Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3588 results about "Solid acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid acids are acids that do not dissolve in the reaction medium. They are often used in heterogeneous catalysts.

Generating Acid Downhole in Acid Fracturing

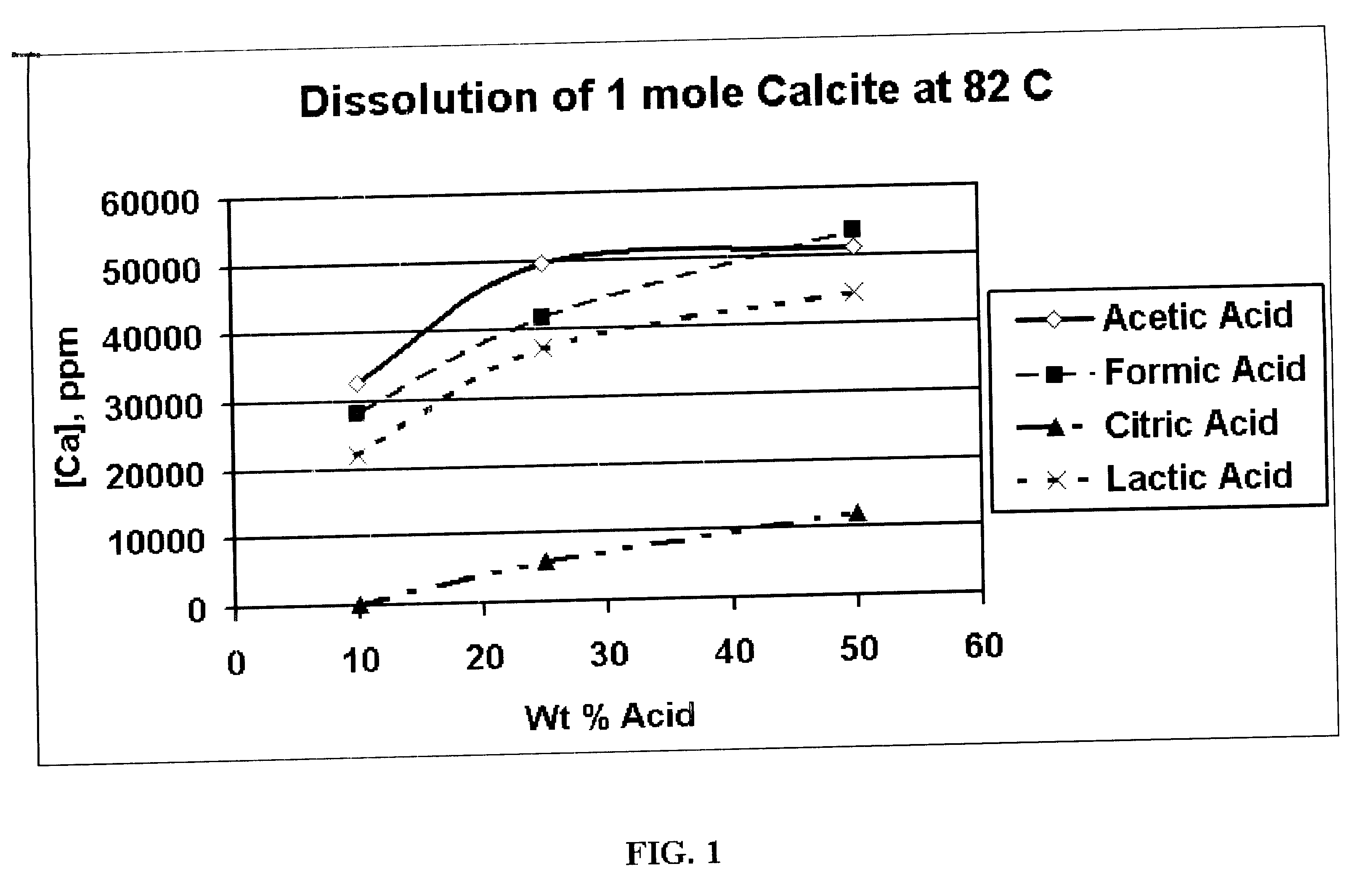

An acid fracturing method is provided in which the acid is generated in the fracture by hydrolysis of a solid acid-precursor selected from one or more than one of lactide, glycolide, polylactic acid, polyglycolic acid, a copolymer of polylactic acid and polyglycolic acid, a copolymer of glycolic acid with other hydroxy-, carboxylic acid-, or hydroxycarboxylic acid-containing moieties, and a copolymer of lactic acid with other hydroxy-, carboxylic acid or hydroxycarboxylic acid-containing moieties. The solid acid-precursor may be mixed with a solid acid-reactive material to accelerate the hydrolysis and / or coated to slow the hydrolysis. Water-soluble liquid compounds are also given that accelerate the hydrolysis. The method ensures that the acid contacts fracture faces far from the wellbore.

Owner:SCHLUMBERGER TECH CORP

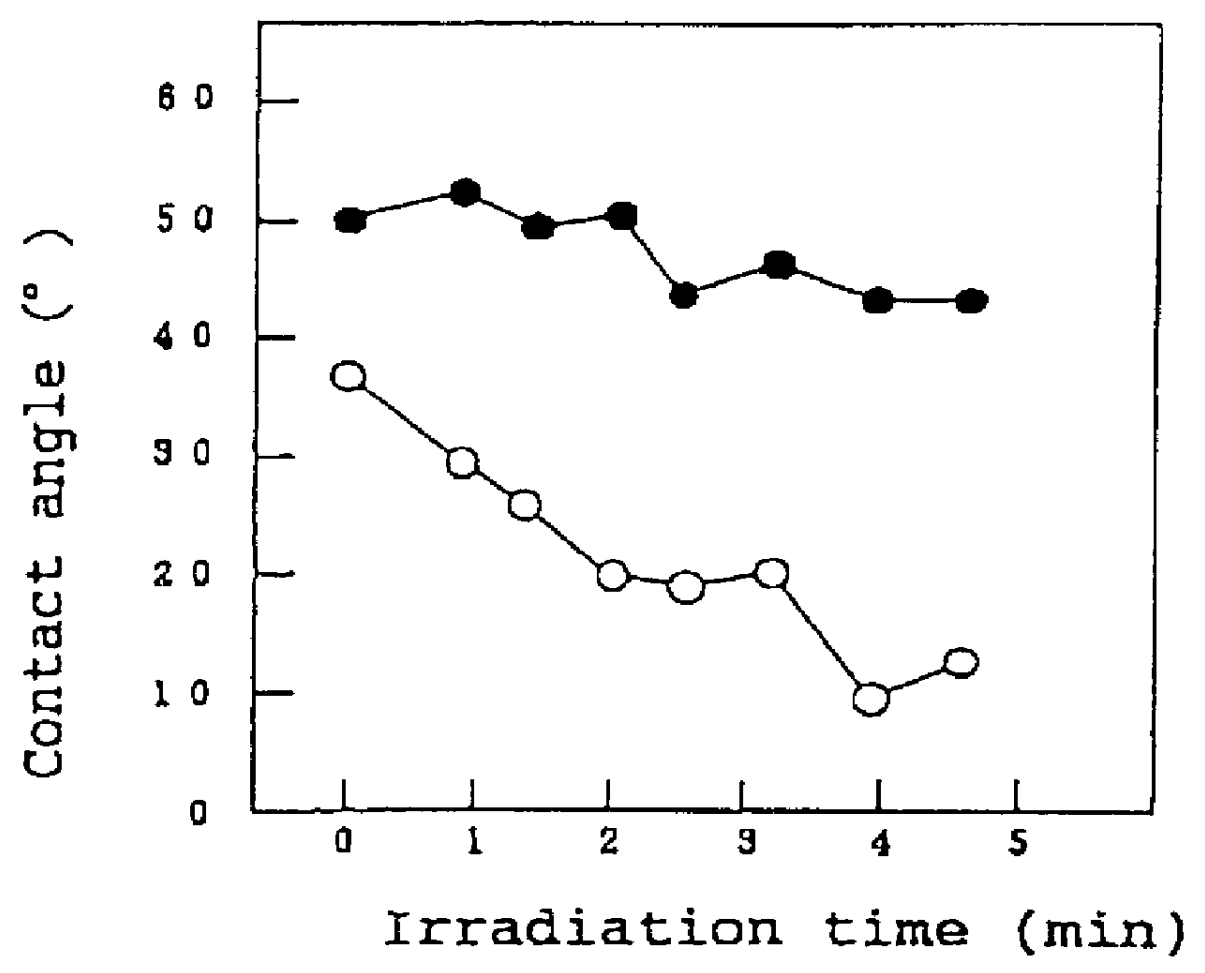

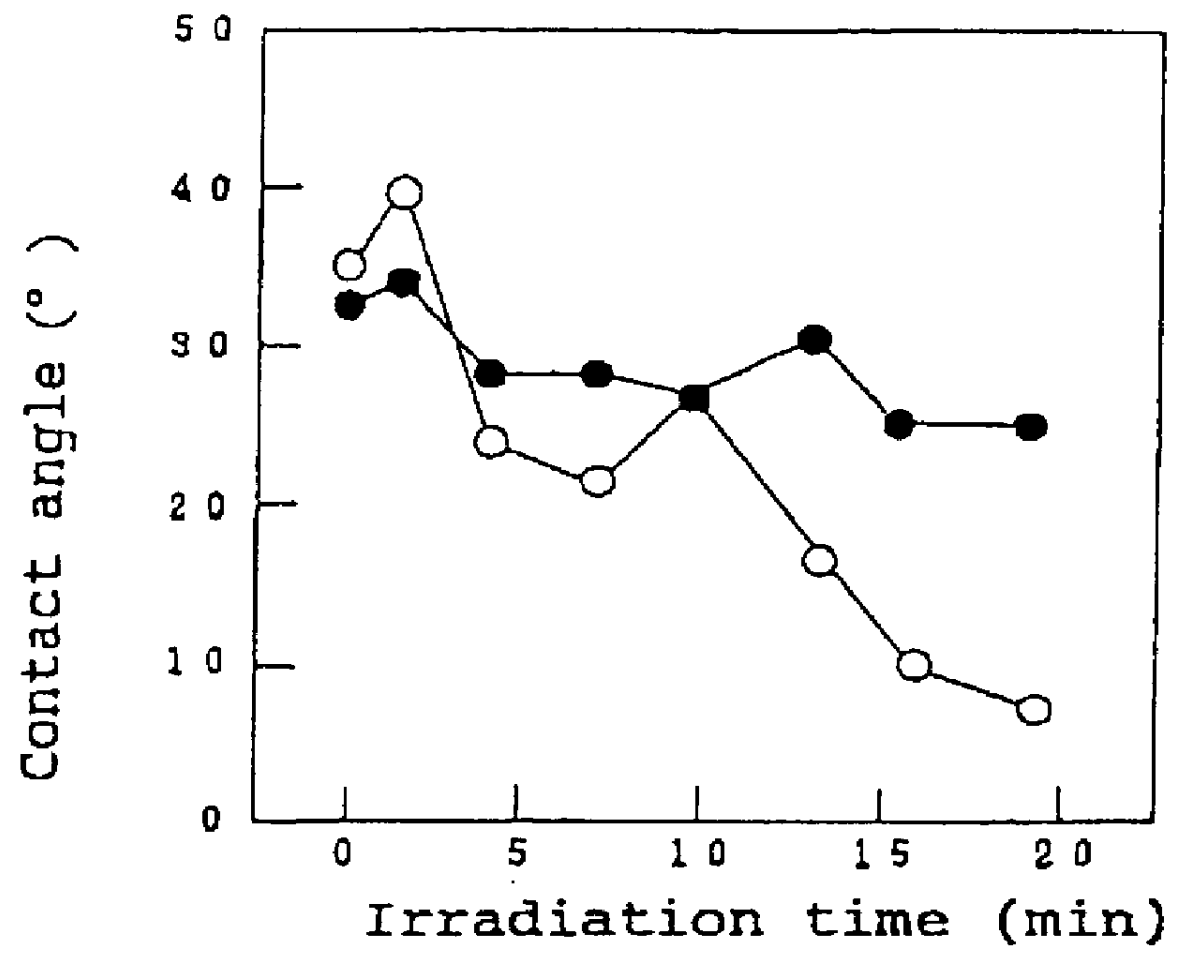

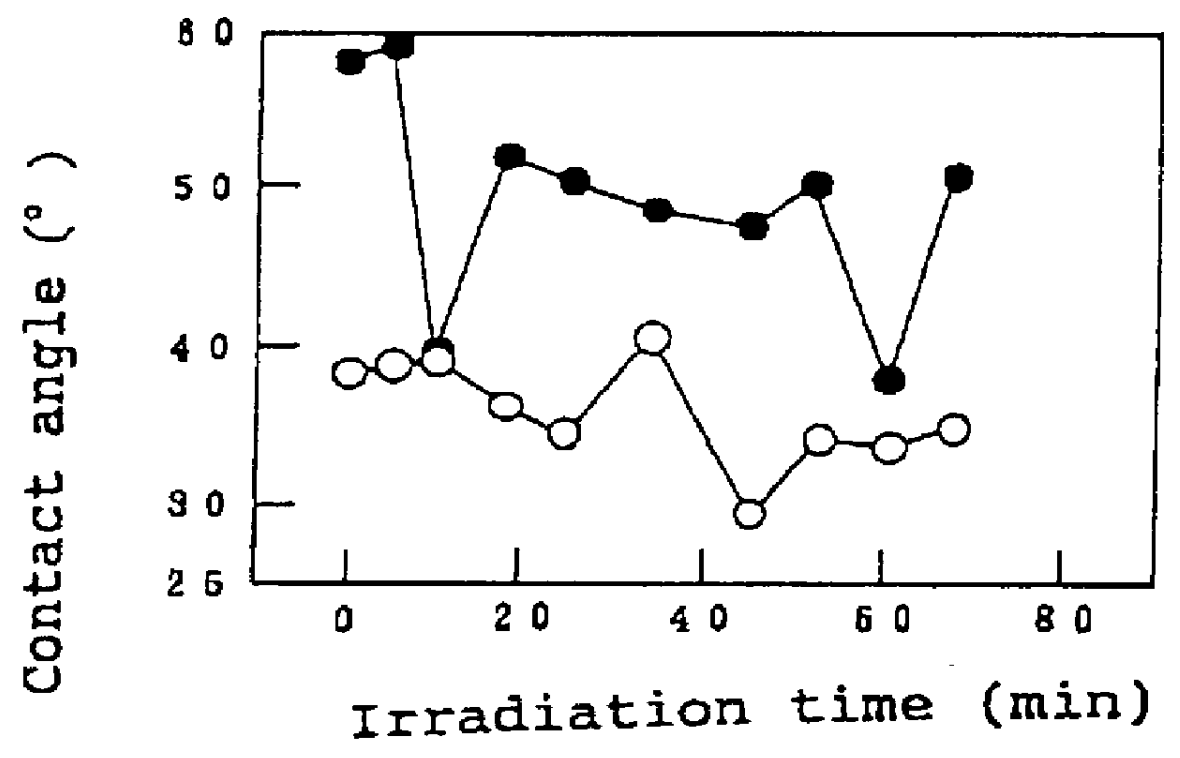

Method for photocatalytically hydrophilifying surface and composite material with photocatalytically hydrophilifiable surface

InactiveUS6090489AImproved oil repellencyEasy to disassembleOther chemical processesPretreated surfacesAtmospheric airSolid acid

A method for hydrophilifying the surface of a substrate by taking advantage of photocatalytic action. The substrate has a photocatalytic titania coating (10). The surface of the photocatalytic coating (10) bears the solid acid that increases a hydrogen bond component ( gamma Sh) in the surface energy in the solid / gas interface of the coating. Photoexcitation of the photocatalyst enhances the hydrogen bond component ( gamma Sh) in the surface energy of the photocatalytic coating (10), accelerating the physical adsorption of molecules of water in the atmosphere through a hydrogen bond (16) onto hydrogen atoms in a terminal OH group (12), bonded to a titanium atom, and a bridge OH group (14) on the surface of the coating. This results in the formation of a high density, physically adsorbed water layer (18) on the surface of the photocatalytic coating (10), thus permitting the surface of the substrate to be easily hydrophilified. The method is applicable to antifogging, antifouling, selfcleaning and cleaning of articles.

Owner:TOTO LTD

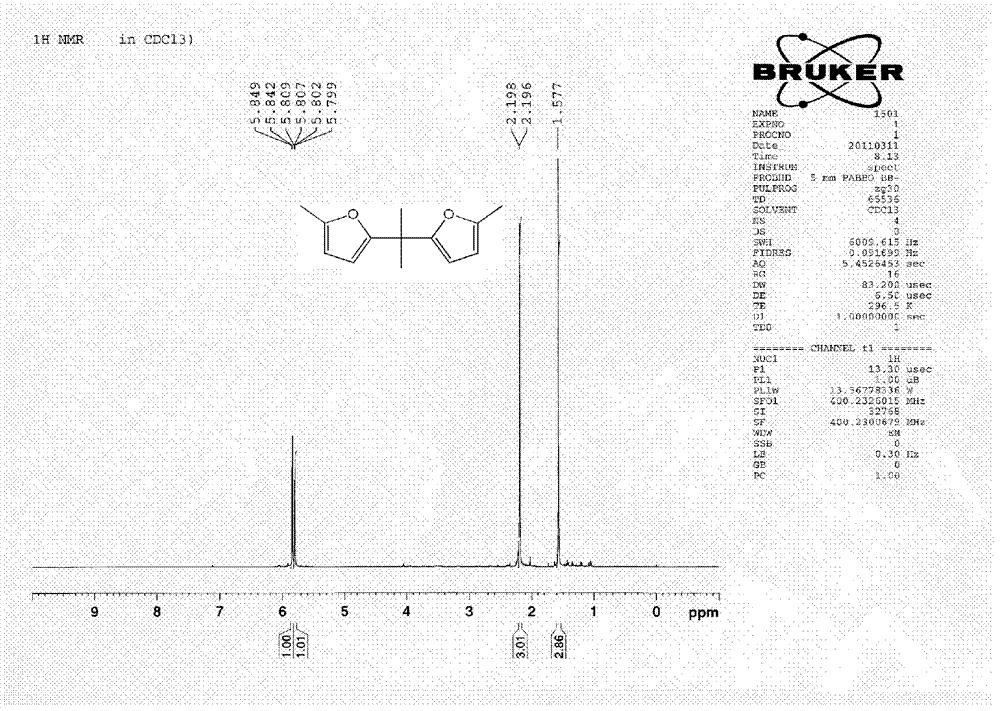

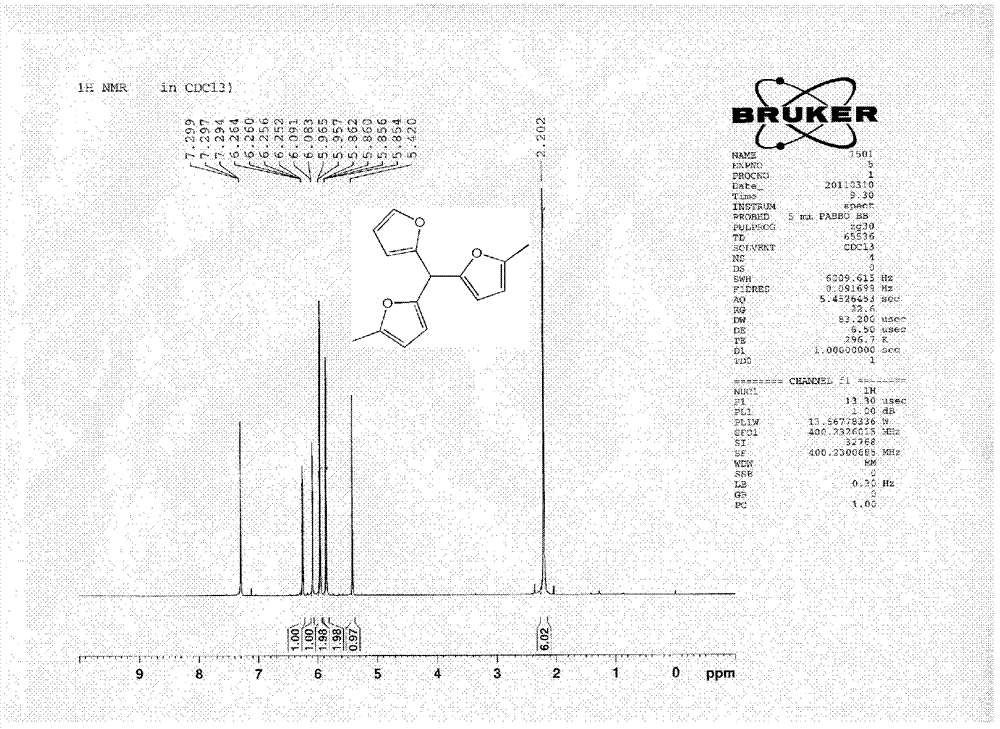

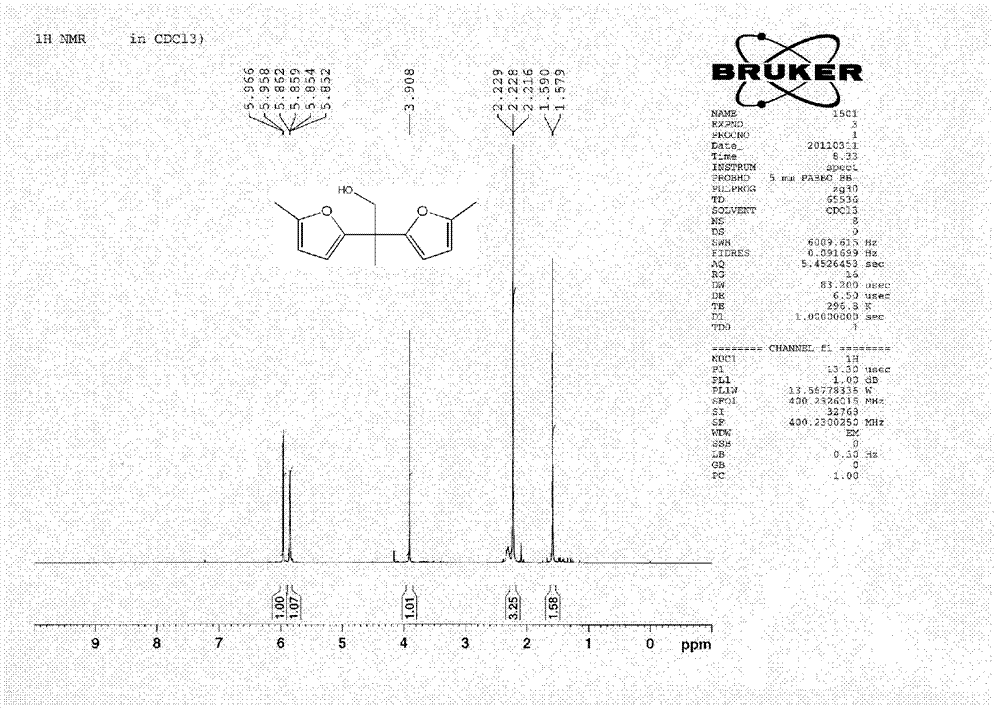

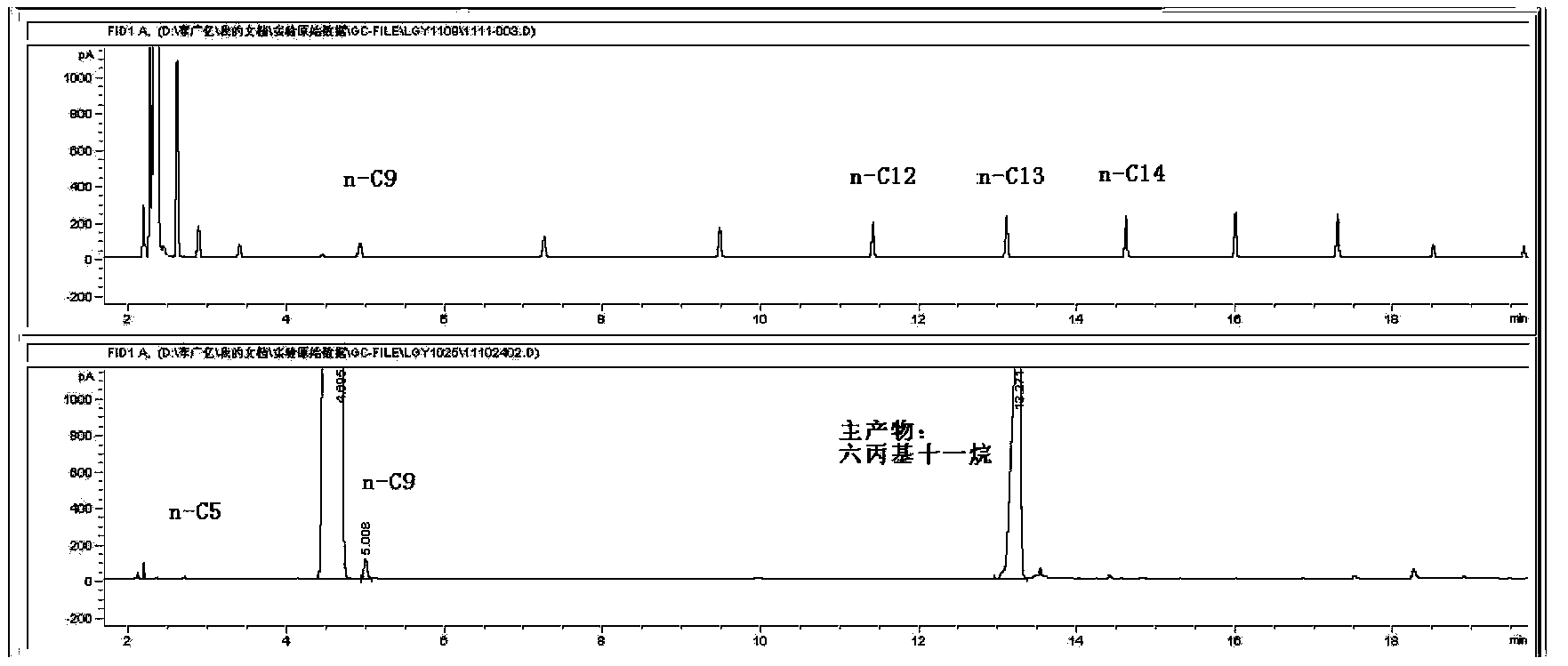

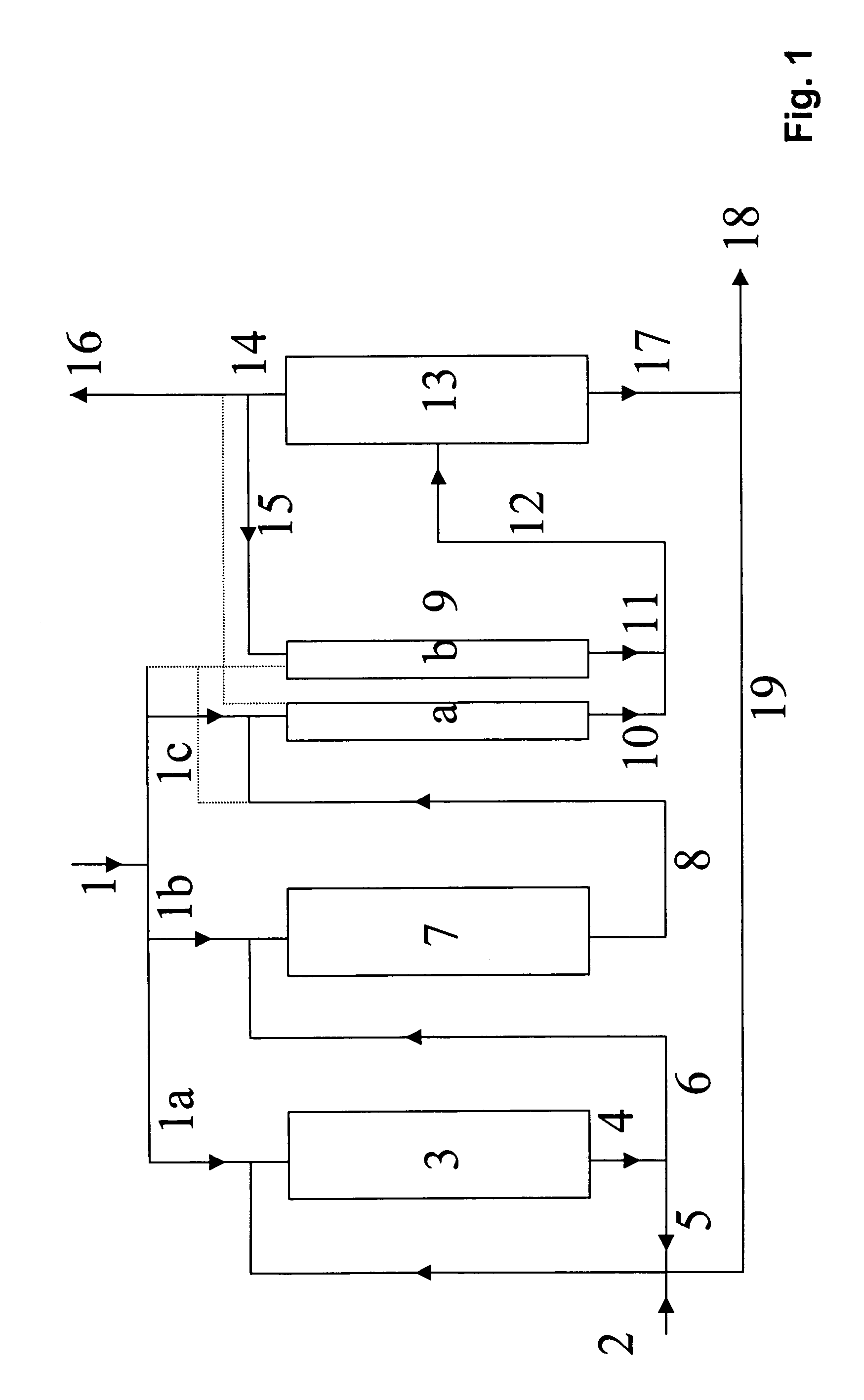

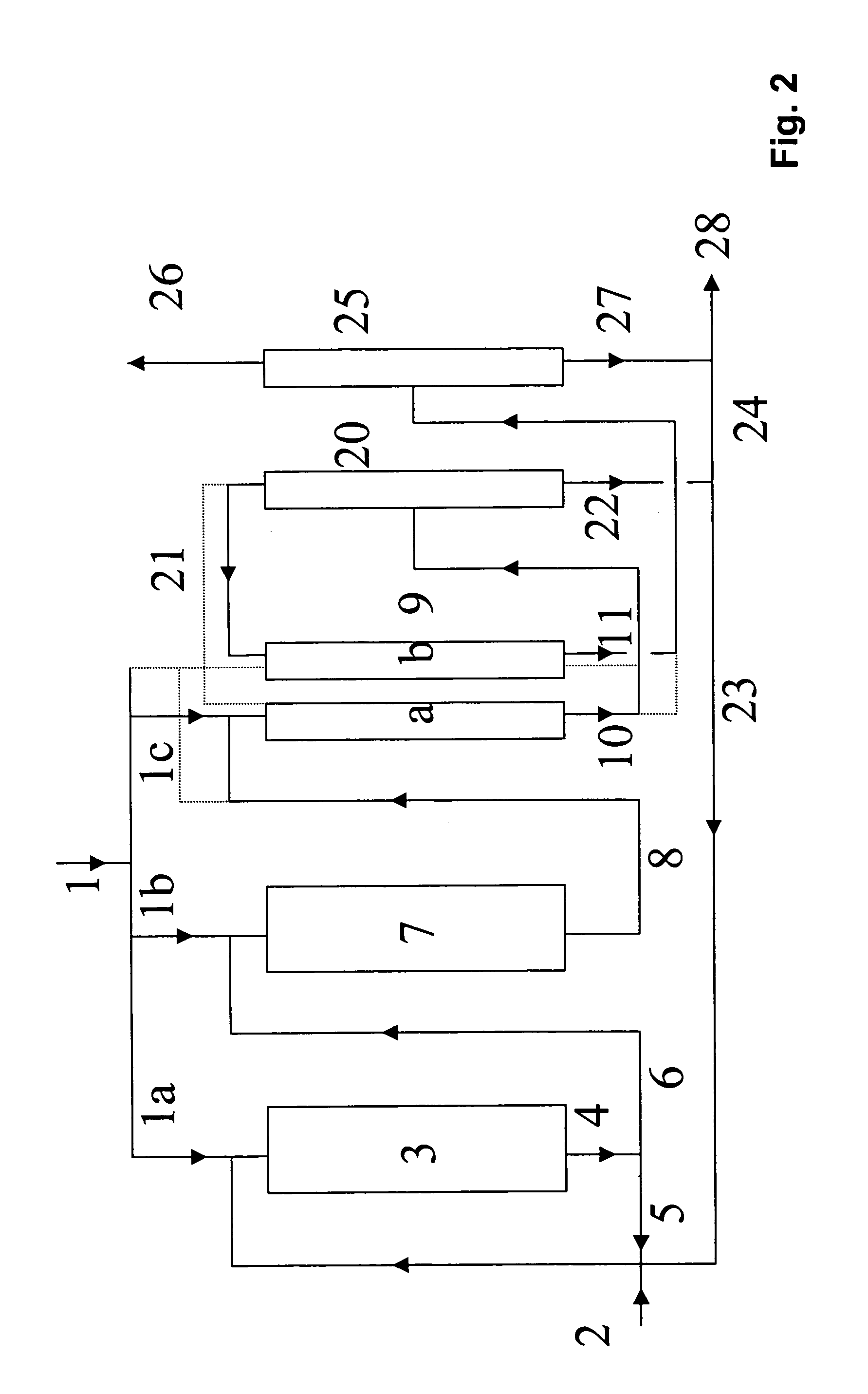

Preparation method of aviation kerosene or diesel

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

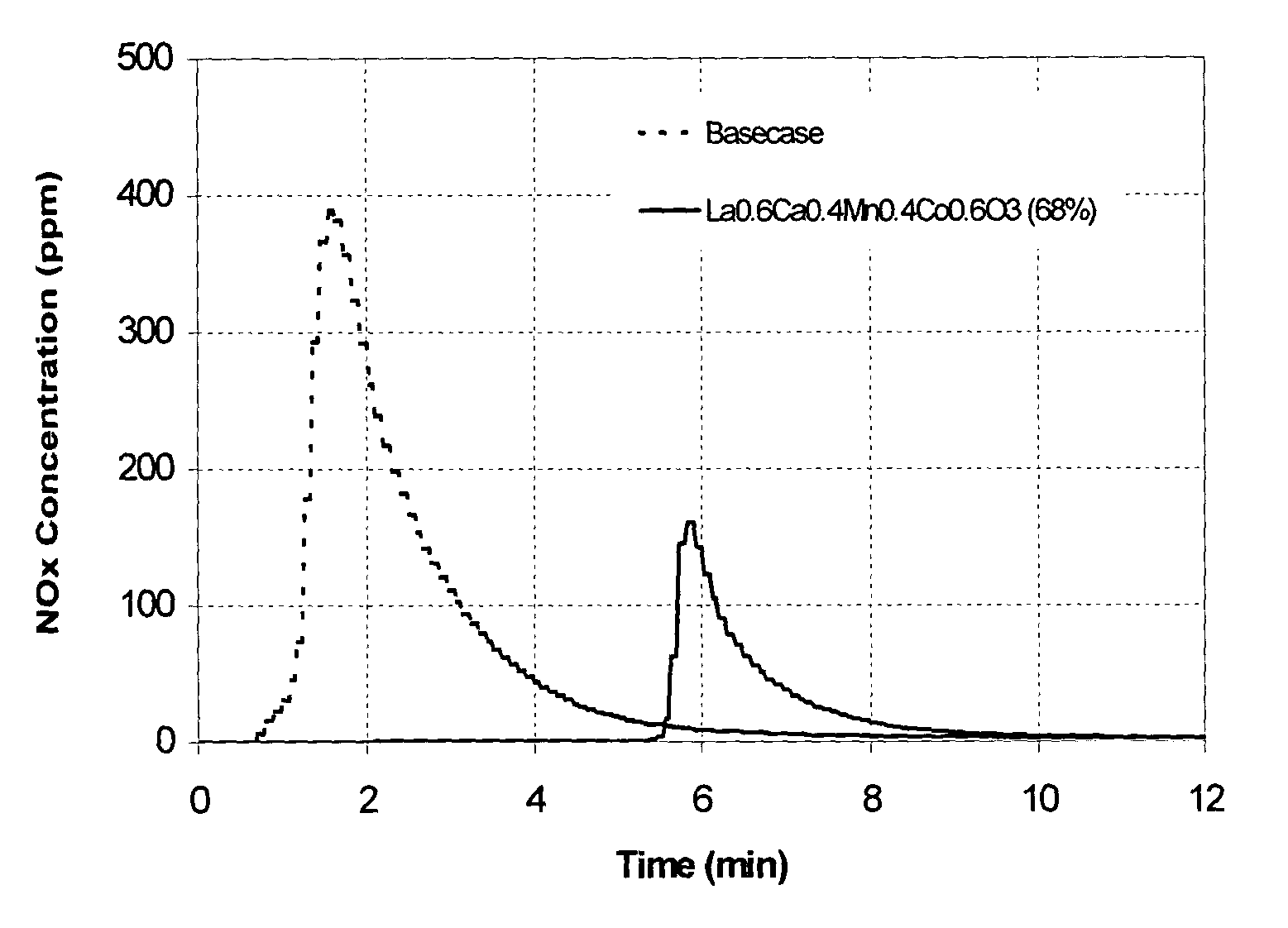

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst system contains at least one solid acid component and at least one metal-based component which consists of (a) oxygen and / or sulfur and (b) a metal combination selected from the group consisting of: i) at least one metal from Group 3 and at least one metal from Groups 4-15 of the Periodic Table of the Elements; ii) at least one metal from Groups 5-15 of the Periodic Table of the Elements, and at least one metal from at least one of Groups 1, 2, and 4 of the Periodic Table of the Elements; iii) at least one metal from Groups 1 and 2, at least one metal from Group 3, and at least one metal from Groups 4-15 of the Periodic Table of the Elements; and iv) two or more metals from Groups 4-15 of the Periodic Table of the Elements, wherein the at least one of oxygen and sulfur is chemically bound both within and between the metals and, optionally, (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone. Further the emissions of NOx from the regeneration cycle of the catalyst system are reduced.

Owner:EXXONMOBIL CHEM PAT INC

Solid-acid isomerization catalyst and process

ActiveUS7041866B1Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component comprising at least one Group III A (IUPAC 13) component, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

InactiveCN102686521AStabilizationImprove purification effectWater contaminantsCatalyst activation/preparationIridiumWater use

Disclosed are: a catalyst which can exhibit an excellent catalytic activity and excellent durability for a long period in the wet oxidation treatment of waste water; a wet oxidation treatment method for waste water using the catalyst; and a novel method for treating waste water containing a nitrogenated compound, in which a catalyst to be used has a lower catalytic cost, the waste water containing the nitrogenated compound can be treated at high purification performance, and the high purification performance can be maintained. The catalyst for use in the treatment of waste water comprises an oxide of at least one element selected from the group consisting of iron, titanium, silicon, aluminum, zirconium and cerium as a component (A) and at least one element selected from the group consisting of silver, gold, platinum, palladium, rhodium, ruthenium and iridium as a component (B), wherein at least 70 mass% of the component (B) is present in a region positioned within 1000 [mu]m from the outer surface of the component (A) (i.e., the oxide), the component (B) has an average particle diameter of 0.5 to 20 nm, and the solid acid content in the component (A) (i.e., the oxide) is 0.20 mmol / g or more. The waste water treatment method uses a catalyst (a pre-catalyst) which is placed on an upstream side of the direction of the flow of the waste water and can convert the nitrogenated compound contained in the waste water into ammoniacal nitrogen in the presence of an oxidizing agent at a temperature of not lower than 100 DEG C and lower than 370 DEG C under a pressure at which the waste water can remain in a liquid state and a downstream-side catalyst (a post-catalyst) which is placed downstream of the direction of the flow of the waste water and can treat the waste water containing ammoniacal nitrogen.

Owner:NIPPON SHOKUBAI CO LTD

Solid acid cleaning block and method of manufacturing

InactiveUS6432906B1Enhance and extend performanceOrganic detergent compounding agentsAnionic surface-active compoundsGeneral purposeSolid acid

A stable, substantially homogeneous, solid block cleaning composition can be made for general purpose cleaning and for cleaning hard surfaces such as floors of varying surface composition. Unique solid block materials contain substantially useful concentrations of liquid acid materials, but are in the form of a stable solid. The acidic solid detergent can be dispensed using a water spray creating a concentrate which can then be diluted in proper ratio to form the use-solution. Such use-solutions may be applied to remove a variety of soils subject to acid cleaning including soils containing water hardness components, inorganic soils, and the like. The acid cleaners can be used alone or in combination with other cleaners in a cleaning protocol for a variety of hospitality, industrial or institutional cleaning locations having a broad spectrum of contaminated soil residue.

Owner:ECOLAB USA INC

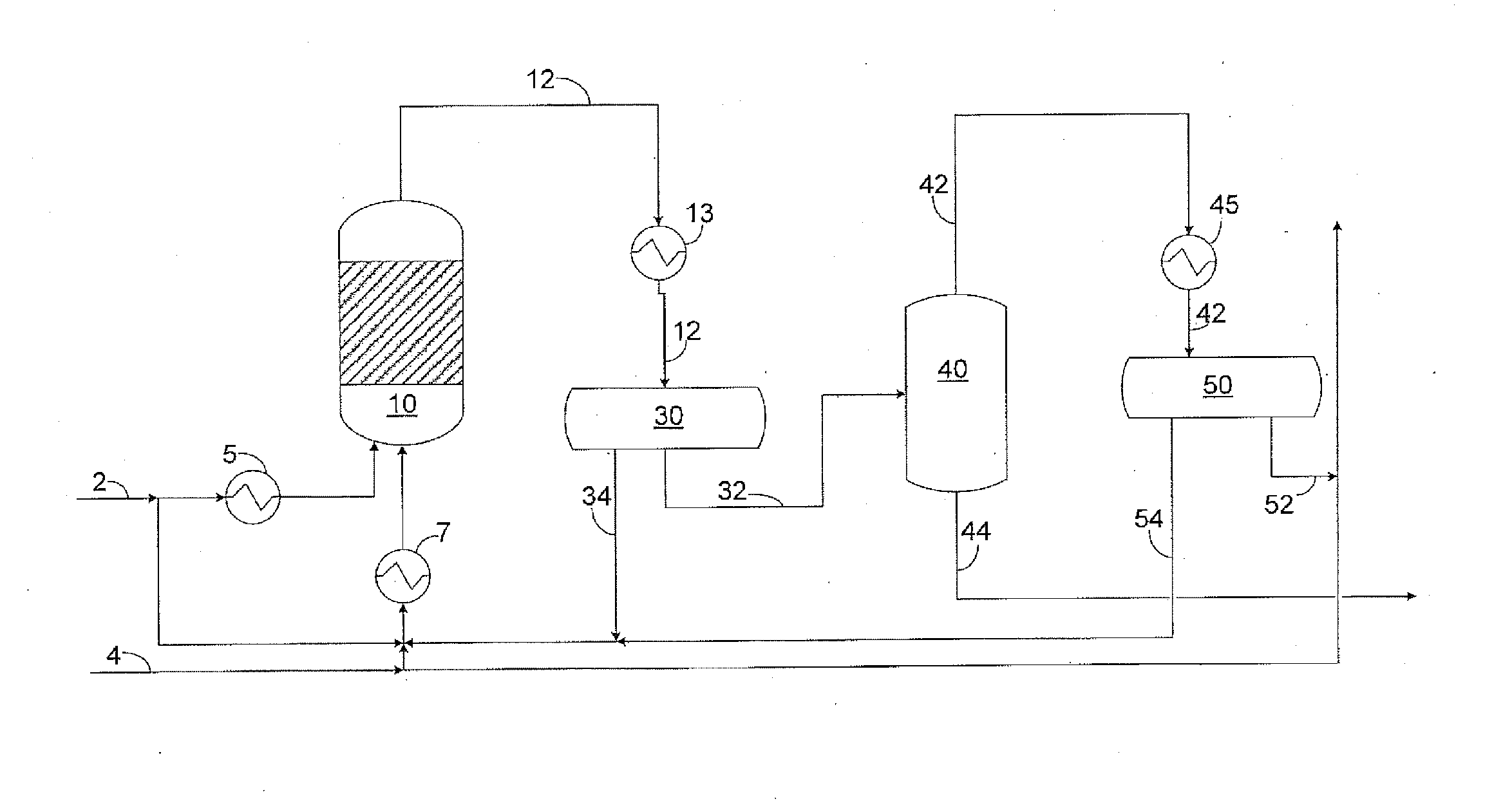

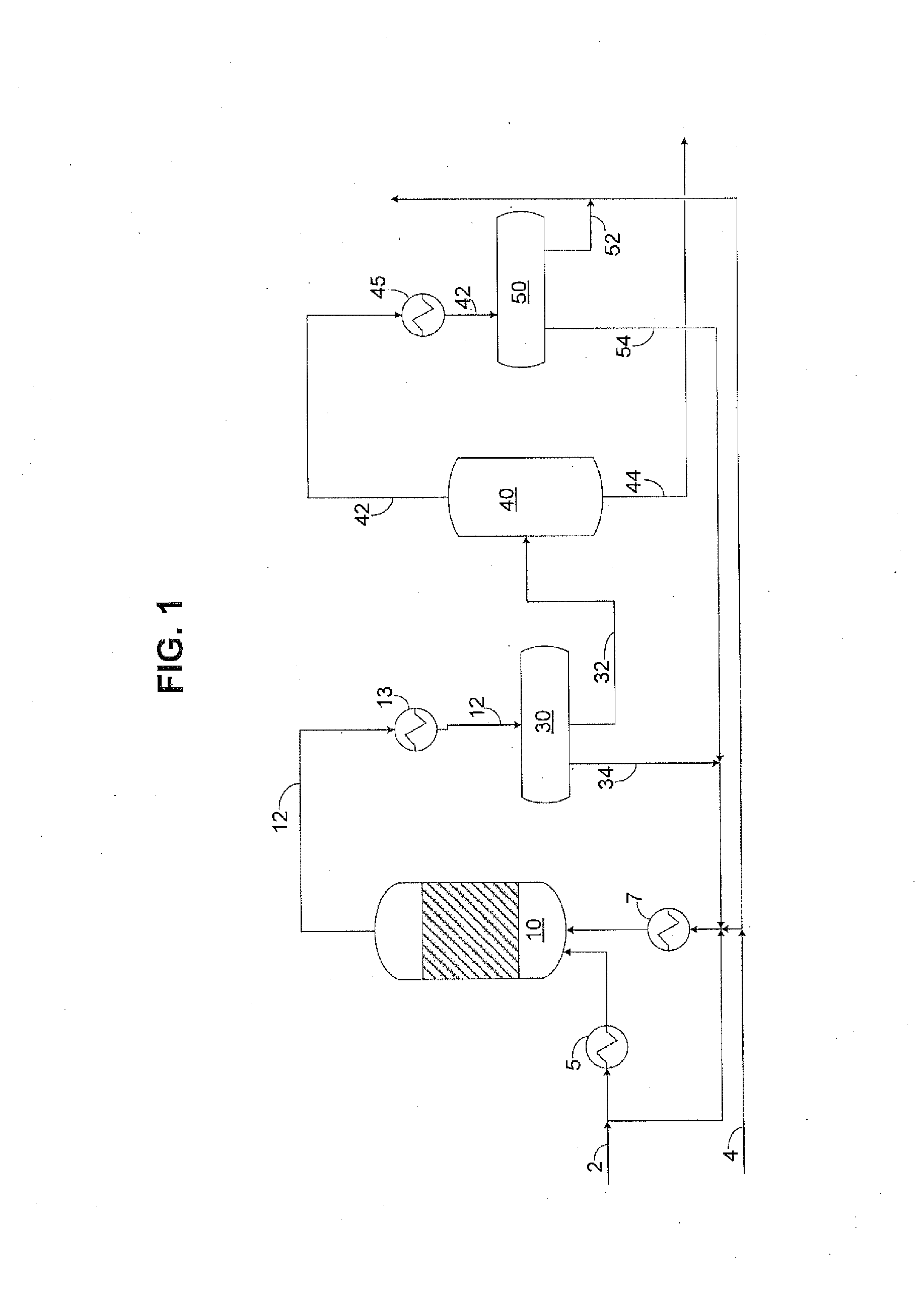

Production of fuels and lube oils from fischer-tropsch wax

Dewaxed fuel and lubricant base stocks are made by (a) producing a synthesis gas from natural gas, (b) reacting the H2 and CO in the gas in the presence of a cobalt Fischer-Tropsch catalyst, at reaction conditions effective to synthesize a waxy hydrocarbon feed boiling in the fuel and lubricant oil ranges, which is hydrodewaxed in a first stage to produce a dewaxed fuel and a partially dewaxed lubricant fraction. The partially dewaxed lubricant fraction is separated into heavy and lower boiling fractions each of which is separately hydrodewaxed, to produce lubricant base stocks. A hydrodewaxing catalyst comprising a hydrogenation component, binder and solid acid component used to hydrodewax at least one, and preferably at least two of the waxy feed and partially dewaxed heavy and lower boiling lubricant fractions.

Owner:EXXON RES & ENG CO

Method for preparing biodiesel by solid acid-base catalyst

InactiveCN1580190AWide variety of sourcesNo pollution in the processBiofuelsLiquid hydrocarbon mixture productionWater bathsBiodiesel

The invention relates a kind of preparation method of bio-diesel oil under the condition of solid ac and alk catalyzing. The character is that under the condition of solid ac and alk catalyzing, gain the bio-diesel oil using the craft of exchange reaction of soja oil with carbinol. Afer the reaction, apart catalyser from reaction liquor by centrifugal machine till delimination in quiet placing, the above is rough output, the below is admixture of glycerol and carbinol. Distil the of above to gain bio-diesel oil and to gain the pure glycerin in the same way. The distilled carbinol can be used again and again. The invention has many advantages, for example, its raw material can be rebirth, its craft is easy and only need normal equipment. Even treat the used oil, the whole process is easier compared with the method in solid ac and alk catalyzing, besides, the process will not produce foul water so it is environmental. Every plant of the bio-diesel accords with standards compared with foreign similar competitive grade and the main plants are close to its of 0# (GB252-1994, superior product)diesel of China.

Owner:BEIJING UNIV OF CHEM TECH

Method for contemporaneously dimerizing and hydrating a feed having butene

ActiveUS20130104449A1Increased research octane numberImprove responseLiquid hydrocarbon mixtures productionCatalystsButeneOligomer

Methods for producing alcohols and oligomers contemporaneously from a hydrocarbon feed containing mixed butenes using an acid based catalyst are provided. Additionally, methods for producing fuel compositions having alcohols and oligomers prepared from mixed olefins are also provided as embodiments of the present invention. In certain embodiments, the catalyst can include a dual phase catalyst system that includes a water soluble acid catalyst and a solid acid catalyst.

Owner:SAUDI ARABIAN OIL CO

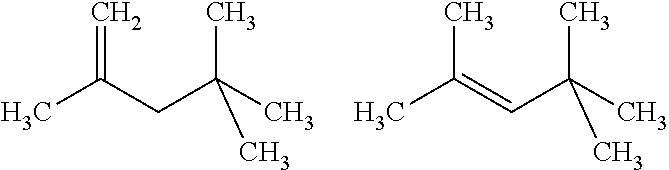

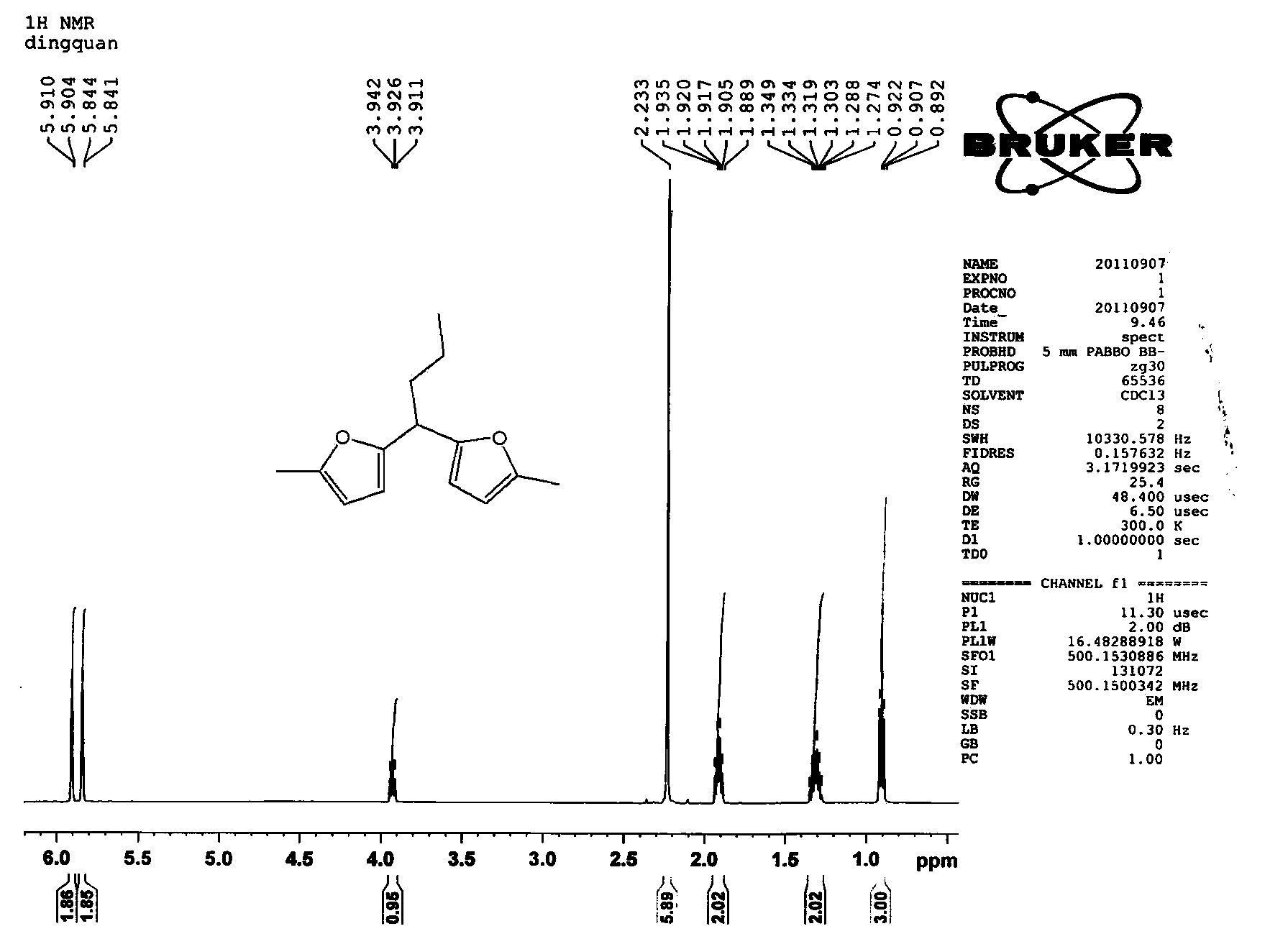

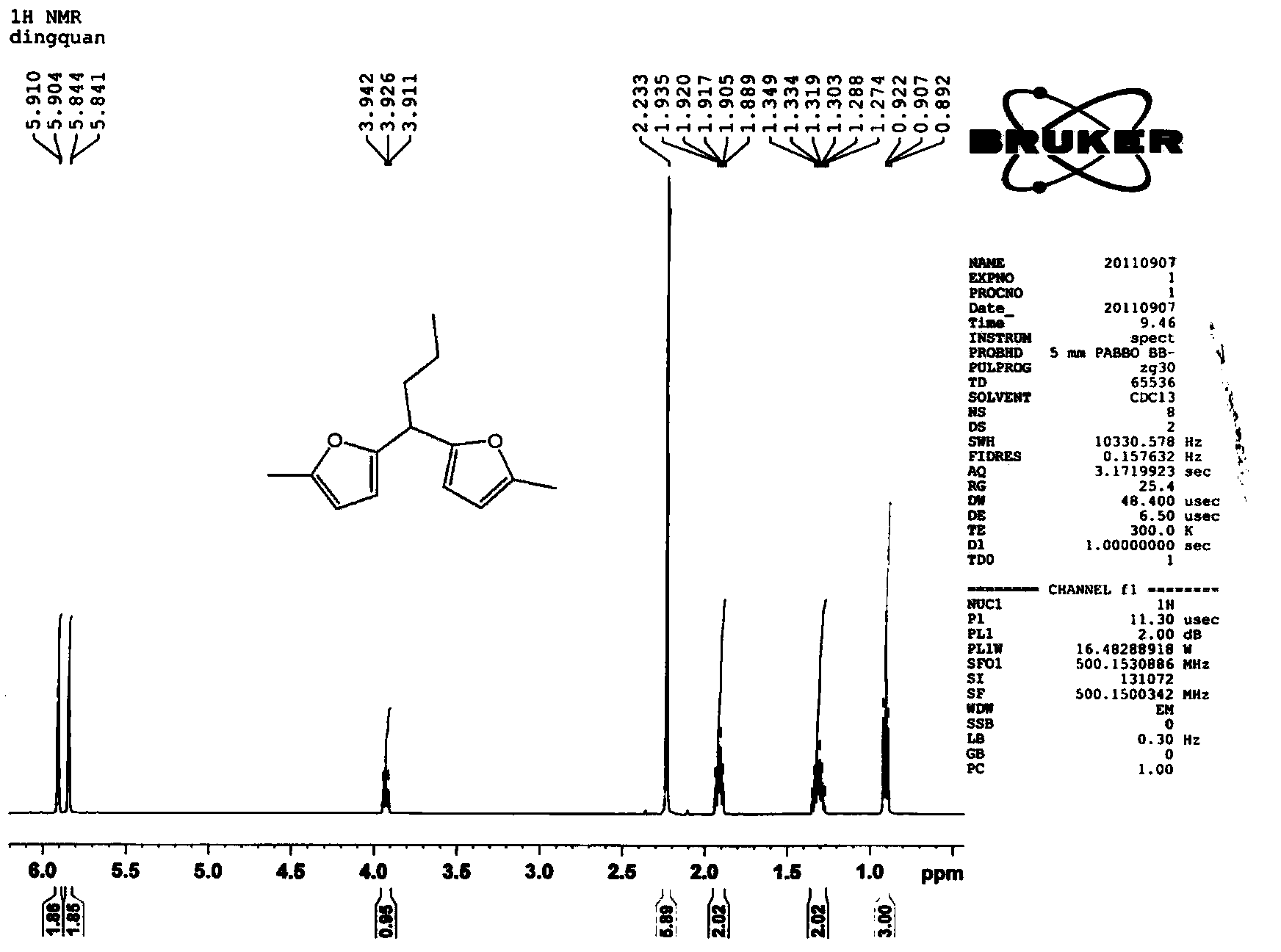

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation for hydrophobic solid acid catalyst

InactiveCN1613559AAcidicHydrophobicMolecular sieve catalystsCatalyst activation/preparationHydration reactionAlkyl transfer

A hydrophobic solid, acid catalyst for the acid catalyzing reaction, such as esterifying reaction, alkylation reaction and hydration reaction, is prepared by attaching the inorganic metal salt to the high-hydrophobicity carrier. Its advantages are high catalyst activity and selectivity, high stability, and high hydrophobicity.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Selective fracture face dissolution

A method is given for acid fracturing a subterranean formation for improving the flow of fluids. The principal source, optionally the sole source, of the acid is a solid acid-precursor, optionally injected with an additional solid that is inert and that masks a portion of the newly created fracture faces so that the fracture face etching by the acid is not uniform. The method ensures a good flow path for fluids between the fracture tip and the wellbore.

Owner:SCHLUMBERGER TECH CORP

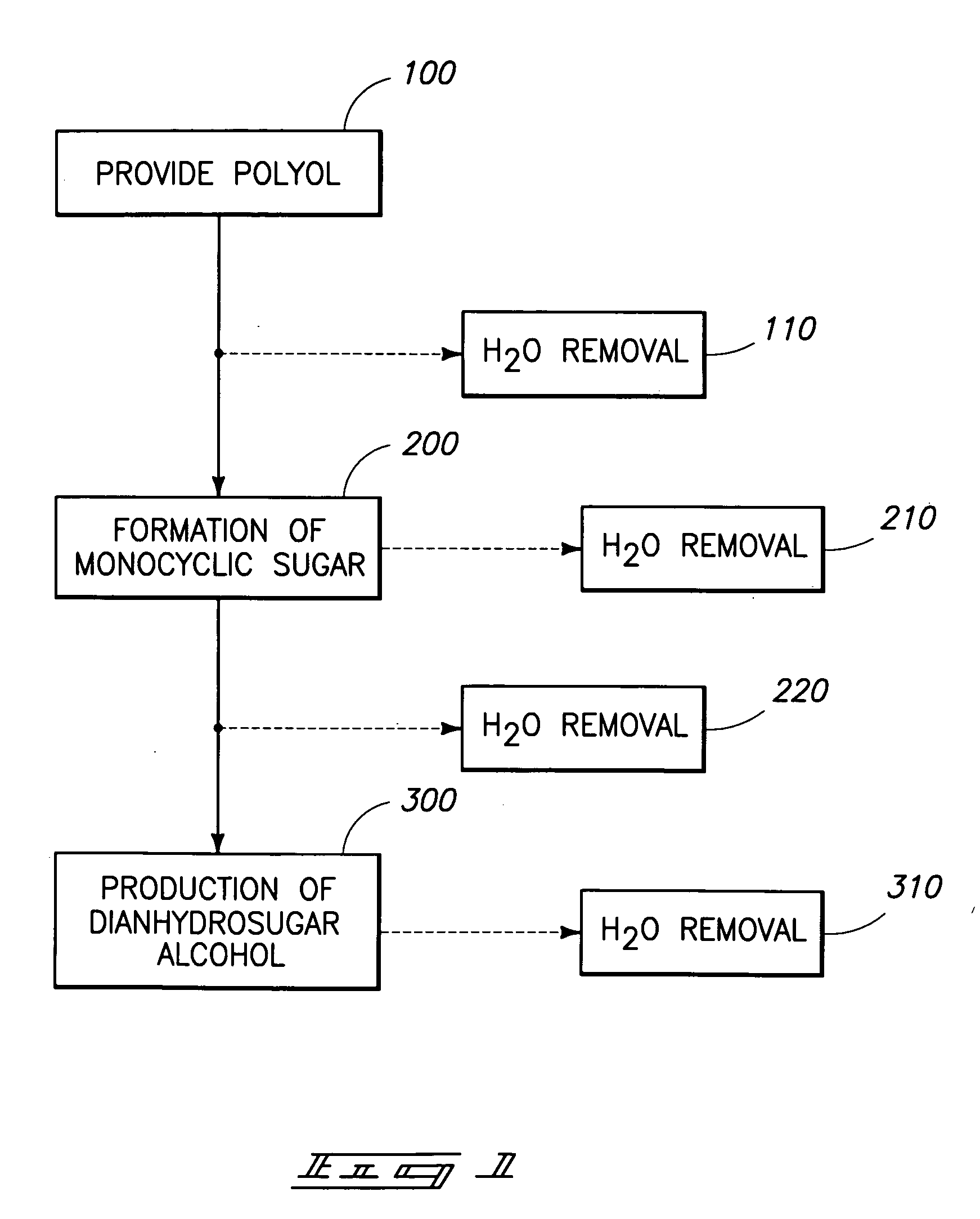

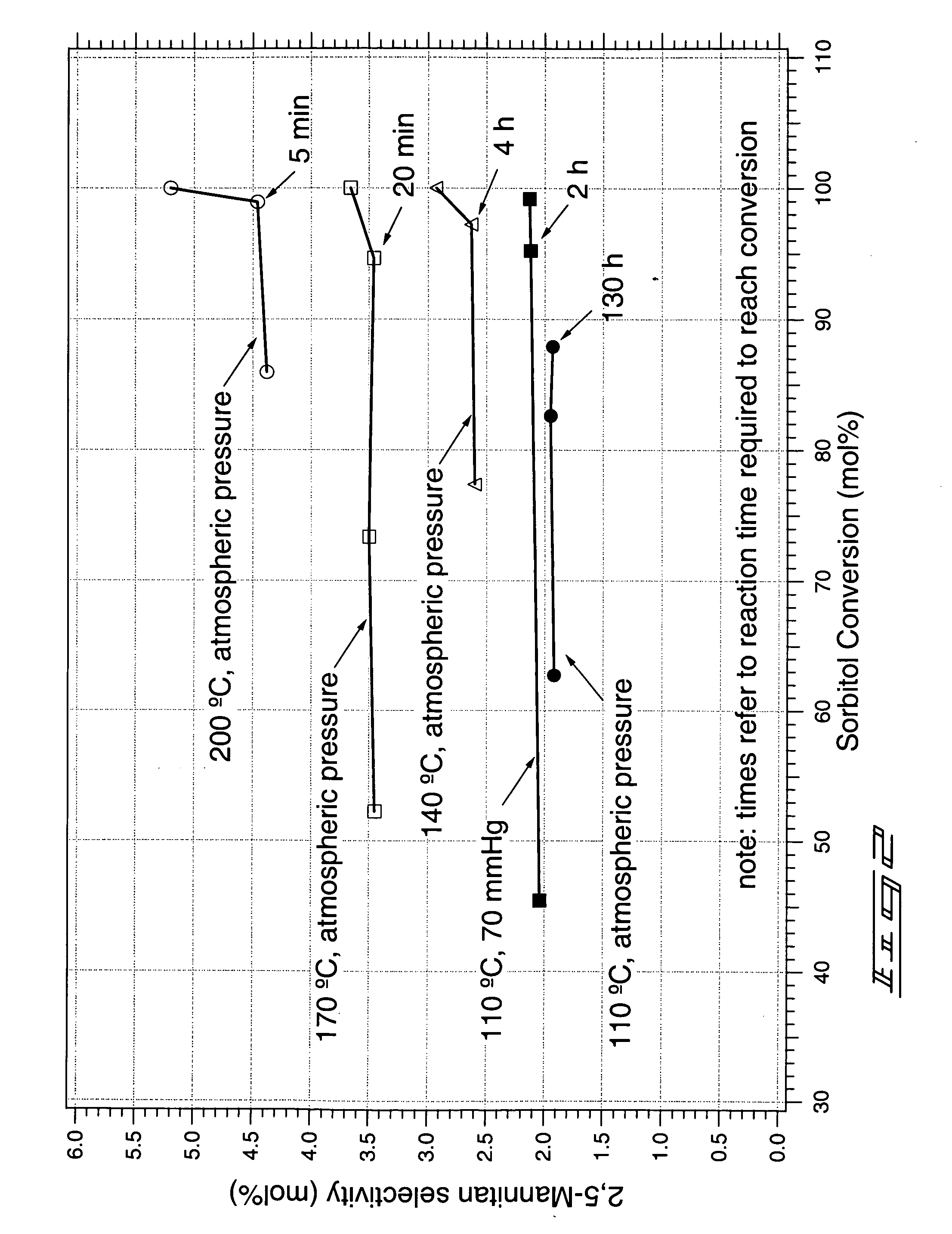

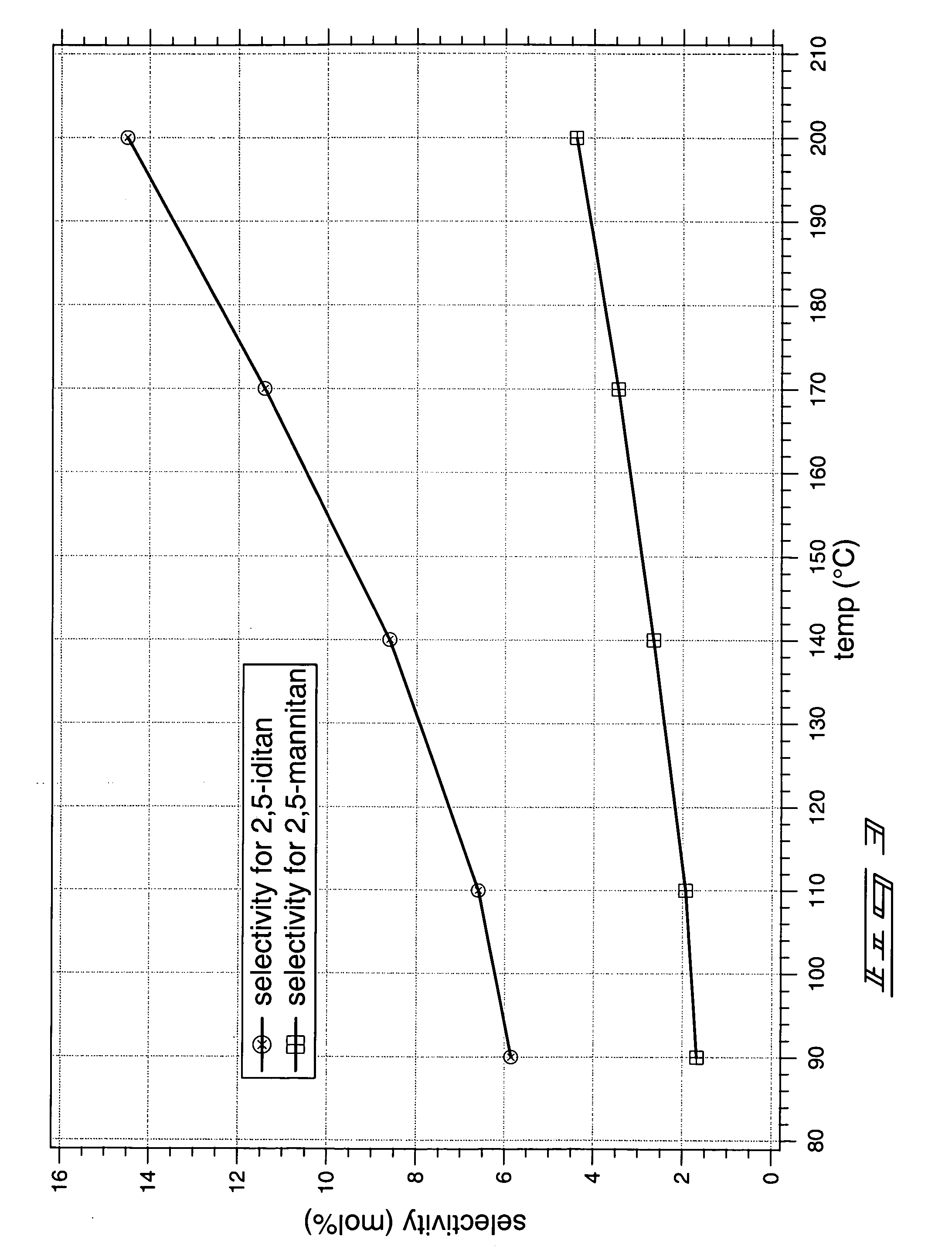

Method of forming a dianhydrosugar alcohol

The invention includes methods of producing dianhydrosugars. A polyol is reacted in the presence of a first catalyst to form a monocyclic sugar. The monocyclic sugar is transferred to a second reactor where it is converted to a dianhydrosugar alcohol in the presence of a second catalyst. The invention includes a process of forming isosorbide. An initial reaction is conducted at a first temperature in the presence of a solid acid catalyst. The initial reaction involves reacting sorbitol to produce 1,4-sorbitan, 3,6-sorbitan, 2,5-mannitan and 2,5-iditan. Utilizing a second temperature, the 1,4-sorbitan and 3,6-sorbitan are converted to isosorbide. The invention includes a method of purifying isosorbide from a mixture containing isosorbide and at least one additional component. A first distillation removes a first portion of the isosorbide from the mixture. A second distillation is then conducted at a higher temperature to remove a second portion of isosorbide from the mixture.

Owner:BATTELLE MEMORIAL INST

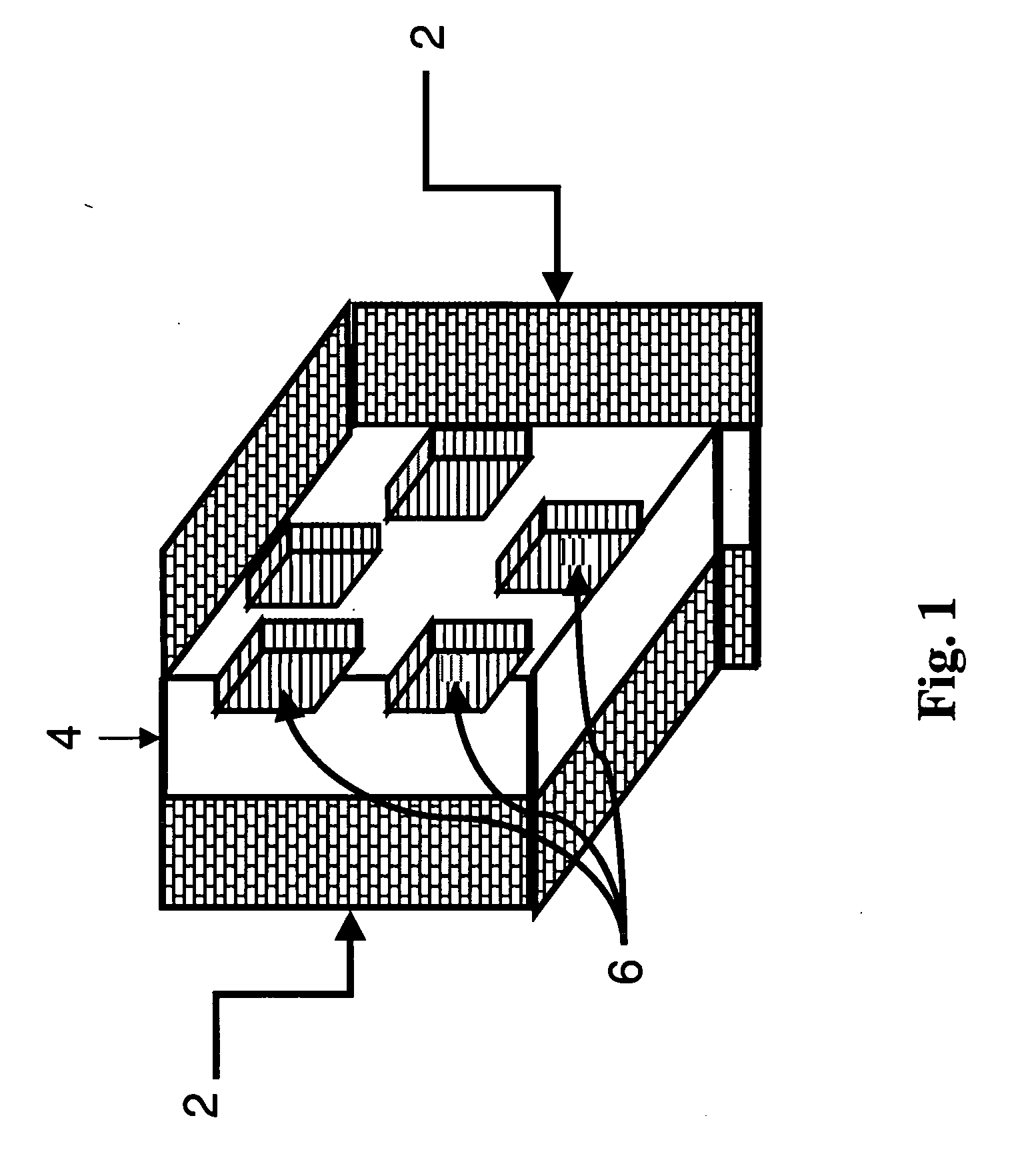

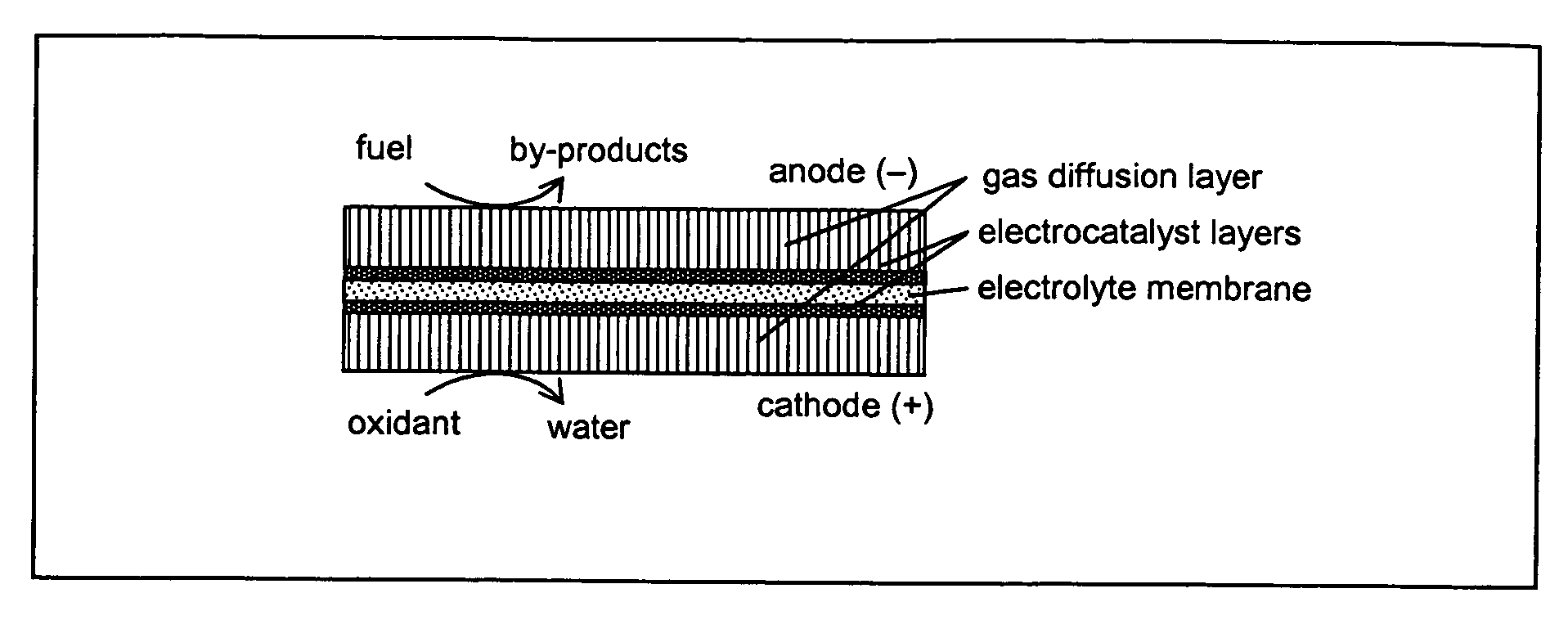

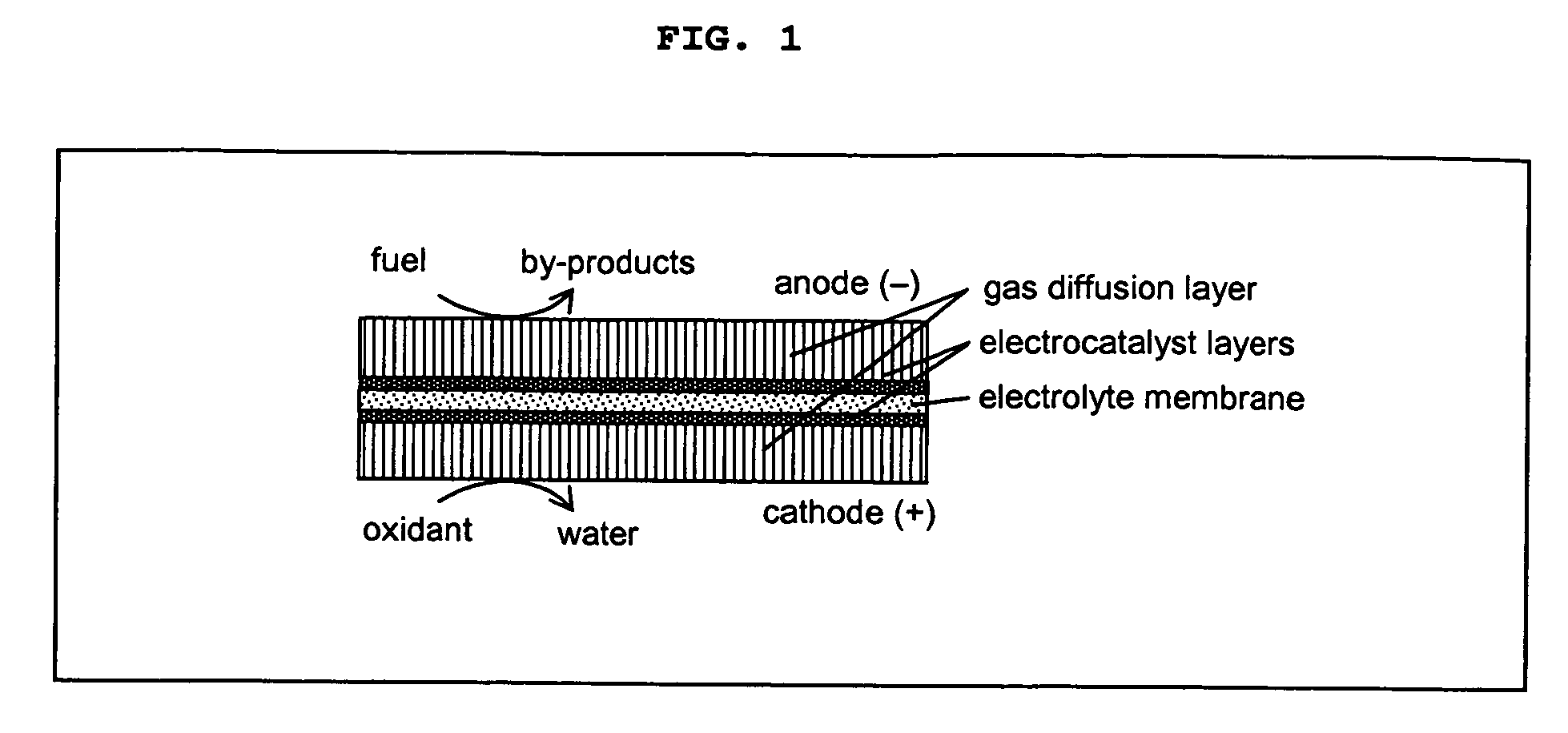

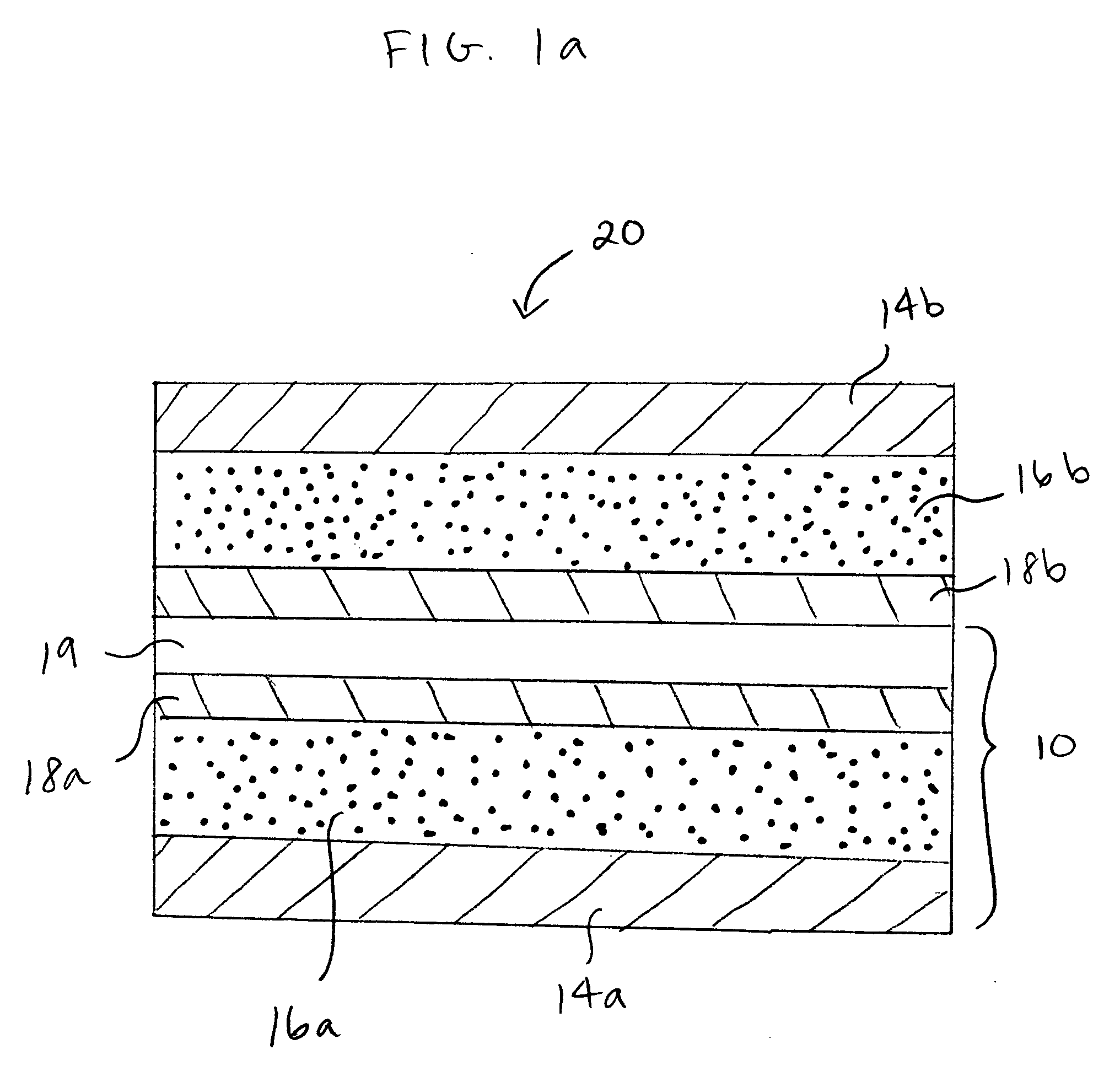

Processing techniques for the fabrication of solid acid fuel cell membrane electrode assemblies

ActiveUS20060014068A1Improve proton conductivityMaterial nanotechnologyElectrolyte holding meansFuel cellsSolid acid

Processes, techniques, and compositions used to fabricate high performance solid acid fuel cell membrane electrode assemblies are disclosed. The techniques include preparing the solid acid electrolyte material, depositing the electrolyte membrane, depositing the electrocatalyst layer, preparing the electrodes, fabricating the gas seals, and constructing the membrane electrode assembly.

Owner:CALIFORNIA INST OF TECH

Ester production method by transesterification reaction using solid acid catalyst

Owner:JAPAN ENERGY CORP

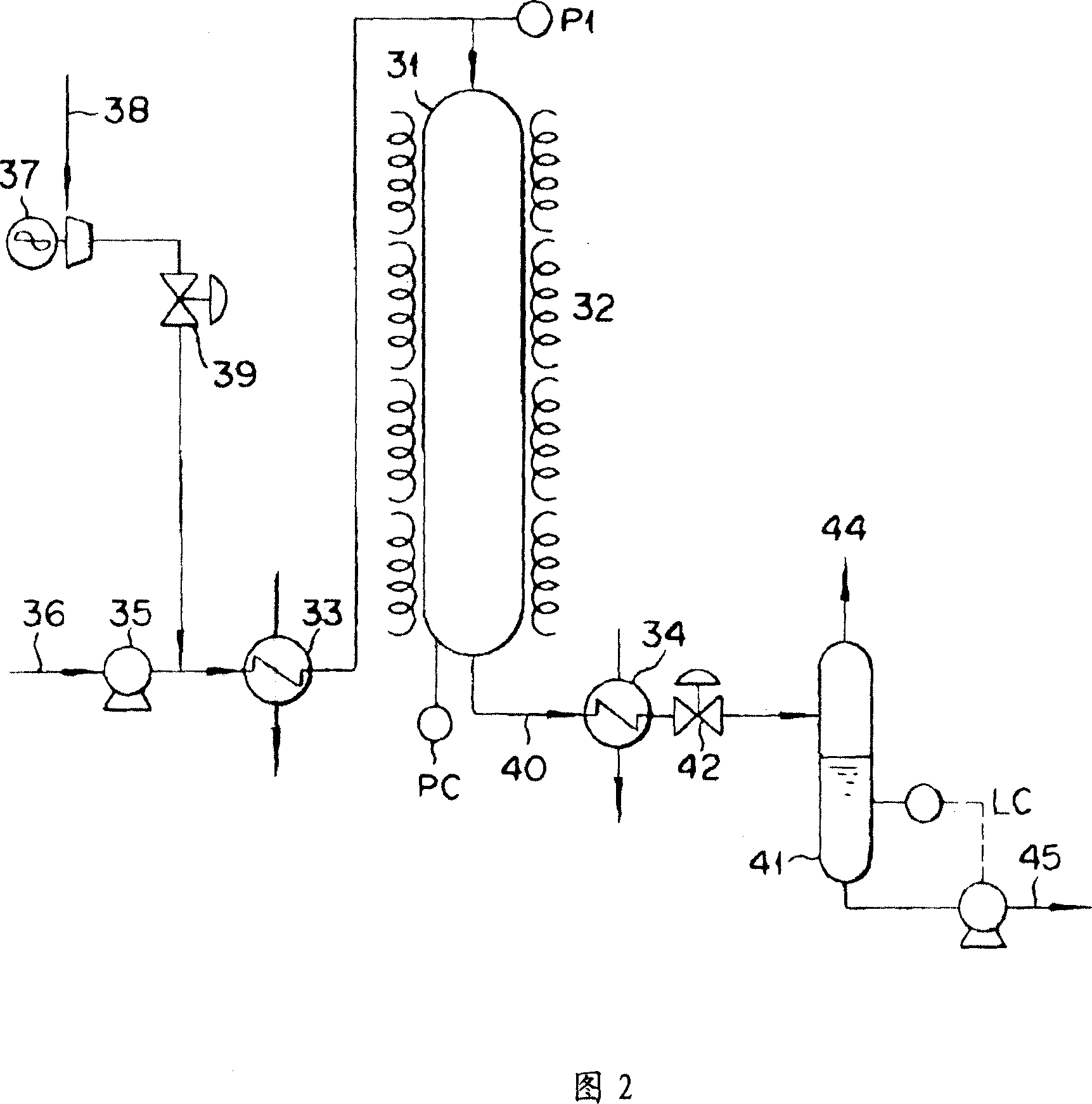

Process for preparing tert-butanol from isobutene-containing hydrocarbon mixtures

InactiveUS7002050B2Increase productionOrganic compound preparationOxygen compounds preparation by reductionHydrocarbon mixturesSolid acid

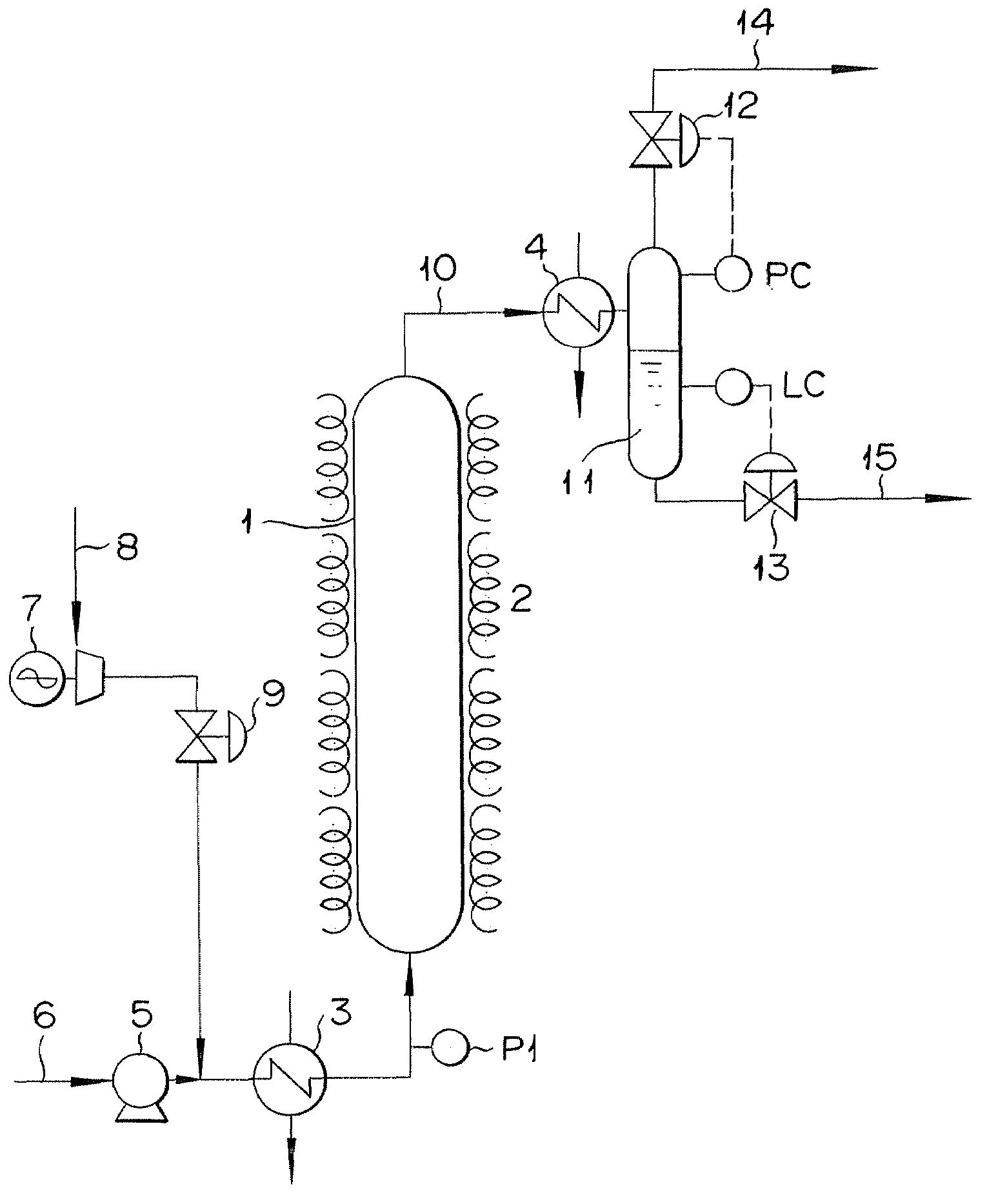

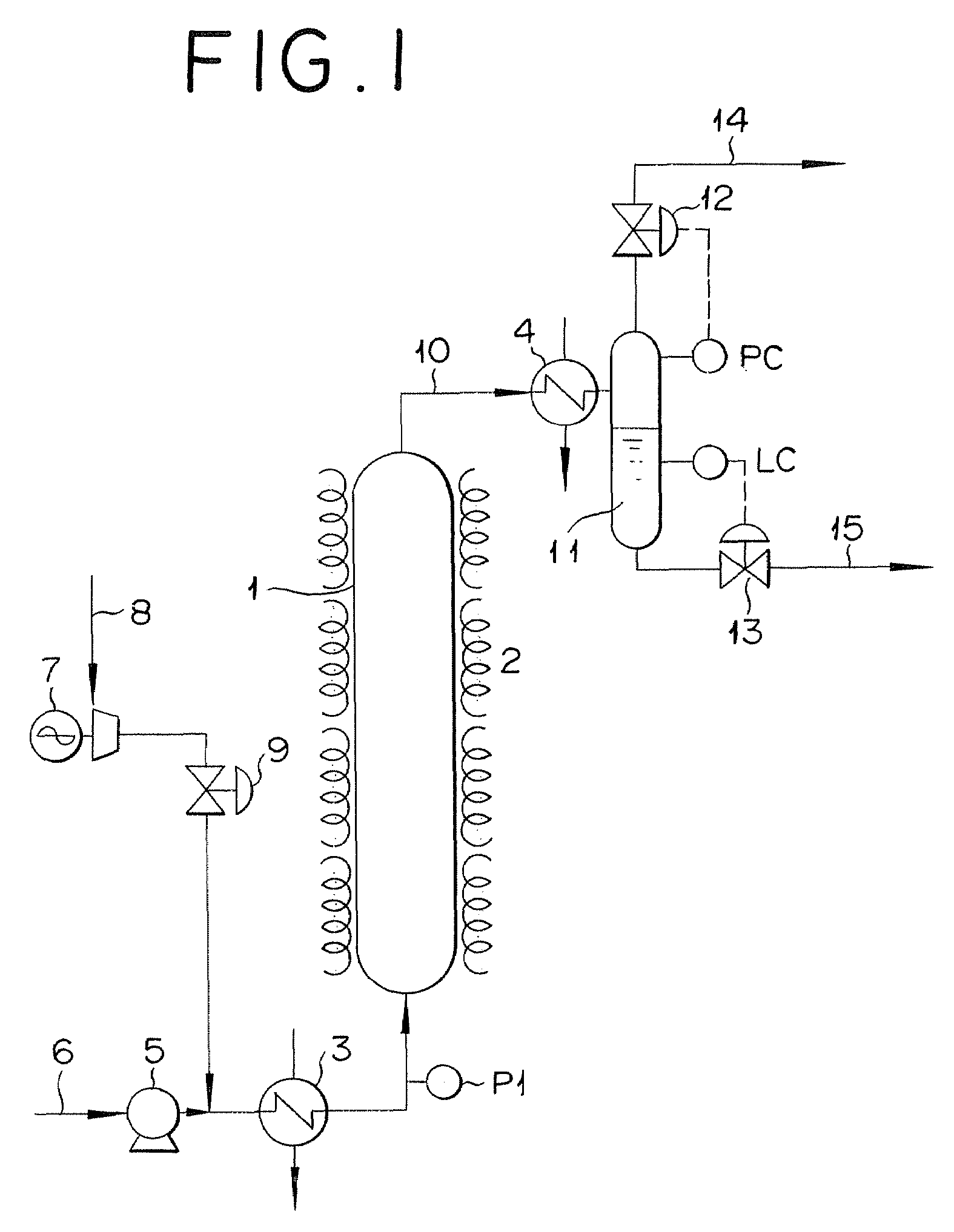

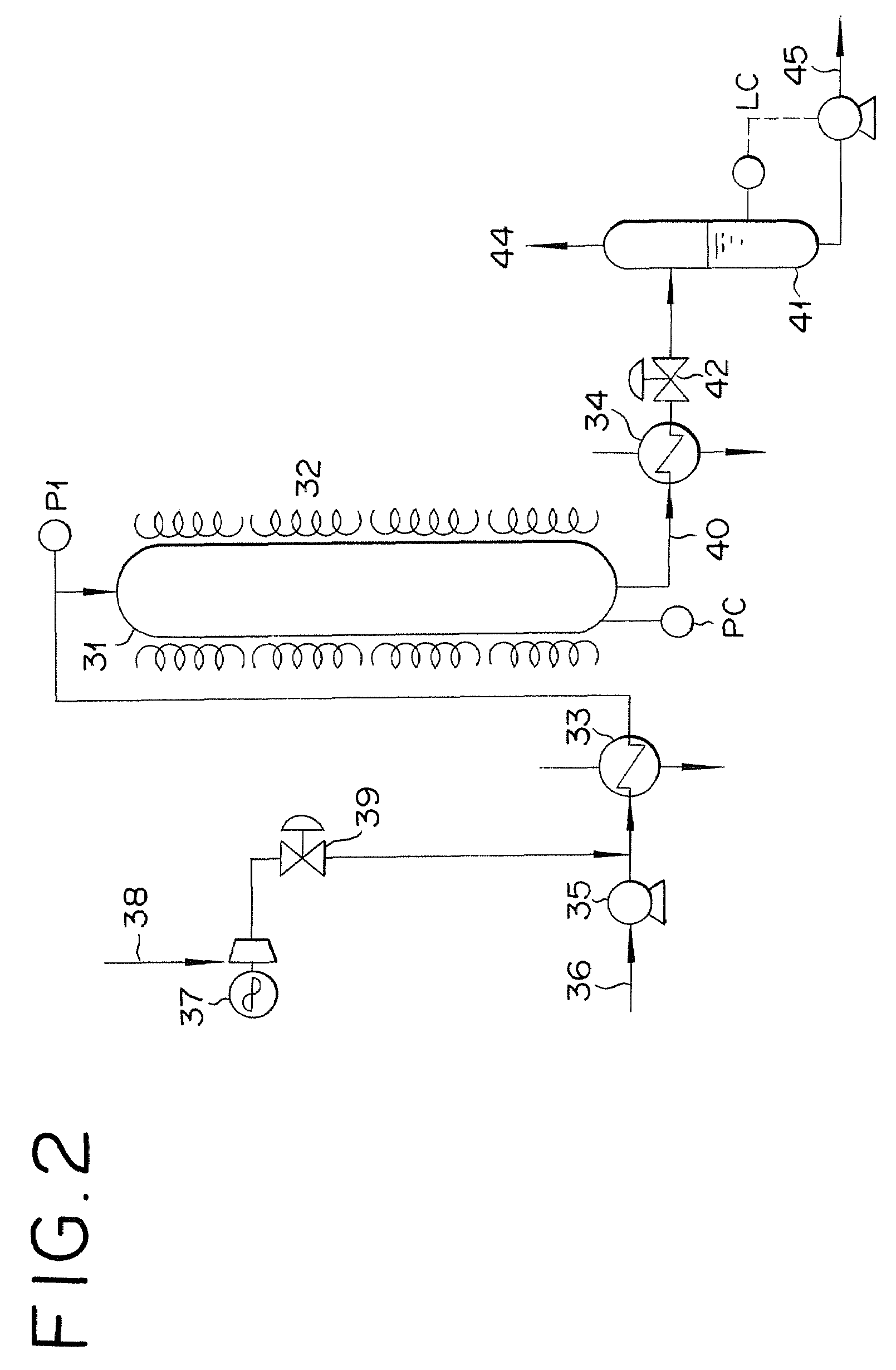

The present invention relates to a process for preparing tert-butanol (TBA) by reacting an isobutene-containing hydrocarbon mixture with water over a solid acid catalyst in a reactor cascade, wherein at least one reactor is supplied alternately with two different isobutene-containing hydrocarbon mixtures, of which one has both a higher tert-butanol content and a higher water content than the other mixture.

Owner:EVONIK DEGUSSA GMBH

Method for functionalizing porous metal-organic framework materials, solid acid catalyst using same, and method for evaporating alcohol using the solid acid catalyst

InactiveCN102744105AThe functional method is simpleThe functional approach worksOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholSorbent

The present invention relates to a method for functionalizing porous metal-organic framework materials which have a large surface area and molecular- or nano-scale pores, and which can thus be used for an absorbent, gas storage, a sensor, a membrane, a functional thin film, a catalyst, a catalyst carrier, and the like, to a method for preparing a solid acid catalyst using same, and to a method for evaporating alcohol using the catalyst.

Owner:KOREA RES INST OF CHEM TECH

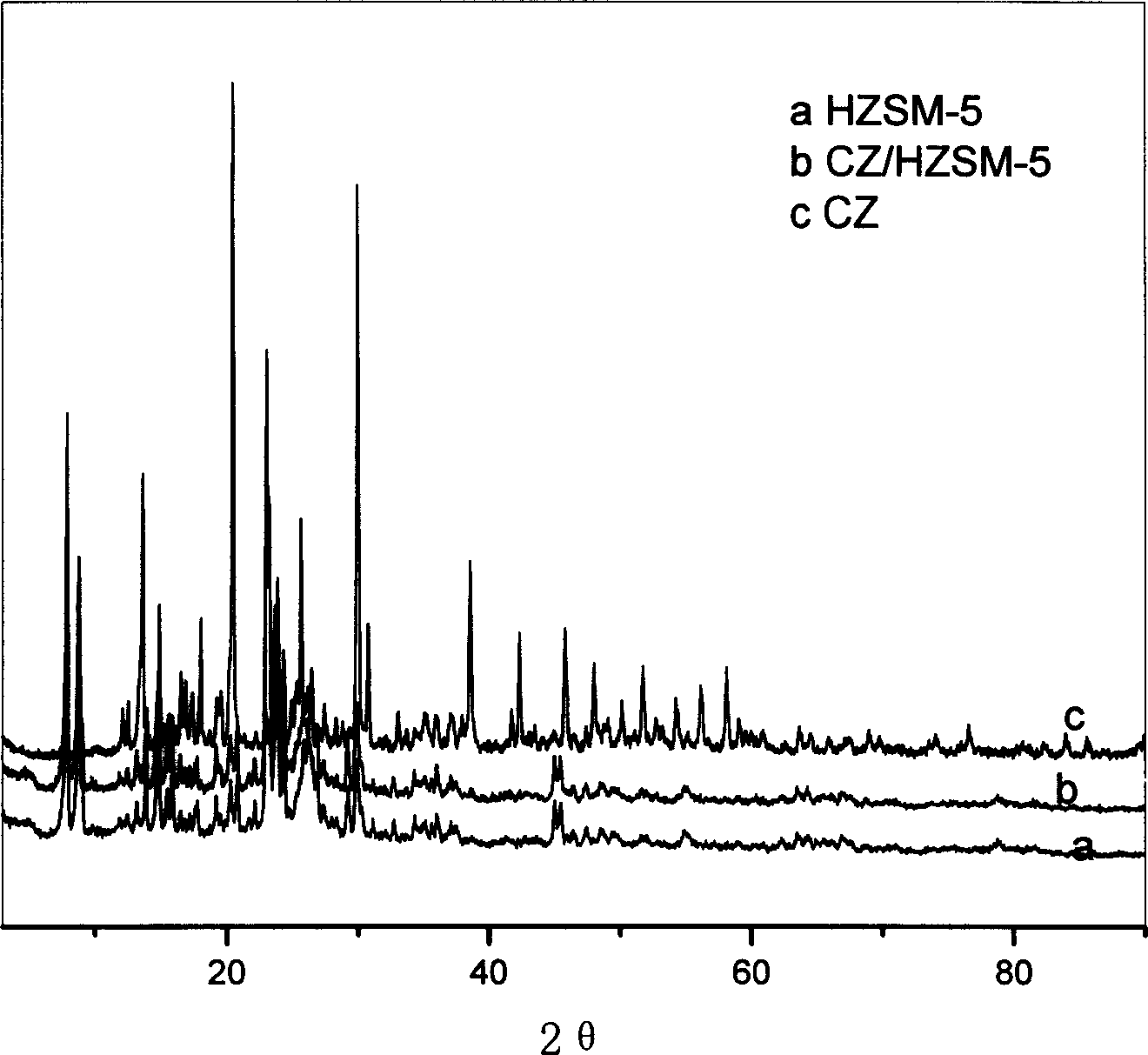

Solid acid catalyst and process for preparing the same

InactiveUS6326328B1High catalytic activityHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIsomerizationPartial oxidation

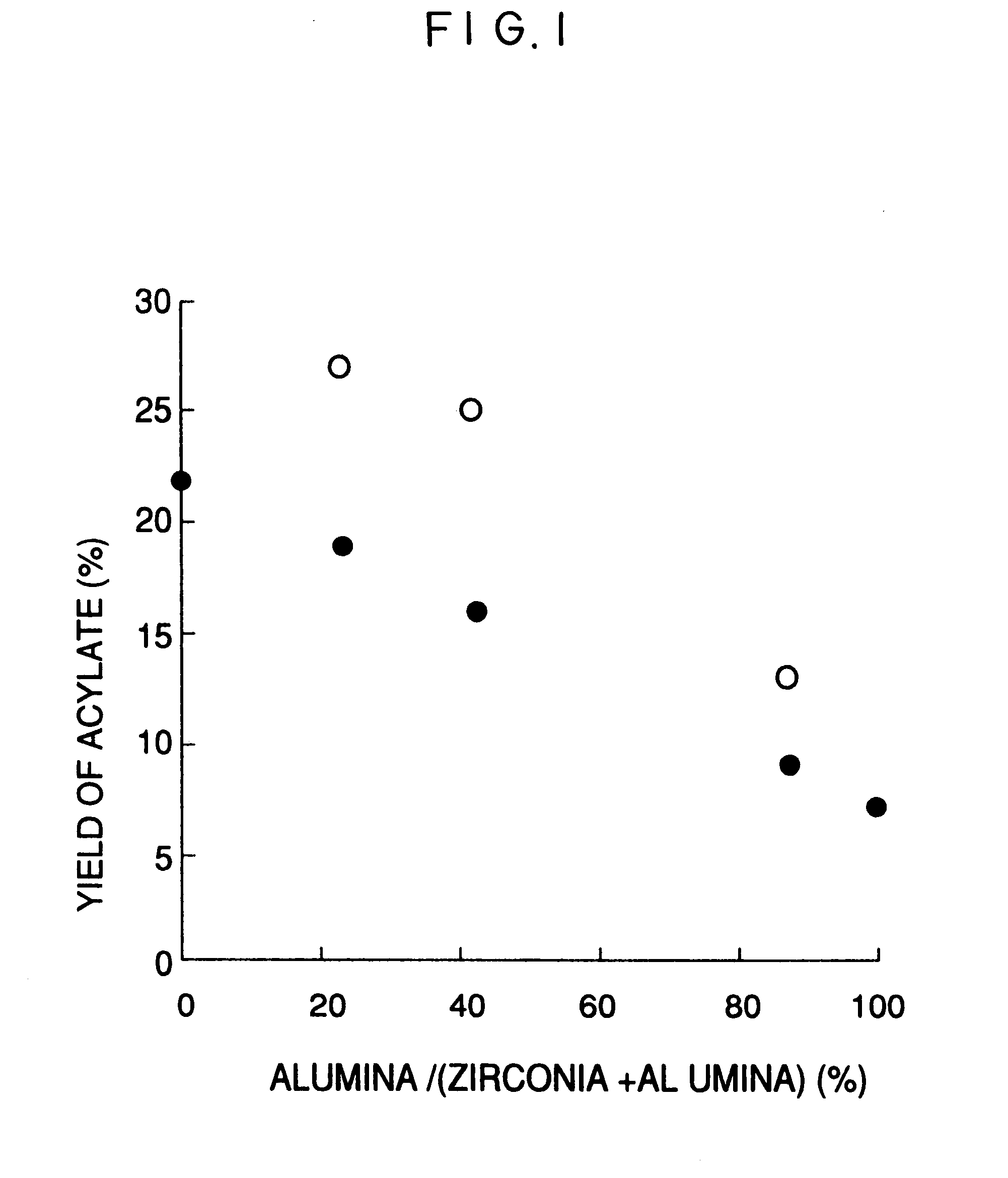

The present invention relates to a shaped solid acid catalyst for the isomerization of hydrocarbons and so on, which has a high activity and is excellent in strength and easily handleable, and processes for the preparation thereof. This catalyst comprises a support comprising portions of zirconia having a tetragonal form and portions of alumina, and a sulfureous component and, if necessary, a Group 8, 9 or 10 metal component both being supported on the support, and has a specific surface area of 150 m2 / g or above. The catalyst can be prepared by kneading aluminum hydroxide, zirconium hydroxide and a sulfureous compound, shaping the kneaded mixture, calcining the shaped material at such a temperature as to form tetragonal zirconia and, if necessary, supporting a Group 8, 9 or 10 metal component on the calcined material and calcining the resulting molding at 300 to 700° C.

Owner:JAPAN ENERGY CORP

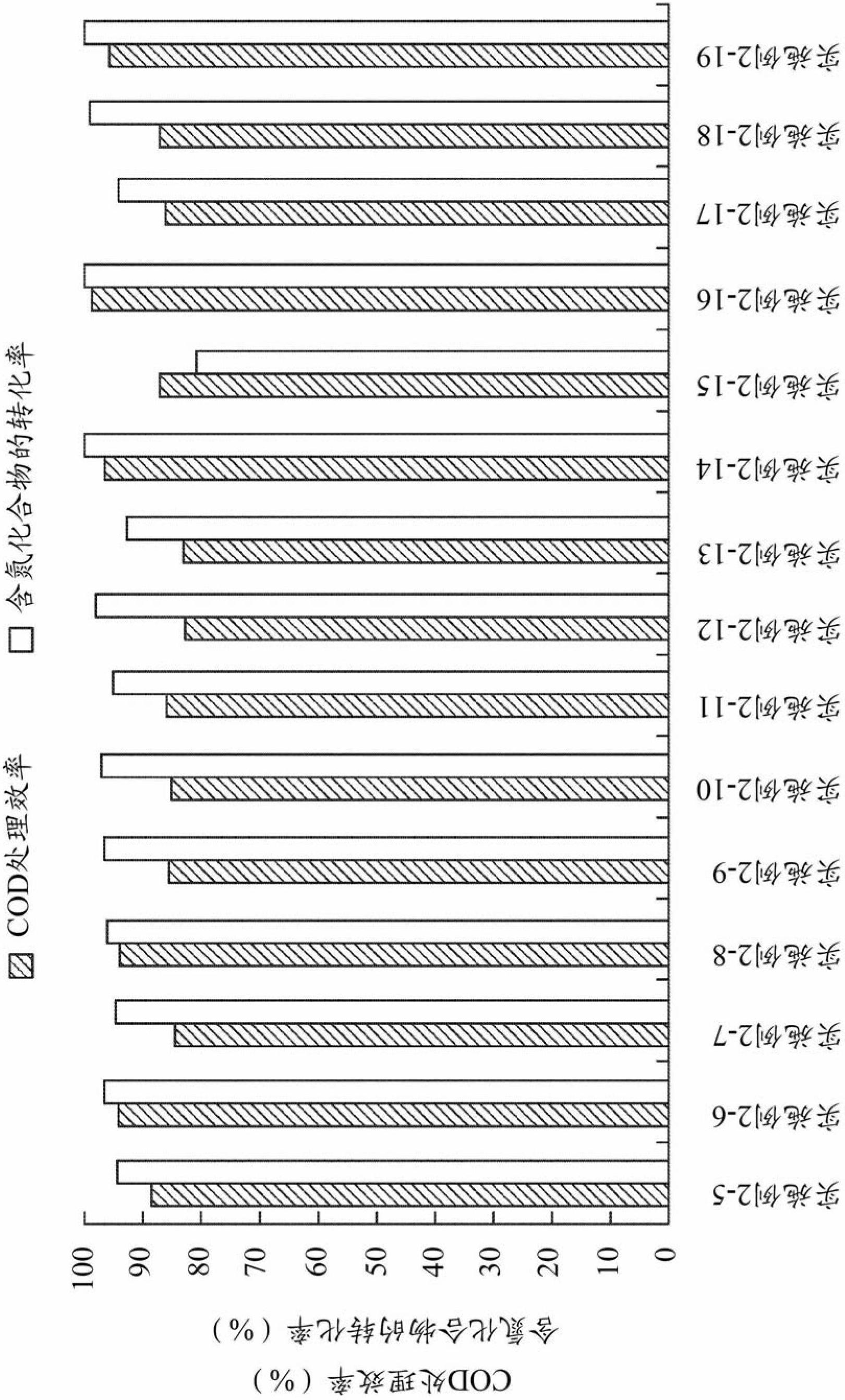

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

ActiveCN101045204AHigh mechanical strengthIncreased durabilitySludge treatmentMetal/metal-oxides/metal-hydroxide catalystsIridiumCerium

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

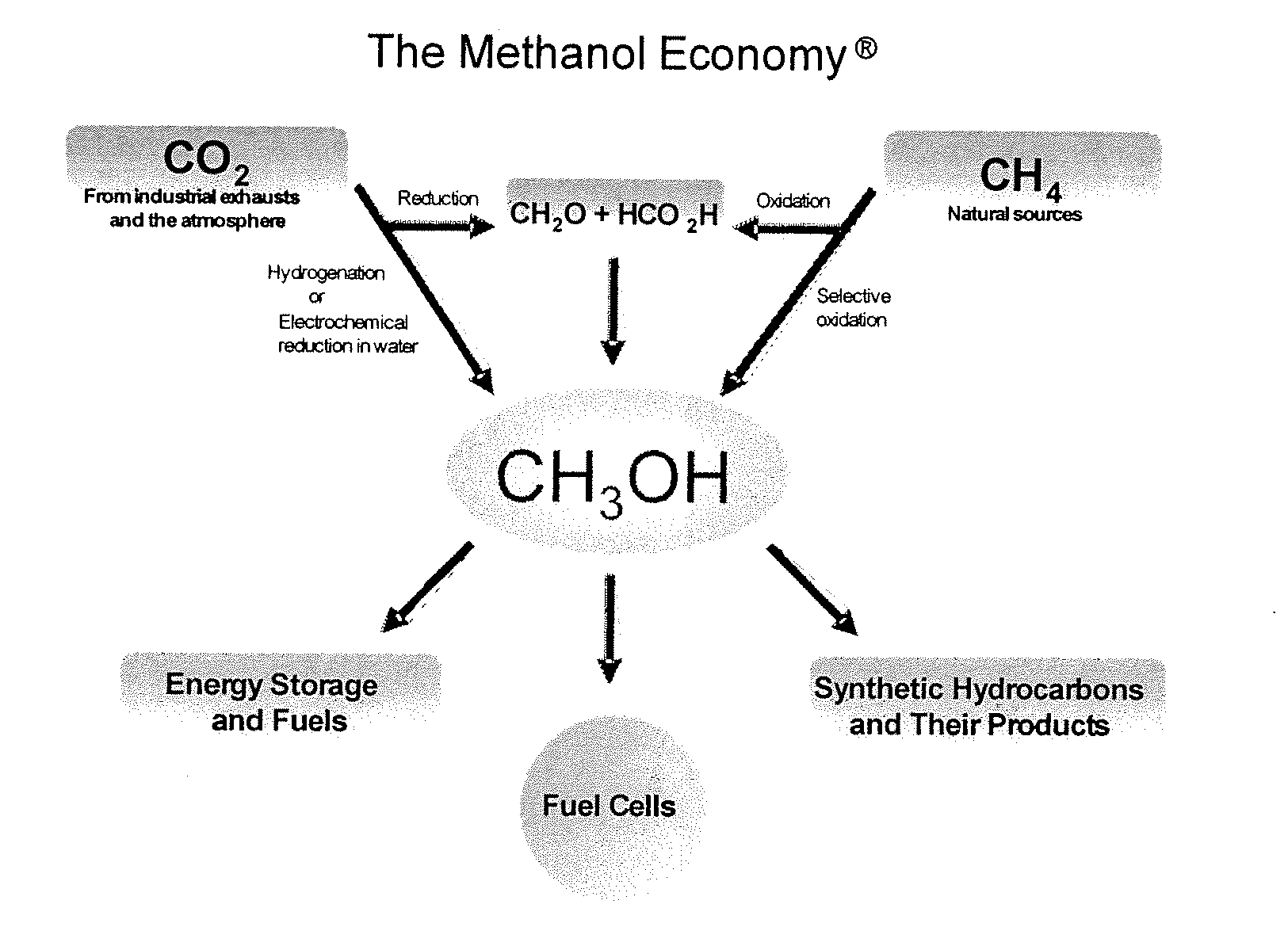

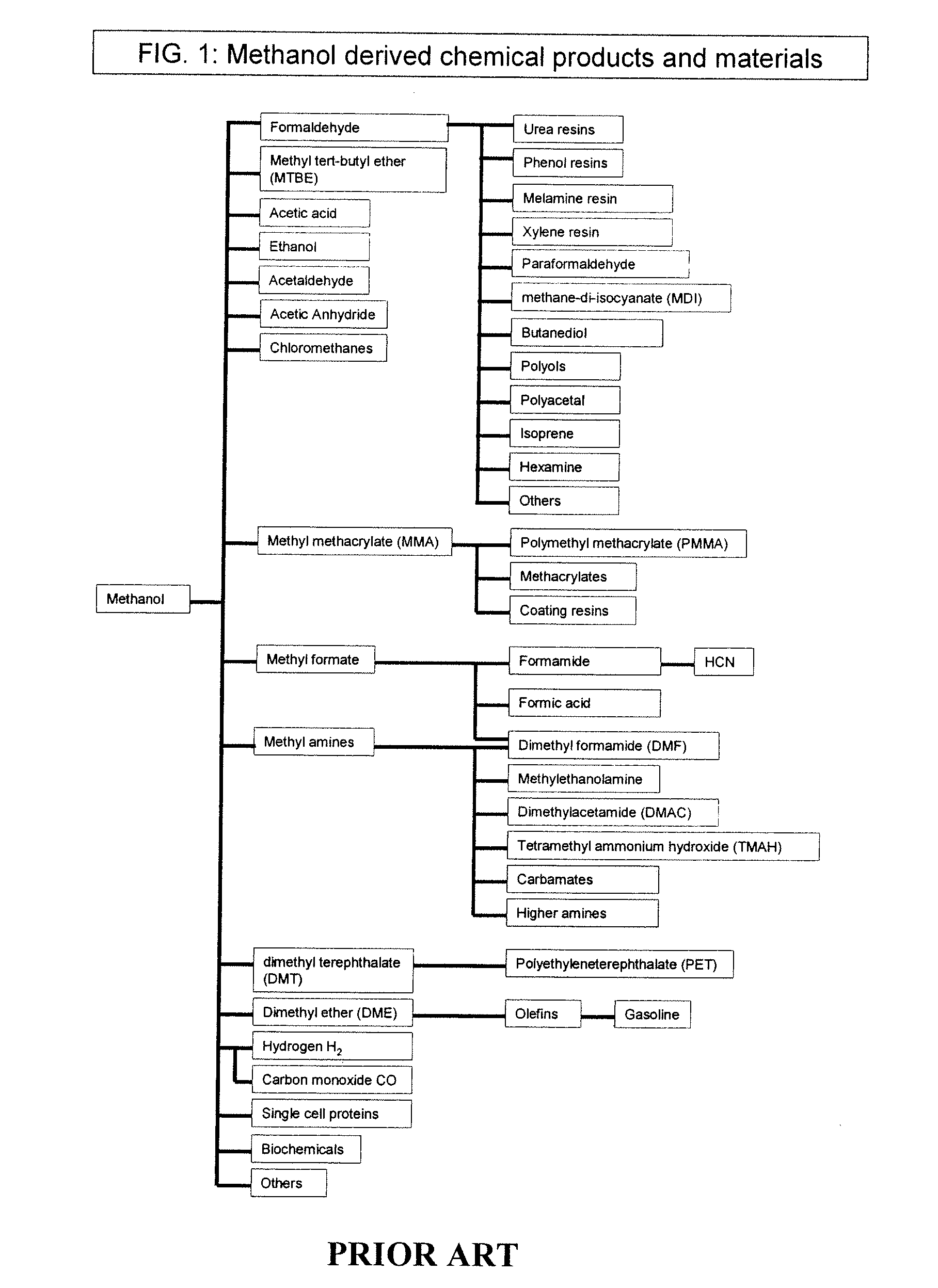

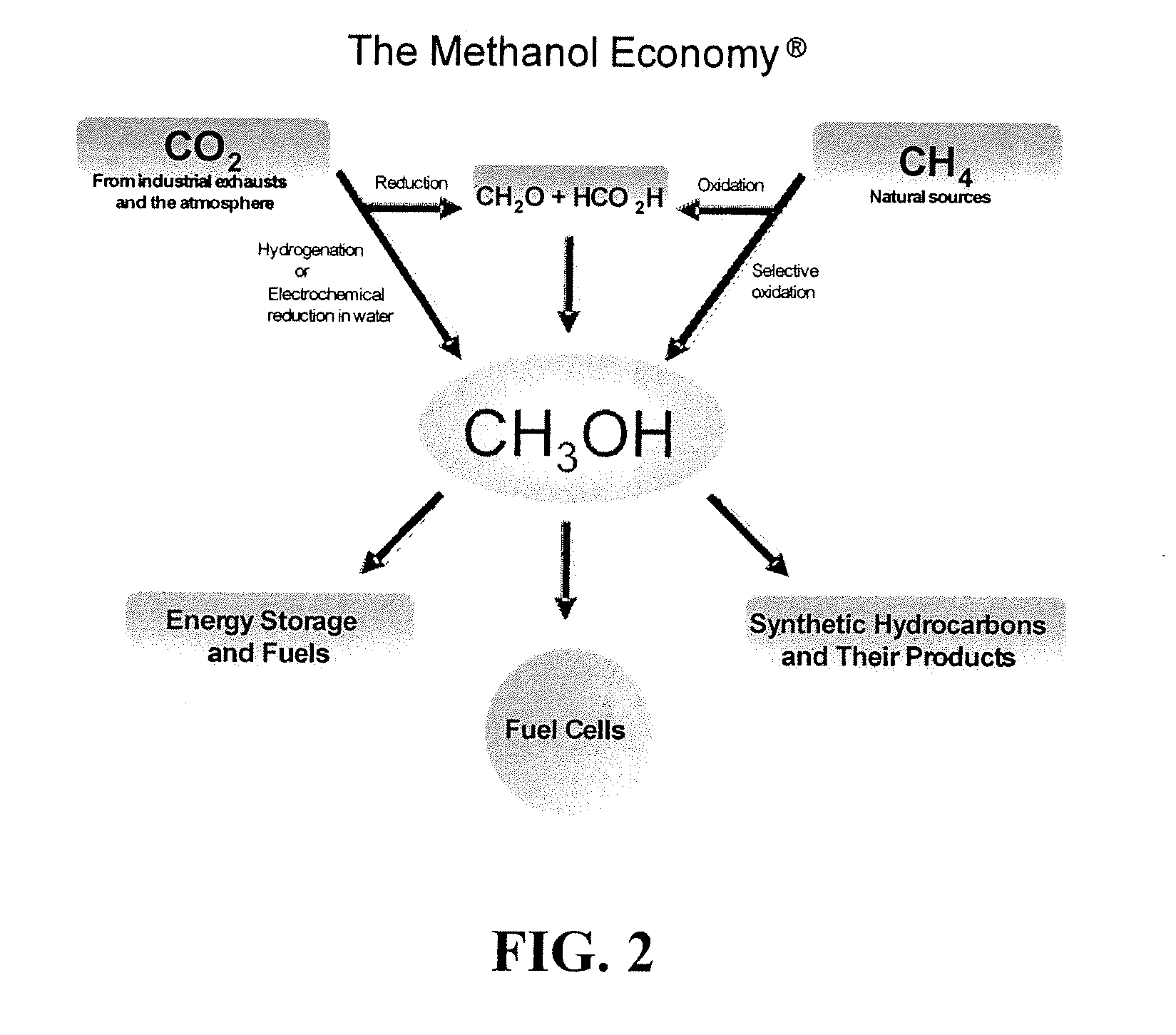

Conversion of carbon dioxide to methanol and/or dimethyl ether using bi-reforming of methane or natural gas

ActiveUS20080319093A1Raw materials are simplePromote recoveryPreparation by oxidation reactionsHydrogenCatalytic methodHydrogen

The invention discloses a method of converting carbon dioxide to methanol and / or dimethyl ether using any methane source or natural gas consisting of a combination of steam and dry reforming, in a specific ratio to produce a 2:1 molar ratio of hydrogen and carbon monoxide with subsequent conversion of the CO and H2 mixture exclusively to methanol and / or dimethyl ether. This method is termed the BI-REFORMING™ process. Dehydrating formed methanol allows producing dimethyl ether (DME) using any suitable catalytic method, including use of solid acid catalysts. When recycling formed water into the bi-reforming step the conversion of carbon dioxide with methane produces exclusively dimethyl ether without any by-product formation and complete utilization of hydrogen

Owner:UNIV OF SOUTHERN CALIFORNIA

Unitary solid chlorine dioxide effervescent tablet and preparation method thereof

InactiveCN101228868AFast dissolutionImprove chemical yieldBiocideDisinfectantsEffervescent tabletChlorine dioxide

The invention discloses a one-variable solid effervescent tablet and a preparation method for the tablet. The material system of the effervescent tablet comprises chlorite, solid acid source, free halogen source, activated Promoter, desiccant, bond, release agent, effervescent and surfactant. The preparation technique includes: after the coating processing with chlorite grains, drying and mixing well with other raw materials according to a specific proportion and technique requirements to prepare compound raw materials, and then pressing into tablets with different specification and shaping on the tablet machine to fit for application in various occasions. The effervescent tablet can quickly release chlorine dioxide and acquire pellucid water solution of chlorine dioxide while dissolving in the water, which is high in stability, rapid in dissolving rapid and strong in bactericidal ability.

Owner:石家庄卫科生物科技有限公司

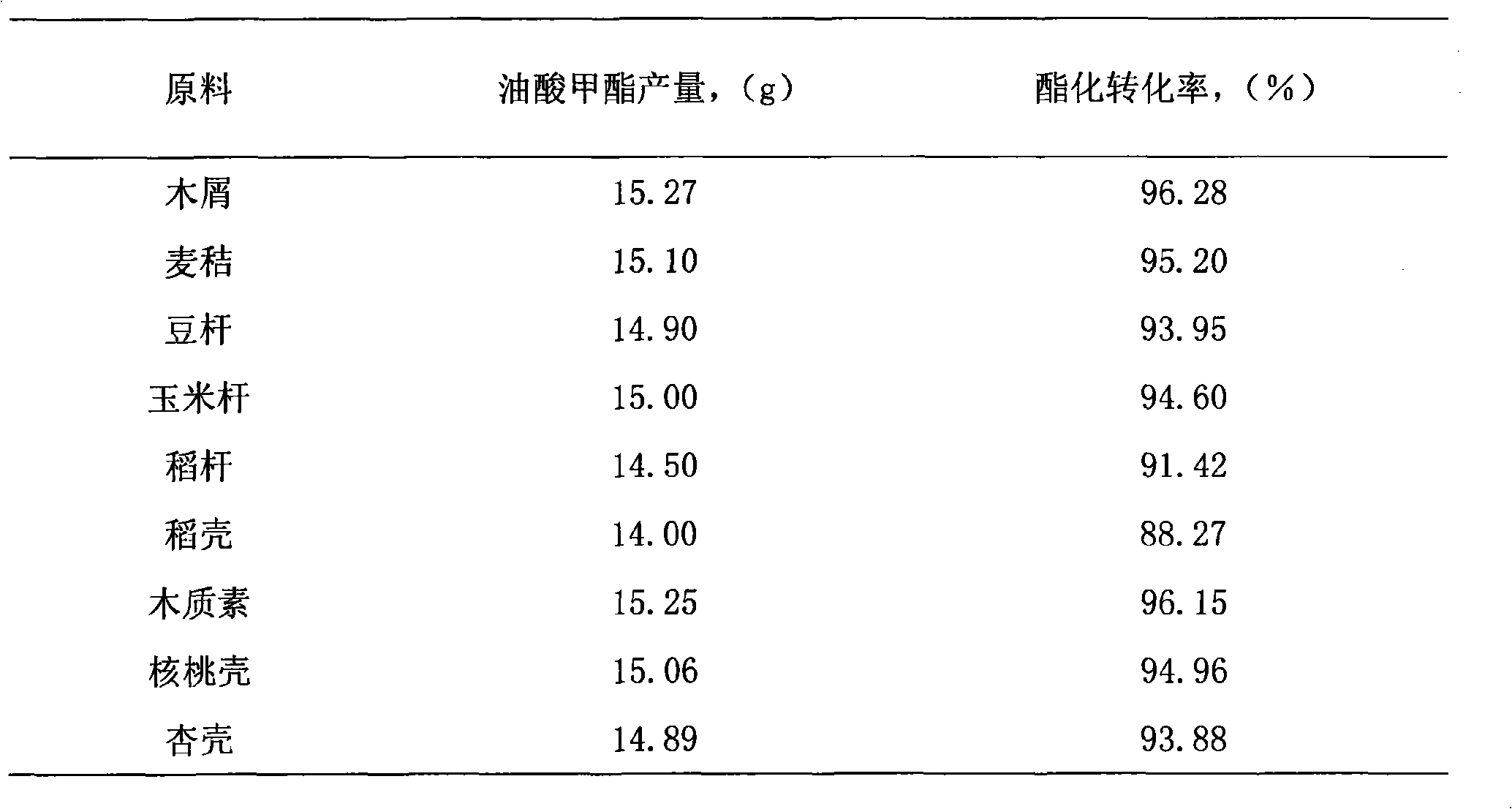

Method for preparing biocarbon solid acid catalyst and biodiesel

InactiveCN101298566AReduce manufacturing costAbundant and renewable resourcesPhysical/chemical process catalystsPreparation by ester-hydroxy reactionBiodieselSolid acid

The invention pertains to the new material technical field, and relates to a method for preparing a carbonaceous solid acid catalyst and biodiesel by taking pure natural biological substances as raw materials. The method is characterized by: taking the pure natural and renewable biological substances as the raw materials; adopting the technical route and method of low-temperature carbonization firstly, oxidation secondly and sulfonation then according to the constituent and structural characteristics to prepare the bio-carbonaceous solid acid catalyst; and adopting a continuous rectification-water separating esterification reaction technology to produce the biodiesel by carrying out the catalytic esterification reaction of a free fatty acid or waste oil and short chain alcohol. The raw materials adopted by the invention are rich in resources, low in price, pure natural and renewable, which pertains to waste utilization; the preparation technology is simple with moderate and controllable reaction conditions; the catalyst has the advantages of high activity, good stability, easy recycling and no corrosion to equipment, which is an really environment-friendly catalyst, thus being applicable to the large scale industrial production of the biodiesel. The method can also be applied to a plurality of organic reactions such as alkylation, hydrolysis and hydration, etc.

Owner:DALIAN UNIV OF TECH

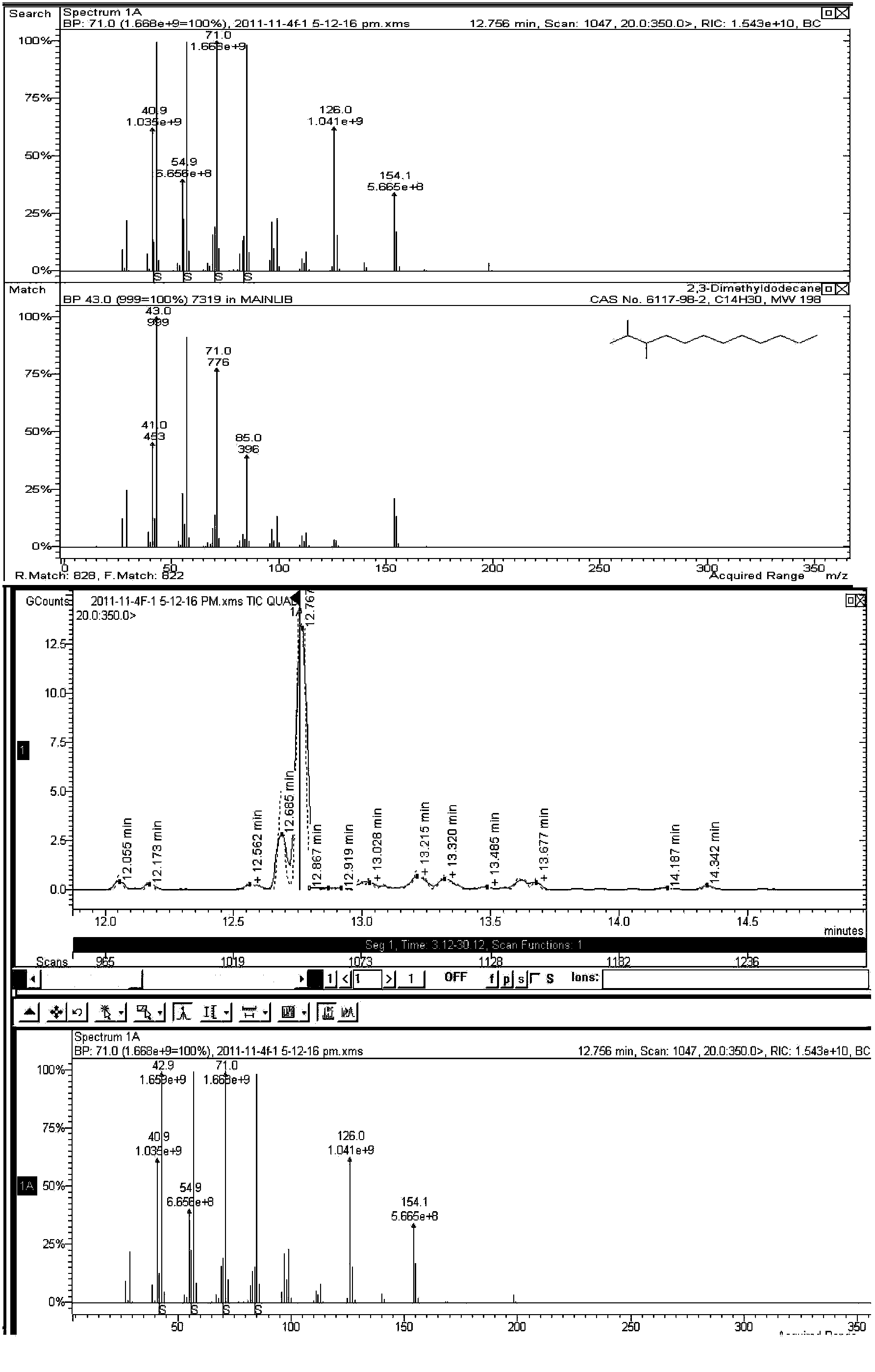

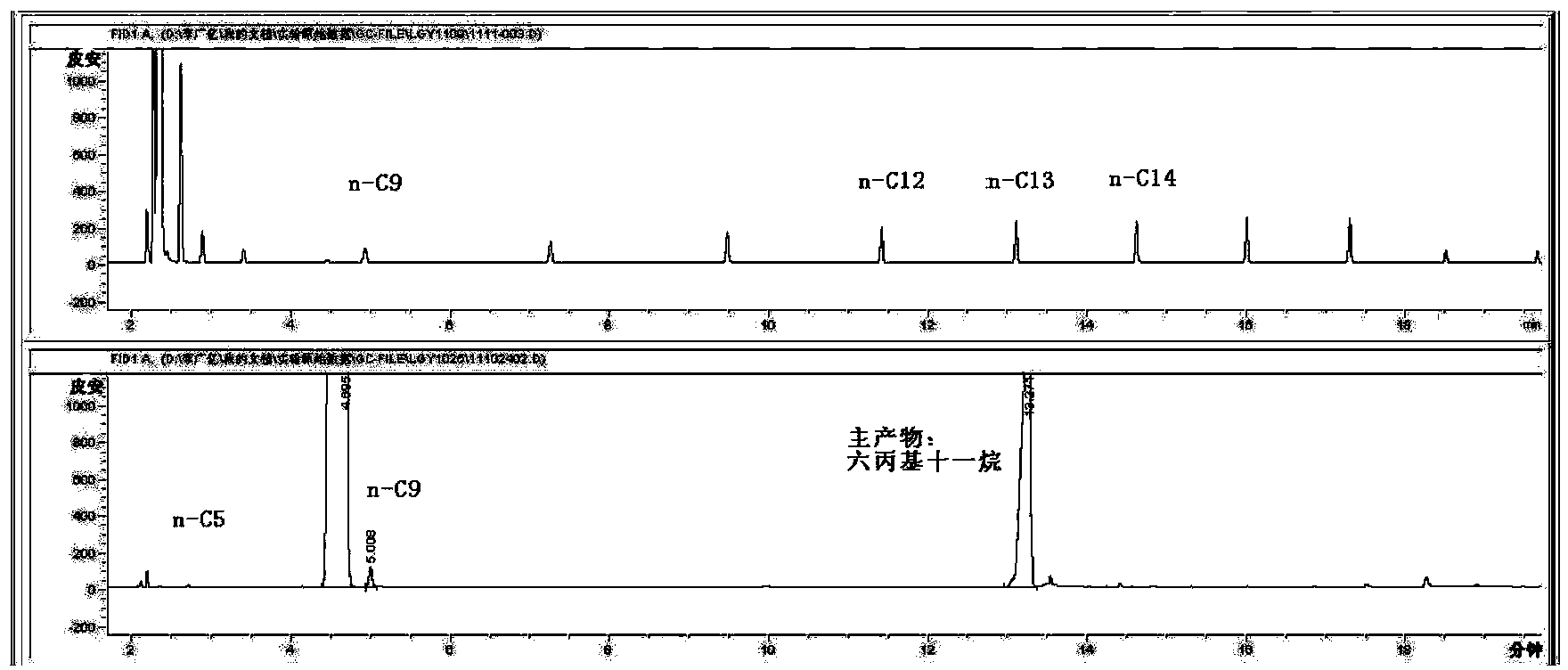

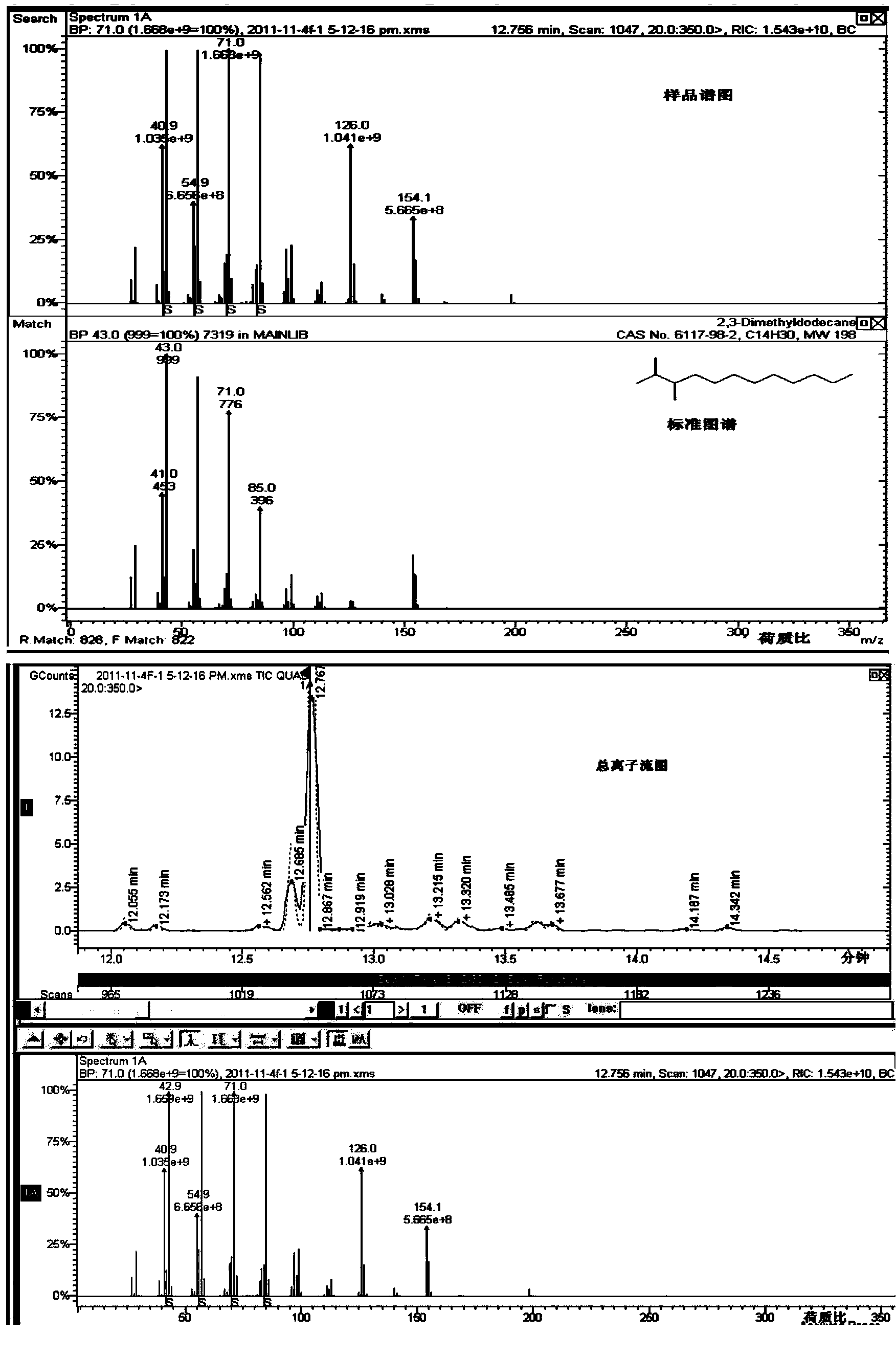

Method for preparing aviation kerosene from furyl oxygen-containing organic compounds by hydrogenation deoxidation

ActiveCN104119943AReduce energy consumptionSimple operation processMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneFuran

The invention relates to a new method for preparing hydrocarbons in the scope of aviation kerosene from C8-C16 furyl oxygen-containing organic compounds as raw materials by hydrogenation deoxidation reaction, wherein the C8-C16 furyl oxygen-containing organic compounds are obtained by C-C coupling of lignocellulose based platform chemical compounds; low temperature direct hydrogenation deoxidation under the condition of no solvent of the furyl oxygen-containing organic compounds can be realized by use of a metal-solid acid dual-functional catalyst to obtain a series of low freezing point branched alkanes having the chain in the length range of the aviation kerosene in high yield. The catalyst is composed of two parts of an active metal A and an acid vector X. The catalyst related in the method ahs the characteristics of being in no need of a solvent, simple in operation process, mild in reaction conditions, good in aviation kerosene (or diesel) selectivity, and the like, and is an ideal hydrogenation deoxidation catalyst for preparing liquid fuels from the furyl oxygen-containing organic compounds by the hydrogenation deoxidation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing furfural compounds from biomass

The invention relates to a method for preparing furfural compounds from biomass. The method specifically comprises the preparation of a solid acid catalyst and a reaction process of the solid acid catalyst. The method disclosed by the invention can also be applied to biomass derivatives. The method comprises the steps of adding biomass or biomass derivatives and the solid acid catalyst to a reactor, filling with protective gas, and adopting an organic solvent / saturated inorganic salt aqueous-solution two-phase reaction system, thereby obtaining furfural and 5-hydroxymethylfurfural in a high yield manner under mild conditions. The method has the advantages that after the reaction is completed, the produced furfural and 5-hydroxymethylfurfural are efficiently extracted into an upper-layer organic phase, the solid acid catalyst and an unreacted substrate are retained in a bottom-layer water phase, the furfural, the 5-hydroxymethylfurfural or a mixture of the furfural and the 5-hydroxymethylfurfural can be obtained through simple separation, and fine chemicals and liquid fuels can be prepared in a manner that the furfural, the 5-hydroxymethylfurfural or the mixture of the furfural and the 5-hydroxymethylfurfural serves as a reaction intermediate; and the used catalyst is pollution-free and can be recovered and reused, so that the method has good industrial application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

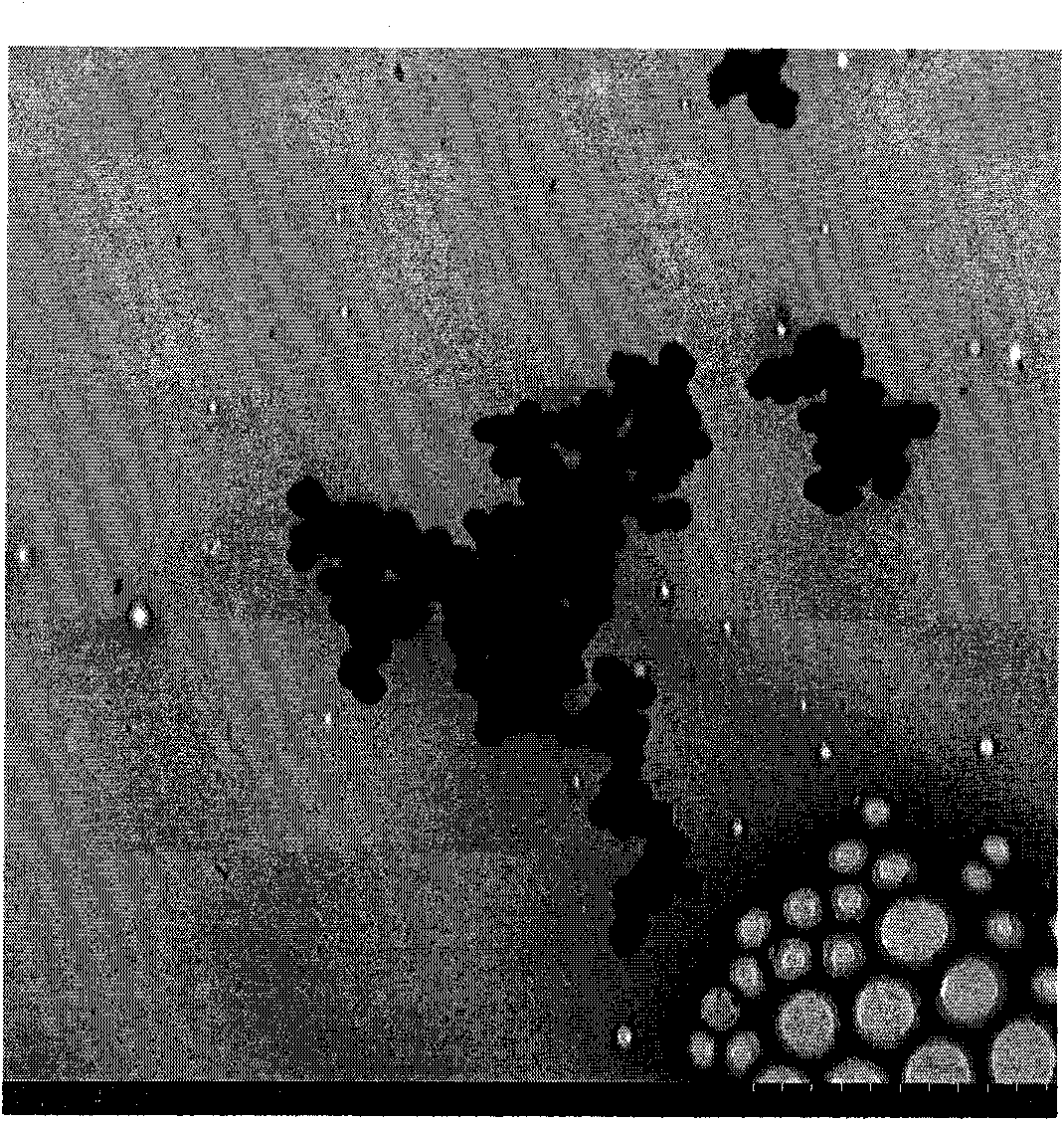

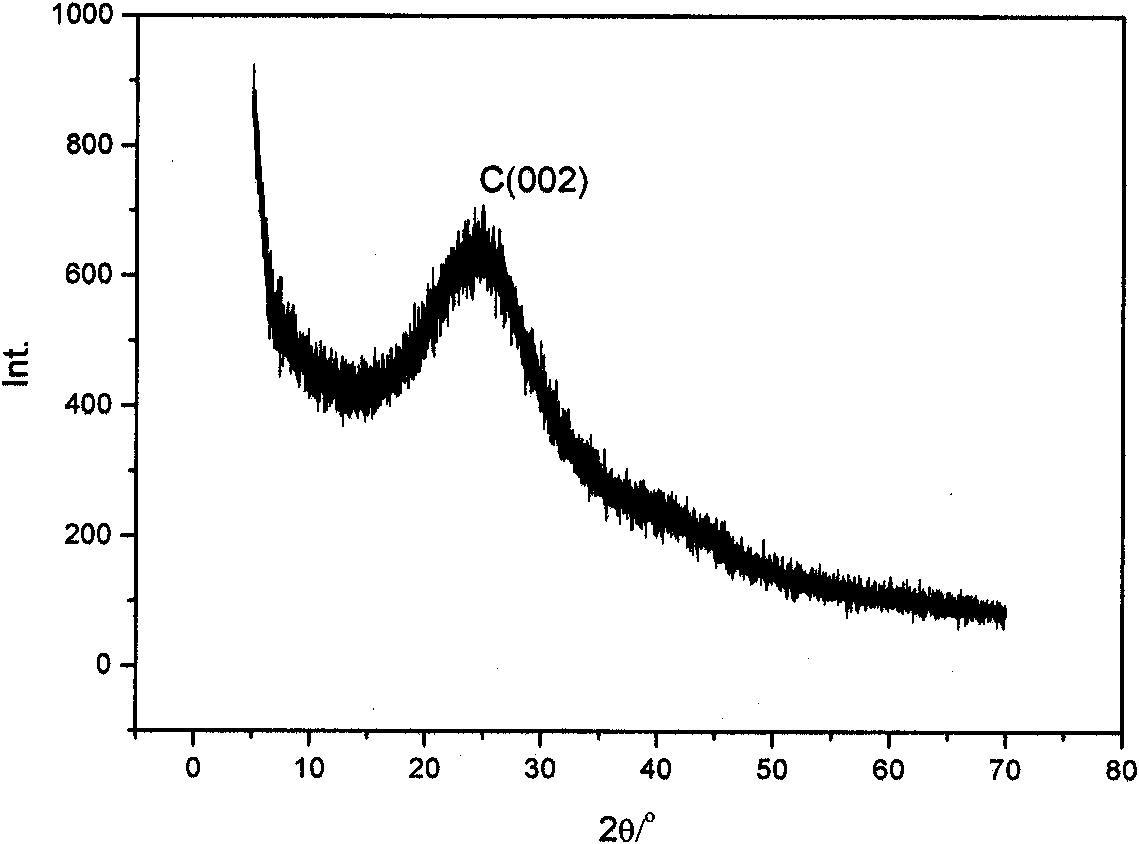

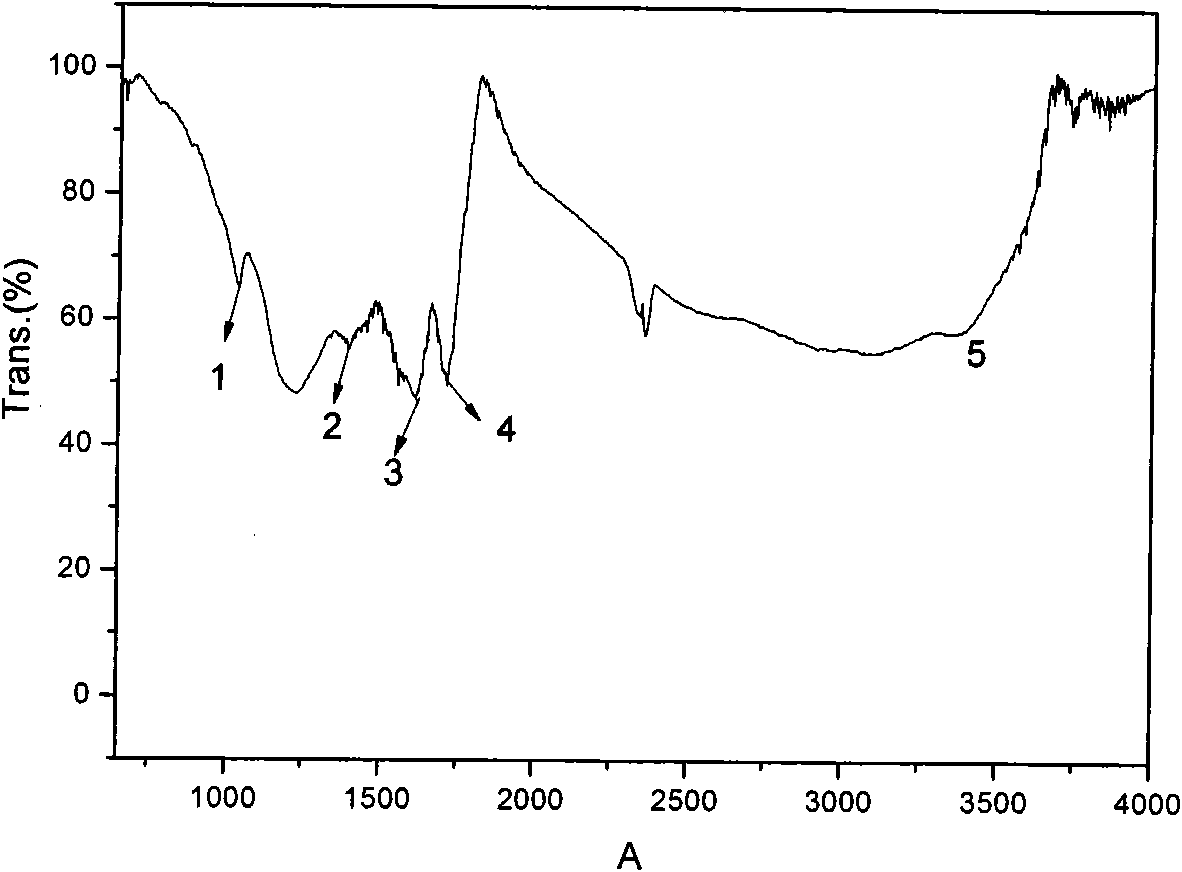

Preparation method of nanometer carbon-based solid acid

InactiveCN101670299ACheap and readily availableModerate reaction conditions and energy savingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolid acidHydrolysis

The invention relates to a preparation method of a nanometer carbon-based solid acid which adopts biomass as carbon source to prepare carbon precursor under the hydrothermal condition and performs sulfonation reaction to obtain the carbon-based solid acid. The method comprises the following steps: 1) adding biomass in water, stirring evenly to perform a reaction, standing at 120-200 DEG C to prepare a carbon material; 2) filtrating and washing the carbon material obtained in the step 1, drying at 25-120 DEG C to obtain the dried carbon material; 3) taking the dried carbon material obtained inthe step 2 to perform sulfonation reaction at 25-180 DEG C in the presence of sulfonating agent and obtain a carbon-based solid acid catalyst; and 4) washing the carbon-based solid acid catalyst withhot water and drying at 25-120 DEG C. The method of the invention can reduce the production cost of the solid acid and improve product performance. The prepared nanometer carbon-based solid acid can be applied to the reactions such as esterification, hydrolysis, hydration and the like.

Owner:青岛生物能源与过程研究所

Method for preparing low carbon olefin by coupled catalytic cracking of petroleum hydrocarbon

A process for preparing lower carbon number hydrocarbons through linkage petroleum hydrocarbon catalysis decomposition, wherein petroleum hydrocarbon and organic oxygen compounds are used as raw material, and fluid bed reactor is utilized under the action of solid acid catalyst and high temperature water vapor through linkage petroleum hydrocarbon catalysis decomposition to prepare lower carbon number hydrocarbons. The reaction condition is, temperature 500-720 deg.C, the weight ratio of the catalyst and the petroleum hydrocarbons is 5-40:1, the weight ratio of the organic oxygen compounds and the petroleum hydrocarbons is 0-2:1, the weight ratio of the water vapor and the petroleum hydrocarbons is 0-1:1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

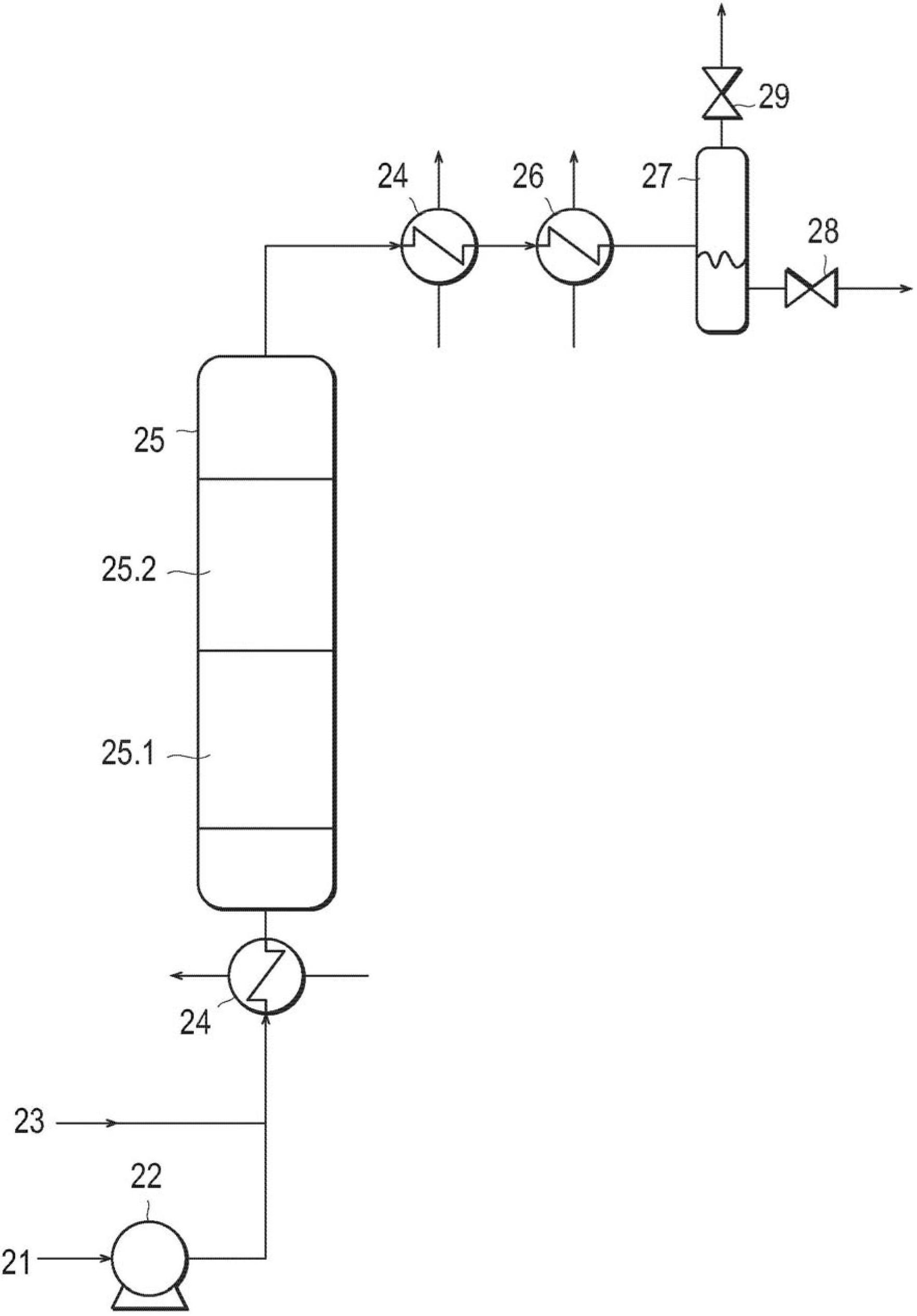

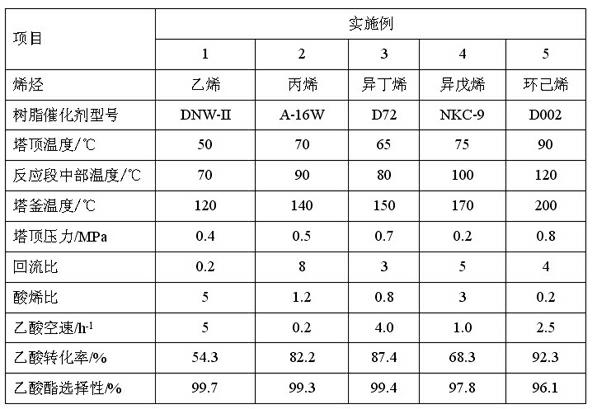

Method for preparing alcohols from olefin

ActiveCN102146019AImprove conversion rateSimple processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidAlcohol

The invention discloses a method for preparing alcohols from olefin. The method comprises an esterification process and a hydrogenation process. The method comprises the following steps of: performing countercurrent contact on olefin and acetic acid in a catalytic distillation tower on the surface of a solid acid catalyst, and synthesizing corresponding acetic ester by catalytic esterification; and then catalytically converting the acetic ester and hydrogen into corresponding alcohols in a fixed bed reactor by using the synthesized acetic ester as a raw material under a copper-containing hydrogenation catalyst and reaction conditions. The method has the characteristics of simple process flow, mild reaction conditions, low energy consumption, high raw material conversion rate and good production selectivity. Moreover, the method for preparing the corresponding alcohols from the olefin can be also used for preparing acetic ester and ethanol products which are wide in application.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

InactiveUS20070210010A1High activityIncreased durabilitySludge treatmentWater/sewage treatment by substance additionIridiumManganese

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com