG UNIV

Catalyst for removing mercaptan sulfur in catalytic gasoline at low temperature and preparation method of catalyst

InactiveCN103316705AHigh sweetening activityLow fluid yieldMolecular sieve catalystsRefining to eliminate hetero atomsSolid acidAlumina composite

The invention relates to a catalyst for removing mercaptan sulfur in catalytic gasoline at low temperature and a preparation method of the catalyst, belonging to the field of gasoline desulfurization. The catalyst for removing the mercaptan sulfur in the catalytic gasoline at low temperature is prepared by taking aluminium oxide or nano HZSM-5 molecular sieve and alumina composite solid acid as carriers, and comprises the following components based on the total mass of the catalyst: 5-20% of zinc oxide, 5-15% of ferric oxide, 0.5-5% of lanthanum oxide and 0.5-5% of phosphorus oxide. The catalyst disclosed by the invention is applicable to a low temperature hydrogenation sweetening reaction of the catalytic gasoline and has the characteristics of high sweetening activity, low olefin hydrogenation saturation activity, high liquid yield, nearly no loss of octane number and the like.

Owner:DALIAN UNIV OF TECH

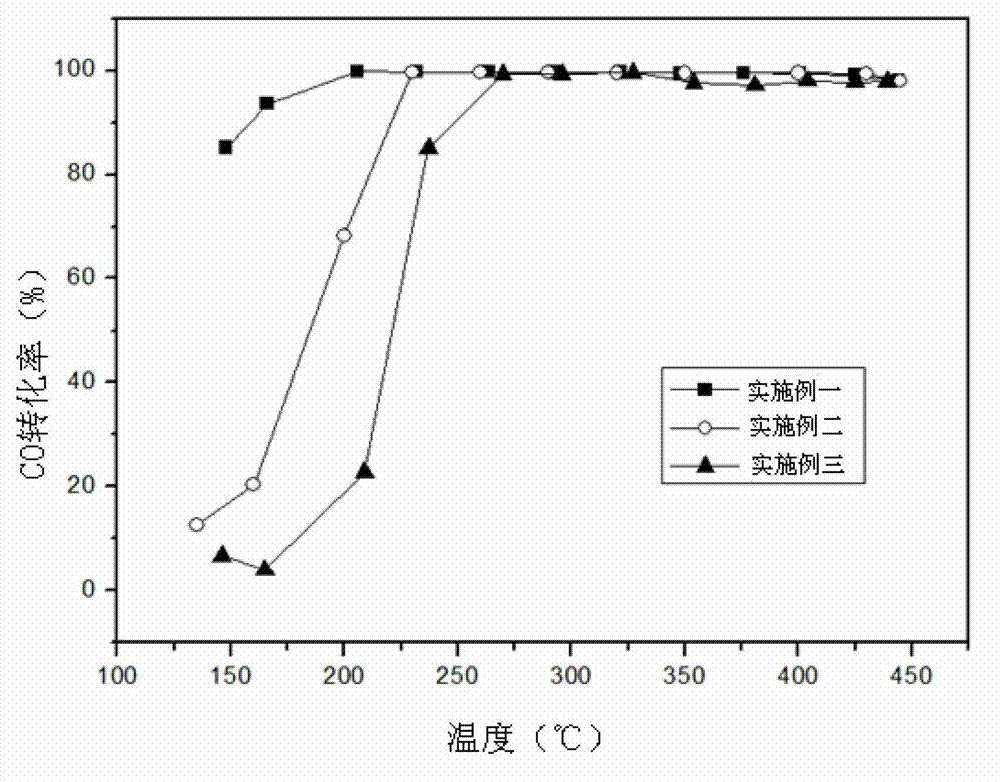

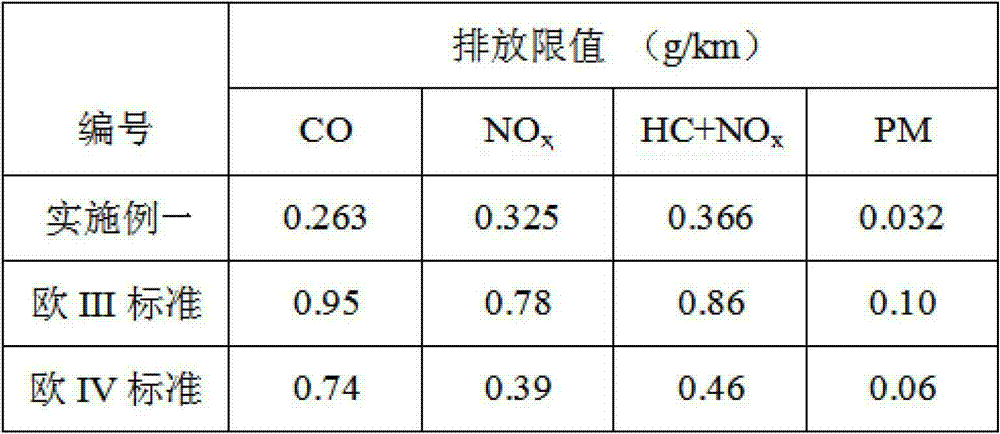

Automobile tail gas purifier high performance nano assembly catalyze coating material and method of preparing the same

InactiveCN101249459AImprove performanceImprove heat resistanceCatalyst carriersDispersed particle separationCeriumAlumina composite

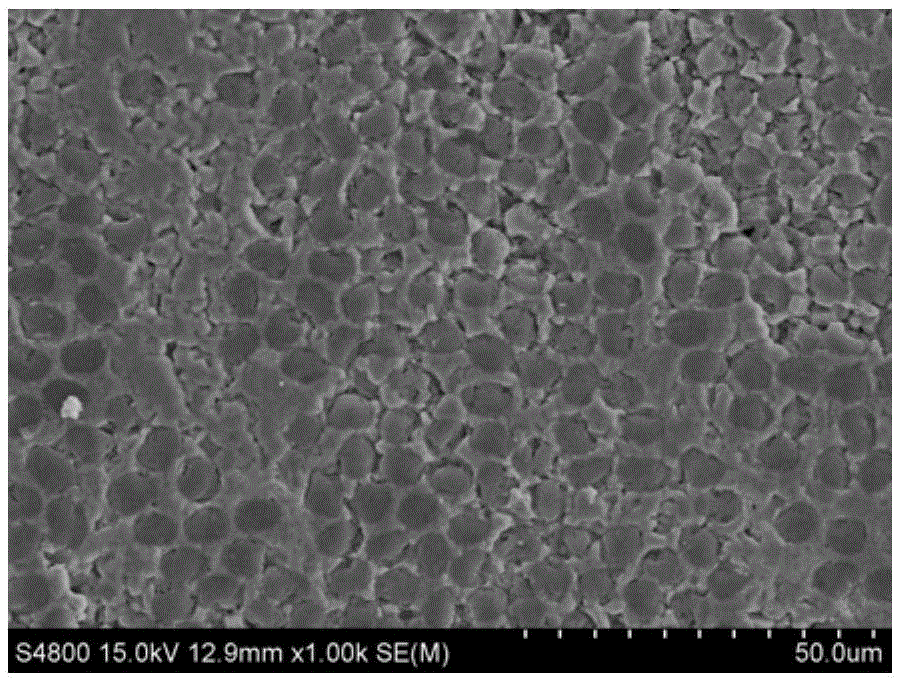

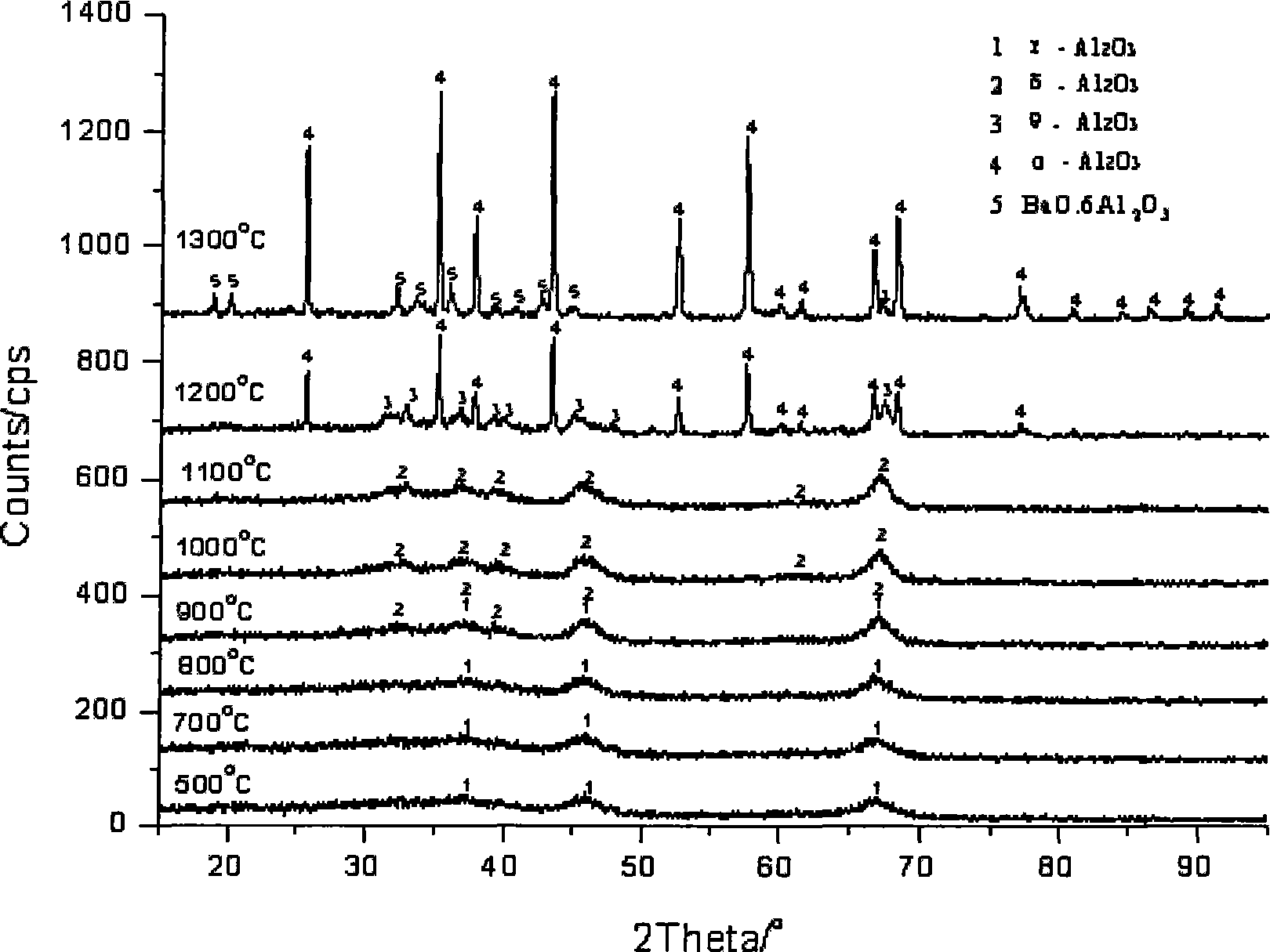

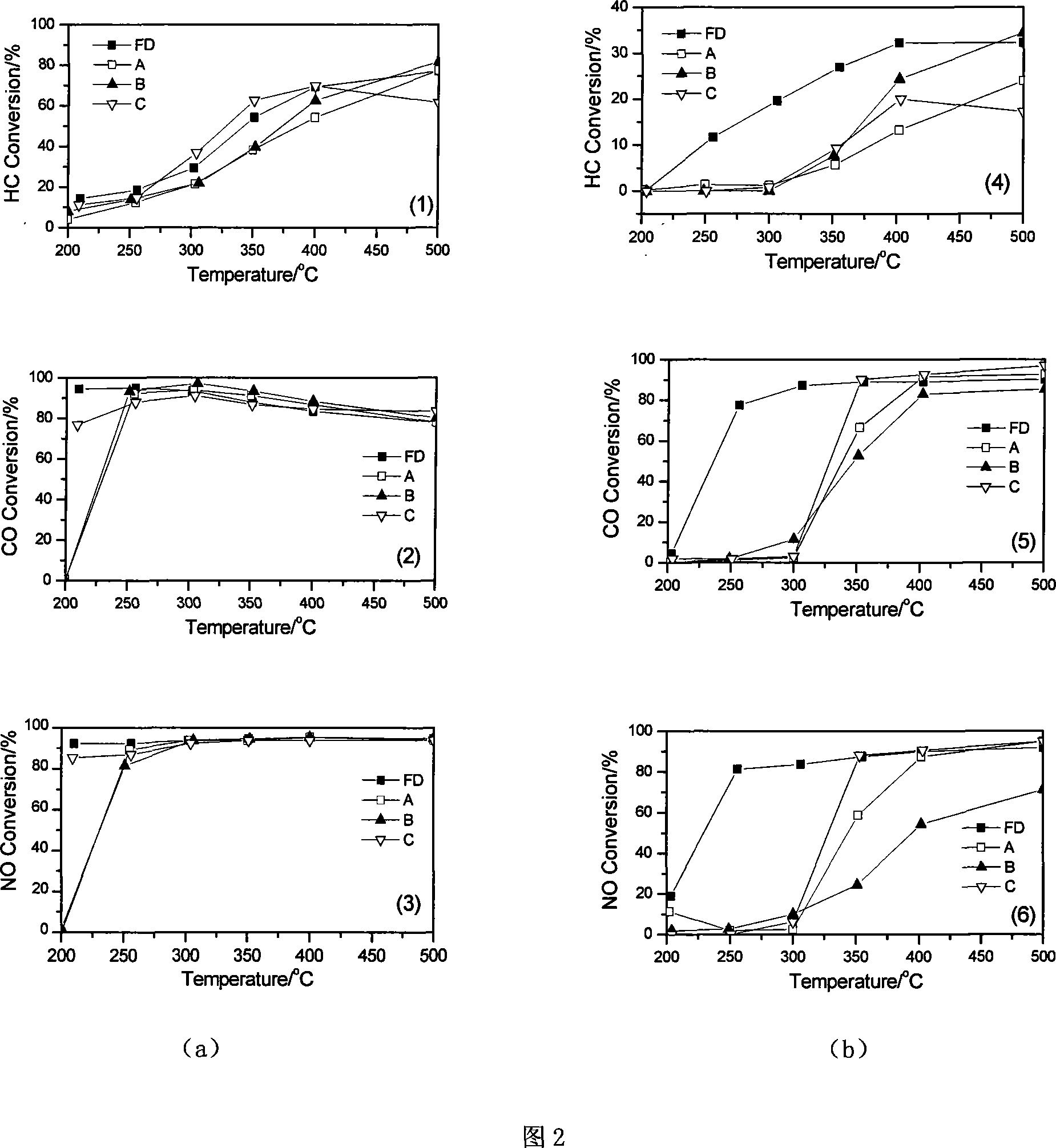

The invention provides a high performance nanometer combined catalytic coating material of an automobile tail gas purifier and preparation method thereof. The coating material is prepared from alumina composite oxides nano-material with high heat resistance and large specific surface area and cerium zirconium composite oxides nano-material of high oxygen storage property by ball milling at a certain ratio through nanometer combination technology, and controlling appropriate pore structure, surface structure and particle size under the action of certain assistant. The coating material can still retain original excellent performance of the nano-materials at 500-1100 DEG C. The inventive catalytic coating material retains original excellent performance of the nano-materials, has larger specific surface area and higher hydrogen storage capability compared with the prior material, and can be used in automobile tail gas catalyst for the purification of the automobile tail gas to realize low discharge and ultra-low discharge of automobile tail gas pollutant. The preparation method is scientific, reasonable, easy in operation and low in cost; and has remarkable socioeconomic benefit.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

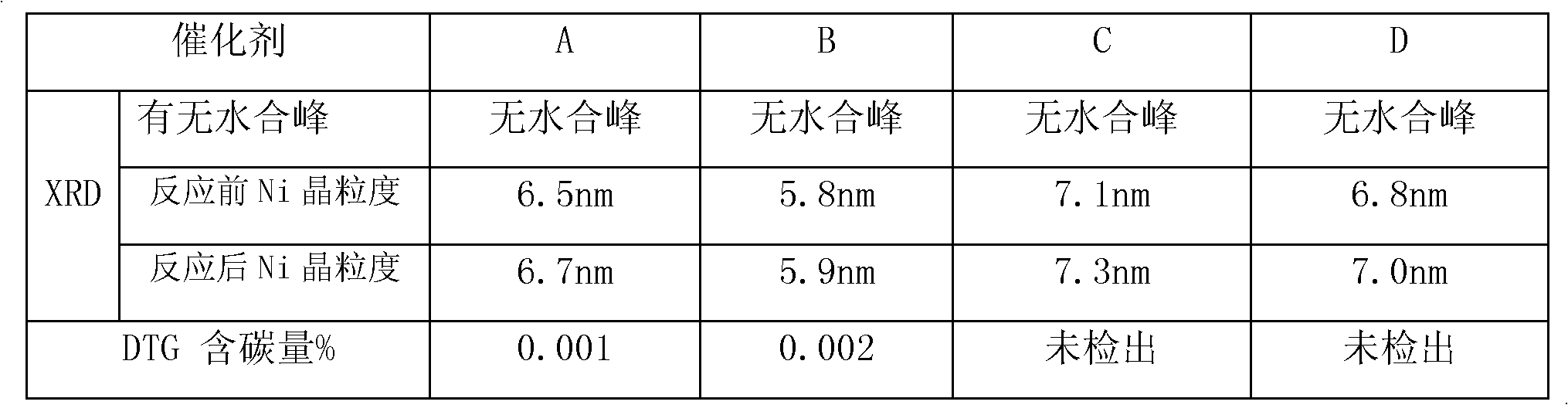

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

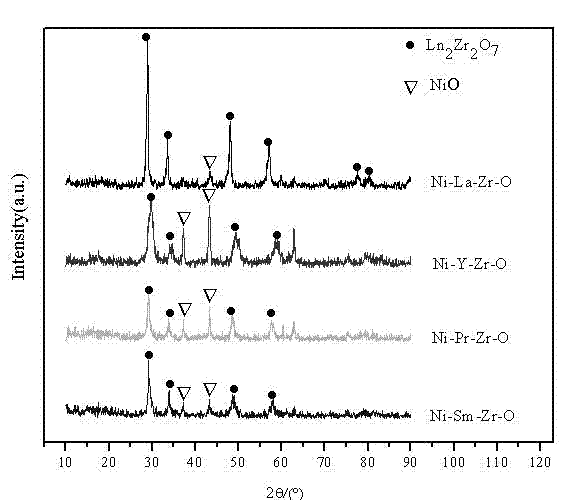

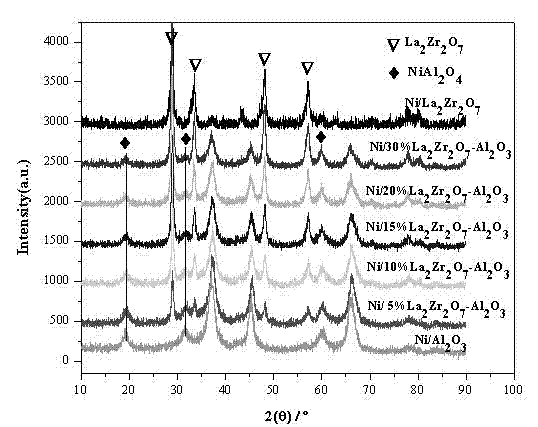

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

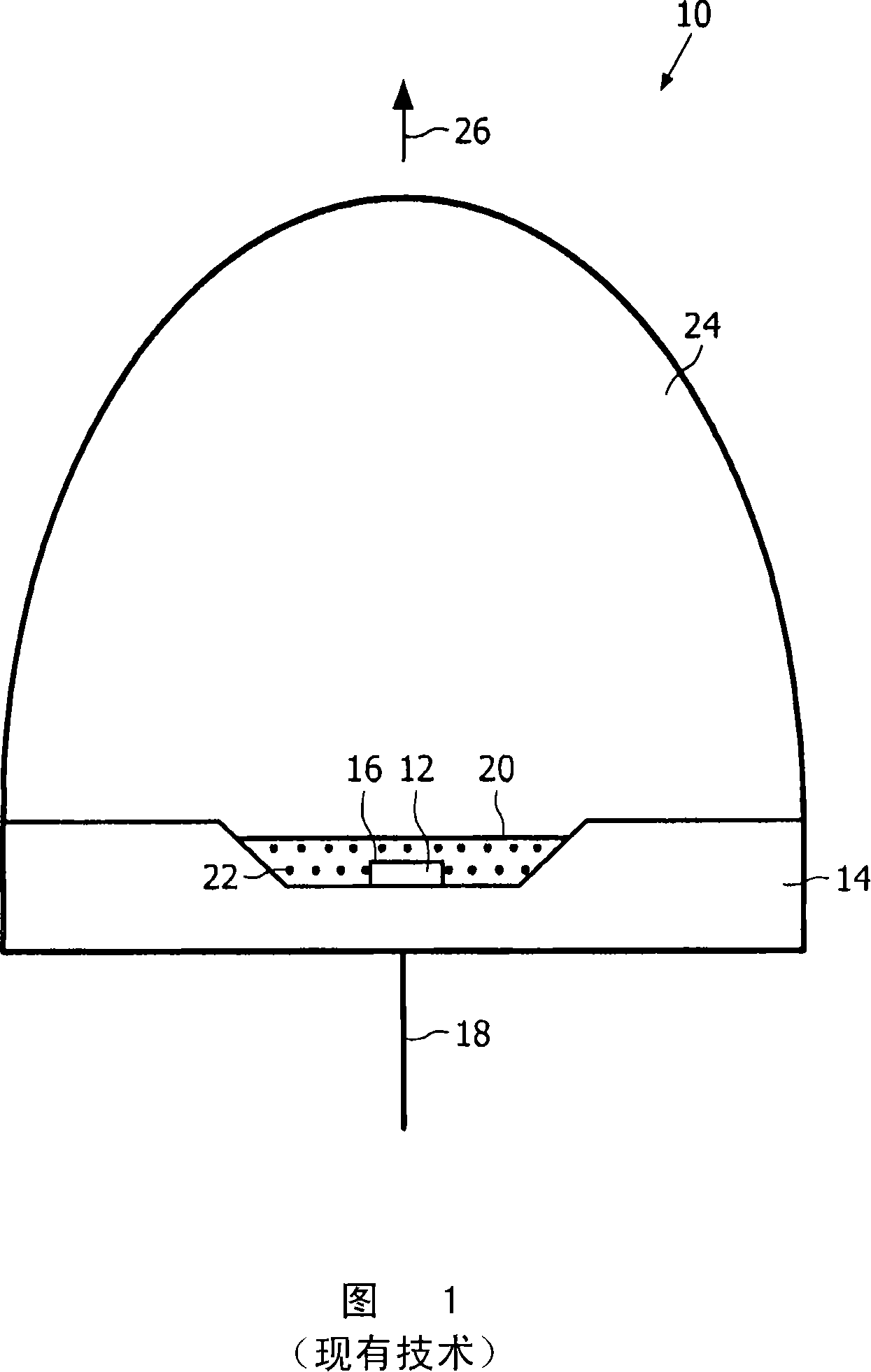

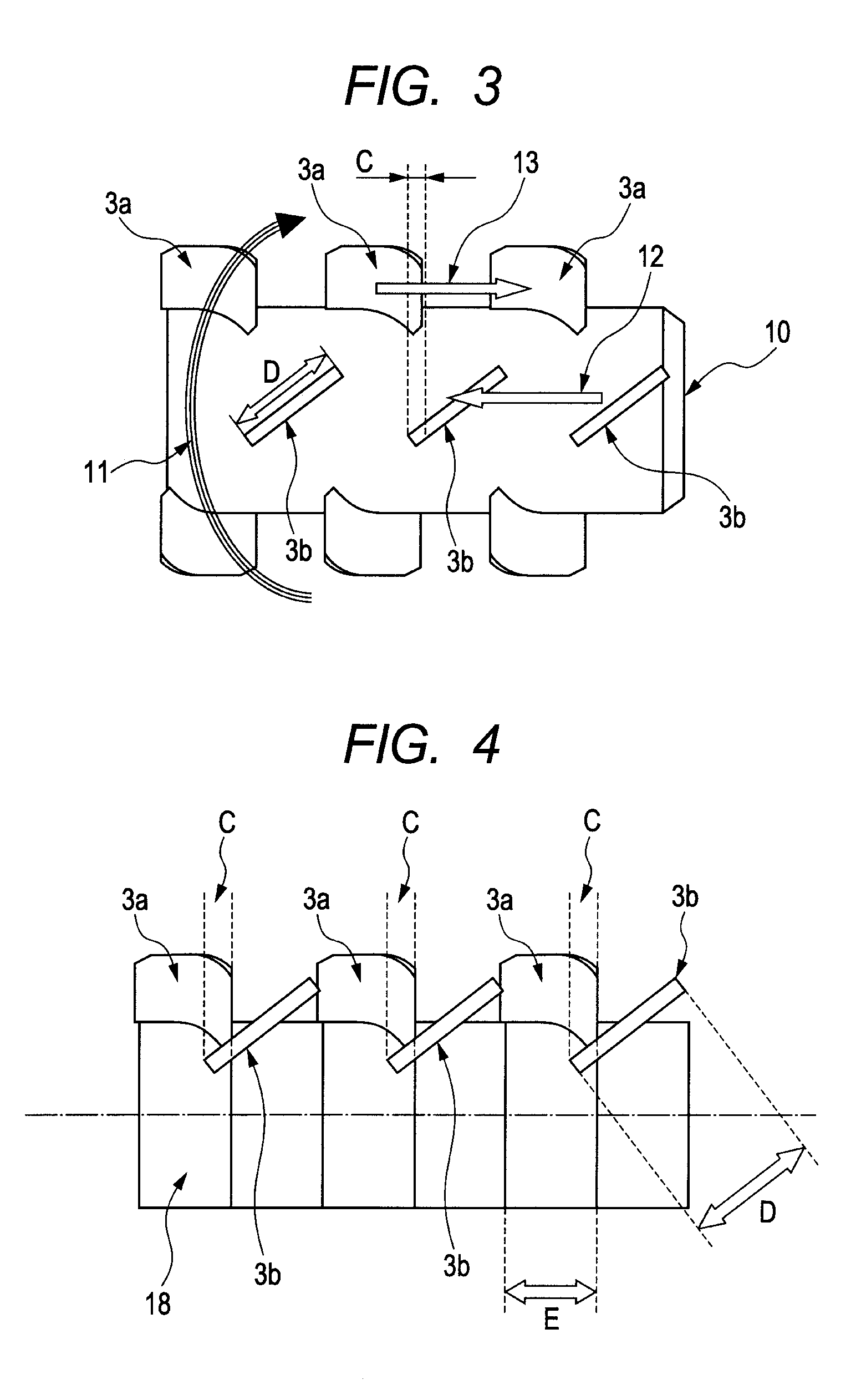

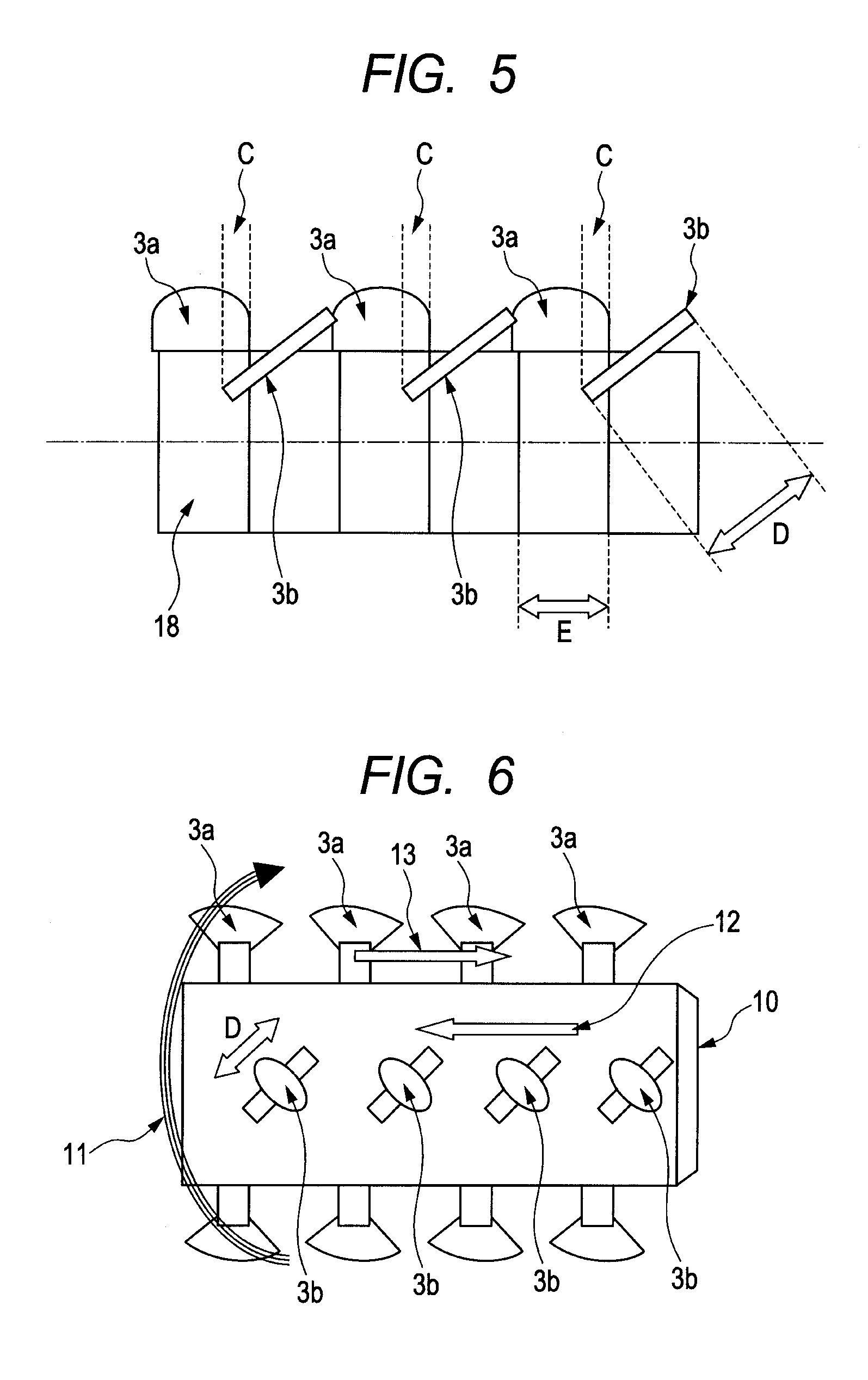

Phosphor in polycrystalline ceramic structure and a light-emitting element comprising same

ActiveCN101142857AReduce the temperatureGood thermal propertiesElectroluminescent light sourcesLuminescent compositionsPorosityCeramic composite

The invention relates to a phosphor in a polycrystalline ceramic structure and a light-emitting element provided with the same comprising a Light-Emitting Diode (LED) in which a composite structure of phosphor particles is embedded in a matrix, characterized in that the matrix is a ceramic composite structure comprising a polycrystalline ceramic alumina material, hereafter called luminescent ceramic matrix composite. This luminescent ceramic matrix composite can be made by the steps of converting a powder mixture of ceramic phosphor particles and alumina particles into a slurry, shaping the slurry into a compact, and applying a thermal treatment, optionally in combination with hot isostatic pressing into a polycrystalline phosphor-containing ceramic alumina composite structure. The luminescent ceramic matrix composite further allows a method of tuning the light-diffusing properties by changing at least one of the fractions of phosphor particles and second ceramic particles, the grain size of the particles of the ceramic composite structure, the difference in the refractive index of the particles of the ceramic composite structure, and the porosity in the polycrystalline phosphor-containing ceramic composite structure.

Owner:LUMILEDS HLDG BV

Magnetic carrier

InactiveUS9046800B2Improve the development effectLower performance requirementsDevelopersEngineeringAlumina composite

Provided is the following magnetic carrier. The magnetic carrier maintains high developing performance even when the number of sheets to be output is large. Its charge-providing performance hardly reduces even when toner or an external additive is spent on the magnetic carrier. In addition, the magnetic carrier is strong in resistance against standing. The magnetic carrier includes a magnetic carrier core and a resinous coating layer formed on a surface of the magnetic carrier core, in which the resinous coating layer contains a resin composition and silica-alumina composite particles.

Owner:CANON KK

Preparation method of activated carbon and alumina composite material

ActiveCN102716716AFirmly and evenly fixedSolve the strength problemOther chemical processesAlumina compositePhenol

The invention provides a preparation method of an activated carbon and alumina composite material, which comprises following steps: phenol and formalin are mixed in proportion, heated and stirred, so as to enable the phenol to be completely dissolved; aluminum hydroxide is added to an obtained processed solution to react, and then an acid solution is added to the processed solution to neutralize the processed solution, so that the reaction is stopped; the mixed solution is cooled to room temperature, decompressed and dehydrated, so as to obtain a liquid mixture; a foaming agent and a curing agent are added to the liquid mixture, and the liquid mixture is rapidly stirred, foamed and cured, so as to obtain a foam body; and the foam body is cut into a certain shape, put into a heating furnace to be carbonized and activated, and then the activated carbon and alumina composite material can be obtained. By adopting the preparation method, two materials, namely activated carbon and alumina can be tightly combined together, and the prepared activated carbon is firmly and evenly fixed in the activated alumina, so that the deficiencies of low strength and short service life of the activated carbon are corrected; and the preparation method is simple and practicable, requires low cost and is suitable for large-scale industrial production.

Owner:大同市贵义炭素有限公司

Preparation method of mesoporous alumina composite adsorbent functionalized by alkali metal

InactiveCN102698704AHigh adsorption capacityImprove adsorption capacityOther chemical processesWater contaminantsFluid phaseSorbent

The invention discloses a preparation method of a mesoporous alumina composite adsorbent functionalized by alkali metal. The method comprises the following steps of: firstly fully agitating and uniformly mixing aluminum salt solution and Pluronic triblock copolymer solution, dropwise adding carbonate solution of the alkali metal in the case of slow agitation, and preparing the mesoporous alumina composite adsorbent functionalized by alkali metal from the obtained sediment via washing, drying and calcining of deionized water and absolute ethyl alcohol after solvent evaporation induced self-assembly or hydro-thermal treatment. The preparation method disclosed by the invention has the advantages of simple process, mild condition, low material cost, in-situ one-pot liquid-phase introduction of alkali metal components and carrier components and the like, and the obtained mesoporous alumina base composite material functionalized by Na- and K- has excellent adsorptive property on greenhouse gases CO2 (carbon dioxide) and highly toxic pollutants Cr (chromium)(VI) in a water body.

Owner:WUHAN UNIV OF TECH

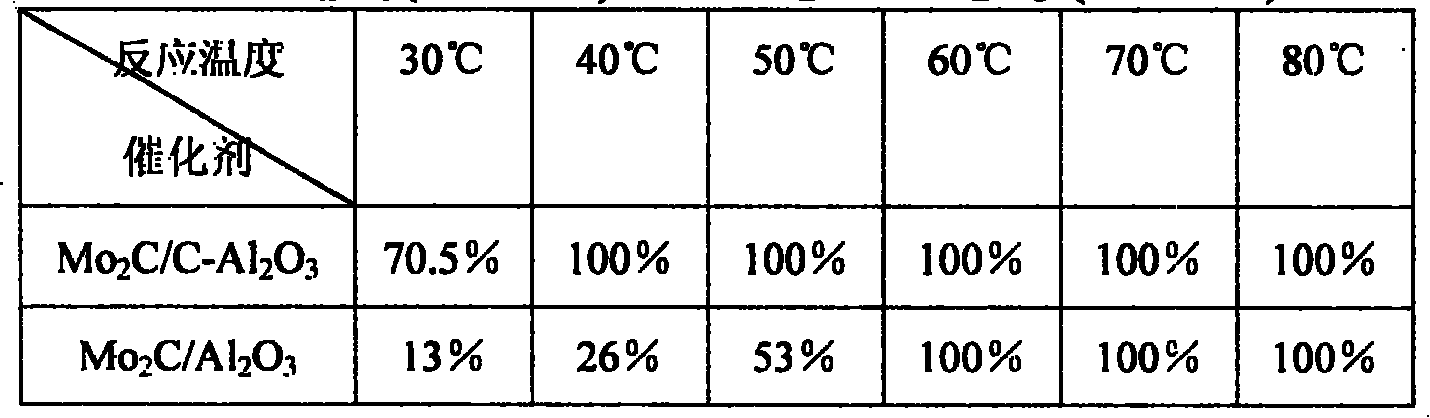

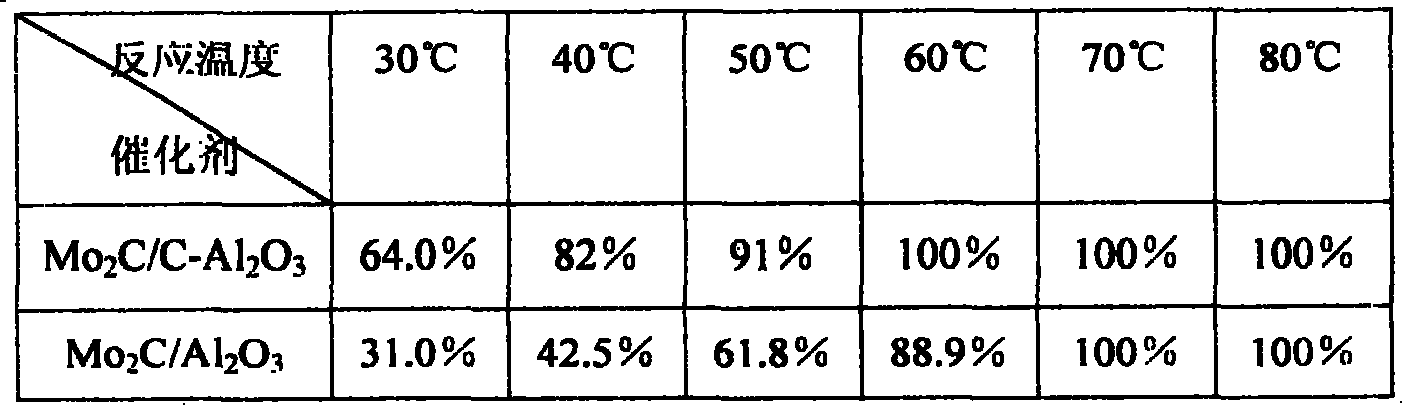

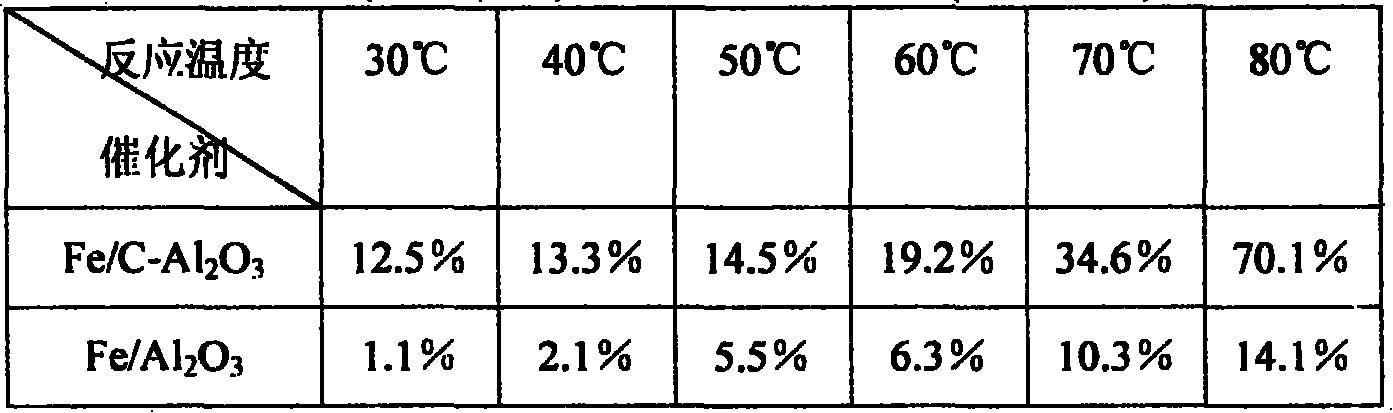

Carbon/aluminum oxide composite carrier catalyst for hydrazine decomposition reaction and preparation thereof

InactiveCN101209424AAvoid carbon deactivationEasy to makeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDecompositionHydrazine compound

The invention provides a carbon / alumina composite carrier catalyst used for hydrazine decomposition reaction and a preparation method thereof. The catalyst showed in the formula is A / C-Al2O3, C-Al2O3 is the carbon / alumina composite carrier, and active constituent A is transition metal Mo, W, Fe, Co, Ni, Ru, Rh, Pd, Ir, Pt or carbonization, nitride and phosphide thereof; wherein, the content of the A is 2-40wt percent and the preparation temperature of the A is 300-900 DEG C. The invention has simple preparation, especially for the preparation of active species of the transitional metal carbonization, which uses H2 instead of CH4 / H2 gas used in the past preparation to have direact reduction; the invention prevents carbon deposition on the surface of the carbonization from inactivating, thus being beneficial to acquire more catalytic active sites.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

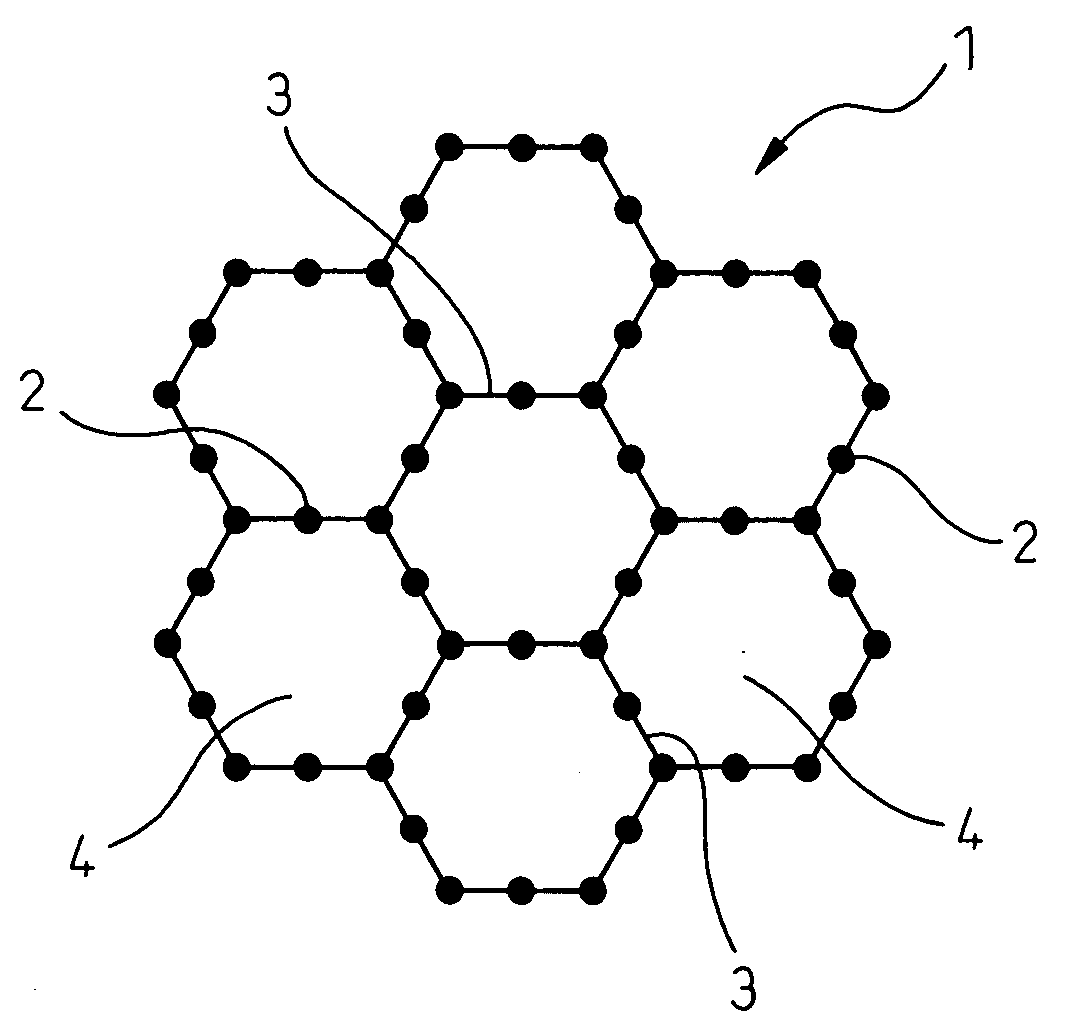

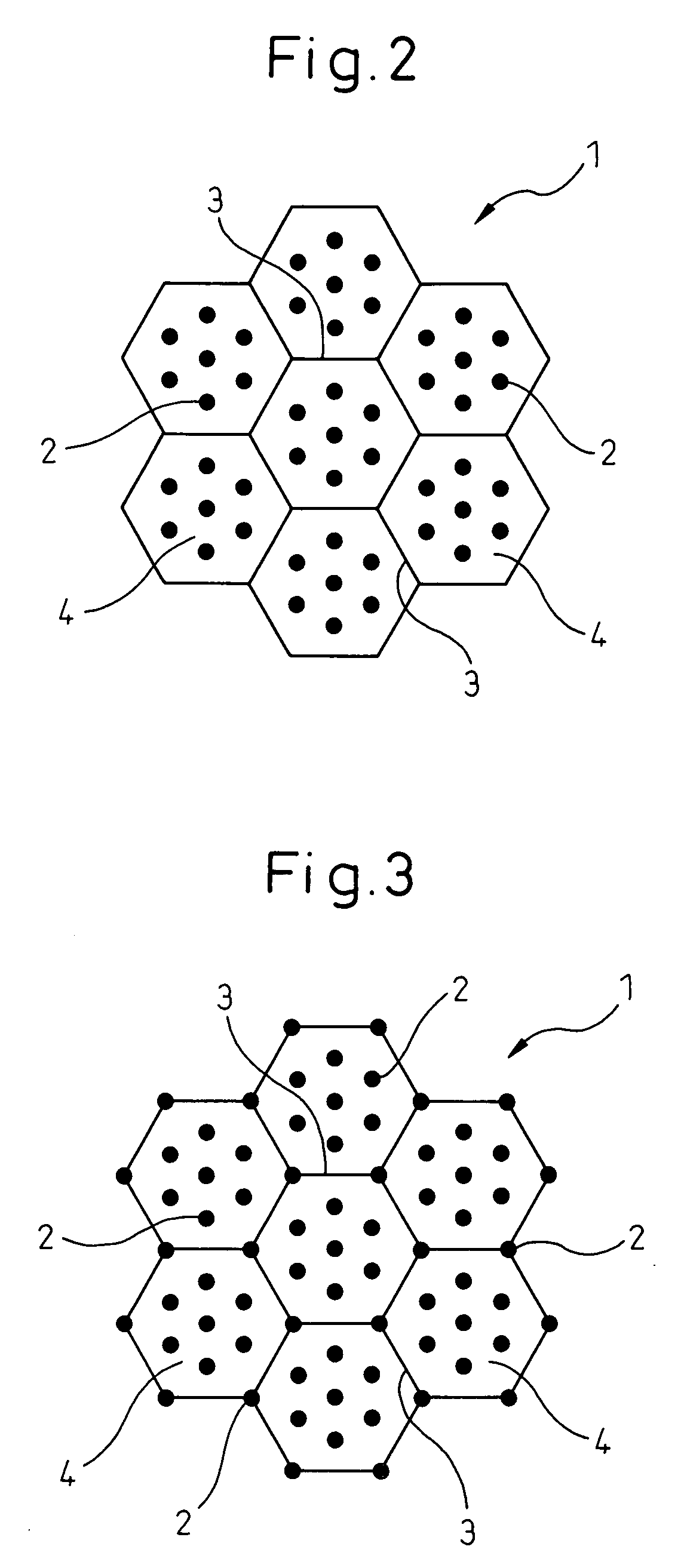

Alumina composite sintered body, evaluation method thereof and spark plug

InactiveUS20070298245A1Improve pressure resistanceCrystal grain boundary is increasedLayered productsSparking plugs manufactureAlumina compositeMaterials science

An alumina composite sintered body 1 in which fine particles 2 are dispersed in the crystal grains 4 and / or at the crystal grain boundaries 3 of an alumina sintered body obtained by sintering alumina crystal grains 4; an evaluation method thereof; and a spark plug using the alumina composite sintered body 1. Arbitrary regions in the cross-section of the alumina composite sintered body 1 are taken as analysis surfaces, and when the cross-sectional areas of the fine particles 2 contained in each analysis surface are measured, the ratio of the cross-sectional areas occupying in the area of the analysis surface is from 1 to 20%; when the cross-sectional areas of the fine particles 2 contained in each of analysis surfaces adjacent to each other are measured, and the cross-sectional area is converted into a circle having the same area, the diameter of the circle is from 0.1 to 4 μm; and when the concentration A (wt %) of the fine particles 2 contained in each analysis surface is compared with the concentration B (wt %) of the fine particles 2 used at the production, the difference between the concentration A and the concentration B is within ±20 wt %.

Owner:DENSO CORP +1

Synthetic methane catalyst and preparation method and application thereof

ActiveCN101920208AApplicable process applicationEasy to manufactureHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The invention provides a synthetic methane catalyst and a preparation method and application thereof. The catalyst is characterized in that: a zirconia or zirconia-alumina composite carrier is taken as a carrier in a catalyst co-precipitation technical process; nickel is taken as an active ingredient; rare earth elements such as La and Ce are added to enhance the activity, selectivity and stability of the catalyst, so that the selectivity of carbon monoxide is over 99 percent; and an appropriate amount of alkali metals and alkaline-earth metals such as Ca, Ba and the like are added to enhance the thermal stability, hydration resistance and anti-carbon performance of the catalyst.

Owner:ENN XINNENG BEIJING TECH

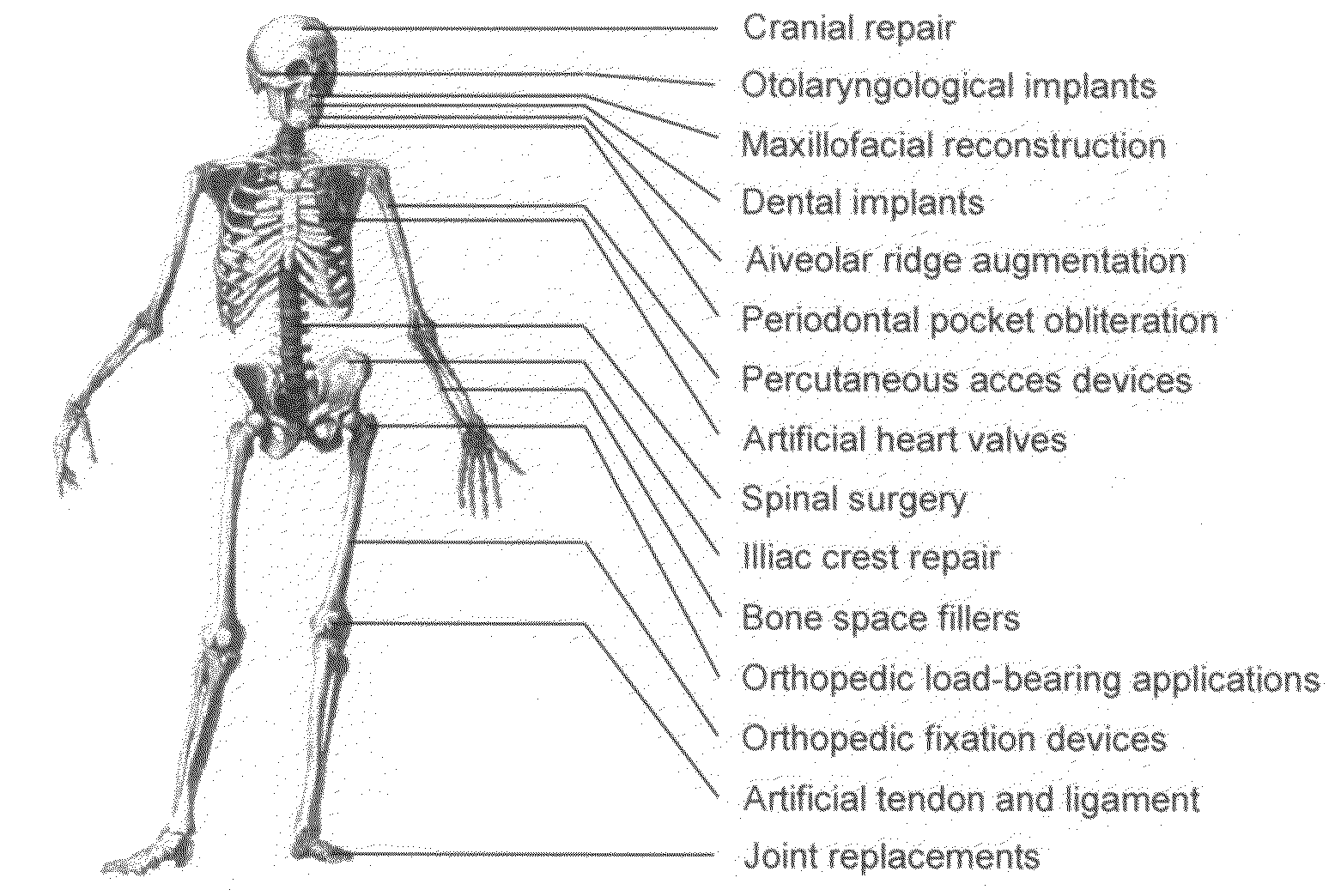

Bioactive graded zirconia-based structures

The present invention provides a functionally graded bioactive glass / ceramic composite structure or bioactive glass / ceramic / bioactive glass sandwich structure for use in such applications as damage resistant, ceramic dental implants, immediate tooth replacement, endodontic posts, orthopedic prostheses, orthopedic stems, bone substitutes, bone screws, plates, and anchors, nonunion fractures repair, alveolar ridge augmentation, missing small bone parts (e.g. fingers, toes, etc), maxilla facial reconstruction, spinal fusion, and scaffolds for bone regeneration, comprising a residual bioactive glass or glass-ceramic layer at all accessible surfaces, followed by an underlying graded glass-ceramic layer, and then an dense interior ceramic. The residual bioactive glass or glass-ceramic layer can be further transformed to a carbonate apatite (CHA) layer by immersing in calcifying solution or simulated body fluid (SBF) with electrolyte composition similar to that of serum. The interior ceramic preferably contains yttria-tetragonal zirconia polycrystal (Y-TZP) or ceria stabilized tetragonal zirconia polycrystal (Ce-TZP) or magnesia stabilized zirconia (Mg-PSZ) or calcia stabilized zirconia (Ca-PSZ) or alumina or zirconia-alumina composites. Further, the invention provides methods for making the same functionally graded bioactive glass / ceramic composite structure or graded bioactive glass / ceramic / bioactive glass sandwich structure.

Owner:NEW YORK UNIV

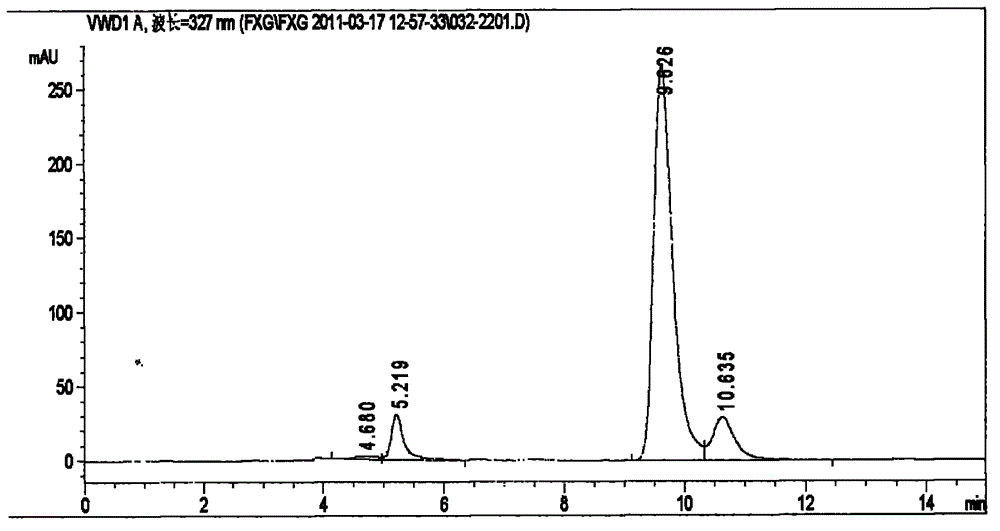

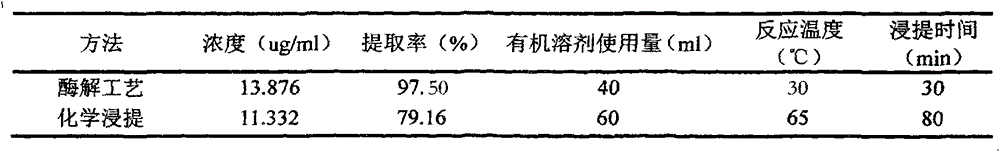

Extraction method of high-purity chlorogenic acid

InactiveCN103333067AHigh extraction rateImprove internal permeabilityOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidMicrofiltration membrane

The invention relates to an extraction method of high-purity chlorogenic acid, which comprises the steps of raw material preparation and pretreatment, enzyme treatment, ultrasonic treatment, preparation of the chlorogenic acid product, and the like. In the preparation process, an inorganic membrane is used, wherein the support of the inorganic membrane is alumina ceramic or honeycomb ceramic, and the inorganic membrane is an alumina composite microfiltration membrane. The raw material is honeysuckle flower, eucommia, cacao tree, coffee or the like. When the raw material is the honeysuckle flower, the extraction rate of the chlorogenic acid is up to 97.5%, and the purity is up to 99%. The method provided by the invention can simply and quickly obtain stable-quality high-purity high-yield safe reliable chlorogenic acid from the raw material.

Owner:GUANGXI JINHAO BIO TECH

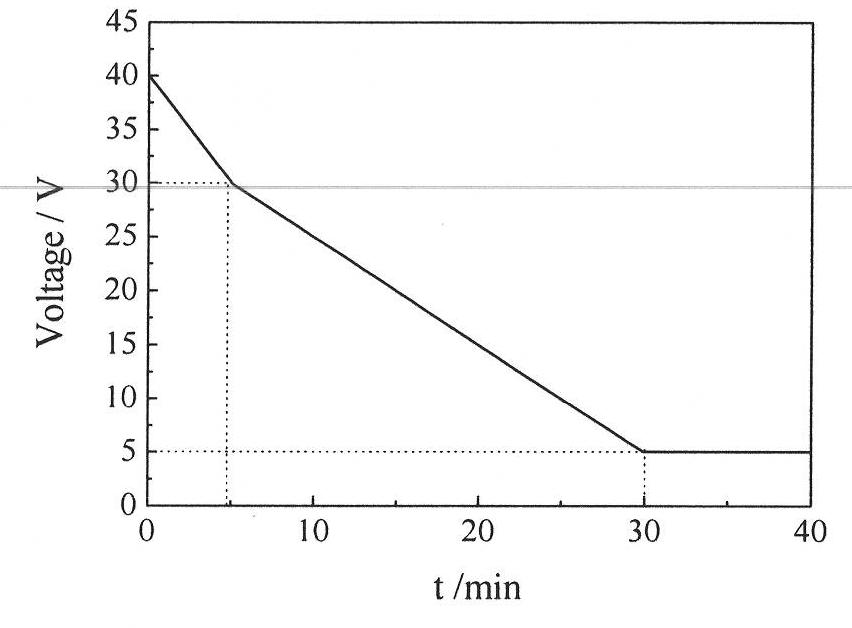

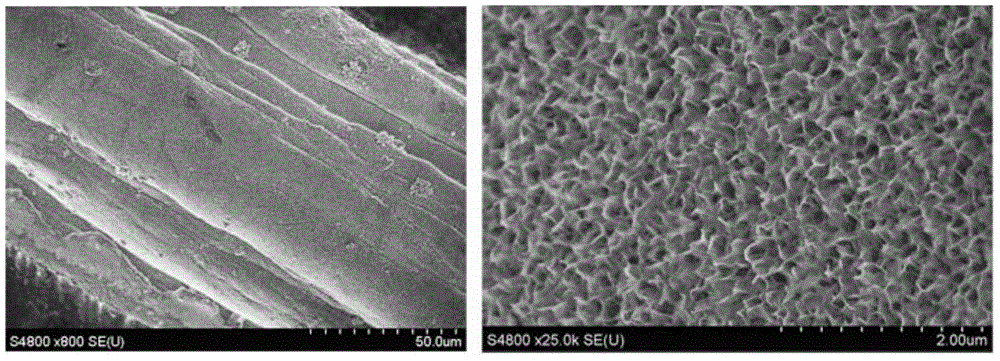

Ordered porous alumina template capable of being directly used in electrochemical deposition and production method

InactiveCN101851771AHigh success rate of preparationNot easy to damageSurface reaction electrolytic coatingNanowireAlumina composite

The invention discloses an ordered porous alumina template capable of being directly used in electrochemical deposition and a production method. The ordered porous alumina template is characterized in that the thickness of a barrier layer of the ordered porous alumina template is 100-300nm; non-oxidized aluminum matrix can be directly used as an electrode for the electrochemical deposition without removing the barrier layer and plating electrodes. The production method comprises the following steps: annealing an aluminum foil to eliminate stress generated in the process of cutting the aluminum foil; washing the annealed aluminum foil to remove blot on the surface of the aluminum foil; removing a natural oxidization layer on the aluminum foil; electropolishing the aluminum foil; carrying out primary anodization on the polished aluminum foil; removing the primary oxidization film on the primary oxidized aluminum foil; and carrying out secondary anodization on the aluminum foil on which the primary oxidization film is removed. The template produced by using the method of the invention has high success rate of production, is difficult to damage, simplifies the production process flow of nanowire / ordered porous alumina composite materials, and is beneficial to research on properties of the composite materia.

Owner:TONGJI UNIV

Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

InactiveCN102206793AHighlight substantive featuresEvenly dispersedCatalytic pyrolysisMagnesium matrix composite

The invention discloses a preparation method of a carbon nanotube-alumina composite reinforced magnesium-based composite material, which relates to the manufacture of magnesium-based alloy by using a casting method. The preparation method comprises the steps of: step 1, calcining and reducing raw materials of ferric nitrate nonahydrate and alumina in the ratio of (0.07-1.00):1 to obtain an iron / alumina composite catalyst, and finally, performing catalytic pyrolysis reaction by using the mixed gas of nitrogen gas and ethylene in the volume ratio of (6-12):1 for uniformly dispersing carbon nanotubes on the surface of the alumina, so as to prepare a carbon nanotube-alumina composite reinforced phase; and step 2, adding the carbon nanotube-alumina composite reinforced phase to a molten magnesium base material, and stirring and casting to prepare the carbon nanotube-alumina composite reinforced magnesium-based composite material, wherein the added carbon nanotube-alumina composite reinforced phase accounts for 1-15% of the molten magnesium base material by mass percentage. According to the invention, the defect of a magnesium-based alloy texture in the magnesium-based composite material produced in the prior art is overcome, the excellent enhancing effect of the carbon nanotubes in a magnesium matrix can be brought into full play, and the comprehensive performance of the magnesium-based composite material is ensured to be enhanced.

Owner:HEBEI UNIV OF TECH +1

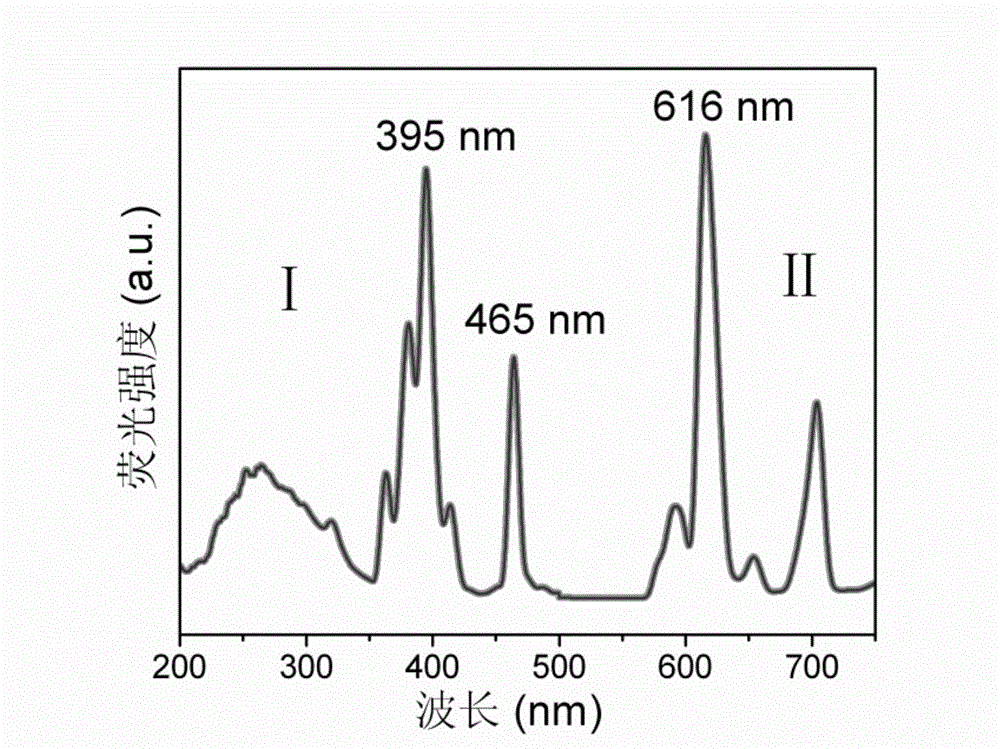

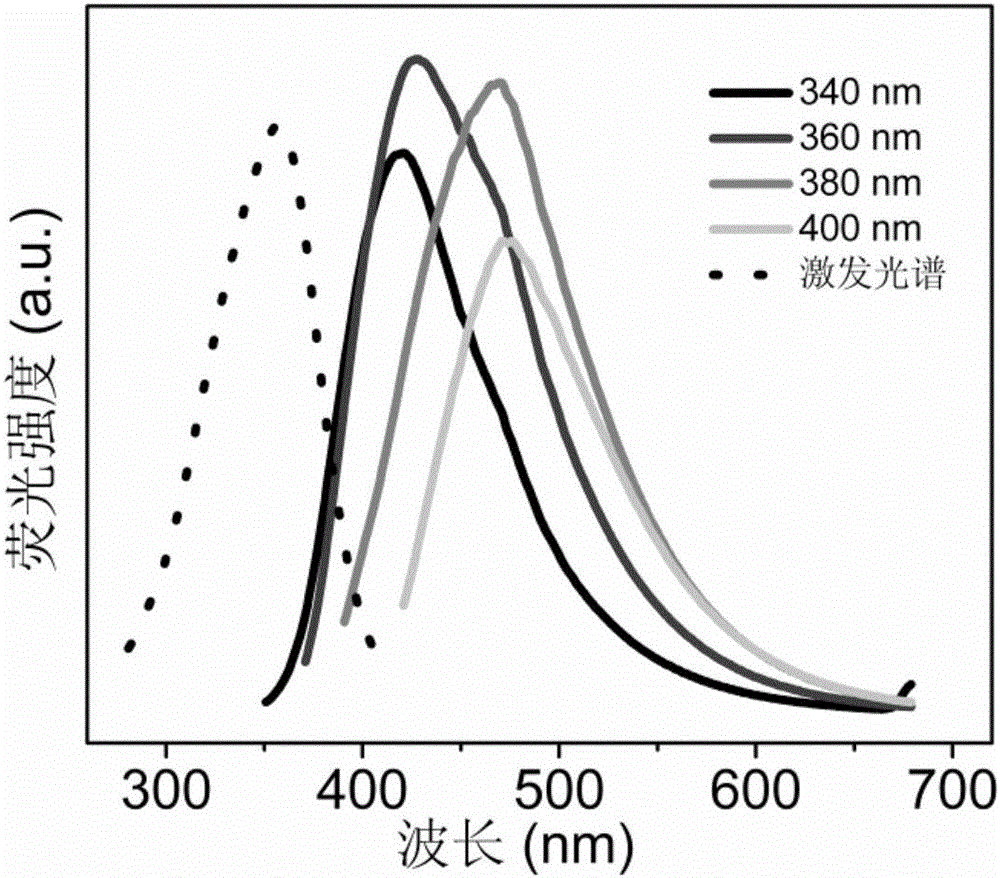

Carbon quantum dot/Eu<3+>/mesoporous alumina composite luminescent material and preparation and application thereof

ActiveCN106675558ASimple preparation processShort timeThermometers using physical/chemical changesLuminescent compositionsLinear relationshipRare earth

The invention belongs to the field of composite functional materials and particularly relates to a color-tunable fluorescent carbon quantum dot / Eu<3+> / mesoporous alumina composite luminescent material, preparation thereof and application of the carbon quantum dot / Eu<3+> / mesoporous alumina composite luminescent material in the aspects of temperature sensing and optical devices. The composite luminescent material comprises fluorescent carbon quantum dots, of which surfaces contain hydroxyl or amino, and trivalent-europium-doped mesoporous alumina. According to the composite luminescent material, rare-earth trivalent europium, which emits red light under an ultraviolet lamp, and the fluorescent carbon quantum dots which emit blue light are doped into pore passages of the mesoporous alumina, then, composite fluorescent powder with dual emission peaks is obtained, and the ratio of fluorescence intensity of the two emission peaks in a relatively wide temperature range has a good linear relationship and stability, so that the rapid and effective detection and sensing of temperature can be excellently achieved, and the composite luminescent material can be applied to the aspect of temperature sensing. Due to a tunable color, the composite luminescent material can also be applied to the optical devices.

Owner:SOUTH CHINA AGRI UNIV

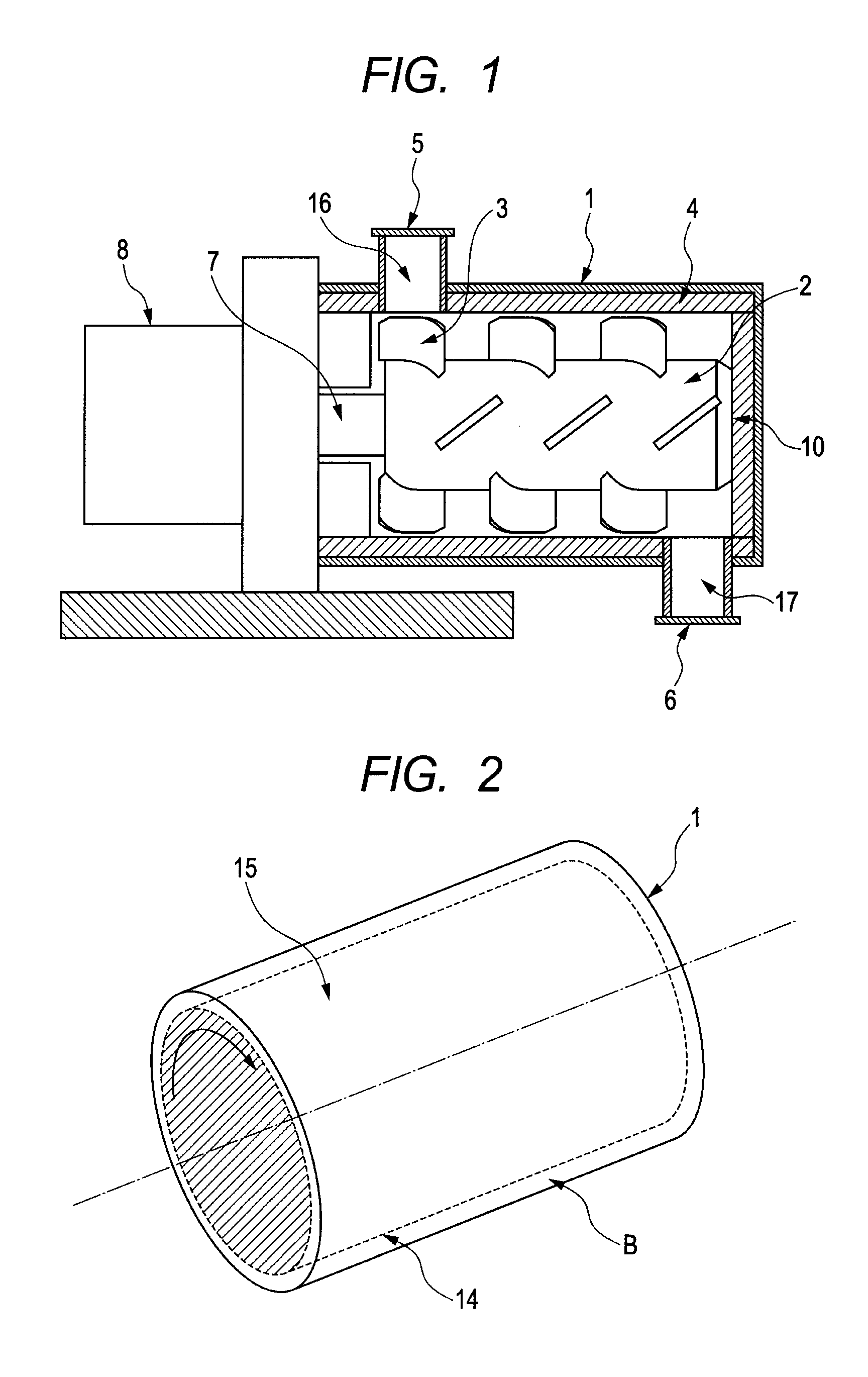

Novel nano composite methanation catalyst and preparation method thereof

ActiveCN104043454AHigh surface uniformityGood dispersionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationAlumina composite

The invention discloses a novel nano composite methanation catalyst and a preparation method thereof. The preparation method comprises the following steps: adding a tetrabutyl titanate and ethyl alcohol mixed solution dropwise into an ethyl alcohol and nitric acid mixed water solution at room temperature, and hydrolyzing tetrabutyl titanate so as to obtain sol; drying the sol to form gel, and forging to obtain nano TiO2 powder; mixing pseudo-boehmite and deionized water to obtain a turbid liquid, and adding nitric acid to obtain semitransparent sol gama-AlOOH; adding the nano TiO2 powder into the semitransparent sol gama-AlOOH, drying overnight, and baking to obtain TiO2 / gama-Al2O3 nano powder as a methanation catalyst carrier; dipping a nickel nitrate solution on the methanation catalyst carrier, drying, and forging to obtain a NiO / TiO2 / Al2O3 catalyst; and dipping an additive on the carrier, thereby obtaining a NiO-M / TiO2 / Al2O3 catalyst. According to the invention, nanoscale titanium oxide and a nanoscale aluminum oxide composite material act as the carriers, and NiO acts as an active component, so that the novel nano composite methanation catalyst is prepared.

Owner:HUANENG CLEAN ENERGY RES INST +1

Preparation method of polycrystal zirconia fiber and zirconia/alumina composite fiber

ActiveCN102465357ALow priceLow environmental requirementsInorganic material artificial filamentsArtificial filament heat treatmentFiberAlumina composite

The invention relates to a preparation method of a polycrystal zirconia fiber and zirconia / alumina composite fiber, which is characterized by comprising the following steps of: with zirconium carbonate and hydrochloric acid as raw materials and water or a mixture comprising water and alcohol as a solvent, preparing uniform and transparent polyhydroxy zirconium chloride sol under a refluxing state; adding a phase stabilizer, a grain growth inhibitor and a water-soluble polymer spinning aid to the sol and distilling at reduced pressure to prepare an inorganic zirconium spinning solution, or adding aluminum sol, the phase stabilizer, the crystal grain growth inhibitor and the water-soluble polymer spinning aid to the sol and distilling at reduced pressure to prepare an aluminum-zirconium composite spinning solution; and preparing gelatin fiber through centrifugal fiber throwing or blowing spinning, and carrying out heat treatment to obtain the polycrystal zirconia fiber and zirconia / alumina composite fiber. The preparation method disclosed by the invention has the advantages of low price of raw materials, simple equipment, low requirement on environment, no need of inertial environment, short flow time of the whole process and suitability for industrial production.

Owner:山东鲁阳浩特高技术纤维有限公司

Double-oxidization catalyst for purifying diesel engine exhaust and preparation method thereof

ActiveCN103084176AImprove purification effectImprove low temperature cold start conversion efficiencyDispersed particle separationCatalyst activation/preparationPtru catalystAlumina composite

The invention discloses a double-oxidization catalyst for purifying diesel engine exhaust and a preparation method thereof. The double-oxidization catalyst comprises a front-stage carrier and a rear-stage carrier which are orderly arranged along the axial direction of an engine exhaust port, wherein the front-stage carrier is arranged near the engine exhaust port; the rear-stage carrier is arranged far away from the engine exhaust port; a front-stage coating is coated on the front-stage carrier; a rear-stage coating is coated on the rear-stage carrier; slurries for preparing the front-stage coating and the rear-stage coating respectively contain deionized water, rare-earth complex oxide, modified aluminum oxide, a binder and active ingredients; and at least one of the two slurries for preparing the front-stage coating and the rear-stage coating also contains silica-alumina composite oxide. By adopting the double-oxidization catalyst for purifying the diesel engine exhaust and the preparation method thereof, the loading amount of the active coating is effectively increased; dropping of the coatings is overcome; the coatings are even and have significant catalytic activity; and purification of the diesel engine exhaust can be effectively achieved.

Owner:ZHEJIANG DA FENG AUTOMOBILE TECH

Chromium oxide and alumina composite coating and preparation method thereof

InactiveCN104708863AChange the coefficient of thermal expansionImproved thermal cycling performanceLayered productsVacuum evaporation coatingHydrogenAlumina composite

The invention relates to a chromium oxide and alumina composite coating and a preparation method thereof. The coating can be used to prevent hydrogen from penetrating into a structural material or device in the hydrogen related field. The composite coating is composed of chromium oxide and / or alumina, and is loaded on a substrate. The composite coating can be a single-layer composite coating or a multi-layer gradient composite coating. The single-layer composite coating is composed of chromium oxide and alumina. The multi-layer gradient composite coating is composed of at least two xCr2O<3-(1-x)>Al2O3 composite layers, wherein the x is the mass percentage of Cr2O3 and varies gradually. The composite coating combines the hydrogen penetration resistant performances of a chromium oxide layer and an alumina layer, and has the characteristics of simple preparation technology and excellent hydrogen penetration resistant performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Aluminum matrix-mesoporous alumina composite material and preparation method and application of aluminum matrix-mesoporous alumina composite material

ActiveCN104148040AImprove thermal conductivityImprove permeabilityHydrogenCatalyst carriersAlumina compositePore diameter

The invention discloses an aluminum matrix-mesoporous alumina composite material and a preparation method and application of the aluminum matrix-mesoporous alumina composite material. The composite material consists of an aluminum matrix and a mesoporous alumina layer growing on the surface of the aluminum matrix, wherein the mass percent of mesoporous alumina is 0.05-50%, and the most probable pore diameter of a mesopore is 2-20nanometers. The preparation method of the composite material comprises the following steps: firstly, carrying out in-situ growth on pseudo-boehmite on the surface of the aluminum matrix via the reaction of aluminum and water under a hydrothermal condition, and then carrying out high-temperature roasting and crystal transformation on the generated pseudo-boehmite. The composite material provided by the invention has the advantages of good heat conductivity, high permeability, easiness in forming, filling and storage, and the like, is an ideal catalyst carrier, and can be used for preparing a catalyst loading activity metal or activity metal and auxiliary metal oxides as the catalyst carrier.

Owner:易高卓新节能技术(上海)有限公司

Method for preparing porous alumina composite material through biological template method

InactiveCN103736442ALarge specific surface areaPresent diversityPhysical/chemical process catalystsOther chemical processesFiberMaterials preparation

The invention relates to a method for preparing a porous alumina composite material through a biological template method. The method comprises the following steps: duplicating a macro-pore tubular structure of a plant leaf, which is used as a biological template, through alumina in a material preparation process to obtain biomorphic alumina with a macro-pore fiber tubular structure; growing an LDHs (layered double hydroxides) nanosheet in a macro-pore channel of the biomorphic alumina in situ through an in-situ growth technology to obtain a porous LDHs / alumina composite material; roasting the porous LDHs / alumina composite material at the temperature of 500-800 DEG C to obtain the porous alumina composite material. The LDHs nanosheet is grown in the macro-pore channel of the biomorphic alumina, so that the specific surface area of the biomorphic alumina can be remarkably increased, and the pore structure of the biomorphic alumina is diversified. The porous alumina composite material can be widely applied to the fields of adsorption, catalysis and the like.

Owner:SOUTHEAST UNIV

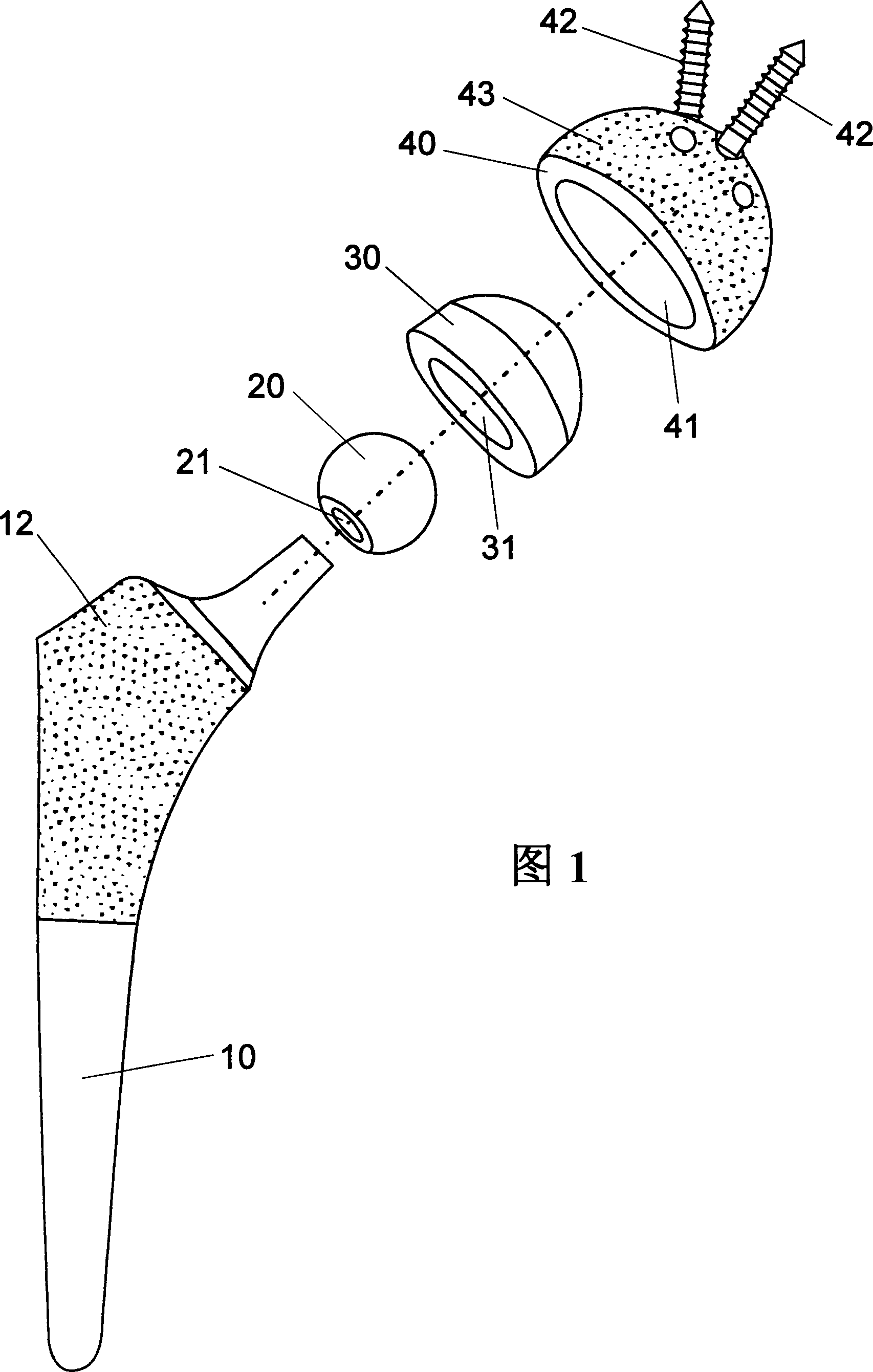

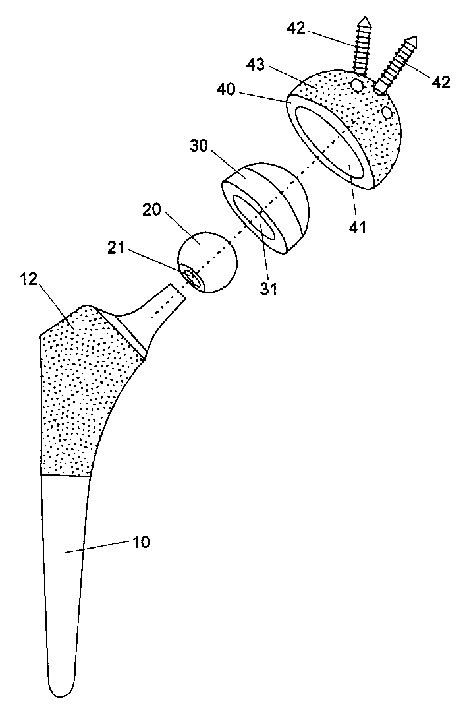

Artificial joint made from zirconia-alumina composite ceramic

An artificial joint made of zirconia-alumina composite ceramics, which includes a first bone component and a second bone component. One end of the second bone component is slidingly engaged with a part of the first bone component to form a joint part, wherein At least one of the first bone component and the second bone component are formed from a zirconia-alumina composite ceramic including a matrix phase composed of zirconia particles and a second phase composed of alumina particles dispersed therein. phase, the zirconia particles contain ceria as a stabilizer, the amount of ceria is such that the matrix phase is mainly composed of tetragonal zirconia, and the zirconia-alumina composite ceramic has a thickness of 0.1-1 μm, preferably 0.1-0.8 μm. , an average particle size of 0.1-0.65 μm is particularly preferred. This artificial joint provides good movement of the joint with high reliability over the long term.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

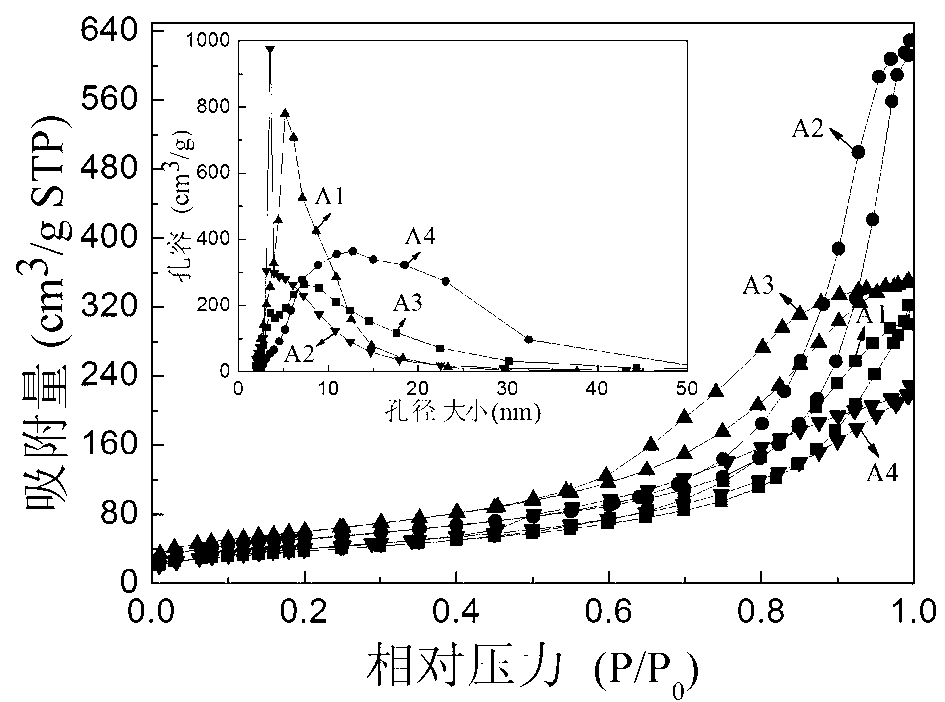

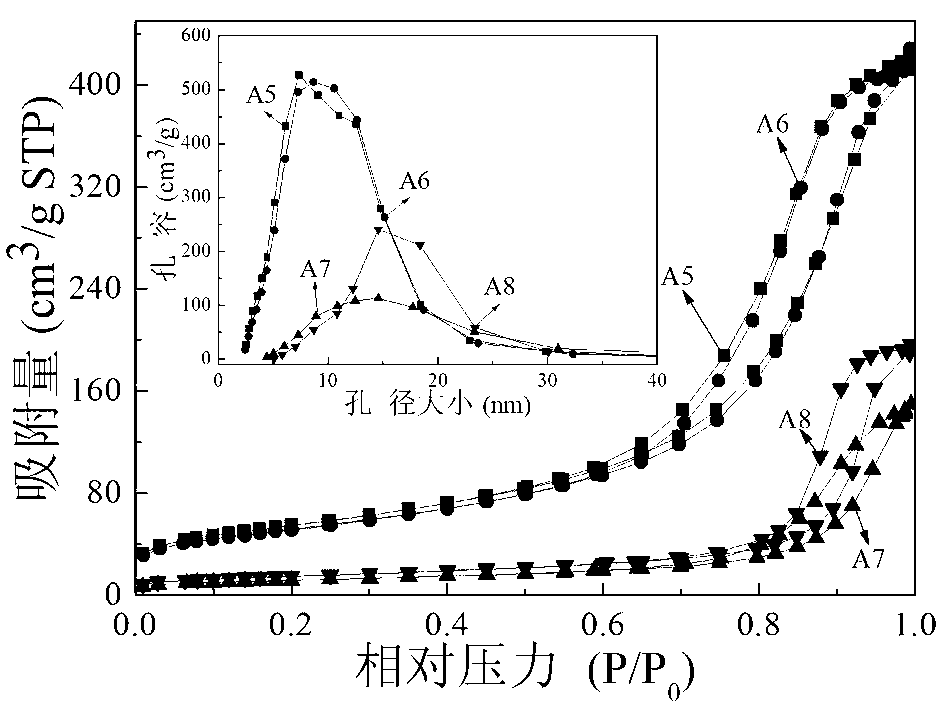

Wide mesoporous alumina composites having trimodal pore structure

ActiveUS7790130B2Improve performanceReduced responseMaterial nanotechnologyChlorine/hydrogen-chloride purificationParticulatesSorbent

Wide mesoporous alumina composites are produced by an “in situ reaction” route comprising agglomeration of an alumina powder that is capable of rehydration together with a second reactive powder such as carbonate. In one method of production, the powders are fed to a rotating forming device that is continuously sprayed with liquid under conditions to form particulates. The discharging beads are then subjected to curing and thermal activation to produce the final catalyst or adsorbent. The alumina participates in a pore altering process involving the carbonate component upon formation of hydroxycarbonate intermediates such as Dawsonite. Large fraction of the pore volume of the final product consists of wide mesopores in the 15-50 nanometers range. The alumina composites exhibit a characteristic trimodal pore structure that includes also small micro-meso pores and macropores larger than 200 nanometers.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com