Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Foreign - Similar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing biodiesel by solid acid-base catalyst

InactiveCN1580190AWide variety of sourcesNo pollution in the processBiofuelsLiquid hydrocarbon mixture productionWater bathsBiodiesel

The invention relates a kind of preparation method of bio-diesel oil under the condition of solid ac and alk catalyzing. The character is that under the condition of solid ac and alk catalyzing, gain the bio-diesel oil using the craft of exchange reaction of soja oil with carbinol. Afer the reaction, apart catalyser from reaction liquor by centrifugal machine till delimination in quiet placing, the above is rough output, the below is admixture of glycerol and carbinol. Distil the of above to gain bio-diesel oil and to gain the pure glycerin in the same way. The distilled carbinol can be used again and again. The invention has many advantages, for example, its raw material can be rebirth, its craft is easy and only need normal equipment. Even treat the used oil, the whole process is easier compared with the method in solid ac and alk catalyzing, besides, the process will not produce foul water so it is environmental. Every plant of the bio-diesel accords with standards compared with foreign similar competitive grade and the main plants are close to its of 0# (GB252-1994, superior product)diesel of China.

Owner:BEIJING UNIV OF CHEM TECH

Forklift weighing device and automatic forklift weighing method

InactiveCN104724638ASolve the problem of inaccurate weighingAutomatic correction of weighing errorsLifting devicesSpecial purpose weighing apparatusEngineeringForeign - Similar

The invention discloses a forklift weighing device. The forklift weighing device comprises a double-fork hanging plate, a forklift portal hanging plate and two weighing sensors. The two weighing sensors are rigidly fixed through a fixing rod and then fastened between the double-fork hanging plate and the forklift portal hanging plate, and one sensor is located over the other sensor. The invention further discloses an automatic forklift weighing method based on the weighing device. The method includes the following steps that firstly, corresponding sensing signals of goods weight are acquired through the weighing device; secondly, the sensing signals are sampled and processed; thirdly, the processed sensing signals are converted into weight values; finally, correction and compensation are conducted on the weight values through fuzzy correction. Weighing errors are automatically corrected through fuzzy correction, the intelligent degree is high, control accuracy is high, the errors are small, compared with foreign similar devices, the cost of a system is low, and high promotional value is achieved.

Owner:XIAMEN UNIV OF TECH

Cement grinding aid

The invention provides a cement grinding aid, and relates to the field of cement production technology. The cement grinding aid comprises components by mass percent: 55-65% of water, 10-12% of sodium nitrite, 8-10% of industrial salt, 3-5% of calcium lignosulphonate, 3-5% of sodium acetate, 5-8% of triethanolamine and 3-5% of glycol. After the cement grinding aid is adopted, the quality and the performances of cement are improved while the power consumption is saved; the performances of the cement reach the level of the performances of foreign similar products, and the cost and the price of the cement are lower than those of the foreign similar products; and the dosage of cement clinker is reduced, and the cement strength can be improved.

Owner:安徽省振华工贸股份有限公司

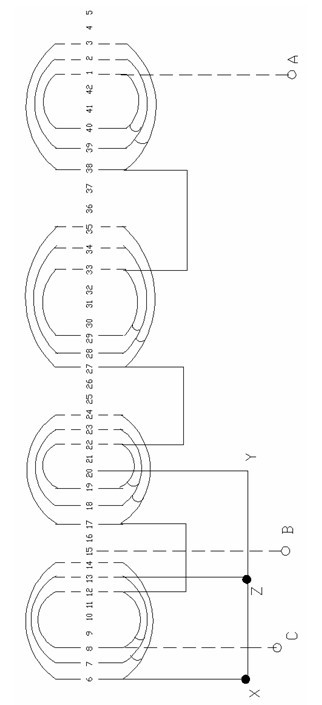

Mixed concentric single and two-layer winding for servo permanent magnet synchronous motor

InactiveCN101984540AImprove machining accuracyLess total harmonic contentSynchronous machine detailsWindings conductor shape/form/constructionHarmonicPermanent magnet synchronous motor

The invention relates to a mixed concentric single and two-layer winding for a servo permanent magnet synchronous motor. A motor stator winding is a single and two-layer winding formed by mixing two concentric windings, wherein the number of turns of the coil of each of the two concentric windings is 3, and the pitches and the numbers of turns of the two concentric windings are different. Compared with the short-pitch two-layer winding for the foreign similar motor, the formed mixed concentric single and two-layer winding has the advantages that the fundamental wave winding coefficient is improved by 2.08%, the phase belt harmonic waves are reduced by 45%, the magnetic potential sine property is better, the heating is small, the temperature rise is low, the vibration noise is small, the torque pulsation is small, the insulation between groove layers is reduced by 28.59%, the cost is reduced, the efficiency is improved, the operating quality of the motor is improved, and the machining precision is improved.

Owner:TELLHOW SCI TECH CO LTD

Preparation method of high-molecular copolymer cationic polyacrylamide flocculant

ActiveCN104558399AApplicable treatmentHigh viscosity average molecular weightWater/sewage treatment by flocculation/precipitationPolymer scienceTetrachloroethane

The invention relates to a preparation method of a high-molecular copolymer cationic polyacrylamide flocculant. The product is prepared by copolymerization of acrylamide-methacrylic acid-2-oxylactone trimethylammonium chloride. Acrylamide (AM), trimethylamine hydrochloride, chloropropylene oxide, tetrachloroethane, methacrylic acid and deionized water, etc. used as raw materials undergo aqueous solution polymerization at normal pressure. During the reaction process, an additive, a polymerization inhibitor, an emulsifier and an initiator are added, and monomer concentration is controlled to 30-50%. Then, a cationic flocculant which meets usage requirements and has 2-5*106 of viscosity-average molecular weight can be prepared stably. Yield is greater than 95.0%. The whole polymerization only takes 6-7 hours to prepare the flocculant. Water quality index of sewage treated by the use of the prepared flocculant is more superior, and usability of the flocculant is approximately the same as that of a foreign similar product.

Owner:CHINA PETROLEUM & CHEM CORP +1

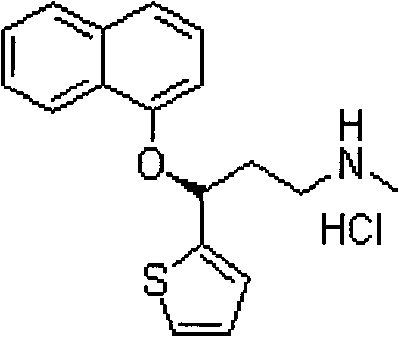

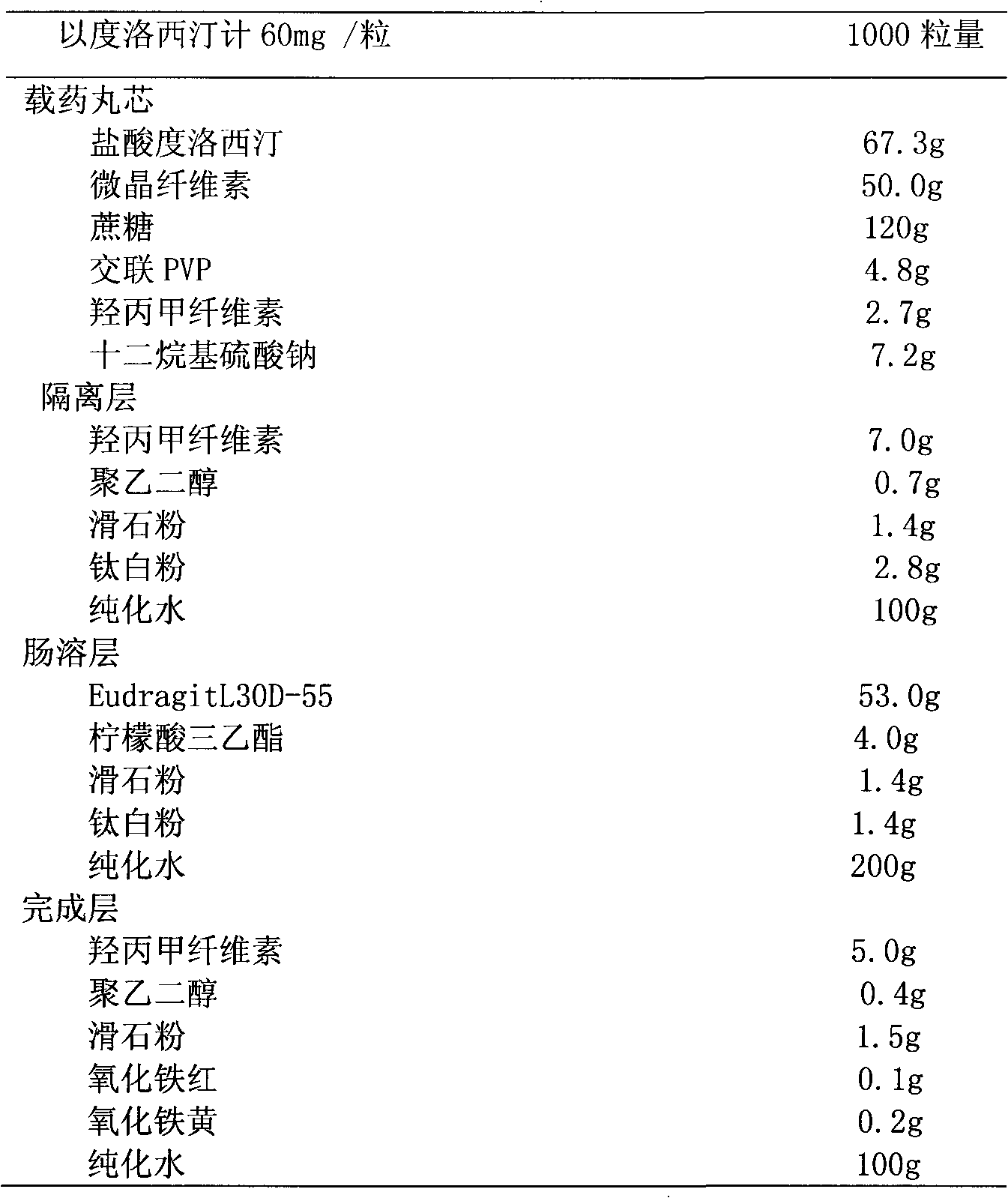

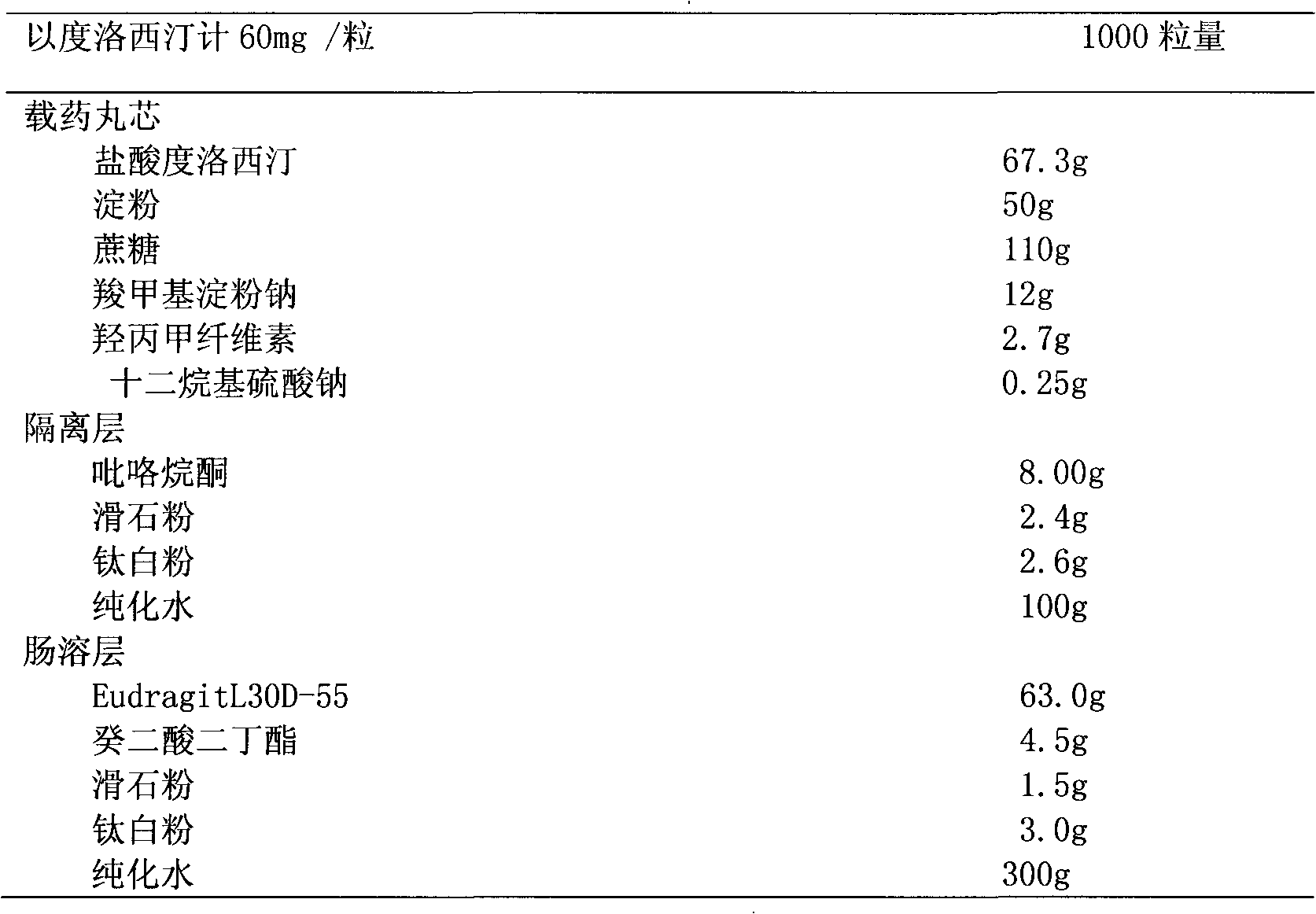

Duloxetine hydrochloride enteric capsules and preparation method thereof

InactiveCN102908331AGood reproducibilityUniform contentOrganic active ingredientsNervous disorderForeign - SimilarPharmaceutical formulation

The invention relates to the technical field of medicinal preparations, in particular to duloxetine hydrochloride-containing enteric capsules and a preparation method thereof. The enteric capsules consist of capsule shells and coated pellets, wherein the coated pellets also comprise duloxetine hydrochloride-containing medicine carrying pellet cores and coating layers; and the medicine carrying pellet cores contain a disintegrating agent. In preparation of the medicine carrying pellet cores, the duloxetine hydrochloride raw material is subjected to super micronization, so that the particle size distribution that the diameter of 99 percent is not greater than 50 mum, the diameter of 90 percent is not greater than 35 mum, the diameter of 50 percent is not greater than 20 mum and the diameter of 5 percent is not greater than 10 mum is achieved; and after the disintegrating agent is added into the medicine carrying pellet cores, the release speed of the medicine in intestines is increased. According to the duloxetine hydrochloride-containing enteric capsules and the preparation method thereof, a method of directly preparing the medicine carrying pellet cores is adopted, so that the complexity for loading a medicine on blank pellets of the existing domestic and foreign similar products is reduced, the technological process is simplified, and the duloxetine hydrochloride raw material is firstly crushed to a certain particle size range and then prepared into the medicine carrying pellet cores; and the prepared capsules have uniform medicine content and high reproducibility and are suitable for industrial production.

Owner:ZHEJIANG JIUZHOU PHARM SCI & TECH CO LTD

Preparation containing calcipotriol and betamethasone dipropionate

ActiveCN104666312AEnsure safetyGuaranteed curative effectOrganic active ingredientsAerosol deliveryForeign - SimilarPharmaceutical formulation

The invention belongs to the field of medicine preparations, and particularly relates to a preparation technology of calcipotriol. According to the preparation technology, the problem of the stability of calcipotriol and betamethasone dipropionate is solved. Benzyl alcohol and triethanolamine are added to auxiliary materials. The paste prepared by the technology is stable in property. Compared with foreign similar products, the cost is lower; and the method is suitable for industrialized production.

Owner:CHONGQING HUAPONT PHARMA

Preparation method of pitch-based spherical activated carbon suitable for industrial production

The invention belongs to the technical field of activated carbon preparation, and in particular relates to a preparation method of pitch-based spherical activated carbon suitable for industrial production. According to the preparation method, pitch and an aromatic hydrocarbon fluxing agent are taken according to a reasonable proportion and are fused at suitable temperature, and pitch spheres are prepared by a melt gas phase granulation method; the technology is simple and efficient, replaces an original melt liquid phase pelletizing method which is tremendously time-consuming and low in pelletizing rate, and is used to realize continuous industrial production at a pelletizing stage; the pelletizing yield exceeds 80% or above; the pitch-based spherical activated carbon reaches the requirements for the quality of foreign similar products after being treated by subsequent pre-oxidation, carbonization and activation.

Owner:俞祥敏 +1

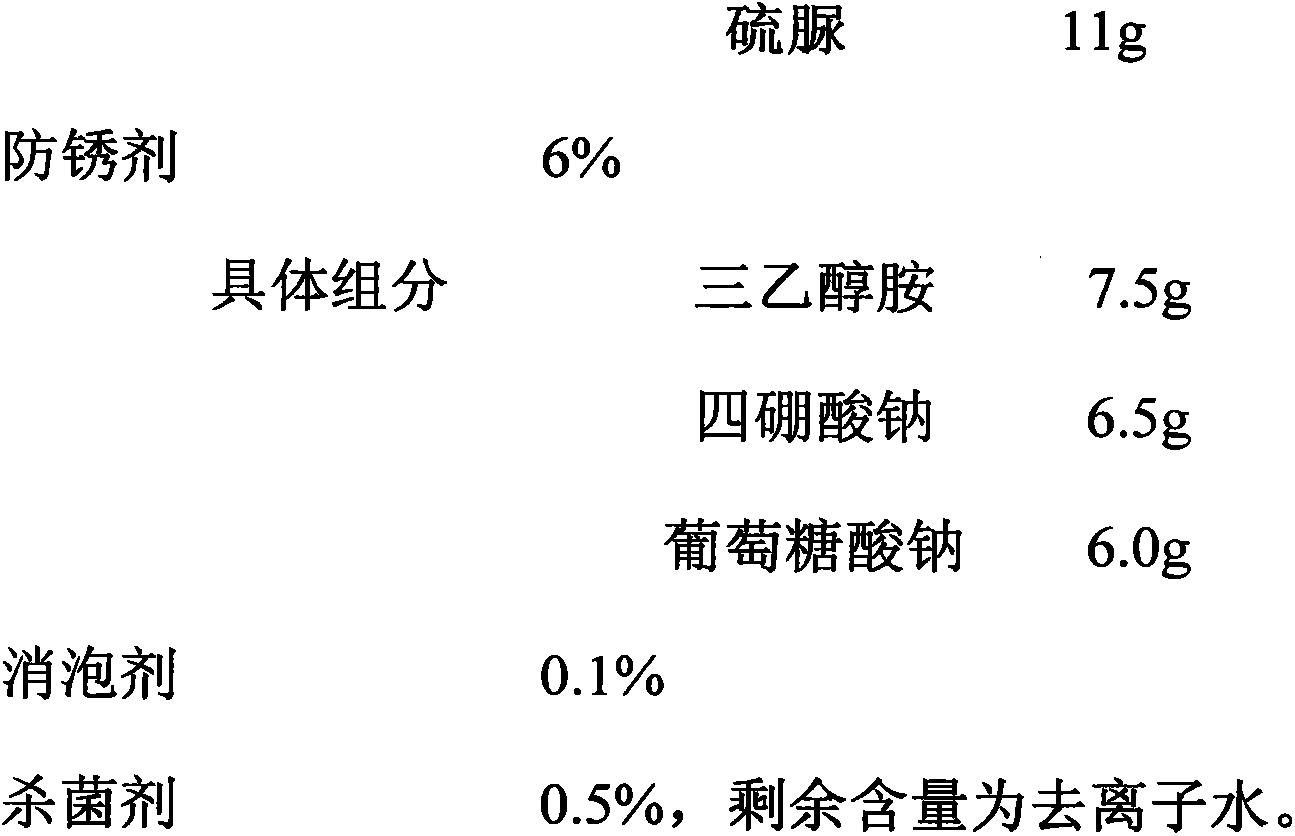

Full-synthetic metal cutting liquid

InactiveCN103820197ASimple preparation processImprove performanceLubricant compositionThioureaPerformance index

A full-synthetic metal cutting liquid comprises the following components in percentage by weight: 18-20% of an extreme-pressure lubricant, 6-7% of an antirusting agent, 0.1-0.5% of a defoaming agent, 0.5-1% of a bactericide and the balance of deionized water, wherein the extreme-pressure lubricant comprises 5.1-5.7% of boric acid, 8.6-9.2% of diethanol amine and 4.3-5.1% of thiourea, and the antirusting agent comprises 2.1-2.3% of triethanolamine, 1.9-2% of sodium tetraborate and 1.7-1.9% of sodium gluconate. A method for preparing the metal cutting liquid comprises the following steps: (1) synthetizing organic boric acid ester; (2) synthetizing the extreme-pressure lubricant; (3) preparing the antirusting agent; (4) preparing the full-synthetic metal cutting liquid. Proven by the results, the prepared metal cutting liquid is transparent and stable, is high in extrusion resistance, wear resistance and rust resistance, can be used for processing various materials such as aluminium alloy, cast iron, carbon steel and copper, is equal to foreign similar high-grade products in performance indexes, and achieves the effects of environmental protection, energy conservation and consumption reduction.

Owner:SOUTHWEST UNIVERSITY

Aluminium magnesium alloy wire for cable braided shield and production method thereof

The invention relates to an aluminium magnesium alloy wire for cable braided shield and production method thereof, which contains, in weight percentage, 3.2-3.9% magnesium, 0.15-0.35% chromium, 0.1-0.5% boron, and the surplus is aluminum. Its production methods is: carrying out the production on the raw material having boron according to the process of smelting, primary stretch forming, heat treatment, rough drawing, secondary drawing, heat treatment, carefully drawing, and a automatically monitored tubular annealing process that is adopted after the carefully drawing process. The aluminium magnesium alloy wire for cable braided shield adopting the present inventive rate, has a resistivity no more thatn 0.051 omega.mm[2] / m in 20 DEG C, which reaches a level of the foreign similar advanced product; the aluminium magnesium alloy wire for cable braided shield produced by the present inventive method, has a break force no less than 5.1N, and a breaking elongationoun rate no less than 10%.

Owner:临安市新联线缆材料有限公司

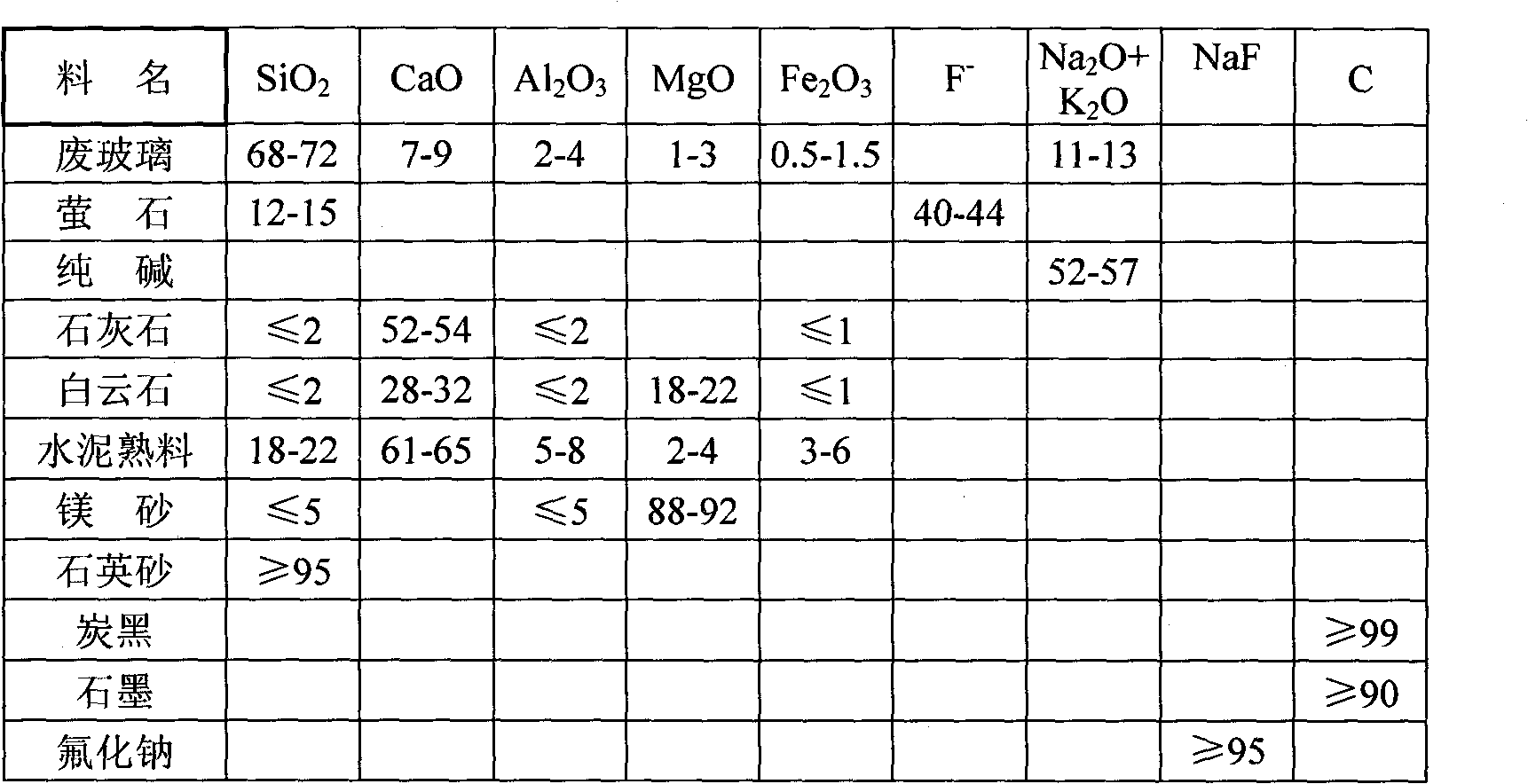

Medium carbon steel casting powder for H-section steel continuous casting

InactiveCN102990025ALower melting temperatureViscosity, proper melting speed properSteelmakingTwo step

The invention relates to medium carbon steel casting powder for H-section steel continuous casting, belonging to the technical field of steelmaking and continuous casting. The medium carbon steel casting powder comprises the following components in percentage by weight: 33-39 percent of CaO, 35-39 percent of SiO2, 4-7 percent of Al2O3, 0-3 percent of MgO, 5-9 percent of F<->, 10-12 percent of Na2O, and balance of composite carbon which comprises 7 percent of graphite and 1-2.5 percent of carbon black, wherein the CaO and the SiO2 are used as base materials; and the Na2O, the MgO, the Al2O3 and the F<-> are used as flux. A preparation process comprises two steps, i.e. the step of producing pre-molten materials and the step of producing finished product casting powder. The prepared casting powder has physical properties that the melting point is 1080-1096DEG C, the viscosity at 1300DEG C is 0.17-0.35Pa.s and the melting speed is 30-40s. The thickness of the molten flux layer of the casting powder is 10-13mm. According to the requirement of carbon steel on the casting powder during production of an H-section steel continuous casting machine, the flux film control goals of lower melting temperature, lower viscosity, proper melting speed and higher thermal resistance are realized, and the situation that the surface of a casting blank is longitudinally cracked because the temperature gradient of the cross section of the casting blank is too large is avoided. The medium carbon steel casting powder has a better using effect than the using effect of domestic and foreign similar products, and can fully meet the process requirement on the carbon steel during H-section steel continuous casting.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

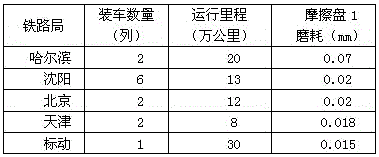

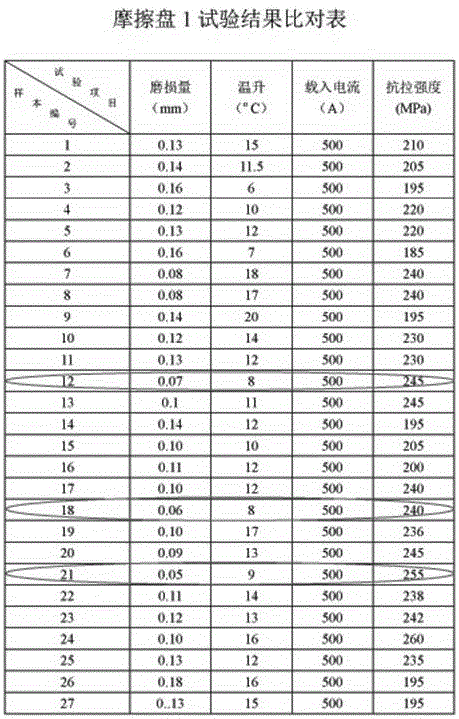

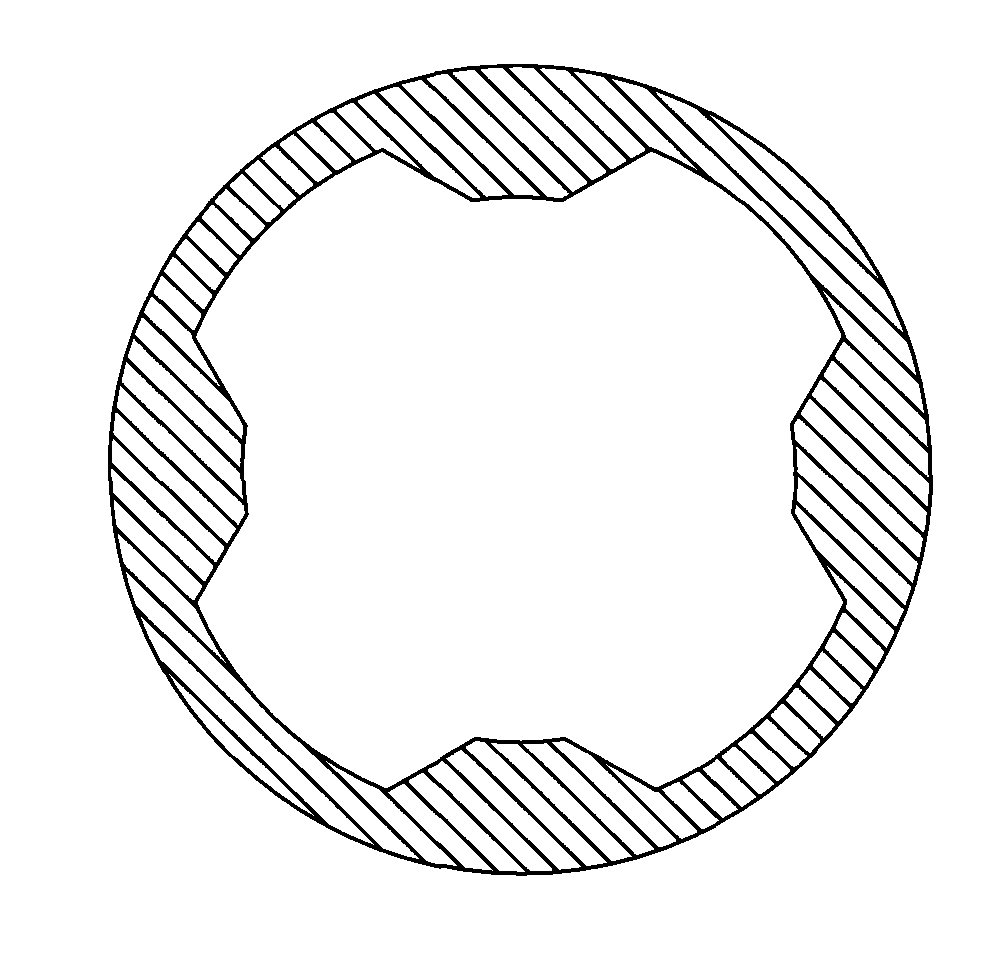

Friction disc for high-speed rail and preparation method of friction disc

InactiveCN106399747AThe result data is idealLiquid metal is better filledFoundry mouldsFoundry coresSand castingLiquid metal

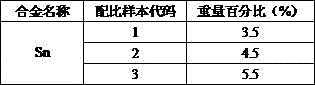

The invention relates to a friction disc for a high-speed rail and a preparation method of the friction disc. The friction disc comprises the following components including, by weight, 3.5-5.5% of Sn, 4.0-6.0% of Zn, 1.0-3.0% of Ni, 1.5-3.5% of Pb, 0.2-0.4% of Be and the balance Cu. A vacuum suction fired mold is adopted for casting, gas in a cavity is sucked away from tiny pores in a shell, the cavity is better filled with liquid metal, the phenomena of pores and insufficient pouring are prevented, the appearance and inherent quality of products are improved, and the machining yield is up to 98%. The requirements of the friction disc for the abrasion resistance and electrical conductivity are higher, common sand casting structures are loose, casting defects are prone to occurring, and meanwhile the hardness is low. Precise die forging manufacturing is adopted, the blank allowance is even, the texture is compact, the hardness can reach the drawing requirement, and tests show that the abrasion resistance reaches and exceeds the level of foreign similar products.

Owner:YANGZHOU YIFENG BRONZE PROD

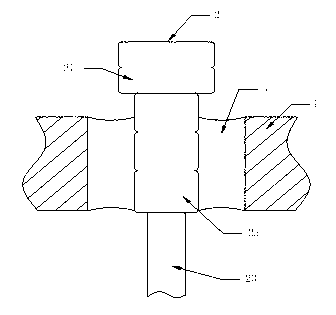

Packaging structure for glass sealing electronic component

ActiveCN103268870AReduce lossSemiconductor/solid-state device detailsSolid-state devicesLead bondingForeign - Similar

The invention relates to an electronic component packaging structure and in particular relates to a packaging structure for a glass sealing electronic component. The packaging structure comprises a metal substrate, wherein a sealing hole is formed in the metal substrate; a lead is arranged in the sealing hole; glass is arranged between the lead and the wall of the sealing hole; the lead comprises an upper lead part of which the upper part is exposed out of the metal substrate and the surface of the glass and penetrates through the sealing hole; the upper lead part has a columnar structure; a lower lead part is connected to the lower part of the upper lead part; and the diameter of the upper lead part is larger than that of the lower lead part. According to the packaging structure for the glass sealing electronic component, the defects that the lead bonding is instable, the glass is cracked and broken, the gas tightness is low and the overall device is low in reliability in domestic similar electronic components are overcome. Compared with foreign similar electronic components, the packaging structure has the advantages that when the design is applied to a high-power packaging shell, the lead can be lower in loss by increasing the current to a certain degree.

Owner:ZHEJIANG CHANGXING ELECTRONICS FACTORY

Waterborne expansion fire-proof coating with weather resistance and fire resistance and preparing method

InactiveCN106752477AImprove fire resistanceEasy constructionFireproof paintsUltraviolet lightsChlorinated paraffins

The invention discloses a waterborne expansion fire-proof coating with the weather resistance and the fire resistance and a preparing method. The waterborne expansion fire-proof coating is mixed by A components and B components; the A components are prepared from a thickening agent, a dispersing agent, an antifoaming agent, a sterilizing agent, titanium dioxide and water; the B components are prepared from modified acrylic emulsion, pentaerythritol, tripolycyanamide, ammonium polyphosphate, chlorinated paraffin, a coalescing agent and water. The waterborne expansion fire-proof coating is an environment-friendly waterborne expansion fire-proof coating, and has the advantages of being good in ultraviolet light resistance, low in water absorption rate, high in fire resistance and the like, and the defects that the physical and chemical performance, the fire resistance and the like of domestic similar products are poor are overcome. Compared with foreign similar products, the physical and chemical performance and the stability of the fire resistance of a product are improved; meanwhile, the coating has the good construction performance, the decorative performance is high, the product storage stability is good, the raw materials are easy to obtain, and the cost is moderate; the weather resistance of the product meets the requirements of the standard technology.

Owner:TIANJIN FIRE RES INST

Solid catalytic production method of biodiesel

InactiveCN101113351AWide variety of sourcesNo pollution in the processBiofuelsLiquid hydrocarbon mixture productionWater bathsVegetable oil

The invention relates to the technical field of a production method of the bio-diesel, in particular to a solid catalytic production method of the bio-diesel. The method is that: lower alcohol and vegetable oil are mixed, stirred and heated with existing of solid acid or solid base catalyst to result in transesterification; after the reaction, the catalyst is separated by a centrifuge; the reacted mixture is stood and divided into an upper layer and a lower layer, the upper layer is coarse products and the lower layer is mixed liquid of glycerol and the rest methanol; at last the bio-diesel is obtained by distilling the upper coarse ester. The yield of the bio-diesel produced by the invention can be more than 99 percent and all performance indexes of the product basically meet the standard of foreign similar products and are close to the main performance indexes of Chinese 0 model diesel (GB 252-1994, superior grade product).

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

Urea-formaldehyde resin foaming thermal insulation material

InactiveCN101289567AAdvanced technologyFormulation ScienceOther chemical processesThermal insulationPhosphoric acid

The invention relates to urea-formaldehyde resin foaming heat insulating material. The invention is characterized in that: the material is mixed by A composition liquid and B composition liquid, wherein, the A composition liquid is mixed liquid of urea and urea-formaldehyde resin water solution; the B composition liquid is mixed liquid mixedly formed by phosphoric acid, non-ionic surfactant and water; and the urea-formaldehyde resin foaming heat insulating material can be formed by mixing the A composition liquid and the B composition liquid according to the weight proportion of 1:1. The material belongs to high-efficient heat insulating material, has a heat conductivity coefficient less than or equal to 0.035W / (m.k), can improve the heat insulating performance of outside enclosure structures of buildings to the utmost extent, has a performance index which also achieves and even exceeds foreign similar products, is environment-friendly, has low cost, sells the price of 60 to 75 percent of import products, has large development space and application prospect, and is a regeneration product of the prior foaming heat insulating materials.

Owner:TIANJIN YOUNINGFUMU BUILDING ENERGY SAVING SCI & TECH DEV CO LTD

Han children asthma susceptibility gene detection model and kit thereof

InactiveCN101831501AInnovativeRace-specificMicrobiological testing/measurementForeign - SimilarSusceptibility gene

The invention relates to a Han children asthma susceptibility gene detection model which consists of nine SNP loci including FcER1 E237G, FcER1 C-109T, ADRB2 R16G, IL4RA Q551R, IL4RA I75V, IL4 C-590T, IL13 A2044G, IL13 C1923T and IL13 C-1112T. The invention also provides a Han children asthma susceptibility gene detection kit. The invention has the advantages that the Han children asthma susceptibility gene detection model is established for the first time in China, thus having innovation; and compared with foreign similar research, the Han children asthma susceptibility gene detection model has species specificity. The Han children asthma susceptibility gene detection kit which detects the nine SNP loci has good asthma detection efficiency (OR=345.3478, P value is less than 0.0001, the accuracy is 92.97%, the sensitivity is 97.92%, and the specificity is 88.02%).

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

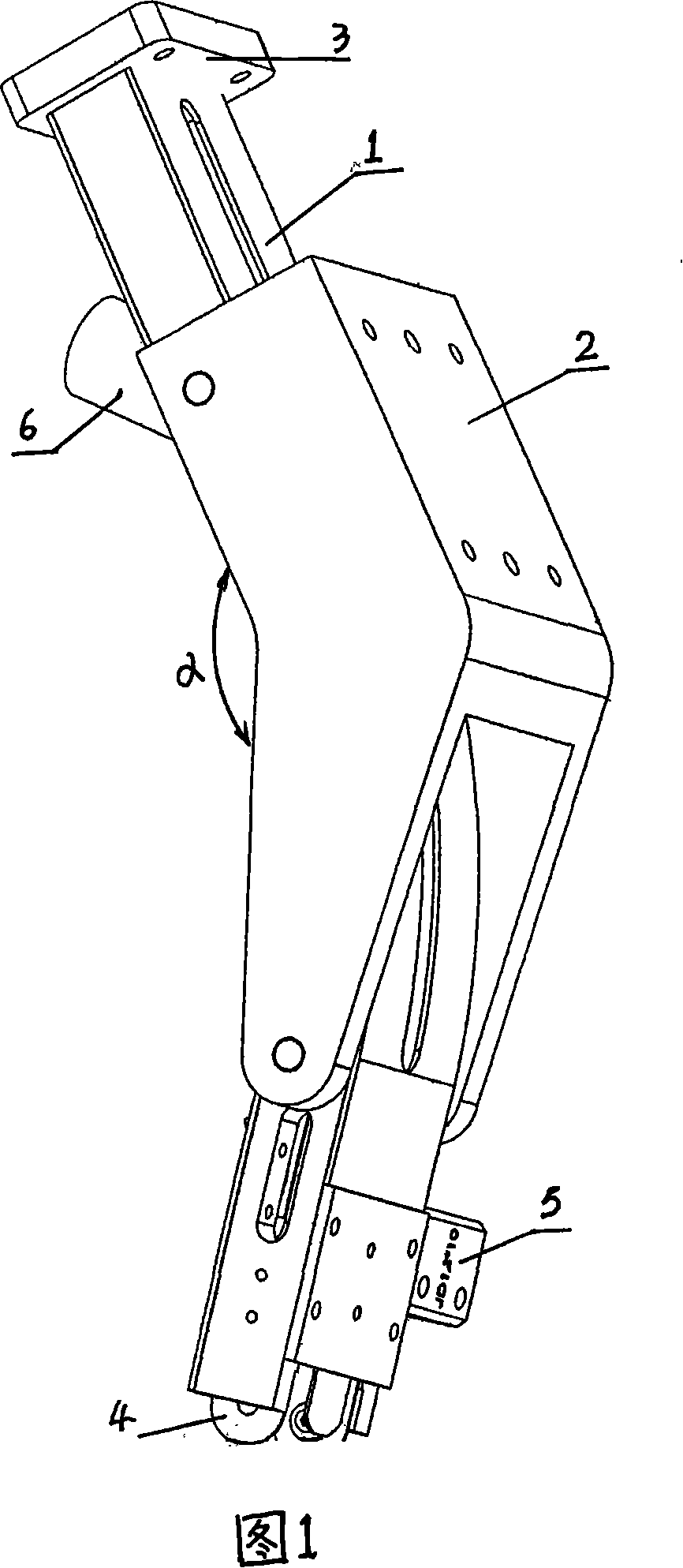

Bottle cap ring-cutting machine cap-hanging device

ActiveCN101104277ASimple structureReduce manufacturing costMetal working apparatusPerformance indexForeign - Similar

The invention, which relates to a cap-hanging device for the bottle cap loop cutter, is characterized in that the device comprises a bottle-cap transport track (1) and a fixed base (2) in which the bottle-cap transport track (1) is fixed; the input terminal of the bottle-cap transport track (1) is provided with an output port joint (3) of an external injection molding machine and the output terminal of the bottle-cap transport track is provided with an elastic flake (4); the bottle-cap transport track (1) ,whose output terminal is inclined, is arch-shaped; a cylinder (5) is arranged in front of the output terminal of the bottle-cap transport track, the controlling input terminal of the cylinder(5) is connected with the signal output terminal of the speed measuring electromagnetism valve, whose input terminal is connected with the ring stand shaft of the bottle-cap loop cutter. The invention takes advantage of the bottle-cap transport track to bend into certain radian so that a complex screw mechanism of the cap-hanging device under current technology is avoided. The invention is simple in structure, low in manufacturing cost and the speed of cap-hanging can reach 2000PCS / min. The invention whose performance index reaches the standard of the overseas equipment costs only 10% of the foreign similar product.

Owner:DONG GUAN JIN FU IND CO LTD

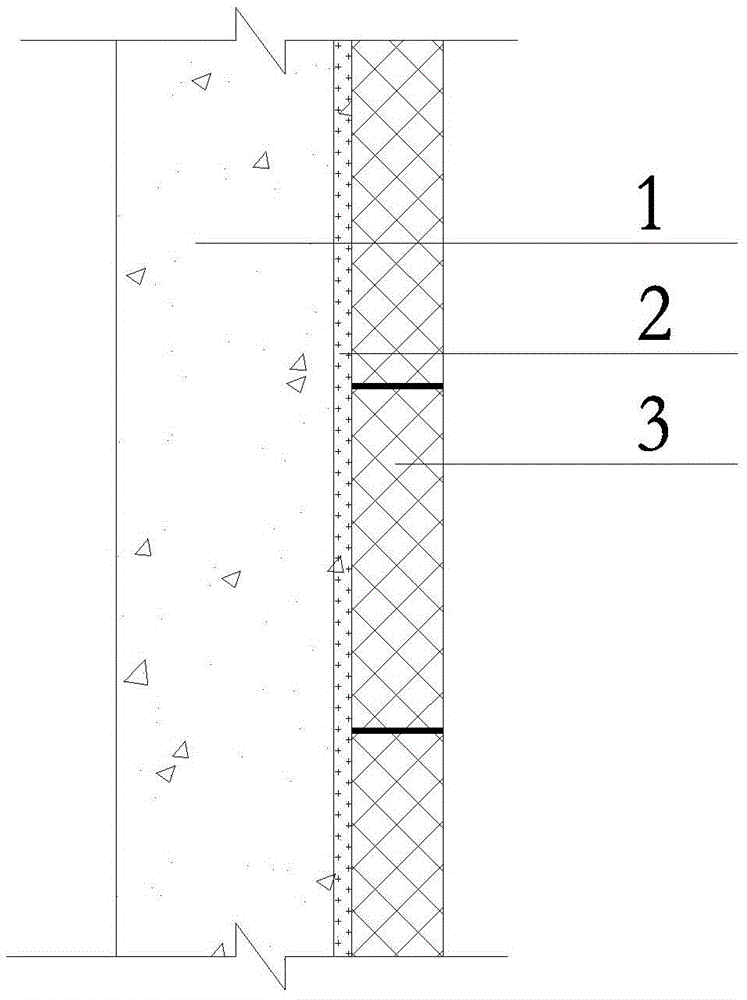

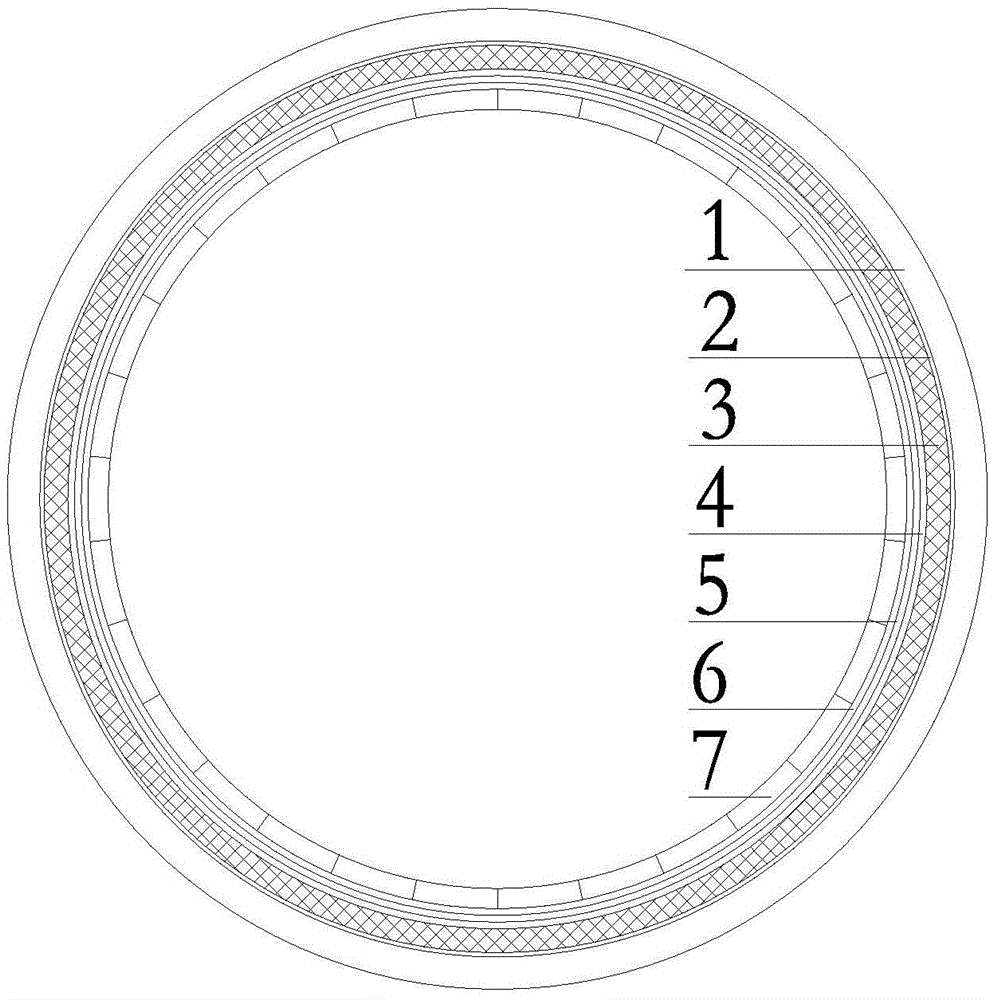

Corrosion control system for reinforced concrete single-cylinder chimney after wet desulfurization and manufacturing method of corrosion control system

InactiveCN105465808AAvoid corrosionAvoid destructionPolyureas/polyurethane adhesivesAnti-corrosive paintsHydrofluoric acidBrick

The invention discloses a corrosion control system for a reinforced concrete single-cylinder chimney after wet desulfurization and a manufacturing method of the corrosion control system. The corrosion control system sequentially comprises a chimney cylinder body reinforced concrete wall layer (1), a heat preservation and insulation layer (2) and an acid-proof brick liner layer (3) from outside to inside and also comprises a quick-drying mortar repairing layer (4) coated on the inner wall of the acid-proof brick liner layer (3), a base coating layer (5) coated on the inner wall of the quick-drying mortar repairing layer (4), an anticorrosion adhesive layer (6) coated on the inner wall of the base coating layer (5) and a light anticorrosion vitrified tile (7) coated on the inner wall of the anticorrosion adhesive layer (6). With the adoption of the corrosion control system, the performance of resisting hydrofluoric acid corrosion is strengthened, the disadvantage of the traditional domestic similar chimney anticorrosion material of intolerance in hydrofluoric acid corrosion is effectively overcome, and the cost is lower than that of a foreign similar product; and meanwhile, the elasticity of the anticorrosion adhesive layer deforms along with changes of temperature, and thus damages caused by the stress to the corrosion control system are avoided.

Owner:北京恺岚科技发展有限公司

Calcium-phosphate-based 3D printing material for biomedicine and preparation method thereof

InactiveCN106668934AHigh mechanical strengthGood biomedical performanceAdditive manufacturing apparatusProsthesisPolymer scienceWater soluble polymers

The invention belongs to the field of 3D printing materials and discloses a calcium-phosphate-based 3D printing material for biomedicine and a preparation method thereof. The preparation method specifically comprises the steps of dipping amorphous calcium phosphate into pure water containing metal ion, rare earth ion and water-soluble polymer; drying and grinding to obtain the calcium-phosphate-based 3D printing material. A bone tissue printed with the 3D printing material of the invention has the advantages of having high mechanical strength, good biomedical performance and high printing accuracy completely exceeding that of foreign similar imported products and having very wide application prospect.

Owner:ZHONGSHAN POLYTECHNIC

Modified unsaturated polyester colored finish paint or primer

InactiveCN102816511AImprove fullnessEasy to polishPolyurea/polyurethane coatingsPolyester coatingsLacquerHardness

The invention relates to a modified unsaturated polyester colored finish paint or primer, which is characterized in that: the paint is prepared by mixing a polyurethane component with an unsaturated polyester component according to a weight prescribed ratio of polyurethane component to unsaturated polyester component of 1: (0.5-1). Compared with the prior art, the modified unsaturated polyester colored finish paint or primer has excellent technical indexes and can replace foreign similar products, and has the advantages of high hardness, good fullness, strong adhesion, good flexibility, easiness in construction and the like.

Owner:FOSHAN OVS SANITARY WARE MFG

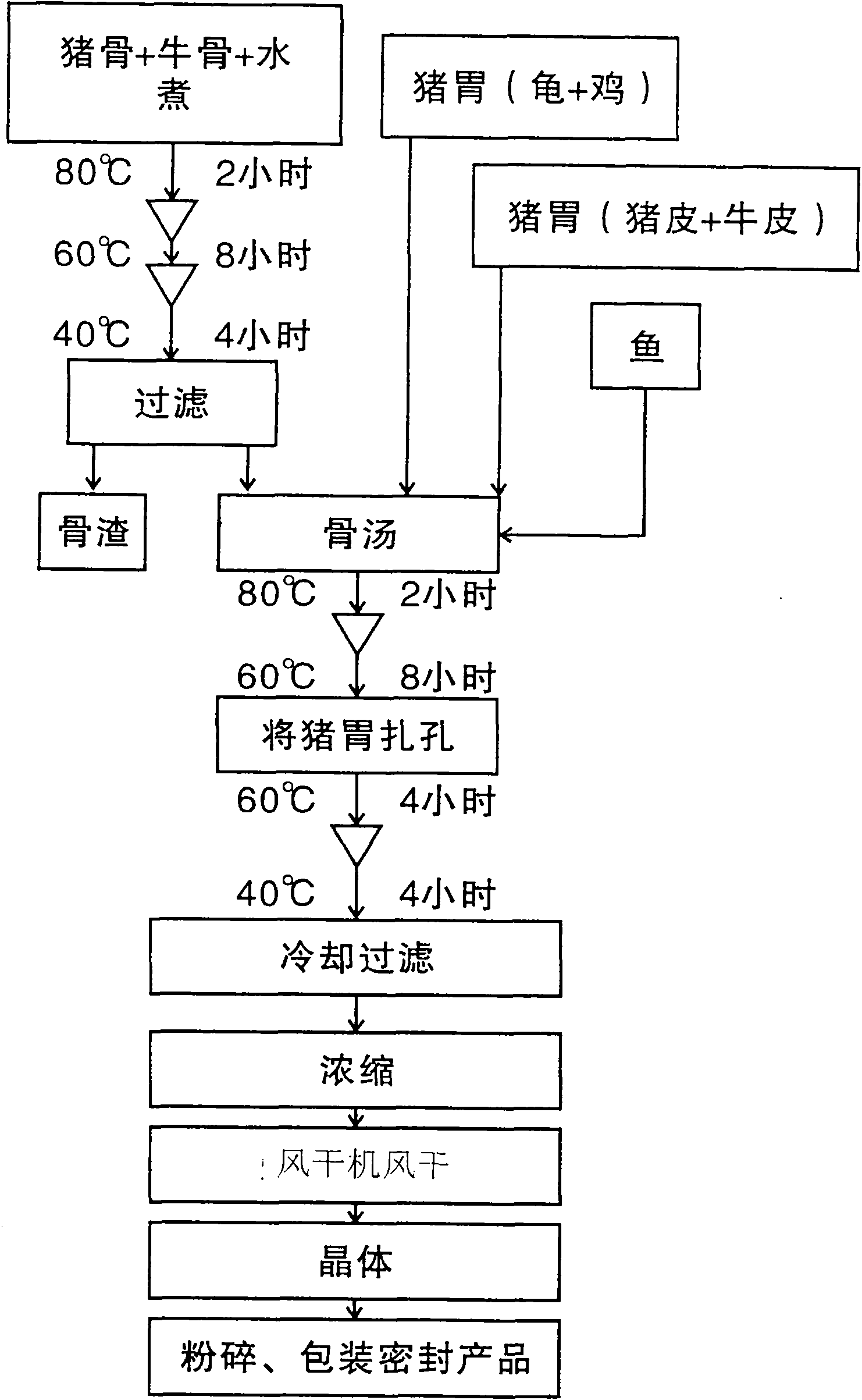

Production method for selenium-containing collagen

InactiveCN101849604AHas the value of development and promotionSimple production processProtein composition from fishProtein composition from meatFiltrationEngineering

The invention relates to a production method for selenium-containing collagen. The method adopts bones to make soup, turtles and chicken are contained in one pig stomach, pig skins and cow skins are contained in another pig stomach, the processed pig stomachs and fish are put together into a casserole filled with bone soup, and repetitive boiling, filtration, concentration, air drying, crushing and packaging are conducted to obtain the collagen product. The production technology of the invention is simple and unique, the expensive instruments and equipment are not required, the production period is short, the cost is very low, the produced product not only has the advantages and the application values of domestic and foreign similar products but also contains organic selenium, the content of the organic selenium reaches 6.1mg / kg high and cannot be found in the existing literature, the collagen is a special collagen product, the application value and the development and popularization value of the collagen are very high, especially the selenium has great function on cancer fighting and thereby the development prospect is very high.

Owner:袁抗美 +1

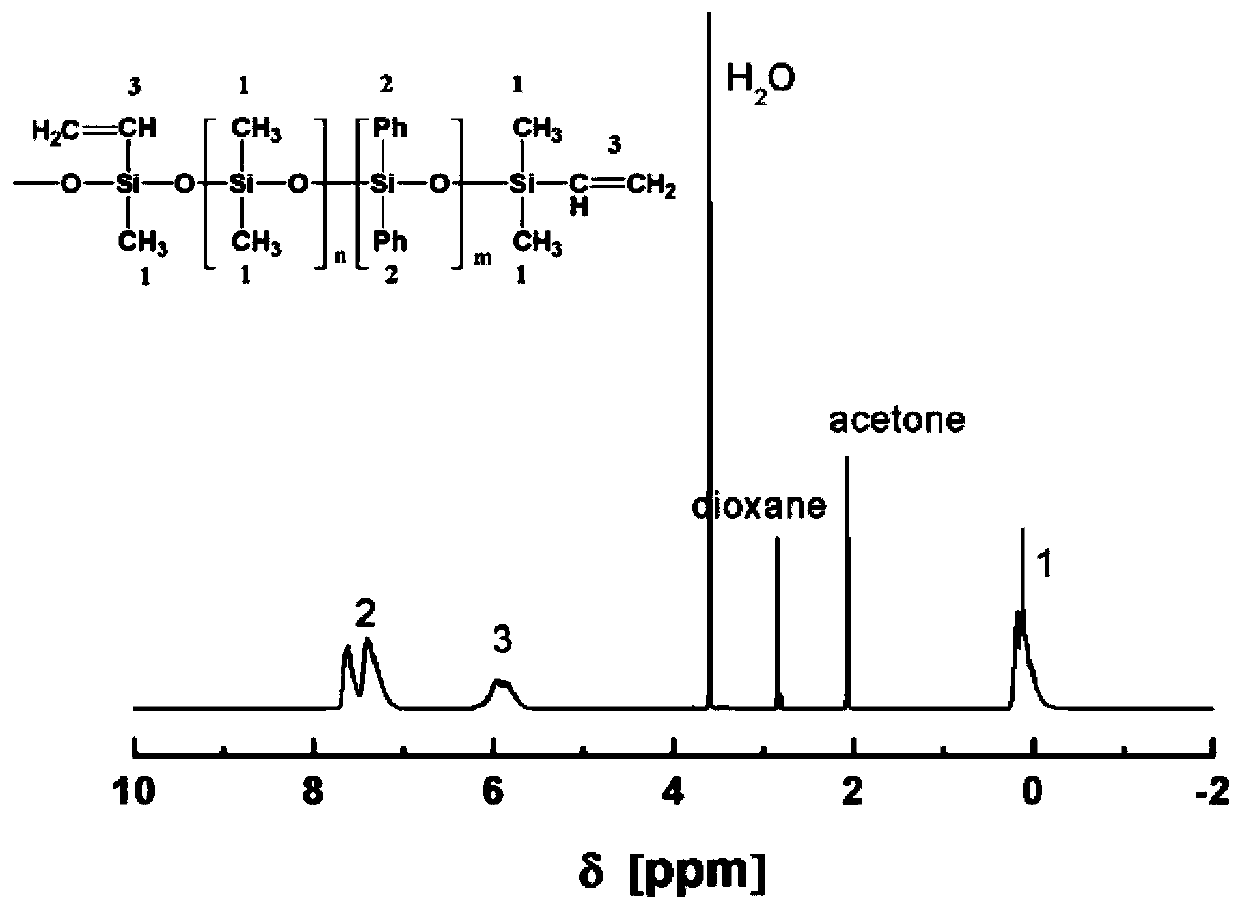

Phenyl vinyl siloxane resin, high-refractive-index light-emitting diode (LED) packaging silicon resin composition and preparation method of silicon resin composition

The invention relates to phenyl vinyl siloxane resin, a high-refractive-index light-emitting diode (LED) packaging silicon resin composition and a preparation method of the silicon resin composition.The phenyl vinyl siloxane resin is prepared by the following steps: S1, mixing monomers, and adding an organic solvent to obtain a mixed solution, and adding a hydrolysis catalyst; S2, dropwise addingwater at 0-60 DEG C for a hydrolysis reaction, carrying out washing and suction filtration, adding an alkali catalyst to carry out a condensation reaction at a temperature of 120-160 DEG C, and carrying out washing and suction filtration to obtain the phenyl vinyl siloxane resin. The phenyl vinyl siloxane resin provided by the invention is high in refractive index and excellent in flexibility andyellowing resistance. When being used for preparing the LED packaging silicon resin, the phenyl vinyl siloxane resin has high refractive index, excellent tensile strength, excellent bonding strength,excellent light transmittance and excellent yellowing resistance, wherein partial performance reaches or is higher than the level of foreign similar imported products, and basic requirements of LED packaging can be met. A packaged surface-mounted LED device has excellent air tightness.

Owner:SUN YAT SEN UNIV

Sealing system composed of small anaerobic operation bags and chromatography column in series

InactiveCN102199191AReduce stepsEasy to operatePeptide preparation methodsOxidoreductasesFiltrationShielding gas

The invention relates to a sealing system composed of small anaerobic operation bags and a chromatography column in series, mainly used for isolation and purification of anaerobic protein from plants and microorganisms. The method comprises the following steps: putting reagents, vessels into anaerobic operation bags, sparging all reagents and buffers with a stream of nitrogen, adding sodium hydrosulfite to remove dissolved oxygen, breaking tissues or cells using a high-speed ball mill method, precipitating a crude enzyme solution, isolating and purifying the crude enzyme solution by gel filtration chromatography and ion exchange chromatography, so as to obtain the anaerobic protein. Foreign similar method is realized by putting all useful apparatus, devices into a huge anaerobic device with the disadvantages of occupying large area, high cost of shielding gas and difficult operation; while no relative technologies have been reported in China. The invention has the advantages of easy operation and low cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Impregnating resin for high-frequency and low-frequency electronic transformers

ActiveCN103773198ASimple preparation processGood composition stabilityPolyester coatingsTransformerLow temperature curing

The invention discloses impregnating resin for high-frequency and low-frequency electronic transformers. The impregnating resin comprises the following materials in percent by weight: 45-60% of polyester resin, 10-20% of a curing agent, 5-10% of oily phenolic resin, 0.02-2% of a functional additive and 25-40% of a diluting agent. Compared with the prior art, the impregnating resin has the advantages that (1) the manufacturing process is simple and the stability of composition is good; (2) not only are the mechanical strength and the bonding force improved, but also the softness is improved, the aspects of heat resistance and strong permeability are also excellent, the heat-resistant level can reach F level, and the comprehensive performance is better; (3) the impregnating resin also has the advantages of fast low-temperature curing, strong permeability, good internal drying performance, excellent secondary solderability and stable storage and the like. The impregnating resin disclosed by the invention does not contain dangerous and forbidden matters specified by the European ROSH regulations, completely meets the requirement on the impregnation process of the electronic transformer, and is excellent electronic-insulating impregnating varnish which can be comparable with foreign similar products.

Owner:浙江博菲电气股份有限公司

Inner-complex cooling pipe and method for producing the same

The invention discloses an inner-complex cooling pipe, which comprises an outer pipe and an inner pipe, wherein the inner pipe is positioned in the outer pipe, and an even number of axial channels which are not connected with each other are arranged between the outer wall of the inner pipe and the inner wall of the outer pipe. The invention also discloses a method for producing the inner-complex cooling pipe. A product produced by drawing has high surface finish; rounded smooth transition is adopted among various surfaces of a workpiece to ensure product ventilation and water smooth and to meet use requirement to the maximum; the product is formed by one-time stretch and has high size precision, few errors and convenient assembly; the qualification rate of the product is increased by 55 percent; and the product has short production period, high output and low cost. Compared with the conventional production process, the staff are reduced by 20 percent, the electricity bill is reduced by 10 percent, and copper materials are saved by 25 percent; the production cost of a producer is reduced to the maximum and the cost performance of the product is improved by using a drawing method to produce a four-channel complex product and the price is only about 38 percent of that of a foreign similar product, thereby really achieving the aim of high efficiency and energy conservation.

Owner:江苏金圣铜业科技有限公司

Preparation method of gel type styrene cation resins for chromatographic separation

ActiveCN103433010AImprove adsorption capacityHigh mechanical strengthOther chemical processesFructoseChromatographic separation

The invention provides a preparation method of gel type styrene cation resins for chromatographic separation. According to the preparation method, styrene polymer white spheres are produced by selecting a temperature rising method and reaction time in an industrially known production standard process formula of gel type styrene cation exchange resins, then a chelating agent and fluoboric acid are added in sulfuric acid during sulfonation, and chromatographic separation resins can be obtained by carrying out standard process sulfonation reaction. Compared with gel type styrene cation exchange resins which are not added with the chelating agent and the fluoboric acid during the sulfonation, the chromatographic separation resins prepared by utilizing the preparation method have the advantages that the adsorption capacity can be improved by 50%, and the mechanical strength can be improved by 20%. According to the chromatographic separation resins prepared by utilizing the preparation method, the content of fructose can be increased, the production cost can be lowered, and foreign similar products can be replaced.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Quality improver for quick-frozen rice noodle food

InactiveCN109601973ASolve key technical problems with obvious industrial characteristicsSatisfied without crackingFood ingredientsVegetable oilVitamin C

The invention discloses a quality improver for quick-frozen rice noodle food. The quality improver consists of the following raw materials by mass: 20-34 parts of vegetable oil, 20-34 parts of glycerol, 4-10 parts of glycerol monostearate, 4-8 parts of soybean phospholipids, 1-3 parts of whey protein, 0.4-1 part of Arabic gum, 0.1-0.4 part of xanthan gum, 0.4-1 part of propylene glycol alginate, 4-10 parts of pre-gelatinized starch, 12-20 parts of guar gum, 2-4 parts of sodium pyrophosphate, 0.2-0.8 part of vitamin C, 0.2-0.8 part of diacetyl tartaric acid ester of glyceride, 1-3 parts of sodium tripolyphosphate, 2-4 parts of sodium dihydrogen phosphate, 1-5 parts of sodium hexametaphosphate and 30-50 parts of deionized water. The quality improver effectively solves the key technical problems of obvious industrialization characteristics of quick-frozen food, i.e., the type-preserving freeze-thaw resistance in the production process and under freezing conditions, prevents ice crystal formation and starch retrogradation during freezing, meets the requirements of the quick-frozen food on no freezing cracking, surface gloss, soft but not hard taste, and cooking resistance, and surpasses domestic products and achieves the same or better effects as foreign similar products.

Owner:南通寿星食品有限公司

Gas and water atomizing nozzle

InactiveCN101690919AQuality assuranceLow costLiquid spraying apparatusLeaking waterThermal expansion

The invention discloses a gas and water atomizing nozzle, which comprises a valve body and a spray nozzle, wherein the spray nozzle is connected to the valve body through threads; the spray nozzle comprises a spray nozzle shell, a guide core and a positioning plug; the guide core is arranged in an inner cavity of the spray nozzle shell; and the positioning plug is arranged at the rear end of the spray nozzle shell through thread connection. The spray nozzle and spray nozzle components are detachable, when the spray nozzle of the gas and water atomizing nozzle is blocked, the spray nozzle only needs to be detached and cleaned, and the spray nozzle is arranged on the valve body again after being cleaned; and the spray nozzle or the whole gas and water atomizing nozzle does not need to be replaced, so that the cost is lower. Openings at both ends of a first through hole and a second through hole of the valve body are provided with a first welding line and a second welding line respectively, the gas and water atomizing nozzle is welded with an air inlet pipe and a water inlet pipe when used, the welding lines are filled after a welding rod is melted, and the welding is firm, so that the gas and water atomizing nozzle overcomes a defect that domestic and foreign similar gas and water atomizing nozzles leaks water in the detaching process because expansion and contraction influence the sealing effect, and the quality of the gas and water atomizing nozzle is ensured.

Owner:北京洋鑫利源喷雾科技有限公司

Production process of ABS valve body material for cars

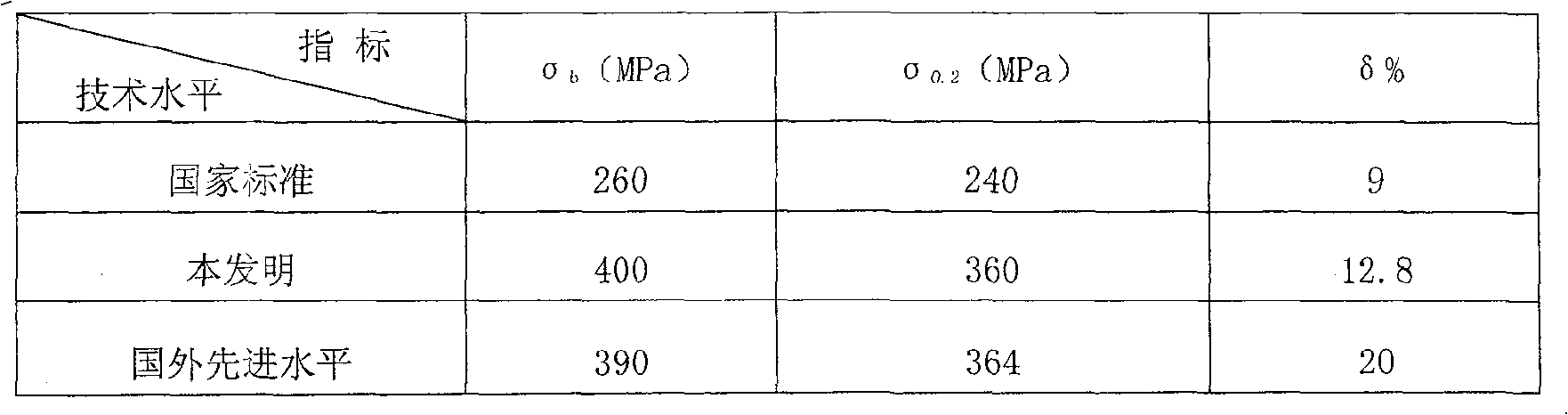

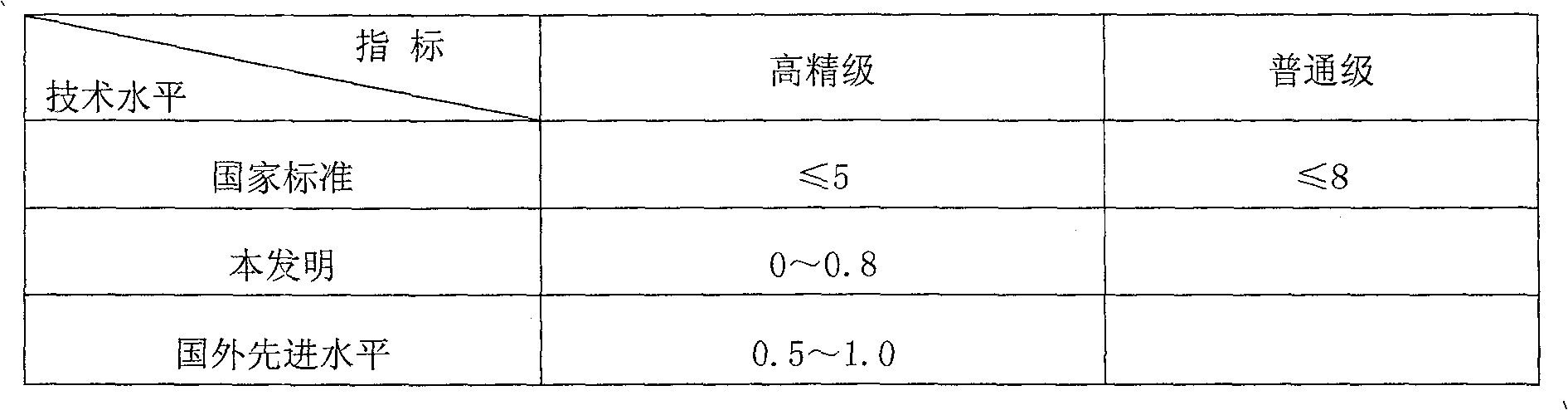

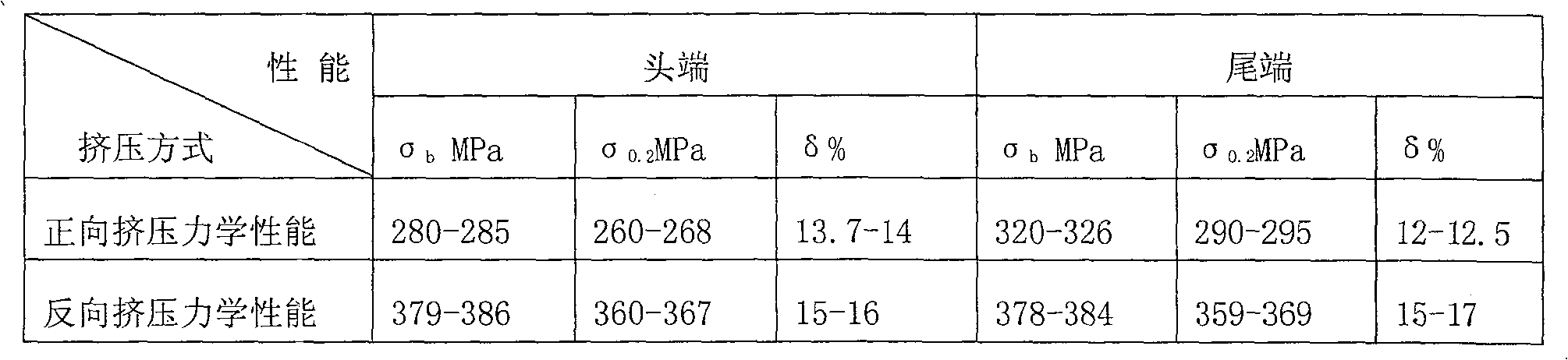

The invention provides a production process of the automobile ABS valve body material, which includes the following steps: preparing raw materials, melting, refining and standing, filtering and casting, homogenizing, ingot processing, ingot heating, indirect extruding, on-line water quenching, stretch rolling, artificial aging and finished product inspecting. By adopting the optimized alloy component in combination with indirect extrusion technology and on-line heat treatment technology, particularly the indirect extrusion technology, the inventive production process achieves the high uniformity of material structure, head-and-tail measures and mechanical property, thereby solving the problems of 6061 alloy coarse grain zone and mechanical property, increasing the production yield index, reducing the energy consumption of unit product, obtaining the material of which the mechanical property, metallographic structure, dimensional precision and the surface quality reach the advanced level of foreign similar products, achieving the import substitution of the material and laying the foundation of automobile localization.

Owner:西北铝业有限责任公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com