Medium carbon steel casting powder for H-section steel continuous casting

A technology of mold slag and H-shaped steel, which is applied in the field of steelmaking and continuous casting, can solve the problems of many mold slag accidents, which have not been found, and the surface quality of the slab is difficult to control, so as to achieve good surface quality of the slab and avoid longitudinal cracks on the surface of the slab , The effect of the thermal image is normal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

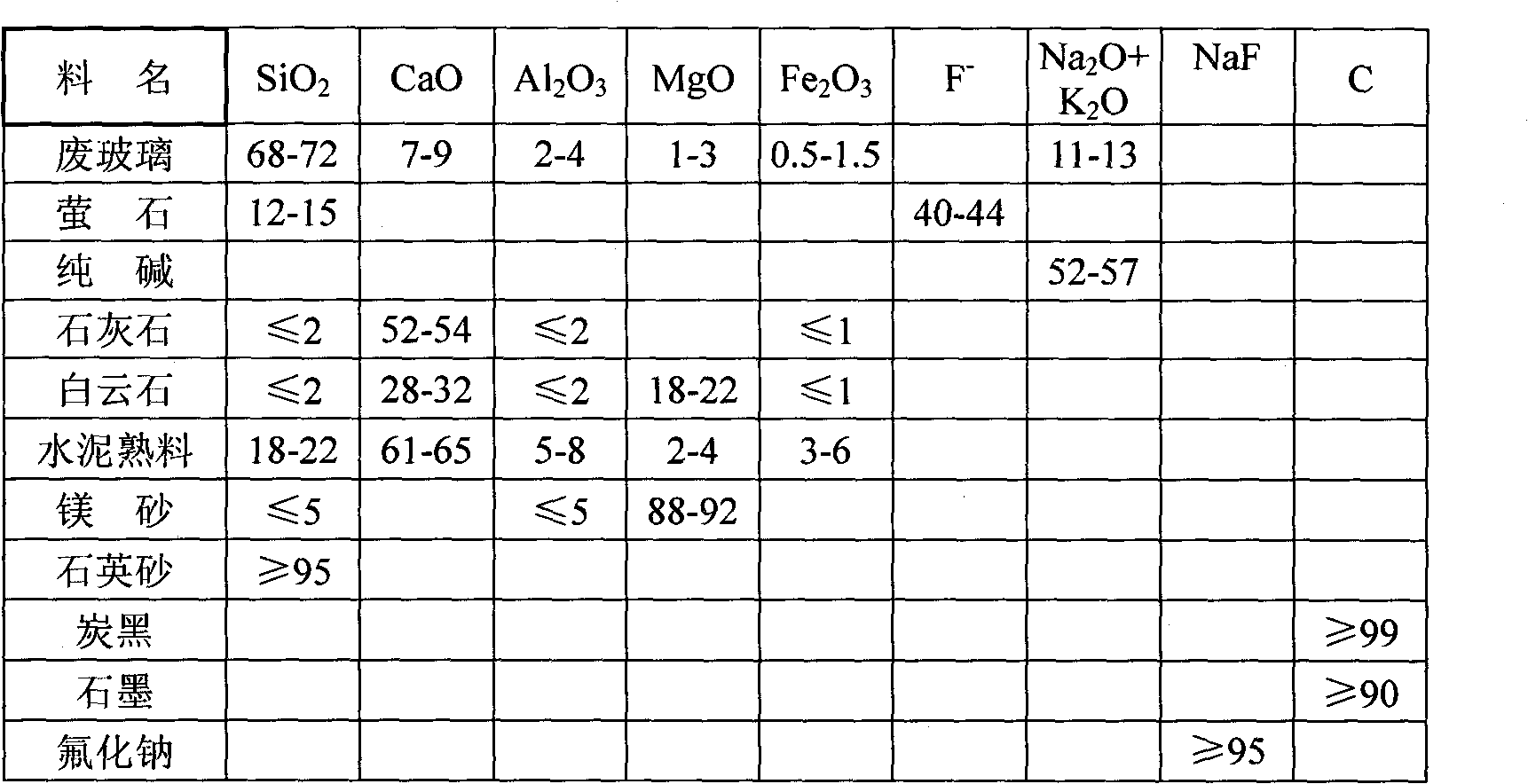

[0021] Crumble raw materials such as limestone, quartz sand, waste glass and fluorite into particles of 0.1-1 mm, and then mix them with powdery raw materials such as soda ash according to the chemical composition requirements described in Example 1 (see the table below) to form agglomerates , drying, melting in the shaft furnace with coke as fuel, and use as a semi-finished product after condensation and crushing. When the premelt slag is discharged from the furnace, a large flow of water is used to flush the slag for forced cooling to obtain a glassy phase premelt. Different proportions of graphite and carbon black are used for composite carbon matching, and together with the above-mentioned premelted materials, the finished mold powder is made through water milling, spray granulation, screening, cooling, testing, and packaging. The physical and chemical properties of the finished mold powder are shown in the table below.

[0022]

Embodiment 2

[0024] Limestone, quartz sand, waste glass, fluorite and other materials are broken into 0.1-1mm particles, and then mixed with powdery raw materials such as soda ash according to the chemical composition requirements described in Example 2 (see the table below) to form agglomerates , drying, melting in the shaft furnace with coke as fuel, and use as a semi-finished product after condensation and crushing. When the premelt slag is released from the furnace, a large flow of water is used to flush the slag and force cooling to obtain a glassy phase premelt. Different proportions of graphite and carbon black are used for composite carbon matching, and the above premelted materials are taken through water milling, spray granulation, screening, cooling, testing, and packaging to make finished mold powder. The physical and chemical properties of the finished mold powder are shown in the table below.

[0025]

Embodiment 3

[0027] Limestone, quartz sand, waste glass, fluorite and other materials are broken into 0.1-1mm particles, and then mixed with powdery raw materials such as soda ash according to the chemical composition requirements described in Example 3 (see the table below) to form agglomerates , drying, melting in the shaft furnace with coke as fuel, and use as a semi-finished product after condensation and crushing. When the premelt slag is released from the furnace, a large flow of water is used to flush the slag and force cooling to obtain a glassy phase premelt. Different proportions of graphite and carbon black are used for composite carbon matching, and the above premelted materials are taken through water milling, spray granulation, screening, cooling, testing, and packaging to make finished mold powder. The physical and chemical properties of the finished mold powder are shown in the table below.

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com