Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2935 results about "Steel casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel casting is a specialized form of casting involving various types of steel. Steel castings are used when cast irons cannot deliver enough strength or shock resistance. Examples of items that are steel castings include: hydroelectric turbine wheels, forging presses, gears, railroad truck frames, valve bodies, pump casings, mining machinery, marine equipment, turbocharger turbines and engine cylinder blocks.

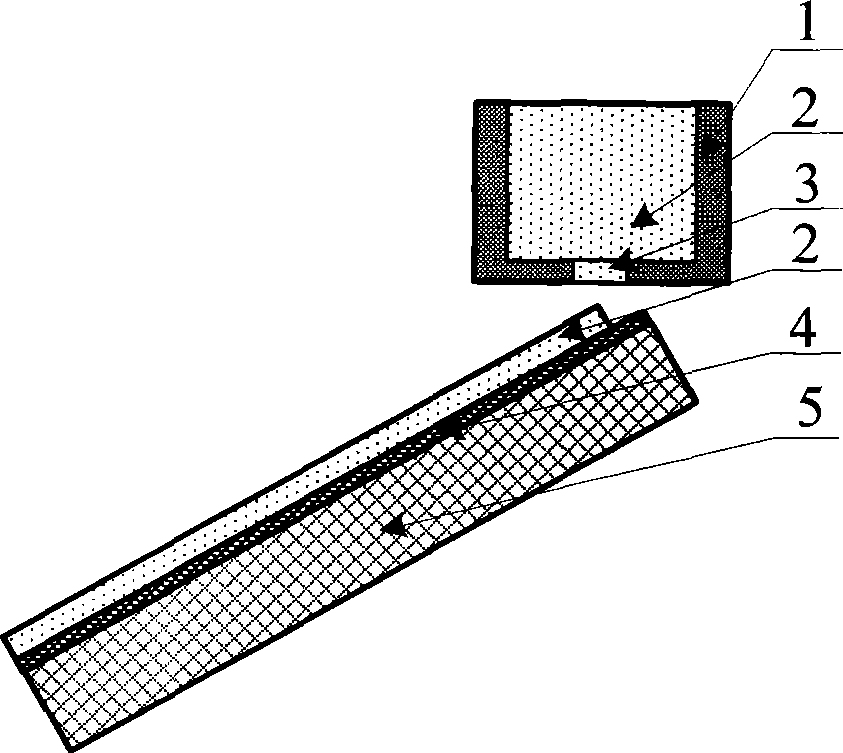

Wearable compound layer material for machine parts and manufacturing method and equipment thereof

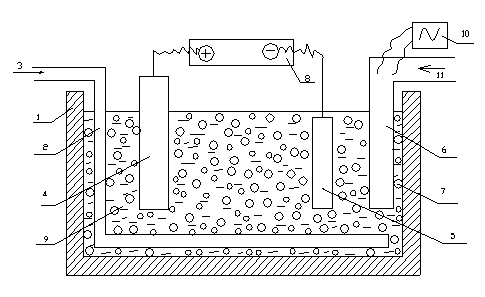

The invention relates to a wearable compound layer material for machine parts and a manufacturing method and equipment thereof. The wearable compound layer material is a metal-based wearable compound layer material which is composed of a matrix metal and lots of particles or fibers dispersed and distributed in the matrix metal, thereby having a multi-phase structure. The wearable compound layer material is manufactured by a direct-current electroplating or pulse electroplating method. The direct-current electroplating or pulse electroplating equipment is composed of parts such as an electroplating power source, an electroplating tank, a metal anode or a metal alloy anode, a machine part substrate cathode, a stirring device, a solution circulating device, a heating and temperature control device, an additive supplementing device and the like. The wearable compound layer material for machine parts provided by the invention is obviously superior in performance to good-quality cast iron wearable parts, good-quality cast steel wearable parts and wearable parts for surface heat treatment of common steel and good-quality steel commonly employed in the present product. The wearable compound layer also has high-temperature abrasive resistance and excellent corrosion resistance while having excellent abrasive performance; and the internal stress of the coating is very low.

Owner:肖云捷

Short-process comprehensive red mud utilization method and equipment

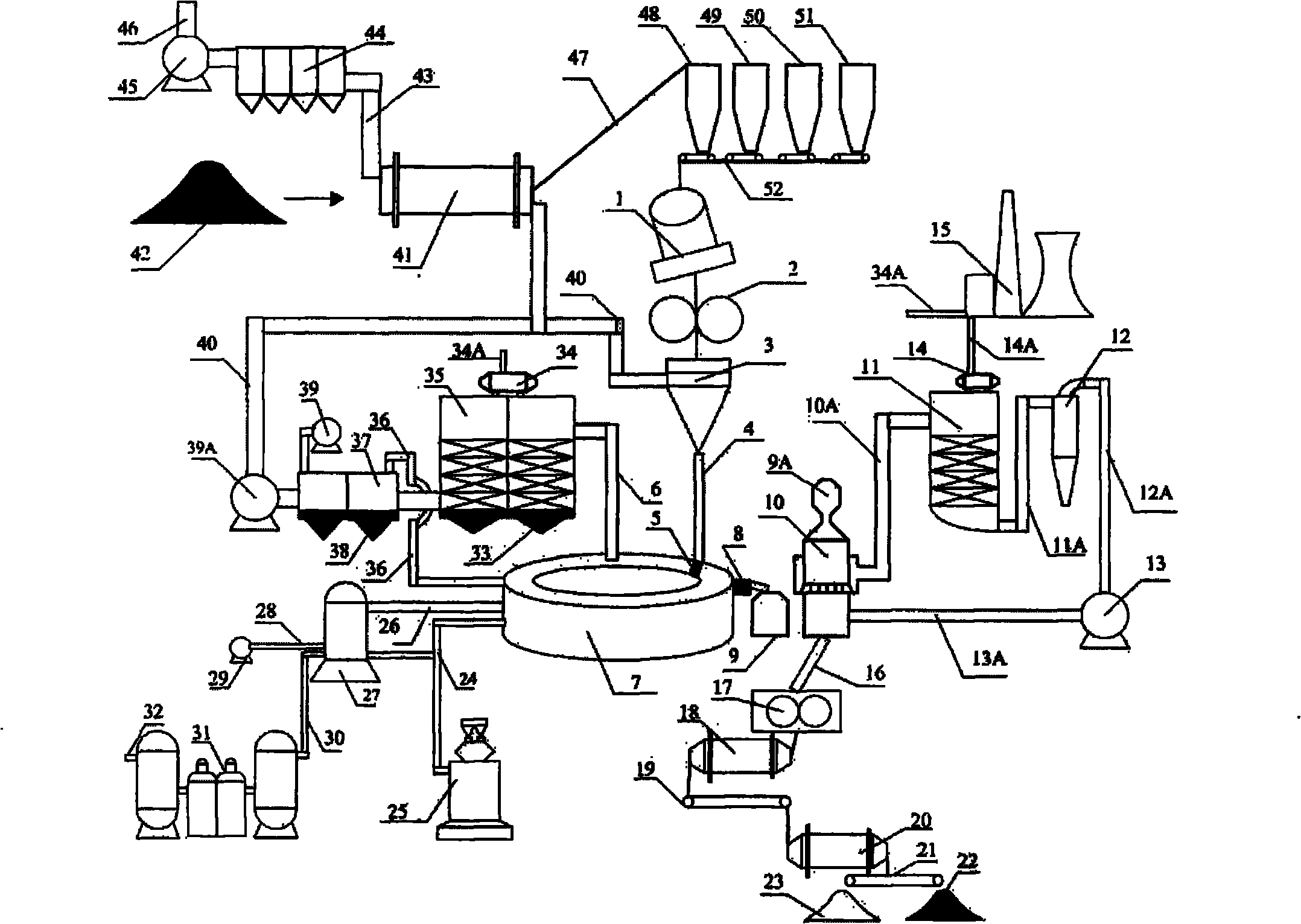

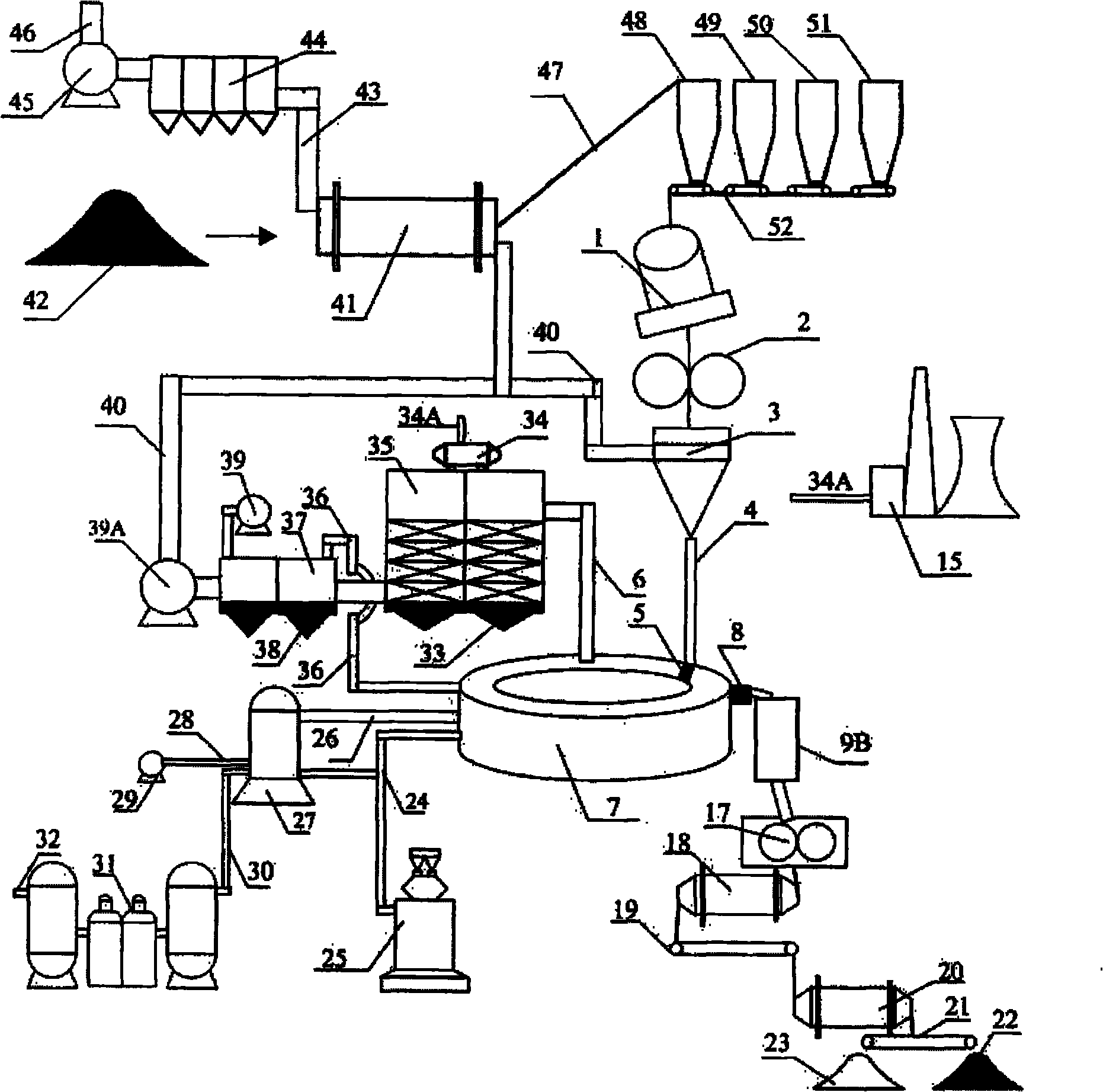

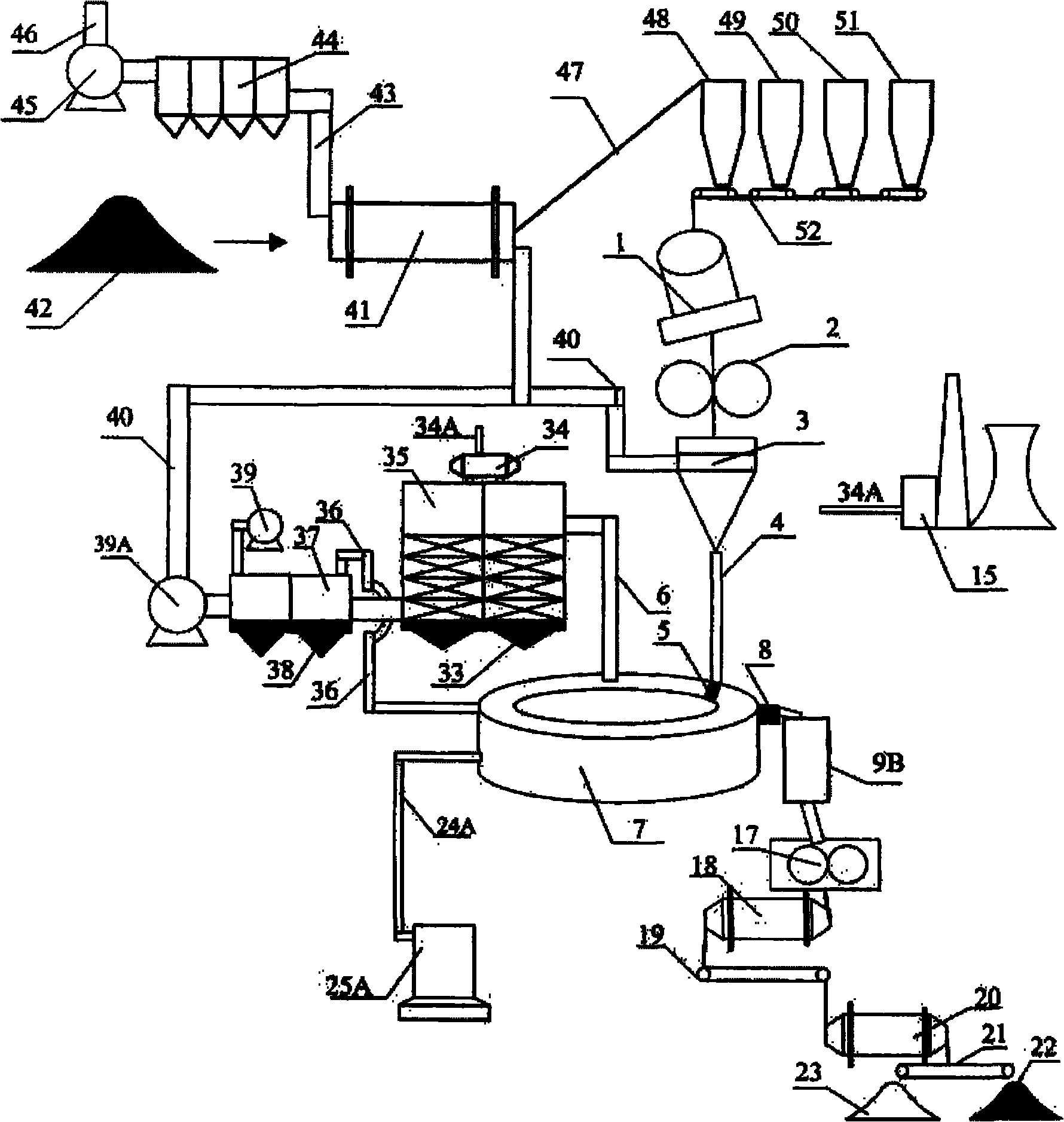

The invention relates to a short-process environmentally-friendly comprehensive red mud utilization method and equipment for comprehensively utilizing energy, which can be used for refining iron in high-pollution red mud difficult to treat, with high efficiency, high quality and high benefits, and applying the iron to electric furnace steel making or steel casting and the like, without using coke, so as to realize the large-scale comprehensive utilization of the red mud. High-temperature smoke of a revolving bed is used for waste heat generation, secondary-combustion hot wind preheating, pellets preheating and red mud drying, a dry quenching pellet technology is used for applying the heat of high-temperature pellets to waste heat generation so that waste heat is fully utilized, a low-cost pressure swing adsorption oxygen generation technology is utilized, and therefore, the comprehensive energy consumption and the production cost are low. Aluminum silica residues are used for producing high-grade cement or used as the raw material for refractory materials; and Na2O and K2O and other alkaline metallic oxide powder are used for refining metal Na and K, or used for producing the raw materials of fertilizers, or used as chemical raw materials. Accordingly, the problems on environmental pollution, land occupation for stacking and safety due to the red mud are thoroughly solved, and the economic and social benefits are obvious.

Owner:董亚飞

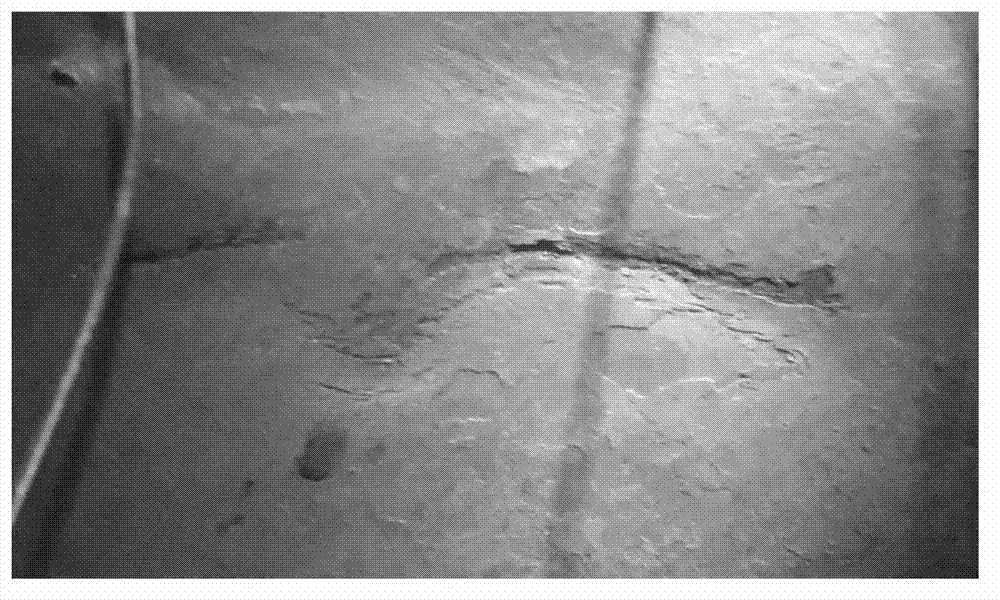

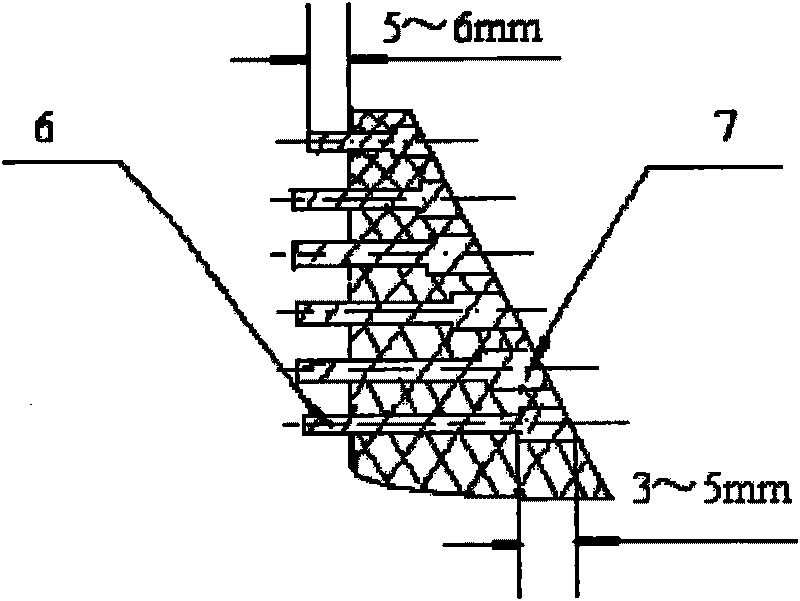

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

The invention discloses a transverse crack control method of high nitrogen steel continuous casting plate billet angle containing vanadium, the method can not only effectively eliminate transverse crack defect of the continuous casting billet surface and skin inferior angle, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting the mold cooling water amount, the wide face cooling water amount is 3000-30500 L / min, the narrow face cooling water amount is set to 360-365 L / min; improving casting pulling rate, the casting pulling rate is stabilized in 0.8-1.5 m / min, the vibration frequency is 140-210 Hz; after spruing the casting pulling rate, quickly putting casting powder into the mold, the alkalinity of the casting powder is 1.0-1.40, the melting point is 1100-1160 DEG C, when at 1300 DEG C, the viscosity is 0.10-0.40 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.55-0.60 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

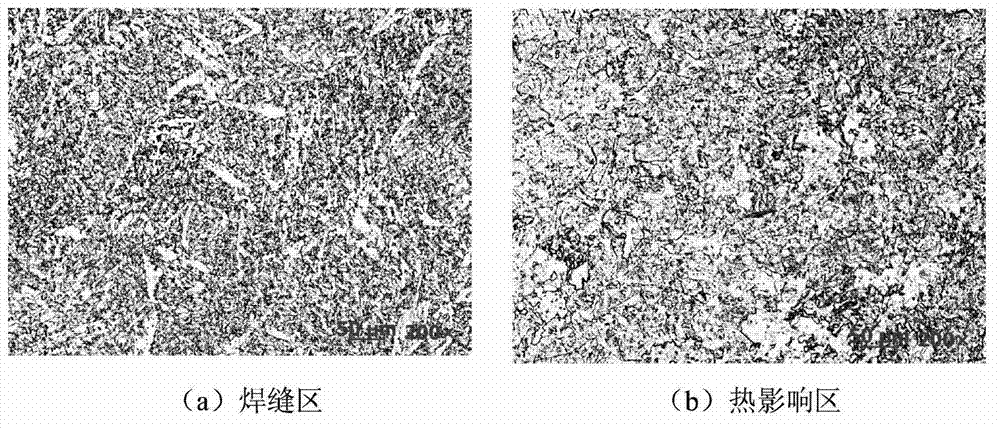

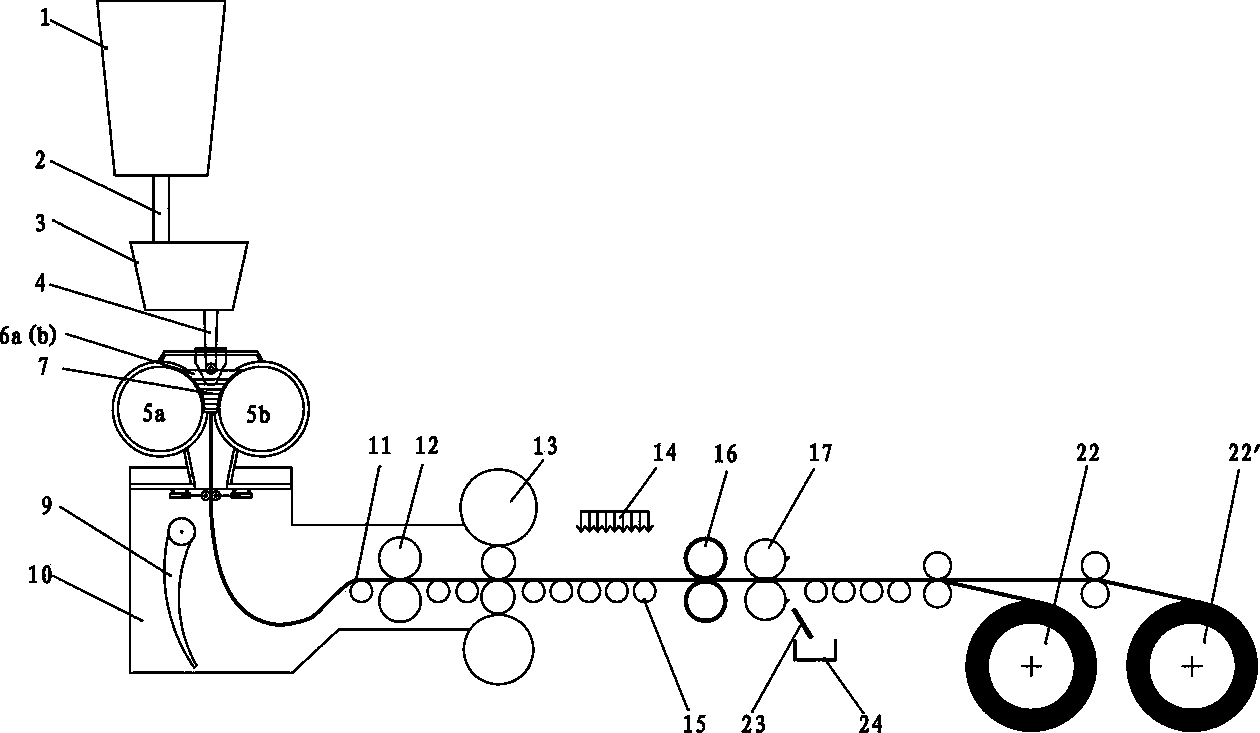

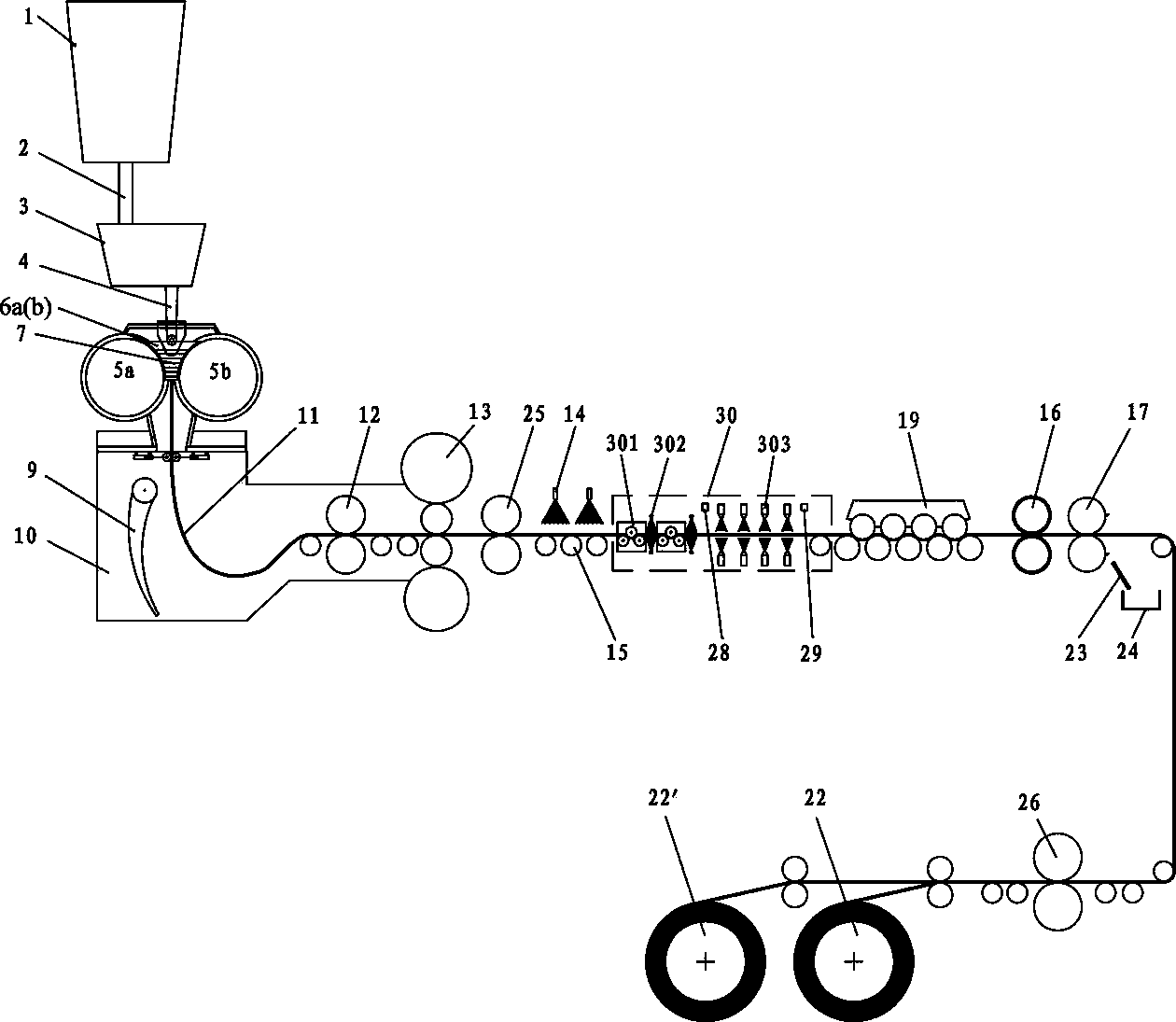

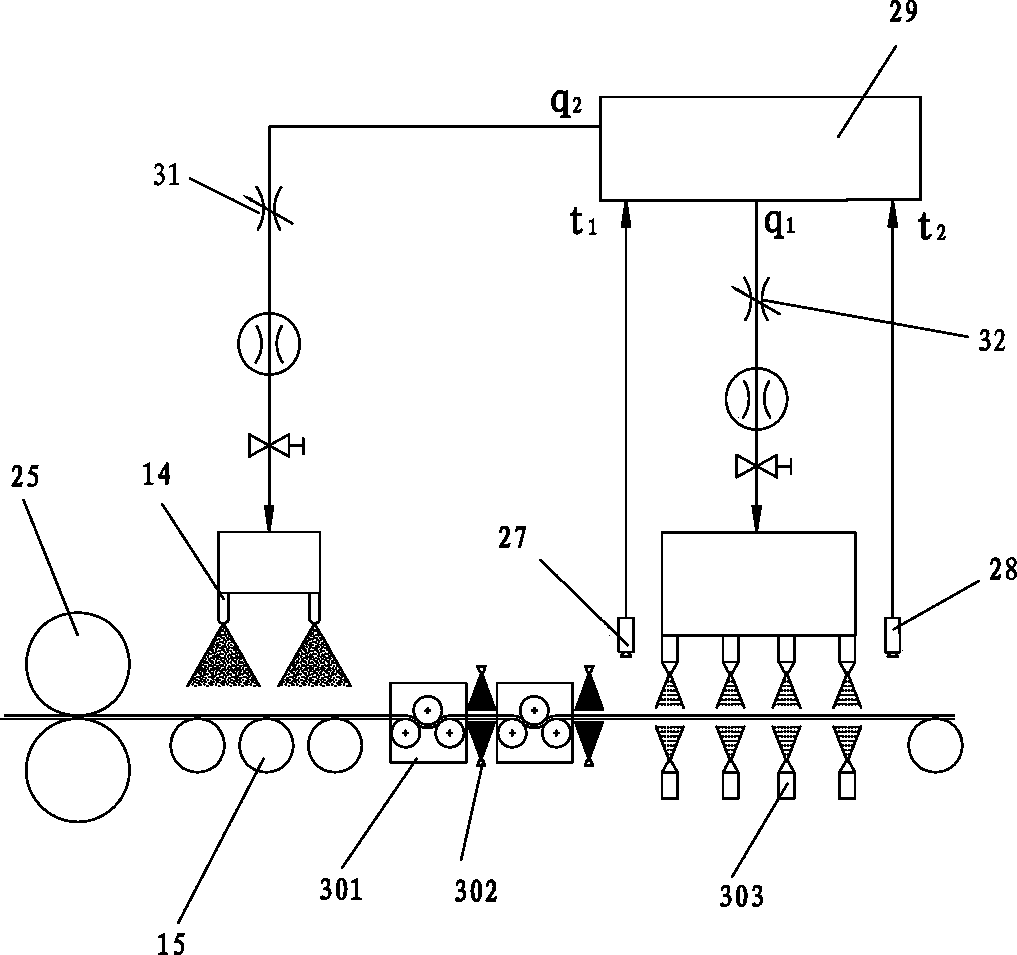

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

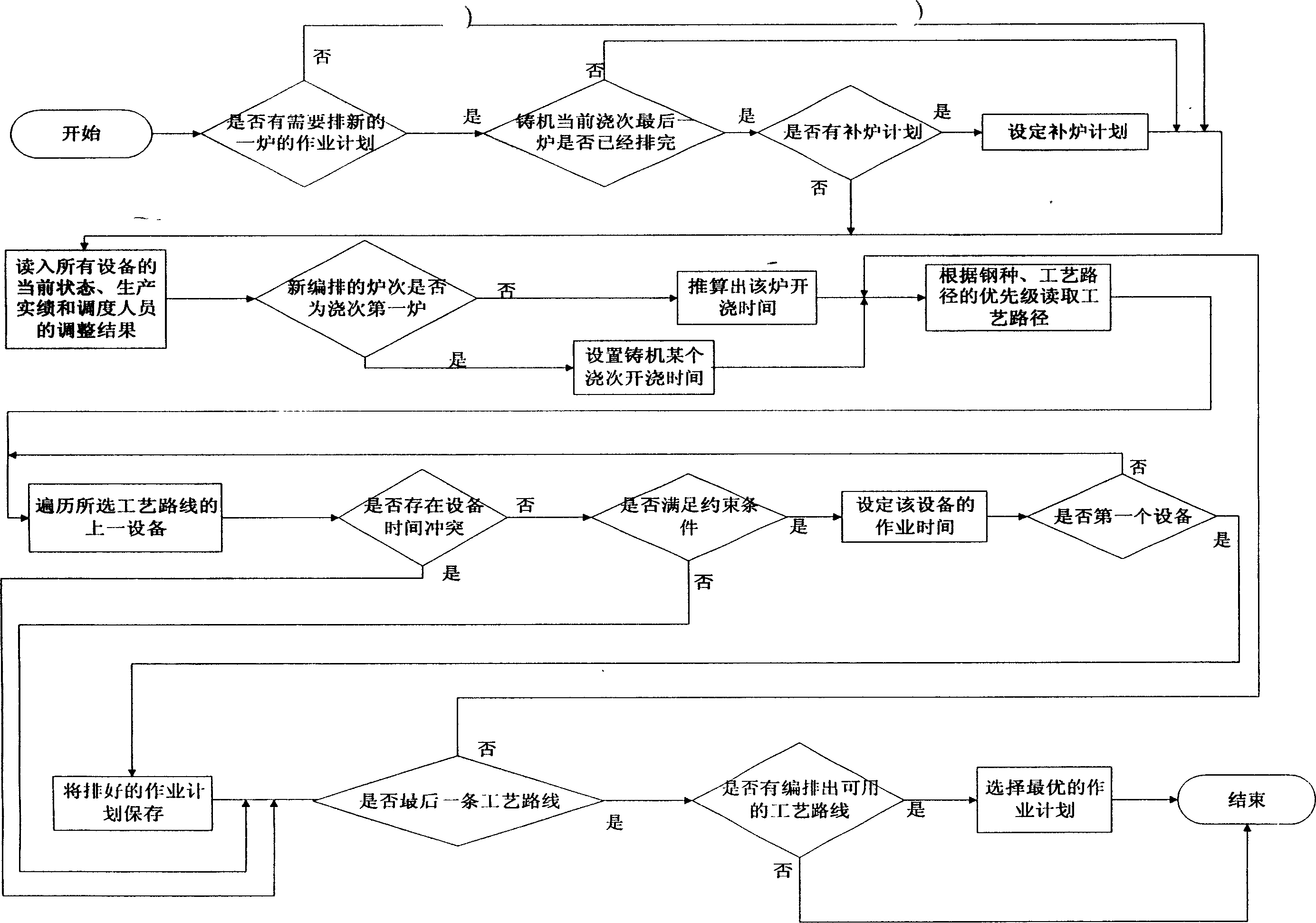

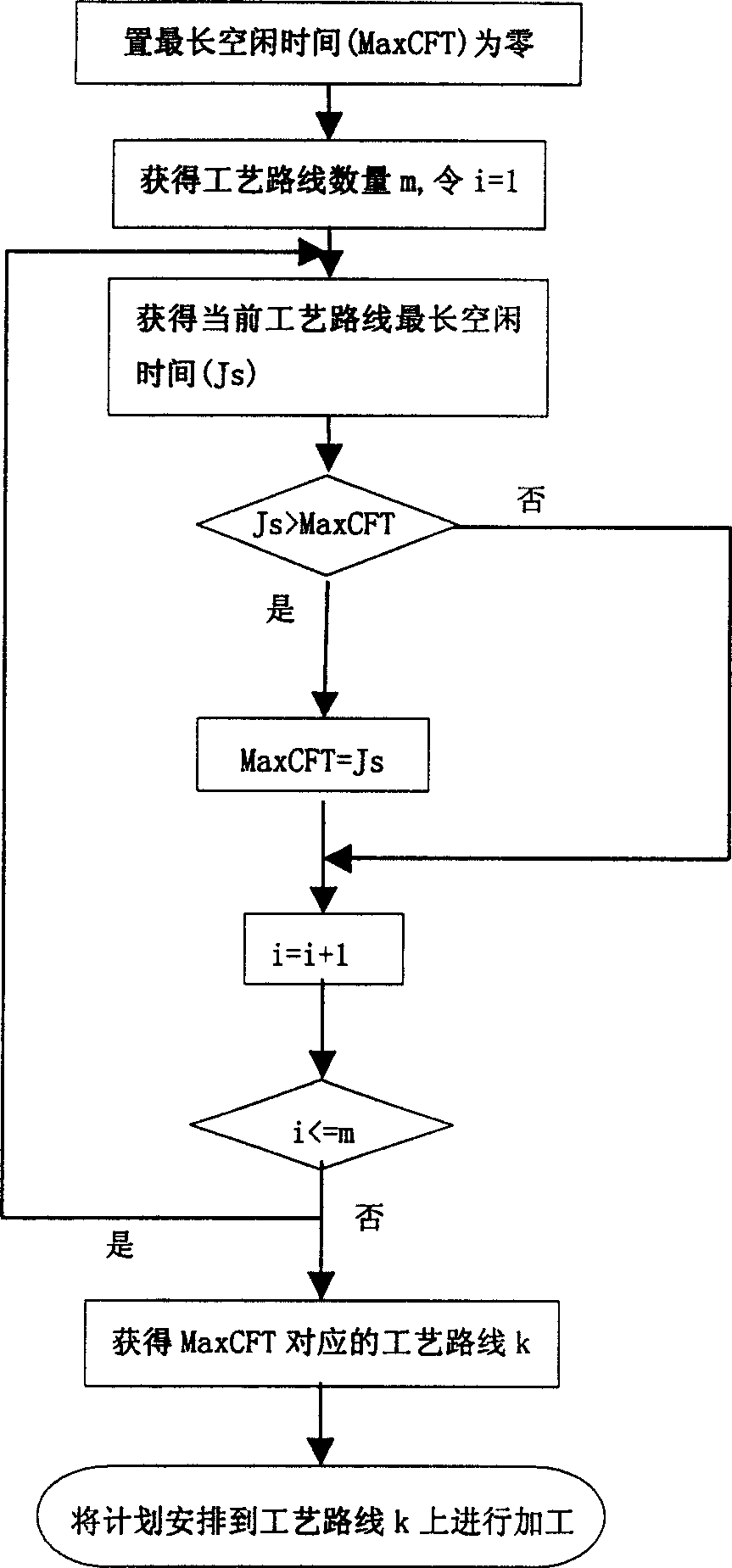

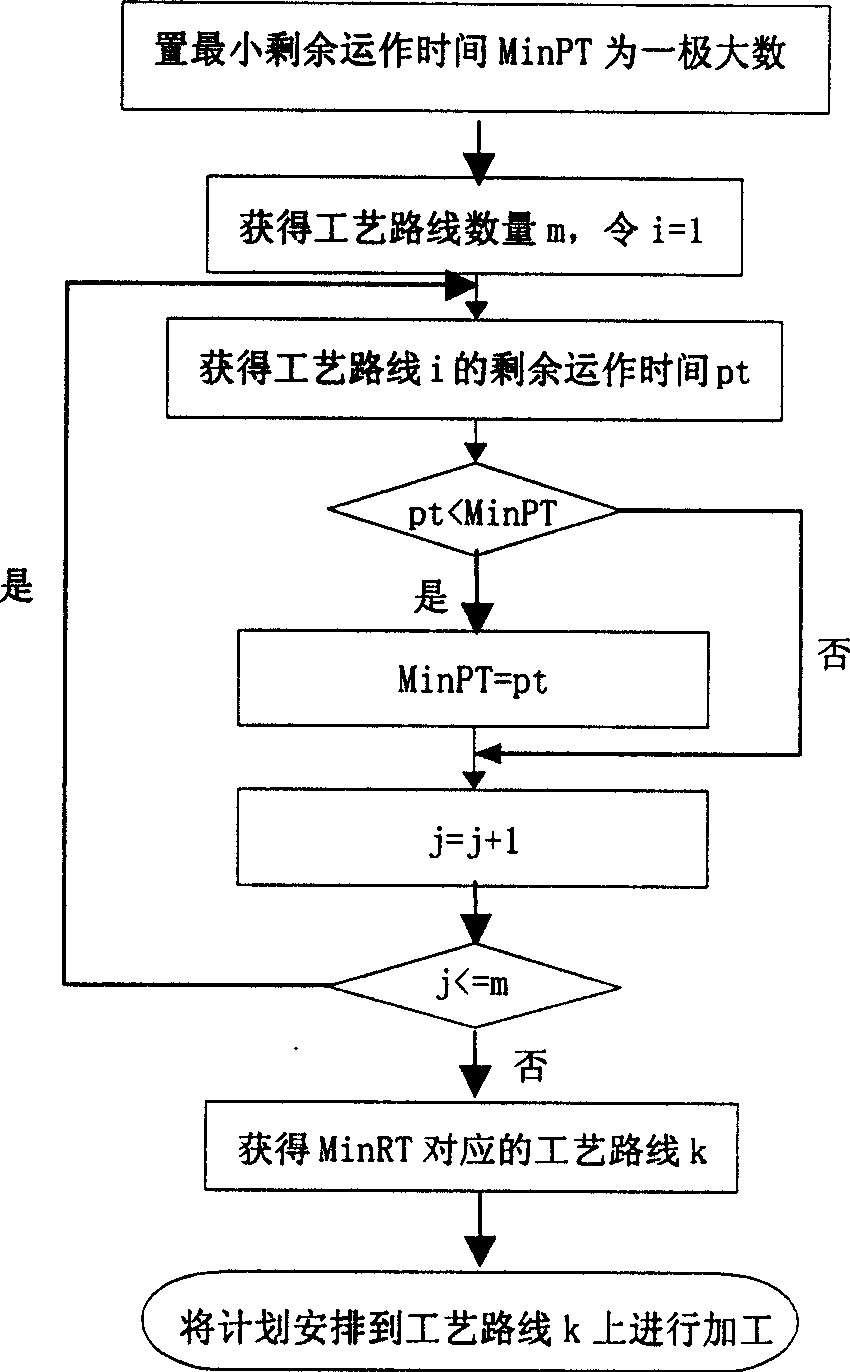

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

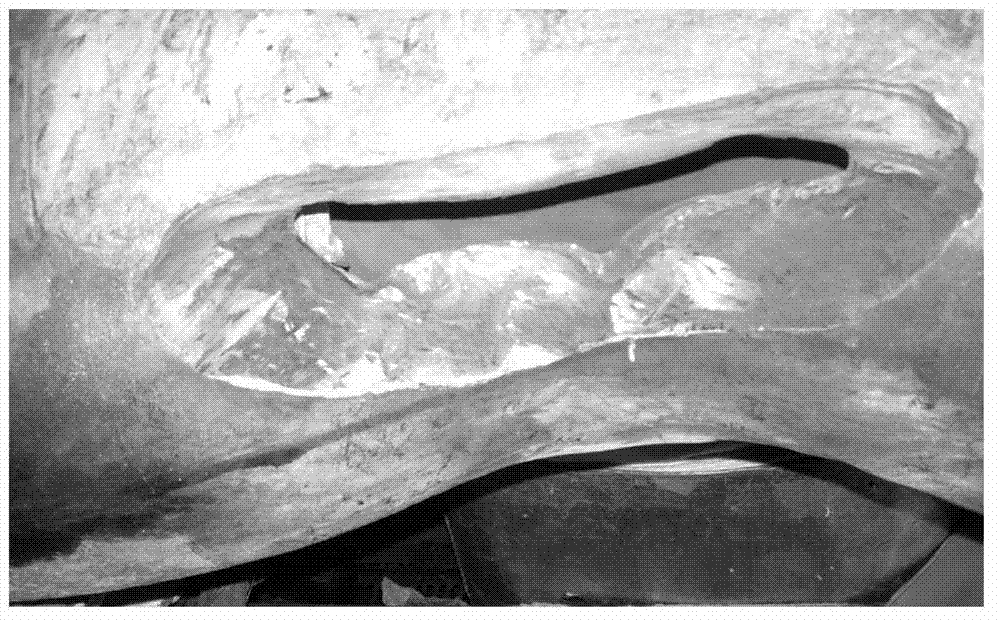

Welding repair method for large-sized heat-resistant steel castings

ActiveCN103962791AEliminate Large Area DefectsRelieve welding stressArc welding apparatusShielded metal arc weldingCrazing

The invention relates to a welding repair method for large-sized heat-resistant steel castings, and solves the problems that the welding stress is difficultly removed, the defects of incomplete fusion, incomplete penetration, delayed crack and slag inclusion are easily caused in a repair process and the repair quality is difficultly guaranteed as the heat-resistant steel castings are poorer in welding performance, complicated in defect position and large in workpiece in an existing manual arc welding type surfacing welding mode for repairing large-sized castings. The method mainly comprises the following steps: 1, removing the defects; 2, performing heat treatment; 3, performing dye check; 4, performing statistics on the repair welding quantity; 5, preheating before welding; 6, performing repair welding on defect parts; 7, cleaning and repairing; 8, performing post-welding heat treatment; 9, performing nondestructive inspection. According to the method, the large-area defects of the castings can be effectively repaired, the repair quality is guaranteed, the processing and use requirements of the castings can be met after repair, and the economic loss of scrapped important or major castings is reduced. The method is used for repairing the large-area defects of the large-sized heat-resistant steel castings.

Owner:HARBIN JIANCHENG GRP

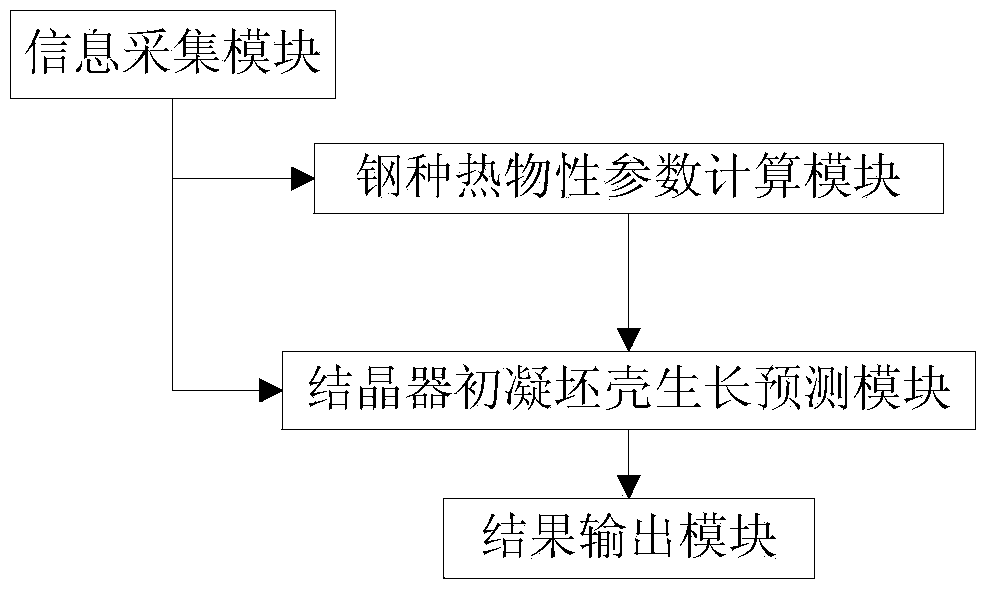

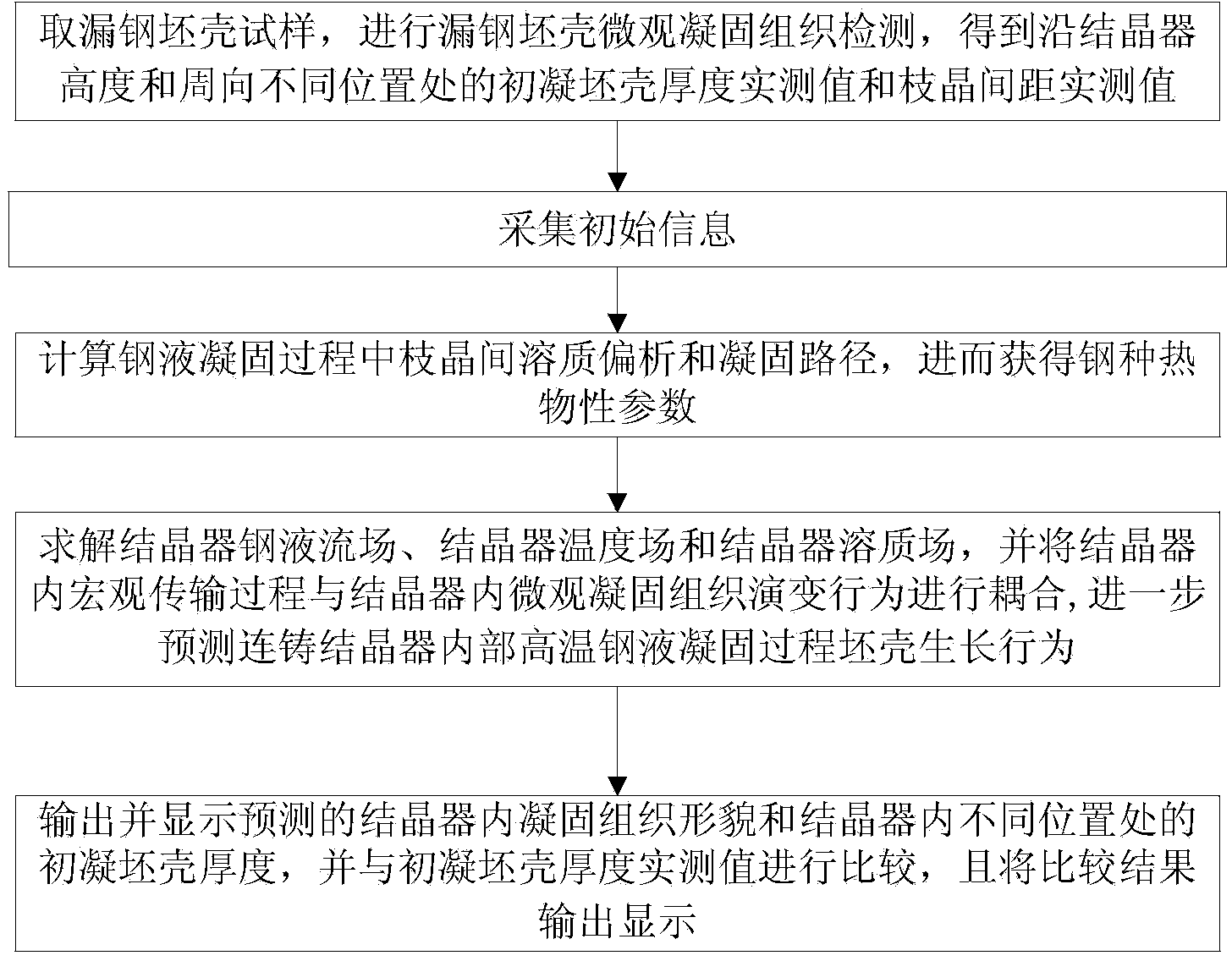

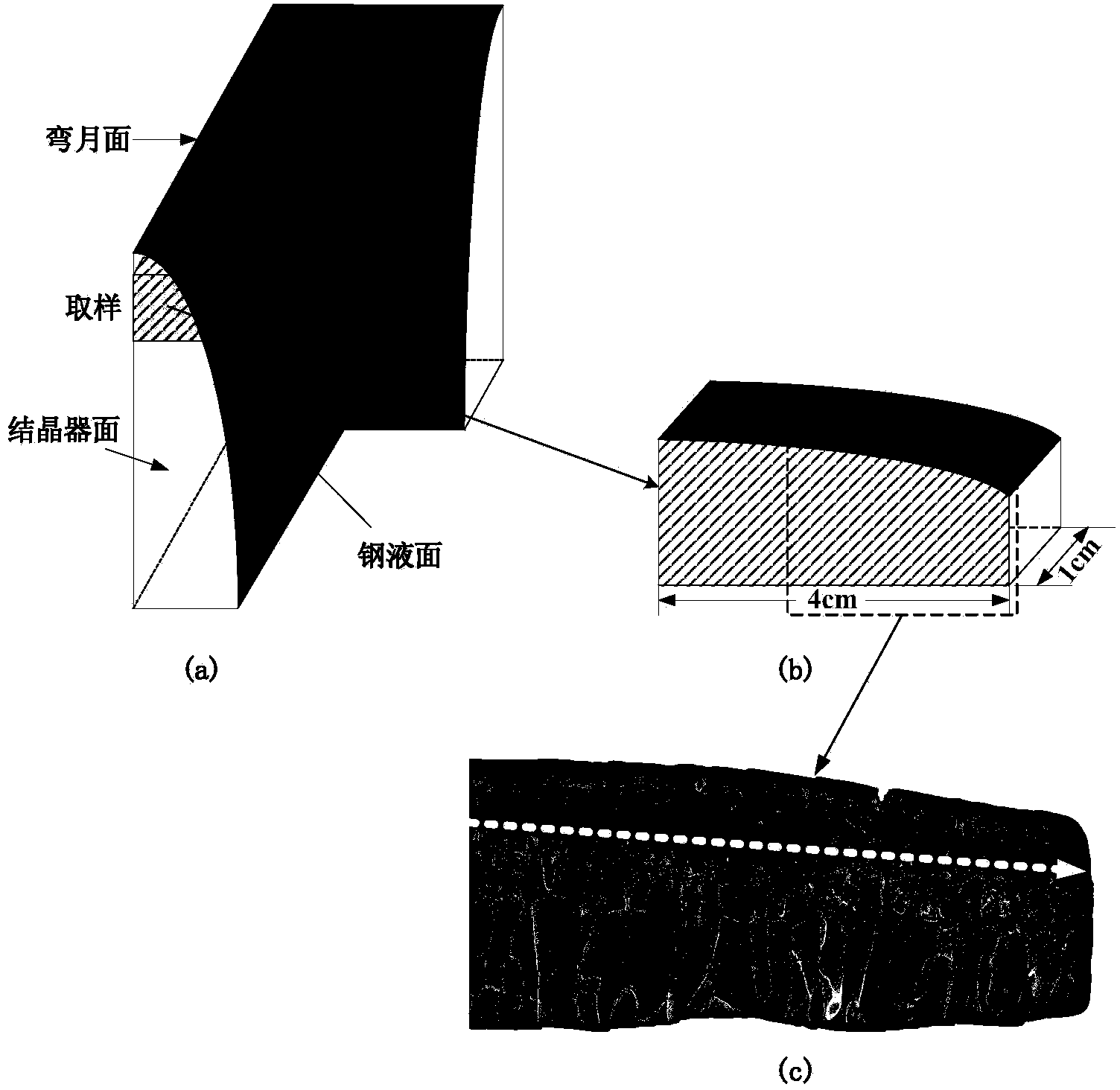

Prediction system and method for thickness of initially solidified shell in continuous steel casting crystallizer

ActiveCN104384469APredict growth behaviorPredicting Microscopic Solidification BehaviorMetallurgyPrediction system

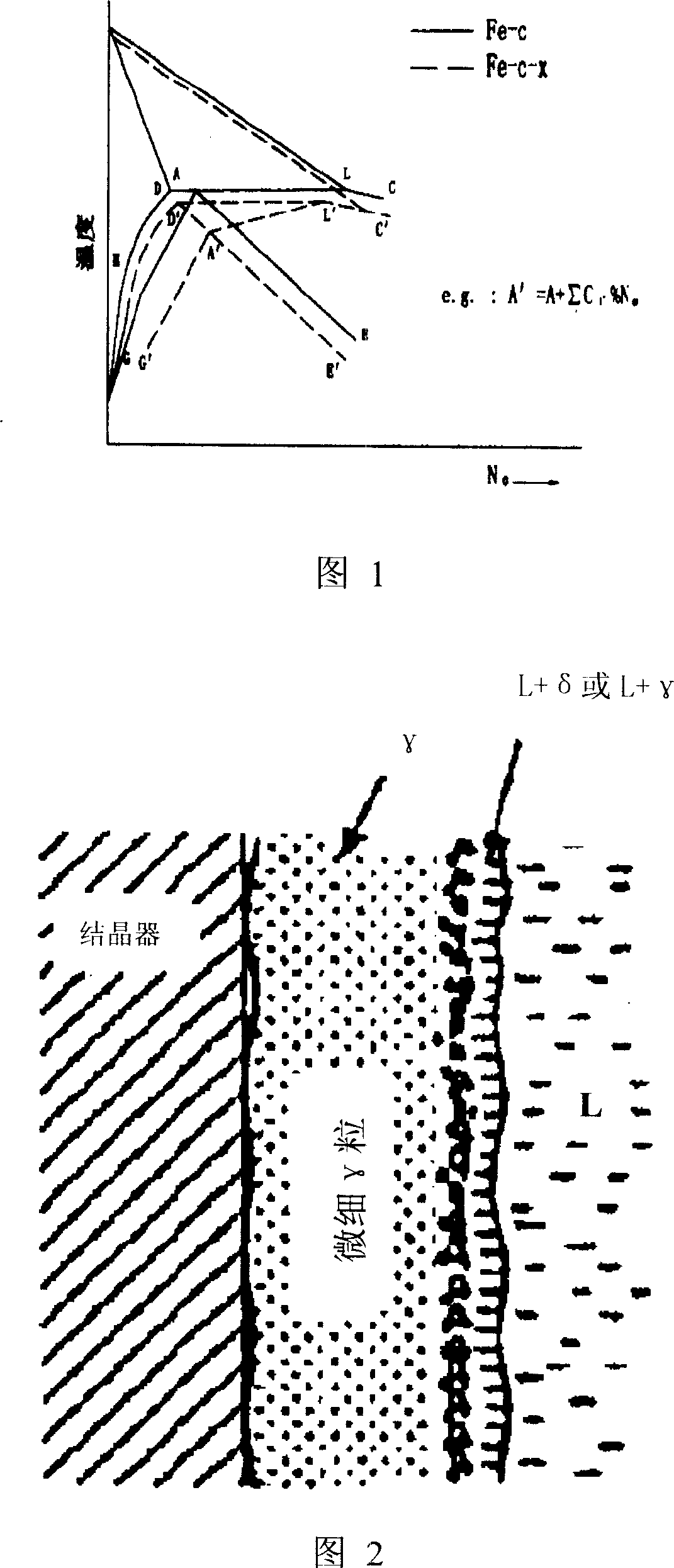

The invention provides a prediction system and method for the thickness of an initially solidified shell in a continuous steel casting crystallizer. The system comprises an information collection module, a steel grade thermophysical parameter calculation module, a crystallizer initially solidified shell growth prediction module and a result output module. The method comprises the following steps: detecting a bleed-out shell microcosmic solidification structure; collecting initial information; computing the interdendritic solute segregation and solidification path in a molten steel solidification process to obtain a steel grade thermophysical parameter; solving a crystallizer molten steel flow field, a crystallizer temperature field and a crystallizer solute field, coupling a macroscopic transport process in the crystallizer and the evolution behavior of the microcosmic solidification structure in the crystallizer, and further predicting the shell growth behavior in the solidification process of high-temperature molten steel in the continuous steel casting crystallizer; outputting and displaying the comparative results of the predicted morphology of the solidification structure in the crystallizer, the predicted initially solidified shell thicknesses in different positions in the crystallizer and the actual thickness of the initially solidified shell. The system and the method can accurately predict the microcosmic solidification behavior of the initially solidified shell in the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

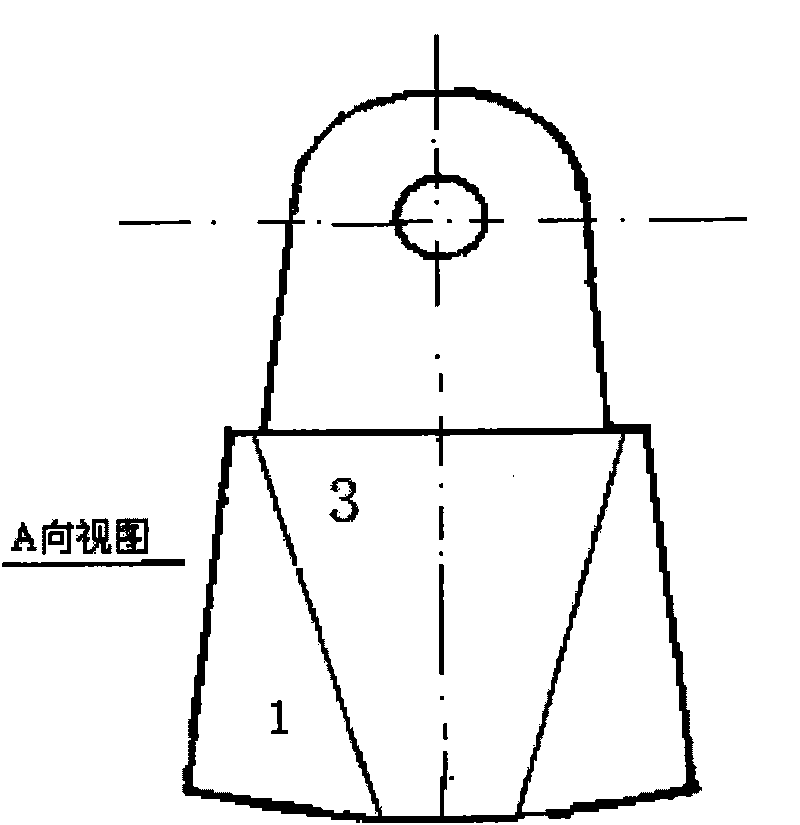

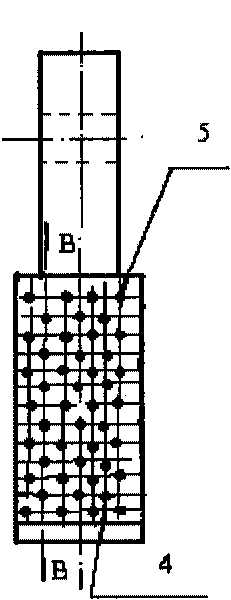

Crusher hammerhead cast of steel bond hard alloy bar and casting method of vanishing mould thereof

InactiveCN101717895AGood effectSimple processFoundry mouldsFurnace typesChemical compositionHardness

The invention discloses a crusher hammerhead cast of a steel bond hard alloy bar and a casting method of a vanishing mould thereof. The hammerhead is cast by low-alloy steel and is cast with the steel bond hard alloy bar in the casting process; the low-alloy steel contains the following chemical components by weight percent: 0.24 wt% to 0.295 wt% of C, 1.32 wt% to 1.56 wt% of Si, 0.028 wt% to 0.035 wt% of S, 0.032 wt% to 0.038 wt% of P, 0.82 wt% to 1.22 wt% of Mn, 1.67 wt% to 2.10 wt% of Cr, 0.42 wt% to 0.51 wt% of Mo, 0.05 wt% to 0.08 wt% of V, 0.05 wt% to 0.07 wt% of Ti, 0.08 wt% to 0.15 wt% of RE and 93.942 wt% to 95.29 wt% of Fe. The casting method of the hammerhead comprises the production process of the low-alloy steel, and the casting process and the thermal treatment process of the vanishing mould. The hammerhead product cast with the steel bond hard alloy bar has the advantages of good strength and toughness and high rigidity and abrasive resistance, is suitable for various working conditions, and can crush objects with different hardness.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

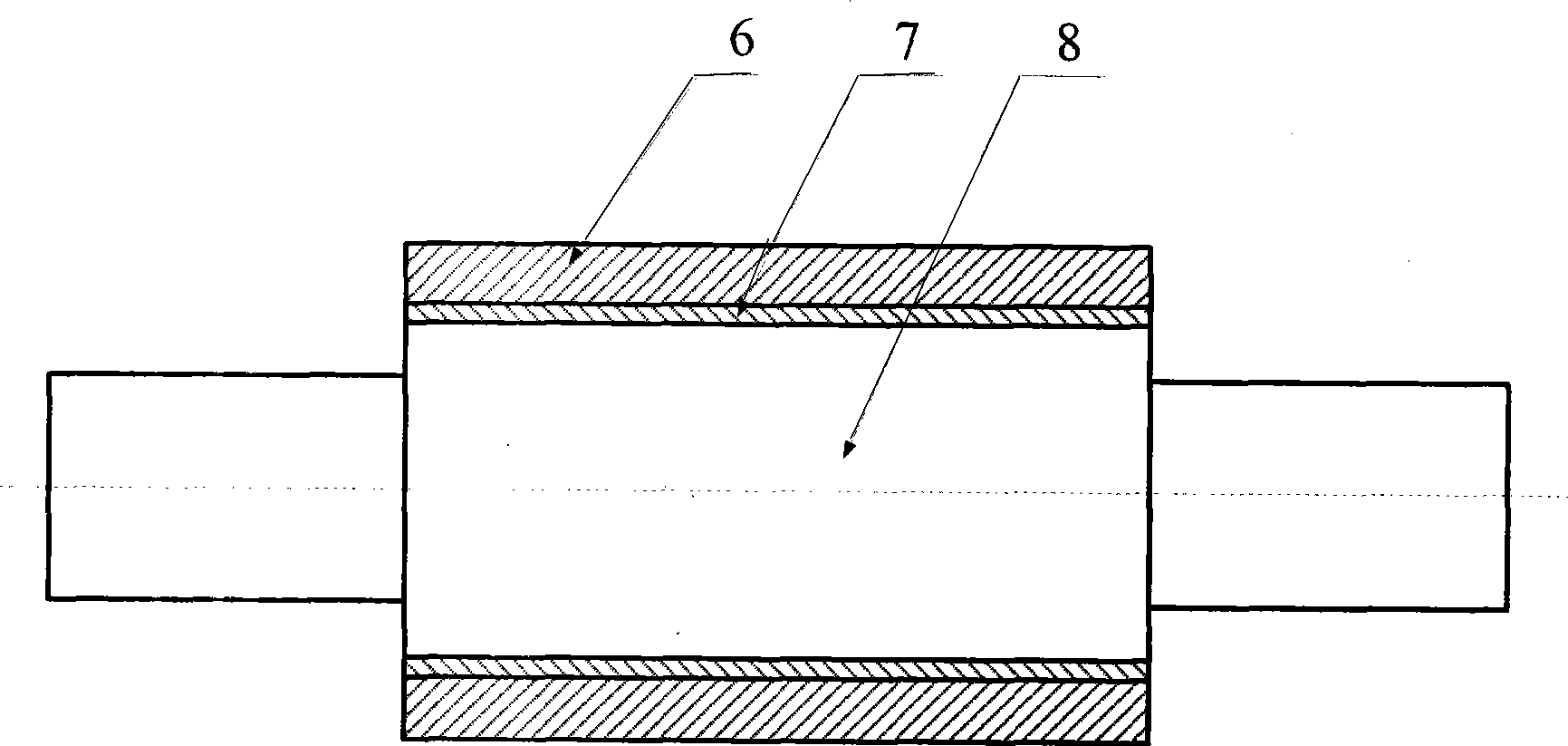

Centrifugal casting production method of high-boron high-speed steel composite roller

A manufacturing method for centrifugally casting high-boron high-speed steel composite roller belongs to the technical field of rolled steel. The invention aims to provide the manufacturing method for centrifugally casting the high boron high-speed steel composite roller without element segregation. The manufacturing method comprises the following steps: injecting high-seed steel liquid into a metal casting mould rotating at high speed on a centrifugal machine after the high-seed steel liquid is cooled by an inclined cooling plate; spaying, cooling and casting the high-seed steel liquid during a pouring process; and then centrifugally pouring an intermediate layer; finally pouring cast steel or alloyed ductile cast iron in a rolling core in a static state; and then obtaining the high-boron high-speed steel composite roller. The high-boron high-speed steel composite roller has the advantages of fine tissues on an external layer, compactness and no element segregation; and a boron element on the external layer cannot be mixed into a rolling core.

Owner:BEIJING UNIV OF TECH

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-alloy high-strength cast steel, and smelting and heat treatment method thereof

The invention discloses low-alloy high-strength cast steel, and a smelting and heat treatment method thereof. The cast steel comprises the following chemical components in percentage by weight: 0.17-0.22% of carbon, 0.20-0.60% of silicon, 0.80-1.20% of manganese, less than or equal to 0.020% of phosphorus, less than or equal to 0.015% of sulfur, 0.45-1.05% of chromium, 0.4-0.9% of nickel, 0.4-0.95% of molybdenum and less than or equal to 0.30% of copper, and the balance of iron and inevitable impurities. An electric arc furnace oxidation-reduction method or a medium-frequency induction furnace is used for smelting. After a wind power planet carrier casting poured by the low-alloy cast steel disclosed by the invention is heated, the mechanical properties can be stably achieved, the strength of extension is greater than or equal to 830Mpa, the yield strength is greater than or equal to 790MPa, the extension rate is greater than or equal to 12%, and the impact absorption power with a lower temperature of minus 40 DEG C is greater than or equal to 27J.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Crystallizer casting powder for high-aluminum steel continuous casting

The invention relates to a crystallizer casting powder for high-aluminum steel continuous casting. The casting powder comprises the following elementary components in percentage by weight: not less than15% but not more than 40% of CaO, not less than 3% but not more than 15% of SiO2, not less than 10% but not more than 20% of Al2O3, not more than 3% of MgO, not more than 3% of Fe2O3, not less than6% but not more than 15% of F, not more than 1.5% of Na2O, not less than 3% but not more than 10% of Li2O, not less than 5% but not more than 20% of BaO, not more than 5% of SrO, not more than 5% o B2O3, not less than 2% but not more than 15% of C, and the balance of impurities. The preparation method of the casting powder comprises the following steps of: calculating and weighing the required raw materials according to ratio ranges of the elementary components, mixing and uniformly smelting the mixture in an ore heating furnace, cooling, crushing, adding required carbon materials, carrying out fine grinding, and finally drying and granulating in a spray granule drying tower. The casting powder has the capability of reducing the reactivity of slag steel so that the performance deterioration of the casting powder caused by the reaction of the slag steel can be slowed, the interfacial tension of the slag steel is improved so as to prevent slag entrainment, excellent casting blank lubricating and heat-transfer controlling characters are ensured, the capability of absorbing Al2O3 inclusions is improved, and a high-aluminum steel casting blank which has excellent surface quality and high quality can be cast.

Owner:CHONGQING UNIV

Multi-component alloy cast steel bucket tooth and production process thereof

InactiveCN102140612AImprove wear resistanceExtended service lifeSoil-shifting machines/dredgersAlloyWear resistance

The invention discloses a multi-component alloy cast steel bucket tooth comprising the following chemical components in percentage by weight: 0.30%-1.00% of C, 1.50%-3.00% of Cr, 0.60%-1.00% of Mn, 1.00%-2.00% of Si, 0.20%-1.00% of Mo, 0.5%-1.50% of Ni, 0.005%-0.1% of Ti, 0.15%-0.25% of Re, not more than 0.030% of P / S and the balance of Fe. The multi-component alloy cast steel bucket tooth cast by the production process is a new steel type different from the traditional bucket tooth, and in the gravel working condition, the wear resistance of a material is improved and the service life of the bucket tooth is prolonged; the tensile strength Rm of the bucket tooth is not less than 1700MPa, the hardness HRC is 52-55, and the Charpy impact Akv is not less than 15J; and the bucket tooth has excellent strength and toughness and high hardness.

Owner:SHANGHAI SANY HEAVY IND

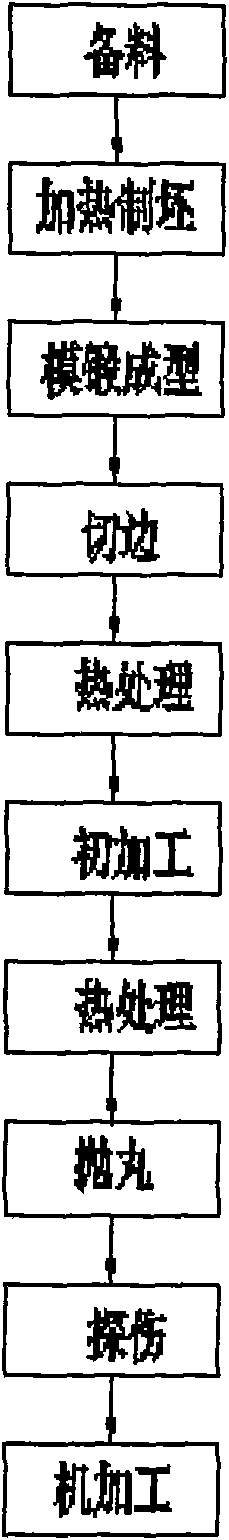

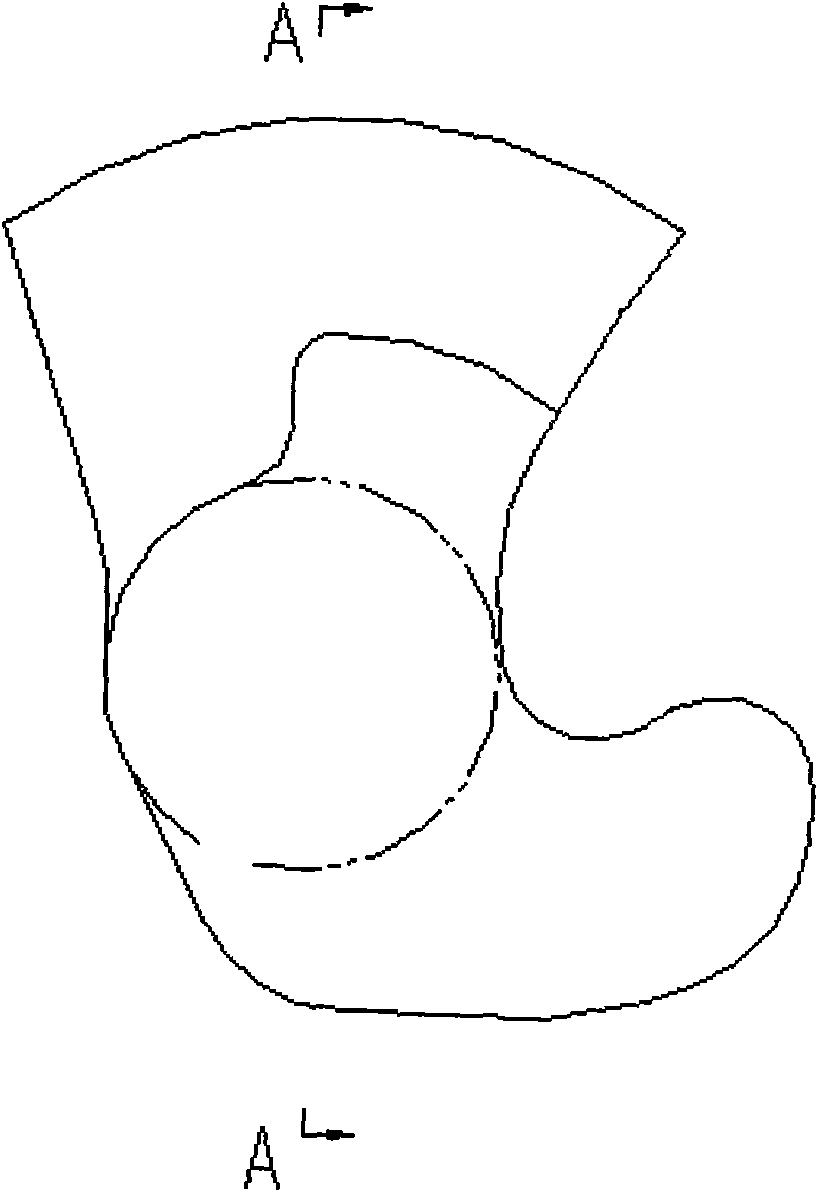

Forging method of coupler knuckle for railway vehicle

InactiveCN101559555AGood mechanical propertiesAvoid air holesOther manufacturing equipments/toolsMaterials preparationToughness

The invention discloses a forging method of a coupler knuckle for railway vehicles. The coupler knuckle for railway vehicles is formed by forging, and coupler knuckle products for railway vehicles with qualified performance and size are forged by the working procedures of material preparation, heating and blank forming, die forging and forming, trimming, heat treatment, preliminary processing, heat treatment, shot blasting, fault detecting and machining. The forging method of the coupler knuckle for railway vehicles, in which the coupler knuckle for railway vehicles has compact texture, high toughness and good fatigue performance, solves the defects of air pore, shrinkage porosity, inclusion, crack, short service life and the like of the coupler knuckle of the existing cast steel vehicle coupler.

Owner:CHONGQING CHANGZHENG HEAVY IND

Technique for producing dual-liquid dual-metal composite wear-resistant lining plate by lost foam casting

Owner:武汉智科耐磨材料科技发展有限公司

Ultrahigh-strength and high-toughness welded cast steel

InactiveCN101074472AGood effectImprove hardenabilityHeat treatment process controlSmelting processUltimate tensile strength

A high-strength and high-toughness welding cast steel consists of C 0.12-0.17 wt%, Si 0.10-0.50 wt%, Mn 0.8-1.2 wt%, S+P<=0.025 wt%, Ni 4.00-4.50 wt%, Cr 0.7-1.2 wt%, Mo 0.40-0.50 wt%, V 0.04-0.08 wt%, Cu 0.20-0.40 wt% and iron residue. The process is carried out by selecting electric furnace + AOD duplex smelting process, pouring and heating to obtain final product. The yield strength reaches above 800 MPa, V-shaped notch impact reaches above 55J at -20 degree. It can be used for ship, ocean and petrochemical industries.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Cast steel for bearing parts in mechanical lifting system and its making process

The present invention relates to one kind of cast steel for bearing parts in mechanical lifting system and its making process. The cast steel of Cr-Ni-Mo line consists of C 0.15-0.30 wt%, Mn 0.60-1.10 wt%, Si 0.3-0.8 wt%, Ni 0.4-1.1 wt%, Cr 0.4-1.1 wt%, Mo 0.15-0.40 wt%, S less than 0.025 wt%, P less than 0.025 wt%, and residual elements including Cu, W and V less than 0.60 wt%. The making process of the cast steel includes the following technological steps: making steel in MF furnace or electric arc furnace; casting in sand mold with equivalent circular kiel test rod; normalizing, quenching and tempering of both cast part and test rod in the same furnace; and non-destructive detection of the cast part.

Owner:河南石油勘探局南阳石油机械厂

Clay molding sand for cast steel and preparation method thereof

The invention discloses clay molding sand for cast steel and a preparation method thereof. The clay molding sand is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 20-30 parts of forsterite sand, 8-12 parts of bentonite, 5-8 parts of composite powder, 4-6 parts of talcum powder, 2-3 parts of nanometer aluminum oxide, 3-5 parts of pine sawdust, 2-4 parts of alpha-starch, 1-2 parts of dextrin, 3-6 parts of calcium phosphate, 1.5-2.5 parts of sulfite lye and 4-8 parts of water. The molding sand is high-temperature resistant, high in strength and high in impact resistance, can be used for overcoming the defects on hot spot parts and avoiding sand adhesion, and a phenomenon that the sand mold is broken due to impact force of liquid steel casting is avoided. Moreover, the clay molding sand is low in air release amount, good in air permeability effect and high in liquidity, the defects of air holes, cold shut and shrinkage porosity in the casting can be effectively overcome, and the yield of the casting is improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

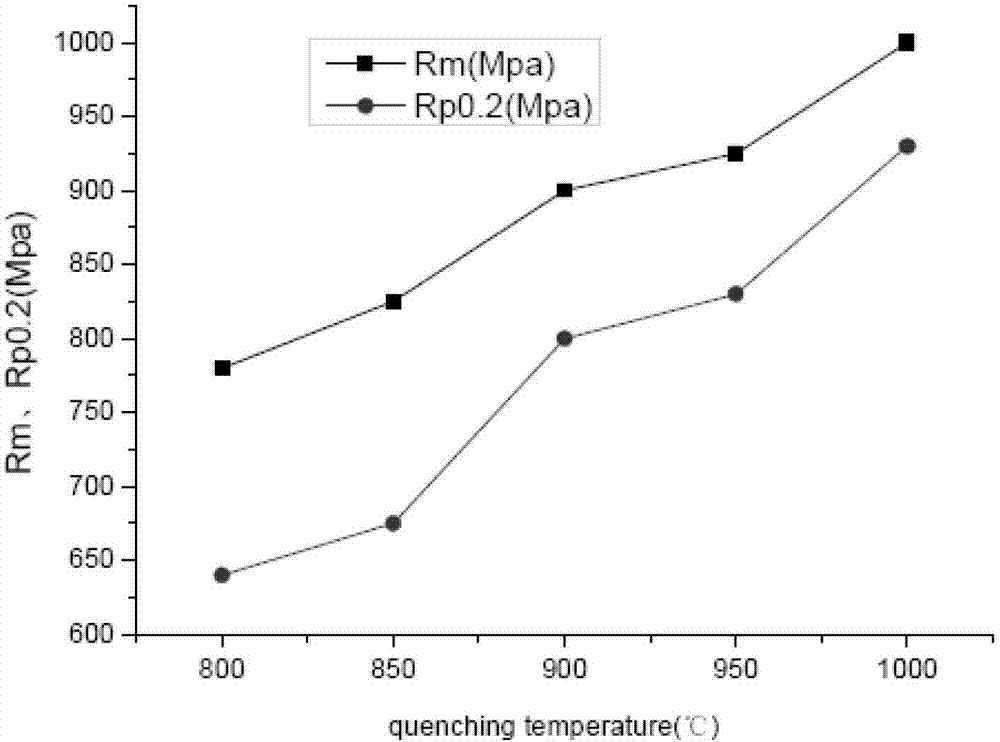

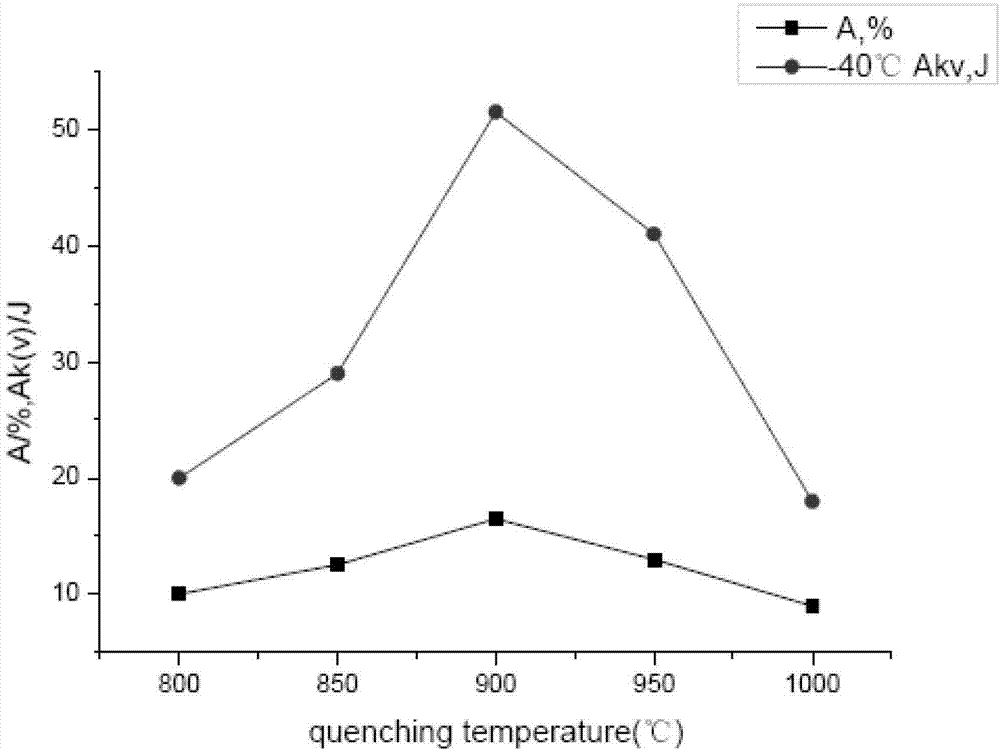

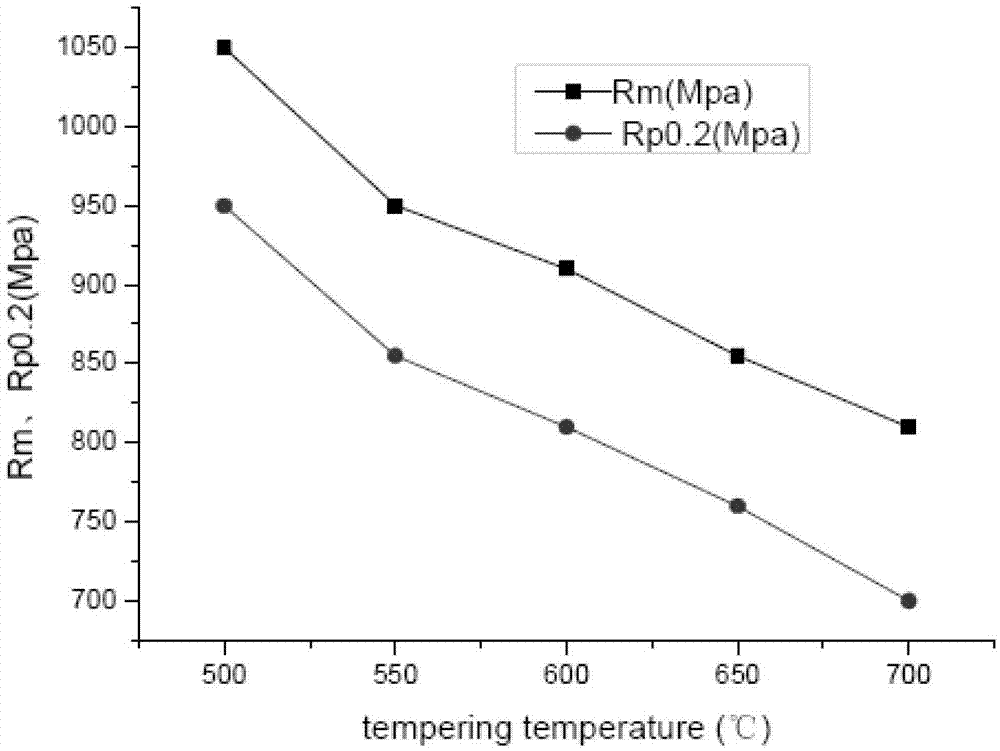

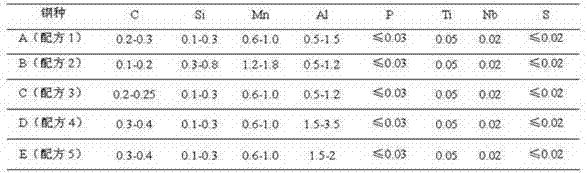

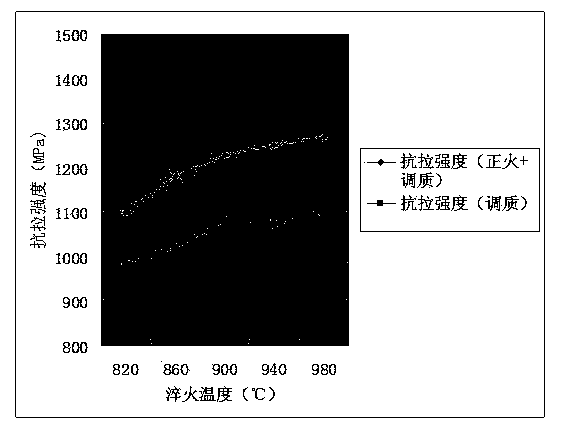

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

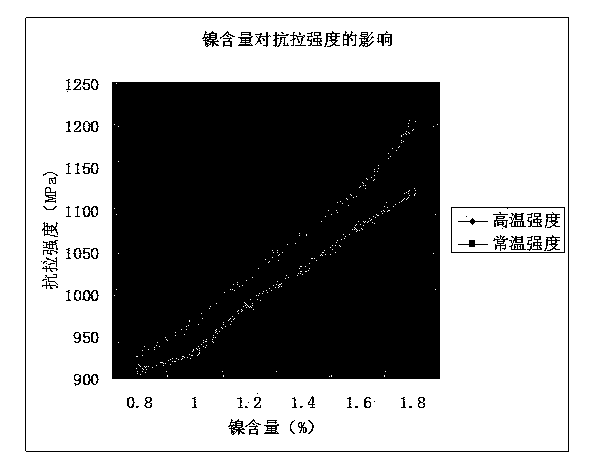

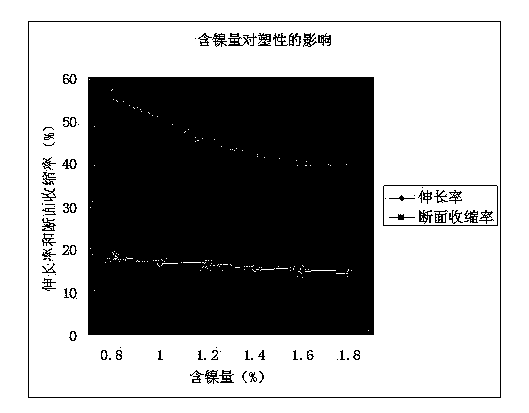

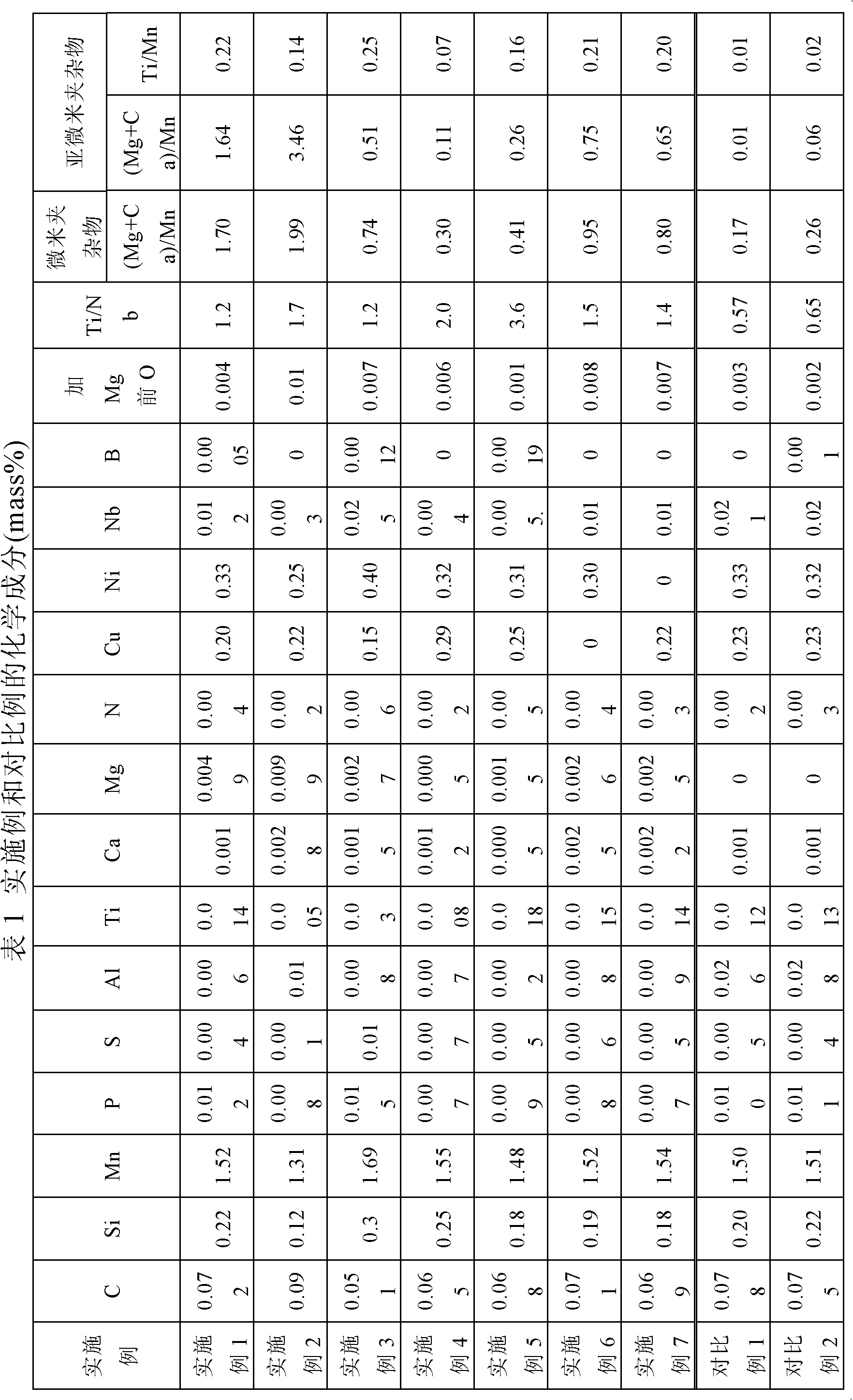

High-heat-input welding thick steel plate and manufacturing method thereof

Disclosed are a high-heat-input welding thick steel plate and a manufacturing method thereof. The manufacturing method includes following steps: a) smelting, refining and continuous casting; b) rolling; and c) cooling. Steel consists of components including, by weight percentage, from 0.05 to 0.09% of C, from 0.10 to 0.30% of Si, from 1.3 to 1.7% of Mn, from 0.005 to 0.03% of Ti, from 0.003 to 0.025% of Nb, from 0.001 to 0.01% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.006% of N, from 0.0005 to 0.01% of Mg, smaller than or equal to 0.01% of Al, smaller than or equal to 0.003% of Ca, more than one of smaller than or equal to 0.3% of Cu, smaller than or equal to 0.4% of Ni and smaller than or equal to 0.002% of B, and the balance Fe; and Ti / Nb is larger than or equal to 1.2, deoxidant Mn, Si, Al, Ti, Ca and Mg are successively added in a steel liquid deoxidizing process, wherein (Mg+Ca) / Mn is larger than or equal to 0.3 for micrometer impurities with the grain size larger than or equal to 1.0 micrometer in the steel, (Mg+Ca) / Mn is larger than or equal to 0.1 for sub-micron impurities with the grain size ranging from 0.1 micrometer to 1.0 micrometer in the steel, and Ti / Mn is larger than or equal to 0.07. A large quantity of impurities which are distributed in a dispersion manner are formed, growth of austenite grains in a welding heat affected zone can be restrained, growth of intra-granular ferrite is promoted, and the high-heat-input welding performance of the thick plate is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

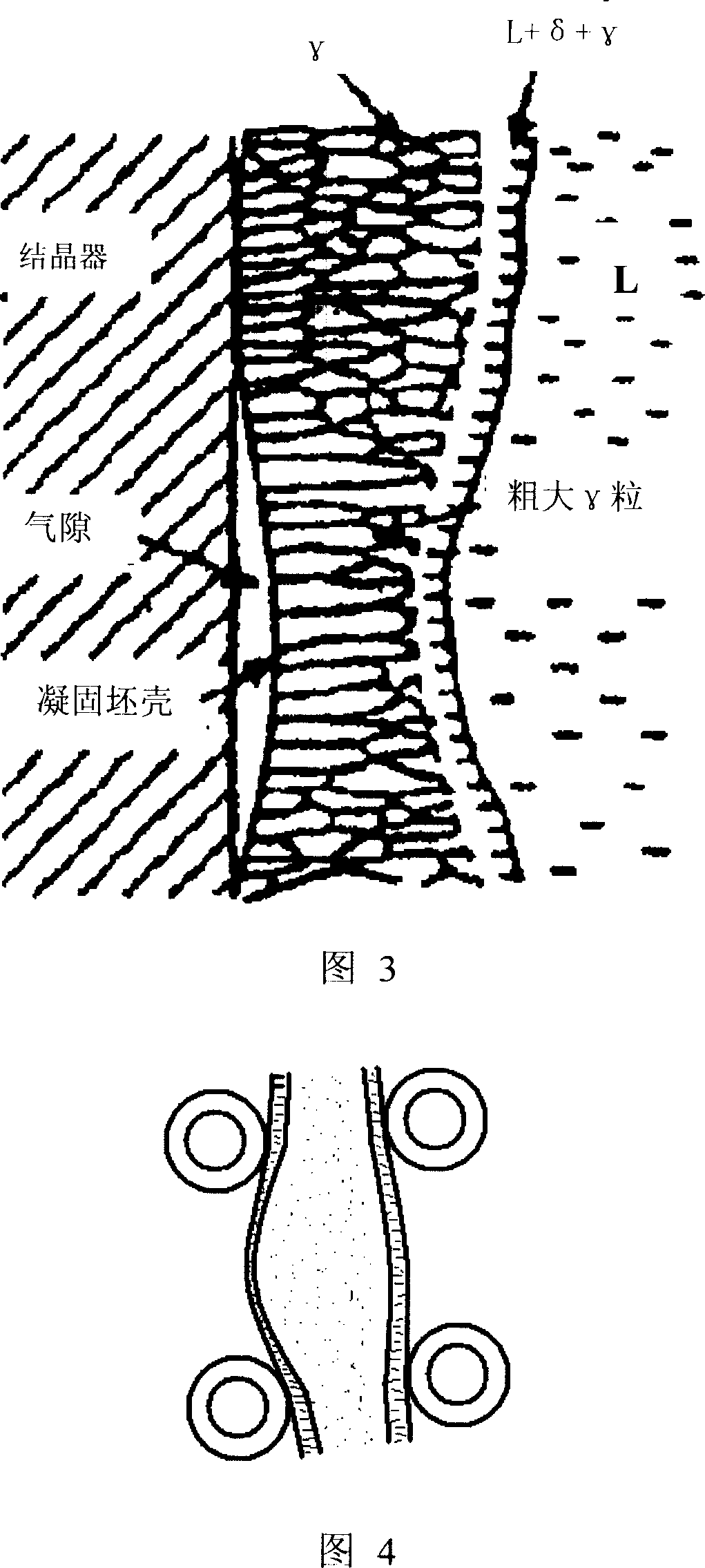

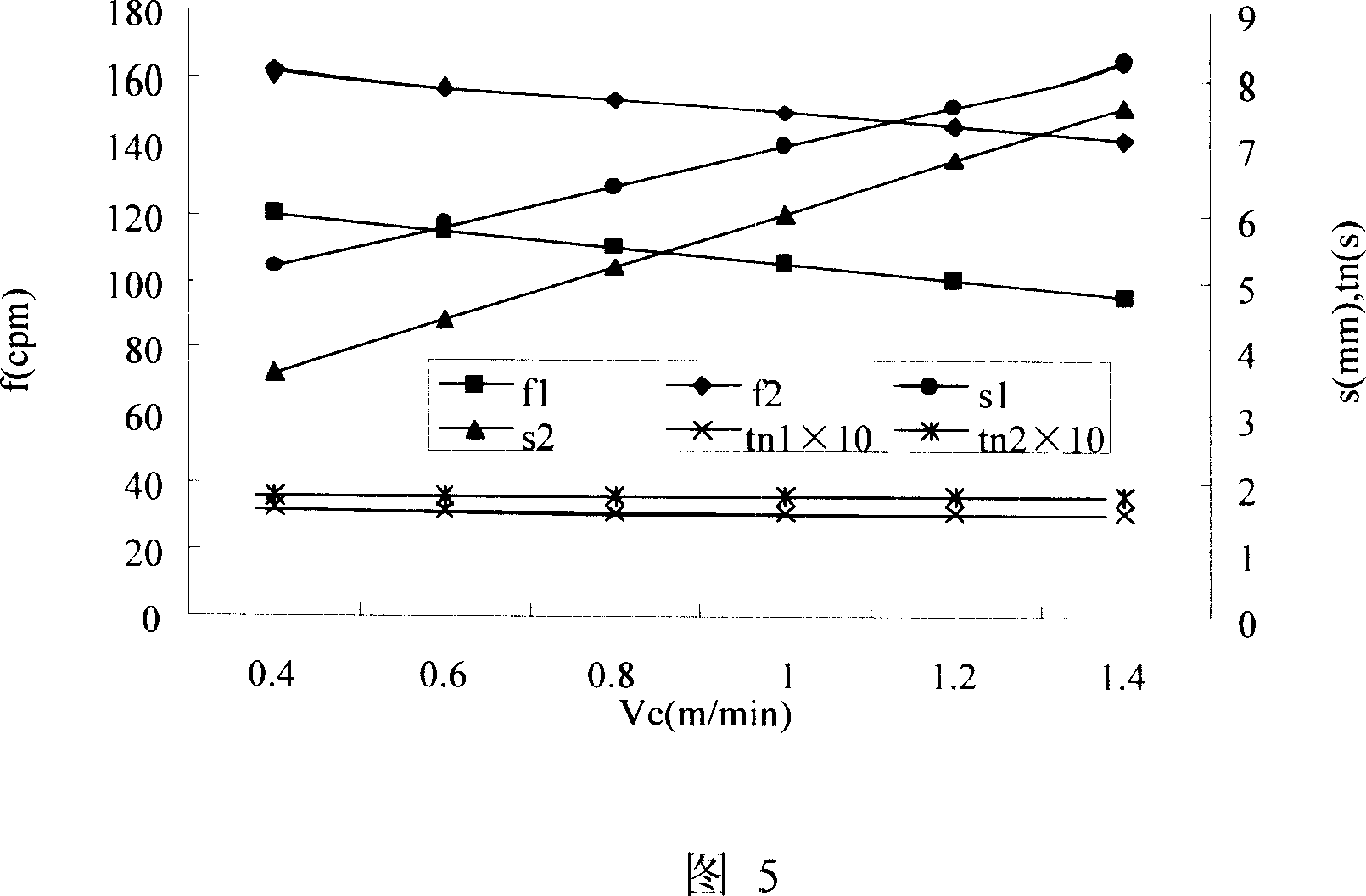

Method for producing low-alloy peritectic steel by medium-thickness slab caster

ActiveCN101586205AEliminate longitudinal cracks on slab surfaceEliminates lateral depressionsManufacturing convertersSlab casterFully developed

The invention provides a method for producing low-alloy peritectic steel by a medium-thickness slab caster, which comprises the following steps: firstly, converter smelting: alkalinity of molten steel is increased during the tapping, top slag is modified after the tapping so as to realize the tapping without slag, tapping final phosphorus is controlled within ingredient range, and other ingredients are lower than the upper limit value; secondly, LF furnace refining: deep deoxidation is performed, the mixing is performed by adopting argon; thirdly, casting: the casting is performed by adopting the medium-thickness slab caster, the slag is protected by adopting a high-alkalinity crystallizer with high melting speed, and the blowing argon protection of the crystallizer is realized. The method for producing the low-alloy peritectic steel lightens the fluid level fluctuation caused by peritectic reaction during the casting production, eliminates longitudinal division and transverse depression on the surface of a low-alloy peritectic steel casting blank so that the qualification rate of the casting blank reaches 100 percent, and fully develops the capacity of the medium-thickness slab caster producing the low-alloy peritectic steel massively at high pulling rate.

Owner:ANGANG STEEL CO LTD

Method for preventing liquid fluctuating of continuous casting peritectic steel crystallizer

The present invention is method of preventing liquid surface fluctuation in the peritectic steel crystallizer for continuous casting, and belongs to the field of continuous casting technology. The method includes controlling the flow rate of cooling water, controlling the pressure of the last driving roll in the straightening section and adopting peritectic steel protecting slag of new formula. The present invention can eliminate liquid surface fluctuation in the peritectic steel crystallizer and reduce the cracking rate of peritectic steel casting blank greatly.

Owner:武钢集团有限公司

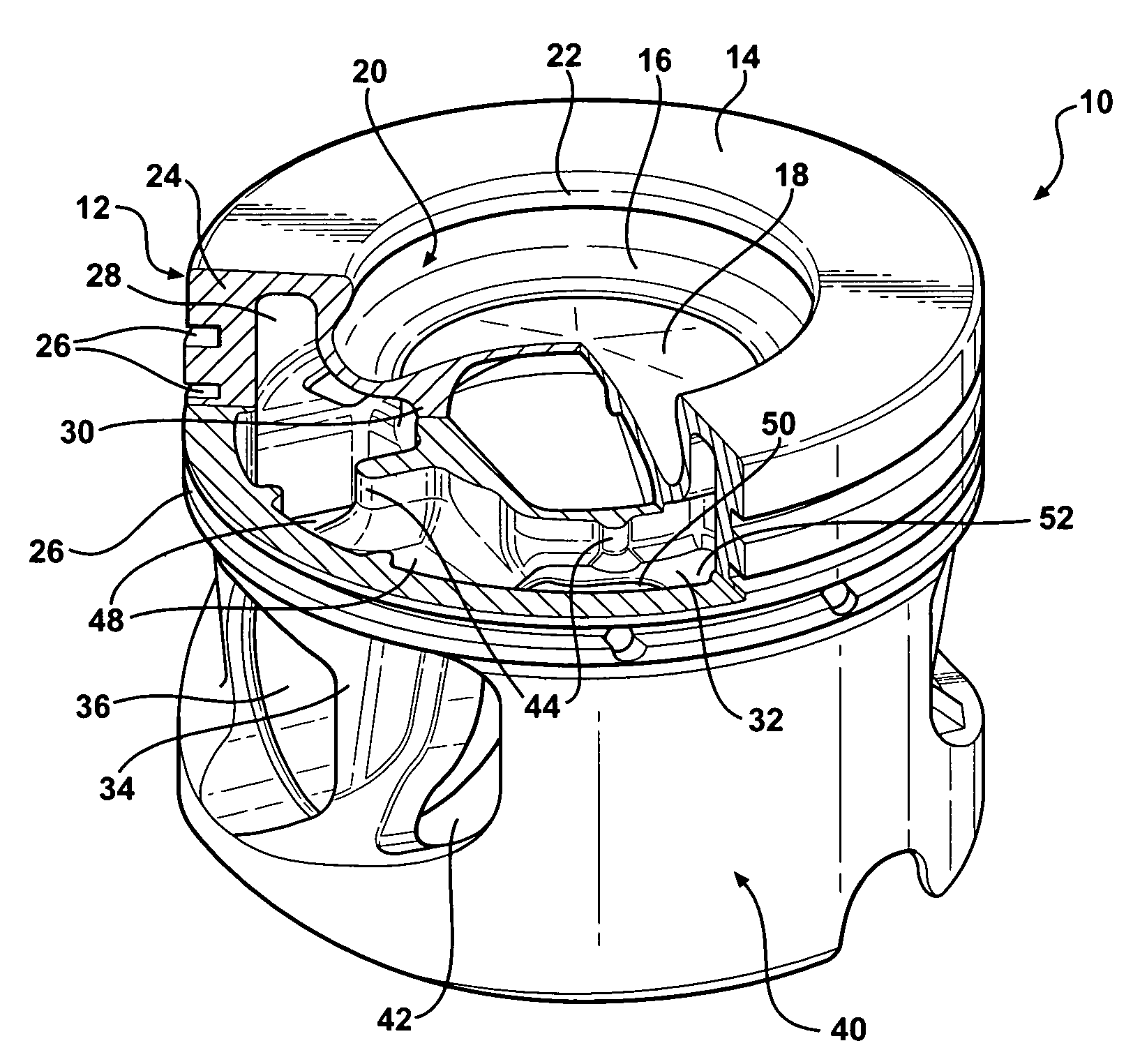

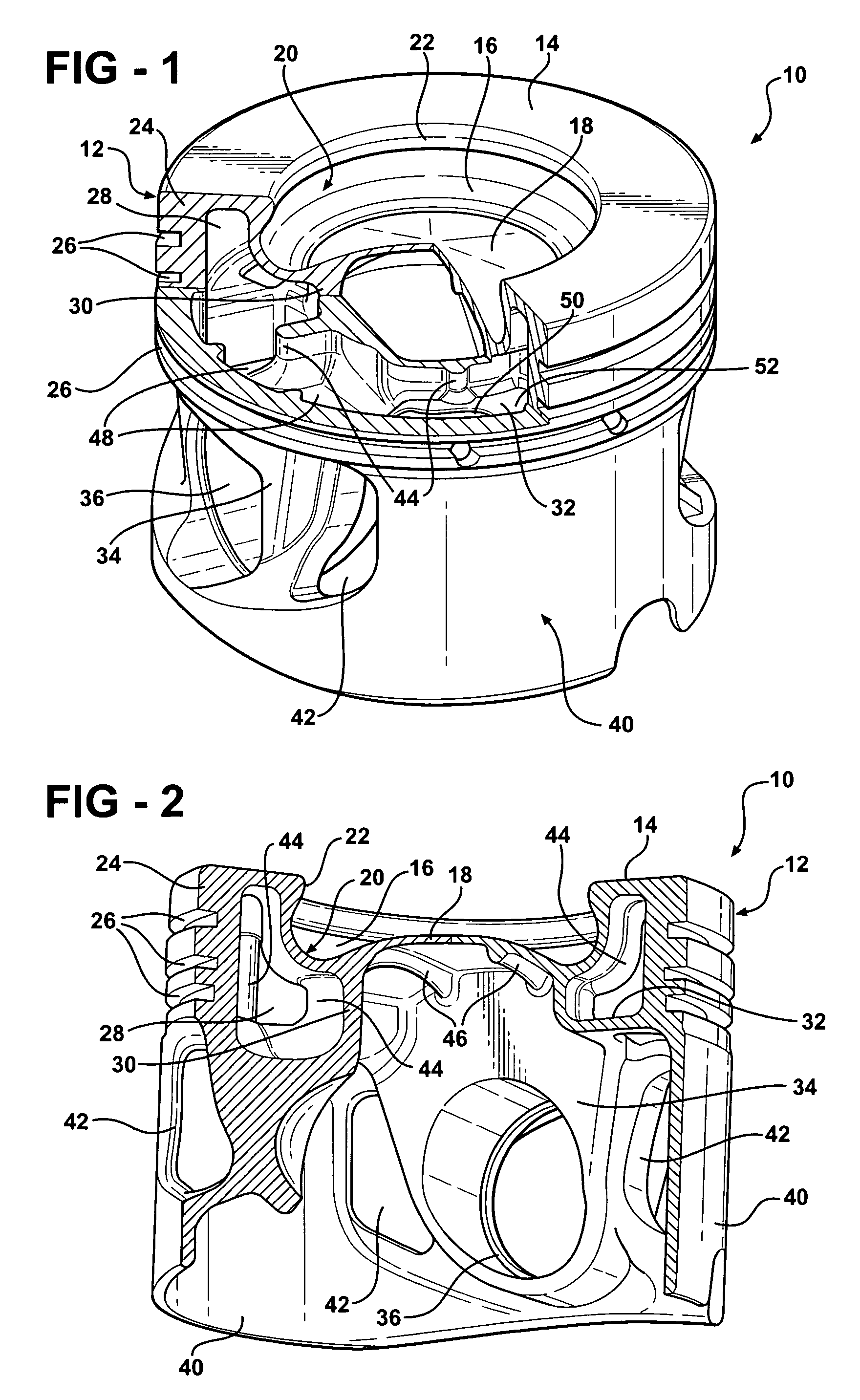

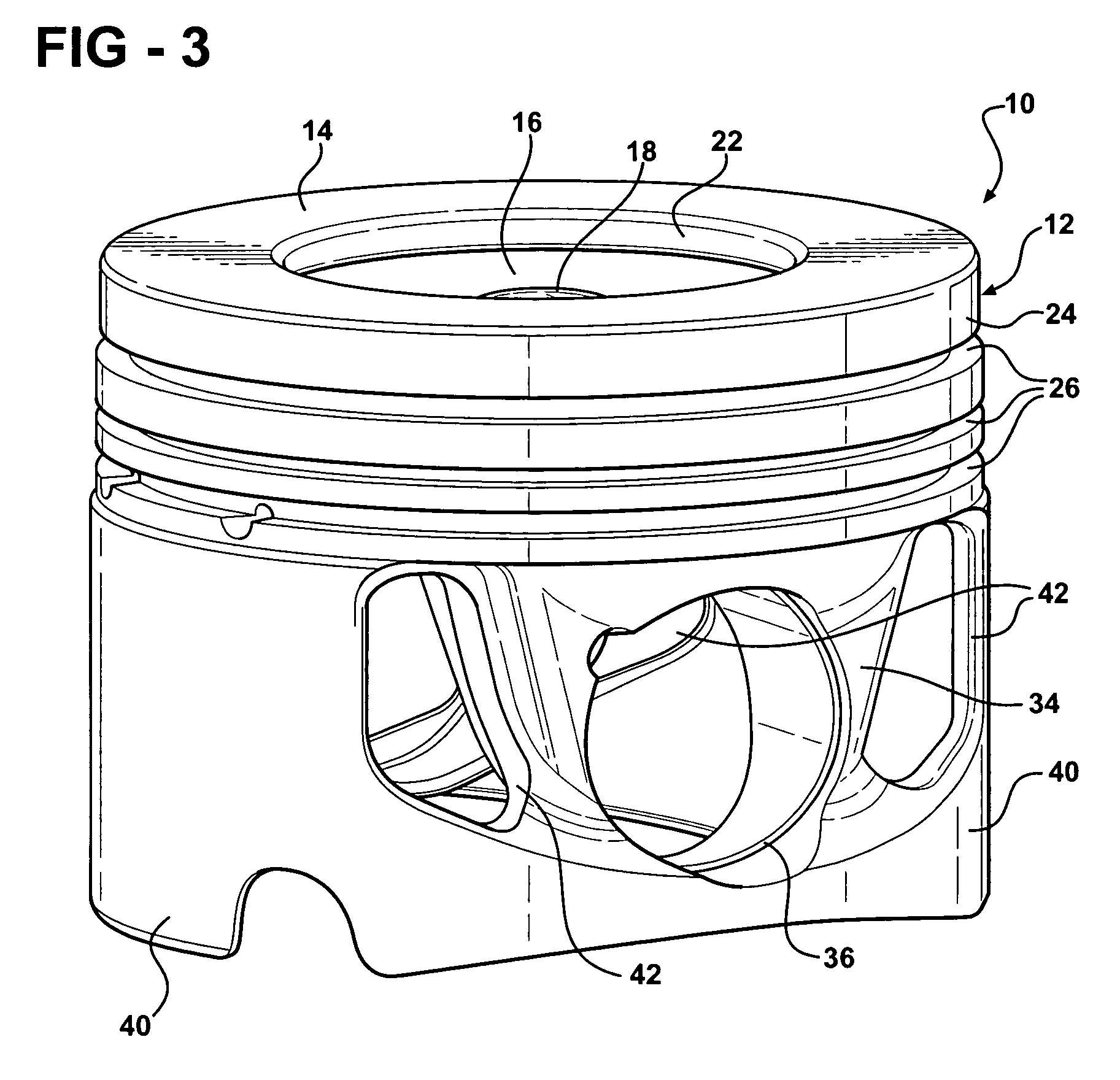

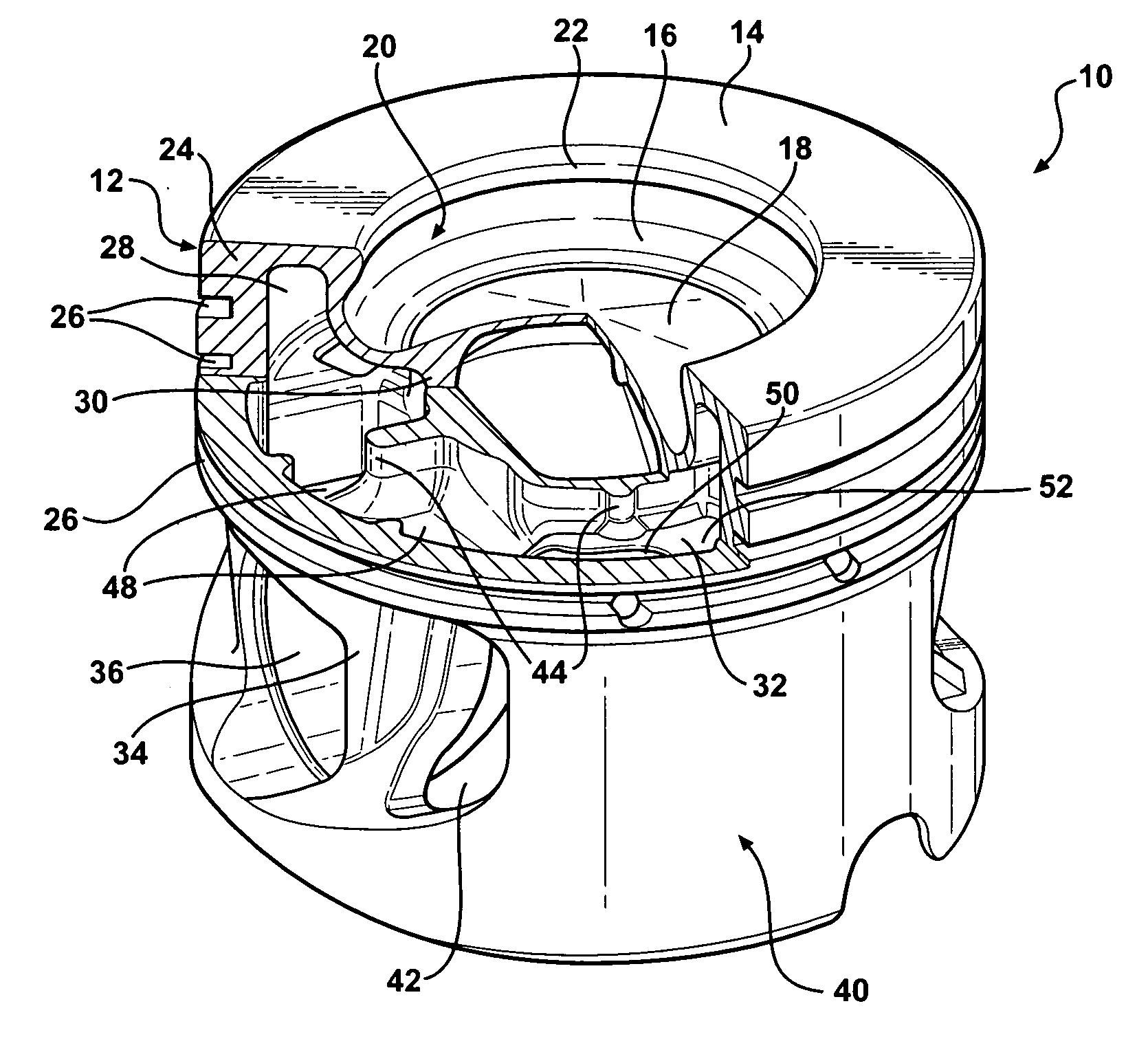

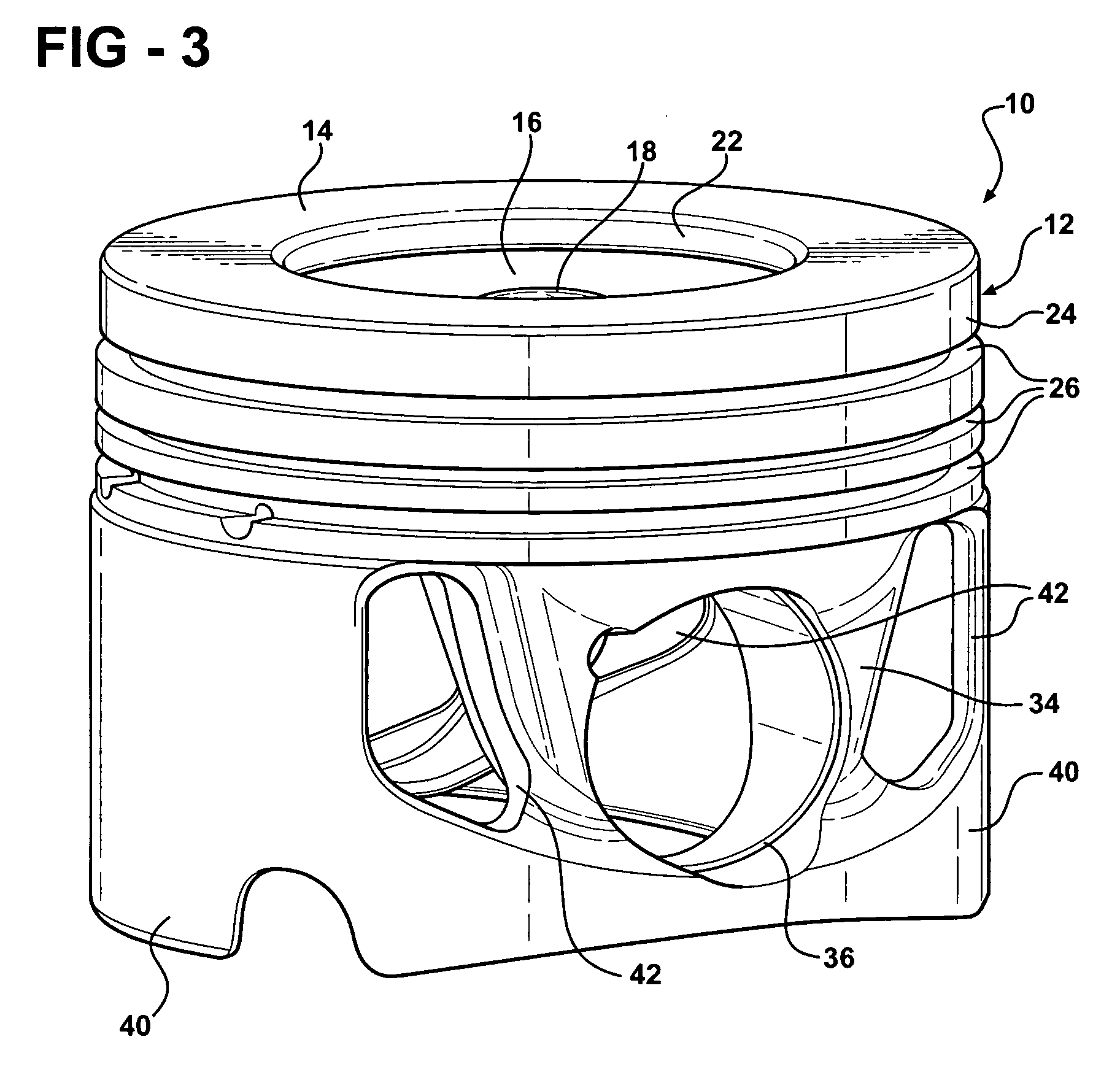

One piece cast steel monobloc piston

A piston for diesel engine applications has a piston body cast entirely of one piece of steel and includes a piston head with a combustion bowl, a ring belt and an oil cooling gallery. A pair of pin bosses and a piston skirt are cast as one piece with the piston head out of the same steel material.

Owner:FEDERAL MOGUL WORLD WIDE LLC

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

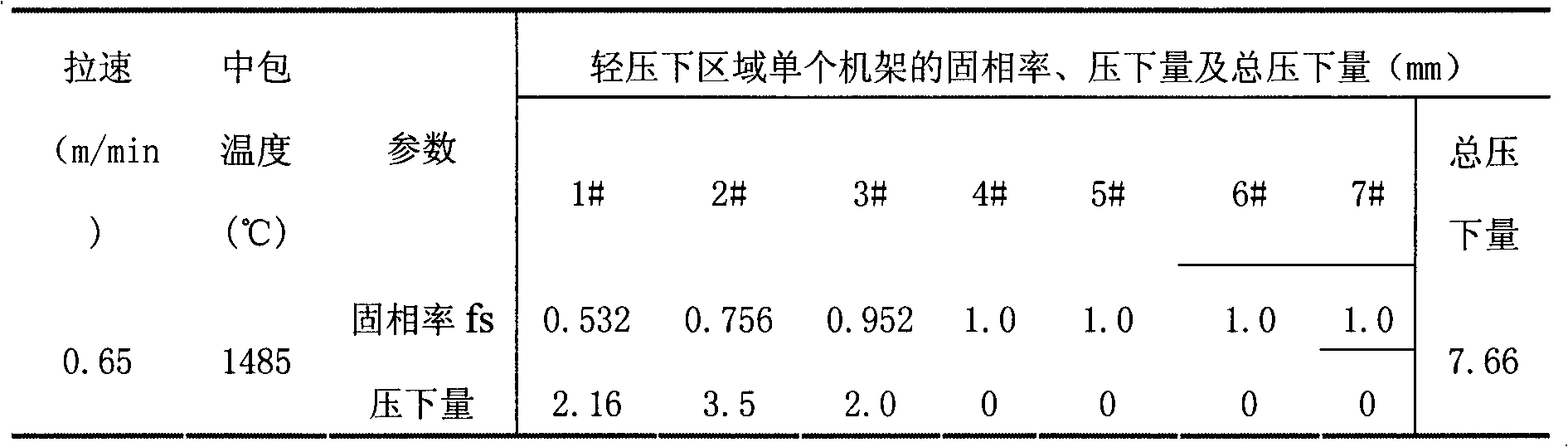

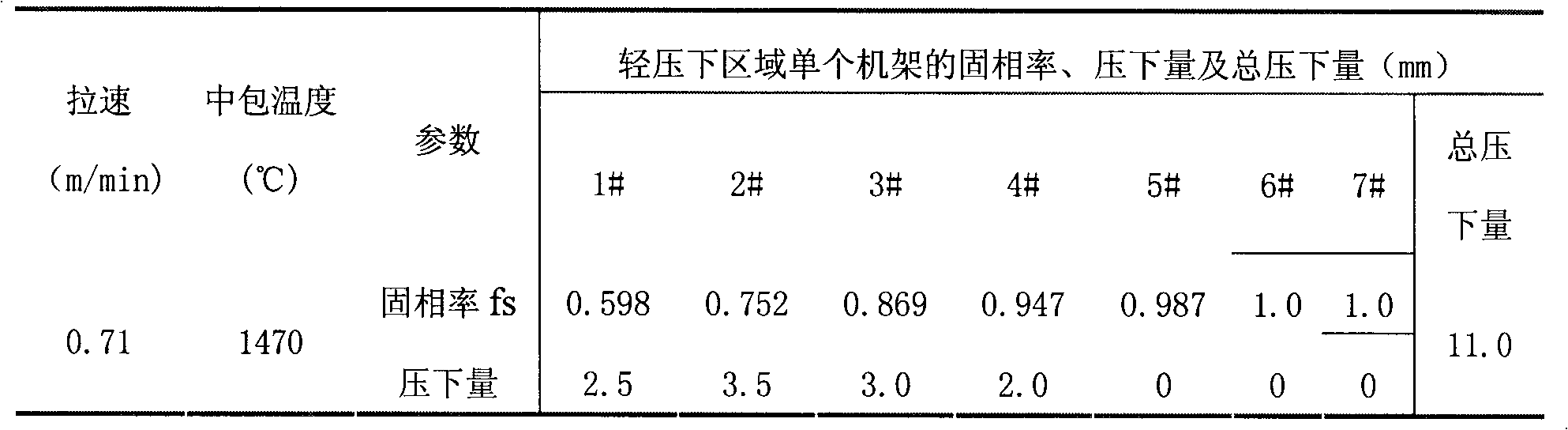

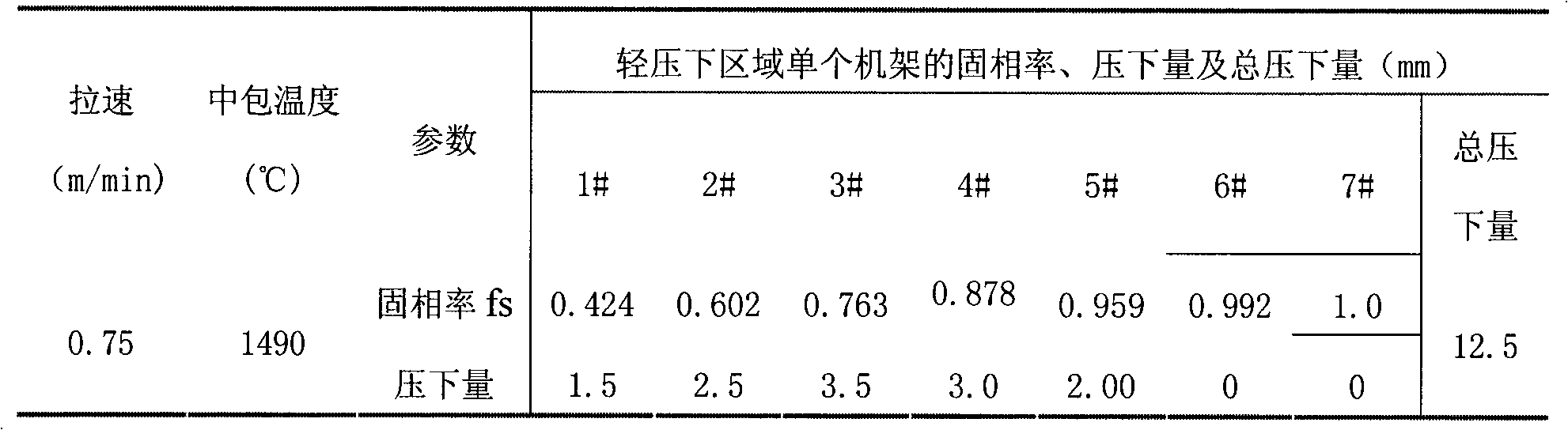

GCr15 bearing steel bloom continuous casting dynamic soft reduction process

InactiveCN101642774AEasy to loosenMeet technical requirementsMetal rolling arrangementsMetallurgySteel casting

The invention relates to a GCr15 bearing steel bloom continuous casting dynamic soft reduction process, which belongs to the technical field of metallurgical continuous casting and is used for solvingthe problems that the GCr15 bearing steel bloom continuous casting is easy to cause central segregation, central looseness, central parosity and other casting slab internal quality defects. The technical scheme is as follows: the reduction of a continuous casting soft reduction region is controlled through the change of central solid phase rate fs of a casting slab, and the relationship between the reduction of a soft reduction rack and the central solid phase rate of the casting slab is given out. The adoption of the soft reduction process of dynamic control can significantly reduce the central segregation of the GCr15 bearing steel casting slab, the central carbon segregation index of the casting slab is 0.95-1.08, and the average central segregation is 1.03; the process can also obviously improve the central looseness and the central parosity of the GCr15 bearing steel casting slab, the proportion of the central looseness of the casting slab which is not more than 1.0 grade is morethan 90%, and the central parosity is not more than 0.5 grade.

Owner:XINGTAI IRON & STEEL +1

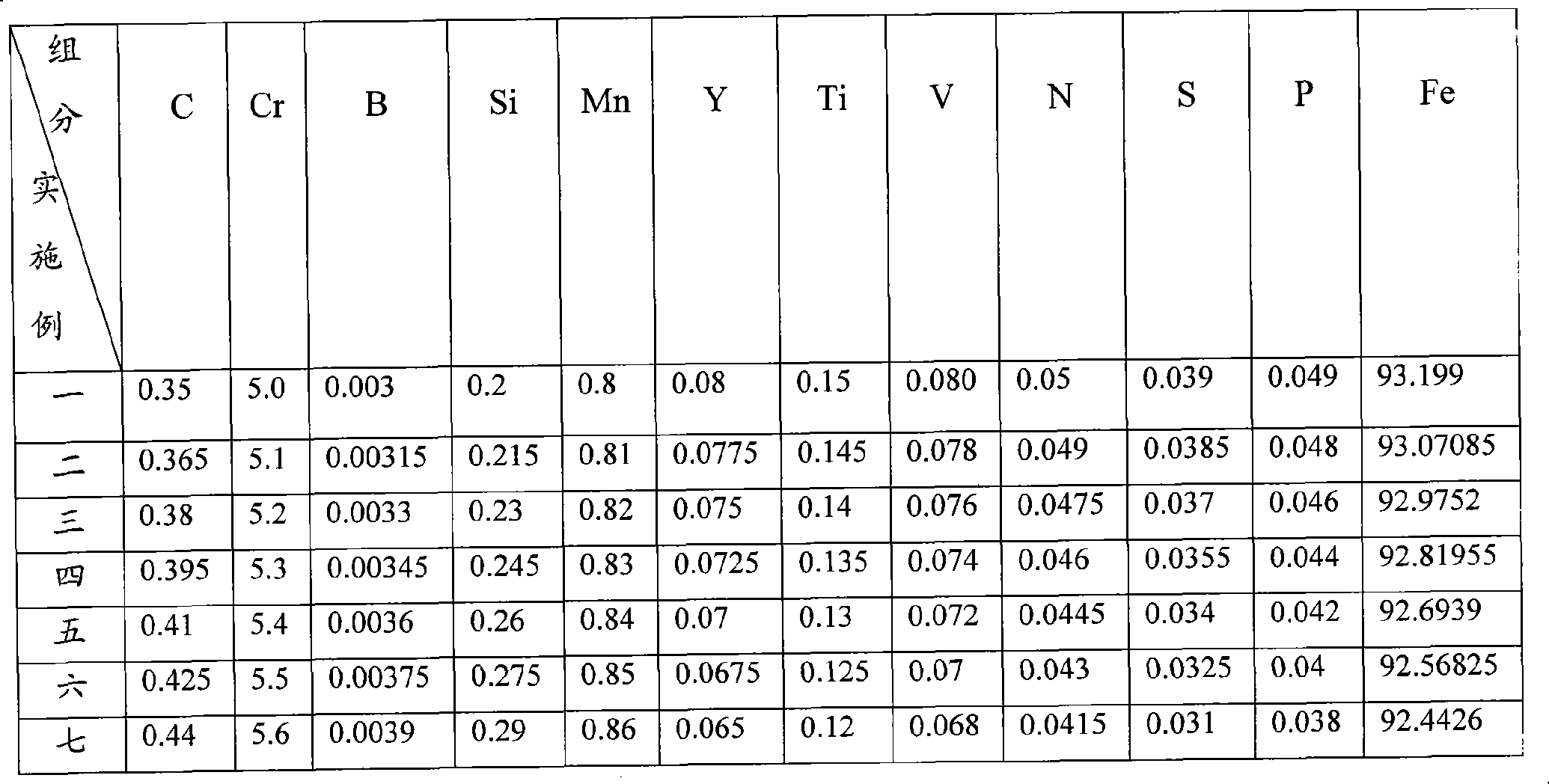

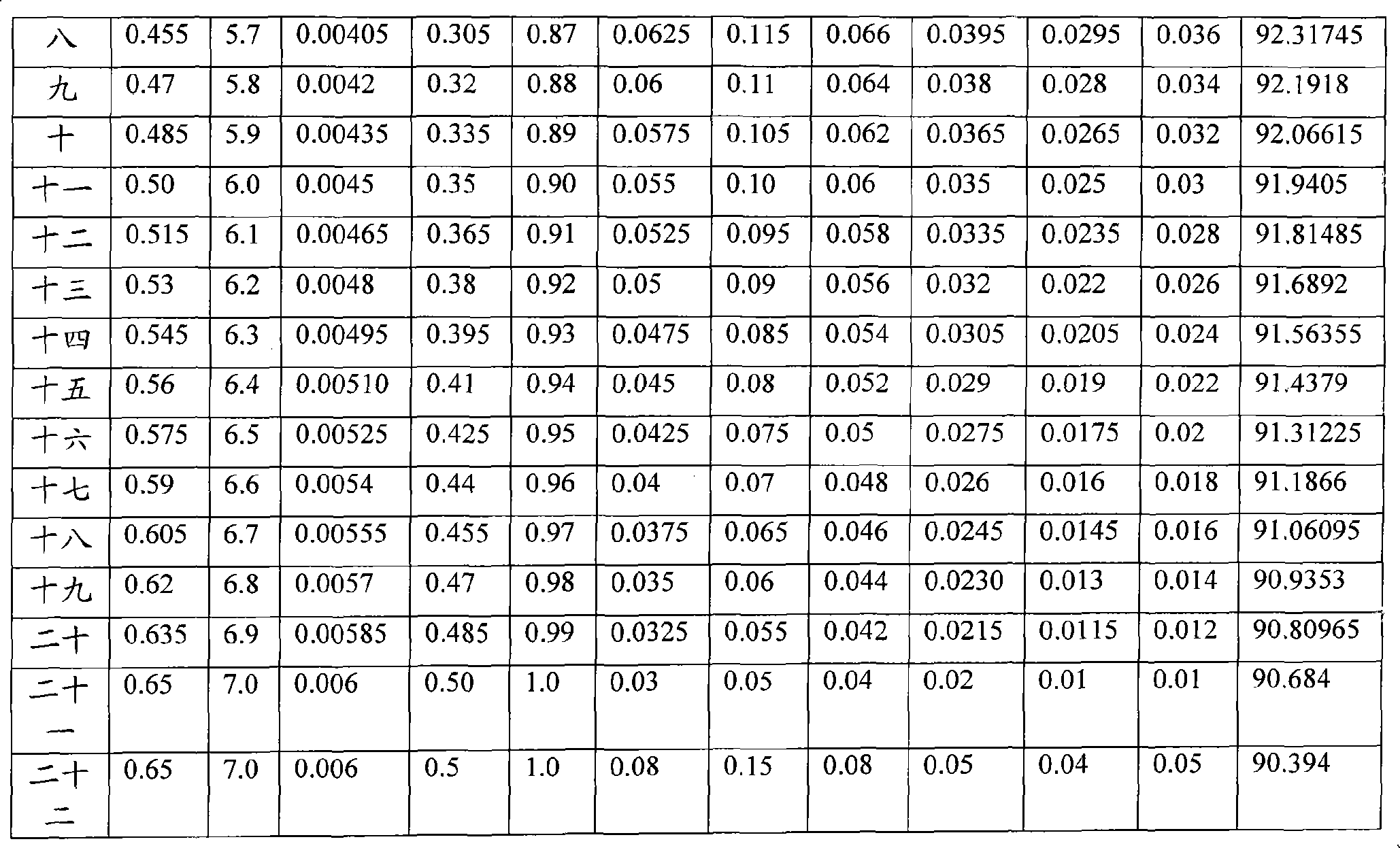

Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

The invention belongs to the technical field of metal wear-resistant materials and particularly relates to a wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium and a heat treatment method thereof. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium comprises the components of the following mass percentages: 0.35 to 0.65 wt percent of C, 5.0 to 7.0 wt percent of Cr, 0.003 to 0.006 wt percent of B, 0.2 to 0.5 wt percent of Si, 0.8 to 1.0 wt percent of Mn, 0.03 to 0.08 wt percent of Y, 0.05 to 0.15 wt percent of Ti, 0.04 to 0.08 wt percent of V, 0.02 to 0.05 wt percent of N, less than 0.04 wt percent of S, less than 0.05 wt percent of P and the balance of ferrite. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium can be manufactured by an electric furnace using a sand casting. The invention carries out step quenching by using two types of quenching oils with different temperatures, thus leading to depth of more than 60mm of the quenching full hardening layer of the cast steel, high hardness, good uniformity of the hardness, and no cracks in the heat treatment. The casting steel is free of expensive alloying elements such as molybdenum or nickel, raw materials resource is rich, the manufacture cost is low and economic benefit is good.

Owner:SHENZHEN UNIV

One piece cast steel monobloc piston

A piston for diesel engine applications has a piston body cast entirely of one piece of steel and includes a piston head with a combustion bowl, a ring belt and an oil cooling gallery. A pair of pin bosses and a piston skirt are cast as one piece with the piston head out of the same steel material.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Casting method for large thin-wall valve body steel casting

ActiveCN103506580AImprove production efficiencyReduce manufacturing costFoundry mouldsFoundry coresPhysical modelCasting defect

A casting method for a large thin-wall valve body steel casting comprises the following steps: 1, manufacturing a composite physical model: manufacturing an upper half valve body external mold, a lower half valve body external mold, the overall frame of a second core box, and an irregular-shaped section template; filling a mixed filler between the frame and the section template; tamping, smoothly trimming the filler; performing natural curing after the dimensional requirement is met; 2, sand mulling; 3, modeling and core manufacturing; 4, painting, mounting the core, and combining boxes; 5, smelting and casting; 6, performing post-treatment. The large thin-wall valve body steel casting is prepared through the steps. The casting method adopting the composite model can improve the model manufacturing efficiency, saves wood, and reduces the model manufacturing cost; through the adoption of stepped flat ingate system, as well as the manner that a chiller, a riser and compensation are combined, the thin-wall valve body steel casting is protected from fracture, insufficient casting, cold shut, wrinkling, and other casting defects, so as to realize the sequential solidification of the valve body steel casting, and meet the technical requirement of the valve body steel casting.

Owner:YICHANG MARINE DIESEL ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com