Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

A technology of on-site welding and repairing methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as difficult completion, achieve good quality, eliminate welding residual stress, and prevent cracks from recurring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It is known that the main steam valve is the main thermal equipment of the thermal power plant. It not only bears the high temperature and high pressure load for a long time under the stable operation condition, but also is subjected to the alternating stress when it starts, stops and changes in compliance. Therefore, in the main Weak parts of steam valves or areas with internal manufacturing defects are prone to cracks and failure.

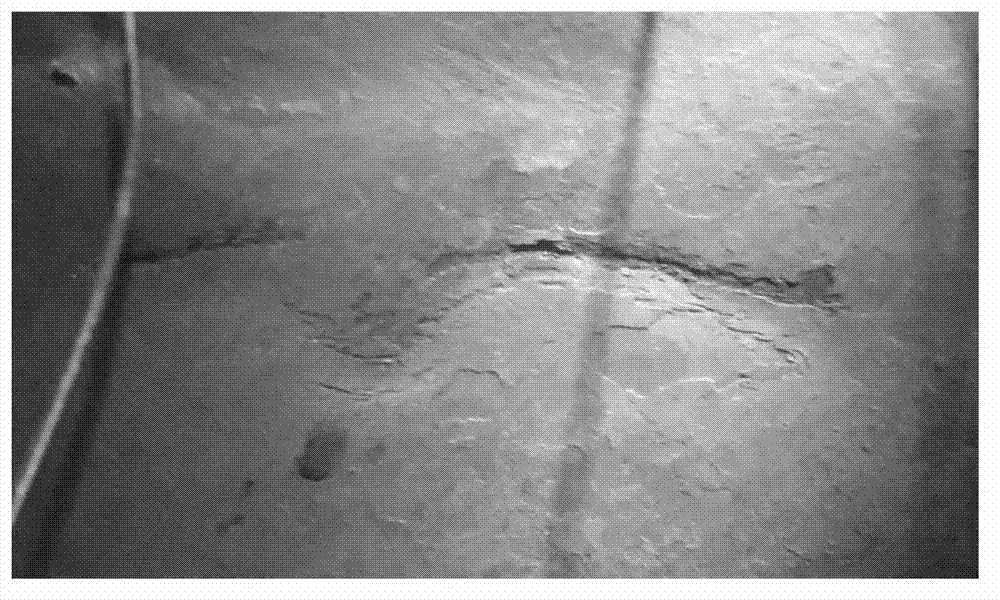

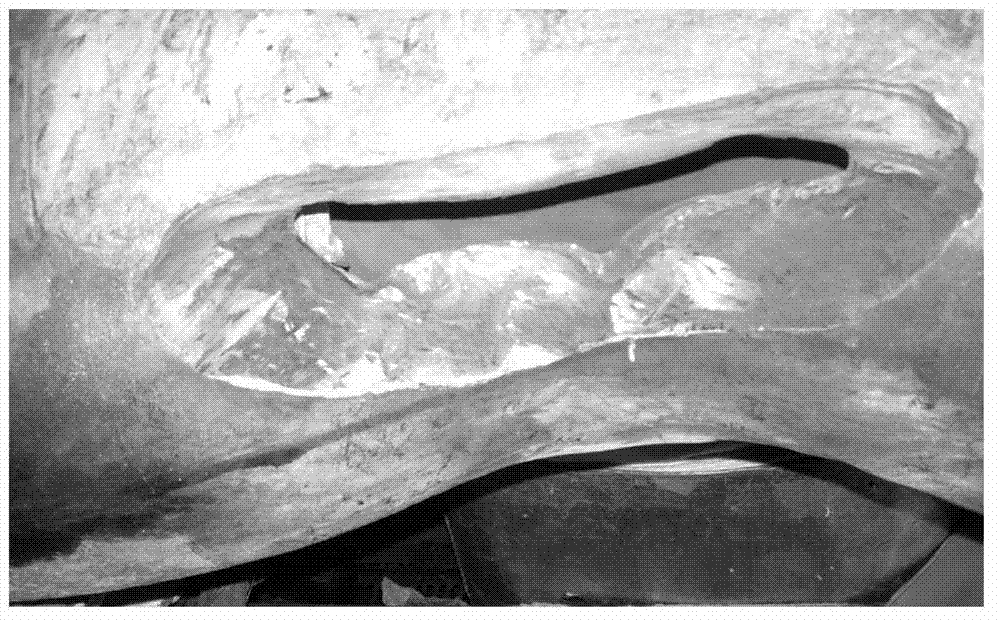

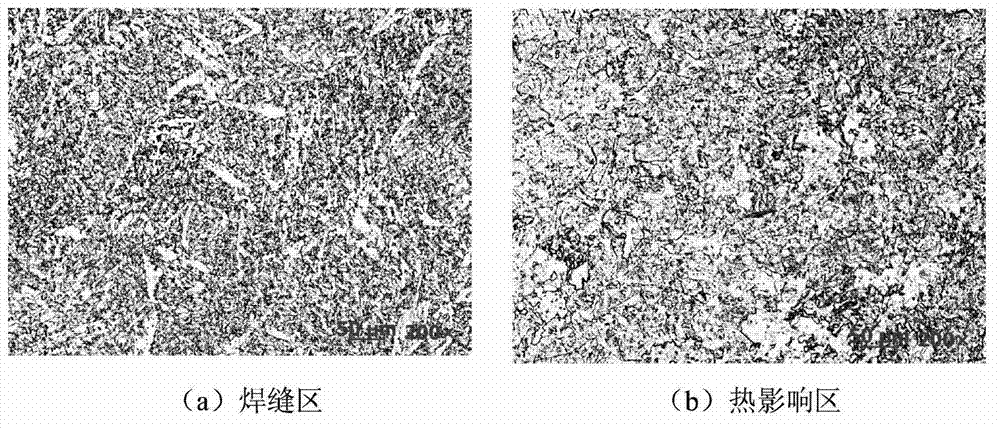

[0030] In April 2011, the No. 2 steam valve body of a Russian supercritical 500MW coal-fired unit of a power generation company (the material is ZG15Cr1Mo1V low-alloy heat-resistant steel) had penetrating cracks, causing steam leakage, and then the No. 1 main steam valve valve It is also found that there are multiple cracks and other defects in the body. Below is a crack with a length of about 100mm on the outer surface of No. 2 valve (see figure 1 , the crack opening width is 2-3 mm, corresponding to one inner wall crack, and the leakage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com