Nitride semiconductor light emitting diode and method of manufacturing the same

a light-emitting diode and nitride technology, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of limited substrate used to grow such a nitride semiconductor material, metal, such as ag or al, the ohmic contact layer b>16/b> is very sensitive to heat, so as to improve current diffusion effect and reflexibility, improve the structure of the p side electrod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

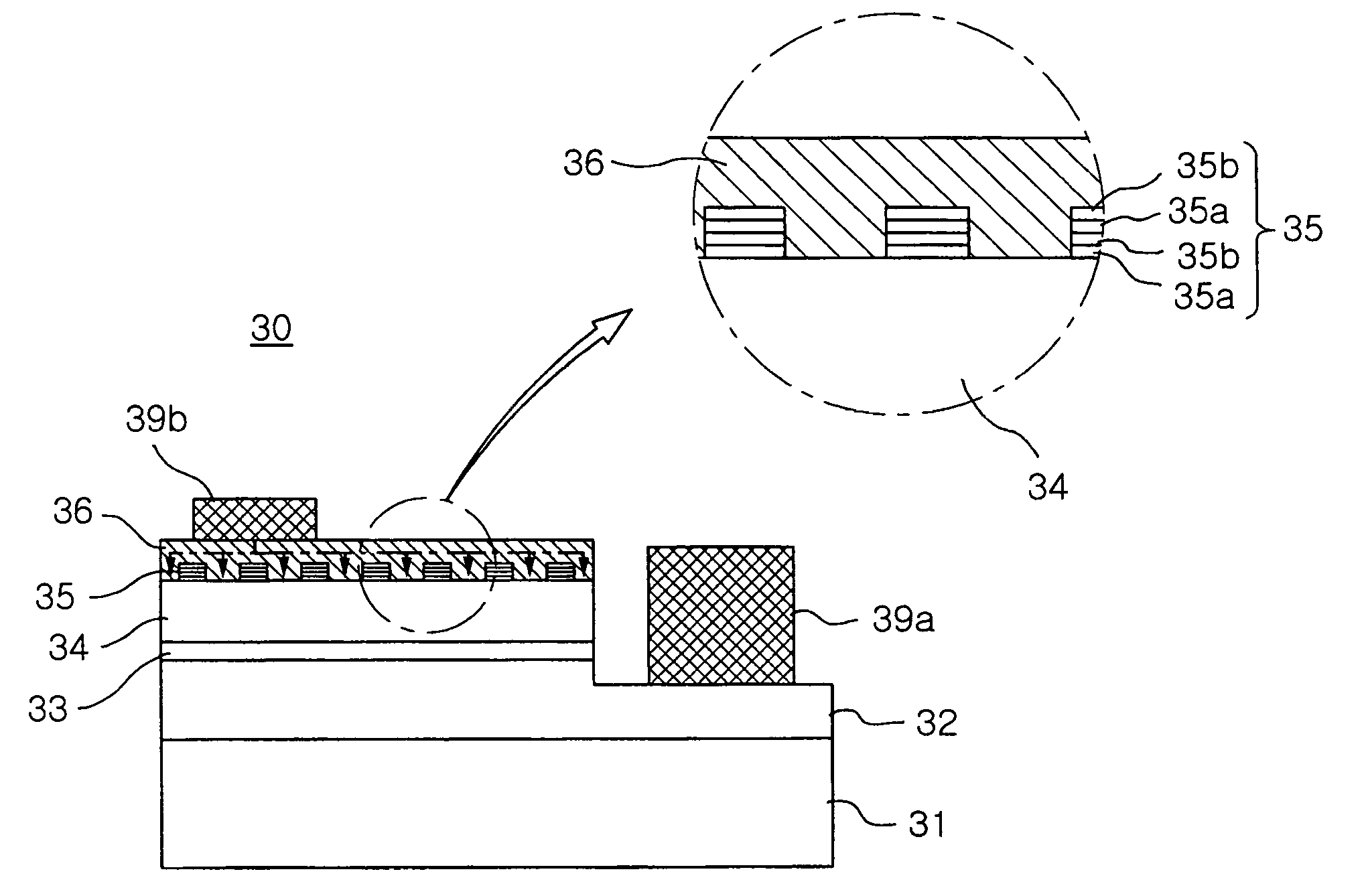

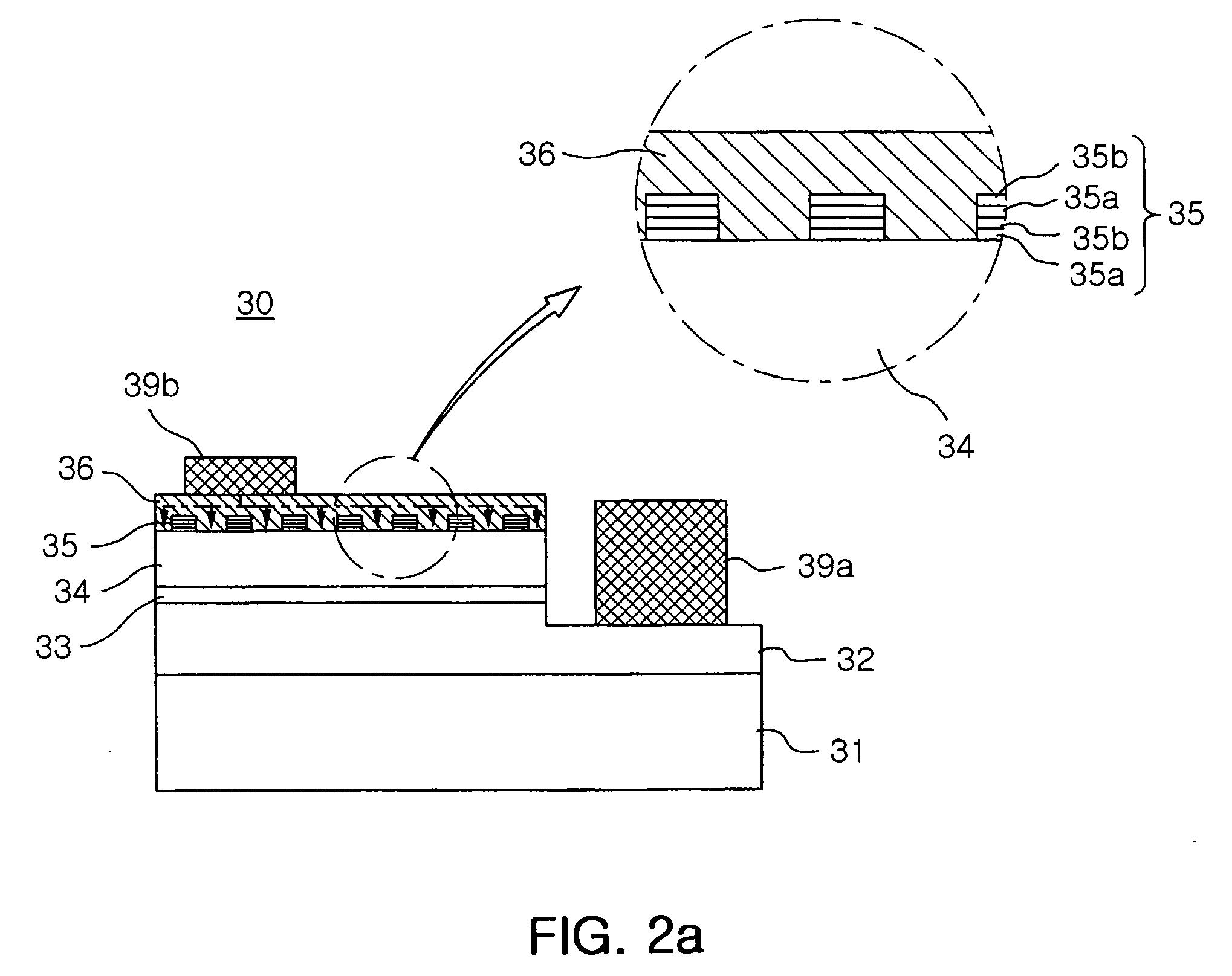

[0030] A detailed description of components of a nitride semiconductor light emitting diode according to the present invention will be given hereinafter.

[0031] P-Type and N-Type Nitride Semiconductor Layers

[0032] The p-type and n-type nitride semiconductor layers are single crystals each having the following formula: AlXInyGa(1-X-y)N (where, 0≦x≦1, 0≦y≦1, and (0≦x+y≦1), and are grown by means of Metal Organic Chemical Vapor Deposition (MOCVD), Molecular Beam Epitaxy (MBE), or Hydride Vapor Phase Epitaxy (HVPE). The typical nitride semiconductor layers include GaN, AlGaN, and GaInN.

[0033] The P-type nitride semiconductor layer may contain impurities, such as Mg, Zn, and Be. The n-type nitride semiconductor layer may contain impurities, such as Si, Ge, Se, Te, and C. Between the substrate and the nitride semiconductor layer is usually disposed a buffer layer for lattice matching. The common buffer layer may be a low-temperature core growth layer, such as AlN or GaN.

[0034] Active L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com